Patents

Literature

1610results about "Shoe gluing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

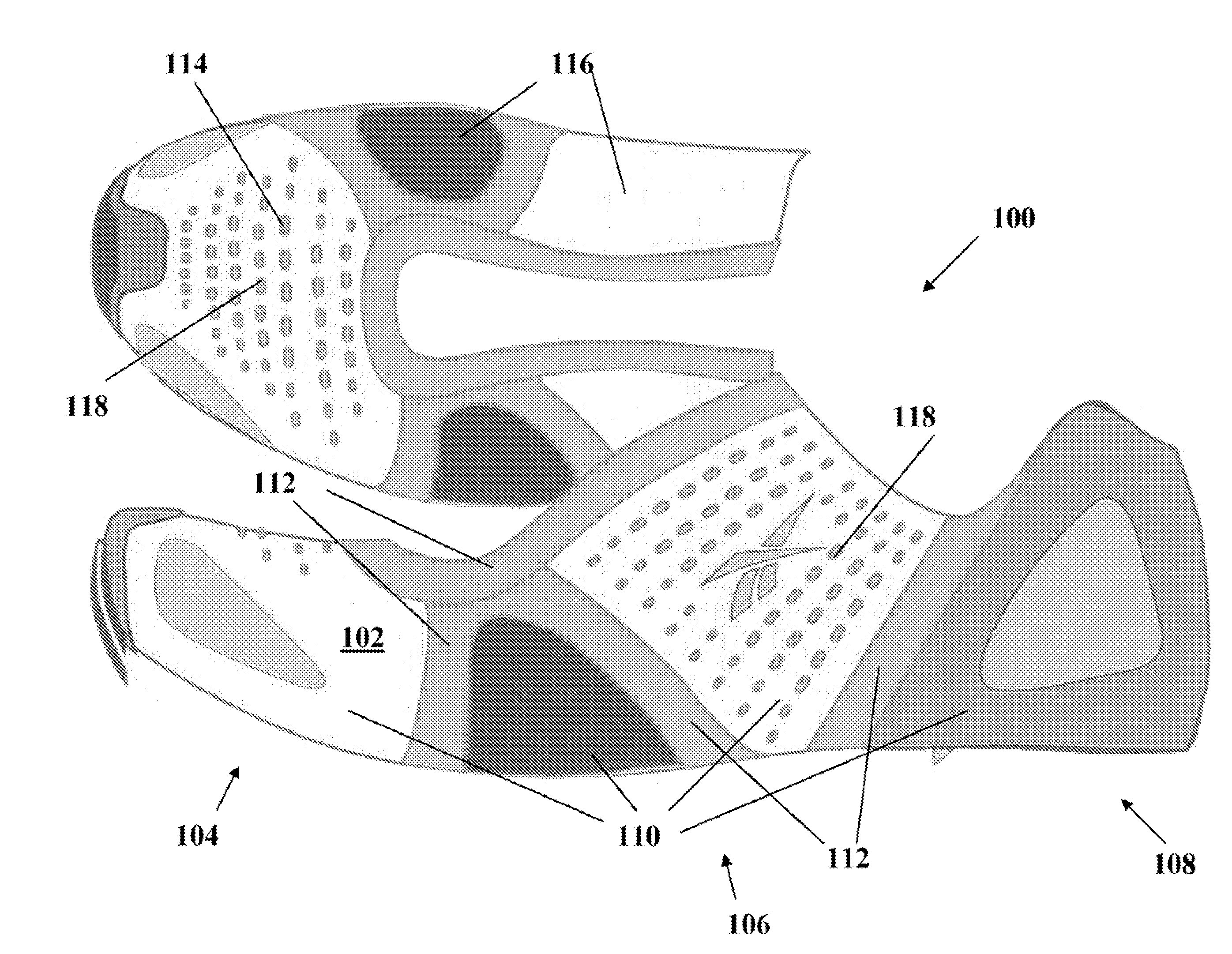

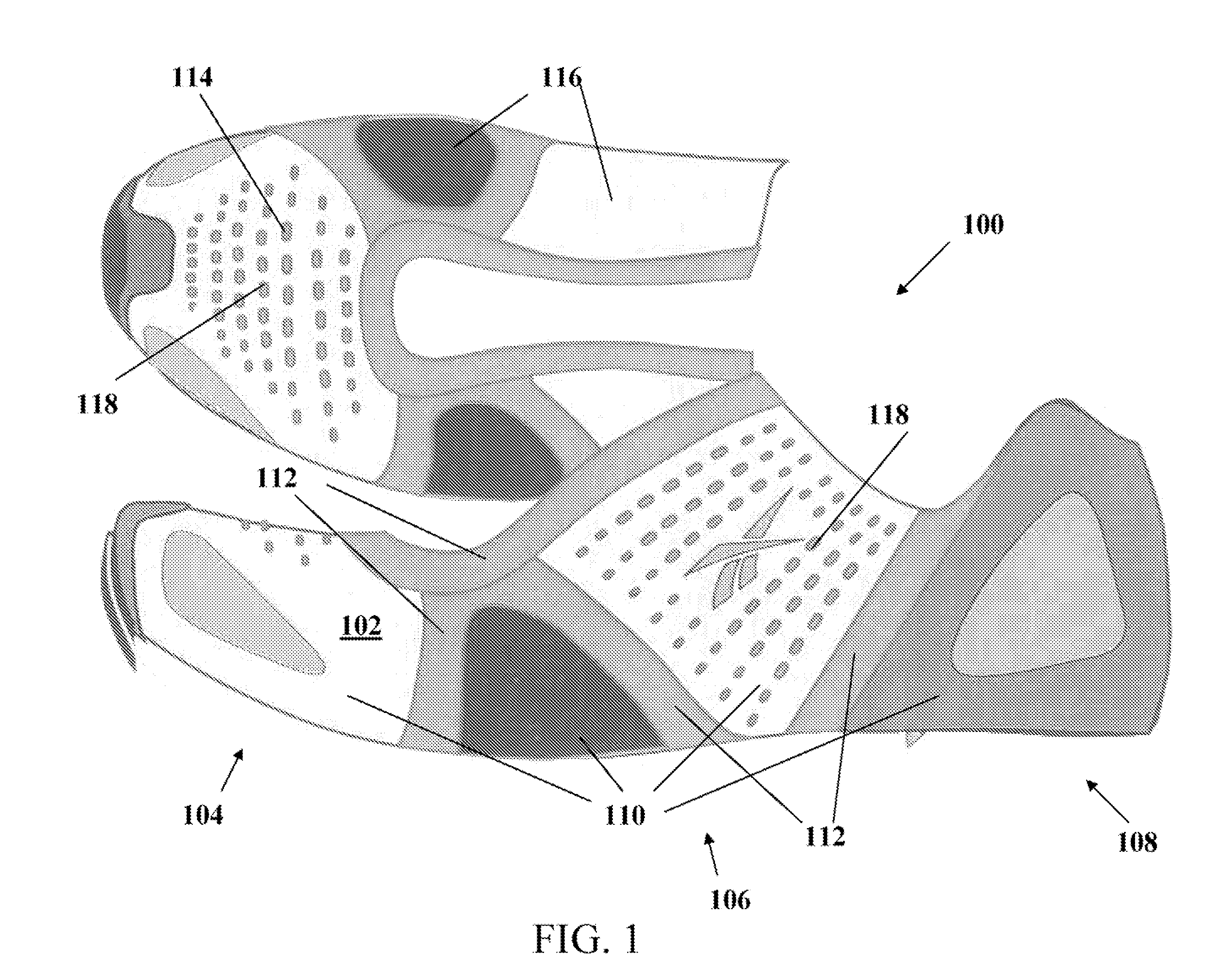

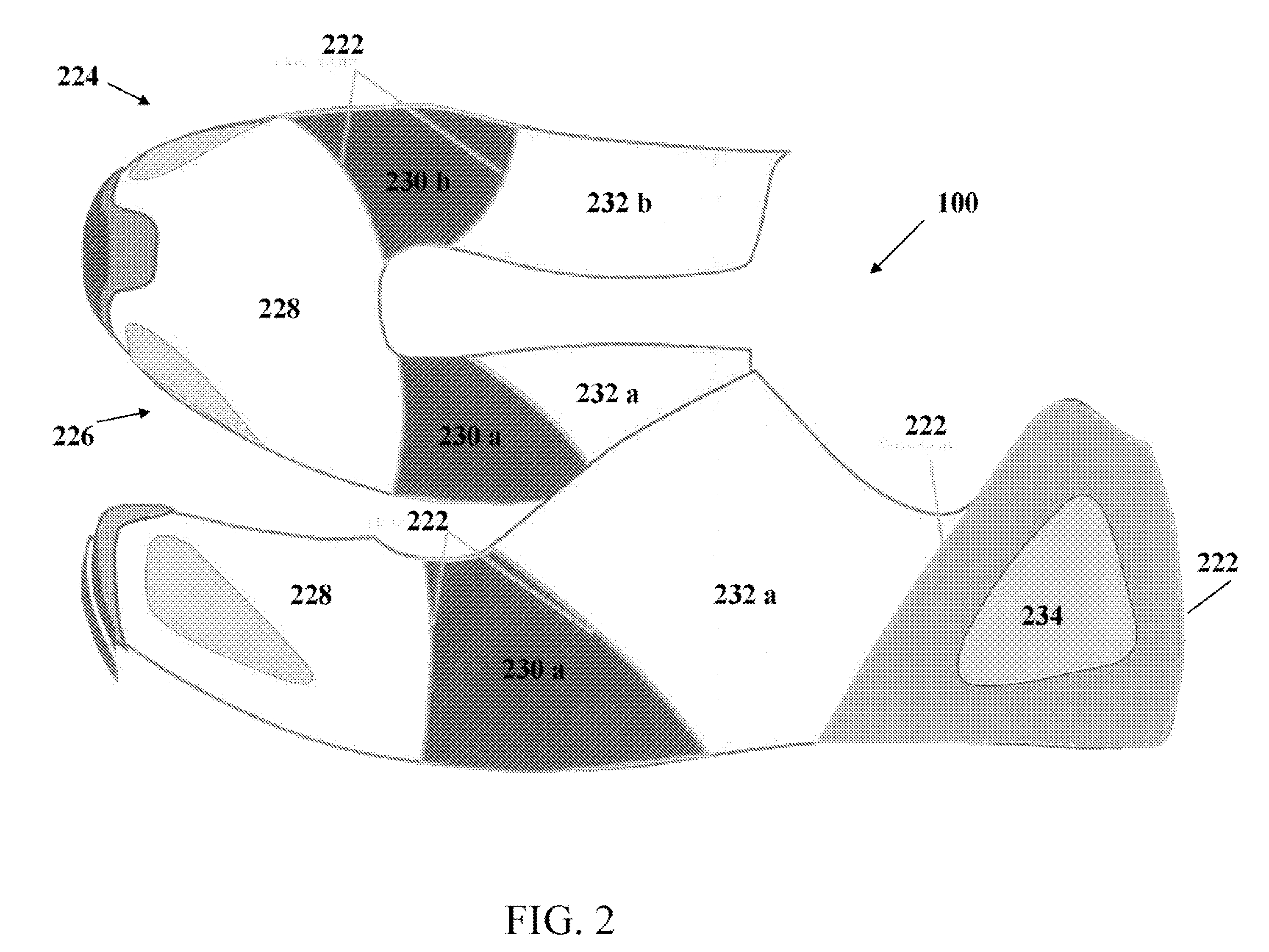

Smooth Shoe Uppers and Methods for Producing Them

Shoe uppers having smooth seams and methods for producing them are disclosed. In one embodiment the upper uses thermoplastic seam tape which forms bonds between contiguous upper sections after being subjected to heat and / or pressure. In another embodiment, different parts of the shoe can be joined using hidden seams. Close seams can also be covered with a transfer material adapted to give the interior and / or exterior of the upper a smooth surface. In yet another embodiment, a method is disclosed which allows three-dimensional upper sections to be bonded on a last using thermoplastic seam tape.

Owner:REEBOK

Method for manufacturing shoes and shoes manufactured by the method

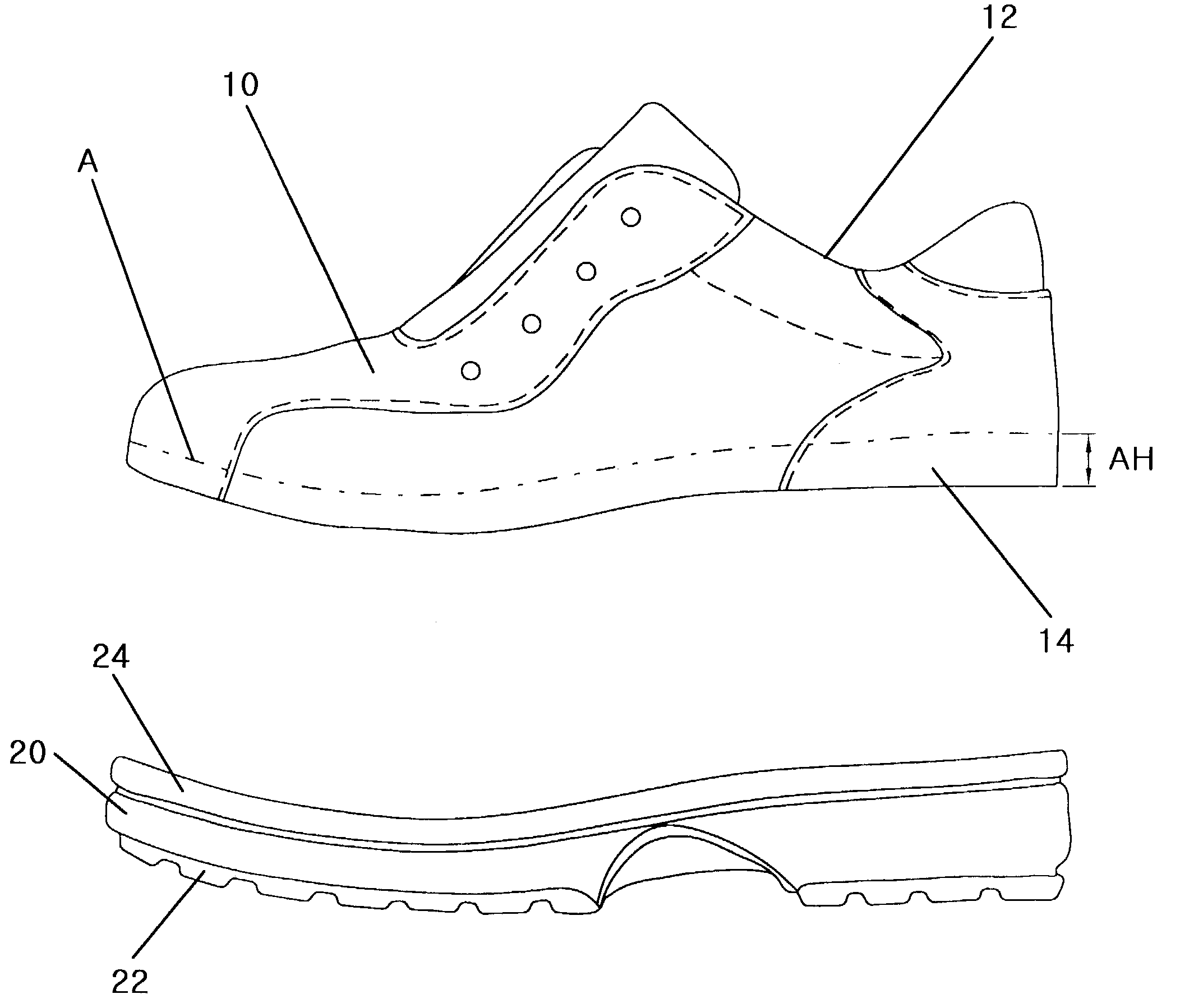

InactiveUS6978557B2Reduce the amount requiredShorten the timeSolesDomestic footwearMolding machineEngineering

A method for manufacturing shoes is provided. The method includes preparing an upper and an outsole, applying an adhesive agent to the outer surface of an upper seal portion and the inner surface of an outsole seal portion, stitching together the outer surface of the upper seal portion and inner surface of the outsole seal portion, activating the adhesive agent by applying heat to the stitched seal portions, and molding the upper and the outsole by using a molding machine. Therefore, since the amount of the upper can be reduced and a separate insole is not necessary, the total weight of the shoes can also be reduced. The flexibility of shoes can also be enhanced.

Owner:JUNG IN LEE

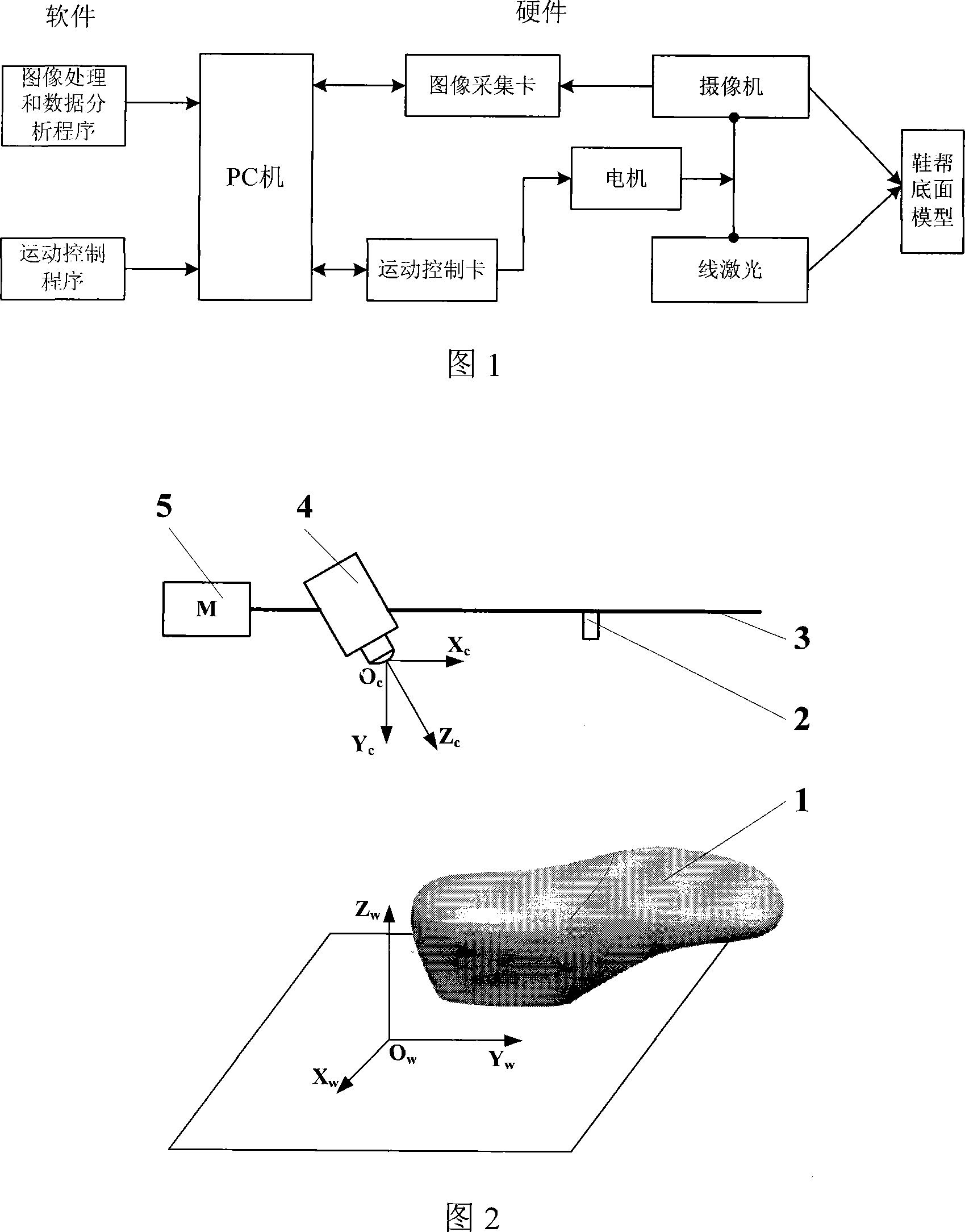

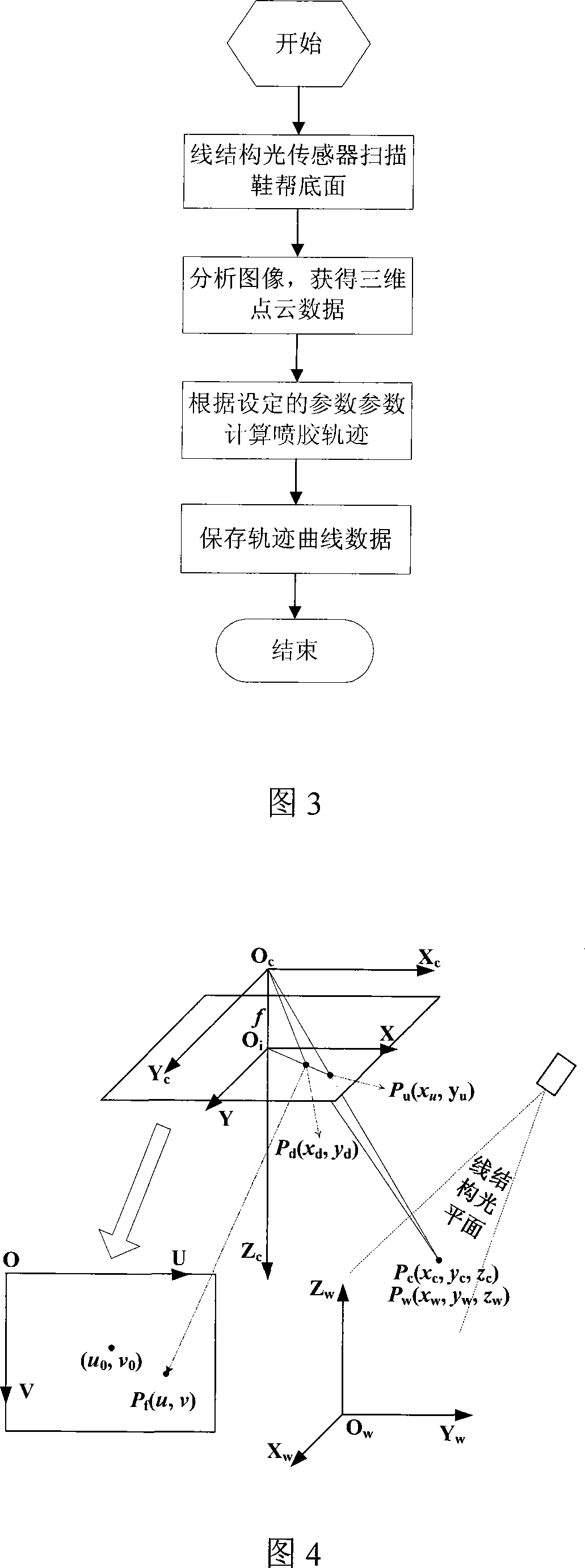

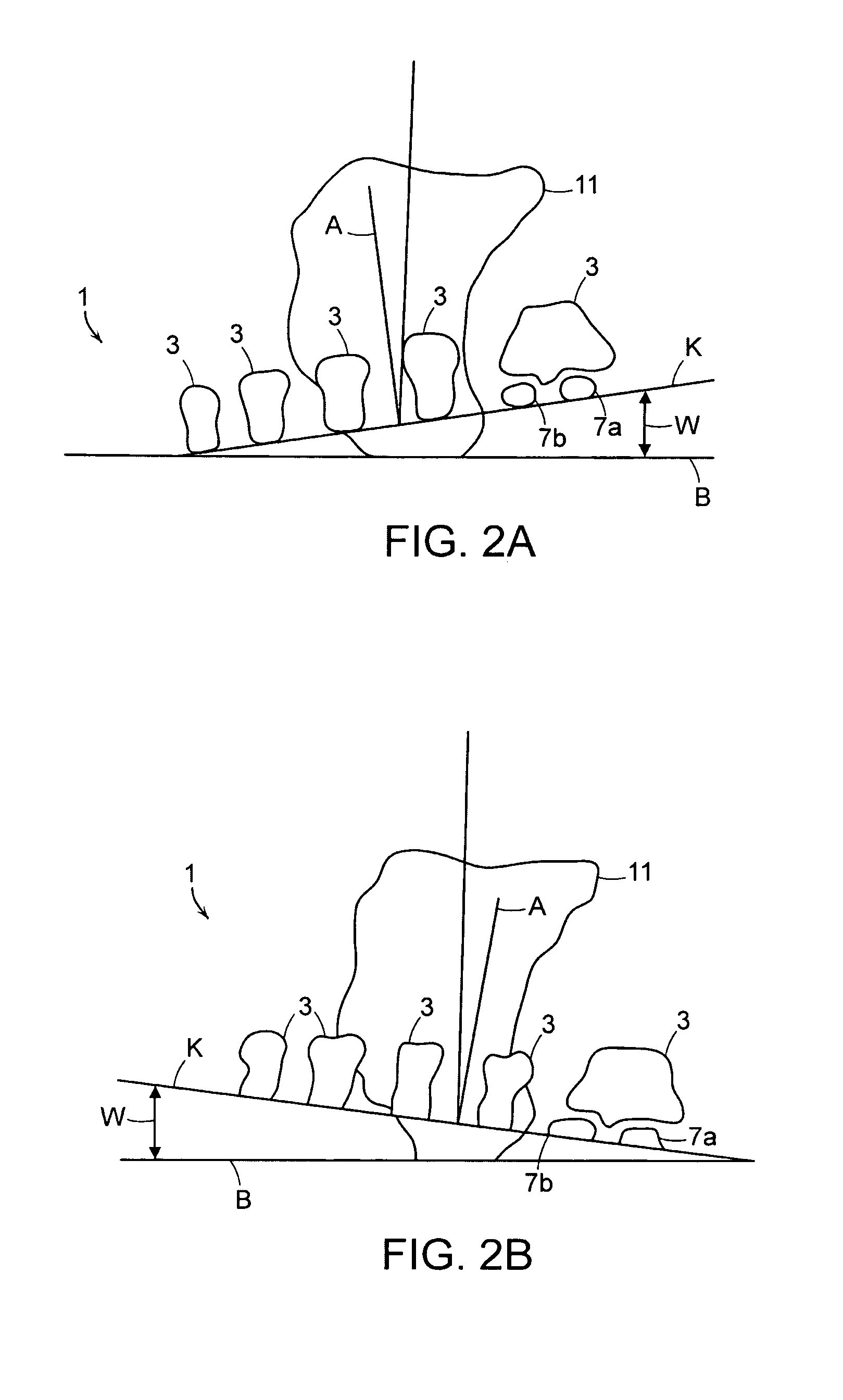

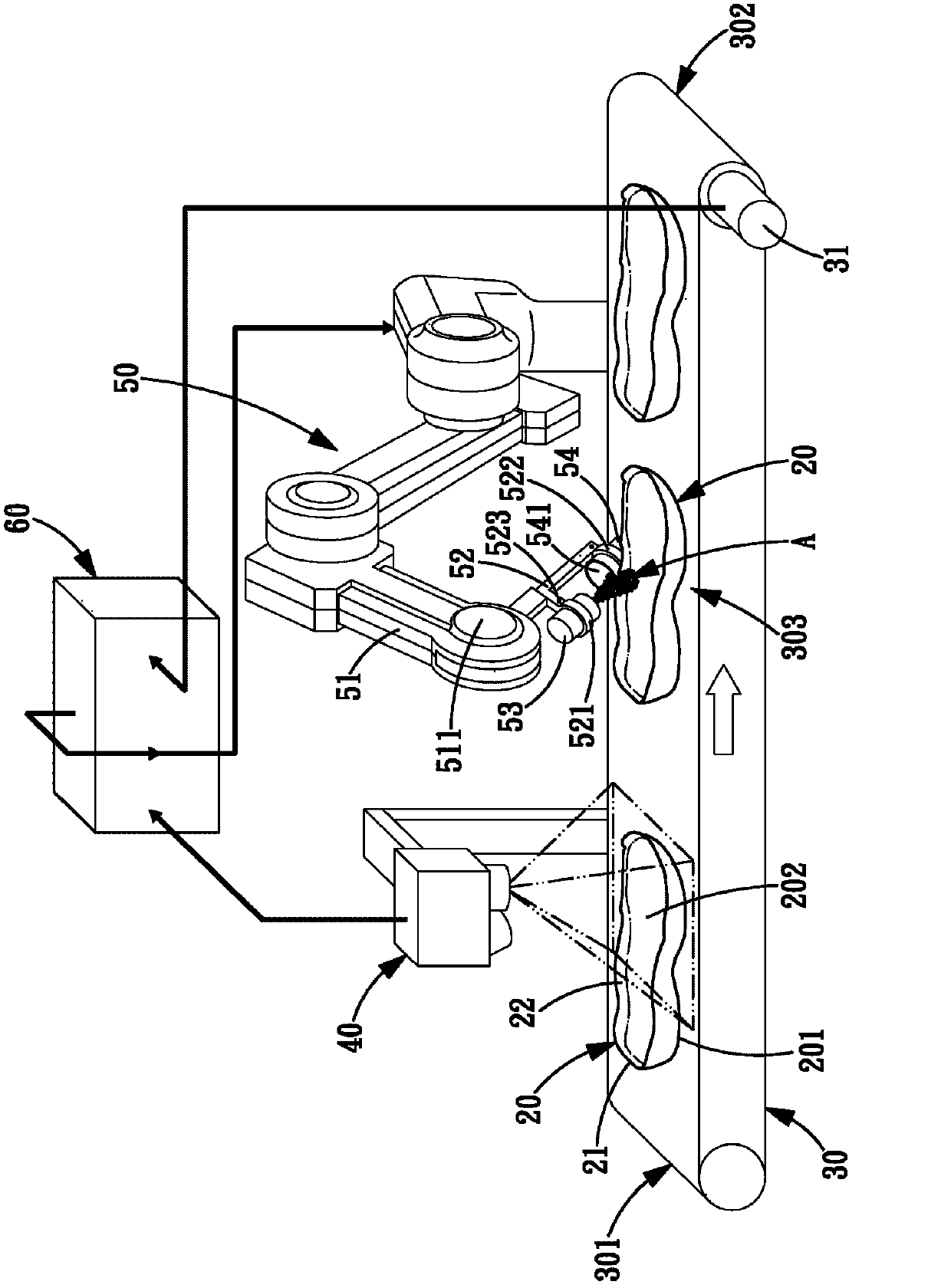

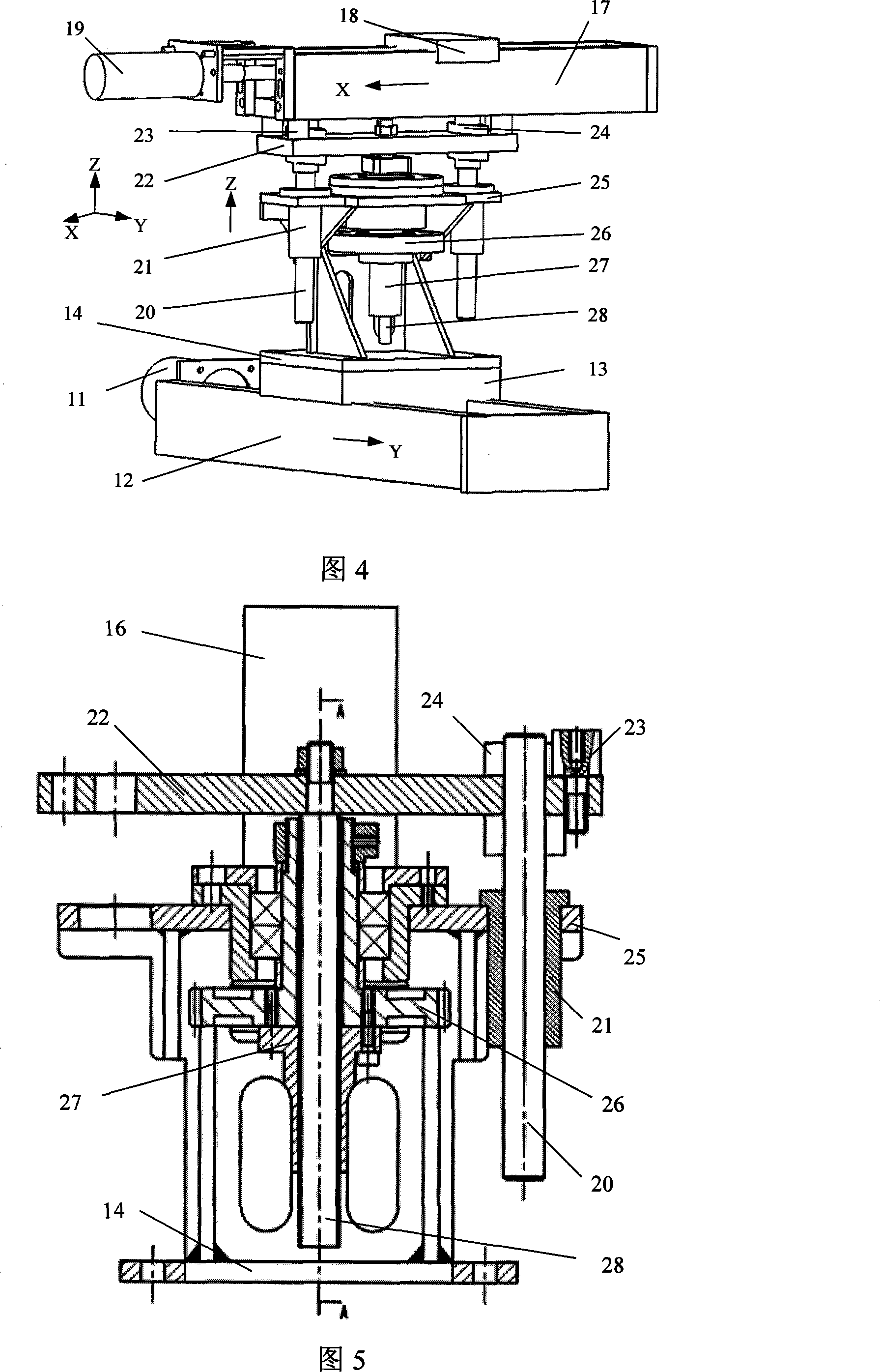

Method and system for automatic generating shoe sole photopolymer coating track based on linear structure optical sensor

InactiveCN101161151ALower skill requirementsReduce labor intensitySolesInsolesPoint cloudImaging processing

The present invention discloses a method and system for generating sole glue-spraying track automatically based on linear structure light sensor. Obtaining upper underside three-dimensional coordinates data using linear laser, vidicon, mobile platform and computer, and generating glue-spraying track automatically. The linear laser scans upper underside continuously, and the vidicon collects laser scanning image at the same time, then distilling laser beam center in the image and transforming to three-dimensional coordinates through image processing, thus obtaining point-cloud data of upper underside, generating glue-spraying track according to the point-cloud data. Compared with the method by machine, the generating method of the present invention has the advantage of high orientation precision, simple operation method, strong adaptability, high efficiency etc., and has great superiority.

Owner:ZHEJIANG SCI-TECH UNIV

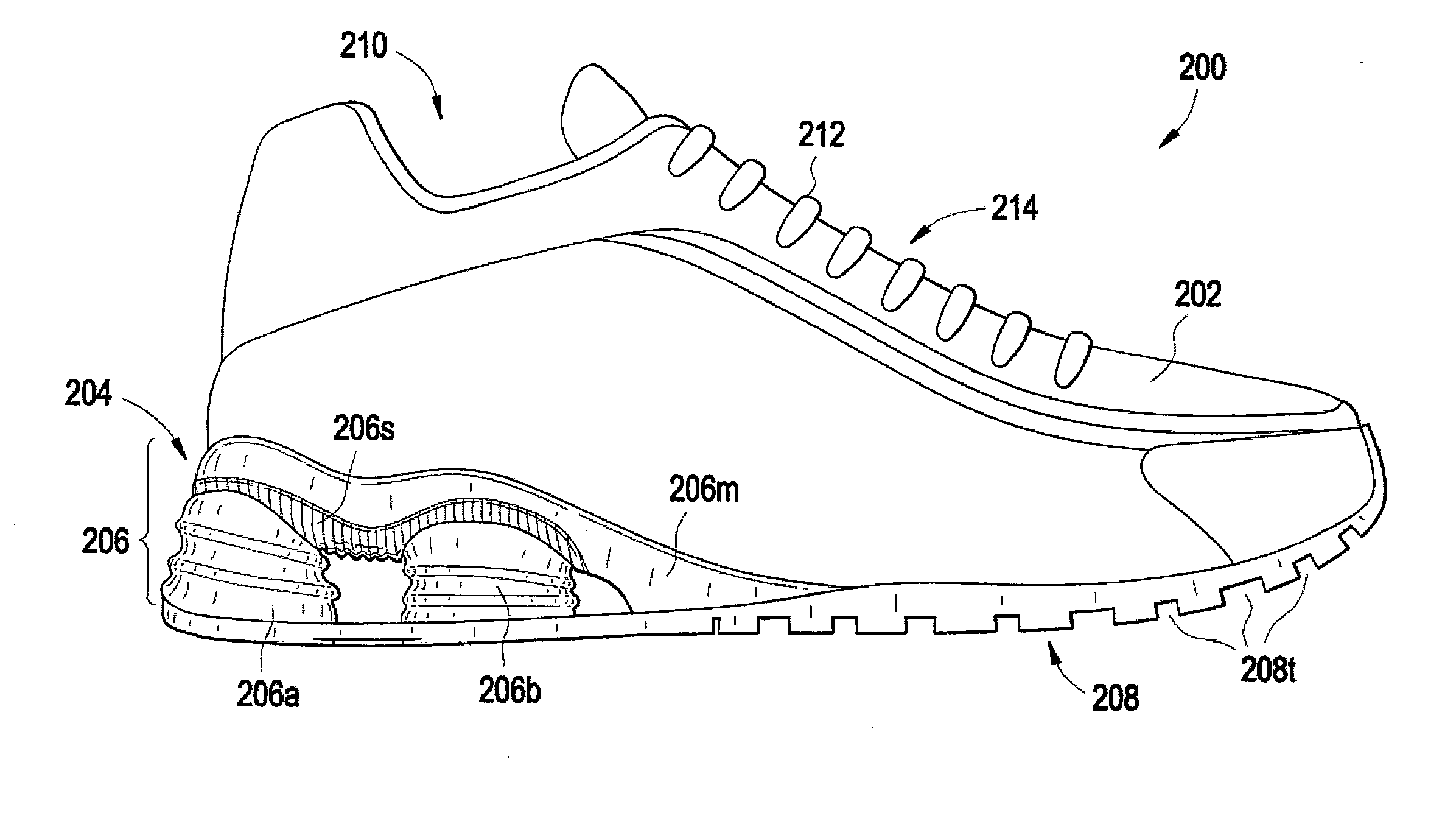

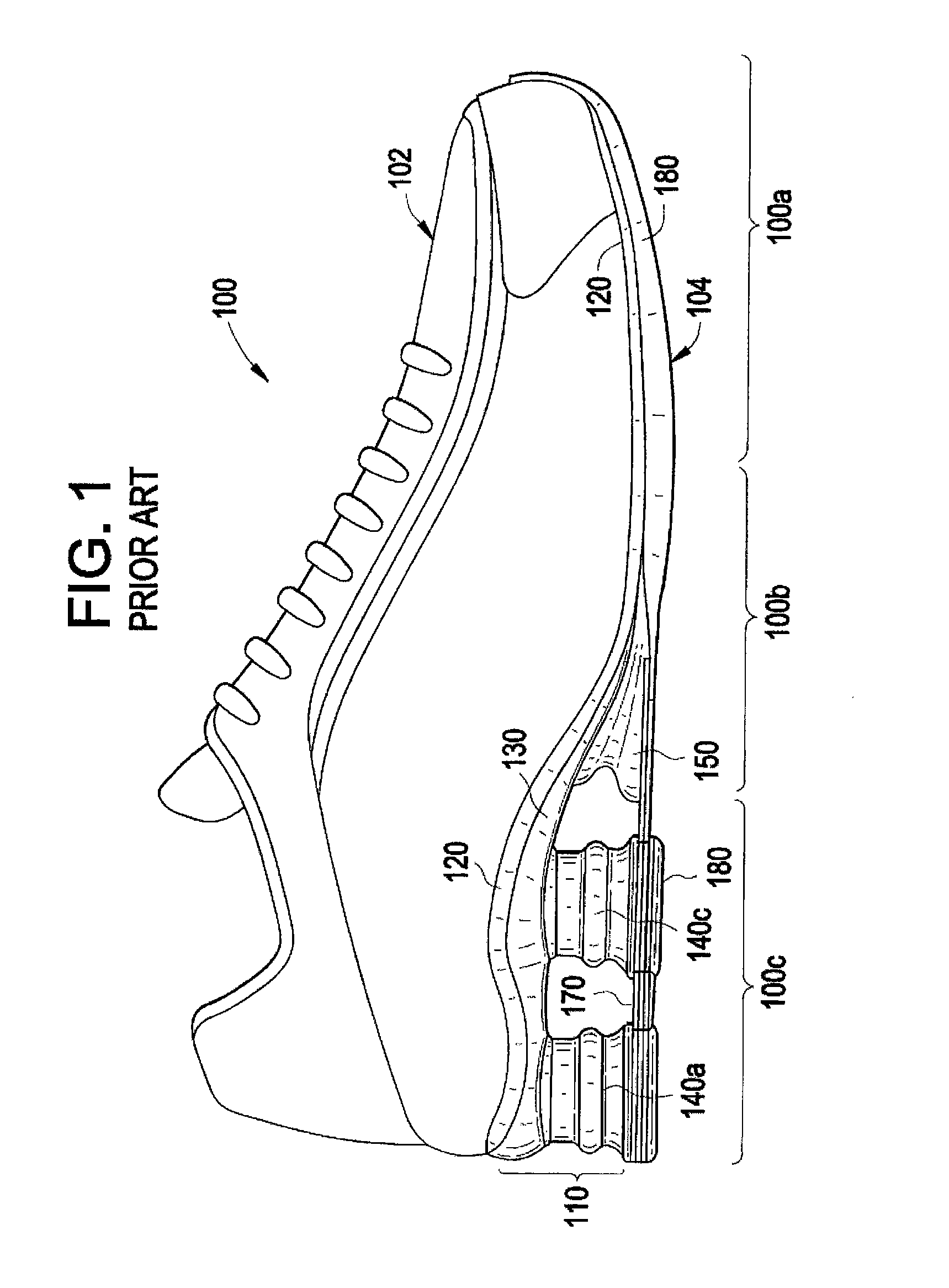

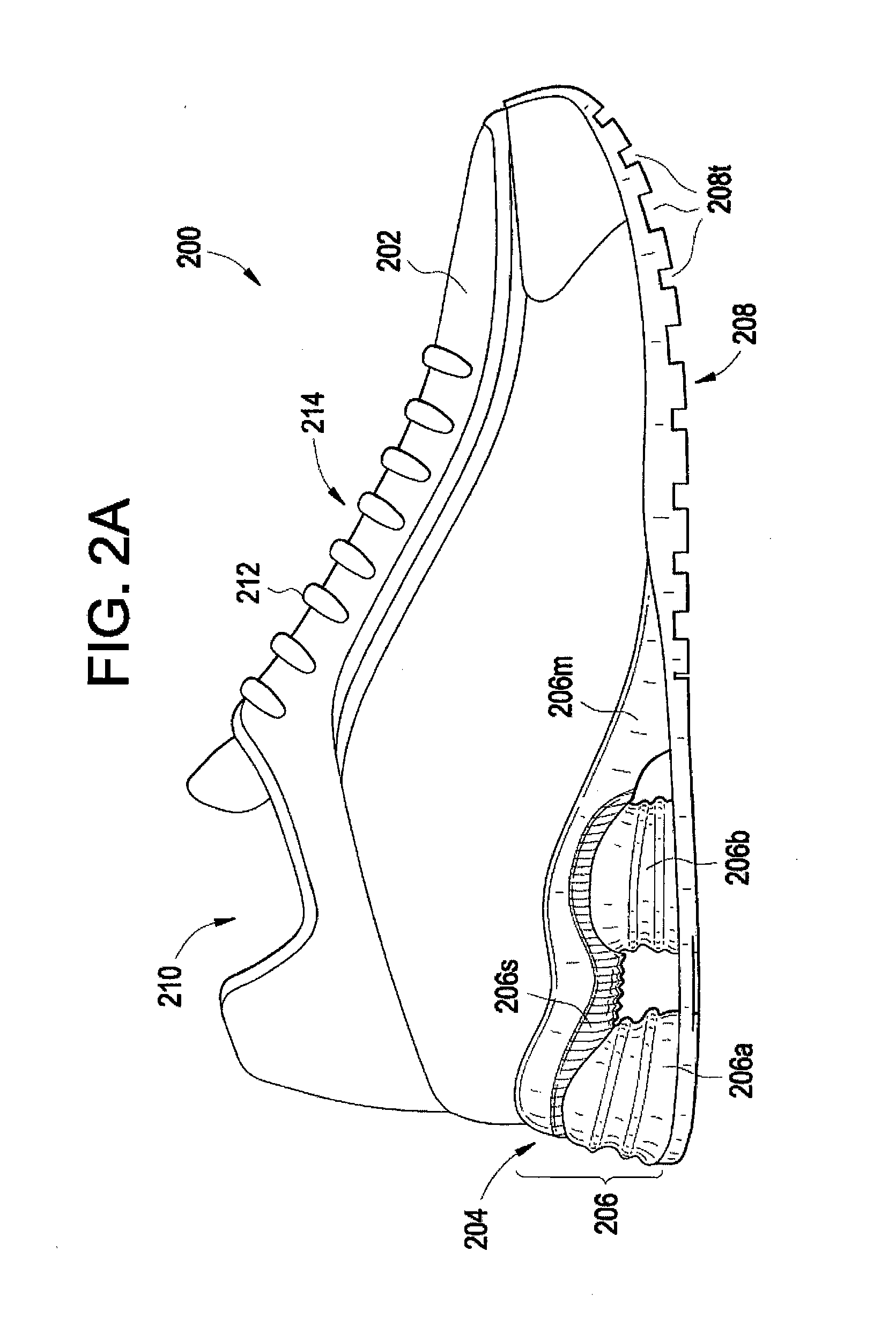

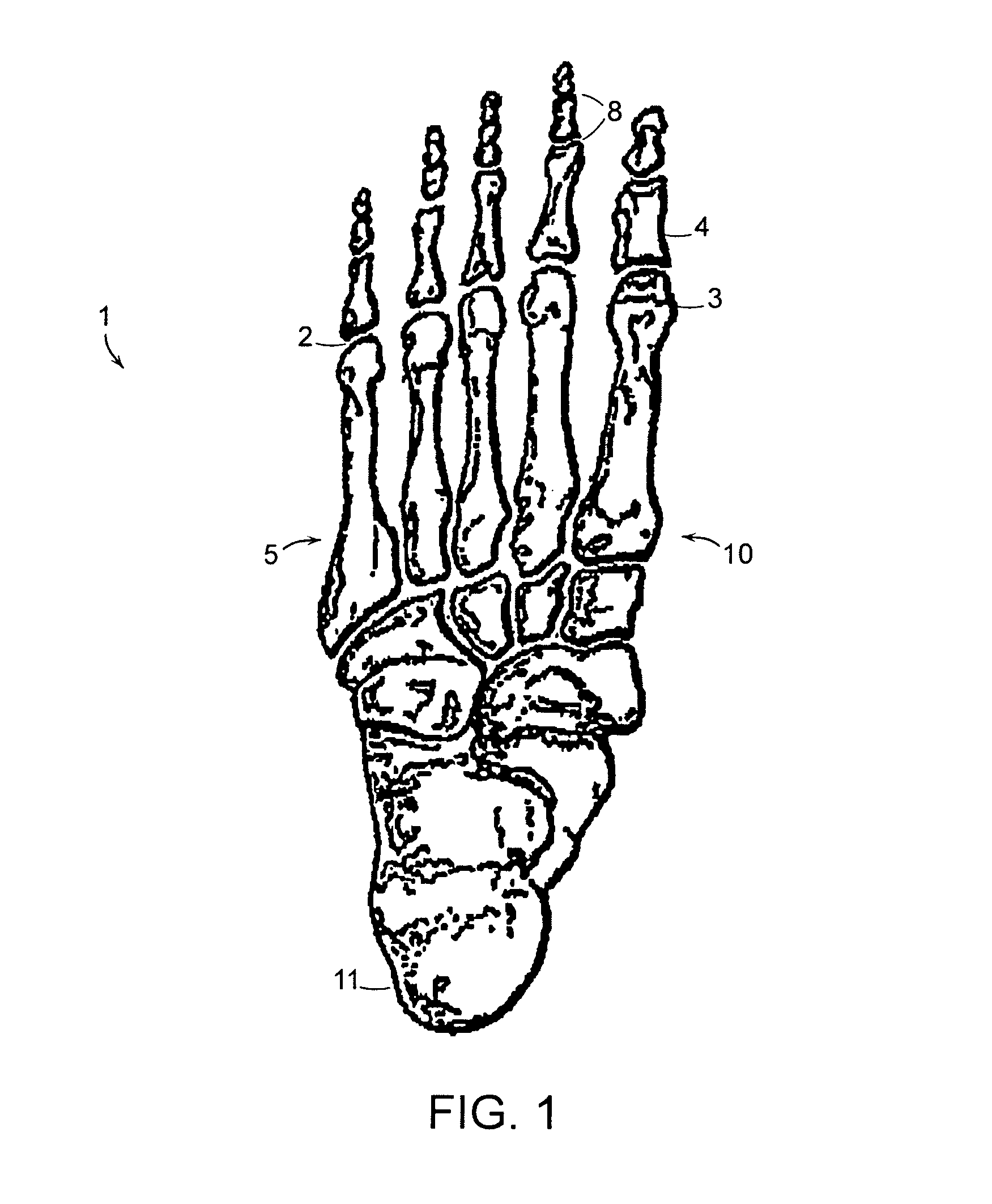

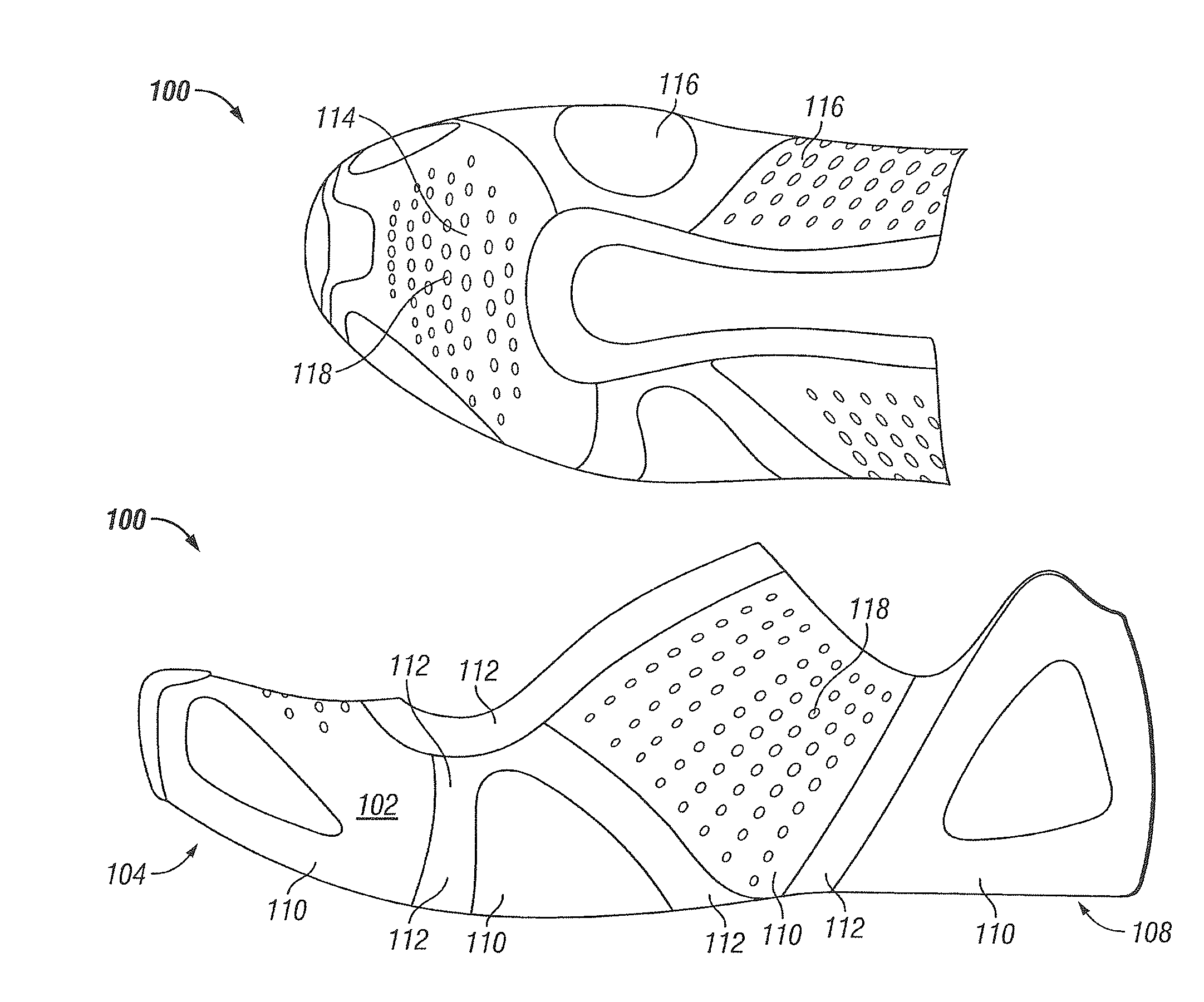

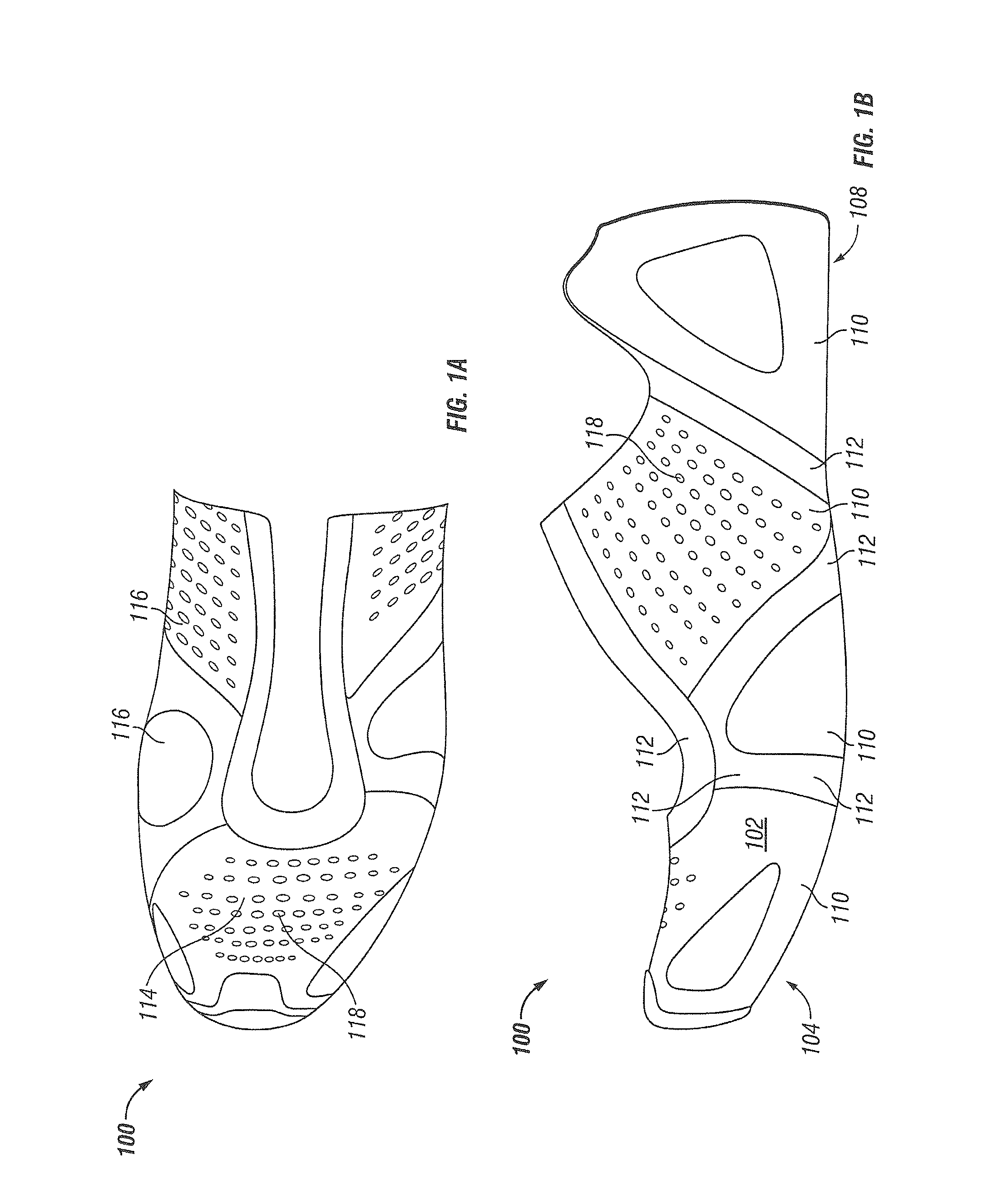

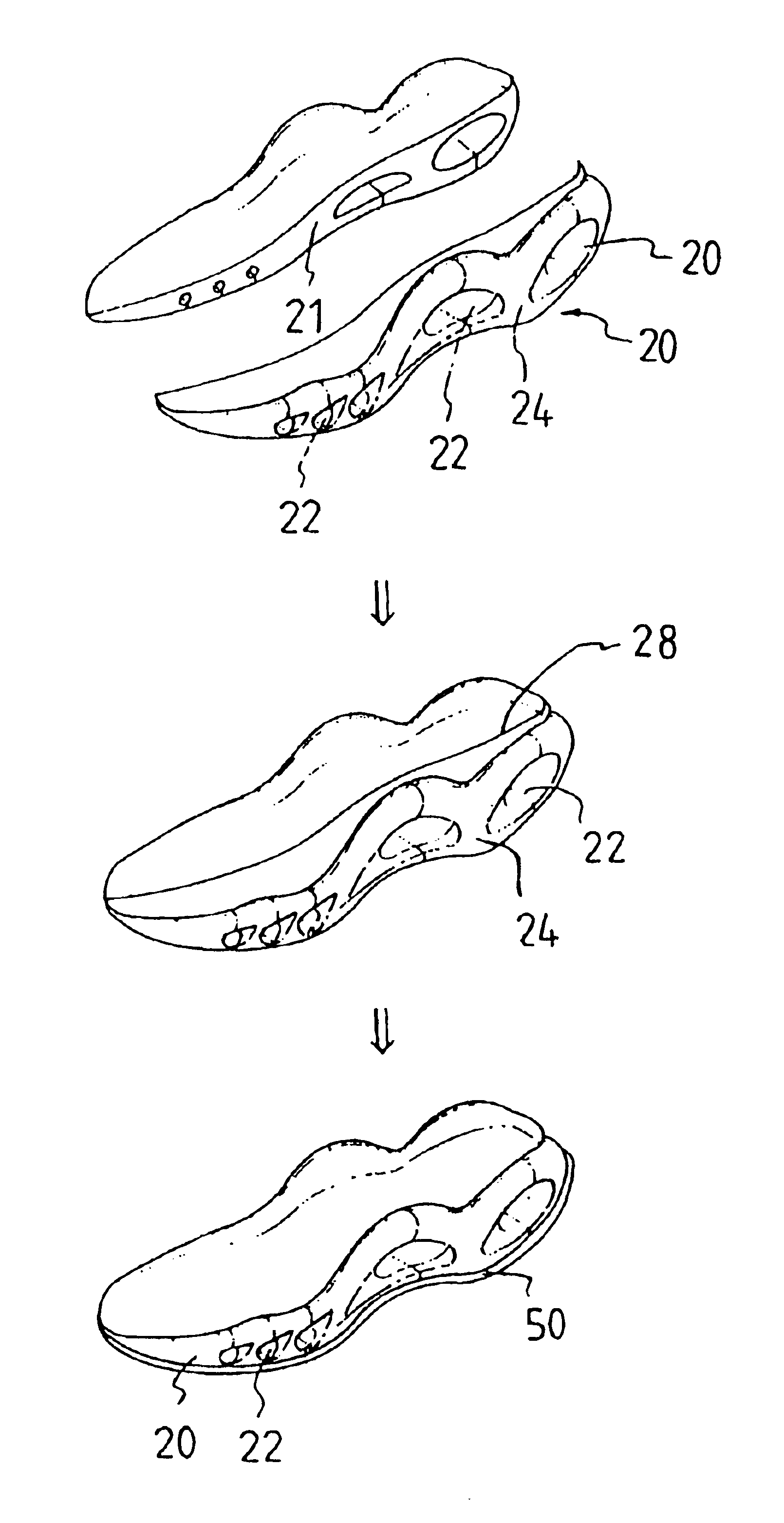

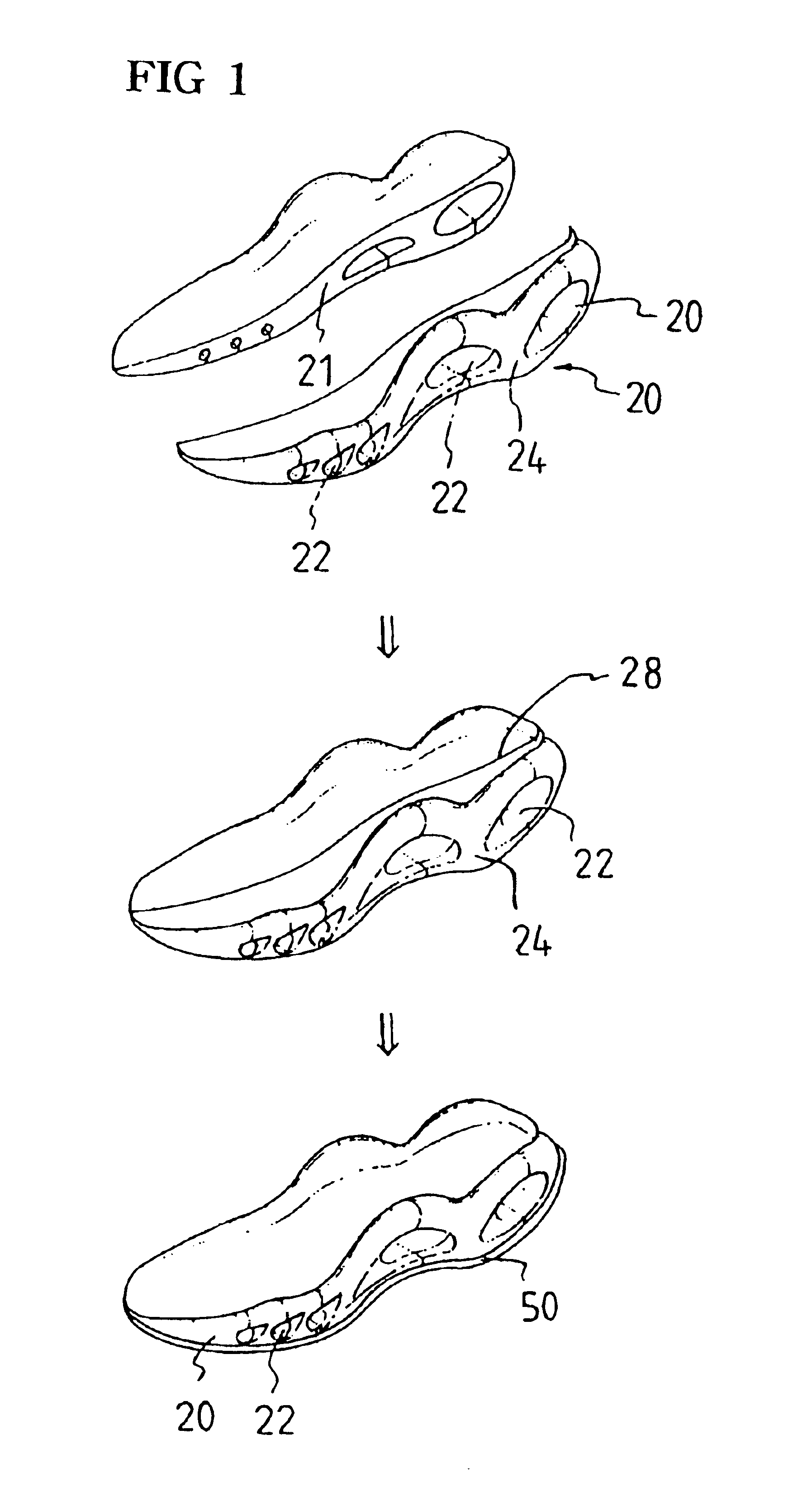

Article of Footwear with an Internal and External Midsole Structure

Articles of footwear having both interior and exterior midsole components may include: (a) an upper that at least in part defines an interior chamber; (b) an interior midsole component within the interior chamber, wherein, at a forefoot region, the interior midsole component includes a longitudinal flexion line and a plurality of transverse flexion lines; and (c) an exterior sole structure engaged with the upper. This exterior sole structure may include: (a) an exterior midsole component in a heel region of the article of footwear that does not extend under the forefoot region of the article of footwear and (b) an outsole component that extends under the forefoot region. If desired, the outsole component may extend under the exterior midsole component in the rearfoot region. The interior midsole component may include a plurality of pod elements separated from one another by the flexion lines.

Owner:NIKE INC

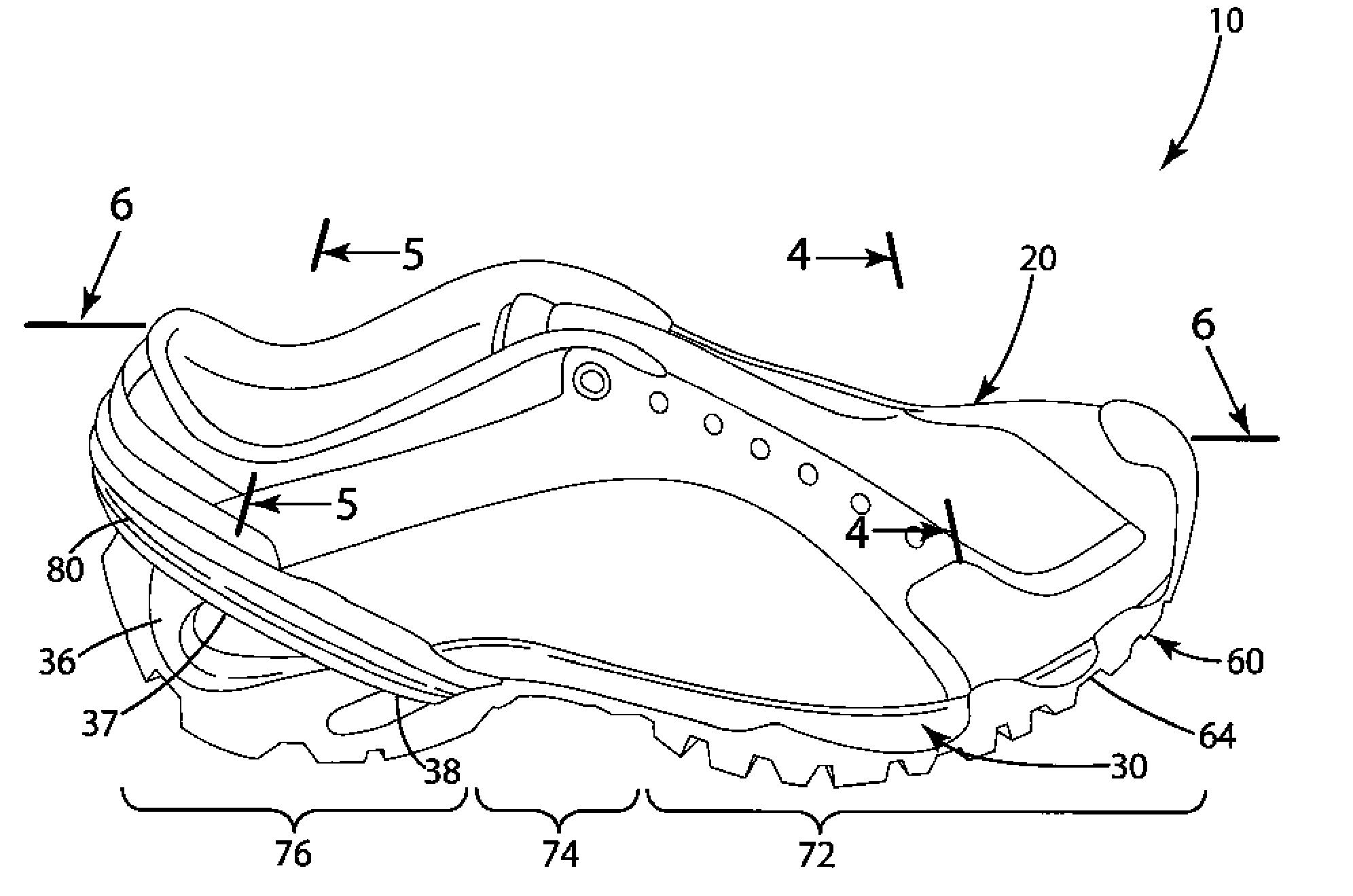

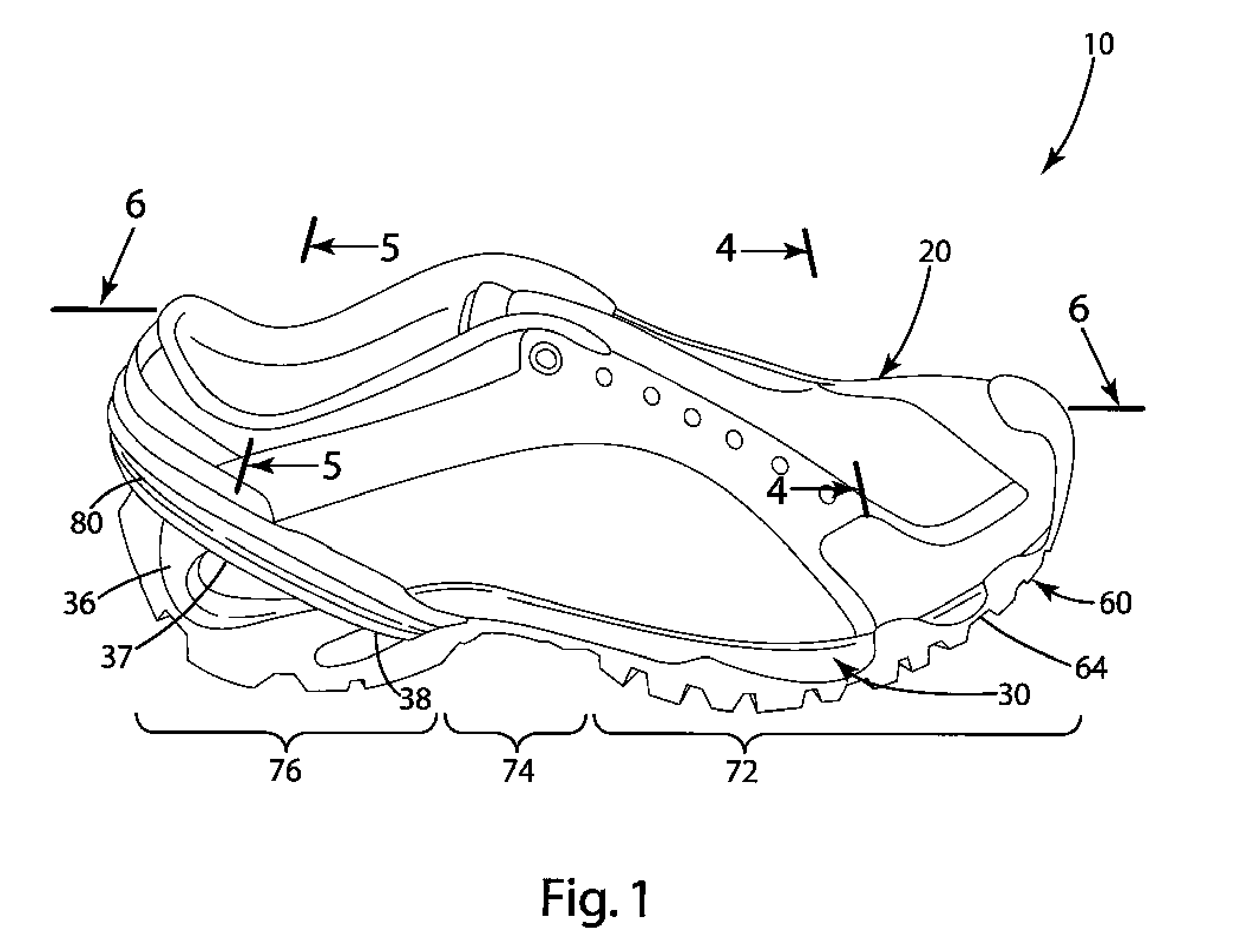

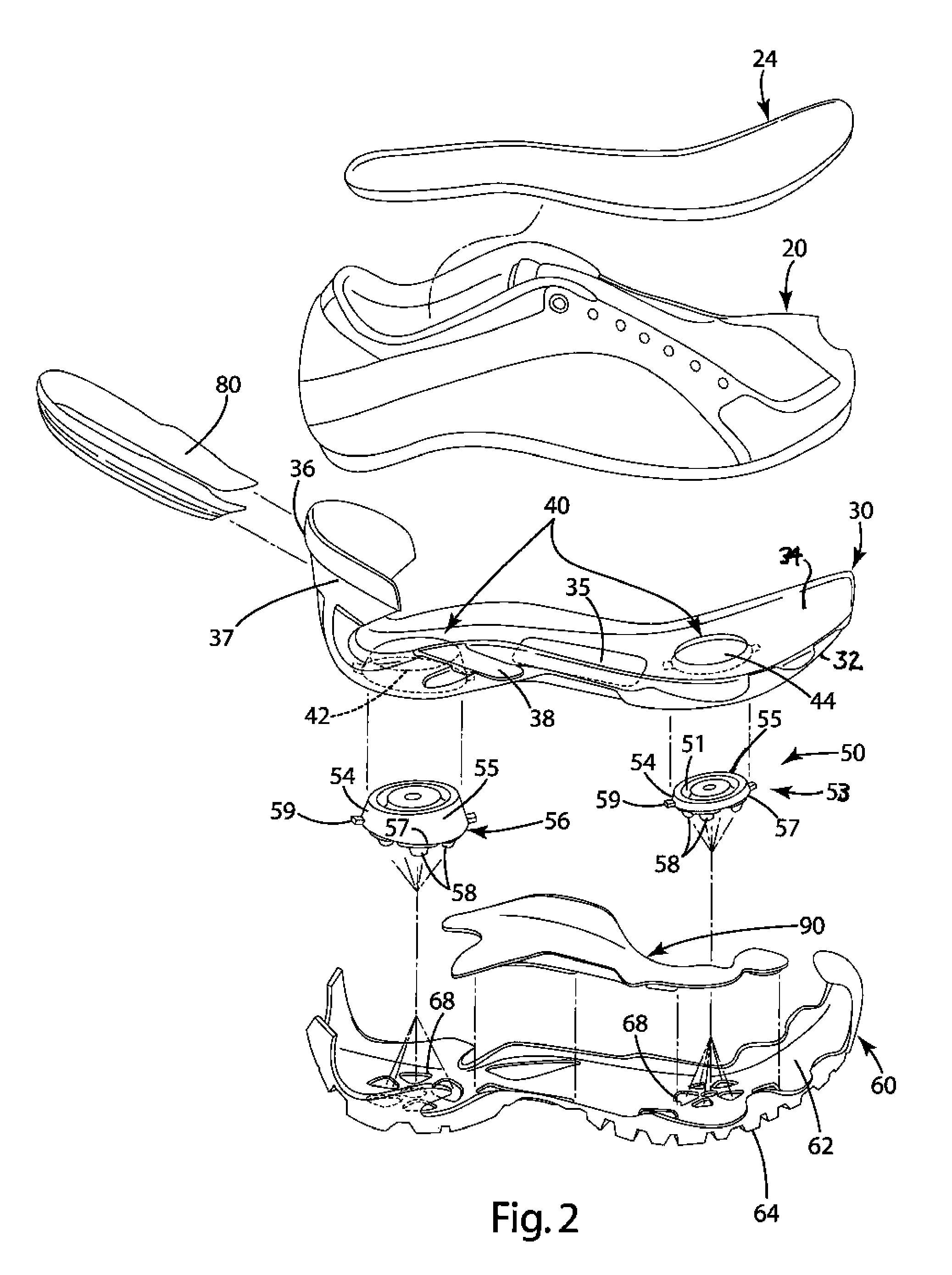

Footwear construction and related method of manufacture

A footwear construction including a sole component and shock pods that absorb impact forces caused by activity. The sole component can be a midsole defining at least one shock pod hole that reduces in dimension from a midsole lower surface toward a midsole upper surface. A shock pod can be joined with the midsole, and extend from the lower surface toward the upper surface. The midsole can be constructed from a harder material than the material from which the shock pod is constructed. A outsole can be joined with the midsole so that a lower portion of the shock pod, for example a traction lug, extends through the outsole to form a ground contacting surface. The shock pod and the shock pod hole can be of corresponding frustoconical shapes. A method is provided including joining a shock pod with a midsole, and joining an outsole with the midsole.

Owner:WOLVERINE OUTDOORS

Semimanufactured Waterproofed Products, Particularly Shoes, Clothing Items and Accessories

InactiveUS20080127426A1Improve adhesionPhysical treatmentInsolesWork in processBiomedical engineering

Owner:OUTDRY TECH

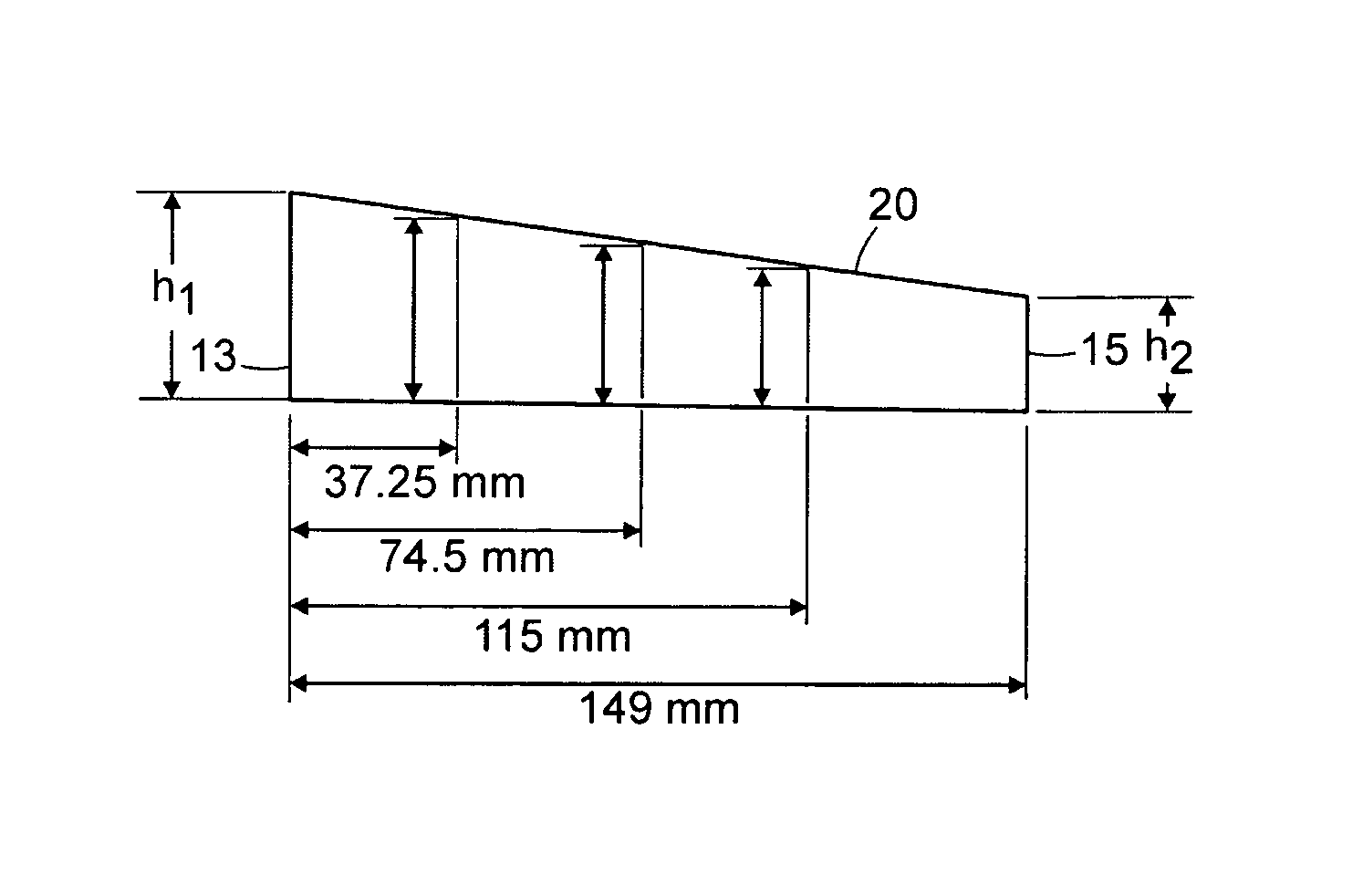

Sole elements of varying density and methods of manufacture

The invention relates to sole elements and methods for manufacturing sole elements for shoes, in particular for sport shoes, with a specific density distribution in a transverse and / or longitudinal direction. The methods include the steps of manufacturing a sole element preform from a polymer material with a thickness varying in the transverse and / or longitudinal direction depending on the desired density distribution and the press-forming of the sole element preform in a forming tool to form the finished sole element from the sole element preform.

Owner:ADIDAS

Upper of footwear and manufacturing method thereof

InactiveUS20140338222A1Improve productivityKeeping quality consistentInsolesUpperProduction rateEngineering

Owner:SONG SOO BOK

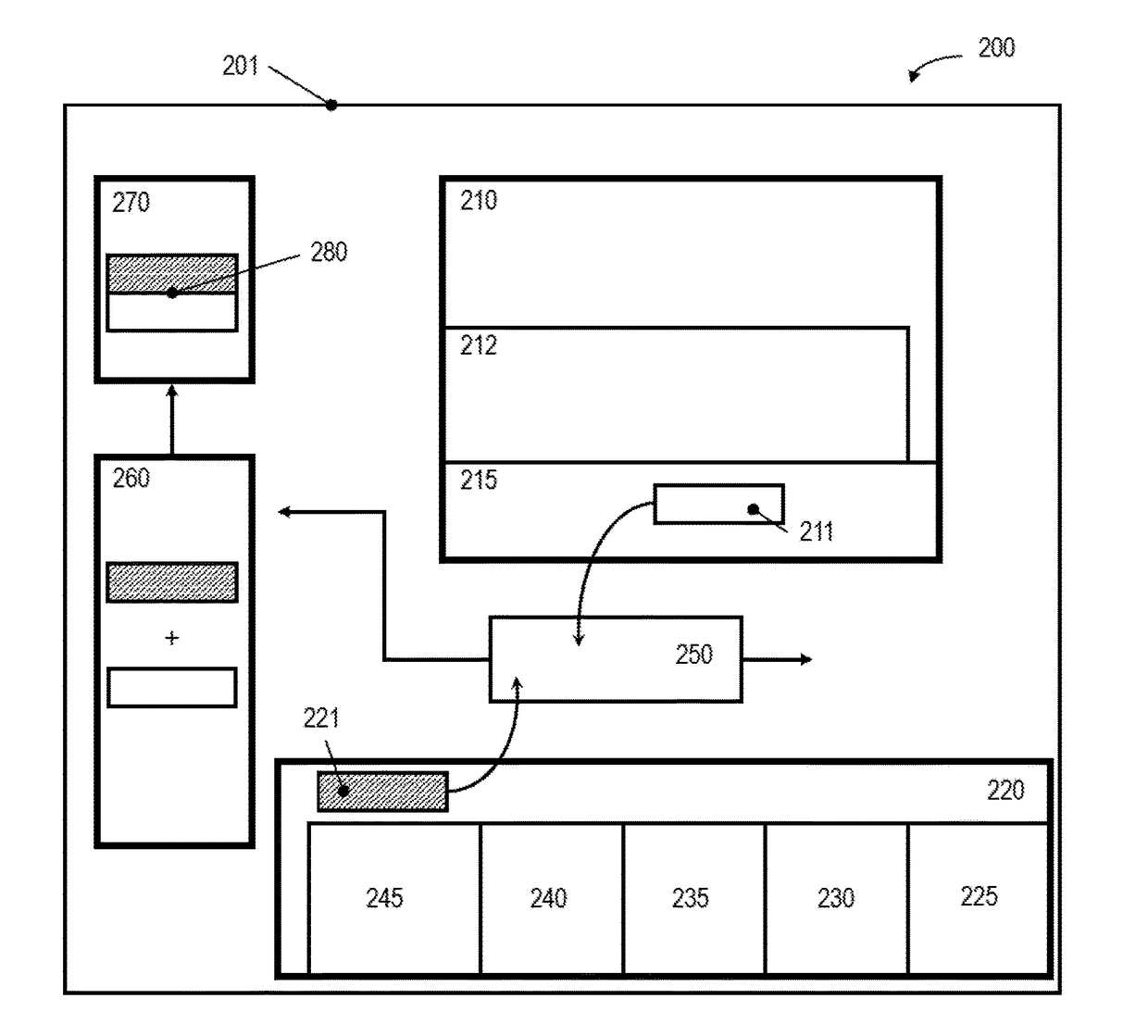

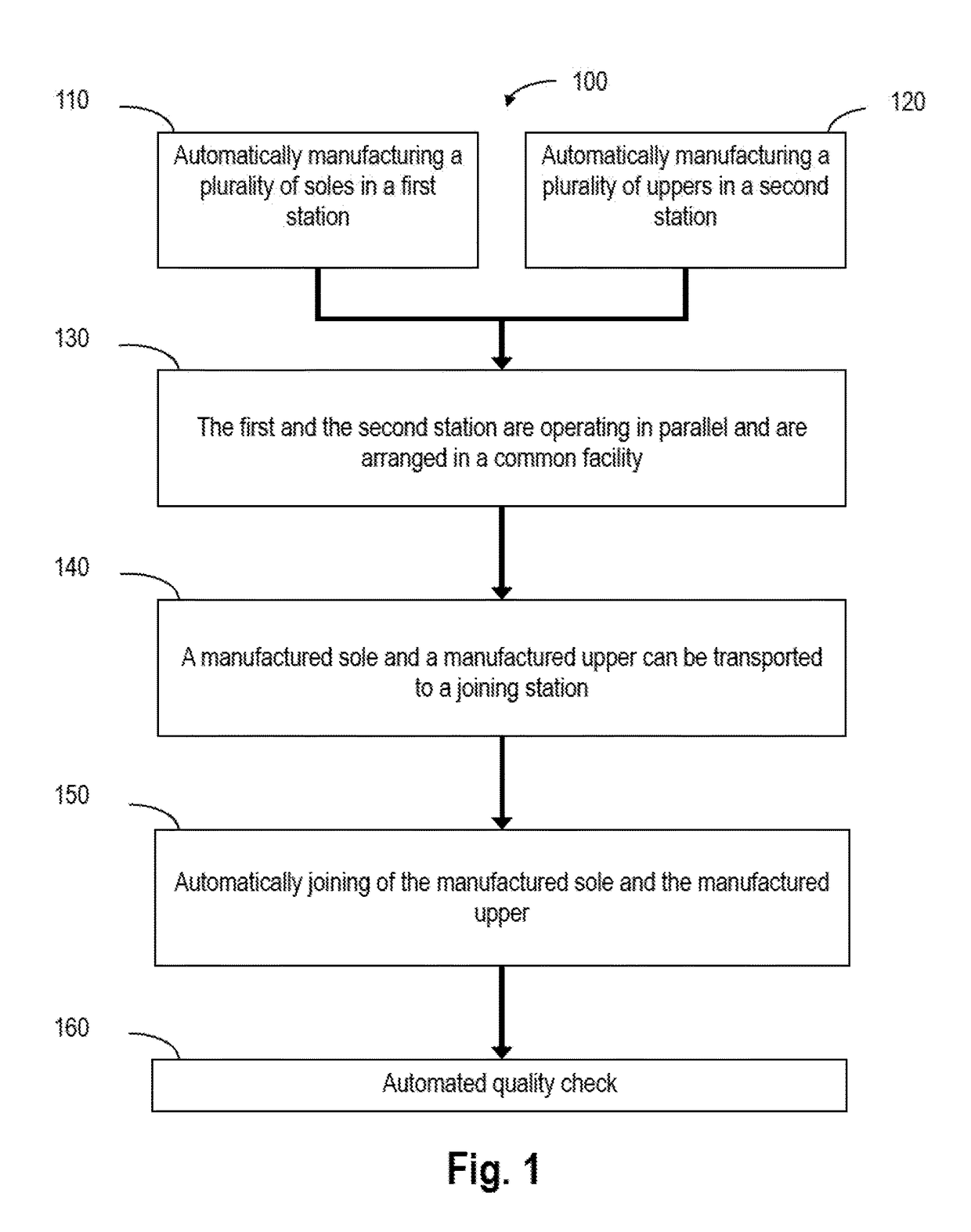

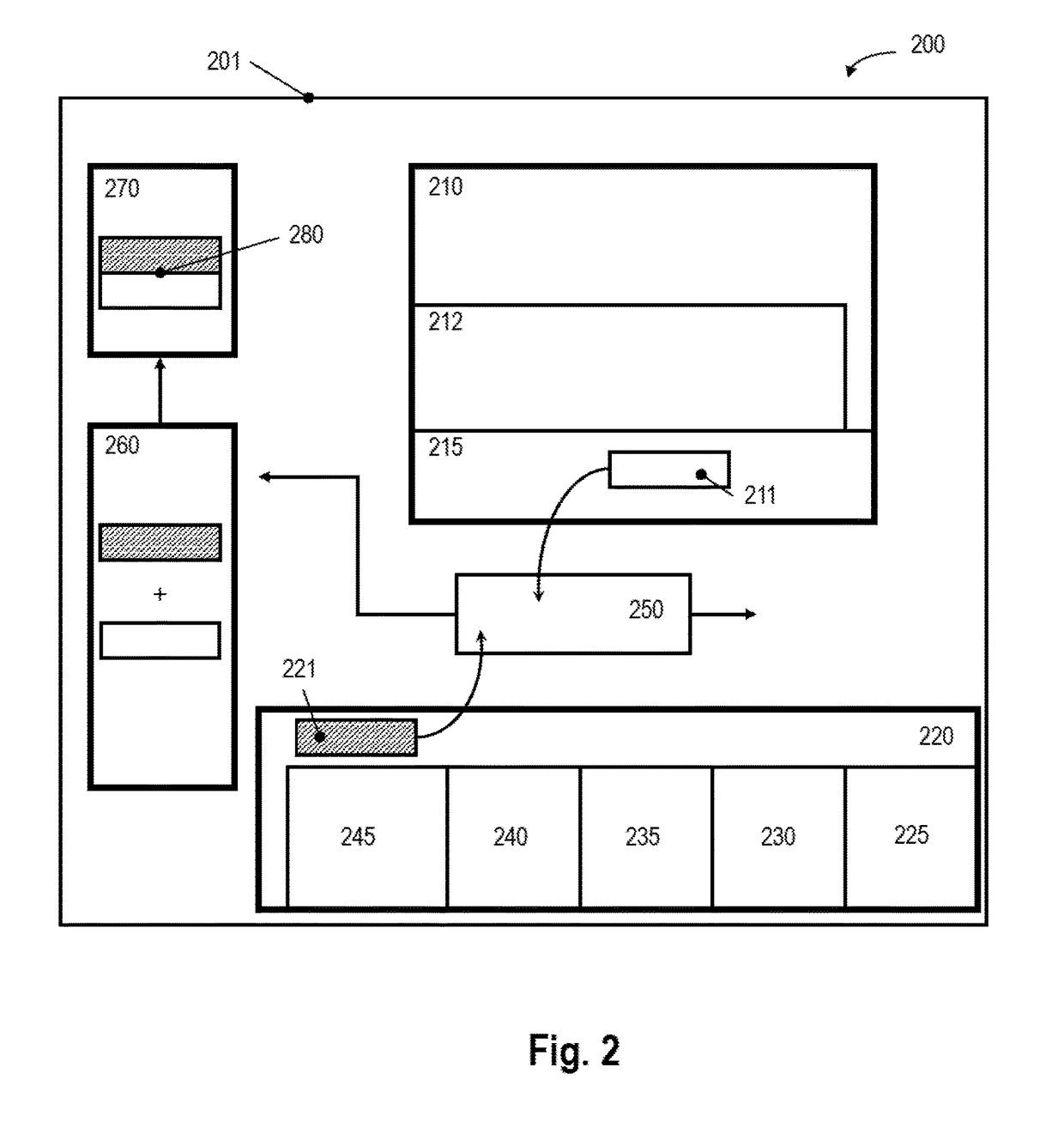

Method and system for automatically manufacturing shoes

InactiveUS20170340067A1Simplify the manufacturing processEfficient executionSolesHeelsManufacturing engineering

Described are a method and a system for automatically manufacturing shoes. The method includes automatically manufacturing a plurality of soles in a first station and automatically manufacturing a plurality of uppers in a second station, wherein the first and the second station are operating in parallel and are arranged in a common facility so that a manufactured sole and a manufactured upper can be transported to a joining station and be automatically joined there.

Owner:ADIDAS

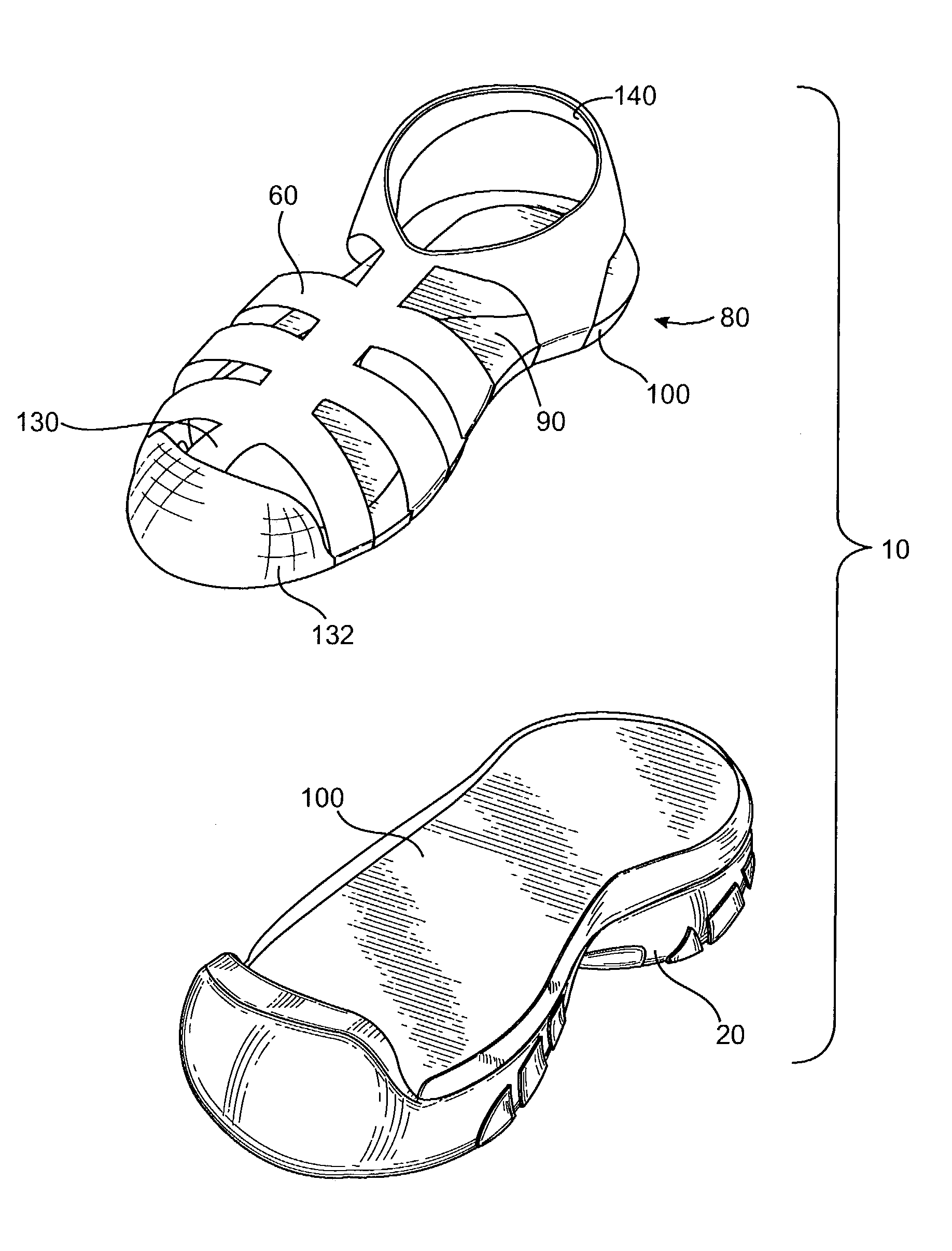

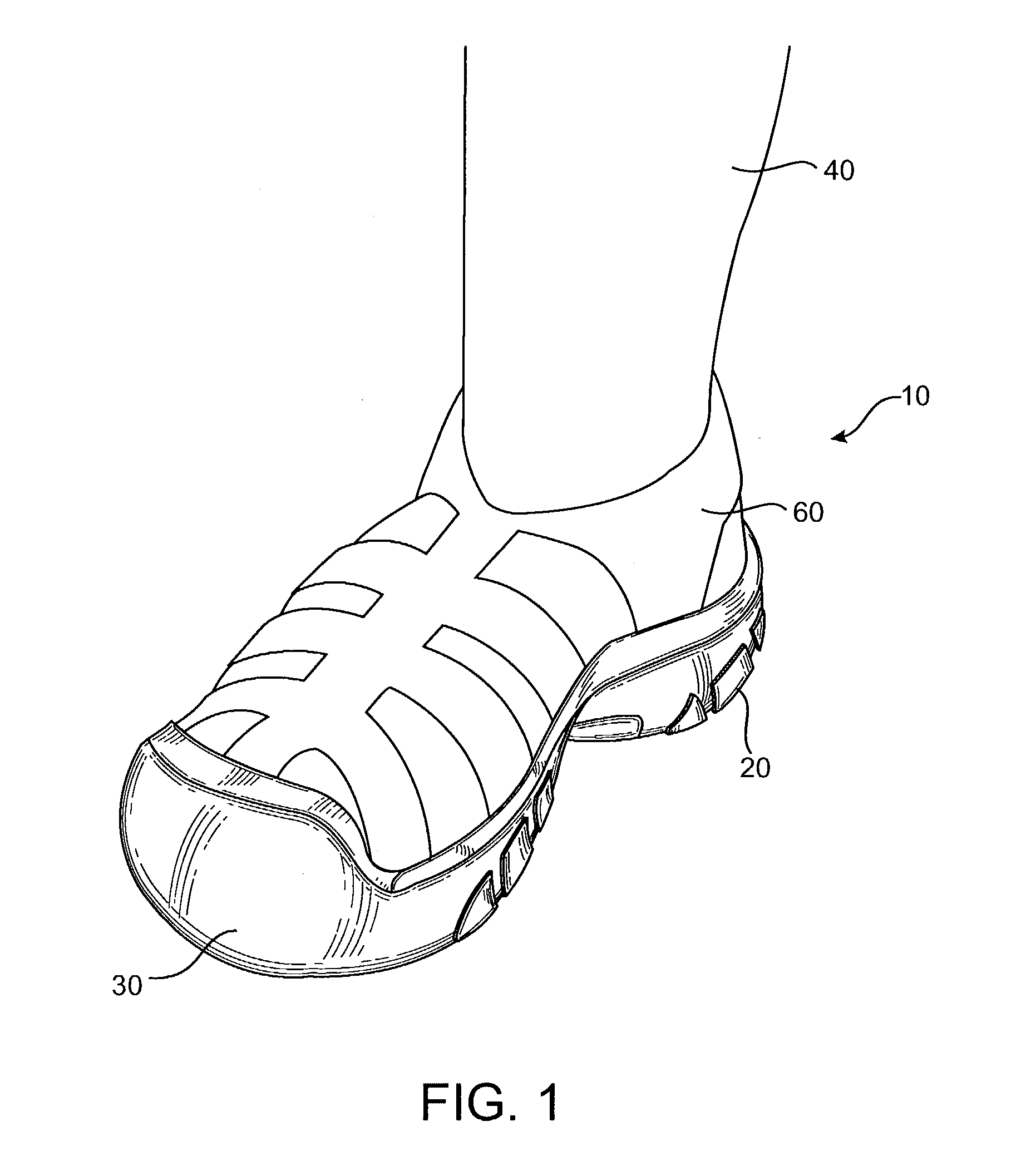

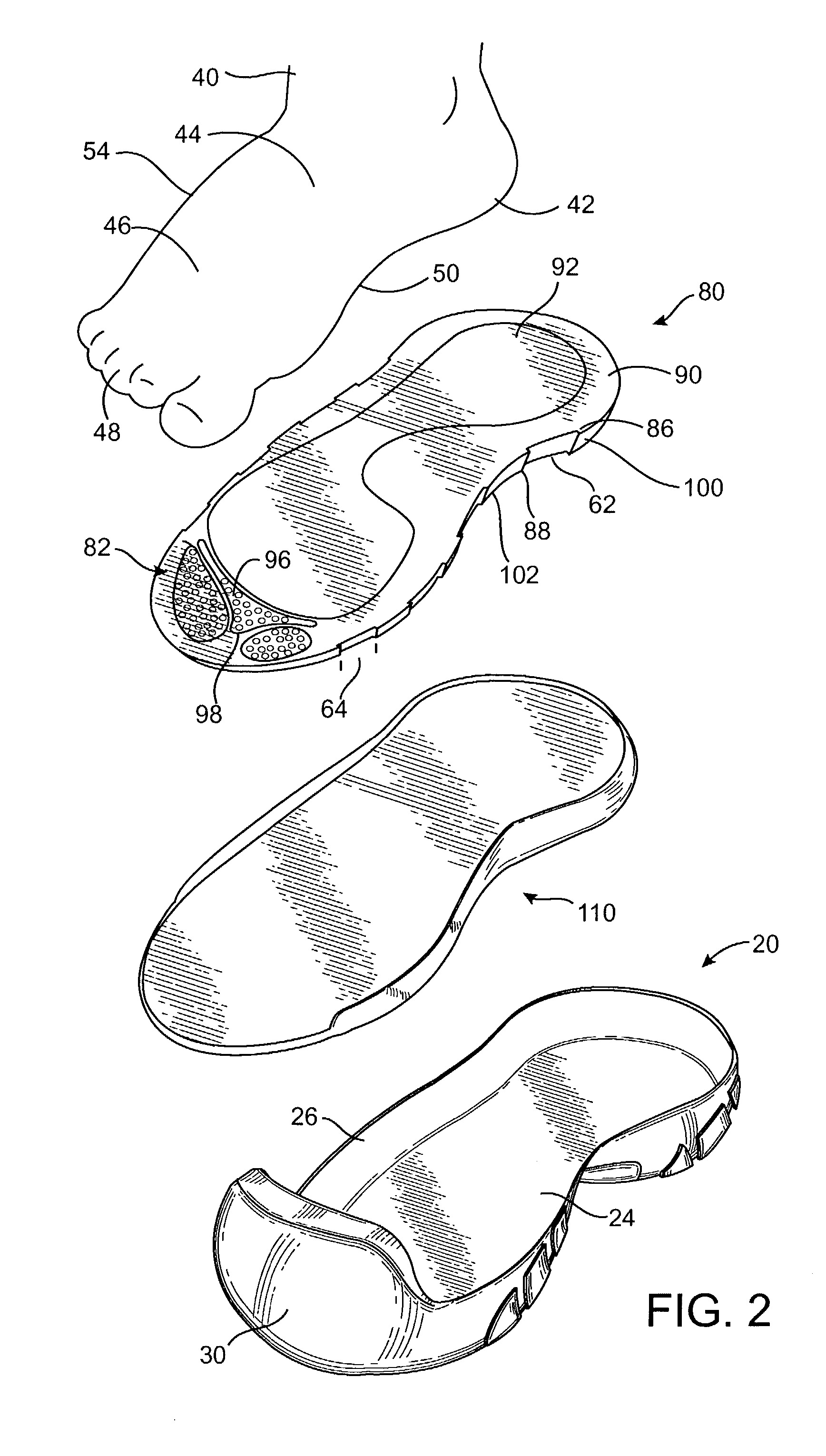

Toe protection sandal

A sandal including a molded rubber outsole configured to support a lower surface of a foot including a heel, midfoot, and a forefoot; a toe cap extending from the outsole and configured to cover a top of at least a portion of the forefoot, the toe cap molded integrally with the outsole; and a plurality of sandal straps fixed to the outsole to retain the sandal on the foot, at least one of the sandal straps fixed to the toe.

Owner:KEEN INC

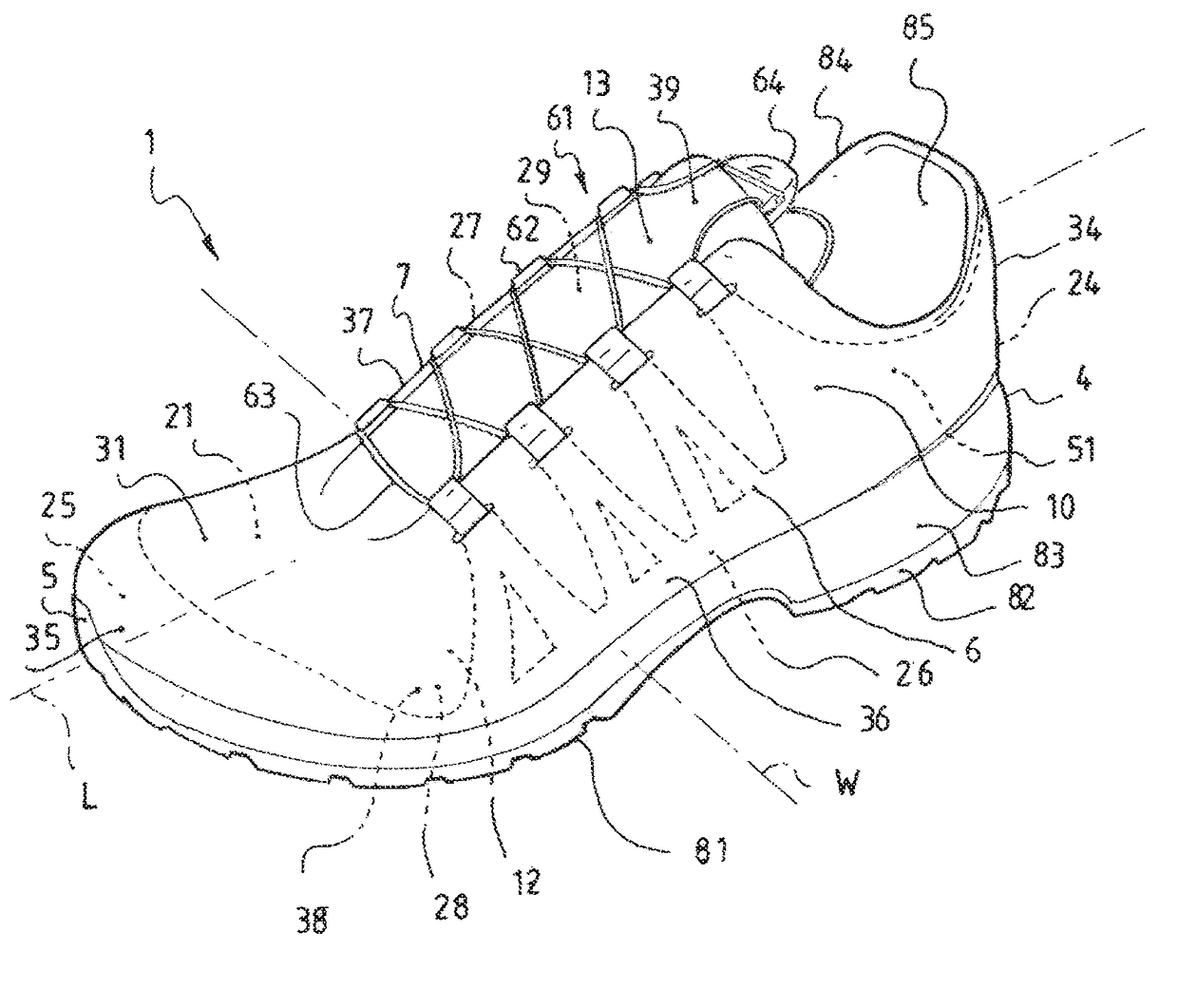

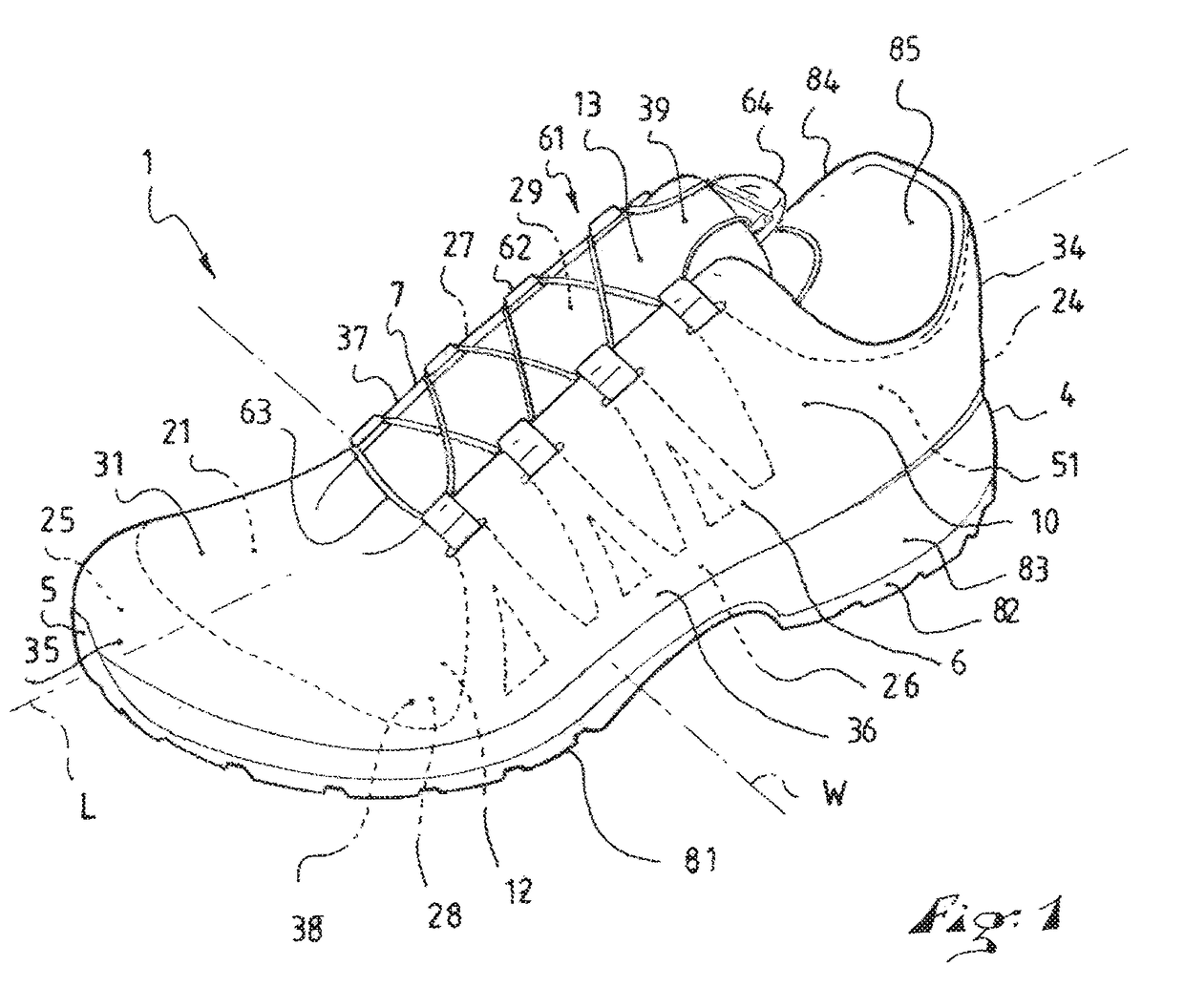

Breathable shoe

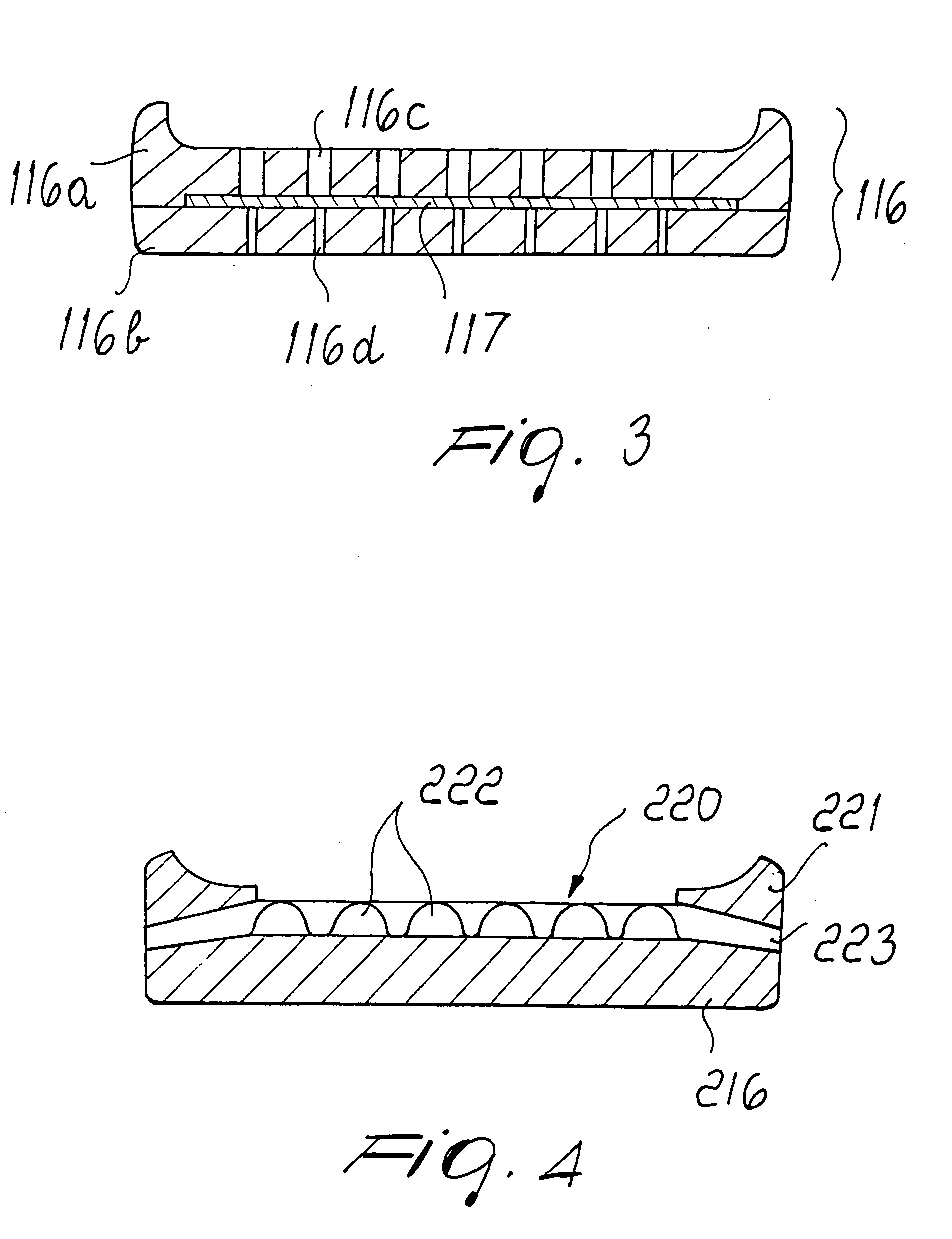

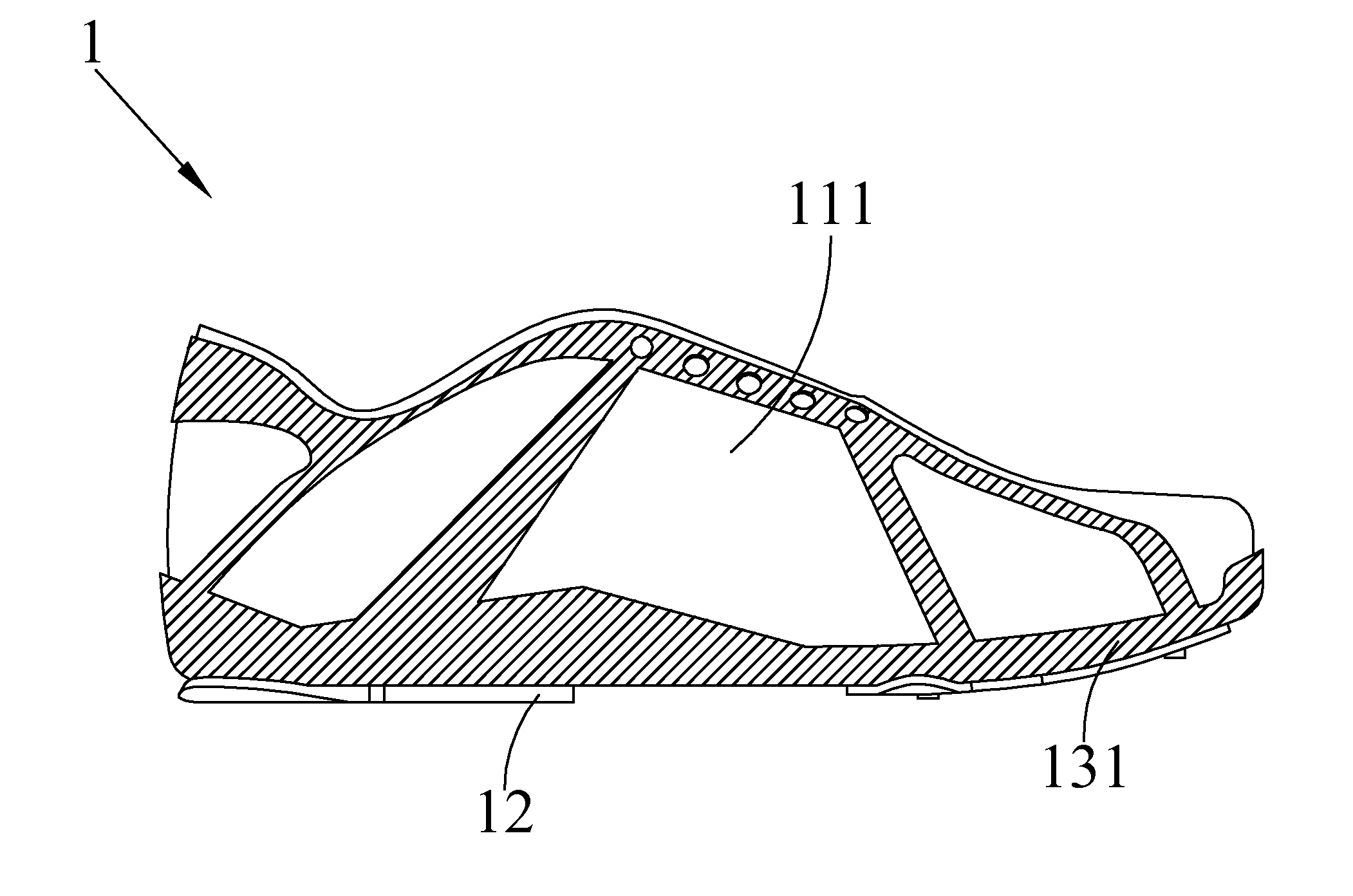

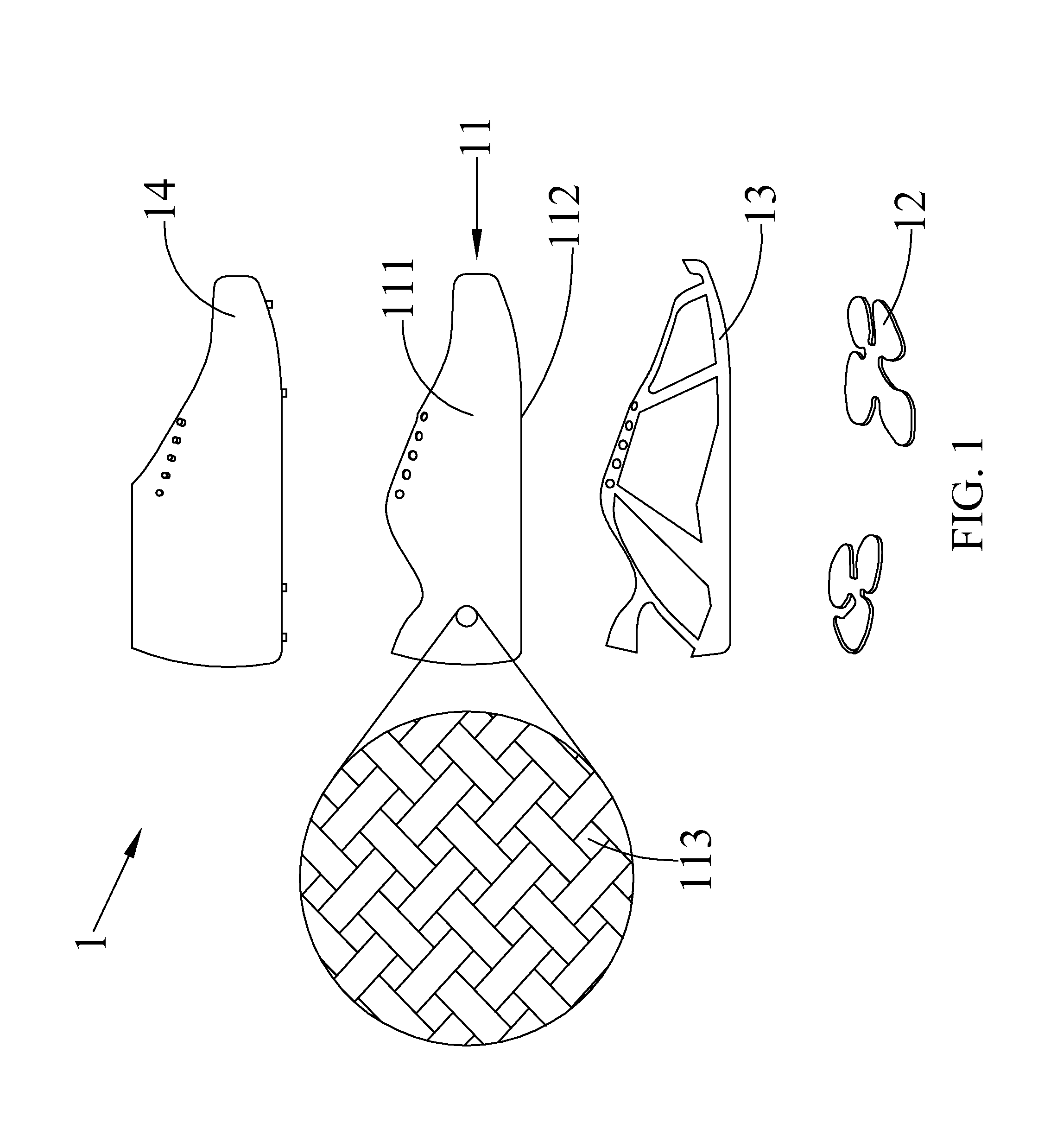

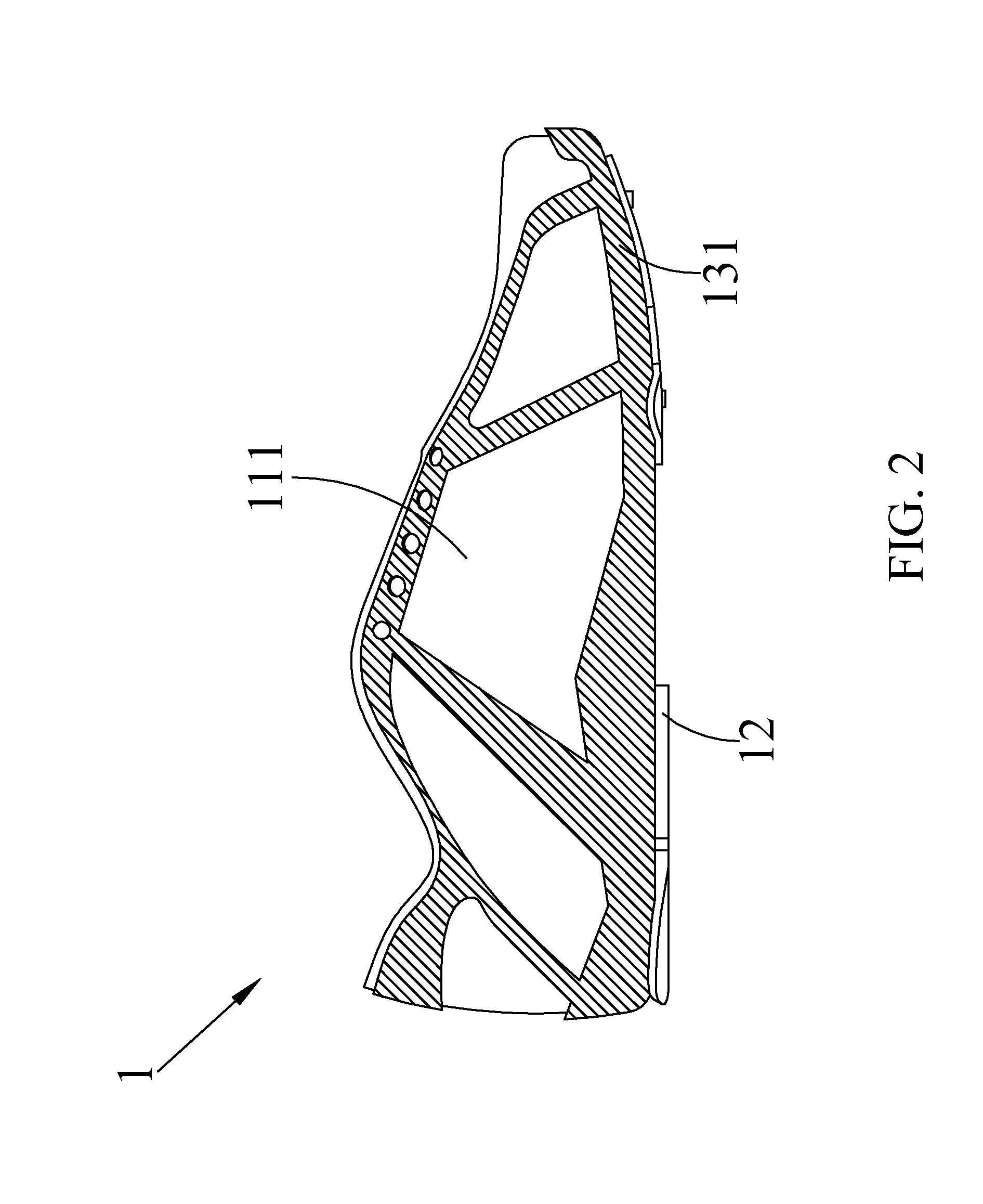

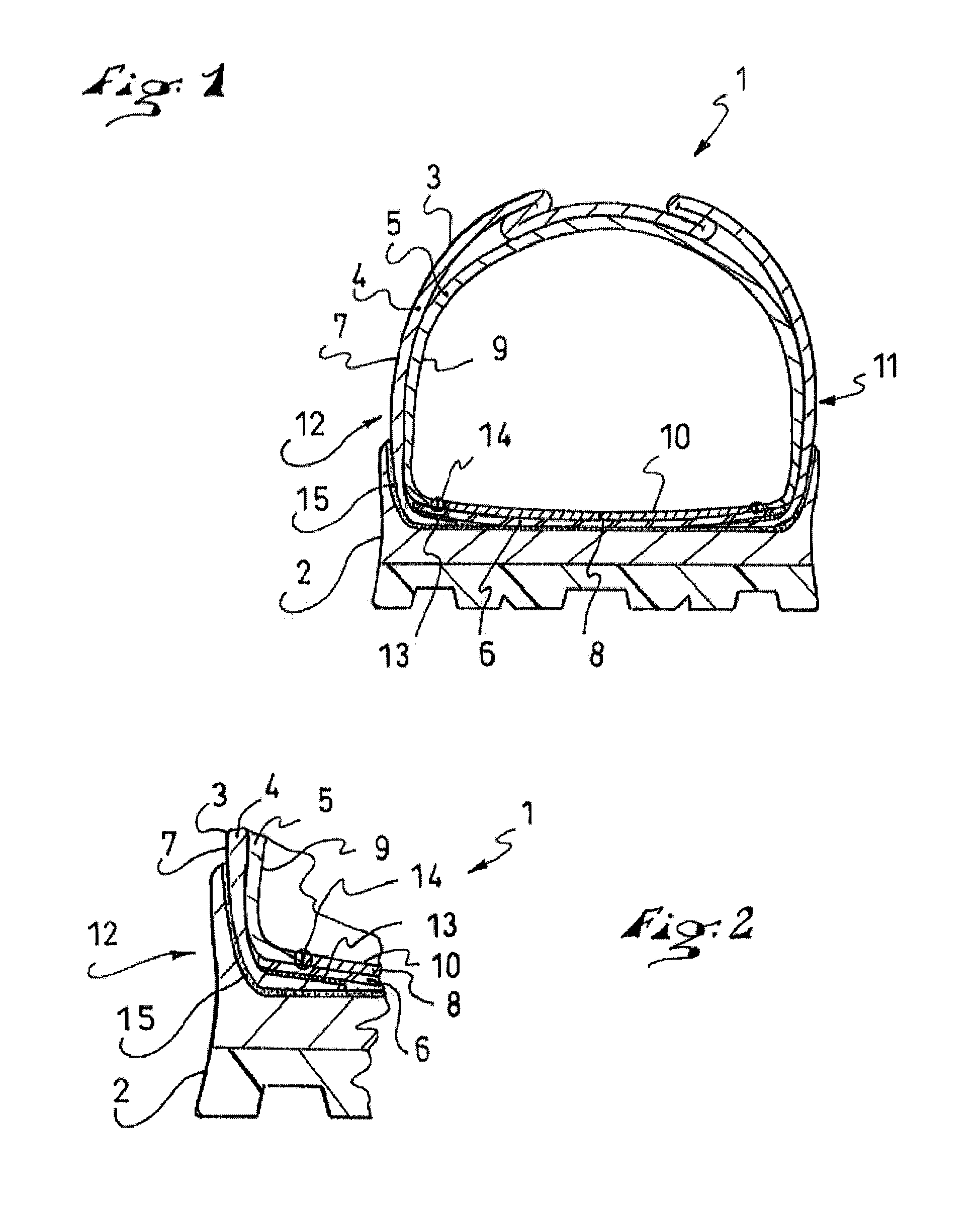

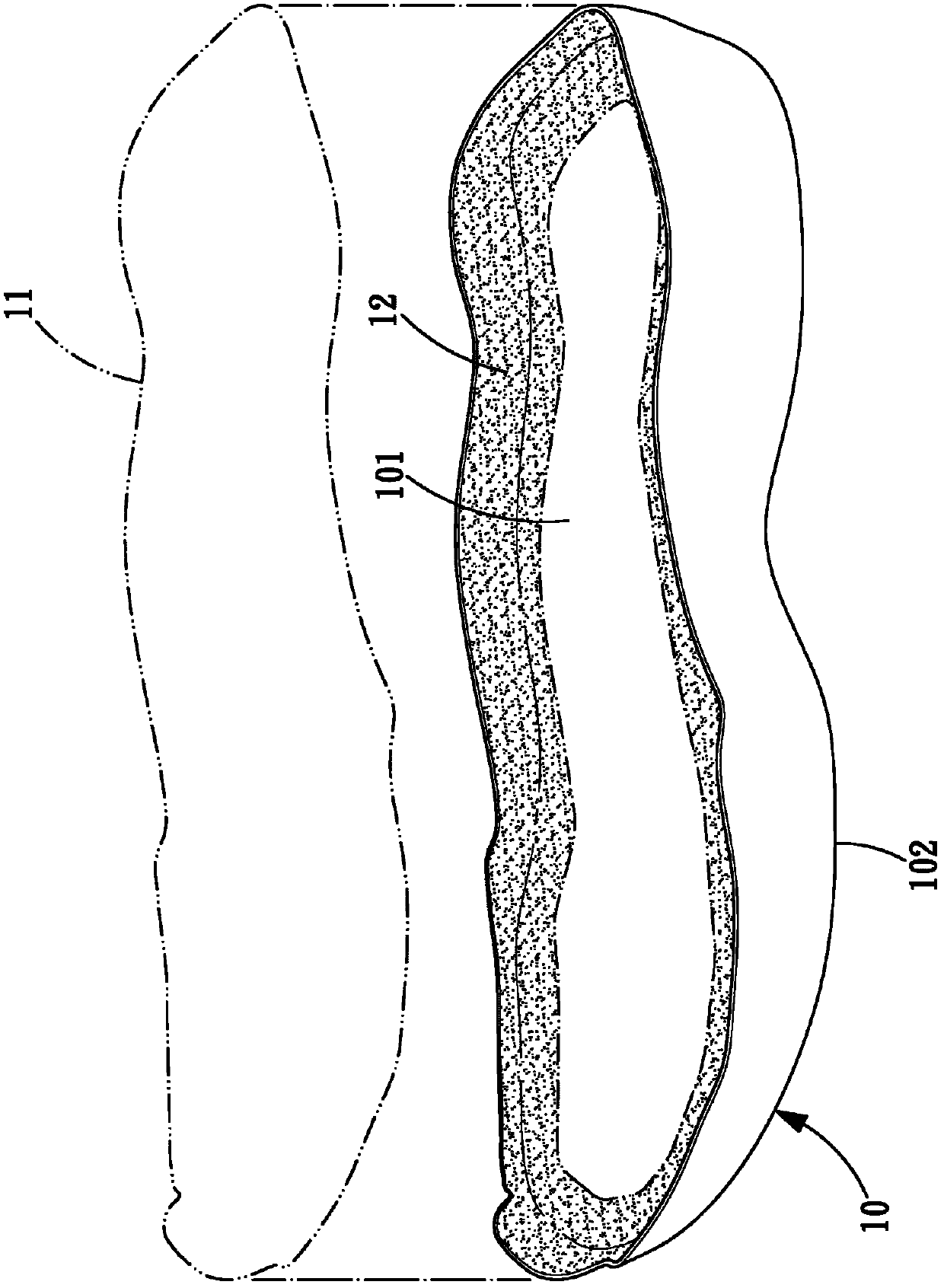

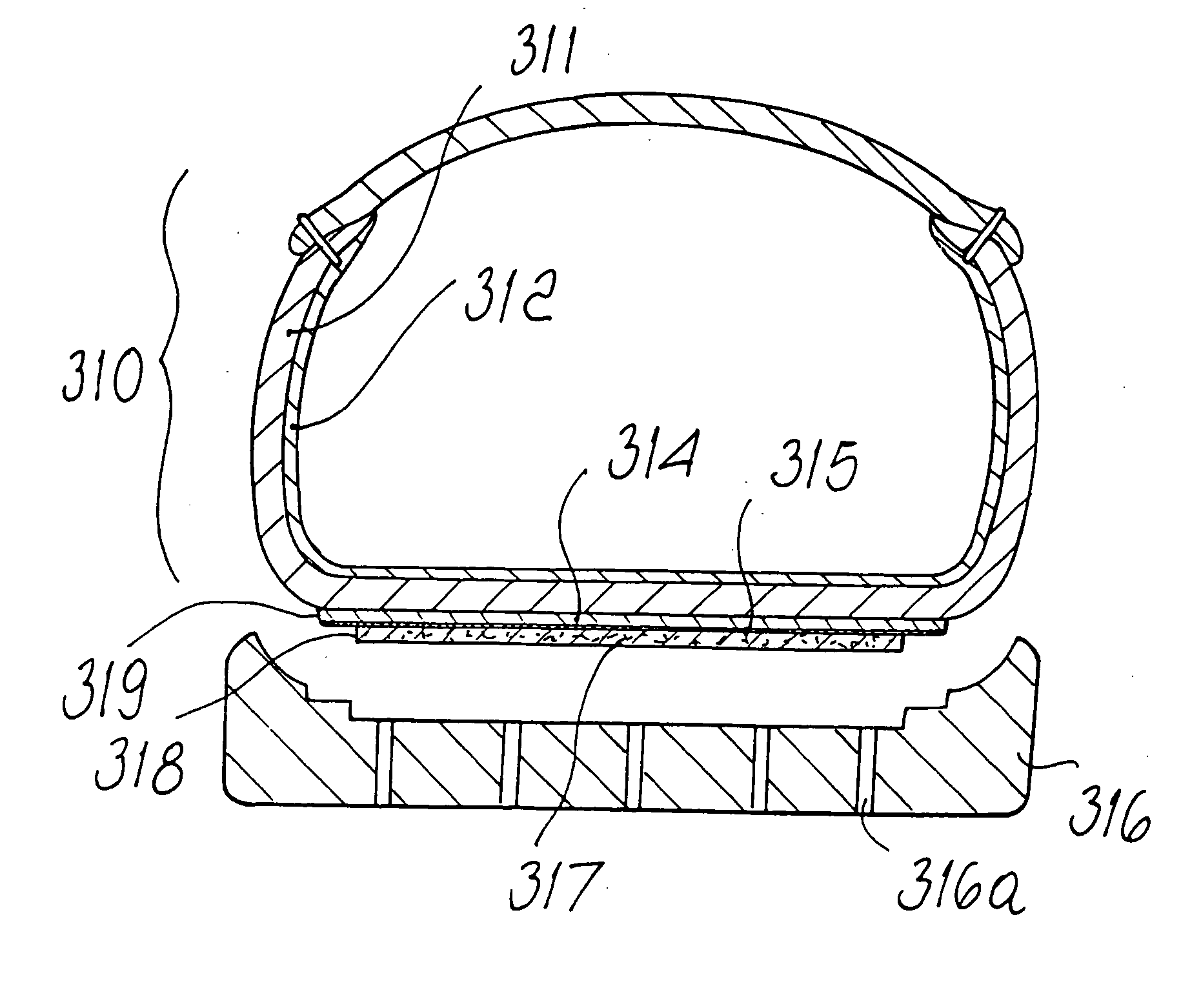

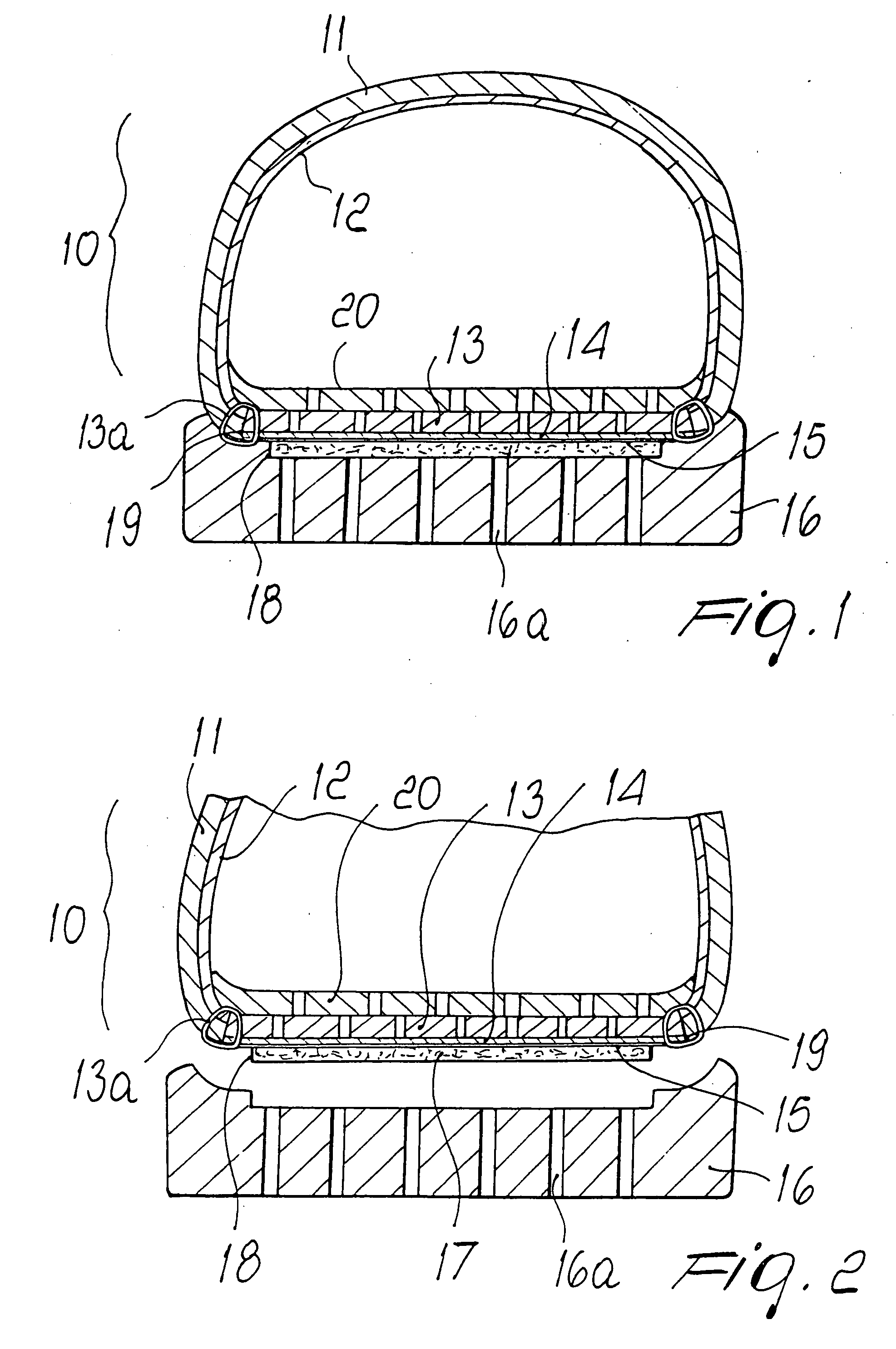

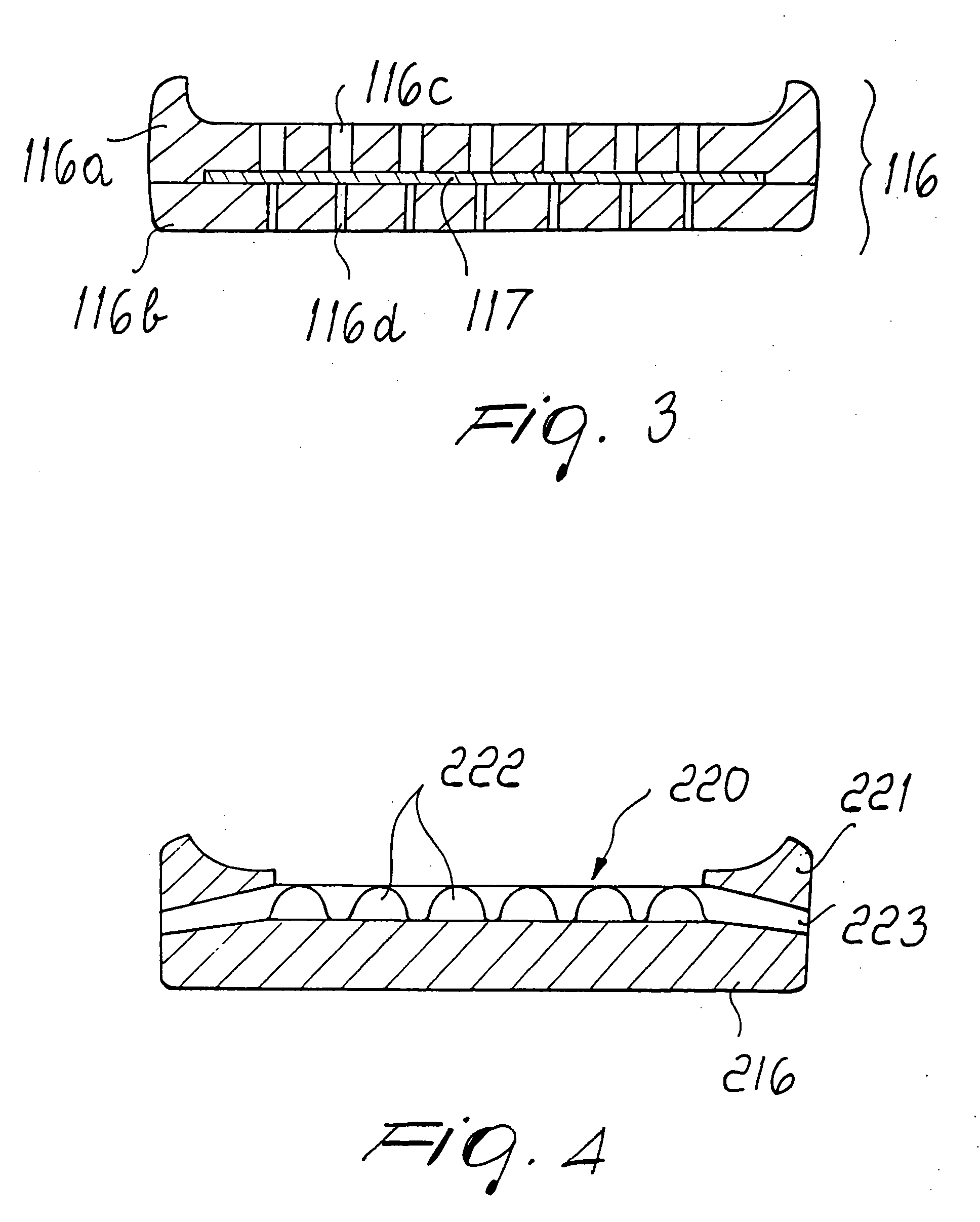

A breathable shoe, including: an upper assembly (10;310;410) having a breathable upper (11;311;411); a membrane (14;314;414) made of a material which is waterproof and breathable, and a sole (16;116;216;316;416) made of perforated elastomer, which are all mutually attached such that the membrane is arranged between the upper assembly and the sole, and the sole is sealed perimetrically to the membrane, in a manner to prevent moisture to enter into the upper assembly from the sole through the membrane, and to permit moisture to leave the inside of the upper assembly through the membrane and through the sole. In one preferred embodiment, the membrane is first attached to the upper assembly so that the upper assembly is a unitary upper assembly including the membrane, and such unitary upper assembly is subsequently attached to the sole.

Owner:GEOX SPA

Shoes of automated process production and shoemaking method thereof

Owner:LONG JOHN TSUNG RIGHT IND +1

Custom article of footwear, method of making the same, and method of conducting retail and internet business

The present invention teaches a custom article of footwear, a method of making the same, and a method of conducting retail and Internet business. In particular, the components of the custom article of footwear can be selected from a wide range of options, and they can be easily removed and replaced, as desired.

Owner:ADIDAS

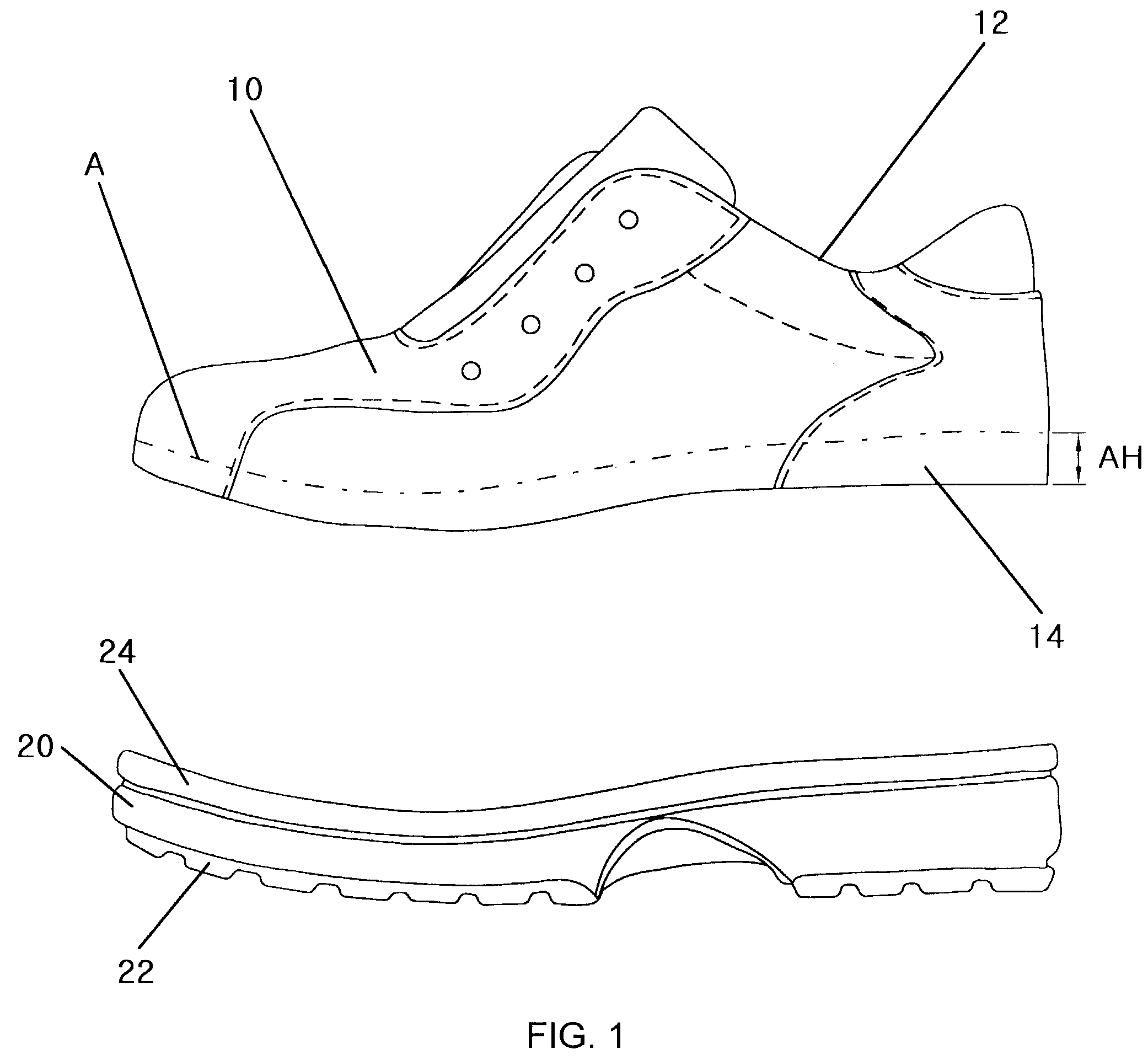

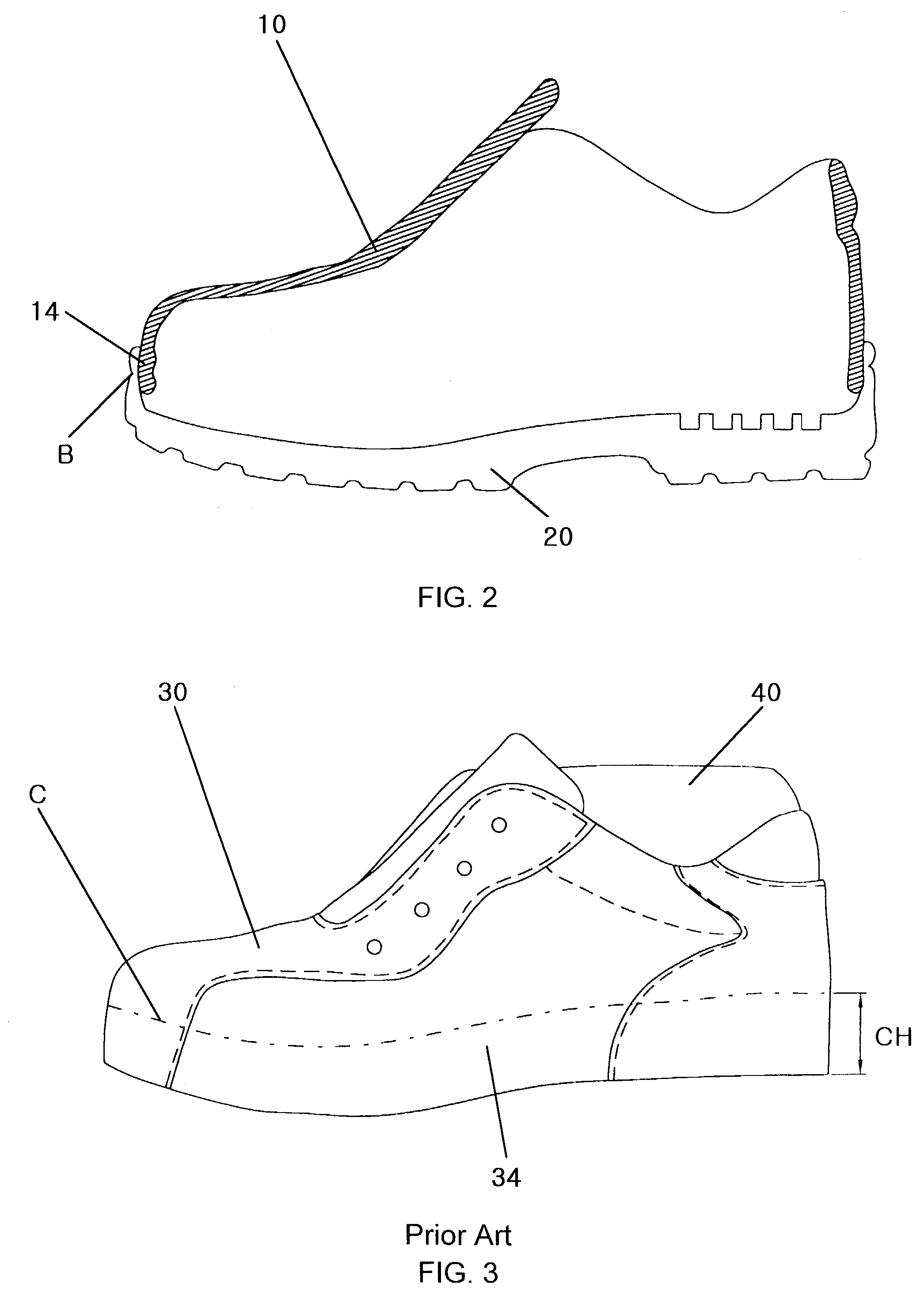

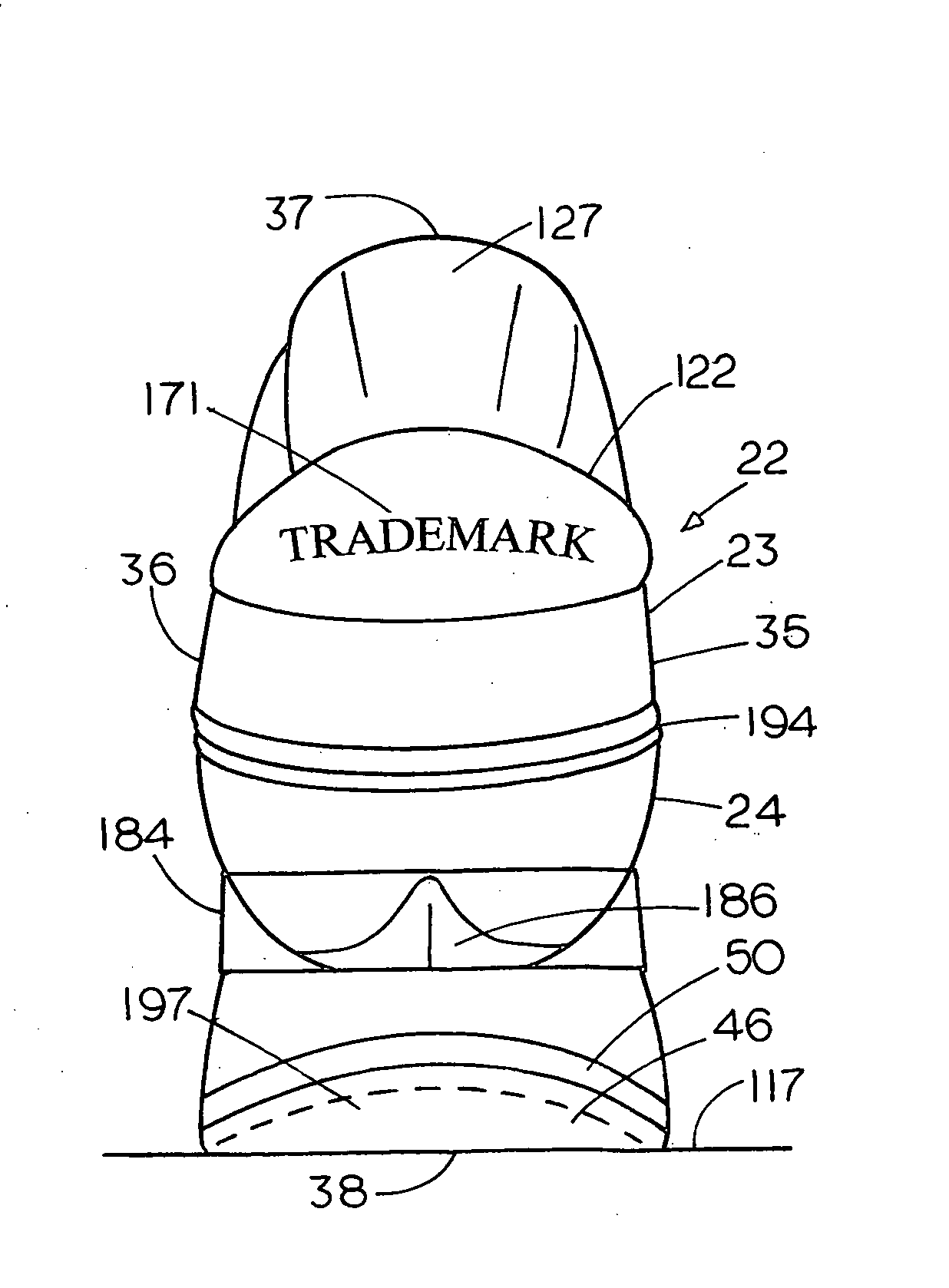

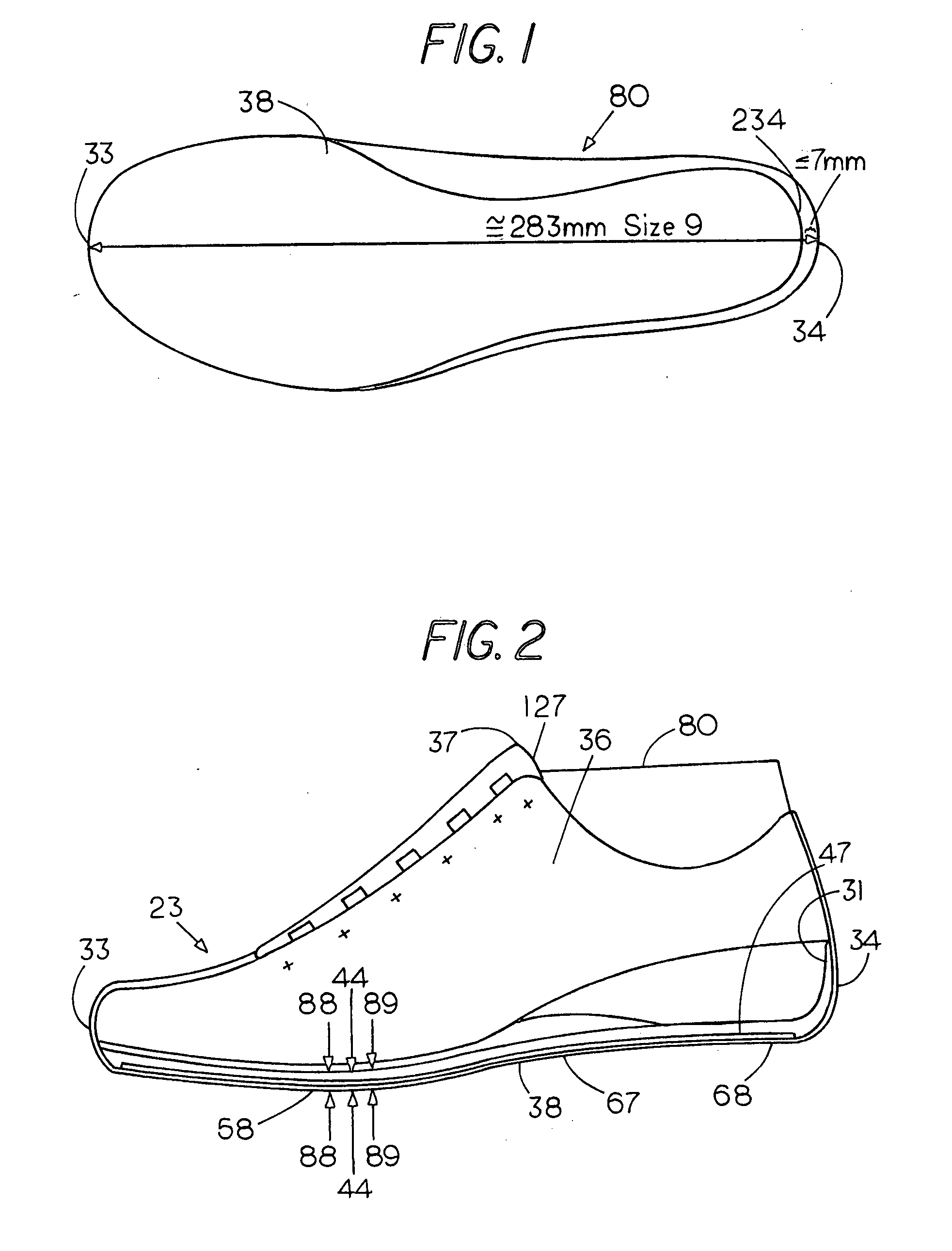

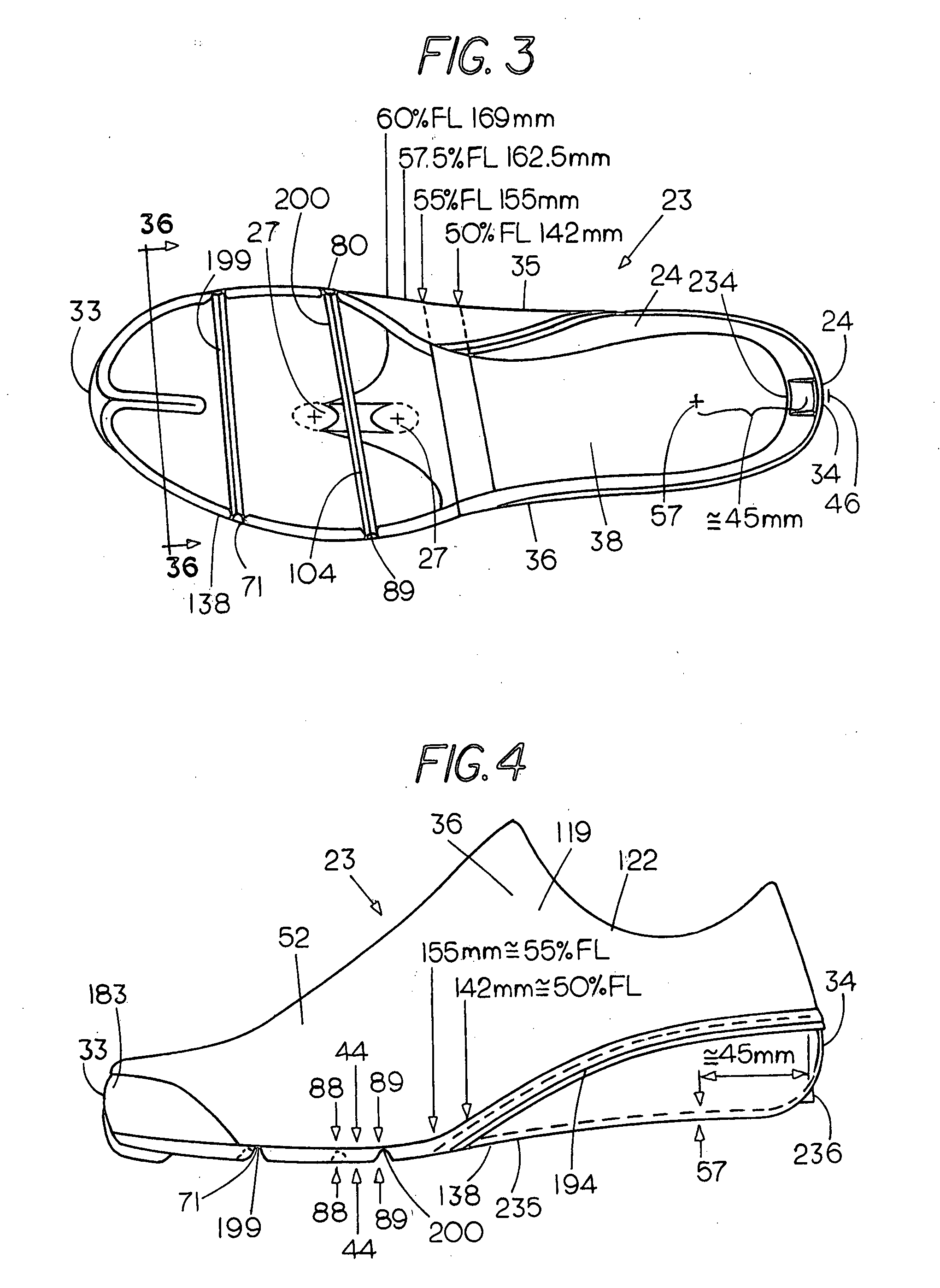

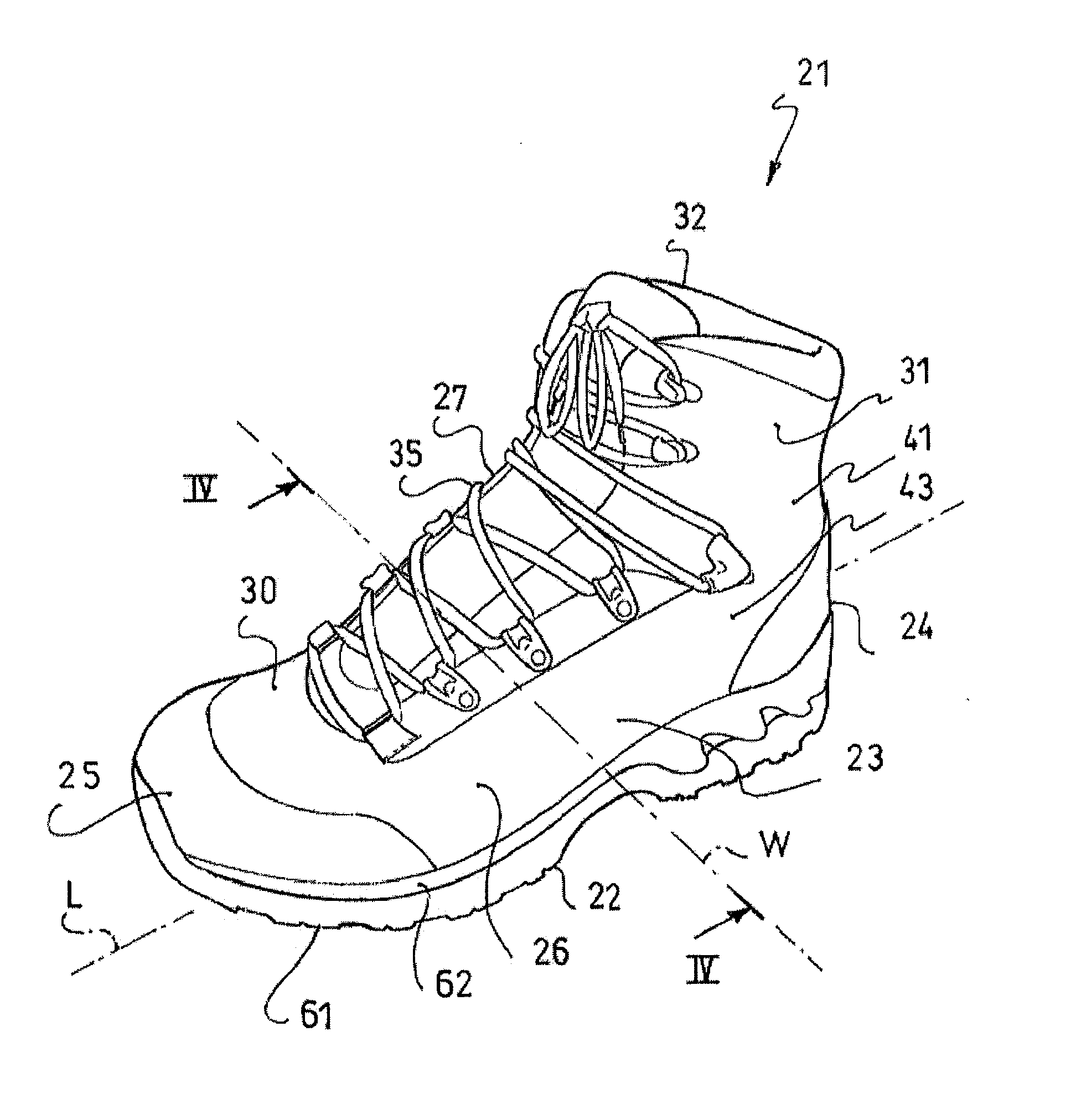

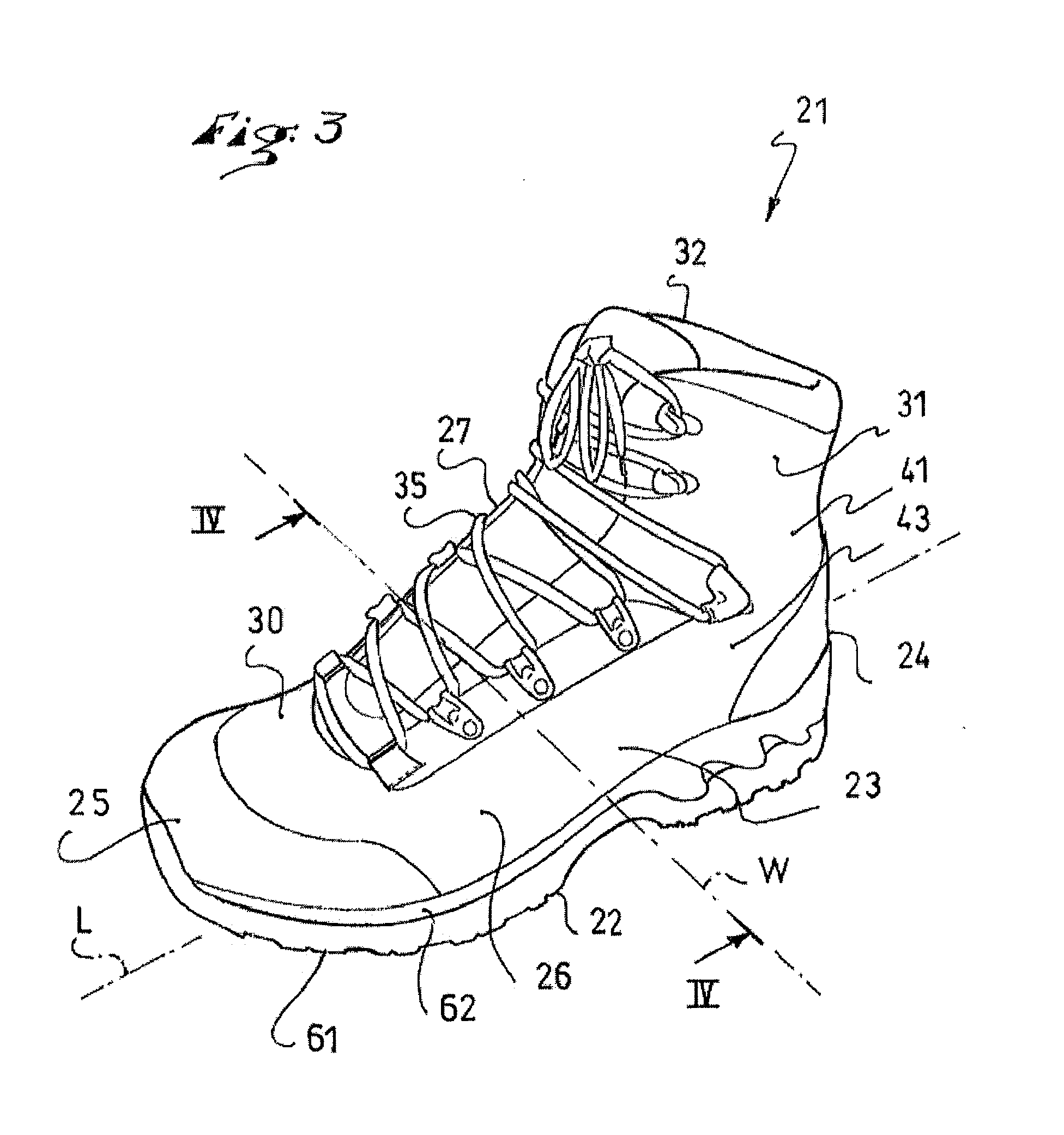

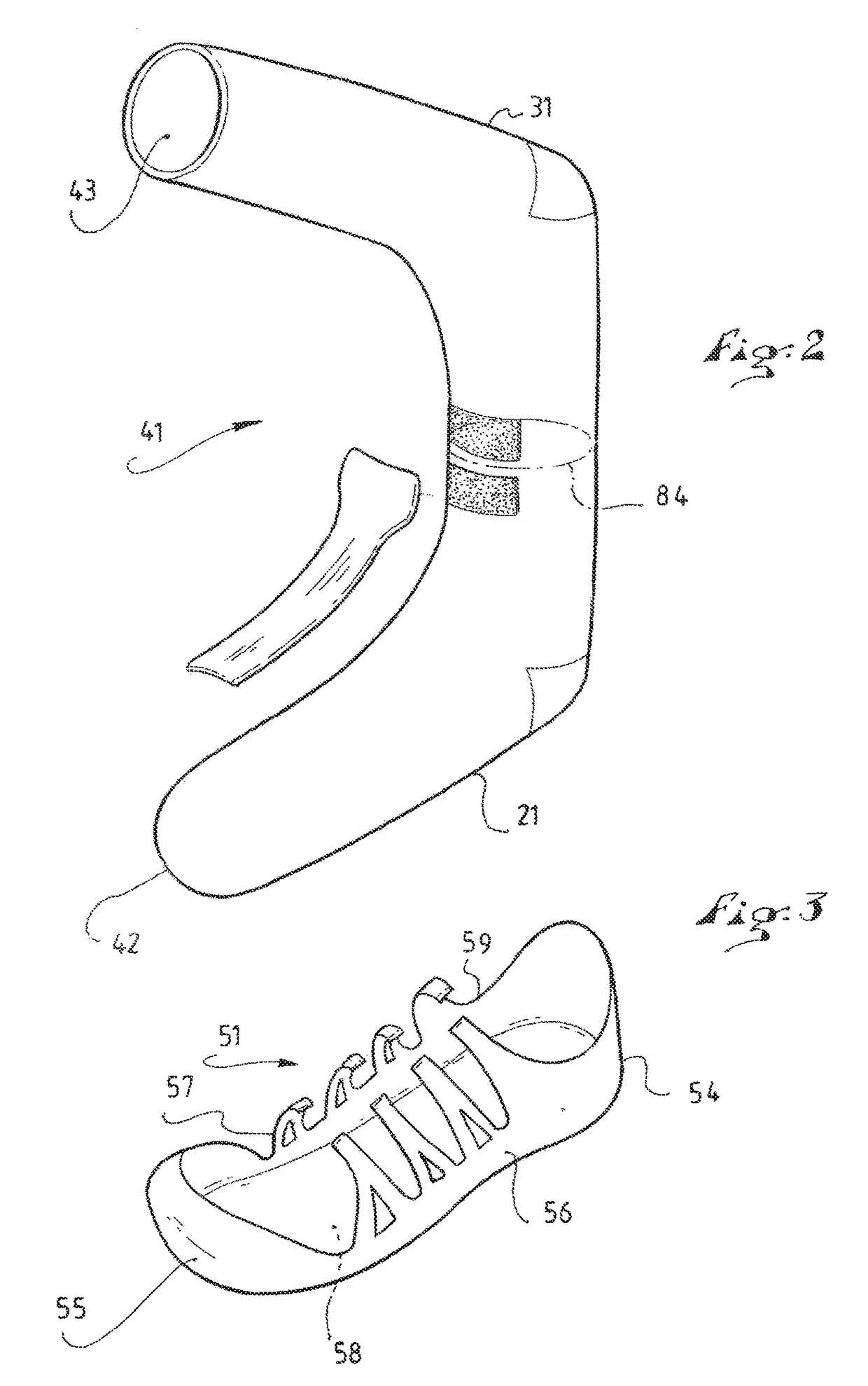

Footwear with improved sole assembly

InactiveUS20110119956A1Good flexibilityGood energy dissipationSolesDomestic footwearEngineeringMedial side

An article of footwear, including a sole assembly and an upper, the article of footwear extending lengthwise from a rear end to a front end, widthwise between a lateral side and a medial side, and heightwise from the outer sole assembly to an upper end, the article of footwear including a first fitting element as well as a second fitting element. The first fitting element includes a first envelope and a first sole of the strobel type, the first envelope being fixed to the first strobel sole at least with stitching. The second fitting element includes a second envelope and a second sole of the strobel type, the second envelope being fixed to the second strobel sole at least with stitching.

Owner:SALOMON SA

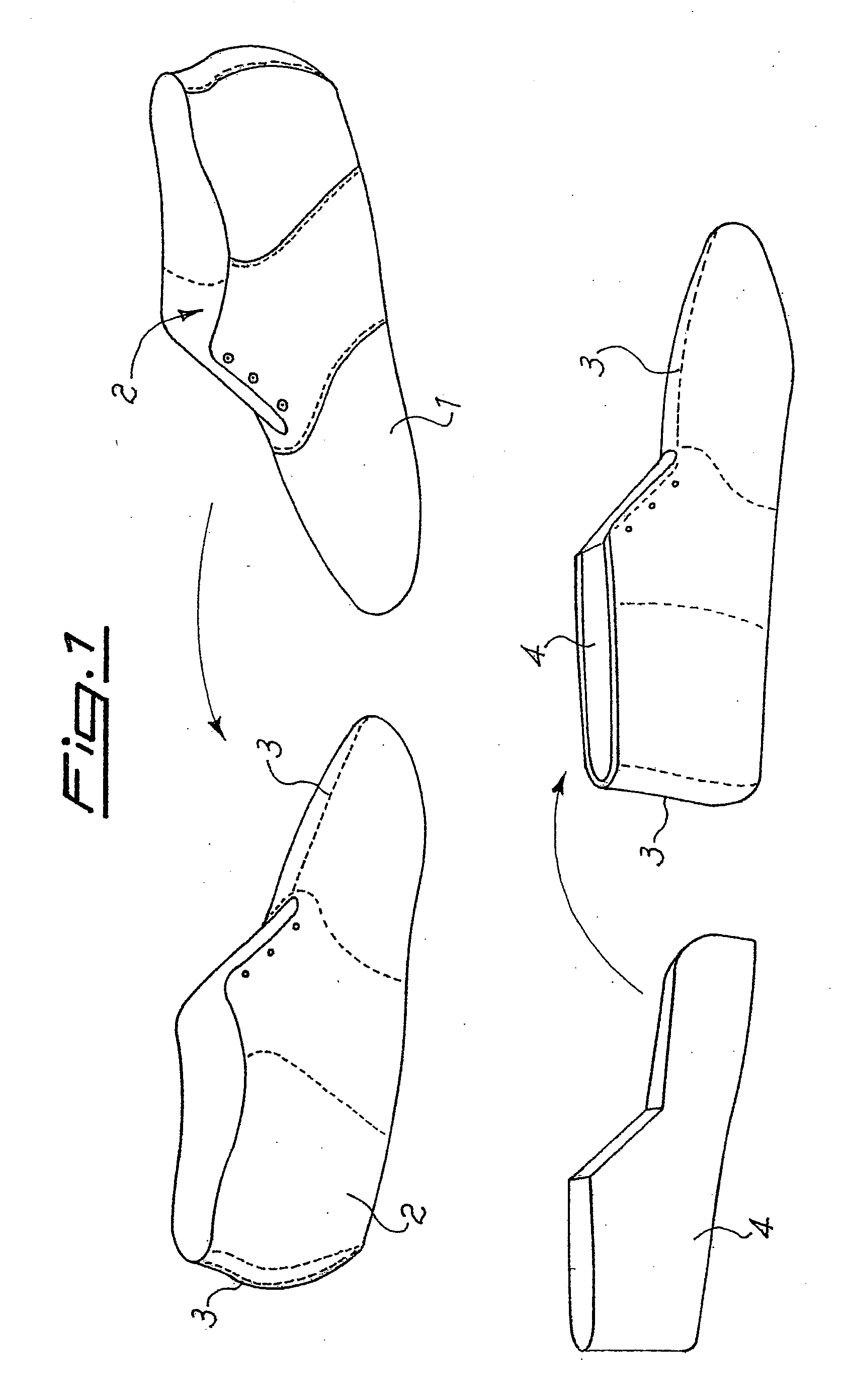

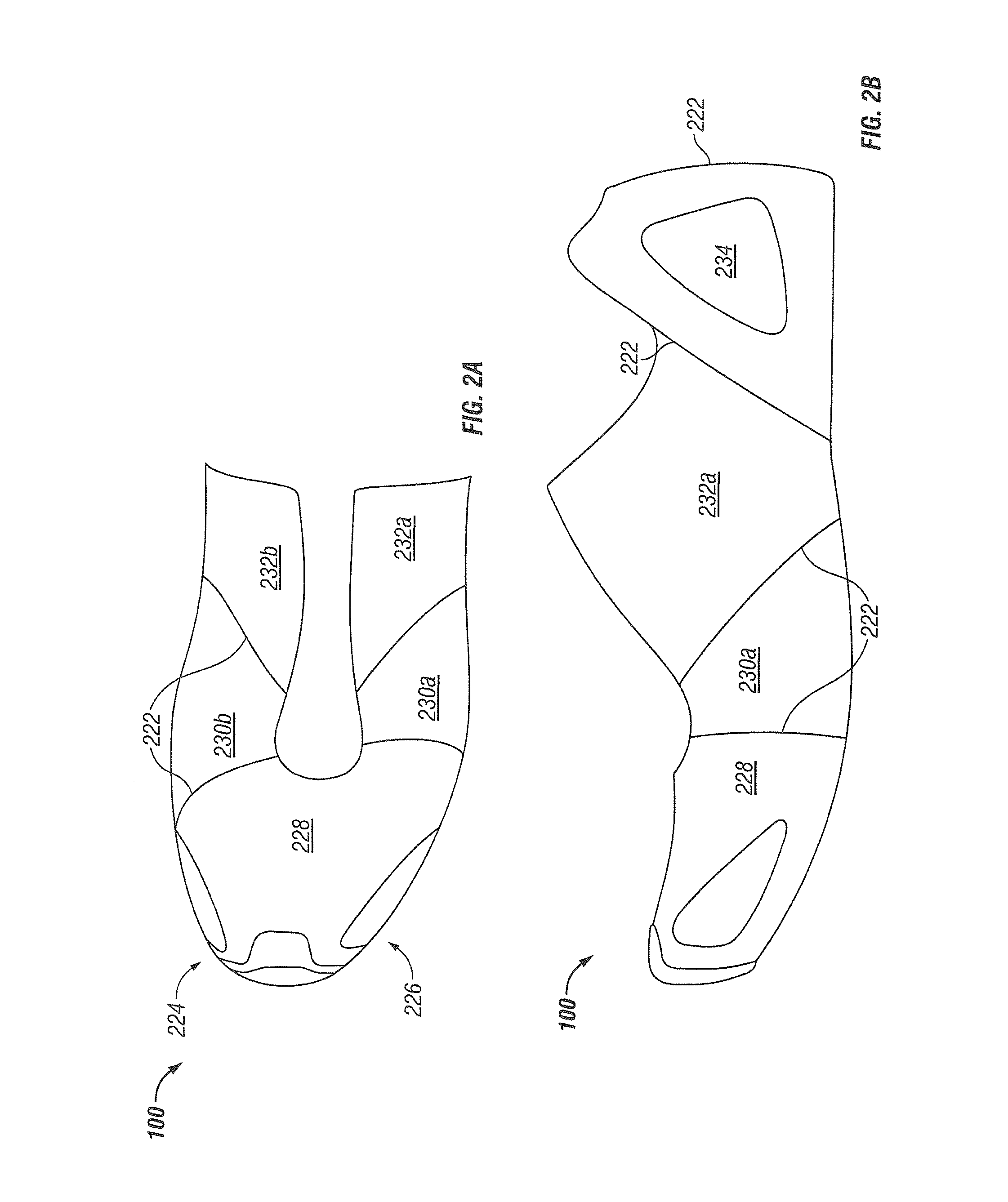

Smooth shoe uppers and methods for producing them

Shoe uppers having smooth seams and methods for producing them are disclosed. In one embodiment the upper uses thermoplastic seam tape which forms bonds between contiguous upper sections after being subjected to heat and / or pressure. In another embodiment, different parts of the shoe can be joined using hidden seams. Close seams can also be covered with a transfer material adapted to give the interior and / or exterior of the upper a smooth surface. In yet another embodiment, a method is disclosed which allows three-dimensional upper sections to be bonded on a last using thermoplastic seam tape.

Owner:REEBOK

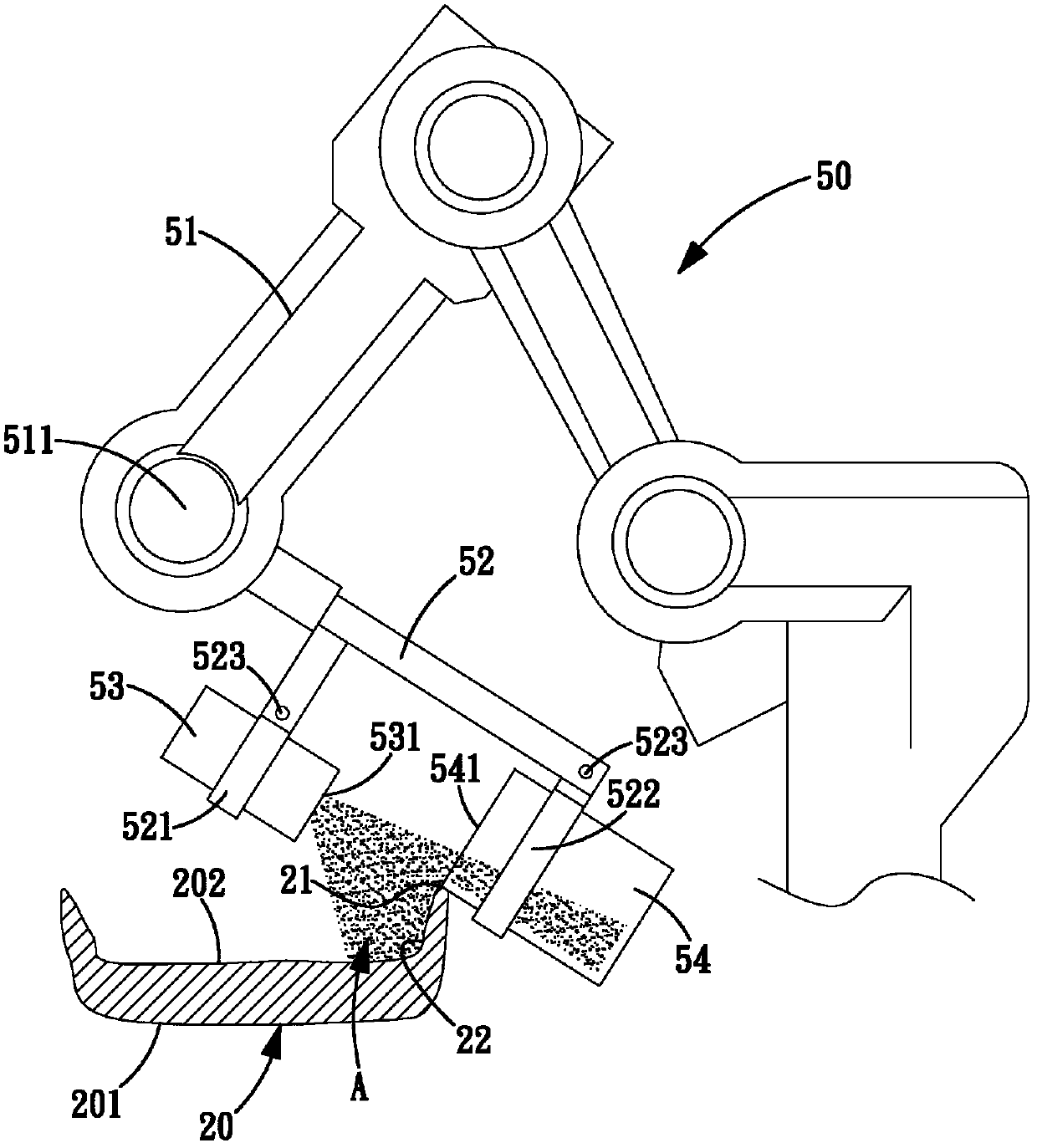

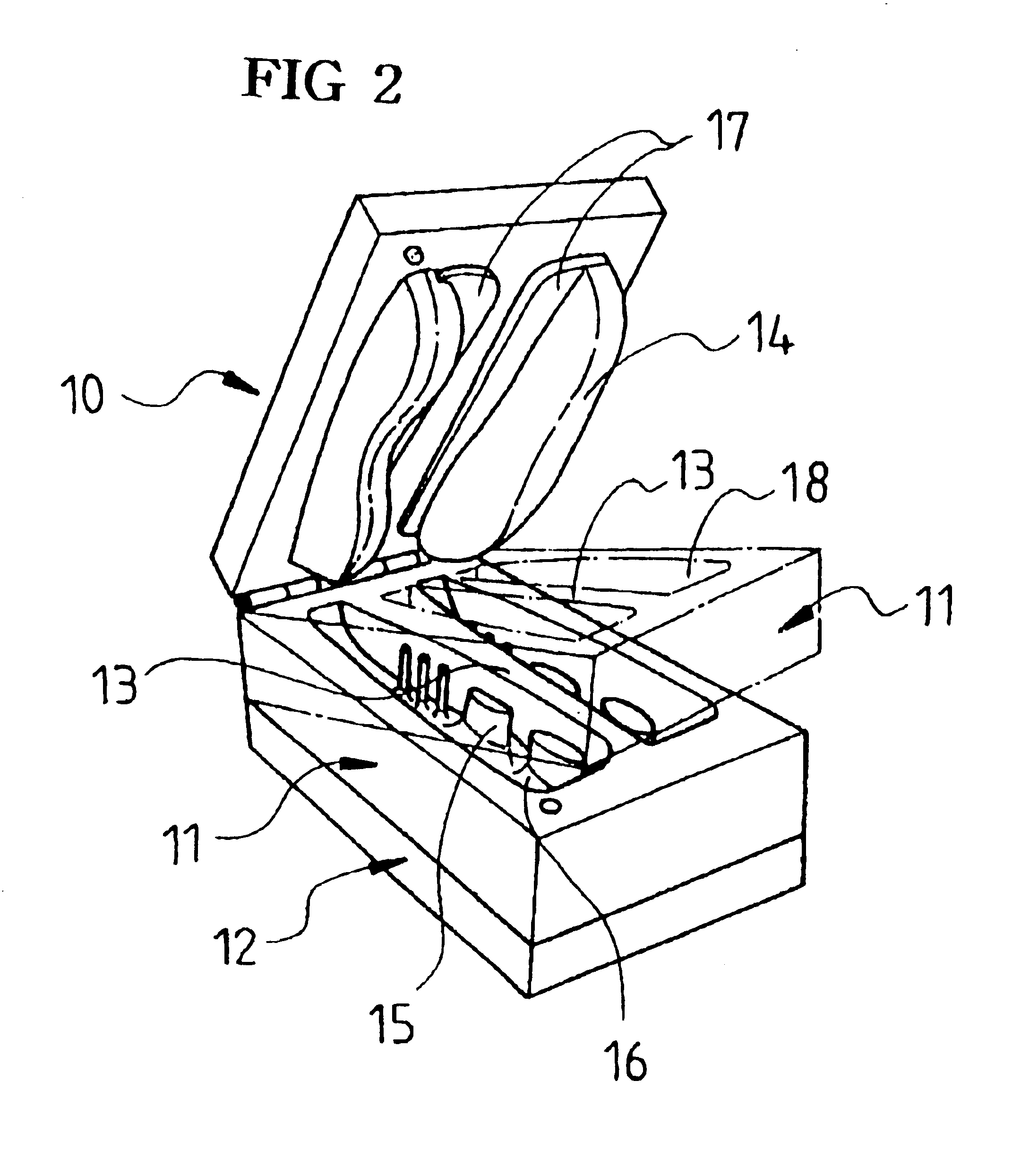

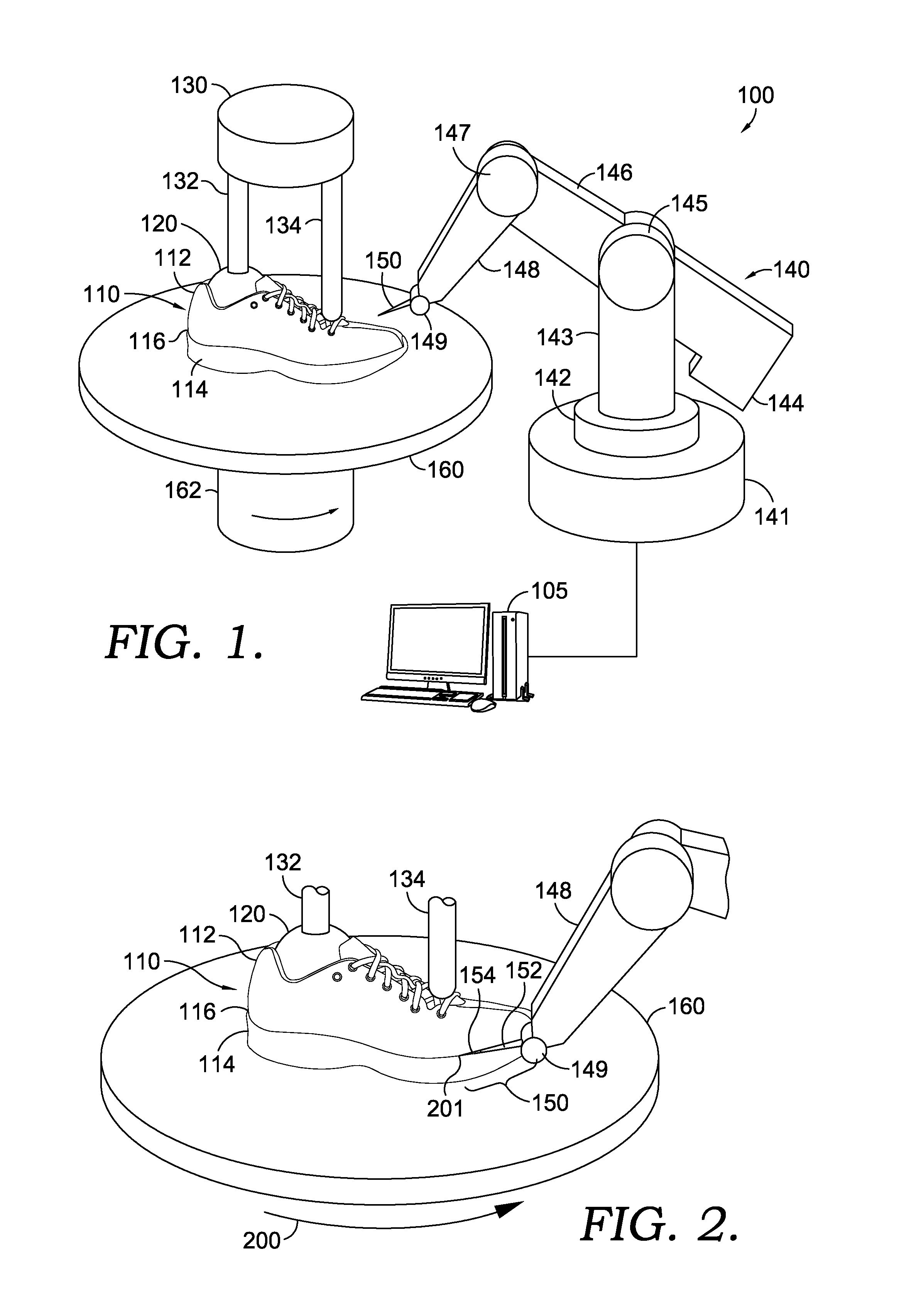

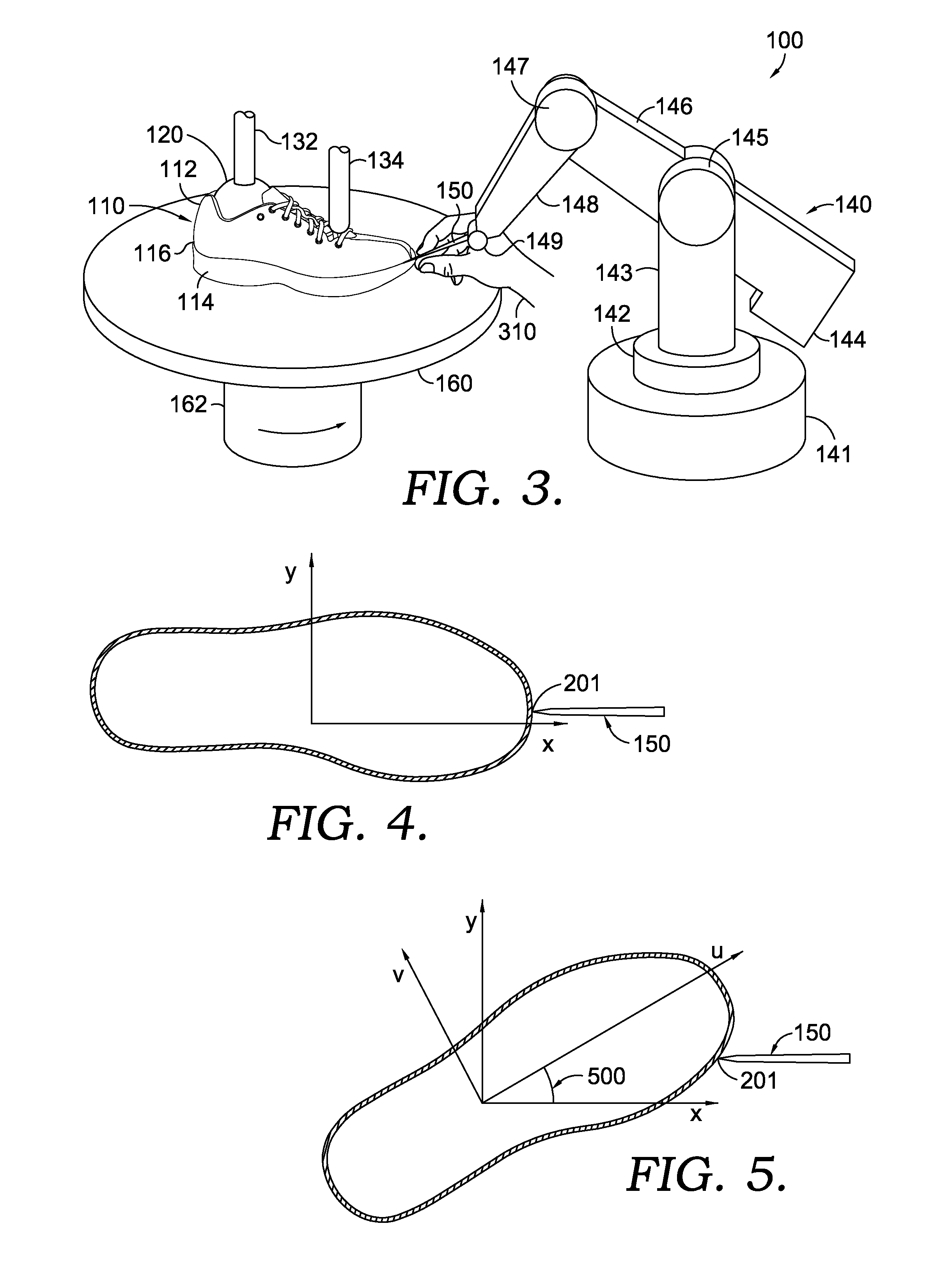

Automatic spraying system of sole bonding agent and spraying method thereof

InactiveCN103284407AAvoid defacementEnsuring Link Structural StrengthShoe gluingEngineeringUltimate tensile strength

The invention discloses an automatic spraying system of a sole bonding agent and a spraying method thereof. A spray gun and a glue accommodating container are arranged at the tail end of a mechanical arm, the spray gun and the glue accommodating container are arranged on the inner and outer sides of a sole top surface contour side line in a corresponding form manner, sole top surface scanning data and sole position data read by a computer are matched to enable the spray gun to spray the bonding agent on the inner side of the sole contour side line and enable the bonding agent to slightly exceed the sole contour side line, then the bonding agent is sprayed in the spraying area of the sole top surface, the bonding agent exceeding the contour side line is enabled to drop into the glue accommodating container, so that automatic accurate sizing on the sole top surface is achieved, the strength of a connecting structure of the sole and an upper is guaranteed, and simultaneously, the bonding agent is prevented from polluting the sole appearance.

Owner:ORISOL ASIA

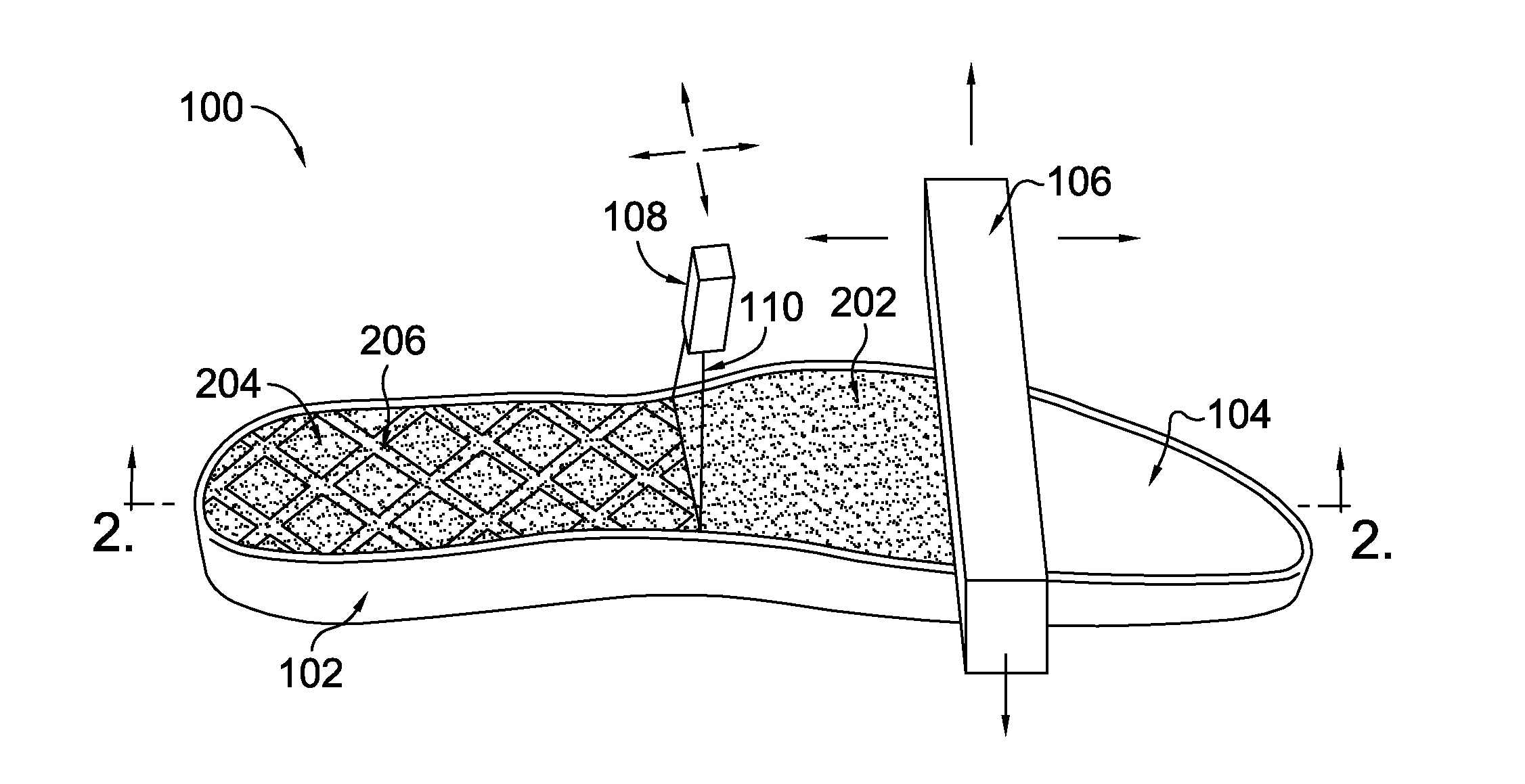

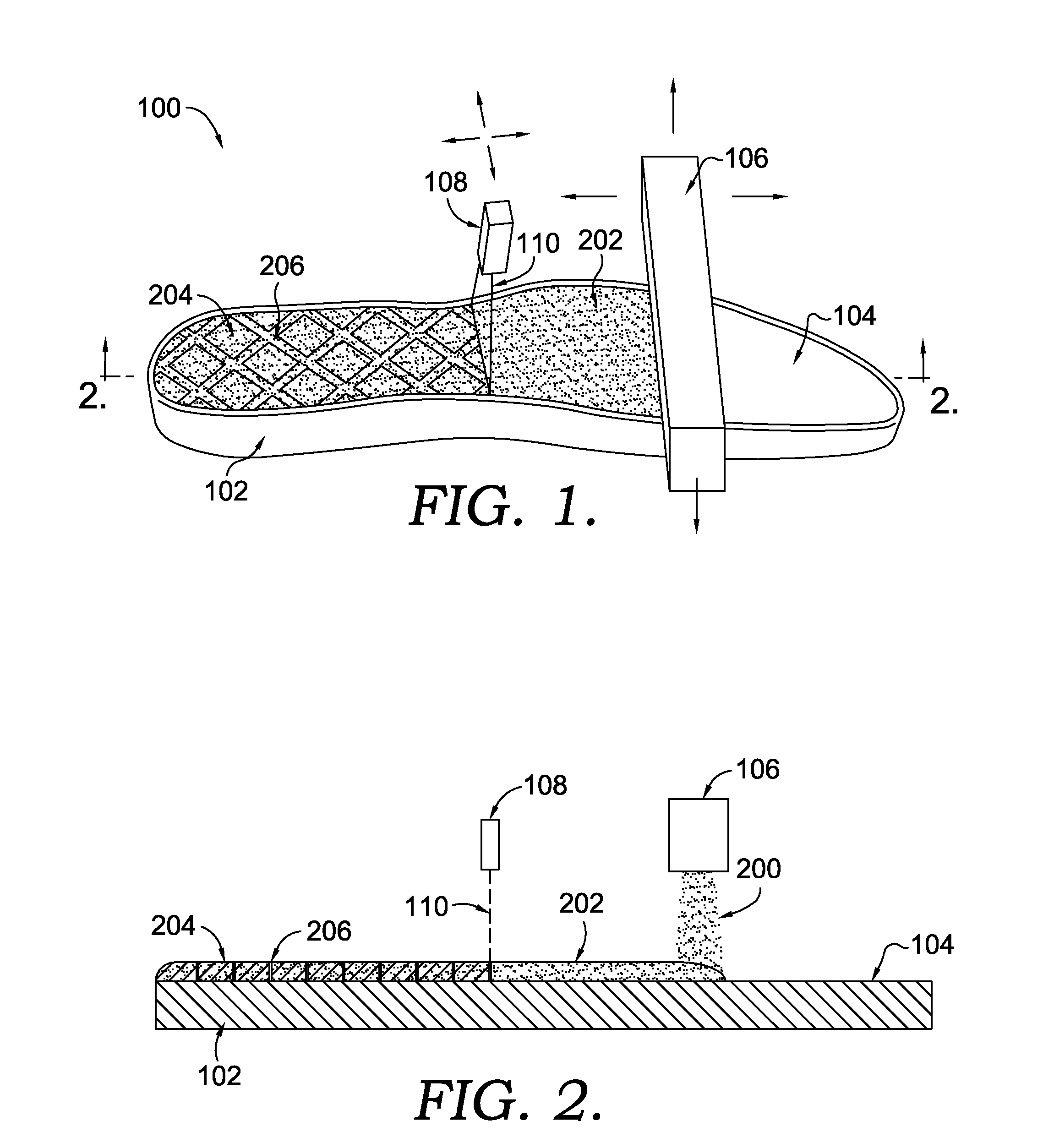

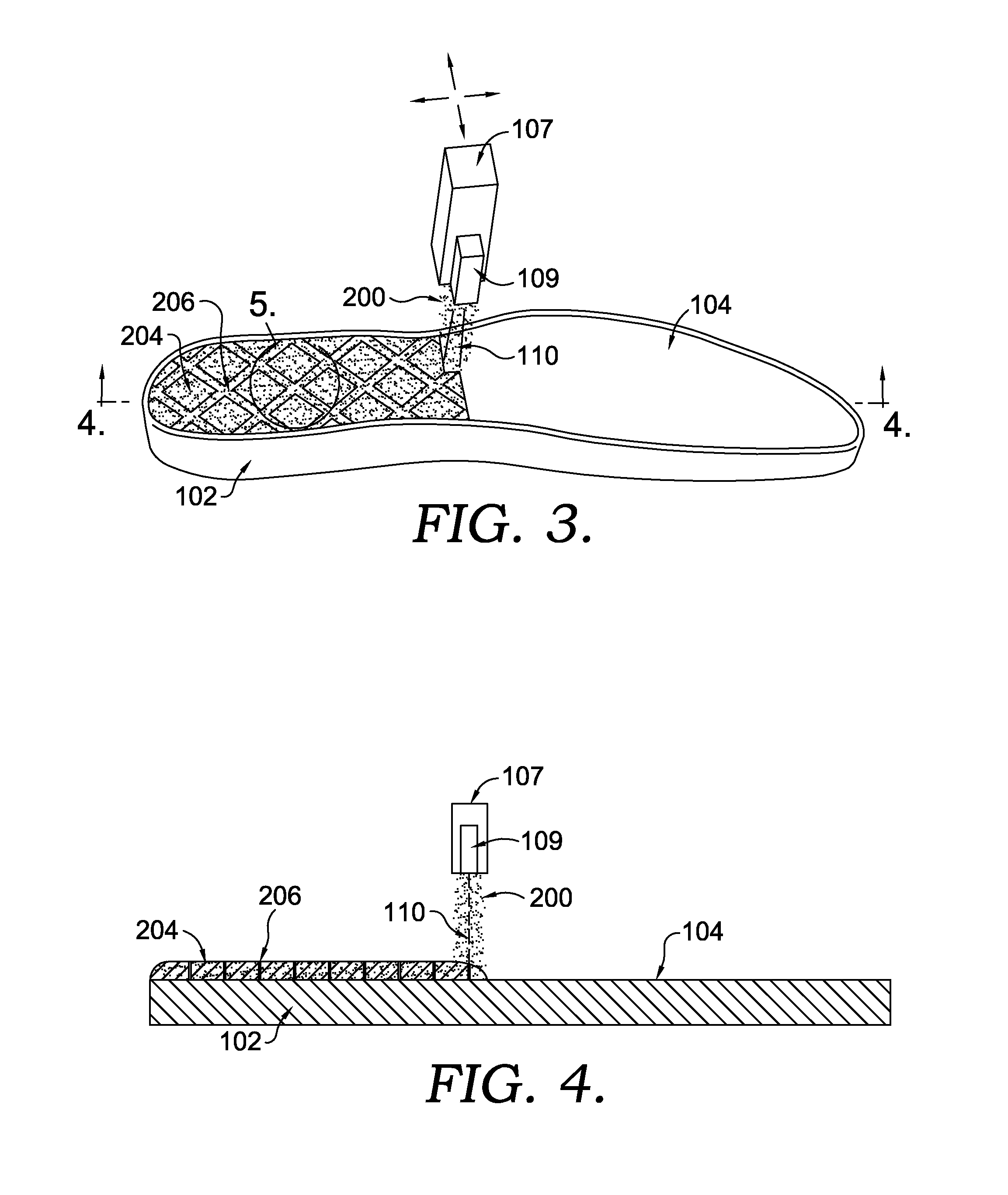

Selectively Applied Adhesive Particulate on Nonmetallic Substrates

The manufacturing of articles relies on the bonding of two or more components to form some forms of the articles, such as a shoe sole bonded with a shoe upper. The bonding may be achieved with an adhesive particulate that is applied to a surface of a substrate. The adhesive particulate is selectively fused to the substrate with a controlled energy source, such as a laser. The selective application of laser energy allows for specific geometric structures of adhesive particulate to be formed on the substrate. The substrate having the fused adhesive particulate is mated with another component allowing the fused adhesive particulate to bond the first substrate and the second component.

Owner:NIKE INC

Shoe outer sole, method for its manufacture, and mold therefor

Outer sole for shoe has midsole formed from two conjoined midsole pieces, and bottom outsole piece. At least midsole pieces are formed by injection molding. Midsole has plurality of through holes therein to provide cushioning capability. Certain embodiments include elements for maintaining and restoring cushioning capability of through holes when subjected to compressive, deforming forces. Through holes vary in size, shape, and pattern of arrangement to provide different cushioning capabilities.

Owner:PARK YOUNG SOUL

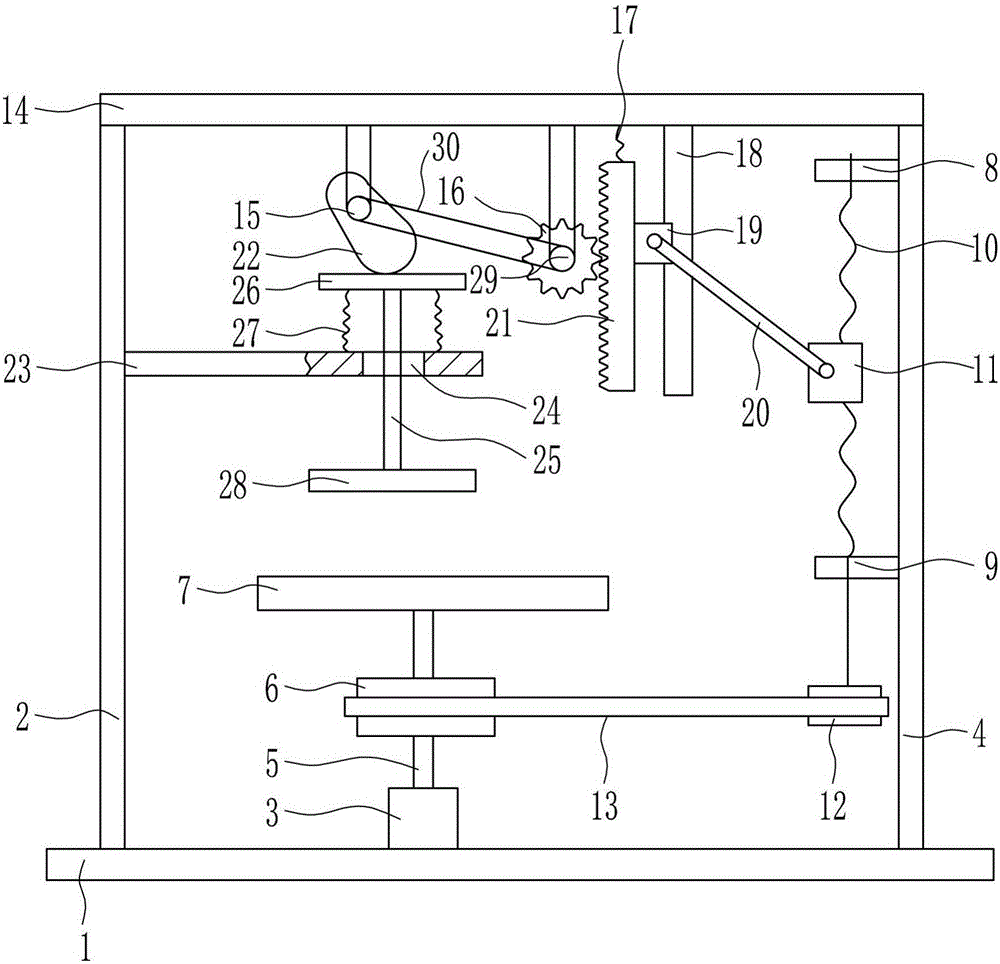

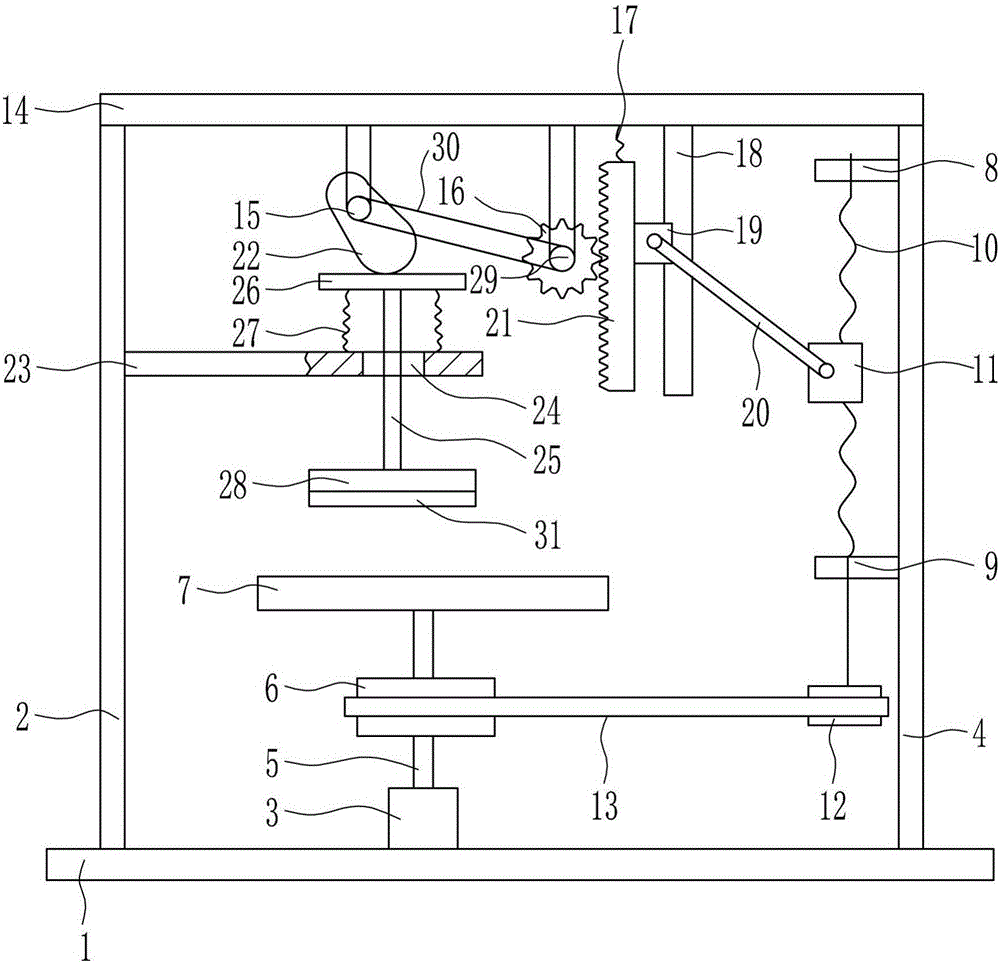

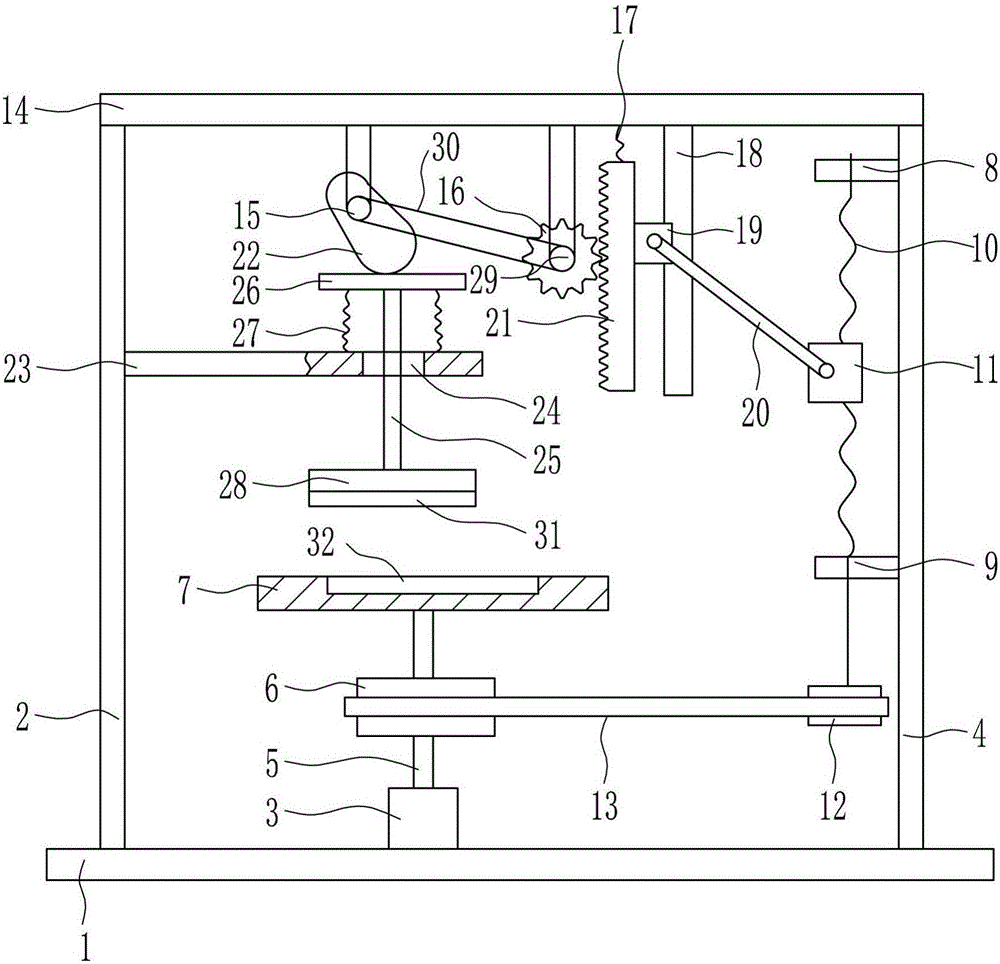

Rapid shoe sole press-fit device for shoe production

The invention relates to a shoe sole press-fit device, in particular to a rapid shoe sole press-fit device for shoe production. The technical problem to be solved in the invention is to provide the rapid shoe sole press-fit device for shoe production which is good in press-fit effect, easy to operate and high in working efficiency. In order to solve the technical problem, the rapid shoe sole press-fit device for shoe production provided by the invention comprises a bottom plate, a left side plate, a motor, a right side plate, a rotating shaft, a big belt pulley, a placement plate, an upper bearing block, a lower bearing block, a lead screw, a nut, a small belt pulley, a flat belt, a top plate, a driven wheel, a gear, a first spring, a sliding rail, a slide block, a connecting rod, a rack, a cam, a guide plate, a lifting rod, a movable plate, a pressure block, a driving wheel, a first belt and the like. According to the rapid shoe sole press-fit device for shoe production provided by the invention, with the adoption of a manner of the pressure block and the placement plate, the pressure block moves up and down to press the shoe sole with glue on the placement plate.

Owner:张浩杰

Method for manufacturing breathable shoe

A breathable shoe, including: an upper assembly (10;310;410) having a breathable upper (11;311;411); a membrane (14;314;414) made of a material which is waterproof and breathable, and a sole (16;116;216;316;416) made of perforated elastomer, which are all mutually attached such that the membrane is arranged between the upper assembly and the sole, and the sole is sealed perimetrically to the membrane, in a manner to prevent moisture to enter into the upper assembly from the sole through the membrane, and to permit moisture to leave the inside of the upper assembly through the membrane and through the sole. In one preferred embodiment, the membrane is first attached to the upper assembly so that the upper assembly is a unitary upper assembly including the membrane, and such unitary upper assembly is subsequently attached to the sole.

Owner:GEOX SPA

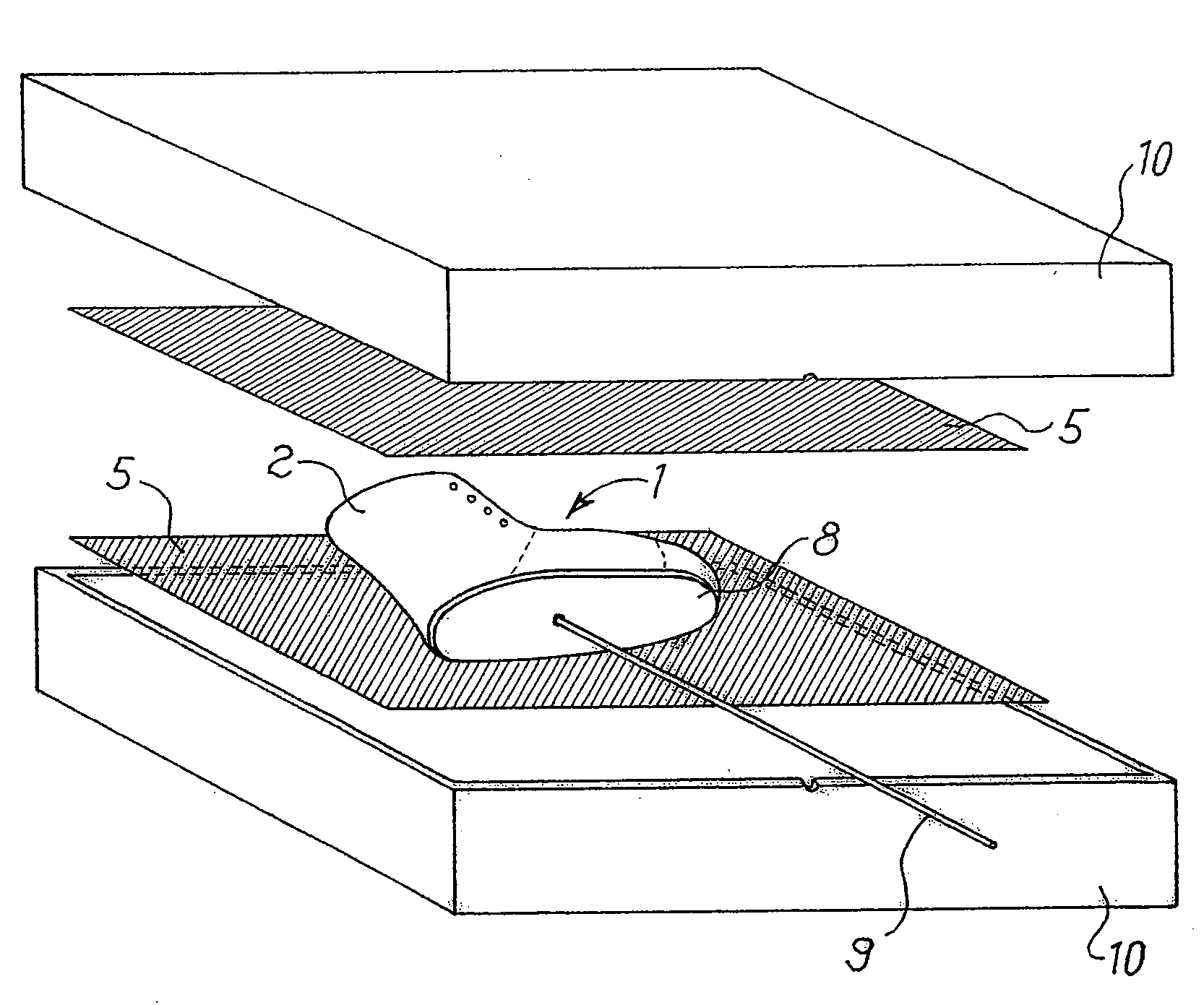

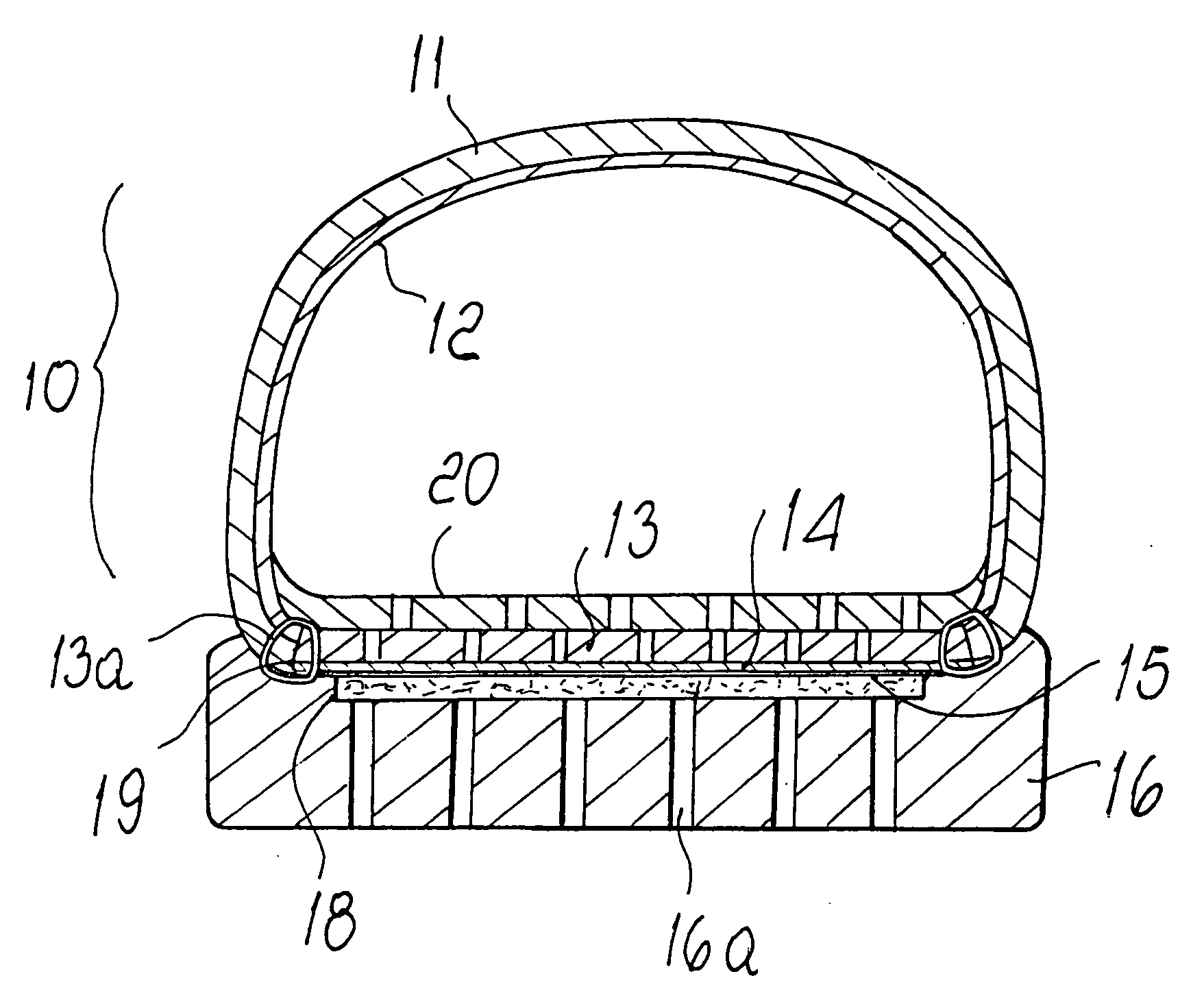

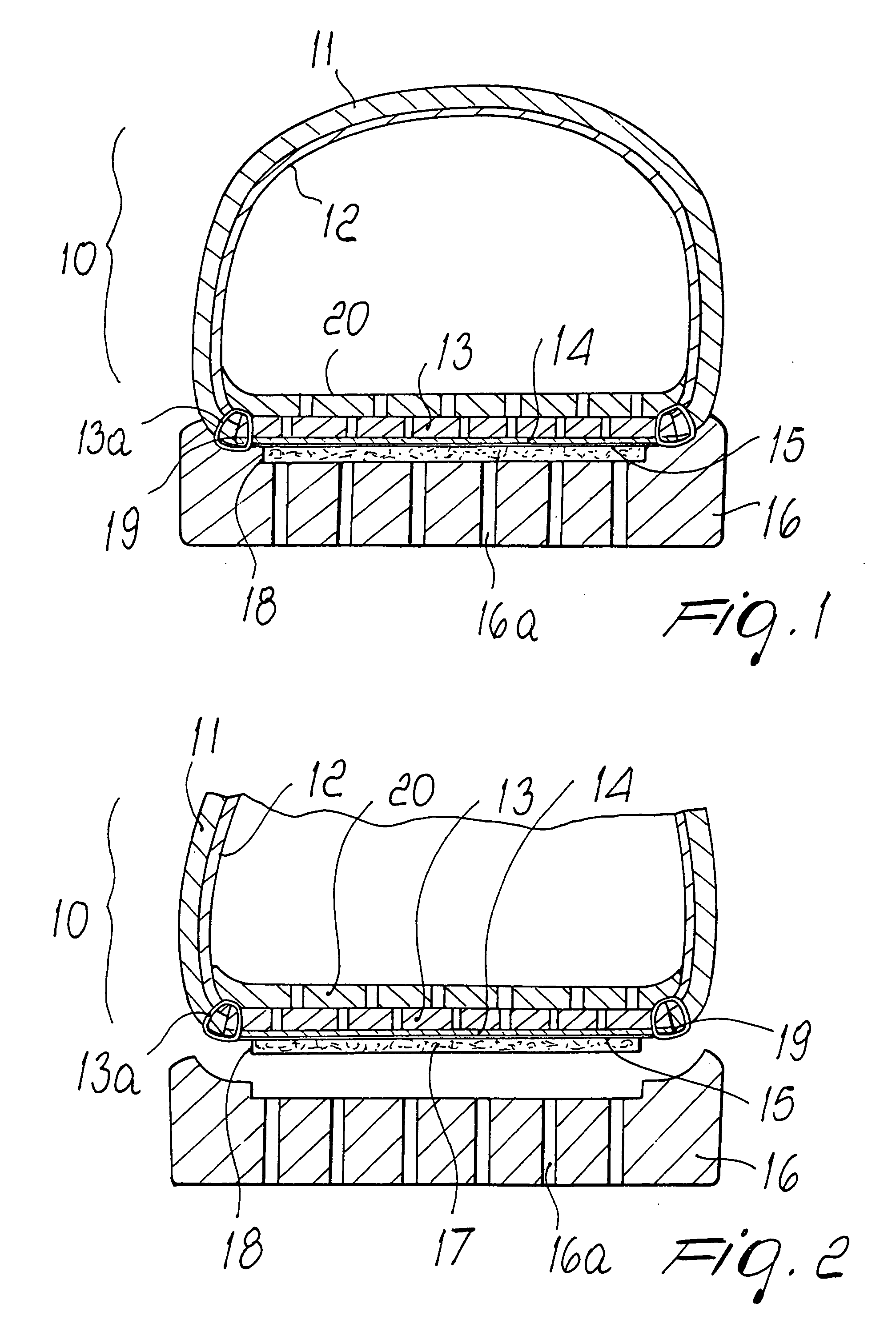

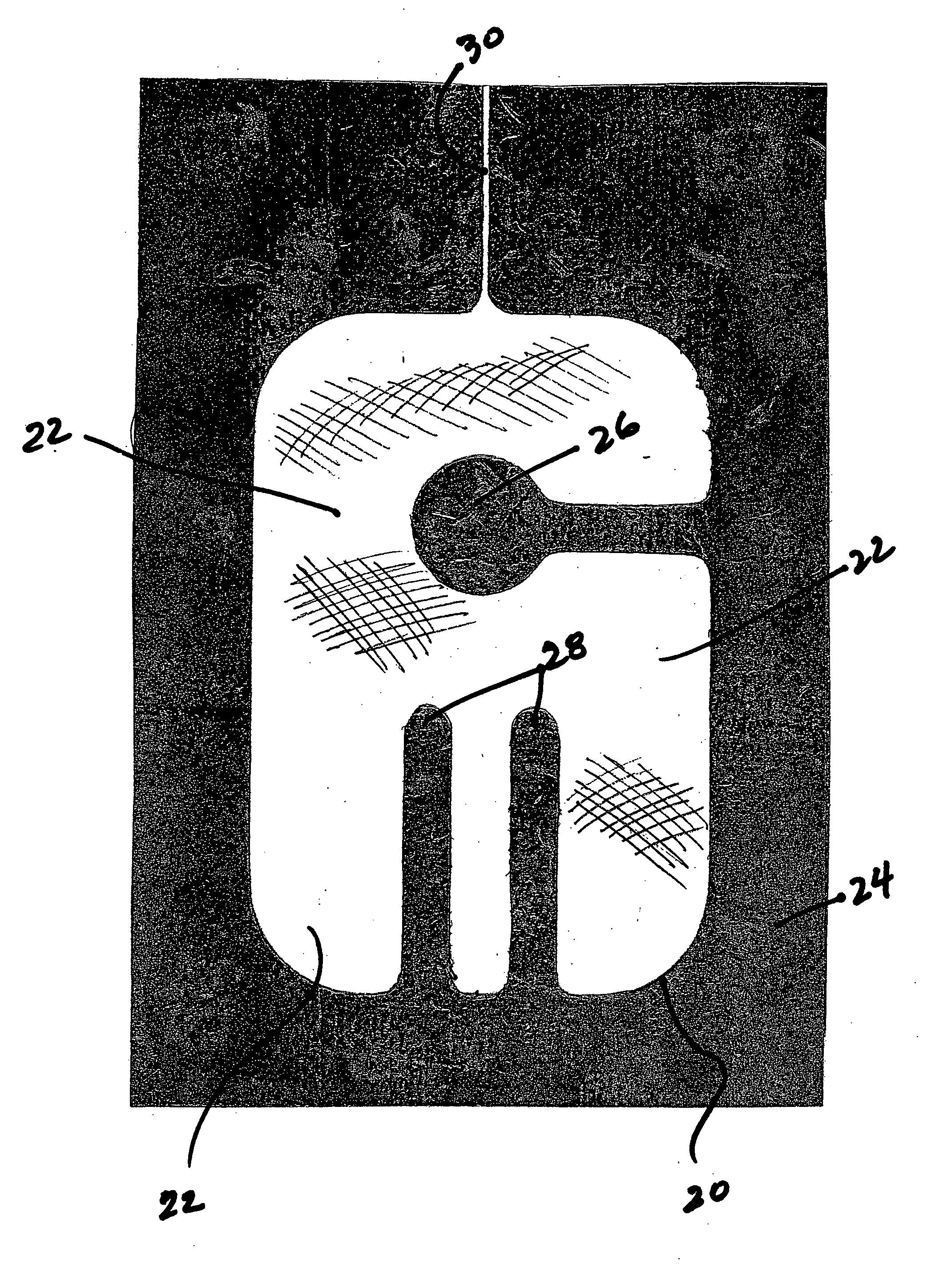

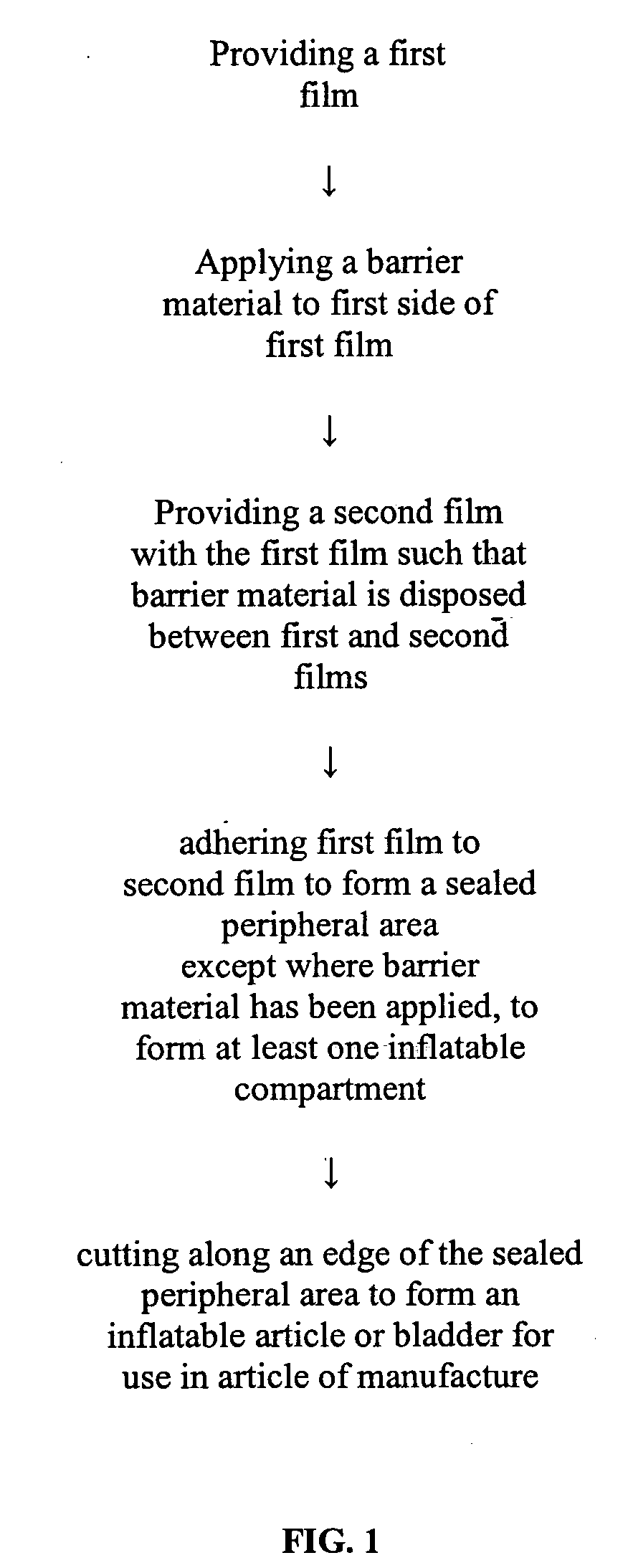

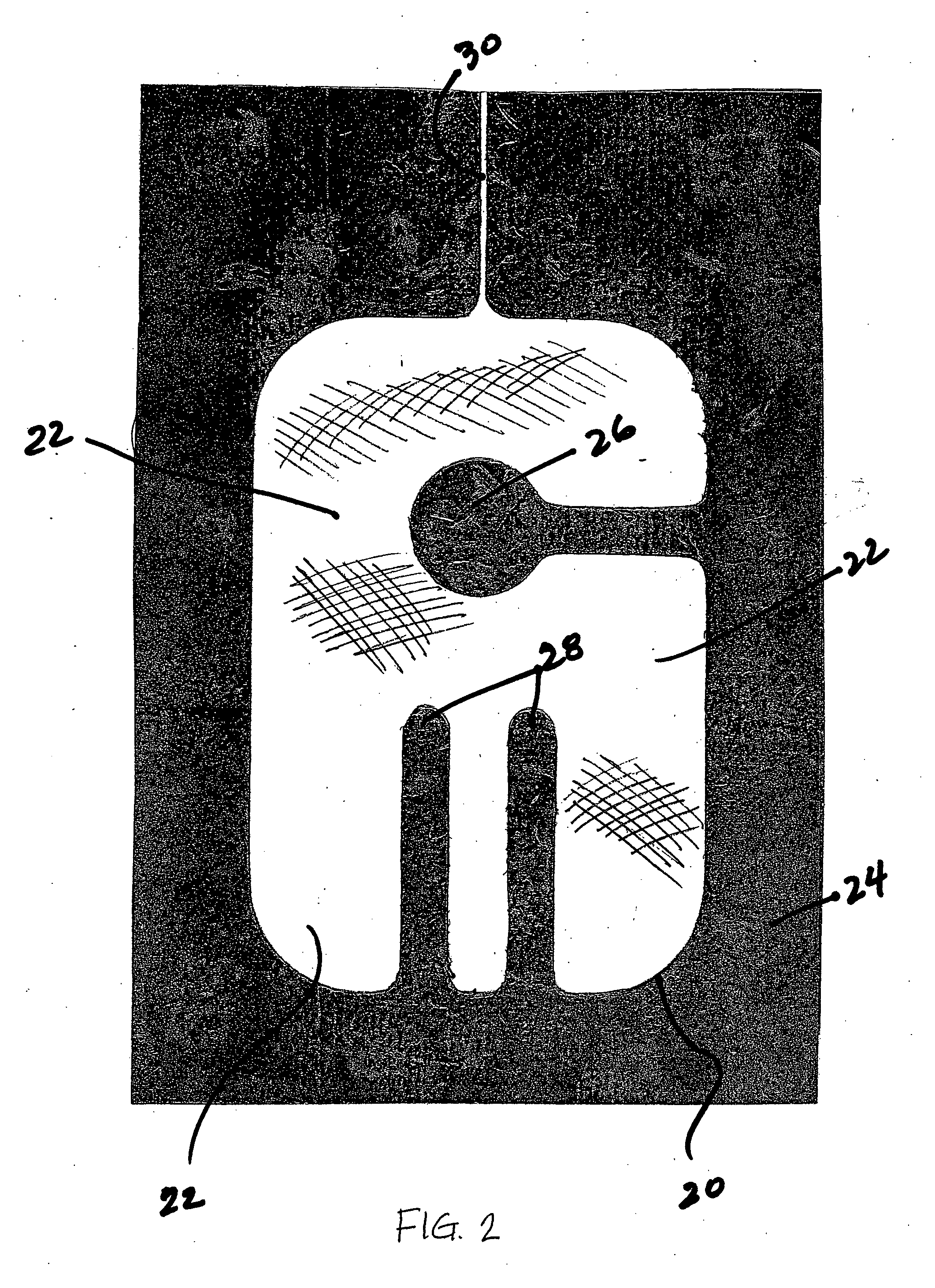

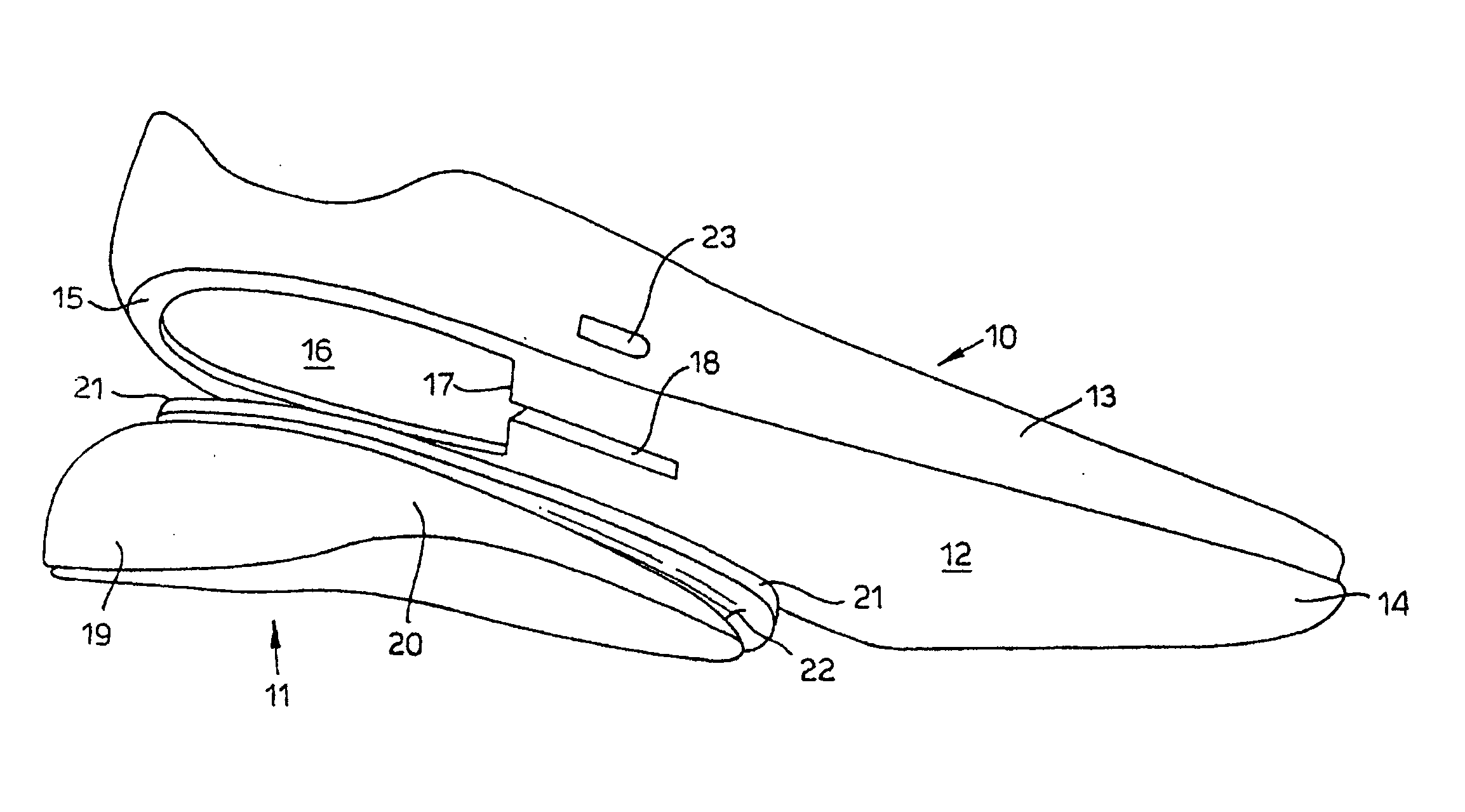

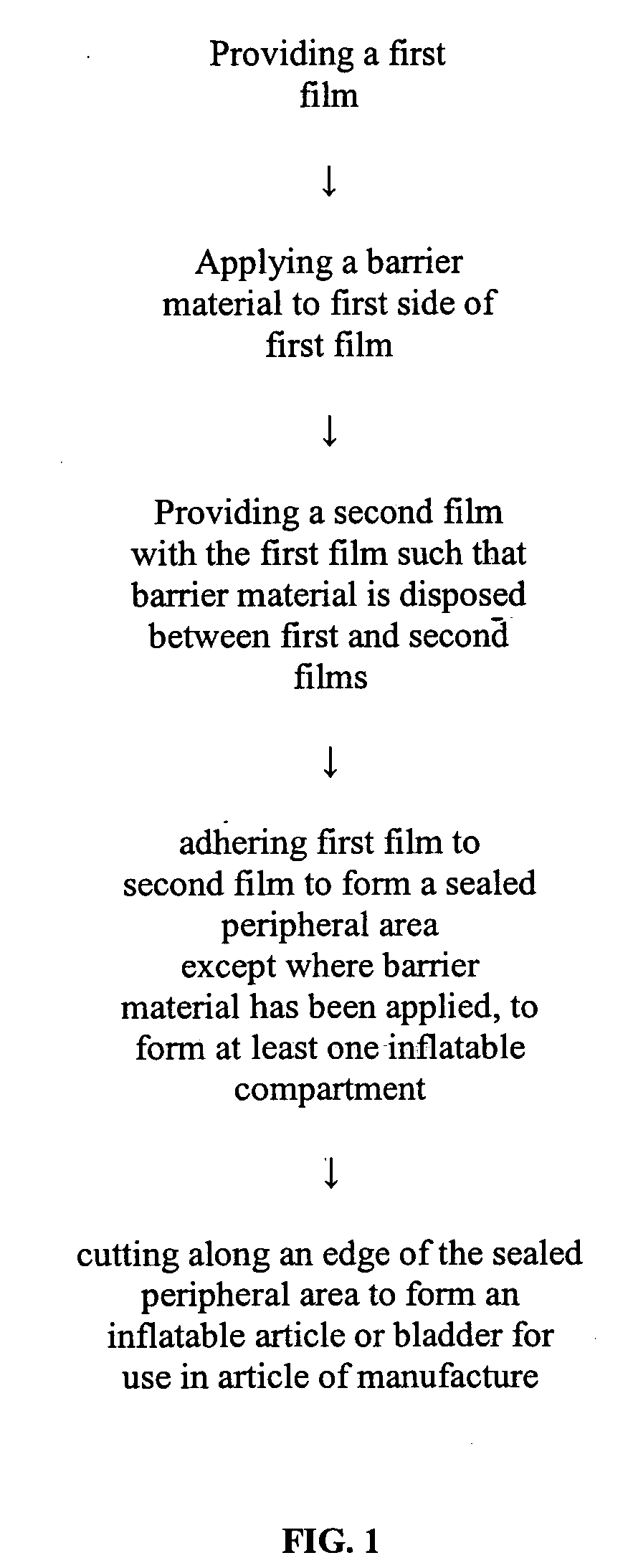

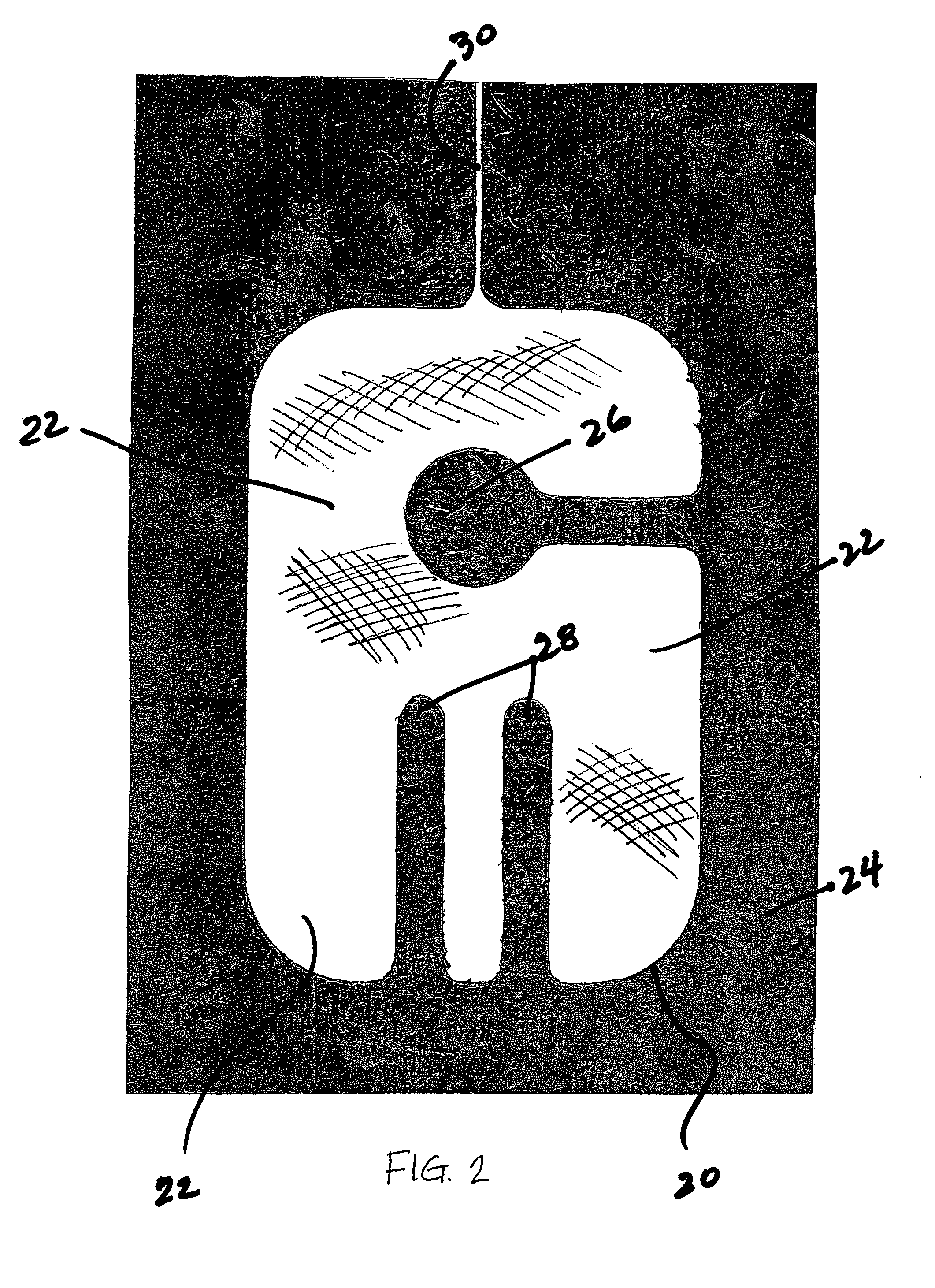

Method for manufacturing inflatable footwear or bladders for use in inflatable articles

ActiveUS20070000605A1Easy to modifyAvoid the needSolesLamination ancillary operationsTime efficientSports equipment

The present invention is a method for manufacturing inflatable articles, or bladders for inflatable articles, that is time-efficient, simple, inexpensive and permits the uninterrupted manufacture of numerous and even customized article or bladder configurations and sizes, without expensive configuration-specific, metal tooling. The method includes the steps of applying a barrier material to a side of a first film, providing a second film with the first film so that the barrier material is disposed between the first and second films, adhering the first film to the second film so that the films are sealed together in areas except where the barrier material has been applied to form at least one inflatable compartment and sealed peripheral edge, and cutting along the sealed peripheral edge to form an inflatable article or bladder for use in an article of manufacture. The barrier material may be a paint, ink, paper or surface treatment that effectively prevents the first film from adhering to the second. The inflatable article or bladder of the present invention may be used as or in athletic equipment, for example, including footwear.

Owner:REEBOK

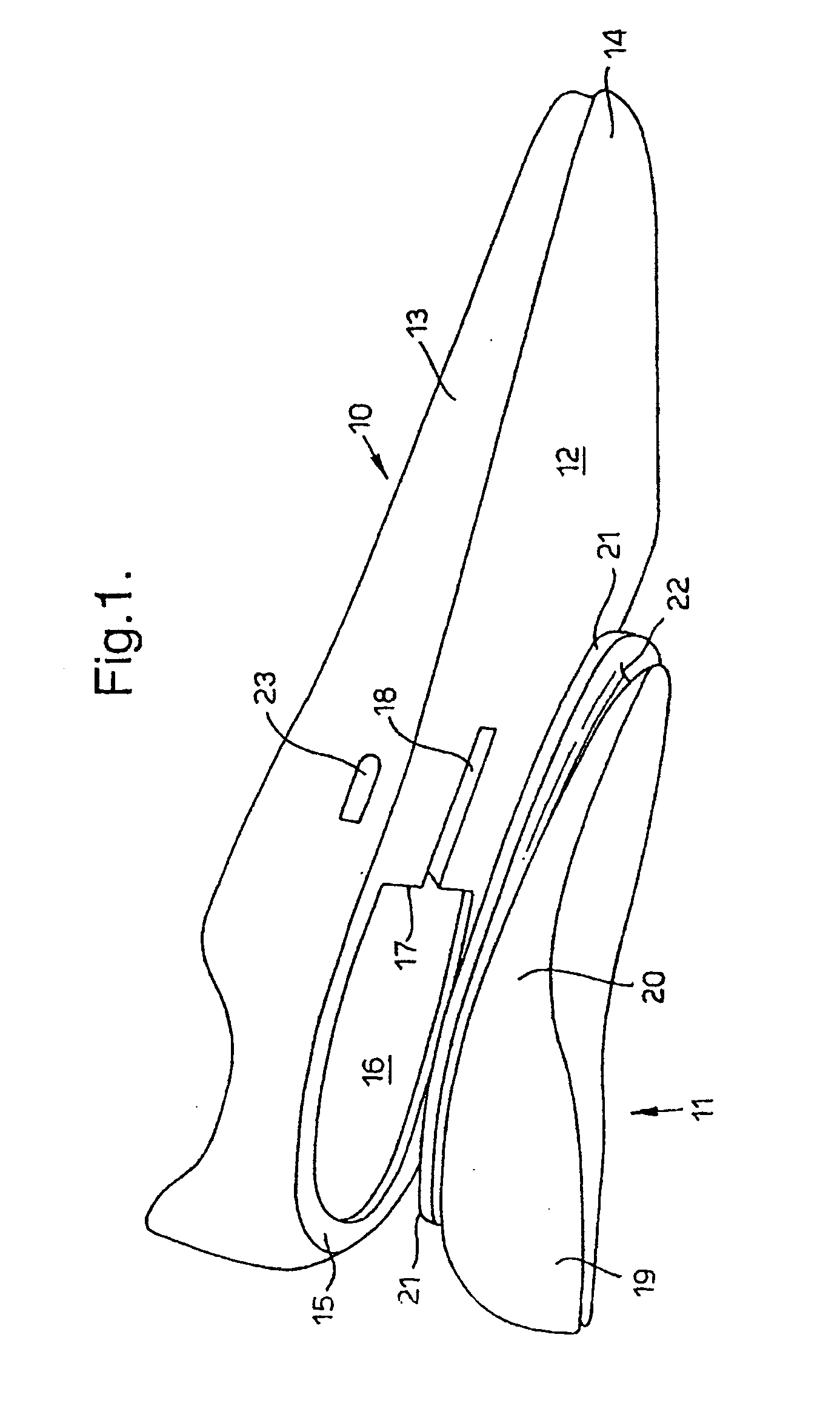

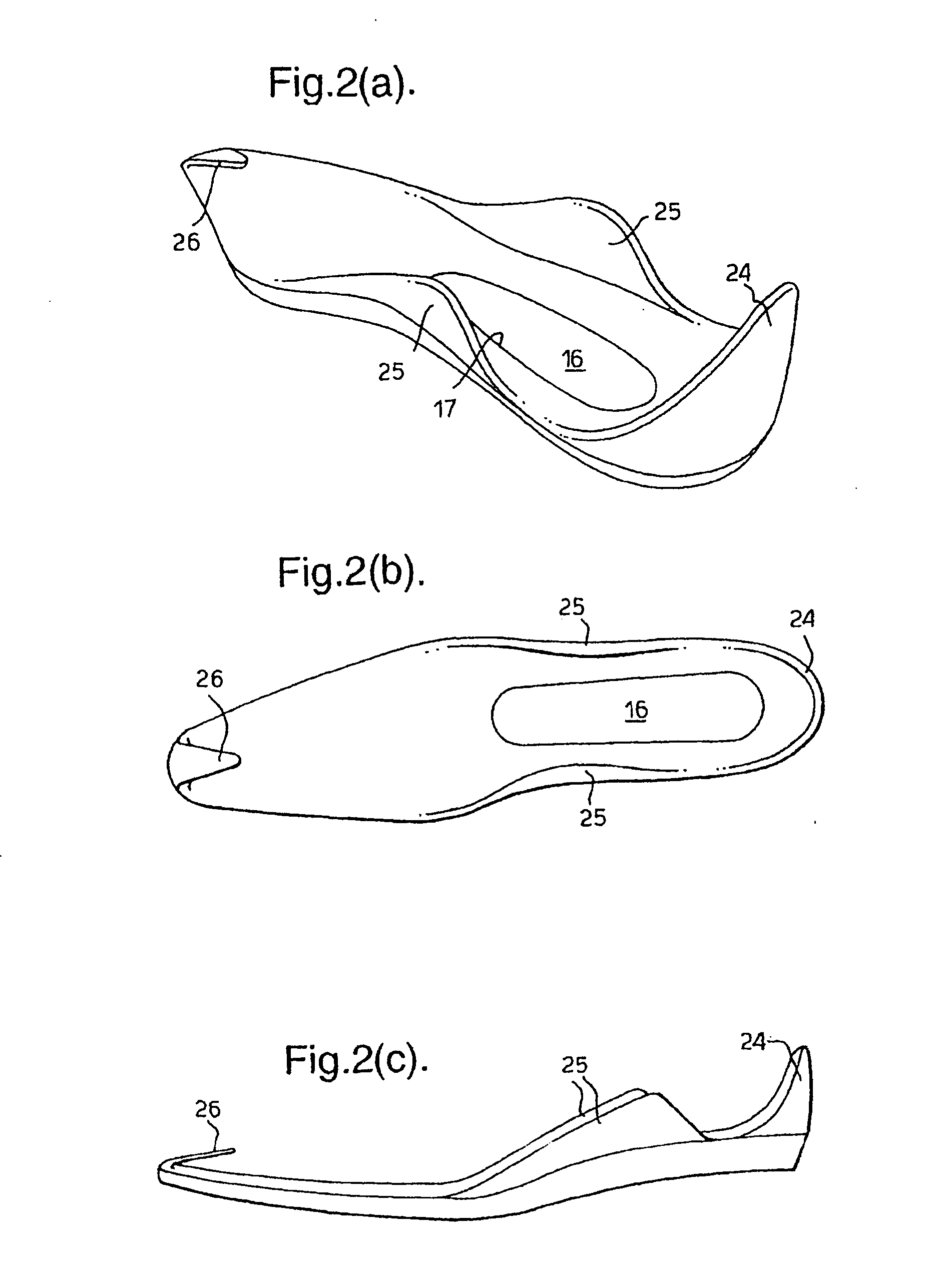

Shoes

A sub-assembly or kit for forming a shoe comprises a flexible member for incorporation in the base of a shoe. The flexible member is capable of a plurality of foot supporting shapes to adapt to heels of different heights. A removable heel and shaping member has a heel part supporting the rear end of the flexible member at a heel height. A shaping part is removably fastened to the flexible member to cause the flexible member to adopt a particular foot supporting shape or configuration adapted to the heel height.

Owner:KIT SHOE

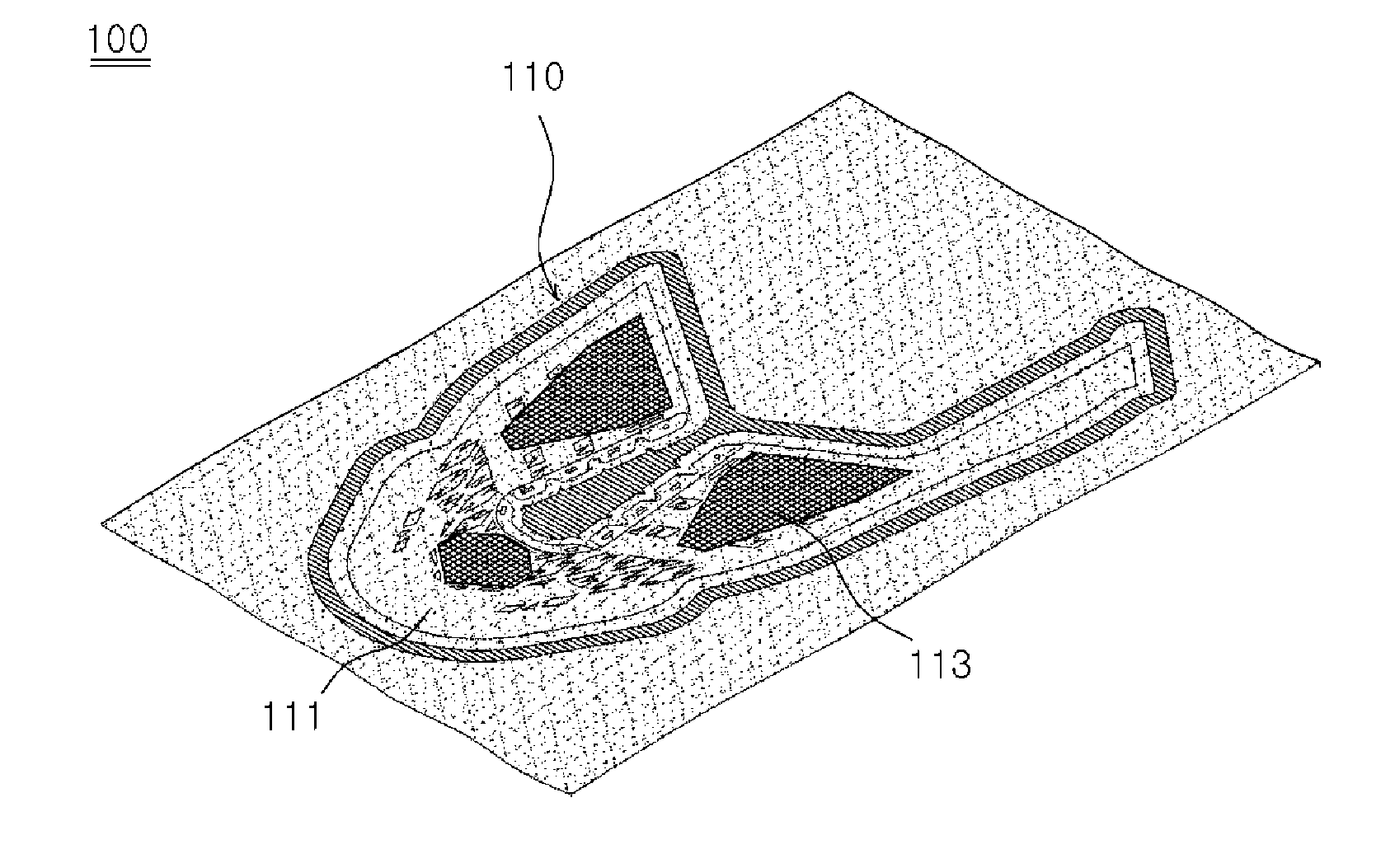

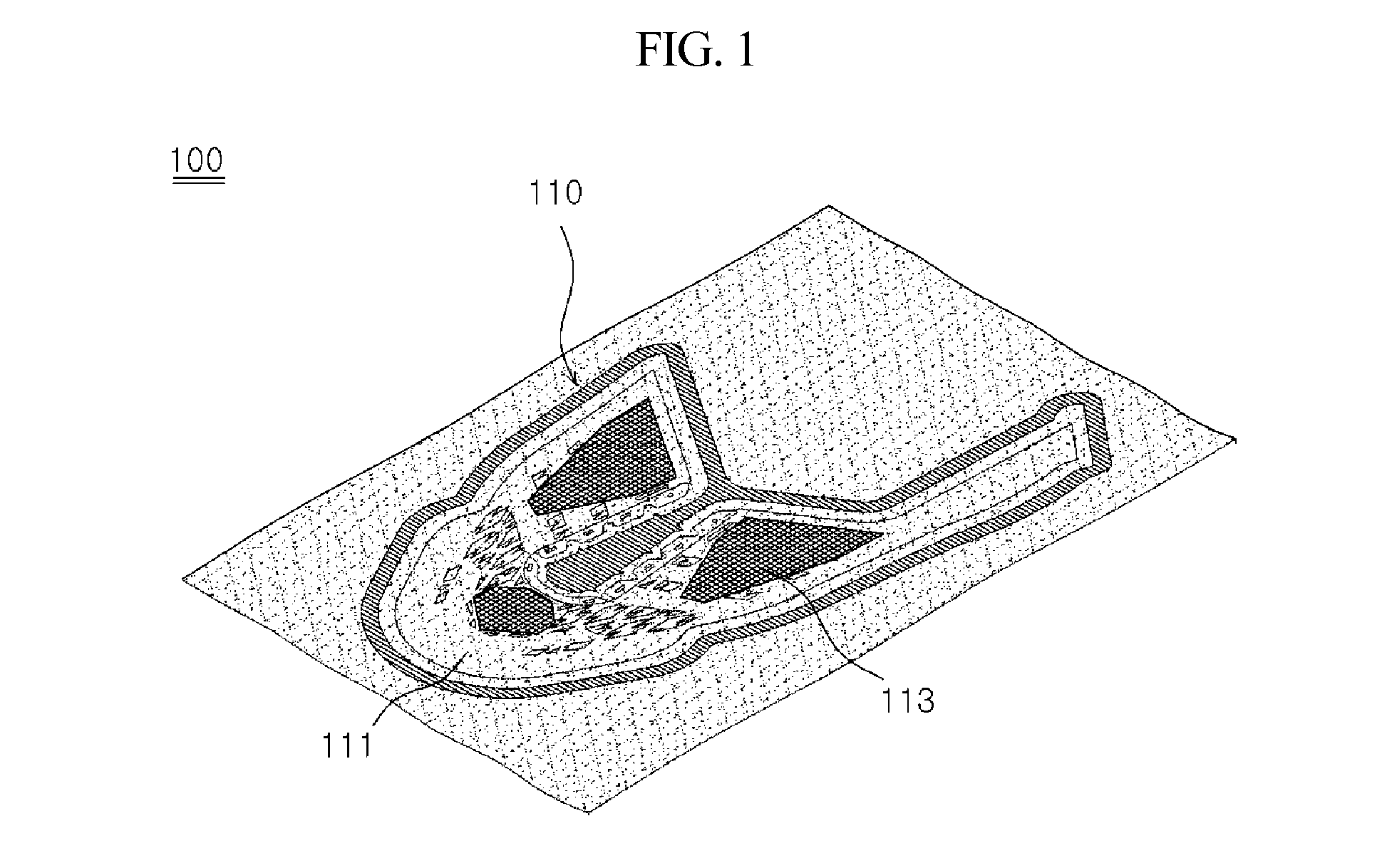

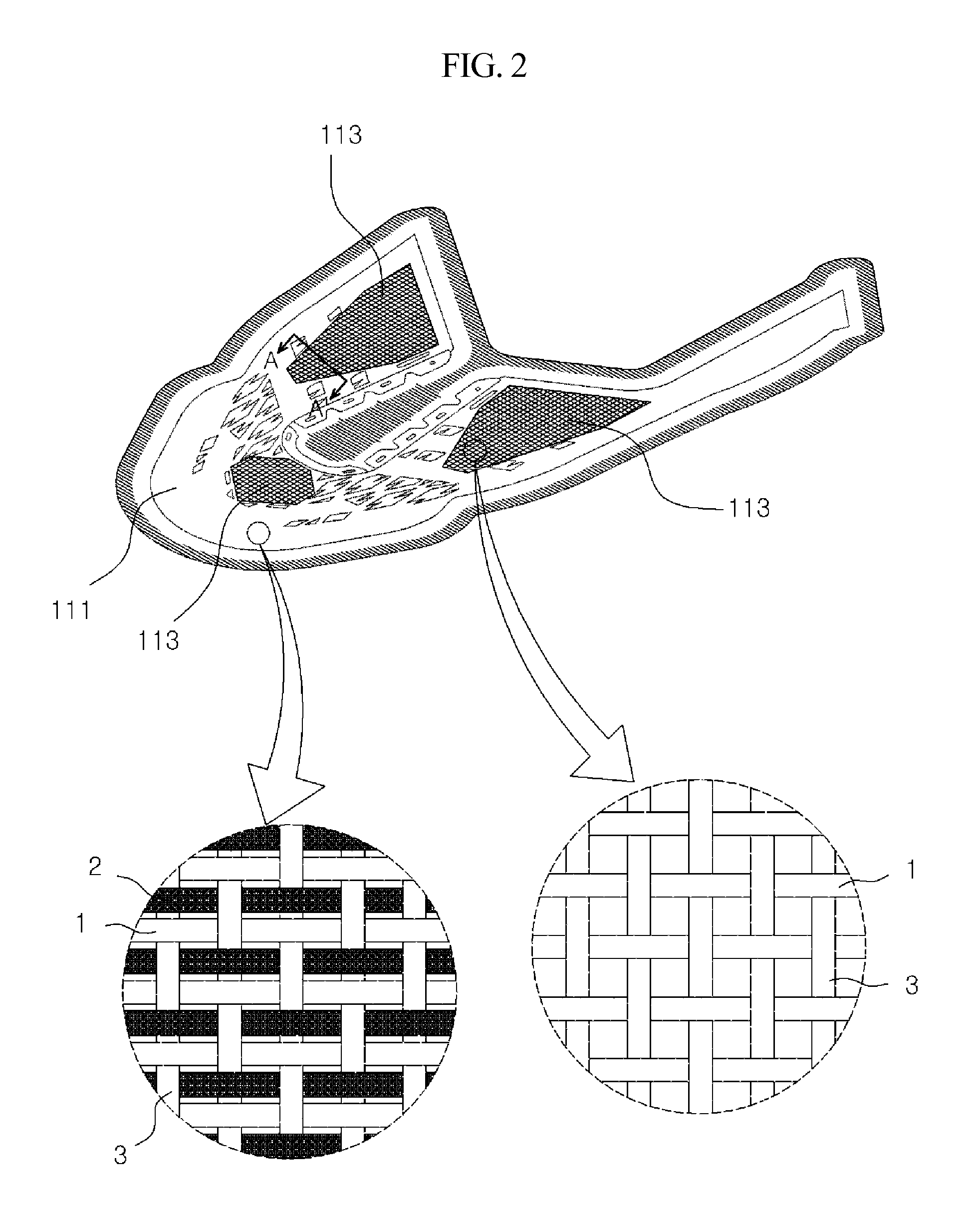

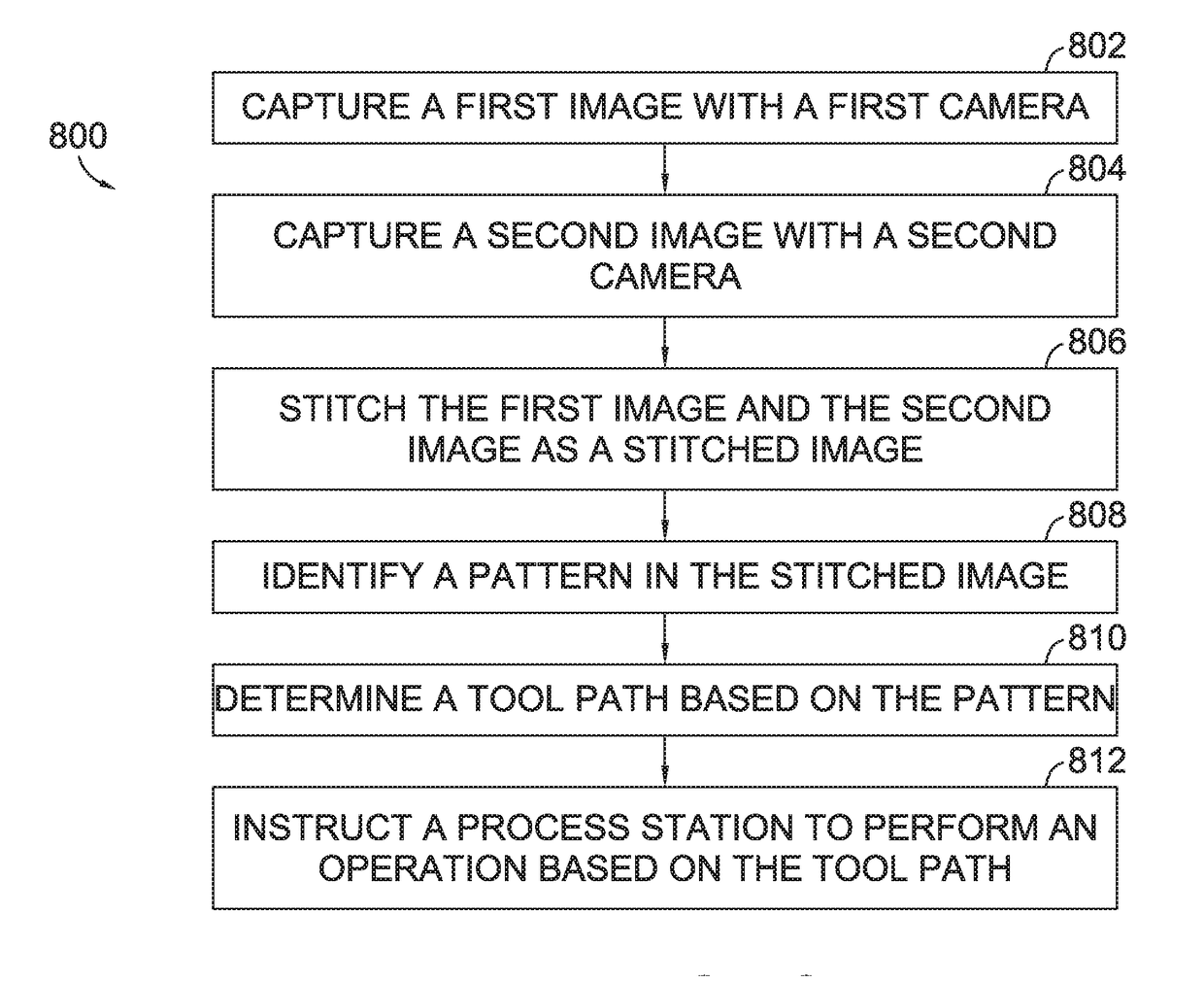

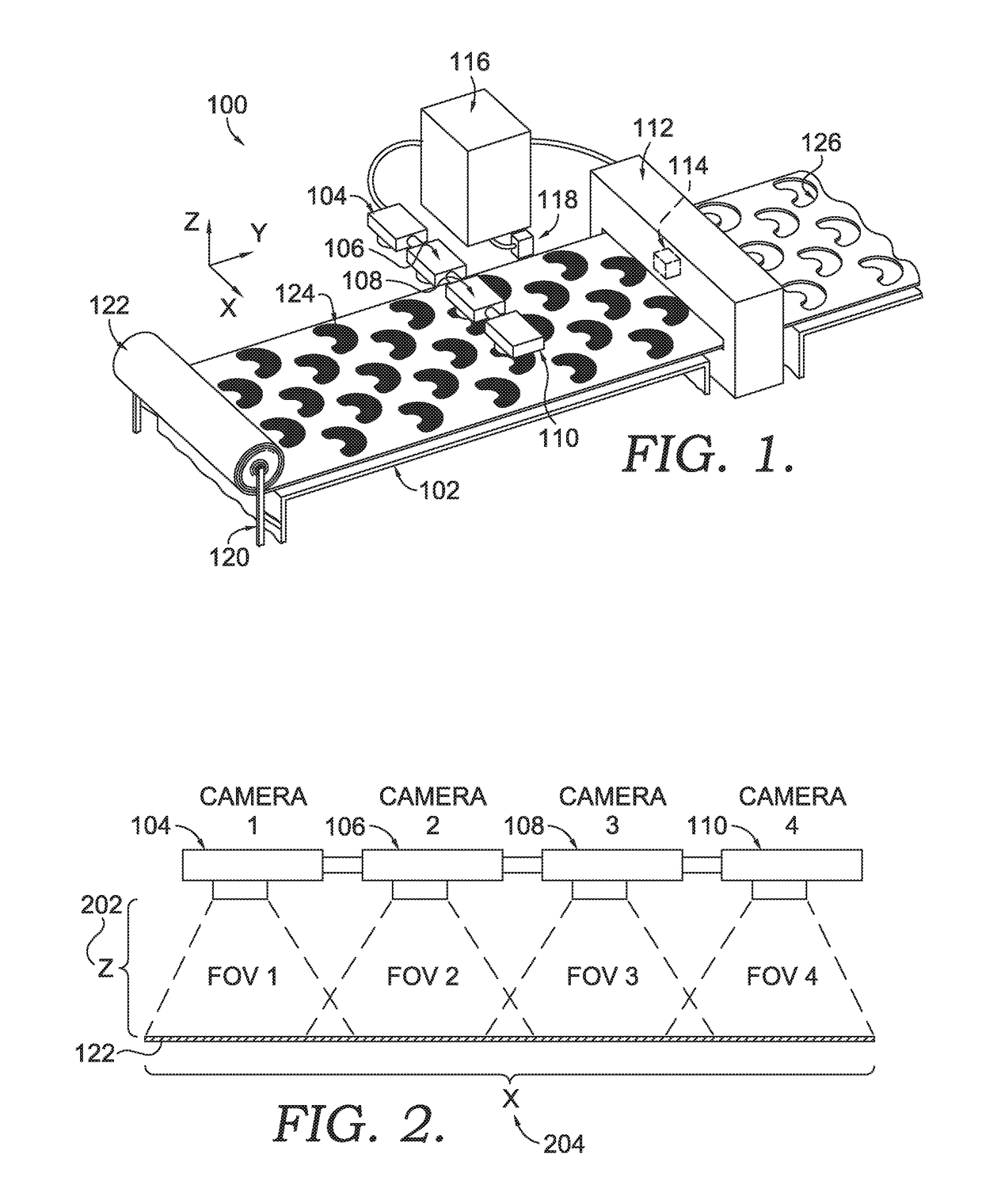

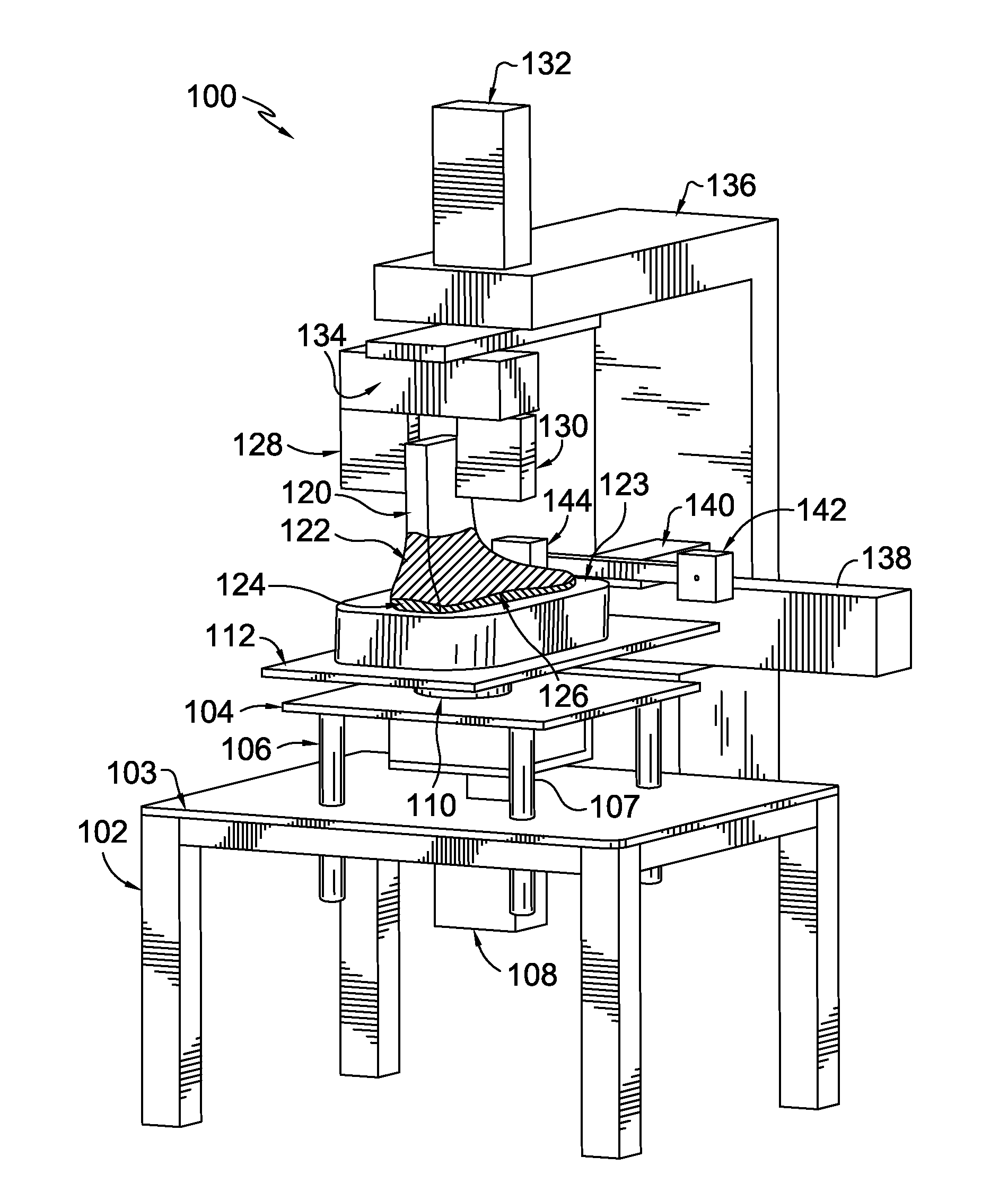

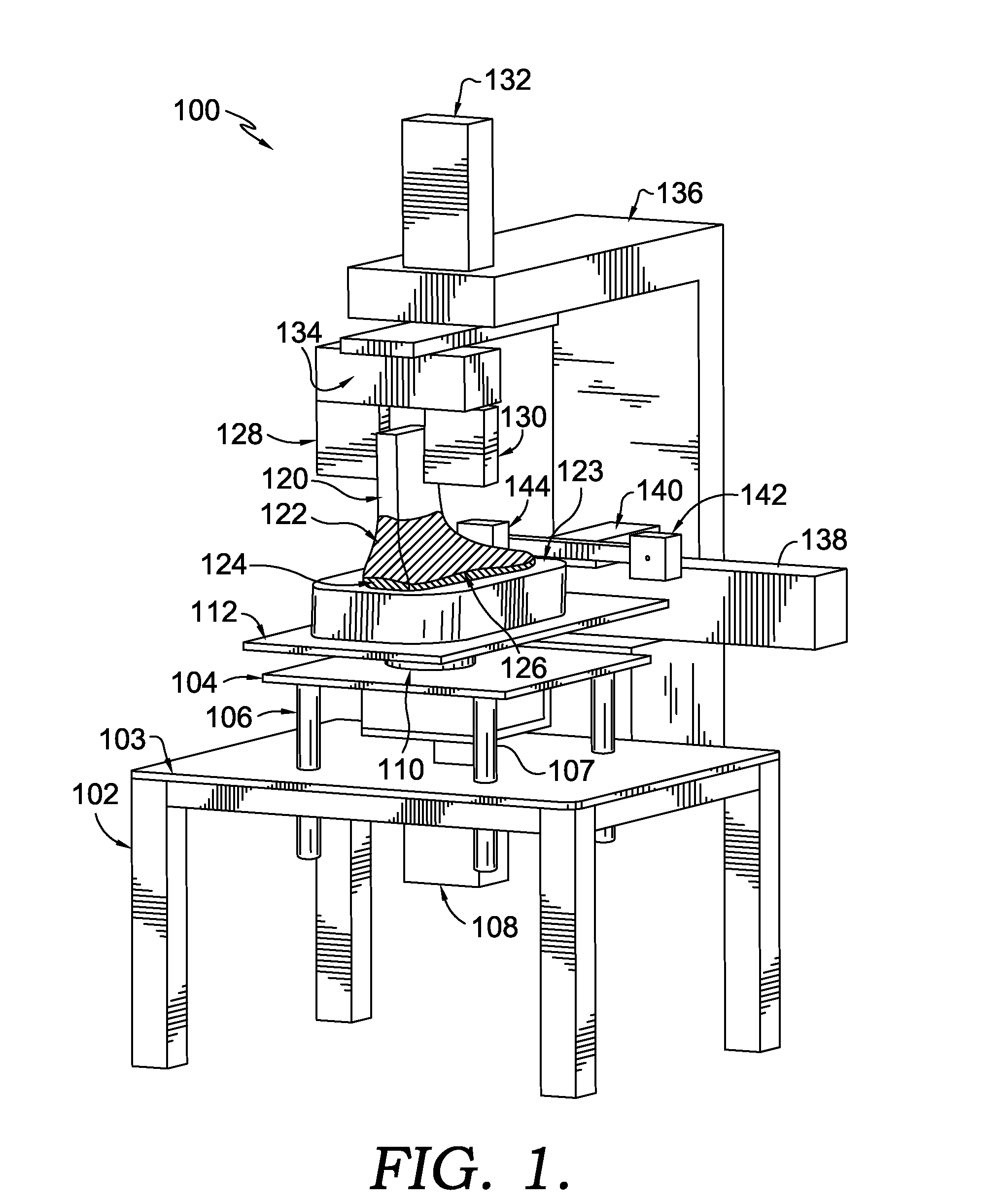

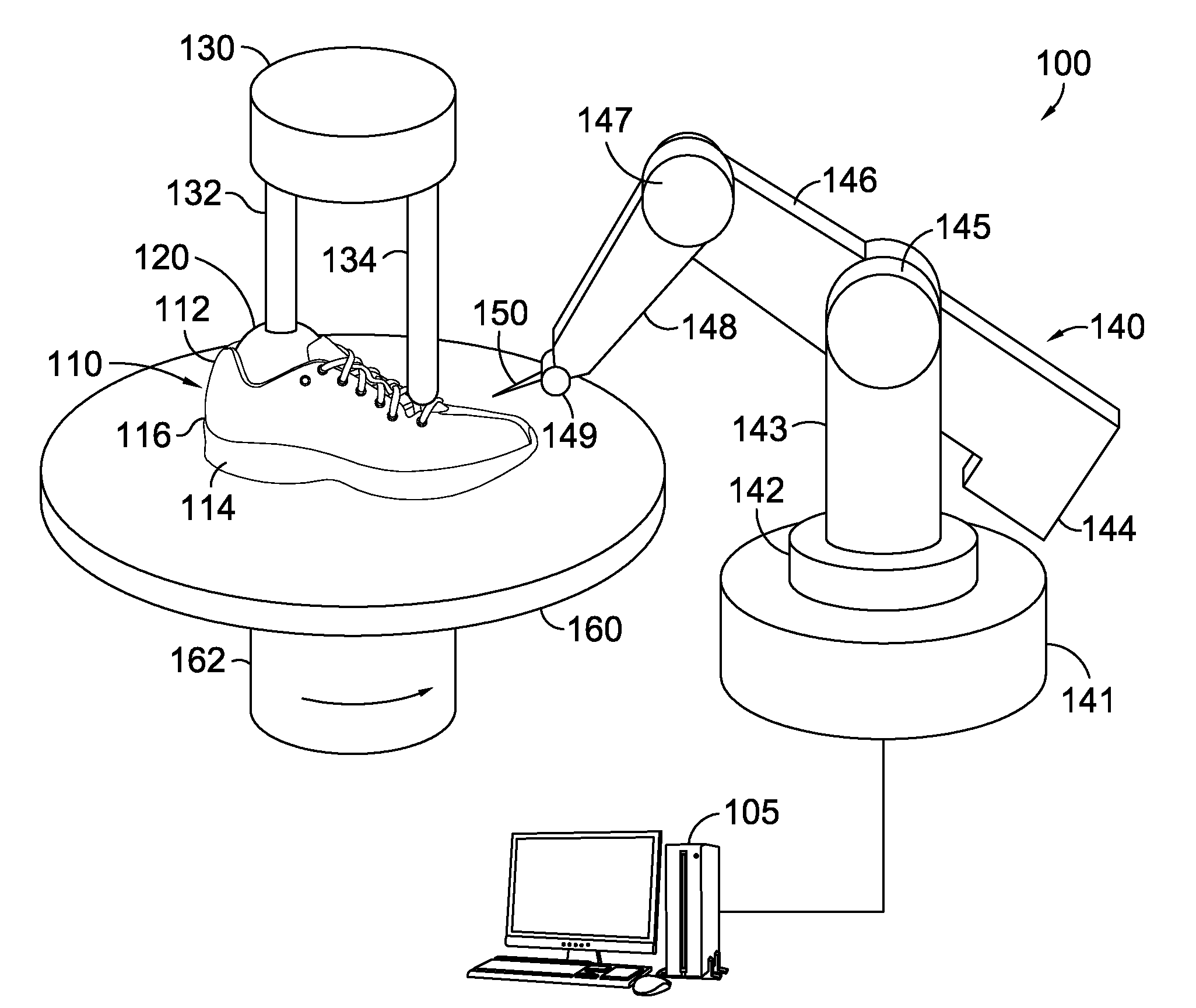

Image stitching for footwear component processing

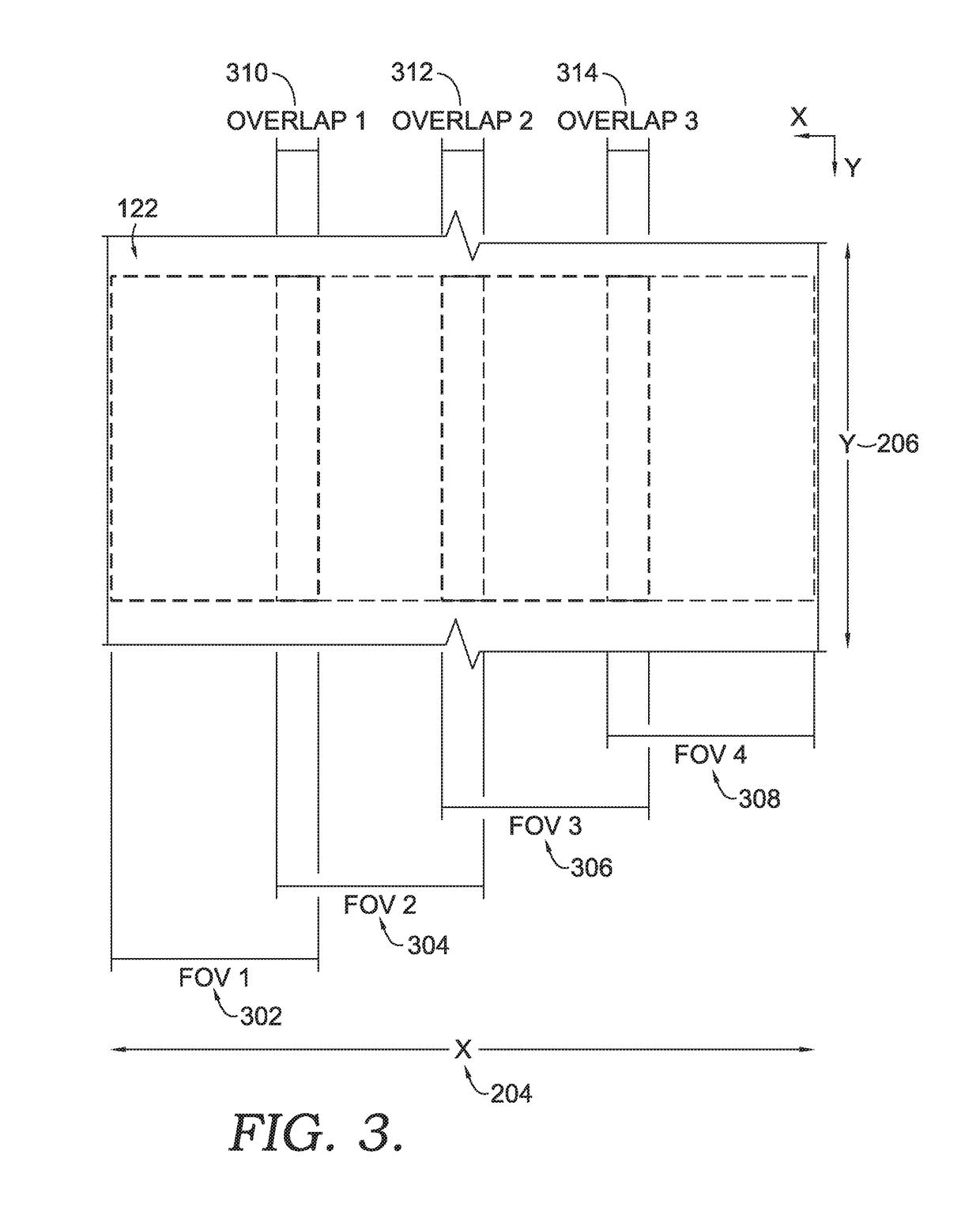

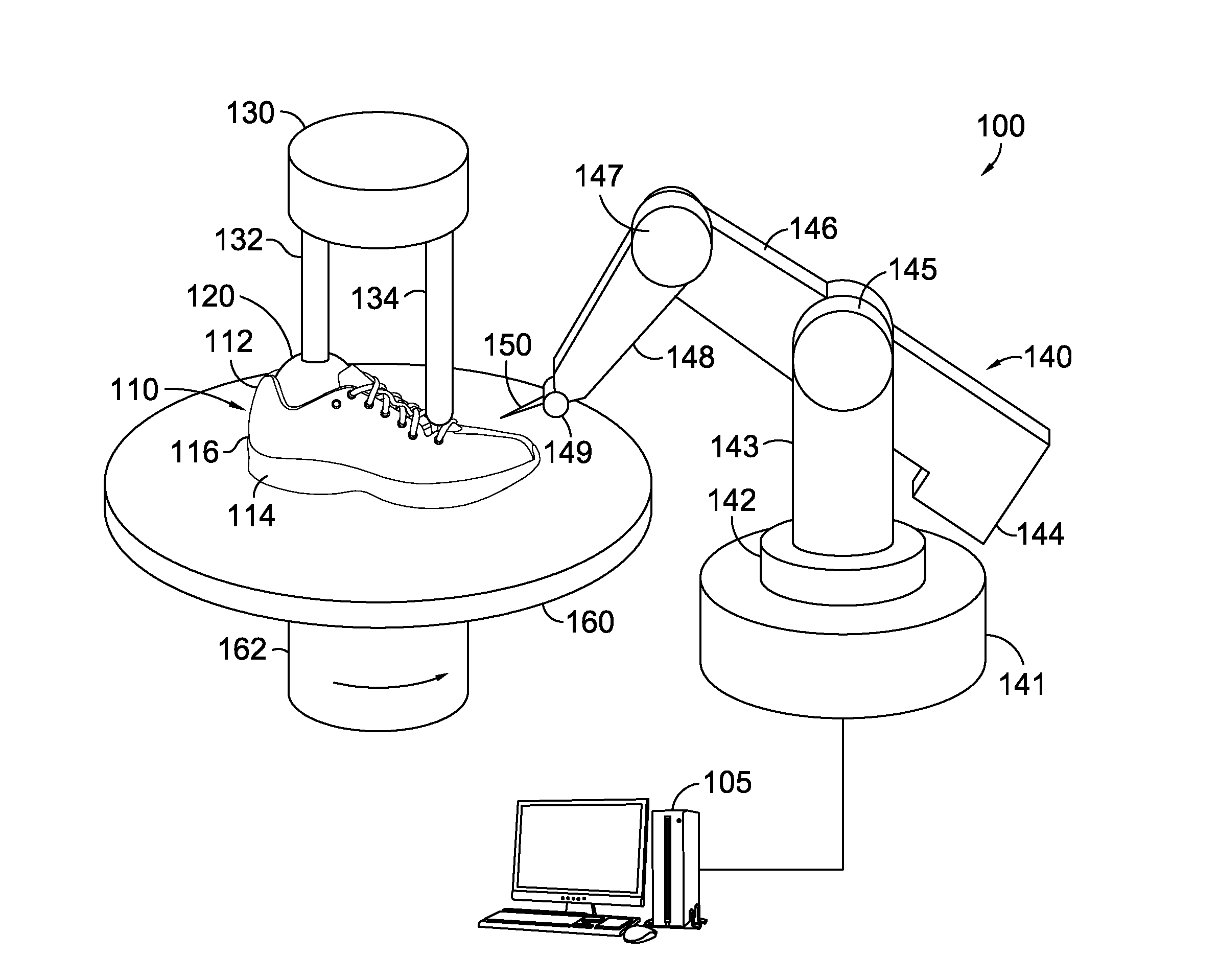

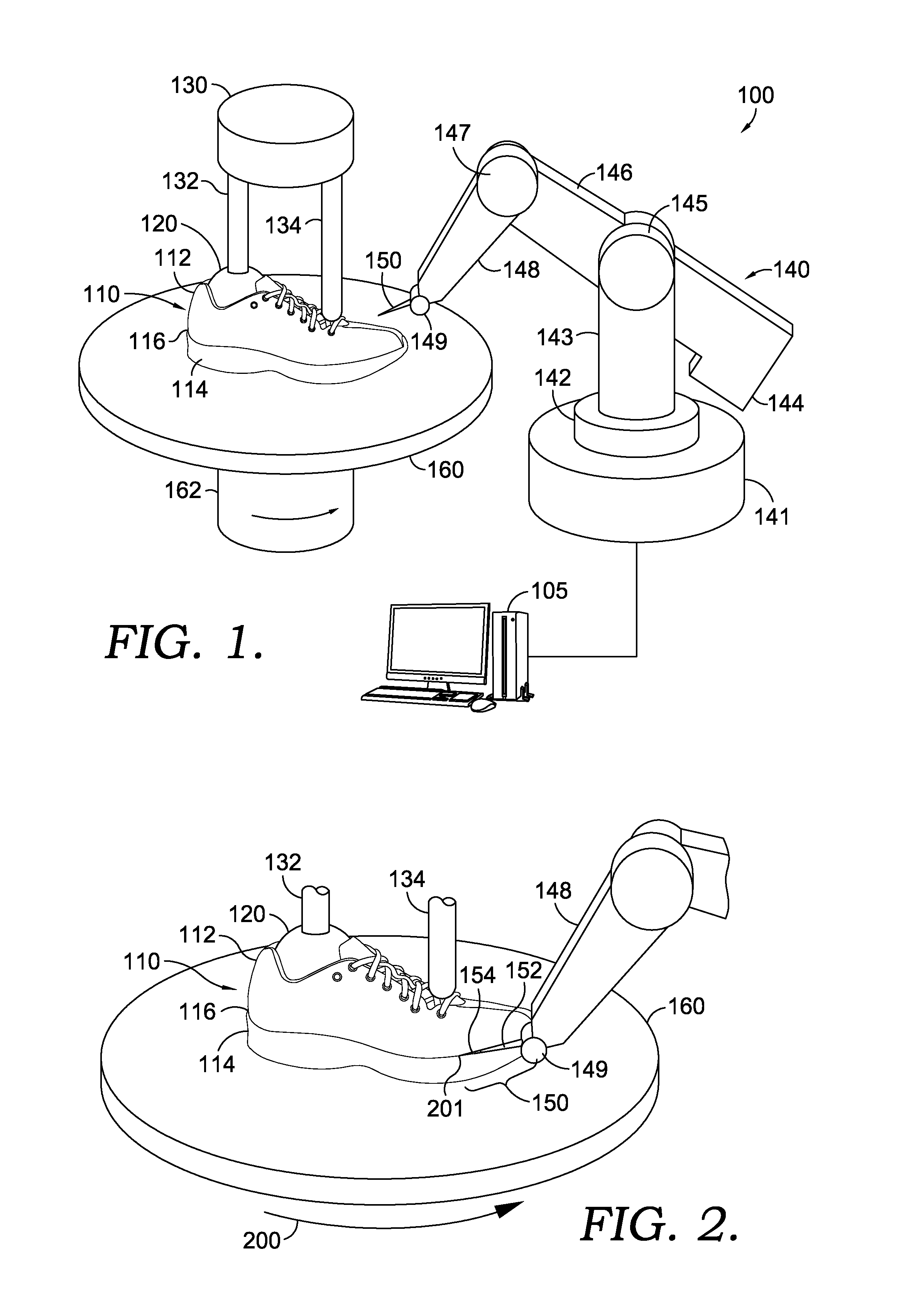

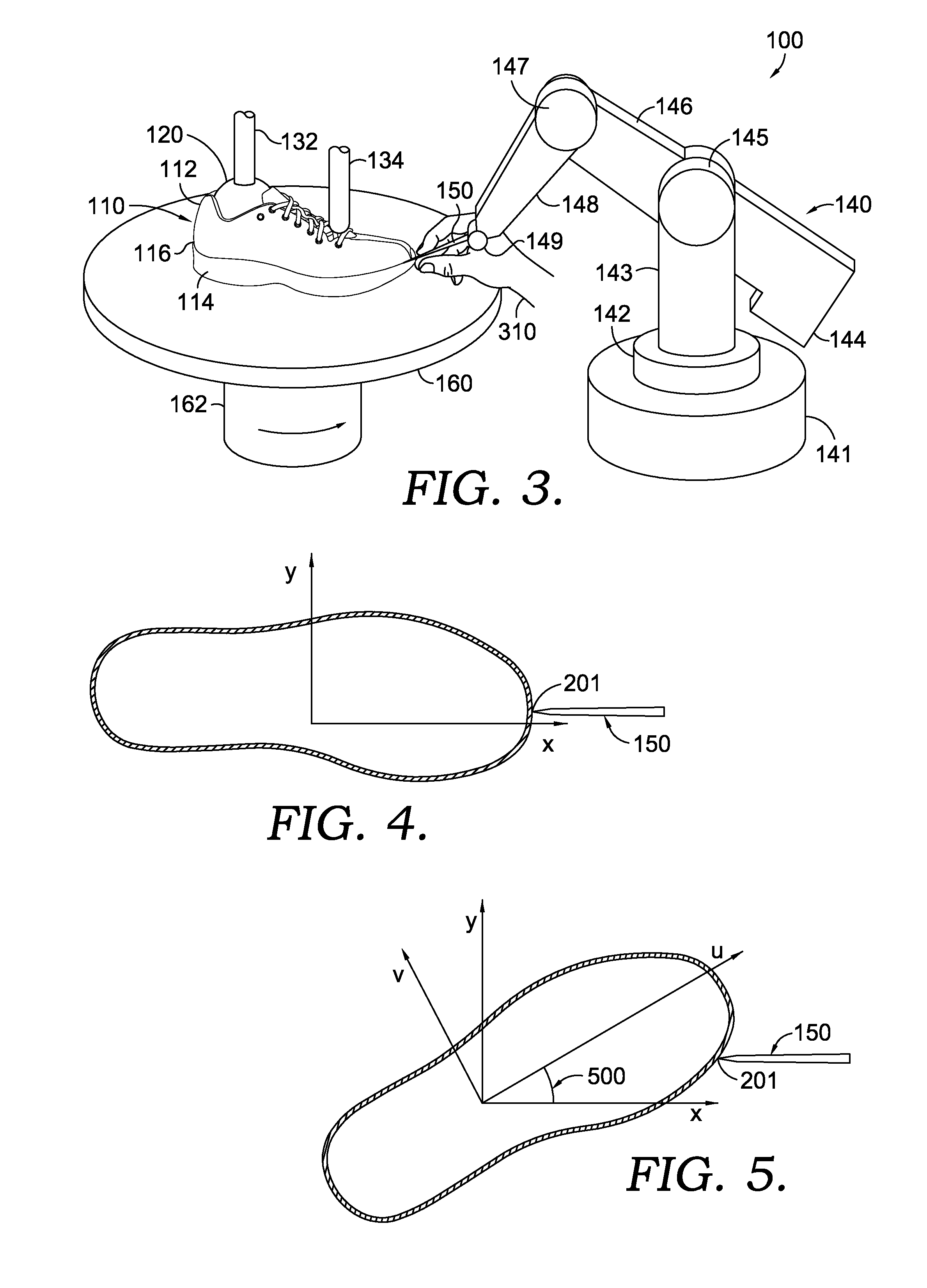

A multiple camera vision system captures discrete images having overlapping fields of view. Each of the cameras is calibrated and the images from the cameras are stitched together as a stitched image. A stitched image from the multiple cameras is then used in a calibration process to prepare the multiple camera vision system to be used in connection with a processing operation. A stitched image is used as an input for identifying a feature of the material and for determining a tool path for the material. The tool path determined with the stitched image is provided to a process station to perform an operation on the material.

Owner:NIKE INC

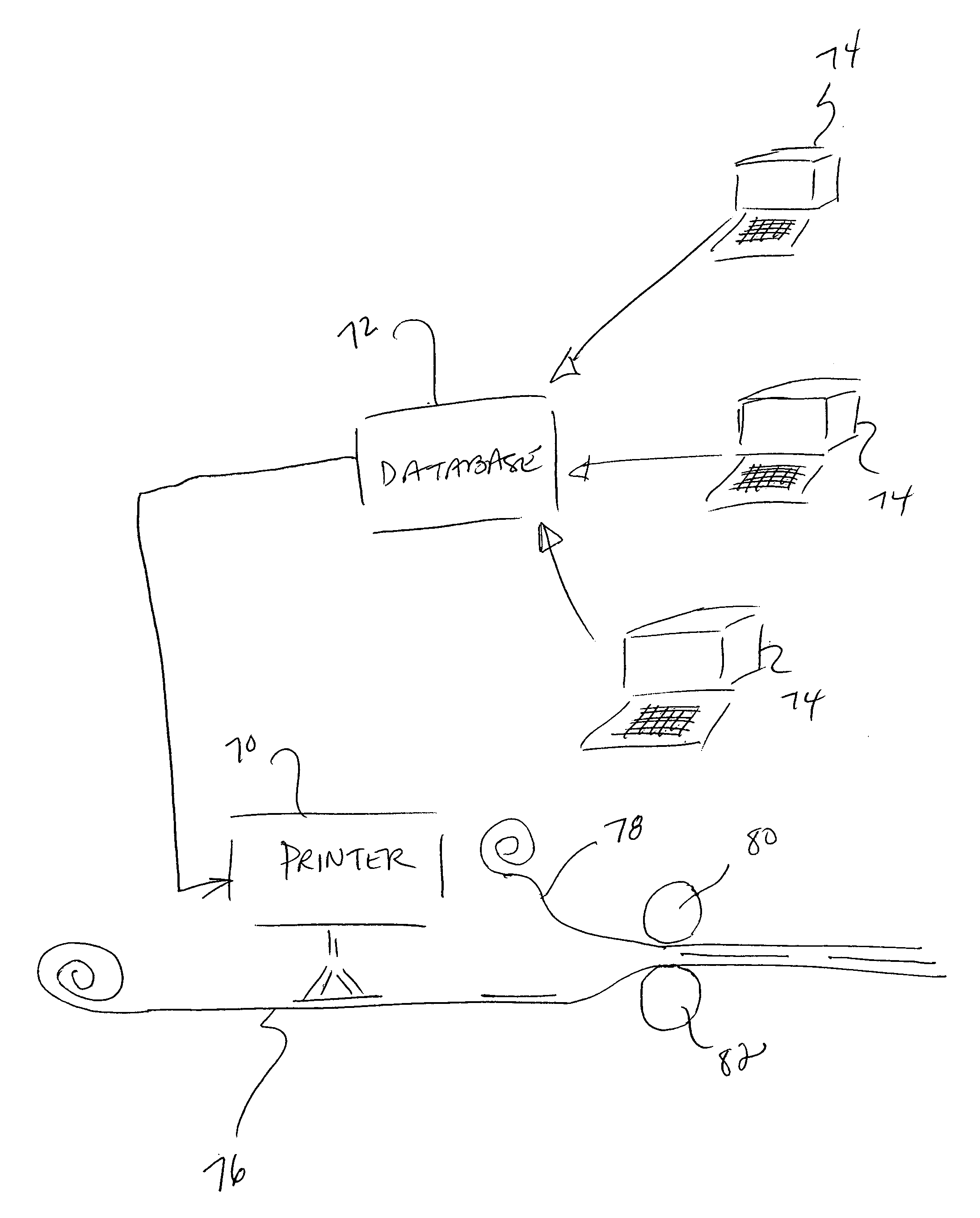

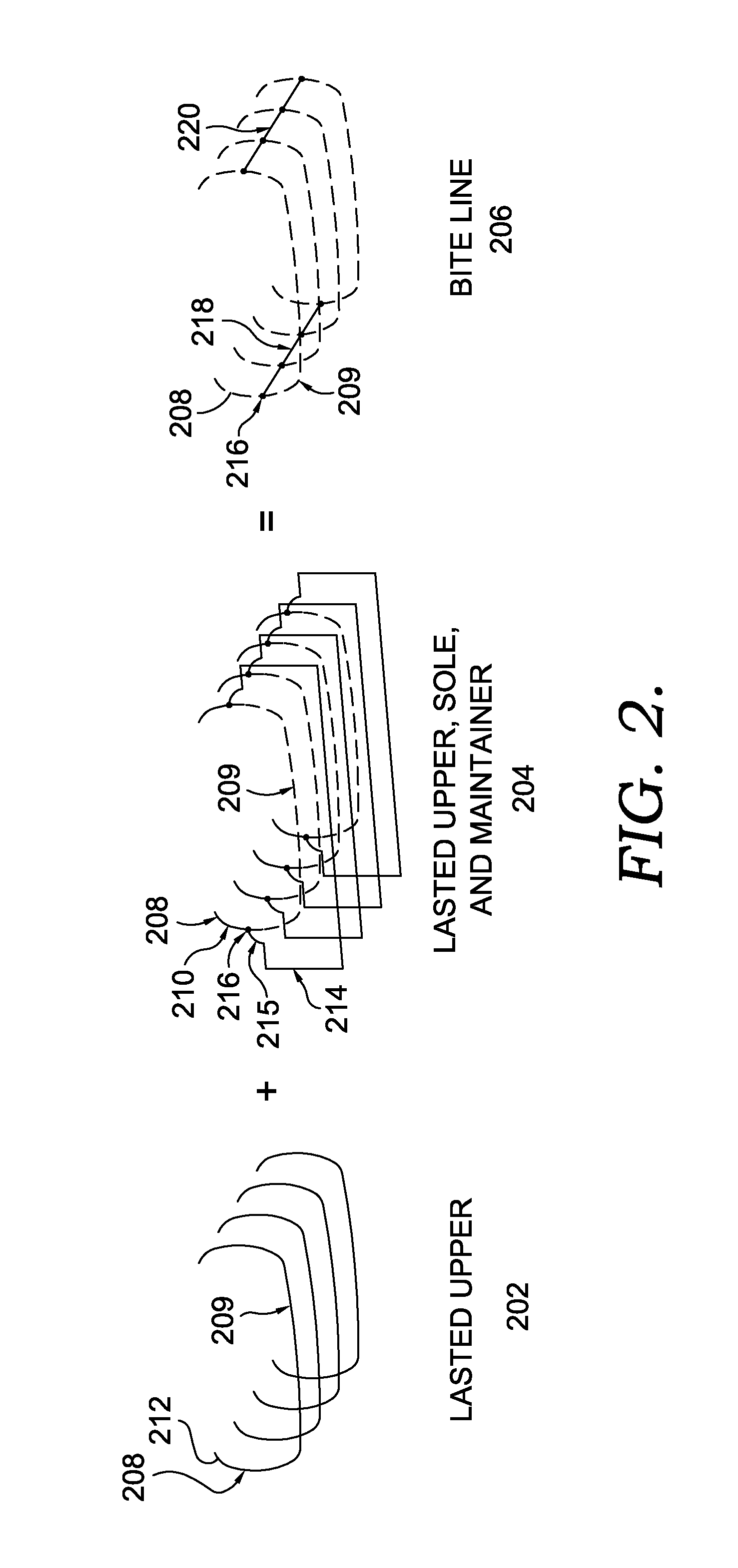

Digital Bite Line Creation For Shoe Assembly

ActiveUS20140096403A1Sufficiently pliableSufficient resilienceFoot measurement devicesShoe gluingVisibilityAdhesive

A system and method may simultaneously apply a limited visibility bite line to a temporarily assembled shoe upper and shoe sole while also generating a digital bite line. The digital bite line may be used to generate a tool path for the application of adhesives to the shoe upper and / or to the shoe sole assembly to permanently assemble the shoe. The limited visibility bite line may comprise a mark or other indicia observable only under specific viewing conditions and / or only for a limited amount of time or until removal. The limited visibility bite line may be used for quality control check purposes to verify, for example, the proper application of adhesives or the proper assembly of the shoe. The limited visibility bite line may be unobservable to the ultimate purchaser and / or wearer of the shoe.

Owner:NIKE INC

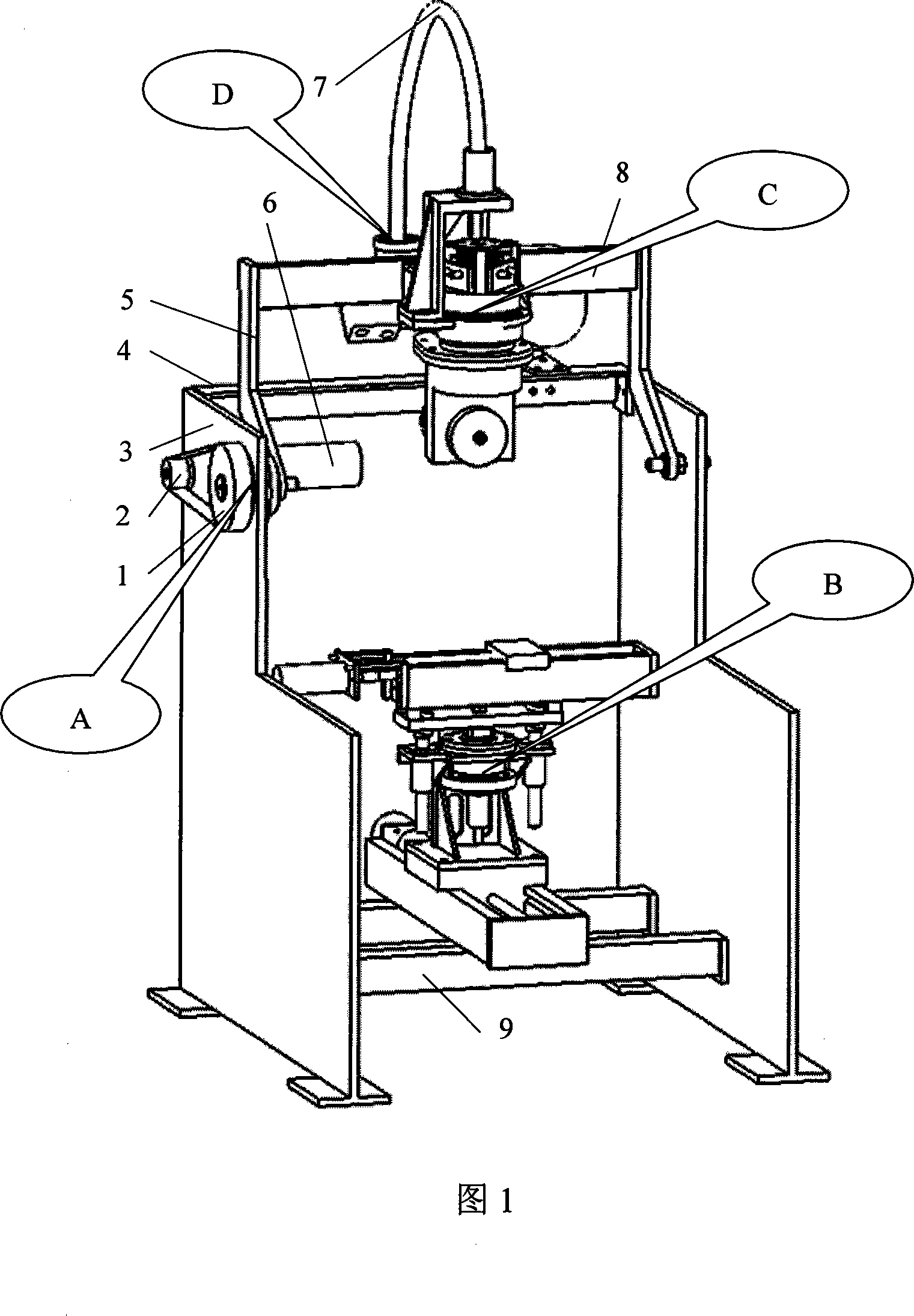

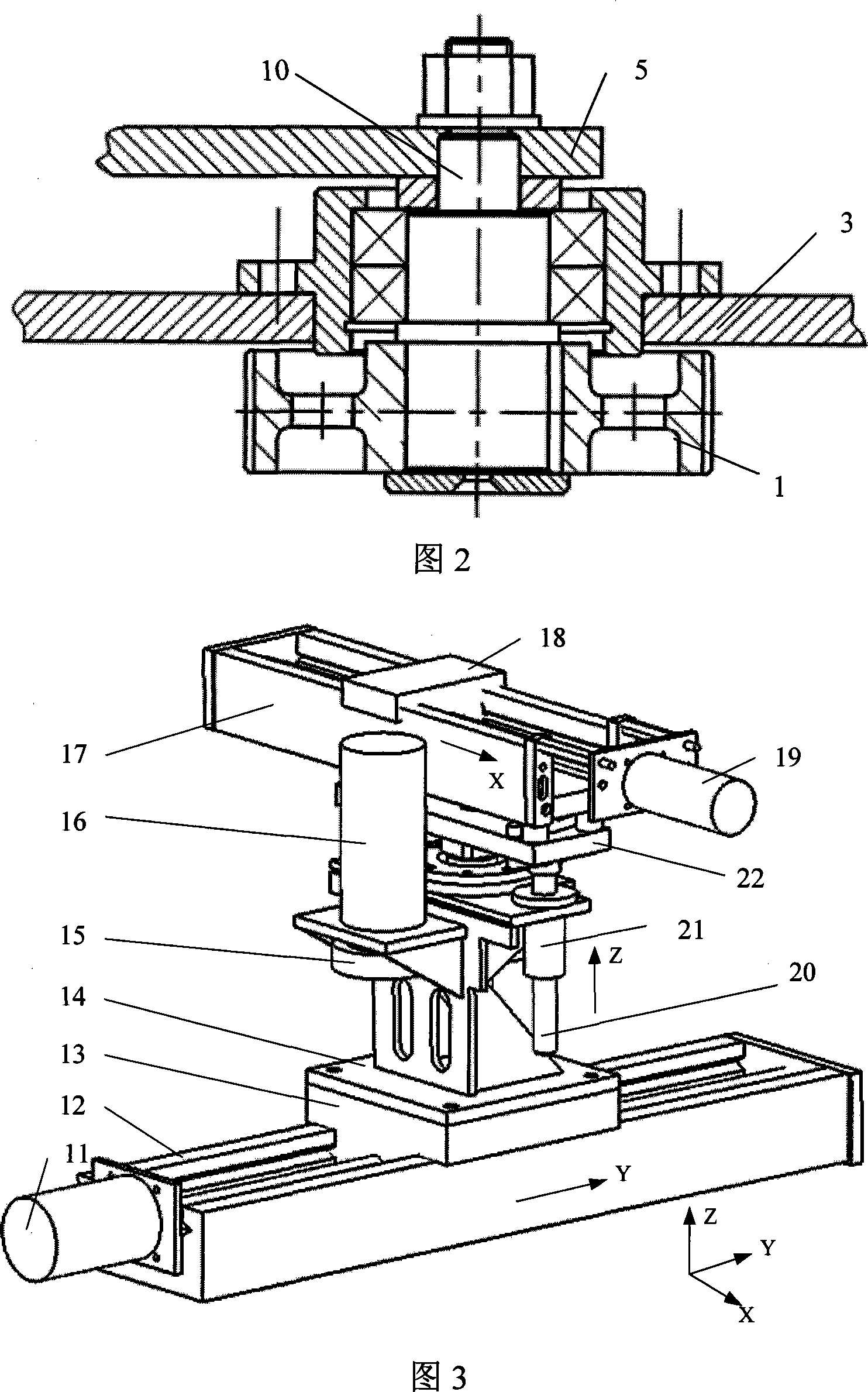

Five-freedom shoemaking automatically grinding glue-spraying processing device

InactiveCN101214098APrecision grindingPrecise gluingSolesShoe gluingThree phase asynchronous motorEngineering

The invention discloses a shoemaking automatic buffing and gel spraying processing device with five degrees of freedom, which is realized mainly through a mobile mechanism and a rotation mechanism. The mobile mechanism can control the movement of a work piece at three space orthogonal positions. A buffing head mechanism or a gel spraying mechanism is respectively connected with an arm swinging binding part. The rotation of a swing arm and a buffing head box or a spray gun is respectively driven through an AC servo motor, which leads to that the buffing plate or the spray gun can swing along two orthogonal directions to realize the posture regulation of the buffing plate or the spray gun. A three-phase asynchronous motor drives the buffing plate to rotate at a high speed through a flexible shaft to realize the buffing work. The automatic buffing and the gel spraying work can be respectively realized through different connections of the buffing head mechanism or the gel spraying mechanism with the arm swinging combining part.

Owner:ZHEJIANG SCI-TECH UNIV

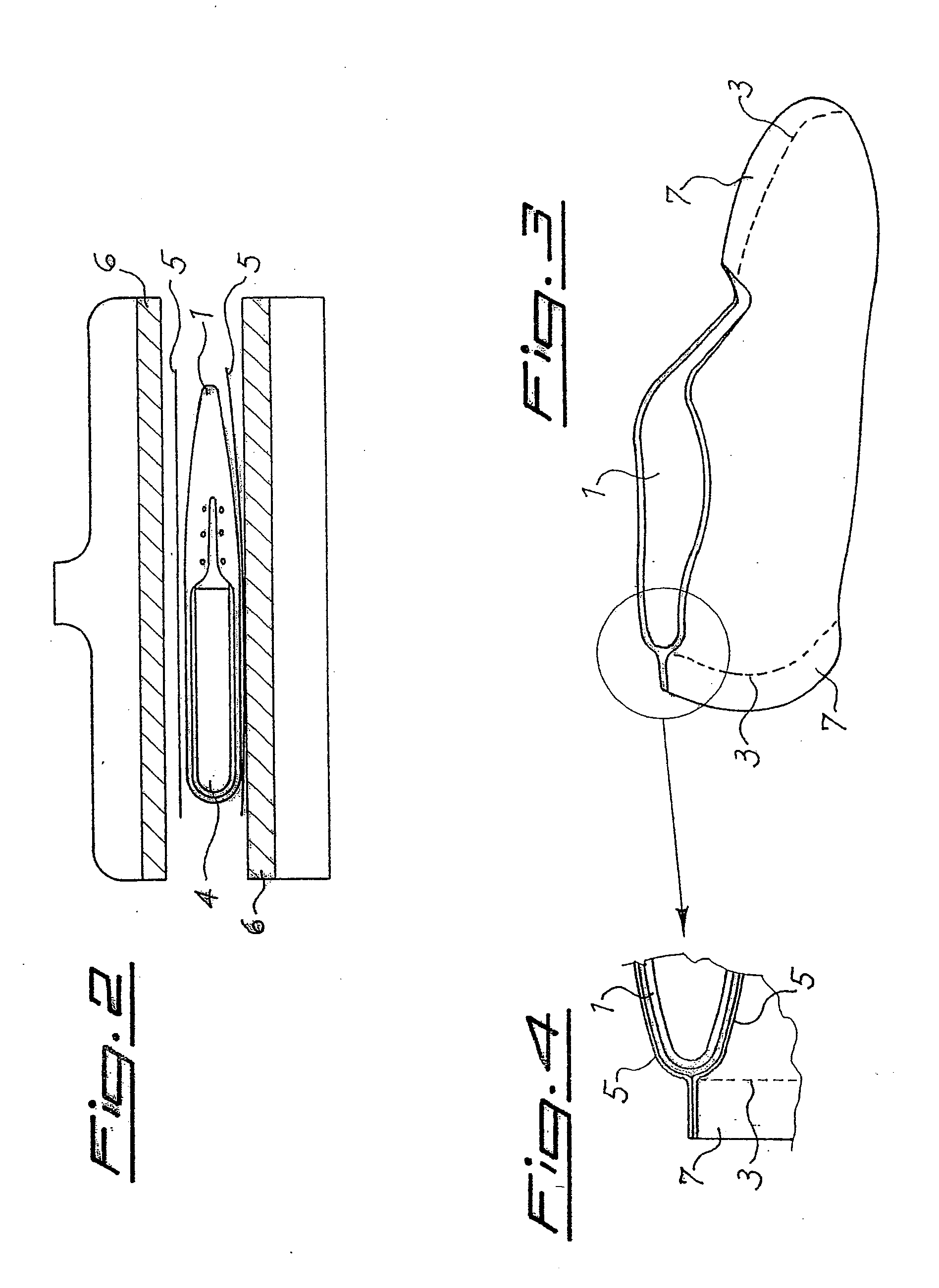

Method for manufacturing inflatable footwear or bladders for use in inflatable articles

The present invention is a method for manufacturing inflatable articles, or bladders for inflatable articles, that is time-efficient, simple, inexpensive and permits the uninterrupted manufacture of numerous and even customized article or bladder configurations and sizes, without expensive configuration-specific, metal tooling. The method includes the steps of applying a barrier material to a side of a first film, providing a second film with the first film so that the barrier material is disposed between the first and second films, adhering the first film to the second film so that the films are sealed together in areas except where the barrier material has been applied to form at least one inflatable compartment and sealed peripheral edge, and cutting along the sealed peripheral edge to form an inflatable article or bladder for use in an article of manufacture. The barrier material may be a paint, ink, paper or surface treatment that effectively prevents the first film from adhering to the second. The inflatable article or bladder of the present invention may be used as or in athletic equipment, for example, including footwear.

Owner:REEBOK

Divergence detection of a shoe bite line

Systems and methods are provided for collecting three-dimensional surface data of a lasted shoe upper that is mated with a sole that is configured for the lasted upper. The mated three-dimensional data is used with three-dimensional data of the lasted shoe upper in an unmated configuration with the sole to determine a location of an edge defined by the intersection of the lasted upper and the sole when mated. The bite line identifies an edge where the upper and a sole assembly will intersect on a finished shoe, which may represent a bounding line for application of adhesive to the lasted upper for boding the sole thereto.

Owner:NIKE INC

Method for manufacturing footwear, footwear produced using said method, and machine for manufacturing footwear

Owner:SALOMON SA

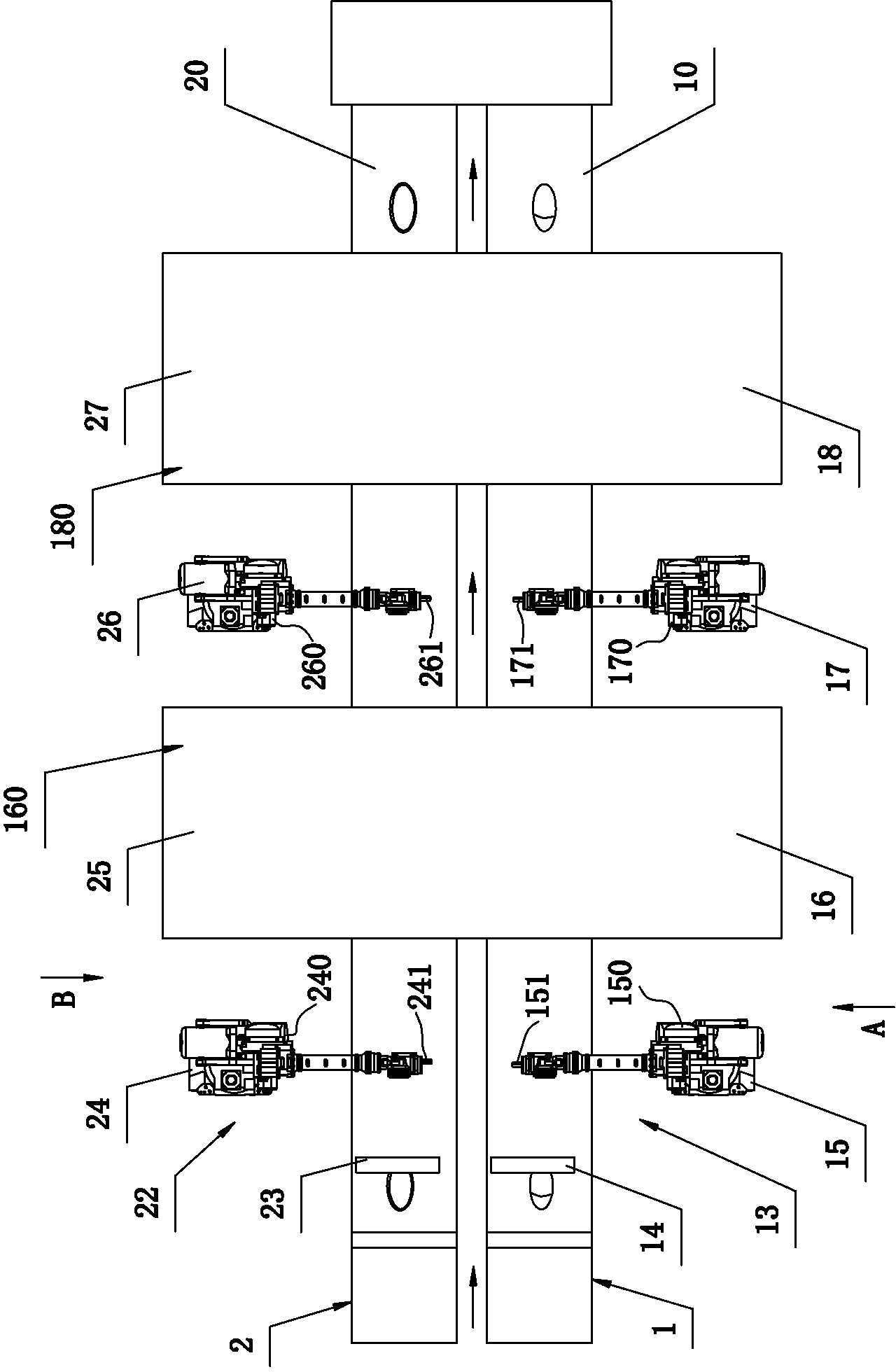

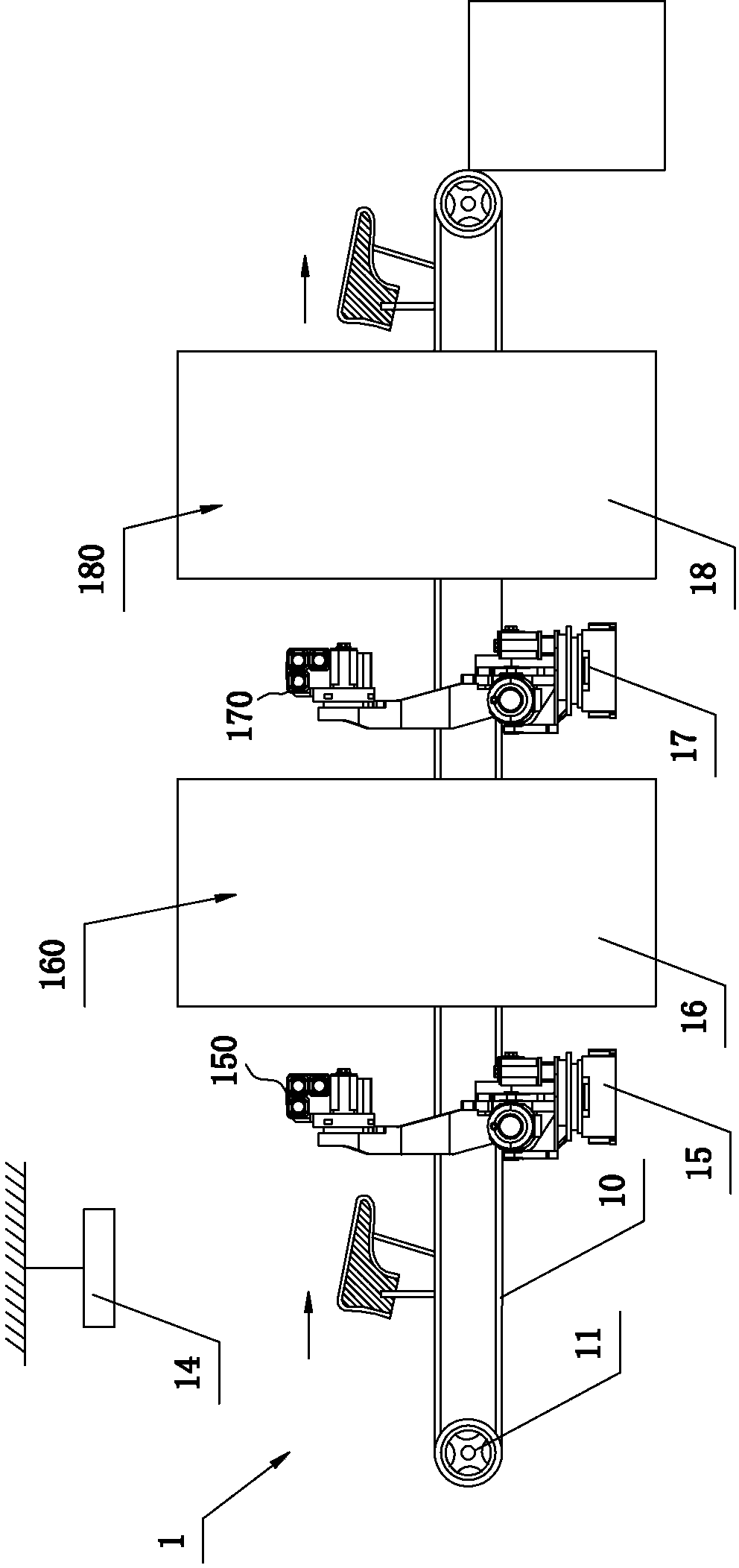

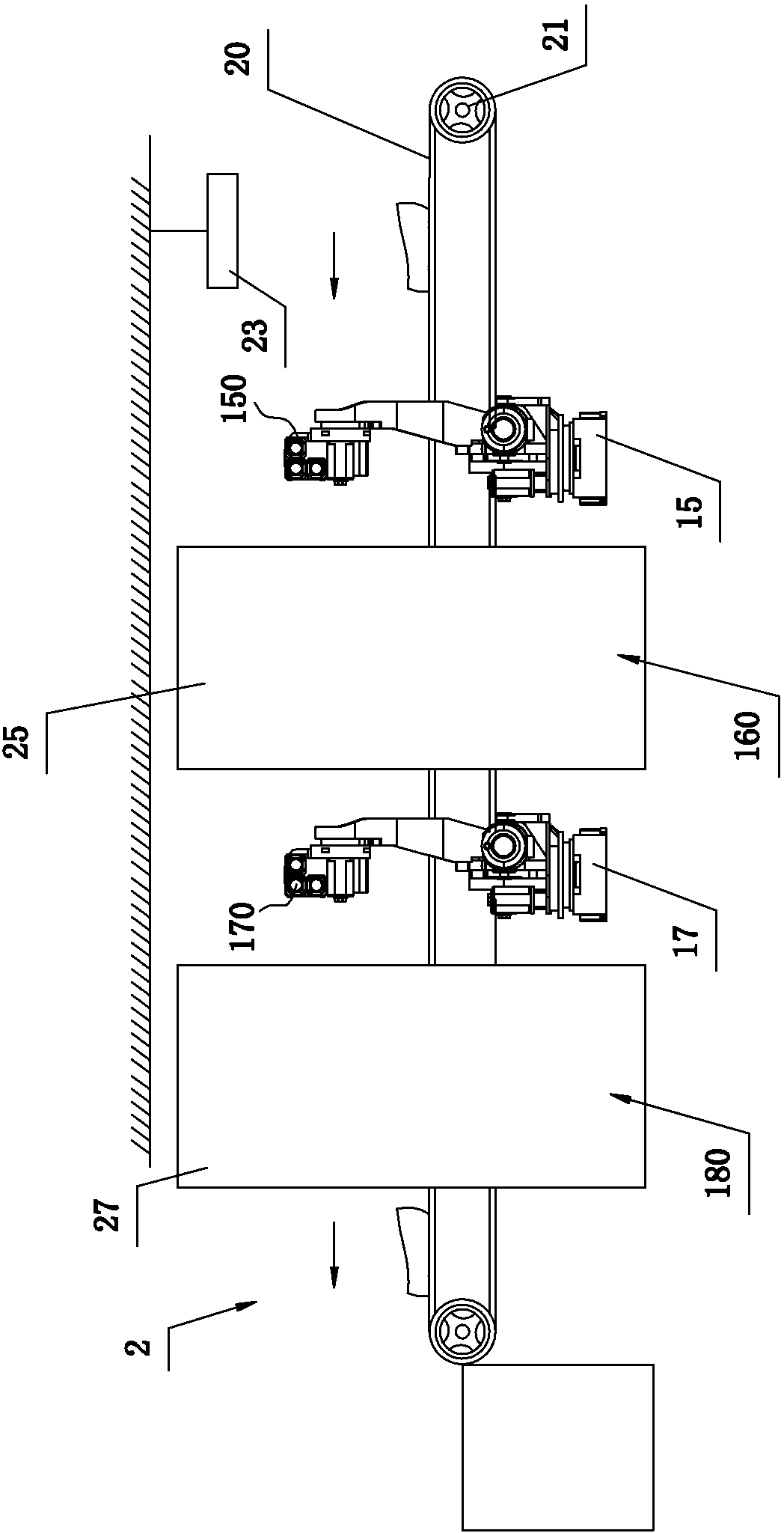

Automatic manufacturing method and automatic production line for shoes

InactiveCN104161355AConsistent glue volumeImprove the consistency of spray glue effectShoe gluingProduction lineManipulator

The invention relates to an automatic production line for shoes. The automatic production line comprises an automatic vamp gluing device and an automatic sole gluing device. The automatic vamp gluing device comprises a first conveying belt, a first driving assembly and a first automatic glue spraying control assembly. The first automatic glue spraying control assembly comprises a three-dimensional scanning mechanism, a first processing water spraying mechanism, a first processing water drying mechanism, a first glue spraying executing mechanism and a first glue drying mechanism, wherein the three-dimensional scanning mechanism, the first processing water spraying mechanism, the first processing water drying mechanism, the first glue spraying executing mechanism and the first glue drying mechanism are located above the first conveying belt and adjacently connected in sequence. The first glue spraying executing mechanism comprises a controller, a first six-degree-of-freedom mechanical hand and a first spray gun, wherein the enable end of the controller is connected with the three-dimensional scanning mechanism, and the first spray gun is installed on the arm of the first six-degree-of-freedom mechanical hand. The invention further relates to an automatic manufacturing method for the shoes. According to the automatic production line and the automatic manufacturing method for the shoes, glue wastage can be greatly reduced, the vamp glue spraying effect consistency is improved, then the follow-up vamp and sole gluing firmness degree is improved, the service life of the shoes is prolonged, and the quality of the shoes is improved.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

Digital bite line creation for shoe assembly

ActiveUS8966775B2Sufficiently pliableSufficient resilienceFoot measurement devicesDiagnostic recording/measuringDigital subscriber lineVisibility

A system and method may simultaneously apply a limited visibility bite line to a temporarily assembled shoe upper and shoe sole while also generating a digital bite line. The digital bite line may be used to generate a tool path for the application of adhesives to the shoe upper and / or to the shoe sole assembly to permanently assemble the shoe. The limited visibility bite line may comprise a mark or other indicia observable only under specific viewing conditions and / or only for a limited amount of time or until removal. The limited visibility bite line may be used for quality control check purposes to verify, for example, the proper application of adhesives or the proper assembly of the shoe. The limited visibility bite line may be unobservable to the ultimate purchaser and / or wearer of the shoe.

Owner:NIKE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com