Automatic spraying system of sole bonding agent and spraying method thereof

A spraying system and adhesive technology, applied in footwear, shoe-bonding parts, shoe-making machinery, etc., can solve the problems that the spray gun cannot accurately control the spray flow and cannot spray the adhesive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

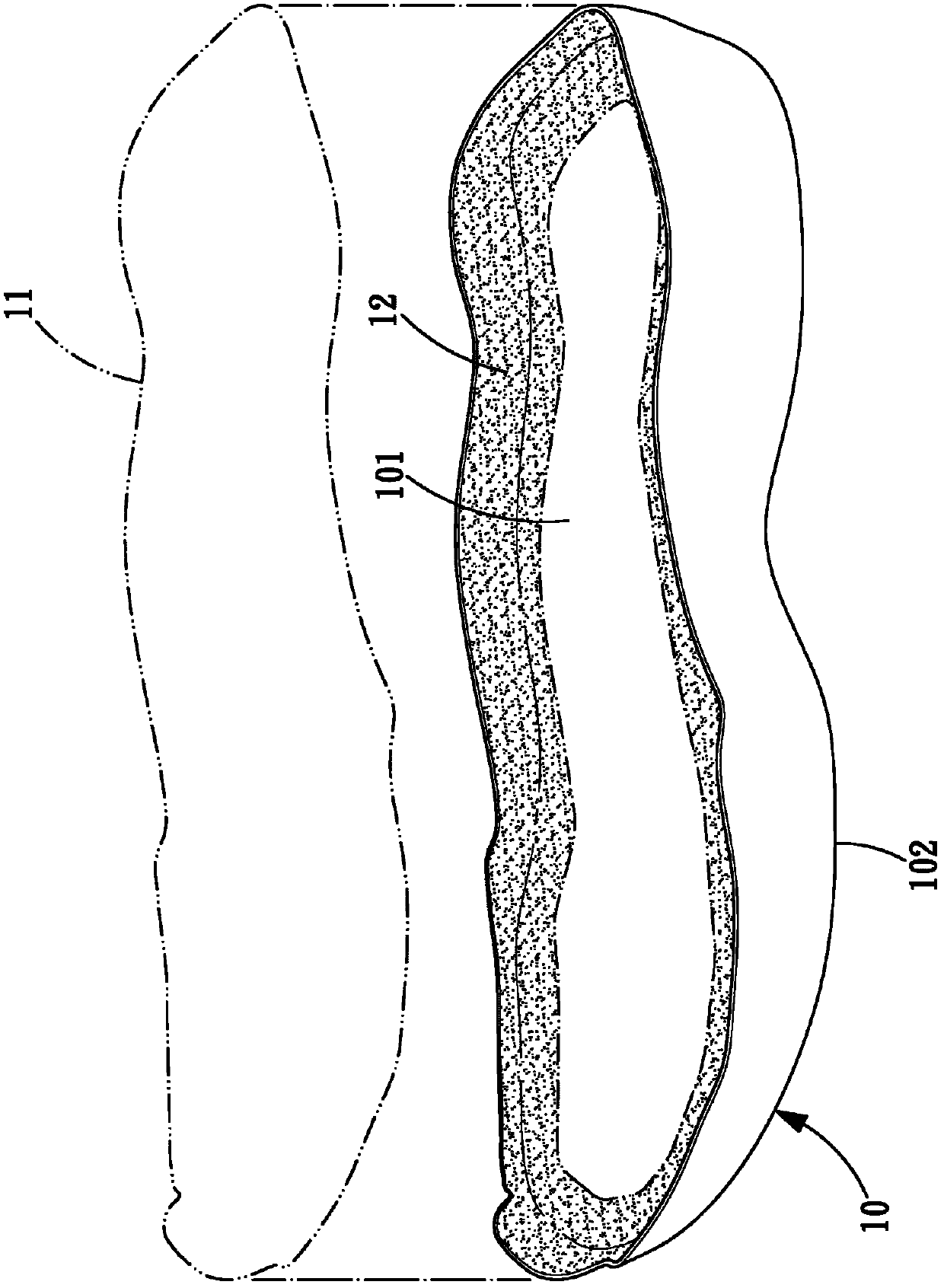

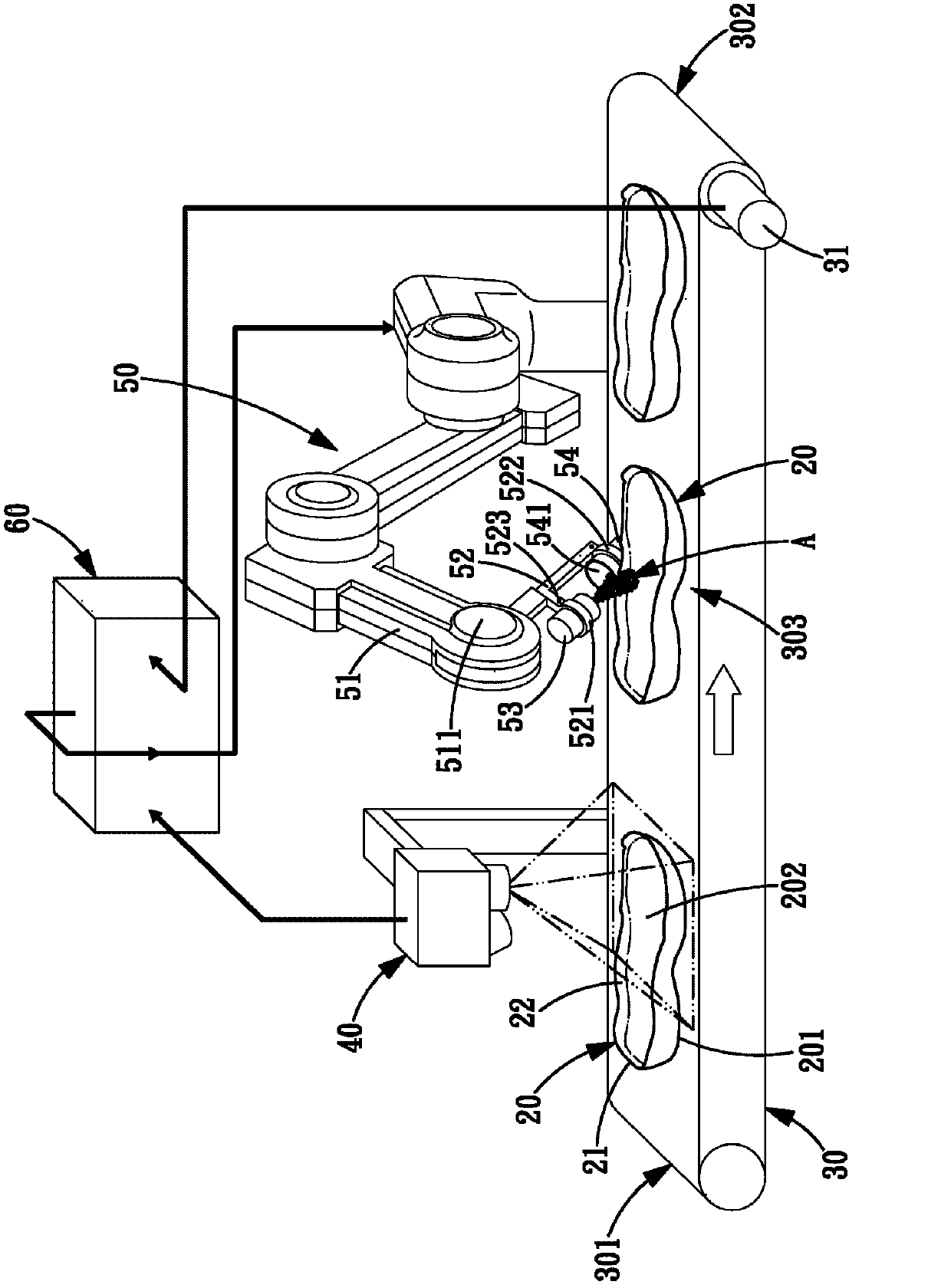

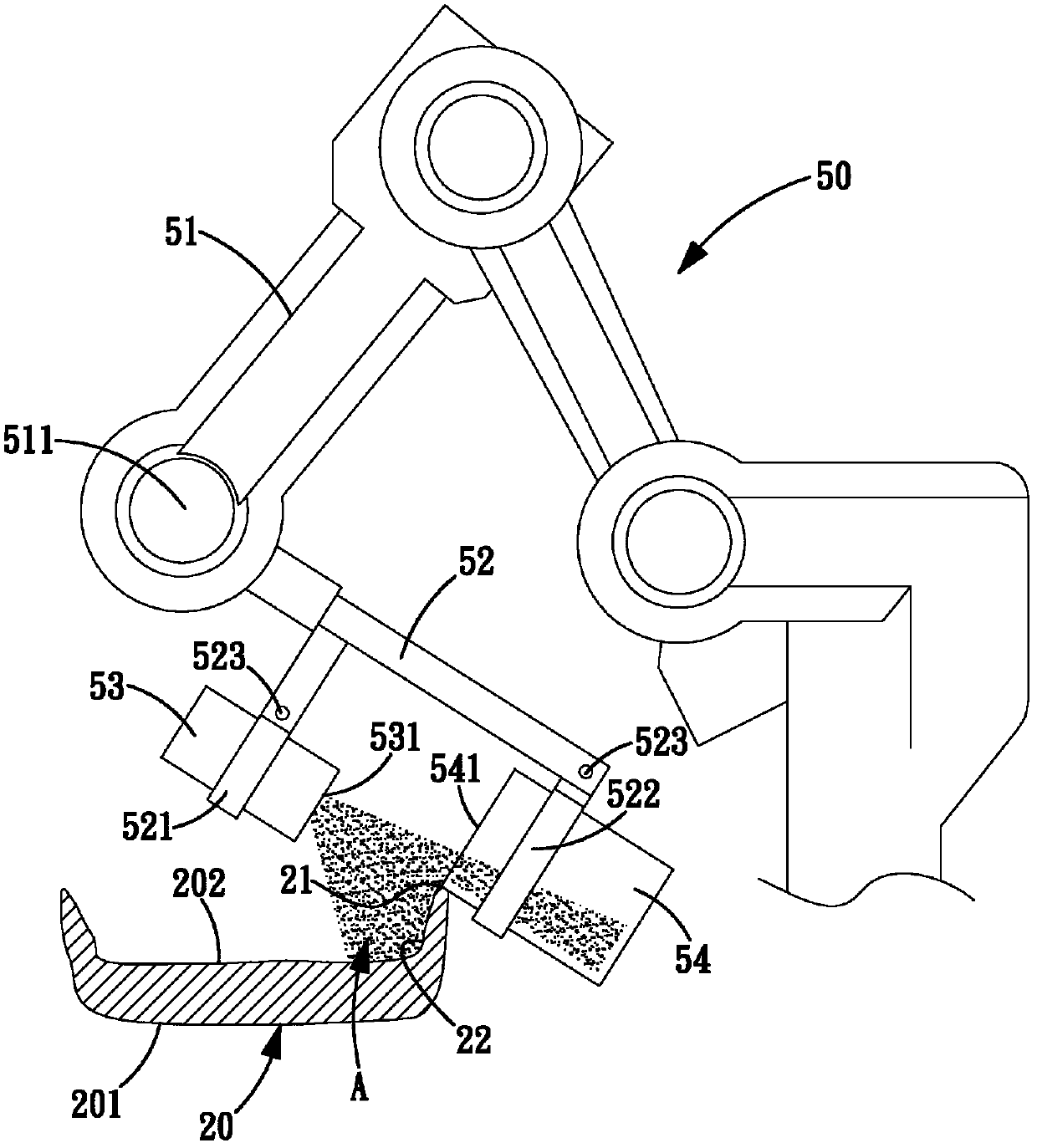

[0046] First, with figure 2 Cooperate image 3 , 4 Description, a preferred embodiment of the automatic spraying system for shoe sole adhesive provided by the present invention, the system is mainly for spraying an adhesive A on a sole 20, the sole 20 is as follows figure 2 As shown, a bottom surface 201 and a top surface 202 are formed, and a contour line 21 is formed on the periphery of the top surface 202, and a spraying area 22 is provided on the top surface 202 of the sole 20 along the inner side of the contour line 21; the system mainly includes a conveying Taiwan 30, a three-dimensional scanner 40, a spraying device 50 and a computer 60, wherein:

[0047] The conveyor table 30, such as figure 2 As shown, there is a relative starting end 301 and a terminal end 302, and a glue spray section 303 is arranged between the two ends, so that the sole 20 is transported from the starting end 301 to the terminal end 302 of the conveying platform 30, and the conveying platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com