Subassembly for sliding roof

A component and component technology, applied in the field of sub-components, can solve problems such as complex structure, inability to shift, and guide rails that should not be tilted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

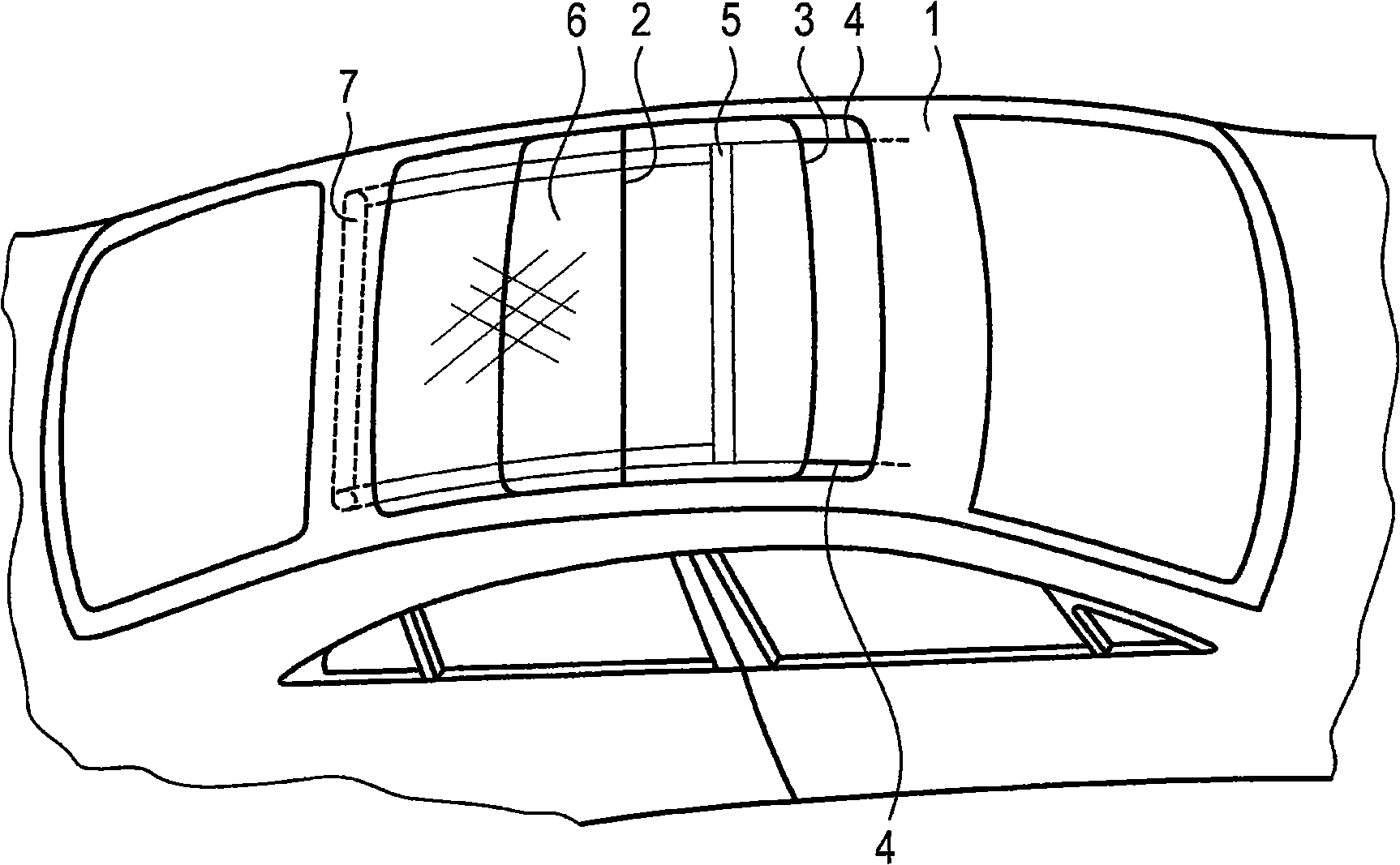

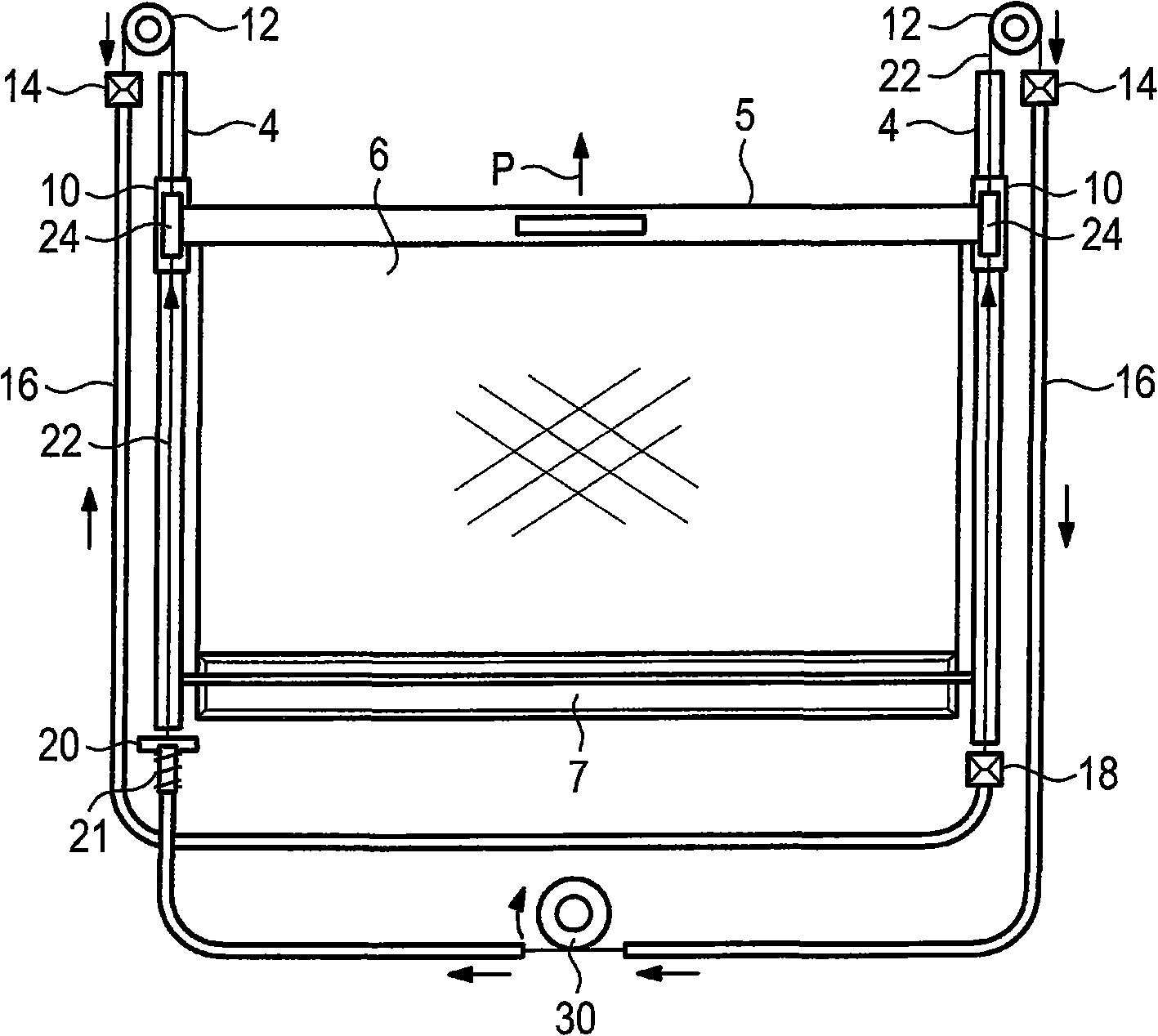

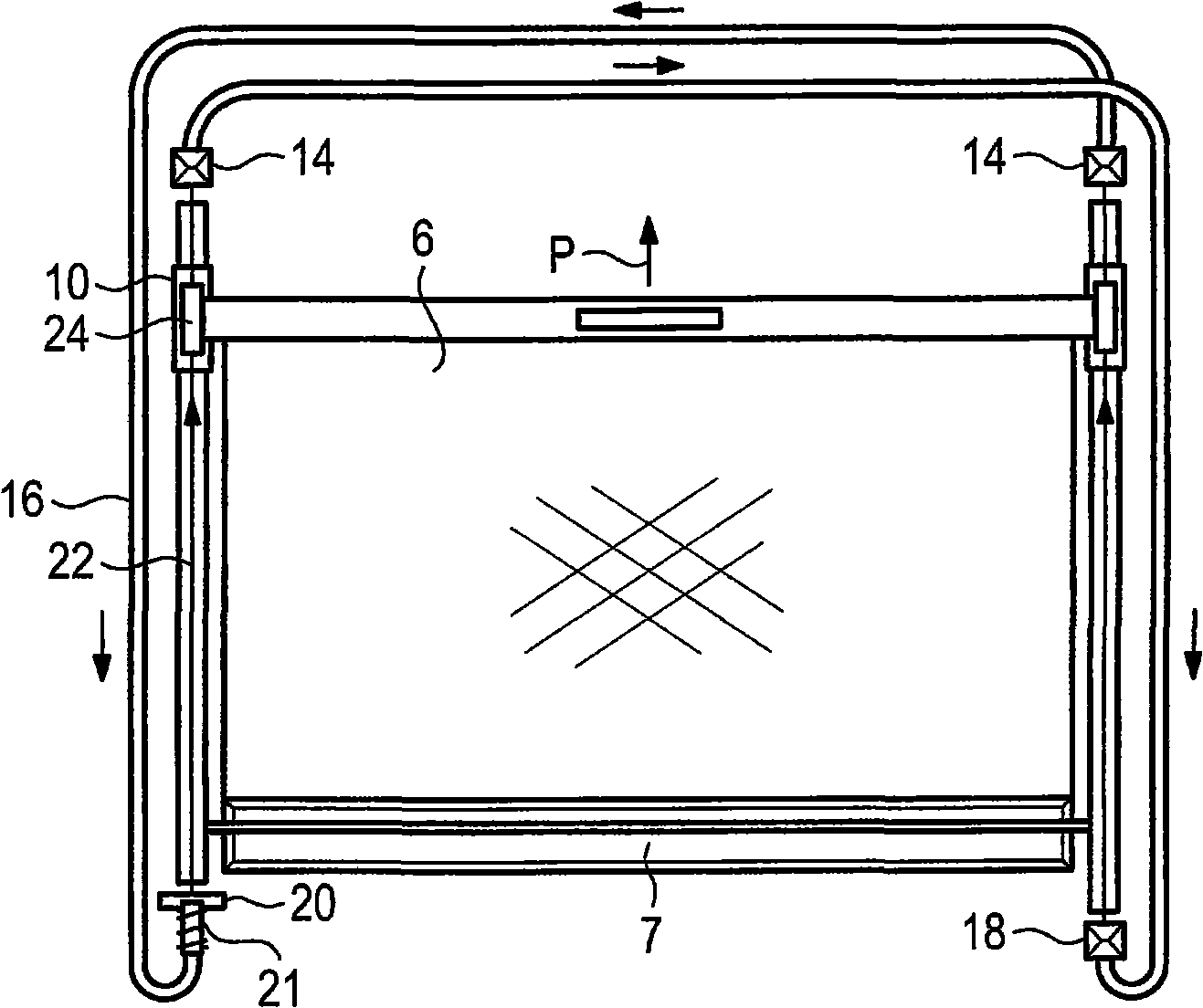

[0020] figure 1 A roof 1 of a motor vehicle is shown schematically, which is equipped with a sliding roof. The sliding roof has a rear cover part 2 and a front cover part 3 , the front cover part being shown in a partially pushed back position, wherein it overlaps the rear cover part 2 . The cover 3 serves to partially or completely open a roof opening formed in the roof 1 . Between a pushed back position (wherein the bow is at the rear) and a pulled forward position (wherein the bow is at the front and the roller blind sheet 6 provides shade for the interior) the sunshade roller blind can be positioned on the cover shift down.

[0021] To this top 1 are attached rails 4 to which a cover 3 can be displaceably attached. A component 5 is displaceably guided in the guide rail 4 , which in the exemplary embodiment shown here is a bow of a roller blind. The roller sunshade comprises a roller blind 6 extending between a bow 5 and a roller shaft 7 arranged at the rear, the bow be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com