Patents

Literature

291results about How to "Avoid defacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

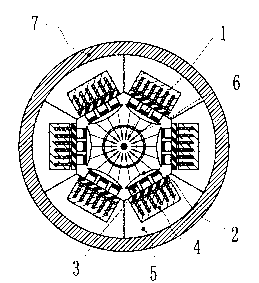

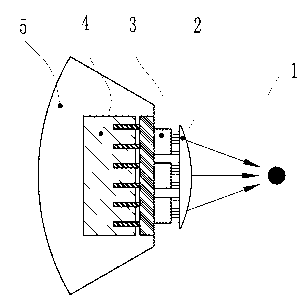

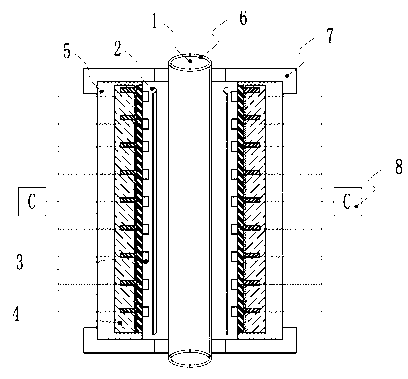

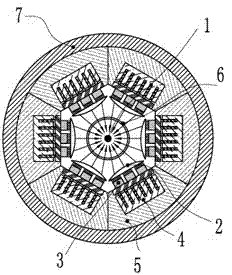

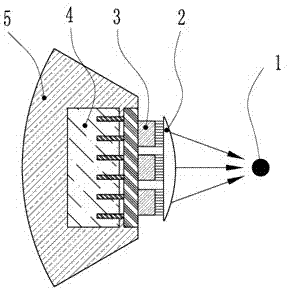

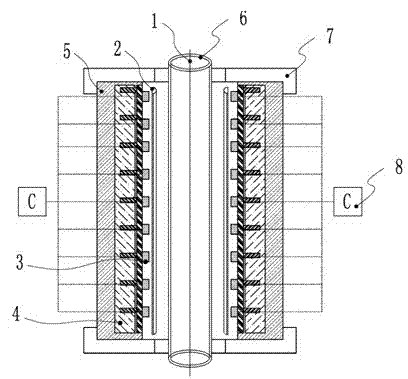

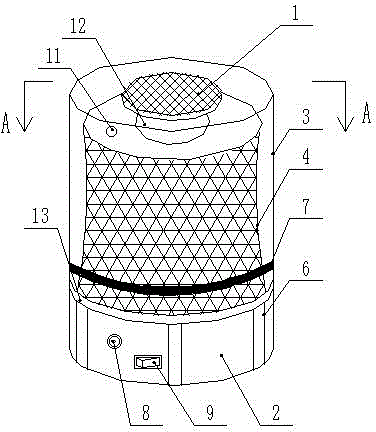

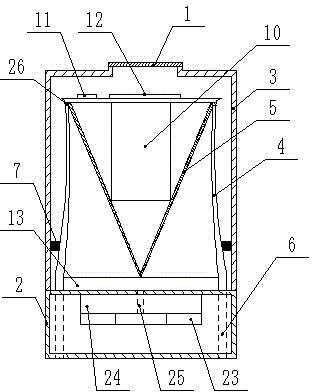

Ultraviolet curing equipment and method for optical fiber coating

ActiveCN103319100AImprove curing efficiencyExtended service lifeLight pillarUltraviolet light emitting diodes

The invention relates to ultraviolet curing equipment and method for an optical fiber coating. The equipment comprises a cylindrical mounting base, wherein an inner cavity of the cylindrical mounting base is provided with UVLED (Ultraviolet Light Emitting Diode) light source modules in a peripheral direction and an axial direction; a cylindrical focusing lens is arranged in front of light-emitting surfaces of the UVLED light source modules, so that ultraviolet rays emitted from the UVLED light source modules are focused on a same curing axis. The ultraviolet curing equipment disclosed by the invention is long in service life, small in heating amount and low in energy consumption; a layout space of light sources is large, so that the output of the UV light sources of a plurality of UVLED light source modules are focused on the curing axis to form a UV light column with high light intensity; an optical fiber absorbs UV and is cured when passing through the UV light column; the light strength of the light column is high and the light sources are from multiple directions, so that the equipment has higher curing efficiency and better curing uniformity, the curing time is shortened, the work efficiency of wiredrawing of the optical fiber is improved, and the curing quality of the coating is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

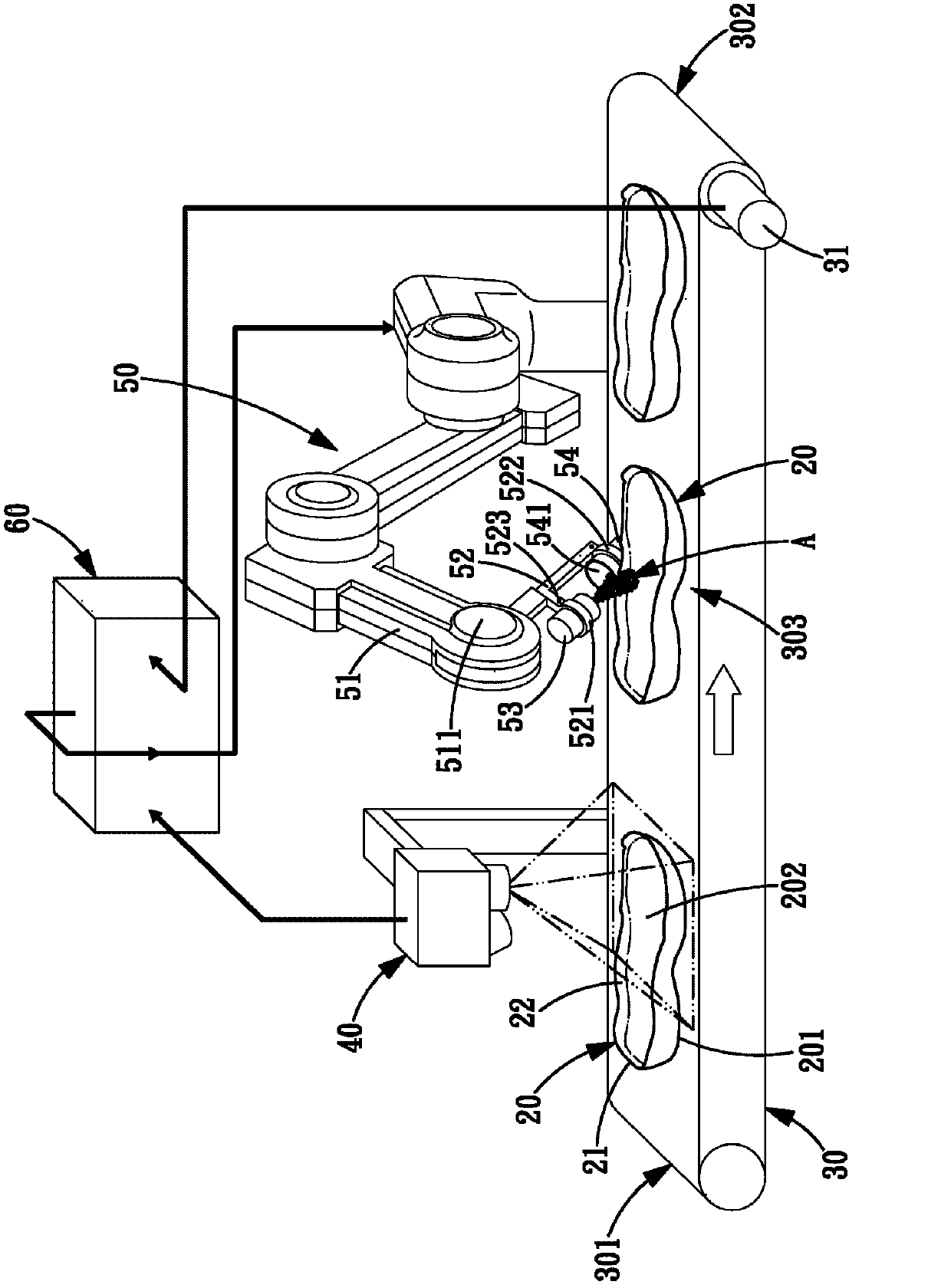

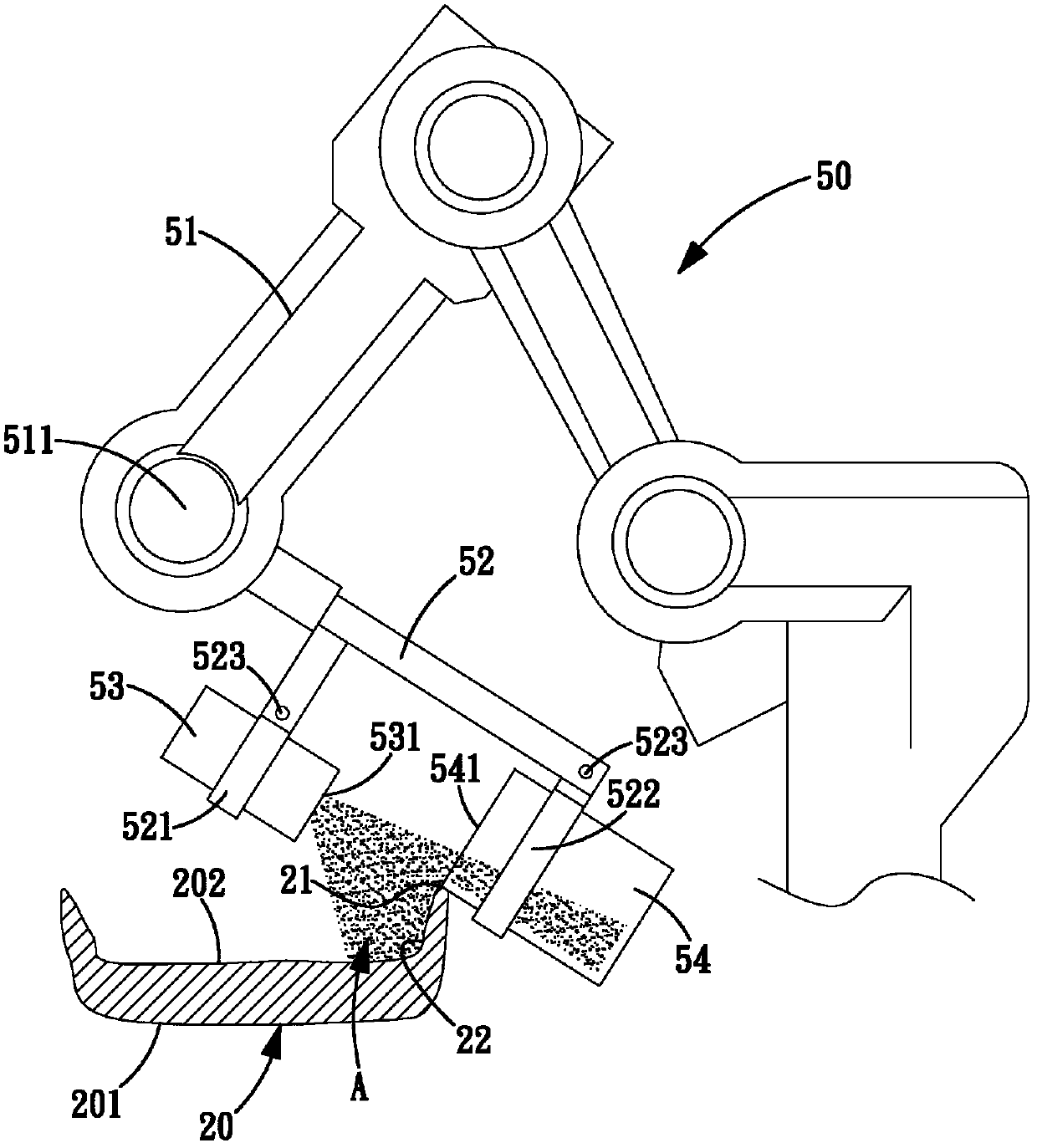

Automatic spraying system of sole bonding agent and spraying method thereof

InactiveCN103284407AAvoid defacementEnsuring Link Structural StrengthShoe gluingEngineeringUltimate tensile strength

The invention discloses an automatic spraying system of a sole bonding agent and a spraying method thereof. A spray gun and a glue accommodating container are arranged at the tail end of a mechanical arm, the spray gun and the glue accommodating container are arranged on the inner and outer sides of a sole top surface contour side line in a corresponding form manner, sole top surface scanning data and sole position data read by a computer are matched to enable the spray gun to spray the bonding agent on the inner side of the sole contour side line and enable the bonding agent to slightly exceed the sole contour side line, then the bonding agent is sprayed in the spraying area of the sole top surface, the bonding agent exceeding the contour side line is enabled to drop into the glue accommodating container, so that automatic accurate sizing on the sole top surface is achieved, the strength of a connecting structure of the sole and an upper is guaranteed, and simultaneously, the bonding agent is prevented from polluting the sole appearance.

Owner:ORISOL ASIA

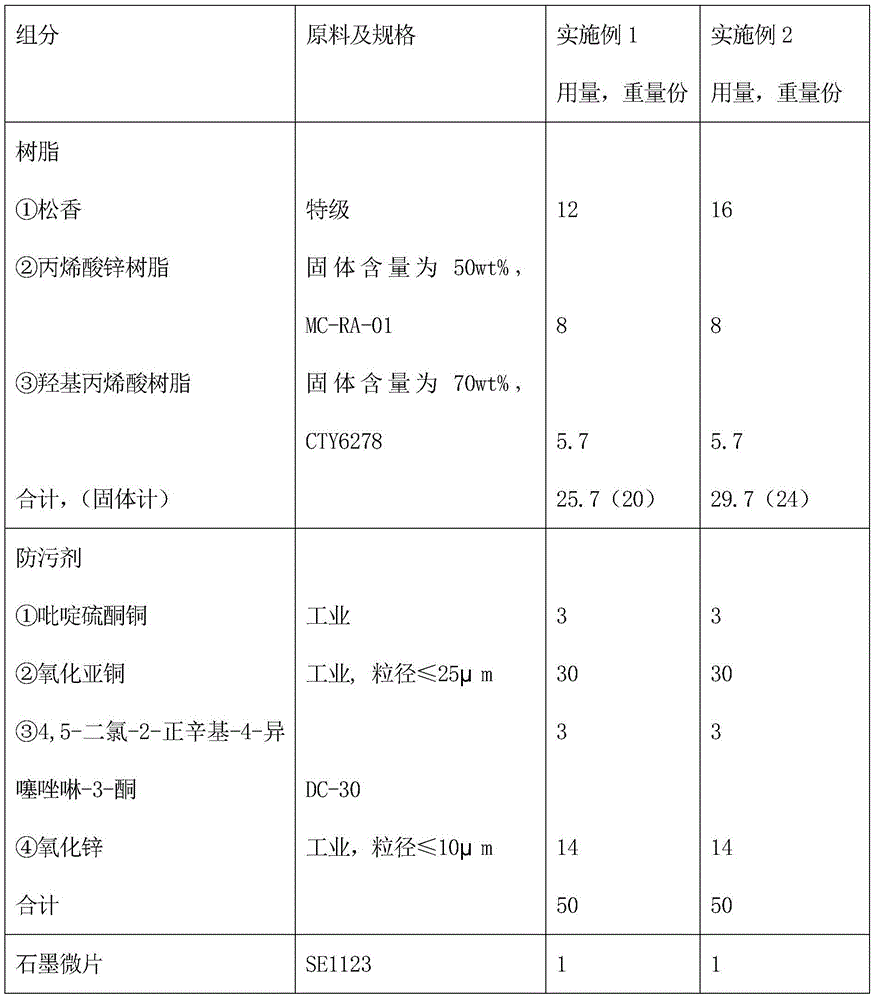

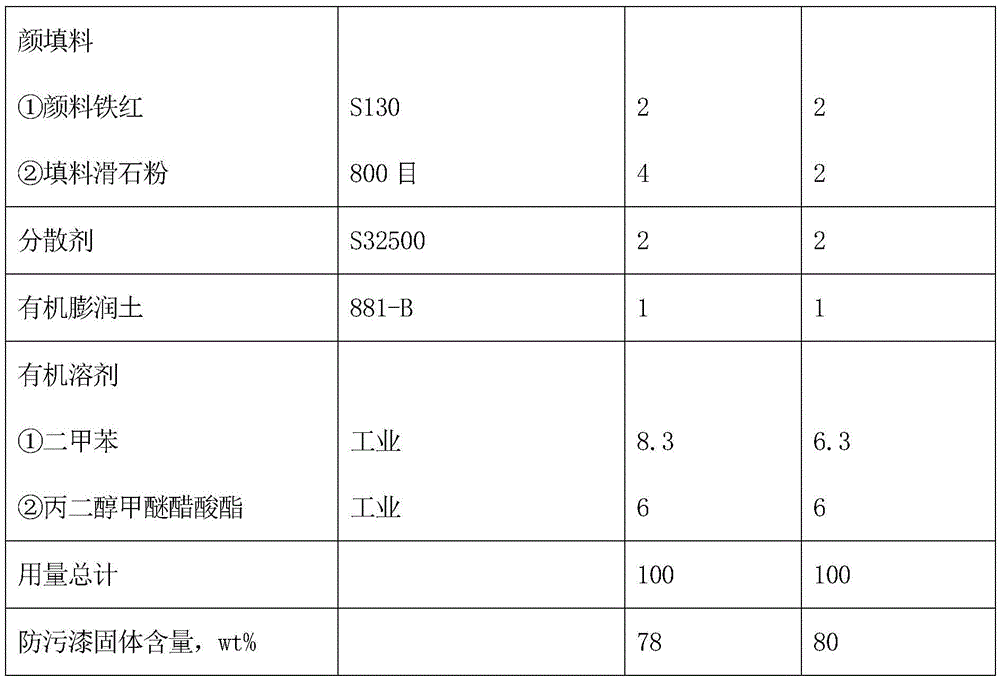

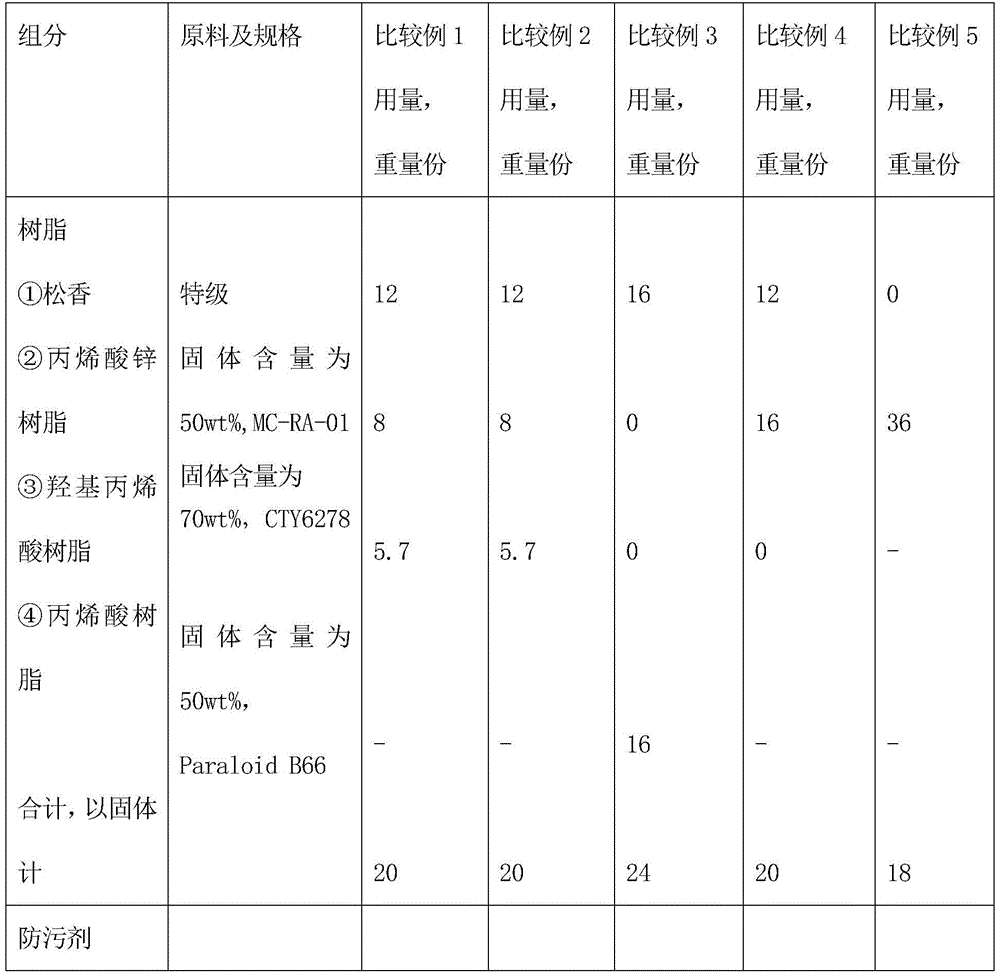

Self-polishing antifouling paint and preparation method thereof

ActiveCN105482702AHigh strengthImprove hydrophobicityAntifouling/underwater paintsRosin coatingsSodium PyrithioneCrack resistance

The invention relates to a self-polishing antifouling paint and a preparation method thereof. Every 100 parts by mass of the antifouling paint is composed of 18-24 parts of solid-based resin, 50-55 parts of antifouling compound, 0.5-1.5 parts of graphene microchip, 3-6 parts of pigment and filler, 1-2 parts of dispersing agent, 1-2 parts of organobentonite and the balance of organic solvent. The resin is composed of a hydroxy acrylic resin, a zinc acrylate resin and rosin. The antifouling compound is composed of zinc pyrithione, 4,5-dichloro-2-n-octyl-4-isothiazolinyl-3-one, cuprous oxide and zinc oxide. The preparation method comprises the following steps: respectively preparing the graphene microchip-zinc oxide-hydroxy acrylic resin slurry and cuprous oxide-rosin-zinc acrylate slurry, and mixing to obtain the self-polishing antifouling paint. The obtained self-polishing antifouling paint product has the advantages of stable quality, long antifouling period, favorable polishing effect, high strength, cracking resistance and low VOC (volatile organic compound).

Owner:CHINA NAT OFFSHORE OIL CORP +3

Dimension-adjustable porous micro-structured surface antifouling material

ActiveCN102399487AImprove hydrophobicityImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesPolymer scienceAcrylonitrile

The invention belongs to the technical field of marine life fouling prevention, and relates to a dimension-adjustable porous micro-structured surface antifouling material prepared from mixed materials of organosilicon acrylic acid copolymer resin, an amine nucleation promoter, and a curing agent according to a certain volume ratio. First, organosilicon acrylic acid copolymer resin, the amine nucleation promoter, and the curing agent are well mixed, and the mixture is used for coating, such that a dimension-adjustable porous micro-structured surface is formed under room temperature. The volumeof the amine nucleation promoter takes 0.5% to 2.0% of the volume of organosilicon acrylic acid copolymer resin, and the volume of the curing agent takes 1%-3% of the volume of organosilicon acrylic acid copolymer resin. A mass ratio of a prepolymer containing double-bond organosilicon to propylene monomers is 2:1-1:2. The content of acrylonitrile monomers takes 0-25% of a total mass of the propylene monomers. The adjusting method is advantaged in simple technology, reliable principle, convenient adjustment, and flexible operation. The material is advantaged in good antifouling effect, and issuitable to be used in equipment fouling preventing occasions in various marine environments.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Air flow measuring instrument

InactiveCN101441097AAvoid breakingAvoid defacementElectrical controlVolume/mass flow measurementMeasuring instrumentEngineering

Owner:HITACHI ASTEMO LTD

Long-life self-polishing antifouling coating

ActiveCN101550305AAvoid defacementEnvironmentally friendlyAntifouling/underwater paintsPaints with biocidesAcrylic resinSolvent

The invention discloses long-life self-polishing antifouling coating, and relates to high-solid long-life self-polishing ship bottom antifouling coating with antifouling validity of more than three years, in particular to novel marine antifouling coating containing an antifouling agent system without internationally non-permissible toxins and reaching the national environment-friendly requirements. The long-life self-polishing antifouling coating is characterized by comprising copper acrylic resin, composite antifouling agents, pigments, fillers, anti-sedimentation agents, solvents, and the like, and being red brown. The coating is applicable to the ship bottom of a ship as an antifouling coating, can effectively prevent the ship bottom from fouling by the marine organisms within 3-5 years, does not contain organic tin (TBT) and DDT toxins, is environment-friendly and constructed conveniently, can keep the speed of a ship uninfluenced, and saves fuel; and the coating further has good overcoatability.

Owner:上海海悦涂料有限公司

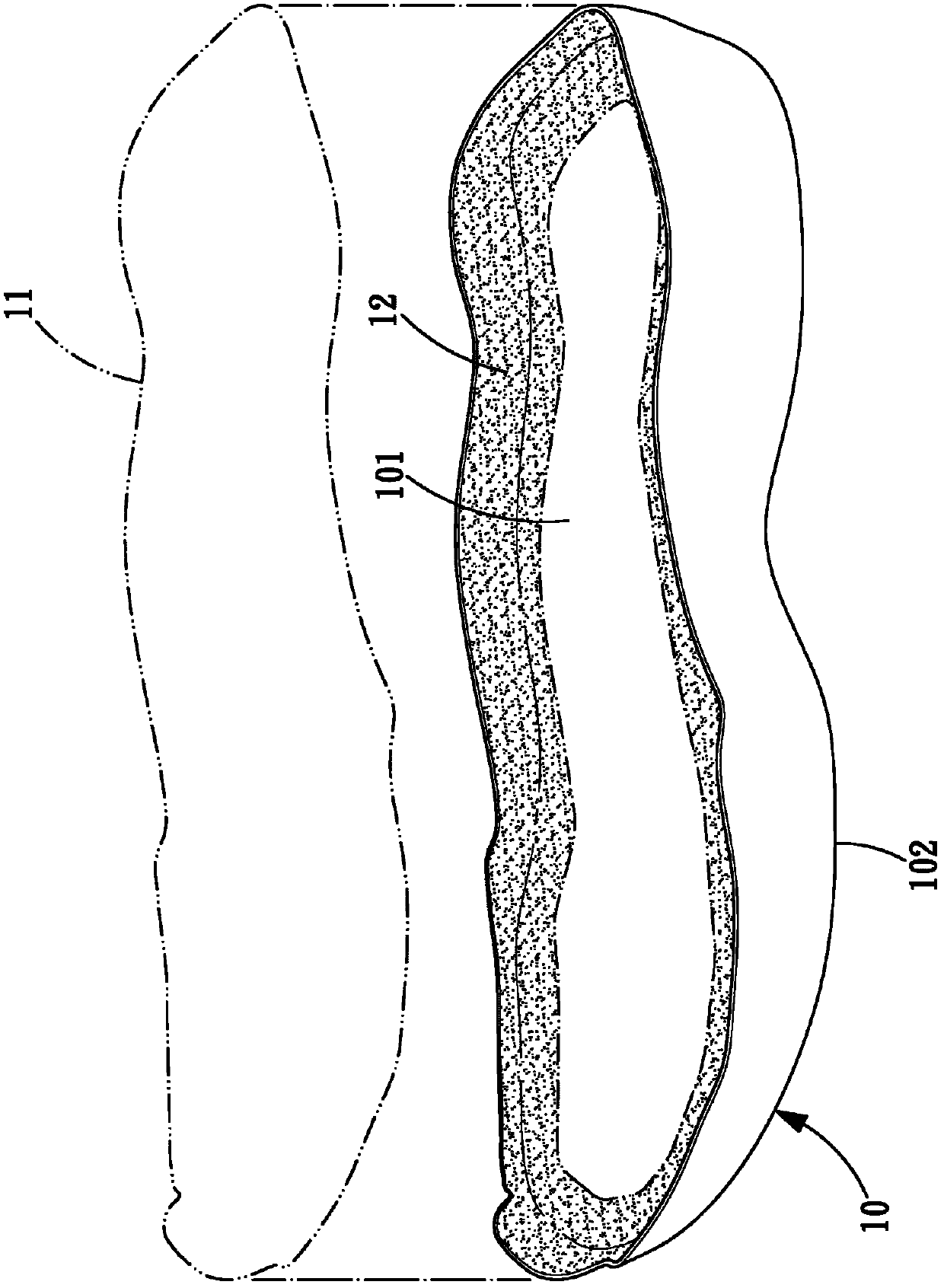

Infant car seat and elastic crotch belt thereof

InactiveCN101954897AWon't interfere with rideAvoid defacementKids chairsChild seatsElastomerCar seat

The invention provides an infant car seat and an elastic crotch belt thereof. The crotch belt assembly is used for the infant car seat and the infant car seat comprises a safety belt, wherein the safety belt comprises a shoulder belt and the crotch belt assembly; a buckling tool is arranged on the shoulder belt; the crotch belt assembly comprises a crotch belt set with a buckling tool body, a crotch belt protection sheet for covering the crotch belt body, and an elastic body; the buckling tool body is connected to one end of the crotch belt assembly, and the other end of the crotch belt assembly is connected to the infant car seat; the buckling tool body is used for connecting the buckling tool to combine the shoulder belt; the crotch belt protection sheet has a containing space; the elastic body is arranged in the containing space, and at least a part of the elastic body is arranged in the infant car seat; the crotch belt assembly is maintained in the required position in a nonuse state by utilizing the elastic body; users can not regulate and remove the crotch belt; and the elastic body can be exchanged and shielded by the crotch belt protection sheet to avoid the elastic body from being contaminated and damaged and dropping.

Owner:WONDERLAND NURSERYGOODS CO LTD

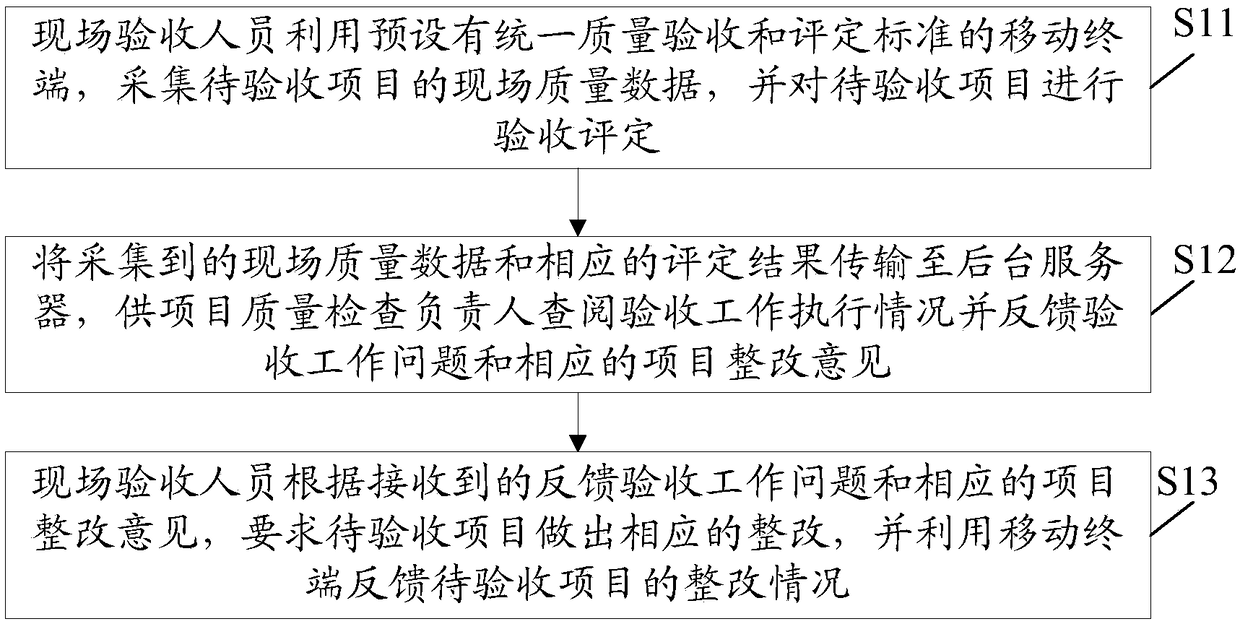

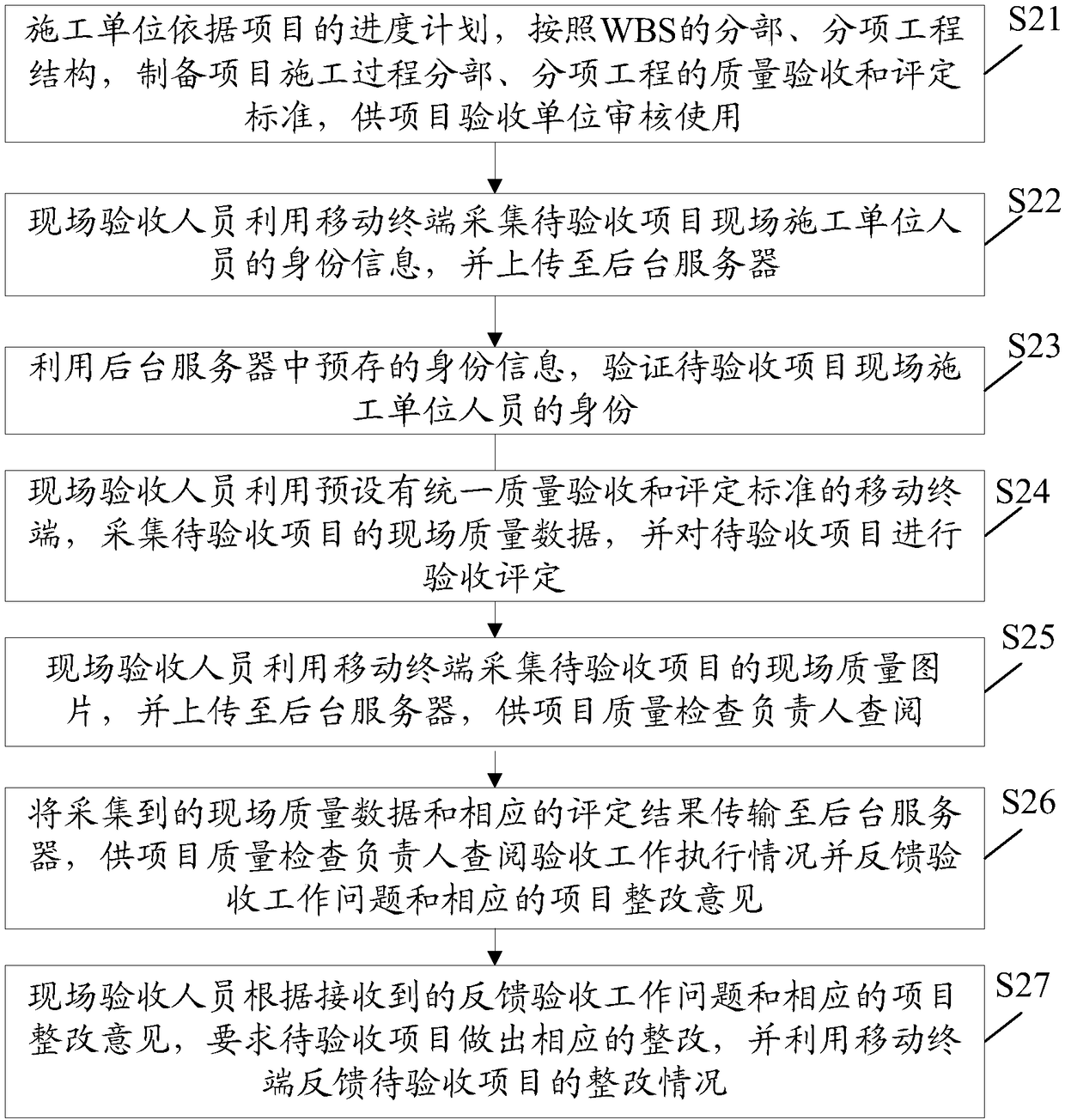

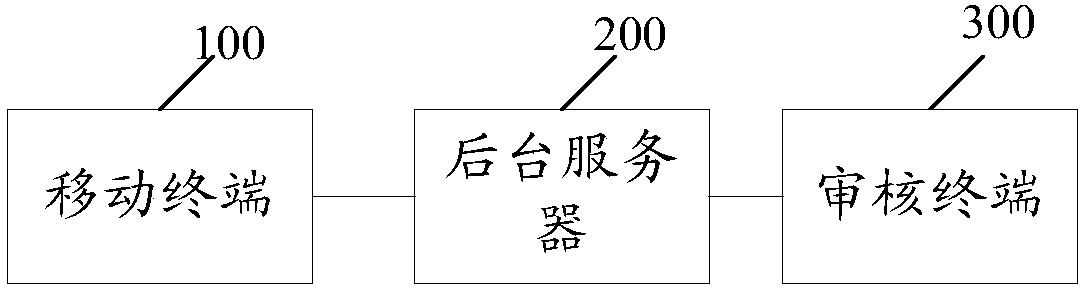

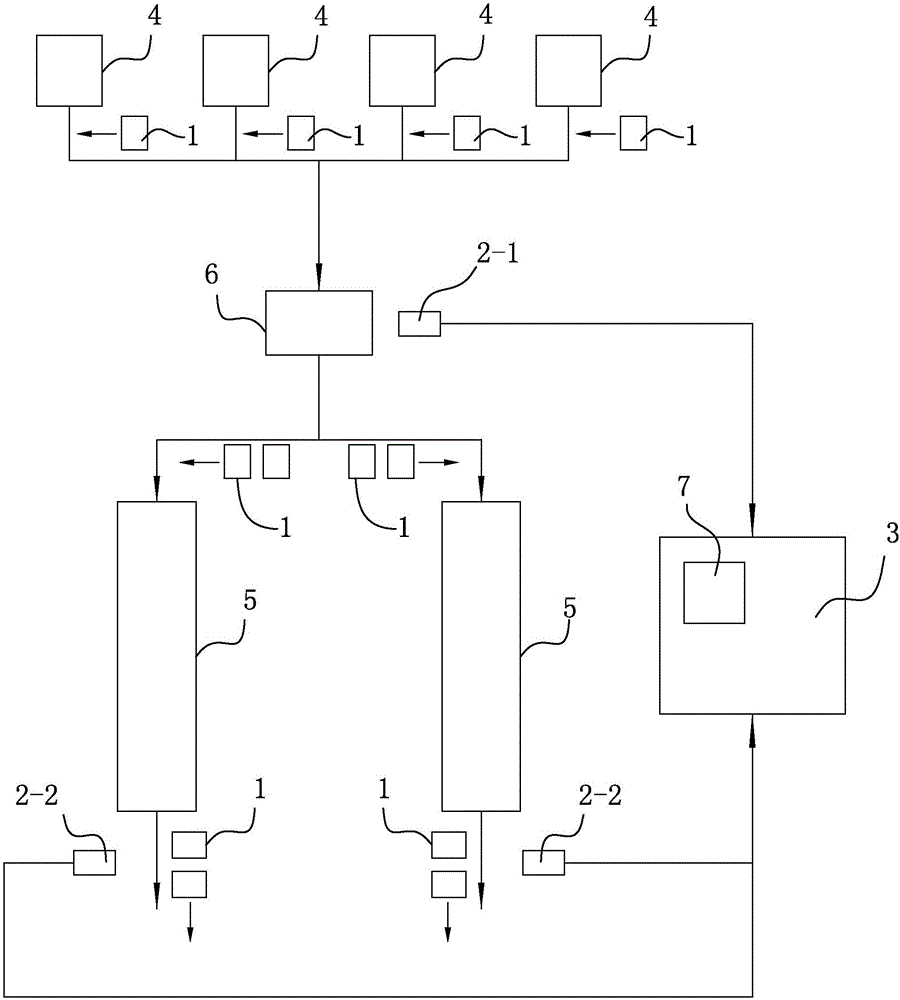

Electric power engineering project site quality acceptance management method and system

InactiveCN109325724AQuality is safe and reliableImprove efficiencyOffice automationEvaluation resultTechnical standard

The invention discloses a method and a system for site quality acceptance management of an electric power engineering project. The method comprises the following steps: a site acceptance personnel collects site quality data of items to be accepted by using a mobile terminal preset with a unified quality acceptance and evaluation standard, and performs acceptance evaluation on the items to be accepted; Transfer the collected site quality data and the corresponding evaluation results to the background server for the project quality inspection person in charge to check the implementation of acceptance work and feedback the acceptance work problems and the corresponding project rectification opinions; The on-site acceptance personnel shall, according to the received feedback acceptance work problems and the corresponding project rectification opinions, request the items to be accepted to make corresponding rectification, and feedback the rectification situation of the items to be acceptedby the mobile terminal. The invention realizes the on-site operation truly through the on-site operation of the mobile terminal, eliminates the phenomenon of 'two skins', makes the on-site operation control of the capital construction in place, executes each link according to the standard, and ensures the safe and high-quality construction of the engineering project.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

Advanced wastewater treatment technology for sewage treatment and upgrading and reconstruction

ActiveCN103848542ASolve the problem that phosphorus cannot be removed by using aloneReduce pool capacityMultistage water/sewage treatmentPolyacrylamideSewage

The invention discloses an advanced wastewater treatment technology for sewage treatment and upgrading and reconstruction. The advanced wastewater treatment technology is a combined technology of an efficient settling basin and a riser fiber filter cloth filter tank added between a secondary sedimentation tank and a disinfecting tank of the original process of a sewage treatment plant; an efficient sedimentation tank is composed of two modules of a quick mixing region and an efficient sedimentation region; a FeCl3 chemical is fed to the quick mixing region so as to be agitated to react with sewage; the adding amount of the FeCl3 chemical is 5-8mg / L; the standing time of the quick mixing region is 1.5-2 minutes; the standing time of the efficient sedimentation region is 15-20 minutes; the standing time of the riser fiber filter cloth filter tank is 8-12 minutes; effluent of the secondary sedimentation tank is firstly processed by the efficient sedimentation tank, and then processed by the riser fiber filter cloth filter tank, finally achieves the first level A of discharge standard for sewage treatment after passing through the disinfecting tank. By adopting the advanced wastewater treatment technology, the problems that the efficient sedimentation tank process is independently used, so that effluent SS is unstable, and the filter cloth filter tank is independently used and thus phosphorus cannot be removed are effectively solved, a flocculating agent does not need to be excessively fed again, the dosing cost is greatly reduced, and fouling on an online monitoring instrument probe caused by feeding polyacrylamide (PAM) is avoided.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

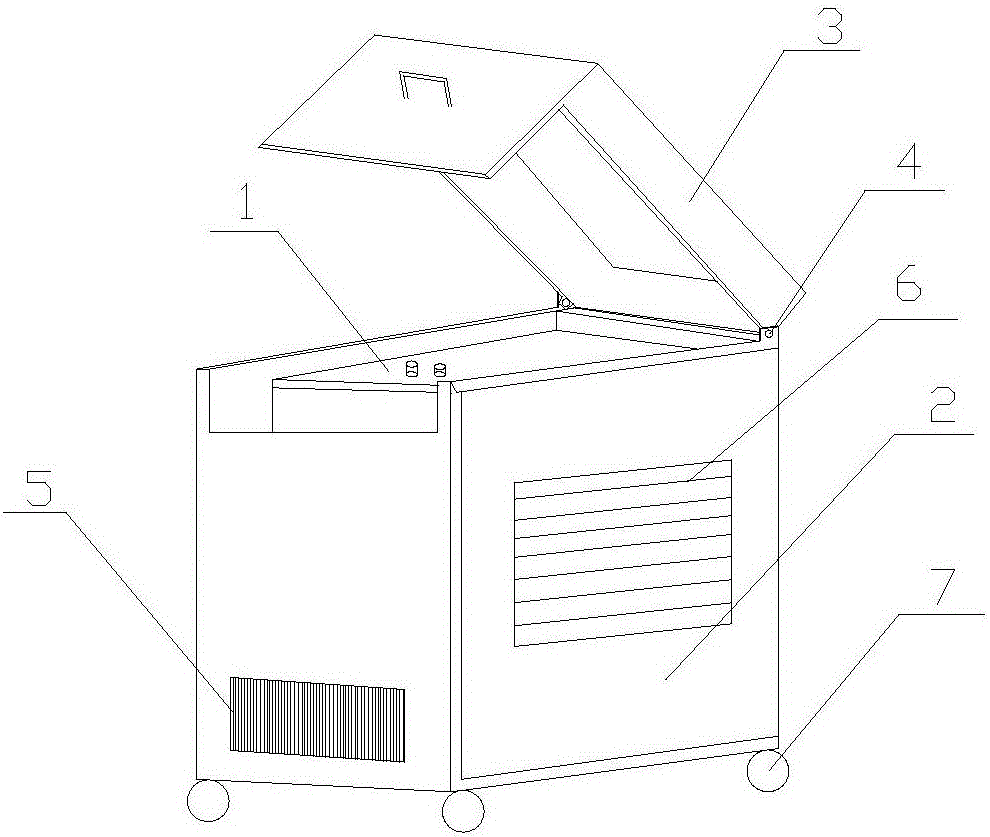

Movable electric welding machine good in cooling performance

InactiveCN106041276AReduce work intensityReduce heatCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsMechanical propertyAutomotive engineering

The invention provides a movable electric welding machine with good heat dissipation performance, which includes a control panel, a casing, a dustproof device, connecting bolts, heat dissipation holes, a heat dissipation device, and retractable wheels. The control panel is arranged on the top of the casing end face; the dust-proof device is installed above the casing; the heat dissipation holes are arranged on the front side and the left side of the casing; the heat dissipation device is installed on the right side of the casing; the telescopic wheels are arranged on lower end of the housing. The present invention facilitates the movement of the electric welding machine through the setting of the retractable wheels, improves the mechanical performance of the electric welding machine, and is more convenient to use. At the same time, the setting of the heat dissipation device is beneficial to reduce the heat generated when the electric welding machine is working, and improves the safety of the electric welding machine To prolong the service life, the setting of the dust-proof device is beneficial to keep the control panel of the electric welding machine clean and prevent the operation instructions of the control panel from being stained.

Owner:李少帅

Special antifouling corrosion-resistant paint for marine ships

InactiveCN104277635AReduce surface tensionStable structureAntifouling/underwater paintsPaints with biocidesFiberSodium Pyrithione

The invention discloses a special antifouling corrosion-resistant paint for marine ships, which is prepared from the following raw materials in parts by weight: 60-85 parts of organosilicon modified acrylic resin, 15-40 parts of fluorocarbon resin, 20-35 parts of solvent, 3-9 parts of boron carbide, 15-30 parts of kieselguhr, 20-40 parts of nano titanium dioxide, 10-30 parts of capsaicin, 10-25 parts of fiber floss, 3-10 parts of sodium silicate, 3-10 parts of zinc powder, 1.3-3 parts of zinc pyrithione, 2-3.8 parts of sodium hexametaphosphate, 0.3-0.8 part of titanate coupling agent, 2-10 parts of dioctyl dinbutyl phthalate, 0.9-2.6 parts of wetting and dispersing agent, 0.5-1.8 parts of defoaming agent, 0.6-1.9 parts of leveling agent and 0.2-0.6 part of film formation assistant. The special antifouling corrosion-resistant paint for marine ships has the advantages of favorable corrosion resistance, favorable antifouling property and high adhesive force with the substrate.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

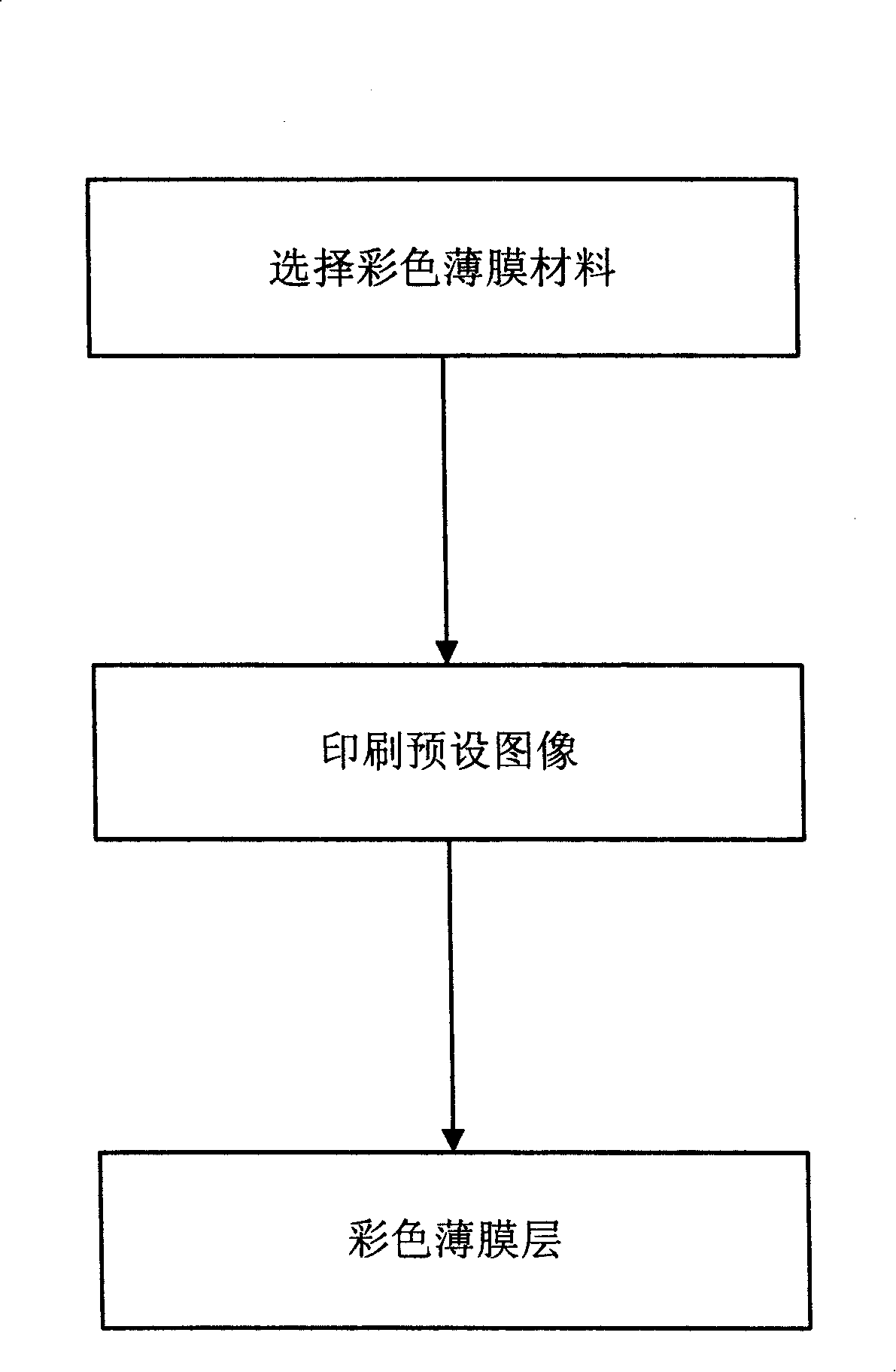

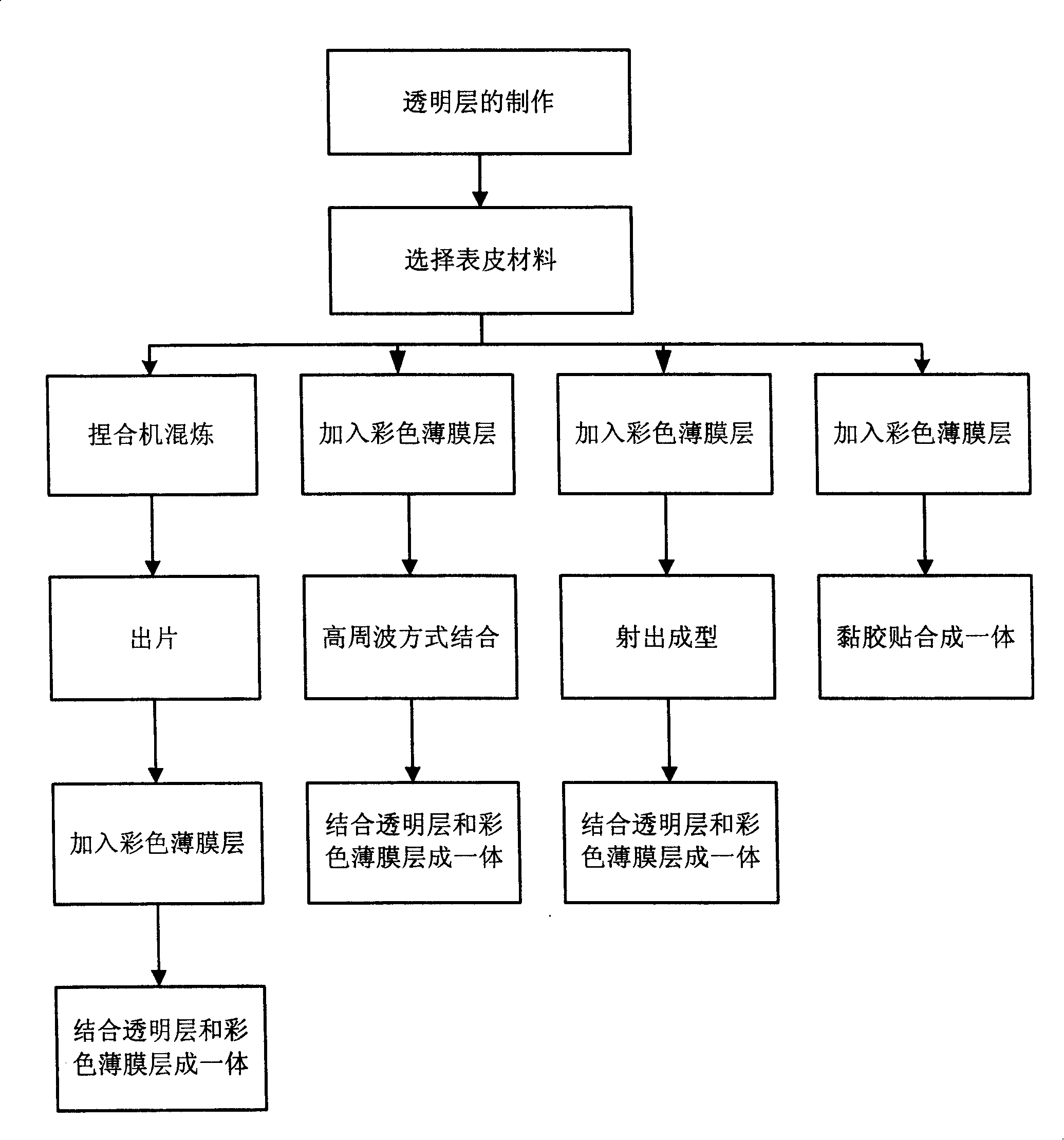

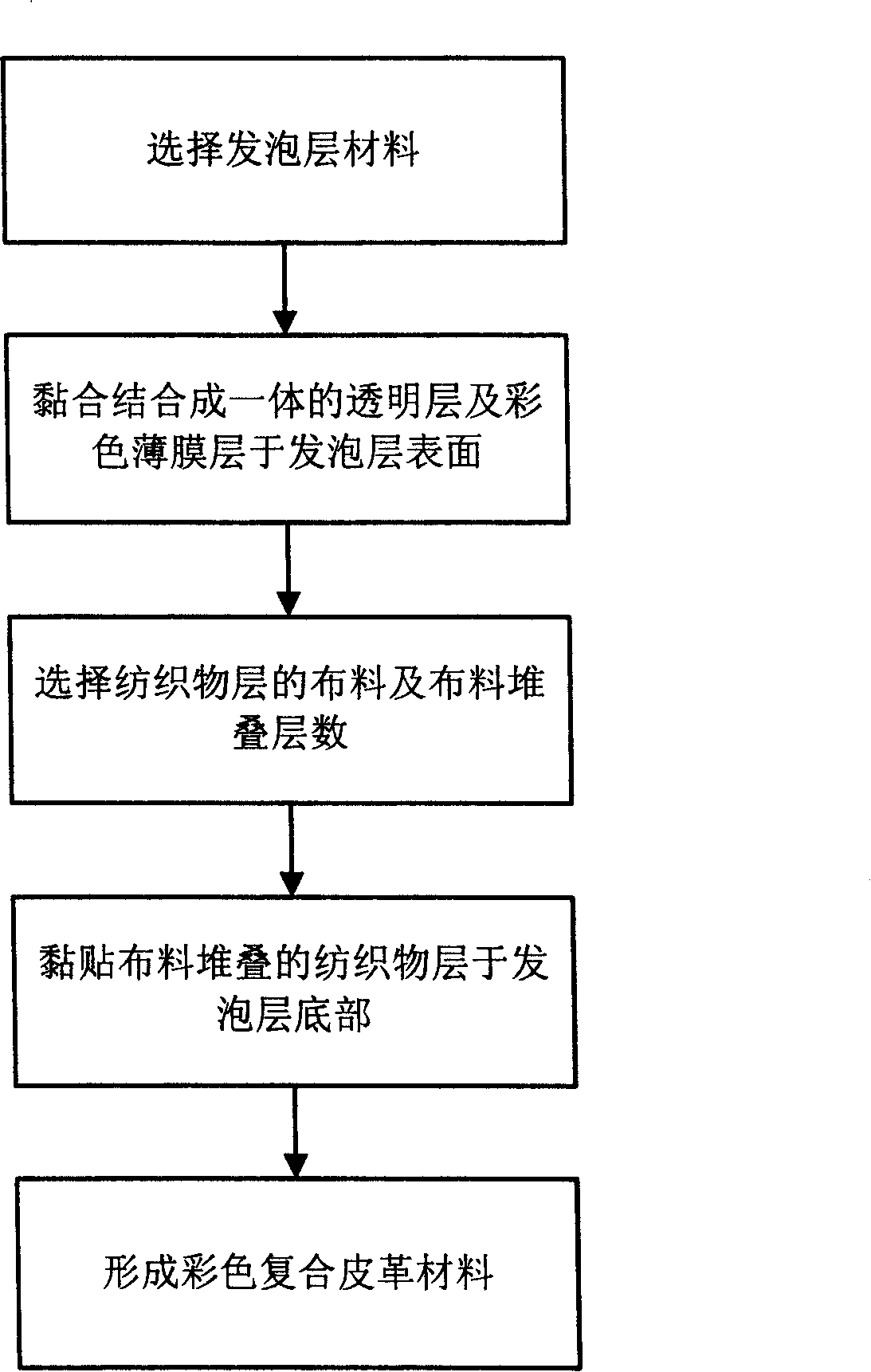

Method for preparing colourful complex leather material

InactiveCN101161452ANo peeling phenomenonExcellent physical adhesionSynthetic resin layered productsClear LayerThin layer

The invention discloses a manufacturing method of color composite leather substance, comprising a clear layer, a color thin layer, a foaming layer and a textiles layer. The clear layer and the color thin layer by clear layer material use manner of ejection forming, high frequency alloying and compressed binding or glue jointing by a compresser or a feeding piece machine, combining with clear layer and color thin layer to form in one body, and applying to the surface of foaming layer, sited on the foaming layer to join with the textiles layer, in order to form composite leather substance.

Owner:郑添来

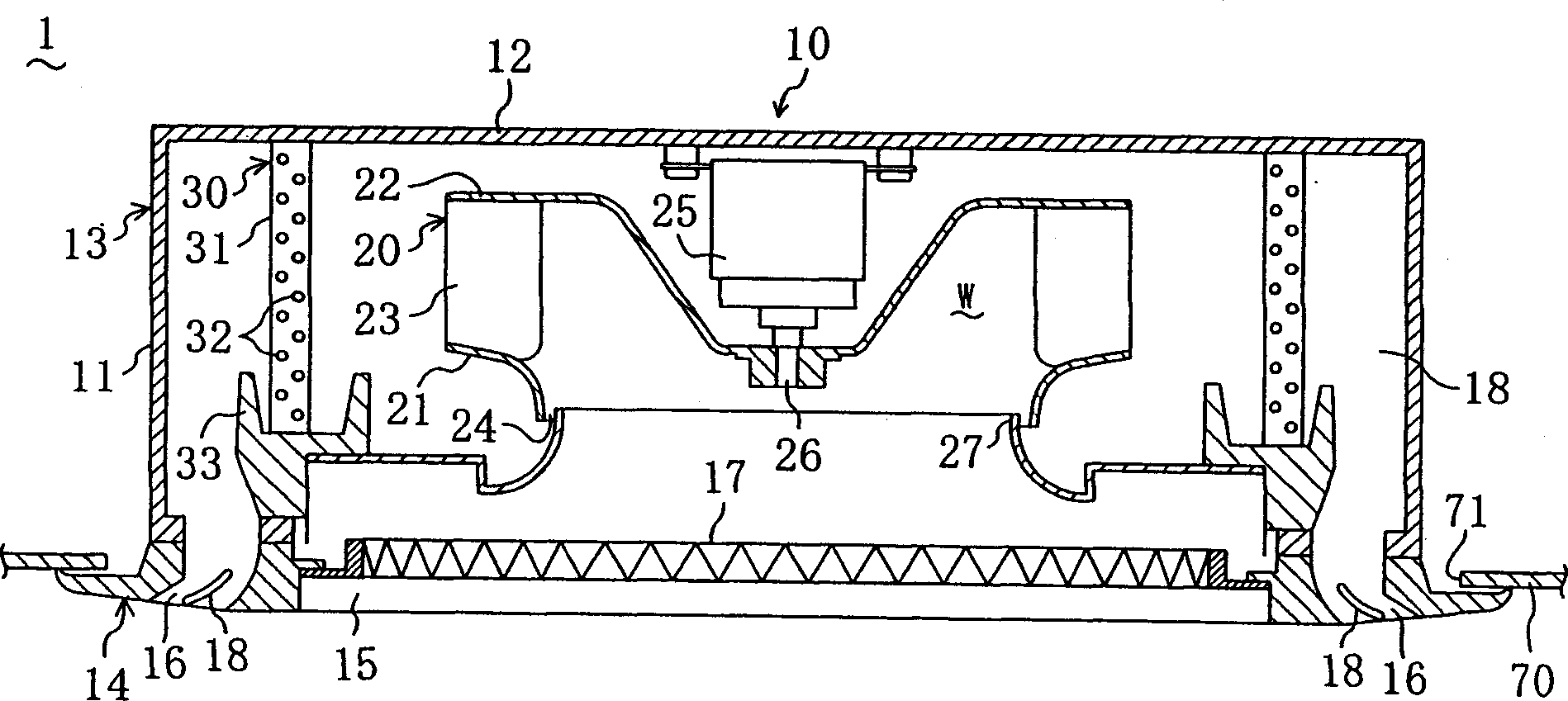

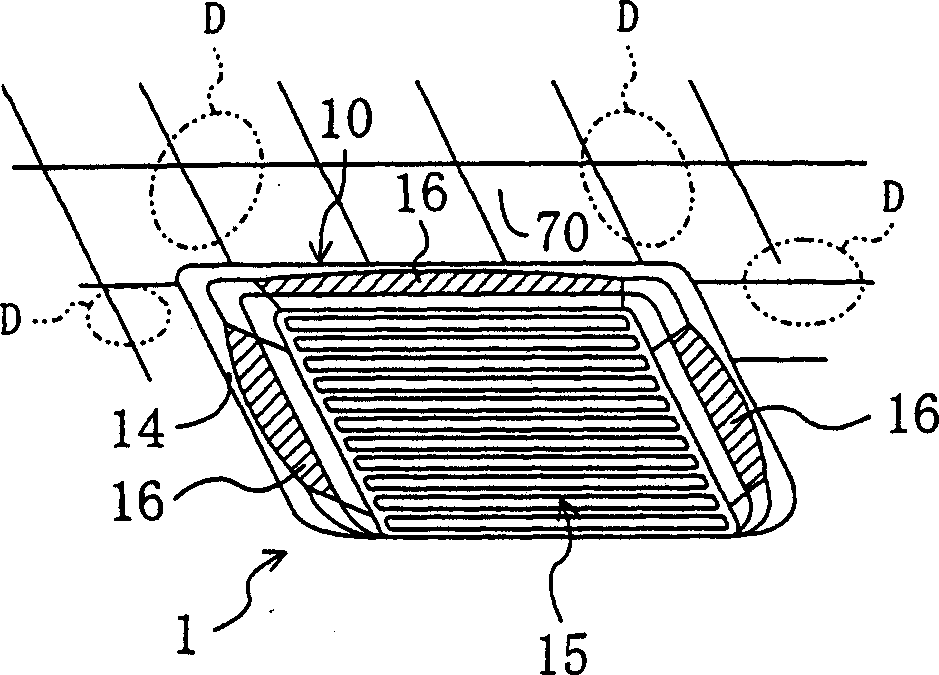

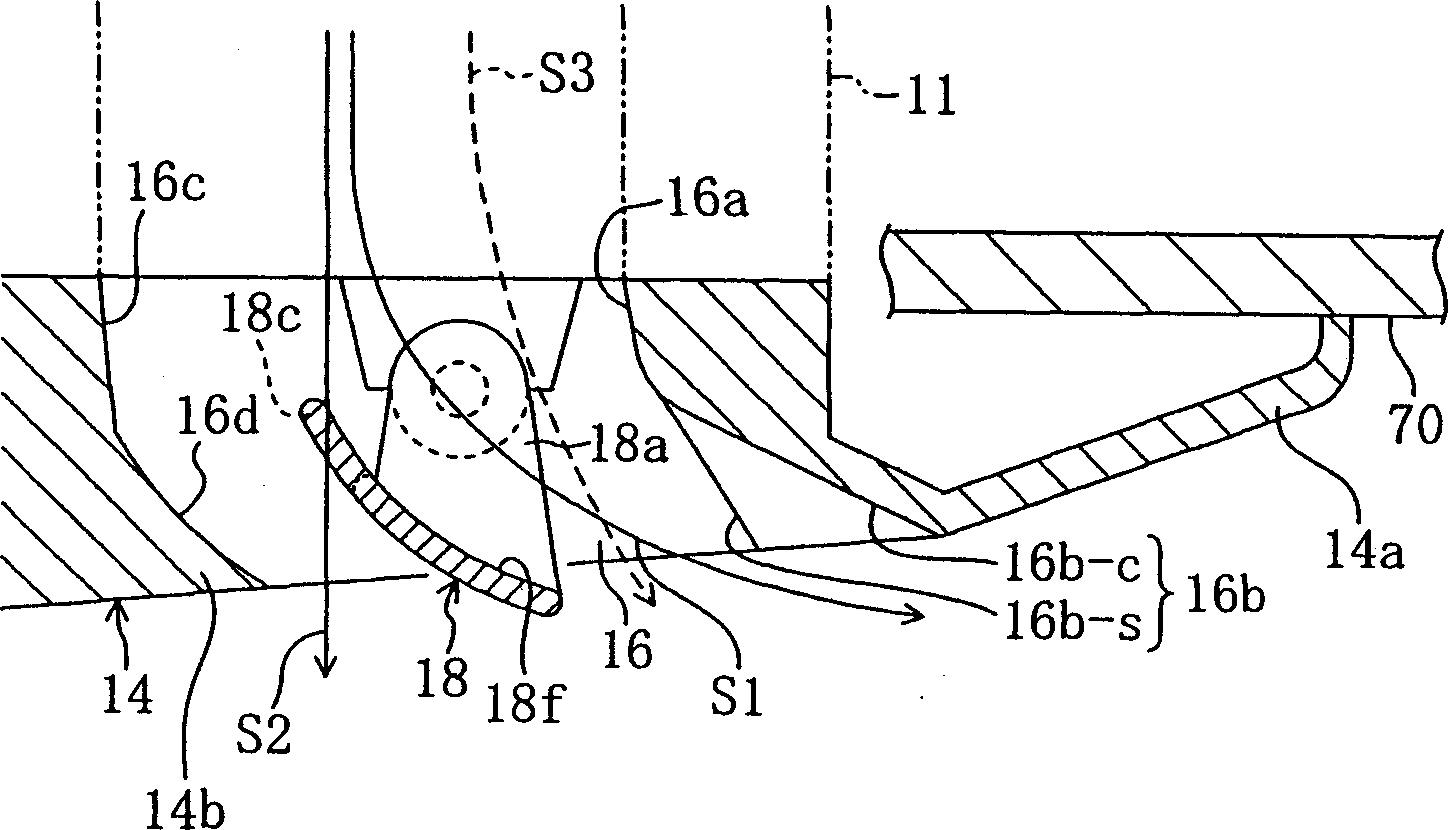

Decoration plate, blowing mouth unit and air-conditioing device for air conditioner

InactiveCN1342874AEnsuring Air Conditioning EfficiencyEliminate discomfortLighting and heating apparatusHeating and ventilation casings/coversEngineeringElectrical and Electronics engineering

Decorative panel for air conditioning system, air outlet blow-off unit, and air conditioning system. Improvements in the shape of a horizontal vane (18) mounted at an air vent (16) of an airconditioner make it possible to set an adequate emission direction according to the operating status of the airconditioner, and in order to prevent, without fail, occurrence of ceiling fouling when an extension portion (16L) is defined at a lengthwise end of the air vent (16), the horizontal vane (18) is provided, at a position substantially corresponding to an inside end of the extension portion (16L) of the air vent (16), with a guide plate (18g) for guiding conditioned air in a direction substantially orthogonal to the lengthwise direction of the air vent (16).

Owner:DAIKIN IND LTD

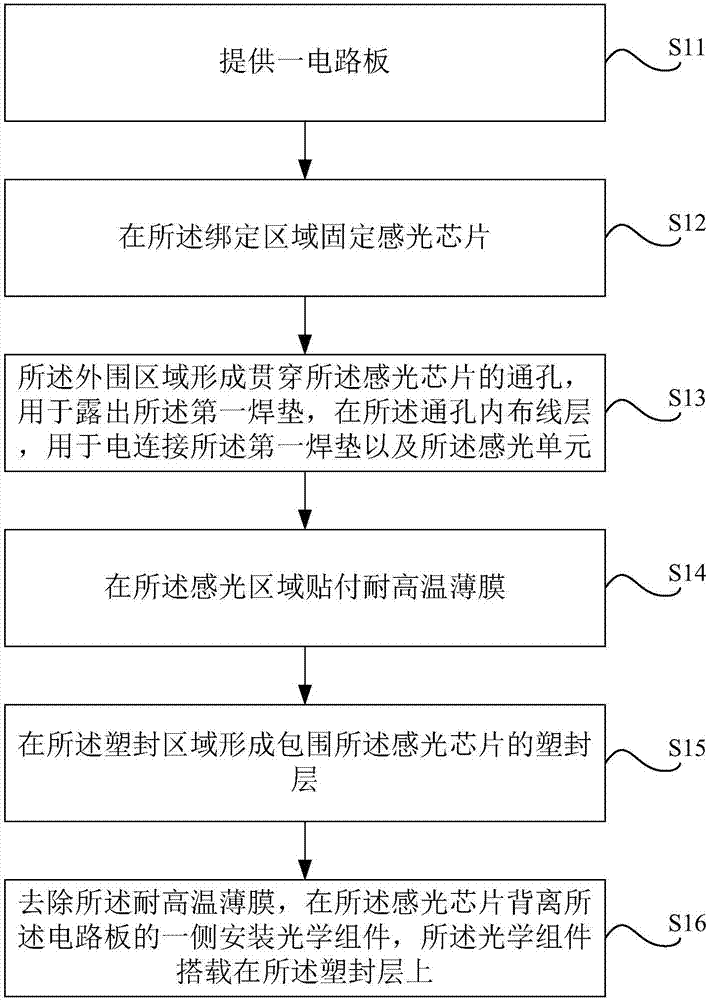

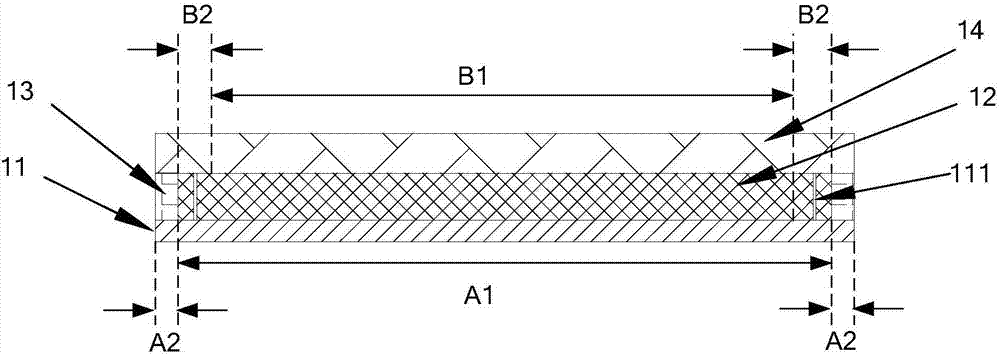

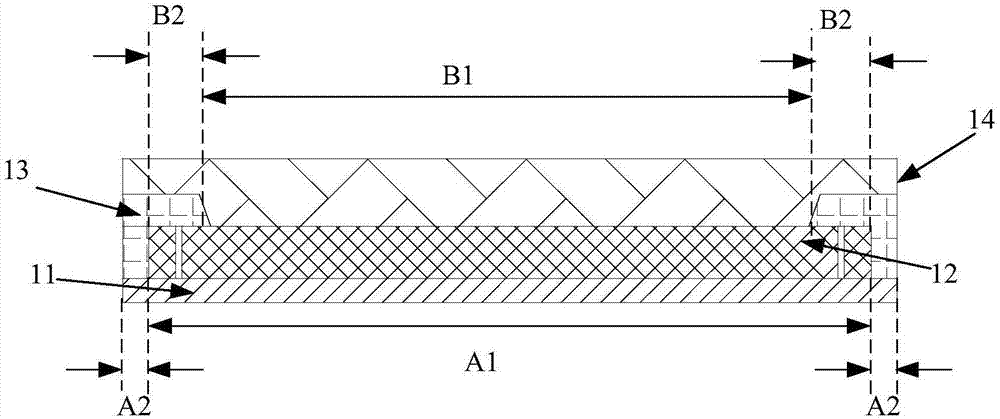

Camera module and encapsulation method thereof

ActiveCN107580170AReduce areaReduced installation areaTelevision system detailsColor television detailsOptical ModuleEngineering

The invention discloses a camera module and an encapsulation method thereof. According to the technical scheme, when a plastic encapsulation layer is formed, a photosensitive region of a photosensitive chip is protected by virtue of a high-temperature-resistant film, so that the situation that the photosensitive region is stained by a plastic encapsulation material is avoided; the photosensitive chip is sealed and protected by virtue of the plastic encapsulation layer, the plastic encapsulation layer serves as a bearing structure of an optical module, the material forming the plastic encapsulation layer has relatively strong hardiness after being cured and can be used for mounting the optical module, and an additional component does not need to be used for mounting the optical module, so that the area of a plane at which the camera module is located is reduced, and the required mounting area of the camera module is further reduced; and the plastic encapsulation layer has a sealing-protecting effect and is simple in formation process and low in cost.

Owner:TRULY OPTO ELECTRONICS

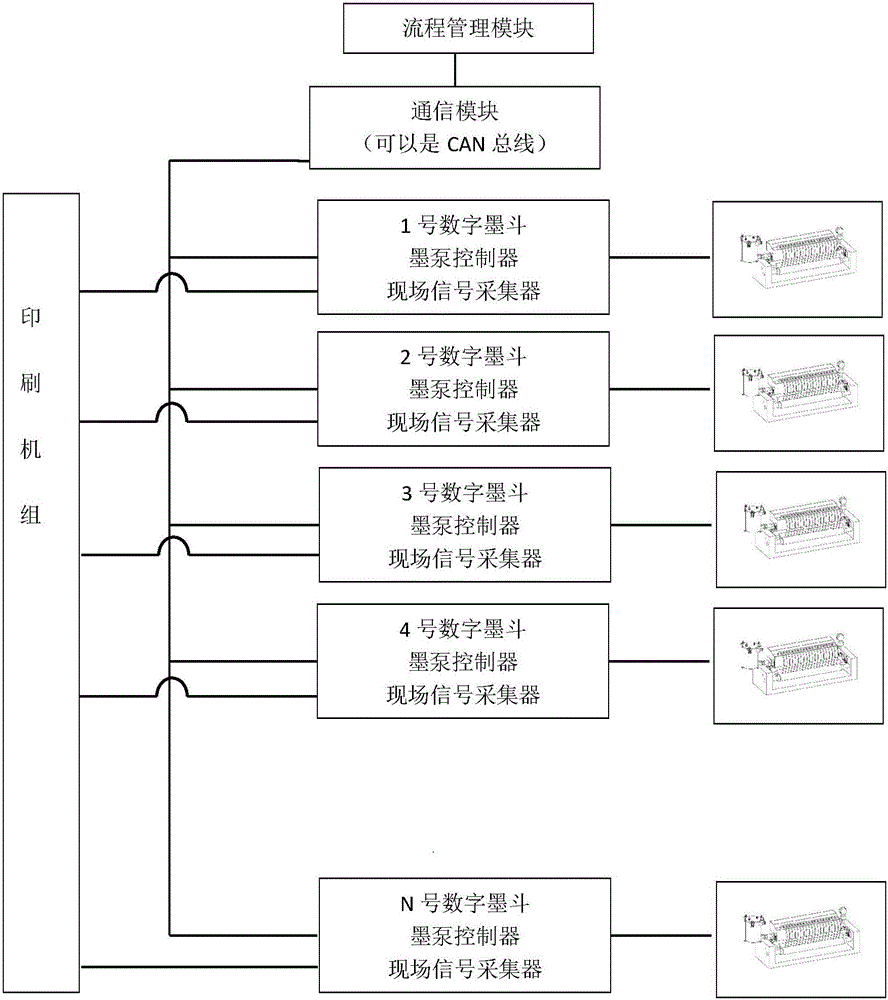

Digitized accurate ink supply method of printing machine

ActiveCN105818533ARealize precise quantitative controlReal-time supplyPrinting press partsEngineeringPrinting ink

The invention discloses a digitized accurate ink supply method of a printing machine. Metering printing ink conveying units replace ink keys on a traditional printing machine; each metering printing ink conveying unit directly conveys printing ink to corresponding ink areas; and the volume or mass serves as metering basis, quantitative supply of the printing ink for each ink area is achieved. In the working state, the ink supply flow speed of each metering printing ink conveying unit is obtained through calculation according to the consumption amount of the printing ink of corresponding color plates and the corresponding ink areas in each printed sheet and the operation speed of the printing machine, and the ink supply flow speed of each metering printing ink conveying unit is calculated and adjusted in real time along with change of the operation speed of the printing machine. By means of the digitized accurate ink supply method of the printing machine, real-time accurate adjustment can be achieved, the automation degree and digitization degree are high, the adjustable range is wide, one-way printing ink conveying is achieved, and printing ink return is avoided.

Owner:杭州科雷智能印刷科技有限责任公司

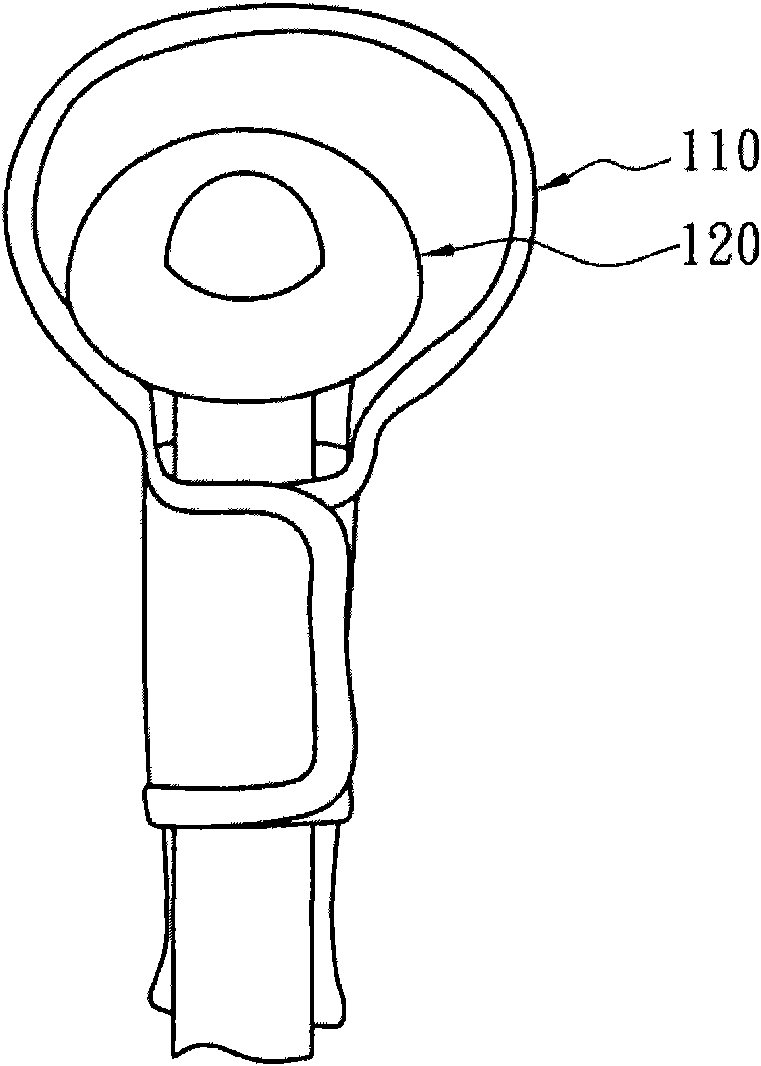

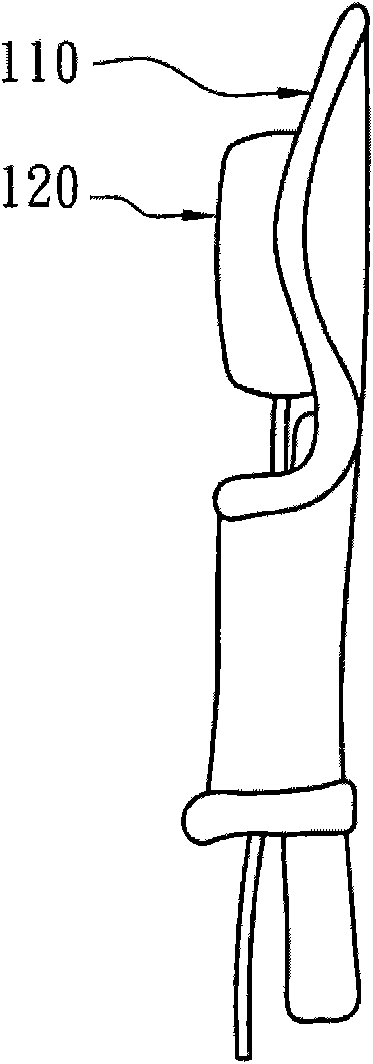

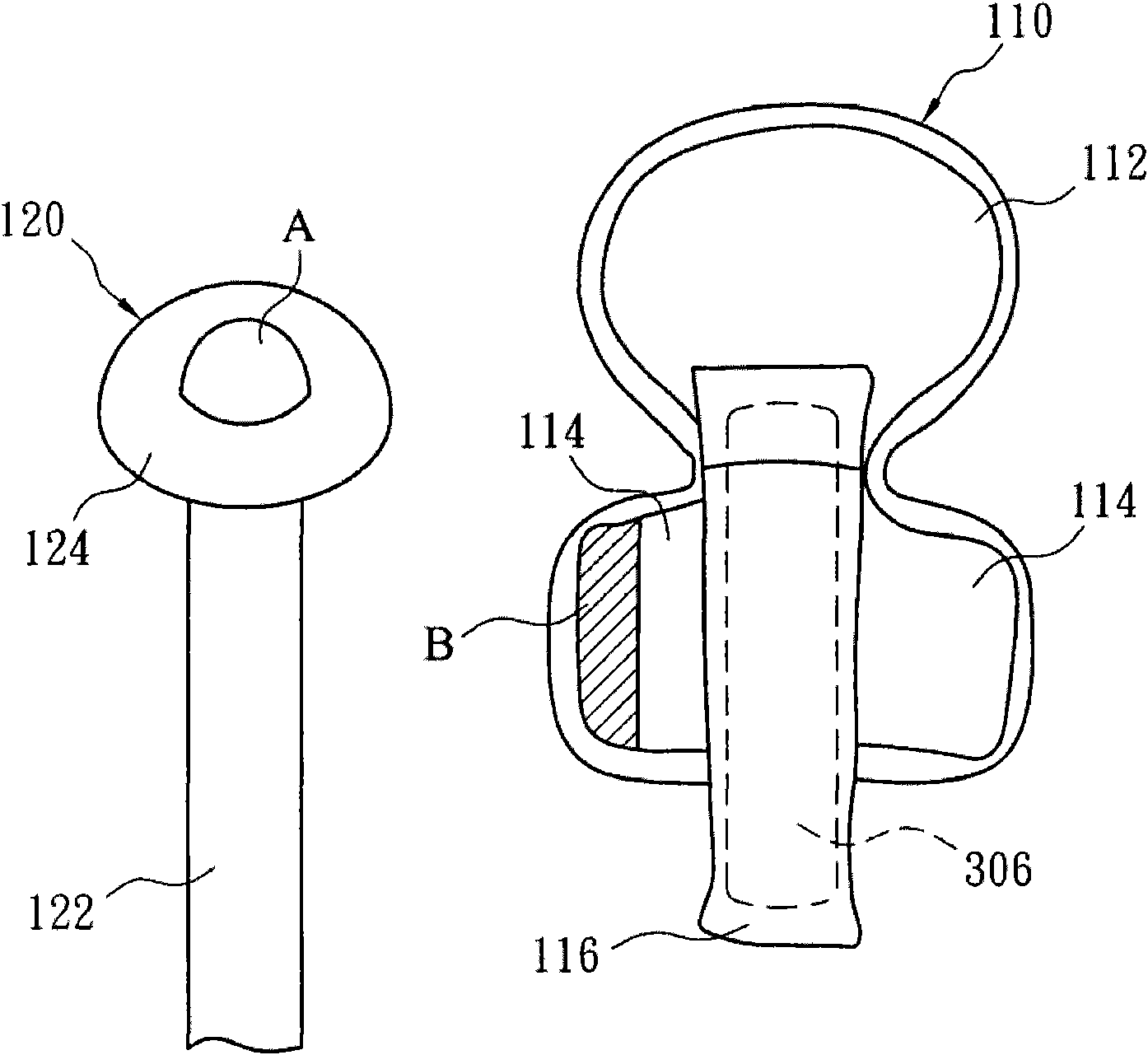

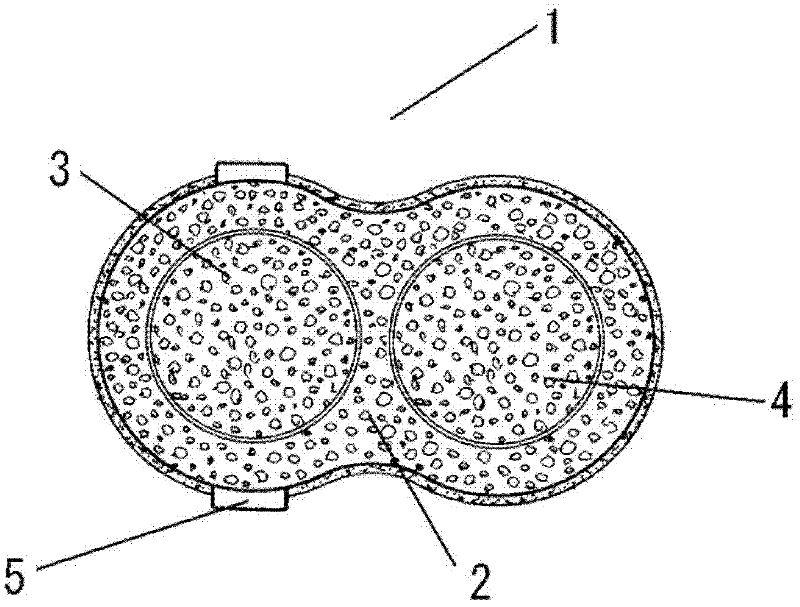

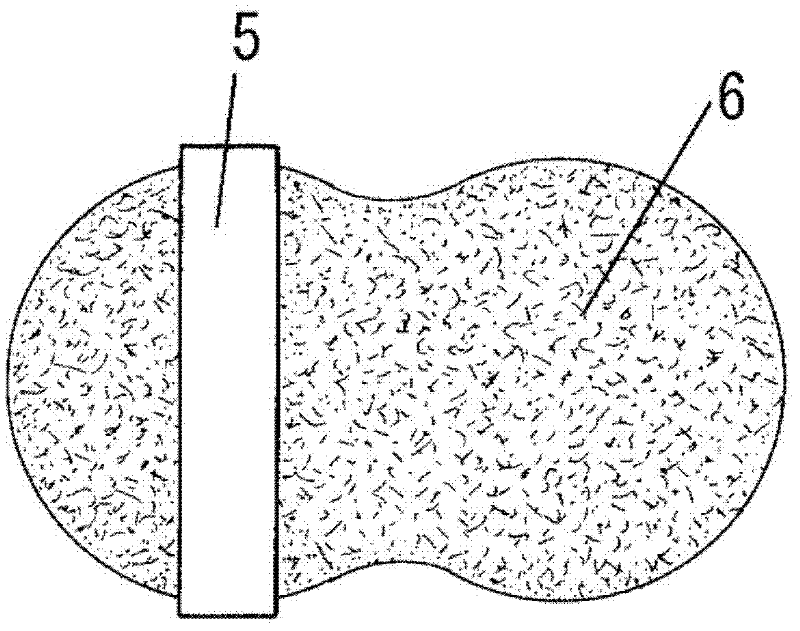

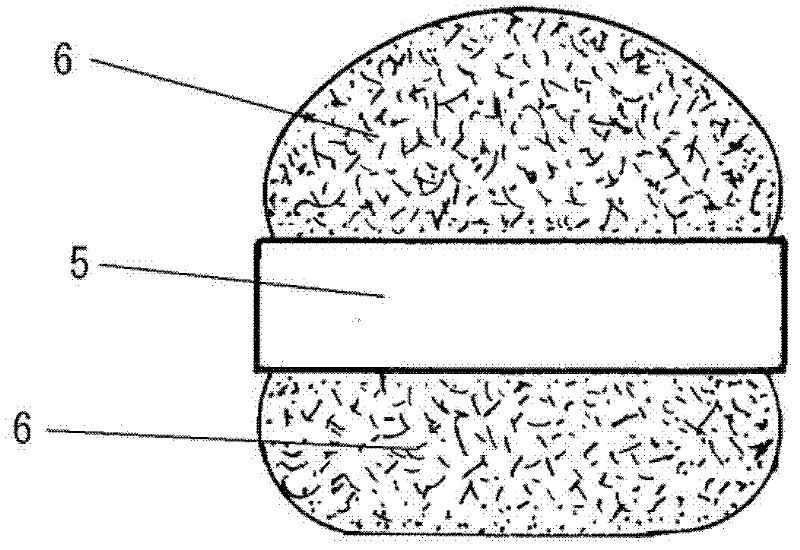

Powder puff provided with cosmetic materials

ActiveCN102326951AAvoid defacementEasy to storePackaging toiletriesPackaging cosmeticsStainMaterials science

In the past, besides a powder puff provided with cosmetic materials, other cosmetic powder puff used for wiping the cosmetic materials on skin is also preferentially provided, and in order to prevent the cosmetic materials attached on the cosmetic powder puff from spreading to stain other goods and prevent stain caused by the cosmetic materials peeled off from the powder puff provided with cosmetic materials, the powder puff needs to be packed into a carry-on article. The present invention provides the powder puff provided with the cosmetic materials, and is characterized in that: a part of a single side in which the cosmetic materials are contained is provided with a coating area of the cosmetic materials, the other part of the single side is provided with an area used for wiping the cosmetic materials coated on the skin, and the coating area of the cosmetic materials and the area used for wiping the cosmetic materials can be bended in an overlapping way, a back of either of the two areas and / or an end of at least one of the two areas are provided with a construction member for fixing the bending part, so as to prevent that the bending part is back but the cosmetic powder puff is open when the cosmetic powder puff is bended.

Owner:KK TAIKI

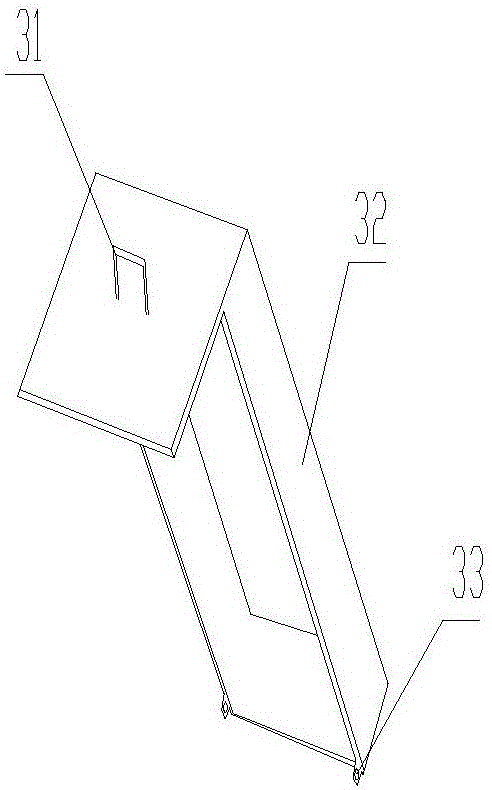

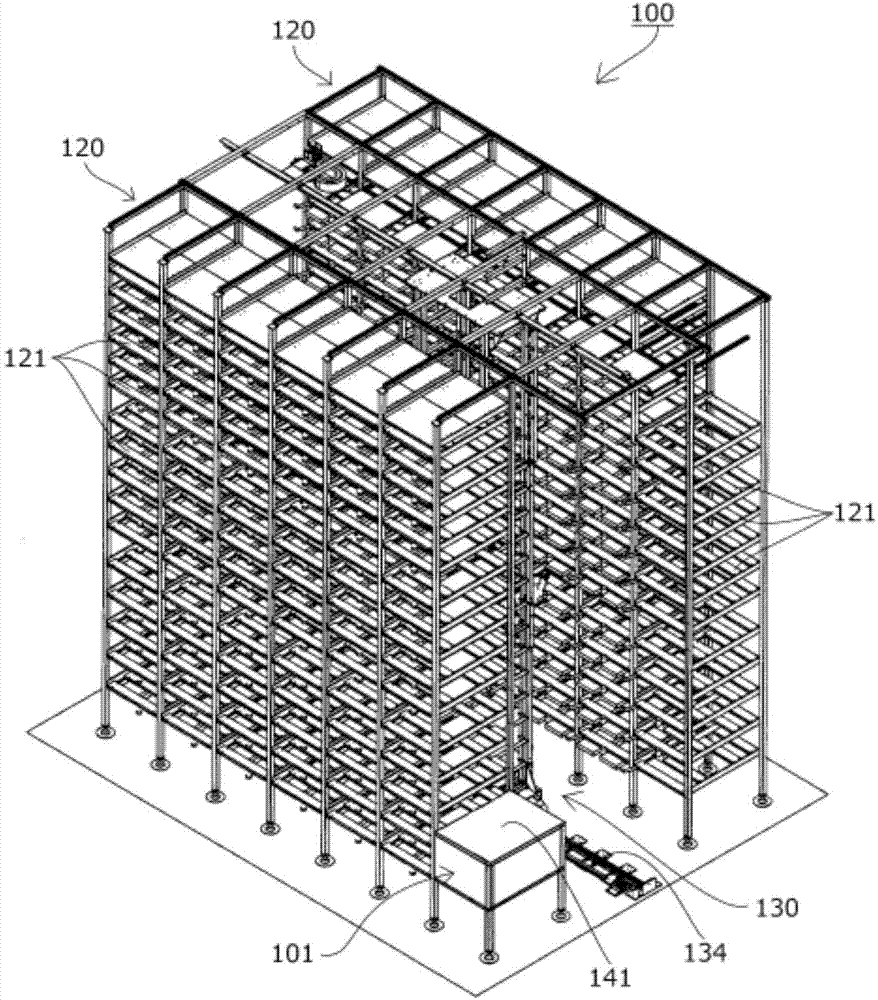

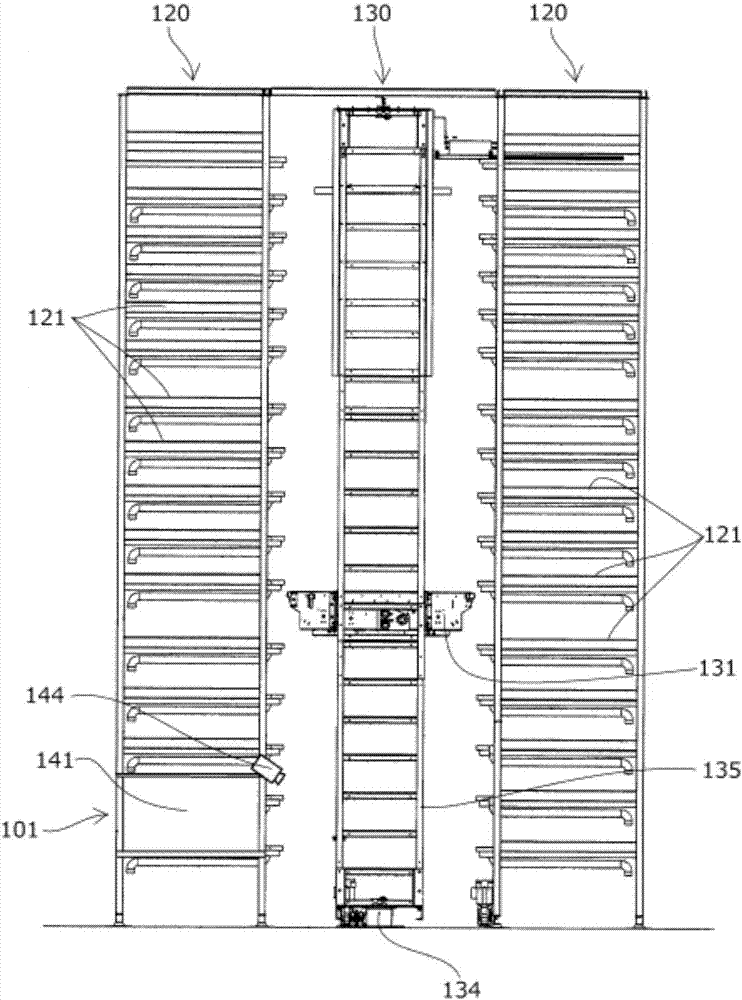

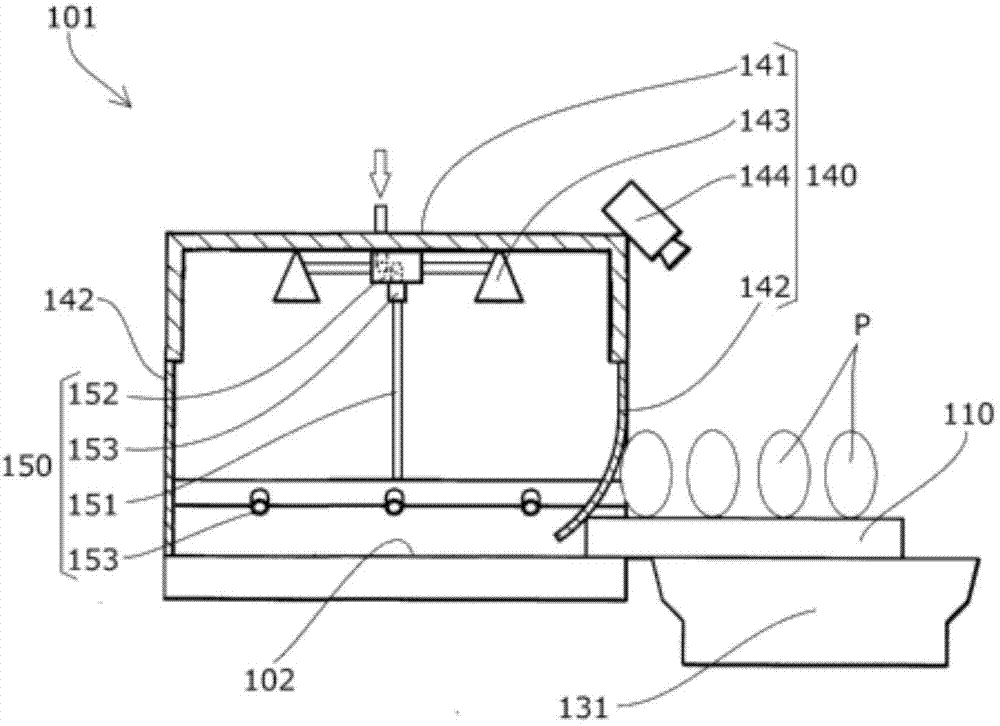

Plant cultivation apparatus

InactiveCN104853588AReduce the effects of flyingIncrease configuration freedomSelf-acting watering devicesClimate change adaptationPlant cultivationBiology

The purpose of the present invention is to provide a plant cultivation apparatus with which increased equipment complexity is limited and adverse effects on constituent members are prevented while the apparatus is also capable of automatically sprinkling leaf surfaces with a chosen timing and number of repetitions and capable of improving production efficiency. The apparatus is provided with: multiple cultivation shelves (121) for housing multiple cultivation trays (110); a transport means (130) for conveying the cultivation trays (110); and a sprinkling means (140) for sprinkling a sprinkling liquid on the plant leaf surfaces. The sprinkling means is disposed on the cultivation tray (110) conveyance path or at the conveyance destination and is provided with: an isolating member (141) for forming a partitioned space; and sprinkling nozzles (143) for sprinkling the sprinkling liquid toward the interior of the space.

Owner:TSUBAKIMOTO CHAIN CO

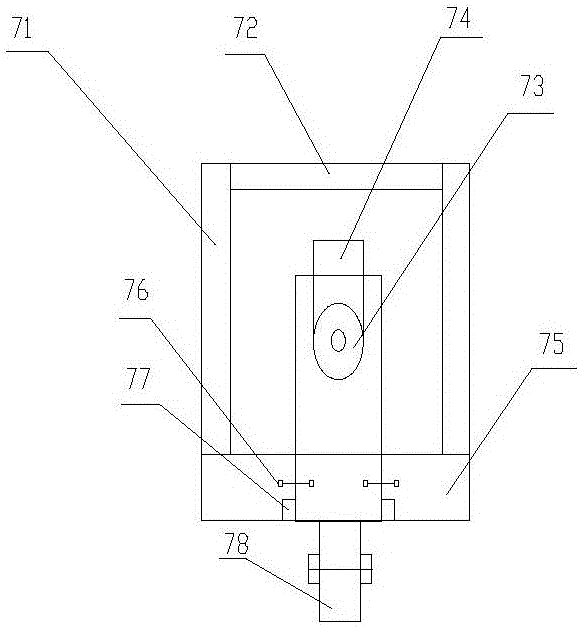

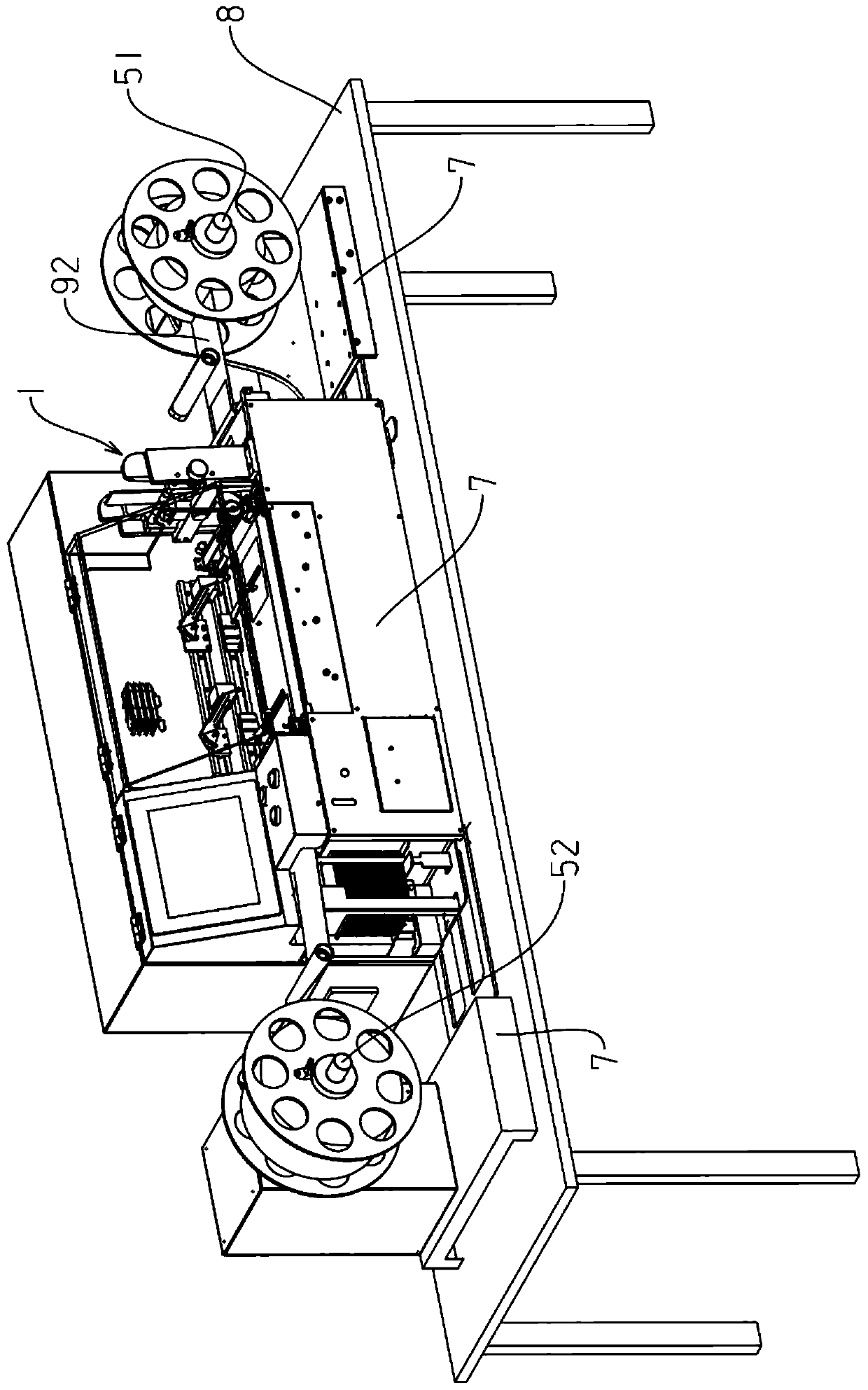

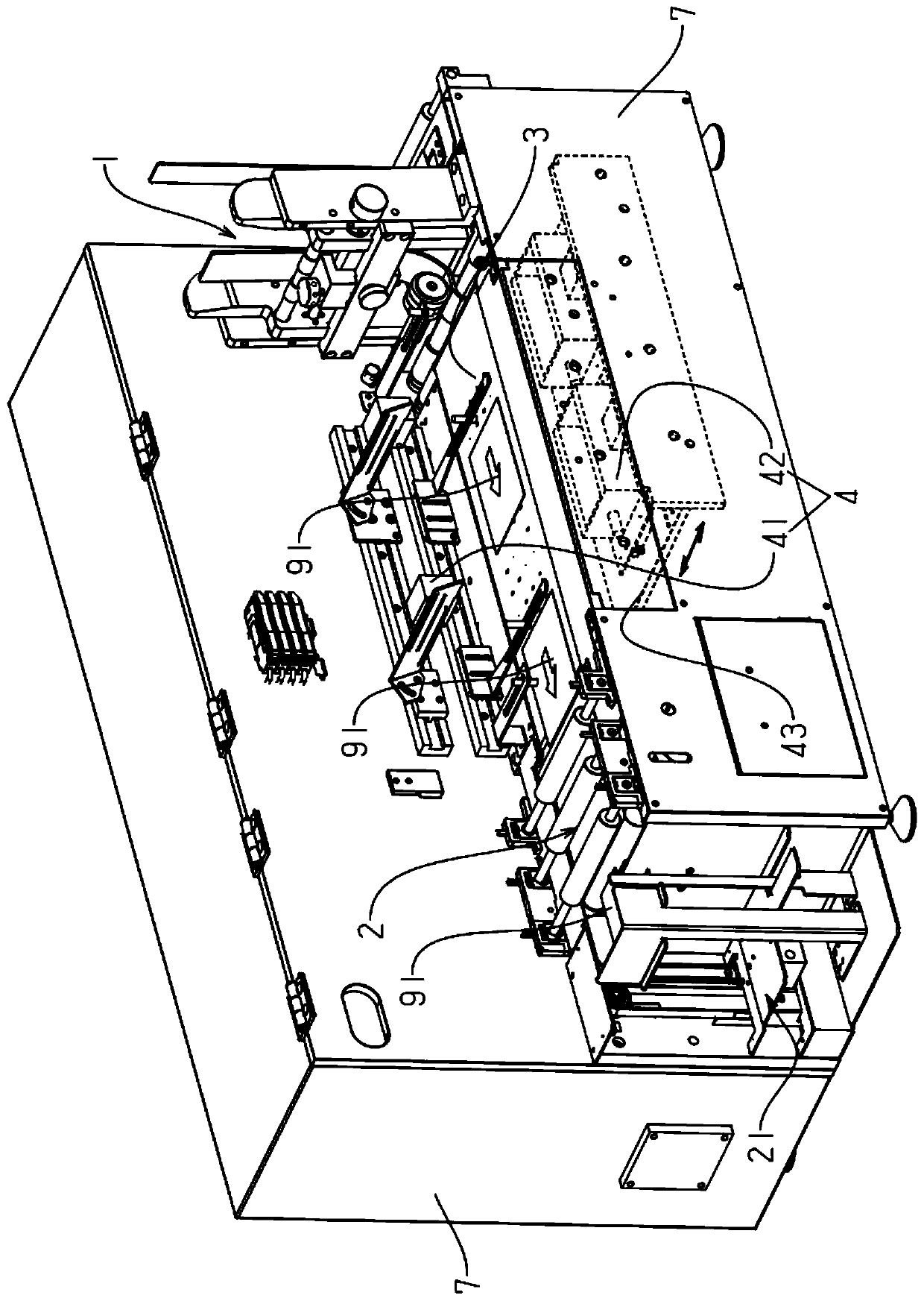

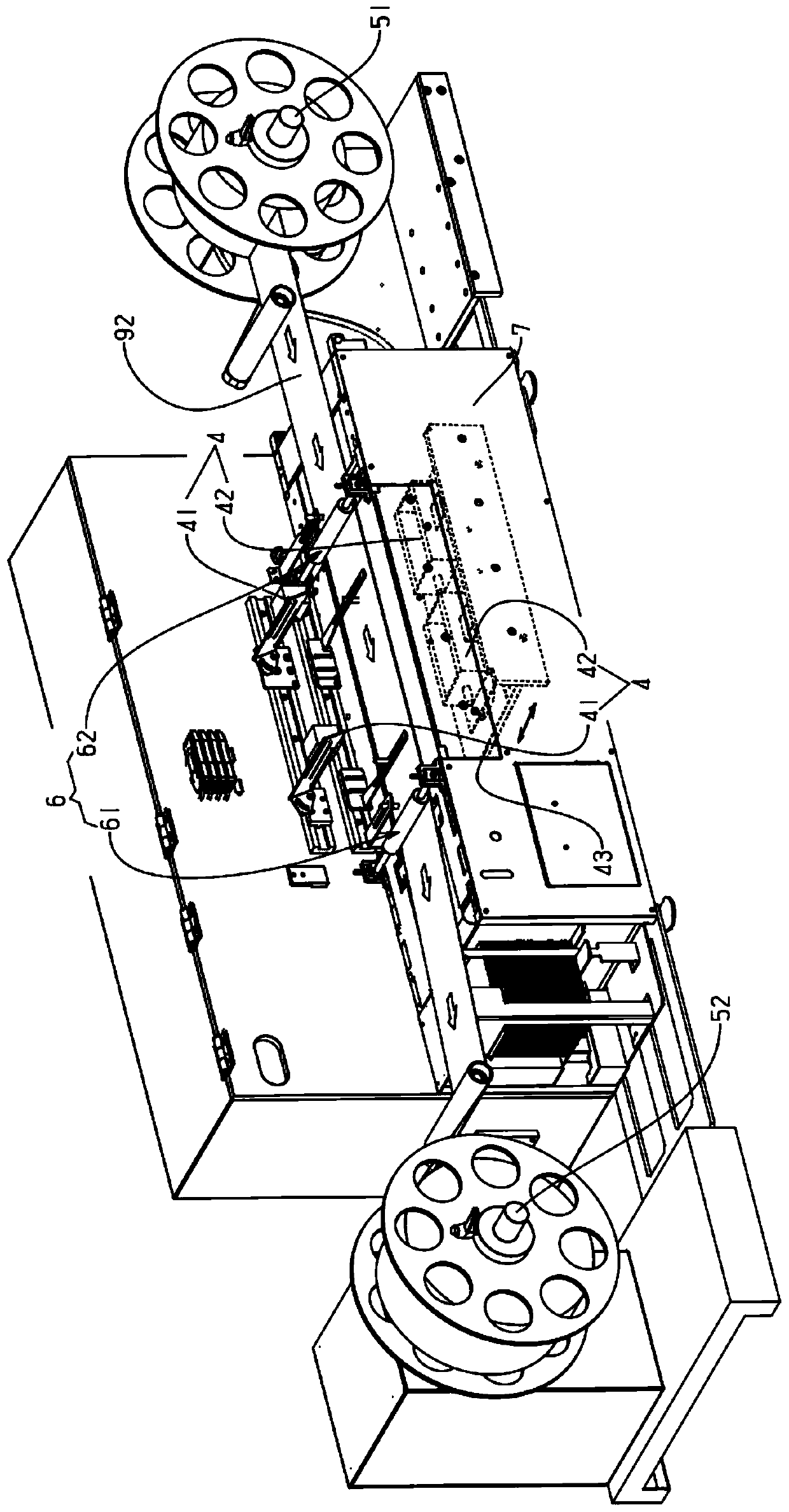

Desktop type label and ticket card dual-purpose detection code writing device

The invention discloses a desktop type label and ticket card dual-purpose detection code writing device. The detection code writing device can be placed on a desktop to work. The detection code-writing device comprises a card issuing mechanism used for issuing a single ticket card, a card collecting mechanism used for collecting the single ticket card, a conveying belt connected with the card issuing mechanism and the card collecting mechanism, an unwinding shaft and a winding shaft, wherein the unwinding shaft and the winding shaft are used for winding and tensioning a label material belt. Adriving mechanism used for pulling the label material belt to be conveyed is arranged between the unwinding shaft and the winding shaft. The desktop type label and ticket card dual-purpose detection code writing device can be suitable for labels in a material belt form and ticket cards in a single form, writing and / or detection verification of the labels and the ticket cards can be completed, andthe device is small, can be placed on a desktop to work, and is convenient to use and wide in application range.

Owner:KUNSHAN JETECH TECH CO LTD

Ultraviolet curing equipment and method for optical fiber coating

ActiveCN103319100BImprove curing efficiencyExtended service lifeUltraviolet light emitting diodesMaterials science

The invention relates to ultraviolet curing equipment and method for an optical fiber coating. The equipment comprises a cylindrical mounting base, wherein an inner cavity of the cylindrical mounting base is provided with UVLED (Ultraviolet Light Emitting Diode) light source modules in a peripheral direction and an axial direction; a cylindrical focusing lens is arranged in front of light-emitting surfaces of the UVLED light source modules, so that ultraviolet rays emitted from the UVLED light source modules are focused on a same curing axis. The ultraviolet curing equipment disclosed by the invention is long in service life, small in heating amount and low in energy consumption; a layout space of light sources is large, so that the output of the UV light sources of a plurality of UVLED light source modules are focused on the curing axis to form a UV light column with high light intensity; an optical fiber absorbs UV and is cured when passing through the UV light column; the light strength of the light column is high and the light sources are from multiple directions, so that the equipment has higher curing efficiency and better curing uniformity, the curing time is shortened, the work efficiency of wiredrawing of the optical fiber is improved, and the curing quality of the coating is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

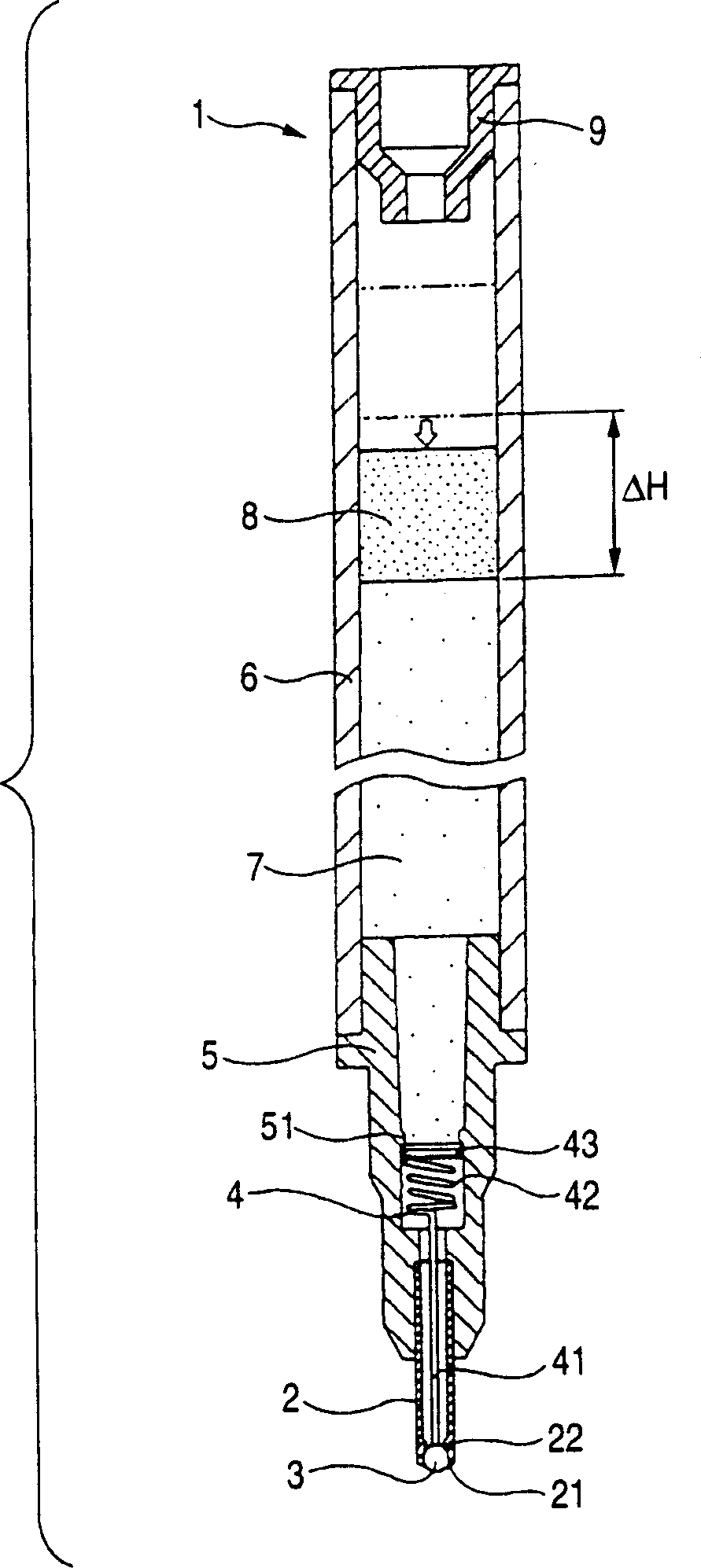

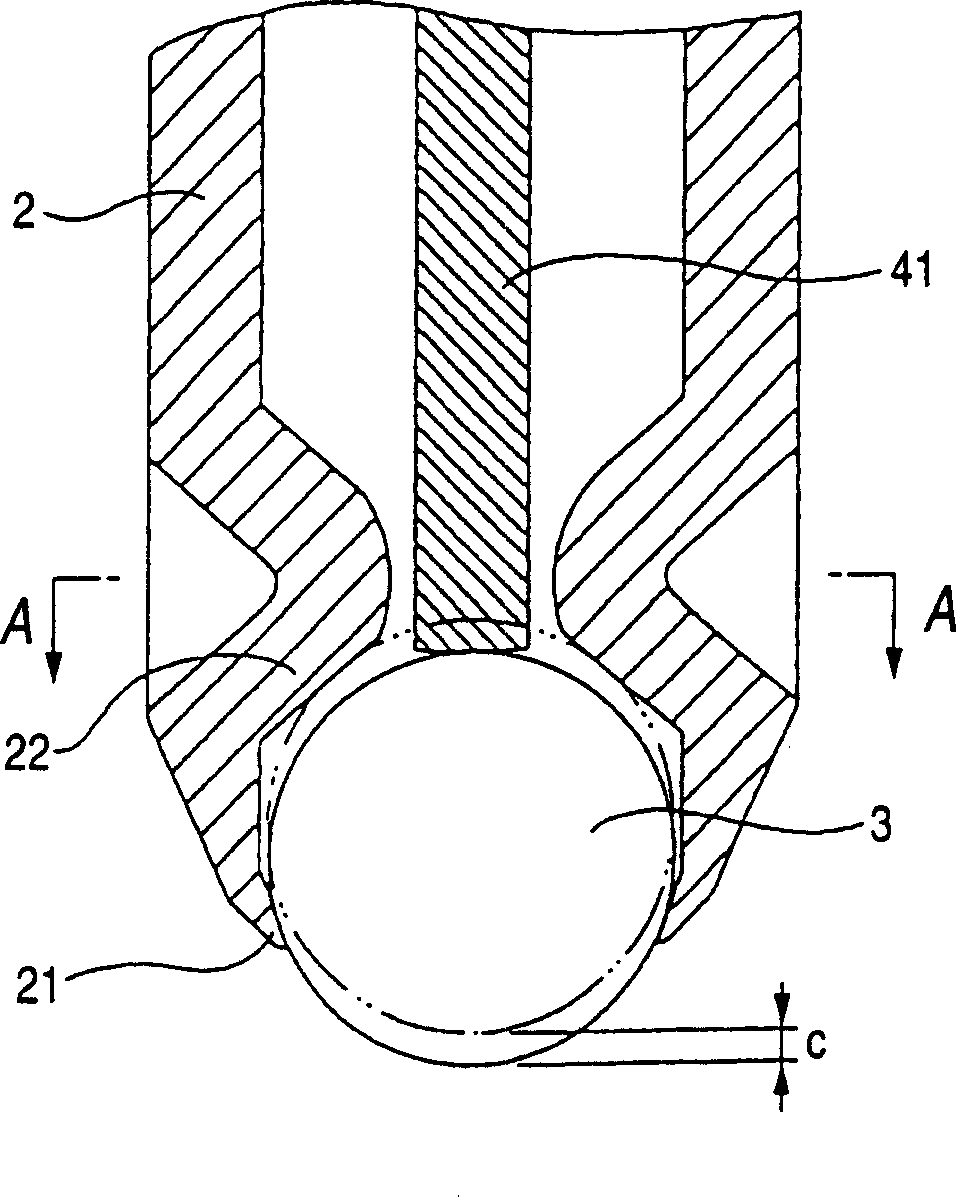

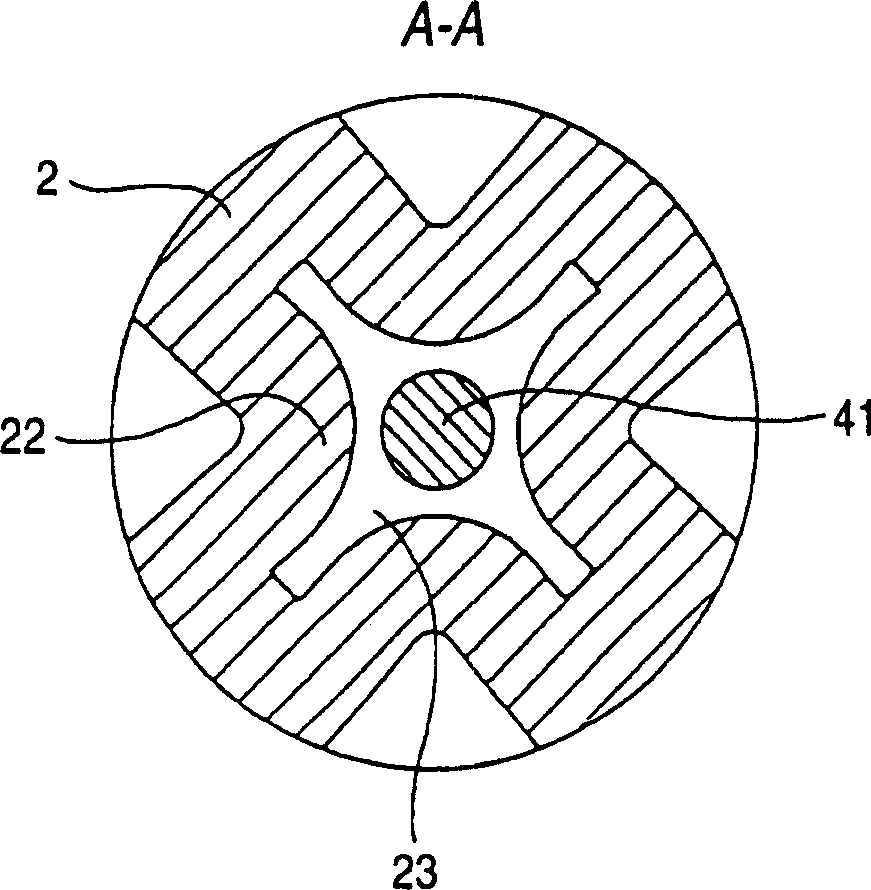

Ball-point pen

Owner:THE PILOT INK CO LTD

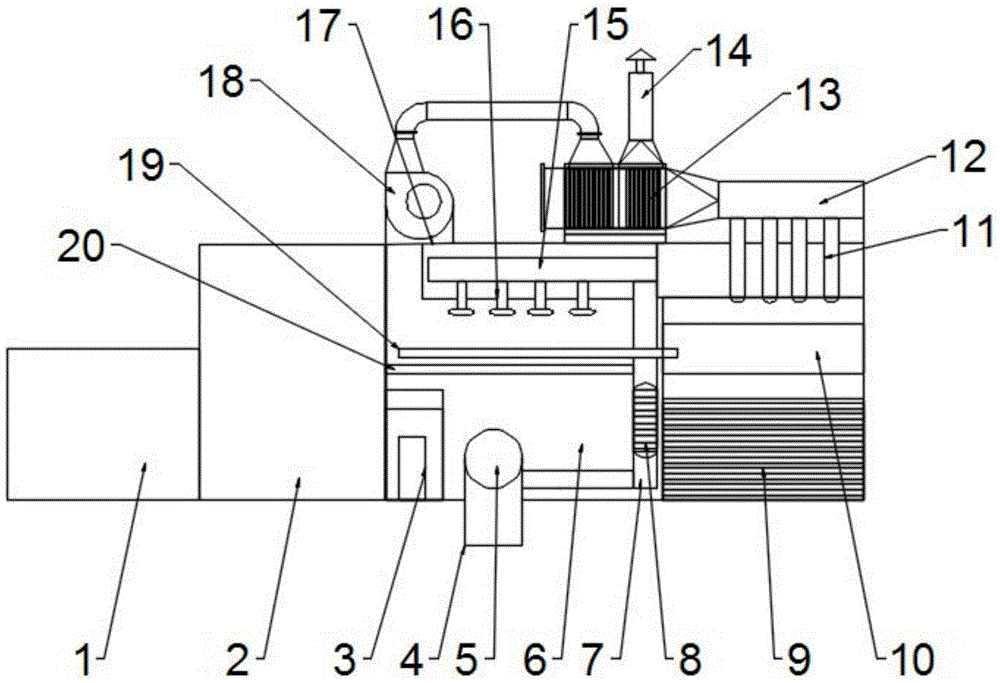

Two-stage backflow drying type high-speed printing device

InactiveCN105522821AWill not defaceAvoid defacementPrinting press partsPulp and paper industryPrinting ink

The invention discloses a two-stage backflow drying type high-speed printing device. The two-stage backflow drying type high-speed printing device comprises a machine body which is arranged on an installation frame. A paper feeding mechanism is arranged on the left side of the machine body. A paper collecting mechanism is arranged on the right side of the machine body. A paper positioning mechanism, a paper passing mechanism, a printing mechanism, an ink delivery mechanism and a control mechanism are arranged in the machine body. All the mechanisms in the machine body are used for conducting normal printing work. A drying chamber is arranged between the machine body and the paper collecting mechanism. A two-stage backheating device is arranged at the top of the drying chamber. According to the two-stage backflow drying type high-speed printing device, printed ink marks can be air-dried rapidly through a drying box and air pipe sets, so that the ink marks are prevented from being stained in the conveying and storing processes; the printing quality and printing efficiency are improved, the production efficiency is greatly improved, and the rejection rate is decreased; in addition, paper which is rapidly dried at the high temperature is buffered and shaped through low-temperature hot air flowing back from the second-stage backheating device, the energy saving rate is greatly increased while the drying quality is improved, and the production cost is reduced.

Owner:李秋芬

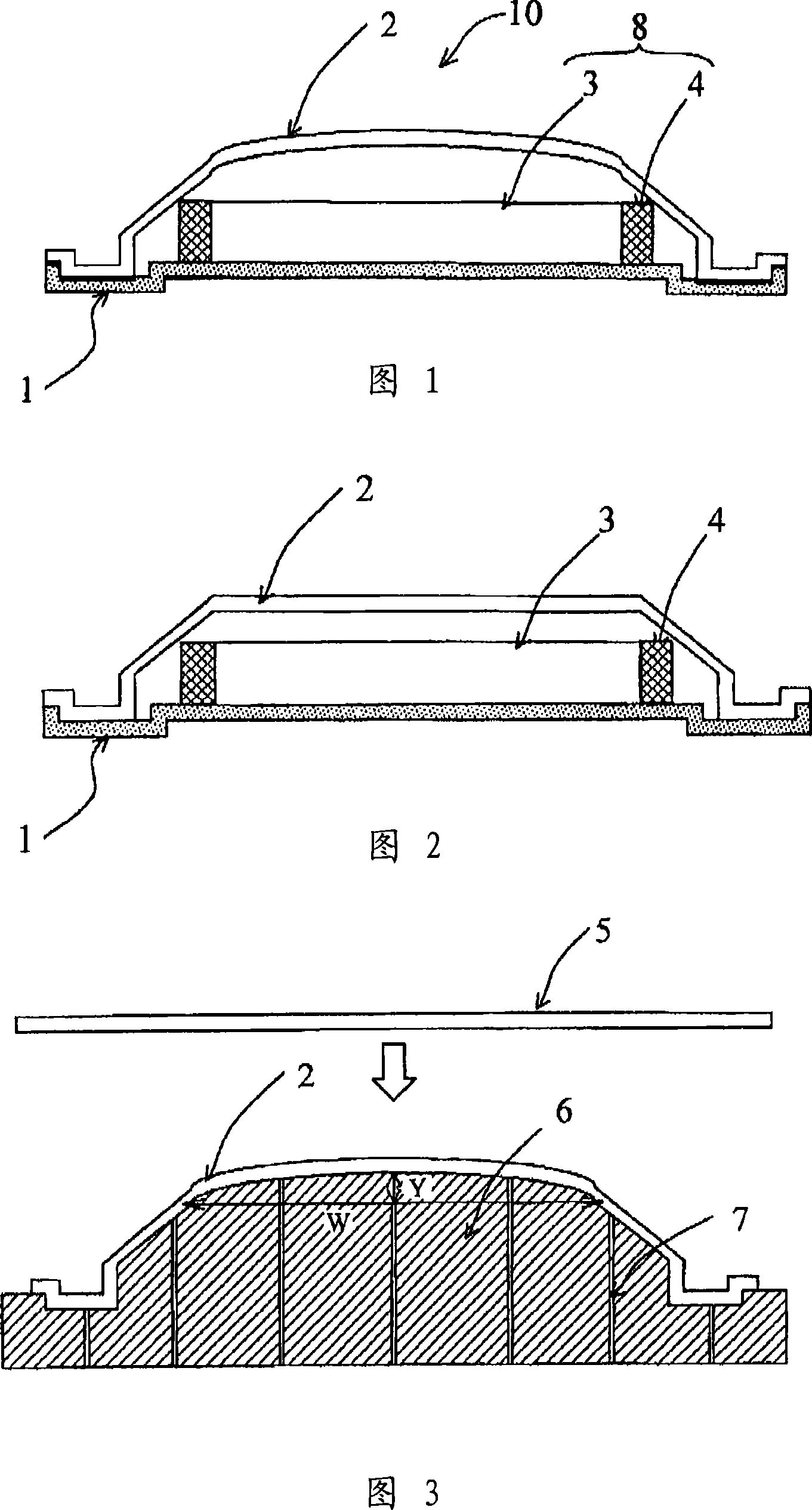

Protection film components containing vessel and manufacturing method thereof

InactiveCN101086612AAvoid defacementGuaranteed qualitySemiconductor/solid-state device manufacturingRemovable lids/coversEngineeringMechanical engineering

Owner:SHIN ETSU CHEM IND CO LTD

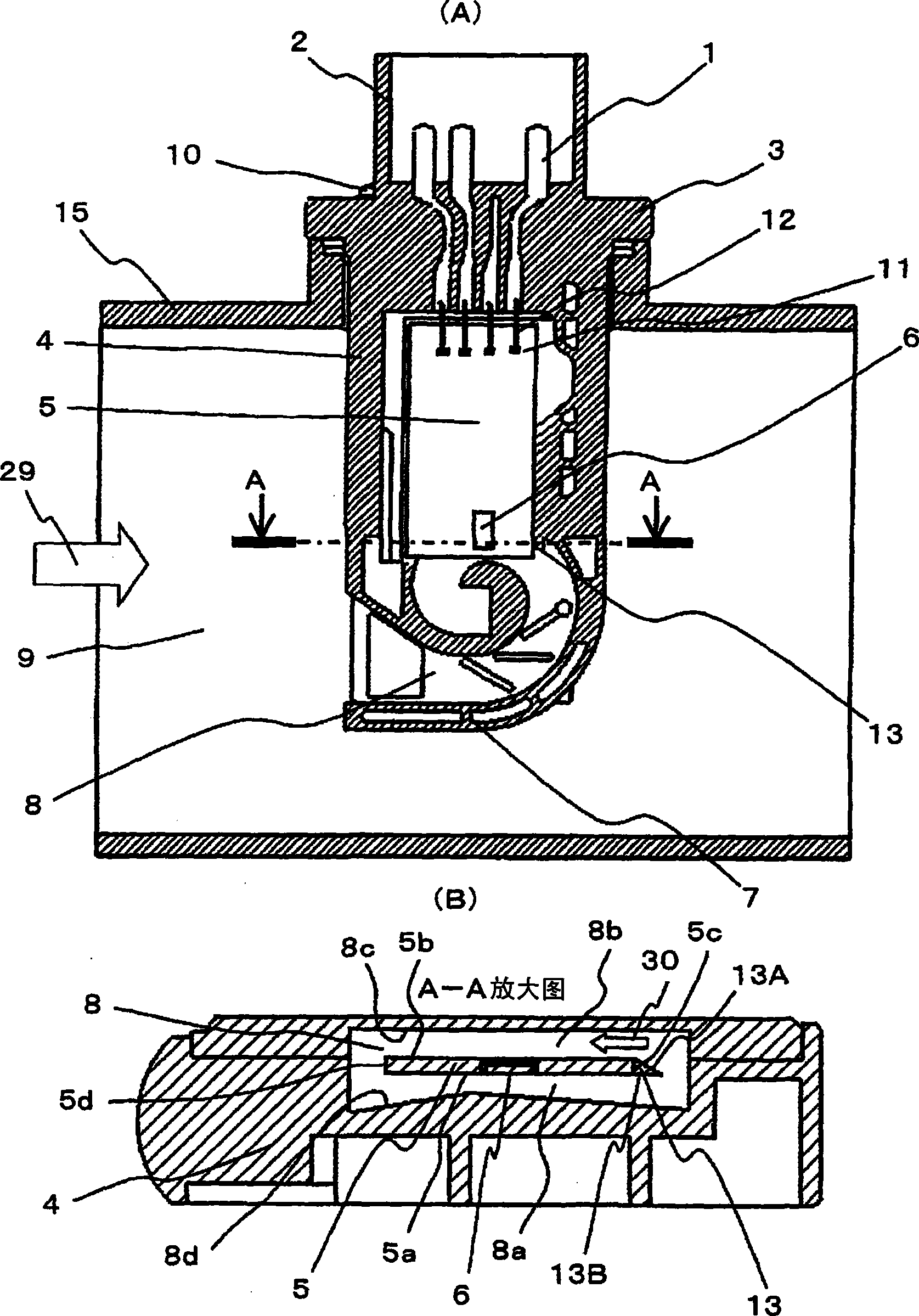

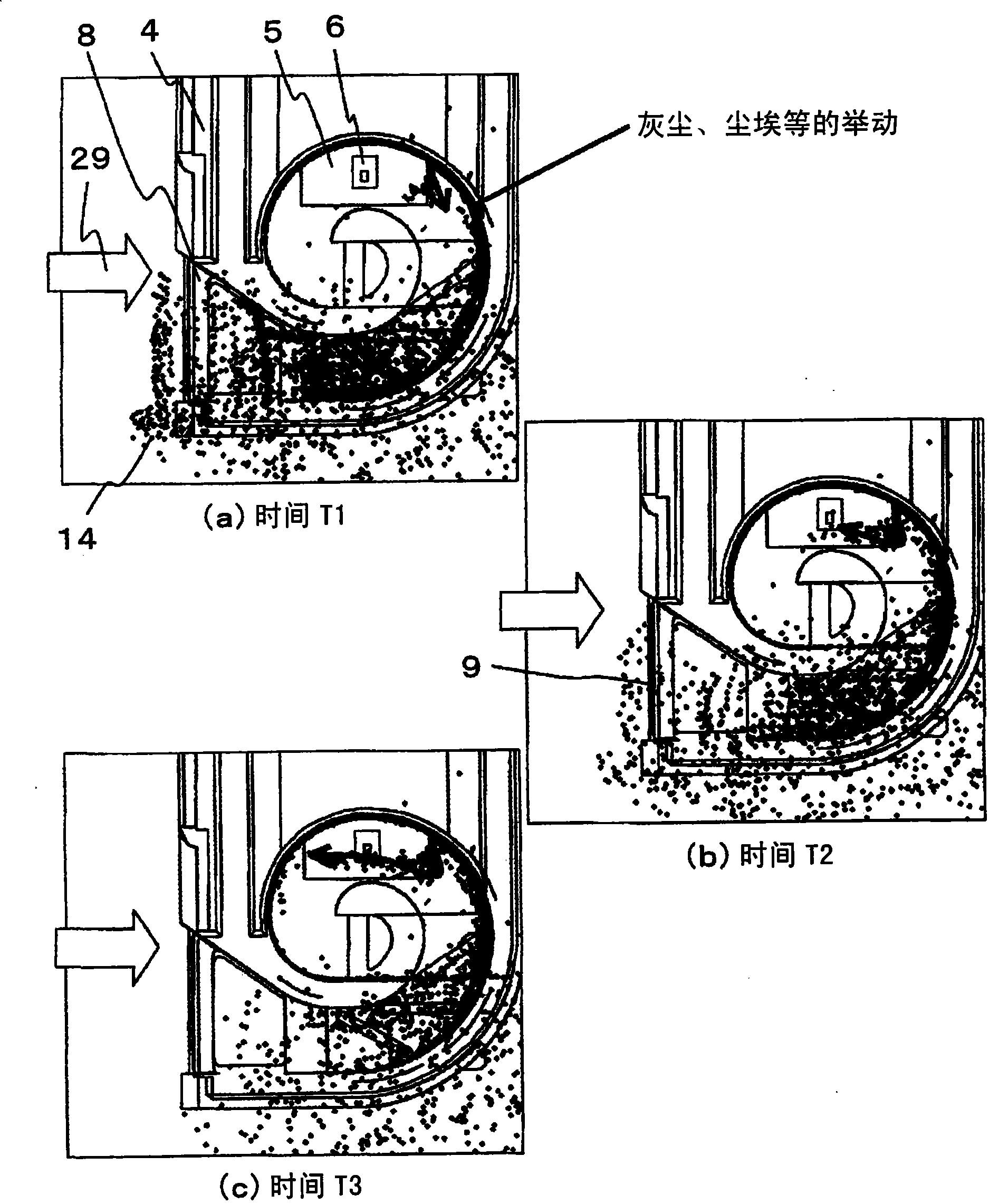

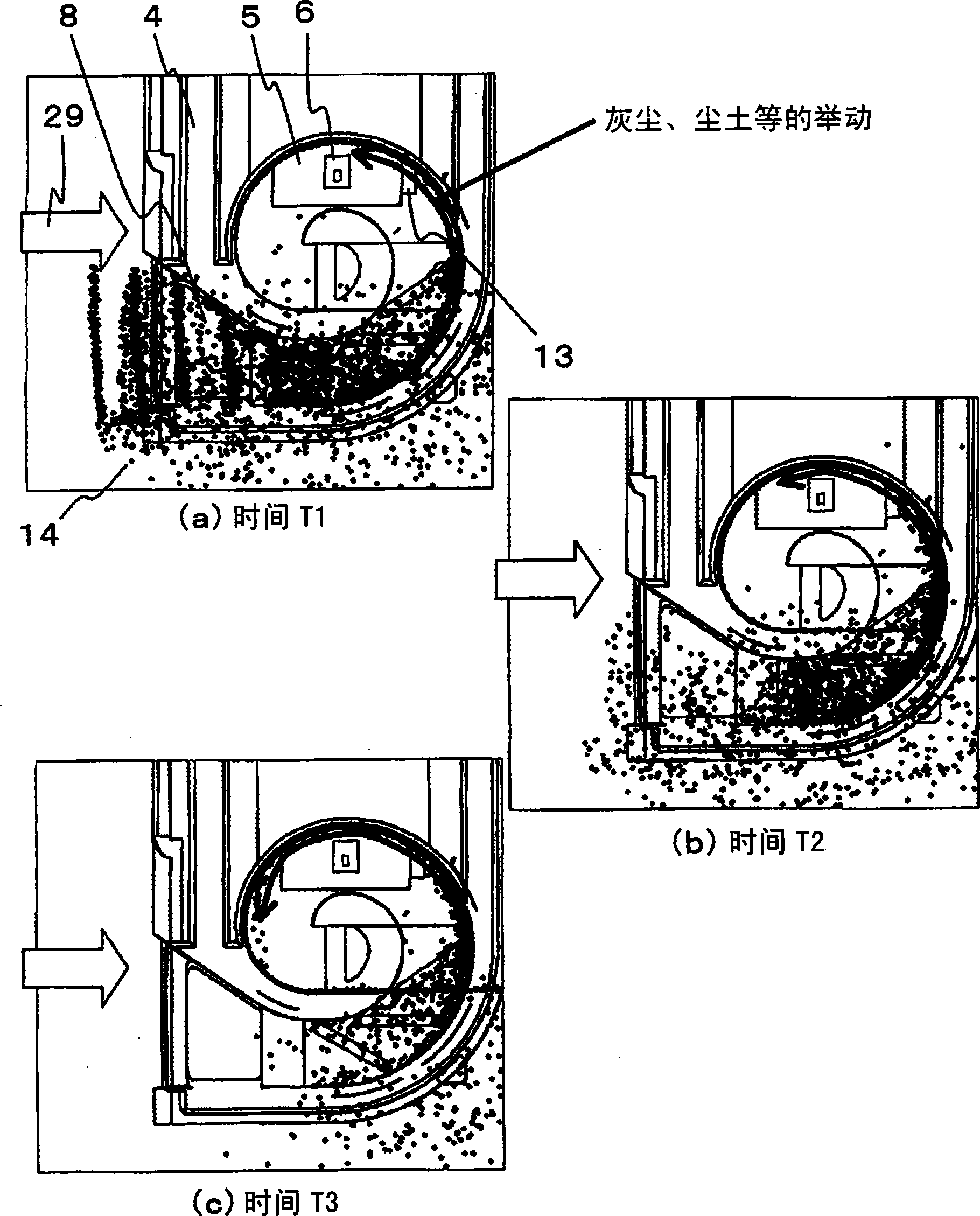

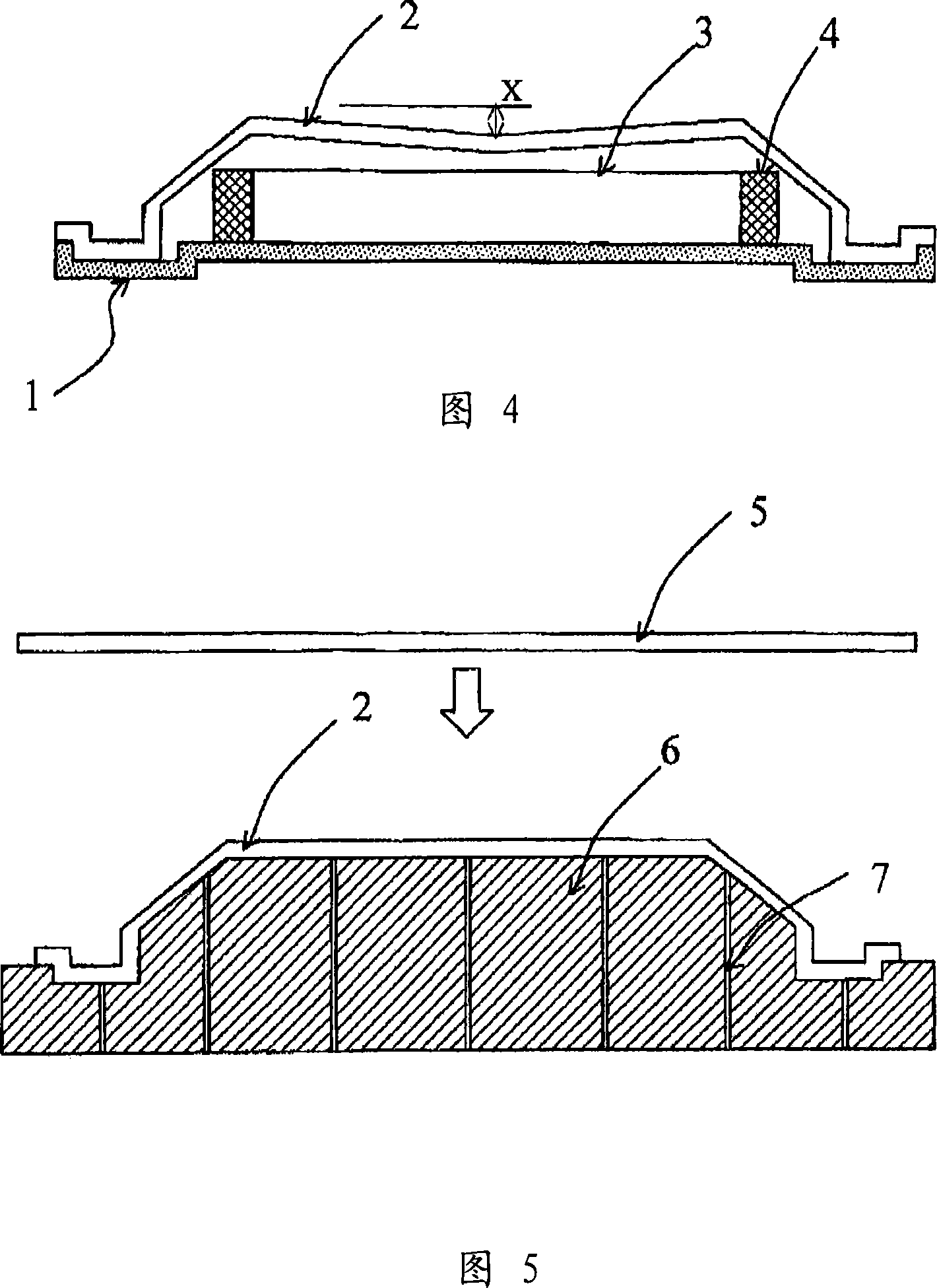

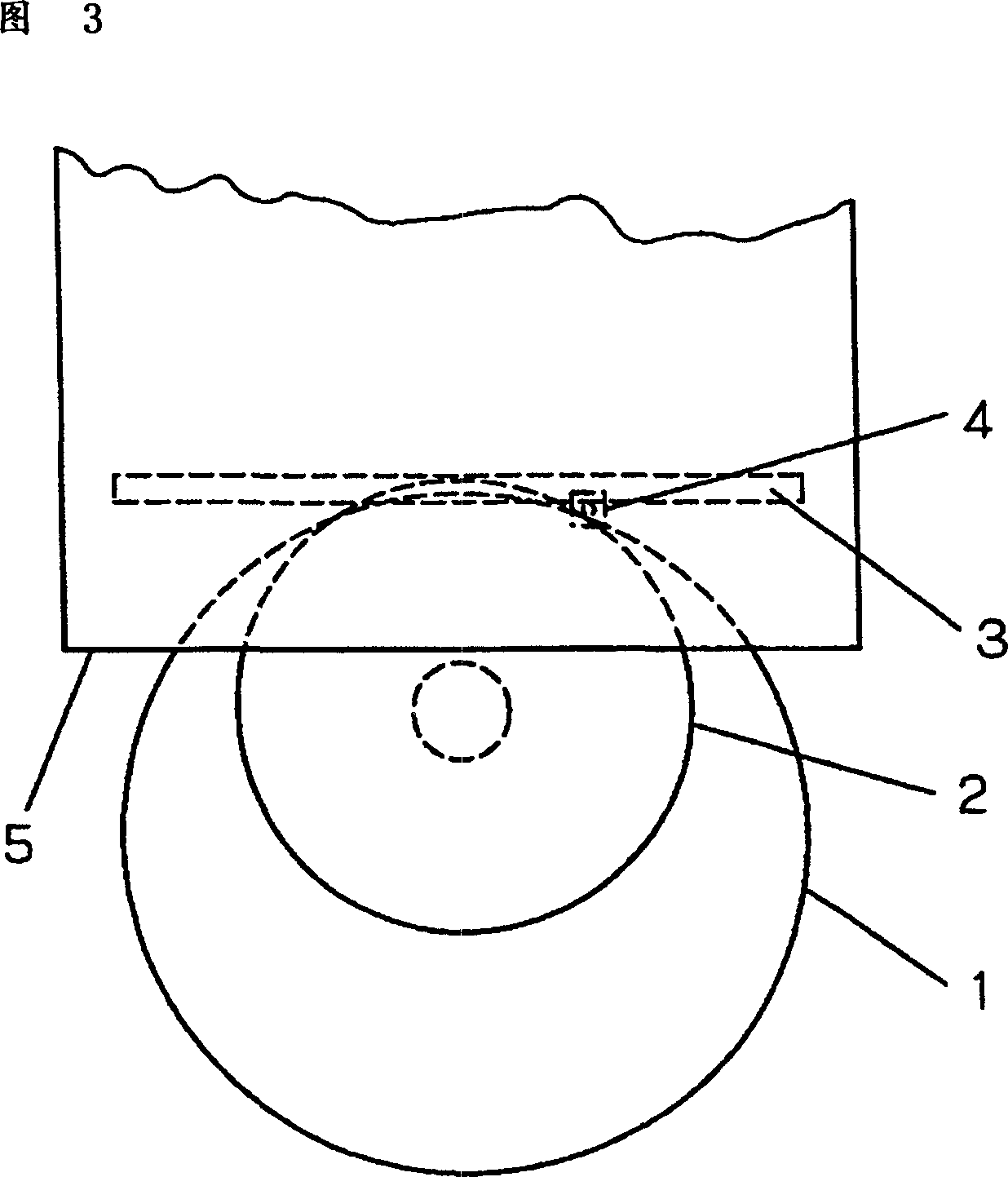

Disk loader

InactiveCN1320263AAvoid defacementAvoid damageRecord information storageRecording on magnetic disksEngineeringDisk loading

A disk loading apparatus is provided which stops disks, even if the disks have different diameters, when disk center holes have been ejected to the substantially same positions out of an apparatus body during the ejection. The disks can be pulled out without soiling a recording surface of the disk. One disk-pass detecting switch detects a pass of the last end of each disk and discriminates sizes of the disks. In addition, a rotation time of a roller after the detection of the pass is controlled depending on disk diameters.

Owner:PANASONIC CORP

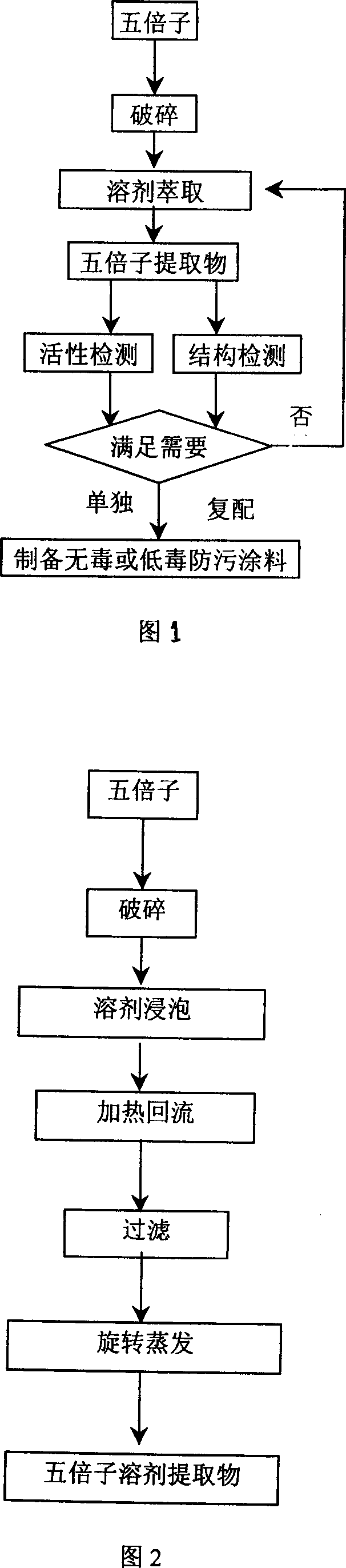

Non-toxic or low-toxicity anti-fouling coating prepared by utilizing Chinese medicinal crop gallnut solvent extract

InactiveCN1935907AReduce dosageReduce pollutionAntifouling/underwater paintsPaints with biocidesOxide compositeSolvent

The invention relates to nontoxic or low toxic anti-fouling paint made by Chinese gall solvent extract which includes resin base metal, dye, anti-fouling agent, and limed rosin, and various auxiliary agents. The anti-fouling agent is formed by Chinese gall extract, or Chinese gall extract and cuprous oxide composite. It is proved that the anti-fouling paint has obvious anti-fouling effect. The new type low toxic anti-fouling paint can effectively prevent marine life defiling, and reduce cuprous oxide use level to realize pollution abatement by properly adjusting the composite proportion of the Chinese solvent extract and cuprous oxide.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Antifouling coating with low surface energy for marine mesh cage cover

InactiveCN1321165CPrevent biofoulingAvoid defacementAntifouling/underwater paintsPaints with biocidesEthyl acetateZinc

The antifouling coating with low surface energy for marine mesh cage cover is used forsolving the problem of damaging life attachment. The antifouling coating with low surface energy is compounded with polyurethane, curing agent, ethyl acetate, zinc oxide, magnesium oxide, PTFE and chloropafaffin in certain weight proportion and through grinding and mixing. The antifouling coating with low surface energy is used in coating marine mesh cage cover.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

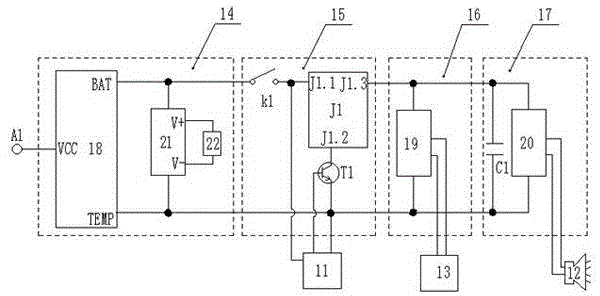

LED sound-light alarm device

ActiveCN104966378APrevent stray entryEffective warningAlarmsElectric transmission signalling systemsEngineeringLoudspeaker

The invention discloses an LED sound-light alarm device, and belongs to the technical field of power safety protection. A solved technical problem is to provide the LED sound-light alarm device which can protect an electric power worker working in a dangerous region from electric shock. An employed technical scheme is that the device comprises an LED lampshade; the bottom of the LED lampshade is connected with a pedestal; the LED lampshade comprises an outer housing, an inner housing, and a reflecting cover; the outer wall of the pedestal is provided with a power input connector and a power switch; the interior of the pedestal is provided with a sound-light alarm circuit board; the outer wall of the top of the pedestal is provided with an LED light-emitting lamp board; the top of the inner housing is provided with an induction chip and a loudspeaker; the sound-light alarm circuit board comprises a power circuit, a control circuit, a boost circuit, a voice alarm circuit, and a power input terminal A1; and the device is suitable for the power field.

Owner:STATE GRID CORP OF CHINA +1

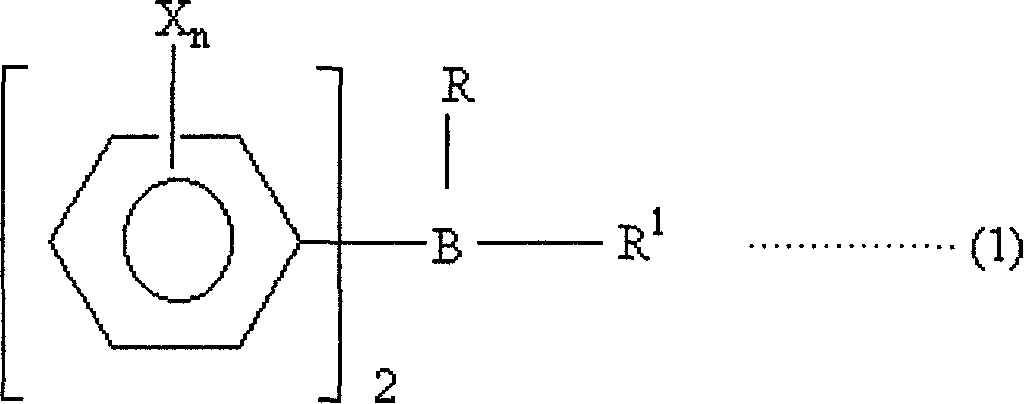

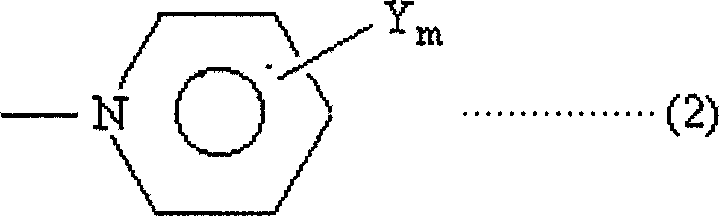

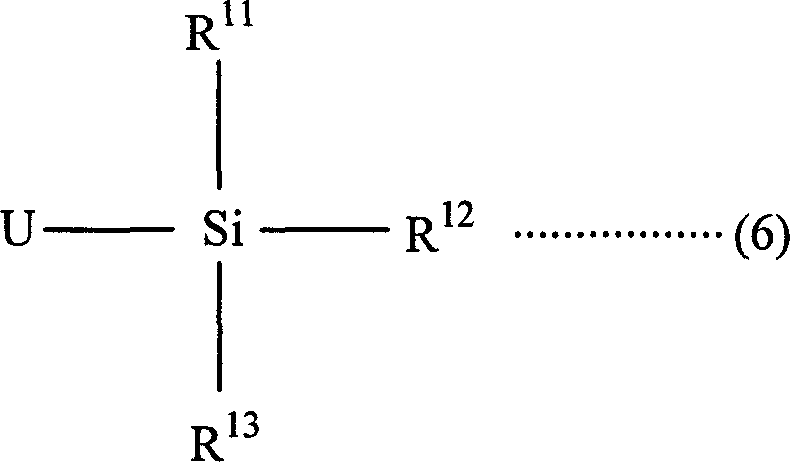

Coating composition, antifouling coating film, underwater structure, and method of preventing fouling of underwater structure

InactiveCN1833010ANo risk of pitting corrosionNo risk of pitting corrosion on aluminumBiocideFishing netsAdditive ingredientCopolymer

A coating composition which develops no coating film defects, such as peeling, in water with time, wears away at a constant rate, has excellent long-term antifouling properties, is applicable even to aluminum boats, and is highly safe environmentally; an antifouling coating film; an underwater structure with unsusceptibility to fouling; and an antifouling method. The coating composition is characterized by containing a copolymer comprising both of an ingredient A) represented by the following formula (1) and an ingredient B) derived from a polymerizable unsaturated metal salt compound represented by R5-(CH2)k-COO-M-Lq.

Owner:NKM COATINGS

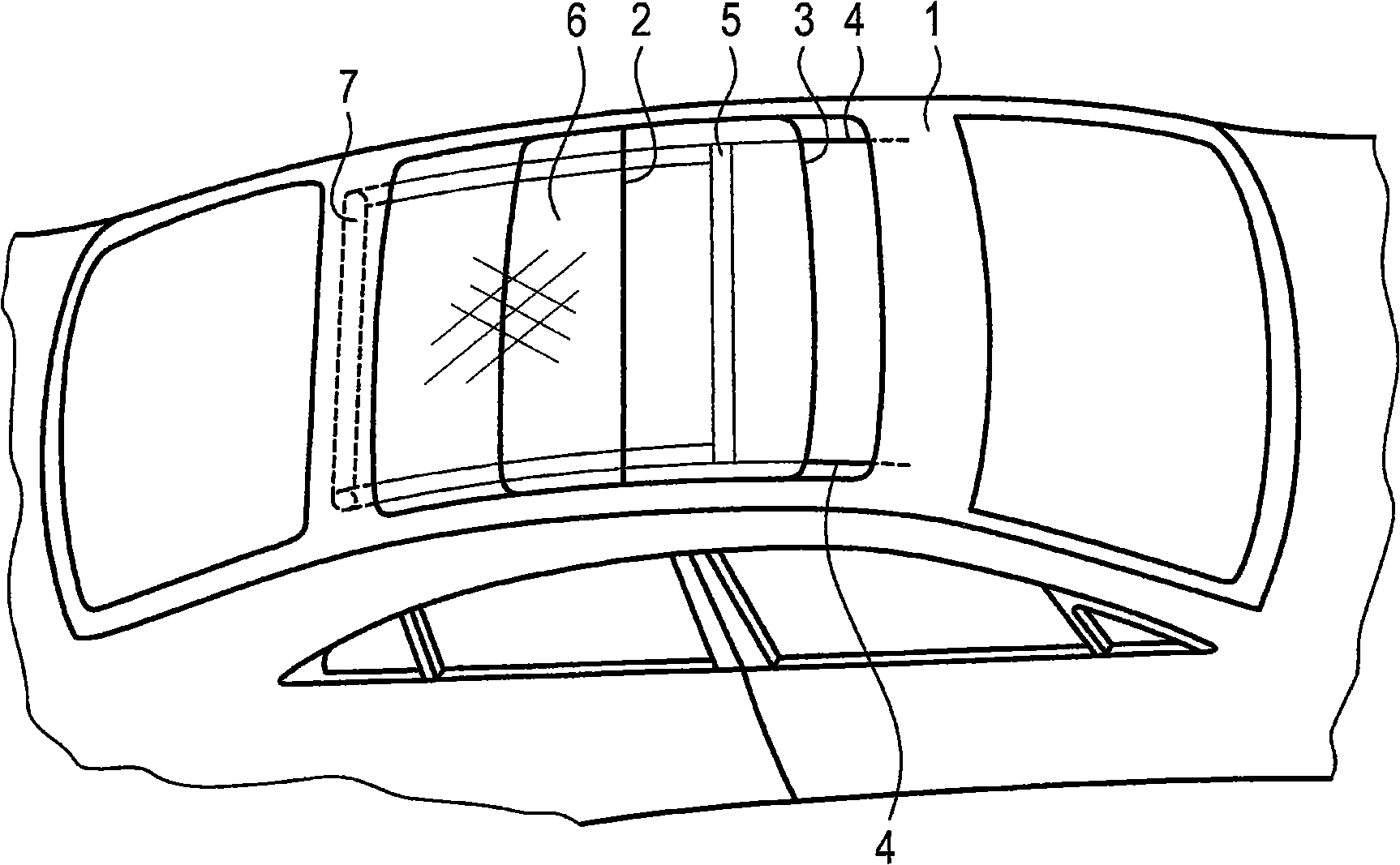

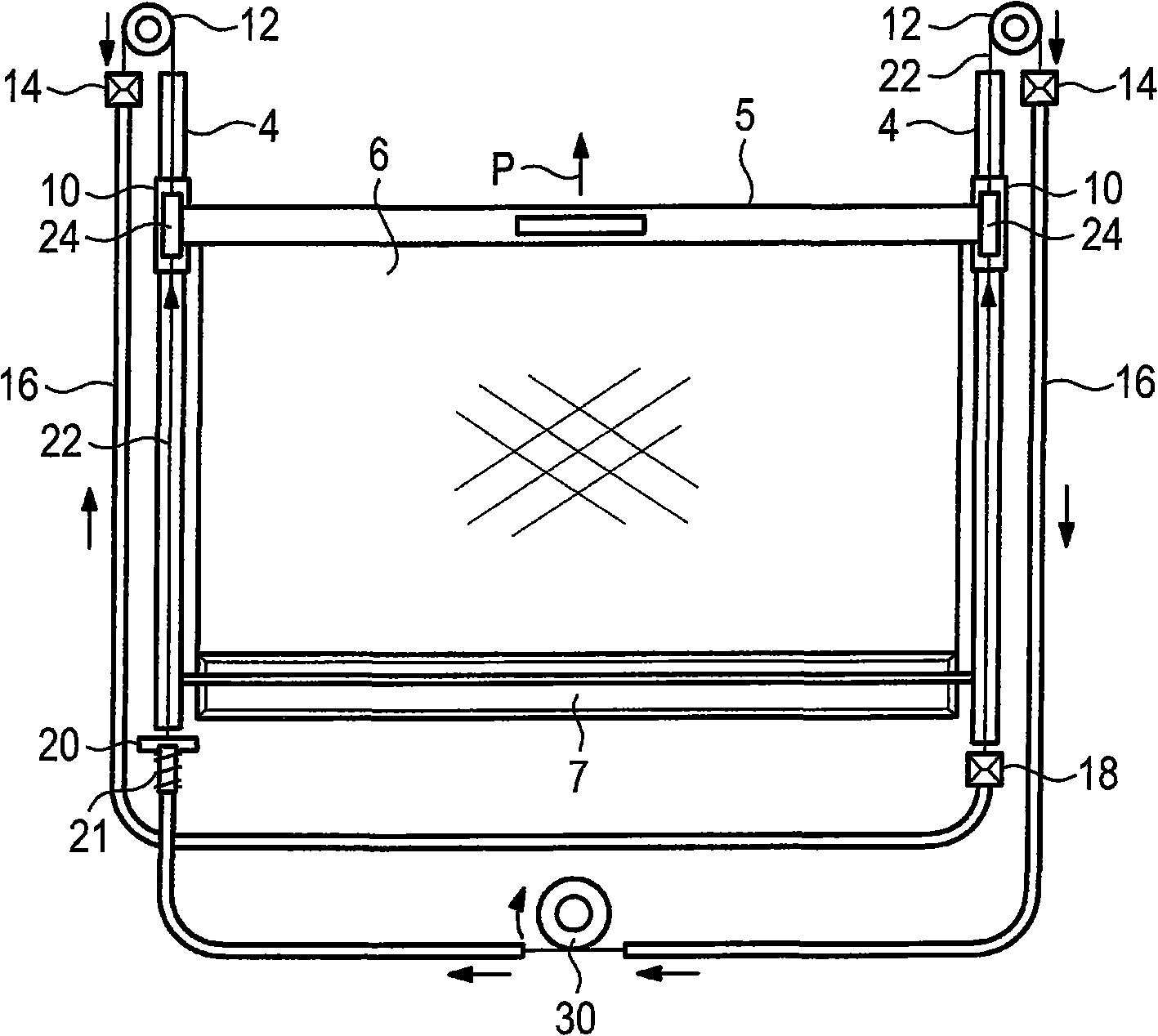

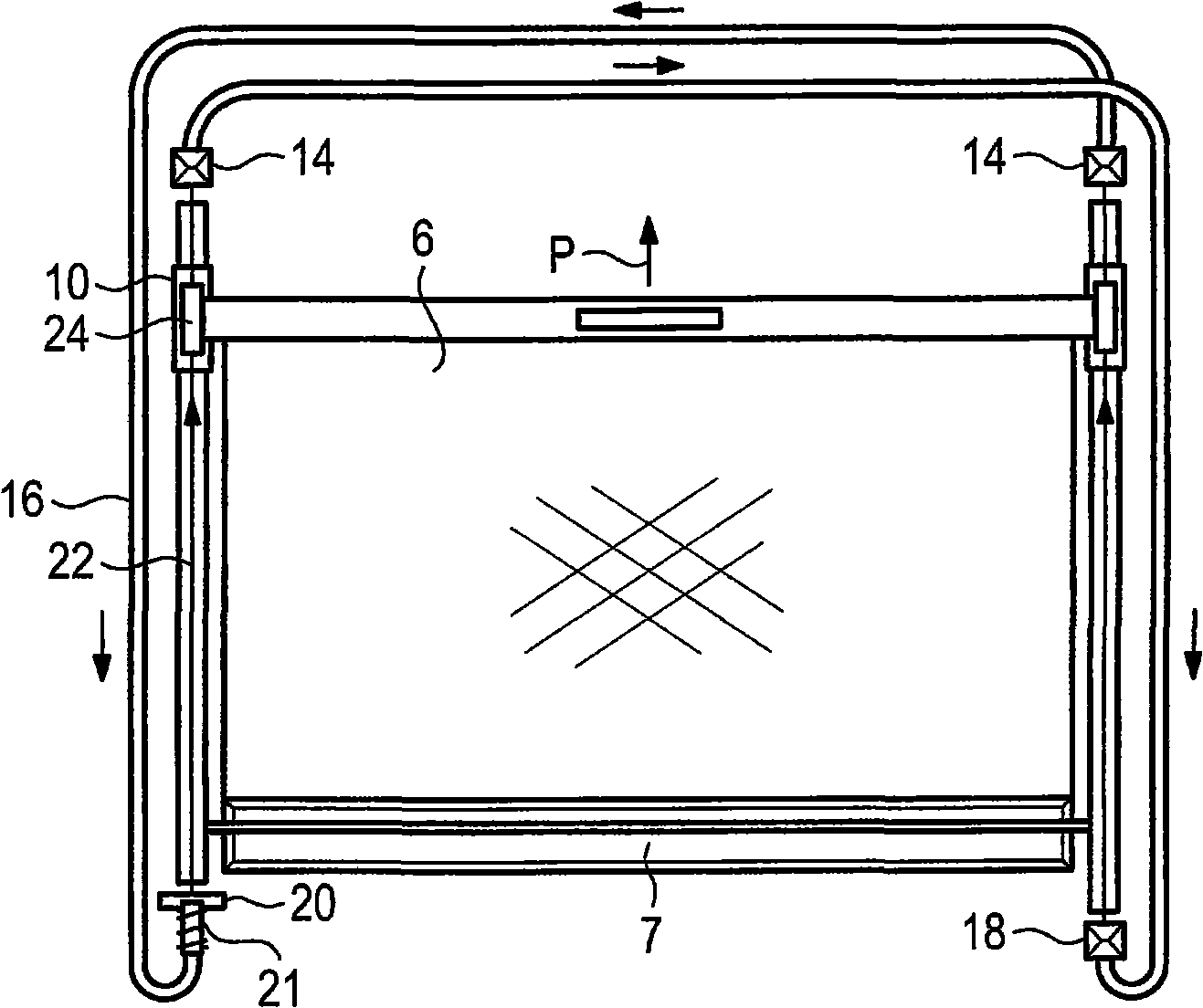

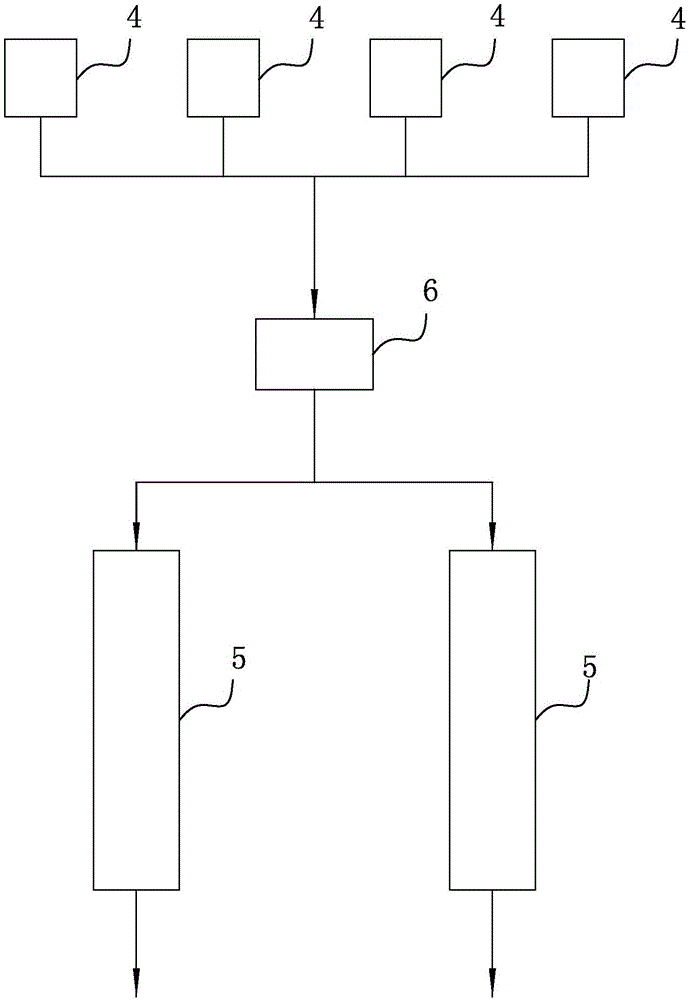

Subassembly for sliding roof

A subassembly for a sliding roof includes right and left guiderails, which lie opposite each other. A component extends between the left and right guiderails and is guided therein. A cable includes a first section that extends between a right front side of the component and a left rear side of the component. The cable also includes a second section that extends between a left front side and a right rear side. Some sections of the cable are guided in a Bowden cable sheath.

Owner:ROOF SYST GERMANY

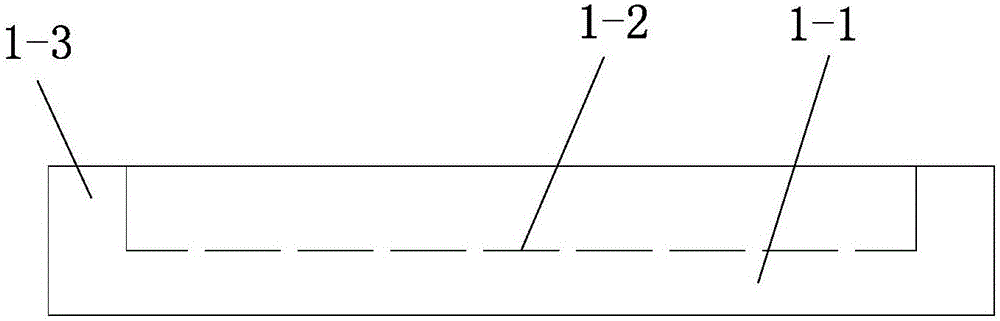

High-temperature kiln product sorting and tracing method and system based on two-dimensional code nameplates

PendingCN106682708AScan accuratelyAvoid defacementCo-operative working arrangementsSortingIdentification deviceAssembly line

The invention relates to a high-temperature kiln product sorting and tracing method and system based on two-dimensional code nameplates. By the provided method and system, high-temperature kiln products can be automatically sorted and traced. According to the technical scheme, the high-temperature kiln product sorting and tracing method based on the two-dimensional code nameplates comprises the following steps: (1) associating products with the two-dimensional nameplates; (2) placing the two-dimensional nameplates on the products, and enabling the two-dimensional nameplates and the products to move forwards along an assembly line; (3) arranging two-dimensional recognizing devices on a sorting opening of the assembly line, sorting the products, and feeding the products into a high-temperature kiln for firing; and (4) finding out the associated products, and tracing the products in batches. The sorting and tracing system comprises a computer, the two-dimensional nameplates, at least one first two-dimensional code recognizing device and a plurality of second two-dimensional code recognizing device. Each two-dimensional code nameplate for sorting and tracing of products of the high-temperature kiln comprises a substrate, a code tagging region is arranged in the middle of a top surface of each substrate, and a two-dimensional code is arranged in each code tagging region.

Owner:浙江恩大施福软件科技有限公司

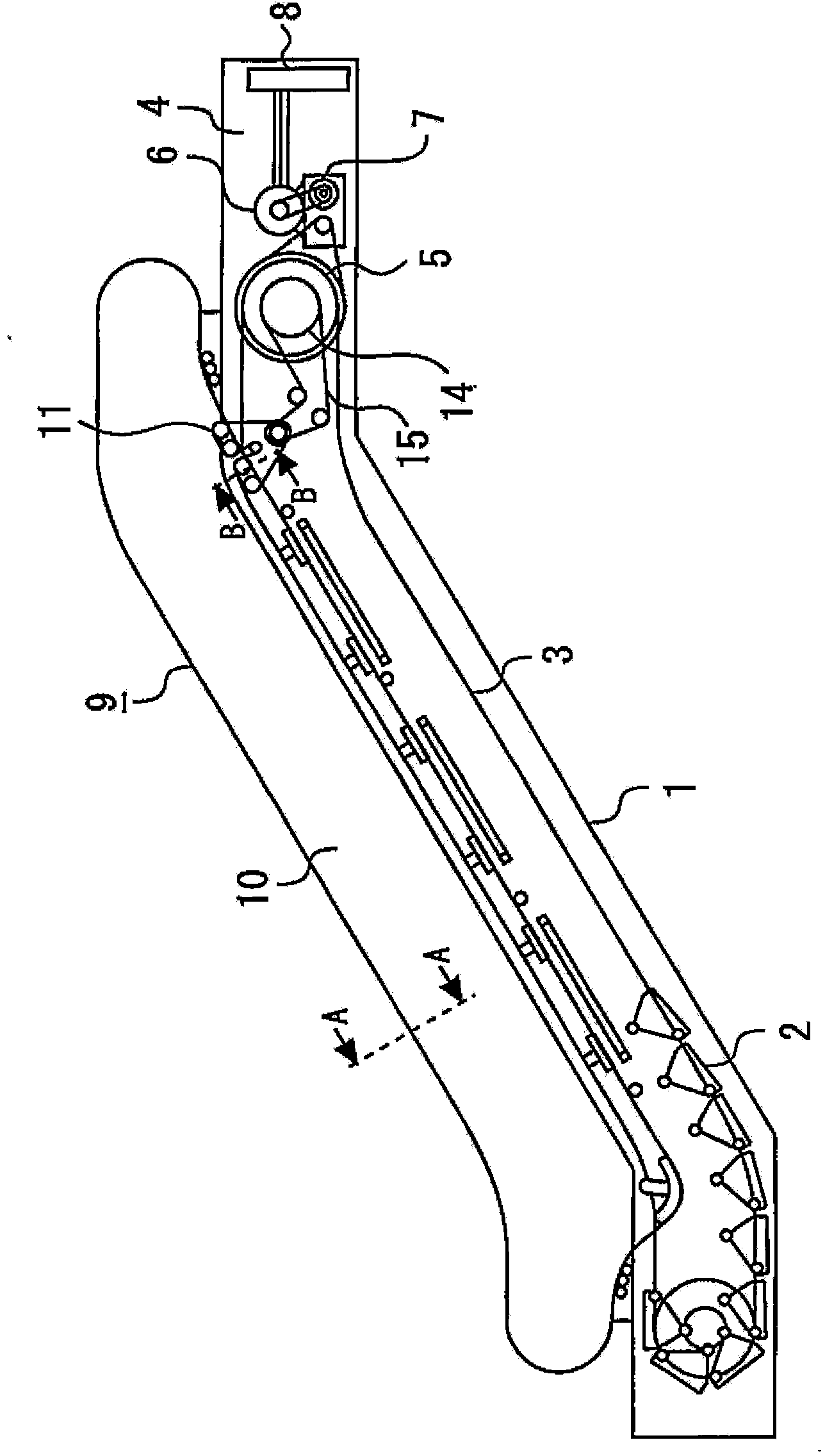

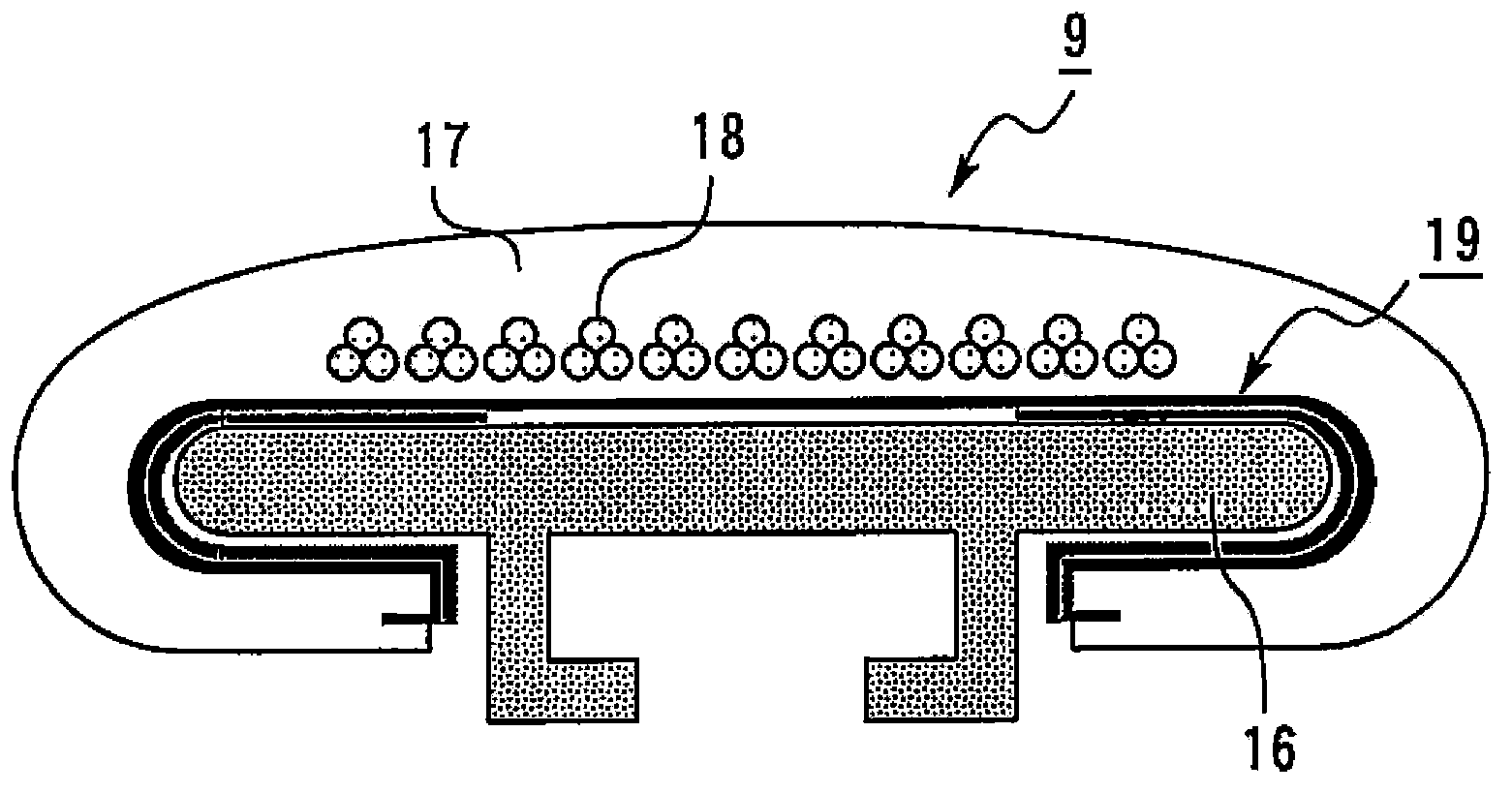

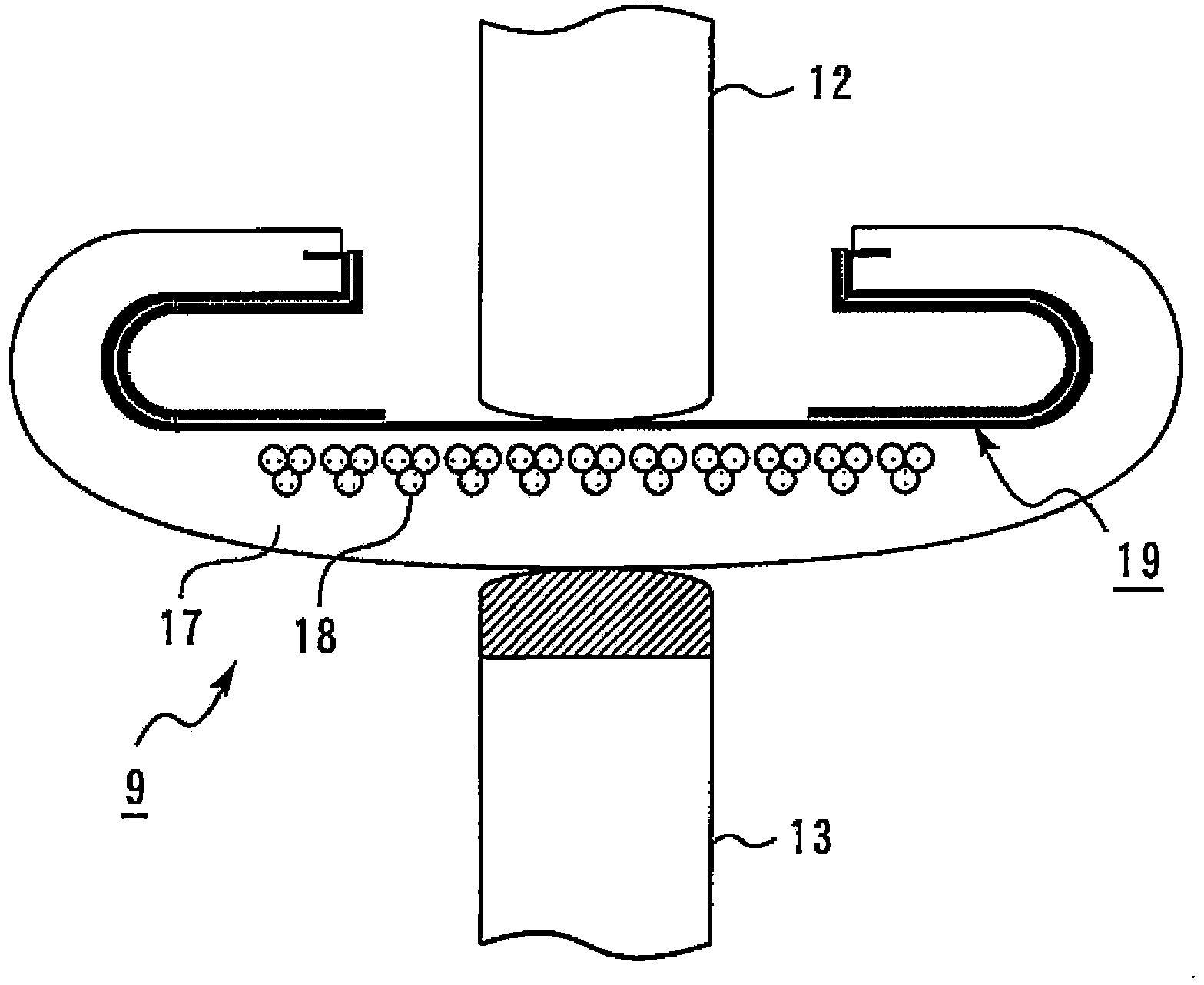

Movable armrest of passenger conveyer and armrest for passenger conveyer

The invention provides a movable armrest of a passenger conveyer and an armrest for a passenger conveyer capable of reducing driving resistance greatly and preventing pollution of the peripheral fibers. The movable armrest (9) is provided with a main body resin part (17), a piece of base cloth (20), and a piece of sliding cloth (21). The main body resin part (17) is provided with a C-shaped cross section, and is in an annular shape. The base cloth (20) is disposed on the inner side surface of the main body resin part (17) along a long edge of the main body resin part (17). The sliding cloth (21) is disposed on the base cloth (20) by overlapping a part of the surface of the base cloth (20). In addition, the sliding cloth (21) is formed by being braided, and exposed parts (24a) of vertical lines (24) are not adjacent to each other. The predetermined fibers is used as the vertical lines (24), because the fibers are provided with the friction characteristics lower than the friction characteristics of the fibers of the base cloth (20), and the wear is easy to occur.

Owner:MITSUBISHI ELECTRIC BUILDING SOLUTIONS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com