Patents

Literature

109results about How to "No peeling phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

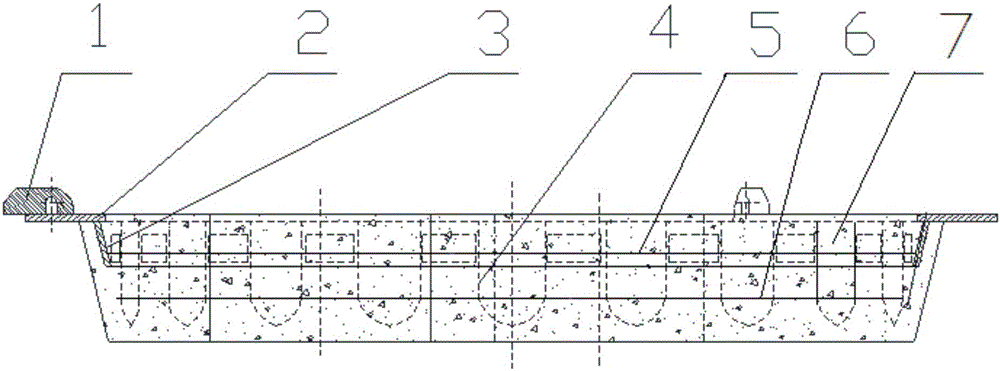

Prefabricated ECC-RC combination beam column joint component

InactiveCN103774754AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

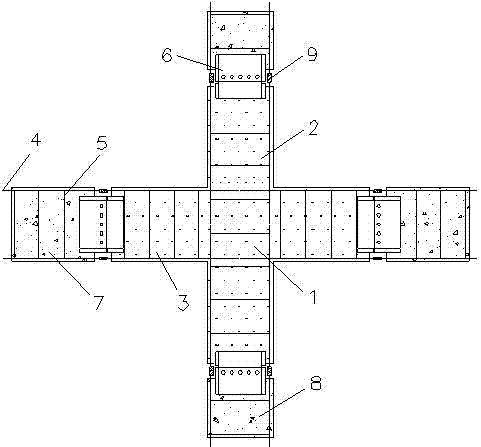

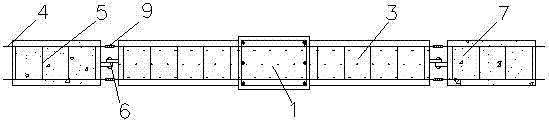

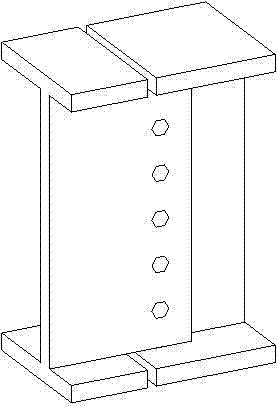

The invention provides a prefabricated ECC-RC combination beam column joint component, wherein ECC refers to engineered cementitious composites, and RC refers to reinforced concrete. The prefabricated ECC-RC combination beam column joint component comprises a joint, an outward-extending column and an outward-extending beam, wherein the joint, the outward-extending beam and the outward-extending column are respectively composed of an ECC material, longitudinal bars and stirrups, the outward-extending length of the outward-extending column is about 1-2 times of the height of the column section, the outward-extending length of the outward-extending beam is about 1-2 times of the height of the beam section, H-shaped steel is embedded in the end of the outward-extending beam and the end of the outward-extending column, the embedded depth ranges from 10 cm to 20 cm, the H-shaped steel and the longitudinal bars extend out of the ends for 10-20 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of a prefabricated RC beam, the embedded H-shaped steel of a prefabricated RC column and the embedded H-shaped steel of the prefabricated ECC joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prefabricated ECC-RC combination beam column joint component, the prefabricated beam column joint component formed by pouring the steel bar reinforced ECC material is applied to an assembly type frame structure, compared with a general reinforced concrete joint component, the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; besides, the high tenacity of the ECC material can reduce residual deformation of the structure after an earthquake, and therefore post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

Nano titanic oxide impregnation preparation method using shell powder as carrier

InactiveCN101352674ASolve associativitySolve for uniformityCatalyst carriersCatalyst activation/preparationFiberTitanium oxide

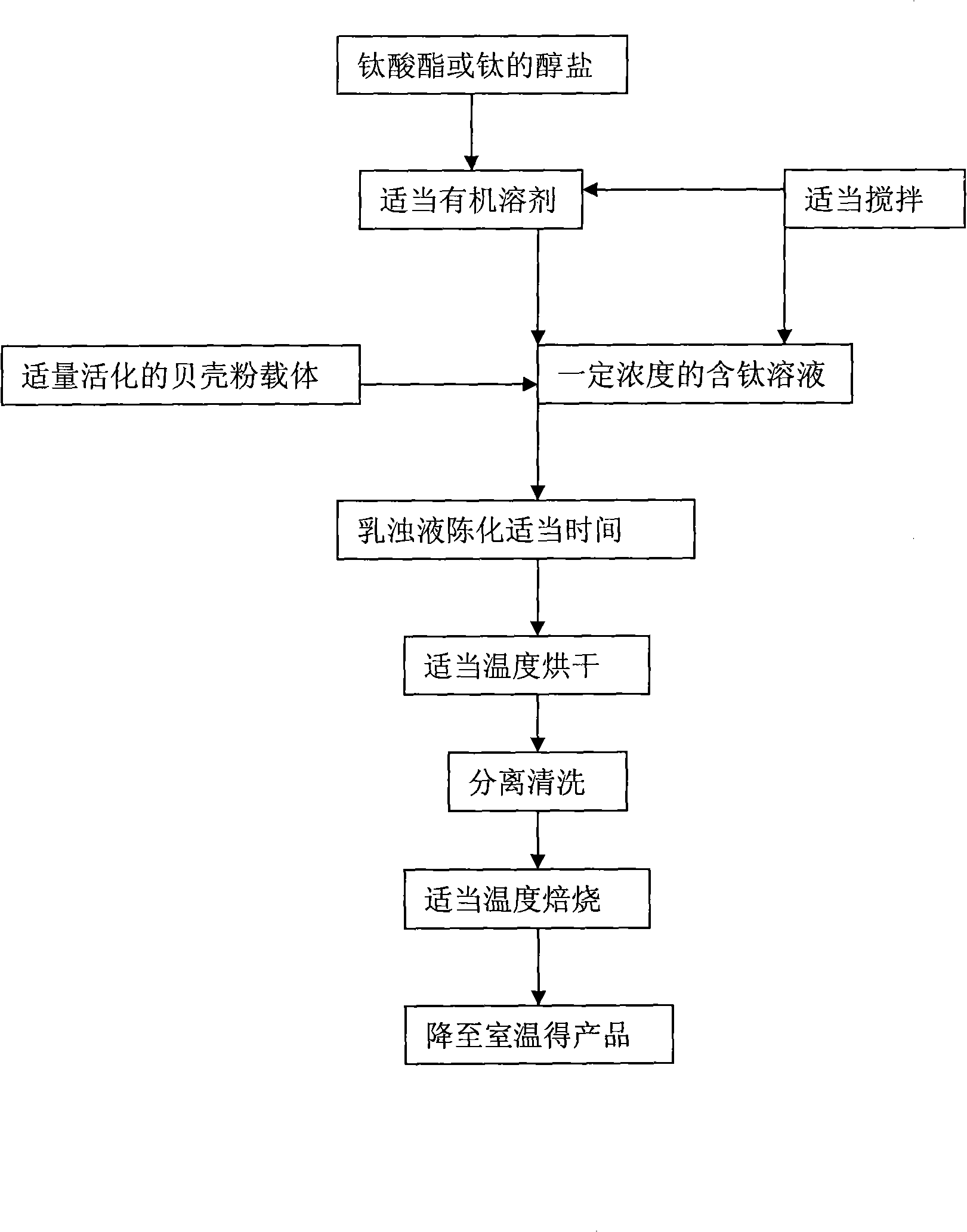

The invention discloses an impregnation preparation method of nanometer titanium oxide which takes shell powder as a carrier, and in particular relates to a reproducible porous nanometer titanium oxide powder which takes the shell powder as the carrier and the preparation method thereof. In the method, titanium oxide is loaded on a shell powder carrier by impregnation; firstly, alkoxide solution of titanium ester or titanium with appropriate concentration is prepared, then an activated shell powder carrier with certain proportion is impregnated in the alkoxide solution, then the obtained solution is stirred and stayed for a certain time, and treated by low temperature and abstersion pretreatment and finally roasted at high temperature, so the nanometer TiO2 forms high-strength bond with the shell powder and promotes the catalytic activity of the nanometer TiO2 at the same time. Impregnation can be conducted for a plurality of times to increase load. The nanometer TiO2 is characterized by small particle size, good compatibility with materials, high catalytic efficiency, good stability, good regenerability, and the like, and can be applied to the fields of plastics, rubbers, fibers, coatings, home electronic appliances, paints, ceramics, water and environmental manipulation, pharmaceutical and hygienic articles, etc. In terms of sources of raw materials and production technology, the preparation method not only reduces the production cost of the nanometer TiO2 catalyst but also is helpful for disposal of the increasingly serious environmental problems, thus bearing great environmental protection significance.

Owner:GUANGDONG OCEAN UNIVERSITY

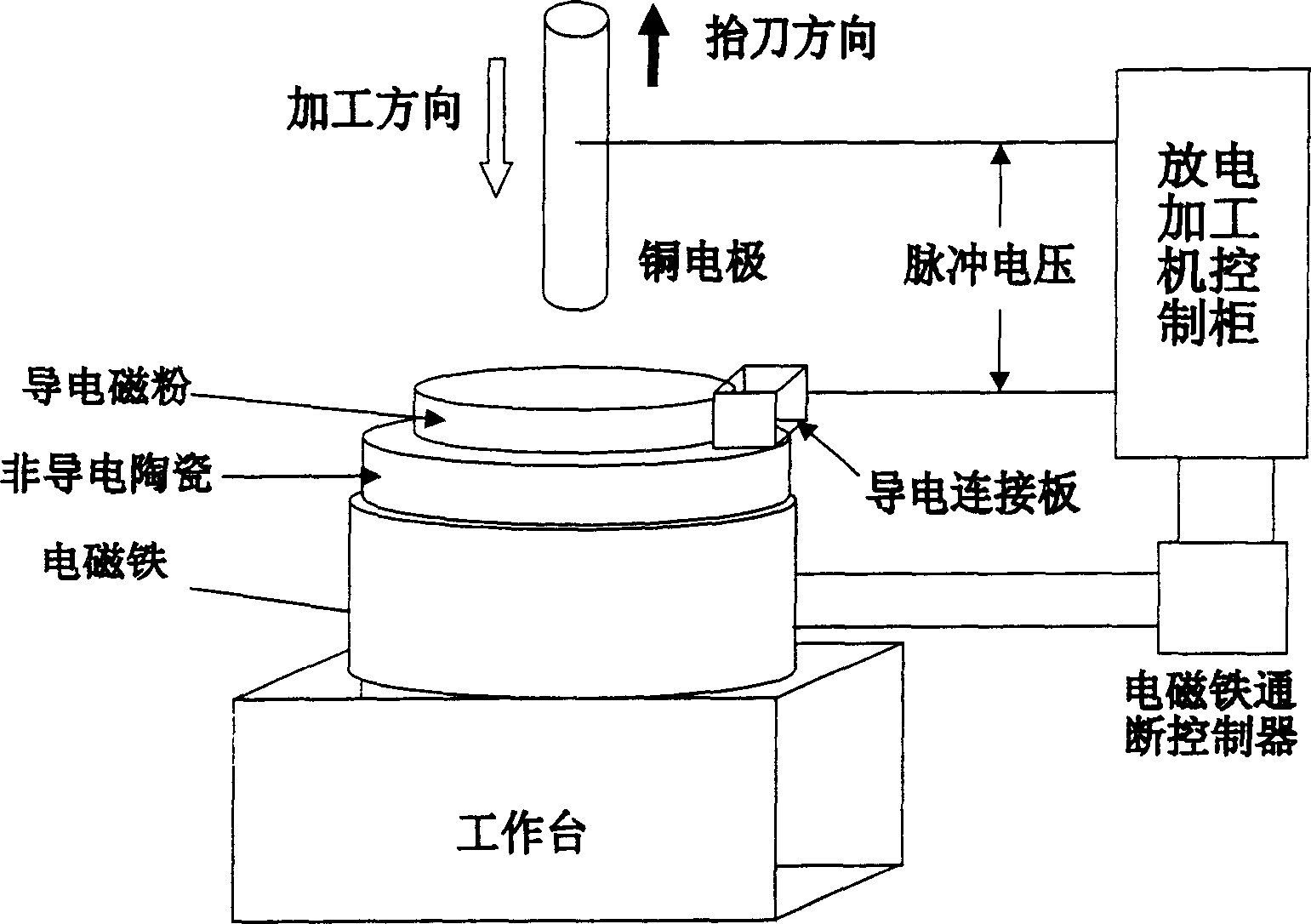

Electrodischarge machining method for working non-conductive ceramic utilizing conductive magnetic powder

InactiveCN1775441AEasy to operateExcellent machinabilityElectrical-based auxillary apparatusCeramicSurface spreading

The electro-discharge machine method for preparing nonconducting ceramics by utilizing conductive magnetic powder includes the following steps: (1) placing electromagnetic iron device on working table of electro-discharge machining machine, form of electromagnetic iron is identical to that of workpiece; (2) on the electromagnetic iron mounting and holding nonconducting ceramics; (3) on said ceramics surface spreading conductive magnetic powder; (4) using conductive magnetic powder as one end of electrode and making it and metal electrode be formed into electrode pair; (5) switching on the power supply of electromagnetic iron, the conductive magnetic powder can be adsorbed on the ceramics surface; (6) setting main electro-discharge machining parameter; and (7) making electro-discharge machining process.

Owner:SHANGHAI JIAO TONG UNIV

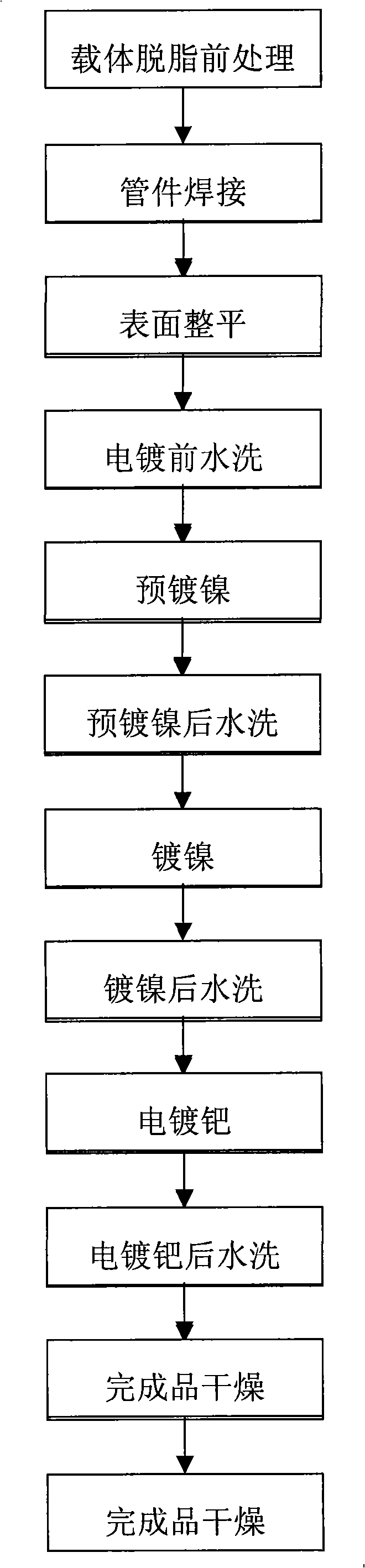

Pd-containing plating solution and uses thereof

The invention relates to palladium-bearing plating solution and a method for providing a palladium film or a palladium alloy film on a porous metal carrier. The method utilizes the electroplating method to prepare the palladium film or the palladium alloy film which uses porous metals as carrier, and can shorten the process time and simplify preparation procedures; simultaneously, the palladium film or the palladium alloy film prepared by the method has excellent compactness, good hydrogen brittleness resistance and high applicability.

Owner:GREEN HYDROTEC

Method for manufacturing spectacle frame made of two materials and spectacle frame made by same

InactiveCN101762885ASimple processingLow costDecorative surface effectsNon-optical partsChemistryPolyamide

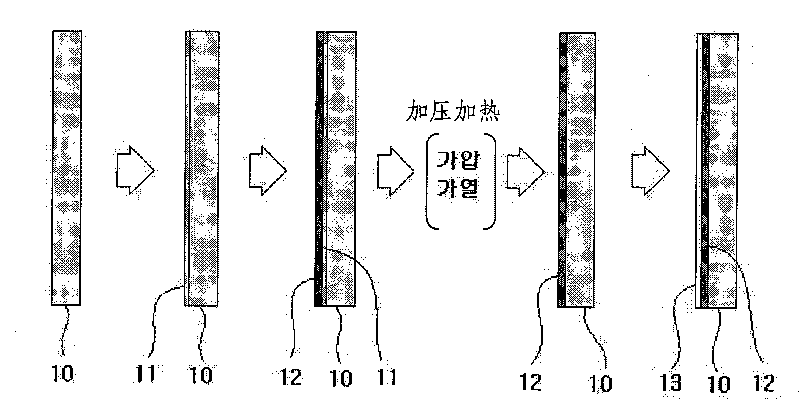

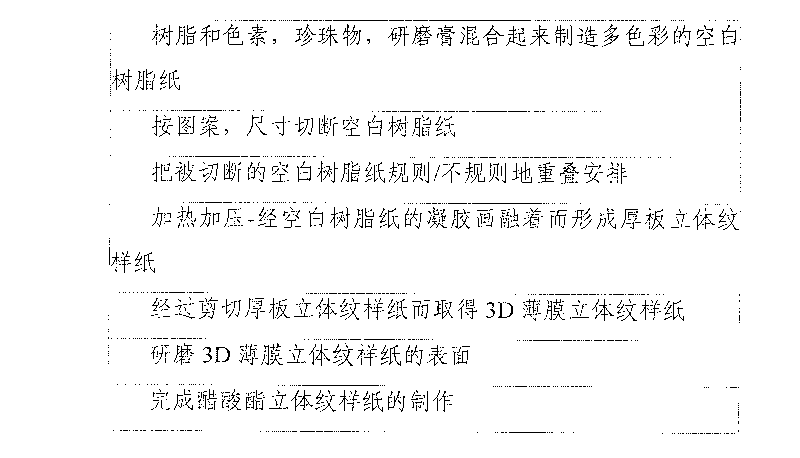

The invention discloses a method for manufacturing a spectacle frame made of two materials and the spectacle frame made by the same. The method comprises the following steps of: mixing resin, pigment, pearl material and grinding paste to manufacture three-dimensional pattern acetate paper with mother-of-pearl inlay patterns; cutting the three-dimensional pattern acetate paper according to a preset pattern; dipping the cut three-dimensional pattern acetate paper into a softening agent for softening processing; utilizing a resin-free adhesive to adhere the softened three-dimensional pattern acetate paper to a preset position of a polyamide spectacle frame substrate; then, tightly connecting and fixing the two materials by a heating and pressuring process while recovering the pattern of the three-dimensional pattern acetate paper; drying the spectacle frame made by the three-dimensional pattern acetate paper and the two materials adhered to the polyamide spectacle frame substrate; cleaning the spectacle frame by a drum; grinding the surface of the spectacle frame; and coating the ground surface of the spectacle frame.

Owner:WENZHOU DONGTIAN IMPORT & EXPORT CO LTD

Whole breast tumor small-interval subserial pathological slice preparation method

ActiveCN109000956AAchieve preliminary cuttingAvoid bending deformationWithdrawing sample devicesPreparing sample for investigationAbnormal tissue growthParaffin wax

The invention discloses a whole breast subserial large slice preparation method. The method comprises the following steps of collecting a tumor sample; performing continuous parallel splitting to obtain sample blocks which are split in parallel; performing soaking and fixing in a neutral formaldehyde solution with the concentration of 4% for 24 hours; removing redundant fat tissues by clipping; performing continuous parallel cutting in parallel to an original slice again to form a slice shape; performing continuous fixing for 48 hours by using the neutral formaldehyde solution with the concentration of 4%; performing sequential dehydration by adopting gradient ethanol; performing transparency treatment by using xylene; performing wax dipping in an electric heating constant temperature incubator at 62-65 DEG C to obtain a paraffin pathological sample; and slicing the paraffin pathological sample by adopting a rotary paraffin slicing machine, wherein each sample block can be subjected toconventional pathological staining including HE through continuous slicing. The thickness of a large slice prepared with the method can reach the conventional slice thickness of 4-5 microns; the slice is complete in tissue structure, smooth, clean and free of folds and pollution; no slice stripping phenomenon occurs; the cell nucleoplasm proportion is clear; and a staining result is consistent with a conventional clinical staining result.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

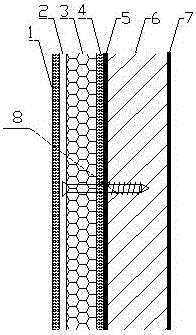

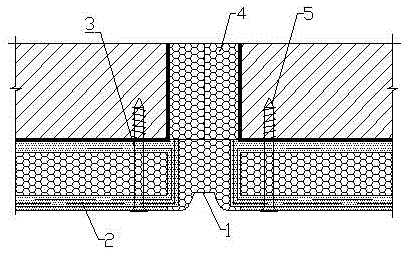

Wind resistance and heat preservation EPS board outer wall structure and construction method thereof

The invention discloses a wind resistance and heat preservation EPS board outer wall structure which comprises a wall body, a galvanized steel wire netting, a bonding layer, an EPS heat preservation plate layer, a gridding cloth, an elastic coating and anchor bolts. The wind resistance and heat preservation EPS board outer wall structure is characterized in that composite mortar is laid on the inner side of a wall body, a plastering layer is arranged on the outer side of the wall body, the galvanized steel wire netting is laid inside the plastering layer, the EPS heat preservation plate layer is stuck to the outer side of the plastering layer, the thickness of an adhesive layer stuck to the surface of the heat preservation plate is controlled to be 4-5 mm, the anchor bolts penetrate through EPS heat preservation plates, the galvanized steel wire netting is fixed to the outer side of the wall body, each EPS heat preservation plate is provided with two anchor bolts and installed on a middle line, the anchor bolts press the bottom layer gridding cloth to form a fire barrier, and the gridding cloth and elastic coating are stuck to the outer sides of the EPS heat preservation plates. The construction method comprises the steps of base layer wall treatment, sticking of the heat preservation plates and the base layer, fixing of the fire barrier, auxiliary fixing of the heat preservation plates, sticking of the gridding cloth and a facing layer, and field testing and inspection.

Owner:克拉玛依市建设工程质量监督站

Wood-plastic composite of wood decorative sheet attaching veneer and preparation method thereof

ActiveCN103831885AUniform and beautiful texturePleasant colorLaminationWood working apparatusSurface layerAdhesive

The invention relates to a wood-plastic composite of wood decorative sheet attaching veneer and a preparation method thereof and aims at solving the problems that an existing wood-plastic composite lacks the natural texture of wood, and it is hard to enable a wood decorative sheet to be adhered to a wood-plastic composite sheet through traditional wood adhesive. The wood-plastic composite is mainly made of a wood-plastic composite sheet, non-woven cloth, a wood decorative sheet and wood adhesive or is made of the wood-plastic composite sheet, the non-woven cloth and the wood decorative sheet. According to the two technical schemes of the wood-plastic composite, the special structure of the non-woven cloth is utilized, wood adhesive is used, and the wood decorative sheet and the wood-plastic composite sheet are finalized in design through a hot-press means, so that preparation is finished. In the other technical scheme, on the condition that no wood adhesive is used, the consistency of the non-woven and the surface of the wood-plastic composite sheet and the penetrating function of the non-woven cloth on surface layer materials at melting time are utilized, and the wood decorative sheet and the wood-plastic composite sheet are finalized in design through hot press and cooling. The wood-plastic composite of the wood decorative sheet attaching veneer and the preparation method are applied in the wood processing field.

Owner:NORTHEAST FORESTRY UNIVERSITY

Process for preparing WC hard alloy coating through laser cladding of hot rolling bar apron board roller way

ActiveCN104250810AYouyi Thermal Abrasion ResistanceImprove heat and wear resistanceMetallic material coating processesCarbide coatingBoron nitride

The invention relates to a process for preparing a WC hard alloy coating through laser cladding of a hot rolling bar apron board roller way, which is characterized in that weight percentage of spherical casting tungsten carbide is 40-60%, a nickel-based alloy is a bonding phase with weight percentage of 60-40%. The process comprises the following steps: preparing and mixing, machining an operational layer and cleaning the surface, removing oil stain by a solvent or a cleaning compound, removing a rust layer by polishing or sandblasting; performing laser cladding treatment, selecting the bonding phase and the spherical casting tungsten carbide powder with appropriate proportion, adjusting powder feeding rate of an automatic powder feeding apparatus for satisfying the powder feeding rate required by the coat layer thickness; and employing diamond or cubic boron nitride for grinding and processing the cemented carbide coating through laser cladding to the required size. On the hot rolling bar apron board roller way with a common stainless steel material, the WC hard alloy coating with thermal wear resistance is formed on a matrix through laser cladding, service life of the hot rolling bar apron board roller way can be increased, and the laser manufacture of the hot rolling bar apron board roller way can be realized.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Preparation method of hollow fiber internal pressure composite film

ActiveCN102489176AGood separation performance and mechanical propertiesAvoid filament ruptureSemi-permeable membranesWater soluble polymersWater soluble

The invention discloses a preparation method of a hollow fiber internal pressure composite film, and aims to provide a preparation method of a hollow fiber internal pressure composite film with high supporting property and high pressure resistance. The preparation method comprises the following steps of: uniformly blending an outer layer film forming material, an outer layer film forming diluent and an outer layer film forming additive in a fusing process to obtain a thermally induced phase separation method outer layer film forming system; dissolving and uniformly mixing an inner layer film forming material, an inner layer film forming solvent and an inner layer film pore forming agent to obtain a non-solvent induced phase separation method inner layer film forming system, wherein the inner layer film pore forming agent contains over 70 percent of water-soluble polymer; and extruding and spinning in a composite way by introducing a core liquid into a central pipe, taking the inner layer film forming system as a middle layer and taking the outer layer film forming system as the outside, quickly soaking into a coagulation bath, fully curing an outer layer and an inner layer under the actions of the coagulation bath and the core liquid, and extracting and washing to obtain the hollow fiber internal pressure composite film. The large-inner-diameter hollow fiber internal pressure composite film prepared with the method disclosed by the invention can be used for replacing a tubular film during application.

Owner:TIANJIN MOTIMO MEMBRANE TECH

Preparation method of aluminum conductive paste of high-performance environment protection solar cell

InactiveCN101752459AImprove photoelectric conversion rateReduce stressFinal product manufactureNon-conductive material with dispersed conductive materialSilicon chipLinear expansion coefficient

The invention discloses a preparation method of aluminum conductive paste of a high-performance environment protection solar cell. The aluminum conductive paste produced by the method is free of lead and solves the problem of environment pollution. The linear expansion coefficient of lead-free glass powder obtained in the preparation process is close to that of a silicon chip, and the success rate after burning is improved. The preparation method of the paste comprises the following steps: (1) preparing glass powder; (2) preparing inorganic adhesive glass metal powder; (3) manufacturing organic carriers; (4) adopting carbon powder of 2-5 mu m for later use; and (5) preparing the aluminum conductive paste: taking the following components by mass percent: 75-85% of aluminum powder coated by aluminum nitride, 9-20% of organic carrier, 3-4% of inorganic adhesive glass metal powder and 1-3% of C powder, wherein the total amount is 100%, and after mixing, grinding with a three-roller mill to particle size of 15-30 mu m to obtain the product with the viscosity of 25000-35000 mpa.s.

Owner:广东鑫皇冠新材料有限公司

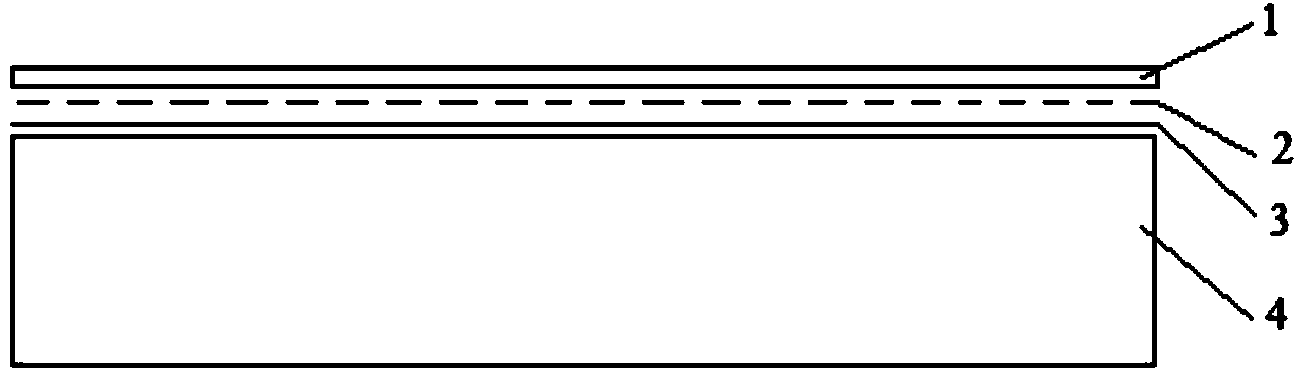

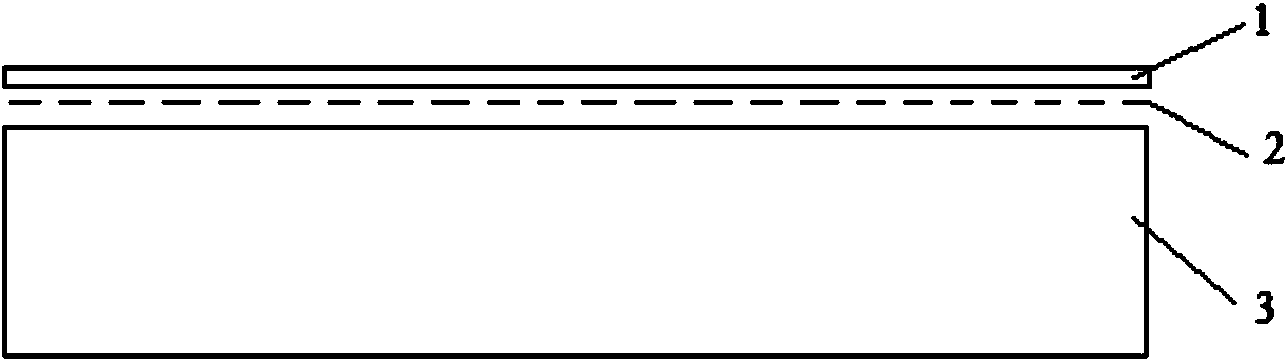

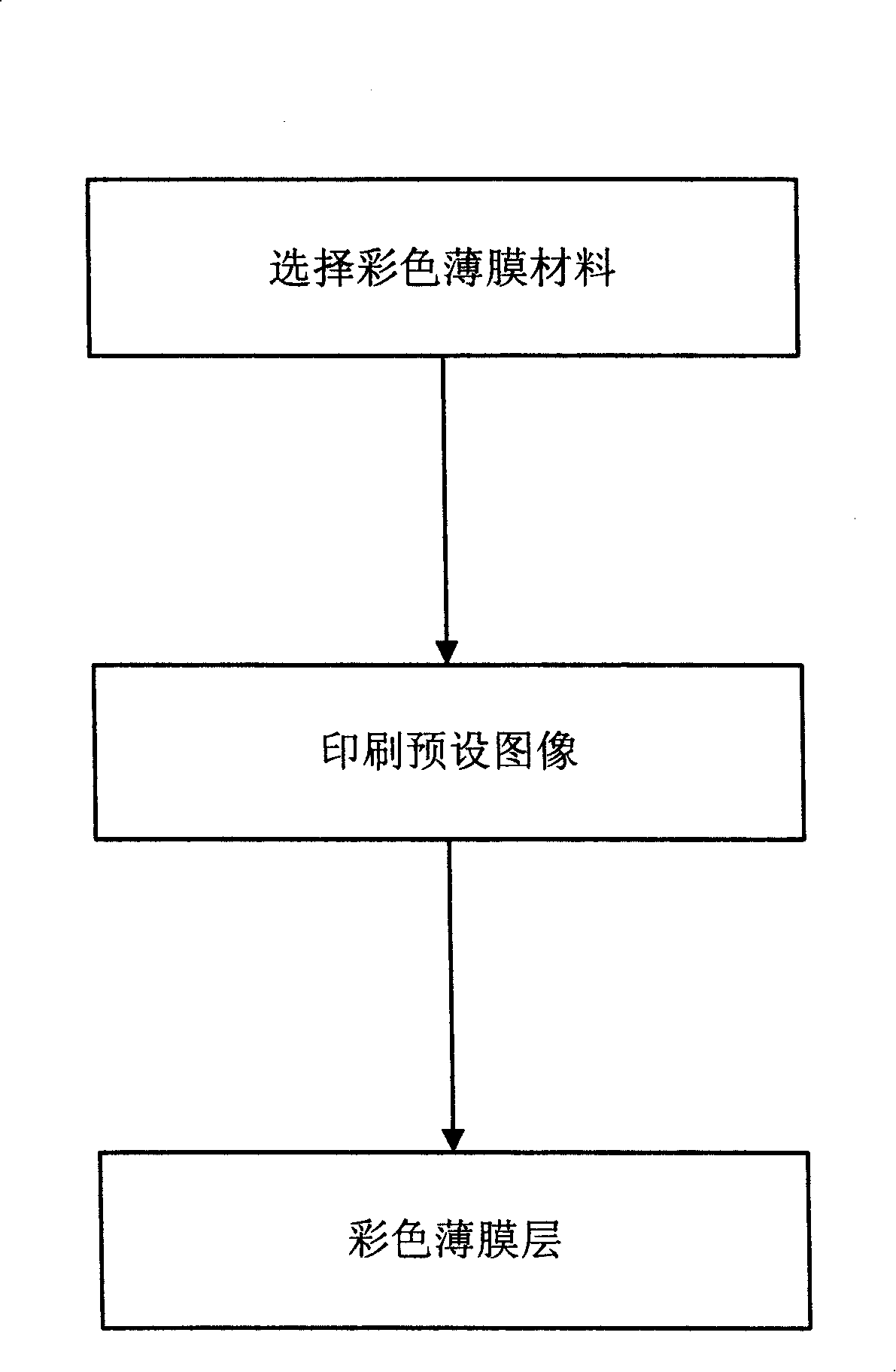

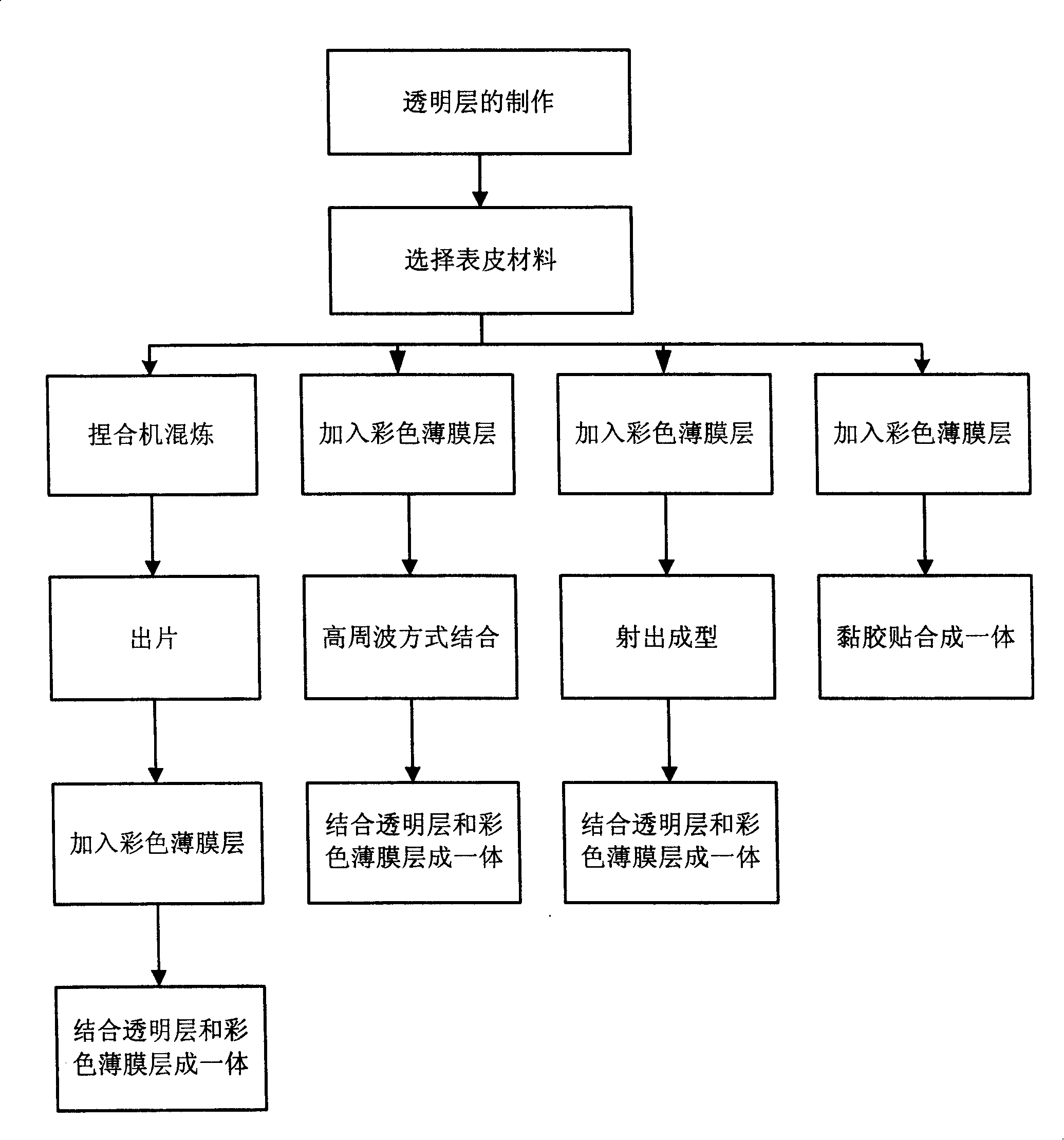

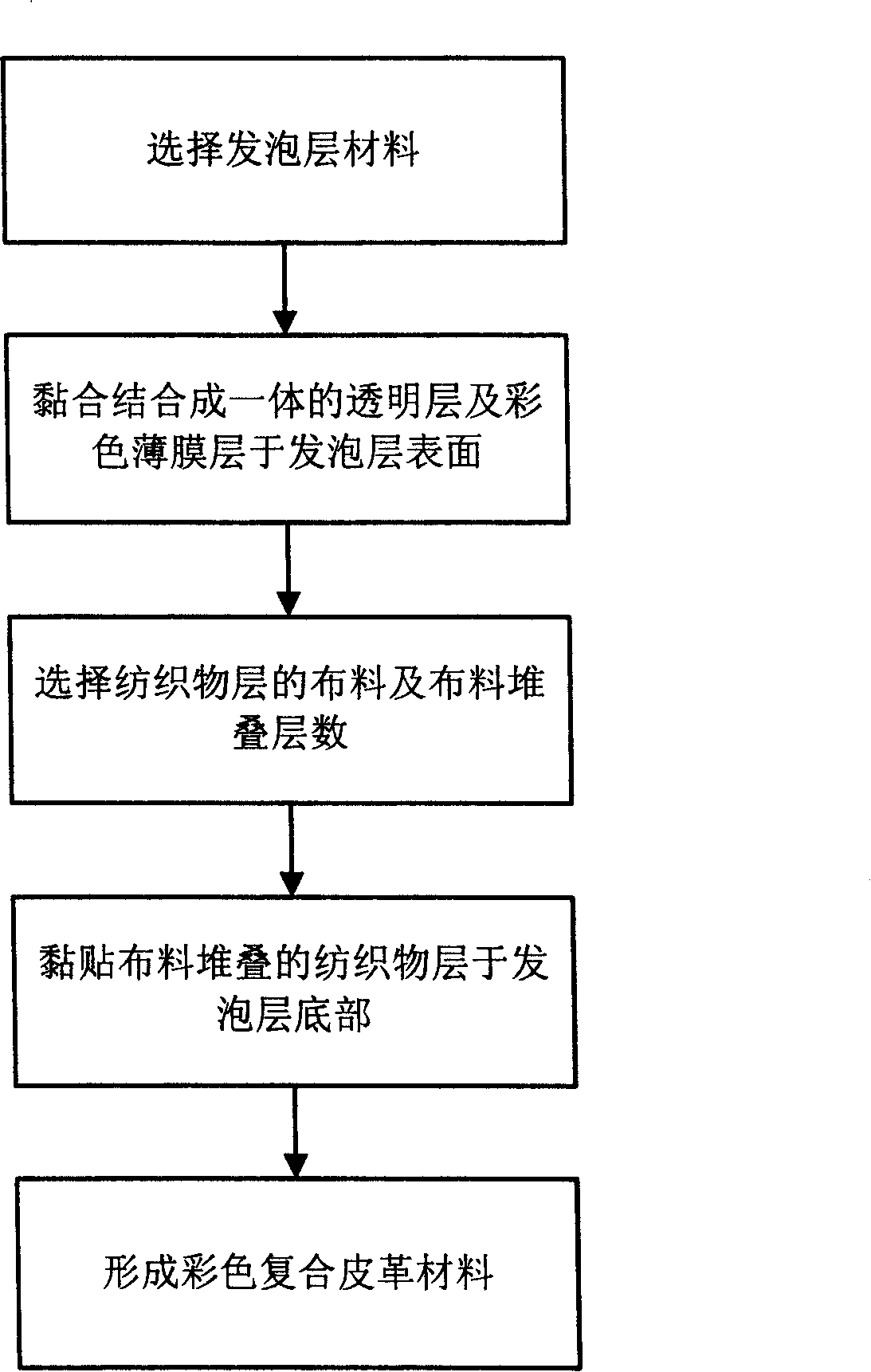

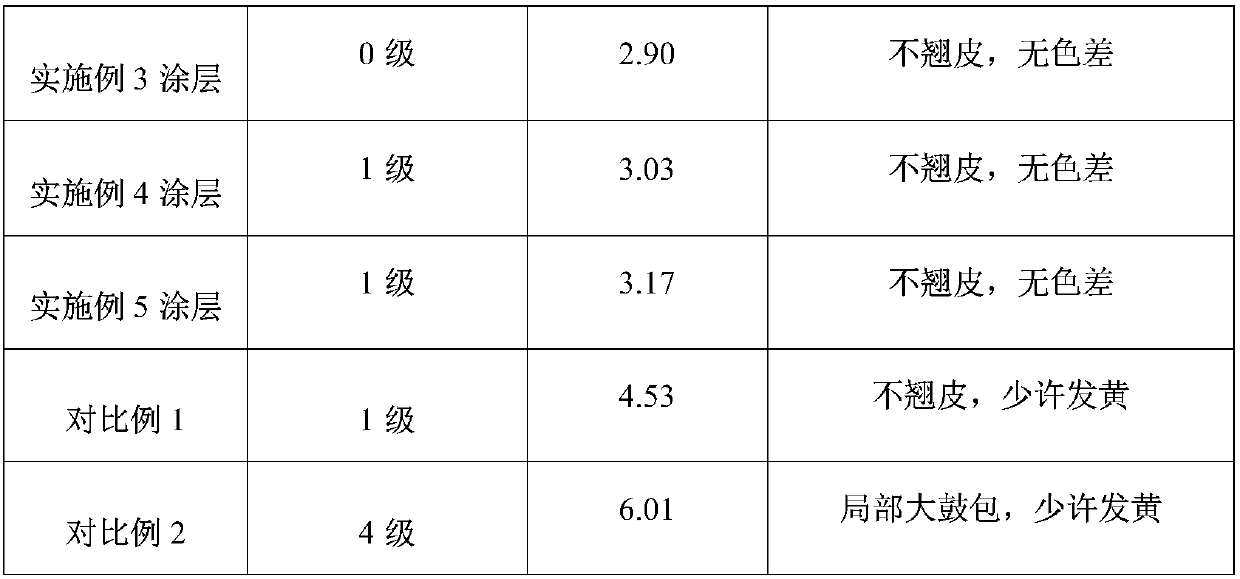

Method for preparing colourful complex leather material

InactiveCN101161452ANo peeling phenomenonExcellent physical adhesionSynthetic resin layered productsClear LayerThin layer

The invention discloses a manufacturing method of color composite leather substance, comprising a clear layer, a color thin layer, a foaming layer and a textiles layer. The clear layer and the color thin layer by clear layer material use manner of ejection forming, high frequency alloying and compressed binding or glue jointing by a compresser or a feeding piece machine, combining with clear layer and color thin layer to form in one body, and applying to the surface of foaming layer, sited on the foaming layer to join with the textiles layer, in order to form composite leather substance.

Owner:郑添来

Preparation process and application of green environment-friendly paper

ActiveCN107012740APromote absorptionSo as not to damageSpecial paperBook keepingGreen environmentWastewater

The invention discloses a preparation process and application of green environment-friendly paper, belonging to the field of environment-friendly papermaking technology. According to the invention, a Chinese ink coloring apparatus is employed for uniformly coating the surface of a semi-dried paper web with a color coating in a full-web Chinese ink coloring manner; since the paper web has moisture, the paper web well absorbs Chinese ink during coloring, and a uniform color coating can be formed; thus, green environment-friendly myopia-preventing homework books, exercise books and examination paper of students prepared from produced paper through printing protect the eyesight of students from damage in use of the books and examination paper. A paper machine is employed for drying, compacting and synchronous dye fixation, so the coating on the surface of the paper is fully fused with the paper and is free of peeling. The whole process flow is integrated with a papermaking procedure, the semi-dried paper web is directly subjected to full-web Chinese ink coloring and then to further drying, and the papermaking procedure is integrated with the drying part of a coloring procedure, so drying time is reduced, energy needed in drying is saved, and high efficiency and energy conservation are realized. Produced wastewater is simple in composition and easy to treat.

Owner:四川北彩印务有限公司

Photovoltaic backing plate refinishing paint as well as refinishing method and applications thereof

The invention discloses a photovoltaic backing plate refinishing paint as well as a refinishing method and applications thereof. The refinishing paint comprises the following raw materials in parts byweight: 40-60 parts of fluorine resin, 10-25 parts of silicone prepolymer, 1-19 parts of epoxy resin, 15-31 parts of inorganic filler, 1-13 parts of auxiliaries, 5-30 parts of diluent, and 5-34 partsof isocyanate curing agent; the refinishing method of a photovoltaic backing plate coating comprises the following steps: (1) cleanly treating the flaws of a photovoltaic backing plate; and (2) filling the prepared photovoltaic backing plate refinishing paint into the flaws, and drying; the applications comprise that the photovoltaic backing plate refinishing paint is applied in refinishing of coatings of coated type, compound type, co-extrusion type and PET type photovoltaic backing plates; and the photovoltaic backing plate refinishing paint not only can meet the strong hydrophobicity situation, but also has the advantages of being low in stress, yellowing-resistant, good in glossiness and strong in adhesivity.

Owner:SUZHOU FIRST PV MATERIAL CO LTD

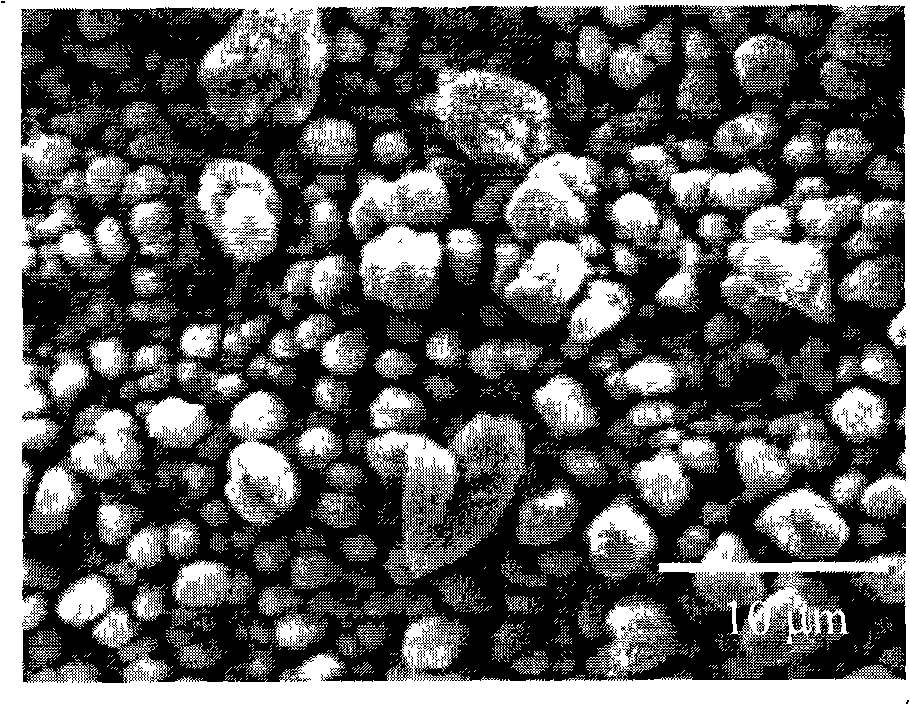

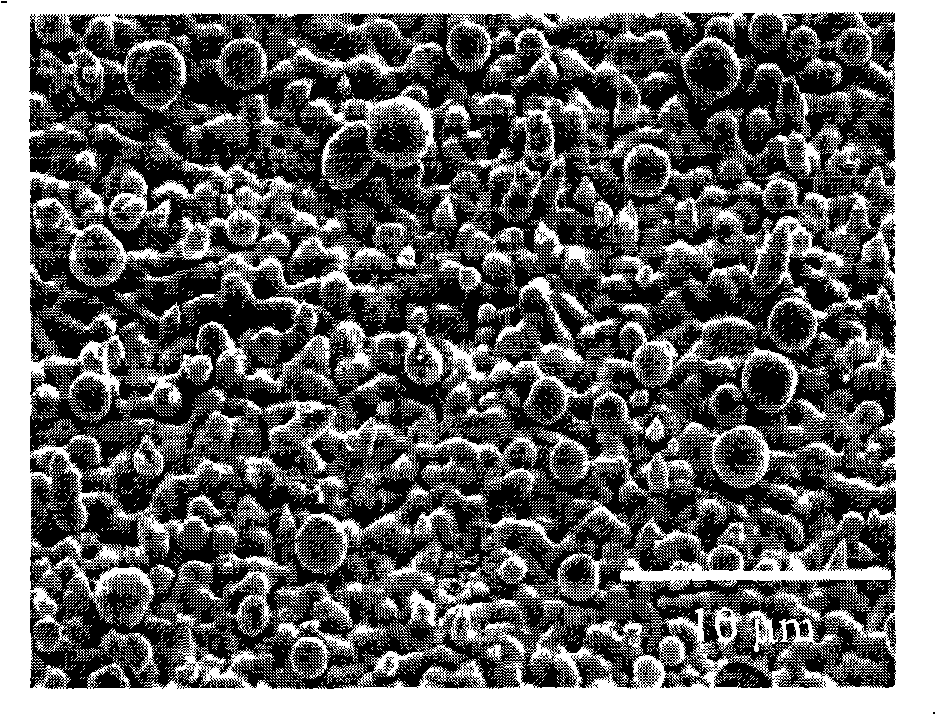

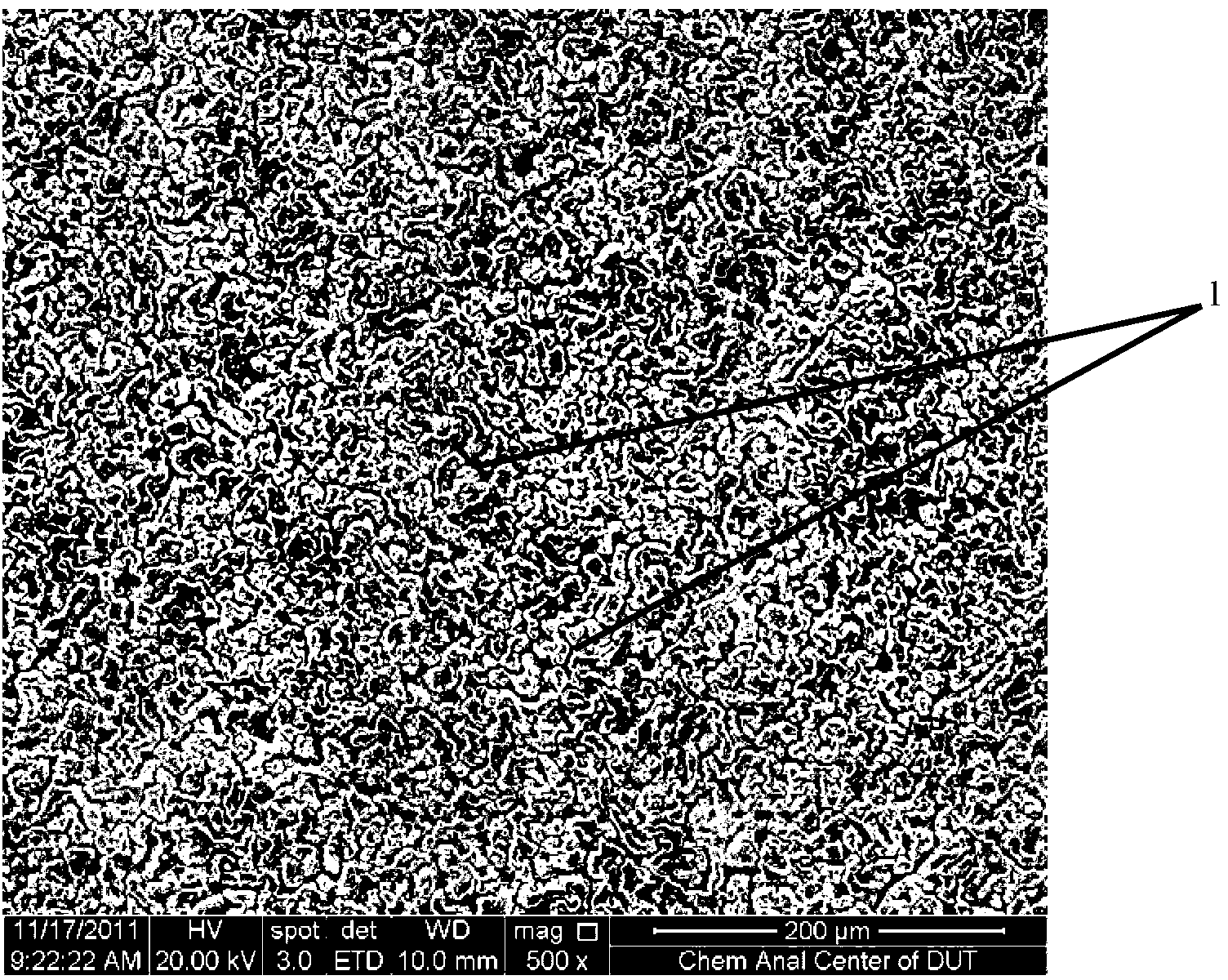

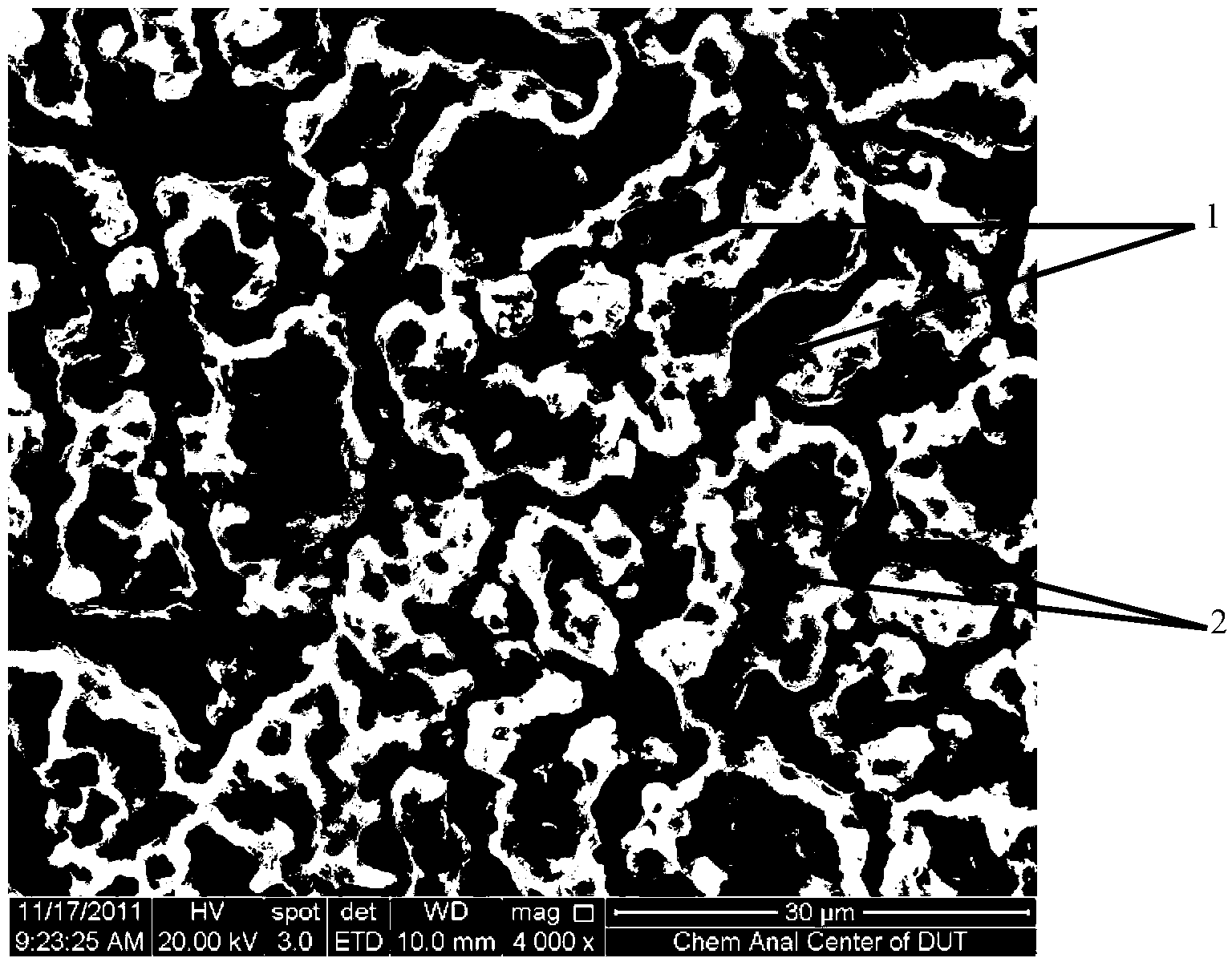

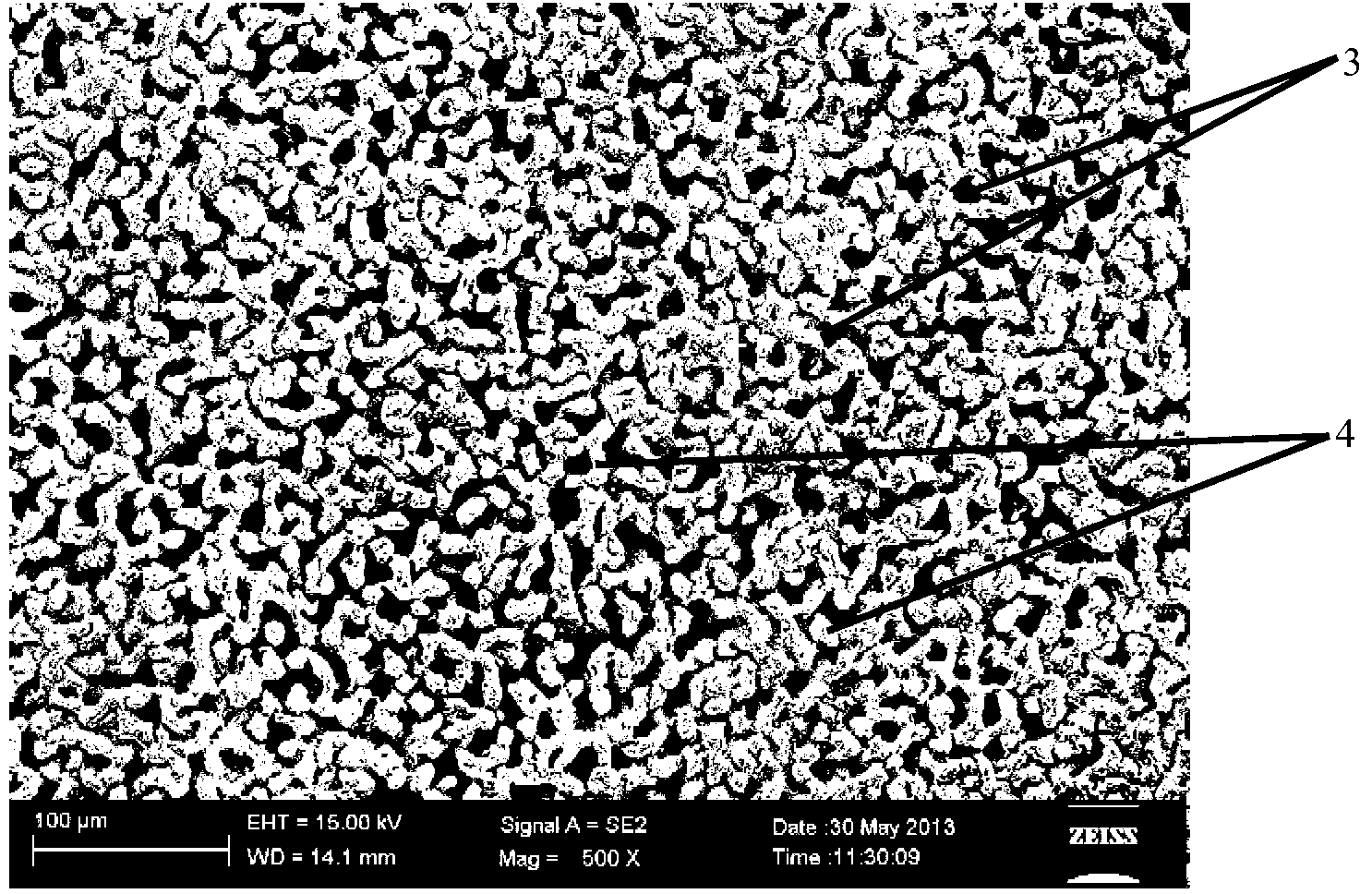

Titanium micro/nanometer double-structured dioxide thin film with high biological activity and preparation method thereof

InactiveCN103290455ASimple preparation processEase of mass production and industrializationSurface reaction electrolytic coatingMicro arc oxidationTitanium metal

The invention relates to a titanium micro / nanometer double-structured dioxide thin film with high biological activity and a preparation method thereof, and belongs to the field of biomedical materials and surface engineering. The preparation method of the thin film comprises steps of: micro-arc oxidizing a cleaned titanium metal surface, and utilizing a lithium tetraborate aqueous solution as an electrolyte and a bipolar pulse micro-arc oxidation power supply as a power supply, wherein the working voltage is 360-500V, the current density is 1-4A / dm<2>, the impulse frequency is 400-700Hz, the duty ratio is 10%-30%, and the oxidation time is 1-30 minutes. The obtained thin film has a structure that homodisperse micron-order grooves and nanometer-order holes are distributed on the surface of the whole thin film in an overlapping manner. The micro / nanometer double-structured dioxide thin film has a special performance, i.e. the film has superstrong wetting ability, and the contact angles of the water and oil are zero. The film has an important meaning on a new generation of a dental implant which can bear large occlusal force and has a short healing phase. The preparation method is simple, the electrolyte is pollution-free, and the film is easy for large-scale production and industrial popularization.

Owner:DALIAN UNIV OF TECH

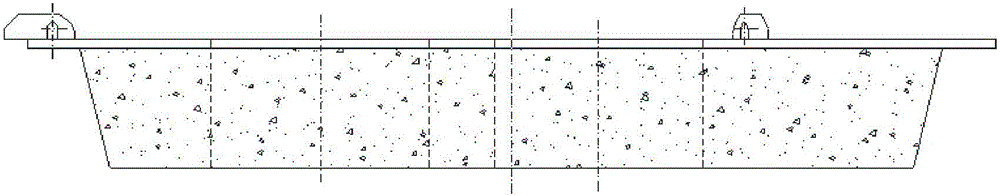

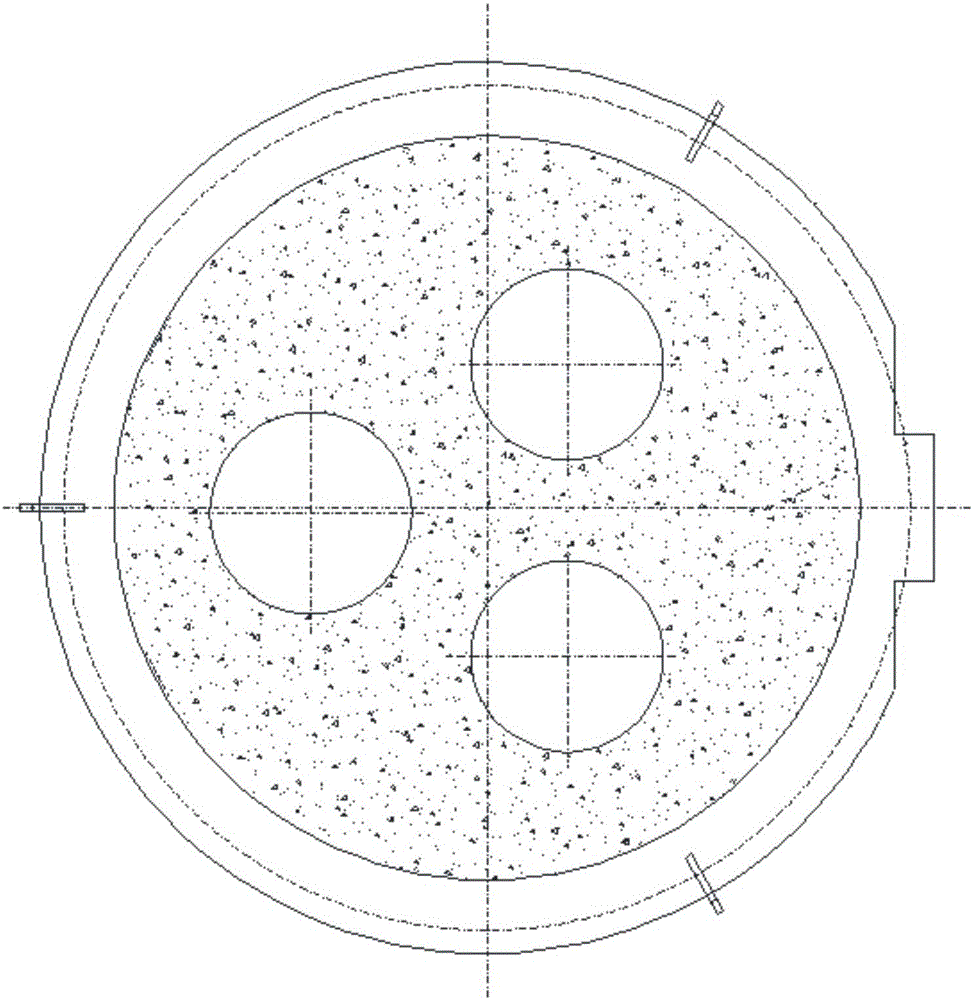

Electric arc furnace cover casting material, electric arc furnace cover and production method of electric arc furnace cover

ActiveCN106007738AEasy to useHigh corrosion resistanceFurnace componentsGraphite electrodeElectric arc furnace

The invention discloses an electric arc furnace cover casting material, an electric arc furnace cover and a production method of the electric arc furnace cover. A steel structure of the electric arc furnace cover also comprises a reinforcing member; the reinforcing member includes U-shaped supporting rods and a first connecting rib; a through hole is formed in an apron board; the first connecting rib penetrates through the through hole and is fixed; the inner side of the apron board is provided with the U-shaped supporting rods fixed with the first connecting rib; a cavity formed by the apron board, a round bearing plate, the U-shaped supporting rods and the first connecting rib is filled with the casting material and forms a whole, the middle of the whole is provided with graphite electrode holes, and graphite electrodes are inserted in the electrode holes. The electric arc furnace cover has the use performance significantly improved and have relatively high etching resistance and antistrip performance; the etching rate of an electric arc furnace cover work layer tends to be consistent; the age of the electric arc furnace cover is increased to 260 times or more from the original of 200-220 times, the service life of the electric arc furnace cover is prolonged, the work efficiency and benefits of an electric arc furnace are improved, the consumption of the ton steel refractory casting material is reduced, and the cost of production is saved.

Owner:瑞泰马钢新材料科技有限公司 +1

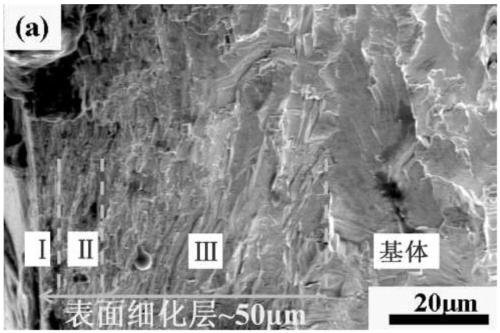

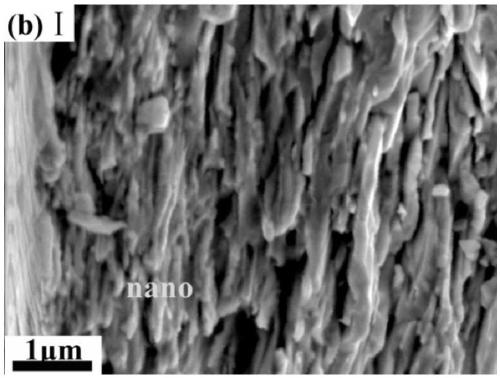

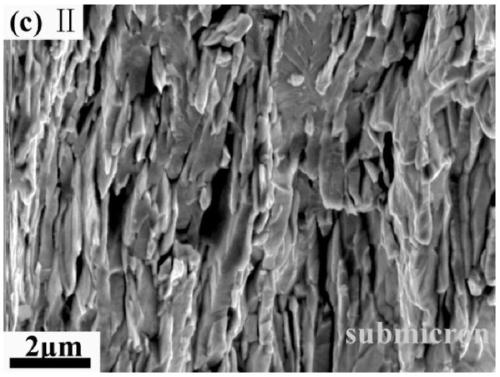

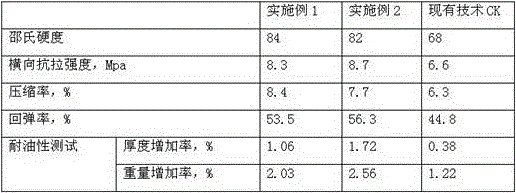

Surface multi-scale structure tungsten material and preparation method of material

The invention relates to a surface multi-scale structure tungsten material and a preparation method of the material, and belongs to the technical field of metal surface treatment. A gradient layer isarranged between the surface structure of the surface multi-scale structure tungsten material and the matrix structure, the grain size of the gradient layer is changed in a gradient mode, and the gradient layer from the surface structure to the matrix structure sequentially comprises a nano-layer, a sub-micron layer and a micro-layer, wherein the grain sizes of the nano-layer, the sub-micron layerand the micron layer are in a nanometer level, a sub-micron level and a micron level respectively. According to the surface multi-scale structure tungsten material, binding between the scale layers is good, no obvious interface exists, and micro-cracking, delamination and other phenomena are avoided. The method is easy and quick to use and suitable for preparing bulk samples.

Owner:PANZHIHUA UNIV

Modified nano building functional material for magnetic oil-resistant fiber and preparation method of material

The invention discloses a modified nano building functional material for a magnetic oil-resistant fiber and a preparation method of the material. The material is prepared from 50-60 parts of butadiene-acrylonitrile rubber, 30-40 parts of polyurethane rubber, 10-15 parts of 12-methyl hydroxy stearate, 8-12 parts of magnesium methacrylate, 6-10 parts of tri(2-butaneneoxime)cinylsilane, 20-25 parts of nylon-66 short fibers, 5-10 parts of polypropylene glycol adipate and 10-16 parts of diethylene glycol dibenzoate. According to the material, added butadiene-acrylonitrile rubber-modified phenolic resin is mixed with the raw materials and cured during heating, and the molten resin is quickly converted into a non-molten haplotype structure from a linear structure under action of methylene decomposed from urotropine; the mechanical property is improved, and the high temperature resistance and the low expansion property are achieved; by combining nano-graphene among layers, the porosity and the specific surface area of a composite adsorption membrane are increased, and the effects are enhanced; asphalt-based carbon fibers are adopted, therefore, the mechanical property of the material is enhanced, and harmful gas and dust substances in tail gas can be greatly adsorbed and removed.

Owner:常熟市瑞思知识产权服务有限公司

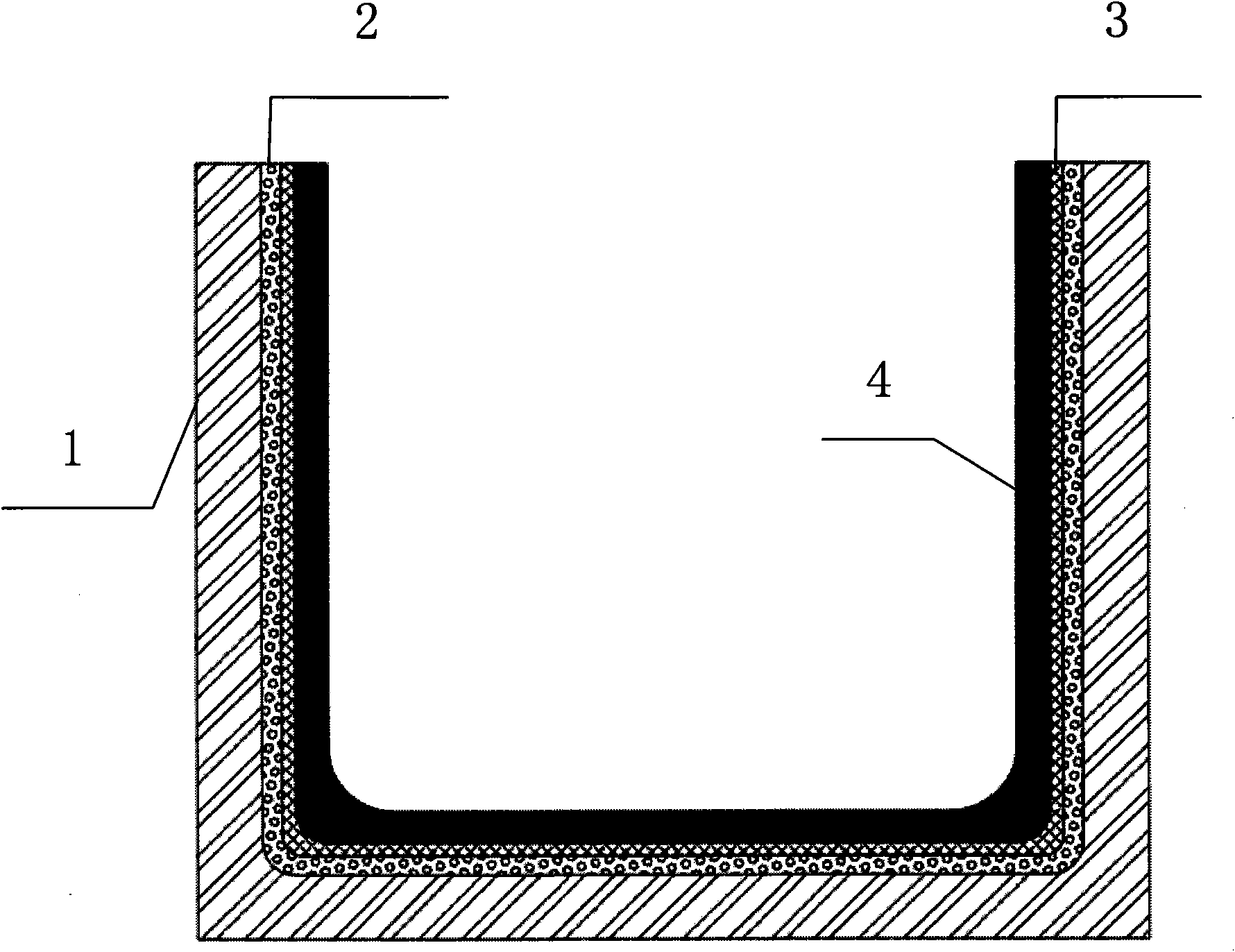

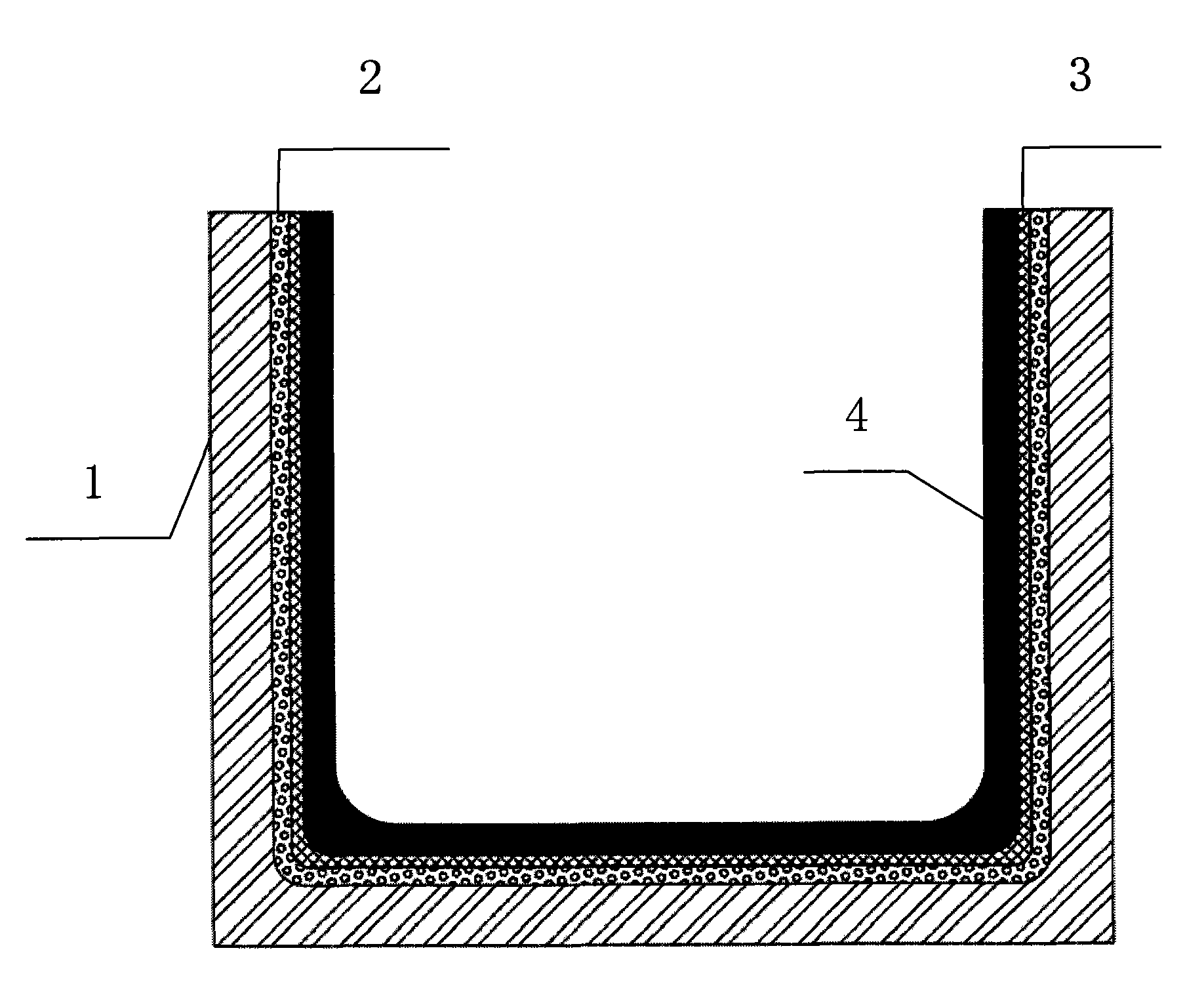

Quartz crucible with composite coating layers for preparing polycrystalline silicon ingot

InactiveCN102400214AImprove high temperature resistanceHigh softening pointPolycrystalline material growthSingle crystal growth detailsInter layerIngot

The invention discloses a quartz crucible with composite coating layers for preparing a polycrystalline silicon ingot, which comprises a matrix, an intermediate transitional layer, a second intermediate layer and an inner surface coating layer. The inner wall of the matrix is provided with the intermediate transitional layer; the intermediate transitional layer is provided with the second intermediate layer; and the second intermediate layer is provided with the inner surface coating layer. By using the quartz crucible with the composite coating layers for preparing the polycrystalline silicon ingot, according to the high-temperature heating steps and the calcining time of the quartz crucible in a usage process, the corrosion resistance capability of the quartz crucible is improved by adopting coating layer materials with different thermal performance to hierarchically coat the matrix of the quartz crucible, thereby achieving the purpose of decreasing the response strength of silicon and the quartz crucible.

Owner:江苏华尔石英材料科技有限公司

Water soluble thermosetting acrylate cold rolled silicon steel coating

InactiveCN1472269AImprove rust resistanceNo peeling phenomenonLiquid surface applicatorsCoatingsHigh resistanceCross-link

A water-soluble thermosetting acrylate paint for cold-rolled silicon steel is prepared from water-soluble acrylic acid, inorganic solid filler and cross-linking agent through proportionally mixing them together, stirring, adding deionized water for deluting it, homogenizing and sand grinding. Its advantages are high resistance to cold and weather, high adhesion, uniform color, and high antirust performance.

Owner:许守煜

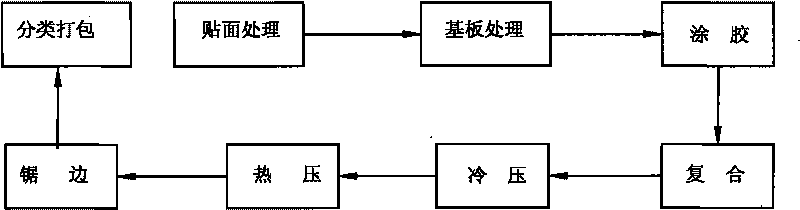

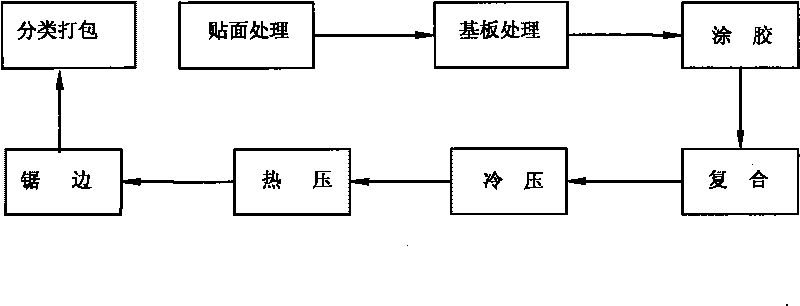

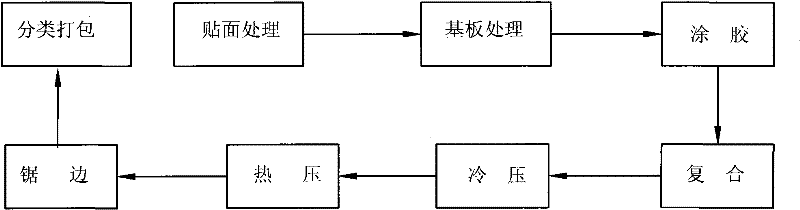

Process for manufacturing decorative veneer plywood

ActiveCN101695848AImprove flatnessHigh peel strengthWood veneer joiningRelative displacementRolling paper

The invention relates to a process for manufacturing a decorative veneer plywood, in which a relative displacement cannot happen between a veneer and a substrate, and a crackle cannot appear on the veneer. The process comprises the substrate, and comprises the following steps: (1) veneer processing, namely rolling paper or leather to be pasted for 25 to 30 seconds by a flat pressing machine at a temperature of between 150 and 170 DEG C, taking the paper or the leather out, laying the paper or the leather flatly, spraying fog on the surface of the paper or the leather, and cooling the paper or leather to prevent the paper or the leather from curling; (2) substrate processing, namely compensating putty to the surface of the substrate, drying, polishing the substrate with an electric abrasive finishing machine, making the flatness of the surface of the substrate reach that of a middle density plate; and (3) compounding, namely coating an adhesive on the processed surface of the substrate, pasting the processed paper or leather on the surface of the substrate, pressing in a cold press for 30 to 40 minutes, taking out, pressing in a hot press for 8 to 10 minutes under a pressure of between 5 and 8 MPa, and sawing edges after the plywood is pressed. The decorative veneer plywood has the advantages that: the decorative veneer plywood has no crack or displacement in the change of seasons, has high peeling strength, and does not have peeling phenomenon.

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

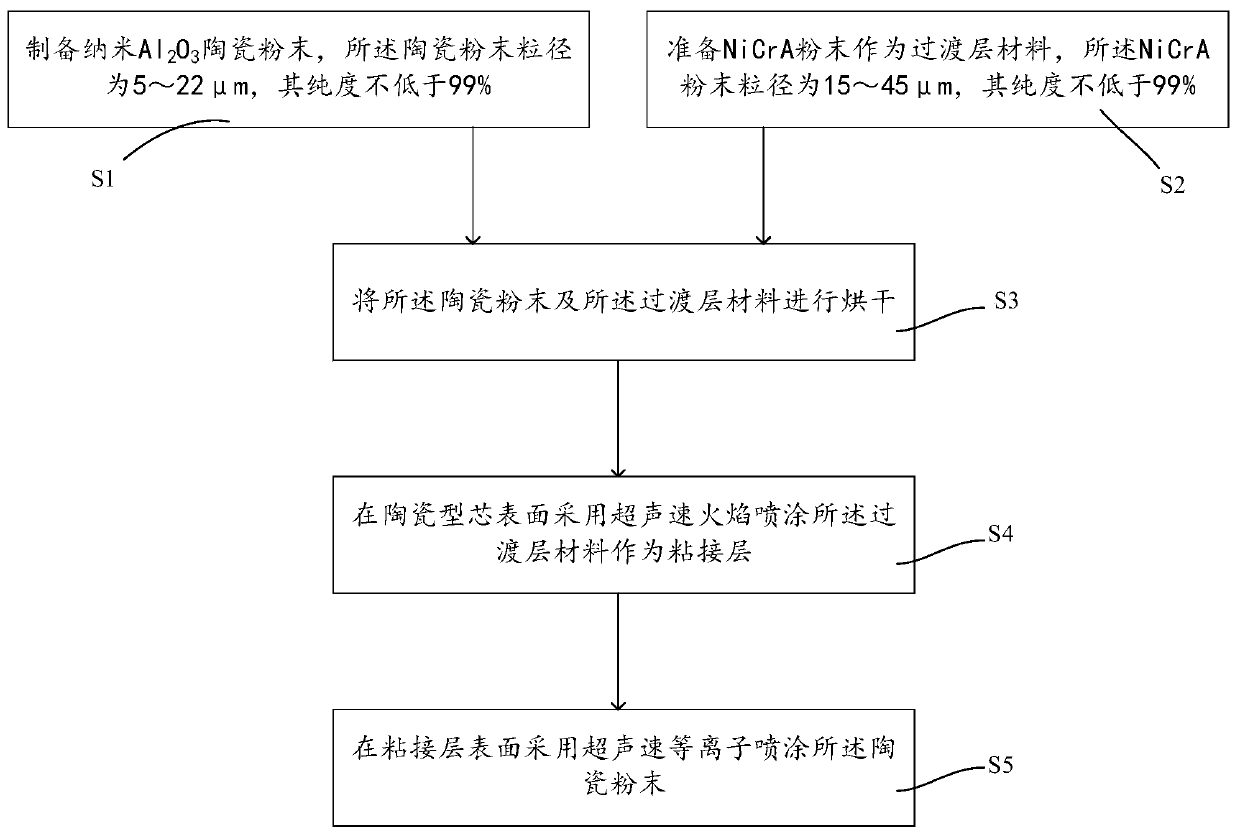

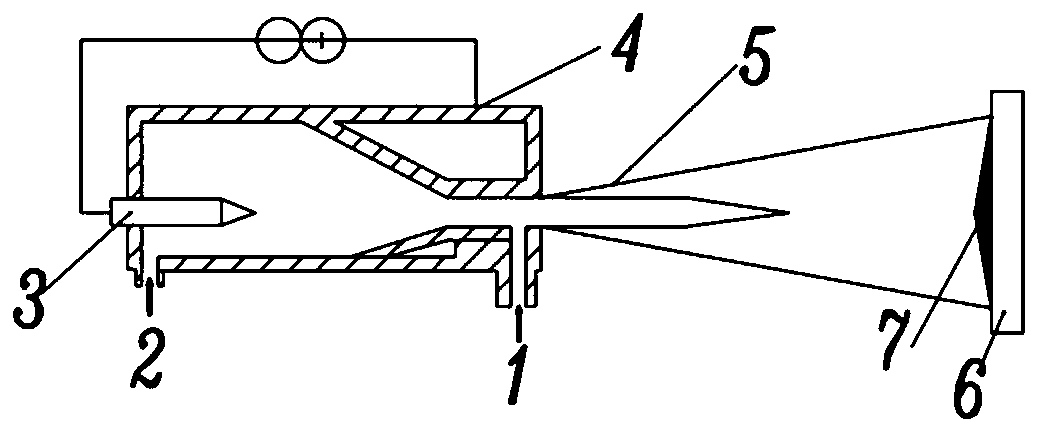

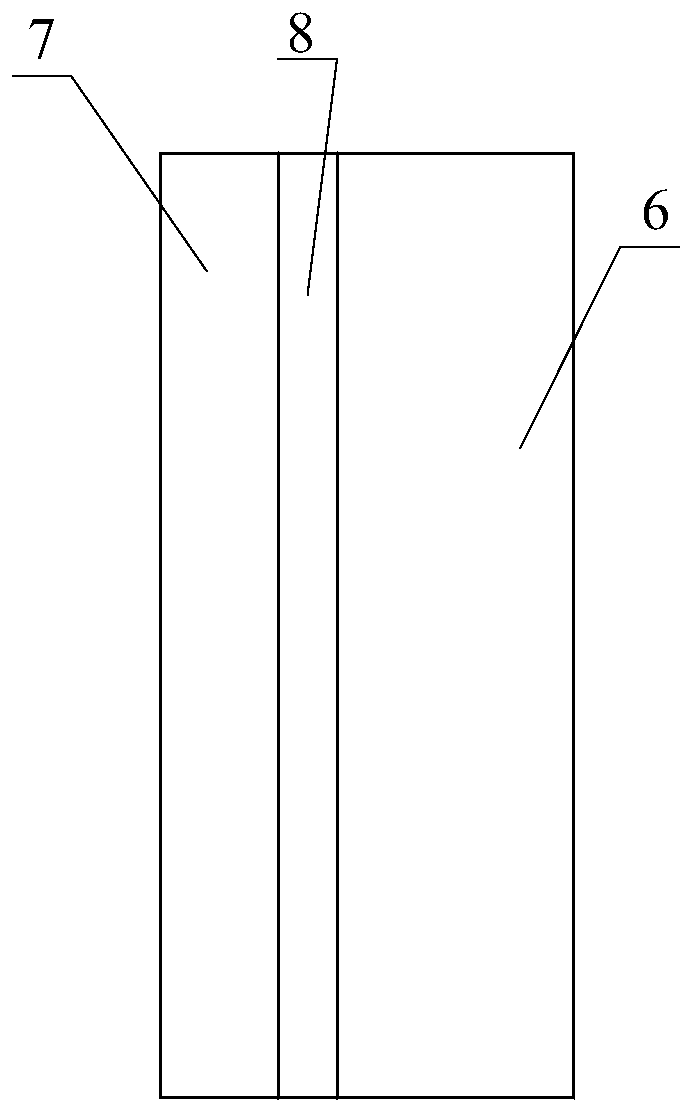

Method for forming ceramic core aluminum oxide coating through supersonic plasma spraying

ActiveCN111593287ALarge roughnessThickness is easy to controlMolten spray coatingNano al2o3Plasma sprayed

The invention discloses a method for forming a ceramic core aluminum oxide coating through supersonic plasma spraying. The method comprises the following steps that S1, nano Al2O3 ceramic powder is prepared, wherein the particle size of the ceramic powder is 5-22 micrometers, and the purity of the ceramic powder is not lower than 99%; S2, NiCrA powder is prepared to serve as a transition layer material, wherein the particle size of the NiCrA powder ranges from 15-45 micrometers, and the purity of the NiCrA powder is not lower than 99%; S3, the ceramic powder and the transition layer material are dried; S4, the transition layer material is sprayed on the surface of a ceramic core by adopting supersonic flame to serve as a bonding layer; and S5, the ceramic powder is sprayed on the surface of the bonding layer by adopting supersonic plasma. The aluminum oxide coating prepared through the method has the advantages of being higher in compactness, higher in hardness, better in bonding strength, resistant in wear, resistant in high temperature, and the like, and excellent in comprehensive performance.

Owner:深圳市万泽中南研究院有限公司 +1

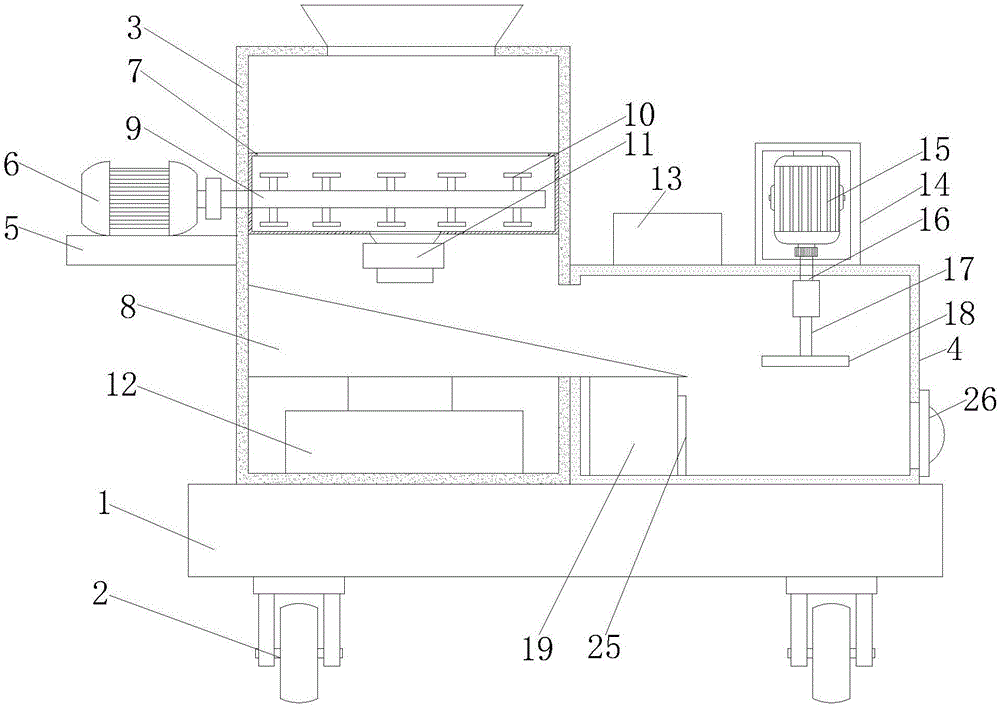

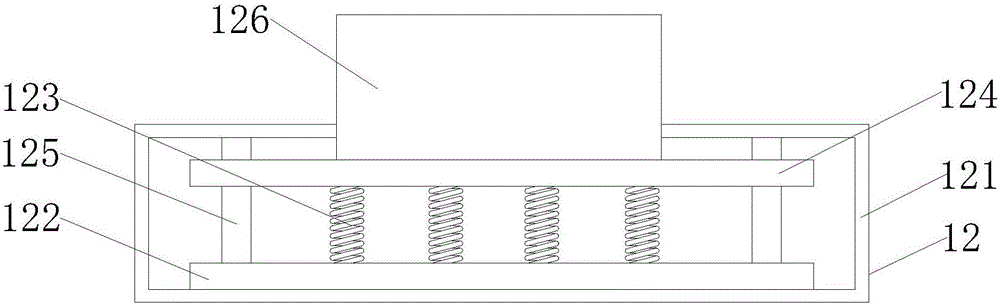

Mixing and stirring device for soil remediation

InactiveCN106823964ANovel structurePracticalTransportation and packagingContaminated soil reclamationSoil remediationEngineering

The invention discloses a mixing and stirring device for soil remediation. The mixing and stirring device comprises a base, wherein rolling wheels are fixedly mounted at the bottom of the base; a first box body and a second box body are sequentially connected to the top of the base from left to right; the top of the first box body is communicated with a feeding pipe; a supporting plate is fixedly connected with the upper part of one side, far away from the second box body, of the first box body; the top of the supporting plate is fixedly connected with a first motor; a U-shaped groove and an inclined plate are fixedly connected in the first box body in sequence from top to bottom; one end of the inclined plate penetrates through the first box body and the second box body in sequence and extends into the second box body. The mixing and stirring device for the soil remediation is novel in structure and high in practicability, and is convenient to operate; the effect of mixing soil with a remediation medicament is realized; the first box body is combined with the second box body, so that the effect of stirring for a plurality of times is realized under the action of the first motor and a second motor; the medicament can be in contact with the soil very well, and the mixing time is saved.

Owner:青岛恒新辉瑞工业技术有限公司

Process for performing laser cladding of superhard high speed steel by hot rolling of stretch reducing roller of seamless steel pipe

ActiveCN104250802AHigh hardnessGood metallurgyMetallic material coating processesMelting tankBroadband

The invention relates to a process for performing laser cladding of a superhard high speed steel by hot rolling of a stretch reducing roller of a seamless steel pipe, which is characterized by comprising the following steps: removing oil and rust on the surface of the stretch reducing roller, washing by alcohol, labeling by partitioning a processing area; preparing the superhard high speed steel powder alloy powder, adjusting an automatic powder feeding apparatus so that the alloy powder from an automatic powder feeding head can just fall in a laser molten pool, adjusting the powder feeding amount; selecting a 3.5*1mm broadband integration mirror, and adjusting defocusing amount to make a focused laser spot as an rectangular shape, employing a synchronization powder feeding apparatus for automatically seeding the alloy powder into a laser molten pool, forming an uniform and compact laser cladding layer on the surface; cladding and then performing flaw detection examination, then performing thermal treatment on the stretch reducing roller. The selected superhard high speed steel powder and the stretch reducing roller matrix have good metallurgy and mechanical compatibility, the cladding layer and the matrix can form firm metallurgy combination, hardness is high, thickness is uniform, and crack and spalling phenomena can not be generated.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

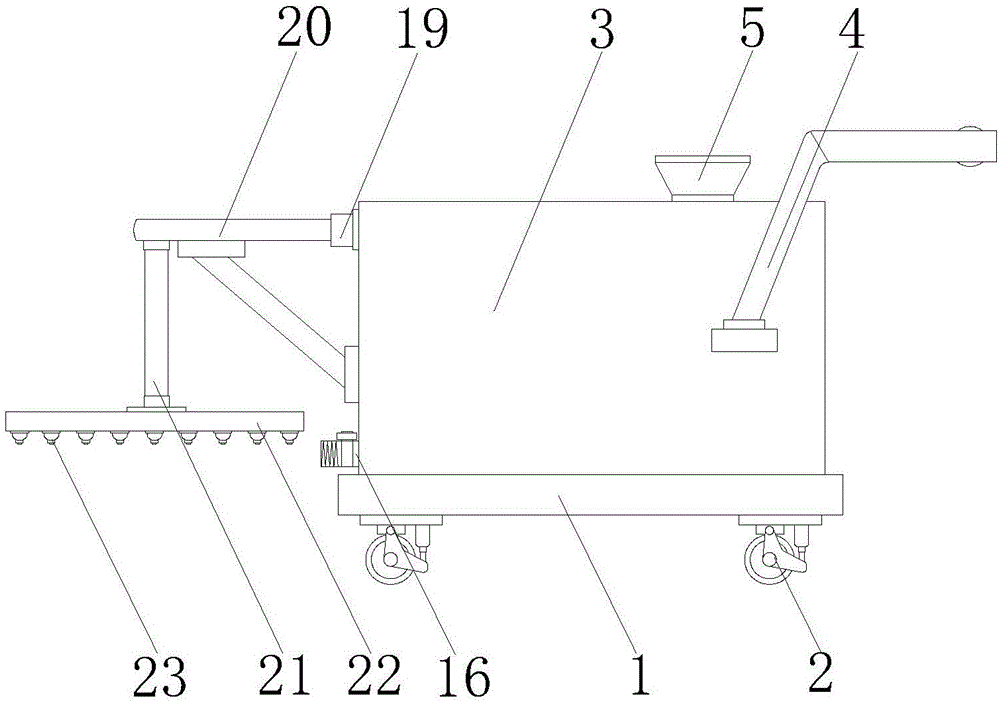

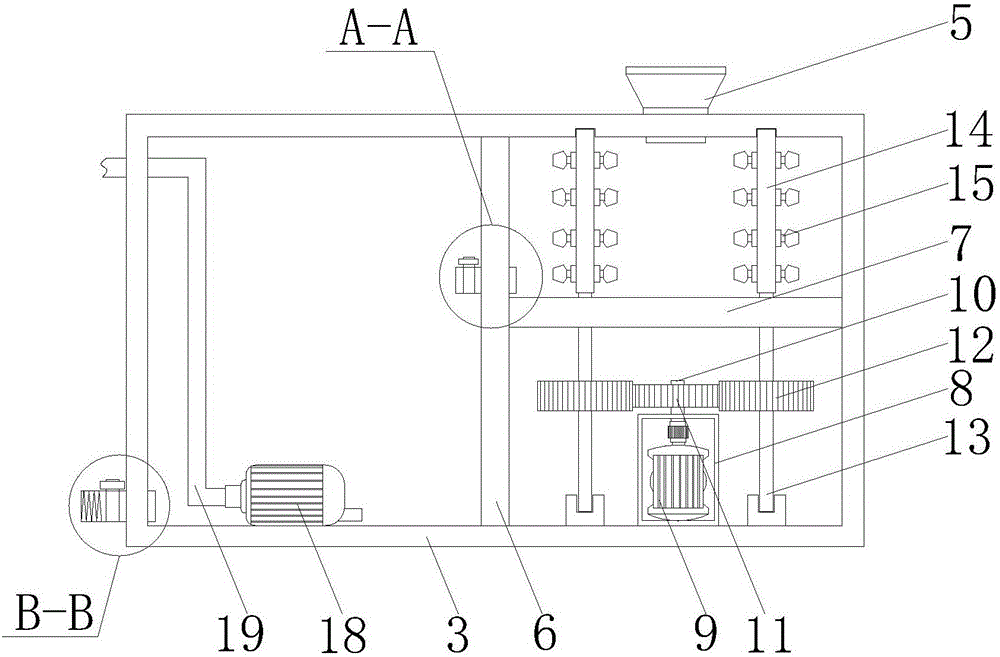

Convenient and rapid chemical leaching device for soil remediation

InactiveCN106694533AImprove work efficiencyPrevent the problem of using after the stirring is completedContaminated soil reclamationSoil remediationMaterials science

The invention discloses a convenient and rapid chemical leaching device for soil remediation. The convenient and rapid chemical leaching device comprises a base, wherein wheel devices are fixedly connected with the two sides of the bottom of the base; a leaching tank is fixedly connected with the top of the base; a hand-push frame is fixedly connected onto the leaching tank; and a feeding hopper communicates with one side of the top of the leaching tank. By adoption of the convenient and rapid chemical leaching device, the problems that a conventional leaching device for soil remediation only has a single leaching function, is incapable of stirring chemical raw materials, and can be used only after the chemical raw materials are stirred are solved; the working time is greatly shortened; the working efficiency of leaching for soil remediation is improved; the defect that the conventional leaching device used for soil remediation and applied to the current market is complex in structure and inconvenient to operate is overcome; more convenience is brought to a user; the use efficiency is improved; the spraying time is shortened; and the waste of chemicals is reduced.

Owner:CHINA UNIV OF MINING & TECH

Laser cladding method of nickel-based alloy laser cladding powder

InactiveCN113249717AImprove cladding effectDense tissueMetallic material coating processesAlcoholAlloy

The invention discloses a laser cladding method of nickel-based alloy laser cladding powder, and relates to the field of laser cladding. The method comprises the following specific steps: step 1, the surface of a workpiece to be subjected to laser cladding is polished by abrasive paper or manually polished by a grinding wheel to remove an oxidation film and oil stain, the polished workpiece is cleaned by absolute ethyl alcohol and acetone, and the cleaned workpiece is dried; step 2, after the step 1 is completed, a heating device is adopted for preheating the cladding position of the workpiece, the preheating temperature T1 is larger than or equal to 200 DEG C and smaller than or equal to 300 DEG C, and the preheating time is 1-2 hours. The surface of the to-be-cladded workpiece is cleaned before cladding, so that the surface is ensured to meet the cladding requirements, the cladding effect of the cladded working layer is improved, the surface of the workpiece is heated again after cladding is completed, a heat preservation layer covers the surface of the workpiece for slow cooling, and therefore, heat stress in the part can be eliminated, heat stress generated by rapid cooling is reduced, the service life of the part is prolonged, and the defects of cracks of a cladding layer, deformation of a matrix and the like are avoided.

Owner:宁夏恒泰化工设备有限公司

Tear-resistant functional rubber material for magnetic modification and preparation method thereof

The invention discloses a tear-resistant functional rubber material for magnetic modification and a preparation method thereof. The tear-resistant functional rubber material for magnetic modification is prepared from epichlorohydrin rubber, butadiene-acrylonitrile rubber, acrylonitrile-butadiene copolymer rubber, diene rubber, styrene-butadiene rubber, regenerated rubber, a heat stabilizer, an adhesive, polydimethyldiallyl ammonium chloride, bentonite and nano cerium oxide. The combination of the epichlorohydrin rubber, butadiene-acrylonitrile rubber, acrylonitrile-butadiene copolymer rubber, diene rubber, styrene-butadiene rubber and regenerated rubber used as main materials greatly enhances the toughness of the material and effectively solves the problem of high cracking rupture tendency of the conveyer belt. The tear-resistant functional rubber material can not generate harmful gases to the human body, has a perfect combination of tear resistance and other properties, and thus, is applicable to various severe working conditions. The nano graphene between every two layers is combined to improve the porosity and specific area of the composite adsorption film and enhance the effect. The asphalt-base carbon fibers are adopted to enhance the mechanical properties of the material, and can greatly adsorb and remove harmful gases and dust substances in the tail gas.

Owner:SUZHOU RUI TE JIE CHEM PROD CO LTD

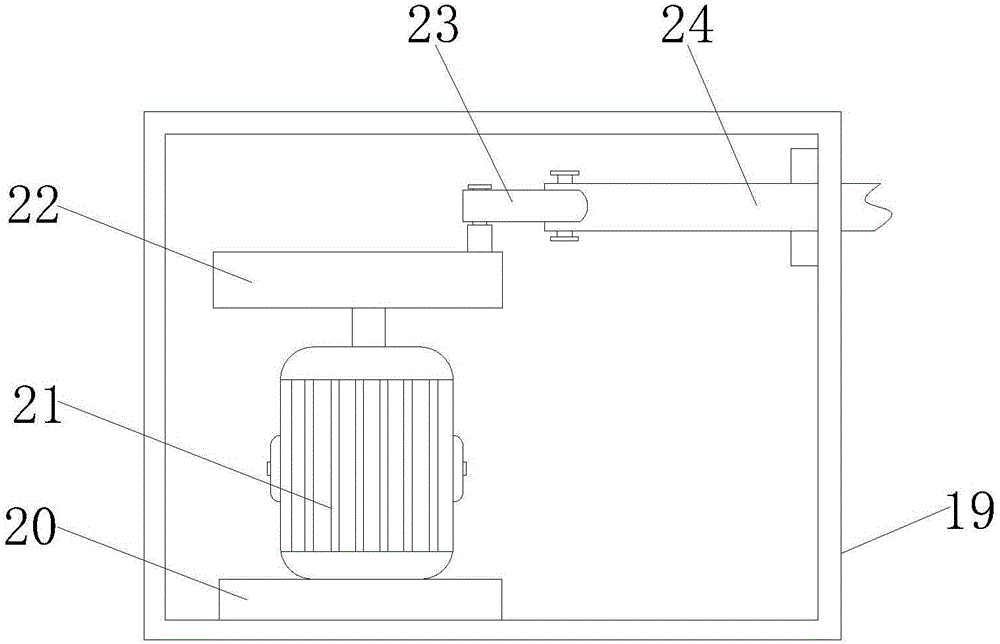

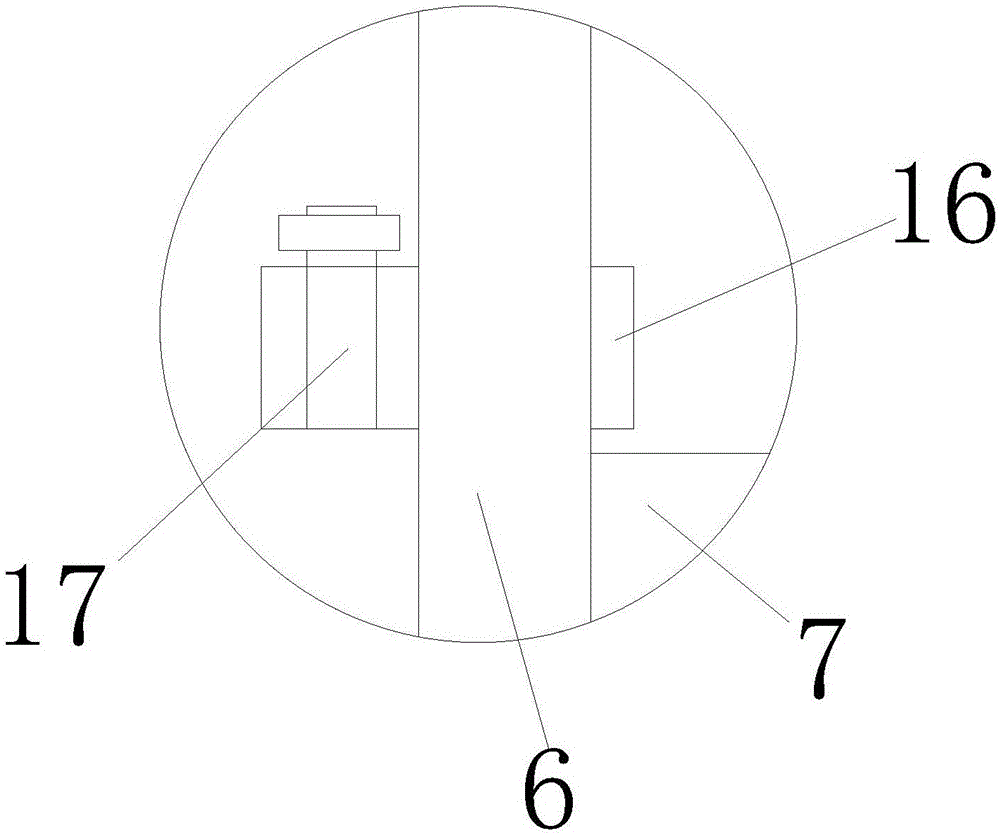

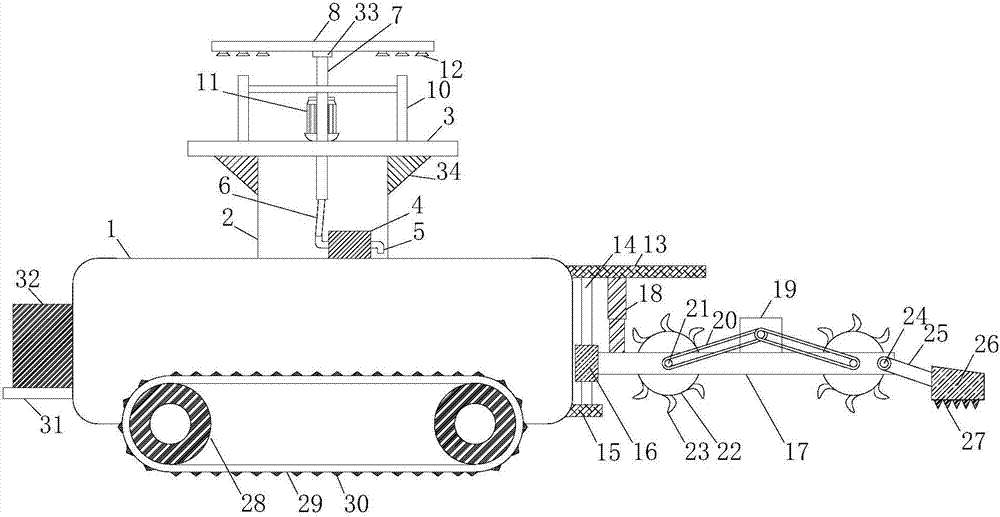

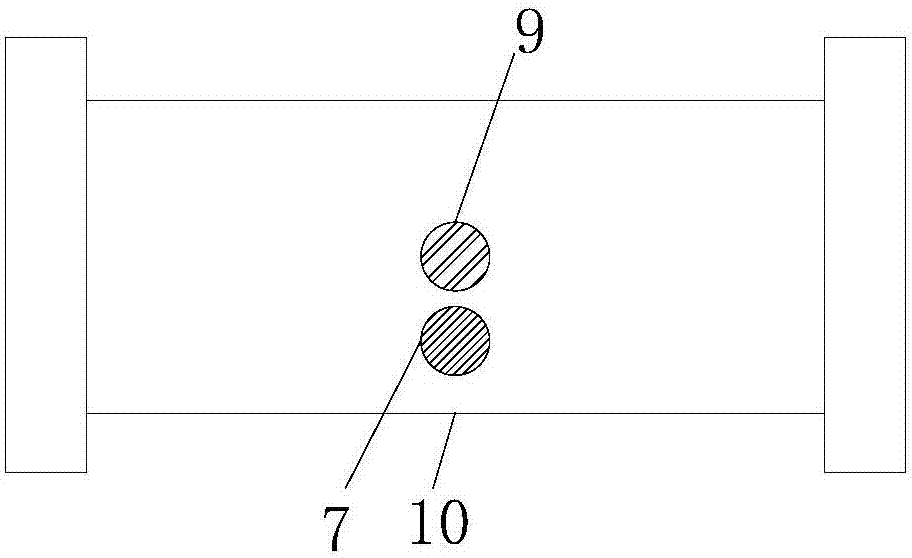

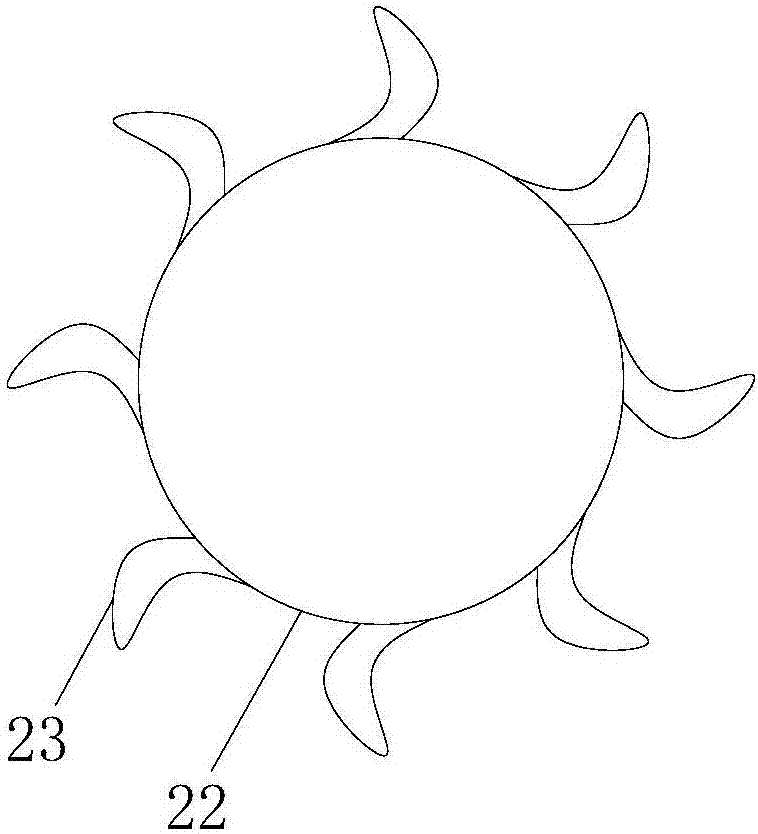

Ecological agriculture rooter for hilly areas

The invention discloses an ecological agriculture rooter for hilly areas. The ecological agriculture rooter comprises a machine body, a water tank is fixedly installed at the top of the machine body, a cover plate is connected to the top of the water tank through threads, a water pump is arranged at the bottom of an inner wall of the water tank, both of a water inlet and a water outlet of the water pump are fixedly connected with water pipes, one end of the water pipe on the water outlet of the water pump is fixedly connected with that of a connecting pipe, one end of the connecting pipe away from the water pump is fixedly connected with a through pipe, and one end, which is away from the connecting pipe, of the through pipe penetrates through the cover plate and is fixedly connected with the bottom of a water spray pipeline at the outside of the cover plate. The ecological agriculture rooter disclosed by the invention is provided with the water tank, the cover plate, the water pump, the water pipe, the connecting pipe, the water spray pipeline, a first motor and a spray head, the water in the water tank finally flows into the water spray pipeline through the water pipe, the connecting pipe and the through pipe after being boosted by the water pump, and the first motor is started to drive the water spray pipeline to rotate so as to spray the water from the spray head to the soil, thereby improving the dry soil and facilitating the operation of a soil overturning wheel.

Owner:青岛恒新辉瑞工业技术有限公司

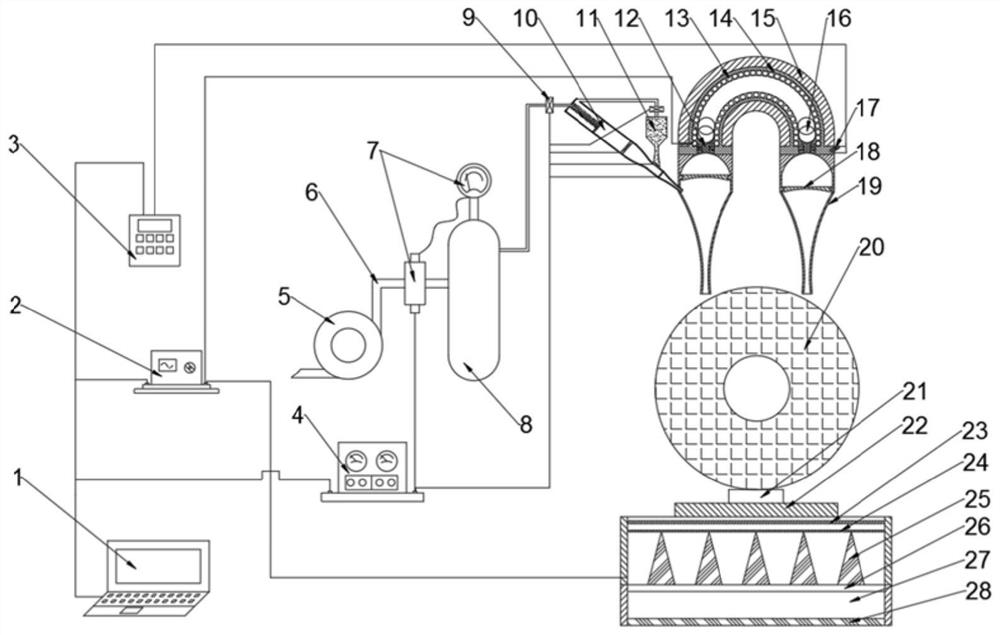

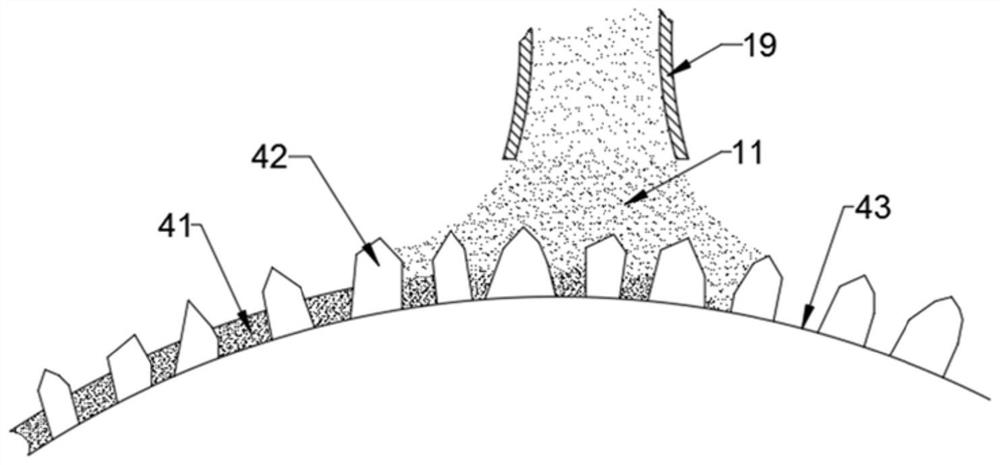

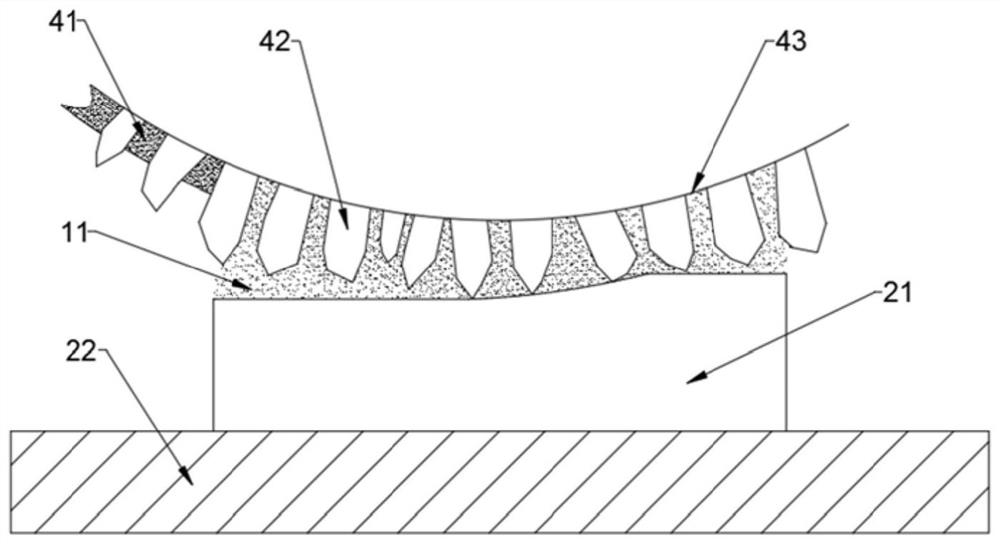

Nanolayer lubricating diamond grinding wheel grinding device based on impact wave cavitation effect

ActiveCN111993270AImprove lubrication and coolingReduce grinding specific energyAutomatic grinding controlGrinding/polishing safety devicesPhysicsDiamond grinding

The invention provides a nanolayer lubricating diamond grinding wheel grinding device based on an impact wave cavitation effect for solving the problem that a grinding solution affected by an air barrier is hard to enter a grinding core region. The device specifically comprises a control system, an accelerating module, an impact wave accelerating module, a machining module and a recovery module. The control system controls operation of the device; the accelerating module is composed of an accelerating pipe, a small La Farr pipe and the like, so that nanoparticles gain initial speeds; the impact wave accelerating module composed of an electromagnetic coil, an impact head, an impact ball, a wave collector, a large La Farr pipe and the like generates two wave sources, wherein one of the wavesources cleans impurities on the surface of the grinding wheel while the other one impacts the nanoparticles with initial speeds to the surface of the grinding wheels to form a nanolayer; in the machining process, the nanoparticles in the nanolayer are released to the grinding core region autonomously, so that the grinding region is self-lubricated and cooled; and the recovery module is used for recovering the nanoparticles to use the nanoparticles repeatedly. The nanolayer lubricating diamond grinding wheel grinding device not only improves the lubricating and cooling effect, but also meets an environmental-friendly development idea.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Process for manufacturing decorative veneer plywood

ActiveCN101695848BImprove flatnessHigh peel strengthWood veneer joiningRelative displacementRolling paper

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com