Patents

Literature

2432results about How to "Small shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Encapsulating composition for LED

InactiveUS20060081864A1Convenient lightingHigh transparencyCoatingsSemiconductor devicesHigh intensitySilicon

An organopolysiloxane composition which cures to a resinous solid has high strength, transparency, and resistance to thermal- and photo-degradation, and is especially suited for encapsulating LEDs. The composition contains specific addition curable organopolysiloxanes having D, T, and Q units, and a proportion of silicon-bonded aromatic groups.

Owner:WACKER CHEM GMBH

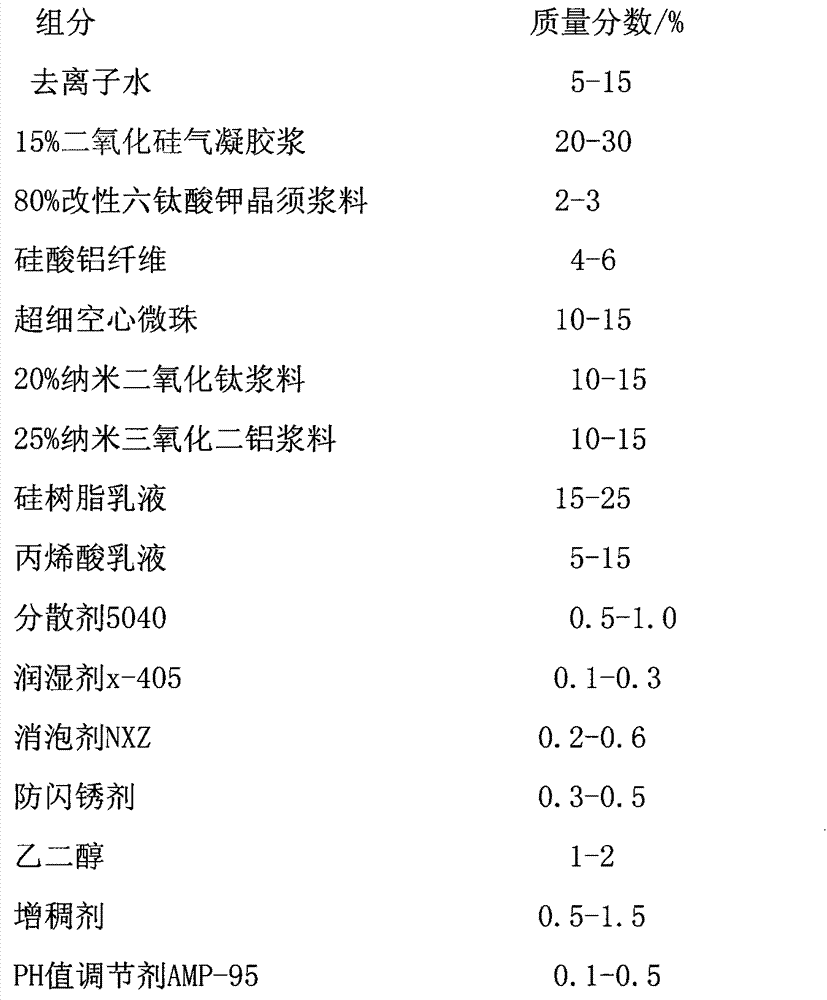

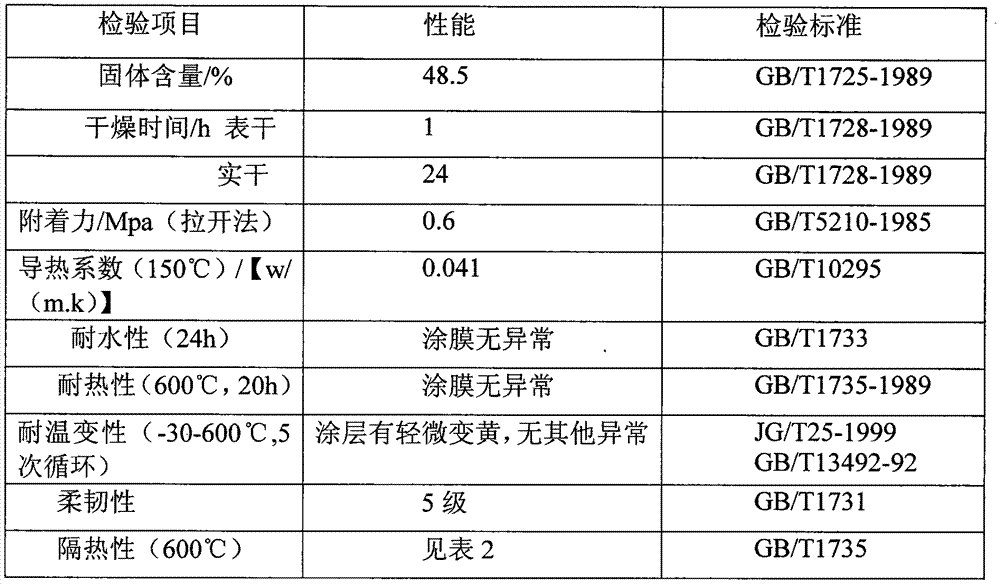

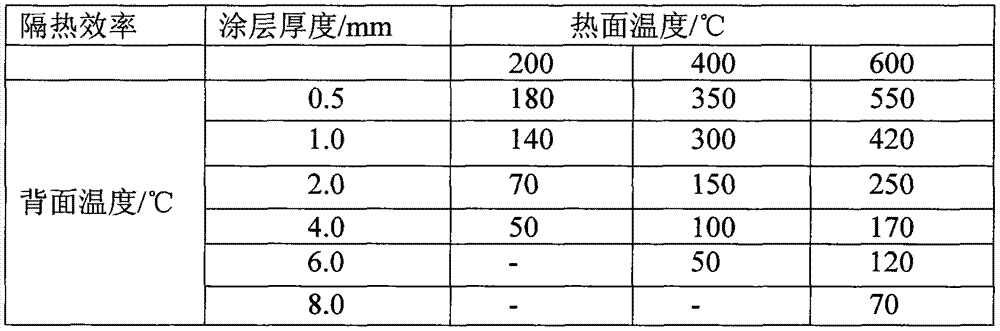

Nanometer high temperature resistant thermal insulation and prevention coating

The invention discloses a nanometer high temperature resistant thermal insulation and prevention coating. SiO2 aerogel, modified potassium hexatitanate whisker, aluminum silicate fiber, ultra-fine cenosphere, nanometer TiO2 and nanometer Al2O3 are used as a thermal insulation filler. A vacuum thermal insulation layer is formed by nano porous structures of SiO2 aerogel and cenosphere. The aluminum silicate fiber is used as a reinforcing and toughening material. The infrared shading performance of potassium hexatitanate whisker, nanometer TiO2 and nanometer Al2O3 are used as a thermal radiation shielding layer. A silicon resin emulsion and an acrylic emulsion are compounded to be an adhesive. Therefore, the nanometer 600 DEG C temperature resistant thermal insulation and prevention coating is prepared with matching of a variety of functional additives. The nanometer high temperature resistant thermal insulation and prevention coating has the characteristics of scumbling, thermal insulation, waterproofing, anti-crack, anti-corrosion, high temperature resistance, weather-proofing, durability and the like and is applicable to the field of industrial high temperature resistant thermal insulation energy conservation.

Owner:株洲中铁中南制造有限公司

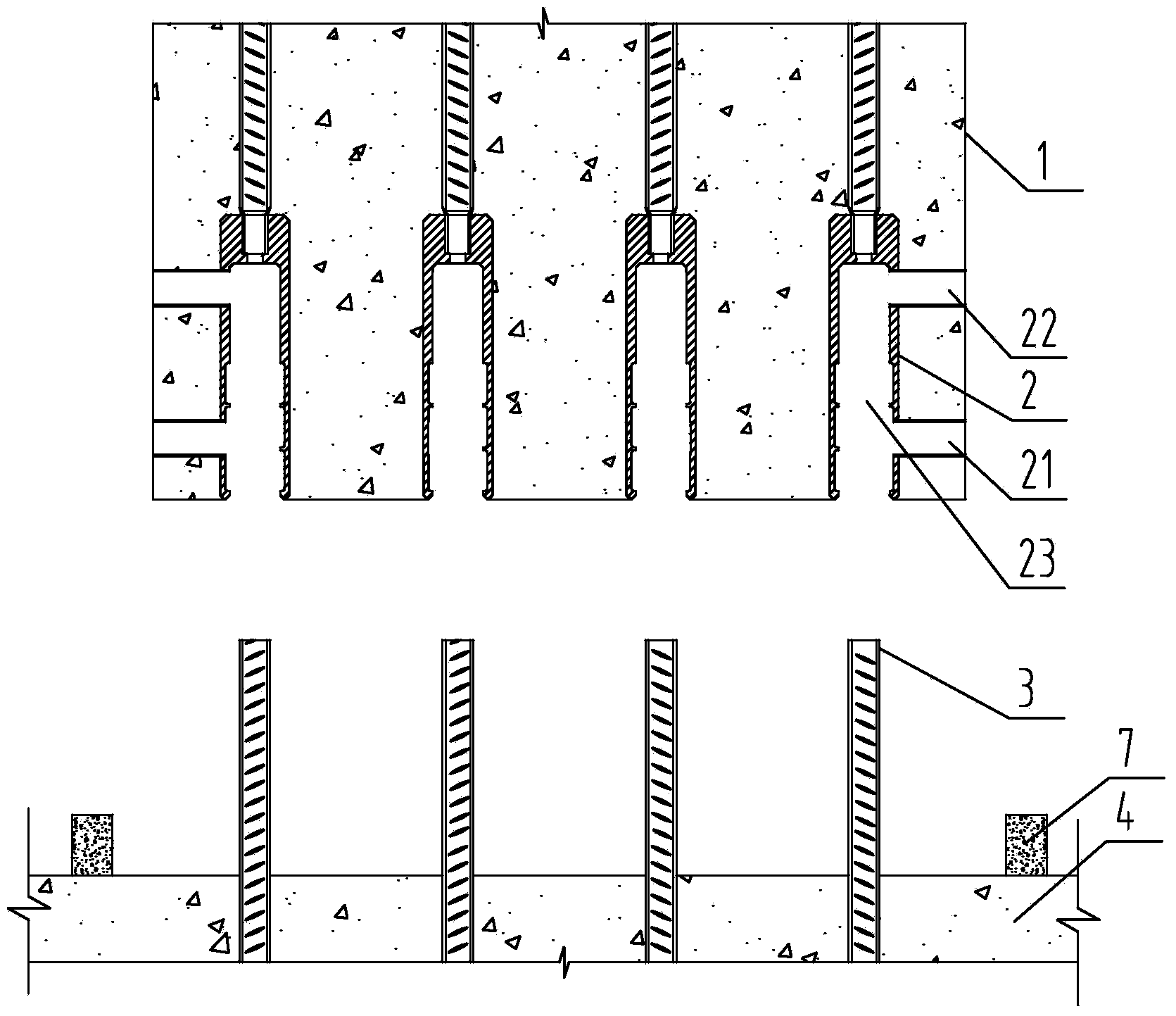

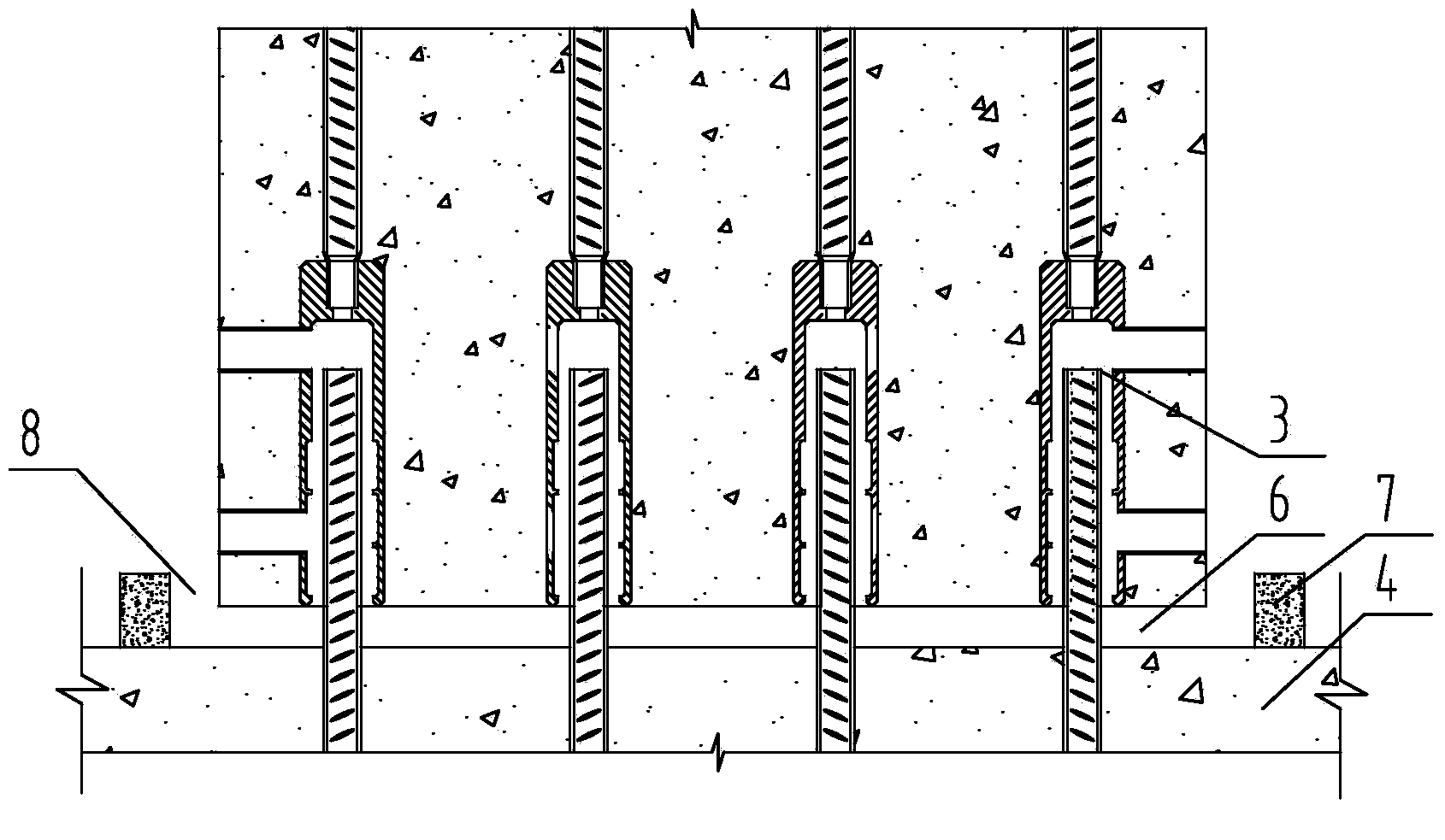

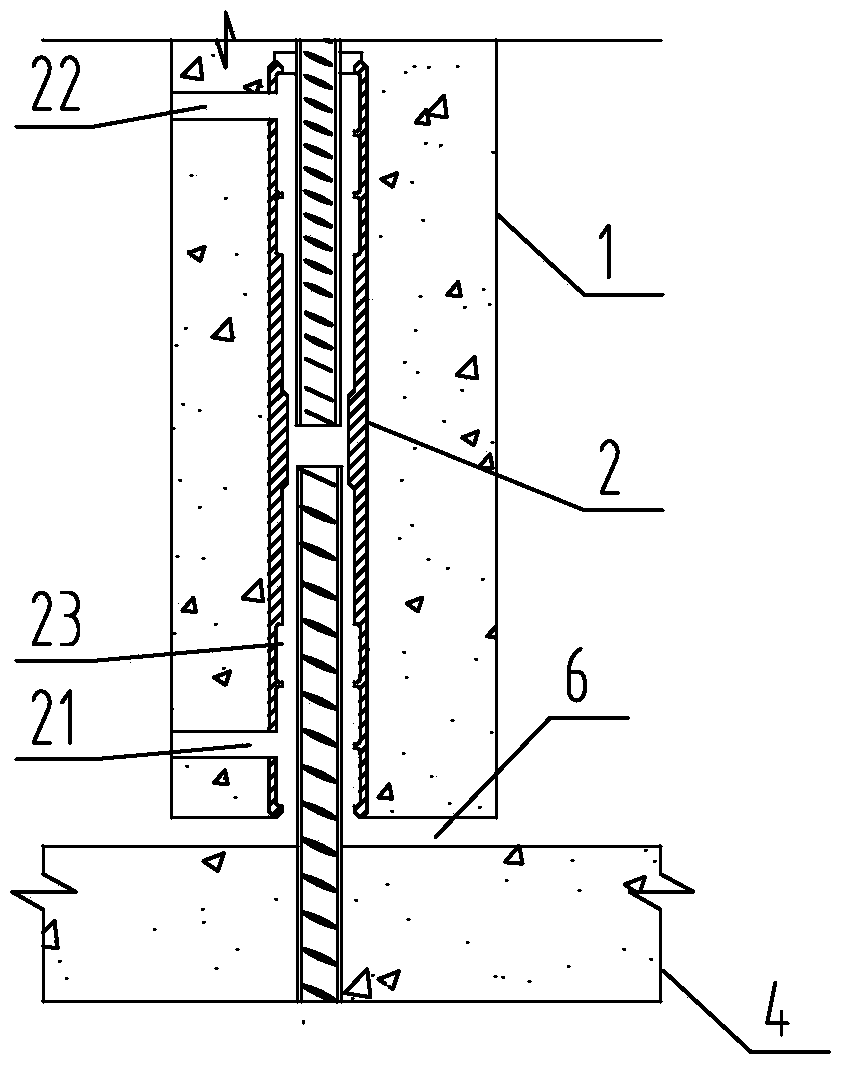

Grouting connection construction method

ActiveCN104314314AFast constructionImprove efficiencyBuilding reinforcementsBuilding material handlingRebarPrecast concrete

The invention discloses a grouting connection construction method which is used for connecting vertical reinforcements of an assembled concrete structure. The grouting connection construction method includes the steps: firstly, embedding a plurality of grouting connection devices at one end of a precast concrete unit to be connected in advance; secondly, lifting the precast concrete unit and then manufacturing a grouting box dam; thirdly, grouting horizontal gaps and then grouting the grouting connection devices. The grouting connection devices are connected with connection reinforcements extending out of a lower unit. Plugging grouting of the horizontal gaps and grouting of the grouting connection devices can be performed within the same day, so that the mounting efficiency of the precast concrete unit is greatly improved, the grouting connection construction method can be implemented in a subzero temperature environment even in winter, construction difficulty is reduced, and working efficiency is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

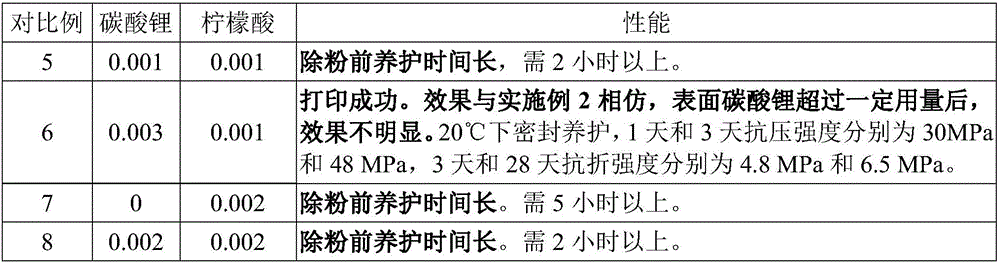

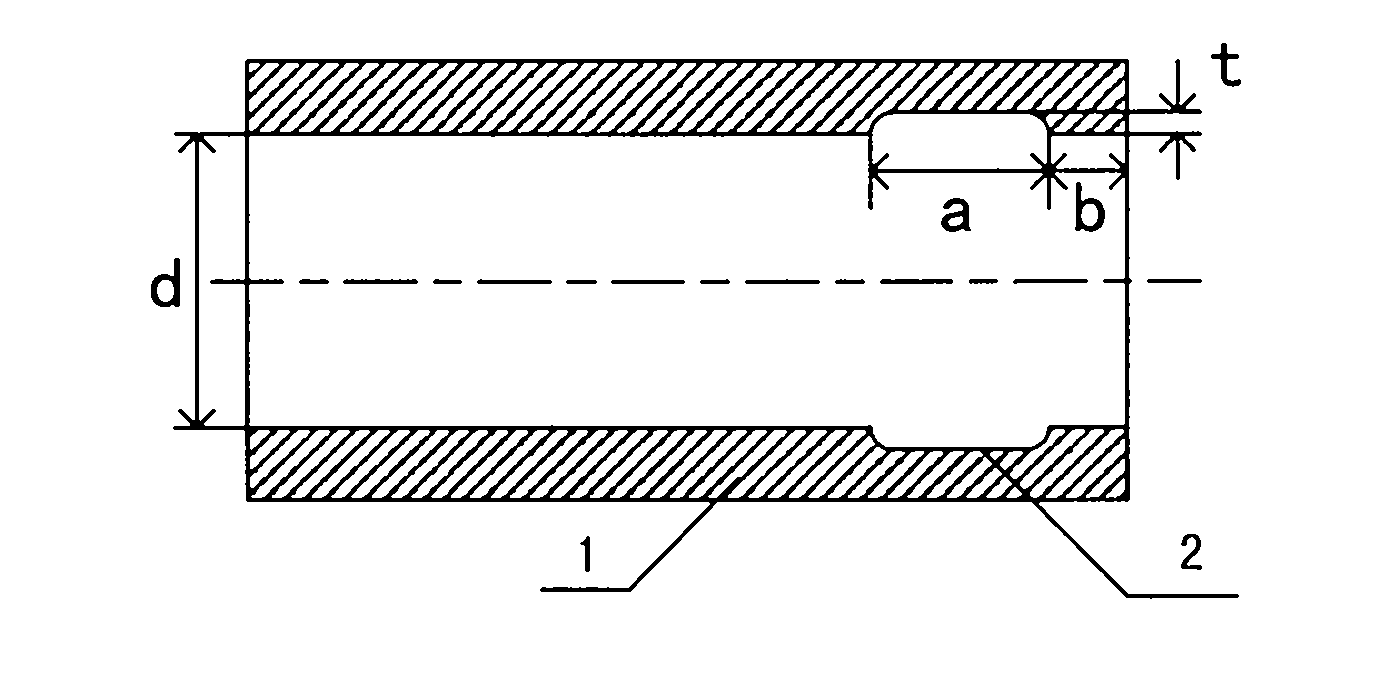

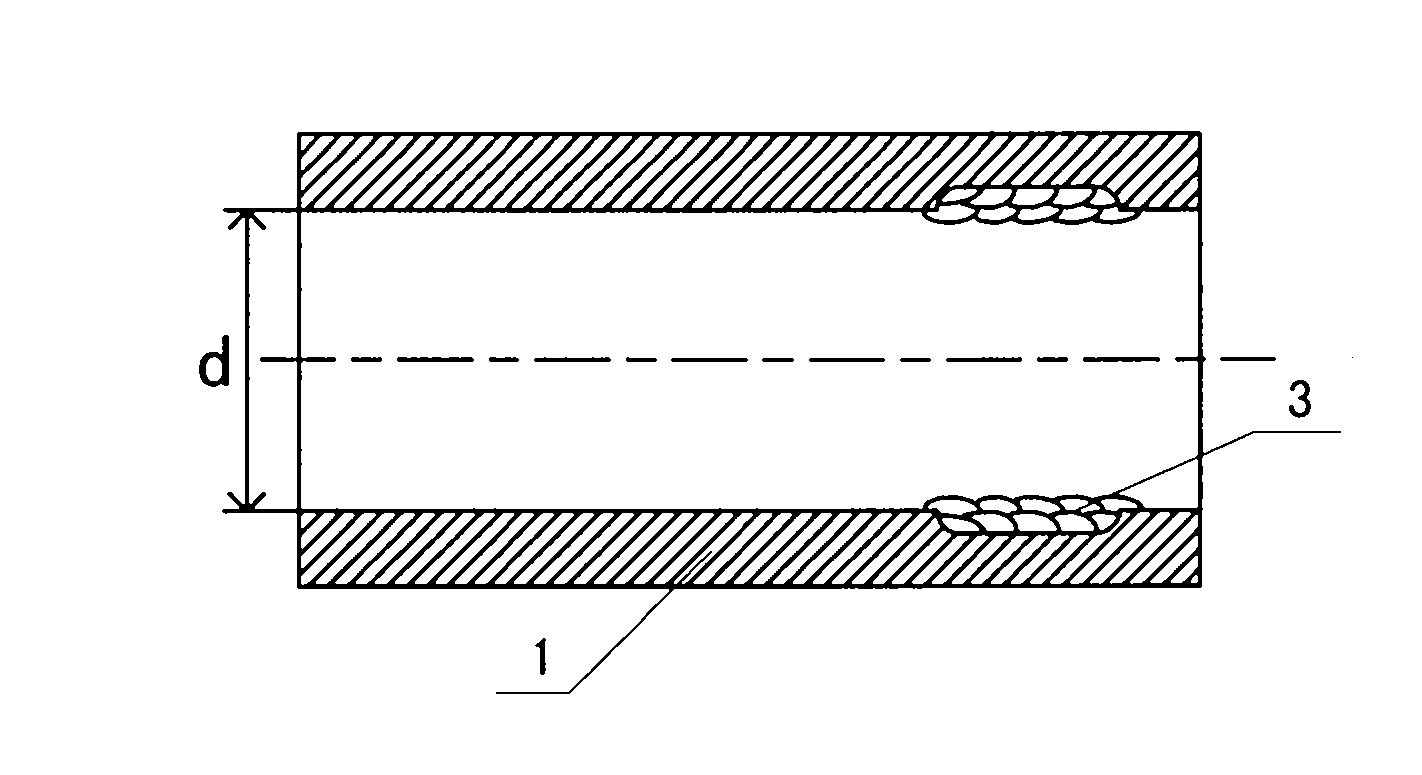

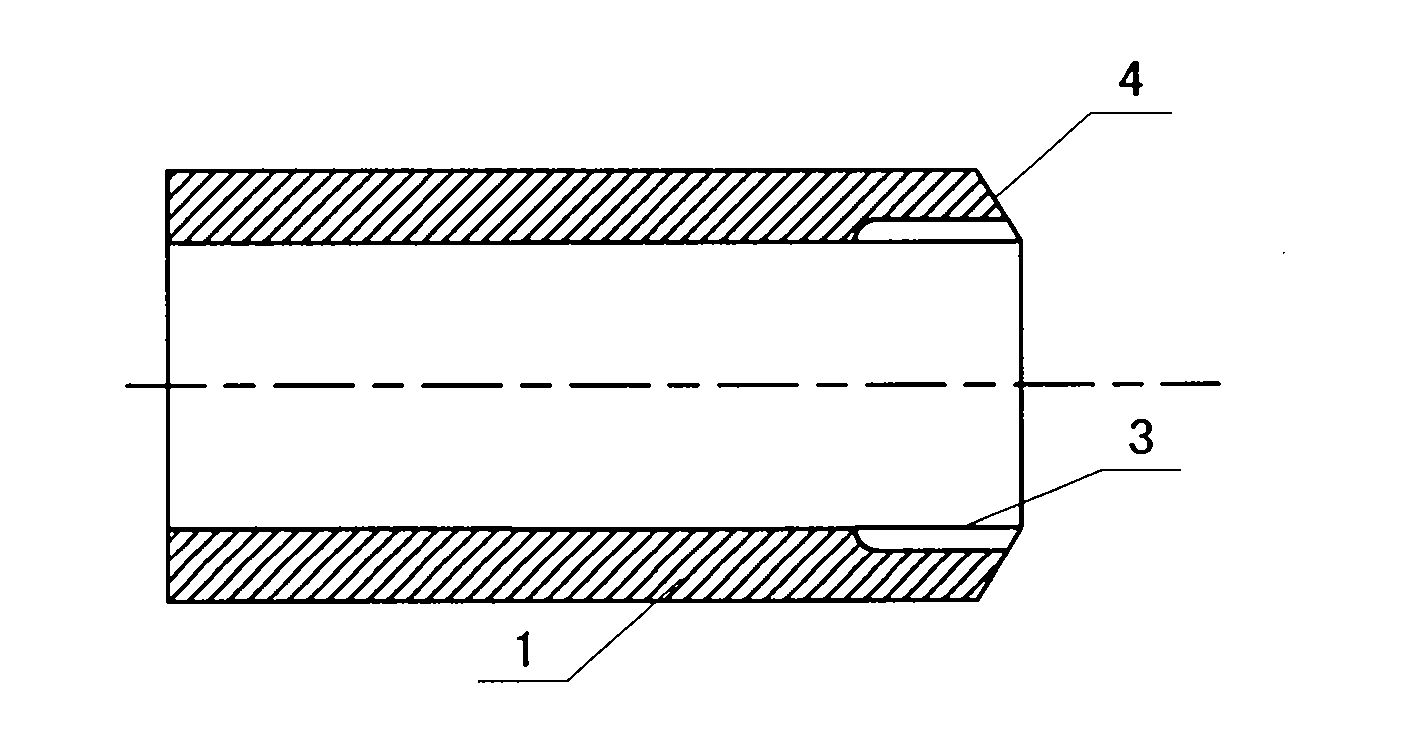

Manufacturing method for sintered body with buried metallic member

ActiveUS20060012087A1Improve uniformitySmall shrinkageSleeve/socket jointsSemiconductor/solid-state device manufacturingMetalRefractory metals

A manufacturing method for a sintered body with a buried metallic member comprises forming an alumina sintered body or an alumina presintered body, forming a metallic member by printing a printing paste including a refractory metal on the alumina sintered body or the alumina presintered body, forming an alumina compact on the metallic member, and sintering the alumina compact, the metallic member, and the alumina sintered body or the alumina presintered body.

Owner:NGK INSULATORS LTD

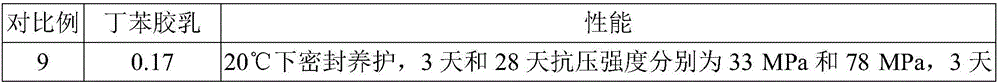

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

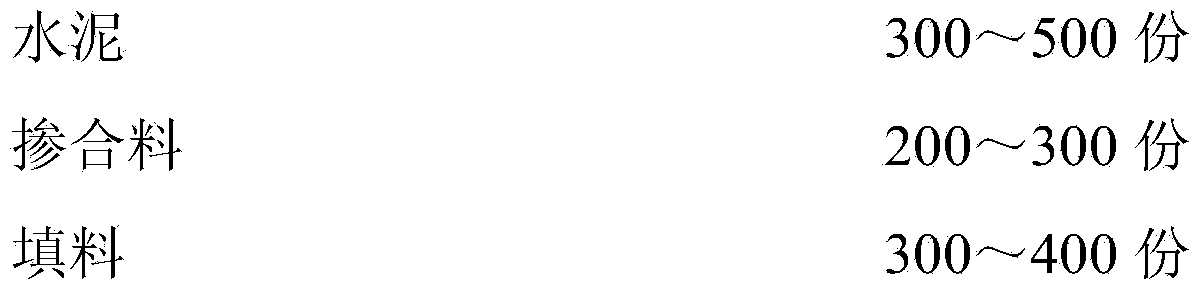

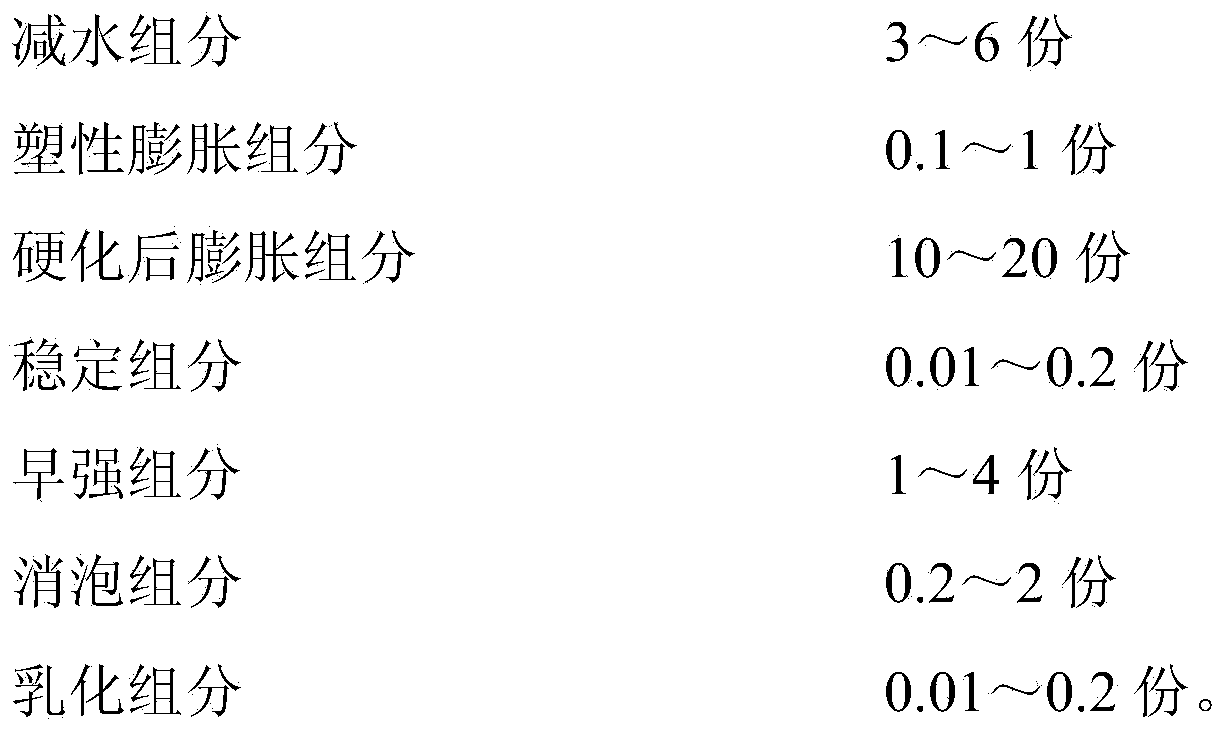

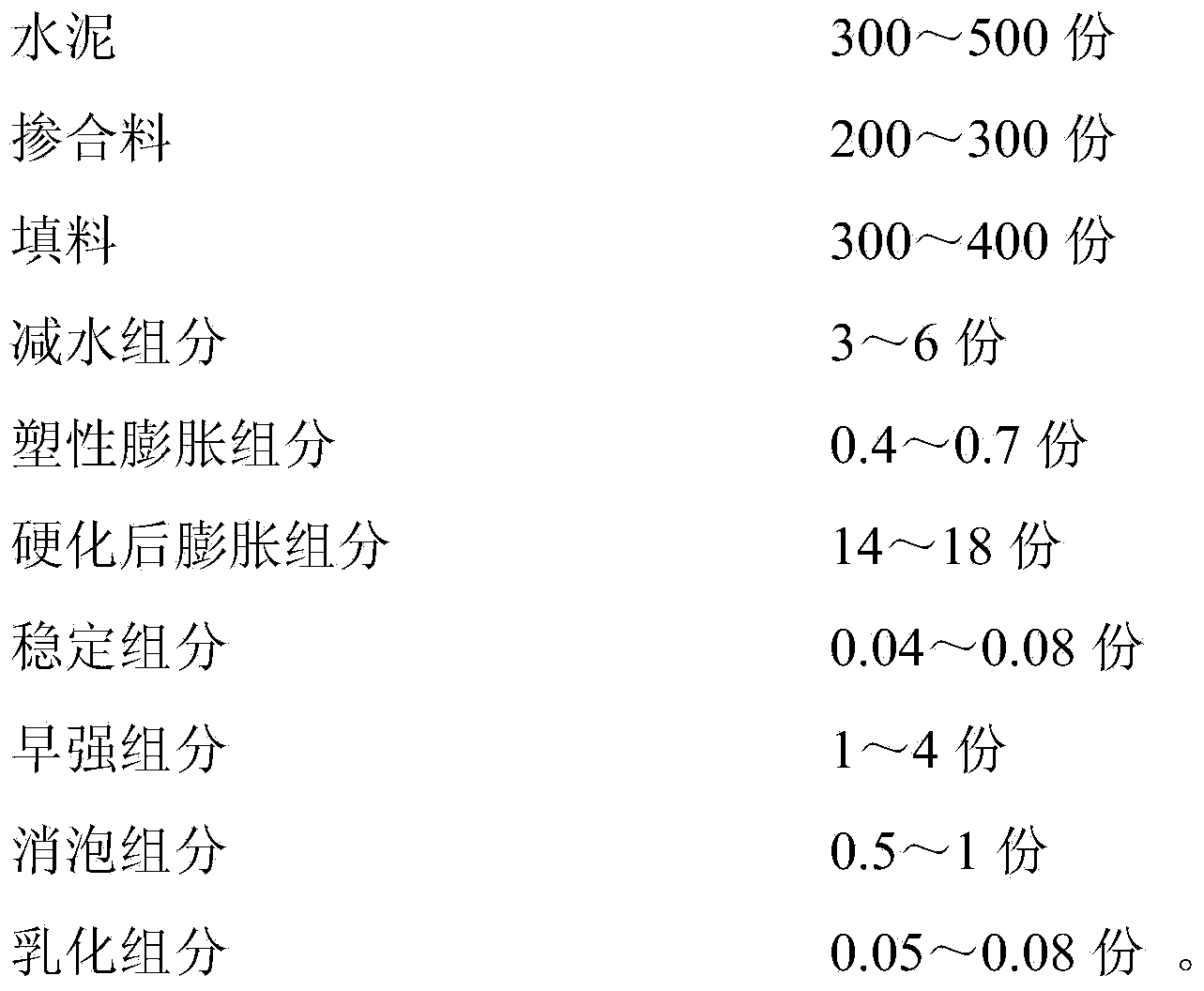

Cement-based grouting material used for strengthening repairing as well as preparation method and application thereof

InactiveCN103880372AHigh injectabilityImprove anti-seepage performanceSwelling ratioCompressive strength

The invention relates to a cement-based grouting material used for strengthening repairing as well as a preparation method and application thereof. The cement-based grouting material comprises the following components in parts by weight: 300-500 parts of cement, 200-300 parts of admixtures, 300-400 parts of fillers, 3-6 parts of water-reducing components, 0.1-1 part of plastic swelling component, 10-20 parts of hardened swelling components, 0.01-0.2 part of stable component, 1-4 parts of early strength components, 0.2-2 parts of defoaming components and 0.01-0.2 parts of emulsifying component. The cement-based grouting material disclosed by the invention has performance advantages such as higher injection-molding performance, initial fluidity not greater than 17s, impermeability not exceeding 1mm, wear resistance not exceeding 10cm<3> / cm<2>, compressive strength within 2 hours not lower than 5MPa, compressive strength within 1 day not lower than 30 MPa, and the like. The cement-based grouting material has composite swelling, the free swelling ratio within 3 hours is 0.02%-2% and grouting is full and dense; the viscosity is low, the volume stability is good and durability is good; the cement-based grouting material does not contain VOC (volatile organic compounds), and is environment-friendly.

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +2

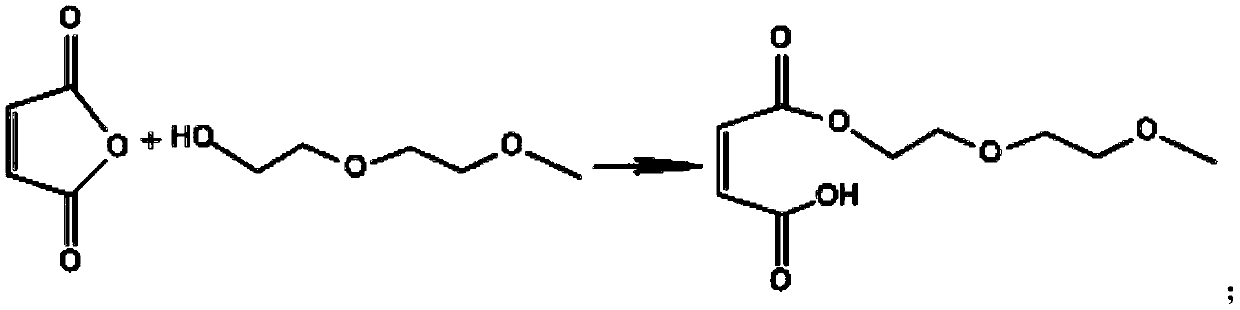

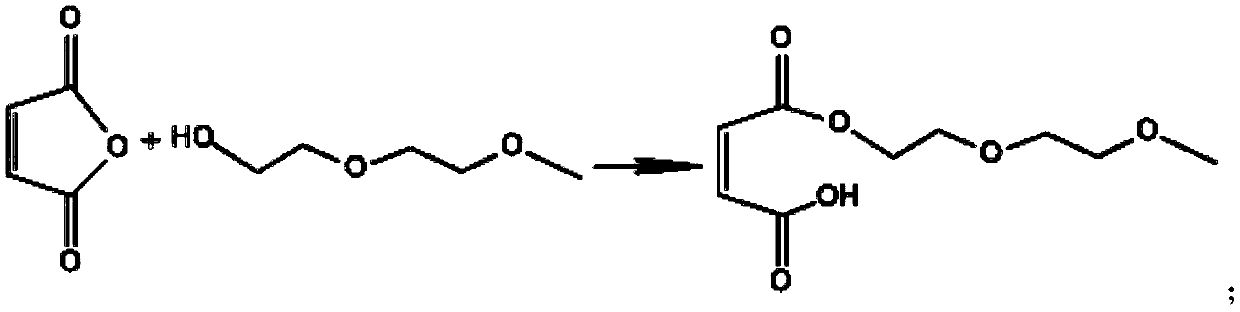

Mud-proof slump-retaining type polycarboxylate superplasticizer with low shrinkage and high adaptability and low-temperature preparation method thereof

InactiveCN110003402AImprove adaptabilityImprove mud slump performanceSuperplasticizerCarboxylic acid

The invention discloses a mud-proof slump-retaining type polycarboxylate superplasticizer with low shrinkage and high adaptability and a low-temperature preparation method thereof. The polycarboxylatesuperplasticizer is mainly prepared by the following steps: carrying out free radical polymerization on 4-hydroxybutylvinyl polyoxyethylene ether, unsaturated carboxylic acid, an unsaturated amide-type monomer, dipolyethylene glycol maleate, an unsaturated quaternary ammonium cationic monomer, an oxidizing agent, a catalyst, a reducing agent, a chain transfer agent and deionized water at 5-15 DEGC through an aqueous solution, regulating pH value by adding a sodium hydroxide solution, and supplementing water. The preparation method of the invention has advantages of low-temperature production, no heat source, simple equipment, no pollution, short reaction time and high production efficiency. The prepared mud-proof slump-retaining type polycarboxylate superplasticizer endows concrete withgood workability, good adaptability, low shrinkage and high strength, has excellent mud-proof slump-retaining property, and greatly reduces construction difficulty.

Owner:SICHUAN TONGZHOU CHEM TECH

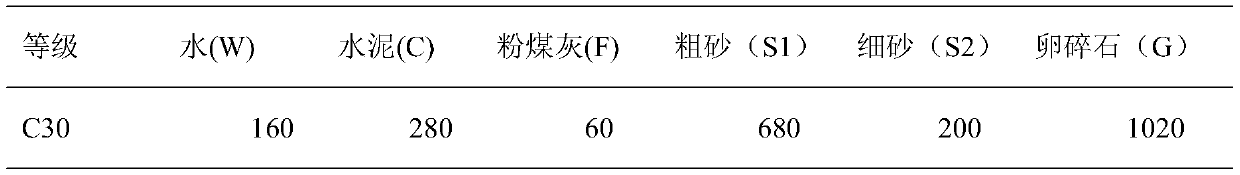

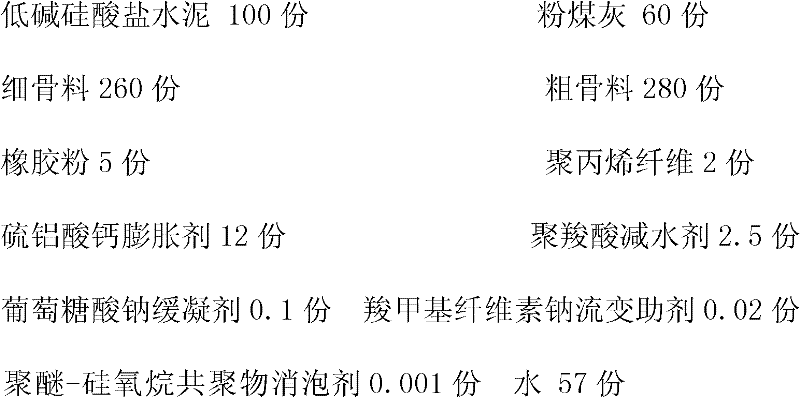

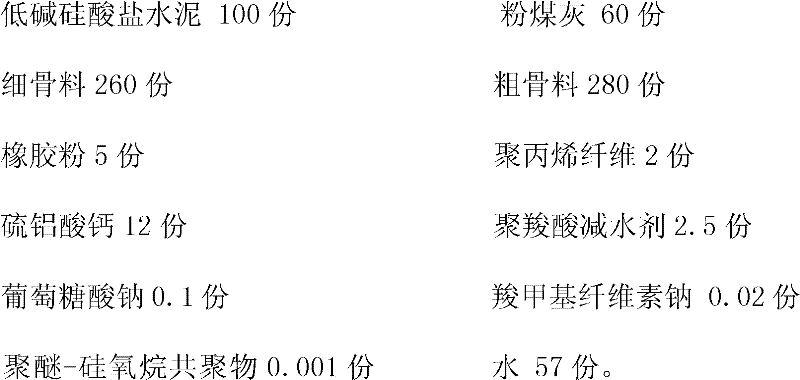

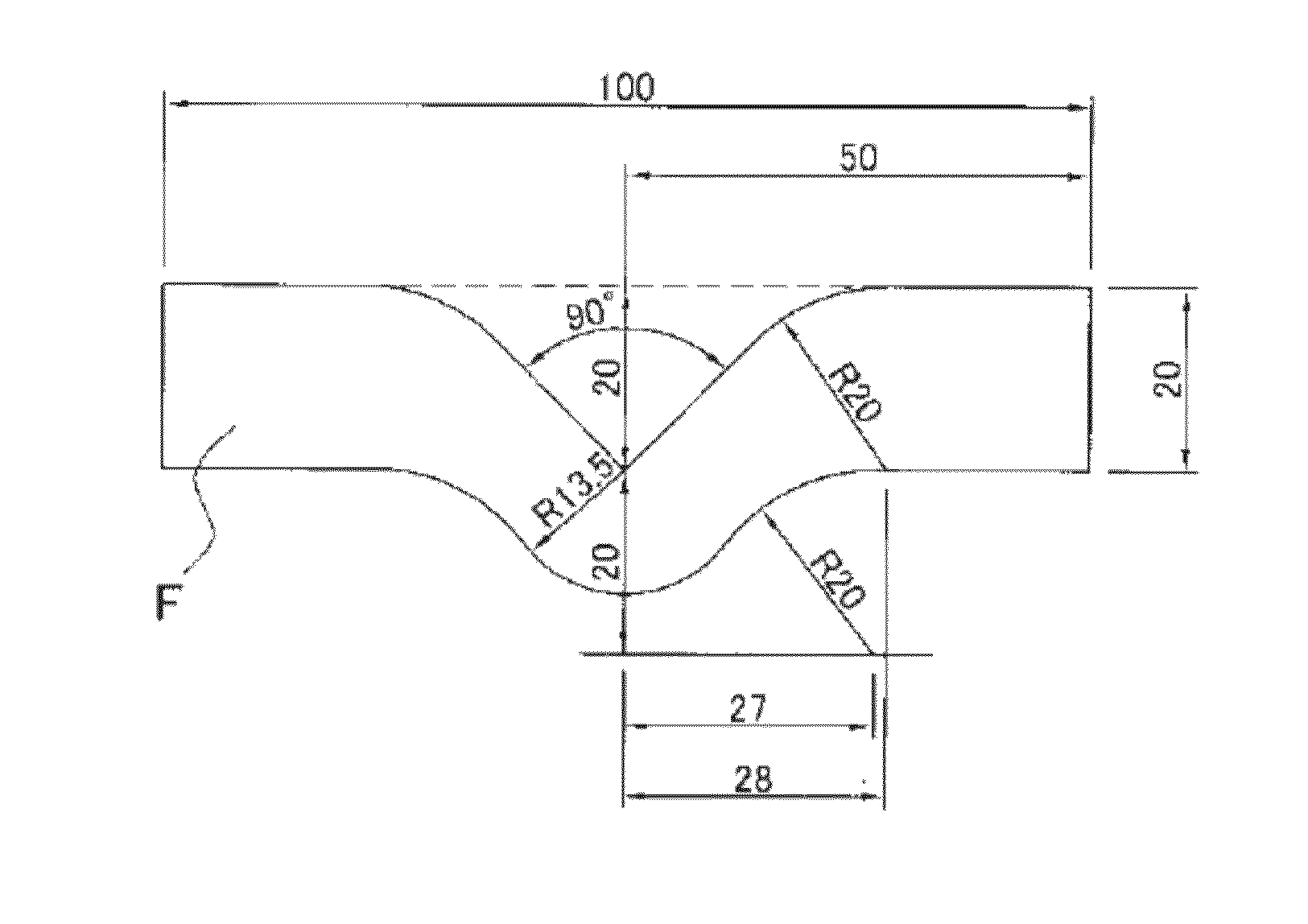

Self-compacting concrete mixture for plate-type ballastless track of railway

The invention discloses a self-compacting concrete mixture for a plate-type ballastless track of a railway, which is composed of the following ingredients in part by weight: 100 parts of cement, 20-80 parts of mineral admixture, 200-300 parts of fine aggregate, 250-350 parts of coarse aggregate, 2-10 parts of parts of rubber powder, 1-3 parts of polypropylene fiber, 10-25 parts of expansion agent, 1.0-3.0 parts of water reducing agent, 0.1-1 part of retarder, 0.01-0.05 parts of rheology accessory agent, 0.001 part of antifoaming agent and 60-80 parts of water; and the self-compacting concretemixture is prepared by blending and stirring the materials. The self-compacting concrete mixture disclosed by the invention has the advantages of large flow state, self-compacting property, non-segregation, low shrinkage, high anti-cracking property and vibration adsorption, and the like, so that the self-compacting concrete mixture can be used as filler between a rail board and a soleplate in a plate-type ballastless track and can also be used as filler between a turnout board and the soleplate in a turnout structure.

Owner:SOUTHWEST JIAOTONG UNIV

Super-high-performance cement base repairing material and preparing method thereof

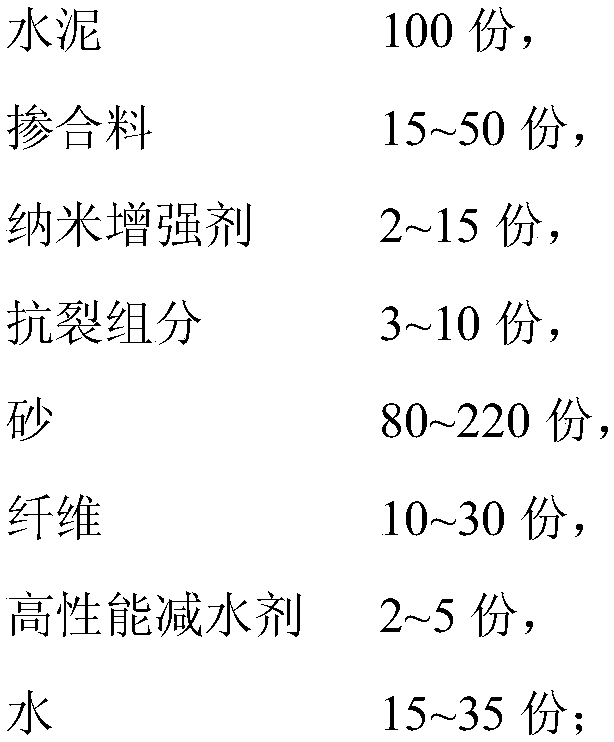

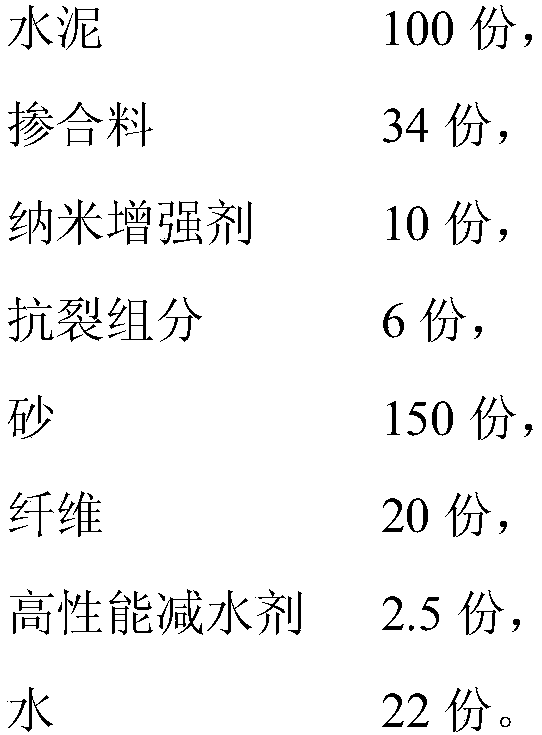

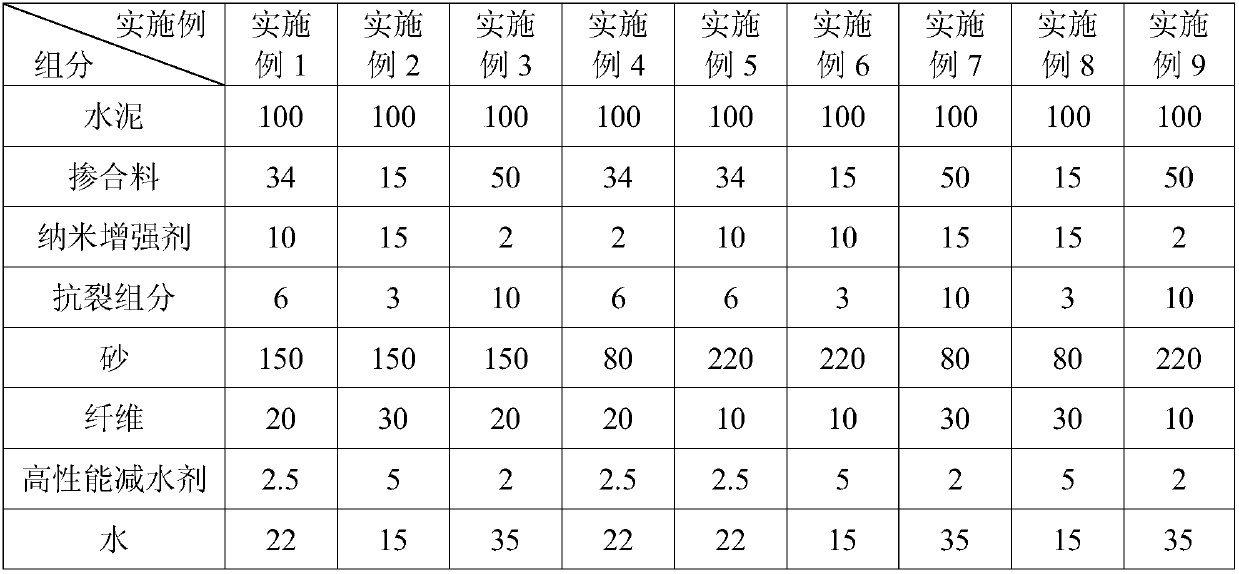

The invention discloses a super-high-performance cement base repairing material and a preparing method thereof. The repairing material is prepared from, by mass, 100 parts of cement, 15-50 parts of admixture, 2-15 parts of nanometer reinforcing agent, 3-10 parts of crack resistance component, 80-220 parts of sand, 10-30 parts of fiber, 2-5 parts of high-performance water reducing agent and 15-35 parts of water. The super-high-performance cement base repairing material has super-high tensile strength, bending resistance and adhesive strength and extremely low shrinkage performance, and has excellent construction performance, high elasticity modulus and super-high durability. The material has effects of repairing, reinforcing, seepage preventing, preventing and the like, and therefore the service life of the repairing material and a structure is prolonged. In addition, the material can be used as a joint material of a structural joint.

Owner:JIANGSU SOBUTE NEW MATERIALS

Polyurethane resin mortar for cement base material repairing

The invention relates to a polyurethane resin mortar composition for cement base material repairing, which comprises raw materials A, B and C, wherein the raw material A comprises the following materials in parts by weight: 100 parts of polyalcohol, 5-60 parts of plasticizer, 0.01-3 parts of catalyst, 0-2 parts of defoaming agent, 0-30 parts of chain extender or crosslinking agent, 0-3 parts of coupling agent and 0-10 parts of stabilizer; the raw material B is isocyanate or prepolymer thereof; the raw material C is solid filler; and the mass ratio of the three raw materials A, B and C is 10:(1-30):(10-200). The composition is used as the repairing material for concrete structures of ballastless tracks and cement asphalt mortar, and has the advantages of high curing speed, good low-temperature curing property, high ductility and the like.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +2

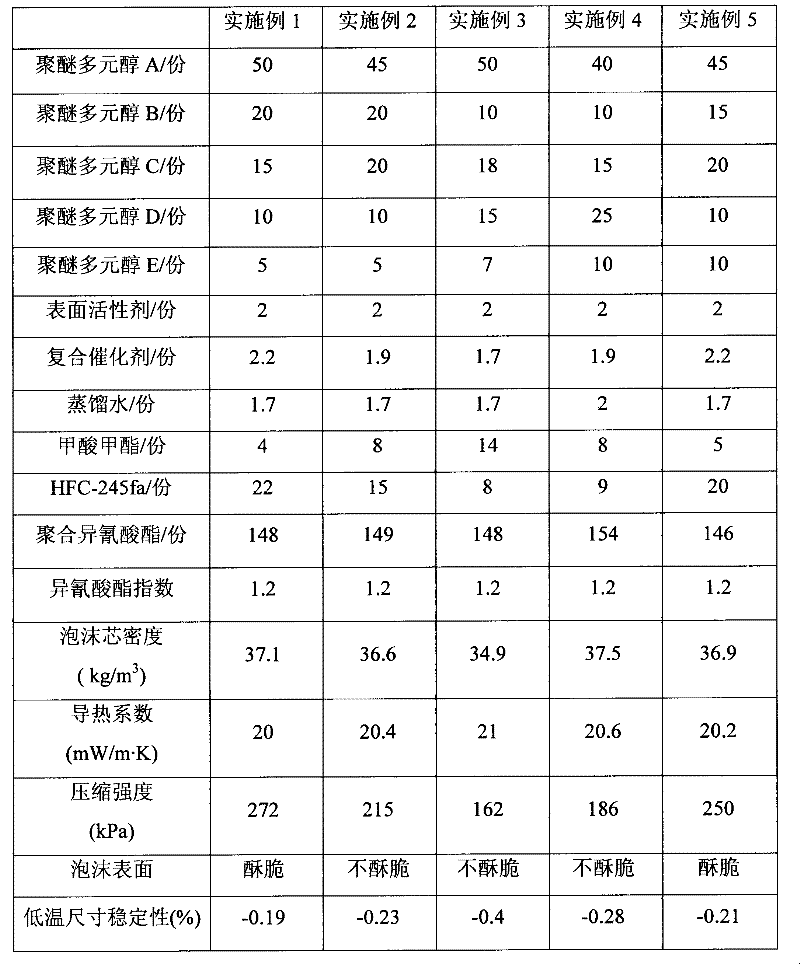

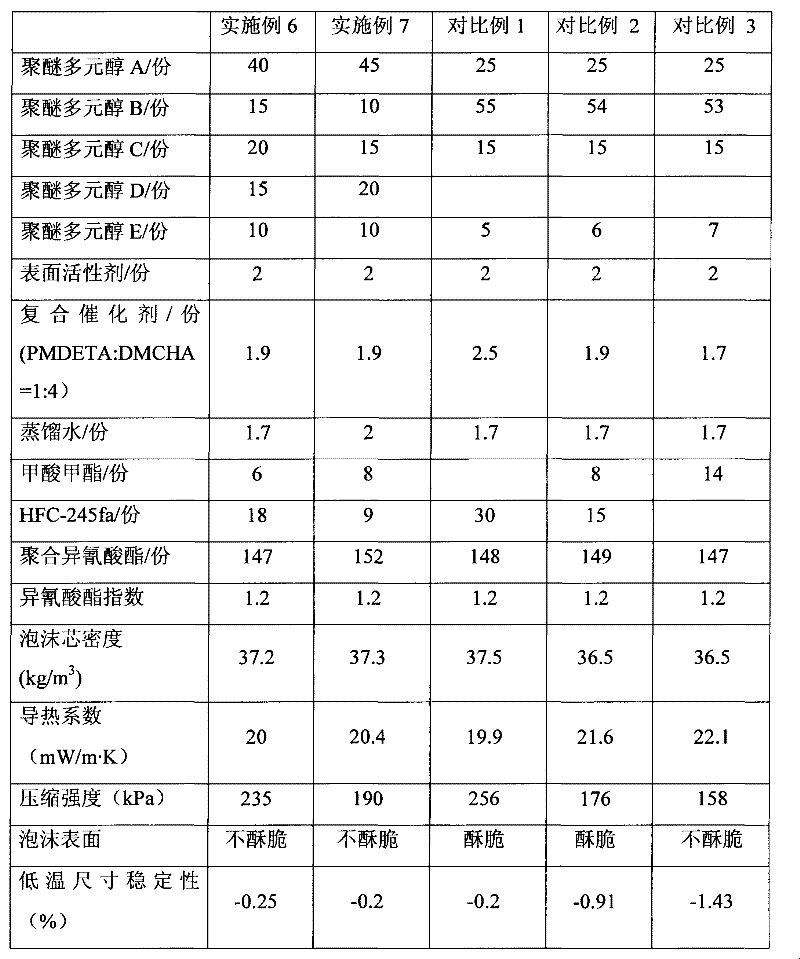

Polyurethane rigid foam and preparation method thereof

The invention discloses polyurethane rigid foam and a preparation method thereof, wherein foam plastic is prepared from the following raw materials by a high pressure foaming machine in parts by weight: 100 parts of combined polyether, 1.5-3 parts of surfactant, 1.5-3 parts of complex catalyst, 1-3 parts of water, 16-26 parts of mixed foaming agent and 140-170 parts of polymerized isocyanate, wherein the mixed foaming agent consists of methyl formate and 1,1,1,3,3-pentafluoropropane (HFC-245fa). The prepared polyurethane foam has low heat conductivity, good dimensional stability and proper cost.

Owner:万华化学(佛山)容威聚氨酯有限公司 +2

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

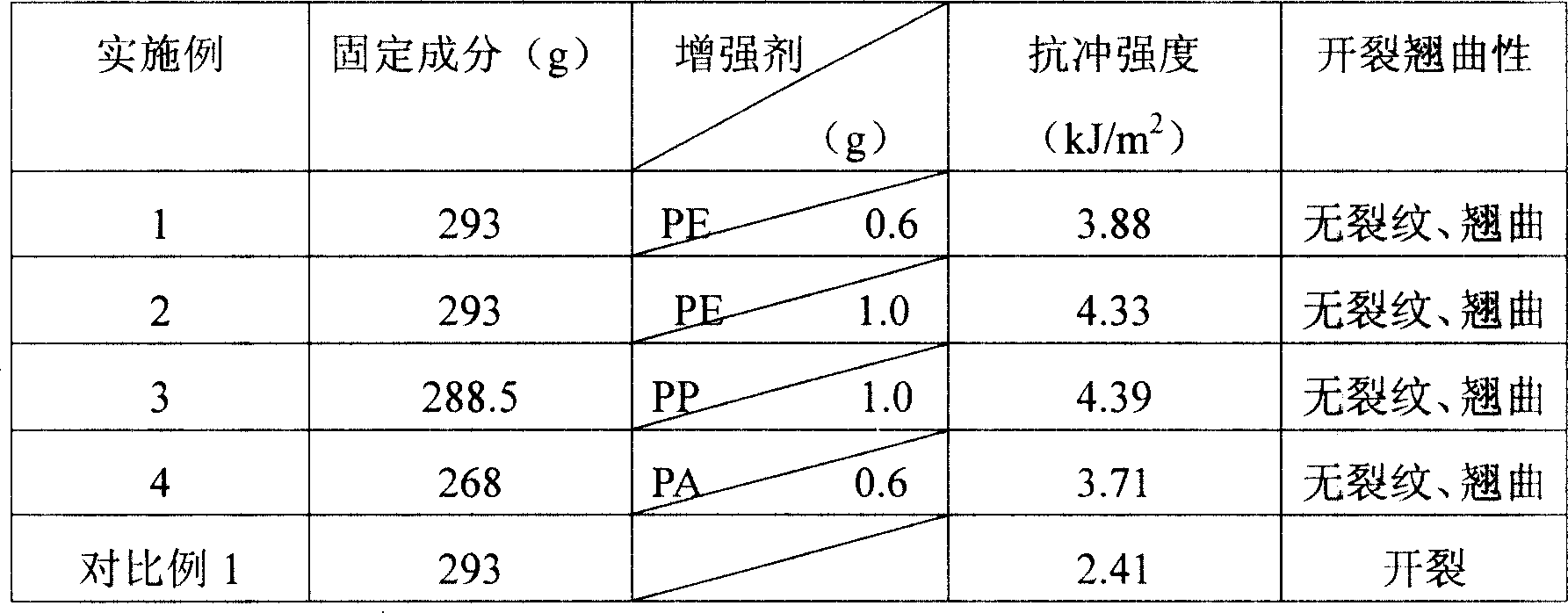

Artwork with modified urea-formaldehyde resin as adhesive and preparing method thereof

InactiveCN101012360AHigh impact strengthImprove cracking performanceDecorative surface effectsOrnamental structuresAqueous solutionPoly methacrylate

The invention discloses a binder and making method of modified urea-formaldehyde resin, which comprises the following steps: adopting urea-formaldehyde resin, fill, reinforcer, deoxidation agent, formaldehyde catching agent, anti-aging agent, anti-shrinking agent, hardener and auxiliary reinforcer; adopting modified copolymer of acrylic acid, sodium acrylate, N, N-dimethylamino propyl methyl acrylamide as anti-shrinking agent; making polyacrylamide solution reacted by acrylamide and ammonium persulphate as formaldehyde catching agent; allocating each component according to proportion; blending evenly; casting; extracting into vacuum; stripping; stewing; drying naturally; coating a layer of polymethacrylate paint on the surface of product; proceeding colorful paint; obtaining the product.

Owner:XIAMEN UNIV

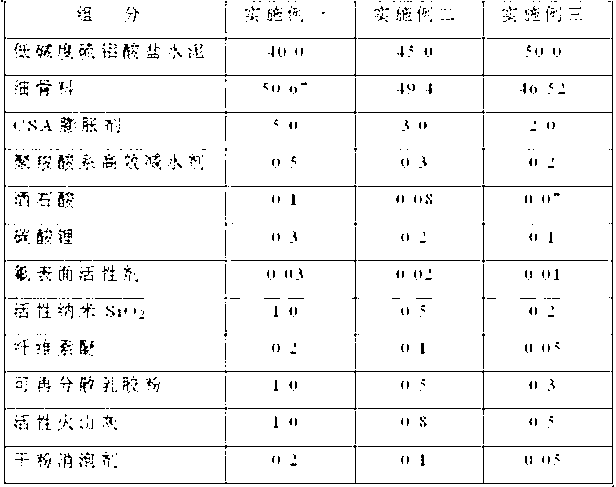

Concrete healant

The invention discloses concrete healant, which comprises following components by weight percent: 30 to 55 percent of gelatinization materials, 40 to 65 percent of fine aggregates, 0.1 to 0.5 percent of water reducing component, 0.05 to 0.5 percent of early-strengthening component, 0.05 to 0.2 percent of delayed-coagulation component, 0.2 to 1.0 percent of nano materials, 0.5 to 1.0 percent of high-activity substances, 0.01 to 0.2 percent of water retention thickening component, 0.2 to 2.0 percent of polymer and 0.02 to 0.2 percent of defoaming agent. The concrete healant not only has characteristics of good mobility, fast strength development, high adhesion strength and small retraction, but also can fill active substances into original concrete gaps and can produce compact crystals, so that the cohesion strength of the new and the old concrete interfaces can be remarkably improved, and the concrete healant is applicable to the concrete mending projects of bridges, caves, industrial workshops and civil construction.

Owner:苏州市姑苏新型建材有限公司

Ceramic polished brick and method for producing the same

The invention discloses a ceramic polished tile, which uses magnesian clay as a main plastic raw material, and mainly uses a SiO2-MgO-CaO-Al2O3 quaternary phase as a formulation system, wherein the SiO2 is between 65 and 85 percent, the MgO is between 5 and 20 percent, the CaO is between 3 and 15 percent, the Al2O3 is between 3 and 15 percent, KNa2O is between 0 and 3 percent, and Fe2O3 and TiO2 are between 0 and 2 percent. The invention also discloses a method for producing the ceramic polished tile. The ceramic polished tile uses the magnesian clay as the plastic raw material so that the source of the raw material is broadened,; and with the addition of talc and quartz, the ceramic polished tile has the characteristics of high brightness, high strength, high hardness, good wear resistance and the like, and has the advantages of wide range of firing temperature, small shrinkage, low product proportion, reduced production cost, low price and high quality, improved product competitive power, and great promoting function for the development of the ceramic polished tile industry.

Owner:况学成 +1

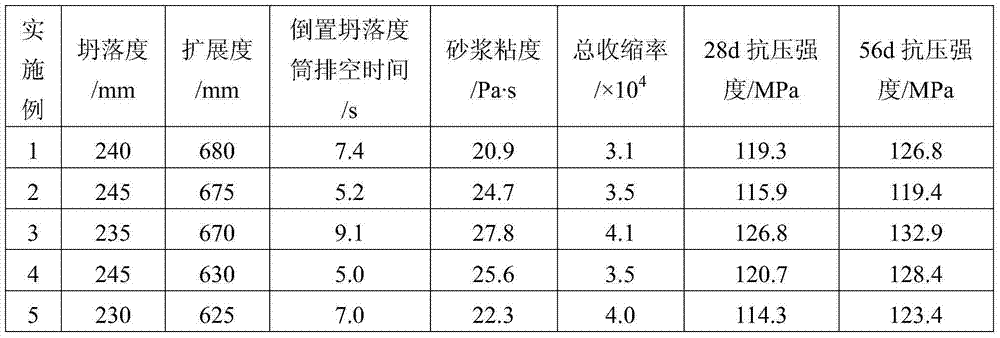

Low-shrinkage, low-viscosity and ultrahigh strength concrete

ActiveCN104844099AReduce hydration temperature riseReduce shrinkage cracksSolid waste managementWork performanceMicrosphere

The invention belongs to the technical field of building materials and particularly relates to low-shrinkage, low-viscosity and ultrahigh strength concrete. Based on a single formula proportional dosage, the low-shrinkage, low-viscosity and ultrahigh strength concrete comprises the following components by weight: 250-300kg of cement, 120-180kg of microspheres, 90-120kg of mineral powder, 820-860kg of machine-made sand, 950-1000kg of gravels, 7-11kg of a water reducer and 115-125kg of water. The components are mixed with stirring for 1.5-2 minutes to obtain a concrete mixture. The concrete provided by the invention is less in binding material use, the total shrinkage percentage is less than (0.03-0.04per mill), the emptying time of an inverted slump cone is 5-10 seconds, the viscosity of mortar in same proportion is 20-28 Mp.s, the 28d compressive strength is 110-130MPa, and the 56d compressive strength is 120-135MPa. The concrete has the characteristics of being low in bonding material use, short in stirring time, excellent in working performance and low in comprehensive cost, and can be produced on a large scale and has a broad application prospect.

Owner:中建商品混凝土(福建)有限公司 +1

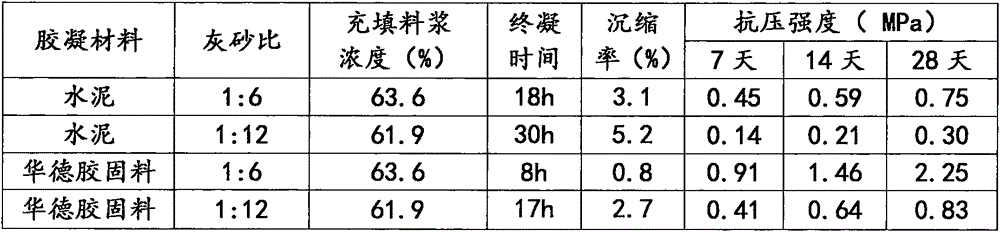

Low-shrinkage early-strength type mine filling cementing material

InactiveCN106746785AReduce surface tensionSmall shrinkageSolid waste managementCement productionGypsumSlag

The invention relates to a low-shrinkage early-strength type mine filling cementing material. The cementing material comprises the following components in percentage by weight: 50-90% of slag powder, 5-25% of cement or cement clinker, 1-30% of mineral additive, 0-10% of gypsum, 0.5-10% of alkali activator and 0.1-10% of shrinkage-reducing and cracking-resistant material. The invention solves the problem that fillers are prone to high shrinkage, cracking, slow setting and low strength when a slag-based alkali activation material is used for full tailing filling of a mine and the concentration of filling slurry is low especially in case of improper curing. The material is used instead of cement for mine filling, has favorable adaptability for tailings of different concentrations (55-80%), and has the advantages of fast filler setting, high strength and low shrinkage.

Owner:北京华德创业环保设备有限公司

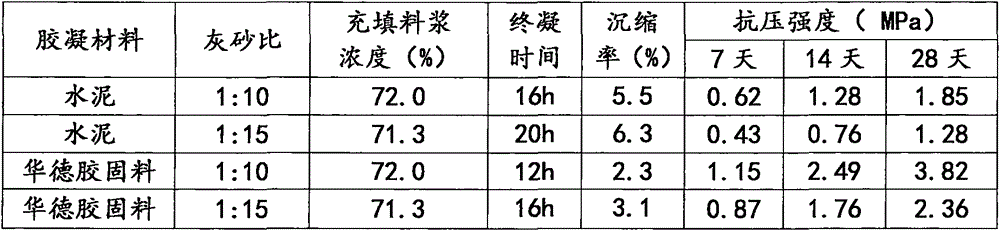

Flame retardant heat-insulation foam concrete and preparation method thereof

The invention discloses flame retardant heat-insulation foam concrete which consists of the materials by mass as follows: 30-60 parts of cement; 30-70 parts of coal ash; 10-40 parts of mineral powder; 0.05-1. 0 part of water reducing agent; 0.02-0.2 part of cellulose ether; 0.05-1.0 part of water repellent; 1-10 parts of anhydrous anhydrite; 0.06-0.2 part of polypropylene fiber; 0.1-0.4 part of foaming agent; and 0.30-0.60 part of water. The advantages are as follows: the foam concrete has high strength, low shrinkage and good water repellent property; the heat insulation performance is good and can meet different heat-insulation requirements of buildings; the preparation technology is simple; and industrial wastes such as coal ash, mineral powder and the like are utilized fully, and the flame retardant heat-insulation foam concrete has excellent environment-protection effects of utilizing waste, saving energy and the like, as well as better economic benefit.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

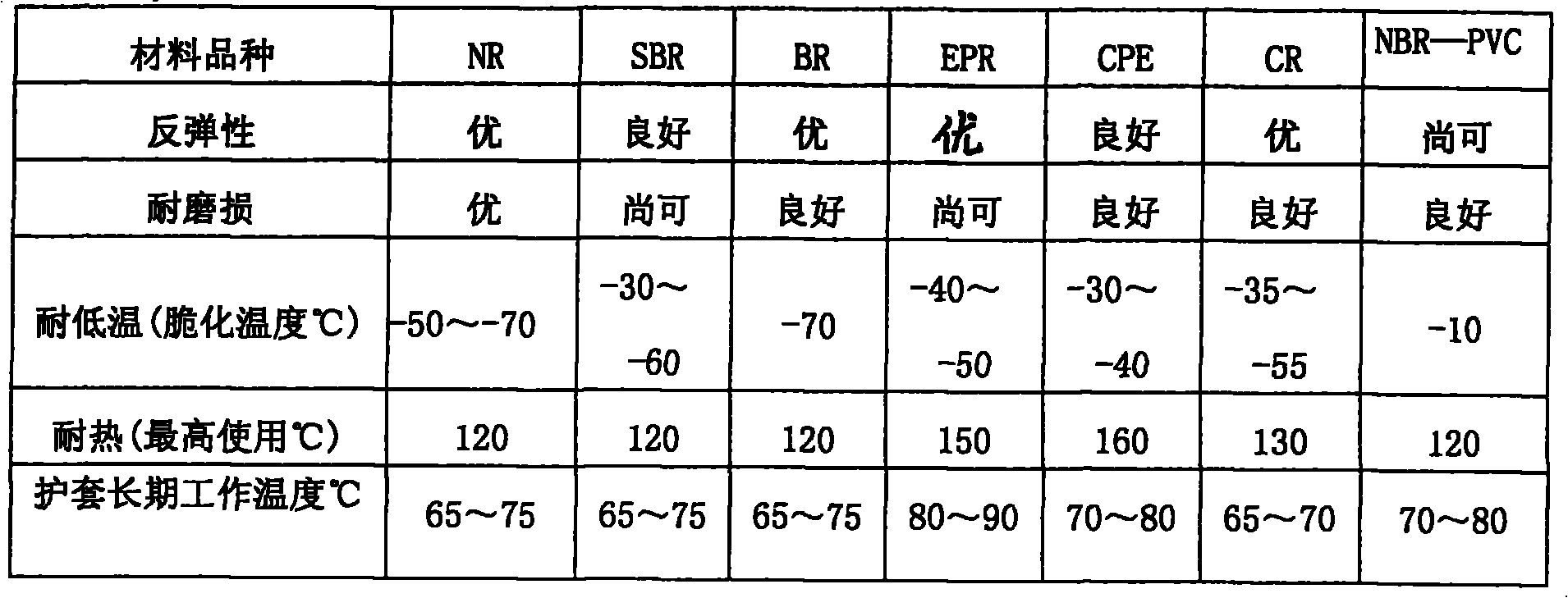

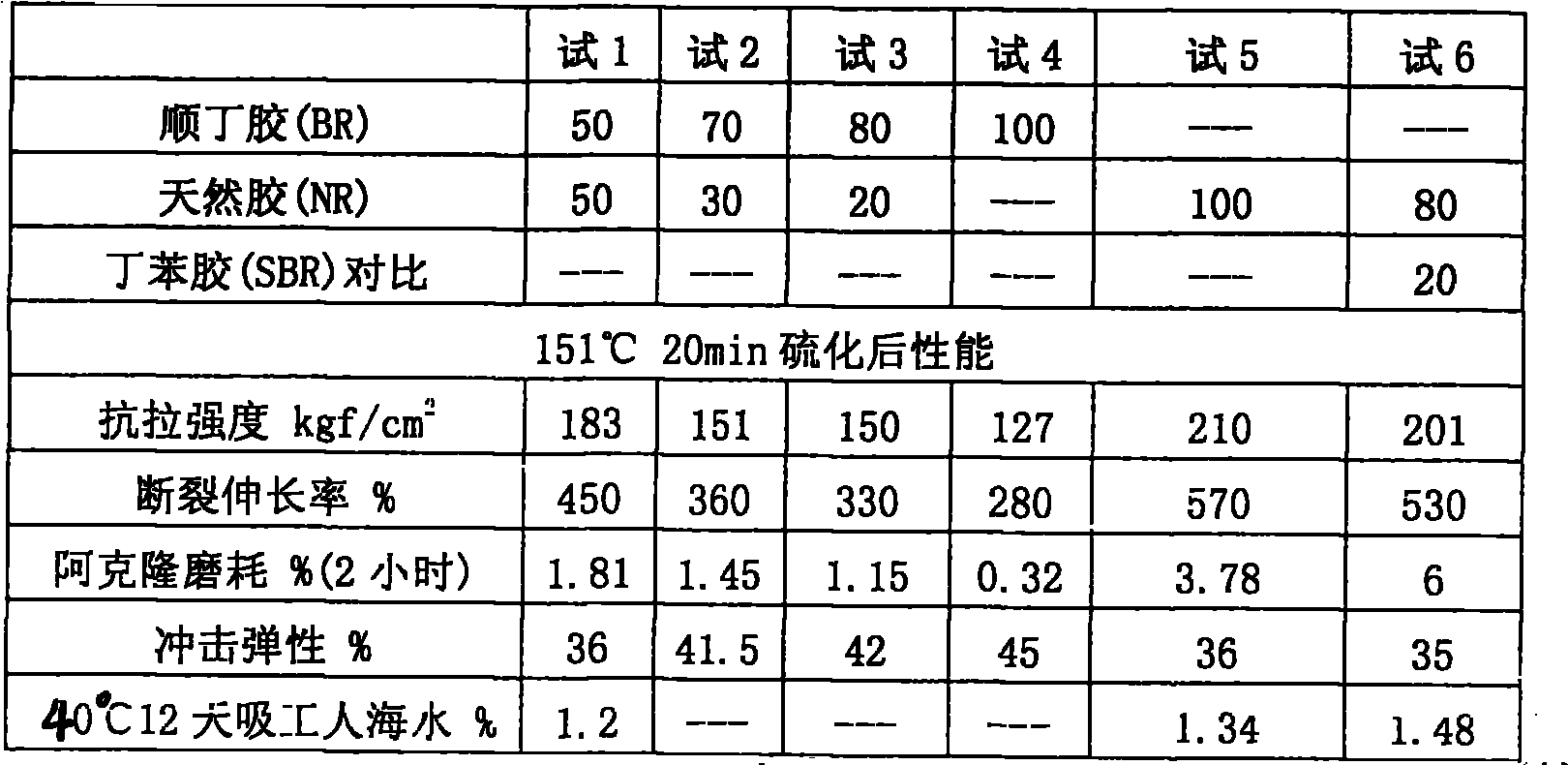

Cable jacket rubber and preparation method

ActiveCN101580606AScorch slowFast vulcanizationRubber insulatorsInsulated cablesTetramethylthiuram disulfideElectricity

The invention relates to a cable jacket rubber and a preparation method, wherein the cable jacket rubber has high elastic resilience, softness and abrasive resistance at a low temperature. The cable jacket rubber is characterized in that a base material of the rubber is formed by mixing 30 to 50 weight percent of natural gum and 50 to 70 weight percent of cis-butadiene rubber; a vulcanizing system in a rubber compounding agent is a low-sulfur high-accelerant vulcanizing system, the addition of sulfur is 0.3 to 0.6 weight percent of that of the base material of the rubbere, the addition of the accelerant tetramethylthiuram disulfide is between 1.0 and 1.3 weight percent, the addition of the accelerant N-cyclohexyl-2-benzothiazole sulfonamide is between 1.8 and 2.2 weight percent, and the addition of the accelerant diphenyl disulfide benzothiazole is between 0.6 and 0.9 weight percent. The cable jacket rubber has wide range of working temperature, and can be bent and distorted randomly without cracking at a long-term usage temperature of between 50 DEG C below zero and 70 DEG C, the impact elasticity is high and can reach 42 percent, the specific elongation is more than 350 percent, and the Akron abrasion loss is less than 2 percent, thus the cable jacket rubber is particularly suitable for wind-power generated electricity tower tube cables.

Owner:WUXI HUAMEI CABLE

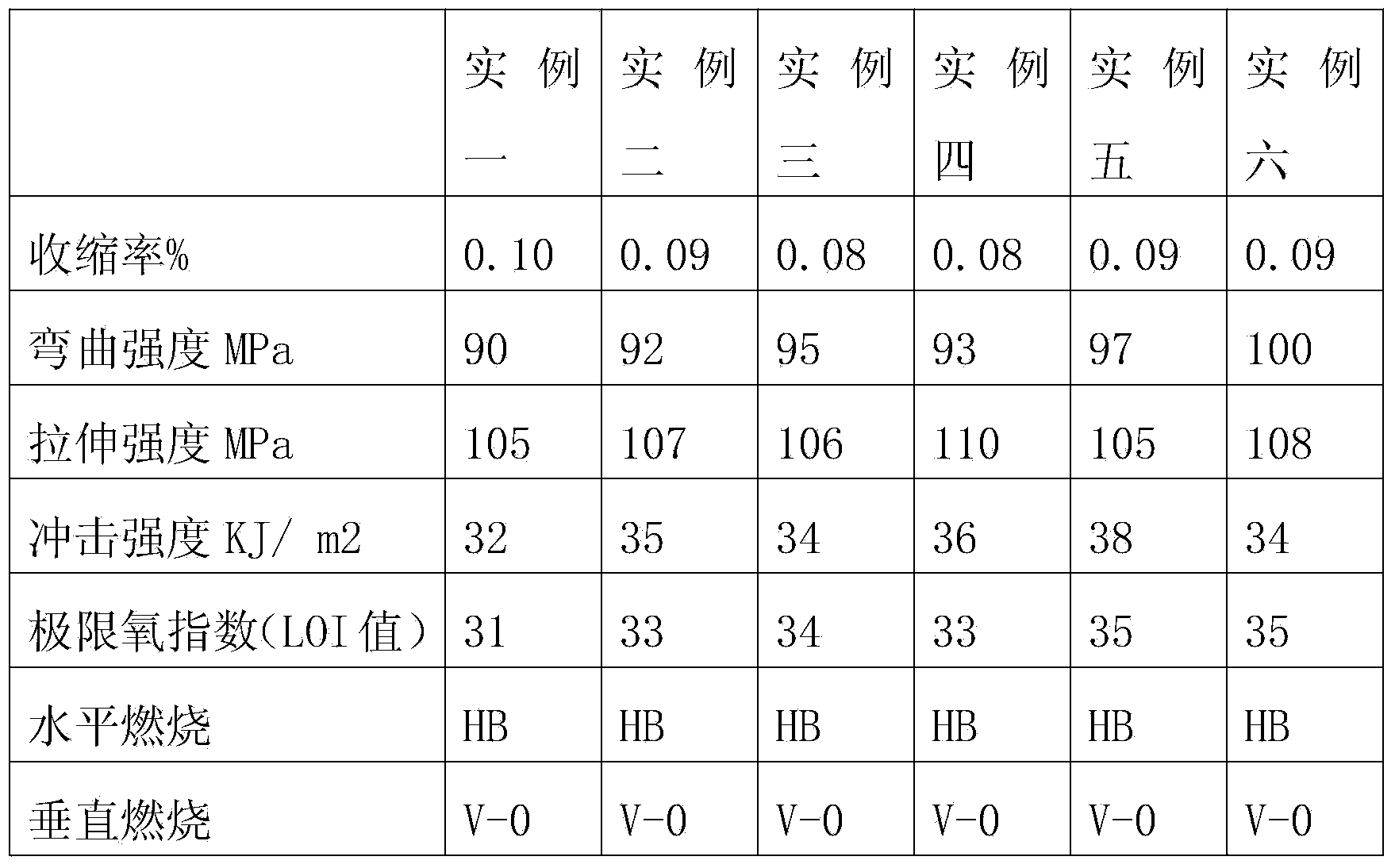

Low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board and preparation method thereof

The invention discloses a low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board and a preparation method thereof. The low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board is prepared from the following components in parts by weight: 50-60 parts of unsaturated polyester resin, 20-30 parts of a low-shrinkage additive, 1-3 parts of an accelerant, 0.5-2 parts of an initiator, 2-5 parts of a medium-temperature curing agent, 0.1-0.5 part of a thickening agent, 8-15 parts of a novel halogen-free flame retardant, 100-130 parts of inorganic filler, 2-3 parts of a release agent and 100-150 parts of fiberglass. The curing degree, the bending strength and the flexibility of the low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board can be improved; residual styrene in the fiberglass reinforced plastic board is reduced.

Owner:扬州万盛实业有限公司

Heat-shrinkable polyester film and package

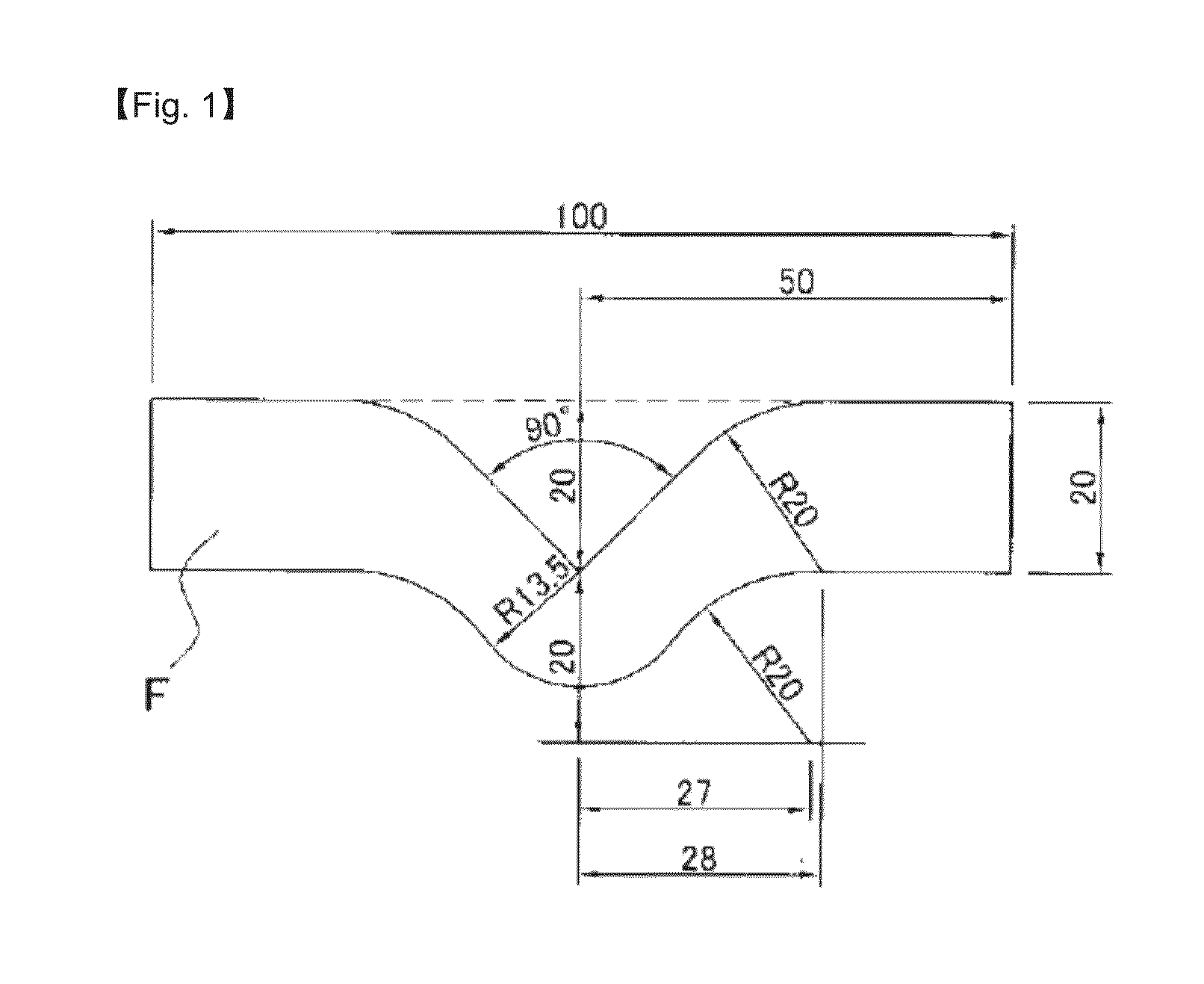

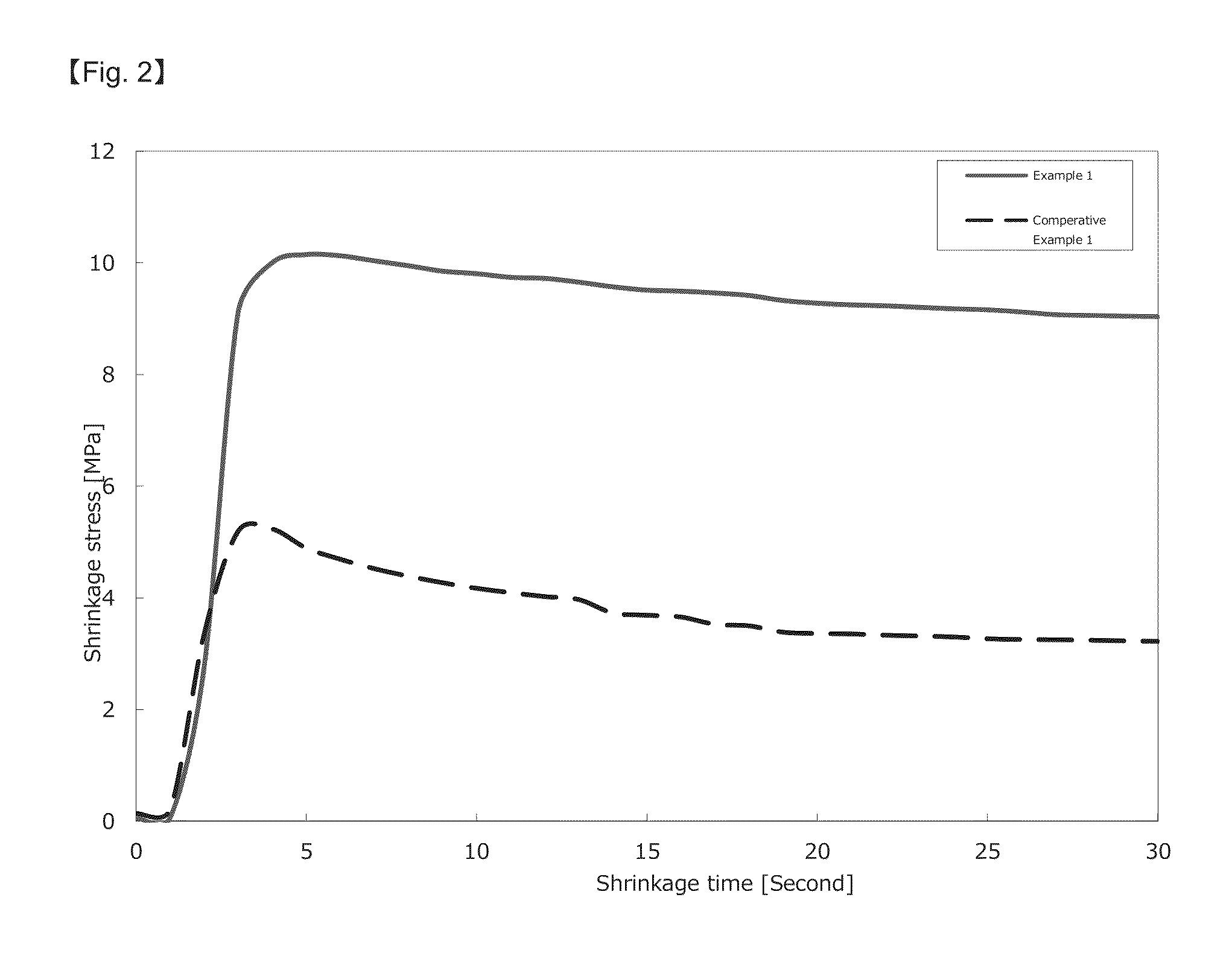

ActiveUS20160090456A1Excellent in shrinkage finish propertyLower performance requirementsLayered productsPolyesterAbsorbance

Provided is a heat-shrinkable polyester film that suppresses deterioration of the shrinkage finish property associated with a decline in performance during aging and does not loosen even after being used as a label. This heat-shrinkable polyester film comprising a polyester of a predetermined composition fulfills all of the following: (1) a ratio A1 / A2 of the absorbancy (A1) at 1340 cm−1 and the absorbancy (A2) at 1.410 cm−1 of the film measured by polarized ATR-FTIR from 0.45 to 0.75 or from 0.40 to less than 0.45 in either the width direction or longitudinal direction of the film; (2) a ratio (shrinkage stress after 30 seconds / maximum shrinkage stress) of the shrinkage stress after 30 seconds when the film is heat shrunk for 30 seconds in 90° C. hot air (shrinkage stress after 30 seconds) and the maximum shrinkage stress of from 75% to 100%; and (3) a hot-water shrinkage in the width direction of from 30% to 55% when, after aging the film for 672 hours in a 30° C., 85% RH atmosphere, the aged film is dipped in 70° C. water for 10 seconds.

Owner:TOYOBO CO LTD

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

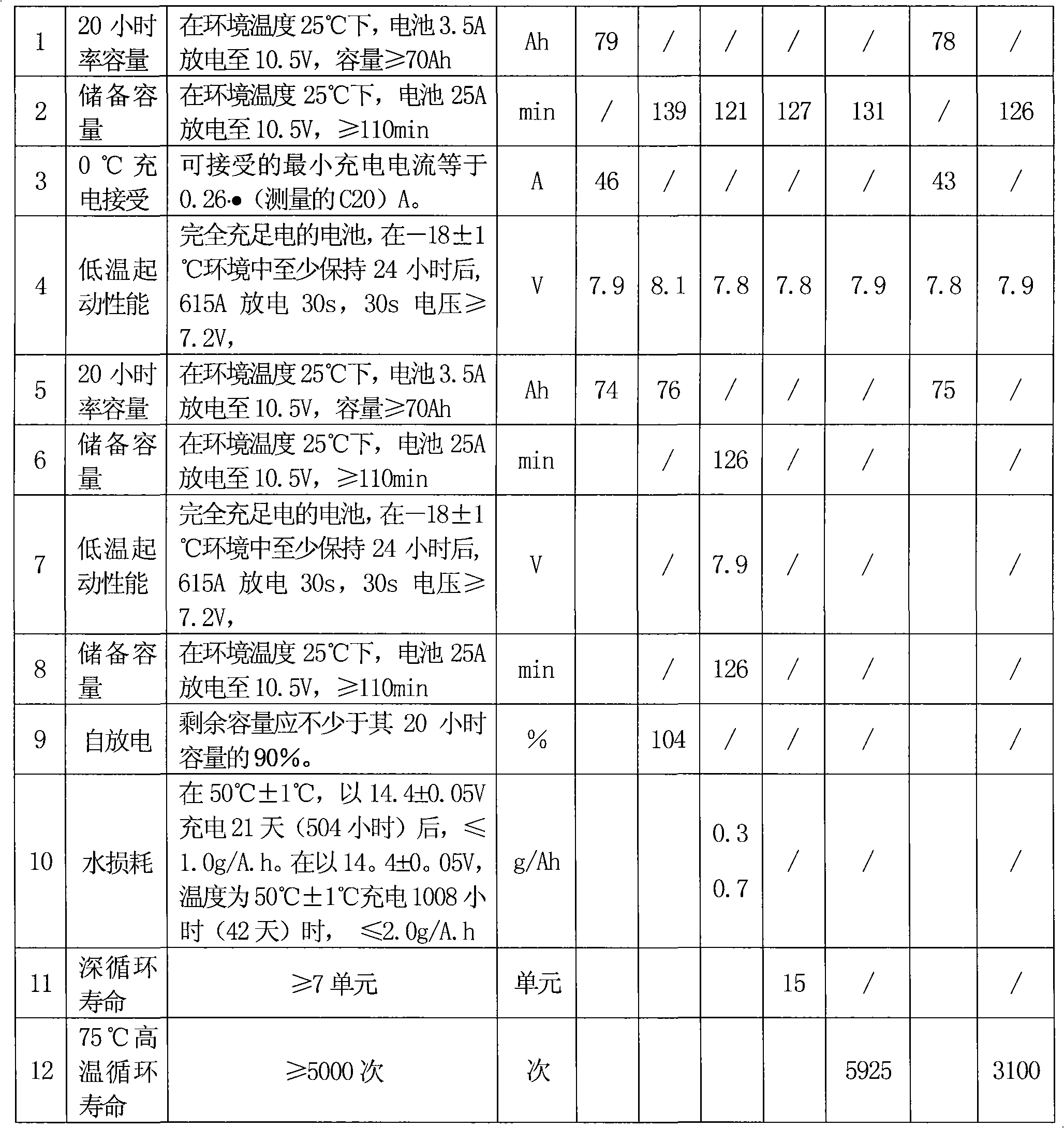

High-temperature lead-acid accumulator cathode diachylon and preparation method

ActiveCN101330140AExcellent high temperature life performanceImproved high temperature life performanceLead-acid accumulator electrodesFiberSodium lignosulfonate

The invention relates to vehicle used high-temperature lead acid battery negative pole lead plaster and a preparation method thereof, belongs to the storage battery technical field and is used for improving the high-temperature service life and the low-temperature starting capacity of the storage battery. The technical proposal is as follows: the lead plaster solid raw material comprises the following materials by the weight unit: 100 units of lead powder, 0.01 to 0.5 units of sodium lignosulfonate, 0.01 to 0.8 units of high-temperature sodium lignosulfonate, 0.01 to 1.0 unit of graphite powder, 0.03 to 0.08 units of fibre, 0.3 to 1.2 units of barium sulfate, 0.2 to 1.0 units of humic acid and 0.1 to 0.4 units of black carbon. The materials, such as the high-temperature sodium lignosulfonate and the graphite powder are added to the compounding recipe of the negative pole lead plaster, thereby the performance of the negative pole active materials is effectively improved at the high temperature by matching with the reasonable compounding recipe ratios of the added materials, the contraction is reduced, thereby the high-temperature service life and the low-temperature starting capacity of the storage battery are enhanced, particularly the high-temperature service life can be above 90 percent higher than the storage battery prepared based on a common compounding recipe.

Owner:FENGFAN

Soft magnetic, deformable composite material and process for producing the same

InactiveUS6537389B1Reduced pore volumeSmall shrinkageInorganic material magnetismSolid state diffusion coatingCeramicMetal

A magnetically soft, moldable composite material include powder grains coated with nonmagnetic thermoplastic compounds or with molecular precursors for ceramics or with intermetallic compounds, the magnetic properties of the magnetically soft composite material being adjustable in that fashion. Also described is a method for manufacturing a magnetically soft, shapable composite material coated in that fashion, which can subsequently be processed into shaped parts.

Owner:ROBERT BOSCH GMBH

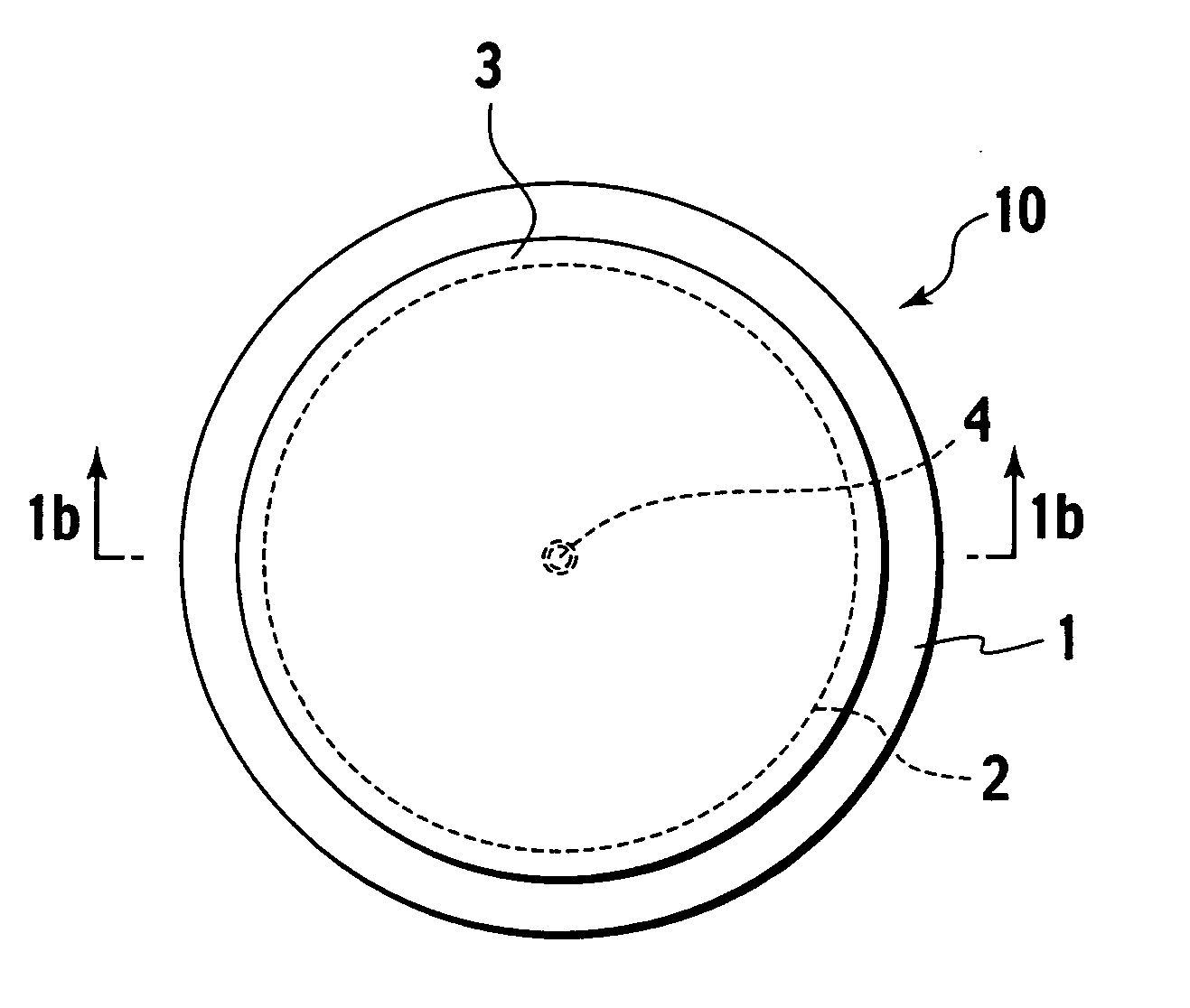

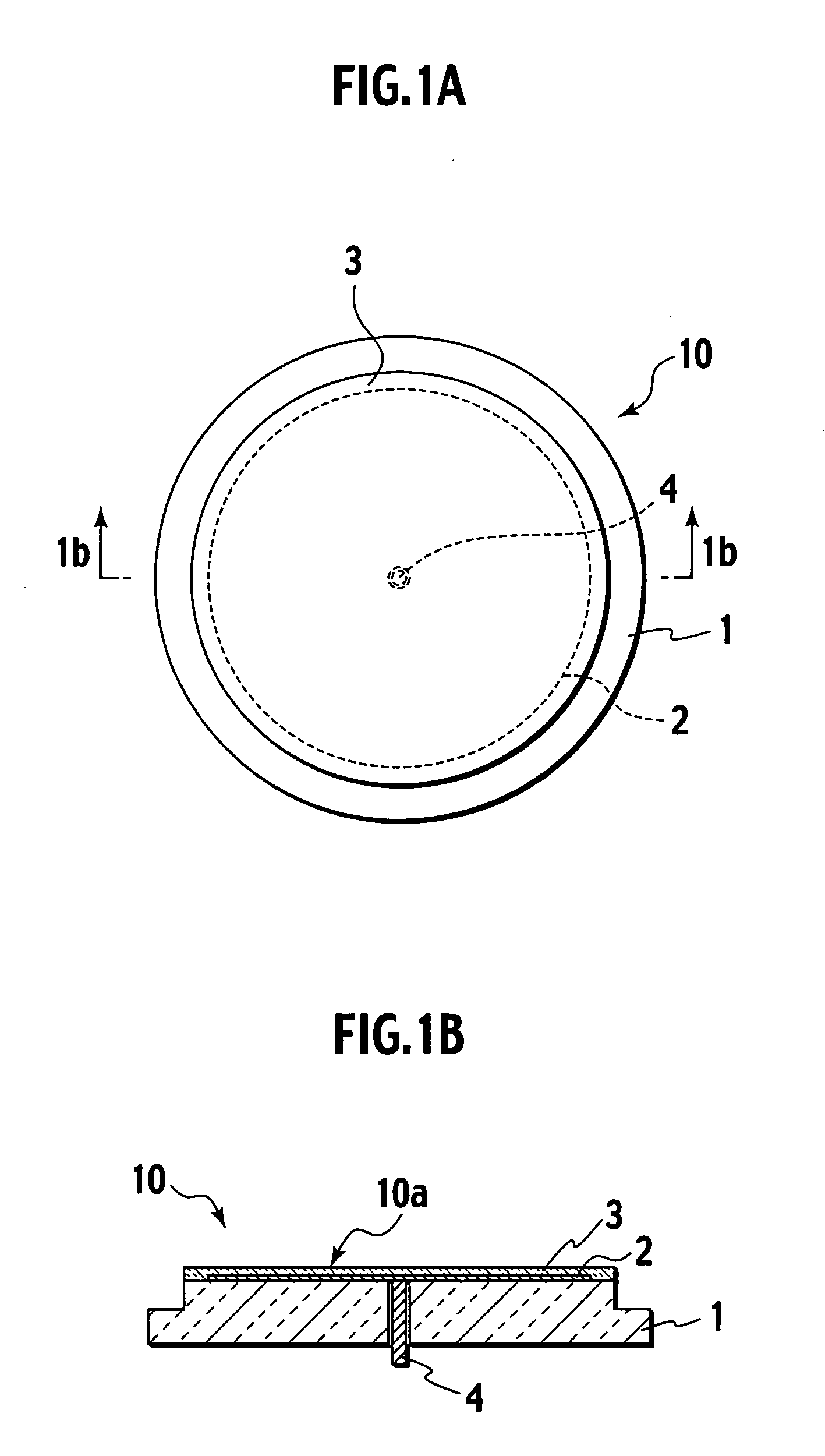

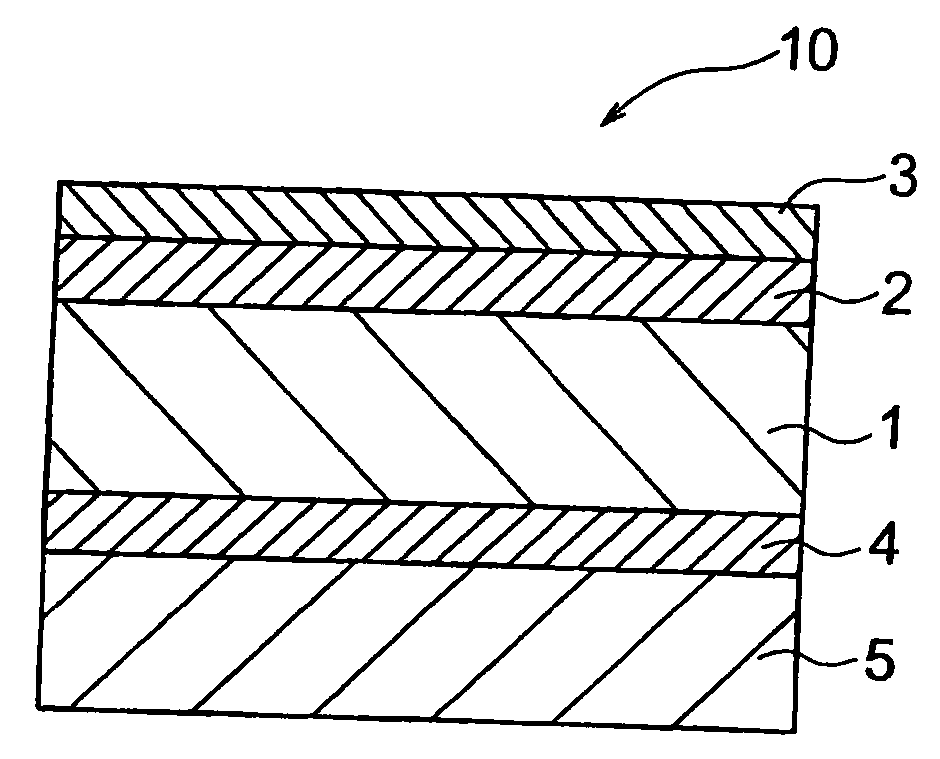

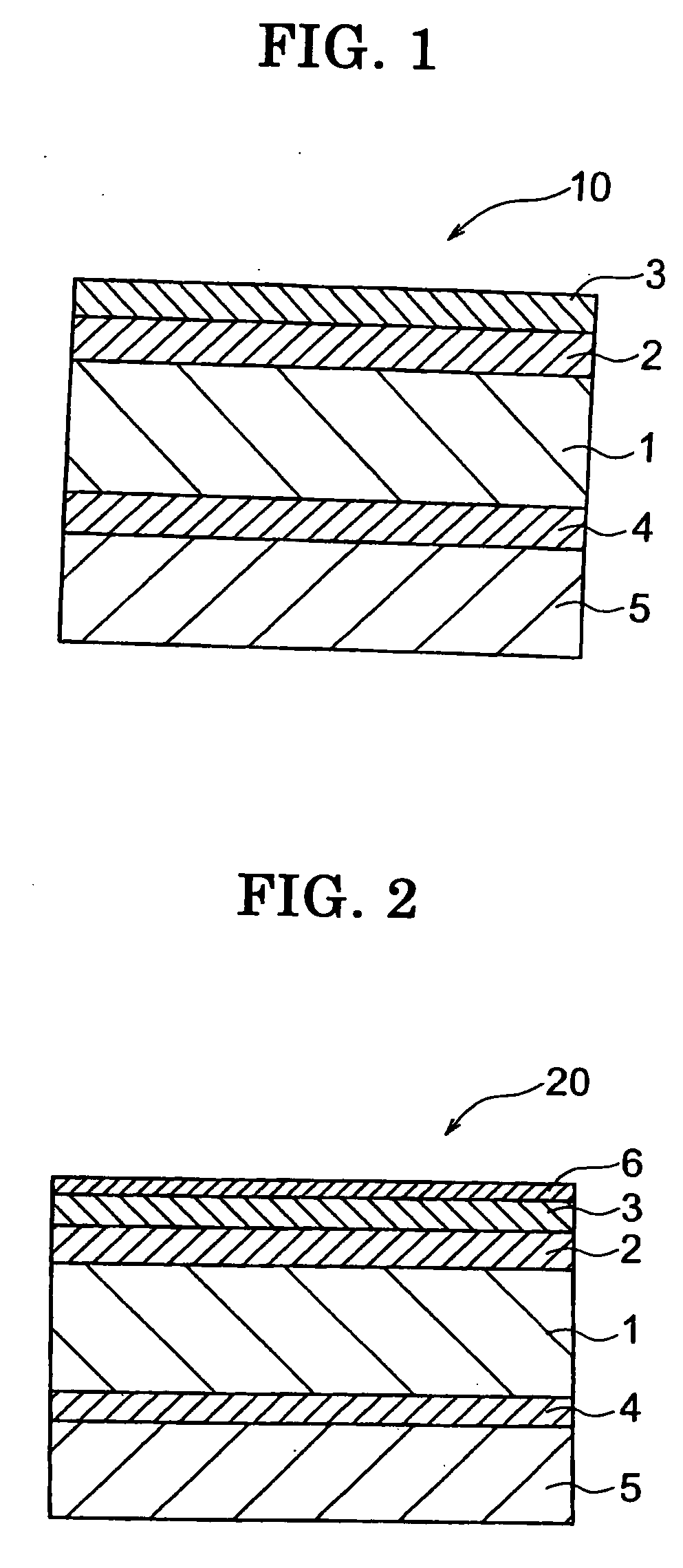

Film for optical applications

ActiveUS20050238879A1Inhibits the formation of defectsImprove crack resistanceSynthetic resin layered productsCellulosic plastic layered productsCarbamateCrack resistance

A hard coat film for optical applications which suppresses formation of defects on the surface derived from roughness of the surface of the substrate film, exhibits excellent scratch resistance and crack resistance and suppresses curling of the substrate film is provided. The film for optical applications comprises (A) a layer of a cured resin 2 which comprises 70% by weight or more of a cured resin derived from a difunctional urethane acrylate-based oligomer having a weight-average molecular weight of 3,000 or greater and has a thickness of 5 to 25 μm and (B) a hard coat layer 3 which comprises a resin cured by irradiation with an ionizing radiation and has a thickness of 1 to 15 μm, layers (A) and (B) being successively laminated on one face of a substrate film 1.

Owner:LINTEC CORP

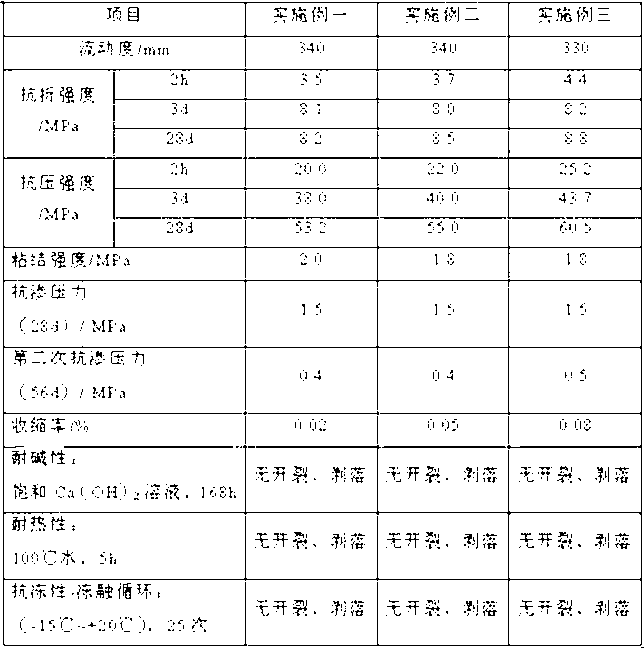

Machine-spraying-type plastering gypsum mortar and preparation technology thereof

ActiveCN104961423ASolve the problems that cannot meet the needs of mechanized constructionReduce dosageBond strengthMaterials science

The invention relates to machine-spraying-type plastering gypsum and a preparation technology thereof and belongs to the technical field of building materials. The machine-spraying-type plastering gypsum is characterized by being prepared from the following raw materials: 200-400 parts of gypsum, 10-60 parts of cement, 520-650 parts of fine aggregate, 80-160 parts of heavy calcium powder, 2-4 parts of redispersible emulsion powder, 2-4 parts of hydroxypropyl methyl cellulose ether, 0.15-0.25 part of an air entraining agent, 5-10 parts of expanded perlite, 0.3-0.8 part of a gypsum retarder and 200-300 parts of water. The machine-spraying-type plastering gypsum is applicable to being directly sprayed to a wall surface by adopting a mortar spraying machine, both time and labour are saved, construction efficiency can be improved, and cost is reduced; bonding performance with the wall surface is good, rebounce is not caused, anti-sagging performance is good, both bonding strength and compressive strength can meet requirements, and cracking of a wall body can be reduced; and usage amount of gypsum is low, and cost can be effectively reduced.

Owner:新疆荣高鸿骏新材料技术有限公司

Method for welding anticorrosion steel pipeline with no internal repaired mouth

InactiveCN103008988AReduce the chance of welding defectsRigid enoughArc welding apparatusChemical industryAlloy

The invention provides a method for welding an anticorrosion steel pipeline with no internal repaired mouth, which is applicable to the anticorrosion treatment of a steel pipeline welding connector with an anticorrosion coating in the petroleum industry and the chemical industry. The method is characterized in that a groove with a certain length and depth is machined on a position which is at a certain distance from the end part of the steel pipe, an anticorrosion alloy material is surfaced on the groove, the end part of the surfaced steel pipe is machined into a V-shaped groove, an anticorrosion coating with sufficient thickness is coated on the inner wall of the steel pipe, the anticorrosion coating covers sufficient length of the anticorrosion alloy surfacing layer, then two steel pipes are in butt connection with each other, layering welding is carried out after the two steel pipes are fixed on one point, an argon tungsten-arc welding method is adopted, the anticorrosion alloy material which is identical to that of the surfacing is selected as the filling material, and argon is filled into the pipe to protect the pipe in the welding process. Due to the adoption of the novel technology for welding the anticorrosion steel pipeline with no internal repaired mouth, the corrosion resistance of the inner wall and a weld mouth of the pipeline can be guaranteed, the internal mouth repairing technology on the spot after the welding can be avoided, characteristics such as simplicity in construction and reliability in performance can be realized, and the method is suitable for the real engineering application of the petroleum and chemical industry fields.

Owner:HARBIN INST OF TECH

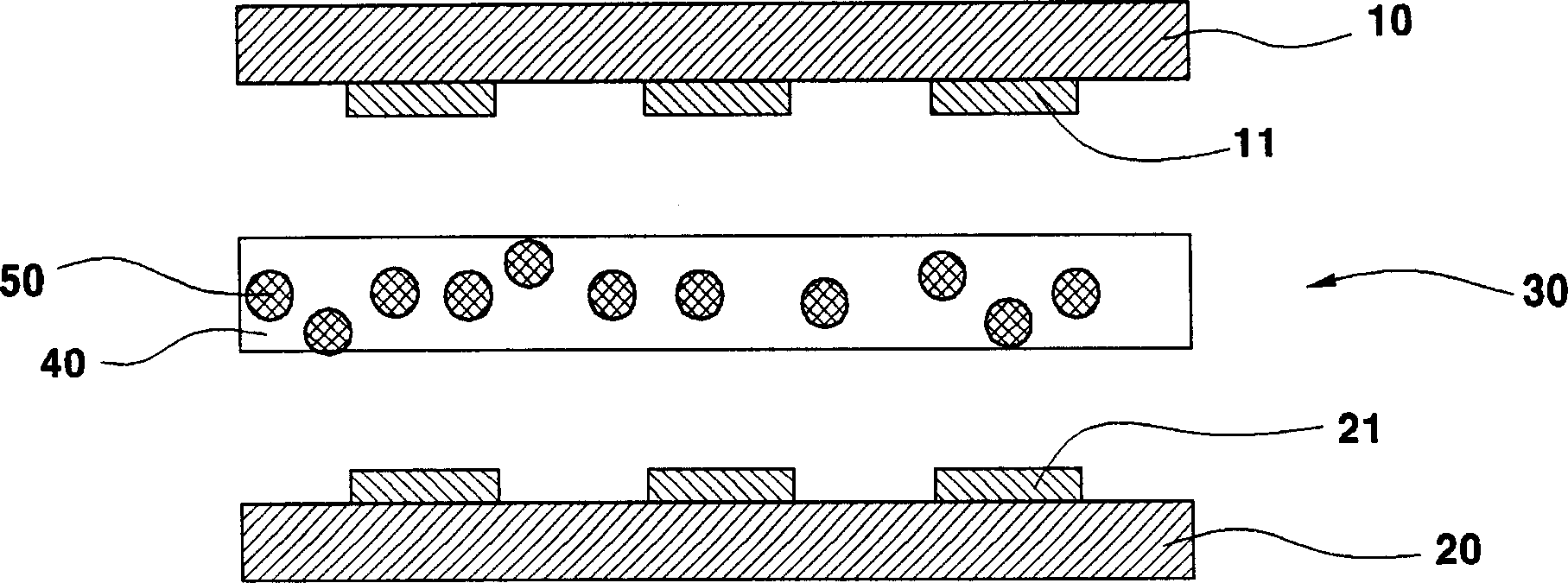

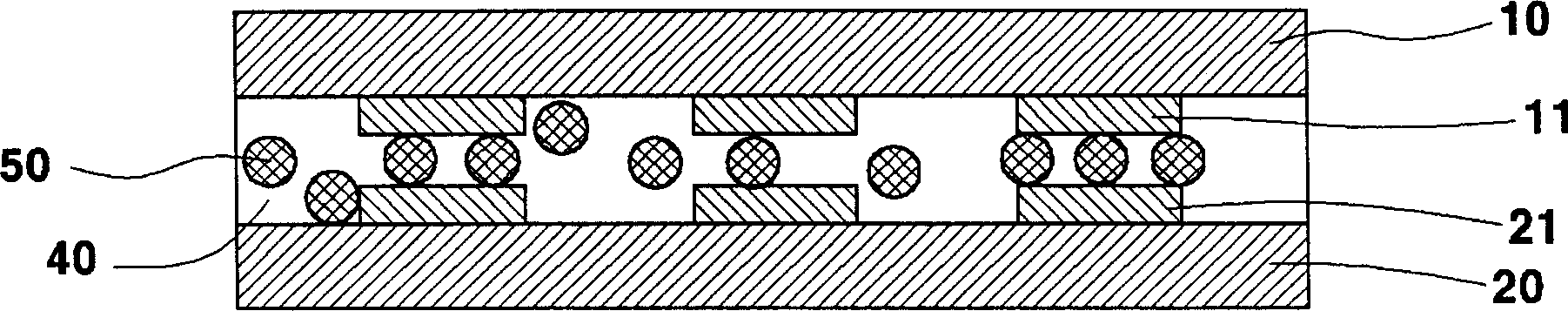

Isotropic conductive adhesive and adhesive film using the same

InactiveCN1712483ASmall shrinkageAvoid short circuitPrinted circuit assemblingVinyl aromatic copolymer adhesivesAnisotropic conductive adhesiveIsotropic conductive adhesives

The present invention provides an anisotropic conductive adhesive comprising an insulating adhesive component and a large number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains alternating Linked rubber resin. When connecting circuits, by minimizing the thermal shrinkage of the anisotropic conductive adhesive in the polymerization reaction or curing reaction, it is possible to prevent peeling of the adhesive or a decrease in the bonding strength of the circuit. It prevents short-circuit between adjacent electrodes and is excellent in long-term reliability.

Owner:H&S HIGHTECH

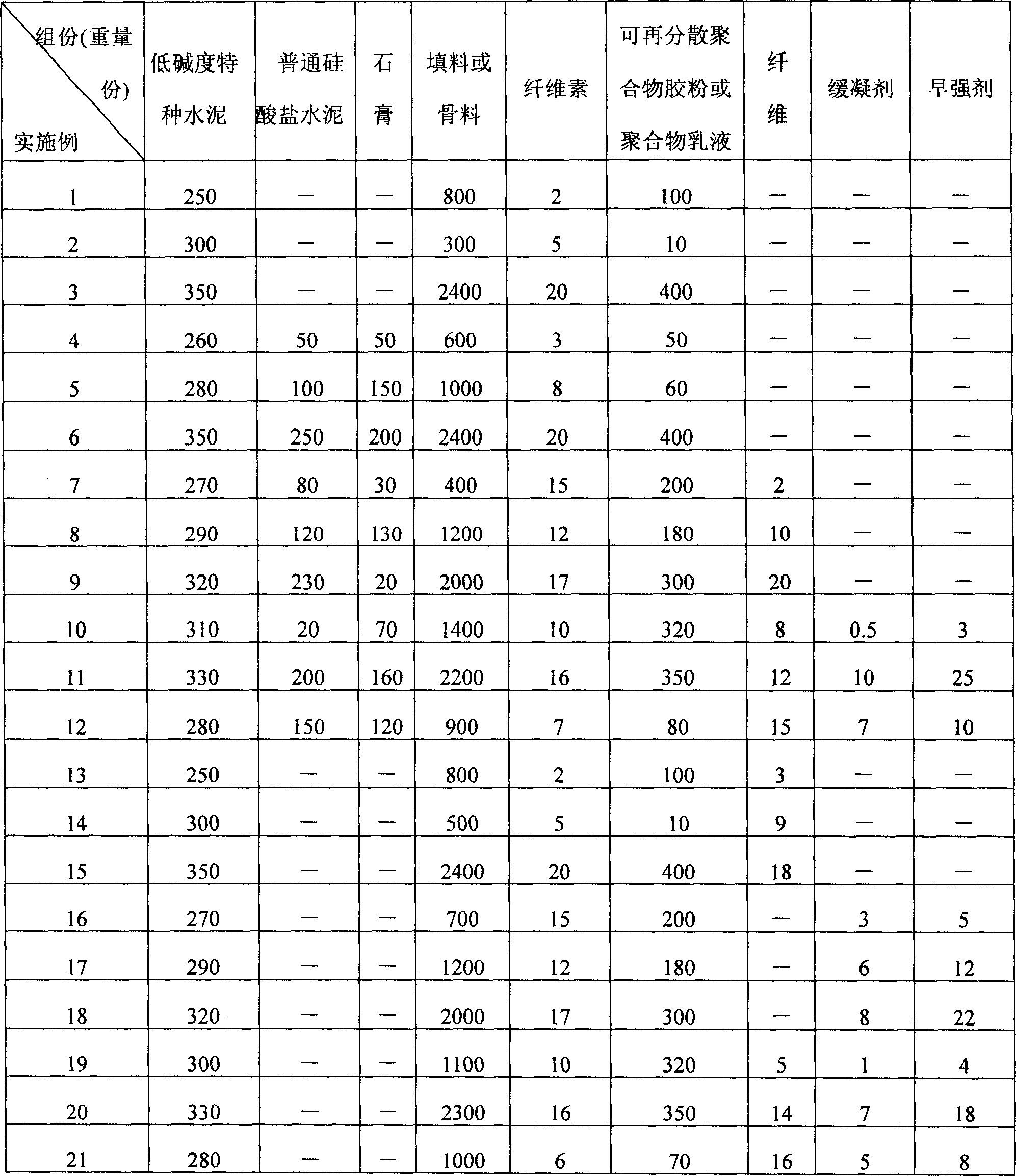

Mortar

InactiveCN1951858AOvercoming brittlenessOvercome defects such as cracking and drummingFiberCellulose

The invention discloses a mortar, which comprises the following parts: 250-350 parts of low-alkaline special typed cement, 0-250 parts of common silicate cement, 0-200 parts of calcium sulfate, 300-2400 parts of filler or aggregate, 2-20 parts of cellulose, 10-400 parts of redispersion polymer gel powder or 10-400 parts of polymer emulsion, 2-20 parts of fiber, 0.5-10 parts of retarder and 3-25 parts of instant coagulant. The low-alkaline cement contains the following clinker with 15%-35% C4A3S, 15%-35% C2S, 0%-35% C3S, 4%-15% CaSO4, 0%-15% C4AF and 0%-5% C3A . The mortar with low-alkaline cement and water can be preserved for 1-7d, whose pH value is 8-9.5.

Owner:王红

Rapid-hardening early-strengthening wearable concrete material for road repair and its preparation method

ActiveCN1699243AHave fast hardening and early strength requirementsSmall shrinkageSolid waste managementSlagMetakaolin

The invention provides a rapid-hardening early-strengthening wearable concrete material for road repair and its preparation, wherein the material mainly comprises the following ingredients, steel slag powdered ore 40-80kg / m3, metakaolin 320-560kg / m3, alkaline exciting agent solution 200-300kg / m3, steel slag fine aggregates 630-1800kg / m3, steel fiber 62-156kg / m3, and polypropylene fiber 1kg / m3.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com