Patents

Literature

196results about How to "Reduce water-cement ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyether class polycarboxylic acid high-efficiency water reducing agent and preparation method thereof

The invention relates to a polyether class polycarboxylic acid high-efficiency water reducing agent and a preparation method thereof, belonging to the field of concrete materials, structures and engineering of building materials. The polyether class polycarboxylic acid high-efficiency water reducing agent raises the temperature of water solutions of 15-55 mass percent of allyl polyethenoxy ether and 0-6 mass percent of chain transfer agent is raised to 50-90 DEG C, one side is dropwise added with a water solution of 0.01-0.9 mass percent of an evocating agent, one side is dripwise added with miscible liquids of 3-15 mass percent of unsaturated acids and one or more than one derivative thereof, the temperature is kept unchanged, and the water solution and the miscible liquids are completely dropped within 2-6 hours, the temperature is preserved for 1-6 hours and naturally cooled to room temperature, and the mixed solution is neutralized by sig water till a PH value reaches 6.8-7.2 so as to obtain the polyether class polycarboxylic acid high-efficiency water reducing agent. The polyether class polycarboxylic acid high-efficiency water reducing agent and the preparation method thereof have simple technique, low cost and good property, can effectively reduce the water-cement ratio of concrete, improves the compaction rate of a pore structure of the concrete, enhances the strength and the durability of the concrete and has great significance on enhancing the engineering quality, prolonging the service life, reducing the engineering cost, reducing the environment pollution, and the like.

Owner:大连华健科技有限公司

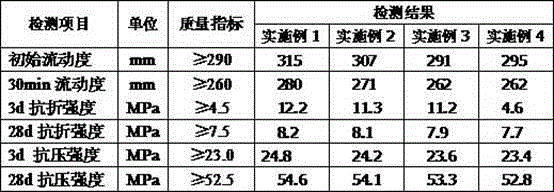

Preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and preparation method thereof

ActiveCN101602589AWide variety of sourcesSimple preparation processSolid waste managementMixing operation control apparatusNeutral phPre stress

The invention discloses a preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and a preparation method thereof. The preformed material includes the following components by weight percent: 65 to 95 percent of silicate cement, 0.01 to 3 percent of high-range water-reducing agent, 0 to 1 percent of stabilizing agent, 0.05 to 5 percent of retarding agent, 1 to 20 percent of expanding agent, 0.2 to 2 percent of corrosion inhibitor, 0.01 to 1 percent of air entraining agent and 0 to 30 percent of mineral materials, wherein by uniformly and proportionally mixing the silicate cement, the high-range water-reducing agent, the stabilizing agent, the retarding agent, the expanding agent, the corrosion inhibitor, the air entraining agent and the mineral materials, the post-tensioned prestressing pipeline vacuum grouting or mudjacking preformed material can be obtained. After being uniformly mixed and stirred with water with neutral pH value according to the water cement ratio ranging from 0.24 to 0.32, the preformed material can be used, the obtained grouting material has the advantages of low water cement ratio, favorable flowability, no water bleeding and delamination, and favorable pumpability; meanwhile, the preparation method of the preformed material is simple and the raw material sources of the preformed material are wide.

Owner:HUBEI CHIDGE TECH

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

High-strength lightweight aggregate concrete and preparation method thereof

The invention relates to high-strength lightweight aggregate concrete and a preparation method thereof, and belongs to the technical field of building material concrete. The lightweight aggregate concrete is prepared from the following raw materials in parts by weight: 105-118 parts of cement, 180-185 parts of light coarse aggregate, 120-125 parts of fine aggregate, 65-70 parts of mineral admixtures, 9-24 parts of modified polypropylene fiber, 3.4-3.8 parts of concrete admixtures and 65-70 parts of water. The preparation method comprises the following steps that the raw materials are weighed according to the formula ratio, the light coarse aggregate is added into water accounting for one half of the total water amount for pre-wetting for 45-60 minutes, then the fine aggregate is added, stirring is carried out for 1-2 minutes, the cement, the mineral admixtures and the modified polypropylene fiber are continuously added, uniform stirring is carried out, then the concrete admixtures andthe rest water are added, and uniform stirring is carried out so as to obtain the high-strength lightweight aggregate concrete. The high-strength lightweight aggregate concrete and the preparation method thereof have the advantages that the strength is high, and the quality is stable.

Owner:武汉中阳明建材有限公司

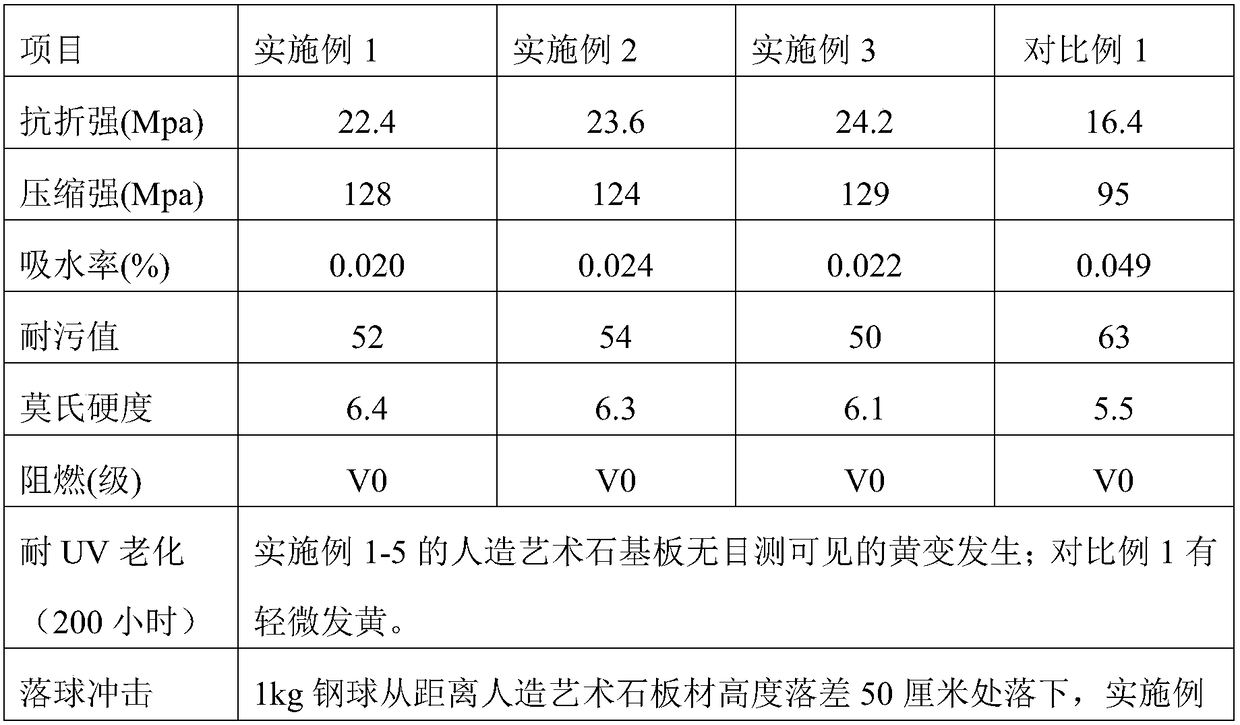

Inorganic environment-friendly manmade art stone and preparation method thereof

The invention relates to an inorganic environment-friendly manmade art stone and a preparation method thereof. The inorganic environment-friendly manmade art stone is prepared from the following raw materials in parts by mass according to a proportional ratio: 55 to 70 parts of quartz sand particles, 4 to 9 parts of quartz sand powder, 17 to 24 parts of cement, 1 to 4 parts of activity additive, 1to 2 parts of expander, 0.3 to 0.4 part of water reducing agent, 3 to 5 parts of emulsion, 0.05 to 0.1 part of water retention agent, and 3 to 5 parts of water. The inorganic environment-friendly manmade art stone has the advantages that by adding the inorganic activity additive, the condition of common alkaline return of the cement type base plate is avoided; by adopting the expander, the self-shrinkage of the cement type base plate is effectively compensated, and the cracking of a forming plate is reduced; the preparation method is simple, the production technology conditions are easy to control, the product quality is stable, and the production cost is low.

Owner:深圳市绿志新型建材研究院有限公司

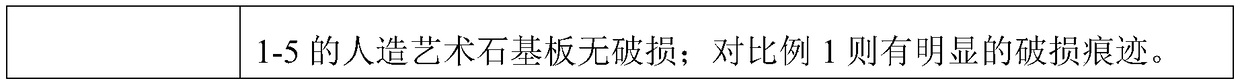

Foam concrete

The invention discloses foam concrete. The foam concrete comprises following raw materials in parts by mass according to a formula: 210-300 parts of cement, 1.0-1.5 parts of a water reducing agent, 5.1-5.5 parts of an early strength agent, 2.1-2.9 parts of a coagulant, 1.7-3.4 parts of fibers, 12-20 parts of a chemical foaming agent, 0-90 parts of superfine slag powder and 100-160 parts of water, wherein the superfine slag powder is formed by aluminosilicate glass particles smaller than 15 mu m, and the specific surface area is 450-500 m<2>*kg<-1>. The compressive strength of the foam concrete is improved on the premise that the foam concrete keeps low density.

Owner:BEIJING MINJIA NEW BUILDING MATERIALS CO LTD

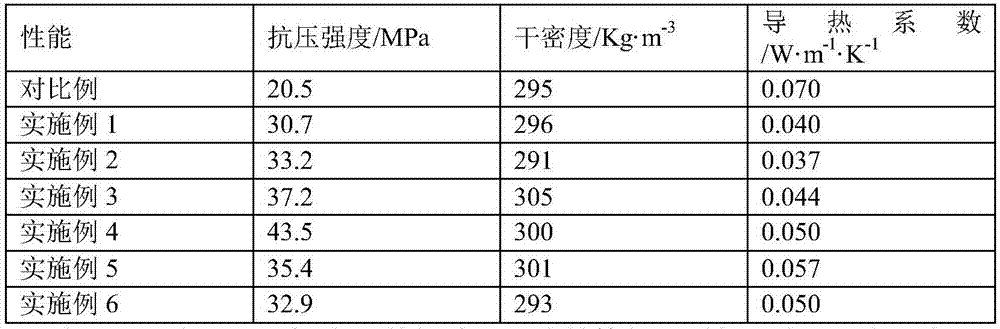

Environment-friendly high-performance cement and production method thereof

ActiveCN103601381AReduce crushing efficiencyImprove liquidityCement productionPlasticizerCement slurry

The invention provides environment-friendly high-performance cement which is characterized by consisting of the following raw materials in parts by weight: 50-60 parts of admixture, 32-40 parts of cement clinker, 6-8 parts of gypsum, 0.03-0.05 part of grinding aid, 3-5 parts of excitation substance, 0.05-0.1 part of antifoaming agent, 0.05-0.1 part of plasticizer, 0.03-0.05 part of anti-precipitating agent and 0.2-0.4 part of water reducing agent. In the environment-friendly high-performance cement provided by the invention, a large mixing amount of cement slurry can be realized by adopting a mechanical-chemical excitation production process, a great quantity of industrial waste residues can be consumed, the yield is increased, and the production cost is lowered; moreover, by adding a functional additive, the performance of the product is improved, and the needs of civil engineering are met.

Owner:广西云燕特种水泥建材有限公司

Concrete light silicon fibre crack-proof intensifier

InactiveCN101058499AReduce water-cement ratioIncrease slumpSolid waste managementSuperplasticizerHigh density

The invention discloses a light-silicon fiber crack-proof reinforcer of concrete in the making domain of organic and inorganic material, which comprises the following parts: anhydrous calcium sulphoaluminate, raw alunite, ripe alunite, anhydrite, naphthalene-system high-effective dehydragent, grammite, polypropylene fibre, sodium lignosulfonate and coal ash. The invention confers high-density and superior constructing property for concrete with modified boundary structure and high-concrete compactness, strength and durability, which improves stretching resistance greatly.

Owner:HUNAN CONSTR ENG GRP COR

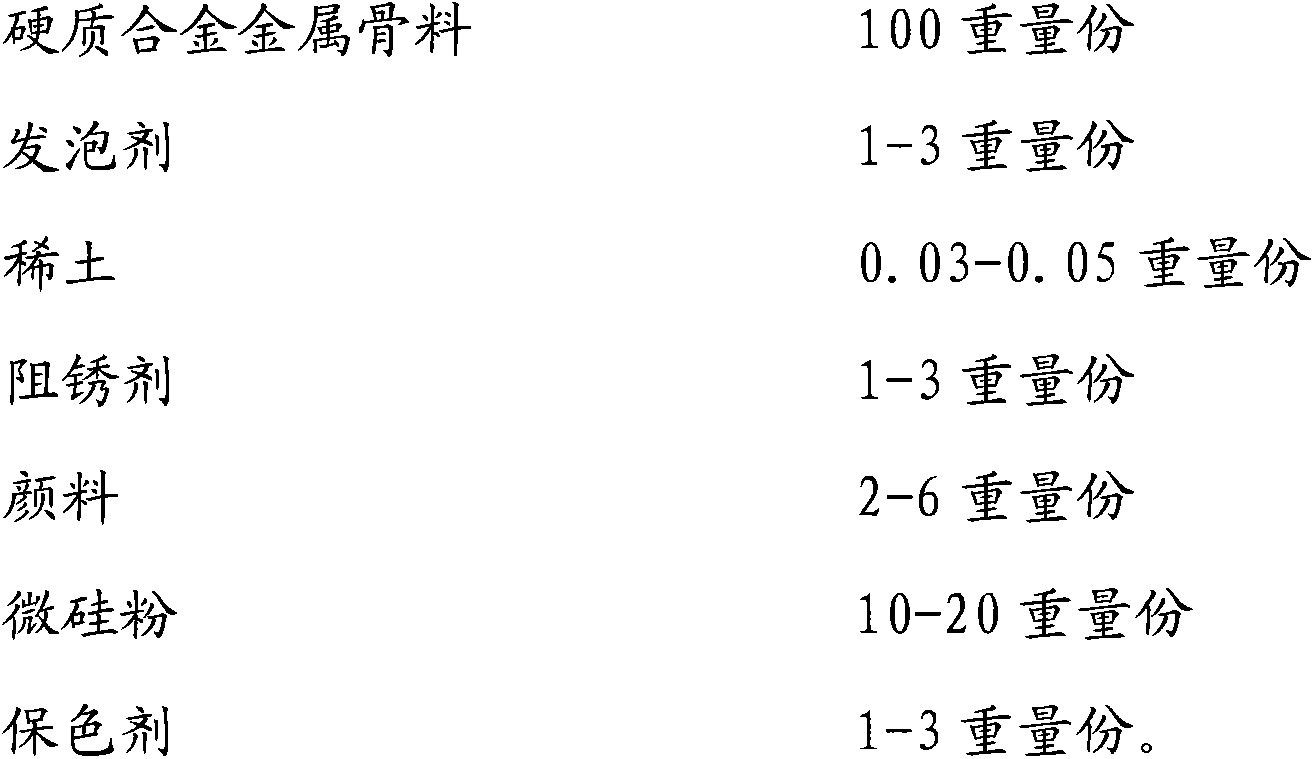

Metal rustproof non-ignition anti-static wear-resistant and anti-impact floor material and preparation method thereof

The invention relates to a metal rustproof non-ignition anti-static wear-resistant and anti-impact floor material and a preparation method thereof. The material is processed by mixing the following components: a hard alloy metal aggregate, rare earth, a foaming agent, a rust inhibitor, a pigment, micro-silicon powder and a color preserving agent. The floor material disclosed by the invention is uniformly mixed with ordinary portland cement, the mixture is sprinkled on the surface of concrete which is just built, the surface is leveled and maintained, and expansion joints are cut so as to obtain a metal rustproof non-ignition anti-static wear-resistant and anti-impact floor. The floor material is mainly applied to storage places for flammable and explosive chemicals, electronic computer rooms, army ammunition depots, regions using precision machinery in operation rooms, storage regions for petroleum and fuel oil, particularly wear-resistant and impact-resistant floors and places with particular requirements for anti-static and non-ignition effects; and simultaneously, the floor has the advantages of large surface density, good anti-seepage performance and rust protection, and can meet the floors with smooth to skid-proof requirements, perform synchronous construction with the concrete floors and shorten the construction period so as to reduce the construction cost.

Owner:曹洪生 +1

Magnesium oxysulfate wall plate and fabrication method thereof

The invention relates to a magnesium oxysulfate wall plate and a fabrication method of the magnesium oxysulfate wall plate. The magnesium oxysulfate wall plate comprises the following raw materials in parts by weight: 100 parts of magnesium oxide, 0.5-5 parts of a modifier, 100-130 parts of a magnesium sulfate solution, 2 parts of bamboo fiber, 3 parts of palm fiber, 10-30 parts of a filling and 1 part of a foaming agent. The fabrication method of the magnesium oxysulfate wall plate comprises the steps of putting the modifier into the magnesium sulfate solution, injecting into an agitator after agitation, putting the bamboo fiber and the palm fiber into the agitator for agitation, putting magnesium oxide in the agitator for agitation, allowing slurry agitated by the agitator to fall into a foam mixing machine, injecting the foaming agent subjected high-pressure foaming into the slurry, performing foam mixing to form uniform foaming slurry, injecting the foaming slurry into a special mold car via a distribution system, and performing foam expelling, fiber stroking, curing, female groove forming, core pulling and push plate mold stripping. The magnesium oxysulfate wall plate is high in structural strength, good in water resistance and stable in physical property.

Owner:江苏宝盛住宅工业有限公司

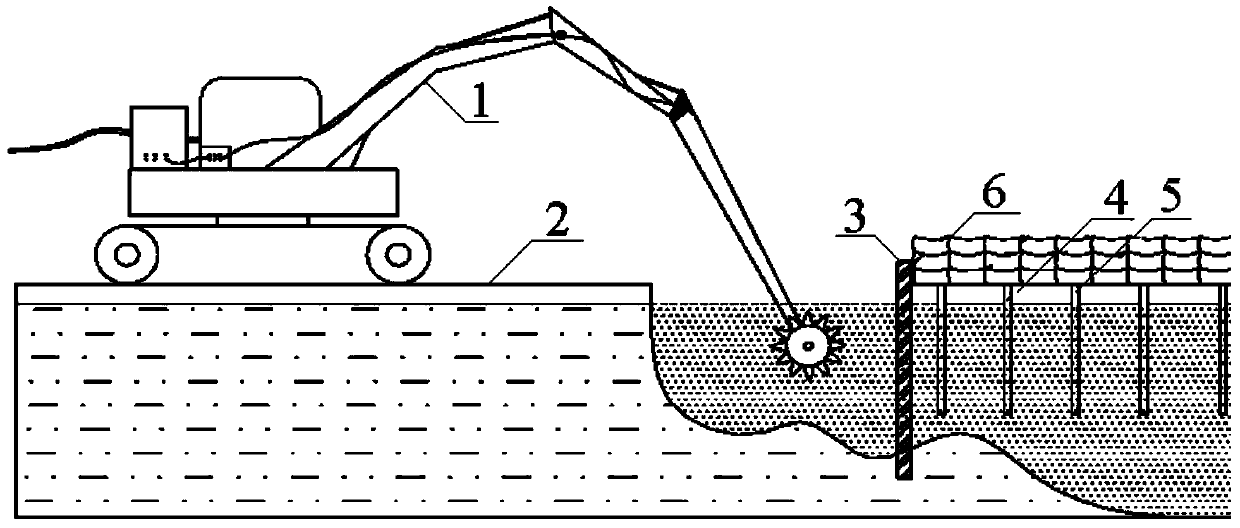

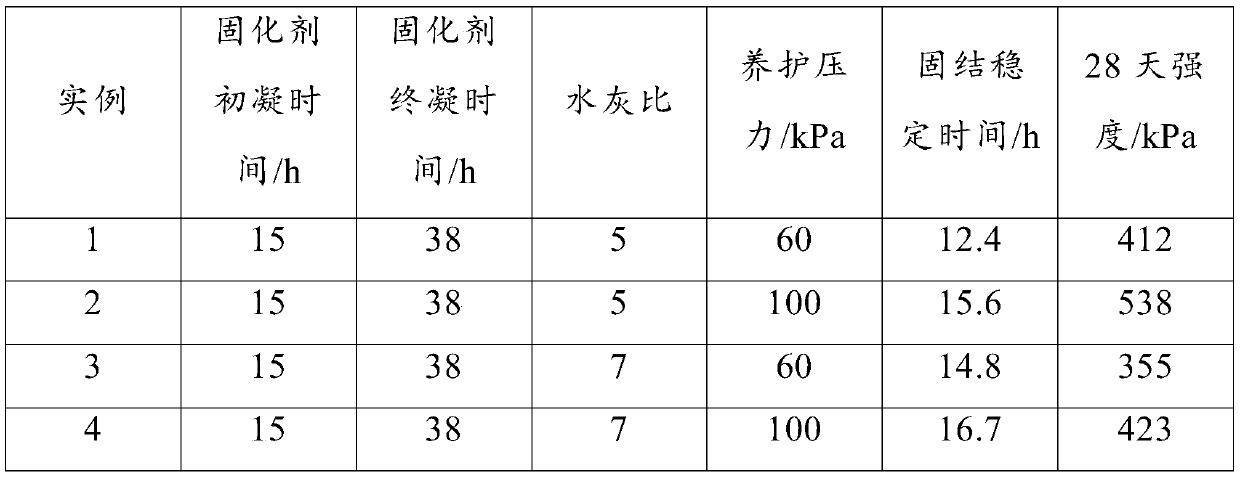

High-efficiency curing method for soft soil site with high moisture content

The invention belongs to the technical field of environment rock-soil engineering and discloses a high-efficiency curing method for a soft soil site with high moisture content. The high-efficiency curing method comprises an in situ chemical curing step and a preloading drainage step; the in situ chemical curing step comprises investigating sites, determining physical and chemical indexes such as depth, area, moisture content, organic matter content, liquid plastic limit and salt content of the soft soil site; blending a curing agent, determining the types, adding ratio, and initial and final setting time of the curing agent based on the physical and chemical indexes; blocking the site, and building partition walls for site blocking in the soft soil site; carrying out chemical curing construction, and uniformly mixing the blended curing agent with to-be-cured soft soil; carrying out preloading drainage construction according to three construction modes of vacuum preloading or surchargepreloading or vacuum surcharge preloading; unloading and repairing the site; after preloading time reaches 28 days, swabbing off drained water from the upper surface layer of curing blocks, unloadingand injecting cement slurry into a drain board for secondary repair and reinforcement by adopting a high-pressure grouting pump.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

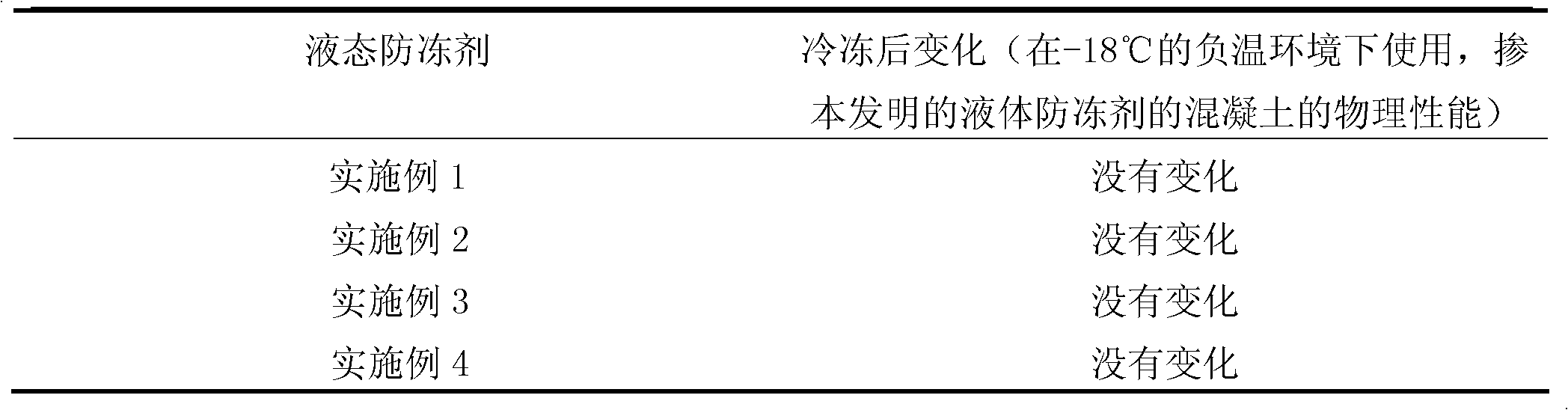

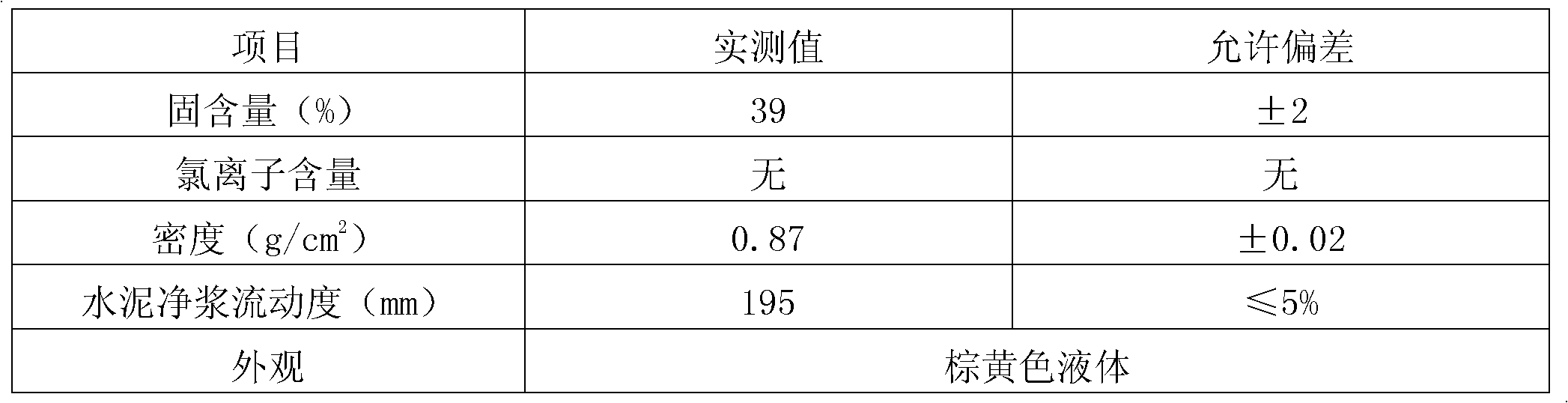

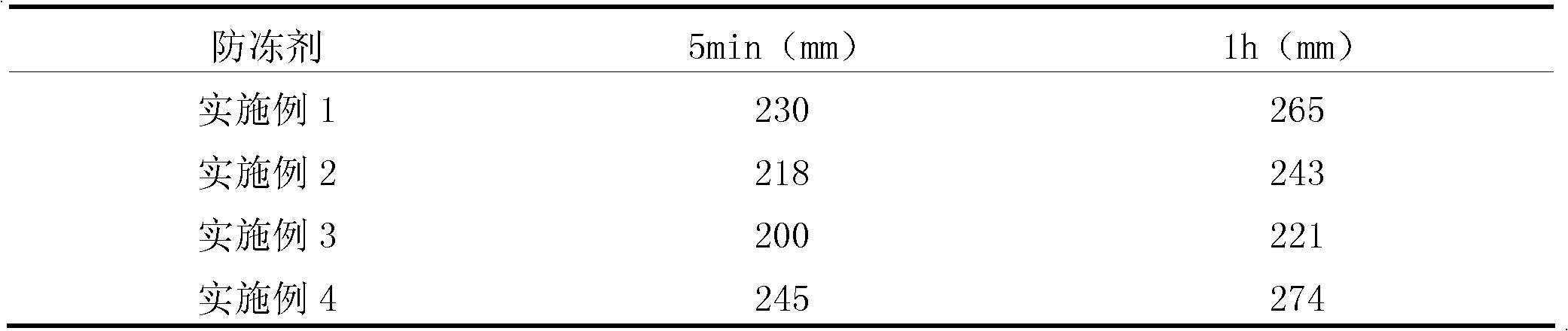

Efficient liquid antifreezing agent for concrete, and preparation method thereof

The present invention relates to an efficient liquid antifreezing agent for concrete, and a preparation method thereof, and belongs to the technical field of building materials. The efficient liquid antifreezing agent for the concrete is characterized in that: the efficient liquid antifreezing agent is prepared from an efficient water reducing agent, a formate, an organic alcohol amine, a carbonate, ethylene glycol, an air entraining agent and water, wherein a ratio of the efficient water reducing agent to the formate to the organic alcohol amine to the carbonate to the ethylene glycol to the air entraining agent to the water is (48-75):(2.0-7.6):(1.2-3.0):(30-57):(65-92):(0.8-1.6):(60-275). The antifreezing agent has characteristics of good freezing resistance, high early strength, chloride-free property, high water reducing rate and high working performance. More importantly that, the addition amount of the antifreezing agent in the cement concrete is small so as to promote the early hydration rate of the cement, such that the early strength of the cement is improved while the high late strength of the cement is ensured so as to improve the mechanical property and the durability of the concrete. In addition, the antifreeze can be used under a negative temperature environment having a temperature more than -18 DEG C.

Owner:WUHAN UNIV OF TECH

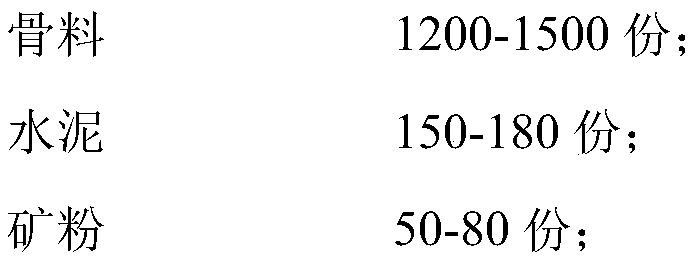

High-performance anti-freezing concrete and preparation method thereof

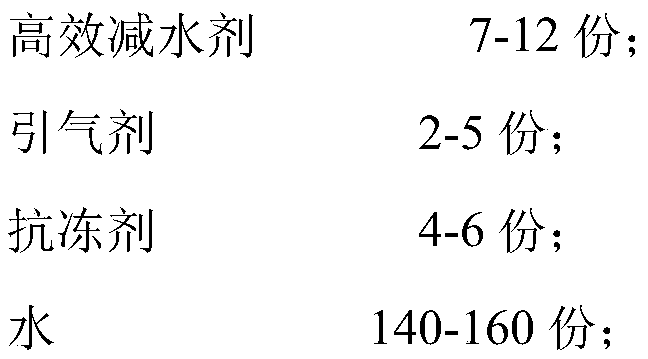

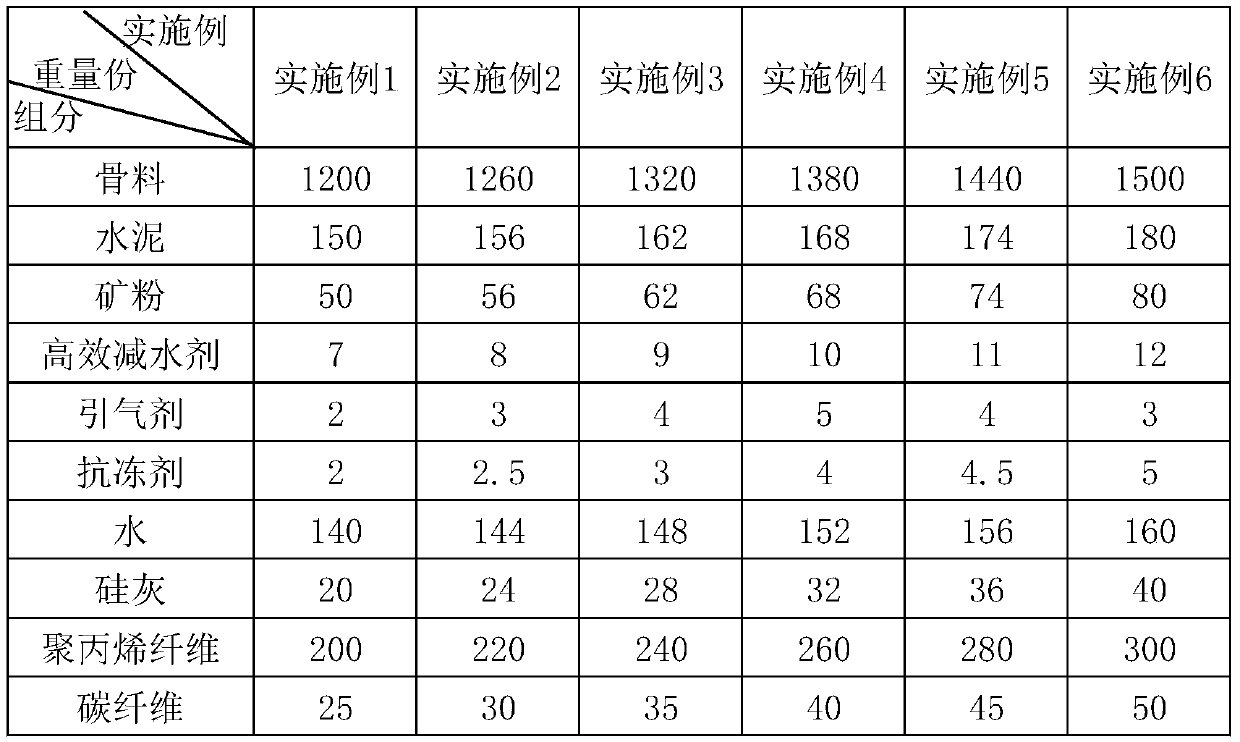

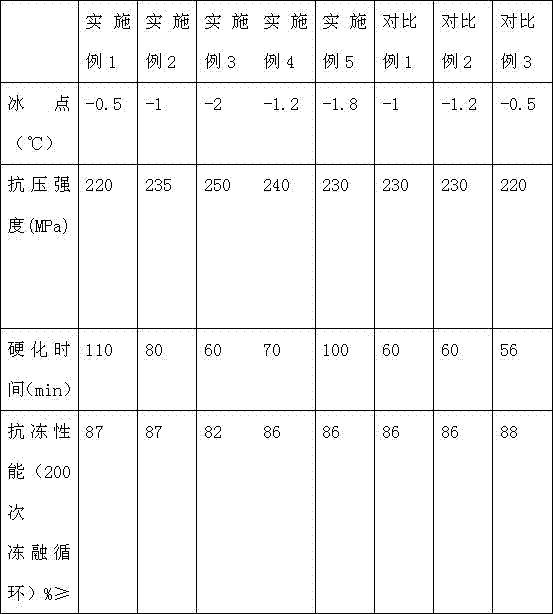

The invention discloses high-performance anti-freezing concrete and a preparation method thereof, and relates to the technical field of concrete preparation and production. The high-performance anti-freezing concrete comprises the following components by weight: 1200-1500 parts of aggregate, 150-180 parts of cement, 50-80 parts of mineral powder, 7-12 parts of a superplasticizer, 2-5 parts of an air entraining agent, 4-6 parts of an antifreeze agent, and 140-160 parts of water, wherein the aggregate comprises stones, medium sand and fine sand in a mass ratio of (4-5): (2-3): 1. The preparationmethod of the high-performance anti-freezing concrete comprises the following steps: S1, pre-dispersing an aggregate; S2, dispersing powder; S3, dispersing an aqueous solution; and S4, dispersing fibers. The anti-freezing concrete has the technical effects that the anti-freezing performance of concrete can be stably improved and the comprehensive performance is excellent.

Owner:武汉君善建混凝土有限公司

Concrete early strength agent and preparation method thereof

The invention discloses a concrete early strength agent and a preparation method thereof. The concrete early strength agent is prepared from the following components in parts by weight: 1-3 parts of sodium chloride, 1-3 parts of sodium nitrite, 10-20 parts of sodium sulfate, 3-6 parts of calcium chloride, 2-6 parts of urea, 5-15 parts of methacrylic acid, 1-3 parts of silane, 1-5 parts of calcium gluconate, 1-5 parts of triisopropanolamine, 5-10 parts of fatty glyceride, 50-80 parts of polycarboxylate superplasticizer and 2-4 parts of finely grinded cement stone. The concrete early strength agent has the beneficial effects of rapidly drying concrete even in a low-temperature environment.

Owner:温州市环美建筑工程有限公司

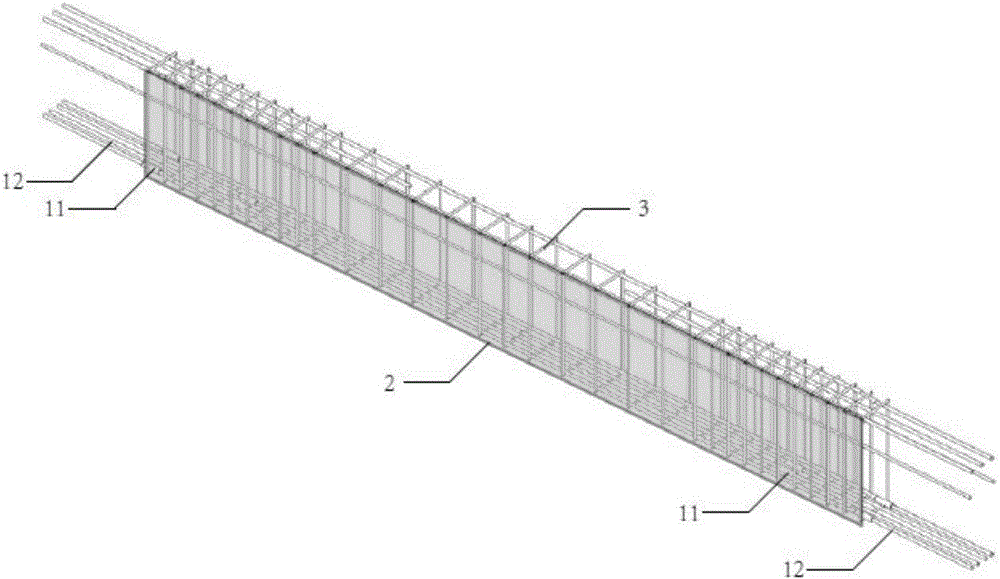

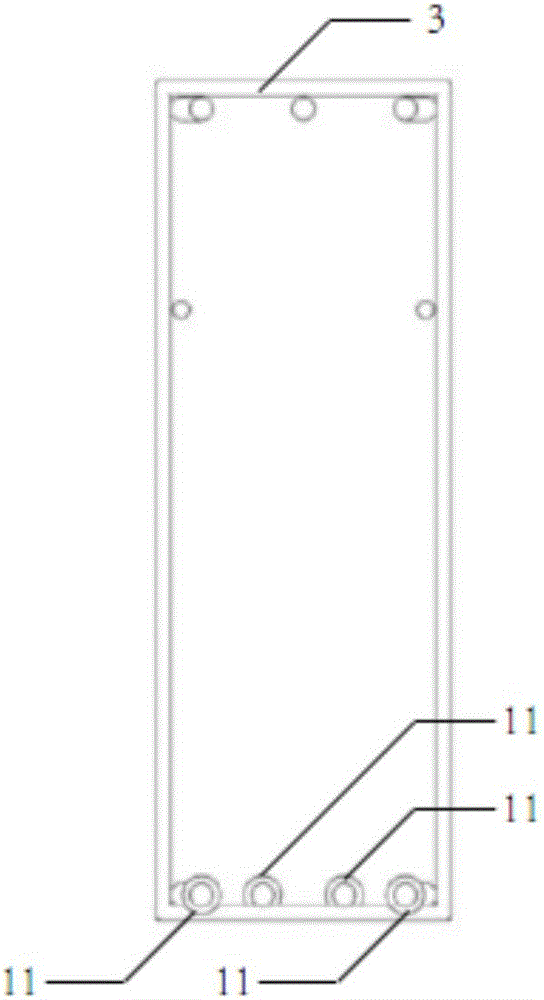

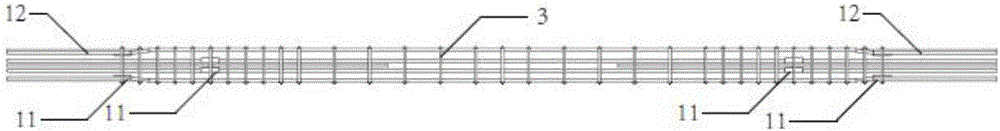

Precast beam reinforcement cage component and assembling method thereof

InactiveCN105952060AMeet construction requirementsEnables step-by-step installation combinationsBuilding reinforcementsBuilding material handlingReinforced concreteRebar

The invention discloses a precast beam reinforcement cage component and an assembling method thereof. The precast beam reinforcement cage component comprises a reinforcing steel bar assembly and a disassembly-free mould connected with the reinforcing steel bar assembly, wherein the reinforcing steel bar assembly is formed by connecting a horizontal reinforcing bar and a stirrup, and the disassembly-free mould is laid along the front side surface, the rear side surface and the bottom surface of a precast beam and is connected with the reinforcing steel bar assembly into a whole by virtue of a locating fixed part. The precast beam reinforcement cage component has the advantages that a large component and a reinforced concrete large-structure-space civil building can be realized, a working procedure is simplified, high-altitude operation is reduced, and current national reinforced concrete reinforcing bar specification can be met; meanwhile, cost is reduced, locating and supporting precision, assembling efficiency and quality of a structural component are improved, site construction is convenient, and a technology is controllable.

Owner:SOUTHEAST UNIV

Dry-mixed mortar prepared from industrial solid waste

The invention provides dry-mixed mortar prepared from industrial solid waste. The dry-mixed mortar is characterized by being prepared from materials in parts by weight as follows: 100 parts of cement, 300-400 parts of river sand, 50-100 parts of steel slag, 0-50 parts of iron mine tailings, 0-50 parts of glass powder, 1-2 parts of an interface reinforcing agent, 1-2 parts of an exciting agent, 0.1-0.5 parts of a water retaining agent, 1-2 parts of a water reducing agent and 0.1-0.3 parts of reinforcing fibers. According to the dry-mixed mortar, the industrial solid waste is fully utilized as aggregate to replace natural river sand, environmental protection is facilitated, resource recycling is realized, and meanwhile, performance such as the freezing resistance, the permeability resistance and the like of the dry-mixed mortar is improved through addition of the industrial solid waste.

Owner:四川震强建筑材料有限责任公司

Anti-crack high slump loss resistance concrete polycarboxylate superplasticizer

The invention discloses an anti-crack high slump loss resistance concrete polycarboxylate superplasticizer, being prepared from the following components in parts by weight: 25-35 parts of isopentenol polyethylene glycol monomethyl ether macromonomer, 40-50 parts of isopentenol polyethylene glycol monomethyl ether macromonomer, 3.5-4.5 parts of 2-propylene acyl amino-2-methyl-1-propane sulfonic acid, 4-5 parts of allyl polyoxyethylene ether, 3-5 parts of maleic anhydride, 2.5-3.5 parts of dimethyl fumarate, 3-5 parts of hydroxyalkyl acrylate, 4-8 parts of sodium hypophosphite, 0.5-1.5 parts of tartaric acid, 80-83 parts of water and 15-21 parts of sodium hydroxide. The anti-crack high slump loss resistance concrete polycarboxylate superplasticizer has good adaptability to cement, is less in amount of admixture and high in water-reducing rate, is capable of reducing water cement ratio and improving fluidity, is low in slump loss and remarkable in early strengthening effect, and is capable of improving the compactness of concrete, saving cement, improving the working performances of the concrete and improving the durability of the concrete.

Owner:HUNAN CONSTR ENG GRP COR +1

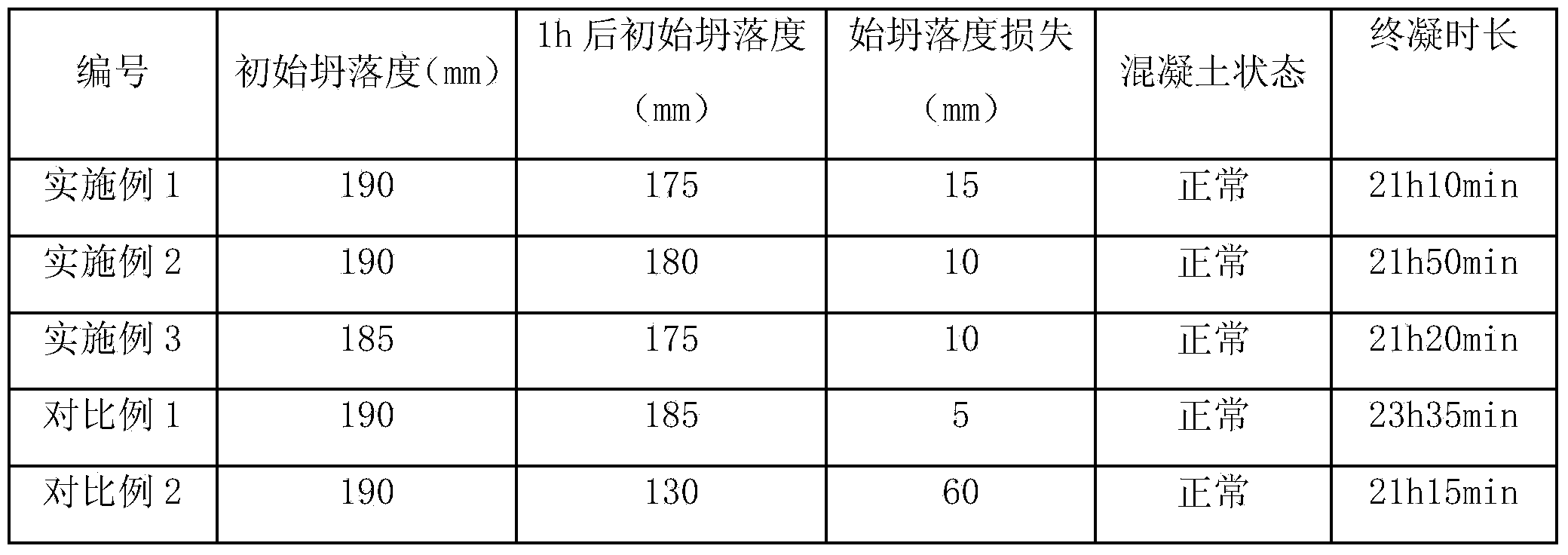

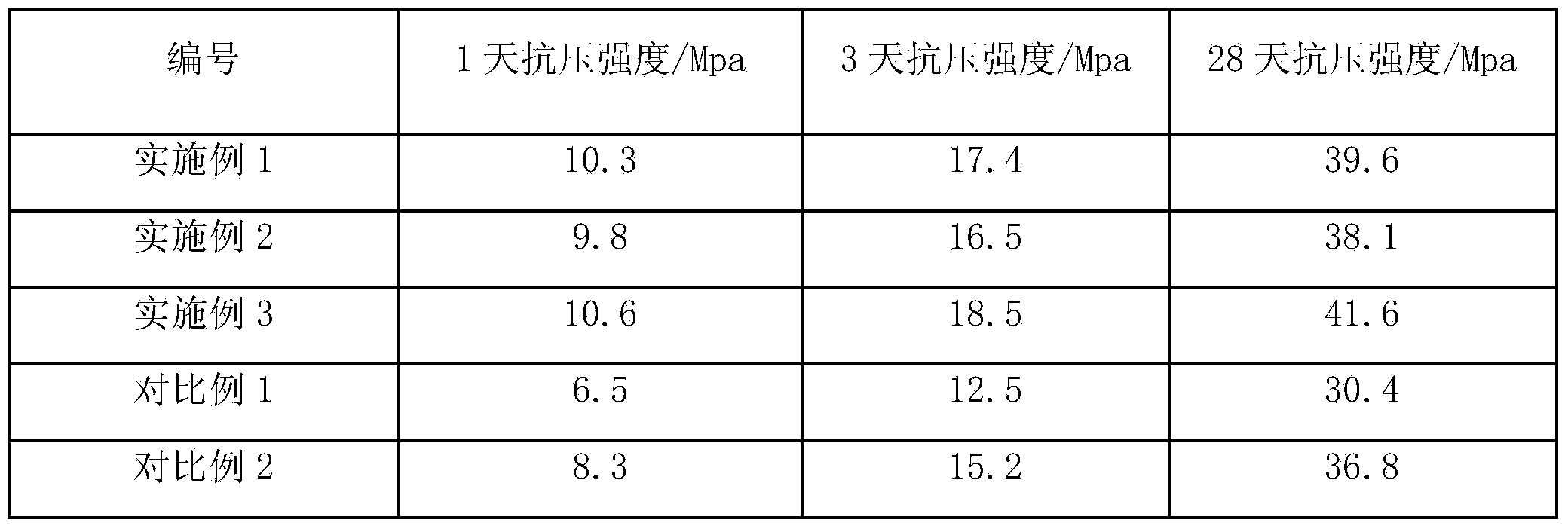

Composite early-strength type polycarboxylate superplasticizer as well as preparation method and application thereof

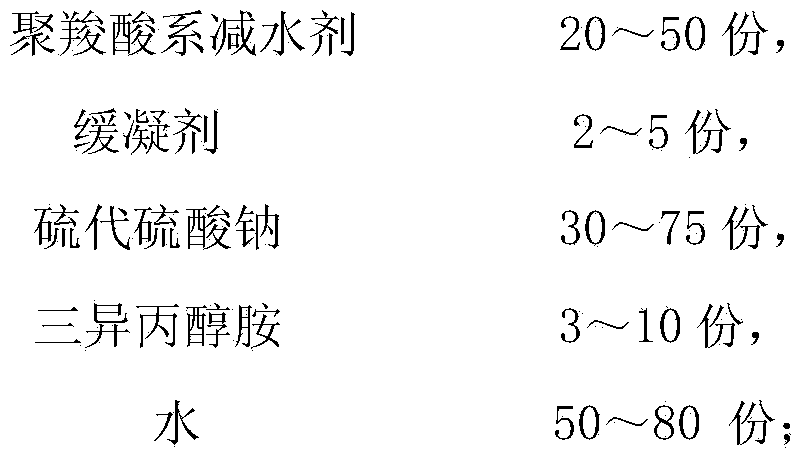

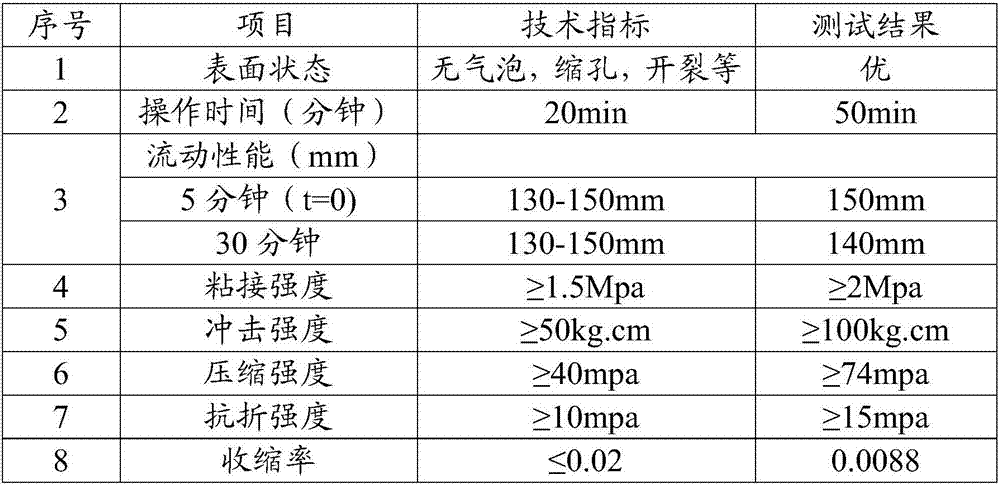

The invention relates to a composite early-strength type polycarboxylate superplasticizer as well as a preparation method and application thereof, belonging to the field of building materials. The technical problem to be solved by the invention is to provide the composite early-strength type polycarboxylate superplasticizer as well as the preparation method and application thereof. The composite early-strength type polycarboxylate superplasticizer is prepared from the following components in parts by weight: 20-50 parts of polycarboxylate superplasticizer, 2-5 parts of retarder, 30-75 parts of sodium thiosulfate, 3-10 parts of tri-isopropanolamine and 50-80 parts of water. Further, the invention also discloses the preparation method of the composite early-strength type polycarboxylate superplasticizer and the application of the composite early-strength type polycarboxylate superplasticizer in C15-C16 concrete. The composite early-strength type polycarboxylate superplasticizer disclosed by the invention has the advantages of excellent early-strength performance, relatively good compatibility among components, low alkali content, low shrinkage rate, low mixing amount and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Waterborne epoxy composite cement mortar material as well as preparation and construction methods thereof

The invention discloses a waterborne epoxy composite cement mortar material. The material comprises a component A, a component B and a component C in the mass ratio being (0.5-1.5): (1-3): (12-18), wherein the component A is a waterborne epoxy emulsion, the component B is prepared from, in parts by weight, 3-10 parts of water, 3-10 parts of a curing agent and 0.01-0.1 parts of a defoaming agent, and the component C is prepared from 30-60 parts of quartz sand, 20-40 parts of cement, 0.1-0.5 parts of a water reducer, 0.2-1.0 part of an additive and 0.1-1.0 part of a defoaming agent. The material is green, environment-friendly and low in cost, has good matching performance in concrete, can be cured in humid interfaces and has reinforcement and permeation resistance functions, the problem that traditional floor coatings peel or have bubbles is solved, the one-time forming thickness can reach 2 mm or above, basic planes are easy to level, and construction is easy. The invention further discloses preparation and construction methods of the material. The preparation condition is mild, the method is simple and suitable for large-scale industrial production, the construction process is simple and feasible, and the construction cost is low.

Owner:深圳市威尔地坪材料有限公司

Fast concrete road and bridge repairing material

The fast concrete road and bridge repairing material has the composition of:early strength aluminosulfate cement 75-95 wt%, portland cement 5-25 wt%, naphthalene water reducing agent 1.5-3.5 wt%, lithium salt below 0.5 wt% and boric acid below 0.5 wt%. it has the features of fast solidification, fast hardening, high strength, less swelling, corrosion resistance, etc. It is used in mixing mortar and concrete without need of other supplementary material. It results in 4H break strength higher than 4 MPa and compression strength higher than 25 MPa of mortar as well as 6H break strength higher than 4 MPa and compression strength higher than 30 MPa of concrete. When used to repair road and bridge, the traffic may be opened after 6 h. It may be also used in reinforcement of other concrete member.

Owner:李乃珍

Waterproofing agent capable of enhancing waterproofing performance and water impermeability of concrete

The invention discloses a waterproofing agent capable of enhancing waterproofing performance and water impermeability of concrete, which is composed of the following components in percentage by weight: 3% of alum, 11% of copper sulfate, 30% of fly ash, 4% of polycarboxylic acid water reducing agent, 26% of expanding agent, 0.6% of air entraining agent, 0.4% of alkyl sodium sulfonate, 17% of silica fume, 2% of epoxy resin, 1% of 6-dehydroprogesterone and 5% of lineae ablicantes arrowroot leaf powder. The fly ash is first-grade fly ash; the expanding agent is an alunite expanding agent EA-L, U-type cement expanding agent UEA, composite expanding agent CEA or calcium aluminate expanding agent AEA; and the air entraining agent is a non-rosin air entraining agent. The waterproofing agent can reduce the porosity, promote the hydration of the cement, enhance the density of the concrete, reduce the shrinkage of the concrete and improve the comprehensive durability of the concrete.

Owner:张淑芬

Method for preparing plaster evacuated mould

InactiveCN101531026AReduce water-cement ratioReduce solubilitySolid waste managementMixing operation control apparatusWater basedTime extension

This invention discloses a method for preparing plaster evacuated mould, including following steps: weighting and mixing the raw material based on that the mass ratio of plaster: inorganic filling material: glass fiber: high efficiency water reducing agent (mass ratio) is 80-90:10-20:3-4:0.5:2.5; weighting water based on the cement water ratio of o.45 to 0.65 by calculating with mass, then pouring the prepared raw materials into a stirring pot, at the same time, opening the stirrer, quickly stirring for 1 to 3 min with the rotating speed of 100 to 300 r / min; coating mineral oil at the four sides and the bottom of the module, then pouring the mixed ground paste into the mould, screeding the upper surface of the plaster evacuated mould, fetching out the concretionary plaster evacuated mould from the module, finally naturally drying the mould. The product prepared by this invention has short time for drying, enlarged delayed coagulation time and can improve the intensity and the hard wearing performance.

Owner:贵州金三利科技建材有限公司

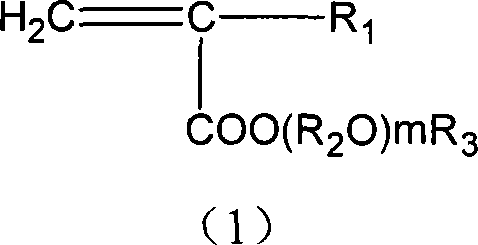

Cement disperser and its preparing method

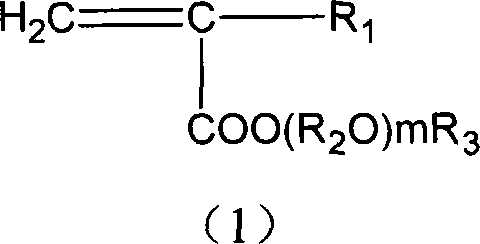

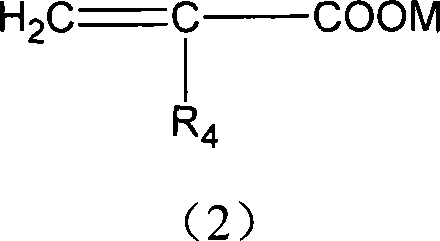

This invention provides a cement dispersant agent and its preparation method, it is the co-polymer of: poly-oxyalkylene (methyl) acrylate, unsaturated monocarboxylic acid or its derivatives monomers or other monomers. The inventive product has functions of: adsorption, air-guiding, dispersing, wetting, solubilizing, stability-increasing, the product makes the concrete having: low water / cement ratio, low viscosity, high fluidizing, slow-set, easy to produce concrete, realizing long-distance transportation. This product has also advantages of: low energy consumption, high efficiency, good repeatability.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

Cement concrete pavement rapid repair material and mortar and preparation method of mortar

InactiveCN111153670AImprove early strengthPrevent "flash freezing" phenomenonAluminatePortland cement

The invention discloses a cement concrete pavement rapid repairing material and mortar and, a preparation method of the mortar, wherein the rapid repairing material comprises the raw materials in parts by mass: 50 to 70 parts of Portland cement, 10 to 20 parts of aluminate cement, 5 to 15 parts of semi-hydrated gypsum, 0.1 to 0.3 part of a defoaming agent, 0.1 to 0.3 part of a water reducing agentand 10 to 20 parts of a polymer emulsion. The rapid repairing mortar comprises the raw materials: intermediate sand, water and the cement concrete pavement rapid repairing material, wherein in partsby mass, the rapid repairing mortar comprises 120 to 140 parts of the intermediate sand, the mass ratio of water and the cement concrete pavement rapid repairing material is 0.3-0.4. The rapid repairing material can prevent poor repairing effect caused by unstable later strength of sulphoaluminate cement, can overcome the defect of brittleness of a cement-based material, also has the characteristic of quickly repairing concrete, and is stable in later strength.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Civil engineering mold bag and method for quickly constructing artificial pillar

ActiveCN107524470ASmall vertical forceImprove the ability to bear the force in the horizontal directionMaterial fill-upEngineeringBuilding construction

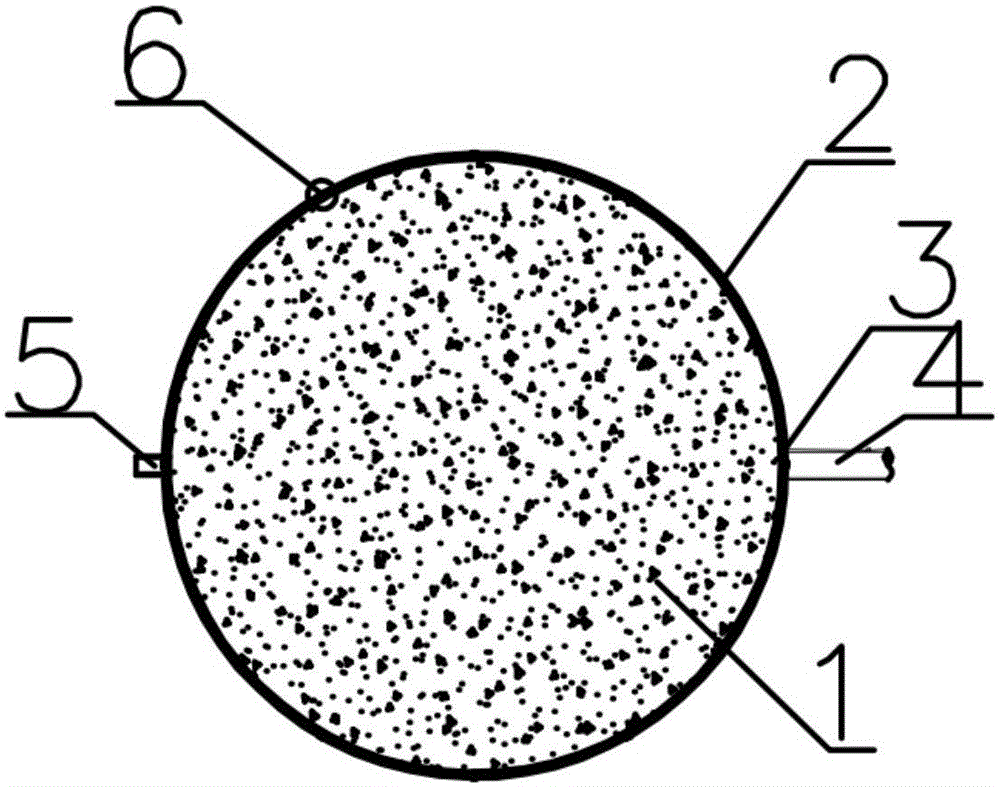

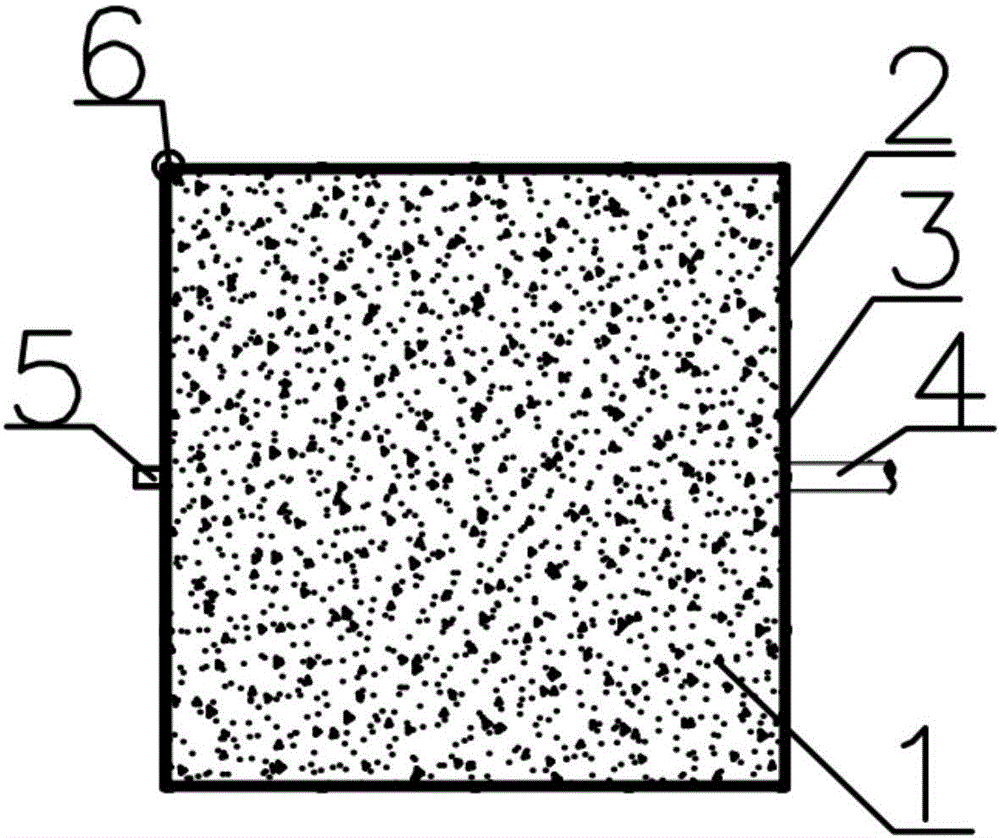

The invention relates to a civil engineering mold bag which comprises a mold bag body (2). At least one opening is formed in the mold bag body (2), and a feeding pipe (4) is arranged at the other end of the mold bag body (2); and the exterior of the mold bag body (2) is sleeved with supporting rings (3) matched with the mold bag body (2) every 50-250 mm, and the supporting rings (3) are fixed to the corresponding positions of the mold bag body (2) through at least one bag loop (6). According to the civil engineering mold bag, the civil engineering mold bag sleeved with the reinforcing supporting rings is used as a soft mold to construct a down hole artificial pillar, a pillar body is formed by grouting at a time, construction is easy and convenient, and the speed is high; the constructed artificial pillar is high in integrality and good in stability; and according to a method for quickly constructing the artificial pillar, the down hole mold erecting working procedure is simplified, the constructing efficiency is improved, transporting is convenient, construction is easy and rapid, and the method is particularly suitable for construction of projects such as mine pillar body underground mining.

Owner:CINF ENG CO LTD

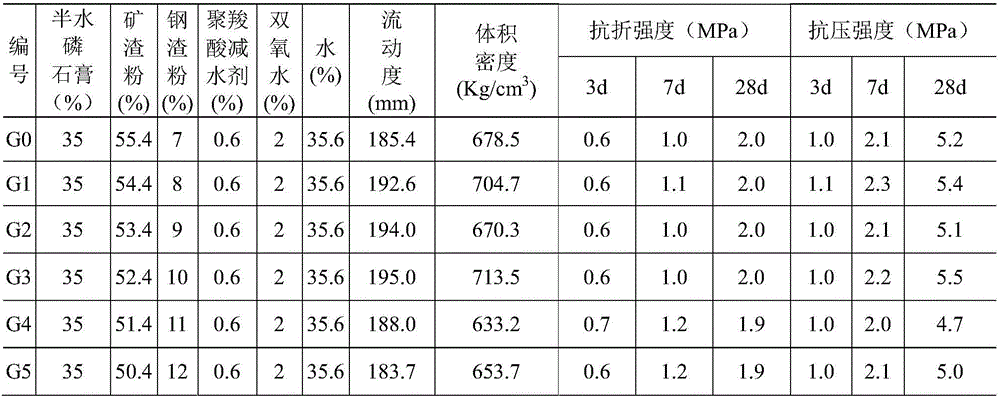

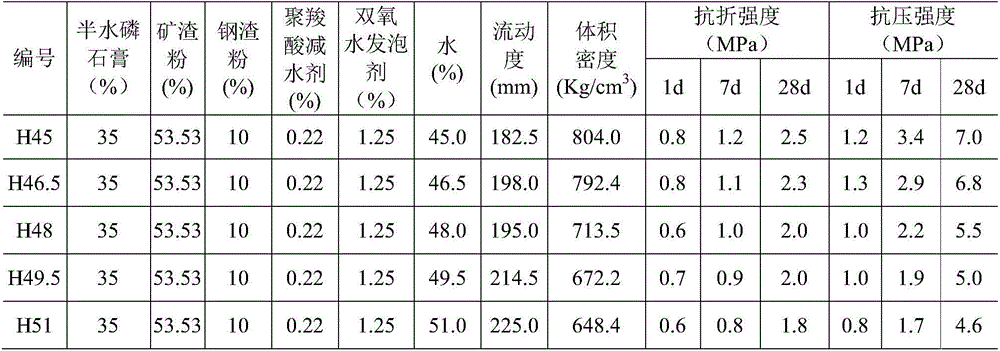

Phosphorus gypsum foam product and method for preparing same

InactiveCN106478127AIncrease profitReduce consumptionSolid waste managementCeramicwareFoaming agentSlag

The invention belongs to the technical field of building materials, and particularly relates to a phosphorus gypsum foam product and a method for preparing the same. The phosphorus gypsum foam product is made of solid waste, admixtures and water. The solid waste includes phosphorus gypsum, steel slag and mineral waste residues, and the admixtures include hydrogen peroxide foaming agents and polycarboxylate water reducing agents. The phosphorus gypsum foam product and the method have the advantages that the phosphorus gypsum foam product is free of cement or cement clinker, the solid waste such as the phosphorus gypsum is high in usage and low in cost, accordingly, the phosphorus gypsum foam product and the method are favorable for consuming a large quantity of phosphorus gypsum which is an industrial byproduct, and waste can be turned into wealth.

Owner:WUHAN UNIV OF TECH

Deicing salt-resisting cement-based channel repairing agent

The invention relates to the field of a repairing agents, and discloses a deicing salt-resisting cement-based channel repairing agent. The repairing agent is prepared fromconsists of the following components: potassium dihydrogen phosphate, magnesium oxide, borax, calcium carbonate, coal ash, silica fume, polyacrylamide, air entraining agent, awater reducing agent, fine aggregates, coarse aggregates and water. The invention also discloses a preparation method of the deicing salt-resisting cement-based channel repairing agent. The deicing salt-resisting cement-based channel repairing agent is short in time of coagulation, high in adhesive strength, excellent in anti-permeability and deicing salt corrosion resistance, and suitable for repairing road side channels, drainage channels and the like damaged by the stripping erosion of the deicing salt.

Owner:沈阳建大博成科技有限公司

Vibration-press-free water stabilizing additive, and preparation and application thereof

InactiveCN107857500AWith directional adsorptionHigh strengthSpecific gravity measurementReducing agentMaterials science

The invention belongs to the technical field of engineering materials, and particularly relates to a vibration-press-free water stabilizing additive, and a preparation and application thereof. The additive comprises a water reducing agent and an expanding agent, wherein the usage amount of the water reducing agent is 1.5-2.5% of the usage amount of cement, and the usage amount of the expanding agent is 7.5-9.5% of the usage amount of the cement. The vibration-press-free water stabilizing additive prepared by the method provided by the invention has a good vibration-press-free compaction effect; when the additive is used in a maximum dry density testing experiment, the experiment efficiency and accuracy can be improved; in practical applications, the resident disturbing degree of engineering construction can be greatly reduced; and as a semi-rigid base construction technology for a special environment, the additive provided by the invention meets the requirements of constructing an environment-friendly society in China.

Owner:JIANGSU EASTTRANS INTELLIGENT CONTROL TECH GRP CO LTD

Self-compacting micro-expansion concrete and preparation method thereof

The invention discloses self-compacting micro-expansion concrete. The concrete comprises a first group of raw materials including water and ester, and a second group of raw materials including cement, mixed sand, crushed stones, an expanding agent, an admixture, water reducer and dipropyl amine. The admixture comprises active mineral admixture. A preparation method of the self-compacting micro-expansion concrete includes the steps that firstly, ester is dispersed in water to be evenly dispersed, the expanding agent and the water reducer are added into a mixture of the ester and water at a certain flow speed, and the mixture is still standing for 12 h or longer; secondly, the mixed sand and the crushed stones are mixed evenly and smashed into particles, then evenly mixed with cement, the admixture and dipropyl amine and still standing for 3 h or longer; thirdly, the mixture obtained in the second step is added into the mixture obtained in the first step at the flow speed of 20-50 kg / h, and stirring is conducted in the addition process at the speed of 10-20 rpm so as to prepare the self-compacting micro-expansion concrete. Flowability of the concrete can be improved, and the construction requirements for delayed coagulation and plasticity maintenance are met.

Owner:中交三公局工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com