Patents

Literature

4327 results about "Antifreeze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

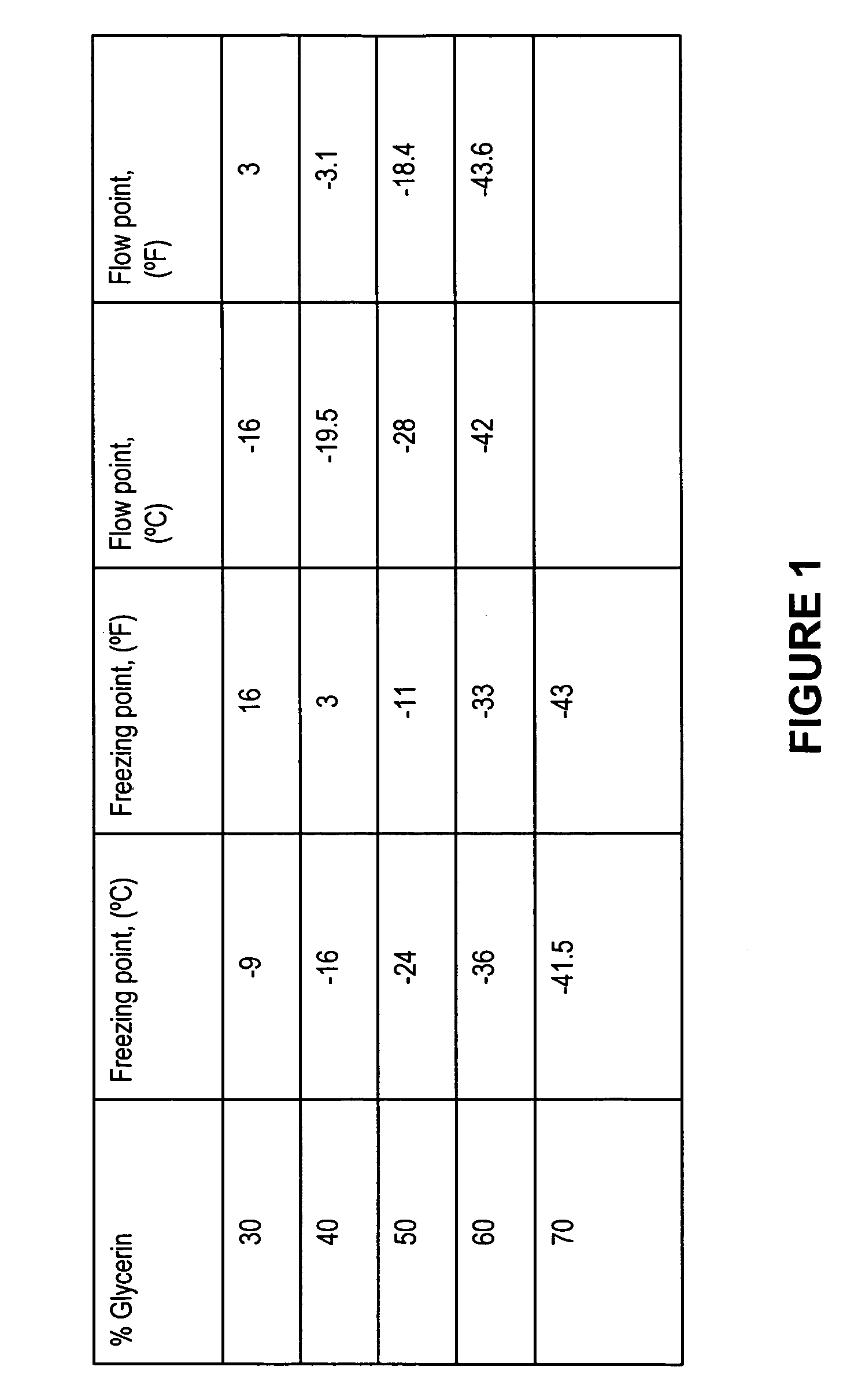

An antifreeze is an additive which lowers the freezing point of a water-based liquid. An antifreeze mixture is used to achieve freezing-point depression for cold environments. Common antifreezes increase the boiling point of the liquid, allowing higher coolant temperature.

Method of producing lower alcohols from glycerol

ActiveUS20050244312A1High selectivityOrganic compound preparationOxygen compounds preparation by reductionAlcoholBoiling point

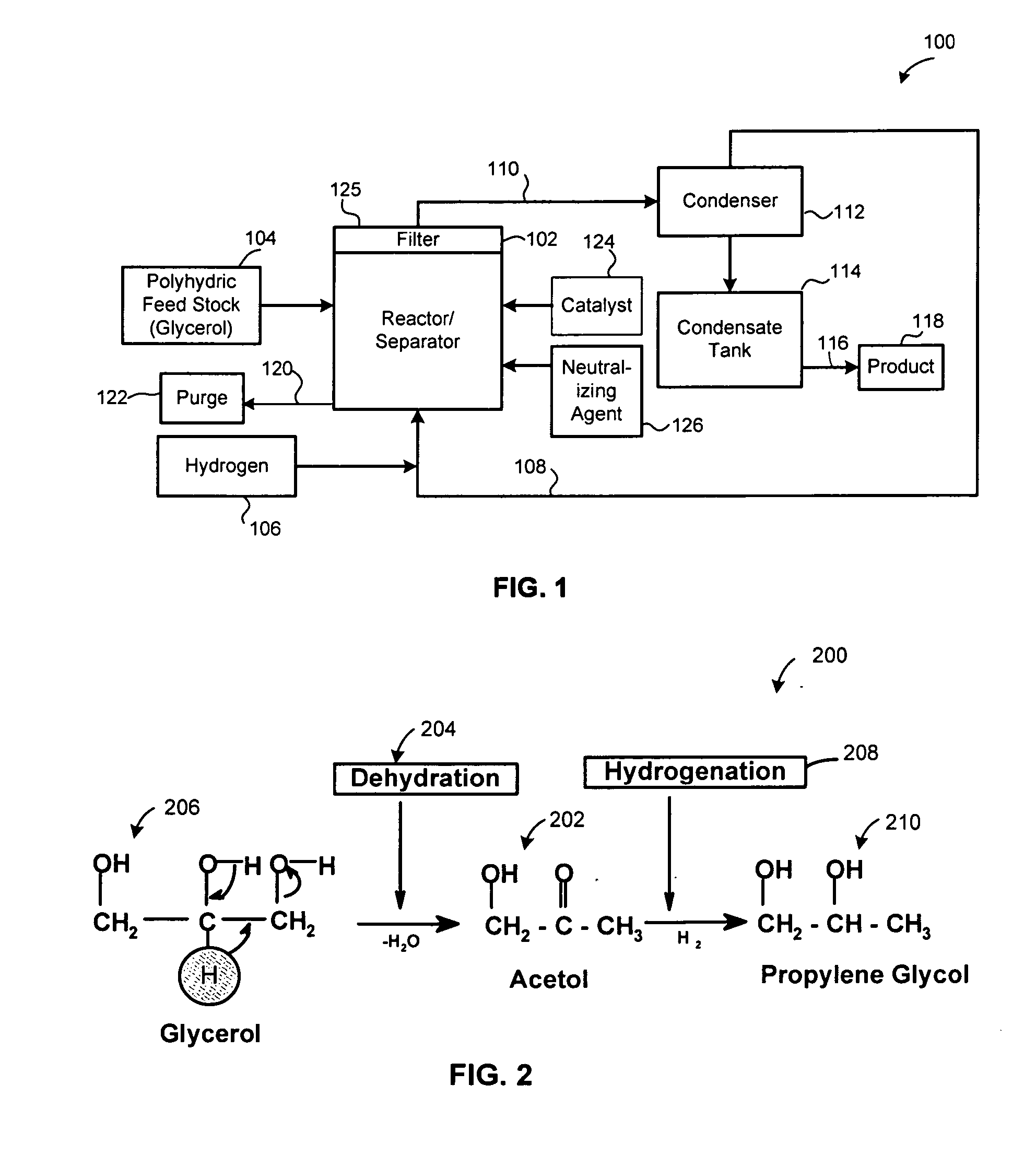

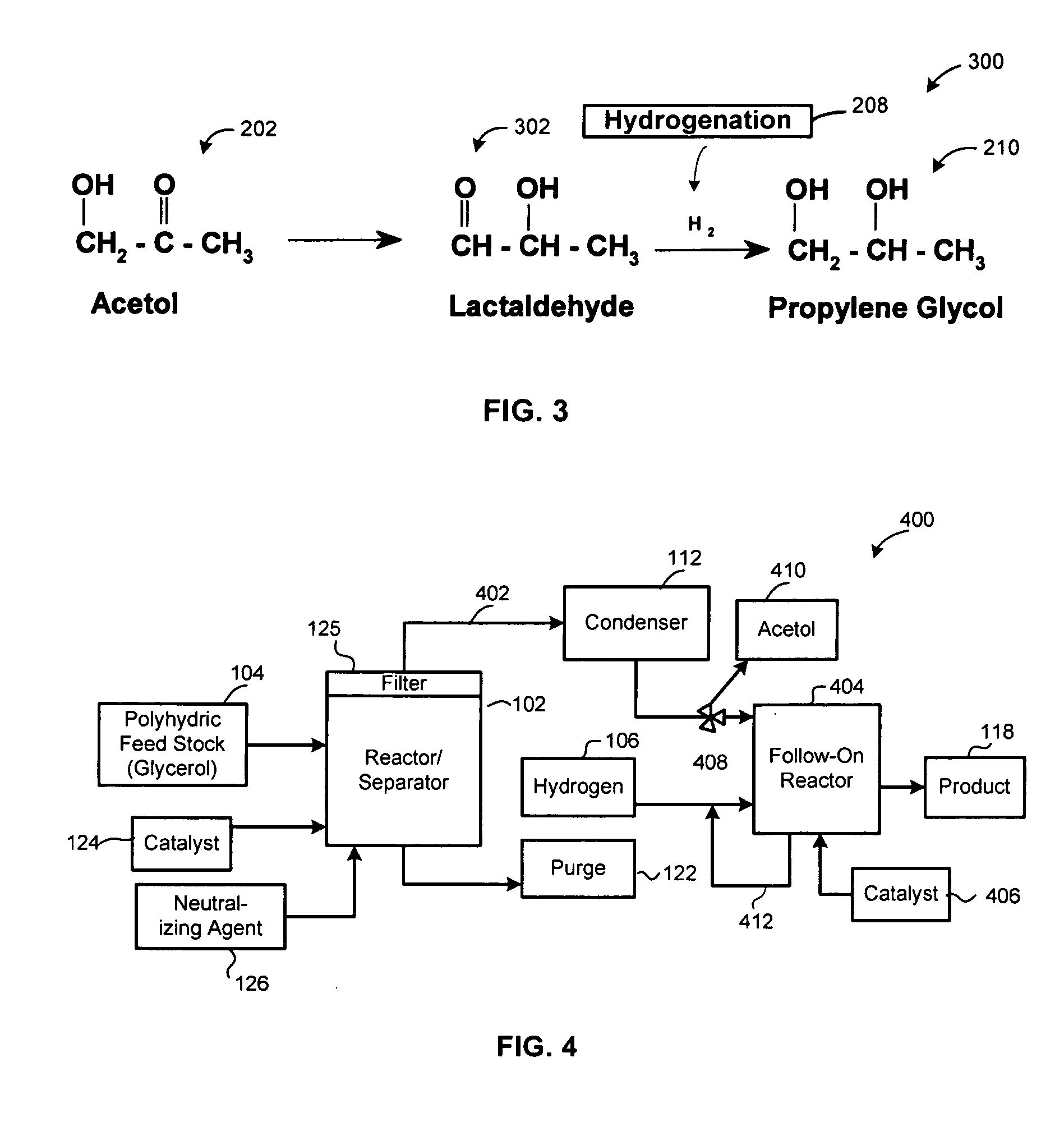

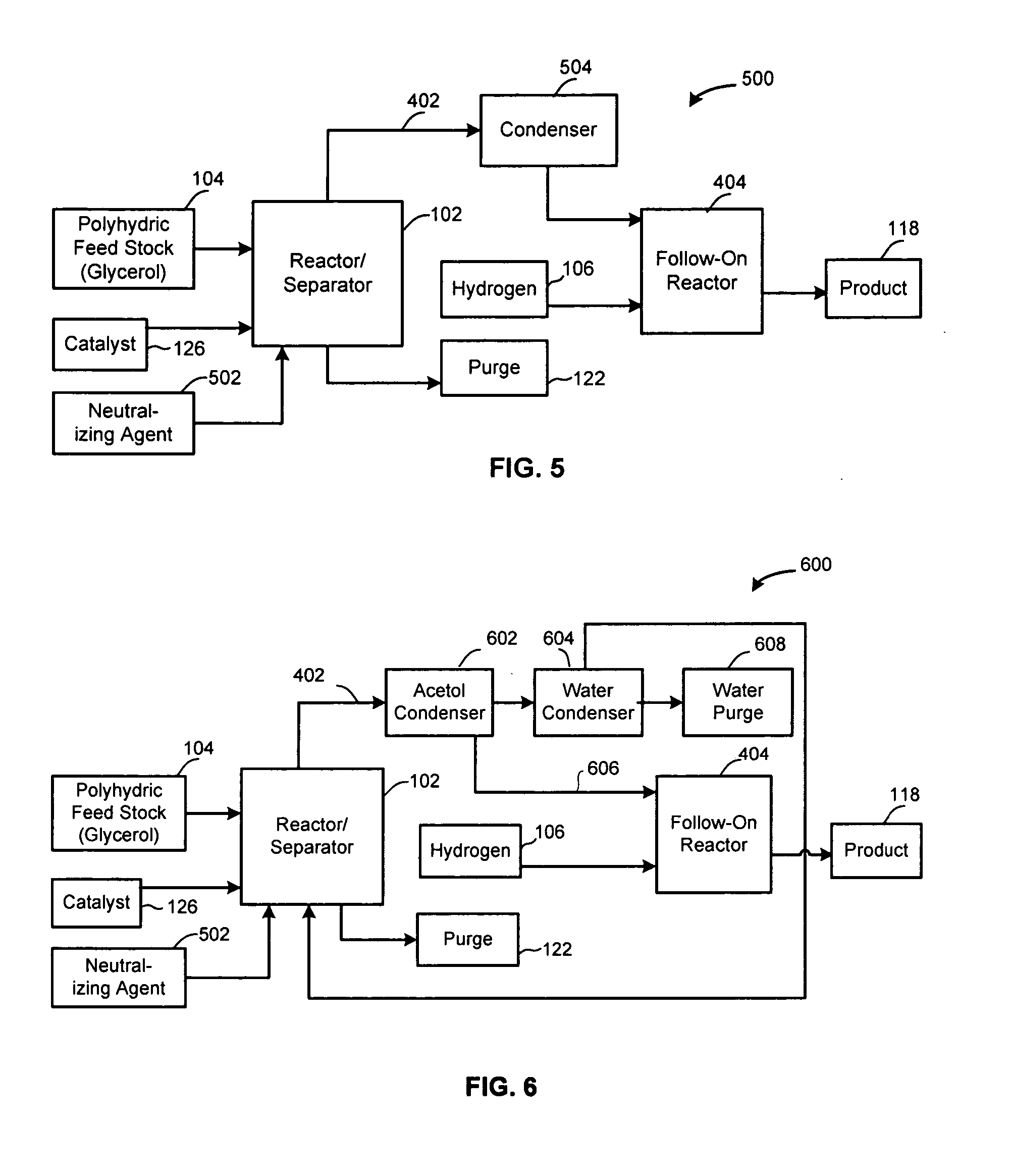

A reactive-separation process converts glycerin into lower alcohols, having boiling points less than 200° C., at high yields. Conversion of natural glycerin to propylene glycol through an acetol intermediate is achieved at temperatures from 150° to 250° C. at a pressure ranging from 1 and 25 bar. The preferred applications of the propylene glycol are as an antifreeze, deicing compound, or anti-icing compound. The preferred catalyst for this process in a copper-chromium powder.

Owner:RENEWABLE ALTERNATIVES LLC +1

Carbon naoparticle-containing hydrophilic nanofluid

InactiveUS20070158610A1Stabilize nanoparticle dispersionImprove thermal conductivityHeat-exchange elementsCarbon nanotubeHydrophile

The present invention relates to a process for preparing a stable suspension of carbon nanoparticles in a hydrophilic thermal transfer fluid to enhance thermal conductive properties and other characteristics such as freezing point of an antifreeze coolant. The process involves the step of dispersing carbon nanoparticles directly into a mixture of a thermal transfer fluid and other additives in the present of surfactants with intermittent ultrasonication. The present invention also relates to the composition of a hydrophilic nanofluid, which comprises carbon nanoparticles, particularly carbon nanotubes, a hydrophilic thermal transfer fluid, and at least one surfactant. Addition of surfactants significantly increases the stability of nanoparticle dispersion.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

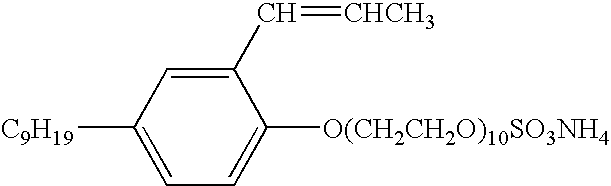

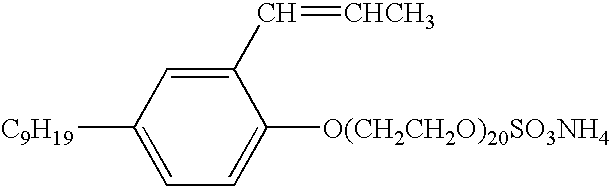

Low-VOC aqueous coating compositions with excellent freeze-thaw stability

InactiveUS6933415B2Improve freeze-thaw stabilityLow in VOCsOrganic compound preparationSpecial tyresFreezing thawingSURFACTANT BLEND

The present invention is an aqueous coating composition having excellent freeze-thaw stability and a low-VOC content. The aqueous coating composition of the invention includes at least one latex polymer derived from at least one monomer and at least one polymerizable alkoxylated surfactant, at least one pigment, and water. In accordance with the invention, less than 3.0% by weight of anti-freeze agents based on the total weight of the aqueous coating composition are used in the composition. The present invention also includes a method of preparing an aqueous coating composition such as a latex paint including the above components.

Owner:BASF AG

Antifreeze gel in a deformable container

An antifreeze gel composition is provided which particularly useful in gel toy to prevent ice formation. The composition includes a water-soluble antifreeze agent such as sorbitol, dextrose; gel was formed by either water-soluble polymers or gums; and salt. The present invention further provides a transparent antifreeze gel and container that is also transparent.

Owner:UANG YUH JYE

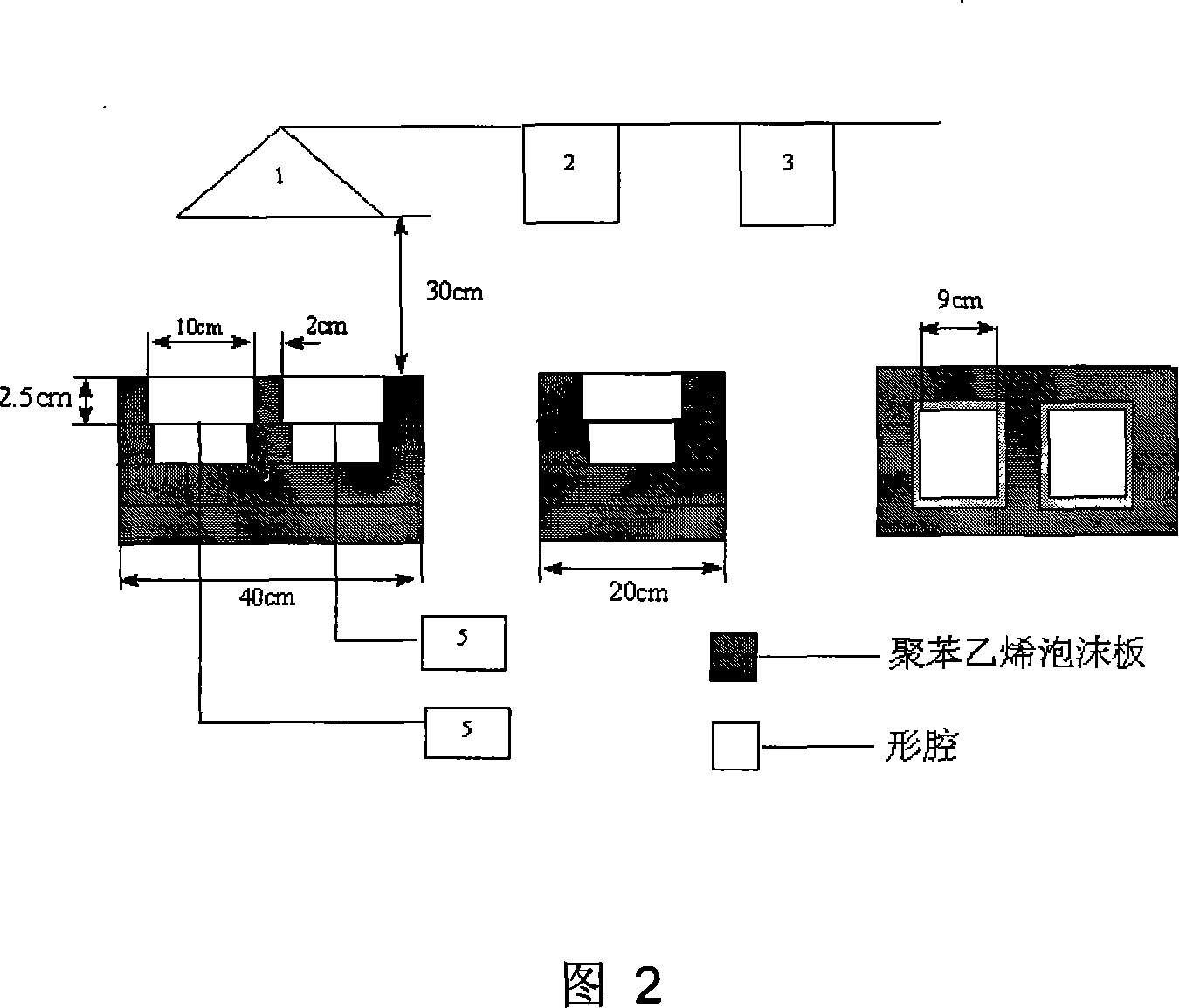

Thermal-insulating external-wall coating of nano-composite water and its production

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

Photocatalyst air freshing coating and preparation method thereof

InactiveCN101423690AEfficient antibacterial and antibacterialTo achieve the purpose of anti-pollution and easy cleaningDeodrantsCoatingsRutileIndoor air

The invention provides a photocatalytic air fresh coating and a preparation method thereof, and belongs to the field of indoor coating material, in particular to a coating for purifying air through a photocatalytic material and an anion generating material. The coating comprises the following raw materials in weight portion: 20 to 32 portions of deionized water, 1 to 2.0 portions of antifreeze agent, 0.1 to 0.2 portion of wetting agent, 0.5 to 0.6 portion of dispersing agent, 0.2 portion of preservative, 0.1 to 0.2 portion of pH regulator, 1 portion of nano titanium dioxide, 2 to 2.5 portions of the anion generating material, 20 to 25 portions of rutile titanium dioxide powder, 2 to 2.5 portions of diatomite, 12 to 15 portions of coarse whiting, 1 to 2 portions of film forming auxiliary, 25 to 45 portions of acrylic acid latex and 1 to 2 portions of thickening agent. The coating can keep the indoor air fresh for a long time and reach the first class indoor air environment standard of the nation. The anion releasing quantity of the coating reaches 2,626 / cm<3> and the antibacterium and bacteriostasis ratio of the coating reaches more than 97 percent.

Owner:XINHE NEW MATERIALS CO LTD

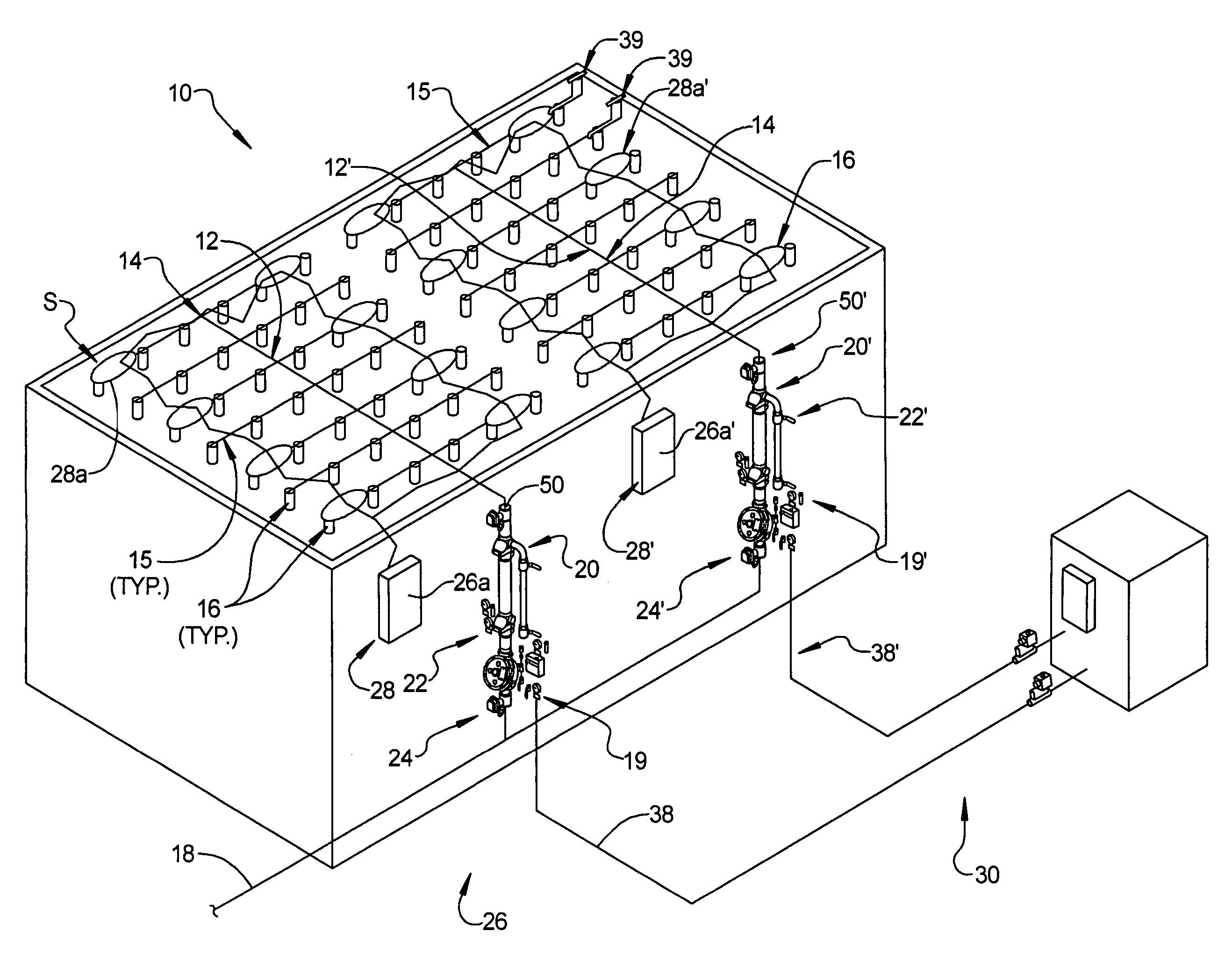

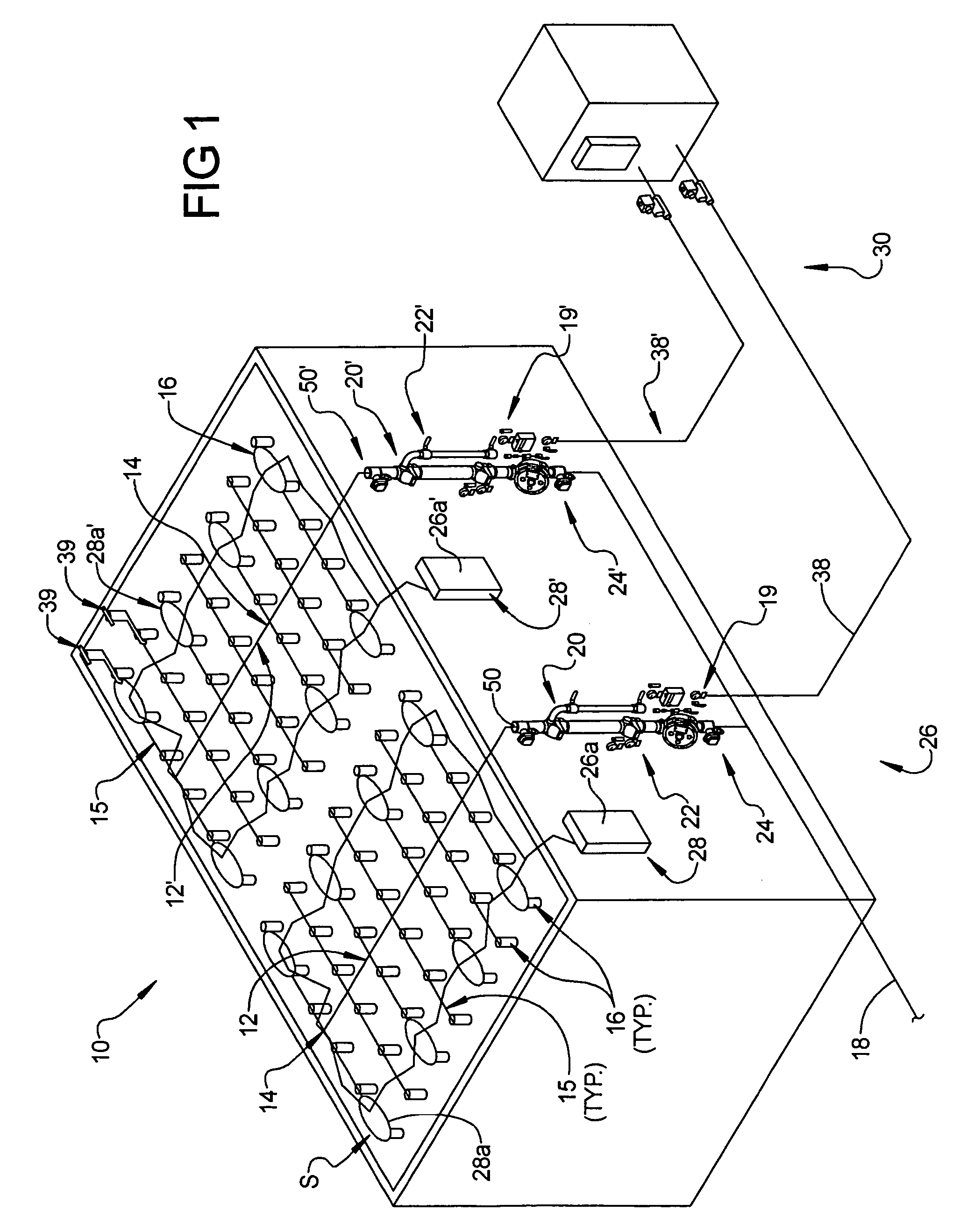

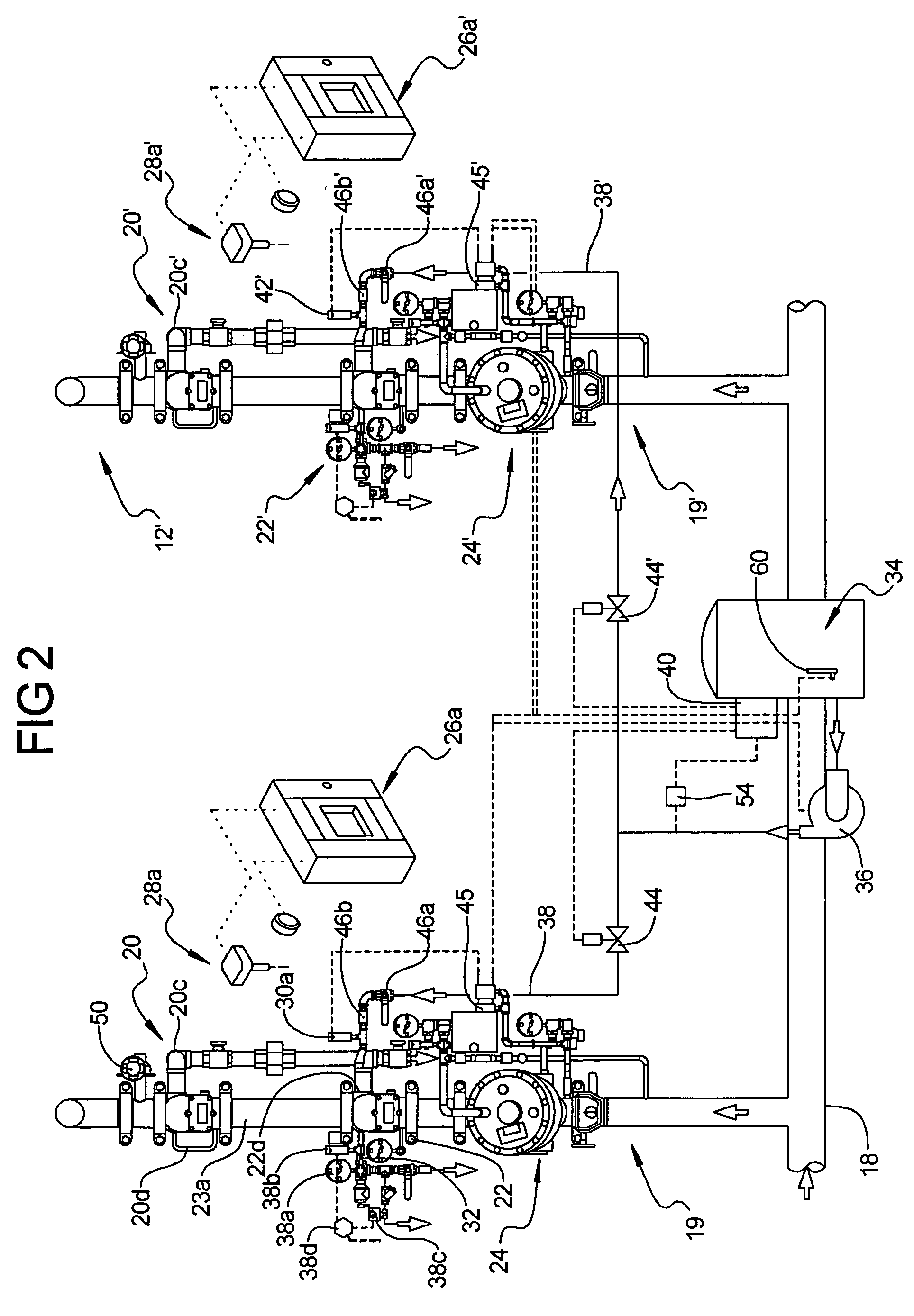

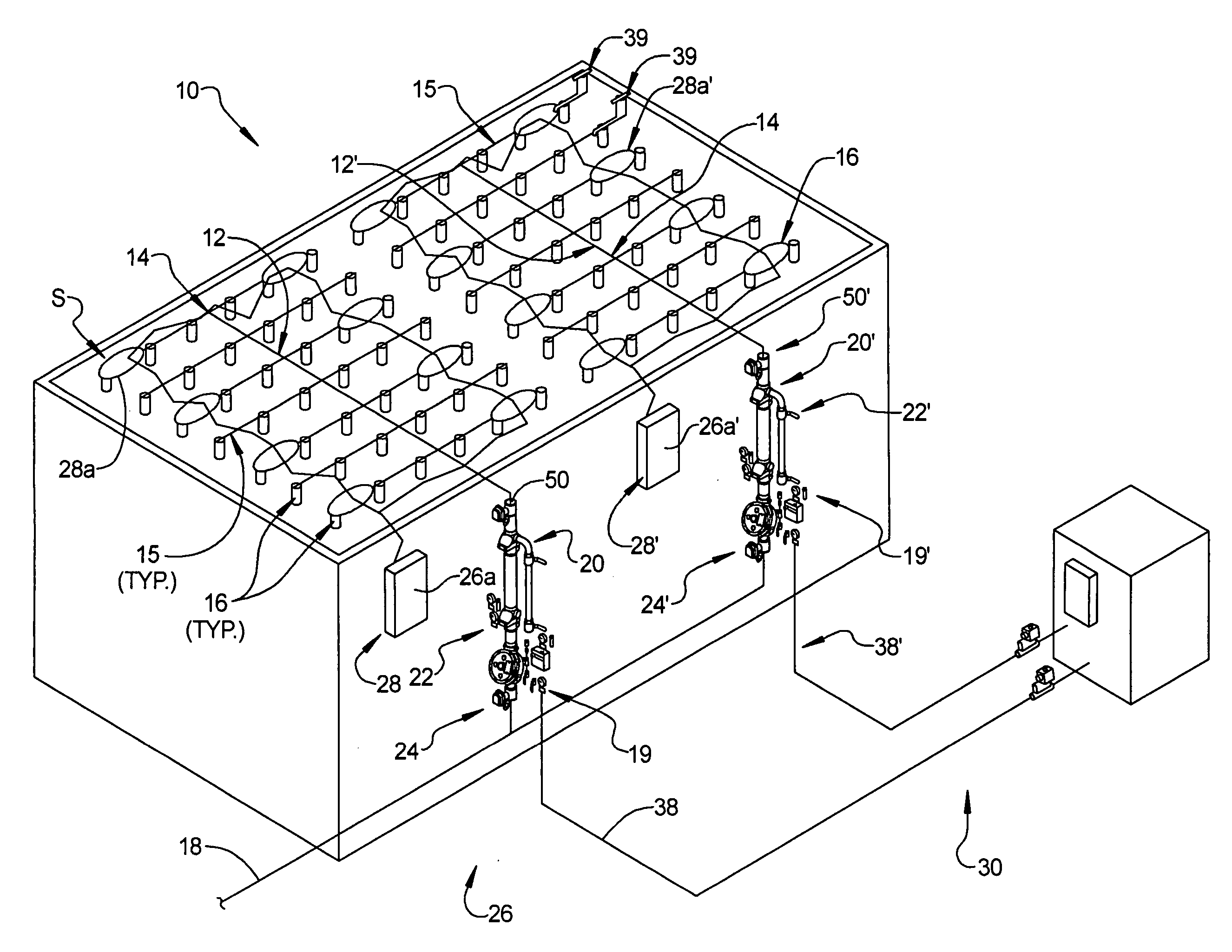

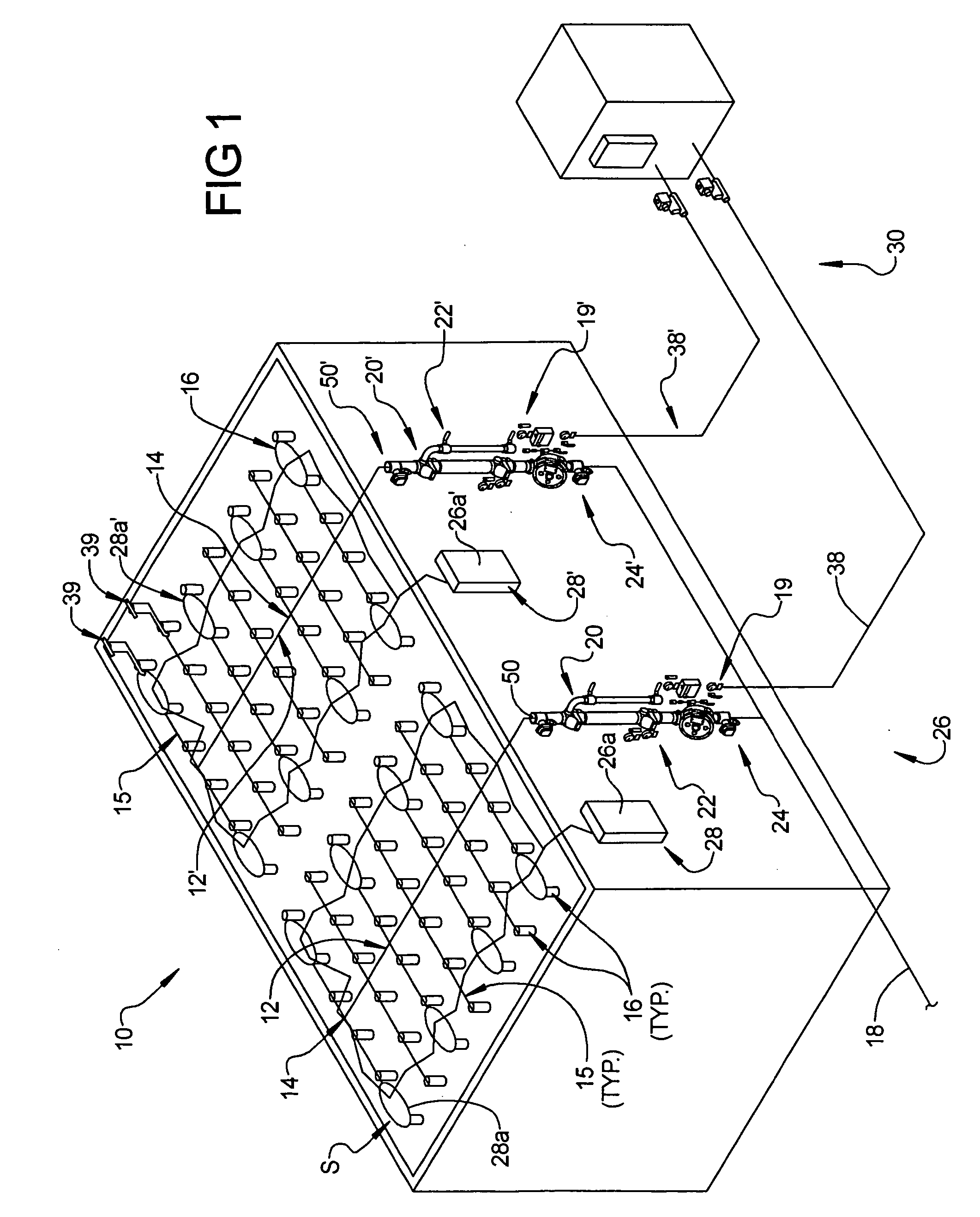

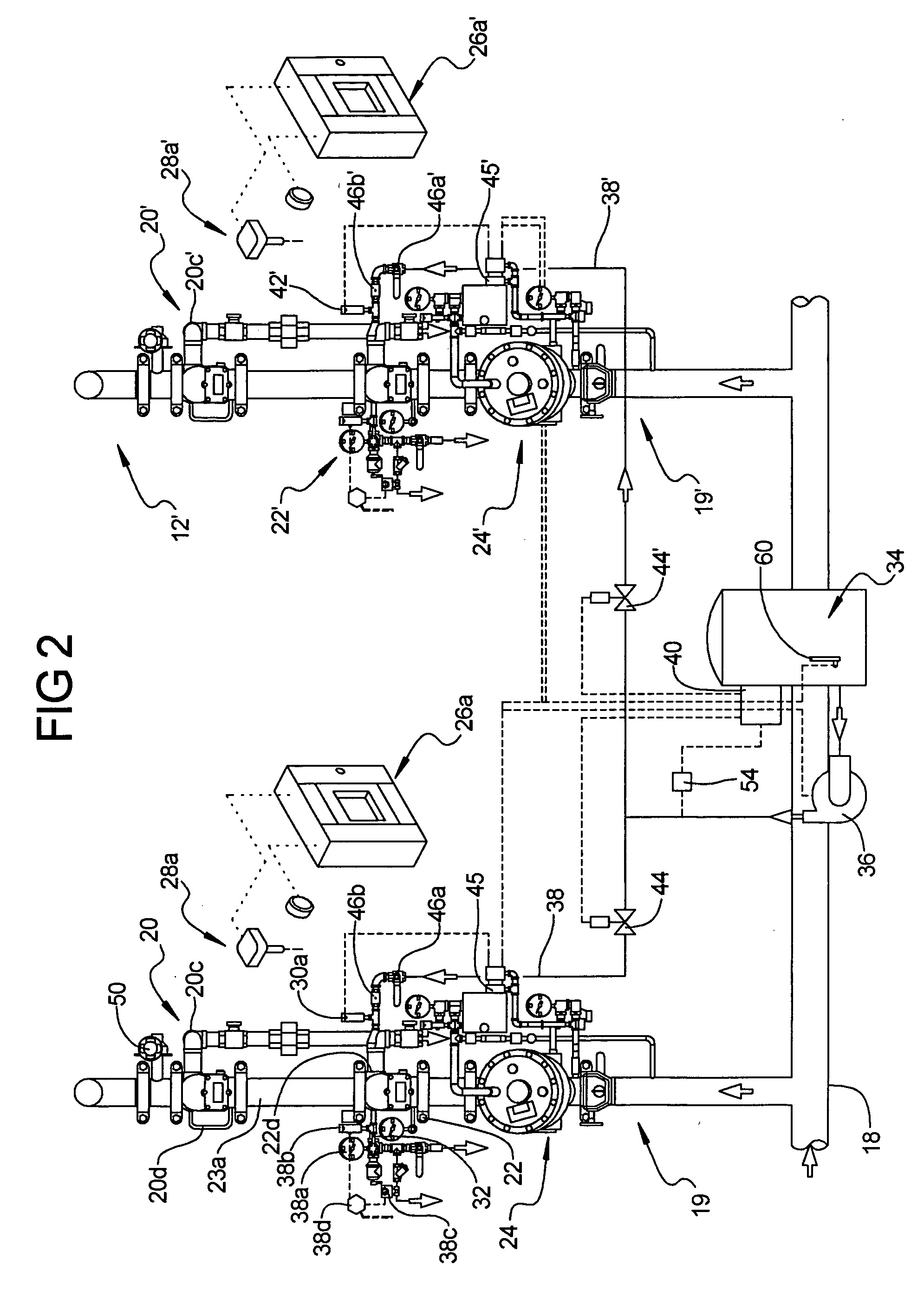

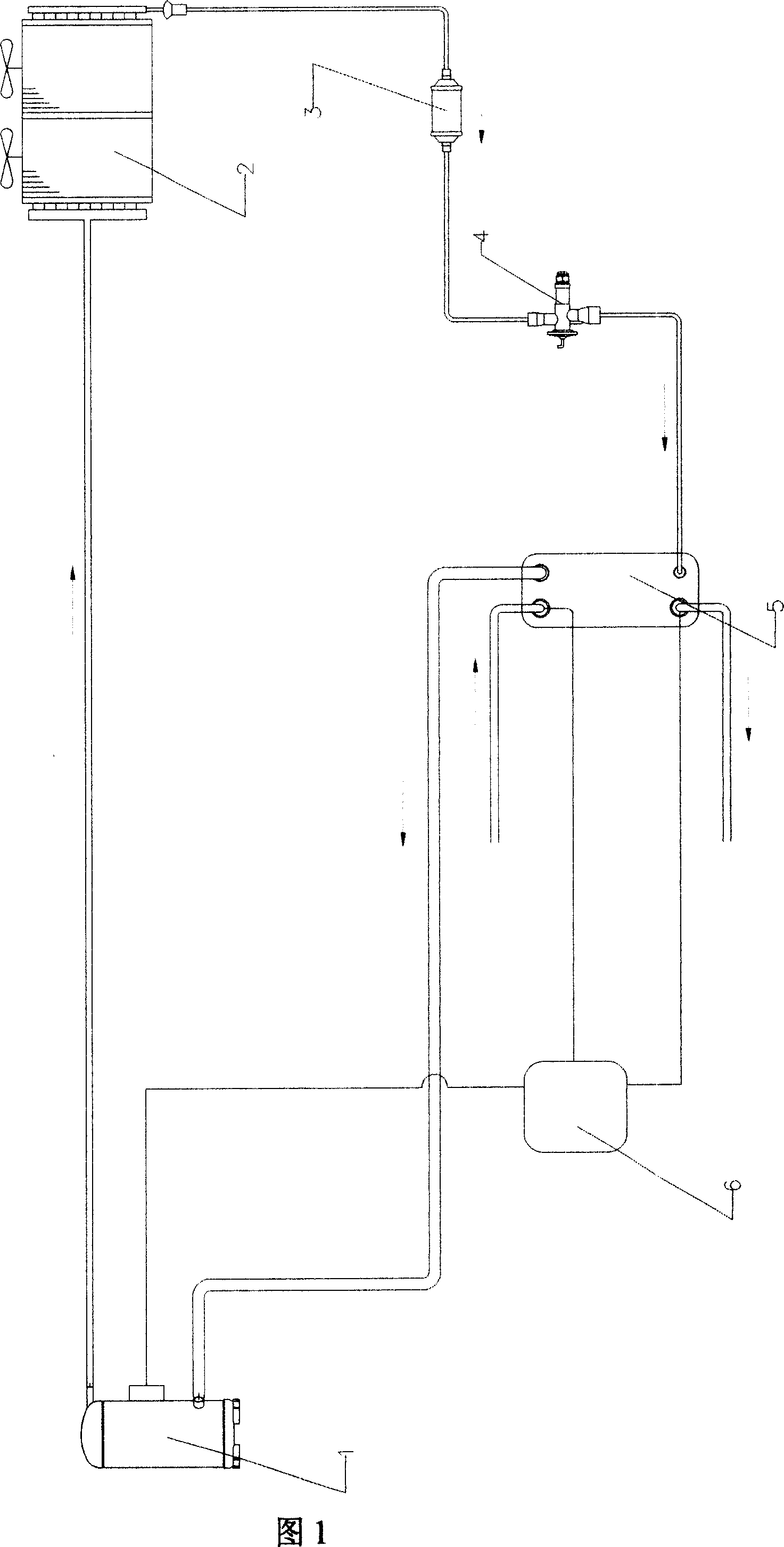

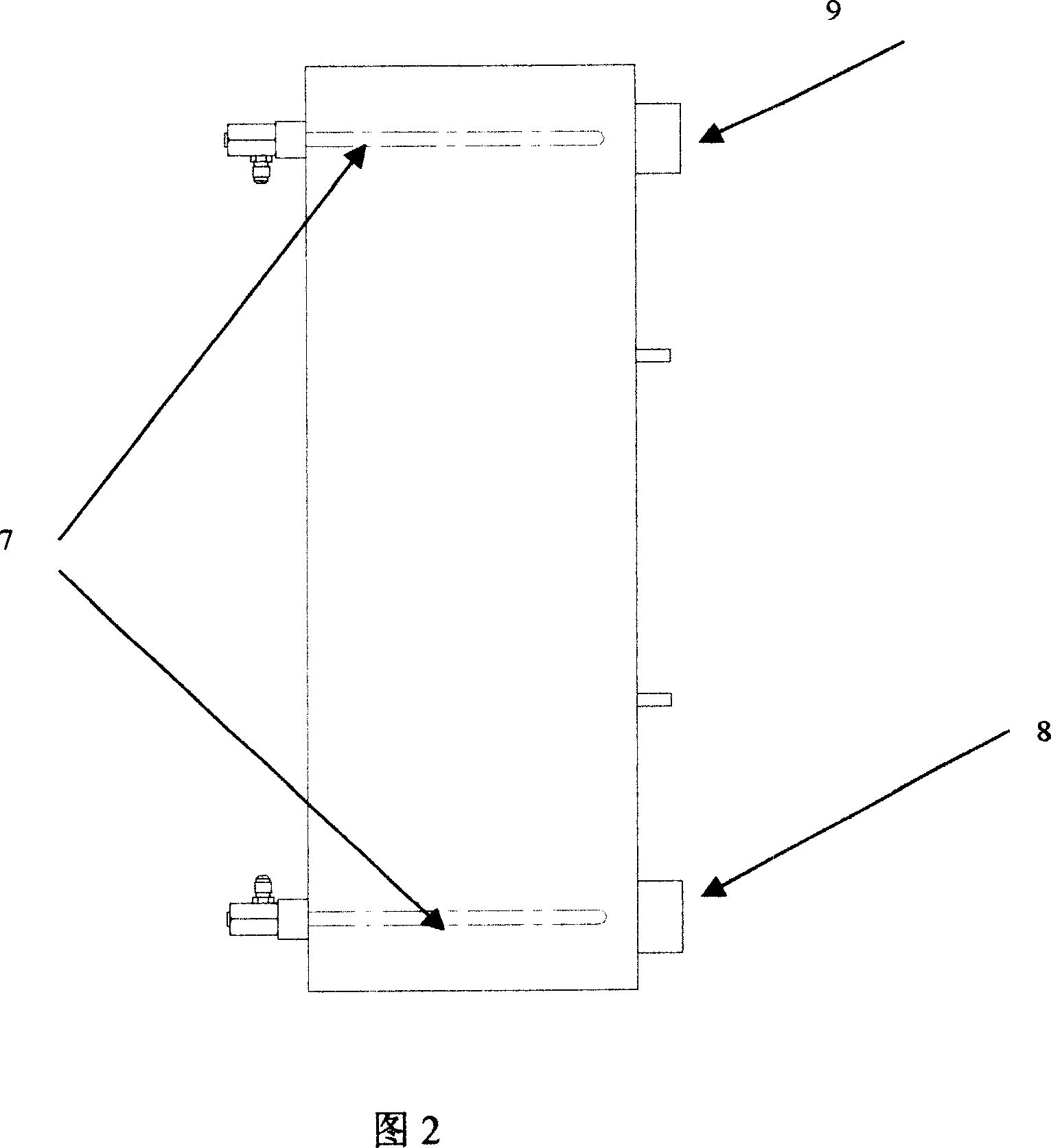

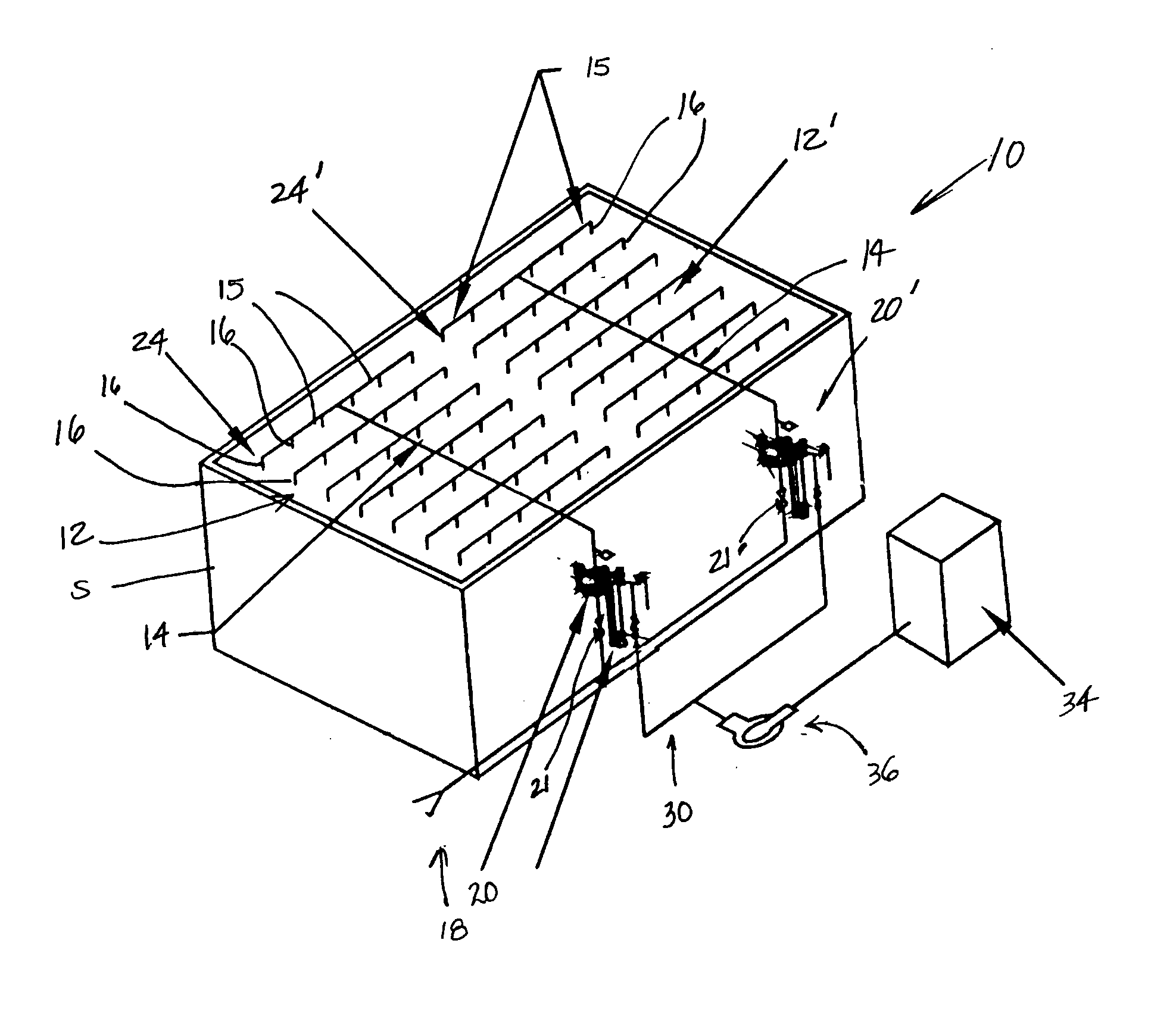

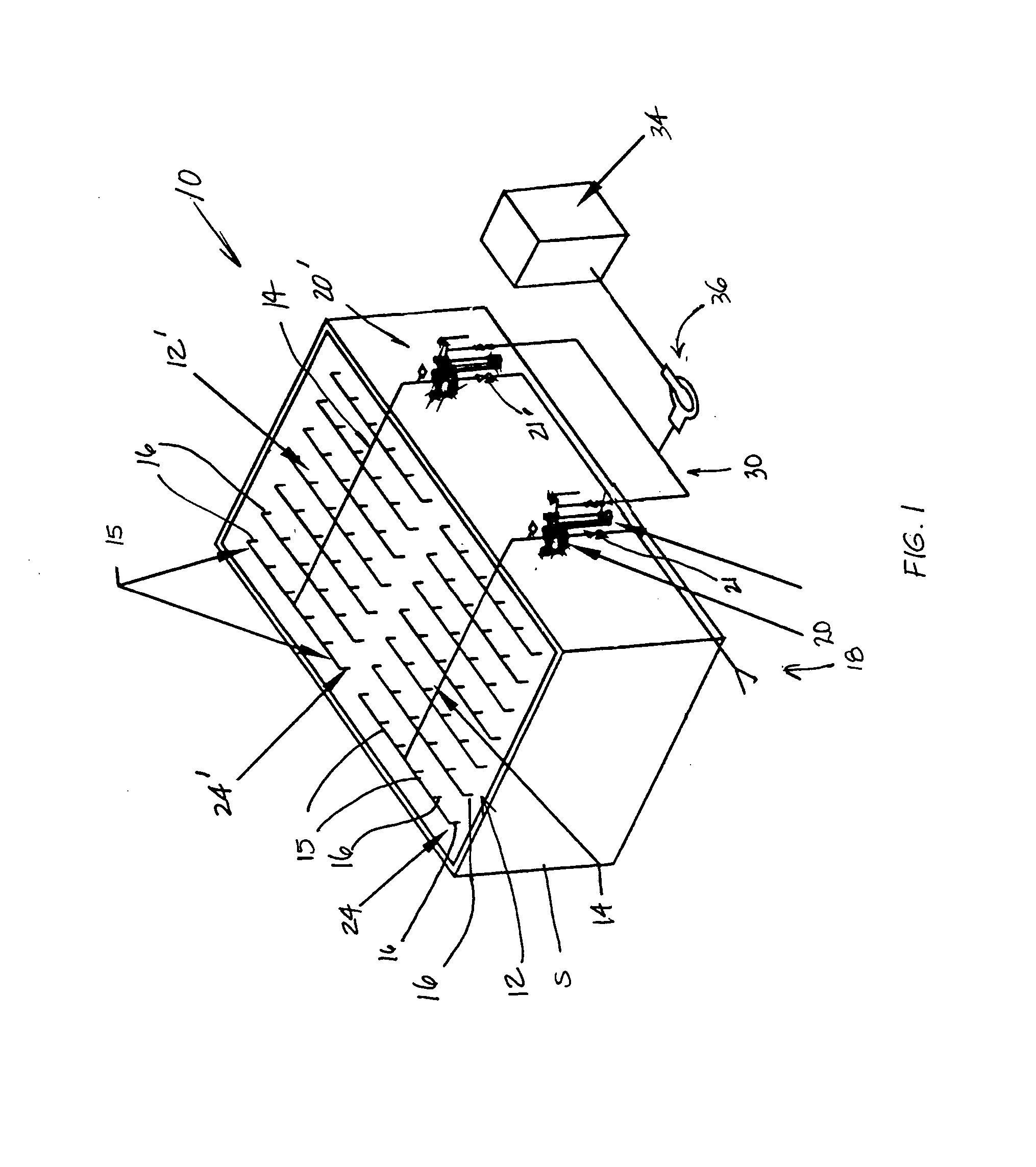

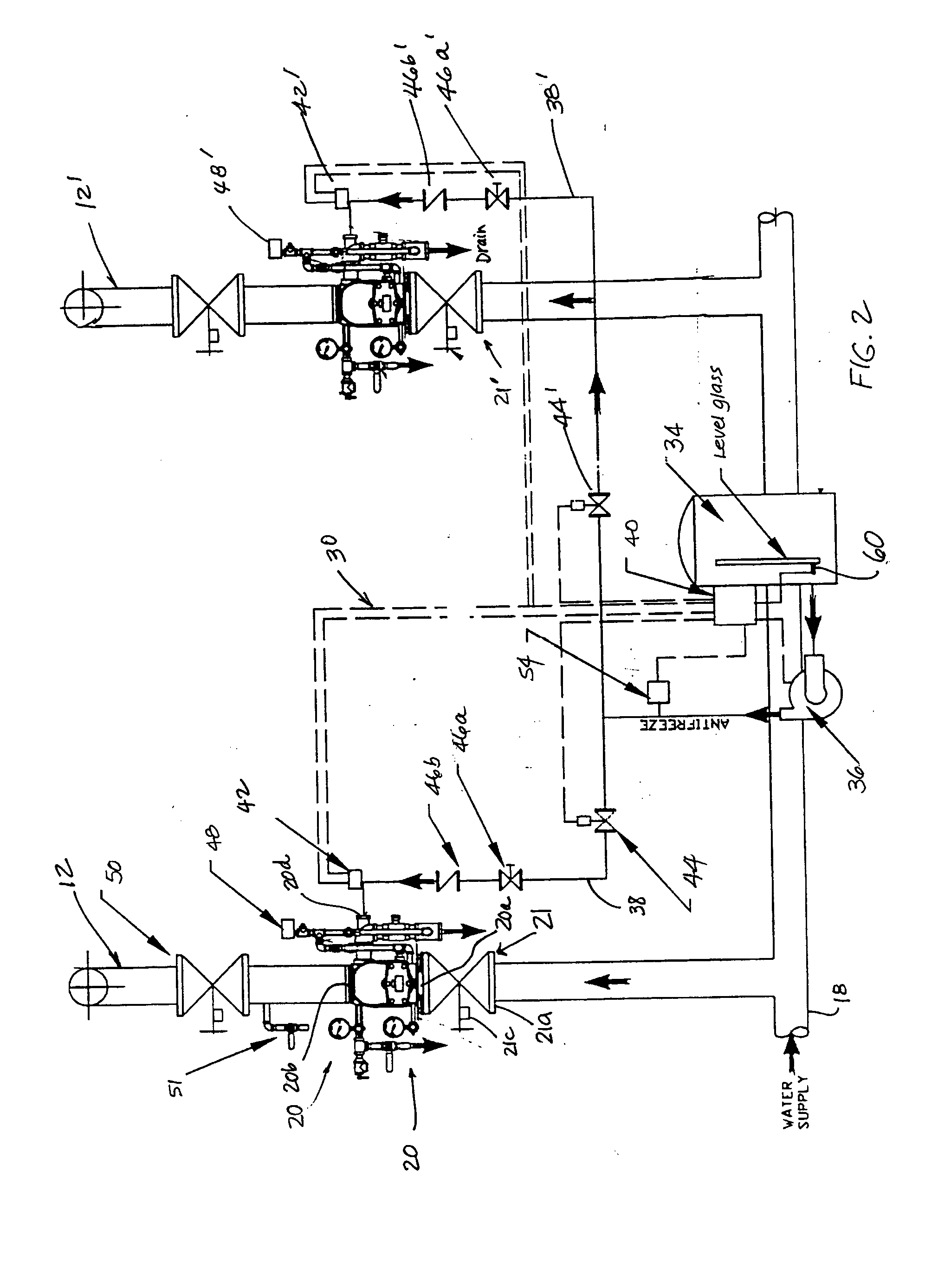

Fire extinguishing system

ActiveUS7389824B2Minimize, if not eliminate compressible gas in the systemPrevent costly contaminationSelf-acting watering devicesMovable spraying apparatusEngineeringCheck valve

An early suppression fast response fire protection system includes a sprinkler piping system with at least one sprinkler head assembly, a water supply system, and a check valve in fluid communication with the sprinkler piping system and the water supply system. An antifreeze solution supply system is in fluid communication with the sprinkler piping system, with the check valve isolating the antifreeze solution from the water supply unless a fire condition occurs. A control is provided that is in communication with a flow detector, which detects the pressure of the antifreeze solution in the sprinkler piping system, and a pressure detector, which detects the flow of water through the check valve, and controls the flow of the antifreeze solution to the sprinkler piping system and maintains the pressure of the antifreeze solution in the sprinkler piping system unless the flow detector detects the flow of water through the check valve in which case the control stops the flow of antifreeze solution to the sprinkler piping system to limit the discharge of antifreeze solution from the fire protection system.

Owner:VIKING

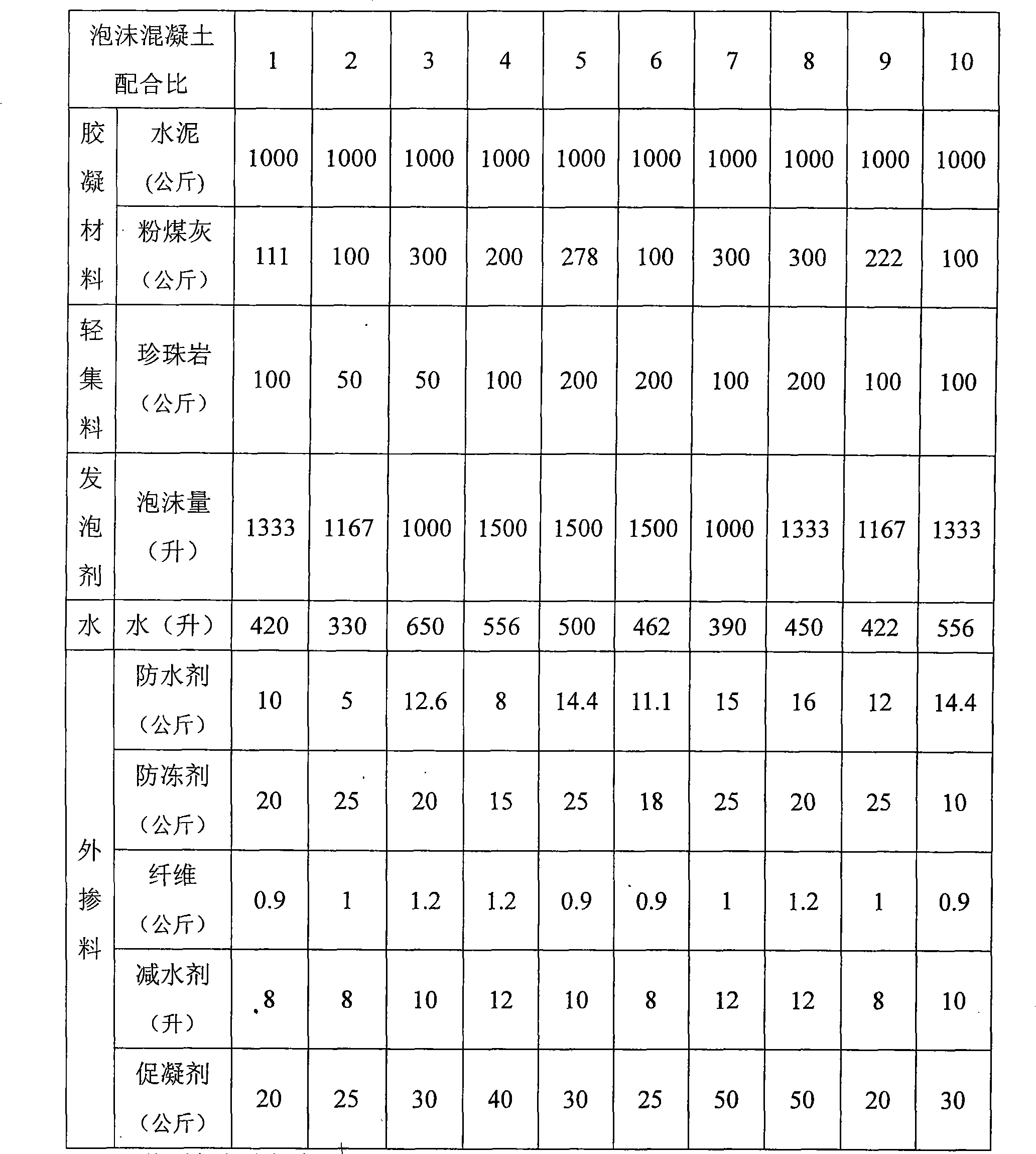

Foam concrete and preparing process thereof

InactiveCN101497533AHigh strengthLight weightCeramic shaping apparatusCement mixing apparatusFoam concreteFiber

The invention discloses foam concrete and a preparation method thereof. The foam concrete comprises a gelling material, light aggregate, water, admixture and foaming agent. The preparation method comprises the following steps: (1) pre-treating raw materials to prevent hard lumps and hard grains in the raw materials from depositing in foam slurry; (2) weighing each component according to a proportion; (3) preparing and adding foaming solution; (4) loading and stirring, namely, adding water into a stirrer, starting the stirrer, and adding cement, coal ash, perlite, waterproof agent, anti-freezing agent, water reducing agent and fiber into the stirrer in turn; (5) foaming, namely, foaming at the same time of stirring the slurry, sealing a valve firstly and then pressurizing the valve by an air compressor; (6) adding foam, namely, after the gelling slurry is well prepared, adding the foam into the gelling slurry under the state of stirring without stopping the stirrer; and (7) casting and molding, namely, when the slurry surface has no floating foam, finishing the preparation of the foam slurry. The foam concrete has the functions of light weight, water proofing, fire resistance, heat insulation, freezing resistance, cracking resistance, shock resistance and the like, and is particularly suitable for engineering insulating layers in cold areas and water-blocking and shock-resistant layers of underground engineering.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Recoverable ground source heat pump

Recoverable Ground Source Heat Pump system with energy storage function which uses and stores off-peak-hours electricity to maintain the ground medium temperature to ensure the efficient operation of the system during on-peak electricity hours. The release and receiving of energy is accomplished through the ground heat exchanger by flowing the fluid through different routings of the circulation loop using reversing vales. Space heating and cooling is assured while the underground medium temperature is recovered. The heat pump system of the invention has less initial investment compared to conventional ground source heat pump and ice energy storage cooling systems; requires less ground space; provide operating energy cost savings; assures performance of operation; and avoids using antifreeze solution in the ground circulation fluid that may cause environmental, safety and erosion problems.

Owner:XU YUNSHENG

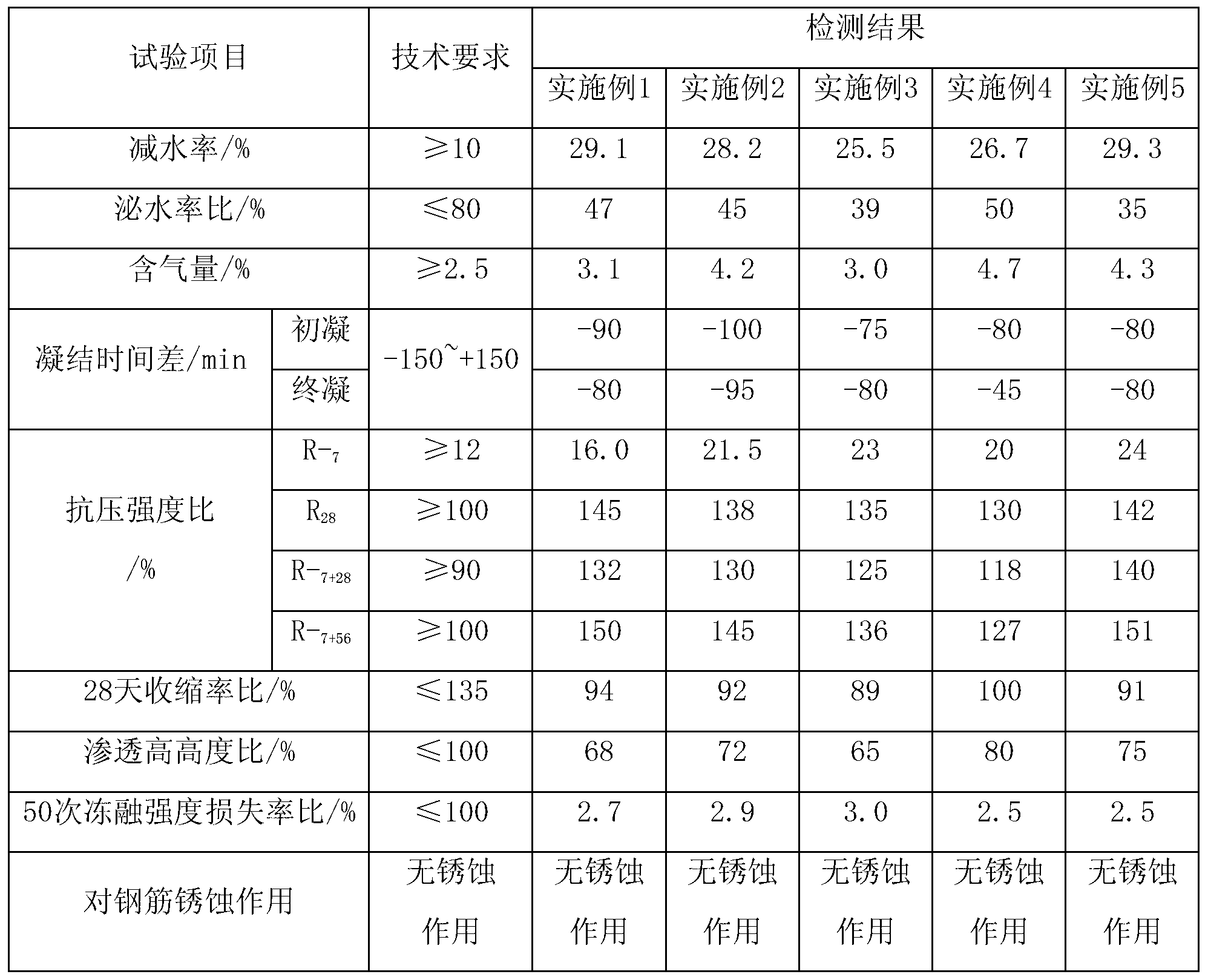

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Emulsified water-blended fuel compositions

This invention relates to an emulsified water-blended fuel composition comprising: (A) a hydrocarbon boiling in the gasoline or diesel range; (B) water; (C) a minor emulsifying amount of at least one fuel-soluble salt made by reacting (C)(I) at least one acylating agent having about 16 to 500 carbon atoms with (C)(II) ammonia and / or at least one amine; and (D) about 0.001 to about 15% by weight of the water-blended fuel composition of a water soluble, ashless, halogen-, boron-, and phosphorus-free, amine salt, distinct from component (C). In one embodiment, the composition further comprises (E) at least one cosurfactant distinct from component (C); in one embodiment, (F) at least one organic cetane improver; and in one embodiment, (G) at least one antifreeze. The invention also relates to a method for fueling an internal combustion engine comprising fueling said engine with the composition of the present invention.

Owner:THE LUBRIZOL CORP

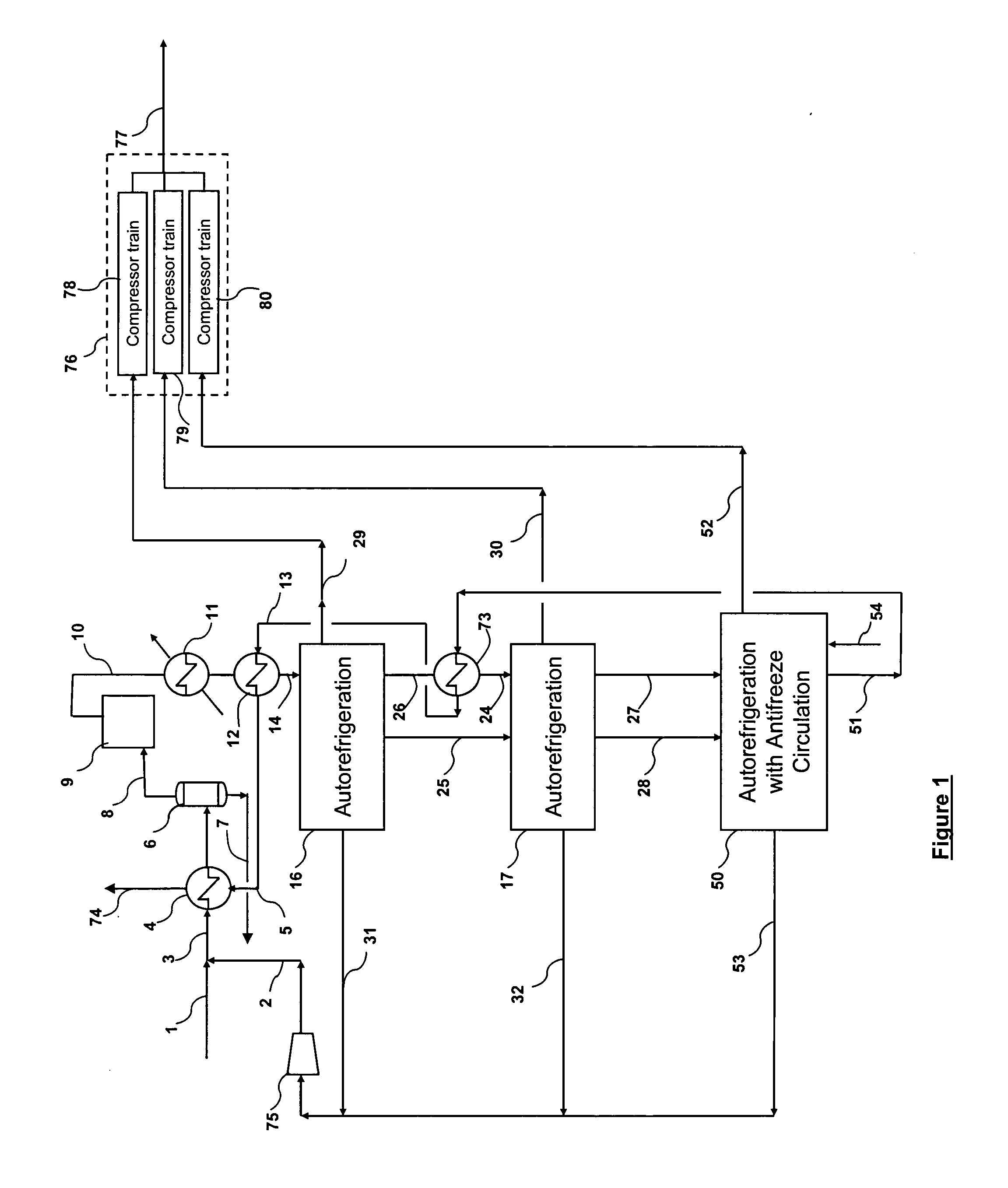

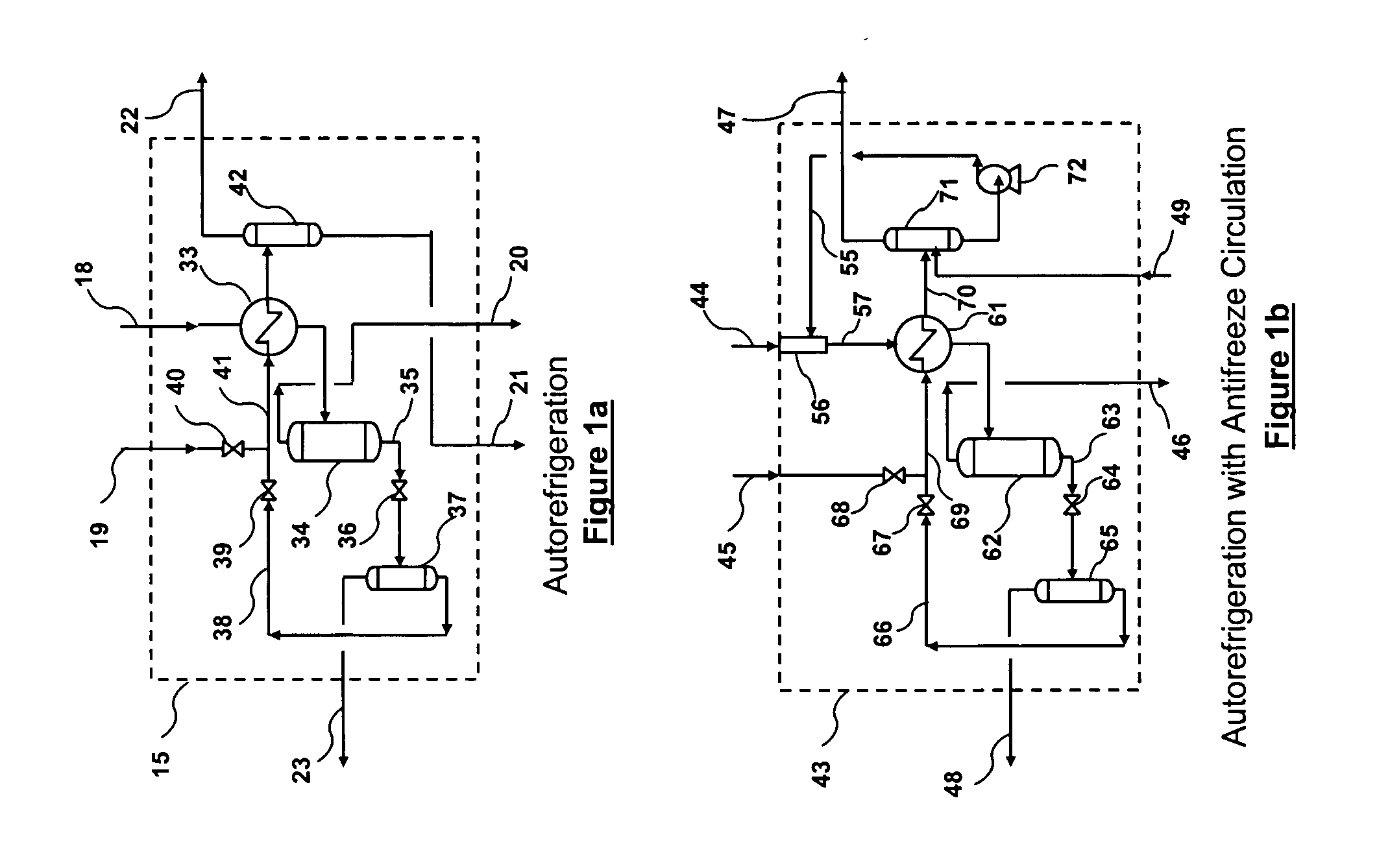

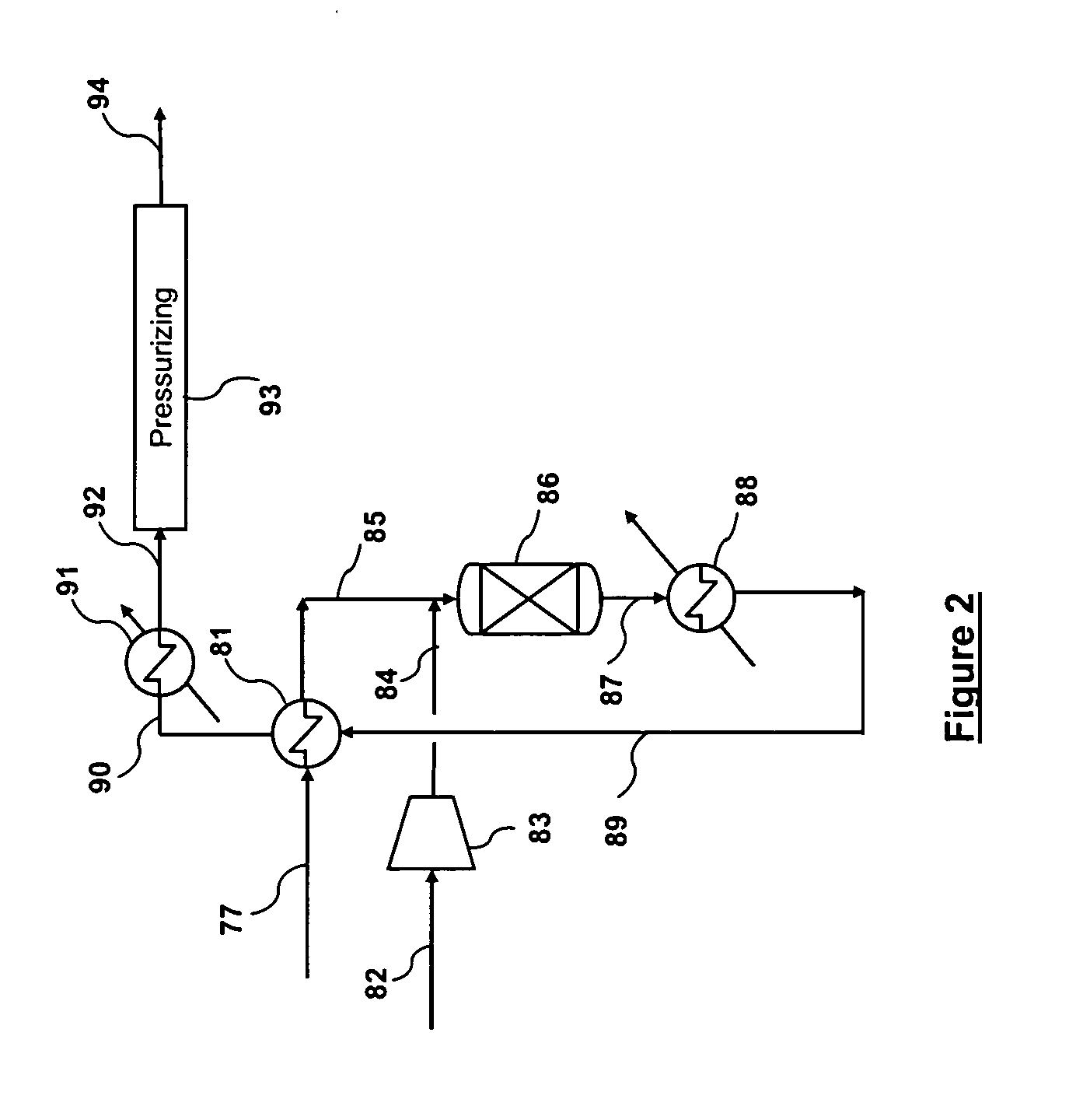

Multi-stage cryogenic acid gas removal

InactiveUS20070221541A1Alleviate power needsIncrease the number ofSolidificationLiquefactionPetroleumPetroleum coke

A relatively simple and energy efficient multiple stage cryogenic process for the purification of a hydrogen-rich stream by the removal of acid gases, mainly CO2 and H2S, by method of autorefrigeration and delivering or producing those acid gases, mainly CO2, at pressure sufficiently high for disposal by containment, commonly known as sequestration. Autorefrigeration is comprised of (a) condensing acid gases from the syngas stream by cooling the syngas, (b) separating the liquefied acid gases from the syngas, and (c) evaporating the liquefied acid gases at a pressure lower than that of the syngas to provide cooling. The process is composed of multiple autorefrigeration stages to generate multiple acid gas product streams with a pressure as high as practical in each stream so as to lessen the power needed to pressurize the acid gas streams for sequestration. The final autorefrigeration stage utilizes an antifreeze liquid that allows the final stage to operate below the freezing point of CO2; thus allowing more acid gas removal. The antifreeze liquid is an alcohol or a mixture of alcohols with a freezing point lower than about minus 110 degrees F. and a boiling point higher than about 100 degrees F. The process includes hydrogen recovery and recycle as well as recovery of the energy contained in the sulfur bearing compounds. The process is especially well suited for CO2 removal / sequestration from a coal (or petroleum coke) gasification process.

Owner:TENNESSEE VALLEY AUTHORITY

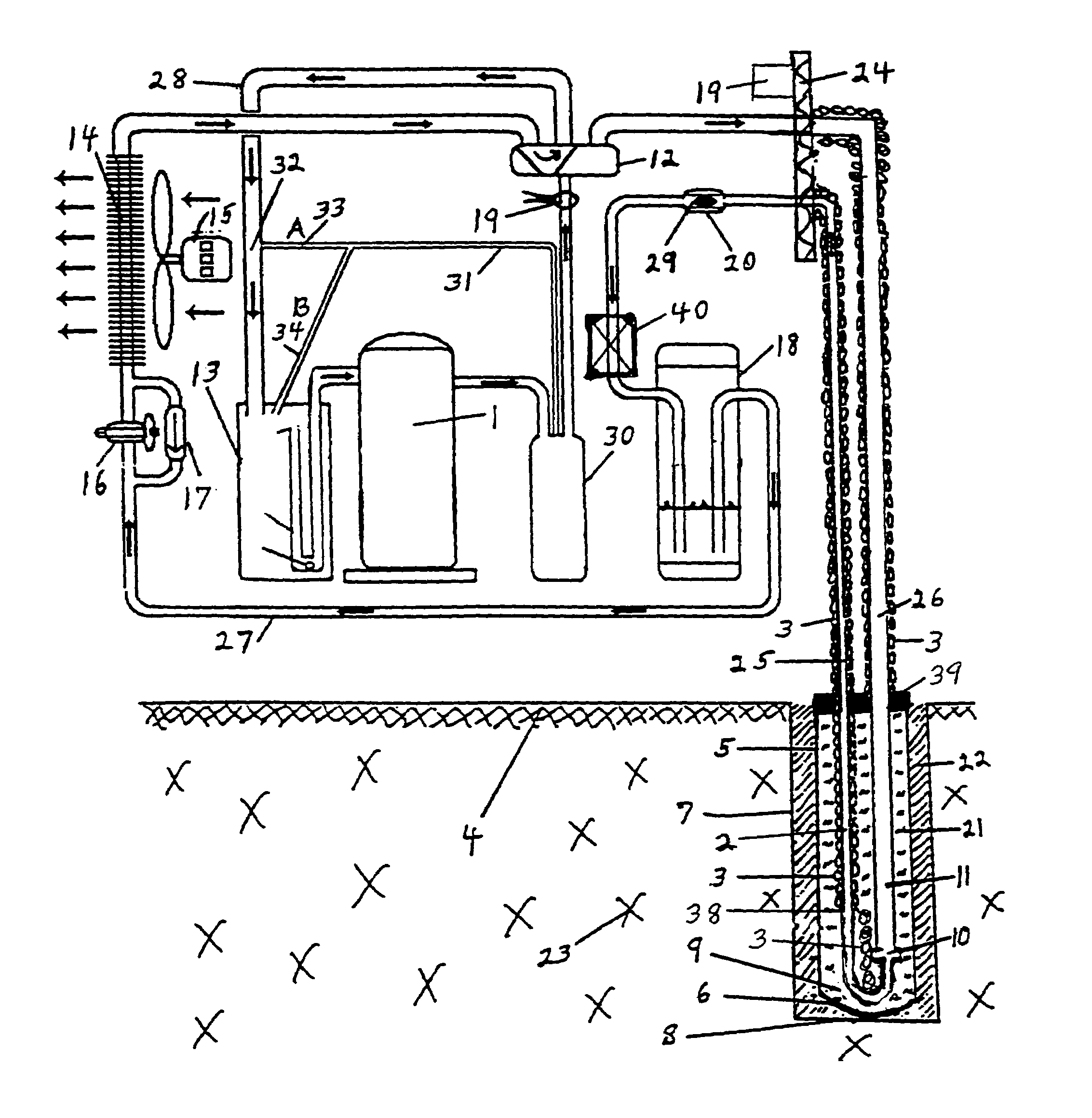

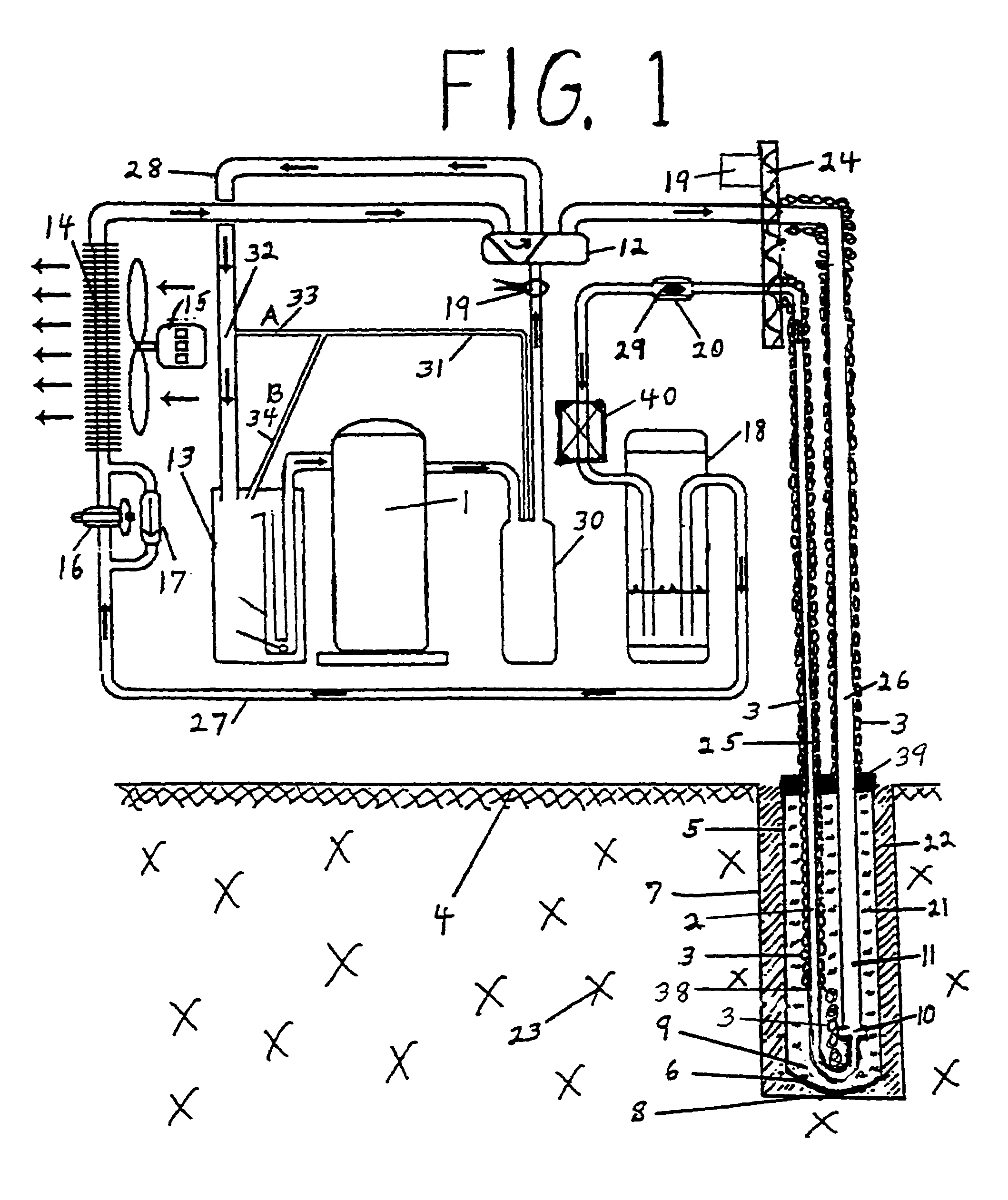

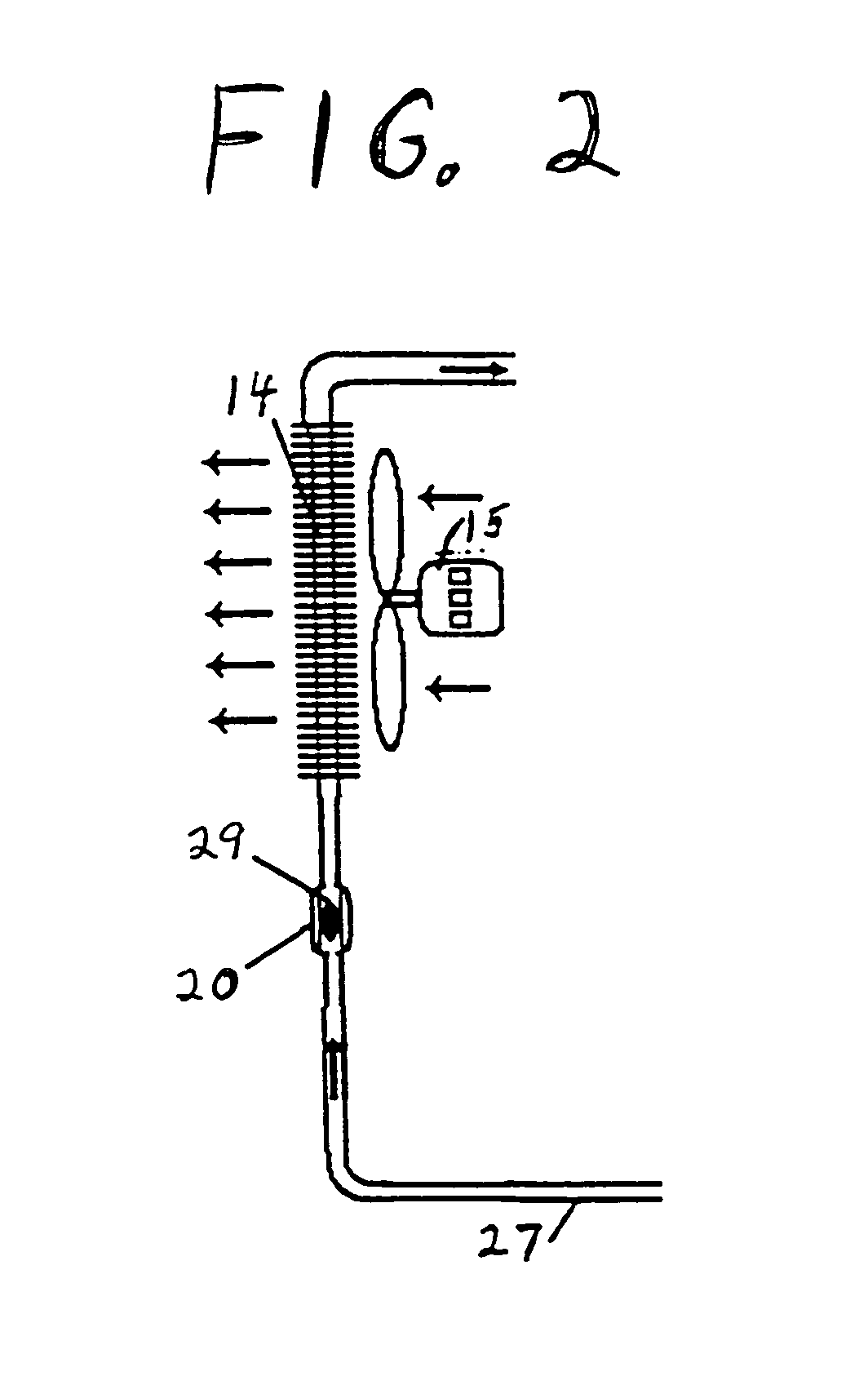

Deep well/long trench direct expansion heating/cooling system

A direct expansion geothermal heat exchange system including certain line set sizes, distances, designs, depths, and lengths, including a long trench system design, certain vapor line coverings and moisturizing means, certain refrigerant operational pressures and type, certain pin restrictor sizes and locations, certain liquid line insulation lengths, certain containment pipe composition, pipe sizing with polyethylene, pipe antifreeze fill percentage, and pipe top sealing, a certain oil return safeguard procedure, certain interior heat exchanger design tonnages with predominate heating loads and with predominate cooling loads, a certain receiver type and capacity, an optional means of placing sub-surface refrigerant transport tubing within respective protective containment pipes, certain trench system and well / borehole system combinations, and certain trench creation means.

Owner:EARTH TO AIR SYST

Real stone paint, and preparation method and construction method thereof

The invention provides a real stone paint. The real stone paint comprises, by weight, 90-130 parts of water, 2-5 parts of hydroxyethyl cellulose, 2-5 parts of a dispersant, 1-3 parts of a wetting agent, 4-8 parts of an antifoaming agent, 2-3 parts of an antiseptic, 100-150 parts of an emulsion, 5-12 parts of a film forming assistant, 1-3 parts of a pH adjusting agent, 5-20 parts of an antifreeze agent and 400-900 parts of a color sand component, wherein the color sand component comprises two or more than two natural stone flours with similar color. The invention further provides a preparation method of the real stone paint. The natural stone flowers with similar color in raw materials are blended in the embodiment of the invention to balance the color difference of all the natural stone flours, so even the color of one of the natural stone flours changes, the color difference of real stone paint products in batches is very small under the contrast of other natural stone flours with similar color, thereby the color difference change of the real stone paint is well controlled.

Owner:DRAGON BRAND COATINGS (BEIJING) CO LTD

Environment-friendly dust fall agent for coal mine

InactiveCN103450855ACohesion effect is goodQuick dustOther chemical processesActive agentSurface-active agents

The invention relates to the field of dust fall agents, in particular to an environment-friendly dust fall agent for a coal mine. The environment-friendly dust fall agent enables water mist on the surfaces of dust particles to quickly wet and permeate the insides of the dust particles, dust particle coagulation is quickened, dust particle sedimentation is quickened, and the dust fall agent is biodegradable. The environment-friendly dust fall agent for the coal mine comprises the following raw materials, by mass ratio, 60-100 parts of surface active agents, 5-30 parts of biodegradable high-molecular polymers, 20-60 parts of solvents, 6-20 parts of antifreezing agents and 0.5-4 parts of metal corrosion inhibitors. The dust fall agent is a concentrated solution, the ratio can reach 1: 1000 to 1: 5000, quick dust fall can be achieved, chloride salt is not contained, the agent is biodegradable after being sprayed, and therefore secondary environment pollution is avoided.

Owner:TAIYUAN RONGYUAN TECH CO LTD

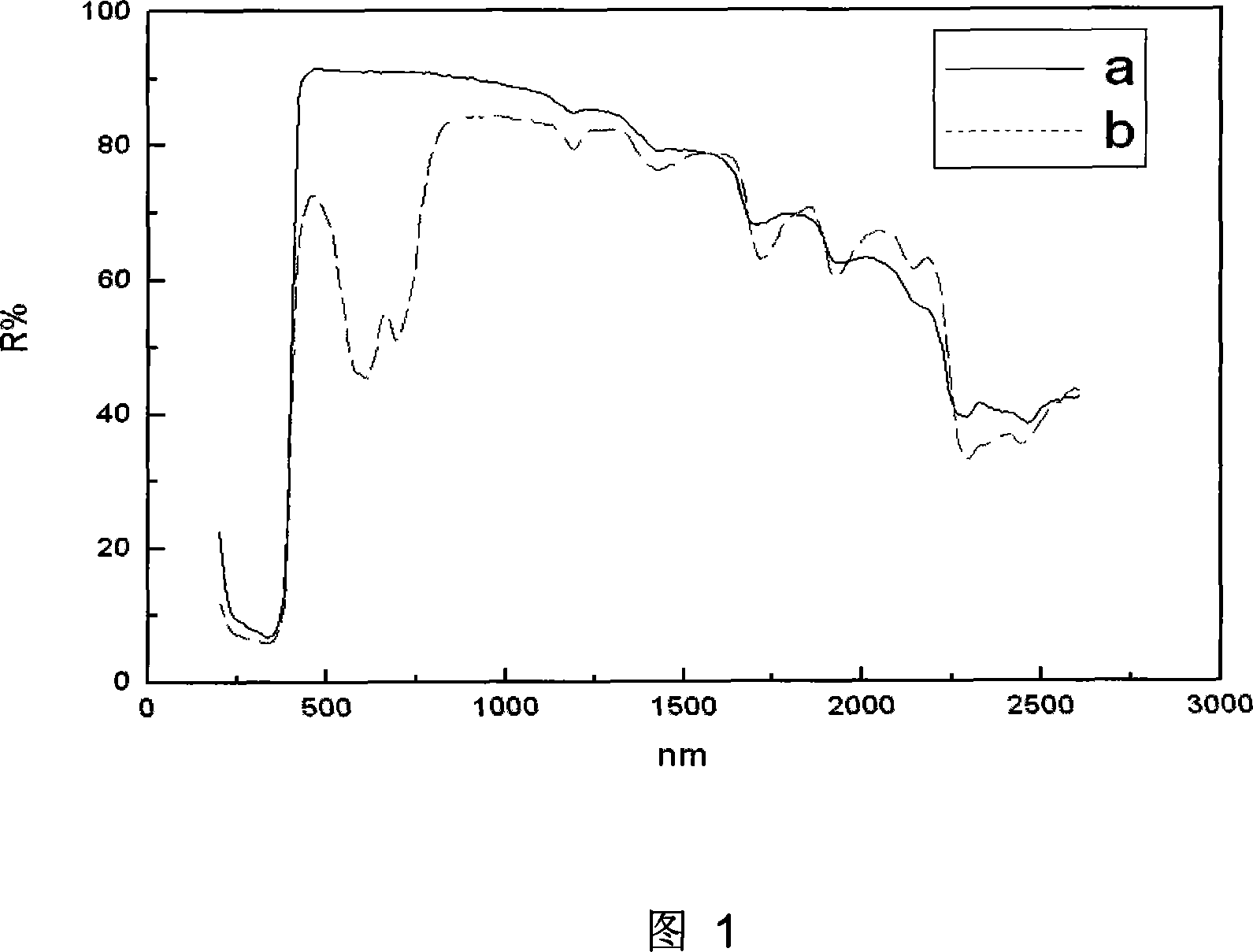

Reflective heat-insulation coating and preparation method thereof

ActiveCN101565581AGood weather resistanceLower thermal equilibrium temperatureReflecting/signal paintsMicrosphereHeat balance

The embodiment of the invention provides a reflective heat-insulation coating and a preparation method thereof. The reflective heat-insulation coating comprises the following raw materials of aqueous pure crylic acid resin, aqueous elastic resin, titanium dioxide, ceramic hollow microspheres, infrared powder, a flame retardant, water, an organic dispersant, a film-forming additive, an antifreeze, a thickener, an anti-foaming agent, a wetting agent, a preservative and a pH value regulator. The coating is a single-component aqueous coating, has no toxicity and good weatherability; extremely fine hollow microsheres are closely arranged by multi-stage in the coating to form a vacuum layer so as to have extremely strong reflection and obstruction function to the solar radiation heat and can effectively reduce the radiation heat transfer and convection heat transfer, thus reducing the heat balance temperature on the surface of the article. The reflective heat-insulation coating leads the building space and the facility container to be warm in winter and cool in summer, reduces the heat island effect and energy consumption of the air conditioner, has obvious energy-saving effect, and reduces the surface temperature by 20 DEG C to a maximum extent and reduces the internal temperature by 5-10 DEG C compared to the normal coating.

Owner:厦门富思特新材料科技有限公司

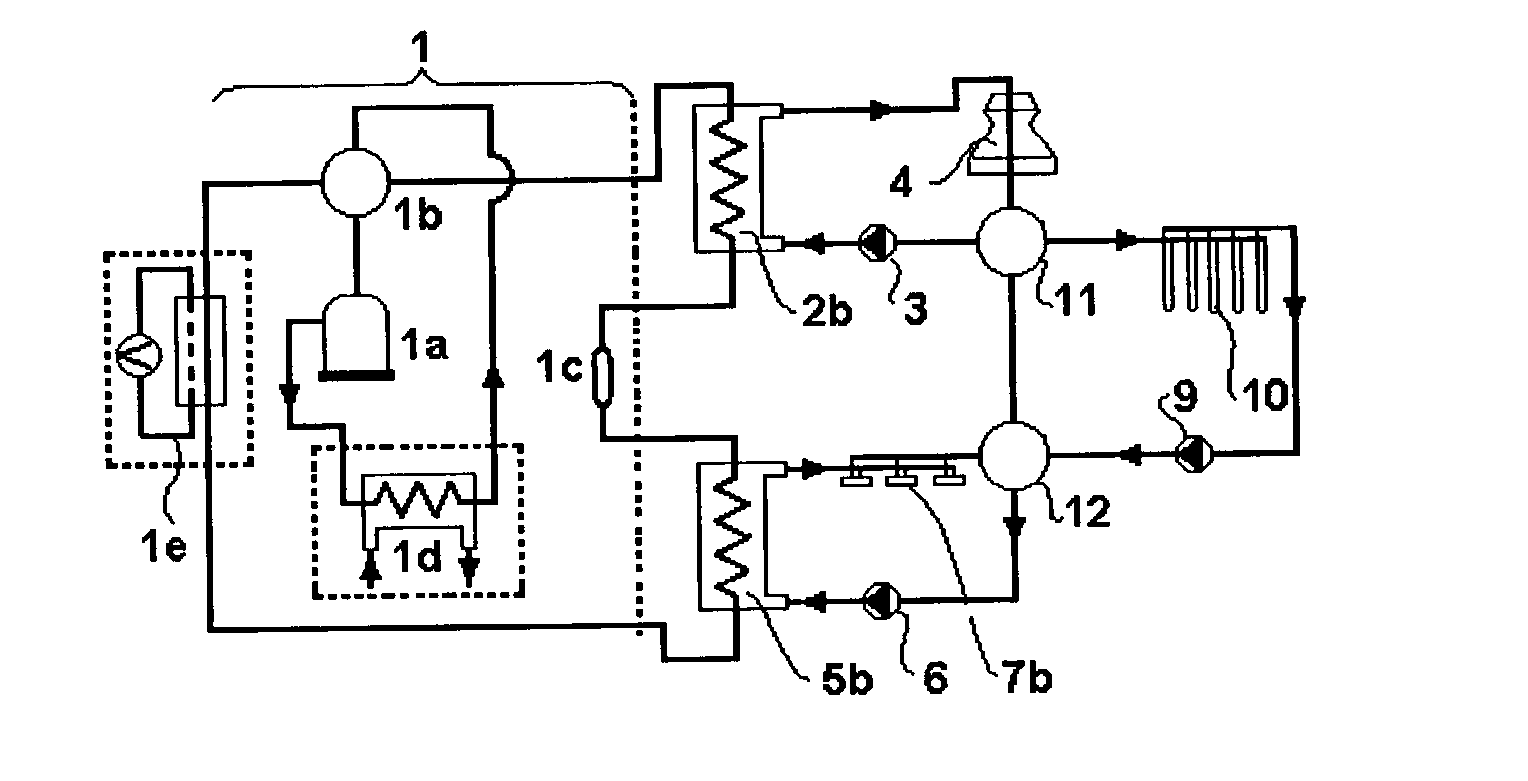

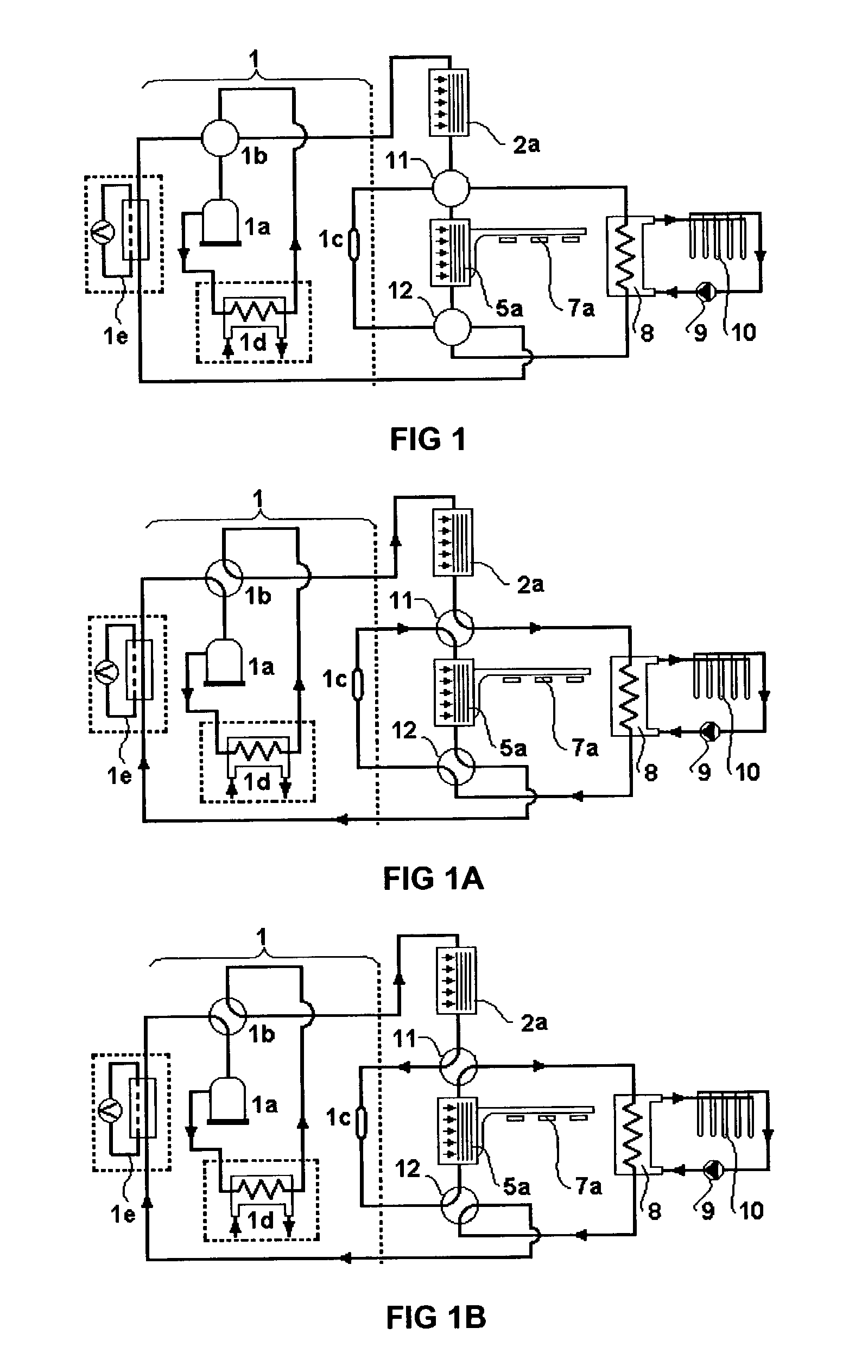

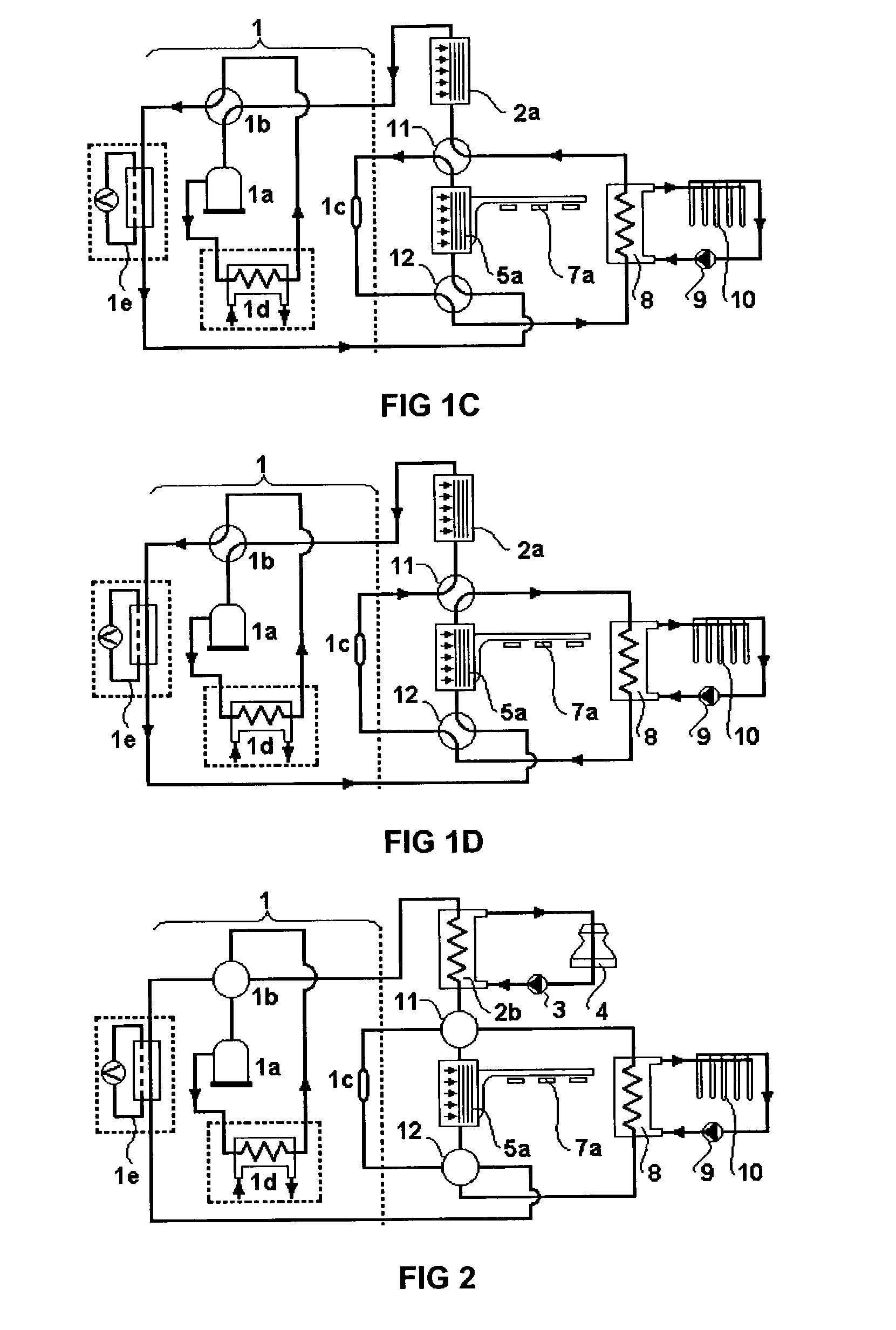

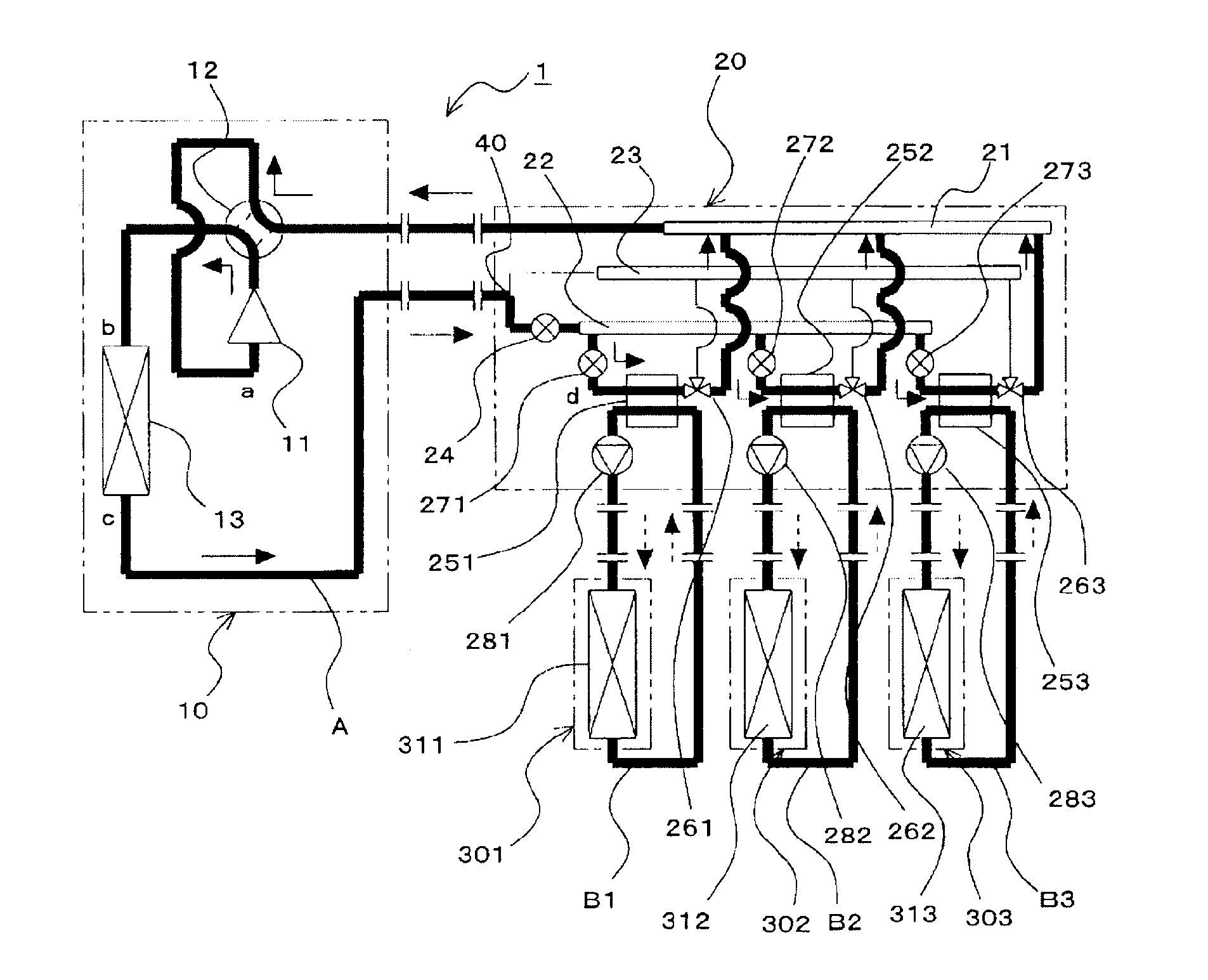

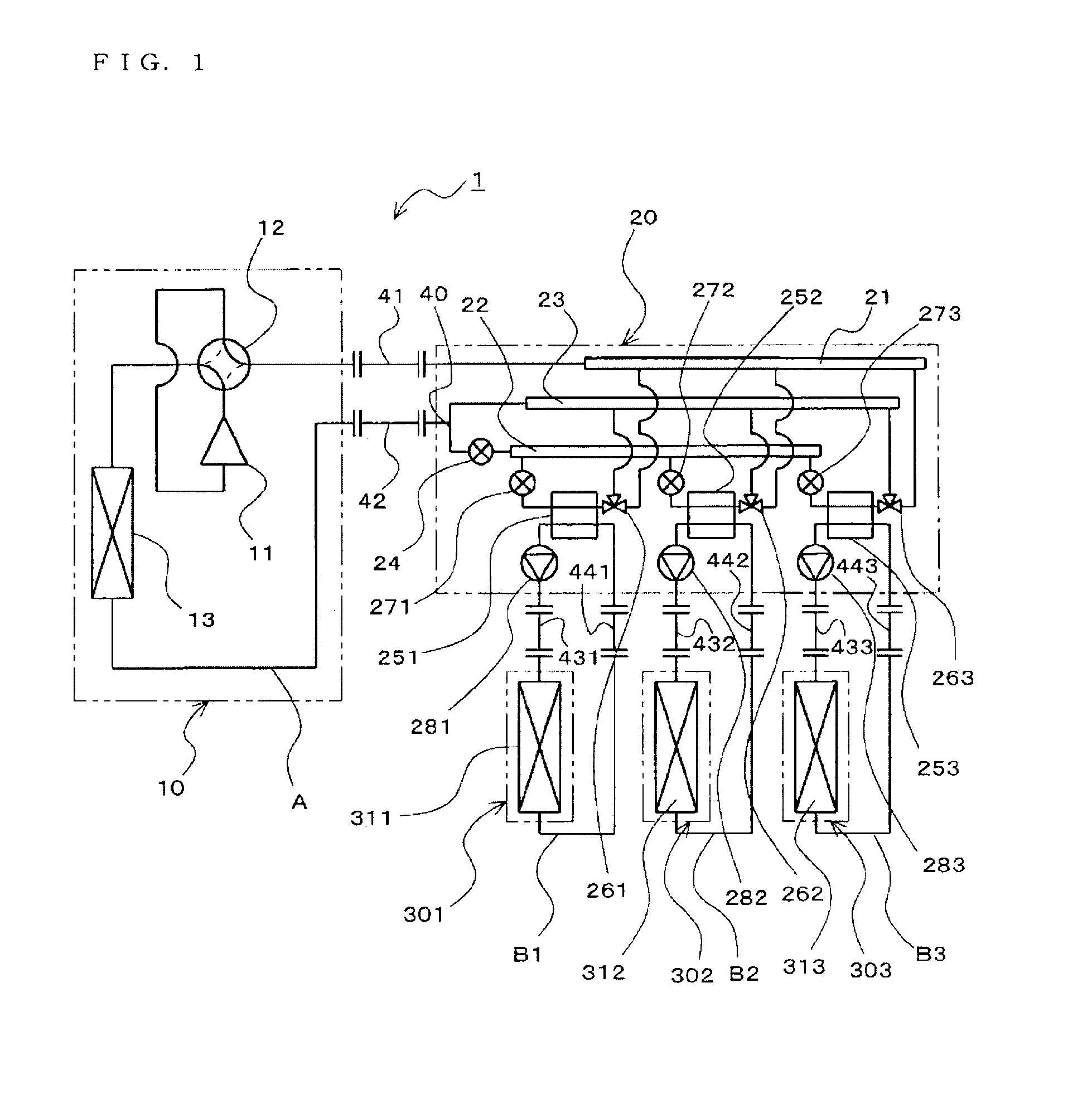

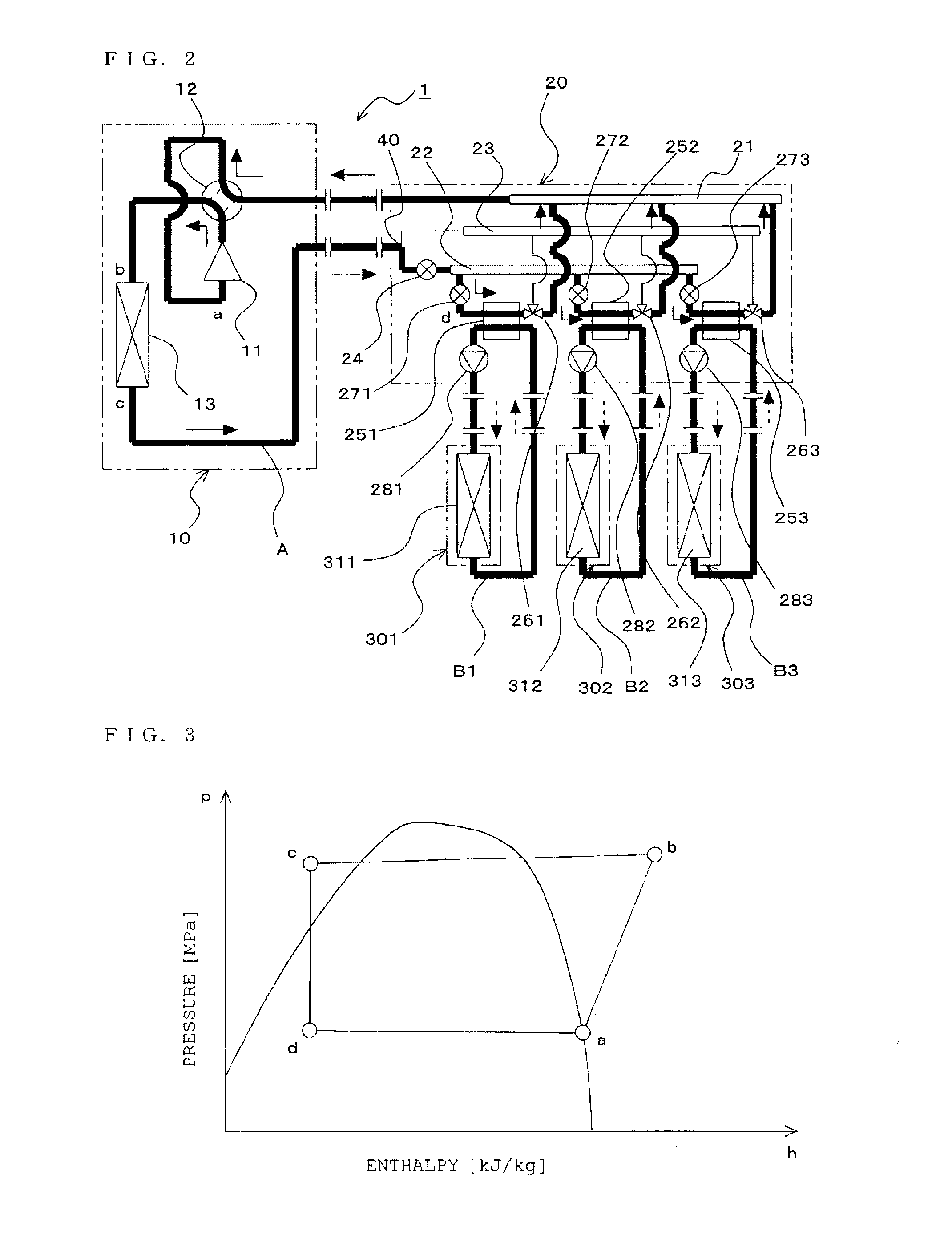

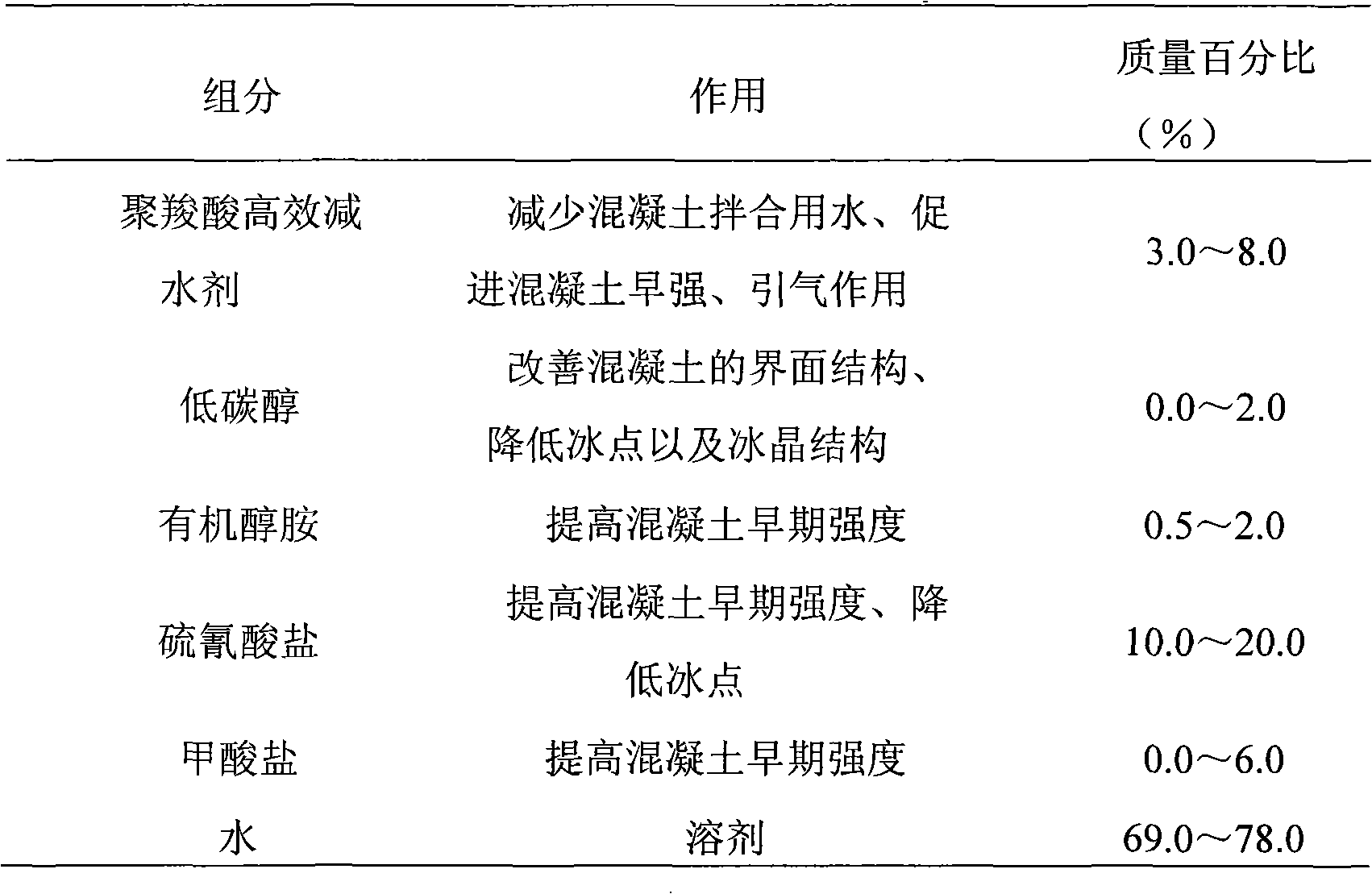

Air conditioning apparatus

ActiveUS20110088421A1Prevent leakageCompression machines with reversible cycleRefrigeration componentsIntermediate heat exchangerEngineering

A heat source-side refrigerant circuit A including a compressor 11, an outdoor heat exchanger 13, a first refrigerant branch portion 21 connected to the compressor 11, a second refrigerant branch portion 22 and a third refrigerant branch portion 23 connected to the outdoor heat exchanger 13, a first refrigerant flow rate control device 24 provided between branch piping 40 and the second refrigerant branch portion 22, intermediate heat exchangers 25n connected at one side thereof to the first refrigerant branch portion 21 and the third refrigerant branch portion 23 via three-way valves 26n and connected at the other side thereof to the second refrigerant branch portion 22, and second refrigerant flow rate control devices 27n provided between the respective intermediate heat exchangers 25n and the second refrigerant branch portion 22, and user-side refrigerant circuits Bn having indoor heat exchangers 31n connected respectively to the intermediate heat exchangers 25n are provided, and at least one of water and an antifreeze solution circulates in the user-side refrigerant circuits Bn.

Owner:MITSUBISHI ELECTRIC CORP

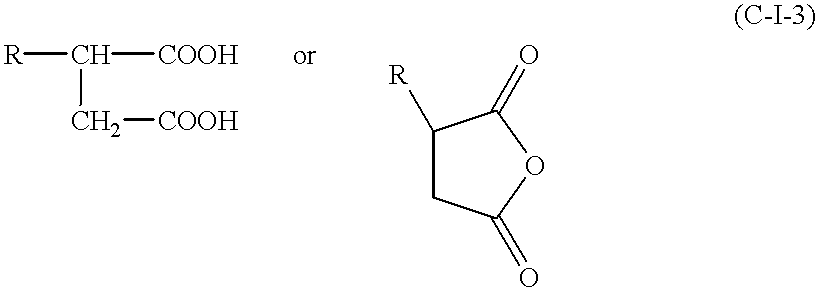

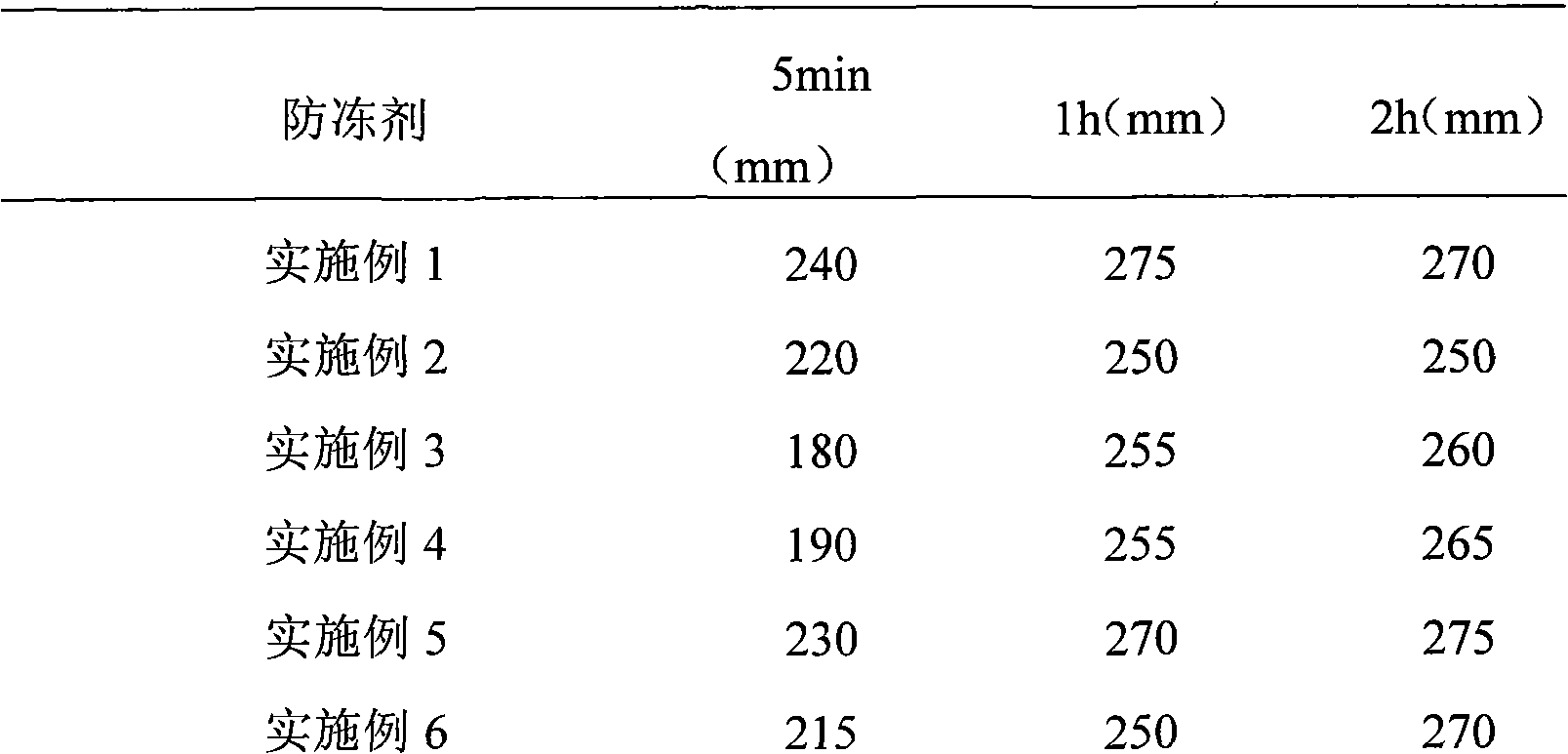

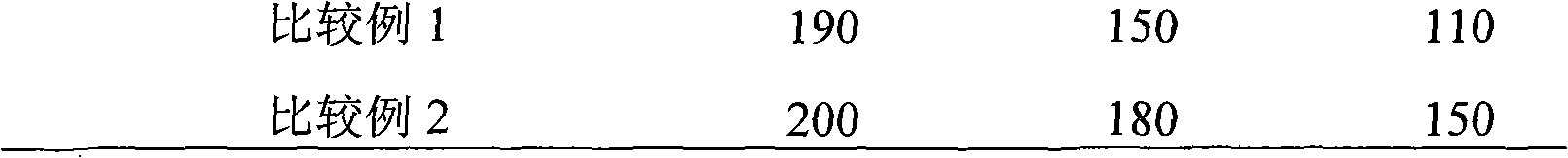

Polycarboxylic acids anti-freeze agent for cement concrete and method for preparing same

The invention relates to poly carboxylic acid system antifreeze applied to cement concrete and a preparation method thereof and belongs to the building material field. The antifreeze is prepared by the optimal combination of an efficient water reduce of poly carboxylic acid, organic alcohol amine, low-carbon alcohol, sulfocyanide and formate. The preferred proportion of the components is that the efficient water reducer to the organic alcohol amine to the low-carbon alcohol to the sulfocyanide to the calcium formate to water is equal to (3.0-8.0) to (0.5-2.0) to (0.0-2.0) to (10.0-20.0) to (0.0-6.0) to (65.0-75.0) (by mass percentage). Compared with the existing antifreeze, the antifreeze of the system has the advantages of high water reducing rate and comparatively good workability and quick growth of strength at negative temperature. The antifreeze has the advantages of low intermingled quantity in the cement concrete, good water solubility, low alkali content, high strength at the early stage and at the later stage of the cement concrete but no chlorine and is applicable to the preparation of various cement concrete at the negative temperature ranging from negative 5 DEG C to negative 20 DEG C in winter in the north area.

Owner:BEIJING UNIV OF TECH

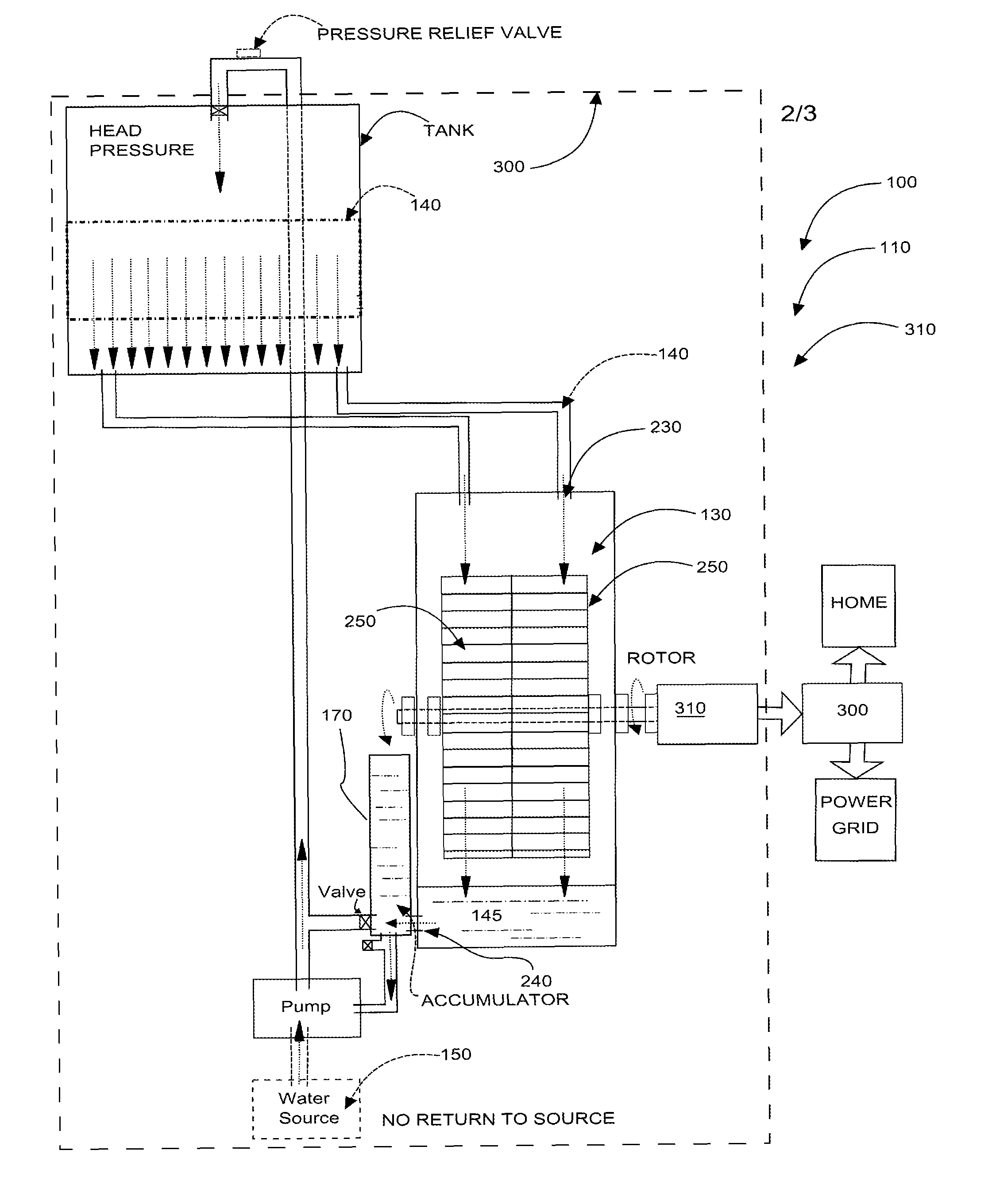

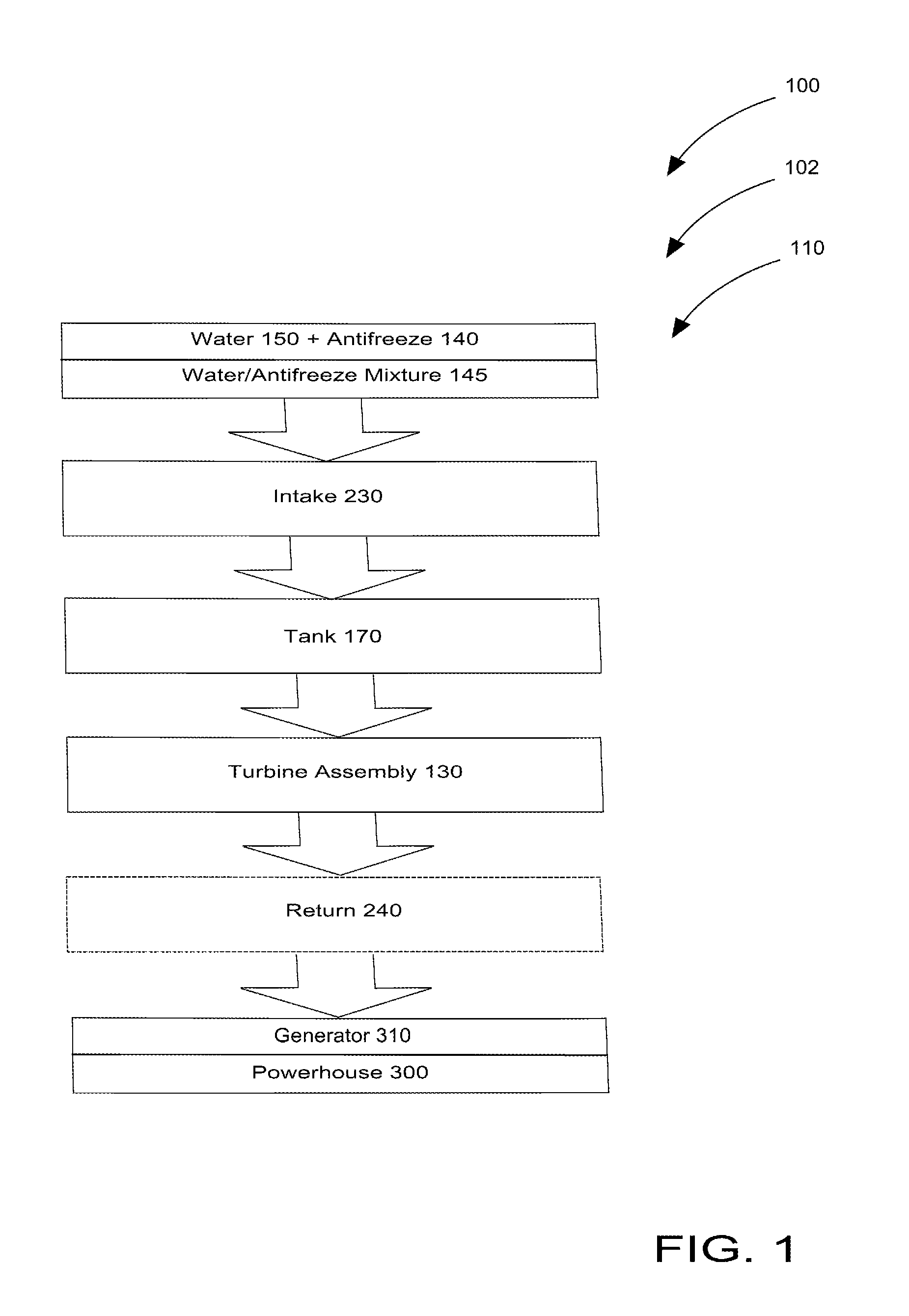

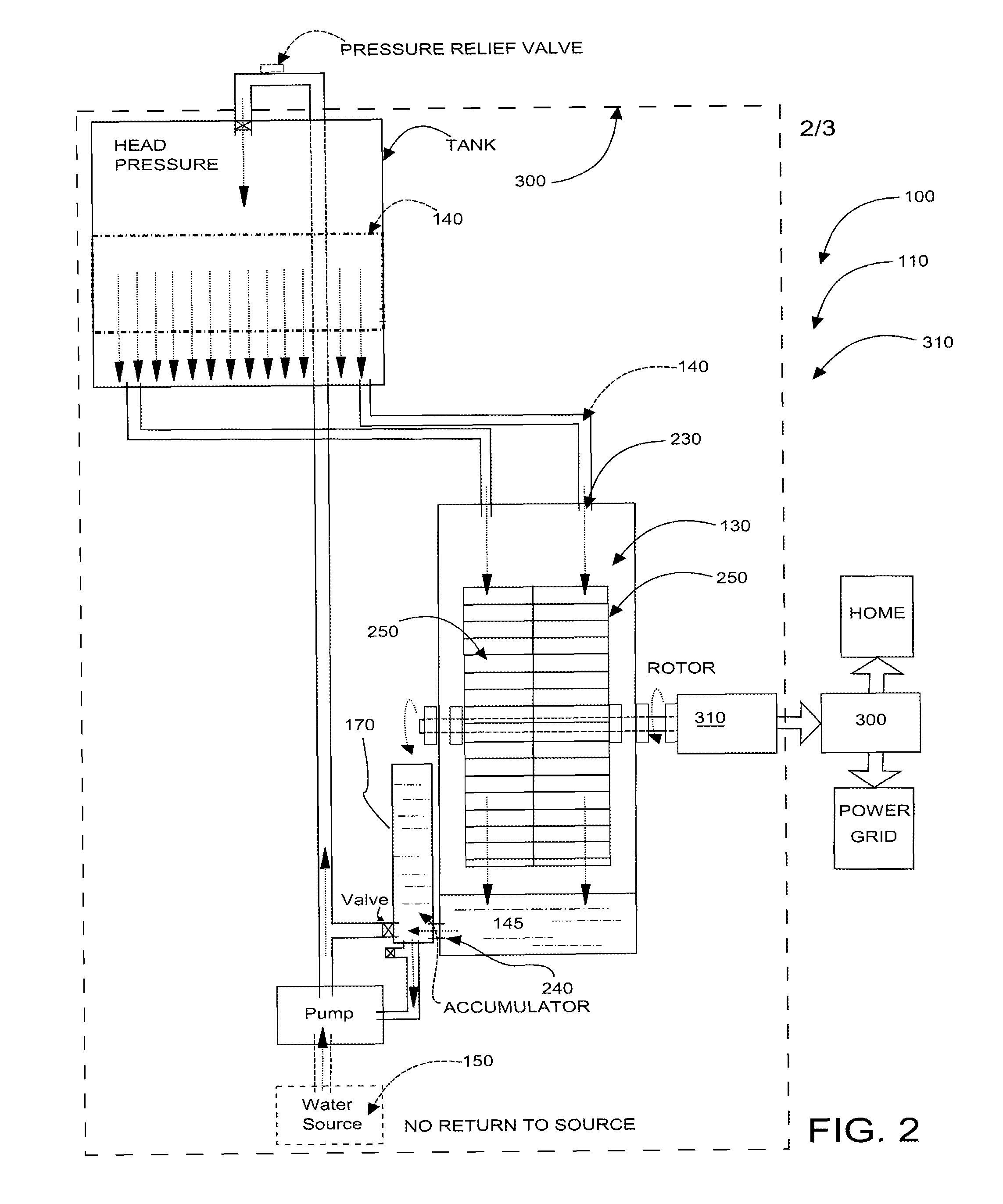

Portable hydroelectric generating system

InactiveUS8127542B1Strong pressure capacityIncrease volume capacityFluid couplingsWorking fluid for enginesWorking fluidWater source

Owner:DOLCIMASCOLO JOSEPH

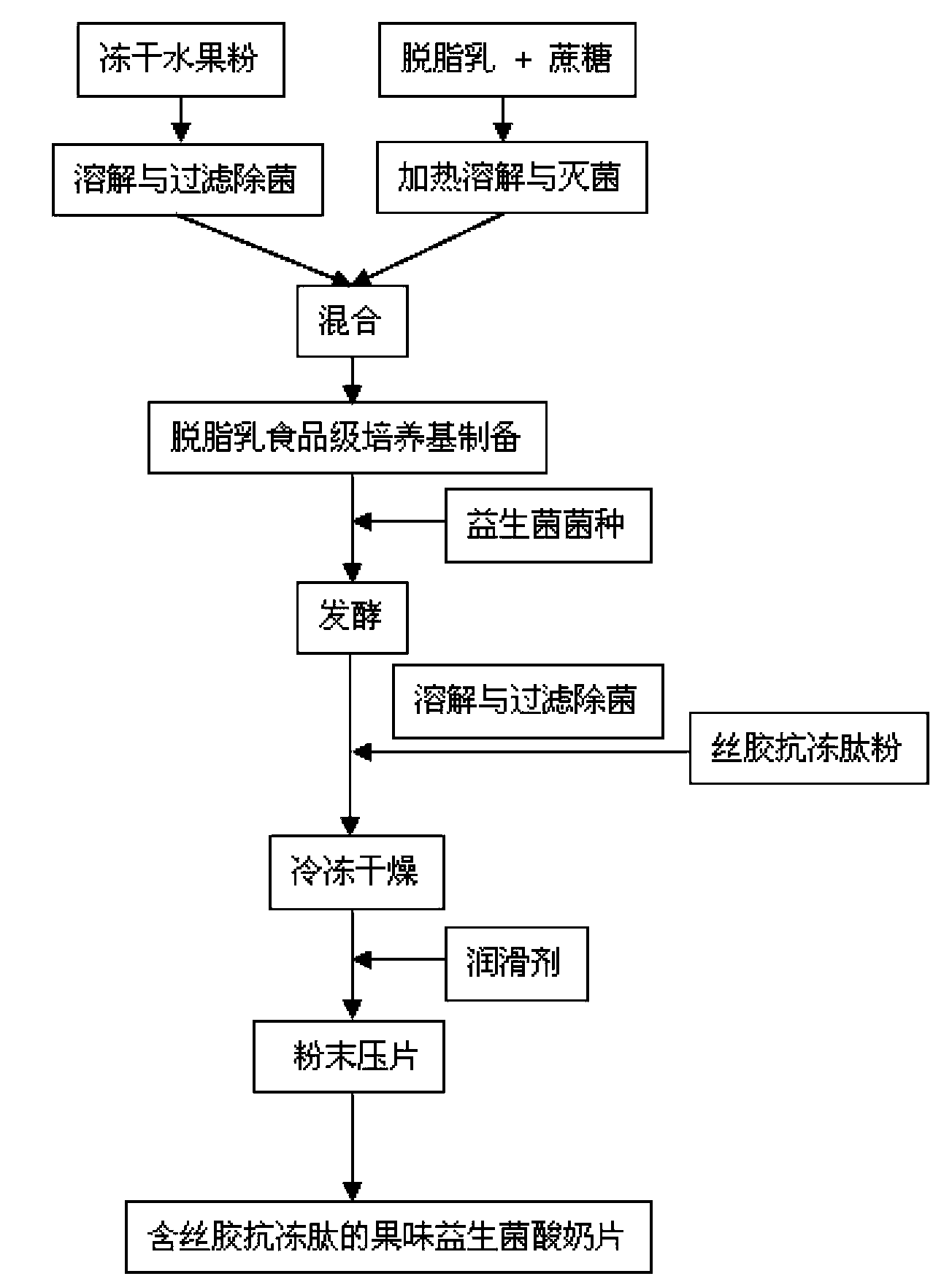

Fruity probiotic yogurt slice containing antifreeze sericin peptide and method for preparing same

ActiveCN103109930BRich in physiological functionsRich in antioxidantMilk preparationProbiotic yogurtBiotechnology

The invention discloses a fruity probiotic yogurt slice containing antifreeze sericin peptide. The raw materials for preparing the fruity probiotic yogurt slice comprise 10-14 parts of skimmed milk powder, 2-5 parts of sucrose, 1-3 parts of sericin peptide, 1-4 parts of fruit material, 0.1-0.6 part of lyophilized active probiotics and 0.1-0.4 part of magnesium stearate. The invention further discloses a method for preparing the product which is the fruity probiotic yogurt slice. The method mainly comprises the following steps of: preparing a skimmed-milk food-grade culture medium, fermenting the probiotics, adding the antifreeze sericin peptide, freezing and drying fermented milk in vacuum, and pressing powder into slices. As the fruity probiotic yogurt slice contains the antifreeze sericin peptide and the lyophilized fruit powder which is rich in the vitamin B group, the number of the probiotics in the fruity probiotic yogurt slice can be increased, the retention time of the activity of the probiotics can be prolonged, and the taste, flavor and nutritional and healthcare values of the fruity probiotic yogurt slice can be improved. The fruity probiotic yogurt slice can serve as a functional food for supplementing the vitamin B group, improving the immunity and promoting the intestinal health.

Owner:SHANGHAI JIAOTONG UNIV

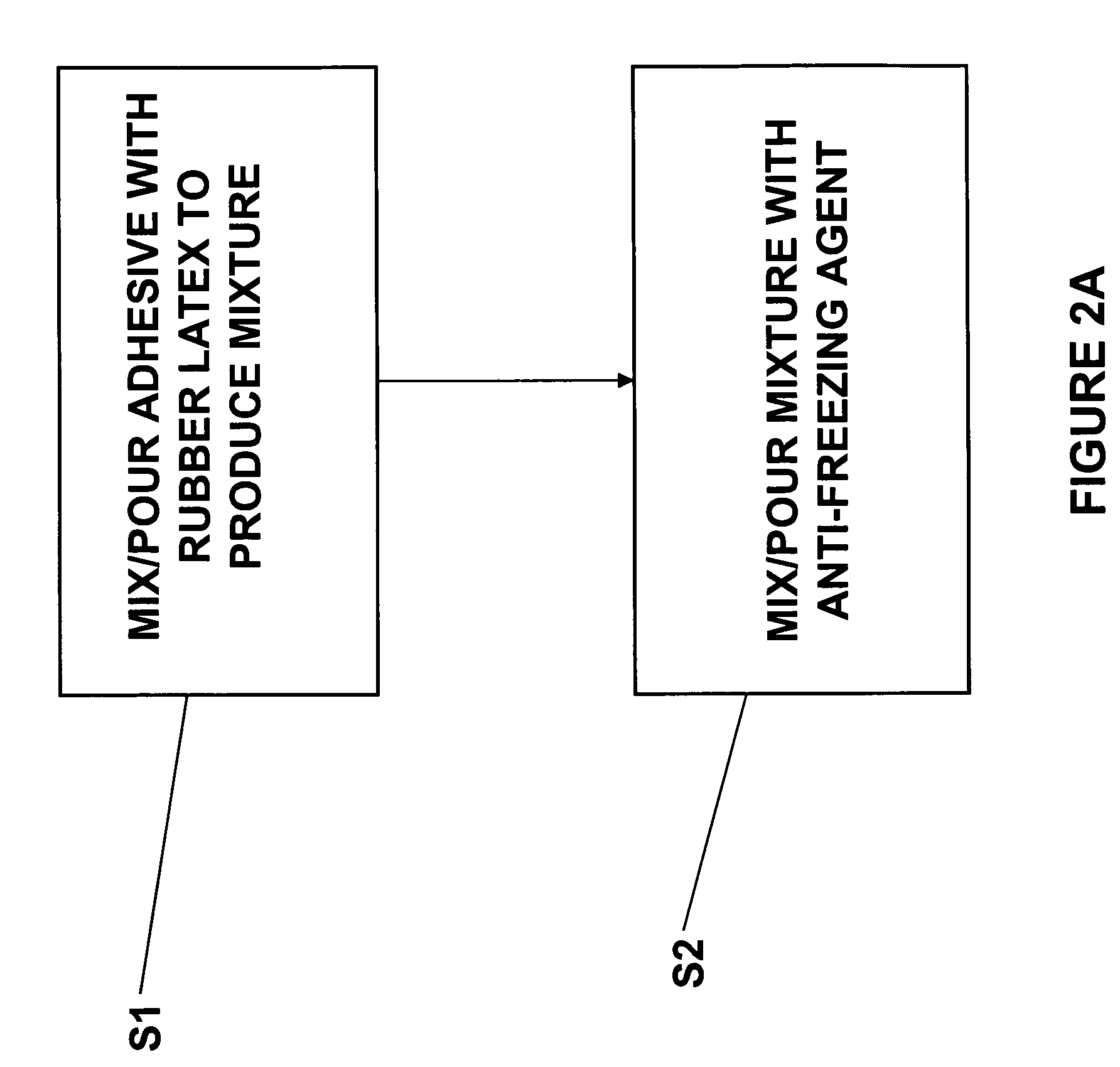

Multifunctional waterproof antiseptic aldehyde-eliminating glue and preparation method

InactiveCN103131270AEasy to useLow toxicityAntifouling/underwater paintsPaints with biocidesResistEmulsion

The invention discloses multifunctional waterproof antiseptic aldehyde-eliminating glue, and belongs to the technical field of construction materials, wherein the glue is mainly for sealing, waterproofness, moisture-proofness, anticorrosion, mold prevention, insect prevention, termite prevention and aldehyde elimination of materials such as bamboo wood, timber, rattan wood, wall faces, ground, emulsion varnish, wallpaper, floor boards and wooden doors. The multifunctional waterproof antiseptic aldehyde-eliminating glue is characterized by comprising 10-90 parts of water-dilutable resin, 0.01-30 parts of antiseptic and mold inhibitor, 0.01-20 parts of insect-resist agents, 0.01-15 parts of termite-resisting agents, 0.1-20 parts of aldehyde-eliminating agents, 0.1-30 parts of coalescing agents, 0.5-15 parts of anti-freezing agents and 5-95 parts of water. After being treated by the multifunctional waterproof antiseptic aldehyde-eliminating glue, products are strong in engaging force, environment-friendly, water-proof, moisture-proof, antiseptic, mold-proof, inset-proof, termite-proof and capable of eliminating aldehyde. Meanwhile, construction is easy and convenient. Besides, the invention further provides a preparation method of the multifunctional waterproof antiseptic aldehyde-eliminating glue.

Owner:刘川

Fire extinguishing system

ActiveUS20060243459A1Minimize, if not eliminate compressible gas in the systemPrevent costly contaminationSelf-acting watering devicesMovable spraying apparatusWater flowEngineering

An early suppression fast response fire protection system includes a sprinkler piping system with at least one sprinkler head assembly, a water supply system, and a check valve in fluid communication with the sprinkler piping system and the water supply system. An antifreeze solution supply system is in fluid communication with the sprinkler piping system, with the check valve isolating the antifreeze solution from the water supply unless a fire condition occurs. A control is provided that is in communication with a flow detector, which detects the pressure of the antifreeze solution in the sprinkler piping system, and a pressure detector, which detects the flow of water through the check valve, and controls the flow of the antifreeze solution to the sprinkler piping system and maintains the pressure of the antifreeze solution in the sprinkler piping system unless the flow detector detects the flow of water through the check valve in which case the control stops the flow of antifreeze solution to the sprinkler piping system to limit the discharge of antifreeze solution from the fire protection system.

Owner:VIKING

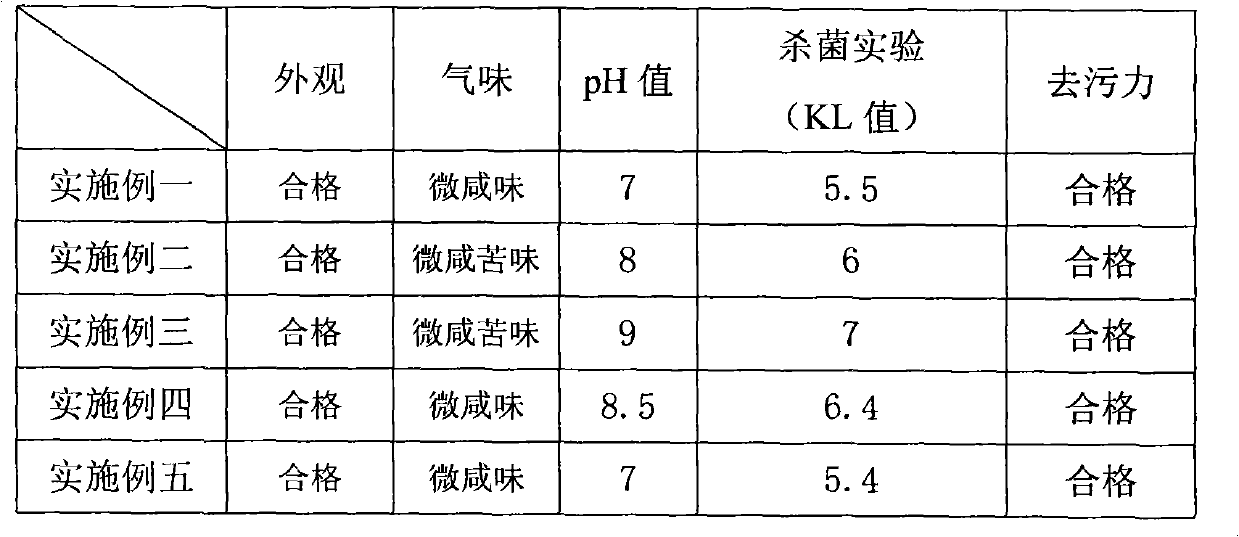

Mineral-element detergent and preparation method thereof

ActiveCN101768524AWill not generateRich in mineral elementsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedRoom temperature

The invention discloses a mineral-element detergent and a preparation method thereof. The mineral-element detergent comprises the following components in part by weight: 20-35 parts of salt lake water concentrate, 5-10 parts of ionic surface active agent, 5-10 parts of non-ionic surface active agent, 10-15 parts of traditional Chinese medicine extract, 0.5-5 parts of emollient, 0.5-5 portions of cosolvent, 0.5-5 parts of antifreeze and balance of de-ionized water. The preparation method comprises the following steps: adding the components based on the proportion, thoroughly mixing, adding the de-ionized water based on the proportion, and uniformly mixing; and carrying out supersonic treatment for 30-50 minutes, stirring at 50-60 DEG C until the solution is uniform and transparent, cooling to room temperature, and filtering to obtain the mineral-element detergent. The product has the advantages of good sterilization and decontamination capability, and ensures no residue, no opaqueness, no precipitation and no secondary pollution after hydrolysis.

Owner:江苏龙舟矿物科技有限公司

Anti-freezing method of air conditioner

ActiveCN1979063AEasy to useRepair in timeSpace heating and ventilation safety systemsLighting and heating apparatusAnti freezingWater flow

The invention relates to a method to improve the antifreeze ability for air condition. It includes the following steps: minimum water flow would be controlled by a flow controller at water outlet, setting an antifreeze value, when water temperature lowering than the value, the set would stop running and output alarm. If the water temperature at water intake is lower than a set temperature value, and the temperature difference at outlet and intake exceeding a set value, and lasting for a time span, it would be judged as not enough water flow. The machine would be stopped and output alarm.

Owner:SHENZHEN MCQUAY AIR CONDITIONING

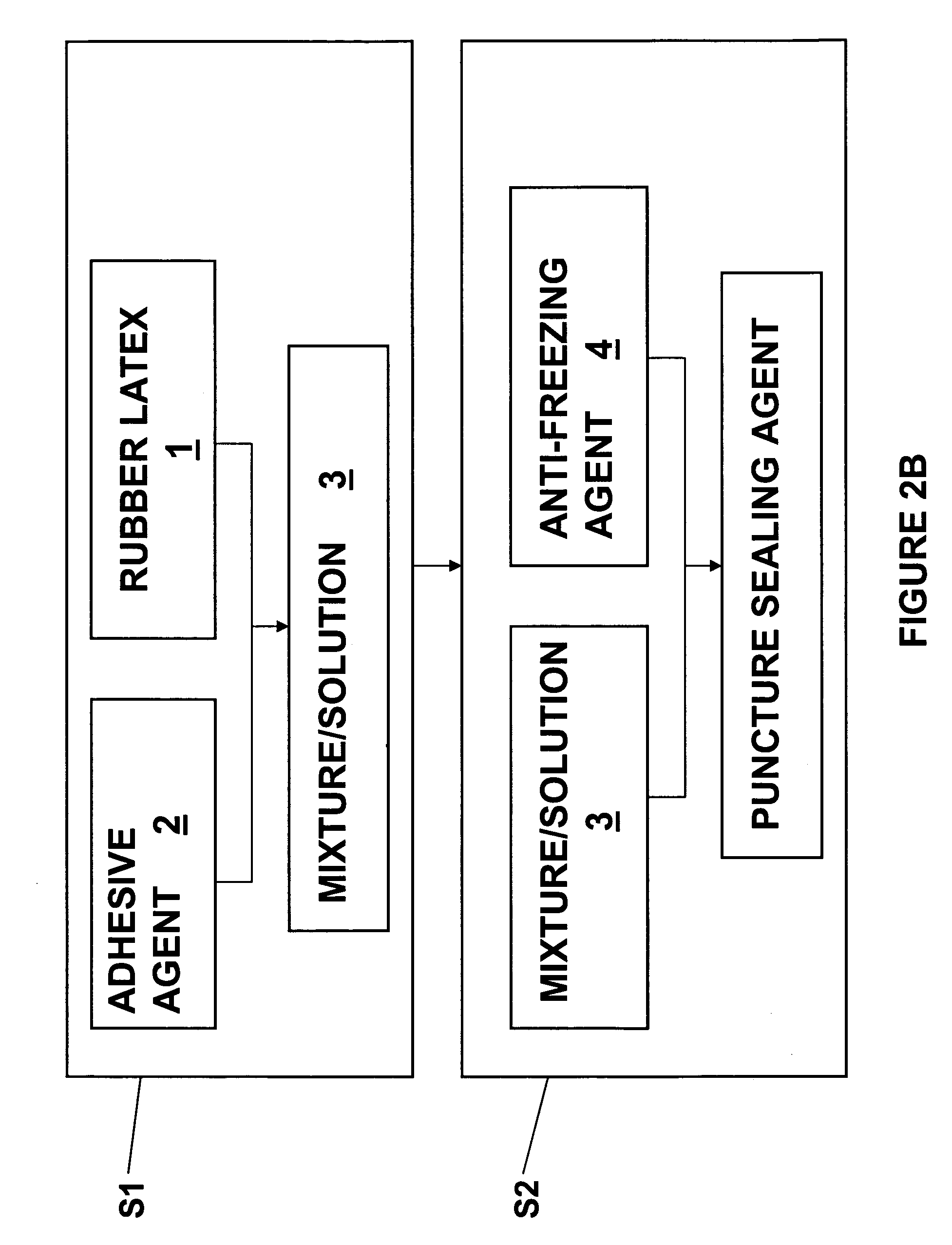

Puncture sealing agent for a tire, and process for producing the same

Owner:ITW GLOBAL TIRE REPAIR INC

Aqueous film-forming foam extinguishing agent special for fire extinguishing bullet and throwing type fire extinguisher

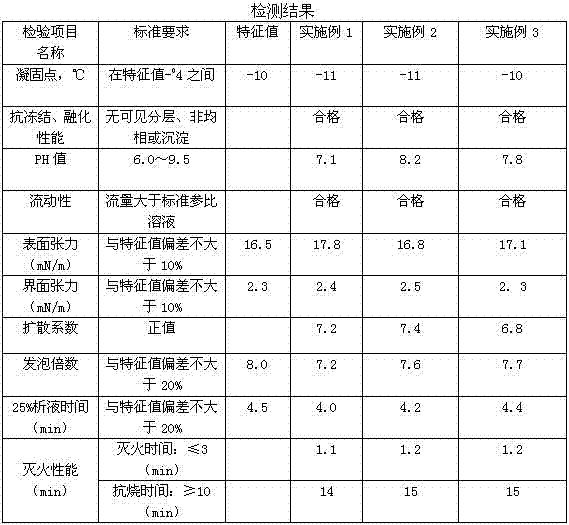

InactiveCN104117176AImprove fire extinguishing effectPrevent re-ignitionFire extinguisherDiethylene glycol diethyl etherAmmonium dodecyl sulfate

The invention provides an aqueous film-forming foam extinguishing agent special for a fire extinguishing bullet and a throwing type fire extinguisher. The aqueous film-forming foam extinguishing agent has the advantages of being small in additive amount, rapid in fire extinguishing, good in recrudescence resisting effect, environmentally friendly, efficient and the like. The aqueous film-forming foam extinguishing agent comprises, by weight, 8 percent to 12 percent of main foaming agents, 8 percent to 20 percent of auxiliary foaming agents, two percent to 10 percent of antifreeze agents, 12 percent to 22 percent of cosolvents, 0.1 percent to one percent of stabilizers, 8 percent to 20 percent of fire retardants, two percent to five percent of burning-resistance agents and the balance water. The main foaming agents are selected from F1157N, F1203 and F1460, the auxiliary foaming agents are selected from lauryl sodium sulfate, ammonium lauryl sulfate, alkyl glycoside, dodecyl dimethyl betaine and cocamidopropyl betaine. The antifreeze agents are selected from ethylene glycol, glycerol and the like. The cosolvents are selected from dodecanol, n-butyl alcohol and diethylene glycol diethyl ether. The stabilizing agents are selected from xanthan gum, Arabic gum, guar gum and sodium alginate tech grade. The fire retardants are selected from ammonium polyphosphate and ammonium dihydrogen phosphate.

Owner:ANHUI TIANYUAN FIRE PROTECTION TECH

Preaction fire extinguishing system for ESFR cold storage applications

ActiveUS20050072580A1Prevent costly contaminationLess damage to piping systemSelf-acting watering devicesEqualizing valvesCool storageWater flow

An early suppression fast response fire protection system includes a sprinkler piping system with at least one sprinkler head assembly, a water supply system, and a check valve in fluid communication with the sprinkler piping system and the water supply system. An antifreeze solution supply system is in fluid communication with the sprinkler piping system, with the check valve isolating the antifreeze solution from the water supply unless a fire condition occurs. A control is provided that is in communication with a flow detector, which detects the pressure of the antifreeze solution in the sprinkler piping system, and a pressure detector, which detects the flow of water through the check valve, and controls the flow of the antifreeze solution to the sprinkler piping system and maintains the pressure of the antifreeze solution in the sprinkler piping system unless the flow detector detects the flow of water through the check valve in which case the control stops the flow of antifreeze solution to the sprinkler piping system to limit the discharge of antifreeze solution from the fire protection system.

Owner:VIKING

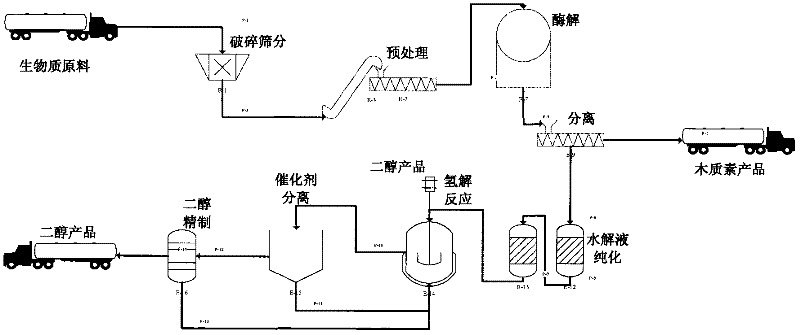

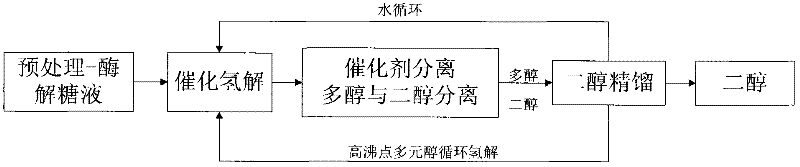

Method for preparing dihydric alcohol from lignocellulosic biomass

ActiveCN102286548AWidely distributedFully distributedOrganic compound preparationHydroxy compound preparationLiquid glucoseFiber

The invention relates to a method for preparing dihydric alcohol from lignocellulosic biomass, which has main steps of: 1, adding alkali liquor, acid liquor or water for pretreatment after lignocellulosic biomass crushing; 2, carrying out enzymolysis and concentrating liquid glucose filtered through enzymolysis after decoloration and ion exchange impurity removal; 3, adding catalysts with hydrogenation hydrogenolysis activity for carrying out hydrogenation hydrogenolysis reaction on the concentrated liquid glucose under the conditions of the pH being 8 to 14, the temperature being 130 to 250 DEG C and hydrogen atmosphere, separating the catalysts, and producing various dibasic alcohol with the carbon number being 2 to 6 after product rectification. The method utilizes the lignocellulosic biomass pretreatment-zymolyting glucose liquid as raw materials, and monosaccharide, soluble polysaccharides and sugar degradation products can respectively react, so both the efficiency and the process controllability can be greatly improved, and products can be independently used through separation and can be directly used for producing unsaturated polyester resin, polyurethane, fuel additives, surface active agents, emulsifying agents, motor vehicle antifreeze fluid and the like without depth separation.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

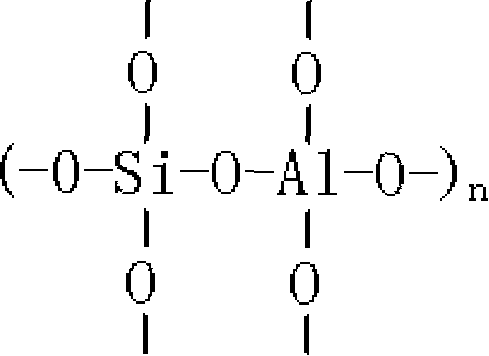

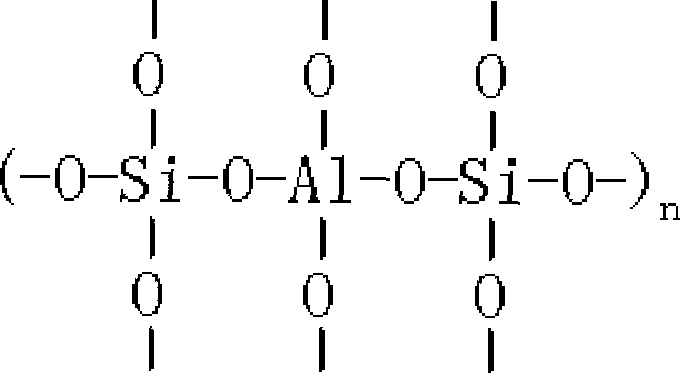

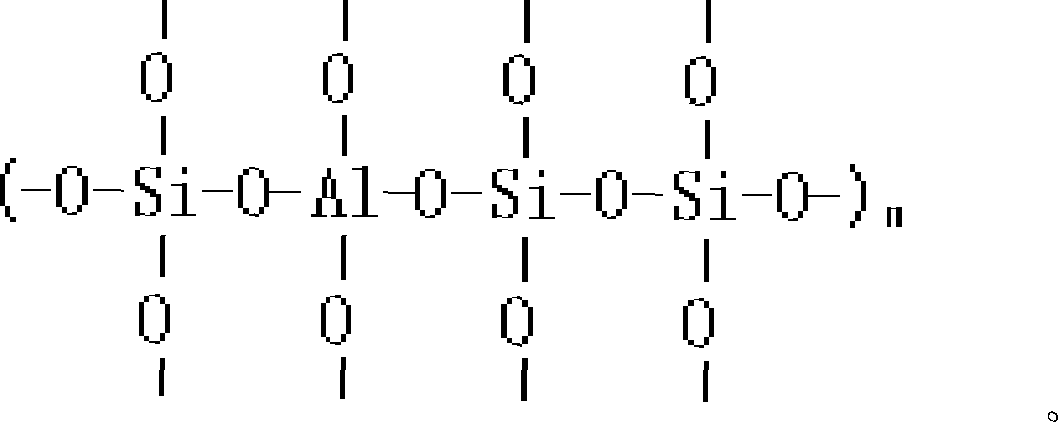

Polymer coating composite and preparation method thereof

InactiveCN101045832ALow costEasy to use on siteSolid waste managementCement productionPolymer scienceOxygen

This invention relates to a dope combination. The film coating it formed is amorphous gelatinous substance, base unit is three-dimensional network formed by connection of silicon - oxygen tetrahedron and aluminium - oxygen tetrahedron. end product takes electrovalent bond and covalent bond as main, vander waas bond as complement, possess linkage structure of organic heavy polymer, and double property of inorganic polymer and organic polymer. The unique performance supple the insufficiency of organic high molecular polymer. It possesses favorable performance of acid-proof, alkali-proof, impervious, antifreeze, seawater resistance and high temperature resistance.

Owner:袁景华 +1

Plant antifreezer and its preparation method

Owner:DAQIAN ECOLOGY & LANDSCAPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com