Patents

Literature

11921results about "Cement mixing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

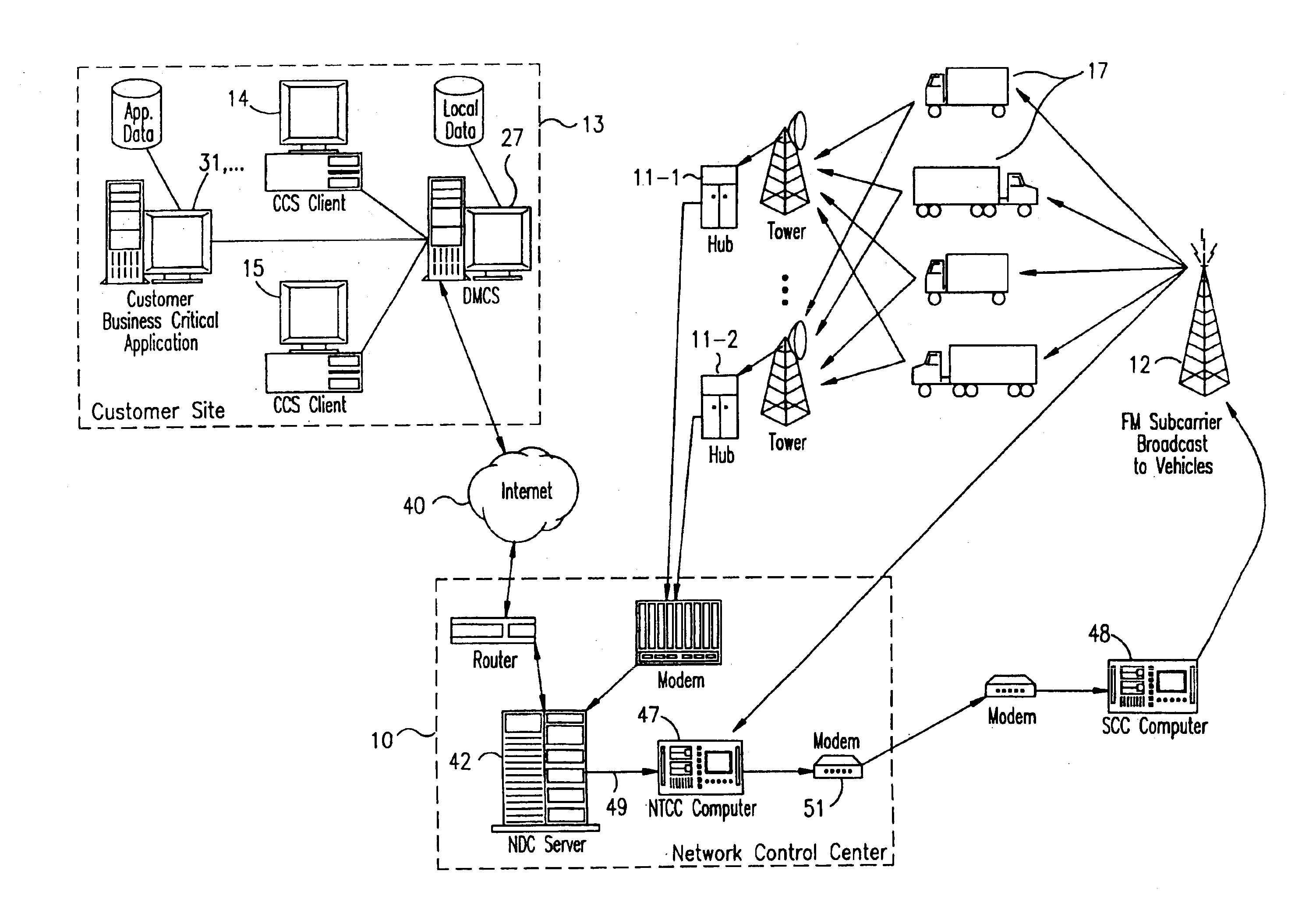

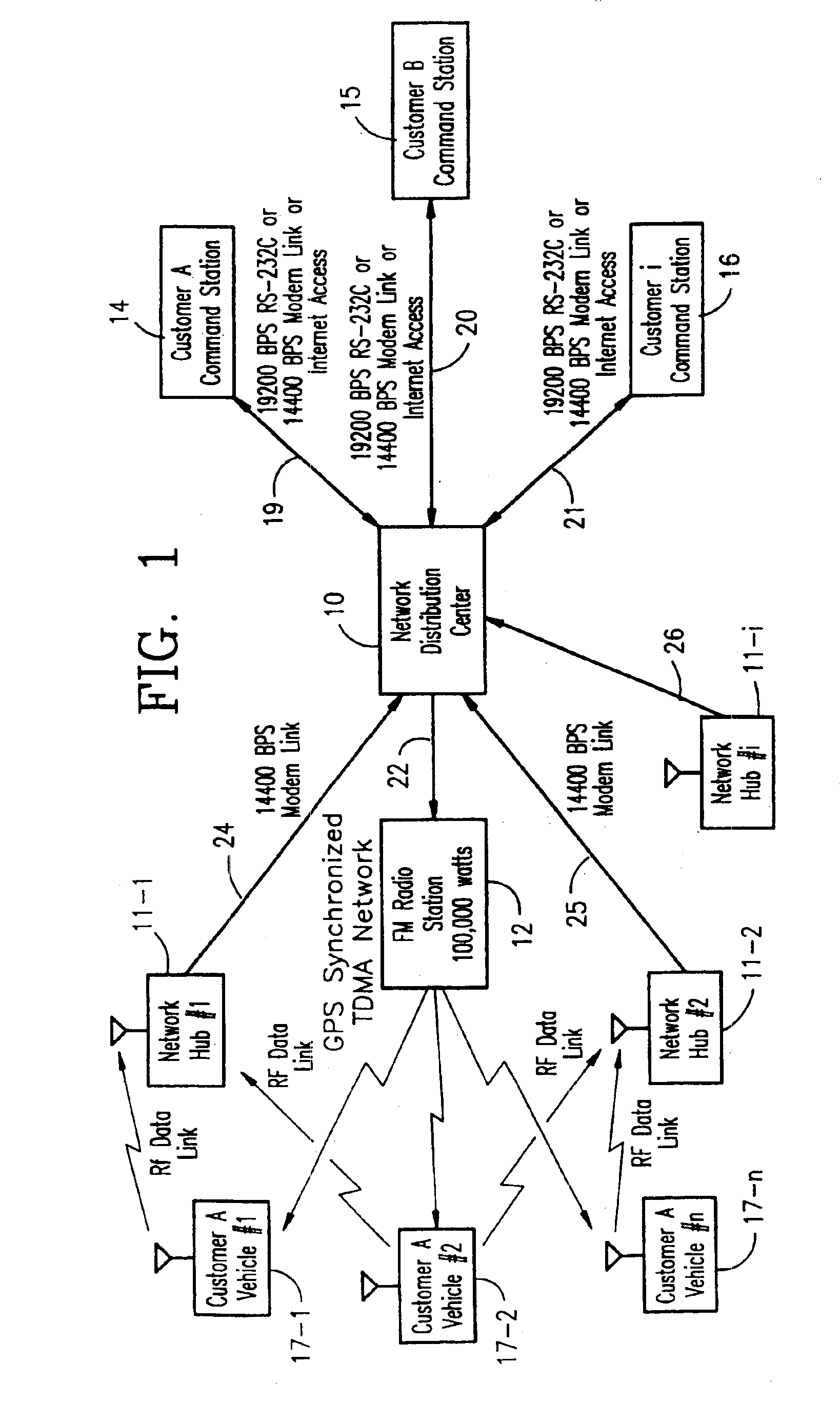

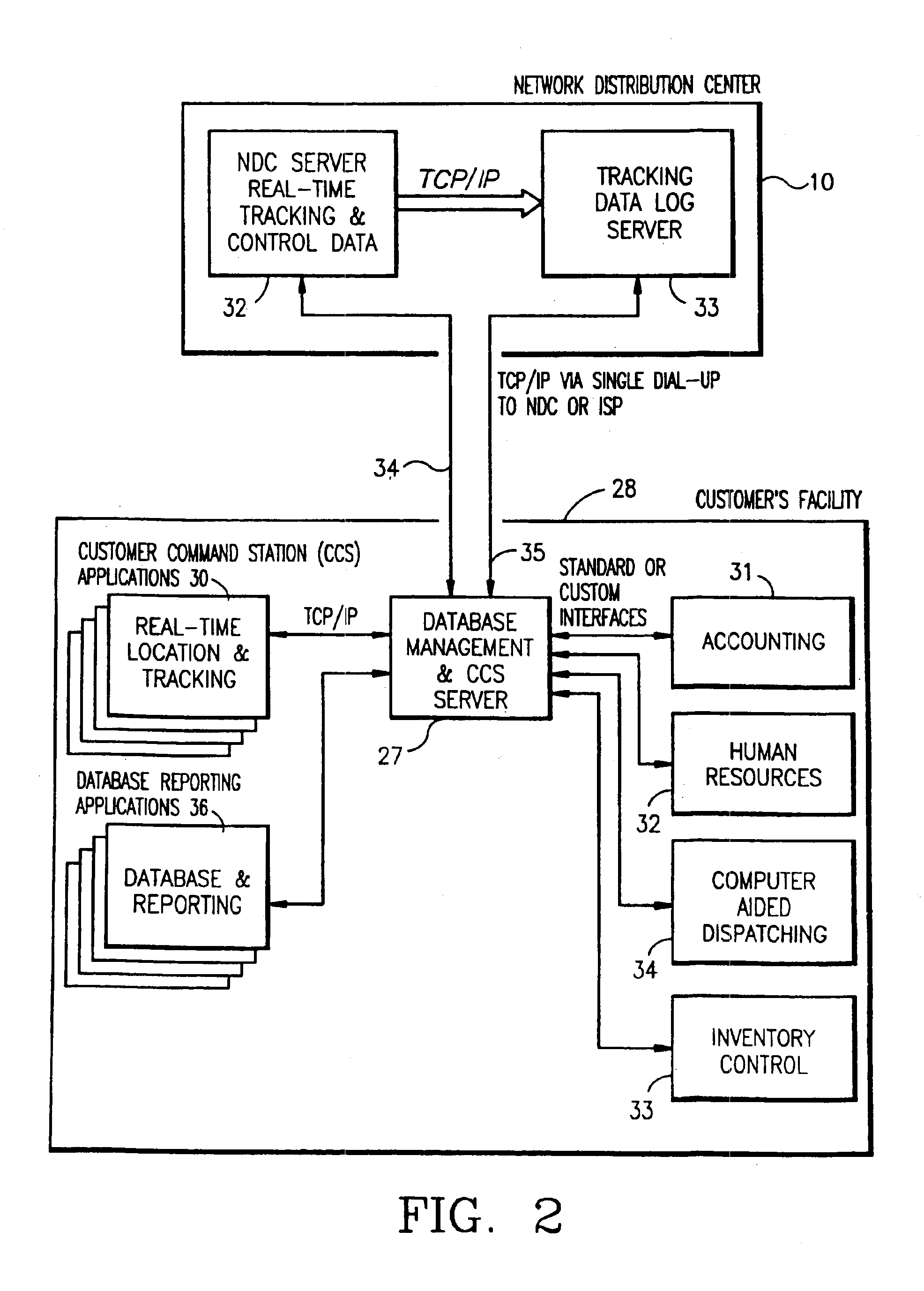

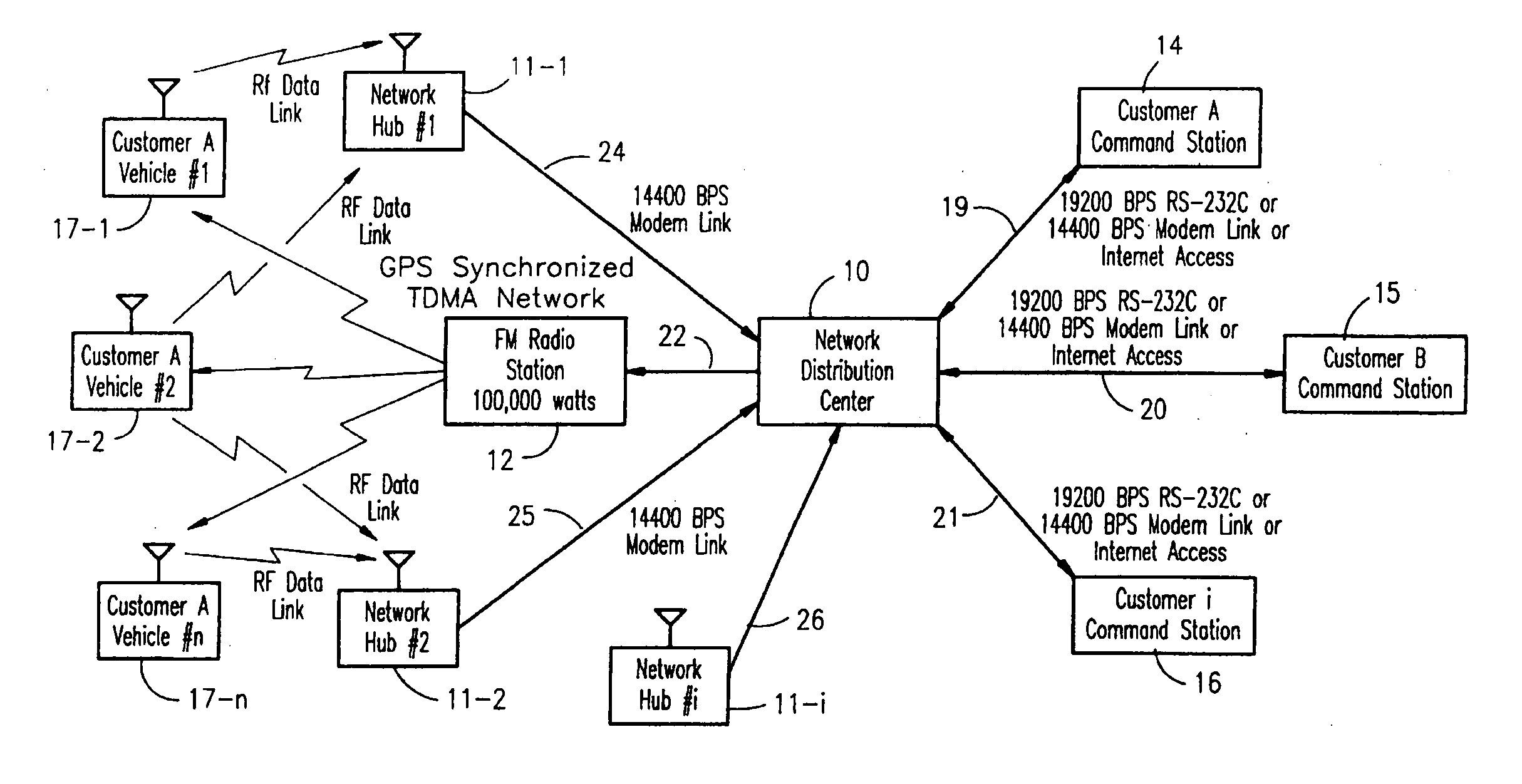

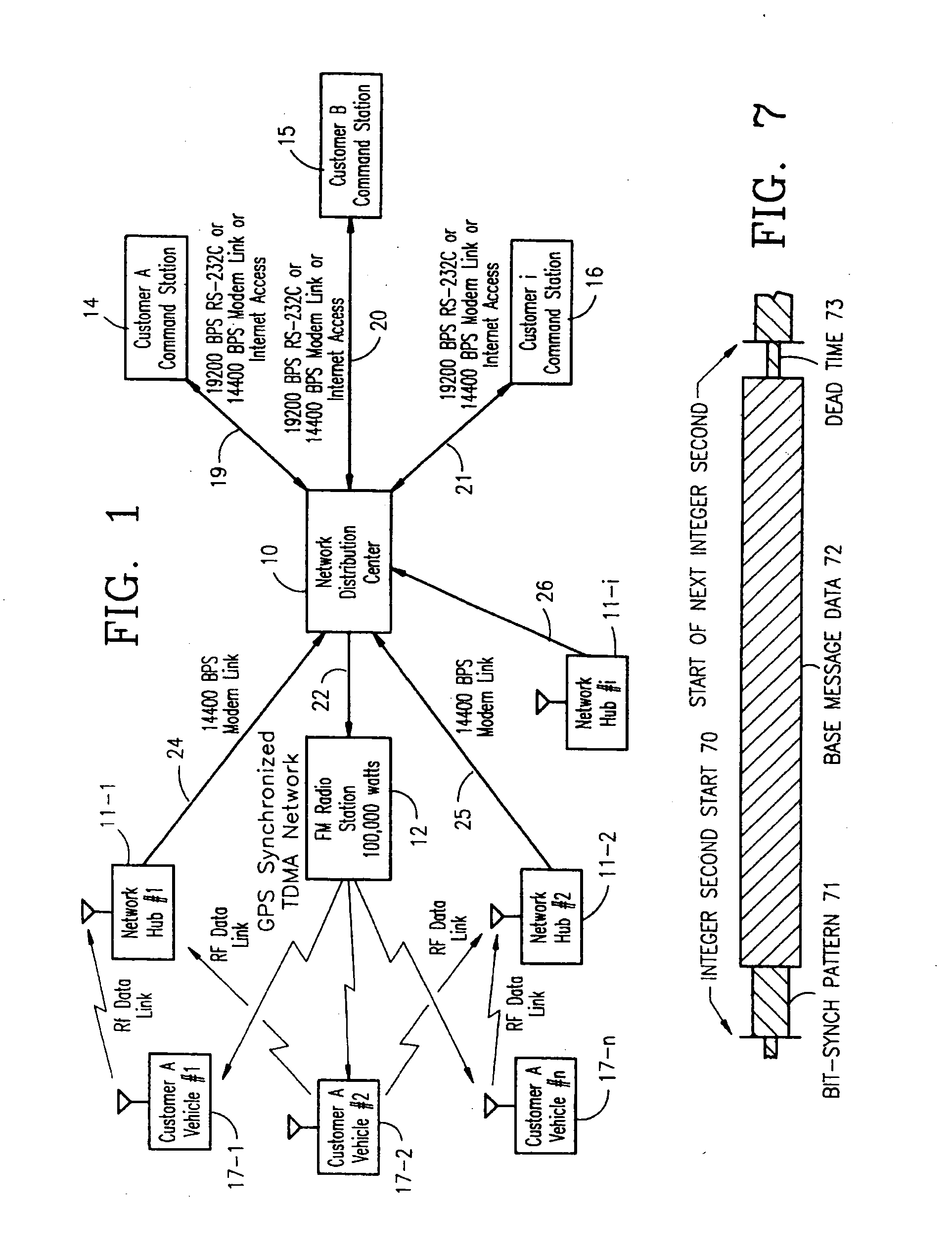

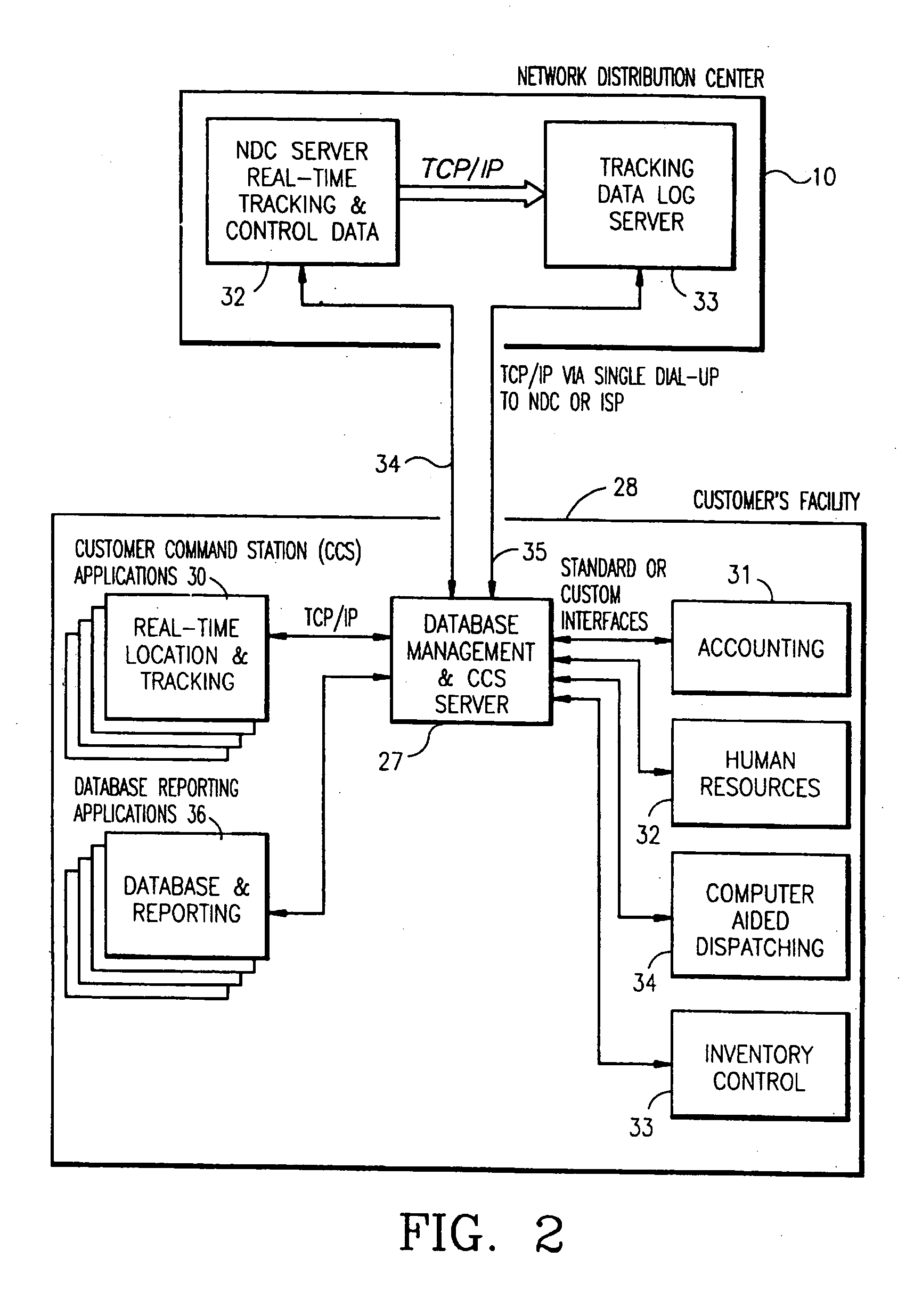

Vehicle tracking, communication and fleet management system

InactiveUS6892131B2Management moreEfficient and reliableVehicle testingRegistering/indicating working of vehiclesFleet managementTruck

A vehicle fleet management information system for identification of location and direction of movement of each vehicle in the fleet in real-time and automatic communication directly with management offices to report its location and heading, and status of predetermined events in which the vehicle may be engaged. One example is a cement delivery truck which monitors location, speed and status information such as start pour, pouring, end pour, wash and leave job, and automatically transmits this information with a management office without requiring affirmative action by the vehicle operator.

Owner:TRIMBLE NAVIGATION LTD

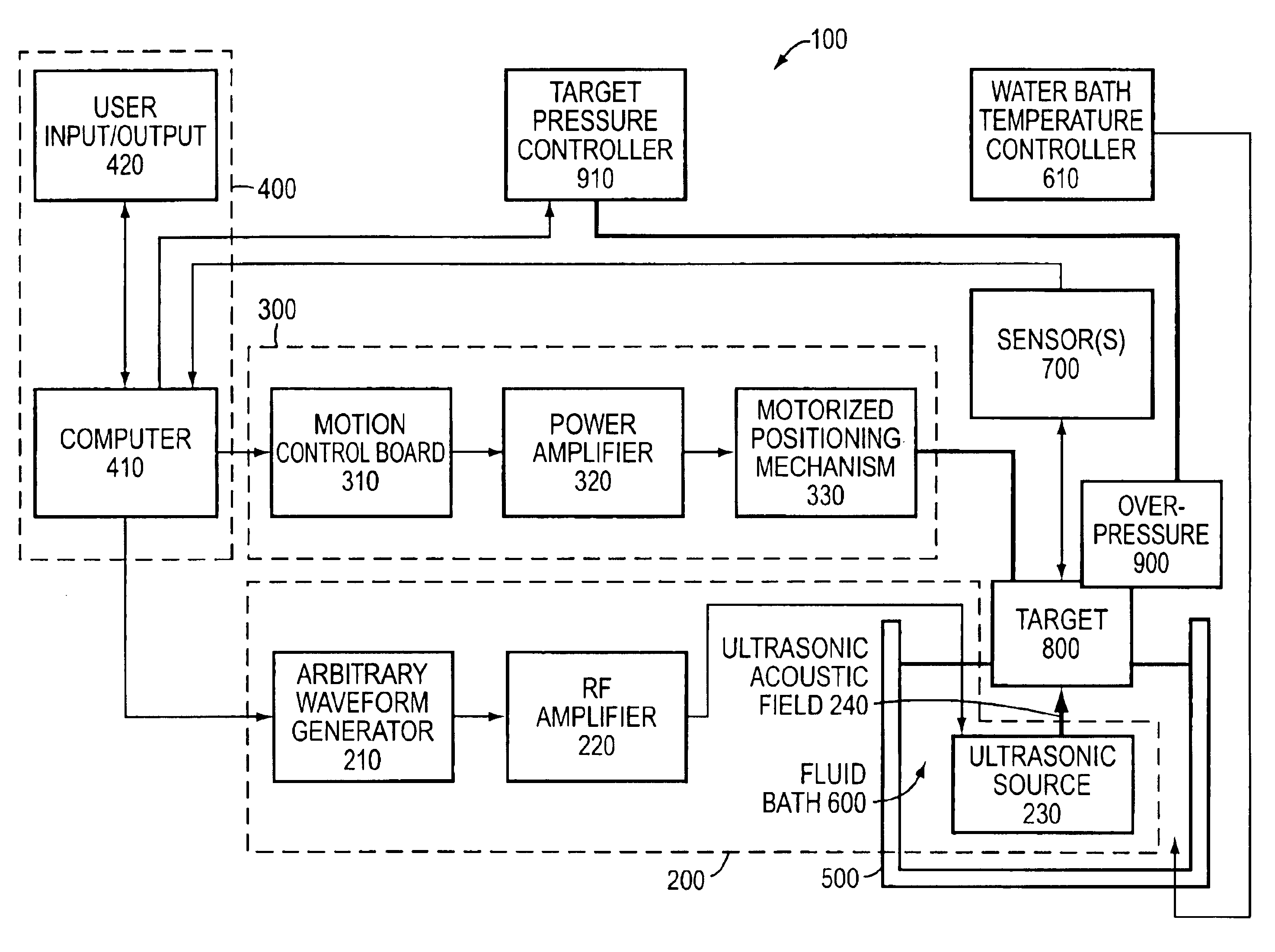

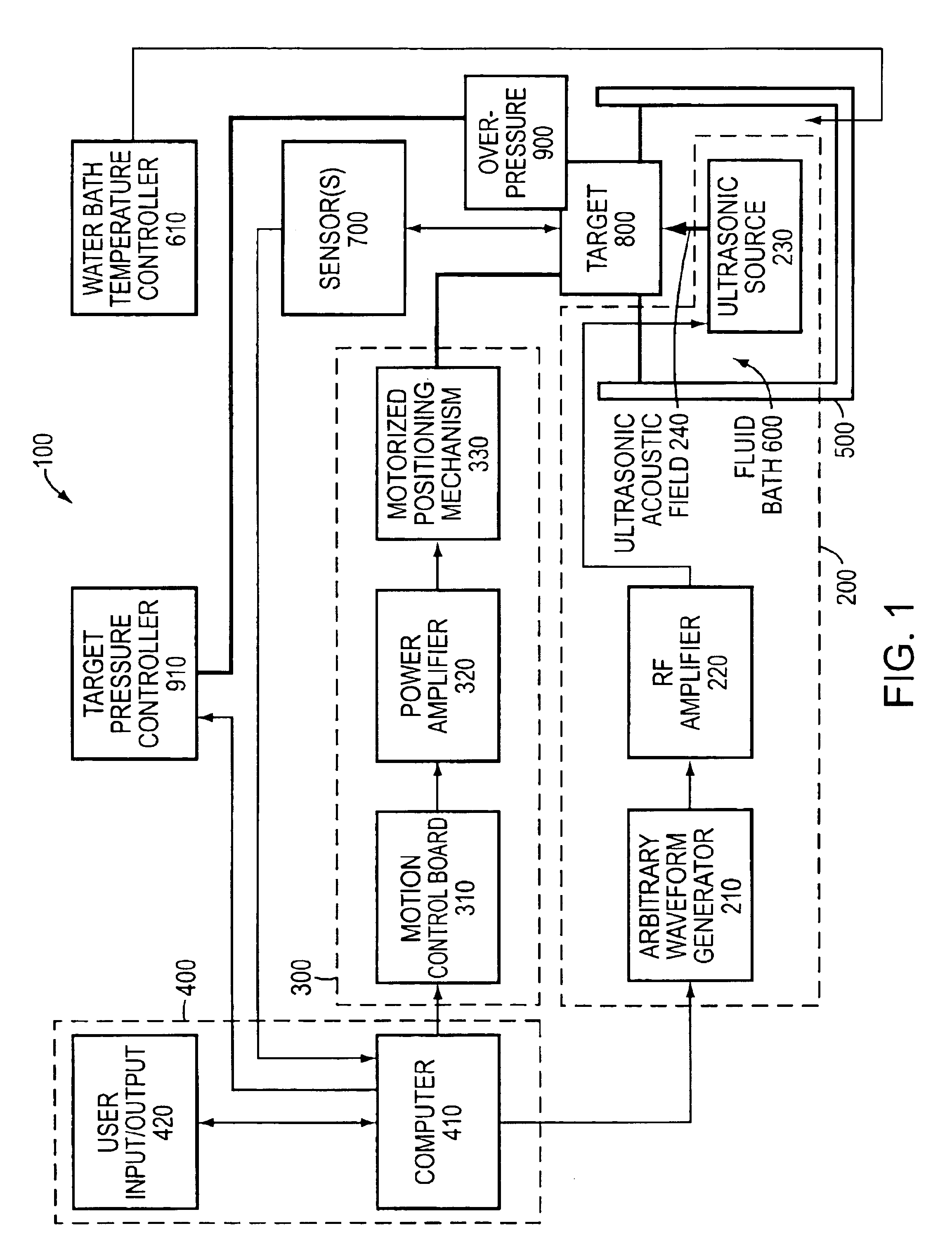

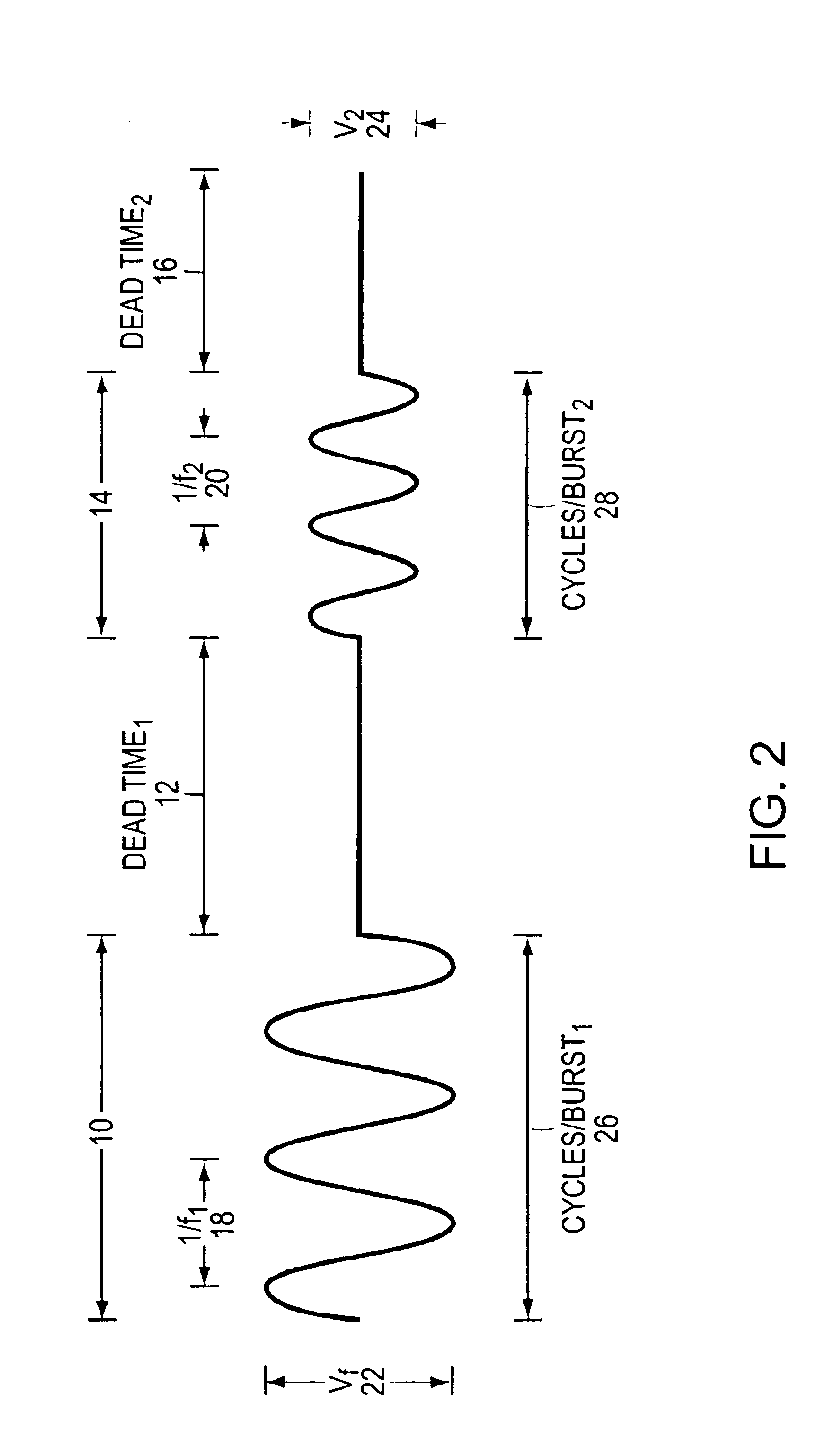

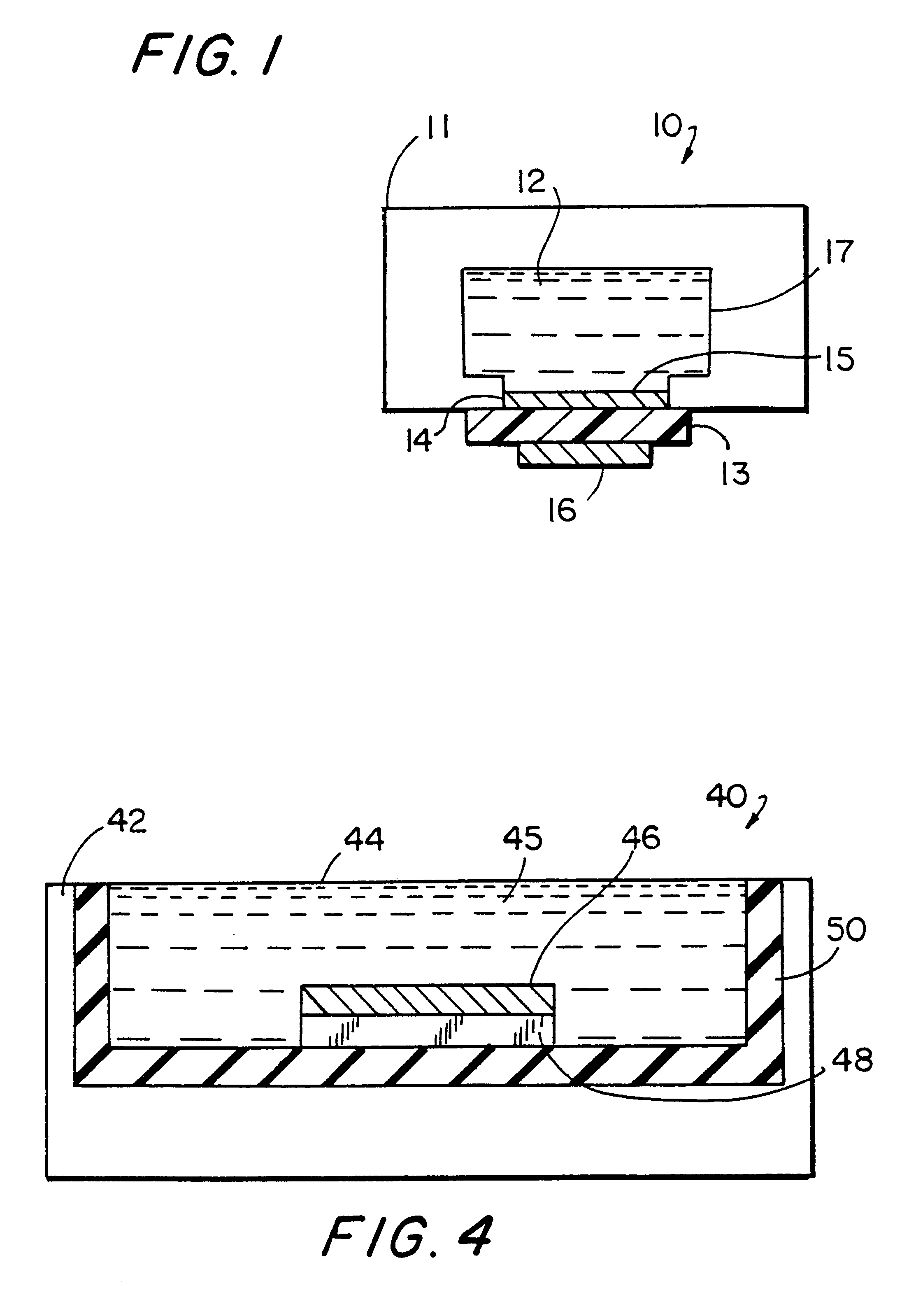

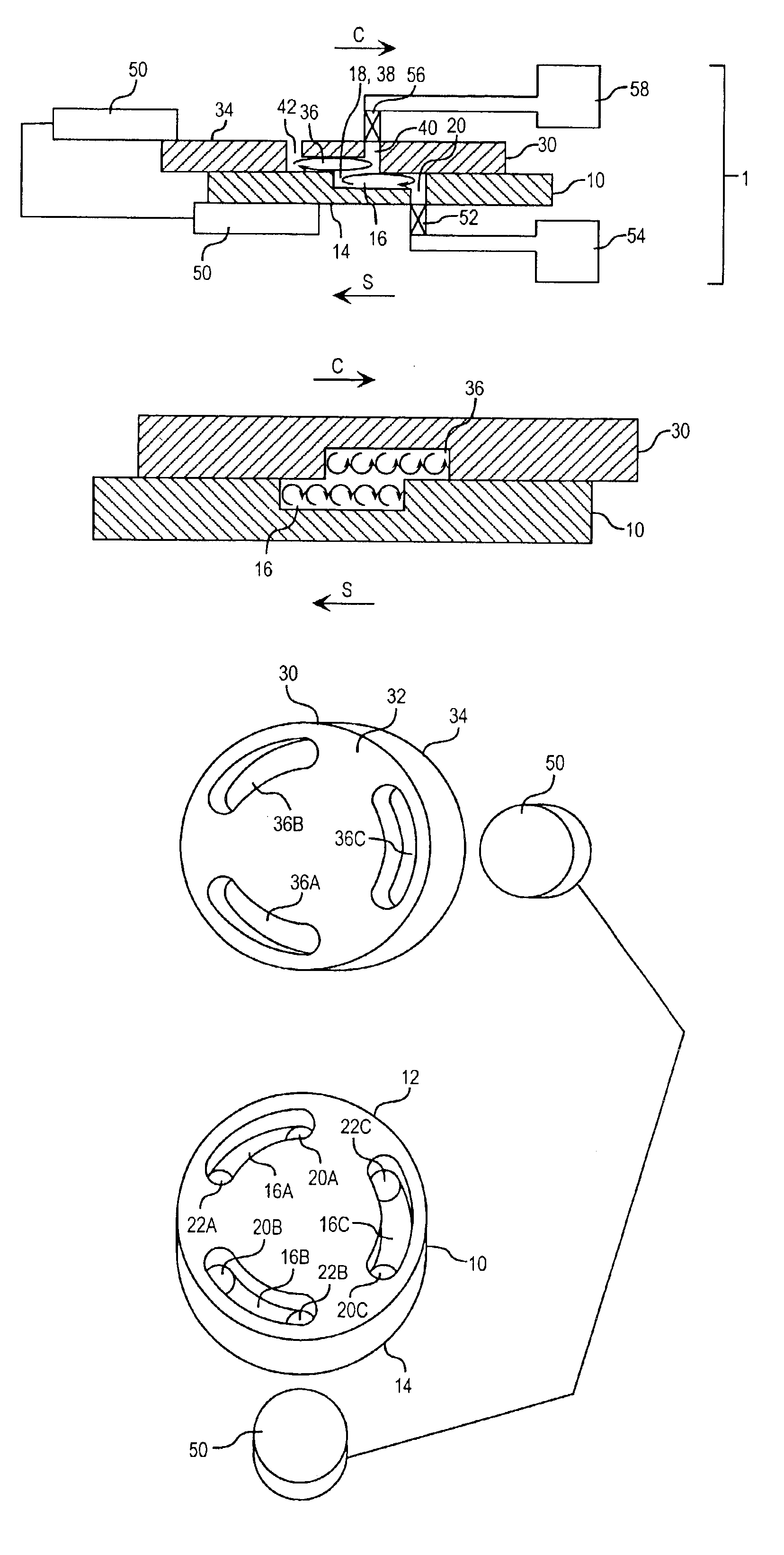

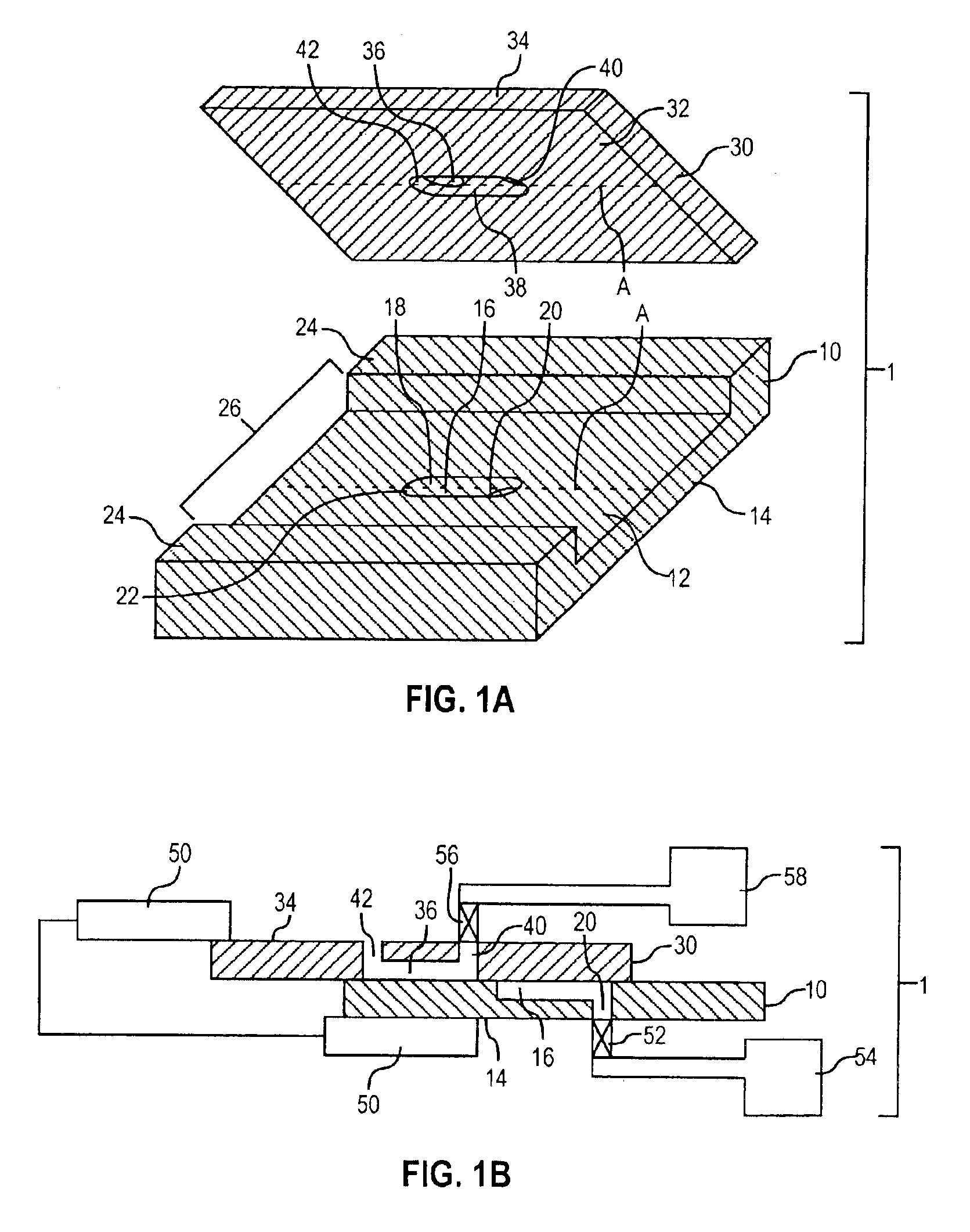

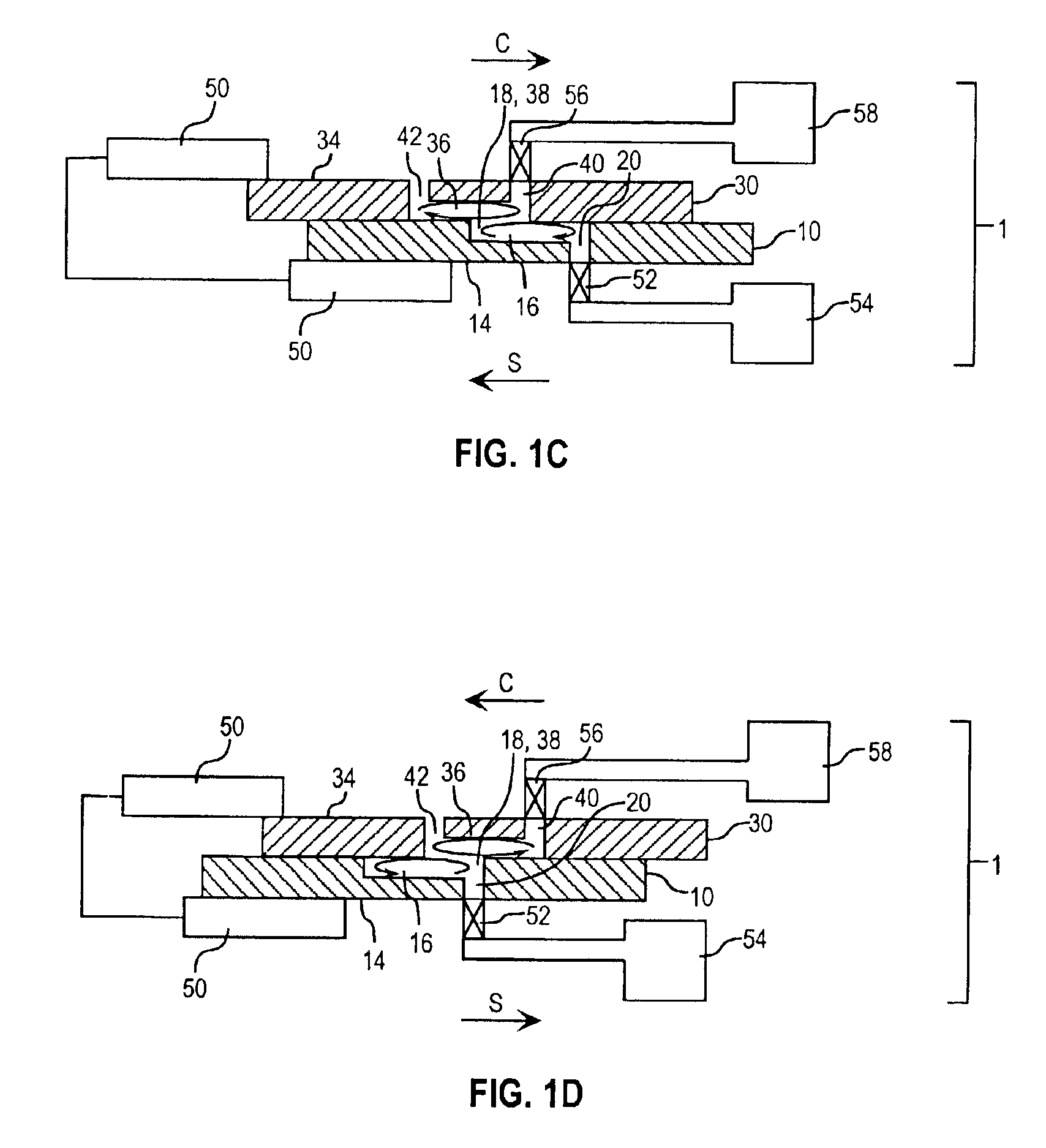

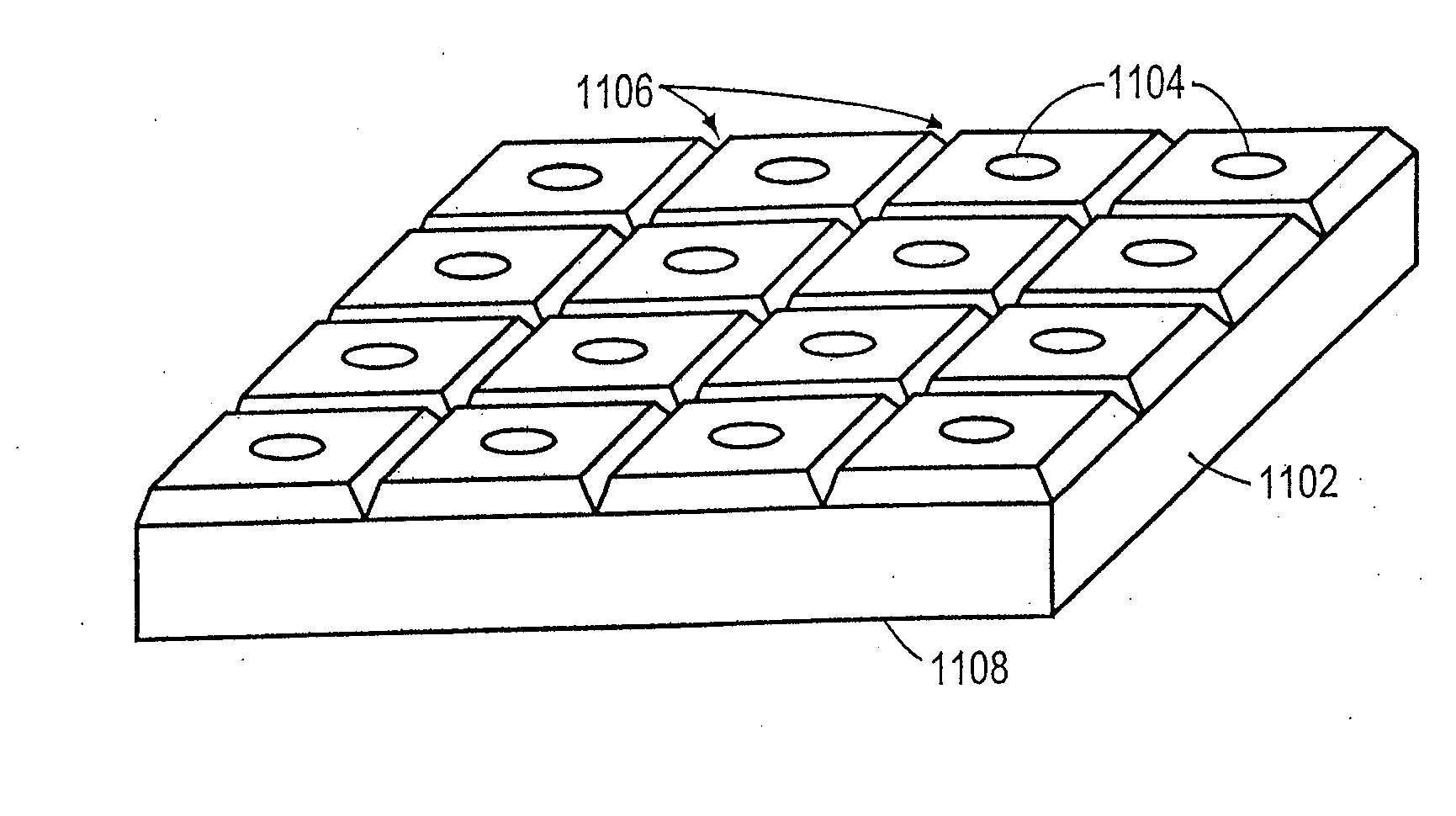

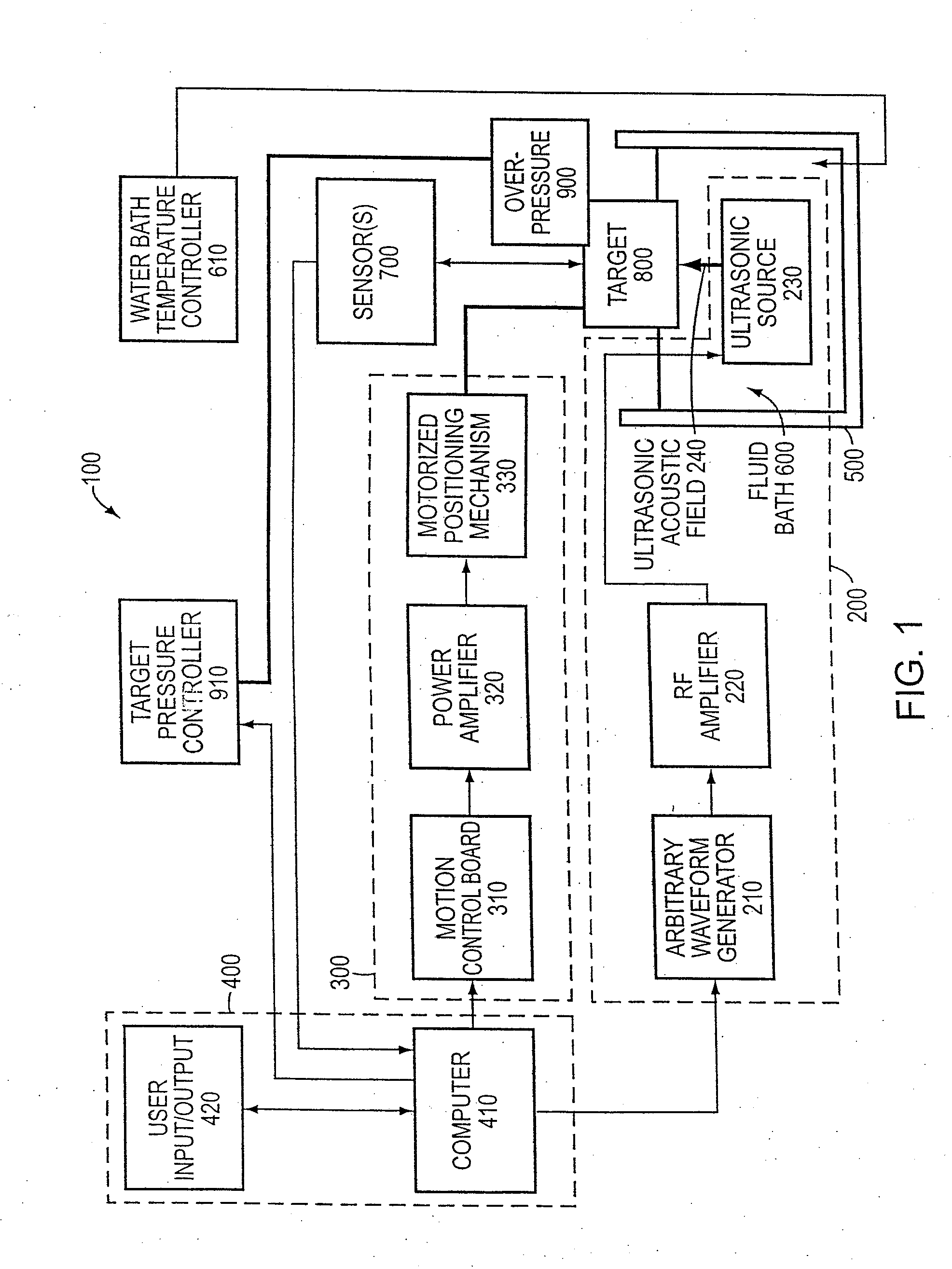

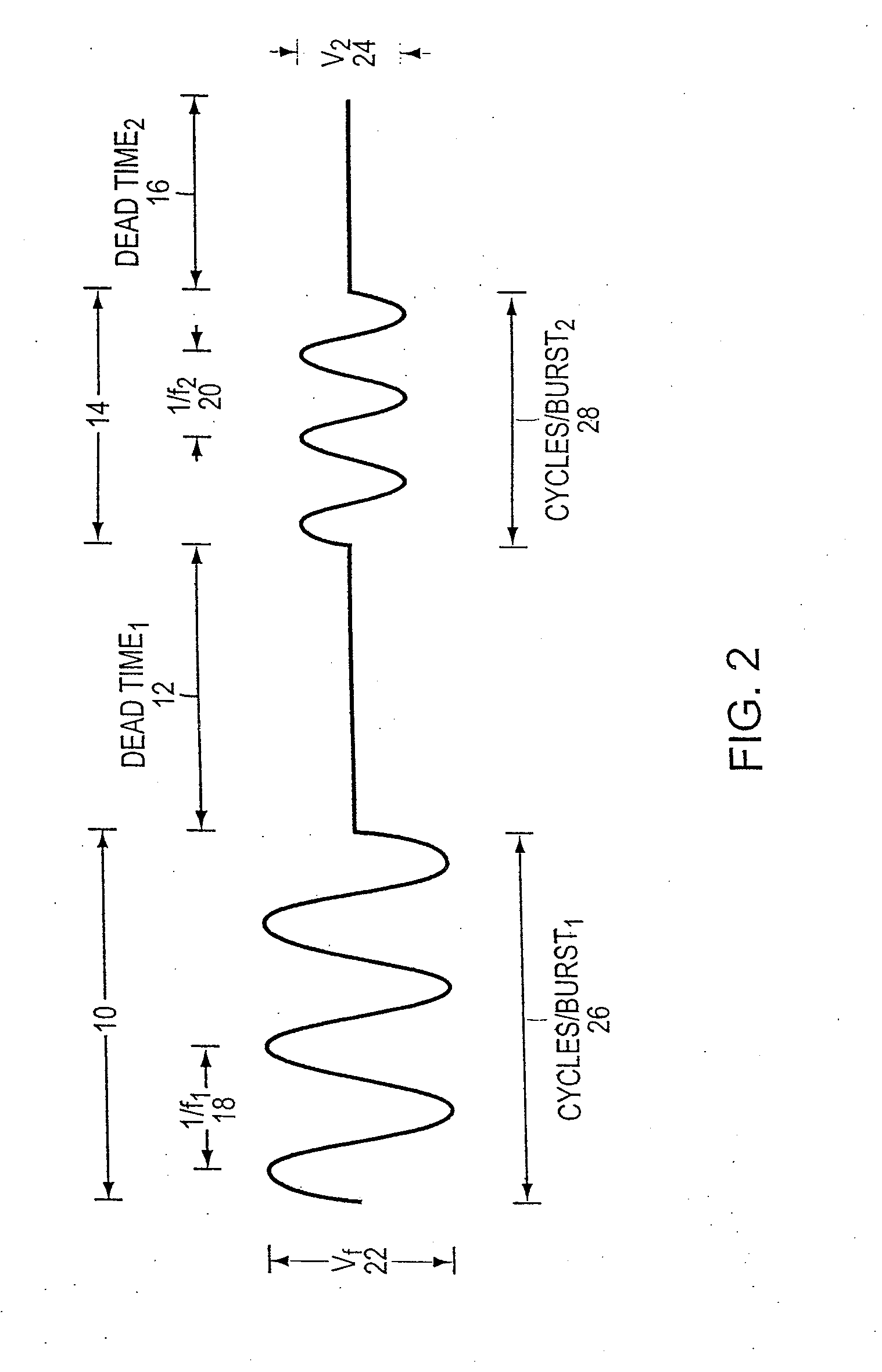

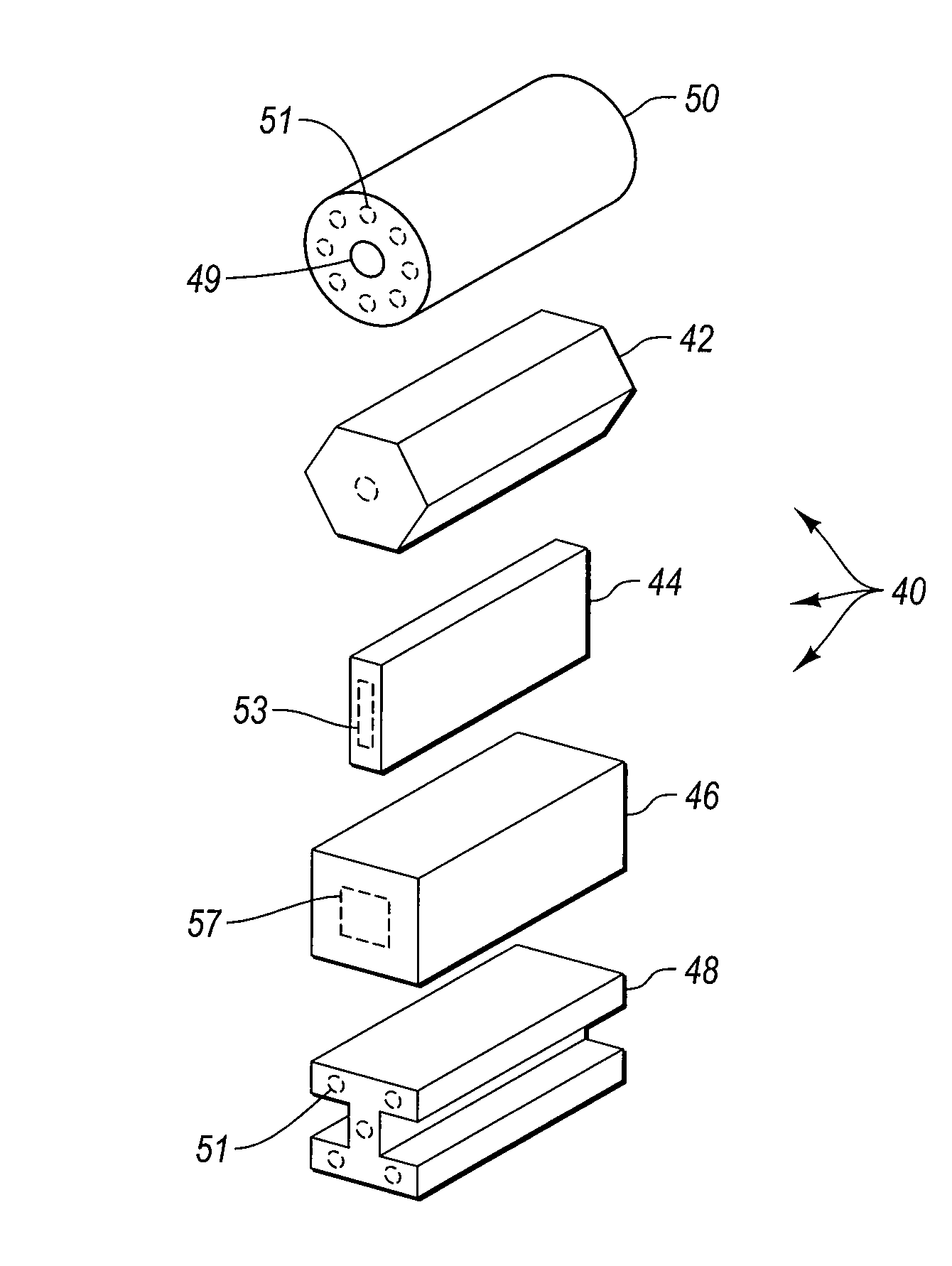

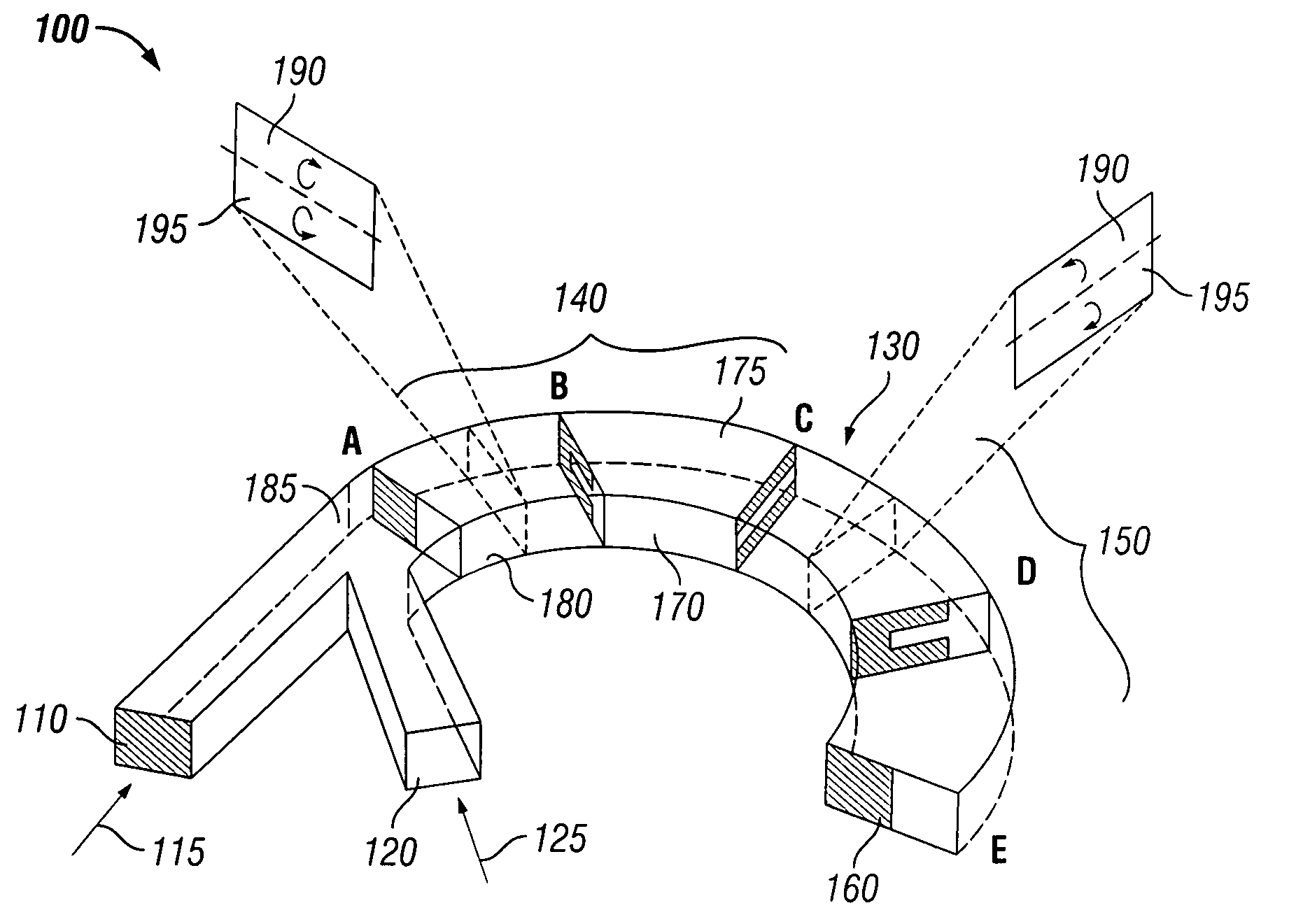

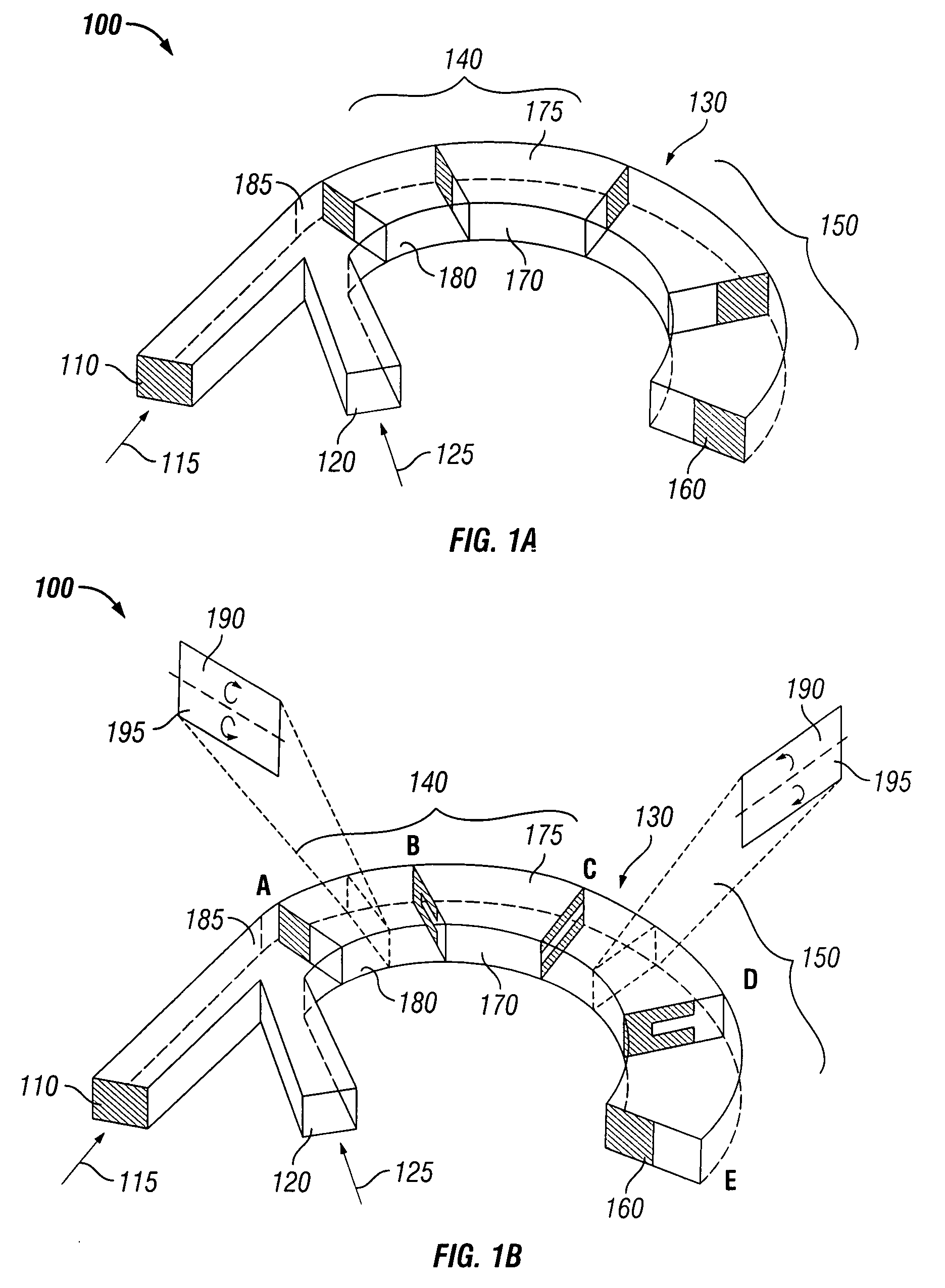

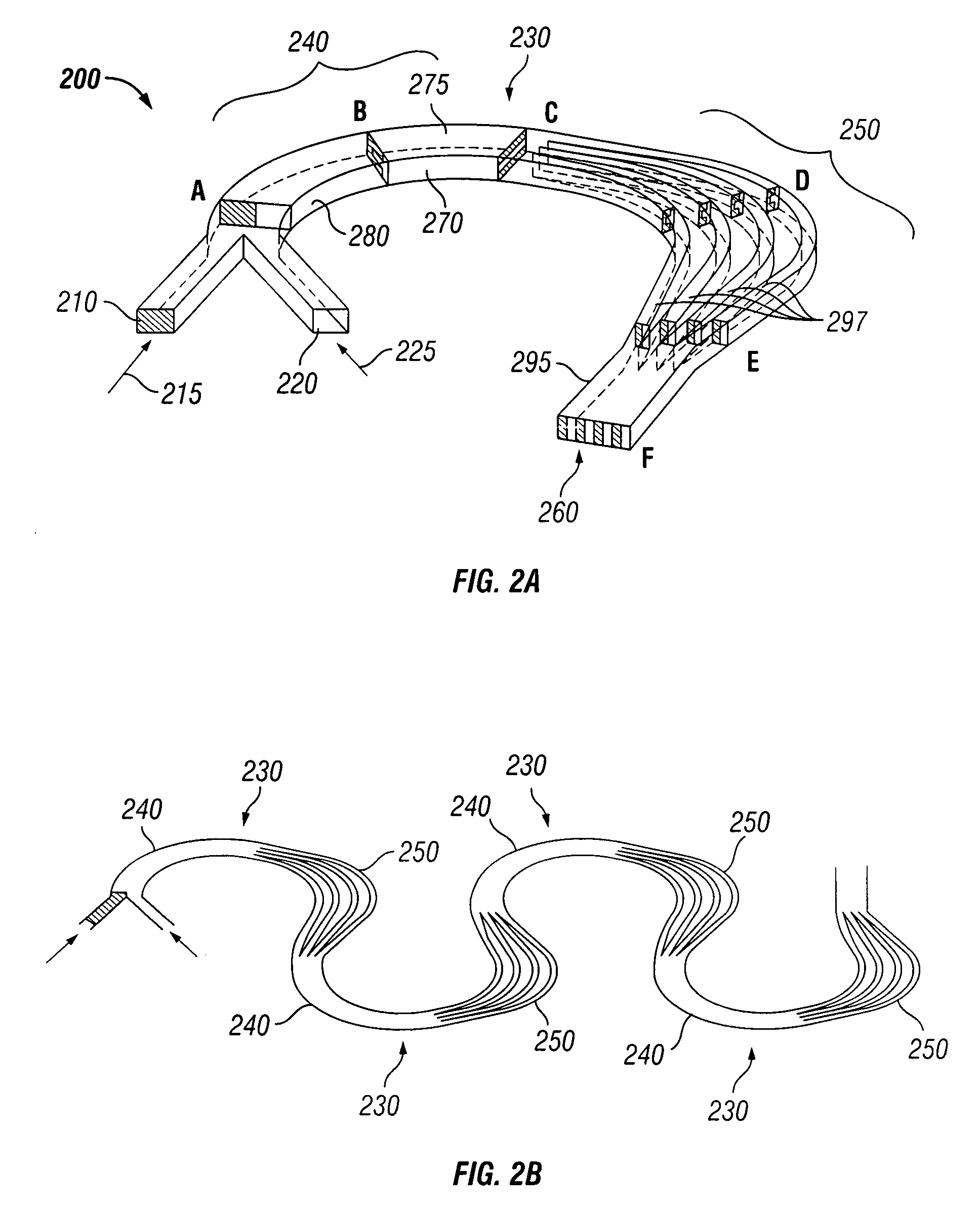

Method and apparatus for acoustically controlling liquid solutions in microfluidic devices

InactiveUS6948843B2Improve reaction speedAccelerating molecular interactionSequential/parallel process reactionsShaking/oscillating/vibrating mixersSound sourcesAcoustic energy

Acoustic energy is used to control motion in a fluid. According to one embodiment, the invention directs acoustic energy at selected naturally occurring nucleation features to control motion in the fluid. In another embodiment, the invention provides focussed or unfocussed acoustic energy to selectively placed nucleation features to control fluid motion. According to one embodiment, the invention includes an acoustic source, a controller for controlling operation of the acoustic source, and one or more nucleation features located proximate to or in the fluid to be controlled.

Owner:COVARIS INC

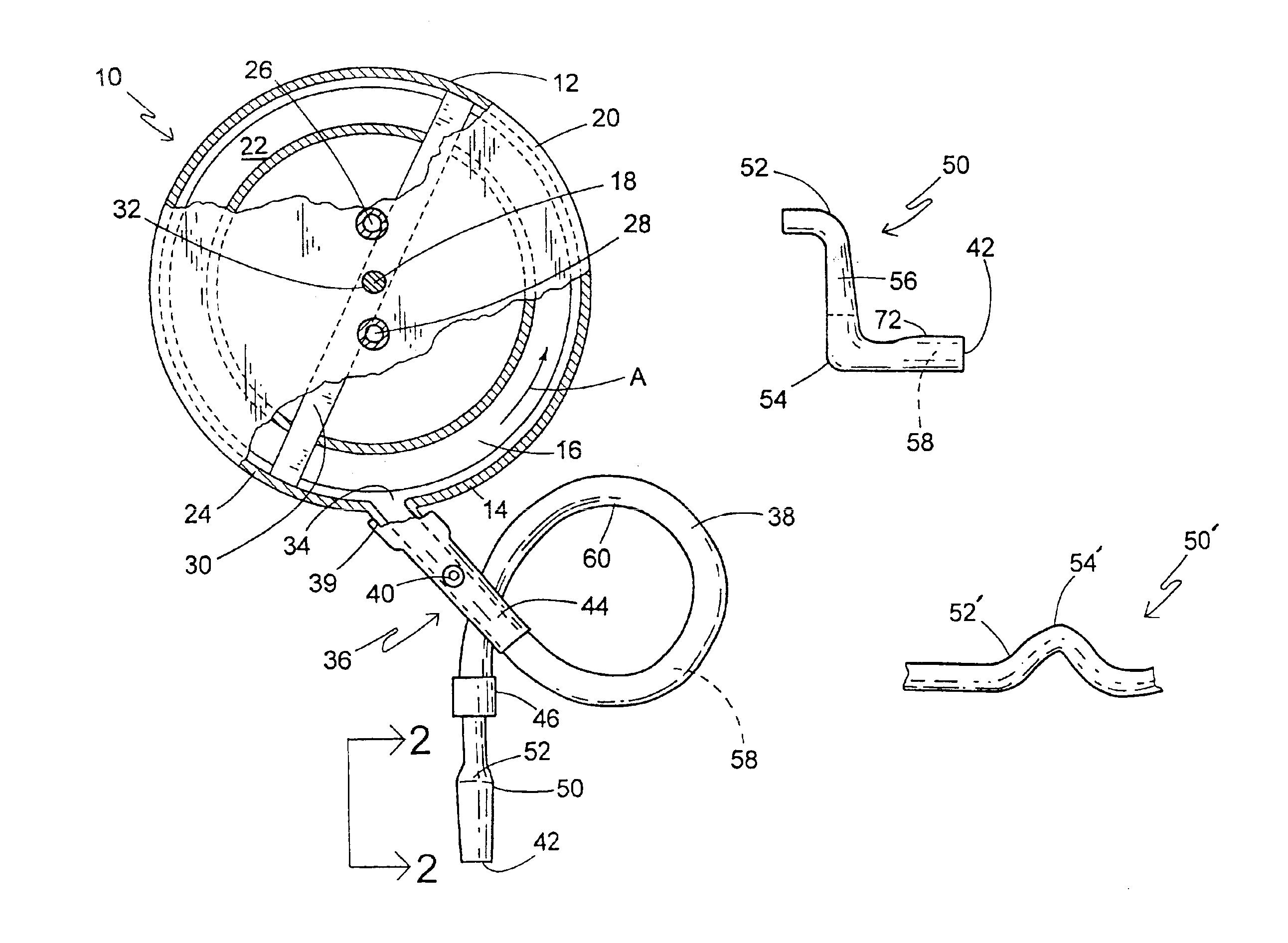

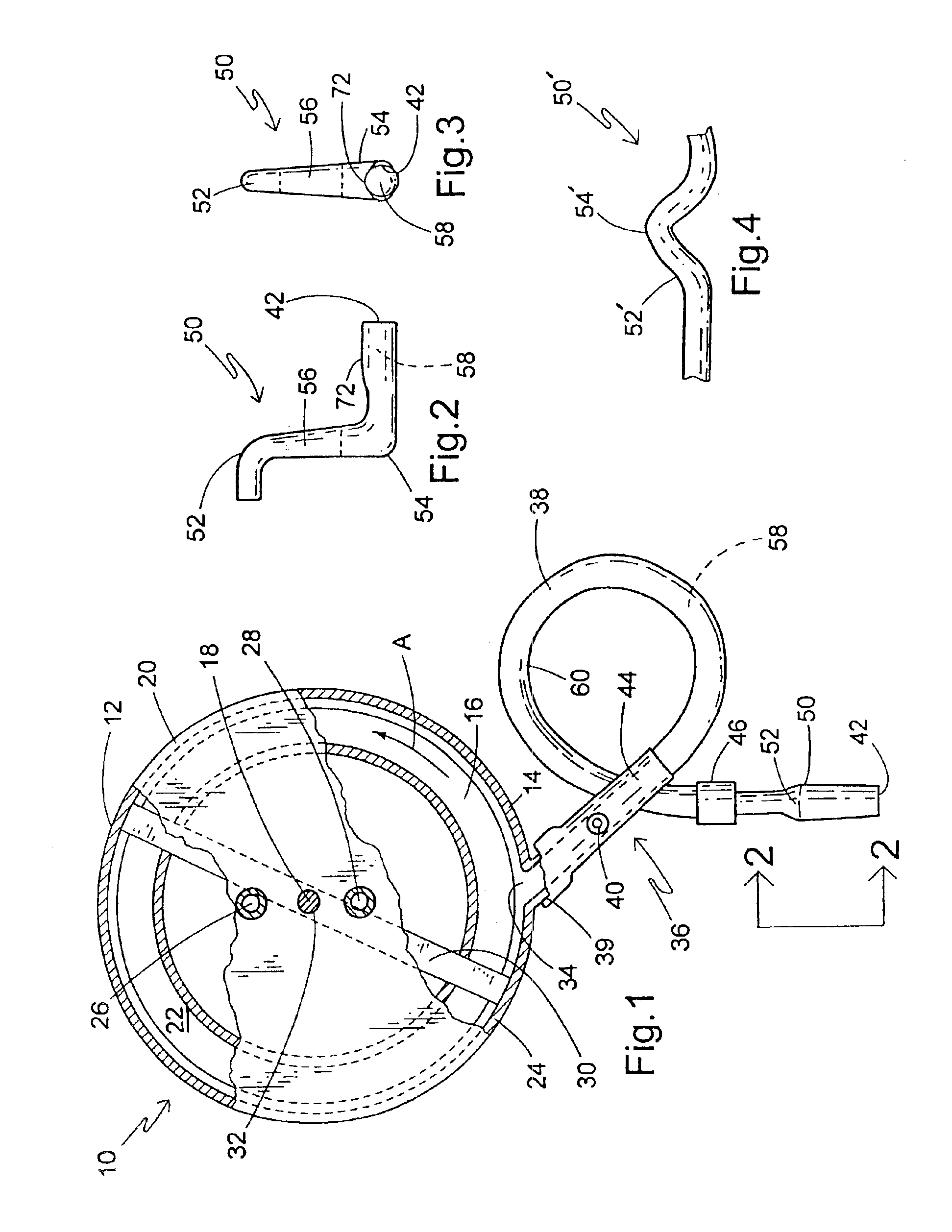

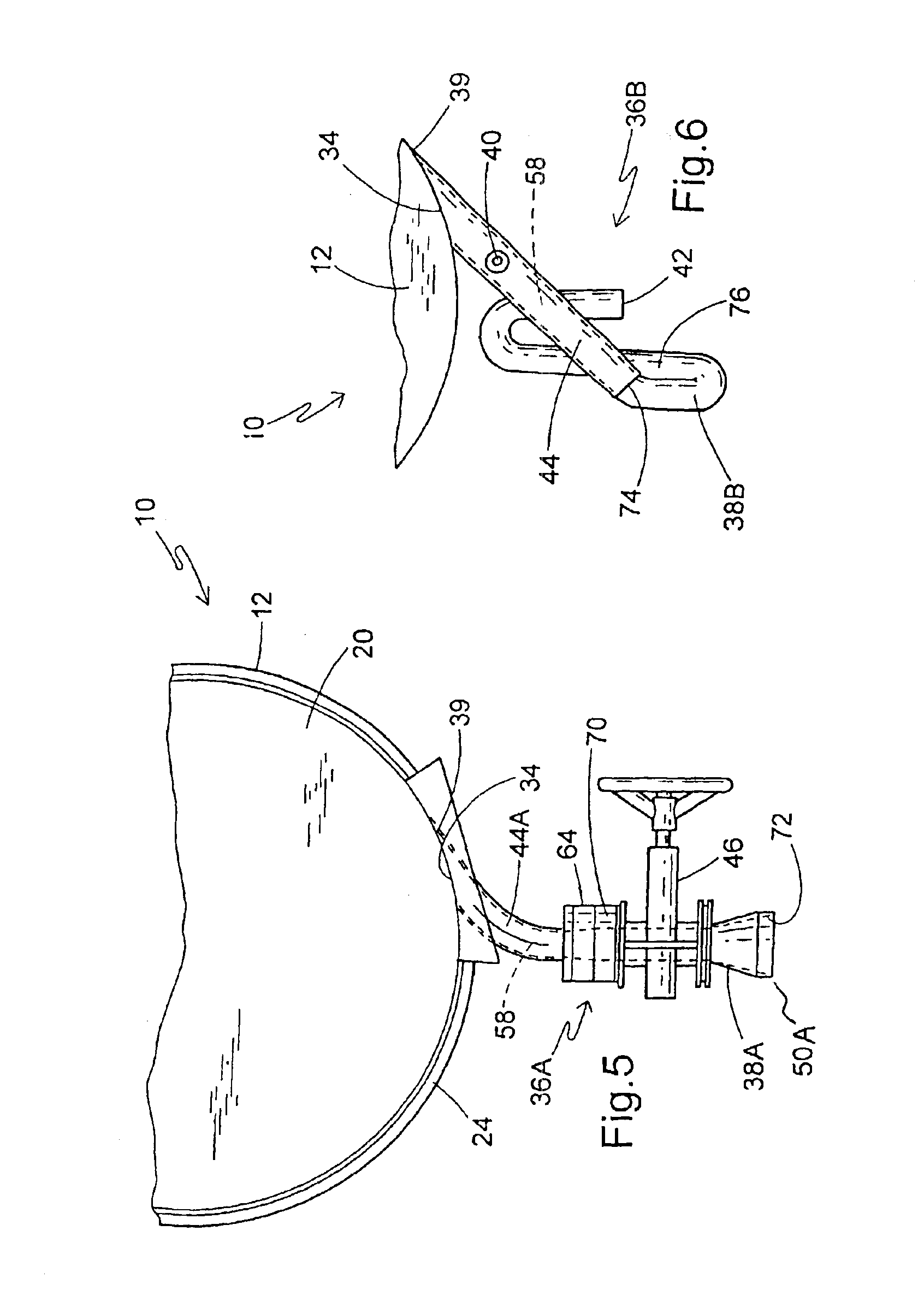

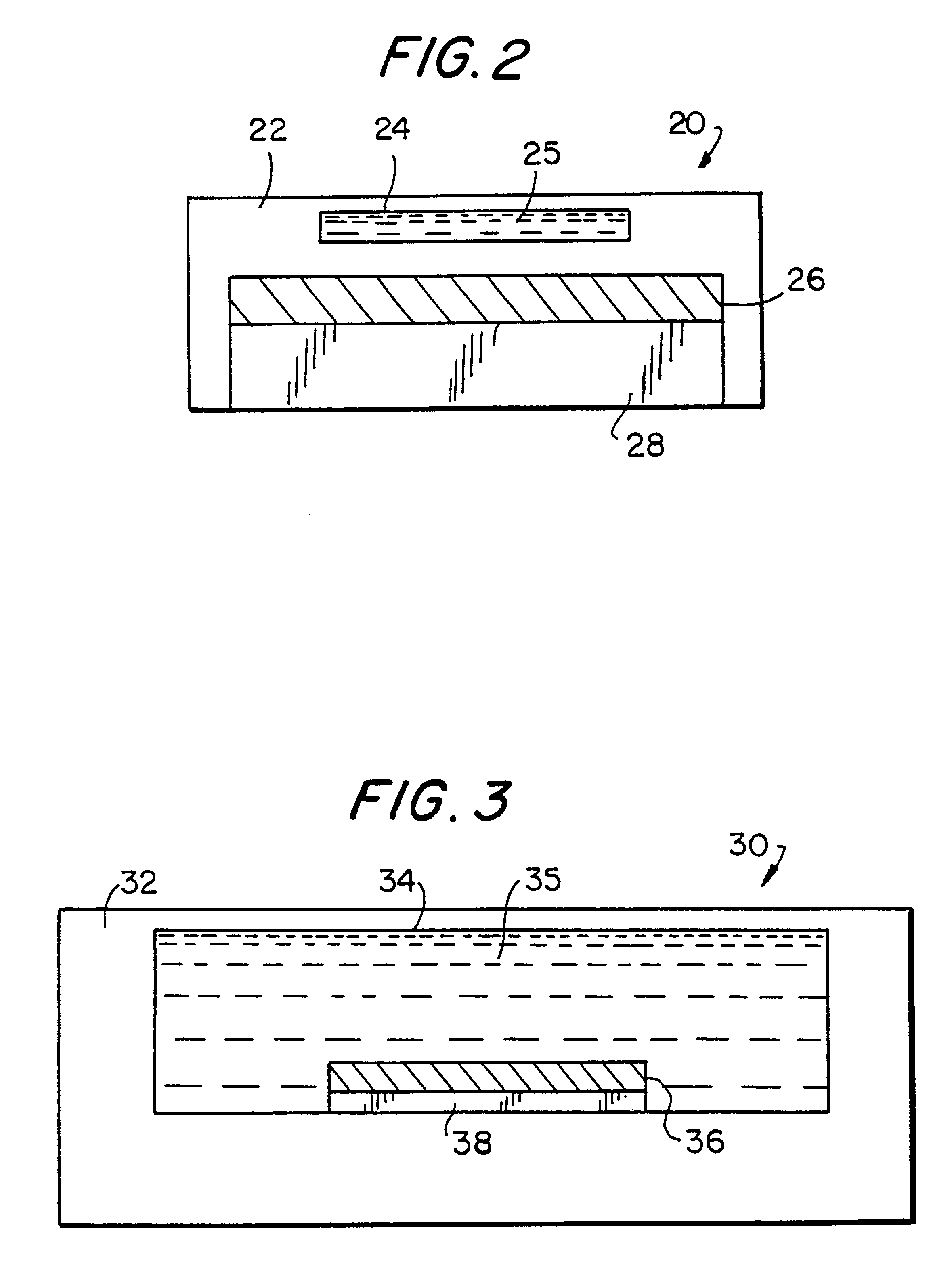

Slurry mixer outlet

InactiveUS6874930B2Unwanted premature setting is preventedReduce generationFlow mixersDischarging apparatusSlurryReducer

An apparatus configured for connection to a mixer for receiving a slurry and altering the flow characteristics of the slurry includes a conduit having a main inlet in slurry receiving communication with the mixer outlet and extending to a spout for discharging the slurry, at least one conduit restrictor associated with the conduit for creating back-pressure between the conduit restrictor and the mixer outlet for keeping the mixer full, and at least one pressure reducer associated with the discharge spout and configured for reducing the pressure of the slurry dispensed from the discharge spout. The apparatus is configured for maintaining a generally laminar flow from the mixer outlet to the discharge spout.

Owner:UNITED STATES GYPSUM CO

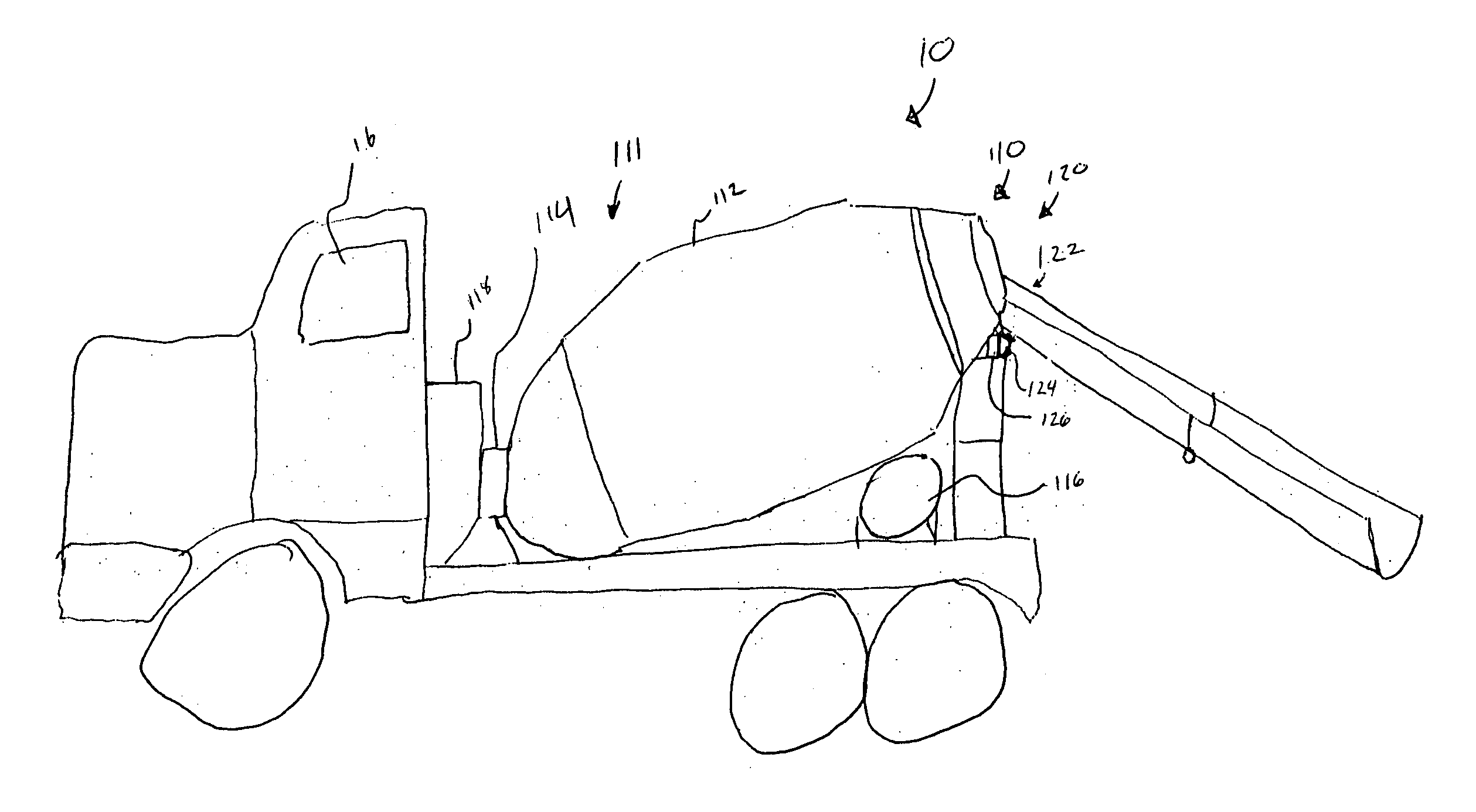

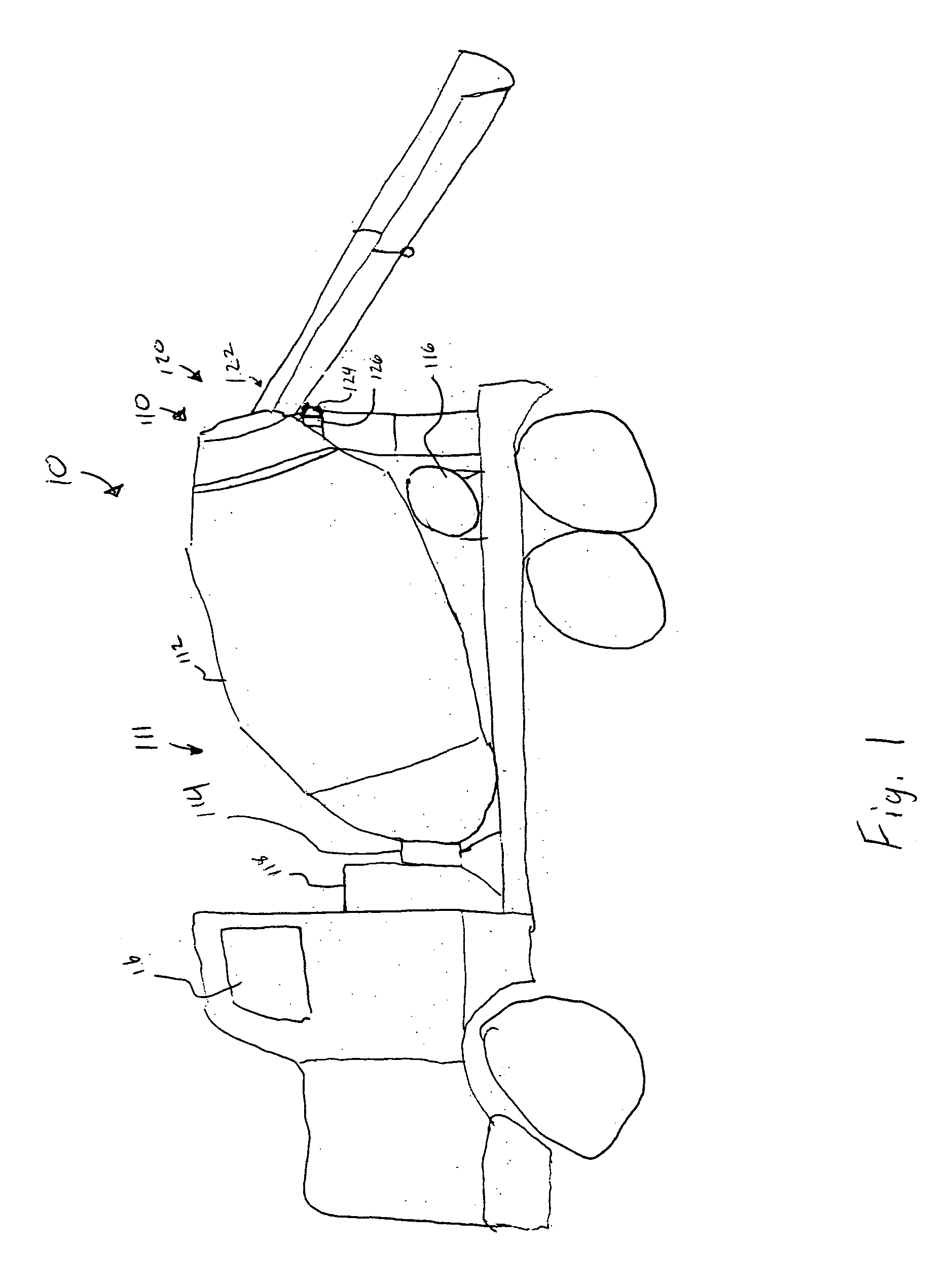

Vehicle tracking, communication and fleet management system

InactiveUS20060142913A1Management moreEfficient and reliableVehicle testingRegistering/indicating working of vehiclesFleet managementEngineering

A vehicle fleet management information system identifies location and direction of movement of each vehicle in a fleet in real-time, and automatically reports such information, as well as status of predetermined events in which the vehicle is engaged, directly to the fleet manager. Each fleet vehicle has an assigned time slot to transmit its reporting information over a communications network without interfering with transmissions from other vehicles in their own respective time slots. A timing control phase lock loop (PLL) provides precise time synchronization for timing corrections from a global positioning system (GPS) based time reference. A dual band full-duplex interface of the network has TDMA on one-half and broadcast on the other half. Microprocessor time processing units in components of the network perform precise clock synchronization. Space diversity performed on received vehicle transmitted messages avoids data corruption. Different vehicles have different periodic transmission intervals, by dynamically allocating the slots for various update rates. Auxiliary reporting slots enable prompt reporting of important data by the respective vehicle transmitters independent of the slower periodic transmission intervals.

Owner:TRIMBLE NAVIGATION LTD

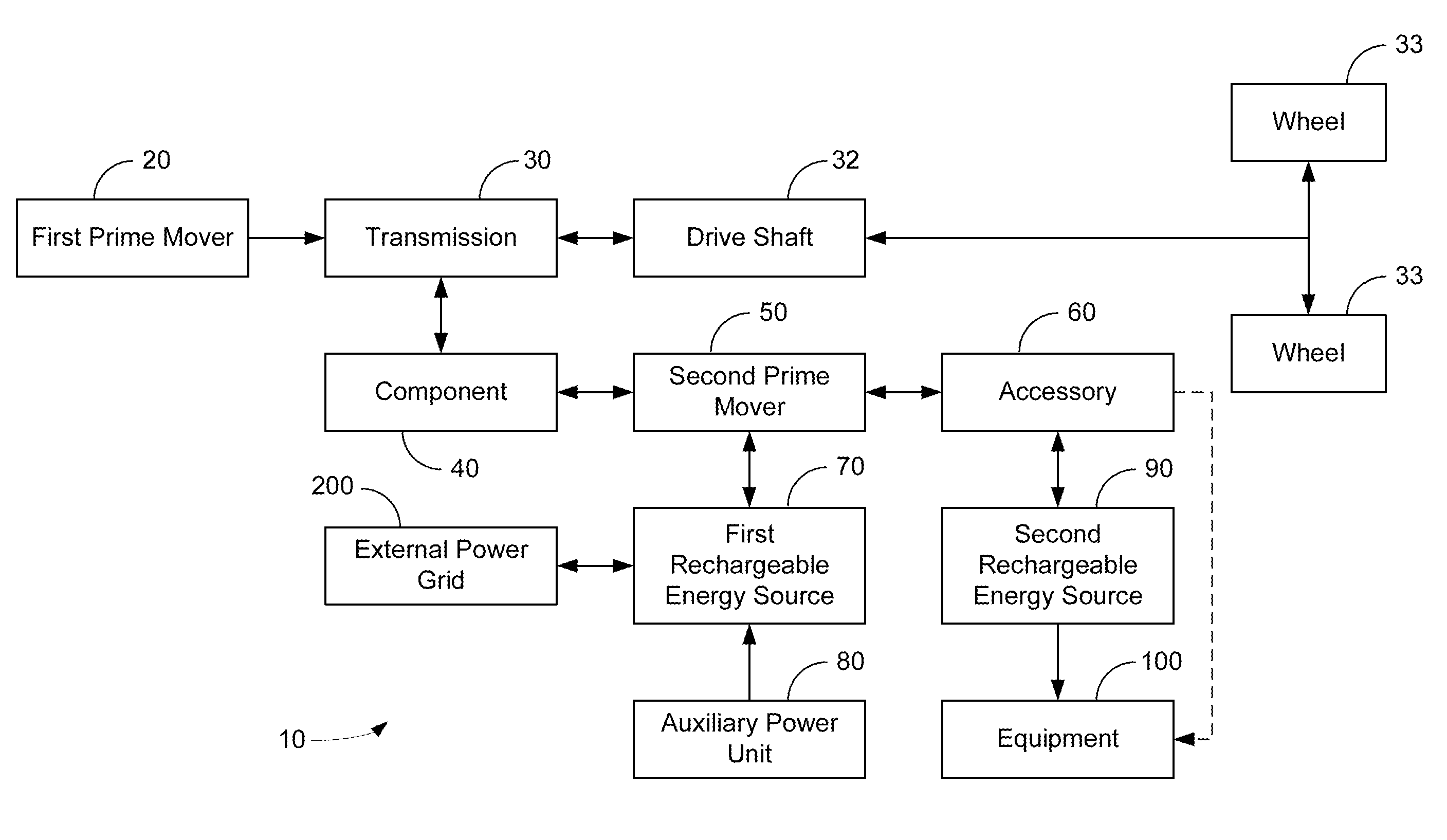

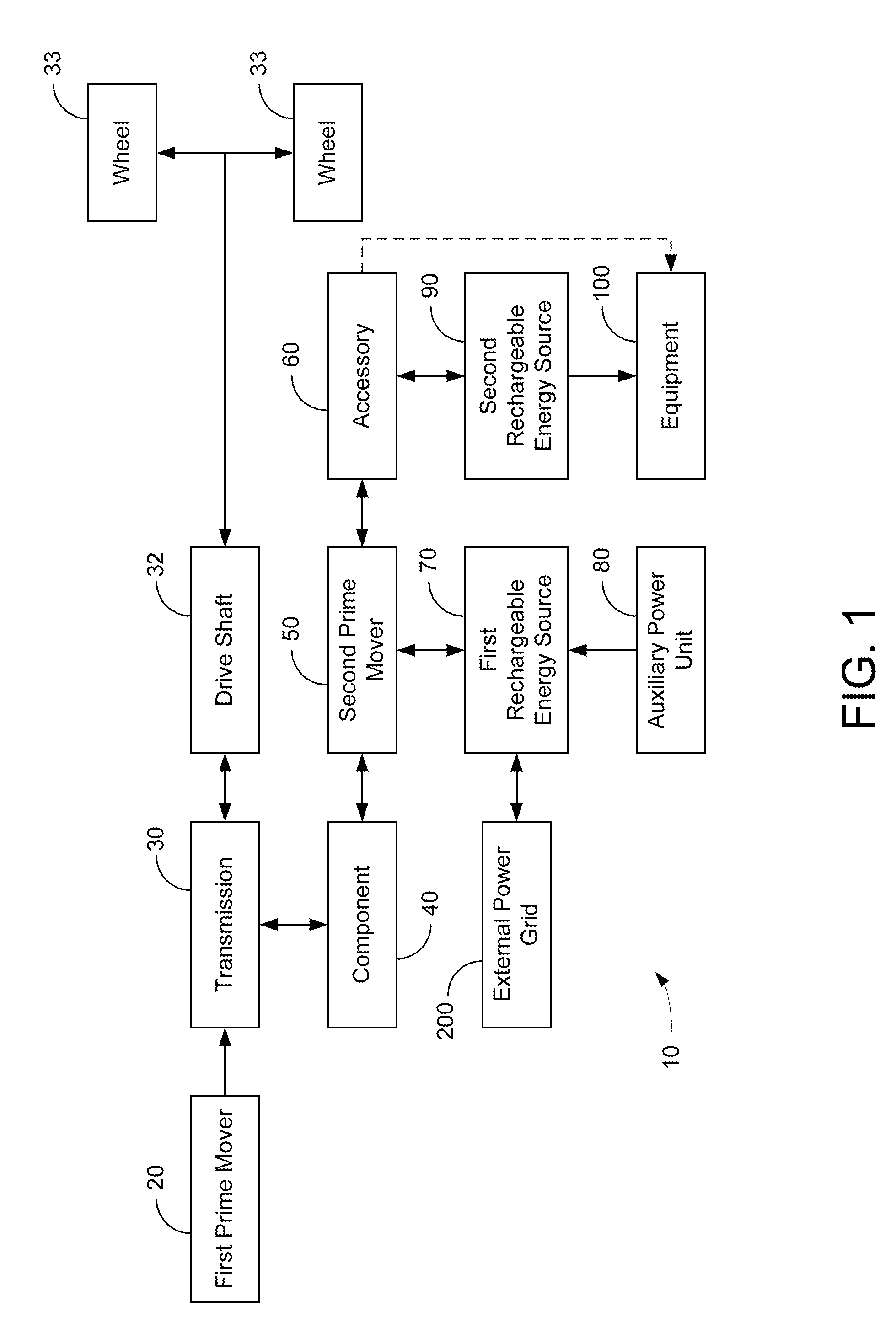

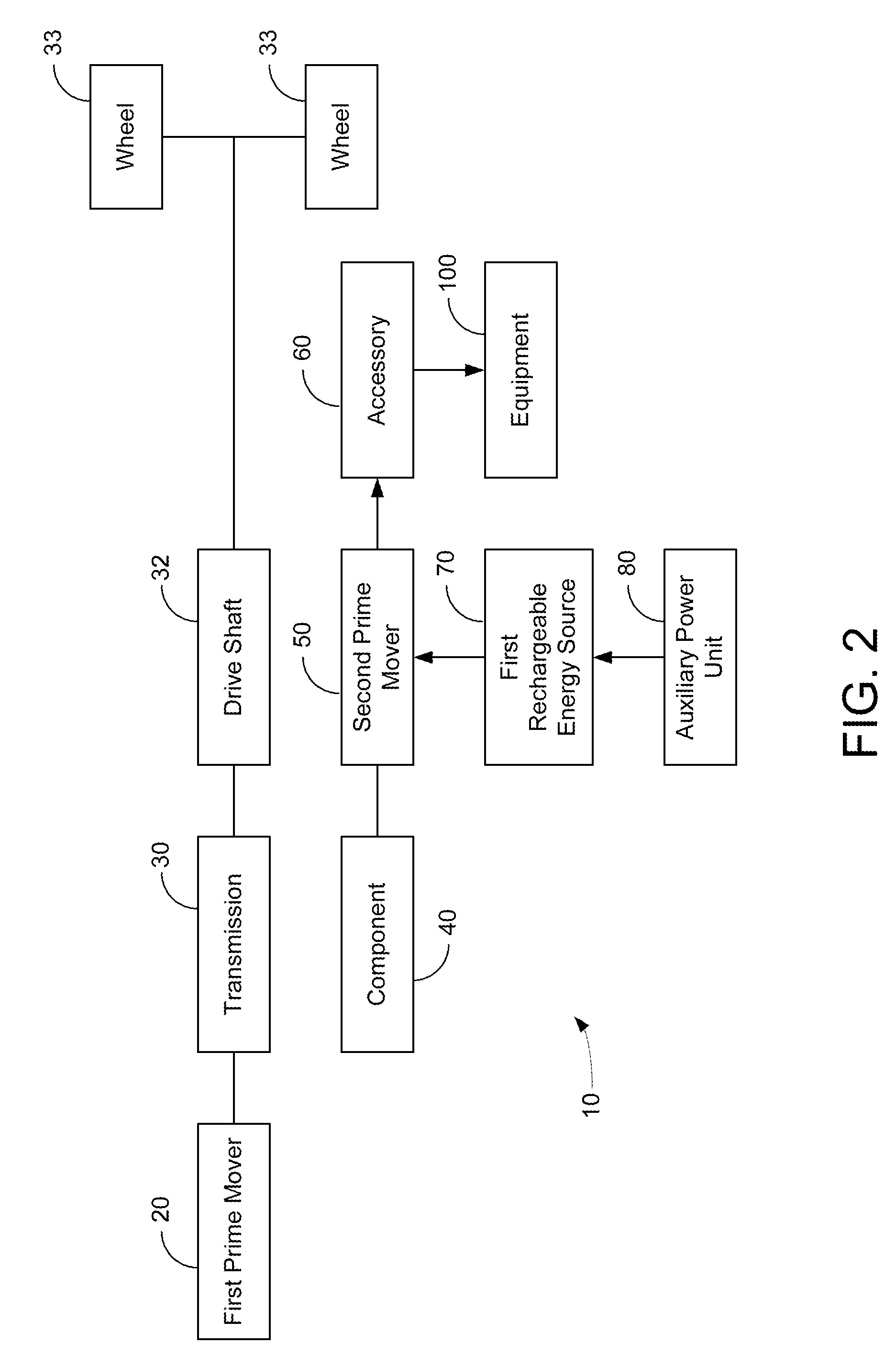

Hybrid vehicle drive system and method and idle reduction system and method

One embodiment relates to a hybrid vehicle drive system for a vehicle including a first prime mover, a first prime mover driven transmission, a rechargeable power source, and a PTO. The hybrid vehicle drive system further includes a hydraulic motor in direct or indirect mechanical communication with the PTO and an electric motor in direct or indirect mechanical communication with the hydraulic motor. The electric motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO. The hydraulic motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO.

Owner:POWER TECH HLDG LLC

Carbon nanotube fiber-reinforced composite structures for EM and lightning strike protection

InactiveUS6986853B2Repaired quickly and efficientlySufficient protectionMaterial nanotechnologyShielding materialsLightning strikeFiber-reinforced composite

A method for repairing fiber-reinforced composite structures while maintaining original EM and lightning protection using carbon nanotubes, fibers, and thermoset resins is disclosed. According to one embodiment of the invention, the method comprises preparing a damaged area for repair; preparing a repair patch for the damaged area, the repair patch comprising nanotubes; applying the repair patch to the damaged area; and curing the repair patch. A repair patch for a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair patch includes a binder and nanotubes. A repair resin for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair layer includes a resin and nanotubes. A putty for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the putty includes a base and electrically conductive carbon nanotubes.

Owner:EIKOS

Assay sonication apparatus and methodology

InactiveUS6413783B1Accurate toleranceEasy to explainImmobilised enzymesBioreactor/fermenter combinationsAssayCell biology

An assay apparatus includes a cell with a working electrode and a sonicating device structurally coupled to the cell for sonication the contents of the cell.

Owner:MESO SCALE TECH LLC

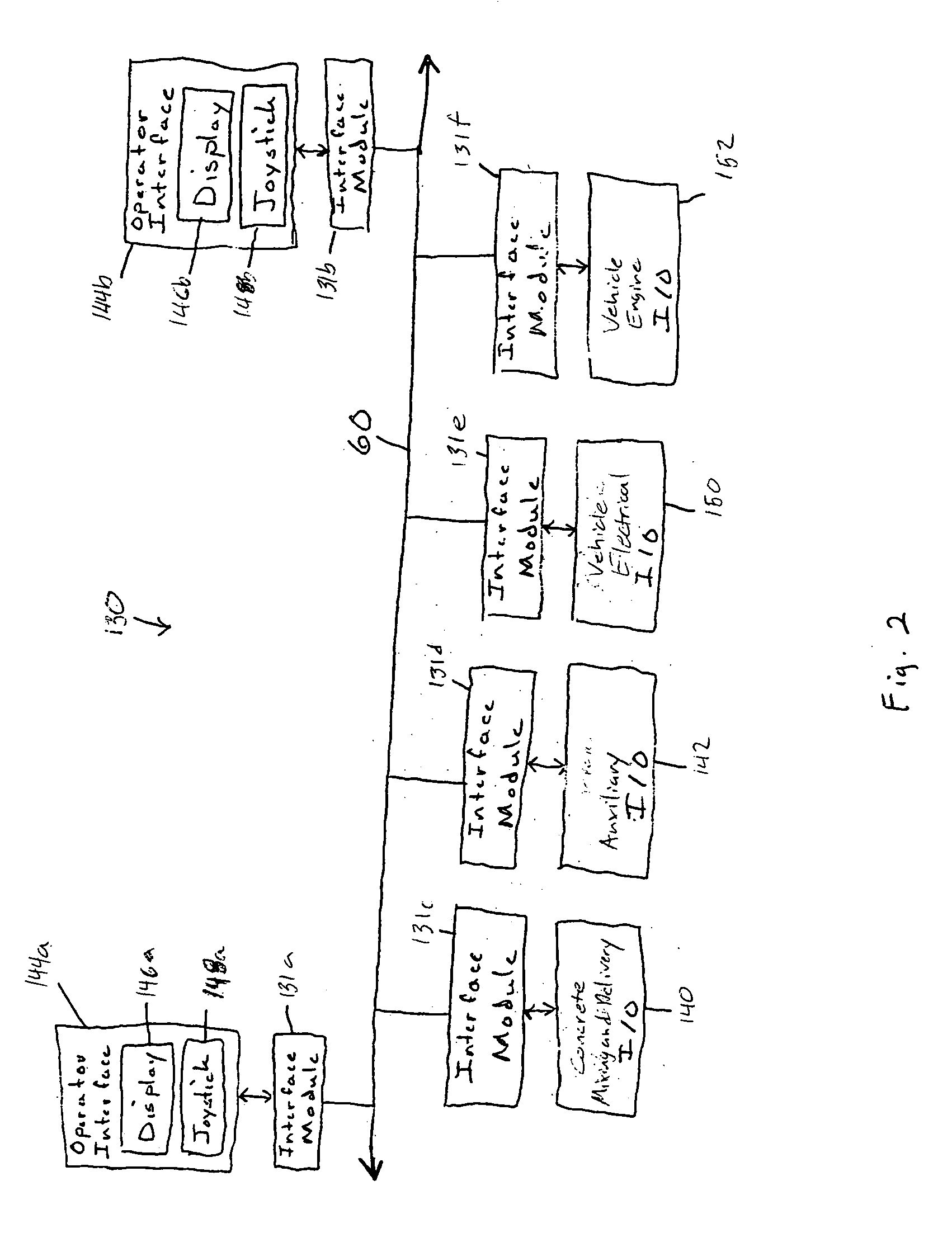

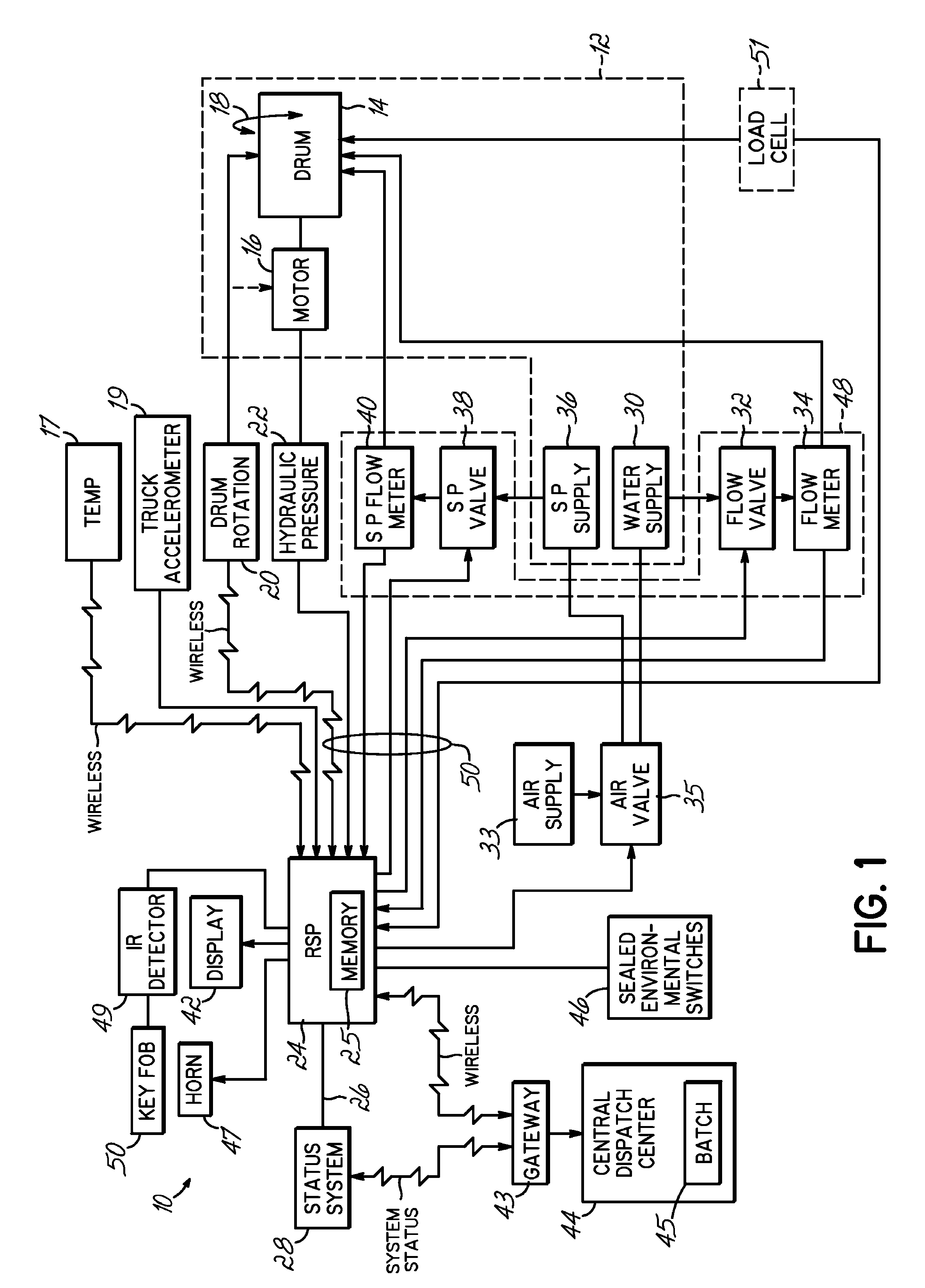

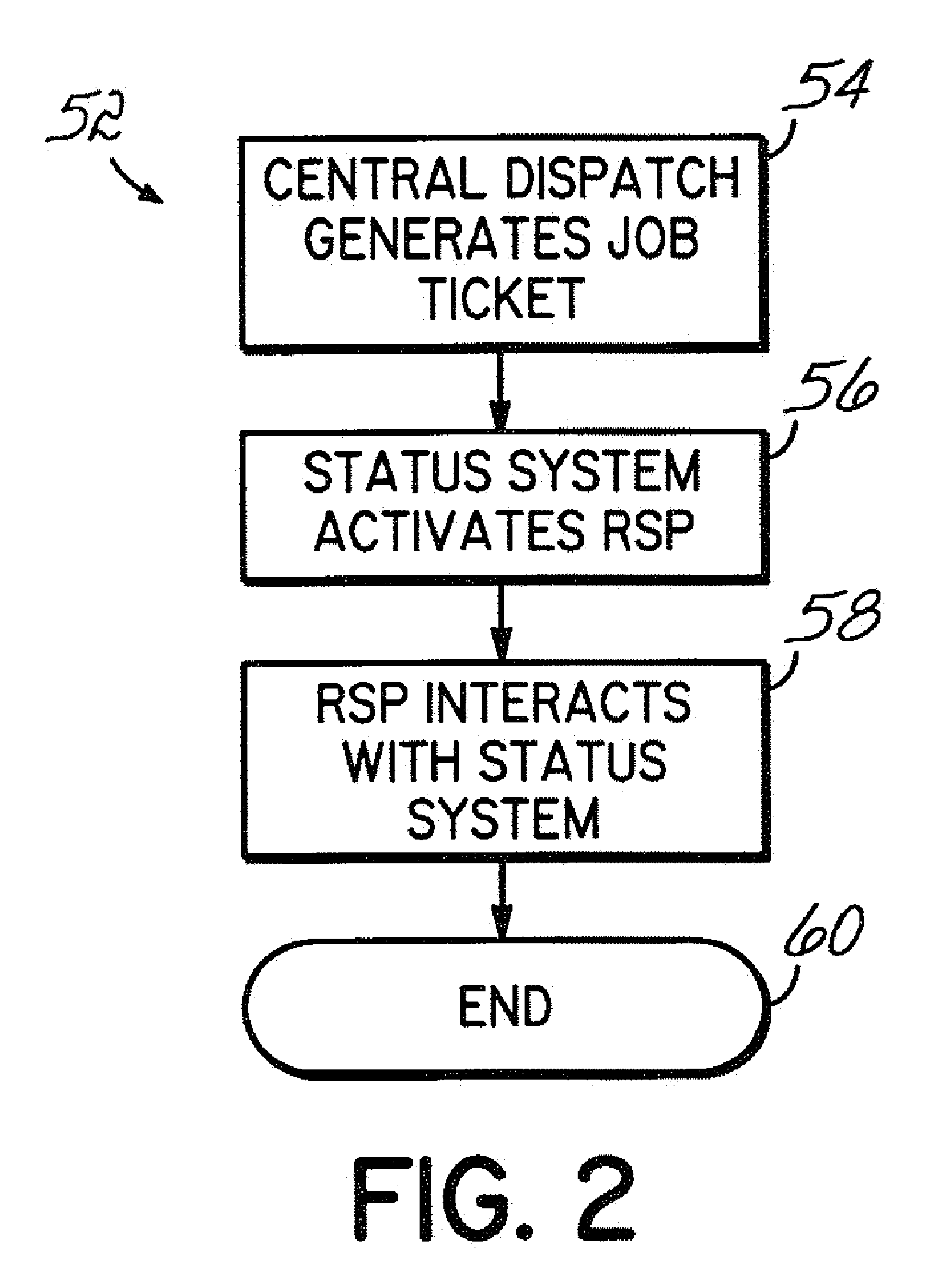

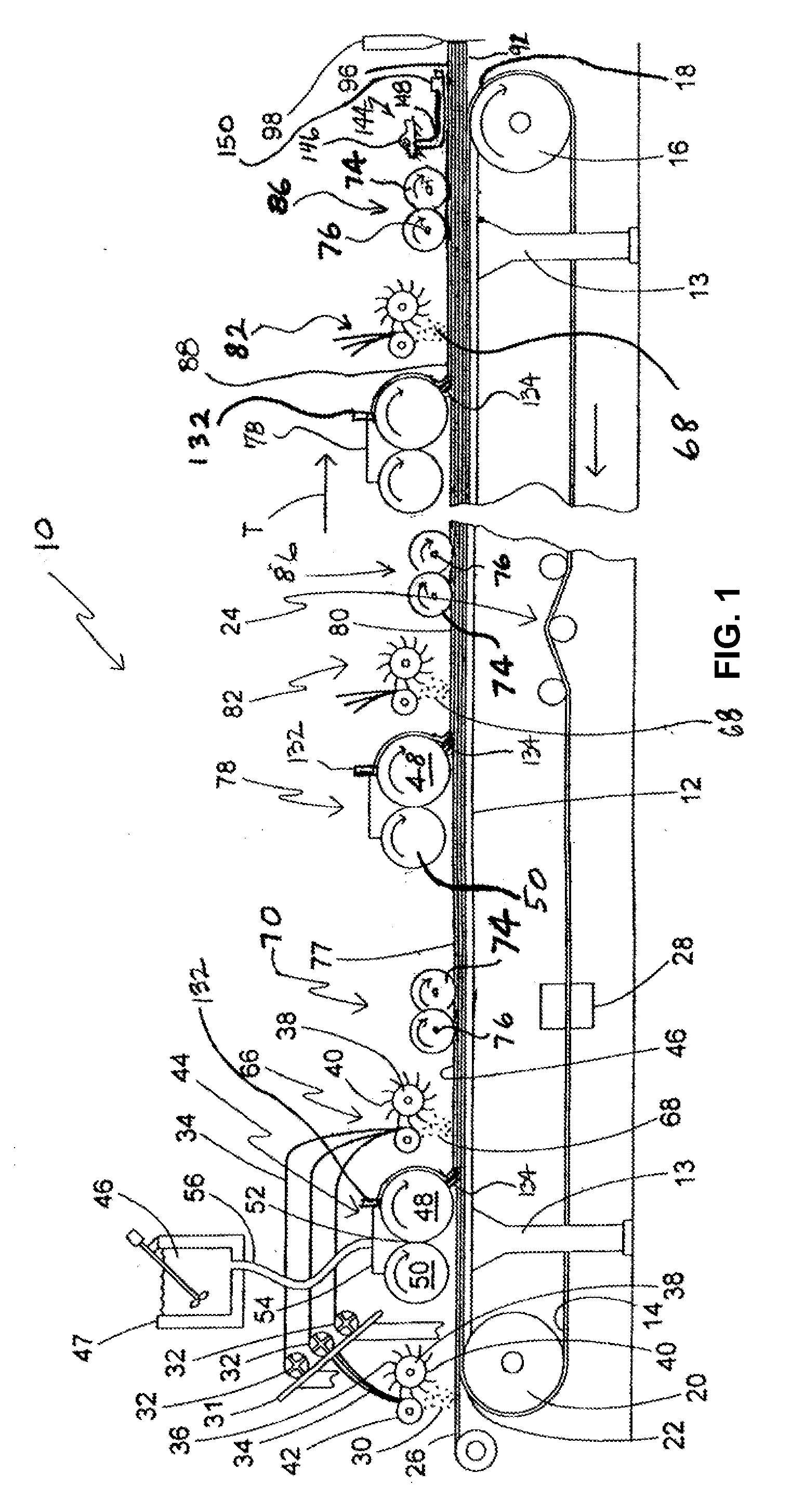

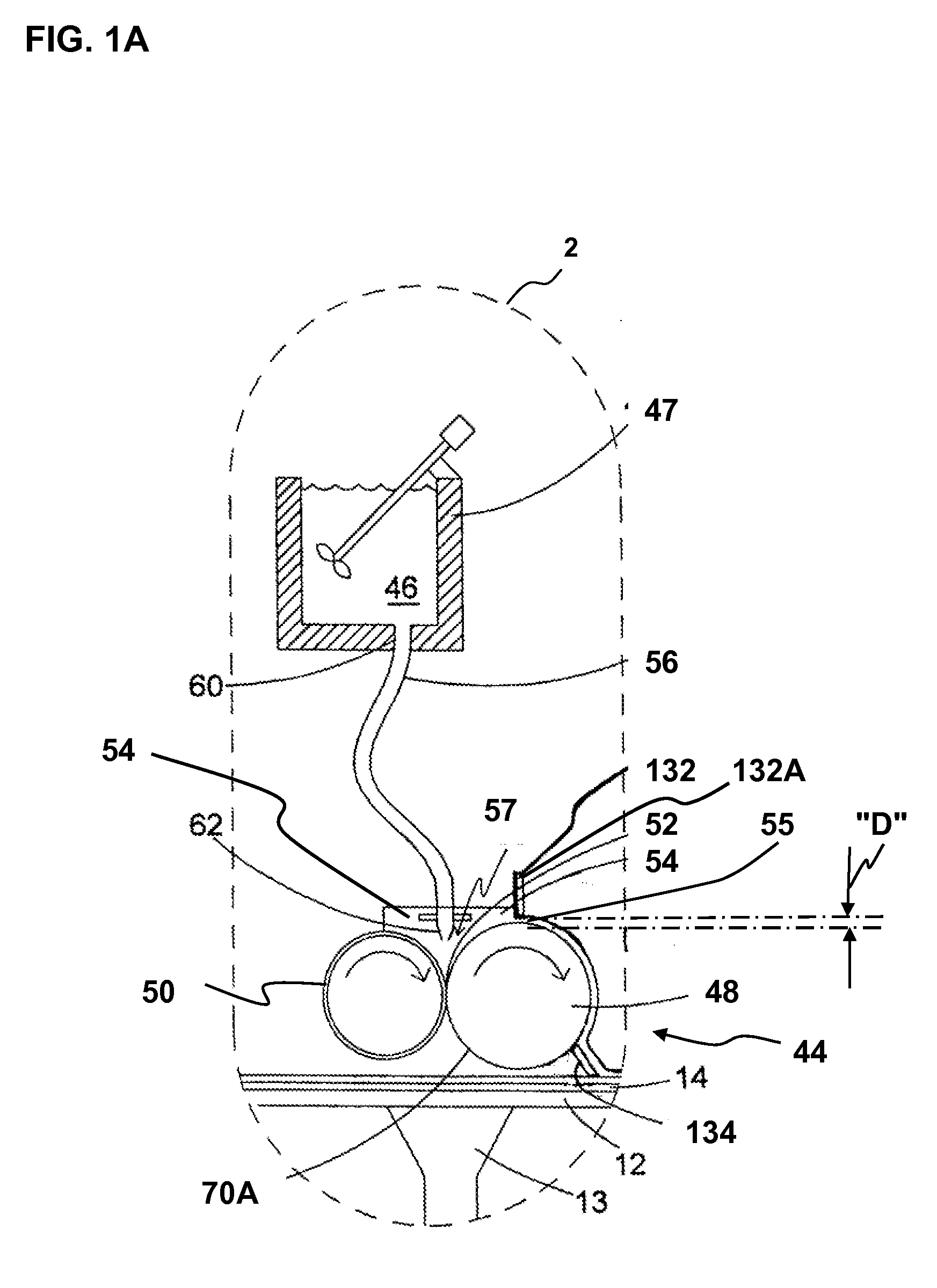

Concrete placement vehicle control system and method

ActiveUS20050004733A1Registering/indicating working of vehiclesRoad vehicles traffic controlControl systemVehicle control

A concrete placement vehicle. The concrete placement vehicle includes a concrete mixing and placement system, at least one vehicle sensor configured to monitor a characteristic of the concrete placement vehicle and at least one concrete system sensor configured to monitor a characteristic of the system for mixing and placing concrete. The vehicle further includes a control system configured to control the operation of the concrete placement vehicle and the concrete mixing and placement system based on inputs received from the at least one vehicle sensor and the at least one concrete system sensor.

Owner:OSHKOSH CORPORATION

Devices and methods for fluid mixing

InactiveUS6916113B2Shaking/oscillating/vibrating mixersFlow mixersMechanical engineeringMaterials science

Owner:AGILENT TECH INC

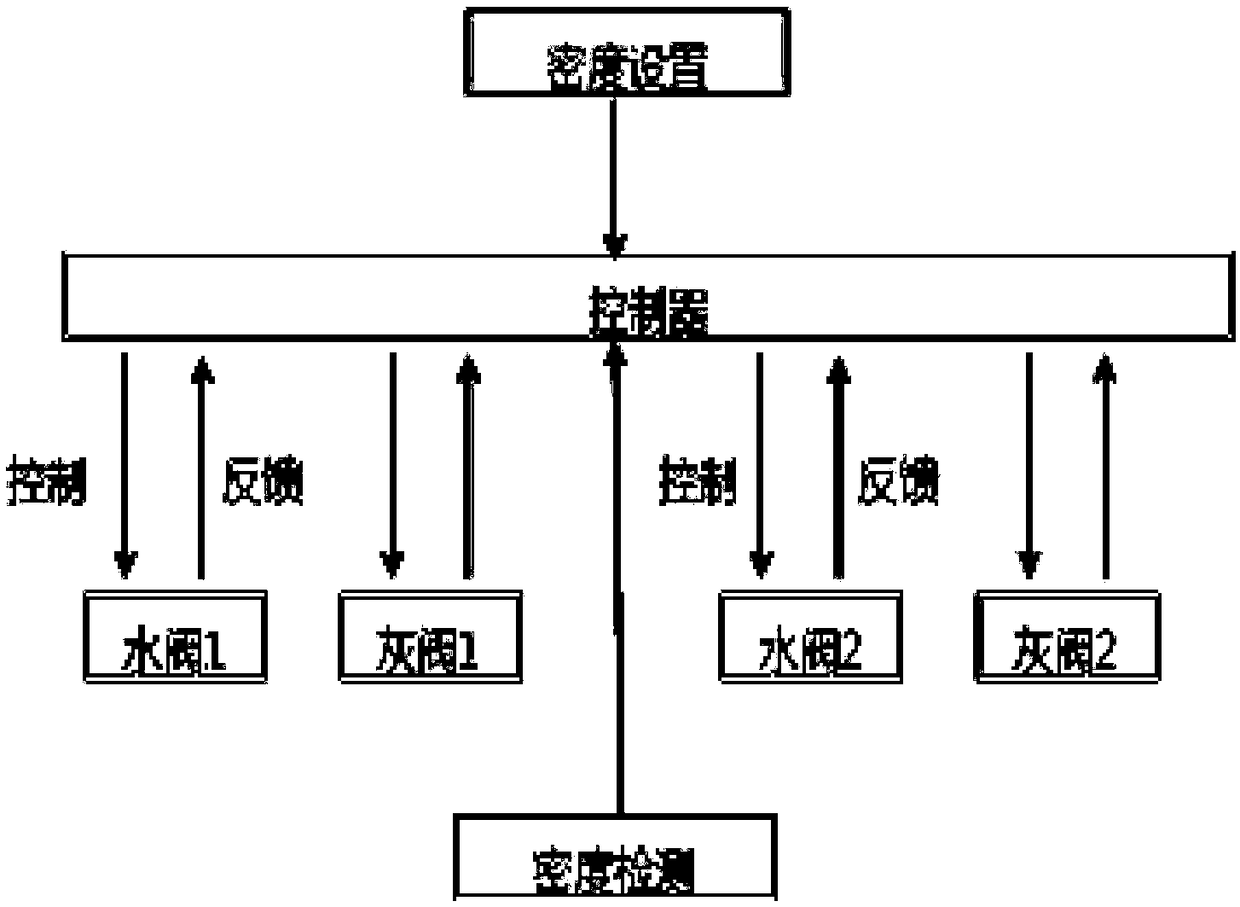

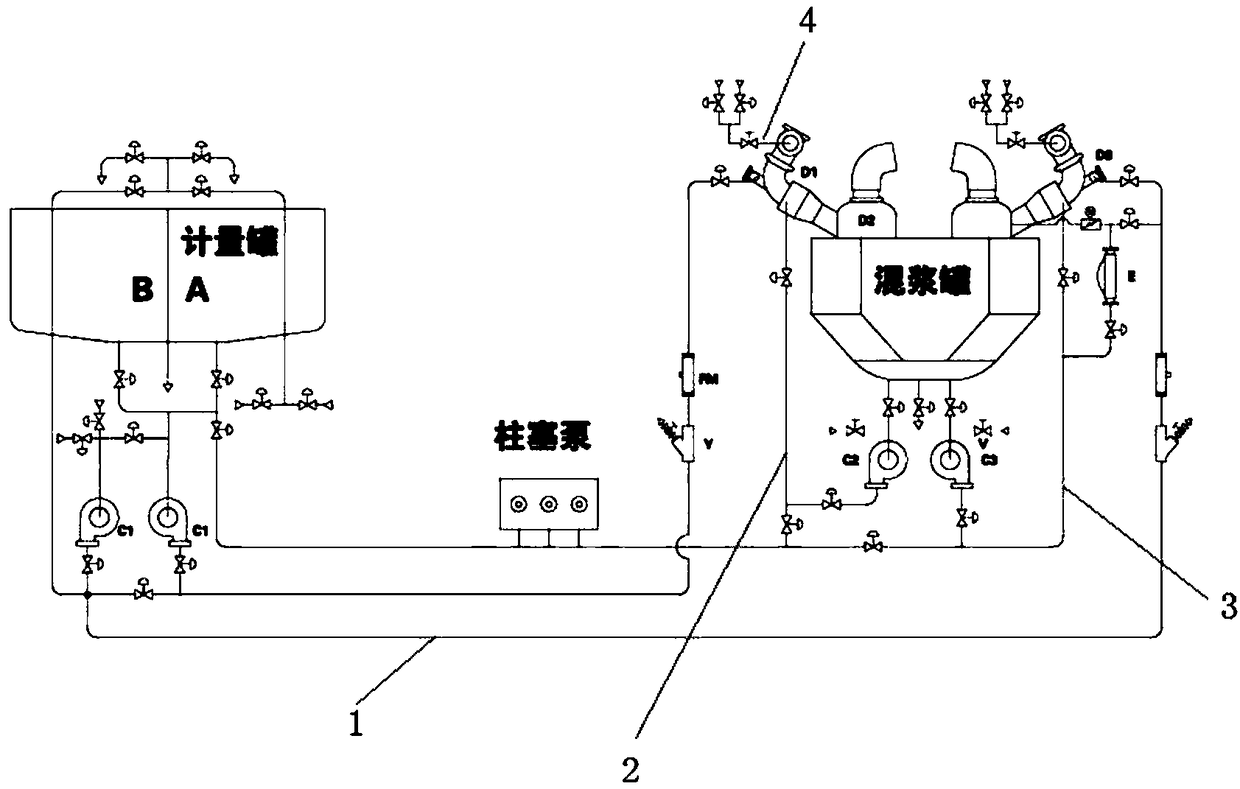

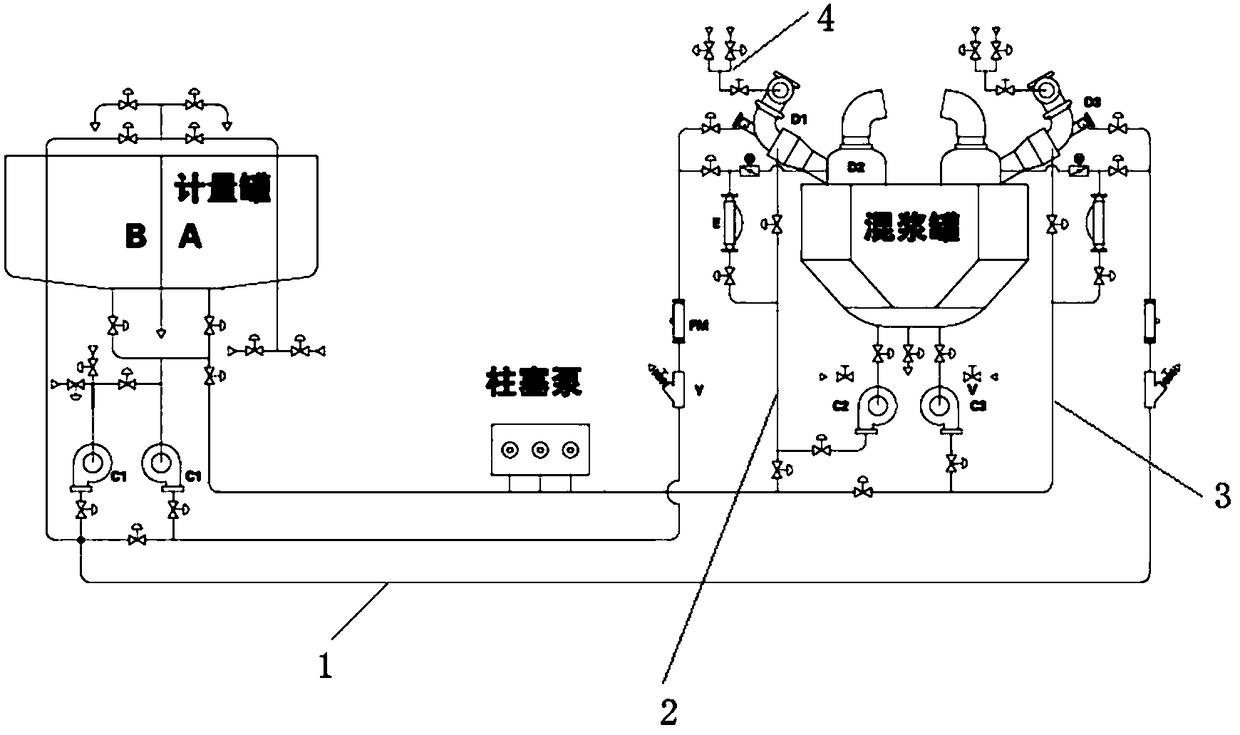

Efficient mixing system for well cementing operation

PendingCN108687954ARealize automatic controlEasy to operateCement mixing apparatusControl apparatusHybrid systemControl system

The invention relates to the technical field of petroleum equipment, in particular to an efficient mixing system for well cementing operation. The efficient mixing system comprises a measuring tank, aclear water manifold assembly, a cement grey feeding manifold assembly, high-energy mixers, a mud mixing tank and a mud manifold assembly. The mud mixing tank is at least connected with two high-energy mixers, and an inlet of the mud mixing tank is connected with diffusion boxes which are connected with the high-energy mixers. Discharged materials of the high-energy mixers are guided into the mudmixing tank through the diffusion boxes, and the at least one diffusion box is connected with a density control system. The multiple sets of mixers are integrated, and the large-discharge-capacity and efficient mixing effect can be achieved with existing operation conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

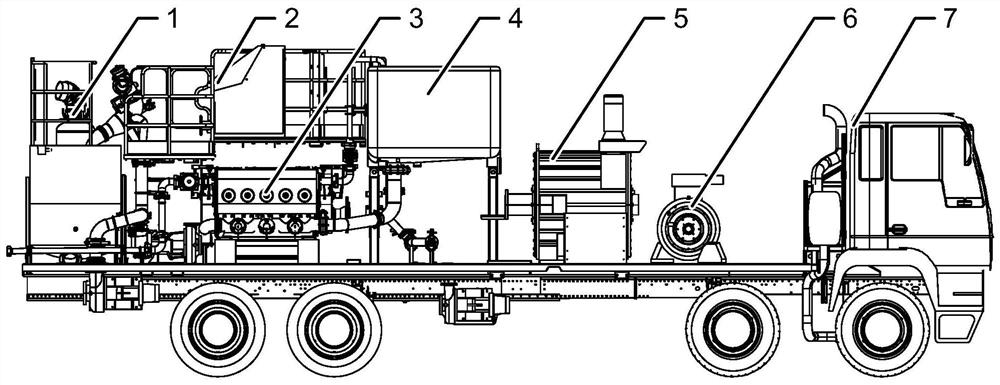

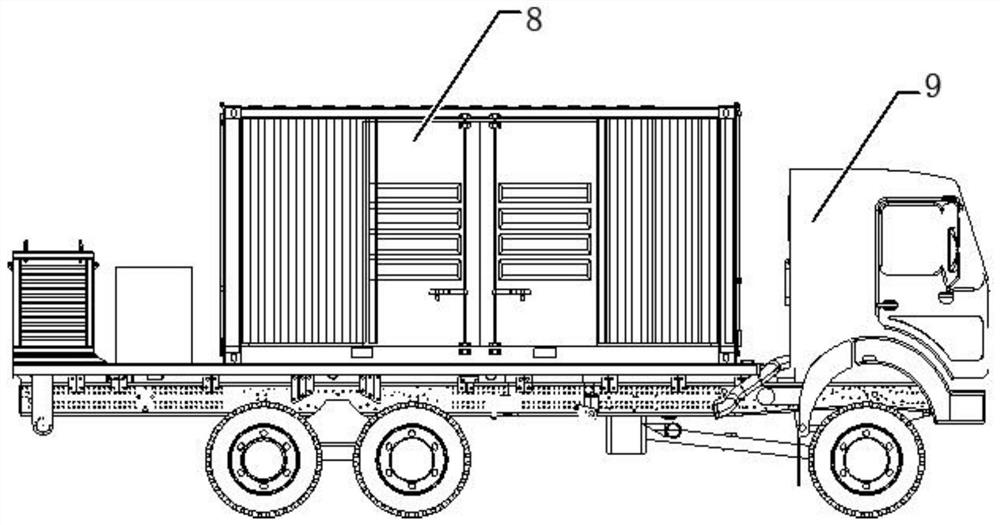

Electrically-driven ultra-large-displacement well cementation equipment

PendingCN111677476AIncrease layout spaceReduce dependenceDischarging apparatusPumpsConvertersFrequency changer

The invention discloses electrically-driven ultra-large-displacement well cementation equipment. The electrically-driven ultra-large-displacement well cementation equipment comprises a first loading body and a second loading body; an auxiliary motor, a main motor, a clear water module, a pumping module, a control module, a hydraulic module and a mixing module are fixedly loaded on the first loading body; and a frequency converter module is fixedly loaded on the second loading body. The electrically-driven ultra-large-displacement well cementation equipment has the beneficial effects that the main motor is adopted to drive a plunger pump, torque converters are reduced, the layout space of the whole vehicle is increased, the auxiliary motor is adopted to drive a whole vehicle hydraulic system, and the number of driving motors is reduced; the frequency converter module and the well cementation equipment are loaded separately, the loading requirement is lowered, the structure is simpler, the occupied space is reduced, one frequency converter module can supply power to all the modules on the multiple first loading bodies at the same time, and use is flexible; and the main motor, the auxiliary motor and the hydraulic heat dissipation device are intensively distributed on the front portion of the first loading body, wiring is simple, connection is convenient, heat dissipation of equipment is intensively achieved, scalding accidents of workers in the operation process are avoided, and operation safety is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

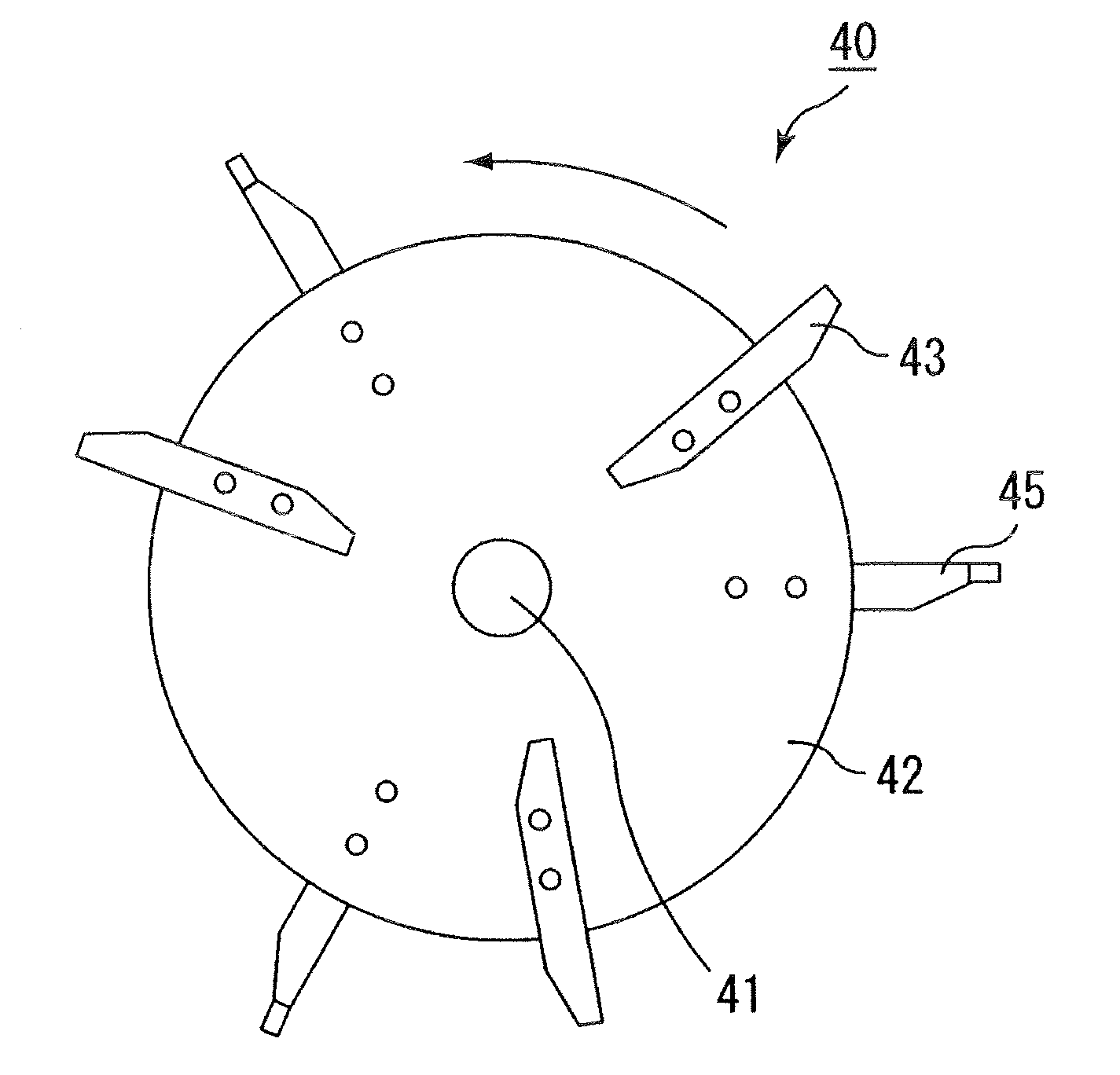

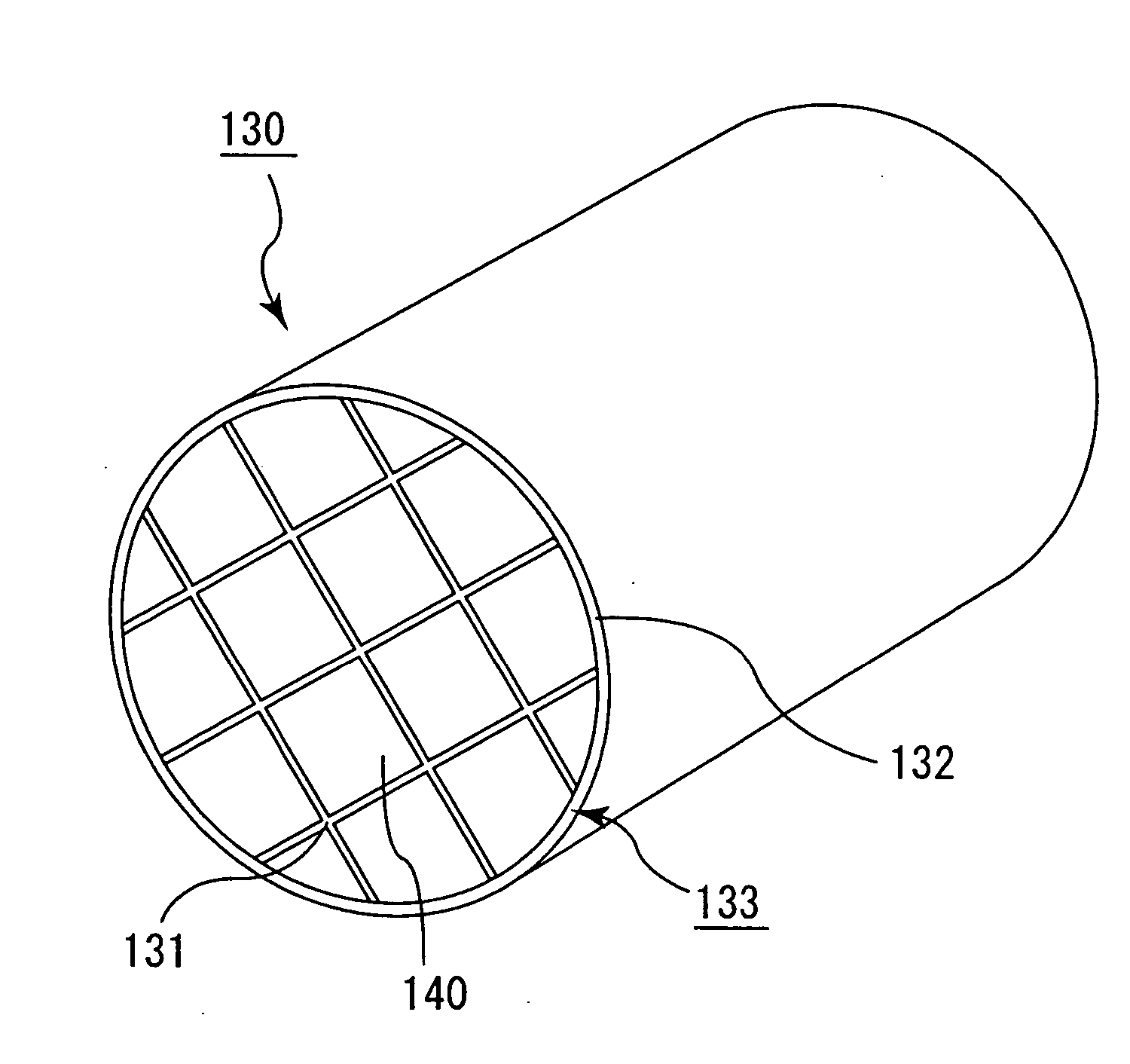

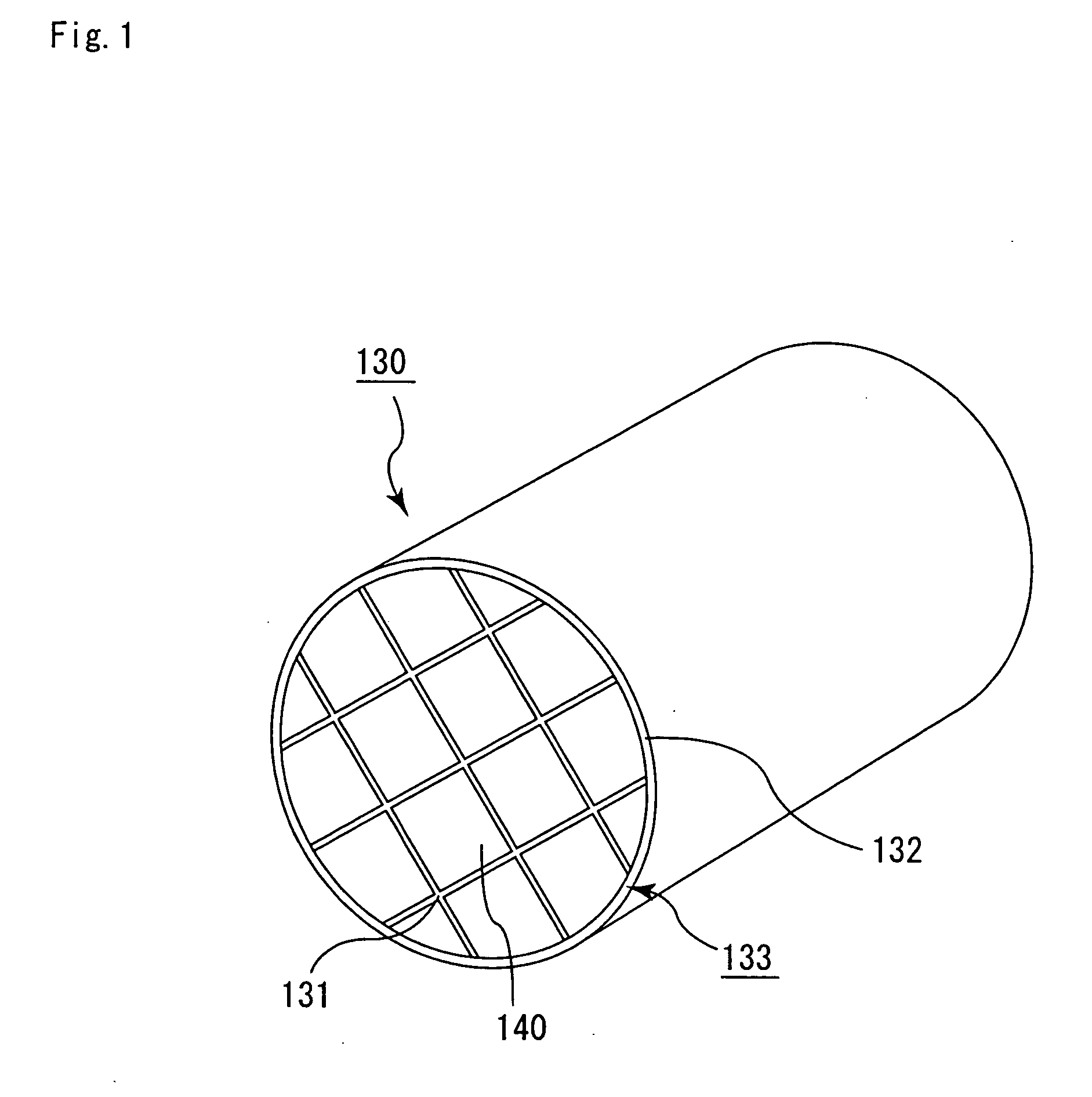

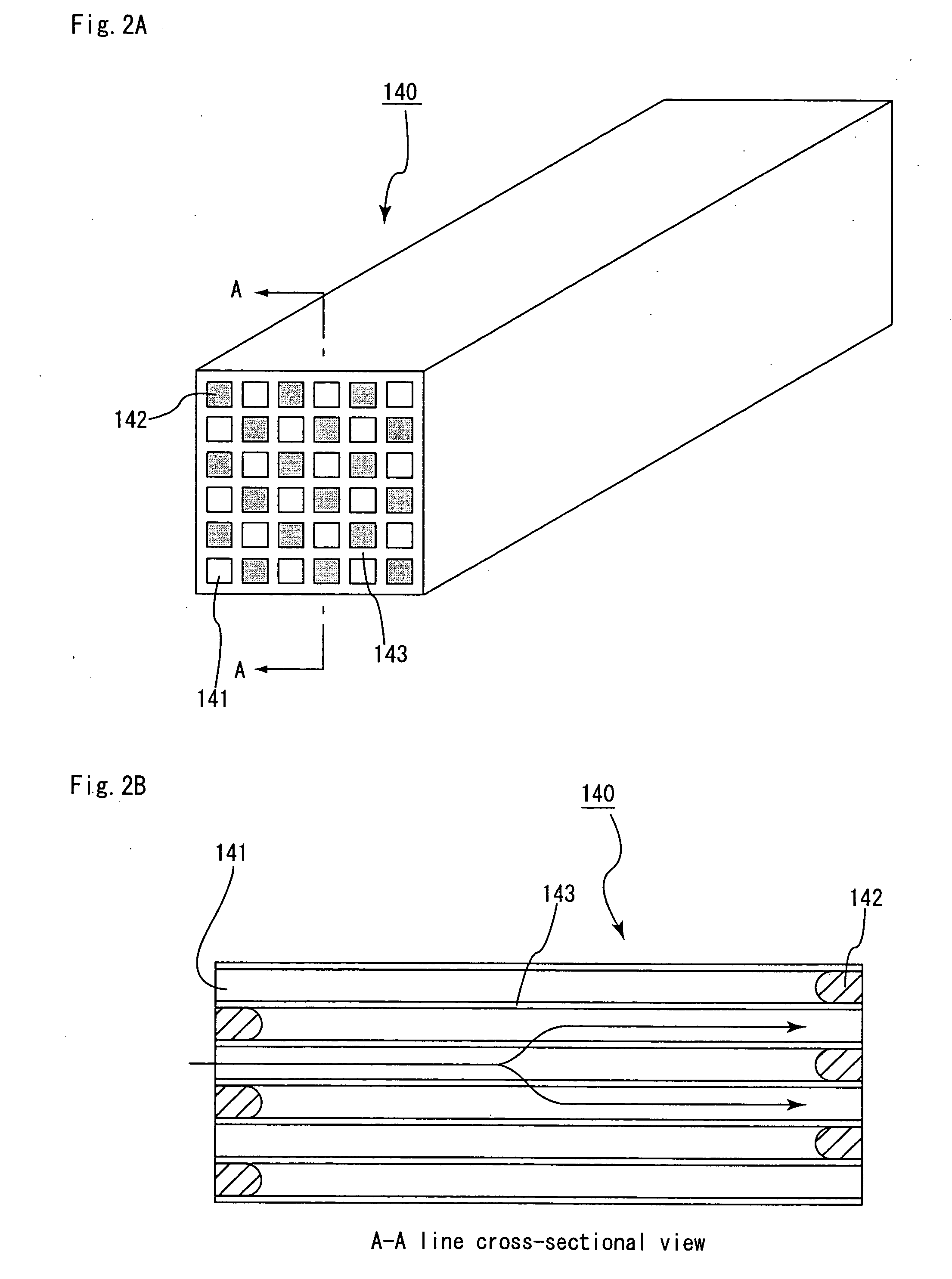

Wet mixing apparatus, wet mixing method and method for manufacturing honeycomb structure

A wet mixing apparatus includes a disc and a casing. The disc has a circular plate-shaped structure, is equipped with a vertically placed rotary shaft member as a central axis and has a plurality of agitation blades provided on a side face of the disc. The casing is provided with a raw material feeding port and a mixture discharging port. The raw material feeding port is disposed above the disc and the mixture discharging port is disposed below the disc.

Owner:IBIDEN CO LTD

Method and apparatus for acoustically controlling liquid solutions in microfluidic devices

InactiveUS20100124142A1Improve reaction speedAccelerating molecular interactionSequential/parallel process reactionsShaking/oscillating/vibrating mixersSound sourcesAcoustic energy

Acoustic energy is used to control motion in a fluid. According to one embodiment, the invention directs acoustic energy at selected naturally occurring nucleation features to control motion in the fluid. In another embodiment, the invention provides focussed or unfocussed acoustic energy to selectively placed nucleation features to control fluid motion. According to one embodiment, the invention includes an acoustic source, a controller for controlling operation of the acoustic source, and one or more nucleation features located proximate to or in the fluid to be controlled.

Owner:COVARIS INC

Cementitious composites having wood-like properties and methods of manufacture

InactiveUS20080099122A1Harder to saw, nail or screwLow densityPlastic recyclingLaminationPorosityBuilding product

A method of manufacturing a cementitious composite includes: (1) forming mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) causing or allowing the hydraulic cement to hydrate to form the cementitious composite. Such a process yields a cementitious composite that is suitable for use as a wood substitute. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

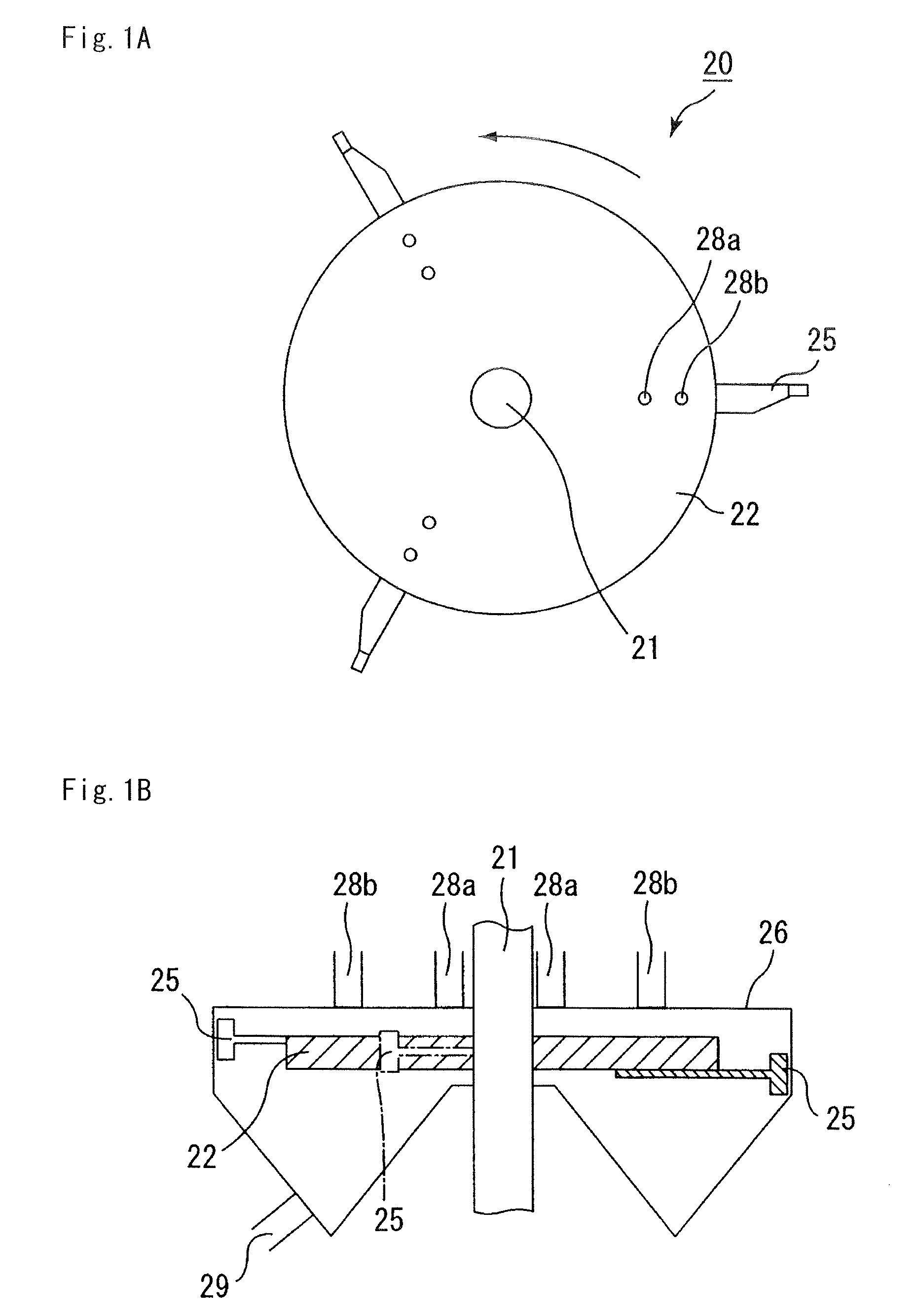

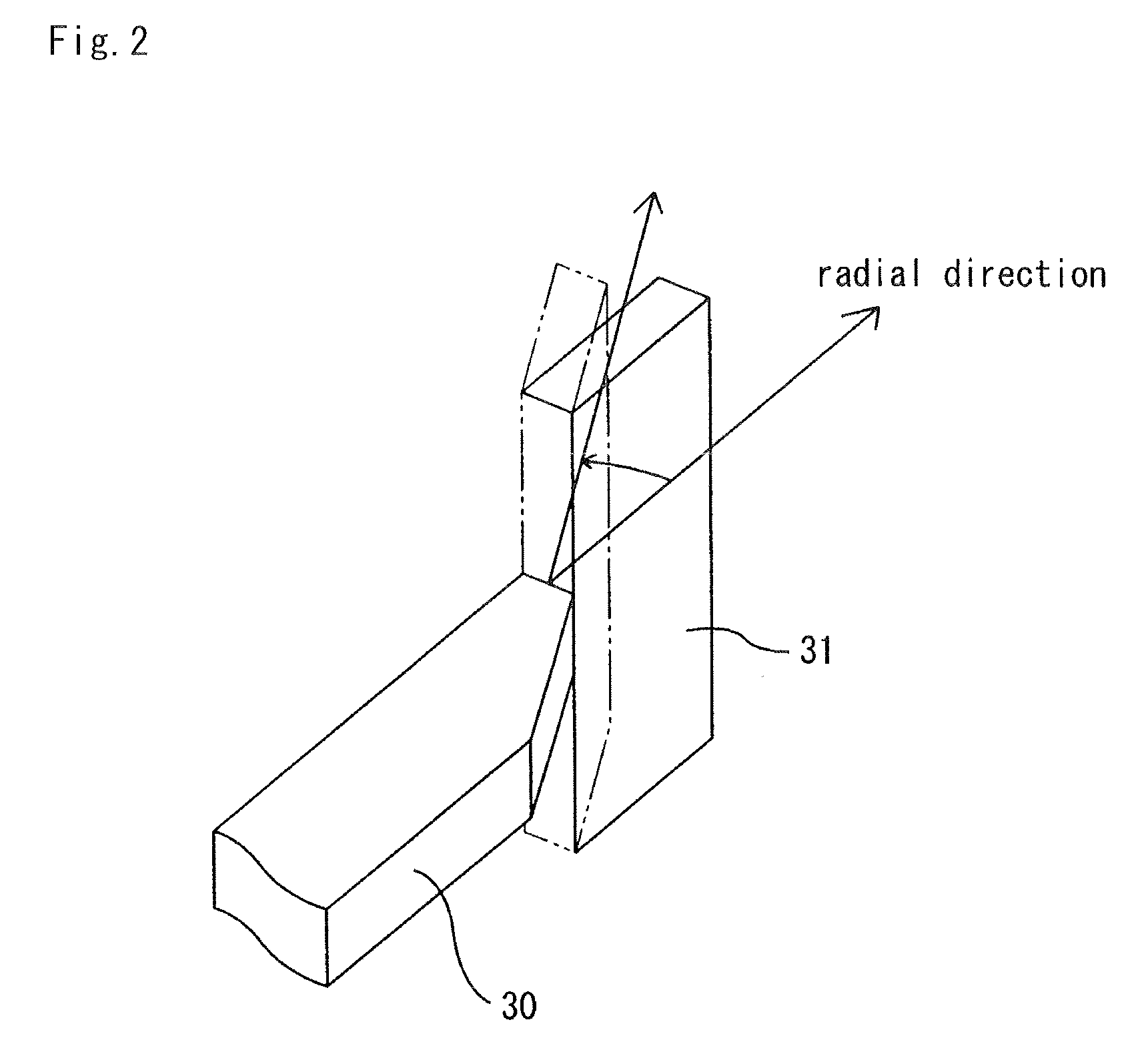

Method for mixing powder, agitation apparatus, and method for manufacturing honeycomb structured body

InactiveUS20070187651A1High hardnessRotary stirring mixersTransportation and packagingHardnessHoneycomb structure

A method for mixing powder according to the present invention is a method for mixing powder by conducting mixing and transporting of at least one kind of powder, comprising: charging said at least one kind of powder into an agitation apparatus; and translating said at least one kind of powder while mixing the powder by rotating an agitation shaft of said agitation apparatus, said agitation apparatus comprising: a screw comprised of the agitation shaft and an agitating blade, said screw configured to rotate along with the said agitation shaft as the center; and, a casing surrounding said screw, wherein either the entire body of said agitating blade is formed of a high hardness member, or, a high hardness coat layer is formed onto at least a portion of said agitating blade.

Owner:IBIDEN CO LTD

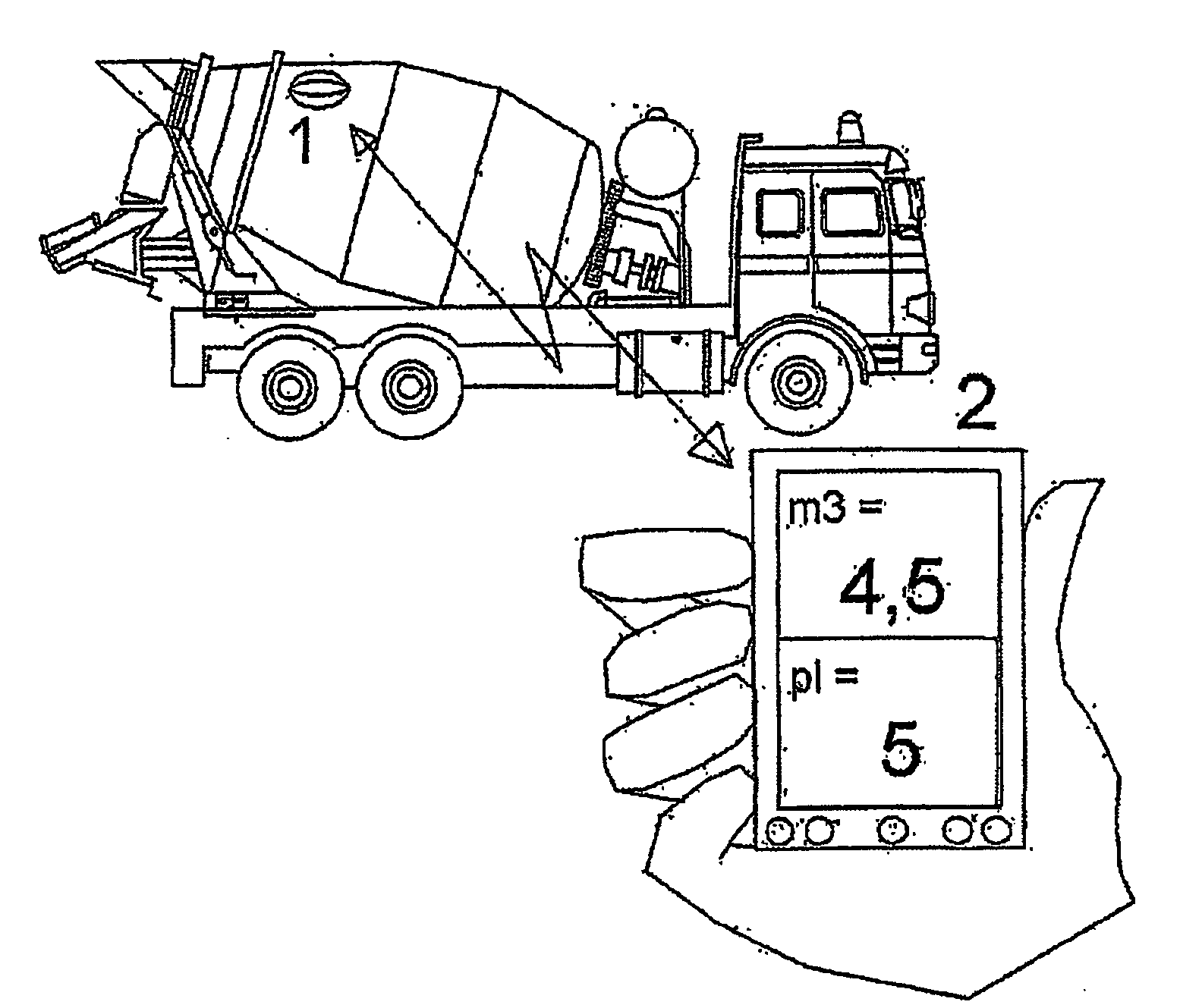

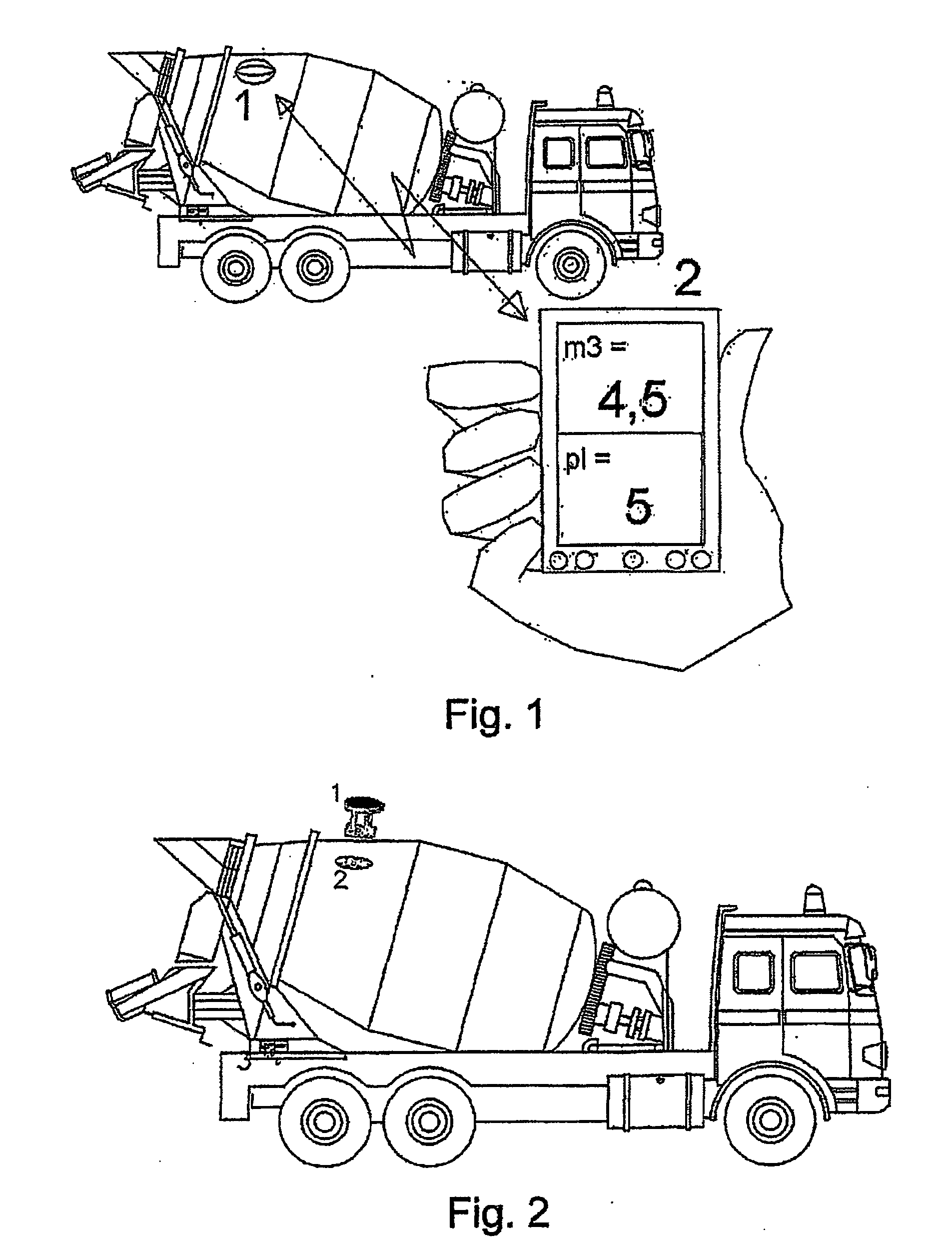

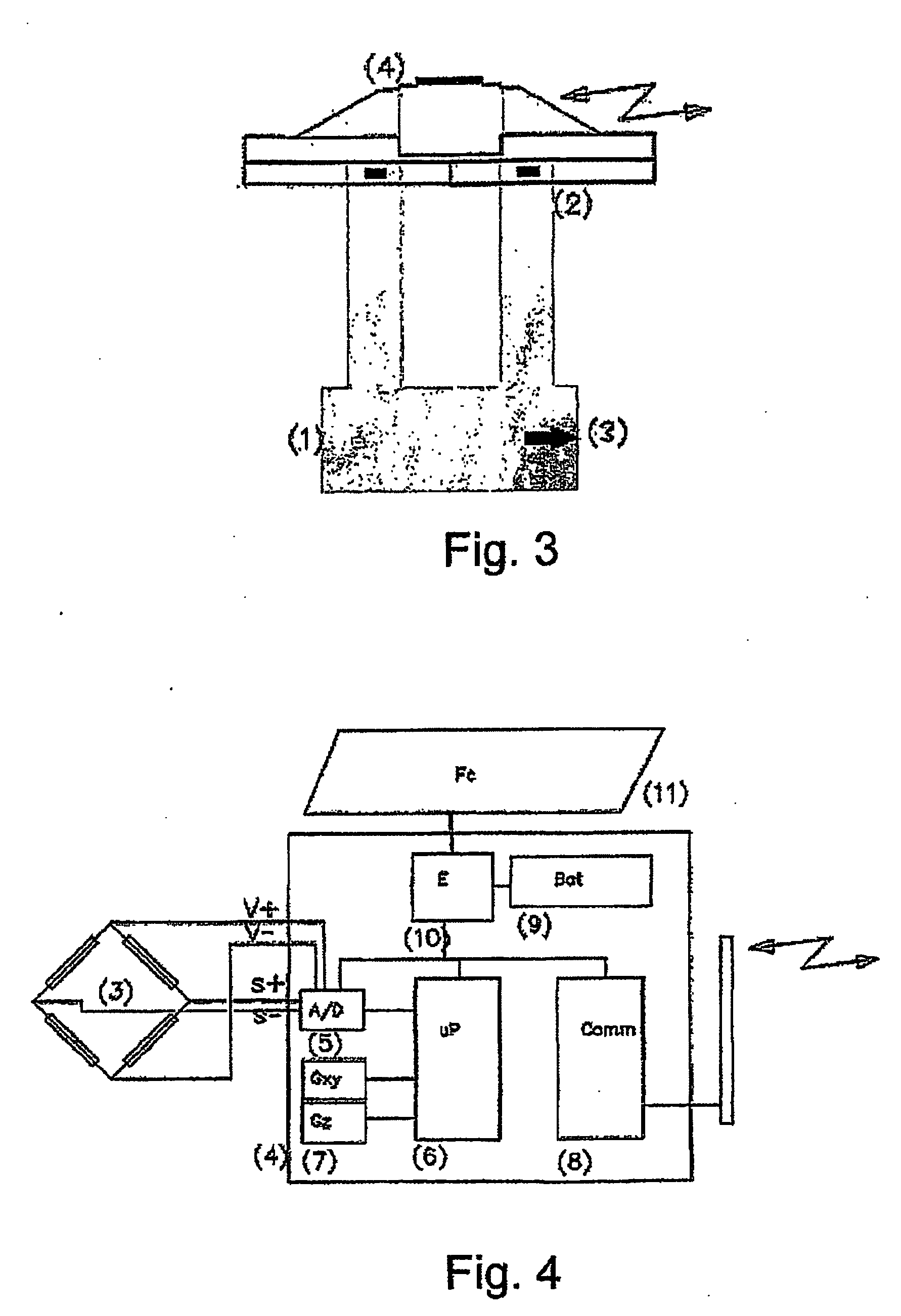

Automatic System for Monitoring the Mixing of Conglomerates

ActiveUS20090171595A1Force measurementAcceleration measurementTelecommunications equipmentBLENDER/MIXER

The invention relates to an automatic system for monitoring the mixing of conglomerates. The inventive system can be used to monitor and measure the volume of a conglomerate, i.e. a concrete, mortar or other similar product, and the conditions in which the conglomerate is being mixed inside a mixer. The invention is characterised in that the system is provided with a sensor which rotates integrally with the mixer and which is fitted with a blade that is sensitive to the stresses exerted by the conglomerate thereon. The invention is also characterised in that the aforementioned information is transmitted to one or more terminals, by means of radio communication or other similar wireless communication means, for use in industrial processes.

Owner:OZAMIZ TAPIA ANTONIO +1

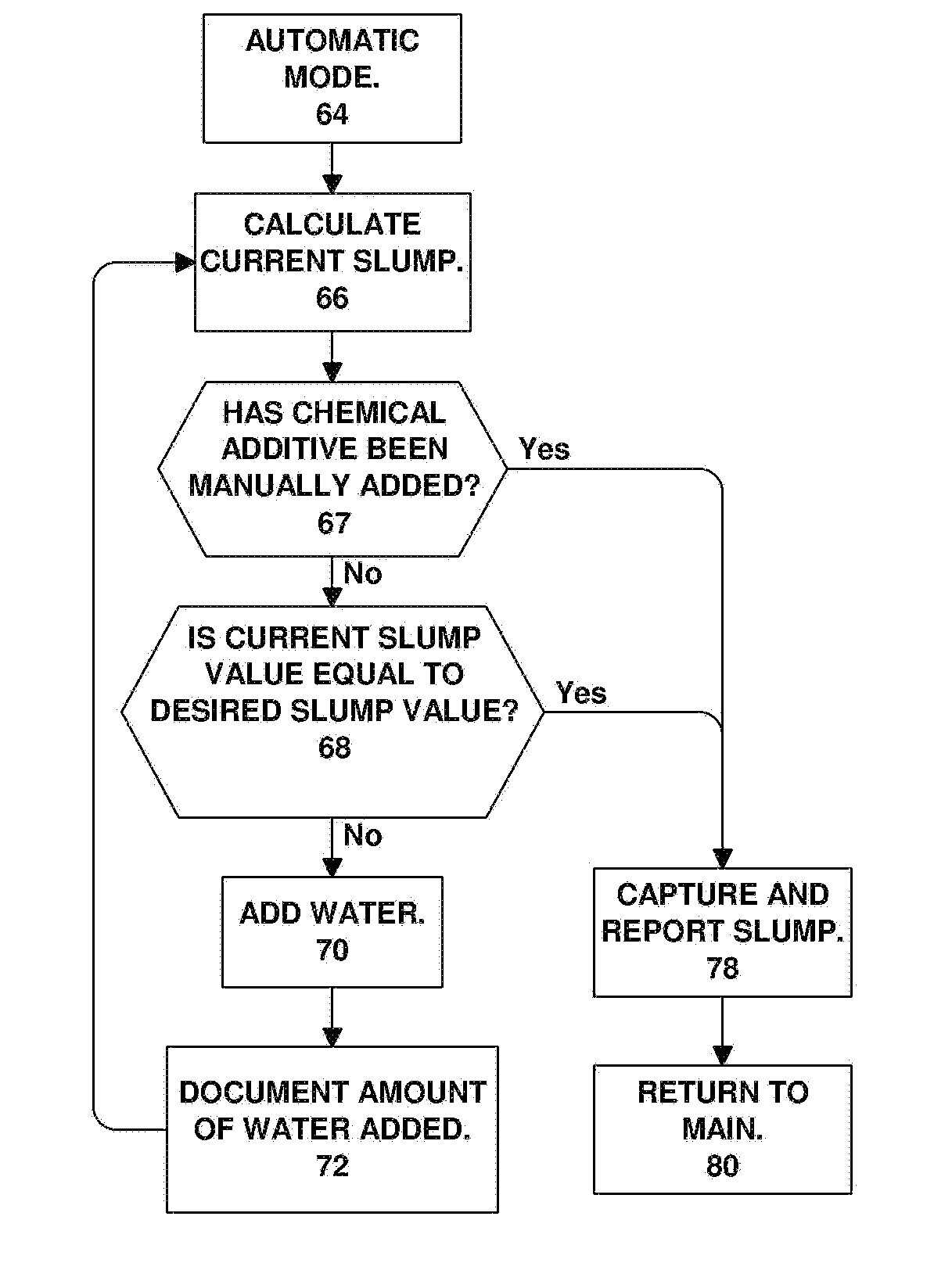

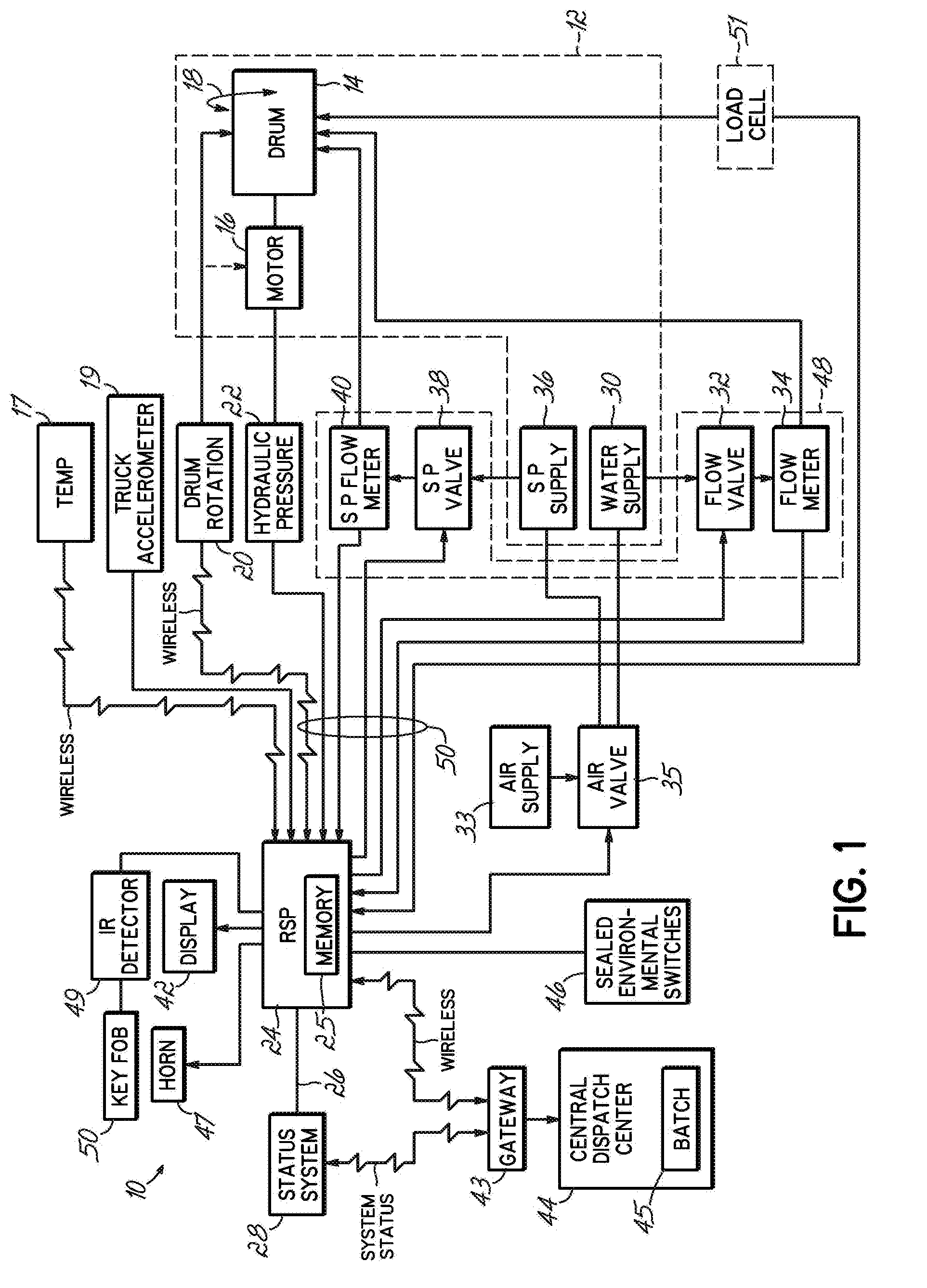

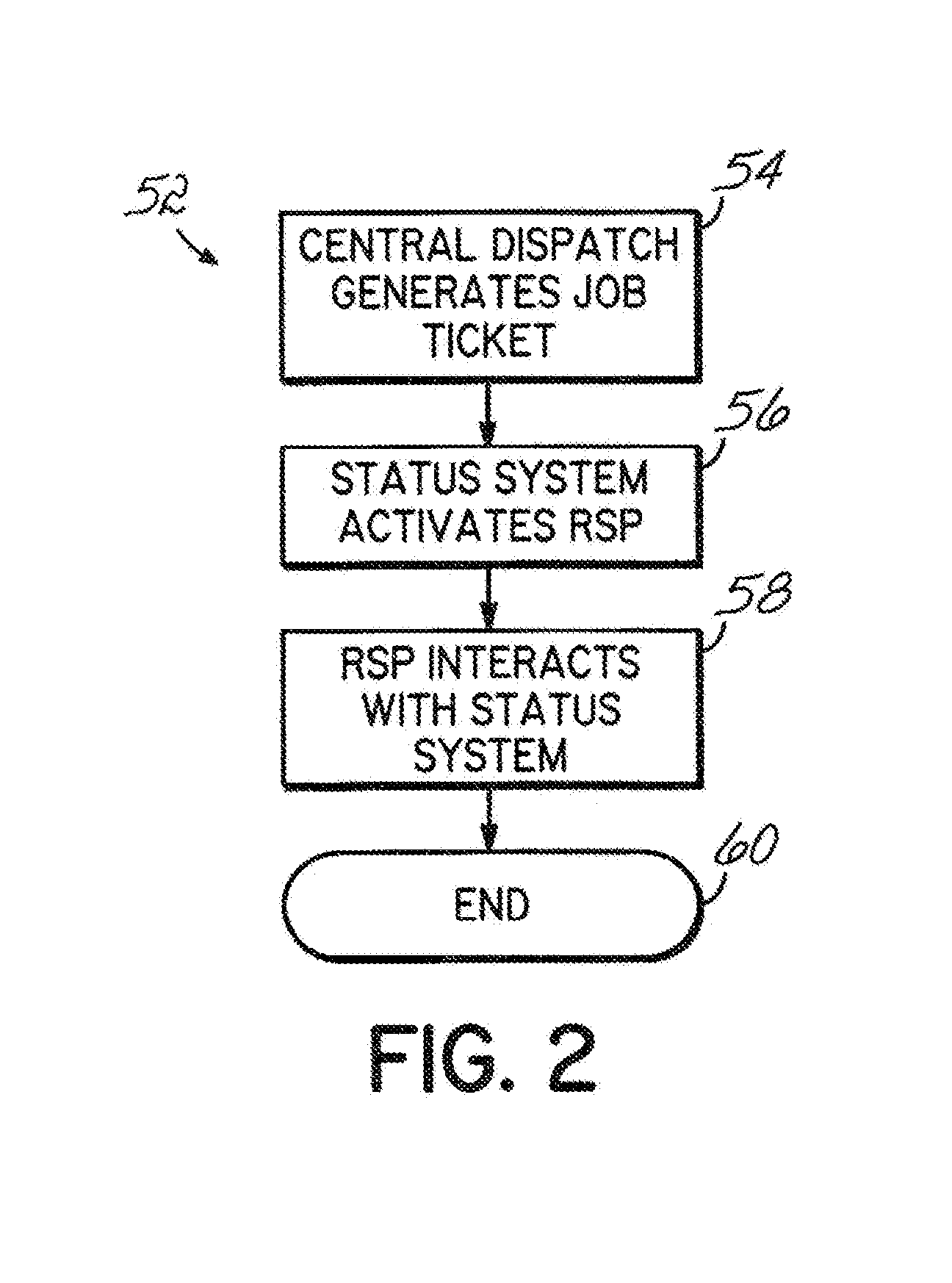

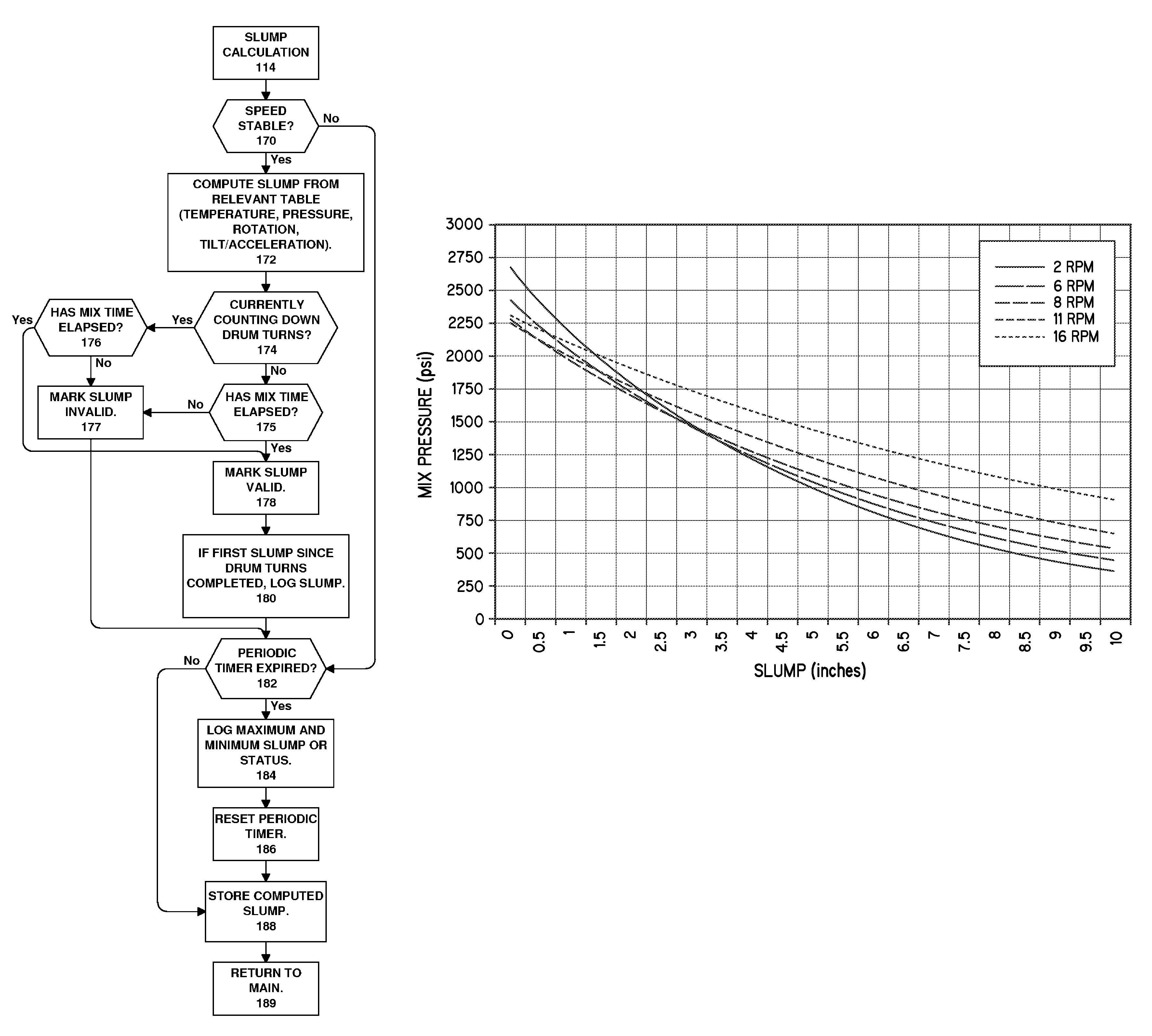

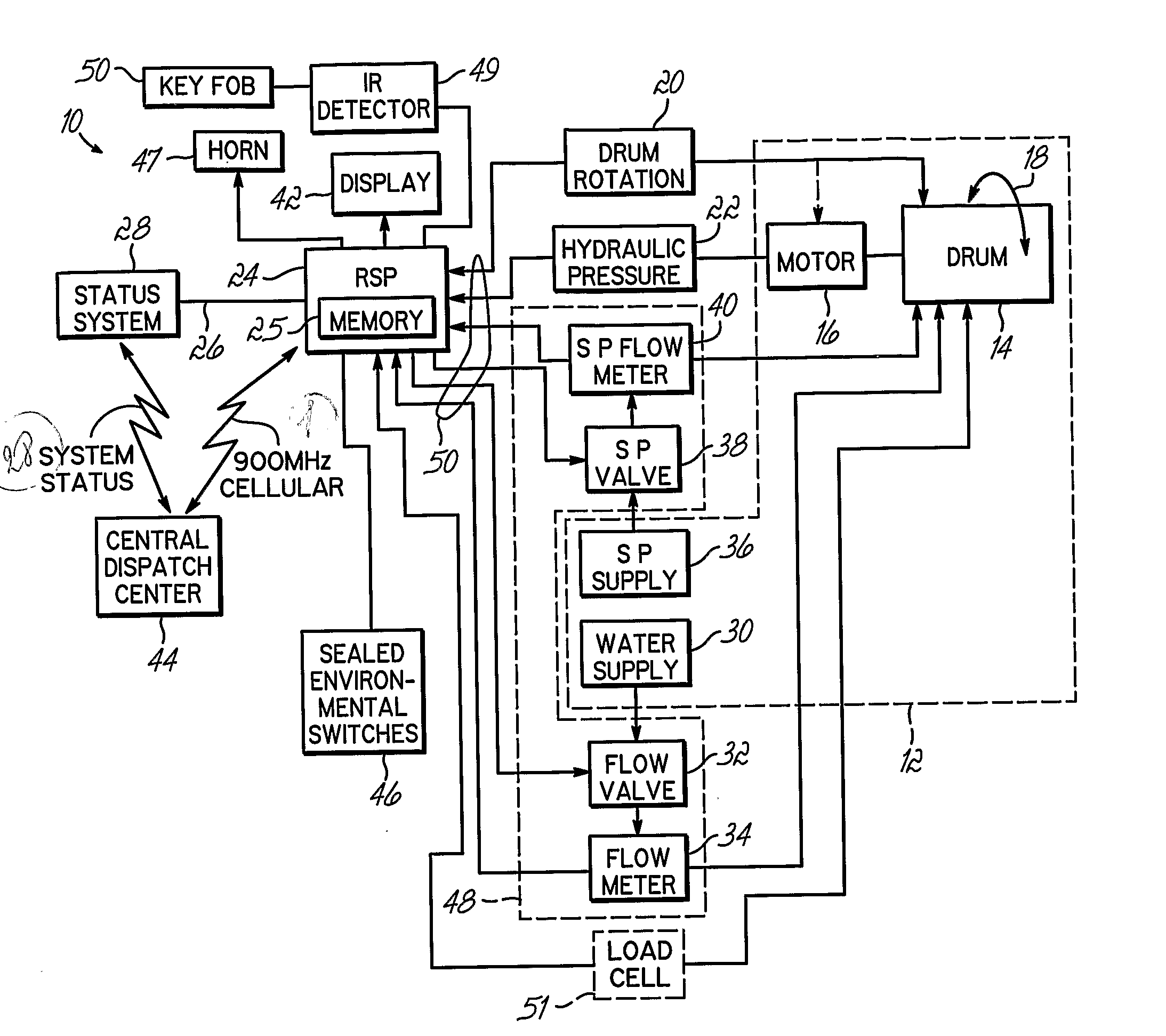

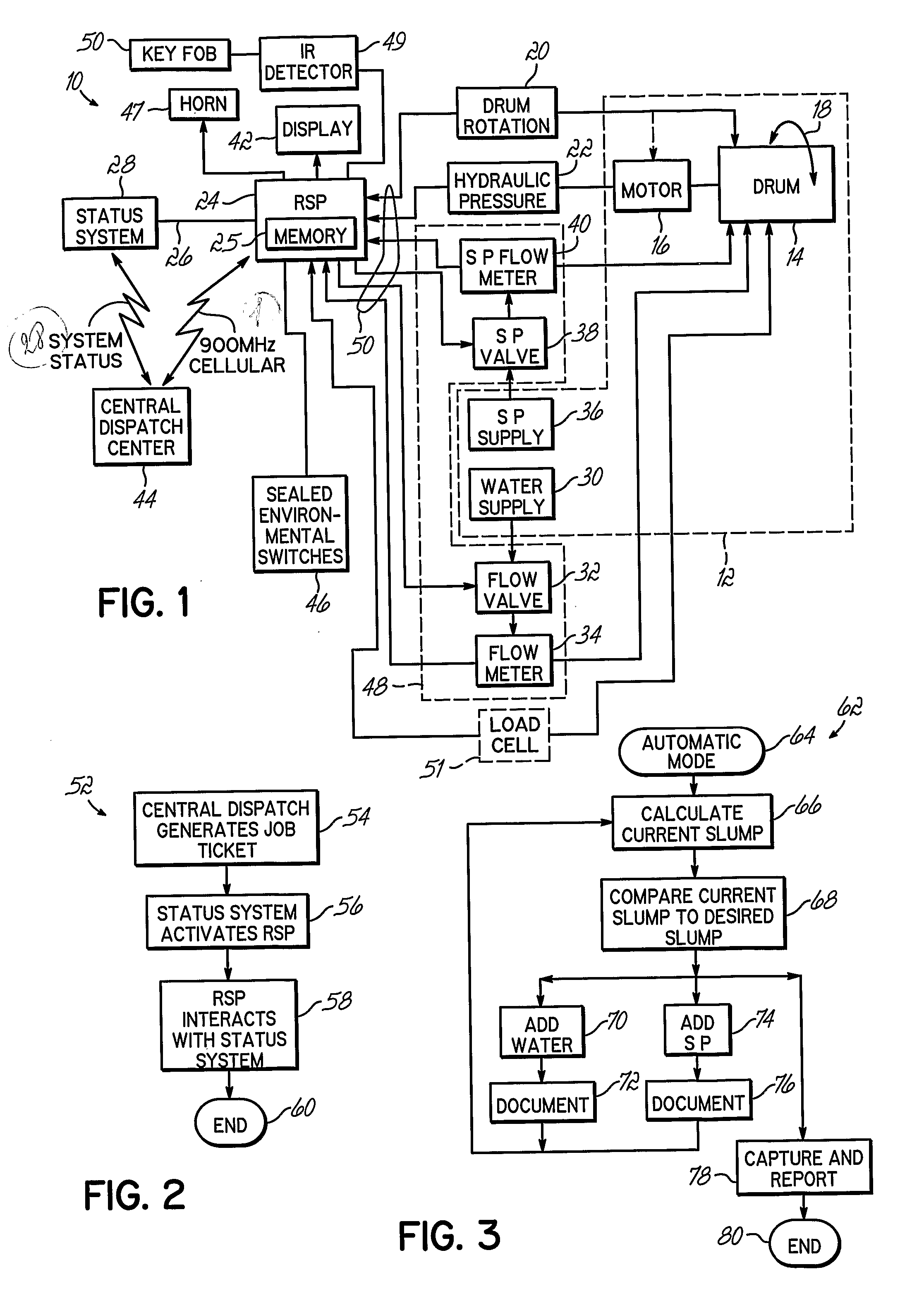

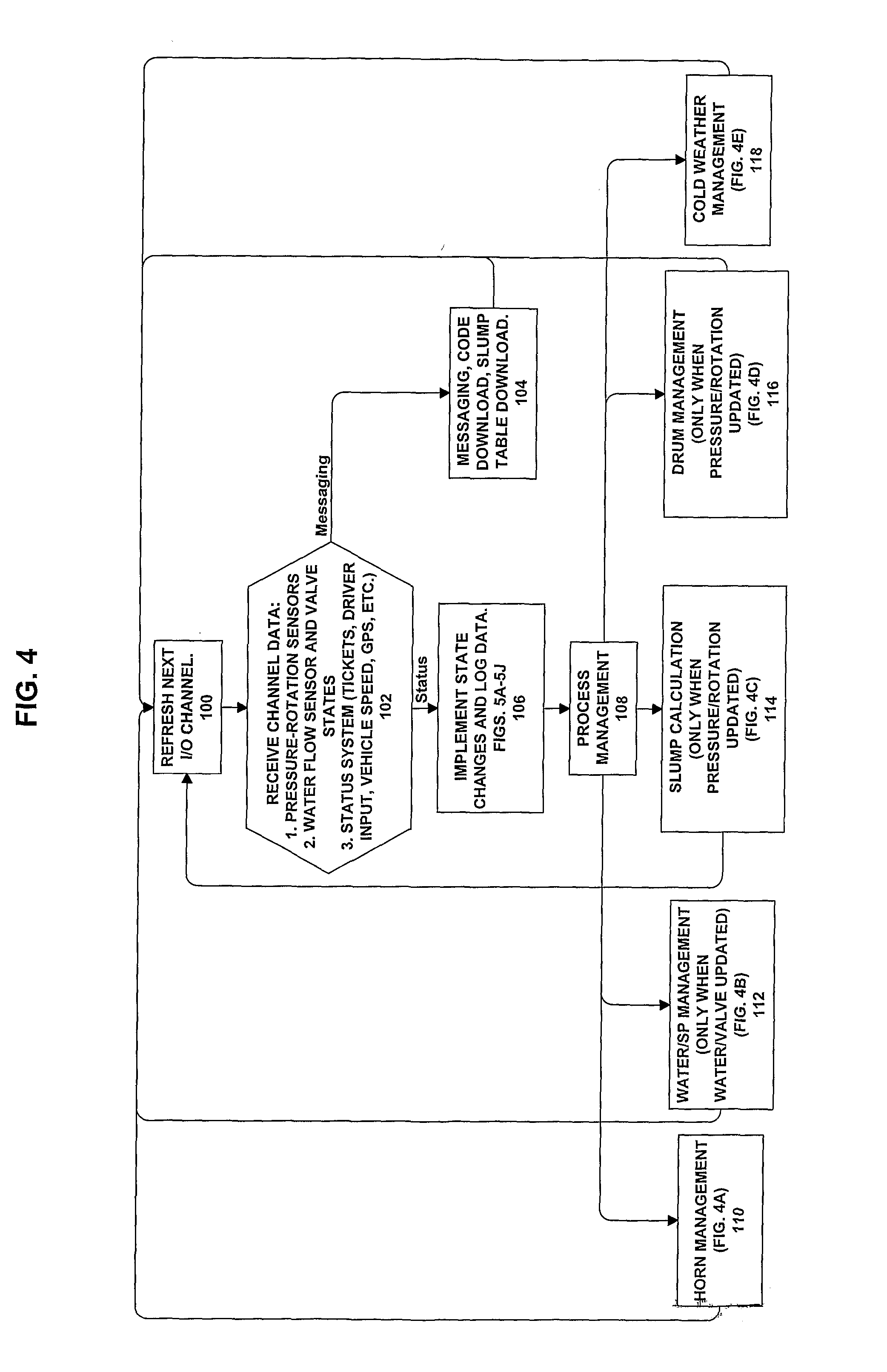

Method and System for Calculating and Reporting Slump in Delivery Vehicles

ActiveUS20090037026A1Easy to useThermometer detailsSampled-variable control systemsDelivery vehicleCold weather

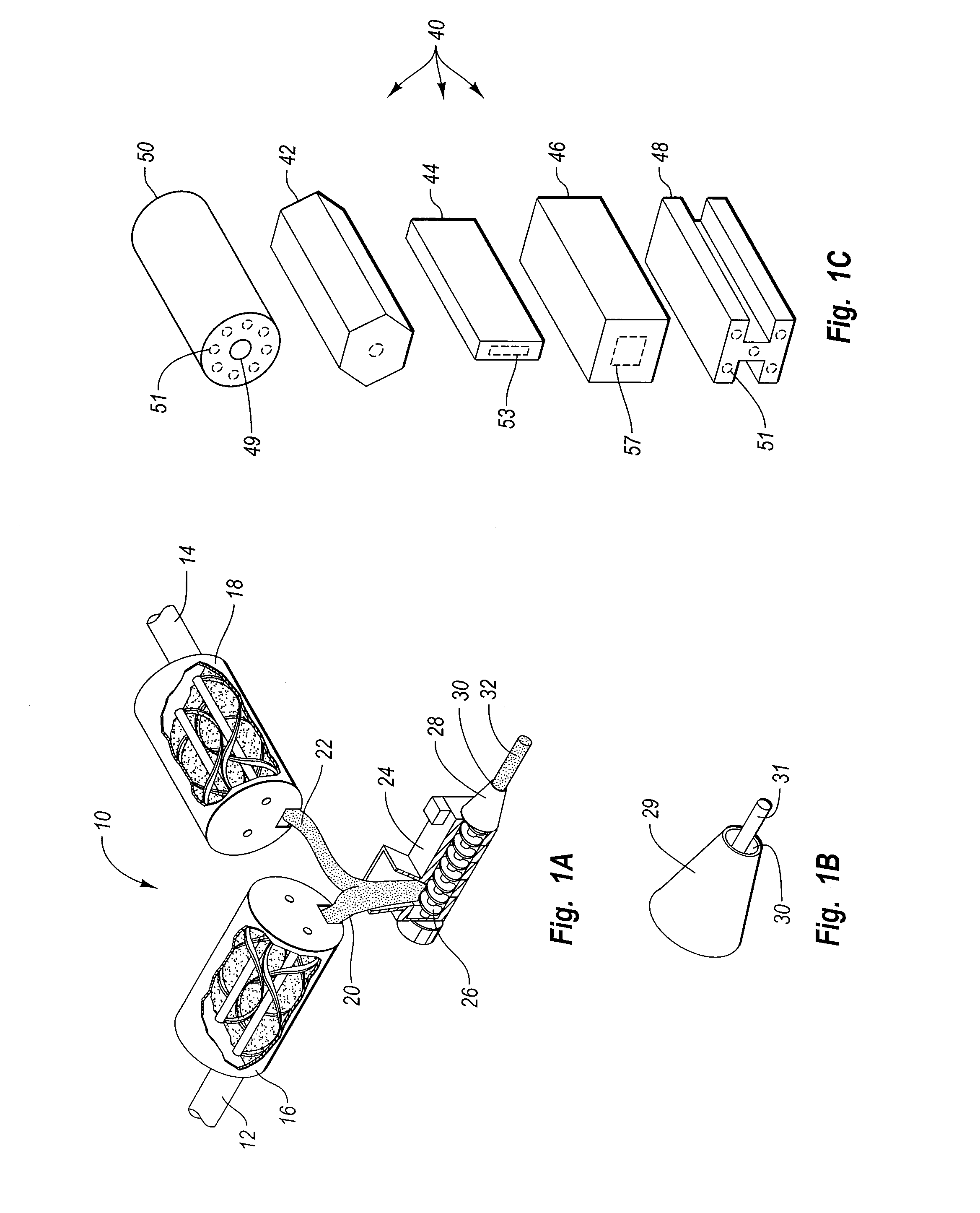

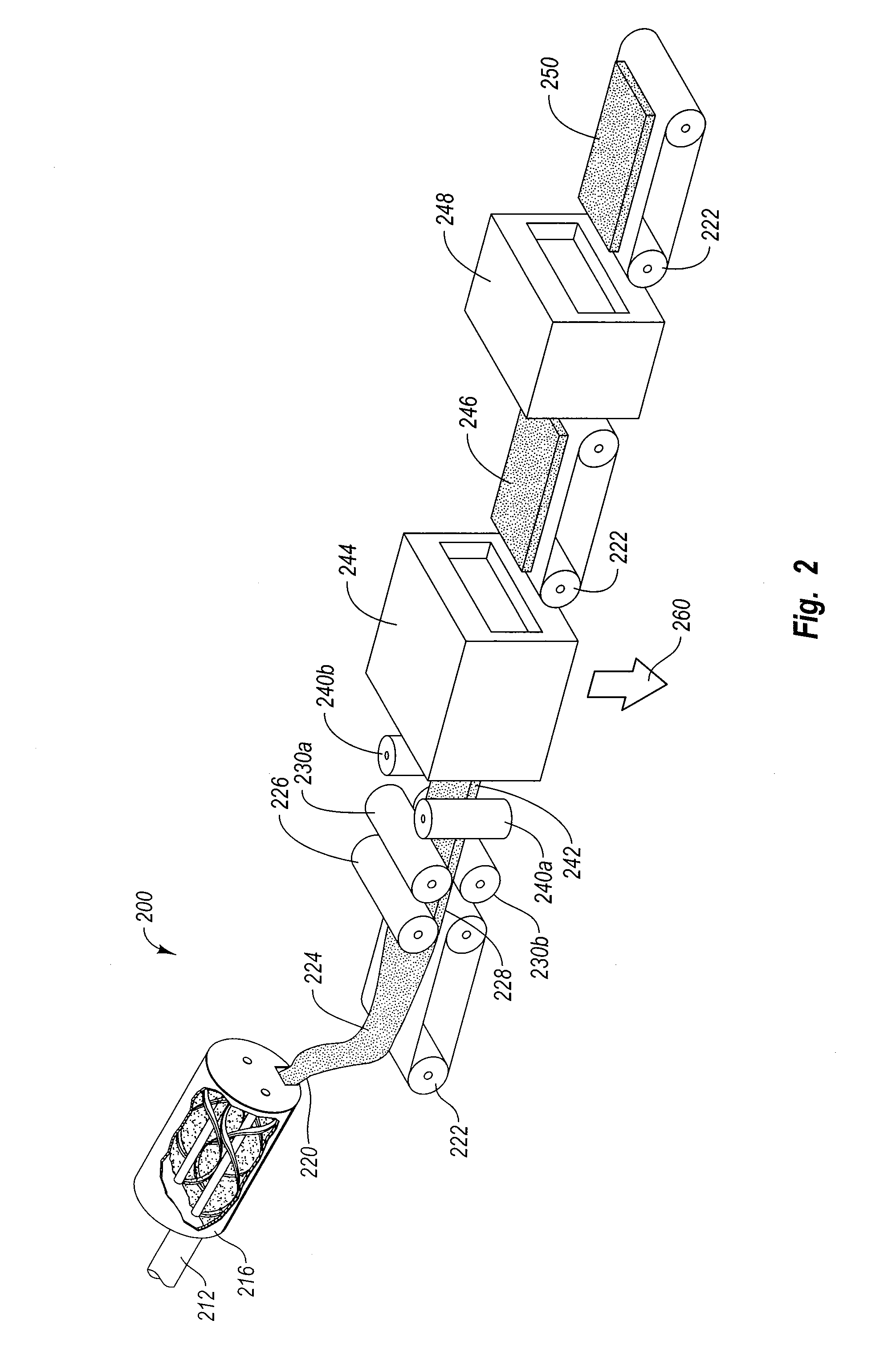

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI

Method and system for calculating and reporting slump in delivery vehicles

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI INC

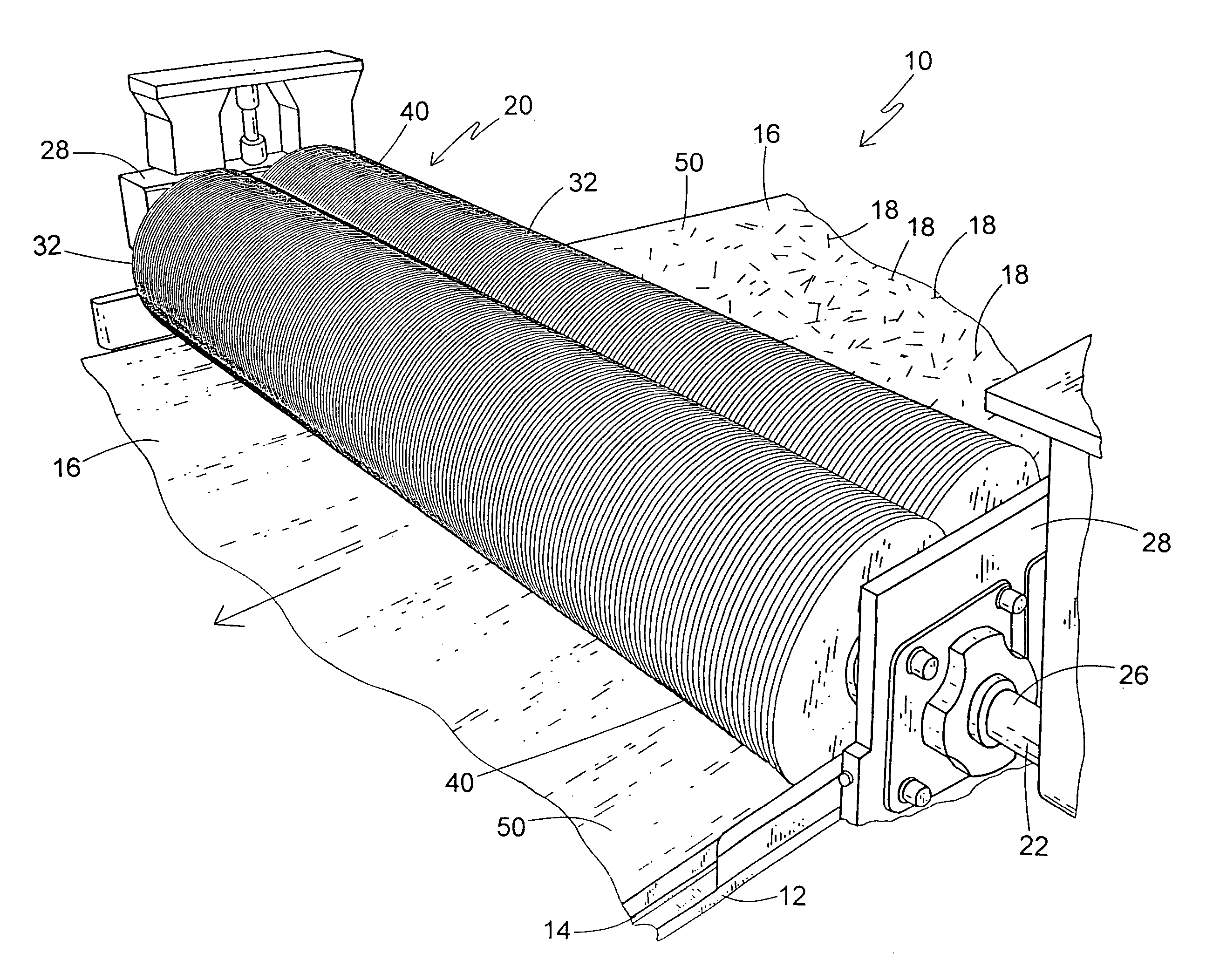

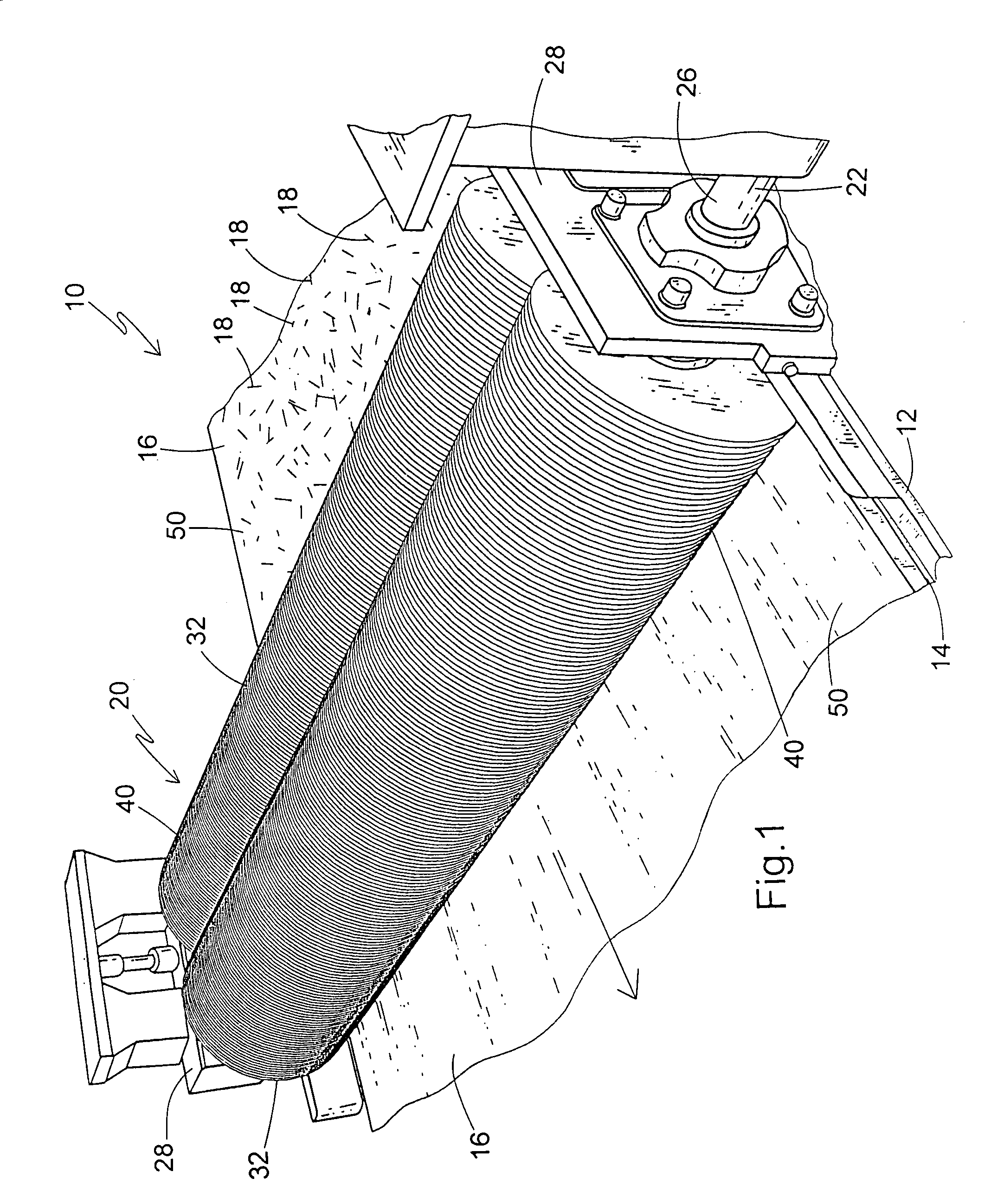

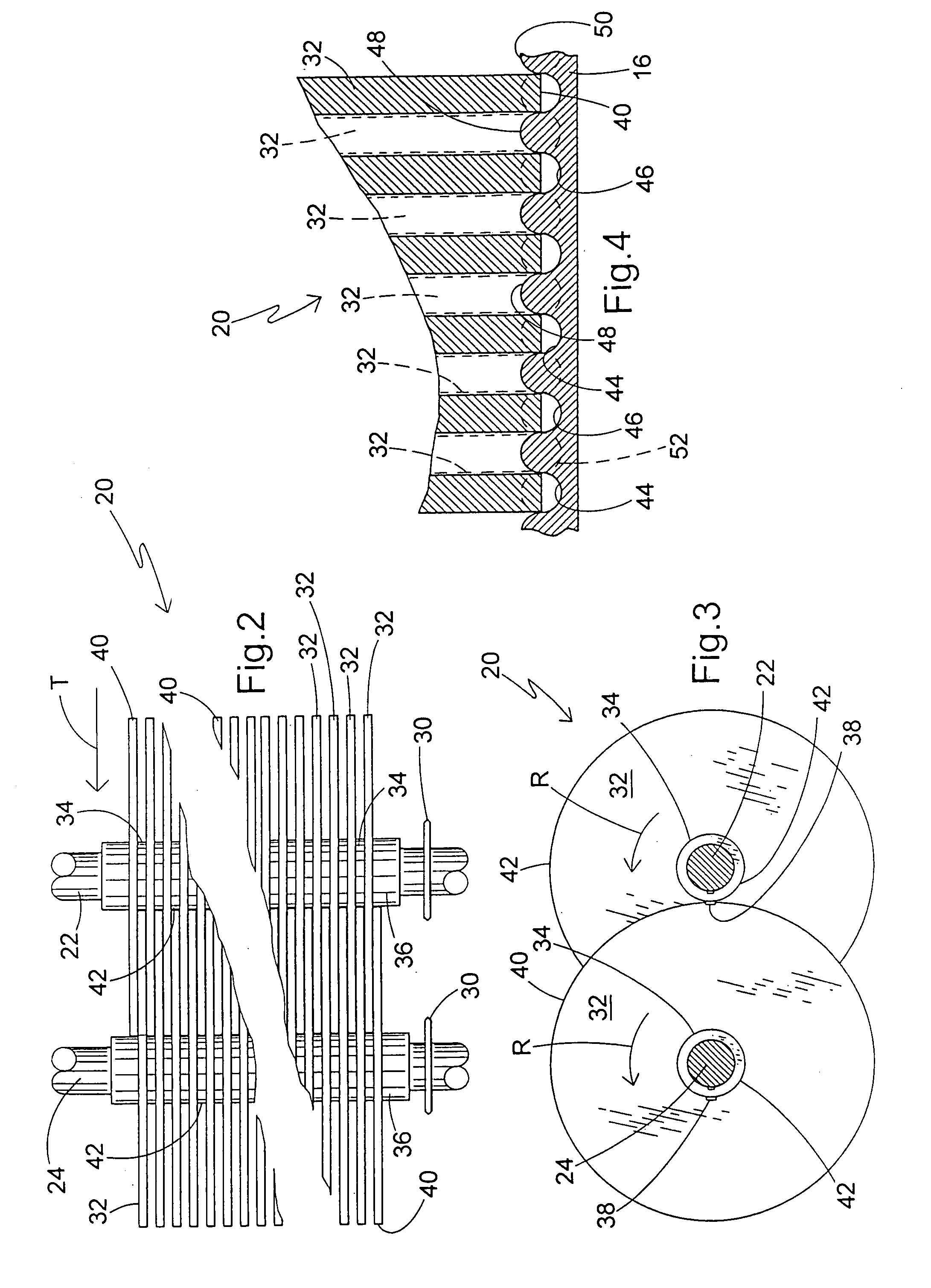

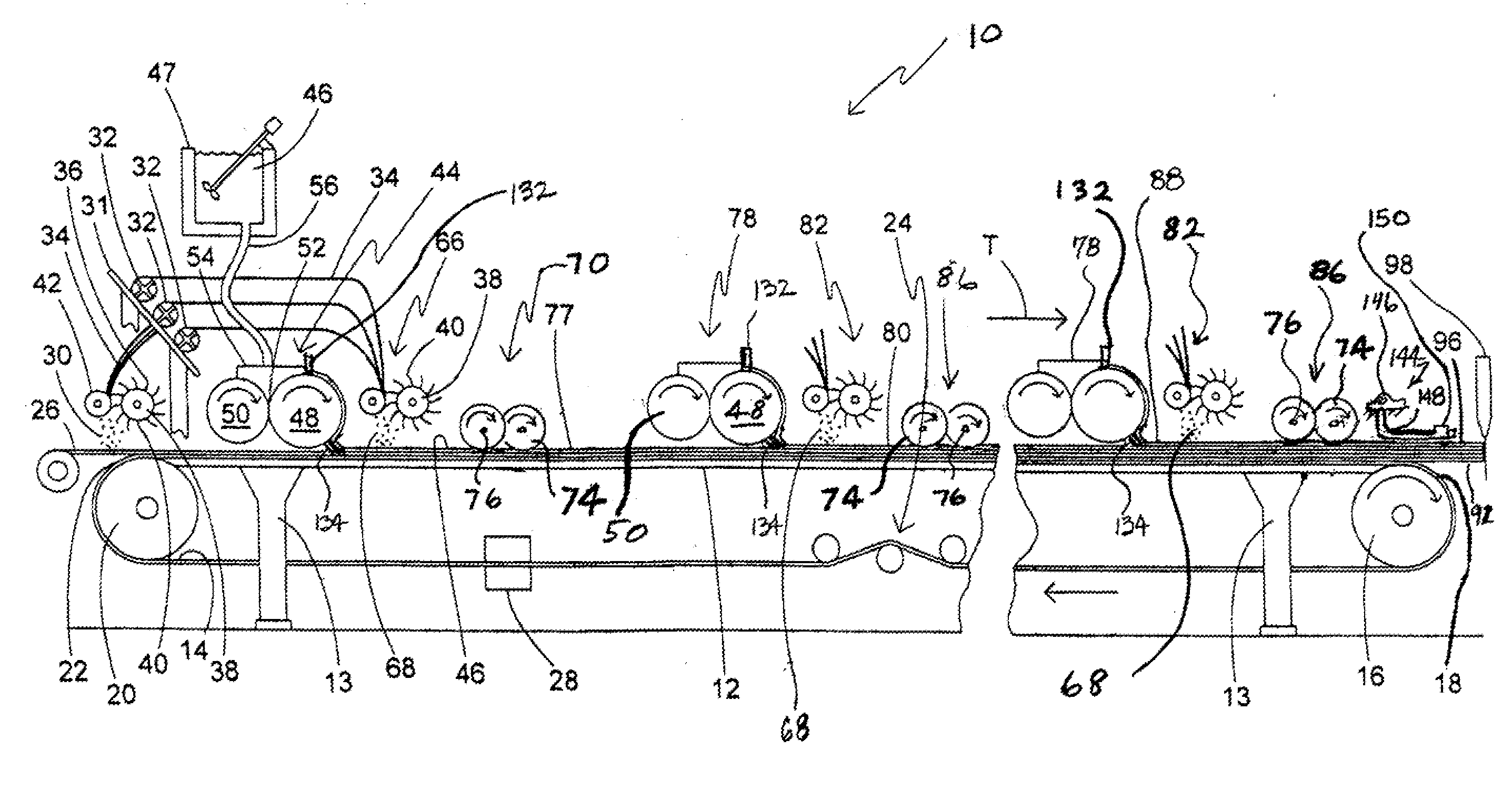

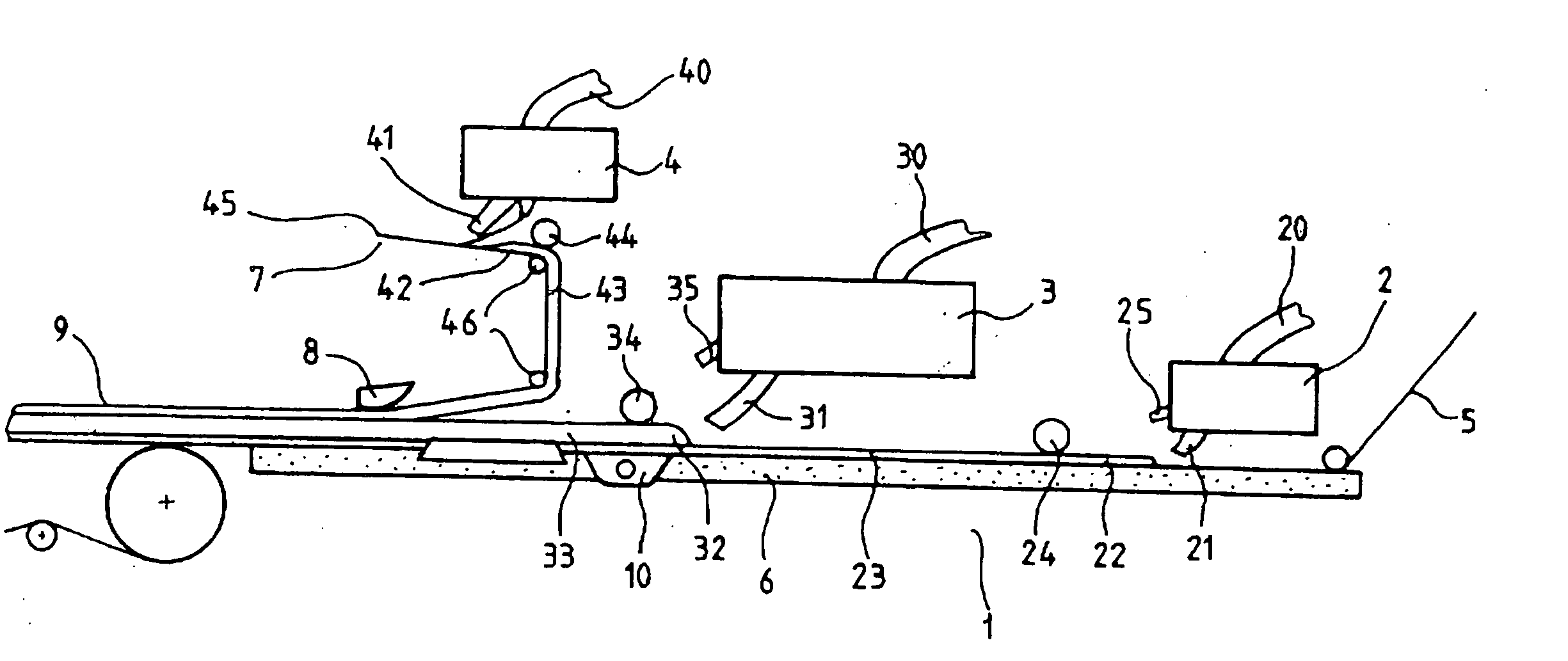

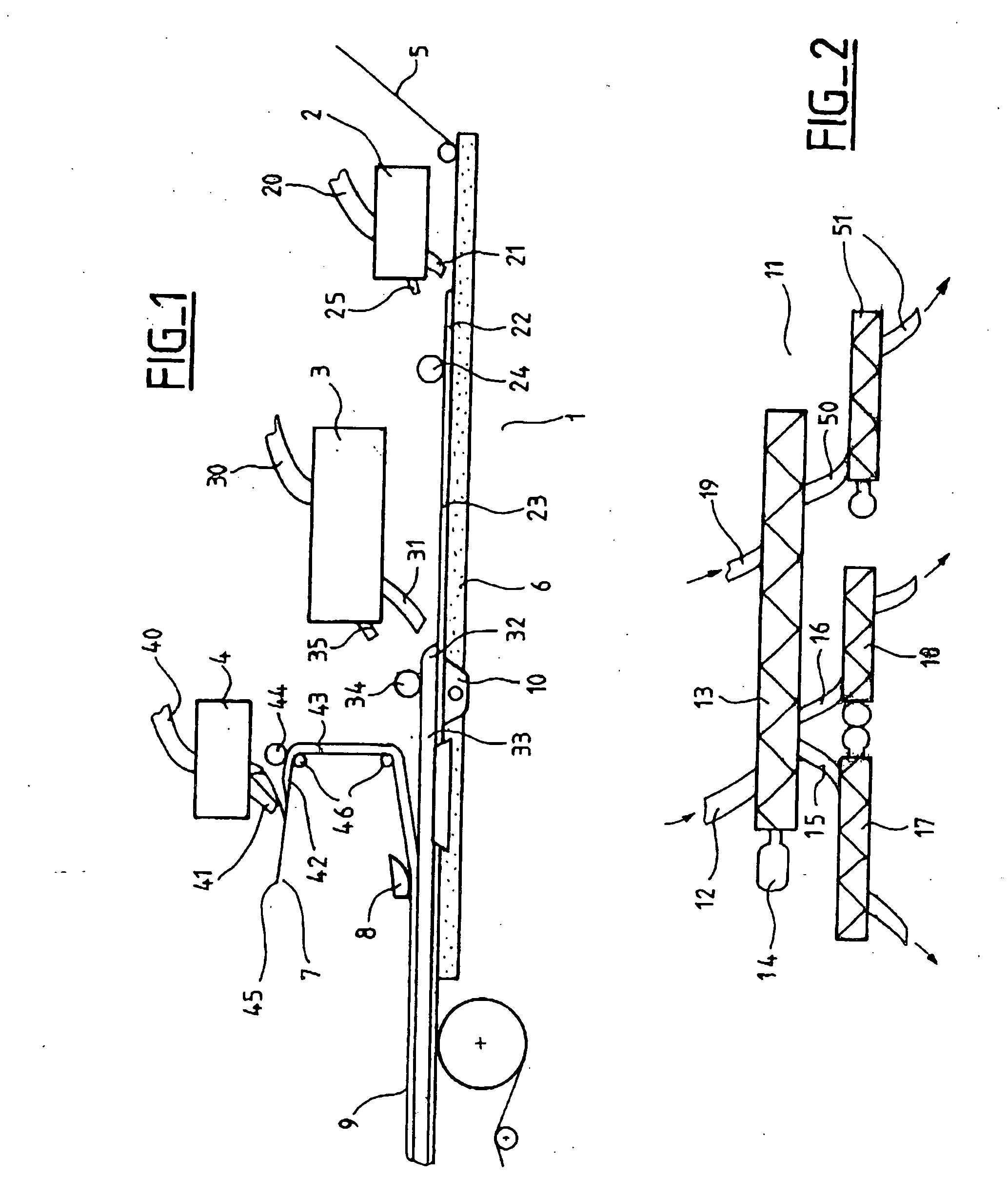

Embedment device for fiber-enhanced slurry

ActiveUS20050064055A1Reduces board line downtimePrevent buildupTransportation and packagingRotary stirring mixersFiberProduction line

An embedment device for use in a structural panel production line wherein a slurry is transported on a moving carrier relative to a support frame, and chopped fibers are deposited upon the slurry, includes a first elongate shaft secured to the support frame and having a first plurality of axially spaced disks, a second elongate shaft secured to the support frame and having a second plurality of axially spaced disks, the first shaft being disposed relative to the second shaft so that the disks intermesh with each other. The intermeshing relationship enhances embedment of the fibers into the slurry and also prevents clogging of the device by prematurely set slurry particles.

Owner:UNITED STATES GYPSUM CO

Method and system for calculating and reporting slump in delivery vehicles

ActiveUS20070185636A1Amount be controlSampled-variable control systemsAnalogue computers for trafficDelivery vehicleControl theory

A system for calculating and reporting slump in a delivery vehicle having a mixing drum (14) and hydraulic drive (16) for rotating the mixing drum, including a rotational sensor (20) configured to sense a rotational speed of the mixing drum, a hydraulic sensor (22) coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, and a communications port (26) configured to communicate a slump calculation to a status system (28) commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum.

Owner:VERIFI

Preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and preparation method thereof

ActiveCN101602589AWide variety of sourcesSimple preparation processSolid waste managementMixing operation control apparatusNeutral phPre stress

The invention discloses a preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and a preparation method thereof. The preformed material includes the following components by weight percent: 65 to 95 percent of silicate cement, 0.01 to 3 percent of high-range water-reducing agent, 0 to 1 percent of stabilizing agent, 0.05 to 5 percent of retarding agent, 1 to 20 percent of expanding agent, 0.2 to 2 percent of corrosion inhibitor, 0.01 to 1 percent of air entraining agent and 0 to 30 percent of mineral materials, wherein by uniformly and proportionally mixing the silicate cement, the high-range water-reducing agent, the stabilizing agent, the retarding agent, the expanding agent, the corrosion inhibitor, the air entraining agent and the mineral materials, the post-tensioned prestressing pipeline vacuum grouting or mudjacking preformed material can be obtained. After being uniformly mixed and stirred with water with neutral pH value according to the water cement ratio ranging from 0.24 to 0.32, the preformed material can be used, the obtained grouting material has the advantages of low water cement ratio, favorable flowability, no water bleeding and delamination, and favorable pumpability; meanwhile, the preparation method of the preformed material is simple and the raw material sources of the preformed material are wide.

Owner:HUBEI CHIDGE TECH

Cement Stabilization of Soils Using a Proportional Cement Slurry

ActiveUS20090044726A1Composition is stableAvoid settingSolid waste managementCement mixing apparatusChemical treatmentCellulose

A novel cement slurry composed of cement and water that can be used in cement stabilization applications. The cement slurry compound itself is chemically treated, by means of a cellulosic or other thixotropic thickening agent(s) to create a thixotropic system wherein the wetted cement remains in suspension and does not settle out prior to use even without further mixing. A chemical retarder / stabilizer is also used to prevent the slurry from prematurely setting during shipping. A novel apparatus and method for mixing the novel cement slurry is disclosed to insure the exact proportioning of all ingredients and the proper wetting of the cement.

Owner:TEXAS INDUSTRIES

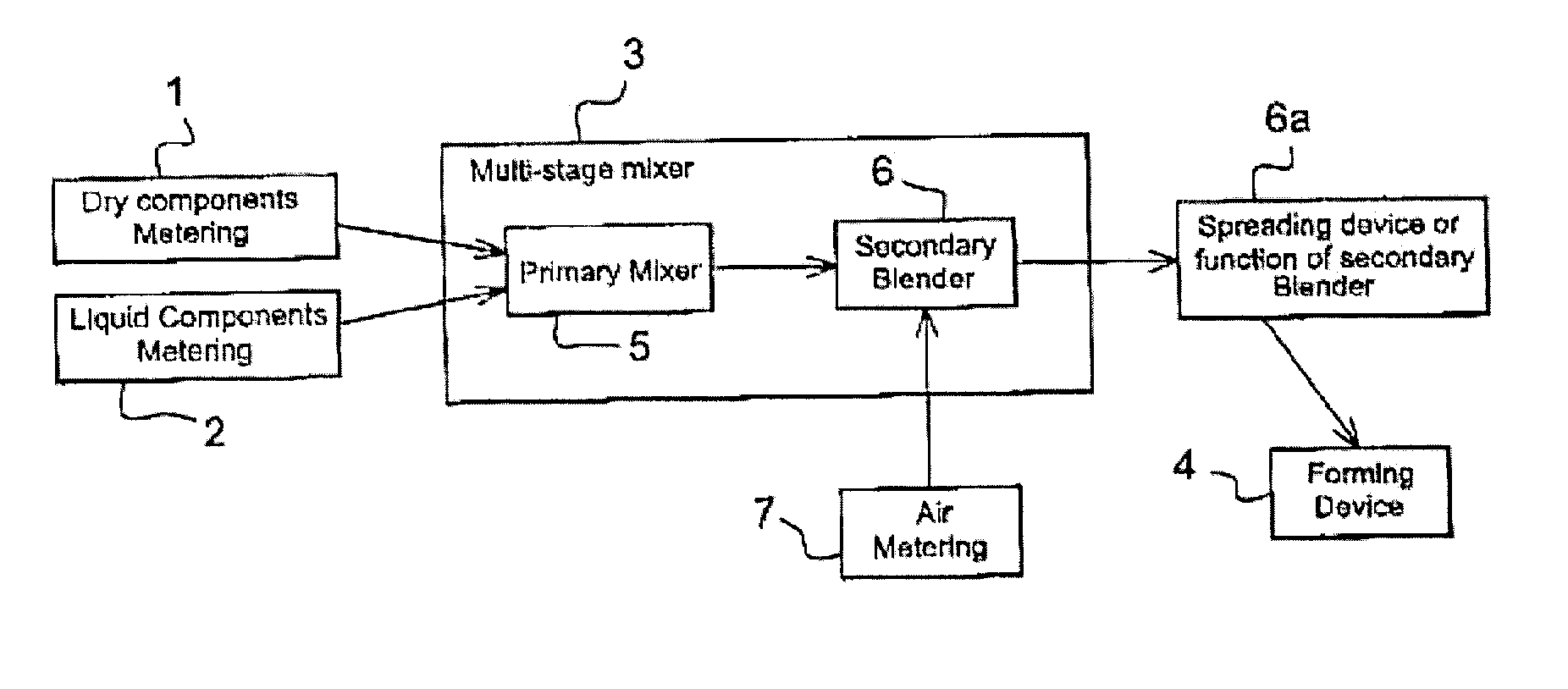

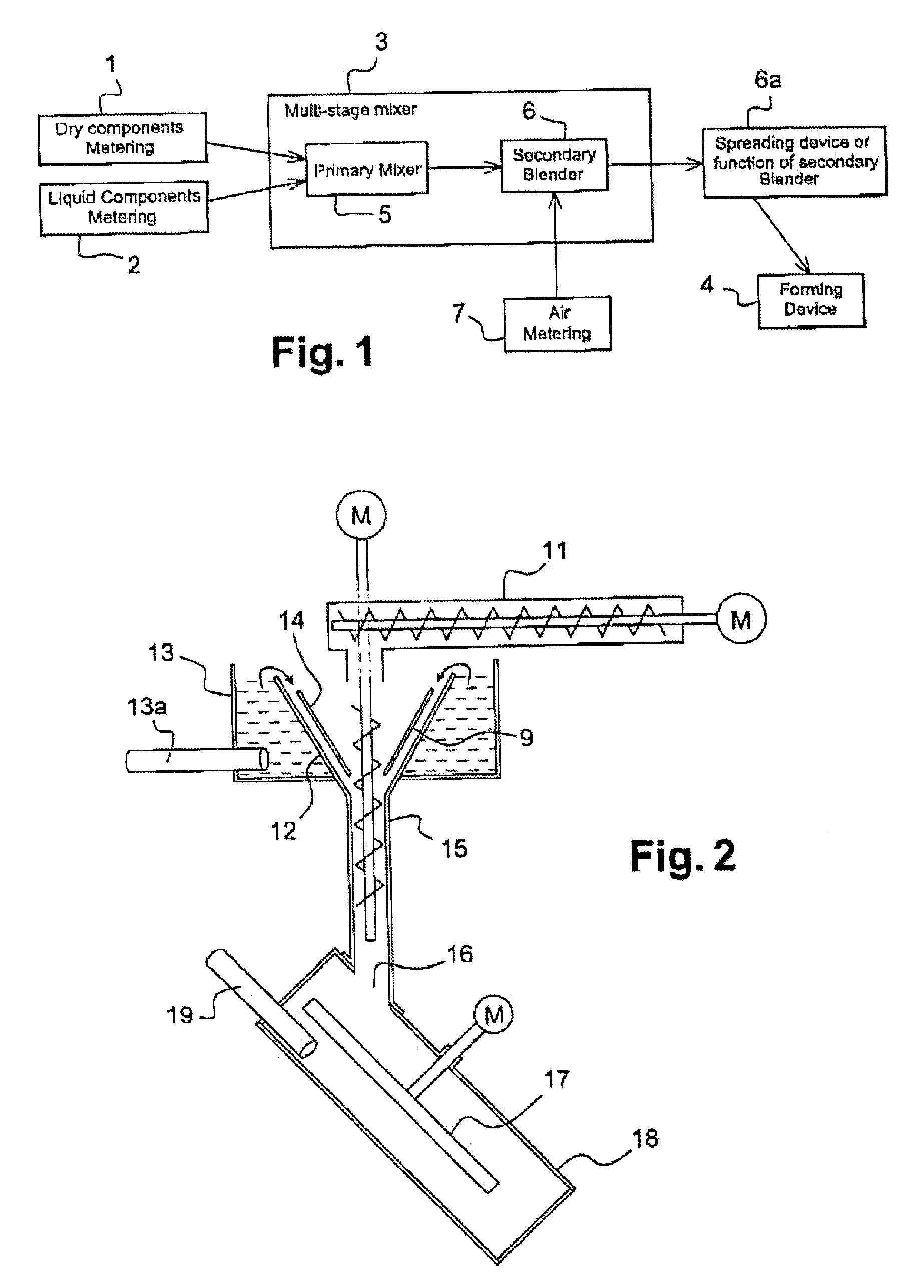

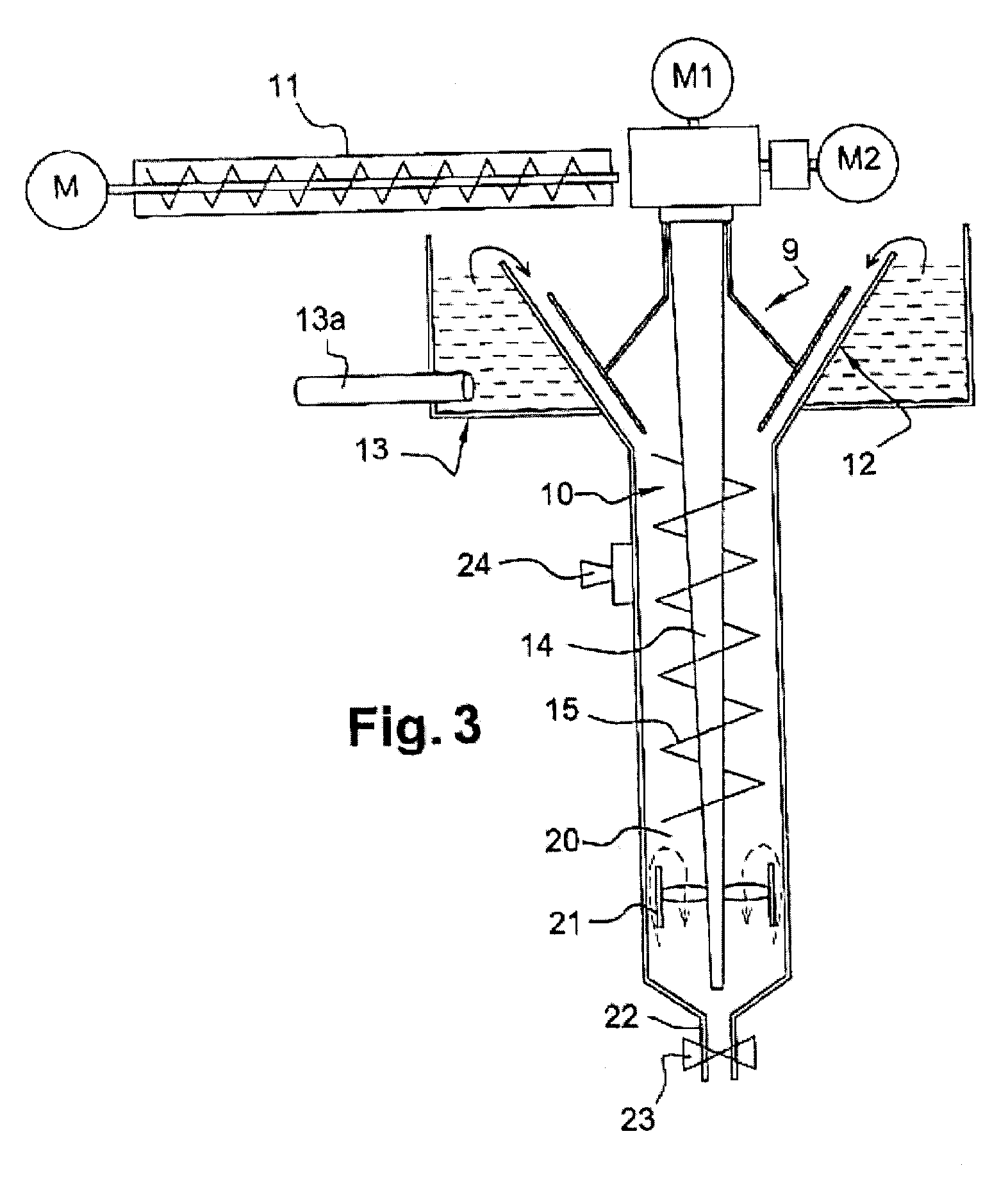

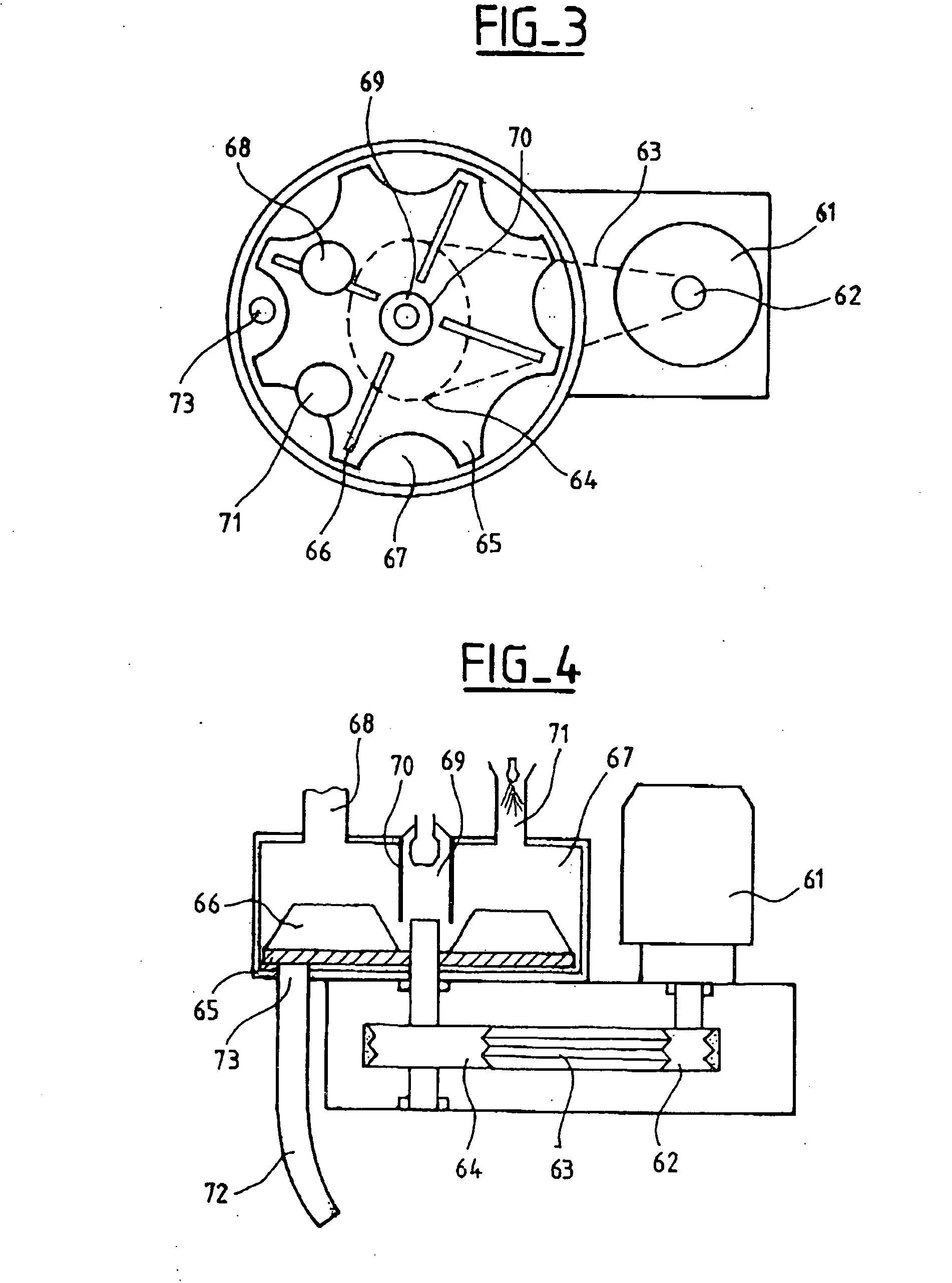

Process And Apparatus For Manufacturing Set Cellular Cement

ActiveUS20050219938A1Less foaming agentLess waterLiquid surface applicatorsTransportation and packagingFoaming agentSlurry

A process for manufacturing set cellular cement, including the steps of: (i) mixing cementitious material, water, foaming agent and optionally additives into a free flowing slurry having a slump of at least 100 mm; subsequently (ii) injecting and distributing air into the slurry of step (i) to form a cellular slurry; subsequently (iii) casting the cellular slurry of step (ii); and finally allowing the cellular slurry to set. And, an apparatus for carrying out the process.

Owner:ETEX BUILDING PERFORMANCE INT SAS

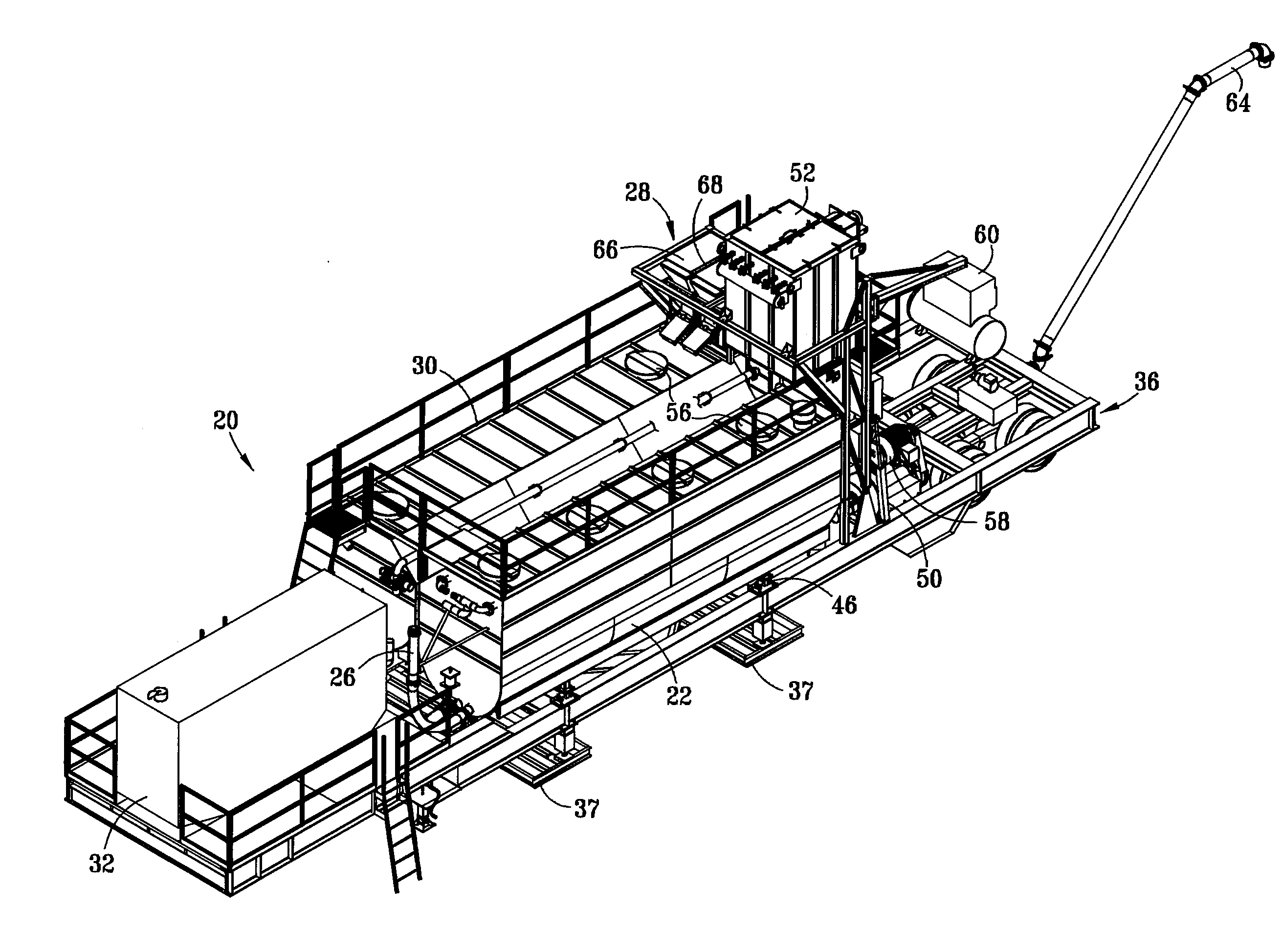

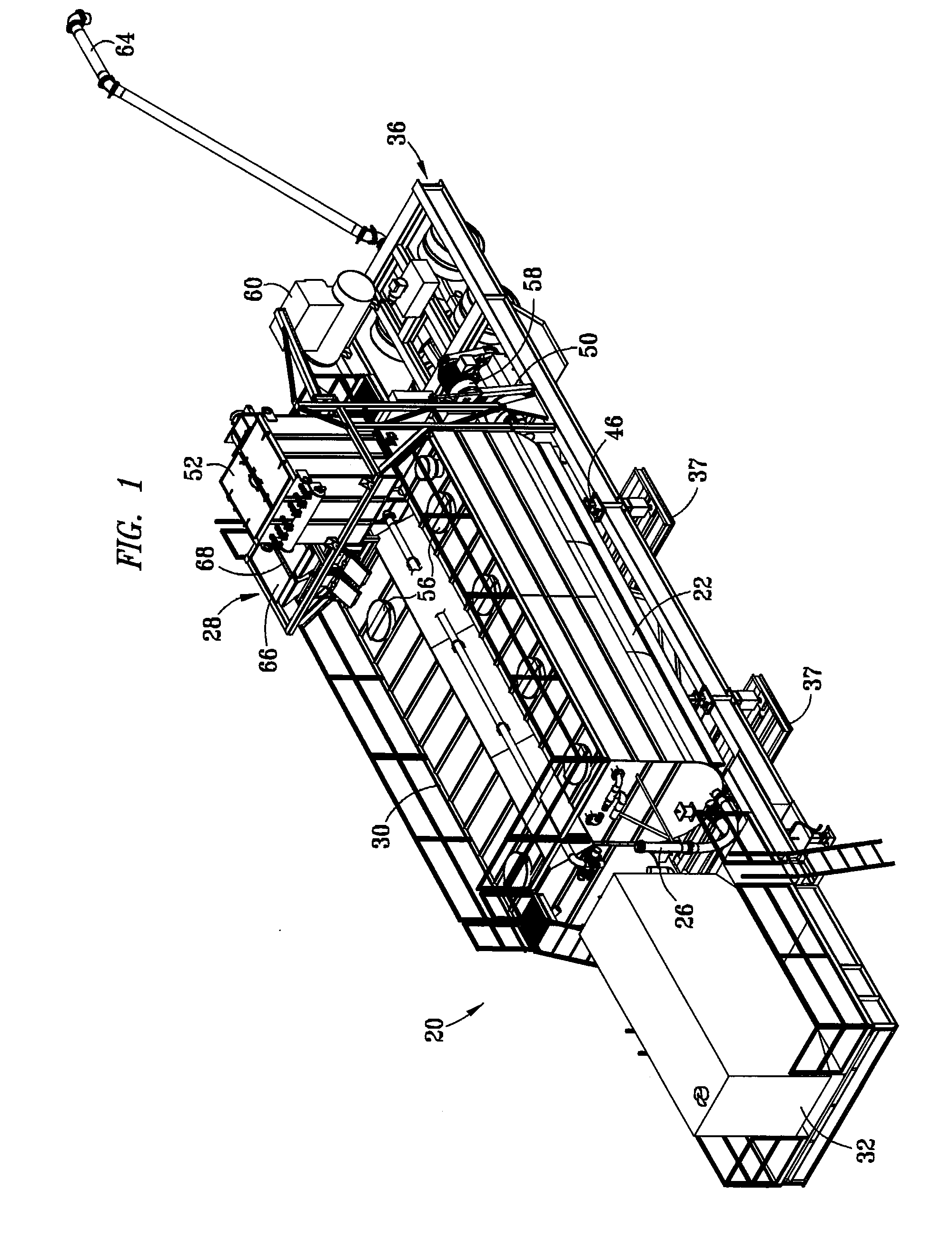

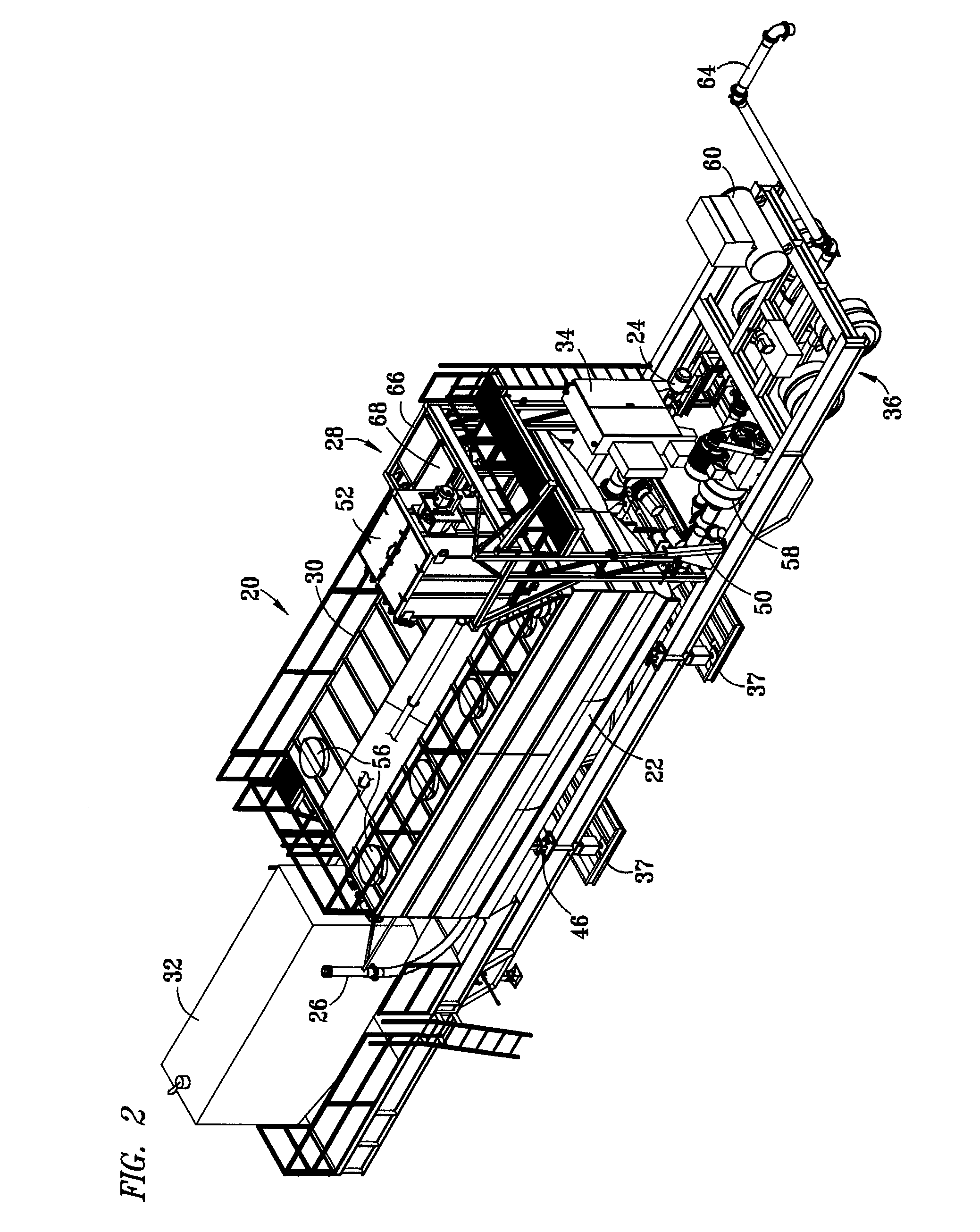

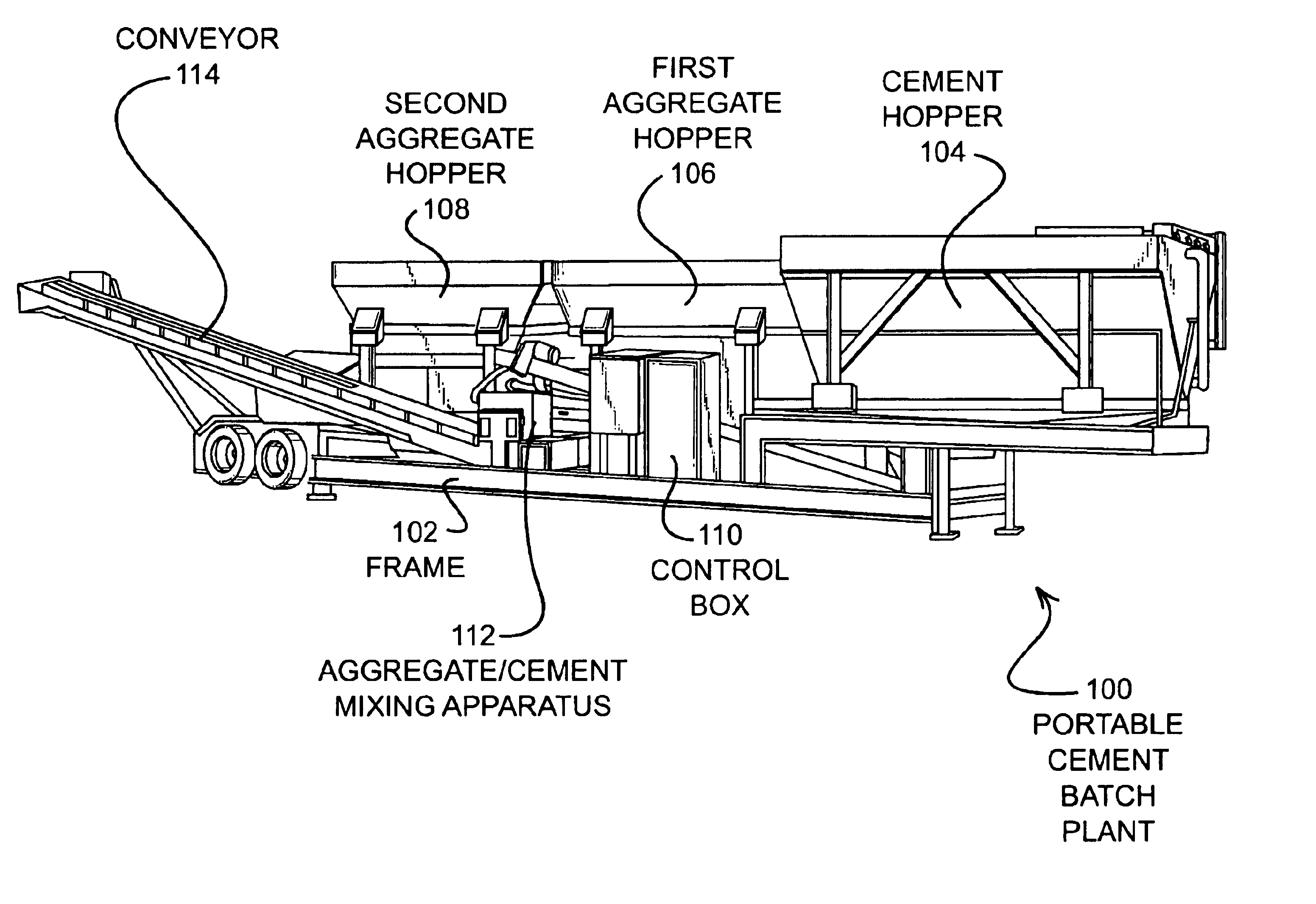

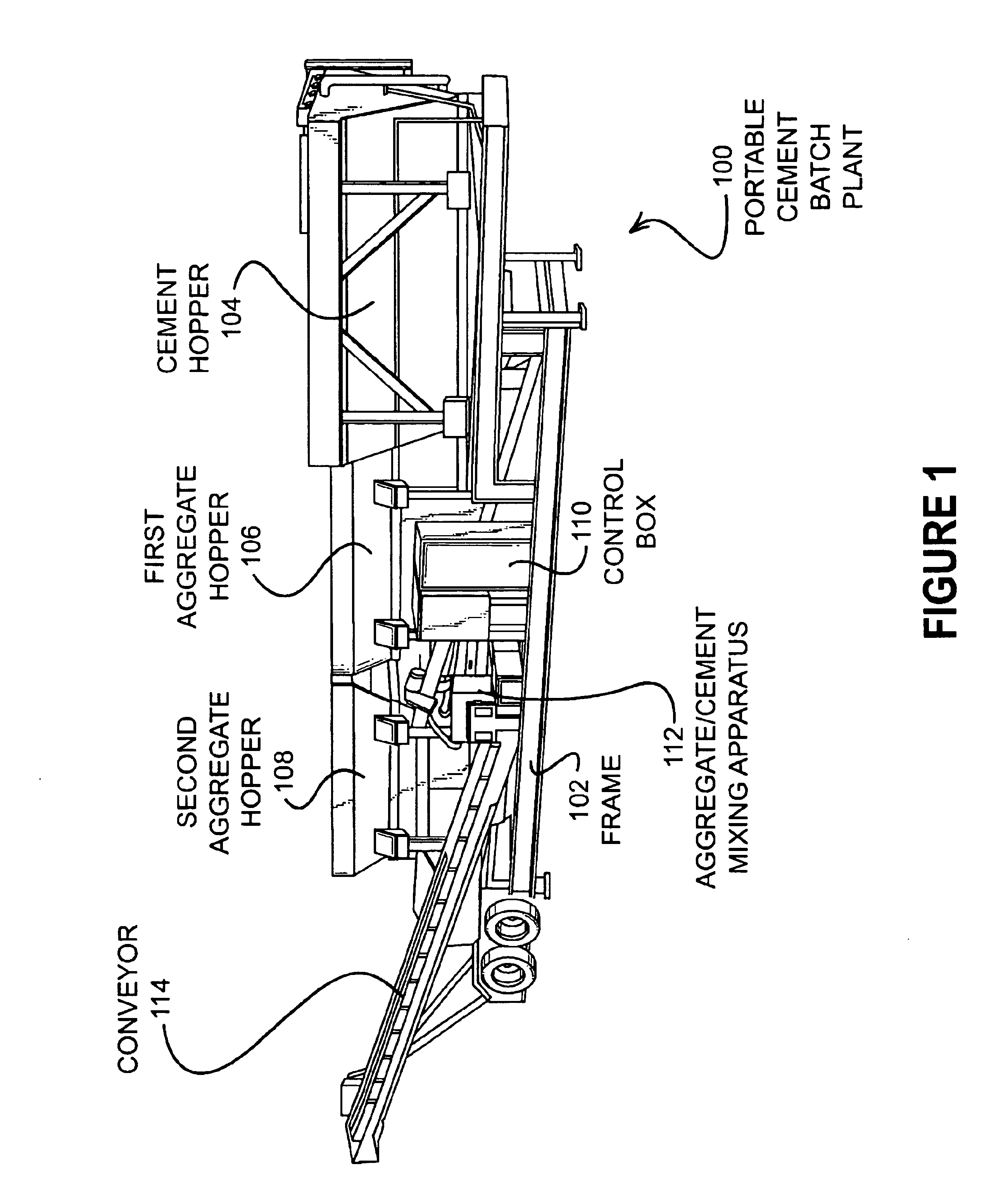

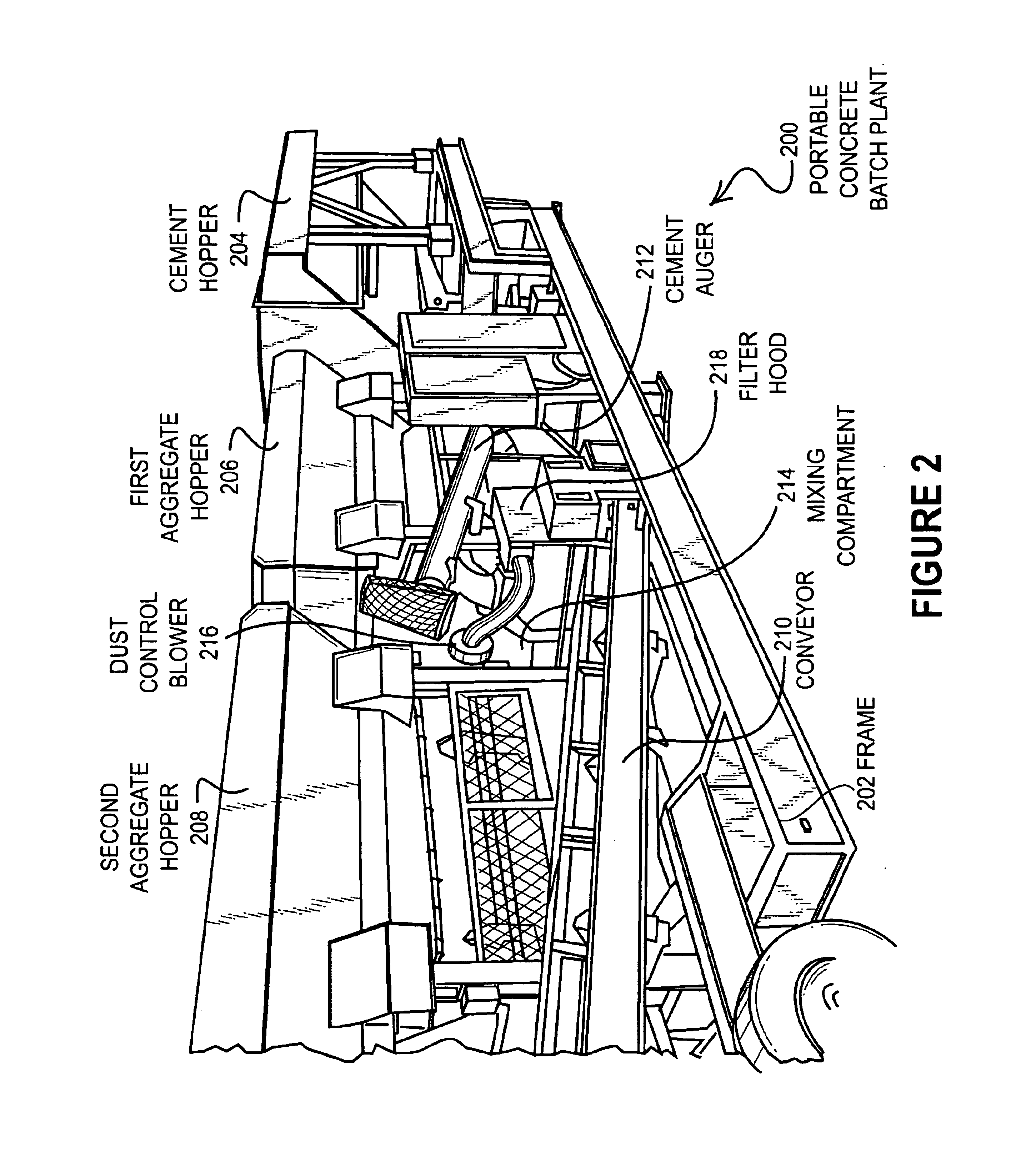

Portable concrete plant dispensing system

ActiveUS6876904B2Dispensed more accuratelyGood repeatabilitySampled-variable control systemsDischarging apparatusDistribution controlControl system

A computer controlled pumping and measuring system is used to dispense chemicals into a concrete mix. The redundant use of positive displacement pumps and flow meters ensure that any problems with the chemical dispensing are immediately caught. The computerized control system may be operable to control exact batch configurations of concrete and aggregate in conjunction with the chemical dispensing, as well as provide precise mixture control and recording of the various components.

Owner:PORT A POUR

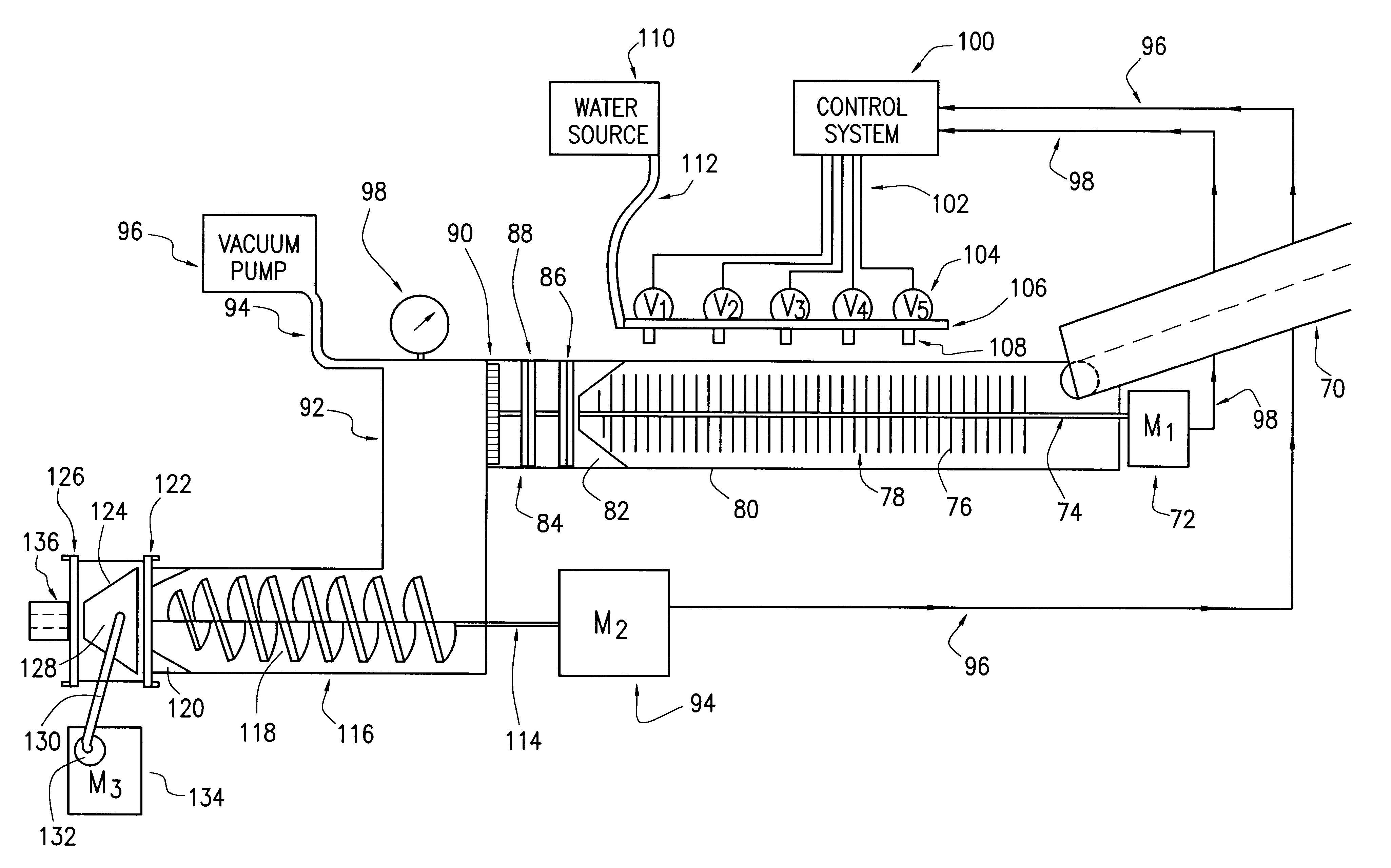

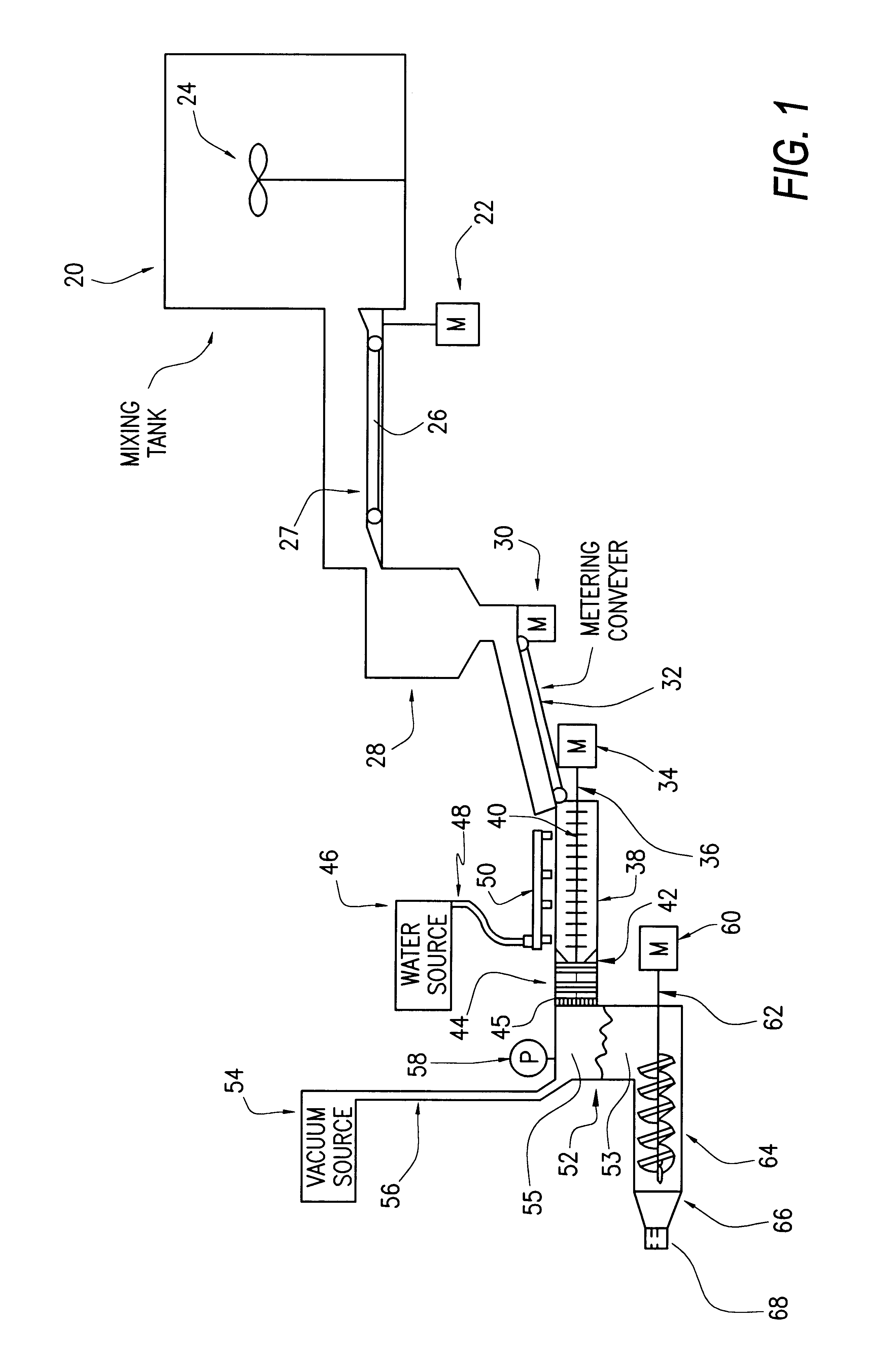

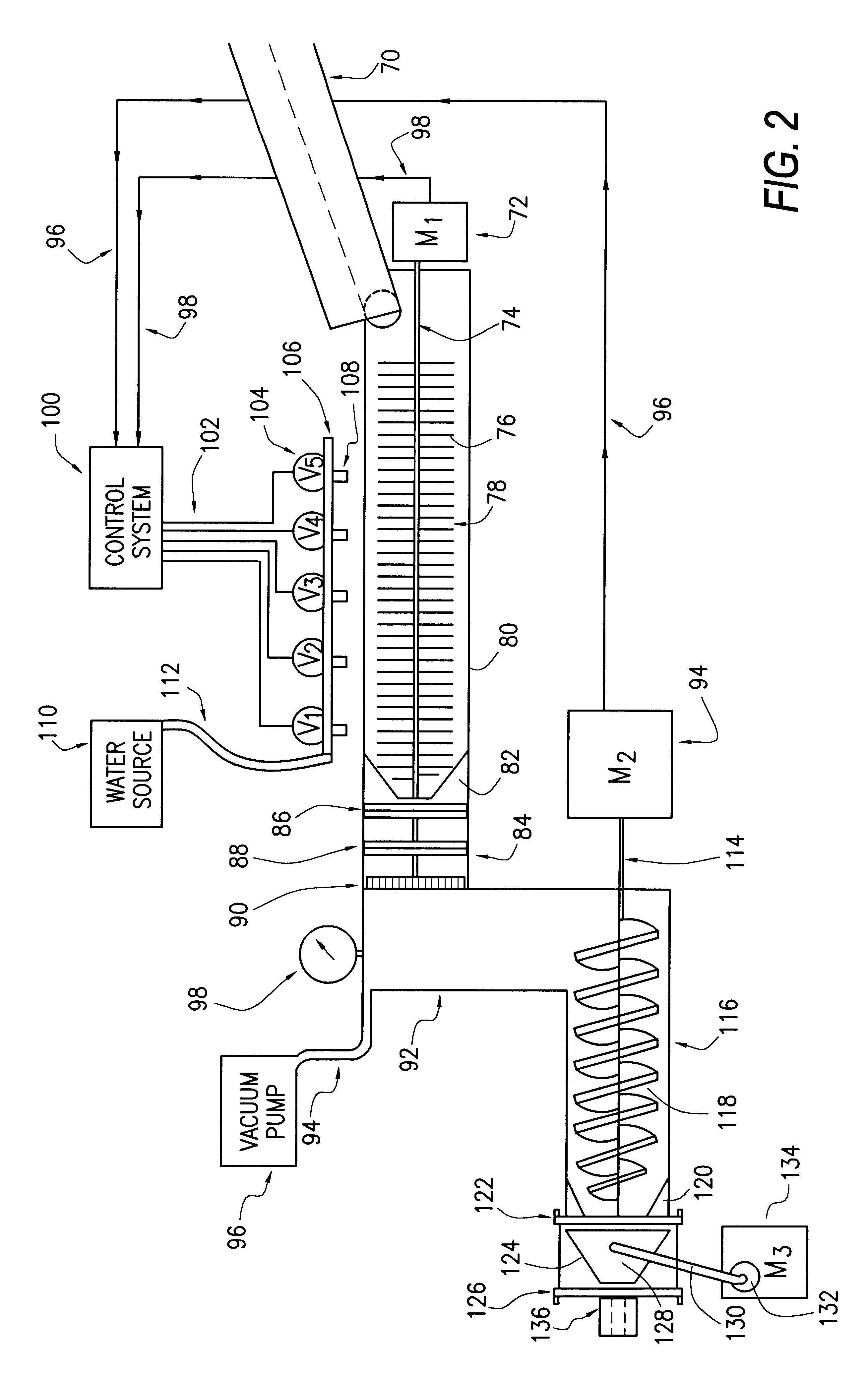

Vacuum extrusion system for production of cement-based articles

InactiveUS6309570B1Reduce frictionReduce the amount requiredFrozen sweetsConfectioneryMaterials scienceExcess water

A system for making extruded cement-based articles. The process can include forming a cement-based feed mixture including water, aggregate and binder and directing the feed mixture to a vacuum zone, wherein sufficient vacuum is maintained in the vacuum zone to remove entrained air and, preferably, excess water, from the feed mixture. The feed mixture is held in the vacuum zone at a negative pressure for a time sufficient to form a vacuum-treated or densified mixture. The vacuum-treated or densified mixture is passed through an extruder at an elevated pressure to provide an extruded cement-based article.

Owner:BLEECKER LEE M

Carbon nanotube fiber-reinforced composite structures for EM and lightning strike protection

InactiveUS20020180077A1Material nanotechnologyShielding materialsLightning strikeFiber-reinforced composite

A method for repairing fiber-reinforced composite structures while maintaining original EM and lightning protection using carbon nanotubes, fibers, and thermoset resins is disclosed. According to one embodiment of the invention, the method comprises preparing a damaged area for repair; preparing a repair patch for the damaged area, the repair patch comprising nanotubes; applying the repair patch to the damaged area; and curing the repair patch. A repair patch for a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair patch includes a binder and nanotubes. A repair resin for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair layer includes a resin and nanotubes. A putty for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the putty includes a base and electrically conductive carbon nanotubes.

Owner:EIKOS

Method for mixing fluids in microfluidic channels

Owner:TEXAS A&M UNIVERSITY

Panel smoothing process and apparatus for forming a smooth continuous surface on fiber-reinforced structural cement panels

InactiveUS20080099133A1Remove pock marks or groovesA large amountSolid waste managementTransportation and packagingProduction lineSurface layer

A vibrating flexible smoothing sheet or shroud disposed transversely of a direction of travel of a formed fiber panel including gypsum-cementitious slurry and embedded chopped fibers. The sheet is used to smooth the surface of the panel as it exits a fiber embedment station of a structural cementitious panel production line to remove grooves and other non-uniform surface imperfections to reduce the need for costly finishing after the panels are cured and cut to size. The flexible sheet is designed to float over the surface of the formed panel without tearing or otherwise damaging the surface of the heavily fiber reinforced surface layers of the panel. The vibrating sheet is pivotally mounted on the side dams of the web production line so it can float over the panel surface during use, but be raised off the line when not in use.

Owner:UNITED STATES GYPSUM CO

Wallboard with antifungal properties and method of making same

This invention provides wallboard with a gypsum core with improved antifungal properties based on the distribution of fungicide and starch. Preferably, the wallboard has a gypsum core having a first surface and a second surface; facing sheets adhered to the first and second surfaces; a fungicide and a starch in the gypsum core; wherein the concentration of fungicide and starch is greater in portions of the core adjacent to the facing sheets than in a center of the core. Also a method for manufacturing wallboard as described above.

Owner:PLATRES LAFARGE

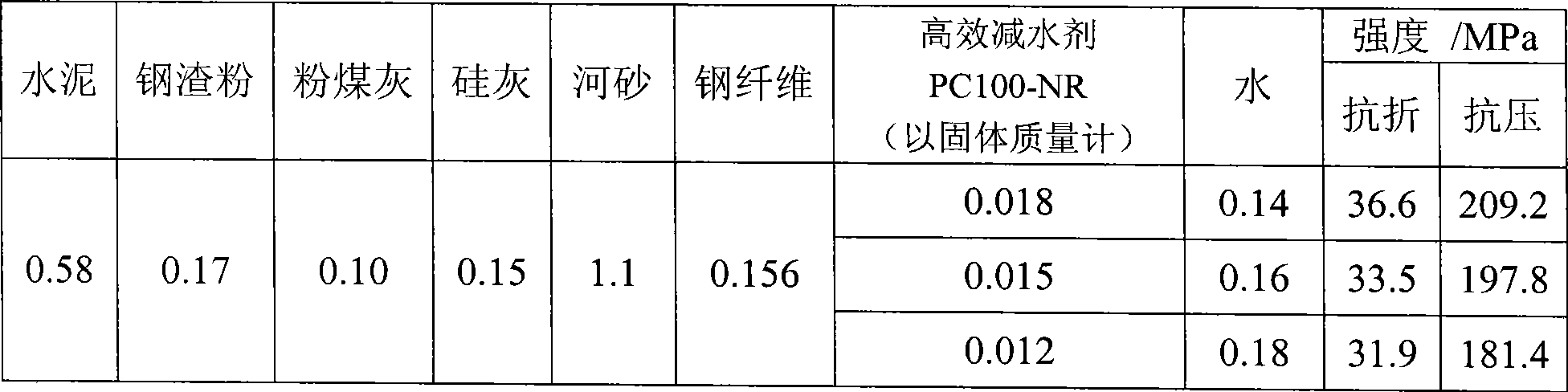

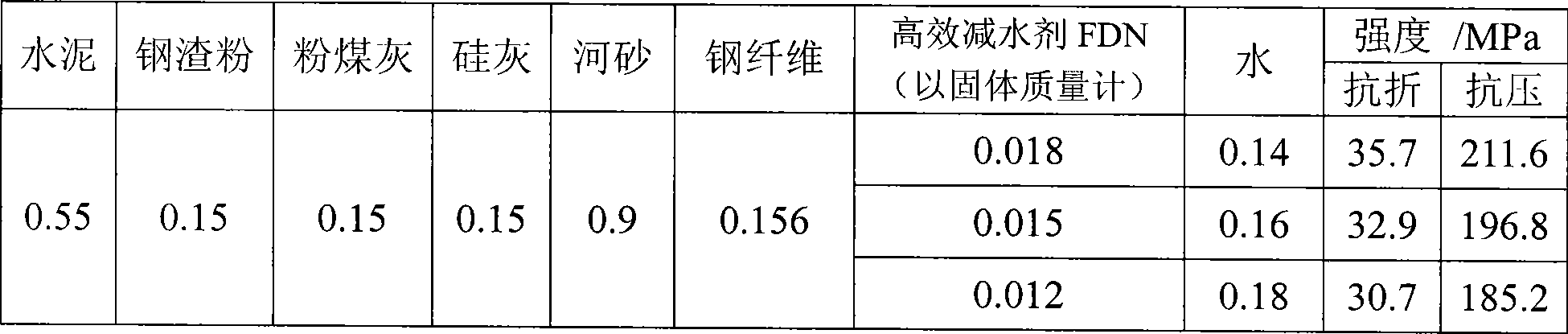

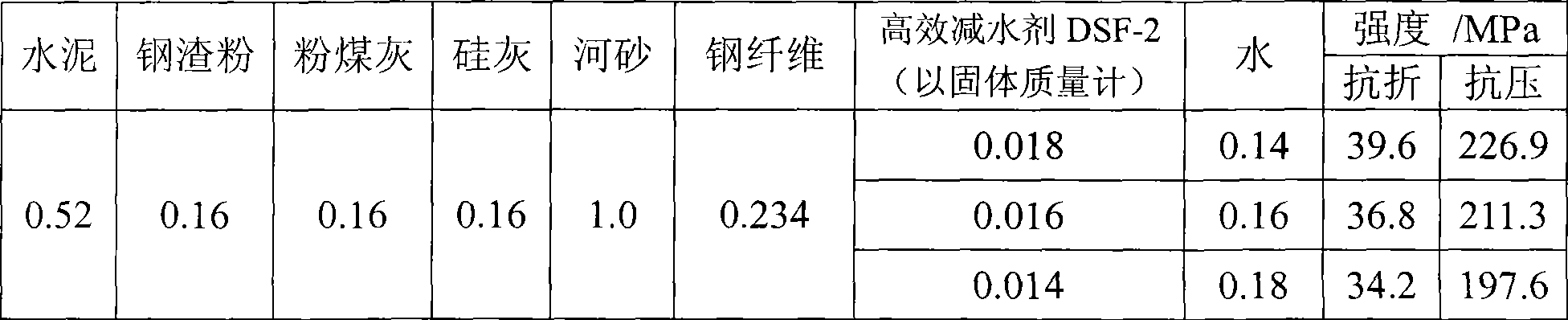

Low cost active powder concrete and preparation thereof

InactiveCN101486554ALow raw material costReduce maintenance costsSolid waste managementMixing operation control apparatusFiberSlag

The invention discloses active powder concrete which is prepared by Portland cement, steel slag powder, fly ash, silicon ash, effective water reducing agent, river sand, mixing water and steel fiber with the mass ratios of 0.52 to 0.58 : 0.16 to 0.18 : 0.10 to 0.16 : 0.13 to 0.16 : 0.012 to 0.018 : 0.9 to 1.1 : 0.14 to 0.18 : 0.156 to 0.234. The preparation method thereof is as follows: each component is sequentially added into a stirring machine for being uniformly stirred and shaped; then after the components are maintained, the temperature is raised to 80 to 90 DEG C at the temperature rising speed of 15 to 20 DEG C / h and then constant temperature maintaining is carried out for 72 to 96h; then, the components are cooled to room temperature at the cooling speed of not more than 20 DEG C / h to obtain the active powder concrete product. The invention employs the industrial wastes like steel slag powder and fly ash to replace quartz powder, partial cement and silicon ash, and employs thin river sand to replace quartz sand to prepare the active powder concrete of 200 grade under the maintaining conditions of normal pressure below 100 DEG C, thus not only being capable of remarkably reducing the material cost and the shaping maintaining cost, but also playing important roles on saving resources and energies, protecting the environment and promoting sustainable development as a large amount of industrial waste slag is used.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com