Patents

Literature

971 results about "Water–cement ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The water–cement ratio is the ratio of the weight of water to the weight of cement used in a concrete mix. A lower ratio leads to higher strength and durability, but may make the mix difficult to work with and form. Workability can be resolved with the use of plasticizers or super-plasticizers.

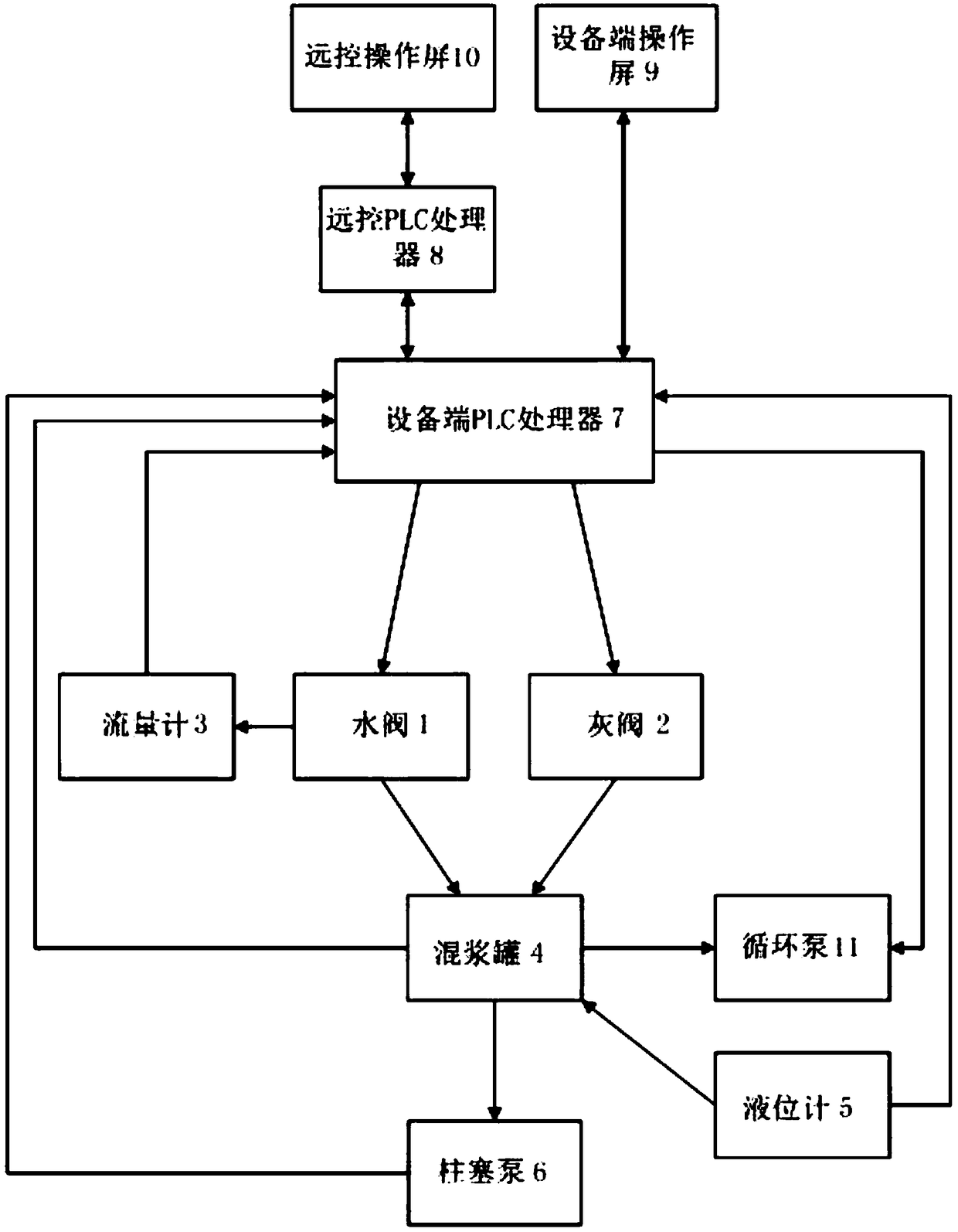

Remote ultra-low-density automatic control system

PendingCN109491318AIncreased level of process automationProgramme control in sequence/logic controllersAutomatic controlSlurry

The invention discloses a remote ultra-low-density automatic control system. The system comprises a control unit, a water valve, a flow meter, a cement valve, a slurry mixing tank, a liquid level meter, a circulation pump and a plunger pump; the cement valve, the water valve, the circulation pump and the plunger pump are connected with the slurry mixing tank separately, the flow meter feeds the water supply amount monitored in real time back to the control unit, the liquid level meter is arranged in the slurry mixing tank, the control unit controls the number of revolutions and preset displacement of the plunger pump to achieve automatic displacement as required, the water demand amount and the cement demand amount are calculated by presetting the water-cement ratio and liquid level valuein the control unit, and therefore the opening degrees of the water valve and the cement valve are controlled; the control unit comprises a remote control unit and an equipment end control unit whichare connected with each other. The remote ultra-low-density automatic control system has the advantage of remote cementing equipment monitoring, remote liquid level automatic control, remote automaticwater supply, remote automatic cement supply, remote automatic premixing, remote automatic density control and remote automatic displacement.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and preparation method thereof

ActiveCN101602589AWide variety of sourcesSimple preparation processSolid waste managementMixing operation control apparatusNeutral phPre stress

The invention discloses a preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and a preparation method thereof. The preformed material includes the following components by weight percent: 65 to 95 percent of silicate cement, 0.01 to 3 percent of high-range water-reducing agent, 0 to 1 percent of stabilizing agent, 0.05 to 5 percent of retarding agent, 1 to 20 percent of expanding agent, 0.2 to 2 percent of corrosion inhibitor, 0.01 to 1 percent of air entraining agent and 0 to 30 percent of mineral materials, wherein by uniformly and proportionally mixing the silicate cement, the high-range water-reducing agent, the stabilizing agent, the retarding agent, the expanding agent, the corrosion inhibitor, the air entraining agent and the mineral materials, the post-tensioned prestressing pipeline vacuum grouting or mudjacking preformed material can be obtained. After being uniformly mixed and stirred with water with neutral pH value according to the water cement ratio ranging from 0.24 to 0.32, the preformed material can be used, the obtained grouting material has the advantages of low water cement ratio, favorable flowability, no water bleeding and delamination, and favorable pumpability; meanwhile, the preparation method of the preformed material is simple and the raw material sources of the preformed material are wide.

Owner:HUBEI CHIDGE TECH

Drifting sand layer and gravel stratum water-moving double-liquid high pressure slip-casting water-blocking construction method

InactiveCN101255698AHigh strengthImprove water stabilitySolid waste managementUnderground chambersWater blockCement slurry

The present invention discloses a running sand layer and sandy gravel layer dynamic-water double-liquid high-pressure slurry-injecting water-shutoff construction method which comprises the following construction steps: drilling a hole, flushing the hole, executing double-liquid high-pressure slurry-injecting operation and sealing the hole. The running sand layer and sandy gravel layer slurry-injecting liquid adopts an ordinary portland cement (P.O.42.5) and 40''Be sodium silicate as material for preparing the slurry, according to the weight proportion of water: cement, namely the cement slurry is prepared with the water cement ratio for 0.5-1.2:1. Then the slurry-injecting liquid is prepared with the volume ratio of cement slurry: sodium silicate for 1:0.08-0.15. The sodium silicate is taken as additive for regulating the initial setting time of the slurry-injecting liquid. The cement slurry can also be doped with fly-ash with cement consumption (weight proportion) for 10%-15%. The invention executes water-insulating construction aiming at the characteristics of large pressure of the underground dynamic water and high flowing velocity in the running sand layer and sandy gravel layer, and can obtain the maximal application sphere and optimum water-shutoff effect.

Owner:HUNAN CONSTR ENG GRP COR

High-strength polypropylene fiber polymer cement mortar and preparation method thereof

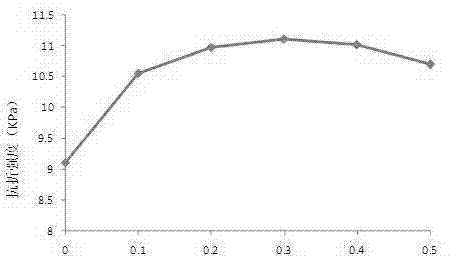

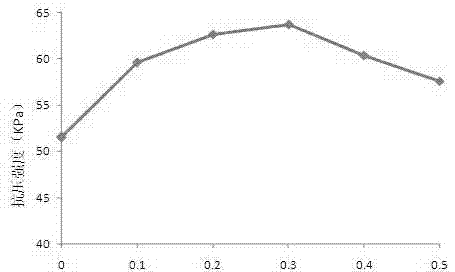

The invention discloses a high-strength polypropylene fiber polymer cement mortar and a preparation method thereof. The mortar is composed of the following components in parts by mass: 0.28-0.3 part of silica fume, 0.68-0.7 part of cement and 1.97-2 part of sand. The SiO3 content in the silica fume is higher than 95%; the water-cement ratio is 0.31; the volume content of the polypropylene fiber is 0.9 kg / m<3>; the water reducer:cementing material ratio is 0.9-1%; the defoaming agent:cementing material ratio is 0.5-0.55%; the coupling agent and diluter:cementing material ratio is 0.3%; the polymer modifier:cementing material ratio is 10-11%; and the reducer:cementing material mass ratio is 3-3.5%. By combining the excellent physical and chemical characteristics of the silica fume, when the silica fume is substituted for cement, the consumption of the cement clinker is saved, and the industrial waste is reutilized, thereby greatly enhancing the pressure resistance and bending resistance of the modified cement mortar.

Owner:ZHENGZHOU UNIV

Cement-based lightweight porous heat insulating material and preparation method thereof

The invention relates to a cement-based lightweight porous heat insulating material and a preparation method thereof. The material is prepared from portland cement or ordinary portland cement, water reducing agent, foam stabilizer, early strength agent, fiber, emulsion powder, water repellent, foaming agent and water according to a certain ratio. The weight ratio of cement, water reducing agent, foam stabilizer, early strength agent, fiber, emulsion powder, water repellent and foaming agent is 100:0.2-2.4:(0.1-3.)0:(1.0-4.0):(0.3-1.5):(0.1-5.0):(0.1-6.0):(3.0-8.0); and the water cement ratio is 0.45-0.55. The dry density of the LWFC material is 250-300kg / m<3>, the compressive strength is 0.5-1.0MPa, the heat conduction coefficient is 0.05-0.08W / m.k, the water absorption rate is 4-8%; the material can not deform and crack, is used as an inorganic incombustible lightweight heat insulating material and can replace the organic combustible heat insulating material represented by polystyrene foam; and the material can be used in the external wall exterior insulation construction of the building energy-efficient project and can also be used in the roof insulation project, the floor heating project or the occasions for preparing the composite heat insulating board and the like.

Owner:NANJING UNIV OF TECH

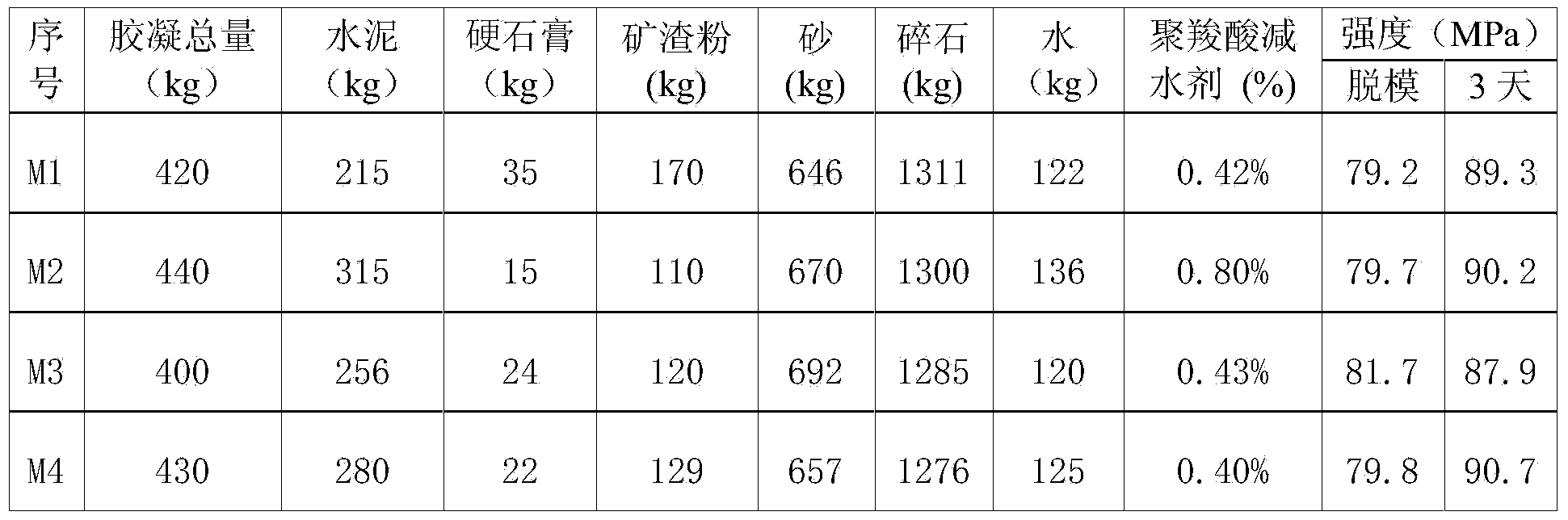

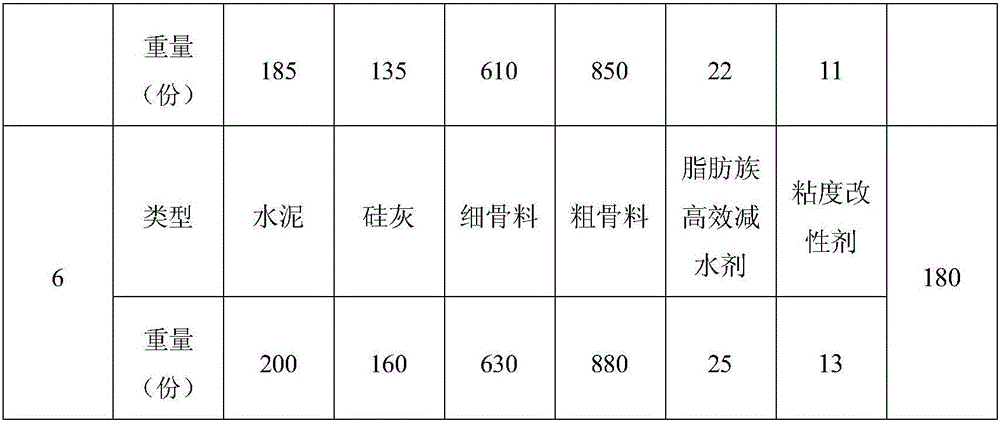

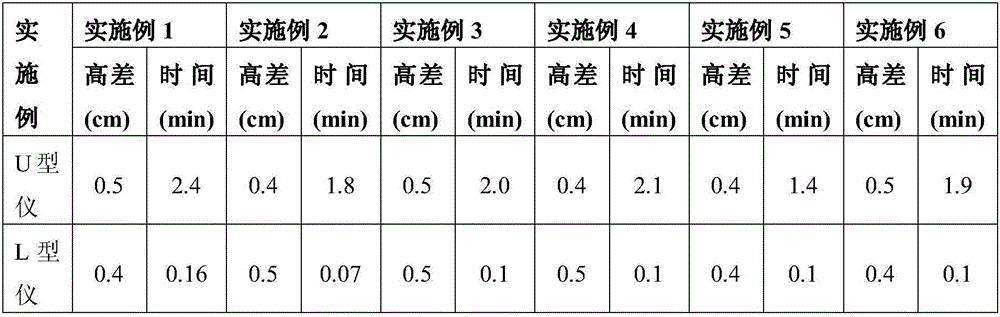

Ultra-high strong concrete having ultra-high pumping performance and method for preparing the same

InactiveCN101323515AImprove liquidityRaw materials are easy to getSolid waste managementPlasticizerSlag

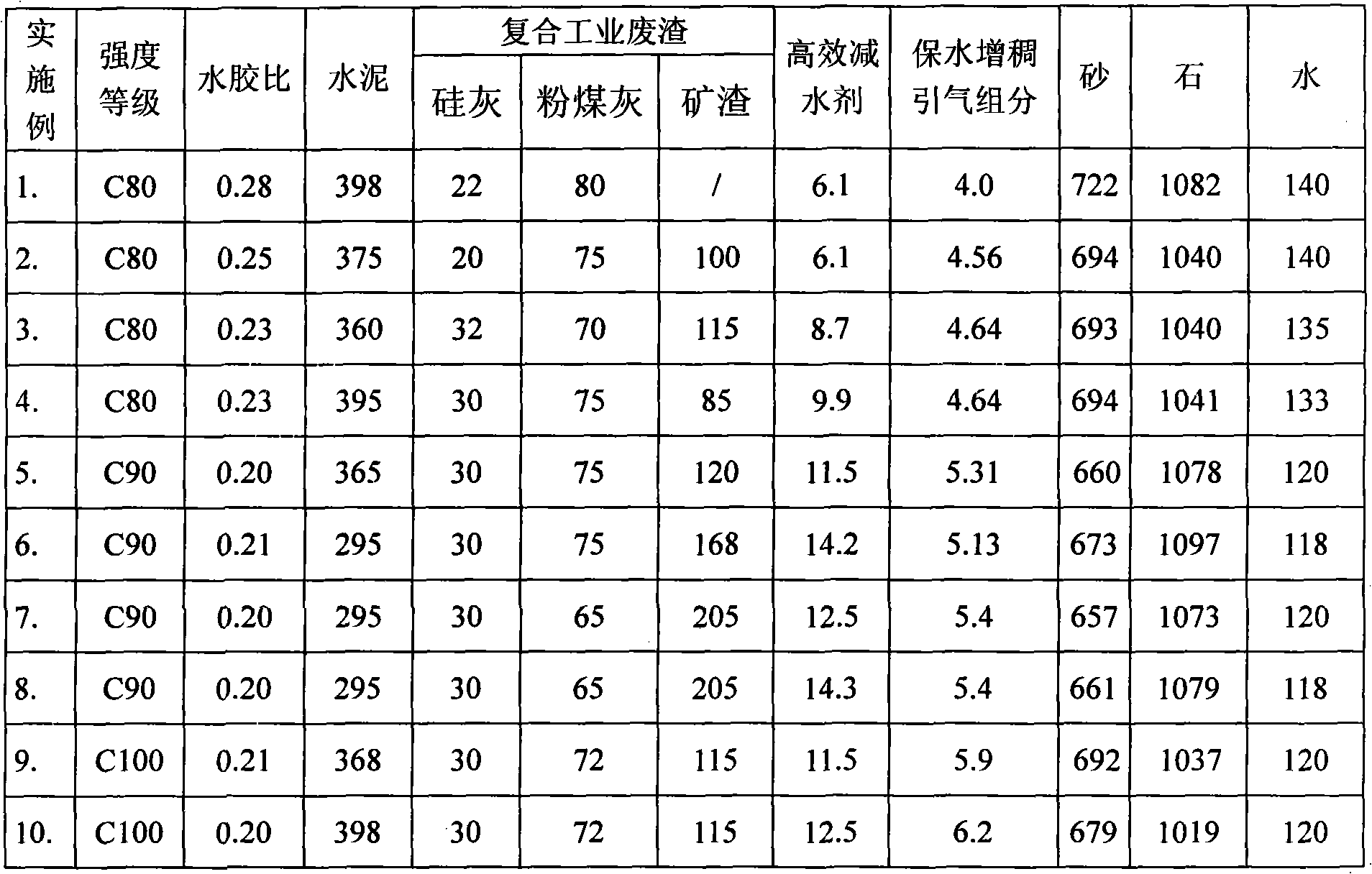

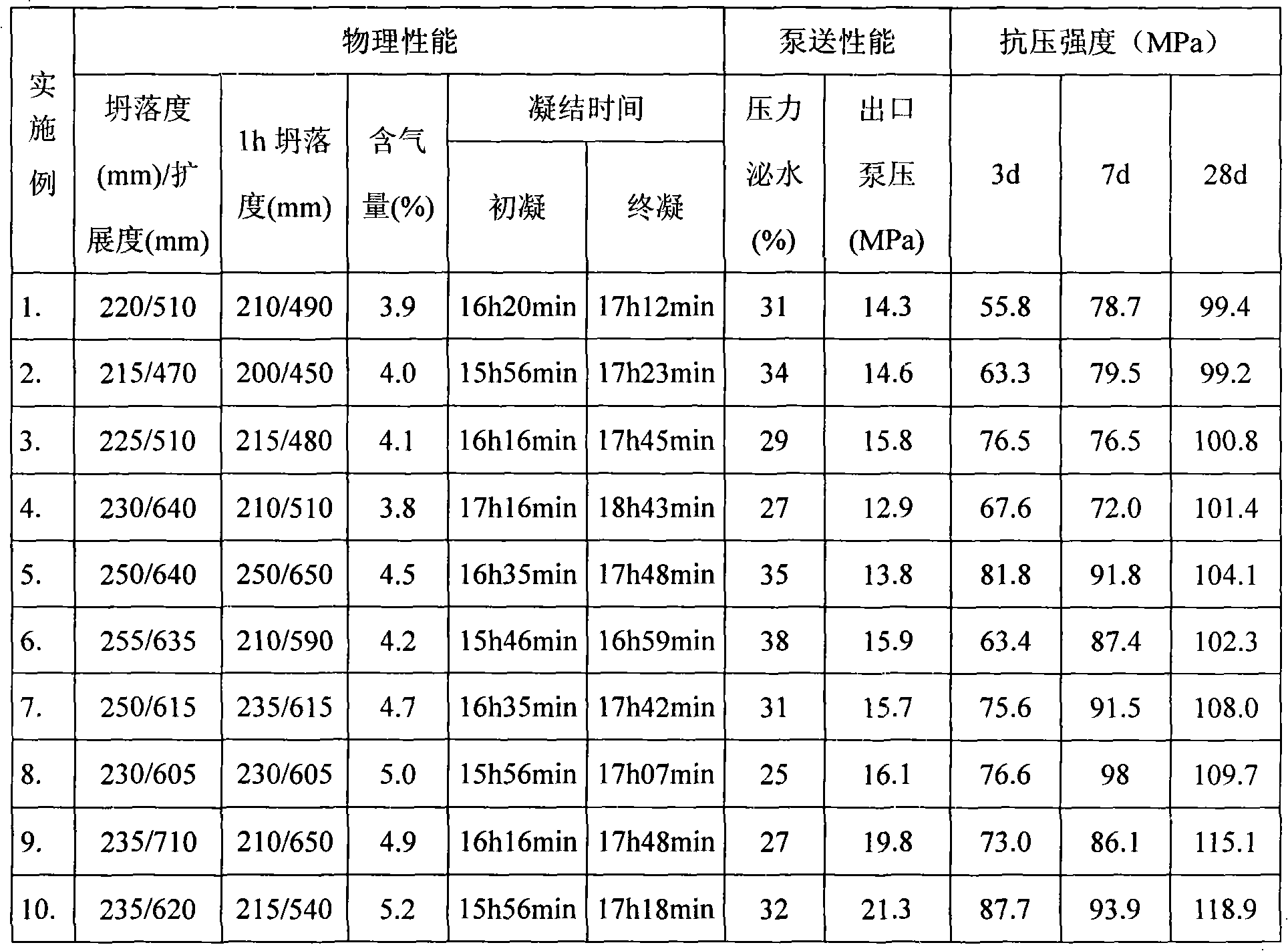

A super-high concrete with super-high pumping capability and a corresponding preparation method particularly relate to the super-high concrete with super-high pumping capability and the preparation method. The concrete is mainly used for high buildings, long-span bridges, high-speed railways, large-scale tunnels, ocean crude oil platforms, nuclear power engineering and defense engineering, etc. large-scale civil engineering. The concrete is composed of the following components by weight percentage: 11.9 to 16.2 percent of cement, 4.2 to 12.2 percent of compound industrial waste slag, 0.25 to 0.58 percent of super plasticizer, 0.16 to 0.25 percent of water-preserving thickening air-inducting component, 4.8 to 5.7 percent of water, 26.7 to 29.4 percent of sand and 41.6 to 44.3 percent of stone; wherein, the total amount of cementitious material (the total amount of cement and various industrial waste slag) is 500 to 615kg, and the compound industrial waste slag occupies 20 to 50 percent of the total amount of cementitious material; the water-cement ratio is 0.20 to 0.28; the super plasticizer occupies the 1.1 to 2.5 percent of the total amount of cementitious material, and the water-preserving thickening air-inducting component occupies 0.8 to 1.0 percent of the total amount of cementitious material, and the sand rate is 30 to 40 percent.

Owner:SOUTHEAST UNIV

High fluidity grouting material and production method thereof

ActiveCN101798208AImprove mobilityEasy to pump over long distancesSolid waste managementNeutral phPortland cement

The invention discloses a high fluidity grouting material and a production method thereof. The high fluidity grouting material comprises the following components in percentage by weight: on the basis of 100 percent of total amount, 60 to 96 percent of conventional portland cement, 1 to 20 percent of calcite powder, 1 to 20 percent of a mineral modifying component, and 2 to 18 percent of swelling agent, wherein measuring on the basis of using the total amount of four substances as base number, 0.01 to 4 weight percent of high efficiency slushing agent and 0.0005 to 1 weight percent of plasticity swelling agent are added in the mixture of the four substances. The high fluidity grouting material can be made of raw materials mixed by adopting a dual-shaft paddle non-gravity high-efficiency mixer. The material has simple industrialized production process and stable product quality, adopts the water-cement ratio of between 0.24 and 0.28, is evenly blended by water with neutral pH value, and has the advantages of high fluidity, no bleeding, no segregation or layering, slight swelling, easy pump delivery, good durability and the like after the material is uniformly mixed by water.

Owner:HUBEI CHIDGE TECH

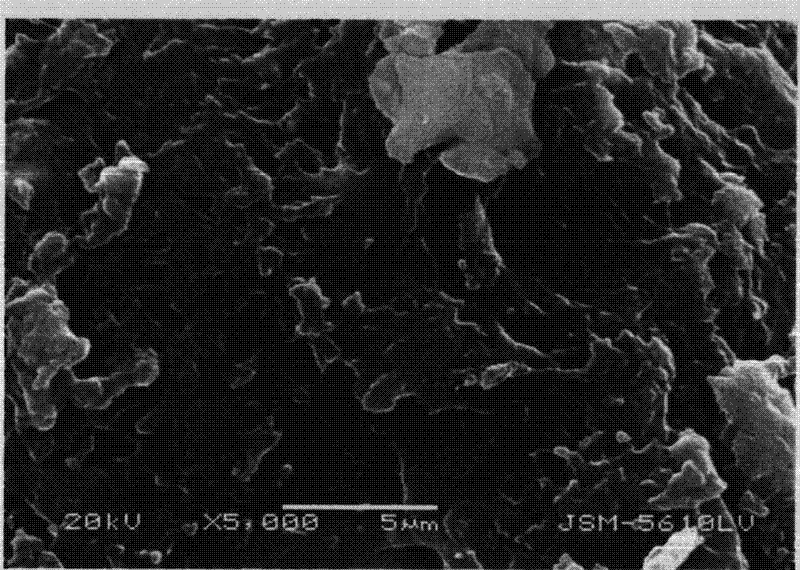

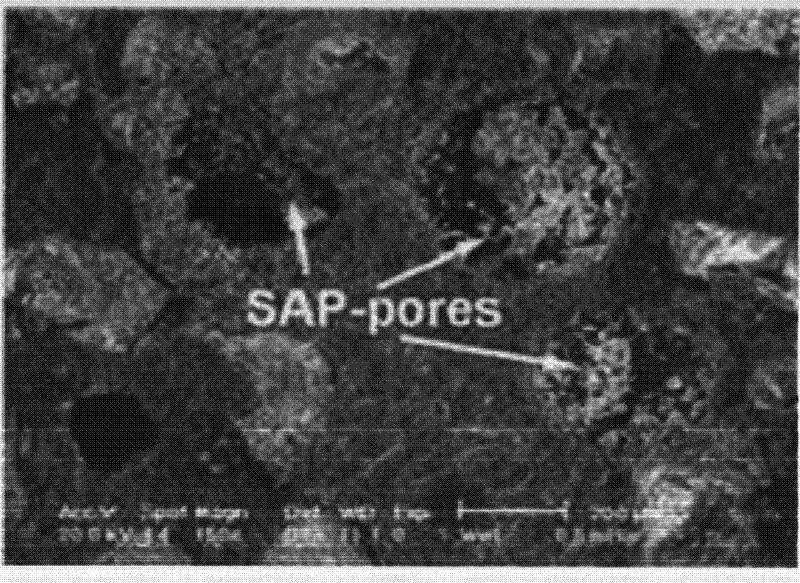

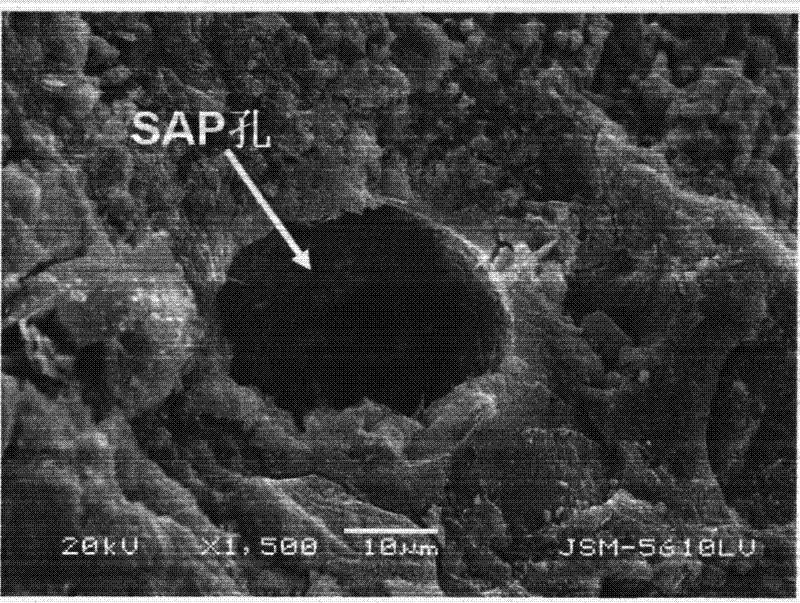

Preparation method for water-preserving and salt-tolerant alkaline concrete internal curing agent

The present invention discloses a preparation method for a water-preserving and salt-tolerant alkaline concrete internal curing agent. According to the method, plant starch, inorganic powder with a layered structure, an anionic monomer, a non-ionic monomer and water are adopted as main raw materials; under effects of an initiator, a cross-linking agent and a certain temperature, treatments of dissolving, reacting, filtering, washing, drying and crushing are performed to obtain the internal curing agent. The internal curing agent of the present invention has the following advantages that: the internal curing agent of the present invention provides the stronger deionized water absorbency than the existing internal curing agent, wherein the deionized water absorbency is increased by 200-500 times; the saline solution absorbency and the alkaline solution absorbency are 35-55% of the deionized water absorbency; the water-preserving rate of the internal curing agent of the present invention is 55-65% after the internal curing agent absorbs the alkaline solution; with adopting the low mixing amount of 0.05-0.5% of the internal curing agent, the strength of the silica fume-doped C60-C100 high-performance concretes is not reduced while the 7-day autogenous shrinkage rates of the concretes are reduced by 65-85%; the internal curing agent of the present invention is applicable for the high strength and early strength concrete pavement, steel pipe concrete under the closed environment, self-compacting concrete and other engineering fields, wherein the fields adopt the design with a low water-cement ratio and a high cementing material content, and adopt a large amount of high activity mineral admixtures.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

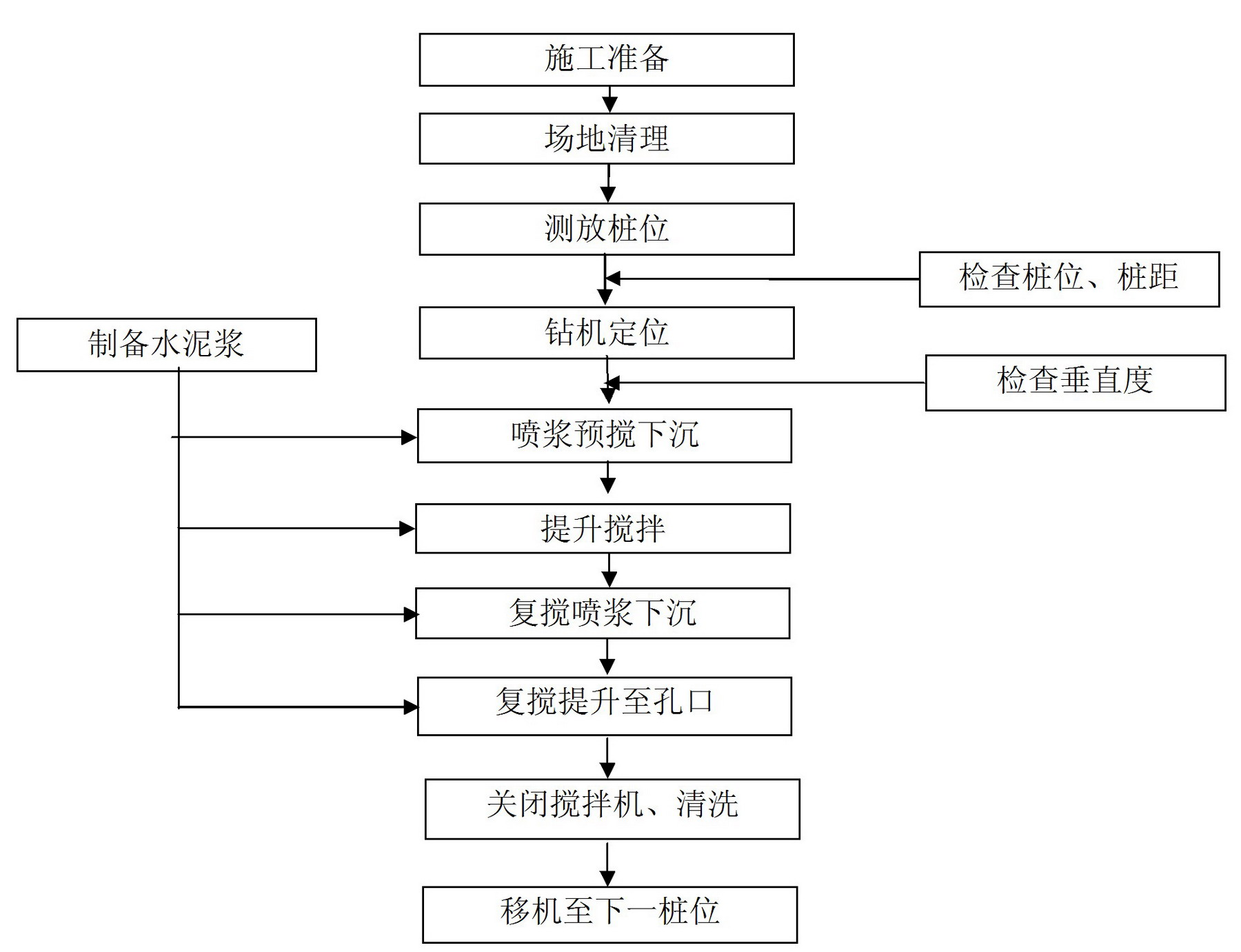

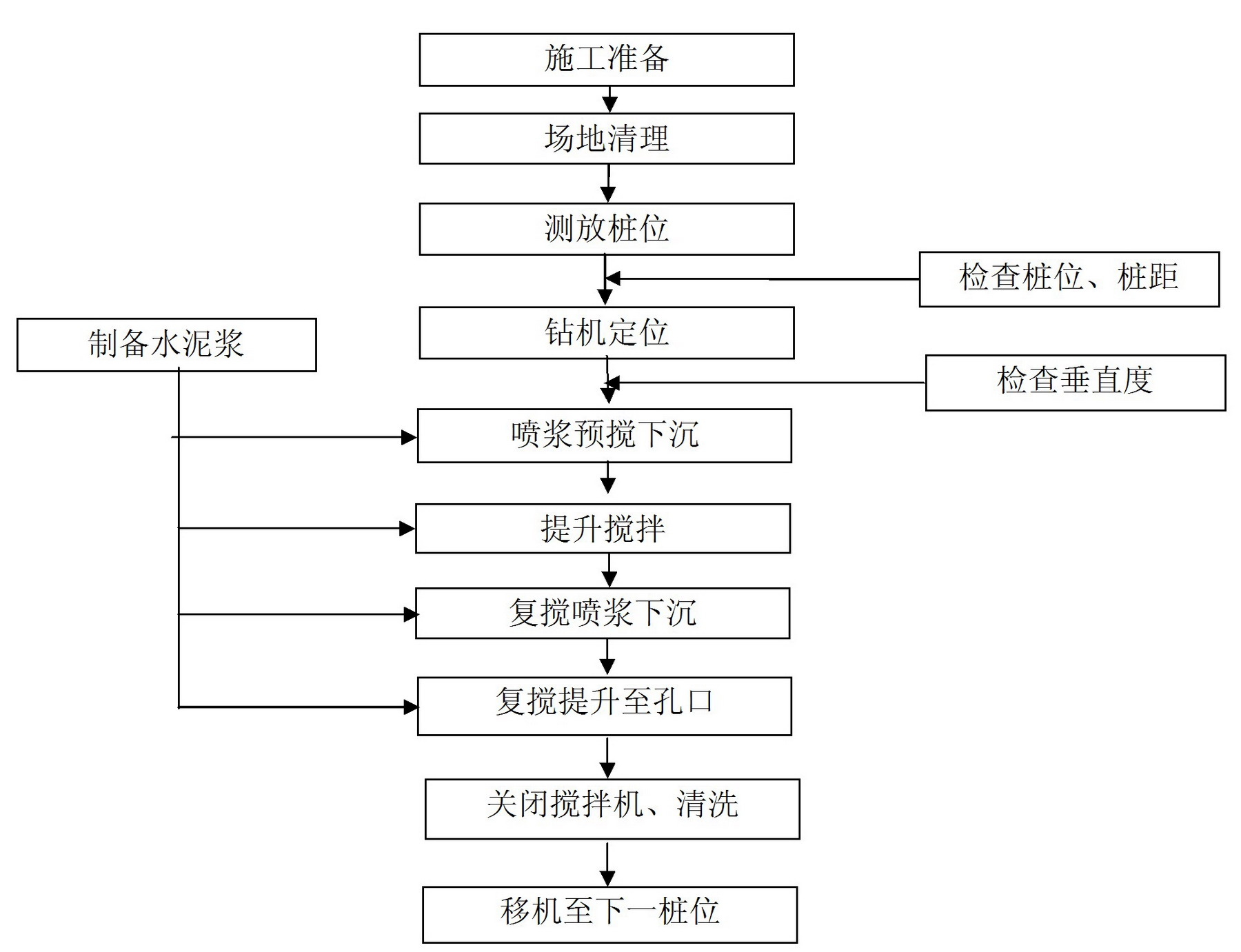

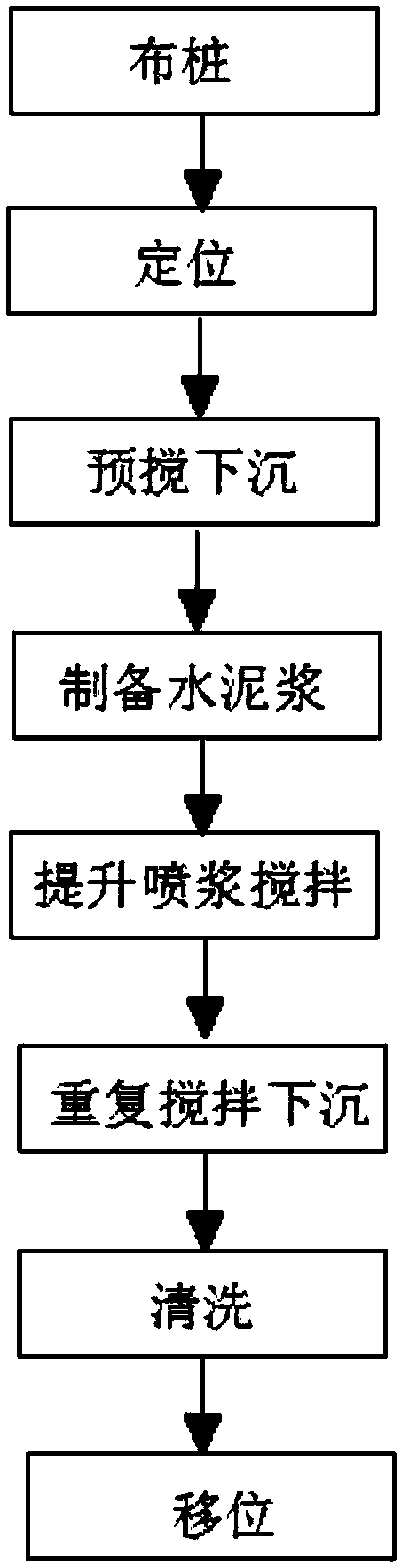

Method for reinforcing soft soil foundation at deep mixing pile

InactiveCN102021906ASave materialReduce dosageFoundation testingBulkheads/pilesEconomic benefitsUltimate tensile strength

The invention relates to a method for reinforcing a soft soil foundation at a deep mixing pile, which comprises the steps of land formation, construction layout, spray mixing and sinking, curing agent grout mixing, stirring and hoisting, repeated spray mixing and sinking, and shifting, etc.; and the main technological parameters are as follows: 0.55 to 0.75 of water-cement ratio, 0.38 to 0.75 m / min of sinking and empty stirring speed, 0.3 to 0.5 m / min of hoisting speed, 18 to 30L / min of guniting quantity and 0.5 to 0.7 MPa of guniting pressure. Compared with the existing cement mixing pile foundation reinforcing process, the method provided by the invention has the advantages of appropriate water-cement ratio, high pile quality, high strength, less reinforcing agent consumption, low cost and remarkable economic benefit, and is easy to evenly stir; and meanwhile, the method also has the following advantages: (1) the cement can be hydrated fully, and during construction, the role of the cement can be exerted completely; (2) the construction quality is easy to control and guarantee; and (3) the construction on deep piles can be performed.

Owner:河南省新开元路桥工程咨询有限公司

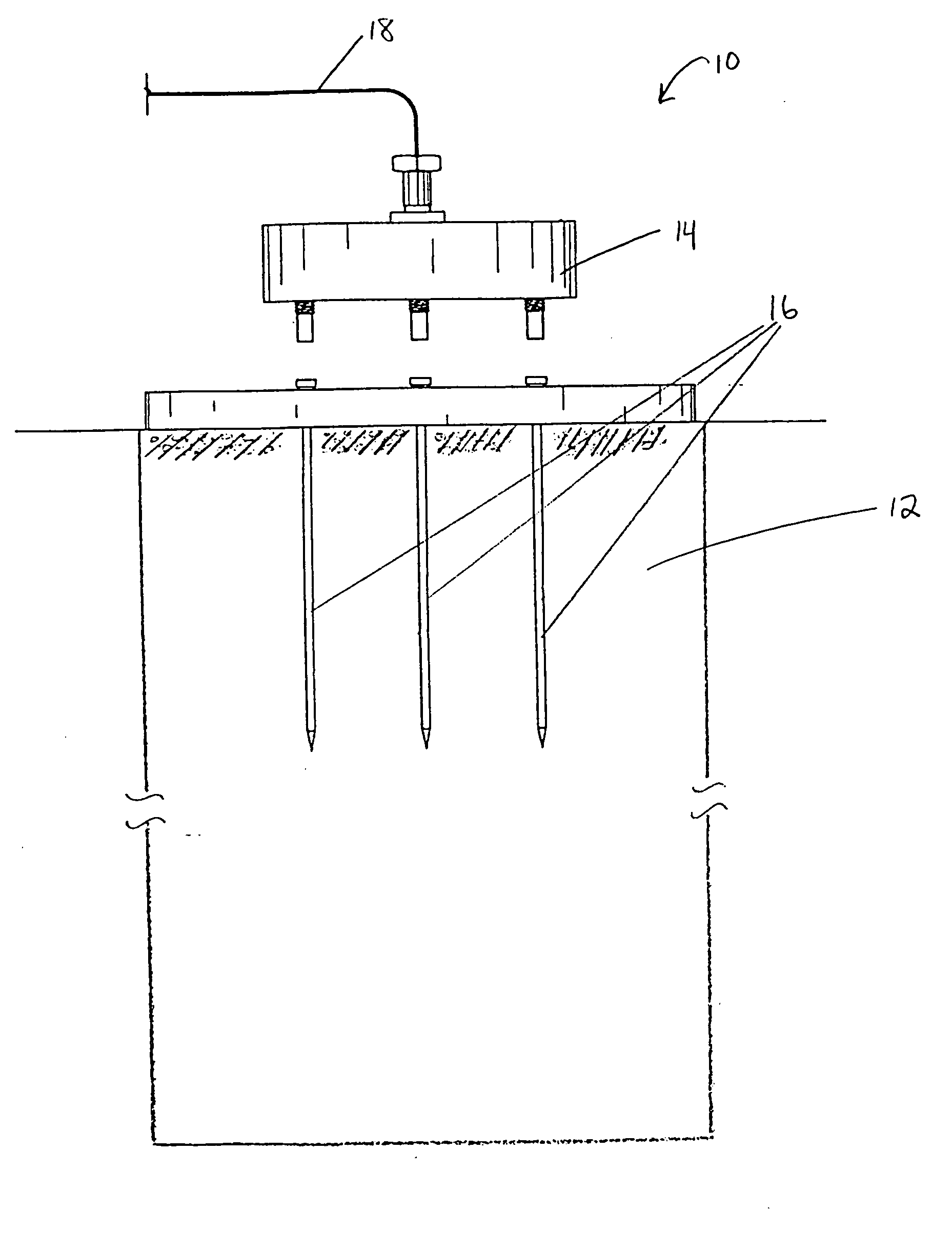

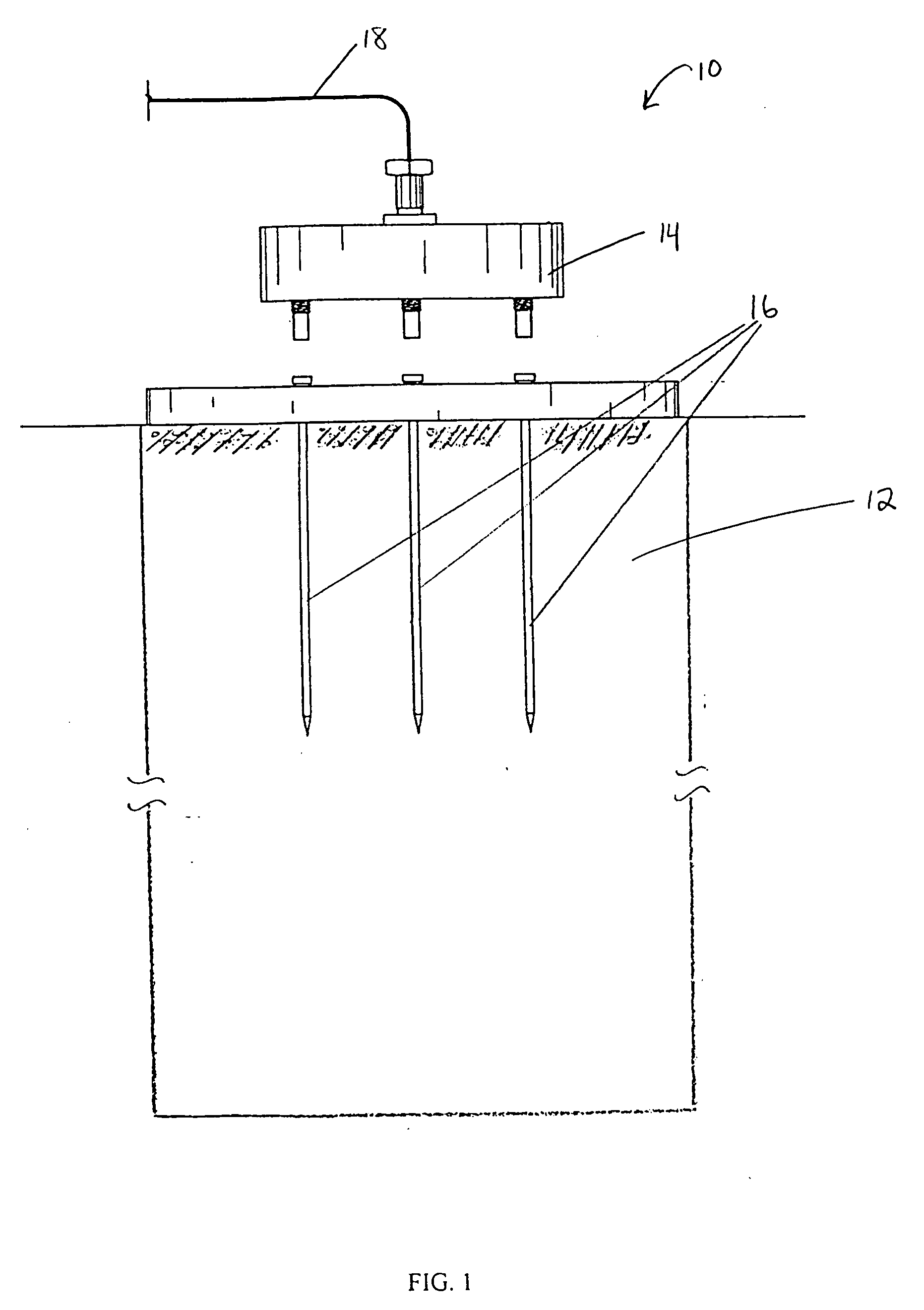

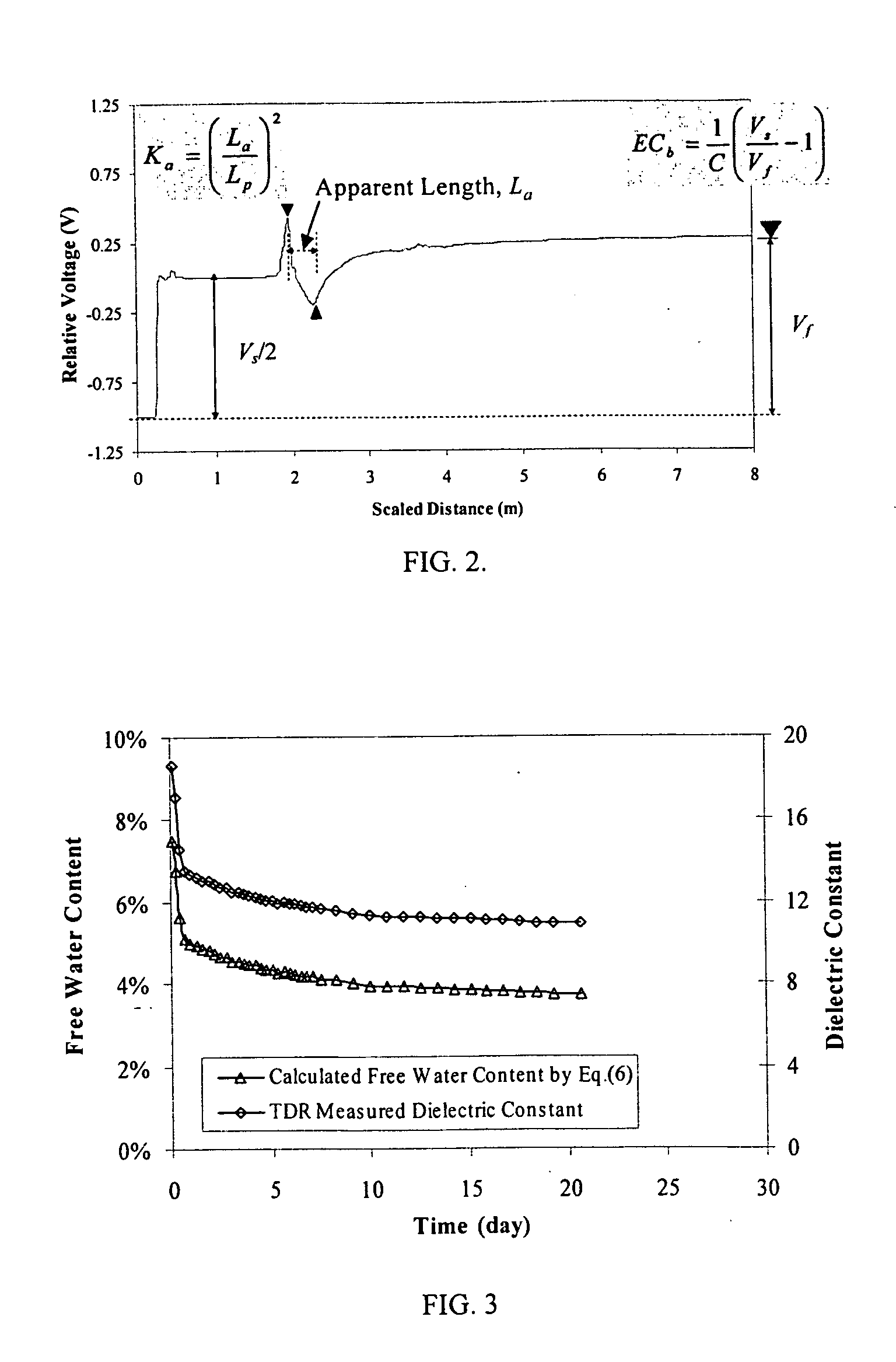

Method and apparatus for measuring properties of concrete

InactiveUS20050210995A1Inflated body pressure measurementFluid pressure measurement by electric/magnetic elementsTime domainElectricity

Methods and apparatus using time domain reflectometry to determine electrical properties of concrete for calculating physical and mechanical properties of the concrete that are indicative of concrete quality and durability. The dielectric constant of a concrete is determined to calculate the gravimetric water content of the concrete for use in finding the water-cement ratio of the concrete. Electrical conductivity of curing concrete is determined to calculate compressive strength of the concrete for use in predicting strength development in the concrete.

Owner:PURDUE RES FOUND INC

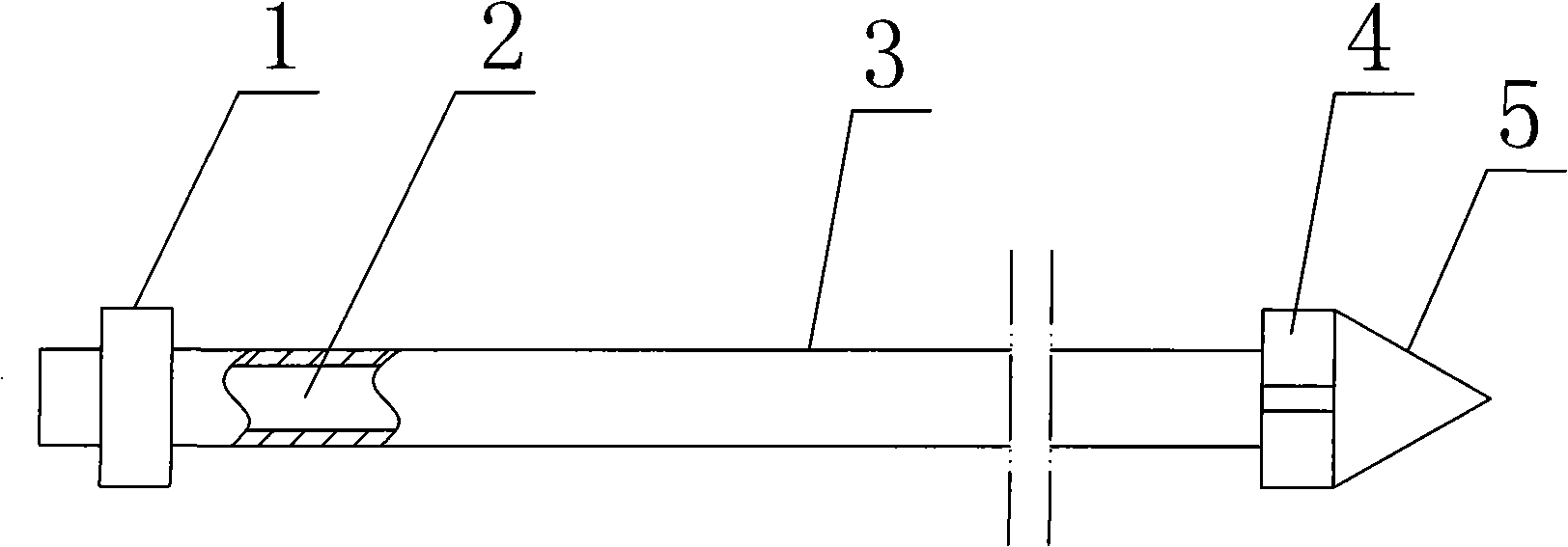

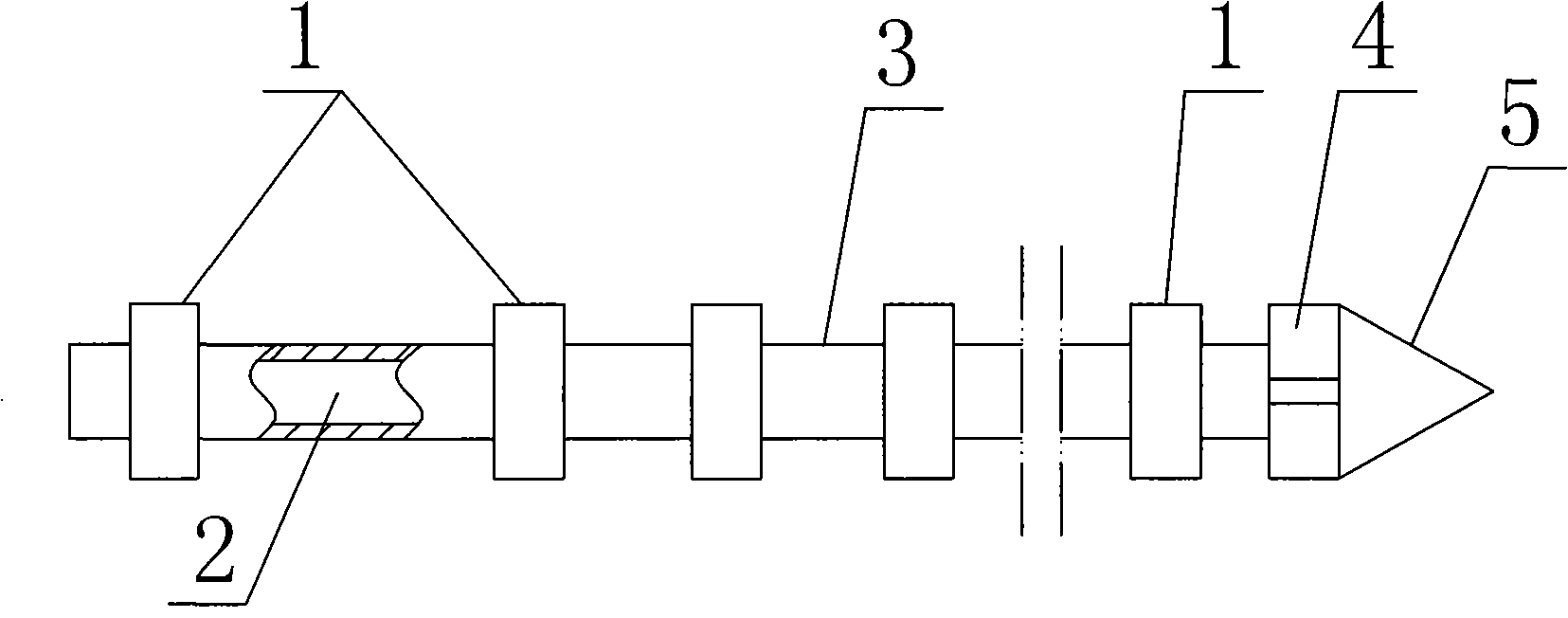

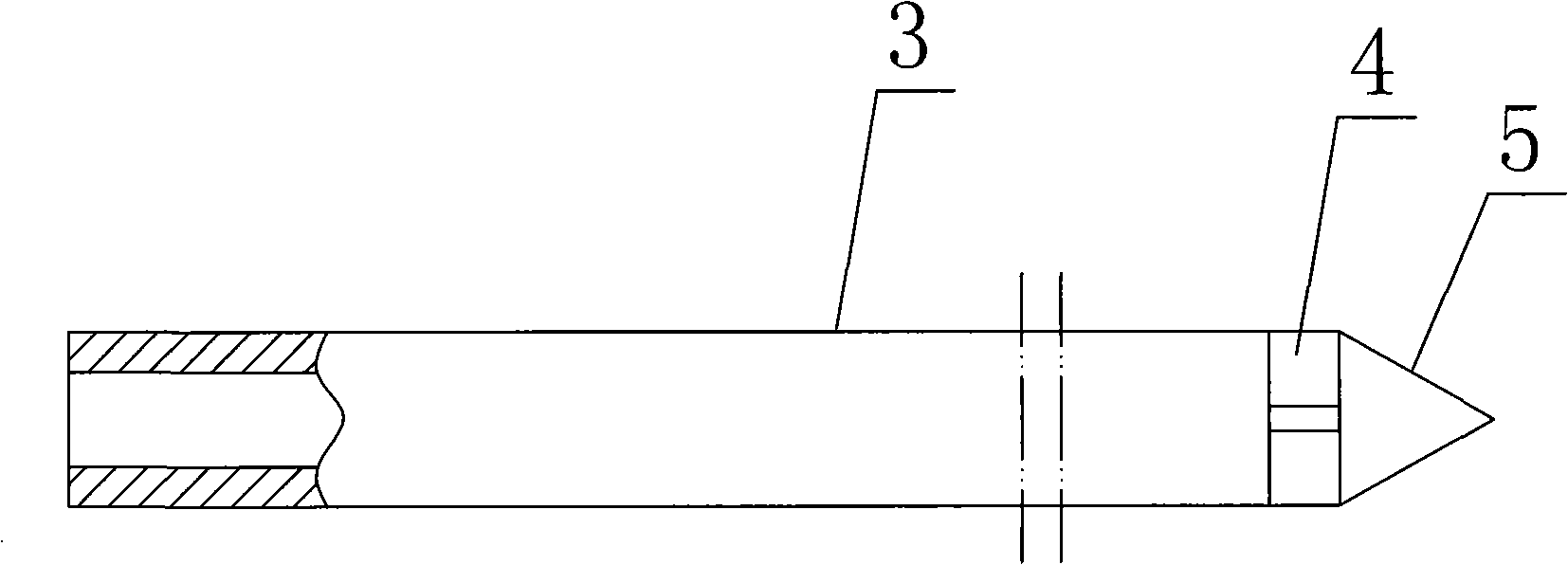

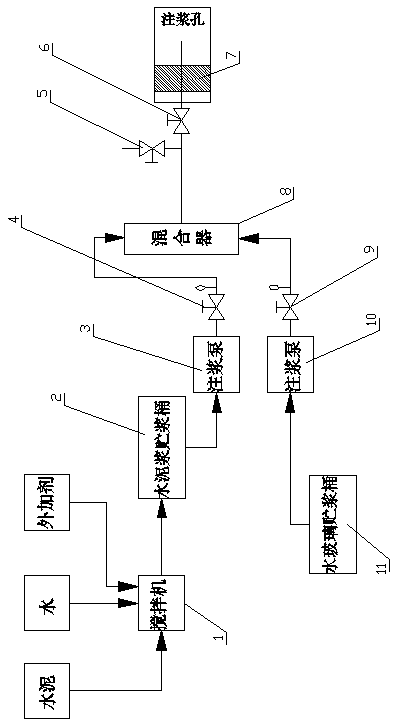

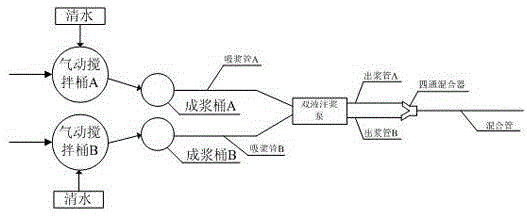

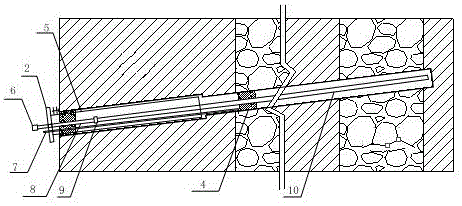

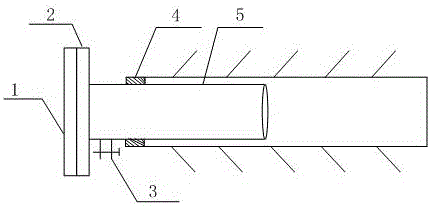

Single/double slurry alternated grouting reinforcement technology of tunnel and device of single/double slurry alternated grouting reinforcement technology

InactiveCN103953365APlay a blocking roleAvoid the shortcomings of not being able to play a filling reinforcement effectUnderground chambersTunnel liningCement slurryMaterials science

The invention discloses a single / double slurry alternated grouting reinforcement technology of a tunnel and a device of the single / double slurry alternated grouting reinforcement technology. The single / double slurry alternated grouting reinforcement technology comprises the steps of preparing slurry, wherein a component A is prepared into cement slurry, the cement slurry comprises water, cement and an additive, a water cement ratio is 0.8-0.9, the cement slurry can flow into a cement slurry storage barrel after being uniformly stirred, a component B adopts water glass solution, and cement and water glass double slurry can be formed after the component A and the component B enter a mixer by connecting a grouting pump through pipelines; grouting, wherein a water glass solution valve can be switched off, a cement slurry valve can be switched on, pure single cement slurry can be firstly injected, mixed injection can be carried out by switching on the water glass solution valve, and the interval injection time of single slurry and double slurry is controlled within 1-3 mins; washing, wherein the pipelines need to be washed immediately after the grouting in one hole is completed. According to the single / double slurry alternated grouting reinforcement technology disclosed by the invention, the solidification time by simply injecting the single slurry is slow and the filling range of the double slurry is small are solved, the slurry can be reasonably controlled to reach to a corresponding stratum position and to be solidified, and the effects of well filling stratum gaps and preventing the ground from collapsing again can be obtained.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Colorful water permeable concrete pavement and construction technique

InactiveCN101293760AReduce intensitySolve the problem of defects with low strengthSolid waste managementRoad surfaceToxic industrial waste

The invention relates to a chromatic pervious concrete pavement material and a construction process thereof, which is characterized in that the formulation of a special concrete binding agent comprises 85 to 92 percents of cement (weight), 5 to 10 percents of silicon ash, and rubber powder, early strength admixture, water reducing agent and paint. The ash collection ratio is 4.0 to 6.0; the water cement ratio is 0.30 to 0.40; dry power shaped binding agent, aggregate and water are added in a concrete agitator according to the blending ratio so as to be churned into a mixture with uniform and proper dryness and humidity, which is then is used for paving and construction after being flattened; a low frequency flat oscillator is used for vibrating, compacting and leveling on the surface; the water is poured for maintenance; oily crylic acid resin is taken as mat coat agent to ensure that the color of the pavement is fresh. The chromatic pervious concrete pavement material and the construction process thereof have the advantages that steel-making industrial waste residue is adopted as the aggregate to change waste into valuables; the problem of low strength of the non-sand water permeability concrete material with a plurality of holes is solved by lower cost; compared with the high molecule permeable material, the cost is low, the strength is high, and the ageing resistance is good; compared with the sintering ceramics permeable material, the cost is low, the energy consumption is reduced, and the permeability effect is strong.

Owner:上海固华墙体环保科技有限公司 +1

Mine fracture grouting material and usage method thereof

The invention discloses a mine fracture grouting material and a usage method thereof. The mine fracture grouting material comprises raw materials of, by weight, 5.5-6.0kg of superfine cement, 0.5-1.0kg of silica powders, 2.5-3.0kg of coal ashes, 0.3-0.5kg of bentonite and 0.05-0.12kg of water reducing agents. According to the mine fracture grouting material, the superfine cement is used as a host material and supplemented by other materials, and the main fracture grouting material has the advantages of being high in concretion rate, tiny in expansibility, low in bleeding rate and good in stability; when the water cement ratio is 1: 1, the 28-day compression strength of the mine fracture grouting material can reach 15MPa; the mine fracture grouting material can be well injected and permeated into fine fractures of rock masses; the problem of ground water environmental pollution caused by chemical grouts is absent, and engineering requirements of reinforcement and impervious effects are satisfied; and grouts manufactured by the mine fracture grouting material can be applicable to mine water management and micropore fractured rock mass reinforcing engineering of hydraulic and hydro-power engineering rock masses.

Owner:NO 1 SURVEYING TEAM OF ANHUI CHARCOAL FIELD & GEOLOGY BUREAU

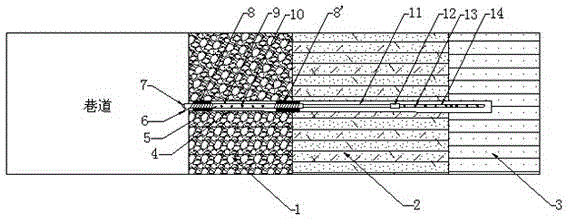

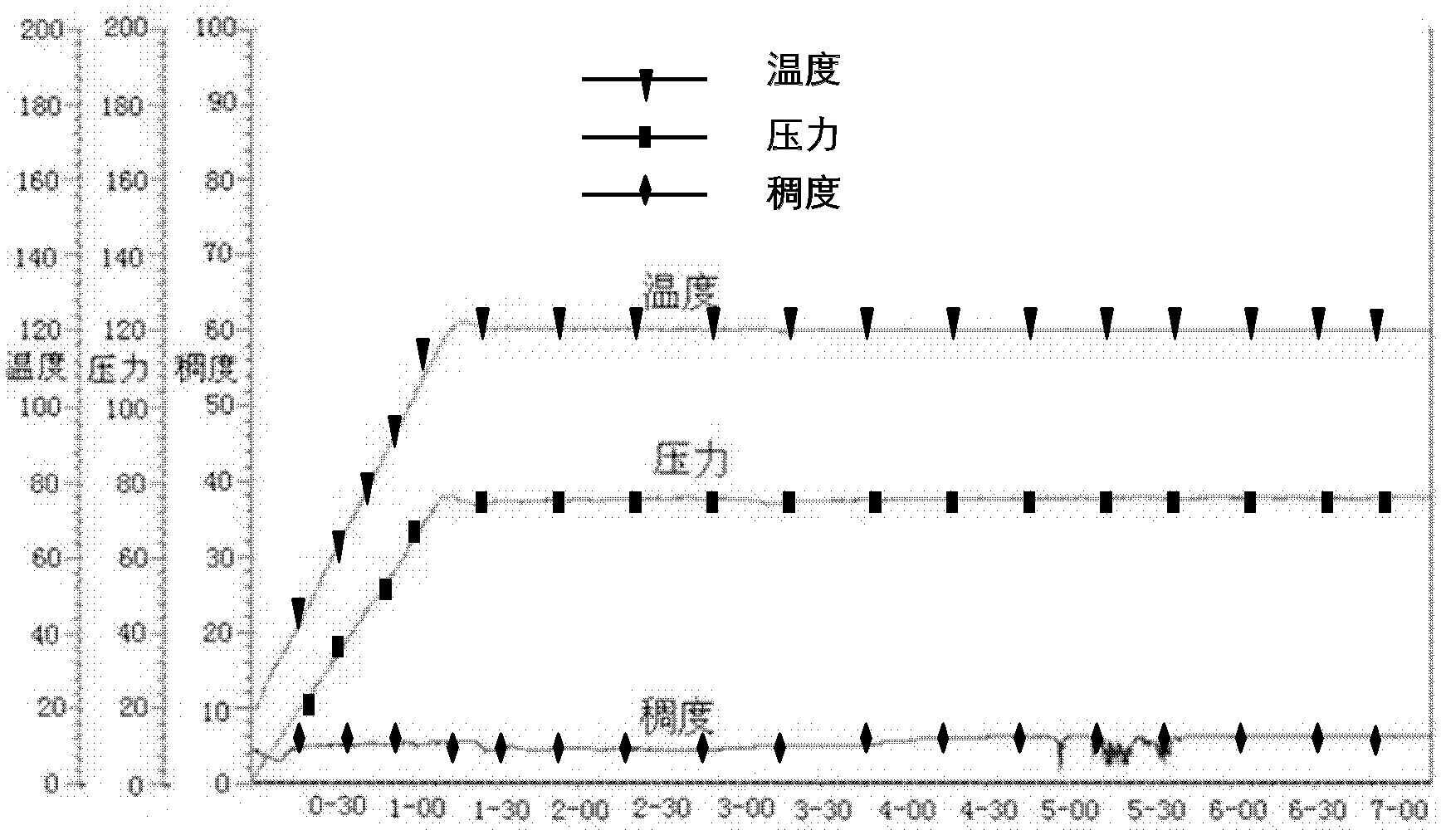

Coal mine tunnel broken surrounding rock layering grouting technology and method

InactiveCN104594914AReduce grouting costsGood grouting effectUnderground chambersTunnel liningViscosityCoal

The invention discloses a coal mine tunnel broken surrounding rock layering grouting technology and method. Novel double-fluid inorganic grouting materials are adopted, and the method is matched with a novel grouting hole sealing device to achieve drilling layering grouting. The method comprises the steps that grouting drilling is constructed at first, the dual-layer grouting hole sealing device is adopted for hole sealing, then, grouting materials with the low water cement ratio, high viscosity and high condensation speed are adopted to be used in cooperation with the low-pressure and low-flow grouting technology, an outer layer grouting pipe is utilized for conducting grouting on a surrounding rock shallow layer broken zone to form an effective grouting stopping layer, then, the water cement ratio of the grouting materials is improved gradually, the material permeability characteristics are improved, the material curing time is prolonged, the grouting pressure is gradually improved, and an inner layer grouting pipe is utilized for completing surrounding rock deep layer grouting. The method adapts to surrounding rock failure and permeability characteristic zoned characteristics, the grout leakage problem is effectively solved, and layering grouting in the same drilled hole is achieved.

Owner:HENAN POLYTECHNIC UNIV +1

Method for reinforcing soft soil foundation by using cement-soil mixing pile

The invention relates to a method for reinforcing a soft soil foundation by using cement-soil mixing piles. The method comprises the steps of 1) arranging pile positions on the soft soil foundation; 2) lifting a mixing machine to one pile position on the soft soil foundation by using a tower crane; 3) starting up the mixing machine, wherein a mixing head cuts soil while rotating and then sinks to design depth; 4) preparing cement grout; 5) lifting the mixing head, spraying the grout and performing mixing to enable the cement grout to be fully mixed with the soil till the mixing head is lifted up to the ground; 6) repeating the step 3 to the step 5, wherein each pile requires for re-mixing and re-spraying; 7) filling clean water into an aggregate bin, starting up a grout pump to clean residual grout in all pipelines and cleaning the mixing head; and 8) moving the mixing machine to the next pile position and repeating the step 2 to the step 7 to carry out the construction of the next pile. Compared with the prior art, the method for reinforcing the soft soil foundation by using the cement-soil mixing piles has the advantages that the water-cement ratio is proper, the goal of uniform mixing is easy to realize, the pile forming quality is high, the strength is high, the construction is convenient to carry out, the construction cost is low and the economic benefits are remarkable.

Owner:STATE GRID CORP OF CHINA +2

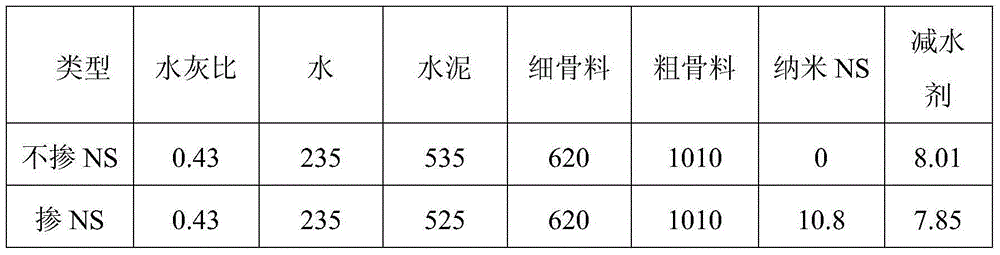

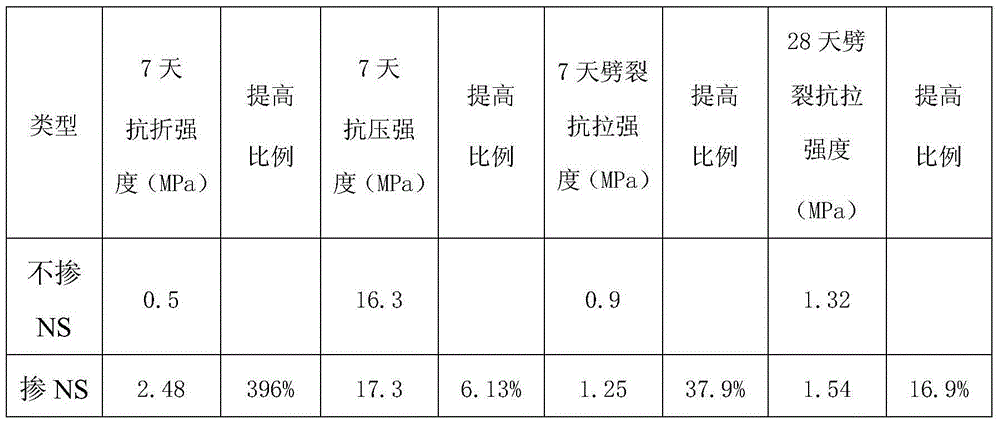

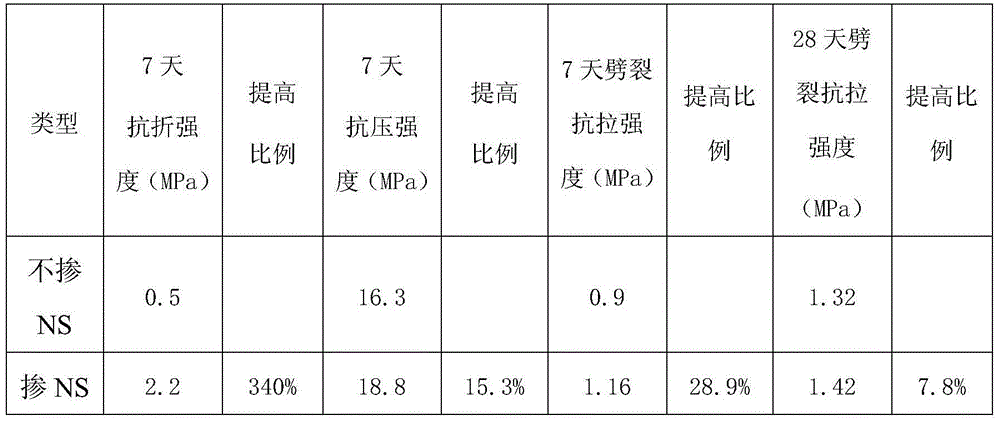

High early-strength high-performance concrete mixed with nano silicon dioxide powder and preparation method thereof

The invention discloses a high early-strength high-performance concrete mixed with nano silicon dioxide powders and a preparation method thereof. The concrete comprises following components, 519-550 kg / m<3> of cement, 1010-1040 kg / m<3> of a crude aggregate, 600-620 kg / m<3> of a fine aggregate, 225-235 kg / m<3> of water, 7.77-9.1 kg / m<3> of a high-performance water reducer and 8.1-16.2 kg / m<3> of nano silicon dioxide. A mixing ratio of the concrete is 37-38% in sand percentage and 0.40-0.43 in water-cement ratio. The fine aggregate is river sand or medium sand and the particle size of the crude aggregate is 5-35 mm. Water reducing rate of the high-performance water reducer is not less than 25%. The average particle size of the nano silicon dioxide is 30+ / -5 nm. The preparation method can improve early strength of the concrete and the concrete can be used for winter construction of a super-high-rise building and a concrete project which has an early-period requirement of a normal temperature condition and a low temperature condition. The concrete is high in practical value.

Owner:HOHAI UNIV

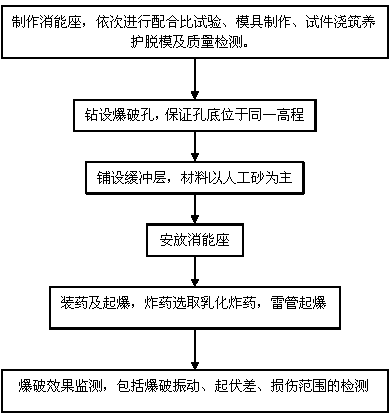

Method for blasting and excavating dam foundation and rock foundation

The invention discloses a method for blasting and excavating a dam foundation and a rock foundation. The method comprises the steps of step 1, drilling blast holes, and paving buffer layers at the bottom parts of the blast holes; step 2, vertically installing energy dissipation seats on the buffer layers, and filling explosive, wherein the energy dissipation seats are prepared by adopting concrete, the concrete is formed by cement, water, iron sand, superplasticizer and gel, the water-cement ratio is 0.24-0.28, the mass ratio of the iron sand and the cement is (1.6-3.0):1, and the mass of the superplasticizer is 1.0%-2.0% of that of the cement; step 3, blasting through a detonator. The method disclosed by the invention has the advantages that the operation is quick and convenient, the construction cost is low, the blast shock waves are reflected for multiple times through the energy dissipation seats, the energy of the blast shock waves is induced to gather in the horizontal direction, the full crushing of rock bodies between adjacent blast holes can be realized, the blasting efficiency can be further increased, meanwhile, the damage to the bottom parts of the blast holes can be further reduced, and the flatness of an excavation surface is increased.

Owner:WUHAN UNIV

Method for producing road water permeable brick by using steel slag

Disclosed is a method for producing a road water permeable brick by using steel slag. The method is characterized in that the steel slag which is from slag fields and are subjected to wheel-style water quenching and pelletization are subjected to screening, wherein the steel slag larger than 5mm is directly used as aggregate, and the steel slag smaller than 5mm is used as cementing materials; each raw material is dried until the moisture content of the raw material is 0.01%-1%; the steel slag smaller than 5mm is ground into micro powders with 400m <2> / Kg specific surface areas, and then cement clinkers, gypsum and slag micro powders are jointly used as the cementing materials for mixing grinding, wherein the proportion of the cementing materials is 70%-80% of the steel slag aggregate, 10%-20% of the slag micro powders, 5%-10% of the steel slag micro powders, 3%-5% of the cement clinkers and 2%-5% of the desulfuration gypsum; and then the steel slag aggregate, the cementing materials and water are stirred according to a water-cement ratio of 0.25-0.35, the mixed materials are filled into a mold for mechanical mashing and pressing, finally molding pressing is performed, and 5 hours of water spraying curing of the steel slag water permeable brick is performed. The method for producing the road water permeable brick by using the steel slags has the advantages of being high in steel slag utilization ratio and simple in production process, the quality of the water permeable brick can reach national standard requirements, and the water permeable brick is difficult to crack.

Owner:北京中冶设备研究设计总院有限公司

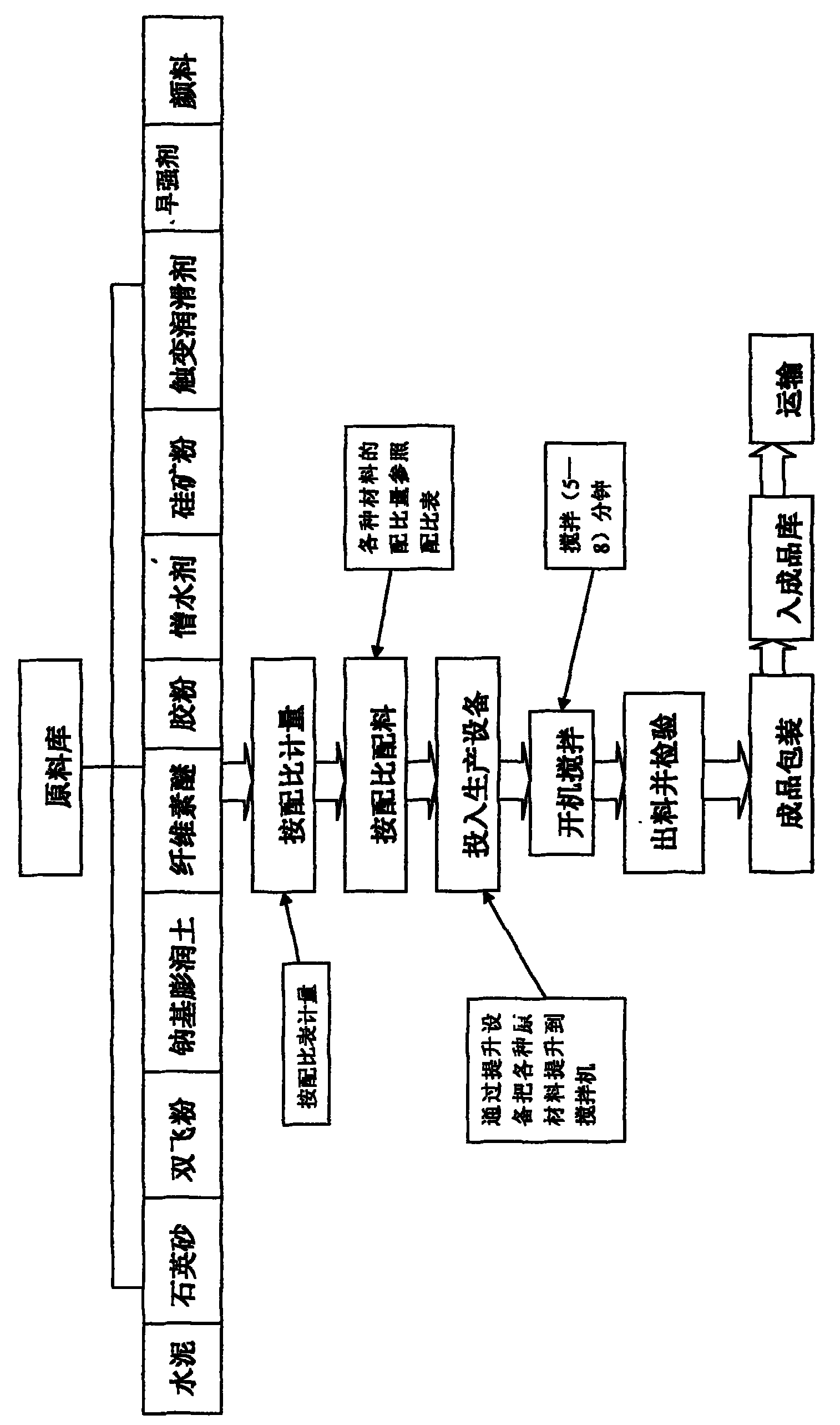

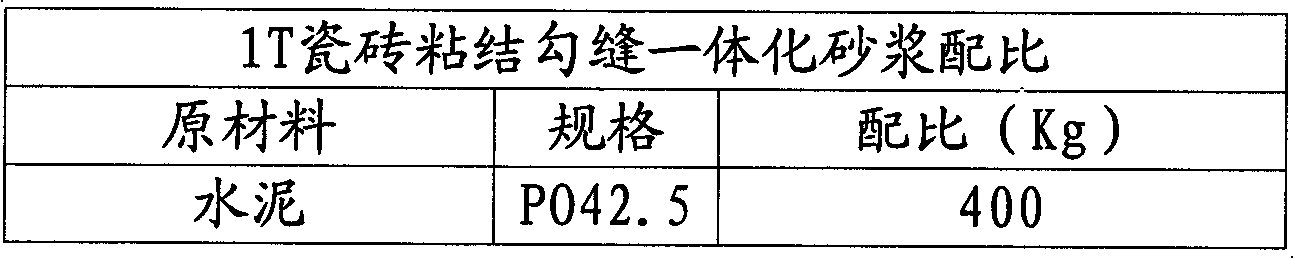

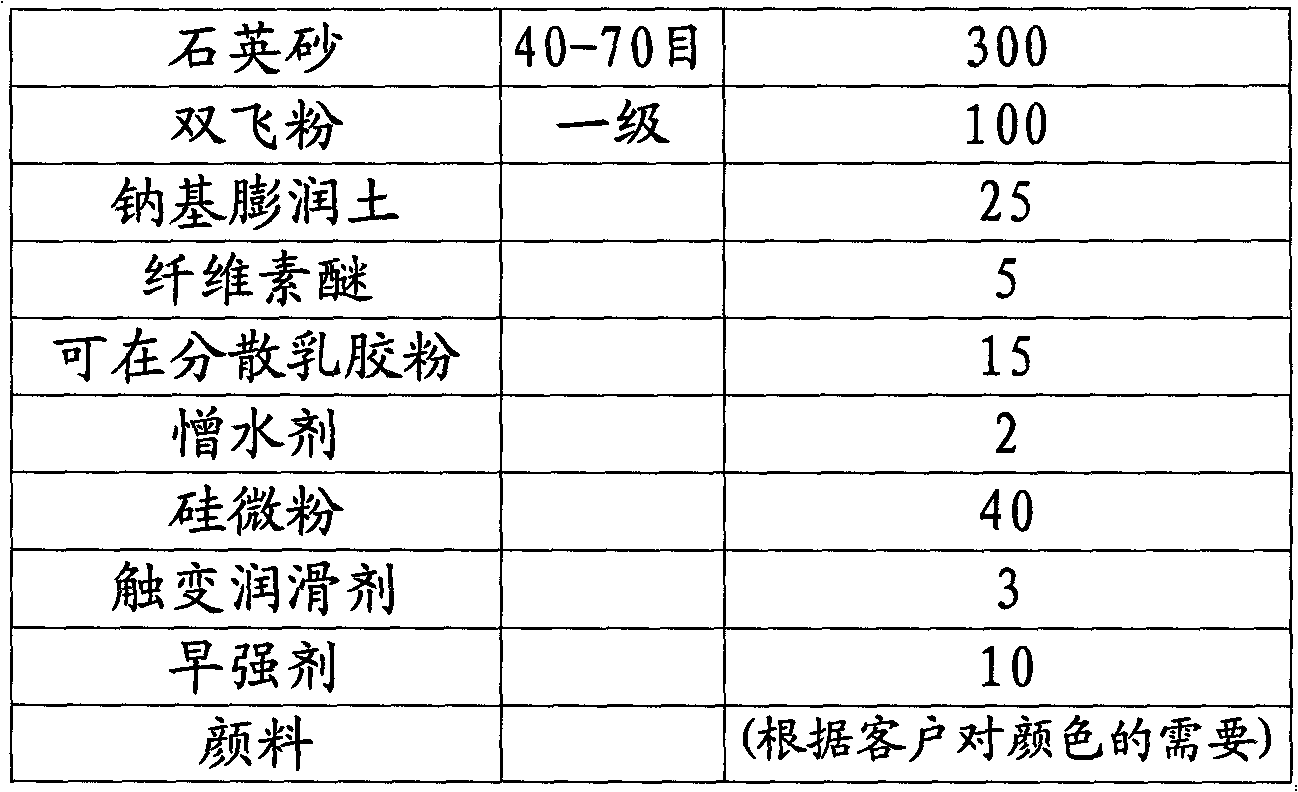

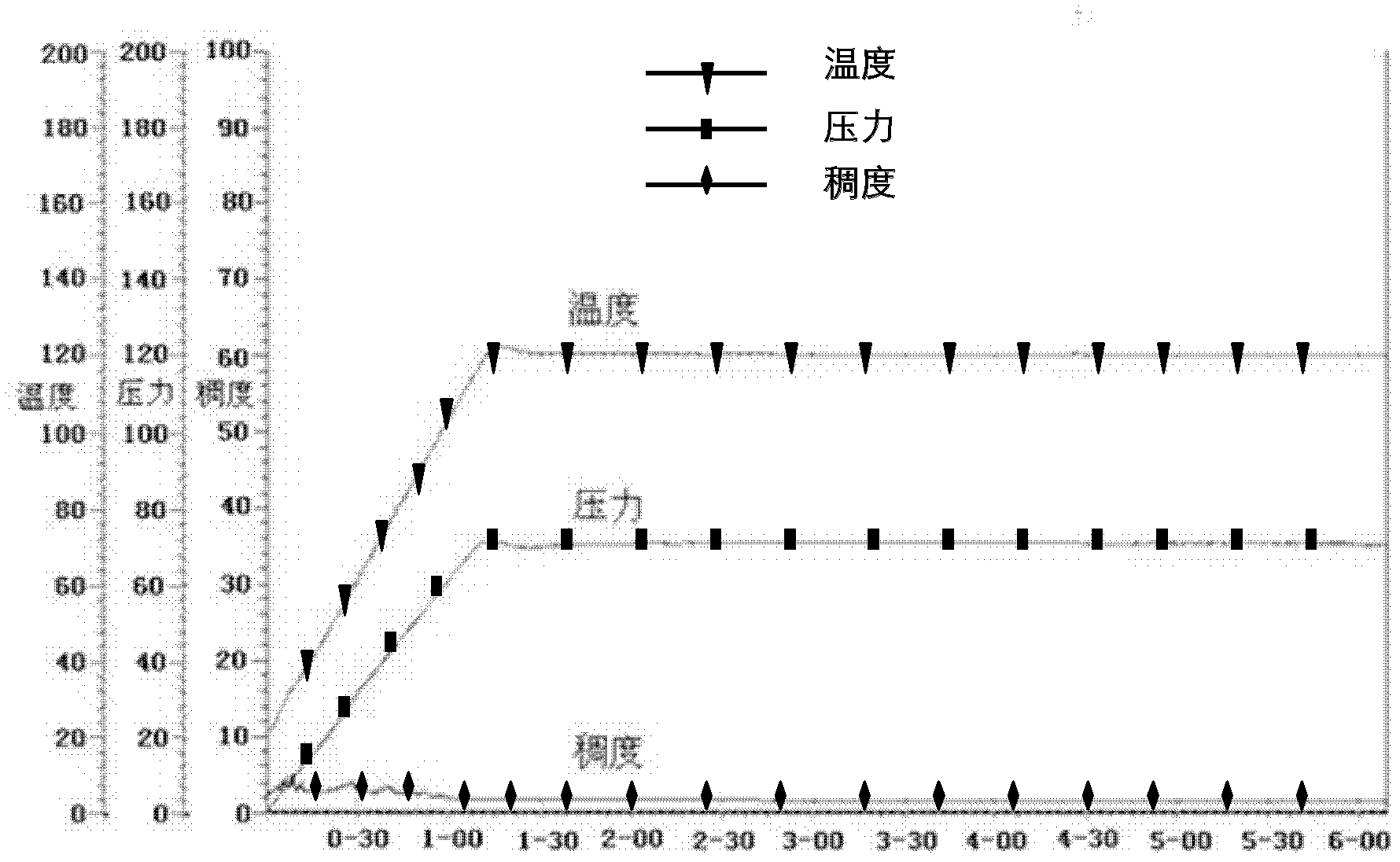

Tile bonding and pointing integrated mortar and its production technology

ActiveCN102424549ASolve the problem of aesthetic influenceReduce construction processCelluloseSodium Bentonite

The invention discloses tile bonding and pointing integrated mortar, which is prepared by subjecting 400 parts by weight of cement, 300 parts by weight of quartz sand, 100 parts by weight of Shuangfei Powder, 25 parts by weight of sodium bentonite, 5 parts by weight of cellulose ether, 15 parts by weight of dispersible latex powder, 2 parts by weight of a water repellent, 40 parts by weight of silicon powder, 3 parts by weight of a thixotropic lubricant, 10 parts by weight of an early strength, and a pigment metered according to a client demand to uniform stirring in a stirrer. The construction process of the tile bonding and pointing integrated mortar comprises: stirring water and cement in a water cement ratio of 0.25 in a stirring bucket into paste with a portable electric mixer, applying the pasty tile glue to the back side of a tile and filling it to the full with a spatula, conducting tiling, tearing off paper after 20min, carrying out pointing with a special circle tool in linewith the size of a tile joint, doing cleaning with a sponge, and cleaning the tile with clear water after 120min. With the mortar of the invention, tile bonding and pointing can be completed in one time. With various colors, the mortar of the invention maintains the color consistency between the underlayer and joints, thus having no influence on appearance. Also, the technology of full applying for pointing can be omitted, and cleaning becomes convenient. Thus, all procedures can be finished at one go.

Owner:贵州皓科新型材料有限公司

Phosphogypsum-based light-weight insulation board and preparation method thereof

InactiveCN105777039ALow densityImprove fire performanceLaminationLamination apparatusSurface layerSlurry

The invention relates to a phosphogypsum-based light-weight insulation board and a preparation method thereof. The phosphogypsum-based light-weight insulation board is prepared from the following raw material components in parts by weight: 100 parts of phosphorus building gypsum, 10-30 parts of high-strength gypsum, 3-12 parts of lightweight aggregates, 0.1-0.3 part of a dispersing agent, 0.3-0.5 part of a retarder, 0.2-0.4 part of a water-retaining agent and 0.1-0.3 part of an air entraining agent. The preparation method comprises the following steps: adding water into a stirring machine in a water-cement ratio of (0.70-0.80):1, adding the air entraining agent, the retarder, the dispersing agent and the water-retaining agent, stirring, then adding a dry material, obtained by uniformly mixing the phosphorus building gypsum, high-strength gypsum and lightweight aggregates, into the stirring machine, continuously stirring to obtain slurry, paving basalt fiber mesh cloth in a bottom die of a gypsum board forming die, pouring into the slurry, vibrating for 1 minute, then paving a layer of basalt fiber mesh cloth on the surface layer, closing a cover die of the gypsum board forming die, carrying out roller forming, taking apart the die after solidification, and drying, so that the phosphogypsum-based light-weight insulation board is obtained.

Owner:WUHAN UNIV OF TECH

Method of preparing low-density well cementation cement check block of oil well by utilizing silicon carbide ceramic microbeads

The invention provides a method of preparing a low-density well cementation cement check block of an oil well by utilizing silicon carbide ceramic microbeads. The method comprises the following steps: preparing silicon carbide closed-hole hollow ceramic microbeads; burdening; mixing; stirring and mixing; carrying out mould testing; carrying out a strength test. The method is characterized by specifically comprising the following steps: stirring and mixing 40-50wt% of G-grade well cementation cement, 10-15wt% of 13-micron superfine cement, 25-35wt% of closed-hole silicon carbide ceramic microbeads with the grain size of 5-50 microns, 5-7wt% of coal ash with the loss on ignition of 1.1%, 1.5-2wt% of calcium oxide with the purity of 99.9%, 0.5-1.0wt% of sodium sulfate and 1-3wt% of micro-silicon in a stirrer for 40 seconds in a micro-silicon of 0.5-0.6(W / C); pouring and carrying out mould testing; maintaining for 24 hours and 48 hours in a water bath maintaining box at a constant temperature of 52 DEG C; soaking for 1 hour in cold water after demoulding and carrying out performance test.

Owner:鑫领域智能科技(邳州)有限公司

Method for blocking water for fracture and hole type reservoir

ActiveCN102587858AWell mixedPrevent leakageDrilling compositionSealing/packingSodium BentoniteAdditive ingredient

The invention provides a method for blocking water for a fracture and hole type reservoir, which is particularly applicable to high-mineralization fracture and hole type reservoirs. The method includes that blocking agent with following ingredients is selected, the ingredients of the blocking agent include, by mass percent, from 5.24 to 9.36% of cement, from 3.03 to 5.35% of microsilica, from 4.01 to 5.43% of sodium bentonite, from 0.52 to 0.55% of polymeric dispersant, from 0.17 to 0.40% of retarder, from 0.0008 to 0.0011% of sodium carbonate aqueous solution by sodium carbonate and the balance water, and water cement ratio of the blocking agent ranges from 4.07 to 6.28; the blocking agent is injected into an oil well according to output volume of 300-800L / min, and after soaking for 72 hours, the well is opened and begins production; and the use level of the blocking agent is equal to 1 / 2 to 2 / 3 of the use level of fracturing liquid during acid-fracturing of an analog crack or communication of reservoir bodies, and is calculated by 5-20m3 / m of a blocking well section for a well without being in acid-fracturing. The density of the blocking agent ranges from 1.09g / cm3 to 1.14g / cm3 and is not changed before and after solidification, solidification strength ranges from 0.22 MPa to 0.43MPa, leakage of the blocking agent due to the density reason cannot be caused in a water blocking process of the fracture and hole type reservoir, and the blocking agent can effectively stay on an oil-water boundary, and selectively blocks a water outlet channel.

Owner:CHINA PETROLEUM & CHEM CORP

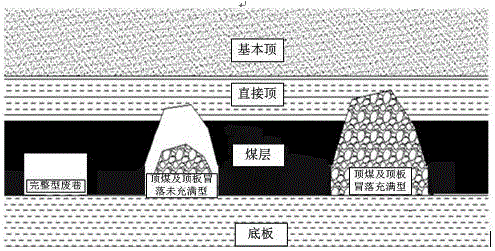

Coal mine residual mining zone falling waste roadway grouting reinforcing technology and method

ActiveCN105952475ASimple processImprove construction efficiencyConstructionsUnderground chambersFracture zoneSlurry

The conventional coal mining technology employs roadway type high fall type coal mining, so mass empty roadways are left in a resource integration mine residual mining zone, wherein most roadways have roof caving problems, thus forming falling waste roadways; when the working face backstopping to penetrate the waste roadways, wall caving and roof caving can easily happen; a grouting reinforcing scheme must be taken to control top board accidents, yet the falling fracture zone is hard in drilling, and easy to leak slurry; the coal mine residual mining zone falling waste roadway grouting reinforcing technology and method uses a novel dual-liquid inorganic grouting material with a large water cement ratio adjustable scope, and employs the graded pore-forming and insert tube grouting technology so as to solve the jamming, hole collapse, and slurry leaking problems in the waste roadway falling fracture zone drilling grouting work, thus preventing working surface exploitation wall caving and roof caving problems; in addition, the method is simple in construction technology, obvious in effect, and wide in practicality.

Owner:HENAN POLYTECHNIC UNIV

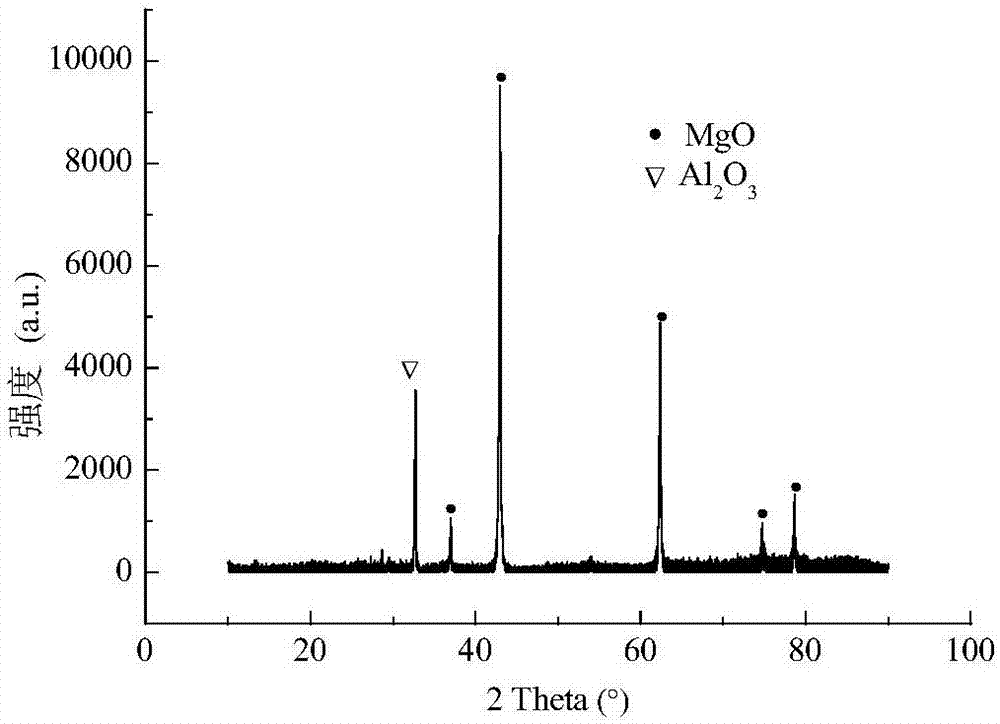

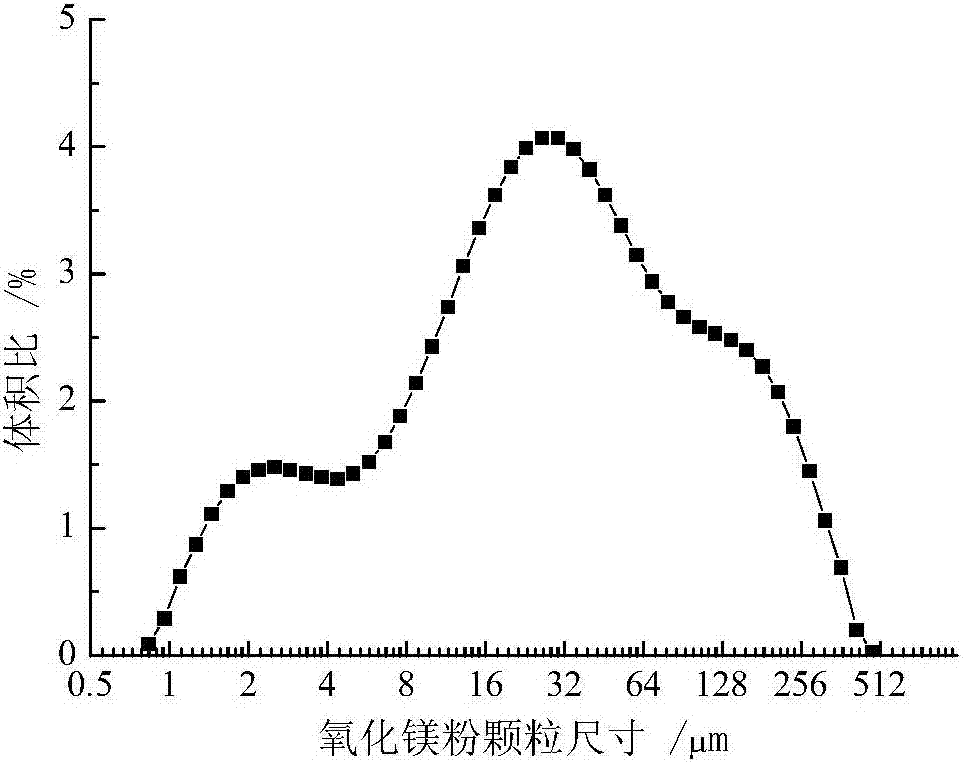

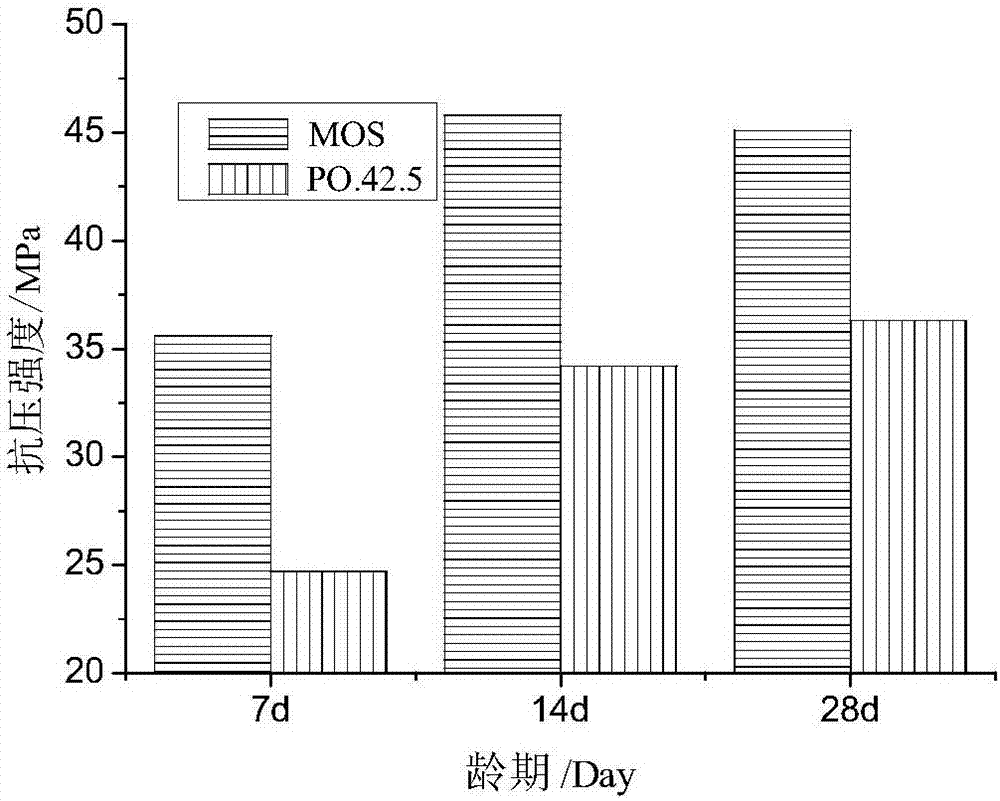

Magnesium oxysulfate-based inorganic composite gelling material with high flexural strength

ActiveCN106882933AImprove mechanical propertiesGood mechanical propertiesPortland cementFlexural strength

The invention discloses a magnesium oxysulfate-based inorganic composite gelling material with high flexural strength. The magnesium oxysulfate-based inorganic composite gelling material is prepared from the following components in parts by weight: 334 to 352 parts of light-calcined magnesium oxide powder, 146 to 154 parts of magnesium sulfate heptahydrate, 1.48 to 2.23 parts of citric acid and 19 to 37 parts of silicon ash. The magnesium oxysulfate-based inorganic composite gelling material has the advantages that by adding the citric acid, the modifying function is realized; by adding the silicon ash, the flexural strength and compressive strength are improved; in each age period, the mechanical property is excellent, and the flexural strength in the 28-day age period is 22 to 23MPa; compared with common portland cement P.0425 with the same water-cement ratio, the flexural strength is increased by 238%; the corresponding softening coefficient of a prepared standard gelling mortar specimen is about 0.85, so that the water-resistant property is higher; the magnesium oxysulfate-based inorganic composite gelling material is completely suitable for important structures soaked in water or in damp environments.

Owner:NINGBO UNIV

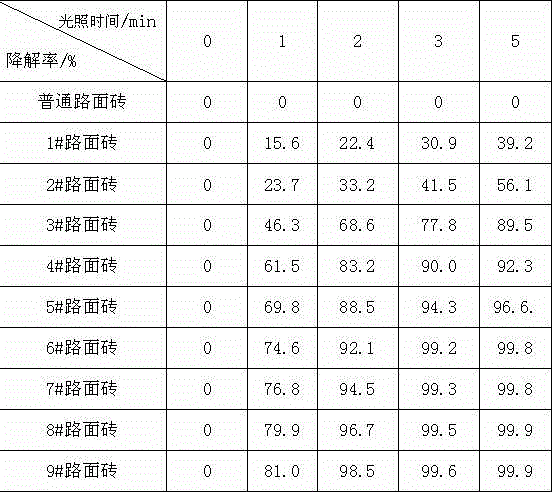

Paving brick for purifying air and preparation method thereof

InactiveCN102873934AWide range of usesHigh strengthCeramic shaping apparatusWater-setting substance layered productBrickRoad surface

The invention discloses a paving brick for purifying air and a preparation method thereof, which belong to the technical field of building materials. The paving brick consists of a surface layer and a bottom layer, wherein the surface layer is prepared from cement, yellow sand, titanium dioxide, a water reducing agent and a pigment in the ratio of 1:3:(0.2-0.4):0.01:0.03, and is in the water-cement ratio of 0.28; and the bottom layer is prepared from cement, yellow sand, broken stone and a water reducing agent in the ratio of 1:3:2:0.01, and is in the water-cement ratio of 0.27. The paving brick has the advantages that (1) the properties of high strength, wear resistance, slip resistance, water permeability and the like existing in the conventional pavement are reserved in the prepared paving brick for purifying air; (2) a large quantity of organic pollution gases in the air can be decomposed under illumination, and the degrading capabilities on toluene and nitrogen oxides generated during emission of automobile tail gas are high; (3) the paving brick has a wide application, can be applied to sections such as town roads, gardens, sub-districts, business streets, pedestrian streets and the like, and has a wide application prospect; and (4) the paving brick does not cause any pollution on the environment, and is convenient to popularize and apply.

Owner:常德市鑫盛建材有限公司

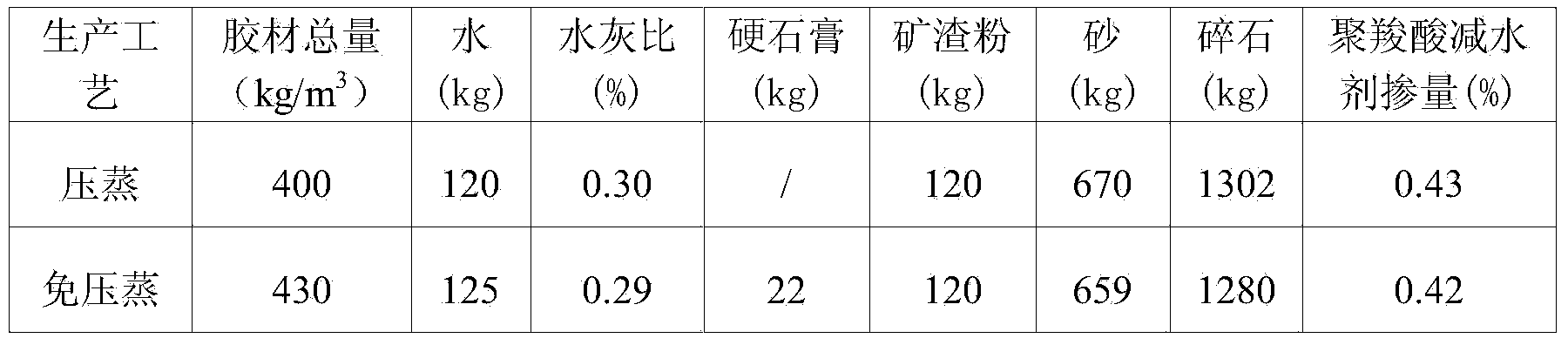

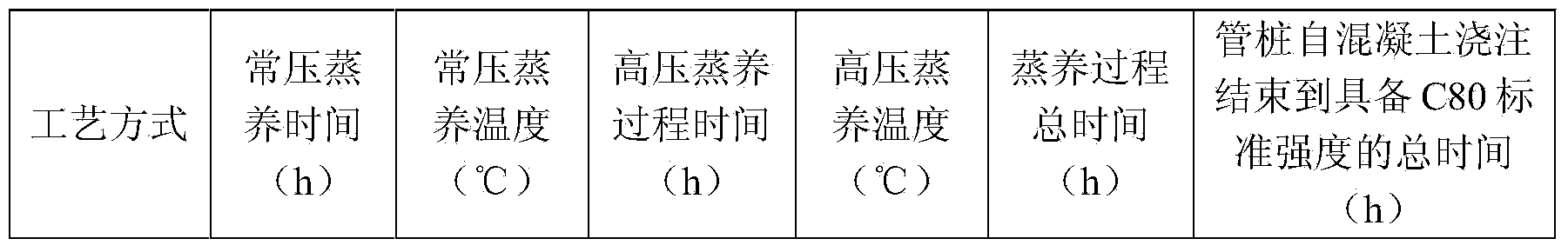

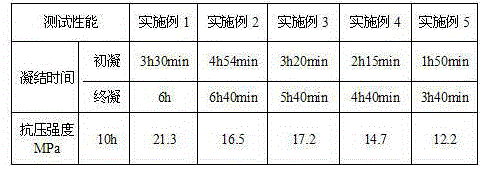

Non-autoclave primary health care (PHC) pipe pile concrete containing early strength composite mineral material and preparation method thereof

The invention relates to non-autoclave primary health care (PHC) pipe pile concrete. The concrete is characterized by being prepared from the following raw materials: a binding material, a water reducing agent, water, coarse aggregate, and fine aggregate, wherein the binding material is prepared from the following raw materials by mass ratio: 3.0-8.0% of rich calcareous material, 25-40% of rich siliceous material and the balance of cement; the water reducing agent accounts for 0.4-0.8% of weight of the binding material; the water cement ratio of the concrete is 29-31%; the sand ratio is 33-35%; the volume-weight is 2480-2500kg / m<3>. The rich calcareous material and the rich siliceous material are compounded at a ratio of 1:4 or 1:6; the cement is excited to hydrate for the second time; the early strength is improved; the C80 strength grade requirements can be met by one-time atmospheric pressure steam maintenance for 6 hours; the performances, such as the volume stability, the carbonizing resistance, corrosion of reinforcement, the chloride penetration resistance, the freeze-thaw resistance, the acid corrosion resistance, the salt corrosion resistance and the like of the PHC pipe pile concrete are improved and changed, and the late durability of the concrete is improved.

Owner:安徽省恒泰新材料有限公司

Pressure bearing and leakage blocking agent

InactiveCN105349125ASmall specific surface areaCuring time controllableDrilling compositionFilling materialsMass ratio

The invention discloses a pressure bearing and leakage blocking agent, which solves the problems of difficult retention, easy mixing, poor caking property and pollution of a drilling fluid of the routine leakage blocking agents. The pressure bearing and leakage blocking agent comprises the following components: an amorphous form aluminosilicate curing agent, an activator, a retarder and an inertia filling material; a ratio of components is calculated according to a following mode: modulus is 1.0-1.4, the activator with mass concentration being 10-20% is taken as a liquid phase, a mass ratio (water cement ratio) of the liquid phase to the curing agent is 0.8-1.2; the addition of the retarder accounts for 0-1% of total amount of the above slurry. The pressure bearing and leakage blocking agent has the advantages of adjustable solidification time, high solidification intensity, large bearing, is not restricted by a leakage channel, so that effective plugging is formed to a leakage layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for quickly repairing concrete road surface

ActiveCN101817663AShort opening hours for trafficIn situ pavingsSolid waste managementSlagPortland cement

The invention discloses a method for quickly repairing a concrete road surface. Each cubic meter of road surface repairing materials adopted by the method comprise the following components by weight: 333 to 387kg of metakaolin, 138kg of slag, 28 to 82kg of ordinary Portland cement, 415kg of water glass, 708kg of medium sand and 1,505kg of stones (5-20mm), wherein the modulus of the water glass is1.4; the water cement ratio of the formula is 0.37 to 0.39; the water content comprises the contained water of the water glass and the externally added water; and the amount of the externally added water is co-determined by the water cement ratio and the contained water of the water glass. Compared with the ordinary cement concrete repairing method, the method of the invention can greatly shortenthe open traffic time; the road repaired by the method of the invention can be used only 8 to 10 hours later at most; and the durability of the repairing materials and the bonding property of the newand old concrete are far superior to those of the ordinary concrete repairing material.

Owner:CHONGQING UNIV

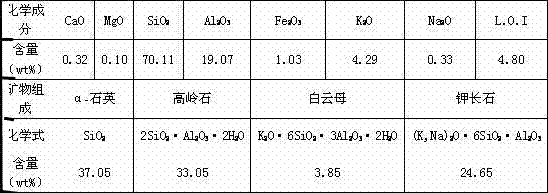

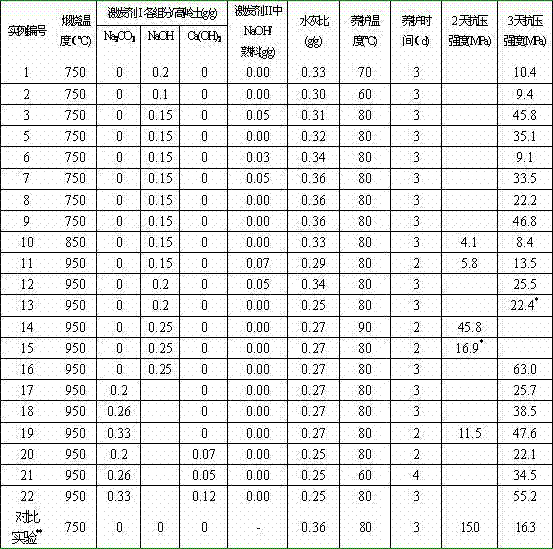

Method for preparing geological polymeric material by using low-grade kaolin

The invention discloses a method for preparing a geological polymeric material by using low-grade kaolin. The method comprises the following steps (1) uniformly mixing low-grade kaolin and an activator I in a certain proportion, wherein the mass ratio of particle size of solid phase in a mixture to material residue on sieve with 200 meshes is less than10%; (2)insulating calcining the mixture in the step (1) at high temperature of 750-950 DEG C for 2-4 hours, grinding the calcined product to obtain the clinker powder, the mass ratio of clinker powder particle size to material residue on sieve with 200 meshes is less than10%; (3) adding an water solution of an activator II in the clinker powder obtained in the step (2), uniformly mixing, vibrating and compacting, keeping the moisture and conserving at 60-90 DEG C for 2-4 days to obtain the geological polymer material; wherein, the water cement ratio of activator II water solution to clinker powder is 0.2 0.4, and the mass ratio of solid phase in activator II to calcined clinker powder is 0 0.07. The present invention has obvious significance for expanding the sources of raw materials, reducing the cost and improving the use convenience.

Owner:HUNAN UNIV OF SCI & TECH

Low-cement-content self-compacting concrete and preparation method thereof

InactiveCN106587788AImprove liquiditySufficient plastic viscosityUltimate tensile strengthCement mortar

The invention provides low-cement-content self-compacting concrete. The low-cement-content self-compacting concrete is composed of the following ingredients: 100-220kg / m<3> of cement, 50-200kg / m<3> of mineral admixture, 500-650kg / m<3> of fine aggregate, 720-900kg / m<3> of coarse aggregate, 15-40kg / m<3> of concrete additive and 60-240kg / m<3> of water. A preparation method of the self-compacting concrete comprises the following steps: (1) putting the fine aggregate, coarse aggregate, cement, a water reducing agent and water into a mixing machine according to the formula ratio, and obtaining cement mortar; (2) putting the mineral admixture into the cement mortar, and mixing; and (3) then putting the rest concrete additive and the rest of water, mixing, and uniformly stirring, so that the self-compacting concrete is obtained. The low-cement-content self-compacting concrete provided by the invention can greatly reduce the cement content, reduce shrinkage by reducing the water cement ratio and improve the stability and strength of concrete, and carbon dioxide emission is reduced as the cement content is reduced, thereby being beneficial to energy conservation, emission reduction, consumption reduction and sustainable development of the environment.

Owner:湖南加美乐素新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com