Method for reinforcing soft soil foundation by using cement-soil mixing pile

A technology of cement-soil mixing piles and soft soil foundations, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large width of plate foundation bottom plate, high foundation cost, and large bottom plate width, and achieve easy construction quality, Significant economic benefits, easy to mix evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

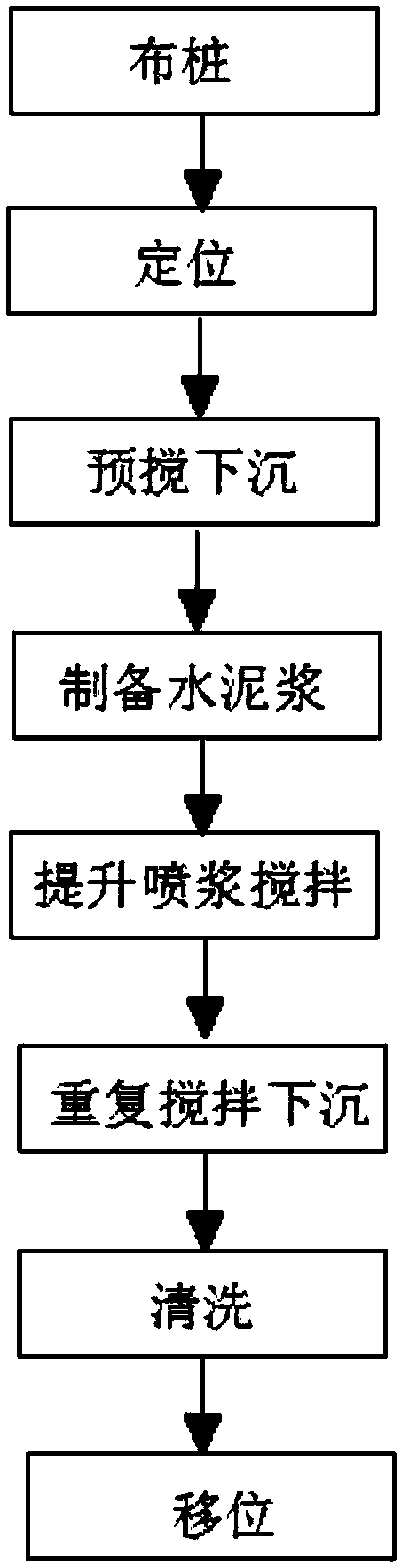

[0034] A method for reinforcing soft soil foundations with cement-soil mixing piles, the process is as follows figure 1 shown, including the following steps:

[0035] (1) Piles: Arrange piles on the soft soil foundation. The piles are arranged in the form of square piles or plum-shaped piles. The depth of the piles is designed to be 6-8 meters, and the diameter of the piles is 0.5-2 meters;

[0036] (2) Positioning: the tower suspension mixer reaches the pile position of the soft soil foundation;

[0037] (3) Pre-mixing and sinking: Start the mixer, the stirring head rotates, cuts the soil, and sinks to the design depth. The sinking speed of the stirring head is 0.4-0.6m / min;

[0038] (4) Preparation of cement slurry: While the mixer is pre-stirring and sinking, prepare cement slurry and pour the cement slurry into the collecting hopper. The water-cement ratio of the cement slurry is 0.4-0.5, and the cement mixing ratio is 10%-15%. , the cement slurry contains 0.5% to 1% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com