Patents

Literature

17089 results about "Reinforced concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforced concrete (RC) (also called reinforced cement concrete or RCC) is a composite material in which concrete's relatively low tensile strength and ductility are counteracted by the inclusion of reinforcement having higher tensile strength or ductility. The reinforcement is usually, though not necessarily, steel reinforcing bars and is usually embedded passively in the concrete before the ...

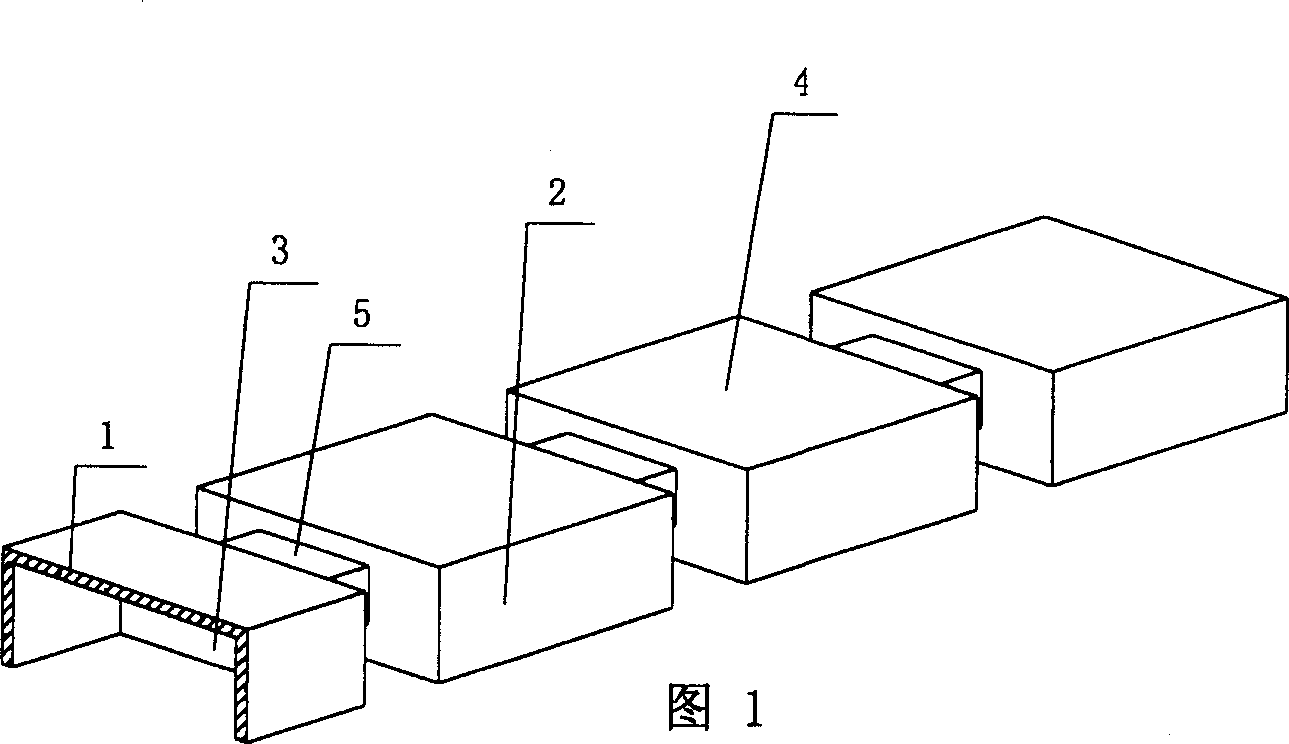

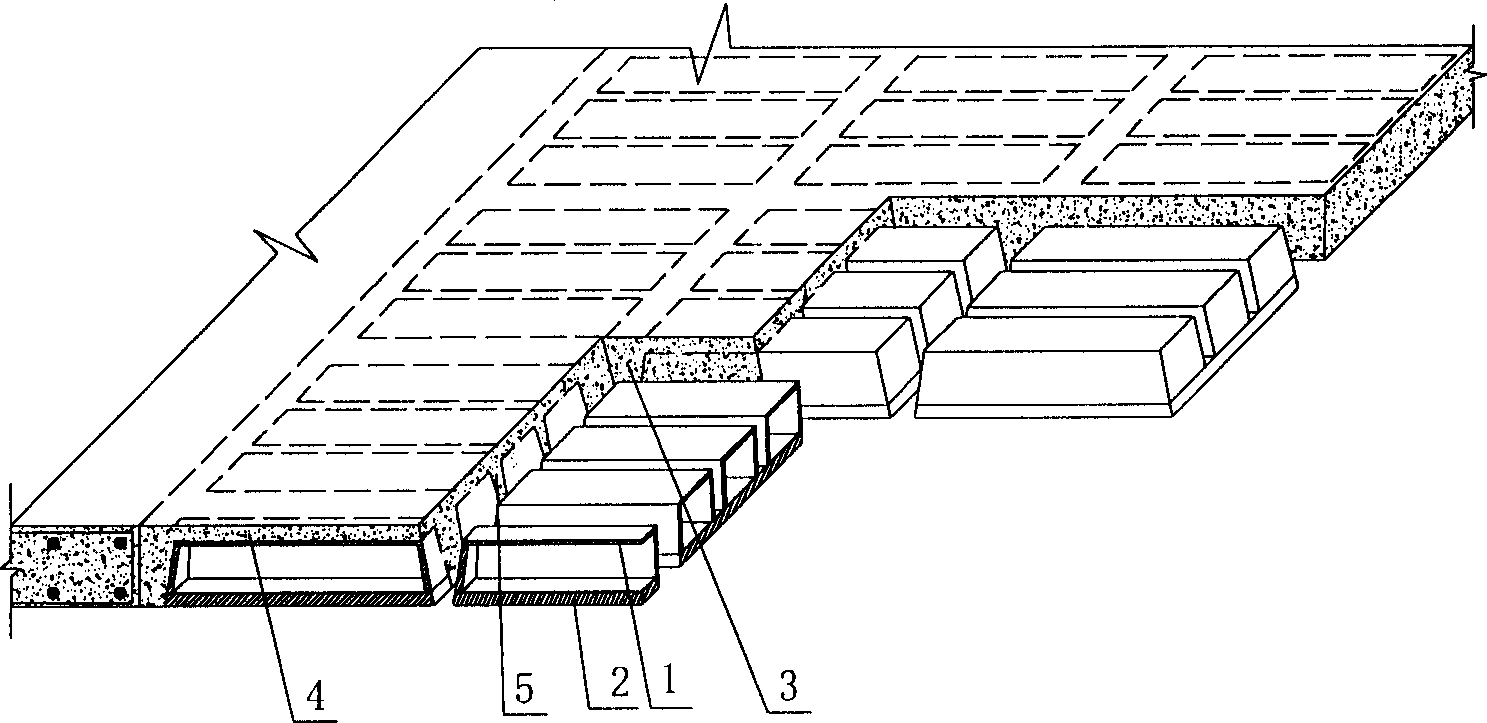

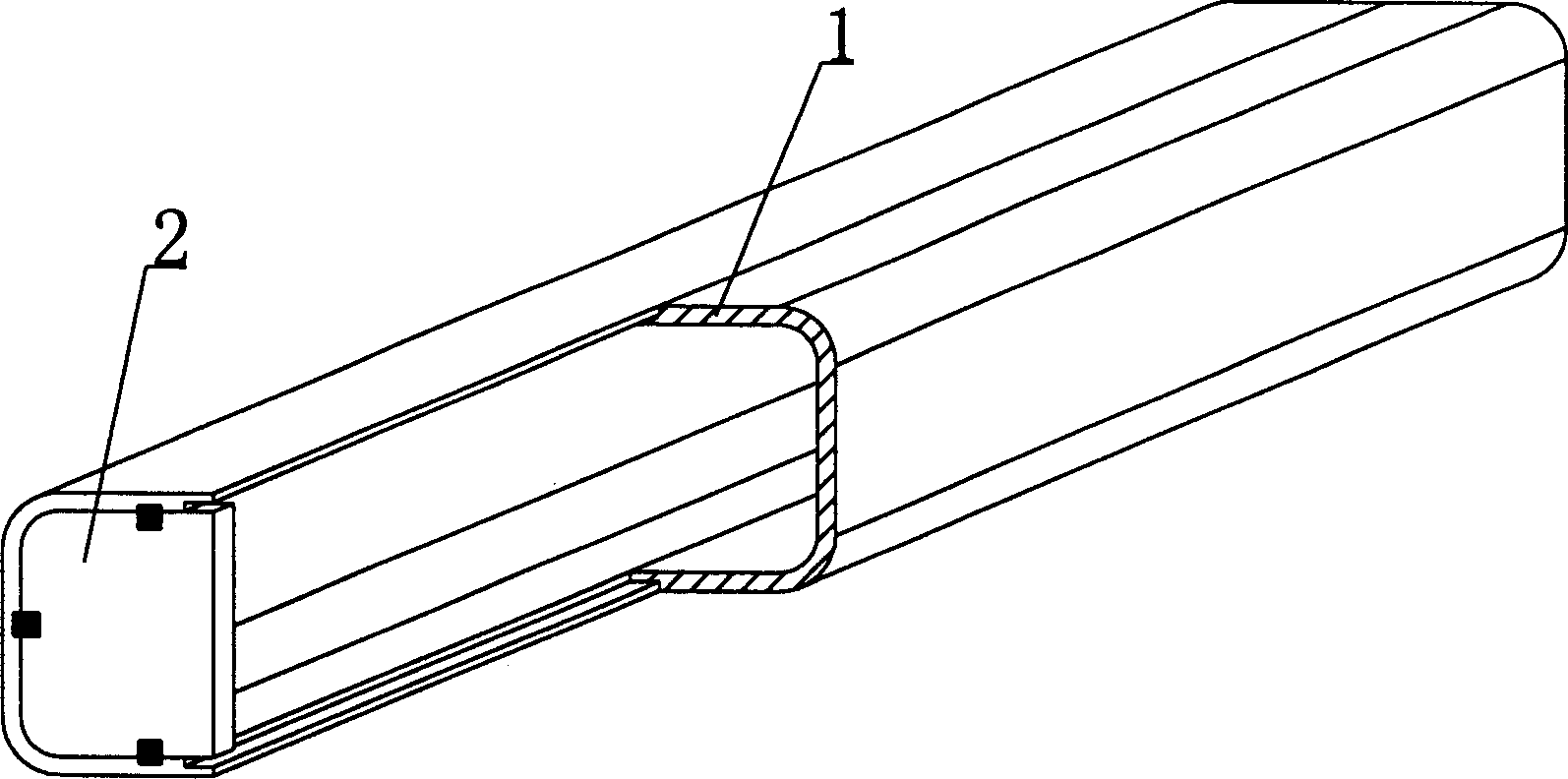

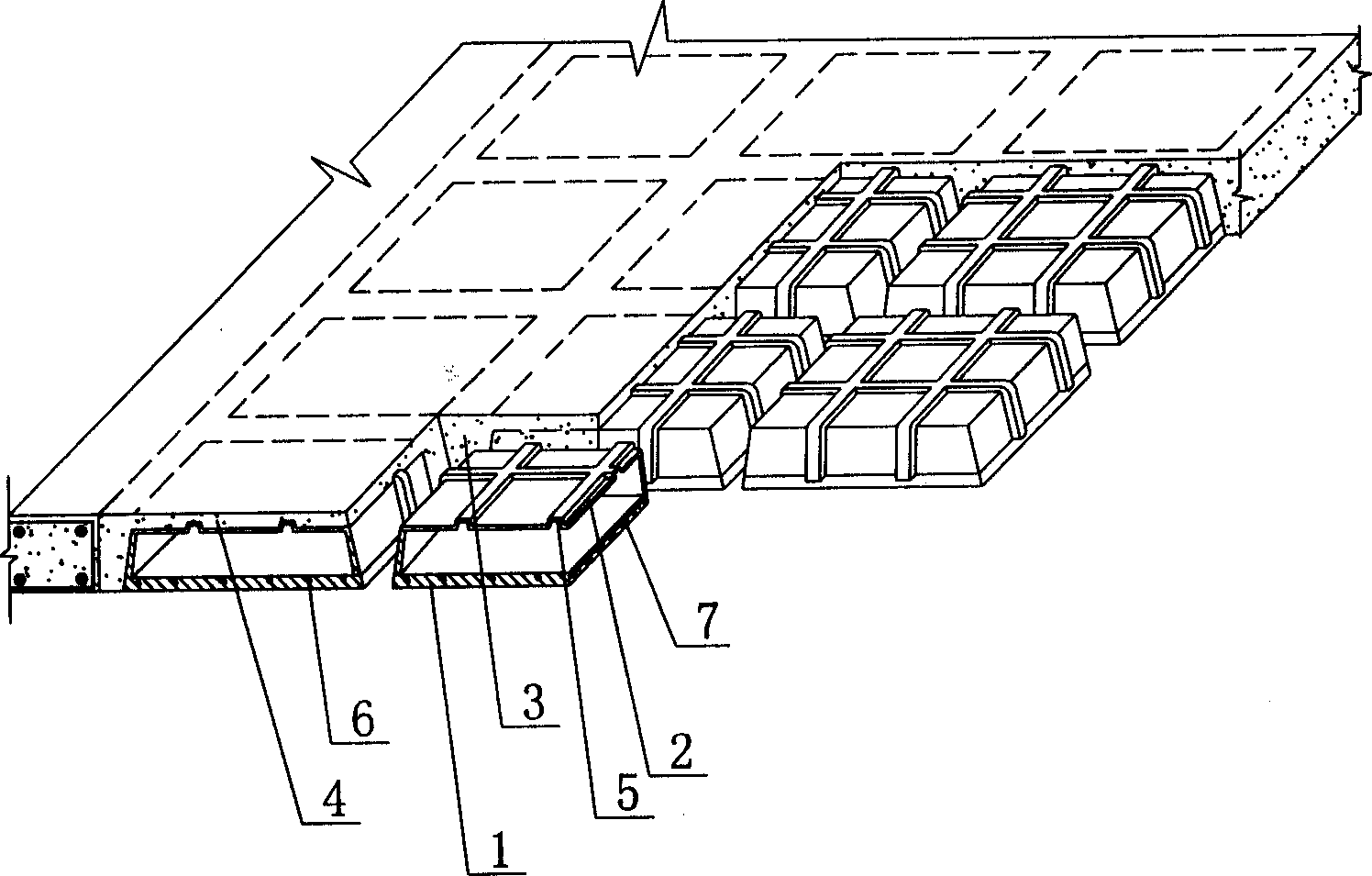

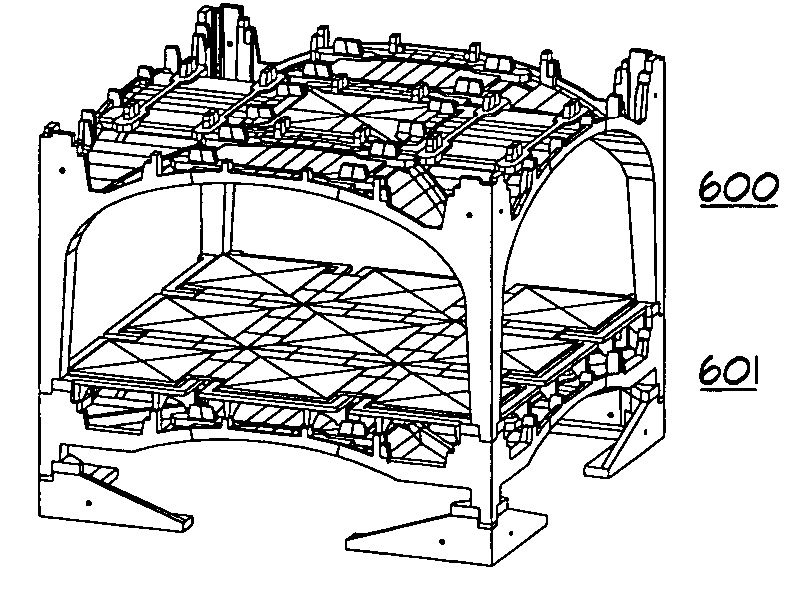

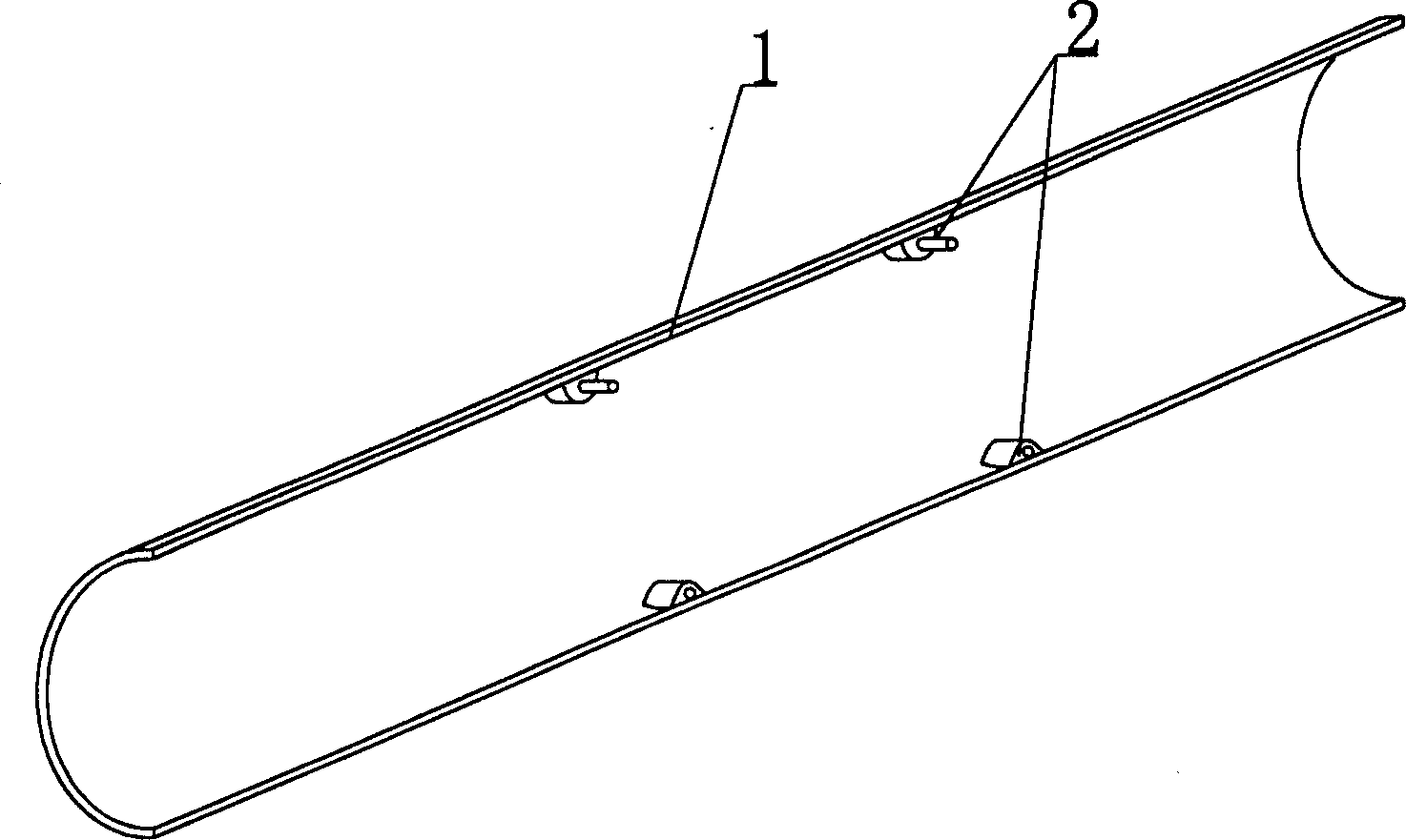

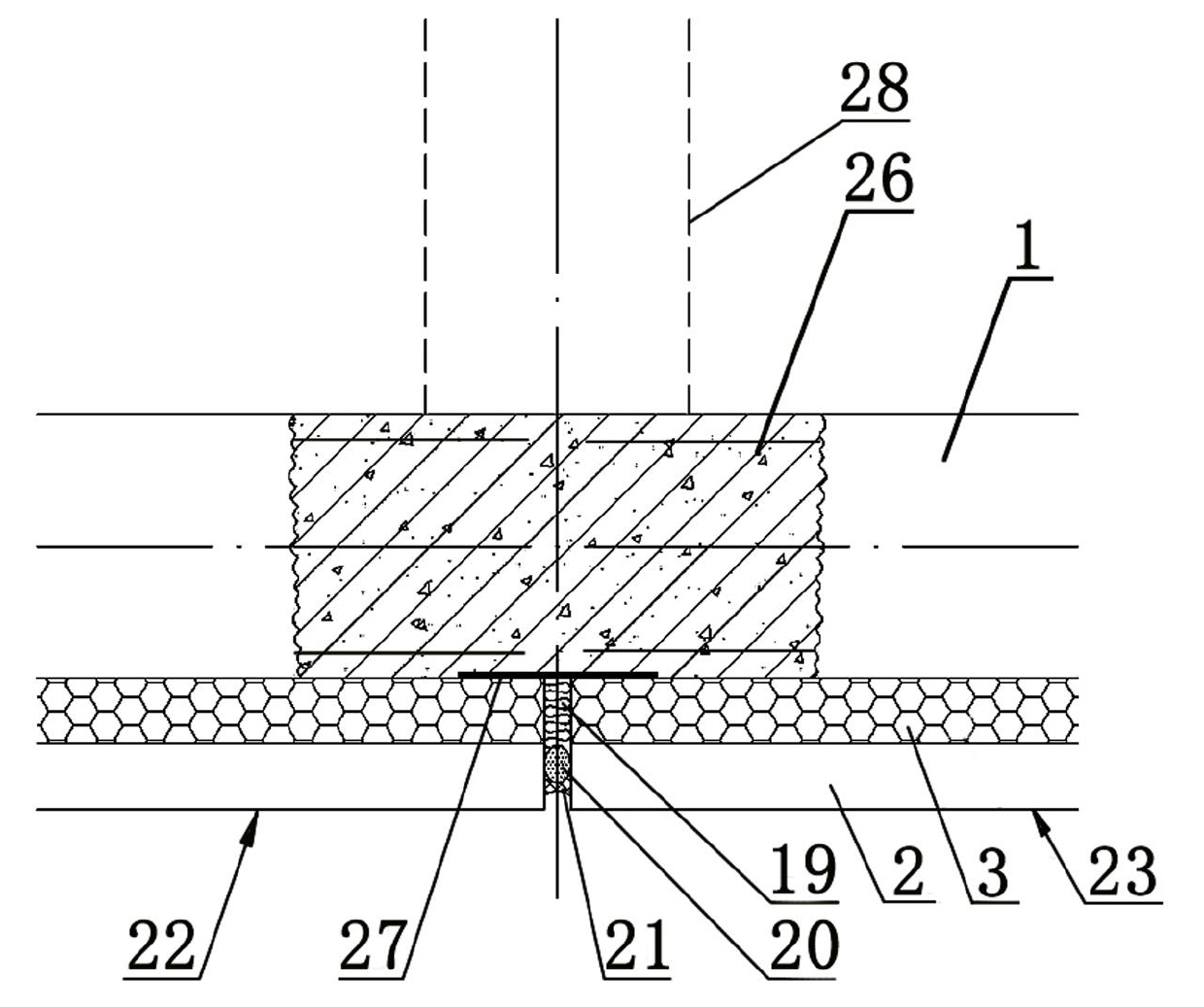

Modular formwork members

InactiveCN1403667ASimple designIncrease production capacityFloorsReinforced concreteUltimate tensile strength

The modular formwork member includes top plate and side walls to constitute cavity formwork. The present invention features that there is at least one connection tube between the adjacent walls of two formworks. When the modular formwork members are used in hollow stringboard, there will be vertical rib formed around the connection tube via in-situ cast and shearing bonding formed in the empty part between the formwork members, so that the hollow stringboard can form reinforced concrete-shearing bonding type bi-directional hollow large board in only once deposition. The present invention has simple formwork, simple construction, low cost and short construction period, and the member has high strength, simple structure, low cost and easy construction.

Owner:湖南邱则有专利战略策划有限公司

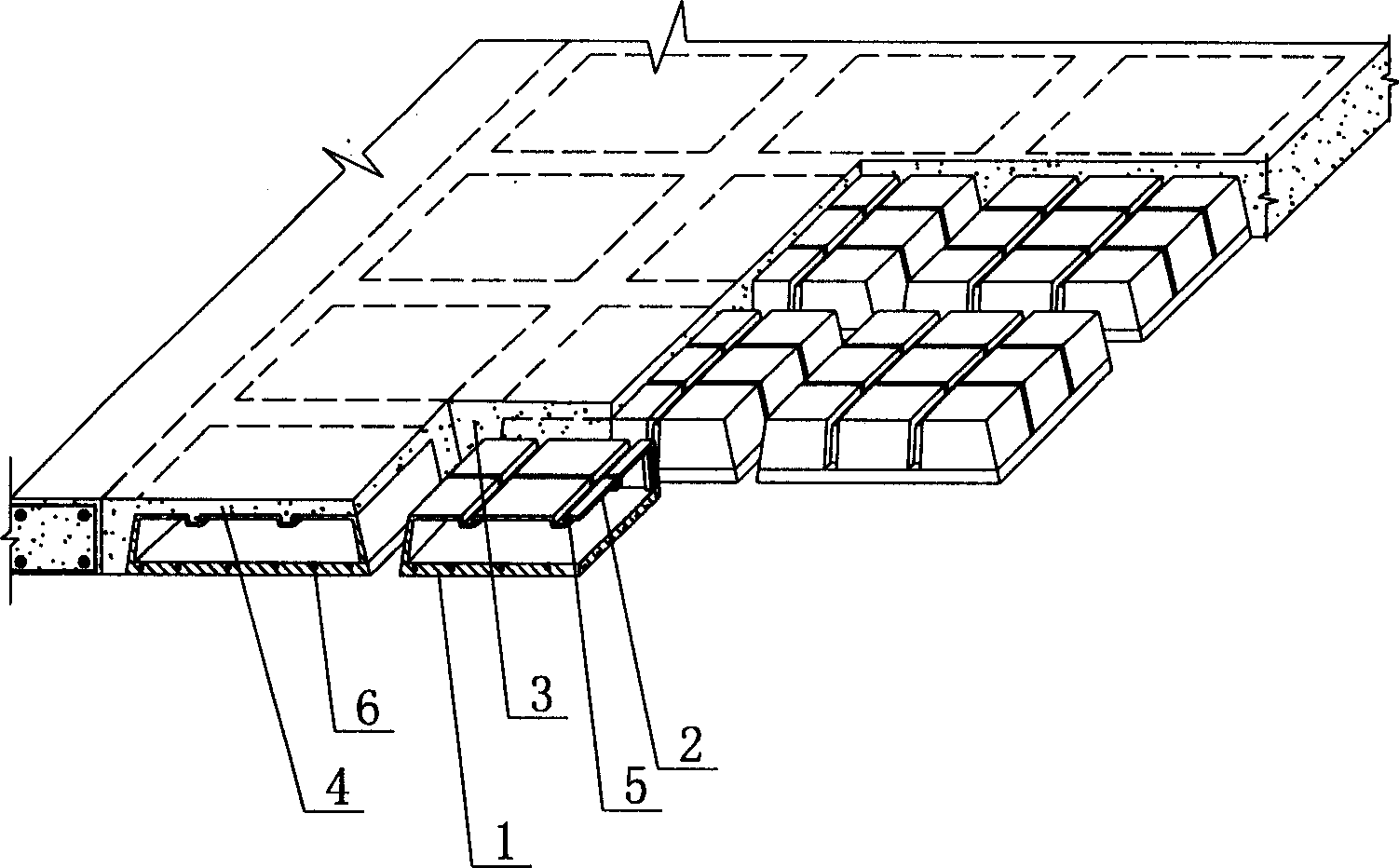

Floor with space structure

InactiveCN1356440AImprove mechanical performanceReduce thicknessFloorsReinforced concreteSpatial structure

A building roof with space structure is coposed of molded waffle members consisting of molded waffle and bottom plate, in-situ cast primary reinforced concrete rib, and in-situ cast reinforced concrete top plate. A prefabricated structured bottom plate has at least 2 molded waffle cavities and at least one in-situ cast secondary reinforced concrete rib. The said primary and secondary ribs constitute a hidden dense rib structure. Its advantages include high anti-earhquake performance and less thickenss, high strength.

Owner:湖南邱则有专利战略策划有限公司

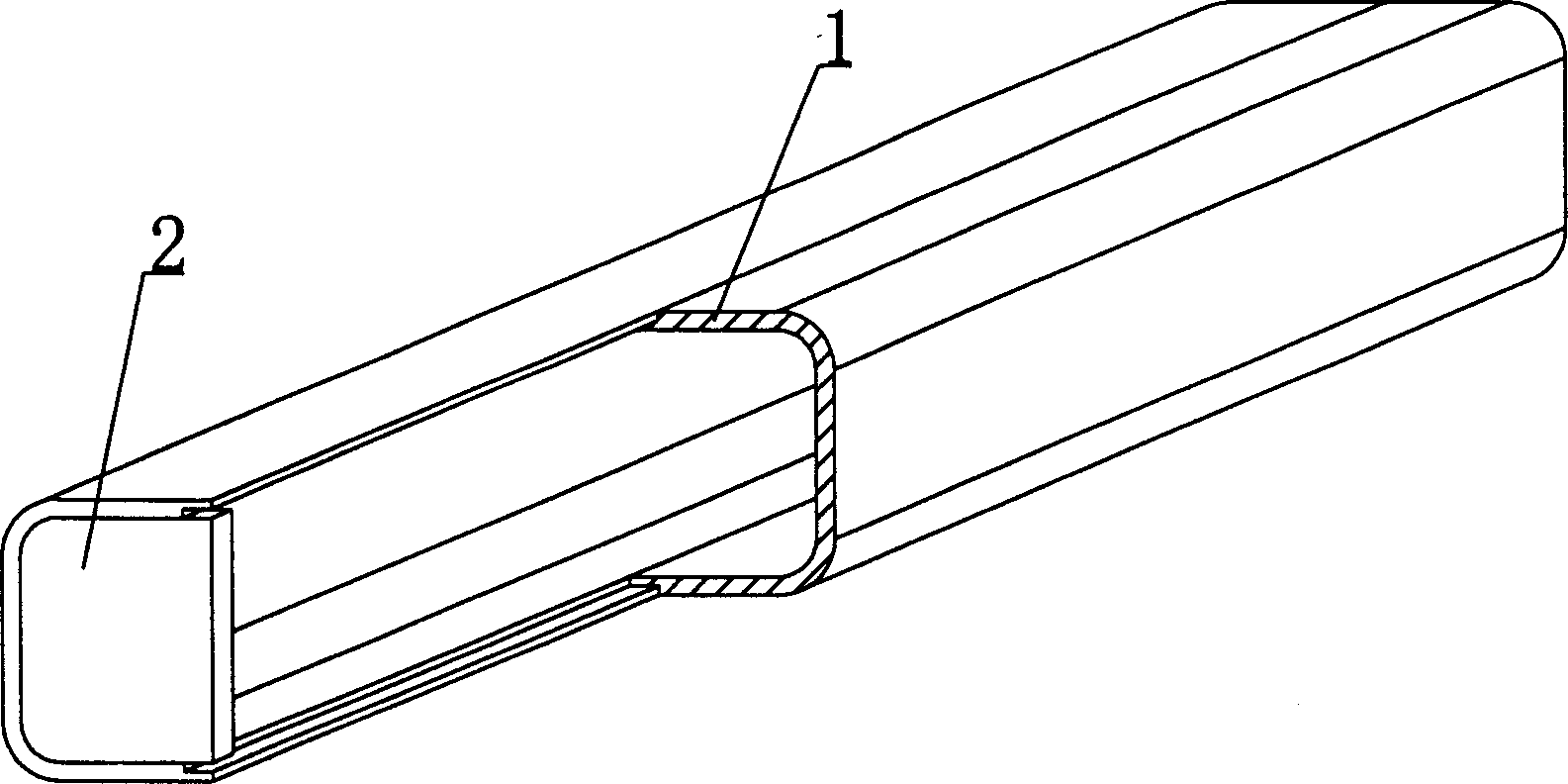

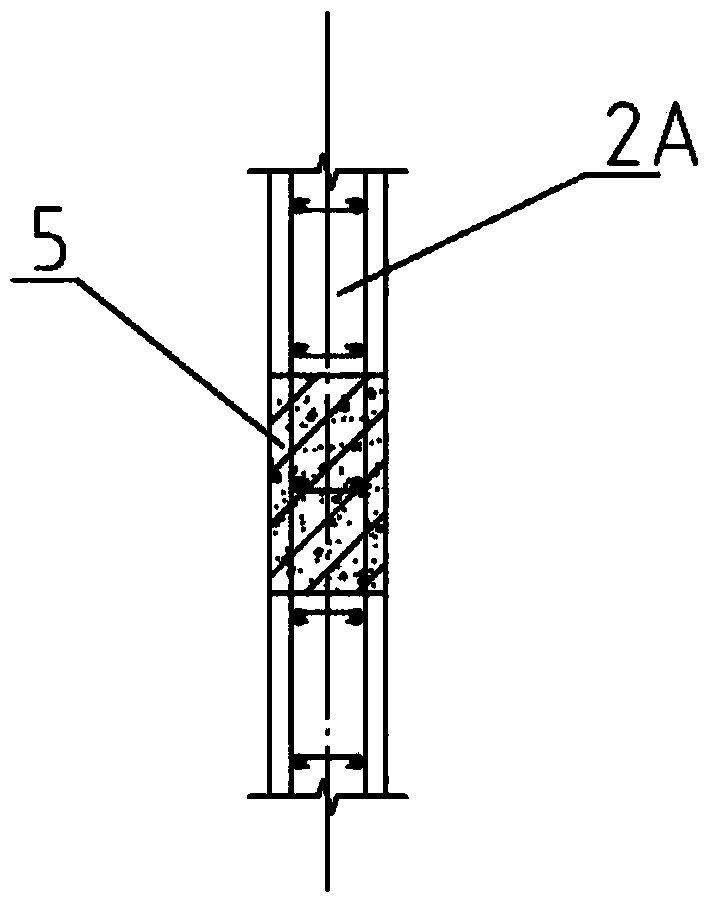

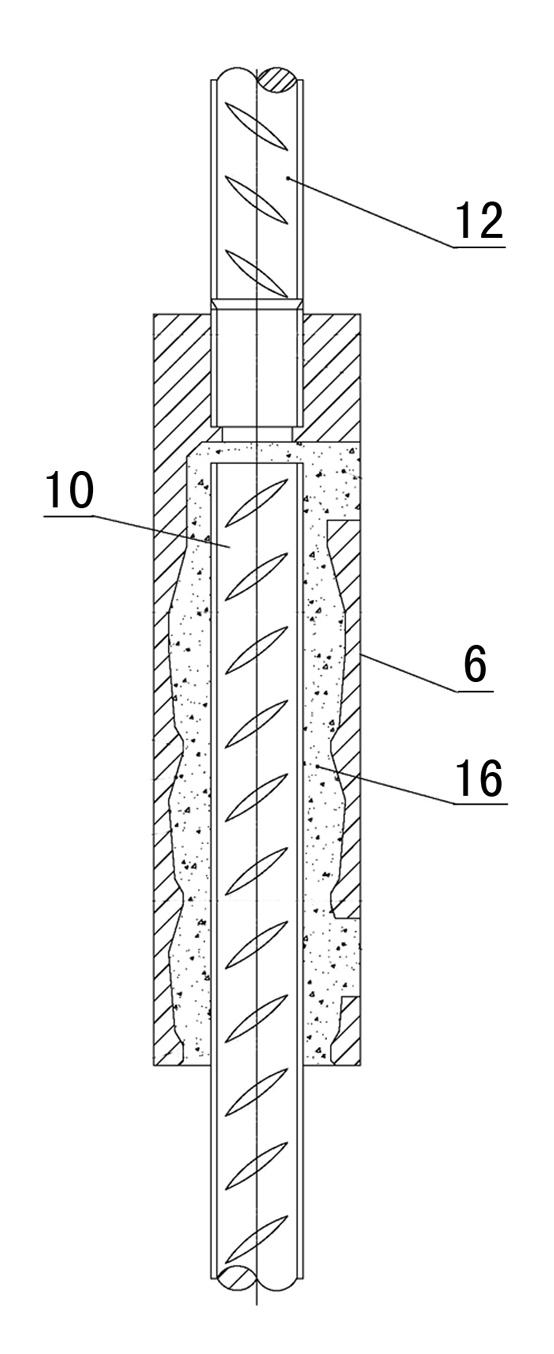

Member for cast-in-situ steel reinforced concrete

A member for in-situ casting the reinforced concrete is composed of two halves, which are fastened together to form a hollow thin-wall member used for in-situ casting hollow floor slab, roof, wall, etc. Said member is made up by die pressing. Its advantages are high strength, low cost, and convenient transportation.

Owner:湖南邱则有专利战略策划有限公司

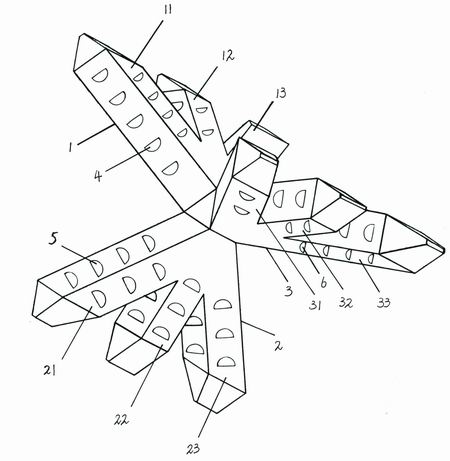

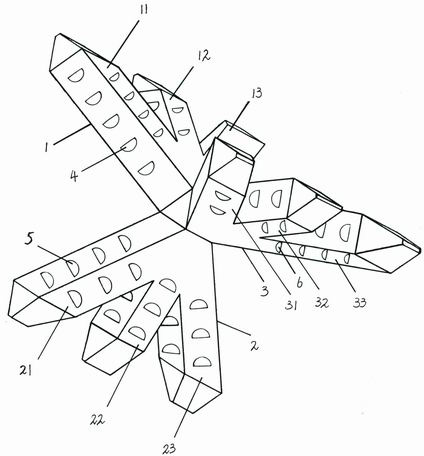

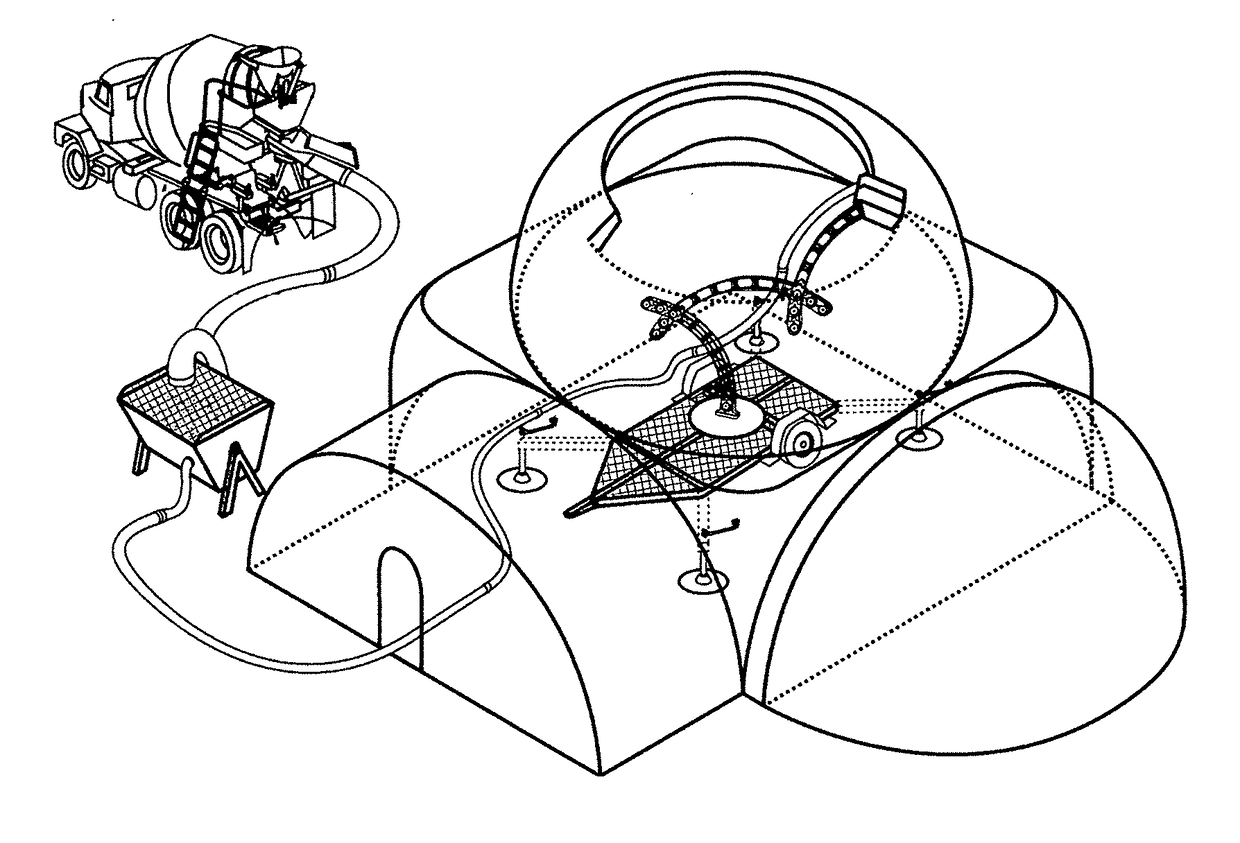

Artificial fish reef

InactiveCN102599081AImprove stabilityImprove hydrodynamic performanceClimate change adaptationPisciculture and aquariaReinforced concreteRebar

The invention discloses an artificial fish reef which comprises an artificial fish reef body, and is characterzied in that the artificial fish reef body is in an inversed Y shape; the inversed Y-shaped artificial fish reef body is composed of an upper part unit, a left lower part unit and a right lower part unit which are cast by reinforced concrete into a whole, wherein the upper part unit is ina vertical downward arrow shape which is formed by an upper left oblique post, an upper middle post and an upper right oblique post; the left lower part unit is in an upward and inclined right oblique arrow shape, and is formed by a left lower left oblique post, a left lower middle post and a left lower right oblique post; and the right lower part unit is in an upward and inclined left oblique arrow shape, and is formed by a right lower left oblique post, a right lower middle post and a right lower right oblique post. According to the invention, the artificial fish reefs are combined and stacked to construct a place for spawning and perching of fishes, and in case that a plurality of artificial fish reefs are combined, the stability and dynamic property of the artificial fish reef can be greatly improved. The artificial fish reef provided by the invention can be used for proliferation of shallow-water-type rocky fishes, shellfishes and algae in a shallow water area of a water depth 6-10 meters.

Owner:SHANGHAI OCEAN UNIV

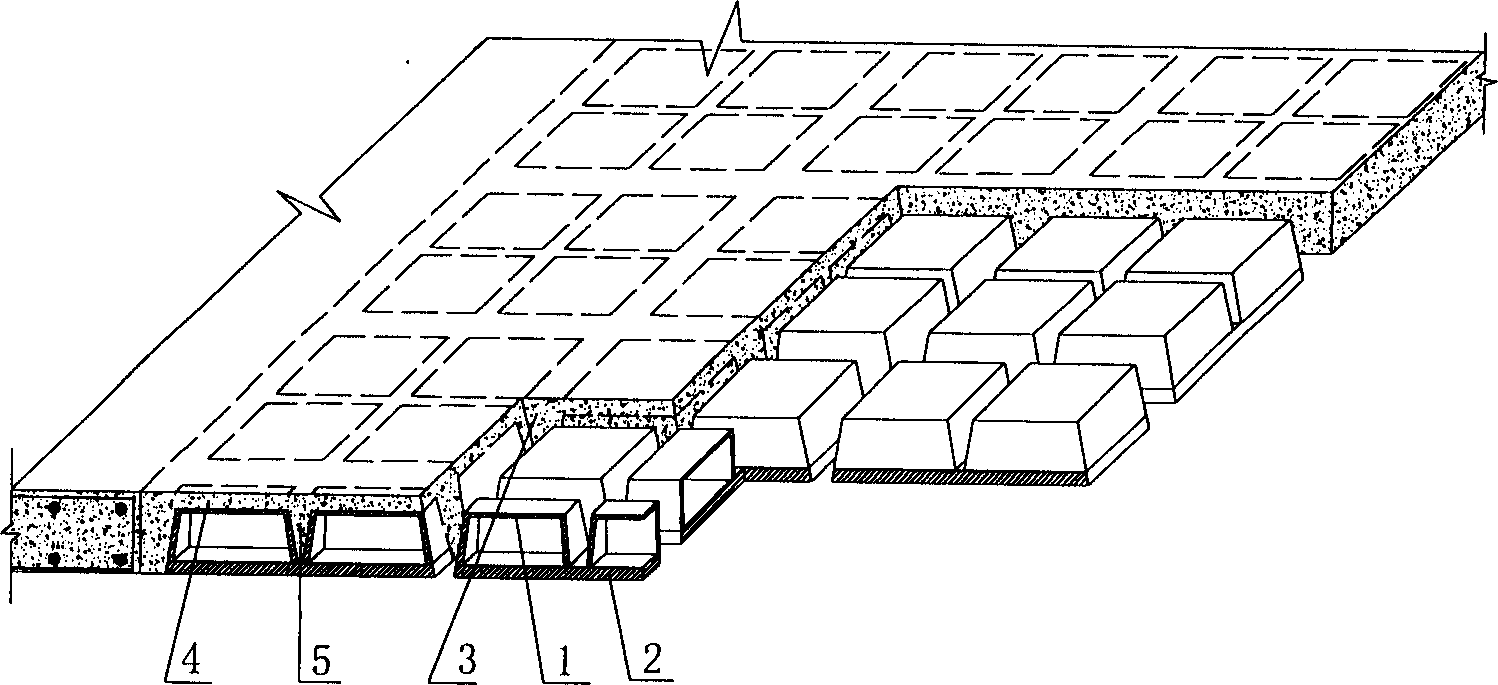

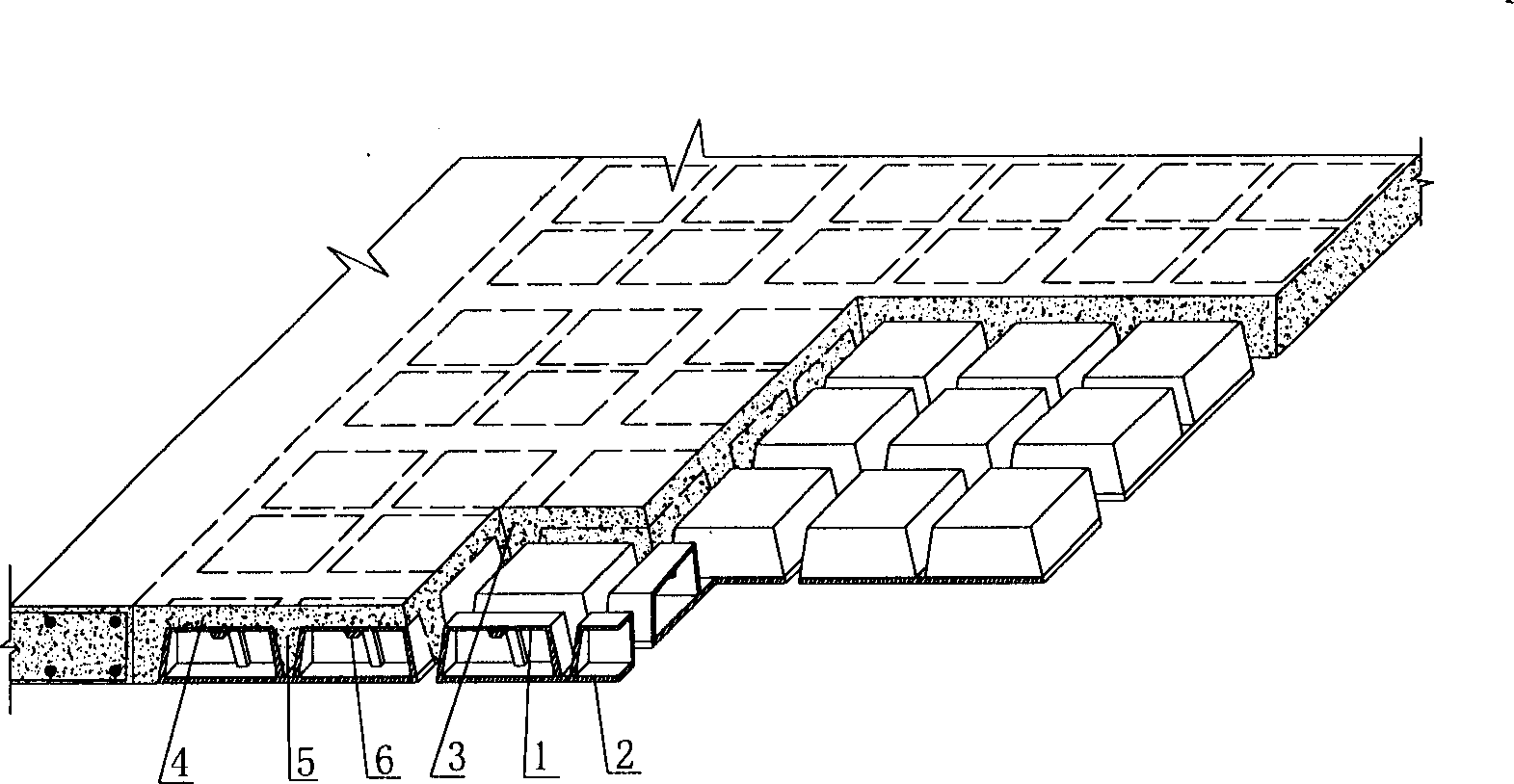

Hollow floor slab with hidden and dense ribs

The floor slab includes bottom plate, hollow form board, in-situ steel bar reinforced concrete hidden ribs and in-situ steel bar reinforced concrete upper plate; and features that the structure bottom plate and hollow form board are connected to form polyhedral structure and that there are reinforcing ribs in the hollow form board. Owing to the structural bottom plate and hollow form board connected into one integral and the hollow form board with reinforcing ribs, the hollow member for the floor slab with hidden and dense ribs has high strength and rigidity and not easy to break, and the floor slab has simple structure, high strength, light weight and easy construction.

Owner:湖南邱则有专利战略策划有限公司

Method of reinforced cementitious constrauction by high speed extrusion printing and apparatus for using same

ActiveUS20180071949A1Low costAdditive manufacturing apparatusConstruction materialReinforced concreteBrick

The present invention relates to methods and apparatuses for an automated reinforced concrete construction system for onsite slip-form molding and casting a variety of cementitious mixes in a cast in place leave in place externally moldable flexible reinforced containment sleeve providing a wide variety of interchangeable full-scale molding configurations simultaneously optimizing a wide variety of cementitious mix curing characteristics, further having optional internal reinforcement net(s), for layer wise interlocking additive printed brick deposition providing improved slip-form mold casting of a wide variety of reinforced concrete structures; the present invention further includes a variety of operating platforms suitable for on and offsite construction as disclosed herein.

Owner:ARMATRON SYST LLC

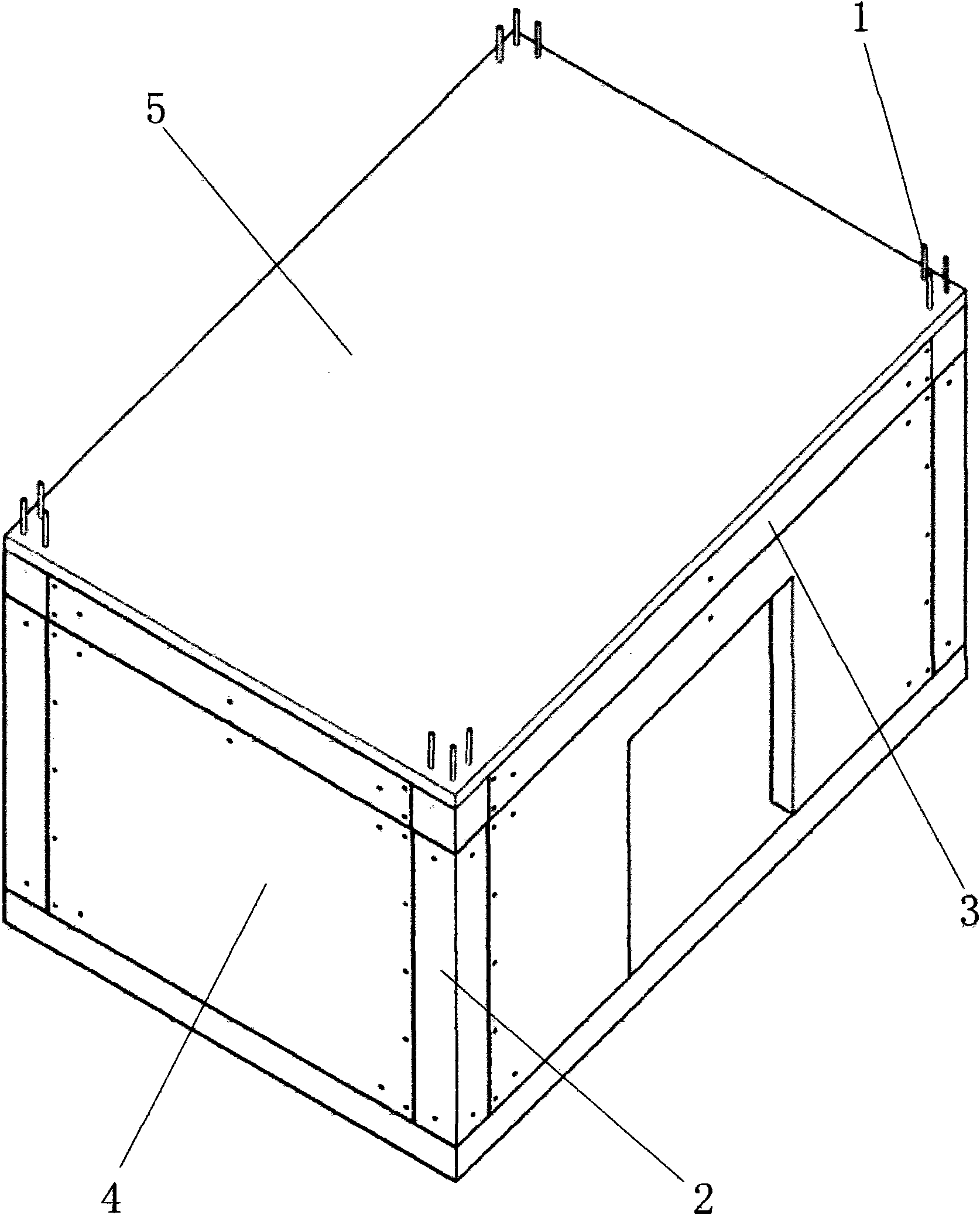

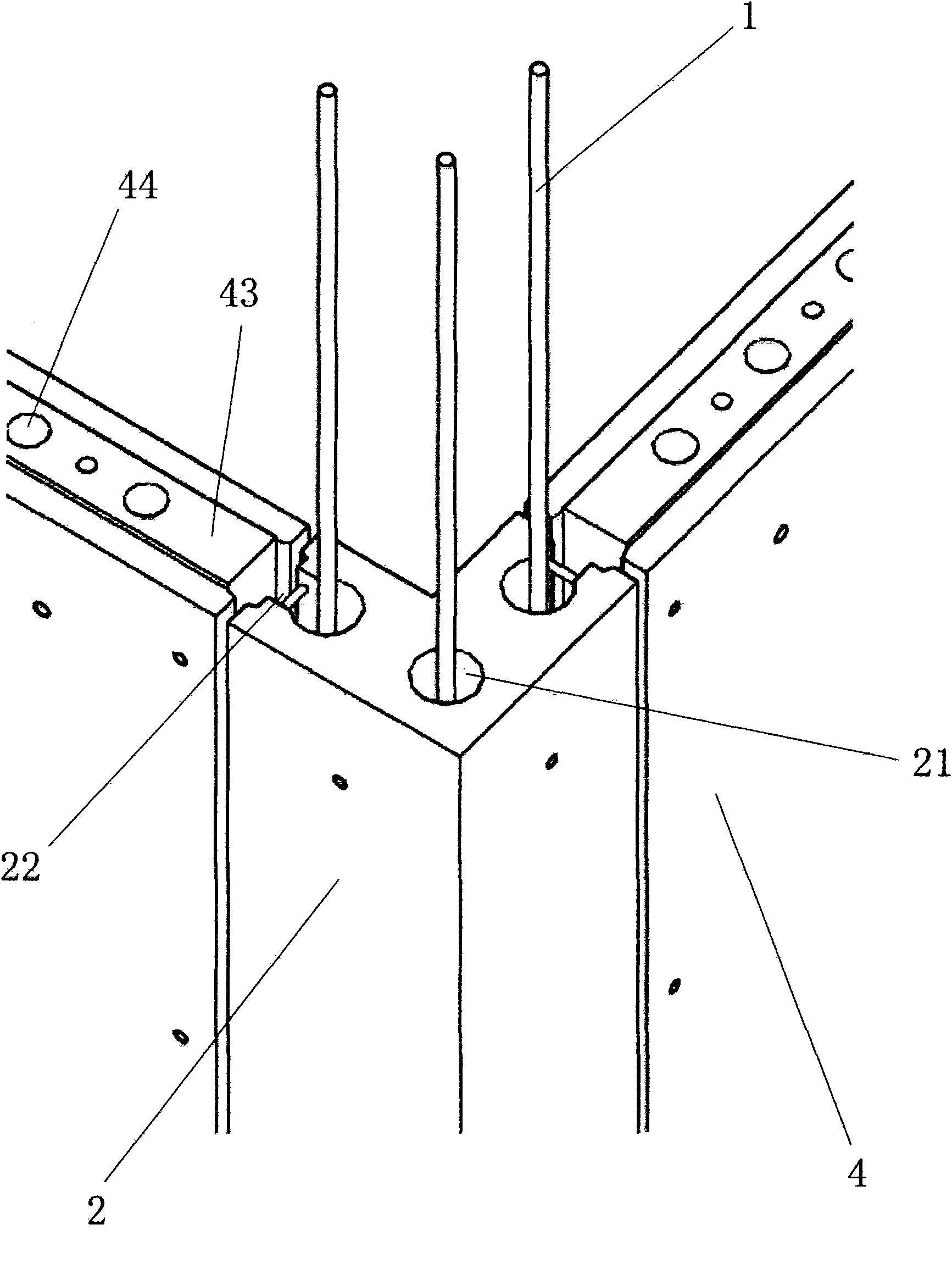

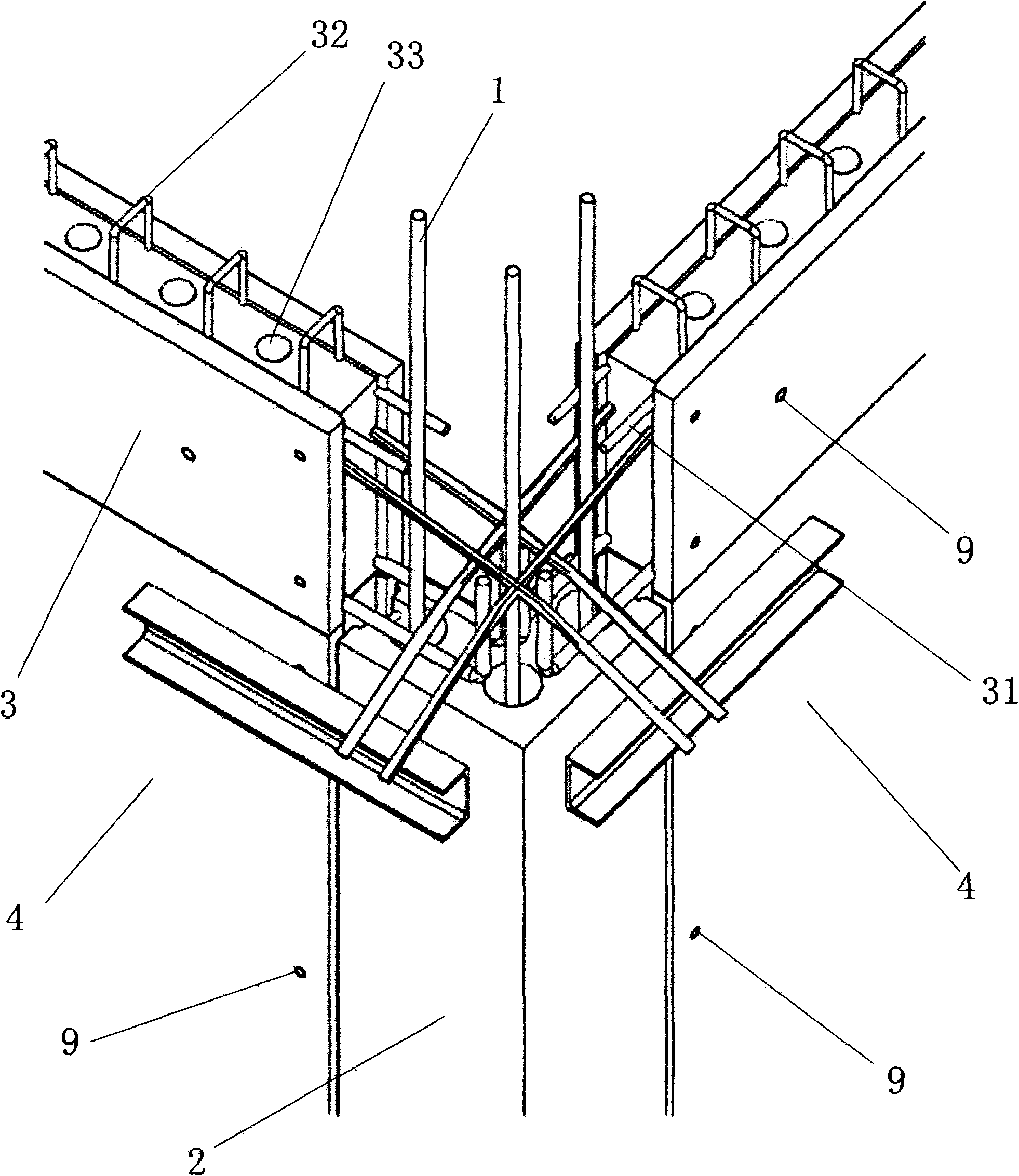

Full-fabricated assembly overall reinforced concrete house and building method thereof

InactiveCN101806095ASmall sizeNo secondary plastering requiredBuilding material handlingFloor slabReinforced concrete

The invention discloses a full-fabricated assembly overall reinforced concrete house which comprises a plurality of column ribs arranged at intervals and respectively and fixedly connected with a foundation, a plurality of column bodies prefabricated in a modularized way, a plurality of wall bodies prefabricated in the modularized way, and a floor slab prefabricated in the modularized way. The invention aims to overcome the defects of the prior art, and improve the full-fabricated assembly overall reinforced concrete house which has simple structure, is convenient to install, saves building materials, is quick to build, and has good overall safety performance. Another purpose of the invention is to provide a method for building the house.

Owner:ZHONGSHAN FAST LIVING PREFABTED HOUSING

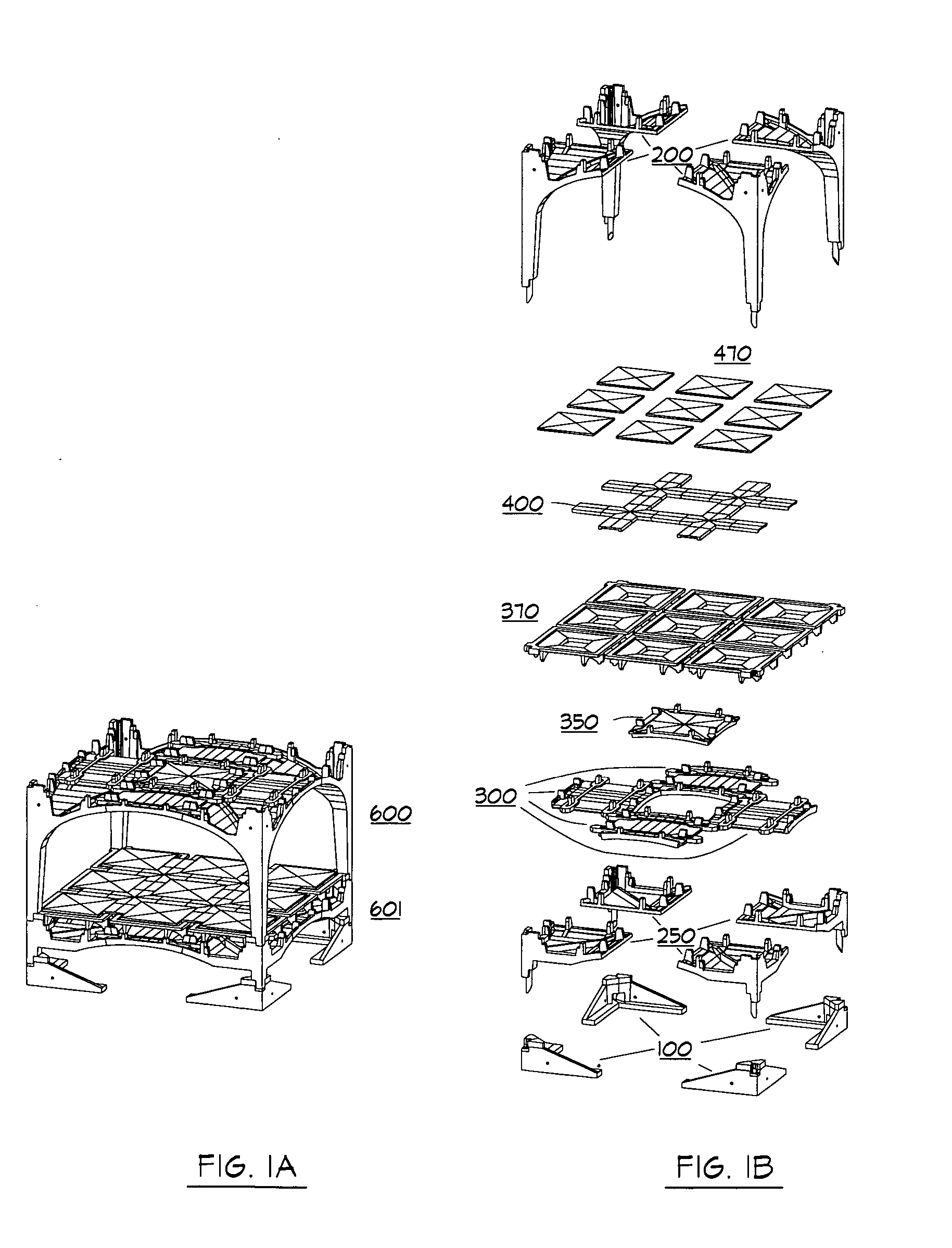

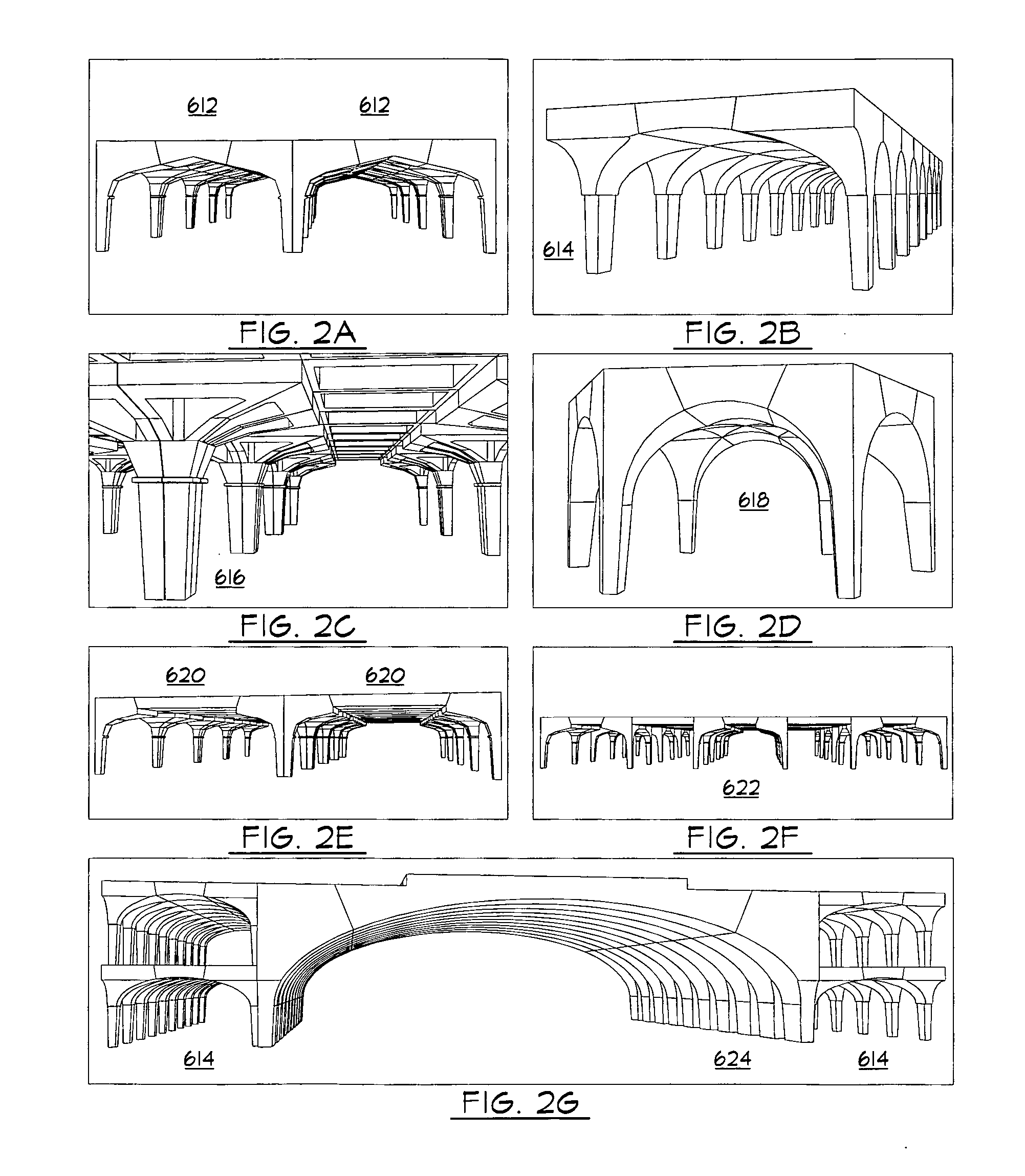

Method and system for prefabricated construction

A structure assembled from a combination of stackable modules, each module assembled from multiple prefabricated, transportable blocks. The blocks are typically reinforced cast concrete formed in reusable molds. Module framing blocks may include arched corner blocks, key blocks that interlock with a pair of corner blocks, and optional center blocks. Other structural elements include roof, floor, and wall components that interlock with the framing modules. Modules may be stacked or nested to form structures including buildings, elevated roadways, and parking garages. Utilities may be provided through optional conduits formed in the corner elements. The framing supports raised floor modules for ease in mechanical system installation and modification. The roof elements support usable terraces and rainwater collection. The blocks are demountable and reusable. The modules are self-supporting during erection, and may be assembled without fasteners.

Owner:POWELL DAVID W

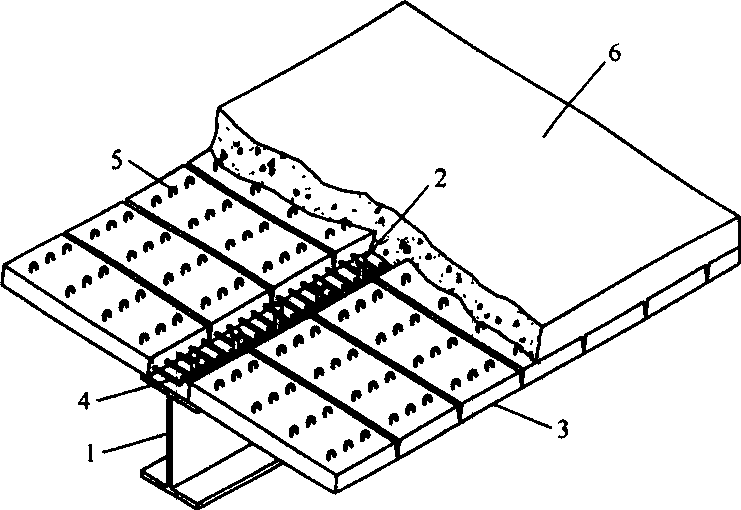

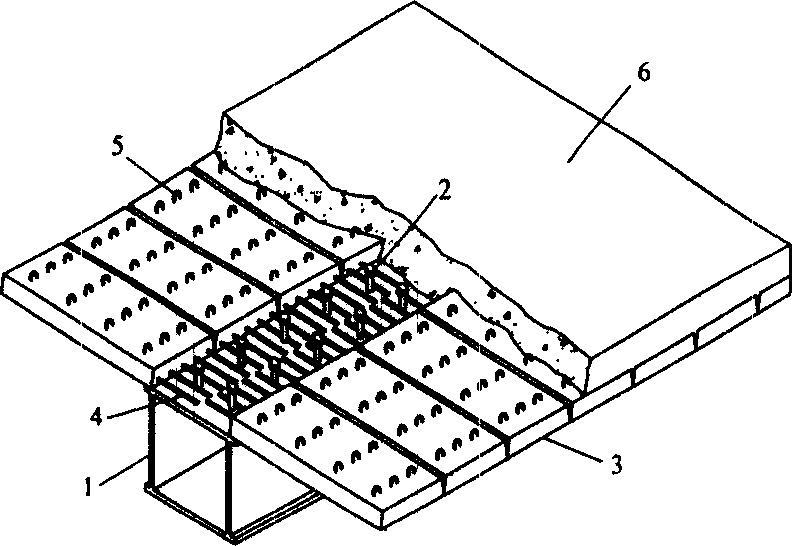

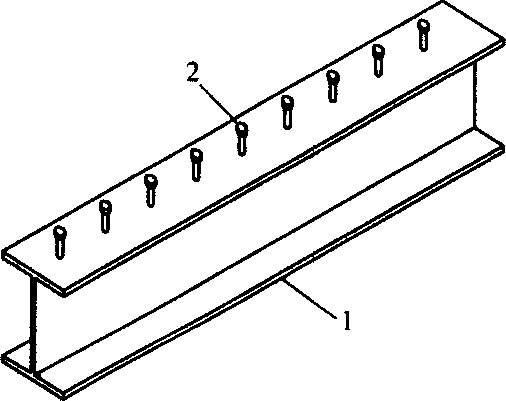

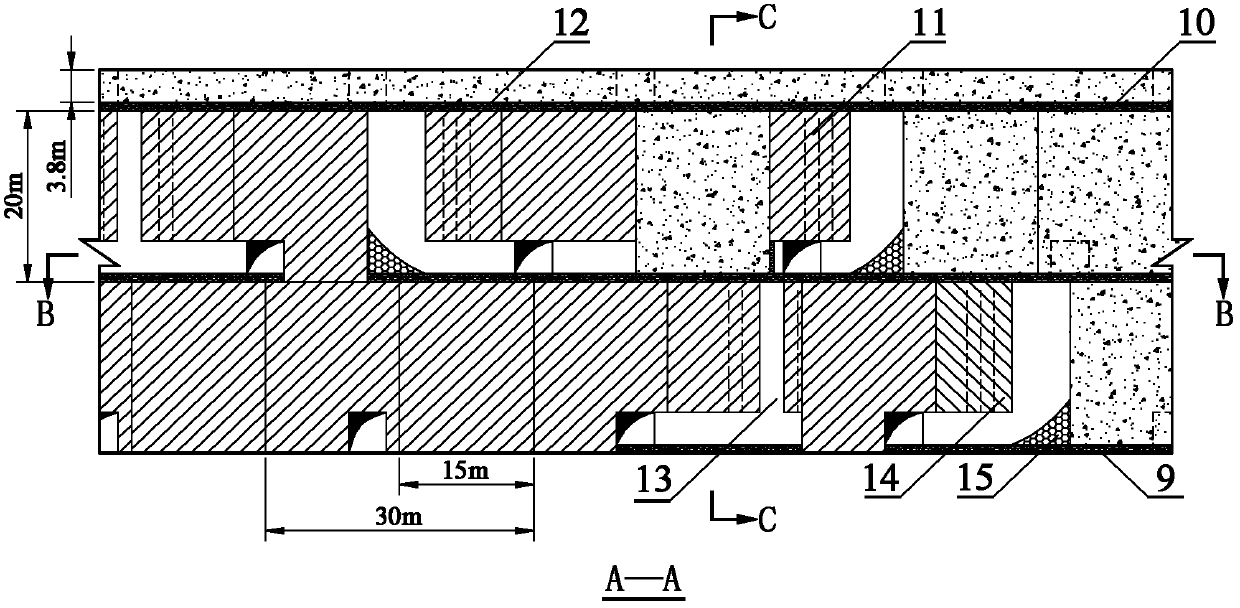

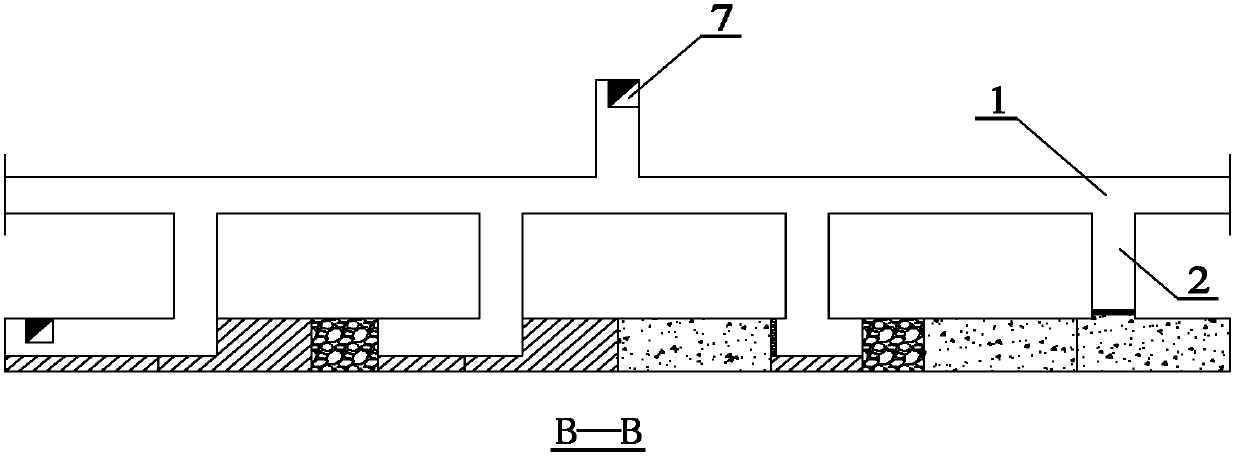

Steel-concrete folding plate combined beam

InactiveCN1587575ASolve construction difficultiesSolve complexityLoad-supporting elementsBridge structural detailsReinforced concreteEngineering

The present invention discloses one kind of combined beam of laminated steel-concrete plate for highway bridge and building as support member of bridge and building. Shear resistant connecting parts are welded to steel beam, prefabricated solid or hollow reinforced concrete boards are set on the steel beam, the steel bar tails are crossed and welded together, and the post-deposited concrete is deposited to form the combined beam. The combined beam has the advantages similar to those of in-situ deposited combined beam as well as saving in formwork and formwork supported step, simple prefabricated board structure, fast construction speed, etc. The present invention has wide application foreground in bridge structure and building structure fields.

Owner:TSINGHUA UNIV

Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

InactiveCN102606159AImprove efficiencyImprove securityUnderground miningTunnel/mines ventillationRoom and pillar miningReinforced concrete

The invention discloses a medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method which comprises the following steps: dividing chamber jambs along the trend of an ore body; adopting a rail-less mining aligning system; pre-constructing a high-strength reinforced concrete artificial top in a segmented drilling lane; adopting a stoping sequence from up to down; performing drilling and blasting ore removal on the ore body through the segmented drilling lane at bottom; adopting medium-length hole drilling and remotely controlling a scraper to discharge ore; after finishing the mining of the chamber, utilizing concrete tailings to perform cemented filling; after finishing the mining of the jambs, utilizing concrete tailings or pure tailings to perform cemented filling; after completely stoping the mine chamber in the frame under the protection of the concrete artificial top, starting to stope the jamb adjacent to the segment, and meanwhile stoping the corresponding mine chamber in the frame of the next segment, and then stoping the corresponding jamb of the next segment; and after completely mining the chamber jamb in the middle segment, immediately turning towards the lower middle segment for stoping. The method provided by the invention has the advantages that the safety for mining the heavy-pitch medium thick crushed or ultra-crushed ore body is high, the resource depletion loss rate is low, the mechanical degree is high, the production capacity is high, and the like.

Owner:CENT SOUTH UNIV +1

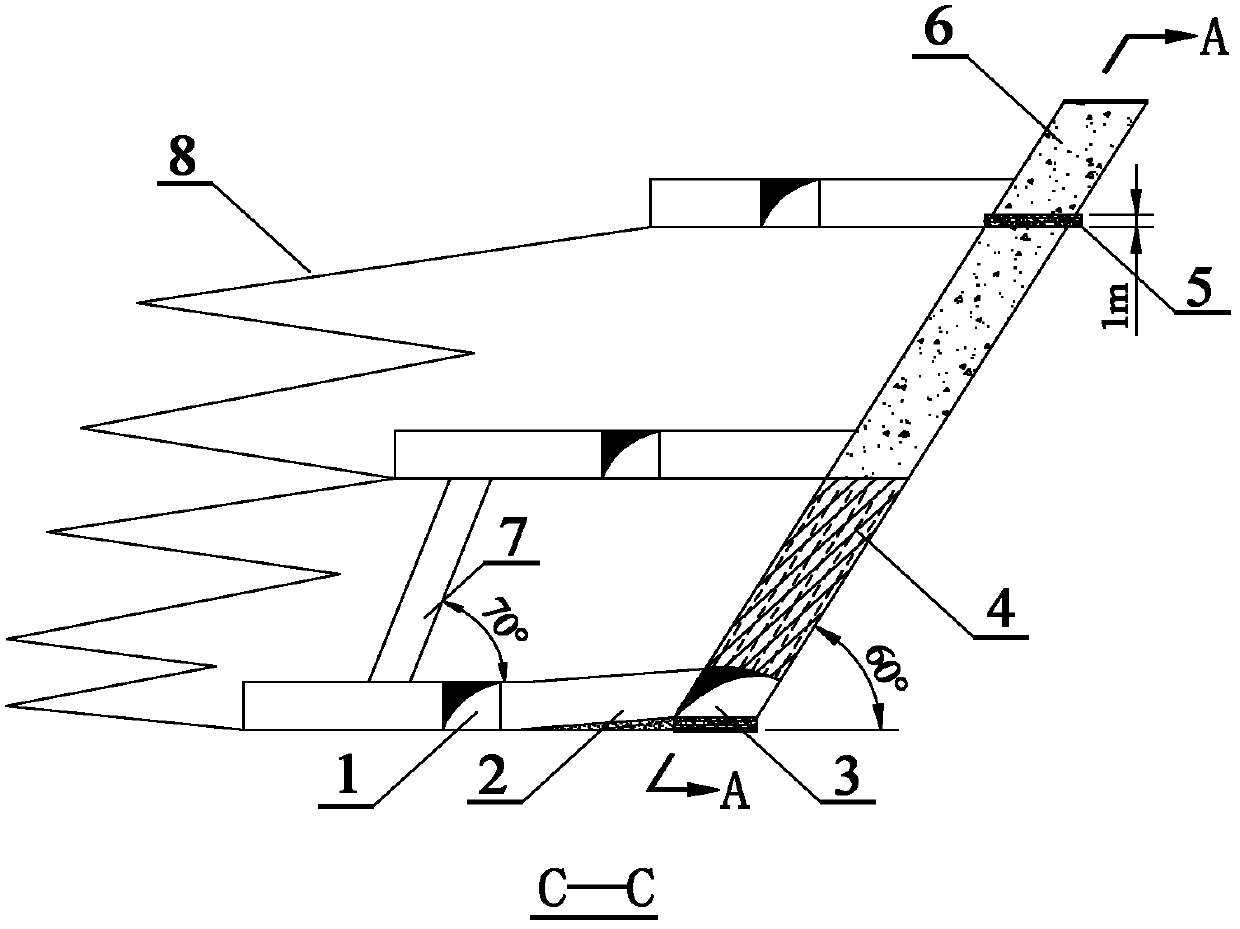

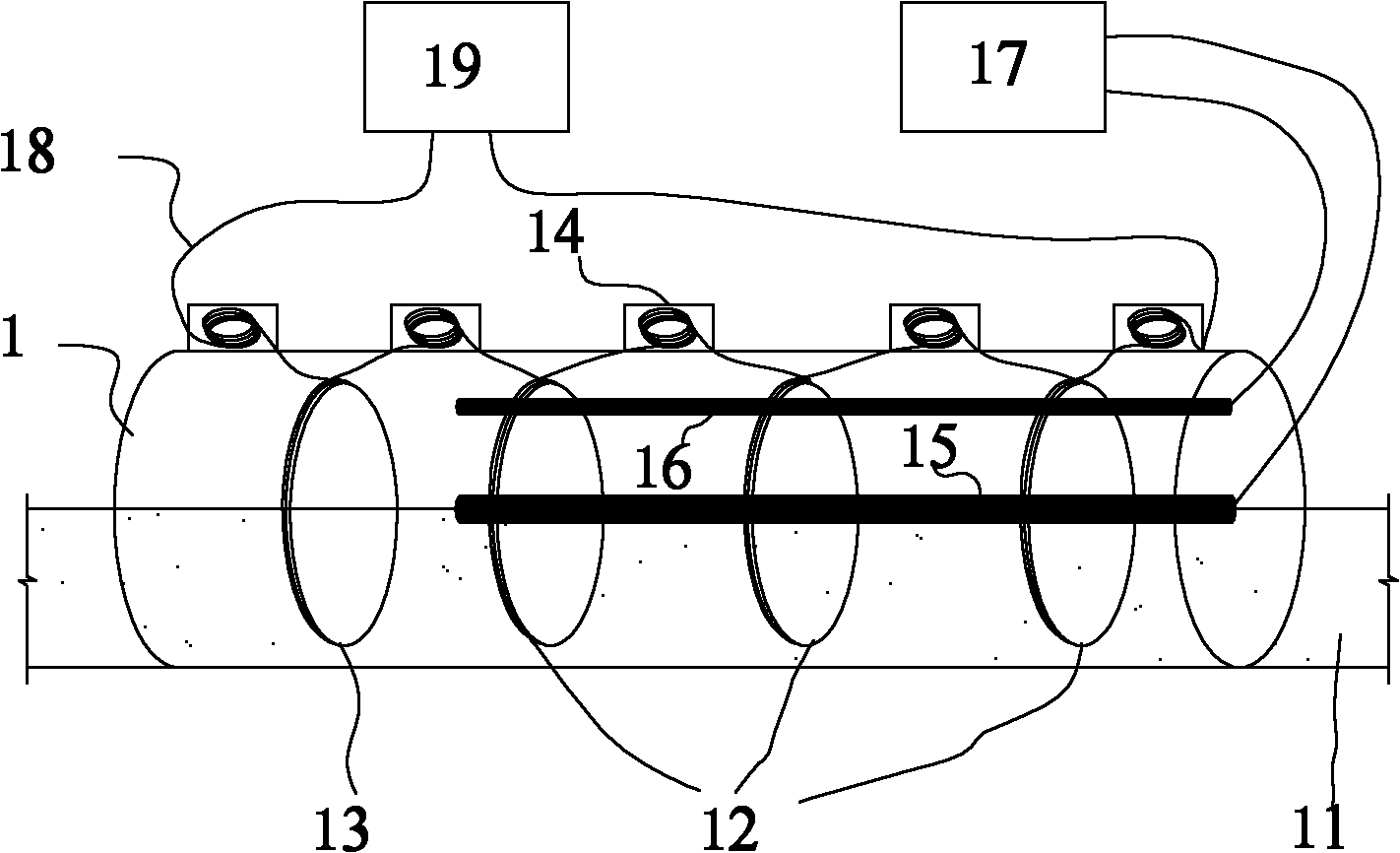

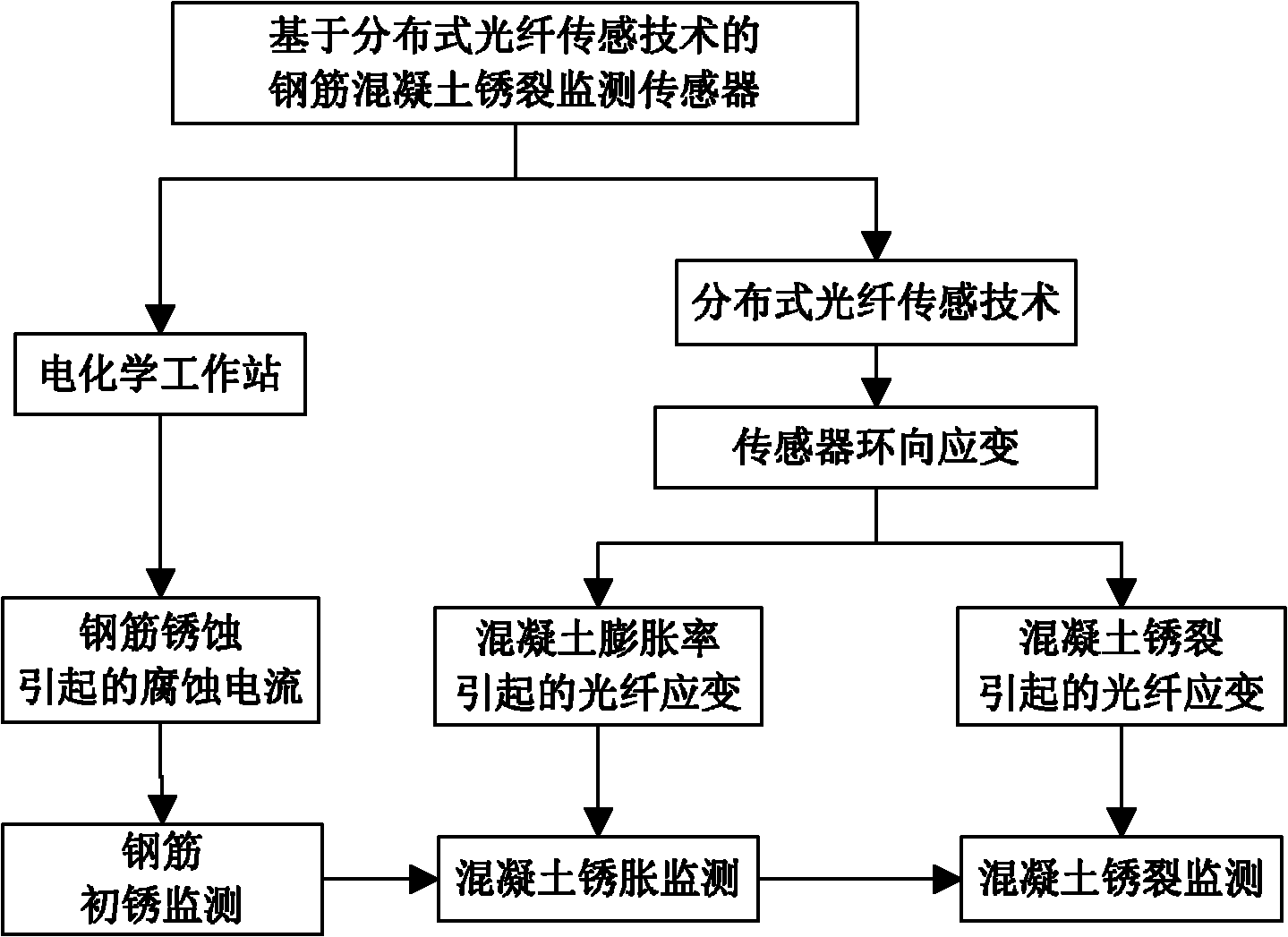

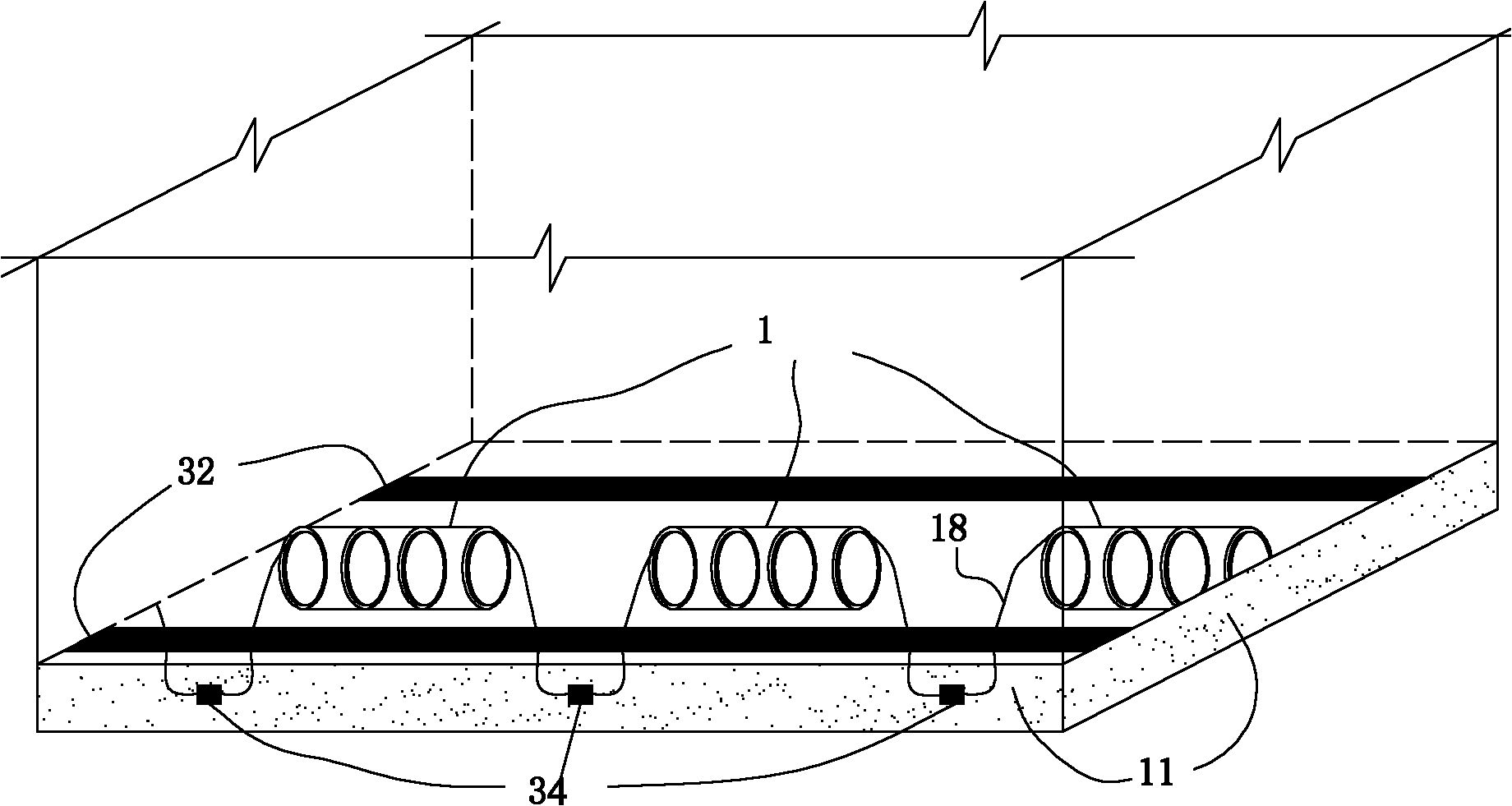

Method for monitoring corrosion cracks of reinforced concrete and sensor

InactiveCN102095677AEfficient managementDistributed withWeather/light/corrosion resistanceUsing optical meansPower flowReinforced concrete

The invention discloses a discloses a method for monitoring the corrosion cracks of reinforced concrete based on distributed optical fiber sensing technique. The method comprises the following steps: periodically detecting the polarization current of a steel bar and a stainless steel segment embedded in a sensor by an electrochemical work station to determine the initial corrosion time of the steel bar; monitoring the optical fiber strain by the distributed optical fiber sensing technique in real time through using sensing optical fibers surrounding the steel bar and laid in the sensor to deduce the corrosion expansion or corrosion crack stage of the reinforced concrete; and determining the corrosion expansion or corrosion crack degree by a calibration curve. The invention also discloses a sensor for executing the above method. The sensor can be used for monitoring the total corrosion cracking process of reinforced concrete at any position without damaging the structure of the concrete by monitoring the polarization current and the sensing optical fiber strain of the corroded steel bar, and can determine the corrosion crack stage and the degree of the reinforced concrete. The sensor is used for monitoring and evaluating the durability of reinforced concrete structure in the field of civil engineering.

Owner:ZHEJIANG UNIV

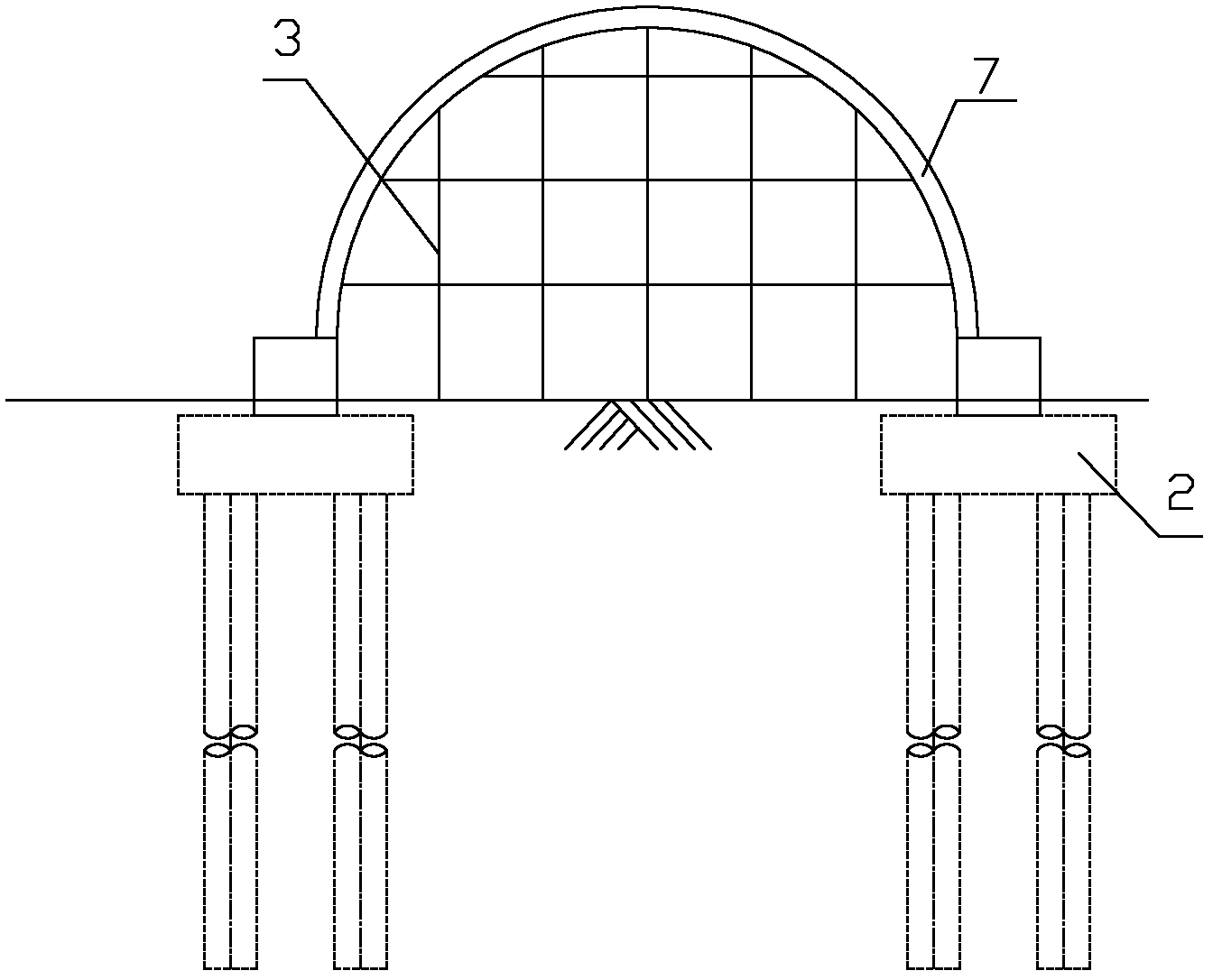

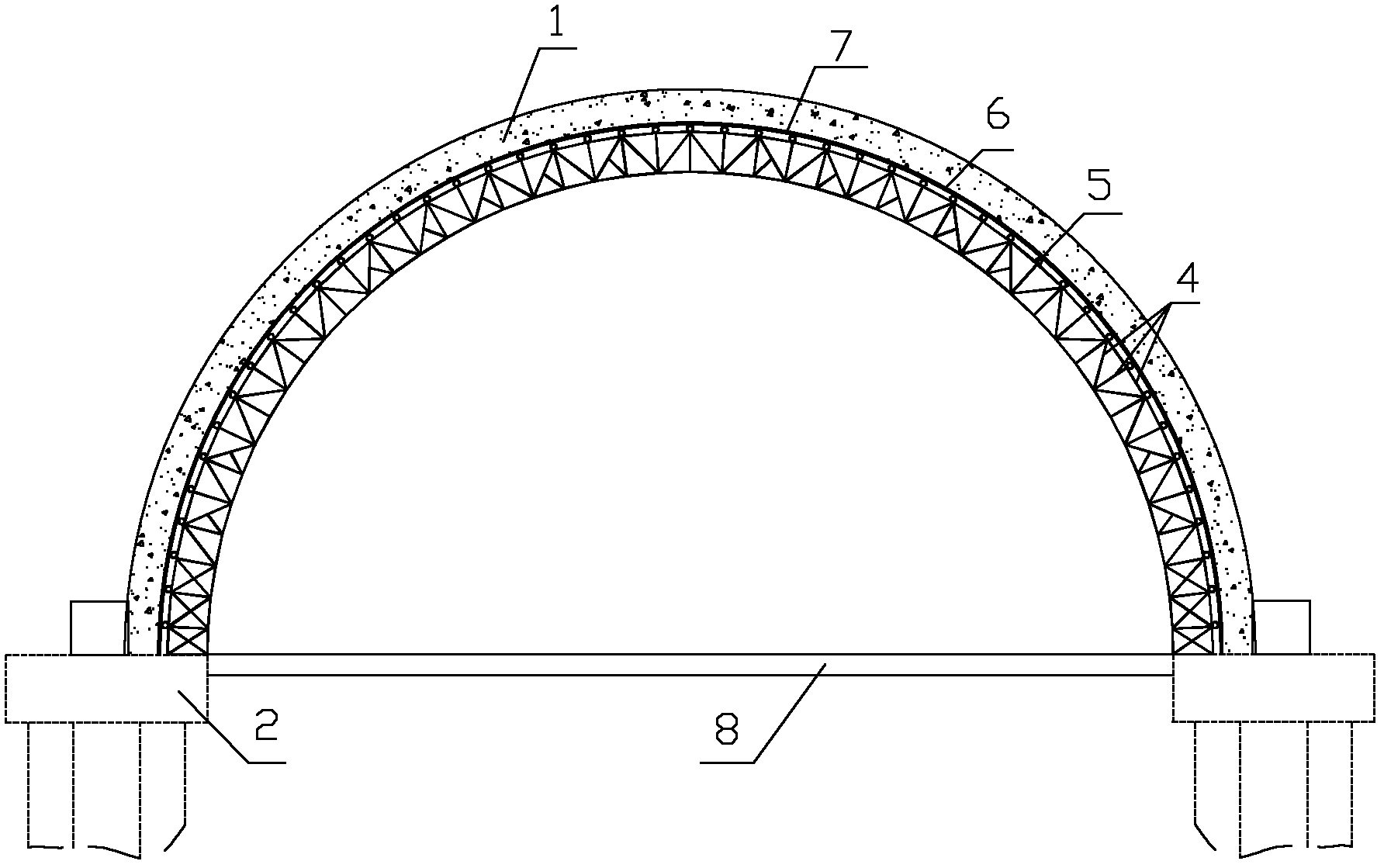

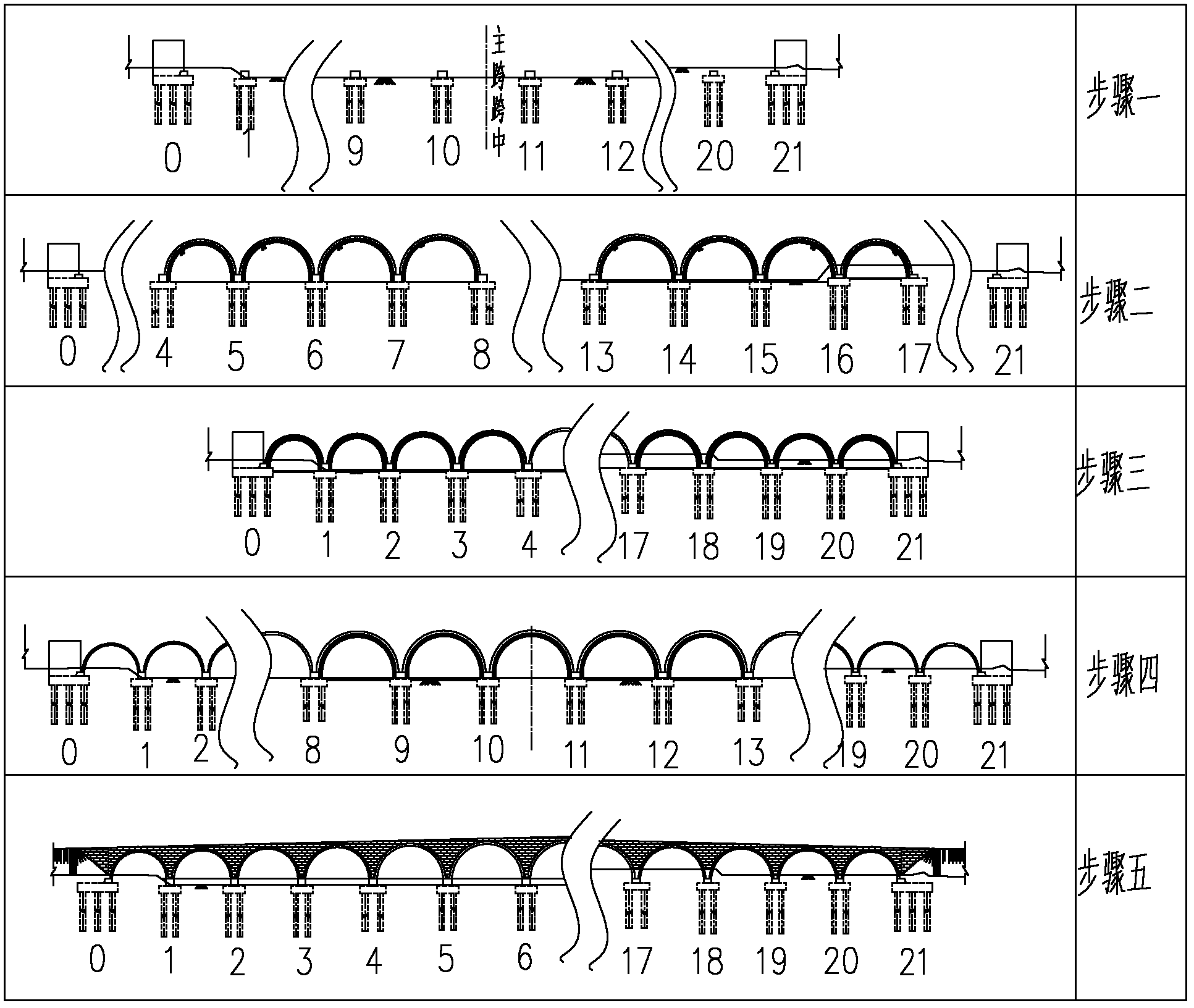

Reinforced concrete arch bridge construction method

ActiveCN102493360AAvoid deformationStable structureBridge erection/assemblyArch-type bridgeReinforced concreteAbutment

The invention discloses a reinforced concrete arch bridge construction method, which comprises the following steps of: 1, constructing a pile foundation, a pile cap, a bridge abutment body side wall and a bridge pier body; 2, erecting arch ring supports from the fourth hole to the eighth hole and from the thirteenth hole to the seventeenth hole on two sides of an arch bridge, arranging a locking system, and finally pouring concrete to arch rings of the eight holes; 3, detaching the arch ring supports in the step 2, erecting arch ring supports from the zero hole to the fourth hole and from theseventeenth hole to the twenty-first hole on the bridge abutment side, arranging a locking system and finally pouring concrete to arch rings of the eight holes; and 4, detaching the arch ring supports erected in the step 3, erecting arch ring supports from the eighth hole to the thirteenth hole in the span, arranging a locking system, pouring concrete to arch rings of the five holes, and folding the whole bridge. Main bodies of the arch ring supports have arch truss structures, a characteristic that steel bars are tensioned is utilized, the structures are firm, the middles of the structures are not required to be supported, materials are saved, the arch ring supports are convenient to detach, and constriction time is saved.

Owner:浙江大东吴集团建设有限公司

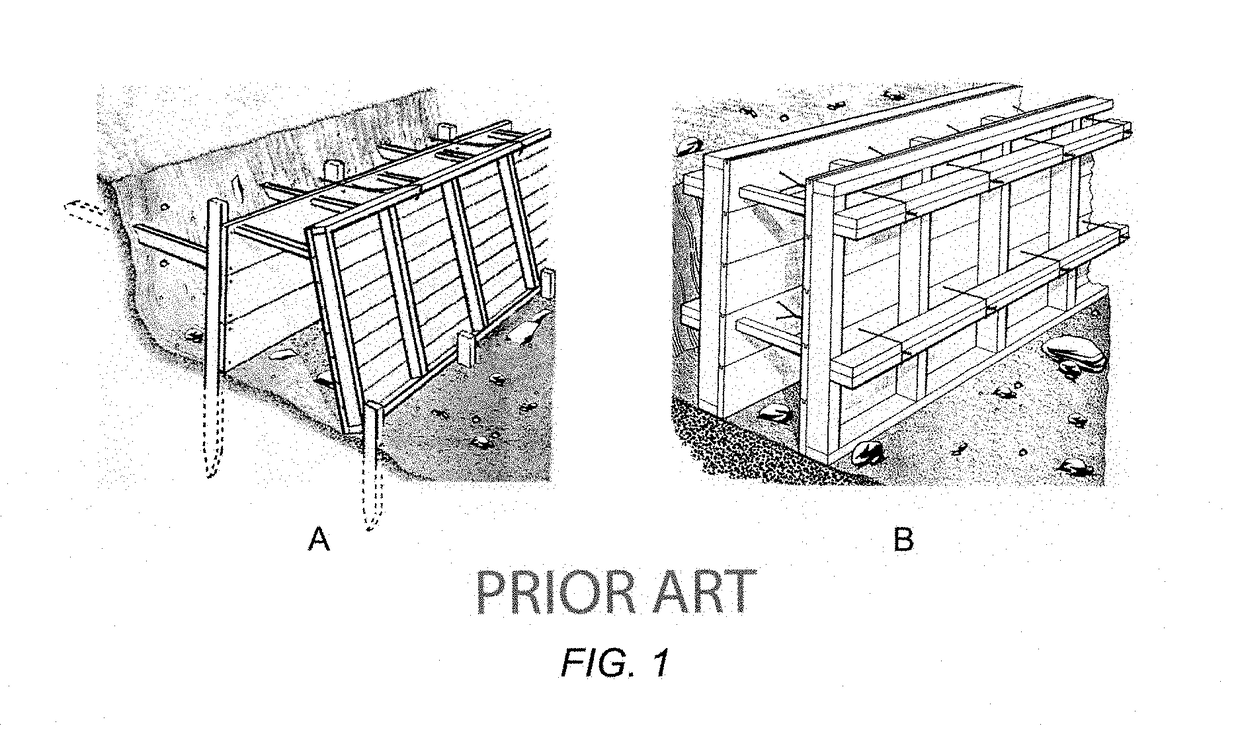

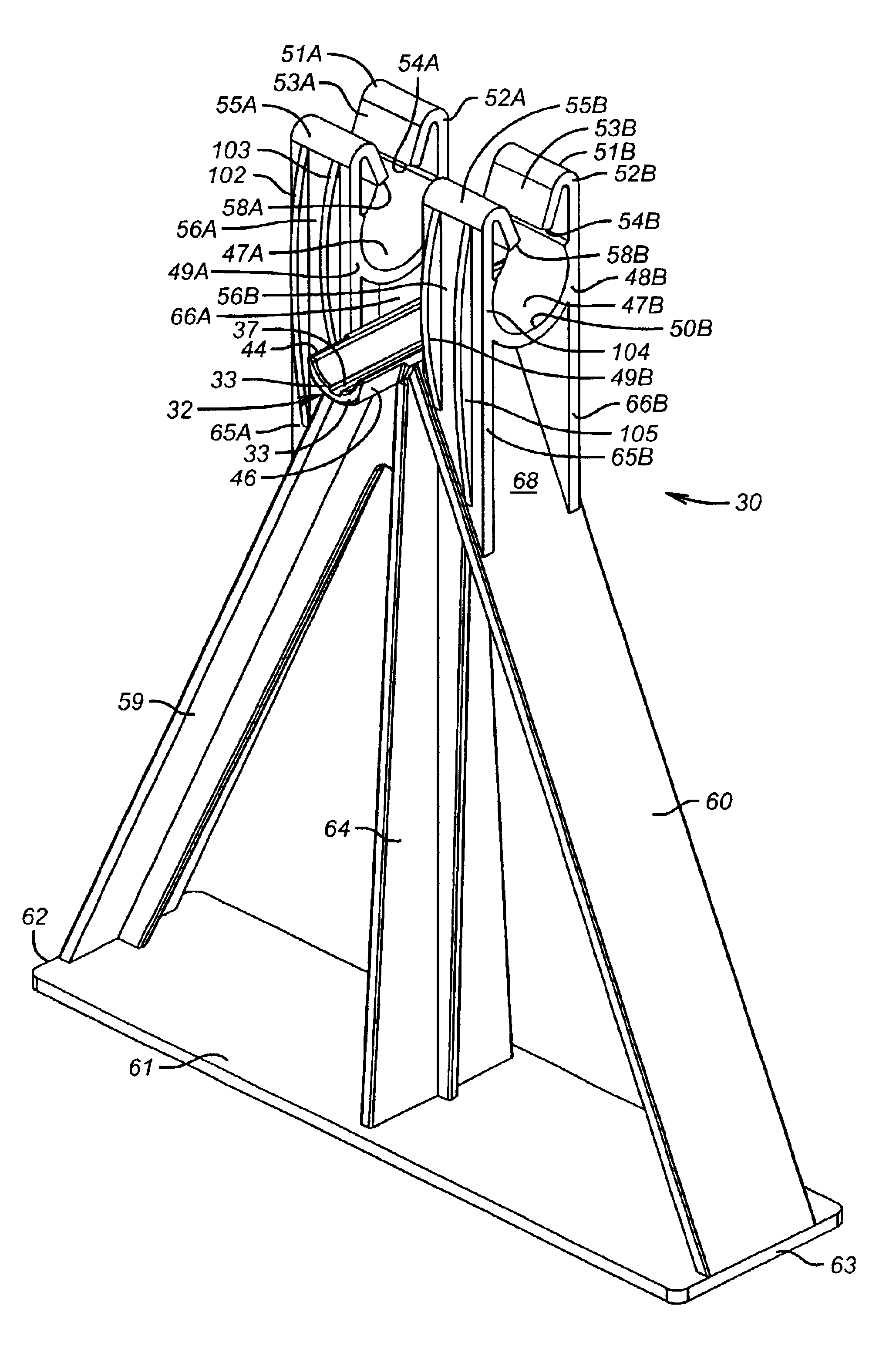

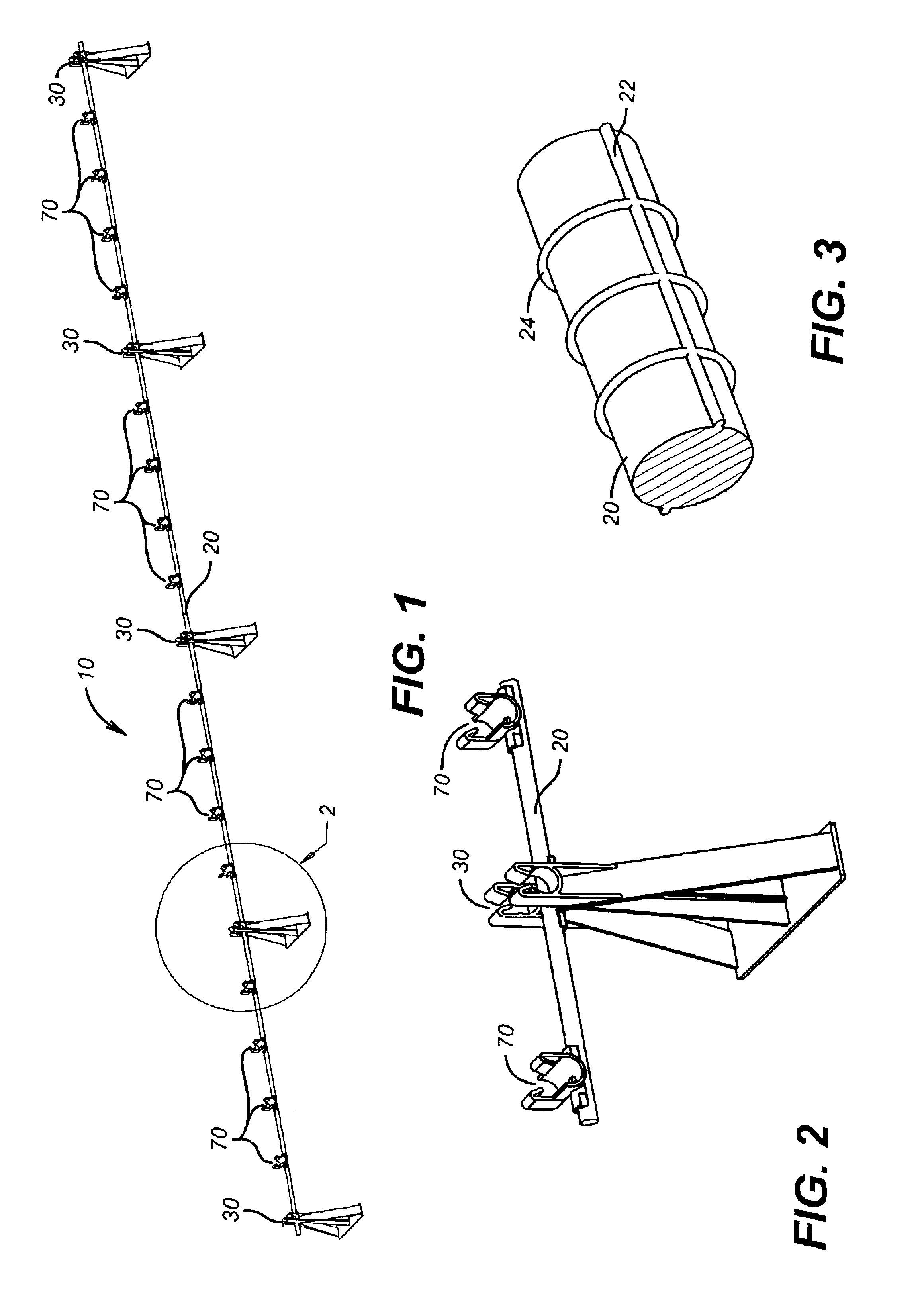

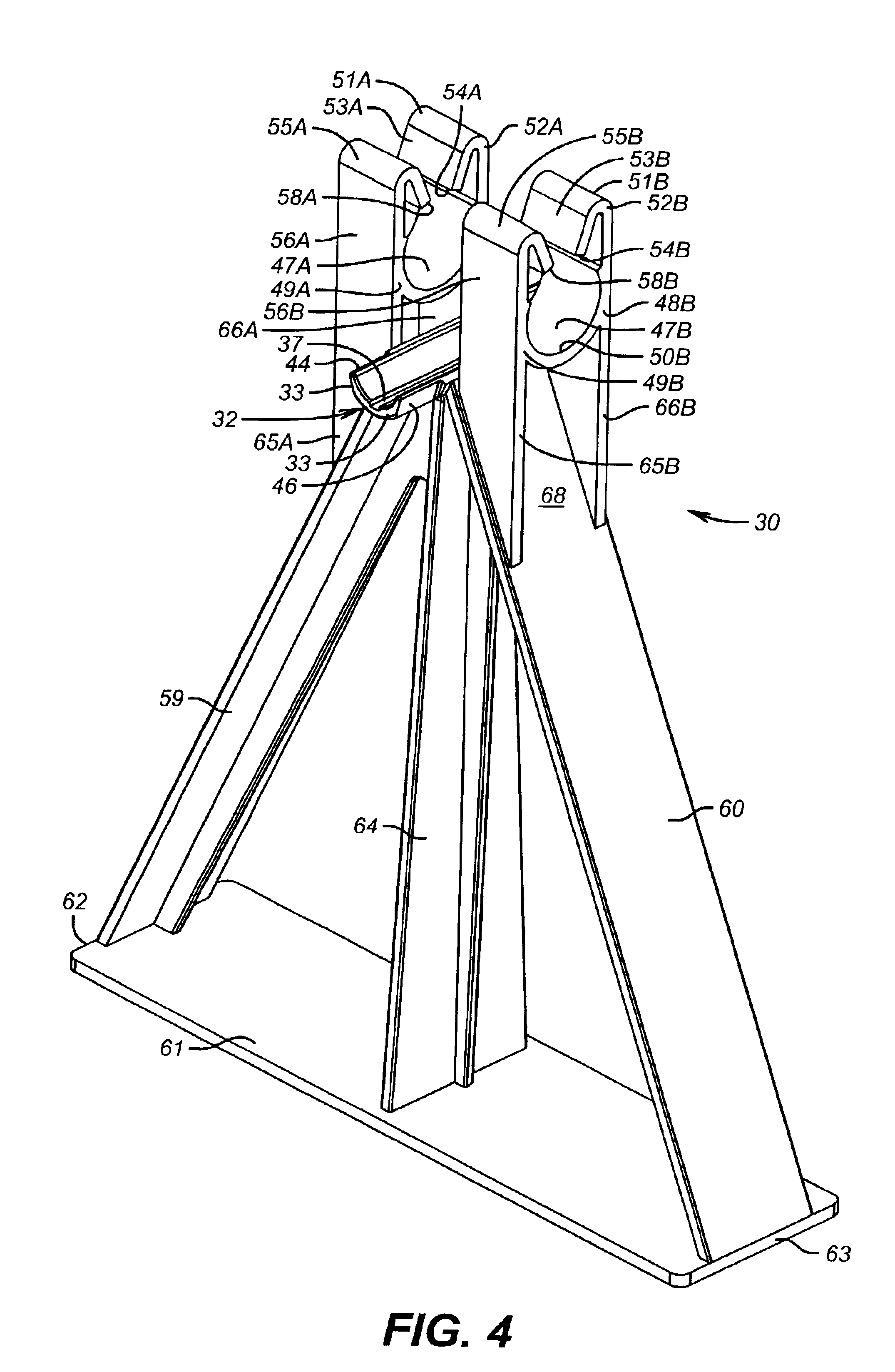

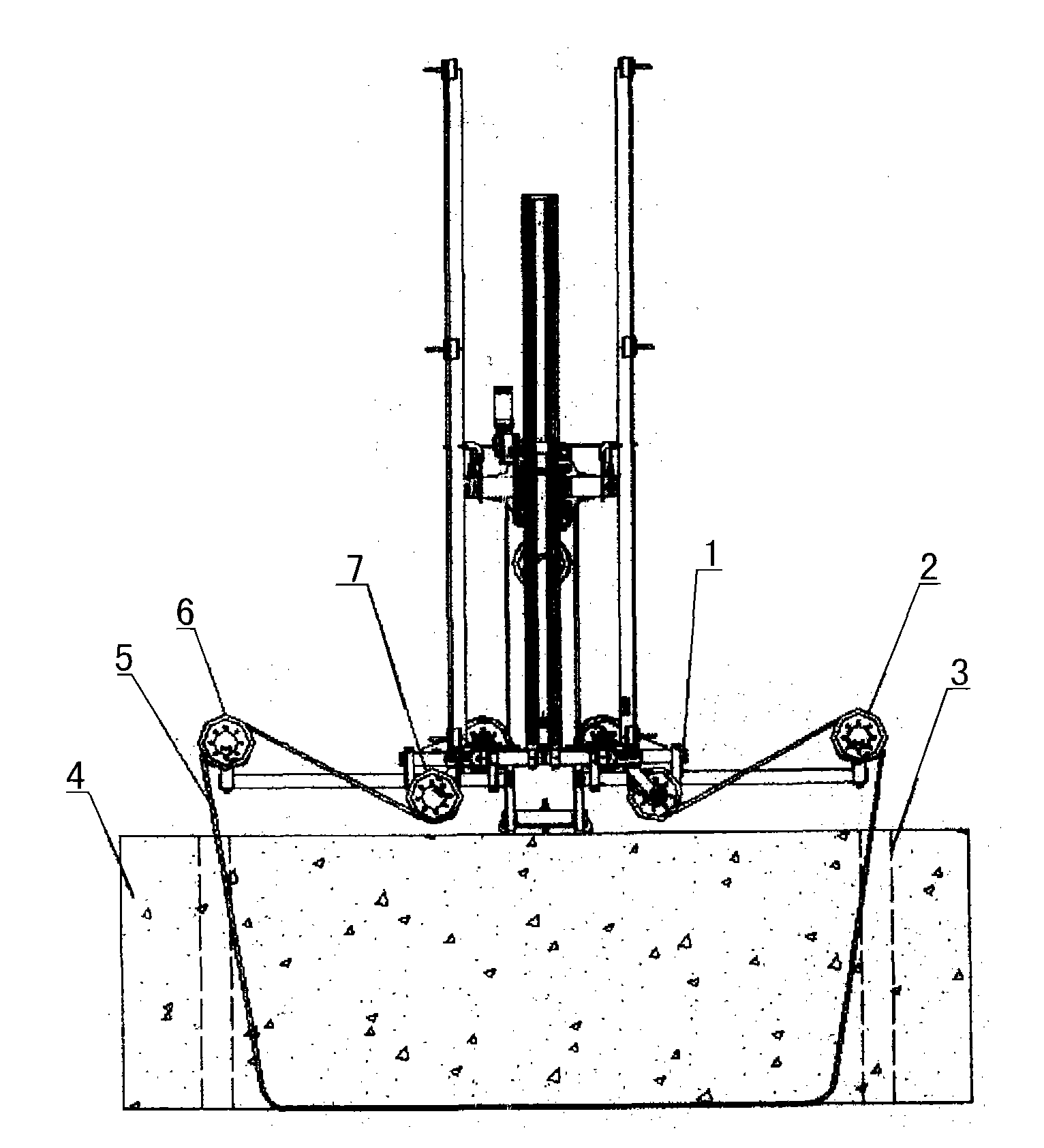

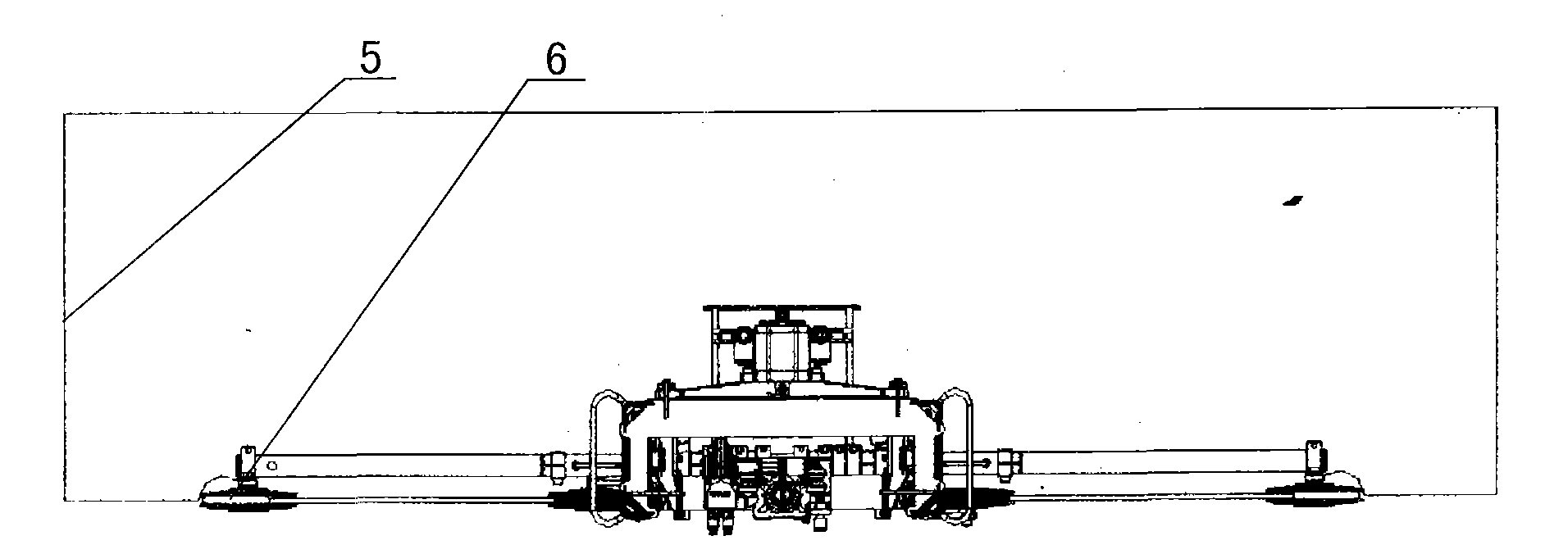

Apparatus for placing rebar in continuously reinforced concrete paving

InactiveUS6837017B2Avoid the needImprove sealingPaving reinforcementsBuilding repairsReinforced concreteEngineering

A transverse bar assembly for use in constructing rebar mats for reinforcement of concrete paving includes a plurality of chairs and clips each having a lower portion that fixes to a transverse bar in the direction of its length and an upper portion for orthogonally receiving and holding locked in place a longitudinal bar, the chair also having a support extending to a base surface.

Owner:HARDY CONSTR TECH

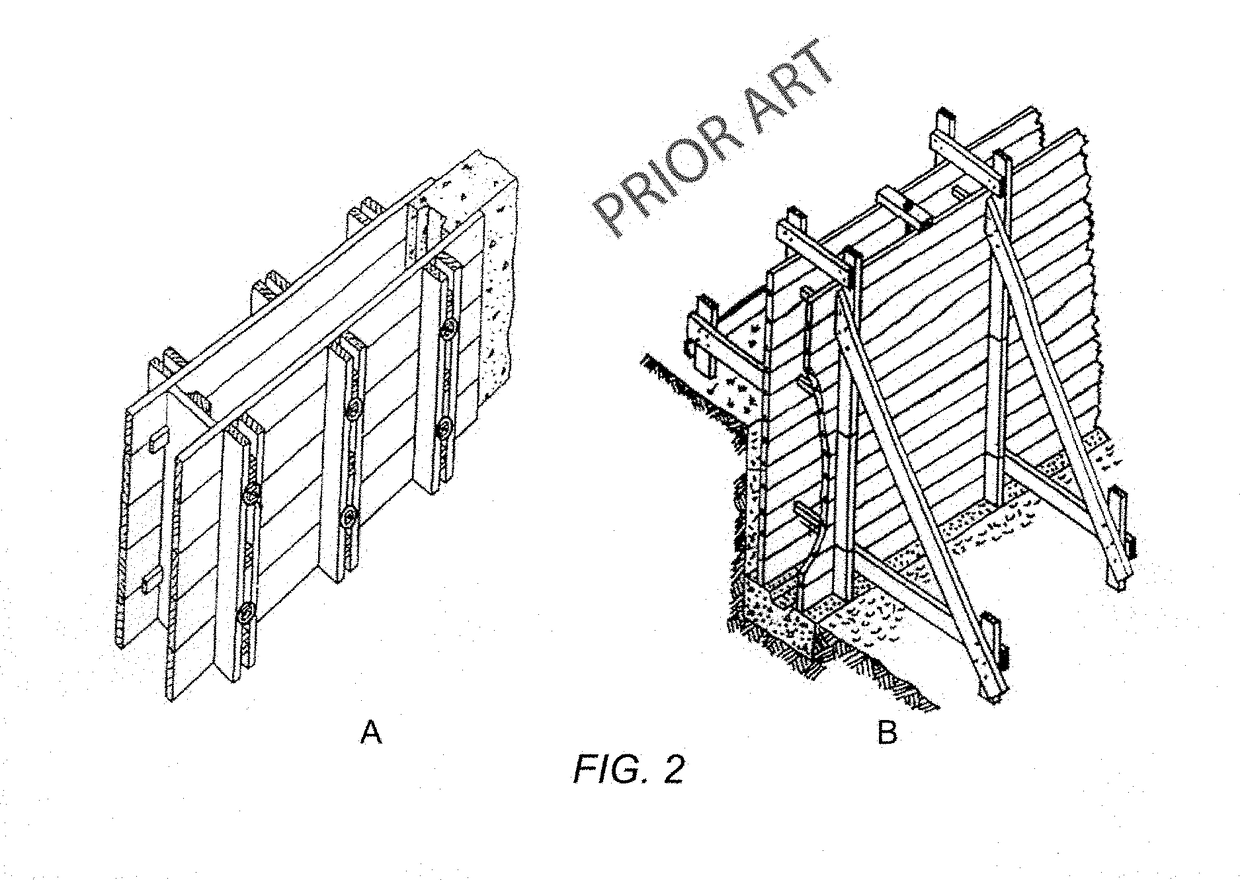

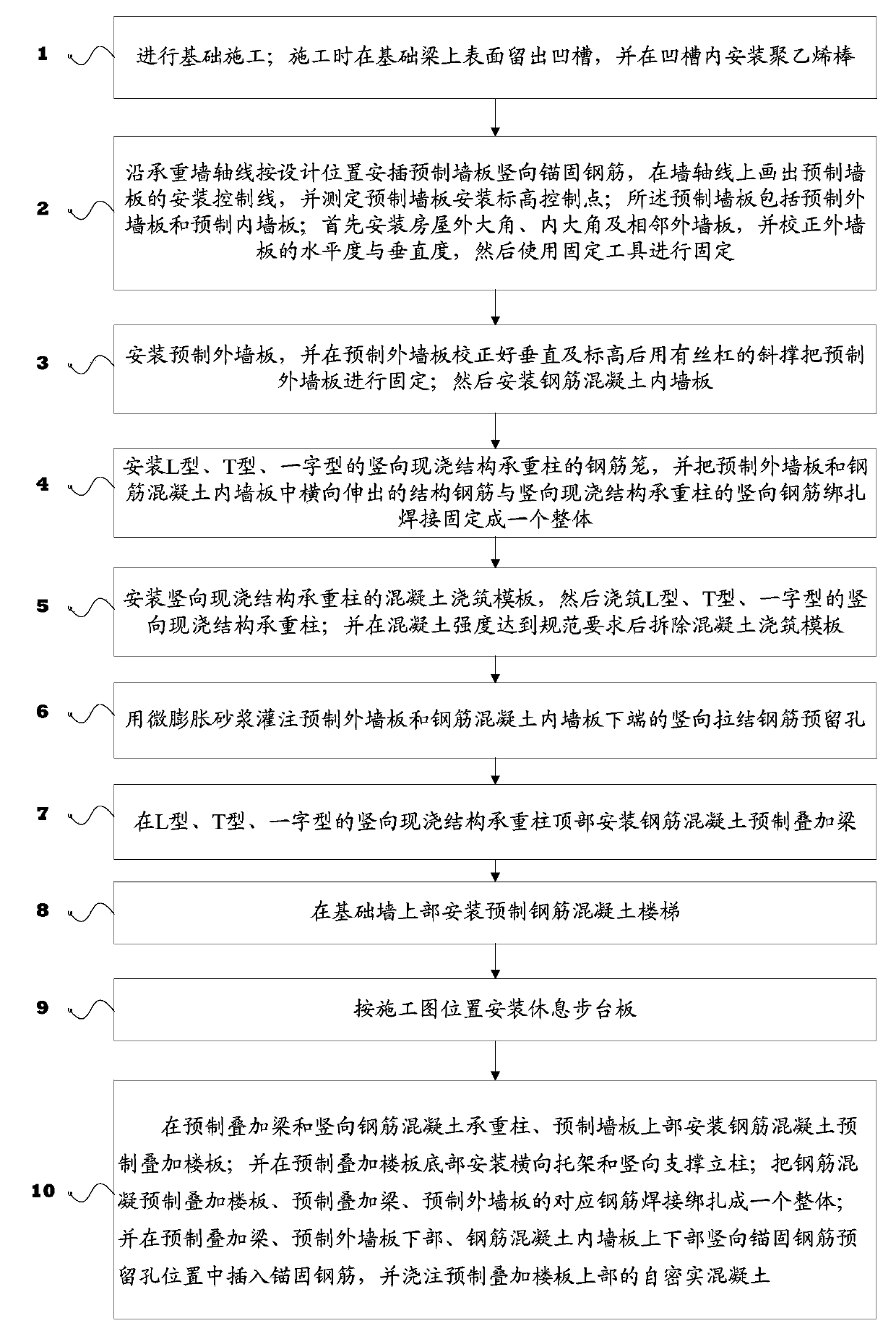

Construction method for reinforced concrete prefabricated house

ActiveCN103422672AImprove construction efficiencyReduce engineering costsBuilding material handlingFloor slabReinforced concrete

The invention provides a construction method for a reinforced concrete prefabricated house. The method comprises the following steps of constructing a foundation; mounting prefabricated wallboards; casting in situ T-shaped, L-shaped and inline vertical heel posts; pouring micro-expansion mortar into vertical steel tie preformed holes in the upper and lower ends of the prefabricated wallboards; mounting reinforced concrete prefabricated superimposed beams; mounting reinforced concrete prefabricated stairs and flat stepping plates; mounting prefabricated superimposed floor slabs on the prefabricated superimposed beams; welding and binding corresponding reinforcements exposed from the prefabricated superimposed floor slabs, the upper ends of the prefabricated superimposed beams and the prefabricated wallboards into a whole, and inserting vertical anchor bars for fixing the upper and lower end parts of the prefabricated superimposed beams and the wallboards, and casting self-compacting concrete on the upper parts of the prefabricated superimposed floor slabs. A 100m-high building can be constructed in an 8 earthquake fortification region such as Beijing by sequential and cyclic construction to a design top layer from bottom to top. According to the method, a technical index of building energy efficiency of 75 percent can be achieved, and the development of a prefabricated house construction technology can be accelerated.

Owner:洪都建设集团有限公司

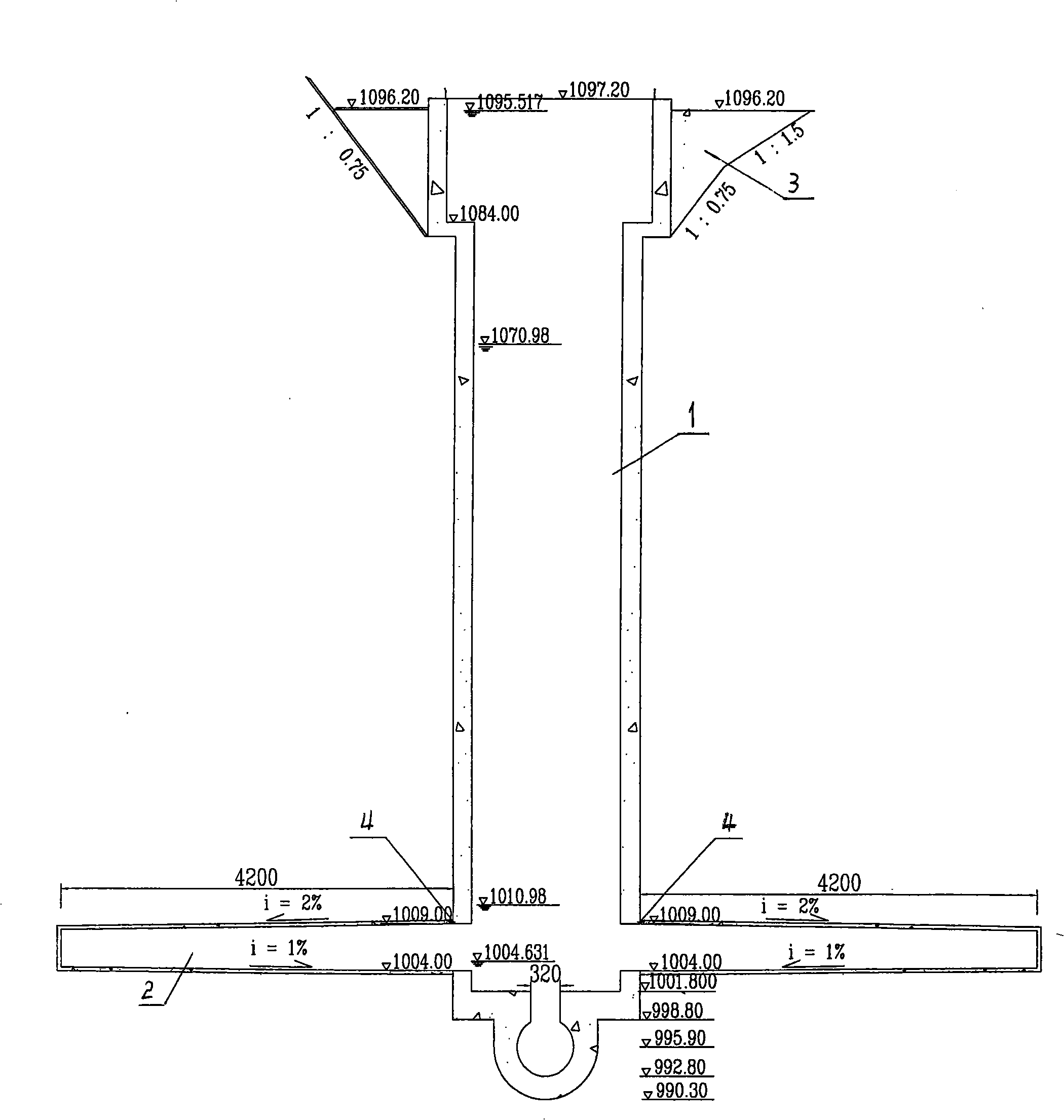

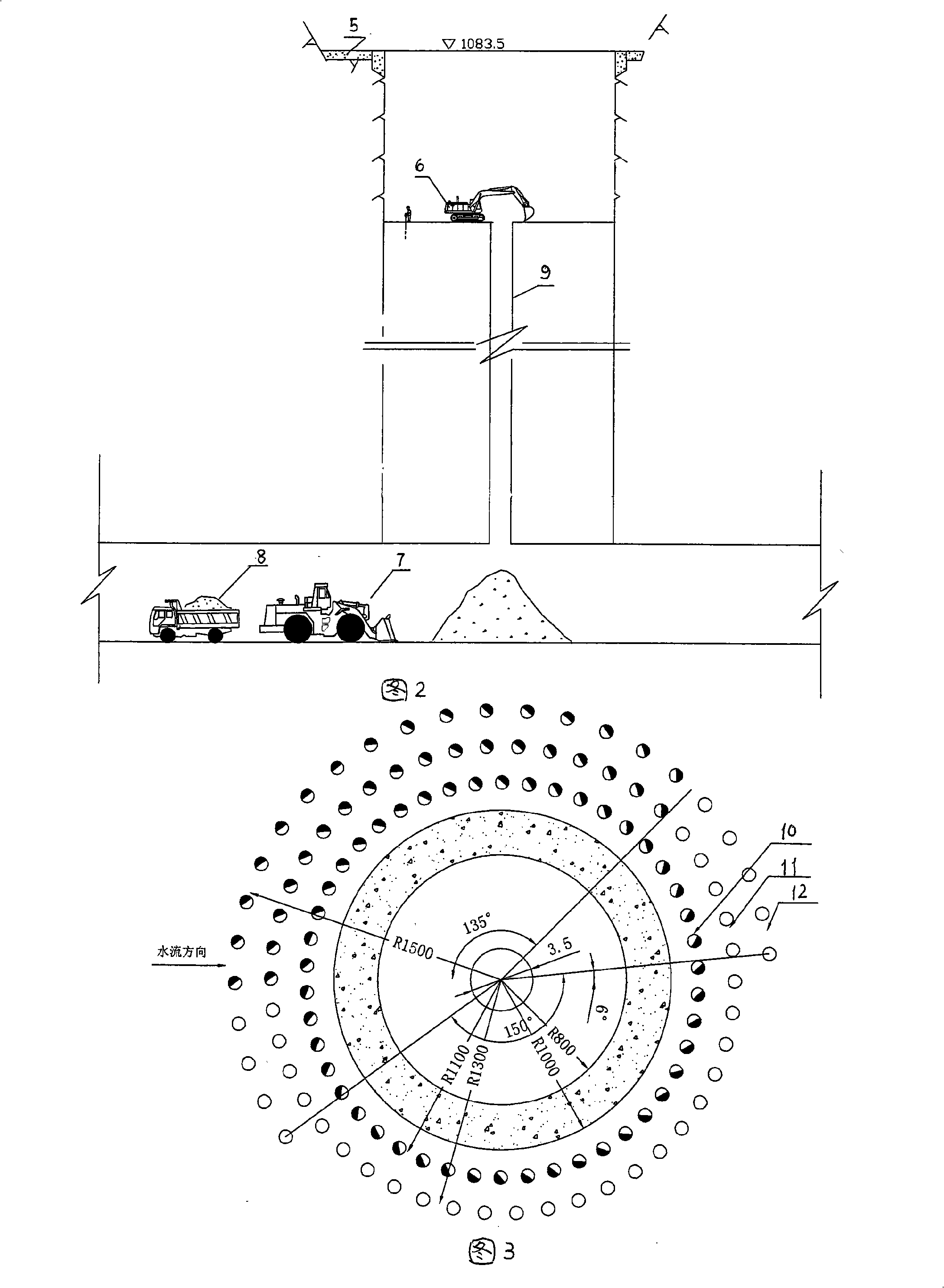

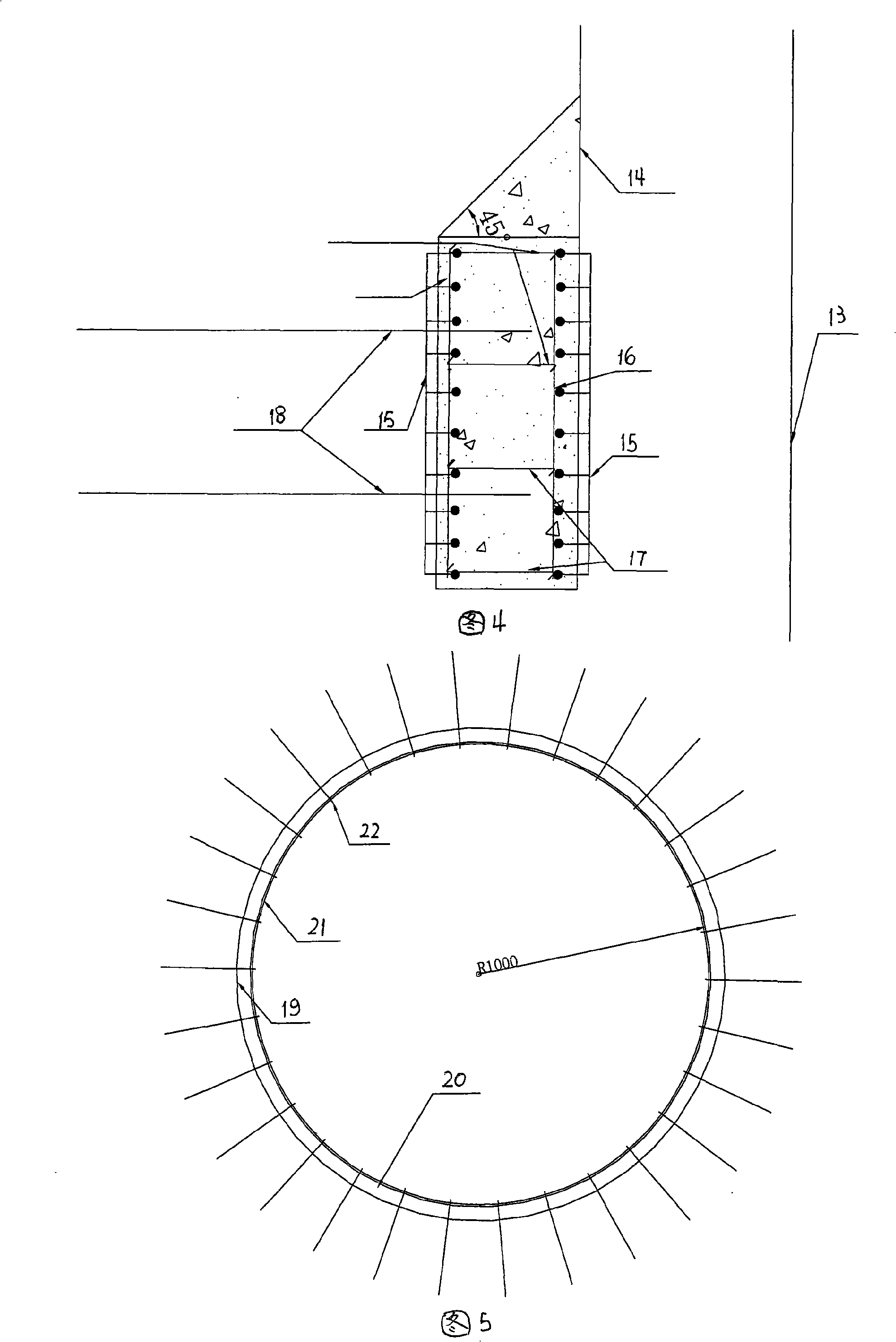

Construction method of hydroelectric power station surge chamber vertical shaft under soft rock geological condition

ActiveCN101349064ASimple designEnsure safetyArtificial islandsUnderwater structuresSteam-electric power stationGeomorphology

The invention relates to a method for constructing a drilled shaft of a surge chamber in a hydropower station under the condition of weak rock geology; the excavation diameter of the drilled shaft is more than or equal to 20 meters; and the depth of the drilled shaft is more than or equal to 50 meters. The method comprises the following steps: firstly, a safe prestress reinforcing measure is adopted; a prestress anchor rope is arranged in a side slope of the drilled shaft; the deep rock holes in the periphery of the drilled shaft are subjected to consolidation and grouting; the periphery of the drilled shaft is cast with reinforced concrete for locking a mouth, etc; the construction sequence of excavating the drilled shaft comprises that: a raise-boring machine drills a guide hole of phi 216 millimeters from top to bottom; the raise-boring machine enlarges and excavates a small guide well of phi 1, 400 millimeters; a slag slipping guide well of phi 2, 500 millimeters is enlarged and excavated manually from bottom to top; and the slag slipping guide well is enlarged and excavated from top to bottom. The slag slipping guide well is excavated by manual drilling and blasting; slag is naturally slipped and mechanically loaded in the bottom of the well; a large well is enlarged and excavated through drilling and blasting by a manual air drill; and the skimmed slag in a hydraulic backhoe well slips to the bottom of a passage through the slag slipping guide well and is mechanically loaded in the bottom of the well. The construction method has the characteristics of having reasonable construction arrangement, alternately and simultaneously carrying out a plurality of construction types and saving the construction period.

Owner:SINOHYDRO BUREAU 5 +1

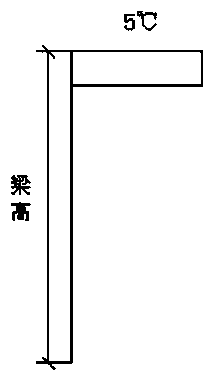

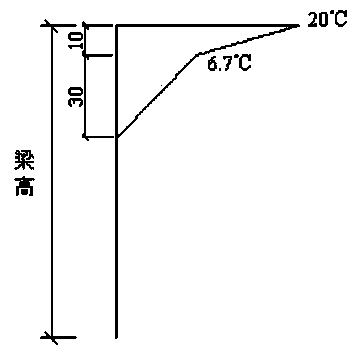

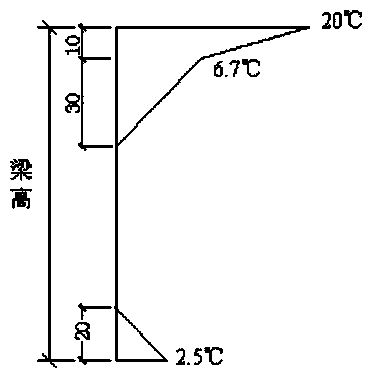

Finite element analysis method for temperature action on prestressed reinforced concrete continuous rigid frame bridge

ActiveCN104166792AAccelerated settlementEfficient solutionSpecial data processing applicationsStructural deformationElement analysis

The invention provides a finite element analysis method for the temperature action on a prestressed reinforced concrete continuous rigid frame bridge. The finite element analysis method is used for analyzing and calculating the stress and displacement distribution in the construction and finished bridge stage under different temperature gradient models, and provides references for designing and optimizing the prestressed reinforced concrete continuous rigid frame bridge. Through calculational analysis based on finite elements and the structural mechanics, the forward-calculation method is adopted for structural distortion and stress analysis according to the actual construction loading sequence of the bridge structure, so that the complex mechanics problem of box girder temperature self-stress, temperature secondary internal force in a prestressed reinforced concrete statically indeterminate structure and secondary stress of the temperature secondary internal force is solved easily, conveniently and efficiently, and the finite element analysis method has important practical value.

Owner:江苏中国科学院能源动力研究中心 +1

Single-component high-performance mortar for repairing and reinforcing concrete

InactiveCN101935201AShrinkage controlImprove bindingSolid waste managementFlexural strengthPollution

The invention provides single-component t high-performance mortar for repairing and reinforcing concrete, which comprises the following components in part by mass: 200g of sand, 55 to 75 parts of ordinary portland cement, 10 to 30 parts of sulphate aluminium cement, 3 to 7 parts of siliceous dust, 8 to 12 parts of flyash, 0.18 to 0.22 part of water reducing agent, 2 to 4 parts of flexibilizer, 0.04 to 0.06 part of water-retaining agent, 1.0 to 2.0 parts of swelling agent and 0.1 to 0.2 part of polymer synthetic fiber. The single-component t high-performance mortar has the advantages of high initial strength, good adhesion, excellent cracking resistance, low ratio of compressive strength to flexural strength, excellent toughness, simple and convenient construction, single component, no toxin or smell, no harm to human bodies, and environmental protection without pollution.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

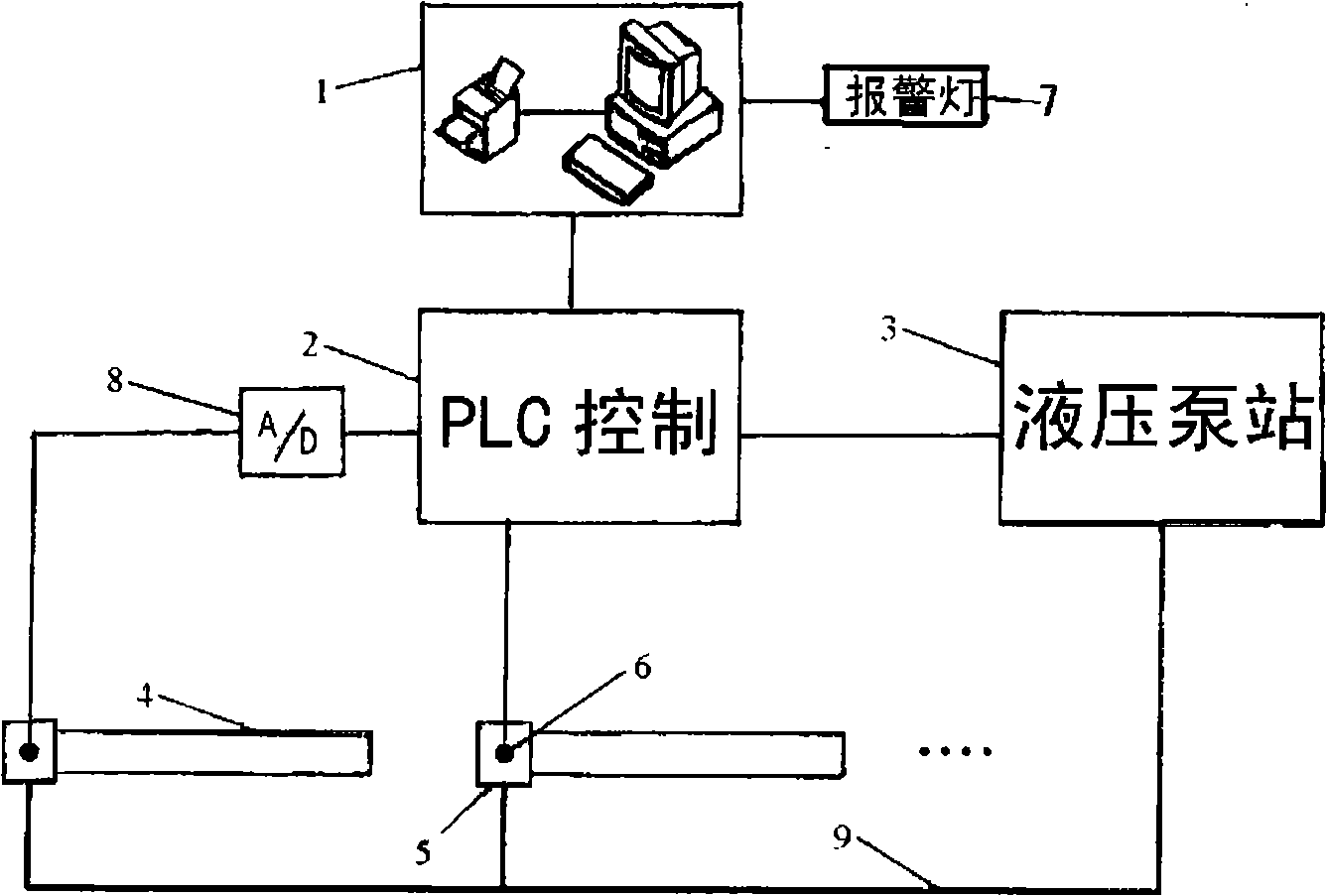

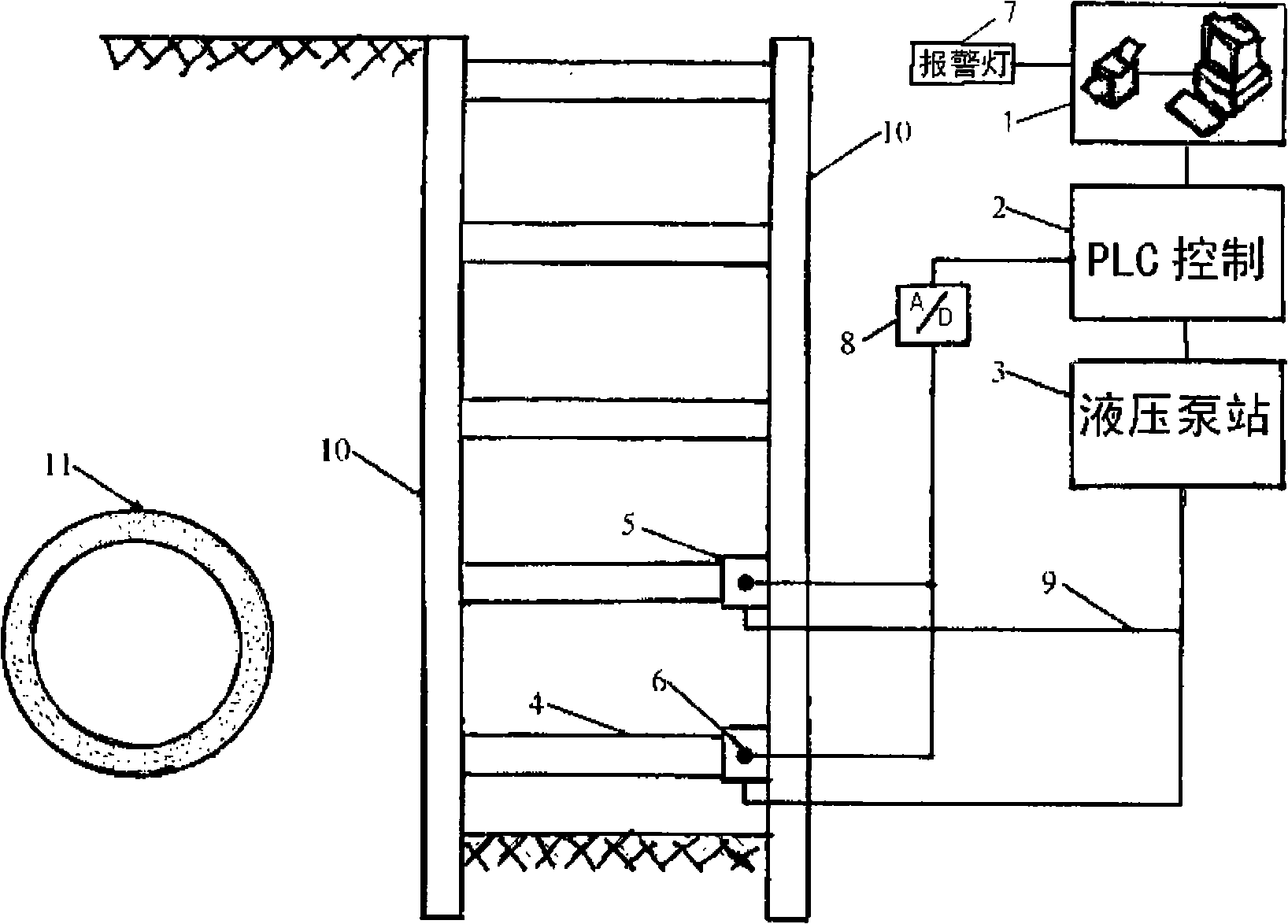

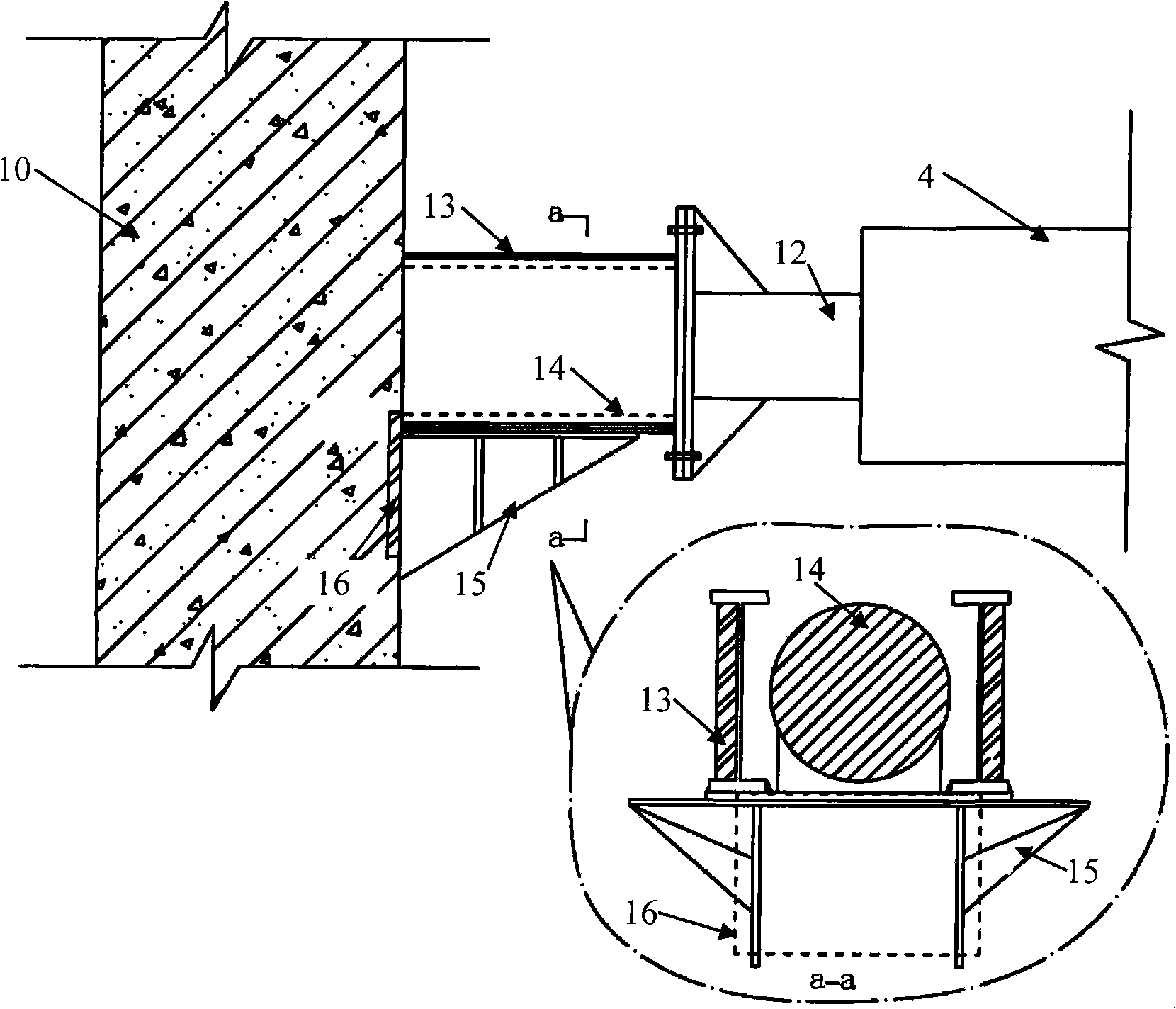

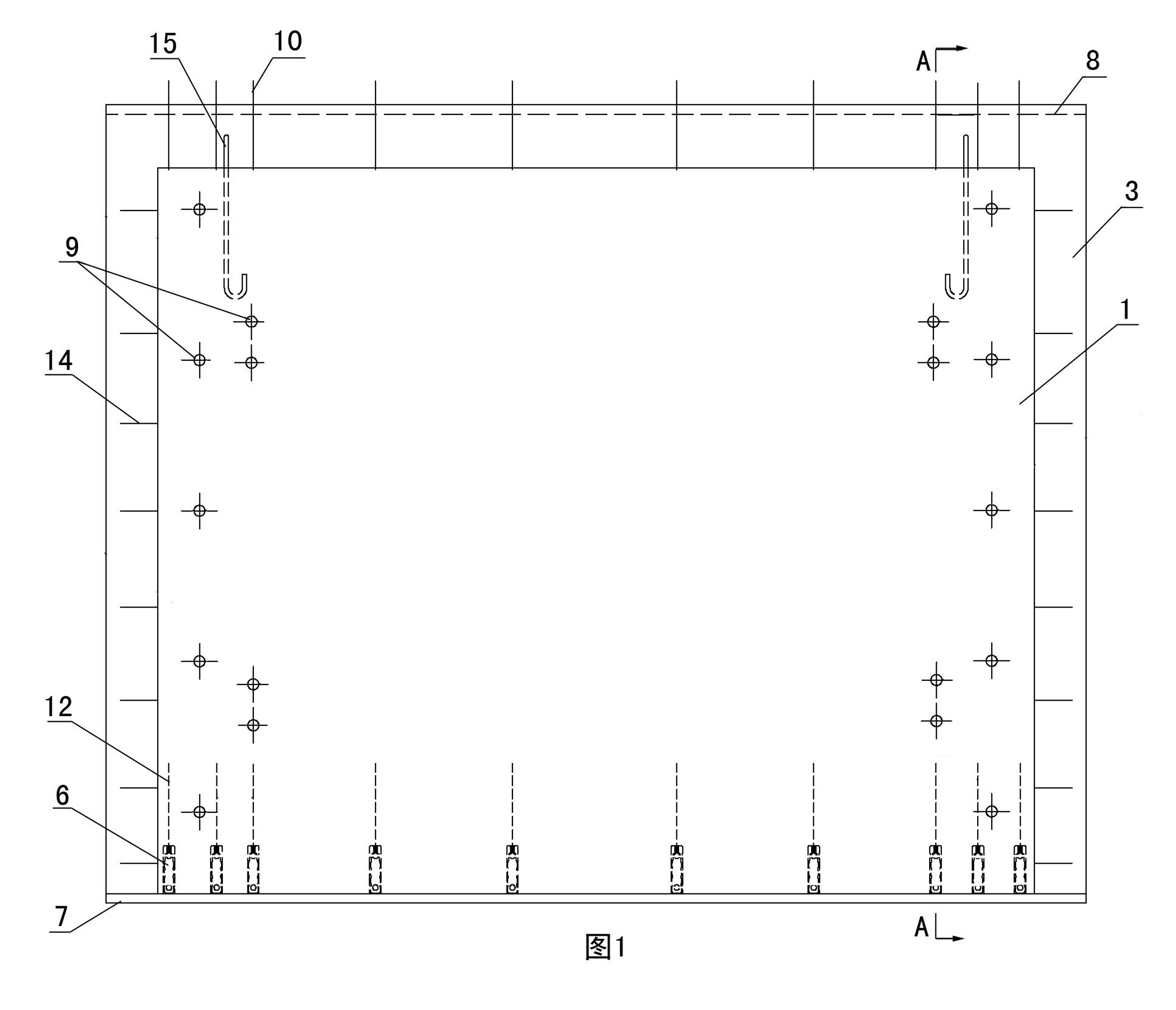

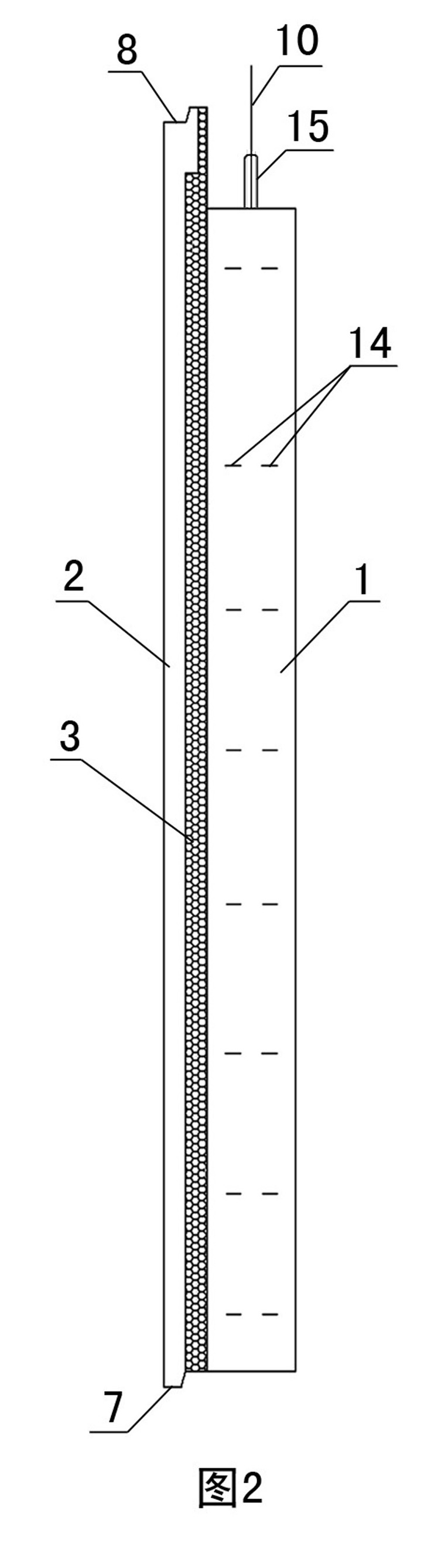

Steel shotcrete support internal force self-compensation, displacement control system and control method

InactiveCN101294389AImprove the force deformation performanceControl deformationExcavationsShotcreteAutomatic control

The invention belongs to the building support component technology field including the stress automatic control and monitoring as well as the structural safety, and relates to a steel tube supporting internal force automatic compensating and displacement controlling system. The system comprises an upper system, a PLC control system module and a field executive system. A steel support is arranged on a reinforced concrete diaphragm wall, a hydraulic jack is arranged on the steel support, and real time pressure monitoring values are fed back through a pressure sensor. The steel support and the hydraulic jack form a pre-stressed steel support structure, the hydraulic jack is connected with a hydraulic pump station through an oil circuit, and is connected with the PLC control system module through the pressure sensor, the hydraulic pump station is connected with the PLC control system module, and a PLC controlling device is connected with the upper system. Through auto-control software and a PLC control system, the automatic control to the axial force of the steel support is realized, thereby controlling the displacement and the settlement of the deep excavation supporting structure and the adjacent basic facilities.

Owner:CSCEC INT CONSTR +1

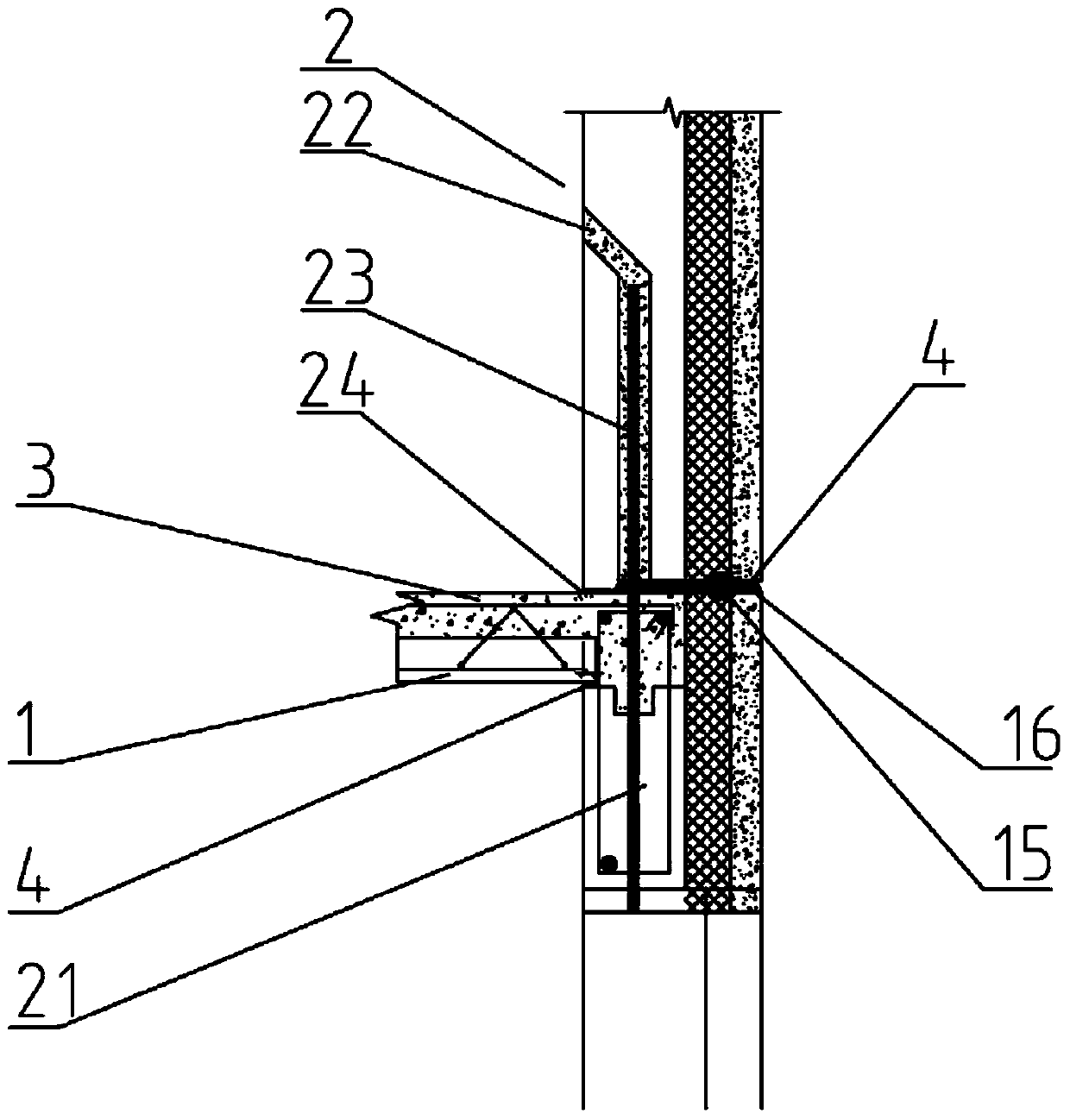

Assembled integral building and construction method thereof

ActiveCN101818539AGuarantee the construction qualityLow costBuilding componentsBuilding material handlingFloor slabReinforced concrete

The invention discloses an assembled integral building and a construction method thereof. The assembled integral building comprises a reinforced concrete wall and floor slabs, wherein the reinforced concrete wall is formed by hoisting and assembling prefabricated composite insulating wallboards integrally at a construction site; a board body of each prefabricated composite insulating wallboard comprises a structure layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; steel meshes are arranged in the concrete of the protective layer; the structural layer, the insulating layer and the protective layer are anchored together by inserting connecting members in a dotted distribution; the left and right edges of the protective layer and the insulating layer protrude out of the structural layer; a lower edge of the protective layer extends downward to form a bulged opening; the top parts of the protective layer and the insulating layer upward protrude out of the structural layer; and an upper edge of the protective layer is provided with a notch which corresponds to the bulged opening of the prefabricated composite insulating wallboard adjacent to an upper layer. The building overcomes the defects of erecting shuttering on site, binding steel bars and concreting in a traditional construction method, speeds up the construction, and lowers the construction cost; and the construction quality of the building structure can be sufficiently guaranteed.

Owner:雄安万科绿色研发有限公司

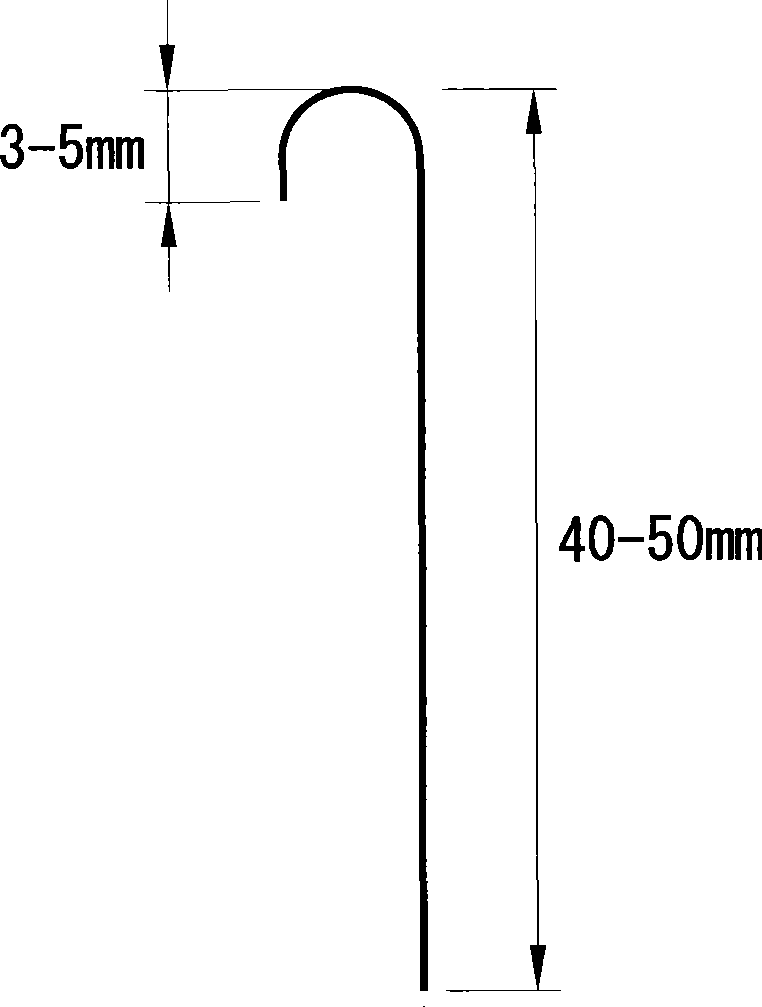

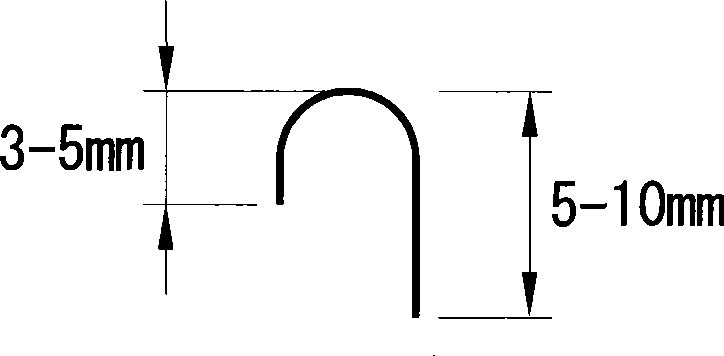

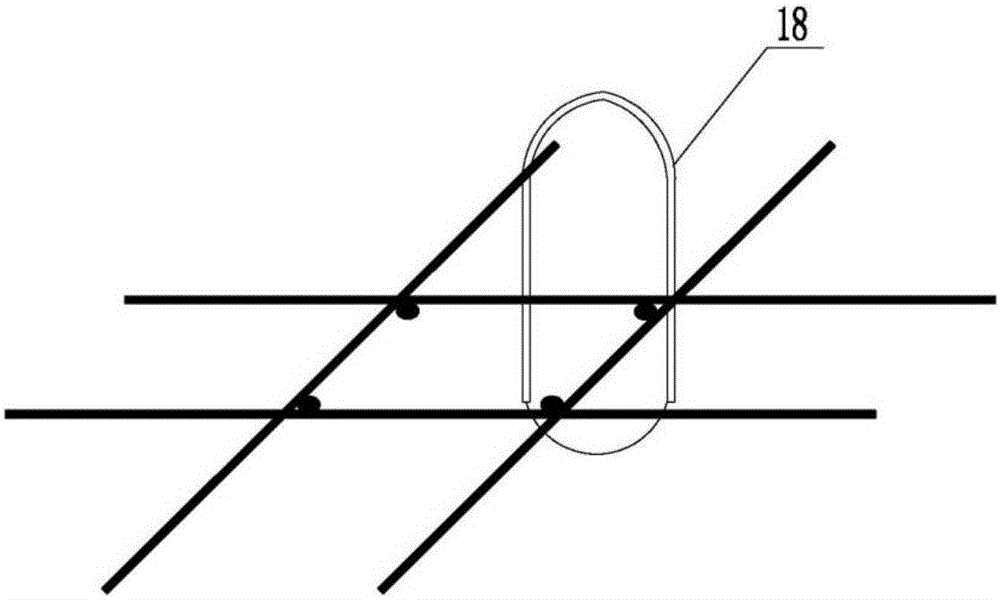

Method for reinforcing construction structure by fiber knitted net and fine concrete

ActiveCN101476396AImprove adhesionAvoid peel damageSolid waste managementMixing operation control apparatusFiberReinforced concrete

The invention belongs to the technical field of concrete reinforcement and relates to a method for reinforcing concrete with a fibrage net and a cement-based material. The method is to pour the fibrage net the total thickness of which is between 10 and 20 millimeters and fine concrete on the outer surface of a structure, and is characterized by comprising the following steps that: drilling holes on the surface of the structure in the process of construction; using the short end foot of a U-shaped shear resistant pin of which the two end feet have different lengths to hook the fibrage net, and inserting the long end foot thereof into the hole after a building structural adhesive is smeared on the long end foot; spraying the fine concrete after the adhesive is solidified; using the short end foot of a U-shaped hook of which the two end feet have different lengths to hook a second layer fibrage net, and inserting the long end foot thereof to the fine concrete; and spraying the fine concrete. The method can avoid the generation of interface micro cracks at high stress, effectively prevent interface peeling damages, reinforces building structures reliably, simply, efficiently and environmental protection, and is applicable to reinforcing and repairing various types of structures.

Owner:浙江固邦新材料有限公司

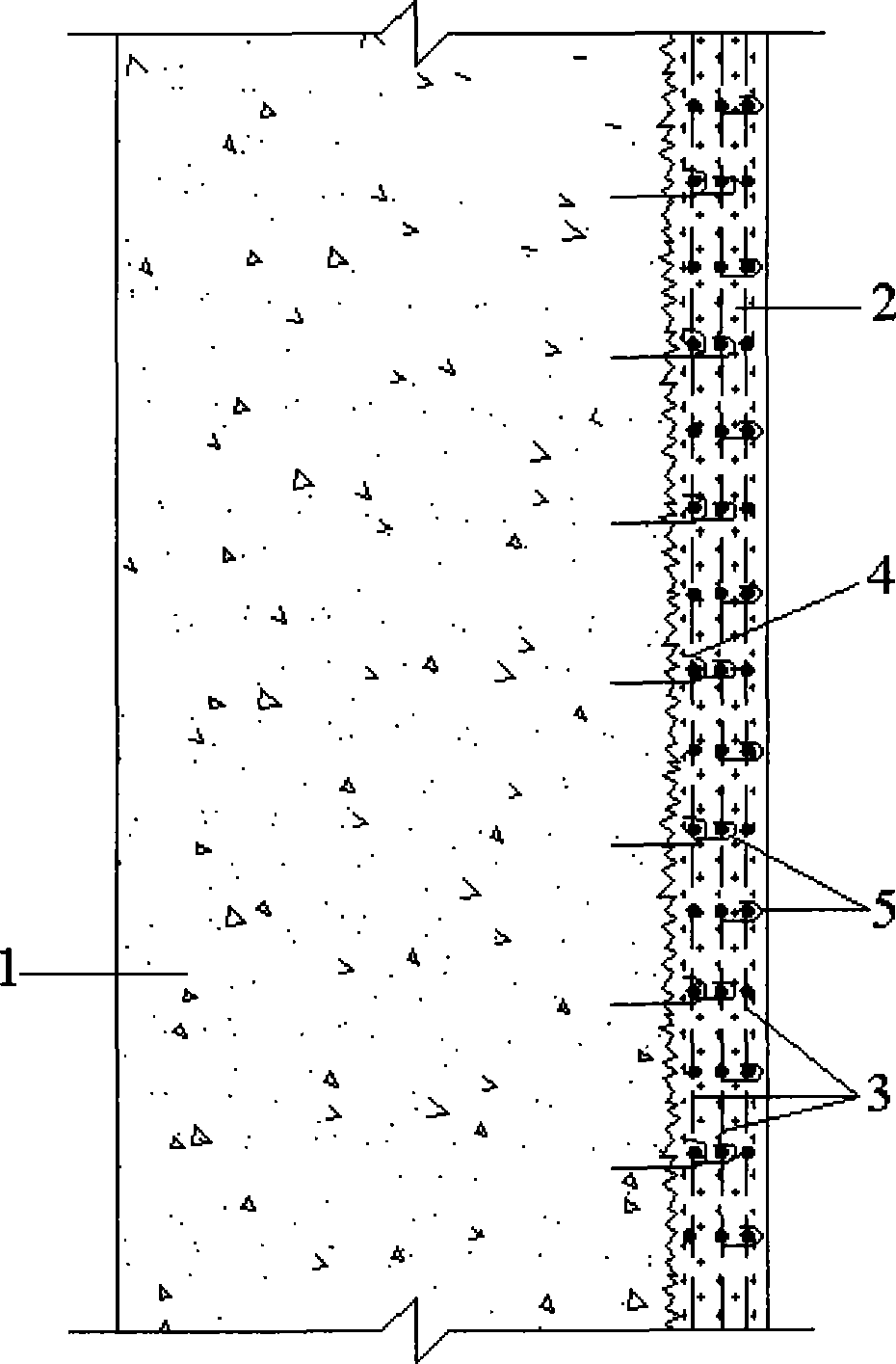

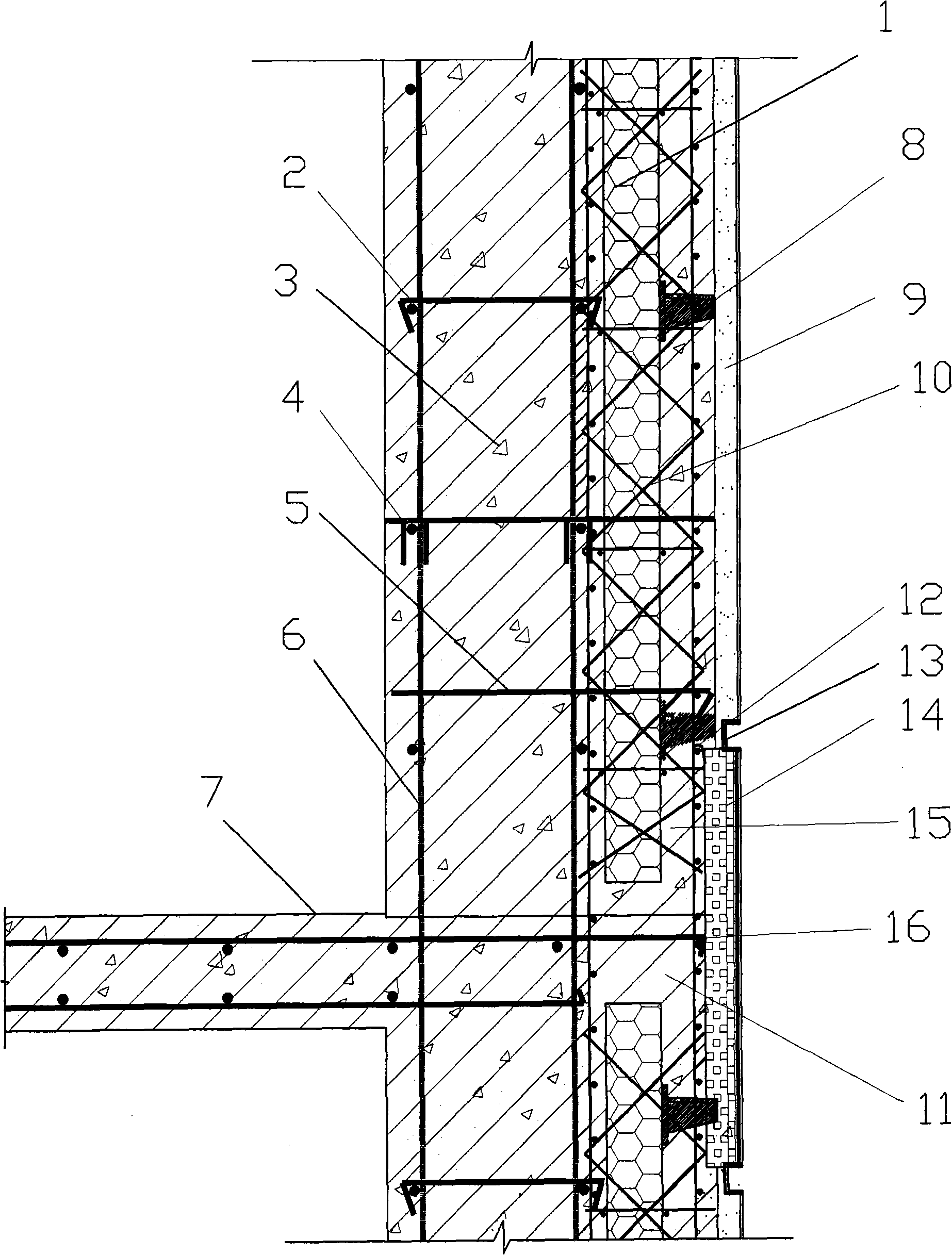

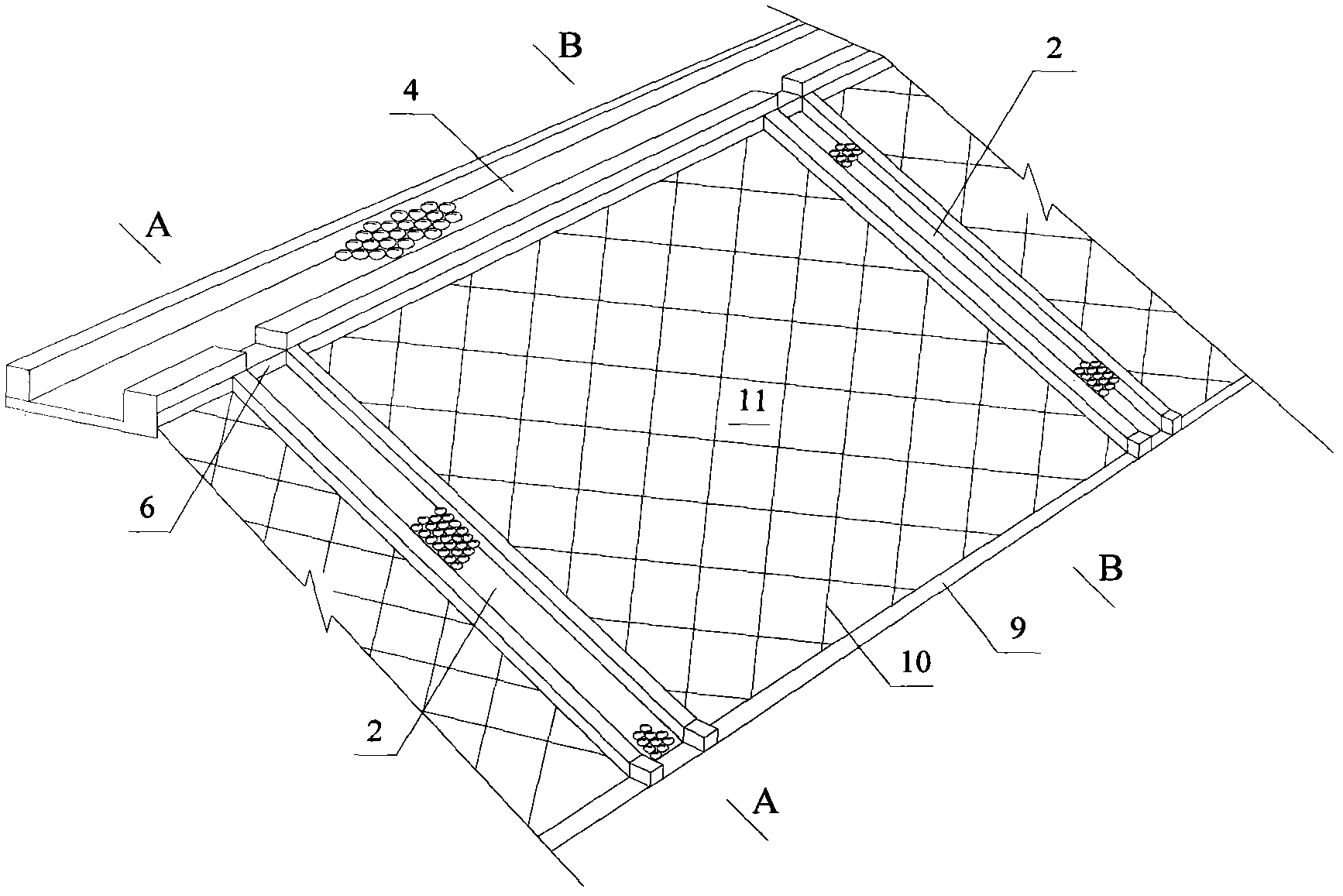

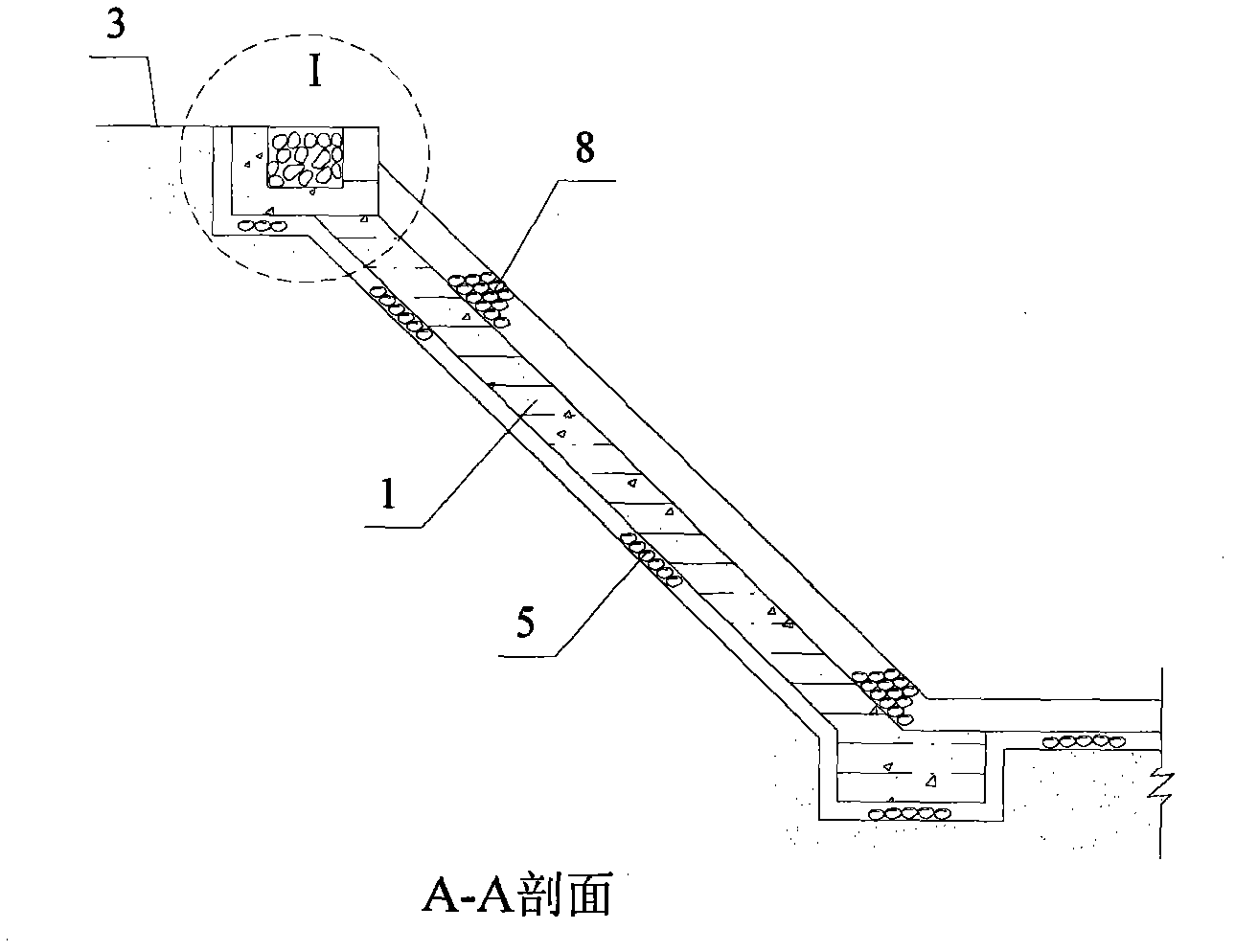

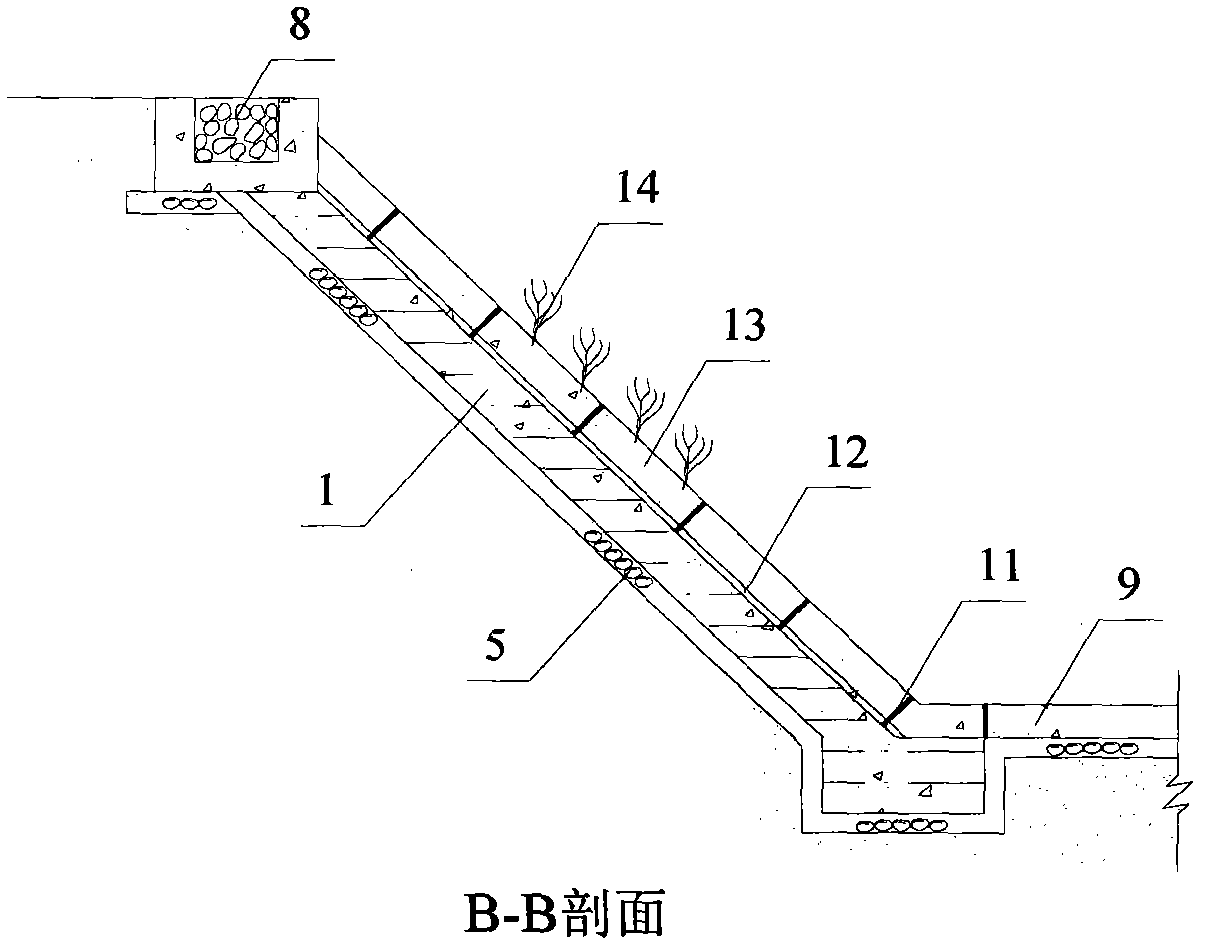

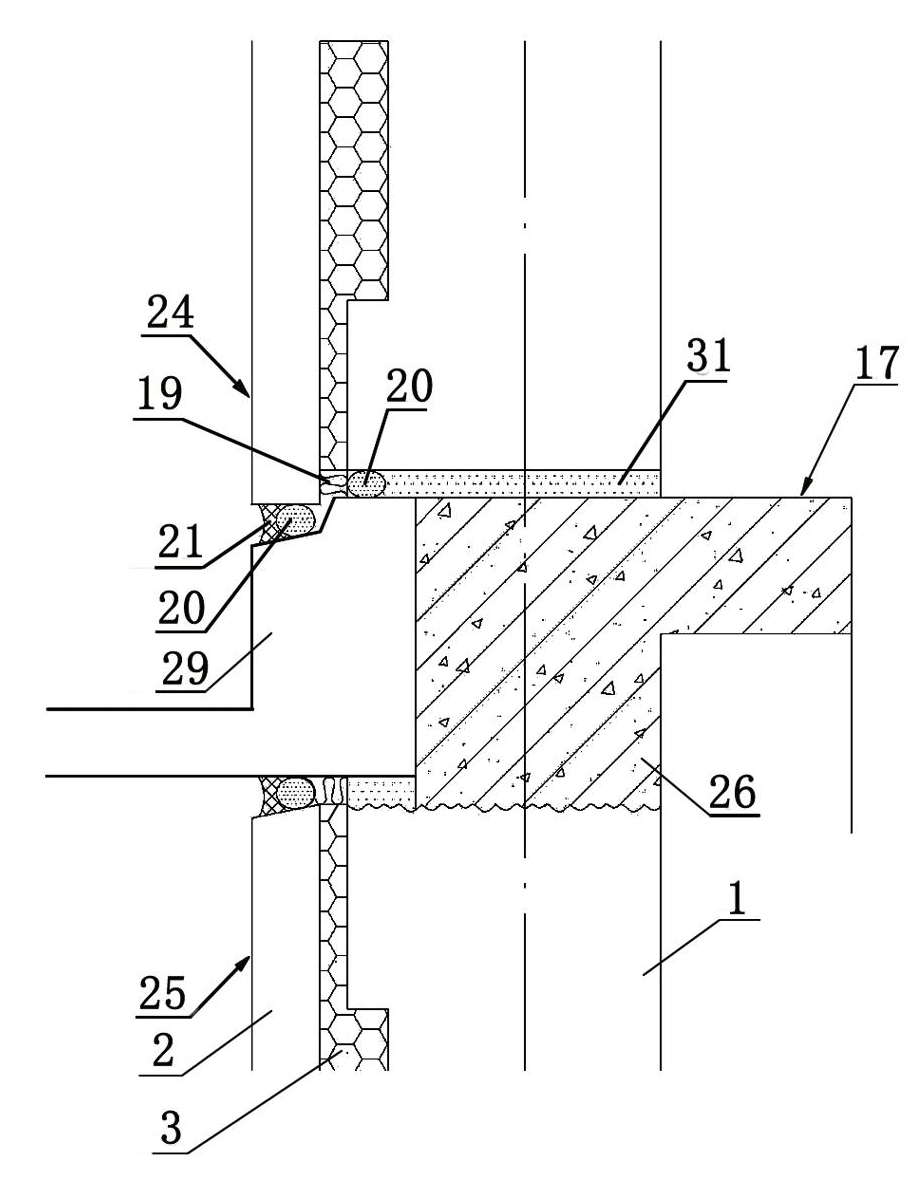

Externally reinforced concrete irrigated and heat preservation wall structure embedded energy-saving system and its construction method

ActiveCN101319525ANovel structureImprove thermal insulation performanceWallsClimate change adaptationInsulation layerSteel bar

The invention relates to an energy-saving system for a reinforced concrete outer-casting built-in heat insulation wall body structure and a construction method thereof, which can effectively solve the problems of external wall heat insulation of a high-rise building with high heat insulation requirement and cracking and falling of a heat insulation layer. The system is produced by a wall body and reinforcing steel bars in the wall body which are cast by concrete. The method comprises the following steps that: a reinforcing steel bar frame of the wall body is produced and arranged, namely parallel vertical reinforcing steel bars and indoor floor-connecting board tie bars perpendicular to the parallel vertical reinforcing steel bars are bound together, a grid board is hoisted and externally suspended outside the vertical reinforcing steel bars of the wall body, and is bound with the vertical reinforcing steel bars of the wall body by hooked bars and binding steel bars as well as framework positioning bearing bars, then a framework is arranged on the framework positioning bearing bars and is firmly bound with reinforcing steel bars of beams and boards of a floor, lapping bars are reserved, a heat insulation grid board is firstly arranged, then reinforcing steel bars of corbel brackets of a balcony and an air conditioning board external wall are bound, finally the concrete is cast, the curing is performed, and the framework is removed to repair the structure. The system has good heat insulation effect, energy conservation, environmental protection, simple method, and huge economic benefit and social benefit.

Owner:HENAN JINYUAN CONSTR

Hard reinforced concrete revetment slope biological repairing method

InactiveCN102071697AEffectively fixedPrevent landslidesSoil drainageCoastlines protectionPlant rootsRainfall runoff

The invention discloses a hard reinforced concrete revetment slope biological repairing method, which is characterized by comprising the steps of: roughing a concrete revetment and constructing drainage ditches at set intervals; digging a water collecting tank on one side of the cross of the revetment and a road, reserving an opening at the joint of the drainage ditch and the water collecting tank, and constructing a watertight concrete overflow bank; filling gravels in the water collecting tank and the drainage ditches; and welding earthwork grids by high-density polyethylene stripes on the protection slope, laying gravel cushion coats in the earthwork grids, and finally pouring biological slurry. The method has the advantages that: the whole project is stable and safe; rain flows into the water collecting tank and passes through grave areas, non-watertight sand-free concrete, a slope cushion coat, plant roots and the like to seep into rivers, so water quality is improved to a relatively large extent; when rainfall runoff is overlarge, the rain overflows from the overflow bank and passes through the graves of the drainage ditches, so the water quality is also purified to a certain extent, meanwhile the slope is protected; the biological slurry poured onto the slope is prepared from biological materials, and has certain anti-erosion strength and can be used as a substrate for plant growth, so the cost is low and the operation is simple.

Owner:HOHAI UNIV

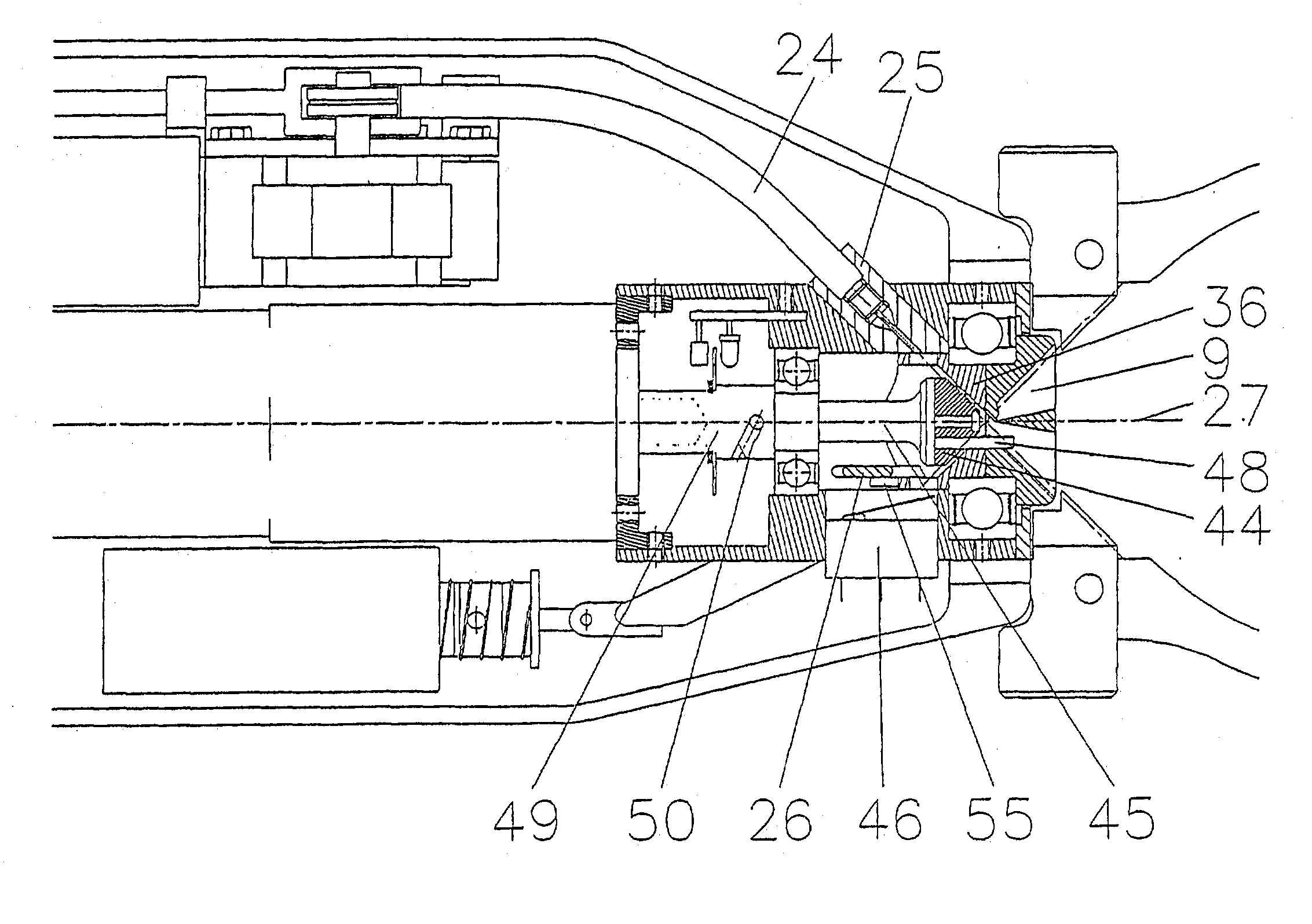

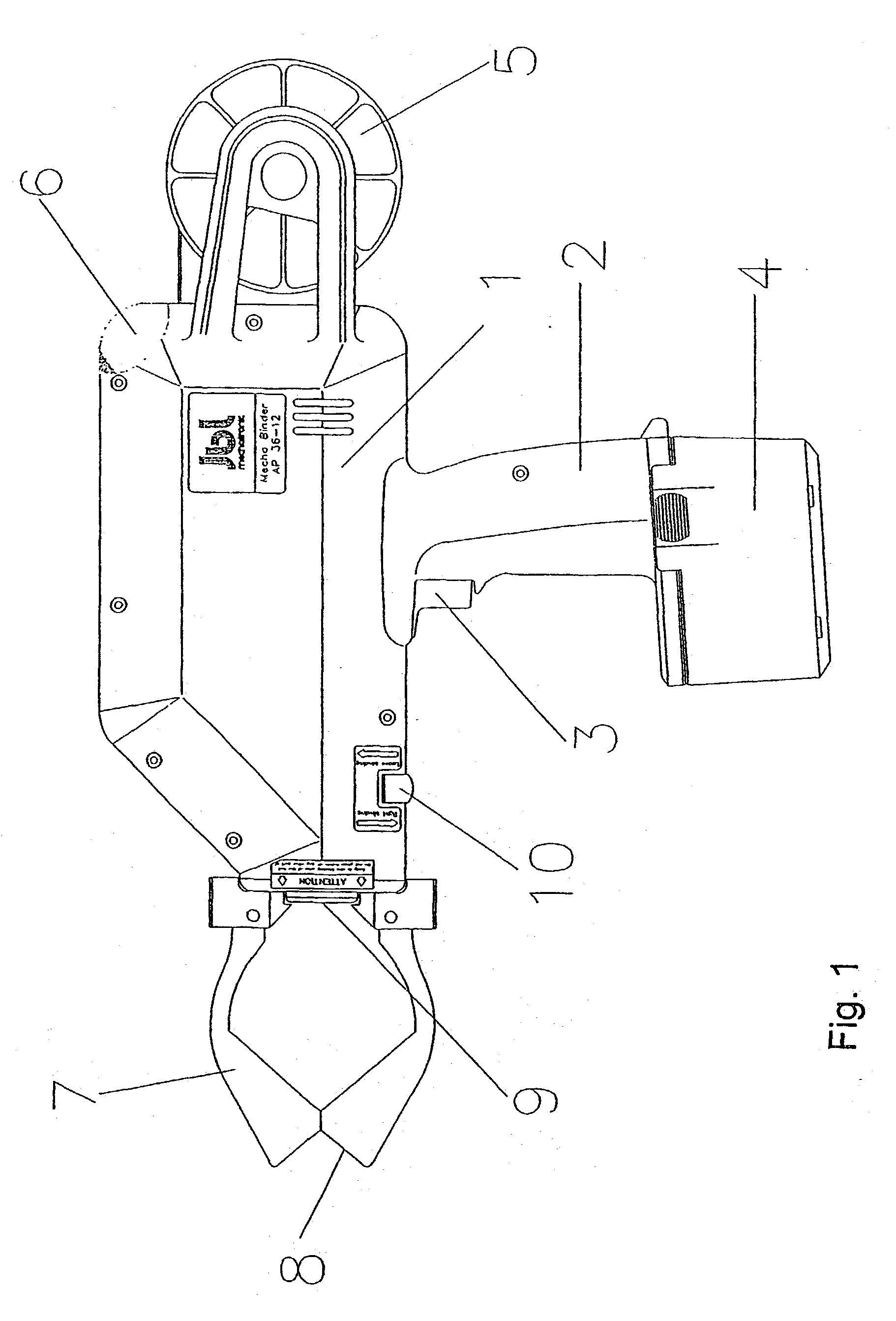

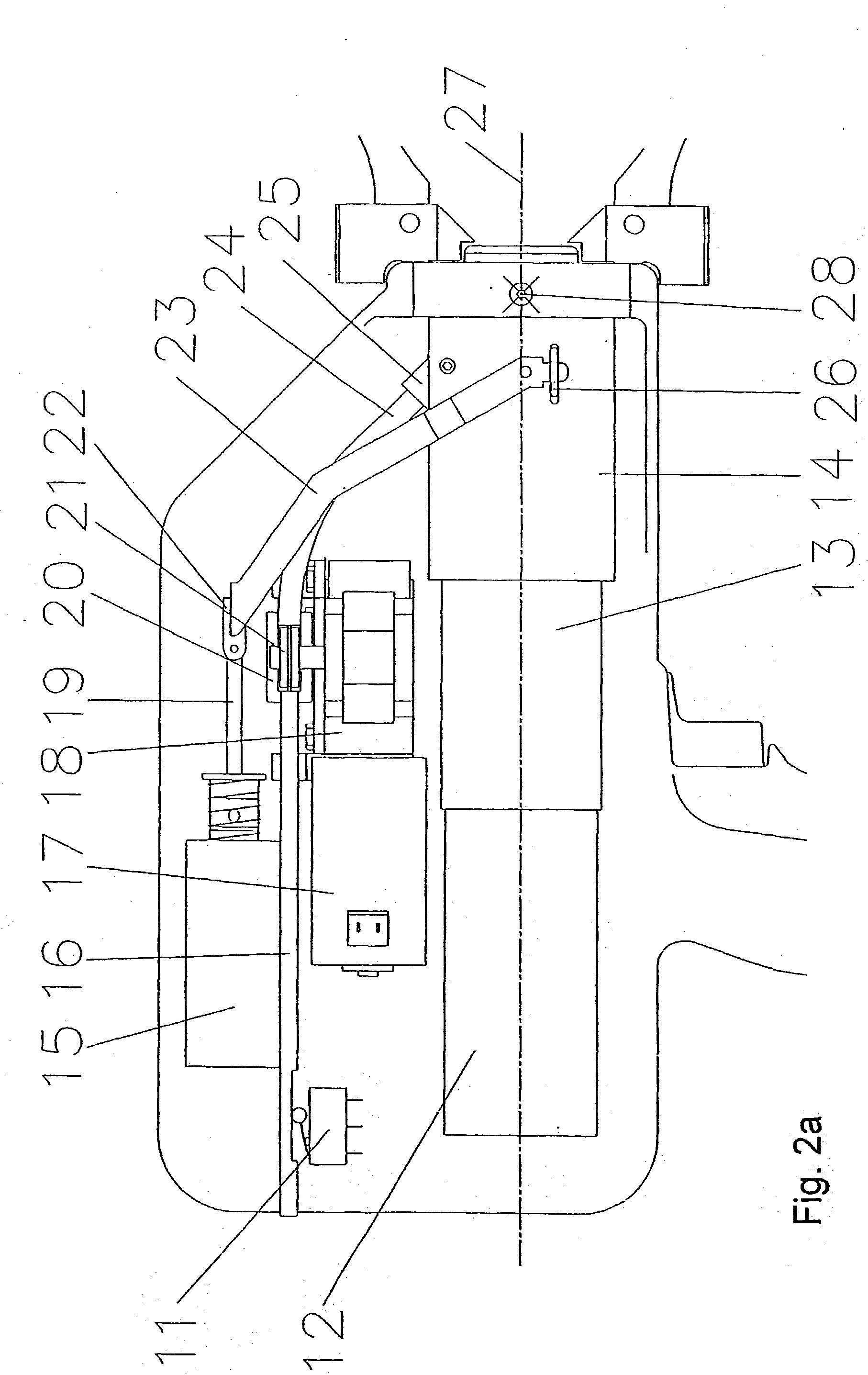

Method and an apparatus for twisting and tightening a wire

InactiveUS20030145900A1Solving the Insufficiency of ElasticityReduce wiringBuilding material handlingBundling machine detailsReinforced concreteEngineering

A method and apparatus for twisting and tightening a wire with a free end portion around at least two objects, e.g. iron bars for reinforced concrete, for binding the objects together. The method and apparatus enables a tighter and stronger binding to be performed even by means of a portable device and with the use of less binding wire than required by conventional devices.

Owner:JENSEN KIM MICHAEL

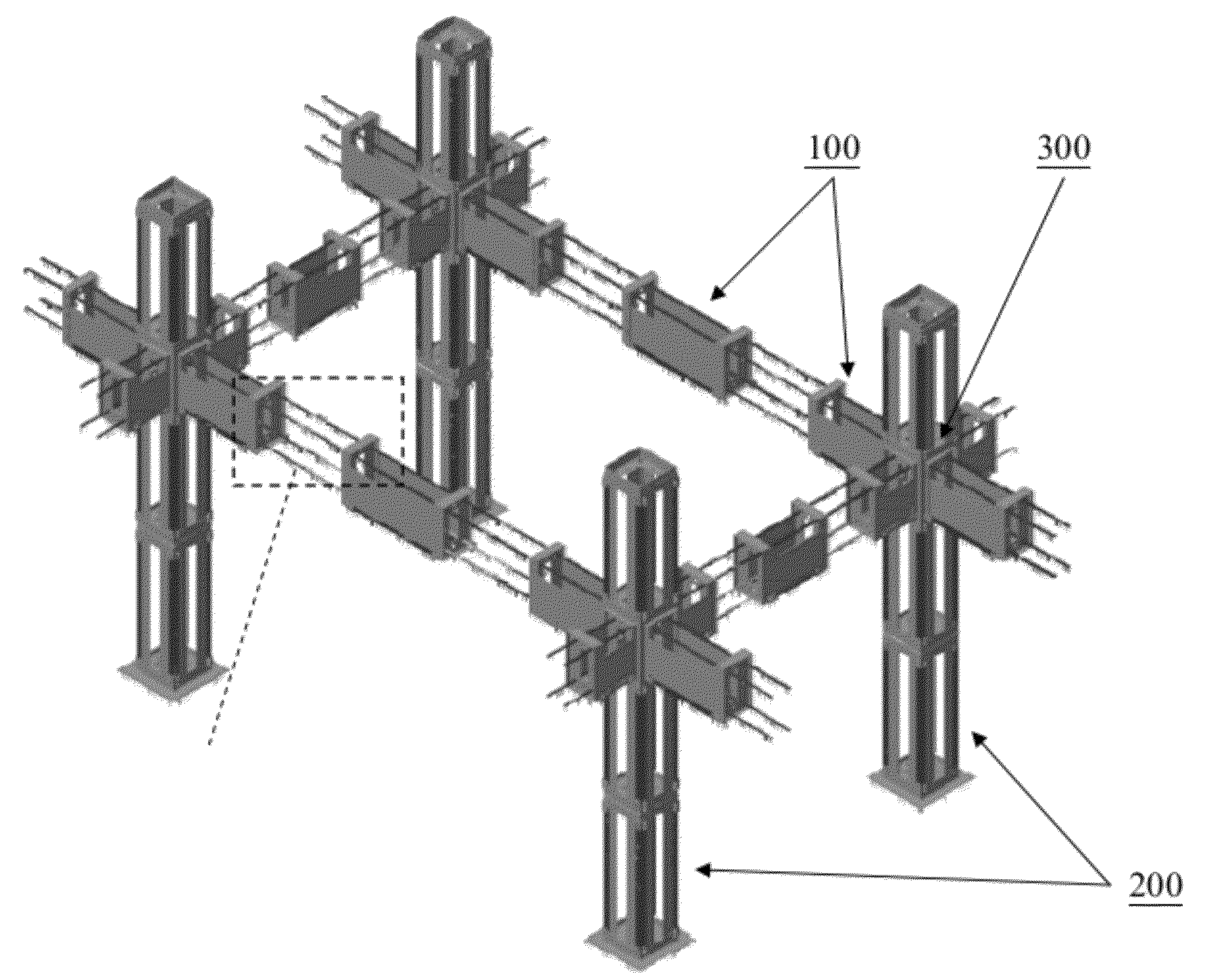

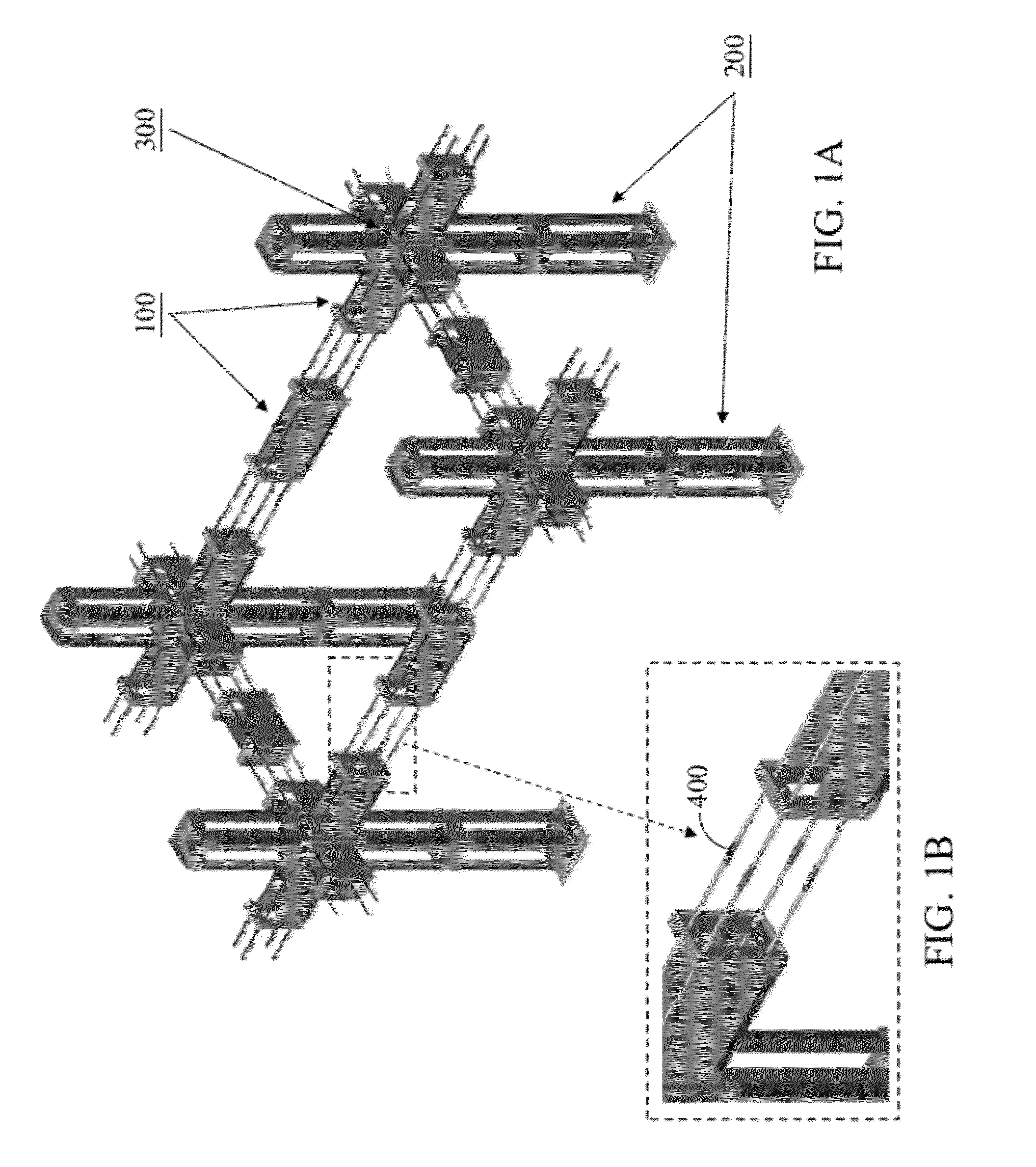

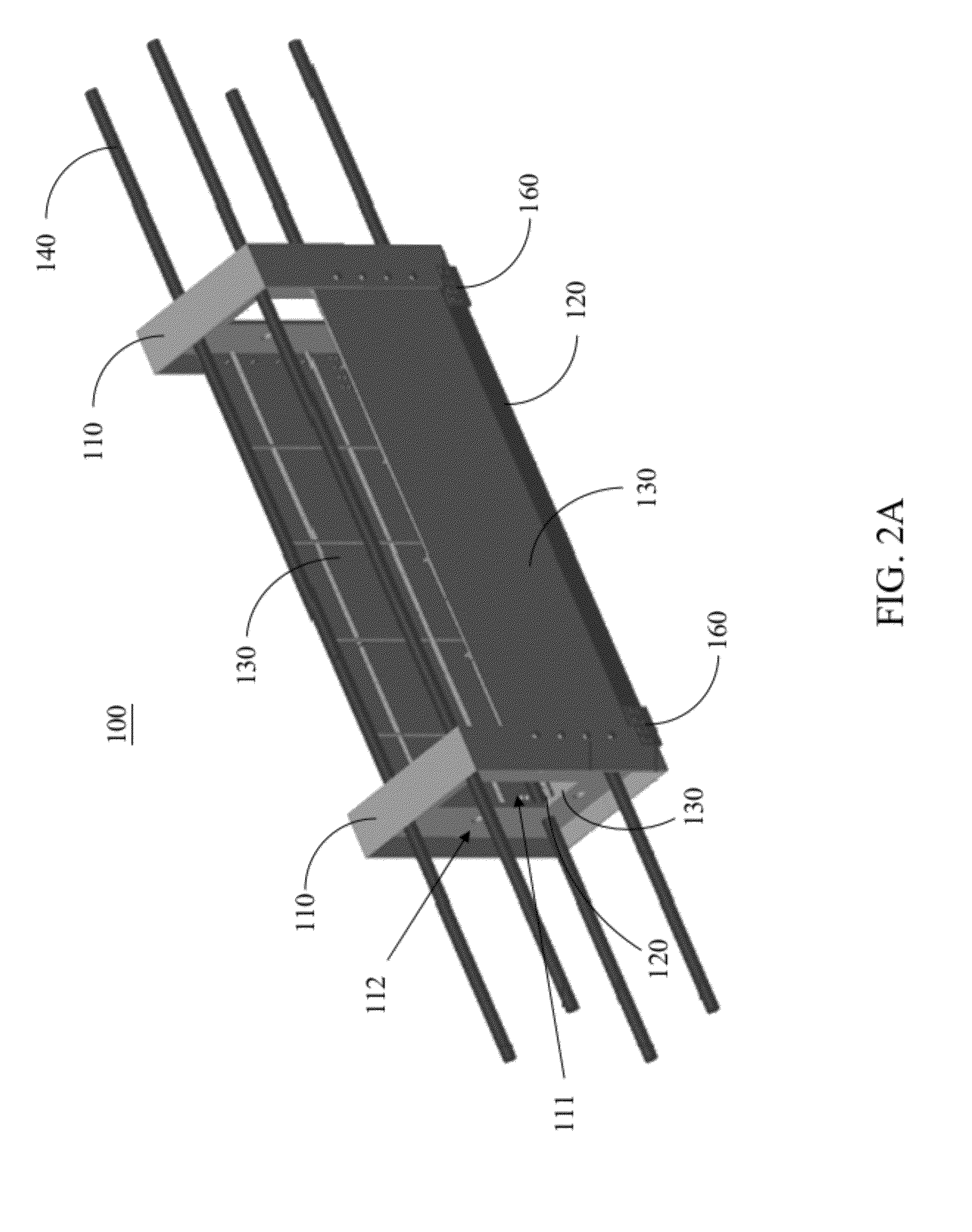

Architectured reinforcement structure

InactiveUS20120304584A1Easy constructionReduced isolationTowersBuilding constructionsReinforced concreteHoneycomb

This invention presents a modified reinforced concrete structure, which has a steel structure composed of a beam steel box unit, column steel box unit, and beam-column joint steel box unit with lap jointing reinforced steels. The side plate and / or end plate of the steel box has through holes for concrete flowing therebetween. In this way, the workability of concrete grouting and tamping are improved, and the phenomena of hive, segregation, or floating can be avoided. It can also enhance the performance of beam-column joints (e.g. with better confinement ability, etc.). Applying the invention, the efficiency and accuracy of constructing beam-column joints can be increased, and in addition to better ensure the structural safety, it can also reduce construction manpower and schedule.

Owner:NAT TAIWAN UNIV OF SCI & TECH

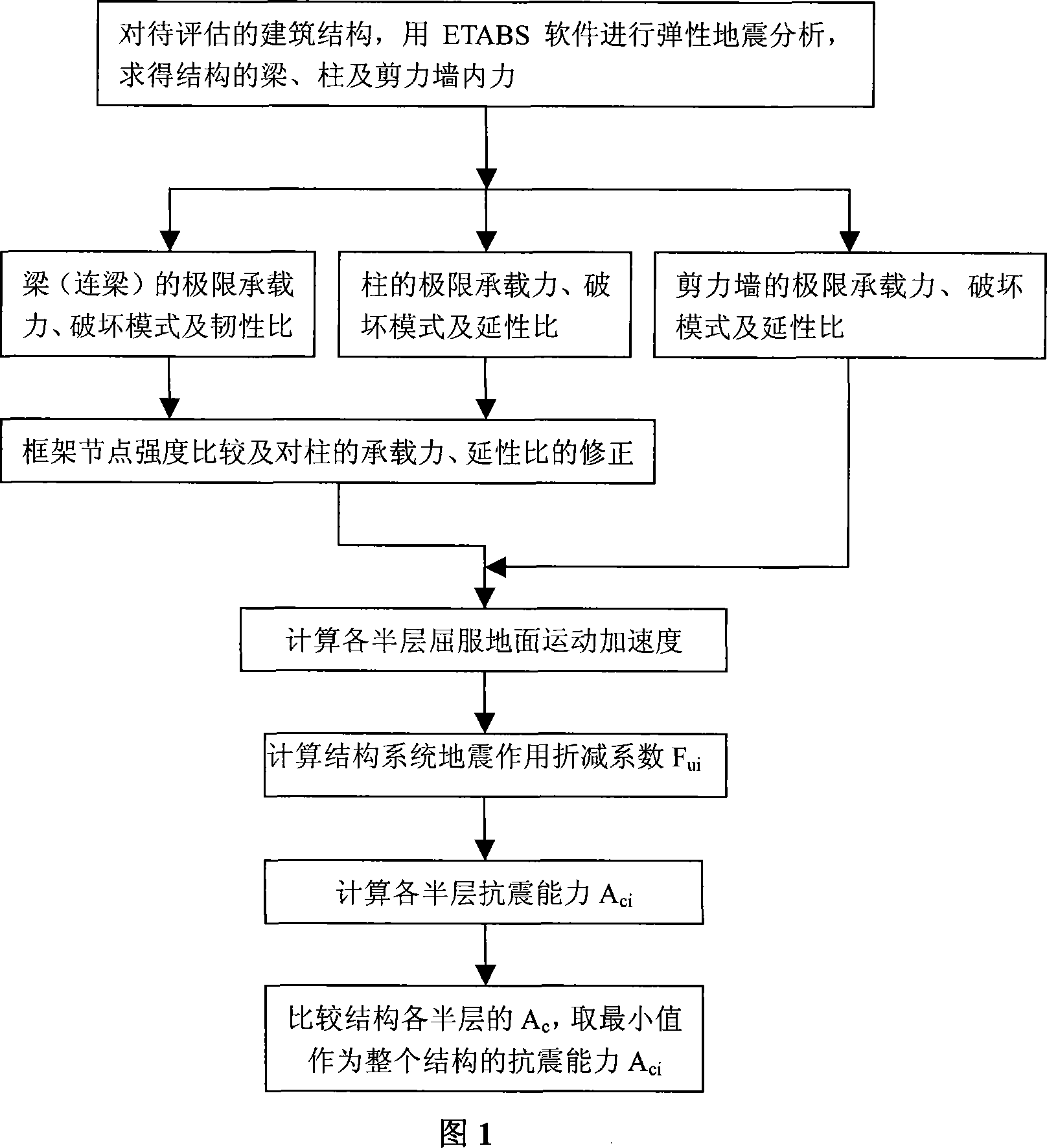

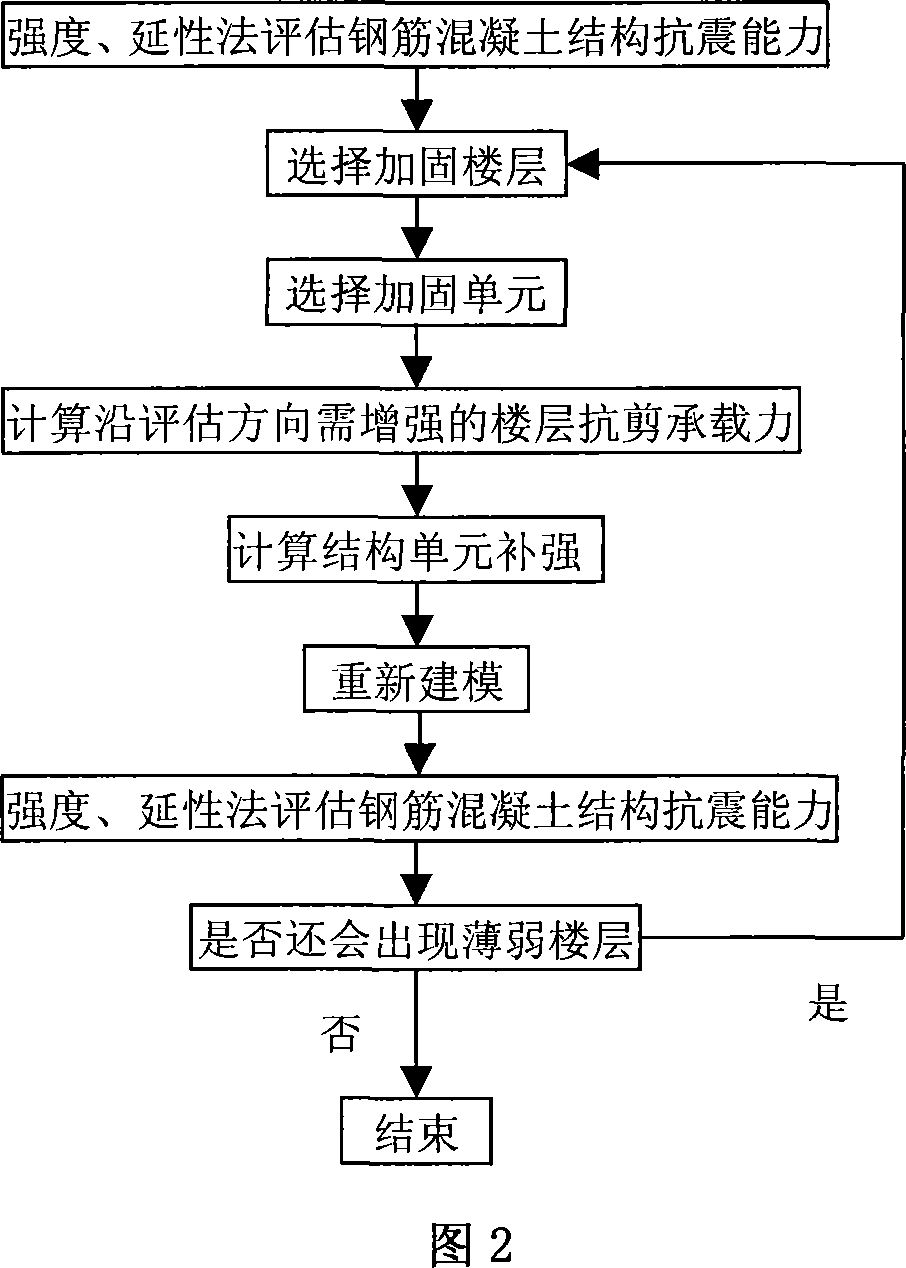

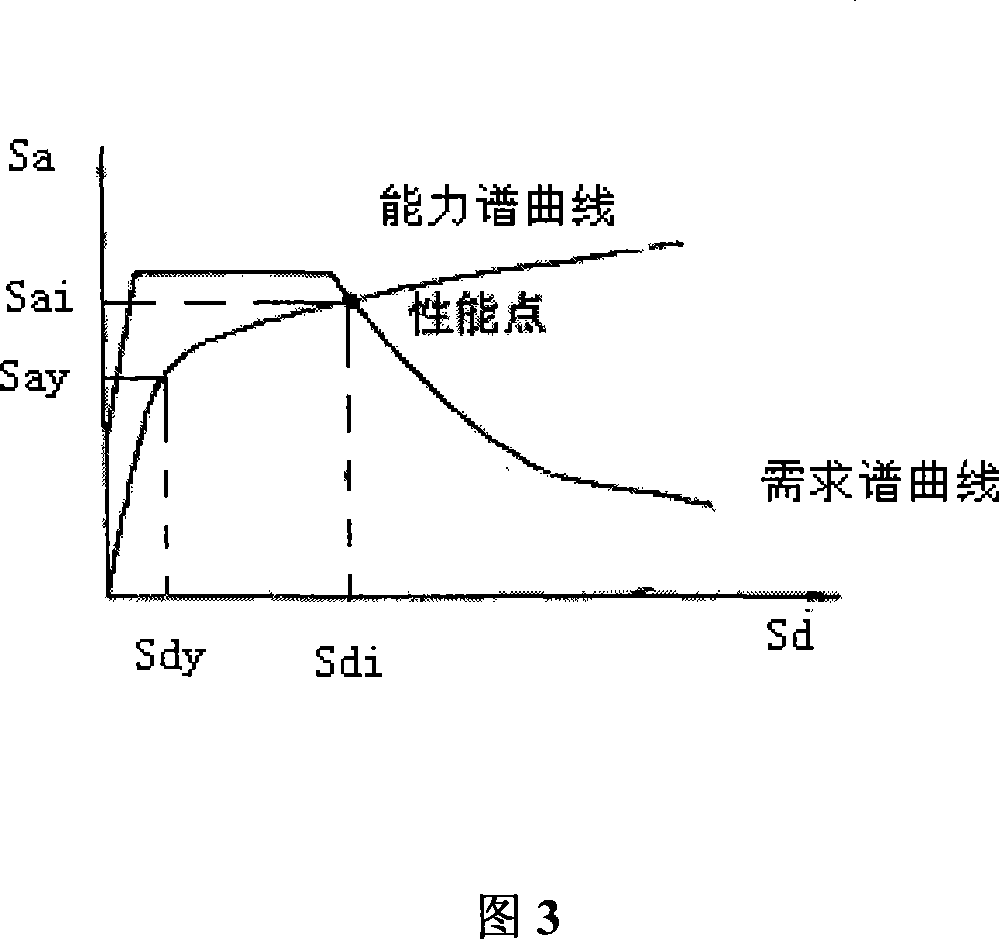

Method for estimating anti-seismic ability of building and its usage

InactiveCN101074995AThe comprehensive seismic capacity index of the floor is clearRealize quantitative evaluationSeismic signal processingSpecial data processing applicationsReinforced concreteMan machine

A method for estimating anti-seismic ability of building includes integrating anti-seismic ability estimation, analysis and reinforcement of weak floor and weak unit, simplified ability chart, etc on the same software platform; utilizing man-machine interactive program to carry out quantitative estimation on anti-seismic ability of steel concrete structure for realizing anti-seismic ability estimation of building.

Owner:杨仕升

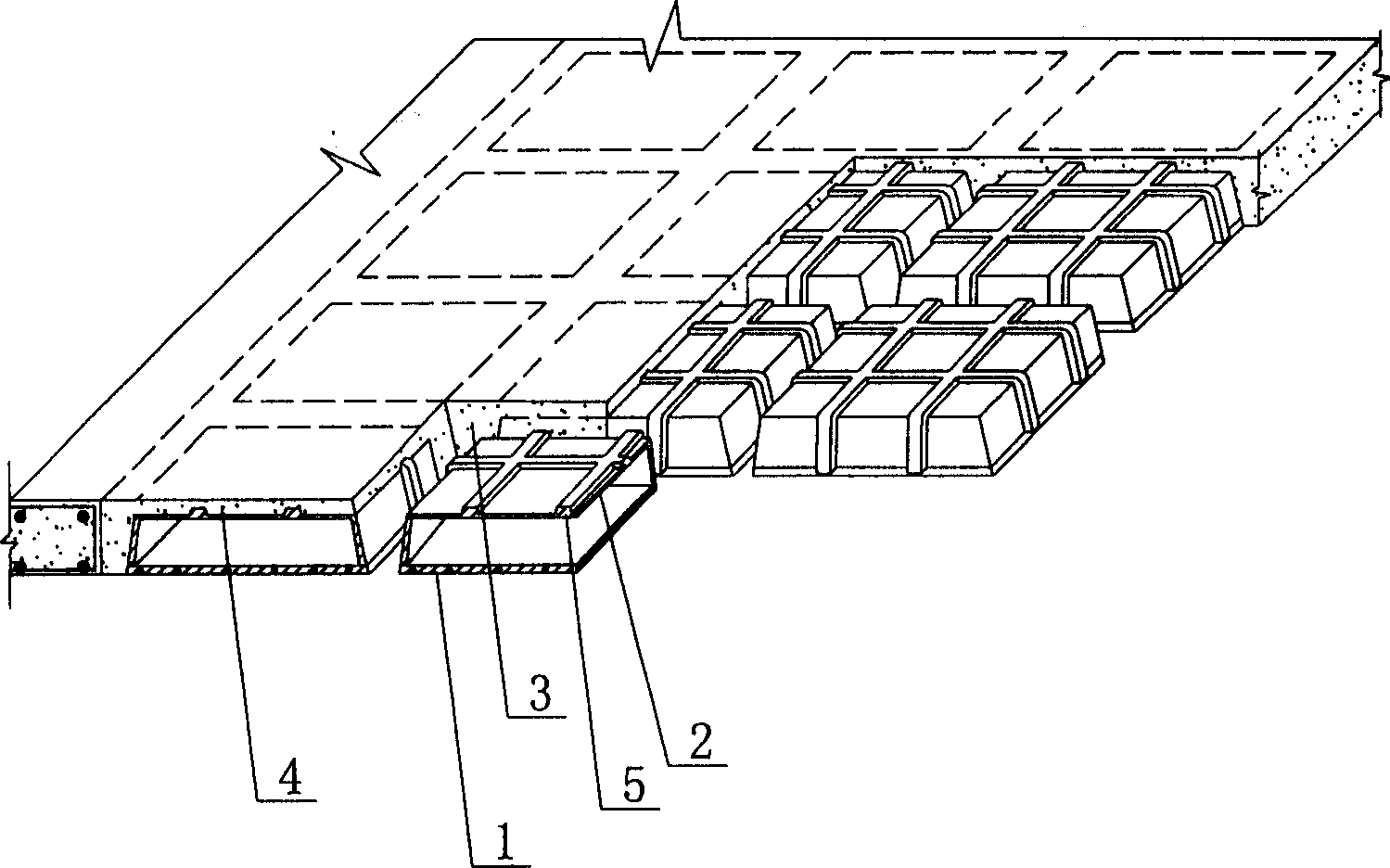

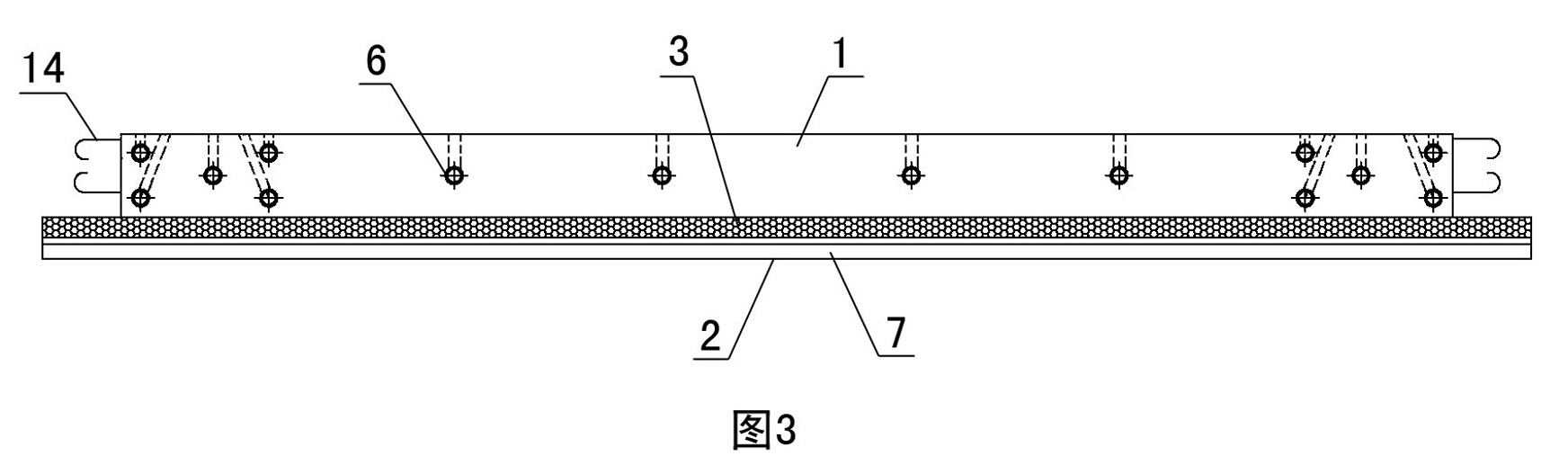

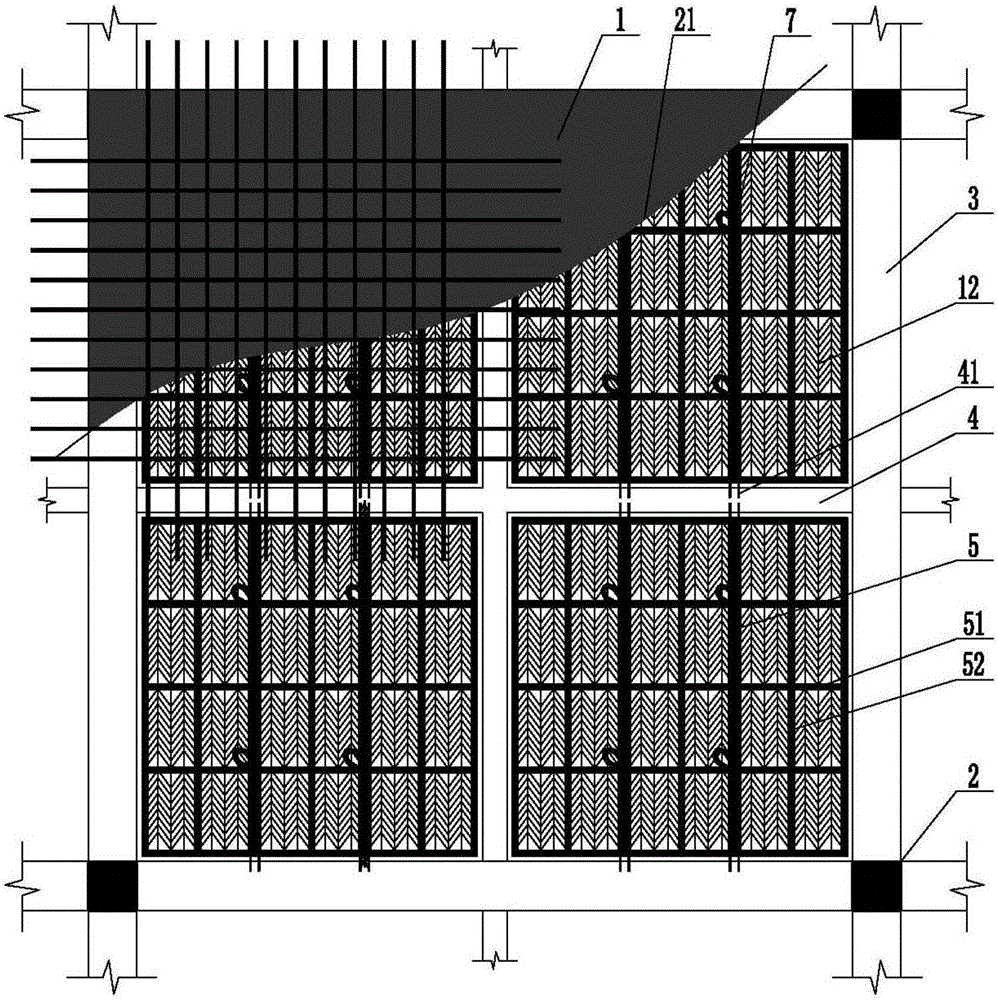

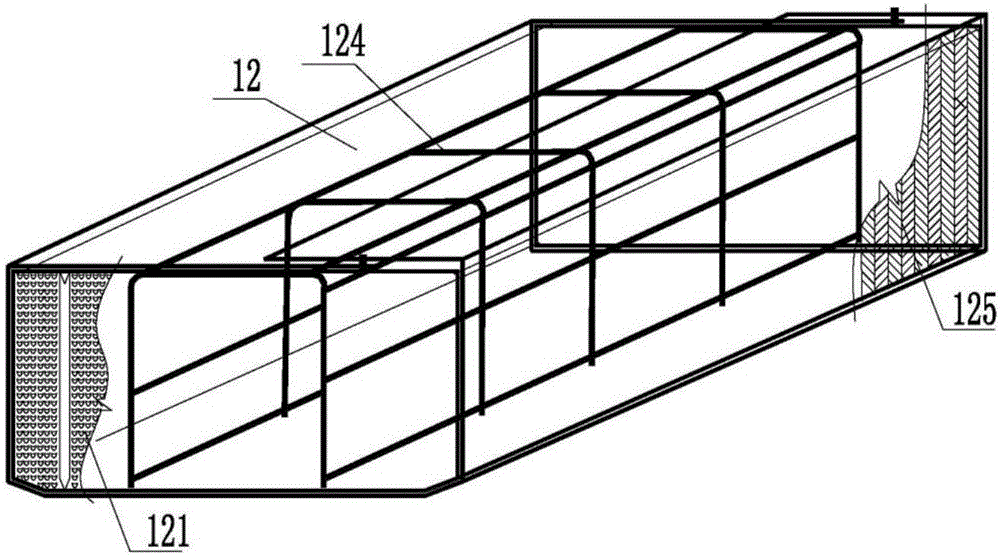

Assembling type overlapped cavity floor cover

The invention provides an assembling type overlapped cavity floor cover. The assembling type overlapped cavity floor cover comprises columns, a main beam, an auxiliary beam, upper-flange-free cavity plate components and cast-in-situ reinforced concrete floor cover upper flange plates. The assembling type overlapped cavity floor cover is characterized in that the auxiliary beam is arranged in a column net formed by the columns and the main beam; the upper-flange-free cavity plate components are arranged on a framework of the auxiliary beam; the assembling type upper-flange-free cavity plate components and the beams are arranged in a vertical or horizontal overlapping manner, the vertical overlapping manner is to overlap the assembling type upper-flange-free cavity plate components to the top surfaces of the beams, and the horizontal overlapping manner is to overlap the assembling type upper-flange-free cavity plate components to the horizontal surfaces of the beams; and reinforced concrete is poured on the upper surfaces of the upper-flange-free cavity plate components to form assembling type cavity floor cover upper flange plates through overlapping, so as to form the assembling type overlapped cavity floor cover.

Owner:王海崴 +2

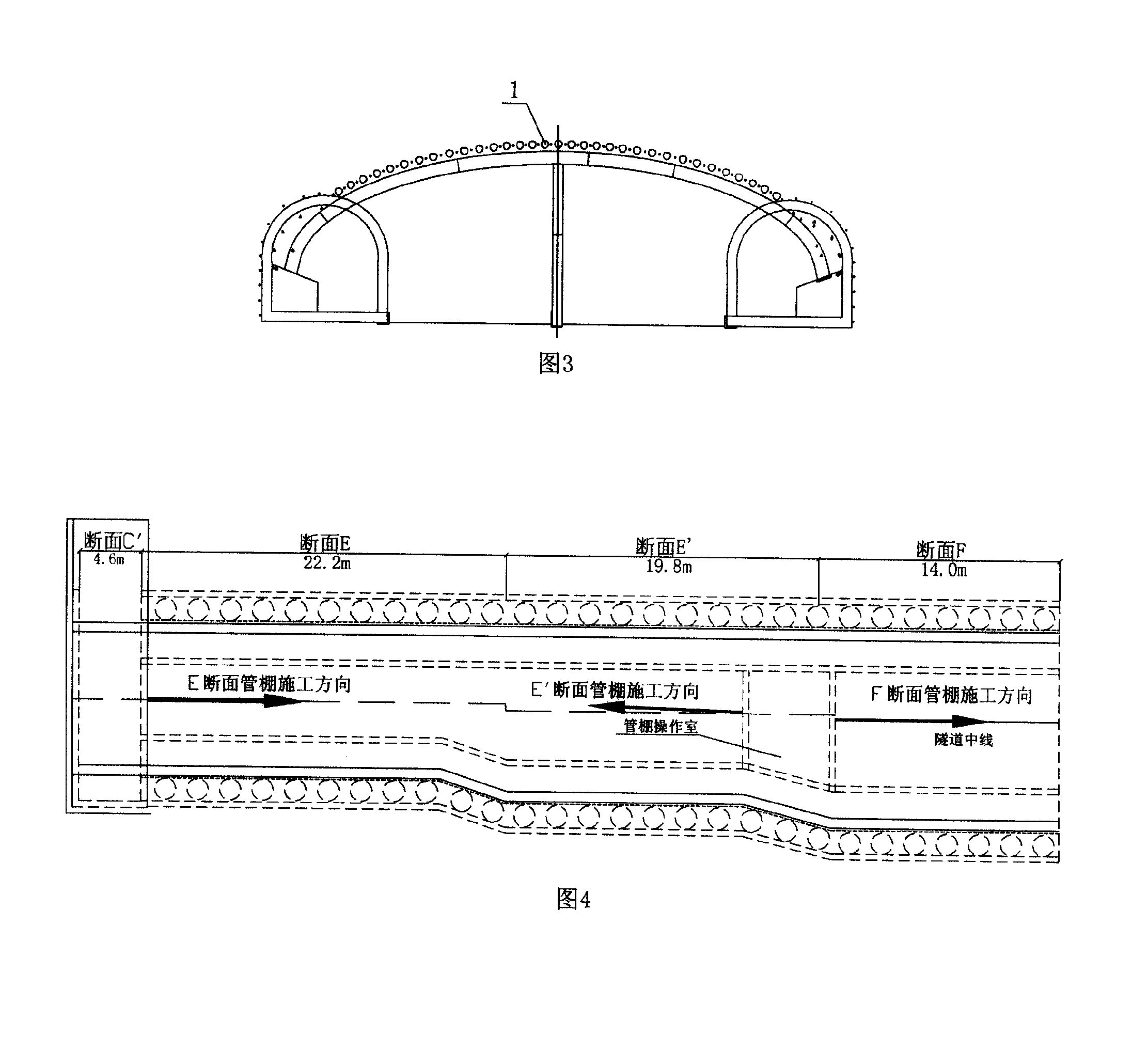

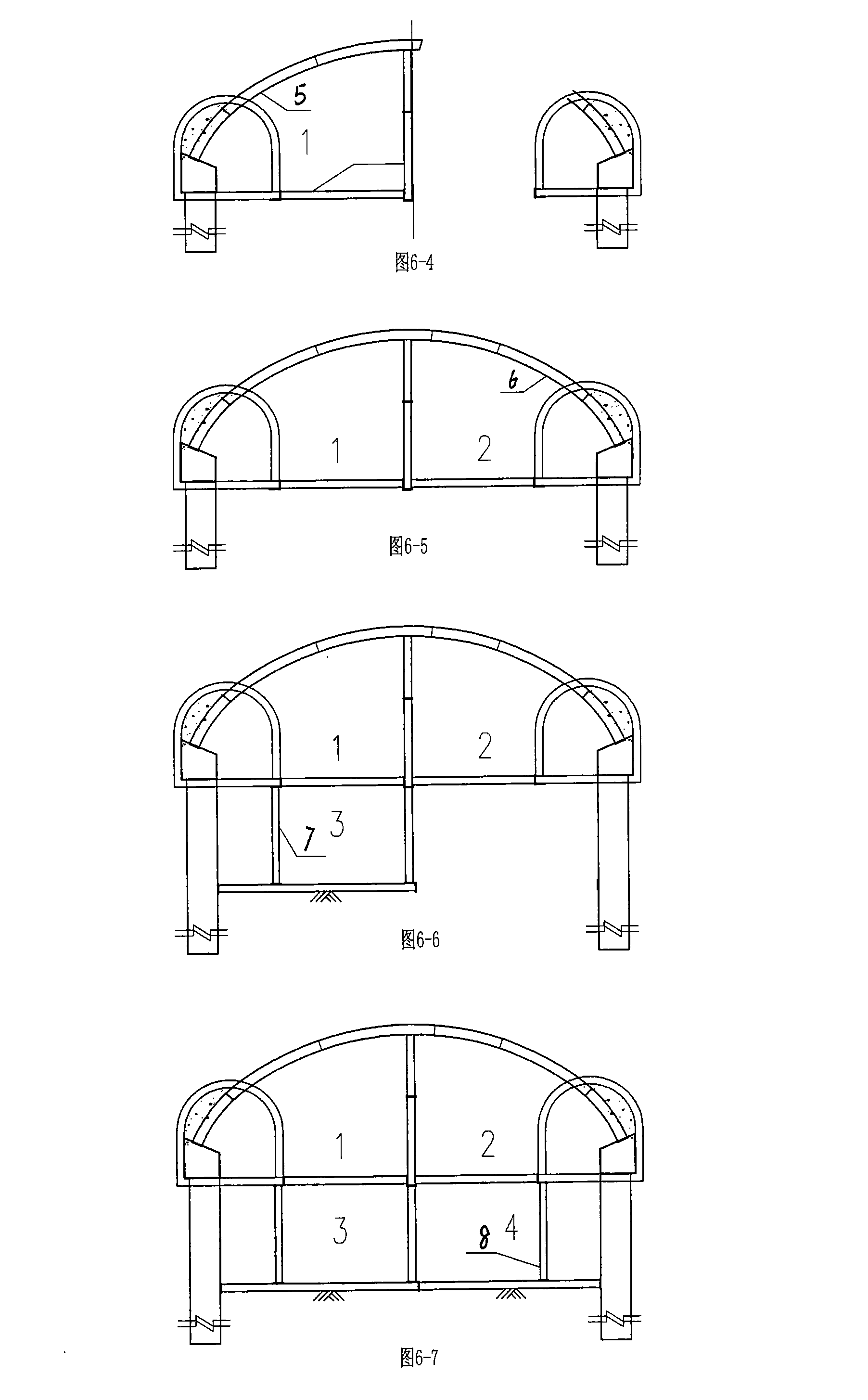

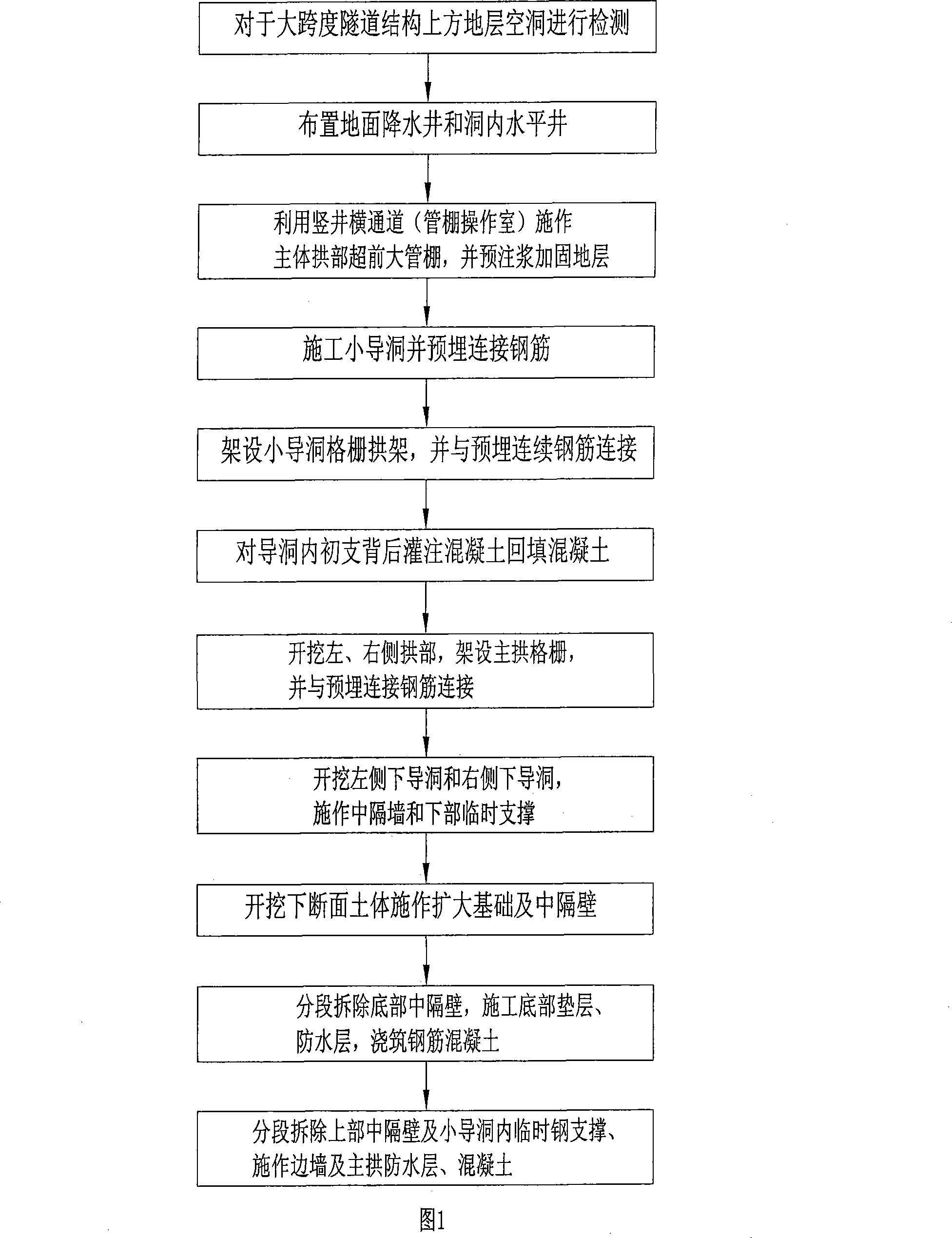

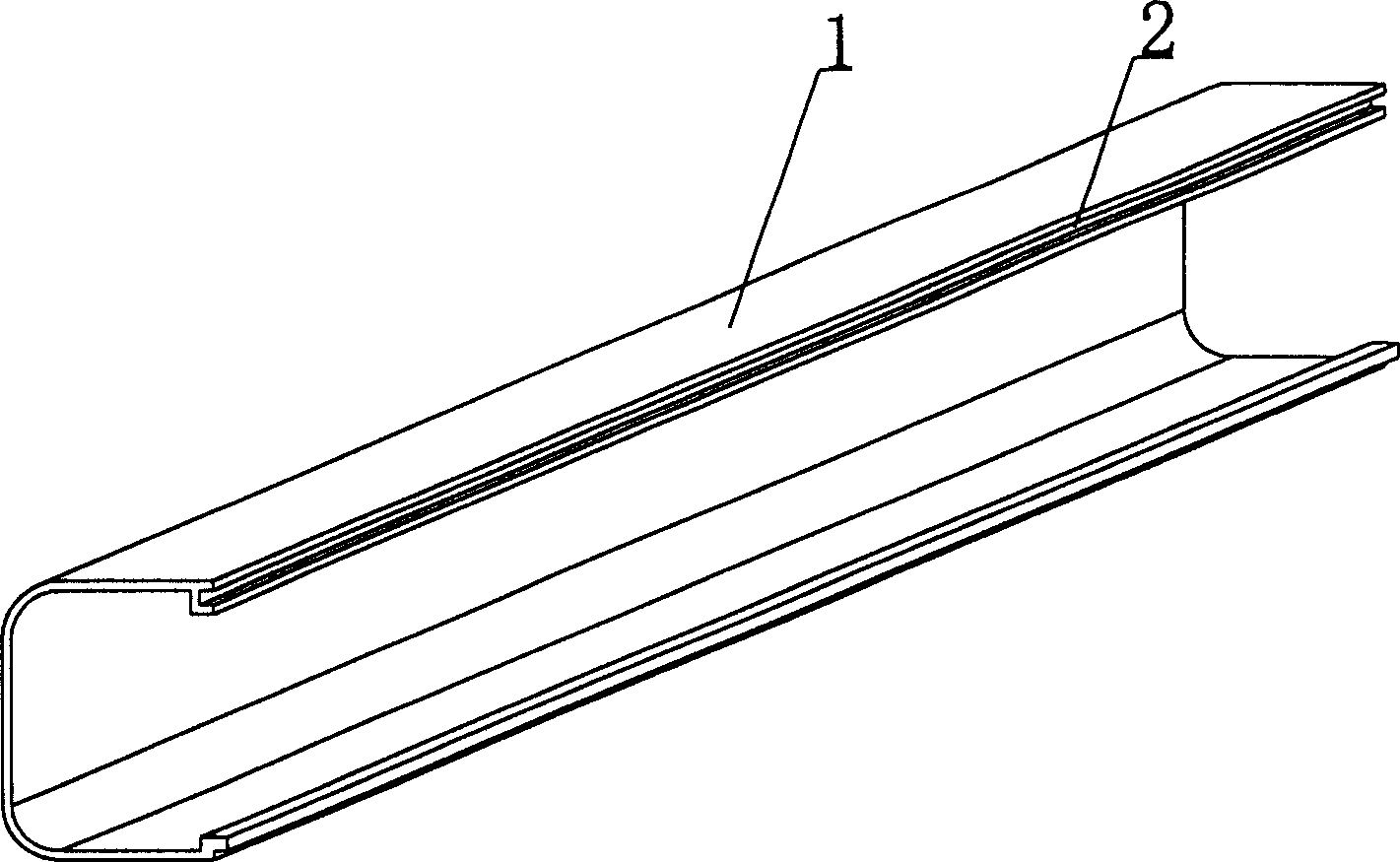

Construction method of shallow buried underground excavating tunnel super large section using PBA method

ActiveCN101225742ASolve comprehensive technical problemsSolve processing problemsUnderground chambersTunnel liningShotcreteTerrain

The invention relates to a method of shallow embedment and concealed excavation based on the PBA method for construction on super large cross-section of tunnel, comprising the following steps: 1. to detect the geologic cavity over the wide span tunnel structure; 2. to arrange the ground dewatering well and the tunnel horizontal well; 3. to take the horizontal channels of vertical well as the front large pipe shed on the arch part of the main body and to inject for strengthening the terrain formation; 4. to carry out the supporting arch construction on the side span of small pilot tunnel and the supporting major arch construction on the main body; 5. to excavate the soil mass of lower cross section as the extended foundation and the central partition wall; 6. to remove the bottom central partition wall section by section, construct bottom underlayer and waterproof layer, pour the reinforced concrete; 7. to remove the central partition wall of the upper part section by section and temporary steel shotcrete in the small pilot tunnel, construct the waterproof layer and concrete of the side wall and the main arch. The method of shallow embedment and concealed excavation based on the PBA method for construction on super large cross-section of tunnel has the advantages of guaranteeing the safety, quality and time limit of the construction, saving cost and enhancing work efficiency.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

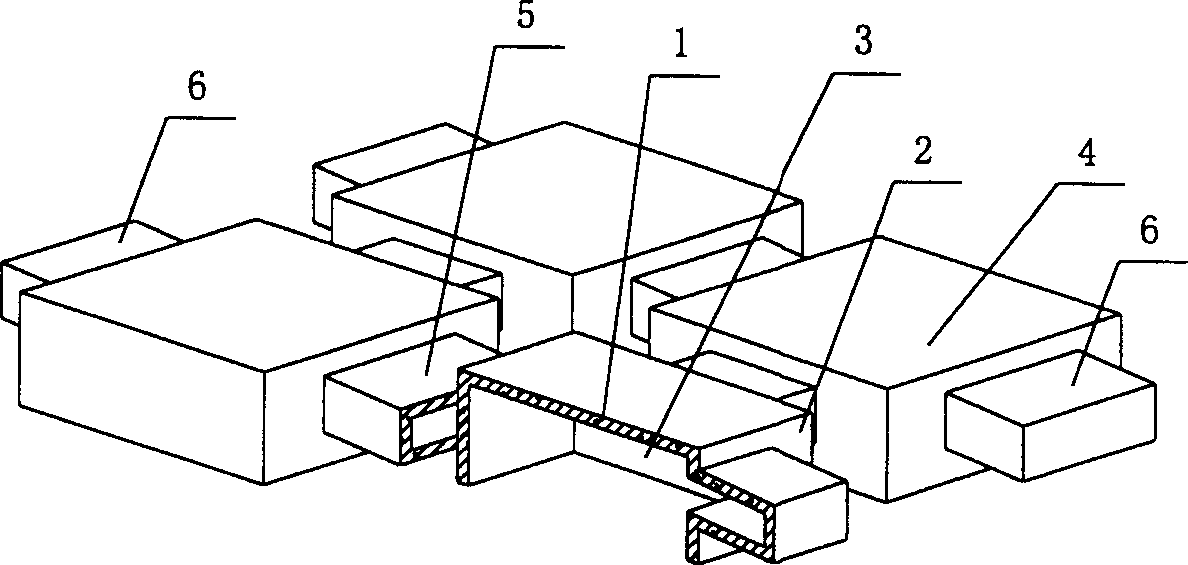

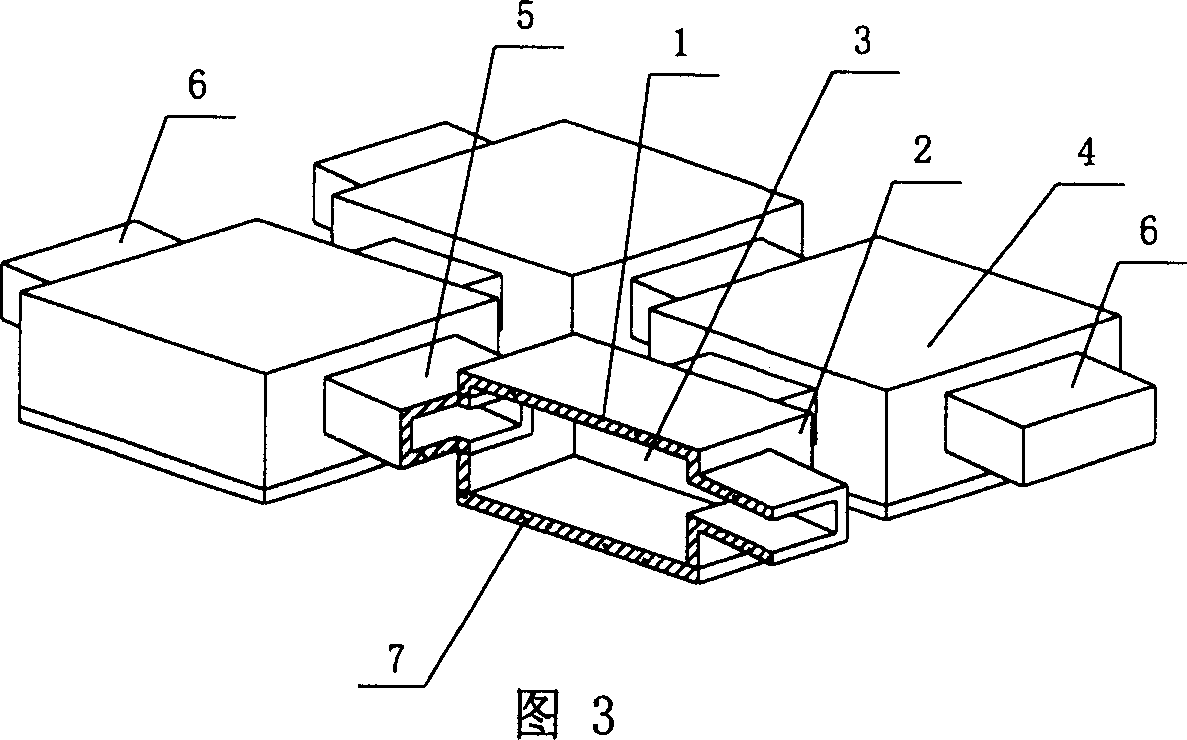

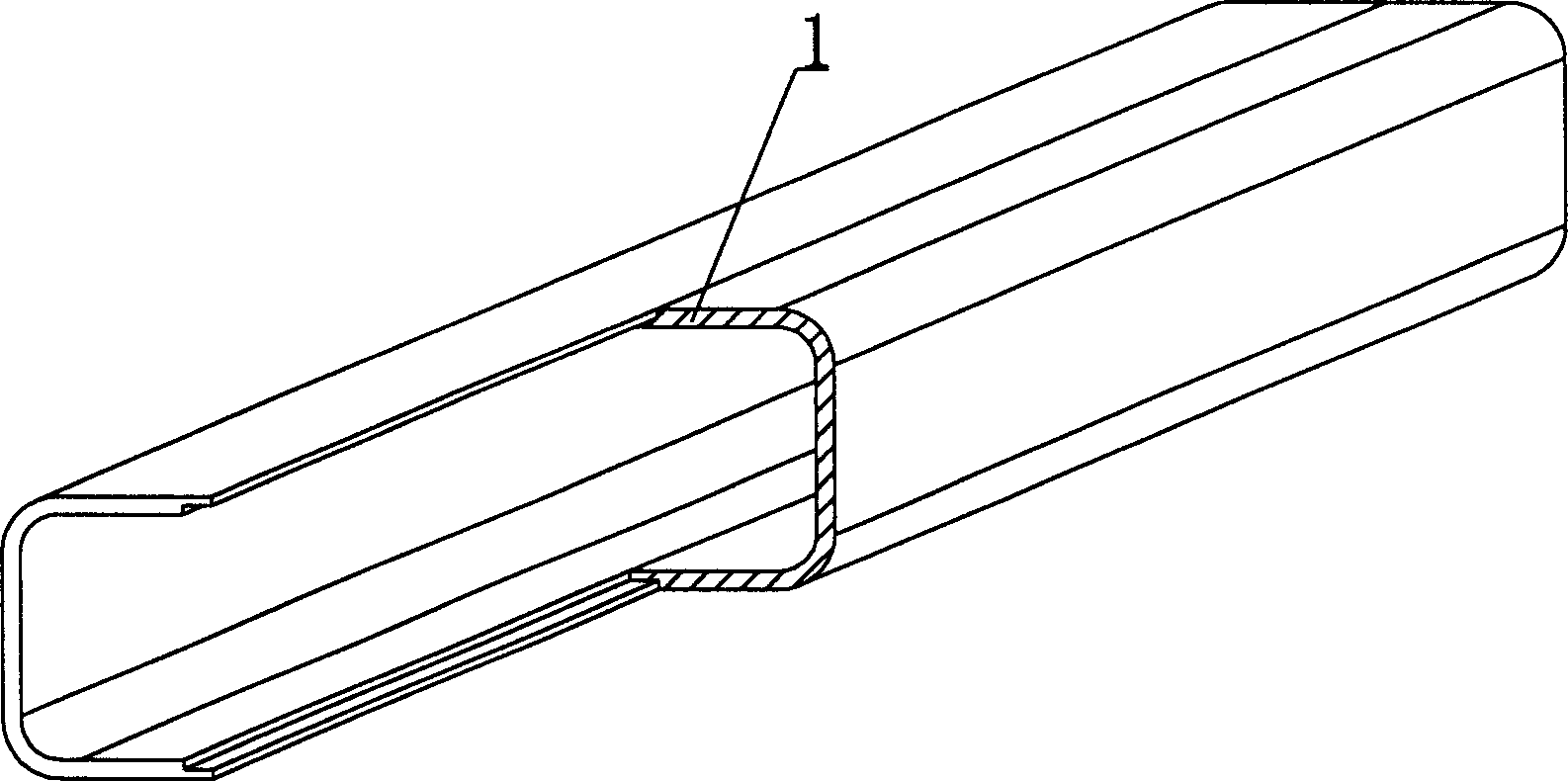

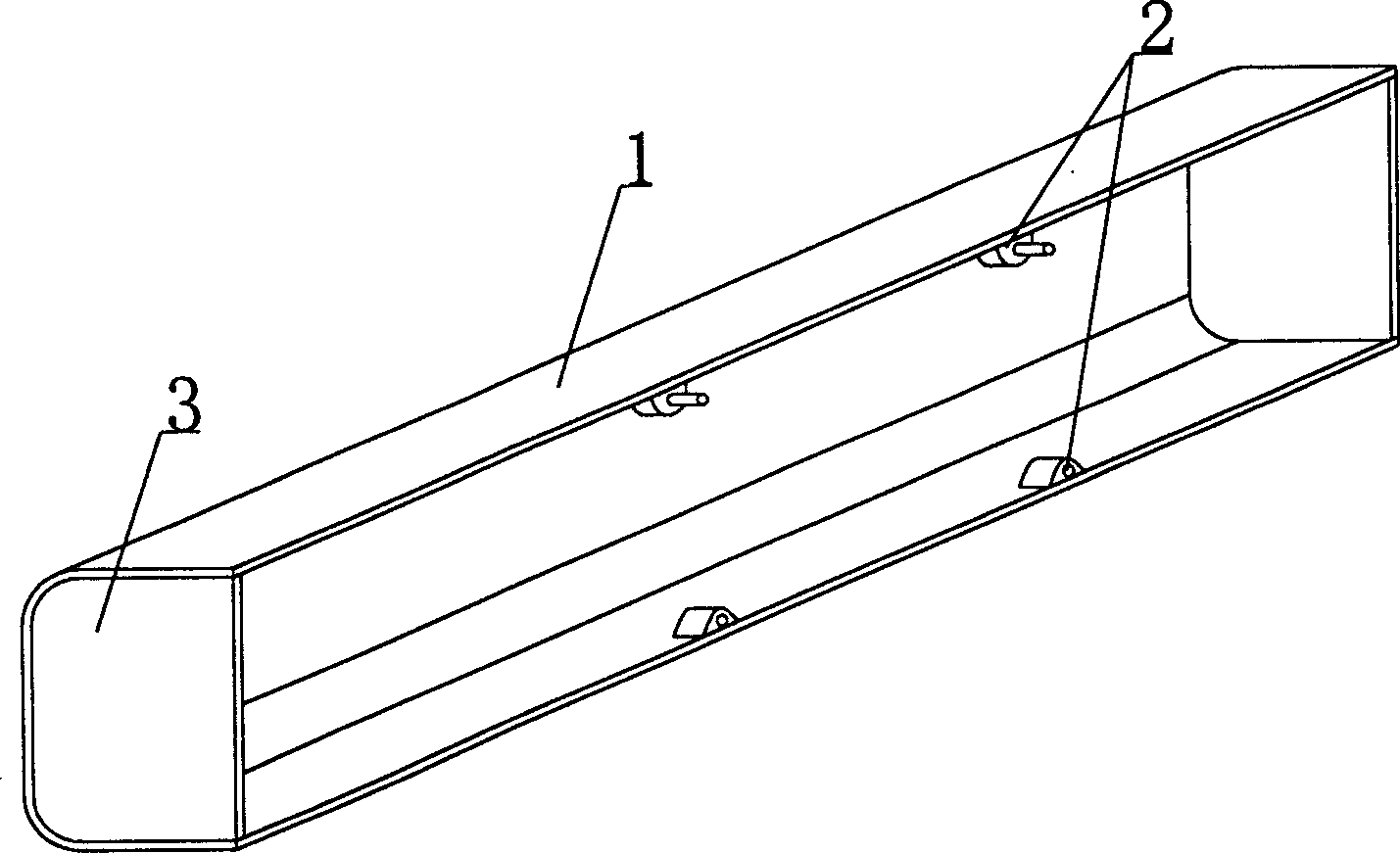

Hole constructing component for in situ cast steel bar reinforced concrete

A hole-forming member for in-situ casting the reinforced concrete is such a one used to combine a whole cavity. The connecting parts are used to combine two or more said members to form a hollow thin-wall member. Its advantages are high strength, low cost and high construction speed.

Owner:湖南邱则有专利战略策划有限公司

Assembled integral shear wall structure system and construction method thereof

ActiveCN101818527ALow costGuarantee the construction qualityWallsBuilding material handlingReinforced concretePolystyrene

The invention discloses an assembled integral shear wall structure system and a construction method thereof. Prefabricated composite wallboards are hoisted and assembled integrally at a construction site; a board body of the prefabricated composite wallboards comprises a structural layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; the insulating layer is an extruded polystyrene foam plastic board; steel meshes are arranged in the concrete of the protective layer; and anchor bolts in a dotted distribution are connected among the structural layer, the insulating layer and the protective layer. Vertical seams and horizontal seams of prefabricated composite walls adopt structural self-waterproofing, so that common quality problems such as leakage and cracks and the like in a traditional process are solved. The prefabricated composite walls simplify construction processes, speed up the construction, and lower the construction cost. Furthermore, products prefabricated in a factory have uniform specifications and unified quality, so that the construction quality of a building construction can be sufficiently guaranteed; the industrialization, standardization, and generalization of the building walls are realized; and the products can be widely applicable to the construction of reinforced concrete buildings in the construction industry.

Owner:华筑(辽宁)建筑工程设计有限公司

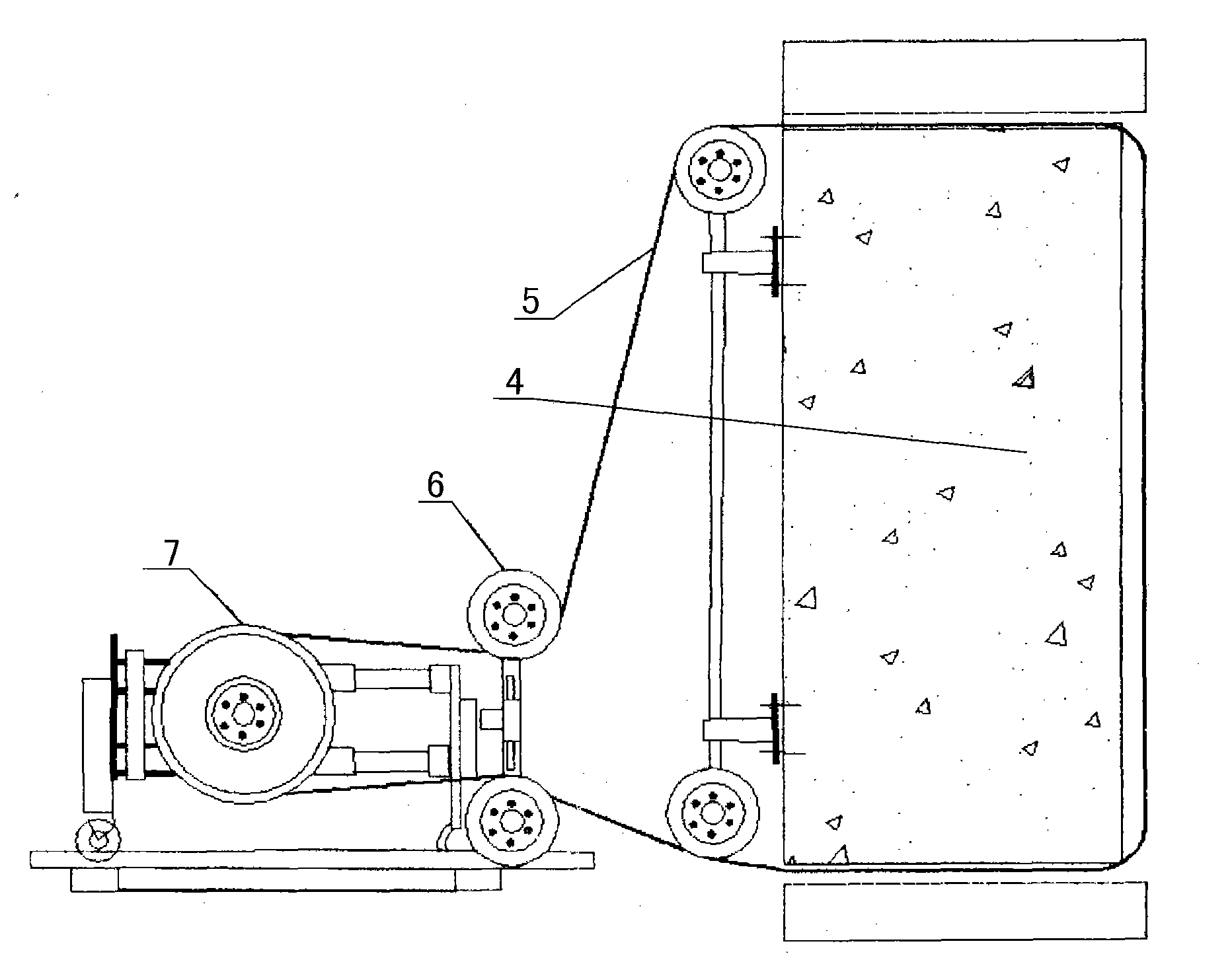

Diamond rope saw static force cutting method

InactiveCN101768926AImprove cutting efficiencySimple construction processBuilding repairsGrinding machinesHydraulic motorReinforced concrete

The invention provides a diamond rope saw static force cutting method, relating to a diamond cutting method. In the invention, an adopted hydraulic pressure diamond rope saw is driven by an hydraulic motor to move at a high speed around the cut surface of a cutting object (4) so as to cut the cutting object (4); the grinding material of diamond rope saw (5) is diamond particles, so the diamond rope saw can be used for cutting stone, reinforced concrete or other hard materials; the power source of the cutting is the hydraulic motor, a hydraulic pump is driven by the hydraulic motor to operate smoothly; and the hydraulic motor can be distantly controlled by a high-pressure oil pipe to reduce vibration and noise in cutting process and enable the cutting object (4) is cut and separated stably. The invention has the advantages of high safety and efficiency and environment protection.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com