Patents

Literature

52765 results about "Rebar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rebar (short for reinforcing bar), known when massed as reinforcing steel or reinforcement steel, is a steel bar or mesh of steel wires used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has weak tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface is often deformed to promote a better bond with the concrete.

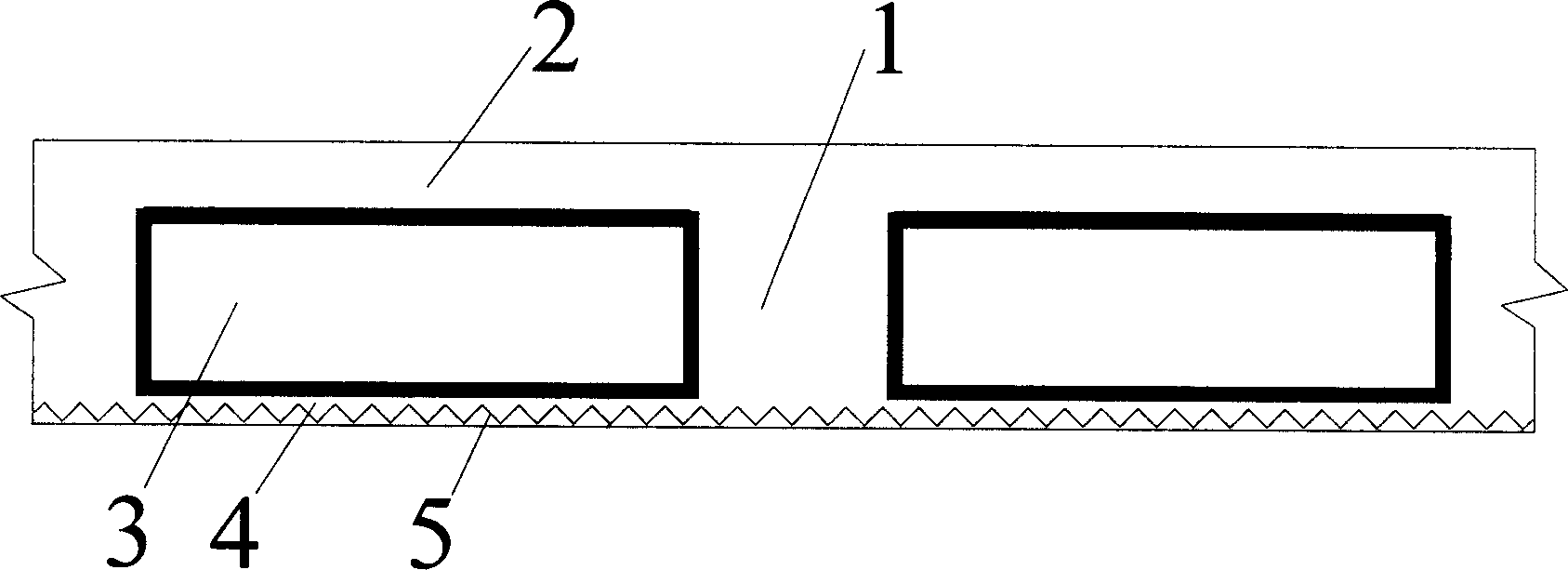

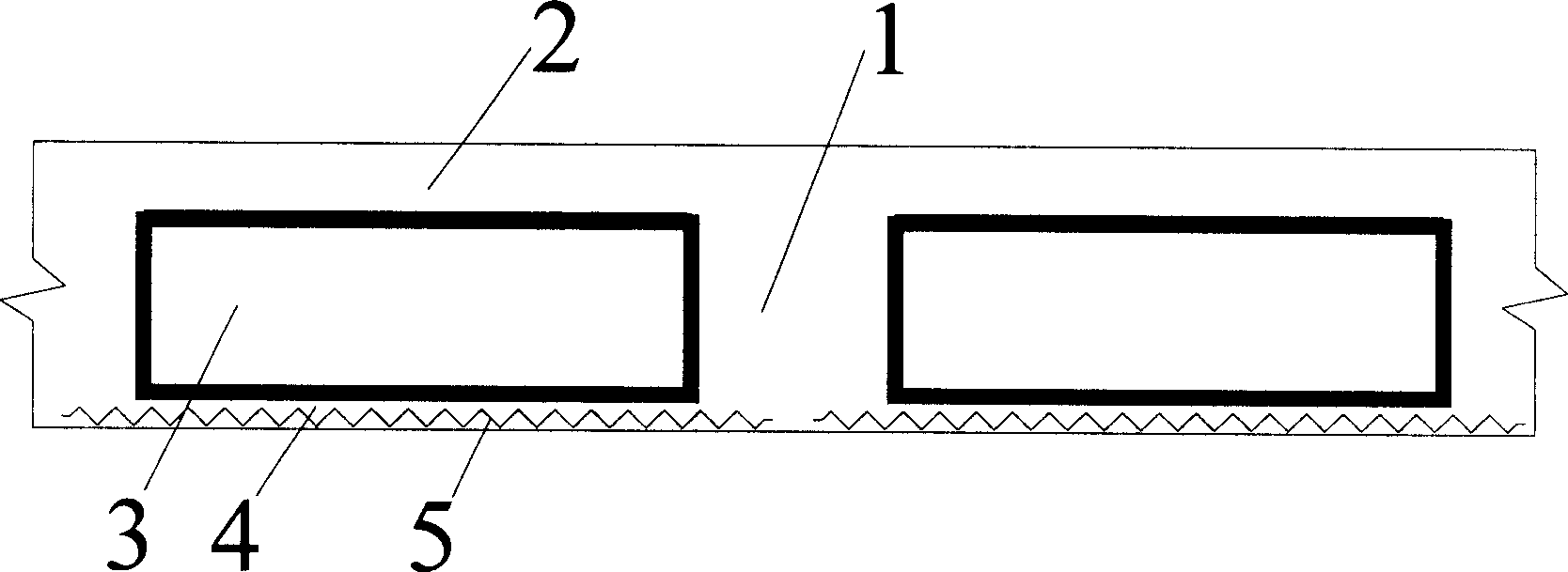

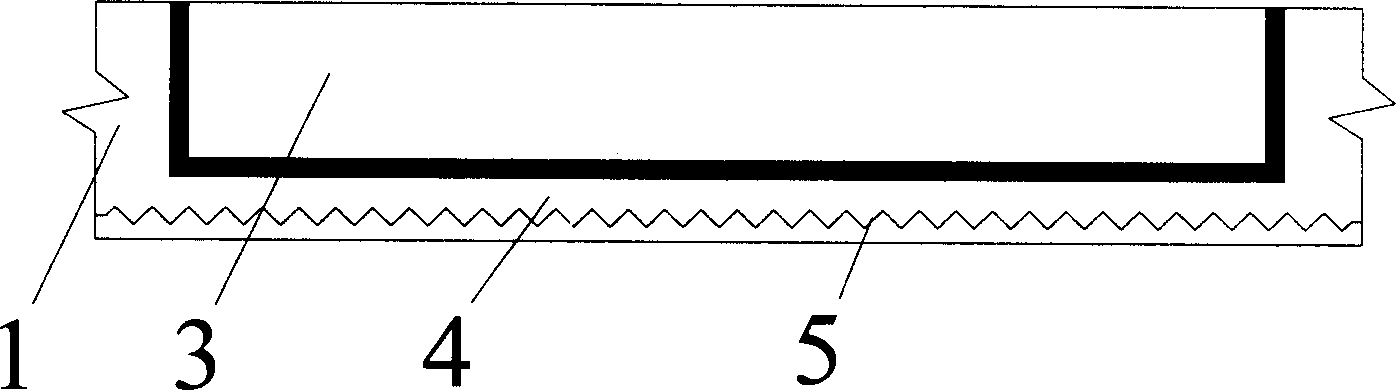

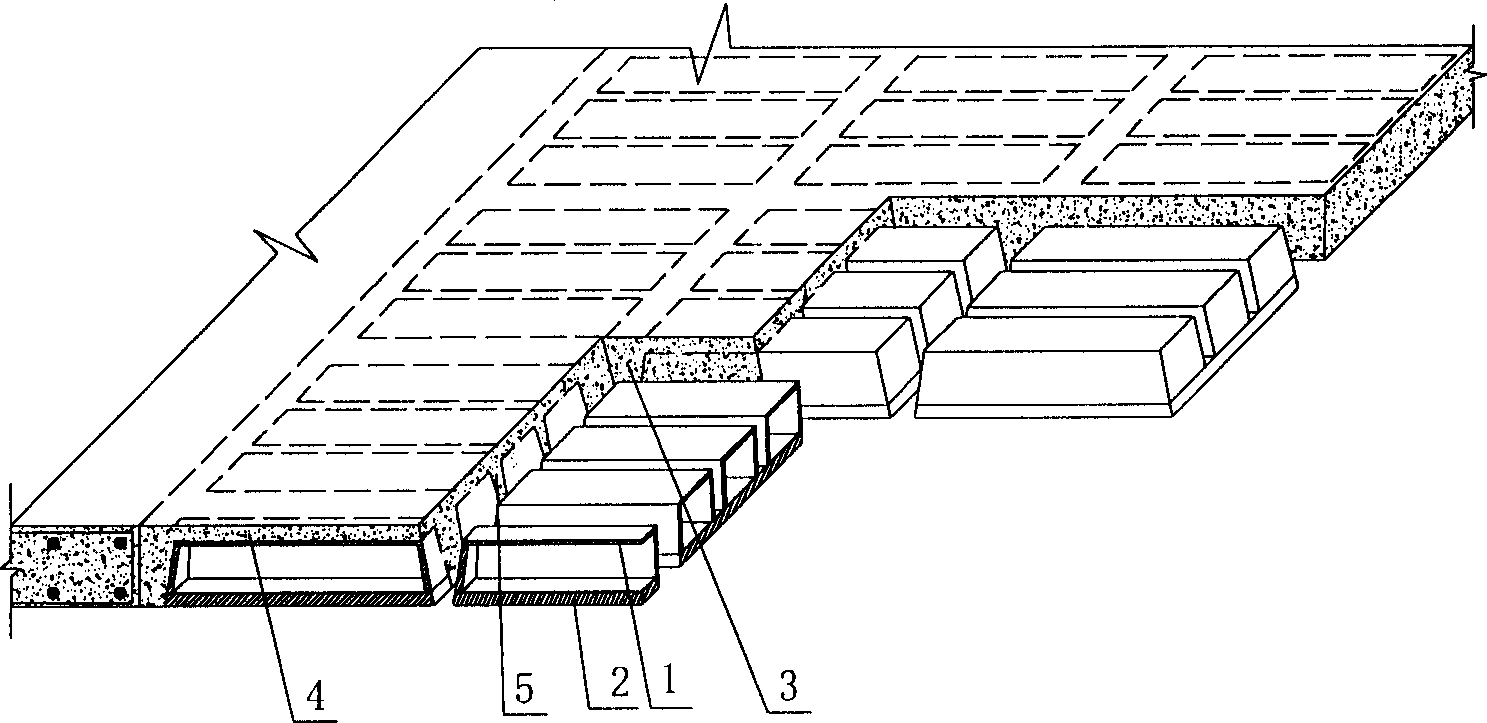

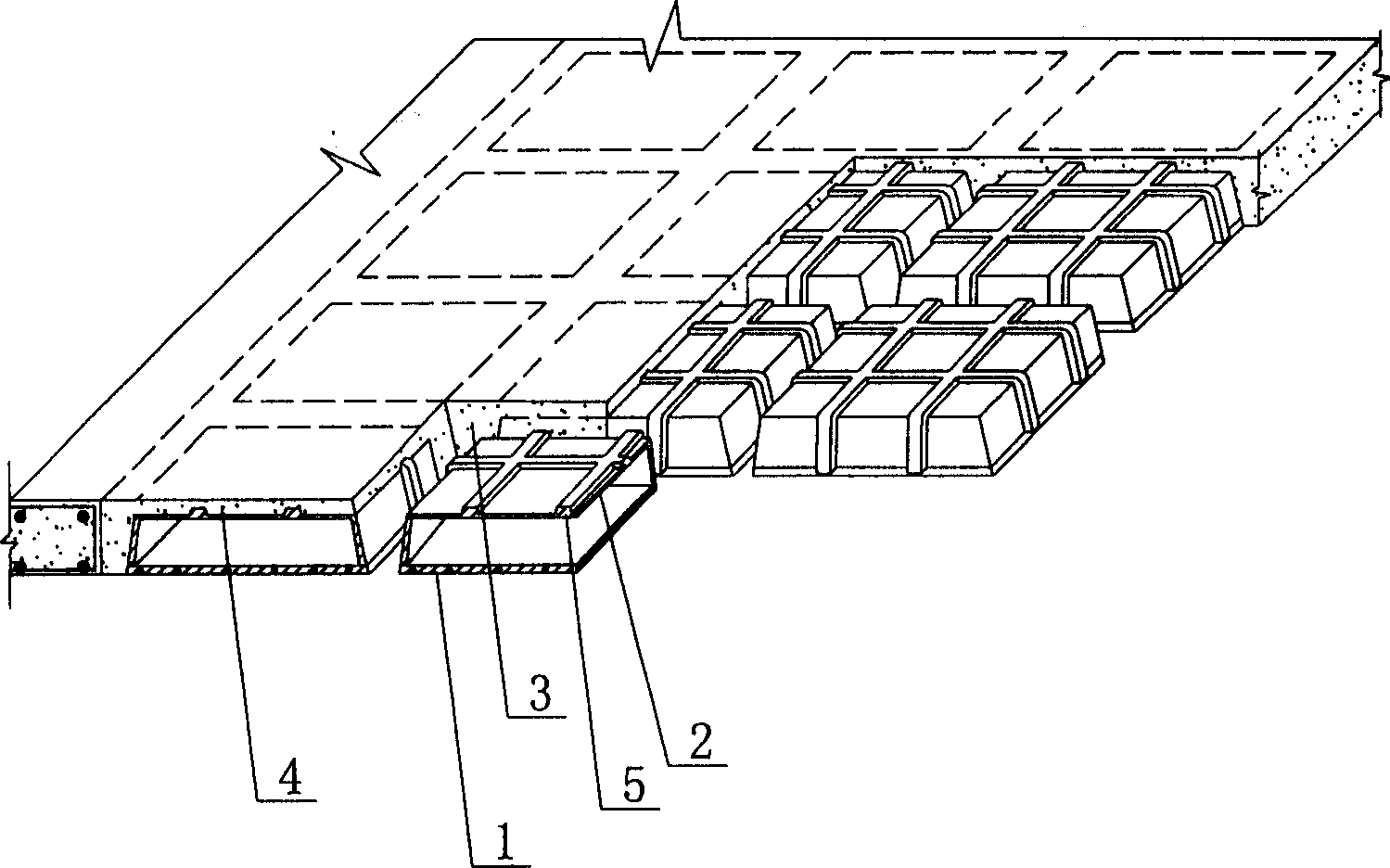

Hollow floor slab with small dense ribs and its production process

InactiveCN1637217ALarge spanSafe and reliable structureFloorsForms/shuttering/falseworksFloor slabLine tubing

The hollow floor slab includes column, solid belt, solid reinforced beam with dense ribs, reinforced facing board, and composite box with lower thin bottom board. The production process includes: a) laying and tying reinforcing steel bar in the floor slab formwork; b) laying the steel wire net and other reinforcing material; c) setting and fixing made composite thin box; d) tying reinforcing steel bar for the facing board; e) fixing reinforcing bars with iron wire; and f) embedding prefabricated pipeline inside the facing board and the dense ribs. The present invention may produce flat sealed floor slab cavity with dense ribs in once deposition.

Owner:HUNAN BDF ENERGY SAVING TECH

Insulative concrete building panel with carbon fiber and steel reinforcement

InactiveUS6898908B2High strengthImprove insulation performanceBuilding roofsConstruction materialFiberCarbon fibers

An insulative, lightweight concrete building panel is provided with one or more fiber or steel reinforcements which are manufactured in a controlled environment and can be easily transported and erected at a building site.

Owner:OLDCASTLE PRECAST

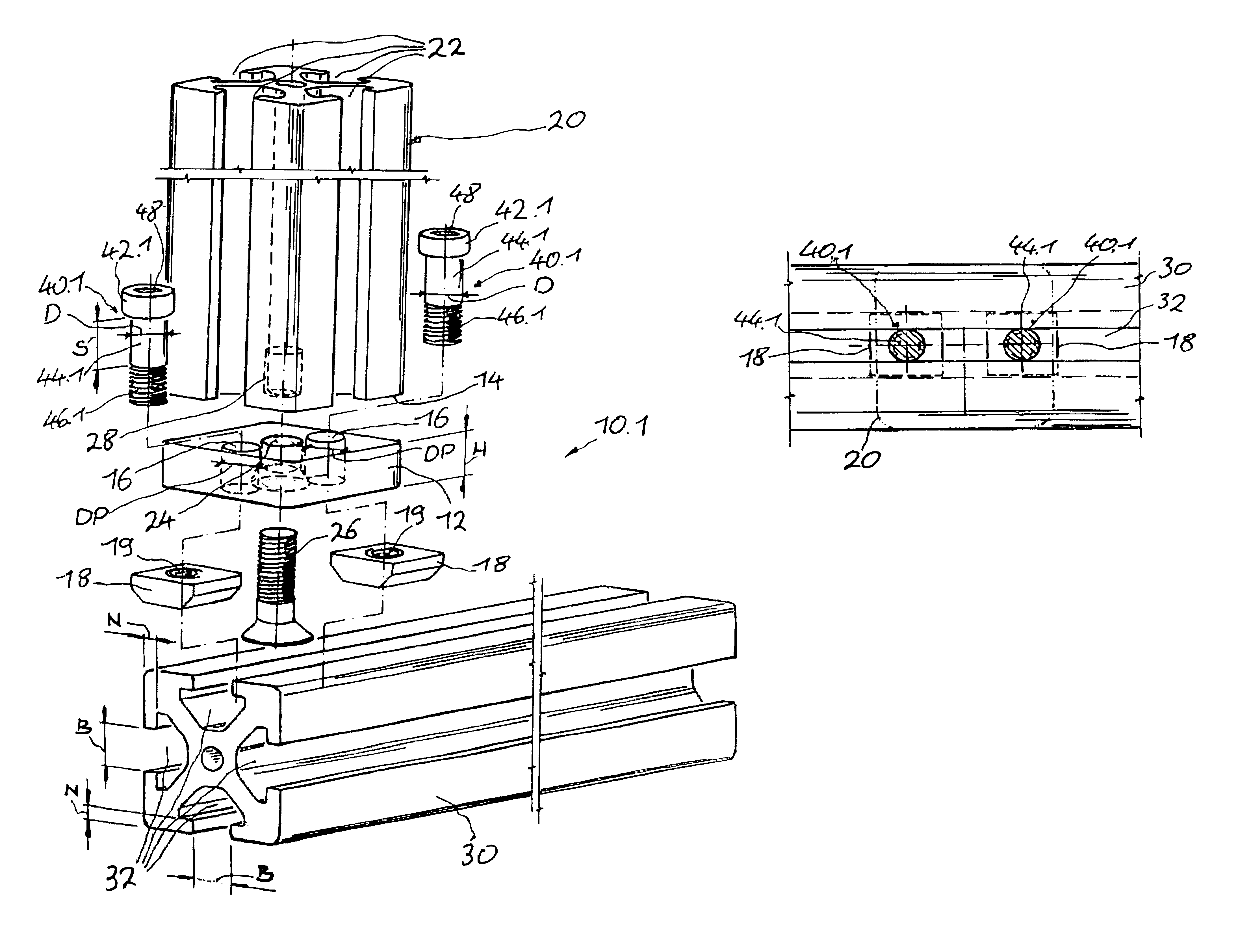

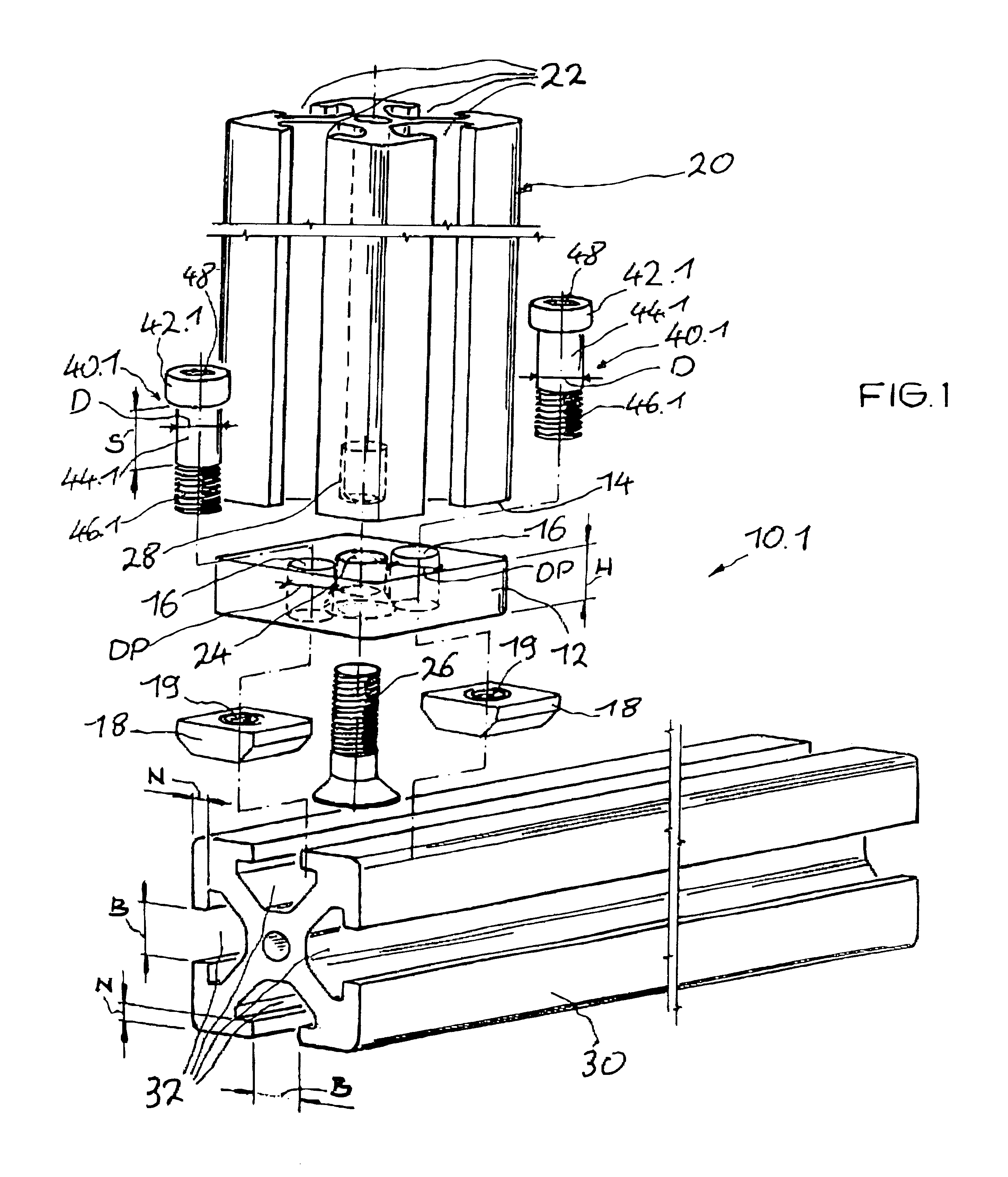

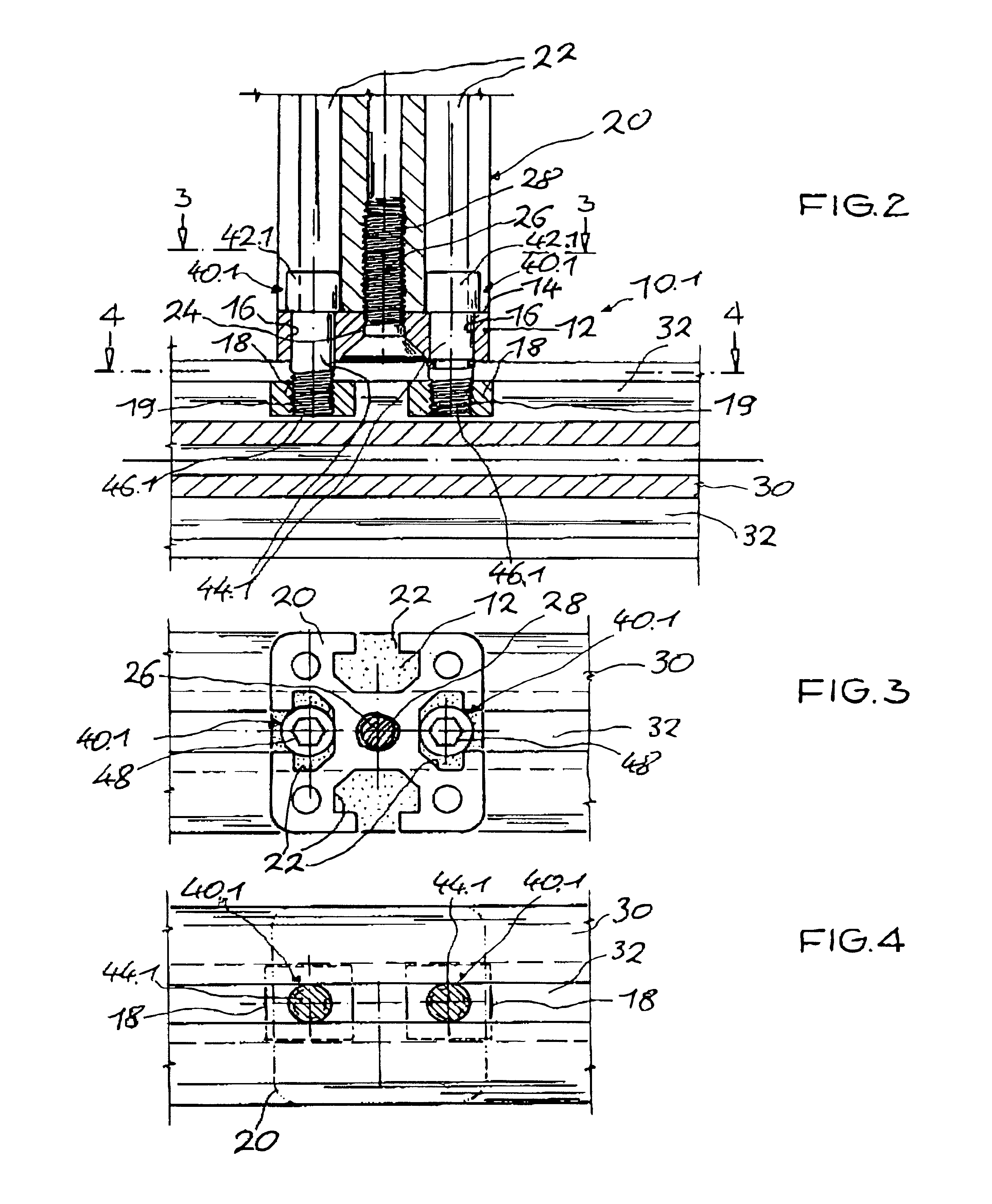

Connecting device for profiled bars with grooves

A connecting device for connecting at least two profiled bars that are essentially perpendicular to one another and have grooves, in conjunction with sliding blocks, one plate connector unit is fastened to the end of a first profiled bar and anchored in a groove in the second profiled bar by way of screw units they extend in recesses in the plate connector unit. The geometry of the screw head of the screw unit is configured such that it centers the screw unit within the groove in the first profiled bar and the engages with a centering effect in the groove in the second profiled bar.

Owner:FMS FORDER UND MONTAGE SYST SCHMALZHOFER

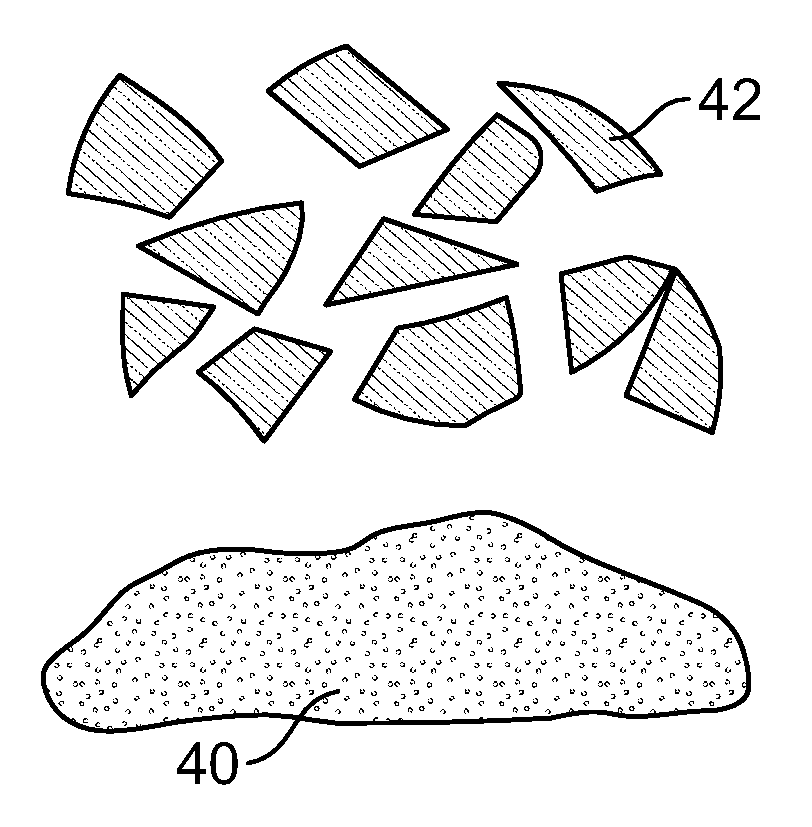

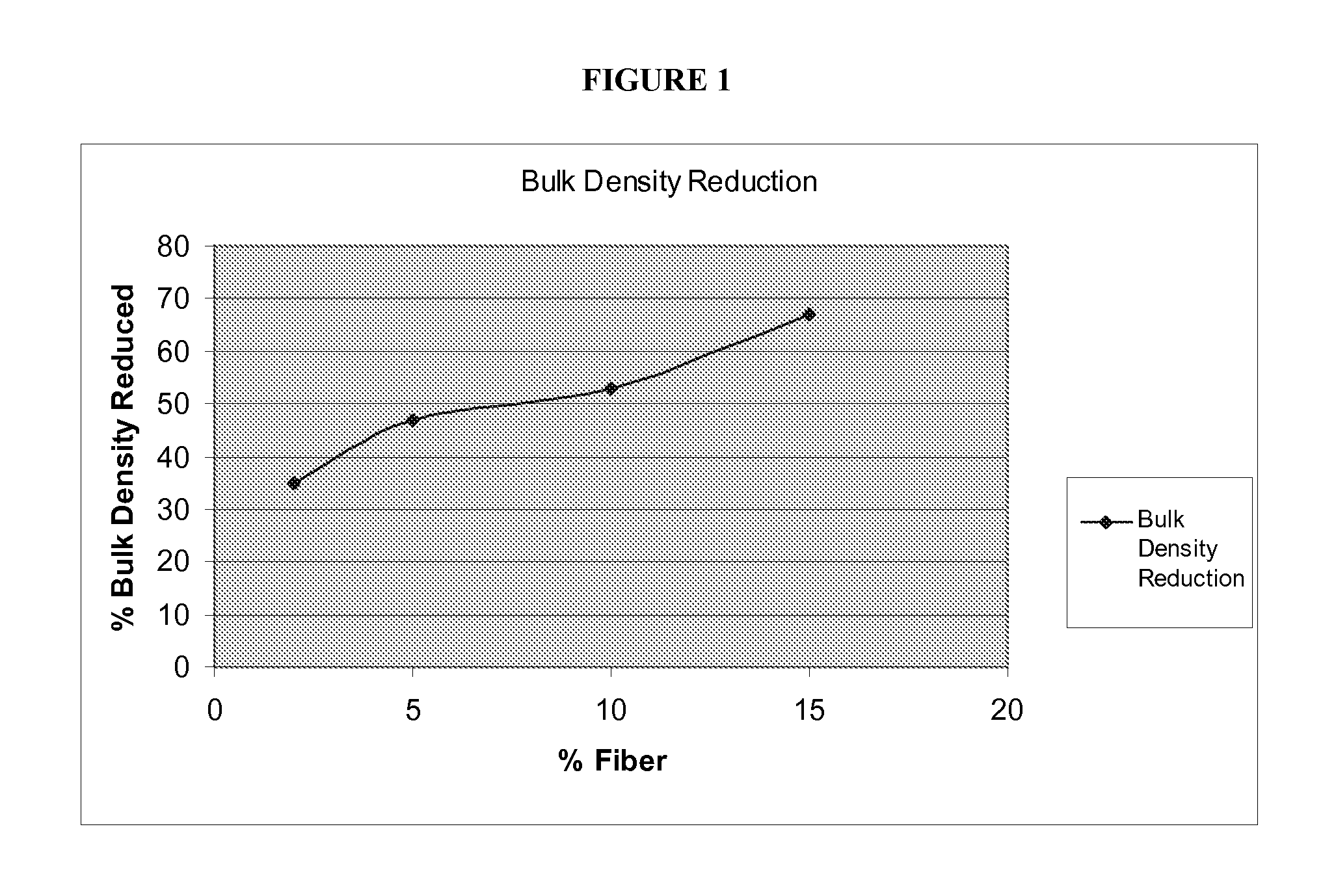

Clumping Animal Litter

Clumping animal litters containing composite particles with increased absorptivity and clump strength are disclosed. Reinforcing fiber materials are combined with a liquid-absorbing material to form composite particles suitable for use as animal litter. The reinforcing fiber materials add structural integrity to the liquid absorbent materials by acting in a manner similar to reinforcing bars (i.e., rebar) in concrete. The fibers need only be present in small percentages to show a consumer noticeable benefit.

Owner:THE CLOROX CO

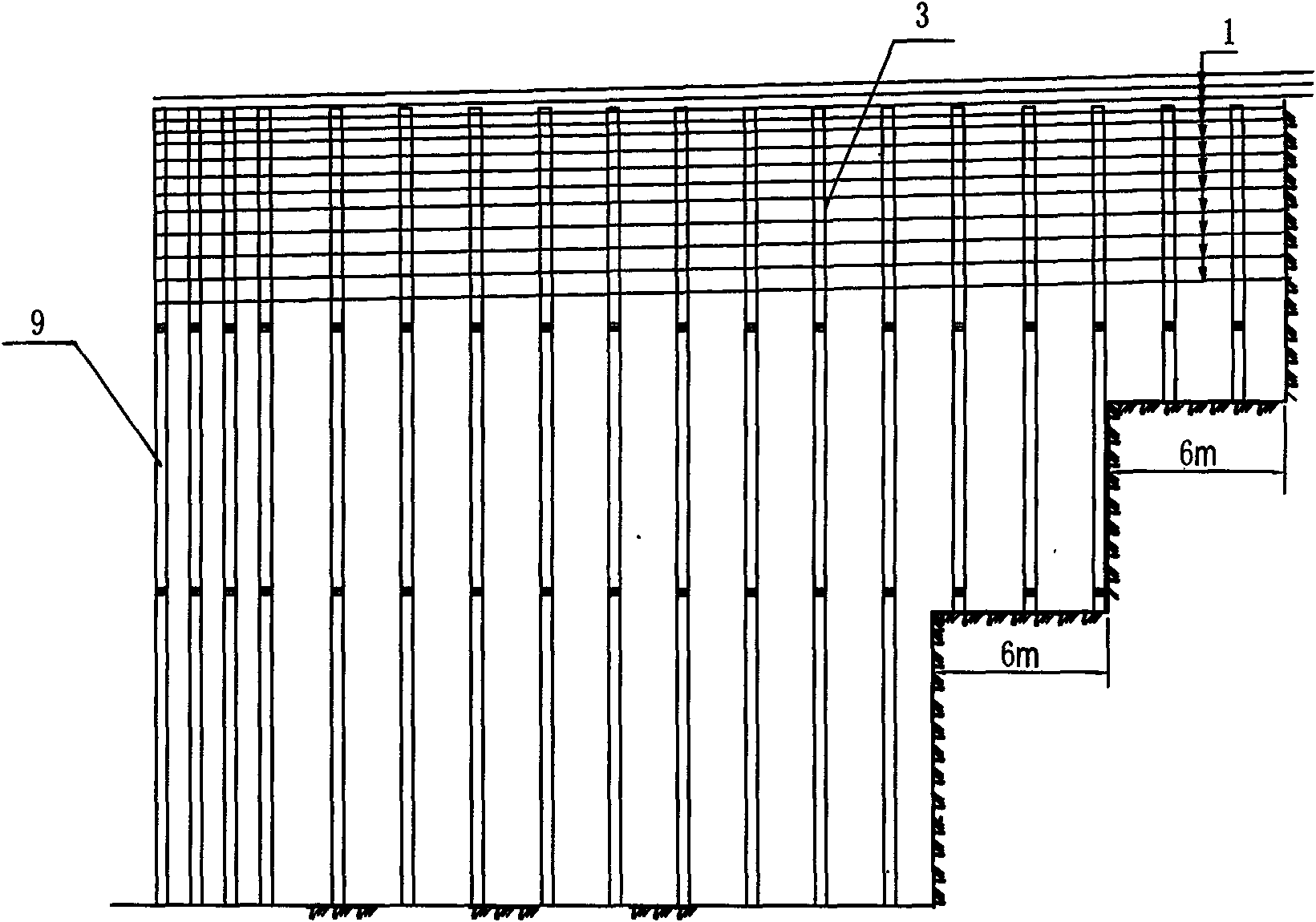

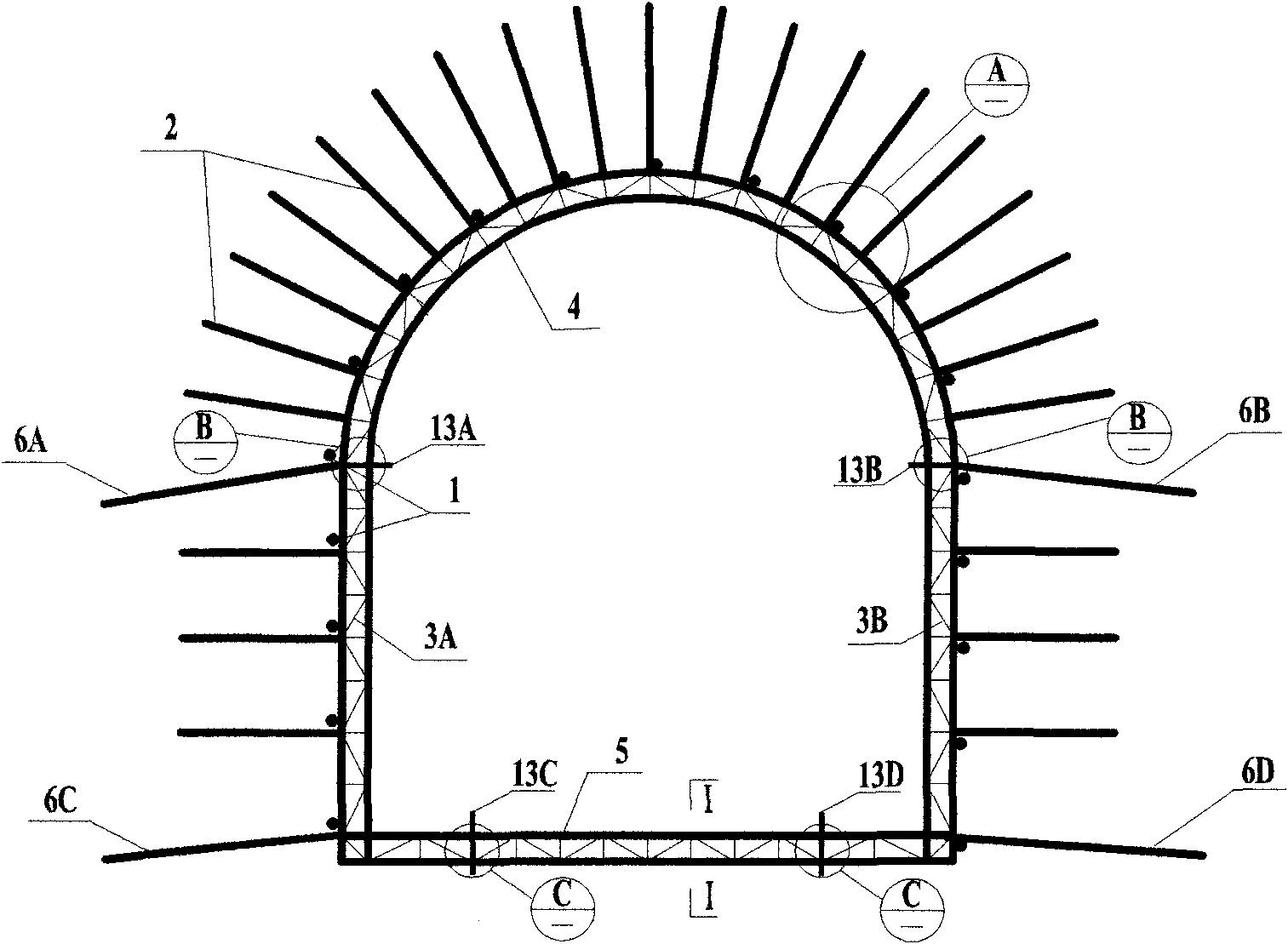

Construction method of V-level surrounding rock tunnel

InactiveCN101614125AAvoid defects such as cavity collapseRealize safe constructionUnderground chambersTunnel liningRock tunnelTunnel wall

The invention relates to a construction method of a V-level surrounding rock tunnel, comprising the following steps: (1) making a drill guiding I-beam steel lagging jack, i.e. mounting an I-beam steel lagging jack, a groove steel trimming beam, a lock pin anchor rod, a guiding steel pipe, a longitudinal connection steel rib and face injecting concrete in sequence; and (2) construction and support in the tunnel, i.e. drilling pipe shelter steel pipe holes, mounting pipe shelter steel pipes, filling slurry inwards. The earthwork construction of a pilot tunnel comprises earthwork construction, primary support, injecting concrete on a pilot tunnel wall, suspending steel bar nets, casting concrete basis, mounting I-beam steel lagging jack, groove steel trimming beam, steel pads, I-shaped steel inclined strut and lock pin anchor rods, welding longitudinal connection steel bar, injecting concrete on the face and removing core soils; mounting a first-level step temporary inverted arch comprises: constructing lower-level earthwork, performing primary support in the pivot tunnel, mounting the second-level step temporary inverted arch, constructing the following level of earthwork, performing primary support, casting and filling inverted arch, and casting lining concrete at a time inside the pivot tunnel. The invention has the advantage of rapid penetration speed and safe construction.

Owner:CHINA RAILWAY NO 9 GRP

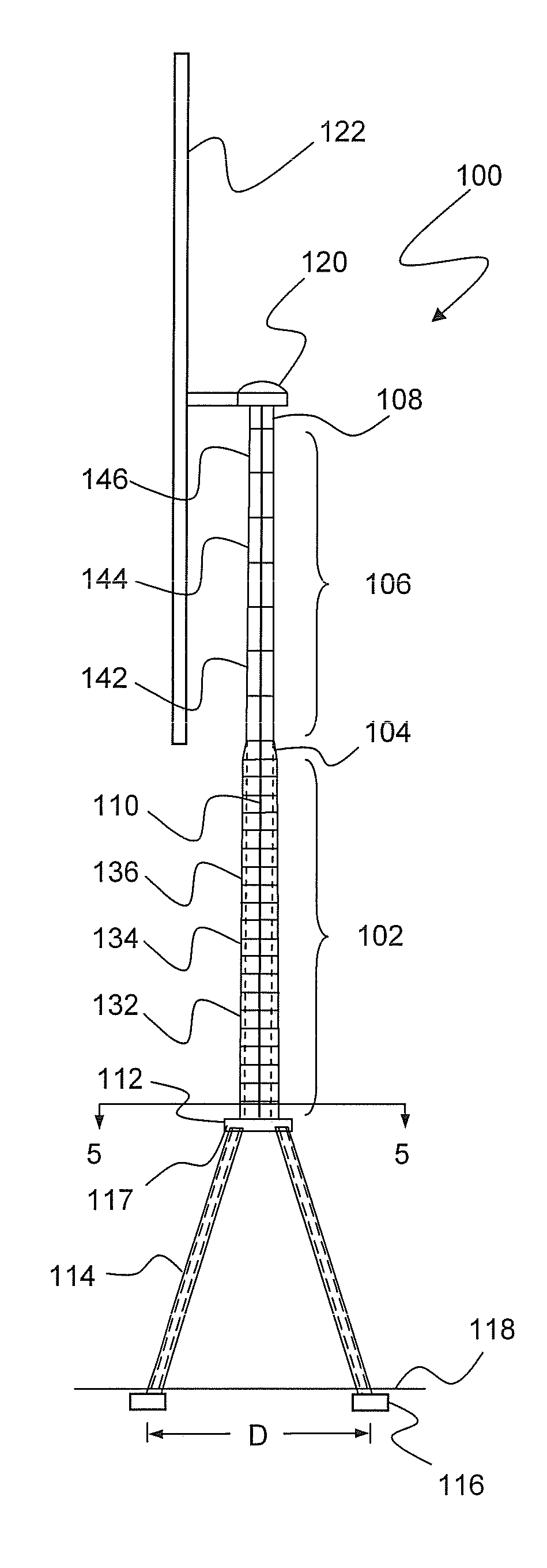

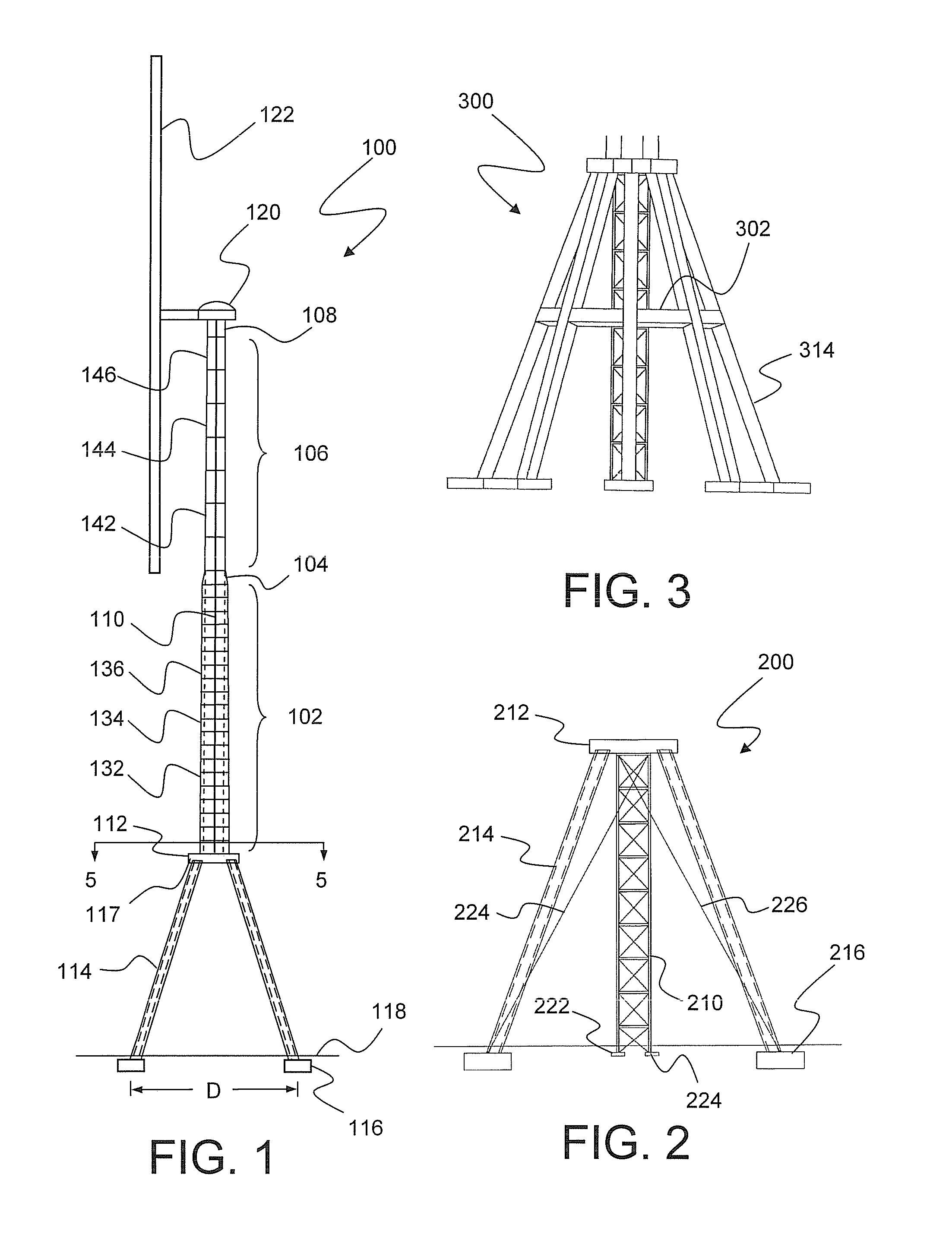

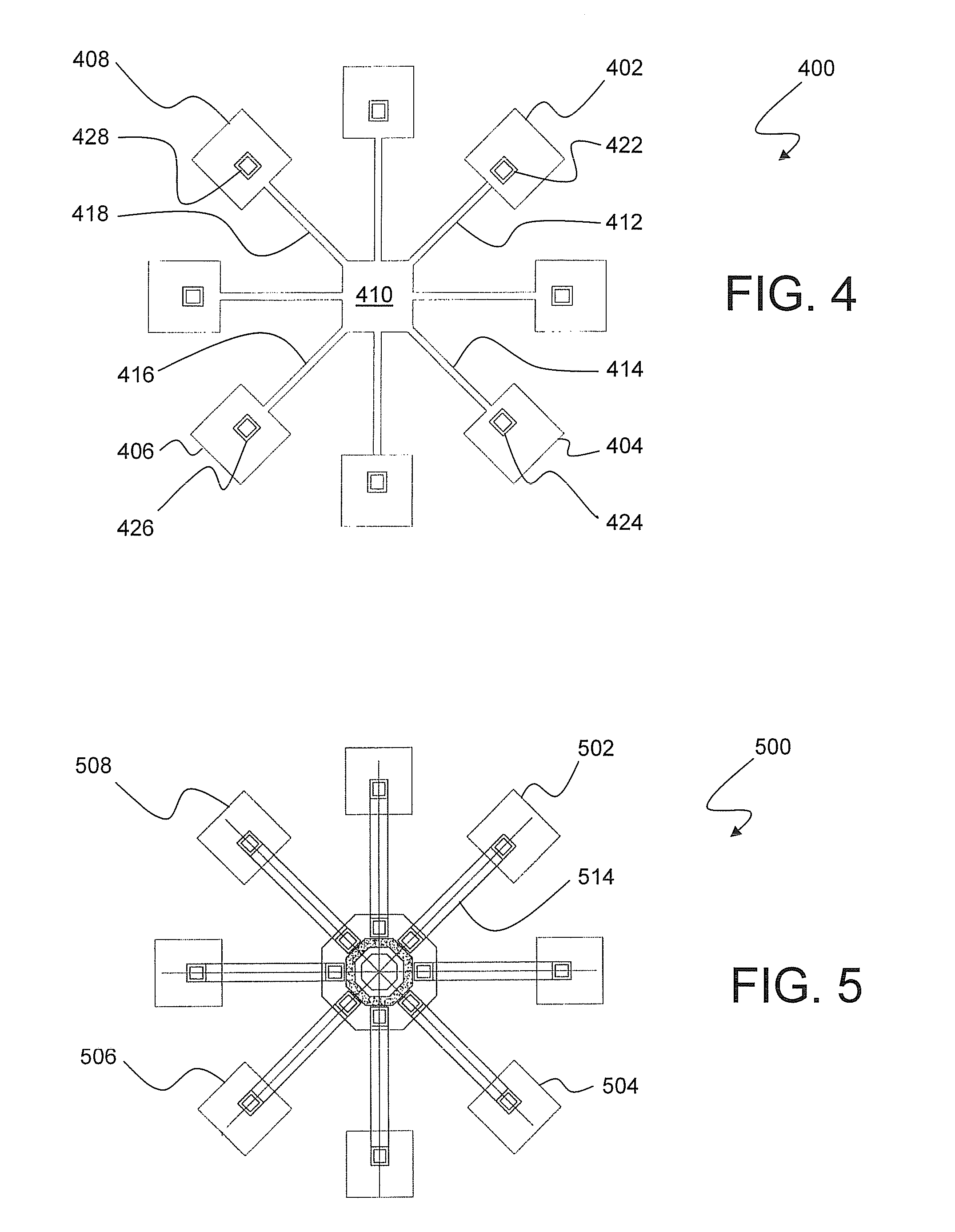

Base support for wind-driven power generators

Disclosed are apparatus and corresponding methodology for providing a base support, such as including concrete, and used such as for a wind-driven generator. Precast concrete cylinders are stacked in place upon a platform that may be partially precast and partially cast in place during assembly and supported, in certain embodiments, by plural concrete legs, the other ends of which are supported on a unitary or subdivided concrete foundation. In other embodiments, the platform may be supported by ribbed concrete panels. The concrete cylinders are glued together using an epoxy and then secured by an internal vertical post tension system extending from the platform to the upper most cylinder. Different types of concrete are used between upper and lower sections of the stacked cylinders. The lower section uses reinforced concrete while the upper section used ultra high performance fiber reinforced concrete.

Owner:TINDALL CORP

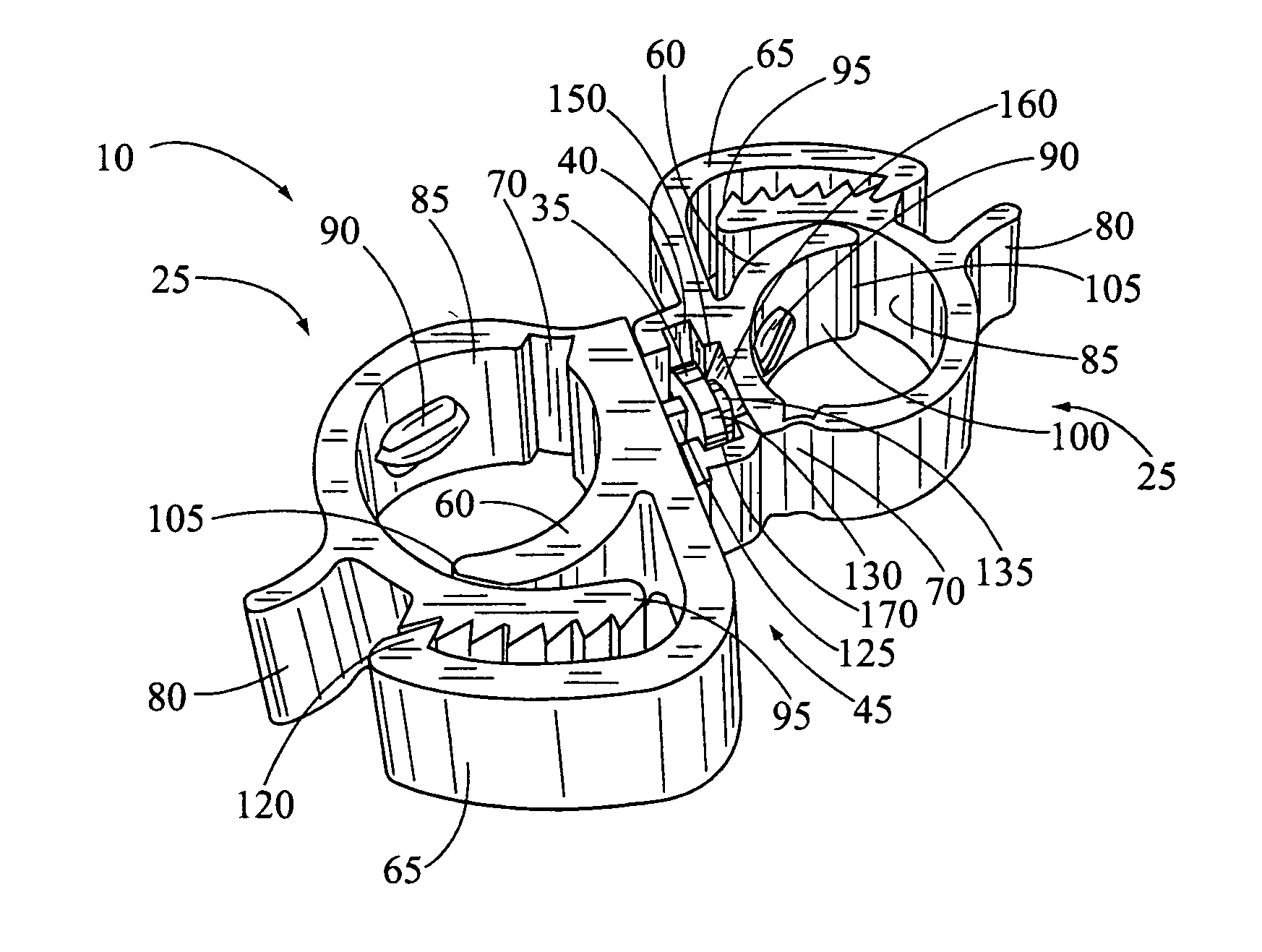

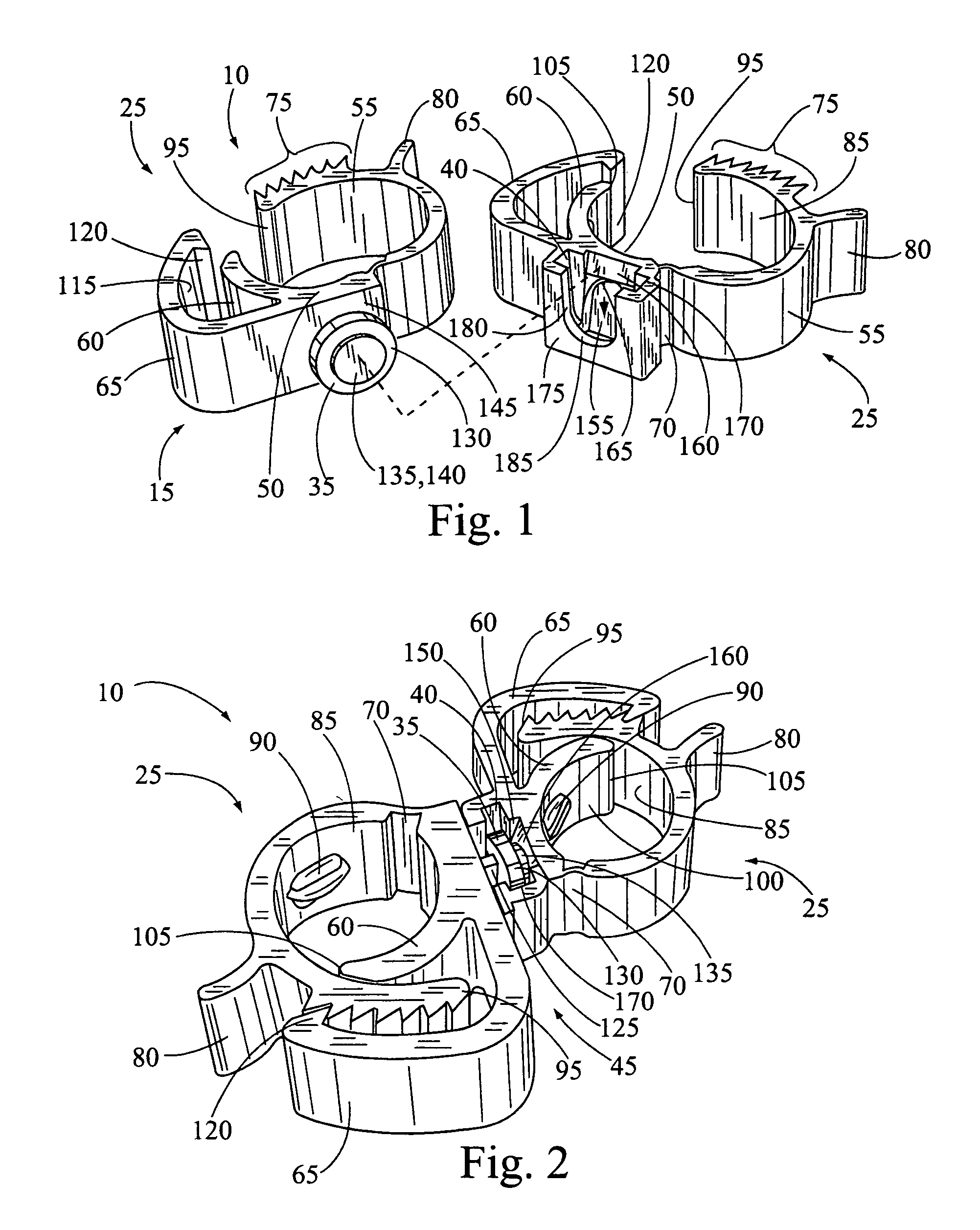

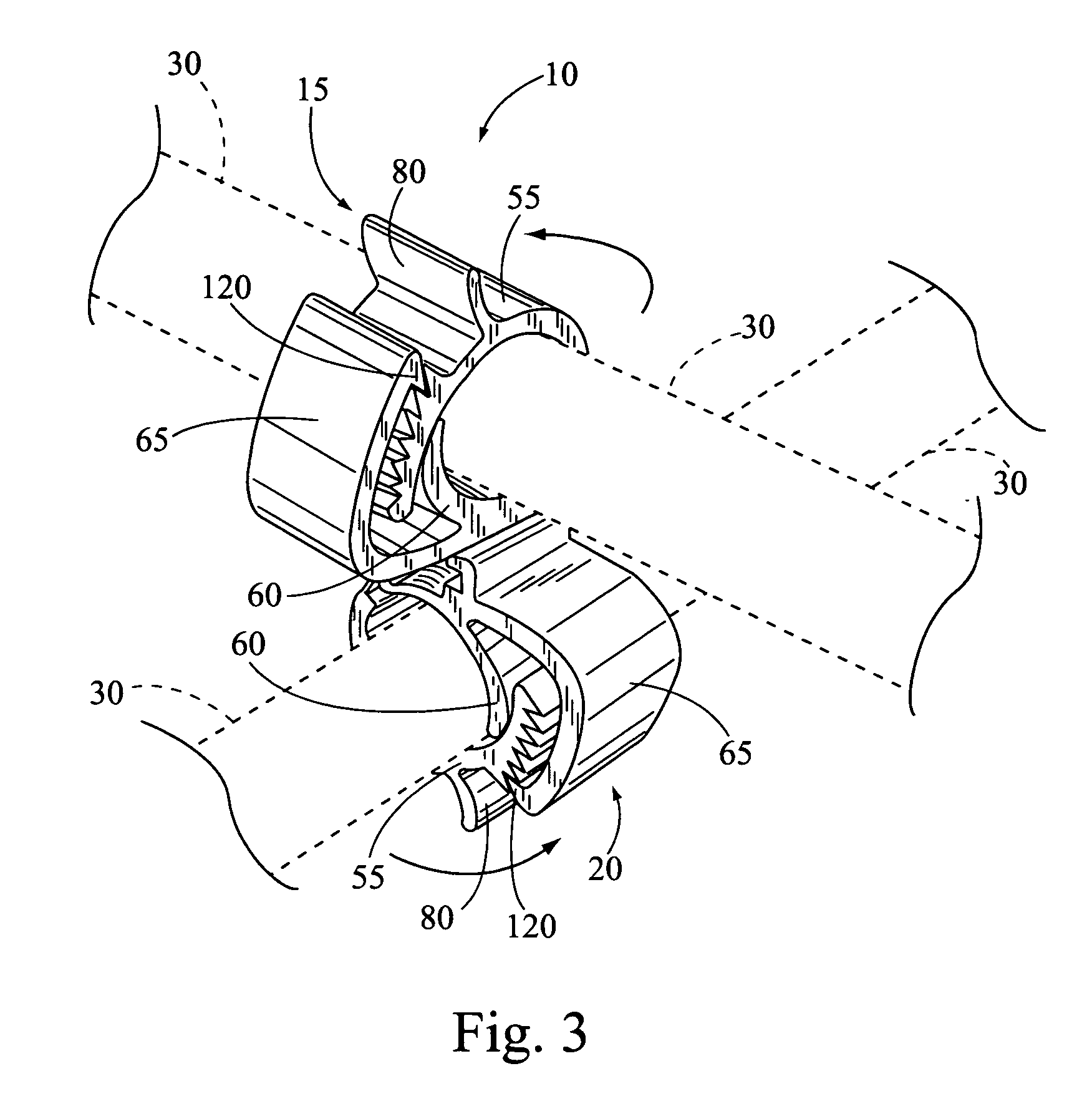

Swiveling multi-clamp fastener

A fastener for joining two pieces of rebar together in a rebar grid used to reinforce subsequently poured concrete is described. The fasteners include two clamp pieces that in certain embodiments completely wrap around a piece of rebar and are tightly secured thereto. Further, each clamp piece can swivel or rotate up to 360 degrees relative to the other clamp piece such that two rebar pieces intersecting at any angle can be coupled together.

Owner:JIFFY CLIP

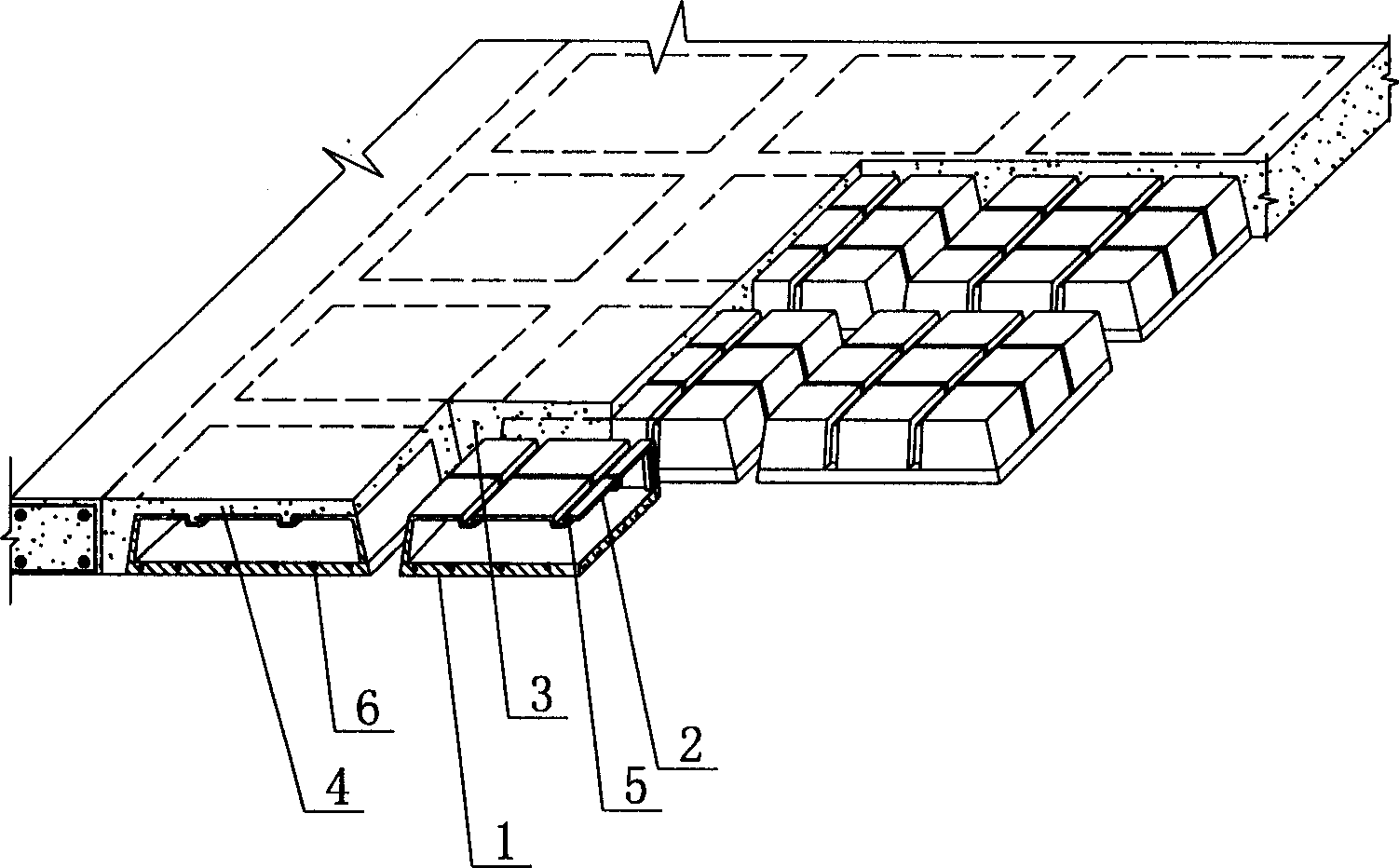

Hollow floor system made of steel bar and foam combined filled member

Owner:HUNAN BDF ENERGY SAVING TECH

Prestress high intensity concrete square pile and its production method and moulding die

InactiveCN101054800AHigh pile rateIncrease profitCeramic shaping apparatusBulkheads/pilesHigh strength concretePre stress

The invention belongs to the architecture field, which relates to an improvement with the foundation pile shape and the structure and the manufacturing method of the foundation pile and the foundation pile shaper in the architecture field, in particular the invention is a prestressing force high strength concrete square pile and the manufacturing method thereof and the shaping device. In the invention a square terminal plate is disposed on the two ends of the square pile, and the four sides of the terminal plate is provided with a groove, while the center is equipped with a circular hole, and between the circular hole and the four sides, a strain hole and a threading hole are arranged symmetrically; a stirrp of a reinforcement cage in a twist is welded on the principal reinforcement continuously, wherein the principal reinforcement is the steel strand or the steel bar; the concrete square pile and the four-side corners of the terminal plate are in a stress elimination arc, and the pile core is a columnar mid level outlet having the same diameter with the terminal plate central circular hole. The manufacturing method is characterized in that, the principal reinforcement has the fix ed length and blanking, and the stirrp of the reinforcement cage is welded in the seam welder with the high degree of mechanisation; the principal reinforcement is stretched in a group of a whole pile fixed value, wherein the stretching performance is good and the balance is consistent; the disposable high pressure has short shaping time, low energy consumption, high product grade; the die design meets with the shaping requirement of the shape, which is convenient to use.

Owner:SHANGHAI ZHONGJI PILE IND

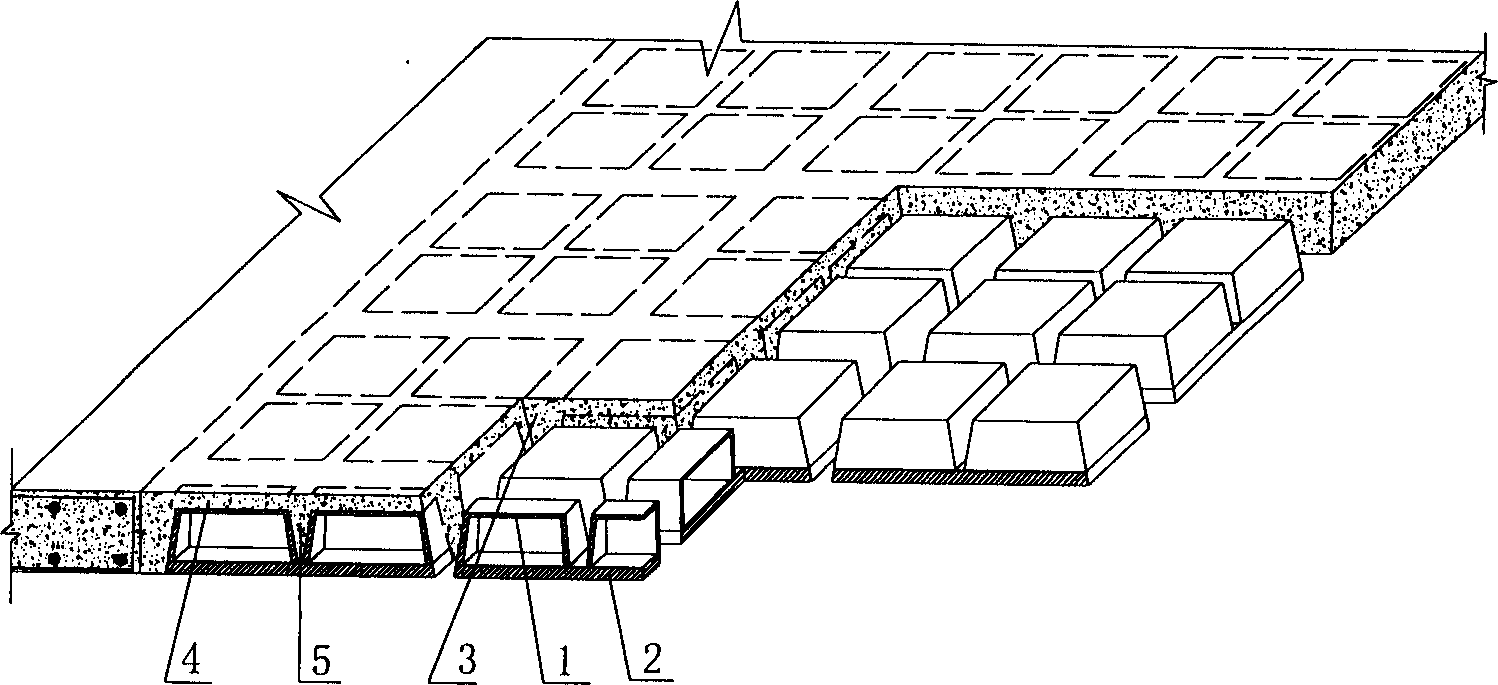

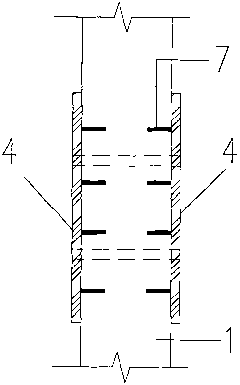

Floor with space structure

InactiveCN1356440AImprove mechanical performanceReduce thicknessFloorsReinforced concreteSpatial structure

A building roof with space structure is coposed of molded waffle members consisting of molded waffle and bottom plate, in-situ cast primary reinforced concrete rib, and in-situ cast reinforced concrete top plate. A prefabricated structured bottom plate has at least 2 molded waffle cavities and at least one in-situ cast secondary reinforced concrete rib. The said primary and secondary ribs constitute a hidden dense rib structure. Its advantages include high anti-earhquake performance and less thickenss, high strength.

Owner:湖南邱则有专利战略策划有限公司

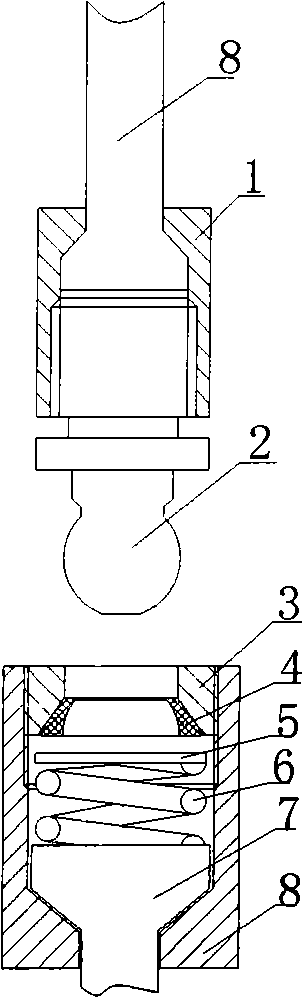

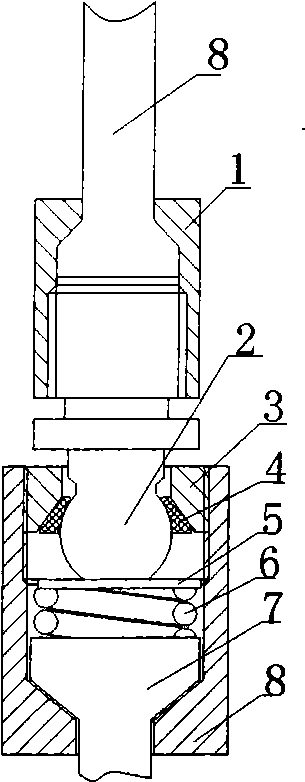

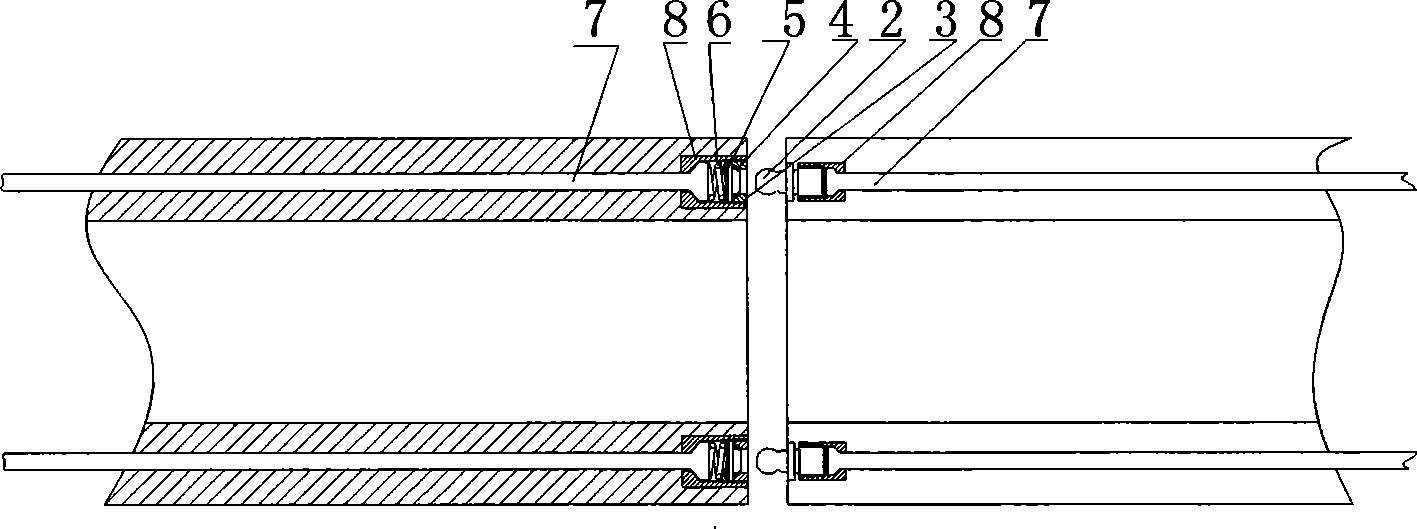

Cutting-free fast tearing butt coupler and butt joint piece

ActiveCN101519876AReliable dockingFirmly connectedCeramic shaping apparatusBulkheads/pilesButt jointSteel bar

The invention relates to a cutting-free fast tearing butt coupler and a butt joint piece, as well as a fabricated part formed by the cutting-free fast tearing butt coupler, a fabricated part formed by the cutting-free fast butt coupler, and butt joint structure between the fabricated parts, and the invention consists of a raising-pulling screw cap, a support-pulling screw cap and a fabricated part longitudinal bar which are positioned at the two ends of the fabricated parts, wherein the raising-pulling screw cap and the support-pulling screw cap have the internal thread structure, the internal thread is tearing screw thread, the center of the cap bottom is provided with a steel bar hole, the periphery of the steel bar hole is a steel bar upset head clamping table, the two ends of the fabricated part longitudinal bar are upset into the upset head which is clamped and connected on the upset head clamping table, a pressure spring is positioned inside the support-pulling screw cap, one end of the pressure spring is positioned on the steel bar upset head, the other end thereof is provided with a tapered sleeve formed by two or a plurality of pieces, a screw thread sleeve is rotatably connected inside the support-pulling screw cap and locates the displacement on the tampered sleeve, the tail part of a connection-peg is connected with the internal thread of the raising-pulling screw cap, and the head part of the connection-peg has the ball-lacking shape and is matched with the tampered sleeve in an elastic joint way.

Owner:周兆弟

Carton with Reinforced Handle

A carton for containing a plurality of articles. The carton has a plurality of panels that extend at least partially around an interior of the carton. The plurality of panels include a top panel, a bottom panel, a first side panel, and a second side panel. At least two end flaps are respectively foldably attached to respective panels of the plurality of panels. The end flaps are overlapped with respect to one another and thereby at least partially form a closed end of the carton. The carton includes a handle in the closed end of the carton having a handle opening for grasping and carrying the carton. At least one end flap of the at least two end flaps has a main panel for at least partially closing the closed end of the carton and a reinforcement panel foldably attached to the main panel.

Owner:GRAPHIC PACKAGING INT

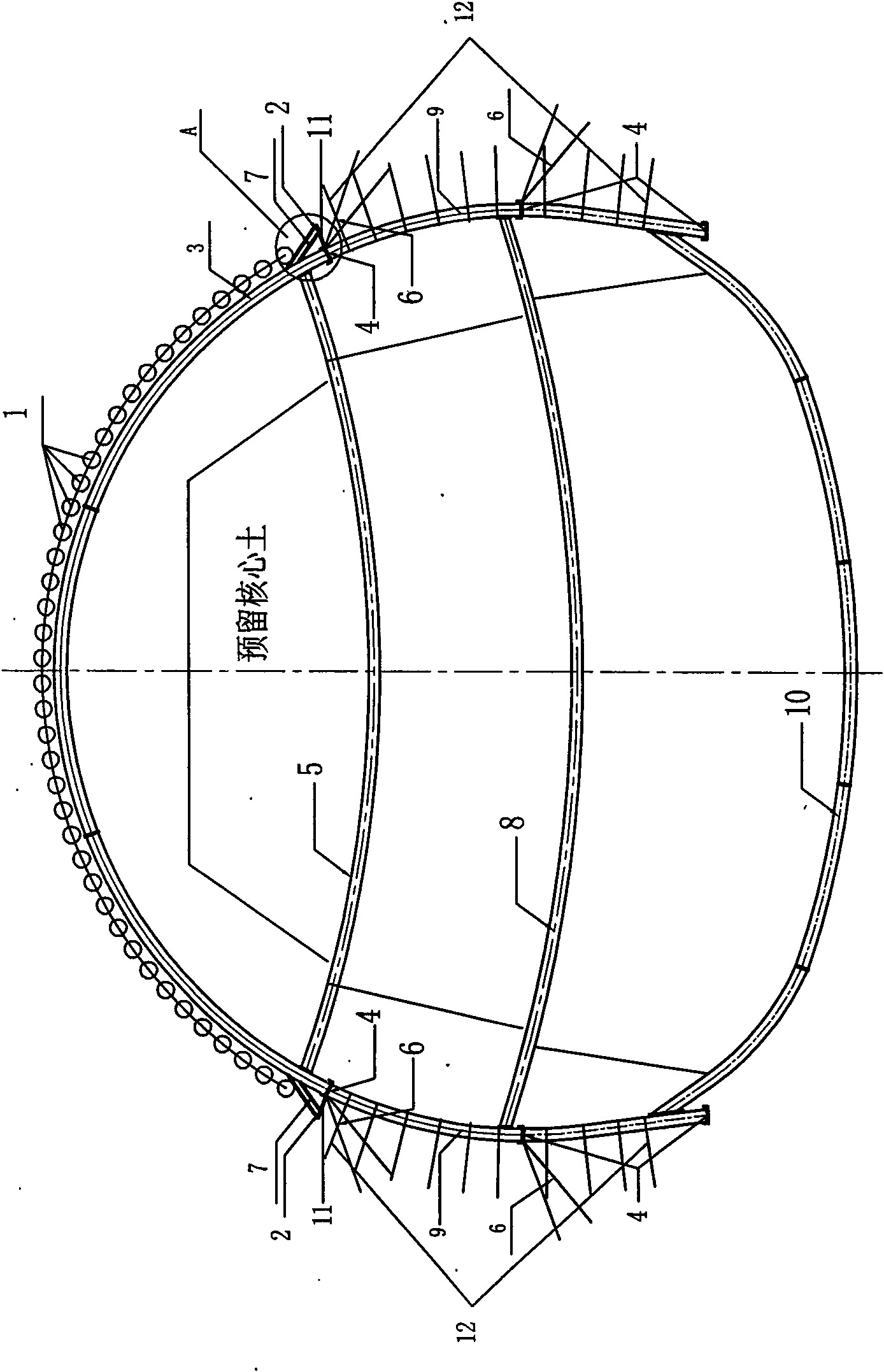

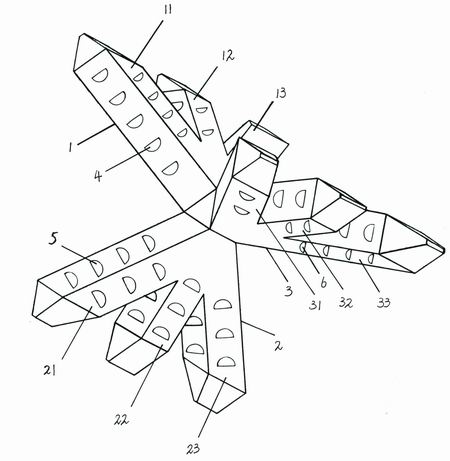

Artificial fish reef

InactiveCN102599081AImprove stabilityImprove hydrodynamic performanceClimate change adaptationPisciculture and aquariaReinforced concreteRebar

The invention discloses an artificial fish reef which comprises an artificial fish reef body, and is characterzied in that the artificial fish reef body is in an inversed Y shape; the inversed Y-shaped artificial fish reef body is composed of an upper part unit, a left lower part unit and a right lower part unit which are cast by reinforced concrete into a whole, wherein the upper part unit is ina vertical downward arrow shape which is formed by an upper left oblique post, an upper middle post and an upper right oblique post; the left lower part unit is in an upward and inclined right oblique arrow shape, and is formed by a left lower left oblique post, a left lower middle post and a left lower right oblique post; and the right lower part unit is in an upward and inclined left oblique arrow shape, and is formed by a right lower left oblique post, a right lower middle post and a right lower right oblique post. According to the invention, the artificial fish reefs are combined and stacked to construct a place for spawning and perching of fishes, and in case that a plurality of artificial fish reefs are combined, the stability and dynamic property of the artificial fish reef can be greatly improved. The artificial fish reef provided by the invention can be used for proliferation of shallow-water-type rocky fishes, shellfishes and algae in a shallow water area of a water depth 6-10 meters.

Owner:SHANGHAI OCEAN UNIV

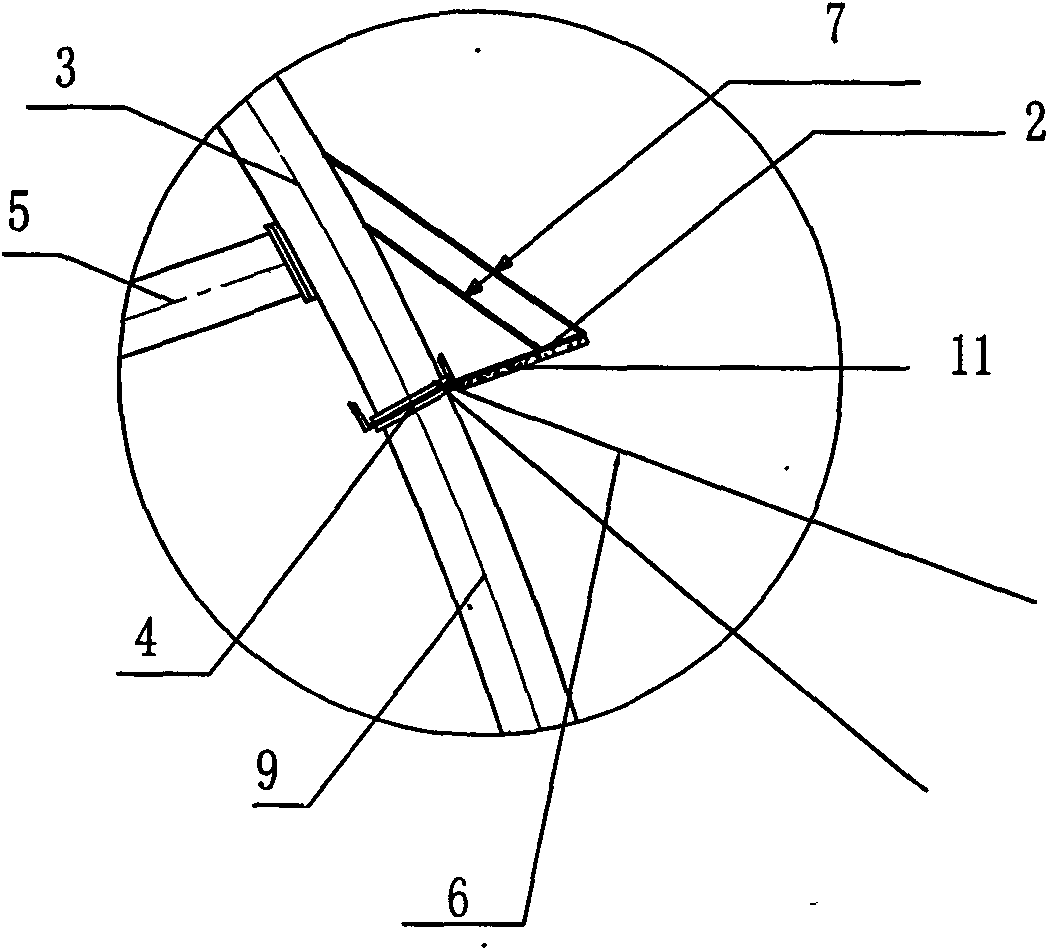

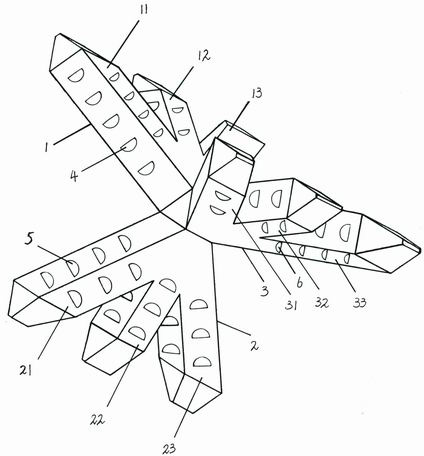

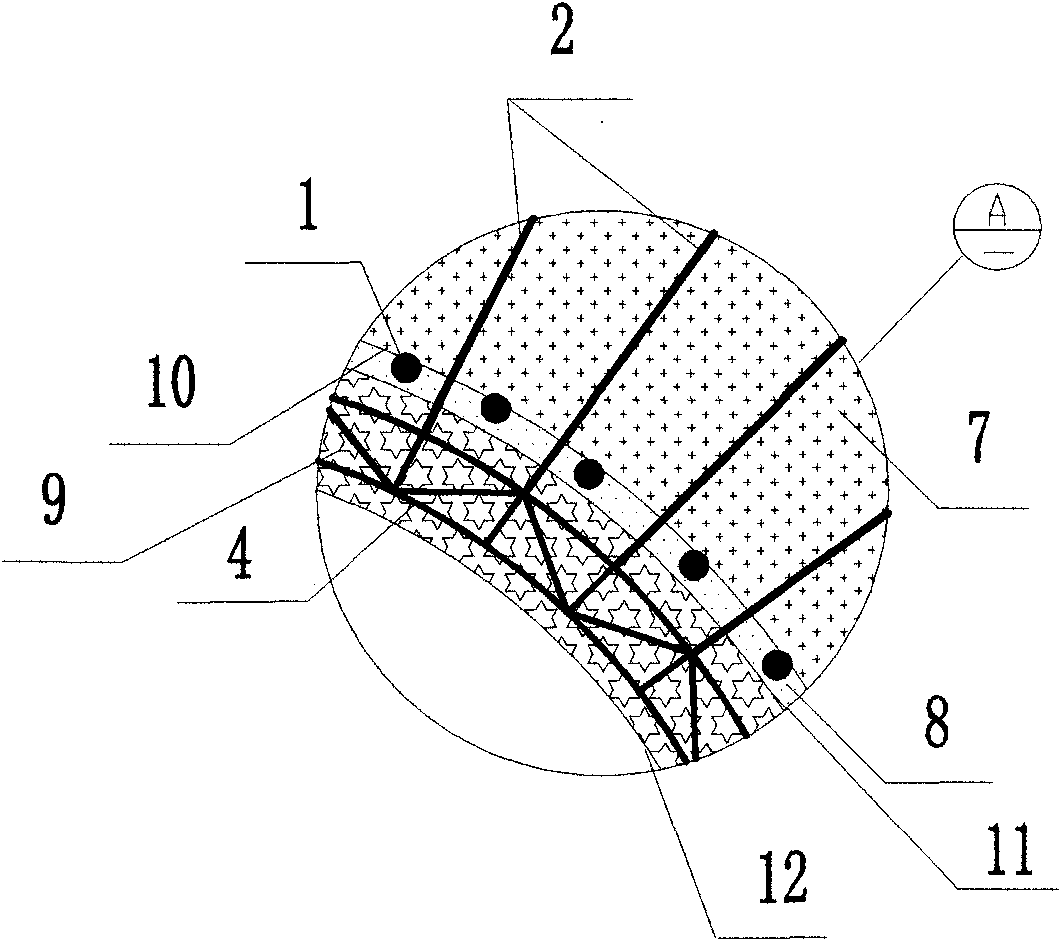

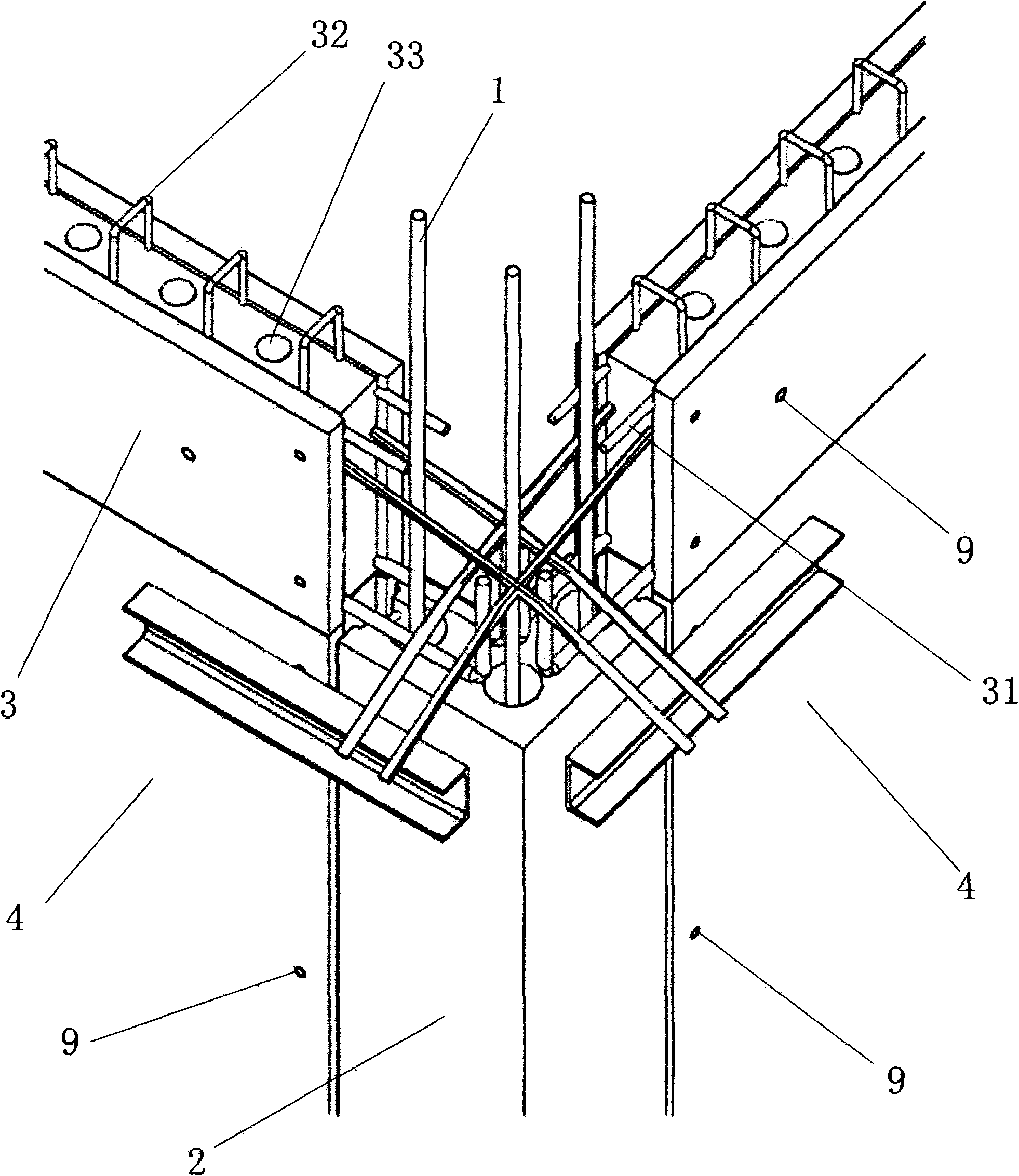

Node connection device for self-centering prestressed concrete frame

InactiveCN101798849ASolve local pressure problemsEliminate or reduce residual deformationShock proofingResidual deformationWhole body

The invention relates to a node connection device for a self-centering prestressed concrete frame. The node connection device is a device used for the connection between the beam and the column of a prefabricated reinforced concrete frame, and aims at improving energy consumption of a frame structure under seismic action and eliminating or reducing the residual deformation and damage of the frame structure. The connection device is characterized in that combined steel parts form an energy consuming device, two external friction steel plates (3) are arranged in the energy consuming device, are respectively and symmetrically arranged on the two sides of a column end reinforcing steel plate (4) and are connected with the column end reinforcing steel plate (4) into a whole body, two internal friction steel plates (8) are arranged between the two external friction steel plates (3), the upper end and the lower end of each internal friction steel plate (8) are respectively provided with a bean end reinforcing steel plate (5), friction discs (15) are respectively arranged between the two internal friction steel plates (8) and the two external friction steel plates (3), and friction-type high-strength bolts (12) penetrate through the external friction steel plates (3), the friction discs (15), the internal friction steel plates (8) and a prefabricated concrete beam (2) and connect all parts together.

Owner:SOUTHEAST UNIV

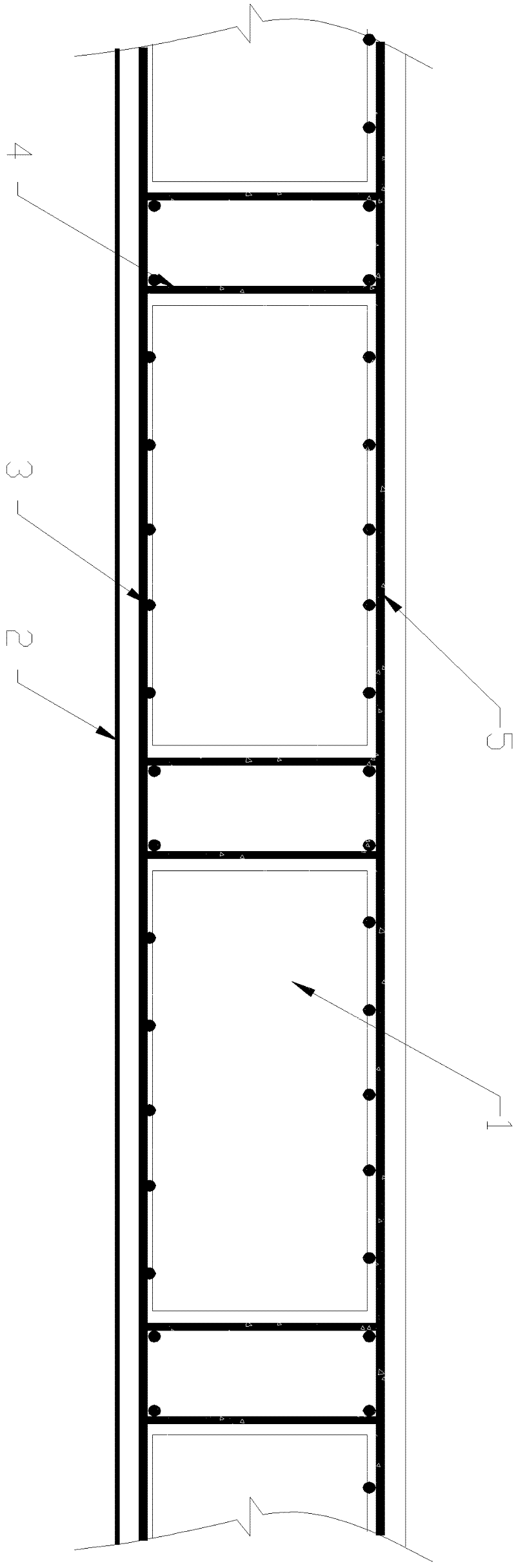

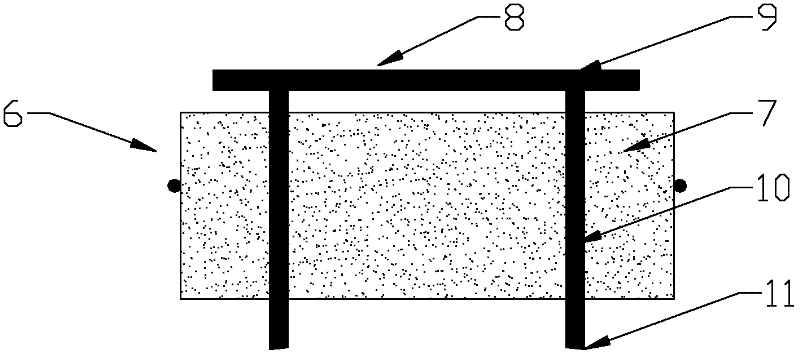

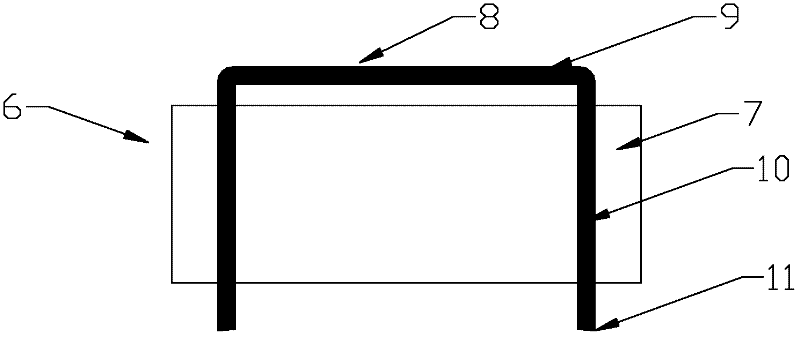

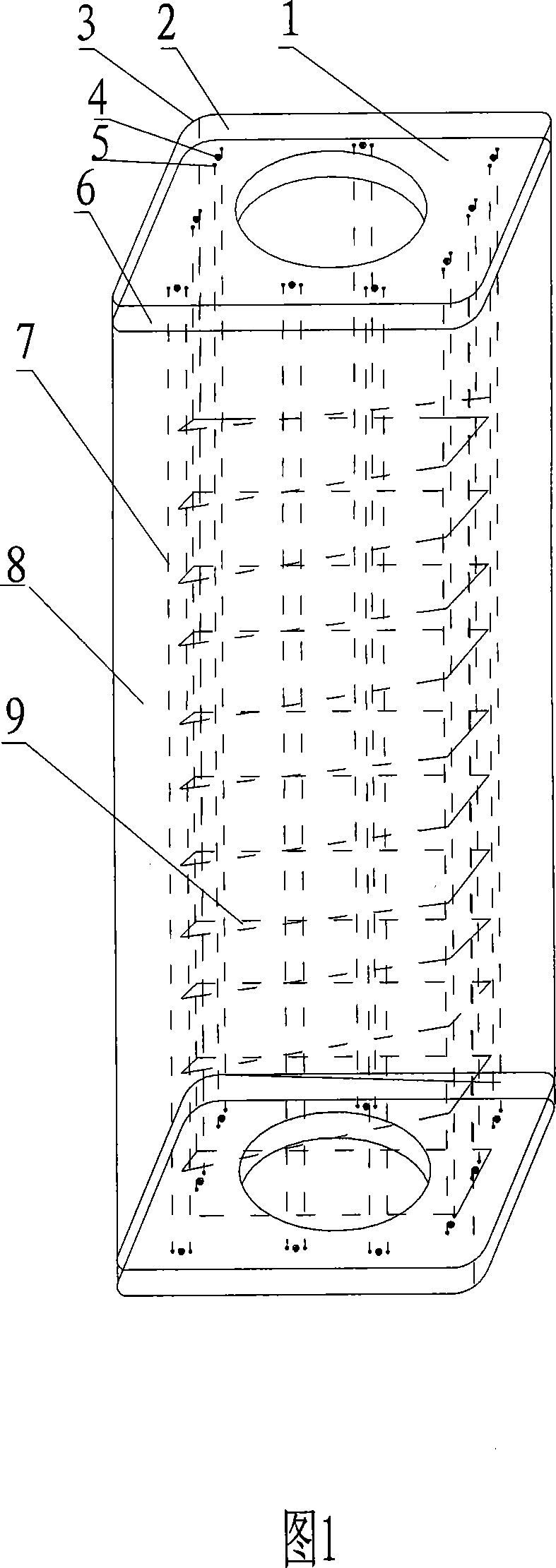

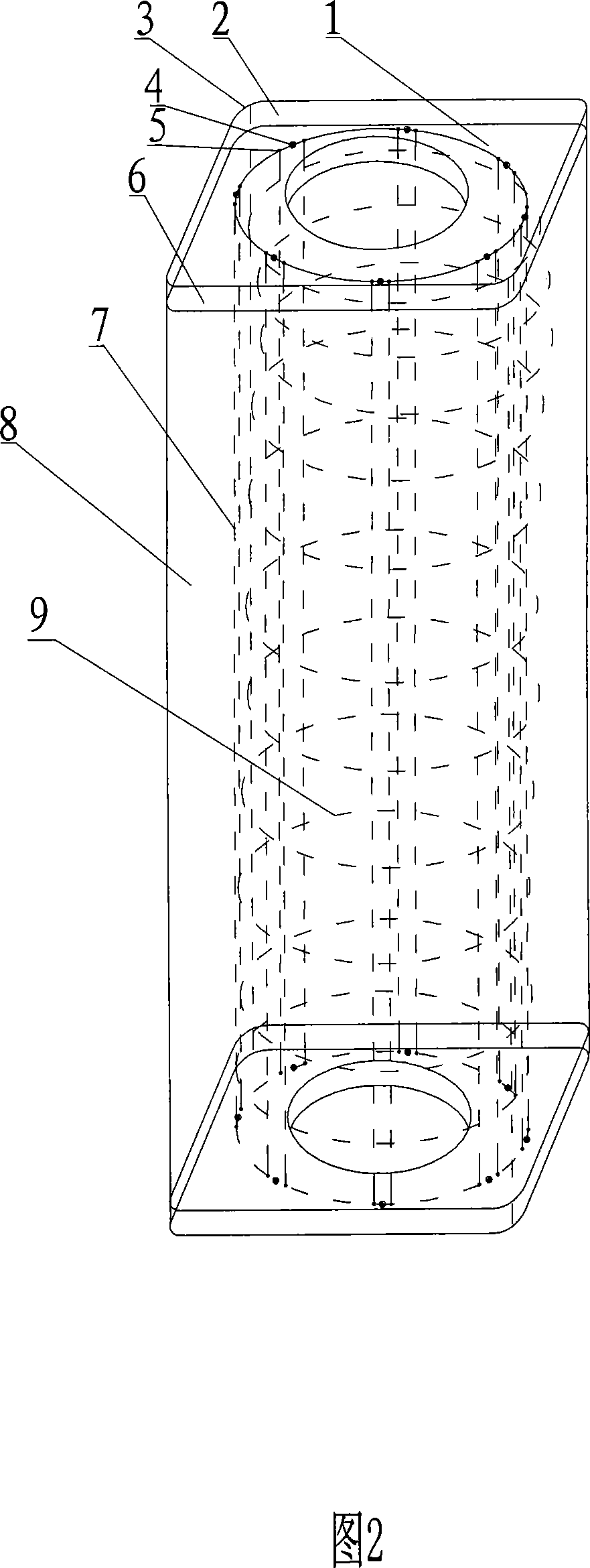

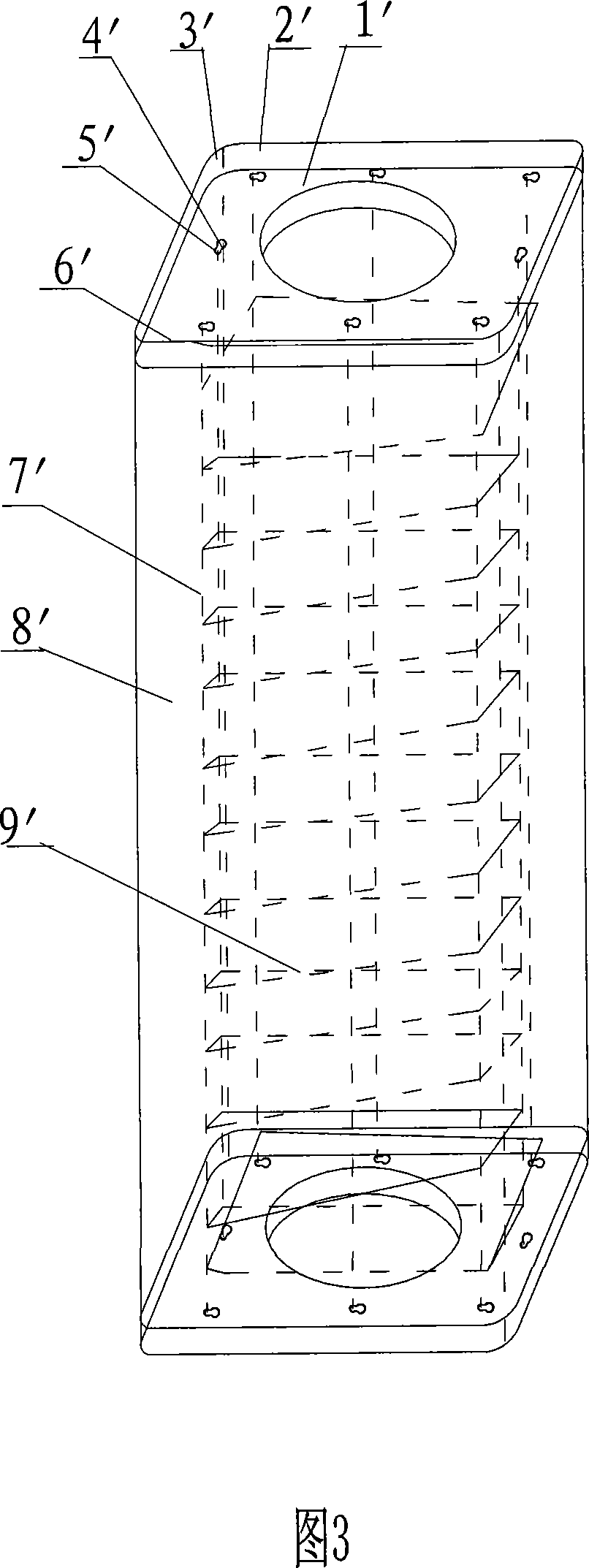

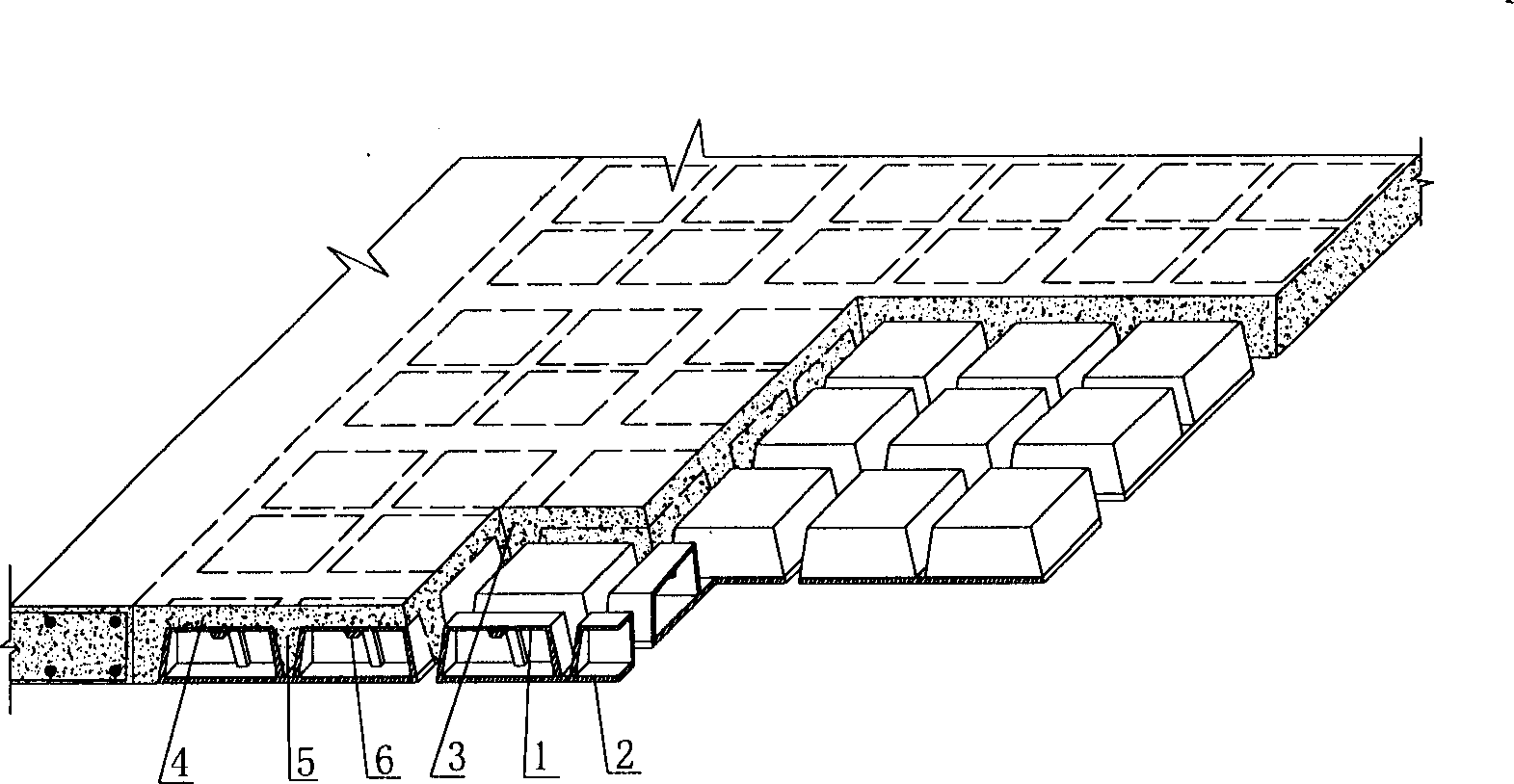

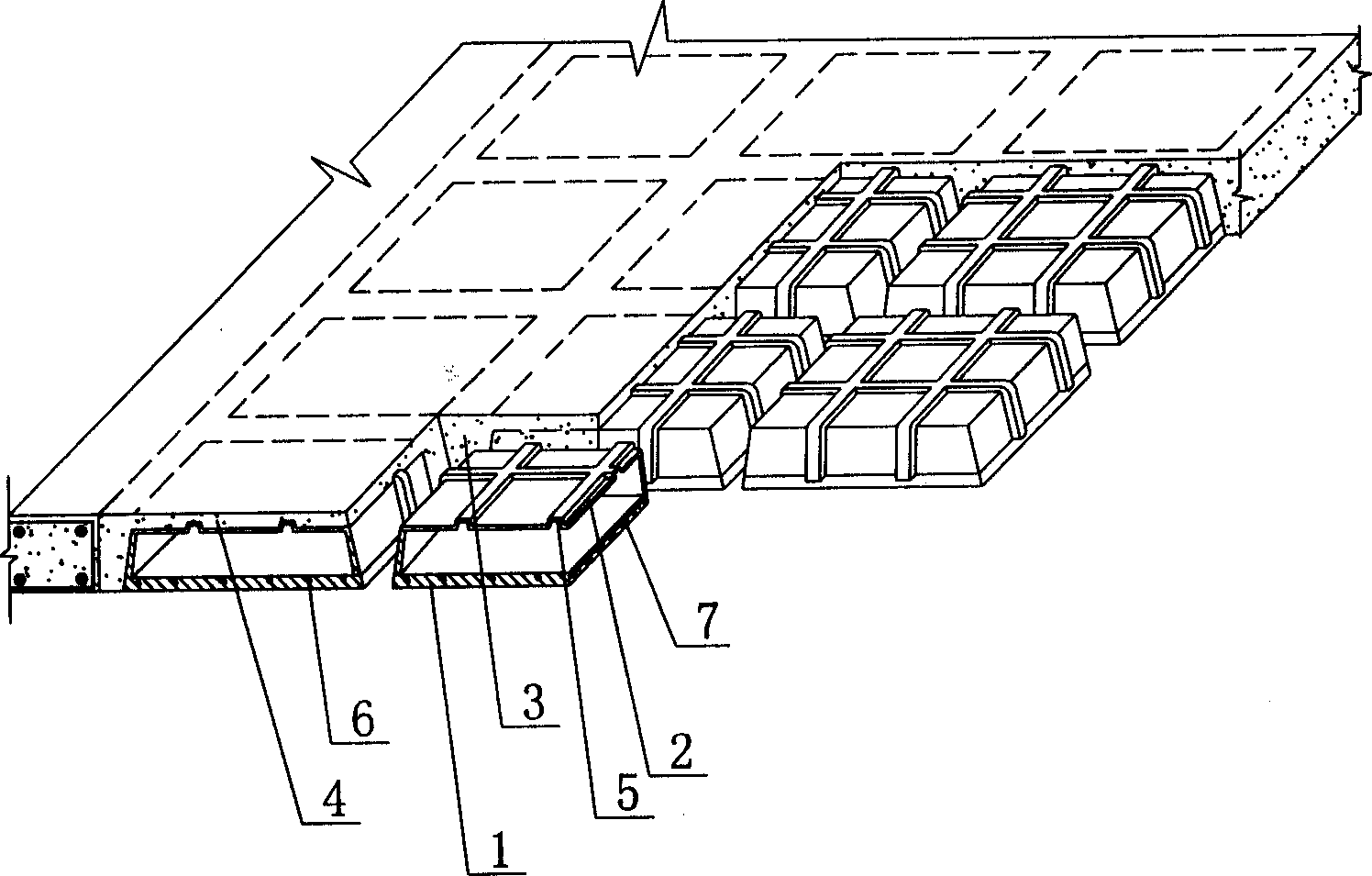

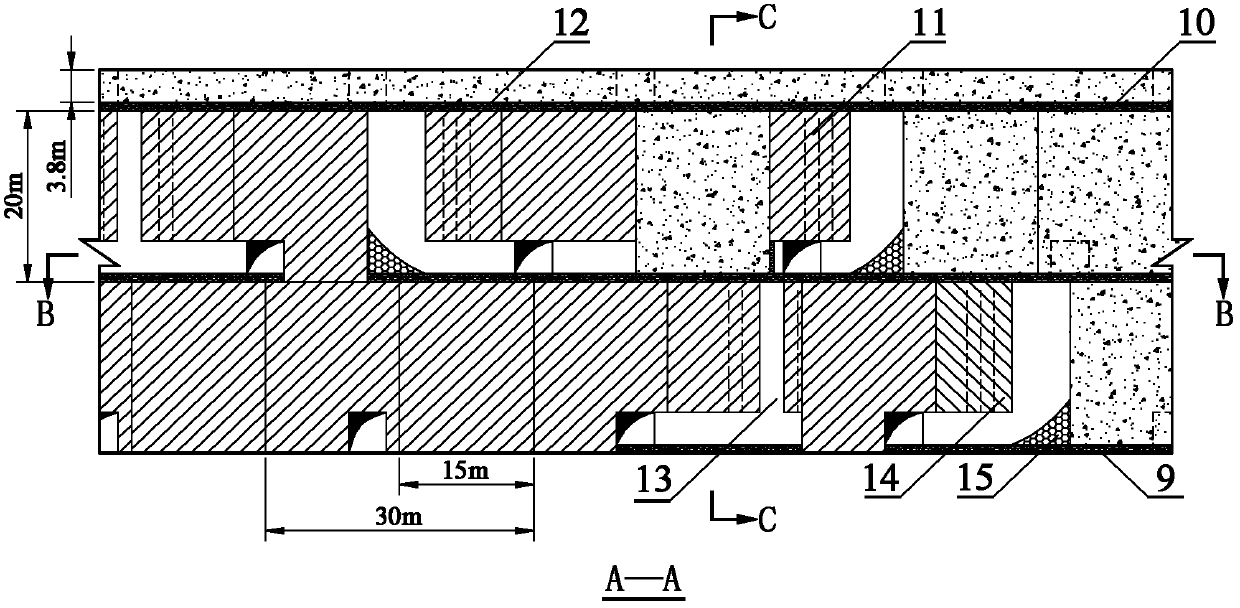

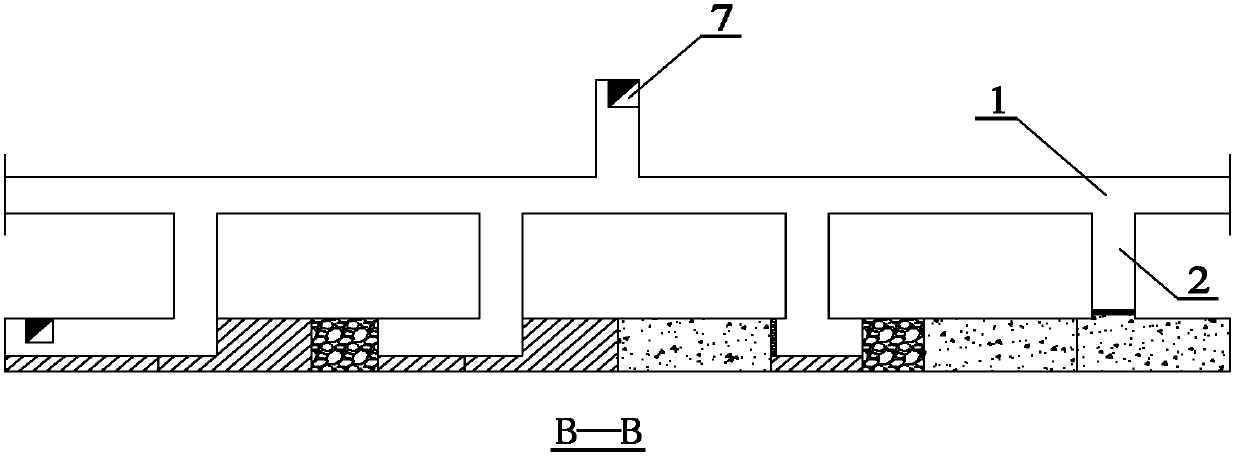

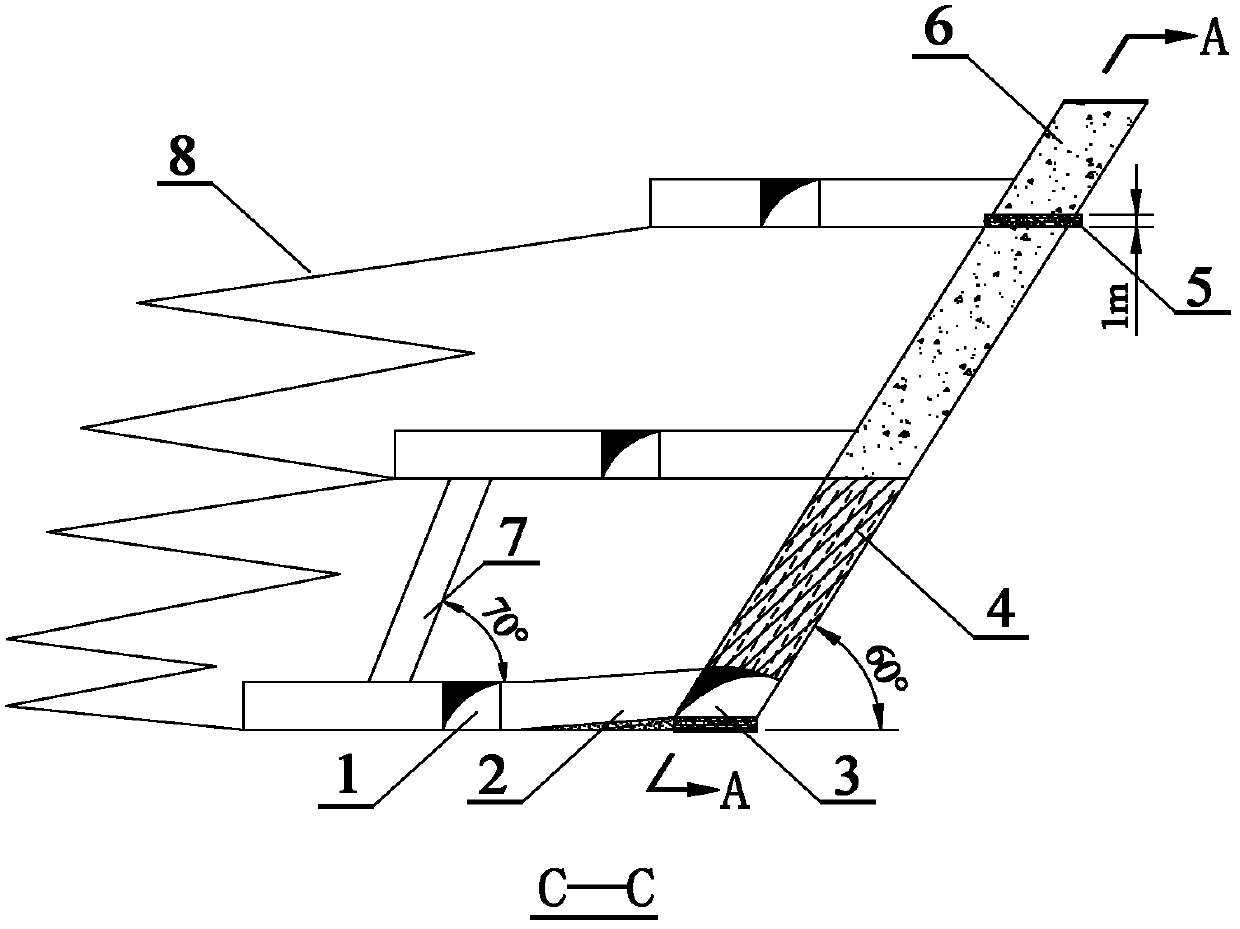

Hollow floor slab with hidden and dense ribs

The floor slab includes bottom plate, hollow form board, in-situ steel bar reinforced concrete hidden ribs and in-situ steel bar reinforced concrete upper plate; and features that the structure bottom plate and hollow form board are connected to form polyhedral structure and that there are reinforcing ribs in the hollow form board. Owing to the structural bottom plate and hollow form board connected into one integral and the hollow form board with reinforcing ribs, the hollow member for the floor slab with hidden and dense ribs has high strength and rigidity and not easy to break, and the floor slab has simple structure, high strength, light weight and easy construction.

Owner:湖南邱则有专利战略策划有限公司

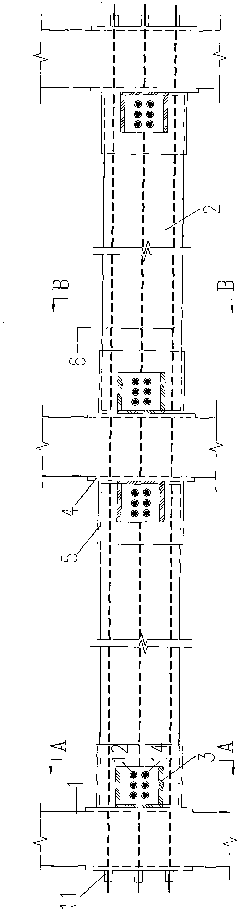

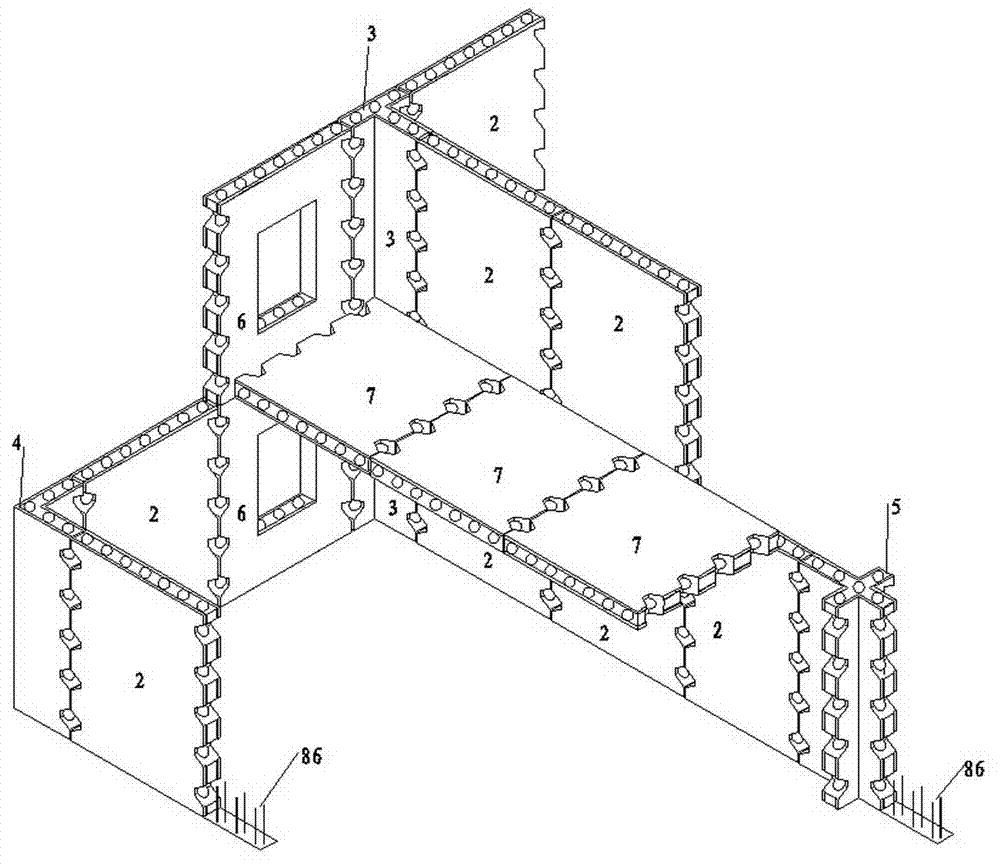

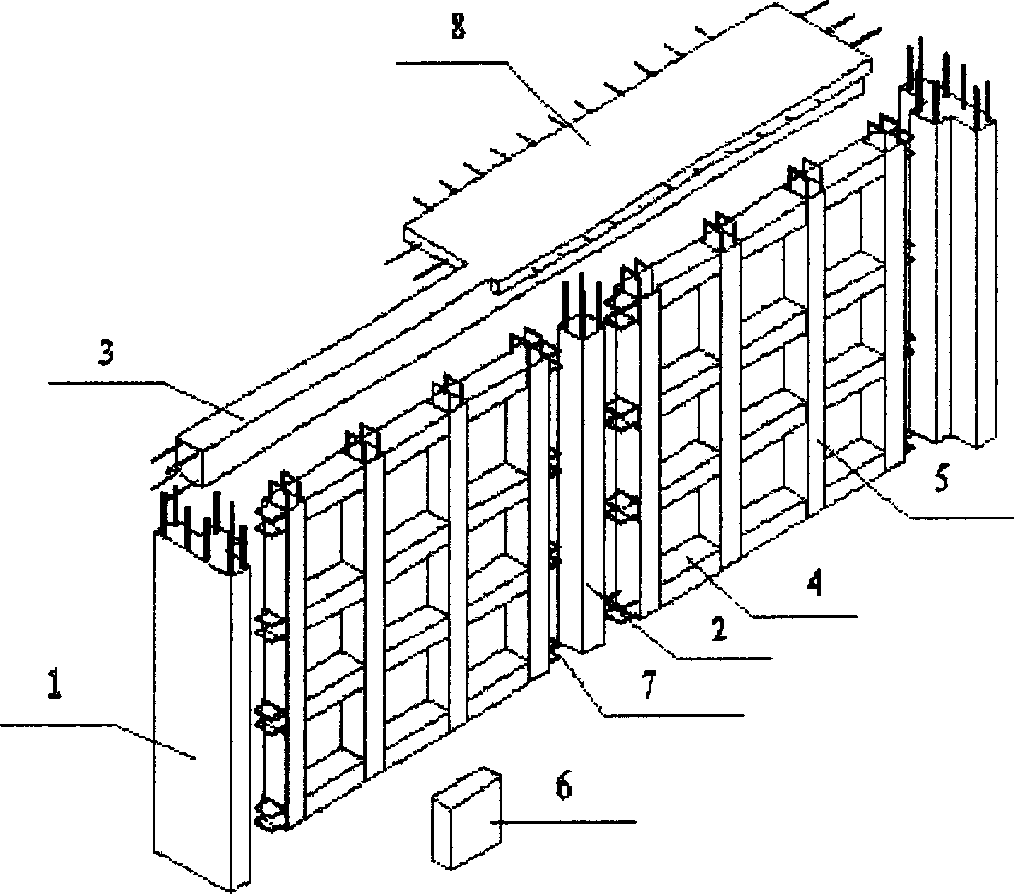

Assembled monolithic shear wall building structure and construction method thereof

InactiveCN102808450AImprove the level of industrializationIncrease productivityConstruction materialWallsTransverse grooveCross wall

The invention relates to an assembled monolithic shear wall building structure and a construction method thereof, and belongs to the technical field of buildings and construction thereof. The assembled monolithic shear wall building structure is formed by connecting prefabricated concrete members which comprise a prefabricated wall plate member, a floor member, a T-shaped wall column member, an L-shaped wall column member, a cross wall column member and a wall member with an opening. The structure is characterized in that a plurality of longitudinal through holes which are parallel to the surface are formed in each prefabricated concrete member; transverse grooves crossed with at least one longitudinal hole are formed on the longitudinal edge at intervals; transverse anchoring steel bars are arranged at the transverse grooves among different prefabricated members; longitudinal anchoring steel bars are arranged in the longitudinal holes; a layer of structural unit or a single-layer building structure is formed by filling concrete in the longitudinal holes and the transverse grooves; and a plurality of structural units are connected to form a multi-layer or high-rise assembled monolithic shear wall structure. The structure can be used in a multi-layer or high-rise shear wall building structure and a frame-shear wall building structure, the industrial level of the building structure can be improved, stress performance is improved, and resources are saved.

Owner:初明进

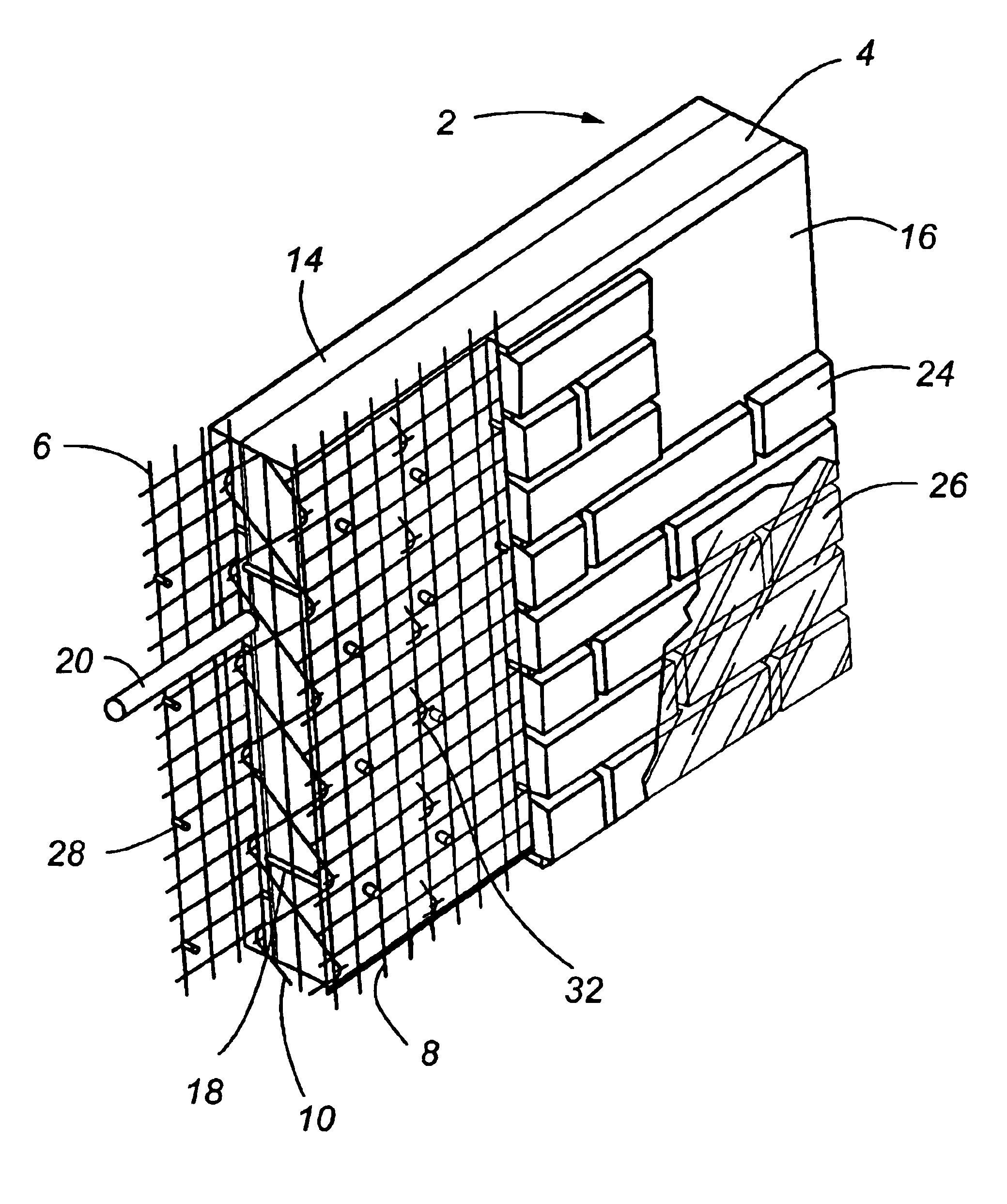

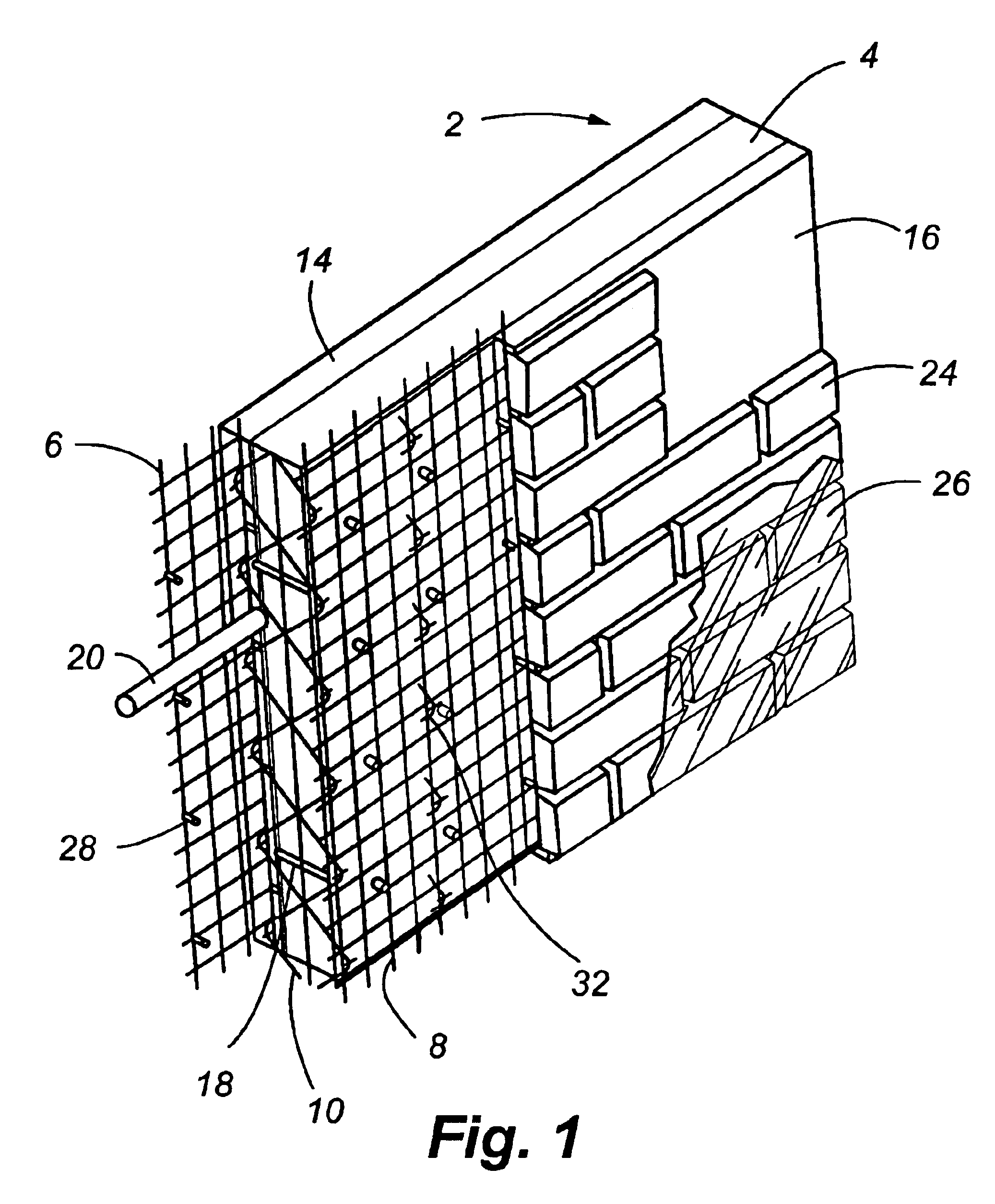

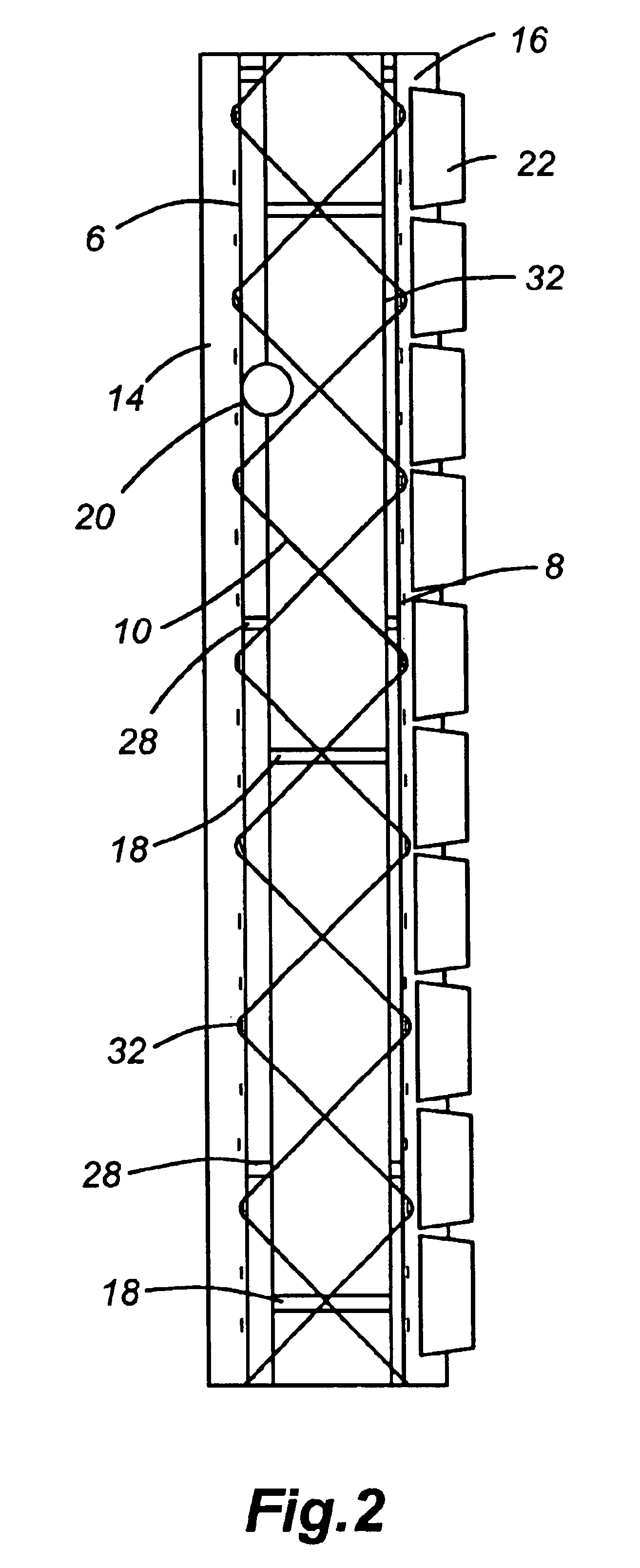

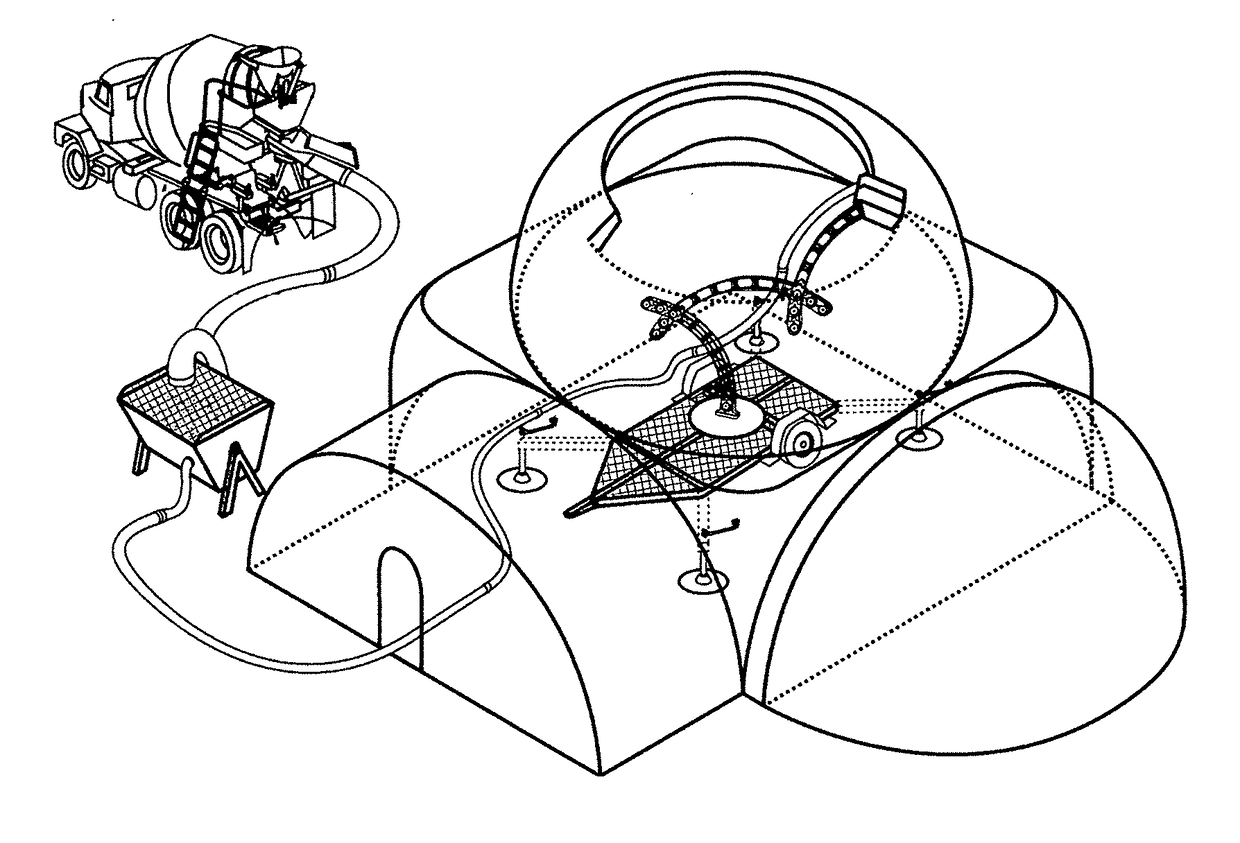

Method of reinforced cementitious constrauction by high speed extrusion printing and apparatus for using same

ActiveUS20180071949A1Low costAdditive manufacturing apparatusConstruction materialReinforced concreteBrick

The present invention relates to methods and apparatuses for an automated reinforced concrete construction system for onsite slip-form molding and casting a variety of cementitious mixes in a cast in place leave in place externally moldable flexible reinforced containment sleeve providing a wide variety of interchangeable full-scale molding configurations simultaneously optimizing a wide variety of cementitious mix curing characteristics, further having optional internal reinforcement net(s), for layer wise interlocking additive printed brick deposition providing improved slip-form mold casting of a wide variety of reinforced concrete structures; the present invention further includes a variety of operating platforms suitable for on and offsite construction as disclosed herein.

Owner:ARMATRON SYST LLC

Quick supporting method for large-deformation roadway easy to fall, break and loosen and apparatus thereof

InactiveCN101852083AImprove stress statusStop looseningUnderground chambersMine roof supportsFiberSupporting system

The invention discloses a quick supporting method for large-deformation roadway easy to fall, break and loosen and an apparatus thereof. The method comprises the following steps of: (1) clearing away the loose stones on the wall of the surrounding rock of the roadway; (2) hanging a reinforcing steel bar mesh along the digging outline of the roadway and initially spraying one thin concrete layer; (3) arranging an anchor rod in the drill hole of the roadway wall; (4) arranging a side-wall steel grating arch to support the surrounding rock of the side wall; (5) arranging a top-supporting steel grating arch, touching the top and supporting the upper surrounding rock; (6) clearing away the floating slag at the bottom of the roadway, arranging a steel grating arch of the inverted arch, supporting and sealing the system into a ring; (7) carrying out the cement injection construction on the anchor rod; (8) welding the exposed part of the cement injected anchor rod on the steel grating arch to form a whole structure; and (9) multi-spraying concrete or steel fiber concrete along the roadway wall. The apparatus comprises an anchor rod, a side-wall steel grating arch, a steel grating arch of top arch, a steel grating arch of inverted arch, and a concrete spray layer of reinforcing steel bar. The invention has the advantage of remarkable support effect, simple method and convenient operation and solves the problem that the bracket and the surrounding rock are not adhered tightly.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

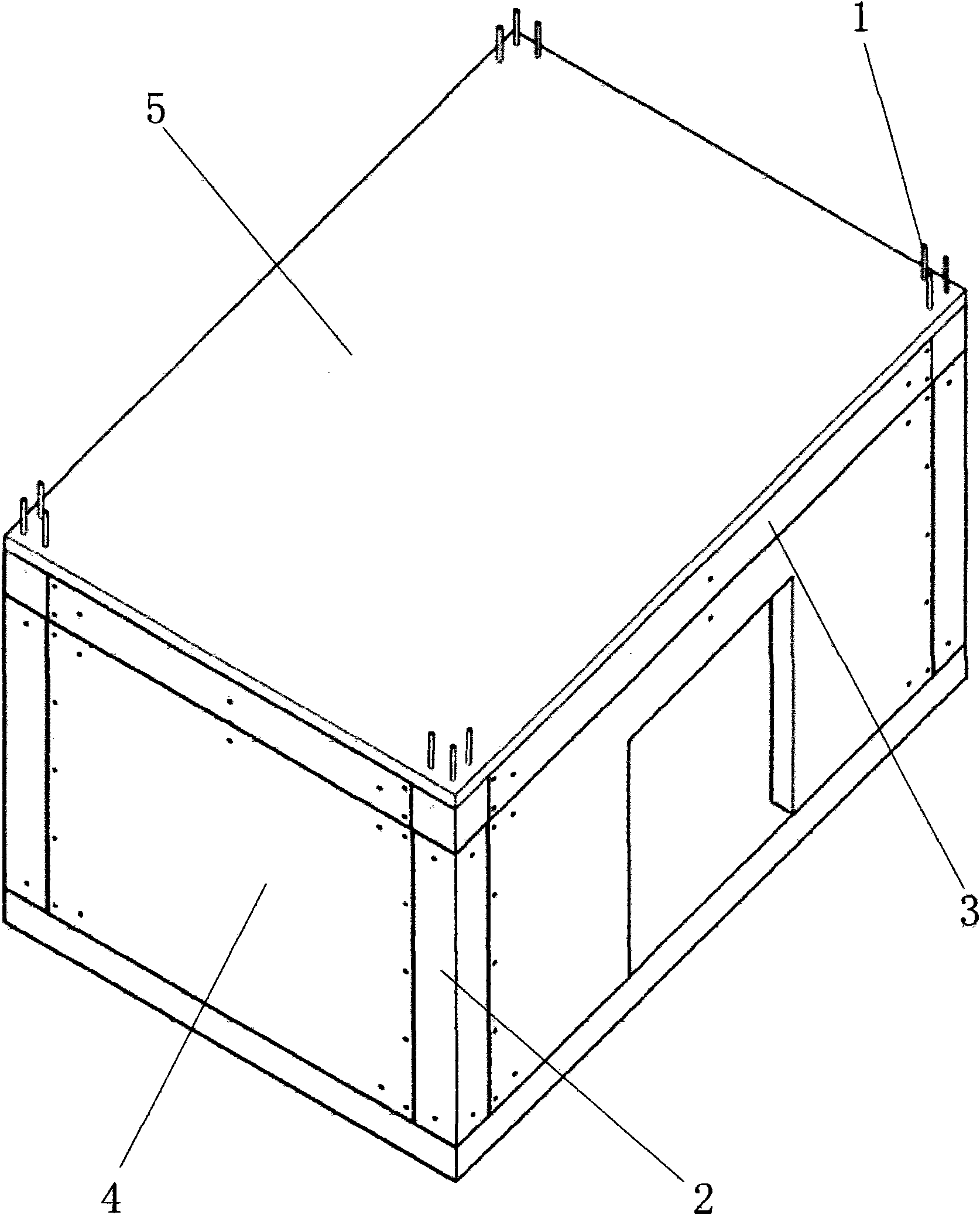

Full-fabricated assembly overall reinforced concrete house and building method thereof

InactiveCN101806095ASmall sizeNo secondary plastering requiredBuilding material handlingFloor slabReinforced concrete

The invention discloses a full-fabricated assembly overall reinforced concrete house which comprises a plurality of column ribs arranged at intervals and respectively and fixedly connected with a foundation, a plurality of column bodies prefabricated in a modularized way, a plurality of wall bodies prefabricated in the modularized way, and a floor slab prefabricated in the modularized way. The invention aims to overcome the defects of the prior art, and improve the full-fabricated assembly overall reinforced concrete house which has simple structure, is convenient to install, saves building materials, is quick to build, and has good overall safety performance. Another purpose of the invention is to provide a method for building the house.

Owner:ZHONGSHAN FAST LIVING PREFABTED HOUSING

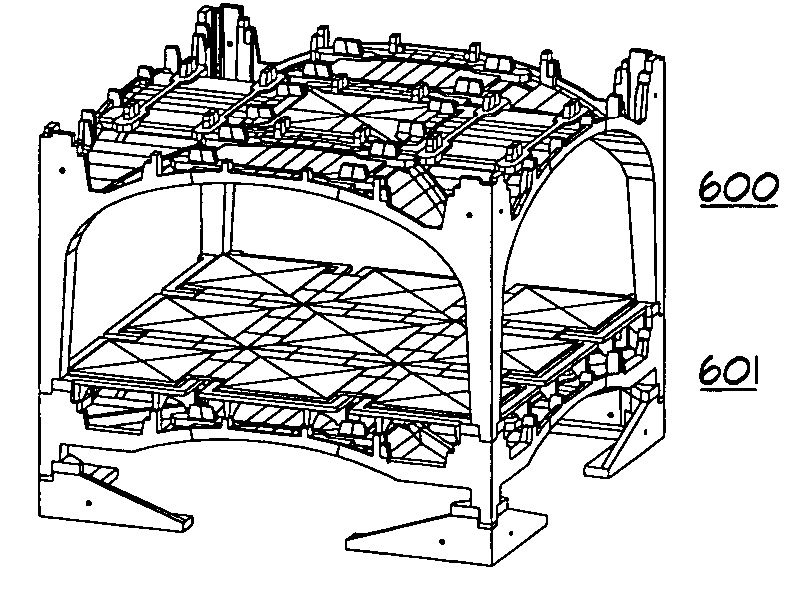

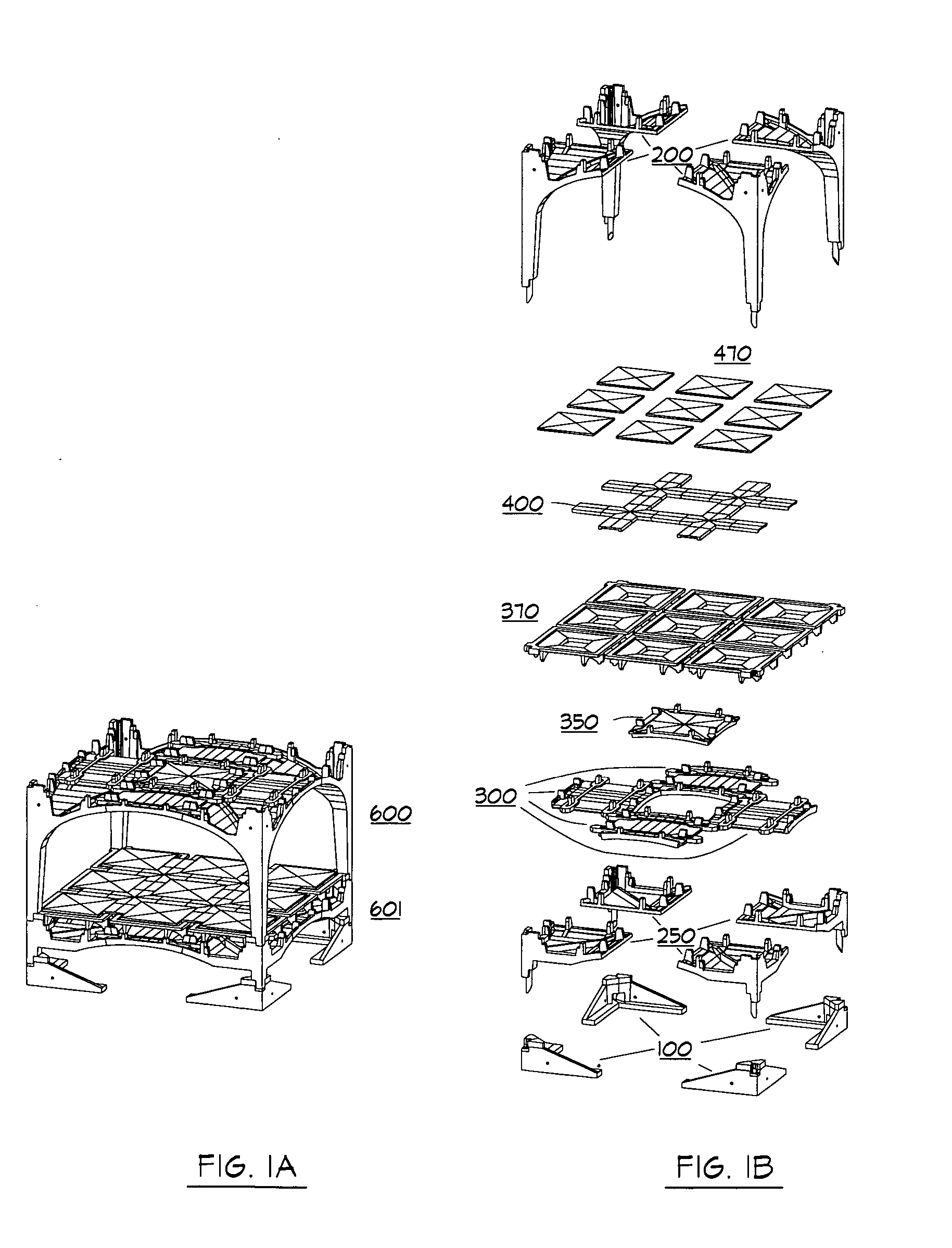

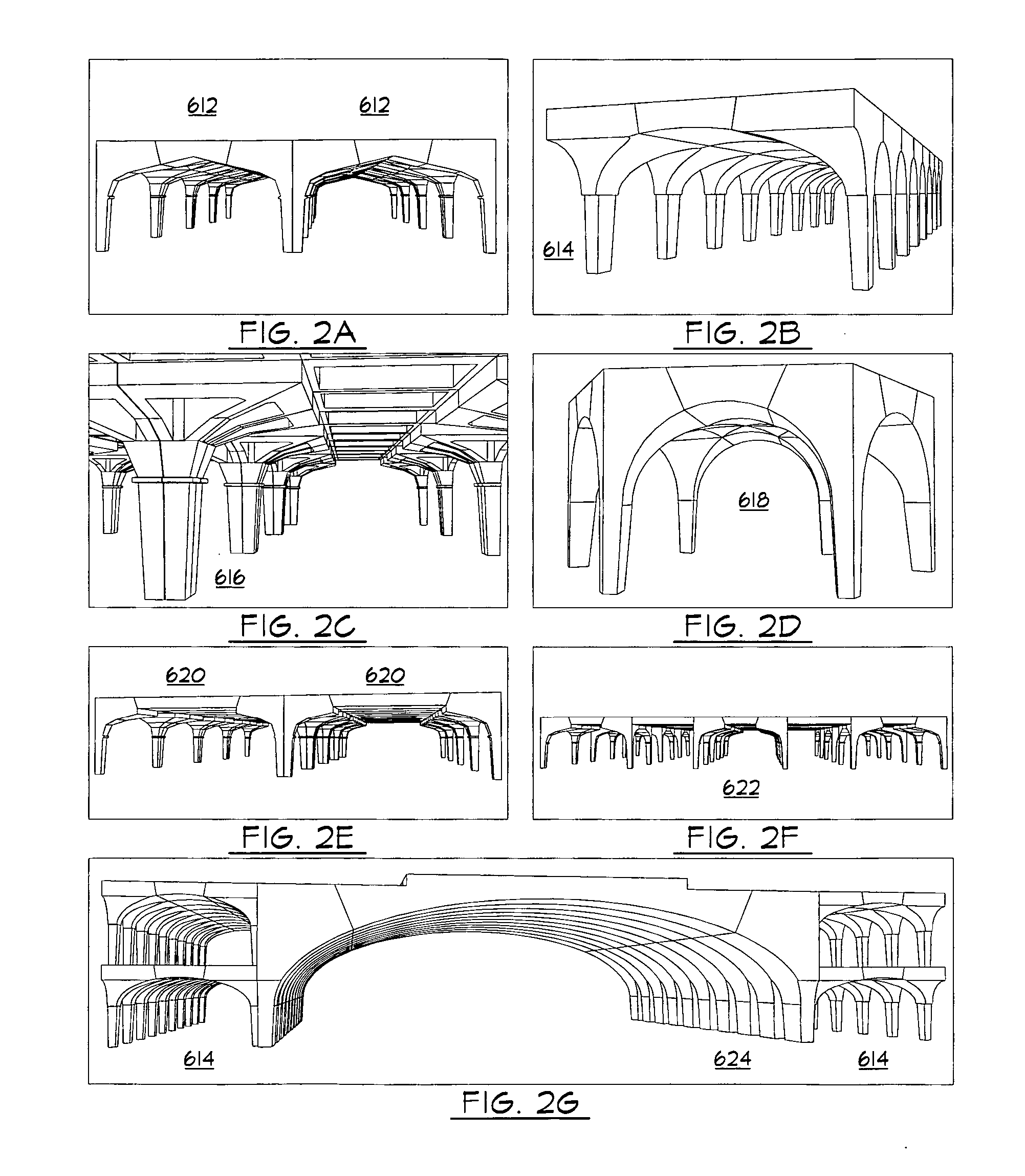

Method and system for prefabricated construction

A structure assembled from a combination of stackable modules, each module assembled from multiple prefabricated, transportable blocks. The blocks are typically reinforced cast concrete formed in reusable molds. Module framing blocks may include arched corner blocks, key blocks that interlock with a pair of corner blocks, and optional center blocks. Other structural elements include roof, floor, and wall components that interlock with the framing modules. Modules may be stacked or nested to form structures including buildings, elevated roadways, and parking garages. Utilities may be provided through optional conduits formed in the corner elements. The framing supports raised floor modules for ease in mechanical system installation and modification. The roof elements support usable terraces and rainwater collection. The blocks are demountable and reusable. The modules are self-supporting during erection, and may be assembled without fasteners.

Owner:POWELL DAVID W

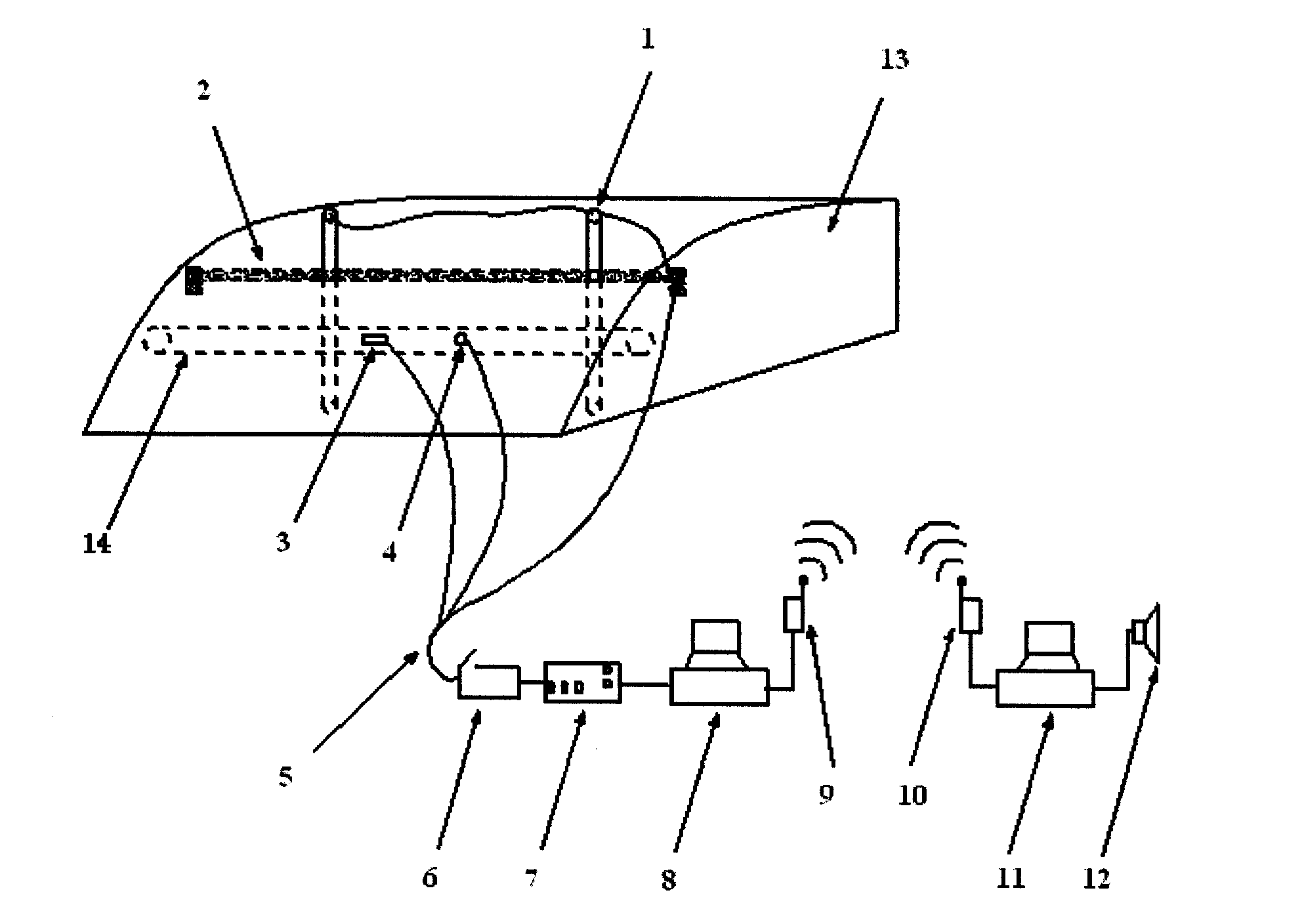

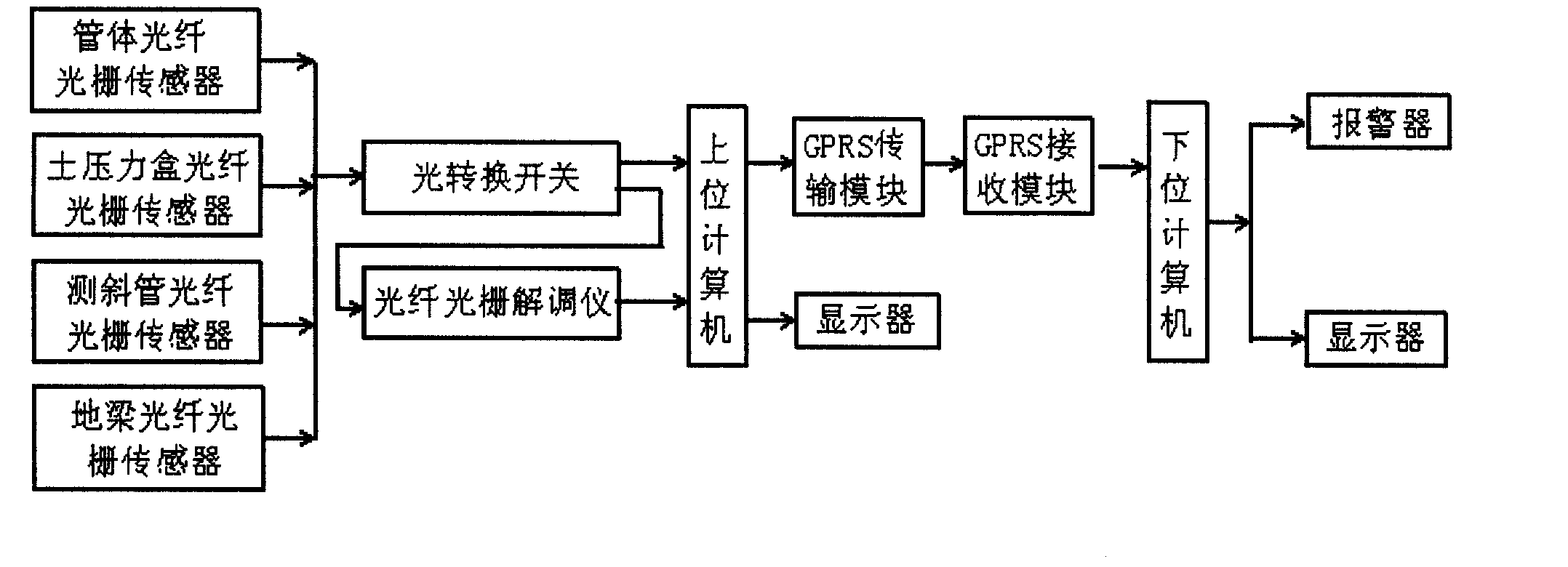

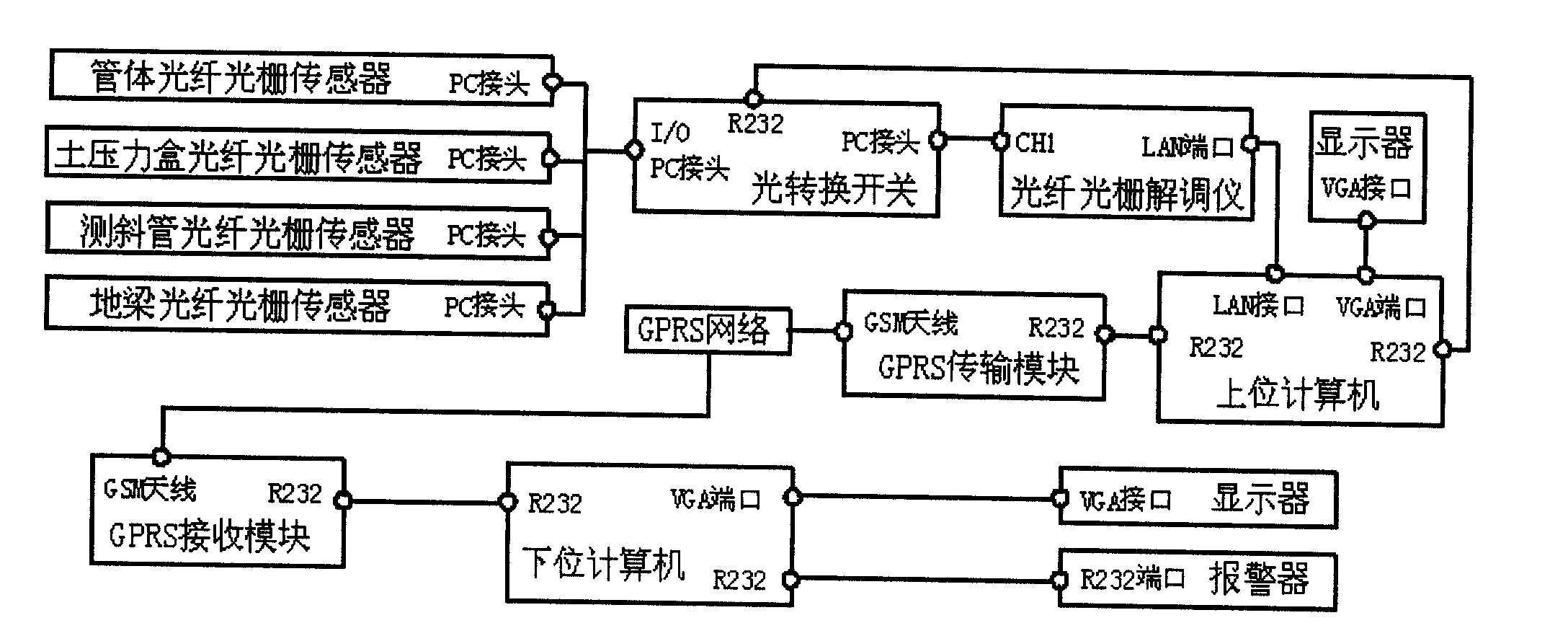

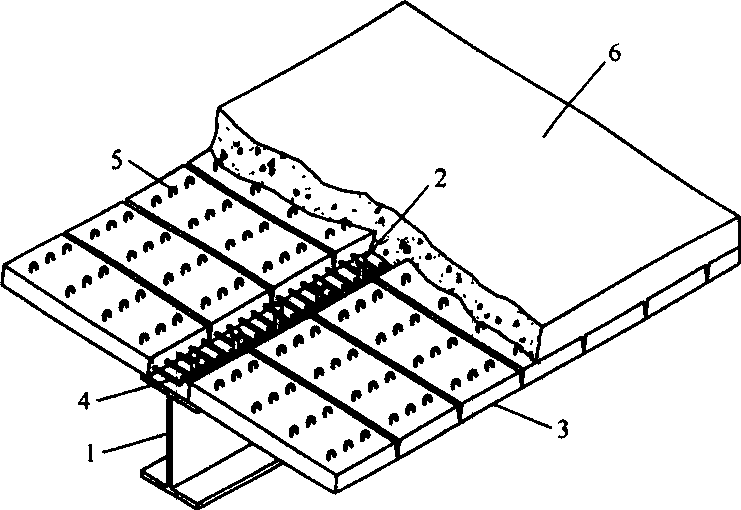

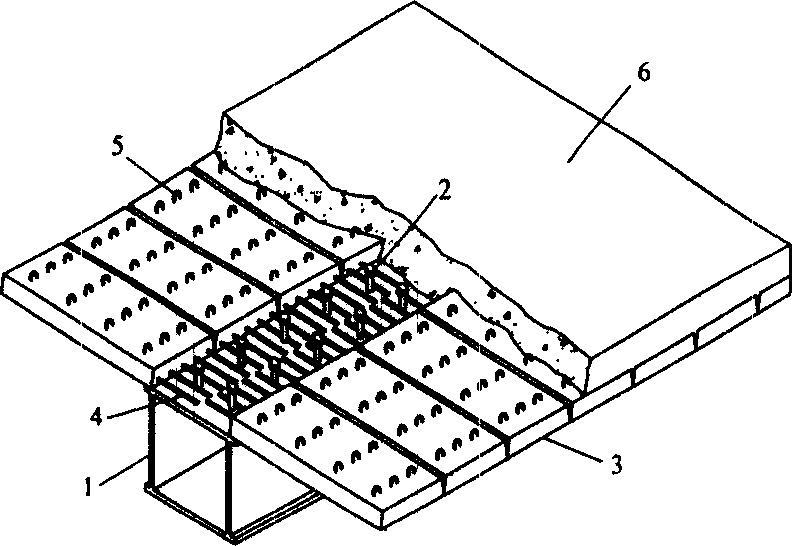

Method and system for monitoring and warning pipeline landslide and method for constructing system

ActiveCN101667324ASimple structureReduce volumeForce measurement by measuring optical property variationUsing optical meansFiberGrating

The invention relates to a method and a system for monitoring and warning a pipeline landslide based on a fiber Bragg grating and a method for constructing the system. The monitoring is performed on four parts including landslide depth displacement, landslide surface displacement, thrust of landslide on a pipeline and pipeline strain, and comprises the steps of: firstly, inserting an inclinometerpipe (1) pasted with a fiber Bragg grating sensor from the landslide (13) to all potential sliding surfaces (15); secondly, embedding a slender concrete ground beam (2) of which two ends are fixedly restrained and the axial direction of a central reinforced bar (17) is stuck to a ground beam fiber Bragg grating sensor (20) in a direction vertical to the deformation direction of the landslide (13)below the surface of the landslide (13); thirdly, measuring the thrust of the landslide (13) on the pipeline by using an earth pressure cell fiber Bragg grating sensor (4) fixed on the pipeline (14);and fourthly, arranging monitoring sections on edges on two sides and the pipeline (14) in the center of the landslide (13), and uniformly arranging three pipe strain fiber Bragg grating sensors (3) on each monitoring section to monitor the axial strain of the pipeline (14).

Owner:PIPECHINA SOUTH CHINA CO

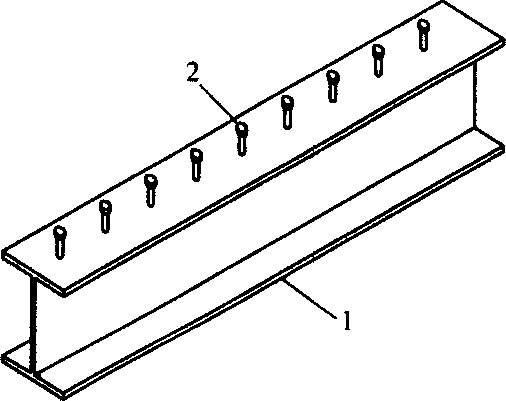

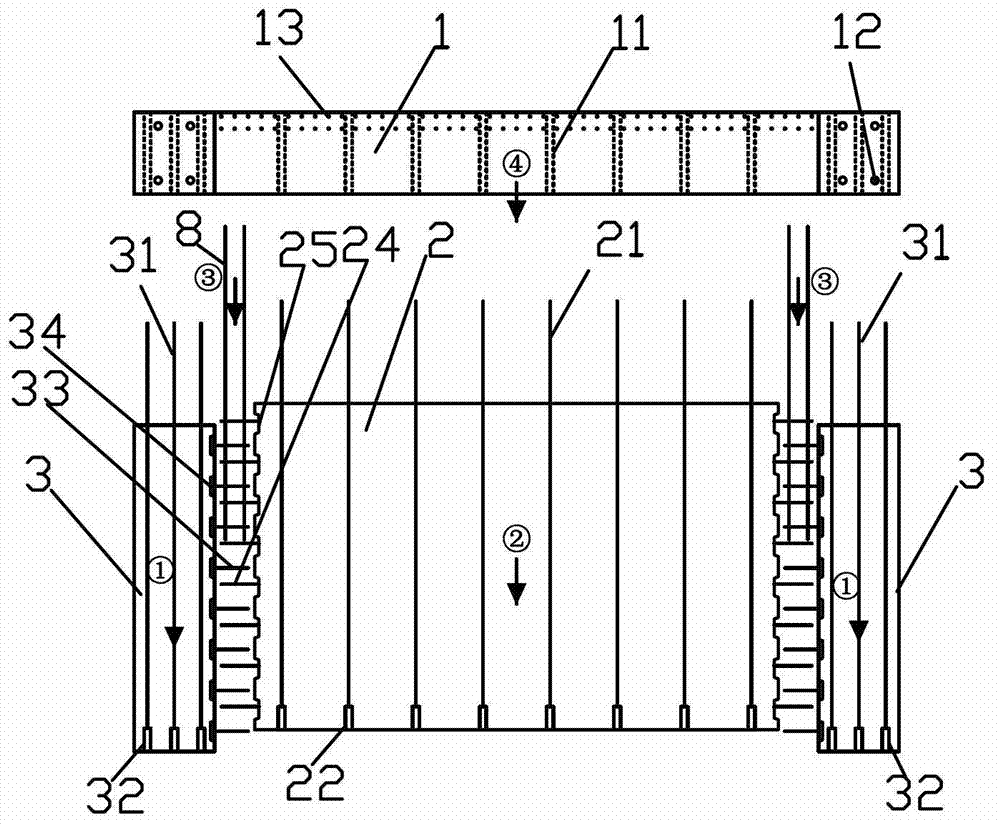

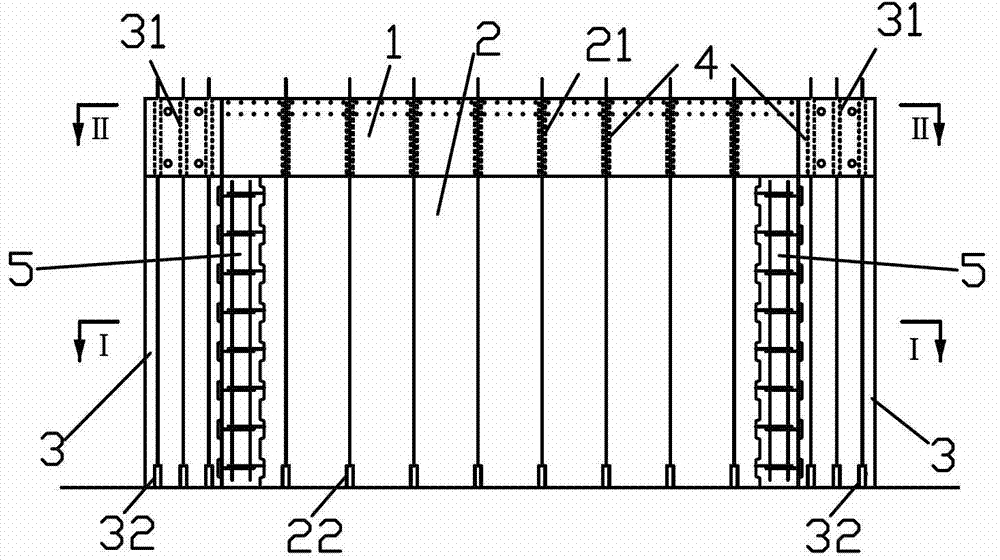

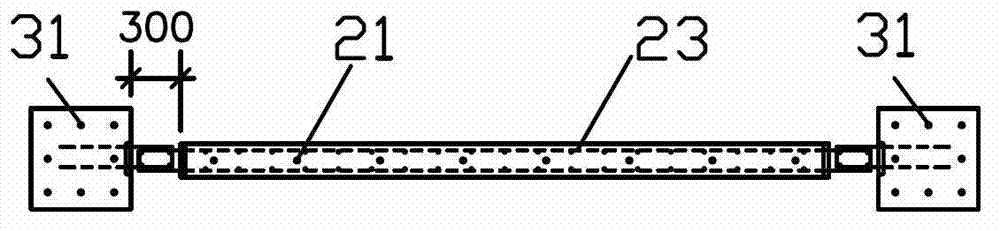

Steel-concrete folding plate combined beam

InactiveCN1587575ASolve construction difficultiesSolve complexityLoad-supporting elementsBridge structural detailsReinforced concreteEngineering

The present invention discloses one kind of combined beam of laminated steel-concrete plate for highway bridge and building as support member of bridge and building. Shear resistant connecting parts are welded to steel beam, prefabricated solid or hollow reinforced concrete boards are set on the steel beam, the steel bar tails are crossed and welded together, and the post-deposited concrete is deposited to form the combined beam. The combined beam has the advantages similar to those of in-situ deposited combined beam as well as saving in formwork and formwork supported step, simple prefabricated board structure, fast construction speed, etc. The present invention has wide application foreground in bridge structure and building structure fields.

Owner:TSINGHUA UNIV

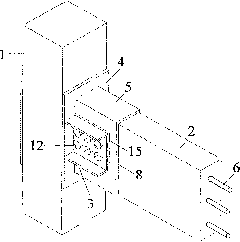

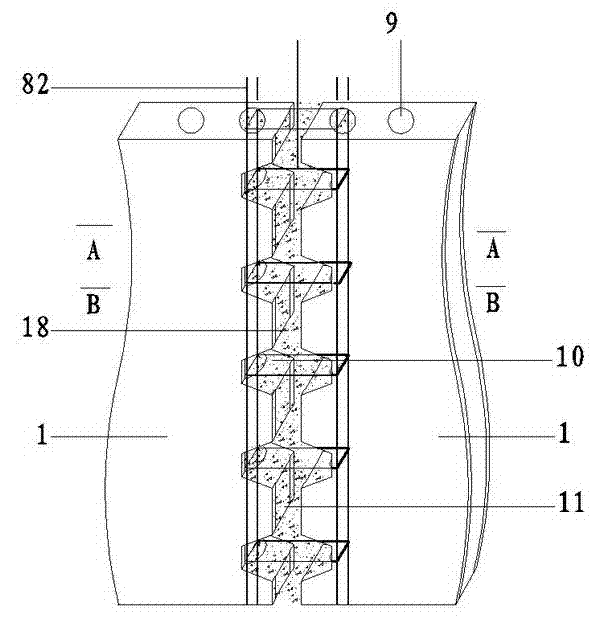

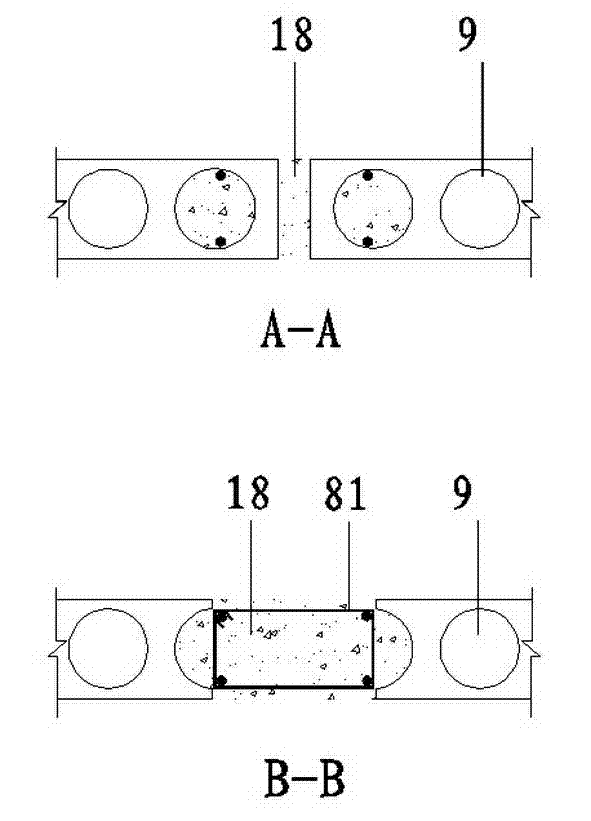

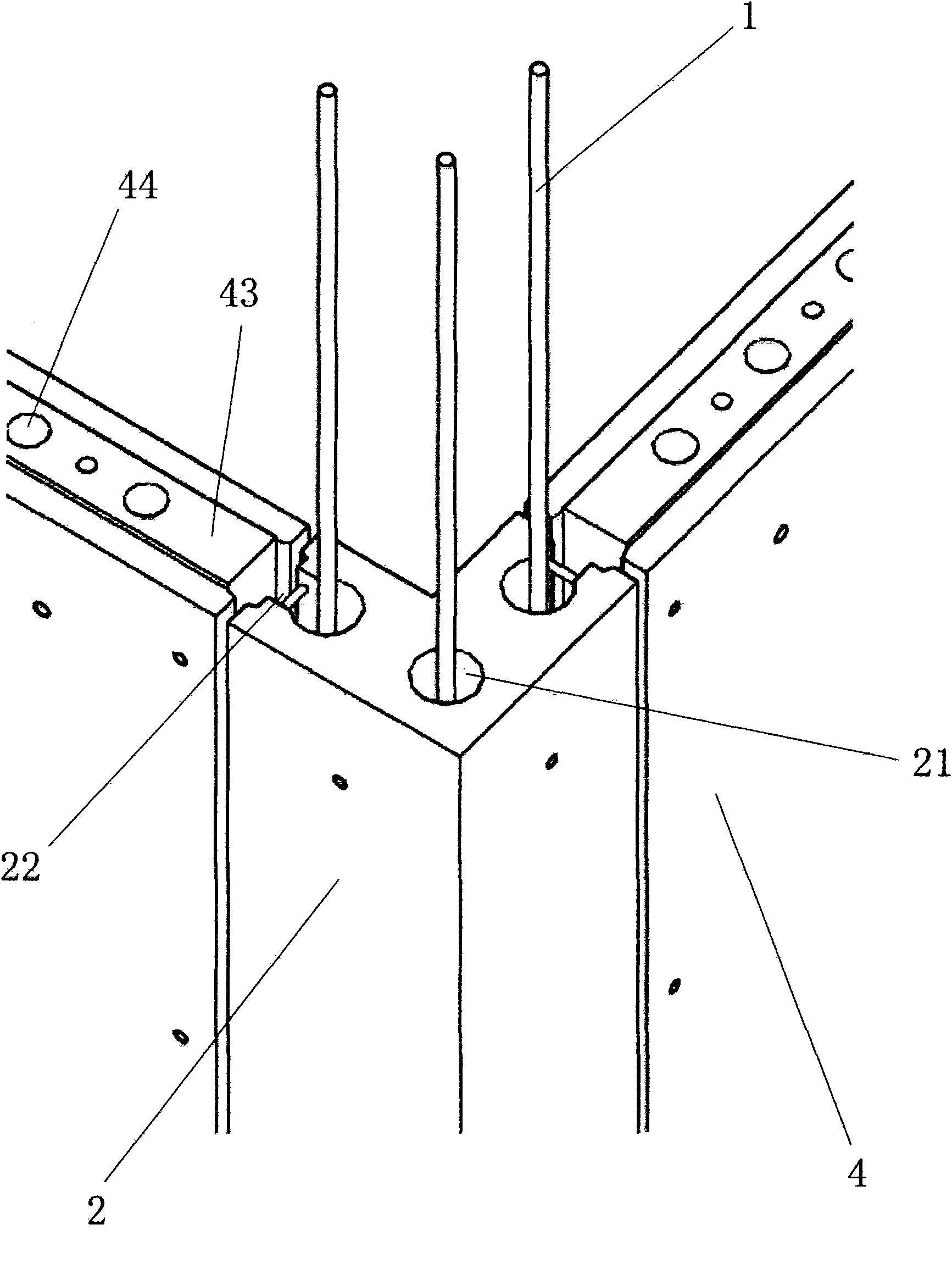

Assembly connecting structure and assembly connecting method of assembled concrete frame and shear wall combination

ActiveCN102808465ASplit location is reasonableEasy to manufactureWallsBuilding material handlingFloor slabRebar

The invention relates to the field of assembled concrete structures, in particular to an assembly connecting structure and an assembly connecting method of an assembled concrete frame and shear wall combination. A cast-in-place strip is disposed between precast columns and precast shear walls to connect column-wall embedded rebars. Vertical through holes are reserved in a precast node-precast beam integrated component to achieve communicated connection of vertical rebars for the upper and lower columns and the upper and lower shear walls. Embedded steel sleeves at the lower ends of the precast columns and the precast shear walls are mutually embedded with projecting rebar segments extending up out of the lower columns and the lower walls, and are integrated with the lower columns and the lower walls through cast mortar. The projecting straight rebars at the upper ends of the precast columns and the precast walls penetrate through the through holes reserved in the precast node-precast beam integrated component and protrude a floor slab, and the precast columns and the precast nodes are firmly integrated with the precast shear walls precast beams by cast mortar. Wet operations such as in-place casting of concrete are reduced to the maximum extent, building quality is improved, construction period is shortened, and energy conservation and emission reduction are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

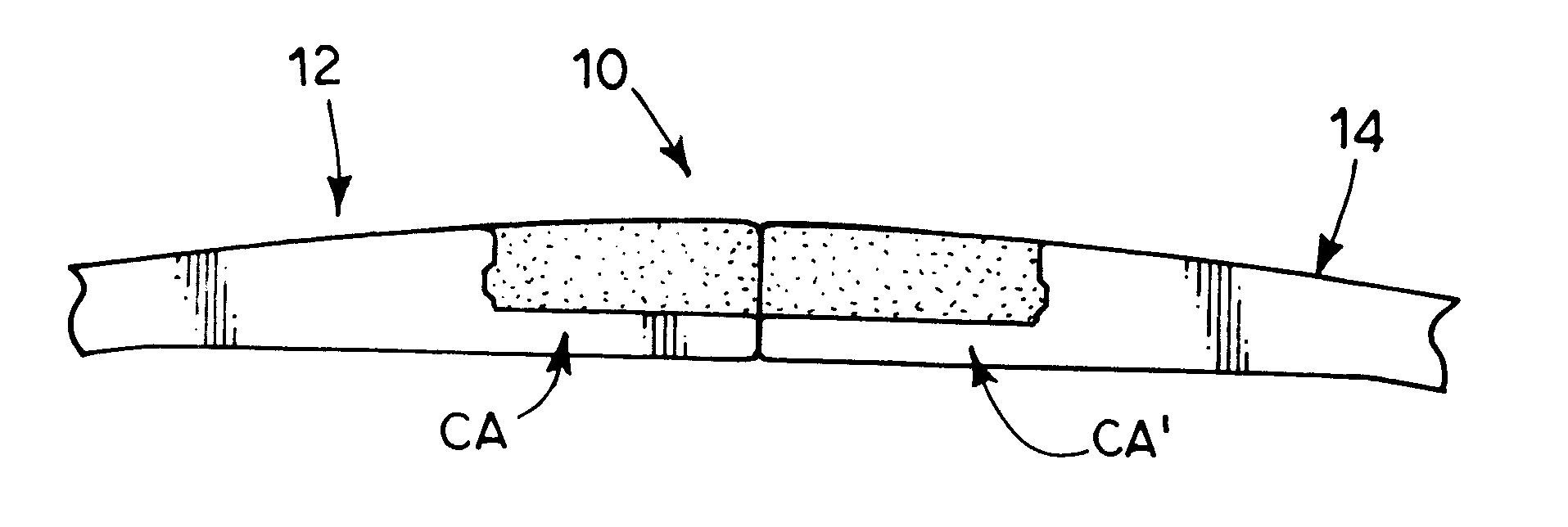

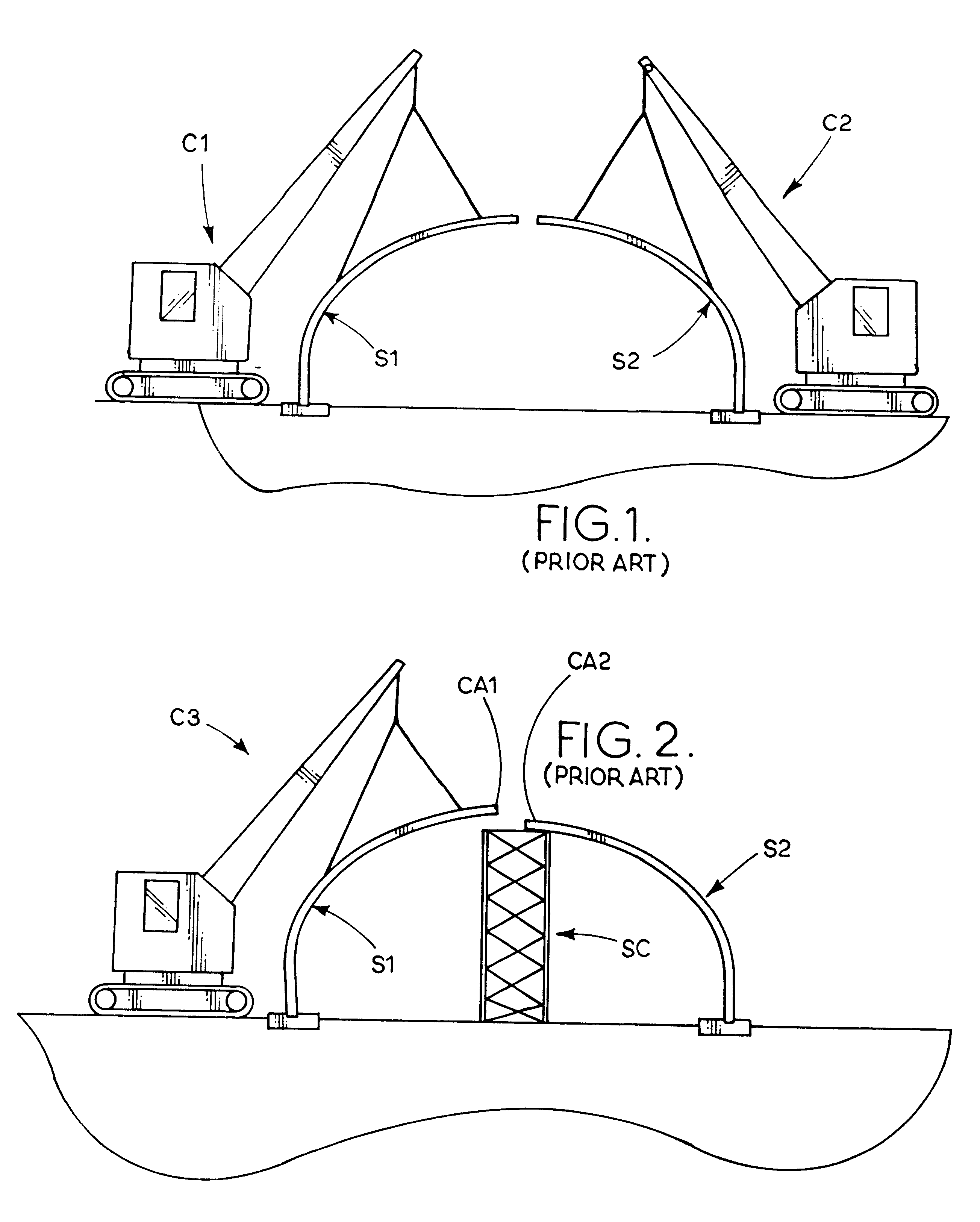

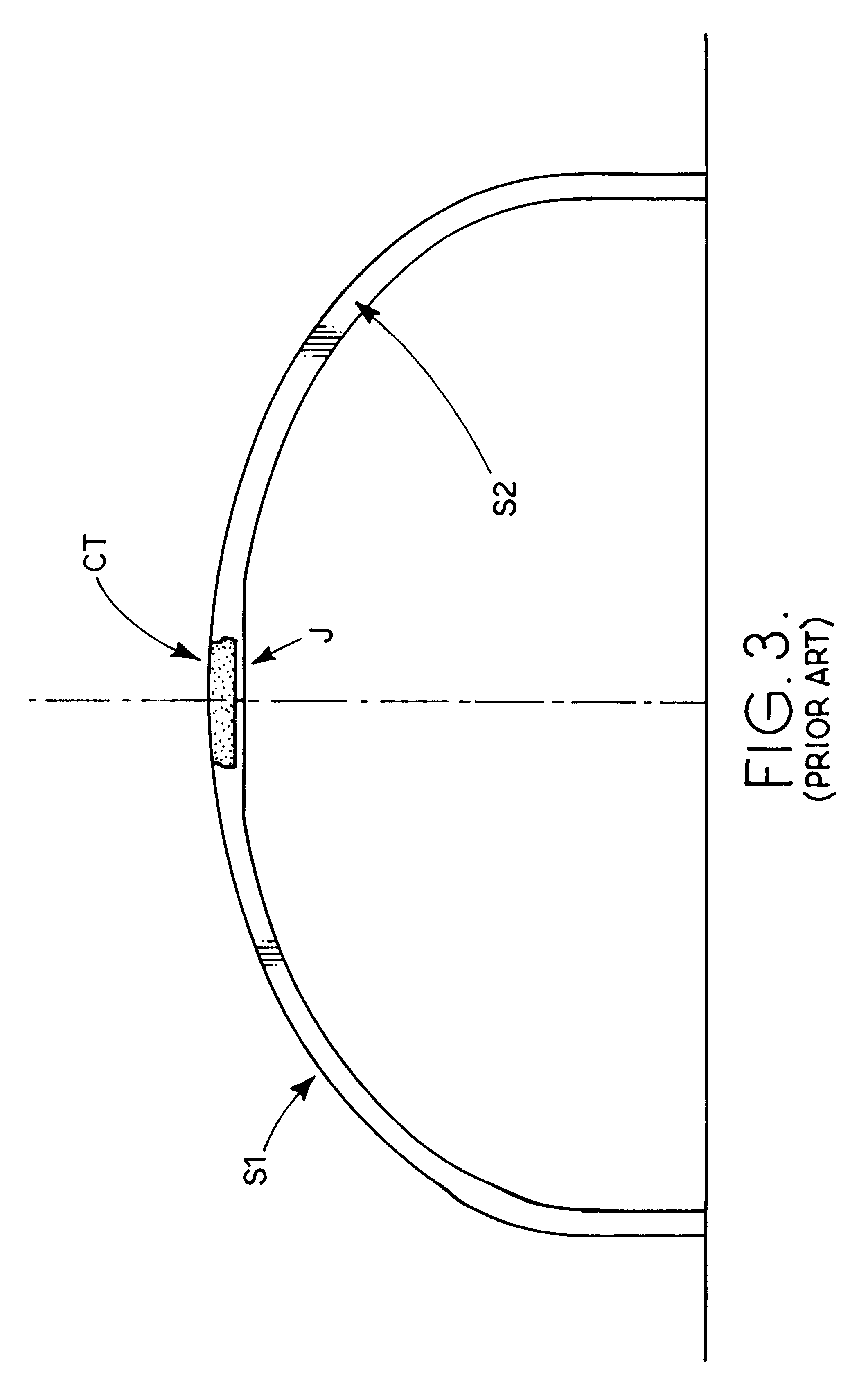

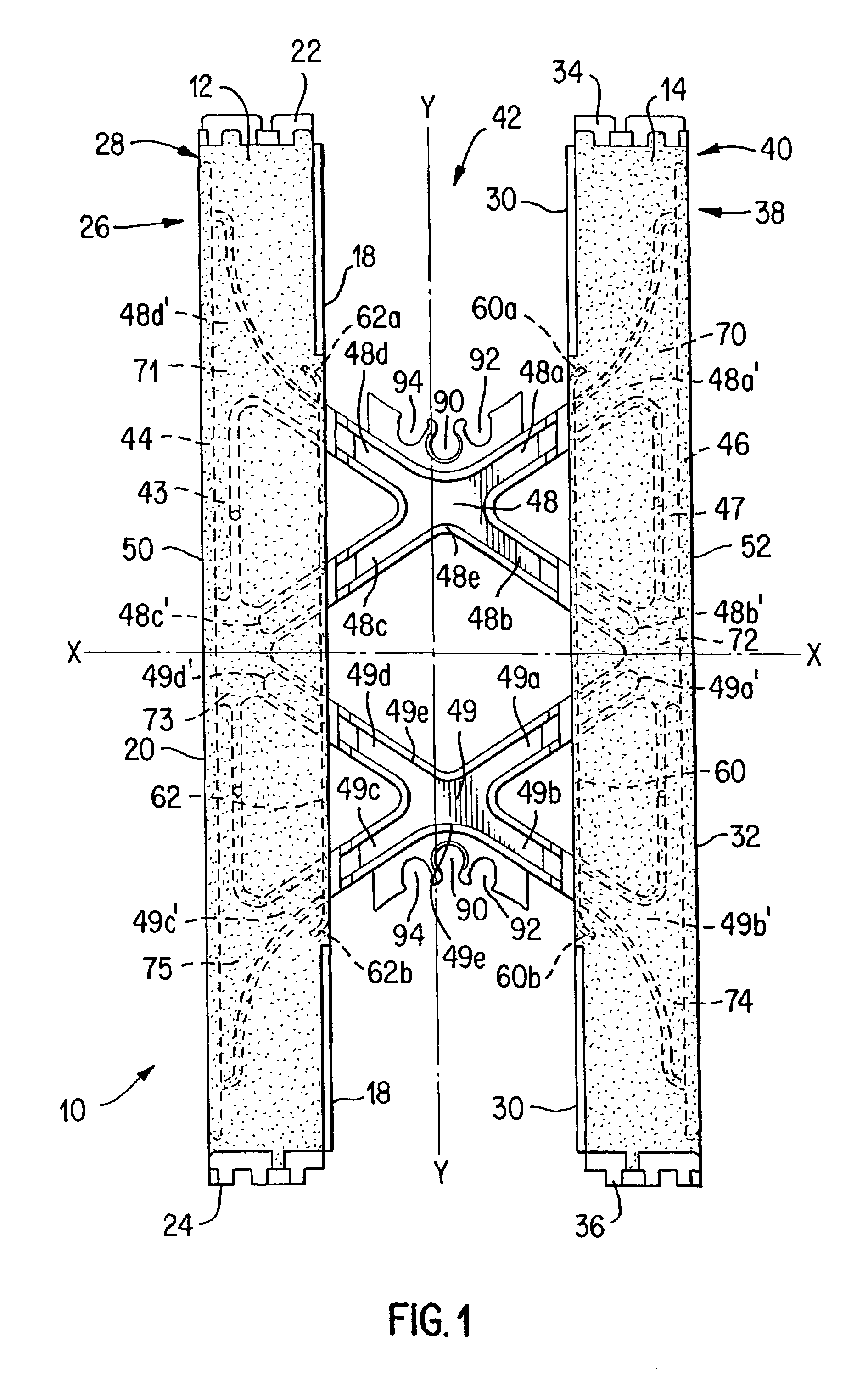

Joint for pre-cast concrete twin-leaf arch sections

InactiveUS6243994B1Efficiently and accurately formForming accuratelyUnderground chambersBuilding material handlingControl theoryPrecast concrete

A joint for pre-cast concrete twin-leaf arch sections is self-aligning when the two arch sections are initially brought into abutting contact with each other. The joint provides a rigid connection between the twin units and is achieved on site by means of re-inforced cast-in-place concrete. Reinforcement splices for the connection are lap splices, and the joint allows pouring the cast-in-place concrete without the need of formwork. For load distributing purposes, a continuous connection of individual arch rings in the longitudinal direction at the arch crown is possible. An initial abutting contact between the twin units is provided by the joint of the present invention. The contact provided by the joint of the present invention is self-aligning, locking, allows the controlled transmission of the abutting force and allows for a temporary connection. The joint includes mechanical elements for aligning and locking the two arch sections together. The mechanical elements include, in the preferred embodiment, a projection on one arch section and a depression on the other arch section. Cast-in-place concrete is placed in boxed-out, or step, sections located adjacent to the mechanical elements and completes the joint.

Owner:CONTECH ENGINEERED SOLUTIONS

Multi-rib structure system and its connection construction method

InactiveCN1804263AAchieve graded releaseMeet the energy-saving requirements of light buildingsWallsFloor slabPre stressing

The invention relates to a ribbed structure which comprises a ribbed composite wall plate, a hidden frame and a floor. Wherein, the ribbed composite wall plate is a network construction element formed by reinforced steel concrete and light material and divided by the reinforced steel concrete beam as rib beam and rib post in small sections with embedding light material stuffing blocks into the grid; the ribbed composite wall plate also comprises the goatee bar extending from the rib beam and rib post, which is four steel bars with certain anchoring length extending from each rib beam and post and is longitude steel bar whose end is a hook in connection to hook hidden frame; or else the goatee bars are two U-shape closed ring extending from each rob beam an post and is inserted with longitude steel bars in connection; the hidden frame is formed by outer frame post, connection post, and hidden beam which are embedded outside the ribbed composite wall plate while using common concrete, profiled bar concrete or steel structural beam and post; the stuffing material is made from light material with certain strength, volume weight and little elastic modulus; and the floor can select on-situ irrigating concrete, on-sit or prefabricated ribbed composite floor, pre-stress layered floor or special-shaped pre-stress hollow floor.

Owner:姚谦峰

Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

InactiveCN102606159AImprove efficiencyImprove securityUnderground miningTunnel/mines ventillationRoom and pillar miningReinforced concrete

The invention discloses a medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method which comprises the following steps: dividing chamber jambs along the trend of an ore body; adopting a rail-less mining aligning system; pre-constructing a high-strength reinforced concrete artificial top in a segmented drilling lane; adopting a stoping sequence from up to down; performing drilling and blasting ore removal on the ore body through the segmented drilling lane at bottom; adopting medium-length hole drilling and remotely controlling a scraper to discharge ore; after finishing the mining of the chamber, utilizing concrete tailings to perform cemented filling; after finishing the mining of the jambs, utilizing concrete tailings or pure tailings to perform cemented filling; after completely stoping the mine chamber in the frame under the protection of the concrete artificial top, starting to stope the jamb adjacent to the segment, and meanwhile stoping the corresponding mine chamber in the frame of the next segment, and then stoping the corresponding jamb of the next segment; and after completely mining the chamber jamb in the middle segment, immediately turning towards the lower middle segment for stoping. The method provided by the invention has the advantages that the safety for mining the heavy-pitch medium thick crushed or ultra-crushed ore body is high, the resource depletion loss rate is low, the mechanical degree is high, the production capacity is high, and the like.

Owner:CENT SOUTH UNIV +1

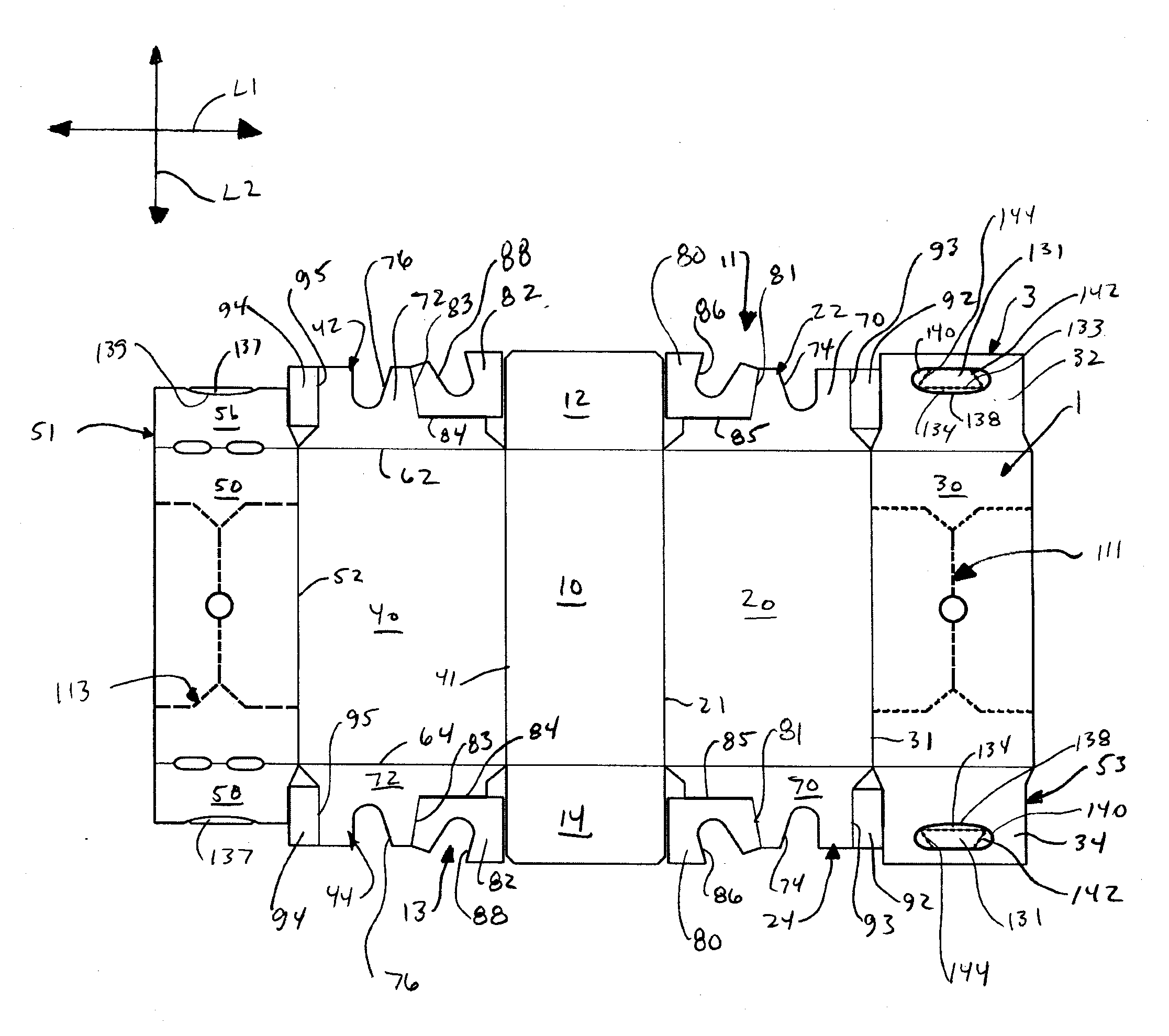

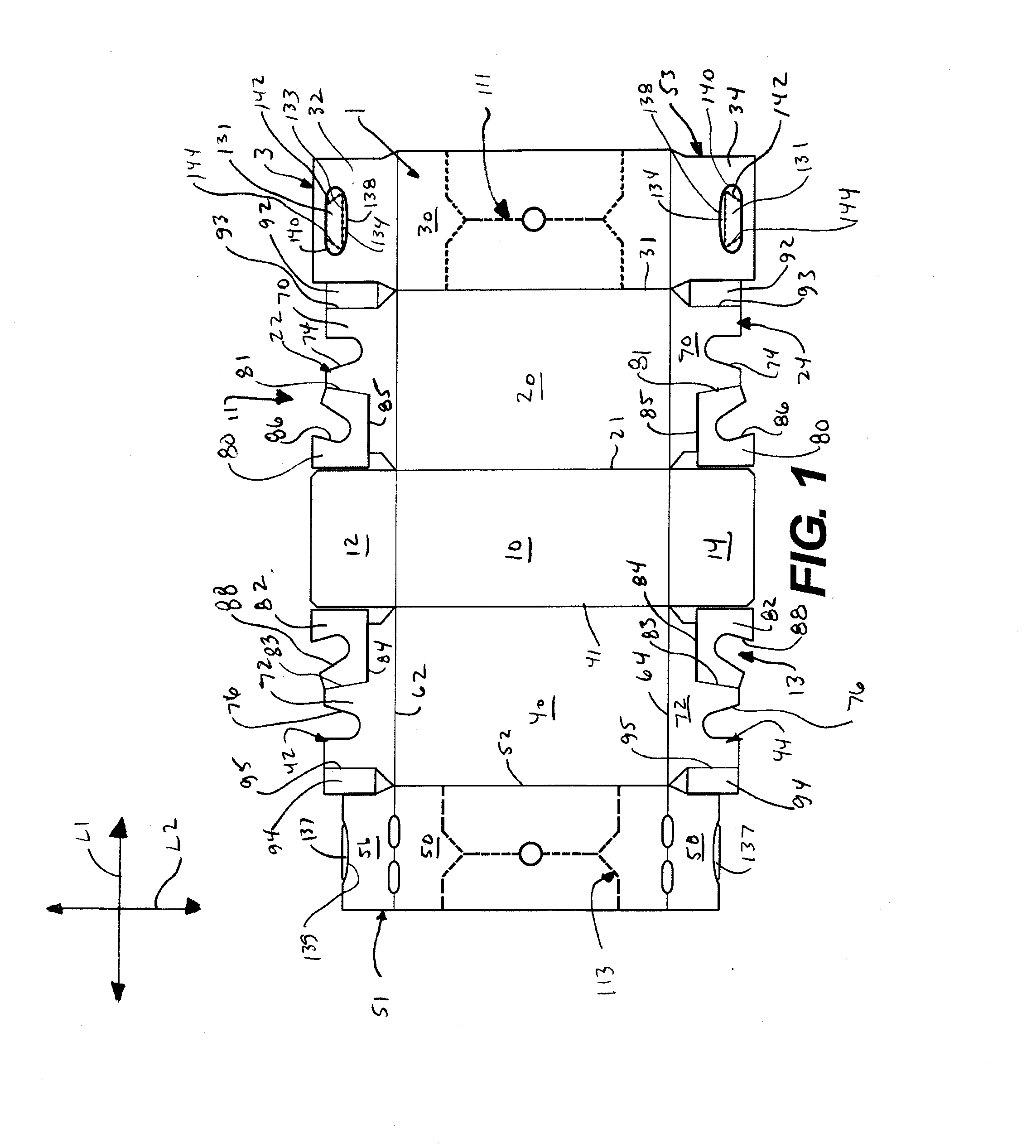

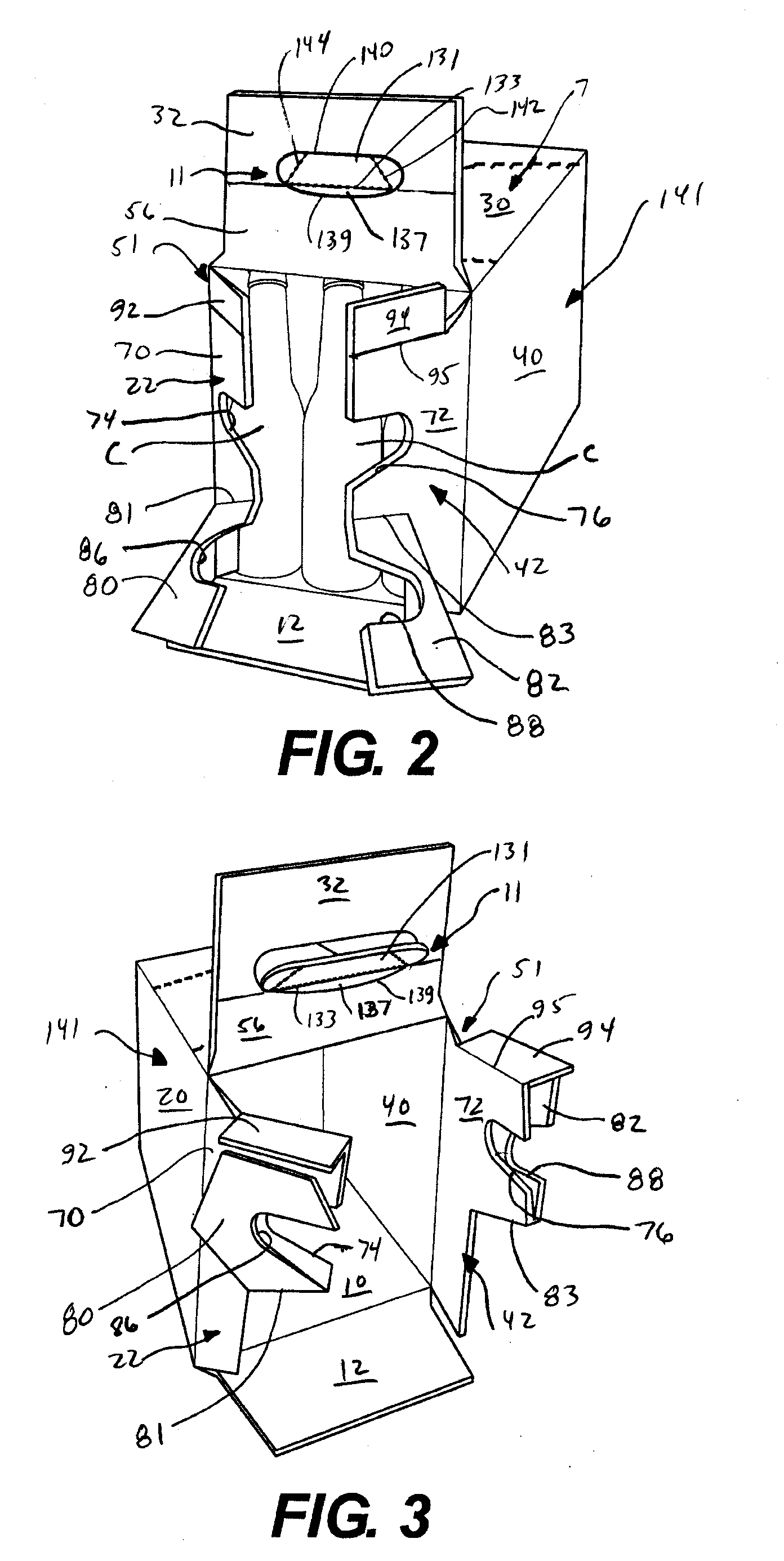

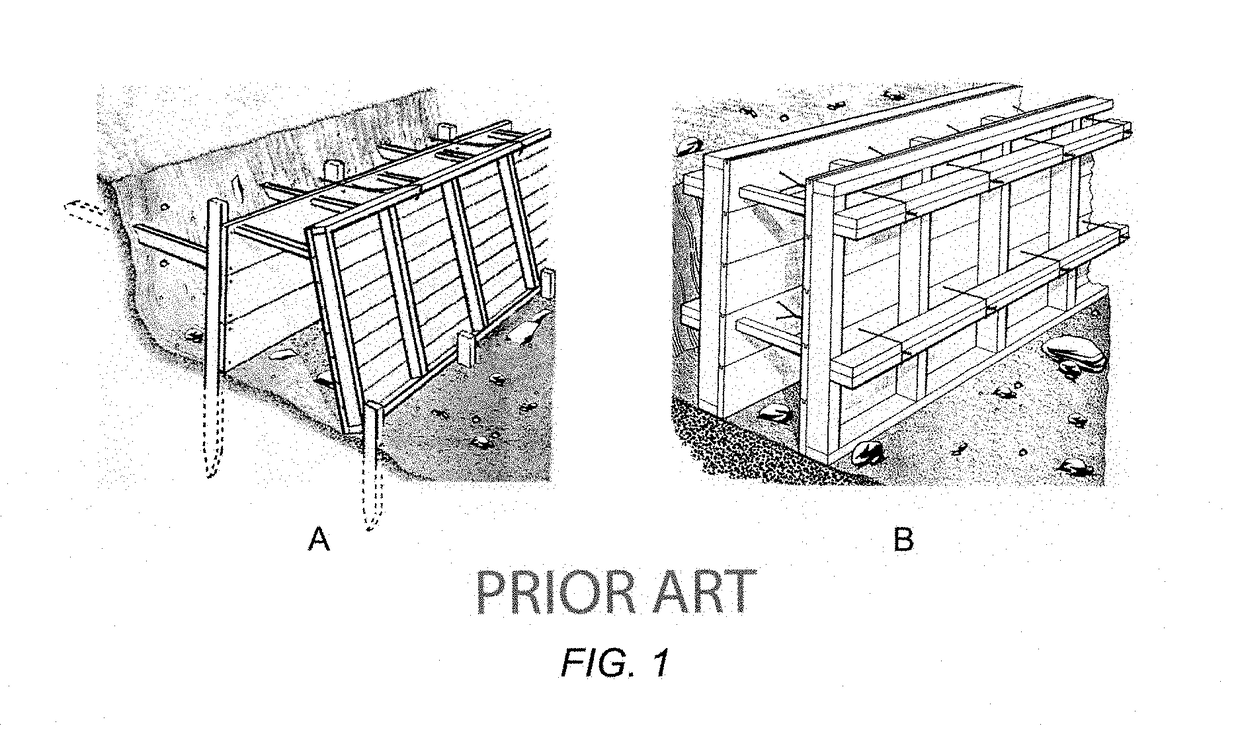

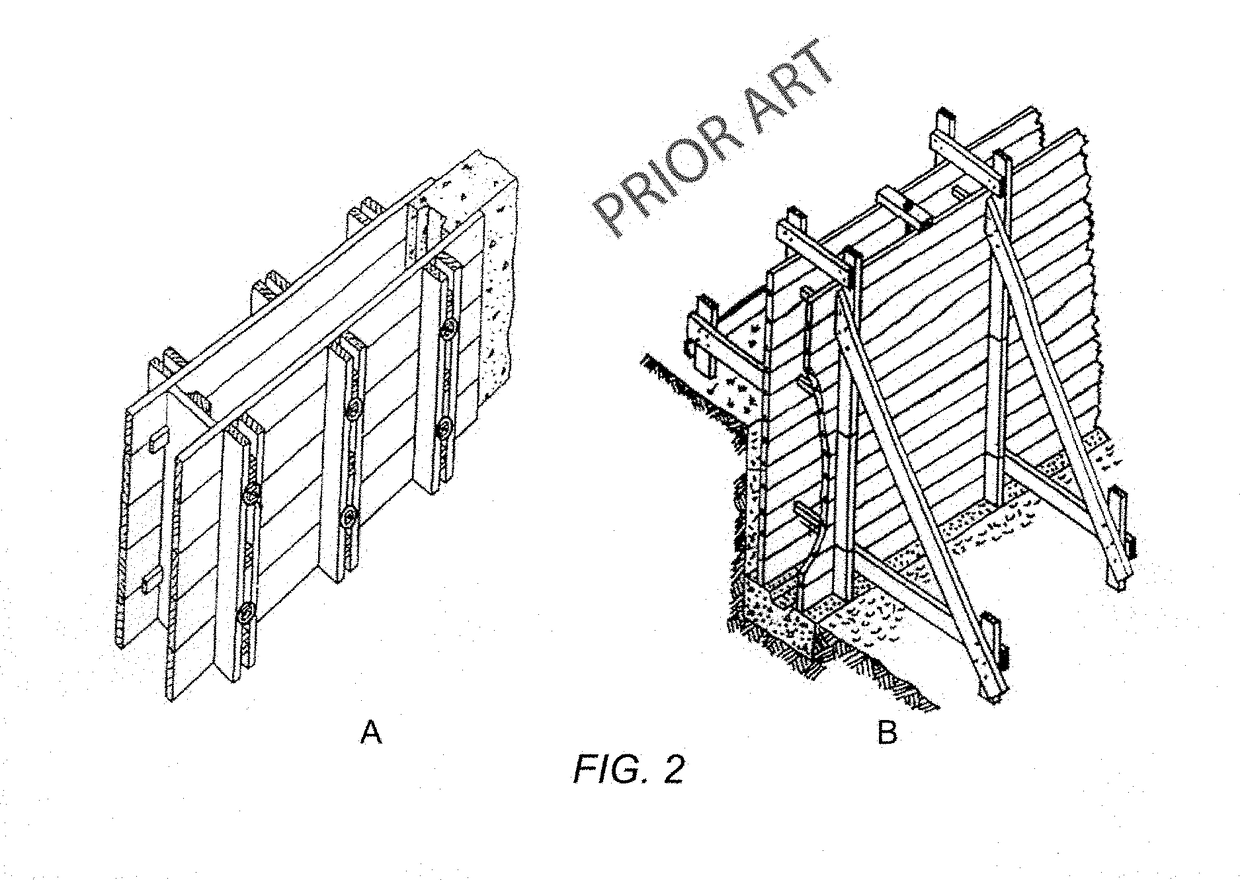

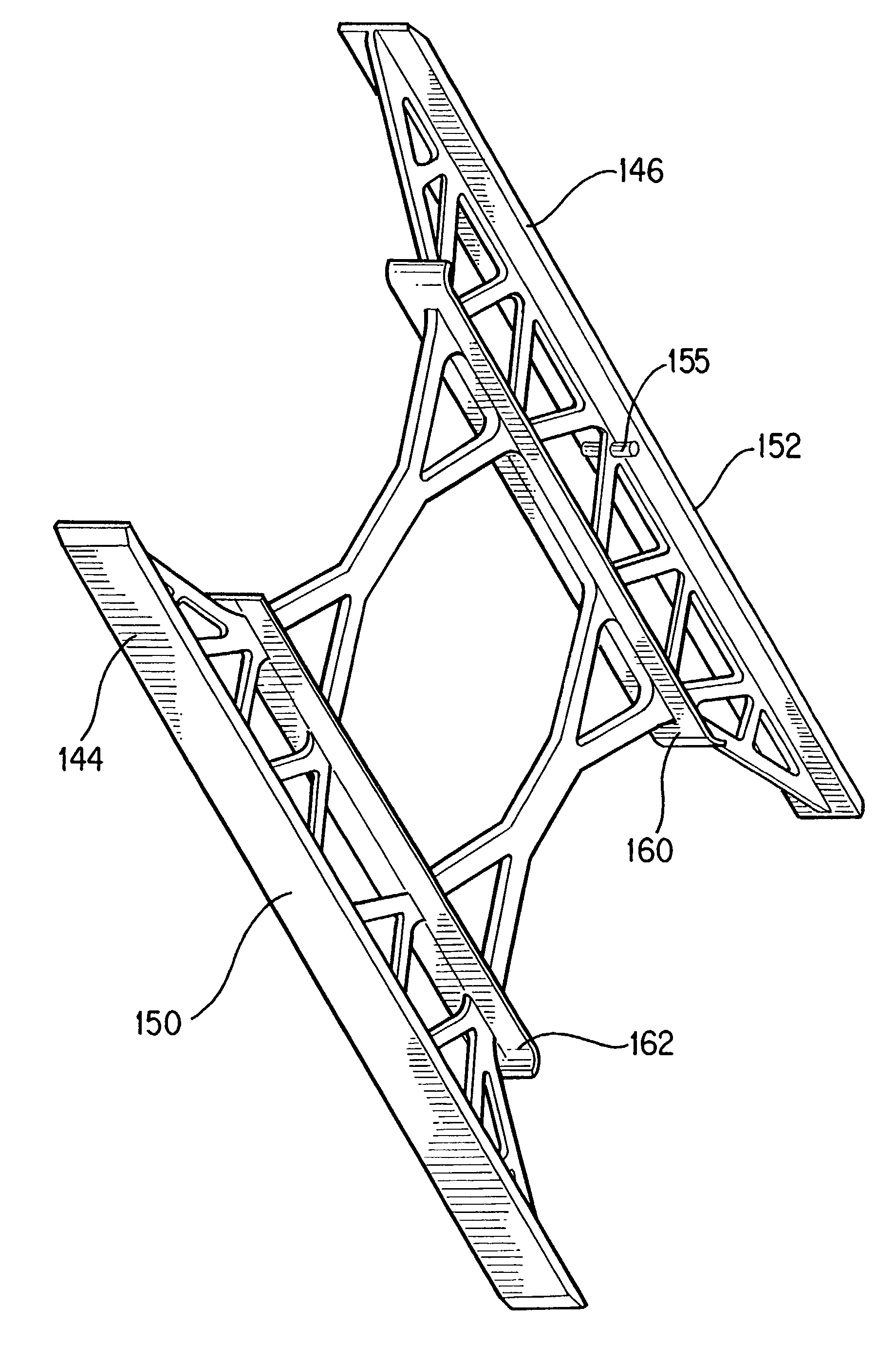

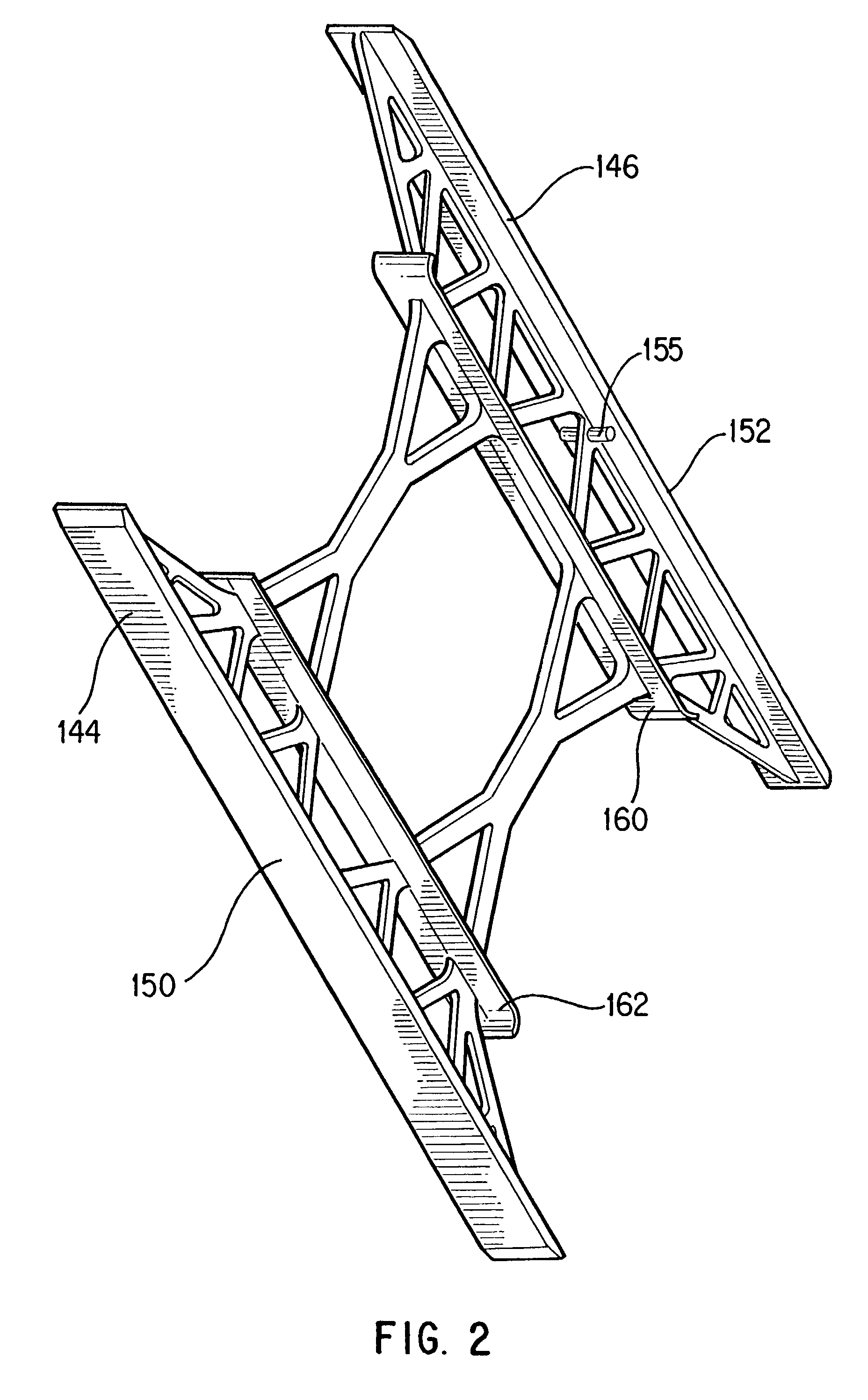

Bridging member for concrete form walls

A building component having first and second high density foam panels and improved bridging members for connecting the panels that extend between and may be molded into the panels. The bridging members include a pair of elongated end plates oriented in a top to bottom direction of the panels, a pair of substantially identical web members joining the end plates and being substantially symmetrically disposed above and below a central horizontal axis of the bridging member, and a pair of strip members oriented in the top to bottom direction of the panels intersecting the web members. The web members have a unique configuration that maximizes load bearing capacity with a minimum amount of material. The strip members may abut against and be substantially flush with respective inner surfaces of the foam panels to assist in positioning and forming the panels during molding. Seating areas for positioning horizontally and / or vertically disposed rebar in predetermined positions are also provided.

Owner:AIRLITE PLASTICS

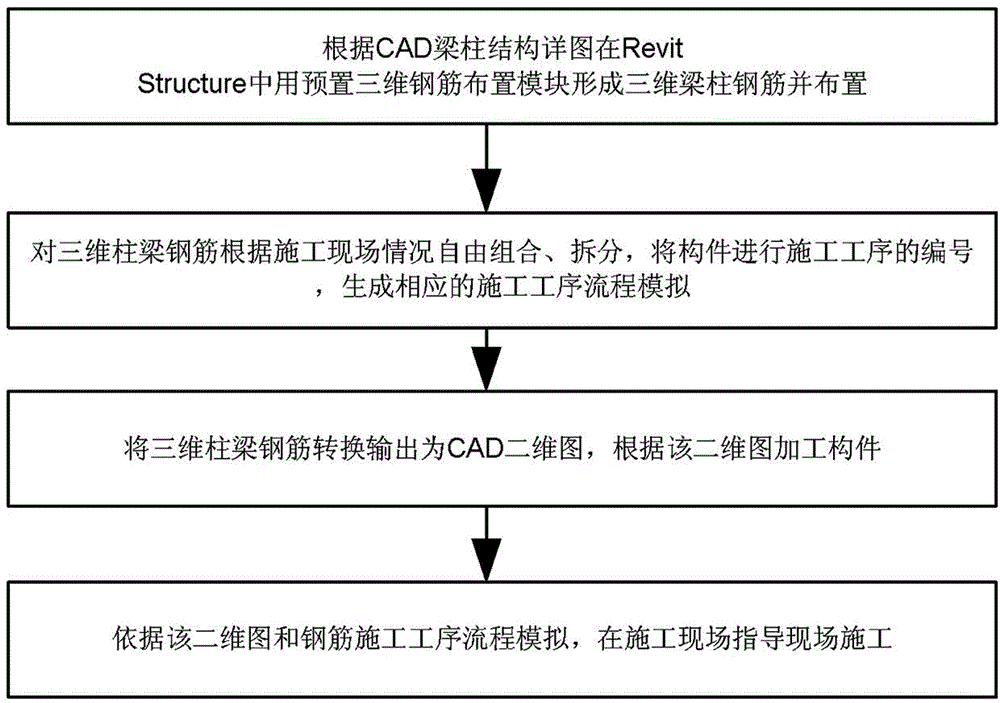

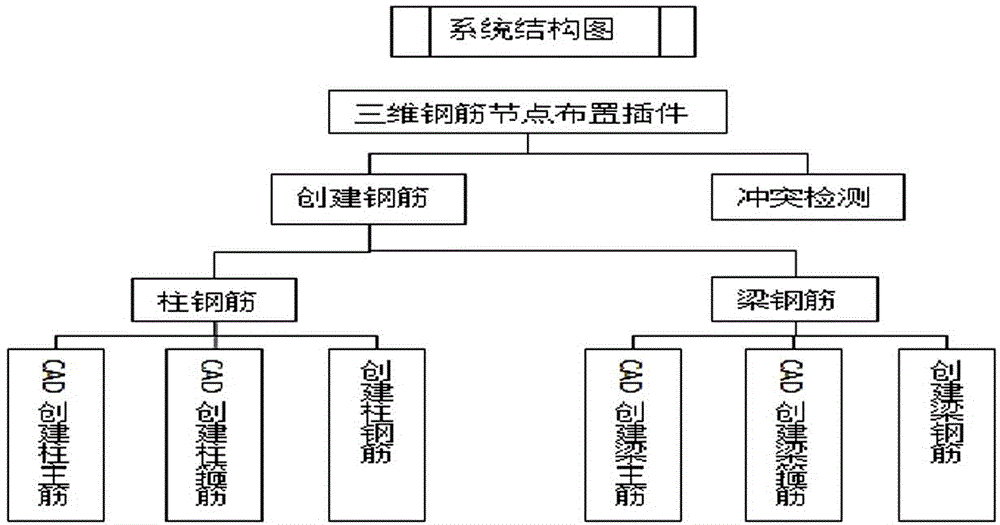

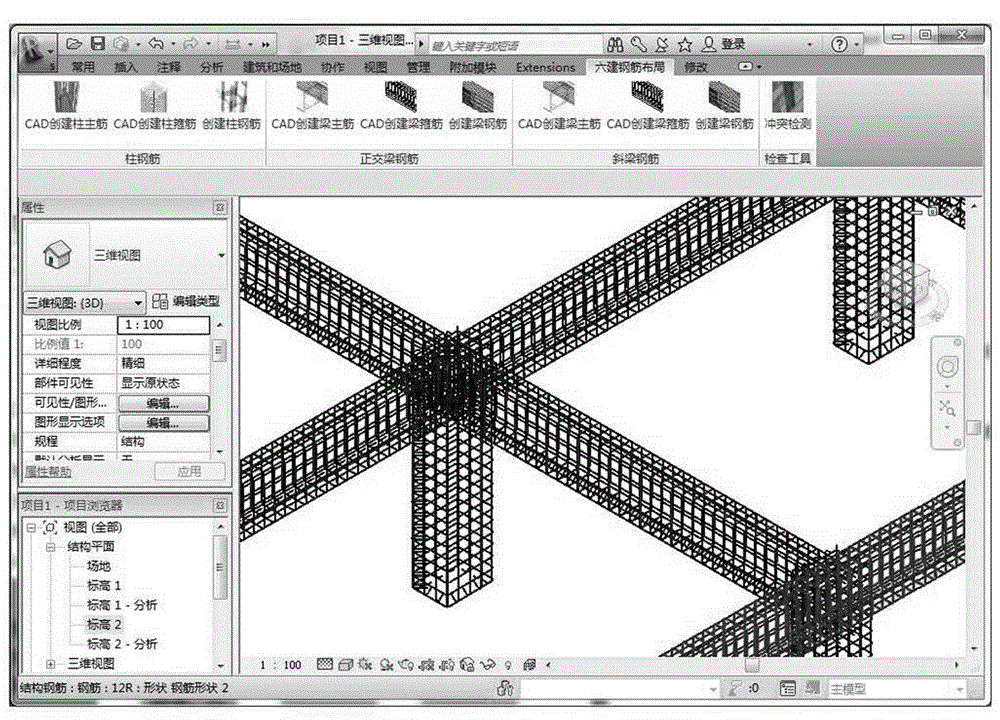

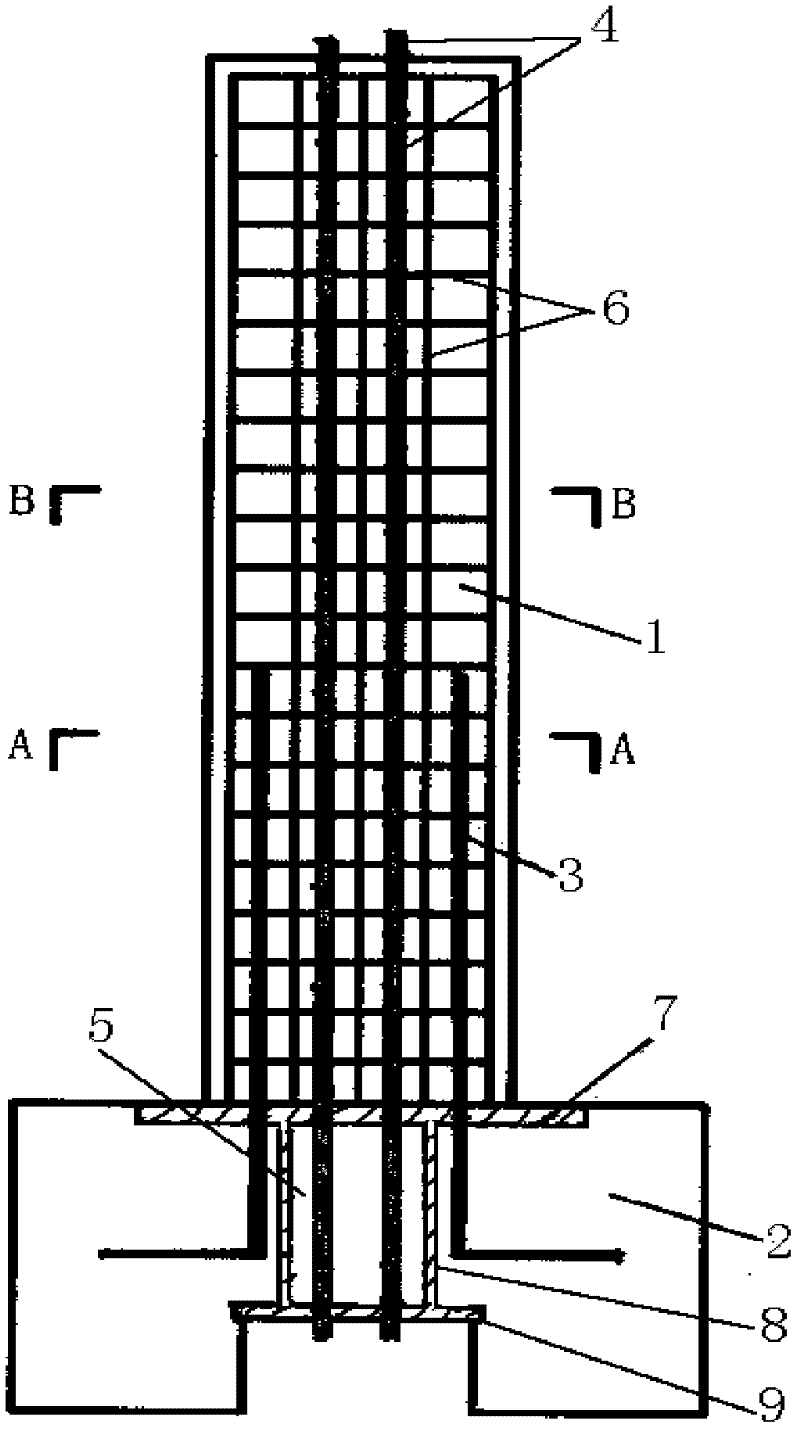

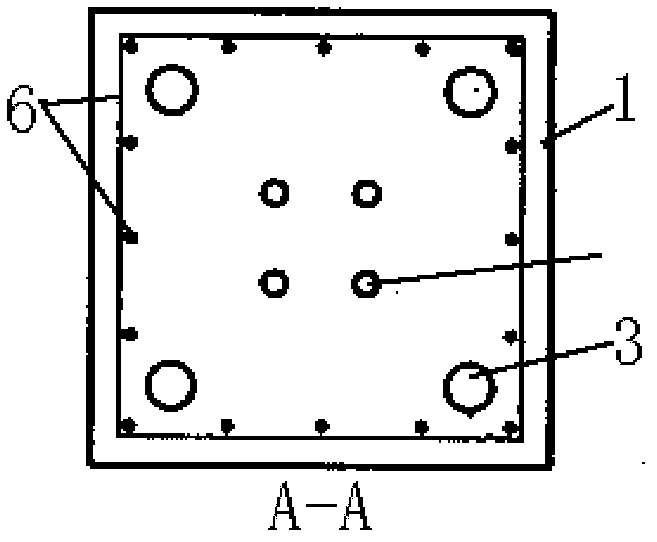

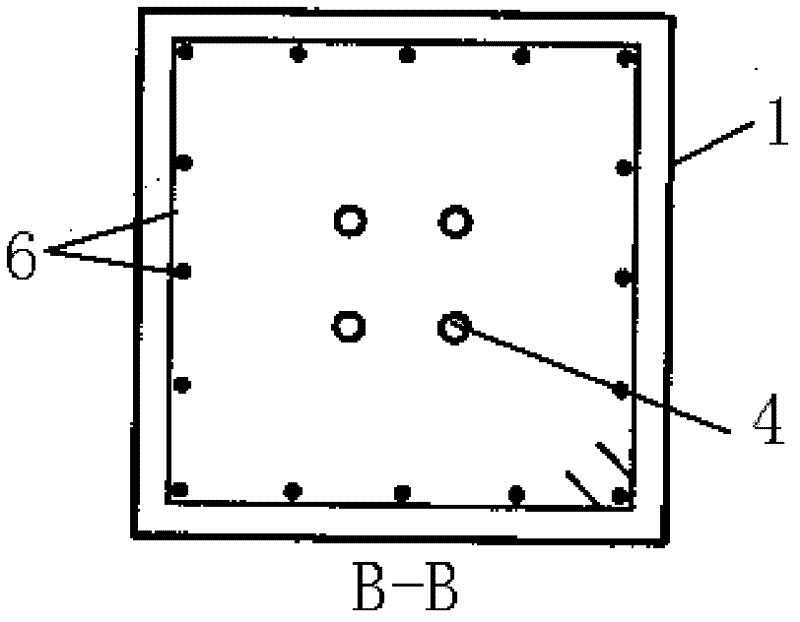

Automatic beam and column steel bar joint arranging and constructing simulation method based on BIM technology

ActiveCN104156544ADeepening time shortenedMeet engineering requirementsSpecial data processing applicationsComputer moduleRebar

The invention relates to an automatic beam and column steel bar joint arranging and constructing simulation method based on a BIM technology. The automatic beam and column steel bar joint arranging and constructing simulation method based on the BIM technology comprises the following steps that three-dimensional beam and column steel bars are formed and arranged by using a preset three-dimensional steel bar joint arranging module in RevitStructure software according to a CAD beam and column structure detail drawing; the arranged three-dimensional beam and column steel bars are freely combined and detached according to construction field situations, components are numbered according to construction procedures, and corresponding construction procedure flow simulation is generated; the arranged three-dimensional beam and column steel bars are transformed into a CAD two-dimensional diagram, and the components are machined according to the CAD two-dimensional diagram; and field construction is guided in a construction field according to the CAD two-dimensional diagram and steel bar construction procedure flow simulation. According to the automatic beam and column steel bar joint arranging and constructing simulation method based on the BIM technology, the deepening time of beam and column steel bar joints is shortened, engineering cost is saved, and workloads are reduced.

Owner:BEIJING LIUJIAN CONSTR GRP

600MPa level quake-proof twisted steel and manufacturing method thereof

The invention discloses 600MPa level quake-proof twisted steel and a manufacturing method of the steel. The twisted steel comprises one or the combination of more than two of the following components in percentage by weight: 0.21-0.26% of C, 0.61-0.80% of Si, 1.30-1.60% of Mn, 0.15-0.21% of V, 0.001-0.050% of Nb, 0.001-0.050% of Ti, 0.10-0.50% of Cr, 0.0001-0.0050% of B, 0.001-0.010% of Mo and the balance of Fe and unavoidable impurities, wherein the components of C, Si, Mn and V are basic components, and the components of Nb, Ti, Cr, B and Mo are optional components. A short-flow process of converter or electric furnace smelting and small billet continuous casting and rolling and cold bed cooling is adopted by the manufacturing method of the twisted steel. The tensile strength of the twisted steel produced by adopting the components and the method is more than 730MPa, the yield strength is more than 600MPa, the percentage elongation after fracture is more than 14%, the maximum force percentage of total elongation is more than 9%, and the yield ratio is more than 1.25, so the international requirement of quake resistance on the twisted steel can be met.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Self-resetting pier column structural system with built-in energy dissipation assembly and implementing method for self-resetting piper column structural system

InactiveCN102409606ASufficient ductility and energy dissipation capacityStrong enoughBridge structural detailsBridge erection/assemblyBridge engineeringResidual deformation

The invention discloses a self-resetting pier column structural system with a built-in energy dissipation assembly and an implementing method for the self-resetting pier column structural system, and belongs to the field of bridge engineering. The self-resetting pier column structural system consists of a pier column, a bridge abutment, energy dissipation steel bars, non-adhesion prestressed steel bars with an elastic resetting function and an embedded part; in the novel pier column structural system capable of effectively reducing residual deformation and ensuring sufficient energy dissipation, a pier is connected with the bridge abutment through the energy dissipation steel bars and the non-adhesion prestressed steel bars. Compared with the conventional pier column node, the self-resetting pier column structural system has the advantages that: the non-adhesion prestressed steel bars are positioned in the axle center of the pier column, a self-resetting restoring force can be generated, and the problem that the conventional pier has large residual deformation under the action of an earthquake load and cannot serve people any longer can be solved well; the self-resetting pier column structural system is flexible in design and definite in structural stress; the pier is ensured to have sufficient strength and rigidity; and the self-resetting pier column structural system can be implemented by a prefabricating or on-site pouring method, is easy and convenient to construct, and is an advanced and practical novel pier column system.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com