Patents

Literature

3636results about How to "Strong enough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

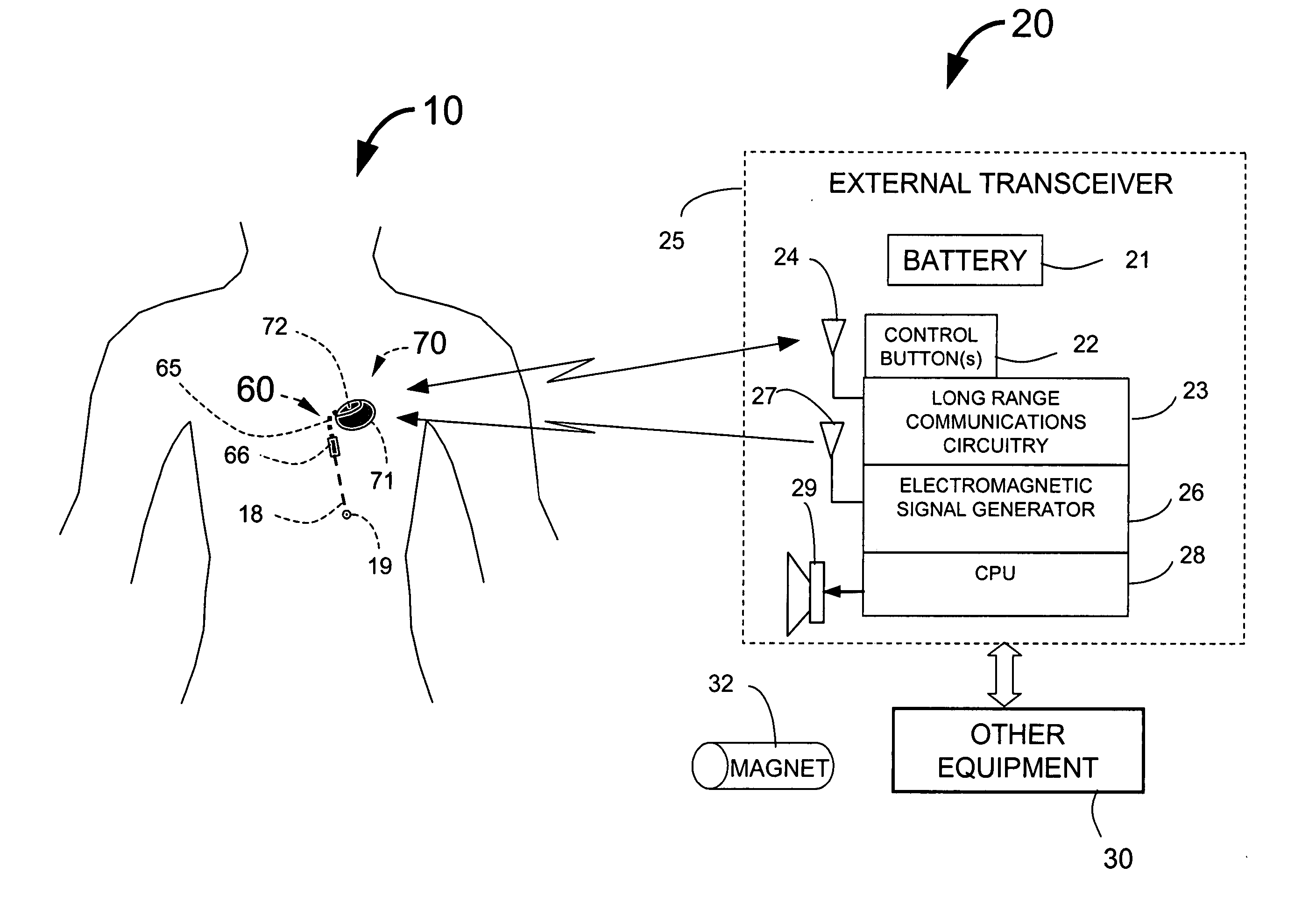

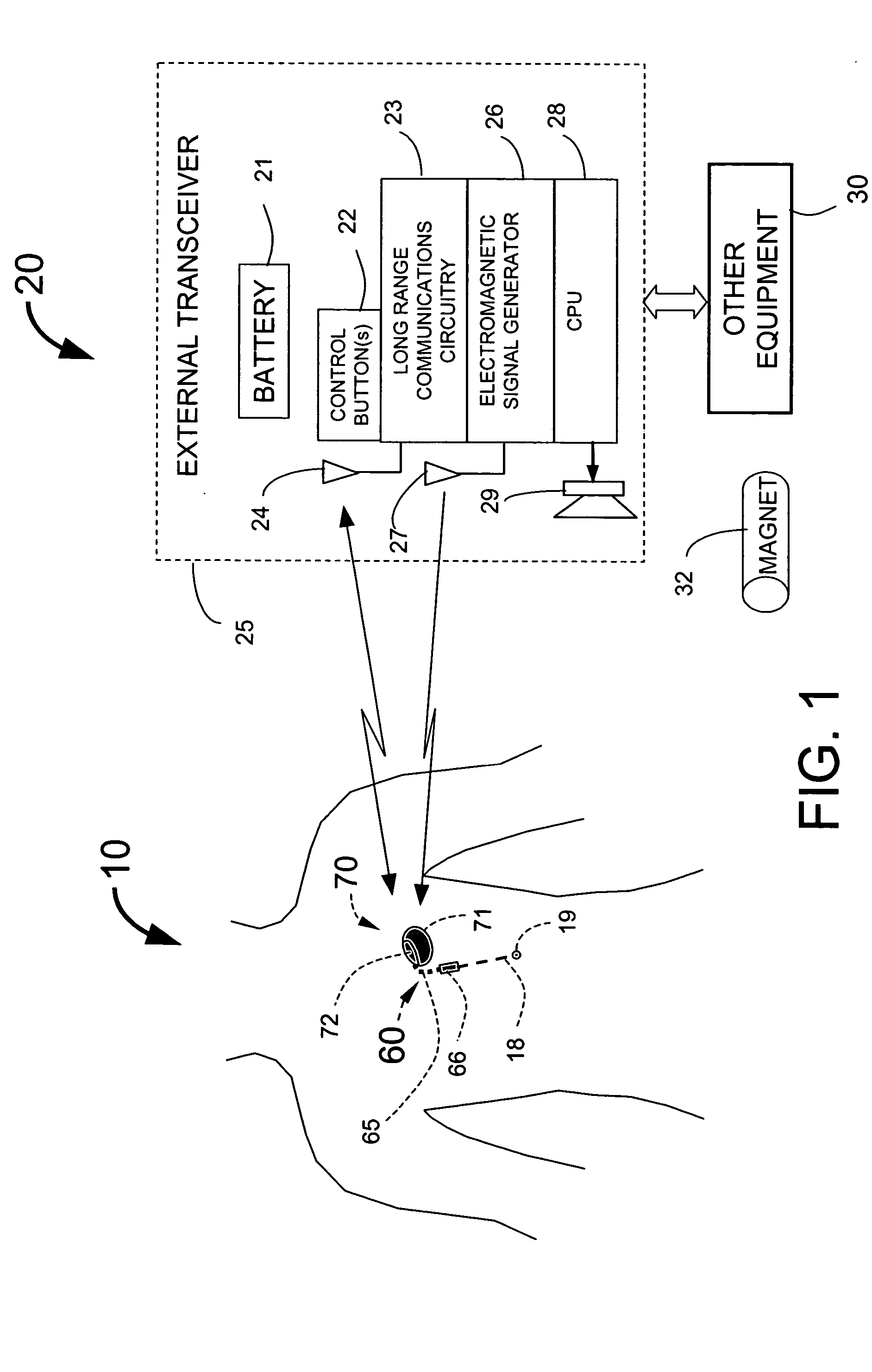

Implantable medical system with long range telemetry

InactiveUS20050113886A1Minimize and eliminate chanceStrong enoughTransvascular endocardial electrodesExternal electrodesImplanted deviceTelemetry Equipment

An implantable medical system for implantation within the body of a patient is provided. The system includes an implanted device having an implant casing and a long range telemetry sub-system housed therein. The system also includes an implantable lead operationally coupled to the implanted device and an antenna coupled to the implant casing to extend therefrom. The antenna is operationally coupled to the long-range telemetry sub-system to enable wireless bi-directional communication between the long range telemetry sub-system and predetermined external equipment disposed outside the body of the patient.

Owner:ANGEL MEDICAL SYST +1

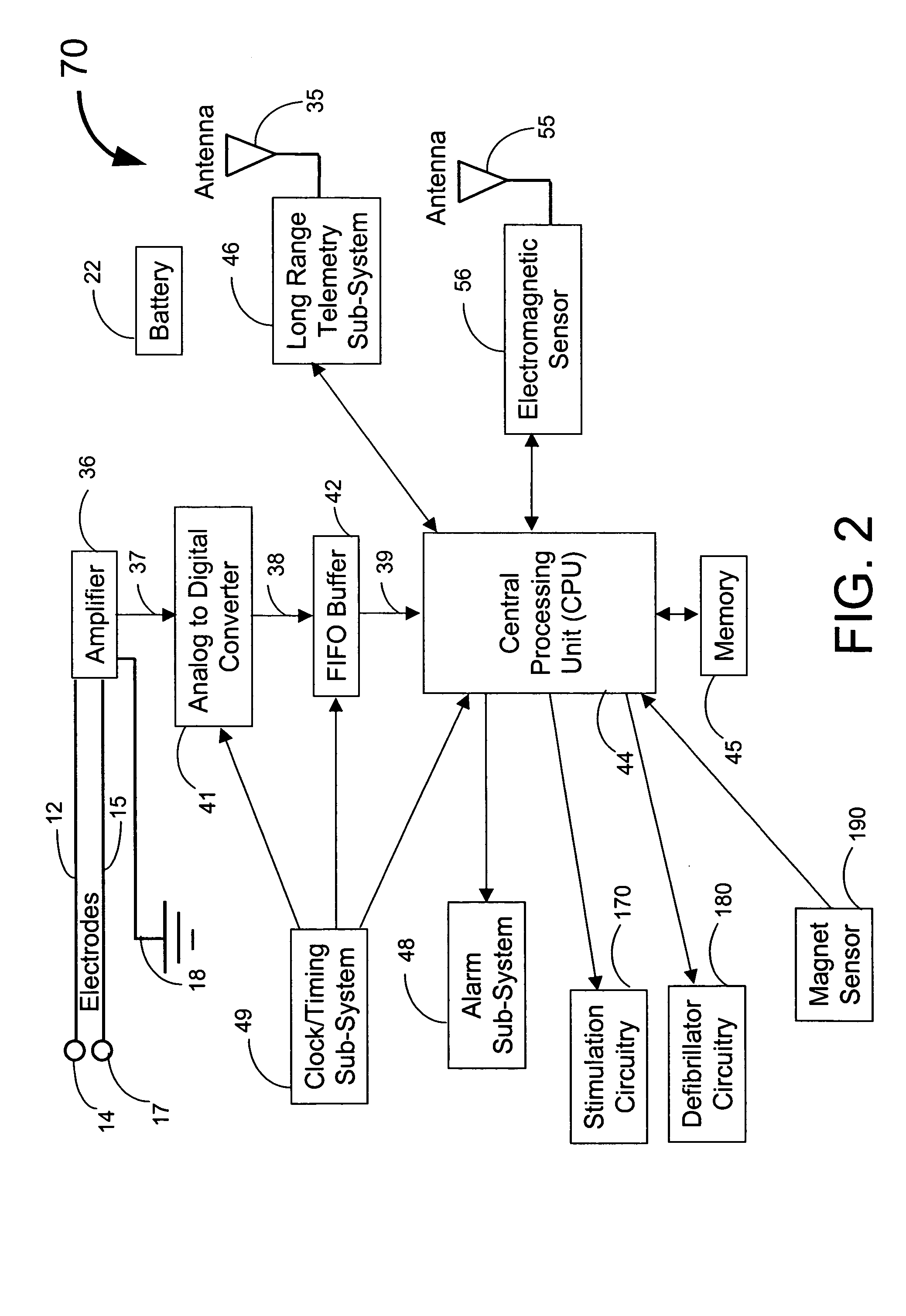

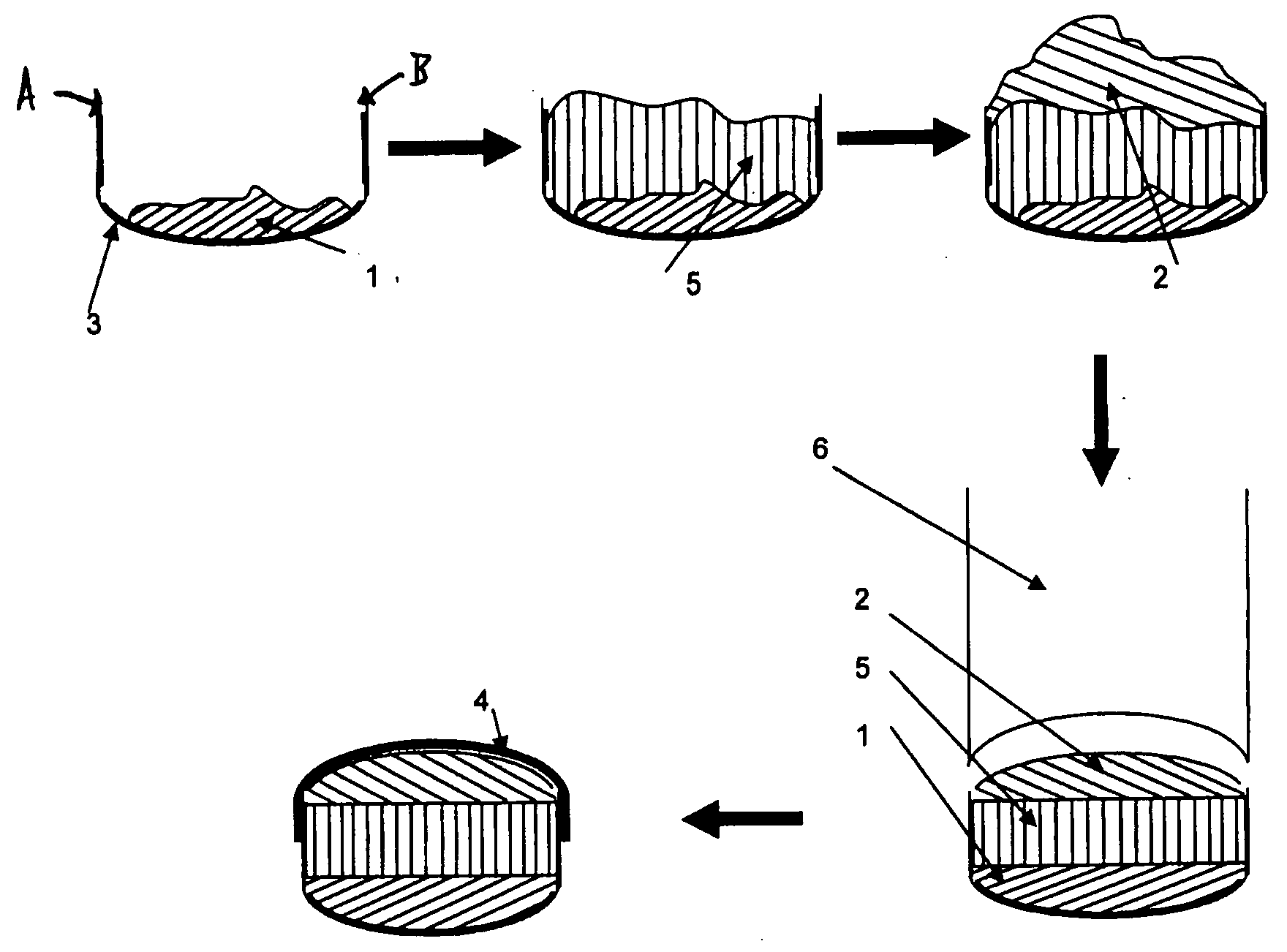

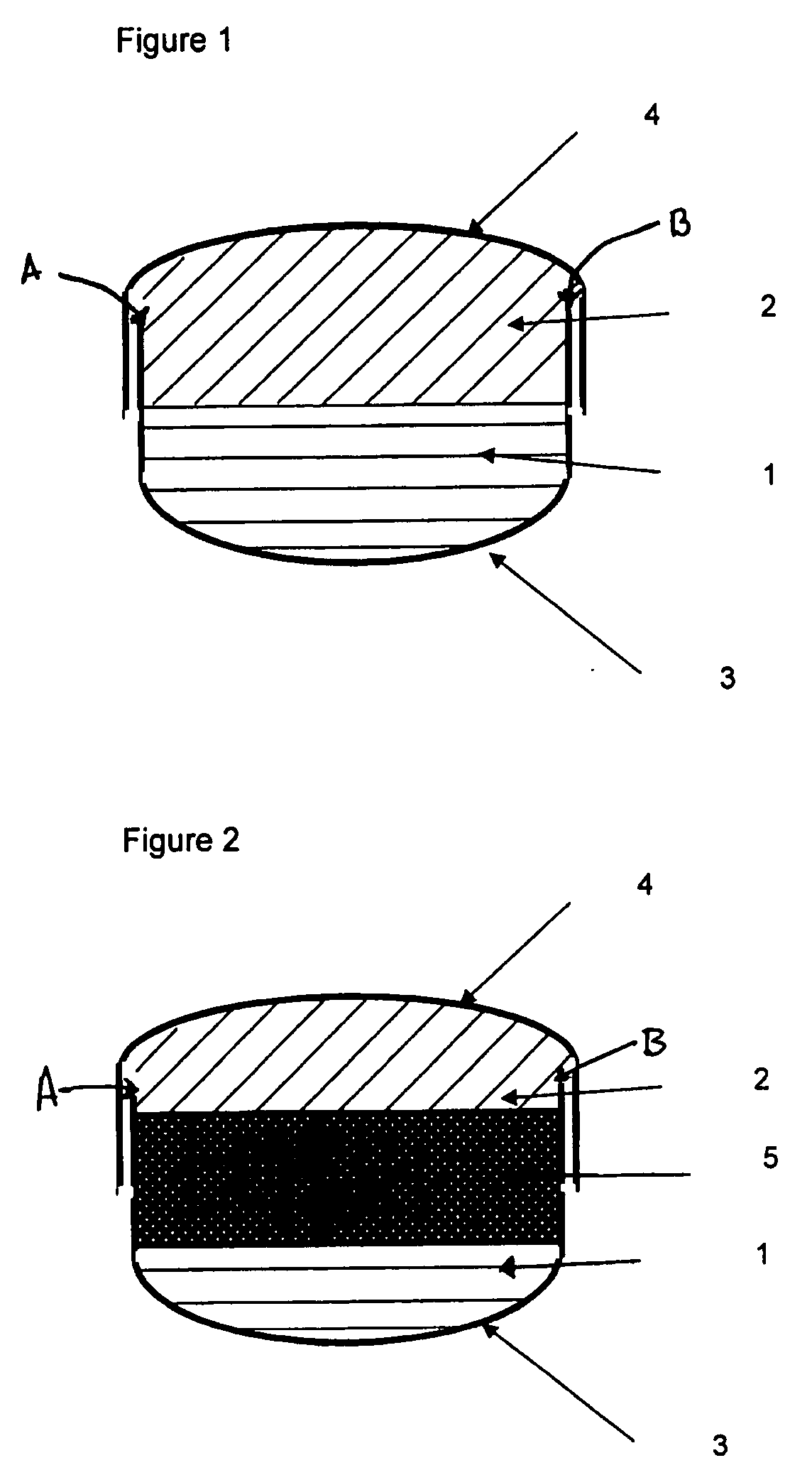

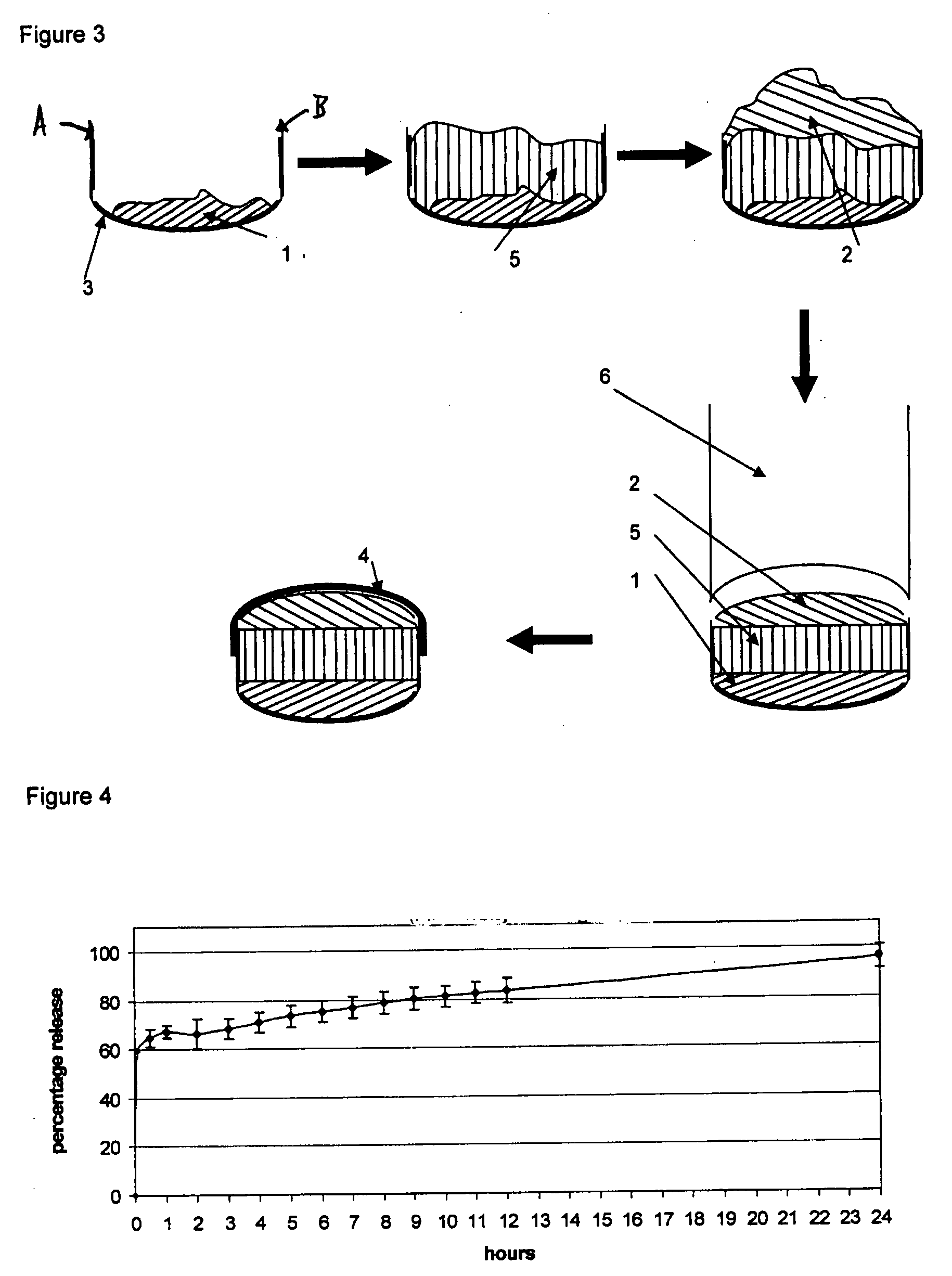

Solid form

InactiveUS20080286344A1Strong enoughAvoids and reduces processing and product drawbackPowder deliveryNervous disorderFilling materialsVolumetric Mass Density

A solid form comprising at least one film enrobing a compacted fill material wherein:i) the compacted fill material comprises at least one active material;ii) the solid form shows a weight loss that is less than 1% during a 30 minutes USP friability test United States Pharmacopeia (USP) 29 Test Number 1216 (page 3046);iii) the compacted fill material has a density of at least 0.5 g / ml based on the total solid volume of the solid form and a tensile strength of less than 0.9 MPa; andiv) the compacted fill material is present in the solid form in at least a first zone and a second zone and the active material is present in at least one of the zones.

Owner:FMC CORP

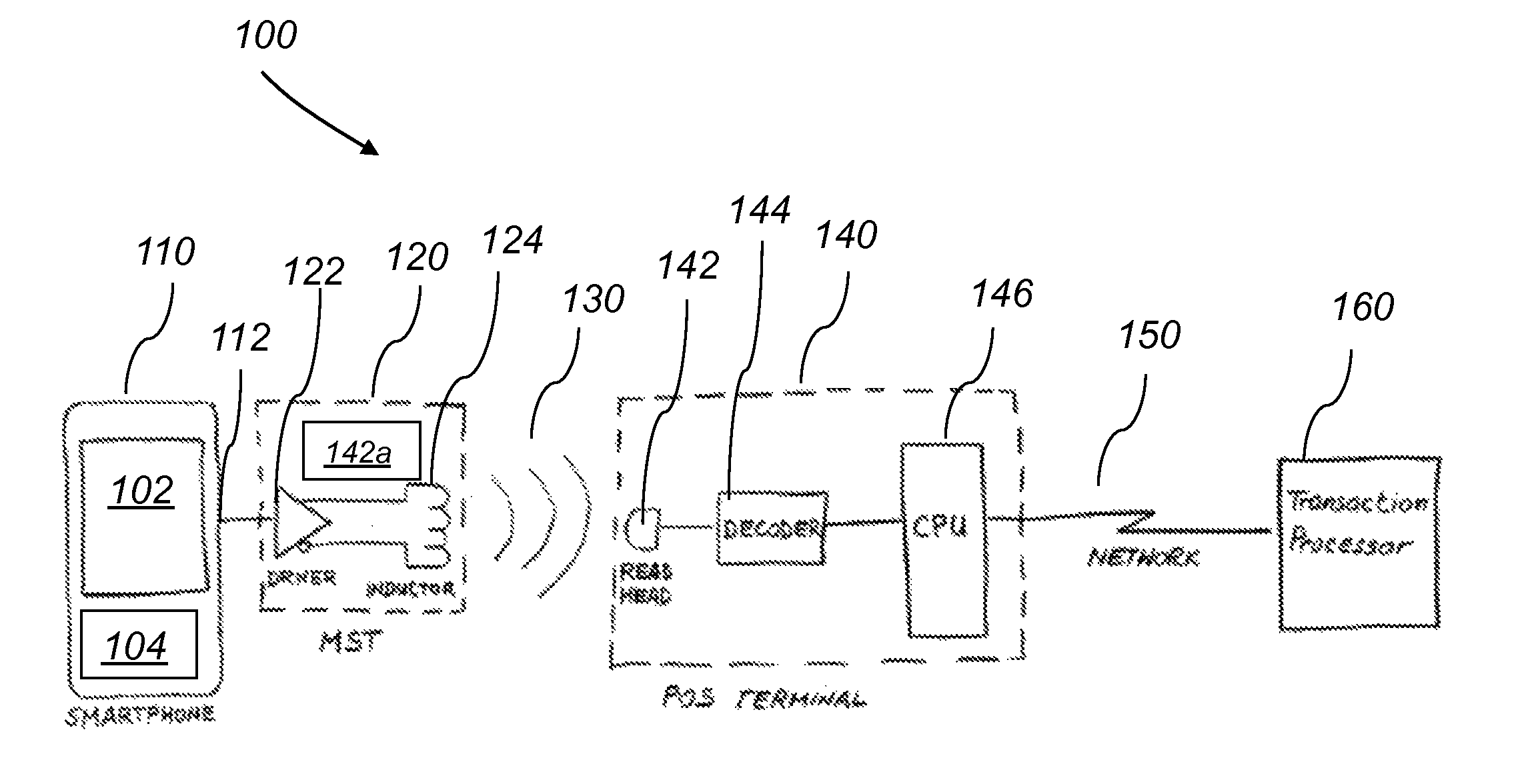

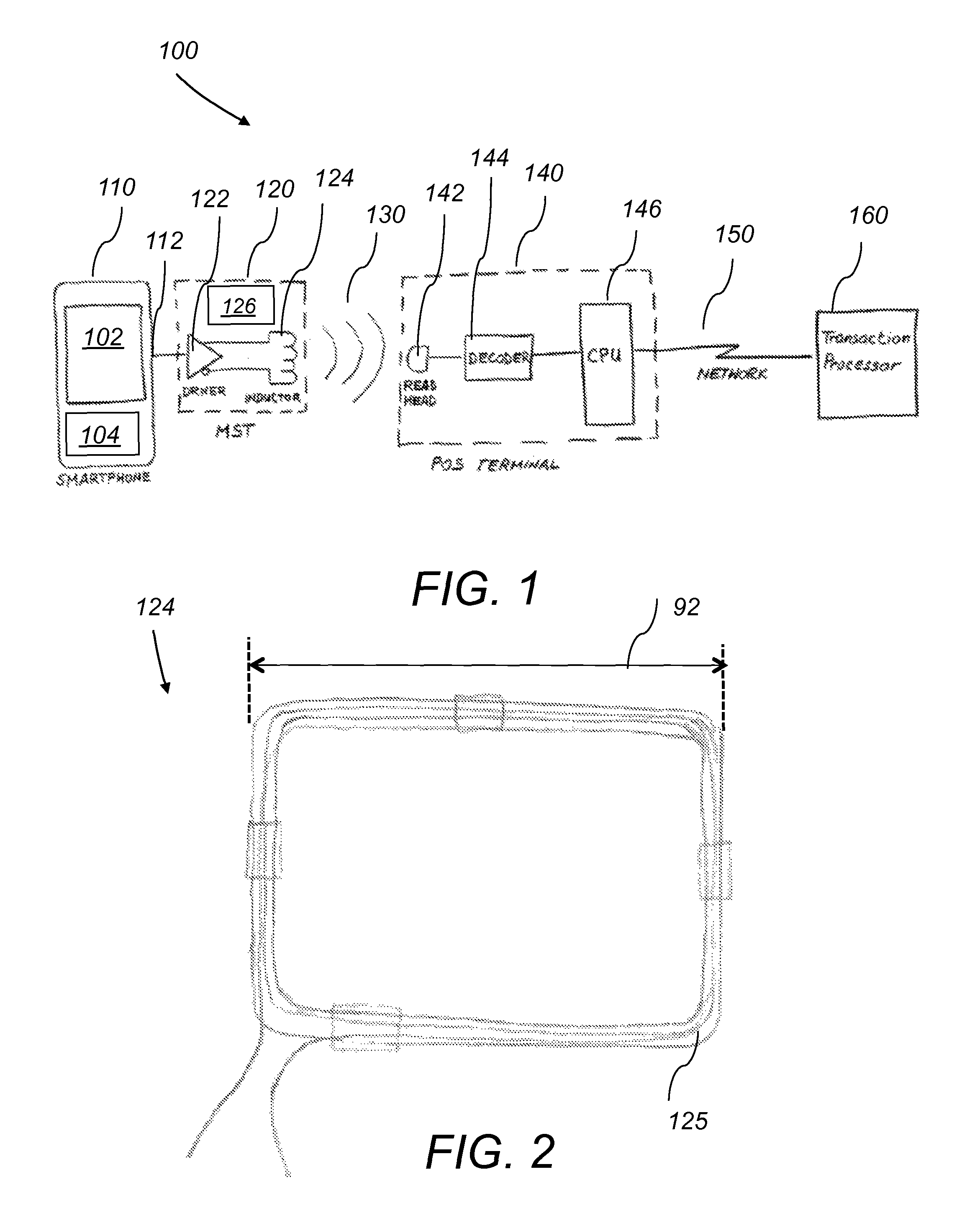

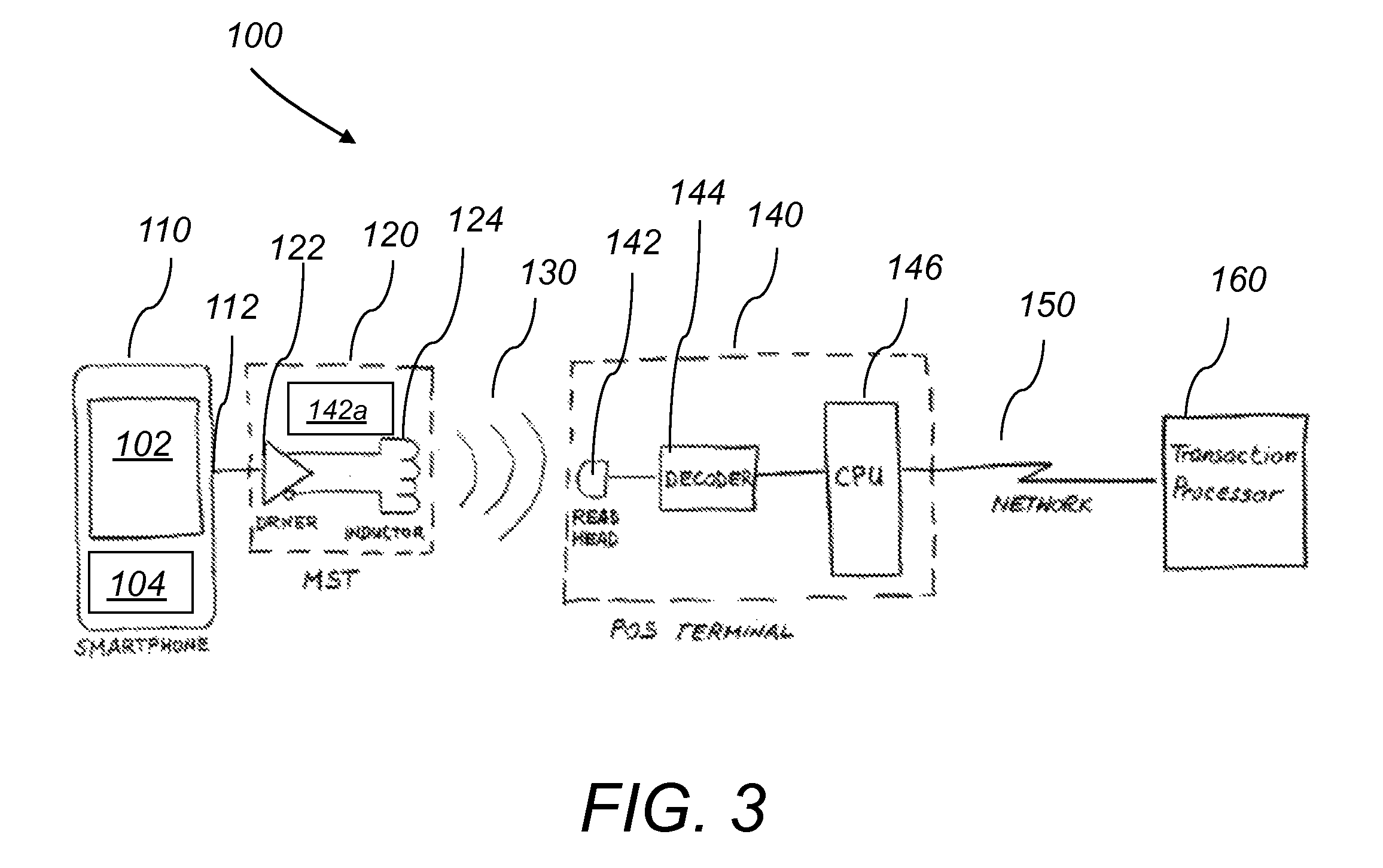

System and method for a baseband nearfield magnetic stripe data transmitter

ActiveUS8814046B1Prevent replayPrevents copy attackNear-field transmissionPayment architectureHigh energyWaveform shaping

A system for a baseband near field magnetic stripe data transmitter includes a mobile phone and a magnetic stripe transmission (MST) device. The mobile phone transmits a stream of pulses including magnetic stripe data of a payment card. The magnetic stripe transmission (MST) device includes a wave shaper, a driver and an induction device. The MST device receives the stream of pulses from the mobile phone, shapes and amplifies the received stream of pulses and generates and emits high energy magnetic pulses including the magnetic stripe data. The emitted high energy magnetic pulses are picked up remotely by a magnetic read head. The MST device shapes the stream of pulses to compensate for shielding, eddy current losses and limited inductance value of the magnetic read head.

Owner:SAMSUNG ELECTRONICS CO LTD

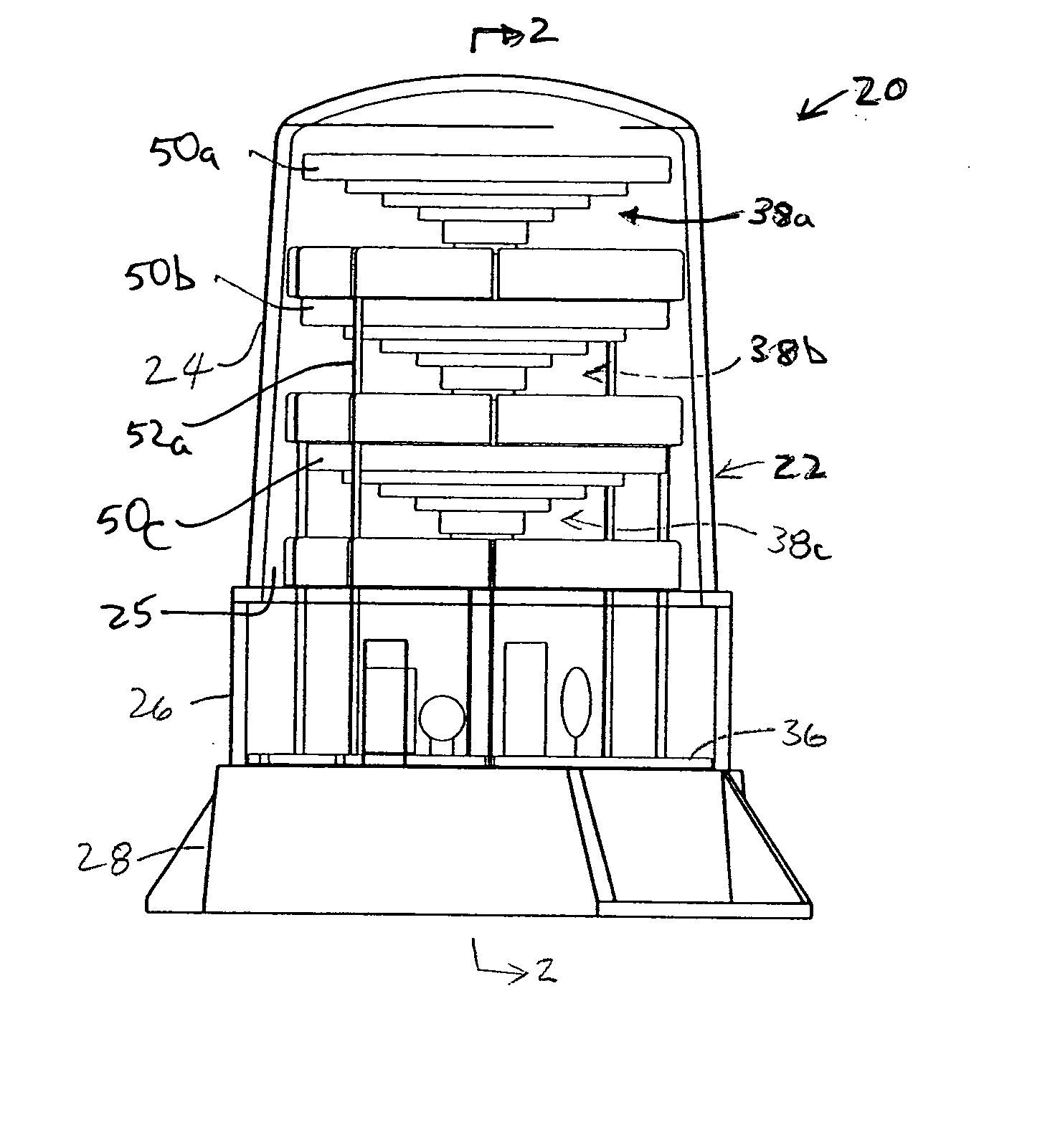

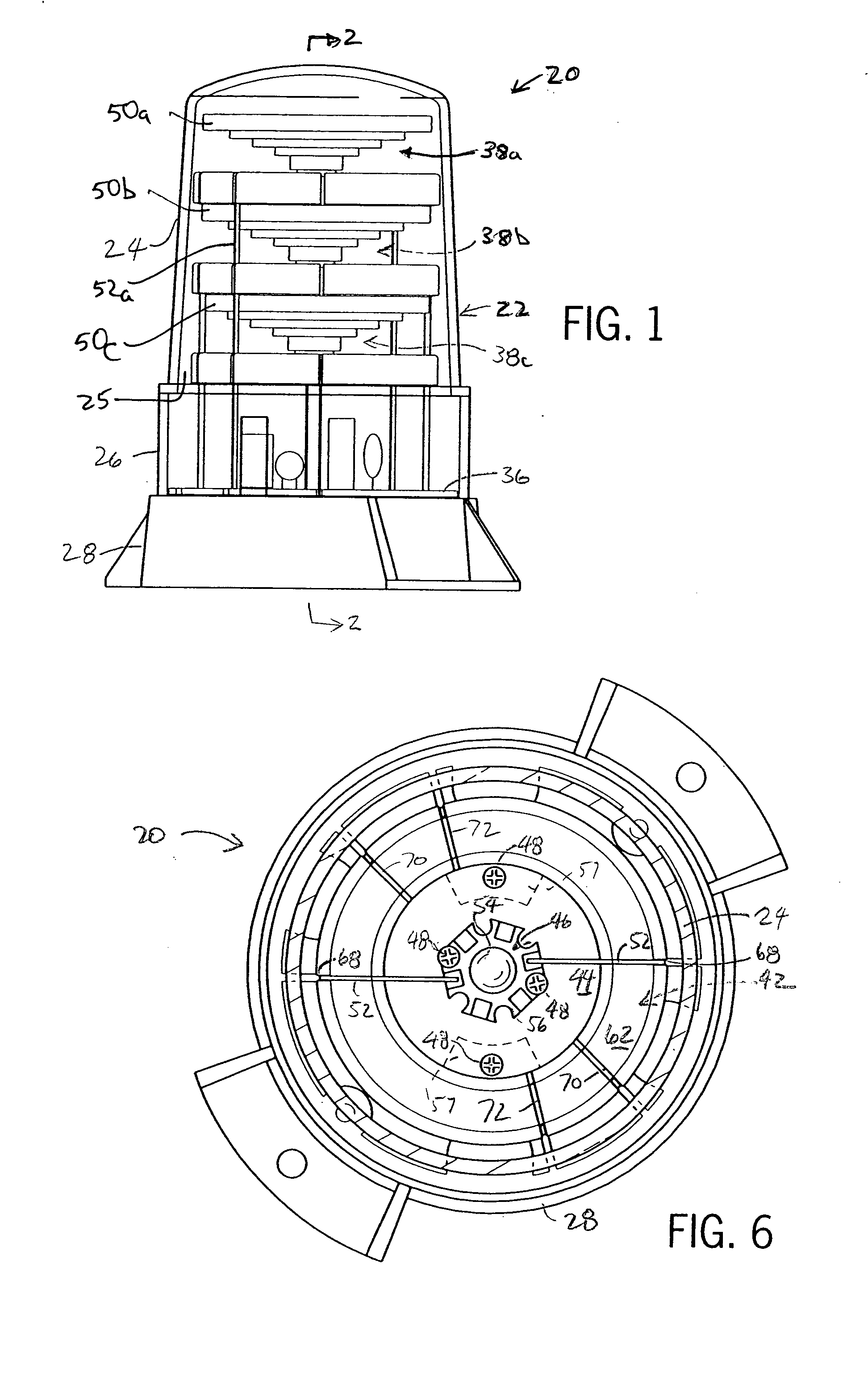

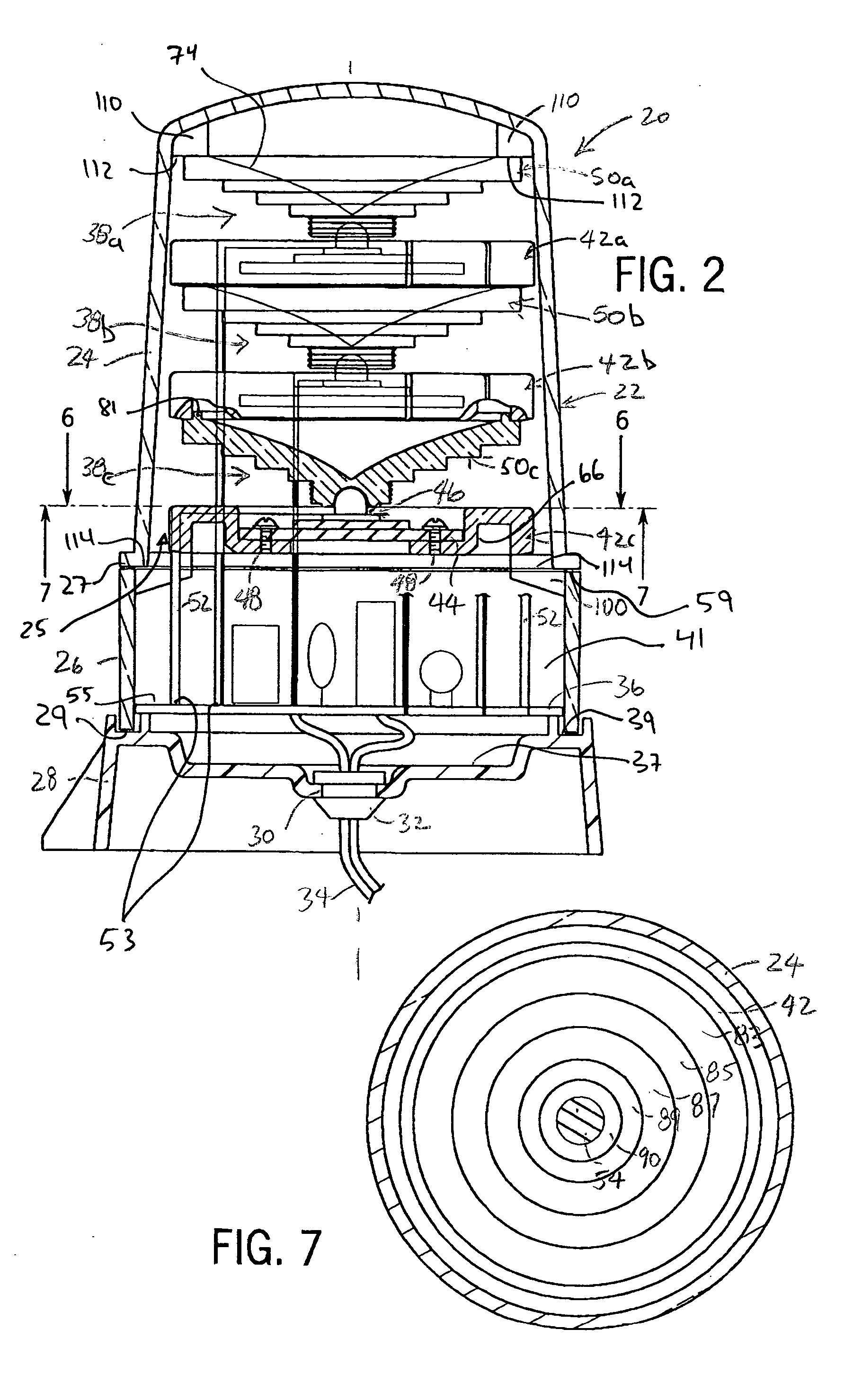

Modular LED light and method

InactiveUS20050068777A1Simple configurationSimple and inexpensive mannerLighting applicationsLight source combinationsEngineeringLight source

An at least partially translucent optical element for distributing light from a light source, the element comprising a hub member formed about a central axis, having an external surface between first and second ends and forming a recess within the first end that extends along the central axis substantially along a length of the hub member between the first and second ends for receiving the source, the external surface forming a lens for dispersing light directed thereat from within the recess out of the element and a reflecting member integral with and extending from the second end, the reflecting member including at least one external reflecting surface that reflects substantially all of the light directed into the reflecting member from within the recess back into the element.

Owner:J W SPEAKER CORP

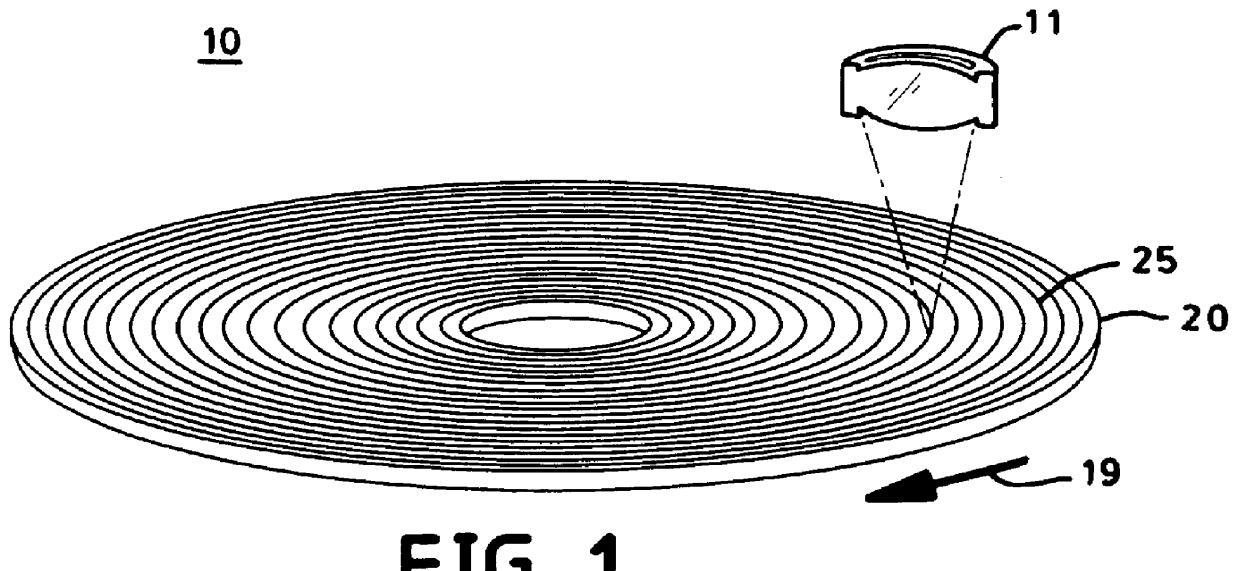

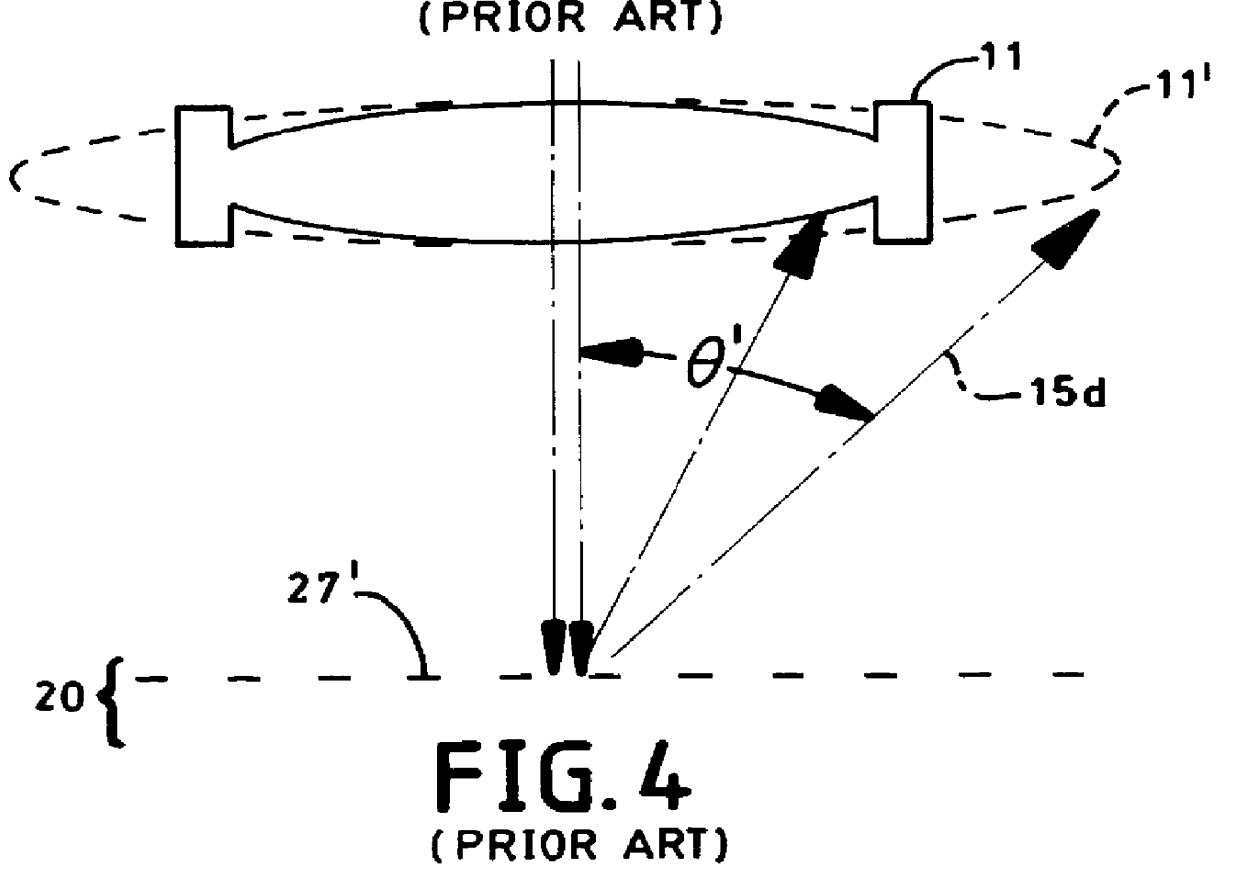

Optical recording systems

InactiveUS6094413AIncrease contrastImprove signal-to-noise ratioNanoinformaticsOptical beam sourcesOptical storageOptical recording

An optical storage system suitable for optical storage and retrieval of information using a storage medium comprising a substrate, an active layer for retention of the data, and an overlying optical layer, or layers for double-sided. The optical layer serves to produce an evanescent field in or adjacent to the active layer in response to an incident beam of radiation. The evanescent field is frustrated or attenuated by the data in the active layer and produces a signal.

Owner:SENSHIN CAPITAL +1

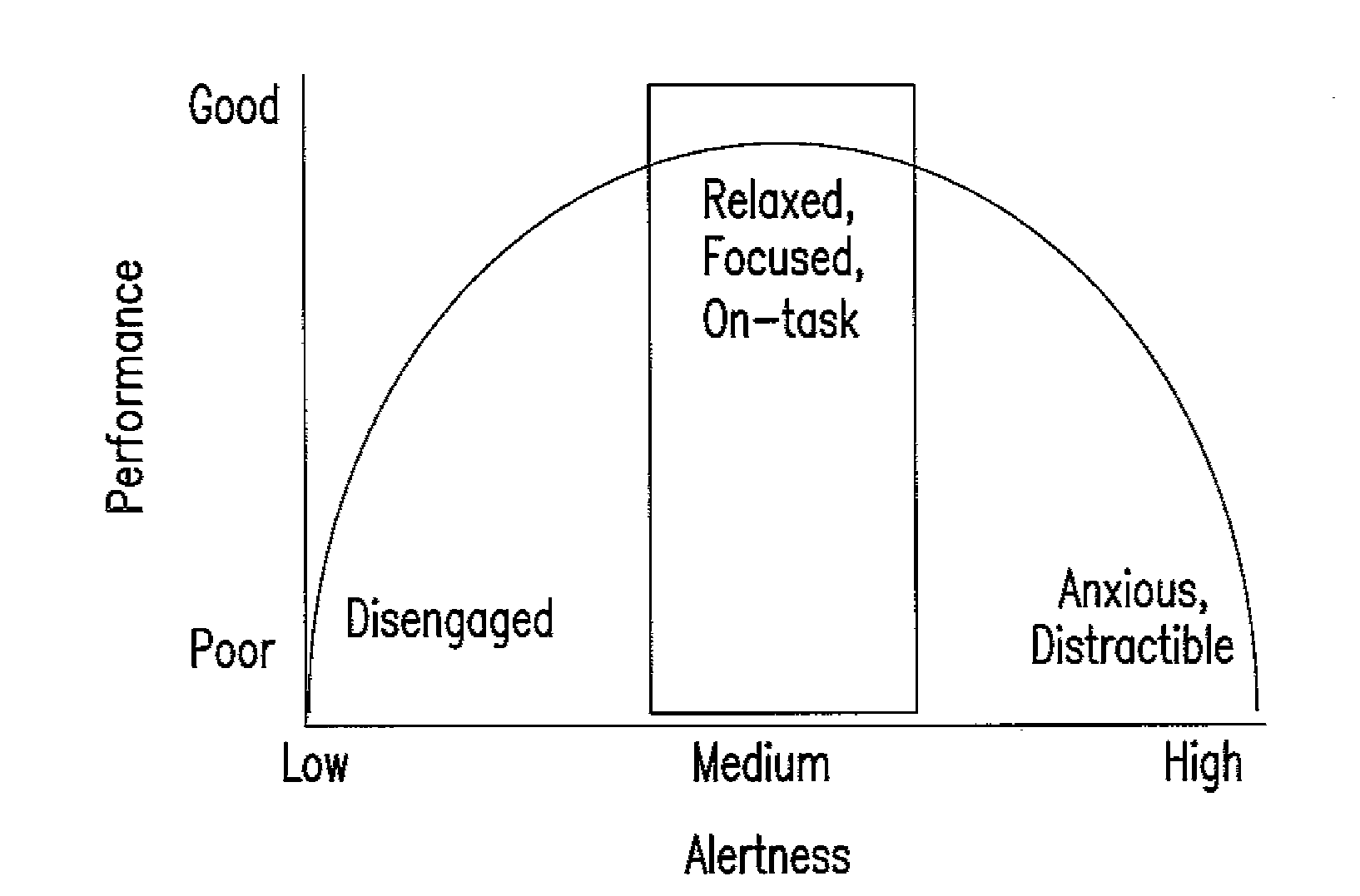

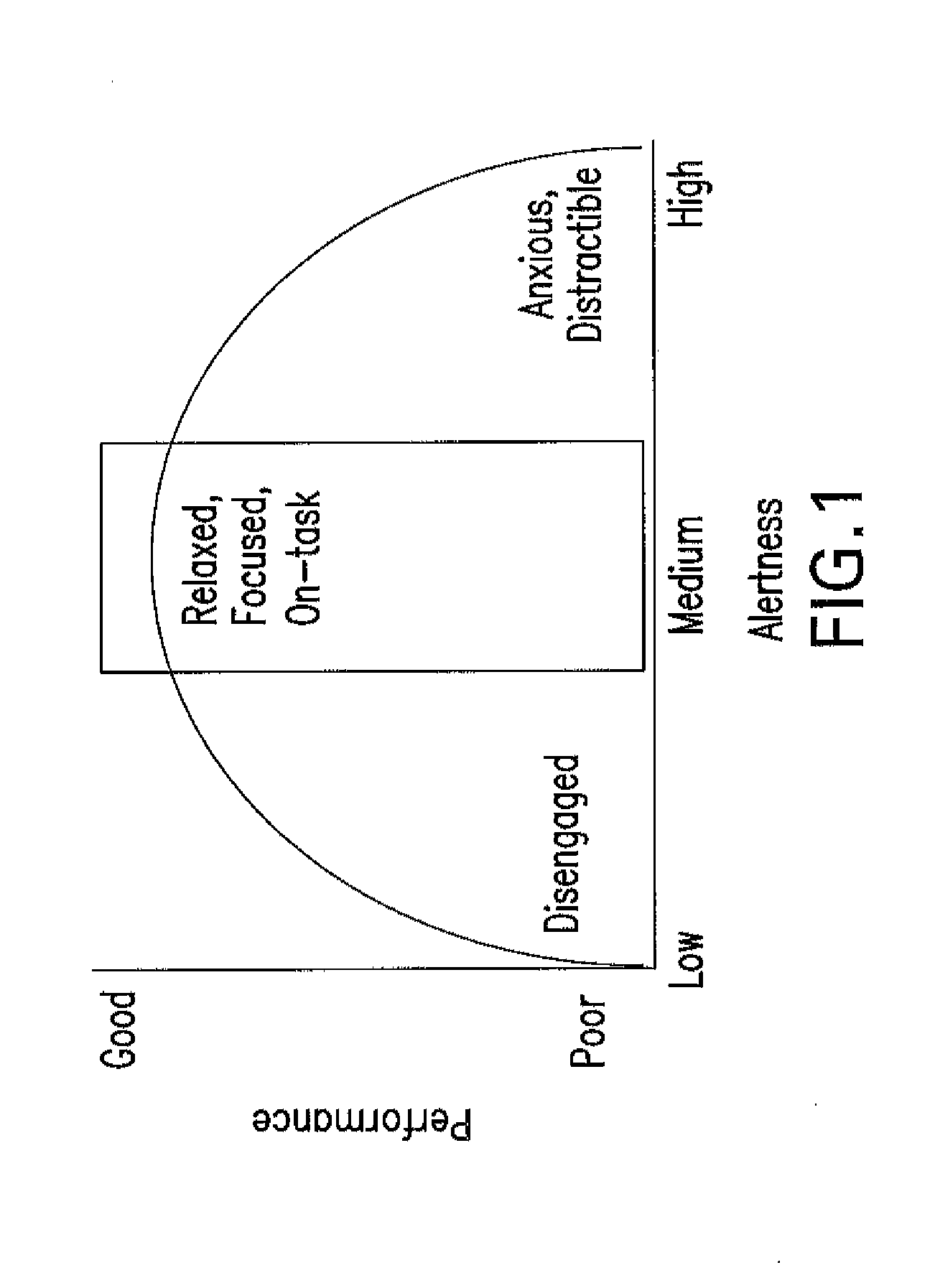

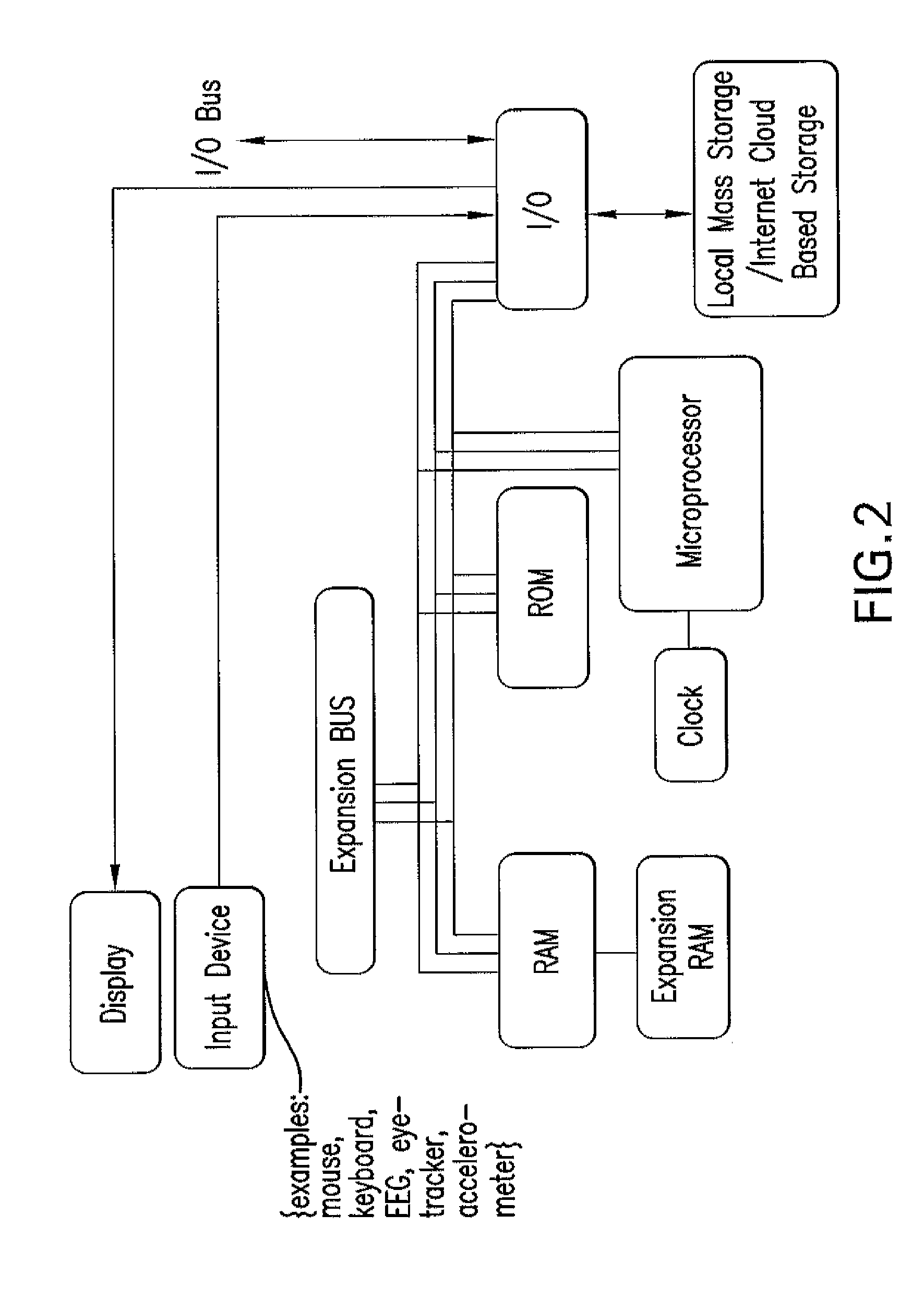

Computer-implemented interactive behavioral training technique for the optimization of attention or remediation of disorders of attention

InactiveUS20120077160A1Enhancing attentional stateGood conditionElectrical appliancesTeaching apparatusTraining courseVisual perception

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

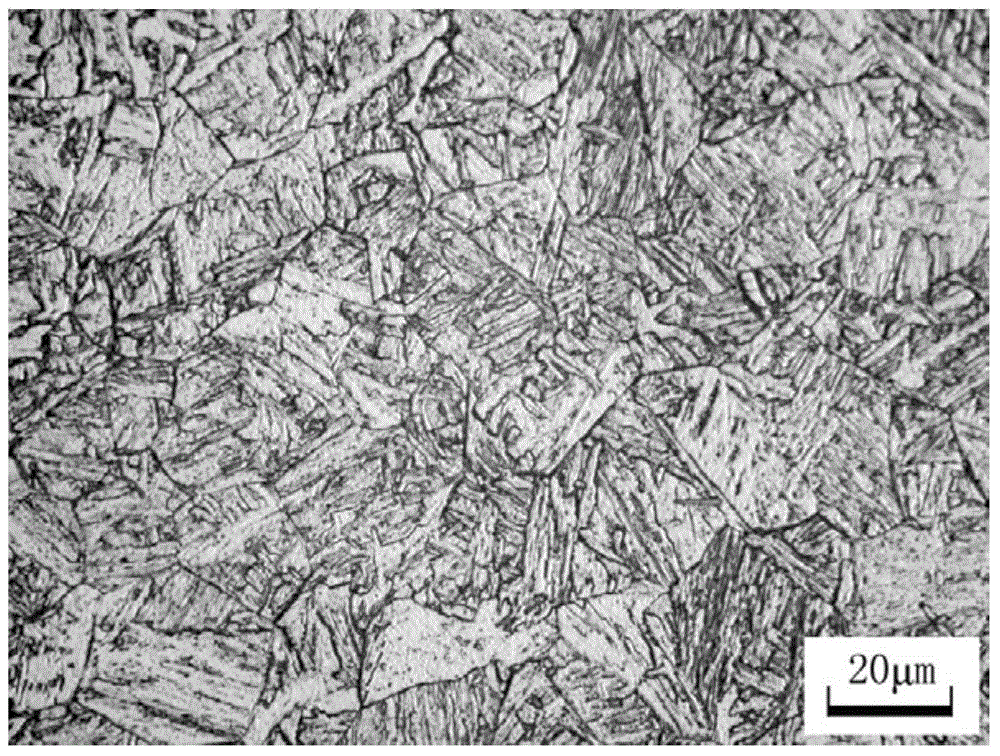

Normalizing type high-strength pressure vessel steel and manufacturing method thereof

The invention provides normalizing type high-strength pressure vessel steel, which comprises the following chemical components in percentage by weight: 0.12 to 0.18 percent of C, 0.15 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, 0.10 to 0.40 percent of Ni, 0.01 to 0.05 percent of Nb and 0.01 to 0.03 percent of Ti, 0.015 to 0.050 percent of Als, one or both of less than or equal to 0.20 percent of V and less than or equal to 0.70 percent of Cu and the balance of Fe and inevitable impurities. In the normalizing type high-strength pressure vessel steel, the specification of the steel is controlled by utilizing a single-rolling process of a steel plate, and the uniform tissue of ferrite and pearlite is obtained by adopting normalizing heat treatment; and in the process of rolling and heat treatment, the sufficient strength and good impact properties are obtained by utilizing the effects of fine-grain strengthening, precipitation strengthening and solid solution strengthening of micro-alloying elements such as the Nb, the V, the Ti and the like. In addition, the normalizing type high-strength pressure vessel steel achieves the excellent welding performance by controlling carbon equivalent and can be welded by adopting methods of manual arc welding, hidden arc welding, gas shielded welding, electroslag welding or tungsten electrode inert gas shielded-arc welding and the like; and the normalizing type high-strength pressure vessel steel has the advantages of little used precious metals, easy control of the component of each element, simple process, low production cost and high efficiency.

Owner:武钢集团有限公司

Folium artemisiae argyi incense

InactiveCN101601866AGood mosquito repellentStrong enoughBiocidePest repellentsChemistryPotassium nitrate

The invention provides folium artemisiae argyi incense with excellent effect of repelling mosquitoes. 50 to 95 weight percent of folium artemisiae argyi powder, 4 to 47 weight percent of debregeasia orientalis skin powder and 0.5 to 3 weight percent of potassium nitrate are evenly mixed with water, and then the mixed solution is formed and dried to prepare the folium artemisiae argyi incense. Preferably, no more than 20 weight percent of starch is also contained. The incense adopting the formula has the advantages of good mosquito repellent effect, air sterilization, enough strength, low raw material consumption and convenient production.

Owner:曾阳平

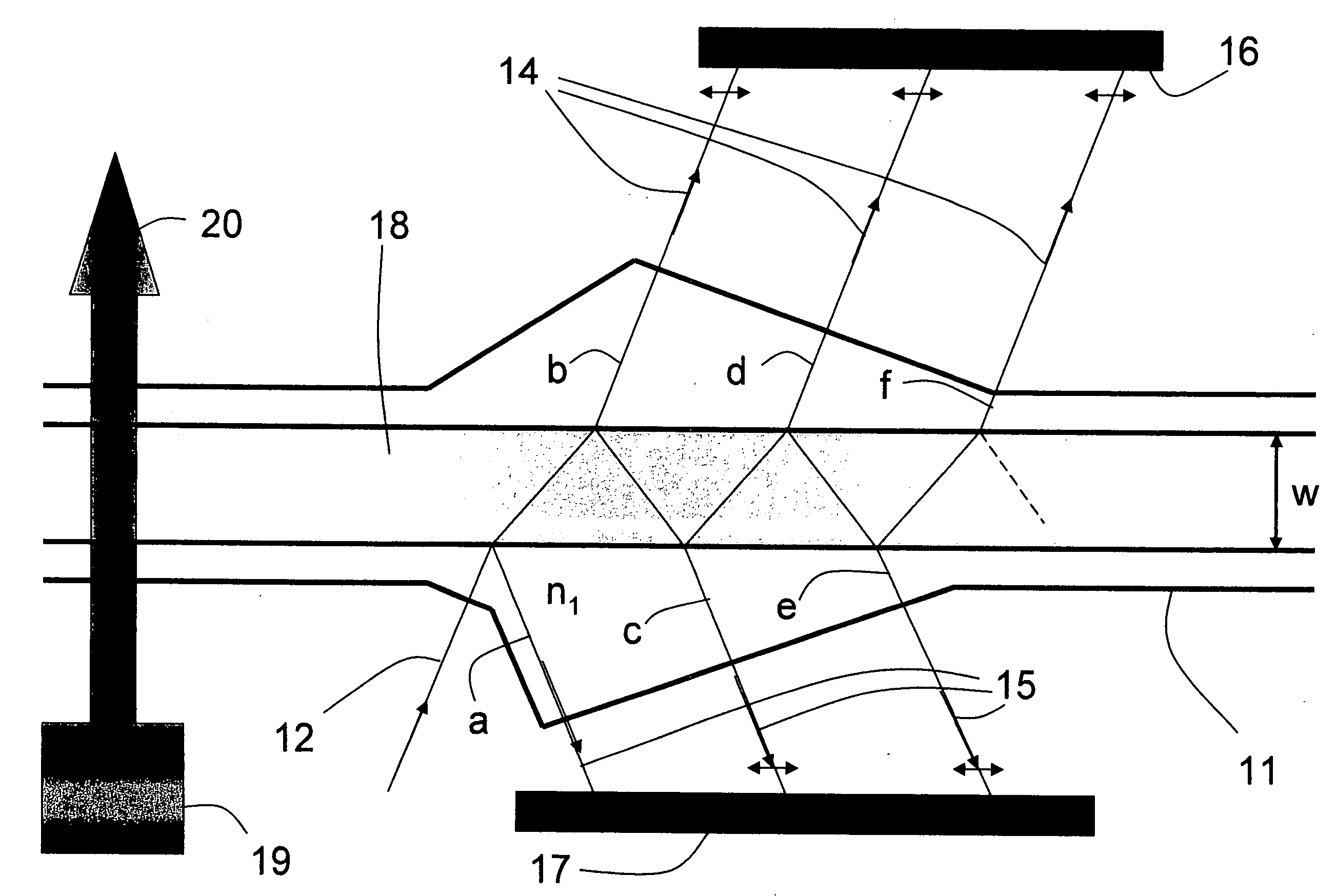

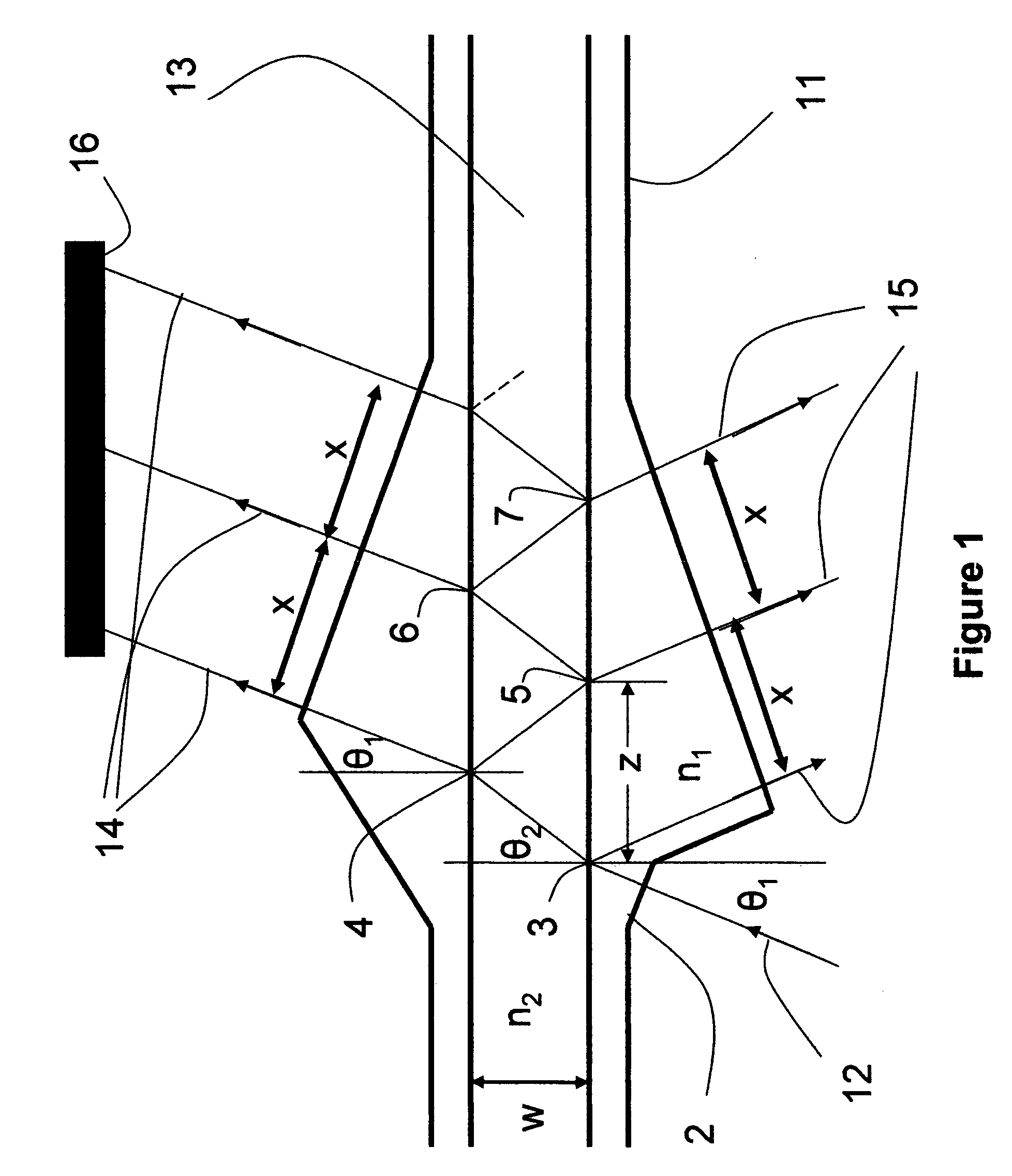

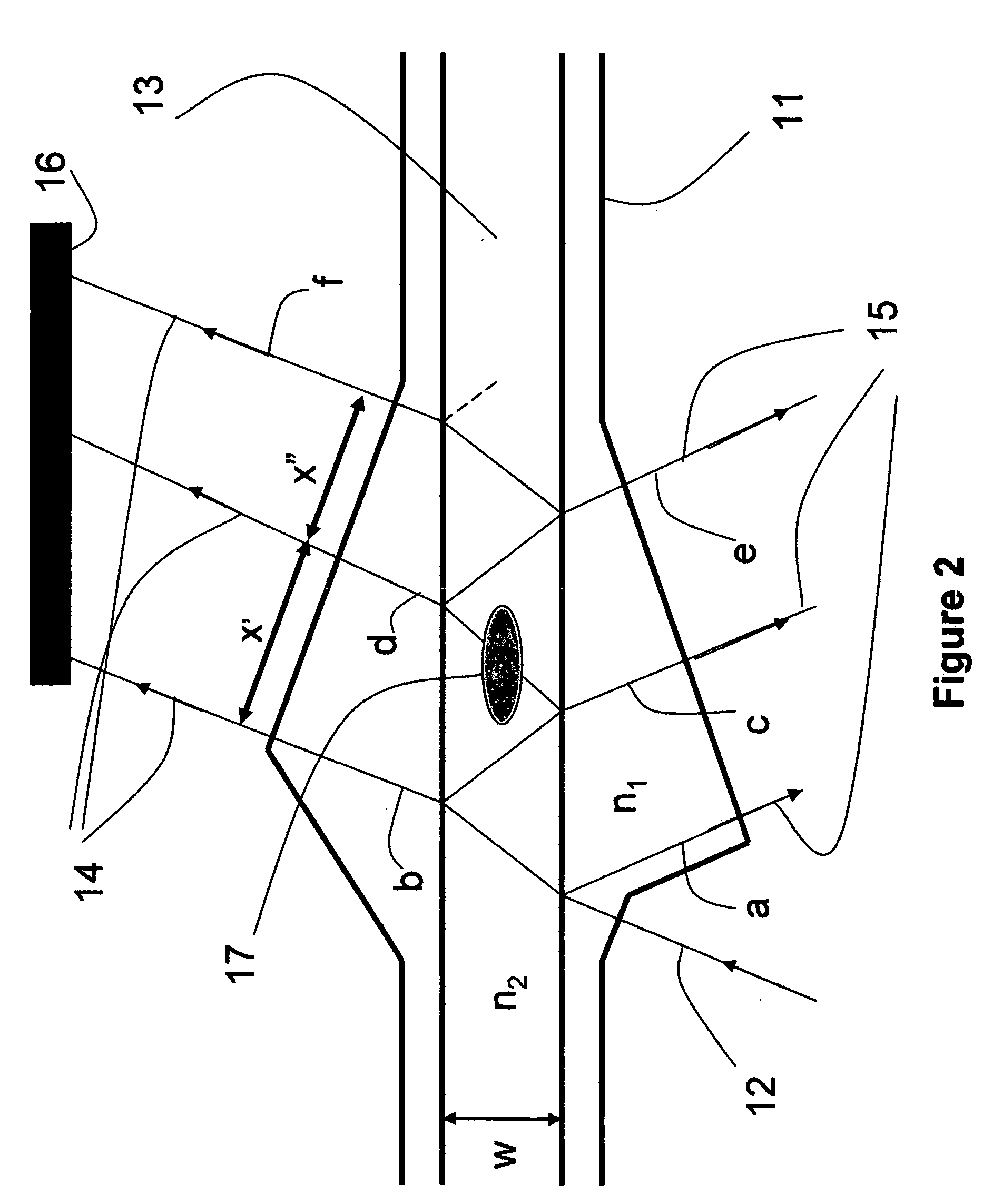

Flow metering system

InactiveUS20060260416A1Accurate measurementStrong enoughVolume/mass flow measurementFlow transducerStream flow

A non-contact fluid flow monitor that enables a two component system comprised of a removable conduit and reusable flow rate sensor is described. The monitor is capable of measuring fluid flow velocity and the dimensions of the removable conduit thereby calculating a true volumetric flow rate. The monitor is further capable of determining the refractive index of the fluid thereby verifying that the fluid flowing through the conduit has this expected property.

Owner:SAGE BURTON H +2

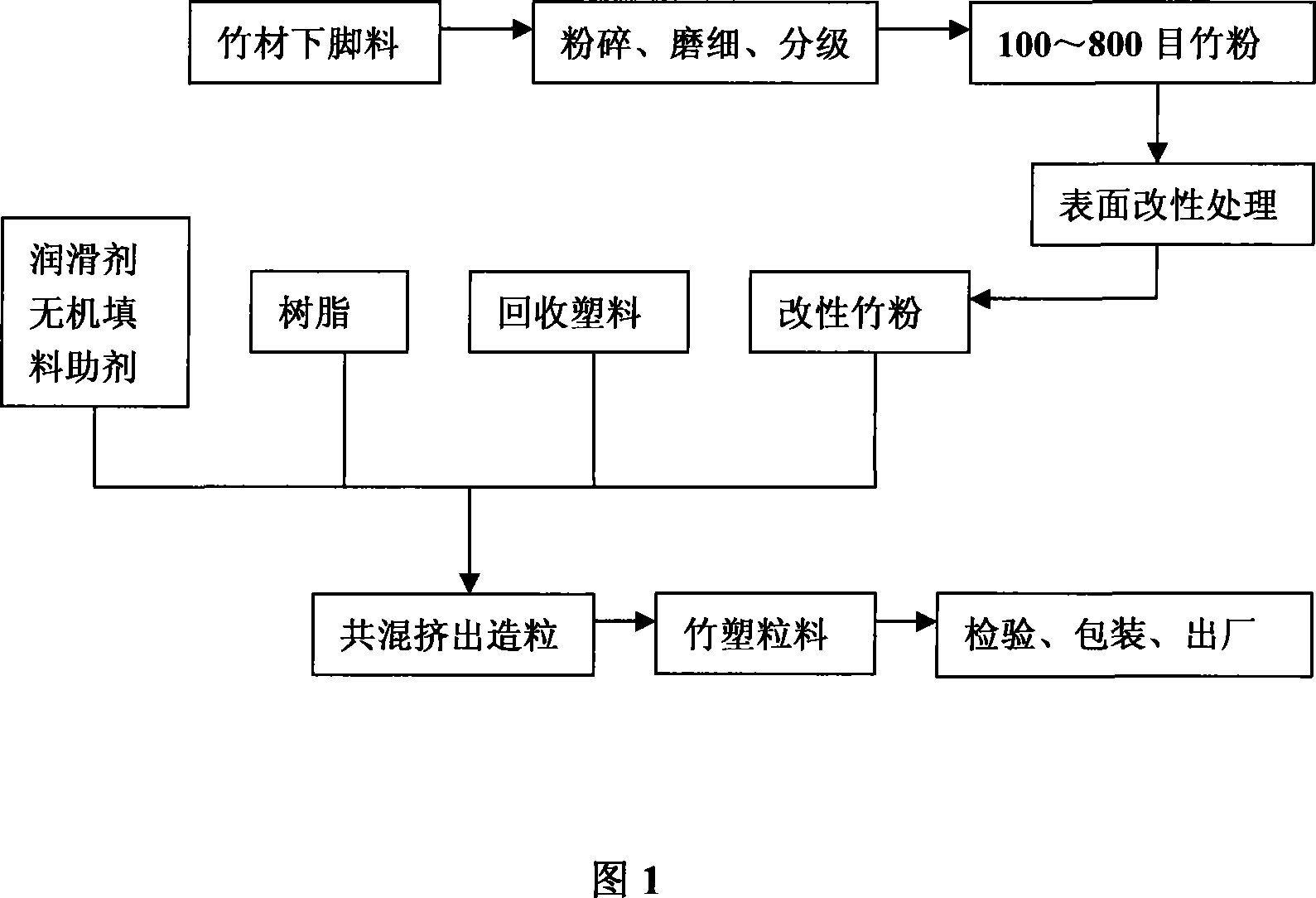

Bamboo-plastic composite material

The invention provides a bamboo-plastic composite material which is obtained by that raw materials such as plastic, recycled waste plastics, bamboo powder, modifier, chemical agent, lubricant, etc. are mixed in different proportions and extruded out to get series bamboo-plastic granule; the invention can be used for manufacturing different products such as bamboo-plastic boards, wood-plastic composite profiles and wood-plastic tubular products, etc. through extruding. The series bamboo-plastic granule can be produced in a continuous large volume and is characterized in that the production efficiency is high, the cost is low and the performance-price ratio is high, etc. The series bamboo-plastic granule can be used for replacing wood, and the cost thereof is lower than wood-plastic materials while the mechanical strength thereof is higher than wood-plastic materials, therefore the series bamboo-plastic granule can be widely popularized for use. The series bamboo-plastic granule is a novel cyclically reutilized material resource after wood-plastic material.

Owner:戴福寿 +1

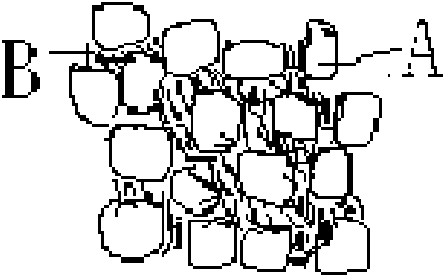

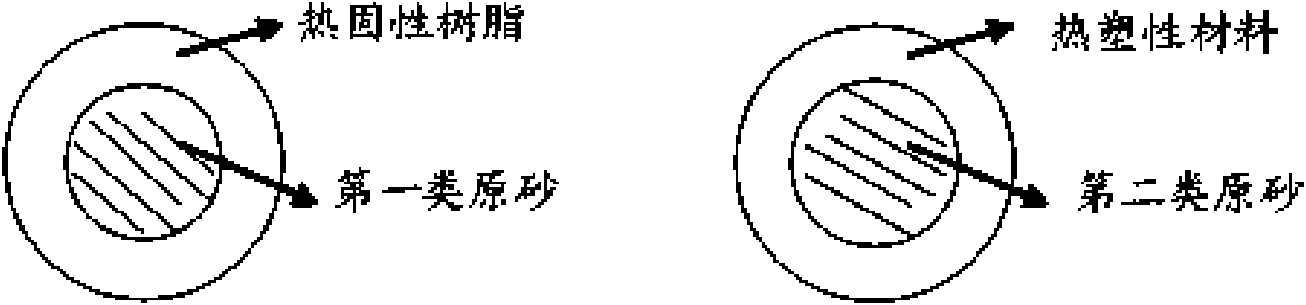

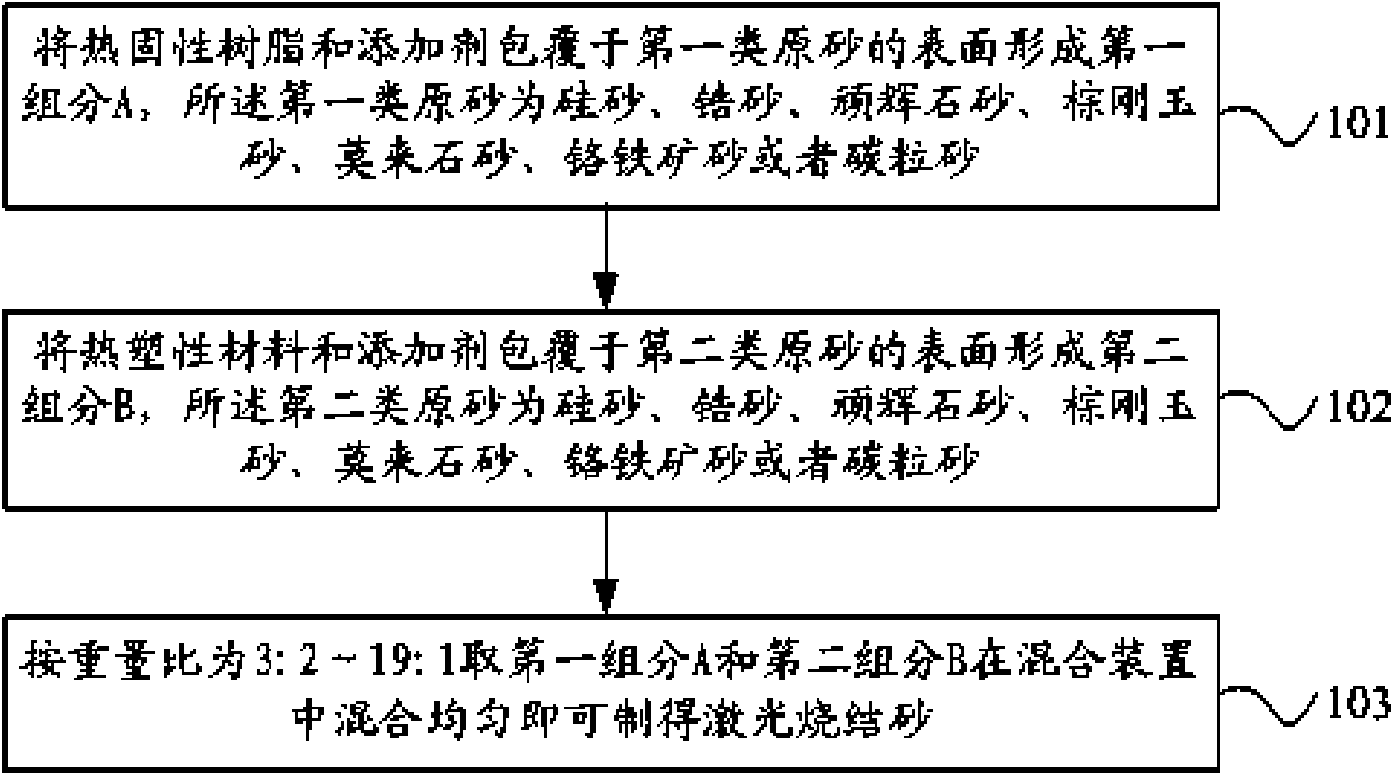

Laser sintering sand, preparation method thereof, sand core and preparation method thereof

ActiveCN101837427AHigh sintered initial strengthMeet the intensityFoundry mouldsFoundry coresGenerating capacityMetal

The invention relates to a laser sintering sand, a preparation method thereof, a sand core and the preparation method thereof. The laser sintering sand consists of a first component and a second component which are evenly mixed, the first component consists of a first type of raw sand with the coefficient of angularity of less than 1.3, thermosetting resin and additives, wherein the thermosetting resin and the additives are coated on the surface of the first type of the raw sand; and the second component consists of a second type of raw sand with the coefficient of angularity of less than 1.1, a thermoplastic material and the additives, wherein the thermoplastic material and the additives are coated on the surface of the second type of the raw sand. The adoption of the laser sintering sand does not need to add an auxiliary support structure during the laser sintering process, thereby improving the molding efficiency and reducing the manual intervention; and the any complex sand core can be manufactured without using a mold, and the sand core simultaneously has high sintering initial strength and can meet the requirements on the thermal strength and the gas-generating capacity of the sand core during the metal casting process.

Owner:安徽隆源成型科技有限公司

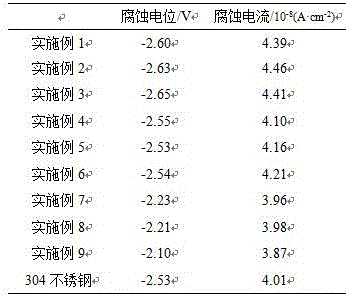

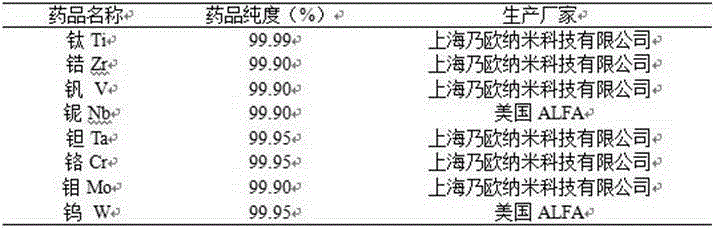

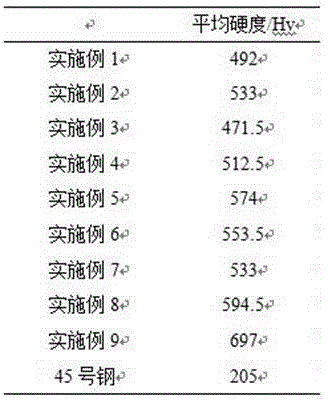

High-entropy alloy powder for laser cladding and preparation method of cladding layer

InactiveCN106086580AHigh bonding strengthEasy to diluteMetallic material coating processesHigh entropy alloysHardness

The invention discloses high-entropy alloy powder for laser cladding and a preparation method of a cladding layer. The high-entropy alloy powder comprises Ti, Zr, V, Nb, Ta and Mo. In addition, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo and W, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo, W and Cr and the preparation method of the cladding layer of the high-entropy alloy powder for laser cladding are provided. The high-entropy alloy powder mainly comprises two characteristics, namely, the high-entropy effect and the cocktail effect, each kind of powder exerts respective advantages, and therefore the cladding layer with high hardness, high corrosion resistance, excellent tempering softening resisting performance and excellent structure performance is obtained. Metallurgical bonding is formed by an alloy layer and a matrix through laser cladding; the bonding strength of the cladding layer and the matrix is greatly improved, and the heating speed is high; metal of the cladding layer is not prone to being diluted by the matrix; little heat deformation is generated; and therefore the part rejection rate is low.

Owner:KUNMING UNIV OF SCI & TECH

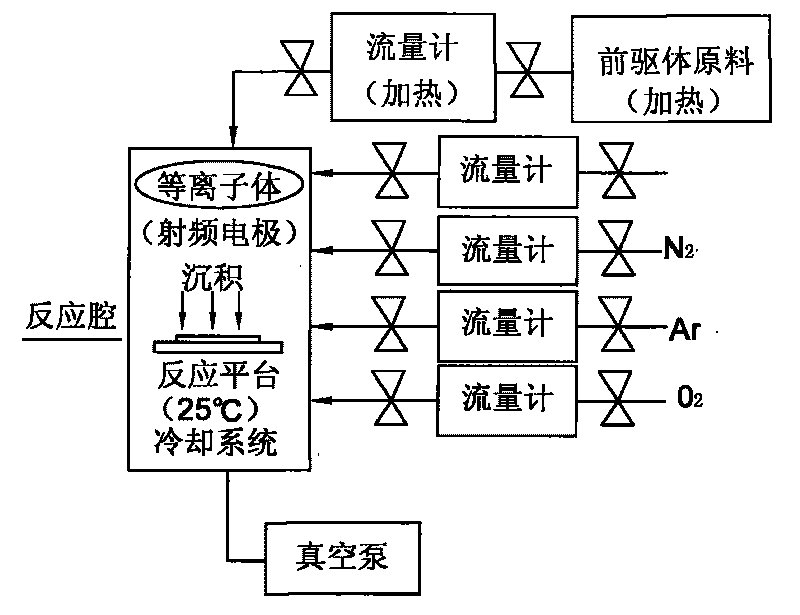

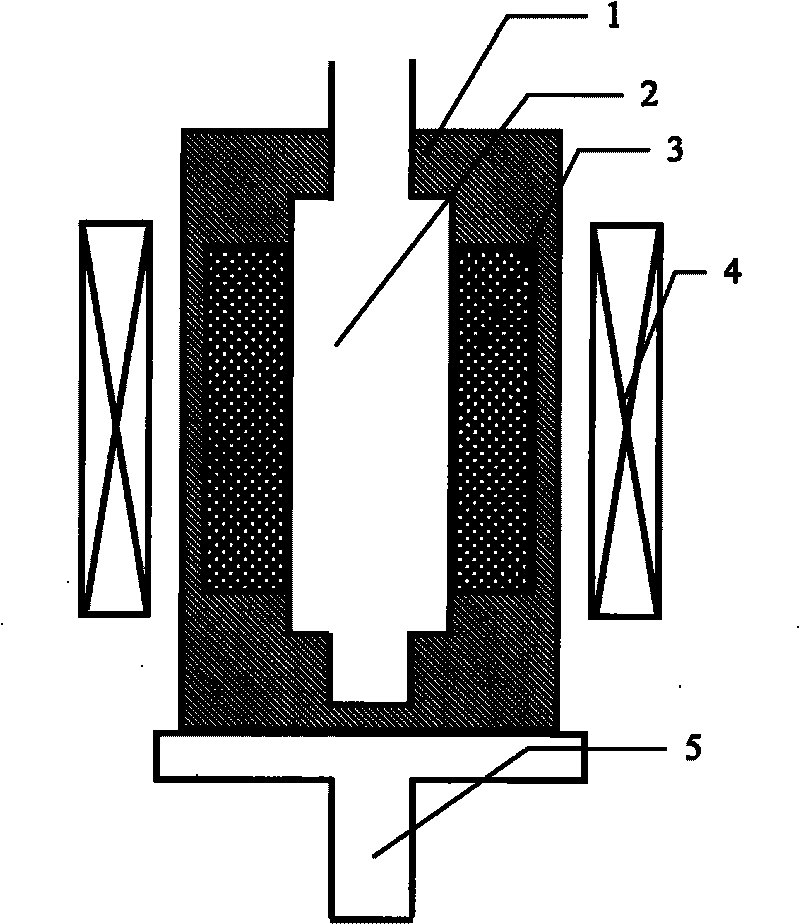

Film encapsulation method

InactiveCN101697343AEasy to operateReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesSilicon oxideOxygen

The invention discloses a film encapsulation method, which adopts a PECVD method and a mode of growing a film on the surface of a device to separate the device from water and oxygen in the air and achieve the aim of physical protection so as to implement encapsulation for the device. The method specifically comprises the following steps: (1) placing the device to be encapsulated into a PECVD device, and setting a mask plate to control the encapsulated area; and (2) using an organic silicon precursor and adopting the PECVD method to deposit an inorganic layer, a polymer layer or a transition layer under the condition of plasma to obtain the required encapsulation structure. The method can finish the preparation of the polymer layer, the inorganic layer and the transition layer in one reaction cavity by adopting the PECVD method so as to simplify the operation steps, reduce the cost and shorten the period; and meanwhile, the prepared encapsulation layer has a transition layer structure of a large amount of polymer or component gradually changed to silicon oxide or silicon nitride from soft polymer, so the encapsulation layer has enough flexibility and is not influenced by interface problem.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Multiplex composite bone tissue engineering bracket material capable of degrading gradiently and preparation method thereof

The invention discloses a multiplex composite engineering scaffold material capable of gradually decomposing bone tissue and a preparation method thereof. The composite scaffold material consists of calcium phosphate bone cement, biological compatible degradable synthetic high polymer and biological compatible degradable natural high polymer, has better mechanical property and gradient degradation characteristic, and can achieve the aim of regenerating and repairing bone tissue defect by implanting a bone growth factor to induce in-vivo stem cells to be differentiated into bone cells, thereby obviously improving initial strength and toughness of the scaffold material, and ensuring enough strength and toughness of the scaffold material during operating and implanting. After compounded with the high polymer material, the scaffold has excellent flexibility, so that the scaffold can be subjected to certain machining, such as cutting and the like.

Owner:SOUTH CHINA UNIV OF TECH

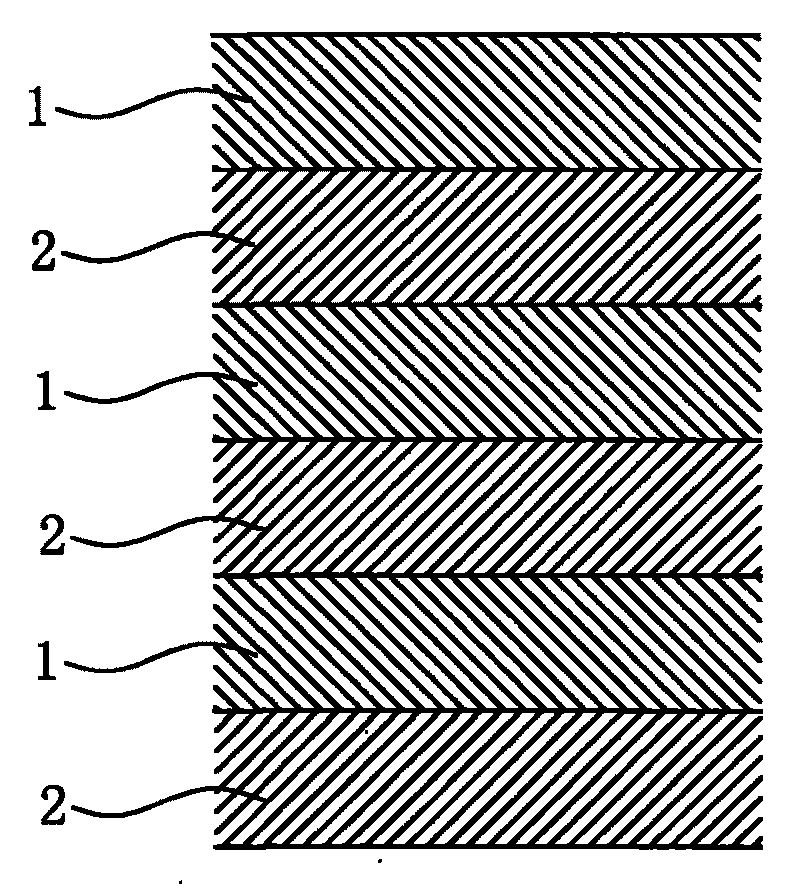

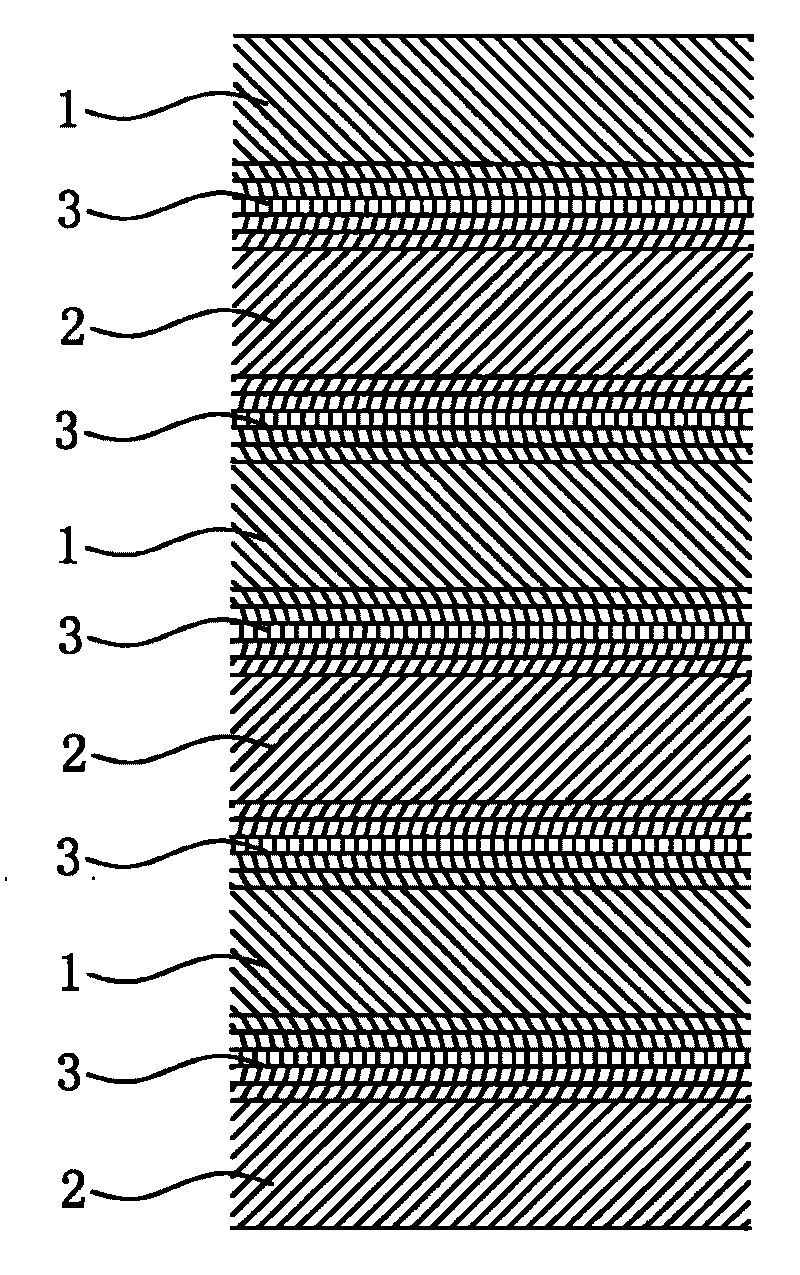

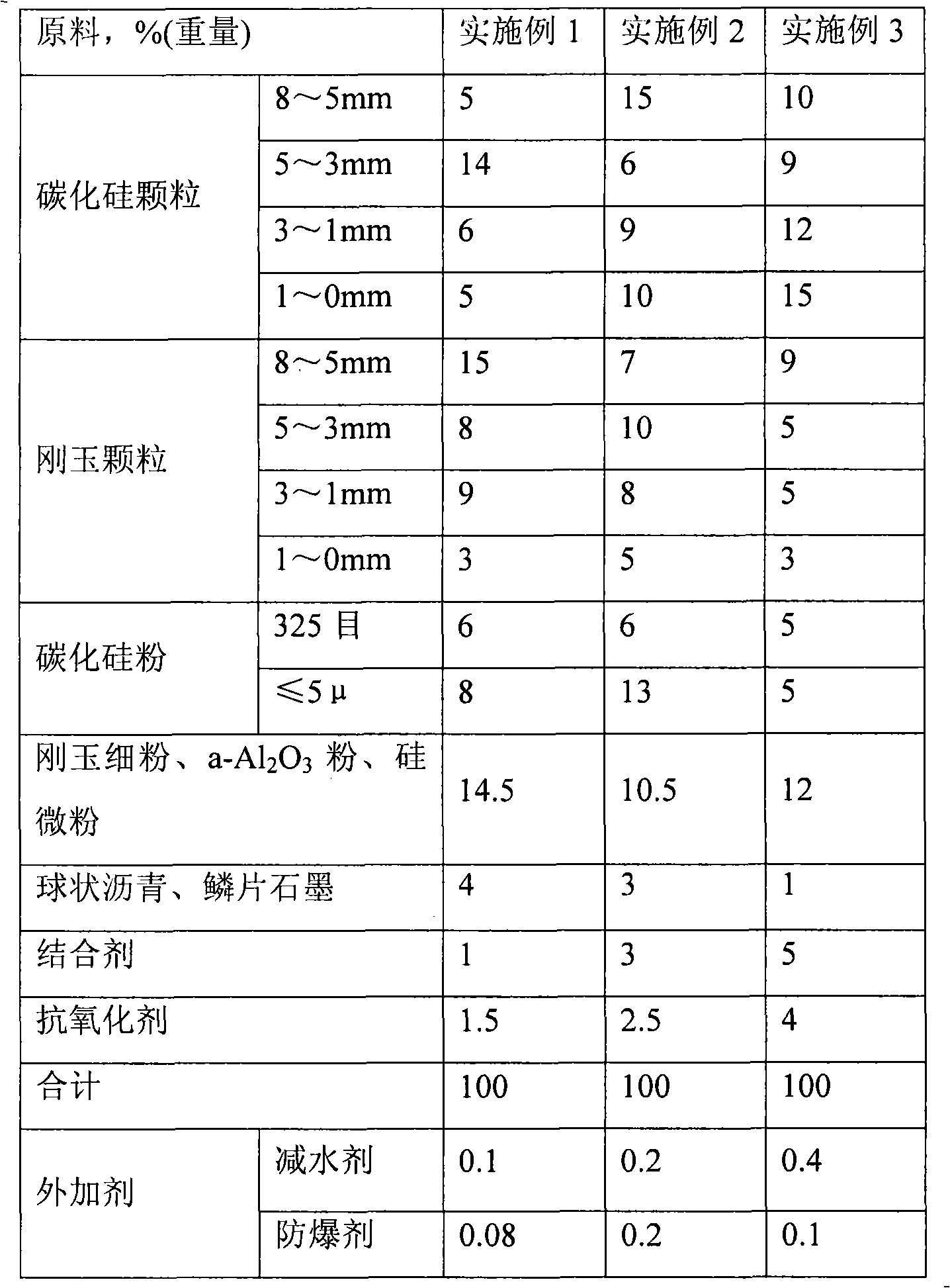

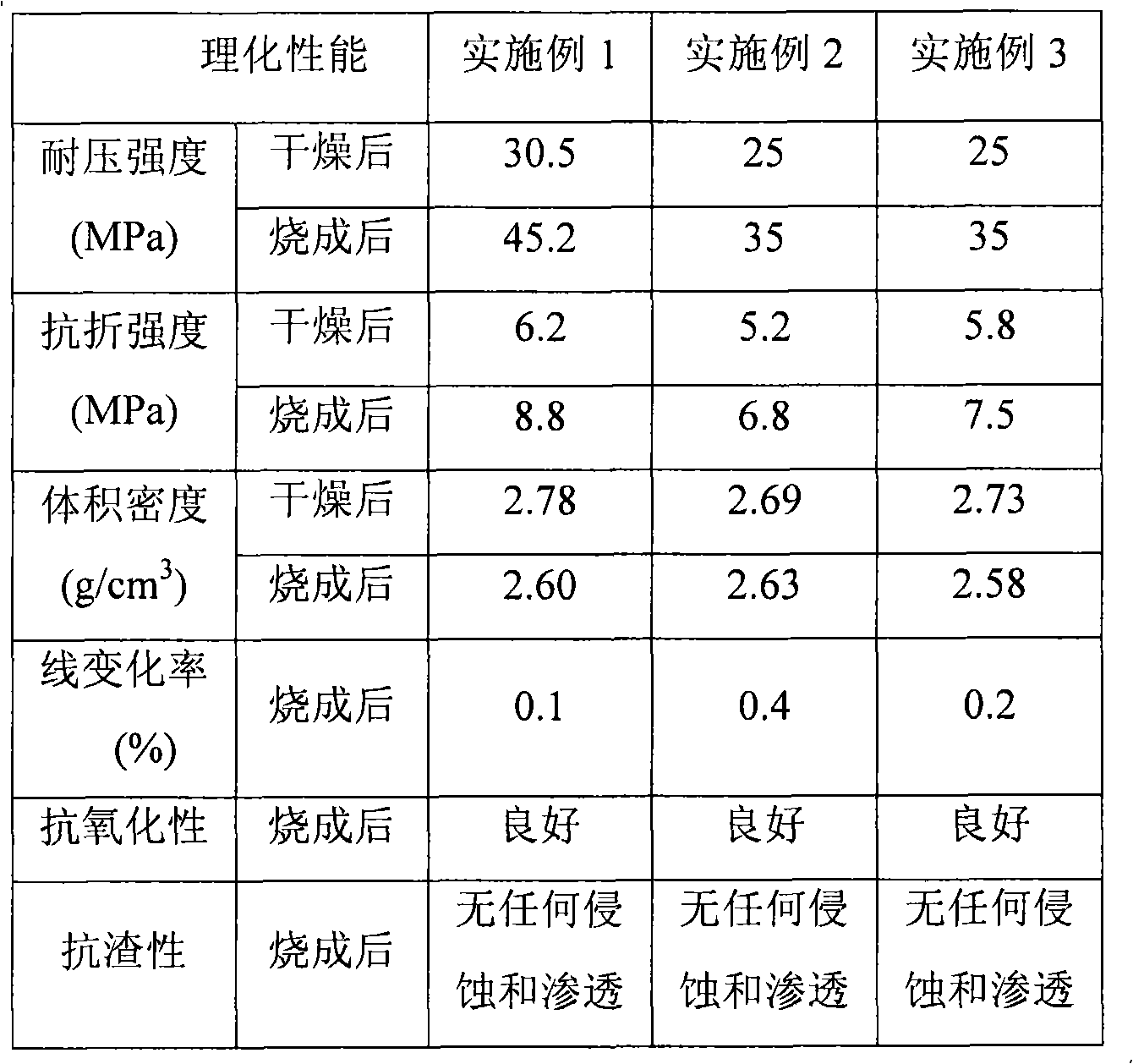

Preparation method of Al2O3-SiC-C castable material for slag line of main trough of blast furnace

The invention relates to an Al2O3-SiC-C castable material for a slag line of a main trough of a large blast furnace and a preparation method thereof. The castable material comprises an aggregate, a matrix, a bonding agent, an antioxidant and an admixture; wherein, the aggregate comprises corundum grains and carborundum grains; the matrix comprises ball pitch, flake graphite, corundum fine powder, a-Al2O3 ultrafine powder, silicon powder and carborundum ultrafine powder; the bonding agent is aluminate cement; the antioxidant is a compound of aluminium powder and silicon powder; the admixture comprises a water reducing agent and a detonation suppressor. The castable material is prepared by the steps of mixing various raw materials evenly, adding water, stirring, casting molding, maintaining and drying. The castable material has strong anti-slag corrosion and anti-scour capabilities, good high temperature resistance, abrasion resistance and thermal shock resistance, slight reheating change and long service life.

Owner:BEIJING TONGDA REFRACTORY TECH CO LTD

Preparation method of room temperature cured high temperature tolerant flexible epoxy adhesive

InactiveCN1546590AImprove temperature resistanceGood flexibilityEpoxy resin adhesivesPliabilityRoom temperature

The invention discloses a preparation method of room temperature cured high temperature tolerant flexible epoxy adhesive, wherein the adhesive comprises a binding component and a hardening component, wherein the binding component includes flexibilizing constituent, heatproof constituent and plasticity agent, the hardening constituent comprises main hardening agent and hardening accelerating agent. The epoxy adhesive provided by the present invention has good tenacity and high binding strength.

Owner:SICHUAN UNIV

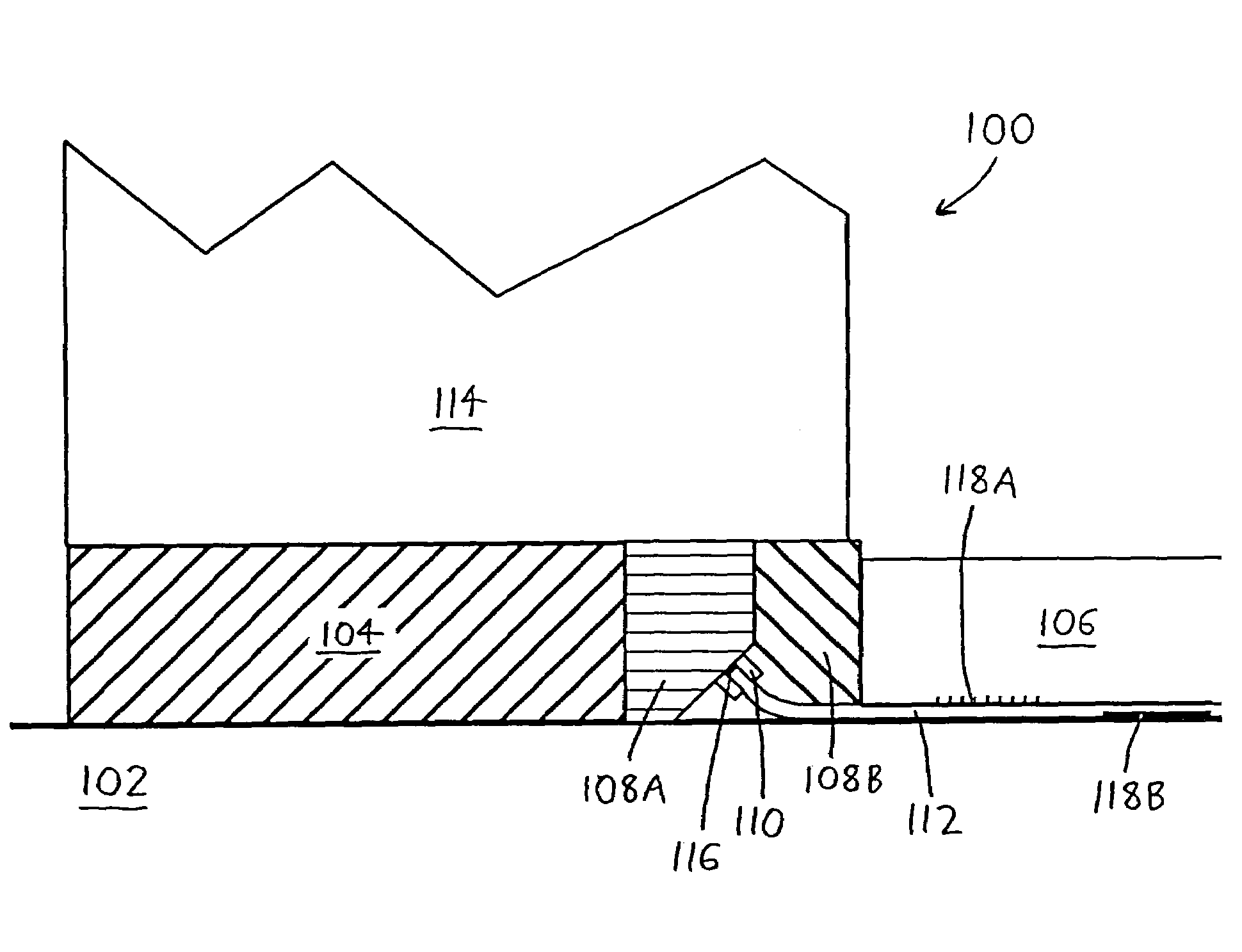

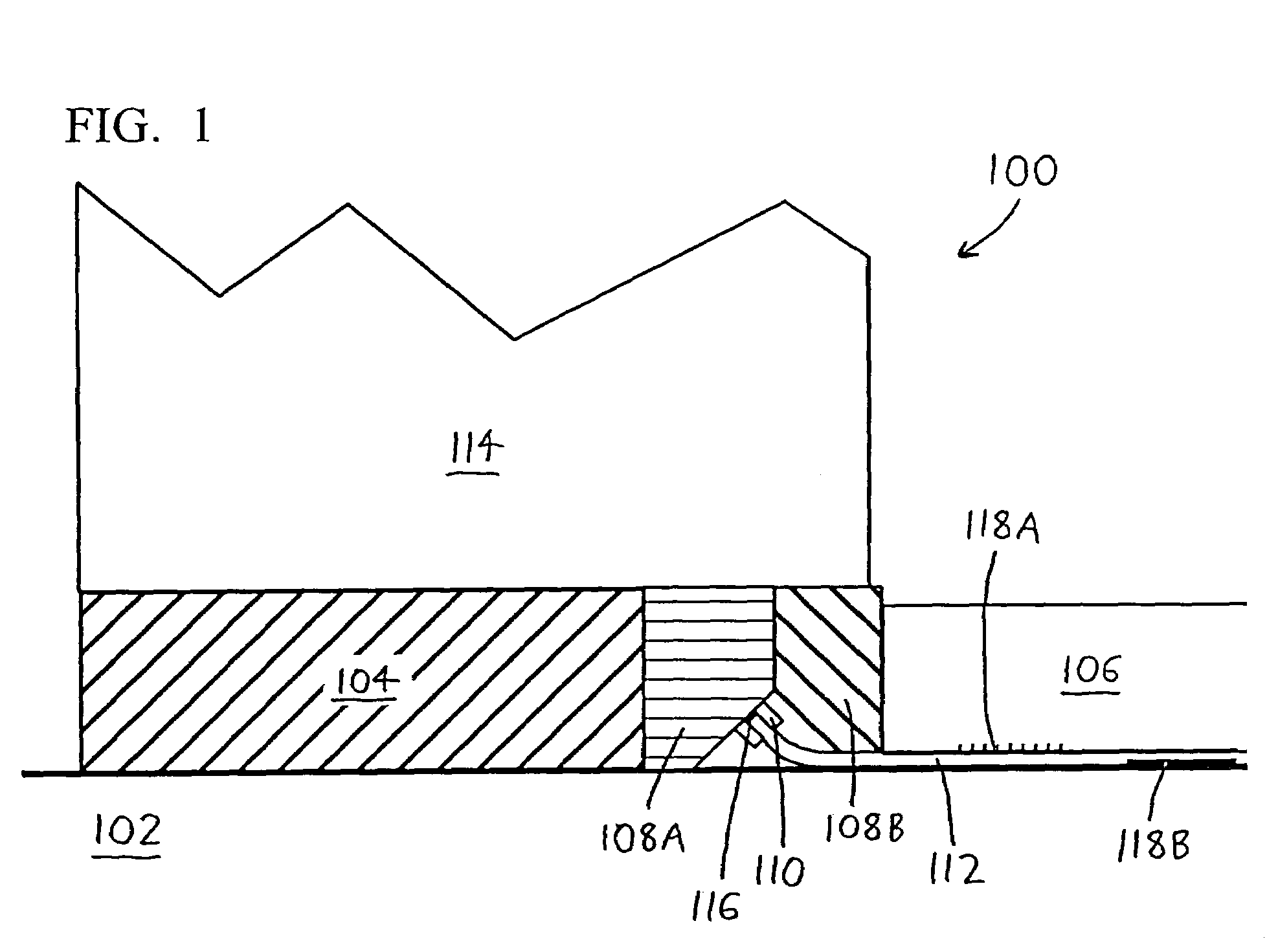

Near-Field Light Transducer Comprising Propagation Edge With Predetermined Curvature Radius

ActiveUS20110038236A1Satisfactory thermally-assisted magnetic recordingImprove light utilization efficiencyCombination recordingRecord information storageSurface plasmonTransducer

Provided is a near-field light transducer with a propagation edge in which the generation of defects is suppressed. The transducer is formed of a Ag alloy and comprises an edge, the edge comprising a portion to be coupled with a light in a surface plasmon mode, the edge extending from the portion to a near-field light generating end surface, and the edge being configured to propagate surface plasmon excited by the light. Further, a curvature radius of the rounded edge is set in the range from 6.25 nm to 20 nm. In the edge and its vicinity, the generation of defects such as cracking and chipping is suppressed. Thereby improved are a propagation efficiency of surface plasmon and a light use efficiency of the transducer. The Ag alloy preferably contains at least one element selected from a group of Pd, Au, Cu, Ru, Rh and Ir.

Owner:TDK CORPARATION

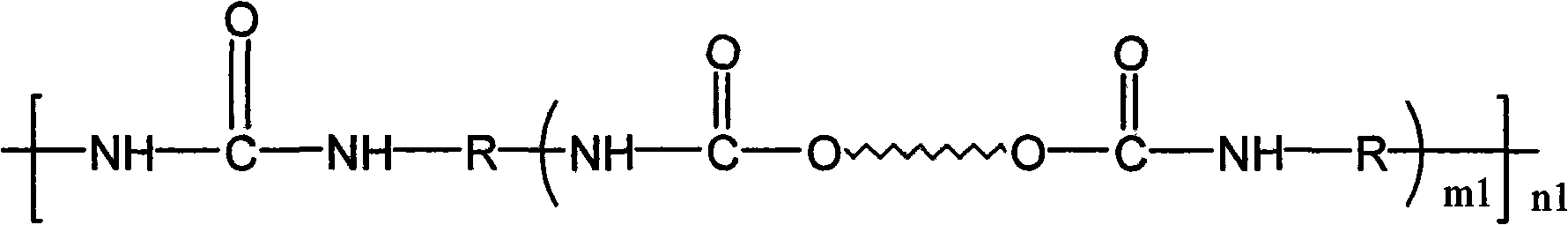

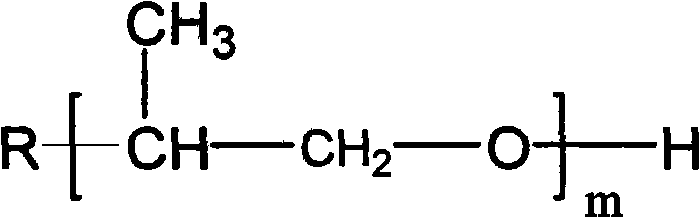

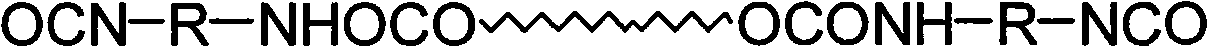

Polyurethane for orthopedic external fixation system in complicated environment and preparation method thereof

The invention relates to polyurethane for an orthopedic external fixation system in a complicated environment, which is prepared by the reaction of modified isocyanate and polyether polyol. The invention also provides a preparation method of the polyurethane. The polyurethane can be used at the environmental temperature of 5 to 15 DEG C or 25 to 30 DEG C, can be used for the fixation of a complicated part which is difficult to process by plaster, macro-molecular badges and the like and has superhigh rigidity and strength; meanwhile, the polyurethane is breathable and easily cleanable and thus, medicinal stuff can freely remove the polyurethane to clean and process the skin surface of an injured part according to curing requirements and requirements of patients.

Owner:优创医疗器械技术张家口有限公司 +1

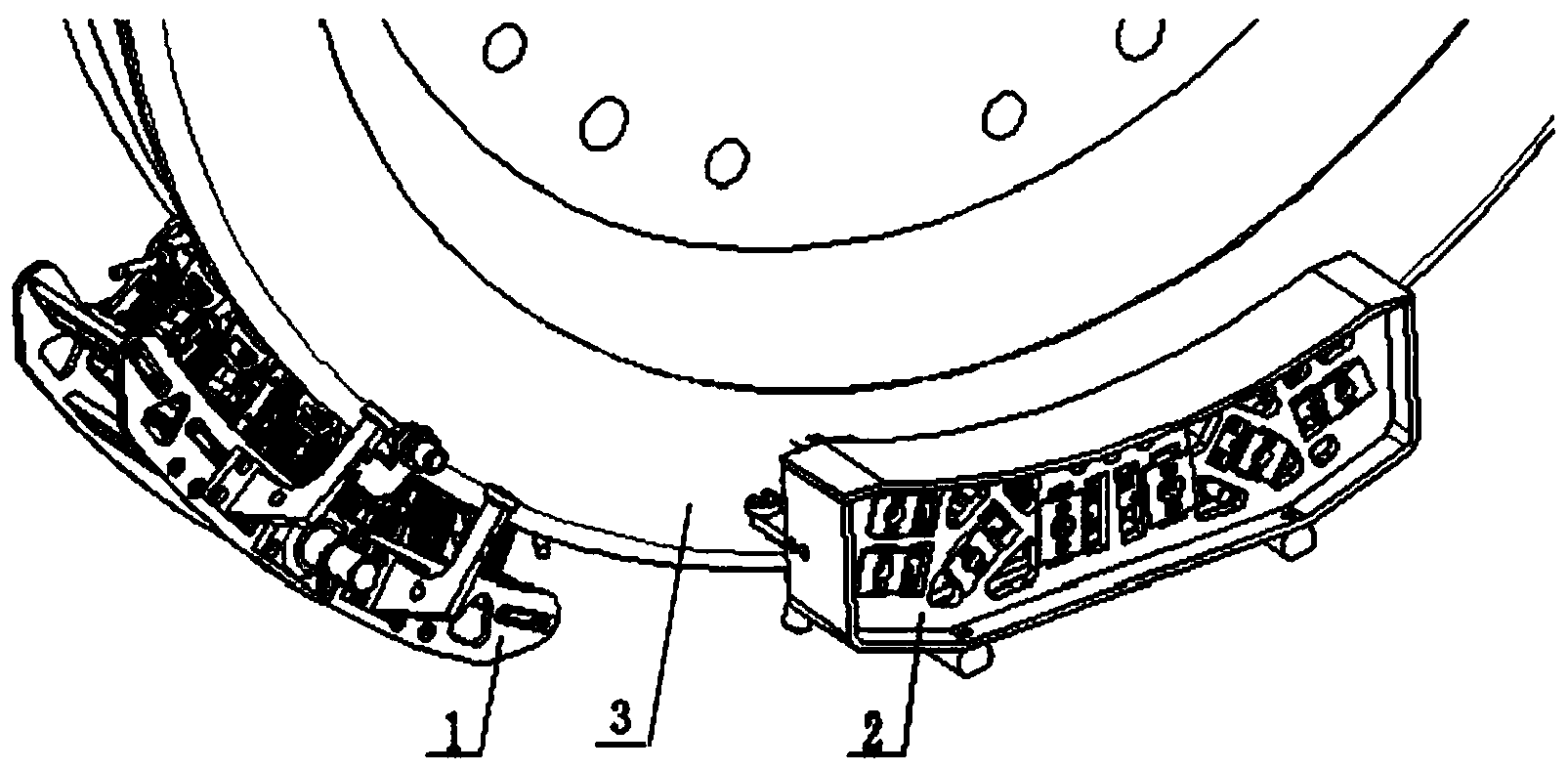

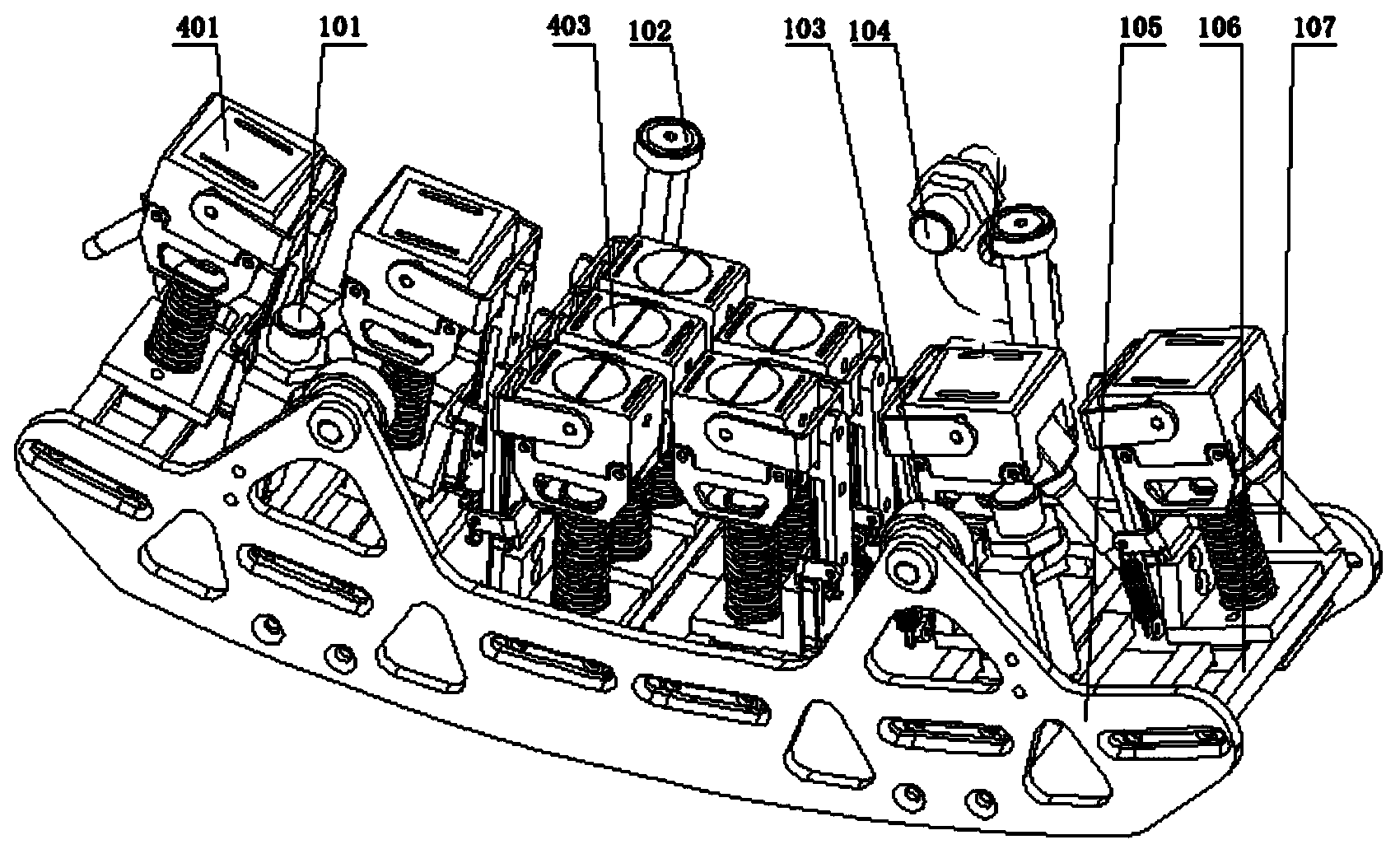

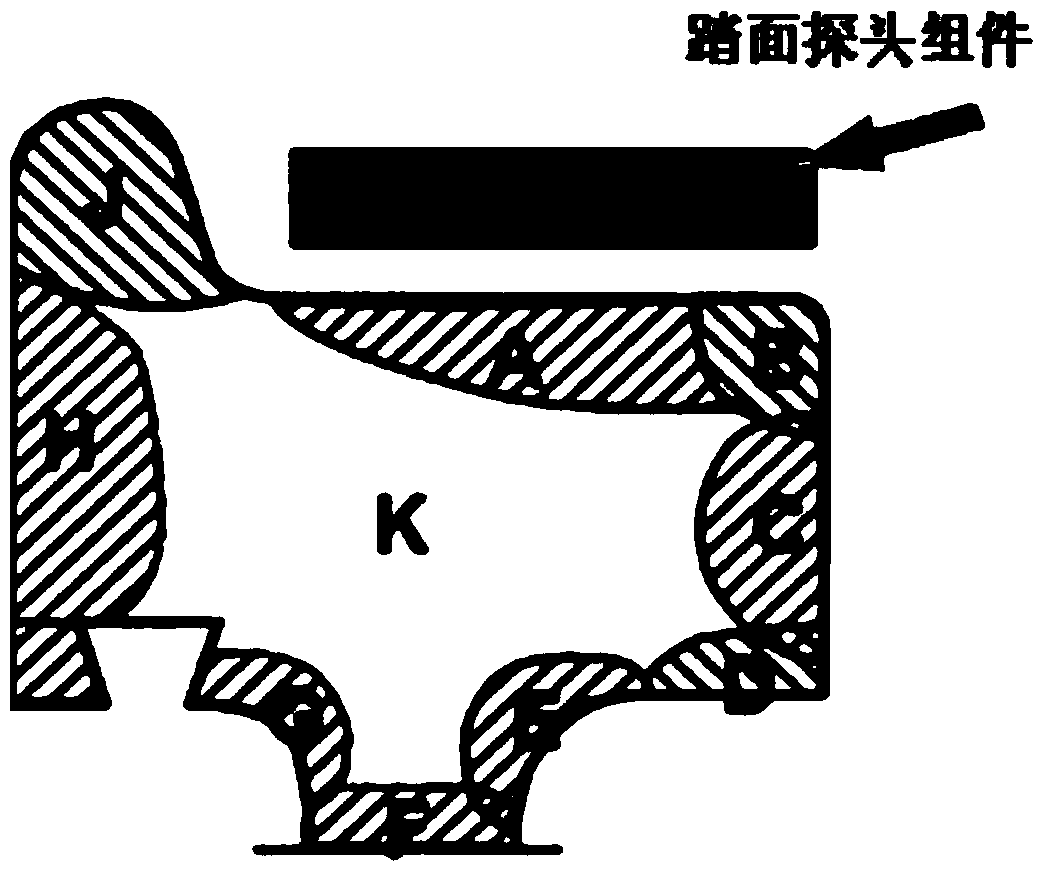

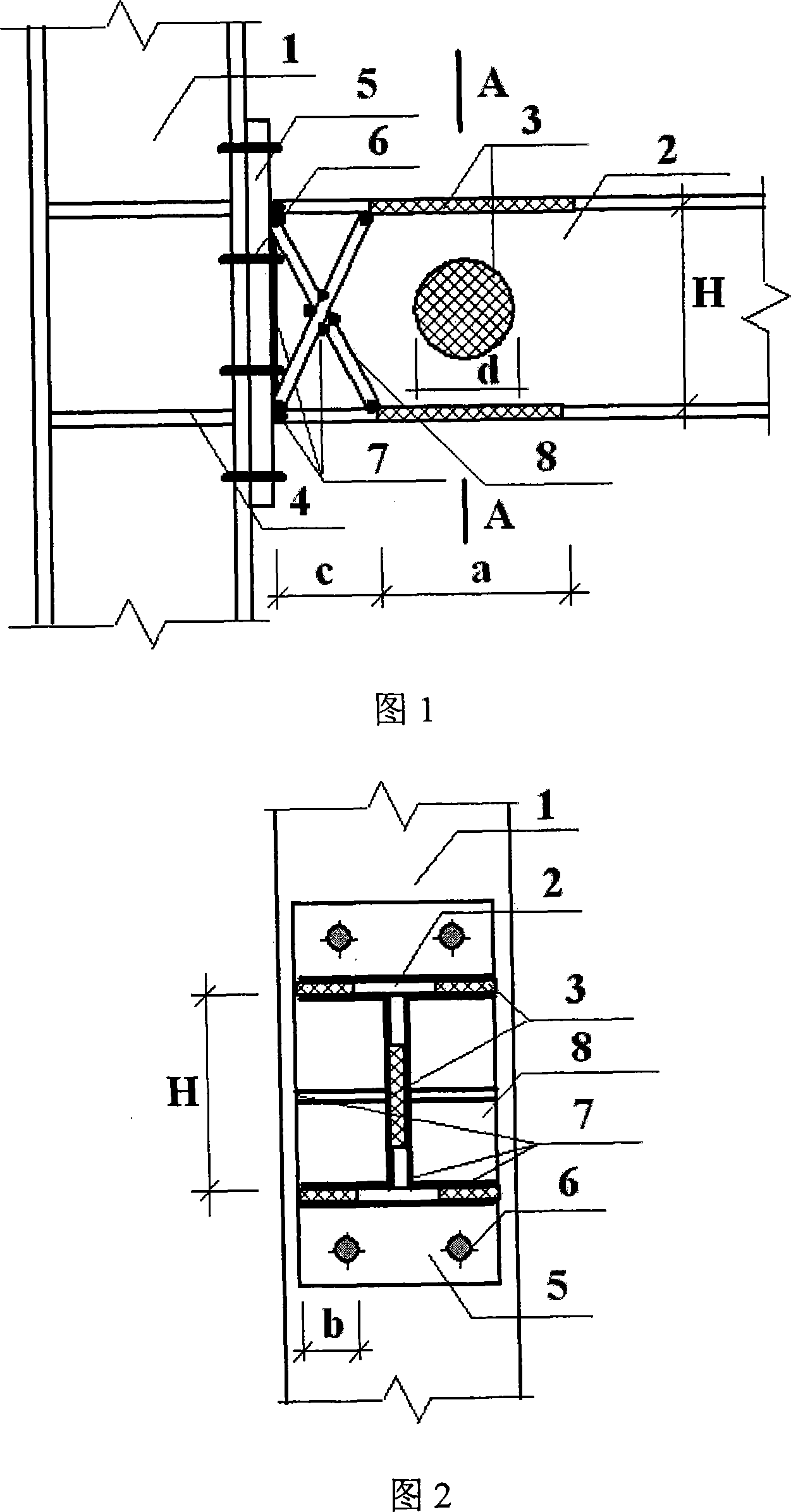

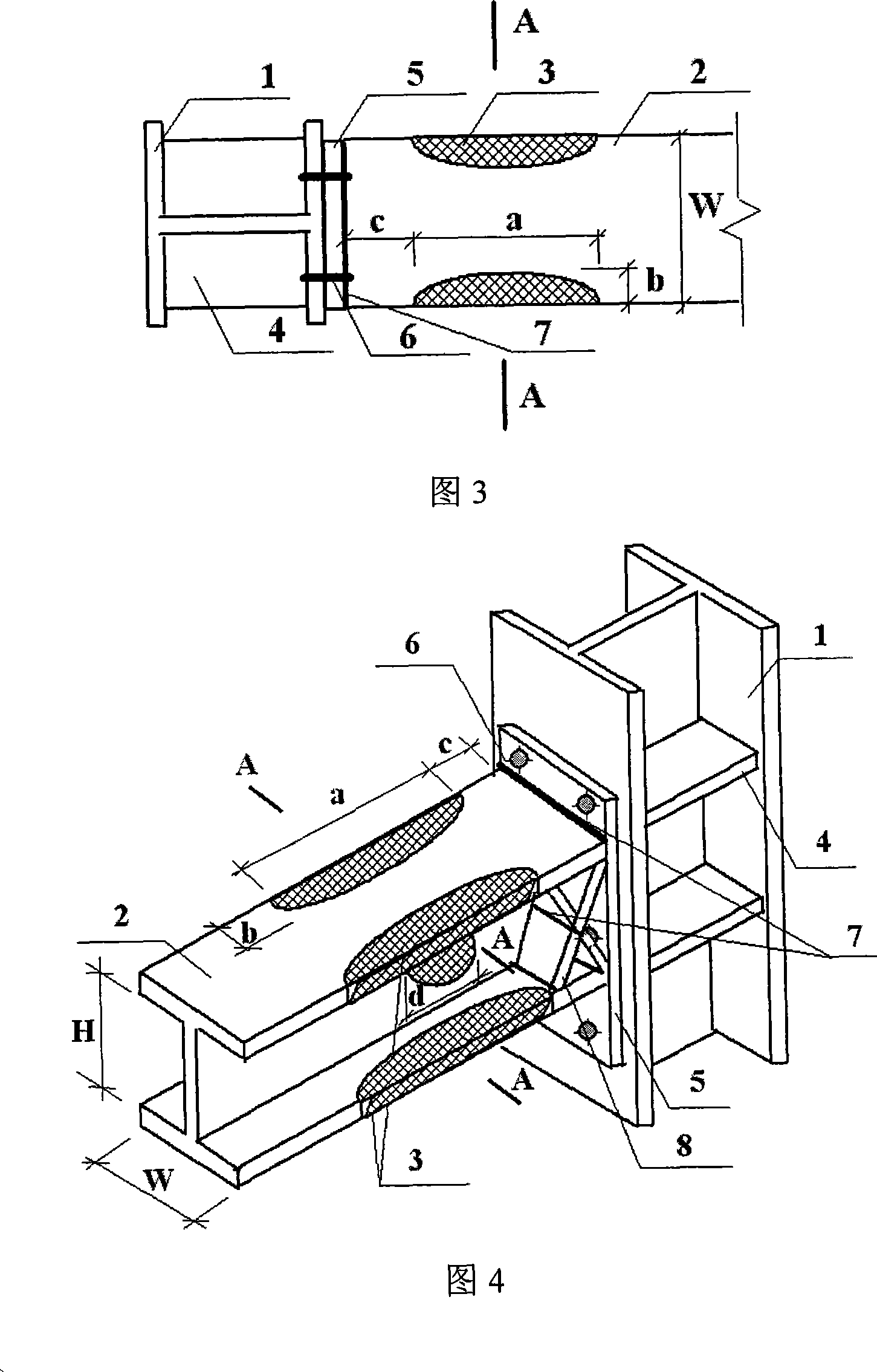

Track vehicle rim and tread flaw detection probe assembly system

ActiveCN103472138AEasy to useProtect the safety of useMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringManipulator

The invention discloses a track vehicle rim and tread flaw detection probe assembly system. The track vehicle rim and tread flaw detection probe assembly system comprises a tread flaw detection probe assembly and a rim flaw detection probe assembly. The tread flaw detection probe assembly leans on the tread of a wheel through a mechanical arm; the rim flaw detection probe assembly leans on the rim surface of the wheel through the mechanical arm; the tread flaw detection probe assembly can automatically detect wheel tread and rim defects from the tread in an online mode and is high in detection efficiency, accurate in detection result, simple in structure and convenient to use and operate; the rim flaw detection probe assembly can automatically detect wheel rim surface and tread detects from the inner lateral side of the rim in on online-mode and is high in detection efficiency, accurate in detection result, simple in structure and convenient to use and operate.

Owner:BEIJING SHEENLINE GRP CO LTD

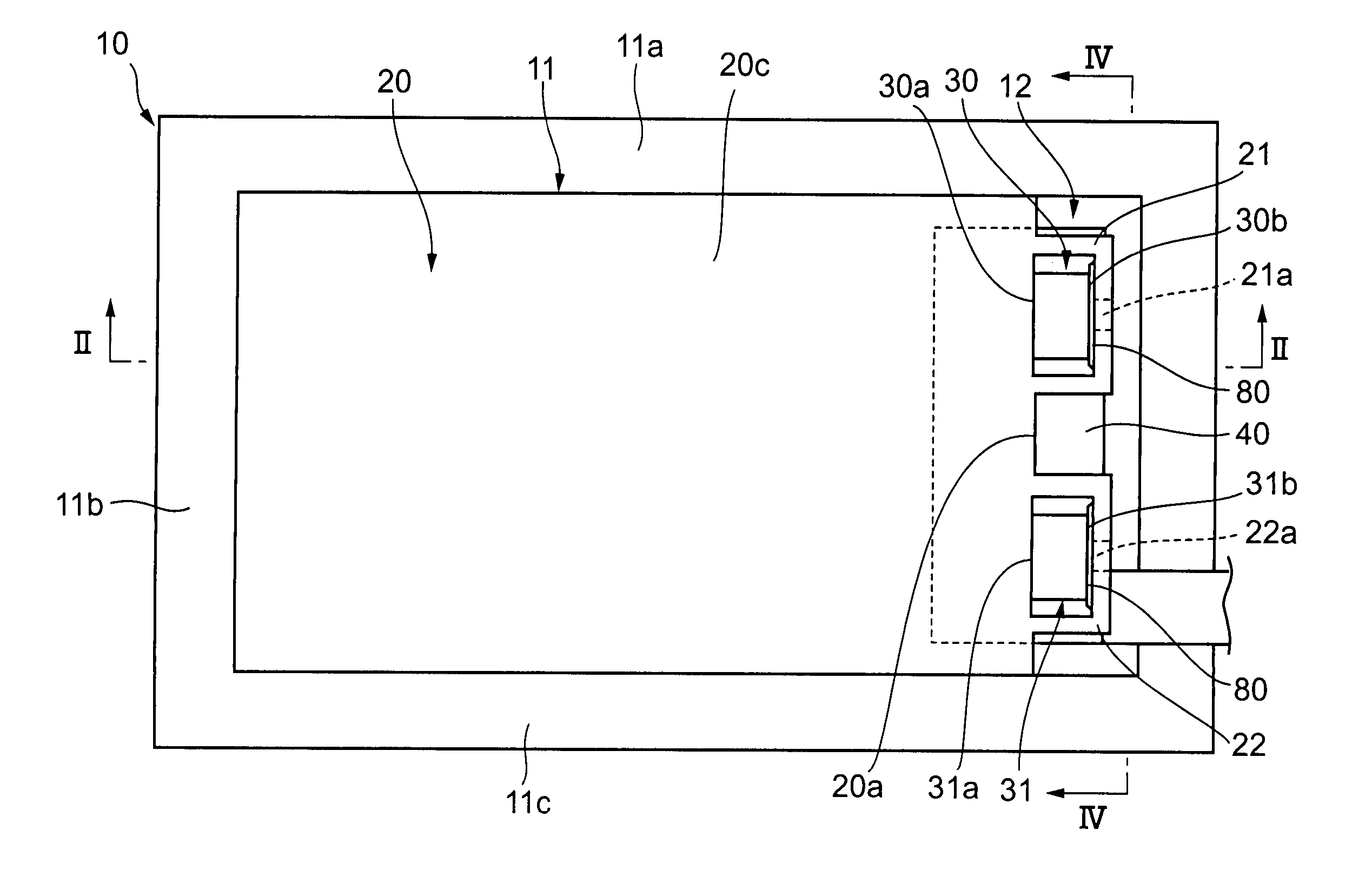

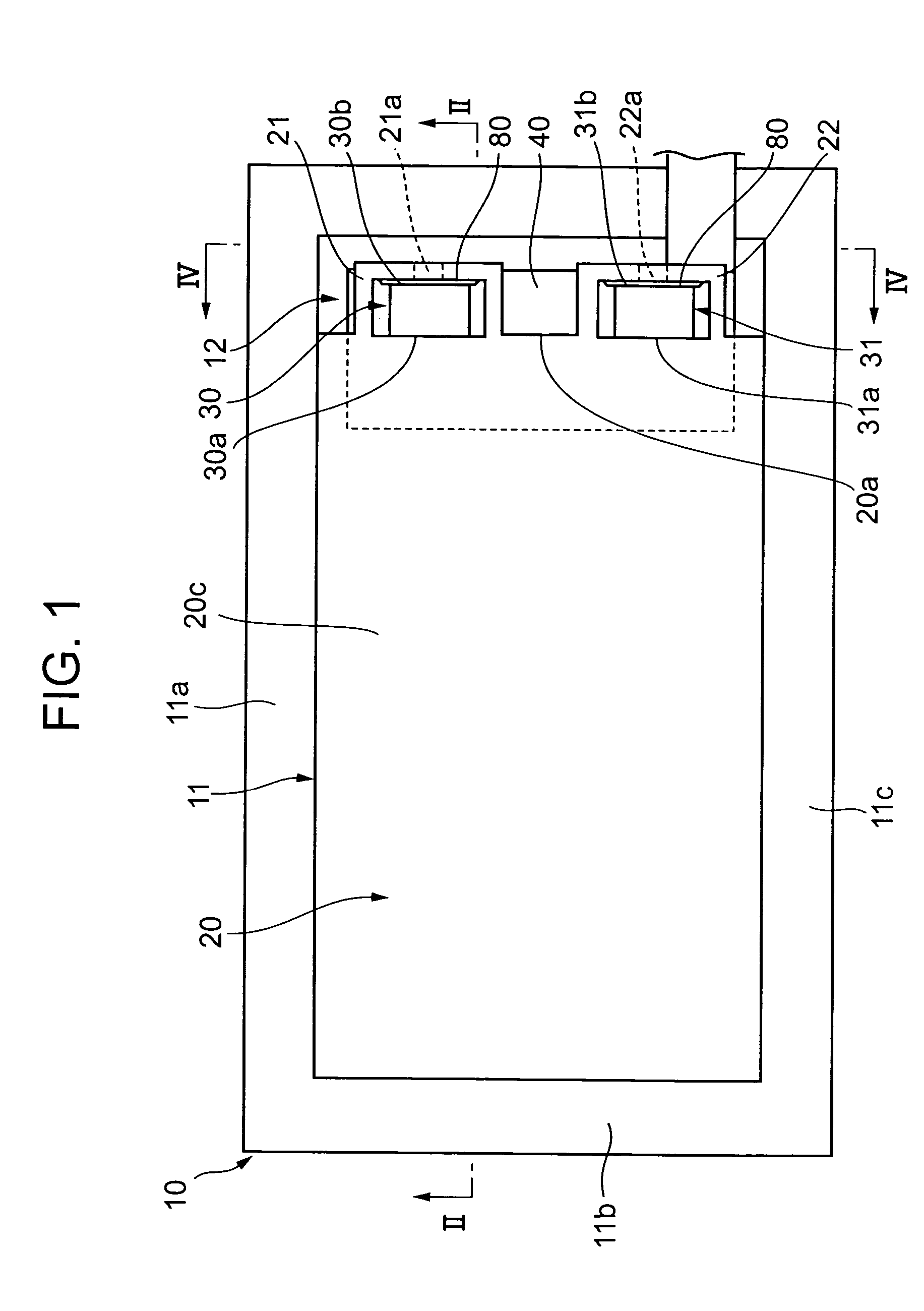

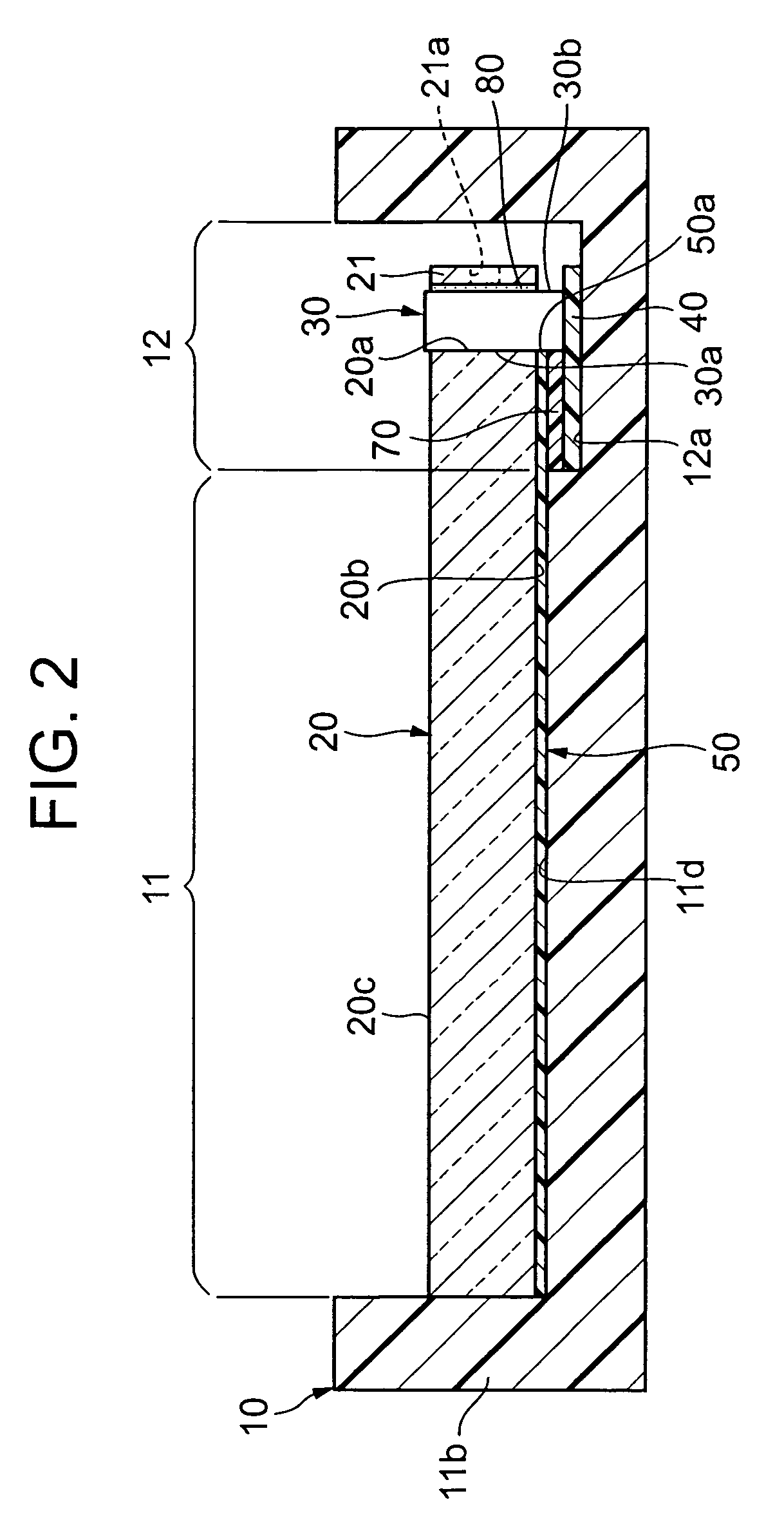

Surface-shaped light irradiation device

ActiveUS7083317B2High strengthEfficient use ofShow cabinetsImpedence networksEngineeringSurface shape

An LED is mounted on a flexible wiring board, and this flexible wiring board is adhered by a both-surface adhesive tape to a back of a light guiding plate to which a light reflecting film is adhered by an adhesive layer. The LED is kept at a desired set position by retaining the LED by a retaining section formed integrally with the light guiding plate in a state where a light emitting surface of the LED air tightly contacts a light entrance end surface of the light guiding plate, and by adhering a rear surface of the LED to an inner surface of the retaining section by an adhesive agent.

Owner:INTERDIGITAL CE PATENT HLDG

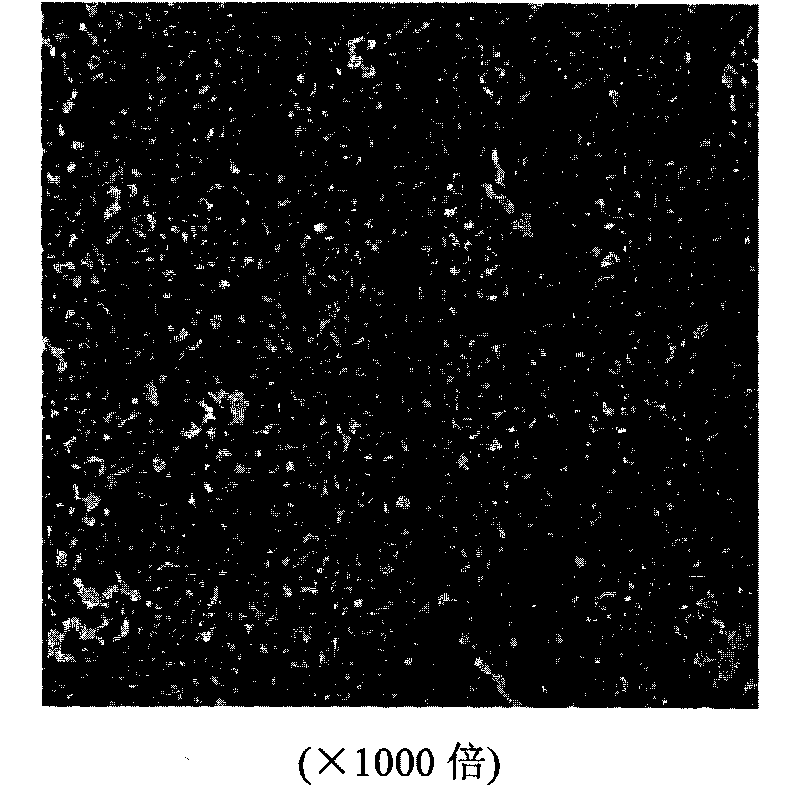

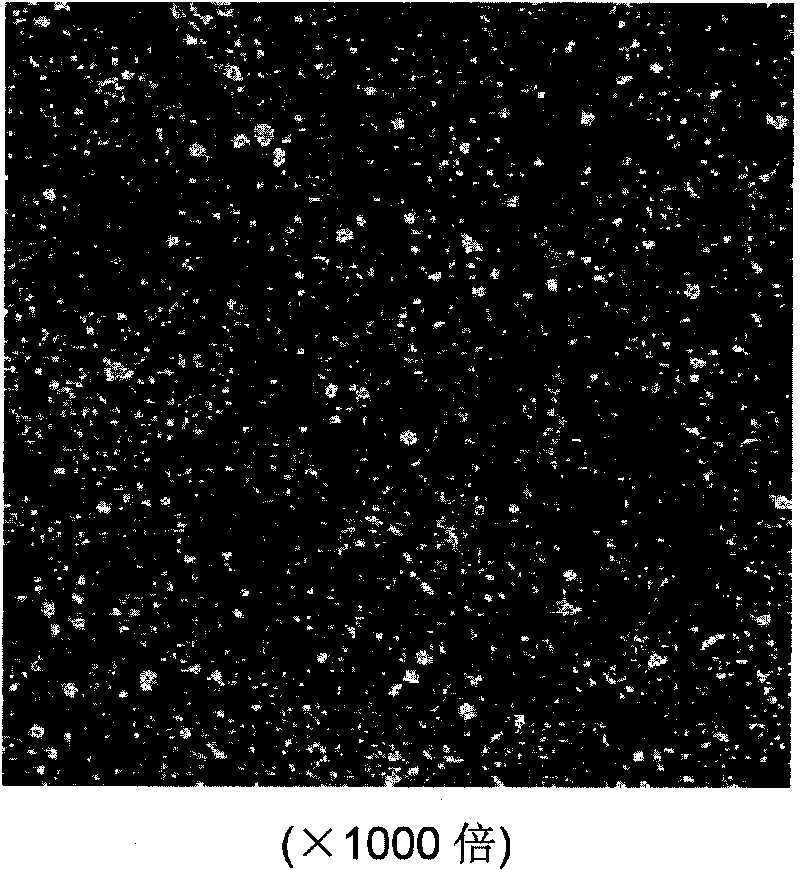

High-speed steel roll and preparation method thereof by centrifugal compounding in electromagnetic field

InactiveCN101705430AInhibition of segregationUniform coagulation tissueFurnace typesRollsCasting moldUltimate tensile strength

The invention relates to a high-speed steel roll and a preparation method thereof by centrifugal compounding in an electromagnetic field, belonging to the technical field of preparation of the high-speed steel roll. The components of a working layer material of the high-speed steel roll are as follows (in weight percent): 1.5 to 2.5 percent of C, 4.0 to 6.0 percent of V, 4.0 to 6.0 percent of W, 1.5 to 4.5 percent of Mo, 2.0 to 4.0 percent of Cr, 0.04 to 0.18 percent of Zr, 0.001 to 0.003 percent of B, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Mn, and the balance of Fe and impurity elements; and in the impurity elements, the required contents of S, P and O are respectively less than 0.01 percent, less than 0.01 percent and less than 0.0010 percent. The roll is cast by adopting a centrifugal compounding method in a pulse electromagnetic field, the frequency of the pulse magnetic field is 0.1 to 10Hz, and the peak strength of a central magnetic field of a cast mold is 1 to 10T. The roll has a plurality of precipitation strengthening phases, and the applied pulse magnetic field leads the strengthening phases and matrix crystal grains to be refined effectively and leads the strengthening phases to be distributed in a dispersed manner, thus overcoming the segregation of alloy elements and greatly improving the performance of the roll.

Owner:JIANGSU UNIV

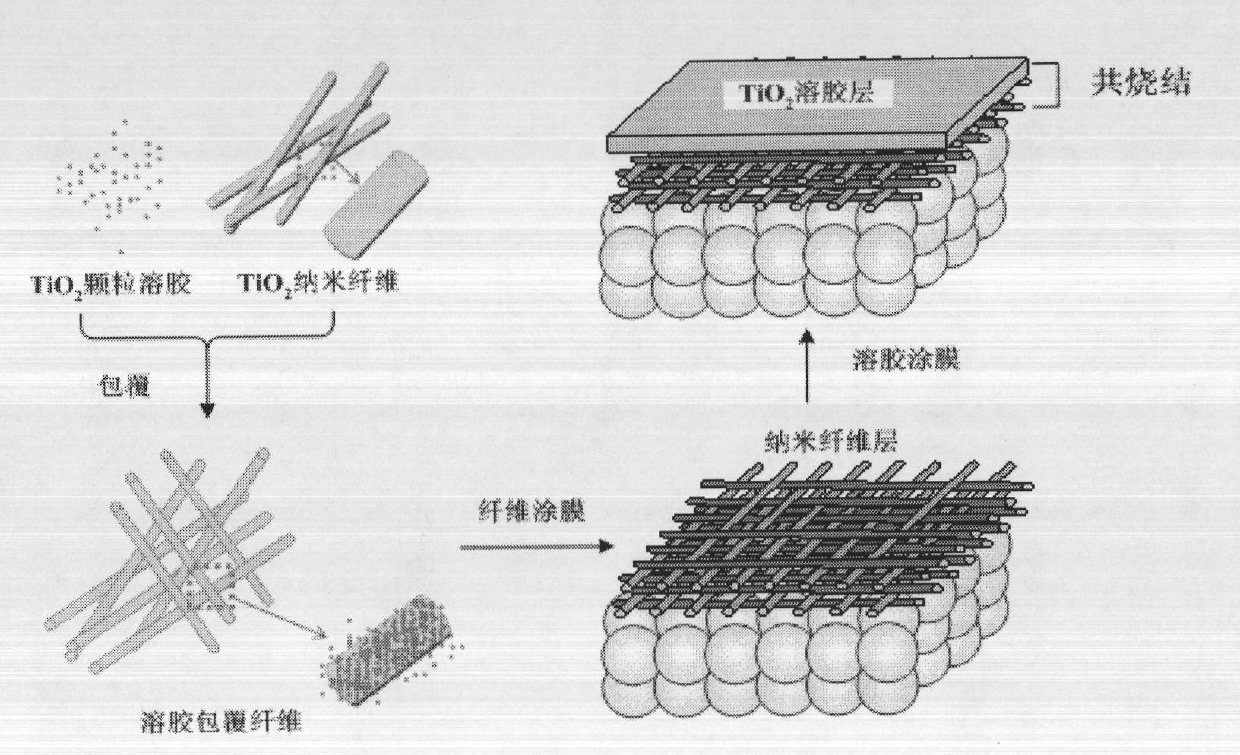

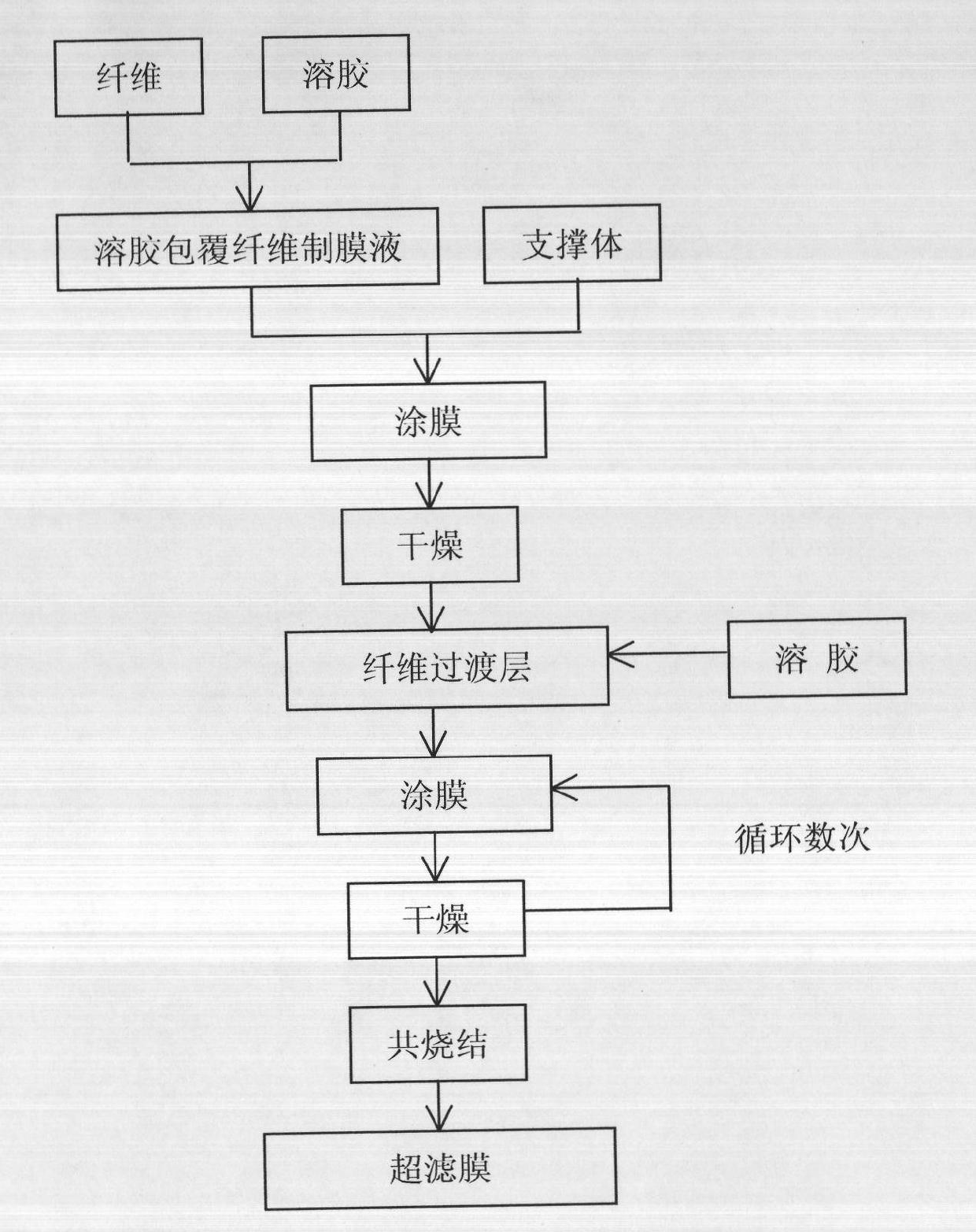

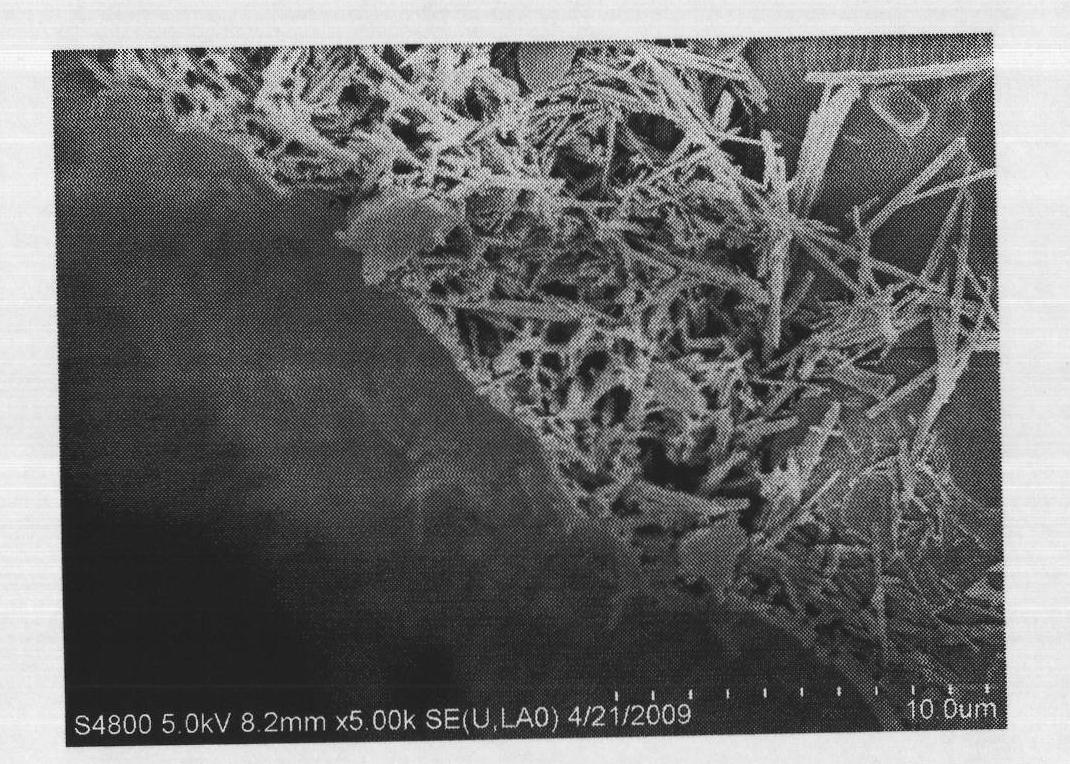

Asymmetrically-structural ceramic ultrafiltration membrane and preparation method thereof

ActiveCN101791524AHigh porosityUniform pore sizeSemi-permeable membranesUltrafiltrationDefoaming Agents

The invention relates to an asymmetrically-structural ceramic ultrafiltration membrane and a preparation method thereof, wherein the preparation method thereof comprises the steps: dispersing one-dimensional fibrous material in sol and sufficiently mixing the material with the gel; by adding deionized water, controlling the weight ratio of gel particle to fiber in membrane preparing solution in a range from 0.01 to 0.4, adjusting pH value of the solution, adding dispersing agent, thickening agent and defoaming agent to formulate the membrane preparing solution, coating membrane on a porous support body and drying the porous support body to form a transition layer; coating the gel-containing membrane preparing solution on the surface of the transition layer, air-drying, oven-drying and roasting the wet membrane, and naturally cooling the membrane to result in the asymmetrically-structural ceramic ultrafiltration membrane. Since the transition layer is composed of fiber and sintering is promoted through the gel, resistance of the transition layer is advantageously lessened and interior combination strength of the transition layer is enhanced; the fiber-constructed transition layer divides large pores into small pores to provide larger total porosity and flowing pore channel, thus high permeation flux is maintained while high selectivity is obtained.

Owner:NANJING UNIV OF TECH

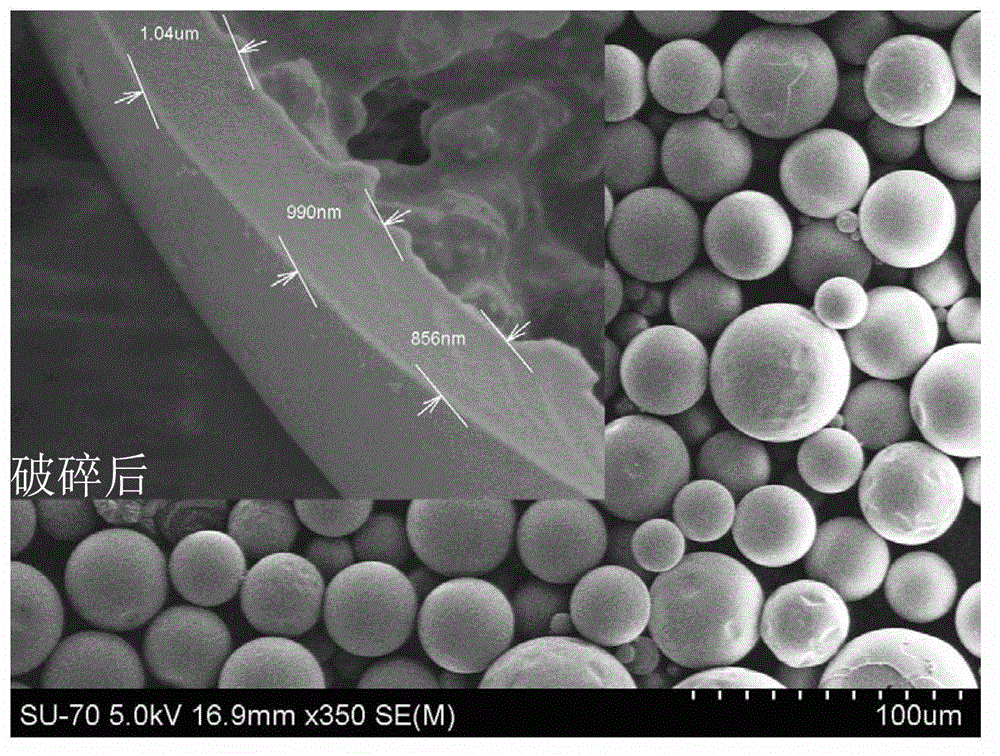

Epoxy microcapsule with polyurea as wall material and preparation method thereof

InactiveCN103331133AIncrease the degree of cross-linkingGood brittlenessMicroballoon preparationMicrocapsule preparationIsocyanatePolyurea

The invention relates to the technical field of self repair materials and provides an epoxy microcapsule with polyurea as a wall material. The core material of the microcapsule comprises liquid epoxy resin, the wall material of the microcapsule is crosslinked polyurea prepared by carrying out an interface reaction on polyisocyanate and water, and the polyisocyanate comprises polyisocyanate containing three elements or more than three elements. The invention also provides a preparation method of the epoxy microcapsule with polyurea as the wall material. The preparation method of the epoxy microcapsule with polyurea as the wall material comprises the following steps of: dispersing polyisocyanate and liquid epoxy resin into water containing a surface active agent to obtain a mixed solution, stirring the mixed solution for 0.5-5 hours at the temperature of 25-90 DEG C, filtering, washing, and drying, so that the epoxy microcapsule with polyurea as the wall material is obtained. The preparation method of the epoxy microcapsule with polyurea as the wall material is simple and practicable and is applicable to industrial production.

Owner:SHENZHEN UNIV

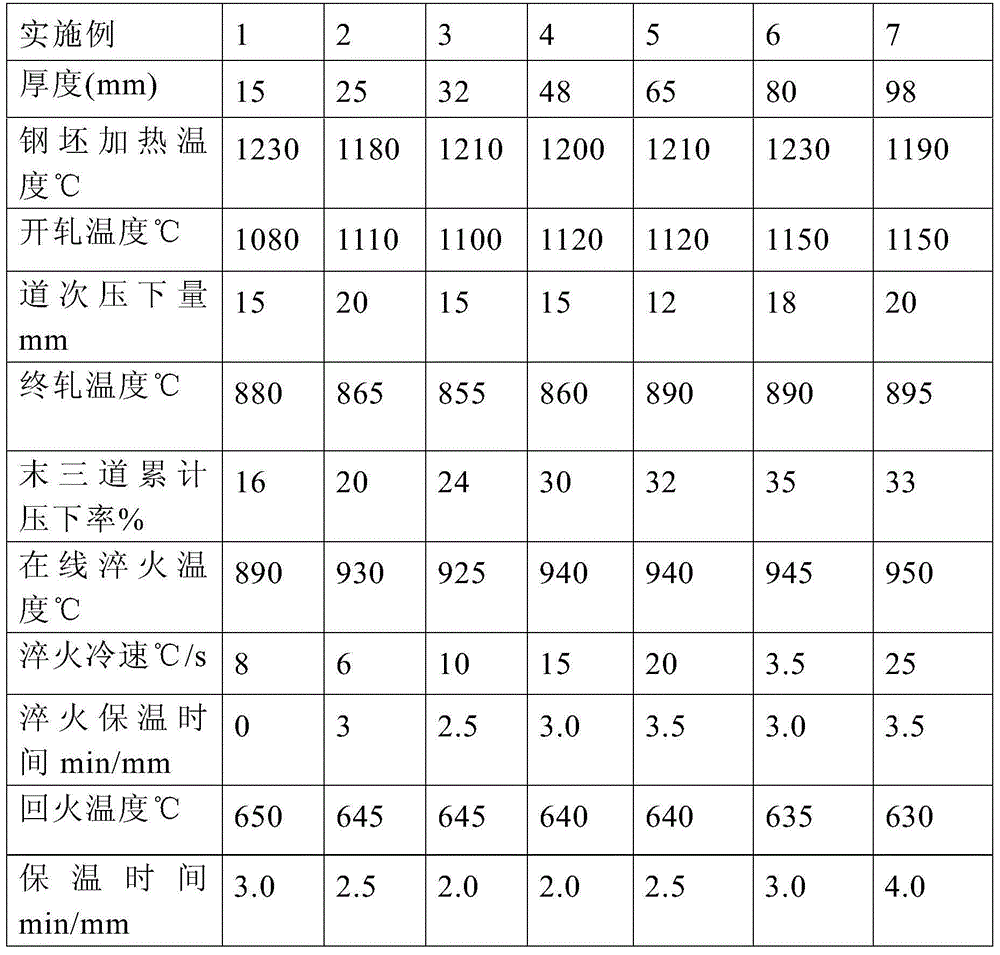

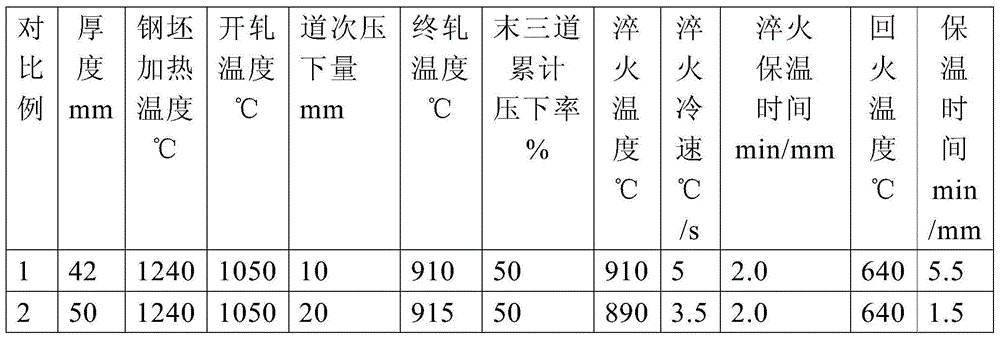

LPG boat storage tank steel plate and production method thereof

ActiveCN104131235AGood comprehensive mechanical propertiesGood cold and hot processing performanceQuenchingSteel plates

The invention discloses an LPG boat storage tank steel plate and a production method thereof. The steel plate comprises 0.05-0.12wt% of C, 0.30wt% or less of Si, 0.50-1.30wt% of Mn, 0.015wt% or less of P, 0.008wt% or less of S, 0.020-0.060wt% of Al, 0.15-1.20wt% of Cu, 0.20-1.50wt% of Ni, 0.35-1.00wt% of Cr, 0.20-0.60wt% of Mo, 0.008-0.020wt% of Ti, one or more of 0.0020-0.10wt% of Nb, 0.030-0.060wt% of V and 0.0005-0.0020wt% of B, and the balance Fe and inevitable impurities. The method comprises the steps of molten iron advanced desulphurization, converter top and bottom blowing, vacuum treatment, continuous casting, casting blank heating, rolling and heat treatment, the heating temperature of a casting blank is 1170-1250DEG C, and the heating rate of the casting blank is not less than 8min / cm; the blooming temperature is 1050-1150DEG C, the finishing temperature is 850-940DEG C, and the accumulated reduction rate of last three passes is not less than 16%; and heat treatment adopts online quenching and tempering treatment, or adopts offline quenching and tempering treatment. The steel plate obtained in the invention has the advantages of excellent mechanical properties, good hot and cold processing performance, excellent weldability and low sensitivity of weld cracks.

Owner:武汉钢铁有限公司

Beam end weakened replacement type steel frame beam shock proof node

InactiveCN101100877AEnsure safetyTo achieve reinforcementShock proofingMetallic materialsSteel frame

This is an anti-knock node for steel frame beam. It is by substituting traditional steel material on the beam end and web by an metal of strong endergonic ability, and adding X shape low carbon armor plate to the beam end to form an endergonic plasticity node.

Owner:BEIJING UNIV OF TECH

Ice lighting device

InactiveUS7237396B1Effectively disposableEasy to installMechanical apparatusDomestic cooling apparatusTotal internal reflectionRefractive index

A lighting device for illuminating ice has a sheet of light-transmitting film located below an ice layer and coupled to a light source. The index of refraction of the light-transmitting film is greater than that of the adjoining ice or air so that the light within the film experiences substantial internal reflection. Light is emitted from the film (and the ice surface) at emission regions that disrupt internal reflection.

Owner:FLEX LIGHTING II

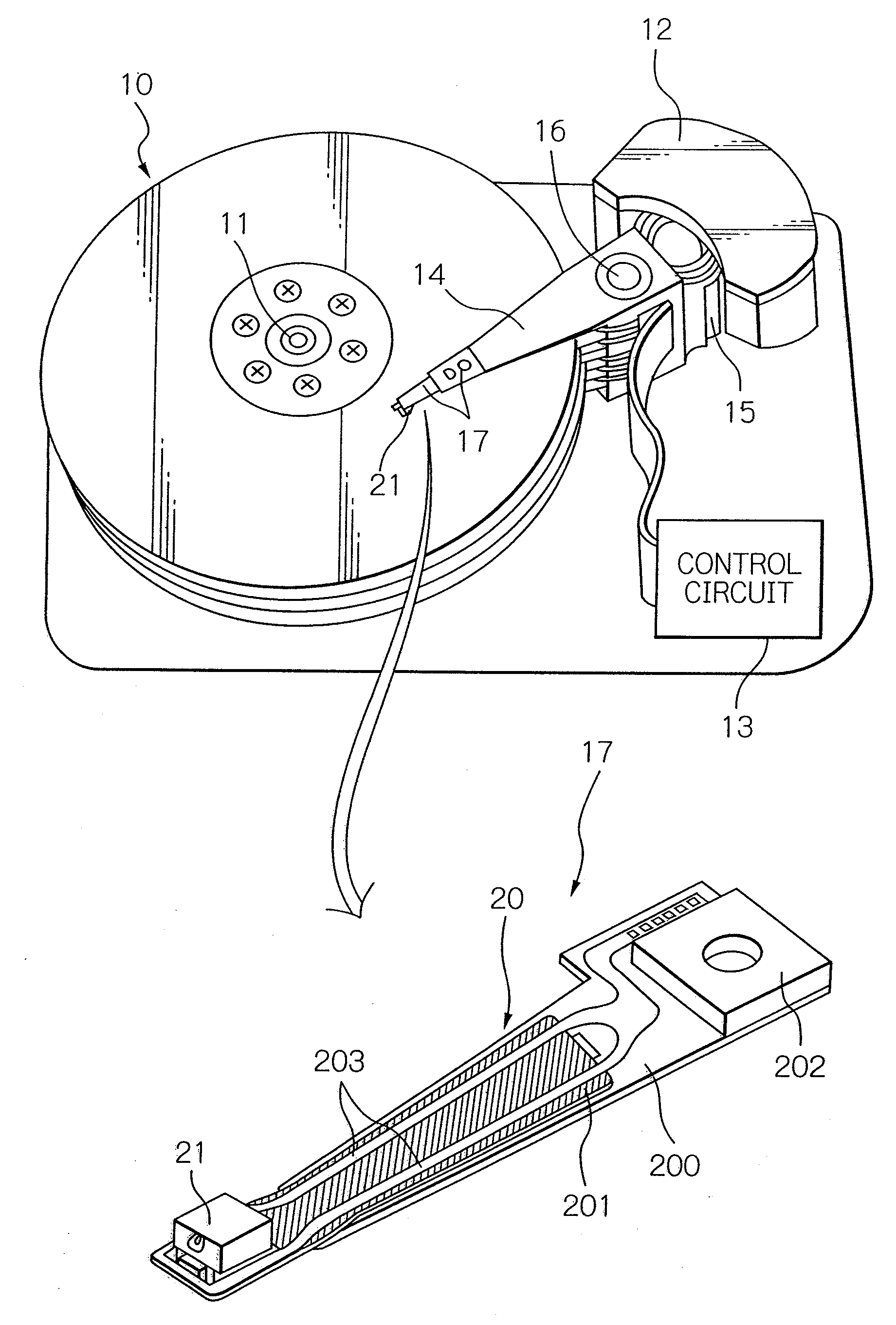

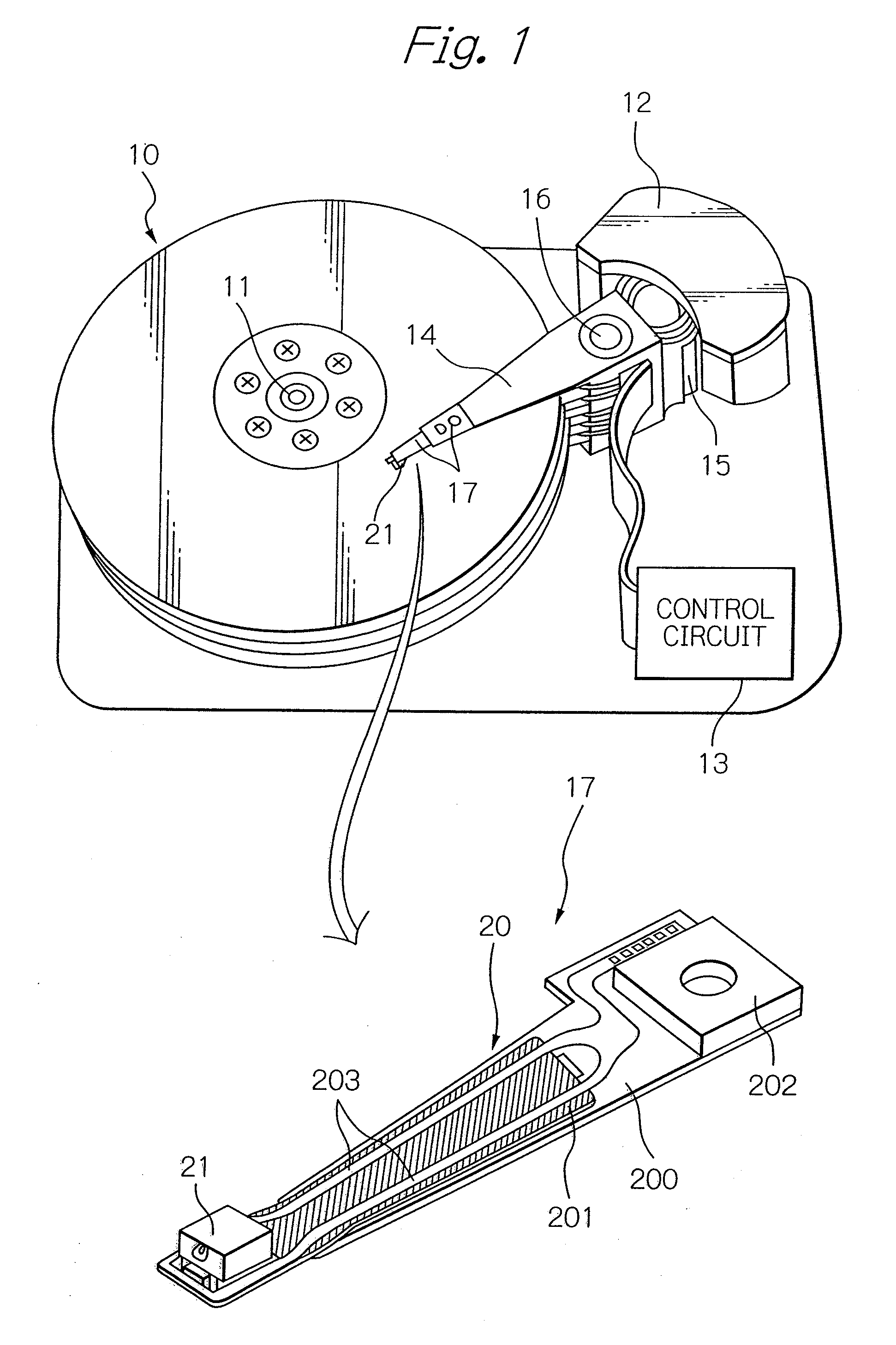

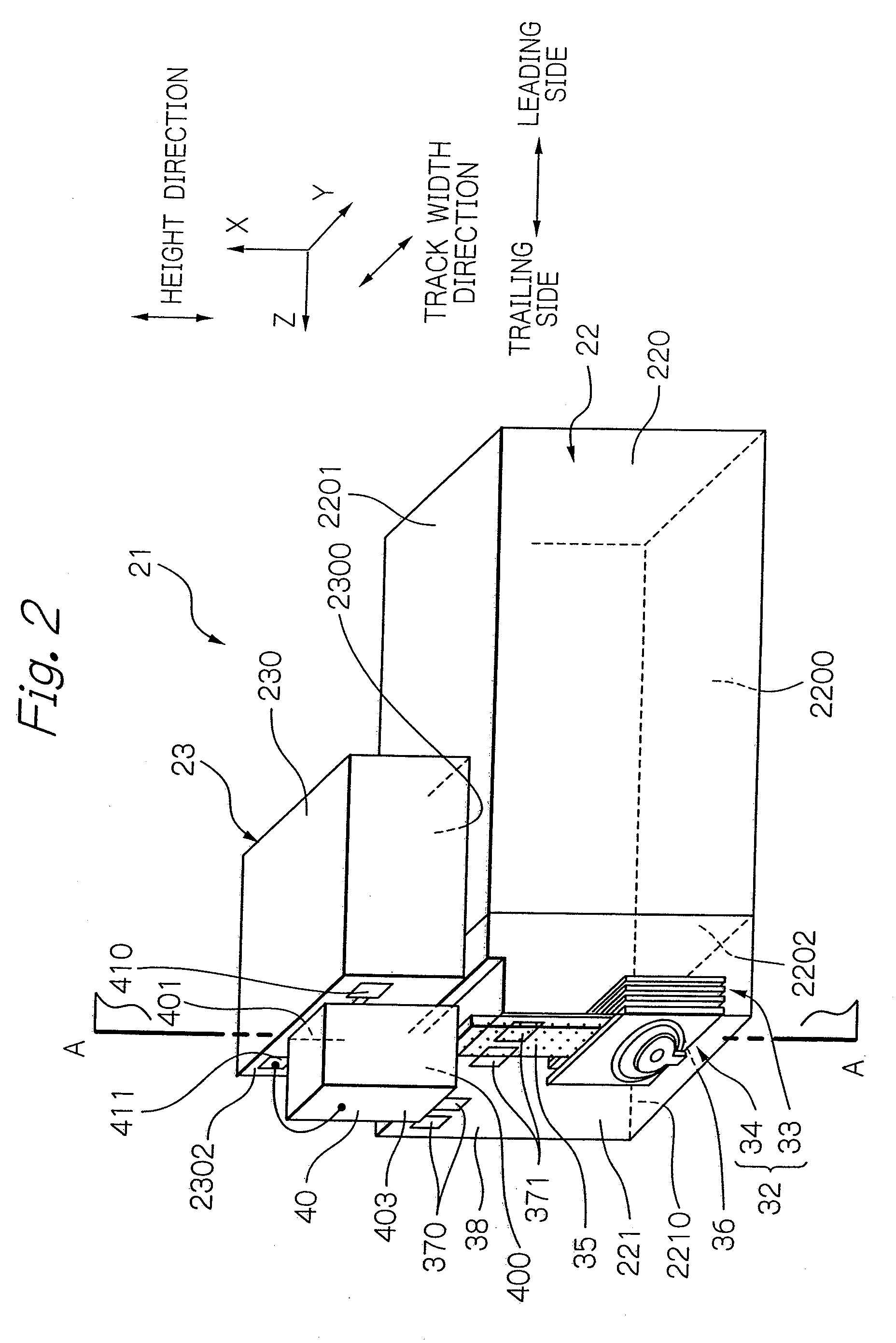

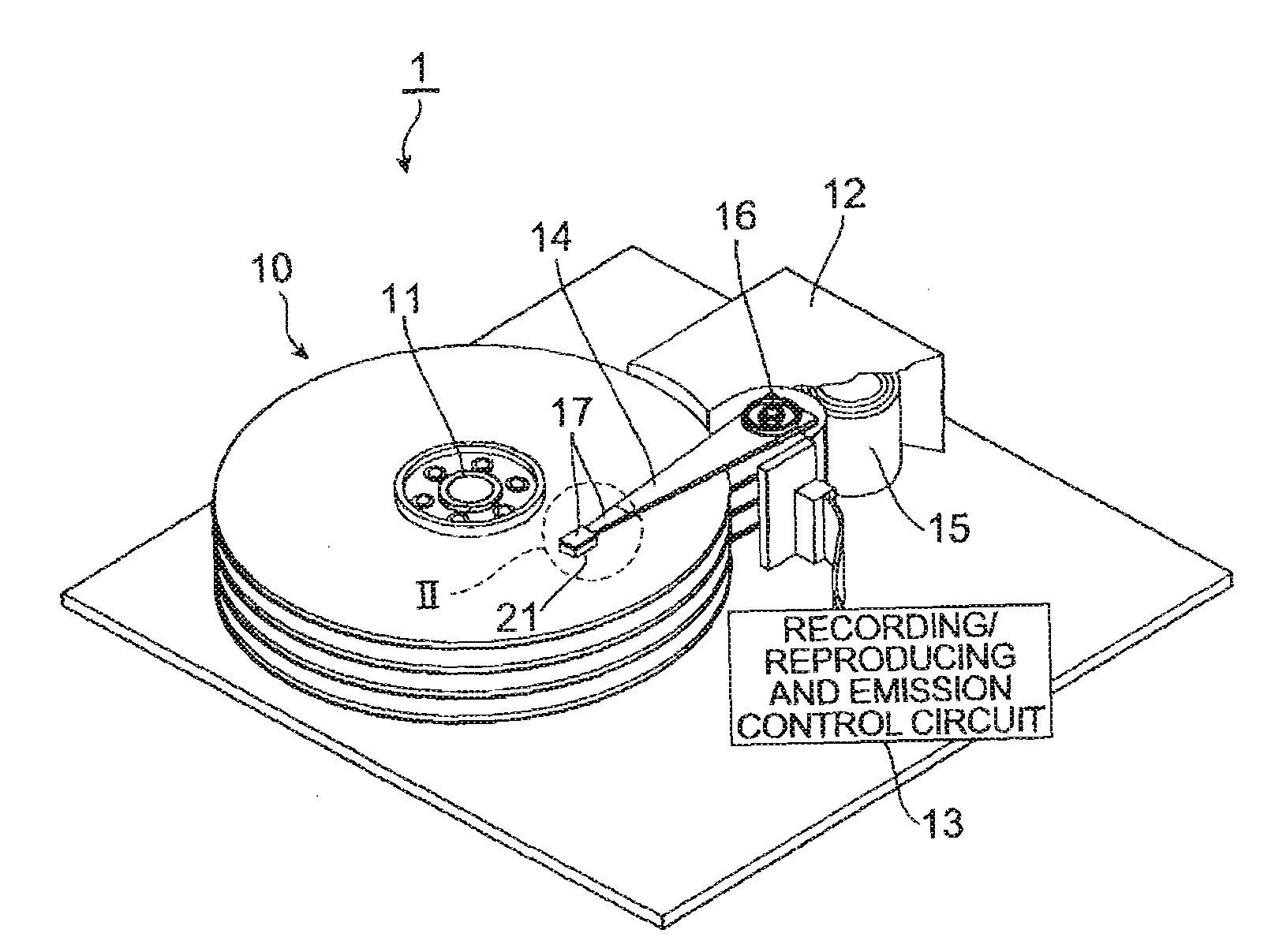

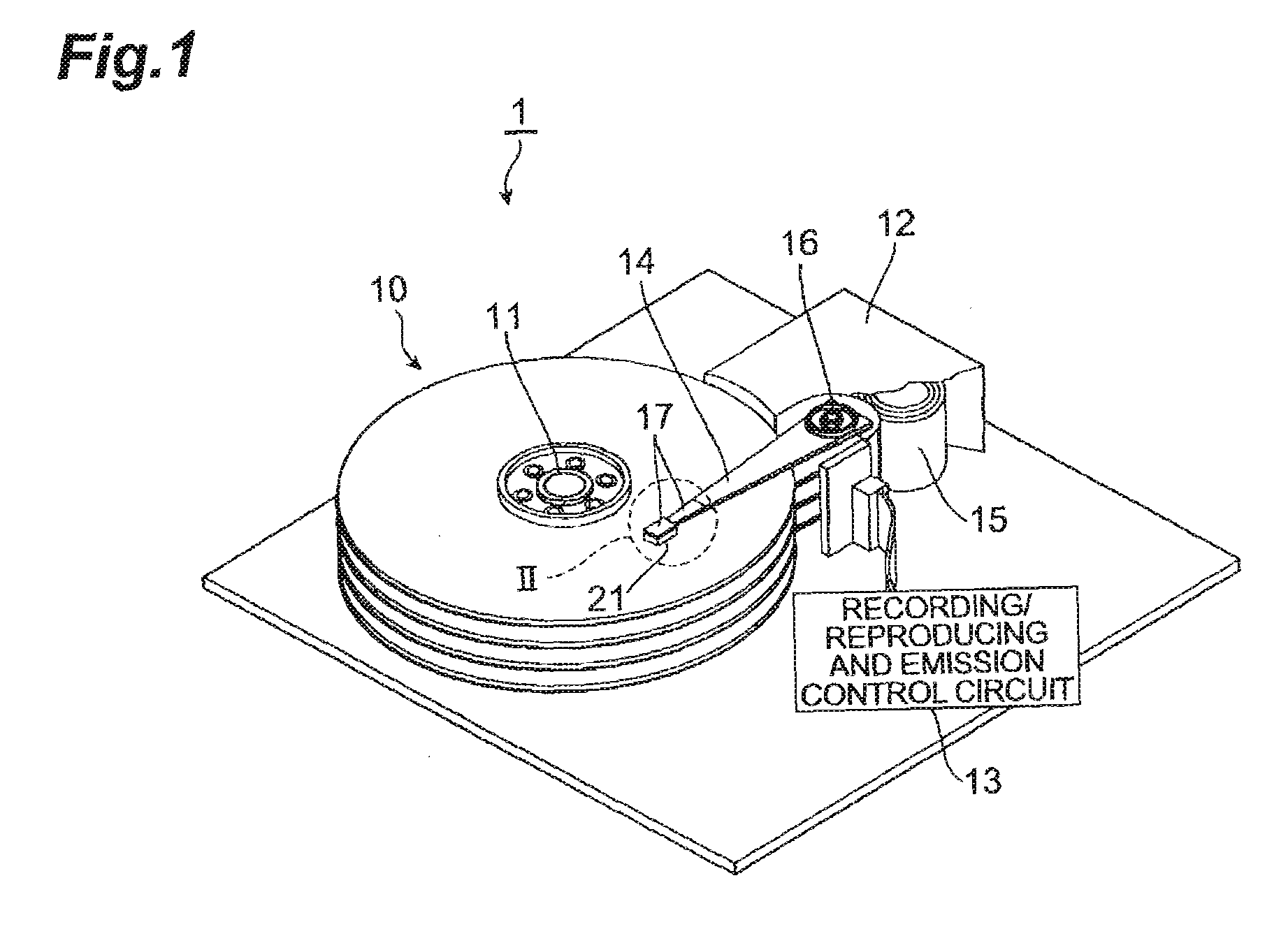

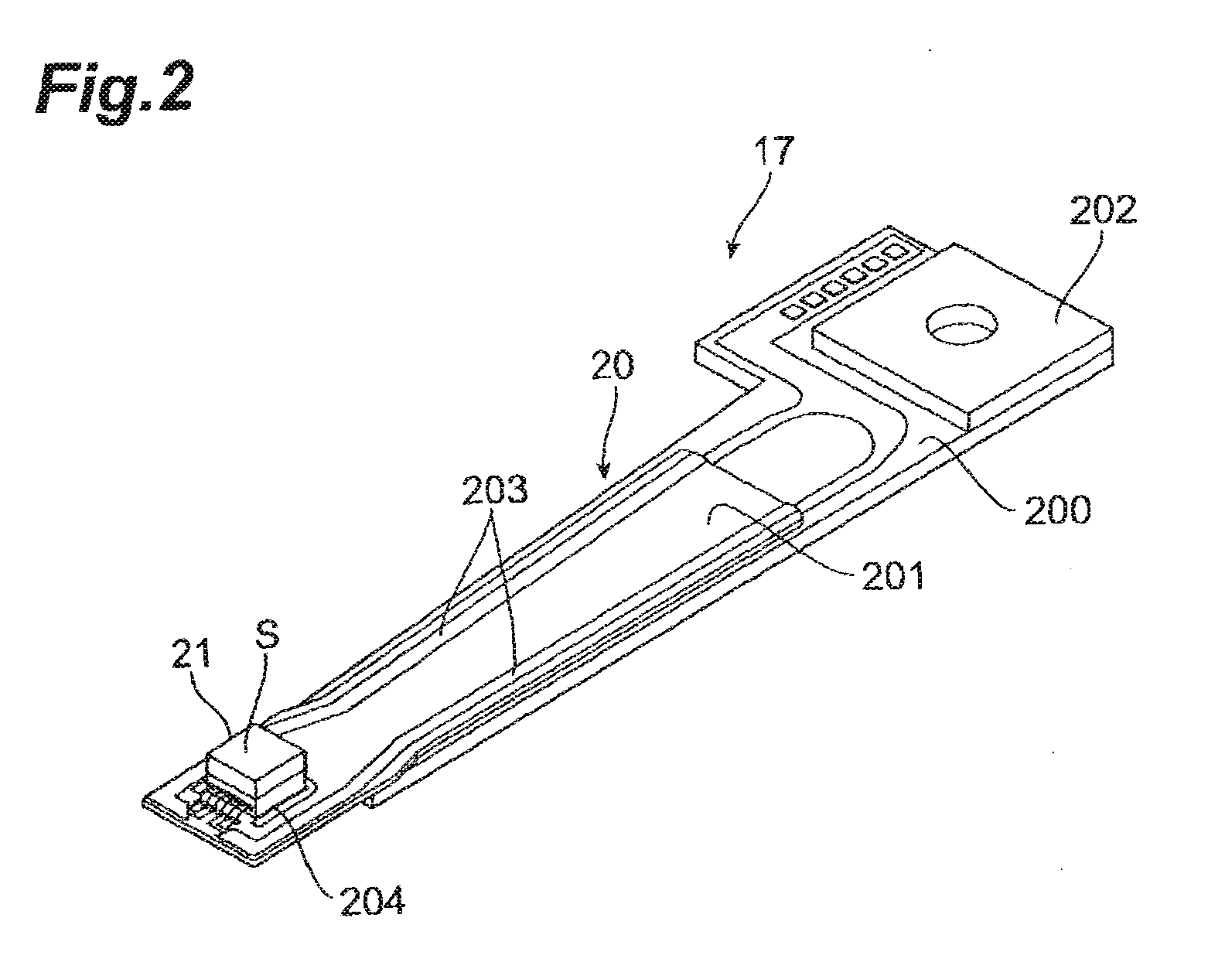

Thermally assisted magnetic head, head gimbal assembly, and hard disk drive

ActiveUS20080239541A1Low coercivityHeat the recording areaCombination recordingRecord information storageHard disc driveMagnetic poles

The thermally assisted magnetic head comprises a medium-opposing surface; a magnetic recording device whose distance from a main magnetic pole to a medium is set longer than a distance from the medium-opposing surface to the medium; a first core for receiving light; and a second core positioned between a first light exit surface of the first core and the medium-opposing surface, having a second light exit surface on the medium side; while a distance between positions where an optical intensity distribution center within the first light exit surface and a center of the main magnetic pole are orthographically projected onto a reference plane including the second light exit surface is greater than a distance between an optical intensity distribution center within the second light exit surface and the position where the center of the leading end of the main magnetic pole is orthographically projected onto the reference plane.

Owner:TDK CORPARATION

Stabilization and solidification method of highly toxic waste residues

The invention relates to a stabilization and solidification method of highly toxic waste residues containing one or more of mercury, arsenic, chromium, cadmium and cyanide. Heavy metal is stabilized through chemicals, and then the highly toxic waste residues are sequentially wrapped with gypsum plus paraffin and epoxy resin. After four times of wrapping and two times of solidification, highly toxic substances in the waste residues are fully solidified into a solidified body, and the generated solidified body is high in strength and long in stability, and can be buried conveniently later.

Owner:扬州杰嘉工业固废处置有限公司

Preparation technique of waste residue composite light-weight thermal-insulation wallboard

ActiveCN102863189ALow costCost enoughSolid waste managementCeramic shaping apparatusAggregate (composite)Engineering

The invention discloses a preparation technique of a waste residue composite light-weight thermal-insulation wallboard, which comprises the following steps: preparing a waste residue base material; preparing a composite admixture A; preparing waste residue light-weight aggregate; preparing a composite admixture B; preparing a wallboard blank material; preparing a wallboard blank; putting the wallboard blank in a curing chamber, and curing in a 75-80 DEG C saturated steam environment for 4-5 hours; and when the difference between inside temperature and outside temperature of the curing chamber is 25-40 DEG C, putting the wallboard blank outside the chamber, and demolding to obtain the waste residue composite light-weight thermal-insulation wallboard. According to the preparation method disclosed by the invention, the wallboard blank can be cured and demolded within 8.5-12 hours, and the demolded wallboard can be immediately put into engineering use, thereby shortening the processing cycle, and preparing the high-strength favorable-water-resistance light-weight wallboard under the conditions of changing wastes into valuable substances and using low production cost. The wallboard can be widely used in various types of construction engineering.

Owner:杜世永

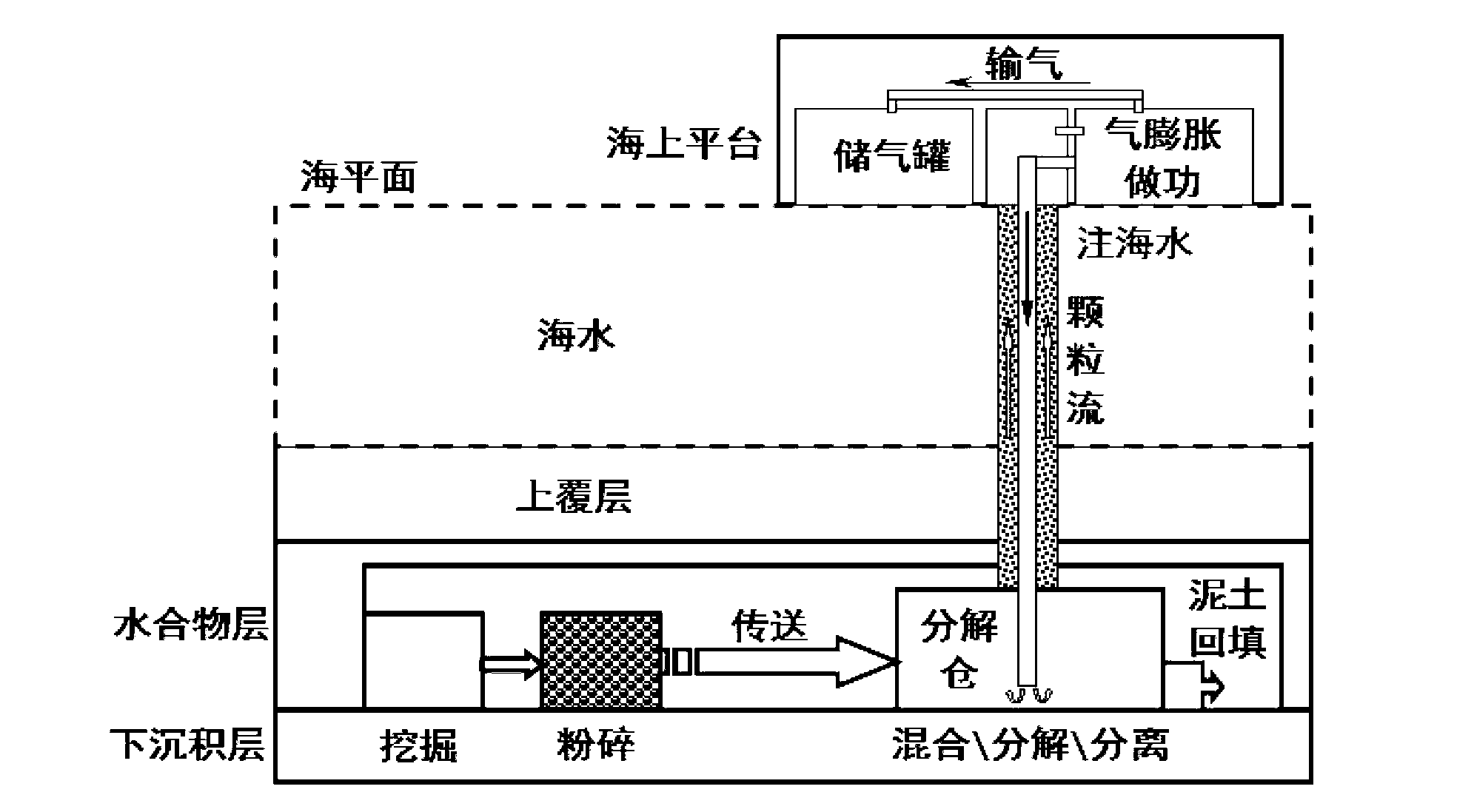

Mechanical-thermal hydrate exploiting method

The invention discloses a mechanical-thermal hydrate exploiting method. The mechanical-thermal hydrate exploiting method comprises the following steps: excavating a hydrate stratum, crushing hydrate sediment into hydrate sediment granules, and conveying the hydrate sediment granules into a decomposing chamber; stirring and mixing relatively hot seawater and the hydrate sediment granules in the decomposing chamber, partially decomposing the hydrate sediment granules, separating the obtained mixture, and removing the separated sediment; upwardly conveying the remaining mixture along an exploiting shaft, further decomposing the hydrate in the mixture in the conveying process, and separating the remaining mixture and generated gas from the sediment in the mixture; and collecting the obtained gas on an exploiting platform. By the method, hydrate decomposing heat can be supplied by a huge heat source from seawater and convective heat transfer; expansion energy of gas which is generated in a centralized way can be made full use; backfill of the sediment can restore certain stratum strength; and leakage of the hydrate decomposing gas from a covering layer can be avoided.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com