Patents

Literature

1727results about How to "Inhibition of segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of lithium ion battery ternary cathode material

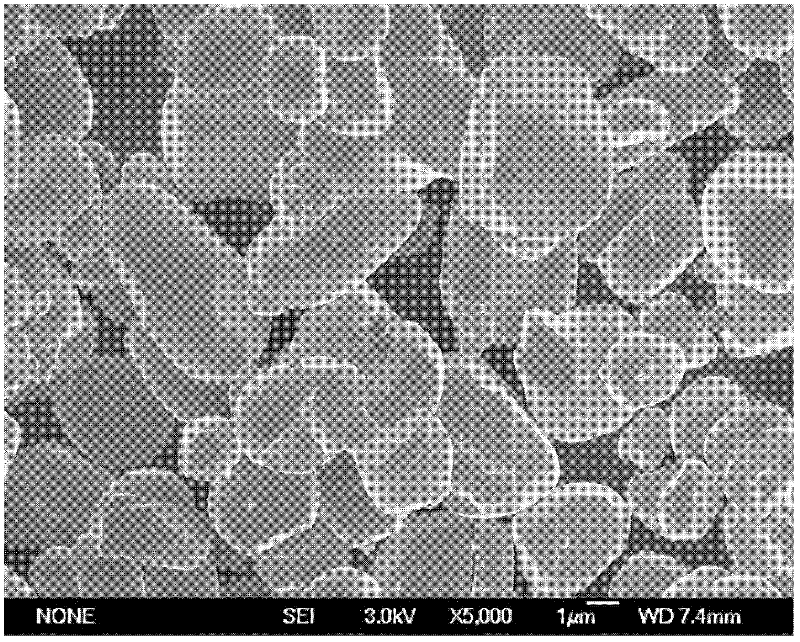

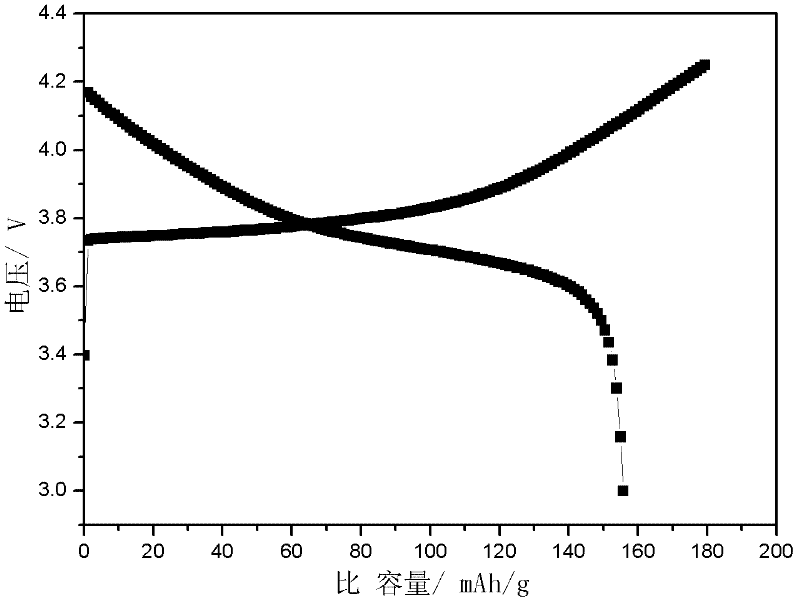

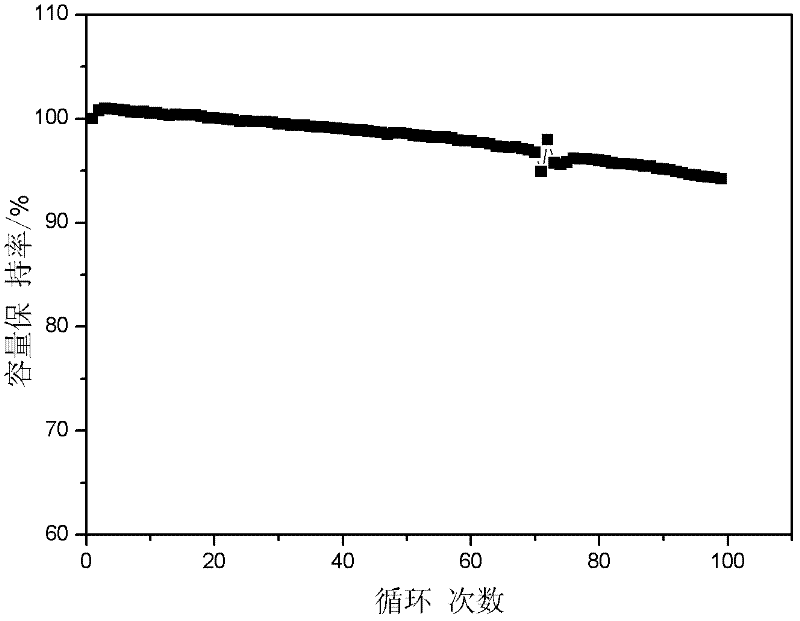

The invention discloses a preparation method of a lithium ion battery ternary cathode material. According to the preparation method, full grinding is performed through a colloid mill to improve the reactivity of a precursor and a lithium salt and the uniformity of a mixed material; and a carbon chain organic additive is added in the process of grinding to improve the viscosity of a sizing material, inhibit raw material segregation in the process of drying, quickly balance the temperature of each part of a system in the process of high-temperature reaction and inhibit agglomeration among particles, so that a uniform-appearance and regular mono-crystal ternary cathode material is obtained. Meanwhile, the ternary cathode material is doped and subjected to surface coating modification, so that the structure of the material is stabilized, the side reaction between the material and electrolyte is inhibited, and the high-temperature cycle performance of the material is improved.

Owner:PULEAD TAIAN TECH IND

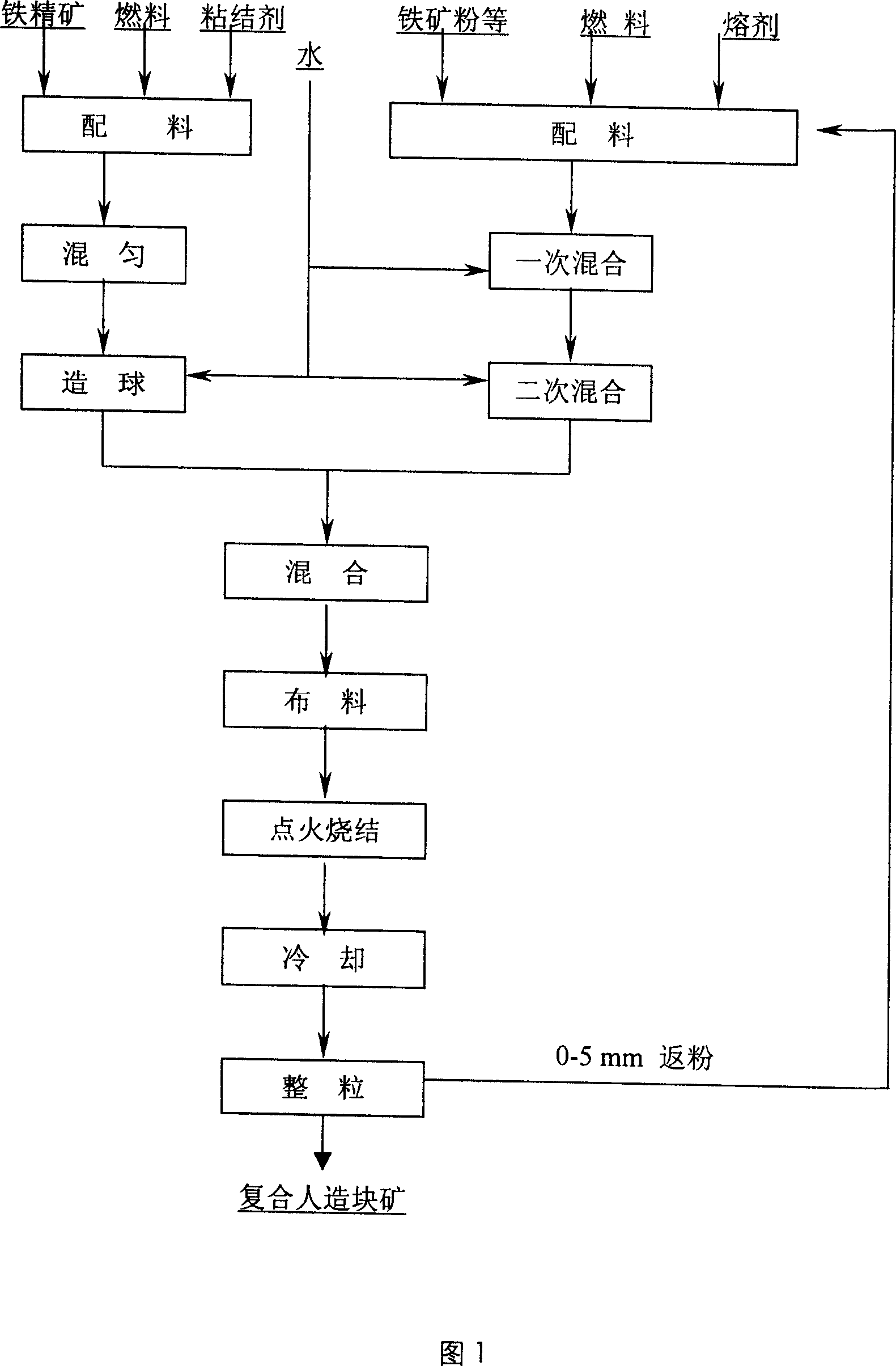

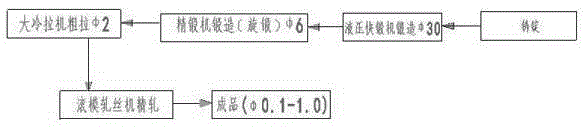

Composite agglomeration technology of iron powdered ore

The invention discloses a ferric powder composite block preparing technology, which is characterized by the following: separating fine ferric ore individually; preparing ball; blending rough particle with ferric powder and other raw materials; paving on the traditional sintering machine; inserting high-alkaline sintering ore of acid ball ore.

Owner:CENT SOUTH UNIV

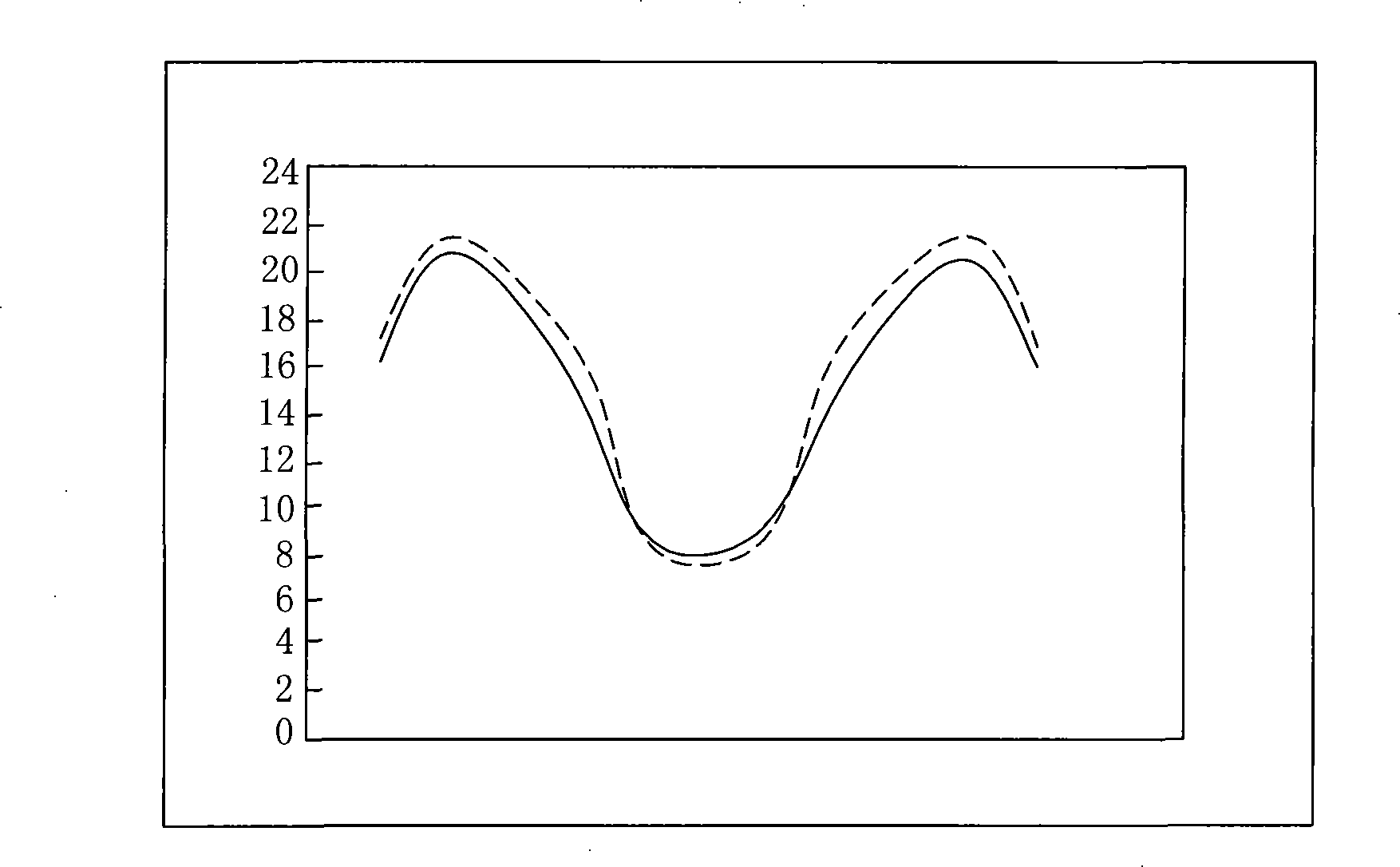

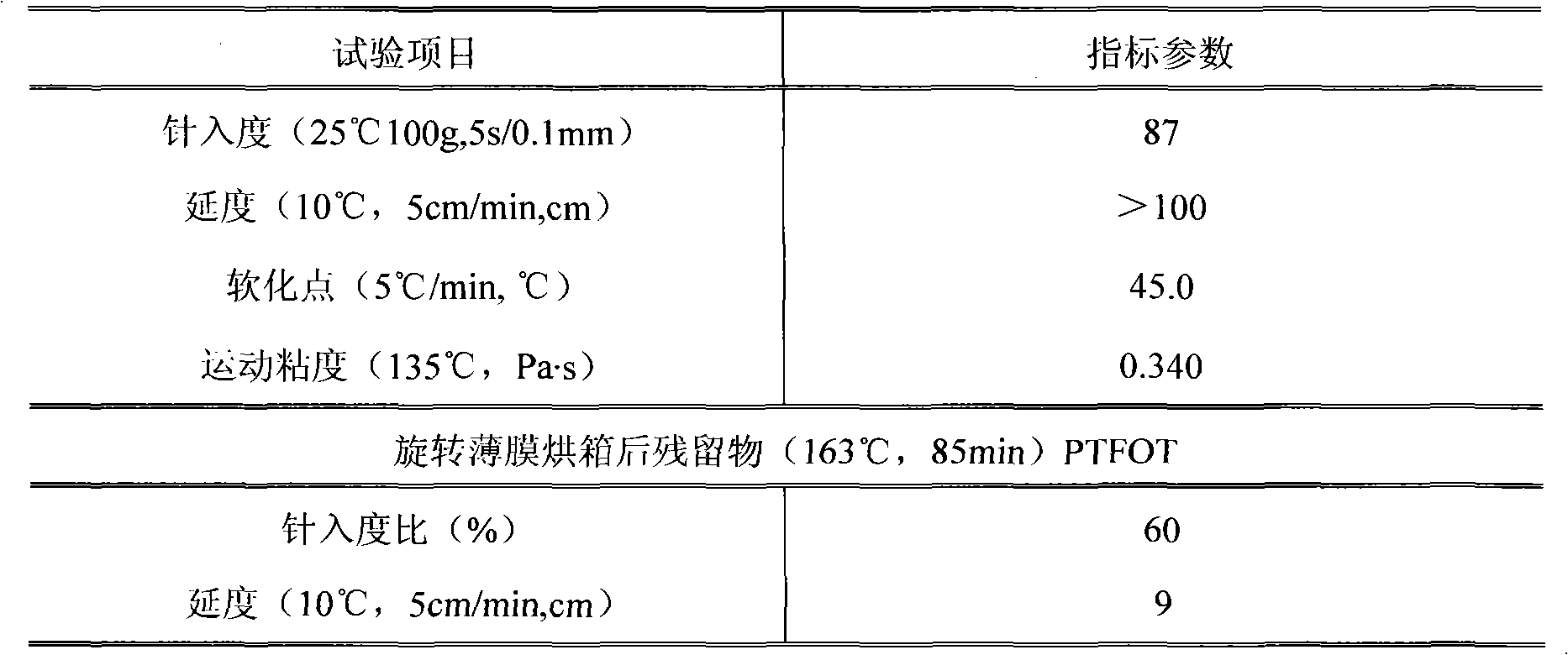

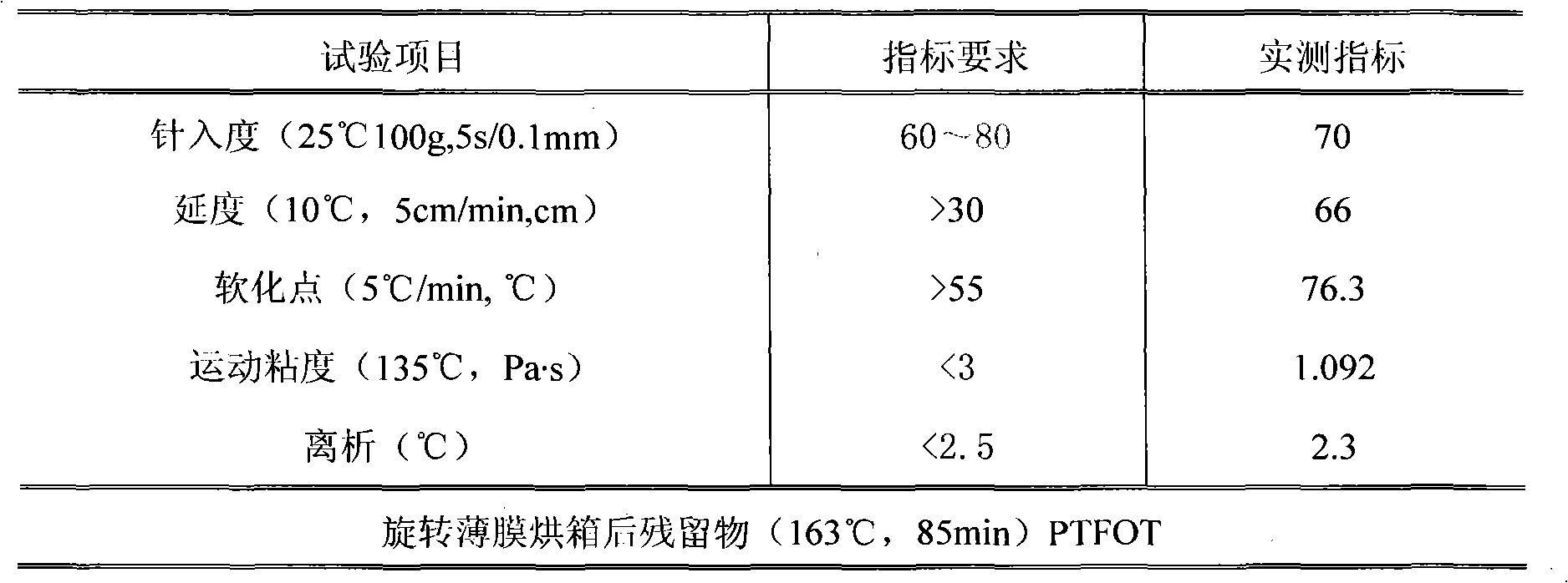

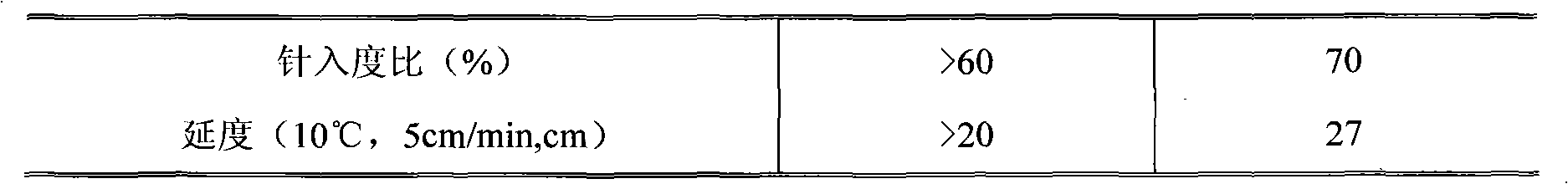

Waste rubber tyre powder modified asphalt and its prepn process

InactiveCN101089049AInhibition of segregationAvoid elastic recoveryBuilding insulationsPolymer scienceWaste rubber

The present invention relates to one kind of waste rubber tyre powder modified asphalt and its preparation process. The waste rubber tyre powder modified asphalt consists of asphalt matrix 100 weight portions, waste rubber tyre powder 10-30 weight portions, compatilizer 1-10 weight portions, dissolution promoter 0.5-30 weight portions, activating modifier 1-40 weight portions and emulsifier 0-5 weight portions. It is prepared through a chemical and physical process including the steps of degrading and activating the waste rubber tyre powder, vulcanizing and cross-linking, stirring and shearing. It is suitable for paving and repairing highway.

Owner:SHANGHAI MIRONGKE ELECTRICAL DIGITAL INTEGRATION

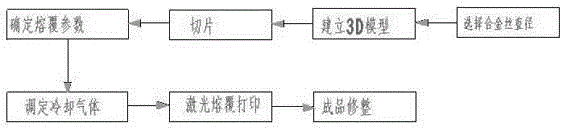

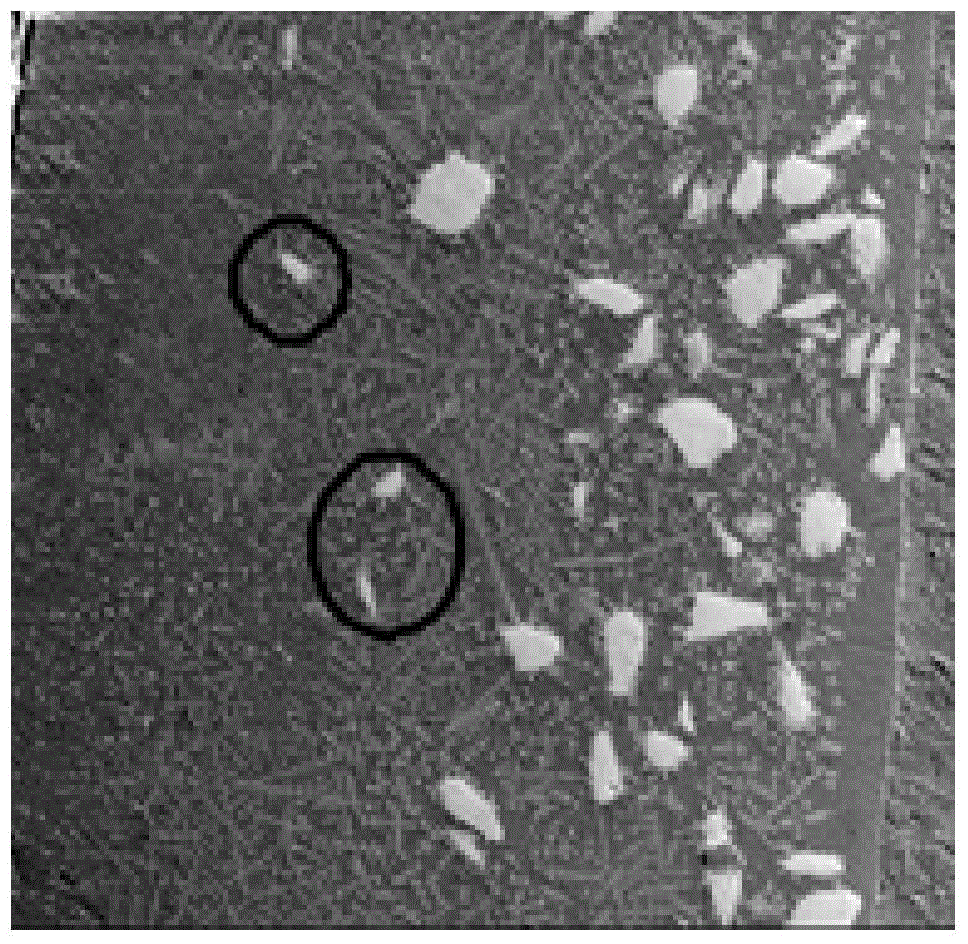

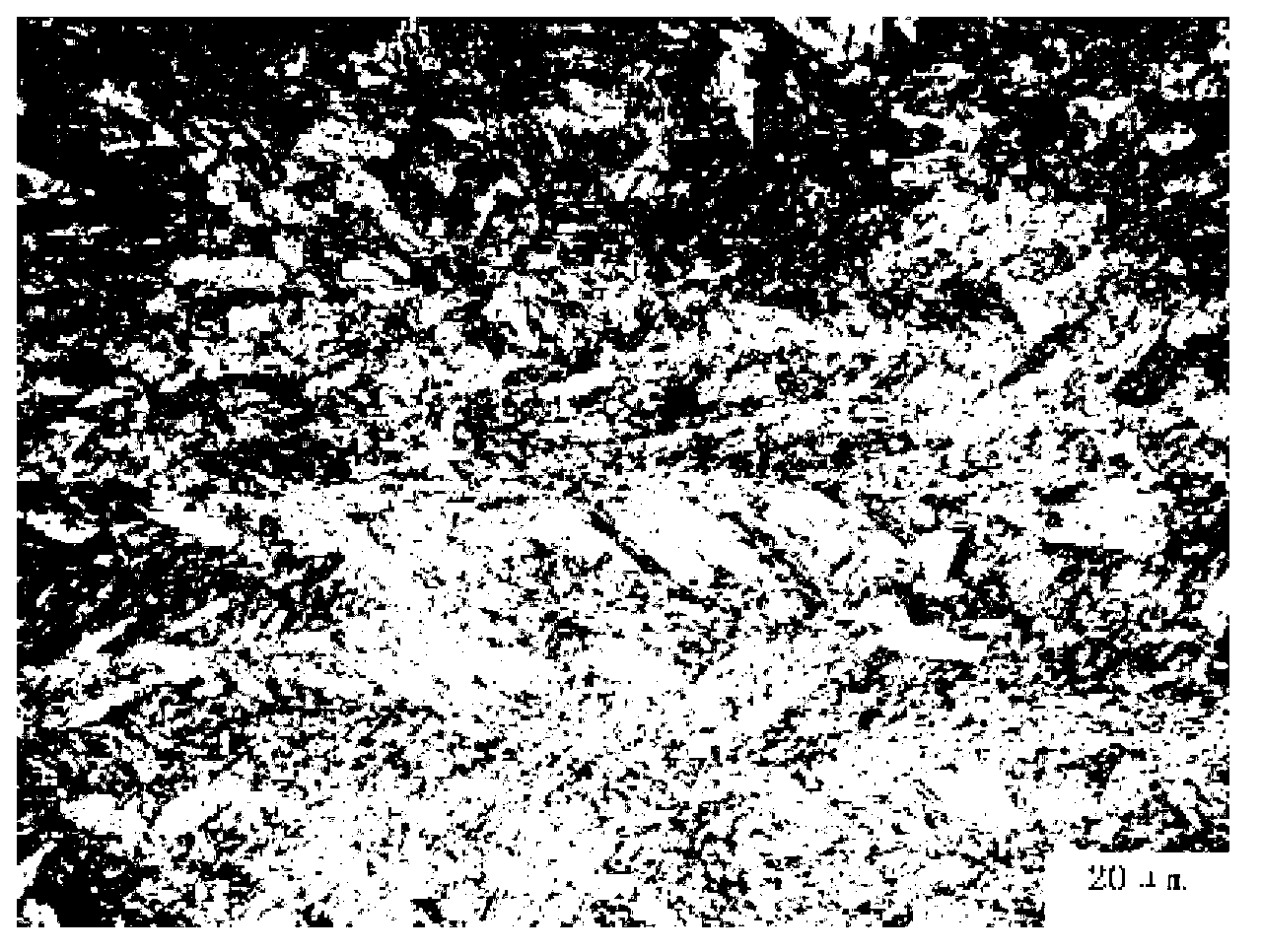

High abrasion-proof laser cladding nickel-base alloy powder and preparation method thereof

InactiveCN102943267AHigh hardnessImprove wear resistanceMetallic material coating processesCarbideAlloy

The invention relates to a high abrasion-proof laser cladding nickel-base alloy powder and a preparation method of the alloy powder. The high abrasion-proof laser cladding nickel-base alloy powder is characterized by comprising matrix alloy powder, hard carbide particles and a bonding agent; and the combined powder comprises 50-98% of matrix alloy powder, 1-45% of WC or TiC or mixed powder of WC and TiC, and 1-5% of bonding agent. The preparation method comprises the following steps of: preparing the matrix alloy powder, adding the carbide particles into the prepared matrix alloy powder, adding the bonding agent into the mixture, stirring, ball milling, combining the powder, drying, crushing and screening. The high abrasion-proof laser cladding nickel-base alloy powder not only is high in hardness, but also has excellent wear resistance and corrosion resistance, thus being especially suitable for laser cladding of alloy workpieces with high surface hardness and high wear resistance. Furthermore, the phenomenon of segregation caused by great differences among the specific gravities of all components in the processes of storage, transportation and using can be effectively prevented.

Owner:江苏新亚特钢锻造有限公司

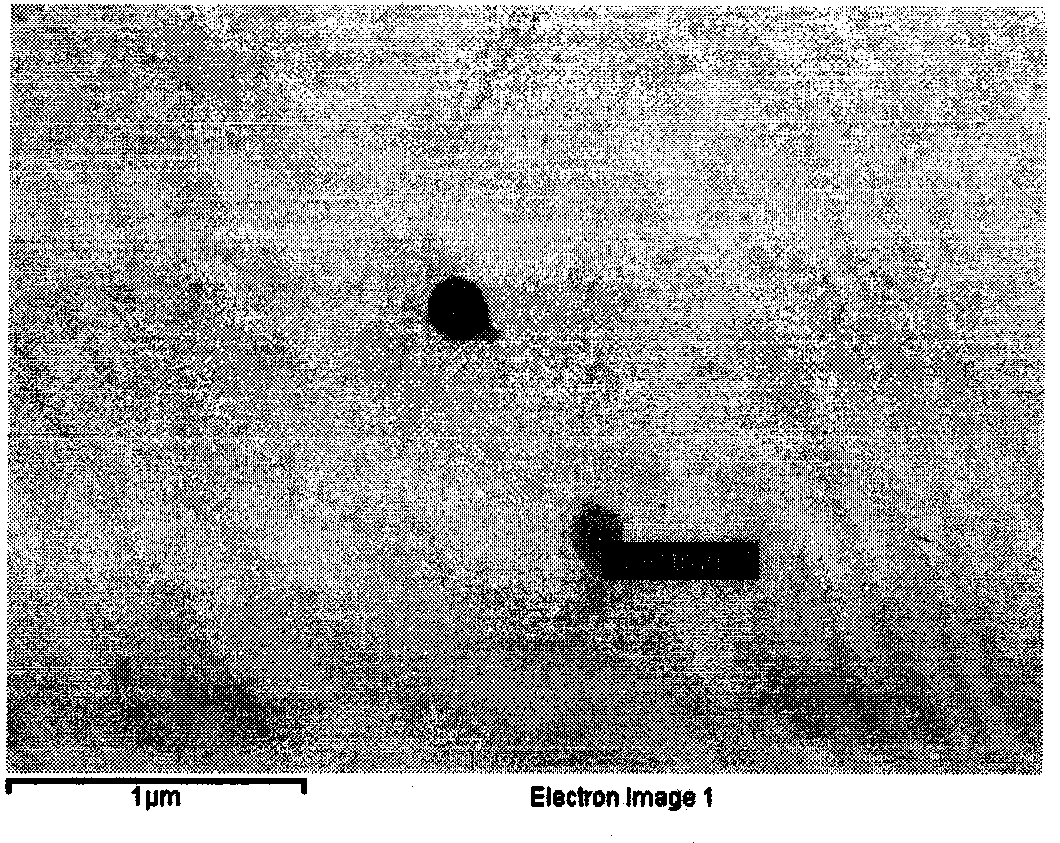

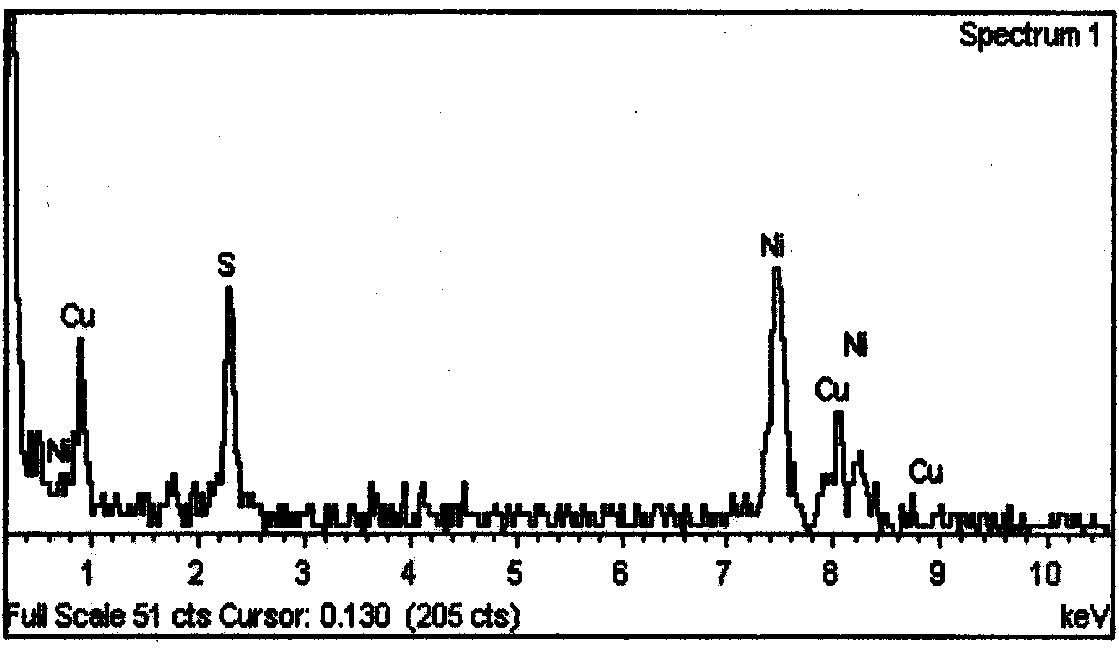

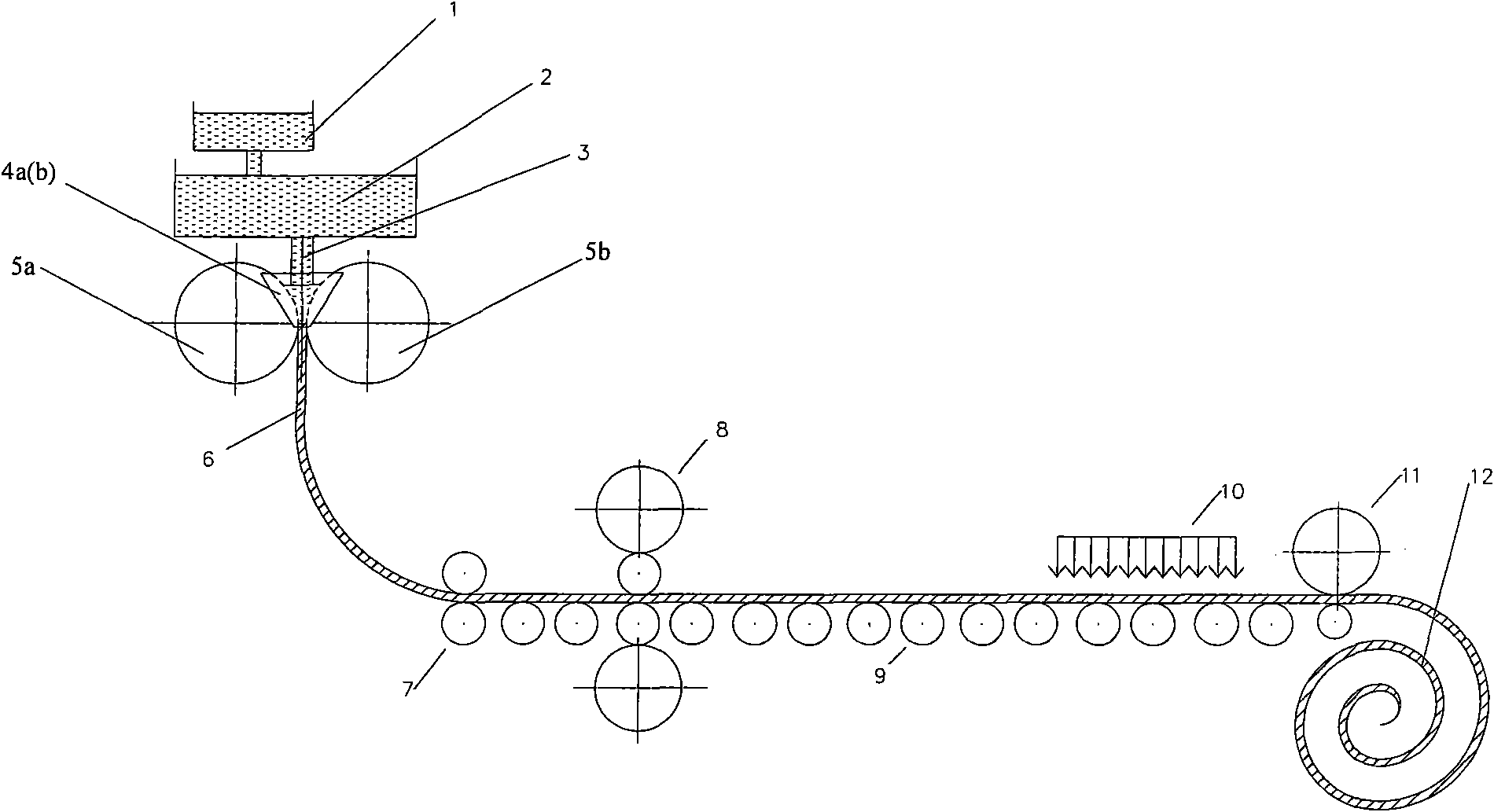

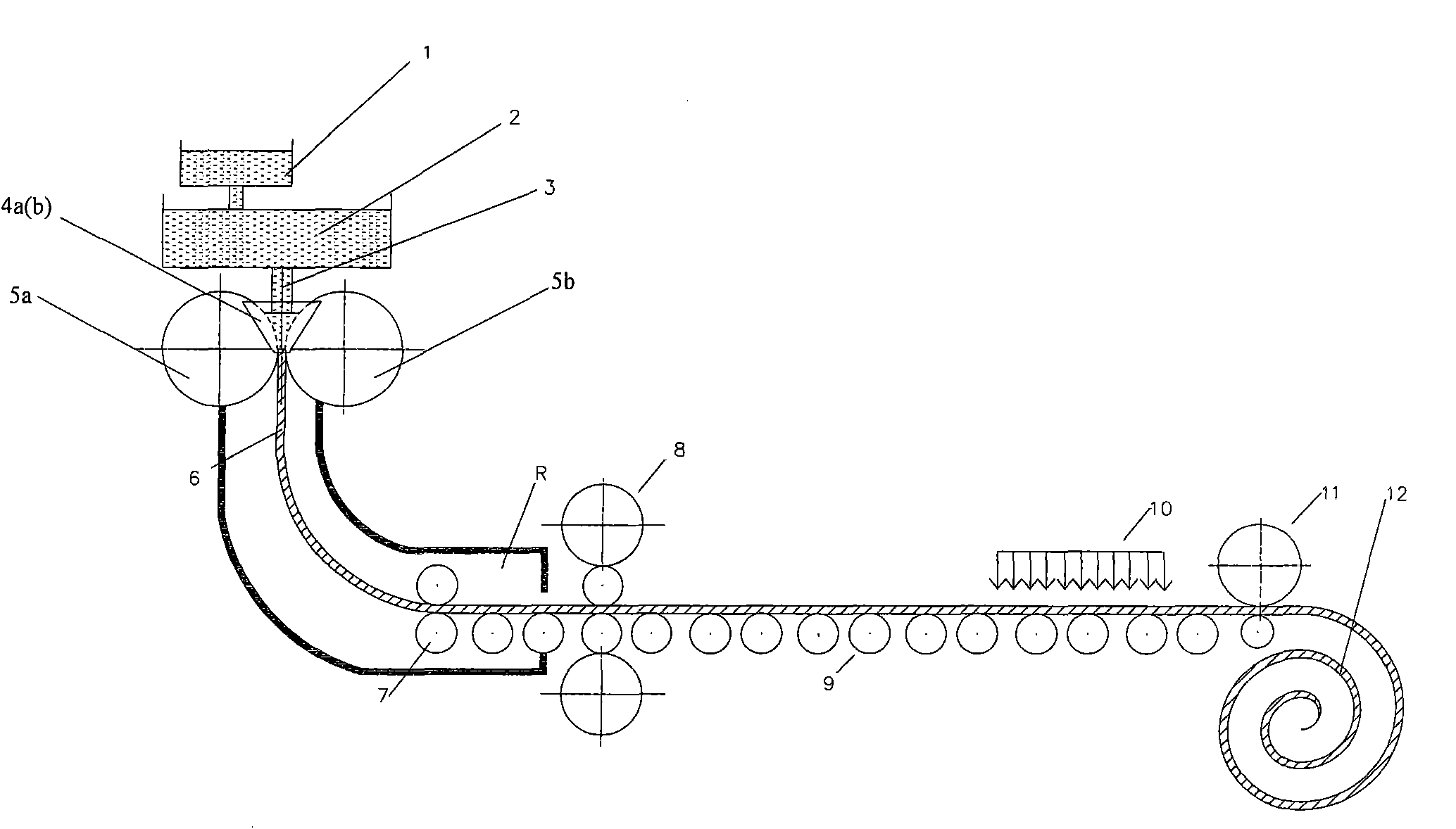

High-strength weather resisting steel with Cu2-xS dispersed precipitates and manufacturing method thereof

ActiveCN101928894AReduce steelmaking costsInhibition of segregationTemperature control deviceManufacturing convertersChemical compositionHigh intensity

The invention relates to high-strength weather resisting steel with Cu2-xS dispersed precipitates, which comprises the following chemical components in percentage by weight: 0.04-0.08% of C, 0.20-0.40% of Si, 0.4-1.0% of Mn, 0.03-0.12% of P, not more than 0.2% of S, 0.01-0.06% of Al, 0.20-0.80% of Cu, 0.40-0.6% of Cr, 0.12-0.40% of Ni, 0.001-0.006% of Ca and the balance of Fe and inevitable impurities. The welding cold crack sensitivity coefficient Pcm is not more than 0.18%. A manufacturing method comprises the following steps of: acceleratedly cooling both sides of a cast belt formed by continuous casting by using a gas and adopting a thin belt continuous casting production technology, wherein the cooling rate is 150-200 DEG C / s; performing the entire double-roller continuous casting process in a closed chamber filled with protective atmosphere; and arranging one to two stands for online hot rolling, wherein the thickness of a finished steel belt reaches 0.6-2 mm. The desulfurization procedure in steel making process can be omitted, and the steel making cost is reduced. The segregation of copper elements is inhibited, meanwhile, a large quantity of dispersed Cu2-xS precipitates can be formed to achieve the effect of dispersion strengthening.

Owner:BAOSHAN IRON & STEEL CO LTD

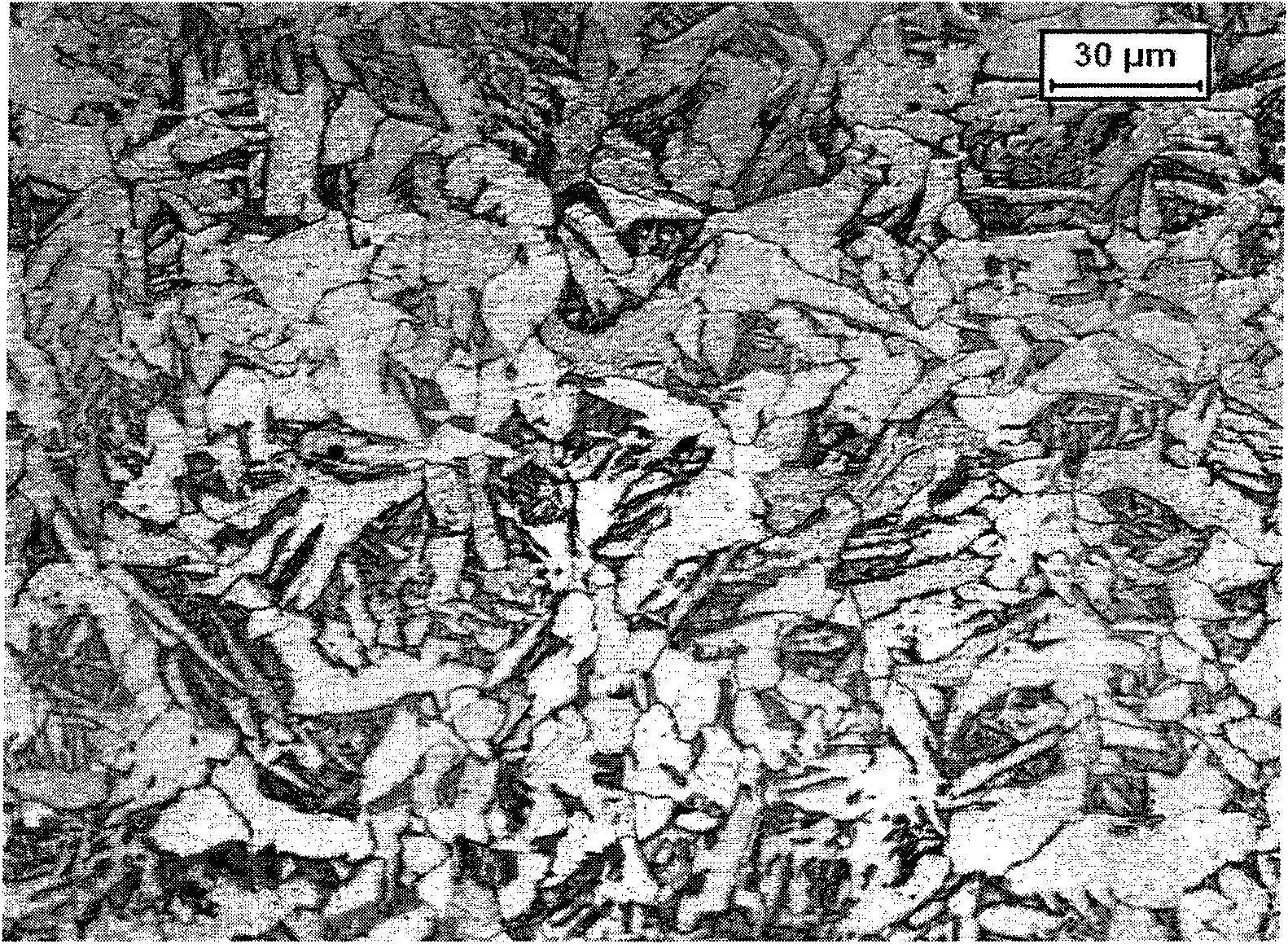

Weathering steel and manufacturing method thereof

The invention discloses weathering steel, which comprises the following chemical compositions in percentage by weight: 0.06 to 0.12 percent of C, 0.20 to 0.40 percent of Si, less than or equal to 1.6 percent of Mn, 0.08 to 0.22 percent of P, less than or equal to 0.008 percent of S, 0.01 to 0.06 percent of Al, 0.20 to 0.80 percent of Cu, 0.40 to 0.75 percent of Cr, 0.12 to 0.40 percent of Ni, 0.001 to 0.006 percent of Ca and the balance of iron and inevitable impurity elements. The weathering steel is manufactured by a thin strip continuous casting process. The manufacturing process comprises the following steps of: performing deep desulfurization on molten steel, performing composite blowing on the top and bottom of a converter, performing RH vacuum circular degassing process, and simultaneously performing calcium treatment; performing twin-roll continuous casting, and making the temperature of the molten steel in a molten bath not lower than 1,535DEG C; controlling rolling in the reduction ratio of not less than 30 percent; controlling cooling at the speed 30 to 50 DEG C / s; and coiling at the temperature of between 600 and 650 DEG C. The weathering steel of which the texture is acicular ferrite has good weatherability and can be widely applied to structural materials.

Owner:BAOSHAN IRON & STEEL CO LTD

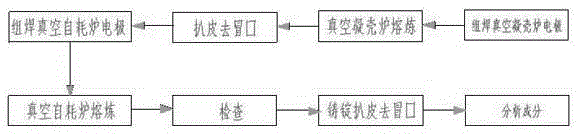

Additive manufacturing method for functional material part based on TiNi memory alloy wire

InactiveCN105268973ALarge molten poolGood for homogenizationAdditive manufacturing apparatusIncreasing energy efficiencyAlloy elementNickel base

The invention belongs to the technical field of forming and manufacturing of metal materials, and particularly relates to an additive manufacturing method for a functional material part based on a TiNi memory alloy wire. The additive manufacturing method comprises the following steps: smelting a titanium-nickel based memory alloy; preparing a titanium-nickel based memory alloy wire; taking the titanium-nickel based memory alloy wire as a raw material; carrying out a laser-cladding additive manufacturing process; and carrying out tissue control and deformation amount control on manufactured parts. A welding pool of a vacuum self-consumption skull furnace is great, and is beneficial for sufficiently homogenizing alloy elements and preventing alloy segregation; and smelting of the vacuum self-consumption skull furnace refers to controlling a cast titanium tissue of a cast ingot, thereby facilitating follow-up cold-hot processing.

Owner:SHENYANG HAINAXIN TECH CO LTD

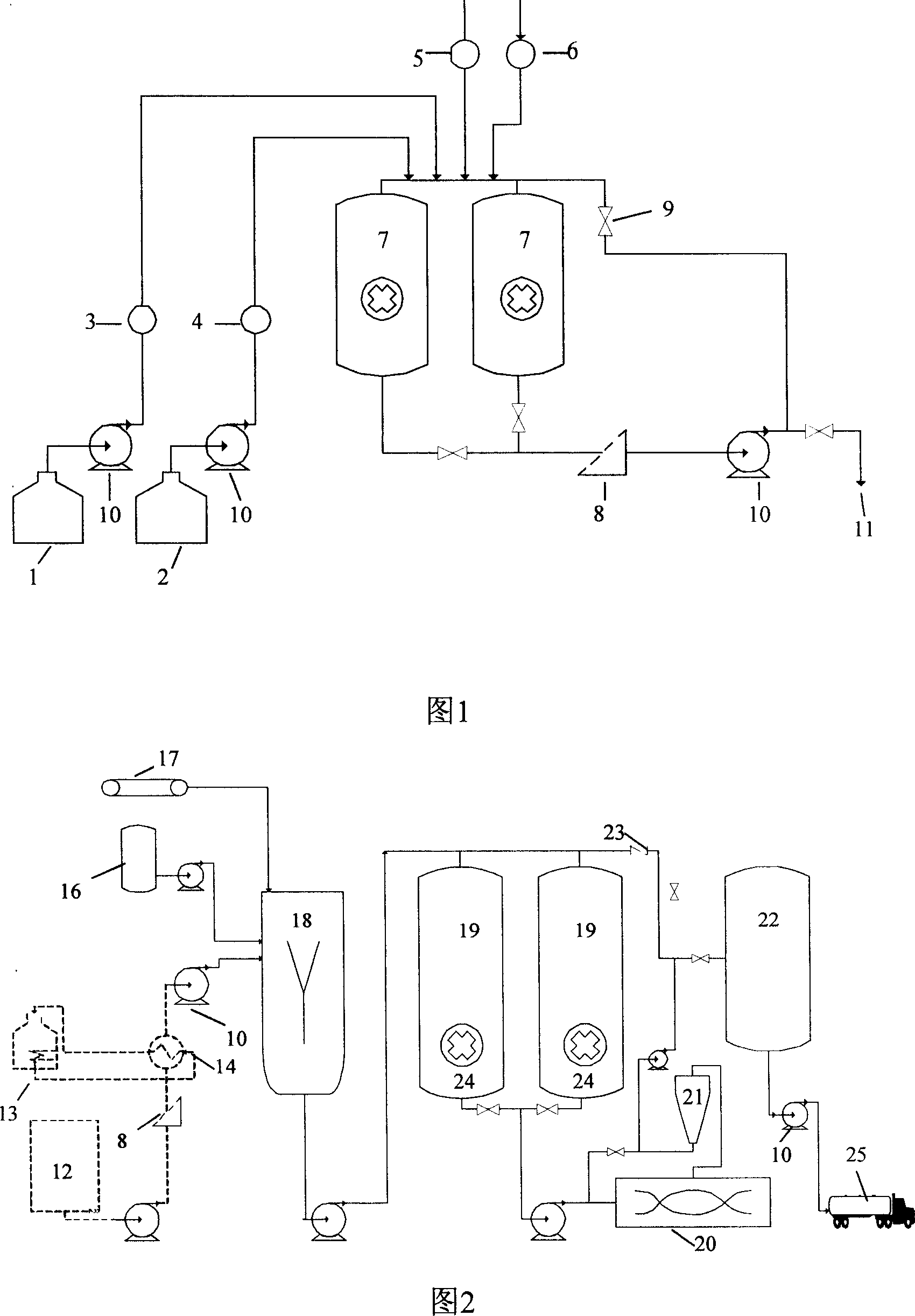

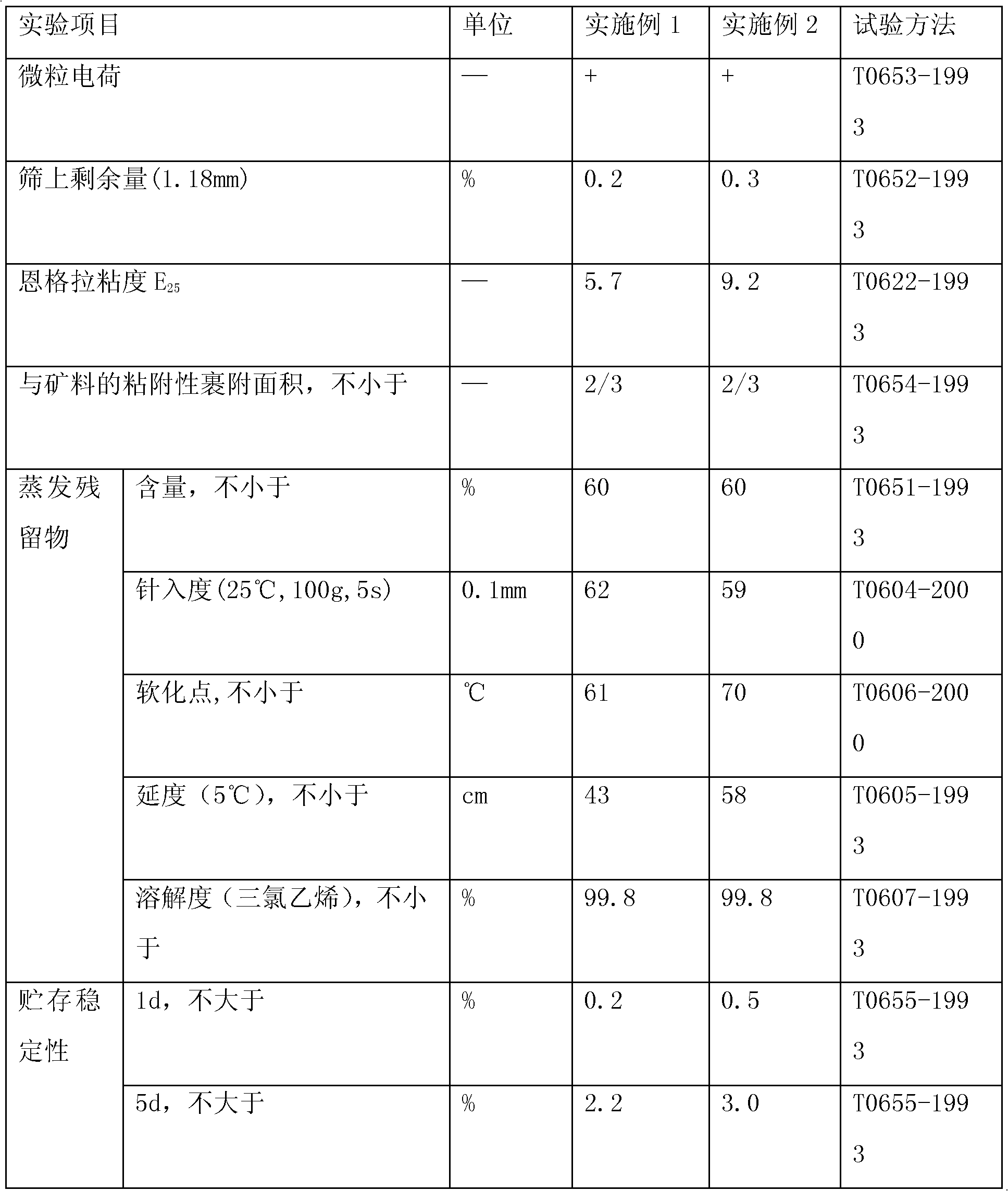

SBS polymer modified emulsified asphalt and preparation method

The invention belongs to the modified emulsified asphalt field, and more specifically relates to a SBS polymer modified emulsified asphalt and a preparation method, the SBS polymer modified emulsified asphalt is prepared by the following raw materials by mass percentages: 40-65% of SBS polymer modified emulsified asphalt, 25-50% of water, 2-10% of cation asphalt emulsifier, 0.1-2.0% of composite emulsified stabilizing agent and 0.2-2.0% of acid, wherein SBS polymer modified asphalt is prepared by mixing and reacting a SBS polymer modifier and matrix asphalt, and the mass of the SBS polymer modifier accounts for 3.5%-5.5% of that of the SBS polymer modified asphalt. The prepared SBS polymer modified emulsified asphalt has stable property, and can be used as a cement asphalt mortar layer and the like for a road tack coat, a seal layer, surface treatment, a slurry seal layer and a high speed railway plate-type ballastless track.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing ultra-high hardness cladding layer through synchronous ultrasonic vibration assisting laser technology

InactiveCN104451673AIncreased microhardnessImprove wear resistanceMetallic material coating processesCeramic coatingLiquid metal

The invention provides a method for preparing an ultra-high hardness cladding layer through the synchronous ultrasonic vibration assisting laser technology. According to the specific scheme, the method includes the steps that ultrasonic vibration is synchronously introduced in the Ni-based metal ceramic coating cladding process, mobility of liquid metal can be improved in the mode, tissue distribution is more uniform, in the solidification process, a growing dendrite net can be broken and made to be dispersed to all portions of melt, small crystal nucleuses which are uniformly distributed are formed, segregation of metal ceramic is avoided, and therefore it is guaranteed that the cladding layer is not prone to cracking when ultra-high hardness is acquired; equipment is simple, calibration and installation are facilitated, energy consumption is low, the working environment is good, and acquired coating metal ceramic particles are uniform in distribution, high in hardness and good in abrasion resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

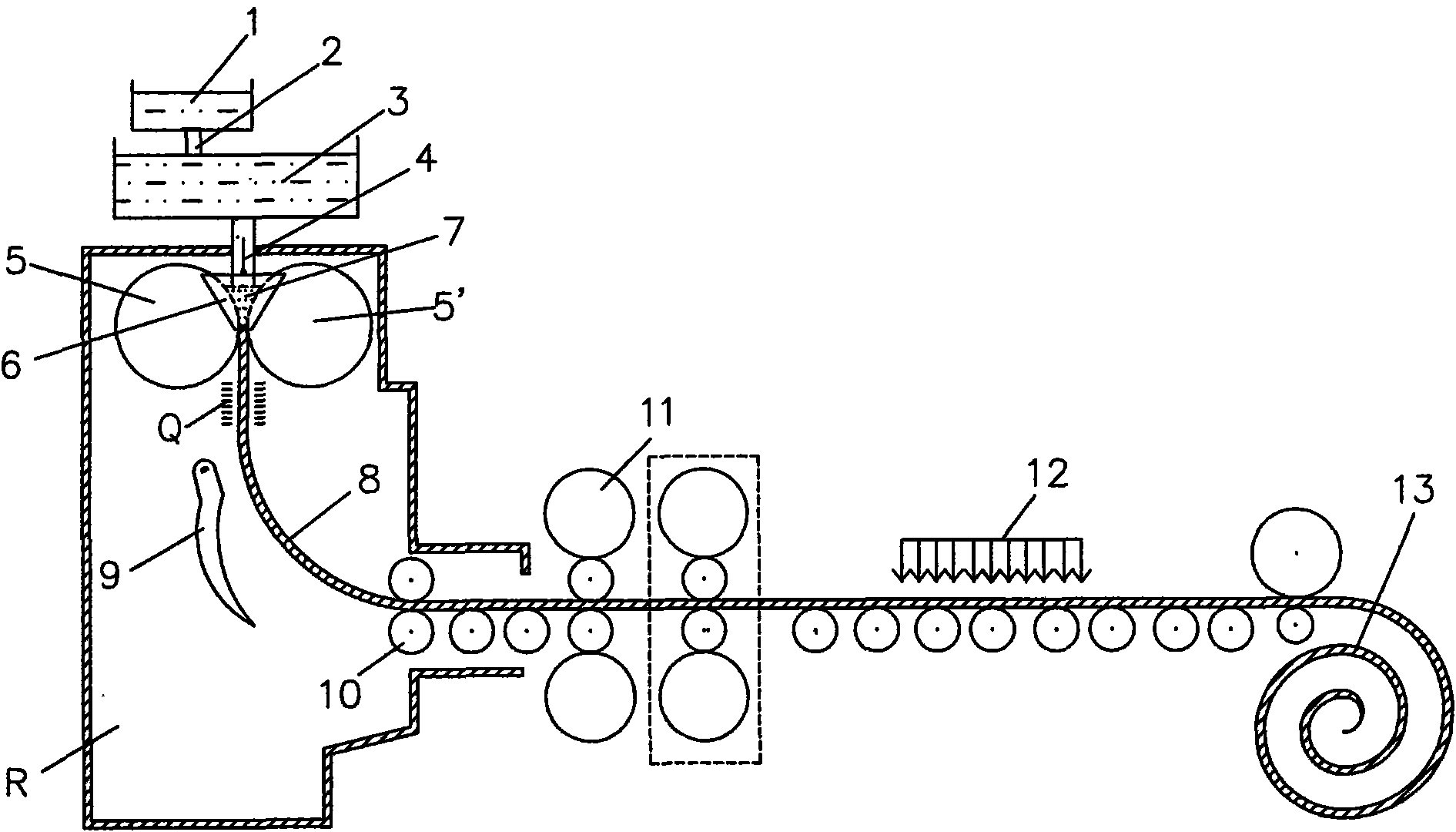

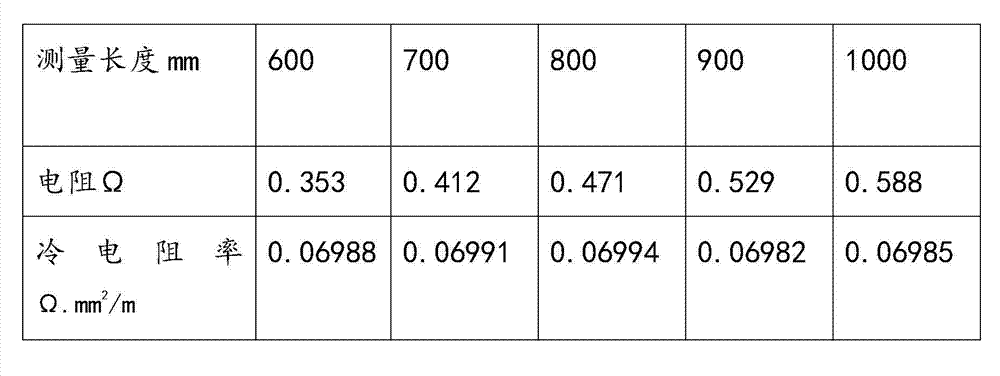

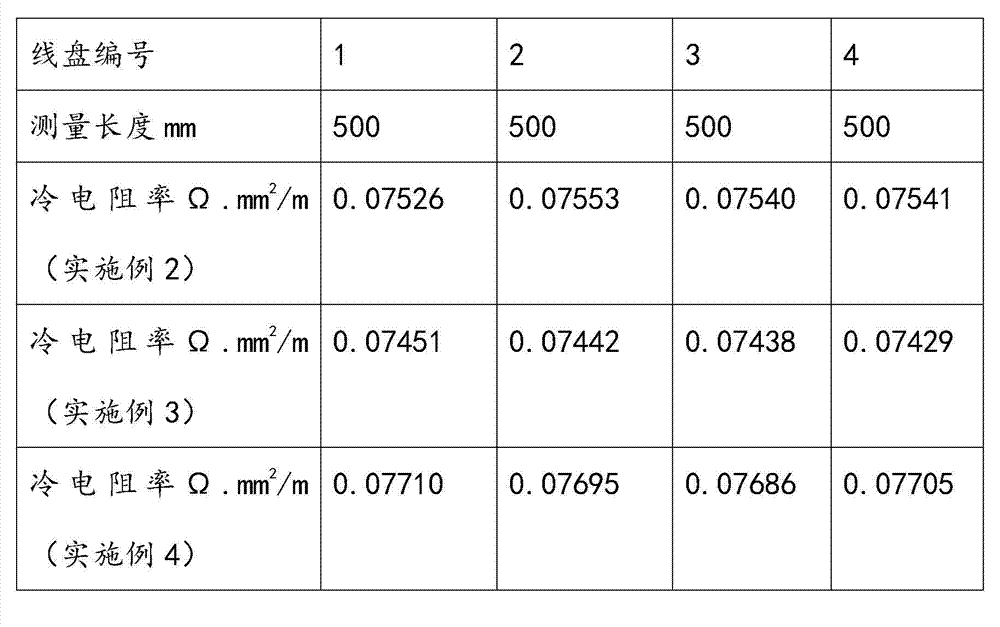

Tungsten-rhenium alloy and preparation method thereof

The invention discloses a tungsten-rhenium alloy which contains 65-75ppm of potassium and 0.45-0.55% of rhenium. The invention also discloses a manufacturing method of the tungsten-rhenium alloy, which comprises the following steps: A. preparing doping tungsten-rhenium powder: mixing doping tungsten powder solid and ammonium rhenate solution to obtain a doping tungsten-rhenium instillation, and drying the instillation to obtain doping tungsten-rhenium powder, wherein in the mixing process, the temperature is kept at 30-50 DEG C and the solid-liquid weight ratio is (100-300):5; B. reducing to obtain tungsten-rhenium mixed powder; C. compacting; D. presintering; and E. sintering to obtain the tungsten-rhenium alloy. The method has the advantages of simple technique, uniform distribution of doping rhenium in the alloy, and favorable material uniformity; and the prepared tungsten-rhenium alloy has favorable high temperature properties and processability, and thus, is an ideal new material for lamp filaments.

Owner:ZIGONG CEMENTED CARBIDE CORP

Gold potassium citrate for gold plating and preparation method thereof

InactiveCN101781784ALow toxicityPH value is stableLiquid/solution decomposition chemical coatingChemical compositionCITRATE ESTER

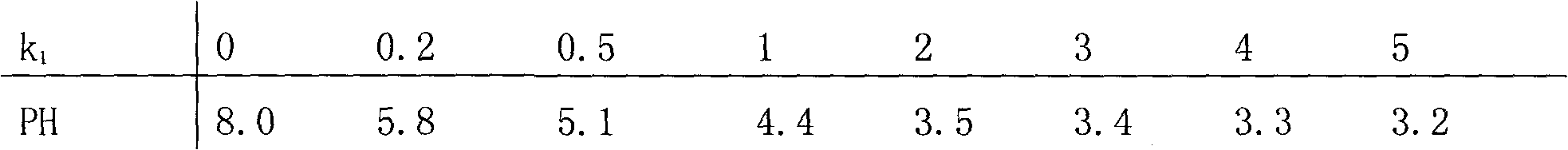

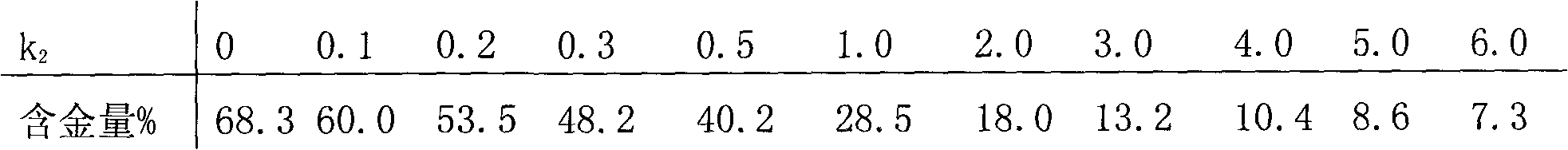

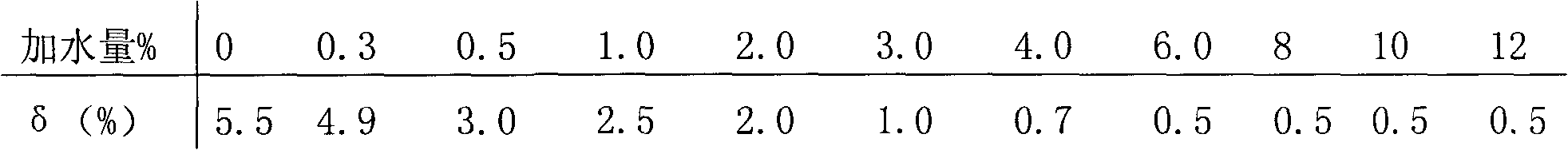

The invention relates to gold potassium citrate for gold plating and a preparation method thereof. The gold potassium citrate is used to substitute for gold potassium cyanide in acidic and neutral gold plating technology. The problem that the product coverage area is too wide when gold citrate is used in the gold plating technology is solved. The technical scheme is that the gold potassium citrate is the mixed crystal of gold potassium cyanide and citric acid potassium salt and the chemical composition of the gold potassium citrate is KAu (CN)2 (K3C6H5O7. k1C6H8O7) k2, wherein KAu (CN)2 is gold potassium cyanide, K3C6H5O7.k1C6H8O7 is citric acid potassium salt which is mixed by potassium citrate K3C6H5O7 and citric acid C6H8O7, k1 is the molar ratio of potassium citrate to citric acid, is more than or equal to zero and is less than or equal to three, and k2 is the molar ratio of citric acid potassium salt to gold potassium cyanide, is more than or equal to one point three and is less than five. The method is mainly suitable for the acidic and neutral gold plating technology.

Owner:张东山

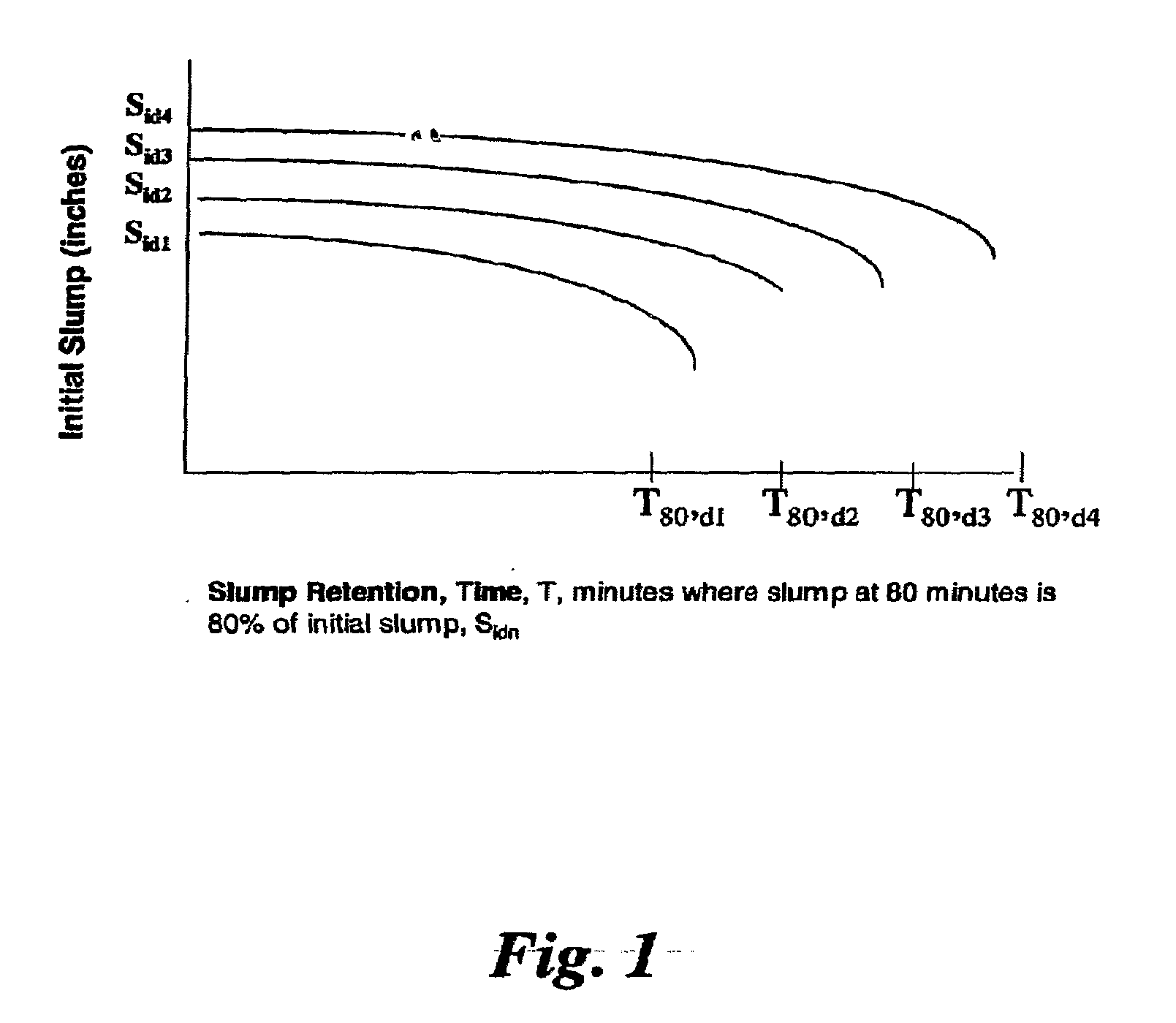

Slump Retention in Cementitious Compositions

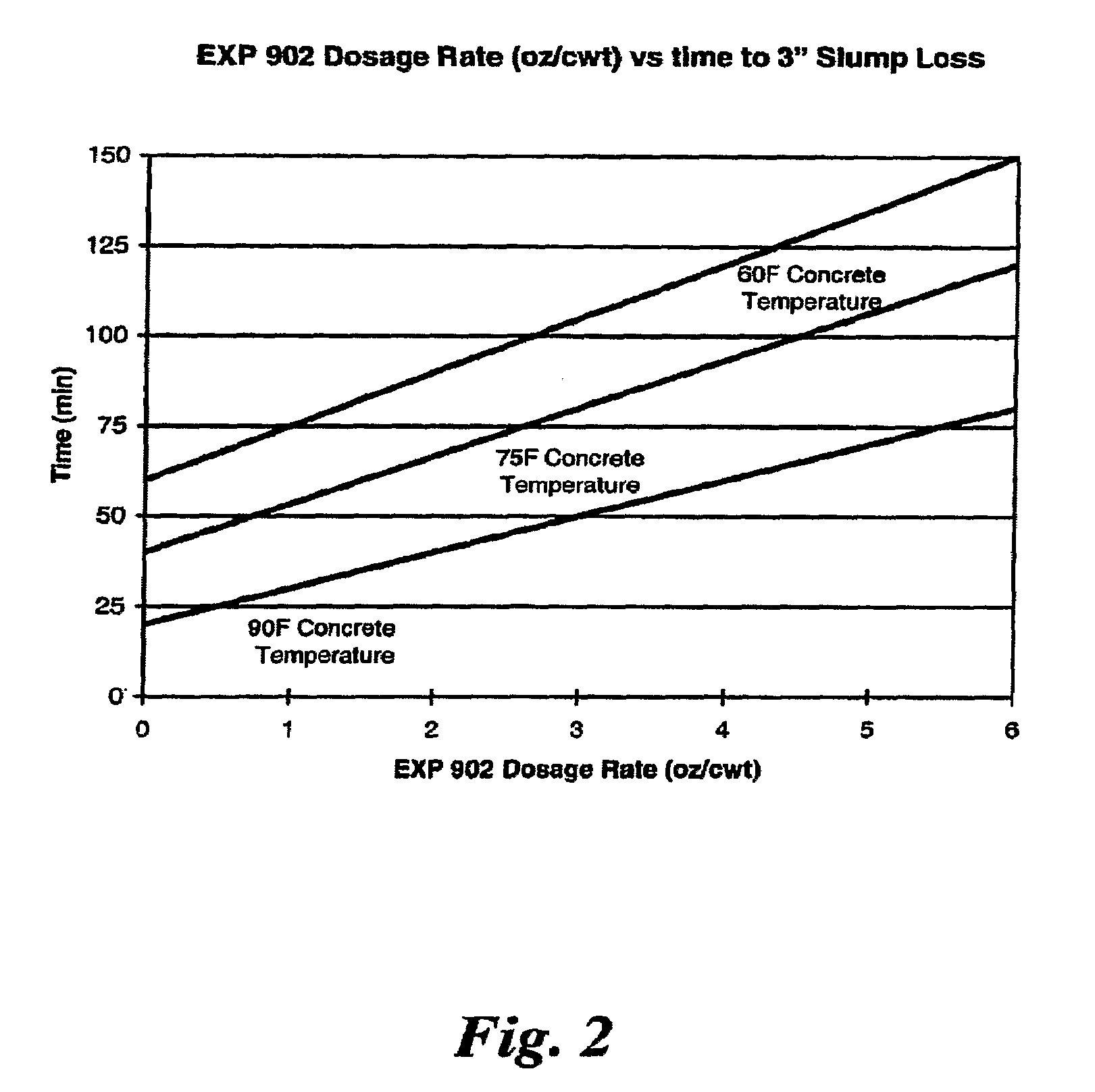

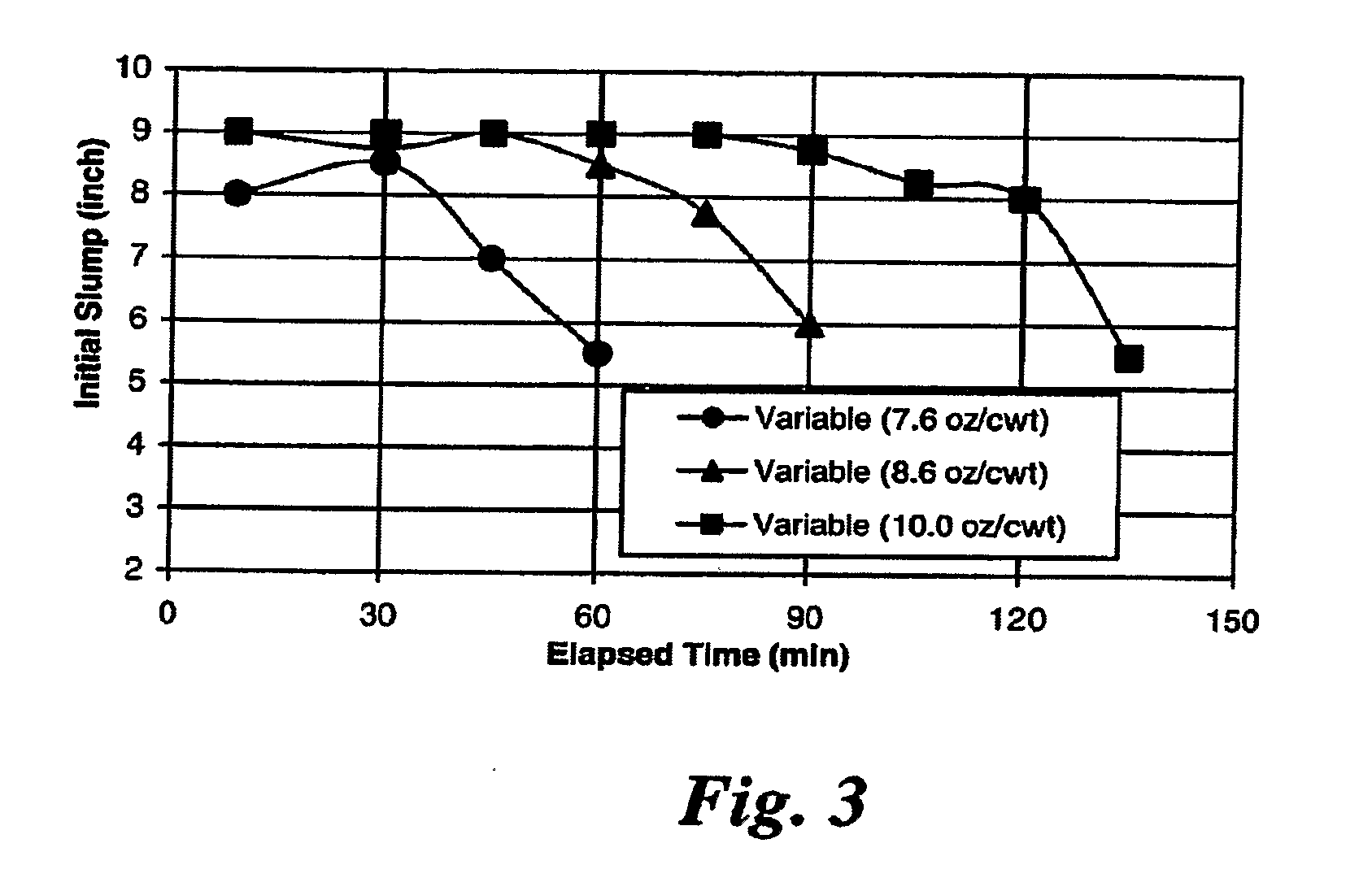

The present invention relates to dispersants such as superplasticizers for hydratable cementitious compositions, and more particularly to methods for achieving variable degrees of longer slump life in concrete and mortar without loss of stability. This is achieved by using two admixture systems. The first admixture composition has multi-components for achieving initial-slump-enhancement, later-slump-retention, and limiting initial slump. The second admixture composition has the later-slump-enhancing component. Alternatively, conventional water reducers or superplasticizers can be employed initially, followed by the later-slump-enhancing admixture composition.

Owner:GCP APPL TECH INC

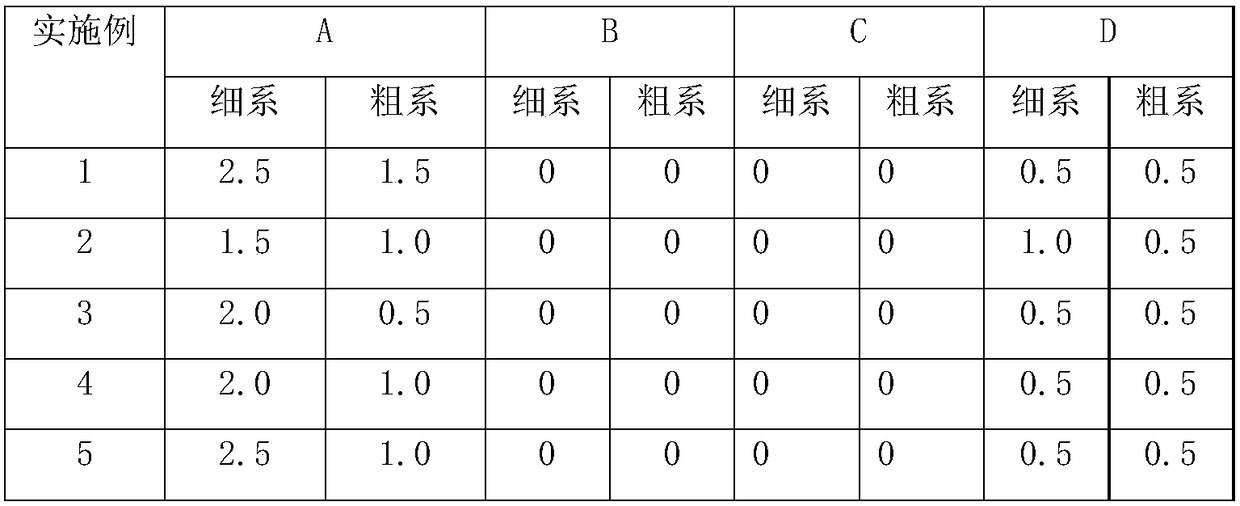

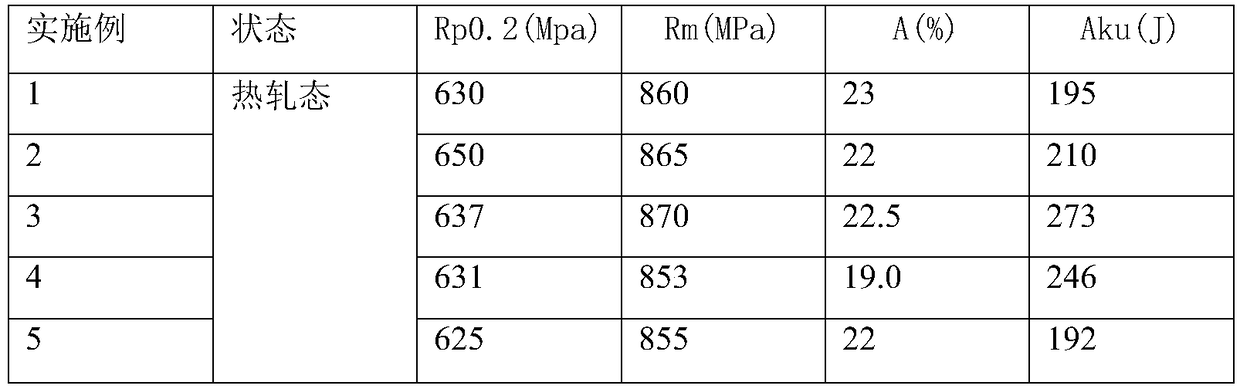

High-strength high-tenacity non-quenched-and-tempered round steel and preparation method

ActiveCN109234627AGuaranteed stabilityHigh yieldFurnace typesHeat treatment furnacesTemperature controlChemical composition

The invention discloses high-strength high-tenacity non-quenched-and-tempered round steel, and relates to the technical field of non-quenched-and-tempered steel. The high-strength high-tenacity non-quenched-and-tempered round steel is prepared from the following chemical components by mass percent: 0.27%-0.33% of C, 0.40%-0.70% of Si, 0.10%-0.30% of Cr, 1.30%-1.65% of Mn, 0.065%-0.100% of S, 0.005%-0.040% of Al, 0.06%-0.020% of V, 0.010%-0.040% of Ti, 0.0120%-0.0250% of N, the balance of Fe and unavoidable impurities, wherein manganese equivalent Mneq is 1.70%-2.10%. The high-strength high-tenacity non-quenched-and-tempered round steel is capable of increasing a free-cutting element S with low cost, forming dispersed distribution of a sulfide and a V (N, C) compound, through continuous uniform cooling rolling and temperature control cooling after rolling, a high-tenacity non-tempering steel bar with a good mechanical property is obtained, wherein rolled metal ballistic work reaches 190 J or more.

Owner:NANJING IRON & STEEL CO LTD

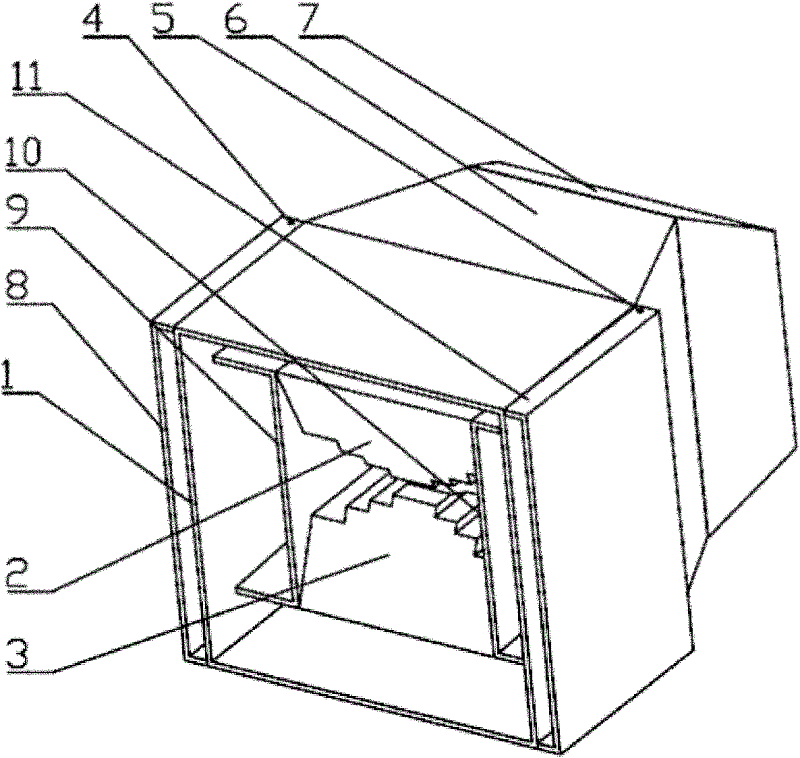

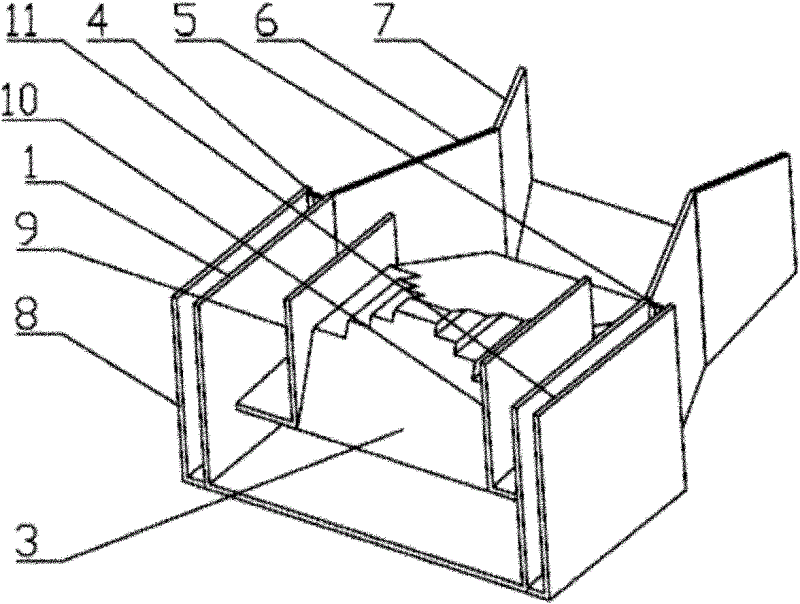

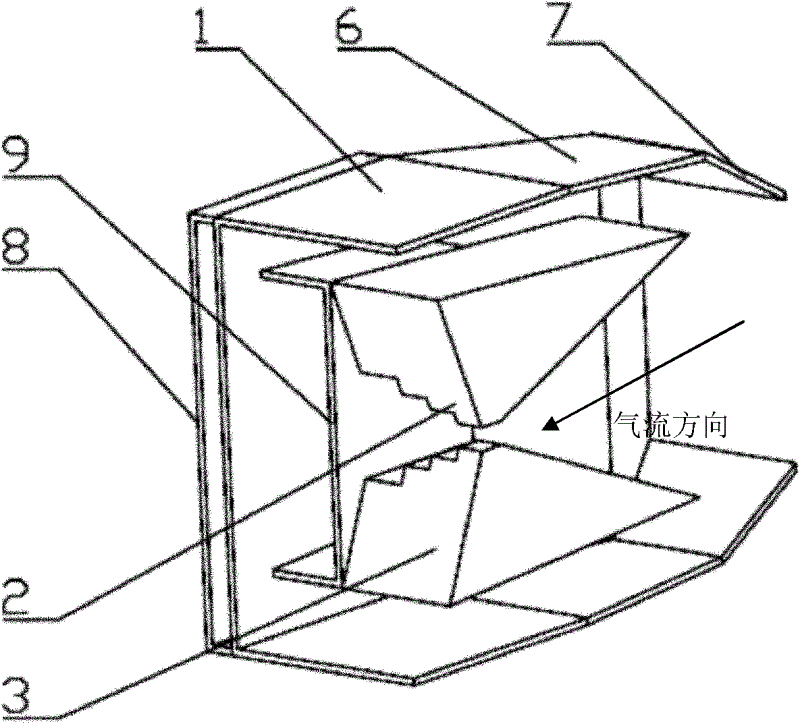

Pulverized coal decoupling combustor with low nitrogen oxide discharge and pulverized coal decoupling combustion method with low nitrogen oxide discharge

InactiveCN102620291ASeparation perimeter lengthSmall steering anglePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationProcess engineeringCoal

The invention relates to a pulverized coal decoupling combustor with low nitrogen oxide discharge and a pulverized coal decoupling combustion method with low nitrogen oxide discharge. The method is implemented through the following two stages: a) stage 1, firstly separating mixed airflow of pulverized coal and air into a concentrated part and a dilute part by virtue of the pulverized coal decoupling combustor provided by the invention, igniting the concentrated pulverized coal airflow, then feeding the concentrated pulverized coal airflow into a hearth, and performing combined combustion on the concentrated pulverized coal airflow and the dilute pulverized coal airflow; and b) stage 2, mixing the mixed airflow with secondary air in the hearth, and fully combusting the pulverized coal semicoke generated in the stage 1 under conditions of rich oxygen and high temperature which is insufficient to generate thermal NOx, wherein in the stage 1, the pulverized coal is pyrolyzed, gasified and gas-fired under reducing atmosphere, volatile components are fully separated out, products of pyrolysis and gasification are utilized to convert fuel-type NOx into more stable N2. According to the invention, an integration design of pulverized coal condensation, stable combustion and low nitrogen oxide discharge can be realized, the equipment structure is compact, the pulverized coal condensation effect is good, the stable combustion capability is strong, and the potential of inhibiting NOx from generating is high.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

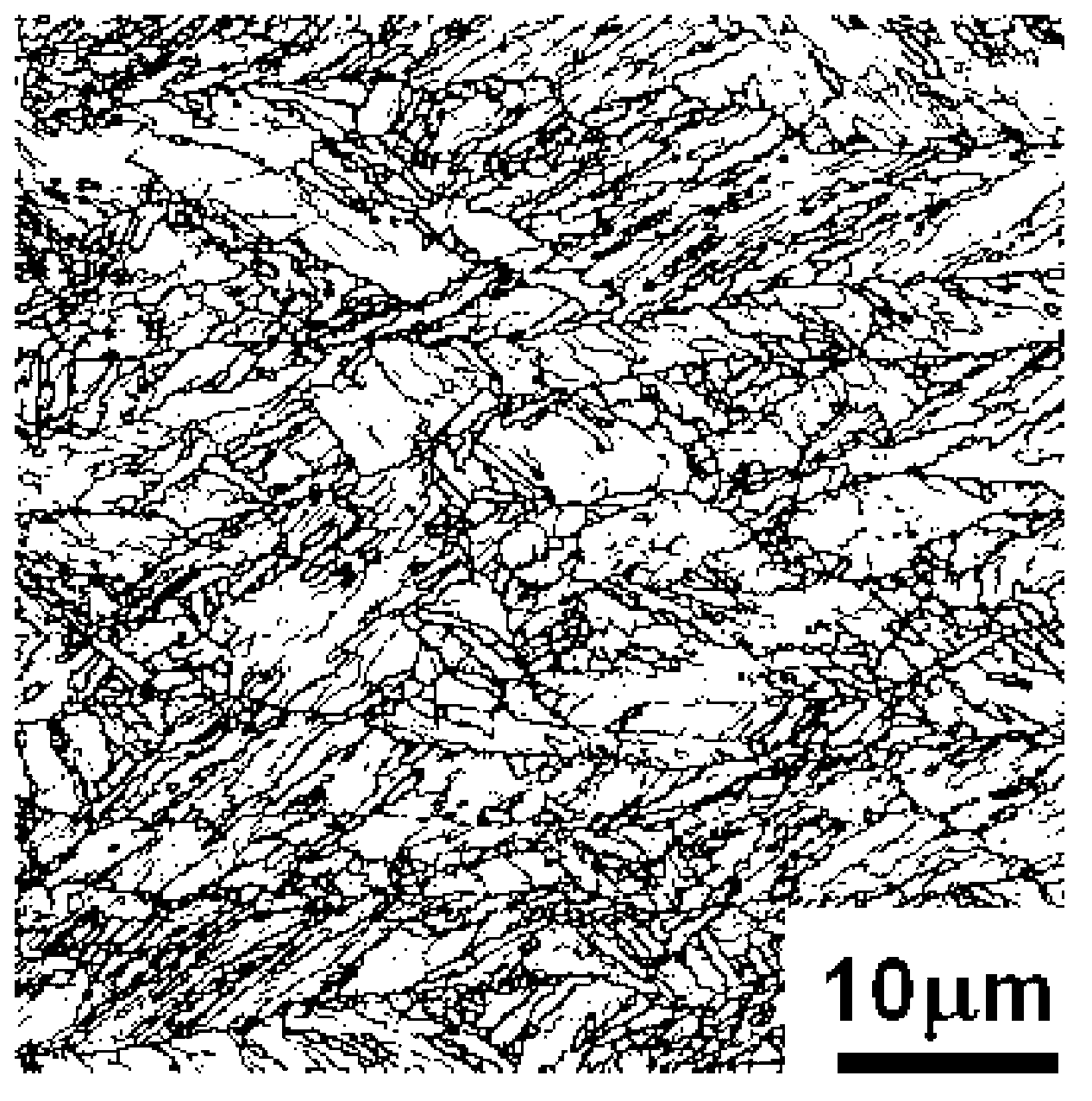

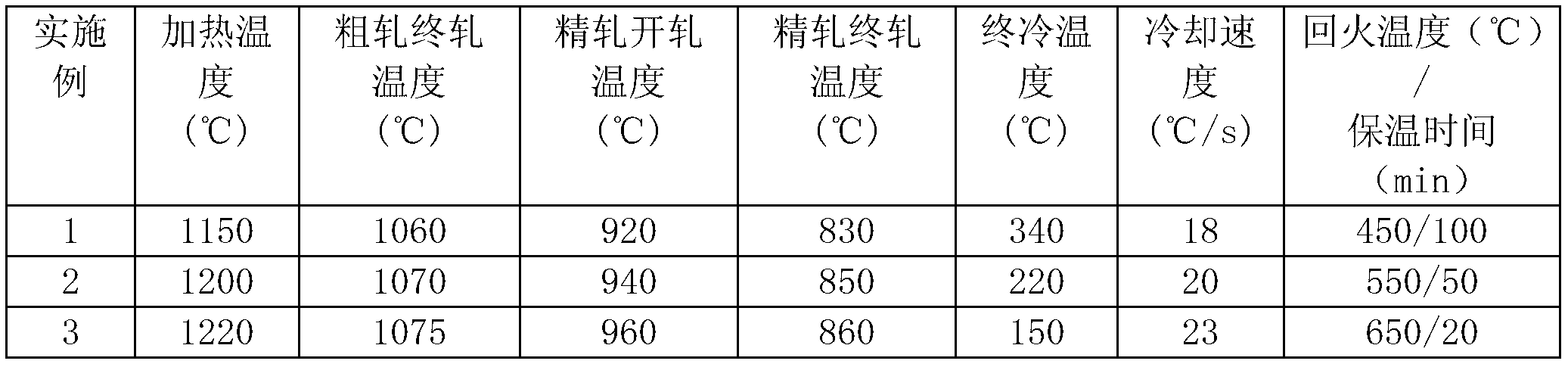

Ultrahigh-strength steel plate steel plate with yield strength of 960MPa-level, and manufacturing method thereof

The invention relates to an ultrahigh-strength steel plate steel plate with yield strength of 960MPa-level, and a manufacturing method thereof. The steel plate comprises the chemical components of: 0.06-0.11% of C, 0.10-0.50% of Si, 1.20-1.60% of Mn, less than 0.015% of P, less than 0.005% of S, 0.20-0.50% of Cr, 0.10-0.30% of Ni, 0.10-0.30% of Mo, 0.02-0.05% of Nb, 0.02-0 .06% of V, 0.008-0.03% of Ti, 0.0005-0.003% of B, 0.02-0.05% of Al, and balance of Fe. According to the invention, through two-stage controlled rolling, and direct quenching and tempering, a refined tempered martensite or lower bainite structure is obtained. Defects such as long process, high energy consumption, large alloy addition amount, and the like of traditional quenching and tempering process are overcome. The obtained steel plate has good toughness and cold bending performance.

Owner:NANJING IRON & STEEL CO LTD +1

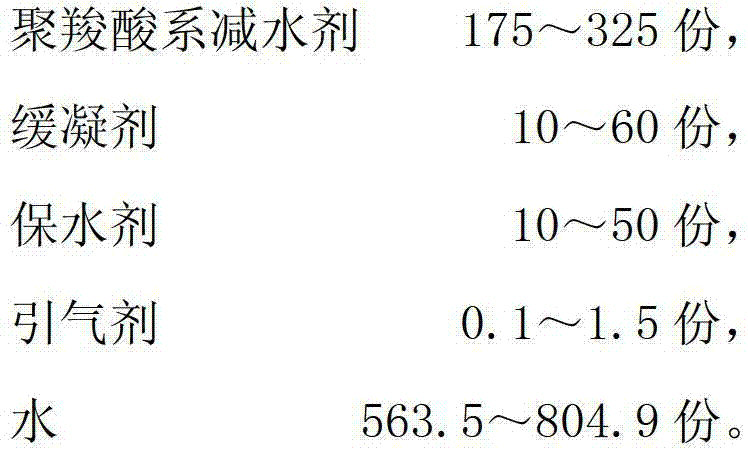

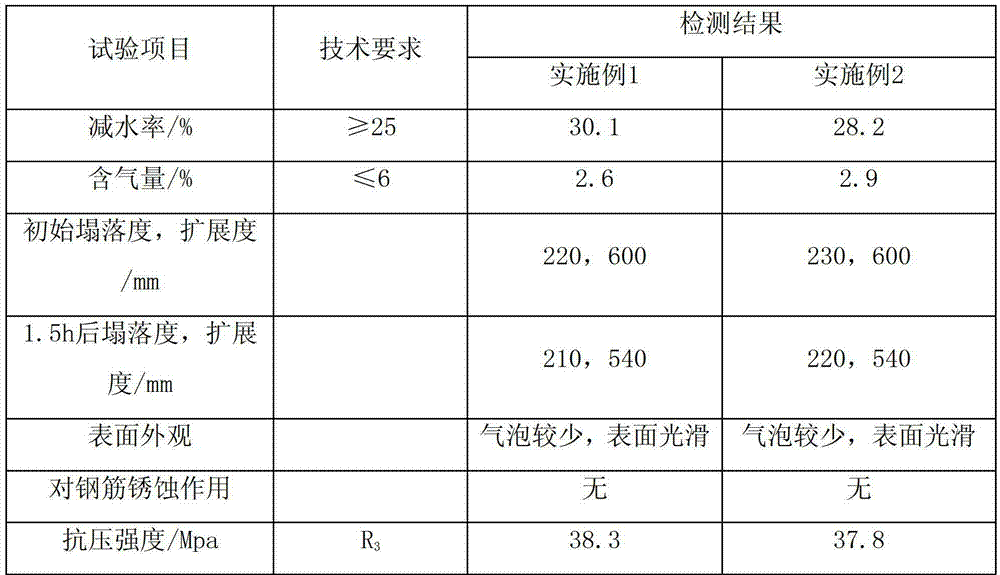

Pumping agent and application thereof

The invention relates to a pumping agent and application thereof, belonging to the field of construction materials. The invention aims to provide the pumping agent and the application thereof. The pumping agent provided by the invention comprises 175-325 parts by weight of polycarboxylic acid water reducing agent, 10-60 parts by weight of retarder, 10-50 parts by weight of water retention agent, 0.1-1.5 parts by weight of air entraining agent and 563.5-804.9 parts by weight of water. The invention also relates to the application of the pumping agent in C15-C70 concrete. The addition amount of the pumping agent accounts for 0.9-2.2 wt% of a cementing material in the concrete. The pumping agent prepared by the invention has the advantages of favorable material adaptability, low addition amount, high water reducing rate, low air content, high concrete strength contribution and the like, mainly solves the problem that the polycarboxylic acid pumping agent is easily subjected to over-addition in practical situations, can effectively prevent the defects of the concrete such as weepage, isolation and the like, and ensures the quality of the concrete.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

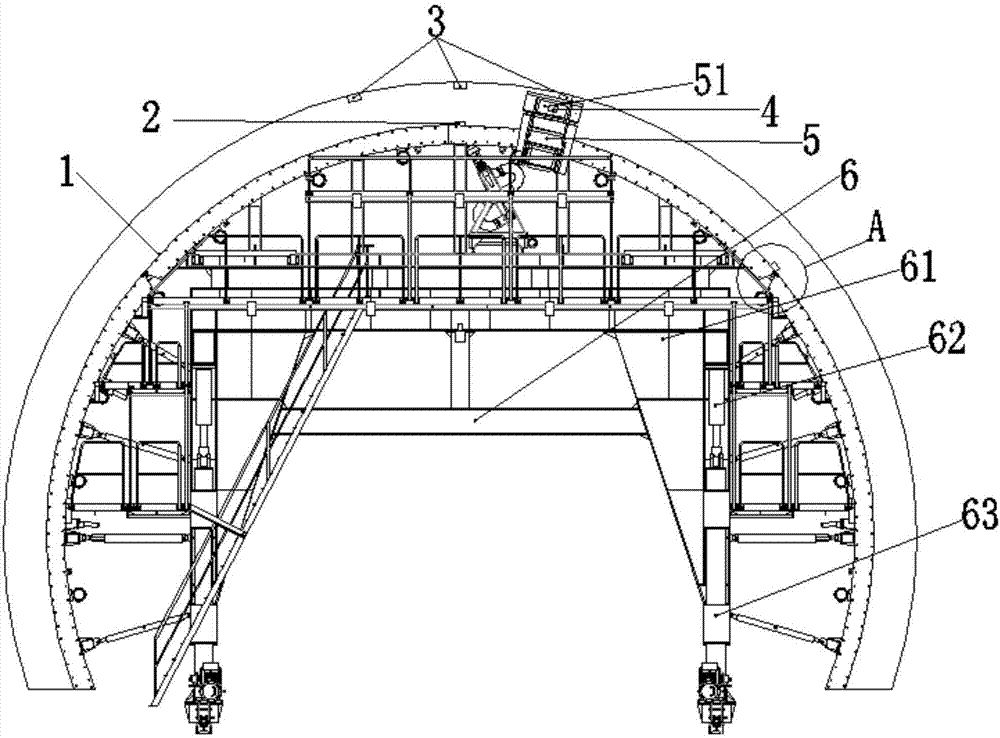

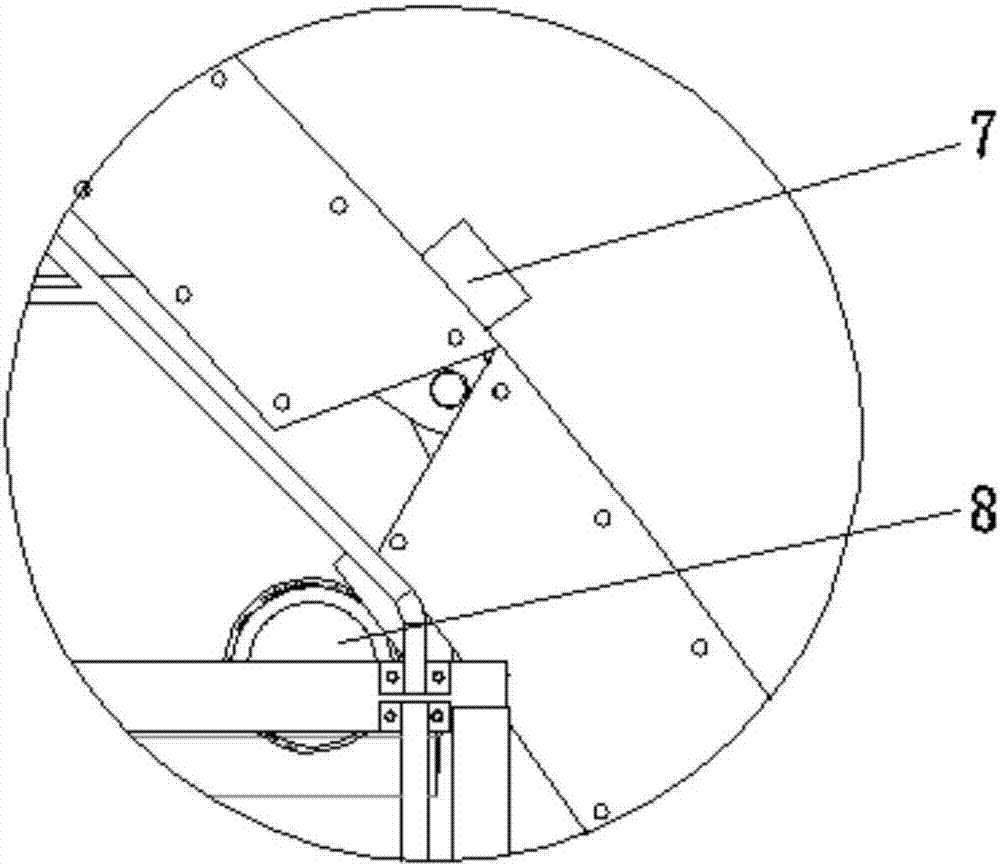

Intelligent tunnel lining trolley

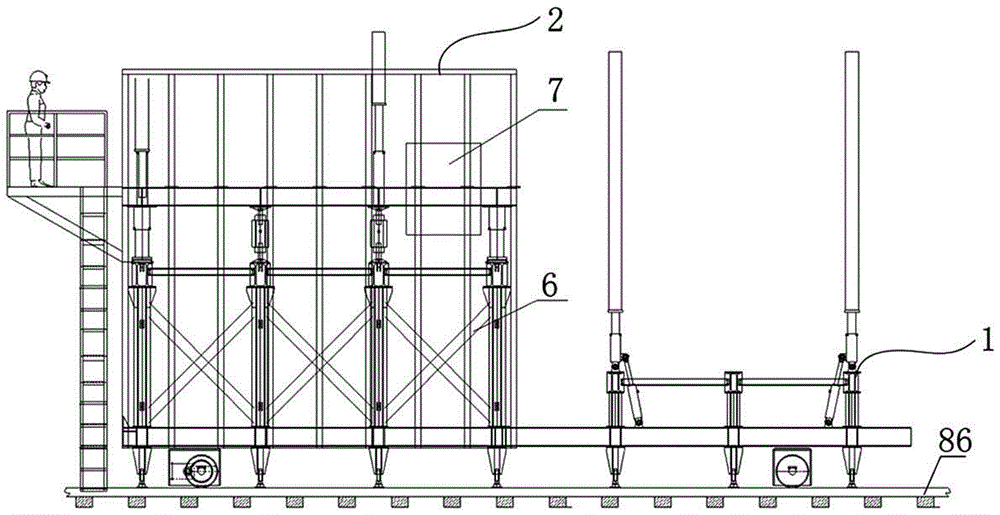

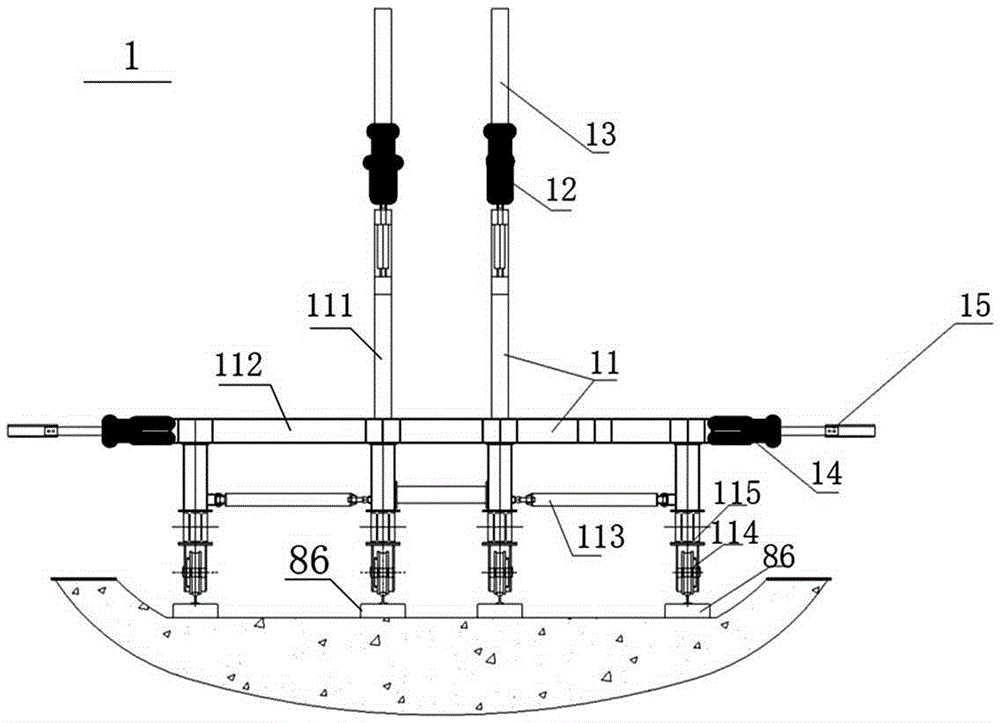

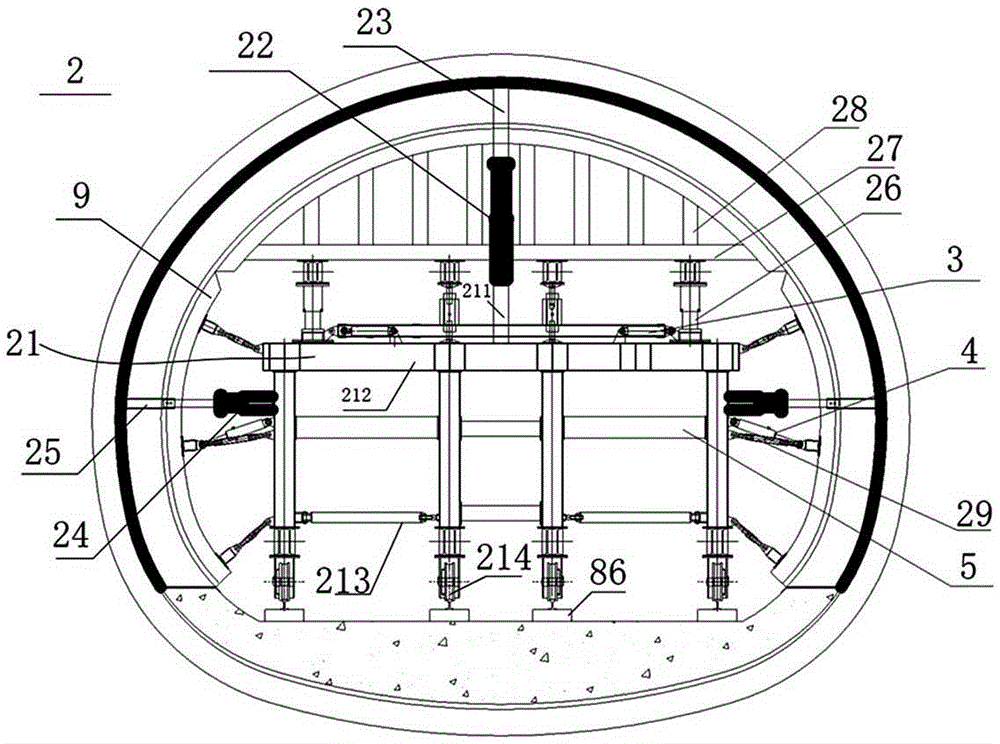

PendingCN107956490AEasy loading and unloadingPlace stableUnderground chambersTunnel liningMonitoring systemSteel frame

Provided is an intelligent tunnel lining trolley, characterized by comprising a door-shaped main steel frame, a concrete pouring informationized monitoring system, an end template, a template cleaningand surface lubricating system, an automatic running gear, and a layered window-by-window pouring and cleaning system. The tunnel lining trolley is simple in structure and reasonable in design, and real-time monitoring of each parameter in a concrete pouring process is realized, automation degree of equipment is improved, cleaning and template surface lubrication operation flow are simplified. The intelligent tunnel lining trolley provides convenience for on-site management and construction, and has certain environmental protection property and very high security.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

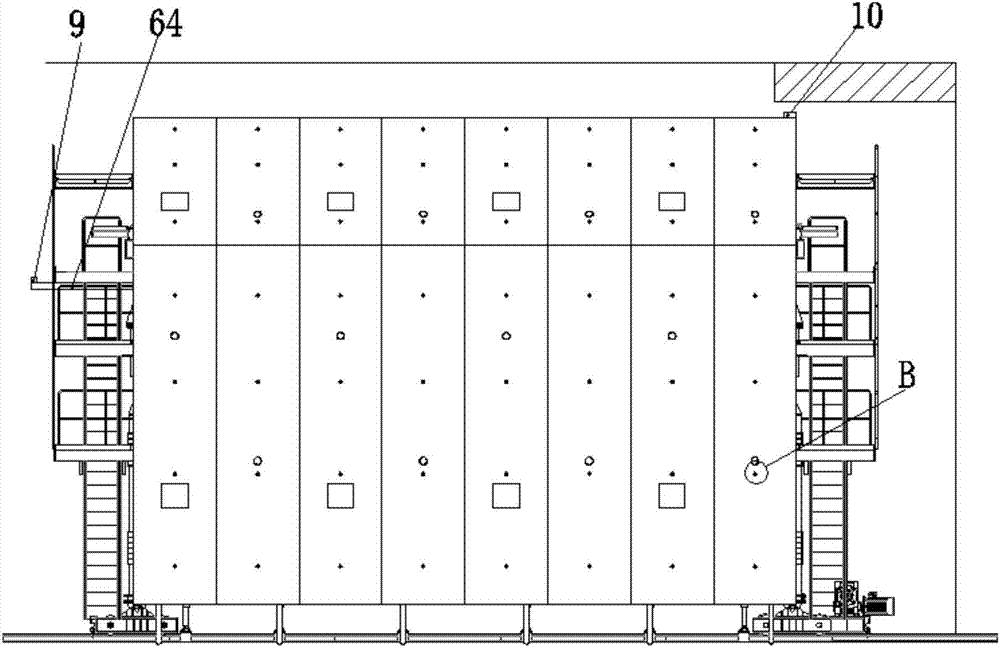

Tunnel underground excavation and lining construction trolley and tunnel underground excavation and lining construction method

ActiveCN105386778ASimple construction methodShorten the construction periodUnderground chambersTunnel liningSupporting systemEngineering

Owner:北京住总集团有限责任公司

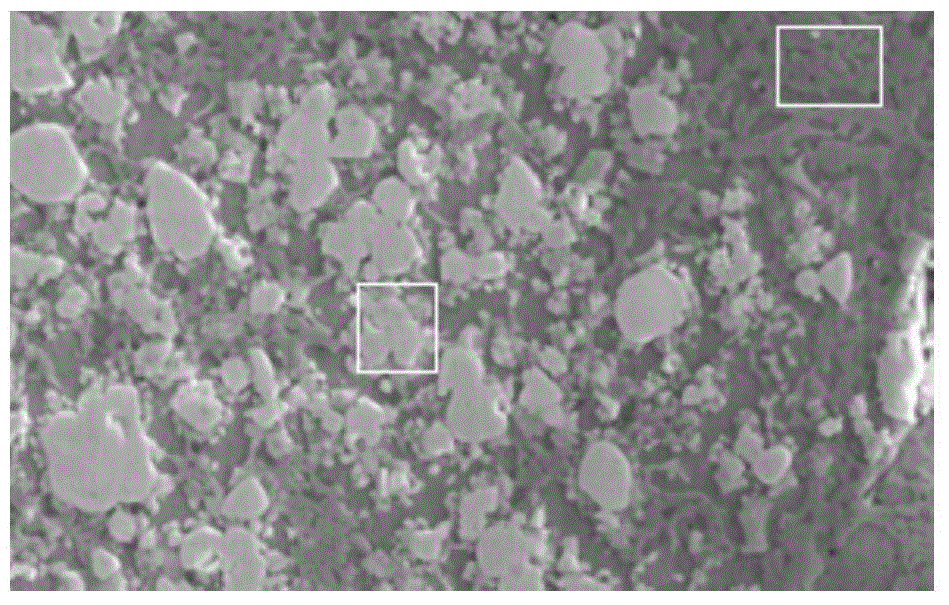

Oxide particle reinforced laser cladding high-wear resistance nickel-base alloy powder and preparation method thereof

InactiveCN103014475AHigh hardnessImprove wear resistanceMetallic material coating processesAlloyHigh surface

The invention provides oxide particle reinforced laser cladding high-wear resistance nickel-base alloy powder and a preparation method thereof. The powder is characterized by comprising basal body alloy powder, oxide hard particles and binding agent, and is proportioned as follows: 50-98 percent of basal body alloy powder, 1-45 percent of one of Al2O3, Cr3C2 and ZrO2 or combined mixture powder of more than two thereof, and 1-5 percent of binding agent are prepared to combined powder. The preparation method comprises the technique steps of preparation of basal body alloy powder, addition of oxide particles, addition of binding agent, stirring and ball milling, powder combination, drying, crushing and screening. The oxide particle reinforced laser cladding alloy powder has higher hardness and toughness, has excellent wear resistance and corrosion resistance, and is particularly suitable for laser cladding of alloy workpieces with higher surface hardness and high wear resistance; and the powder can effectively prevent segregation caused by great difference among specific gravities of all components in the process of storage, transportation and use.

Owner:江苏新亚特钢锻造有限公司

Blast furnace chute polycyclic distributing method

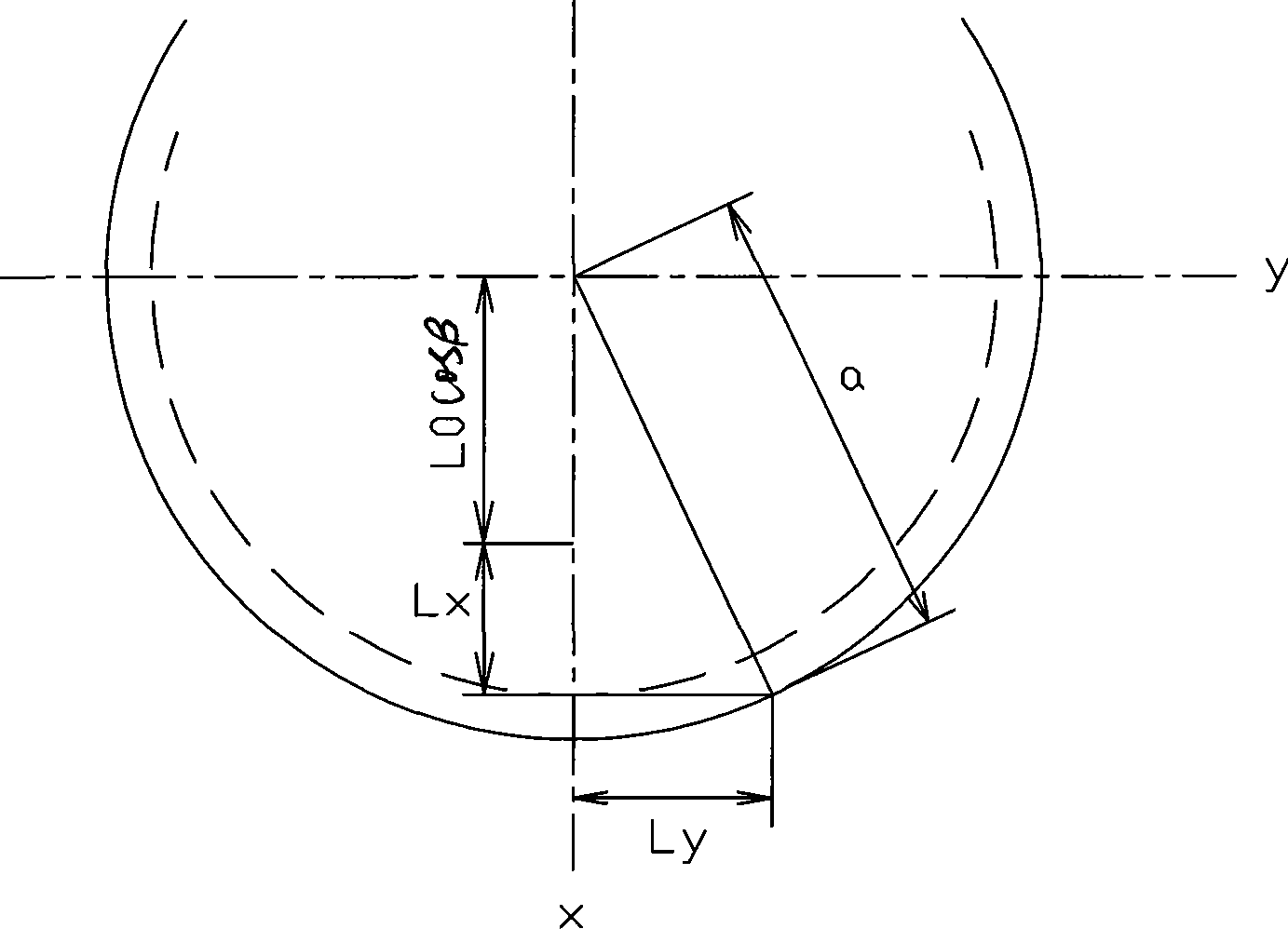

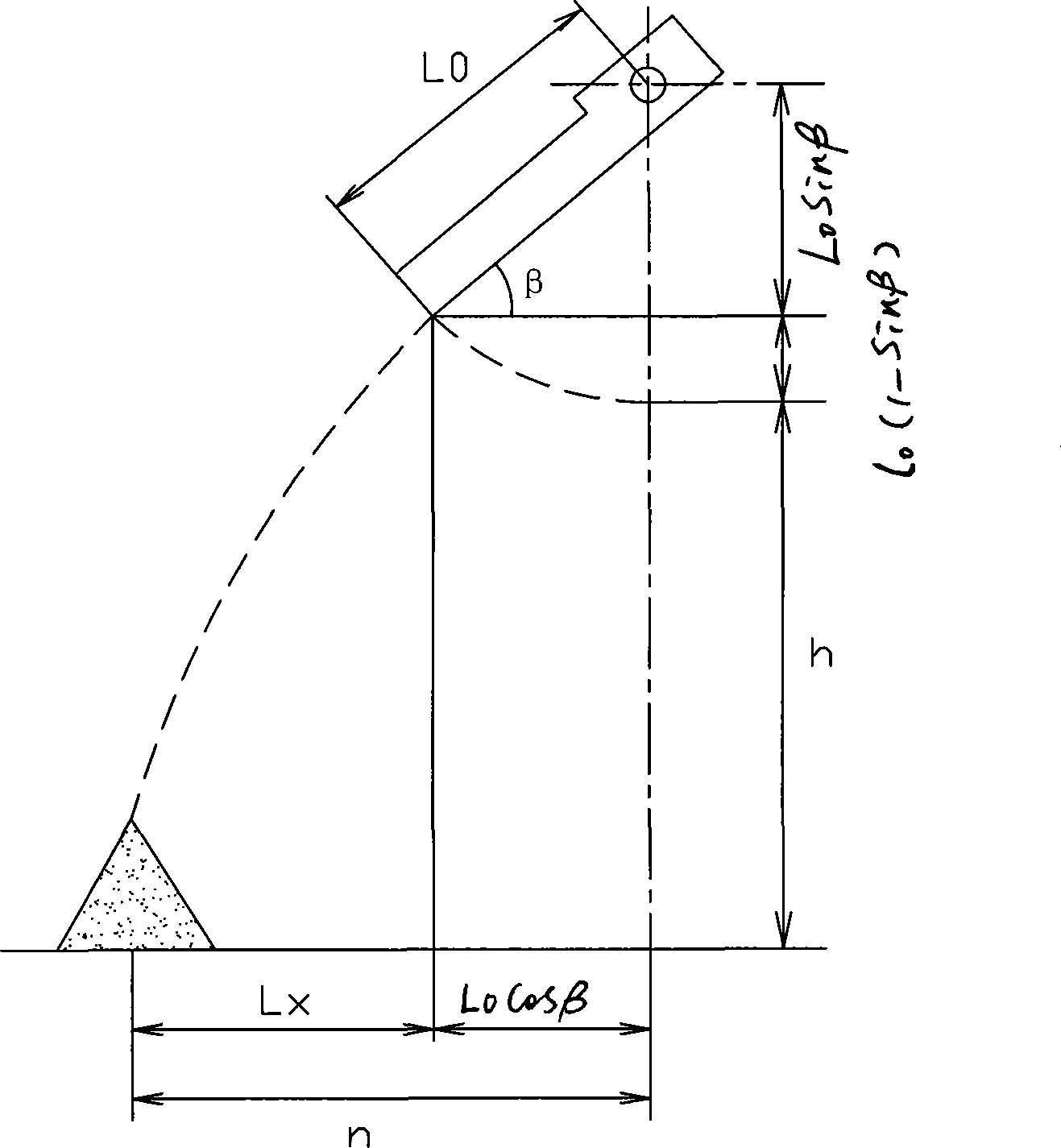

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

High abrasion-proof laser cladding cobalt-base alloy powder and preparation method thereof

InactiveCN102943266AImprove toughnessHigh hardnessMetallic material coating processesCarbideHardness

The invention relates to a high abrasion-proof laser cladding cobalt-base alloy powder and a preparation method of the alloy powder. The high abrasion-proof laser cladding cobalt-base alloy powder is characterized by comprising matrix alloy powder, hard carbide particles and a bonding agent; and the combined powder comprises 50-98% of matrix alloy powder, 1-45% of WC or TiC or mixed powder of WC and TiC, and 1-5% of bonding agent. The preparation method comprises the following steps of: preparing the matrix alloy powder, adding the carbide particles into the prepared matrix alloy powder, adding bonding agent into the mixture, stirring, ball milling, combining the powder, drying, crushing and screening. The high abrasion-proof laser cladding cobalt-base alloy powder not only is high in hardness and toughness, but also has excellent wear resistance and corrosion resistance, thus being especially suitable for laser cladding of parts with high impact resistance and high abrasion-proof property. Furthermore, the phenomenon of segregation caused by great differences among the specific gravities of all components in the processes of storage, transportation and using can be effectively prevented.

Owner:江苏新亚特钢锻造有限公司

SBS modified asphalt stabilizer and preparation method thereof

The invention discloses a stabilizer, in particular to a stabilizer used for SBS modified asphalt and a preparation method thereof; the stabilizer is prepared from the following raw materials according to the parts by weight: 0.5-5 parts of sulfur, 0.2-5 parts of aromatic heterocyclic multifunctional olefin monomers and 90-100 parts of aromatic heavy oils. The invention adopts sulfur as main reactant and aromatic heavy oils as dispersant; the reactant and the reaction promoter can be dissolved in the dispersant to promote the uniform mixing between the reactant and a reaction promoter, increase the uniformity of the reaction of the stabilizer and substrate asphalt and avoid the agglomerate phenomenon caused by locally over crosslinking; the heterocyclic multifunctional olefin monomers areused as the reaction promoter so as to increase the reaction efficiency of the main reactant and the crosslink rate. The invention solves the problems well that SBS is easy to separate from the substrate asphalt and the storage is not stable in the production process of SBS polymer modified asphalt.

Owner:XIAN ZHONGLI ASPHALT CO LTD

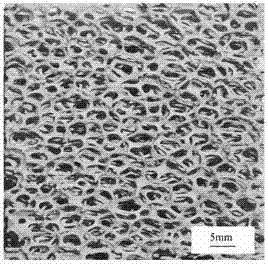

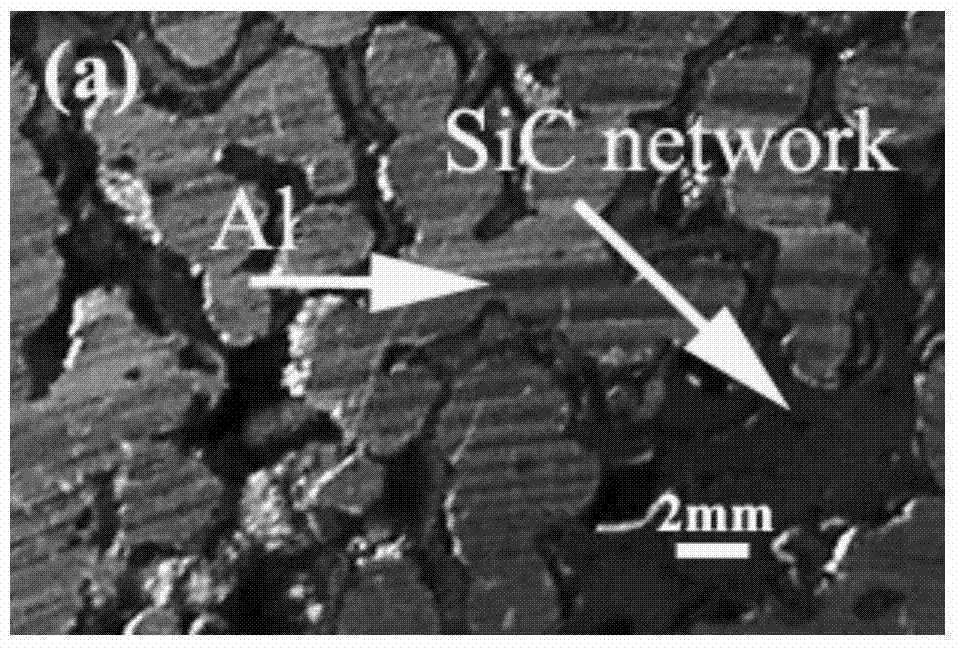

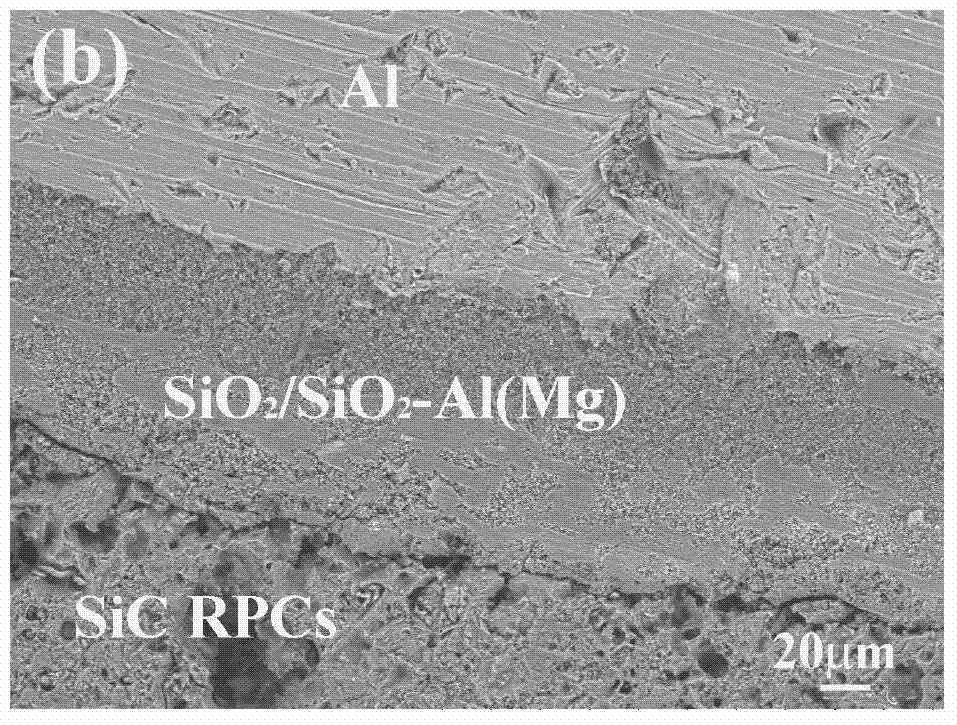

Preparation method of silicon carbide reinforced aluminum base composite material

The invention discloses a preparation method of a SiC / Al composite material. The method comprises the following steps: carrying out ball milling on alumina and / or silicon oxide powder and a dispersant by using a ball milling medium, adding a binder, and continuously carrying out ball milling to obtain a coating slurry, wherein a mass ratio of the powder to the dispersant to water to the ball milling medium to the binder is 1:0.005-0.01:0.1-0.4:2:0.01-0.03; immersing reticulated porous SiC ceramic in the coating slurry for full absorption, centrifuging, and drying; and embedding secondary-coated reticulated porous SiC ceramic into aluminum or aluminum alloy powder, carrying out vacuum pumping heating to fuse the aluminum or aluminum alloy, introducing argon, and carrying out heat insulation and pressure maintenance to obtain the SiC / Al composite material. The SiC / Al composite material obtained through the method is a bicontinuous phase, and the control of an interface structure and an interface reaction is realized through controlling the composition and performances of the coating slurry to realize strong combination between a silicon carbide matrix and the metal Al and uniform continuous distribution in a three dimensional space, so the segregation and the discontinuousness of the silicon carbide reinforcement are avoided, and the performances of the composite material are improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Direct vat set modifier of cast asphalt mixture and preparation method

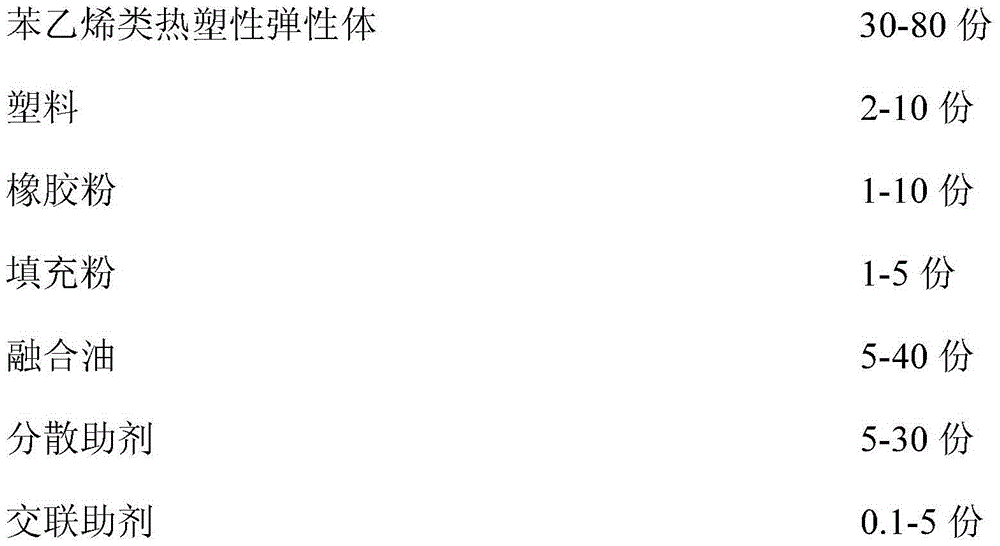

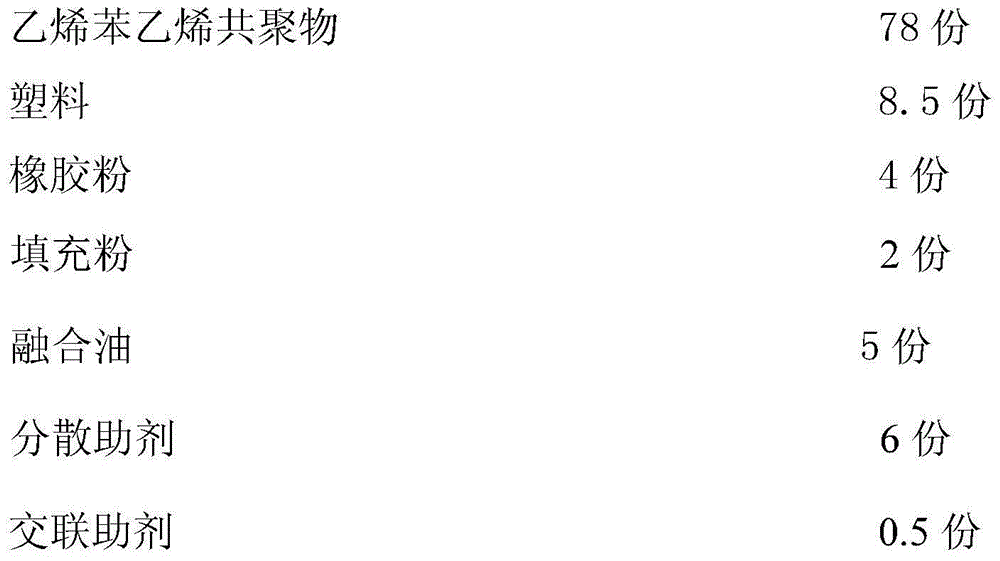

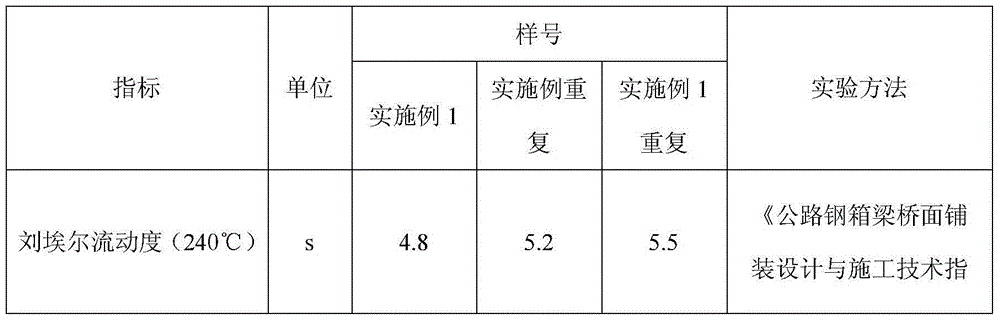

InactiveCN103980650AImprove performanceLess production equipmentBuilding insulationsUltrasound attenuationThermoplastic elastomer

The invention discloses a direct vat set modifier of a cast asphalt mixture and is characterized in that the modifier is composed of the following components, by weight, 30-80 parts of a styrenic thermoplastic elastomer, 10-20 parts of plastic, 1-10 parts of rubber powder, 1-5 parts of a packing powder, 5-40 parts of fuser oil, 5-30 parts of a dispersing auxiliary agent and 0.1-5 parts of a crosslinking auxiliary agent. The invention also discloses a preparation method of the modifier and an asphalt mixture prepared from the modifier. The material can be directly put into a mixing plant cylinder to produce modified asphalt concrete. The produced asphalt concrete completely satisfies engineering needs. In comparison with a traditional SBS modification process, the method provided the invention has the following advantages: the step of producing modified asphalt in a traditional method is saved; production equipment of modified asphalt is save; there is no need in hot storage of modified asphalt; performance attenuation and separation of modified asphalt under hot storage condition are avoided; and positive contributions are made to low temperature and fatigue performance of the asphalt mixture.

Owner:CHONGQING SINO CANADA ASPHALT TECHN SERVICE

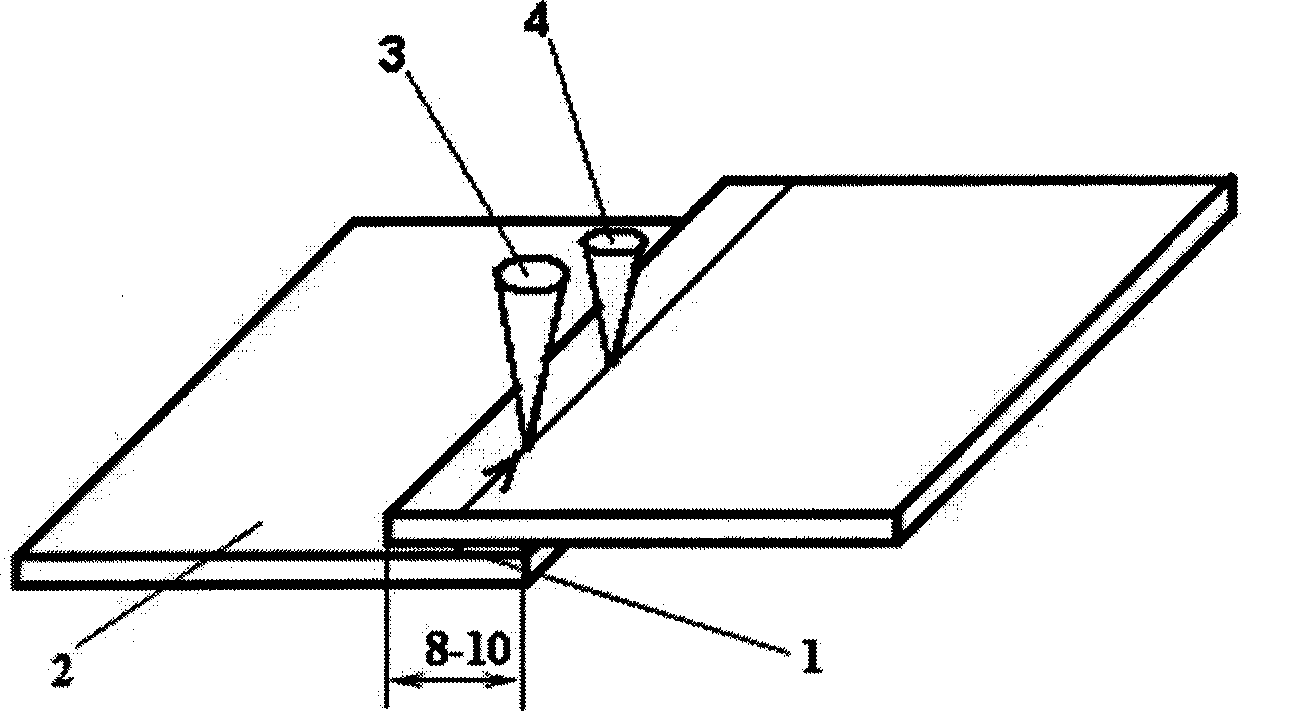

Galvanized steel sheet lap-over laser welding method

InactiveCN101508058AReduce manufacturing costImprove welding qualityWelding/soldering/cutting articlesMetal working apparatusAlloyWeld seam

The invention discloses a laser welding method for lapping galvanized steel sheets, which comprises: placing a Al-Sn alloy foil containing 35 to 45 weight percent of Sn between faying surfaces of the steel sheets; and utilizing two laser beams of which the power is respectively from 2 to 3KW and from 3 to 4KW to weld welding seams, wherein the space of the laser beams is between 20 and 50mm and the welding speed is between 4 and 8m / min. The method has low production cost and stable welding quality; and the strength of the obtained welding seams is greater than that of base metal, no welding spatter exists on the surface, and the corrosion resistance of the welding seams is more than three times higher than that of by a sweeping-out method. The method can be used for laser welding of lapped welding seams of DP series, TRIP series and HSLA series hot galvanized steel sheets, and realizes high efficiency, low pollution and low waste material of welding production.

Owner:HUAZHONG UNIV OF SCI & TECH

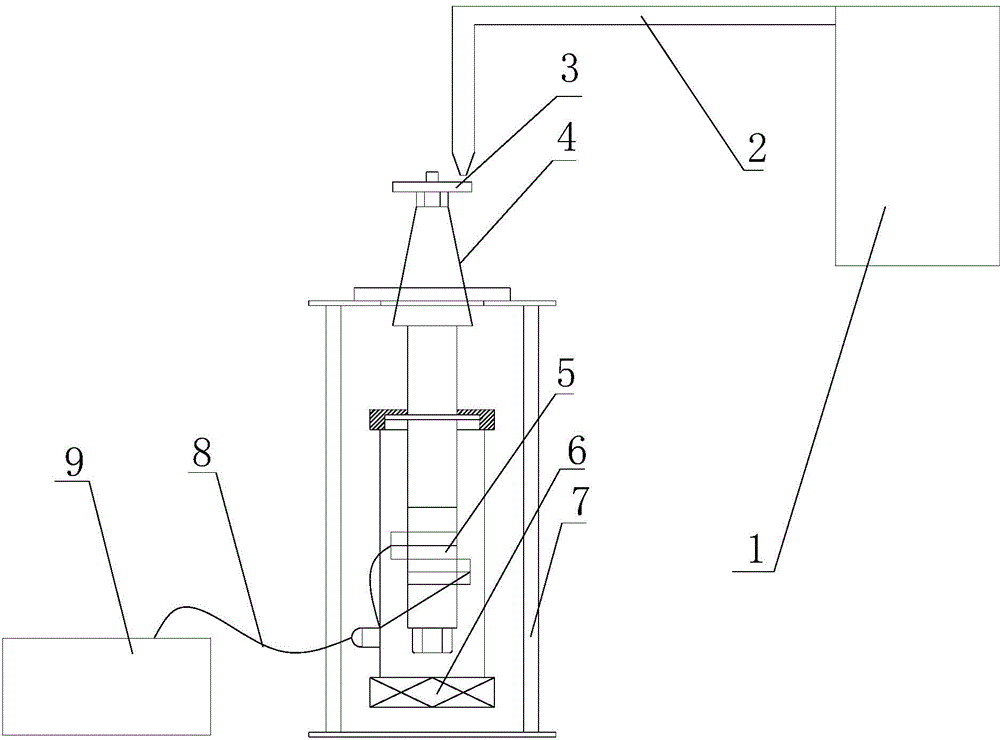

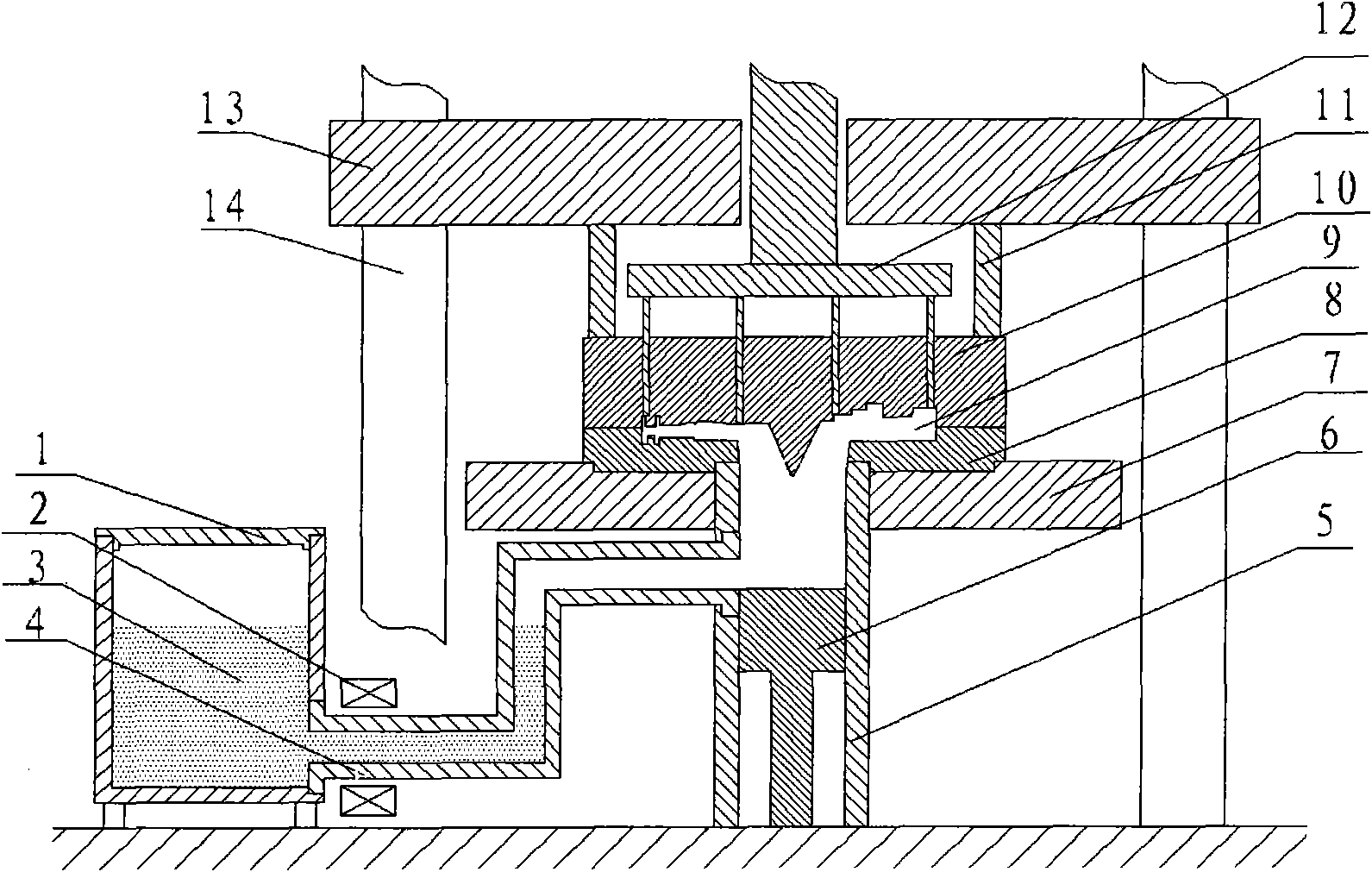

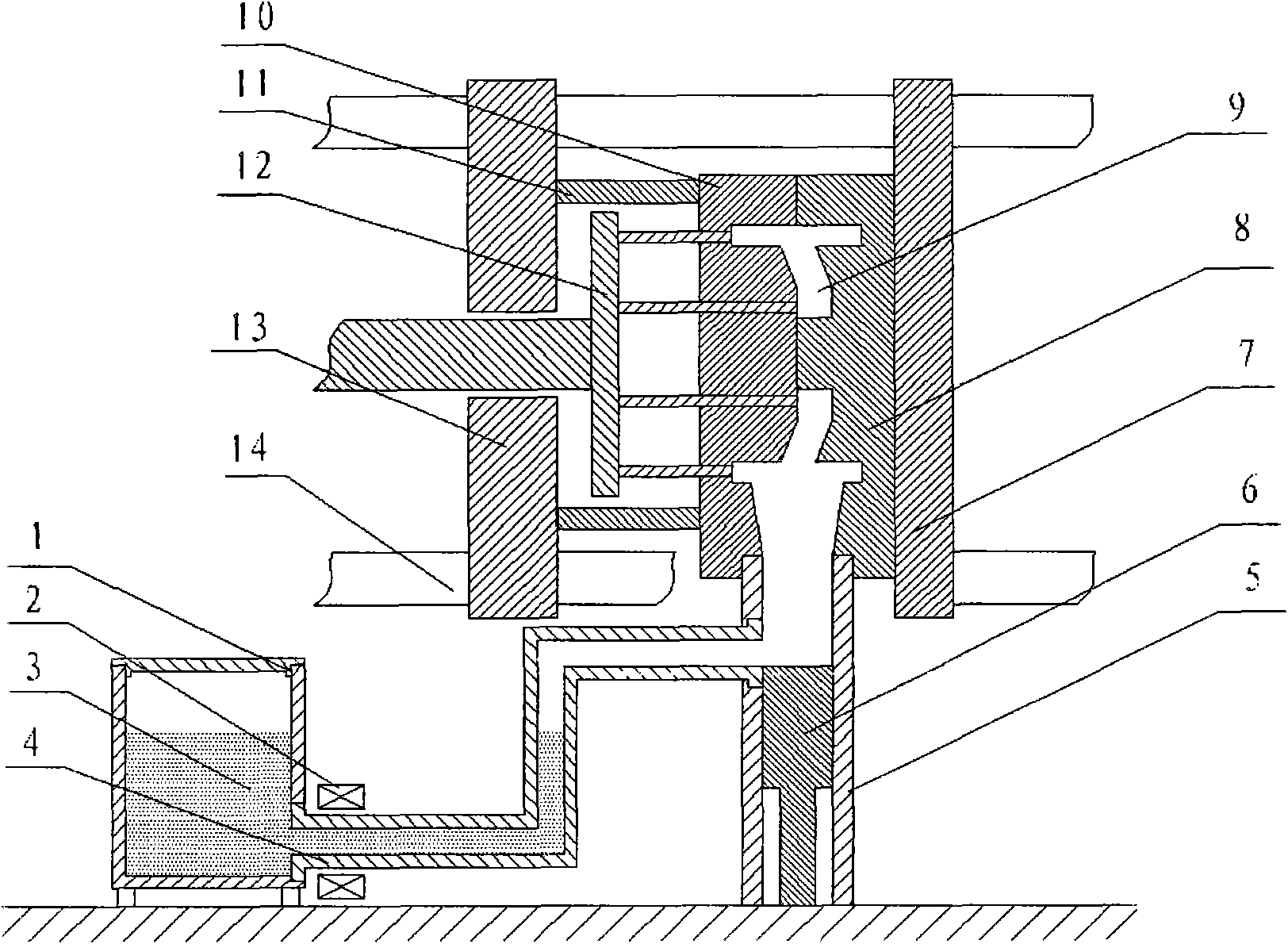

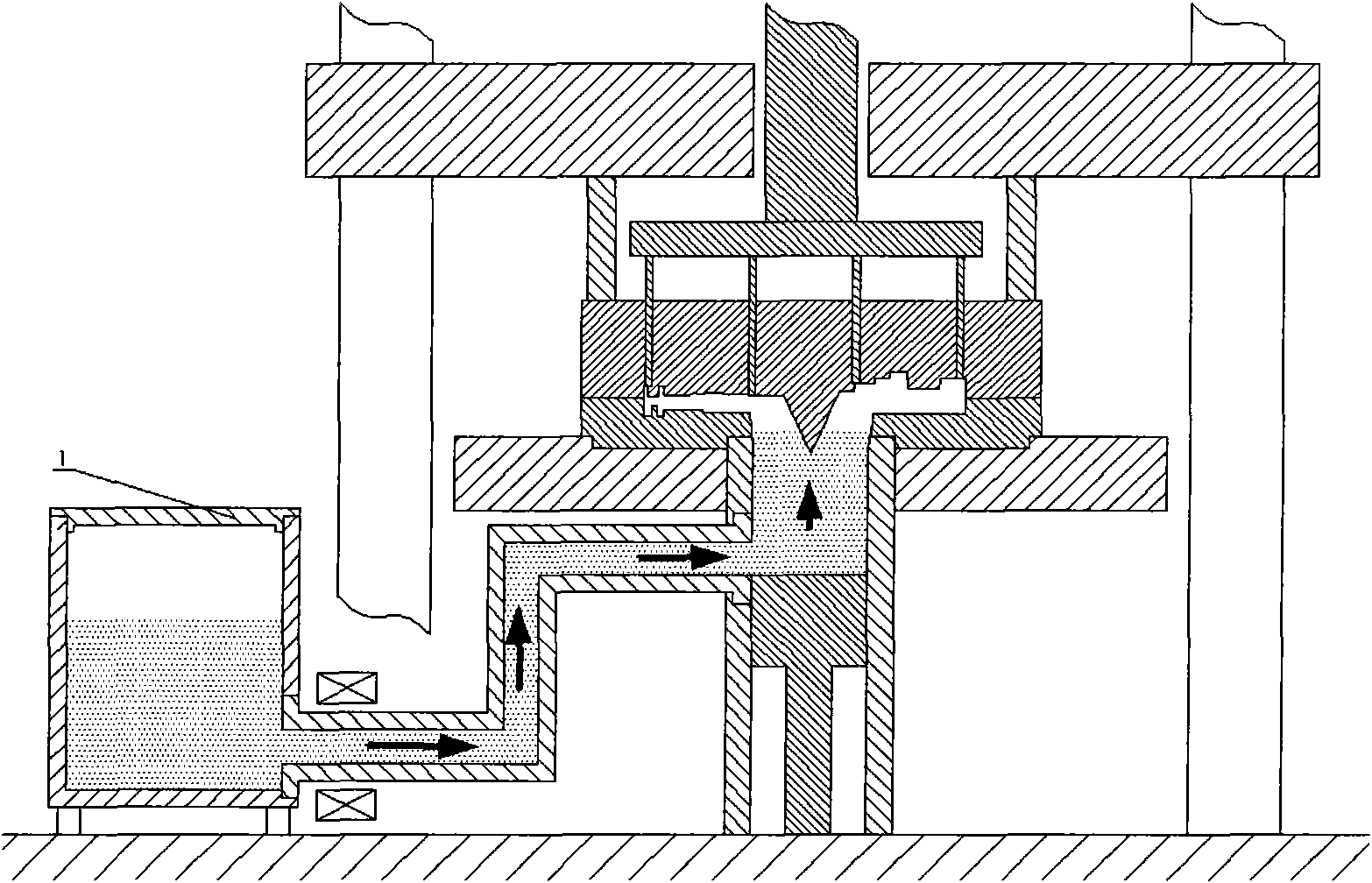

Method for indirect extrusion casting by utilizing filling of electromagnetic force and device thereof

The invention relates to a method for indirect extrusion casting by utilizing the filling of electromagnetic force and a device thereof. In the method, electromagnetic force is utilized to introduce liquid metal into an extrusion chamber to fill part of a mould cavity by a transmission pipeline; when the liquid metal in the mould cavity reaches a preset quantity, the transmission of the liquid metal is stopped; and an extrusion punching head ascends to push the liquid metal to fill the part which is not full in the mould cavity and continuously ascends to extrude and shape the liquid metal, and the liquid metal in the transmission pipeline flows back to a thermal insulation furnace under the function of reverse electromagnetic force. The invention has simple and convenient method, high automatization degree, good stability and skillful structural design of a special device. The liquid metal is transmitted and filled by a sealed transmission pipeline, and oxidation and air suction are reduced; the flow speed and the flow rate are controllable, and the quantification of extrusion casting is realized; at the time of extrusion shaping, the liquid metal in the transmission pipeline flows back, and the production efficiency is enhanced; and the friction and the abrasion of the extrusion punching head and the extrusion chamber are reduced, and the service lives of the extrusion punching head and the extrusion chamber are enhanced.

Owner:SOUTH CHINA UNIV OF TECH

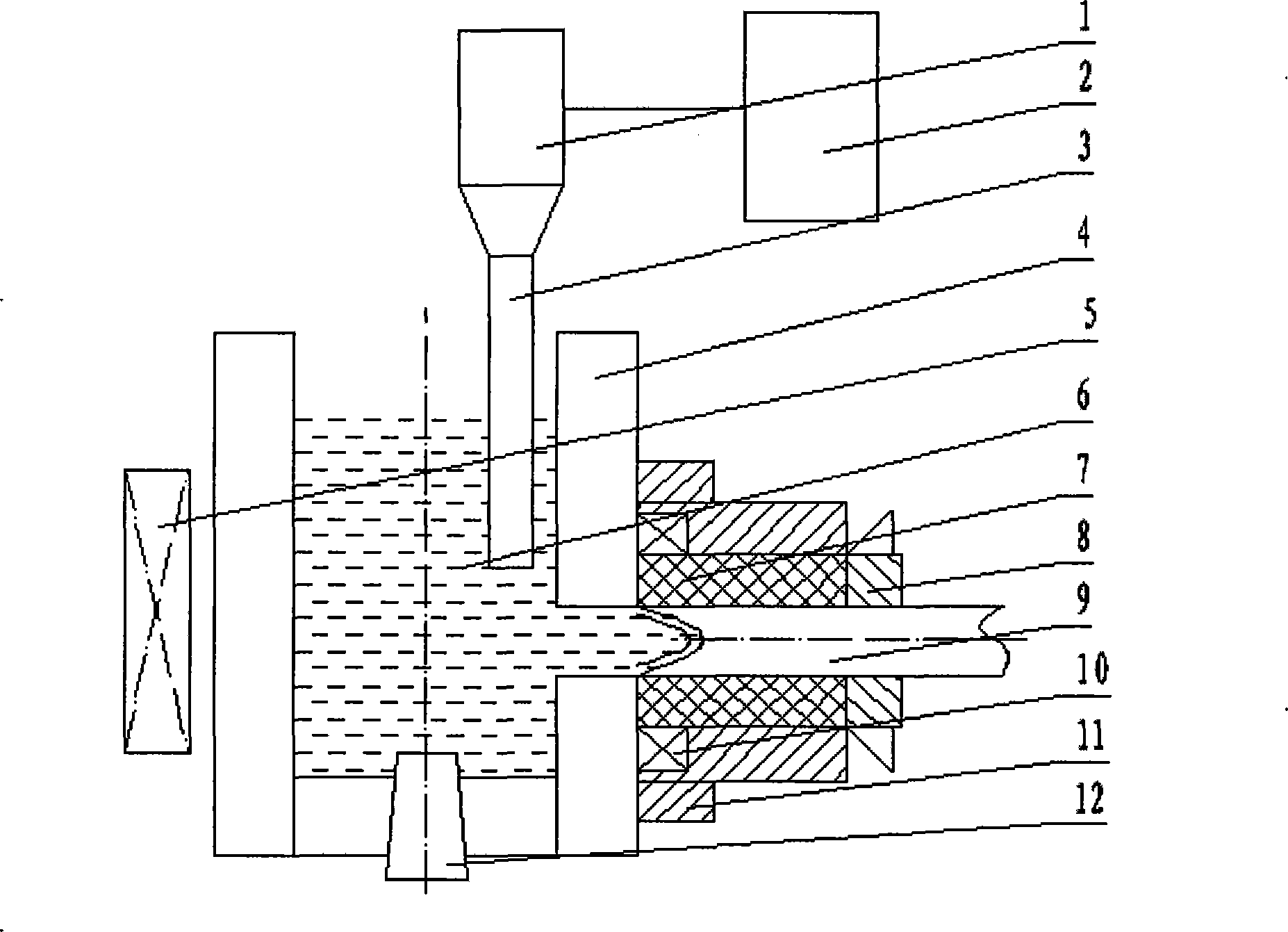

Method and apparatus for improving horizontal continuous casting billet quality by applying composite field

The invention relates to a quality improving method for horizontal continuous casting blanks by applying complex field and the device, belonging to the technical field of preparation of metal material, in particular to the technology of applying complex electromagnetic field and ultrasonic field in the continuous casting process of metal casting blanks. The device is characterized in that a generator of inert gas is arranged at the center of the bottom of a holding furnace; a generator of traveling wave magnetic field is arranged on the side of the holding furnace; a power ultrasonic device is arranged on the holding furnace close to the water port; a restriction electromagnetic coil is arranged on the outer side of a crystallizer. The device has the advantages that: firstly, the production technology is simple, the operation is easy, and the efficiency is high; secondly; the disadvantages of easy broken in rolling and drawing process of casting blank due to more impurity and pores is solved; thirdly, the solidification structure of the casting blanks is uniform, the crystal grain is fine, and the casting blanks can be rolled directly at casting state. The quality improving method and the device are mainly used for the field of metal continuous casting.

Owner:DALIAN UNIV OF TECH

Continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel

The invention discloses continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel. According to the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel, cracks are reduced by adopting low carbon amount and high viscosity, reducing thermal stress inside blank shells and increasing powder consumption amount. The alkalinity of the casting powder is 0.8-1.1, the cracks caused by uneven heat transmission are avoided; through the adoption of 8-12% of Na2O, 6-8% of F- and 3-4.5% of Li2O, weak coldness and even heat transmission of the upper portion in a crystallizer are achieved, inclusion absorbing effects are improved, and the cracks are reduced; through the adoption of 2-8% of MnO, lattice vibration and conduction heat transmission are weakened, and the crystallization properties of the casting powder and the casting blank quality are improved. Raw materials of the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel are easy to obtain, and production cost is low. Through field testing, the casting power is good in spreadability and good in air permeability and can be smelted stably and be free of caking, the consumption amount of the casting powder is around 0.3-0.42kg per ton of steel, the consumption cost is relatively low, and the qualified rate of the first grate casting blanks is improved significantly.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

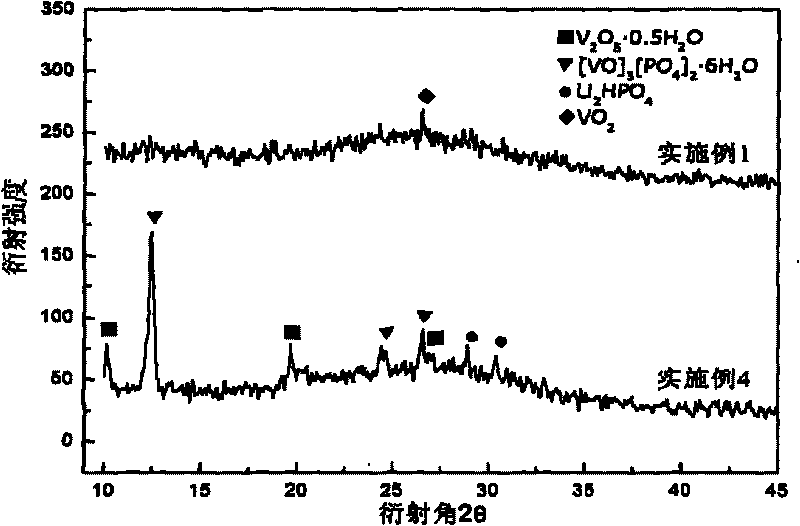

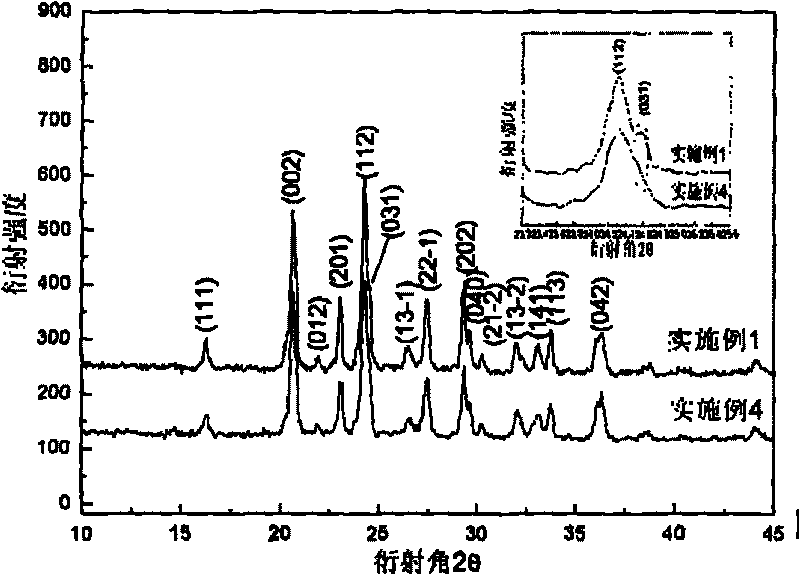

Preparation method of anode material vanadium-lithium phosphate powder for lithium ion battery

InactiveCN101734637AGuaranteed ultra-close contactOvercome the deficiency of not being fully exposedCell electrodesPhosphorus compoundsMolecular levelLithium-ion battery

The invention relates to a preparation method of anode material vanadium-lithium phosphate powder for lithium ion battery, belonging to the technical field of battery material. The preparation method provided in the invention is implemented by homogenizing raw materials followed by secondary drying to obtain a precursor, heating at 550-1000 DEG C in non-oxide atmosphere to prepare vanadium-lithium phosphate powder. In the method, the precursor homogenized on micro-scale is prepared by secondary drying, raw materials can be mixed on molecular level of the solution, all the elements are uniformly mixed, thus avoiding composition segregation, ensuring super close contact among raw materials, overcoming the defect of incomplete contract of raw materials in solid phase technique and greatly reducing reaction activation energy; the whole process dispenses with procedures of grinding, pre-treating, crushing and the like, the prepared material has higher specific discharge capacity and capacity retention rate, and the method is simple in technique, continuous in operation and easy for industrial production.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

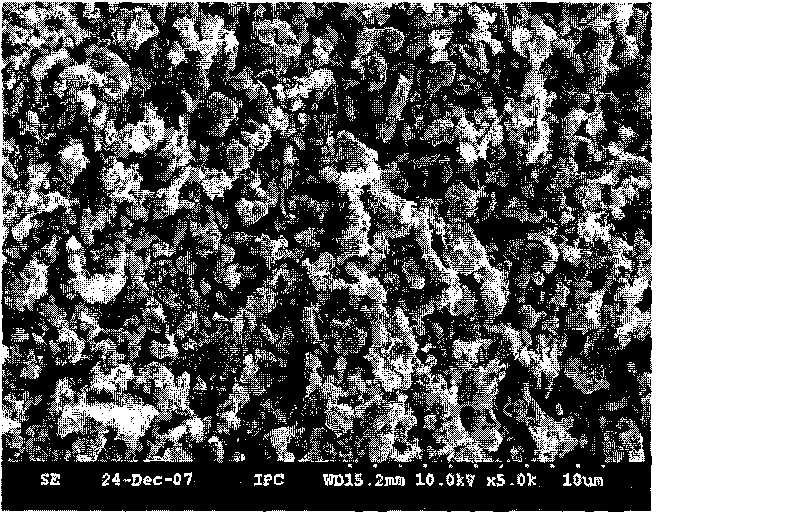

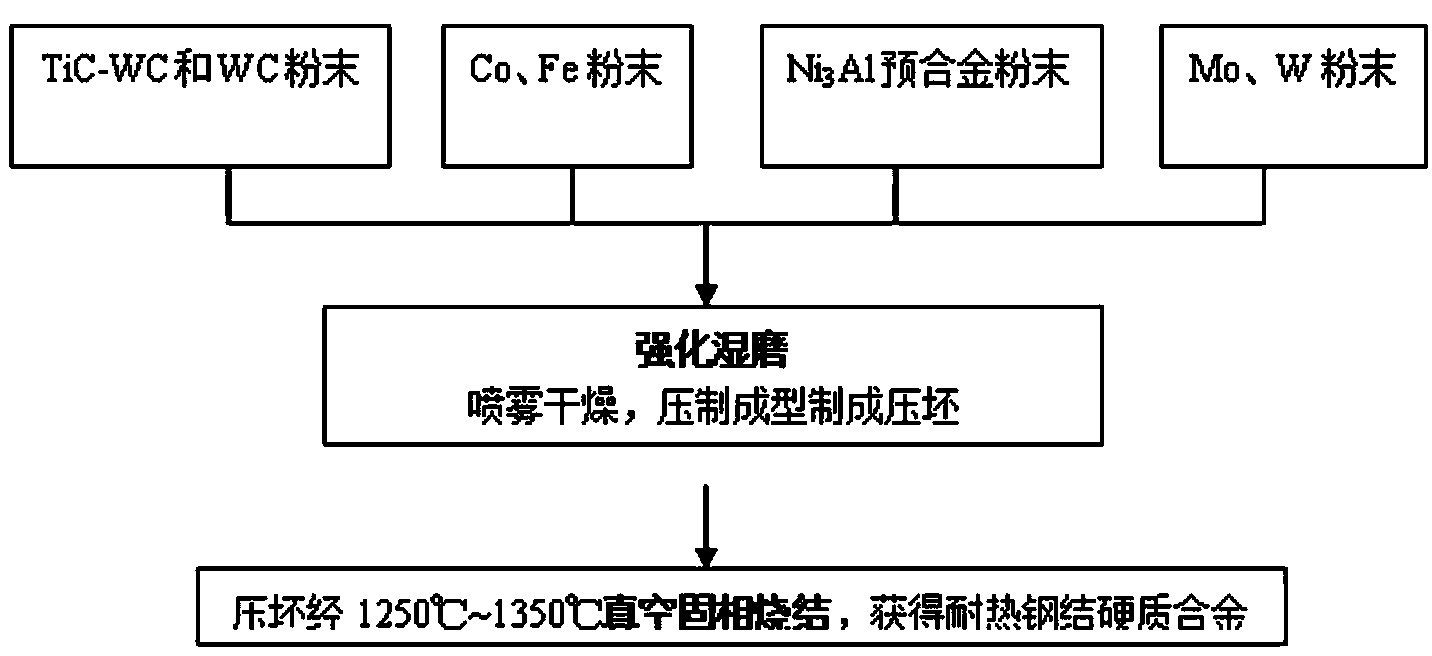

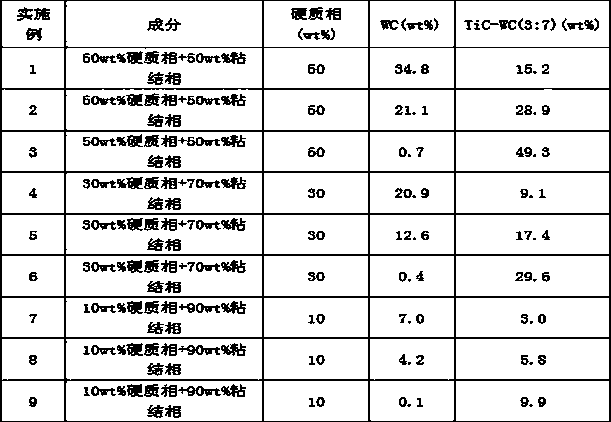

Heat-resistant steel structure hard alloy and preparation method thereof

The invention discloses a heat-resistant steel structure hard alloy. The heat-resistant steel structure hard alloy comprises a 10-50wt% of hard phase and the balance of a binding phase, wherein the hard phase consists of WC and TiC, and the binding phase consist of 18-38% of Co, 23-53% of Ni3Al, 0-2% of Mo, 0-2% of W and the balance of Fe. A preparation method of the heat-resistant steel structure hard alloy comprises the following steps: selecting hard phase raw materials, namely 0.1-34.8% of WC and 3.0-49.3% of statured sosoloid TiC-WC (3:7) powder as well as binding phase raw materials, namely 9.0-34.2% of Co, 11.5-47.7% of Ni3Al, 0-1.8% of Mo, 0-1.8% of W powder and the balance of Fe powder, wherein the total weight of the raw materials of the hard phase accounts for 10-50% of the total weight of the mixed powder; strengthening wet-milling for not smaller than 48 hours according to the ratio of grinding media to material (in terms of weight) of not lower than 6 and a liquid-solid ratio of 600-900ml / Kg; spraying, drying, pressing and molding the wet-milling mixed materials; performing vacuum solid-phase sintering at 1250-1350 DEG C to obtain the heat-resistant steel structure hard alloy, wherein the binding phase is 50%-90% in percentage by weight. The heat-resistant steel structure hard alloy disclosed by the invention is suitable for being used at 600-900 DEG C and is greatly improved in high-temperature oxidization resistance and high-temperature impact toughness.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com