Method and apparatus for improving horizontal continuous casting billet quality by applying composite field

A technology of horizontal continuous casting and compound field, applied in the field of metal continuous casting, can solve the problems of limited scope and effect, and achieve the effect of increasing the stroke and floating time, fast floating speed, and increasing the probability of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

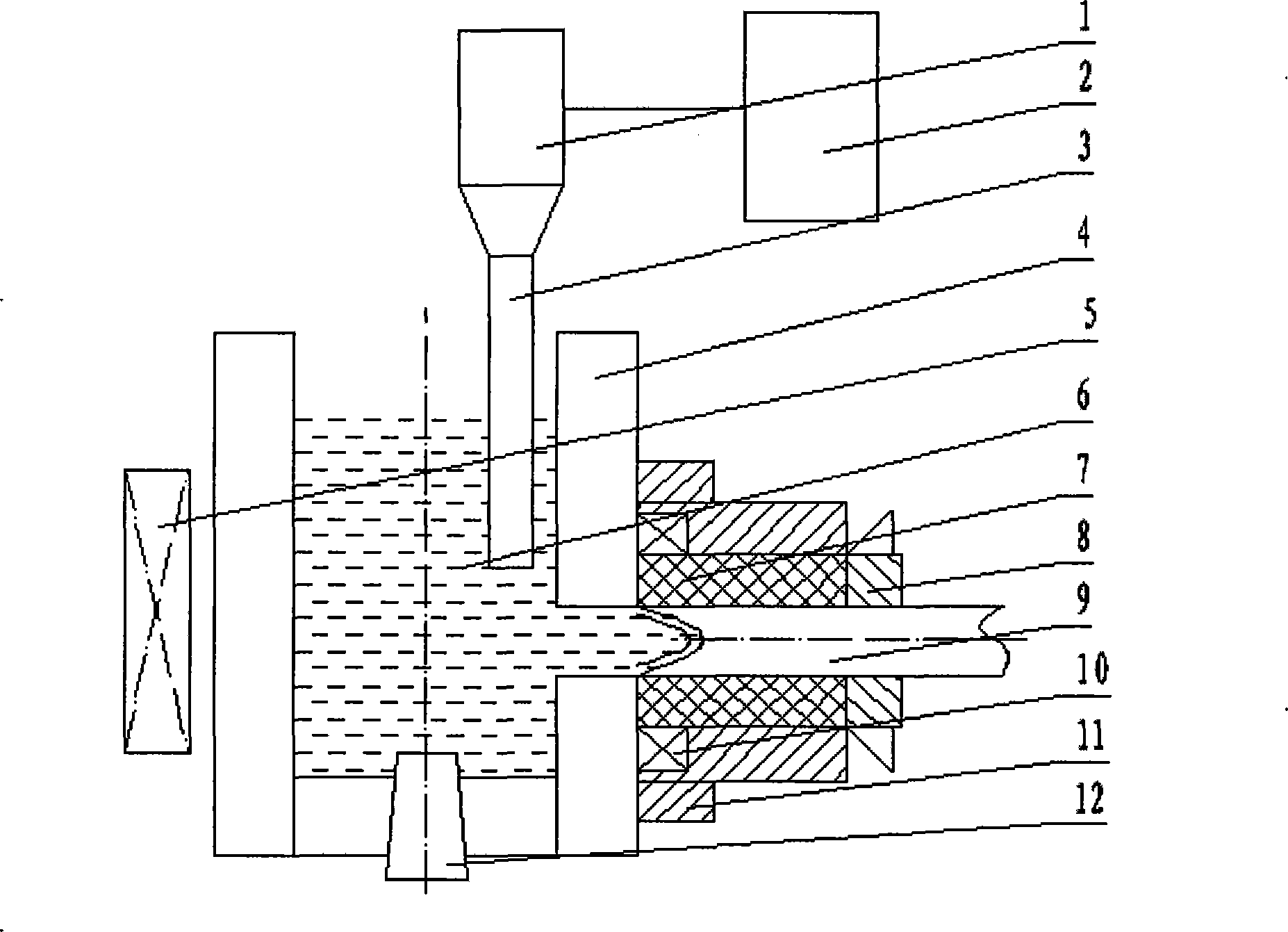

[0020] By setting the power frequency restraint electromagnetic coil 10 outside the crystallizer 7, and setting an inert gas bubble generating device 12 at the center of the bottom of the holding furnace 4, and setting a traveling wave magnetic field generator 5 at the side of the holding furnace 4, the holding furnace 4 is close to the casting port. The power ultrasonic equipment 7 is set at the place, and the Al-1% Si bonding wire blank of Φ10mm is prepared, and the specific steps are as follows:

[0021] Step 1: Preparation of Al-1%Si alloy

[0022] In the resistance furnace, the Al-1% Si alloy is prepared from industrial pure aluminum and aluminum-silicon intermediate alloy, and the alloy is melted to 780°C;

[0023] Step 2: Horizontal continuous casting of Al-1% Si bonding wire billets under the action of composite field

[0024] The alloy is poured into the holding furnace 4, the switch of the inert gas bubble generator 12 is turned on, the traveling wave magnetic field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com