A high tap density lifepo 4 preparation method

A technology of tap density and high-temperature calcination, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of difficult control of carbon layer thickness and particle size, uneven particle size of lithium iron phosphate, and reduction of lithium iron phosphate Problems such as material tap density, to achieve excellent electrochemical performance, simple process steps, and short diffusion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

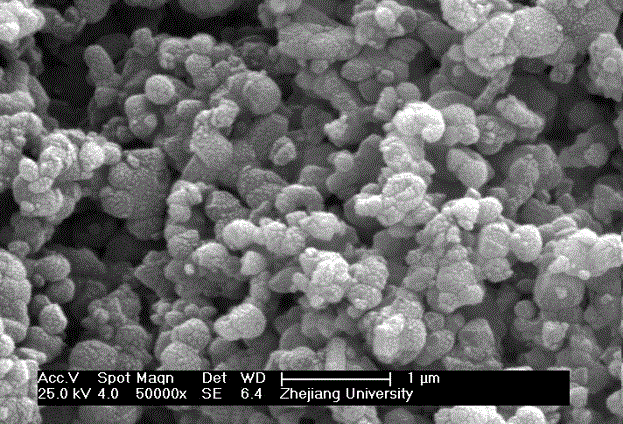

Image

Examples

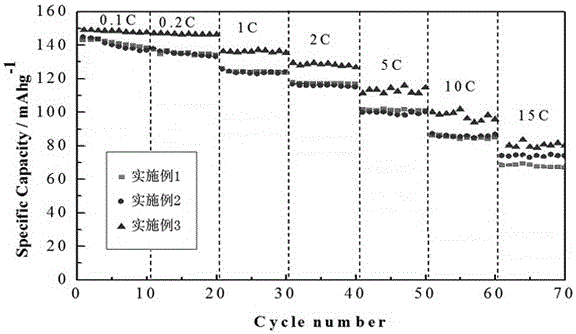

Embodiment 1

[0029] (1) Lithium salt, iron salt, and phosphate are weighed according to the elemental molar ratio Li:Fe:P=1:1:1, mixed evenly, dispersed in a solvent, and then ball milled under vacuum conditions. Among them, the lithium salt It is lithium carbonate, the phosphate is ammonium dihydrogen phosphate, and the solvent is acetone. The technological conditions of one ball milling are: ball milling speed 400r / h, ball milling time 3h.

[0030] (2) The material obtained after one ball milling is subjected to low-temperature pre-calcination under an inert atmosphere. The inert atmosphere is an Ar atmosphere. The inert atmosphere is an Ar atmosphere. The process conditions for low-temperature pre-calcination are: calcination temperature 350°C, calcination time 10h.

[0031] (3) Carry out secondary ball milling on the pre-calcined material, the process conditions of the secondary ball milling are: ball milling speed 300r / h, ball milling time 1.5h.

[0032] (4) The material after seconda...

Embodiment 2

[0036](1) Lithium salt, iron salt, and phosphate are weighed according to the elemental molar ratio Li:Fe:P=4:5:5, mixed evenly, dispersed in a solvent, and then ball milled under vacuum conditions. Lithium salt is formed by carbonic acid Lithium, lithium hydroxide and lithium oxalate are mixed at a mass ratio of 1:1:2, and the phosphate is one or more of ammonium dihydrogen phosphate, diammonium hydrogen phosphate, and ammonium phosphate. The solvent is ethanol, acetone, ethylene glycol, glycerin or water, and the technological conditions of one ball milling are: ball milling speed 200r / h, ball milling time 5h.

[0037] (2) The material obtained after one ball milling was subjected to low-temperature pre-calcination under an inert atmosphere, the inert atmosphere being Ar atmosphere, wherein the inert atmosphere was Ar atmosphere, and the process conditions for low-temperature pre-calcination were: calcination temperature 300°C, calcination time 15h.

[0038] (3) Carry out se...

Embodiment 3

[0043] (1) Lithium salt, iron salt, and phosphate are weighed according to the elemental molar ratio Li:Fe:P=2.0:1:1, mixed evenly, dispersed in a solvent, and then ball milled under vacuum conditions. Among them, the lithium salt It is formed by mixing lithium acetate and lithium oxalate at a mass ratio of 1:1, and phosphate is formed by mixing ammonium dihydrogen phosphate and diammonium hydrogen phosphate at a mass ratio of 2:1, and the solvent is ethanol. The process conditions of a ball mill are: ball milling The rotating speed is 300r / h, and the ball milling time is 4h.

[0044] (2) The material obtained after one ball milling was subjected to low-temperature pre-calcination under an inert atmosphere, and the inert atmosphere was Ar atmosphere, wherein the inert atmosphere was Ar atmosphere, and the process conditions for low-temperature pre-calcination were: calcination temperature 330°C, calcination time 12h.

[0045] (3) Carry out secondary ball milling on the pre-cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com