Patents

Literature

437results about How to "Low drying temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

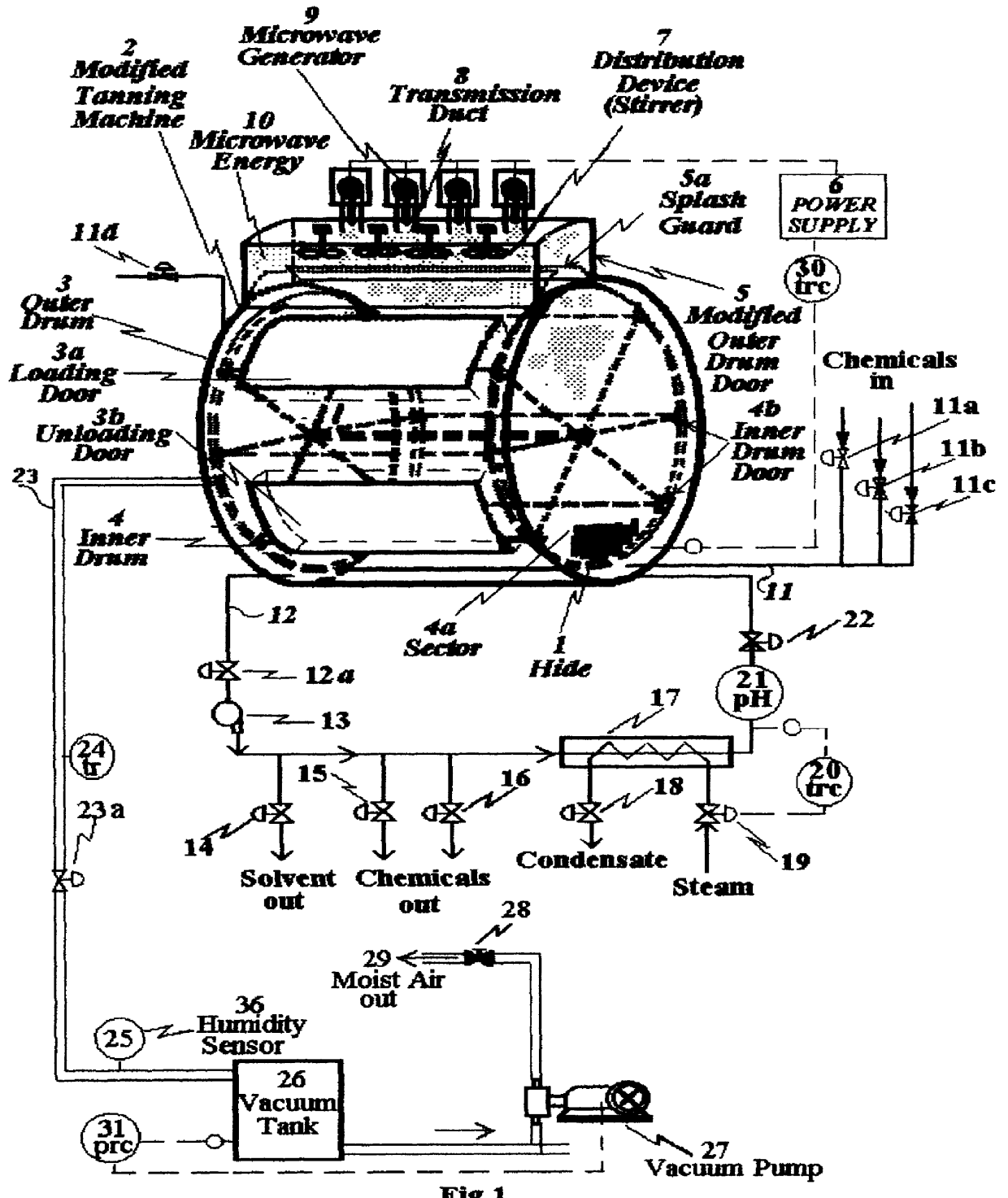

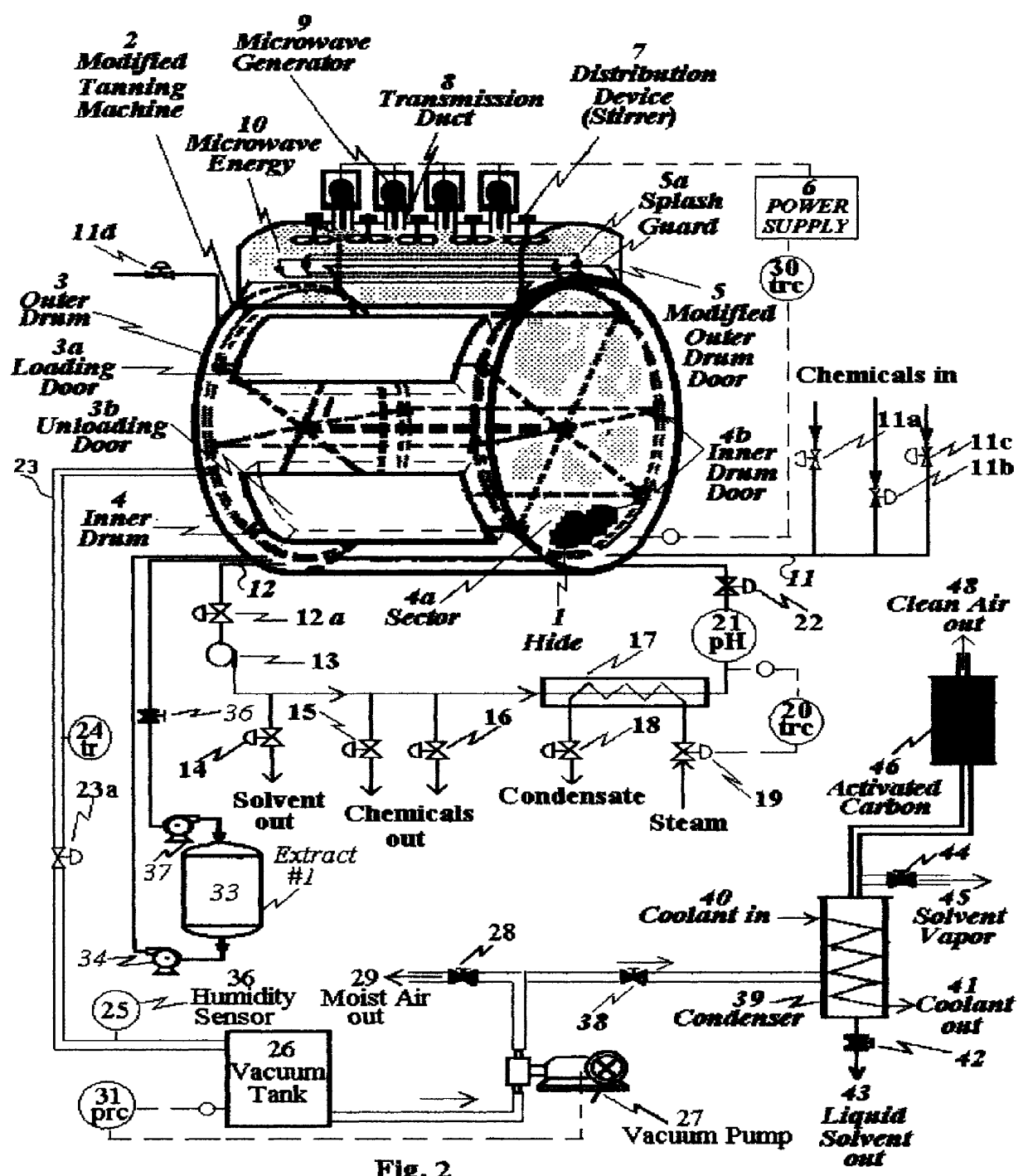

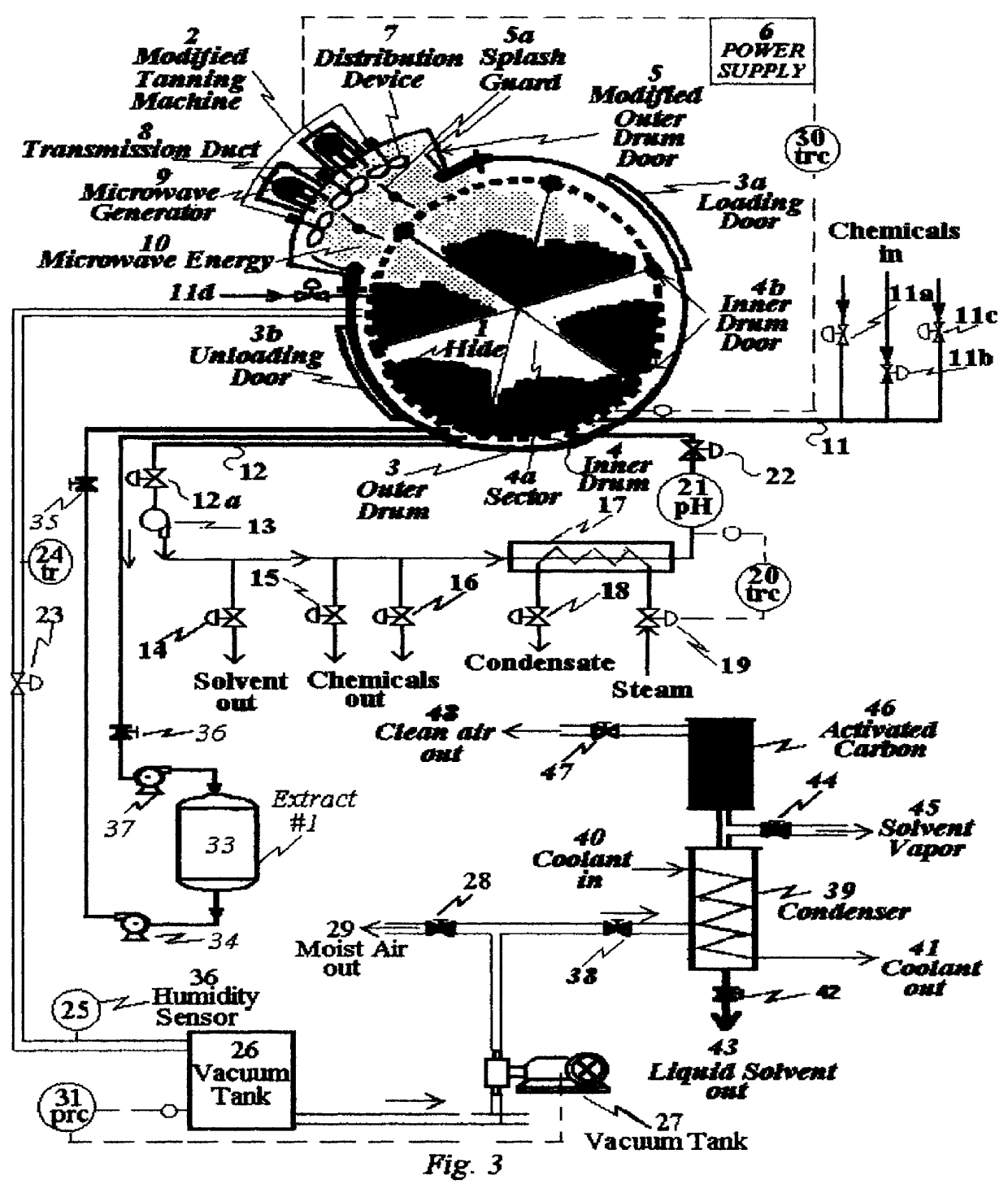

Microwave drying of hides under vacuum in tanning equipment

InactiveUS6092301AHigh market valueQuality improvementDrying solid materials with heatDrying solid materials without heatWater contentSolvent

By providing a hide processor or tanning drum with appropriate equipment for applying vacuum and microwave energy concurrently, these tanning machines become a versatile means of drying to yield dry hides that contain no salt yet store better than salted hides. In this novel process, fresh hides are loaded into the tanning machine where they are washed, demanured and then dried in situ under vacuum with concomitant application of microwave energy. Because the dried hides thus obtained are soft and pliable, they can be mechanically fleshed or shaved to remove the subcutaneous tissues rich in collagen and fat. Alternatively, the hides may be first dried in the tanning machine to below 35% moisture content and degreased using a solvent such as hexane. The solvent remaining in the hides after decantation of the unabsorbed liquid is vaporized at low temperature using vacuum and microwave energy. The hides are then dried in situ to the desired final moisture content. By shaving off the subcutaneous tissues of these hides a dry, fat-free, valuable undenatured collagen product is obtained. If the hides are unhaired before drying, they may be shaved and then accurately split. The process is also suitable for removing hair and fat from hide trimmings to obtain a valuable undenatured collagen product and fat. Furthermore, it can be used to remove fat from connective tissues and other animal offal containing no hair yielding a dry undenatured collagen product.

Owner:KOMANOWSKY MICHAEL

Pelletizing method of ilmenite concentrates and pellet binder

The invention discloses a pelletizing method of ilmenite concentrates and a pellet binder, wherein the method comprises the following steps: uniformly mixing the ilmenite concentrates, the binder anda carbonaceous reducing agent to obtain a mixed material; pressing the mixed material into green pellets; and drying the green pellets to obtain the dry green pellets.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +3

Dendrobium candidum instant powder and preparation method thereof

InactiveCN101700361ALow extraction temperatureIncrease usageDigestive systemFood preparationEffervescent tabletSeparation technology

The invention relates to a dendrobium candidum instant powder and a preparation method of various related formulations thereof. The preparation method of the dendrobium candidum instant powder comprises the steps of: combining low-temperature extract of the dendrobium candidum with raw materials such as maltodextrin and dietary fiber, and the like, wherein the low-temperature extract of the dendrobium candidum is prepared by modern extraction and separation technologies such vacuum exploding, reverse film permeating, freeze drying and spray drying, and the like; and further preparing into formulations such as granules, effervescent tablets, capsules and oral liquid, etc. The invention improves the extraction efficiency of the dendrobium candidum, maximally guarantees the bioavailability of the dendrobium candidum, remains the primary smell of the dendrobium candidum, and leads the dendrobium candidum is conveniently taken.

Owner:刘宏源 +1

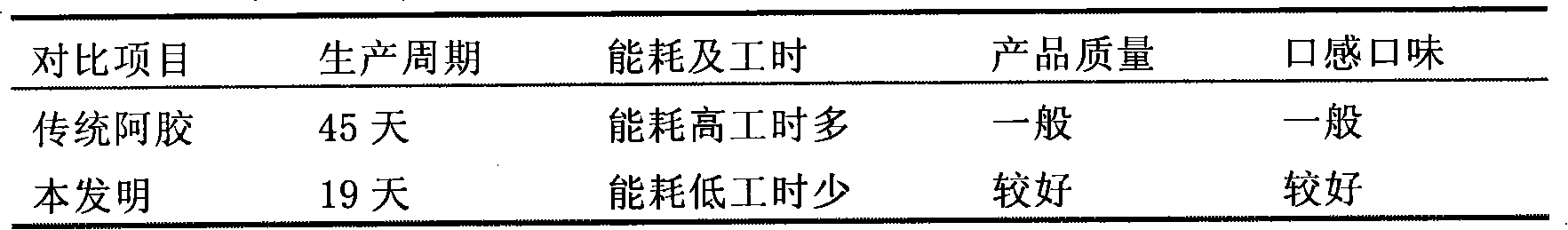

Donkey-hide gelatin preparation and preparation method thereof

ActiveCN101623299AImprove health attributesFragrant smellPowder deliveryAerosol deliveryFiltrationEvaporation

The invention discloses a donkey-hide gelatin preparation and a preparation method thereof. The components of raw materials comprise donkey hides, rock sugar, bean oil, tea oil, yellow wine and the like; and the preparation method comprises the process steps of hide soaking, hide washing, hide scalding, hide melting, filtration, gelatin juice separation, evaporation, impurity extraction, concentration and gelatin forming, vacuum microwave drying, crushing, preparation, treatment on defective products of the donkey-hide gelatin preparation and the like. The donkey-hide gelatin preparation not only technically improves the prior art naturally, avoids pollutions, improves the product quality and the yield, shortens the production period and reduces the energy consumption and the labor hour, but also is added with the tea oil in the formulation to improve the health care attribute of the donkey-hide gelatin preparation and have a better taste.

Owner:山东东阿国胶堂阿胶药业有限公司

Method for preparing carbon nanotube static conductive coating on surface of EVA thin film

InactiveCN101781404ALow drying temperatureShorten drying timeElectrically-conductive paintsConductive coatingSolvent

The invention relates to a method for preparing a carbon nanotube static conductive coating on the surface of an EVA thin film, which comprises the following steps that: first, a carbon nanotube is added into ethanol solvent with the concentration more than or equal to 60 vt percent to be stirred into suspension under the action of dispersant and binder, ball milled to prepare dispersion liquid; and the dispersion liquid is oscillated in ultrasonic wave at 20 to 40DEG C, diluted and sprayed onto the surface of the EVA thin film, dried and cured to prepare the carbon nanotube static conductive coating. The method has simple process and is convenient to operate, and the prepared coating does not fall off or cohere after being used for a long time.

Owner:ANHUI GOLDSUN NANOTECH

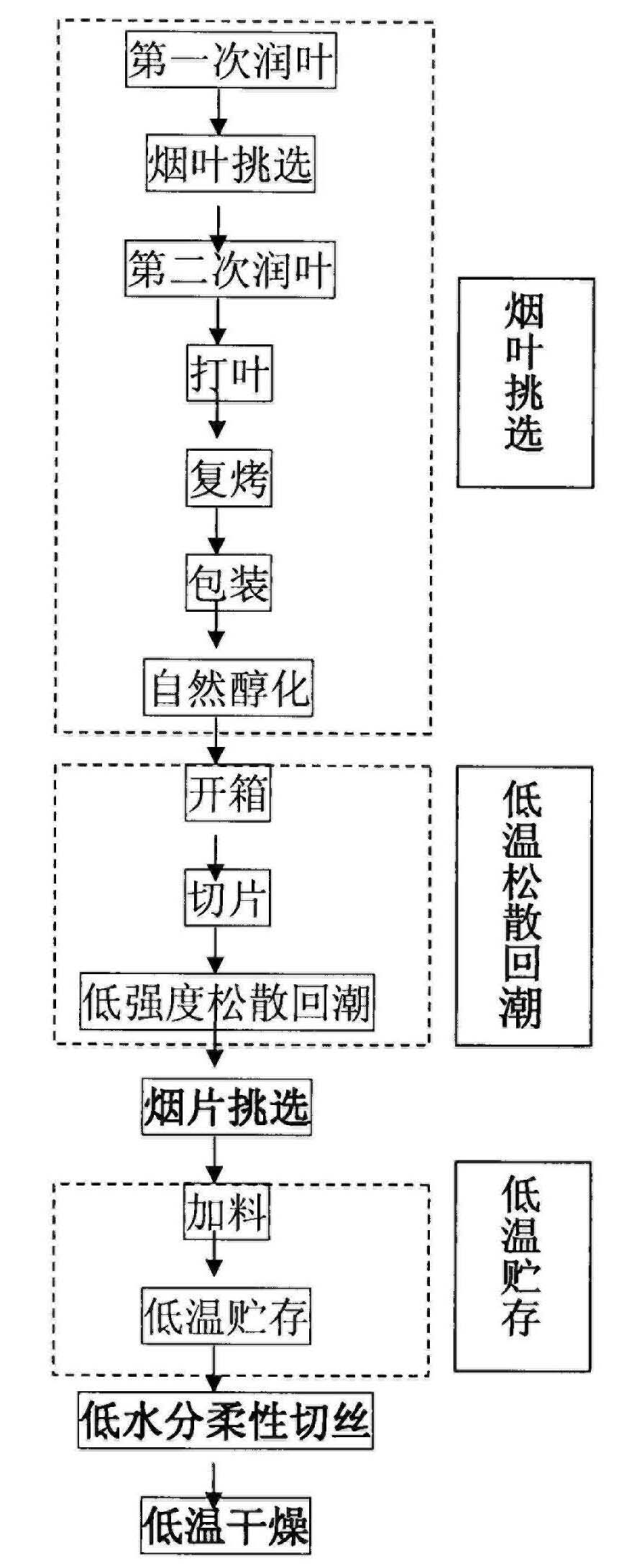

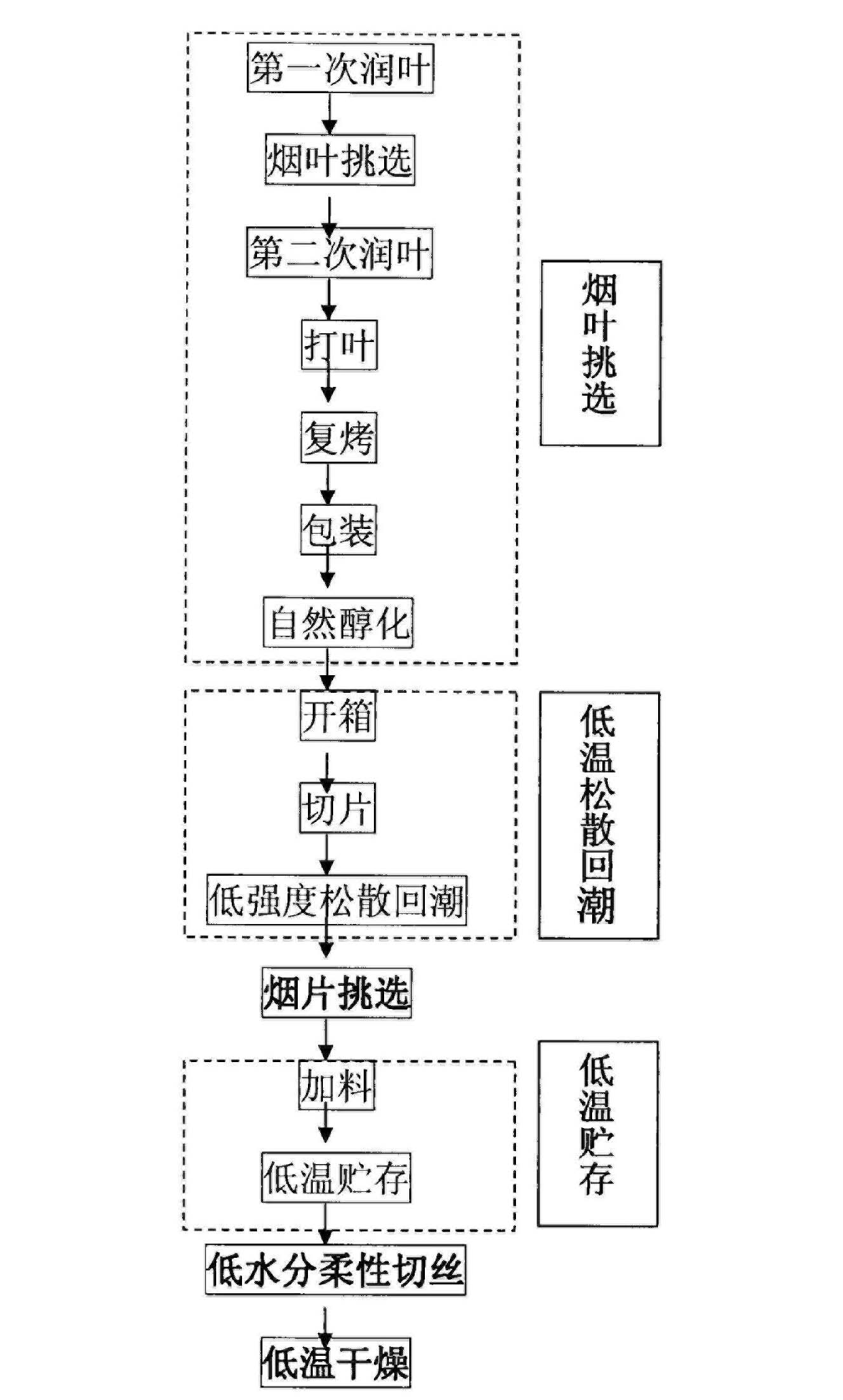

Processing technique for manufacturing golden tobacco shreds

ActiveCN101946975AHigh purityReduced color browningTobacco preparationTobacco treatmentHorticultureAgricultural engineering

The invention discloses a processing technique for manufacturing golden tobacco shreds. The technique is characterized by comprising the processes of tobacco leaf selection, low-strength loose moistening, tobacco sheet selection, low-temperature storage, low-moisture flexible shredding and low-temperature leaf shred drying. The technique has the advantages that: (1) the prepared tobacco shreds are golden and have good appearance quality; on the one hand, the tobacco leaves with poor appearance quality in the tobacco leaf raw material are removed by adopting the tobacco leaf and tobacco sheet selection processes so as to improve the purity of the golden tobacco leaves in the tobacco leaf raw material; on the other hand, the tobacco sheet moisture content during shredding and the knife door pressure of a shredder are reduced by adopting the low-moisture flexible shredding process so that the tobacco shreds producing brown stains after shredding are reduced; and (2) the prepared tobacco shreds have predominant fragrance and good sense quality. The tobacco sheets are treated by adopting the low-strength loose moistening, low-temperature storage and low-temperature drying processes so as to reduce the return air temperature of a tobacco sheet loose moistening device, the storage environment temperature, the leaf shred drying temperature and the tobacco sheet heating time and reduce the fragrance loss of the tobacco sheets during preparing the shreds.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

Preparation method of hydroxy methionine salt and compound

The invention provides a preparation method of hydroxy methionine salt and a compound, comprising the following steps: a. feeding metal hydroxide or basic metal oxide or amphoteric metal oxide and 2-hydroxy-4-methylthiobutyricacid into a closed and corrosion resistant reaction kettle to react for 0.5-12h according to a stoichiometric ratio, taking the low-boiling polar organic solvent or the mixed solvent thereof with water as the reaction medium, stirring, separating the target product, washing and drying to obtain the products; and b. recycling the reaction medium. The preparation method of the invention has short route, no consumption of acid or alkali reagent, low cost, easily-controllable product quality, environmental friendliness and the like, thus being applicable to large-scale industrial production.

Owner:李宁 +1

Negative-pressure microwave combined drying method for preparing mushroom chips from dried mushrooms

The invention discloses a negative-pressure microwave combined drying method for preparing mushroom chips from dried mushrooms, which belongs to the technical field of processing of fruit and vegetable foods. The method mainly comprises the following steps of: foaming the dried mushrooms, fully washing, adding a color fixative for bleaching, cutting (or not cutting), adding a steeping liquor for steeping, draining sugar and scattering; performing negative-pressure spray drying on the pretreated mushrooms for 10-15 minutes, and rapidly dehydrating a high-moisture material in the uniform dryingstate till the moisture content is 20-30 percent; taking semi-finished mushrooms out, and putting the semi-finished mushrooms into a vacuum microwave drying box to be dried for 15-20 minutes till thefinal moisture content is below 6 percent; and charging nitrogen and packing to obtain a crisp mushroom product. The method has the advantages of high moisture evaporating speed, short drying time, uniform drying, product crispness, and capability of well keeping the original luster, appearance and nutrients of the mushrooms.

Owner:建德市农家宝食品有限公司 +1

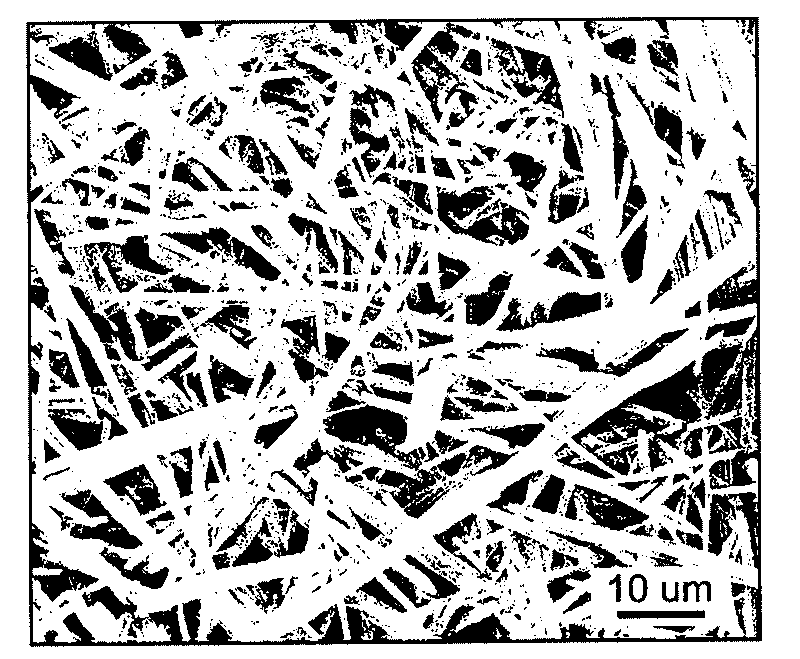

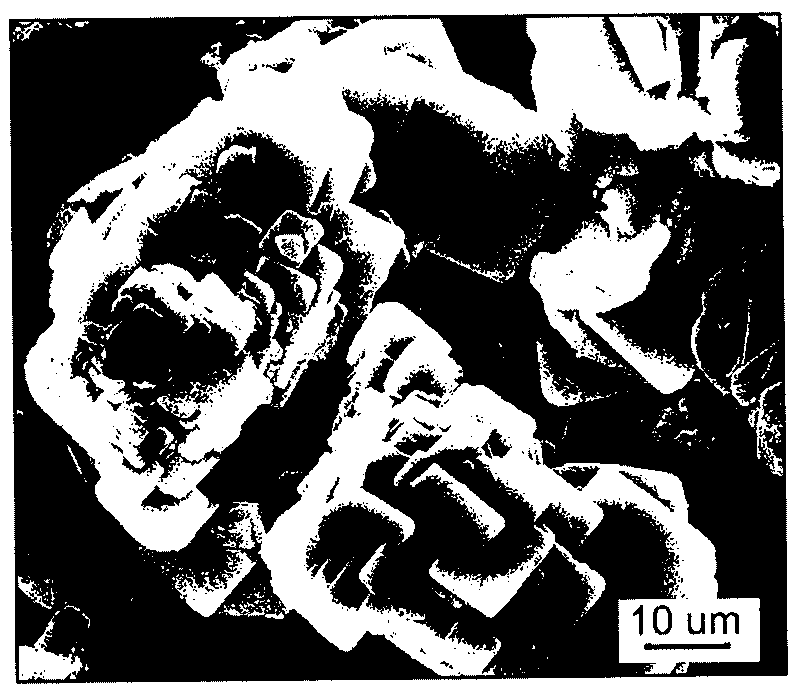

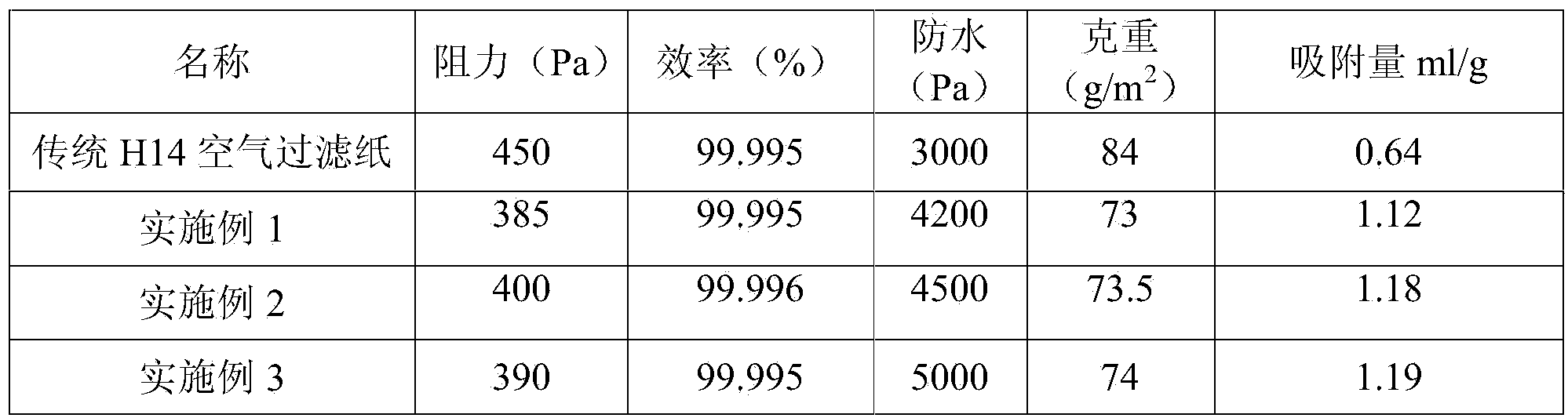

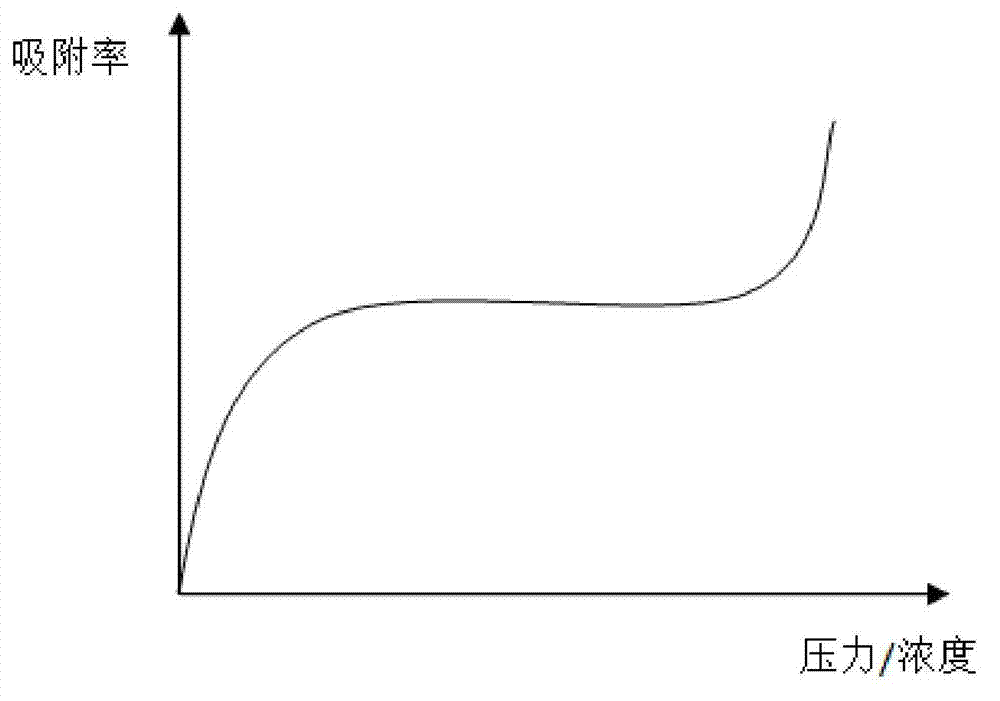

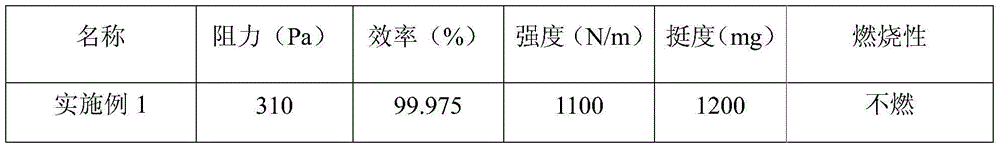

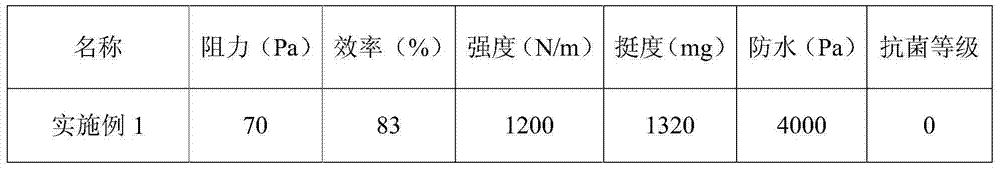

High-performance light-weight air filtering paper and preparation method thereof

ActiveCN104060497AAvoid defects of uneven pore distributionImprove air filtrationWater-repelling agents additionSynthetic cellulose/non-cellulose material pulp/paperGlass fiberAlkali free

The invention discloses high-performance light-weight air filtering paper. The air filtering paper is prepared from alkali-free glass fiber chopped strands, alkali-free glass fiber cotton and an adhesive, wherein the diameter of the alkali-free glass fiber chopped strands is 5-6 microns; the diameter of the alkali-free glass fiber cotton is 0.3-0.8 micron; the mass ratio of the alkali-free glass fiber chopped strands to the alkali-free glass fiber cotton is 1 to (4-9); the adhesive is composed of acrylic resin and a fluorocarbon water repellent. The invention further discloses a method for preparing the air filtering paper. The method comprises the following steps: firstly, selecting glass fibers in the ratio, and dispersing and pulping; secondly, transferring pulp into a machine chest, and adjusting the pH value to be 4-5; thirdly, transferring the pulp into a breast box, and adjusting the pH value to be 6-8; fourthly, performing wet molding to obtain wet paper; and finally, drying the wet paper to obtain the high-performance light-weight air filtering paper. The weight of the air filtering paper is lower than 75g / m<2>, the adsorption amount of the paper is larger than 1.10ml / g, and the air filtering paper is good in waterproof performance and high in filtering efficiency.

Owner:CHONGQING ZAISHENG TECH CORP

Method for preparing biomass solid molding fuel

InactiveCN102021057AReduce consumptionFast evaporationSludge treatment by de-watering/drying/thickeningBiofuelsCompression moldingMolding machine

The invention discloses a method for preparing biomass solid molding fuel, comprising the following steps of: (1) transferring waste residue and sludge from paper making and biomass dry powder into a batcher in proportion to obtain a mixture; (2) transferring the mixture obtained in the step (1) into a stirrer, fully stirring and breaking up the mixture; (3) conveying the mixture obtained in the step (2) into a dryer through a conveyor; (4) further reducing the water content of the mixture through the dryer and transferring the mixture into a distributing bin; (5) transferring the mixture into a molding machine, carrying out compression molding to obtain solid molding fuel and further reducing the water content of the solid molding fuel through screening, cooling and air-drying; and (6) transferring the solid molding fuel obtained in the step (5) into a mechanical packer to obtain a finished product. By effectively using the waste residue and the sludge from paper making and the biomass dry powder, the invention not only enables the waste residue and the sludge from paper making and the biomass dry powder to be treated, but also successfully produces the clean biomass solid molding fuel, and is beneficial to reduction of consumption of mineral energy.

Owner:NINGBO GUOHAI ENERGY TECH

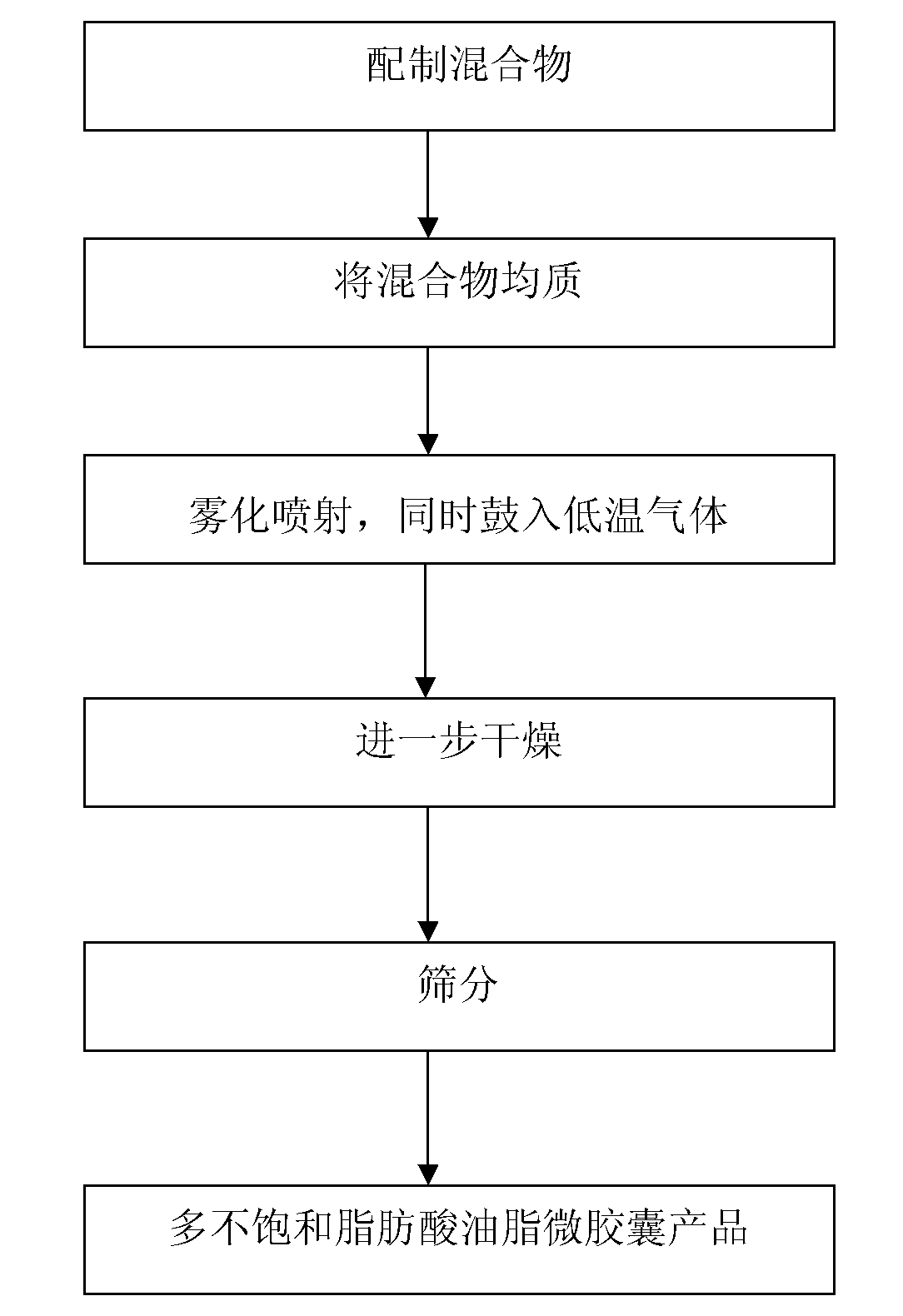

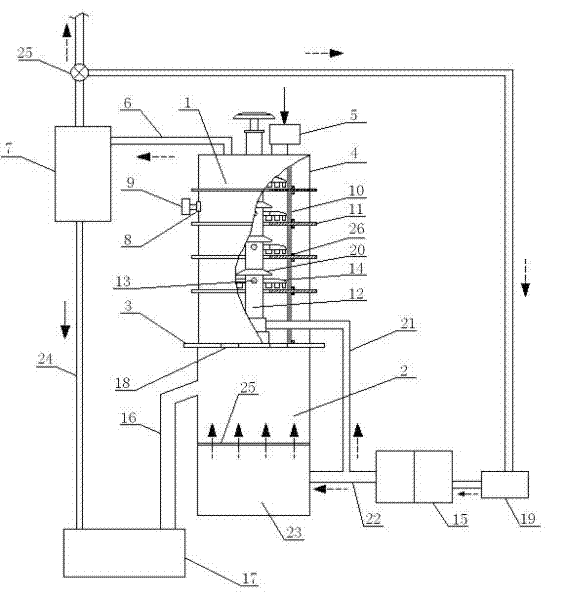

Spray freeze-drying preparation technology for polyunsaturated fatty acid oil microcapsule

The invention relates to a spray freeze-drying preparation technology for a polyunsaturated fatty acid oil microcapsule, which comprises the following technological steps: mixing oil containing polyunsaturated fatty acid with emulsifier and water to obtain mixture; homogenizing the mixture to obtain emulsion; atomizing the emulsion into liquid drops which are sprayed into a spray drying device with temperature of negative 60 DEG C to negative 10 DEG C, wherein powder embedding materials are contained at the bottom part of the spray drying device, and blasting low-temperature gas to fully mix the materials in the spray drying device and to keep the temperature in the spray drying device to be the set temperature; and further drying and screening to obtain polyunsaturated fatty acid oil microcapsule products. The invention has the advantages that the drying temperature of the preparation technology is low, the speed is fast and the nutritional ingredients are not apt to be damaged; the technology is simple and convenient and the automatic mass production can be realized; and the oil embedding rate of the obtained independent polyunsaturated fatty acid oil microcapsule particles is high, the embedding performance is good, the product shelf life is long and the stability is good.

Owner:CABIO BIOTECH WUHAN CO LTD

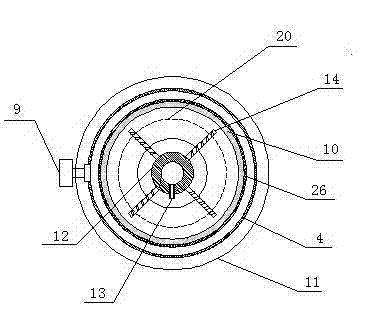

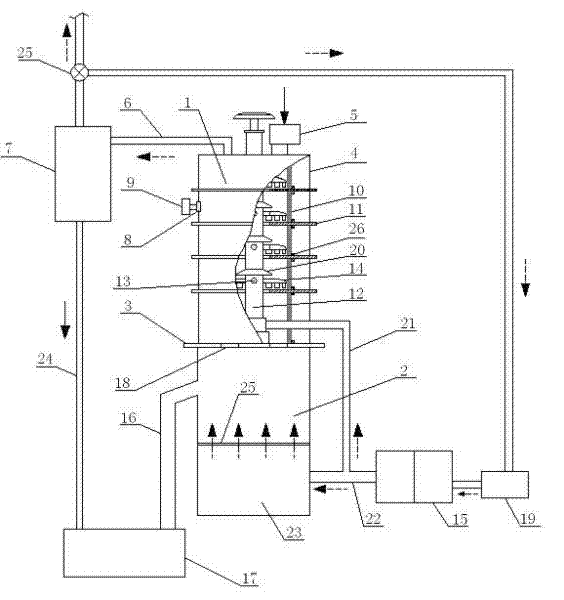

A device for microwave fluidized drying lignite

InactiveCN102261822ALow drying temperatureImprove energy utilizationDrying solid materials with heatHearth type furnacesEngineeringMicrowave

The invention discloses a device for drying lignite by microwave fluidization. The device comprises a microwave heating chamber and a fluidized bed, wherein the fluidized bed is arranged at the bottom of the microwave heating chamber and communicated with the microwave heating chamber; the microwave heating chamber comprises a metal furnace shell capable of shielding microwaves, a material inlet and a smoke gas exhaust port are arranged at the top of the furnace shell, at least one microwave generation device is arranged on the side surface of the furnace shell, a cylindrical ceramic furnace tube through which microwaves can penetrate is further arranged in the furnace shell, a plurality of layers of annular metal baffle plates are arranged along the inner wall of the ceramic furnace tubefrom top to bottom, a rotating shaft is arranged at the center of the ceramic furnace tube, a plurality of rake-shaped structural members which correspond to the metal baffle plates respectively are fixedly arranged on the rotating shaft along the axial direction, and a tapered material guide disc is fixedly arranged on each rake-shaped structural member; and the fluidized bed is in vertical structure, an air chamber of the fluidized bed is connected with a hot air furnace through a first hot air inlet pipe and an overflow pipe connected with a finished product warehouse is arranged at the upper part of the fluidized bed. By adopting the device, the large-scale, fast, low-energy-consumption and deep-drying production of the lignite can be realized.

Owner:KEDA INDUSTRIAL GROUP CO LTD

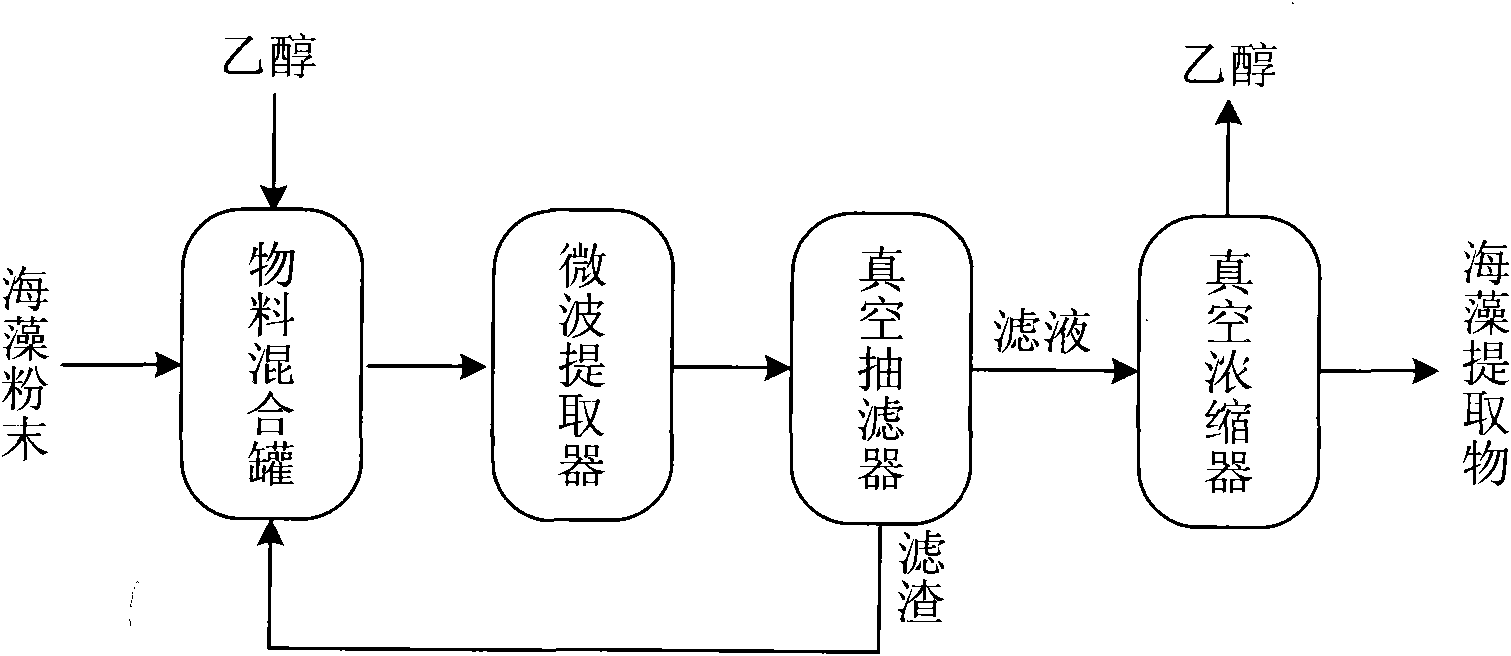

Seaweed flavor powder

The invention relates to edible seaweed, in particular to a seaweed flavor powder, and the flavor powder consists of 50 parts by weight of seaweed extract, 25-100 parts by weight of modified starch or / and dextrin and 1-5 parts by weight of emulsifier, wherein the emulsifier is glycerel monostearte or / and sucrose ester; the modified starch is crosslinked starch or / and gelatinized starch; and the seaweed extract is prepared by carrying out continuous microwave extraction on the edible seaweed by adopting 70-100% of ethanol. The seaweed flavor powder can retain aroma and taste of the seaweed and has the unique flavor of fresh, sweet, salty and fragrant. The seaweed flavor powder can be used as seaweed tea and seaweed soup, or be used on the surfaces of biscuits, cakes and bread or be added therein, or be added into dry noodles and instant noodles for producing foods with seaweed flavor.

Owner:GUANGZHOU UNIVERSITY

Electrode core drying device and method

ActiveCN103206838AFast heatingImprove uniformityDrying using combination processesDrying gas arrangementsAutomatic controlEngineering

The invention discloses an electrode core drying device. The electrode core drying device is characterized by comprising a drying oven, a heating device, a cooling device, a tray, a tray horizontal-moving device and a tray lifting and rotating device. An electrode core drying method includes multiple times of vacuum / inert gas-filled circulating, rotary heating, forceful cooling, exposure-free air butting and the like. By the electrode core drying device and method, inert gas is filled as heat conductive medium during heating, and heating speed is high; electrode cores are rotationally heated and subjected to forced convection, temperature uniformity is improved, and more reliable data are provided for heating temperature calculation. By the aid of vacuum and gas replenishing, water overflow is better facilitated, drying temperature of the electrode cores is lowered, and product quality is improved. During cooling of the electrode cores, cooling by inert gas and forced water cooling of a heating plate are realized, cooling time is greatly shortened, drying program is automatically controlled, the drying system is movable, a flange connector is directly abutted to a liquid injection tank through the drying oven, and secondary water absorption of the electrode cores is avoided.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

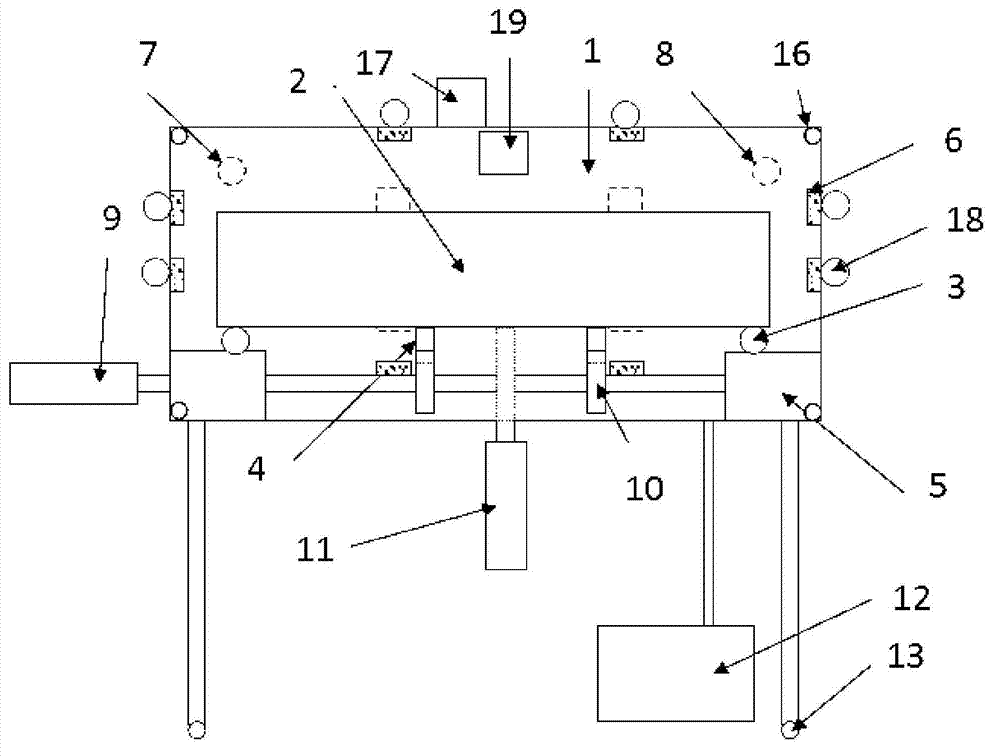

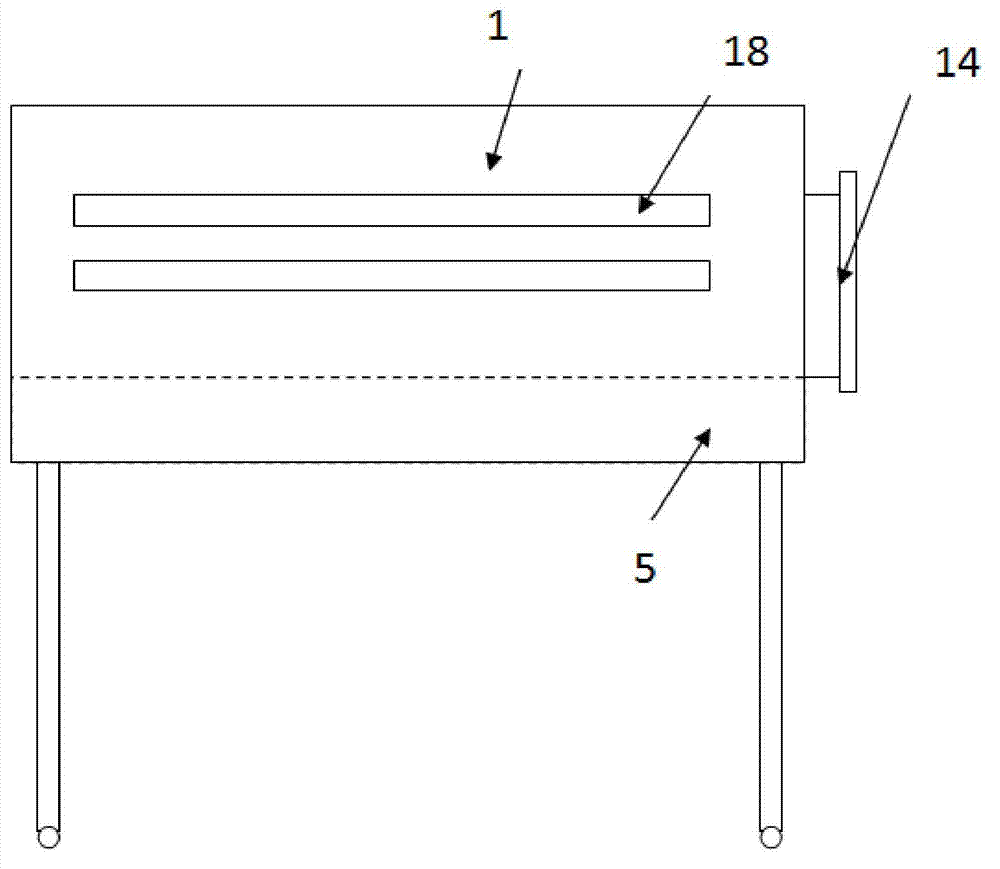

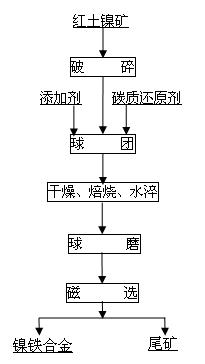

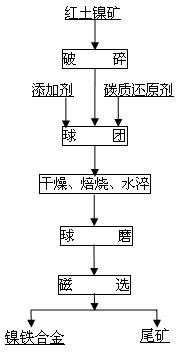

Method for producing ferronickel from lateritic nickel ores

The invention relates to a method for producing ferronickel from lateritic nickel ores, particularly a method for producing ferronickel from lateritic nickel ores by metallizing reduction roasting-magnetic separation. The method is characterized by comprising the following steps: adding additives and a carbonaceous reducing agent into lateritic nickel ores, carrying out reduction roasting, quenching with water, grinding, and carrying out magnetic separation to obtain the ferronickel alloy. In the method, the magnetic separation is directly carried out to obtain the ferronickel alloy powder with high nickel grade; the additives are added to lower the reduction temperature; not all the materials need to be heated to 1500 DEG C, thereby lowering the energy consumption; and the technique has slight influence on the environment, and thus, is an economical method for producing ferronickel from lateritic nickel ores, thereby having wide application prospects.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

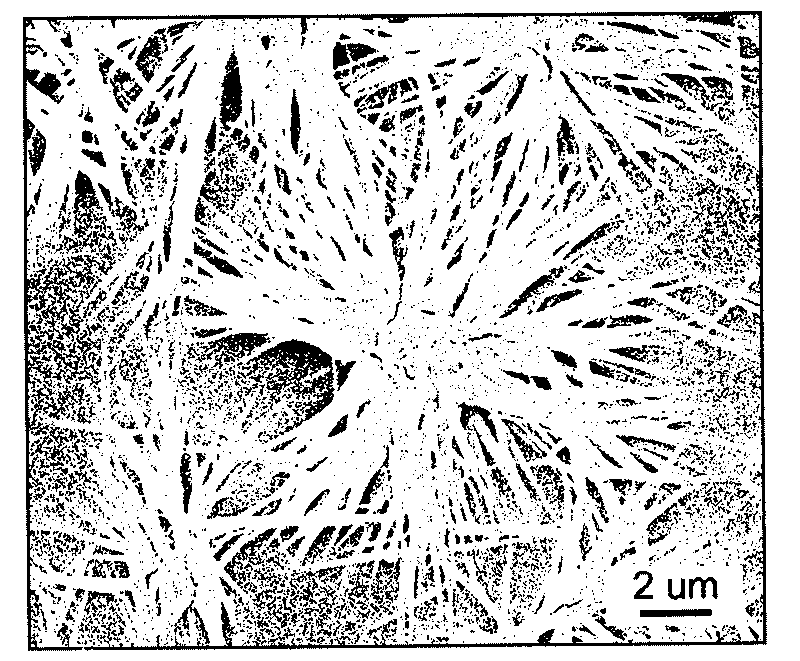

High flame retardancy glass fiber air filtering paper and preparation method thereof

ActiveCN103556544AThe mesh is tightly combinedThe gap is uniform and fineSynthetic cellulose/non-cellulose material pulp/paperFiltration separationEmulsionMicrometer

The invention discloses a piece of high flame retardancy glass fiber air filtering paper which is prepared from alkali-free glass fiber cotton with the diameter being 7-9 micrometers, alkali-free glass fiber cotton with the diameter being 0.3-0.4 micrometer, and a binding material, wherein the mass ratio of the alkali-free glass fiber cotton with the diameter being 7-9 micrometers to the alkali-free glass fiber cotton with the diameter being 0.3-0.4 micrometer is 1:(3.8-4.2); the binding material is a mixture of acrylic emulsion and a halogen-free organic phosphate fire retardant. The invention further discloses a preparation method of the high flame retardancy glass fiber air filtering paper. The preparation method comprises the following steps of firstly, pulping to disperse the raw materials so as to obtain pulp, subsequently gluing wet paper, removing moisture in the wet paper, and finally drying so as to obtain a product. The glass fiber air filtering paper is smooth and uniform in surface, and good in flame retardant property.

Owner:CHONGQING ZAISHENG TECH CORP

Microwave processing method for chrysanthemum tea

The invention relates to a microwave processing method for chrysanthemum tea. The method comprises the following steps of: firstly, picking out satisfactory fresh chrysanthemums, and spreading the chrysanthemums at room temperature to air; performing microwave green removing, quickly reducing the temperature after green removing, and repeatedly kneading the chrysanthemums; and drying, screening, inspecting and packing the chrysanthemums to obtain the finished product of chrysanthemum tea. Compared with the traditional common green removing method through heating, distilling and drying, the method can effectively reserve important drugs and nutrition constituents such as volatile oil, flavone, chlorogenic acid, stevia, choline, amino acids, vitamins, abundant mineral elements and the like contained in the chrysanthemums, and the disinfection effect is improved.

Owner:程雪翔

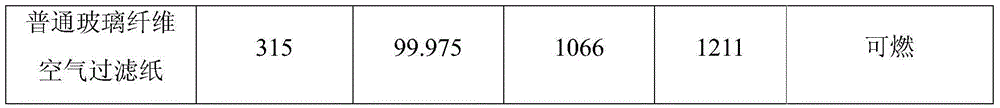

Process method for treating solid waste containing copper and nickel

InactiveCN101597691AImprove environmental pollutionReduce dust and other pollutionProcess efficiency improvementLiquid copperOxide

The invention discloses a process method for treating solid waste containing copper and nickel, which is characterized in that: the solid waste is pretreated by a boiling rotary drying method to obtain a charging material; the charging material is subjected to reduction smelting by a reduction method; the reduction smelting comprises the following steps: adding carbon fuel into a reduction smelting furnace, melting the charging material by heat generated by combustion of the carbon fuel, and simultaneously forming carbon monoxide reduction atmosphere to reduce metallic oxides of copper or nickel; liquid copper or liquid nickel obtained by reduction melting passes through a casting ladle, and crude copper, crude nickel, copper matte or nickel matte is obtained; slag obtained by the reduction melting is subjected to water quenching treatment and then is recycled; and flue gas obtained by the reduction melting is recycled by an off-gas treating system. The process method changes the prior small cupola smelting furnace production technology which is out-dated for treating the solid waste, adopts harmless treatment technology, and greatly improves the problem of environmental pollution caused by small cupola furnace production; and the whole technological process is environment-friendly, and has low consumption and high recovery rate of the copper, the nickel and the like.

Owner:杭州富阳申能固废环保再生有限公司

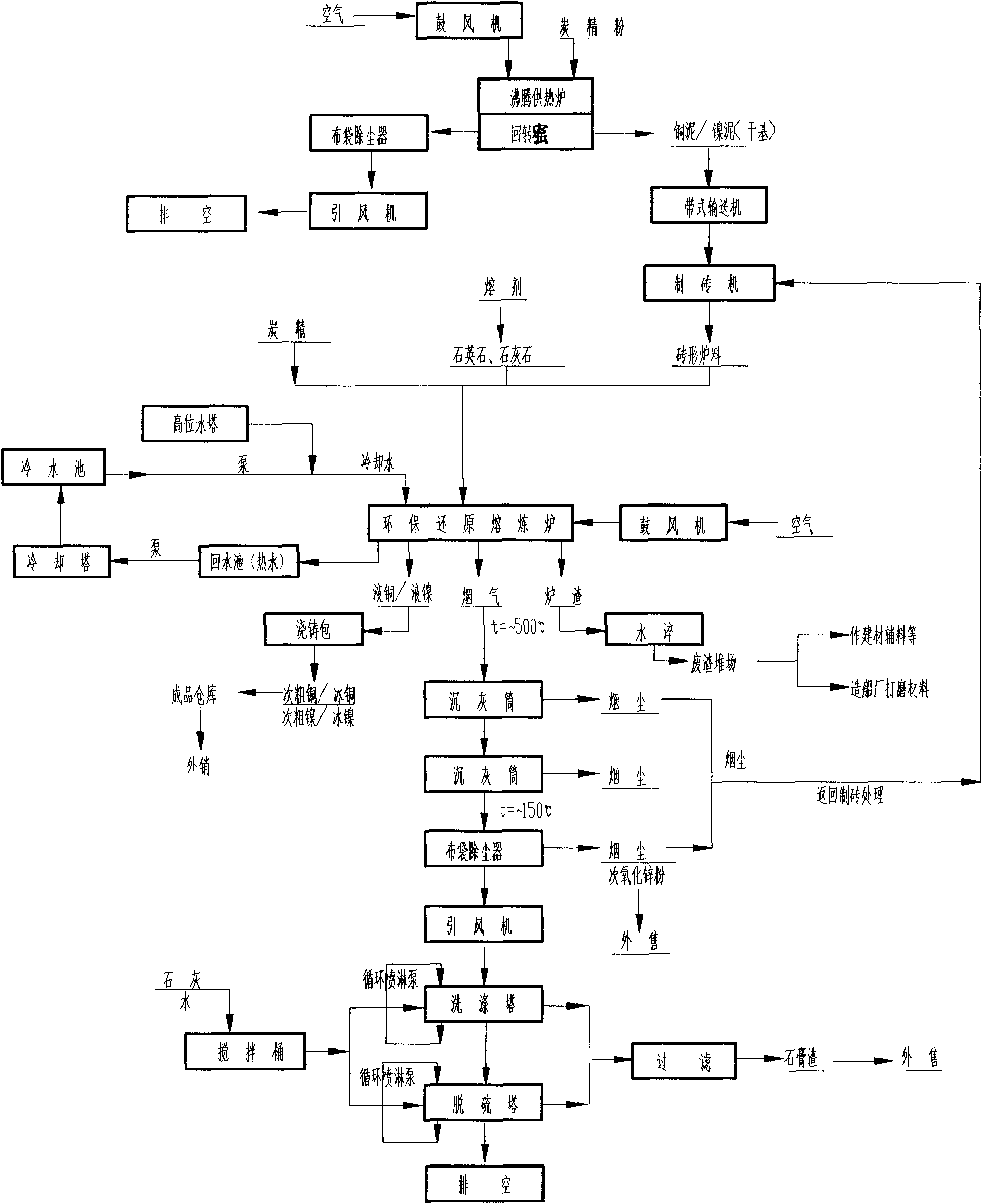

Method for dehydrating biomass

InactiveUS20070225463A1Quality improvementAvoid excessive water contentChemical recyclingDistillationEvaporation

Organic substrates such as grain by-products: wet cake, mash, stillage, wet brewers cake are dewatered in a relatively low energy, low-heated gas flow, negative pressure, four stage process consisting of leaching with organic solvent, mechanical dewatering, evaporation and reclamation of the organic solvent in an environment of a stable gas flow. The dried organic substrate is processed into a dry distiller's grains with solubles which is free-flowing quality substance suitable for food or other uses at much lower substrate drying temperatures generally below 200° F. Conveniently, the solvent and the stable gases are recovered from the water-solvent leaching and dewatering process by a distillation tower and feedback loop system allowing the recycling of the solvent and stable gas while reducing the level of air emissions in the unique drying system.

Owner:FEMAL MICHAEL JOHN +5

Aassociation drying Method for preparing dehydrated vegetable and fruit

InactiveCN101156623AReduce qualityImprove qualityFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by dehydrationOrganic structureFreeze-drying

The invention relates to a dehydrating and drying method for the top-grade vegetable and fruit. After being sliced, the vegetable and the fruit are placed in a microwave vacuum dryer for being dried, the exerting microwave power density is between 0.5 w / g and 1.2 w / g (watt / gram), the vacuum rate is between 2.5KPa and 4.5KPa (remaining pressure), the materials to be dried can do reciprocating movement along with the drying dish in the microwave vacuum dryer. After being dehydrated by about 40-50 percent of the total moisture by the microwave vacuum drying, the materials are taken out and positioned on a stainless steel dish and then are positioned in a freezing dryer, and are frozen and sublimed dry under 25 DEG C below zero, the drying time is about 7-10 hours, and the moisture is lowered to the safe moisture of 6-7 percent. The preserving of the color, the scent, the taste, and the nutritious components of the dehydrated vegetable and fruit which are produced by the invention are quite approximate to that of the single freezing dried products, the volume is 60-70 percent of the volume of the single freezing dried products, the appearance and the organic structure are approximate too, the drying cost is low, and the energy can be saved by 40 percent above.

Owner:JIANGNAN UNIV

Method for processing sludge resources

InactiveCN101671588AFast dehydrationReduce moisture contentSludge treatment by de-watering/drying/thickeningBiofuelsSludge cakeProcess engineering

The invention discloses a method for processing sludge resources. The method comprises the following steps: (1) evenly mixing the crushed dry plant-based wastes generated in the industrial and agricultural production with sludge cake with moisture content of 80wt%-85wt%; the moisture content of the mixture is lower than 55 wt%-60wt%; (2) the mixture is heated and dried until the moisture content thereof is 20 wt%-25wt%; (3) fuel particles are produced through a granulating machine; and (4) the fuel particles are used for heat supply for the drying step. Since the plant-based wastes provided with low moisture content and generated in the industrial and agricultural production are mixed with the sludge cake, the dehydration speed of the mixture in a drying apparatus is higher than that of the single sludge cake, the drying temperature is lower, and the heat consumption is less. The fuel particles obtained by the method can be taken as the energy resources to replace the fossil energy forsewage treatment, and simultaneously, the obtained heated steam also can be taken as resource to sell.

Owner:天津紫荆能源技术有限责任公司

Antibacterial glass fiber air filtering paper and production method thereof

ActiveCN103882780AImprove distributionAvoid decompositionPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperGlass fiberSodium Pyrithione

The invention discloses antibacterial glass fiber air filtering paper which is prepared from alkali-free glass fiber cotton with the diameter of 3.0-3.5mm, alkali-free glass fibers with the diameter of 0.8-1.0 micron, acrylic emulsion, waterproof emulsion and an antibacterial agent, wherein the mass ratio of the alkali-free glass fiber cotton with the diameter of 3.0-3.5mm to the alkali-free glass fibers with the diameter of 0.8-1.0 micron ranges from (4:1) to (6:1); the antibacterial agent is a mixture of pyrithione substances and nano silver. The invention further discloses a method for producing the filtering paper. The method comprises the following steps: pulping the alkali-free glass fiber cotton to obtain a paper pulp suspension solution; molding the obtained suspension solution to obtain wet paper; spraying the acrylic emulsion, the waterproof emulsion and the antibacterial agent to the wet paper; finally, dehydrating and drying to obtain the product. The antibacterial glass fiber air filtering paper disclosed by the invention has an excellent antibacterial performance, low cost and good use durability.

Owner:CHONGQING ZAISHENG TECH CORP

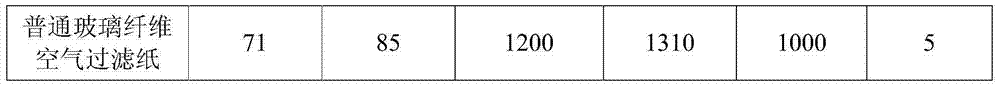

Real leather suede leather stereoscopic printing paste and preparation method

ActiveCN102619106AImprove permeabilityExcellent adhesionDyeing processTextile printerScreen printing

The invention discloses real leather suede leather stereoscopic printing paste and a preparation method. The real leather suede leather stereoscopic printing paste is prepared by preparing polyurethane resin of sodium hydrogensulfite blocked isocyanate by polypropylene glycol, polyethylene glycol, chain extenders, trimethylolpropane, polyisocyanate, solvents, catalysts, methyl ethyl Ketoxime, sodium hydrogensulfite, ice and water, and blending the polyurethane resin with a polyurethane filming fixing agent FS-0517. According to the real leather suede leather stereoscopic printing paste and the preparation method, stereoscopic printing for real leather suede leathers can be achieved by utilizing the flat screen printing technology and drying real leather suede leathers at a temperature between 60 DEG C and 90 DEG C, a concave and convex feel is apparent, the style is elegant and fashionable, stereoscopic print patterns are specific, and the print patterns are stable, and water washing and dry friction resistant.

Owner:LIAONING FIXED STAR FINE CHEM

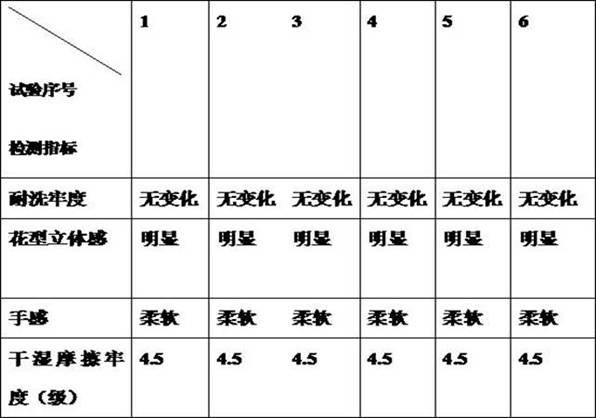

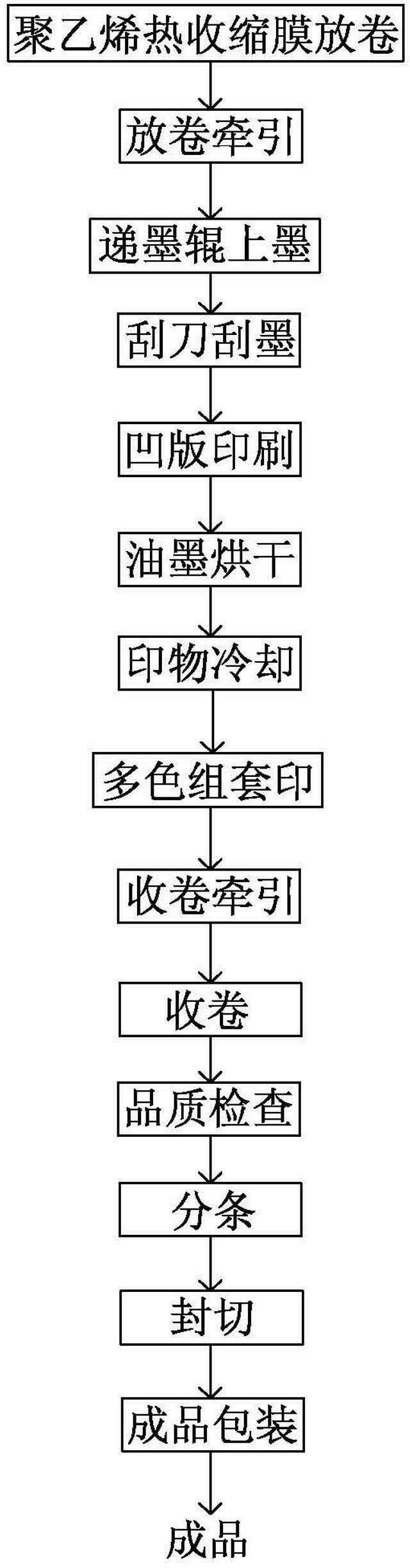

Polyethylene heat shrinkable film gravure printing process

InactiveCN102602177AIncrease temperatureIncrease air volumeRotary intaglio printing pressOther printing apparatusEngineeringElectrical and Electronics engineering

The invention relates to a polyethylene heat shrinkable film gravure printing process which comprises the following steps of: (1) unwinding a polyethylene heat shrinkable film; (2) carrying out unwinding drawing; (3) carrying out inking by a drop roller; (4) scraping ink by a scraper; (5) carrying out gravure printing; (6) drying ink; (7) cooling a printed object; (8) carrying out multiple color class overprinting, wherein the steps (3), (4), (5), (6) and (7) are sequentially repeated; (9) carrying out winding drawing; (10) winding; (11) checking the quality; (12) stripping; (13) sealing and cutting; and (14) carrying out finished product packaging to obtain a finished product, wherein when the step (6) is implemented, the ink printed on the surface of the polyethylene heat shrinkable film is dried by modes of feeding hot blast by an air blower and circulating the hot blast by a drying box and related equipment comprises an air energy heating device, the air blower, an external heating box, a suction fan and the drying box with an effect of an air chipper. The polyethylene heat shrinkable film gravure printing process is used for carrying out gravure printing on the polyethylene heat shrinkable film.

Owner:ZHENGXIN PACKAGING CO LTD DONGGUAN

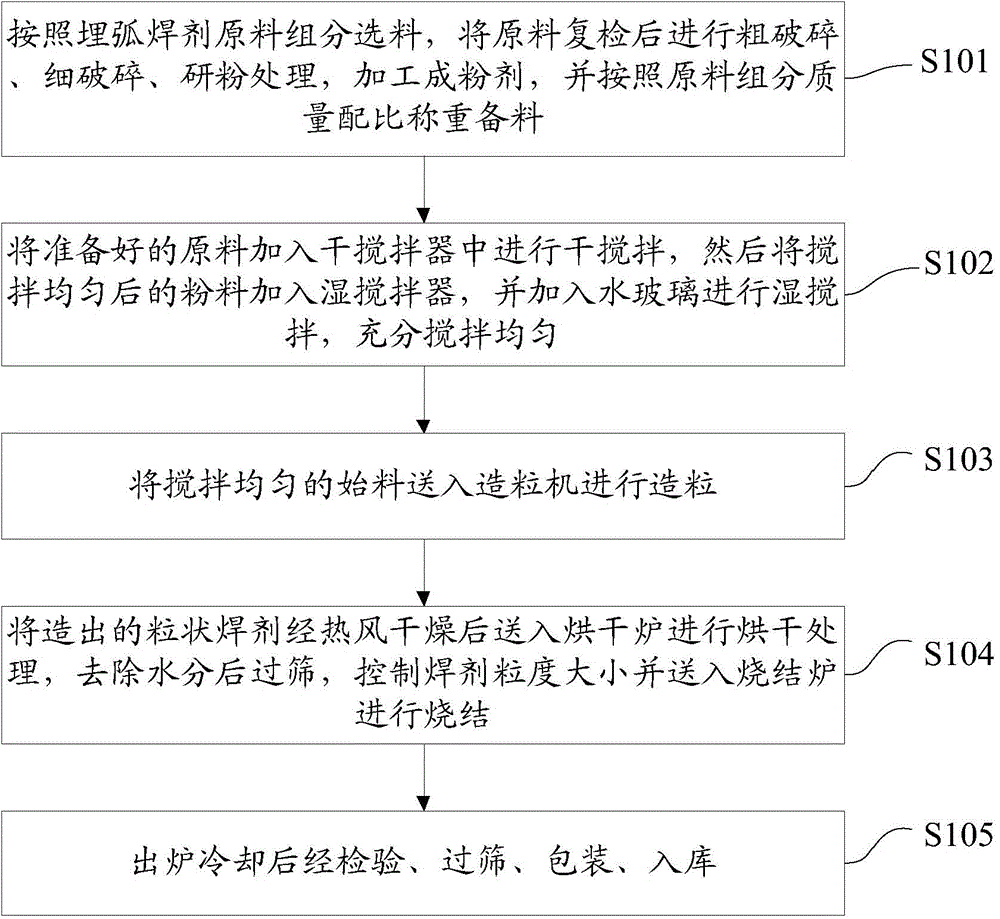

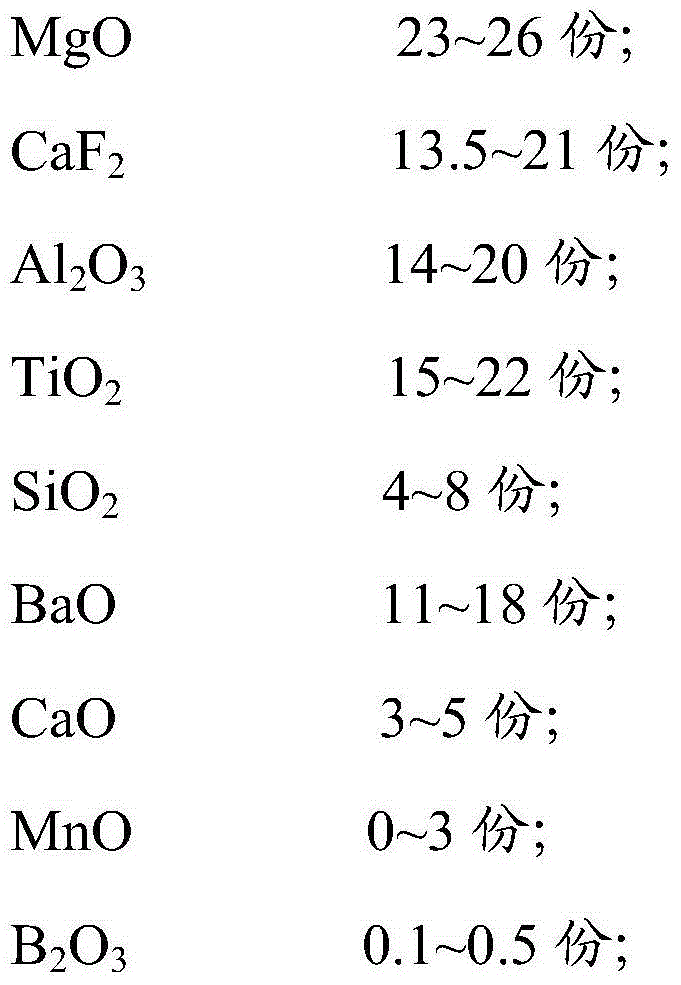

High-basicity and high-tenacity submerged-arc welding flux for oceaneering and preparation method of high-basicity and high-tenacity submerged-arc welding flux

ActiveCN104096987AImprove low temperature impact toughnessEasy to remove slagWelding/cutting media/materialsWelding/soldering/cutting articlesLower limitAlkalinity

The invention provides high-basicity and high-tenacity submerged-arc welding flux applicable to the technical field of welding materials. The high-basicity and high-tenacity submerged-arc welding flux comprises, by weight, 23-26 parts of MgO, 13.5-21 parts of CaF2, 14-20 parts of Al2O3, 15-22 parts of TiO2, 4-8 parts of SiO2, 11-18 parts of BaO, 3-5 parts of CaO, 0-3 parts of MnO, 0.1-0.5 part of B2O3. The lower limit of drying temperature before use of the submerged-arc welding flux is 300 DEG C. By the high-basicity and high-tenacity submerged-arc welding flux, low-temperature impact tenacity of welding seams is improved, and the welding seams have excellent technical welding performance; via reasonable selection and proportional matching of raw materials, the prepared welding flux is low in moisture absorption rate, drying temperature before use of the welding flux is reduced, and energy consumption is reduced as well.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

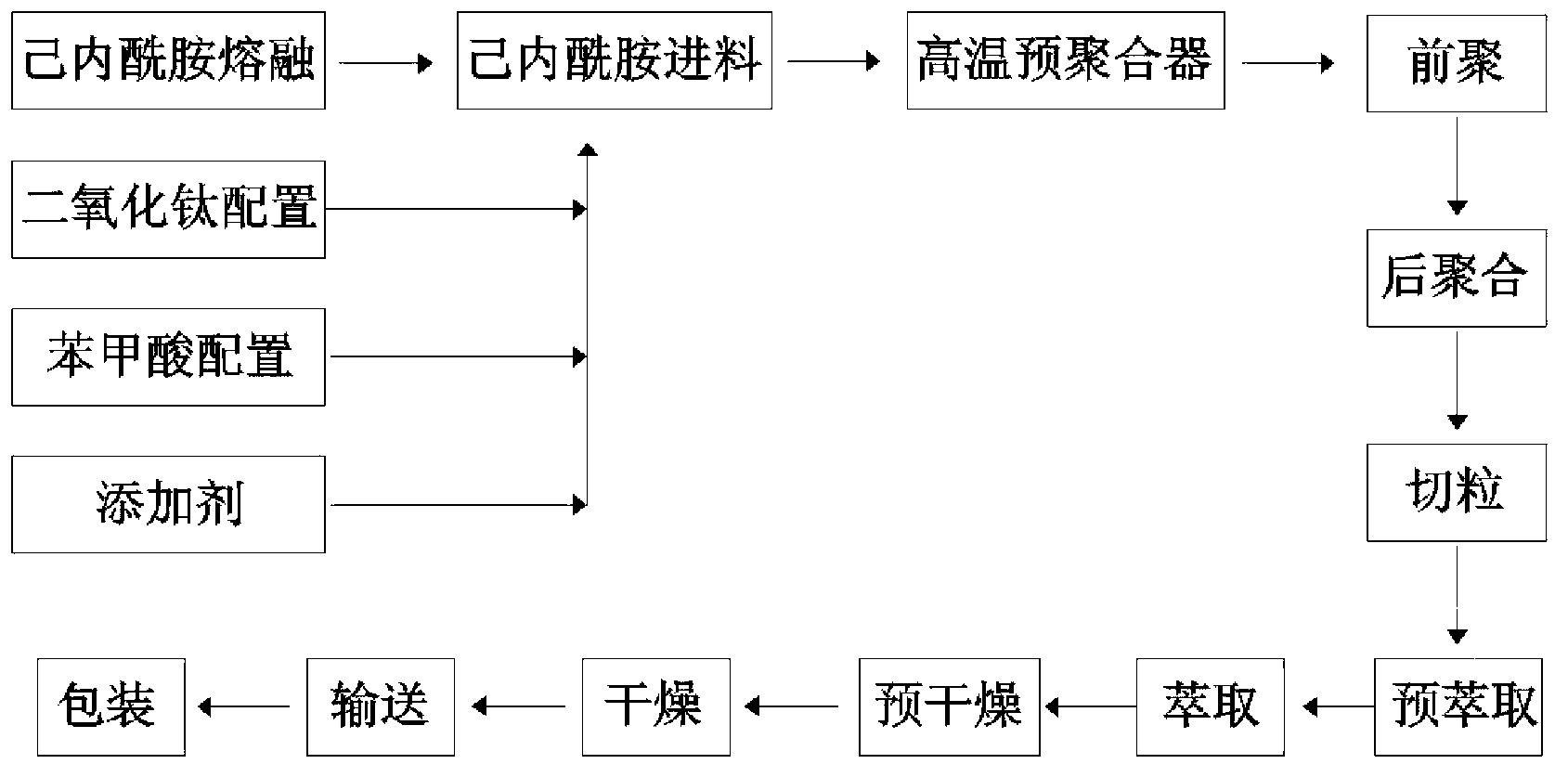

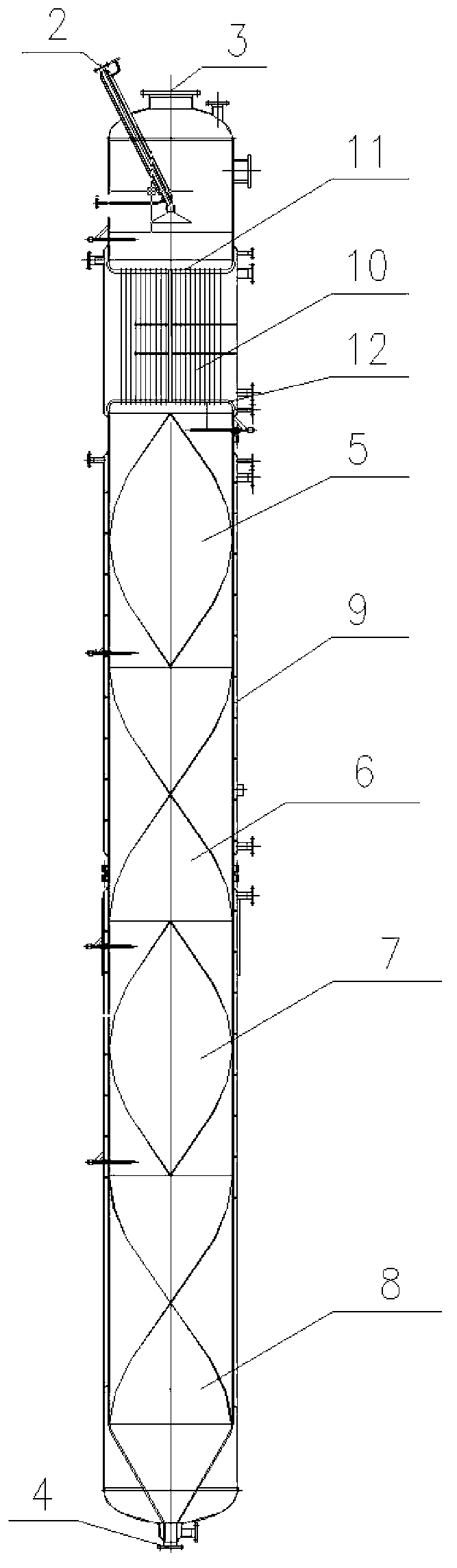

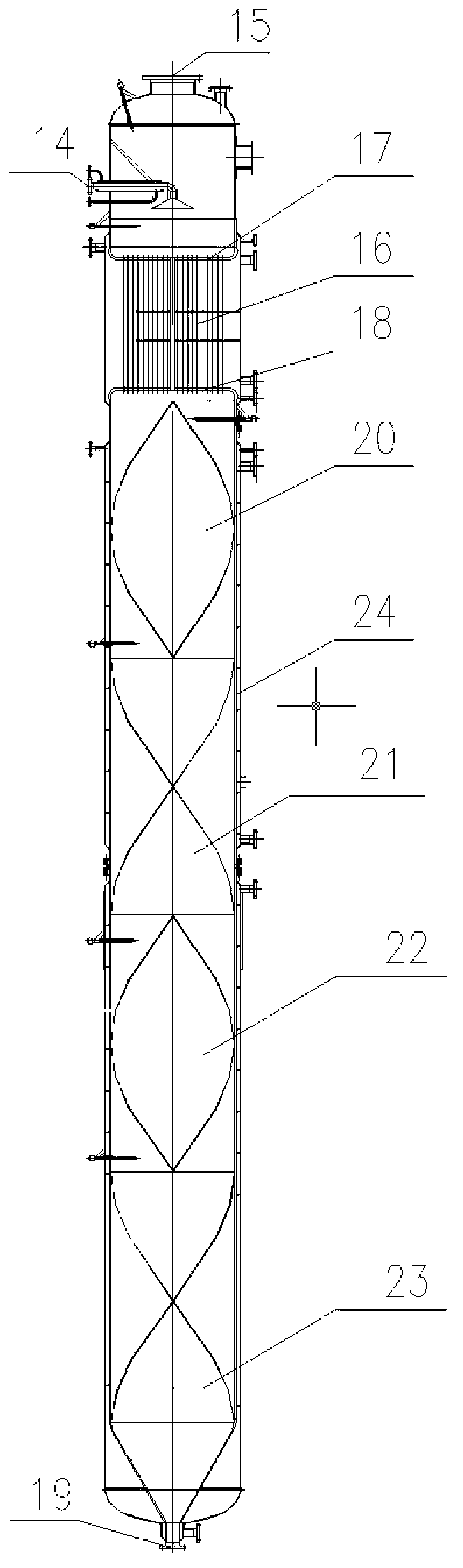

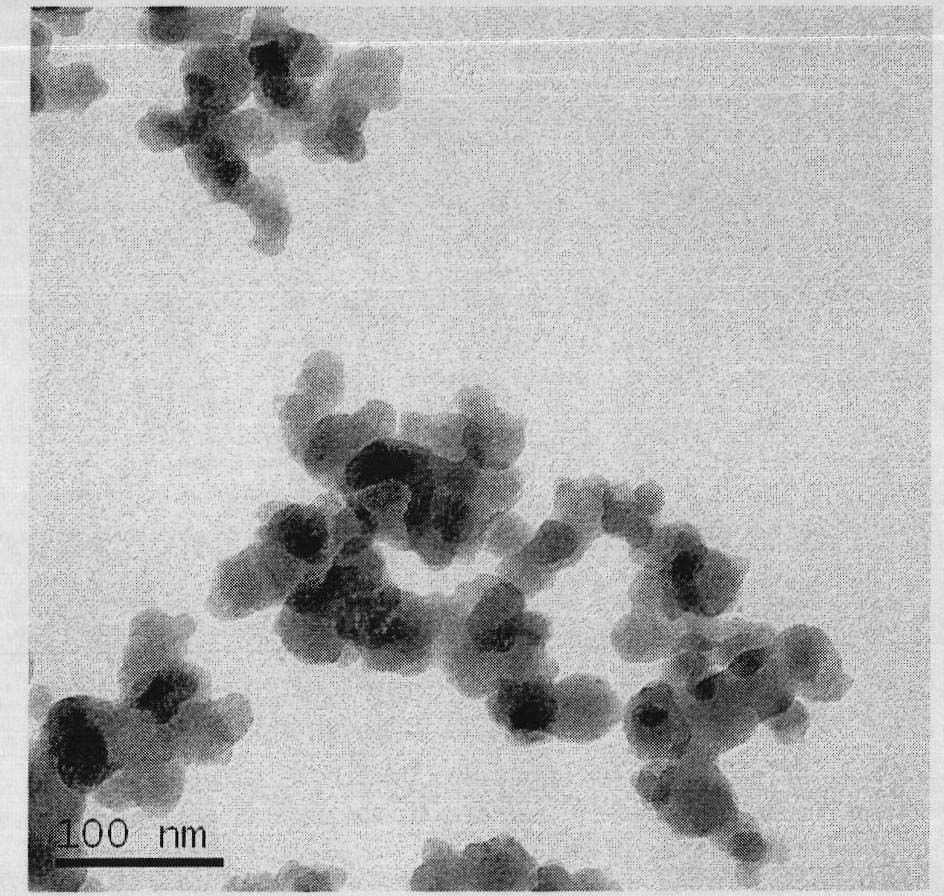

Polyamide polymerization production process and equipment for same

The invention relates to a polyamide polymerization production process and equipment for the same. The polyamide polymerization production process comprises the following steps of: carrying out prepolymerization on melted caprolactam, titanium dioxide, benzoic acid, and the like at a high temperature, and then carrying out front polymerization and post polymerization; pelleting; pre-extracting; extracting; pre-drying; and drying to obtain a product. The production equipment comprises a hexanolactam melting system, a preparation system, a feed system, a high-temperature prepolymerization device, a front polymerization tower, a rear polymerization tower, a pelleting system, a pre-extraction tower, an extraction tower, a pre-drying tower, a drying tower, and the like. According to the invention, static state flow guide spiral mixer assemblies are additionally arranged in the extraction tower and the lower sections of each row of tubes of the high-temperature prepolymerization device, the front polymerization tower and the post polymerization tower; the polyamide hydrolyzing ring opening and dewatering are more uniform and sufficient and faster; the front polyaddition reaction is sufficient and stable; the rear polycondensation stage is more uniform and stable in molecular distribution; the extraction tower more sufficiently and stably extracts a caprolactam monomer; the pre-drying tower can be used for removing the surface moisture of a slice; the drying tower dries combined water; a recovery system can be used for recovering an oligomer and extracts the caprolactam monomer contained in water.

Owner:武汉森大科技研究发展中心

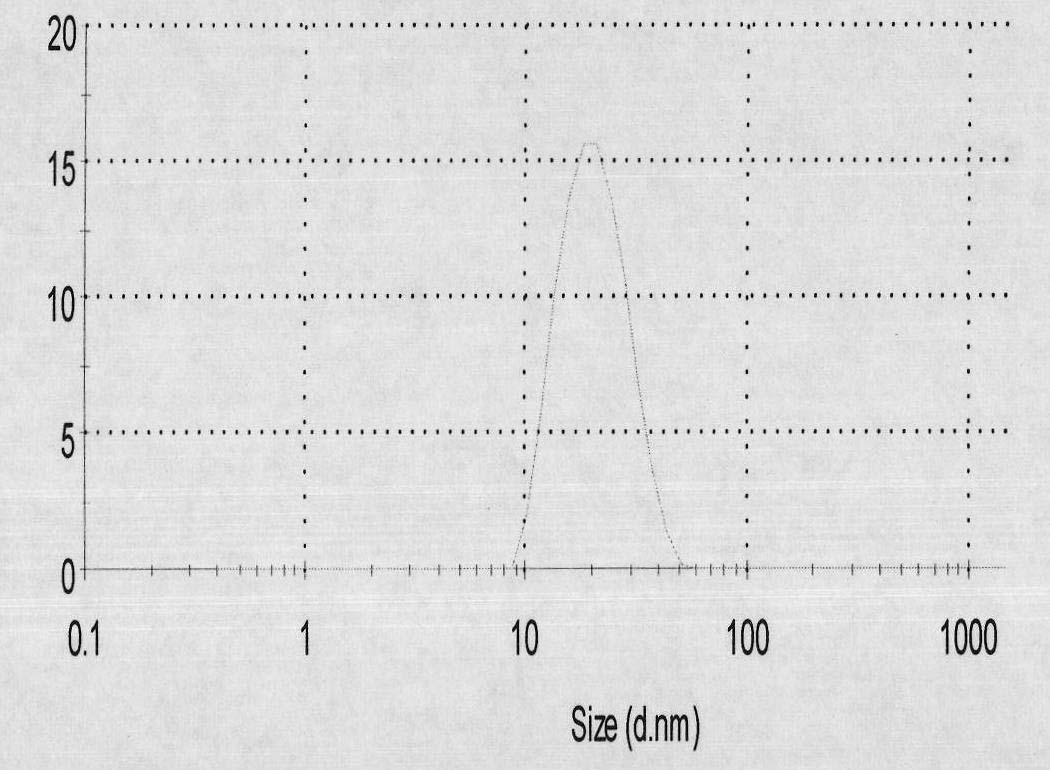

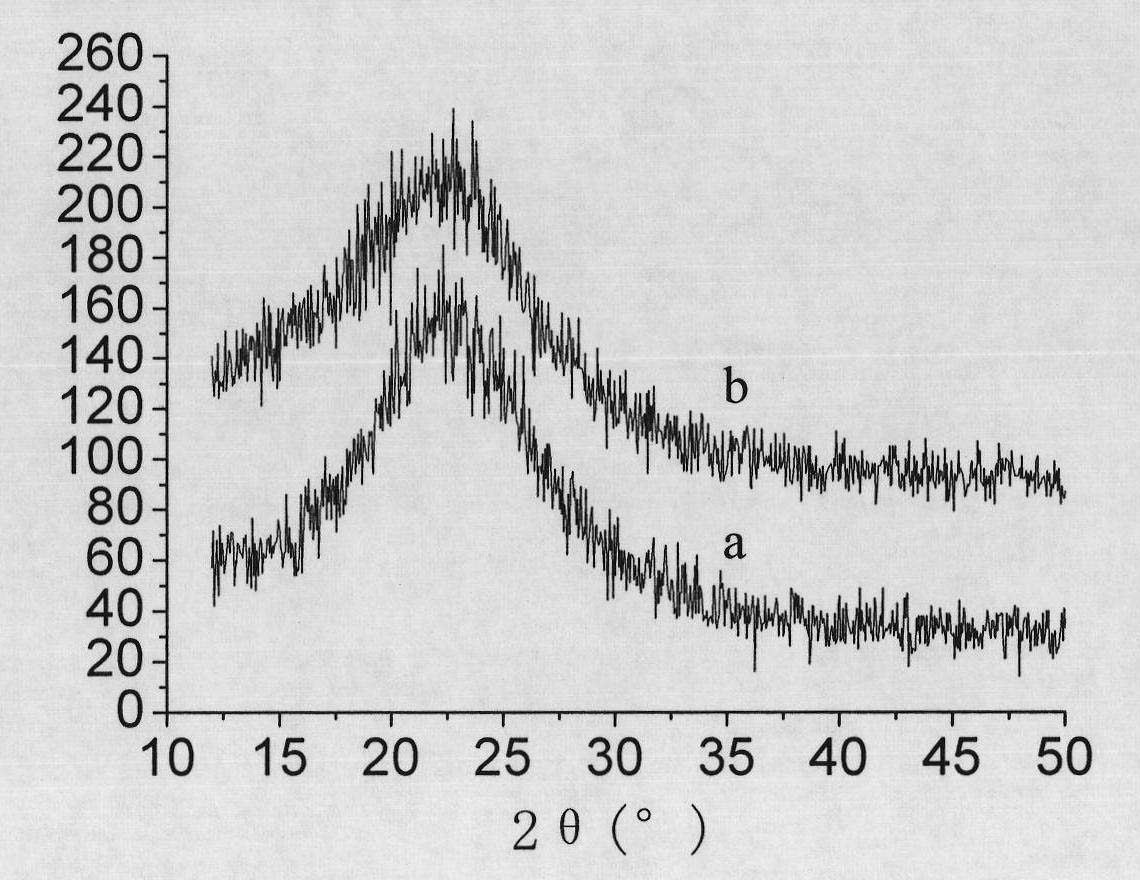

Method for preparing nanometer silicon dioxide

InactiveCN101817532ASimple structureLow costNanostructure manufactureSilicaAdhesiveSODIUM SILICATE SOLN

The invention relates to a method for preparing nanometer SiO2. The method prepares the nanometer SiO2 by adopting composite shearing force field and comprises the following steps of: 1, using solution of sodium silicate as solution A, precipitator as solution B, mixed solution of surfactant and sodium chloride as solution C, and modifier as solution D; 2, pouring the prepared reaction solution A, B, C and D into a feed barrel at room temperature, introducing gas to the feed barrel, and controlling the pH value of a reaction system to perform reaction with stirring of a composite shearing force field; 3, precipitating ivory reaction solution, aging for 24 hours, filtering and washing till no chloridion, and drying to obtain silicon dioxide; and 4, grinding and sieving to obtain a sample. The method has the advantages of low cost of raw materials, simple structures of reaction devices, little investment, simple and feasible process, high yield and realization of large-batch production, can be performed at room temperature, can be widely used in plastic, rubber, adhesive, dope, ink and other products, and has extremely high practical value.

Owner:HUNAN UNIV OF TECH

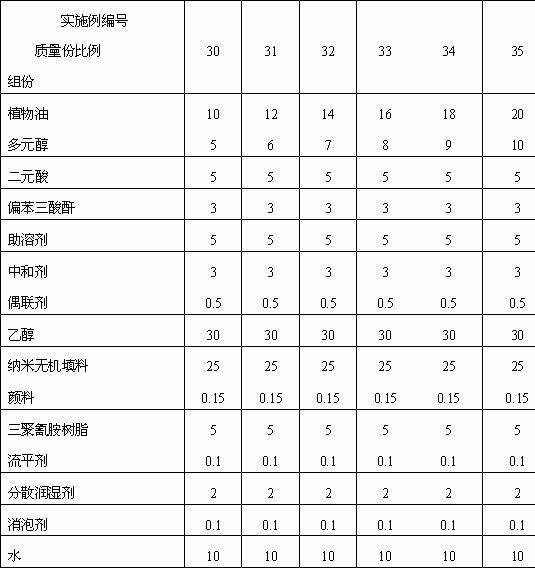

Preparation method of H-grade water-solubility silicon steel sheet paint

ActiveCN102304319AImprove the state of the interfaceNot easy to settlePolyester coatingsSolventSolubility

The invention discloses a preparation method of a H-grade water-solubility silicon steel sheet paint, which comprises the following steps of: taking raw materials such as 10-20 parts of plant oil, 5-10 parts of polyatomic alcohol, 5 parts of binary acid, 3 parts of trimellitic anhydride, 5 parts of cosolvent, 3 parts of neutralizer, 0.5 part of coupling agent, 30 parts of alcohol, 25 parts of nanometer inorganic packing, 0.15 part of pigment, 5 parts of melamine resin, 0.1 part of flatting agent, 2 parts of dispersing moistening agent, 0.1 part of deforming agent and 10 parts of water according to a weight ratio, and preparing an environmental-friendly product with good combination properties for large generators through the synthesis of alkyd resins, the coupling treatment of the nanometer inorganic packing, the mixing and dispersion of materials such as the inorganic substances and the like in a paint, the grinding of the paint vehicle and the like. The preparation method has the advantages of solving the problems of sedimentation, aggregation and blocking of powder in paint liquid under the condition of high content of inorganic powder, obviously increasing the storage stability of the paint liquid and the hardness of a paint film, effectively reducing the discharge of poisonous and harmful gases in the production process and reducing the harm to the health of human bodies.

Owner:四川东材绝缘技术有限公司

Instant psidiumguajava tea and preparation process thereof

The invention provides a highly clear and instant psidiumguajava tea and a preparation process, wherein the tea is produced by mainly adopting fresh or dried young fruit psidiumguajava as a raw material, and has characteristics of convenient production and taking, high safety and no toxic-side effect. According to the present invention, the fresh or dried young fruit psidiumguajava is mainly adopted as the raw material, and cleaning, grinding, ultrasonic enhanced solvent extraction, concentration, purity removing, membrane separation and enrichment, paste forming, spray drying and granulation are performed to obtain the instant psidiumguajava tea; compared with the previous psidiumguajava tea product, the product of the present invention and the preparation process thereof have the following characteristics that: the psidiumguajava fruit, especially the young fruit discarded in the production process is adopted as the raw material to change waste into treasure and obtain the instant psidiumguajava tea product; the psidiumguajava young fruit water extract has a good clinical blood sugar lowering effect, and the preparation process has characteristics of high product yield, low preparation cost, more flavor substance maintaining, and the like; and the highly clear and instant psidiumguajava tea has characteristics of convenient taking, high nutrition and high active ingredient content.

Owner:ZHONGSHAN CUISAN FOOD CO LTD

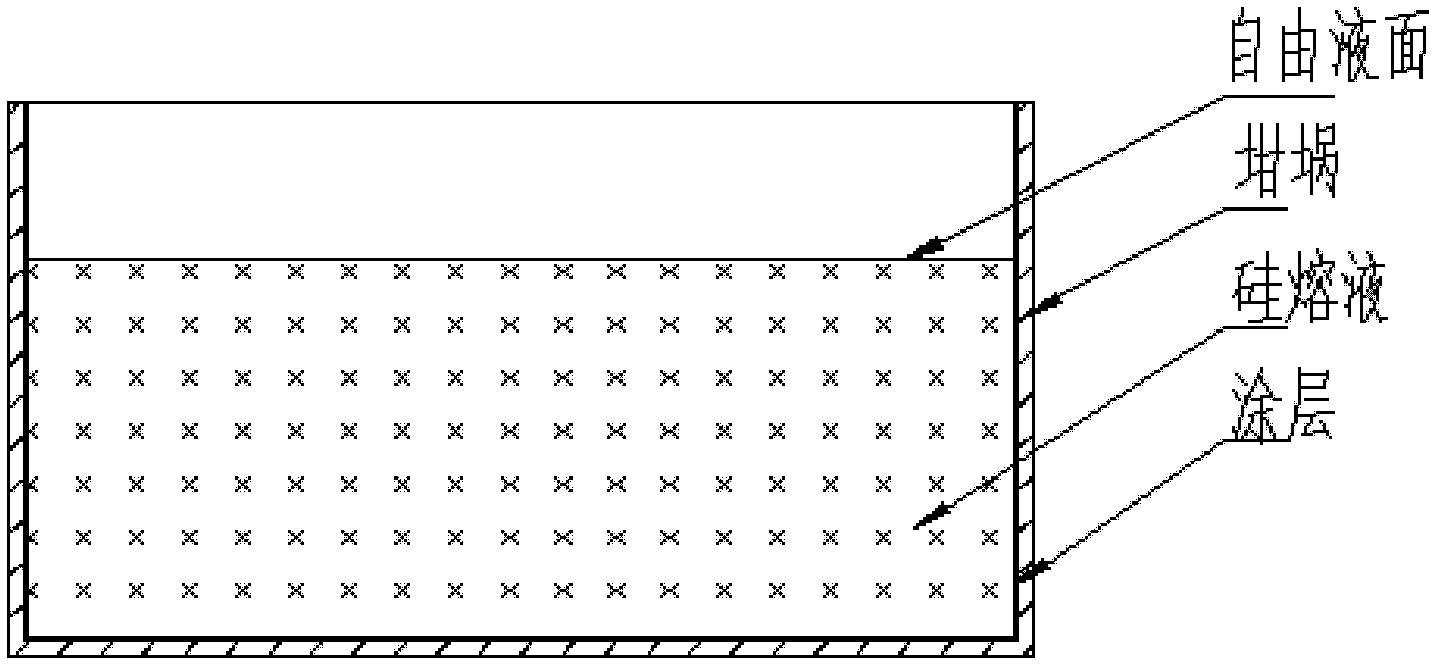

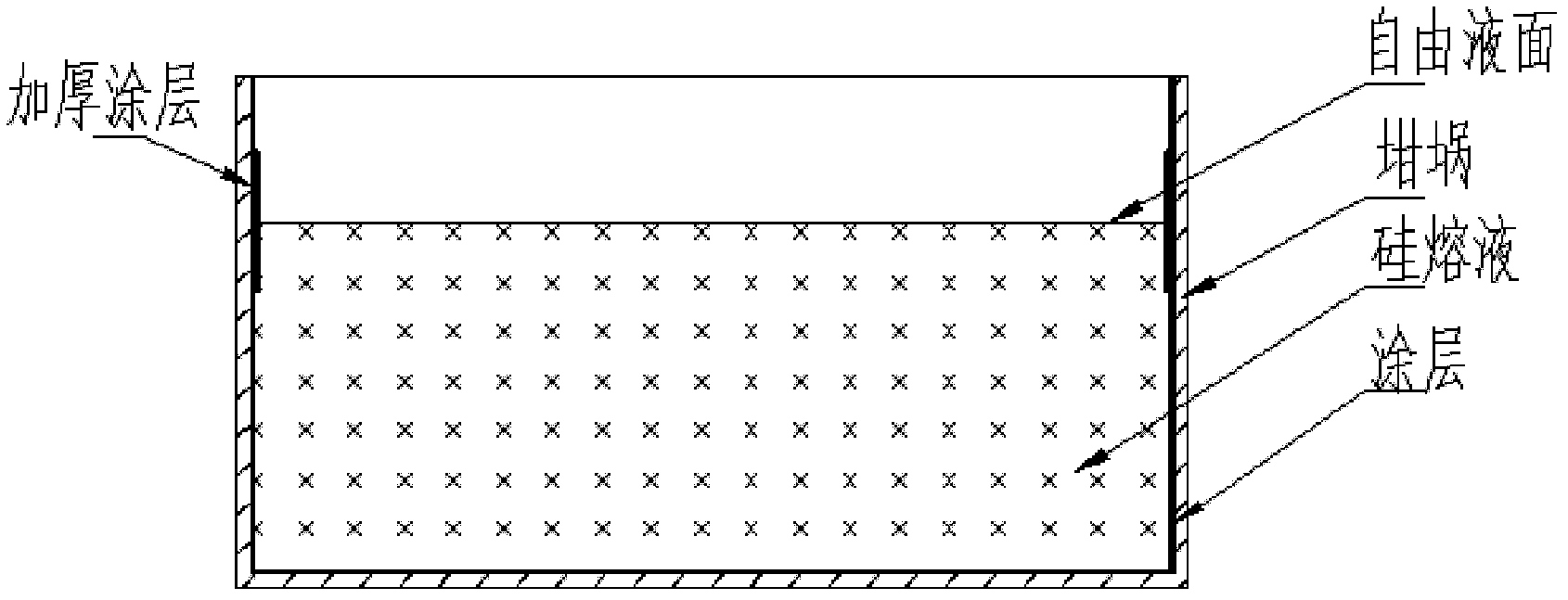

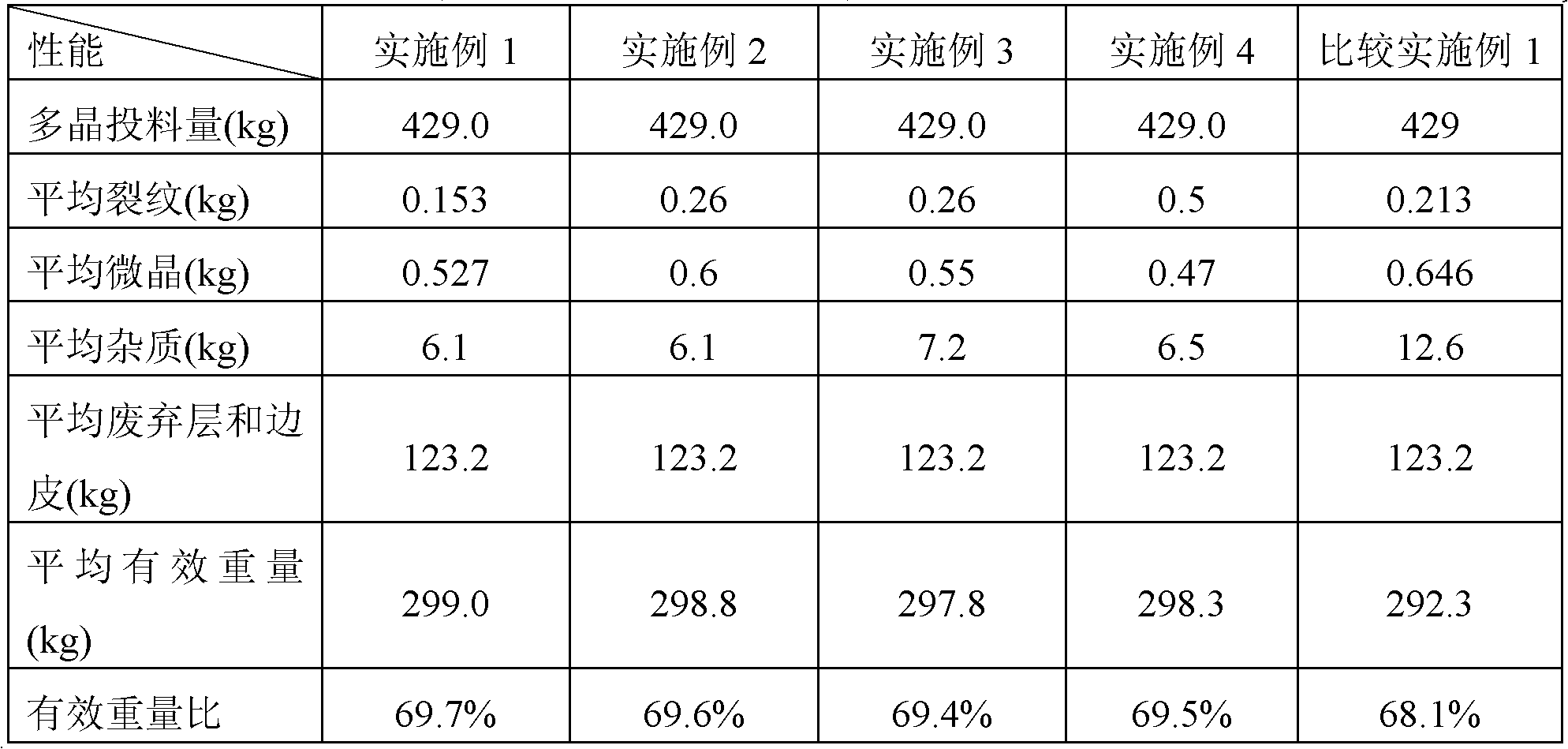

Method for forming coating on inner surface of polycrystalline silicon ingot casting crucible

InactiveCN102909163ASave energyHigh densityPolycrystalline material growthPretreated surfacesCrucibleIngot casting

The invention relates to a method for forming a coating on the inner surface of a polycrystalline silicon ingot casting crucible, in particular to the method for forming the coating on the inner surface of the polycrystalline silicon ingot casting crucible without high-temperature sintering, and also relates to the polycrystalline silicon ingot casting crucible comprising the coating prepared by the method. Since a high-temperature sintering condition is not required in the method for forming the coating on the inner surface of the polycrystalline silicon ingot casting crucible, a large amount of energy can be saved; the effective weight ratio of the polycrystalline silicon cast ingot prepared by using the crucible is higher than that of the cast ingot prepared by the crucible prepared by using the conventional method, so that the production cost is reduced, and the production efficiency is increased.

Owner:ZHENJIANG RENDE NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com