A device for microwave fluidized drying lignite

A fluidized drying and microwave technology, applied in the drying of solid materials, heating to dry solid materials, drying, etc., can solve the problems of reducing the quality of coal coking, complex equipment and technology, and failing to achieve the effect of quality improvement. And the microwave field is evenly distributed, the effect of solving the insufficient penetration depth and increasing the gas-solid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

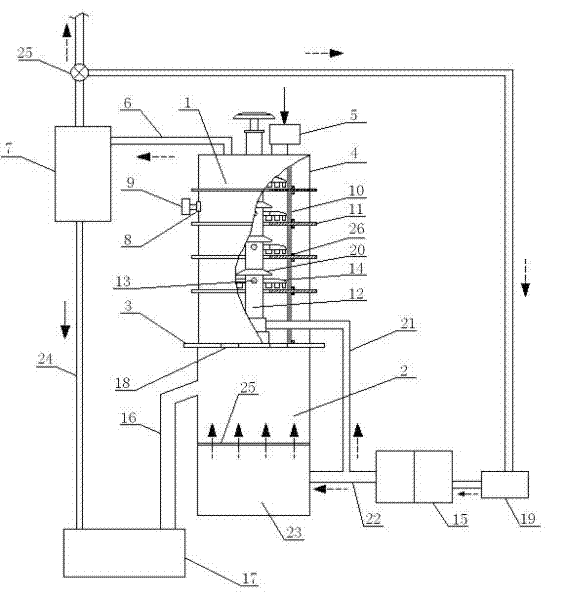

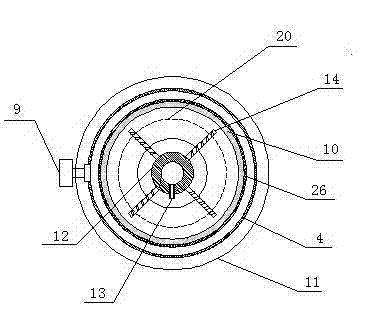

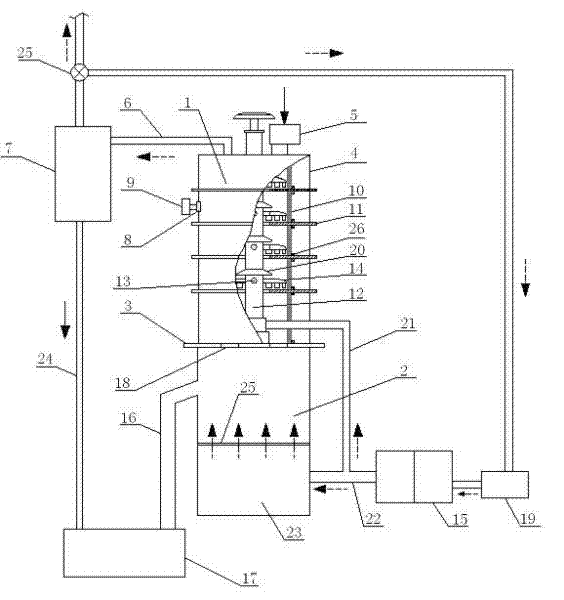

[0018] See figure 1 , figure 2 , a device for microwave fluidized drying lignite, including a microwave heating chamber 1, the bottom of the microwave heating chamber 1 is connected to the fluidized bed 2 through a flange 3, and the flange 3 is provided with a connection between the microwave heating chamber 1 and the fluidized bed 2 Material hole 18; Microwave heating chamber 1 comprises the cylindrical metal furnace shell 4 that can shield microwave, is provided with material inlet 5 and flue gas port 6 on the top of furnace shell 4, and furnace shell 4 is provided with 4 microwave generating devices along the circumference to dissipate microwaves. It can be fed into the microwave heating chamber 1. The microwave generating device is composed of a microwave feed port 8 arranged on the furnace shell 4 and a microwave source 9 installed on the microwave feed port 8. There is also a microwave penetrating microwave oven inside the furnace shell 4. The cylindrical ceramic furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com