Patents

Literature

1129 results about "SODIUM SILICATE SOLN" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing amorphous silica-alumina using carbonization

InactiveCN1597093AEasy to controlSimple processCatalyst activation/preparationReaction temperatureSodium aluminate

A process for preparing the amorphous Si-Al material by the carbonizing method includes such steps as adding part of sodium silicate solution to sodium aluminate solution, introducing CO2 gas to it for a certain time, adding the rest of sodium silicate solution while reacting, stabilizing, filtering, washing and drying. It can be used as the carrier of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

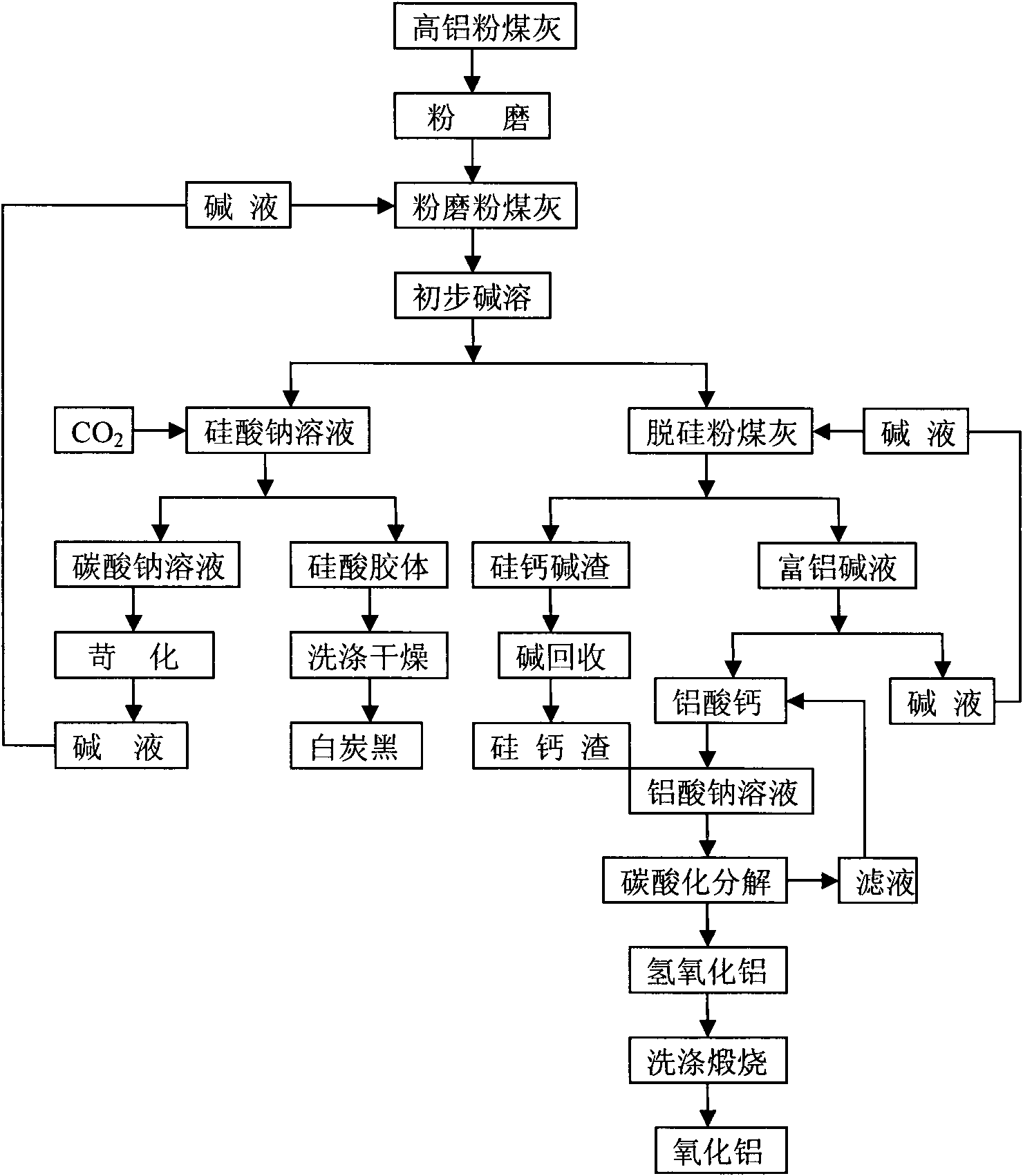

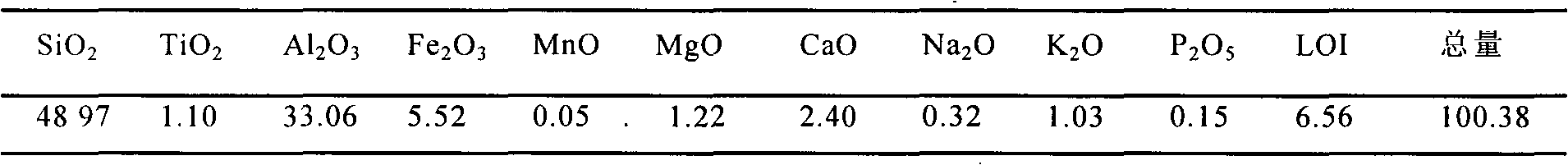

Method for firstly extracting silicon and secondly extracting aluminum from fly ash

ActiveCN101125656AImprove resource utilization valueIncrease Al-Si RatioAluminium oxide/hydroxide preparationSilicon oxidesSODIUM SILICATE SOLNCarbonation

Owner:PINGSHUO INDAL

Method for preparing high-activity silicon collidal sol formed from superfine silicon dioxide particles

InactiveCN101070161AEvenly distributedOvercome the disadvantage of uneven sizeSilicaSilicic acidIon exchange

The invention discloses a kind of preparation method of silica sol of high activity. For this kind of silica sol, the particle is tiny and grain size of it is distributed narrowly. It is characterized in that it takes sodium silicate as raw material, natrium ion is took out using method of exchanging ion and then get active silicic acid solution, prepare silica sol of high activity whose grain size is 6-12 nm, content of silicon dioxide is accounting for 10-30%,content of sodium monoxide is accounting for 0.2-0.3%, and PH value is between 8.5 and 10.5,through controlling proportion, pH value of reaction and heating temperature of active silicic acid solution. Silica sol prepared using this method can satisfy needs of spinning sizing, organic polymerization catalysis and modifying technology. Compared to common ion-exchanging method, preparation method of the invention has advantages of tiny particle, equal granularity, synchronizing dehydration and purification and low energy wasting, and it can control size of particle according to needs of actual utilization.

Owner:LUDONG UNIVERSITY +1

Liquid low-sodium silicate electrolyte used for a storage battery and manufactured by magnetization process, and the usage thereof

InactiveUS20080044726A1Improve liquidityHigh viscosityOther chemical processesMagnetic paintsMagnetizationBiological activation

A liquid low concentration sodium-containing silicate solution as electrolyte for lead-acid storage batteries and its applications, is prepared by mixing a silica gel containing 40˜60 wt % SiO2, the weight units of such a silica gel are 5˜15; add 15-25 weight units water and stir until the concentration of the mixture is 0.65˜0.85 0Be′ measured by a Baum densimeter, adjusting the pH value of this mixture to 1-4 using inorganic acid and magnetizing the mixture under 1000-6000 Gauss magnetic field for 5-10 minutes, stir the magnetized mixture until the viscosity of the mixture is less than 0.02 poise and finally obtain a liquid low concentration sodium-containing silicate solution. The electrolyte can be used as electrolyte or activation solution for common or special lead-acid storage batteries.

Owner:LIDU WANG

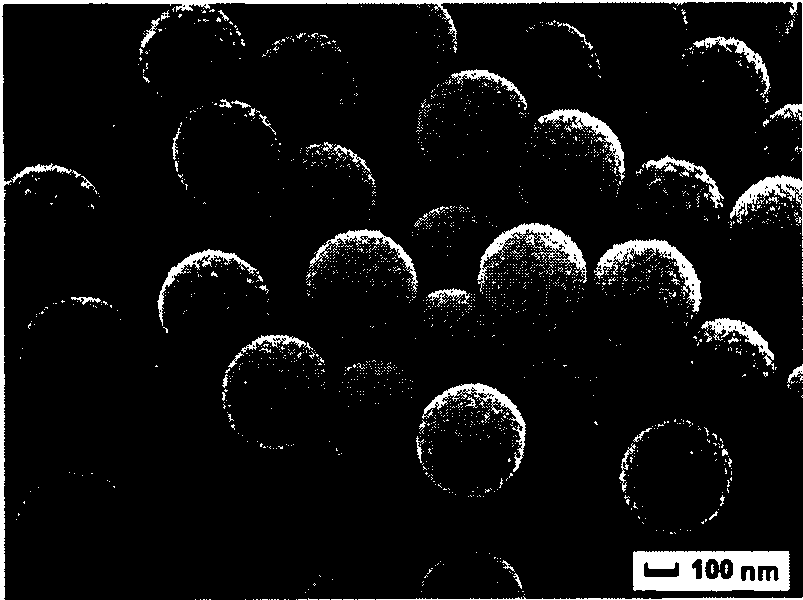

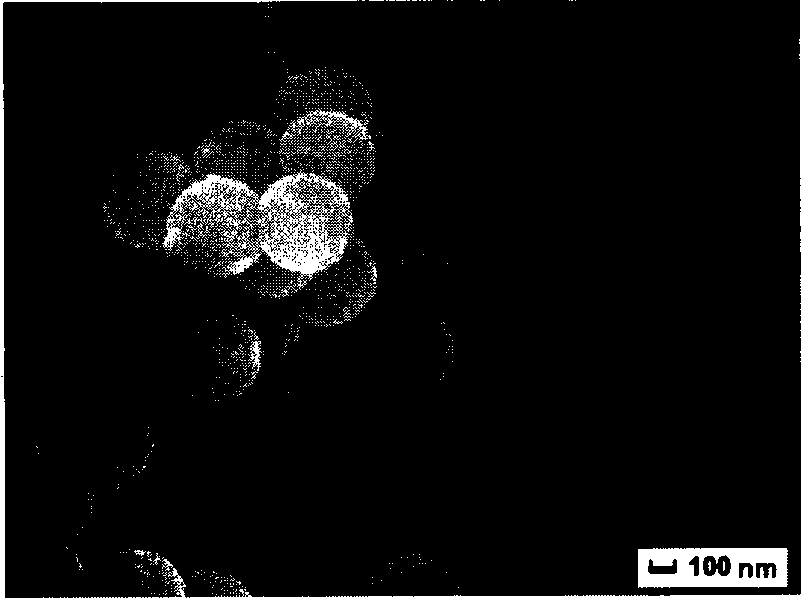

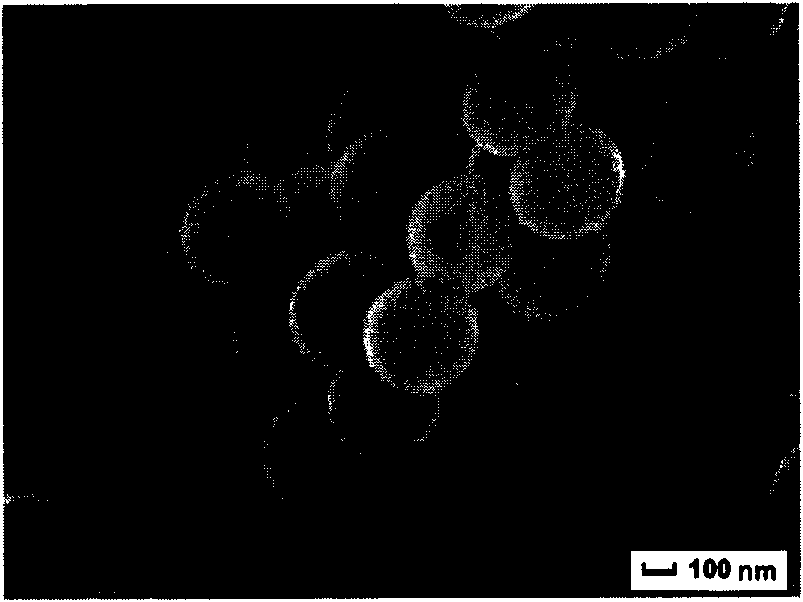

Method for preparing nanoscale silica hollow microspheres

The invention discloses a method for preparing nanoscale silica hollow microspheres, which uses sodium silicate solution and modified polymer respectively as the silicon source and template. Nanoscale silica hollow microspheres are prepared by a sacrificial template method by the following steps: (1) preparing polymer colloidal template microspheres; (2) preparing silicon dioxide-colloidal template complex microspheres; and (3) roasting the complex microspheres to obtain nanoscale silica hollow microspheres. Nanoscale silica hollow microspheres prepared by the invention have the characteristics of uniform size and appearance, fine integrity and high rate of productivity. The method can realize low cost and easy operation by using sodium silicate solution as the silicon source. Therefore, with easy operation and low cost, the method has certain instructing value for the industrialized production of silica hollow microspheres in the future.

Owner:JIANGSU UNIV

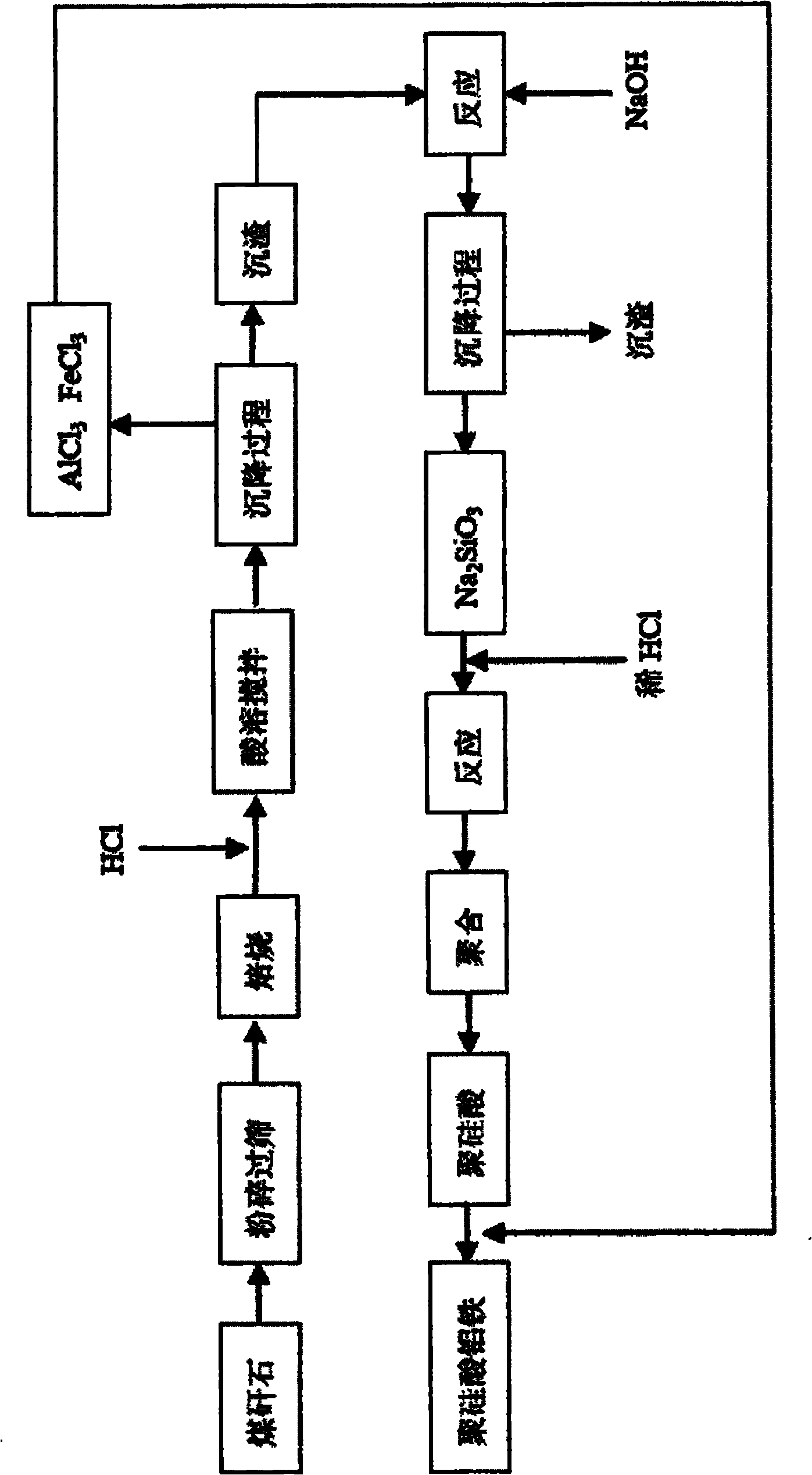

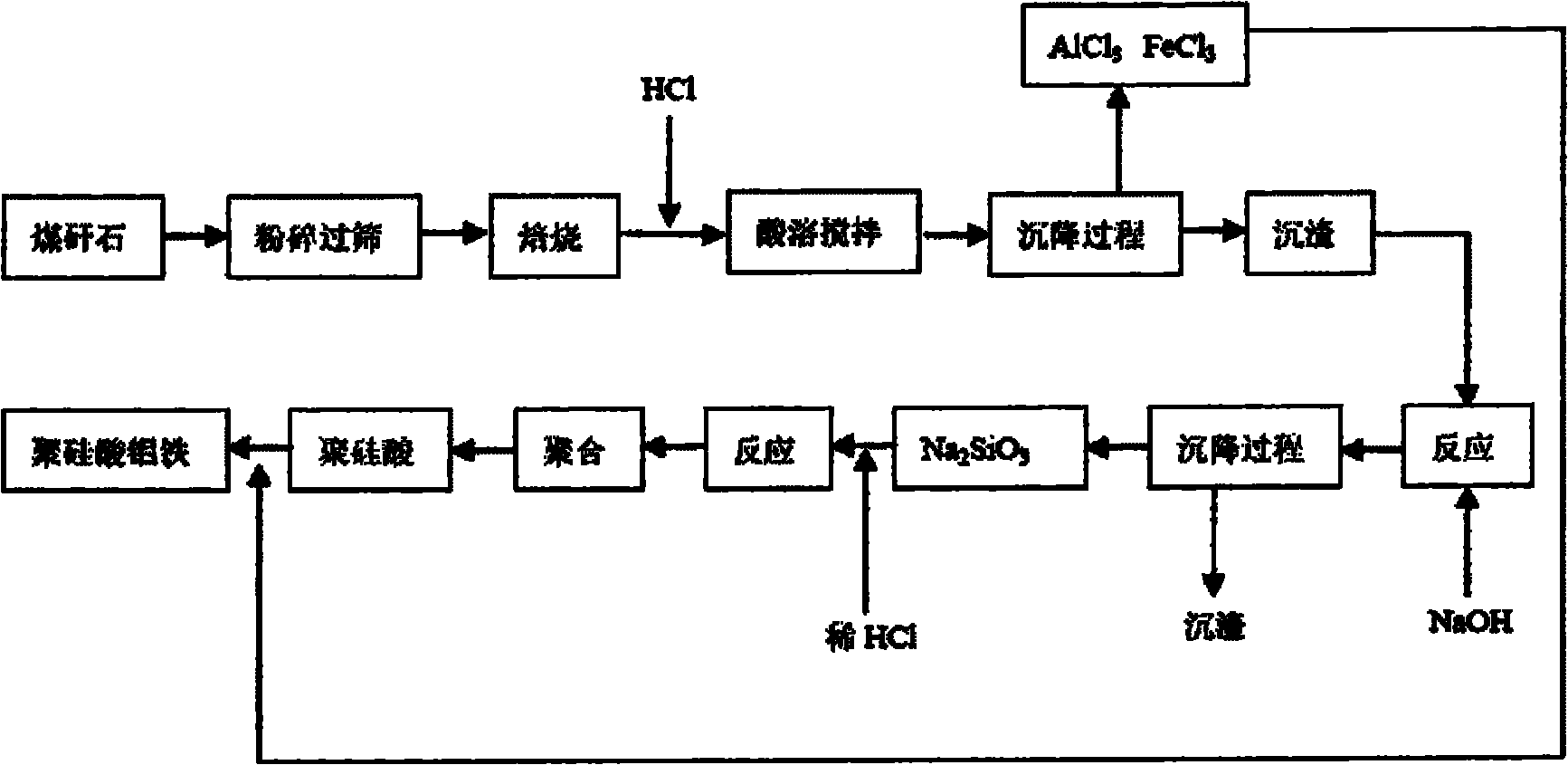

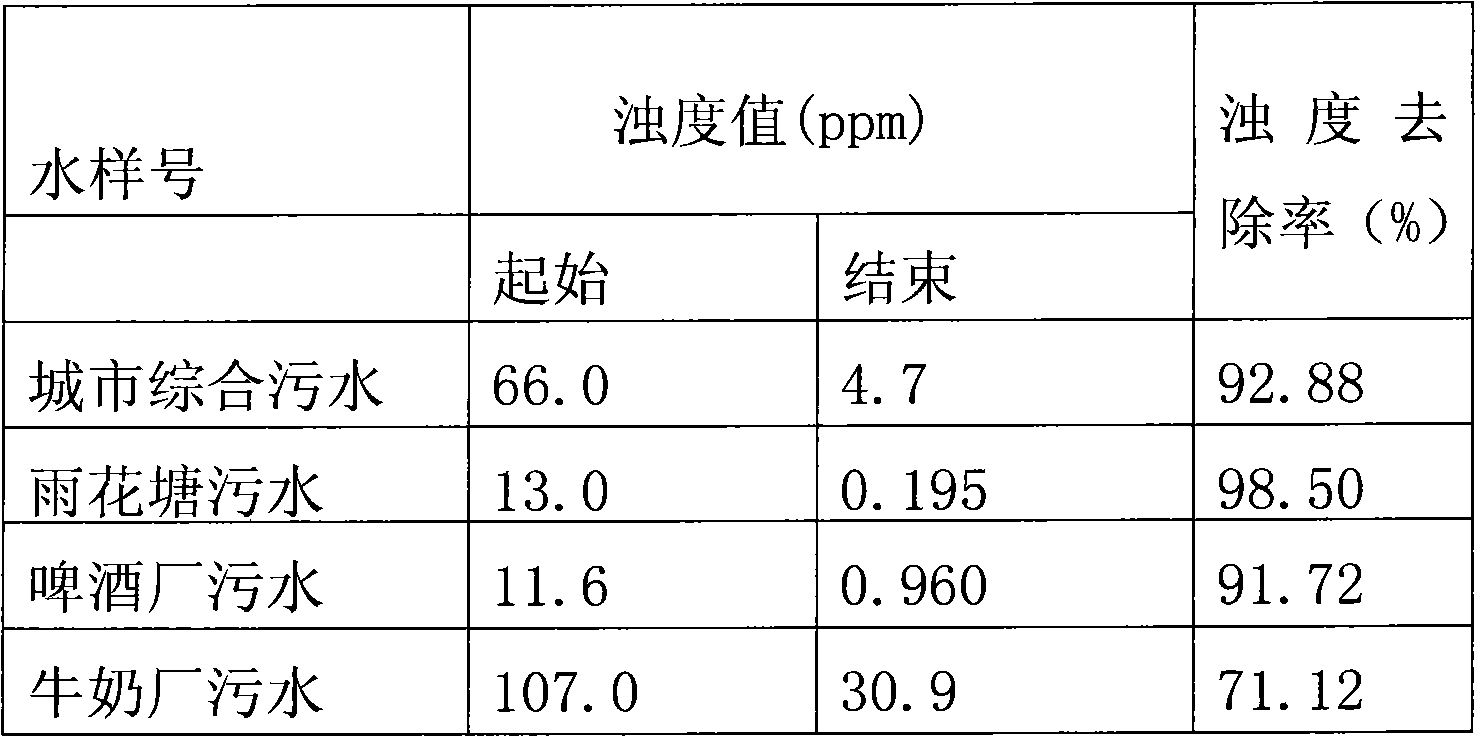

Method for producing poly silicate aluminium ferric flocculating agent by utilizing coal gangue

InactiveCN101823721ASolve the problem of stockpiling and polluting the environmentScientific and streamlined processAluminium silicatesSolid waste disposalSilicic acidMass ratio

The invention relates to the inorganic macromolecule flocculating agent technical field, in particular to a method for producing poly silicate aluminium ferric flocculating agent by utilizing coal gangue. The method includes the following steps: firstly coal gangue is smashed, roasted and mixed with hydrochloric acid by solid-liquid volume ratio of 1:4-6, reaction is carried out, then the obtained reaction liquid is filtered, the obtained residue is for spare use, and the pH value of the obtained filtrate is regulated to be 3-3.5, thus obtaining the poly aluminium ferric solution; then the obtained residue and sodium hydroxide are mixed for reaction by mass ratio of 2-4:1, and the filtrate obtained by filtration of reaction liquid is sodium silicate solution namely; the prepared sodium silicate solution is added with acid for carrying out activation treatment; then the prepared poly aluminium ferric solution and the activated sodium silicate solution are mixed for reaction by mass ratio of 1:1, thus obtaining the poly silicate aluminium ferric flocculating agent. The invention adopts coal gangue as raw material, cost is low, and meanwhile the poly silicate aluminium ferric flocculating agent prepared by the invention has better stability and flocculation effect.

Owner:HEFEI UNIV

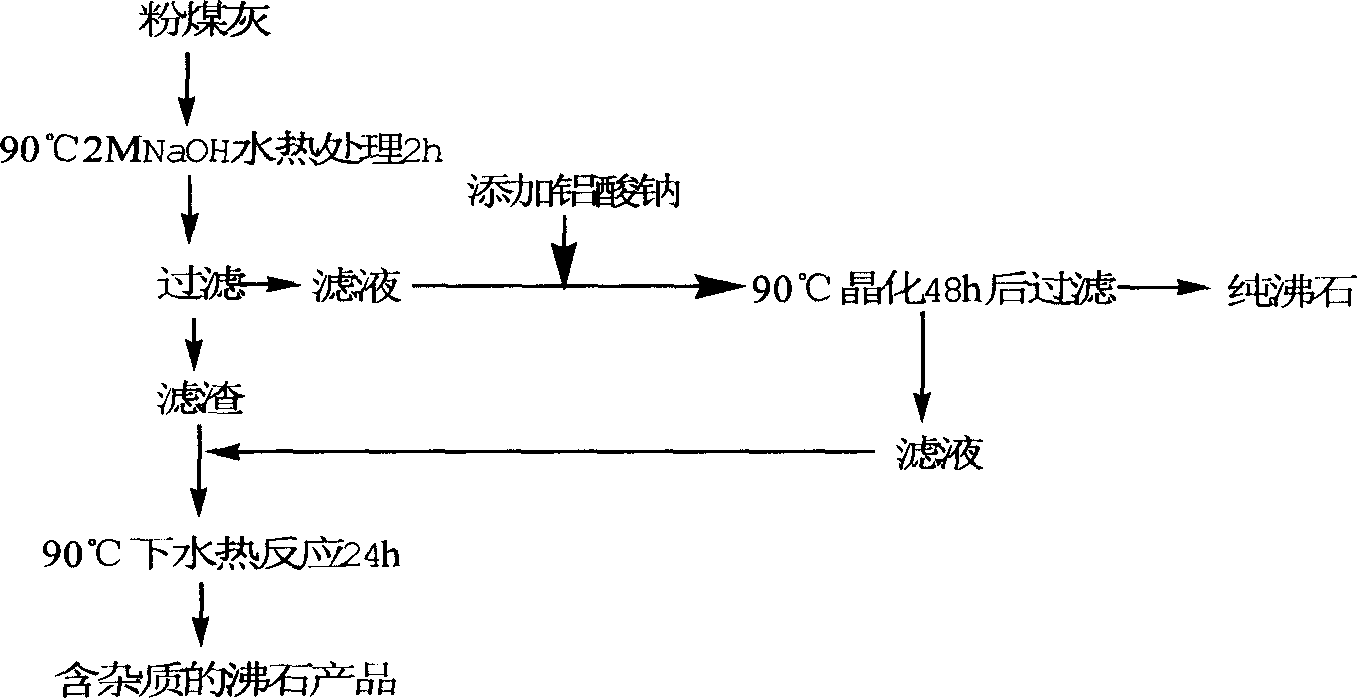

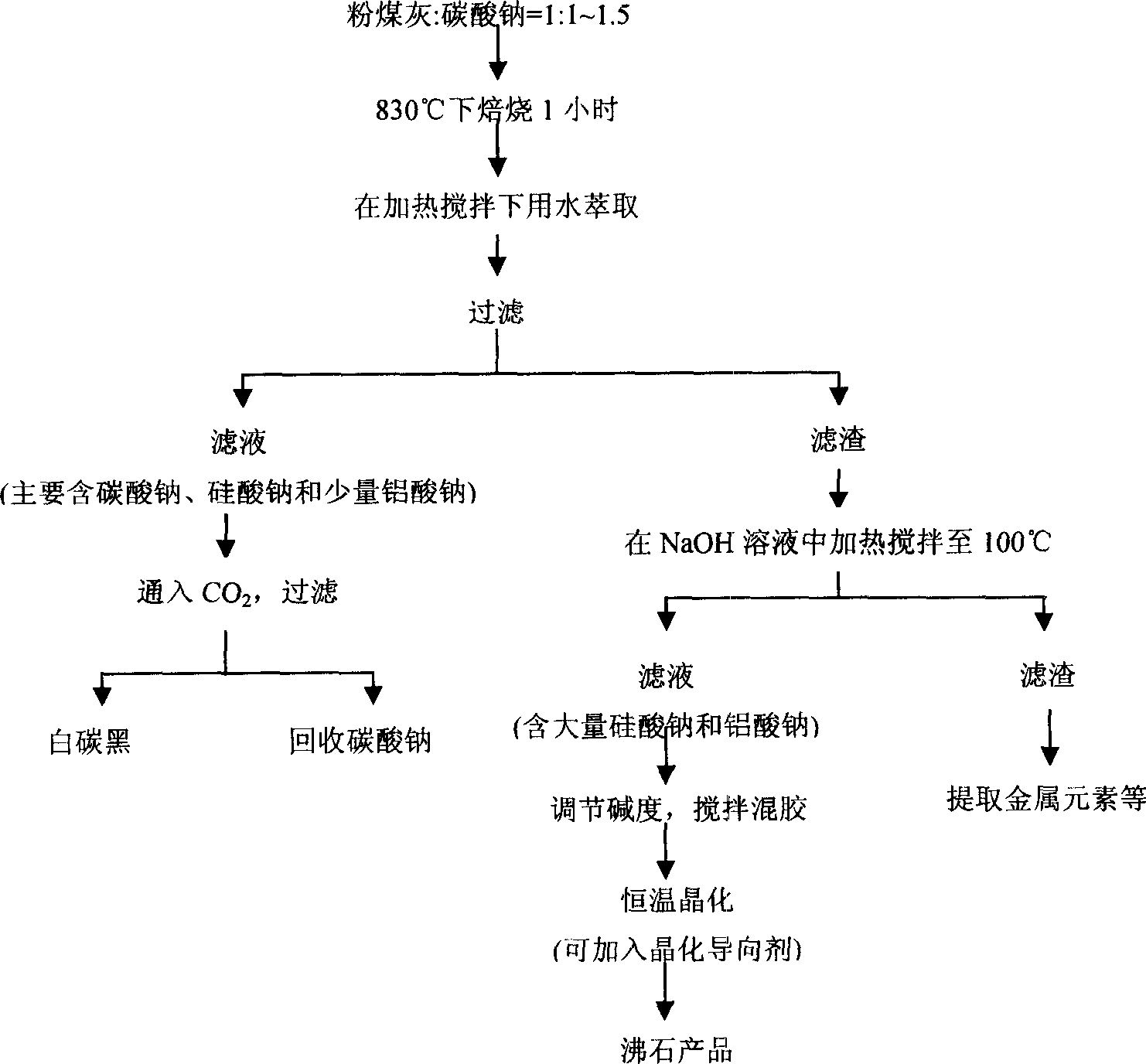

Method for preparing white carbon black and pure zeolite molecular sieve using flyash

InactiveCN1911800AAccelerate emissionsSilicon oxidesCrystalline aluminosilicate zeolitesSolubilityMetallic materials

The process of preparing white carbon black and pure zeolite molecular sieve with fly ash material belongs to the field of inorganic non-metal material preparing technology. The preparation process includes the following steps: roasting the mixture of high silicon fly ash with SiO2 content of 30-65 % and sodium carbonate in the weight ratio of 1 to 1-1.5 at 830 deg.c for 1 hr to obtain roasted product with sodium silicate and sodium aluminosilicate as main components; soaking the roasted product in water in 5 times to leach out sodium silicate with high water solubility, filtering to obtain sodium silicate solution, introducing CO2 to the solution and depositing to obtain white carbon black product; and further leaching desilicated fly ash with alkali solution, heating and stirring to obtain solution of sodium aluminosilicate, which is soluble in strong alkali solution, filtering, regulating pH value and crystallizing to obtain pure zeolite molecular sieve.

Owner:UNIV OF SCI & TECH BEIJING

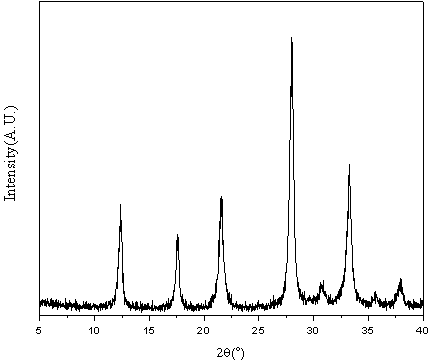

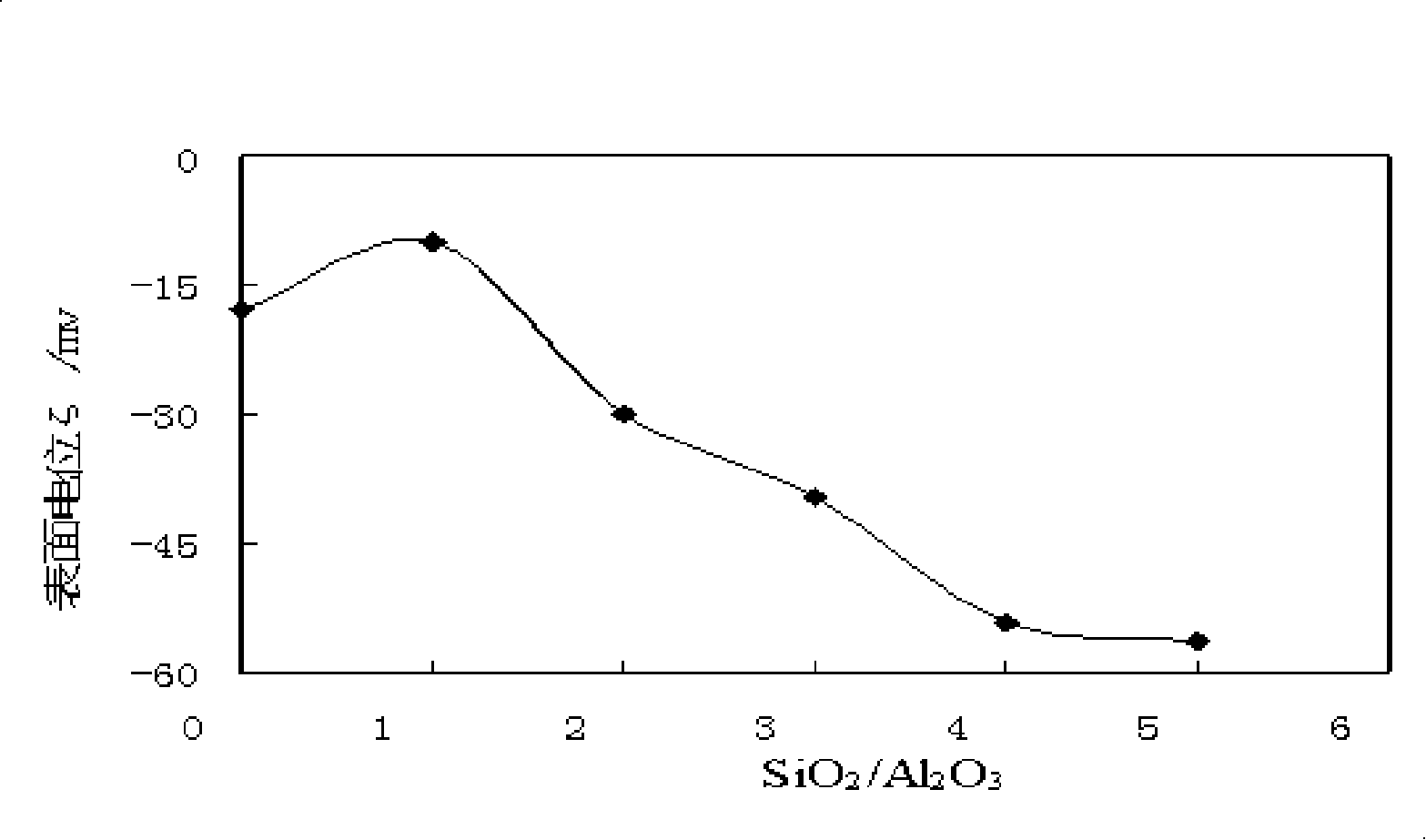

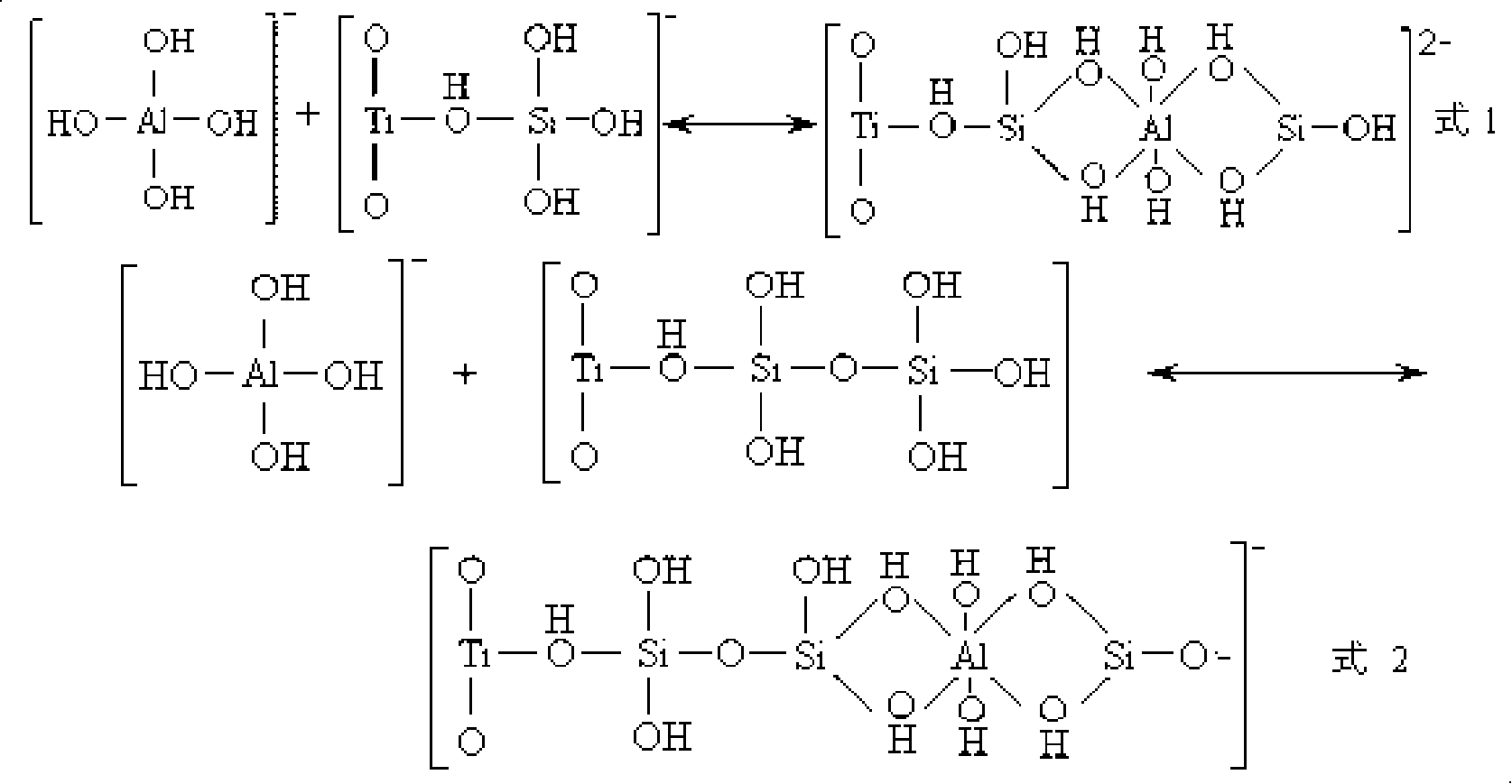

Process for preparing titanium dioxide with dispersion sensitive property and high weatherability

InactiveCN1844263AGuaranteed decentralizationGood weather resistancePigment treatment with non-polymer organic compoundsSODIUM SILICATE SOLNSodium hydroxide

The invention relates to a method for preparation of titanic anhydride which is easy to disperse and is of high weatherability. The method consists of selecting 0.1 %-0.5 % hexametaphosphate, 0.1 %-0.3 % isopropanolamine or triethanolamine as disperser, dispersing the titanic anhydride paste and adjusting the PH value of the sodium-hydroxide solution to 10-11, adding silicate of soda solution and dilute sulphuric acid to cover silica dioxide at 91-95 DEG C, in which the added quantity of the soda solution is 1 %-6 % of the silica dioxide, then adjusting the PH value to 6.5-8.5, adding aluminum sulfate solution and sodium-hydroxide solution, in which the added quantity of the aluminum sulfate is 2 %-3.5 % of the aluminum oxide,maturing for 10 min to cover the aluminum oxide, rinshing and drying, then adding some organosilicon additive, performing comminution by gas stream to obtain the said titanic anhydride which is easy to disperse and is of high weatherability. The advantages of this invention lie in that it can effectively guarantee the dispersion of the paste before mat-forming treatment, can carry out the coating of the inorganic mat-forming treatment in single grain surface of titanic anhydride, and can reach the attempt of improving the weatherability and the dispersibility of titanic anhydride.

Owner:江苏镇钛化工有限公司

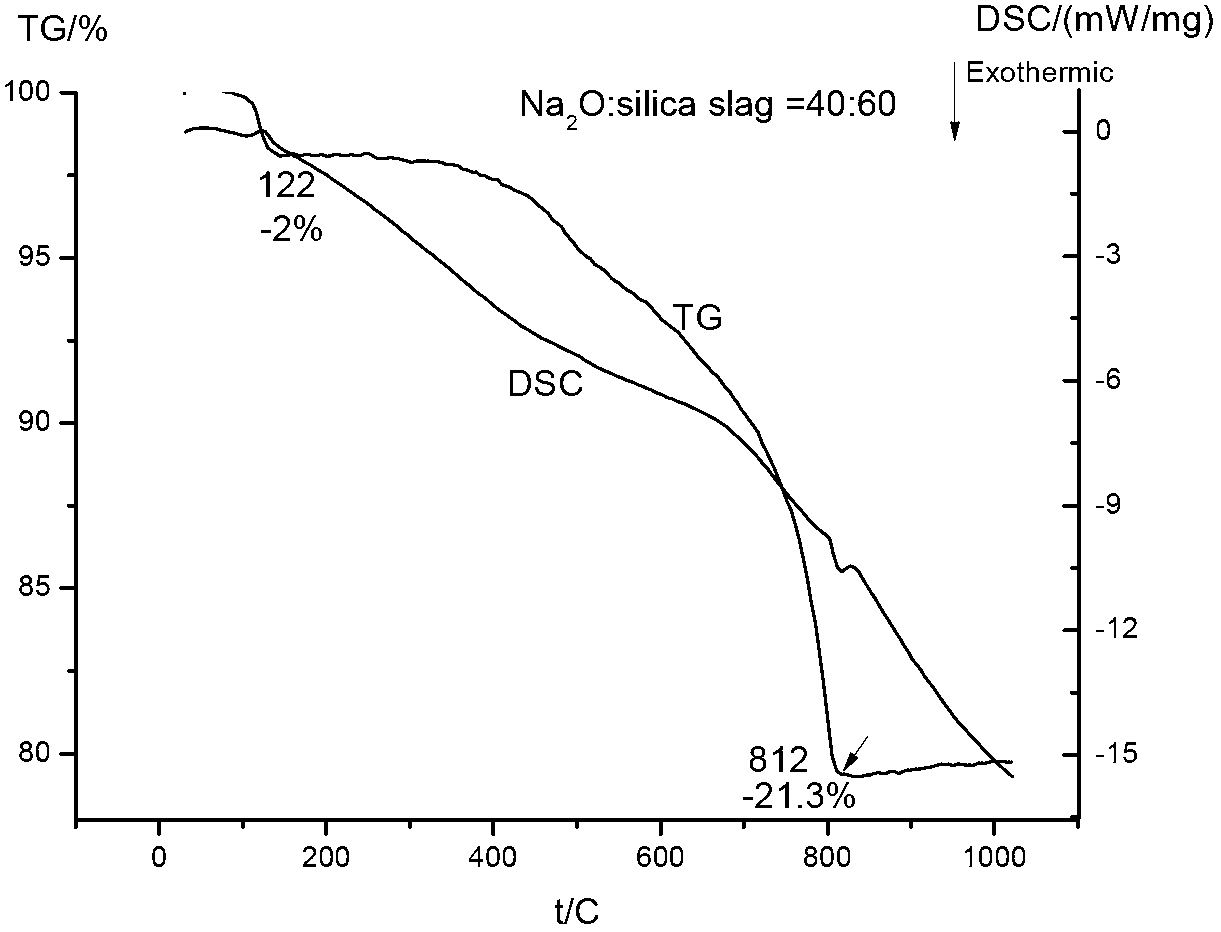

Method for extracting aluminum oxide and white carbon black through two-step alkaline leaching method by adopting high-alumina fly ash

ActiveCN101966999AReduce consumptionNo secondary pollutionSilicaSolid waste disposalSlagDecomposition

The invention discloses a process for preparing aluminum oxide and white carbon black by taking high-alumina fly ash as a raw material and adopting a two-step alkaline leaching method, comprising the following process steps of: preparing a sodium silicate solution by carrying out first-step alkaline leaching on the high-alumina fly ash; preparing the white carbon black by carrying out carbonation decomposition on the sodium silicate solution; preparing aluminum rich alkaline liquor by carrying out second-step alkaline leaching on desiliconization fly ash; preparing a sodium aluminate solution through the aluminum rich alkaline liquor; and preparing the aluminum oxide through the sodium aluminate solution, and the like. The invention prevents the high-temperature sintering in the process of the aluminum oxide prepared through the high-alumina fly ash, has low energy consumption and cyclic utilization of the alkaline liquor obtained through the first-step alkaline leaching and the second-step alkaline leaching, little material consumption; and in addition, silicon-calcium slag generated in the process course are used as raw materials for producing wall materials without generating secondary pollution, therefore the invention meets the requirements for clean production.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for producing high weathering resistance titanium dioxide pigment

The invention supplies a manufacture method for high weathering resistance titanium dioxide pigment that includes the following steps: making slurry; adjusting the pH value of the slurry; adding dispersing agent and filtering; heating; adding sodium silicate solution; adding mixture of sodium silicate and sulphuric acid solution; adding sulphuric acid; adding sodium aluminate solution and sulphuric acid solution; adjusting the pH value; filtering, washing, drying, taking gas smashing and organic process. The invention has strong covering power, good dispersibility and high weathering resistance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing P type molecular sieve by using coal ash as raw material

InactiveCN104291349AInhibition of dissolutionCause dissolutionCrystalline aluminosilicate zeolitesMolecular sieveSodium aluminate

The invention relates to a method for preparing a P type molecular sieve by using coal ash as a raw material. The method for preparing the P type molecular sieve by using coal ash as the raw material comprises the following steps: I, pre-treating and activating coal ash; II, preparing sodium silicate and sodium metaaluminate by using activated coal ash; and III, synthesizing the P type molecular sieve: firstly, uniformly mixing a sodium silicate solution with a sodium salt, then, dropwise adding the sodium metaaluminate solution into the mixed liquid, and finally, adding an organic steric hindering agent and a proper amount of deionized water to form a reaction mixture, wherein the molar ratios of the reaction mixture are as follows: SiO2 / Al2O3=0.4-1.8, M / Al2O3=1-5, Na2O / Al2O3=2-4 and H2O / SiO2=20-150 and the organic spatial steric hindering agent is at least one of ethanol amine, diethanol amine and triethanol amine; packing the mixed materials in a polytetrafluoroethylene container, stirring, then putting in a stainless steel reaction kettle, and carrying out hydro-thermal synthesis for 2-8 hours; and taking out products in the reaction kettle, carrying out centrifugal separation and washing by deionized water, and drying to obtain the P type molecular sieve. The method provided by the invention is short in synthetic cost, short in crystallization time and high in yield of the P type molecular sieve.

Owner:NORTHEAST GASOLINEEUM UNIV

Soil stabilization method

ActiveUS7651294B2Increase aggregate base strengthImprove stabilityIn situ pavingsSingle unit pavingsSoil stabilizationSODIUM SILICATE SOLN

A method of use of a composition for soil stabilization is disclosed. The composition comprises a solution of soluble sodium silicate applied at the disclosed application rate to improve the load bearing capacity for a roadway. The method of the invention addresses the application of the disclosed composition to maximize stabilization of road beds.

Owner:TEAM LAB CHEM LLC

Method for preparing high-modulus sodium silicate

InactiveCN101318663AWide variety of sourcesLow priceAlkali metal silicatesSilicic acidSODIUM SILICATE SOLN

The invention discloses a method for producing high-modulus sodium silicate at low temperature and normal pressure. The method comprises the following steps: the activated silicon dioxide from fly ash-typed industrial waste is leached by caustic lye of soda to produce low-modulus sodium silicate solution, the solution is decomposed by carbonation to prepare silicic acid (SiO2nH2O), then the silicic acid, the low-modulus sodium silicate and / or sodium hydroxide solution are mixed at the modulus index required by the final sodium silicate products and stirred to dissolve at temperature lower than liquid boiling point, therefore, the high-modulus sodium silicate is produced. Compared with the existing drying and wet methods for producing sodium silicate, the method of the invention has the advantages of wide raw material resources, low cost and energy consumption, no pollution; the method can be used for producing the sodium silicate with any modulus (M) from 1 to 4, in particular to the high-modulus sodium silicate, and has great industrialized generalization and application value.

Owner:PINGSHUO INDAL

Sorbent for processing transformer waste oil and method for producing the same

InactiveCN101406824ANon-flammable and explosiveImprove adsorption capacityTransformers/inductances coolingOther chemical processesHazardous substanceSorbent

The invention relates to an absorbent for treating and reclaiming waste liquid oil, in particular for treating and reclaiming waste transformer oil and a production method thereof. The absorbent is characterized in that the absorbent is prepared from the following raw materials according to the weight ratio: sulphuric acid solution, aluminium sulphate solution, sodium silicate solution and ammonia water are mixed, aged, roasted and dried, cleaned and re-roasted; and the finished product of the absorbent is obtained. The absorbent for treating the waste oil has the characteristics of innocuity, noninflammability, nonexplosiveness and so on, and higher capability of adsorbing substances in the waste oil such as acid, carbon microsphere, metal, water content, gel, and the like. The absorbent is sufficiently contacted with the waste oil so as to remove harmful substances in the oil. The absorbent not only has a simple production process, wide raw material sources, low production cost and no environmental pollution, but also has good effect of waste oil treatment, and high yield. The absorbent can save mass production cost for enterprises and energy for the country.

Owner:STATE GRID CORP OF CHINA

Passivated nano-titanium dioxide particles and methods of making the same

InactiveUS20050135994A1Good chemical stabilityReduced tendency to form agglomeratePigmenting treatmentMaterial nanotechnologySodium aluminateSlurry

The invention is directed to a method for reducing the chemical activity and photo activity of titanium dioxide nanoparticles comprising adding a densifying agent, such as citric acid, to an aqueous slurry of the titanium dioxide nanoparticles; treating the aqueous slurry with a source of alumina, such as a solution of sodium aluminate, to form alumina-treated titanium dioxide nanoparticles. In one embodiment the particles are treated with a source of silica, such as a solution of sodium silicate. The nanoparticles of this invention can also be treated with a source of silica and a source of alumina. The treated nanoparticles can be silanized. The titanium dioxide nanoparticles described herein are useful in cosmetic, coating and thermoplastic compositions.

Owner:EI DU PONT DE NEMOURS & CO

High water dispersity titanium dioxide and coating method thereof

ActiveCN101235223ASimple stepsReduce manufacturing costInorganic pigment treatmentDispersityChemical industry

The invention relates to titanium dioxide with high water dispersibility and a coating process, belonging to the chemical industry field, which solves the technical problem that titanium dioxide which is produced by a current process has lower dispersibility. The coating process of titanium dioxide with high water dispersibility of the invention comprises the steps of beating, silicon coating, aluminum coating, scouring, drying and disintegrating and the like, wherein sodium aluminate solution is used to conduct coating in the aluminum coating step, and sodium silicate solution is used to conduct coating in the silicon coating step, wherein the molar ratio of sodium aluminate solution usage which is calculated with A1 2 O3 and sodium silicate usage which is calculated with SiO 2 is 1:4. The process of the invention can be used to prepare titanium dioxide with high water dispersibility, which has widespread application prospect, and the Haegeman index of titanium dioxide which is prepared can reach over 7.0 in emulsion paint.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

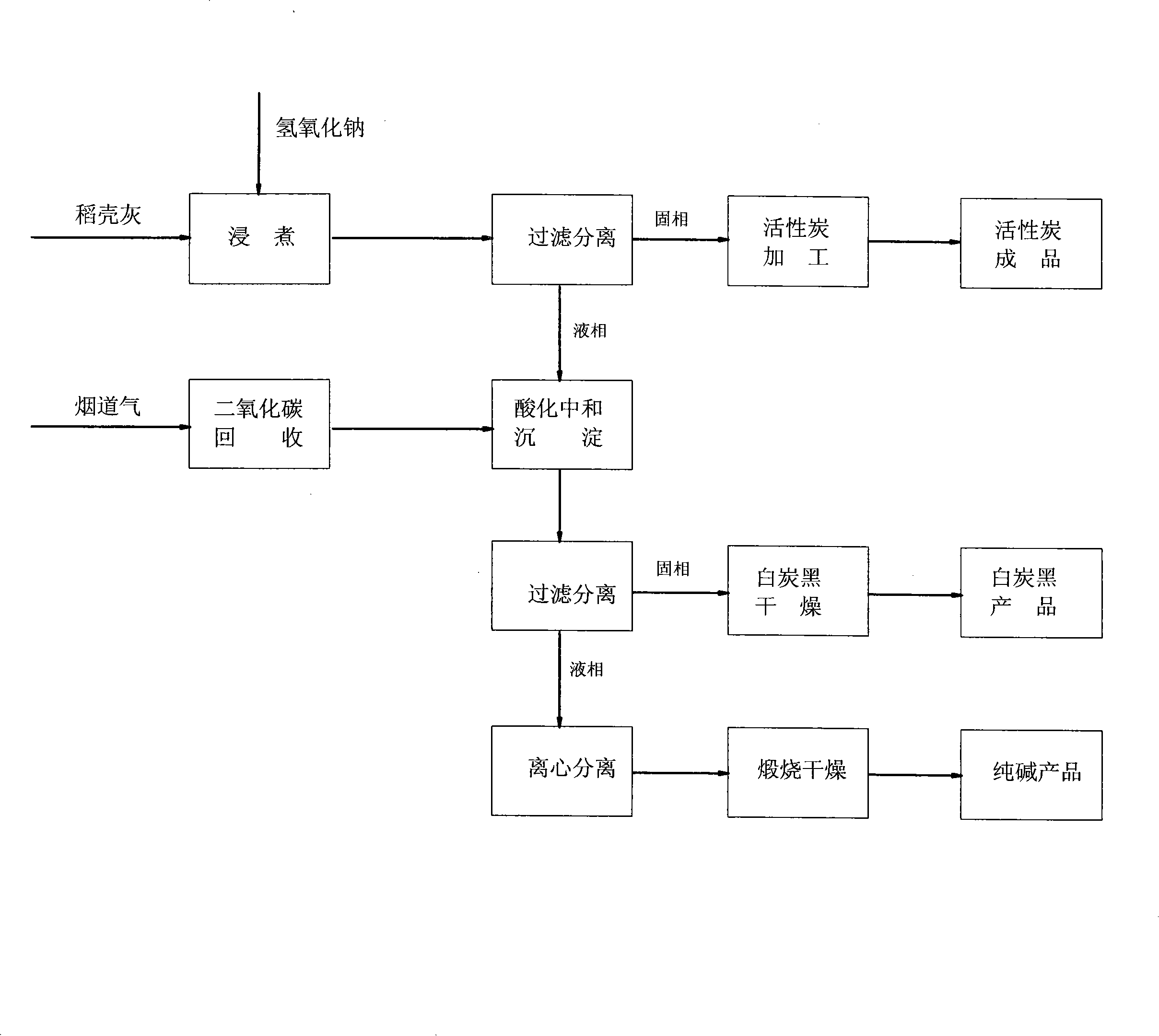

Method for combined production of activative carbon, white carbon black and soda by employing biomass power plant waste

InactiveCN101177264ALow costAvoid dangerSilicon compoundsAlkali metal carbonatesSilica HydrateSODIUM SILICATE SOLN

The invention relates to a combined producing method of active carbon, silica hydrated and soda with the waste of biomass power plant, which comprises the following steps: firstly, immersing and leaching the ash of rice husk of the power plant with lye to generate sodium silicate solution or sol and insoluble substance; secondly, separating the sodium silicate solution or sol from the insoluble substance, and carbonizing and neutralizing the sodium silicate solution or sol with the carbon dioxide recovered from the flue gas of the power plant to generate sedimentation of silicon dioxide and sodium carbonate solution; finally, preparing active carbon, silica and soda with the insoluble substance, the sedimentation of silicon dioxide and the sodium carbonate solution. The invention has the advantages that the ash of rice husk can be fully utilized, the carbon dioxide in the flue gas can be reasonably utilized, thereby the power plant has a great progress toward the target of zero draining, and the production cost and the energy consumption are reduced greatly, and the profit is increased obviously, and the invention has the great social and economic benefit.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

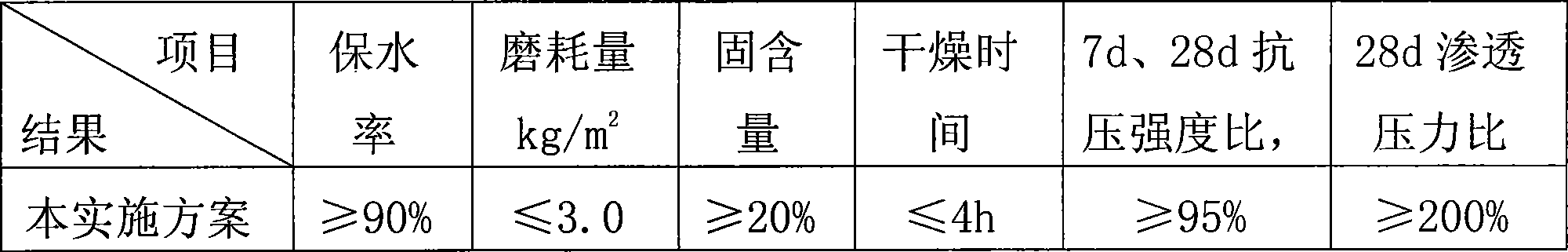

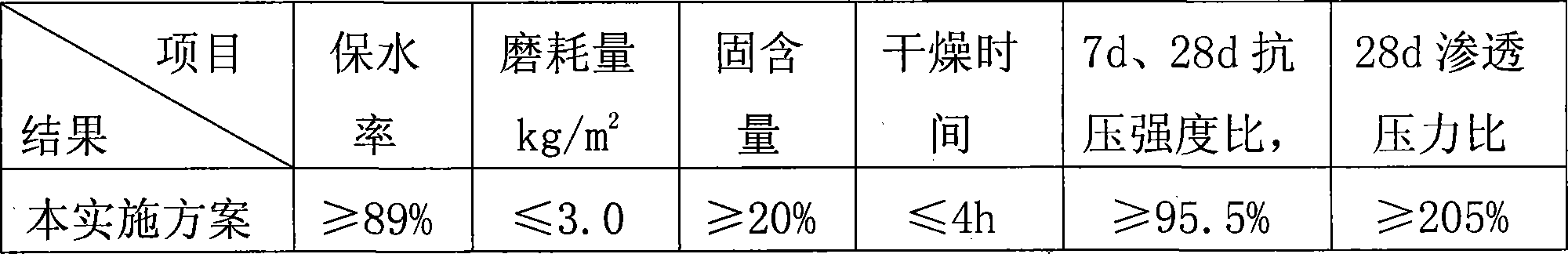

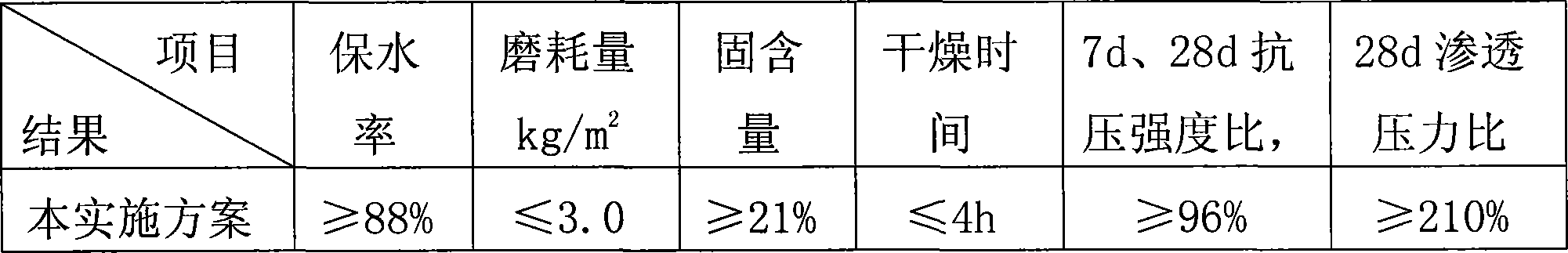

Concrete maintaining agent

The invention relates to a curing agent of concrete, comprising styrene-acrylic emulsion, acrylamide solution, sodium silicate solution and organosilane solution; the styrene-acrylic emulsion is poured into the acrylamide solution; the sodium silicate solution and the organosilane solution are added and uniformly stirred with low speed to form the curing agent of the concrete; water soluble material with good film forming ability is used without solvent; neither volatile substances are generated nor secondary environmental pollution are caused; the invention comprises organosilane, rapidly penetrates into capillary pores wall inside the concrete, and then chemically reacts with part of the water and air in the concrete to generate silicon dioxide; the capillary pore channels are blocked, and a solid waterproof layer is formed to prevent evaporation of internal moisture and avoid invasion of external harmful substance, which helps to improve the durability of the concrete, keeps the concrete in a maintenance state for a long period, and improves durability of the concrete.

Owner:SHANDONG DAYUAN IND

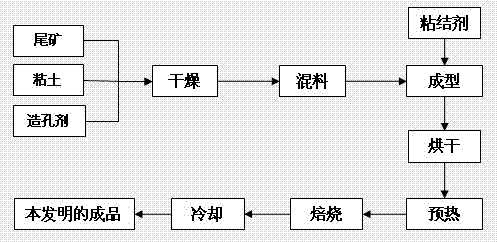

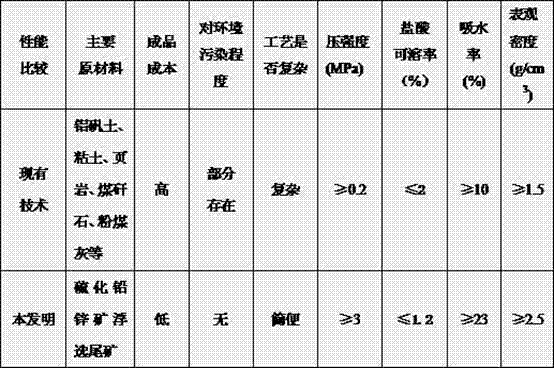

Biological ceramisite filter material made of vulcanized lead zinc ore flotation tailings, and preparation method thereof

InactiveCN103086741AImprove performance qualityLow costSolid waste disposalCeramicwareMining engineeringSulfidation

The invention relates to a biological ceramisite filter material made of vulcanized lead zinc ore flotation tailings. The material is characterized by being prepared from 80-90wt% of vulcanized lead zinc ore flotation tailings, 8-18wt% of clay, 1.5-2.5wt% of pore former and an additional bonder, wherein the pore former is sawdust, bamboo scraps or straws, the bonder is lignin calcium xanthate, sodium carbonate or sodium silicate liquid, and the solid-to-liquid ratio of materials used by the biological ceramisite filter material is (8-12):1. The preparation method comprises the following steps of: weighing based on proportion of main and auxiliary materials; drying; mixing; forming; drying; preheating; roasting; and cooling to prepare a biological ceramisite filter material product made of the vulcanized lead zinc ore flotation tailings. The preparation method is simple and convenient to implement, free from secondary pollution, practical and reliable. The biological ceramisite filter material made of the vulcanized lead zinc ore flotation tailings provided by the invention has the advantages of turning ore waste residue into wealth and greatly lowering the cost of materials, so that the biological ceramisite filter material is a high-quality water treatment agent.

Owner:HOHAI UNIV

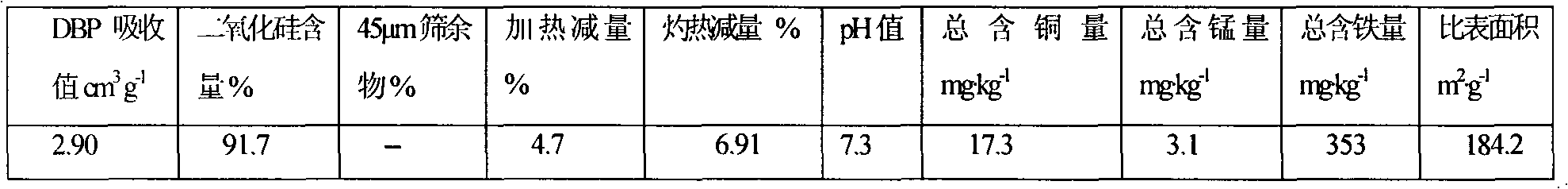

Preparation method of high-quality white carbon black for rubber

The invention relates to a preparation method of high-quality white carbon black for rubber, which comprises the following steps: introducing CO2 gas into sodium silicate solution, heating up, stirring, and reacting till the pH value of solution is reduced to be 9-10.5, stopping carbonation, and conducting solid-liquid separation; conducting cocurrent and carbonation of residual liquid and the CO2 gas till the pH value of the solution is reduced to be 7-8, conducting solid-liquid separation, and obtaining the high-quality white carbon black for rubber by washing and drying solids; and soaking or heat cooking solid sediment separated in first carbonation with strong acid to remove impurities, and also obtaining the high-quality white carbon black for rubber by washing and drying. The white carbon black prepared by the method has high purity, fine and uniform granularity, good whiteness, and higher values of specific surface area and oil absorption of SiO2 particles, and can be directly used as high-quality white carbon black for rubber, with application performance meeting the performance index requirements of national standard white carbon black for rubber products.

Owner:CHINACOAL PINGSHUO GRP

Method for preparing white carbon black from secondary carbon component

The twice carbon separating process for preparing silica white includes introducing CO2 gas to sodium silicate solution to lower the pH value to 9-10.5, solid-liquid separating, further introducing CO2 gas to the solution to lower the pH value to 7-8, solid-liquid separating, washing and stoving to obtain coarse silica while product, soaking or boiling in strong acid solution, washing and stoving to obtain silica while product. The present invention may have the sodium silicate solution obtained through soaking high silicon slag from producing aluminum sulfate, aluminum chloride, ferrous metal and non-ferrous metal and with high impurity content as the material, and the silica while product has high purity, fine granularity and high whiteness.

Owner:PINGSHUO INDAL

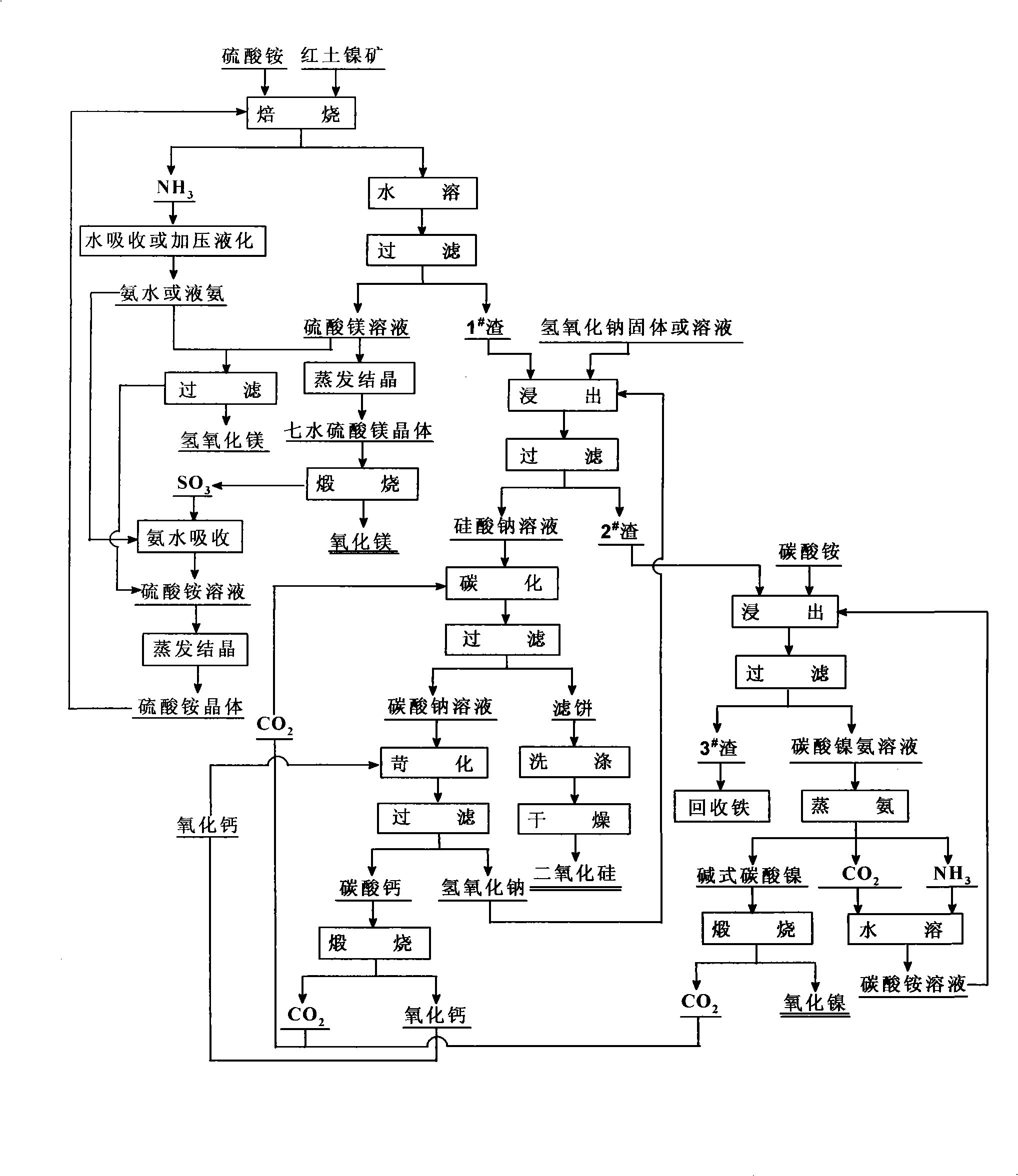

Method for preparing magnesia, silicon dioxide and nickel oxide products from lateritic nickel ore

InactiveCN101525143AHigh value-added comprehensive utilizationCause secondary pollutionSilicaNickel oxides/hydroxidesDiiron TrioxideSODIUM SILICATE SOLN

The invention relates to a method for preparing magnesia, silicon dioxide and nickel oxide products from lateritic nickel ores. The method comprises the following steps: (1), crushing, grinding and roasting the lateritic nickel ores with ammonium sulfate; (2), dissolving and filtering roasted products; (3), evaporating, condensing and crystallizing filtrate to prepare magnesium sulfate; (4), dehydrating and calcining the magnesium sulfate to prepare magnesia; (5), reacting filter residue with an alkaline solution or molten caustic soda, leaching and filtering the product of reaction to obtain a sodium silicate solution; (6), carbonizing, decomposing, filtering, washing and drying the sodium silicate solution to prepare the silicon dioxide; (7), leaching and filtering the residual filter residue by an ammonium carbonate solution; and (8), distilling ammonia from the filtrate and calcining the filtrate to prepare the nickel oxide. The residual residue is ferric oxide containing a small amount of impurities and can be used as an iron-making raw material or deep processed into a product with a high added value. The method is suitable for processing various lateritic nickel ores, has simple technological process and simple and convenient equipment, does not emit solid, liquid and gas waste or cause secondary pollution and uses lower cost to realize the high added value comprehensive utilization of lateritic nickel ore resources.

Owner:NORTHEASTERN UNIV

Process for preparing magnesium alloy chemical conversion coating

ActiveCN1880503AEliminate hazardsImprove corrosion resistanceMetallic material coating processesSodium iodideFluohydric acid

The invention discloses a chemical transmission film preparing technology of magnesium alloy, which comprises the following steps: a. proceeding degreasing disposal for magnesium or magnesium alloy through sodium hydroxide or one or multiple hybrid solutions of sodium phosphate with sodium hydroxide, sodium carbonate and sodium silicate solution; b. proceeding acid cleaning disposal for degreased magnesium or magnesium alloy through hybrid solution of phosphoric acid and sodium phosphate; c. proceeding activating disposal for acid cleaned magnesium or magnesium alloy through hybrid solution of fluohydric acid and sodium phosphate; d proceeding chemical synthesizing disposal for activated magnesium or magnesium alloy through composite solution of calcium nitrate hydrate, sodium nitrite, sodium iodide and hydrogen dioxide solution; e. packing hole of synthetic magnesium or magnesium alloy through deionized water. The invention doesn't utilize chromic composition, which eliminates danger for environment.

Owner:靖江市华信科技创业园有限公司

New process for co-producing ultra-fine white carbon black and calcium carbonate

InactiveCN101898776AAddress effectivenessImprove qualityCalcium/strontium/barium carbonatesSilicaPhysical chemistryCarbide

The invention provides a method for co-producing white carbon black and calcium carbonate. Carbide slag or lime and quartz sand are used as main raw materials. The method comprises the following steps of: introducing sodium silicate solution into carbon dioxide to obtain a mixture of white carbon black and sodium carbonate or sodium bicarbonate, filtering the solution, adding lime or carbide slag into the solution, preparing caustic soda and ultra-fine calcium carbonate by causticizing reaction, adding the quartz sand into the filtered dilute alkali liquor, and reacting the mixture under a heating band pressure to obtain sodium silicate solution so as to realize circulation and co-production.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

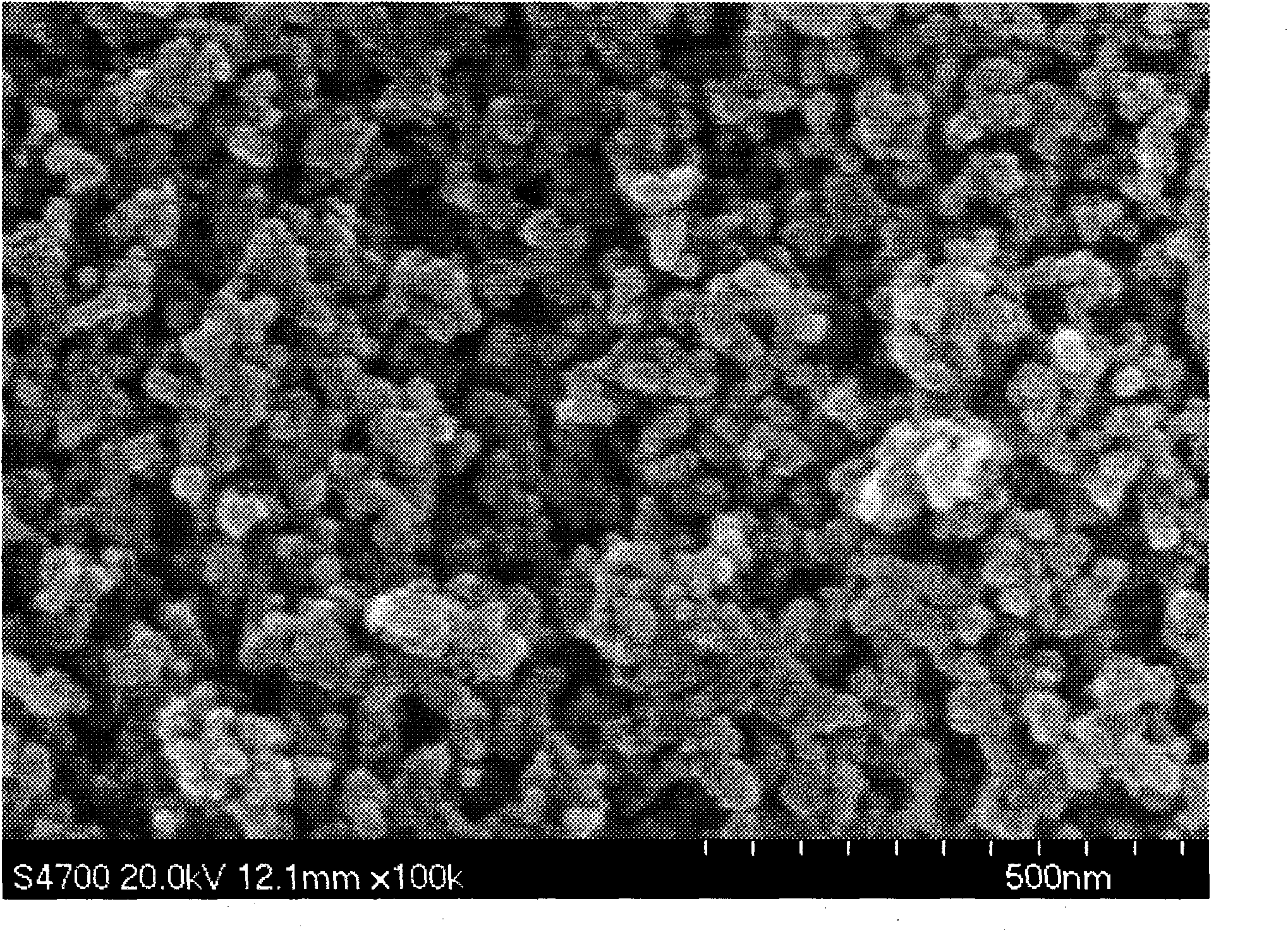

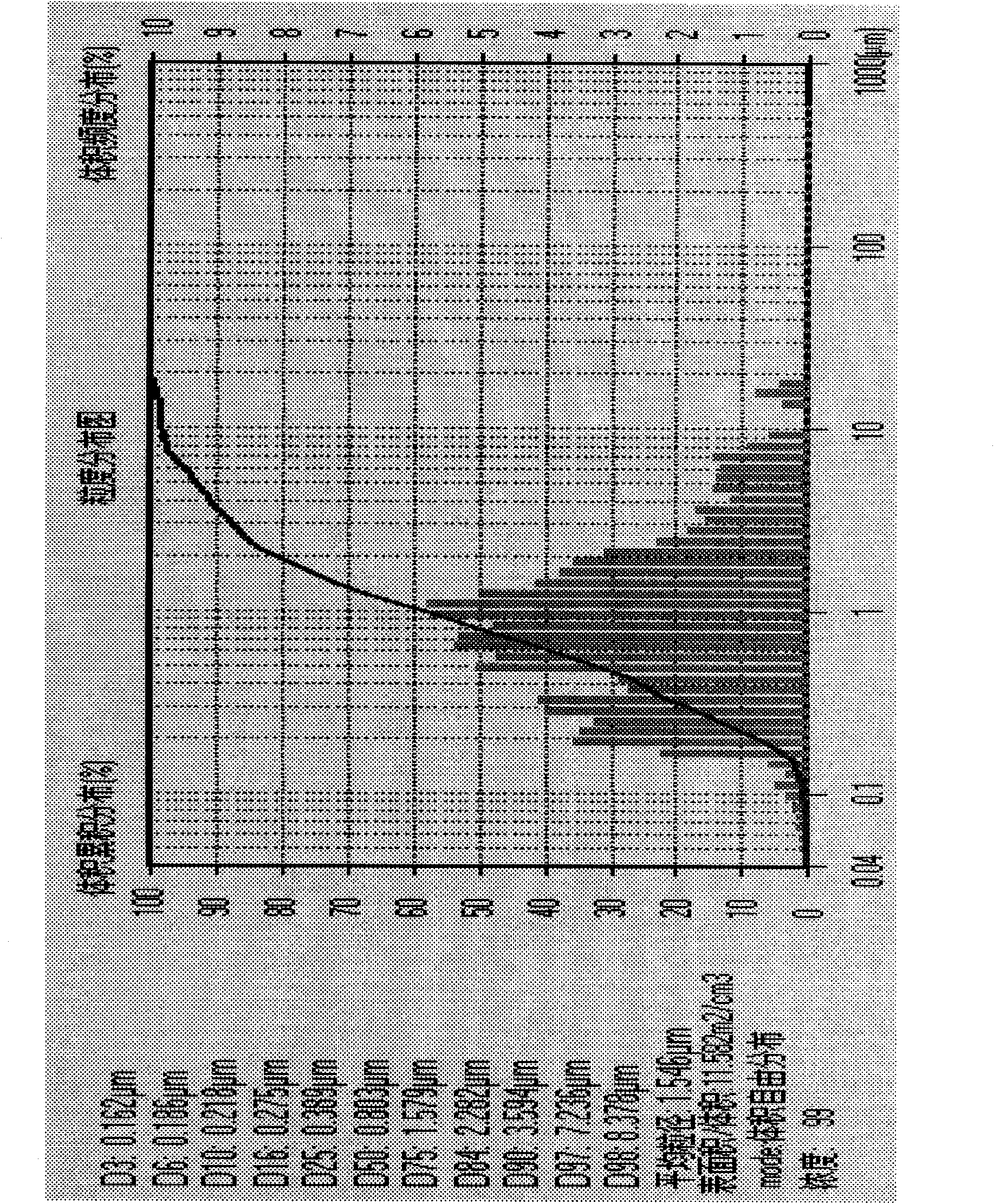

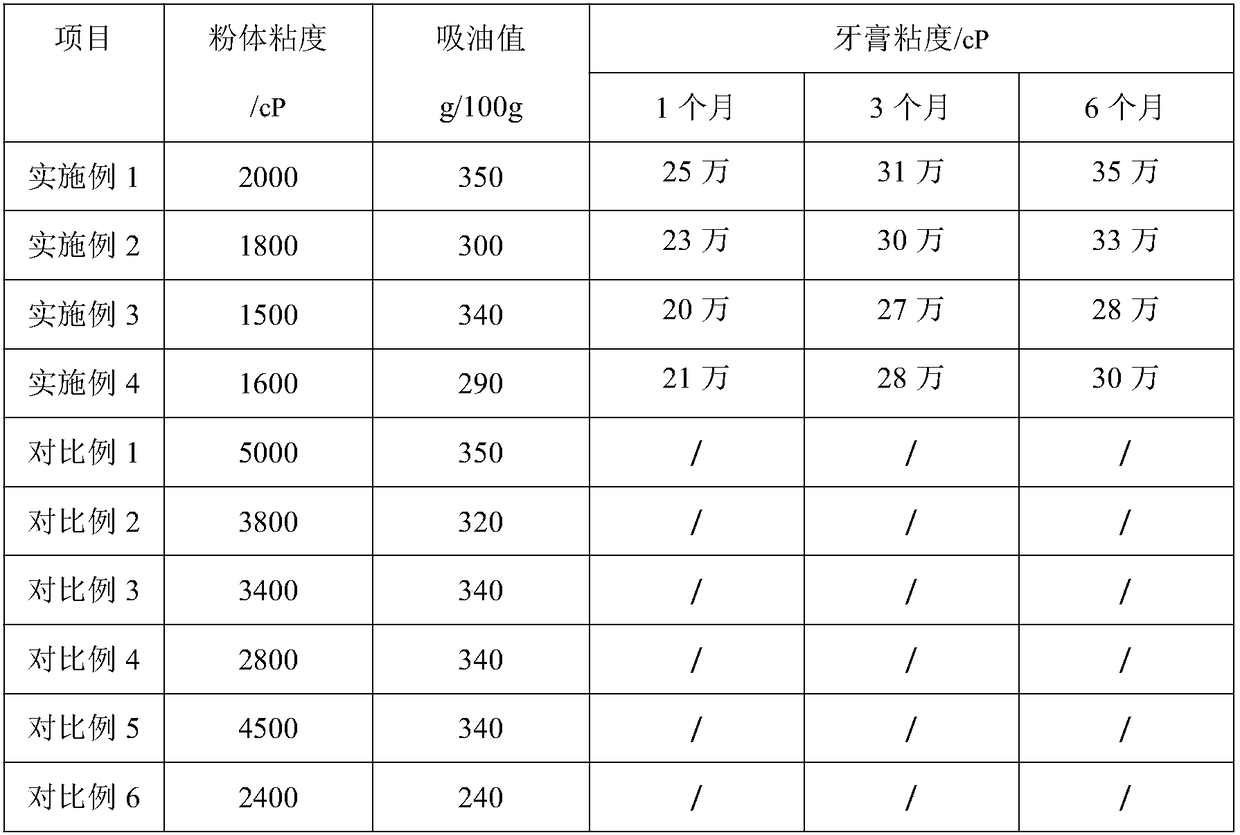

Preparation method of silicon dioxide of toothpaste with low viscosity and high oil absorption value

ActiveCN108516559AReduce manufacturing costEasy to prepareCosmetic preparationsToilet preparationsGlycerolToothpaste

The invention belongs to the technical field of silicon dioxide, in particular to a preparation method of silicon dioxide of toothpaste with low viscosity and high oil absorption value. The preparation method comprises S1, a sodium silicate solution is allocated; S2, water and the sodium silicate solution are added into a reaction kettle and heated to the temperature of 75-80 DEG C, sulphuric acidis added dropwise while stirring is conducted until the pH value is 9-10, and the addition of the sulphuric acid is ceased; S3, the temperature is increased, the sodium silicate solution and the sulphuric acid are added dropwise simultaneously while stirring is conducted, the pH value during the process is maintained at 9-10, the sulphuric acid is continuously added until the pH value is 3.5-4.0after the dropwise adding of the sodium silicate solution is completed, sulphuric acid addition is ceased, and ageing, pressing filtering and washing are conducted to obtain initial products; S4, theinitial products are placed into a pulp beating tank, glycerol is added, beating is conducted after soaking, and pulverizing is conducted by using an airflow pulverizer after spraying drying is conducted to obtain the silicon dioxide of the toothpaste with low viscosity and high oil absorption value. The method is simple, the process is stable, the production cost is low, prepared silicon dioxidepowder is low in viscosity and high in oil absorption value, and the problem of the post growth of toothpaste viscosity can be better solved after the silicon dioxide is applied to the toothpaste.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

Method for producing high covering power titanium dioxide pigment

The invention supplies a manufacture method for strong covering power titanium dioxide pigment that includes the following steps: making slurry; adjusting the pH value of the slurry; adding dispersing agent and filtering; heating; adding sodium silicate solution; adding mixture of sodium silicate and sulphuric acid solution; adjusting the pH value to 7.0-8.0; filtering, washing, drying, taking gas smashing and organic process. The invention has strong covering power, good dispersibility and high weathering resistance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing silicon dioxide aerogel powder

The invention discloses a method for preparing preparing silicon dioxide aerogel powder, which comprises the following steps: adding acid into sodium silicate solution to make a pH value equal to 3 to 6; adding a chemical drying control agent into mixture and standing to form gel; after the gel is sufficiently aged, adding an azeotropic distillation organic solvent into the gel to distill to form a primary dried product; and drying the primary dried product to form silicon dioxide aerogel powder. The method uses the common commercial sodium silicate as the raw material to prepare the silicon dioxide aerogel powder and has the advantages that the raw material is easily obtained; the normal pressure is used for preparation; the chemical drying control agent is adopted to prolong the gelation time to promote uniformity of the gel structure; an azeotropic distillation drying process is adopted to control a stress level when the solvent is dried; a pore volume and a specific surface area of the silicon dioxide aerogel are controlled; the pore volume reaches 1.2 to 3.0ml / g; the specific surface area reaches 300m2 / g to 800m2 / g; and compared with the normal pressure drying, the drying time is shortened and the like. The organic solvent is easy to realize recycling. And the production process is simple and the production cost is low.

Owner:FUJIAN NORMAL UNIV

Method for preparing soluble glass by using waste residues with aluminum extracted by coal gangue

ActiveCN102936016AReduce the temperatureAvoid strong corrosionSolid waste disposalAlkali metal silicatesCongruent meltingSoluble glass

The invention relates to a method for preparing soluble glass by using waste residues with aluminum extracted by coal gangue. The method comprises firstly mixing and grinding the waste residue with aluminum extracted by coal gangue and sodium carbonate to be 1-50mu m particles, then conducting temperature programming in a muffle furnace, conducting low temperature congruent melting reaction for 1-5 hours at the temperature of 500-850 DEG C, and conducting water quenching to obtain coarse sodium silicate solid; and placing the coarse sodium silicate solid in a high pressure reactor, adding distilled water, heating to be 150 DEG C, stirring and dissolving for 5 hours, cooling to be room temperature, filtering and separating to obtain a colorless and transparent sodium silicate solution, and crystallizing to be the soluble glass. The method lowers the temperature for preparing sodium silicate by using a traditional soda ash method by about 600 DEG C, greatly reduces energy consumption, and simultaneously avoids highly corrosive of a traditional caustic soda alkali-dissolution method on production facilities and alkali pollution on the environment.

Owner:SHANXI UNIV

Method for preparing reinforced white carbon black

The invention relates to a preparation method of white carbon black of an important reinforcing material in the rubber industry; the preparation method includes the following steps: (a) diluted sodium silicate solution is added in a reaction kettle; (b) sulphuric acid is added in the diluted sodium silicate solution for reaction; (c) after reaction, the mixed solution stands still and is aged to generate seed crystal; (d) the aged mixed solution is evenly stirred; (e) hot water vapor is pumped into the mixed solution for heating until the temperature of the solution raises to 70-80 DEG C, and diluted sodium silicate is added in till the pH value of the solution reaches 11.0-11.5; (f) hot water vapor is pumped in the solution in the reaction kettle for heating and is cut off when the temperature of the solution raises to 86-95 DEG C and then sulphuric acid is added in the solution; (g) precipitate is separated out when the pH value of the solution reaches 3.0-5.0; (h) the precipitate is filtered, pulped and dried to form finished products. The properties of the white carbon black prepared by the method such as tensile-strength, tear strength, stretching stress, elongation at break, and the like, are all improved.

Owner:WUXI HENGHENG SILICA

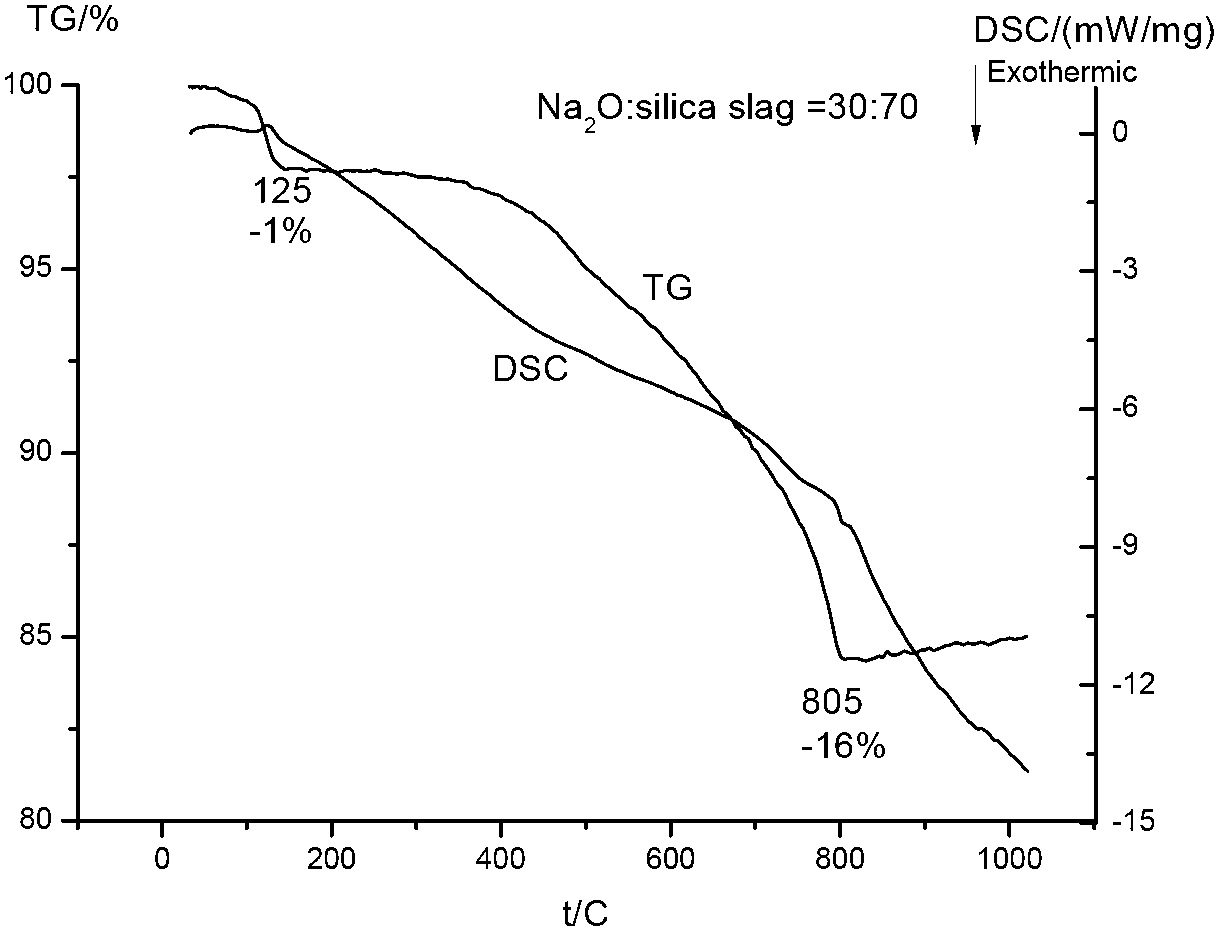

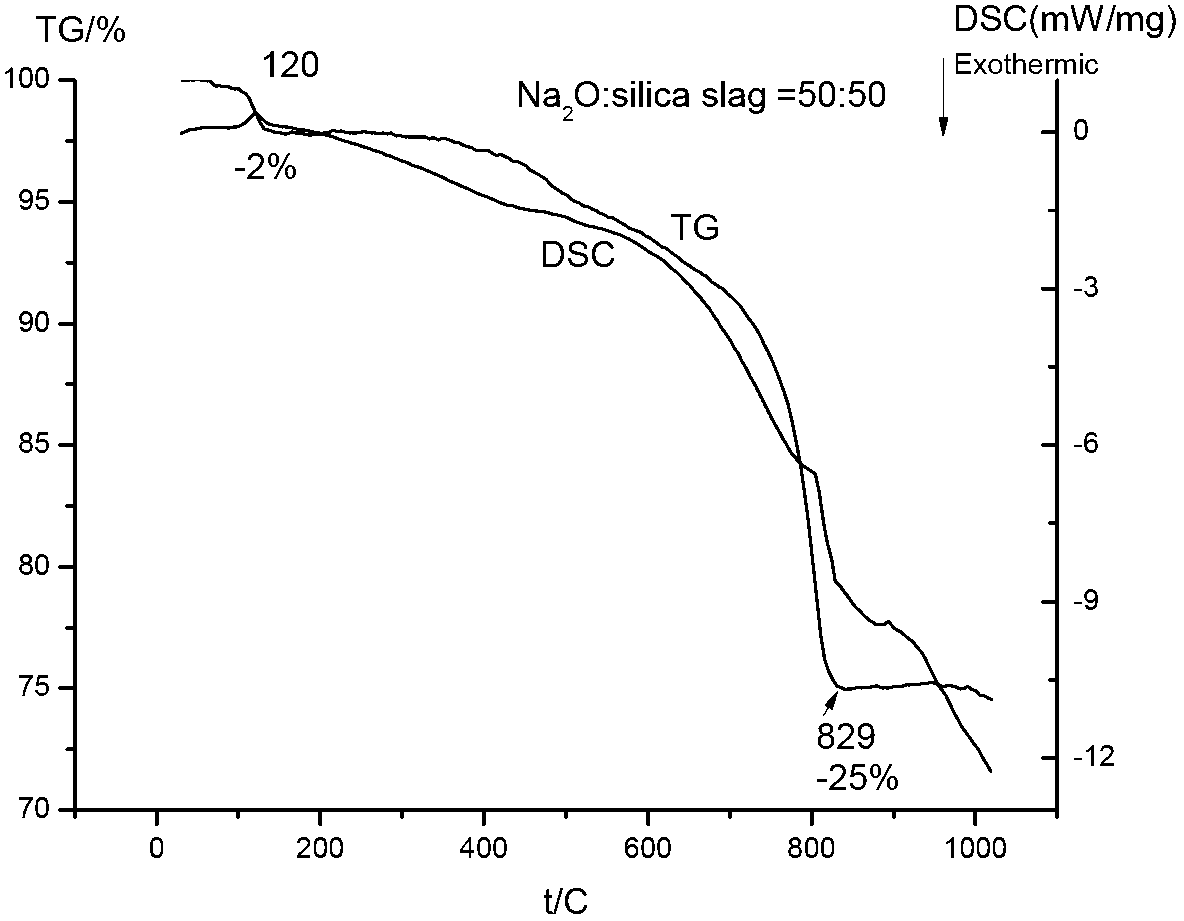

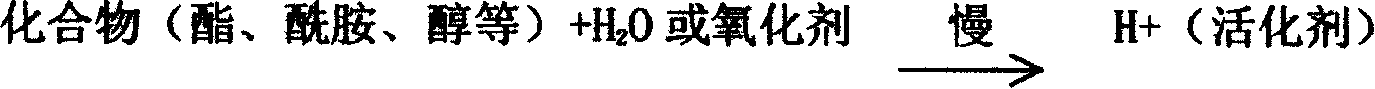

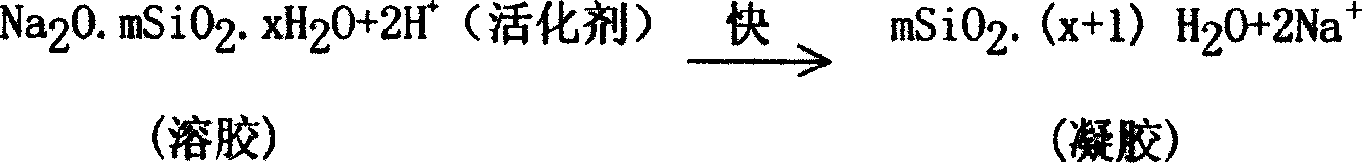

Block up and concoction agnet of inorganic delayed siliceous gel

InactiveCN1563259AOvercome timeOvercome the disadvantage of low temperature resistanceSealing/packingAcetic acidAlcohol

A blocking and regulating agent for organic delay silicic gel is prepared by adding at least one of ethyl acetate, acetamide and alcohol as delay activator into master material of sodium silicate solution. The said acetamide can be replaced by formamide or carbomite and alcohol can be replaced by methanol or sometime ammonium chloride can be added.

Owner:中国石油化工股份有限公司河南油田分公司石油工程技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com