Patents

Literature

4214results about How to "High whiteness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treated filler or pigment containing natural carbonate

InactiveUS6666953B1Reduce weightReduce wearNatural cellulose pulp/paperSpecial paperPhysical chemistryKaolin clay

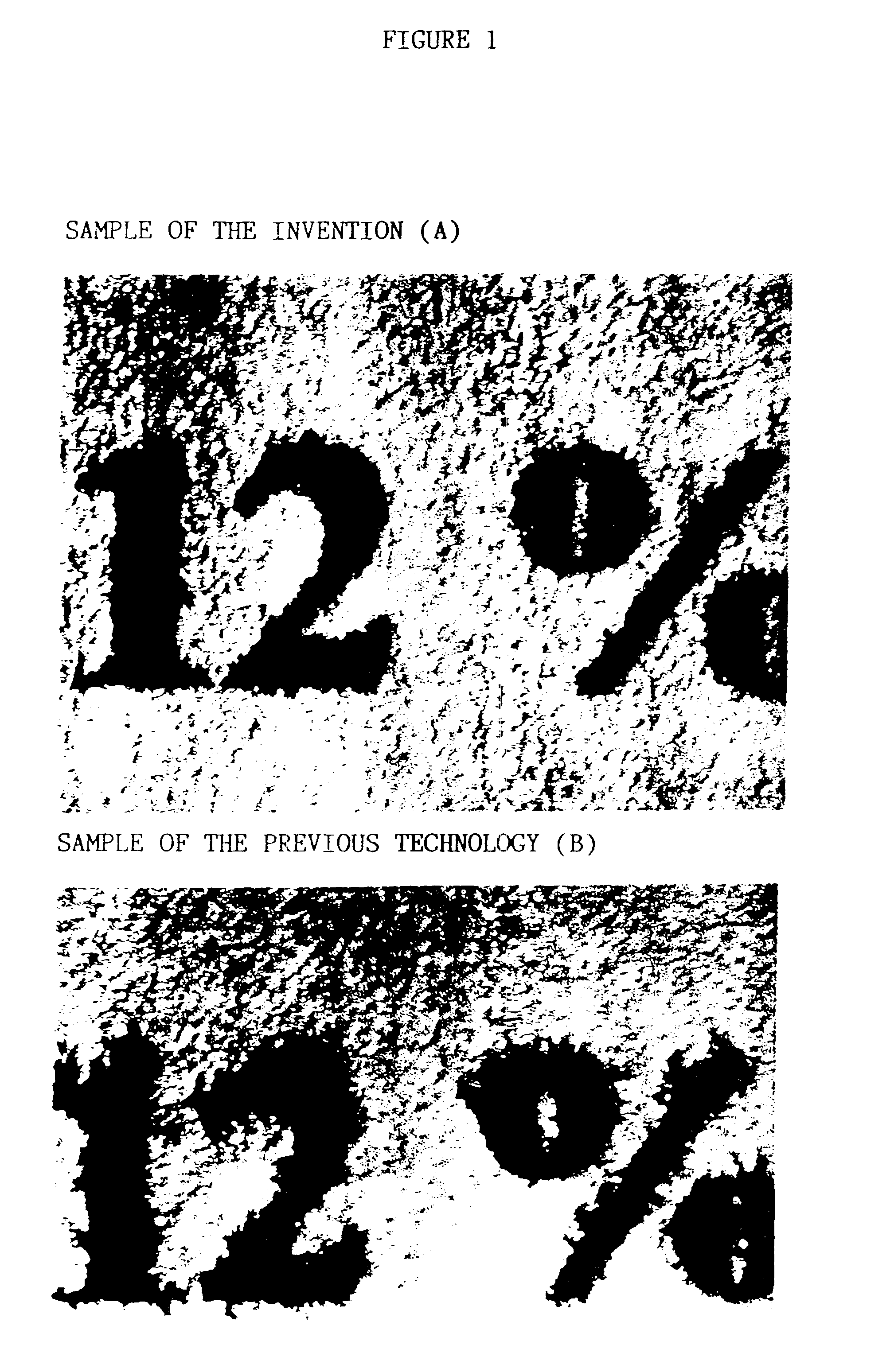

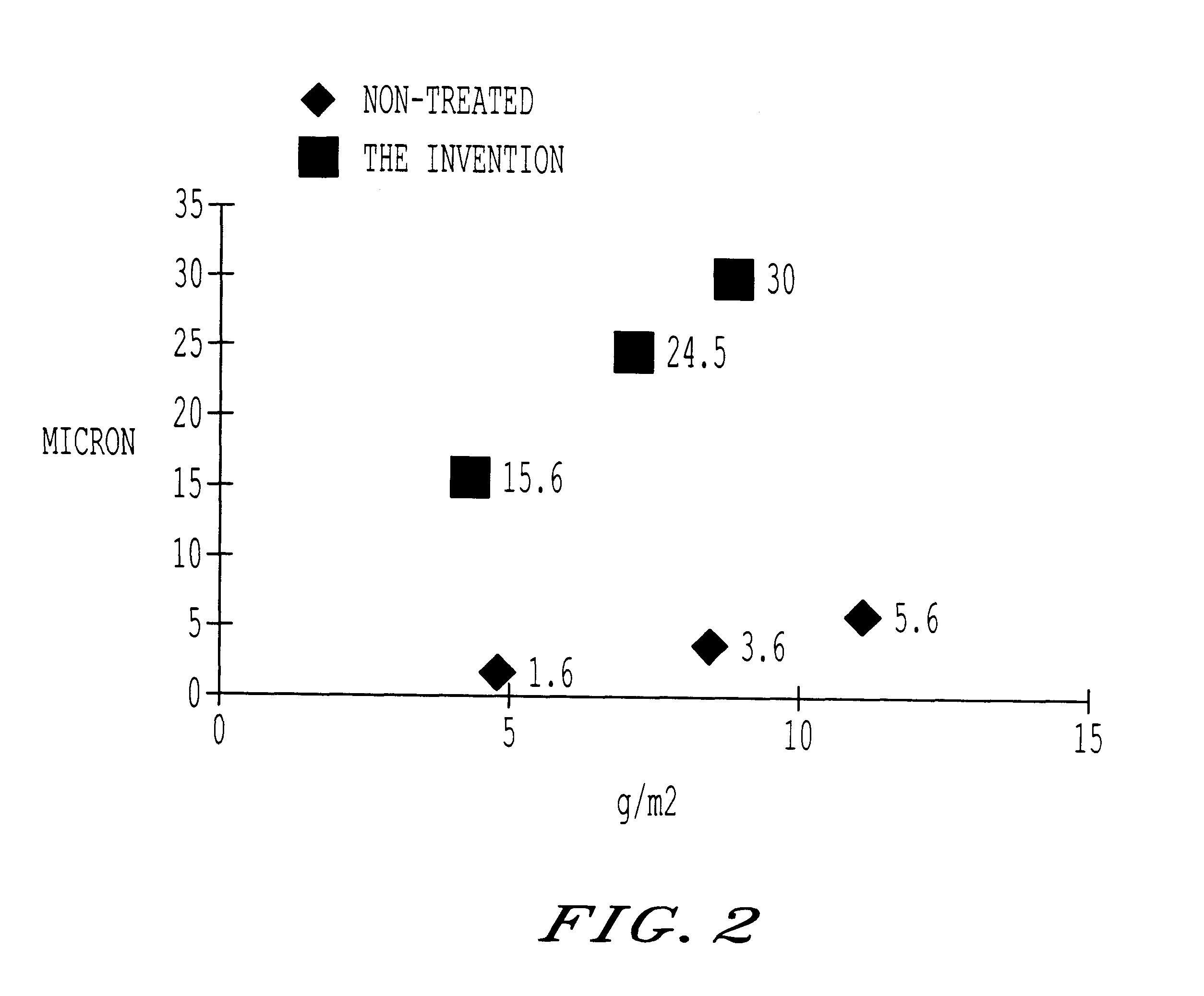

The invention concerns a pigment, filler or mineral containing a natural calcium carbonate, treated with one of more providers of H3O<+> ions and gaseous CO2, allowing a reduction in the weight of paper for a constant surface area without loss of physical properties when it is used as a pigment or coating filler for the said paper. In particular, the invention concerns a pigment, filler or mineral containing a natural calcium carbonate or dolomite or mixtures of talc and calcium carbonate, of kaolin and carbonate or carbonate alone or in combination with natural and / or synthetic fibers or similar, treated with one or more medium-strong or strong providers of H3O<+> ions in the presence of gaseous CO2. Applications are particularly in the paper industry, obtaining in particular good sheet properties i.e. a reduction its weight for a given surface area.

Owner:OMYA DEV AG

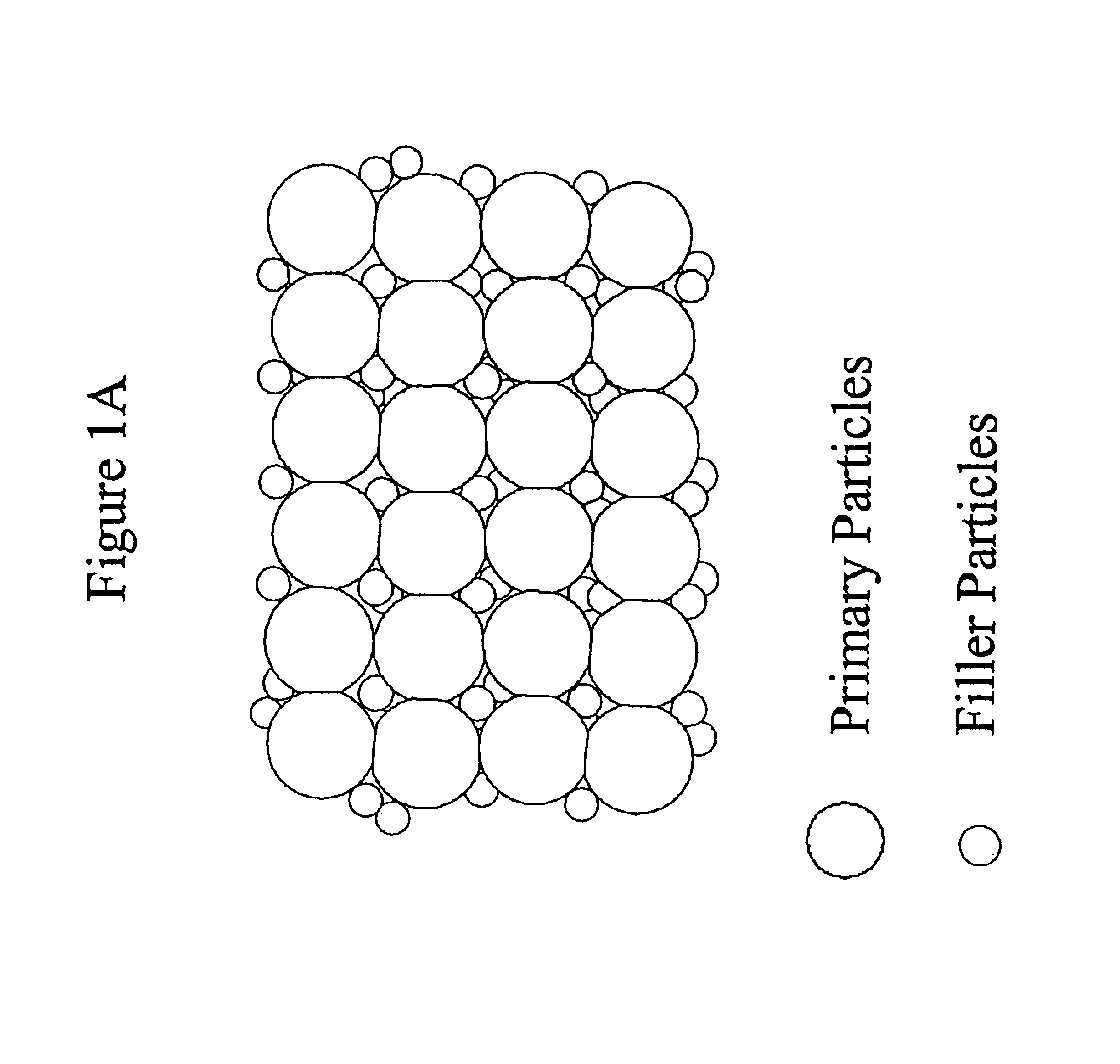

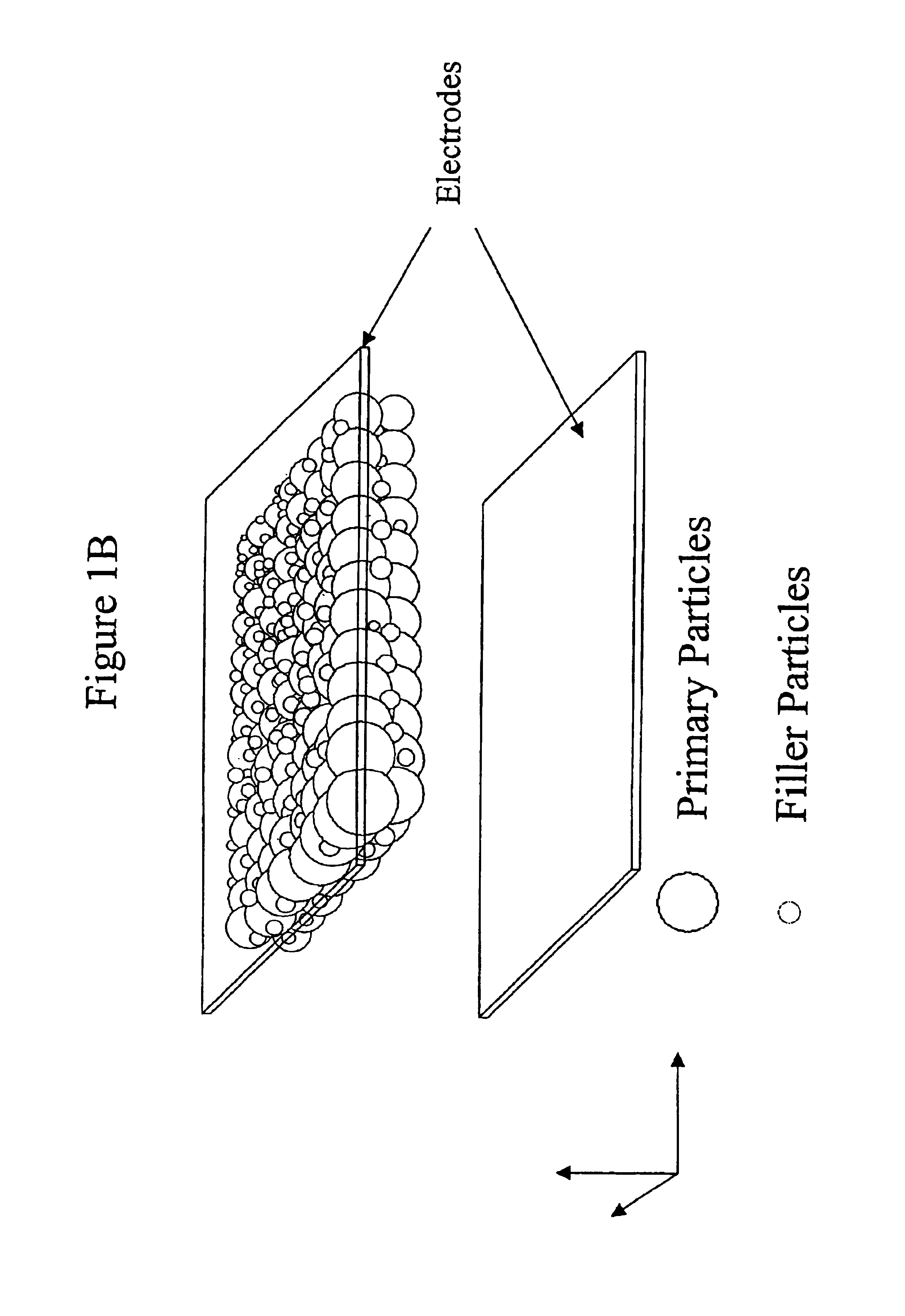

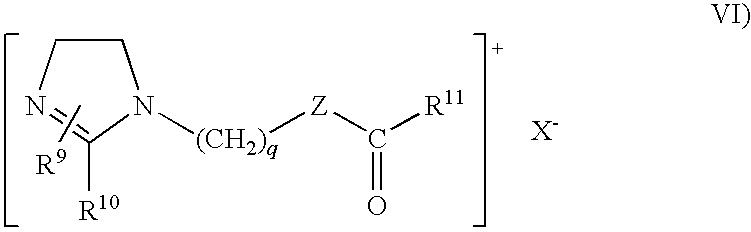

Electrophoretic display with a bi-modal particle system

ActiveUS6956690B2Increase contrastHigh bulk densityStatic indicating devicesNon-linear opticsBi modalElectrophoresis

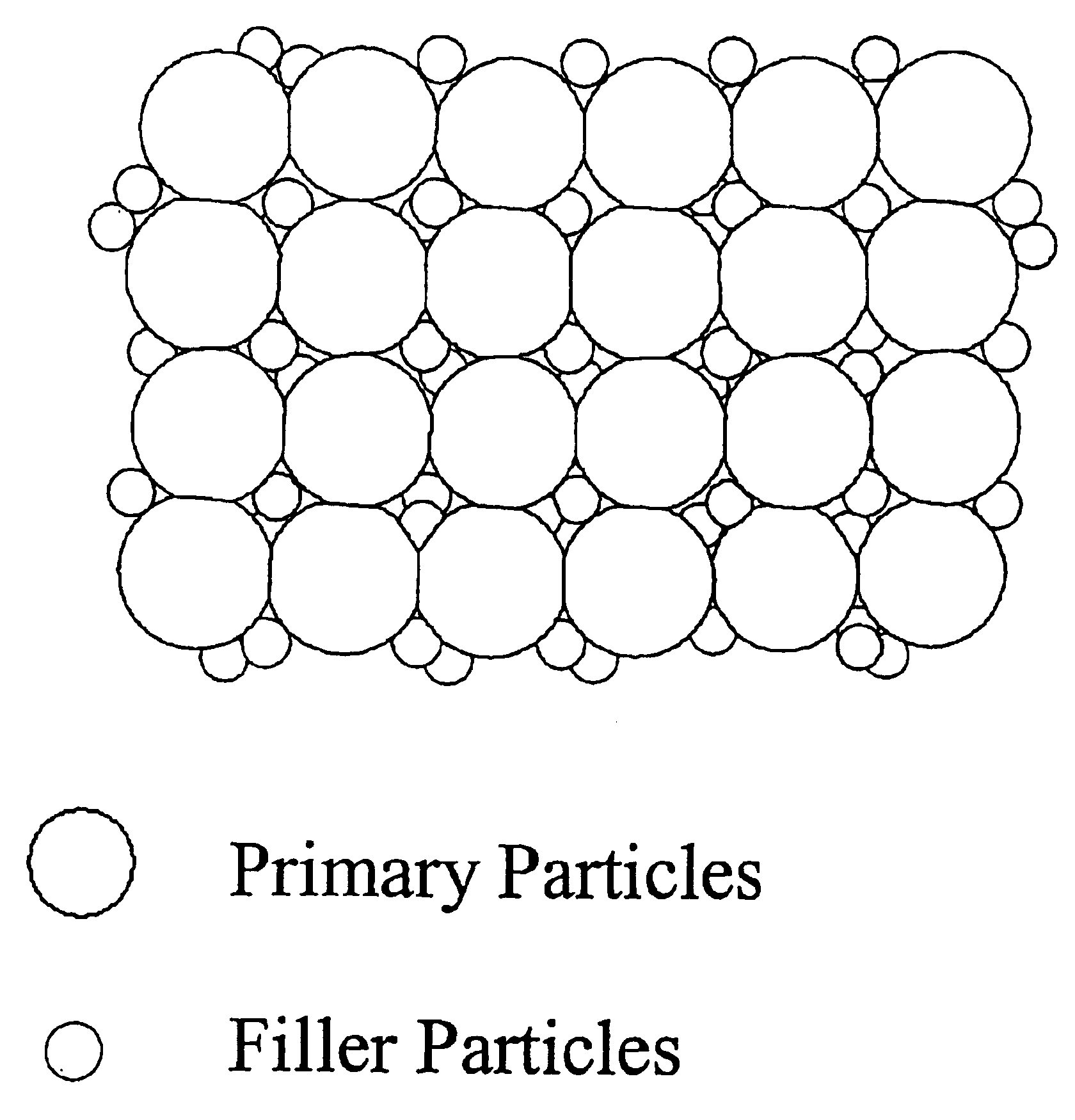

This invention relates to an electrophoretic display having display cells filled with an electrophoretic composition which comprises a bi-modal particle system dispersed in a dielectric solvent or solvent mixture. The display has shown a higher % reflectance or whiteness, a higher contrast ratio, improved threshold characteristics and better bistability.

Owner:E INK CORPORATION

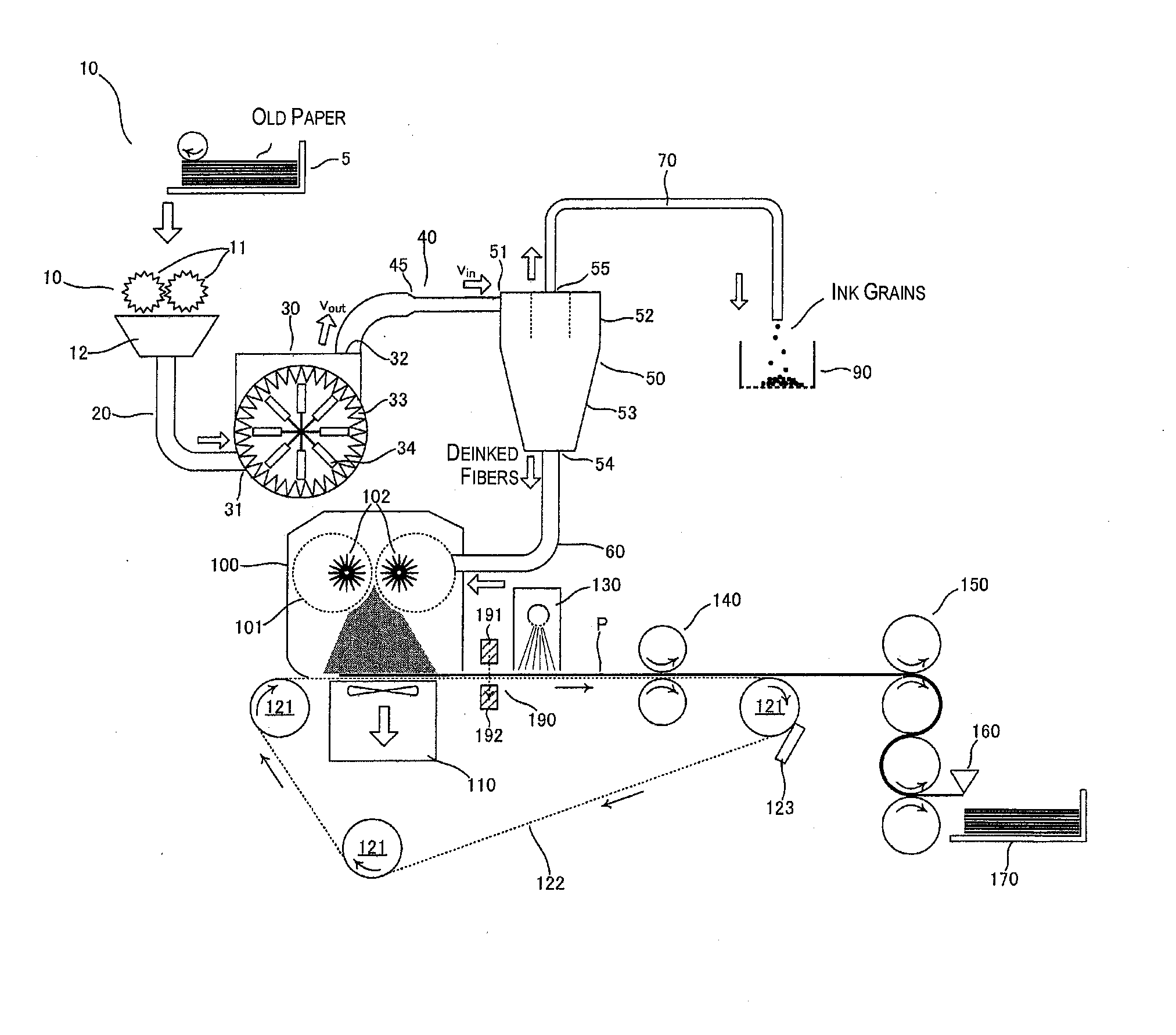

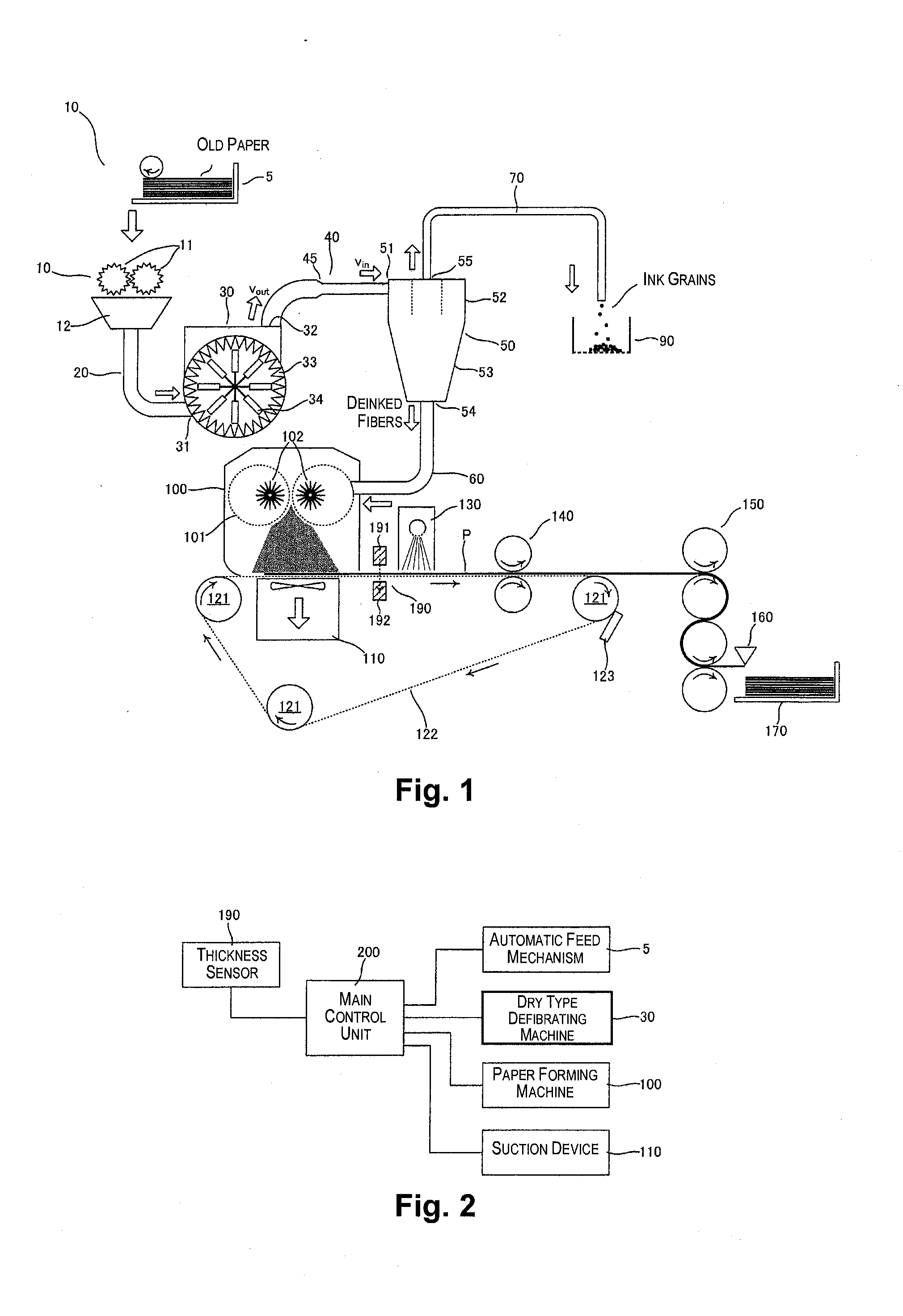

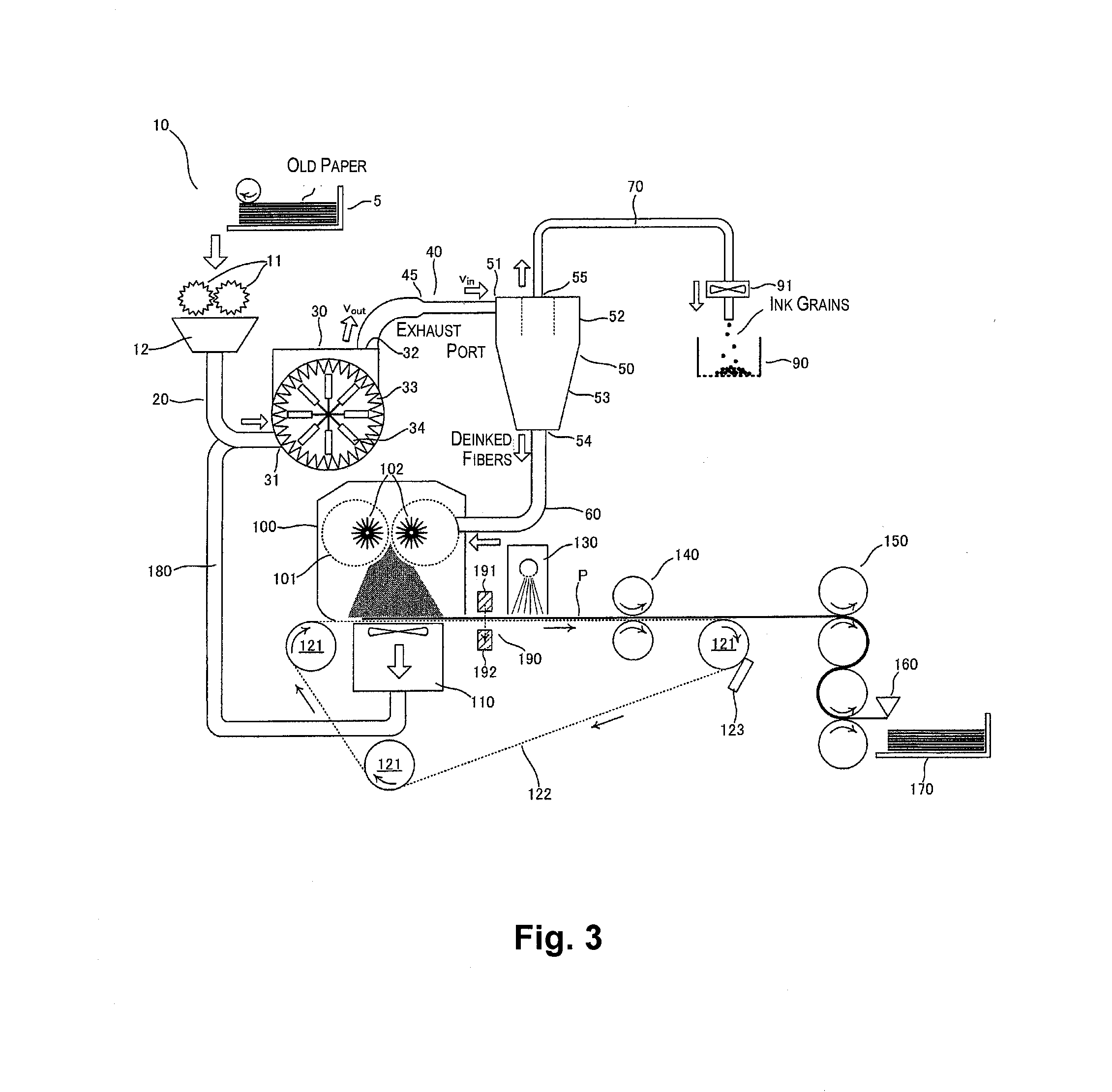

Paper recycling system and paper recycling method

InactiveUS20140027075A1Improve the level ofHigh whitenessPaper recyclingFlat articlesPaper recyclingPulp and paper industry

To provide a paper recycling device capable of recycling paper of increased whiteness level that can be widely used for applications other than paper for newspapers, the paper recycling device of the present invention has a dry type defibrator for crushing and defibrating paper, a first transport pipe for transporting defibrated material that was defibrated by the dry type defibrator, a cyclone for air classifying and deinking the defibrated material transported by the first transport pipe, a second transport pipe for transporting the defibrated material that was deinked by the cyclone, and a paper forming machine for forming paper with the defibrated material transported by the second transport pipe.

Owner:SEIKO EPSON CORP

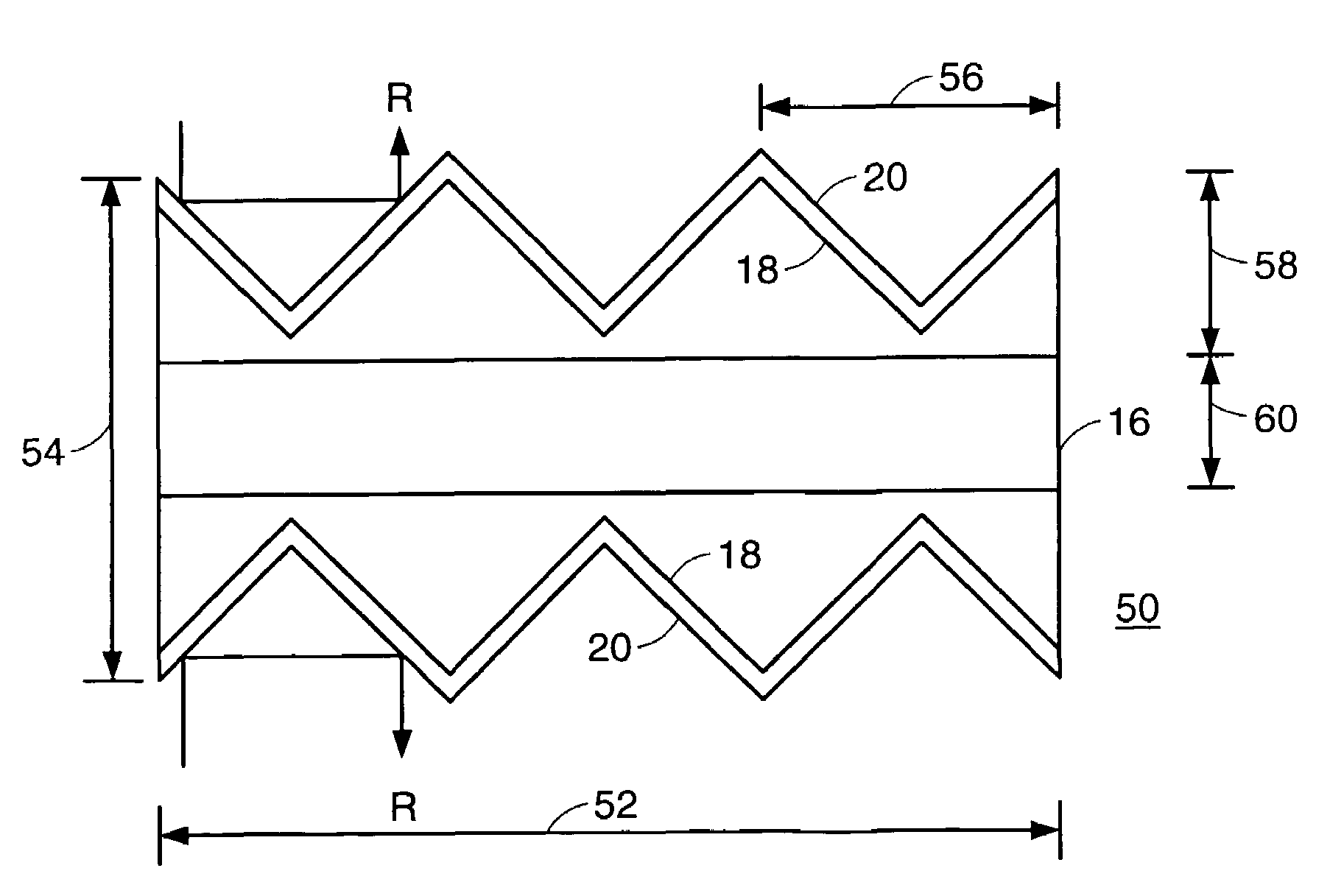

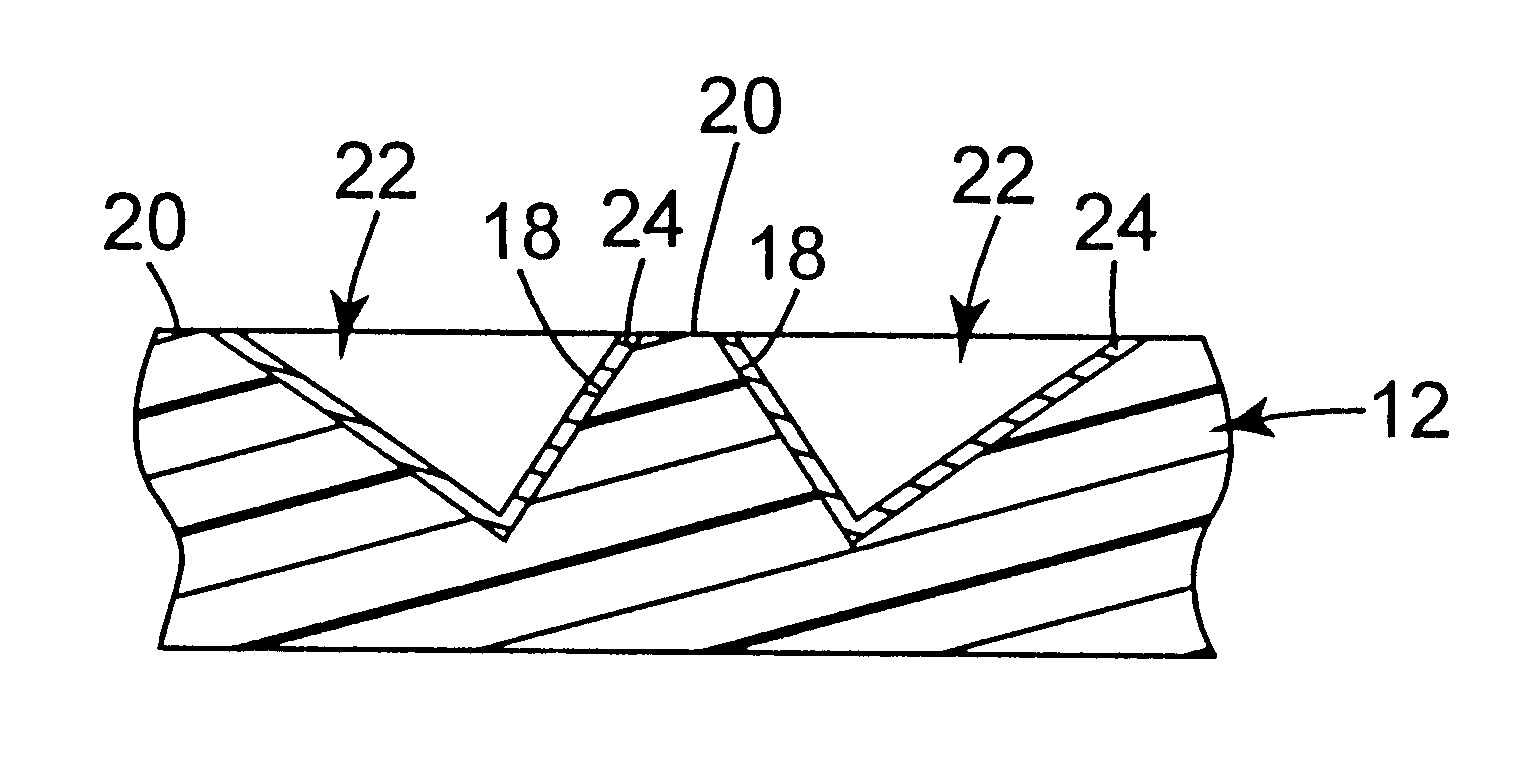

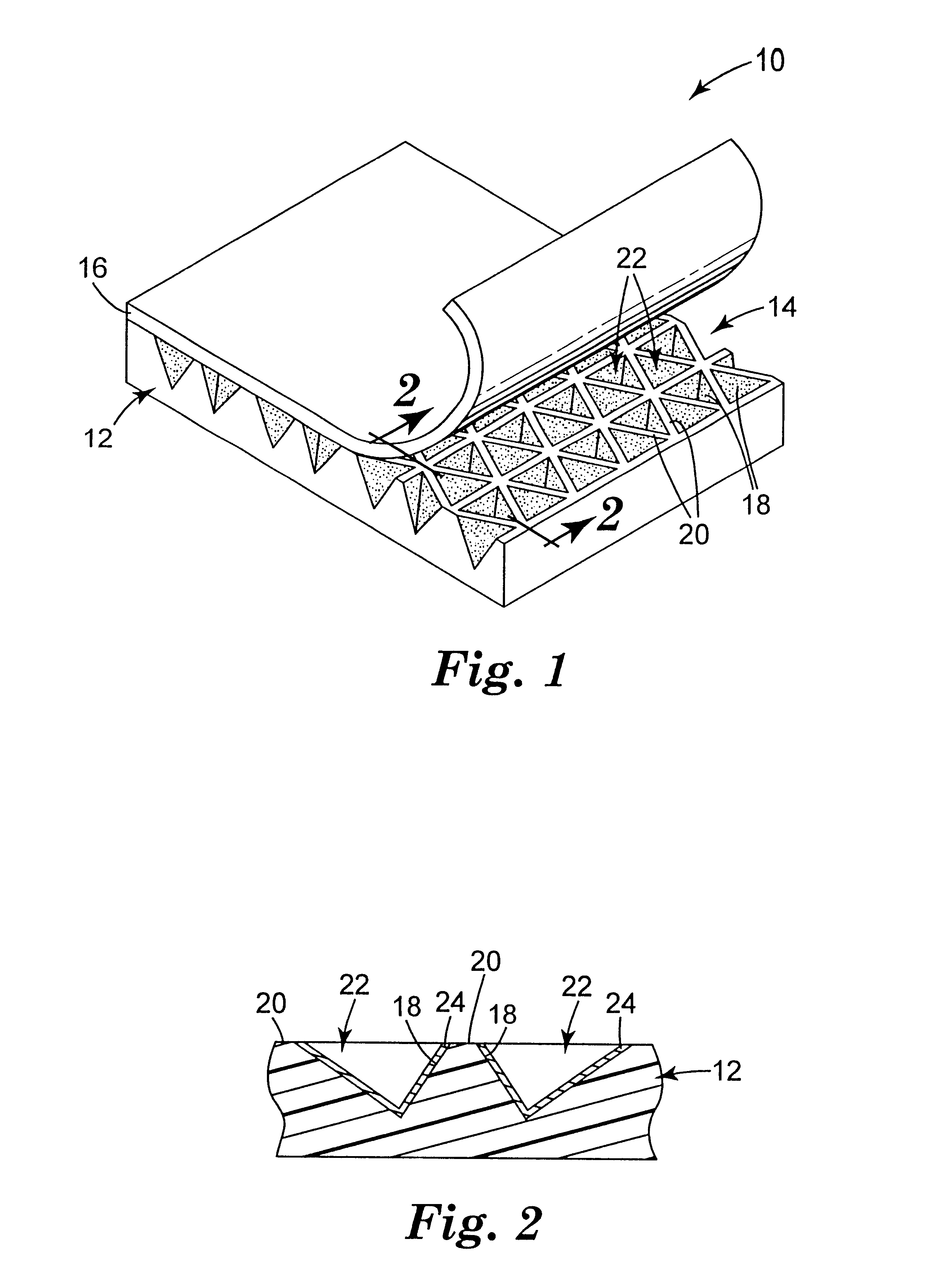

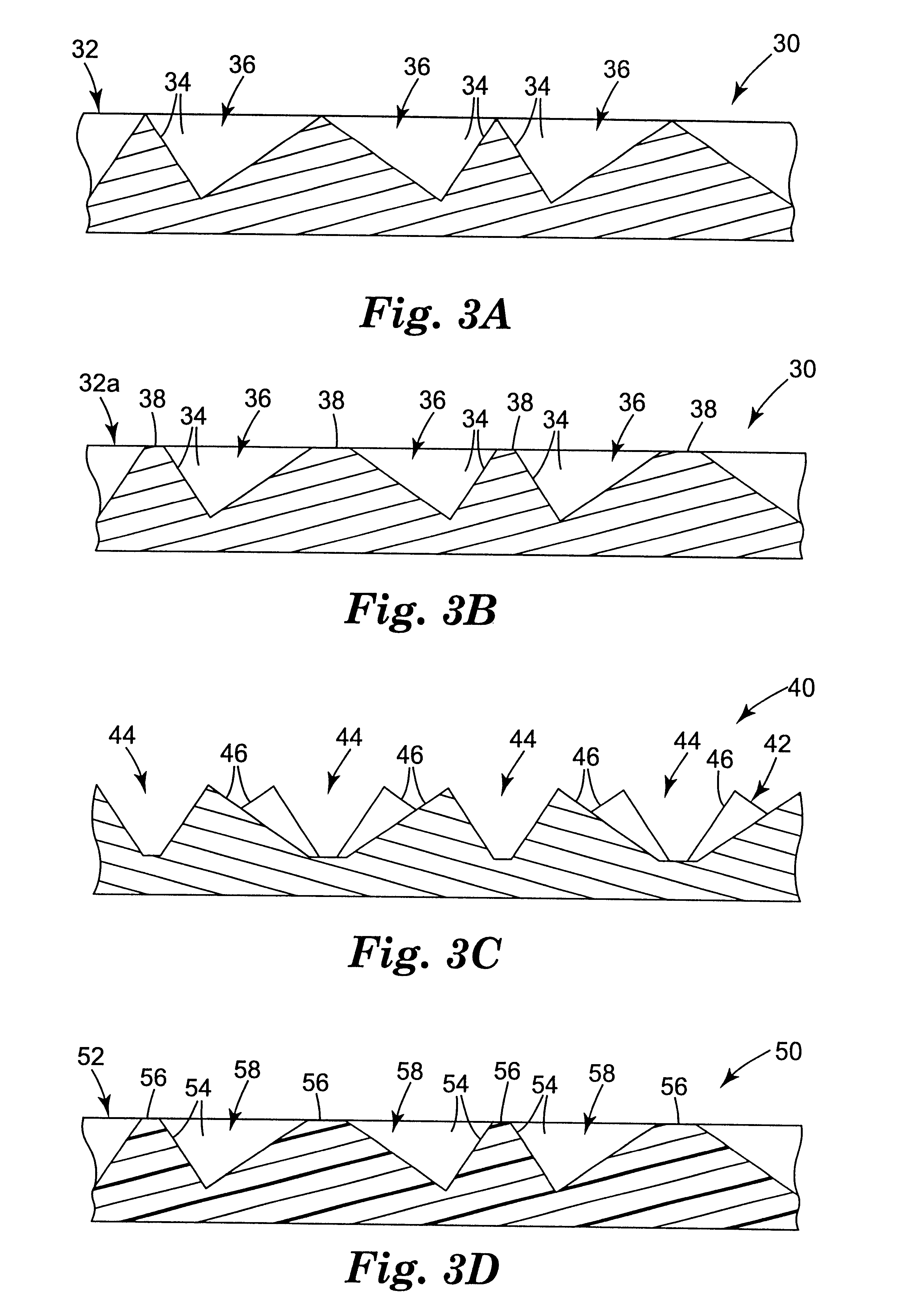

Durable, open-faced retroreflective prismatic construction

InactiveUS6967053B1Improve adhesionImprove the entrance angleReflex reflectorsThin material handlingOptical coatingPrism

Retroreflective sheeting and a method for making the same includes a plurality of open-faced cube-corner surfaces formed from a substantially rigid material to keep the cube-corner surfaces from flexing. An optical coating is formed on the surfaces, and a fill layer is attached to at least a portion of the optical coating. A plurality of voids form the open-faced cube-corner surfaces.

Owner:ORAFOL AMERICAS

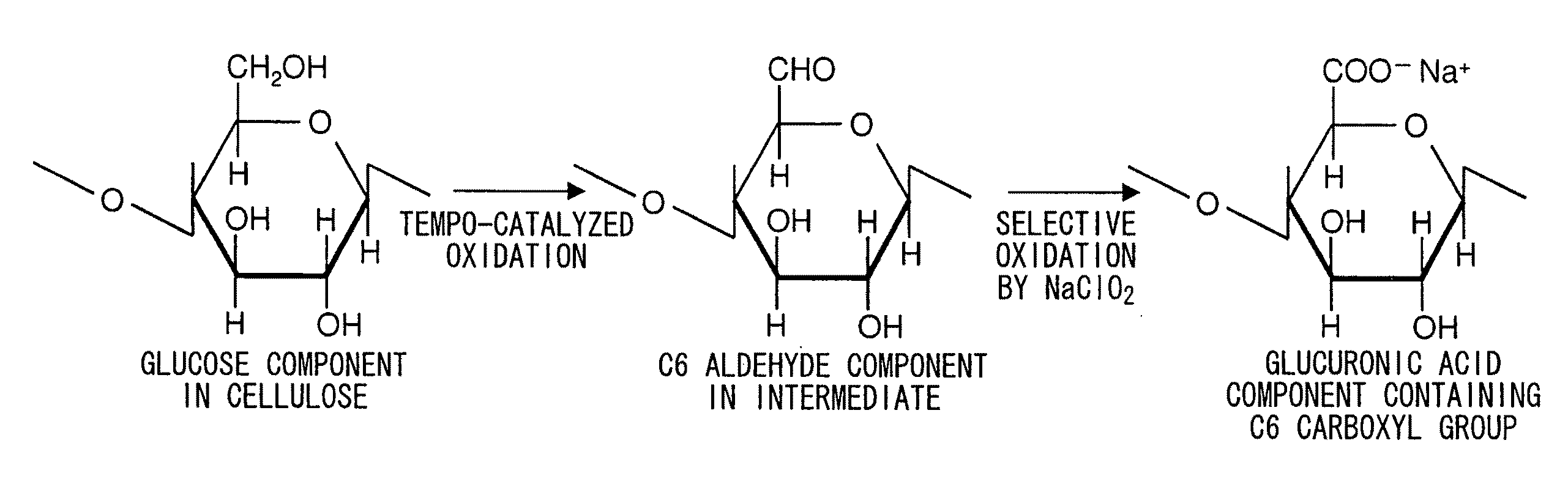

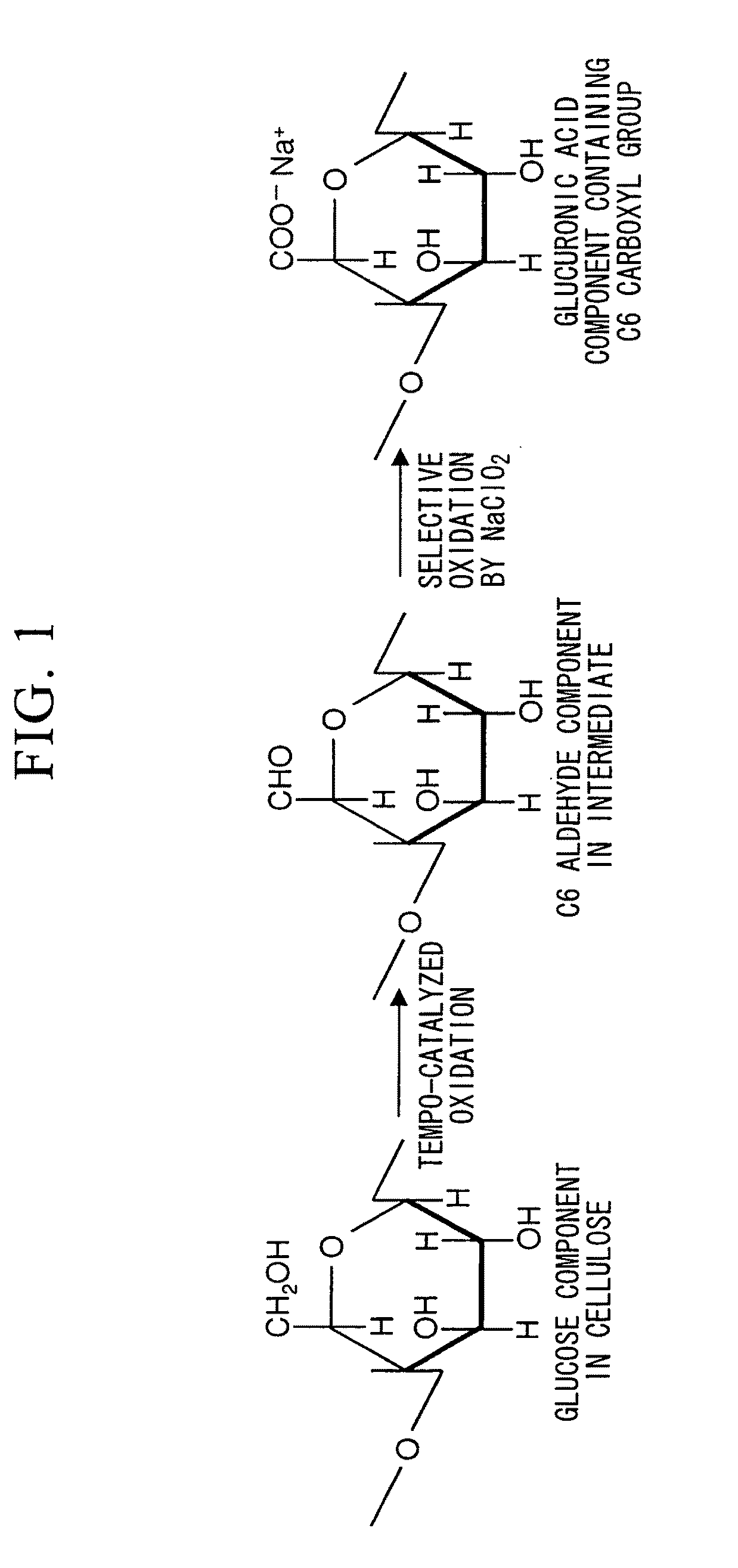

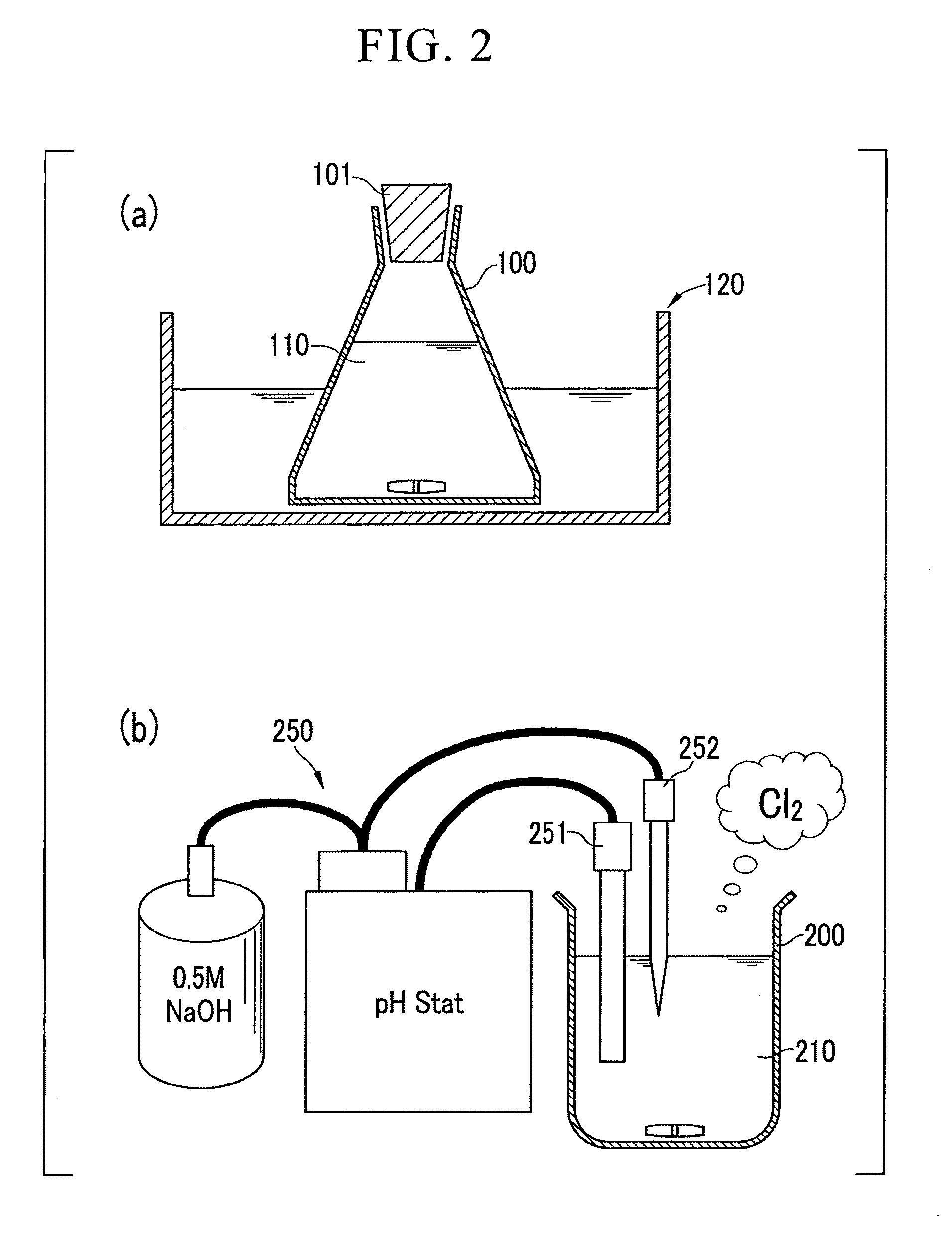

Cellulose nanofiber production method of same and cellulose nanofiber dispersion

InactiveUS20100233481A1High degree of polymerizationHigh strengthNanotechPulp properties modificationCelluloseFiber

The cellulose nanofiber production method of the present invention comprises an oxidation treatment step for oxidizing native cellulose in a neutral or acidic reaction solution containing an N-oxyl compound and an oxidizing agent that oxidizes aldehyde groups, and a dispersion step for dispersing the native cellulose in a medium following the oxidation treatment step. According to the production method of the present invention, a cellulose nanofiber is provided that has long fibers and demonstrates high strength.

Owner:THE UNIV OF TOKYO

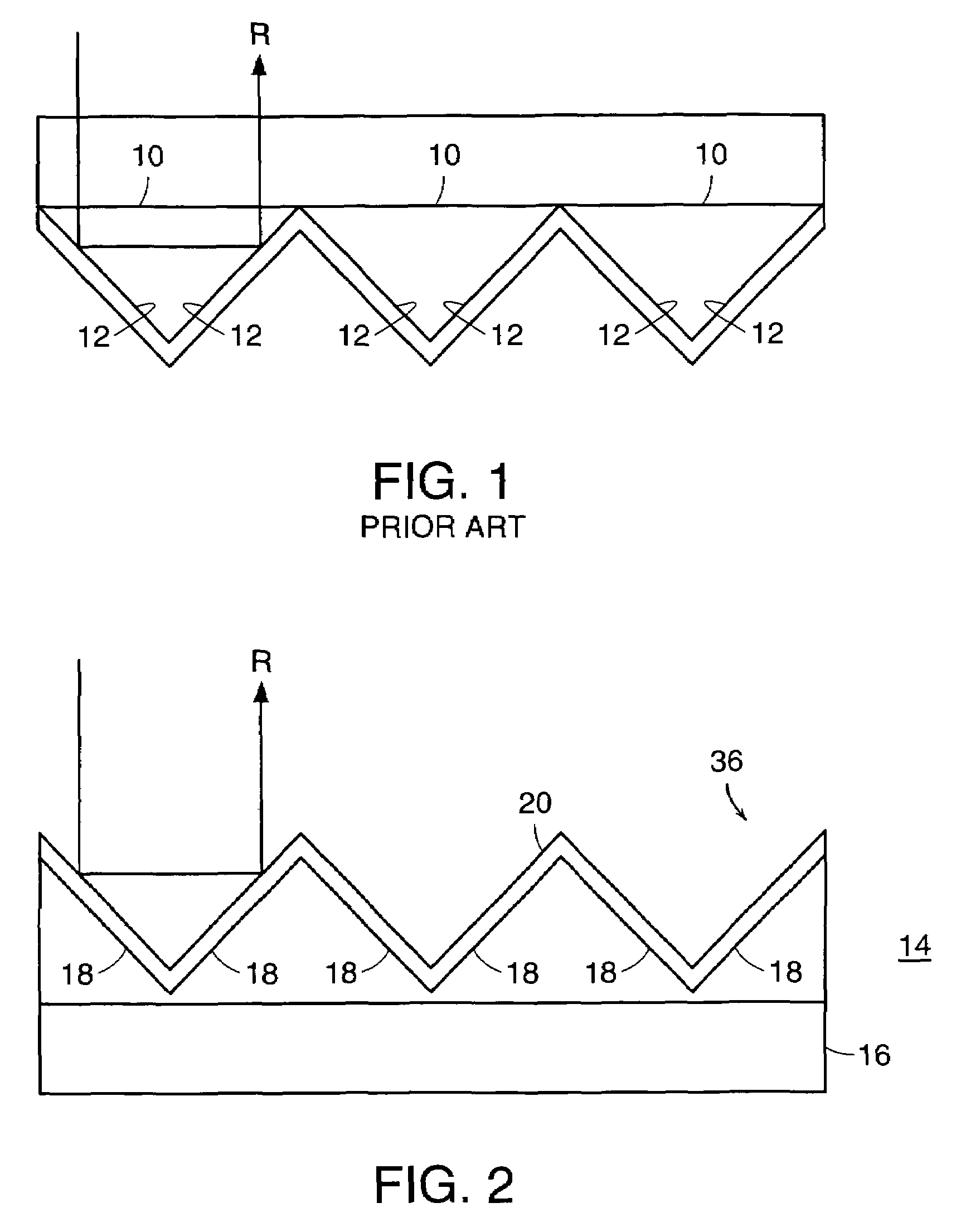

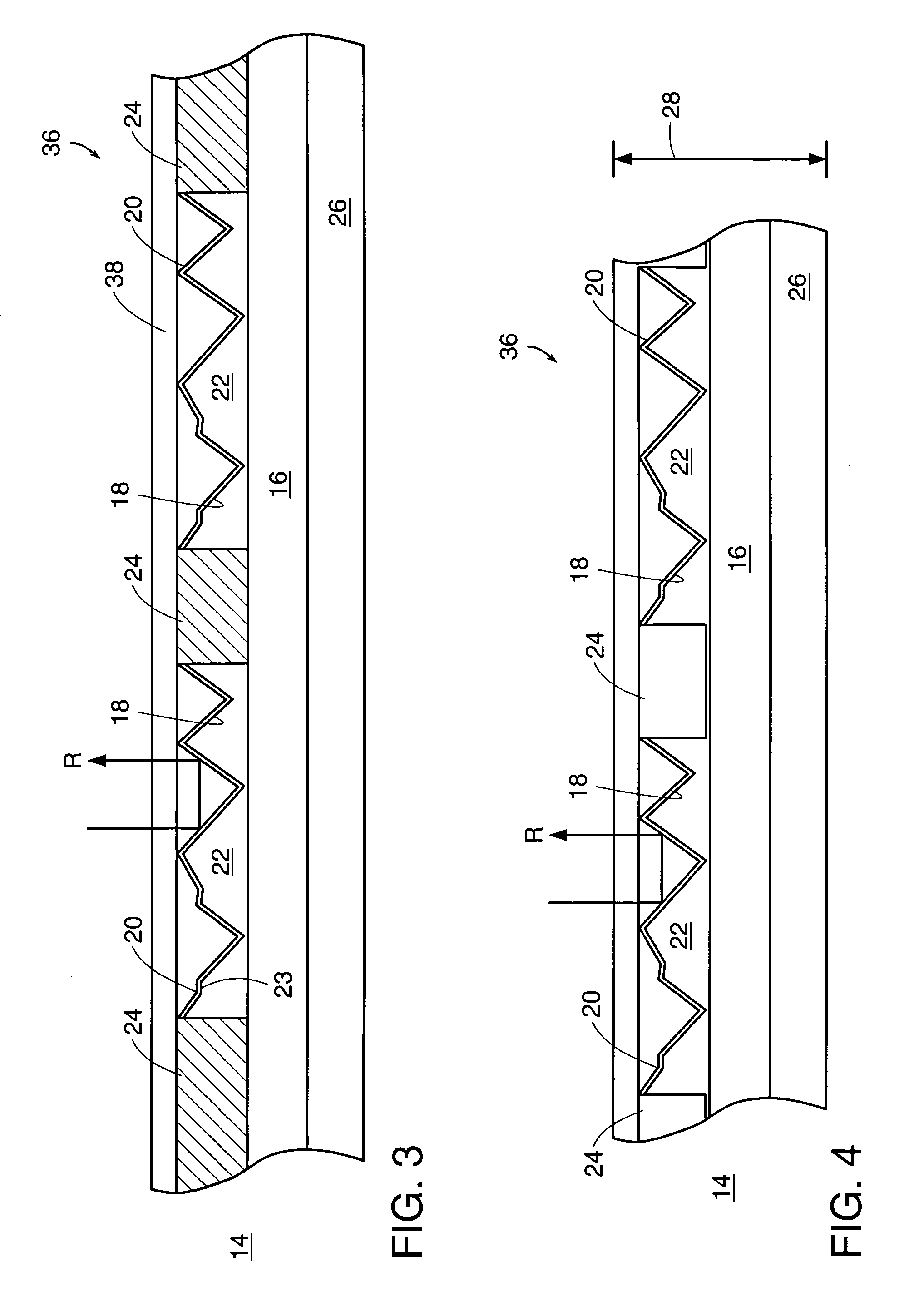

Cube corner cavity based retroreflectors and methods for making same

InactiveUS6287670B1High specular reflectivityEfficient retroreflectionMirrorsDiffusing elementsSurface finishEngineering

Retroreflective sheeting includes a body layer having a structured surface with recessed faces and top surfaces, the recessed faces forming cube corner cavities. The recessed faces have a high specular reflectivity, while the top surfaces have a low specular reflectivity. In some embodiments a substantially continuous film of reflective material covers the structured surface, and a masking substance is provided over the reflective material at the top surfaces. Alternatively, the top surfaces are given a non-smooth surface finish so that the film of reflective material on those portions has a diffuse reflectivity. In other embodiments the film of reflective material is discontinuous, disposed selectively on the recessed faces and not on the top surfaces. A cover layer is also provided, and can bond at least to the top surfaces. Keeping the top surfaces substantially free of reflective material inhibits corrosion and can enhance the bond integrity. The top surfaces are preferably flat, and diffusely reflective to enhance the daytime whiteness of the sheeting.

Owner:3M INNOVATIVE PROPERTIES CO

Cosmetic compositions containing nacreous pigments of large sized synthetic mica

InactiveUS20050142084A1High transparencyHigh glossCosmetic preparationsHair cosmeticsCompressibilityLarge particle

Cosmetic compositions containing nacreous pigments of large particle size coated synthetic mica and method for increasing or improving the gloss, glint, brightness, whiteness, transparency and compressibility of cosmetic compositions employing same.

Owner:SUN CHEM CORP

Coprecipitation method for preparing ultra fine zinc oxide powder possessing high electric conductivity

ActiveCN1590302AImprove conductivityVolume resistivity is stableZinc oxides/hydroxidesIndiumGas phase

The invention relates to a preparation method for preparing nano-scale oxidized zinc powder with high conductivity. The method simultaneously drip mixed salt solution of zincic soluble salt and doping elements such as aluminum, gallium, indium, Yt, scandium, tin, germanium, silicon, as well as precipitating agent into water, to generate coprecipitation to generate doped zinc bloom precursor basic zinc carbonate in condition of controlling temperature and PH value of entire reaction system, and at last, calcining the product in mixed gas atmospheres of hydrogen gas and argon gas, doped superfine zinc bloom conductive powder material can be obtained. The powder material prepared by the invention has small particle-size, uniform grain fineness distribution, and which mean particle diameter is about 10 to 80 nanometer. The electric volume resistivity of the powder can reach 2.5*10^-3 omega.cm, thus its electro conductivity is better than the sample prepared by plasma method and gas-phase method in current market. The preparation method further enhances whiteness degree and conductivity of the oxidized zinc powder, and further reduces the cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Composite foaming agent and preparation method and application thereof

The invention discloses a composite foaming agent, a preparation method thereof and application thereof. The composite foaming agent comprises azodicarbonamide, sodium bicarbonate and an auxiliary foaming agent in a weight ratio of (0.3-0.9):(0.2-0.6):(0.1-0.8). The auxiliary foaming agent is prepared by uniformly stirring attapulgite, zeolite and calcite, soaking the mixture in diluted hydrochloric acid of which the concentration is 0.5 to 6 weight percent, drying the mixture, crushing the dried mixture into powder, blending the powder and powdery white carbon black and uniformly stirring the mixture, wherein the weight ratio of the attapulgite to the zeolite to the calcite to the white carbon black is (0.3-0.8):(0.02-0.6):(0.1-0.8):(0.01-0.8). The composite foaming agent disclosed by the invention has relatively high liquidity and dispersibility, a low decomposition temperature and a long decomposition temperature period.

Owner:常州市英特玛柯橡塑科技有限公司

High-performance jet ink

The invention relates to a high-performance jet ink. The jet ink comprises the following components by weight percent: 20-80% of solvent, 1-45% of cosolvent, 4-20% of adhesive, 0.5-20% of colorant, 0-5% of adhesion force promoter, 0.01-2% of wax powder, 0-2% of brightening agent and 0-5% of other additives. As adhesion force promoter is added in the jet ink, the adhesion performance on base materials such as glass, metal, polypropylene or polyethylene is increased. In addition, wax is added to increase wear resistance and scratch resistance, and brightening agent is added to increase the lustrousness, brilliance and definition of the ink. The product has high adhesion force, good wear resistance, high lustrousness and definition and good compatibility, thus the defects of the existing ink such as low lustrousness, poor wear resistance and low definition can be greatly improved and the jet ink has good market prospect.

Owner:王学珍

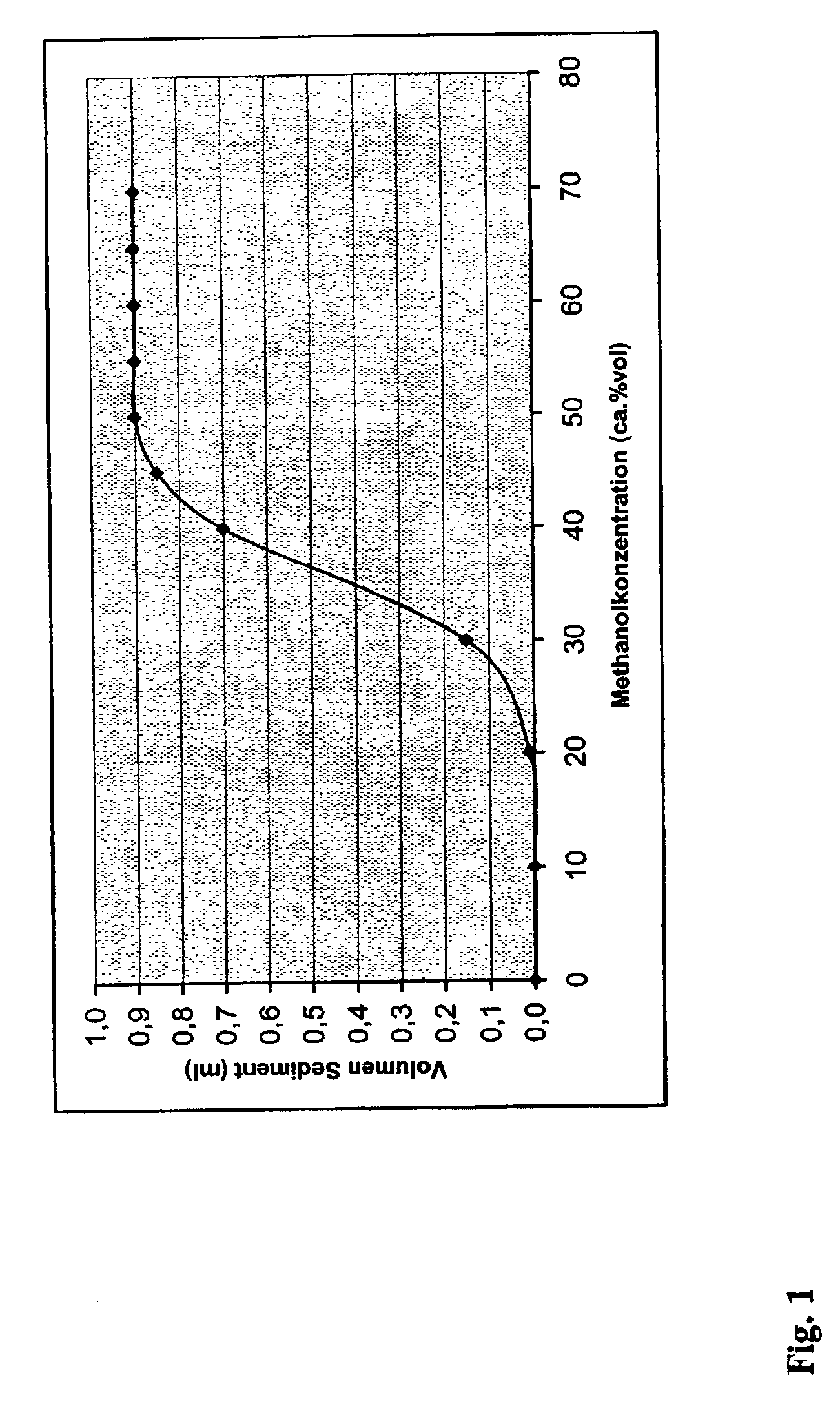

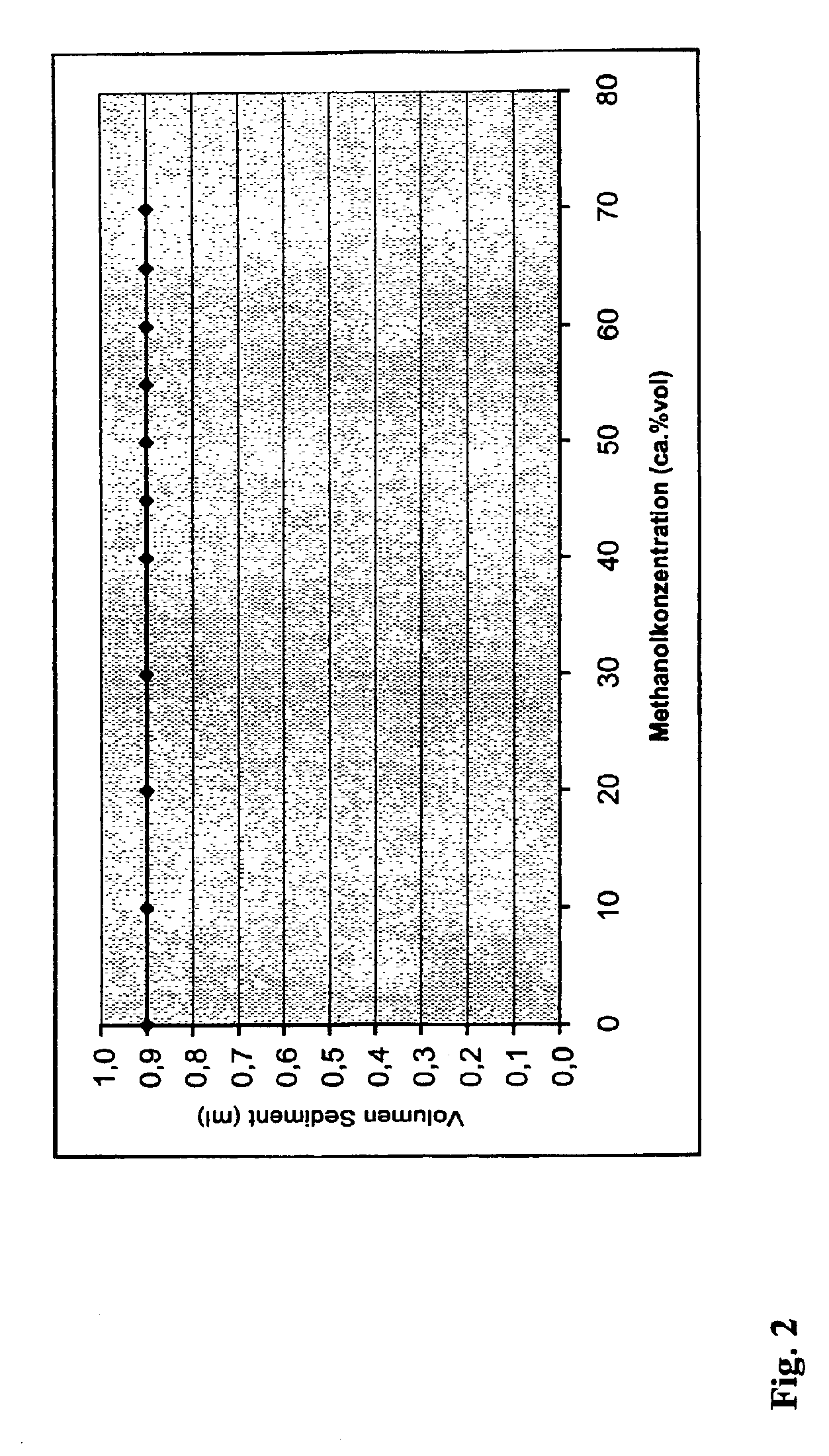

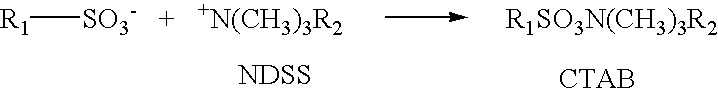

High-whiteness, non-heat-treated hydrophobic precipitated silica

InactiveUS6899951B2High whitenessImprove reinforcementSilicaGlass/slag layered productsDouble bottomSilicon dioxide

The present invention provides a hydrophobic precipitated silica having the following properties:carbon content1.0-8.0%methanol wettability 20-55%reflectance>94%BET / CTAB ratio ≦1DBP absorption<250 g / 100 gBET surface area 50-110 m2 / gCTAB surface area100-150 m2 / gSears number<13.The present invention also provides methods for making and using the hydrophobic precipitated silica and articles and compositions which include the same.

Owner:EVONIK DEGUSSA GMBH

Nano-zinc oxide coated sericite powder composite material and preparation method thereof

InactiveCN104017393AImproves UV resistanceImprove antibacterial propertiesCosmetic preparationsInorganic pigment treatmentCalcium hydroxideOrganic solvent

The invention discloses a sericite / nano-zinc oxide composite material and a preparation method thereof. The composite material is characterized in that the surface of sericite powder is coated with nano-zinc oxide. The preparation method comprises the following step: adding calcium hydroxide or calcium oxide into a mixed system of the sericite powder and zinc sulfate solution so as to directly obtain the nano-zinc oxide coated sericite powder composite material. According to the method, the sericite which is taken as a base material is a natural mineral, so that the raw material is easily available, free of pollution and low in cost; the preparation process is simple, safe, reliable and easy to control; the obtained composite material is stable in quality, and has the good dispersibility in an organic solvent and also has the excellent ultraviolet resistance and the excellent antibacterial and deodorant performance. Thus, the composite material can be applied to the field of coatings, cosmetics and the like. The method has a good potential application value in the field of synthesis of the composite material or other related sciences.

Owner:ANHUI HENGHAO SCI & TECH

Fiber-cast packaging with inner bag and method for the production thereof

InactiveUS20080210584A1Reduce air pollutionImprove water resistancePackage recyclingFlexible coversFiberMolded pulp

A package for free-flowing media comprising a molded pulp vessel partly or completely surrounding two or more film pouches or a film pouch having a plurality of chambers. An environmentally friendly package whose constituents can be reused without any great complexity.

Owner:HENKEL KGAA

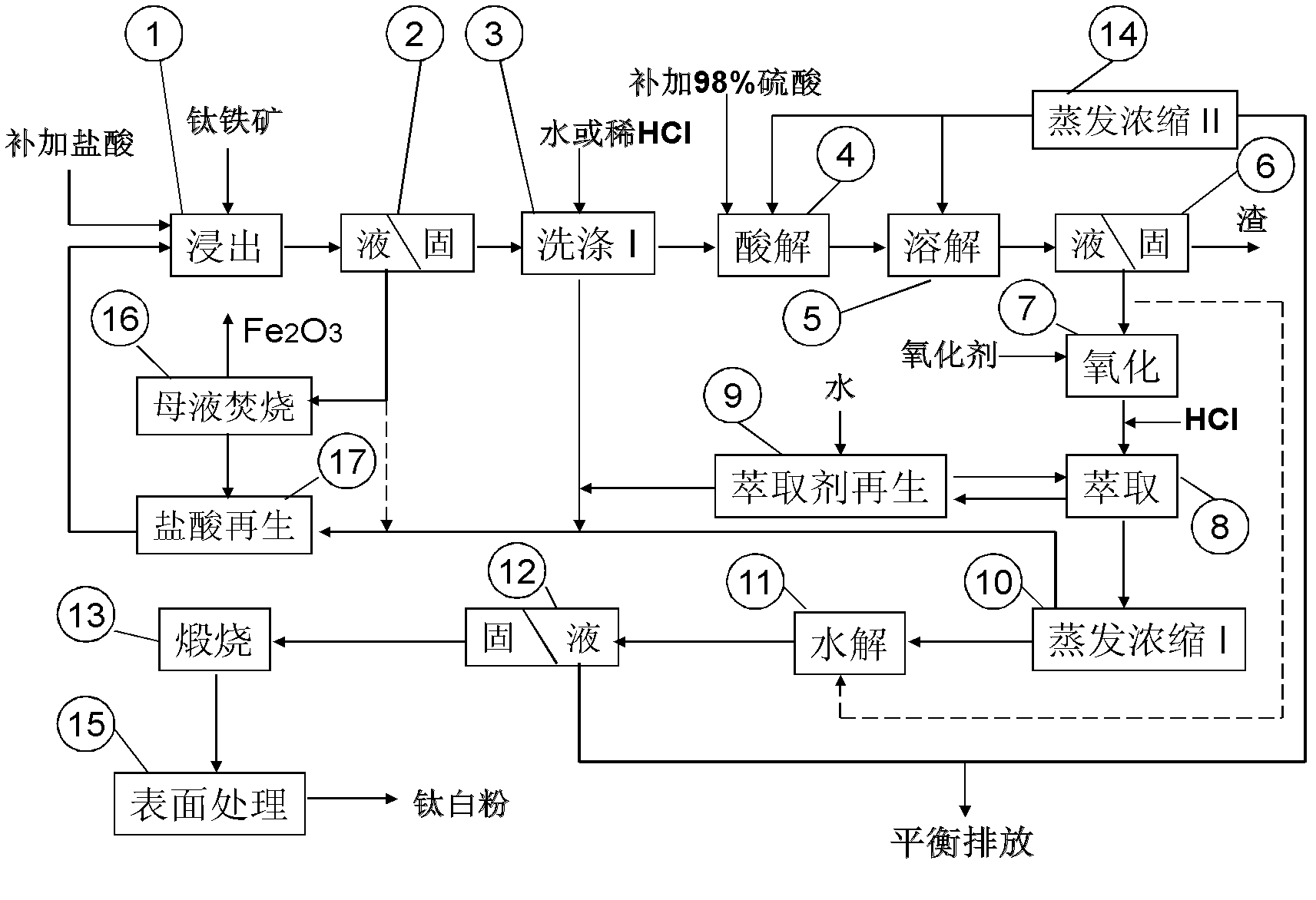

Method for preparing titanium white

The invention provides a method for preparing titanium white. The method comprises the following steps of: preparing titanium solution from high titanium hydrochloric acid leaching residue, which is prepared from a titanium iron material through a hydrochloric acid leaching method, serving as a raw material or one of raw materials through acidolysis by using sulfuric acid; oxidizing the titanium solution, performing organic extraction and purification, and hydrolyzing to obtain metatitanic acid; and performing washing, salt treatment, calcination and surface treatment on the metatitanic acid to prepare the titanium white. According to the method, hydrochloric acid composite system solution containing chlorate is subjected to diffluent disposal and is recycled after the titanium iron material is leached, and is organically matched with a cyclic process of an organic extraction and purification and sulfuric acid system of the titanium solution, so that the titanium solution treatment process and the cost are reduced; and since the used hydrochloric acid, sulfuric acid and organic extraction agent can be recycled, ferrous sulfate (green vitriol) is not produced; and thus, the discharge of dilute sulfuric acid and acidic wastewater is effectively reduced, and the quality of the titanium white is obviously improved. According to the method provided by the invention, high efficiency, cleanness, low cost, low energy consumption and low waste discharge effects of an entire flow are realized; a novel process technology is provided for producing the titanium white by a sulfuric acid method; and fine grained rock type ilmenite with high calcium and magnesium content at the Panxi area can be effectively utilized.

Owner:攀枝花新中钛科技有限公司

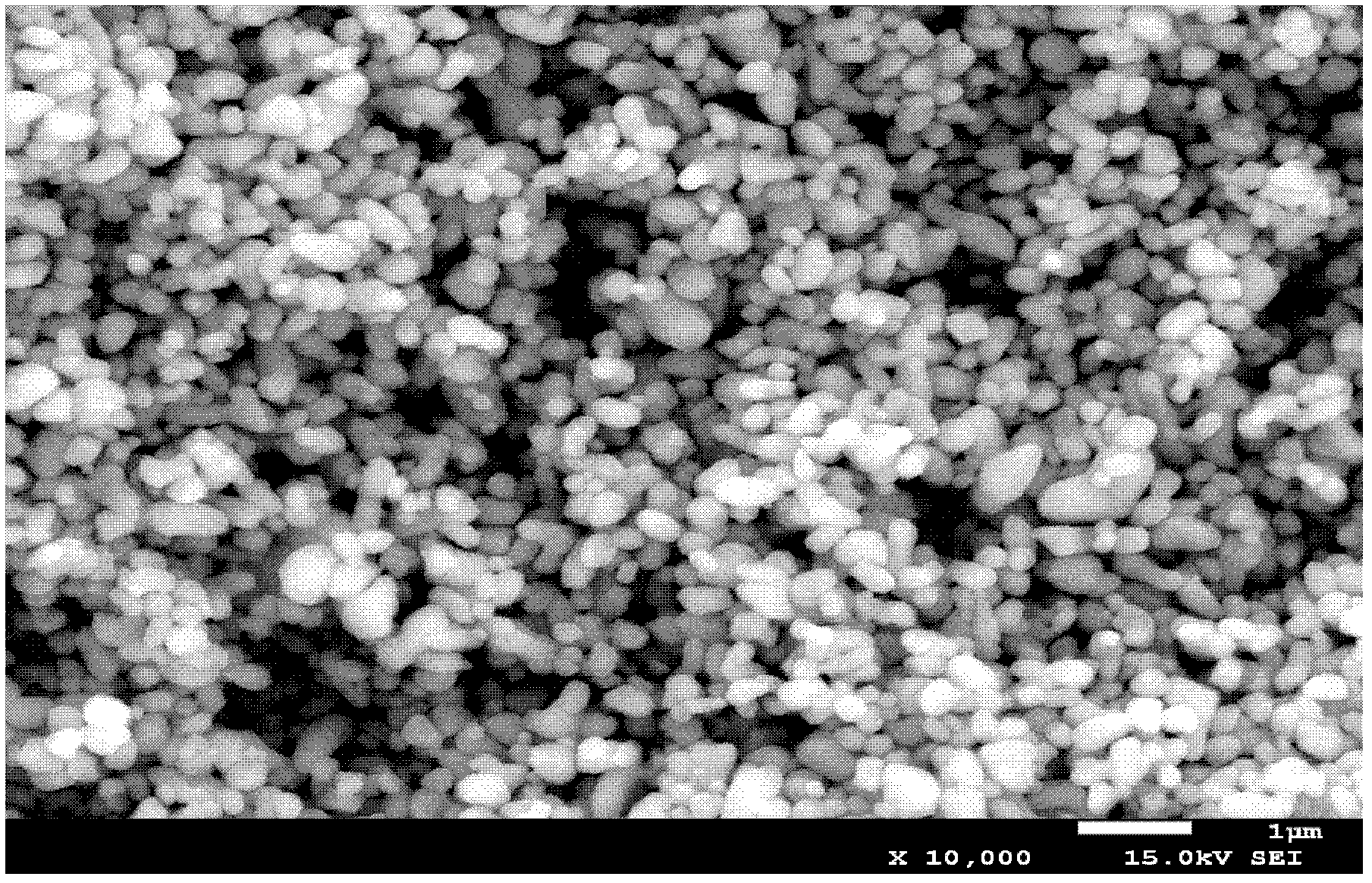

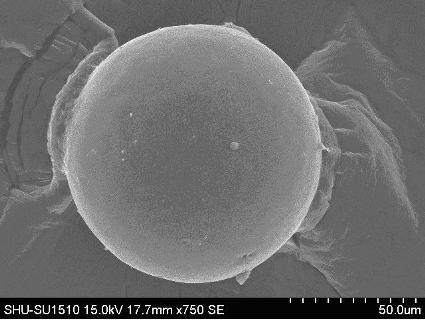

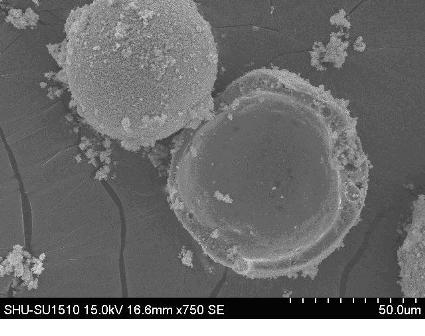

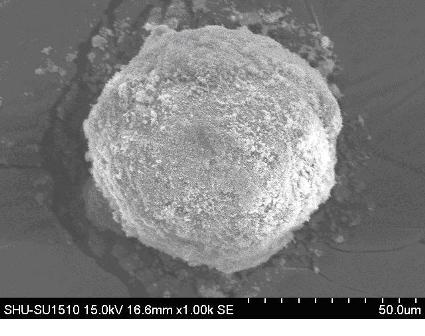

Method for preparing hollow glass microsphere coating titanium dioxide

InactiveCN102002263AEasy to depositExtended service lifePigment treatment with organosilicon compoundsReflecting/signal paintsFiltrationDistilled water

The invention discloses a method for preparing titanium dioxide for coating surfaces of hollow glass microspheres. The method comprises: washing the hollow glass microspheres with alkali liquor to remove impurities and etching to improve activity; performing surface activation and modification by using a silane coupling agent; mixing the activated hollow glass microspheres and distilled water in a mass ratio of 1:10; fully stirring at 40 to 90 DEG C; in the stirring process, dripping solution of titanium sulfate at a constant speed with in 2 to 6 hours according to a mass ratio of the hollow glass microspheres to the titanium sulfate of 1:0.8-1:1.6; slowly adding alkali liquor, keeping the pH value of the reaction system between 5 and 7, and stirring first at a speed of 400r / min for the first 1 / 5 of reaction time and then at a speed of 100 to 300r / min for the rest 4 / 5 of reaction time; and after the reaction is finished, standing, performing suction filtration, washing with distilled water, drying and calcining. The hollow glass microspheres coated with the titanium dioxide can serve as filler for reflective and thermal-insulation coating. Compared with common hollow glass microspheres, the hollow glass microspheres can be used for preparing and synthesizing high-performance coating combining various thermal-insulation mechanisms.

Owner:SHANGHAI UNIV

Washing, Cleaning and Care-Providing Agent

InactiveUS20090170744A1High whitenessCosmetic preparationsToilet preparationsTitanium dioxideChemistry

Washing, cleaning, and care-providing agents that comprise a light-active bleaching-agent system based on titanium dioxide. The titanium dioxide is by preference a titanium dioxide modified with carbon. The washing, cleaning, and care-providing agents exert a good cleaning effect in the context of textile treatment, the treatment of hard surfaces, cosmetic treatment of the human body, and the improvement of (indoor) air, and have a low impact on the treated substrates.

Owner:HENKEL KGAA

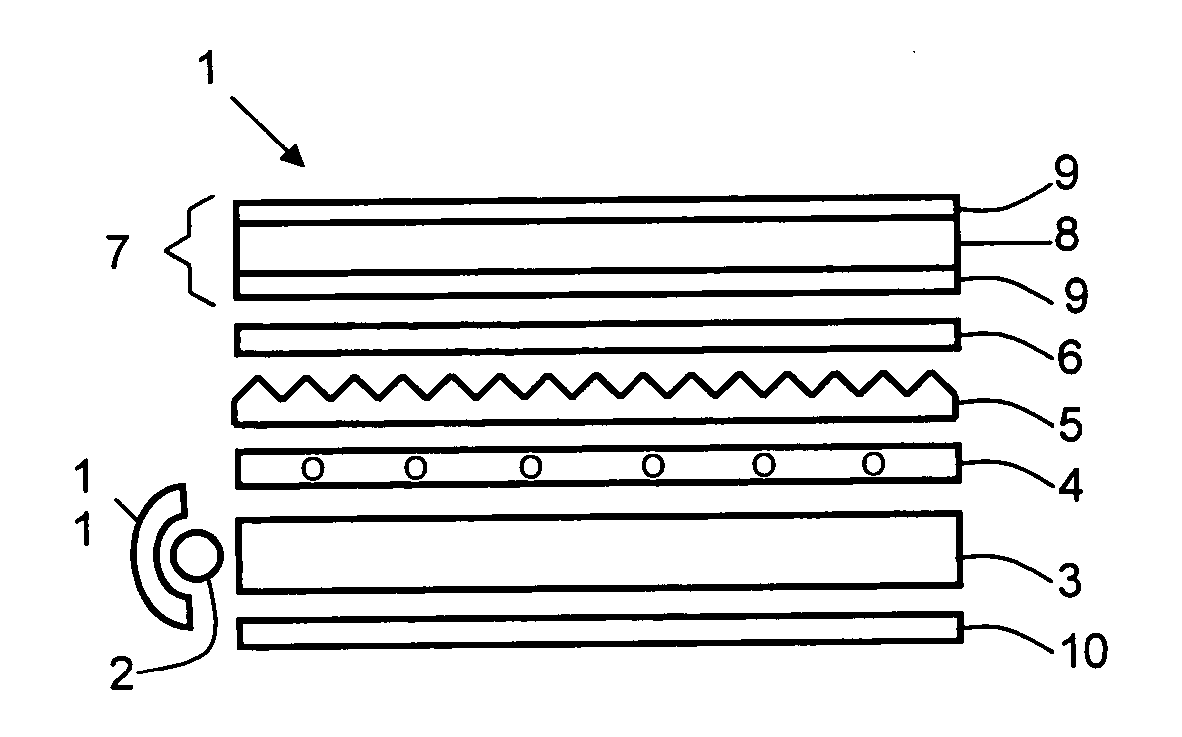

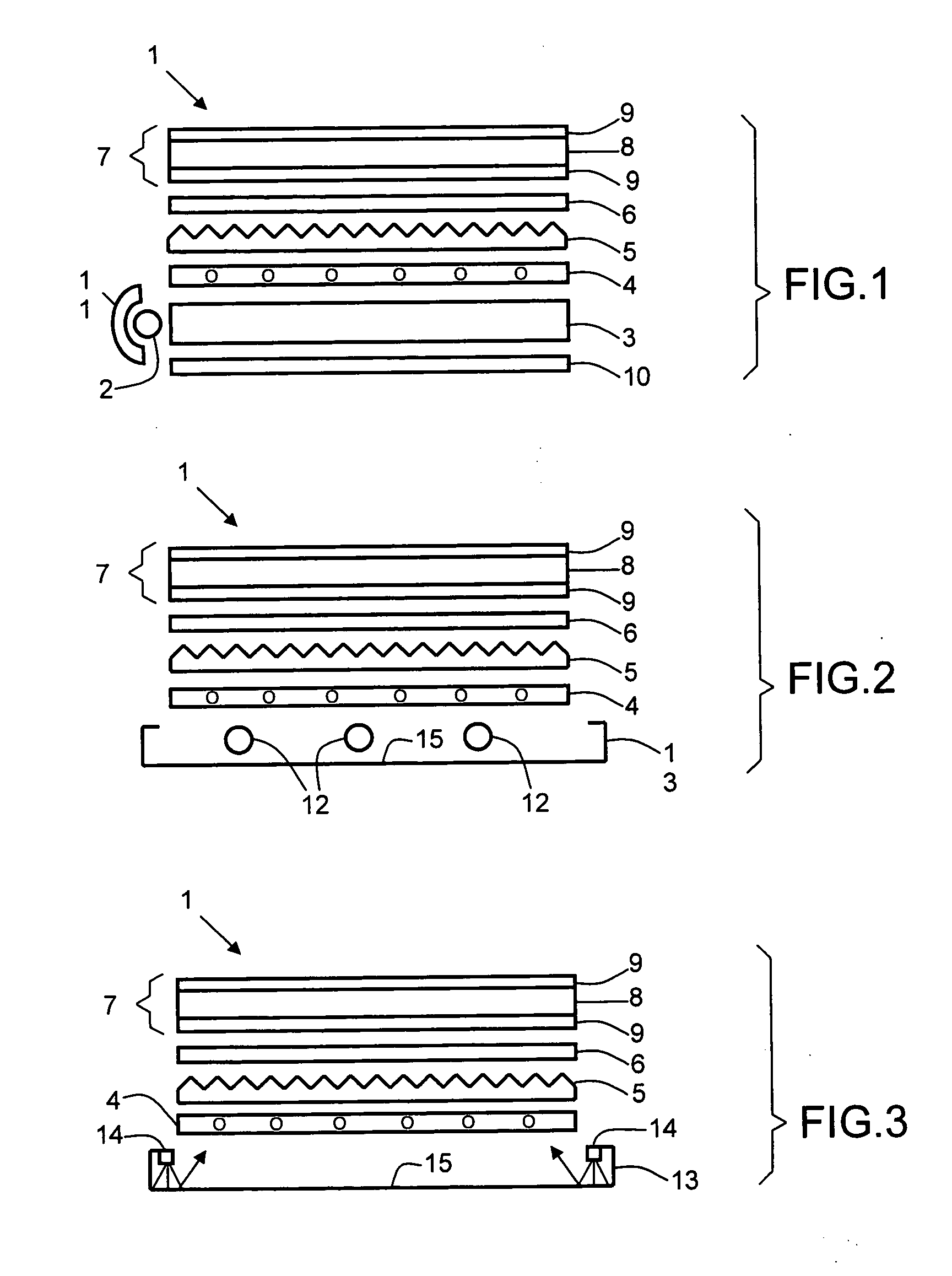

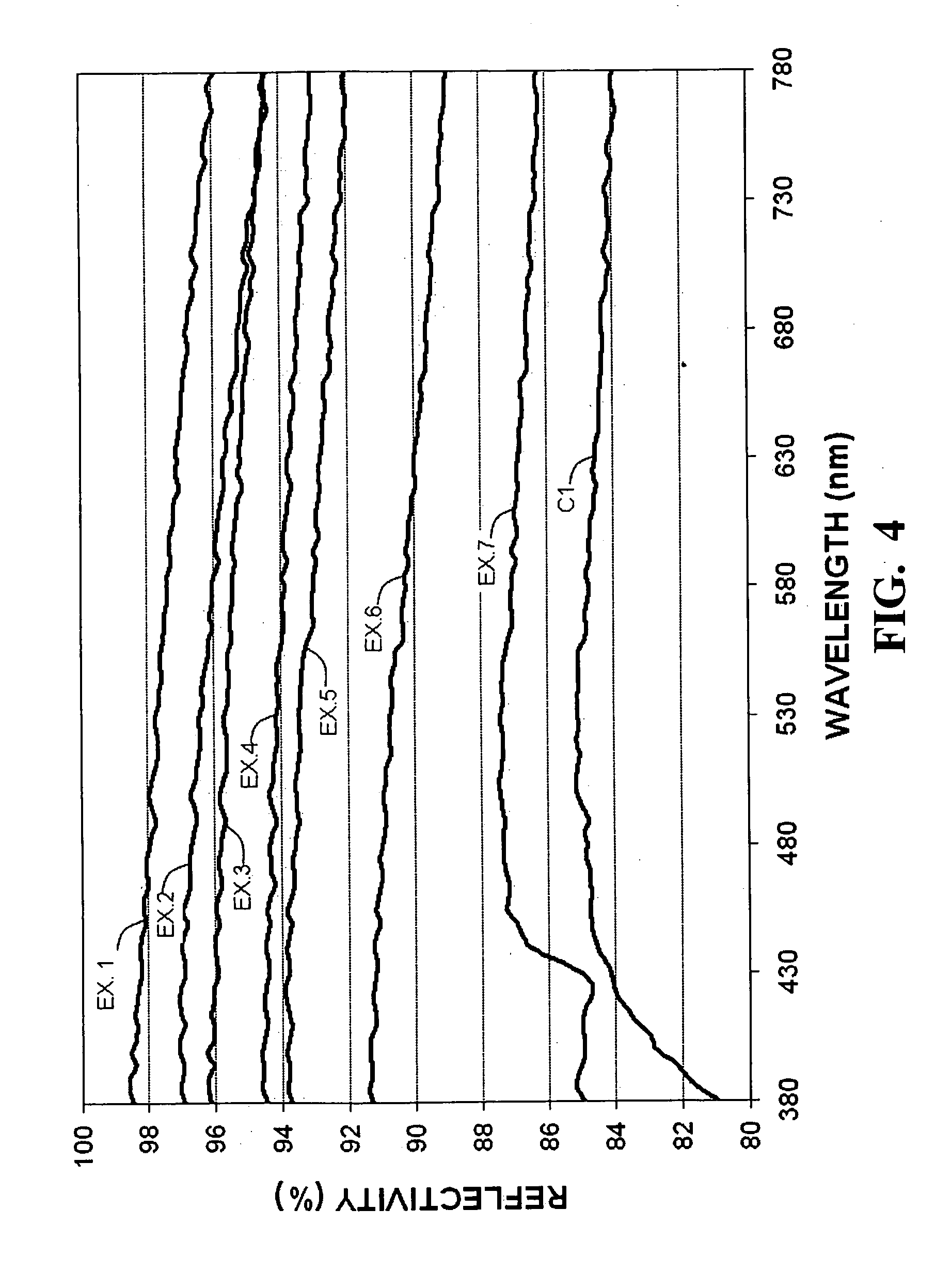

Diffuse reflective article

ActiveUS20060262310A1Improved and inexpensiveImprove reflectivityDiffusing elementsLayered productsFiberOptical cavity

A diffuse reflective article is provided including a diffuse reflector of light positioned within a structure defining an optical cavity. The diffuse reflector is a nonwoven sheet containing a plurality of inter-fiber and intra-fiber pores of optimal light scattering dimension. Also provided is an optical display, including: (i) a structure defining an optical cavity; (ii) a light source positioned within the optical cavity; (iii) a display panel through which light from the light source passes; and (iv) a diffuse reflector positioned within the optical cavity for reflecting light from the light source toward the display panel, wherein the diffuse reflector is a nonwoven sheet containing a plurality of inter-fiber and intra-fiber pores of optimal light scattering dimension.

Owner:DUPONT SAFETY & CONSTR INC

Pretreatment agent for ink jet textile printing, ink jet textile printing ink set, and method of ink jet textile printing

ActiveUS20130249996A1Increase in whitenessHigh whitenessDuplicating/marking methodsInksComposite materialPolymer chemistry

Owner:SEIKO EPSON CORP

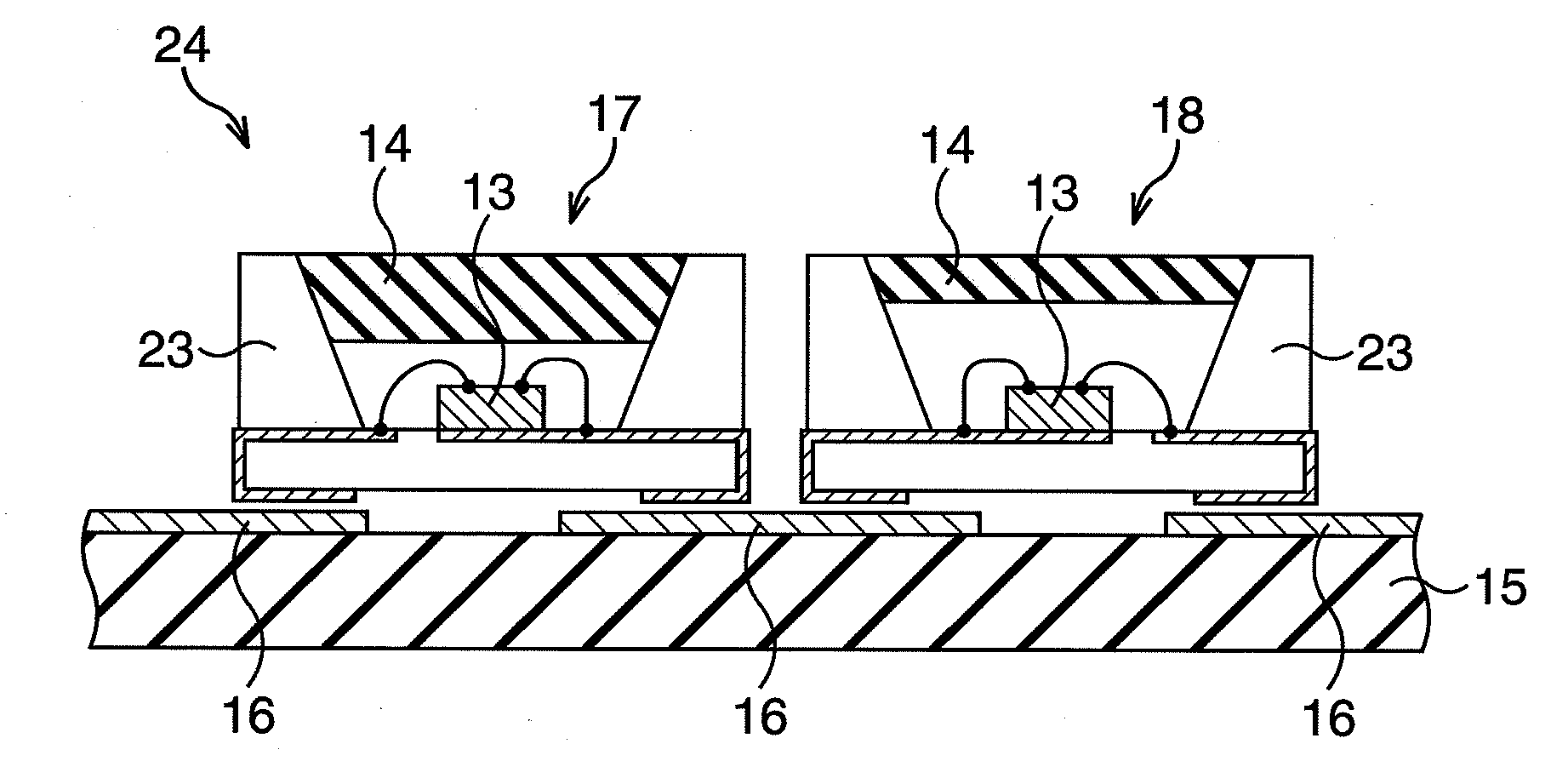

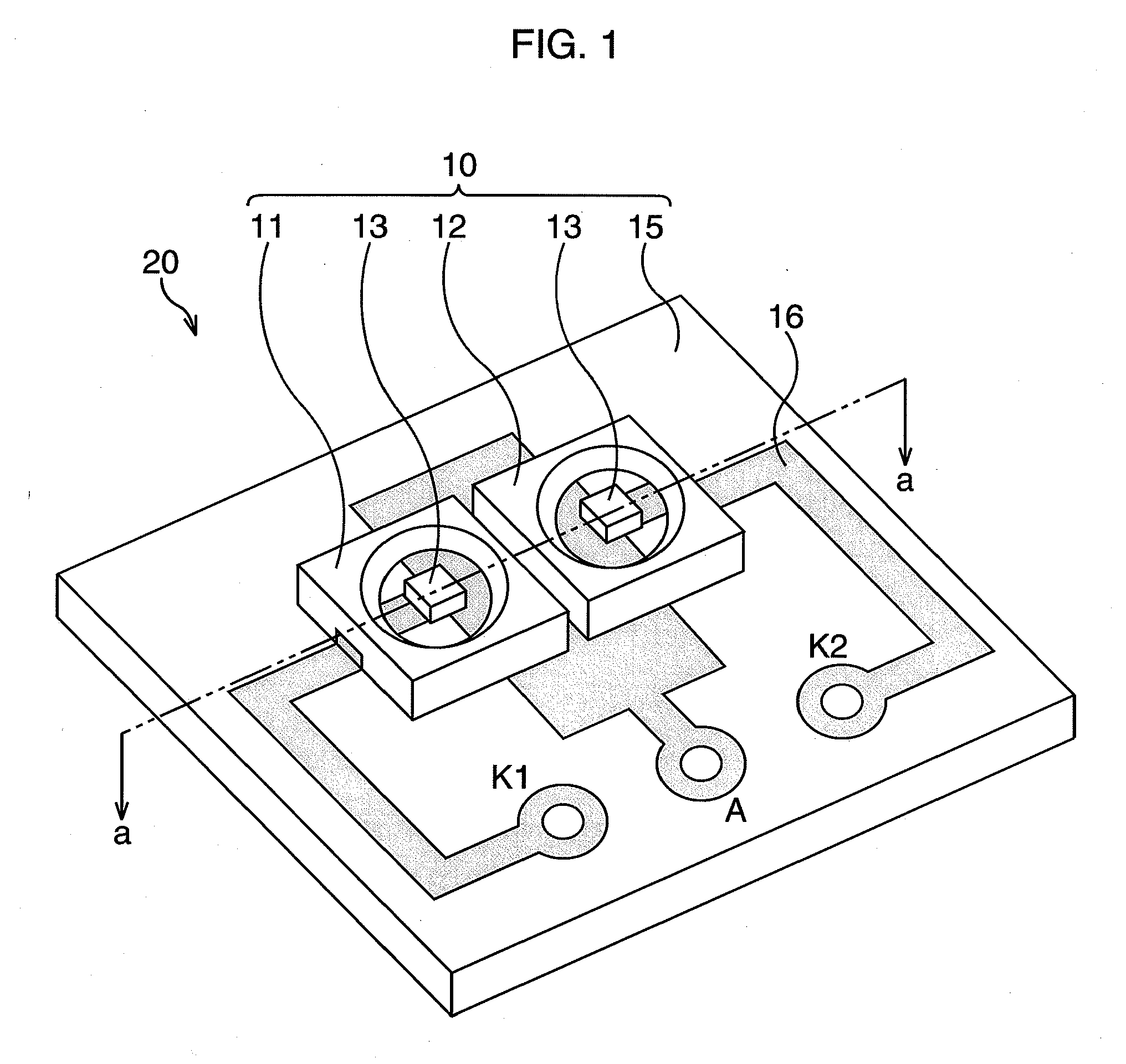

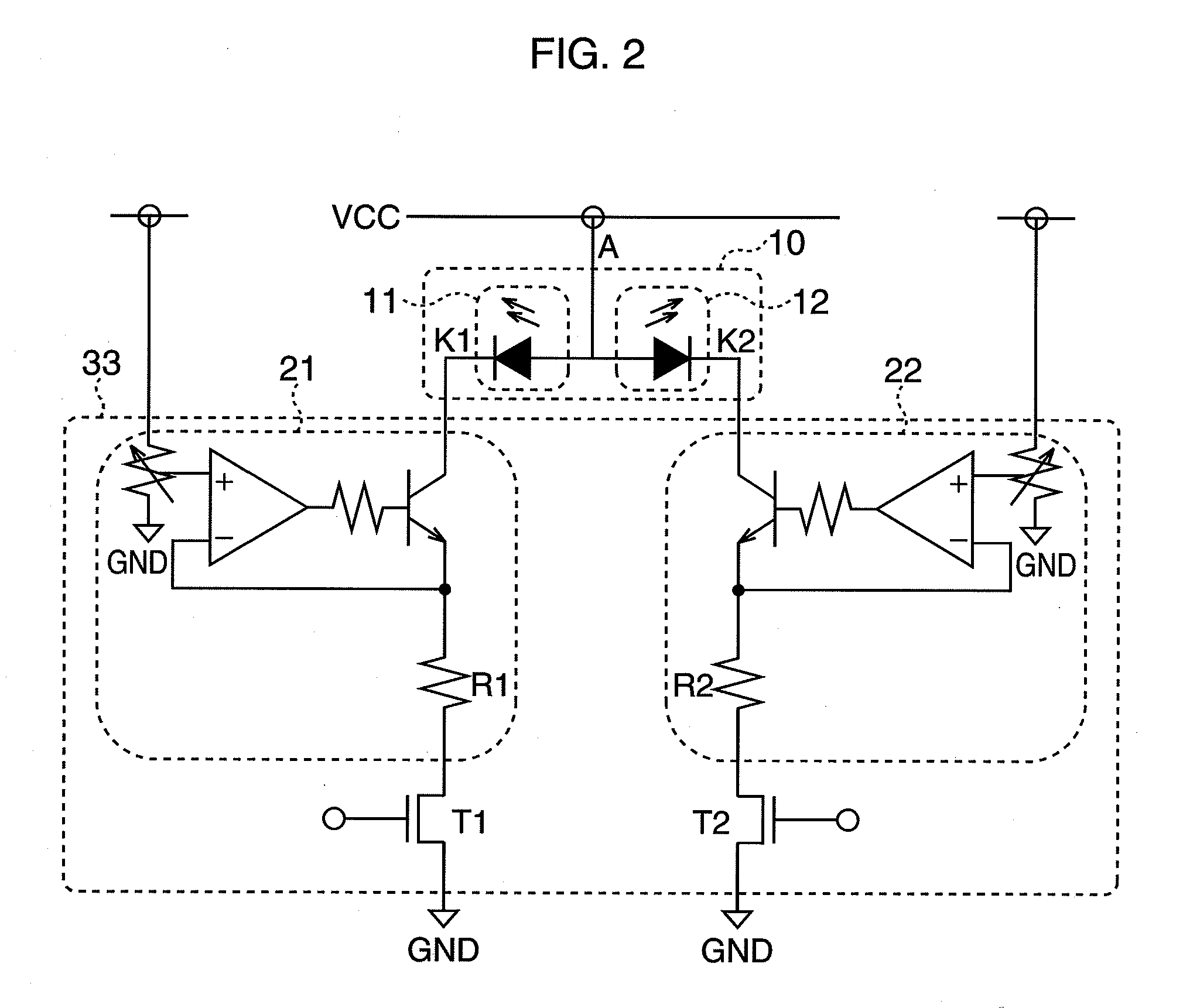

White light emitting diode, white light emitting apparatus, and linear illuminator using the same

InactiveUS20100244731A1High whitenessLow degree of whitenessMechanical apparatusElectroluminescent light sourcesDriving currentControl circuit

A white light emitting apparatus (20) is provided with a first white light emitting diode (11) that emits yellowish white and a second white light emitting diode (12) that emits bluish white in the same direction of the light emitted from the first white light emitting diode (11). The white light emitting apparatus (20) is further provided with a current control circuit that controls drive currents of the first and second white light emitting diodes (11, 12).

Owner:CANON COMPONENTS INC

Modified Polyamides, Uses Thereof and Process for Their Preparation

InactiveUS20090149590A1Conveniently addedImprove hydrolysis resistancePigmenting treatmentAlkaline-earth metal silicatesChemical LinkageAlcohol

A polymeric matrix having improved flowability and wettability is provided, as well as a process for making it. The matrix contains a polyamide and a polyhydric alcohol which is chemically bonded at least to a part of the polyamide, and it is suitable particularly for manufacturing fiber-reinforced polyamide articles exhibiting a very good surface appearance and excellent mechanical properties.

Owner:NILIT

Acrylic photovoltaic module backsheet

ActiveUS20110315189A1Easy to mergeEasy to stickPV power plantsSynthetic resin layered productsPolymer sciencePolyethylene terephthalate glycol

The invention relates to an acrylic layer (in the form of a coating, film or sheet) useful as part of a photovoltaic module backsheet. The acrylic layer contains at least 40 percent of one or more acrylic polymers, including an acrylic polymer matrix and optionally acrylic impact modifiers. The acrylic polymer is preferably a polymer, copolymer, or terpolymer containing at least 50 weight percent of methylmethacrylate monomer units. The acrylic layer is flexible and optionally contains high levels of white pigment. It may also contain fluoropolymers such as polyvinylidene fluoride to improve weathering, processibility and film formation. The acrylic layer adheres to a polymer support layer such as polyethylene terephthalate (PET). A preferred substrate is PET that is pre-treated to improve adhesion, but unprimed PET can also be used. The backsheet provides excellent weatherability, environmental stability and reflectivity as part of a photovoltaic module.

Owner:TRINSEO EURO GMBH

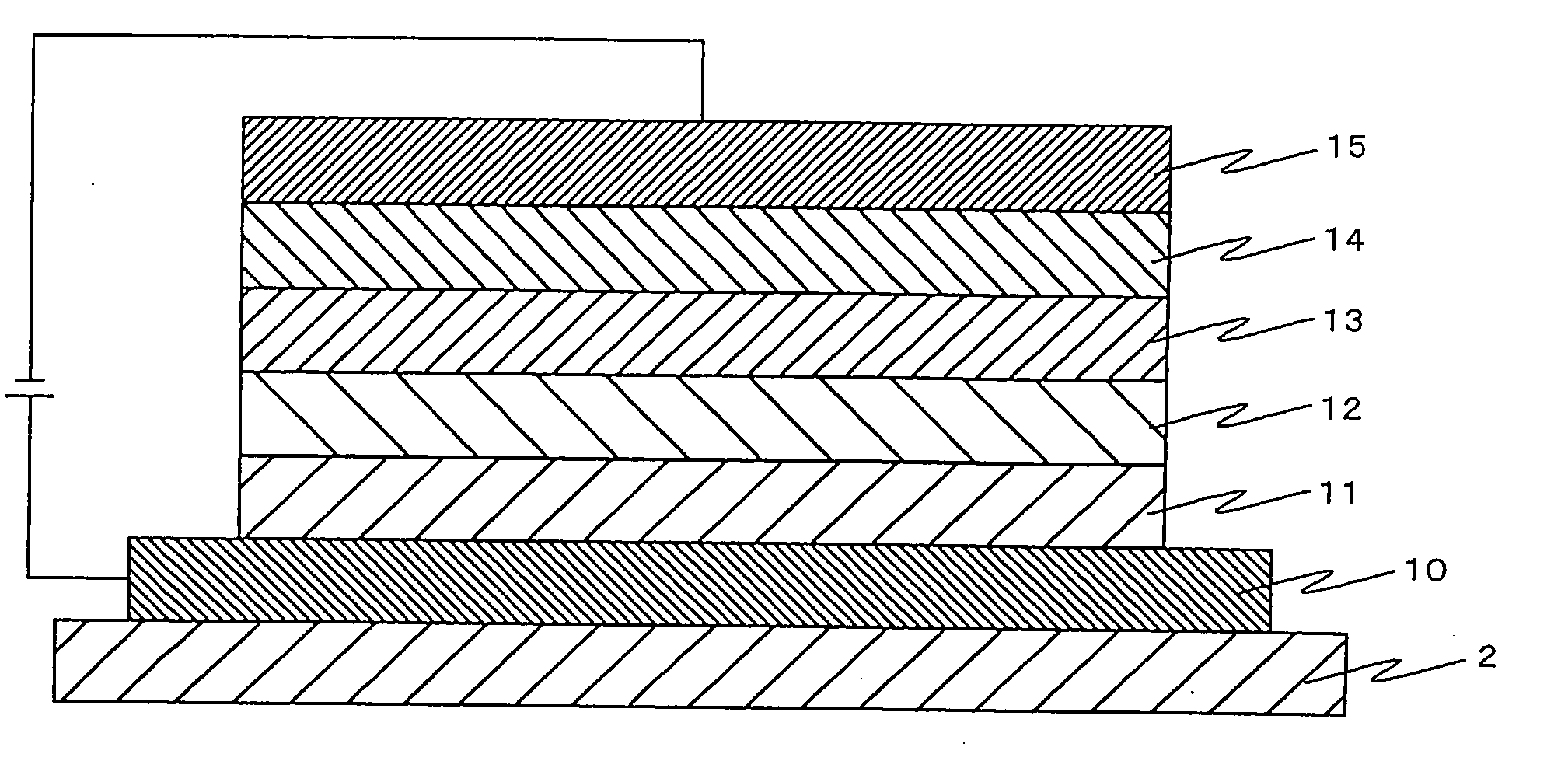

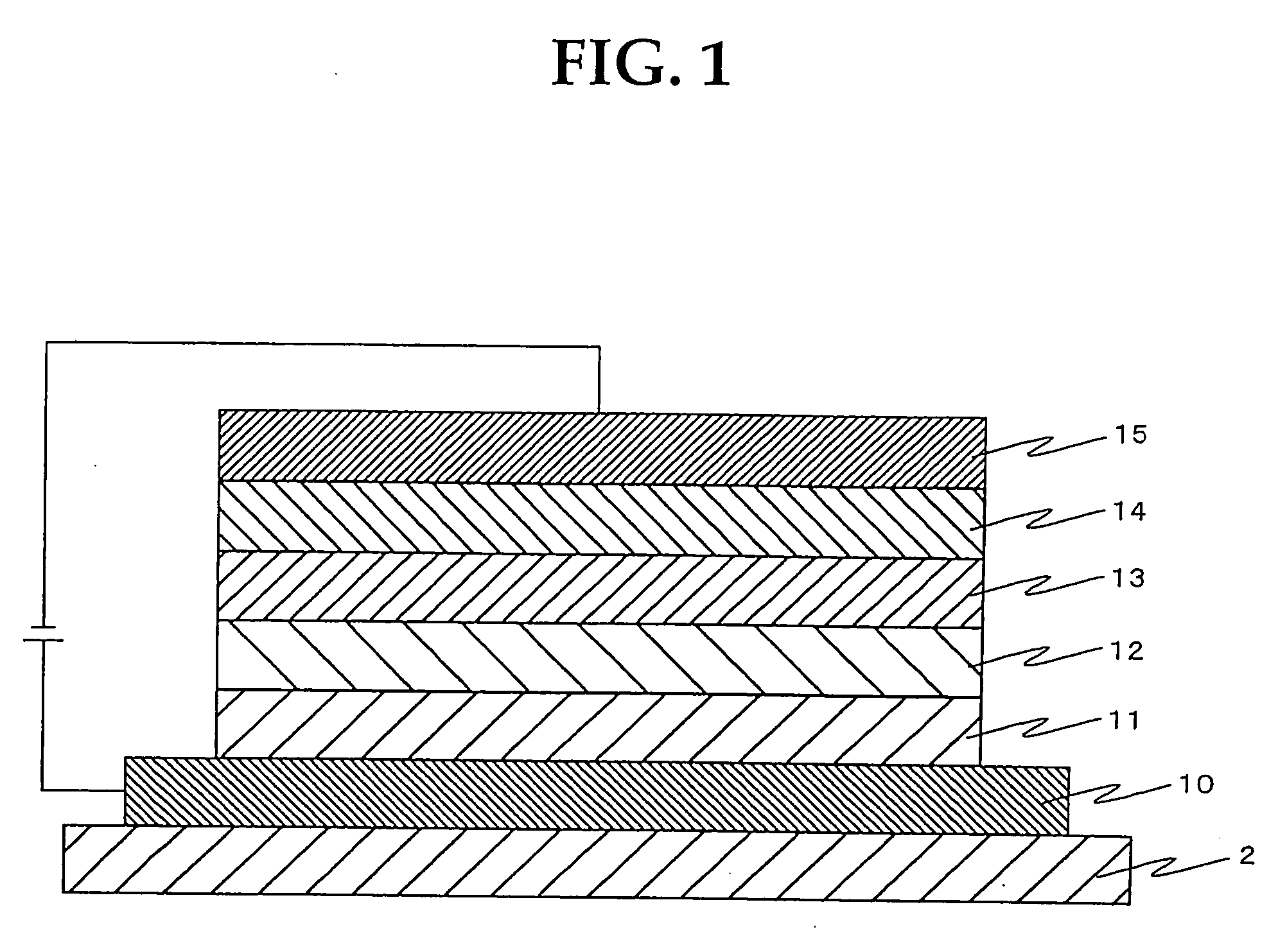

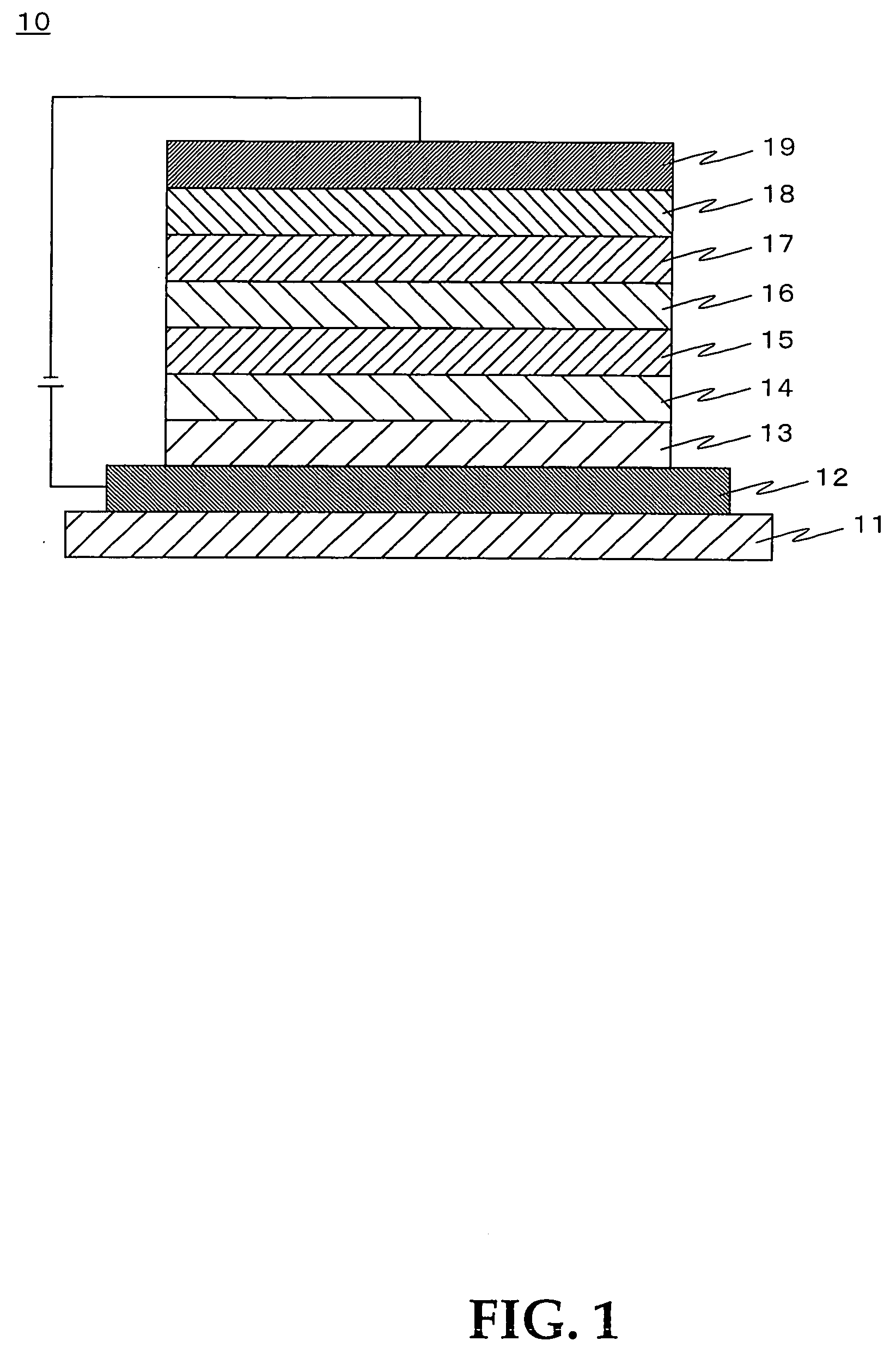

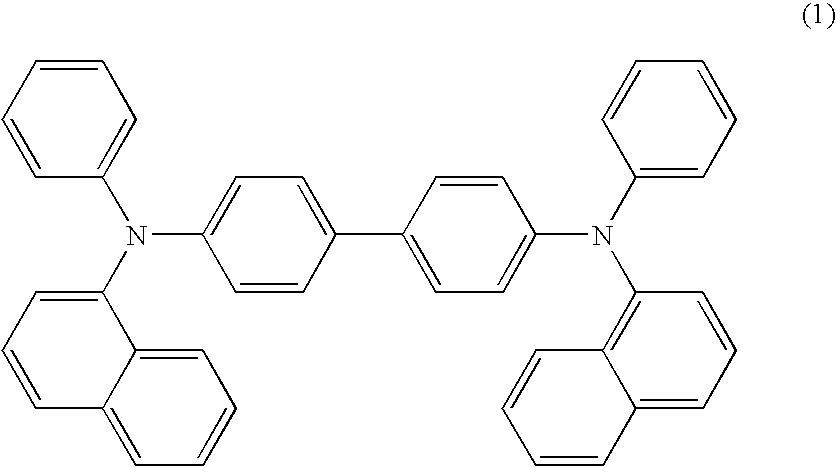

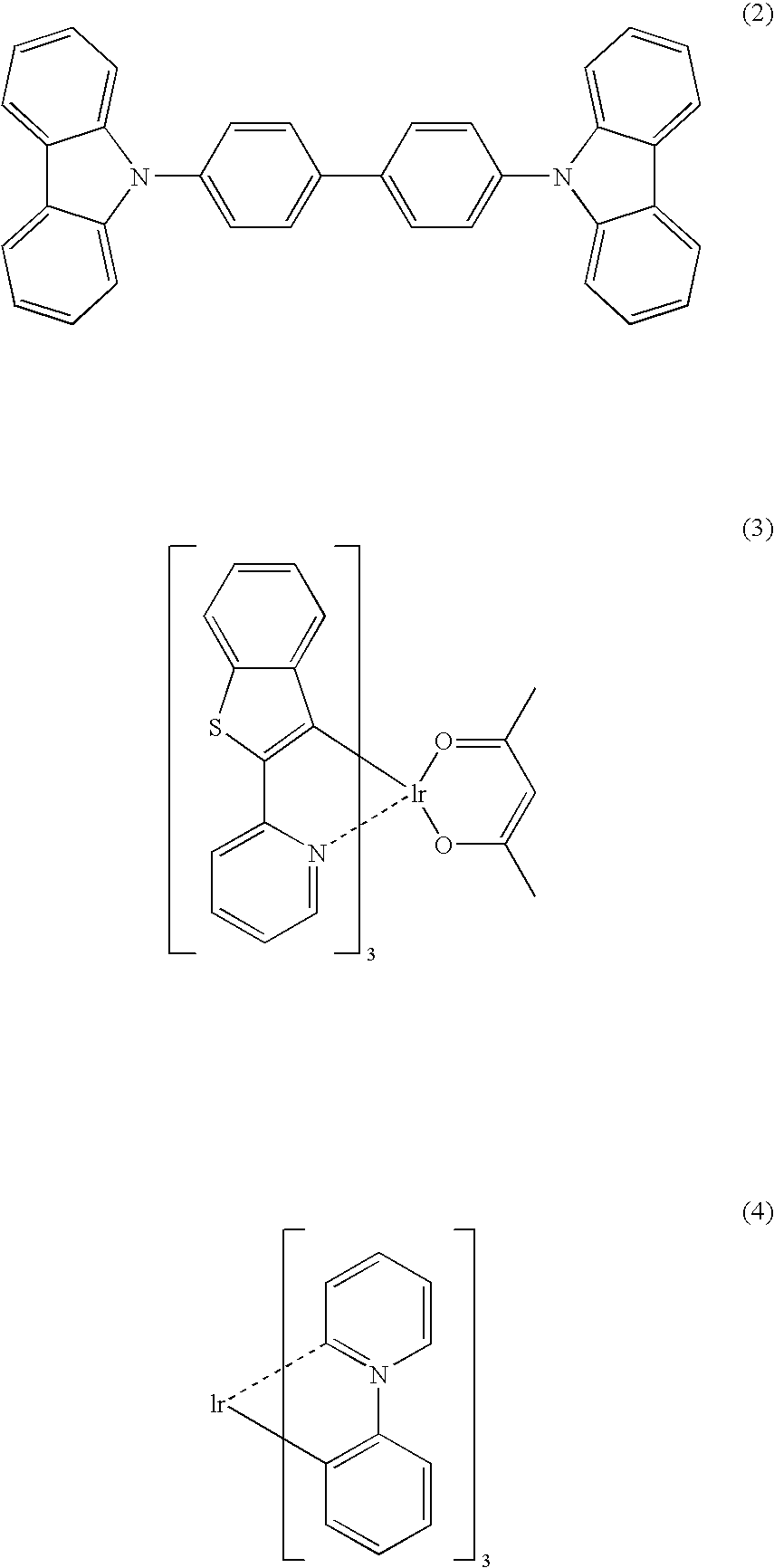

Organic electroluminescent device

InactiveUS20060214553A1Improve efficiencyHigh whitenessDischarge tube luminescnet screensElectroluminescent light sourcesElectron injectionTransport layer

The present invention provides organic EL devices which have on their anode at least a light-emitting layer, an electron-injecting-transporting layer, and a cathode giving an elongated lifetime, organic EL devices giving a superior whiteness, a higher light-emitting efficiency, and an elongated lifetime compared to conventional ones, and color displays using such organic EL devices. On anode (10), hole-injecting-transporting layer (11), light-emitting layer (12), non-light-emitting layer (13), electron-injecting-transporting layer (14), and cathode (15) in this order are laminated. Otherwise, on an anode, a hole-injecting layer, a hole-transporting layer, a red light-emitting layer, a blue light-emitting layer, an electron-transporting layer, an electron-injecting layer, and a cathode in this order are laminated.

Owner:TOYOTA IND CORP

Titanium dioxide pigment and method for producing the same and resin composition using the same

InactiveUS20050228112A1High opacityLow hardnessInorganic pigment treatmentTitanium dioxideColor toneChemistry

The titanium dioxide pigment of the present invention contains an anatase type crystal in an amount of 98-100% and has an average particle diameter of 0.2-0.4 μm and a whiteness of 95-97 in terms of L value of linseed oil. The titanium dioxide pigment of the present invention has characteristics peculiar to anatase type, for example, optical characteristics such as bluish color tone and physical characteristics such as low hardness, and furthermore has high opacity which is not possessed by conventional anatase type titanium oxide pigments.

Owner:ISHIHARA SANGYO KAISHA LTD

Seashell-diatom ooze wall surface decoration wall material and production and construction method thereof

The invention discloses a seashell-diatom ooze wall surface decoration wall material and a production and construction method thereof. The decoration wall material comprises: 20 to 98 parts of shell powder, 8 to 30 parts of silica, 4 to 100 parts of kieselguhr, 2 to 20 parts of medical stone, 3.8 to 48 parts of mica powder, 2 to 10 parts of magnesium-rich silicate, 6 to 26 parts of scolecite, 1.5to 36 parts of hydrosilicate, 0 to 50 parts of titanium dioxide powder, 2 to 50 parts of calcium carbonate, 0.1 to 0.3 part of vegetable fiber, 1 to 30 parts of pigment, 4.8 to 40 parts of kelp powder, 1 to 30 parts of cold soluble polyvinyl alcohol powder and 1 to 20 parts of hydroxypropyl methyl cellulose. The production and construction method comprises: placing the raw material components into a stirrer for uniform stirring; filling the mixture in bags, packing the bags in boxes, sealing the boxes and storing the boxes in a storehouse; adding water into the mixture and stirring the mixture uniformly; and pasting the mixture on a wall surface to be decorated to make various texture patterns. The seashell-diatom ooze wall surface decoration wall material has the advantages of: (1) soft texture and no toxicity, fading nor stripping; (2), characteristics of eliminating indoor pollution, regulating indoor humidity, eliminating odor, isolating noises and offering high skin texture feel; (3) fire proofing and flame retarding; and (4) rich color.

Owner:青岛泉佳美硅藻泥科技有限公司

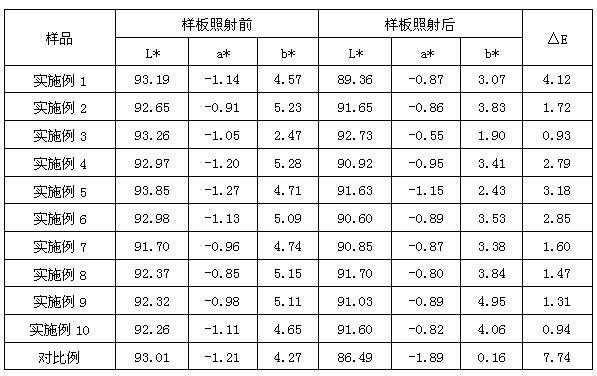

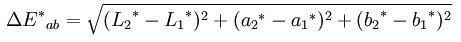

Production method of high-light-fastness rutile type titanium dioxide

ActiveCN101857736AImprove light resistanceHigh whitenessInorganic pigment treatmentTitanium dioxideTitanium

The invention discloses a production method of high-light-fastness rutile type titanium dioxide, which comprises the following steps such as preparing slurry containing rough titanium dioxide, diluting the slurry, adding phosphorus compounds, adding zirconium compounds, adding phosphorus compounds, adding alkaline aluminum compounds, curing, filtering, washing, drying, and crushing. By controlling the adding order and the additive amount of saline components of each material, the added coating agent can precipitate onto the surface of titanium dioxide particles respectively in forms of zirconium phosphate, aluminum phosphate and hydrated aluminum oxide, then through the process like curing, filtering, washing, drying and steam flow crushing, light fastness of the titanium pigment product can be increased, and the characteristics such as high brightness and high opacity can be maintained. Moreover, the dispersibility of the titanium pigment product in an aquosity system is improved, thereby facilitating slurry preparation, slurry storage and the like in use of titanium dioxide.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

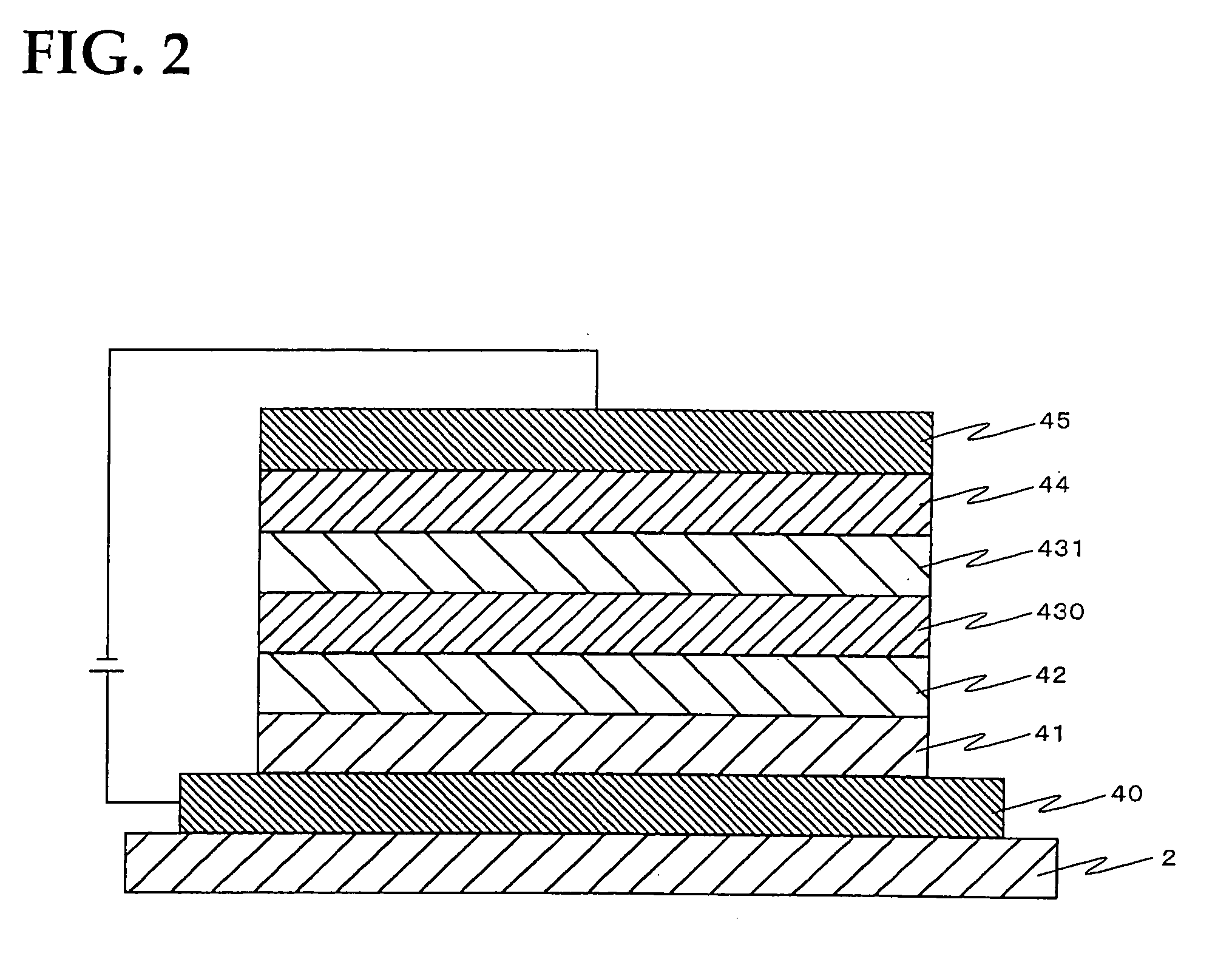

Organic EL devices

InactiveUS20060125380A1Improve efficiencyHigh whitenessDischarge tube luminescnet screensElectroluminescent light sourcesChemistryDopant

Organic EL devices having a light-emitting layer comprising a fluorescent dopant, a light-emitting layer comprising a phosphorescent dopant, and a non-light-emitting interface layer provided between an anode and a cathode wherein the light-emitting layer comprising a fluorescent dopant is provided nearer to the cathode than the light-emitting layer comprising a phosphorescent dopant and wherein the non-light-emitting interface layer is provided between the light-emitting layer comprising a fluorescent dopant and the light-emitting layer comprising a phosphorescent dopant.

Owner:TOYOTA IND CORP

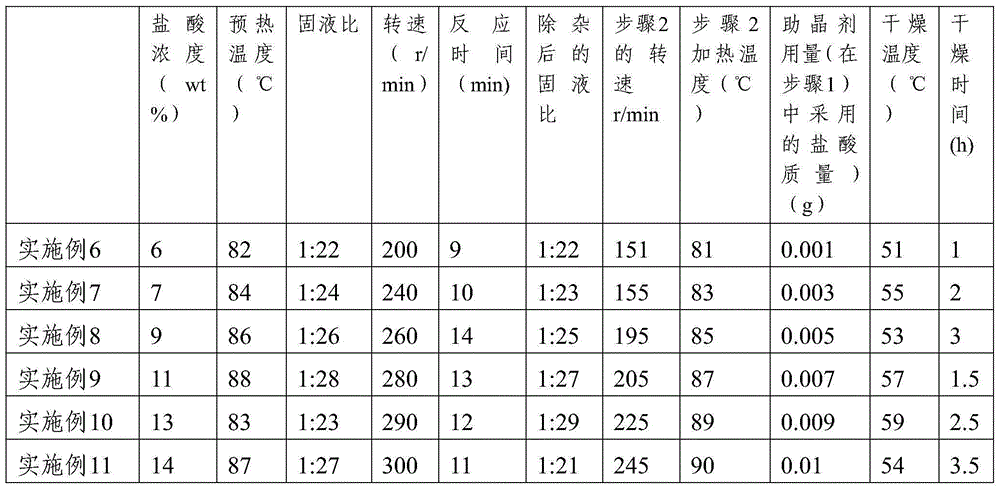

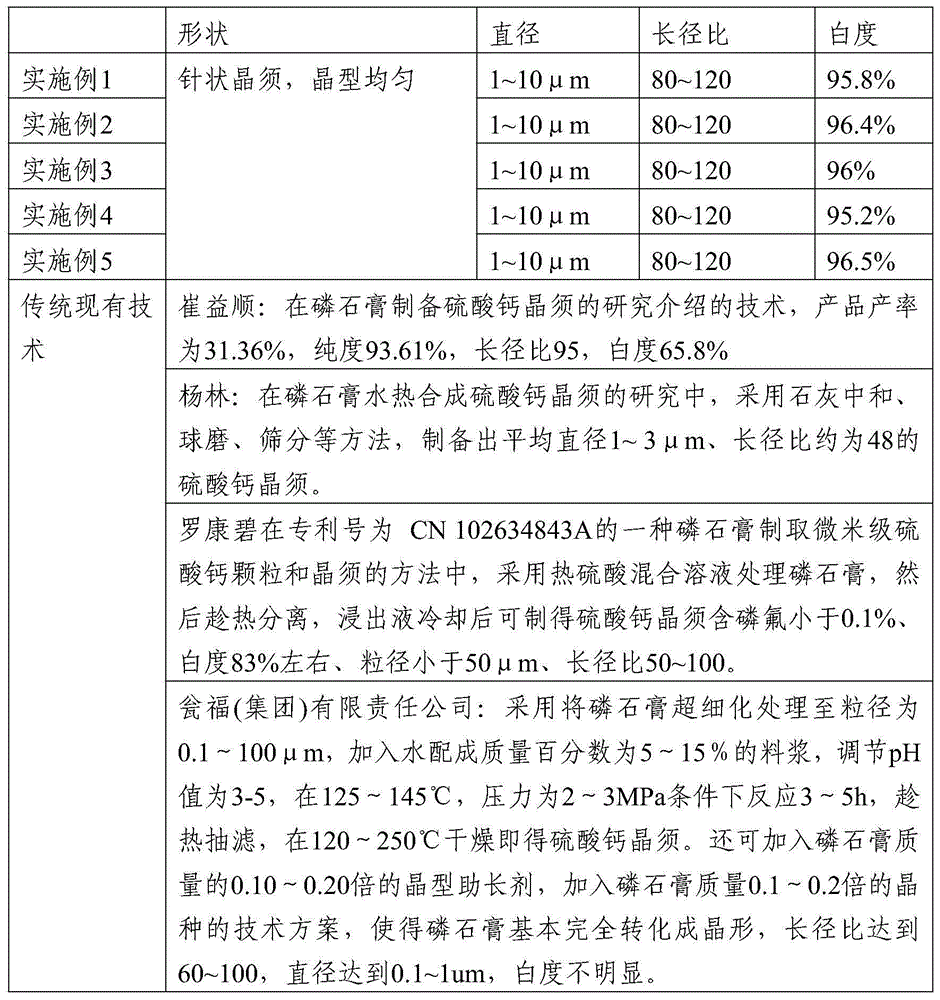

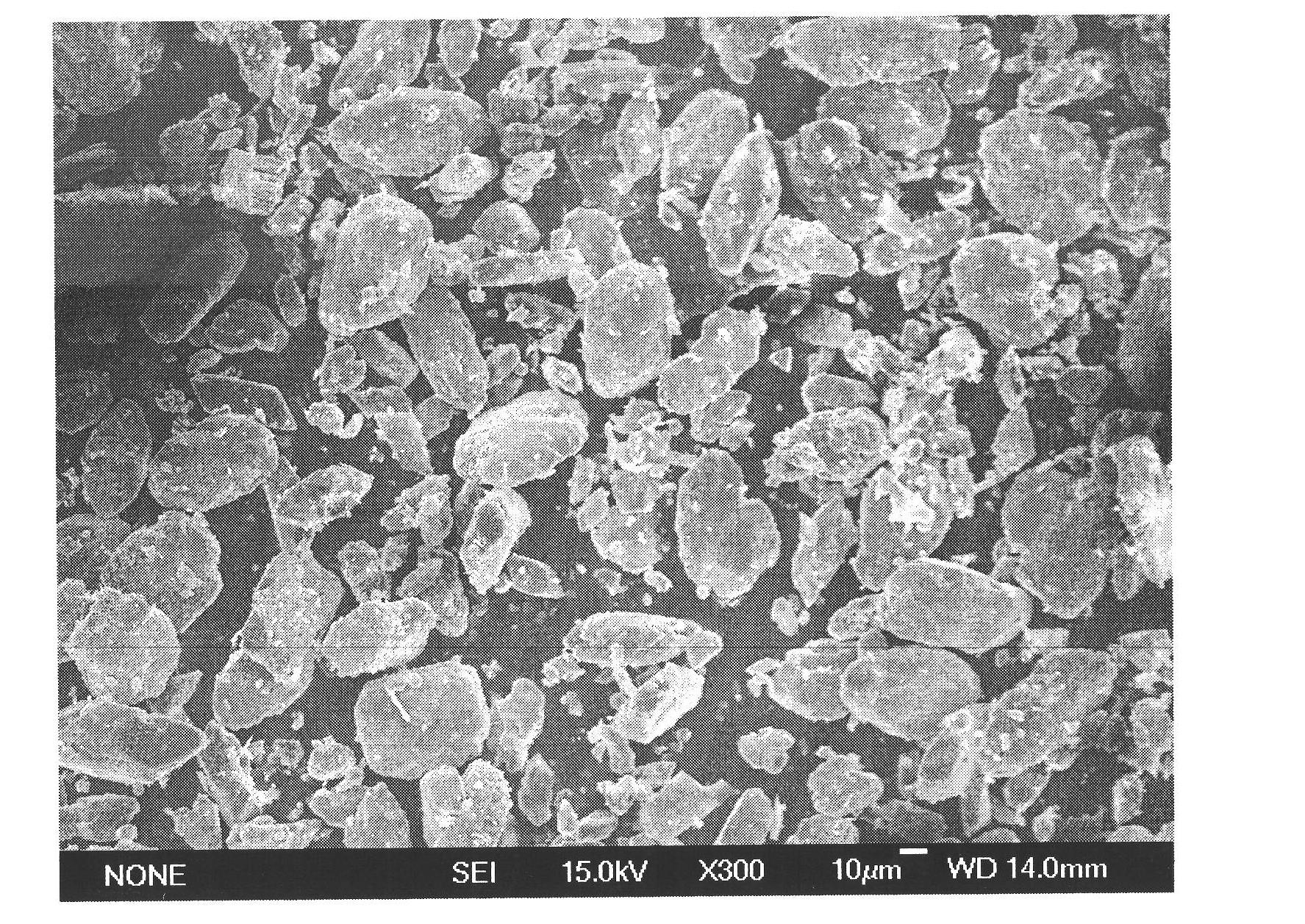

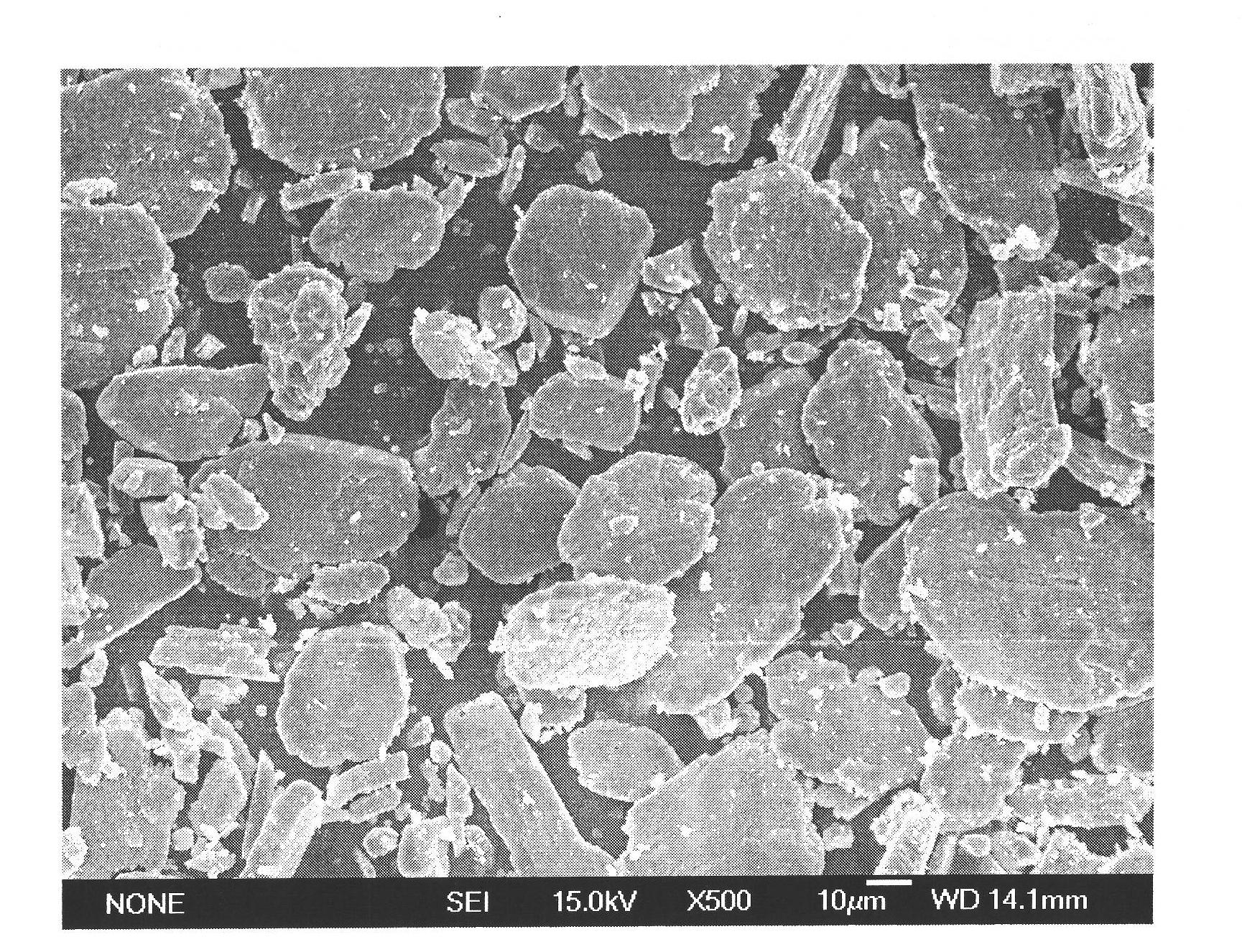

Method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum

InactiveCN104005086ANot to be wastedReduce generation influence ratePolycrystalline material growthFrom normal temperature solutionsProduction rateSulfate

The present invention relates to the technical field of chemical raw material preparation, and particularly to a method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum. The method comprises the following steps: preparing calcium sulfate dihydrate without impurities, preparing a crystal whisker, washing, and drying to obtain the calcium sulfate dihydrate crystal whisker. By preheating hydrochloric acid and matching the hydrochloric acid with phosphorus gypsum at a certain ratio at a constant temperature, the reaction can proceed and the materials is not wasted, the impurities contained in the phosphorus gypsum can be properly removed maximatily, the impact rate of impurities on the generation of calcium sulfate dihydrate crystal whisker is decreased, the content of calcium sulfate component is increased, the production rate of calcium sulfate dihydrate crystal whisker is improved and the production costs of calcium sulfate dihydrate crystal whisker prepared by comprehensively utilizing phosphorus gypsum are reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

Ceramic polished brick and method for producing the same

The invention discloses a ceramic polished tile, which uses magnesian clay as a main plastic raw material, and mainly uses a SiO2-MgO-CaO-Al2O3 quaternary phase as a formulation system, wherein the SiO2 is between 65 and 85 percent, the MgO is between 5 and 20 percent, the CaO is between 3 and 15 percent, the Al2O3 is between 3 and 15 percent, KNa2O is between 0 and 3 percent, and Fe2O3 and TiO2 are between 0 and 2 percent. The invention also discloses a method for producing the ceramic polished tile. The ceramic polished tile uses the magnesian clay as the plastic raw material so that the source of the raw material is broadened,; and with the addition of talc and quartz, the ceramic polished tile has the characteristics of high brightness, high strength, high hardness, good wear resistance and the like, and has the advantages of wide range of firing temperature, small shrinkage, low product proportion, reduced production cost, low price and high quality, improved product competitive power, and great promoting function for the development of the ceramic polished tile industry.

Owner:况学成 +1

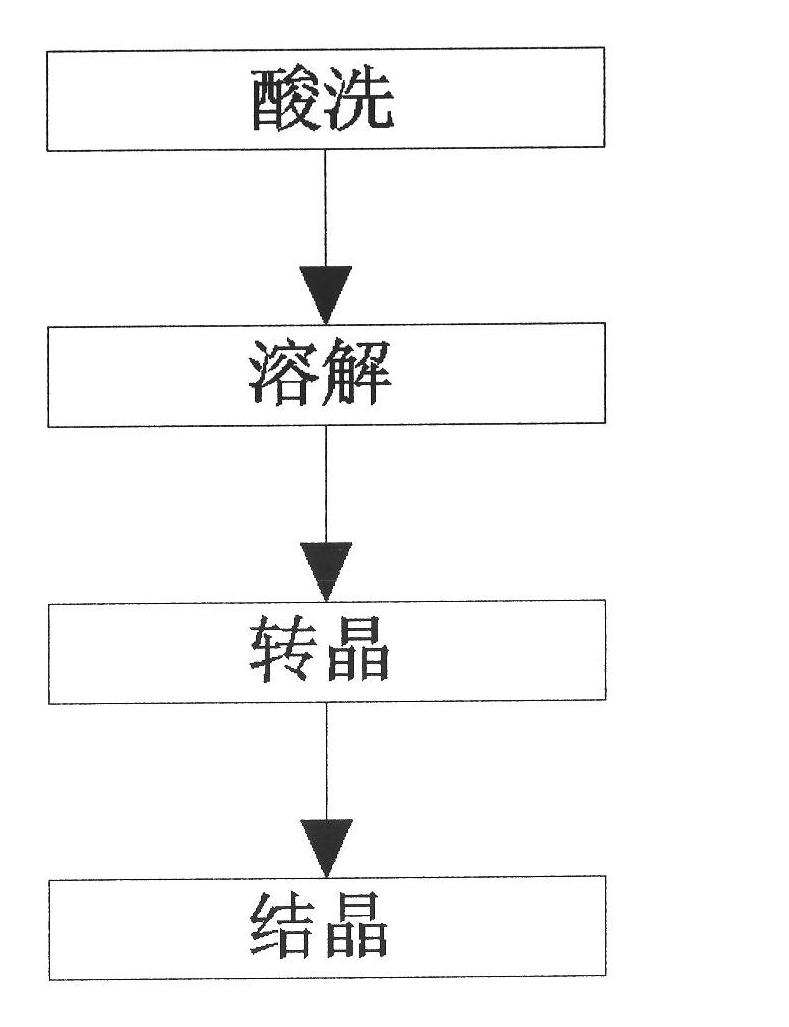

Method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure

ActiveCN102352535ASimple manufacturing processEasy to implementPolycrystalline material growthFrom normal temperature solutionsDispersityCalcium sulfate crystals

The invention discloses a method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure. The method comprises the following steps: 1) pickling; 2) dissolving; 3) rotating crystal; and 4) crystallizing, after crystallizing, carrying out solid-liquid separation, washing filter cake with water, and drying to obtain calcium sulfate crystal whiskers. The method disclosed by the invention has the advantages that: the preparation process is simple and is easy to achieve, and the production efficiency is high; higher-purity and higher-whiteness calcium sulfate crystal whiskers are prepared by adopting a normal-pressure recrystallization method, controlling related process conditions and utilizing the characteristic that the dissolubility of main component calcium sulfate dihydrate of desulfurized gypsum in specific solution changes obviously along with the temperature; obtained calcium sulfate crystal whisker product has regular morphology, low agglomeration and good dispersity; and in addition, inorganic acid solution used for recrystallization can be recycled, and inorganic acid solution is not consumed in the reaction process, thereby creating better economic benefit, environmental benefit and social benefit, reducing the burden of coal-fired power plant and increasing enterprise benefits.

Owner:上海大学浙江嘉兴新兴产业研究院

Scouring and bleaching agent combination and application thereof

InactiveCN101929064AReduce fiber damageAvoid Hole DefectsFibre treatmentBleaching apparatusWater savingAgent Combination

The invention discloses a scouring and bleaching agent combination used as an assistant for the pretreatment of cotton and blended fabrics and application thereof. Based on the total weight of the combination, the scouring and bleaching agent combination comprises the following components in percentage by weight: 40-95% of adsorptive abstergent, 5-20% of surfactant, 0-25% of water soluble alkali, 0-25% of scouring and bleaching synergist and 0-20% of chelate dispersant. When being used with oxydol, the scouring and bleaching agent can achieve a favorable effect of combining the refining procedure and the bleaching procedure. Compared with the traditional process, the treated fabric has better quality. The whole process achieves the advantages of continuous operation, low alkali discharge, water saving, energy saving, time saving and labor saving, thereby improving the production efficiency.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com