Patents

Literature

36 results about "Scolecite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scolecite is a tectosilicate mineral belonging to the zeolite group; it is a hydrated calcium silicate, CaAl₂Si₃O₁₀·3H₂O. Only minor amounts of sodium and traces of potassium substitute for calcium. There is an absence of barium, strontium, iron and magnesium. Scolecite is isostructural (having the same structure) with the sodium-calcium zeolite mesolite and the sodium zeolite natrolite, but it does not form a continuous chemical series with either of them. It was described in 1813, and named from the Greek word, σκώληξ (sko-lecks) = "worm" because of its reaction to the blowpipe flame.

Seashell-diatom ooze wall surface decoration wall material and production and construction method thereof

The invention discloses a seashell-diatom ooze wall surface decoration wall material and a production and construction method thereof. The decoration wall material comprises: 20 to 98 parts of shell powder, 8 to 30 parts of silica, 4 to 100 parts of kieselguhr, 2 to 20 parts of medical stone, 3.8 to 48 parts of mica powder, 2 to 10 parts of magnesium-rich silicate, 6 to 26 parts of scolecite, 1.5to 36 parts of hydrosilicate, 0 to 50 parts of titanium dioxide powder, 2 to 50 parts of calcium carbonate, 0.1 to 0.3 part of vegetable fiber, 1 to 30 parts of pigment, 4.8 to 40 parts of kelp powder, 1 to 30 parts of cold soluble polyvinyl alcohol powder and 1 to 20 parts of hydroxypropyl methyl cellulose. The production and construction method comprises: placing the raw material components into a stirrer for uniform stirring; filling the mixture in bags, packing the bags in boxes, sealing the boxes and storing the boxes in a storehouse; adding water into the mixture and stirring the mixture uniformly; and pasting the mixture on a wall surface to be decorated to make various texture patterns. The seashell-diatom ooze wall surface decoration wall material has the advantages of: (1) soft texture and no toxicity, fading nor stripping; (2), characteristics of eliminating indoor pollution, regulating indoor humidity, eliminating odor, isolating noises and offering high skin texture feel; (3) fire proofing and flame retarding; and (4) rich color.

Owner:青岛泉佳美硅藻泥科技有限公司

Superfine powders and methods for manufacture of said powders

InactiveUS20030234304A1Calcium/strontium/barium carbonatesMaterial nanotechnologySufficient timeAluminum silicate

A method is disclosed for the production of a superfine mineral material powder wherein the subject mineral material is combined with a dry separation agent such as sodium chloride and ground for a sufficient time to produce the superfine mineral material of predetermined size or specific surface area. The separation agent is then removed from the final product by washing it with a solvent such as water. Superfine powders composed of mineral materials where the material is selected from the group consisting of talc, calcium carbonate, zeolite, clay, aluminum hydroxide, aluminum silicate, iron oxide and magnesium oxide are also claimed.

Owner:NANOMAT

Hydraulically set cement body for preservation of organic liquids

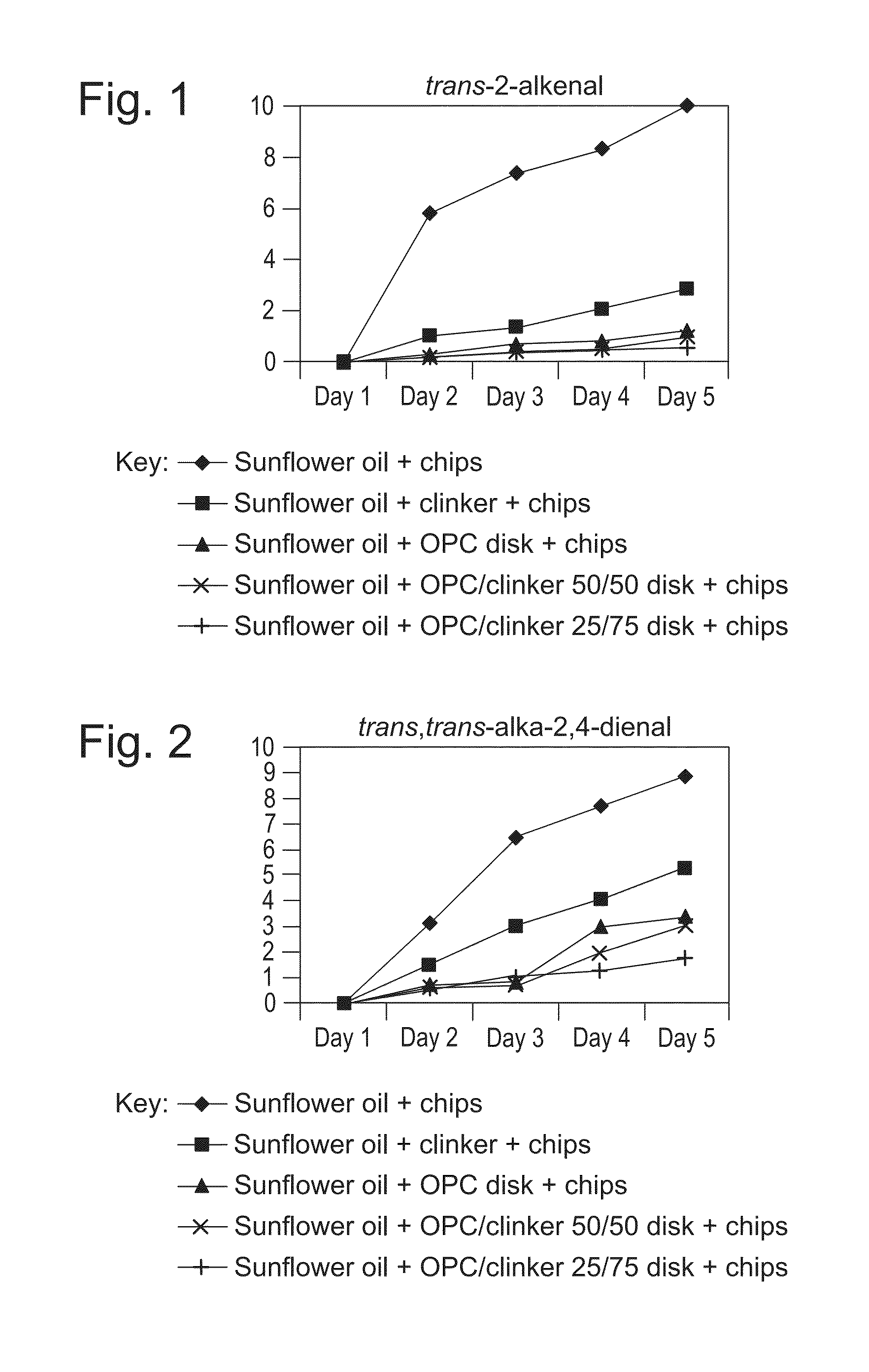

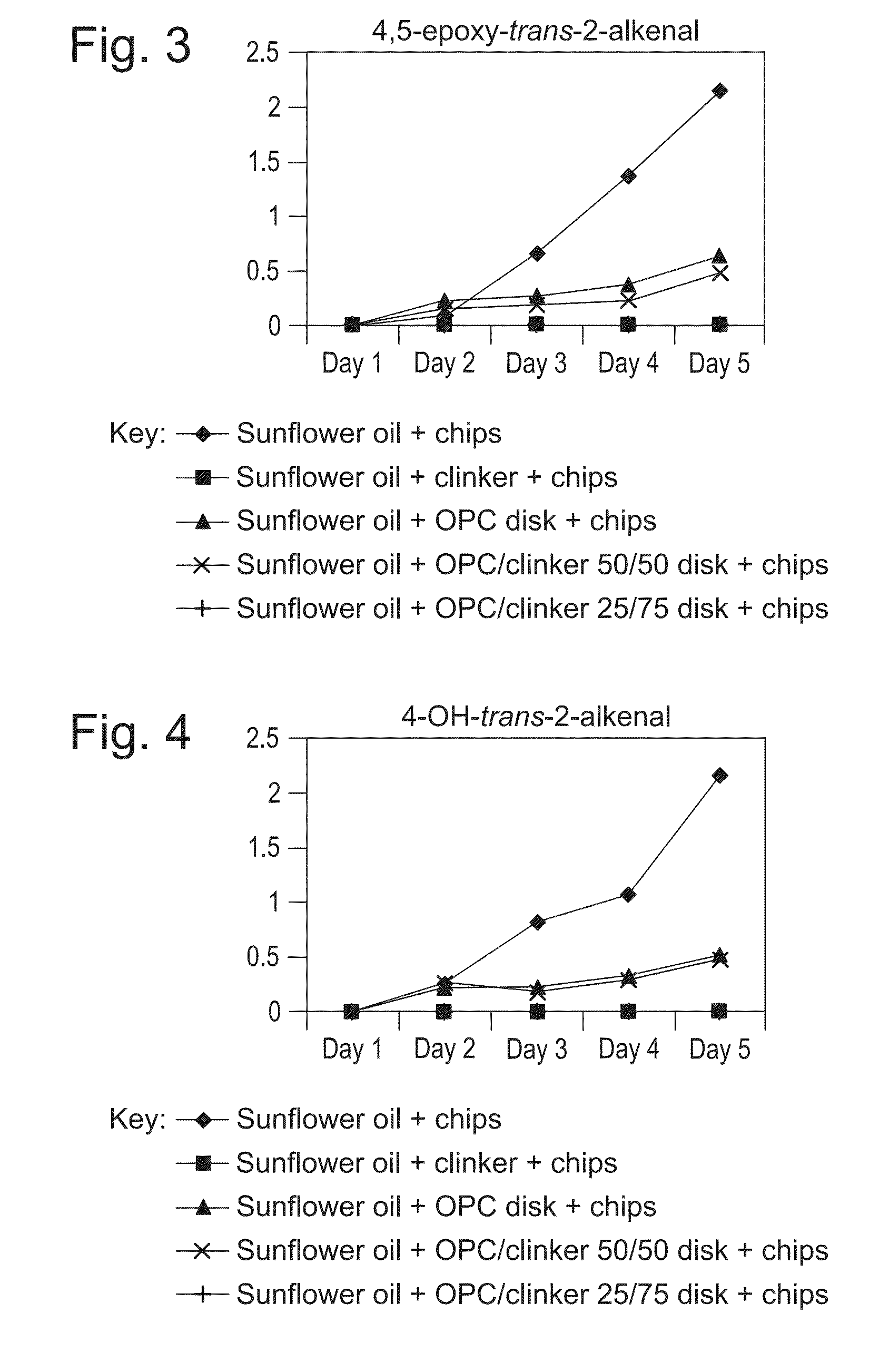

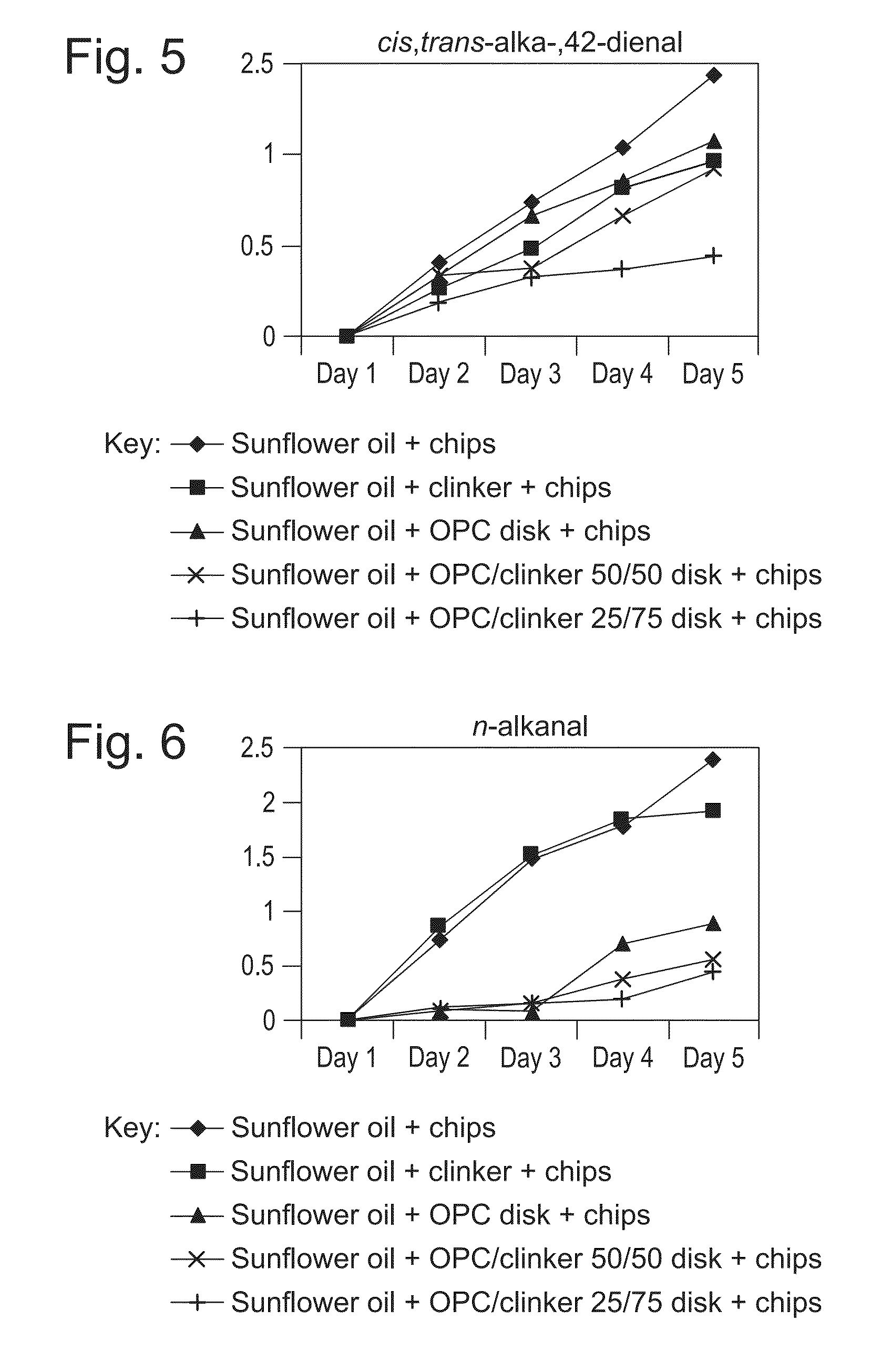

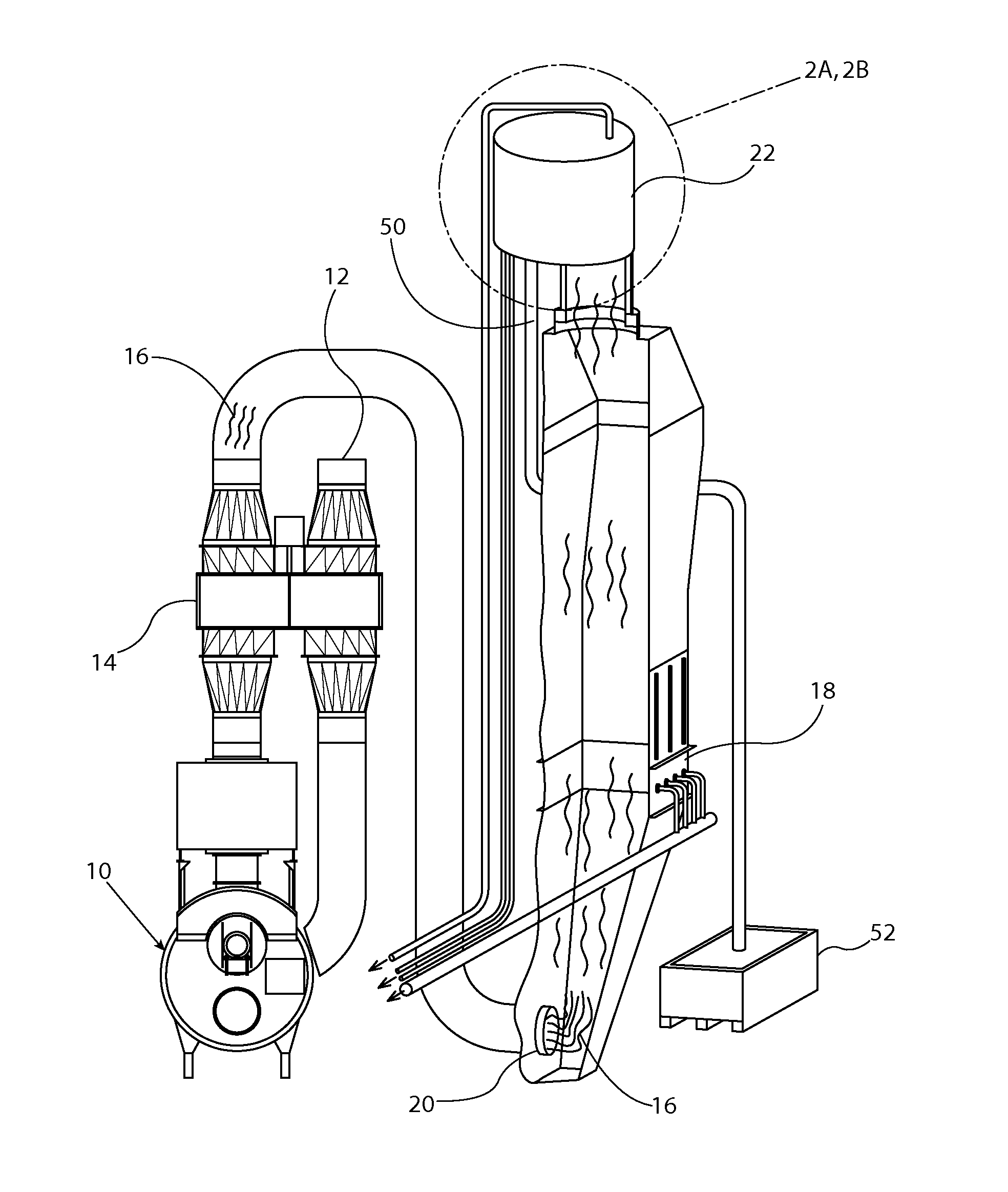

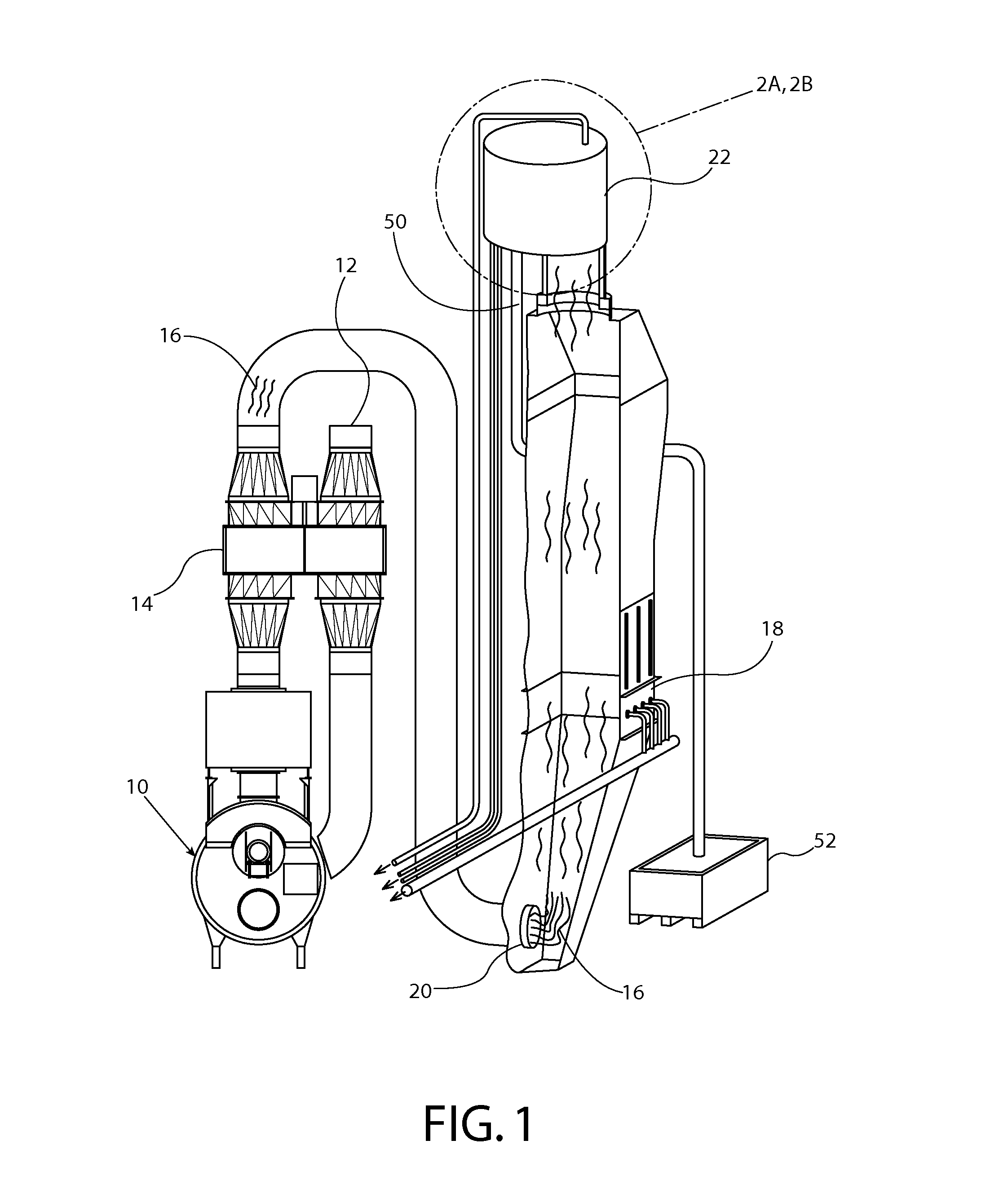

ActiveUS20130112607A1Promote formationNo free waterOther chemical processesEdible oils/fatsCalcium silicateScolecite

An hydraulically set oil-permeable cement body is provided in the form of a stand-alone block or briquette for preserving cooking oil during deep fat frying, said body. It has substantially no free water or having a low free water content for resisting damage on immersion in cooking oil and initial heating and is enclosed in packaging that resists ingress of water or water vapour The block or briquette consists of >50 wt % of a mixture of milled white OPC clinker and white OPC, optionally silica 1-2 wt % and / or titania (TiO2) 1-2 wt % and optionally further ingredients selected from calcium silicate, magnesium silicate, aluminium silicate, natural feldspars, natural sodium zeolites, natural calcium zeolites, synthetic sodium zeolites, synthetic calcium zeolites, wollastonite, calcium hydroxide, clays, pillared clays, activated clays / earths, talcs / kaolinite, amphiboles, granite porphyry, rhyolite, agalmatolite, porphyry, attapulgite and diatomaceous earth. It has the properties that calcium and magnesium substantially do not leach into the oil and that it is porous so that oil can diffuse into it and contaminants can be deposited on and within it.

Owner:BBM TECH LTD

Cleaning stack gas

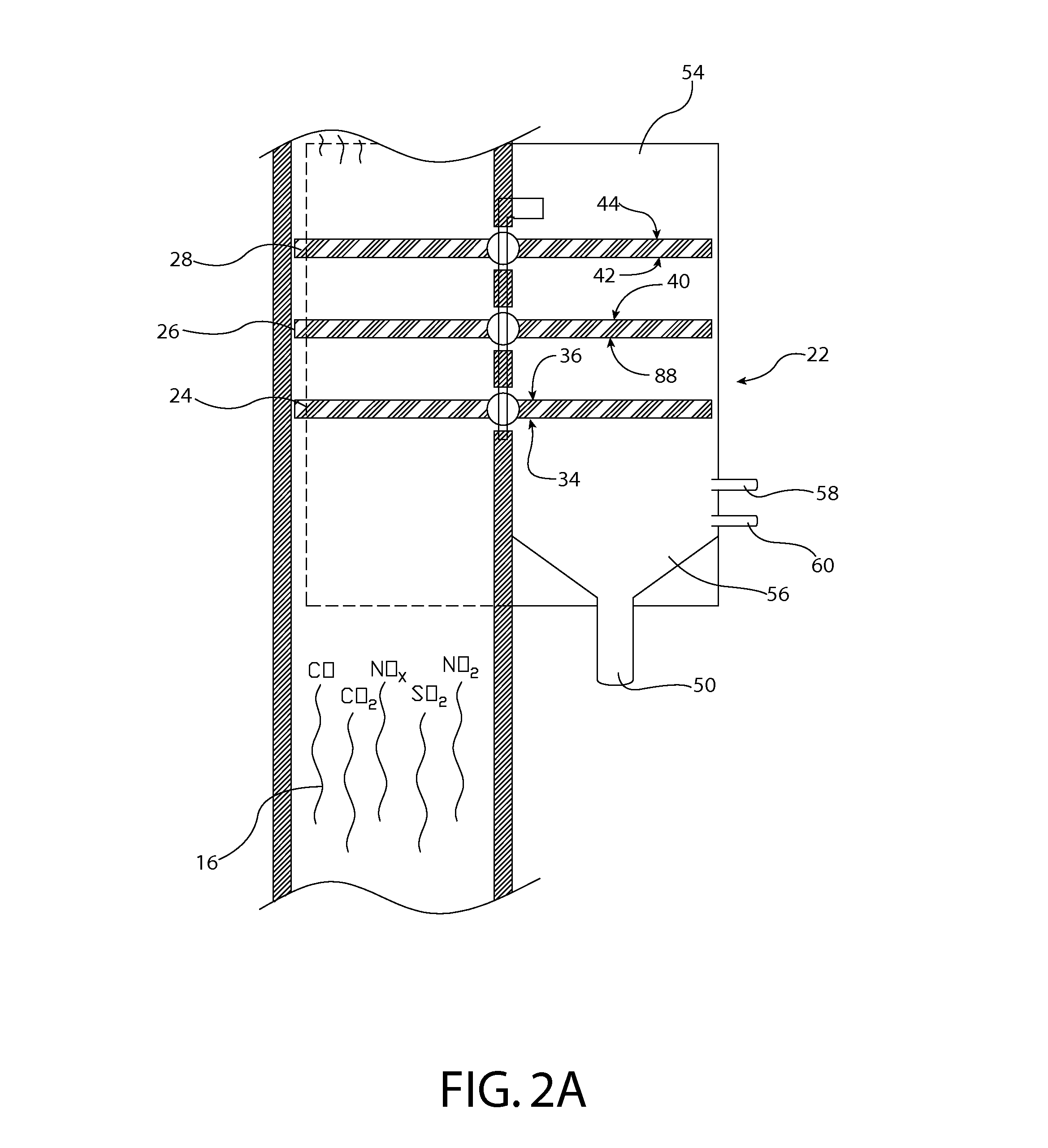

ActiveUS8821818B1Promote recoveryReduce moistureNitrous oxide captureCombination devicesFertilizerChemistry

A method and apparatus for cleaning carbon oxides, sulfur oxides and nitrogen oxides, from stack gas, from combustion of coal, combustion of natural gas or propane, or from a cement kiln by reaction using calcium zeolite and sodium zeolite catalysts. The method also includes cleaning the catalytic beds with nitrogen to remove the collected reactants and recover a fertilizer product and the catalysts for reusable.

Owner:3 D CLEAN COAL EMISSIONS STACK

Epoxy vegetable oil blending modified pullulan grafted pineapple fiber packaging film and preparation method thereof

InactiveCN106117613AAchieve purificationRealize NanoizationCellulose treatment using microorganisms/enzymesRaw material divisionEpoxyCellulose

The invention discloses an epoxy vegetable oil blending modified pullulan grafted pineapple fiber packaging film. The epoxy vegetable oil blending modified pullulan grafted pineapple fiber packaging film is prepared from the following components in parts by weight: 118 to 120 parts of pineapple leaf fibers, 5.5 to 5.8 parts of composite cellulose, 2.3 to 2.5 parts of nano magnesium oxide particles, 4.3 to 4.4 parts of citric acid, 25 to 26 parts of epoxy vegetable oil, 31 to 32 parts of pullulan, 9 to 10 parts of scolecite, 35 to 40 parts of hydroxypropyl starch, 4 to 5 parts of hydroxypropyl methylcellulose, 5 to 6 parts of polyvinyl alcohol, 9 to 10 parts of konjac glucomannan, proper amount of water and proper amount of de-ionized water. A pineapple cellulose film is prepared by combining epoxy vegetable oil blending modified pullulan with a nano-crystallized pineapple leaf cellulose solution and other components and preparing a homogeneous film solution through ultrasonic assisted emulsification and shearing; the pineapple cellulose film is degradable and realizes application of pineapple cellulose and the pullulan to the field of packaging film materials and has good air permeability, spatial structure and stretching-resisting property.

Owner:TONGLING FOUNDER PLASTICS TECH

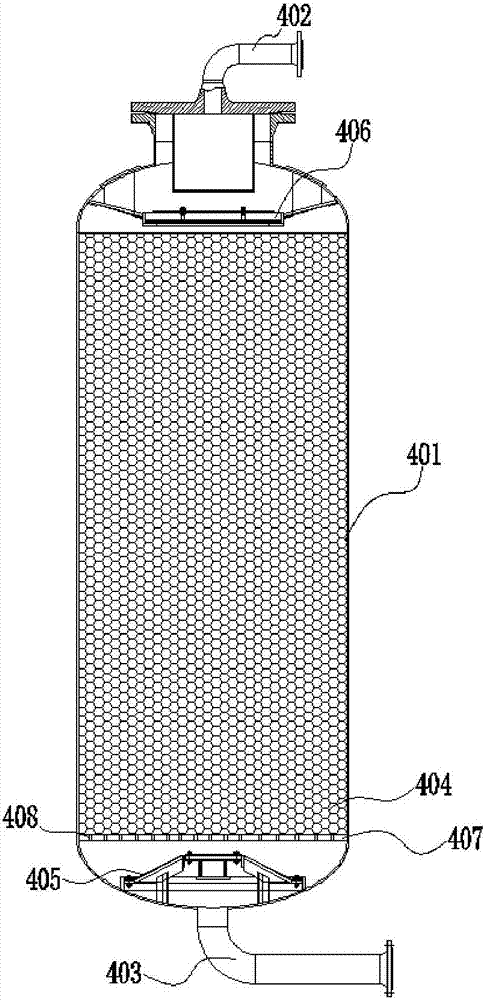

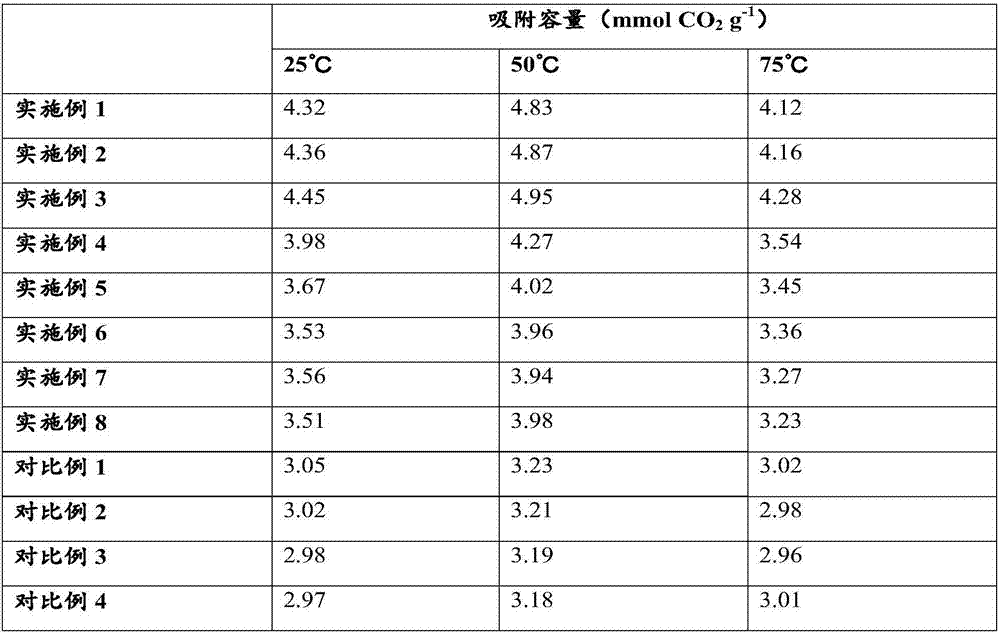

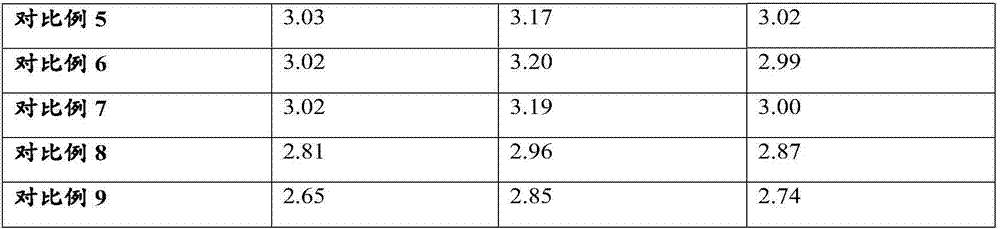

Carbon dioxide adsorbent, carbon dioxide adsorption tower and carbon dioxide recovery system

ActiveCN107115845AImprove adsorption capacityImprove stabilityGas treatmentOther chemical processesScoleciteHazardous substance

The invention provides a carbon dioxide adsorbent, a carbon dioxide adsorption tower and a carbon dioxide recovery system and relates to the technical field of gas adsorption. The carbon dioxide adsorbent is mainly prepared from the following raw materials in parts by mass: 15-20 parts of aluminum oxide, 15-20 parts of silicon oxide, 10-15 parts of analcite, 10-15 parts of scolecite, 10-15 parts of a carbon nanotube, 10-15 parts of a carbon molecular sieve and 10-20 parts of an alkali metal compound. The carbon dioxide adsorbent alleviates the technical problem that an existing solid carbon dioxide adsorbent is poor in adsorption capacity and high in regenerating difficulty and cannot meet the demand of recycling cement industrial carbon dioxide, and the technical effects that a lot of carbon dioxide can be quickly adsorbed, the demand of recycling cement industrial carbon dioxide is met, no harmful and toxic substances in the adsorption process are discharged, and harmonious development of environment and society can be effectively promoted are achieved.

Owner:BEIJING LIULIHE CEMENT +2

Silicon dioxide aerogel doped scolecite water treatment agent and preparation method thereof

ActiveCN108751372AGood dispersionImprove dispersion stabilityWater/sewage treatment by flocculation/precipitationGlycidyl methacrylateScolecite

The invention discloses a silicon dioxide aerogel doped scolecite water treatment agent and a preparation method thereof. The water treatment agent is prepared from the following raw materials in parts by weight: 0.1-0.2 part of triethylamine, 5-7 parts of silicon dioxide aerogel, 100-140 parts of scolecite, 1-1.3 parts of ammonium persulfate, 5-7 parts of glycidyl methacrylate, 3-4 parts of an amino silane coupling agent and 40-50 parts of acrylamide. Due to a synergetic treatment method with the silicon dioxide aerogel, scolecite powder and polyacrylamide, the water treatment agent is good in treatment effect, high in finished product stability, not liable to disperse, good in self-sedimentation effect and convenient to recycle; in addition, both the silicon dioxide aerogel and the polyacrylamide can be uniformly distributed into micro pore structures of the scolecite powder, so that not only is a flocculation effect improved, but also the water treatment agent is easy to clean, highin repeated use rate and convenient in treatment.

Owner:苏州晏荣煜科技发展有限公司

Light plastic door and window

The invention discloses a light plastic door and window which is prepared from the following raw materials in parts by mass: 6-10 parts of sisal fiber, 60-70 parts of a 20-30% sodium hydroxide solution, 30-41 parts of dimethyl carbonate, 2-3 parts of op-10, 20-30 parts of n-butyl acrylate, 0.4-0.6 part of ammonium persulfate, 60-70 parts of vinyl acetate, 36-40 parts of benzyl chloride, 400-430 parts of polyvinyl chloride, 2-4 parts of polyvinyl butyral, 6-8 parts of dibutyl maleate, 2-4 parts of chitosan, 4-7 parts of boron, 0.4-1 part of hexabromocyclododecane, 2-4 parts of sodium antimonate, 10-17 parts of scolecite, 3-5 parts of potassium pyrophosphate, 31-40 parts of light calcium carbonate and 3-5 parts of palm wax. According to the light plastic door and window disclosed by the invention, the sisal fiber is treated by microwaves to improve the dispersibility of cellulose, so that the accessibility of benzyl chloride to cellulose is increased; after etherification treatment, the quantity of hydroxyl is reduced, and cellulose crystalline texture is damaged to obtain thermoplasticity.

Owner:阜阳市锐达不锈钢制品销售有限公司

Heat preservation and insulation plastic for building material and preparation method of heat preservation and insulation plastic

The invention discloses a heat preservation and insulation plastic for a building material. The heat preservation and insulation plastic is prepared from, by weight, 1-2 parts of sodium diacetate, 2-4 parts of pine needle meal, 3-5 parts of hollow glass microspheres, 7-10 parts of polystyrene, 110-170 parts of high-intensity polyethylene, 10-13 parts of scolecite, 0.6-1 part of N-hydroxymethyl acrylamide, 2-4 parts of hydroxy stearic acid, 3-5 parts of dispersed emulsion, 2-3 parts of antimonous oxide, 4-6 parts of Teflon, 0.4-1 part of bagasse, 7-9 parts of polypropylene adipate and 0.1-0.13 part of stannous octoate. According to the heat preservation and insulation plastic, the hollow glass beads and the polystyrene serve as filler, the scolecite modified by the sodium diacetate and the pine needle meal is added, a uniform microporous network can be formed in the plastic, the heat preservation and insulation performance of a finished plastic is effectively improved, and the heat preservation and insulation plastic is particularly suitable for being used as the building material in a cold area.

Owner:宁波辉门科技有限公司

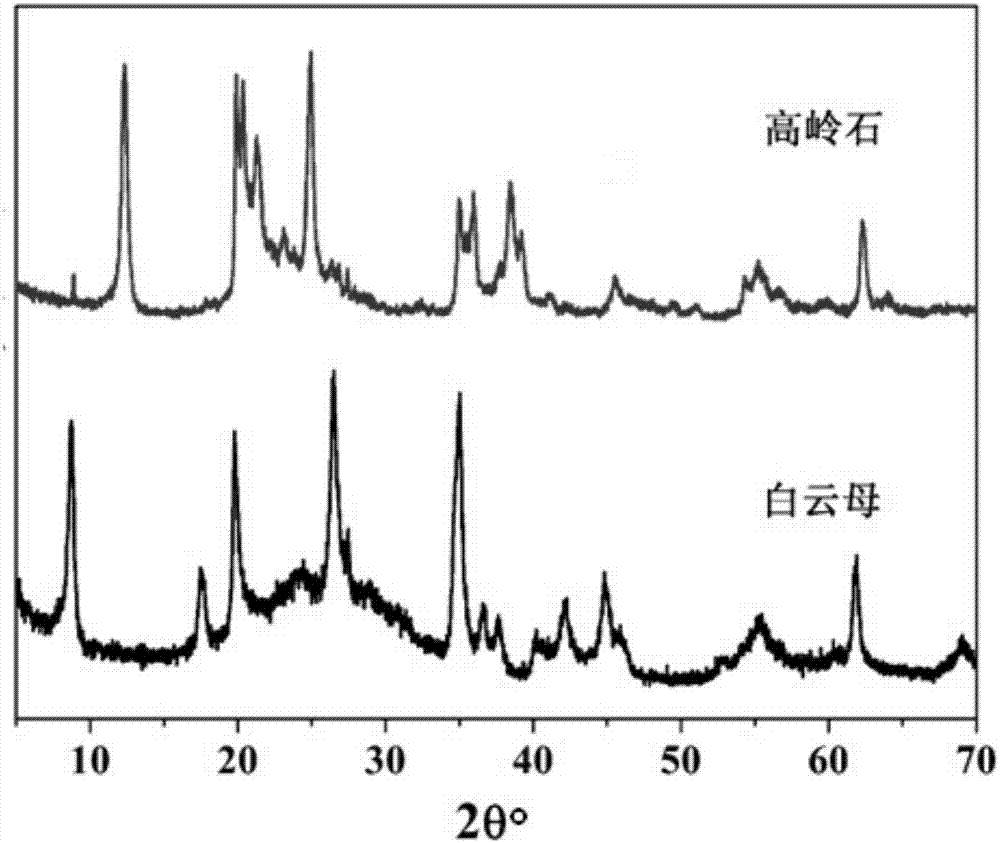

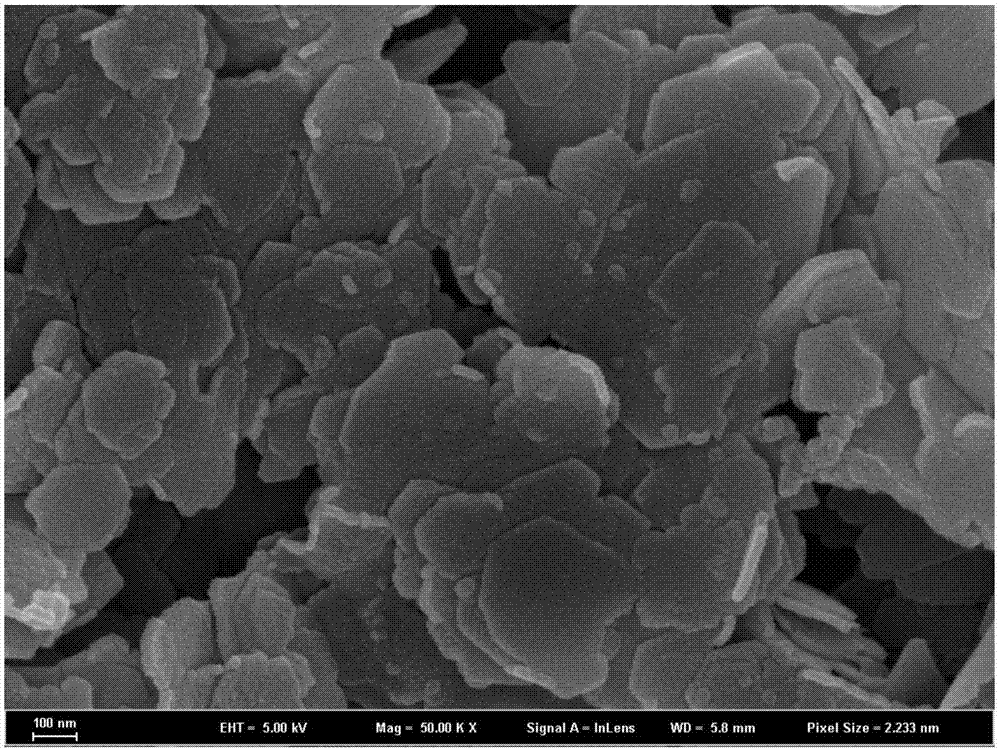

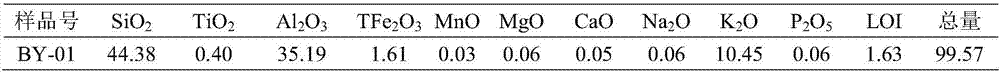

Method for synthesizing nanometer kaolin by using muscovite powder

ActiveCN107572542ASimple processMild reaction conditionsAluminium silicatesAlkali metal nitrate preparationScoleciteSolid phases

The invention relates to a method for synthesizing nanometer kaolin by using muscovite powder. The method comprises the following steps of mixing the muscovite powder and a nitrate solution, performing hydrothermal reaction for 12 to 72h at the temperature of 210 to 260 DEG C, filtering, washing, and drying the obtained solid-phase product at the temperature of 100+ / -5 DEG C, so as to obtain the nanometer kaolin, wherein the liquid-phase product, namely the potassium nitrate solution, can be used for producing the potassium nitrate. The method has the advantages that the muscovite powder and the nitrate are used as raw materials to synthesize the nanometer kaolin, the byproduct is potassium nitrate, and the potassium, aluminum and silicon components in the muscovite are fully utilized; thewhole process technology is simple, the modern industrial requirements of high-efficiency, energy-saving and clean production with 100% of utilization rate of resources and zero emission of three wastes can be met, and the industrialized production can be easily realized.

Owner:昊青薪材(北京)技术有限公司

Heat-preservation pbt material and preparing method thereof

The invention discloses a heat-preservation pbt material.The heat-preservation pbt material is prepared from, by weight, 3-4 parts of scolecite, 3-5 parts of an alkyl ketene dimer, 70-80 parts of caprolactam, 10-13 parts of attapulgite, 1-1.4 parts of zinc acetate, 2-3 parts of gamma-aminopropyltriethoxysilane, 18-20 parts of oxalic acid, 300-370 parts of polybutylene terephthalate, 1-2 parts of fatty alcohol polyoxyethylen ether, 10-14 parts of dimethyl isophthalate, 2-3 parts of ammonium aluminum sulfate, 2-3 parts of tert-butyl hydroquine, 1-2 parts of borax, 2-4 parts of trichloroiminocyanuric acid and 1-2 parts of polystyrene.According to the heat-preservation pbt material, scolecite is added, micropores can be formed in the material, and thus very good heat preservation and heat insulation effects are achieved.

Owner:CHUZHOU YOUSHENG HIGH POLYMER MATERIAL

PE preservative film

The invention discloses a PE preservative film, which is composed of the following components in parts by weight: 100 parts of LLDPE, 80 to 120 parts of LDPE, 6 to 10 parts of scolecite, 2 to 4 parts of silicon oxide, 1 to 2 parts of polyoxyethylene 10 lauryl ether EO=10, and 0.2 to 0.4 part of bis(3,4-dimethylbenzal)sorbitol. The PE preservative film is easy to pull out and shear, can be easily adhered to tableware with a glass ceramic surface or a stainless steel surface, is nearly transparent and does not have any wrinkle.

Owner:上海盈致橡塑制品有限公司

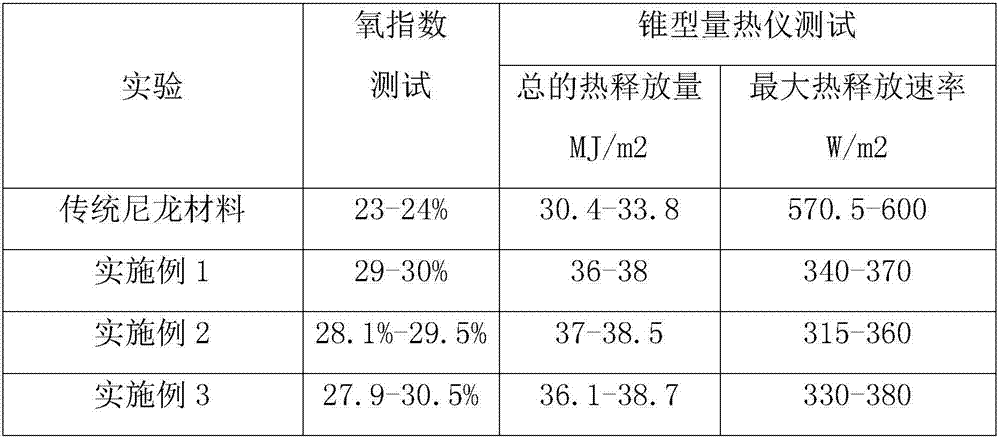

Novel aerogel reinforced nylon thermal insulation composite and preparation method thereof

The invention discloses a novel aerogel reinforced nylon thermal insulation composite and a preparation method thereof. According to the invention, the added phosphatide flame retardant scolecite gel can effectively reduce agglomeration and improve compatibility of the gel with nylon through surface organization, so that the stability strength of the composite finished product is enhanced; meanwhile, scolecite, silicon dioxide aerogel and hexabromocyclododecane can achieve a synergistic flame retardant effect, so that carbon layer area of the composite finished product is increased, a gas phase barrier effect is effectively achieved, and the fireproof performance of the composite is enhanced; and benzyl triphenyl phosphonium chloride is adopted for treating esterification sol, so that dehydration, catalysis and carbon formation can be carried out during combustion, and the flame retardant fireproof performance of the finished product is further improved.

Owner:QINGYUAN CHUQU INTELLIGENT TECH CO LTD

Deodorizing fertilizer for rice planting and preparation method thereof

InactiveCN106631329AReduce odorGood sustained release effectCalcareous fertilisersMagnesium fertilisersScolecitePalygorskite

The invention discloses deodorizing fertilizer for rice planting. The deodorizing fertilizer is prepared from the following raw materials in parts by weight: 13 to 20 parts of bamboo charcoal powder, 10 to 14 parts of palygorskite, 26 to 30 parts of chicken manure, 10 to 17 parts of scolecite, 0.3 to 1 part of formamide, 0.1 to 0.3 part of potassium sorbate, 10 to 16 parts of orange peel powder, 2 to 3 parts of herba pogostemonis, 5 to 7 parts of soybean milk residue, 1 to 2 parts of rose petal powder, 2 to 3 parts of monopotassium phosphate, 0.8 to 1 part of fenugreek gum, 3 to 4 parts of calcium oxide, 0.2 to 1 part of waste yeast, 30 to 40 parts of potassium phosphate, 100 to 120 parts of urea and 7 to 9 parts of magnesium sulfate. According to the deodorizing fertilizer disclosed by the invention, mountain flour are treated by using an amide dispersion solution, and a glue solution is added, so that nutrient substances in the deodorizing fertilizer can be dispersed to microporous surfaces in the mountain flour, and very good slow release effect is obtained; the rose petal powder, the herba pogostemonis and the like are added in the deodorizing fertilizer, so that the odor of fertilizer is effectively reduced.

Owner:巢湖春友种业科技有限公司

No-deposition automobile leaf-spring coating and preparation method thereof

InactiveCN107033723AWell mixedIncrease the degree of cross-linkingAnti-corrosive paintsSodium bicarbonateEpoxy

The invention discloses a no-deposition automobile leaf-spring coating. The coating is prepared from raw materials in parts by weight as follows: 4-6 parts of scolecite, 0.7-1 part of formamide, 7-9 parts of hydroxyethyl methylacrylate, 0.8-1 part of phosphorus pentoxide, 2-3 parts of p-methoxyphenol, 0.6-2 parts of tetrabutylammonium bromide, 17-20 parts of acrylic acid, 6-8 parts of methyl methacrylate, 140-150 parts of epoxy resin E-51, 0.07-0.1 parts of ammonium persulfate, 2-3 parts of sodium bicarbonate, 0.6-1 part of sodium dodecyl benzene sulfonate, 0.3-1 part of naphthenic soap, 0.6-2 parts of ascorbic acid, 0.5-1 part of nickel aminosulfonate, 1-2 parts of triphenyl phosphite, 0.3-1 part of N,N-diethyl aniline and 0.7-1 part of lauryl dimethyl amine oxide. The coating is low in cost, and the problems that automobile leaf-spring coatings are low in utilization rate, non-environment-friendly and poor in anti-rust capacity currently are solved.

Owner:TONGLING SIDE TECH

Preparation method of cerium-doped muscovite composite powder

The invention relates to a preparation method of cerium-doped muscovite composite powder. The preparation method comprises the preparation step of mixing cerium nitrate hexahydrate, oxalic acid dihydrate and muscovite in a planetary ball mill according to certain proportions, wherein the ball-material ratio is about 5:1. The cerium-doped muscovite composite powder prepared by the method providedby the invention can increase the consistency of lithium-based grease and has little influence on a soap fiber structure of the lithium-based grease.

Owner:SHAANXI JUJIEHAN CHEM CO LTD

Fiber-reinforcement automobile clutch friction material and preparation method thereof

The invention discloses a fiber-reinforcement automobile clutch friction material. The fiber-reinforcement automobile clutch friction material comprises, by weight, the raw materials of 1-2 parts of polyepoxysuccinic acid, 0.8-1 part of alkanolamide, 3-5 parts of glass fibers, 6-10 parts of scolecite, 2-3 parts of carbon fibers, 4-7 parts of polydicyclopentadiene, 2-3 parts of 1,3,5-Triglycidyl isocyanurate, 0.6-1 part of ethyl acetate, 3-5 parts of vinyl tri-methoxysilane, 50-60 parts of acetone, 20-30 parts of dimethyl sulfoxide, 25-30 parts of absolute ethyl alcohol, 50-60 parts of methyl methacrylate, 20-26 parts of butyl acrylate, 0.3-1 part of 1-mercaptododecane, 20-34 parts of titanous sulfate, 16-20 parts of glucose, 60-70 parts of nano carbon powder, 200-300 parts of isopropyl alcohol, 80-100 parts of nylon 66 and 0.04-0.06 part of azobisisobutyronitrile. The glass fibers and the carbon fibers are adopted for the friction material, and compatibility between resin and inorganic fillings can be effectively improved.

Owner:来安县隆华摩擦材料有限公司

Respirator nylon material and preparing method thereof

The invention discloses a respirator nylon material. The respirator nylon material is prepared from, by weight, 130-200 parts of nylon 6, 30-40 parts of glass fiber, 0.8-2 parts of triglycidyl isocyanurate, 1-2 parts of fatty alcohol-polyoxyethylene ether, 8-10 parts of acetyl tributyl citrate, 17-20 parts of scolecite, 2-3 parts of maleic anhydride, 1-2 parts of aluminum sulfate, 2-4 parts of hydroxystearic acid, 0.7-2 parts of hexamethyl phosphoryl triamide, 0.6-1 part of antioxidant 1010, 3-4 parts of polyisoprene, 0.4-1 part of trimethylolpropane, 0.1-0.13 part of ammonium persulfate, 0.6-1 part of polydimethylsiloxane, 2-3 parts of calcium fluoride and 0.8-1 part of polybenzimidazole. Glass fiber is dispersed in the ethanol solution of polybenzimidazole, corrosion resistance is enhanced, added hexamethyl phosphoryl triamide can effectively improve the compatibility with all the raw materials and improve tenacity and stability of the finished product. The nylon material is high in antibacterial rot resistance and water resistance, high in surface strength and excellent in comprehensive performance.

Owner:NINGBO TONGGUAN ELECTRIC AUTOMATION EQUIP

Planting method of high yield peanut

InactiveCN106386127AReduce morbidityLittle impact on qualityCalcareous fertilisersFertilising methodsScoleciteViscose

Owner:巢湖春友种业科技有限公司

Phosphorized polypropylene geogrid

The invention discloses a phosphorized polypropylene geogrid. The phosphorized polypropylene geogrid comprises the following raw materials in parts by weight: 110-120 parts of high-density polypropylene, 2-3 parts of asphalt, 4-6 parts of scolecite, 1-2 parts of ammonium dihydrogen phosphate, 1-2 parts of potassium phosphate, 0.6-1 part of erucyl amide, 0.6-1 part of pentaerythritol, 0.1-0.3 part of 2, 4- imidazolidinone, 2-3 parts of trioctyl phosphate, 0.1-0.2 part of butyltin mercaptide, 6-10 parts of blast furnace slag, 7-10 parts of wollastonite powder, 0.4-1 part of sdium chloride, 2-3 parts of rare earth adjuvant and 1-2 parts of aluminum nitride powder. The rare earth adjuvant added into the phosphorized polypropylene geogrid can sufficiently mix high-strength boron carbide with attapulgite and rare earth elements, and together with a preservative calcium acetate and a stabilizer polyvinylpyrrolidone and through surface treatment of a silane coupling agent, the formed adjuvant not only has good surface strength, good toughness, excellent weather resistance, strong corrosion resistance and good stability, and can effectively improve the overall quality of a finished product and improve adaptability to soil and resistance to outside pressure.

Owner:ANHUI JIEAOMAKE SYNTHETIC MATERIAL TECH

Preparation method of modified scolecite adsorption material

InactiveCN108745297AImprove adsorption capacityGood antibacterial effectOther chemical processesDispersed particle separationWheat germMethyl carbonate

The invention discloses a preparation method of a modified scolecite adsorption material. The preparation method comprises following steps: stearic acid is adopted for activation of scolecite, blending reaction with triethanolamine is carried out so as to obtain an ester amination solution, and in the reaction process, sesbania gum containing wheat germ powder is introduced, so that the absorptionperformance of an obtained finished product is improved, water purifying effect is improved; and at last the ester amination solution and a dimethyl carbonate solution of alumina are subjected to blending reaction, so that the antibacterial effect of the finished product is improved further. The modified scolecite adsorption material is high in stability, and excellent in quality and environmentprotection performance.

Owner:合肥拖油瓶信息科技有限公司

Impact-resistance and corrosion-prevention floor and preparing method thereof

The invention discloses an impact-resistance and corrosion-prevention floor. The impact-resistance and corrosion-prevention floor is prepared from, by weight, 6-7 parts of dioctyl azelate, 17-20 parts of zirconium oxychloride octahydrate, 10-15 parts of hydrochloric acid with the concentration of 40-47%, 90-100 parts of phosphoric acid with the concentration of 80-85%, 3-4 parts of tetrakis hydroxymethyl phosphonium sulfate, 4-7 parts of a methylamine water solution with the concentration of 25-30%, 5-7 parts of trifluoroethyl methacrylate, 0.2-0.4 part of 2-octyl-2H-isothiazol-3-one, 0.06-0.1 part of ammonium persulphate, 0.01-0.02 part of divinyl benzene, 1-2 parts of azodicarbonamide, 170-200 parts of polyvinyl chloride, 10-14 parts of scolecite, 2-4 parts of polyethylene imine, 0.3-1 part of ammonium ethoxylated alkyl sulfate, 1-3 parts of sodium benzoate and 2-4 parts of calcium ricinoleate. The floor has good impact resistance and is good in bearing performance and high in safety.

Owner:CHUZHOU YONGTONG TRAFFIC EQUIP

Domestic wet garbage decomposition and pushing agent

PendingCN114226402AHigh ion exchange capacityImprove catalytic performanceAgriculture tools and machinesSolid waste disposalCalcium silicateAndesite

The invention discloses a domestic wet garbage decomposition and pushing agent, and relates to the technical field of decomposition accelerators, the domestic wet garbage decomposition and pushing agent comprises a mineral humus compound, and the mineral humus compound comprises a mineral concentrated solution, a fungus bed material, organic waste, humus and a PH adjusting material. The mineral concentrated solution is a natural ionized mineral concentrated solution obtained by adding a sulfuric acid aqueous solution with the concentration of 10-20% into basalt and andesite and then extracting acid-soluble components, and the fungus bed material is saw dust and can also be made of saw dust, rice husks, bran, activated carbon, ceramic beads, polyvinyl alcohol, calcium silicate, zeolite, moss and silica gel. When the device is used for organic garbage decomposition, especially wet garbage classification, garbage can be decomposed, eliminated and treated within a short time, meanwhile, peculiar smell generated in the decomposition process is small, the decomposition removal rate is increased, few wet garbage remains after decomposition is completed, and the effect of high classification efficiency is achieved.

Owner:东莞华梦环保新材料技术有限公司

Preparation method of corrosion-resistant magnetic ferrite core

InactiveCN111875369AImprove temperature resistanceImprove corrosion resistanceInorganic material magnetismInductances/transformers/magnets manufacturePyrophylliteScolecite

The invention discloses a preparation method of a corrosion-resistant magnetic ferrite core, which comprises the following steps: 1, selecting a magnetic core material on the market, melting at 1000-1500 DEG C for 15-25 minutes, adding modified pyrophyllite, and stirring the components at the rotating speed of 100-500 r / min for 15-25 minutes to obtain the corrosion-resistant magnetic ferrite core.According to the magnetic ferrite core, a magnetic core material in the market is adopted and subjected to melting treatment, wherein the melting temperature is 1000 DEG C and the melting time is 15min; then modified pyrophyllite is added, the temperature resistance of the material can be improved after the modified pyrophyllite is modified; meanwhile, the added modified scolecite and modified ore can be further mixed and dissolved with a raw material product, and the magnetic ferrite core is obtained. Therefore, the corrosion resistance of the product is improved.

Owner:天长市烁源磁电有限公司

Corrosion-resistant environment-friendly snow melting salt and preparation method thereof

InactiveCN106753245AWith snow melting performancePollution controlBiocidePlant growth regulatorsPhosphatePolyvinyl chloride

The invention discloses a corrosion-resistant environment-friendly snow melting salt which is prepared by mixing the following raw materials in parts by weight: 2-3 parts of acetic acid, 3-5 parts of potassium succinate, 4-6 parts of ammonium succinate, 10-17 parts of sodium gluconate, 30-41 parts of potassium dihydrogen phosphate, 1-2 parts of citric acid, 3-5 parts of quicklime, 1-2 parts of benzotriazole, 20-30 parts of scolecite, 60-80 parts of sodium chloride, 0.1-0.2 part of sodium 5-nitroguaiacolate, 0.1-0.13 part of calcium hexafluoroacetylacetonate, 5-7 parts of anhydrous sodium acetate, 4-6 parts of phosphoric acid and 0.01-0.02 part of coco fatty acid diethanol amide. The snow melting salt has the snow melting property, has the functions of removing NOx and SO2 generated by coal combustion and HCl generated by PVC (polyvinyl chloride) combustion, controlling the atmospheric pollution and the like, and greatly lowers the corrosion to the reinforced concrete pavements (bridges) and sewer lines. The sodium 5-nitroguaiacolate is added to improve the inhibitory effect on absorption of other nutrient elements by vegetable cells due to the increase of sodium ion concentration.

Owner:HUANGSHAN UNIV

Antibacterial packaging bag material and preparation method thereof

The invention discloses an antibacterial packaging bag material, which is prepared from the following raw materials in parts by weight: 1 to 2 parts of sodium benzoate, 5 to 7 parts of allyl polyethylene glycol, 0.4 to 1 part of octyl isothiazolone, 2 to 4 parts of aluminum stearate, 3 to 5 parts of diacetone alcohol, 10 to 13 parts of scolecite, 1 to 2 parts of polyvinyl butyral, 0.4 to 1 part ofnickel aminosulfonate, 1 to 2 parts of melamine, 2 to 4 parts of glycerol tristearate, 0.6 to 1 part of trimethylolpropane, 110 to 130 parts of polypropylene and 3 to 5 parts of borax. According to the antibacterial packaging bag material, compatibility between filler and the polypropylene is effectively improved, and the stability and the strength of a finished product are improved.

Owner:桐城市强峰包装有限公司

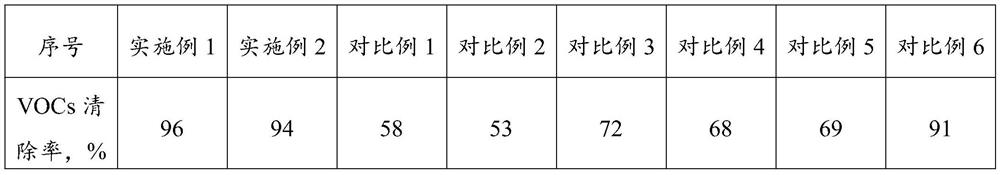

High-performance adsorption catalytic material and preparation method thereof

InactiveCN112221534AIngenious ideaSimple preparation processGas treatmentMolecular sieve catalystsCalcium silicateScolecite

The invention discloses a high-performance adsorption catalytic material and a preparation method thereof, wherein the material is composed of active calcium silicate, zeolite, a modifier YH-A, a modifier YH-B, a deodorant freshener and a coupling agent. The adsorption catalytic material is prepared by mixing and stirring the raw materials according to a certain sequence. The material disclosed bythe invention is simple in preparation process and low in cost, and has a good removal effect on VOCs.

Owner:HUNAN YINGHONG SCI & TECH

Refractory material for direct current electric arc furnace bottom and preparation method thereof

The invention discloses a refractory material for a direct current electric arc furnace bottom. The refractory material is composed of the following raw materials by weight part: 6-10 of steel powder, 3-4 of terpene resin, 2-3 of phenolic resin, 17-20 of zirconium boride, 30-40 of zinc powder, 60-67 of graphite in soil form, 10-14 of flax fiber, 2-3 of glacial acetic acid, 26-30 of tetraethyl orthosilicate, 80-102 of 6-10% ammonia water, 100-110 of 3-5% hydrogen peroxide, 2-3 of potassium borohydride, 3-4 of scolecite, 0.1-0.13 of trimethylolpropane, and 3-4 of dimethyl carbonate. The tetraethyl orthosilicate involved in the invention is hydrolyzed into silanol sol under the condition of adding the catalyst glacial acetic acid, the silanol sol is mixed with a fiber activation solution and an ultrasonic dispersion solution prepared from scolecite, by evaporation of the solvent, a heterocomplex containing calcium, carbon and silicon can be obtained, and finally high temperature carbonization is carried out, and the carbon source is provided by the fiber activation solution, thus obtaining a carbon silicon calcium composite additive. The carbon silicon calcium composite additive has the advantages of stable chemical properties, high heat conductivity coefficient, small thermal expansion coefficient, thermal shock resistance, light weight, and high strength.

Owner:MAANSHAN JINSHENG IND DESIGN

Anti-oxidation nylon breather valve material and preparation method thereof

The invention discloses an anti-oxidation nylon breather valve material. The material is prepared from, by weight, 1-2 parts of 4-tert-amylphenol, 3-4 parts of lauryl mercaptan, 1-2 parts of 2,6-di-tert-butyl-p-cresol, 0.7-1 part of saturated stearamide, 4-6 parts of acetyl triethyl citrate, 0.7-1 part of naphthenic soap, 100-140 parts of nylon 6, 1-2 parts of nickel sulfamate, 27-40 parts of scolecite, 3-4 parts of aluminum stearate, 4-6 parts of polyethylene wax, 0.1-0.2 part of hexamethyl cyclotrisiloxane, 0.1-0.2 part of tribasic lead sulfate, 6-8 parts of sodium fluosilicate, 0.4-1 part of dibenzothiazyl disulfide, 0.1-0.2 part of dicumyl peroxide and 5-7 parts of acrylamide. Antioxidant performance of the finished material is effectively improved by adding 4-tert-amylphenol, 2,6-di-tert-butyl-p-cresol and the like. The breather valve material has good hardness and impact strength, and storage stability of the finished product is effectively improved by adding naphthenic soap, nickel sulfamate, tribasic lead sulfate and the like.

Owner:NINGBO TONGGUAN ELECTRIC AUTOMATION EQUIP

Coated sewage treatment agent and preparation method thereof

InactiveCN108745313AImprove surface activityImprove stabilityOther chemical processesWater/sewage treatment by sorptionWaxMANNITOL/SORBITOL

The invention discloses a coated sewage treatment agent which is prepared from the following raw materials in parts by weight: 16-20 of sodium carboxymethylcellulose, 4-6 of oxidized polyethlene wax,0.7-1 of 2-sulfhydrylbenzimidazole, 1-2 of stearamide, 3-5 of mannitol, 30-40 of modified sol, 70-90 of scolecite and 10-14 of polyacrylamide. For the coated type sewage treatment agent provided by the invention, by adopting sodium carboxymethylcellulose for coating treatment, the stability strength of the structure of a finished product is effectively improved; and the material provided by the invention has very good adsorption performance and good stability without containing polluting substances and causing secondary pollution and is high in repeated utilization rate and excellent in comprehensive performance.

Owner:黄益良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com