Patents

Literature

3789 results about "Glass-ceramic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass-ceramics have an amorphous phase and one or more crystalline phases and are produced by a so-called "controlled crystallization" in contrast to a spontaneous crystallization, which is usually not wanted in glass manufacturing. Glass-ceramics have the fabrication advantage of glass, as well as special properties of ceramics. When used for sealing, some glass-ceramics do not require brazing but can withstand brazing temperatures up to 700 °C. Glass-ceramics usually have between 30% [m/m] and 90% [m/m] crystallinity and yield an array of materials with interesting properties like zero porosity, high strength, toughness, translucency or opacity, pigmentation, opalescence, low or even negative thermal expansion, high temperature stability, fluorescence, machinability, ferromagnetism, resorbability or high chemical durability, biocompatibility, bioactivity, ion conductivity, superconductivity, isolation capabilities, low dielectric constant and loss, high resistivity and break-down voltage. These properties can be tailored by controlling the base-glass composition and by controlled heat treatment/crystallization of base glass. In manufacturing, glass-ceramics are valued for having the strength of ceramic but the hermetic sealing properties of glass.

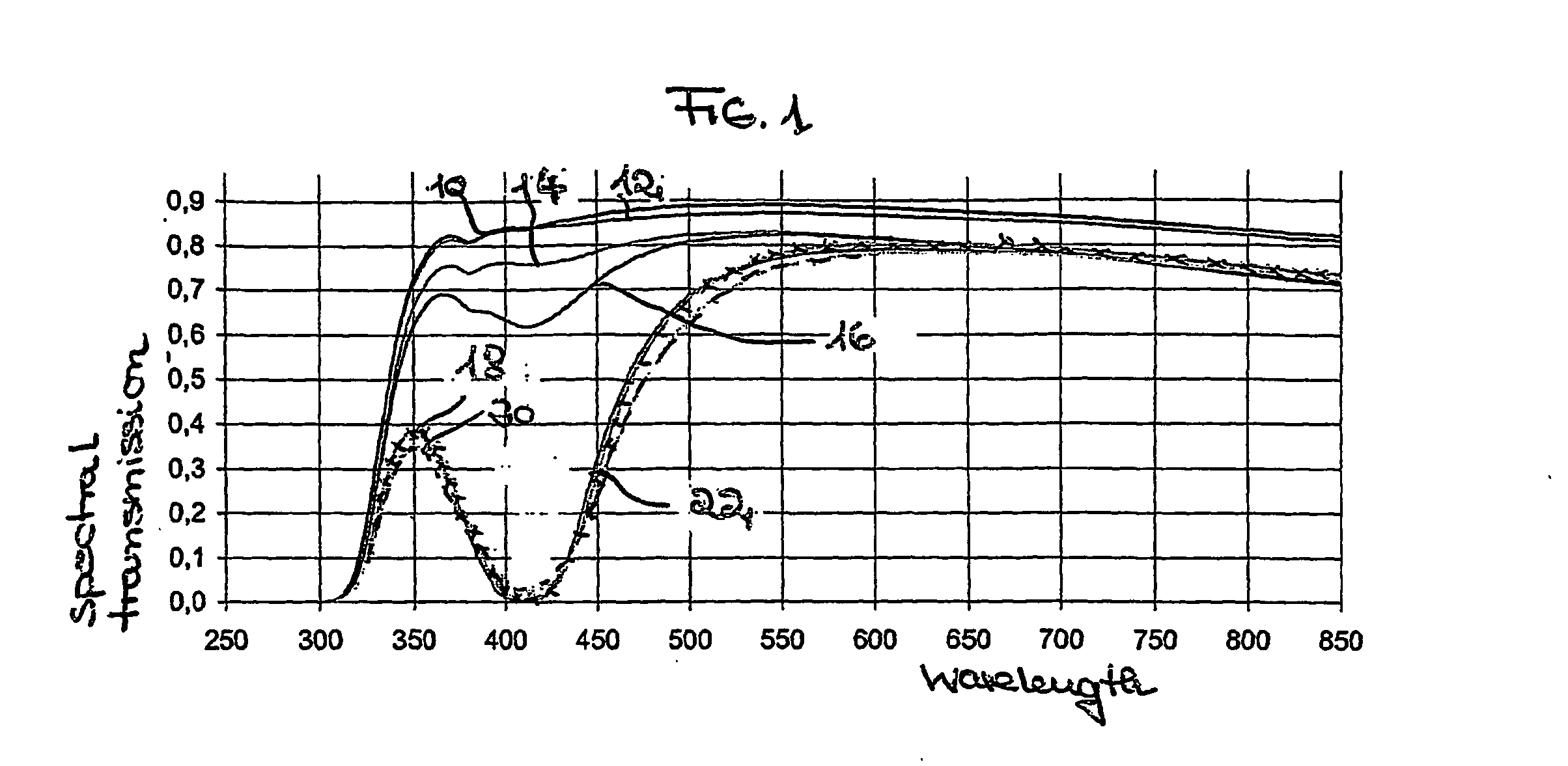

Antimicrobial glass and glass ceramic surfaces and their production

InactiveUS20070172661A1Long term efficacyBiocidePretreated surfacesAntimicrobial surfaceGlass-ceramic

The application relates to an article having a antimicrobial surface with a metal ion concentration, especially a Ag-concentration in a depth of about 0 um to about 2 um of the article measured from the surface higher than 0,6 wt %, preferably 0,8 weight-%, most preferably 1 weight-%.

Owner:SCHOTT AG

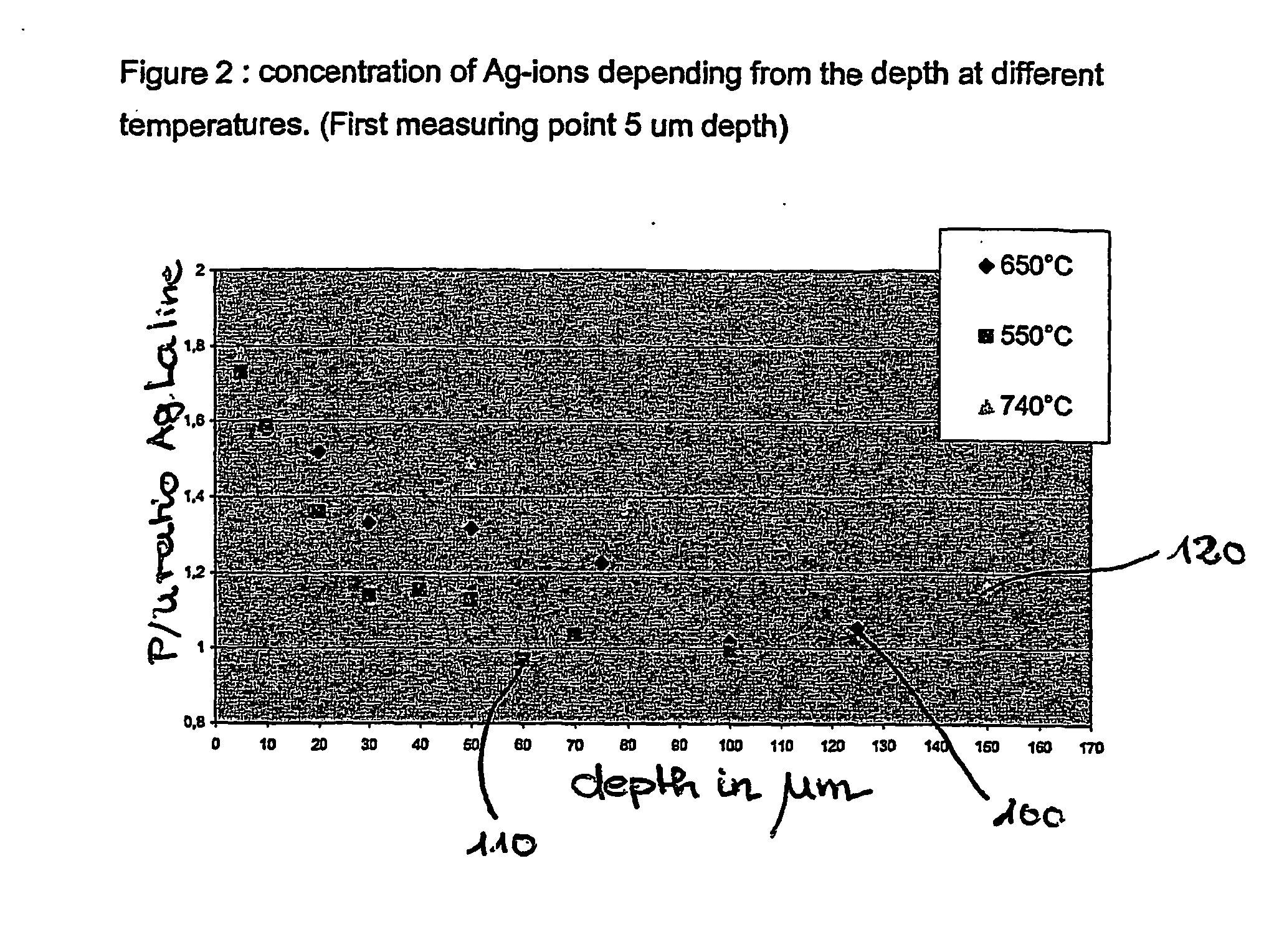

Composition of a thermaly insulating coating system

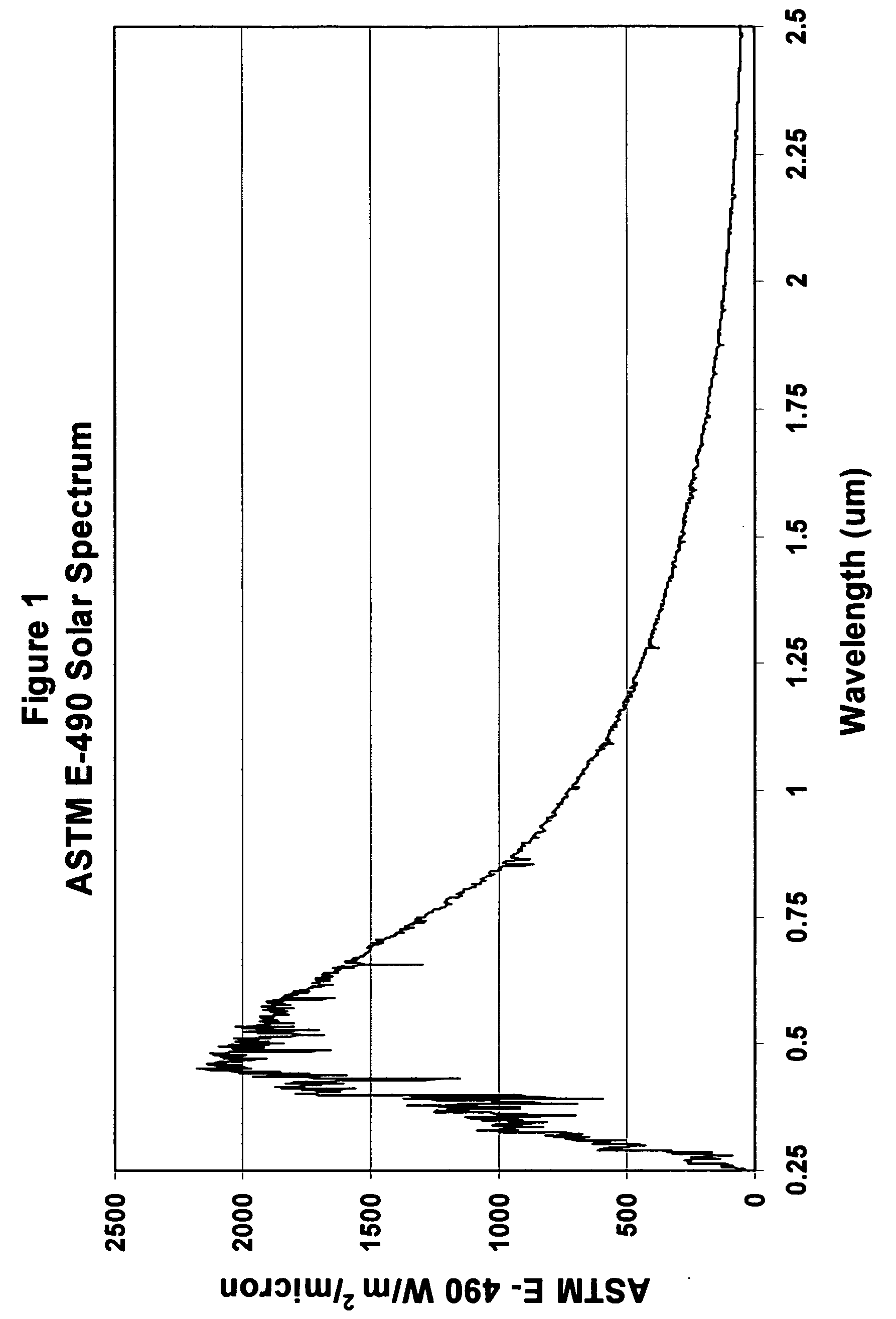

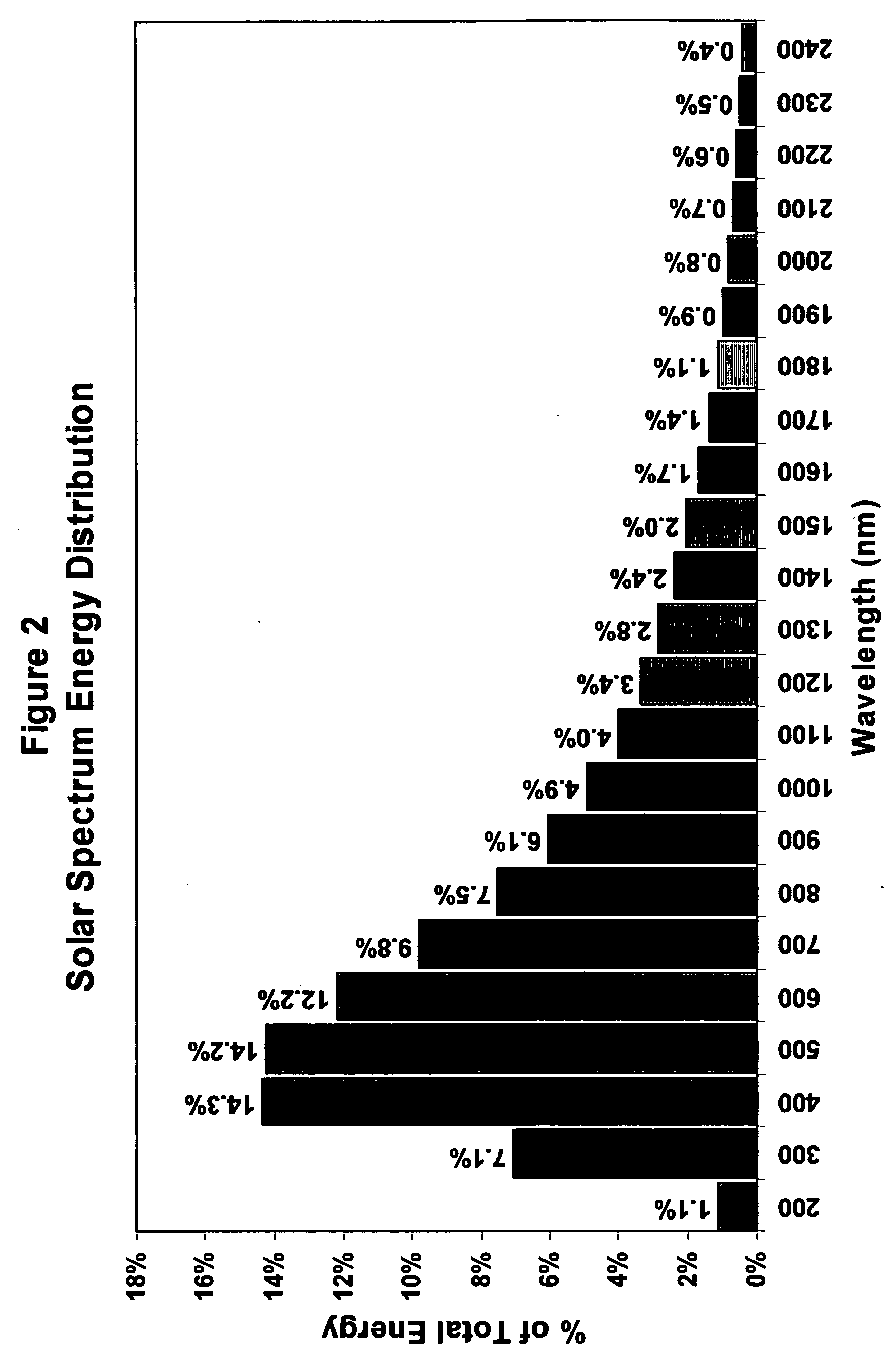

InactiveUS20050126441A1High infrared reflectivityLow thermal conductivityPigmenting treatmentCeramic layered productsCoating systemSolar spectra

A composition for a Coating System (paint) which forms an insulating material being designed to both reflect infrared radiation and have reduced thermal conductivity. The coating system may be either a single Thermal Coating or may be a Thermal Coating used in combination with a Thermal Primer. The Thermal Coating is formulated using conventional techniques and a resin used in paint manufacture, but utilizes primary pigments and extender mineral pigments which preferentially reflect in the infra red area of the solar spectrum. A method of characterizing particulate materials for their infra red reflectivity is described, which provides a means for preferential selection of particulate additives based on their relative visible light and infrared reflectivity. Additionally the incorporation of hollow micro-spheres is desired to reduce thermal conductivity. The Thermal Primer is designed to provide adhesion between the Thermal Coating and the substrate on which it is applied and uses conventional techniques to achieve those properties. However it has been found advantageous to incorporate hollow micro-spheres with low thermal conductivity, such as glass, ceramic or polymeric micro-spheres and / or an extender pigment with low thermal conductivity such as calcined clay to further reduce heat flow through the Coating System.

Owner:ANTHONY DAVID SKELHORN

Glass-ceramic materials, precursor glass thereof and process-for making the same

The present invention relates to: novel glass-ceramics of β-quartz and / or of β-spodumene; articles made from said novel glass-ceramics; and ithium alumino-silicate glasses, which are precursors of said novel glass-ceramics; methods of preparing said novel glass-ceramics and articles made from said novel glass-ceramics. The present invention relates to the use of SnO2 and of Br, as an agent for fining the glass-ceramic glass precursor.

Owner:EUROKERA SOC & NOM COLLECTIF

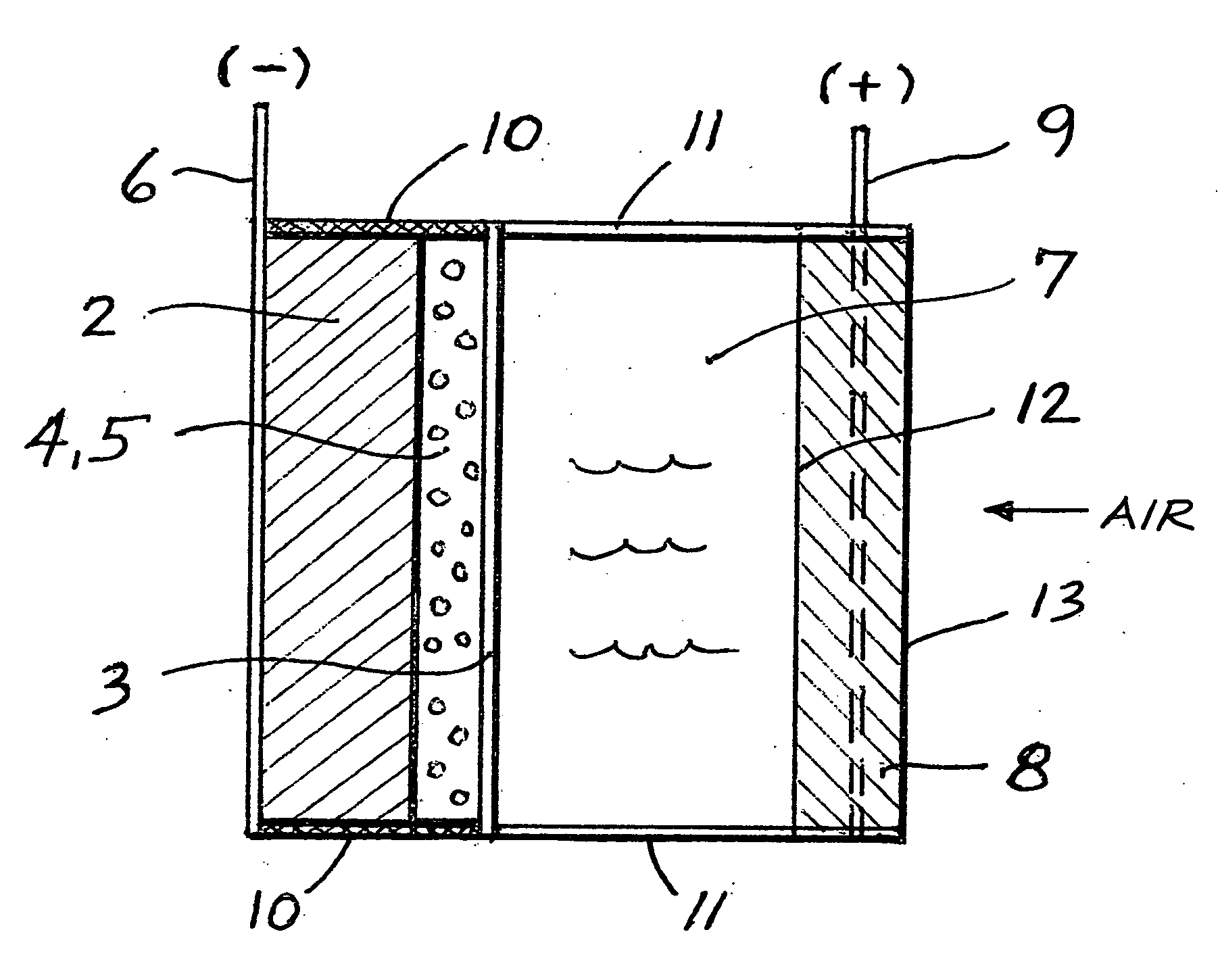

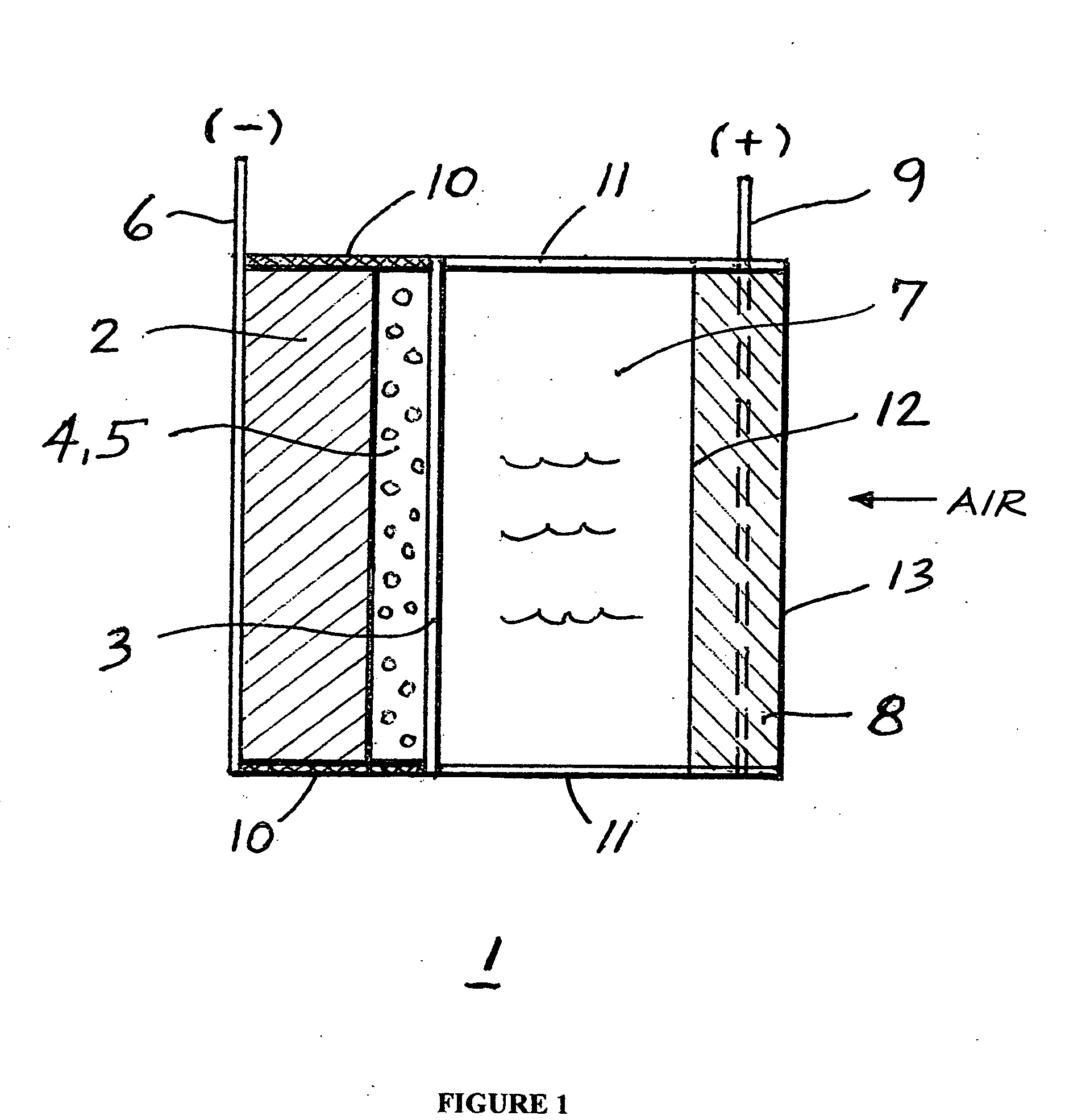

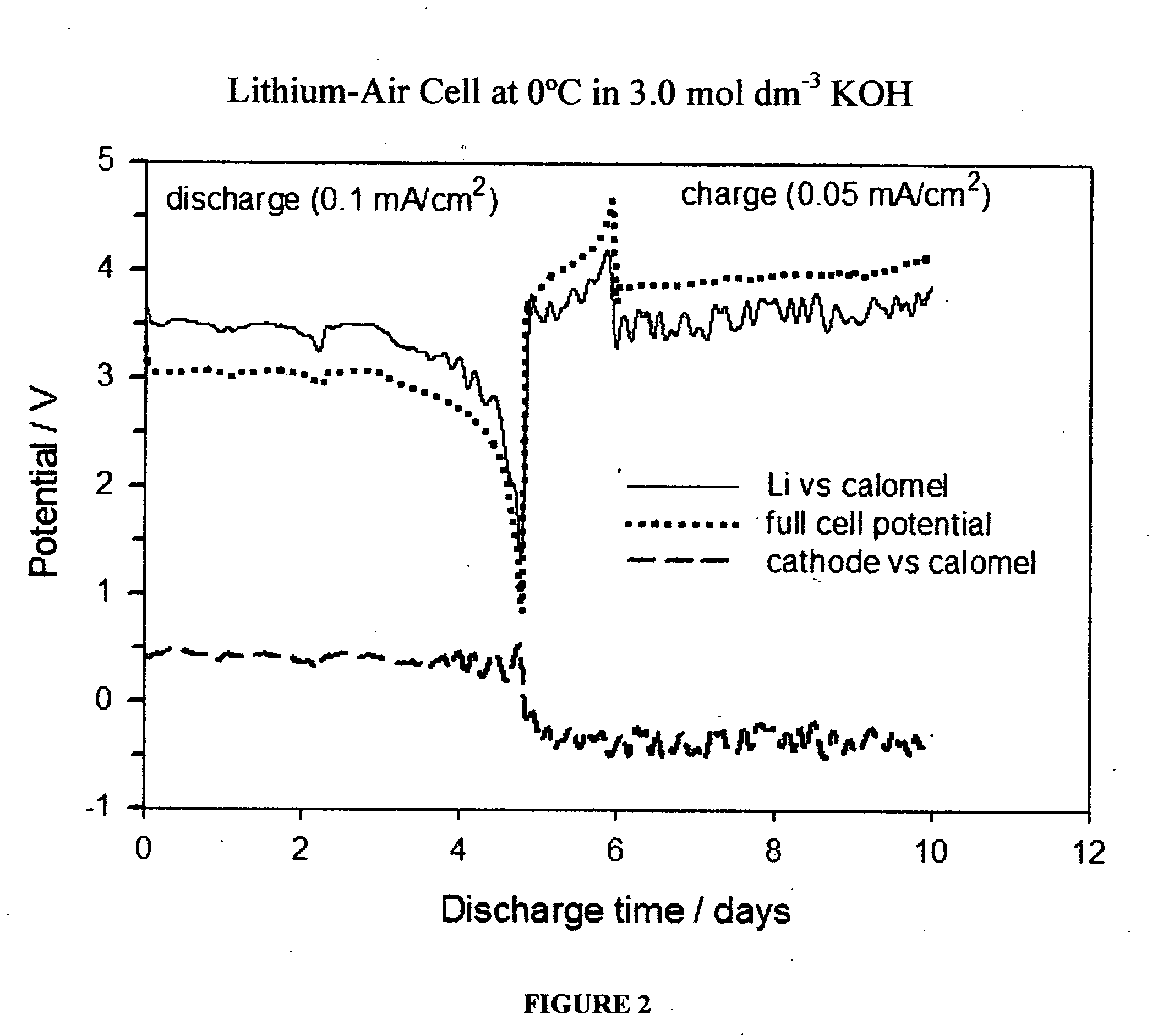

Solid electrolytes based on lithium hafnium phosphate for active metal anode protection

InactiveUS20060078790A1Avoid harmful reactionsCell electrodesNon-aqueous electrolyte cellsPhosphateOrganic liquids

Active metal electrochemical structure, in particular an active metal negative electrode (anode) protected with an ionically conductive protective architecture incorporating a glassy, ceramic or glass-ceramic solid electrolyte material based on lithium hafnium phosphate, and associated electrochemical devices and methods, provides advantages over conventional structures. The protective architecture prevents the active metal from deleterious reaction with the environment on the other (cathode) side of the architecture, which may include aqueous, air or organic liquid electrolytes and / or electrochemically active materials.

Owner:POLYPLUS BATTERY CO INC

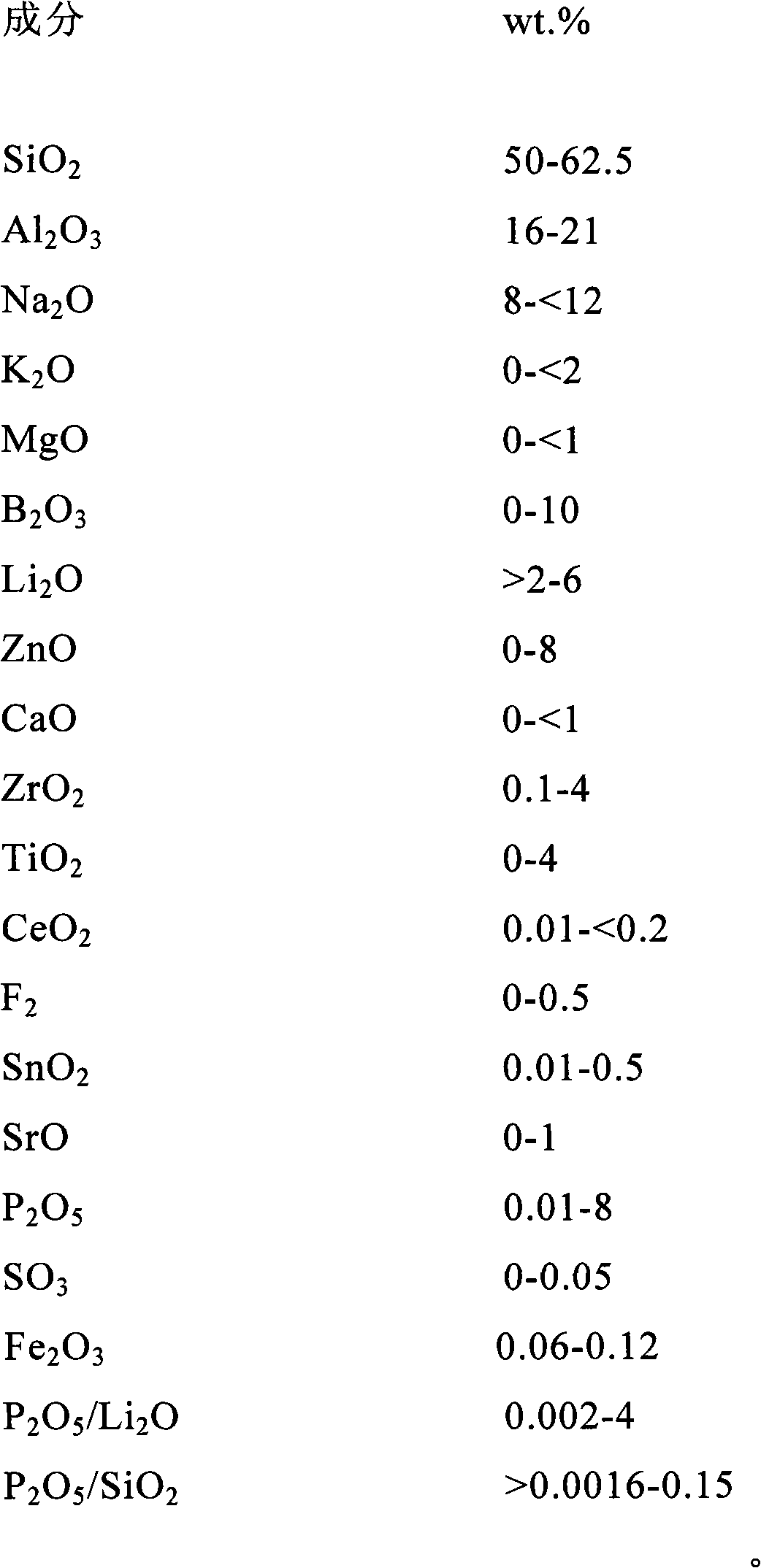

Aluminosilicate glass for chemical tempering and glass ceramics

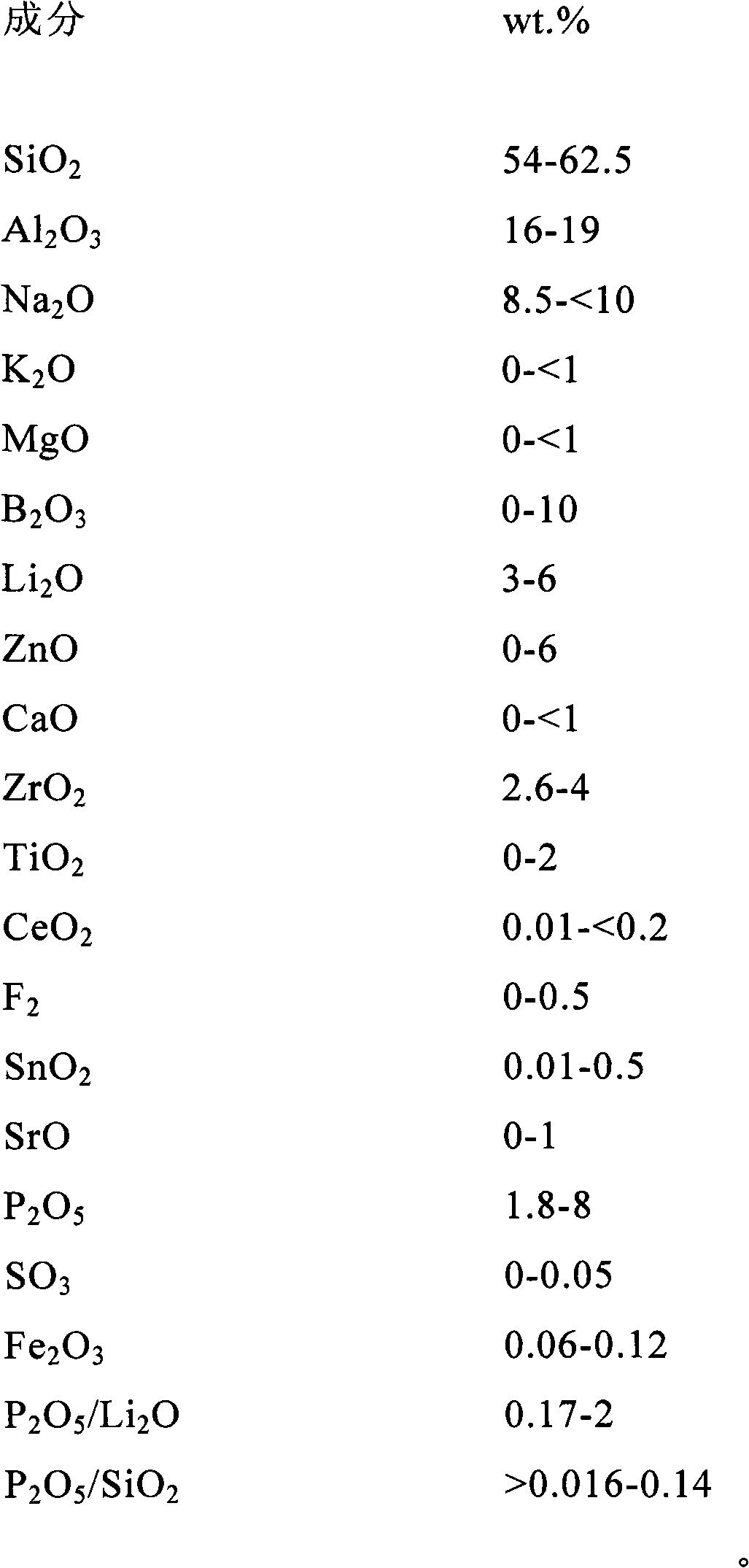

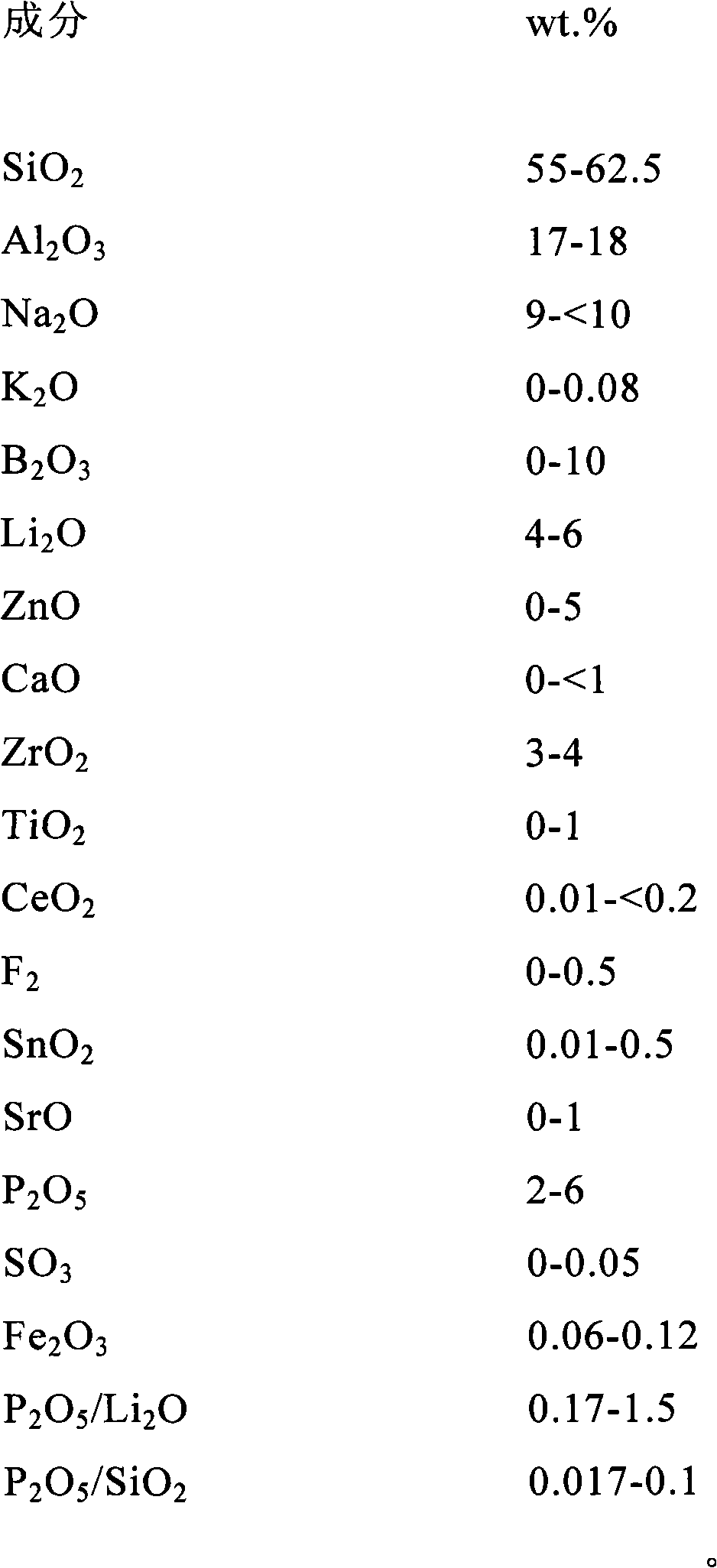

The invention discloses aluminosilicate glass for chemical tempering and glass ceramics, and particularly discloses aluminosilicate glass which contains Li2O and P2O5 and can be chemically tempered. The glass of the invention can realize high ion exchange speed by the addition of 0.01-8 wt% of P2O5. The glass of the invention contains 2-6 wt% of Li2O, which can reduce the glass melting temperature and the glass-transition temperature. The glass of the invention has a low glass-transition temperature (Tg) of 480-590 DEG C, and the glass hardness is at least 600 Kg / mm2. After chemical tempering, the glass of the invention has a large surface stress layer depth (DoL) and a high surface crushing stress (CS). After tempering in pure KNO3, a potassium ion stress layer is formed, which has a DoL of at least 20 microns and a CS of at least 600 MPa. After tempering in a mixed salt of KNO3 and NaNO3 or two-step tempering in KNO3 and NaNO3, a potassium and sodium ion stress layers can be formed simultaneously, which have a DoL of at least 50 microns and a CS of at least 600 MPa. In addition, the aluminosilicate glass of the invention can be converted into glass ceramics through further heat treatment.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

Flat float glass

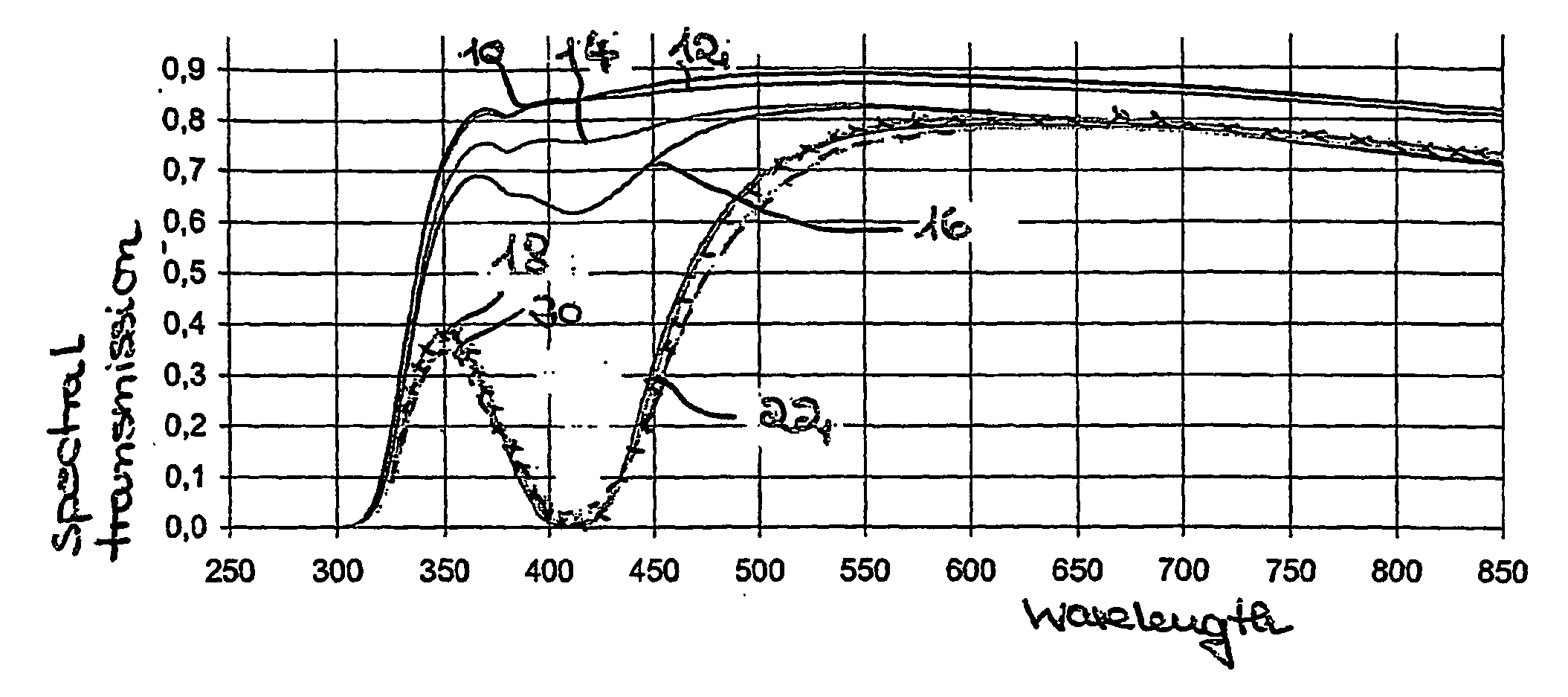

InactiveUS20020023463A1High degreeLess sensitiveGlass furnace apparatusGlass rolling apparatusArsenic oxideThermal expansion

This invention relates to a flat float glass that can be prestressed or transformed into a glass ceramic with high quartz mixed crystals or keatite mixed crystals. To eliminate undesirable surface defects during floating and to achieve superior characteristics of the glass or of he glass ceramic, in particular with regard to a low coefficient of thermal expansion and high light transmittance, the glass has a concentration of less than 300 ppb Pt, less than 30 ppb Rh, less than 1.5 wt. % ZnO and less than 1 wt. % SnO2, and is refined during melting without the use of the conventional fining agents arsenic oxide and / or antimony oxide.

Owner:SCHOTT AG

Glass-ceramic materials, precursor glass thereof and process for making the same

The invention relates to: a method of preparing glass-ceramics of β-quartz and / or of β-spodumene; a method of preparing articles made from said glass-ceramics; novel glass-ceramics of β-quartz and / or of β-spodumene; articles made from said novel glass-ceramics; and lithium aluminosilicate glasses, which are precursors of such novel glass-ceramics. The present invention relates to the use, as agent for fining the glass-ceramic glass precursor, of fluorine and at least one oxide of a multivalent element.

Owner:EUROKERA SOC & NOM COLLECTIF

High strength glass-ceramics having petalite and lithium silicate structures

Glass and glass ceramic compositions having a combination of lithium silicate and petalite crystalline phases along with methods of making the glass and glass ceramic compositions are described. The compositions are compatible with conventional rolling and float processes, are transparent or translucent, and have high mechanical strength and fracture resistance. Further, the compositions are able to be chemically tempered to even higher strength glass ceramics that are useful as large substrates in multiple applications.

Owner:CORNING INC

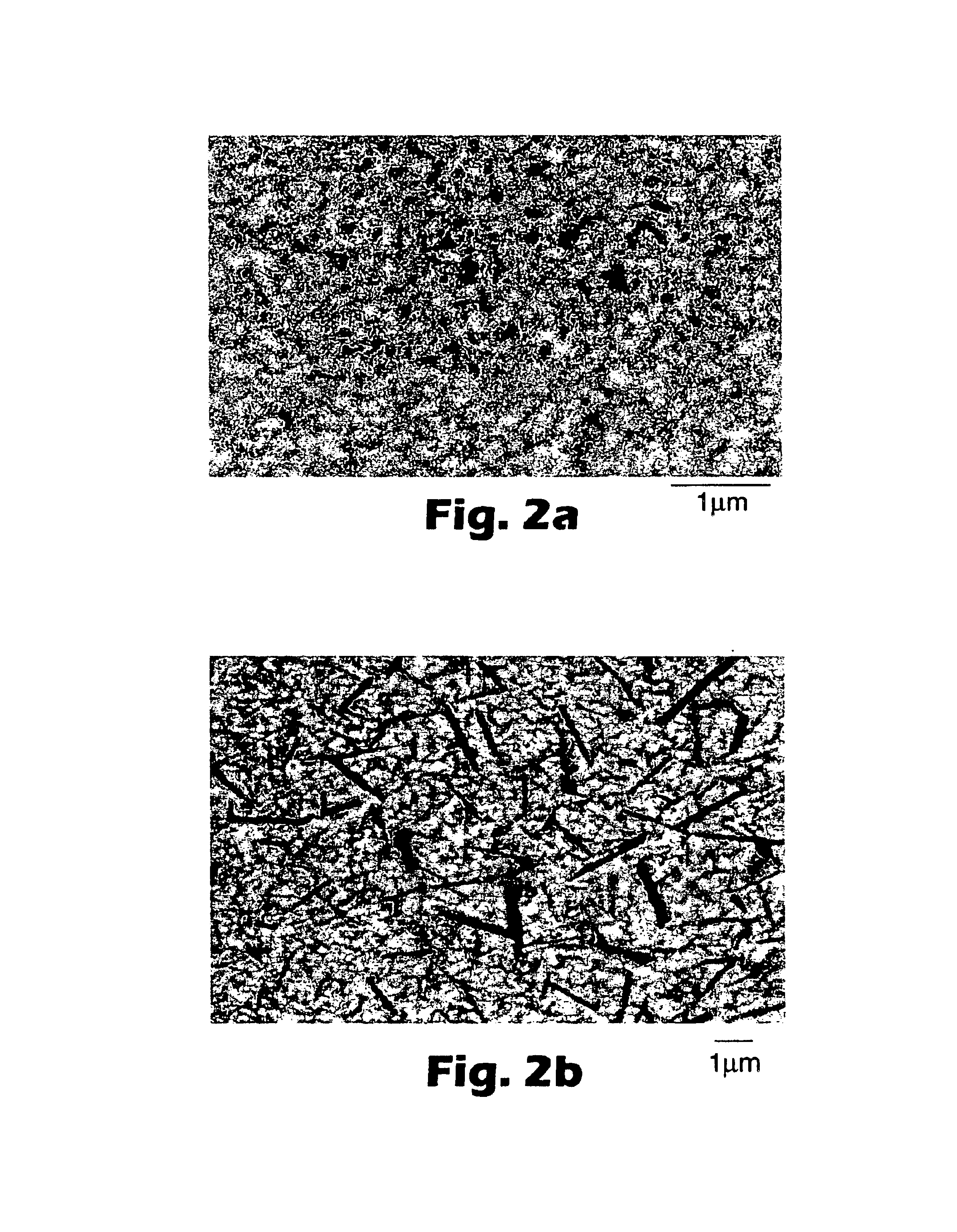

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS7507268B2Facilitates formation and homogeneityEliminates and minimizes heat transferPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3—Y2O3—ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

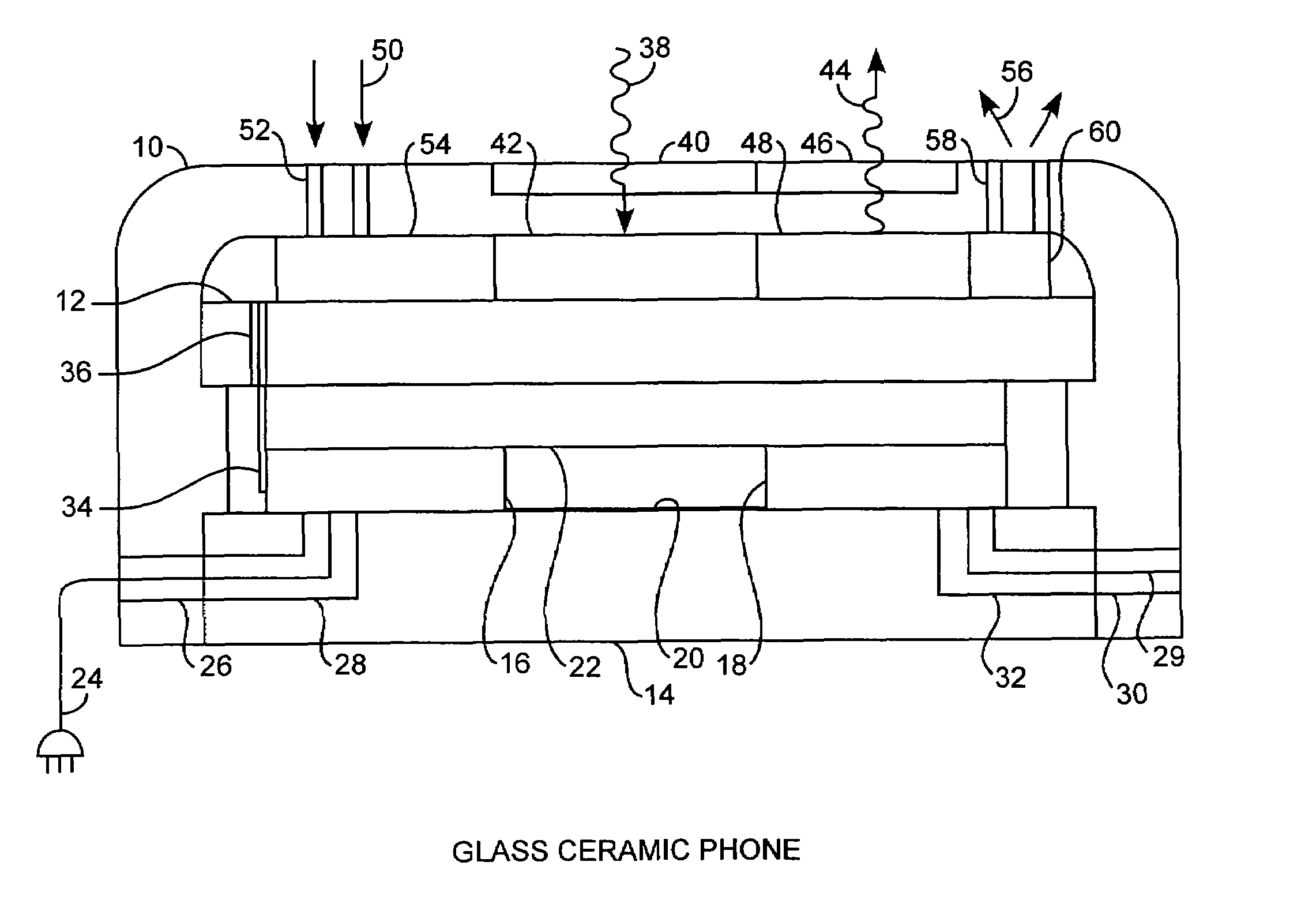

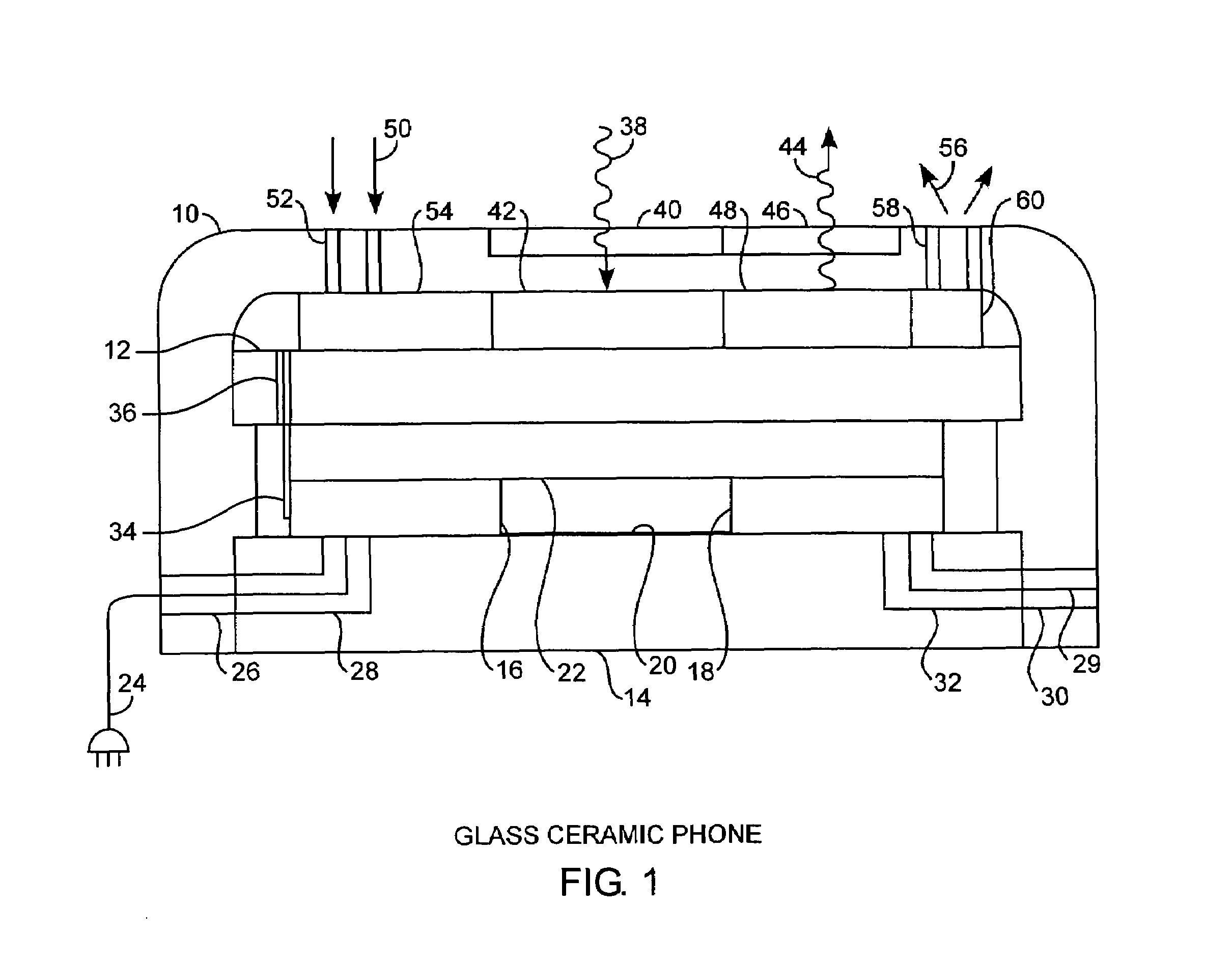

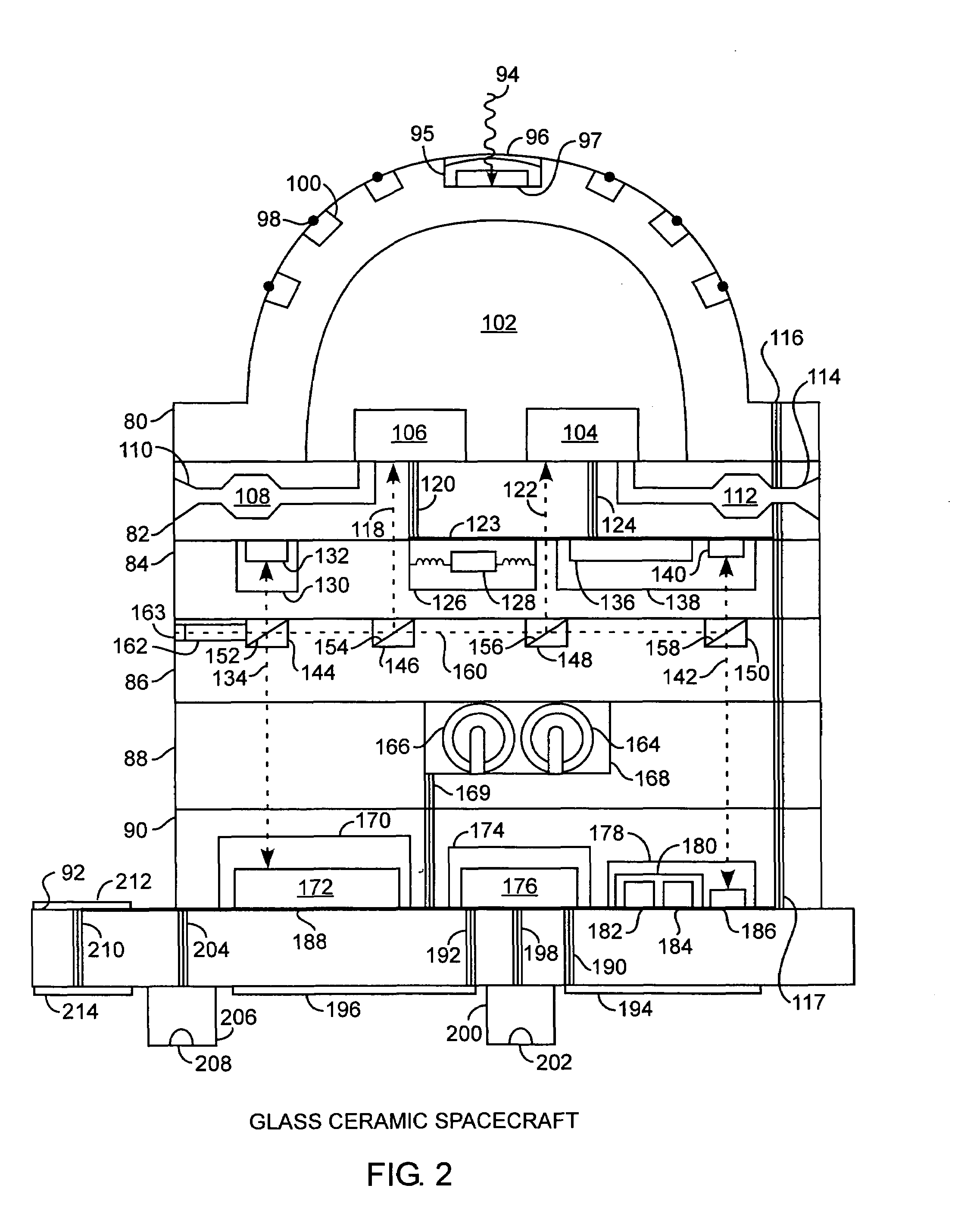

Integrated glass ceramic systems

ActiveUS6952530B2Improve structural strengthLow thermal conductivityCosmonautic propulsion system apparatusCosmonautic power supply systemsElectricityOptical communication

Integrated glass ceramic spacecraft include a plurality of glass ceramic components including molded, tempered, annealed, and patterned glass ceramic components coupled together for forming a support structure or frame or housing through which is communicated optical signals through an optical communications grid and electrical signals through an electrical communications grid, with the optical communications grid and electrical communication grid forming a composite electrooptical communications grid for spacecraft wide intercommunications. The support structure multifunctions as a frame, a housing, a support, a thermal control system, and as part of an electrooptical communications grid while encapsulating a plurality of optical, electronic, electrical, and MEMS devices between which is communicated the electrical and optical signals over the electrooptical communication grid.

Owner:THE AEROSPACE CORPORATION

Use of ceramics in dental and orthodontic applications

Owner:3M INNOVATIVE PROPERTIES CO

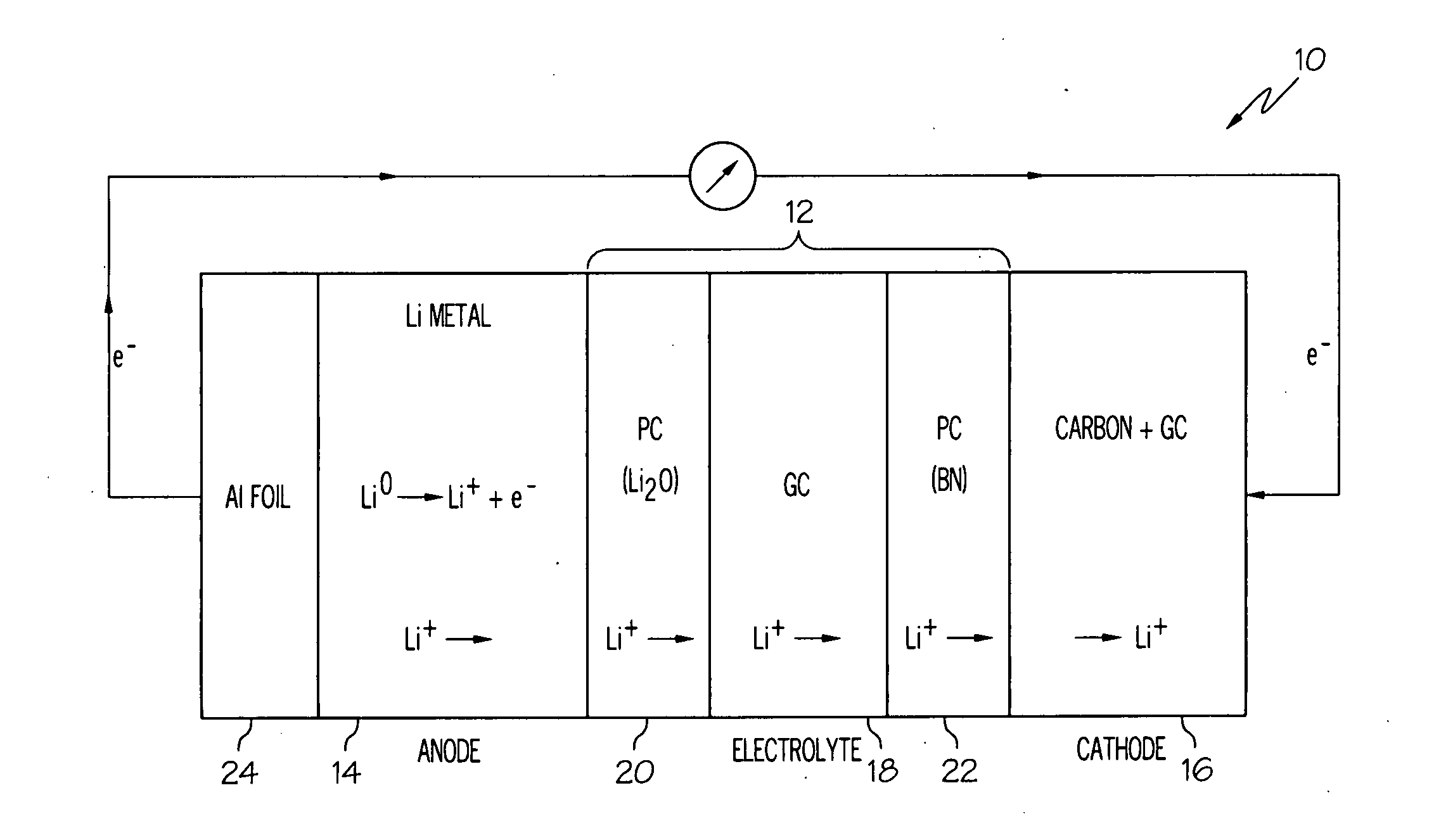

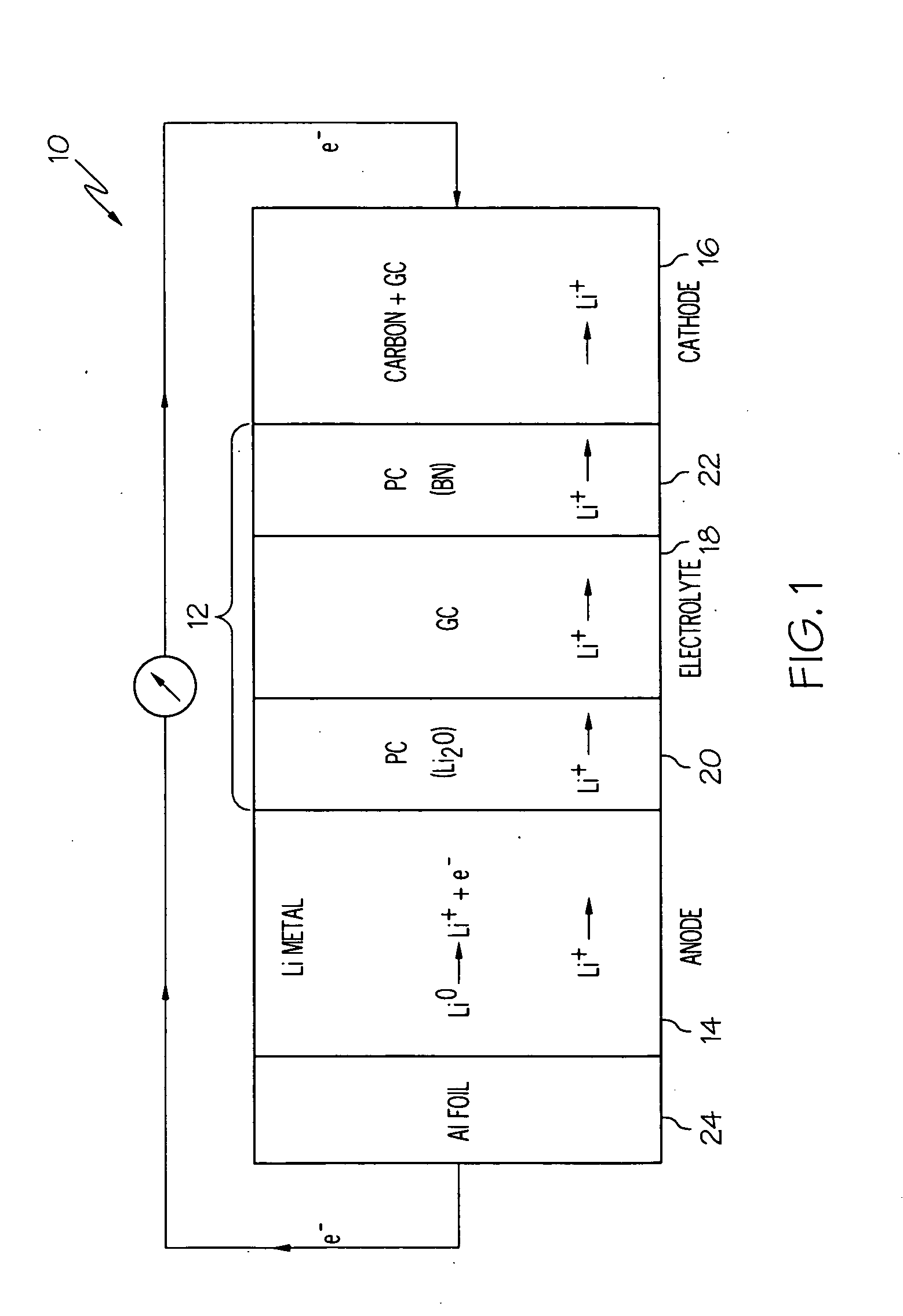

Lithium-air cells incorporating solid electrolytes having enhanced ionic transport and catalytic activity

ActiveUS20090317724A1Enhanced ionic transportEasy to transportSolid electrolytesFuel and secondary cellsLithiumOxygen

Liquid-free lithium-air cells are provided which incorporate a solid electrolyte having enhanced ionic transport and catalytic activity. The solid electrolyte is positioned between a lithium anode and an oxygen cathode, and comprises a glass-ceramic and / or a polymer-ceramic electrolyte including a dielectric additive.

Owner:UNIV OF DAYTON

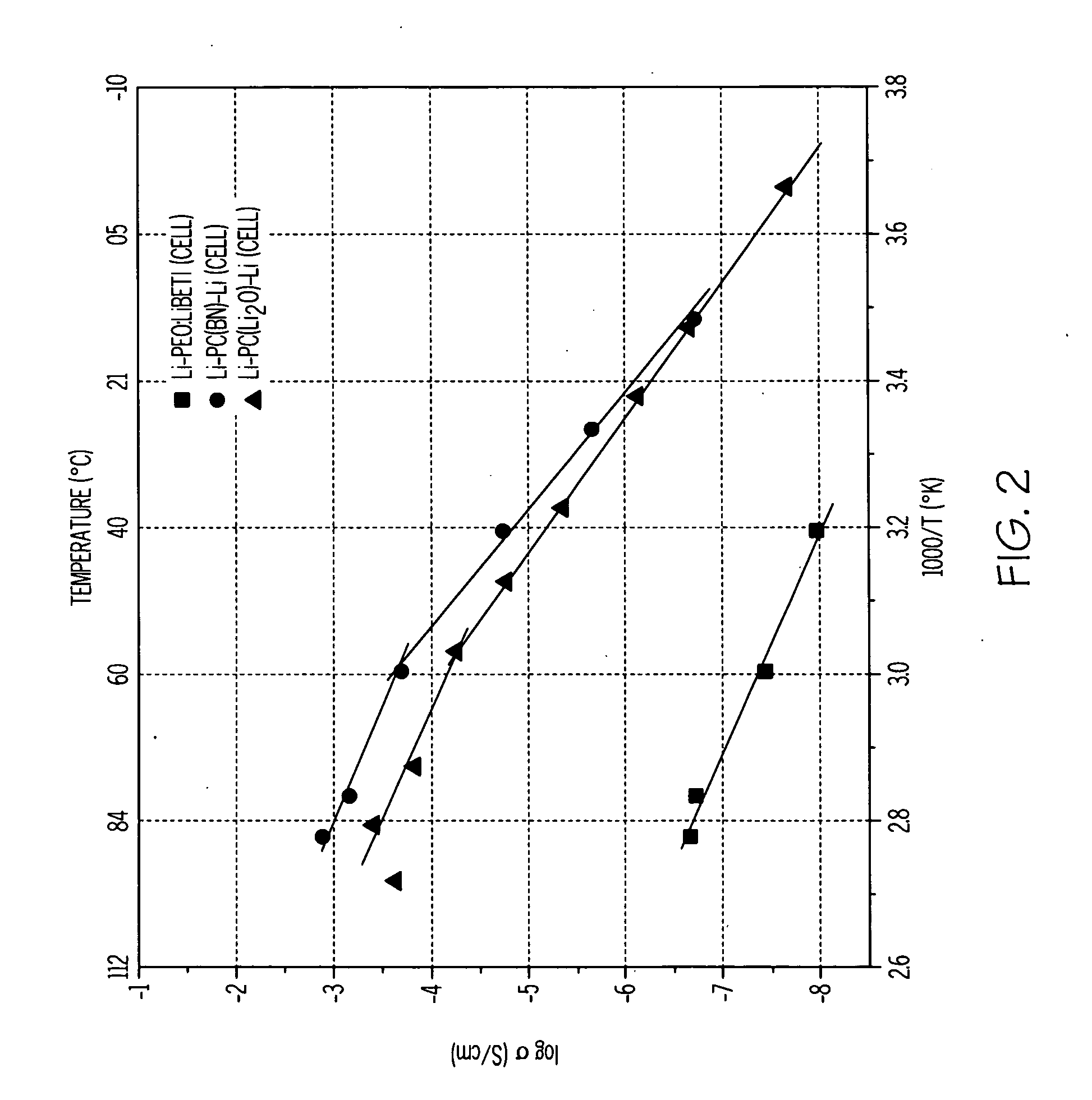

Solid composite electrolyte membrane and method of making

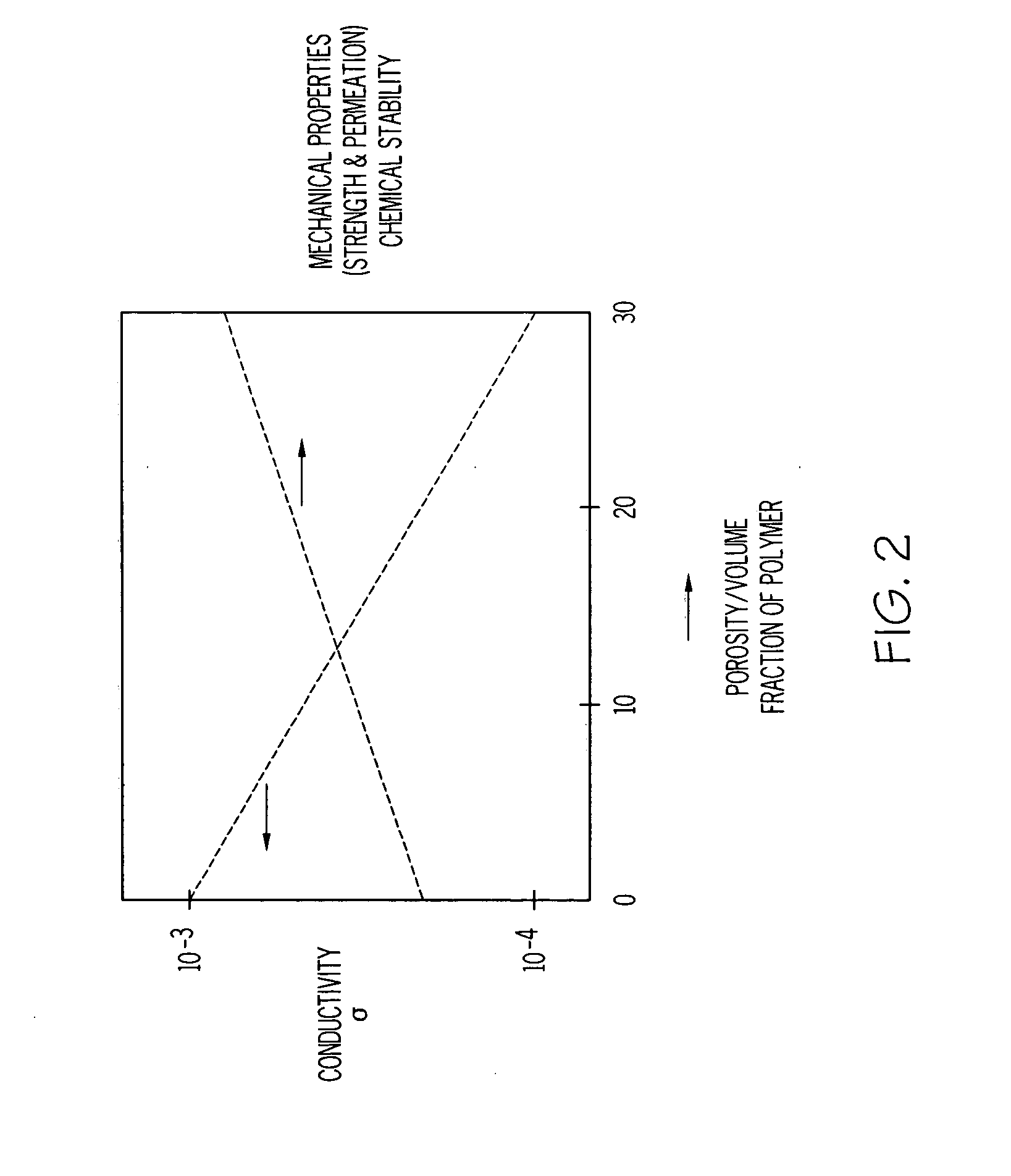

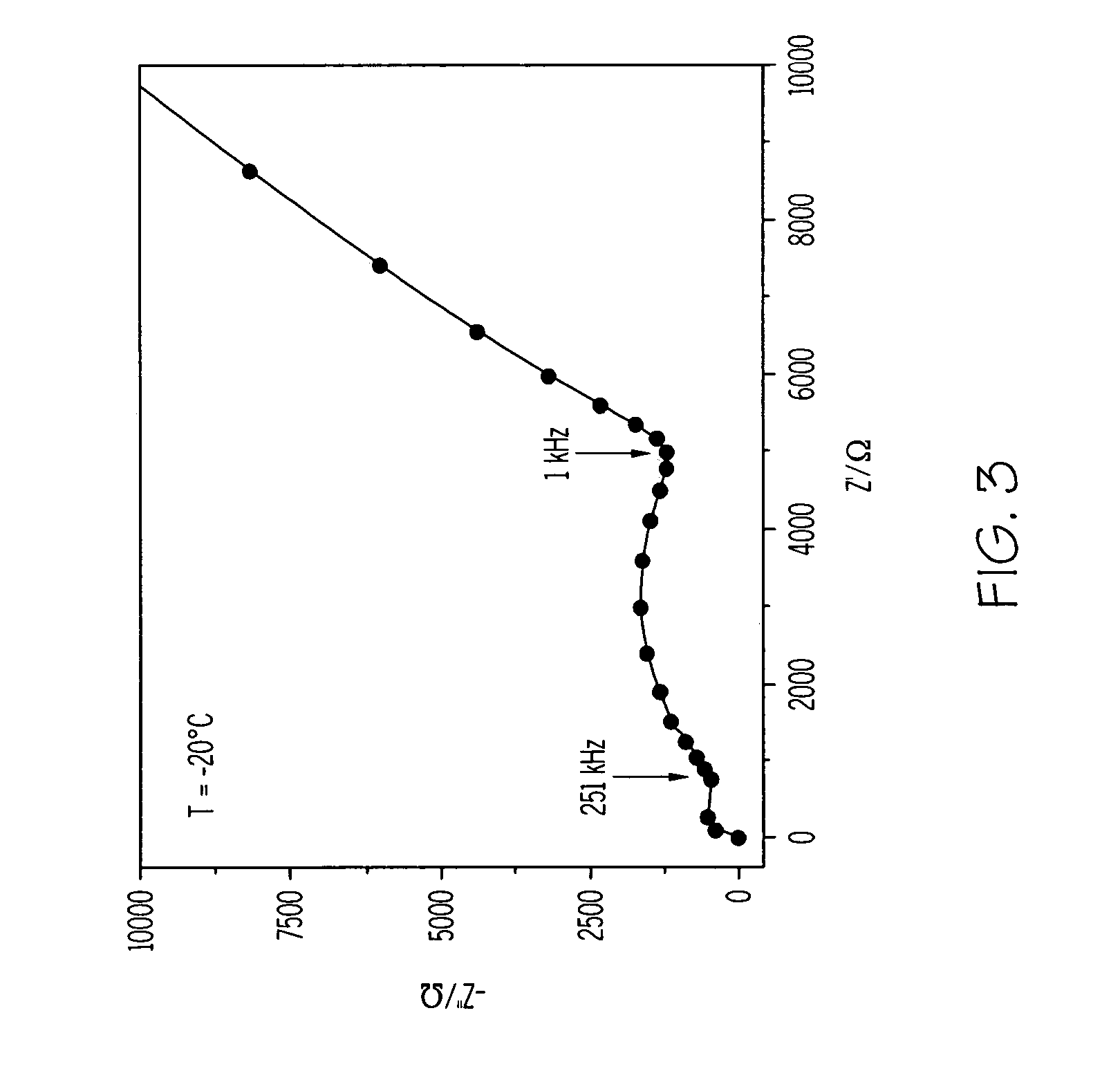

ActiveUS20070117026A1Improve conductivitySolid electrolytesSolid electrolyte cellsPorosityComposite electrolyte

A solid composite electrolyte membrane for use in a lithium battery is provided which exhibits a conductivity ranging from about 10−4 S cm−1 to about 10−3 S cm−1 at ambient temperature. The membrane is formed by providing a glass or glass-ceramic powder formed from a mixture of lithium carbonate, alumina, titanium dioxide, and ammonium dihydrogen phosphate. The powder is mixed with a conditioning agent and at least one solvent, followed by the addition of a binder and one or more plasticizers. The resulting slurry is cast into a tape which is then subjected to a binder burn-off and sintering process to form the membrane. The resulting membrane may be a glass-ceramic composite having a porosity ranging from 0 to 50%, or the membrane may be further infiltrated with a polymer to form a water-impermeable polymeric-ceramic composite membrane.

Owner:UNIV OF DAYTON THE

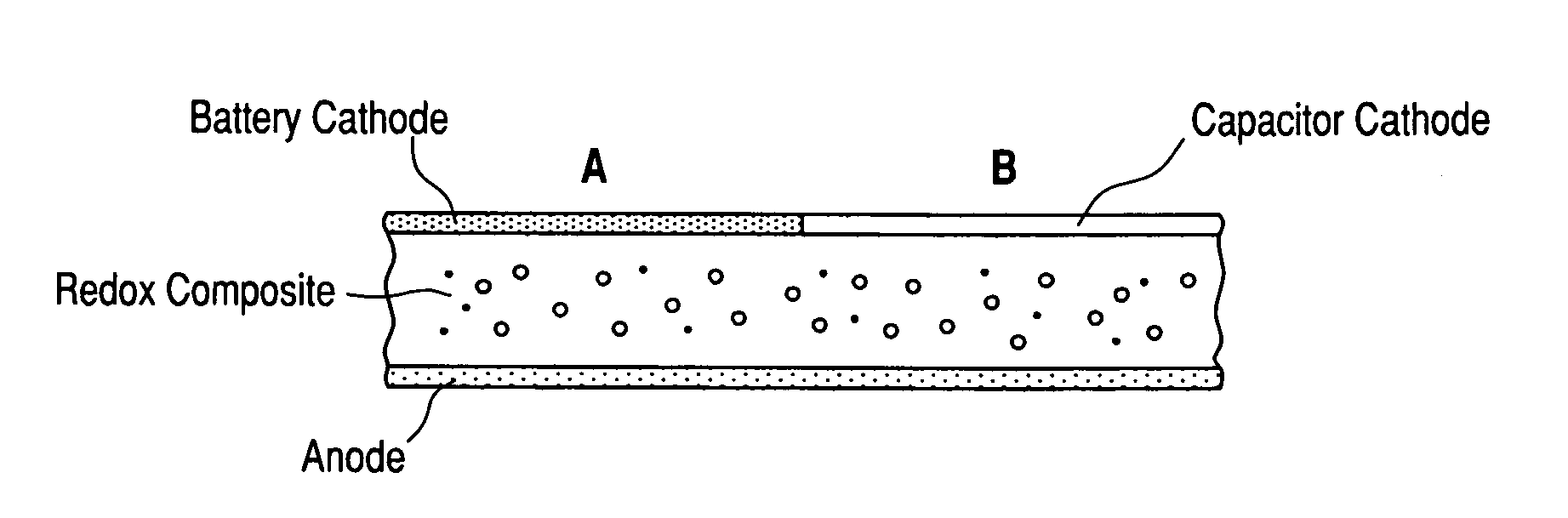

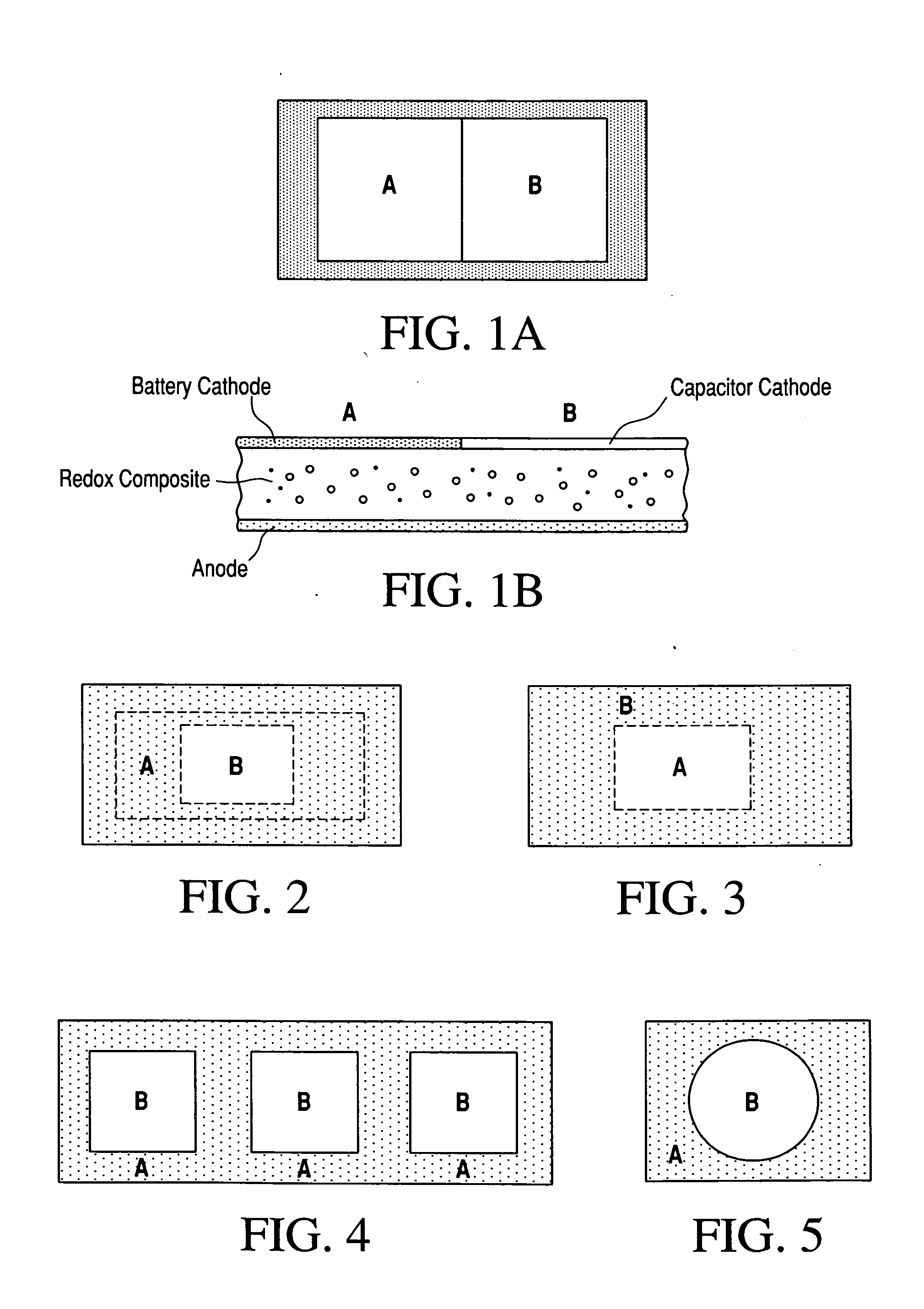

Composite ionic conducting electrolytes

InactiveUS20130026409A1High operating requirementsOptimize volumeFuel and primary cellsHybrid capacitor electrolytesComposite electrolyteConductive polymer

Ionically conducting, redox active additive composite electrolytes are disclosed. The electrolytes include an ionically conductive component and a redox active additive. The ionically conductive component may be an ionically conductive material such as an ionically conductive polymer, ionically conducting glass-ceramic, ionically conductive ceramic, and mixtures thereof. Electrical energy storage devices that employ the ionically conducting, redox active additive composite electrolytes also are disclosed

Owner:RECAPPING +1

High-strength dental restorations

InactiveUS20050127544A1Improve adhesionHigh strengthHair accessoriesImpression capsDental ProductHigh intensity

Lithium disilicate based glass-ceramics contain high strength ceramic components for use in the manufacture of dental products. The glass-ceramics have good pressability, i.e., the ability to be formed into dental products by heat-pressing using commercially available equipment. The strength of the dental articles is increased with the inclusion of the high strength ceramic components.

Owner:ARDENT

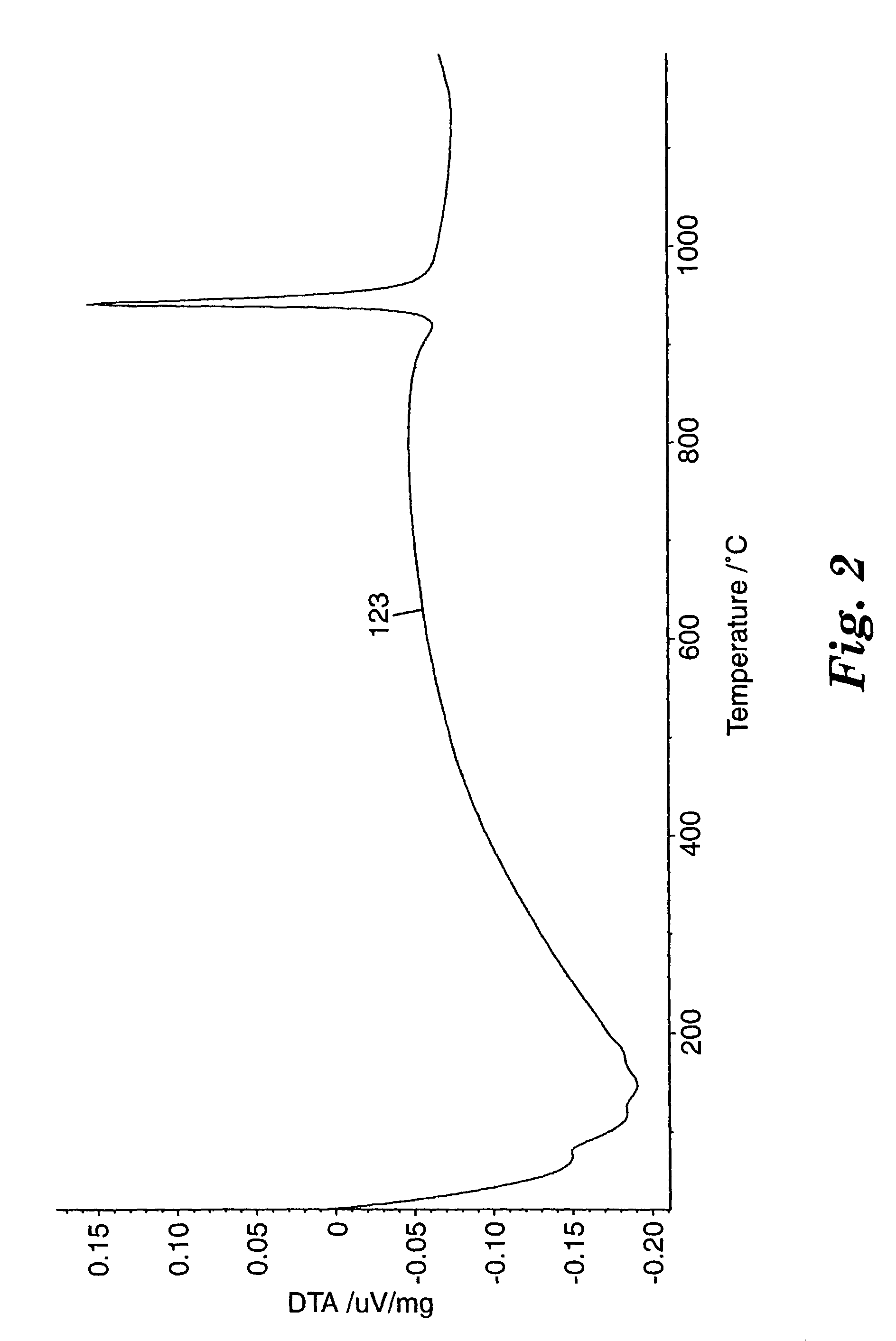

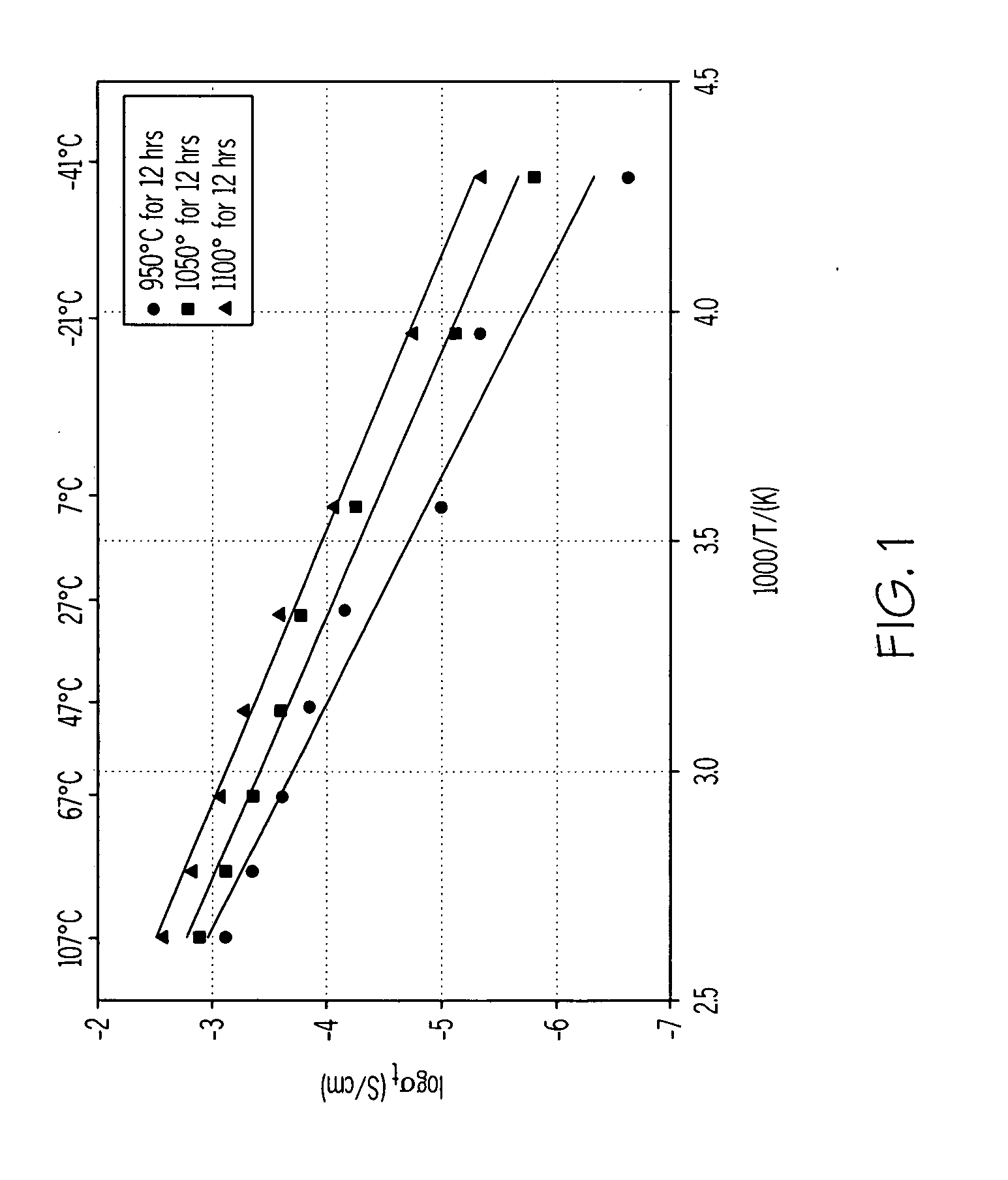

Alkali ion conductive glass-ceramics and electric cells and gas sensors using the same

InactiveUS7211532B2Improve performanceImprove conductivityMaterial analysis by electric/magnetic meansSecondary cellsLithiumAlkali ions

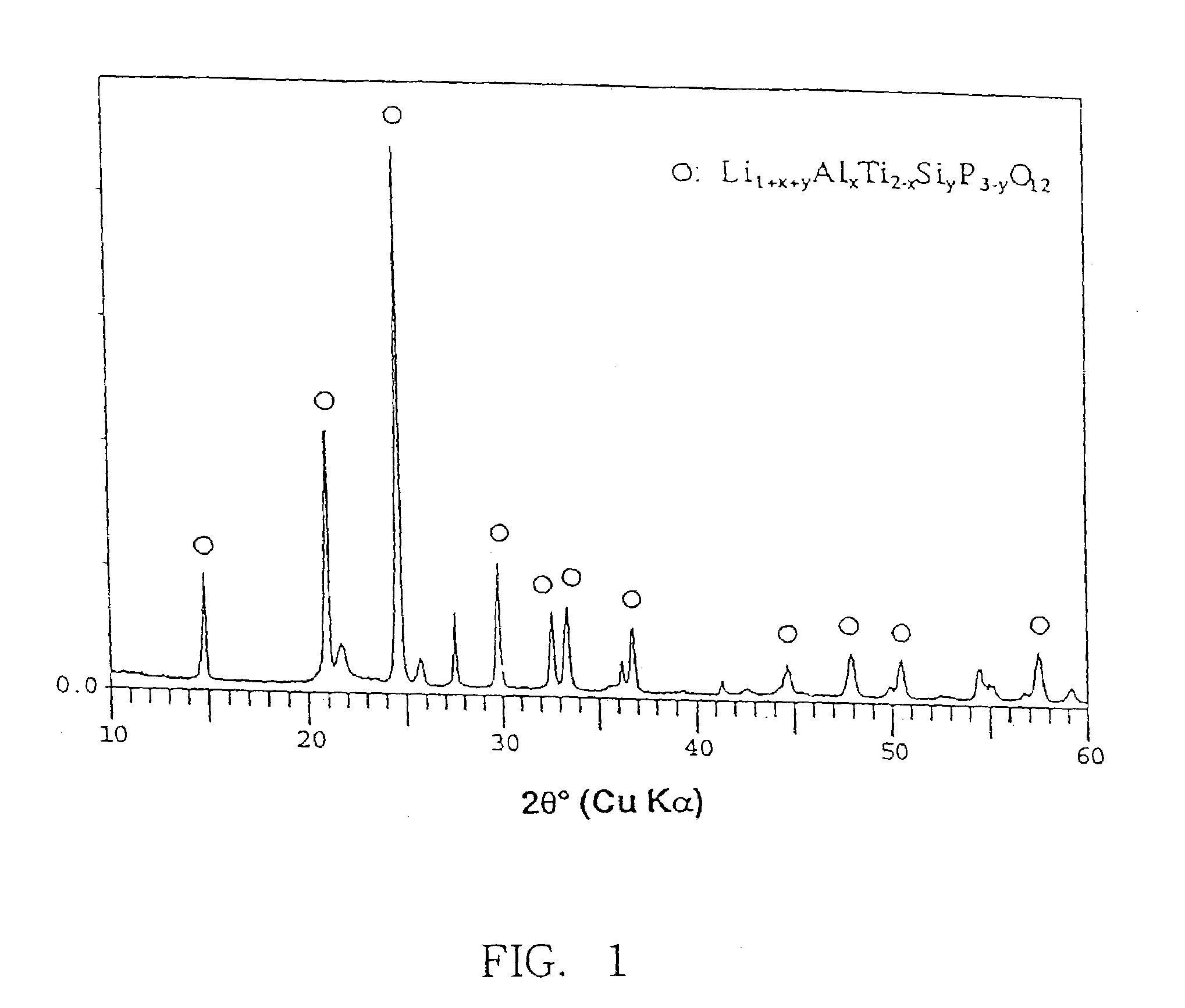

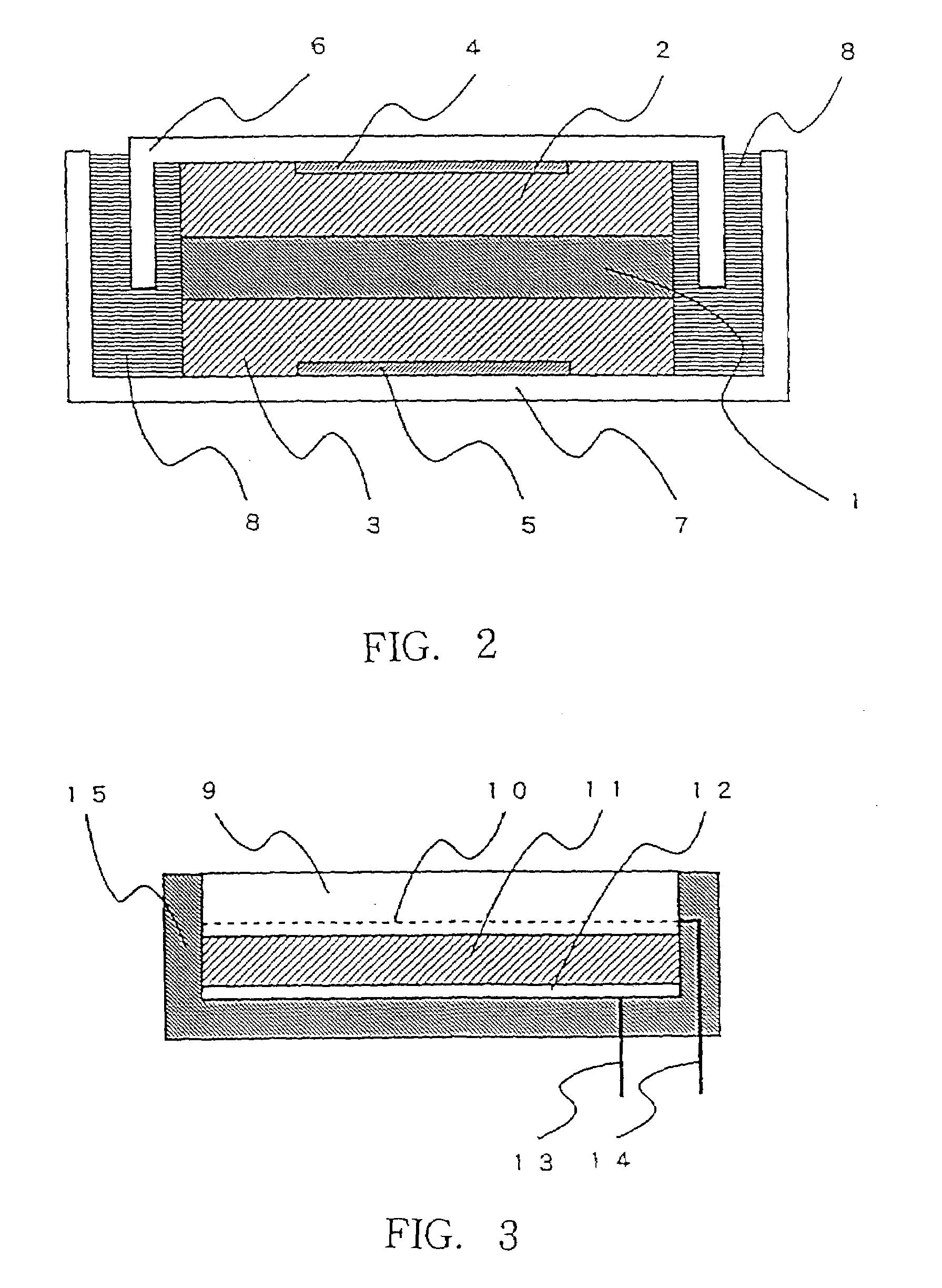

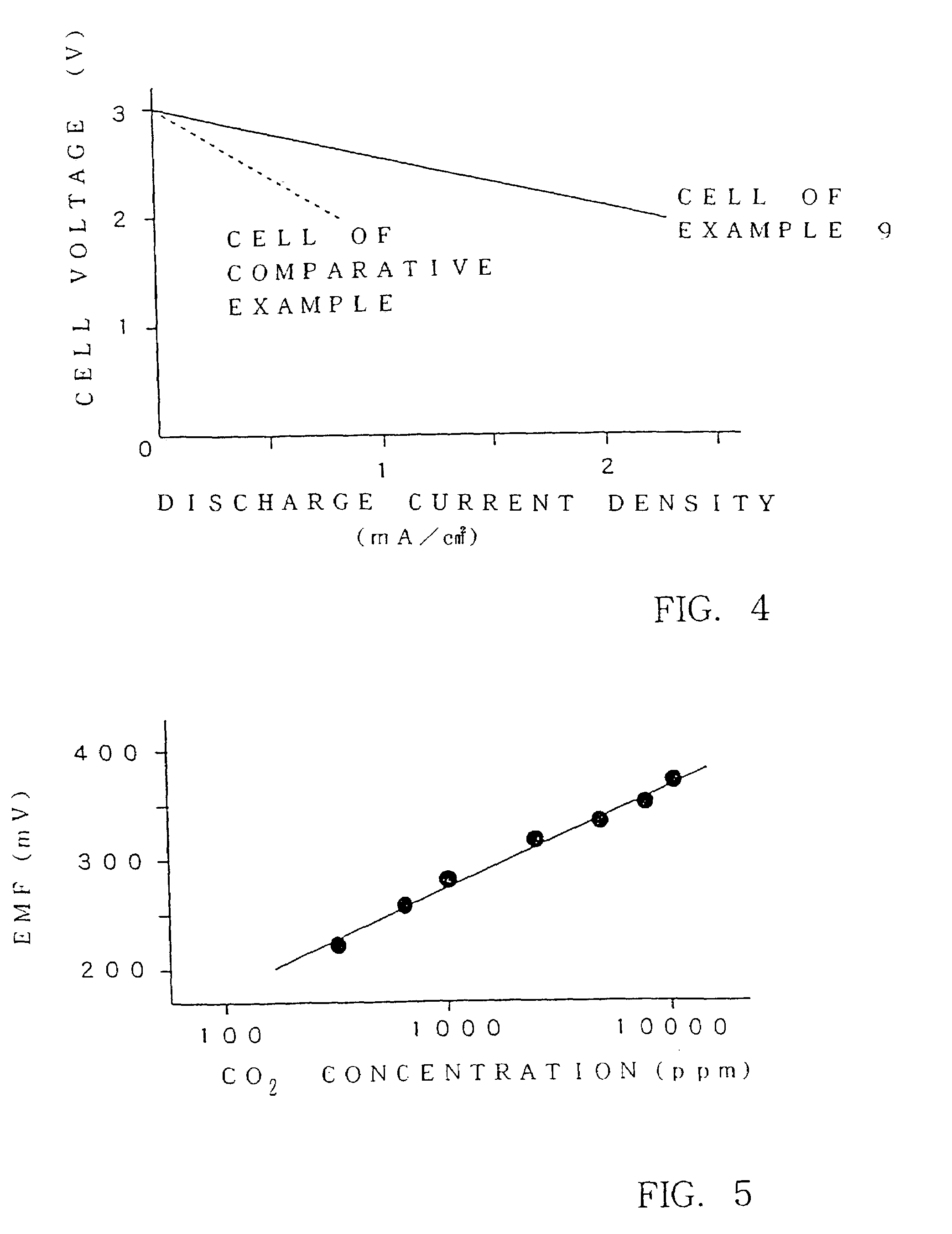

There are provided glass-ceramics having a high lithium ion conductivity which include in mol %:P2O538–40%TiO225–45%M2O3 (where M is Al or Ga) 5–15%Li2O10–20%and contain Li1+X(Al, Ga)XTi2−X(PO4)3 (where 0<X<0.8) as a main crystal phases. There are also provided glass-ceramics having a high lithium ion conductivity which include in mol %:P2O5 26–40%SiO20.5–12%TiO2 30–45%M2O3 (where M is Al or Ga) 5–10%Li2O 10–18%and contain Li1+X+YMXTi2−XSiYP3−YO12 (where 0<X≦0.4 and 0<Y≦0.6) as a main crystal phase. There are also provided solid electrolytes for an electric cell and a gas sensor using alkali ion conductive glass-ceramics, and a solid electric cell and a gas sensor using alkali ion conductive glass-ceramics as a solid electrolyte.

Owner:OHARA

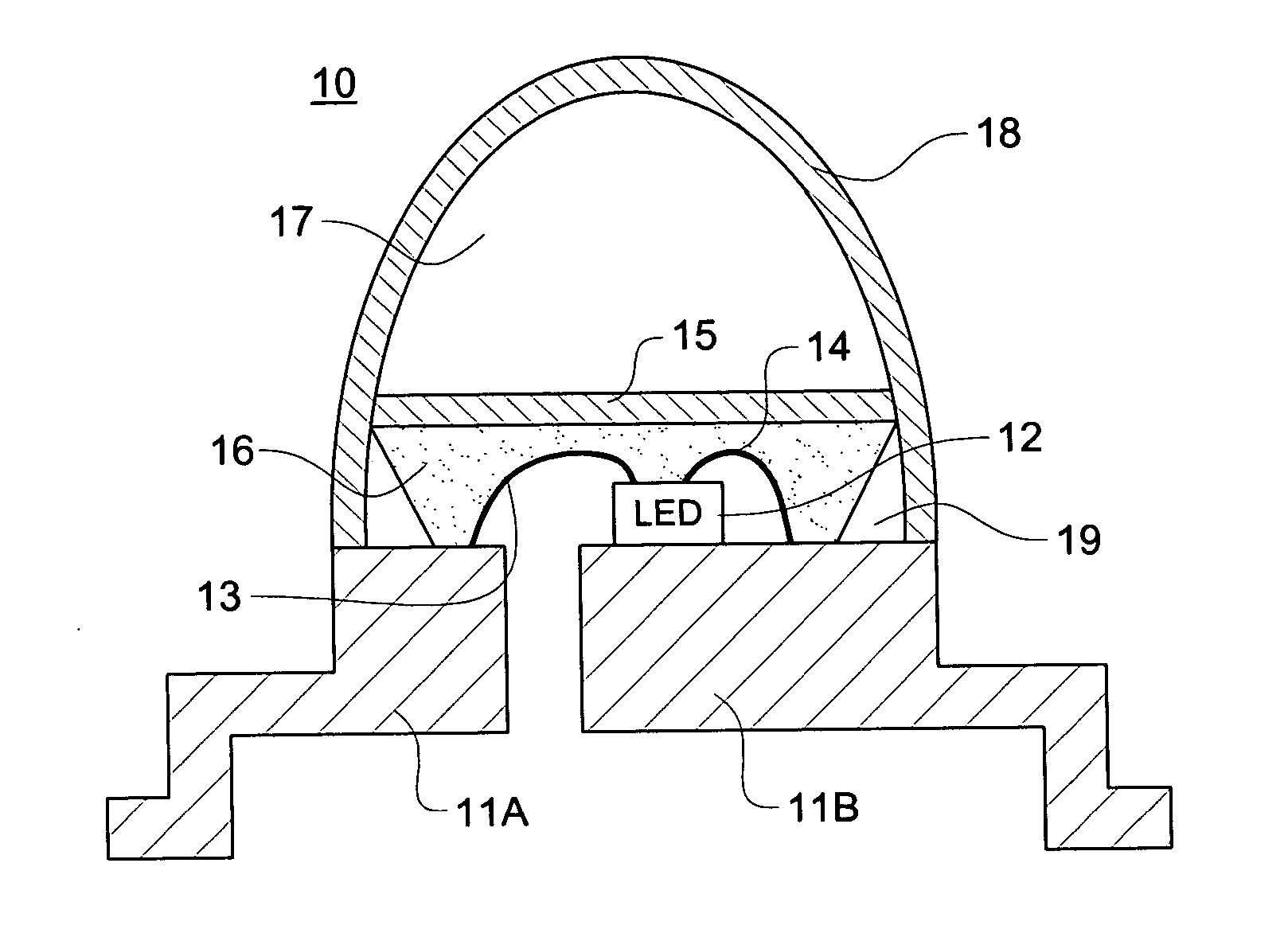

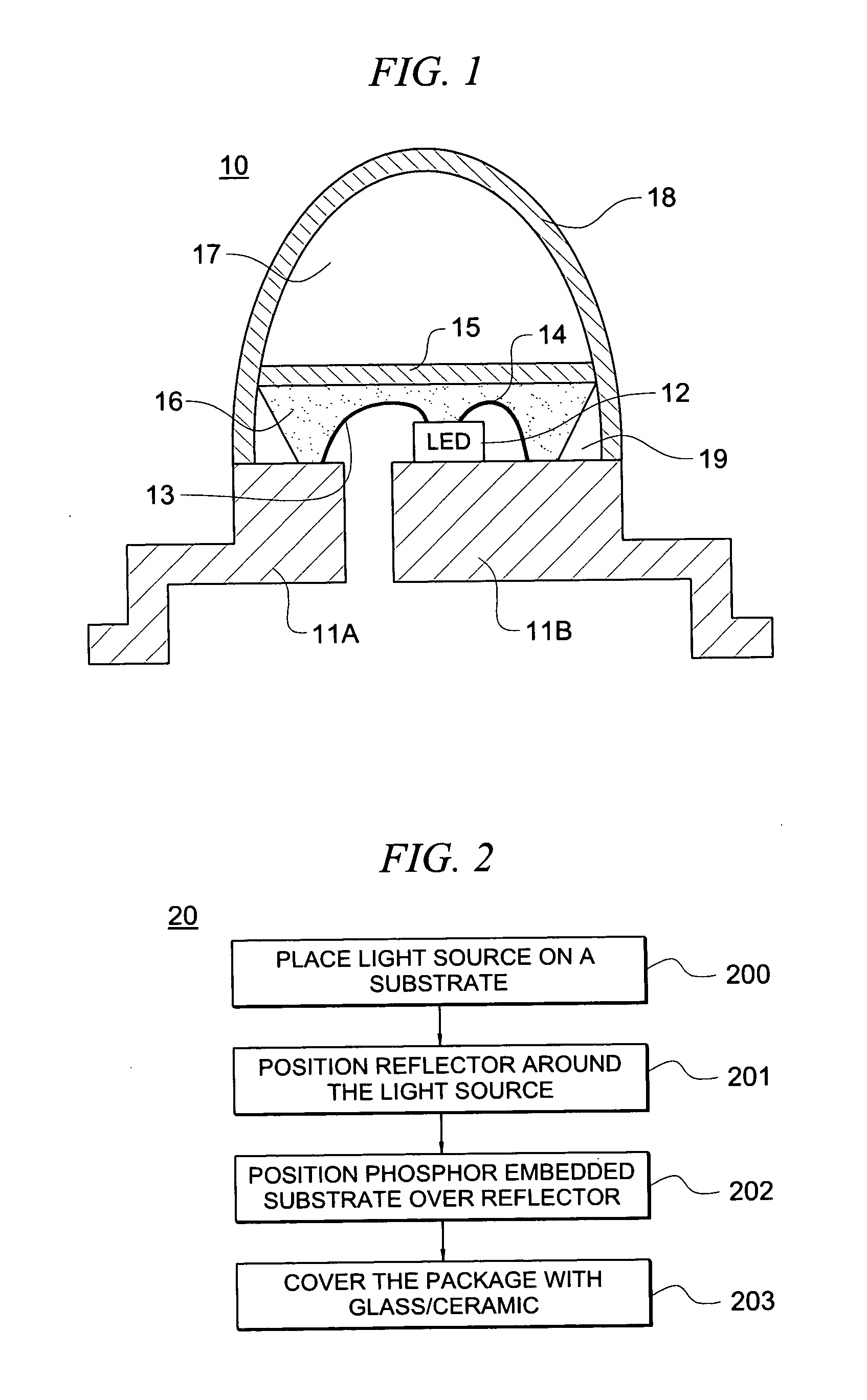

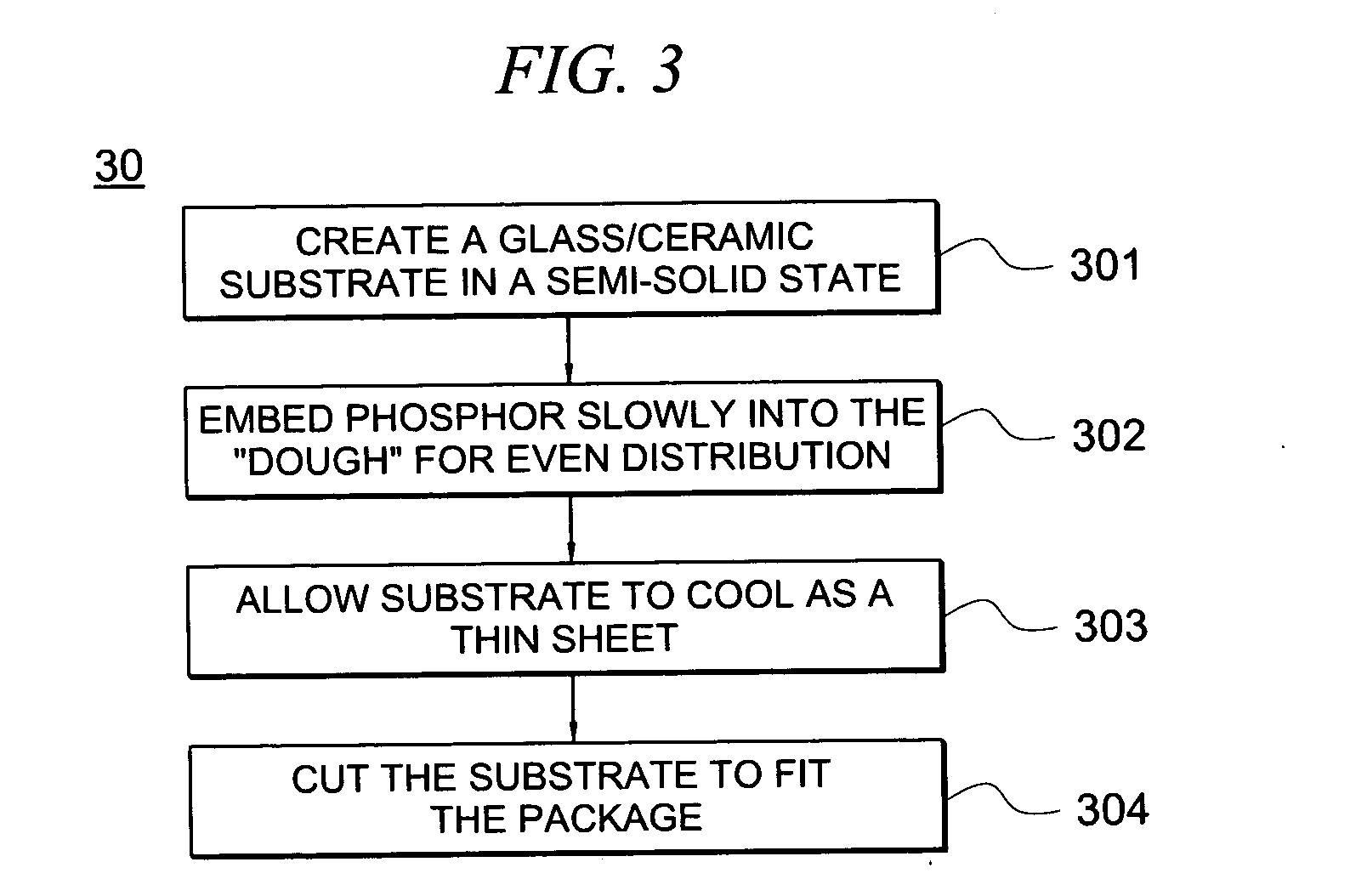

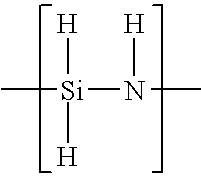

High light output lamps having a phosphor embedded glass/ceramic layer

A lamp having a glass / ceramic composite having phosphor embedded therein is disclosed for use with high power light sources. In one embodiment, the phosphor is embedded in a thin film as quantum dots. In one embodiment, a glass shell surrounds the light source and the composite phosphor matrix to protect the lamp from outside environmental conditions.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

Polysilane-containing coating solution

InactiveUS20050279255A1Easy-to-clean propertyLow shrinkageFireproof paintsImpression capsBrickSolvent

A coating solution comprising 0.1 to 35% by weight of an inorganic or organic polysilazane having repeating units represented by the general formula below and soluble in a solvent and 0.1 to 10% by weight of catalyst such as 4,4′-trimethylenebis(1-methylpiperidine) based on a pure polysilazane content. By applying the coating solution onto the surface of base materials such as metals, plastics, glass, ceramic, wood, cement, mortar, bricks, etc., a silica coating strongly adhered to the base materials can be formed excellent in corrosion resistance and anti-scratch properties and simultaneously excellent in characteristics such as abrasion resistant, long-lasting anti-fouling properties, wetting properties to water, sealing properties, chemical resistance, oxidation resistance, physical barrier effect, heat resistance, fire resistance and antistatic properties.

Owner:CLARIANT INT LTD

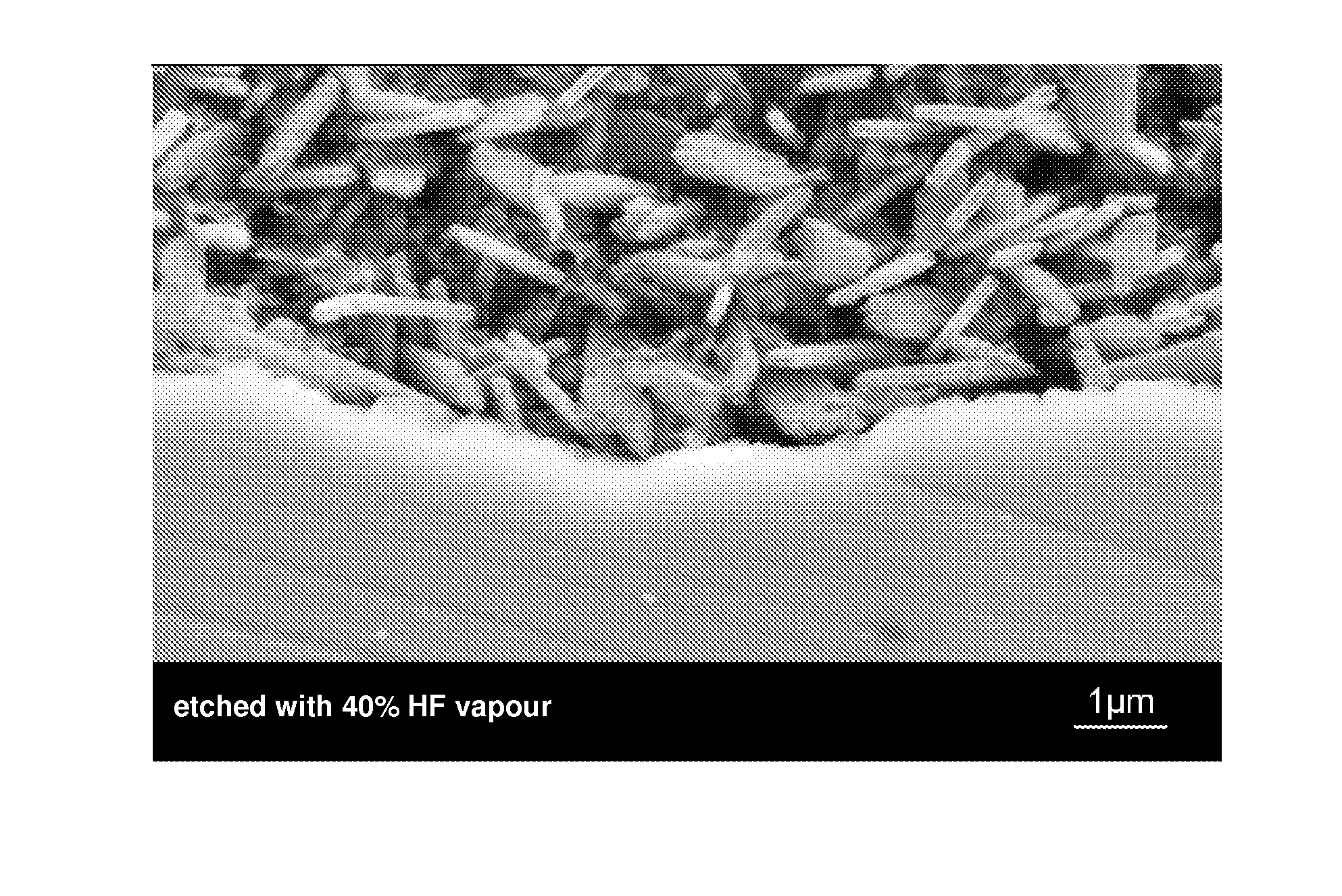

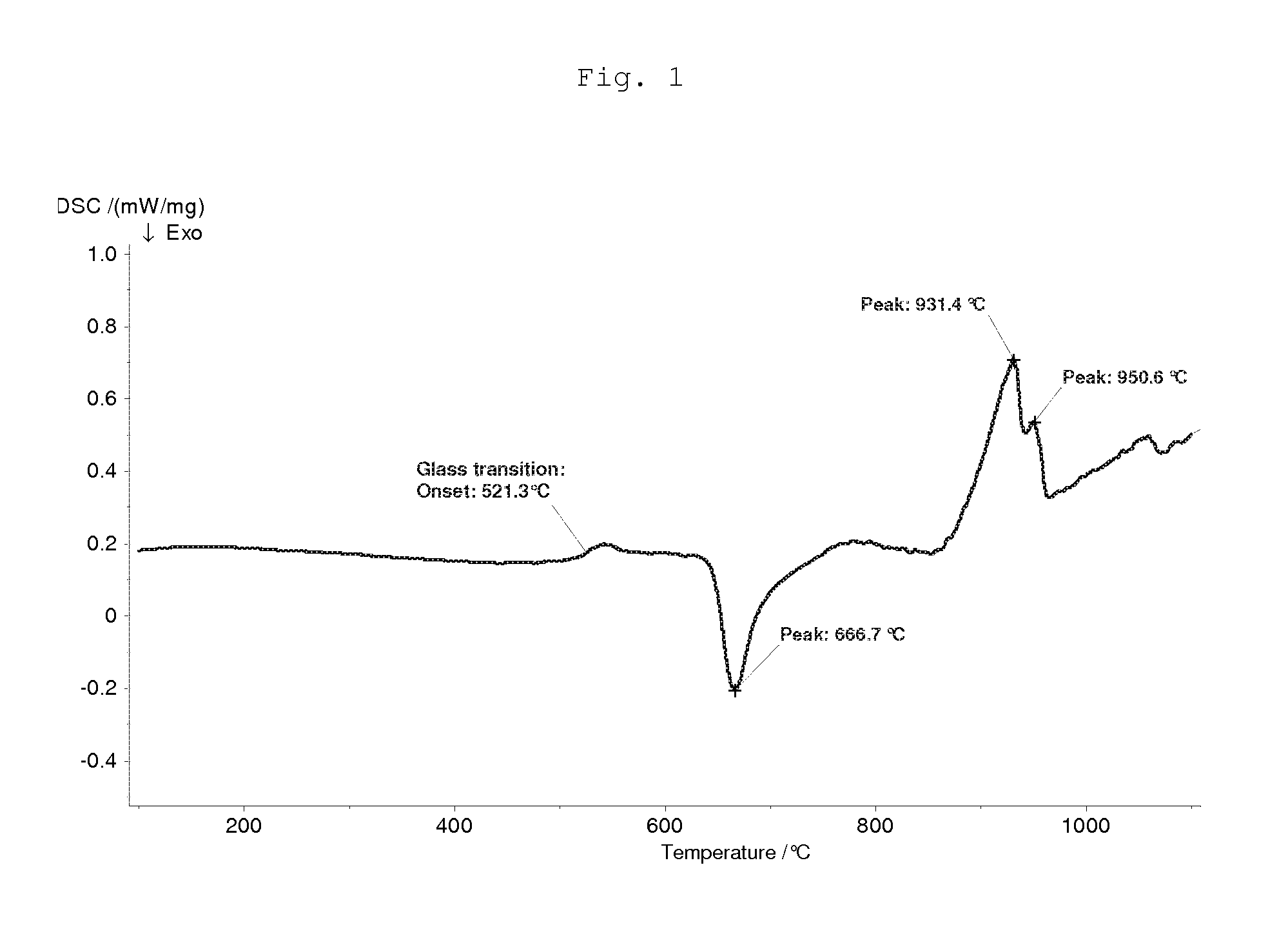

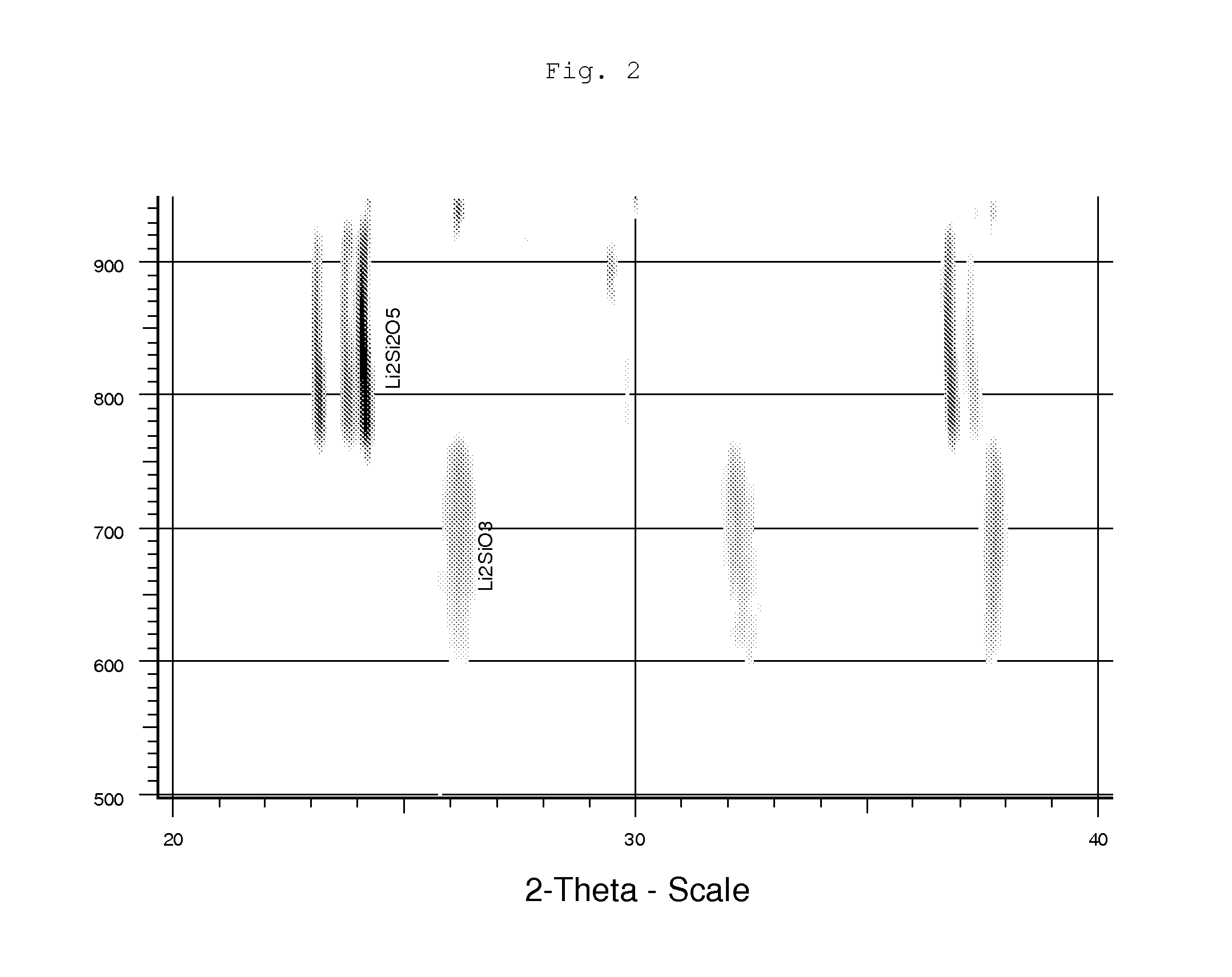

Lithium Silicate Glass Ceramic and Glass With ZrO2 Content

ActiveUS20110256409A1Substantial deterioration in translucencyInhibition formationPretreated surfacesTooth crownsLithiumSolid Bond

Owner:IVOCLAR VIVADENT AG

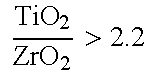

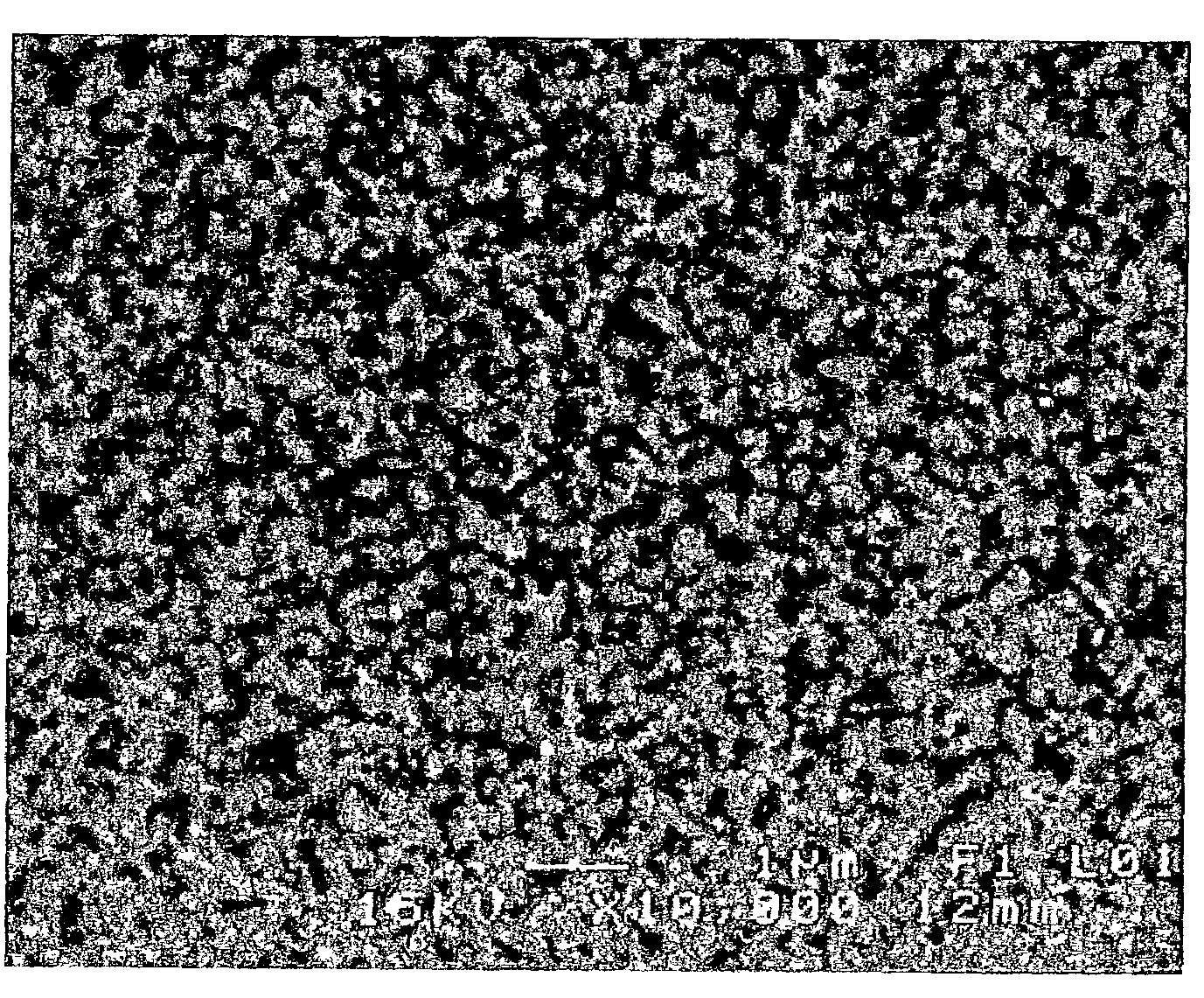

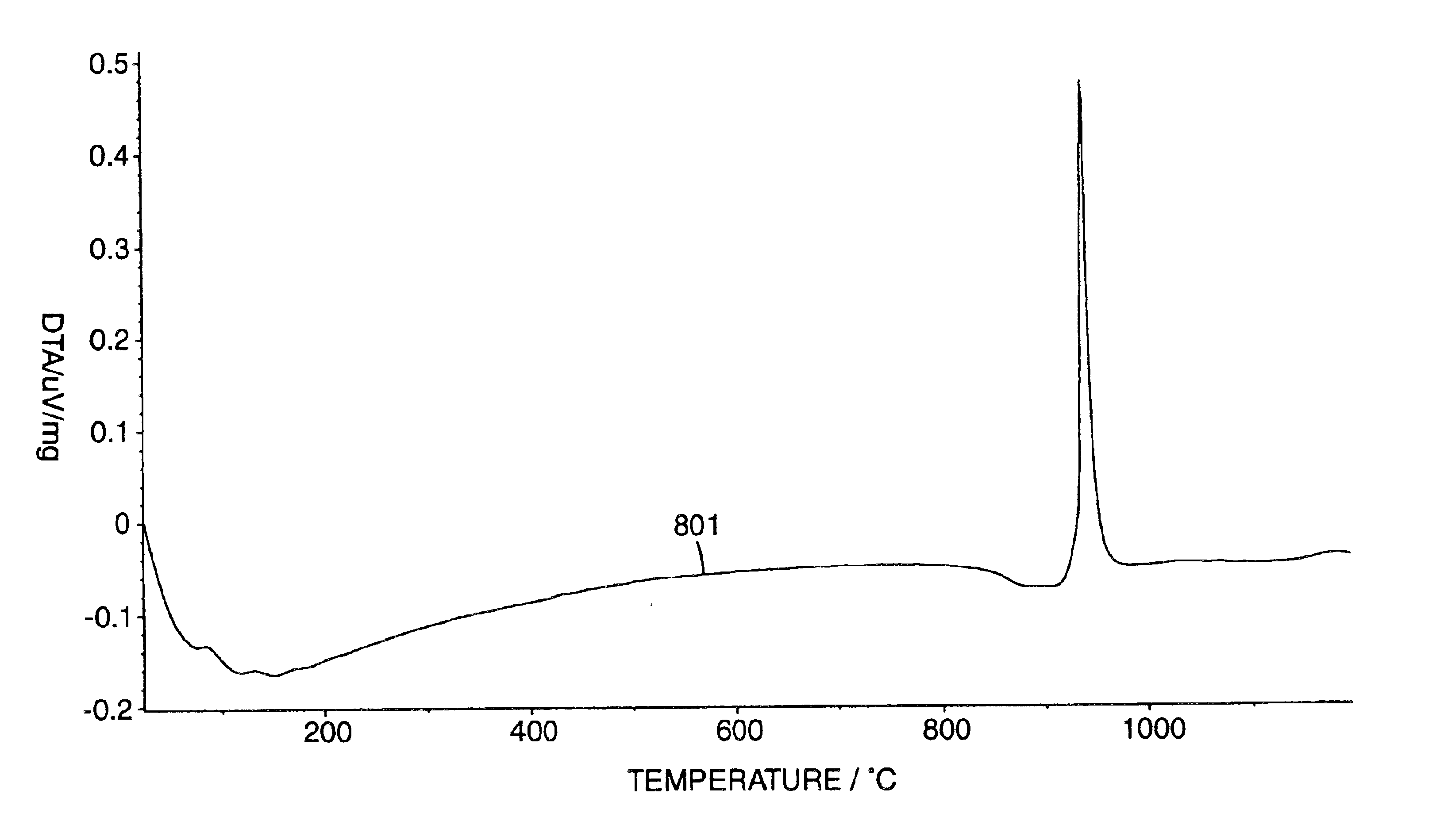

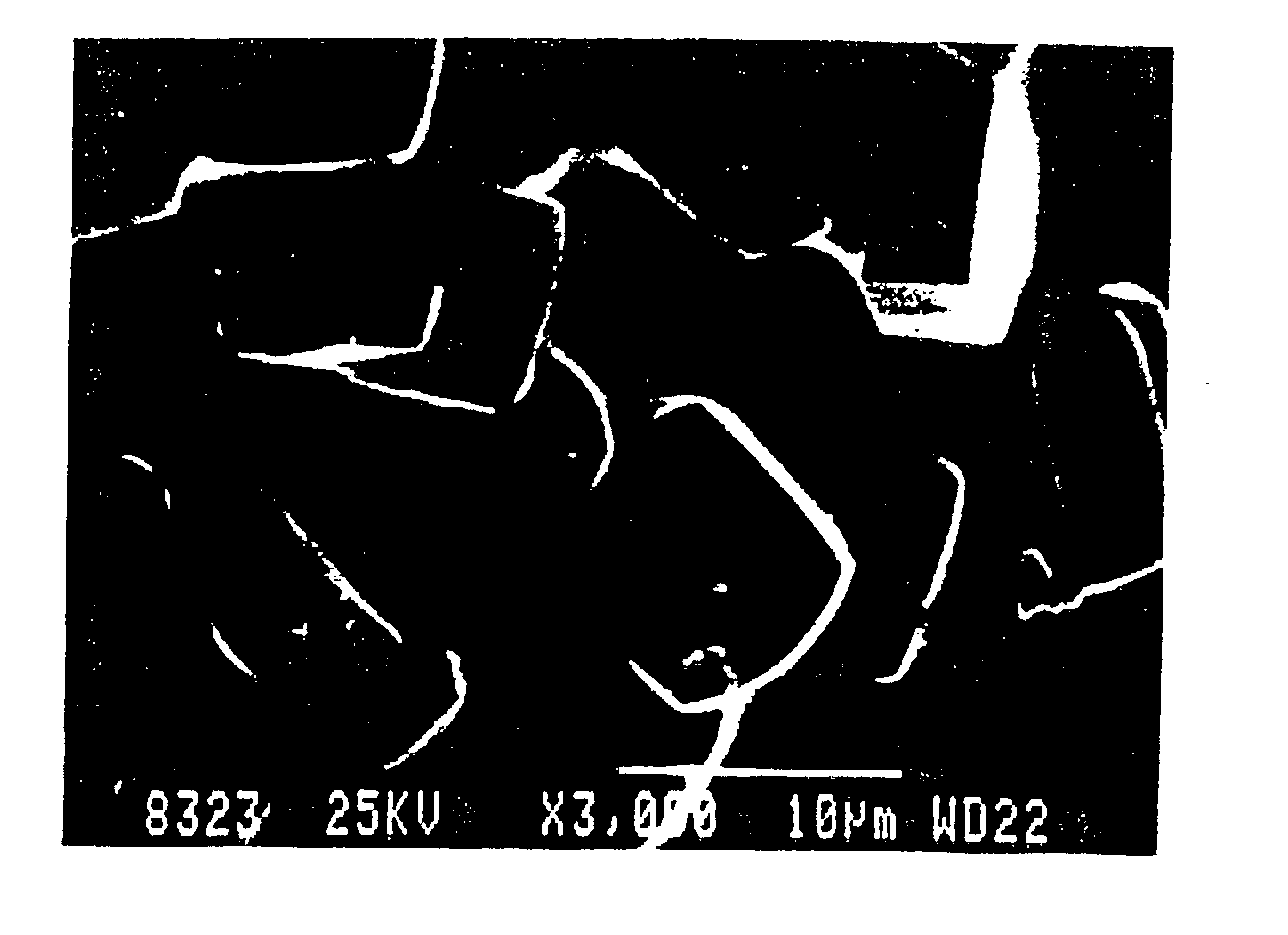

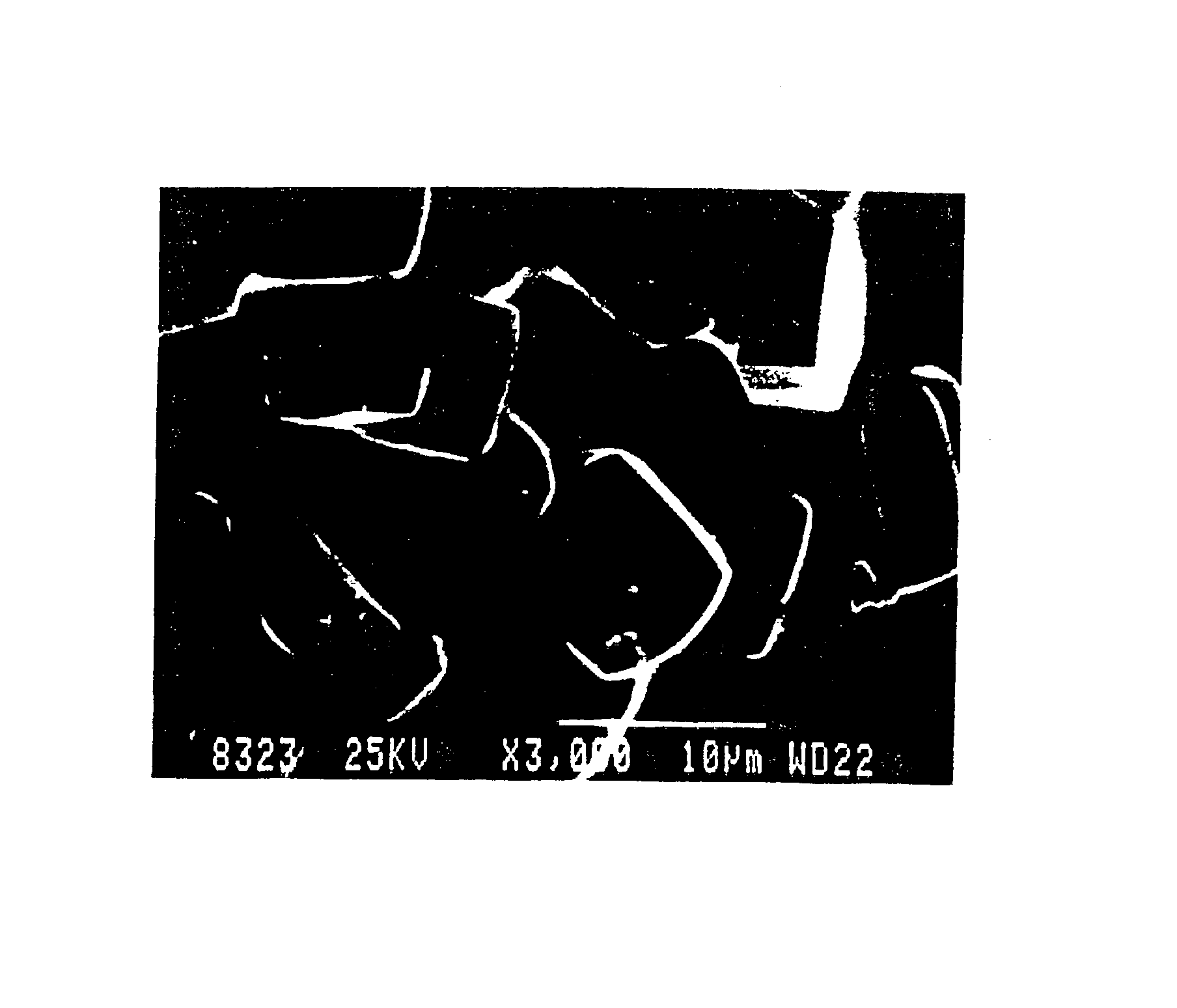

Beta-spodumene glass-ceramic materials and process for making the same

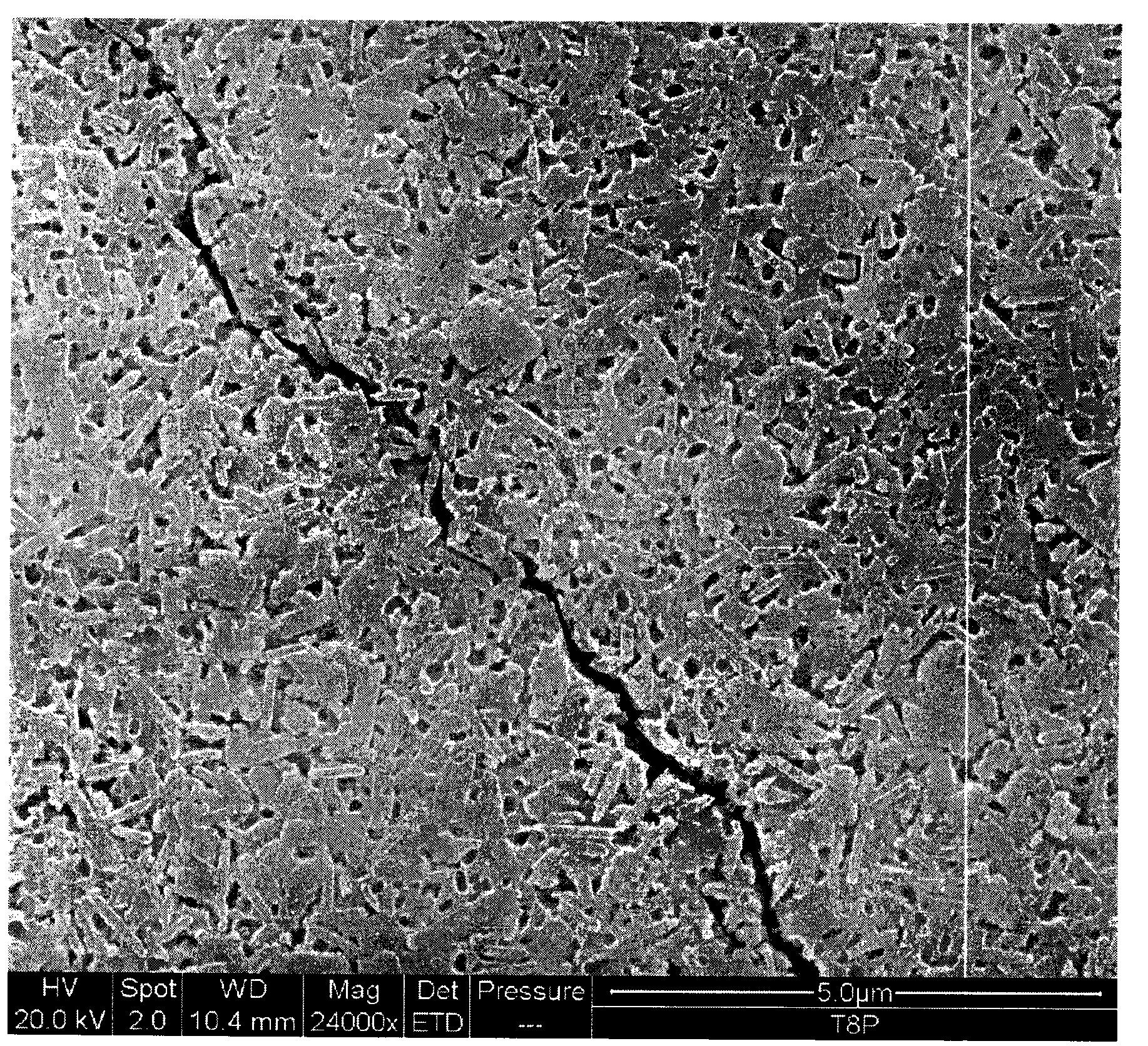

InactiveUS7476633B2Increase brightnessReduce the temperatureGlass tempering apparatusSolid solutionGlass-ceramic

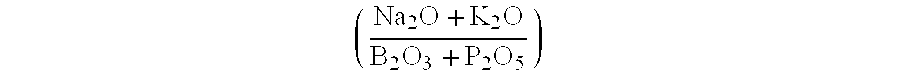

The present invention relates to glass-ceramic materials, processes for making the same and articles comprising the same. The glass-ceramic material has a composition, by weight of the total composition, comprising 55-68% SiO2; 18-24% Al2O3; 3.3-4.1% Li2O; 1.5-4.0% ZnO; 1.5-5.0% MgO; 2-5% TiO2; 0-2% ZrO2; 0-5% B2O3; 0-8% P2O5; 0-2% Na2O, 0-2% K2O; and at least one component resulting from an effective amount of at least one fining agent; wherein: the total of B2O3 and P2O5 is at least 1.5% by weight, the total of MgO and ZnO is at least about 3.5% by weight, the total of Na2O and K2O is less than about 3.0% by weight, the total of P2O5, B2O3, Na2O and K2O is less than about 11% by weight, the weight ratio of the sum total of Na2O+K2O to the sum total of P2O5+B2O3 (Na2O+K2OB2O3+P2O5)is less than about 0.5; advantageously the total of P2O5, B2O3, Na2O and K2O is less than about 9% by weight and the total of Na2O ad K2O is less than about 2% by weight; and more advantageously the total of P2O5, B2O3, Na2O and K2O is less than about 7% by weight and the total of Na2O ad K2O is less than about 1% by weight. The glass-ceramic material comprises β-spodumene solid solution as the predominant crystalline phase.

Owner:EUROKERA SOC & NOM COLLECTIF

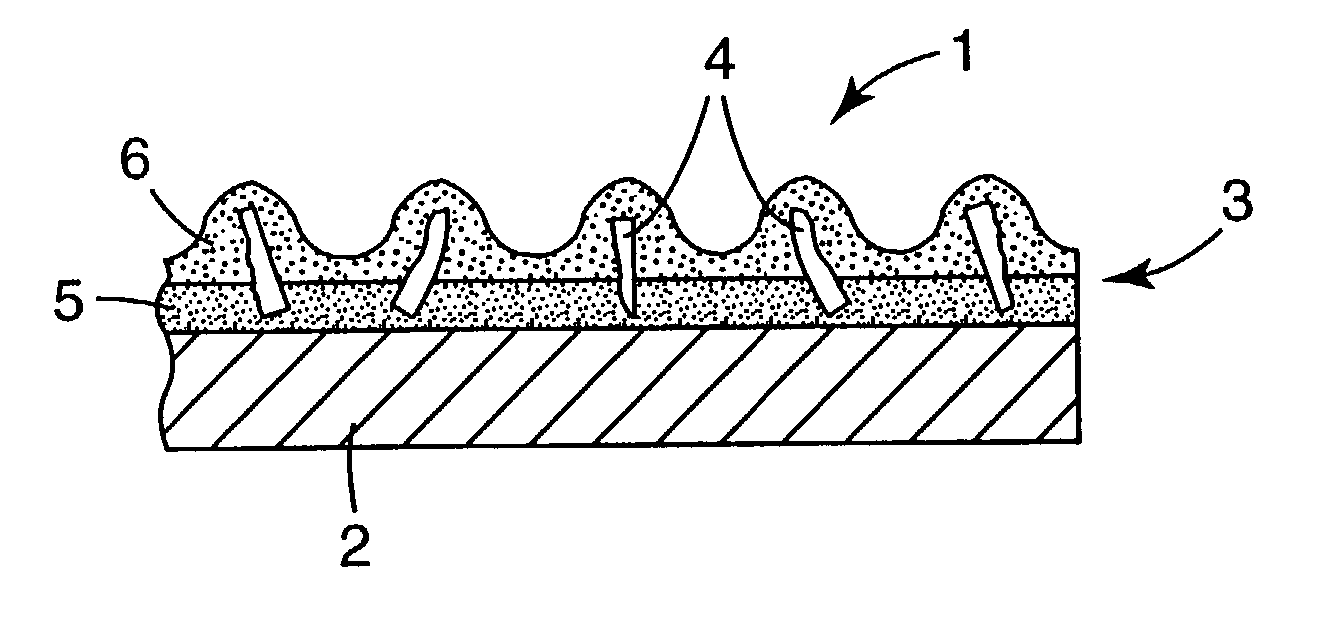

Glass ceramic and metal substrates with a self-cleaning surface, method for the production and use thereof

InactiveUS6872441B2Improve self-cleaningExcellent abrasion resistanceFouling preventionPretreated surfacesRough surfaceGlass-ceramic

The invention relates to glass, ceramic and metal substrates with at least one self-cleaning surface, comprising a layer with a micro-rough surface structure which is arranged on the substrate and made at least partly hydrophobic. The layer contains a glass flux and structure-forming particles with a mean particle diameter within the 0.1 to 50 μm range; the glass flux and structure-forming particles are present in a volume ratio within the 0.1 to 5 range, and the micro-rough surface structure has a ratio of mean profile height to mean distance between adjacent profile tips within the 0.3 to 10 range.To produce the subject of the invention the substrate is coated with a composition containing a glass flux and structure-forming particles, and the layer is burnt in and made hydrophobic.

Owner:FERRO GMBH

Electrochemical cell with sintered cathode and both solid and liquid electrolyte

An electrochemical cell has an anode of electrochemically-active material; a cathode of electrochemically-active, porous, liquid-permeable, sintered, ceramic material; and a solid-state, liquid-impermeable electrolyte medium disposed between the anode and the cathode. The electrolyte may be a layer of glass or a layer of glass ceramic, or may be a combination of a layer of glass and a layer of glass ceramic. The cell may further contain a liquid electrolyte diffused throughout the cathode.

Owner:JOHNSON IP HLDG LLC

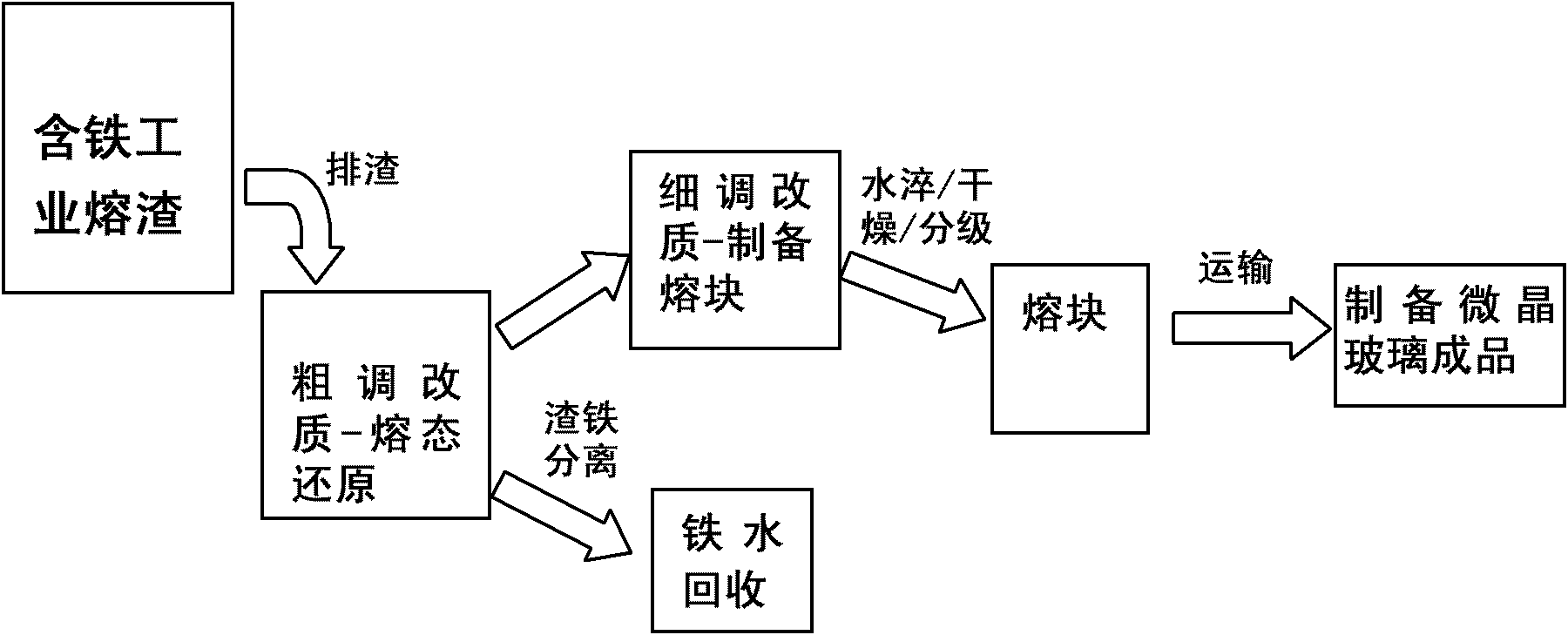

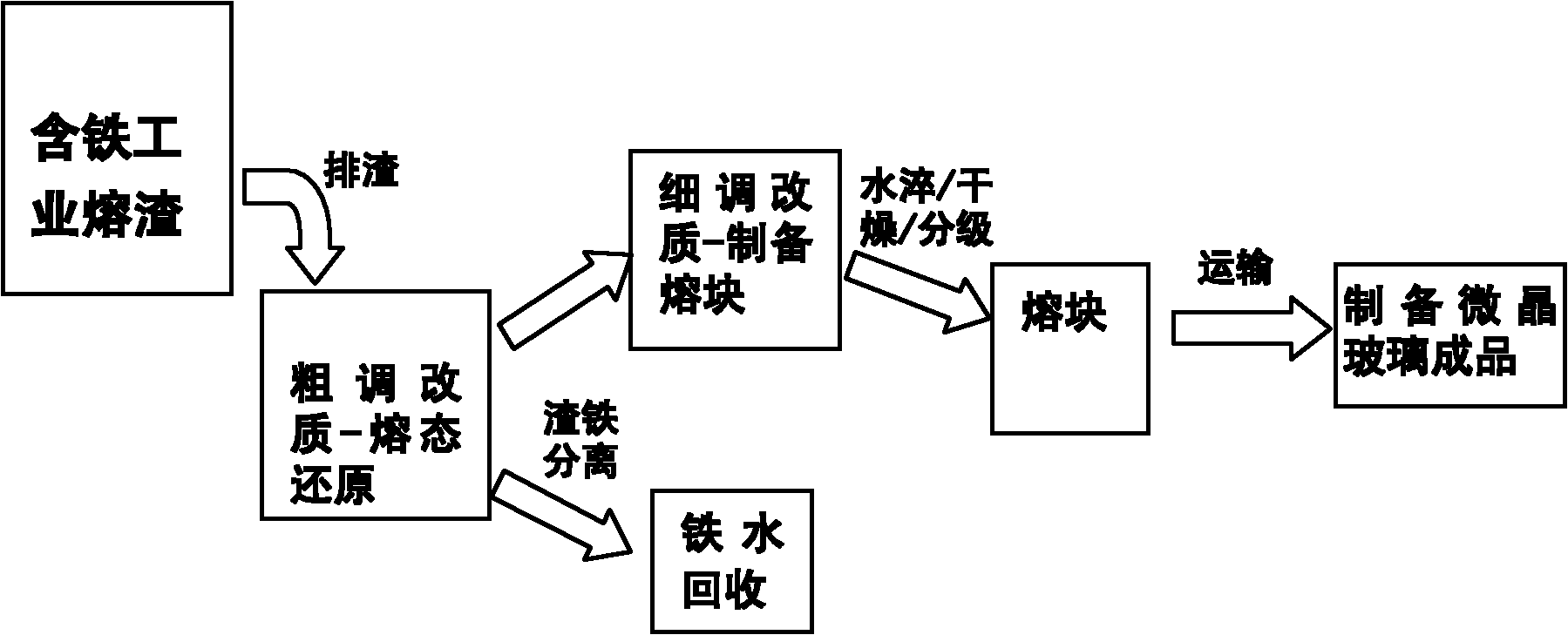

Method for recycling iron on line from iron-containing industrial slag and preparing glass ceramics frit

InactiveCN101914639AGuaranteed slag compositionRecycling and recovery technologiesProcess efficiency improvementMaterials preparationSlag

The invention relates to a method for recycling iron on line from iron-containing industrial slag and preparing a glass ceramics frit, belonging to the technical field of resource comprehensive utilization and material preparation and mainly comprising a two-step method process of iron-containing industrial slag online rough adjustment and modification for reducing iron and fine adjustment and modification for preparing the frit. The method comprises the steps of: discharging high-temperature iron-containing slag into a high-temperature furnace device, and simultaneously adding a reducing agent and a modifying agent to ensure that slag components are adjusted to reach the optimal component point in which iron oxide is reduced; after fully reacted, separating reduced molten iron from the slag, and recycling to obtain high-temperature molten iron; further adding a modifying agent and an adjusting agent into the slag remained after the separation to ensure that the slag components are adjusted to achieve the quality requirement of slag glass ceramics on the frit; and water-hardening, drying and grading the qualified slag to prepare the glass ceramics frit. The invention realizes multiple purposes that the heat of the slag is directly utilized and metal iron is recycled to prepare a high addition value product as well as solid wastes are massively utilized, and the like.

Owner:UNIV OF SCI & TECH BEIJING

B-spodumene glass-ceramic materials and process for making the same

InactiveUS20070213192A1Reduce the temperatureShort durationGlass tempering apparatusSolid solutionGlass-ceramic

The present invention relates to glass-ceramic materials, processes for making the same and articles comprising the same. The glass-ceramic material has a composition, by weight of the total composition, comprising 55-68% SiO2; 18-24% Al2O3; 3.3-4.1% Li2O; 1.5-4.0% ZnO; 1.5-5.0% MgO; 2-5% TiO2; 0-2% ZrO2; 0-5% B2O3; 0-8% P2O5; 0-2% Na2O, 0-2% K2O; and at least one component resulting from an effective amount of at least one fining agent; wherein: the total of B2O3 and P2O5 is at least 1.5% by weight, the total of MgO and ZnO is at least about 3.5% by weight, the total of Na2O and K2O is less than about 3.0% by weight, the total of P2O5, B2O3, Na2O and K2O is less than about 11% by weight, the weight ratio of the sum total of Na2O+K2O to the sum total of P2O5+B2O3 (Na2O+K2OB2O3+P2O5)is less than about 0.5; advantageously the total of P2O5, B2O3, Na2O and K2O is less than about 9% by weight and the total of Na2O ad K2O is less than about 2% by weight; and more advantageously the total of P2O5, B2O3, Na2O and K2O is less than about 7% by weight and the total of Na2O ad K2O is less than about 1% by weight. The glass-ceramic material comprises β-spodumene solid solution as the predominant crystalline phase.

Owner:EUROKERA SOC & NOM COLLECTIF

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS20030110708A1Facilitates formation and homogeneityOxide formationPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3-Y2O3-ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

High-strength lithium disilicate glass ceramic and preparation method thereof

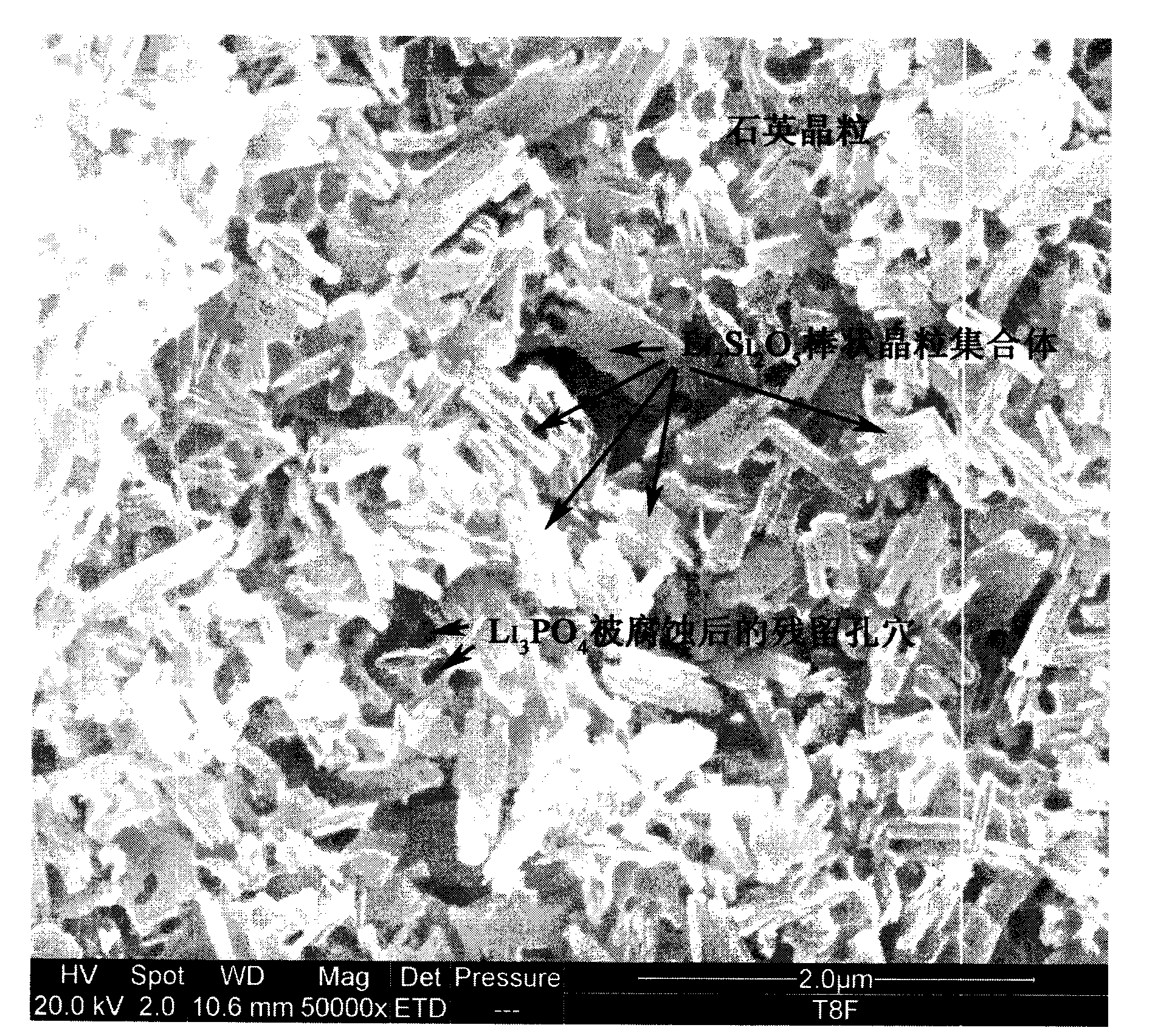

The invention discloses high-strength lithium disilicate glass ceramic and a preparation method thereof. The glass ceramic comprises the following chemical components in percentage by weight: 59-80% of SiO2, 10-18% of Li2O, 0.1-14% of MgO, 0-15% of Al2O3, 1-8% of P2O5, 0-5% of Na2O, 0-7% of CaO, 0-9% of K2O, 0.5-8% of stabilizer and 0-10% of colorant, wherein the stabilizer is selected from one or more of ZrO2, SrO, BaO and Y2O3, and the colorant is selected from one or more of Eu2O3, CeO<+>, Tb4O7, La2O3, Ta2O5, MnO2 and Fe2O3. The lithium disilicate glass ceramic is a material which contains a residual glass phase, a Li2Si2O5 principal crystalline phase and a small quantity of Li3PO1, quartz, cristobalite, zirconium oxide or magnesium-aluminum silicate phase and is prepared by controlling nucleation and crystallization processes after carrying out heat treatment on lithium disilicate matrix glass. The lithium disilicate glass ceramic is very high in bending strength and fracture toughness and favorable in translucence and chemical stability and can serve as a full-ceramic dental material applied to the field of dental restoration.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Cooking surface for cooking food having a glass ceramic surface with a glass coating thereon

InactiveUS6525300B1Reduction factorEasy to processCoil arrangementsHot plates heating arrangementsGlazeThermal expansion

The invention relates to lead- and cadmium-free glass for glazing, enamelling and decorating glasses or glass-ceramics which have a low coefficient of thermal expansion of less than 2x10-6 / K, having the composition (in % by weight) 0-6 Li2O, 0-5 Na2O, 0 to less than 2 K2O, where the sum Li2O+K2+Na2O is between 2 and 12, 0-4 MgO, 0-4 CaO, 0-4 SrO, 0-1 BaO, 0-4 ZnO, 3 to less than 10 Al2O3, 13-23 B2O3, 50-65 SiO2, 0-4 TiO2, 0-4 ZrO2 and 0-4 F, as replacement for oxygen and containing up to 30% by weight of a pigment which is resistant at the firing temperature, where the glass is suitable for glazing, enamelling and decoration in both primary and secondary firing, and both the full-area and sparse glaze, enamel or decoration layers have low abrasion susceptibility after firing, and it relates to processes for the production of a glass-ceramic coated therewith.

Owner:SCHOTT AG

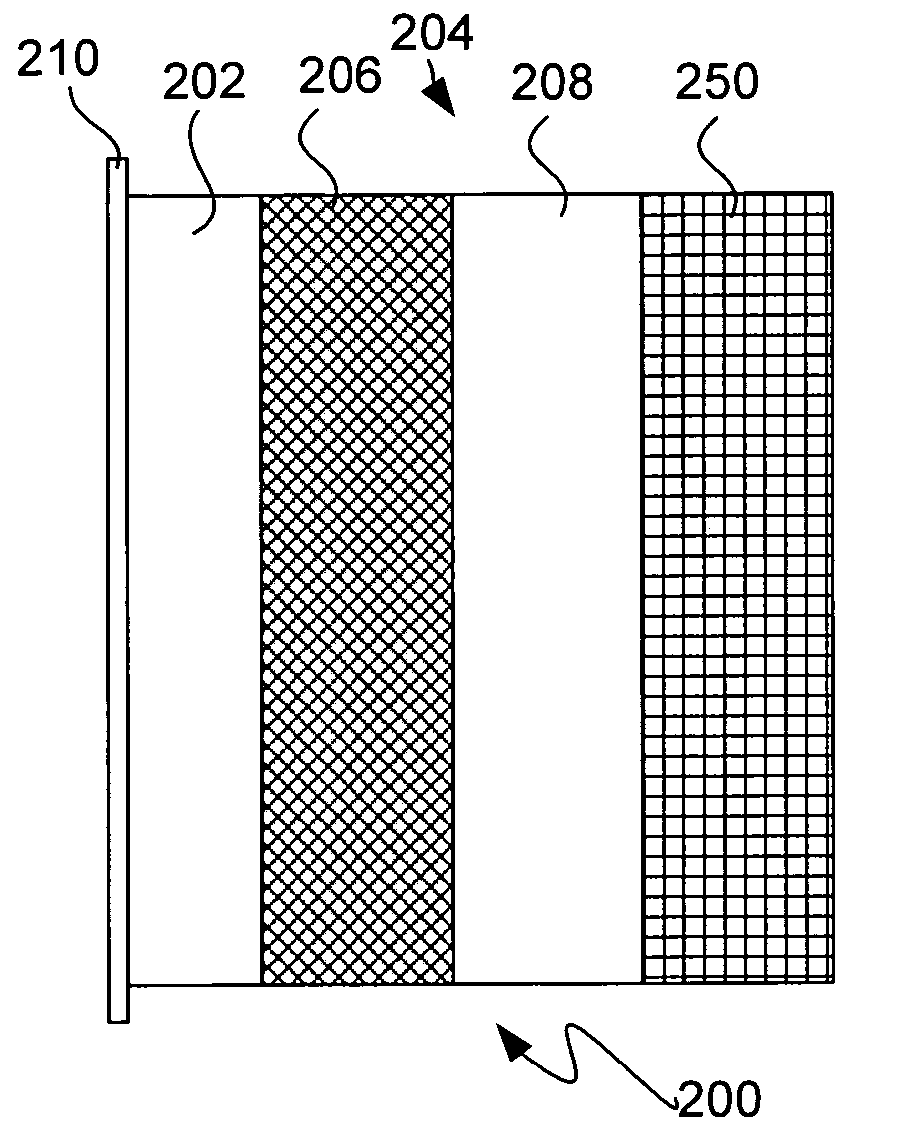

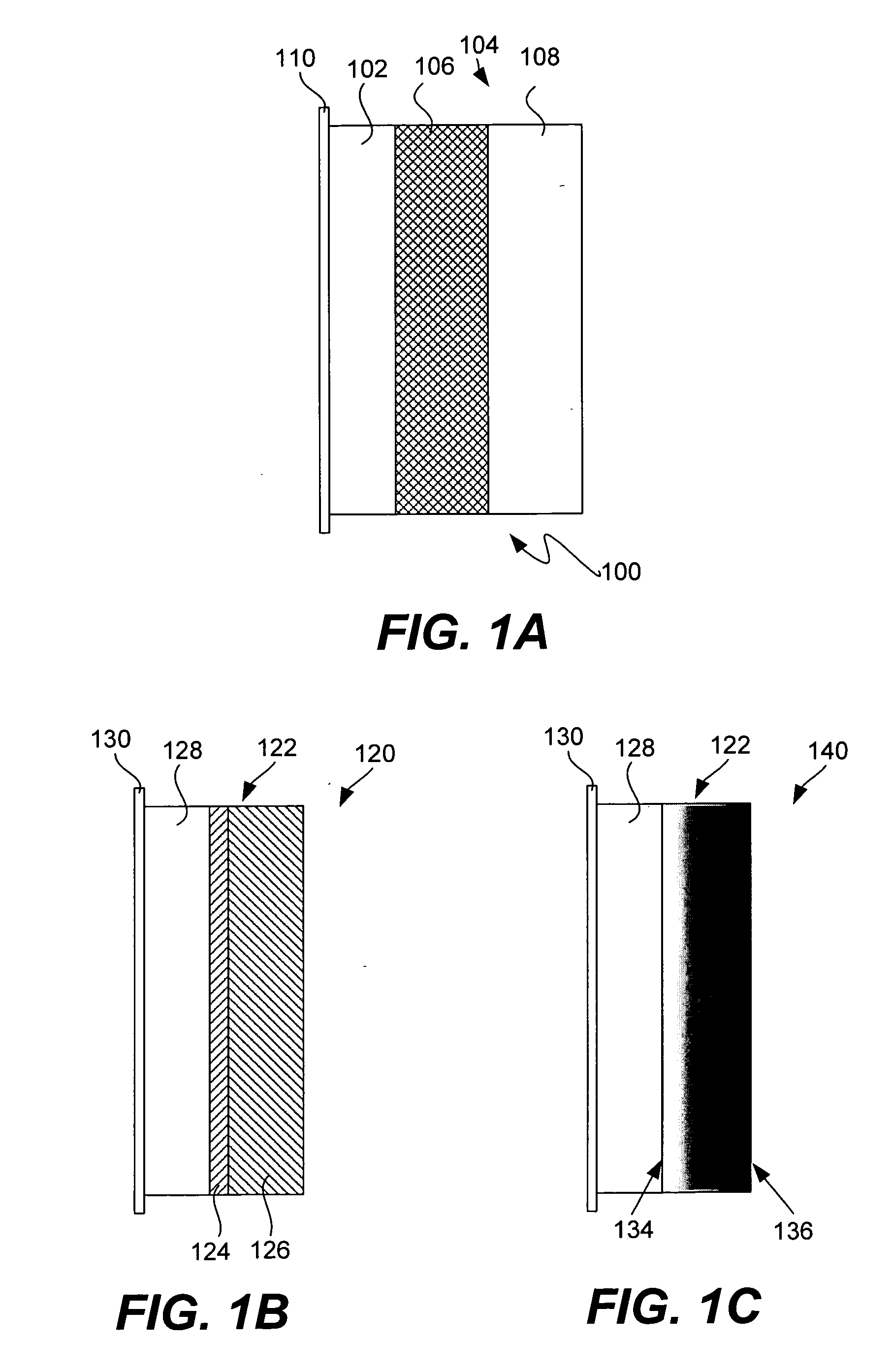

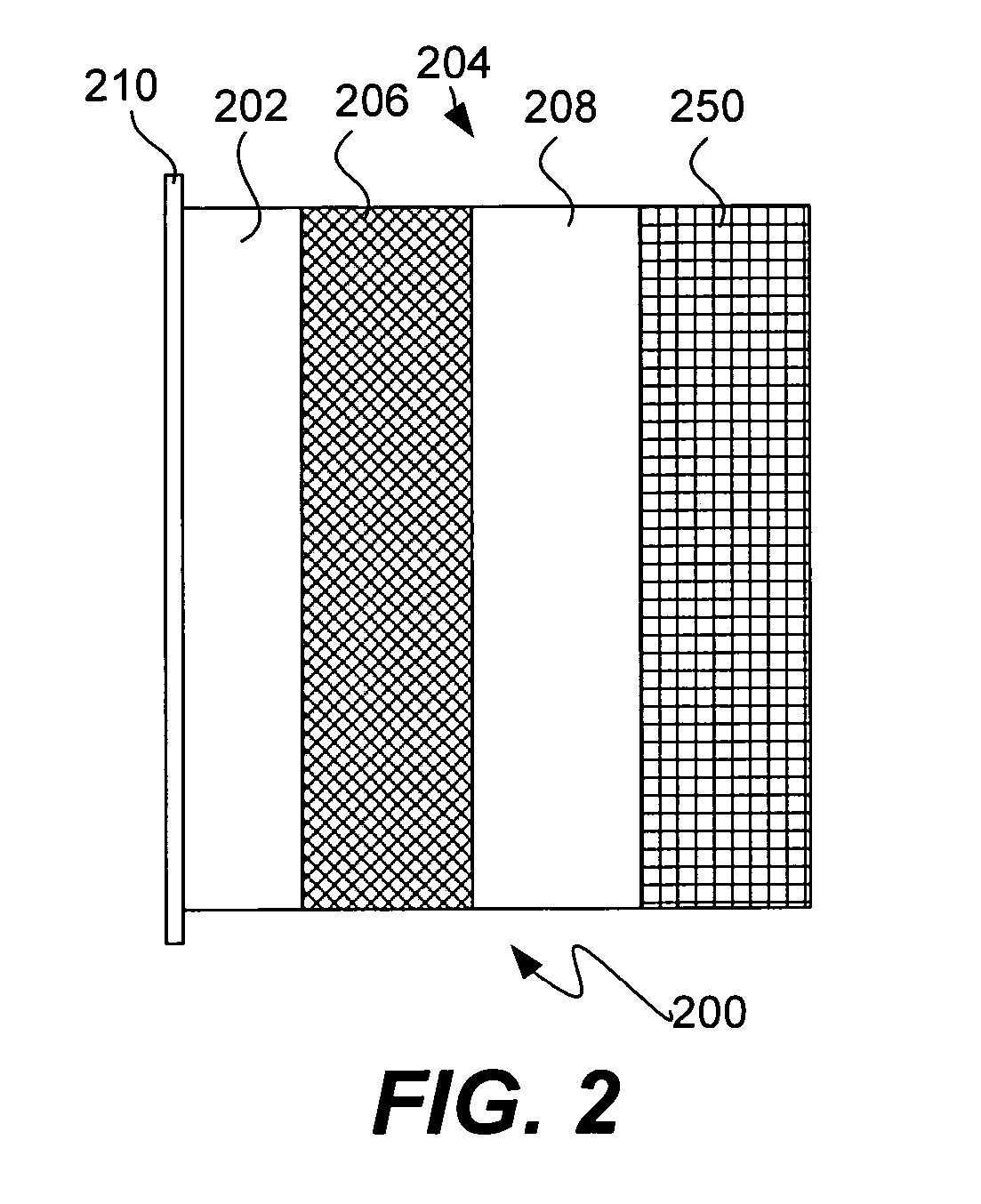

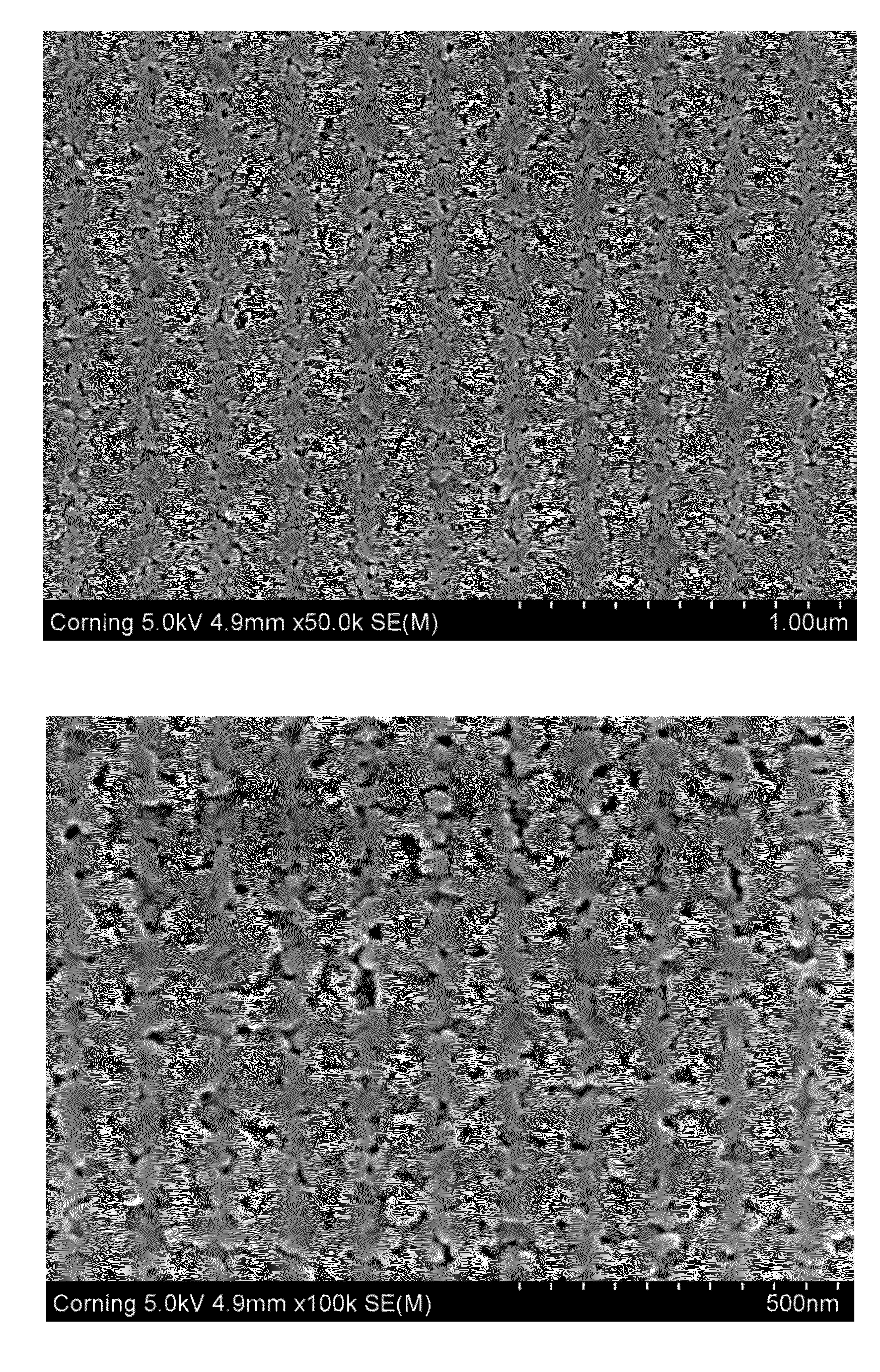

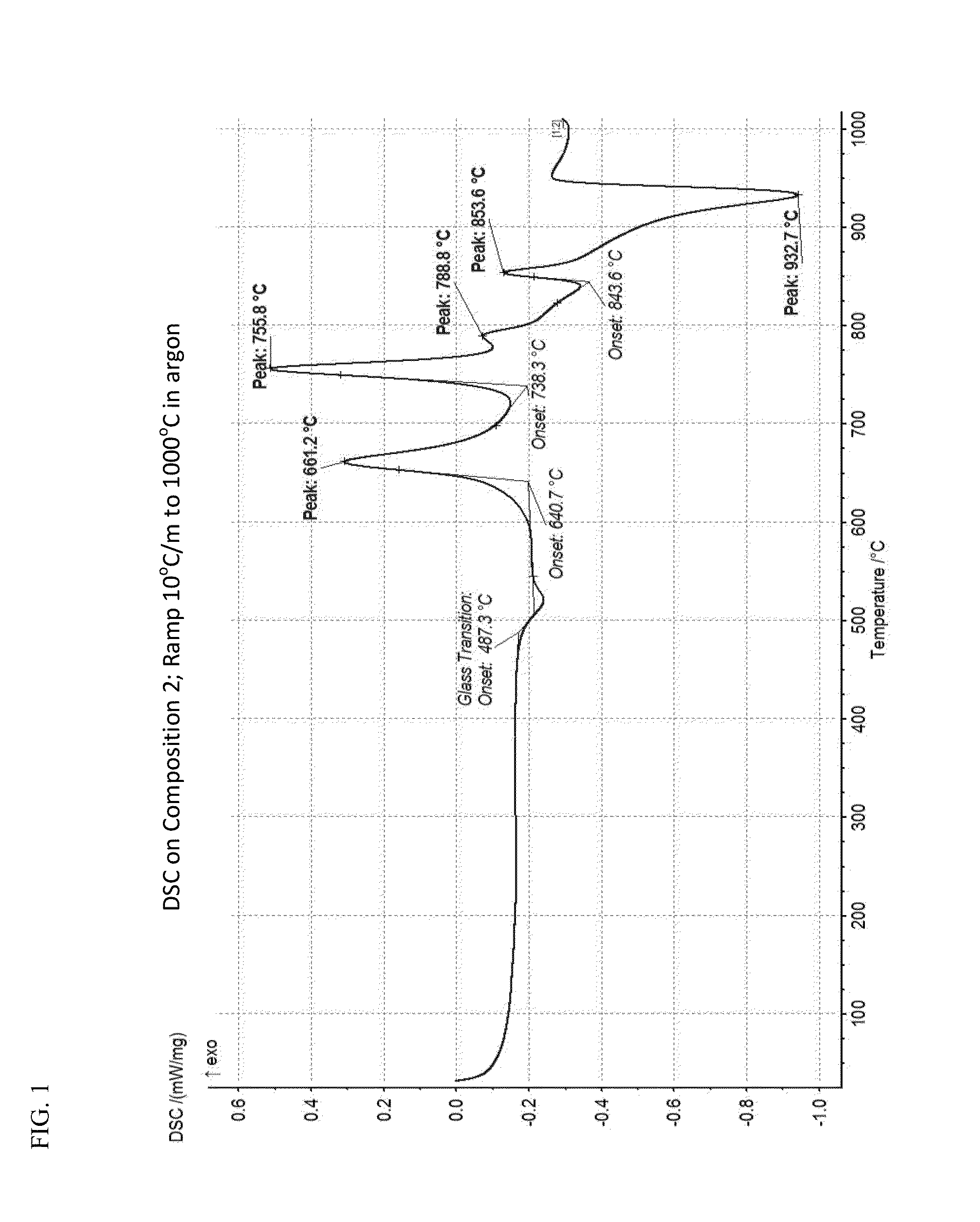

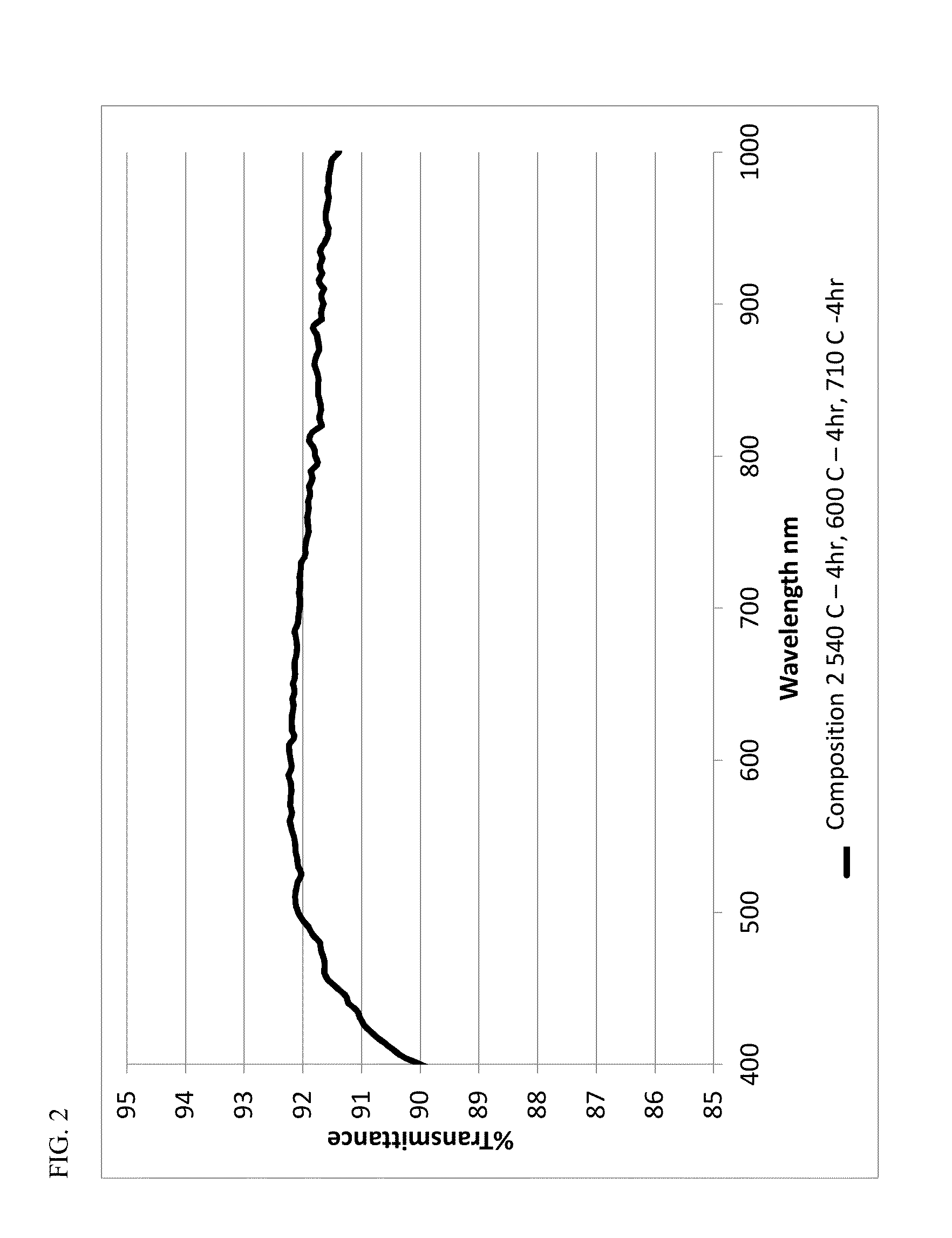

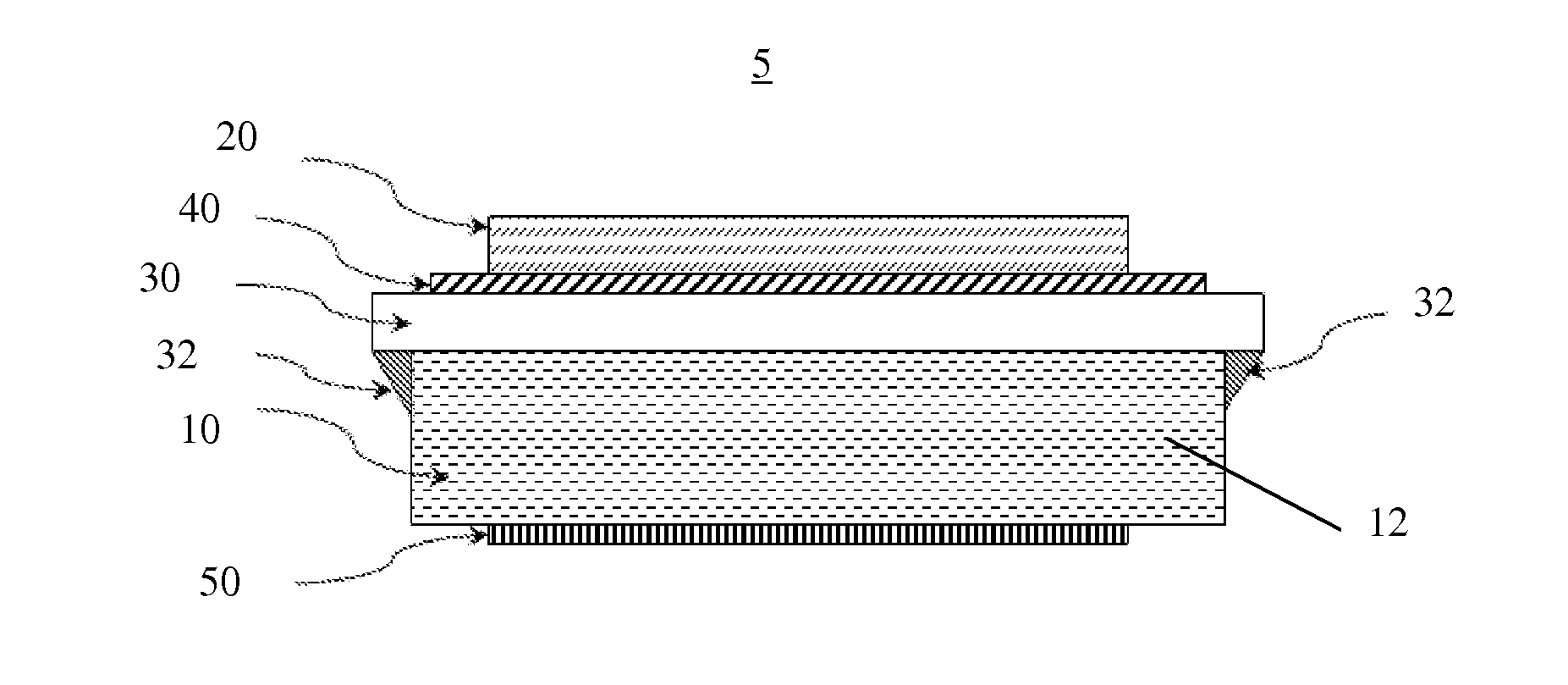

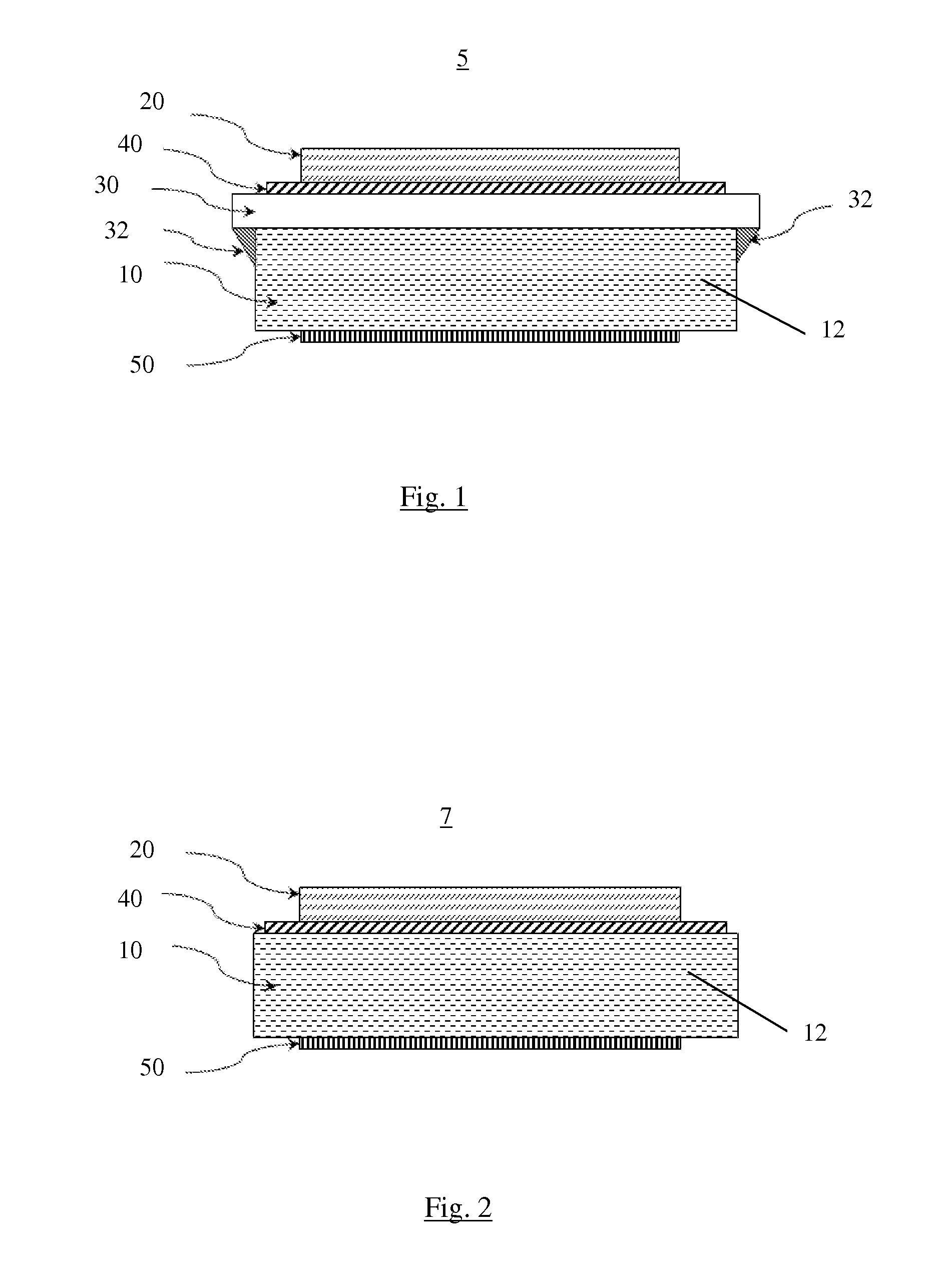

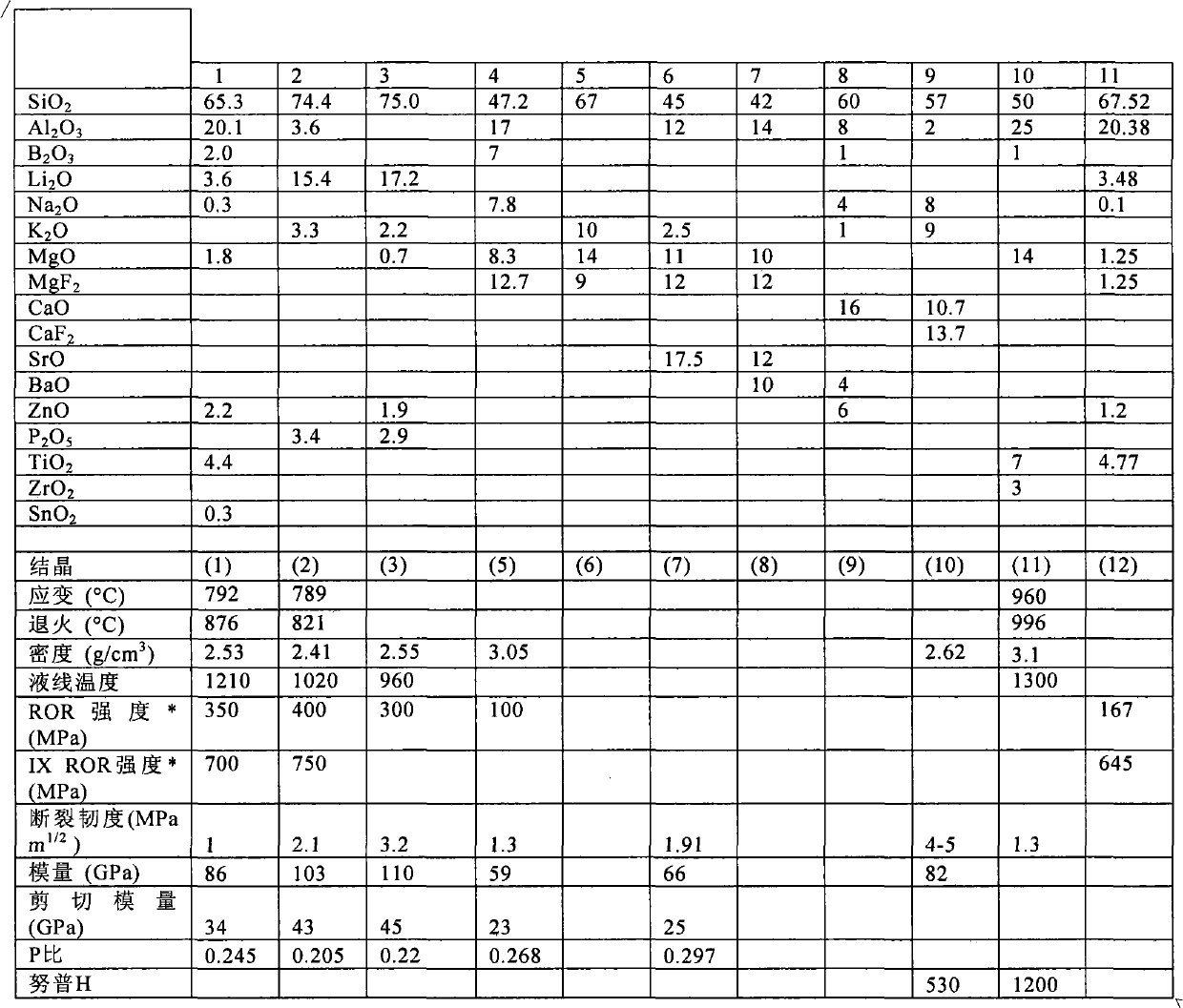

Durable glass-ceramic housings/enclosures for electronic devices

The invention relates glass ceramic articles suitable for use as electronic device housing or enclosures which comprise a glass-ceramic material. Particularly, a glass-ceramic article housing / enclosure comprising a glass-ceramic material exhibiting both radio and microwave frequency transparency, as defined by a loss tangent of less than 0.5 and at a frequency range of between 15 MHz to 3.0 GHz, a fracture toughness of greater than 1.5 MPam 1 / 2 , an equibiaxial flexural strength (ROR strength) of greater than 100 MPa, a Knoop hardness of at least 400 kg / mm2, a thermal conductivity of less than 4 W / m DEG C and a porosity of less than 0.1 %.

Owner:CORNING INC

Glass-ceramic composition for recording disk substrate

InactiveUS6593257B1Improve productivityRaise the ratioMagnetic materials for record carriersBase layers for recording layersGlass-ceramicOxide

A glass ceramics composition for recording disk substrate consists essentially, expressed in terms of weight percent on the oxide basis, of from 65 to 80 wt % of SiO2, from 3 to 15 wt % of Al2O3, from 3 to 15 wt % of Li2O, from 0.2 to 5 wt % of P2O5, and from 0.1 to 15 wt % of ZrO2, wherein a value of ZrO2 / P2O5 is within a range from 1.1 to 8.5, expressed in terms of weight percent on the oxide basis.

Owner:HOYA CORP

Metal-air semi-fuel cell with an aqueous acid based cathode

InactiveUS20070259234A1Long time operationCell energy increasedFuel and primary cellsFuel and secondary cellsFuel cellsOxygen

A metal-air semi-fuel cell is provided, preferably based on lithium anode and a fuel cell type air / oxygen electrode immersed in an aqueous neutral, alkali or acid solution. The lithium anode is comprised of the active metal and one or more separators protecting the anode from reacting with an aqueous solution. The outermost layer on the lithium electrode is a solid-state lithium-ion conducting glass-ceramic which is impervious to and stable towards aqueous solutions. The cathode is comprised of an air or oxygen fuel cell type electrode in contact with the aqueous solution. The lithium anode of this invention also can be replaced by other electroactive metals which react with water and acids, bases and neutral solutions, such as metals from Groups 1 and 2 of the Periodic Table of Elements in addition to Zn, Mg, and Al.

Owner:CHUA DAVID +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com