Patents

Literature

3105 results about "Coating system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

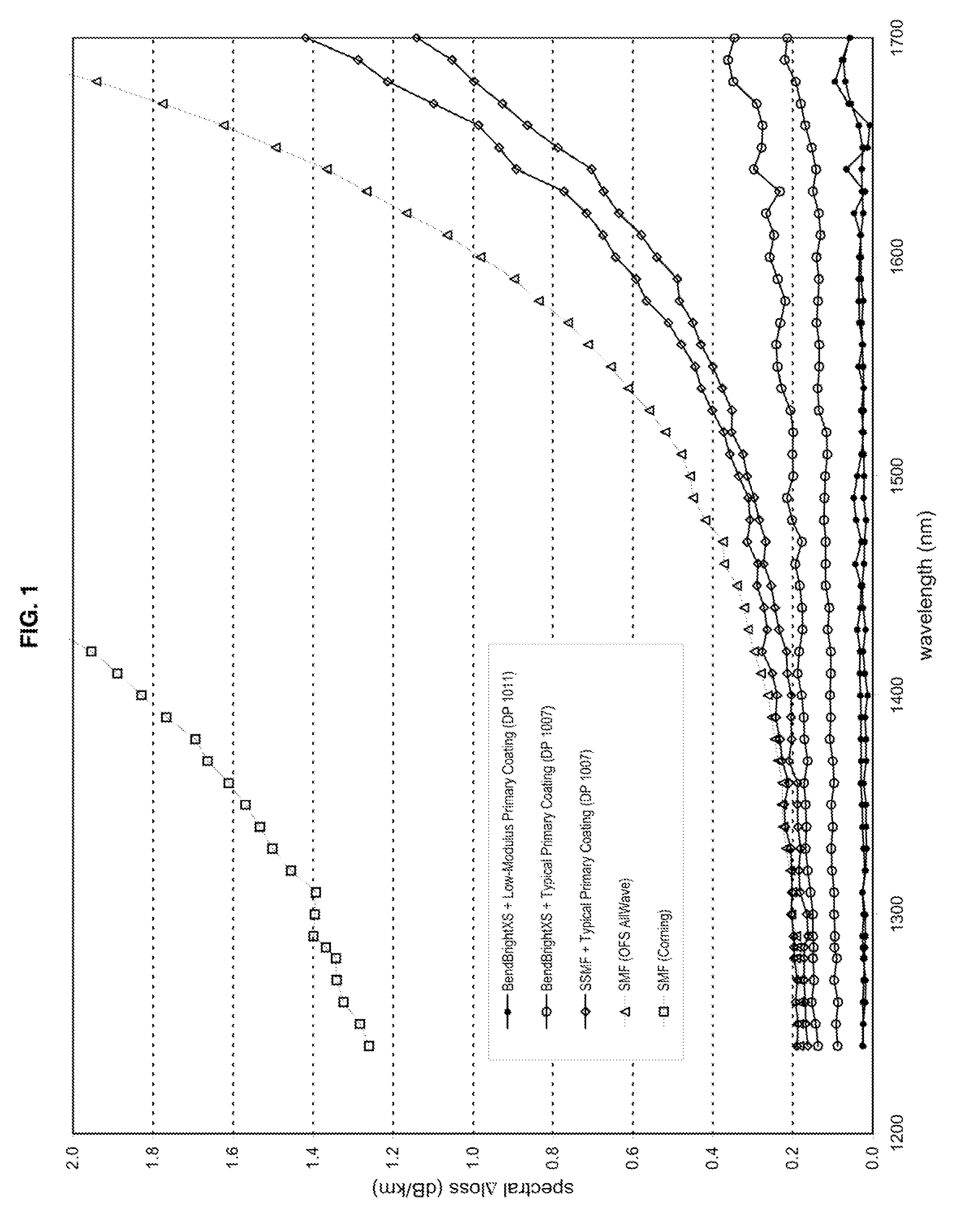

Reduced-Diameter Optical Fiber

ActiveUS20100119202A1Improve protectionEasily matedGlass optical fibreCoupling light guidesFiberGlass fiber

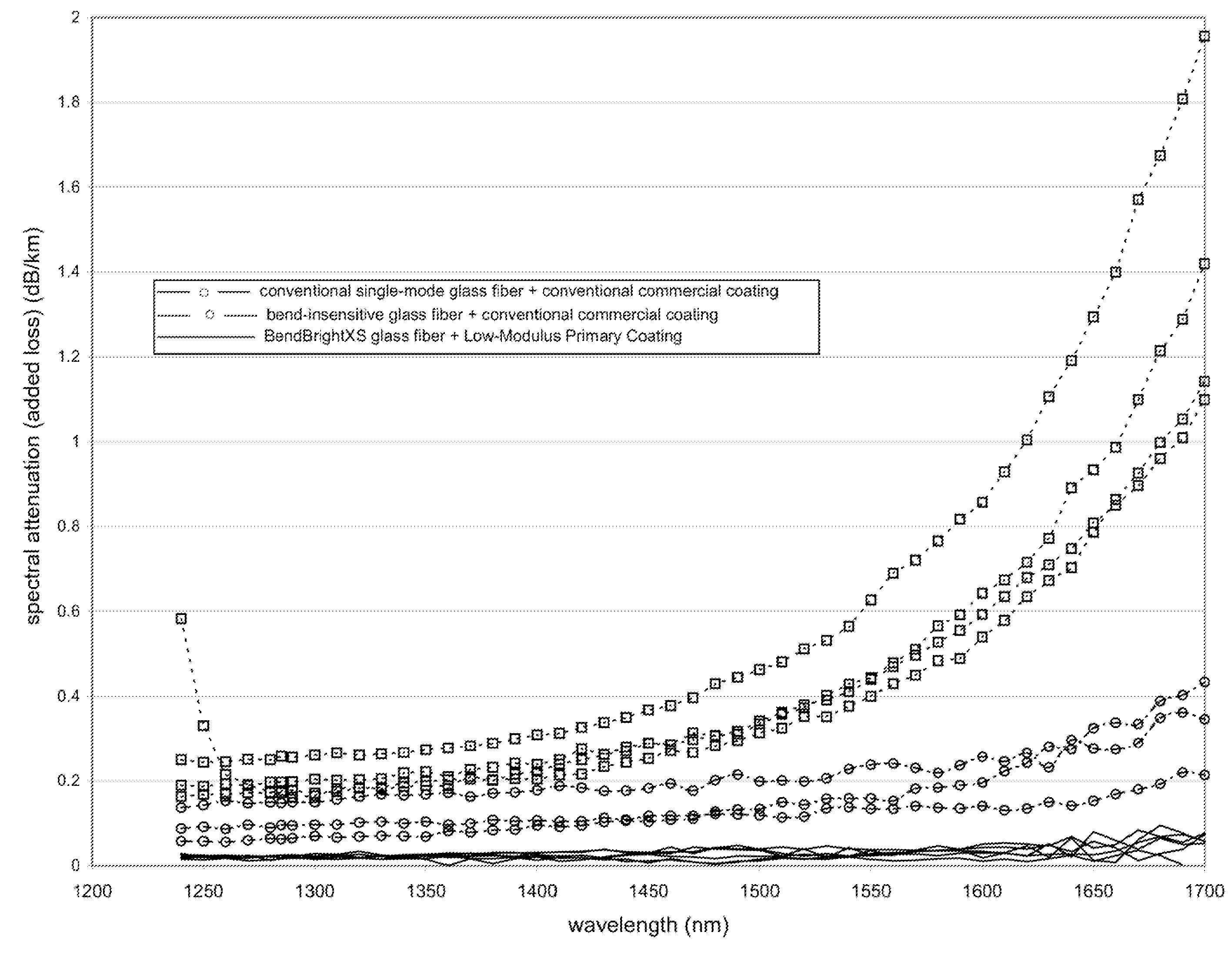

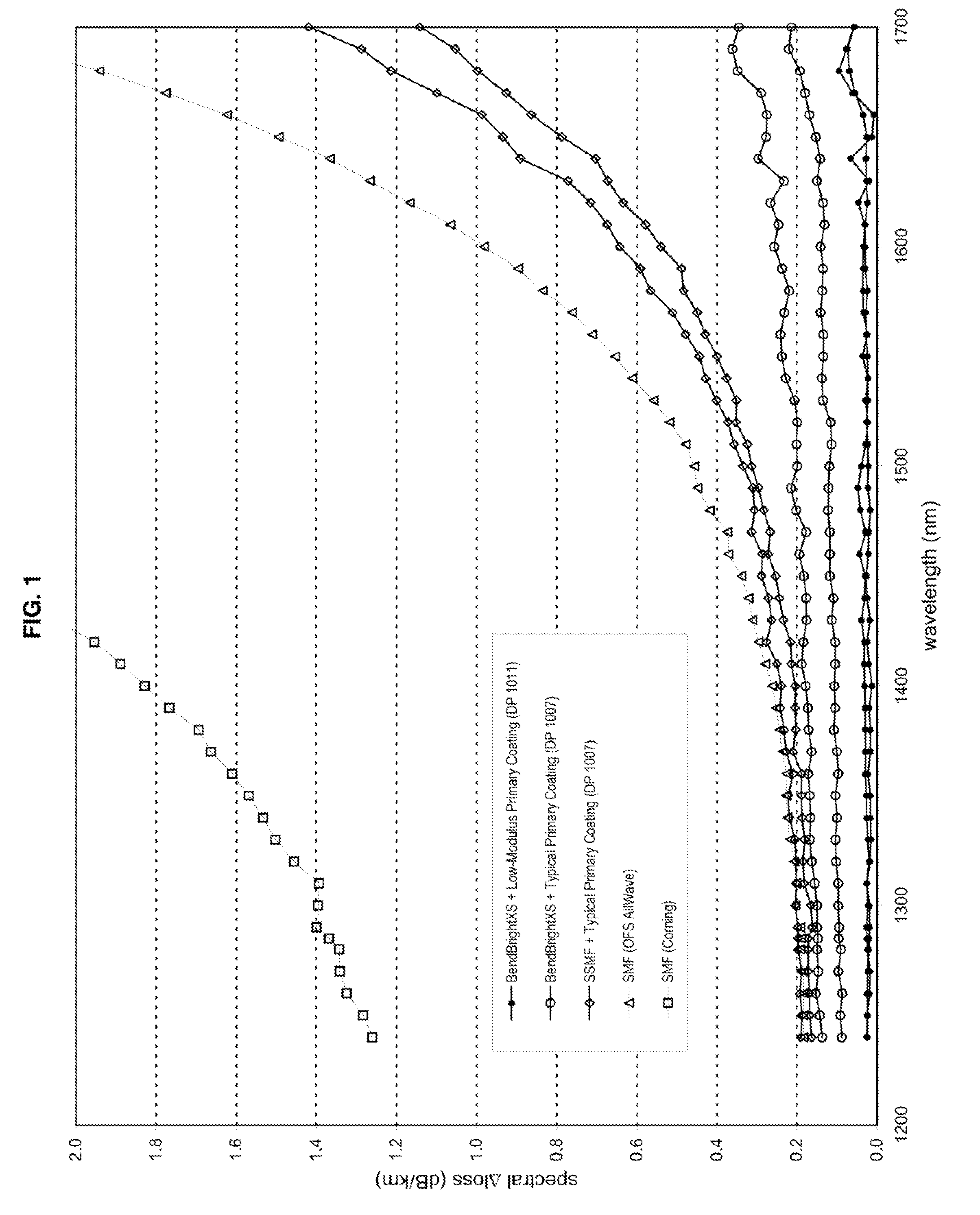

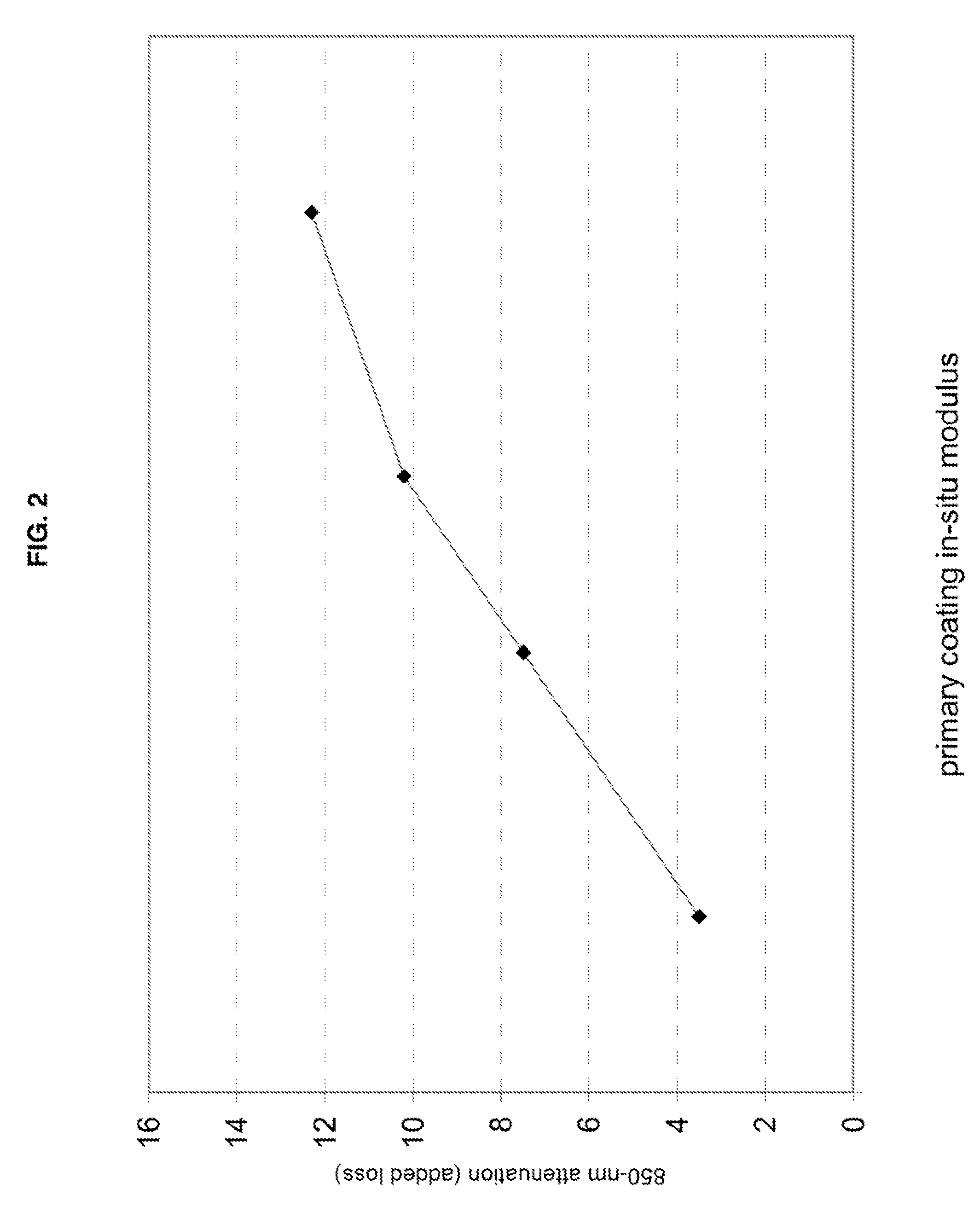

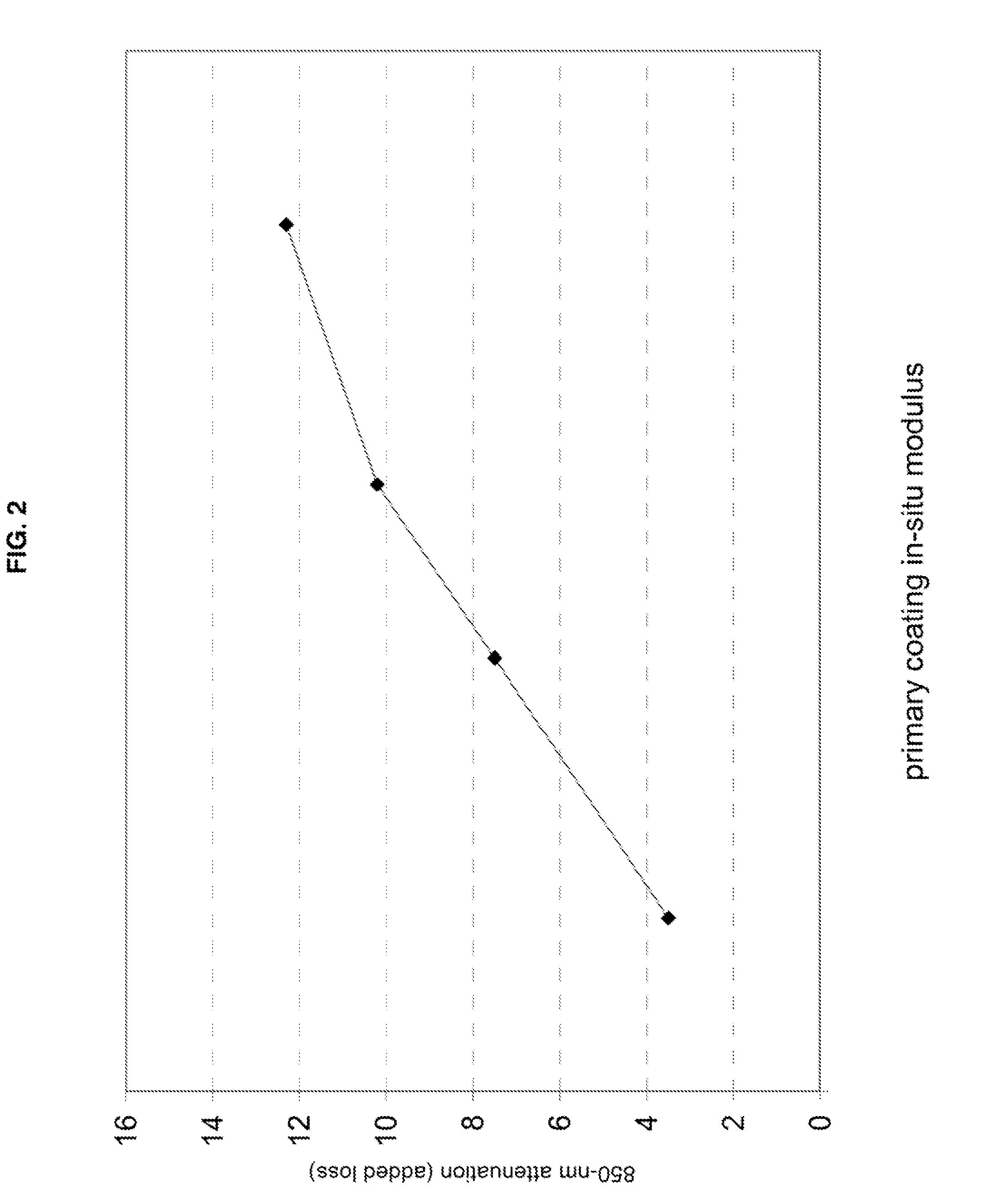

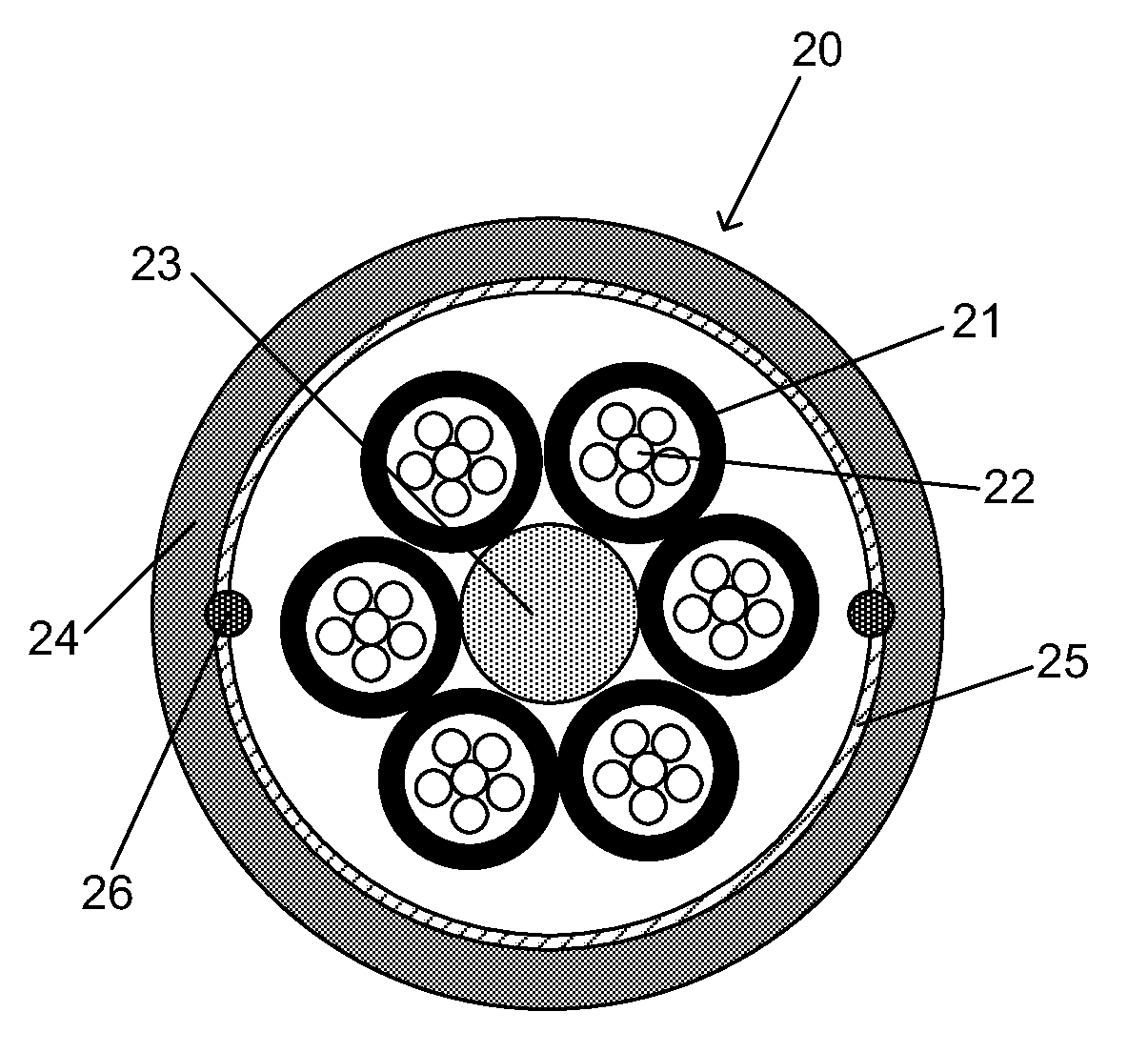

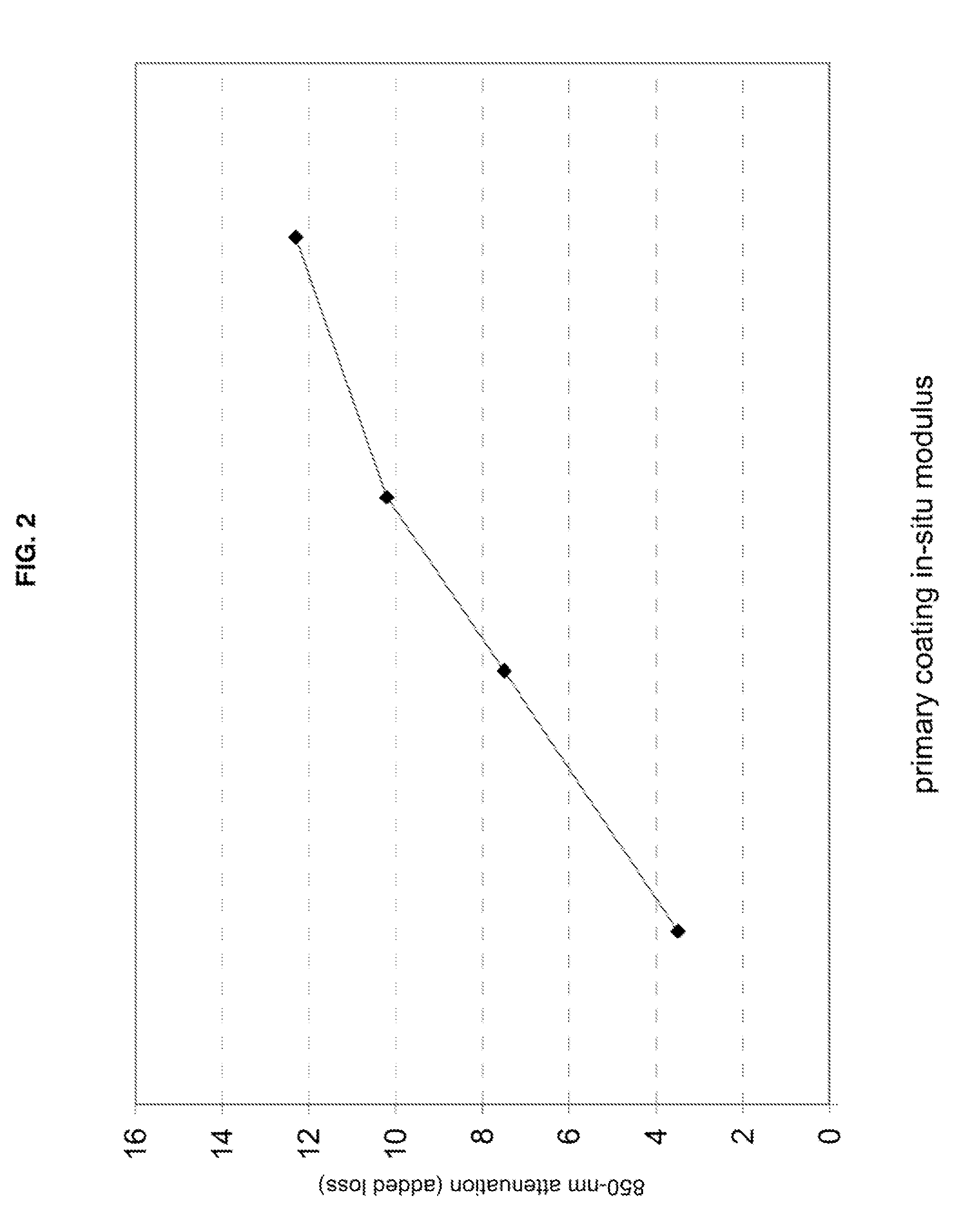

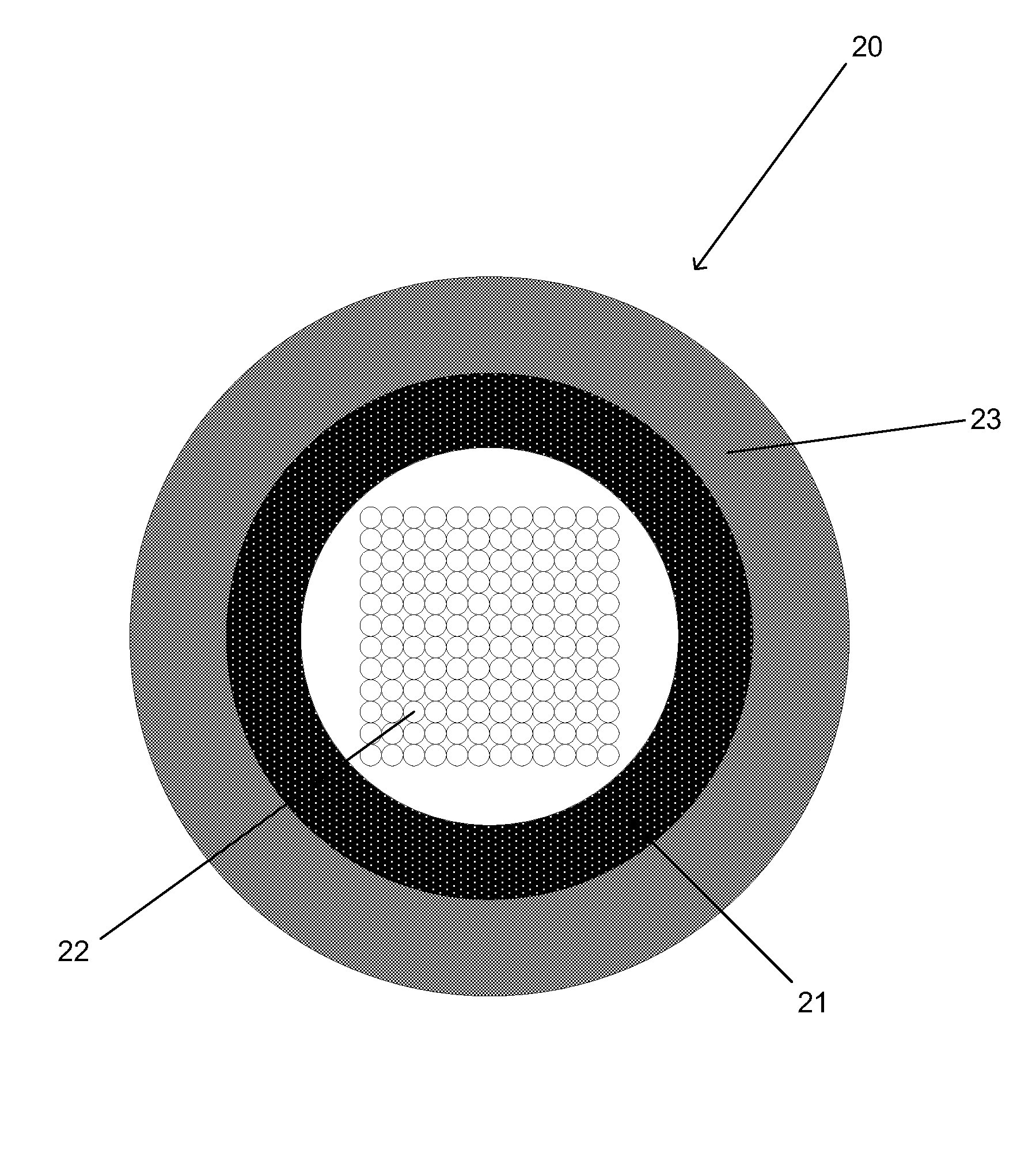

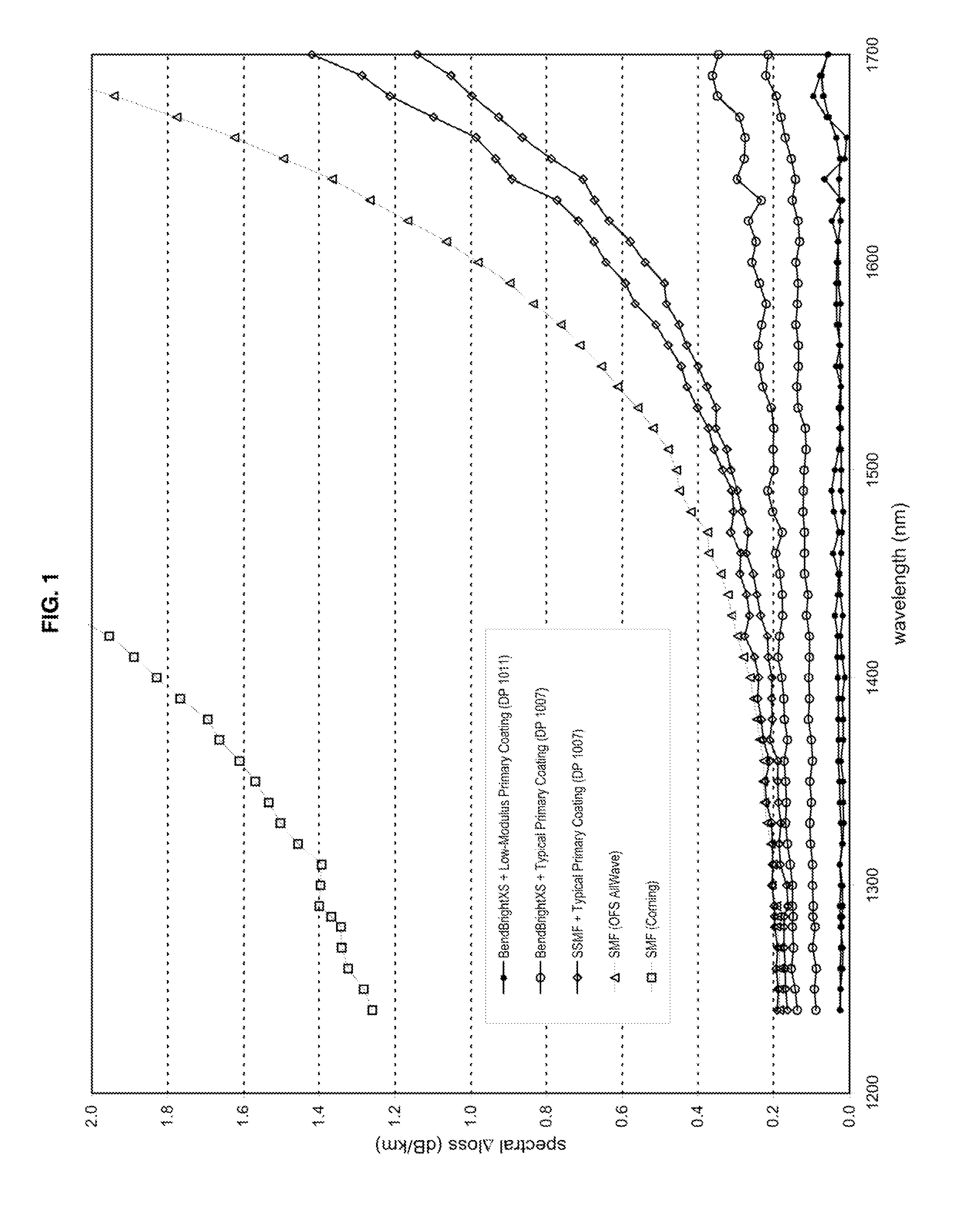

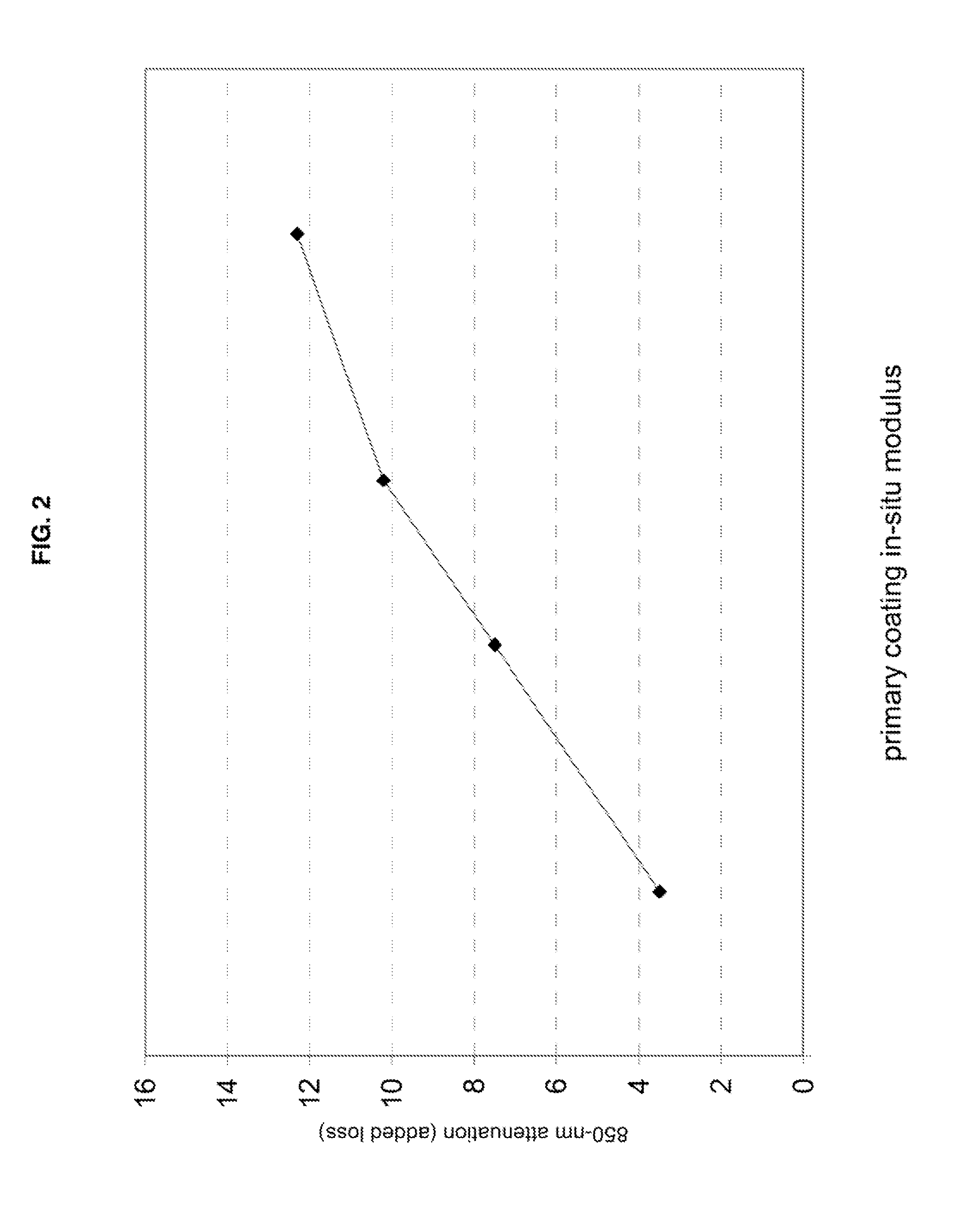

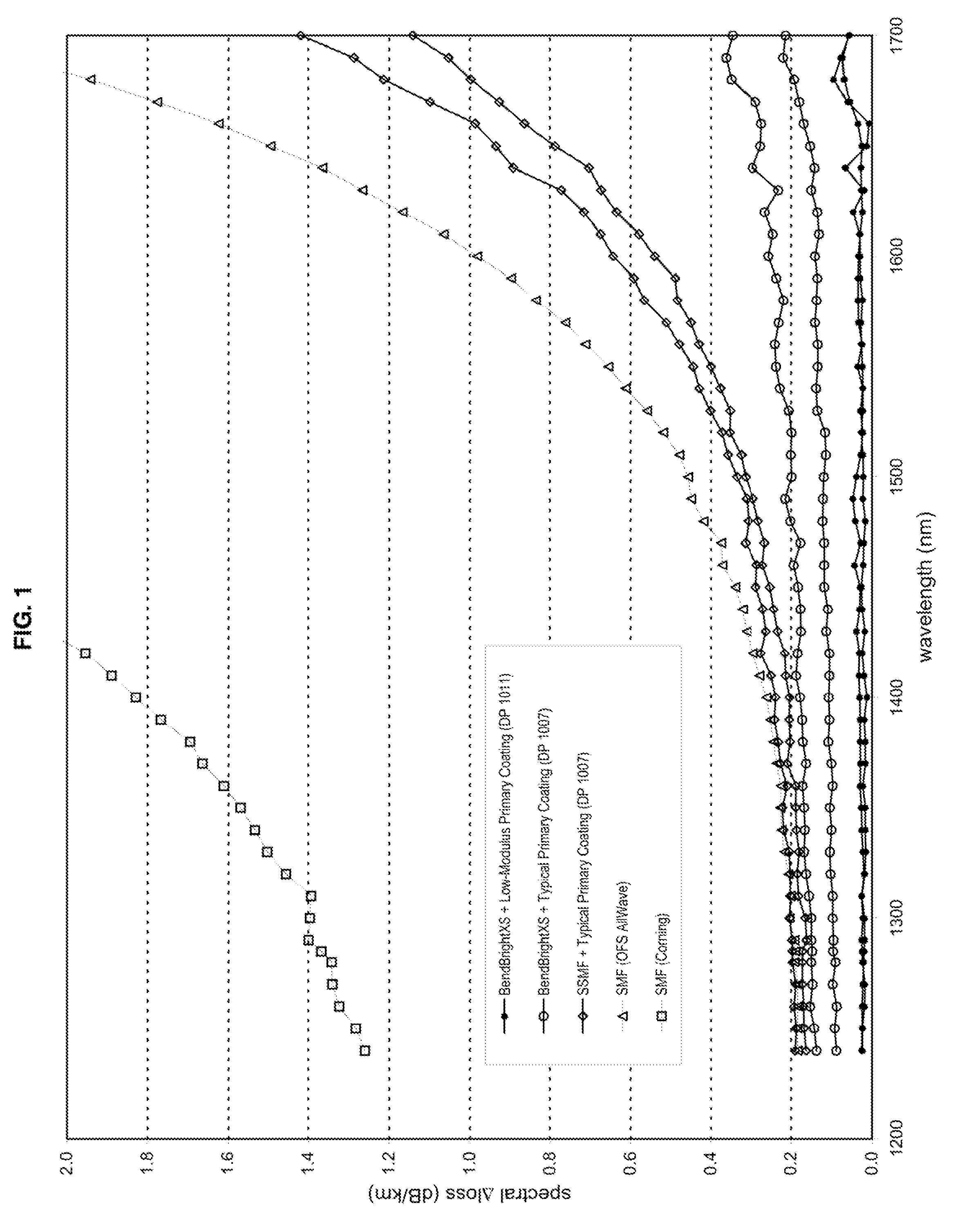

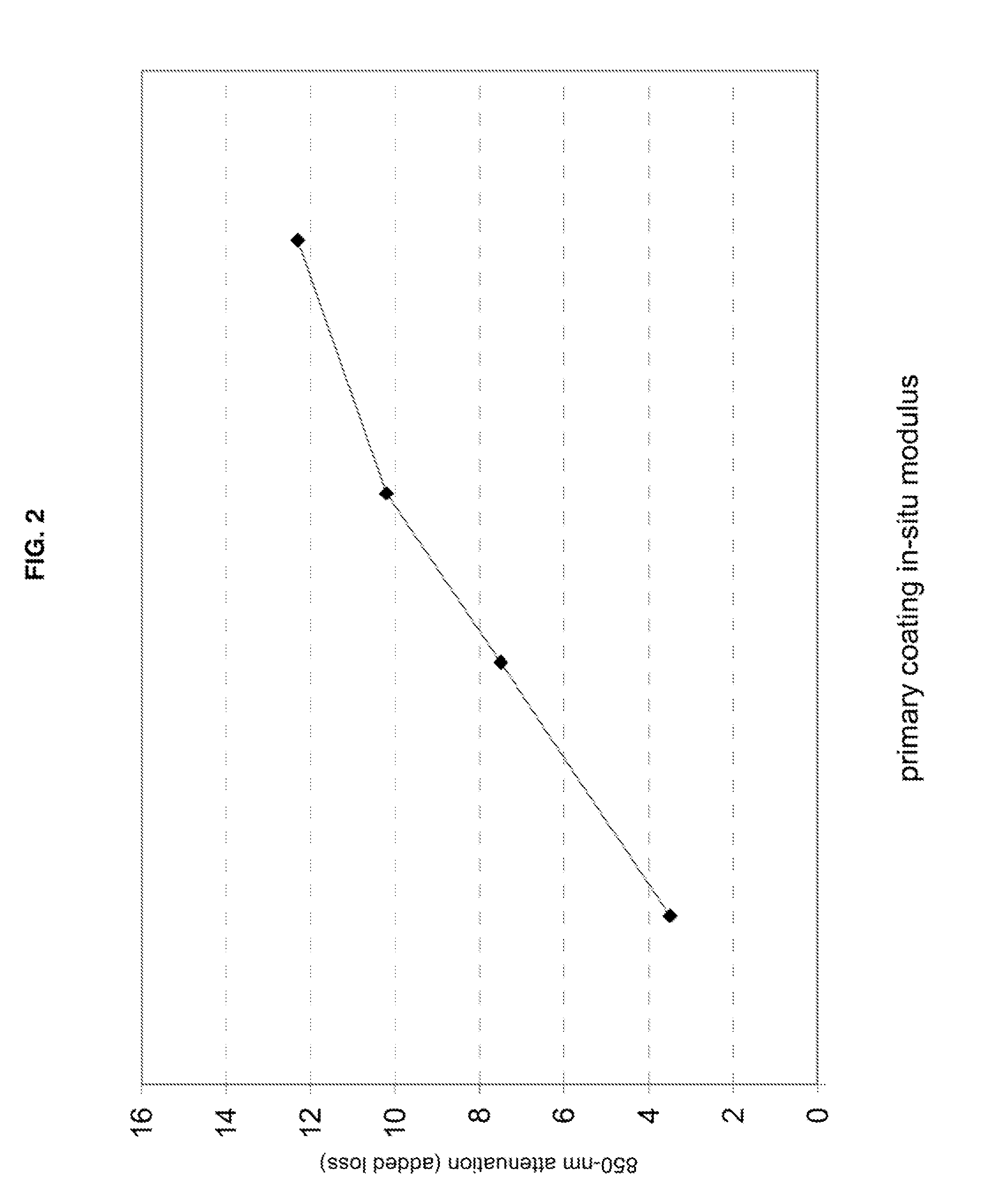

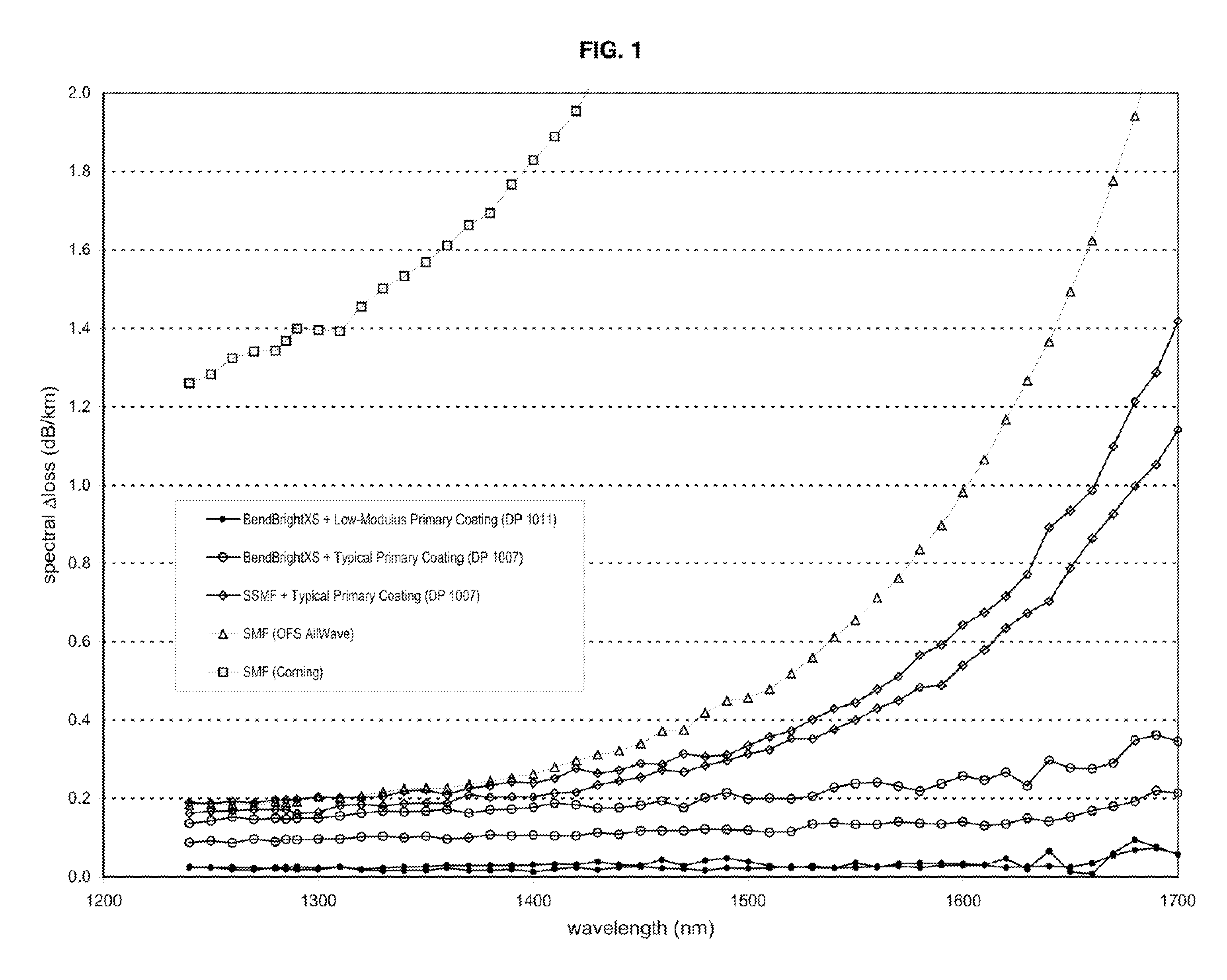

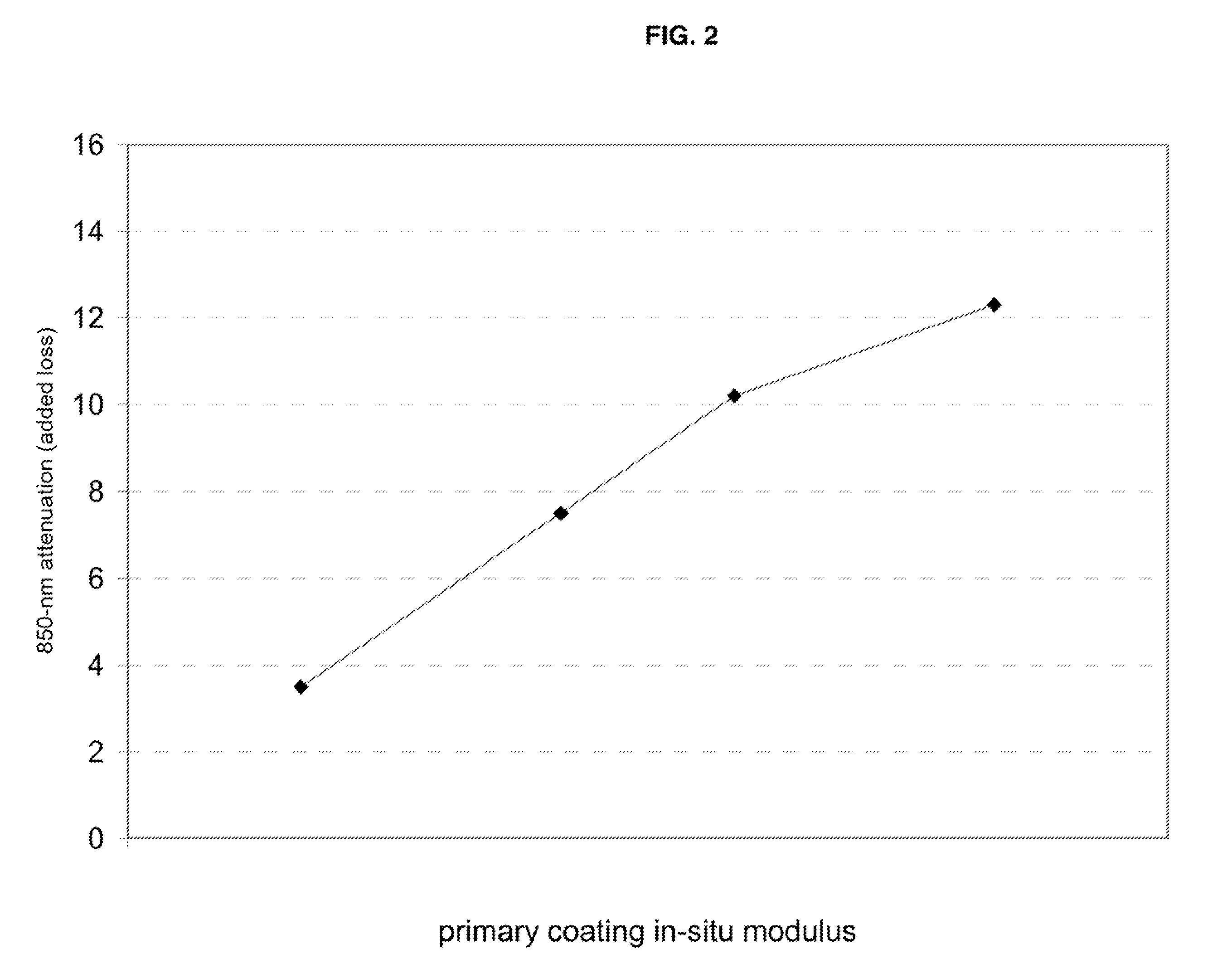

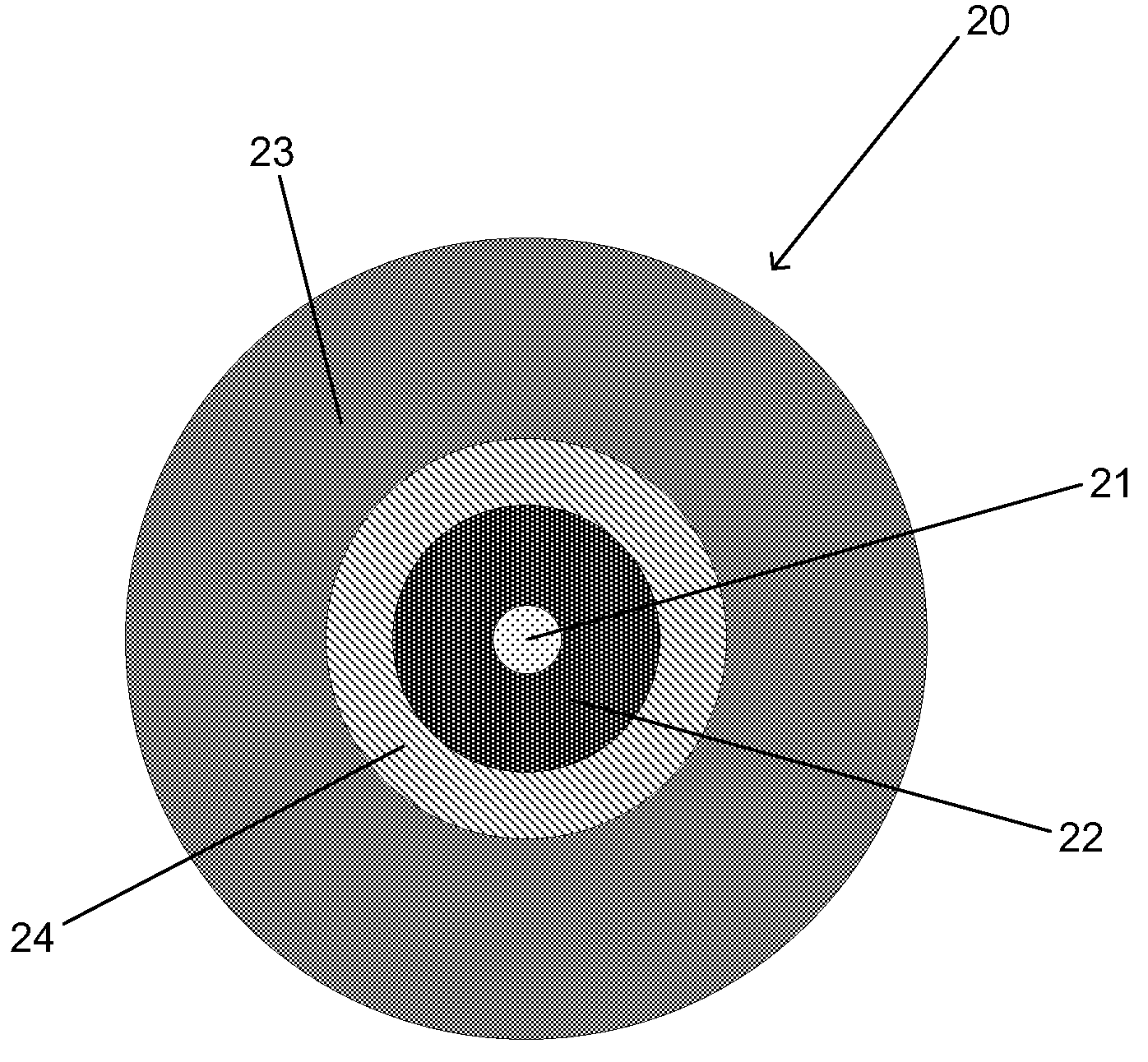

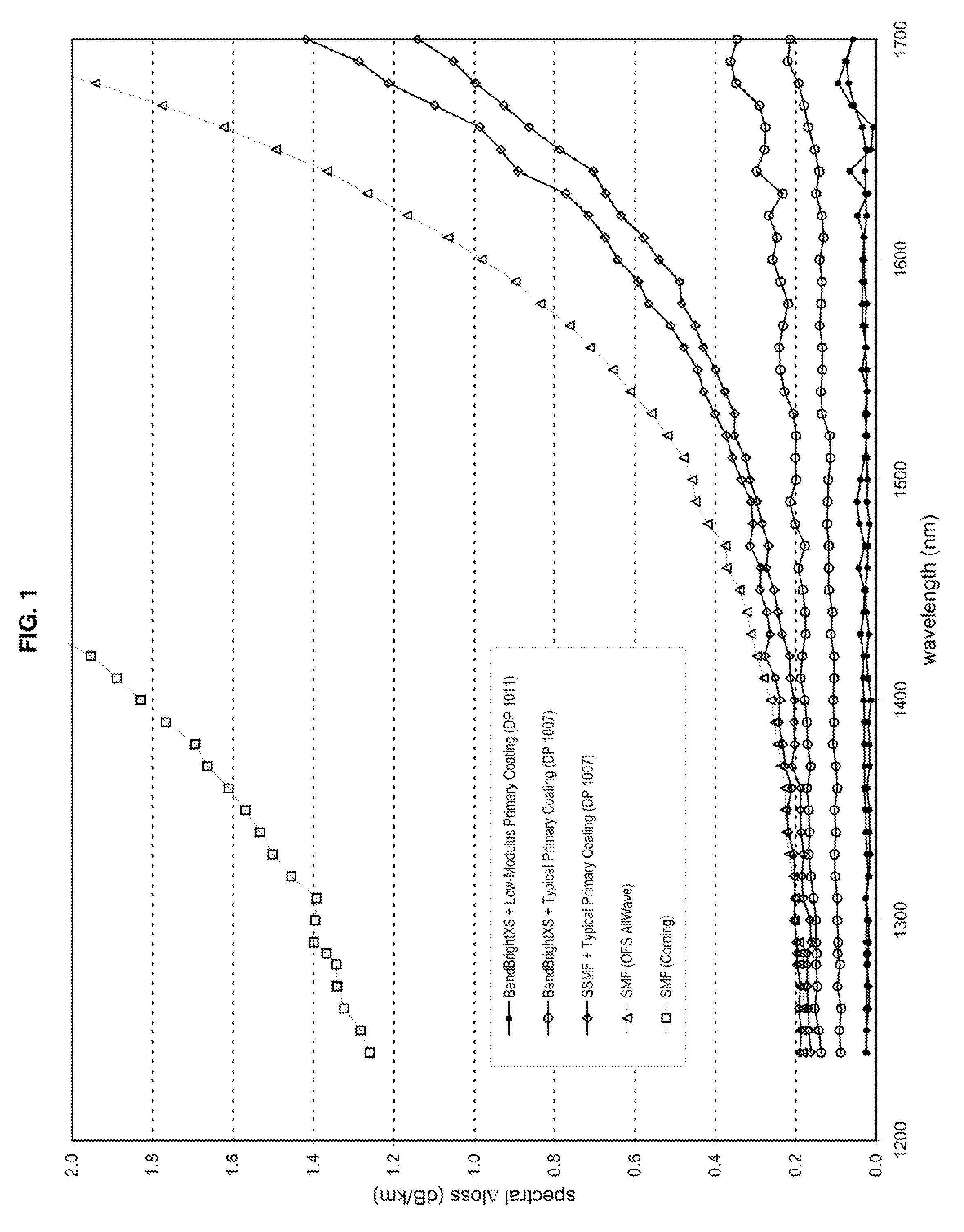

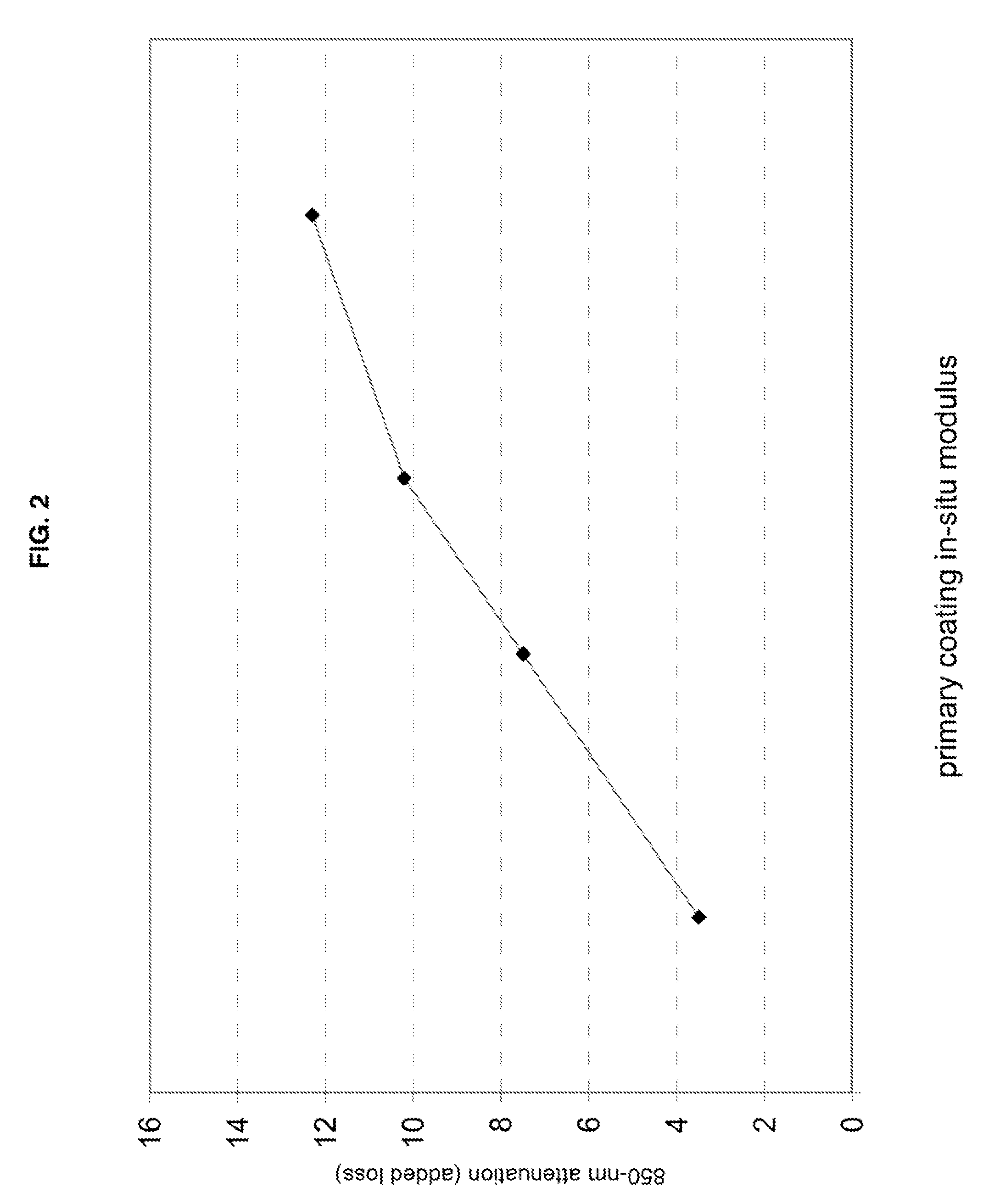

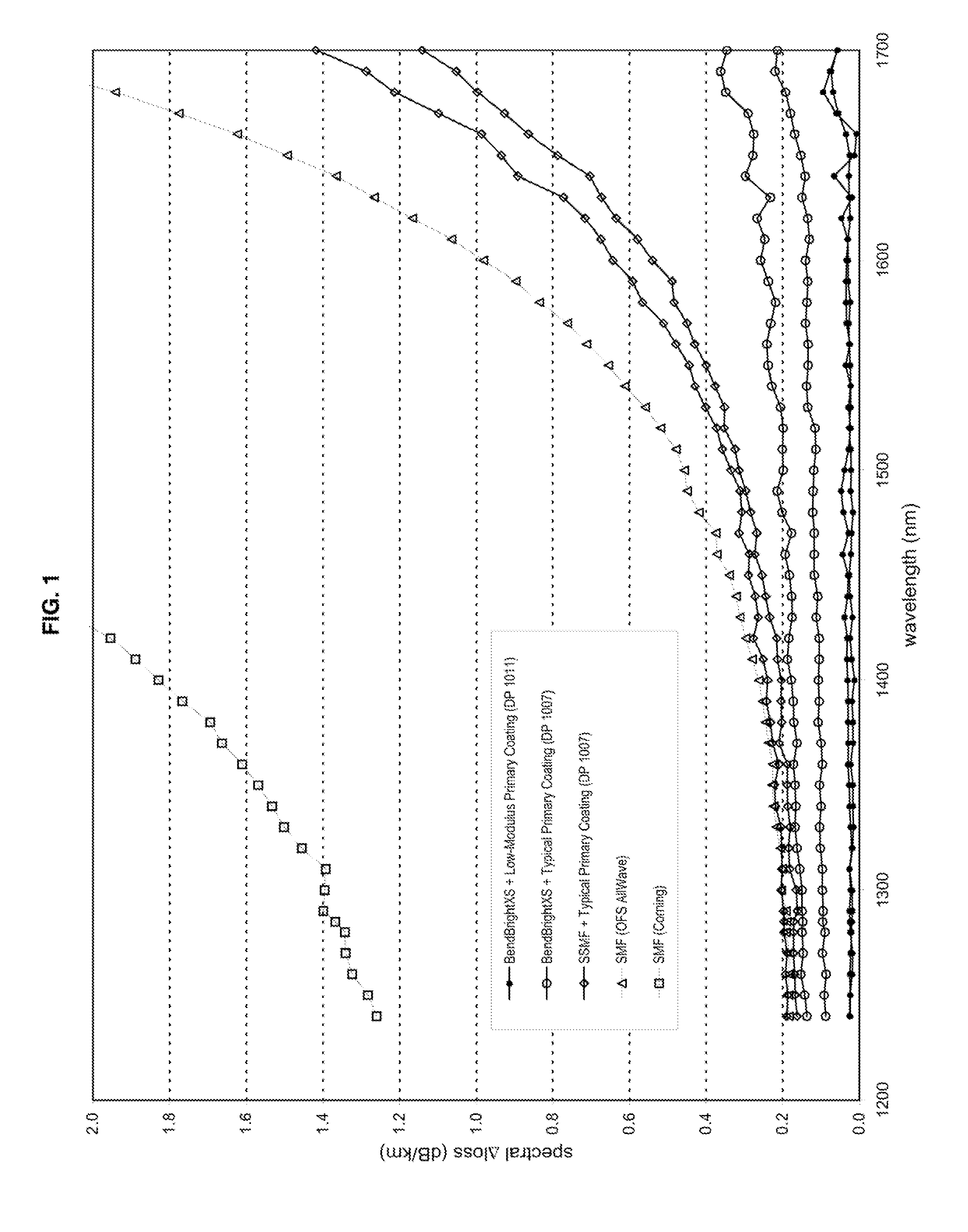

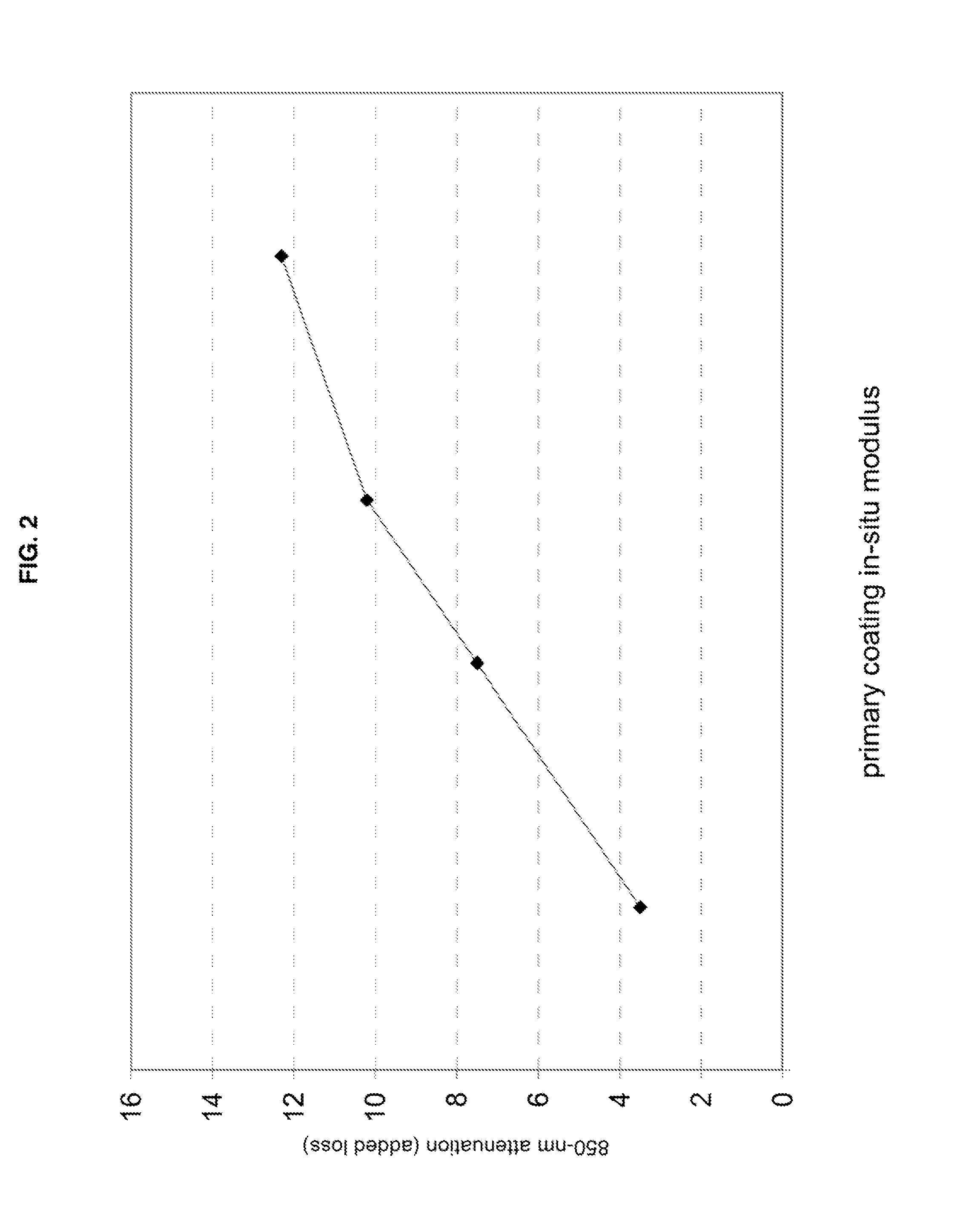

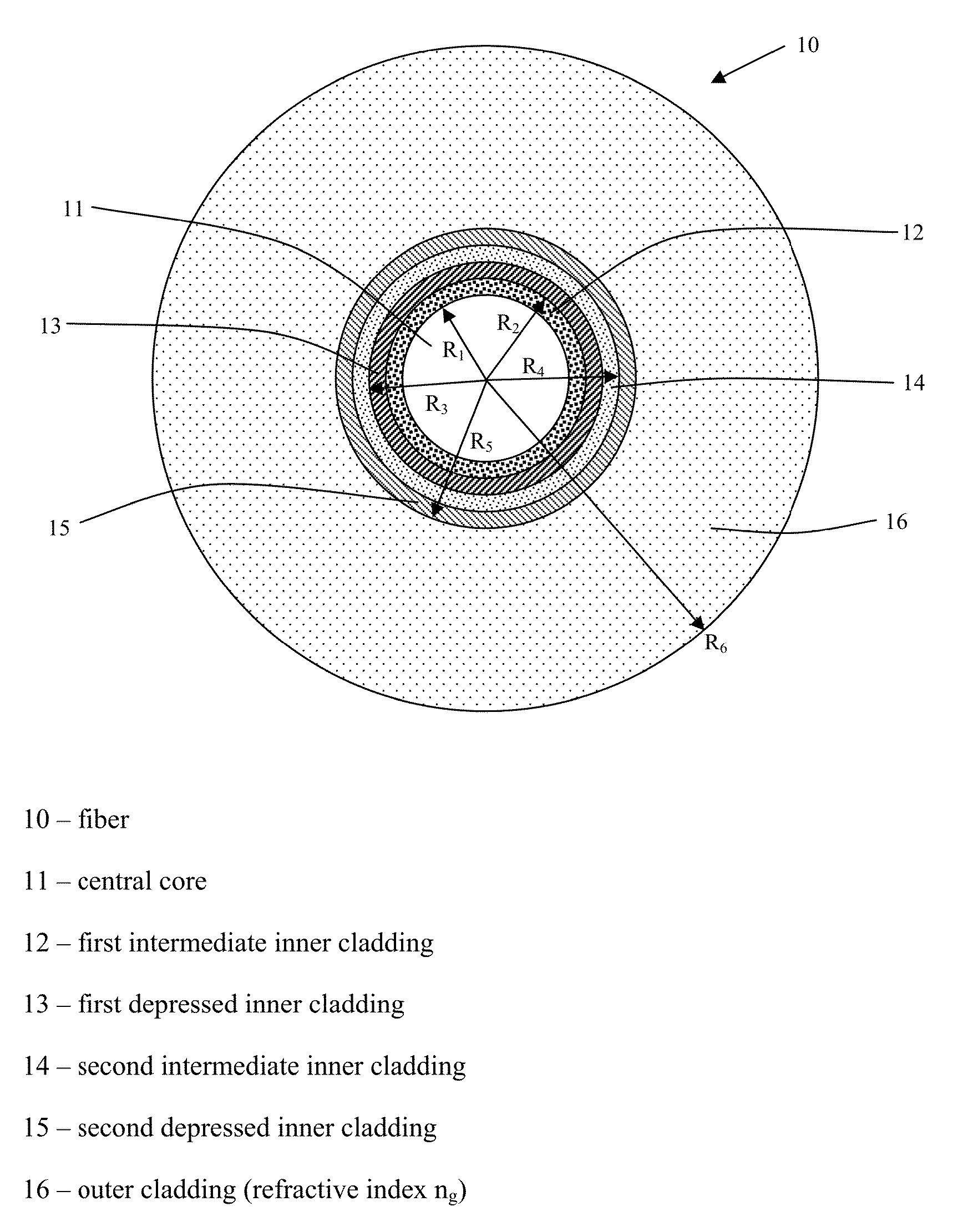

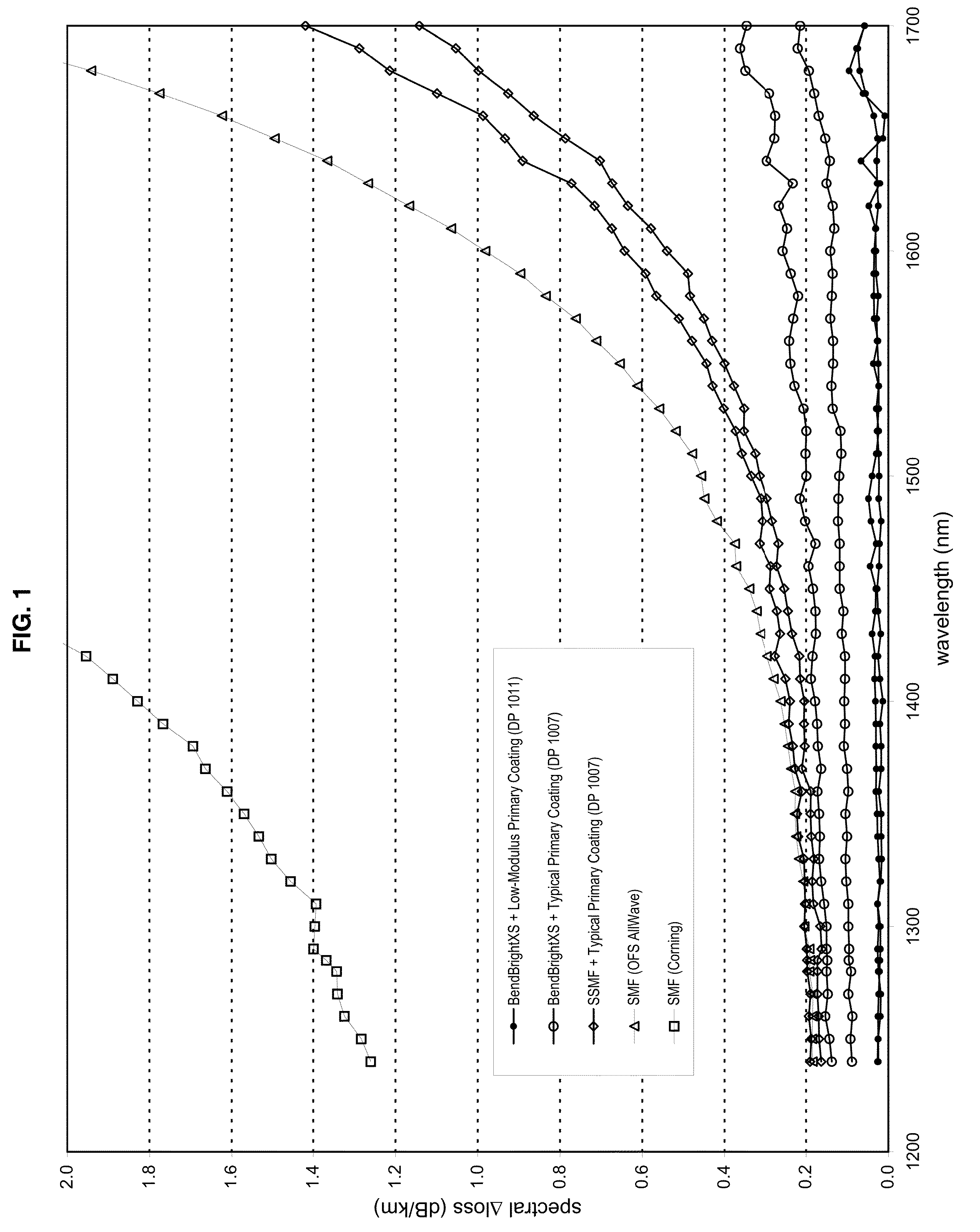

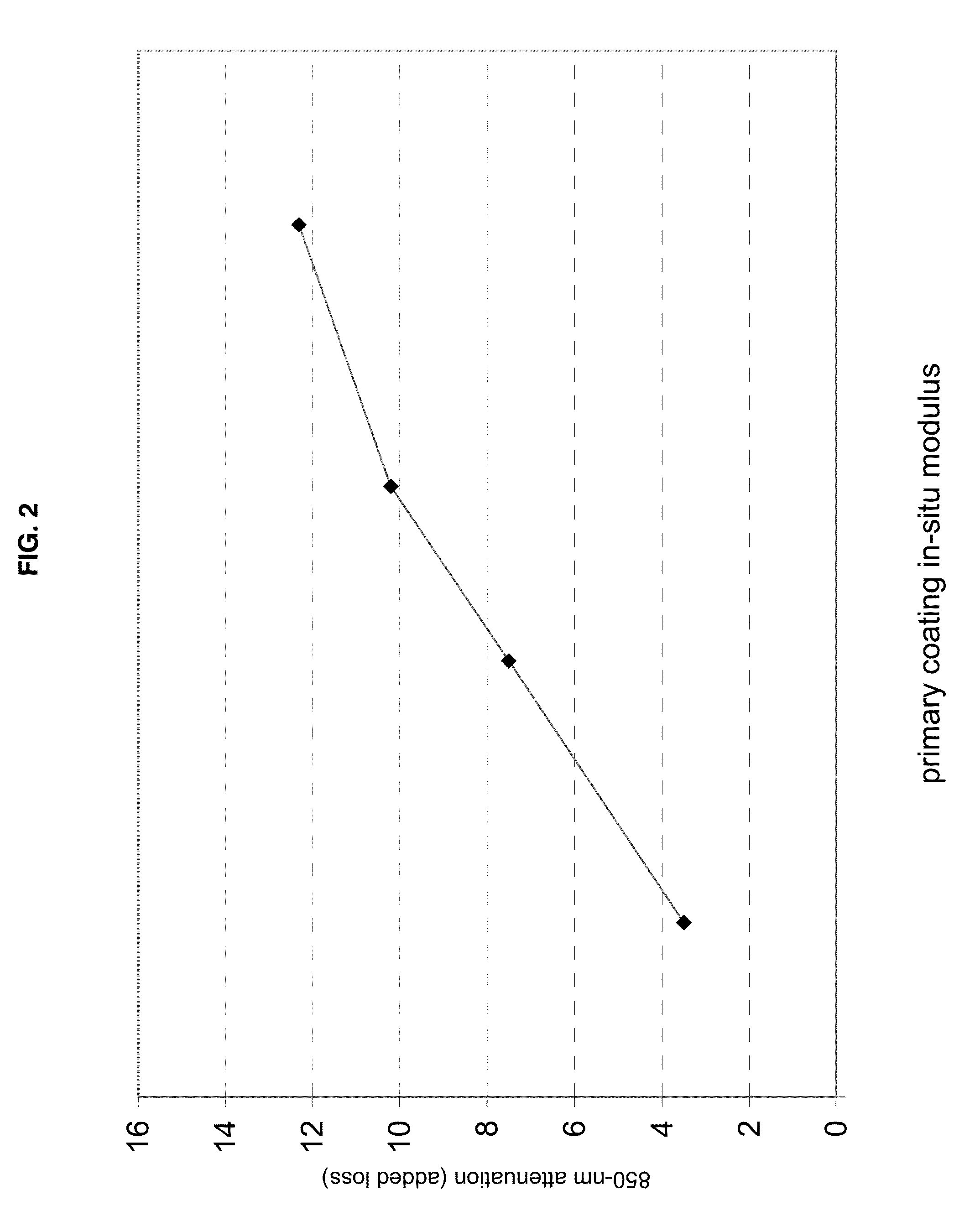

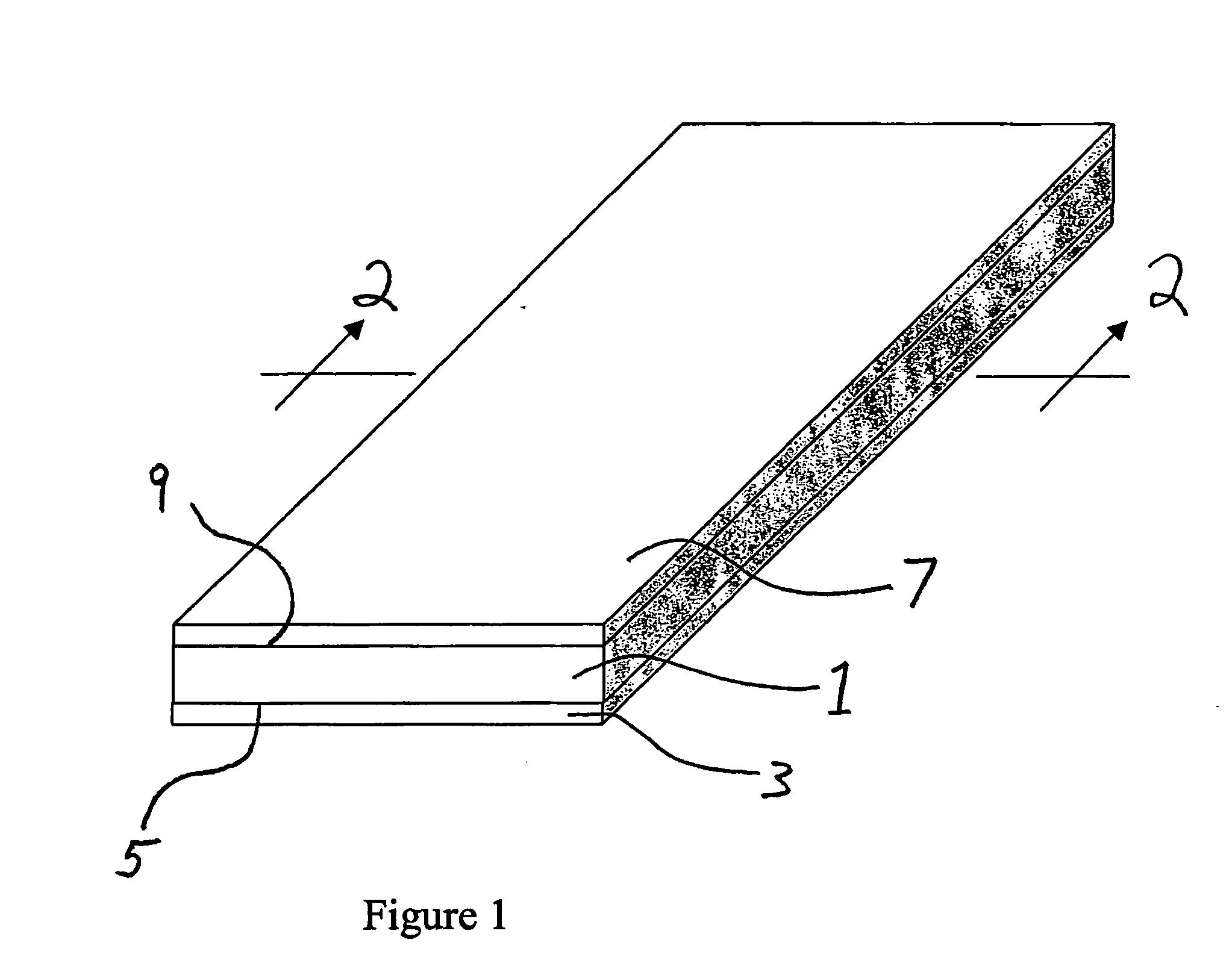

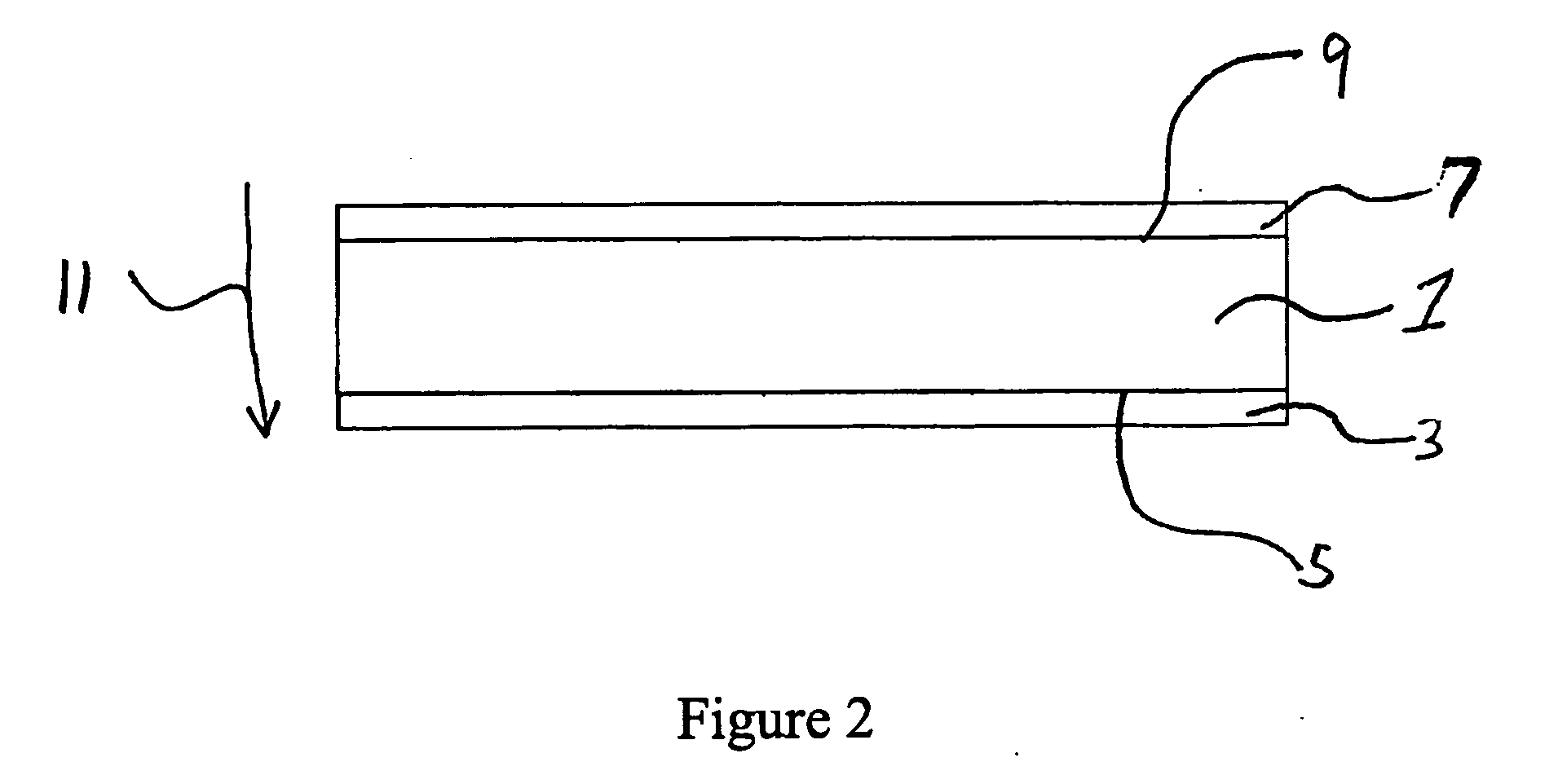

Disclosed is a reduced-diameter optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness. The secondary coating provides improved ribbon characteristics for structures that are robust, yet easily entered (i.e., separated and stripped).The optional dual coating is specifically balanced for superior heat stripping in fiber ribbons, with virtually no residue left behind on the glass. This facilitates fast splicing and terminations. The improved coating system provides optical fibers that offer significant advantages for deployment in most, if not all, fiber-to-the-premises (FTTx) systems.

Owner:DRAKA COMTEQ BV

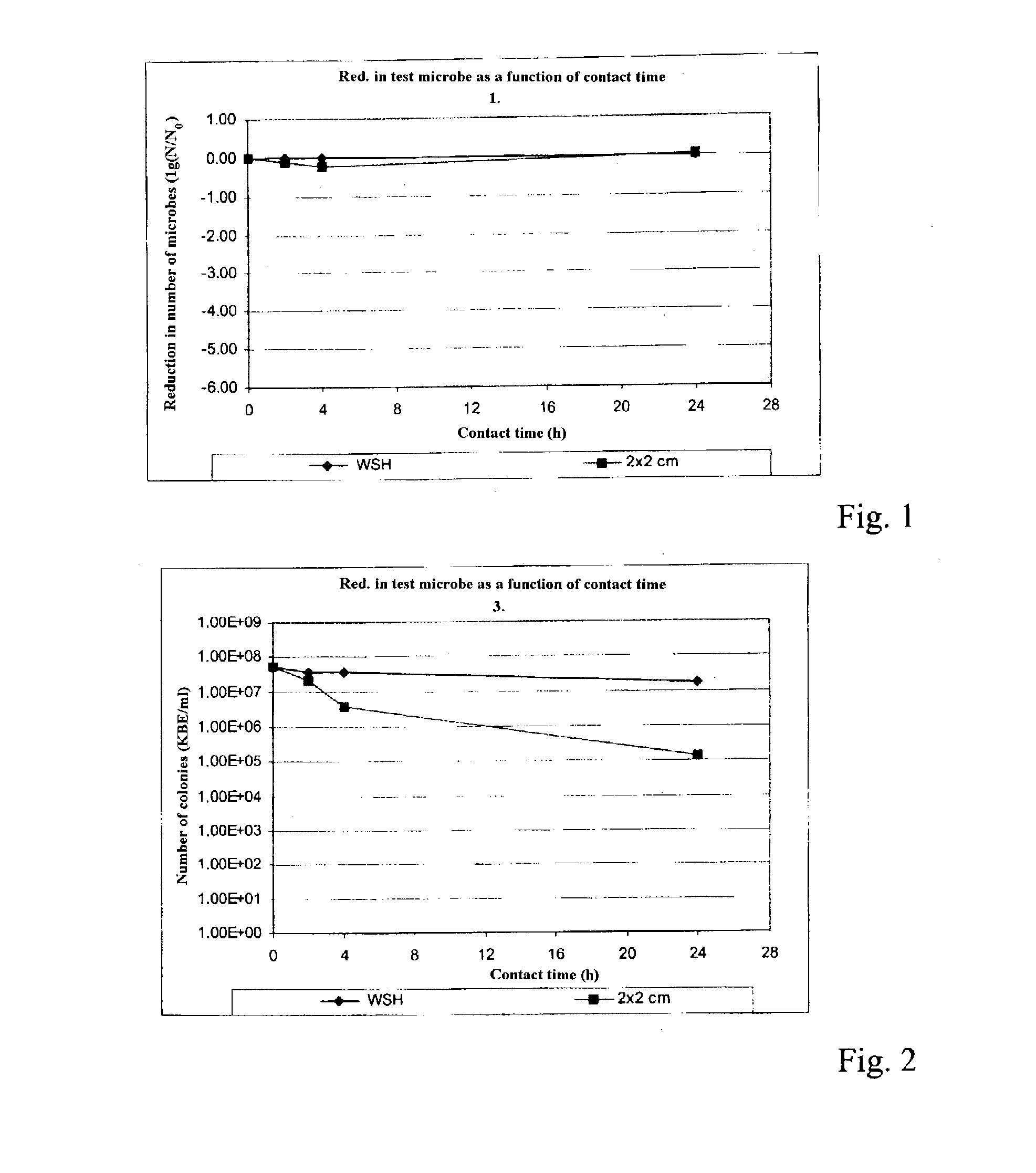

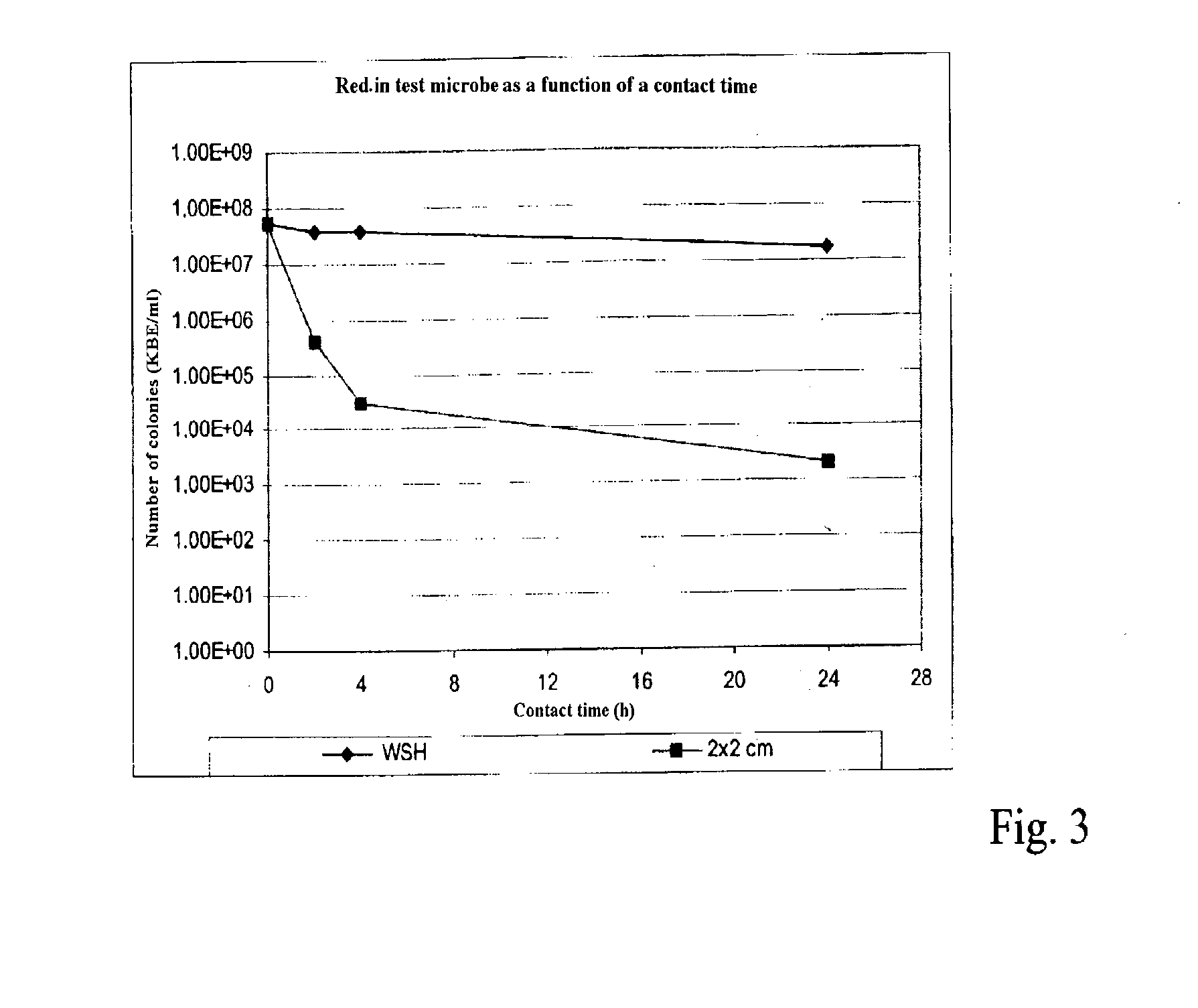

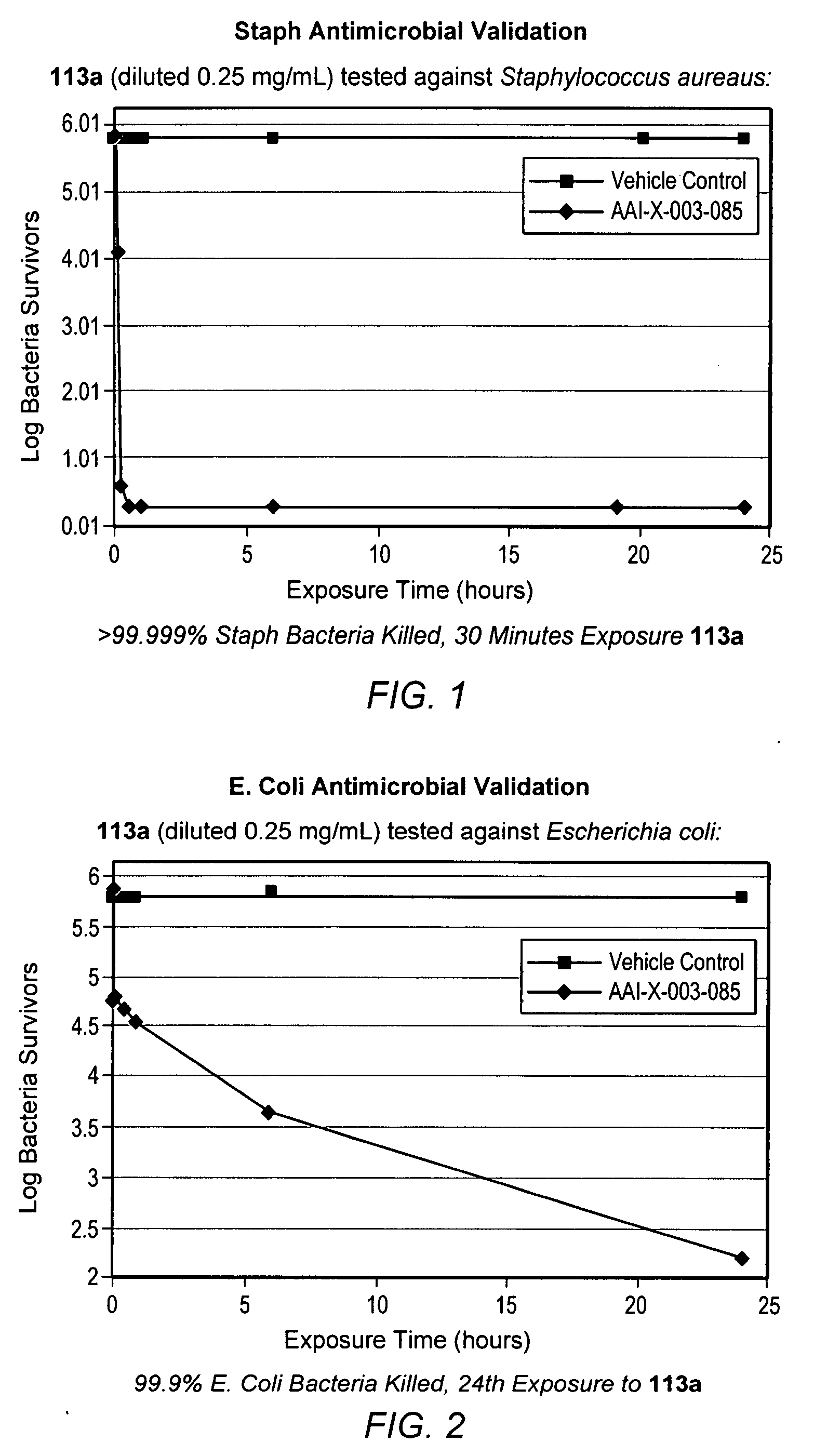

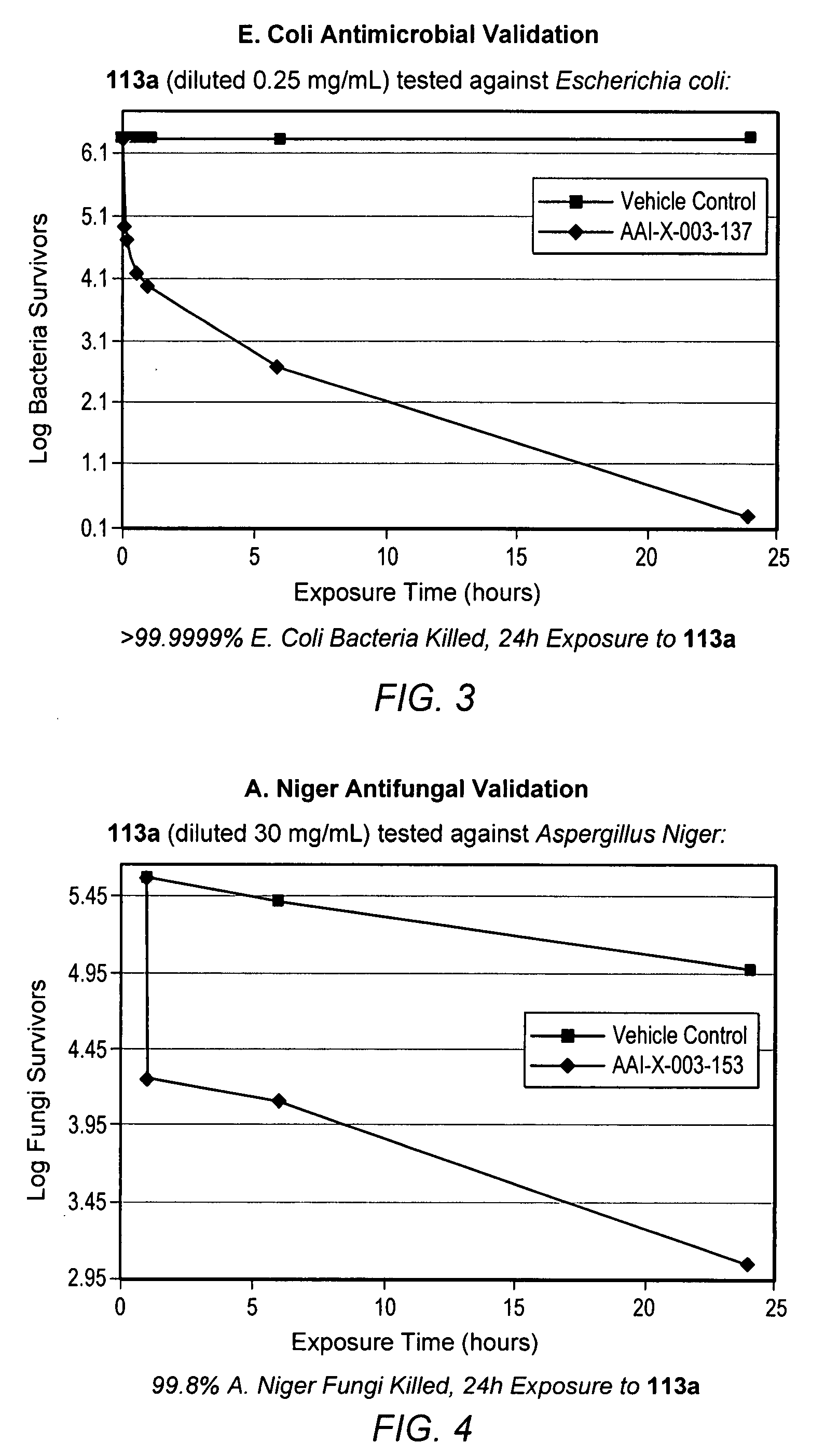

Self-cleaning lotus effect surfaces having antimicrobial properties

A self-cleaning or lotus-effect surface that has antimicrobial properties, commercial products comprising such a surface, and uses thereof. A process for the production of an antimicrobial self-cleaning or lotus-effect surface in which one or more antimicrobial polymer(s) is secured to a surface-coating system for securing structure-formers to generate a self-cleaning surface. This method lastingly binds antimicrobial polymers to the self-cleaning surface. Commercial products comprising an antimicrobial self-cleaning or lotus-effect surface.

Owner:CREAVIS GES FUER TECH

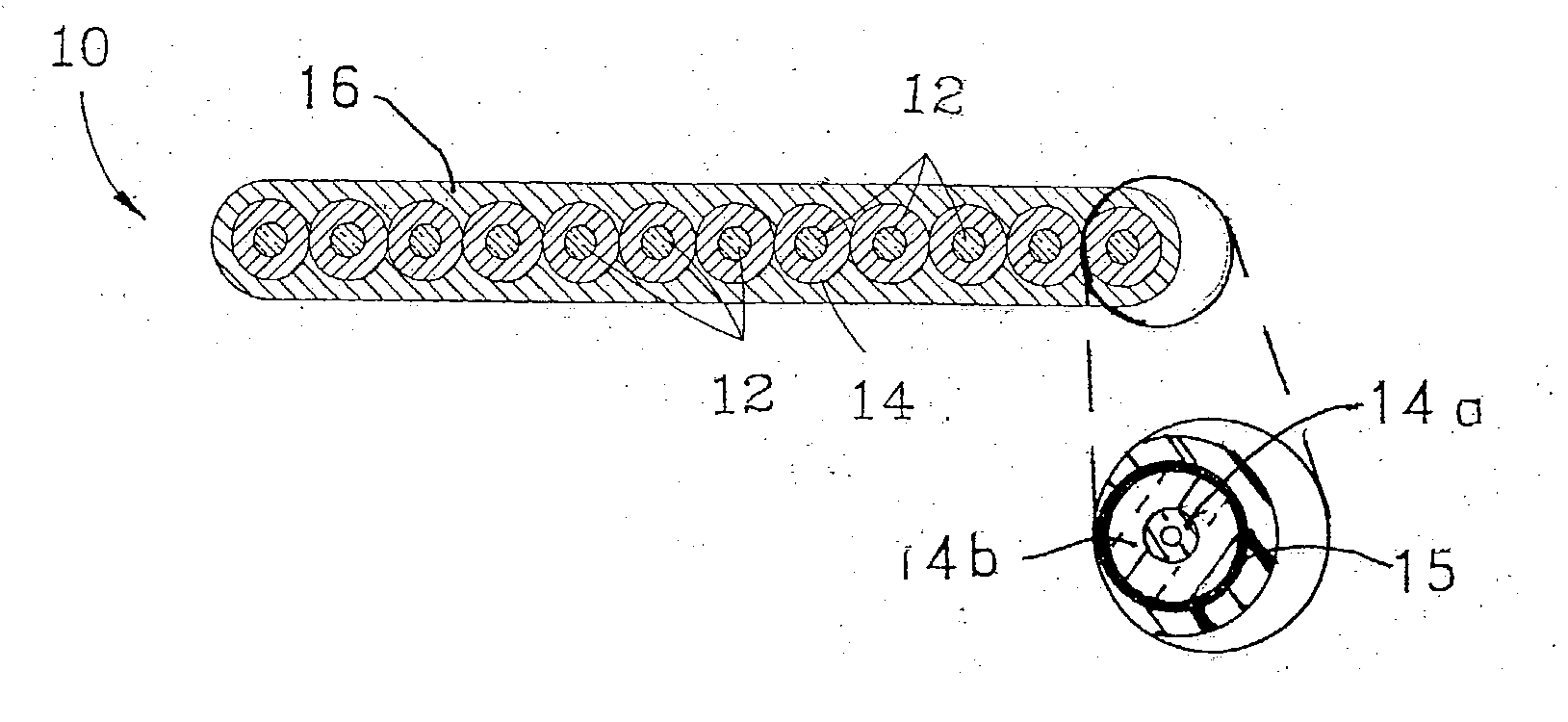

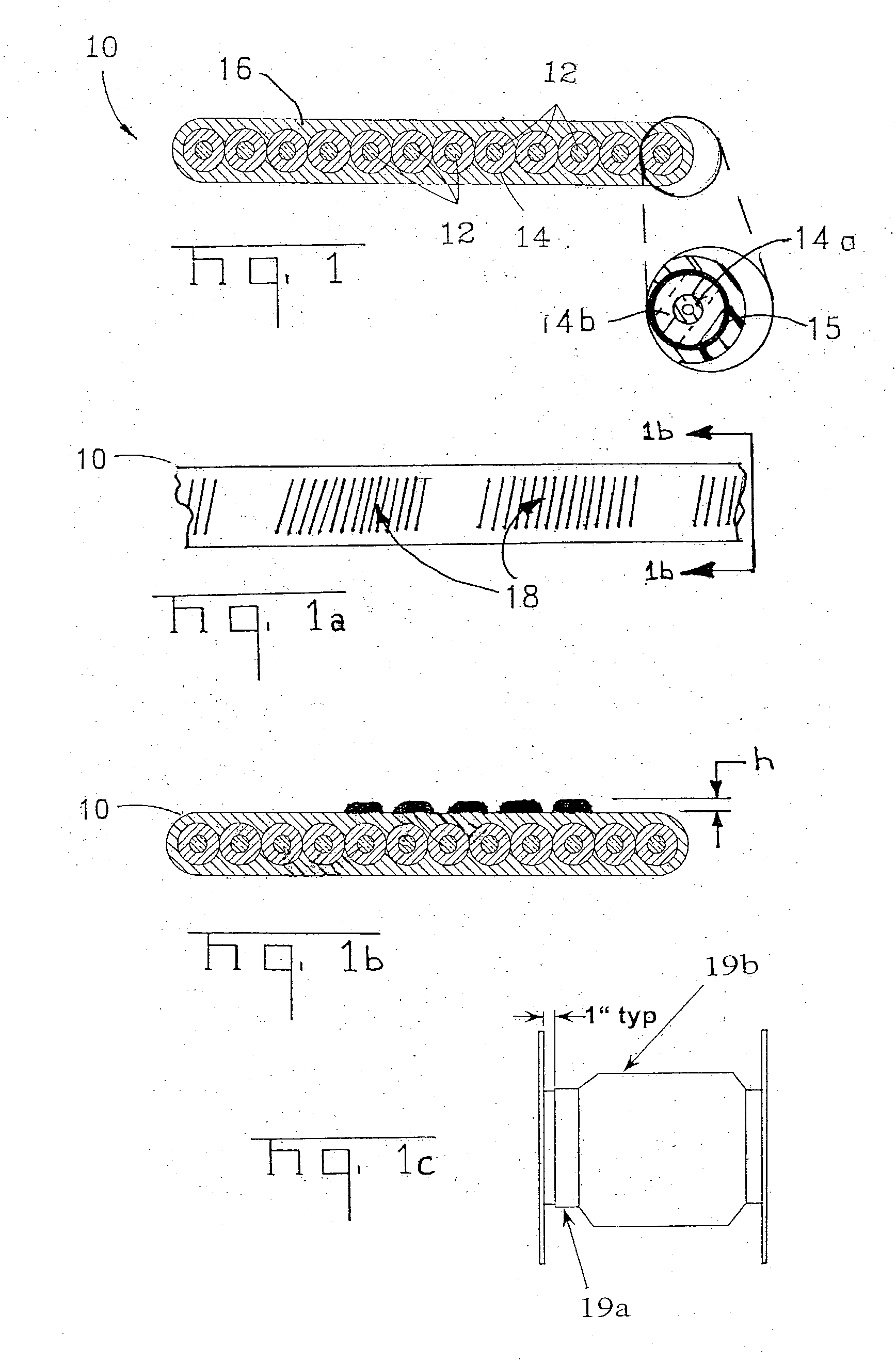

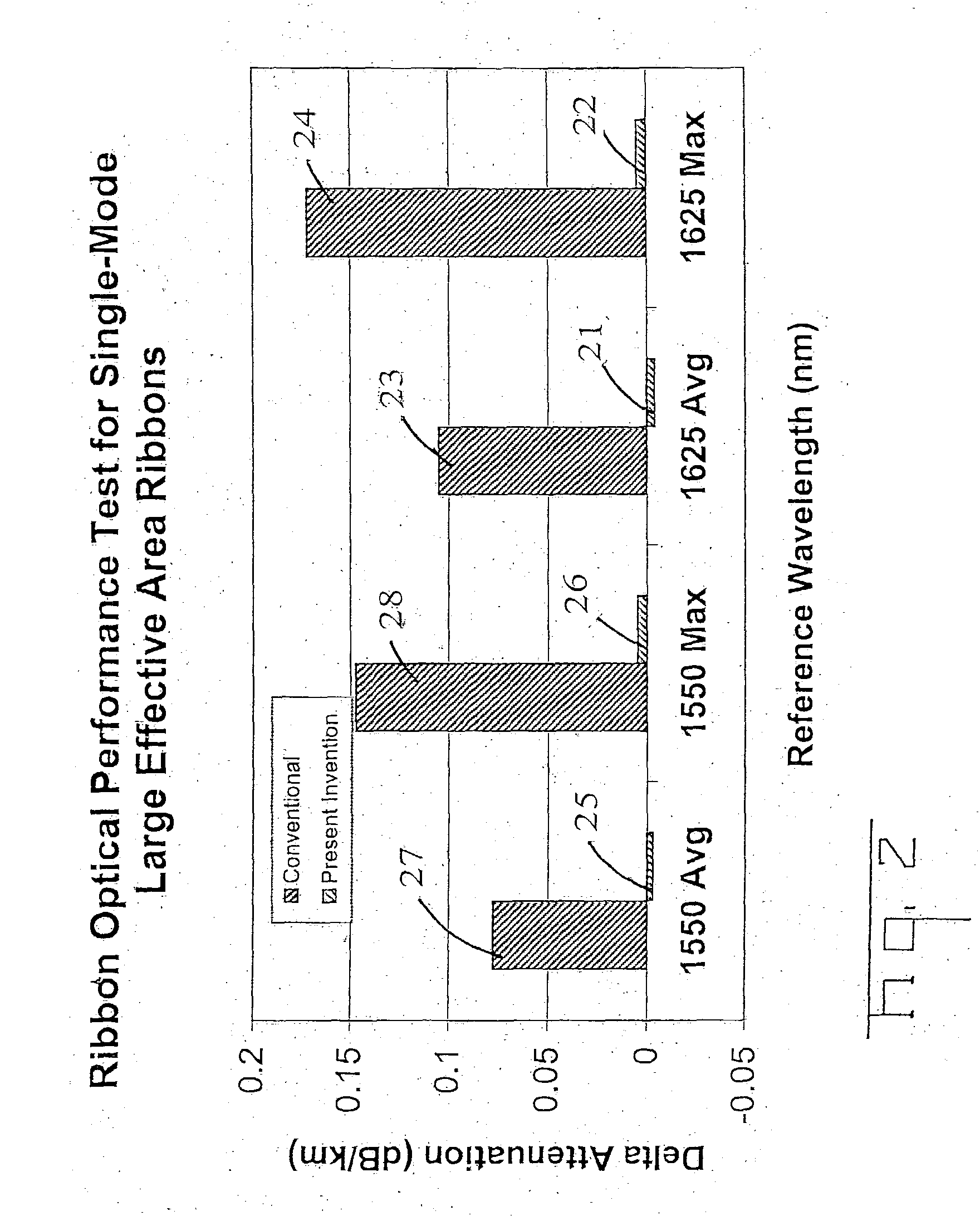

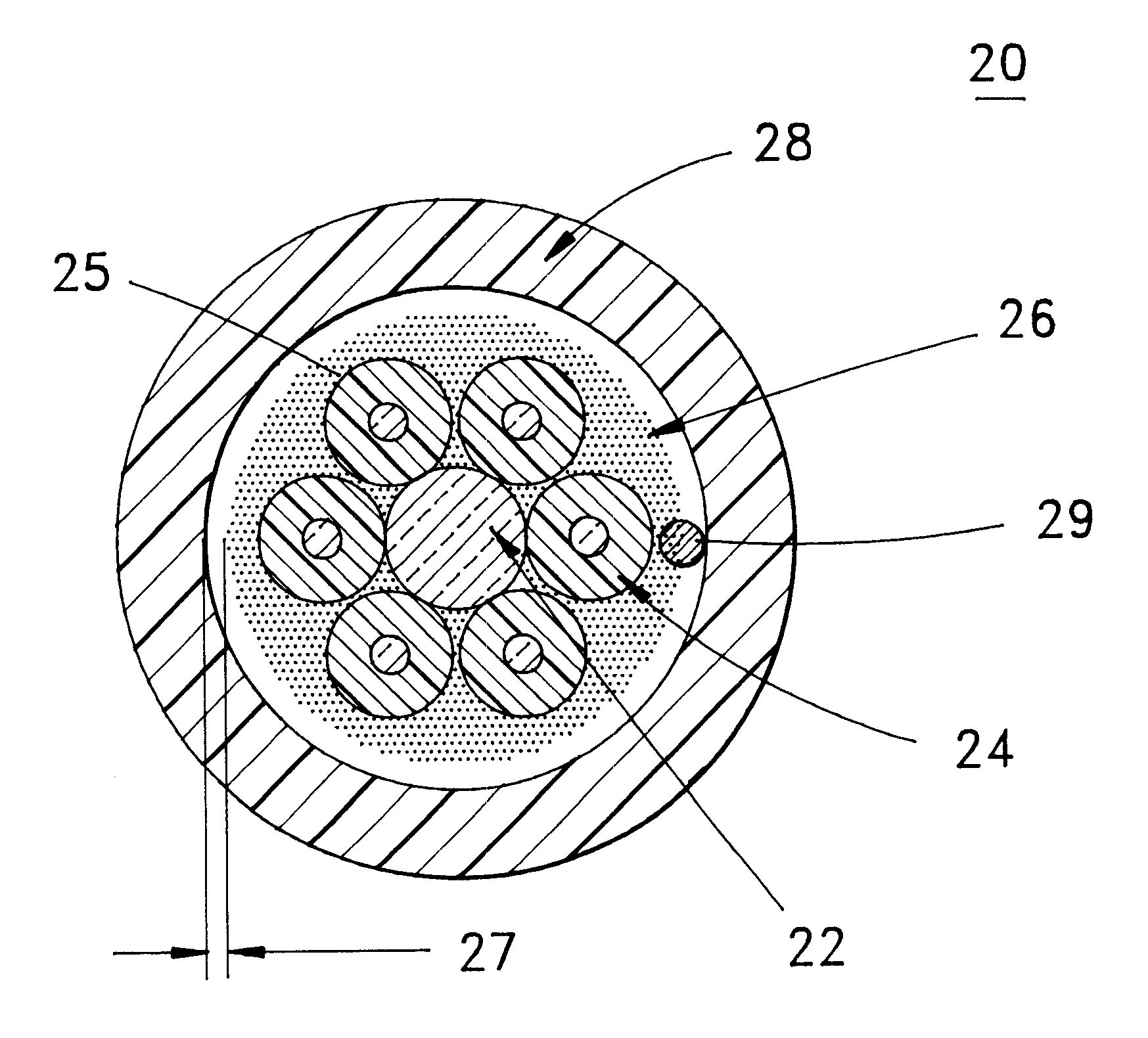

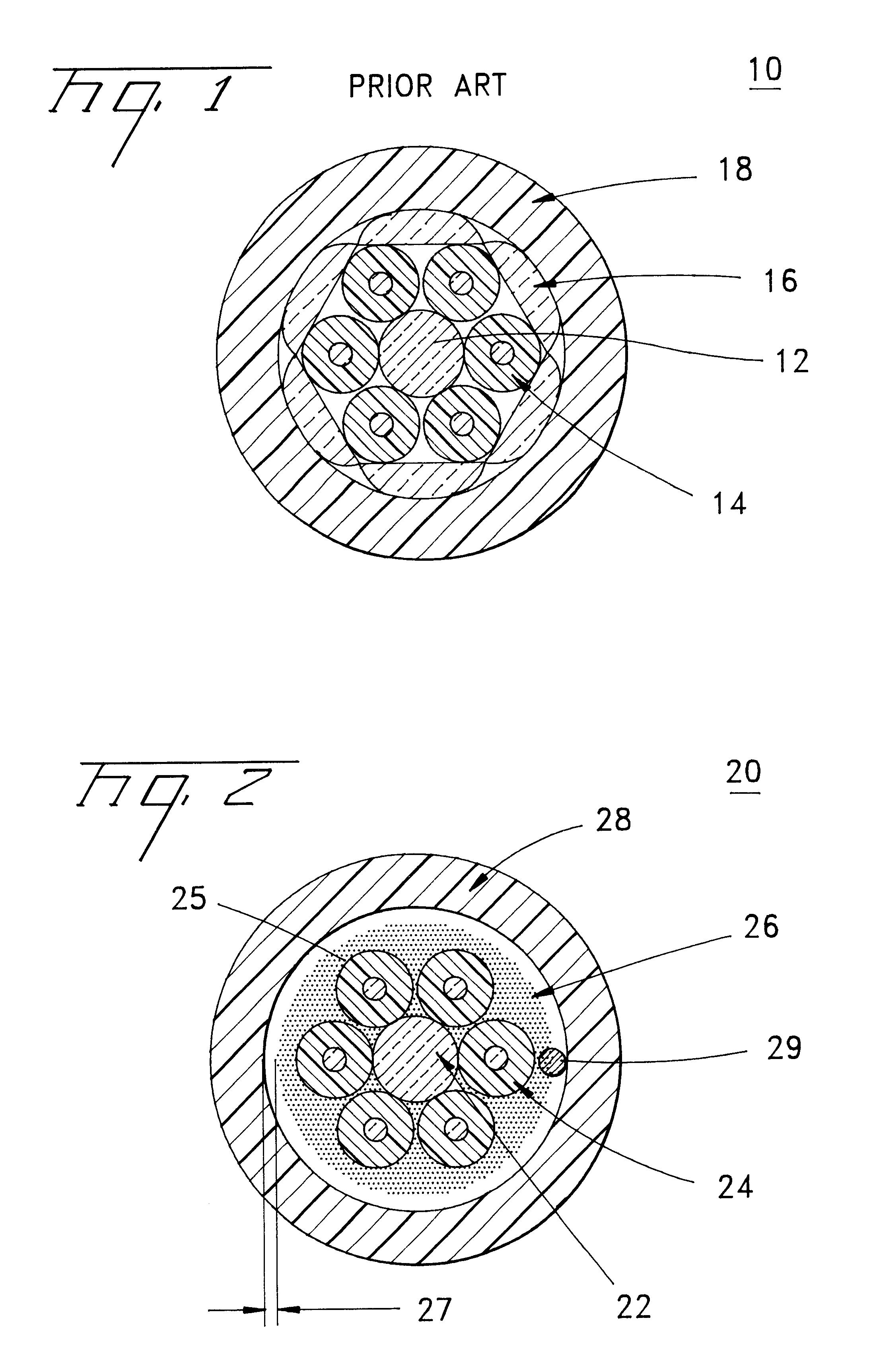

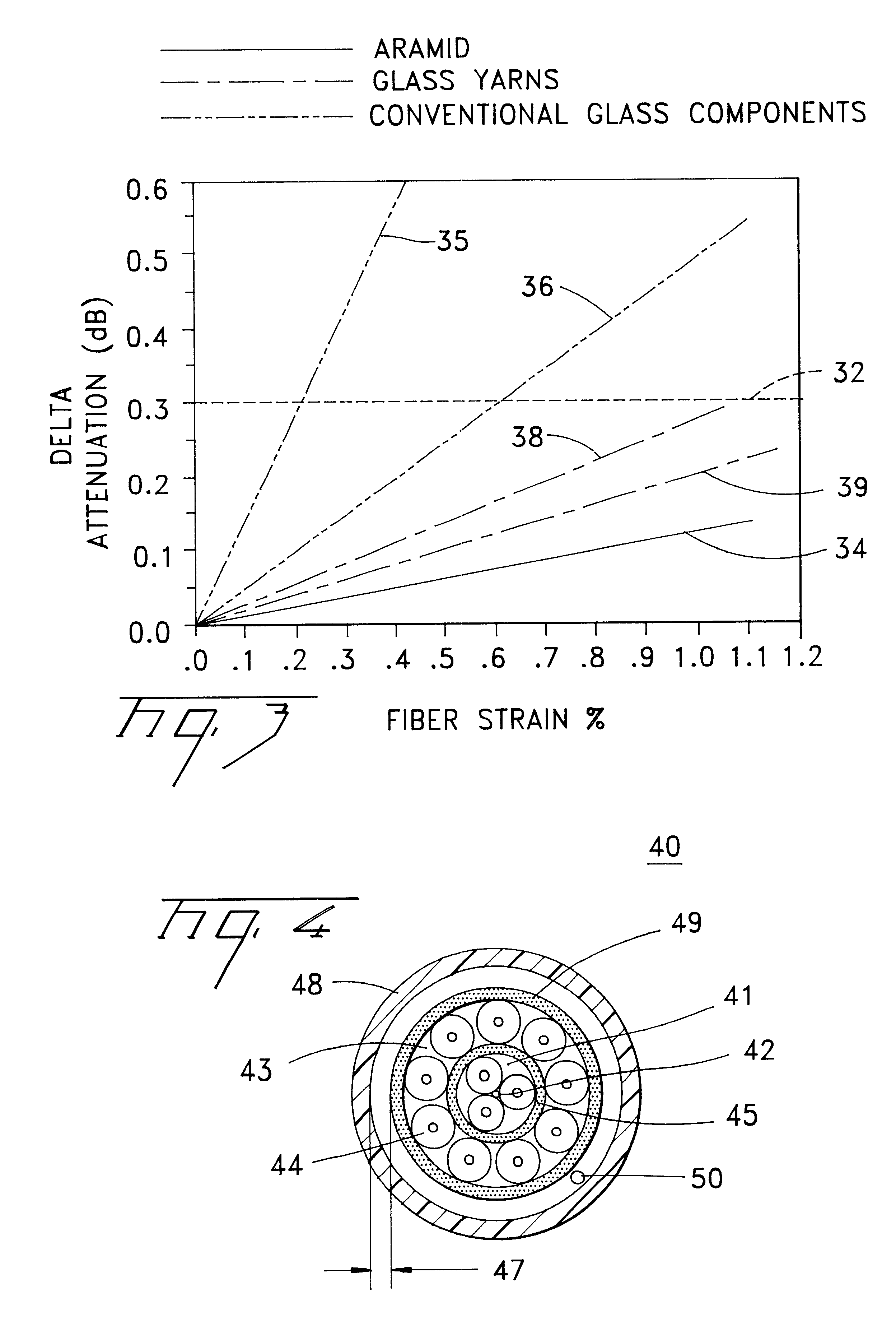

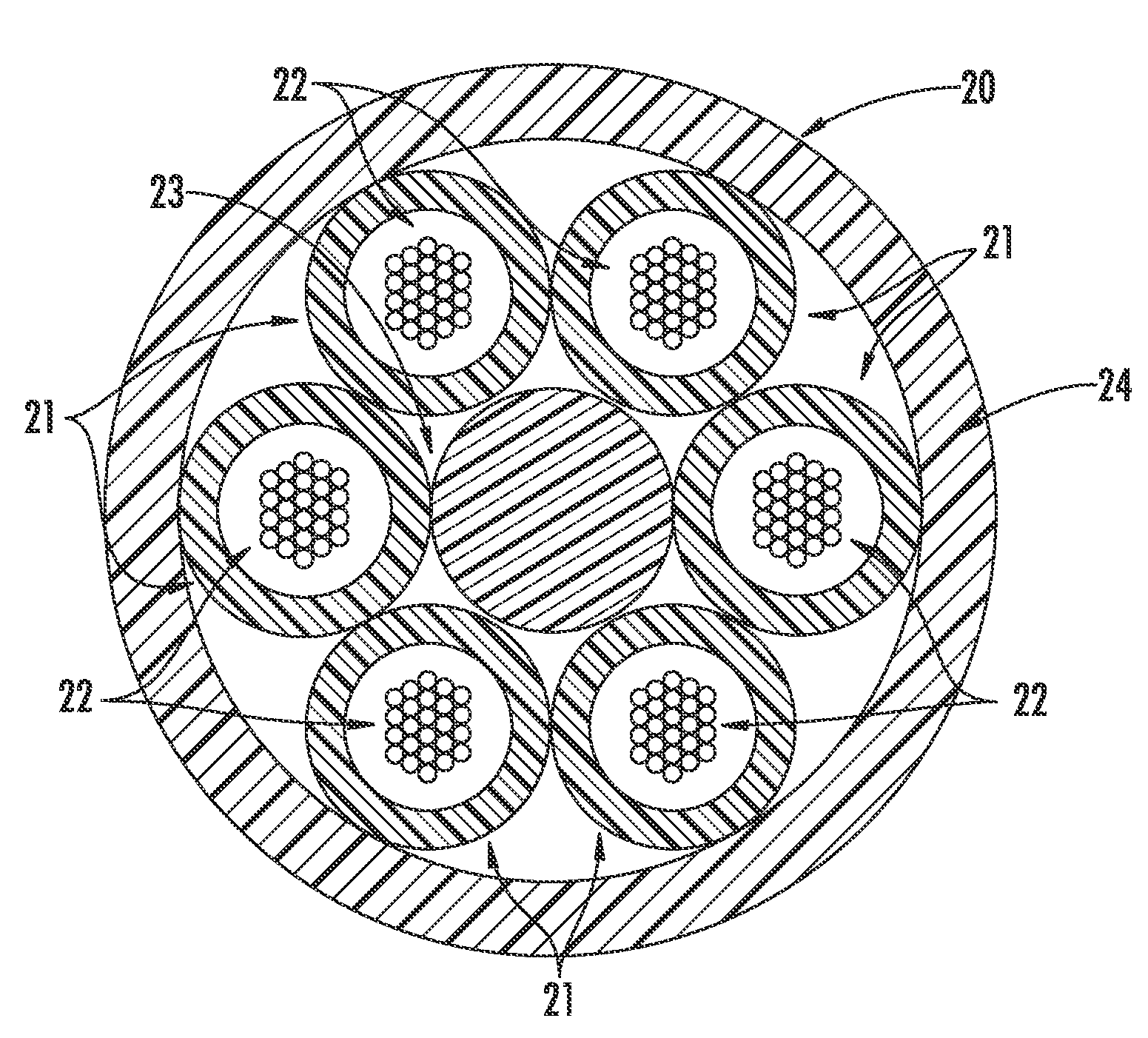

Fiber optic articles, assemblies, and cables having optical waveguides

ActiveUS20050013573A1Optical fibre with multilayer core/claddingFibre mechanical structuresFiberUltrasound attenuation

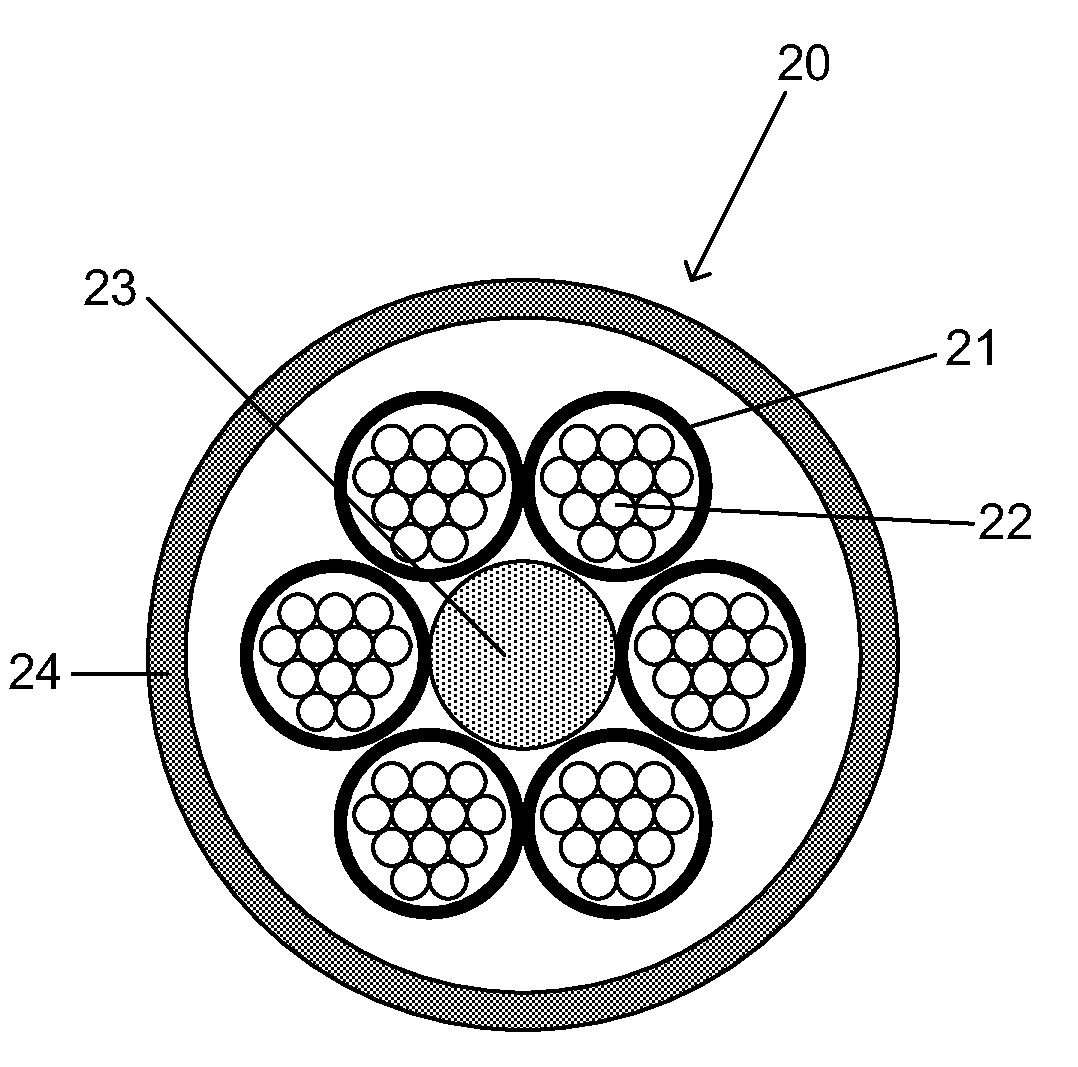

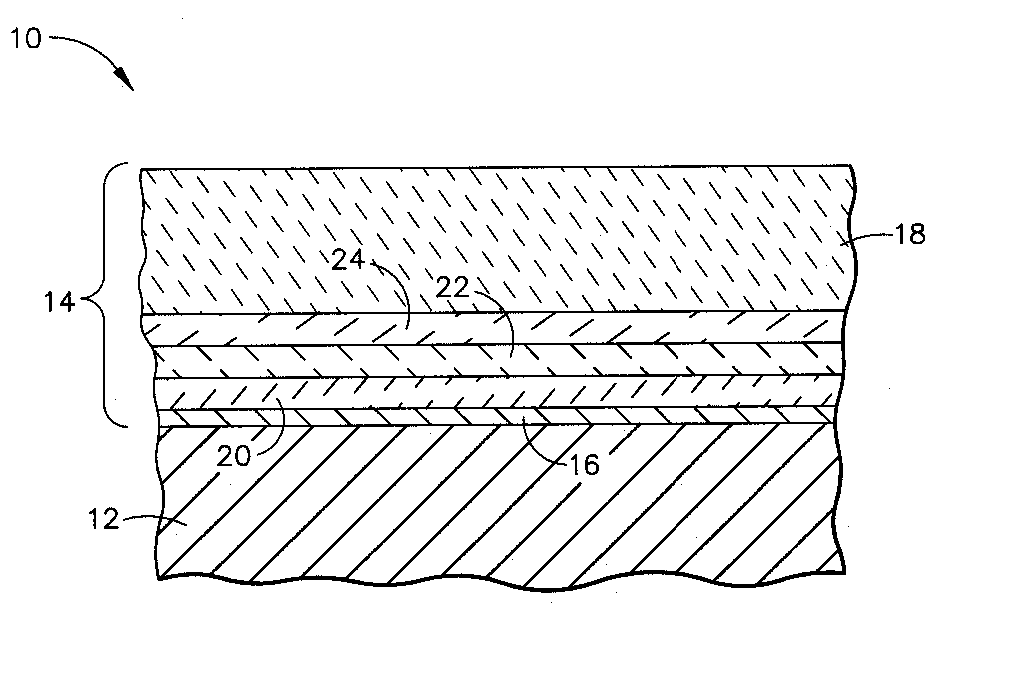

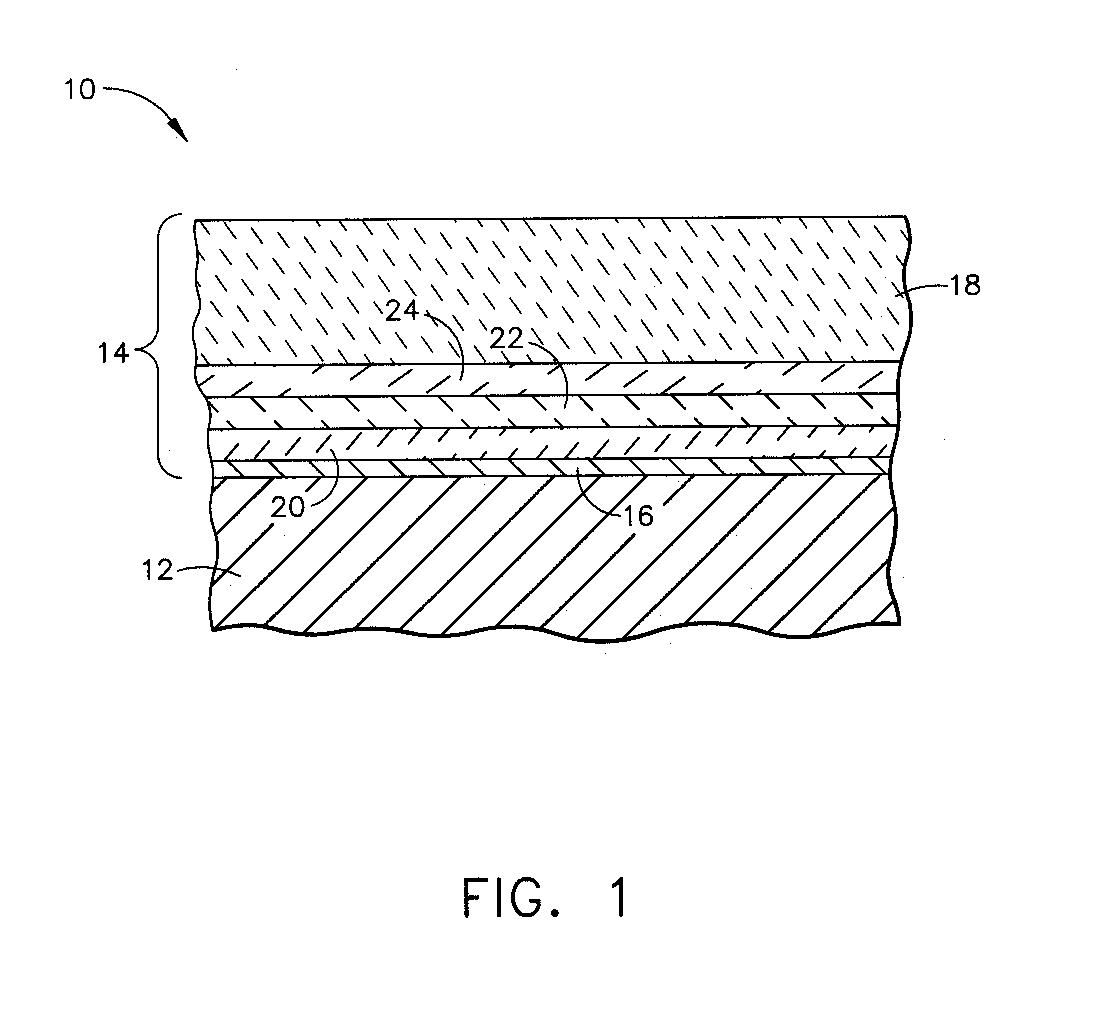

Fiber optic articles, assemblies, and cables preserve optical performance by using optical waveguides having a core, a cladding, and a coating system according to the present invention. Moreover, the optical articles, assemblies, and cables of the present invention may achieve performance levels that were previously unattainable, for instance, the present invention contemplates acceptable optical performance for wavelengths such as 1625 nm and higher. Additionally, articles, assemblies, and / or cables of the present invention advantageously preserve optical performance, i.e., have relatively low delta attenuation, when subjected to manufacturing processes and / or environmental conditions such as temperature cycling. In other words, the articles, assemblies, and cables can withstand increased stress / strain before having significant attenuation.

Owner:CORNING OPTICAL COMM LLC

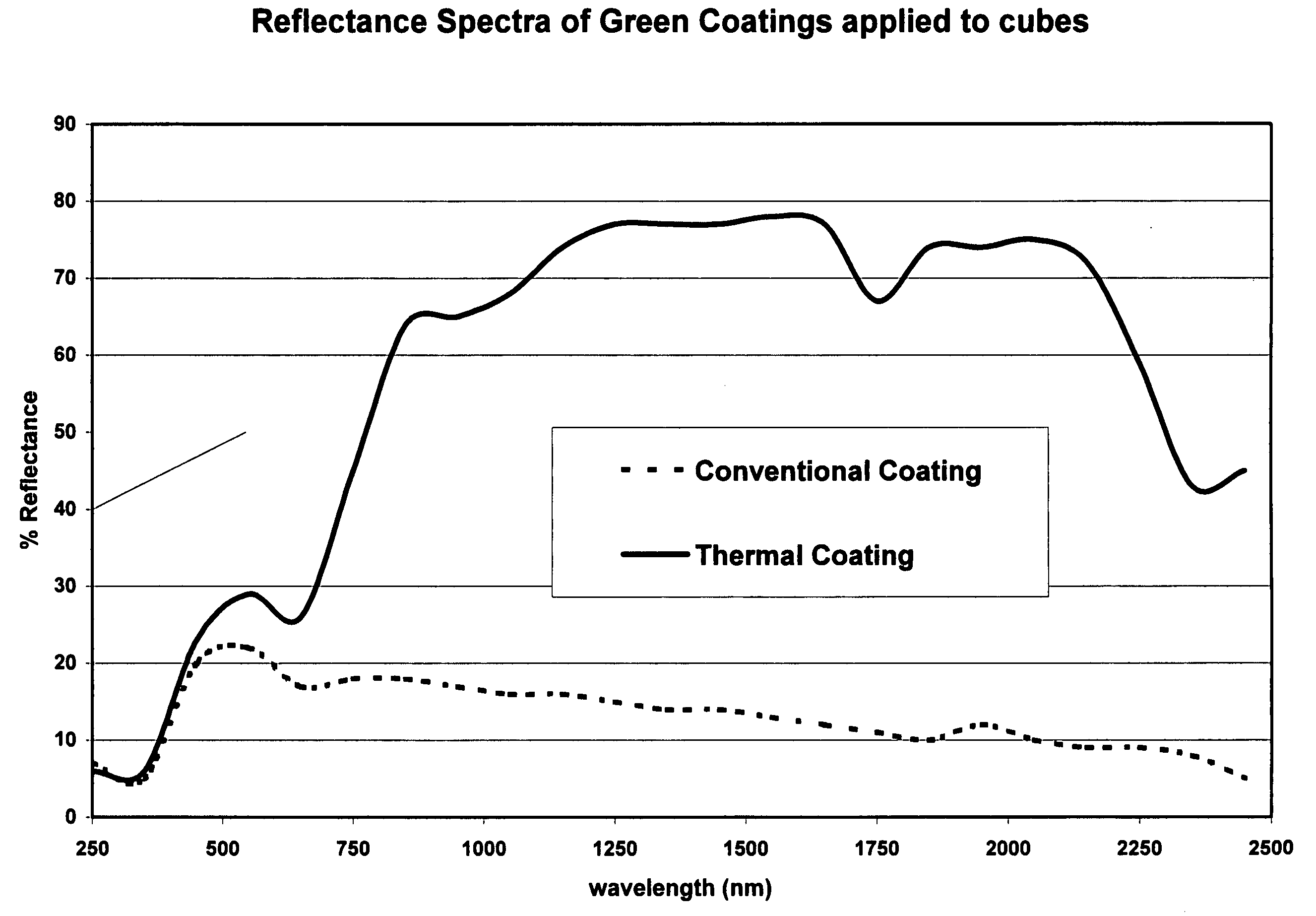

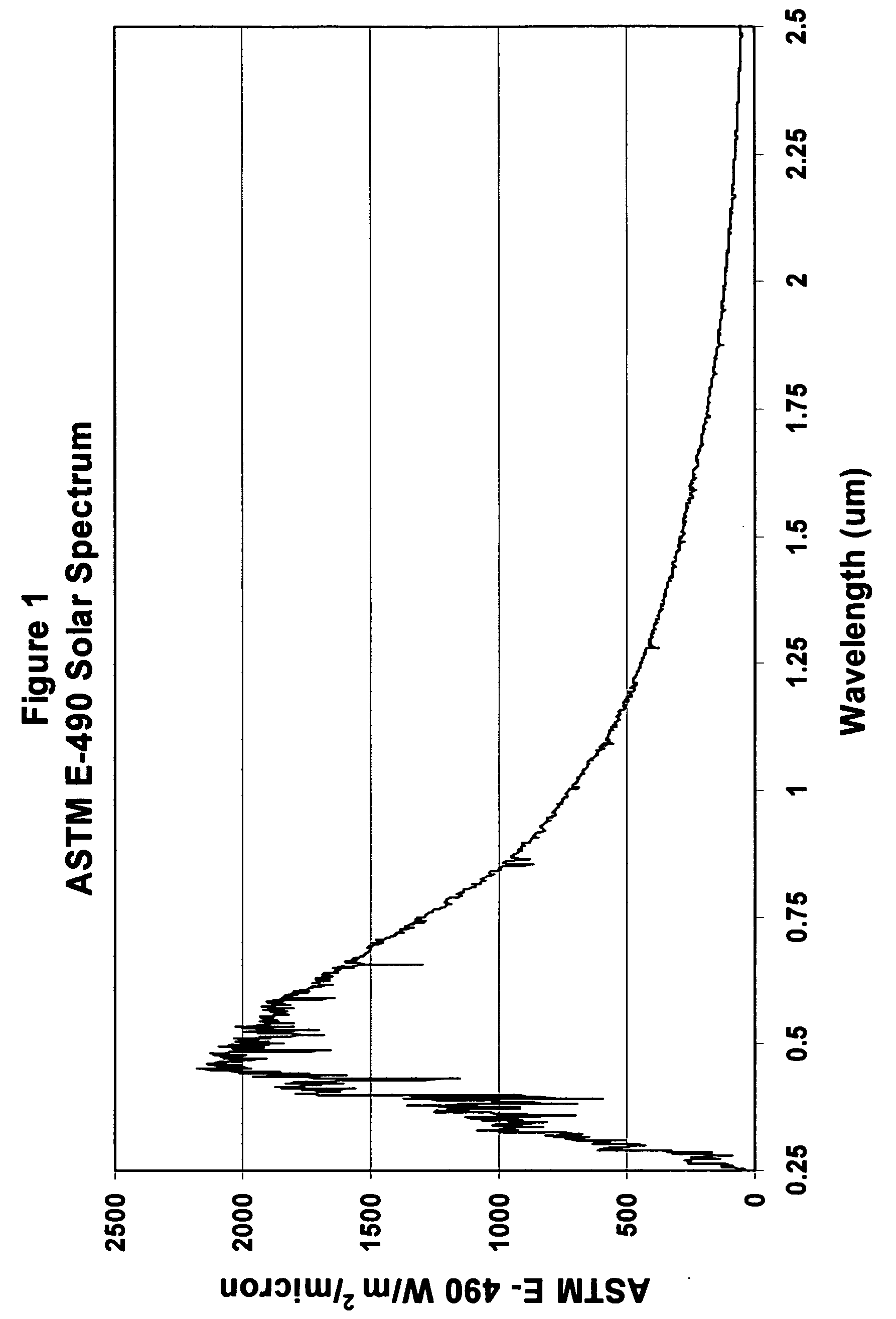

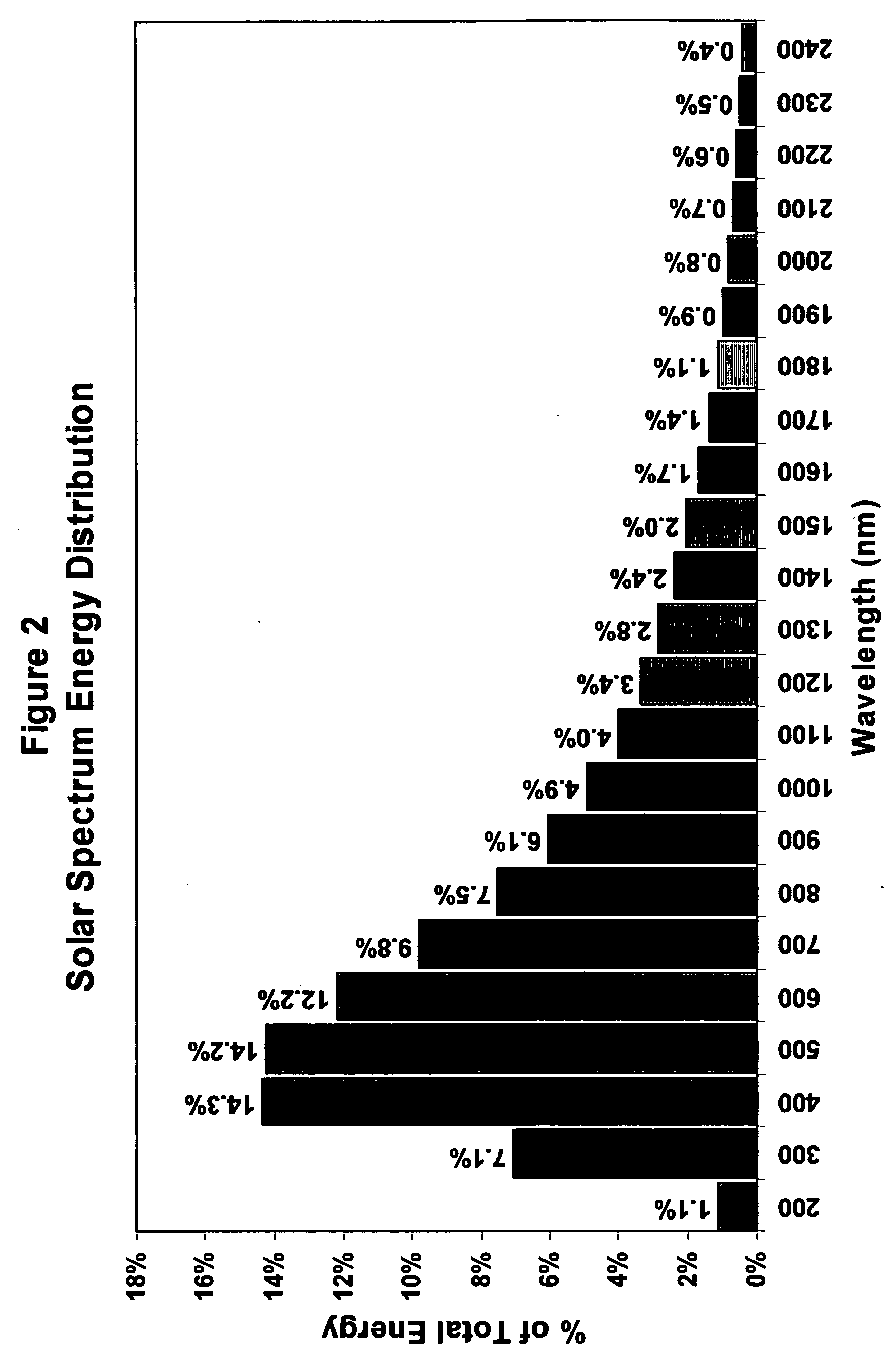

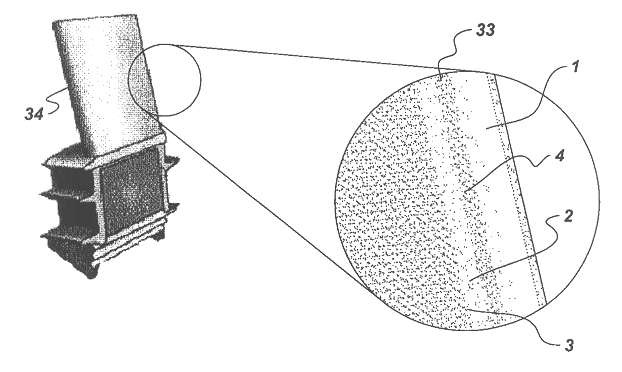

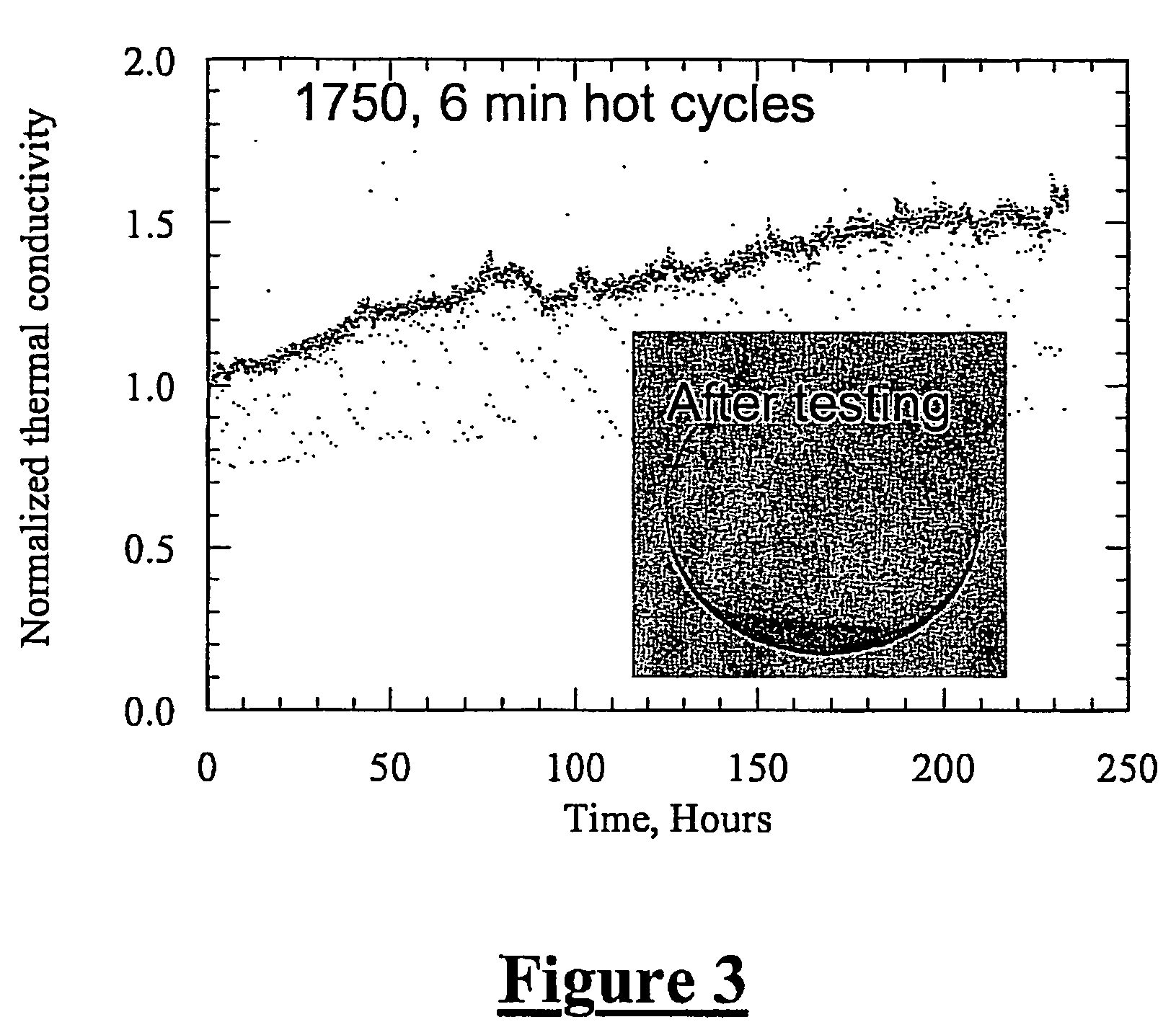

Composition of a thermaly insulating coating system

InactiveUS20050126441A1High infrared reflectivityLow thermal conductivityPigmenting treatmentCeramic layered productsCoating systemSolar spectra

A composition for a Coating System (paint) which forms an insulating material being designed to both reflect infrared radiation and have reduced thermal conductivity. The coating system may be either a single Thermal Coating or may be a Thermal Coating used in combination with a Thermal Primer. The Thermal Coating is formulated using conventional techniques and a resin used in paint manufacture, but utilizes primary pigments and extender mineral pigments which preferentially reflect in the infra red area of the solar spectrum. A method of characterizing particulate materials for their infra red reflectivity is described, which provides a means for preferential selection of particulate additives based on their relative visible light and infrared reflectivity. Additionally the incorporation of hollow micro-spheres is desired to reduce thermal conductivity. The Thermal Primer is designed to provide adhesion between the Thermal Coating and the substrate on which it is applied and uses conventional techniques to achieve those properties. However it has been found advantageous to incorporate hollow micro-spheres with low thermal conductivity, such as glass, ceramic or polymeric micro-spheres and / or an extender pigment with low thermal conductivity such as calcined clay to further reduce heat flow through the Coating System.

Owner:ANTHONY DAVID SKELHORN

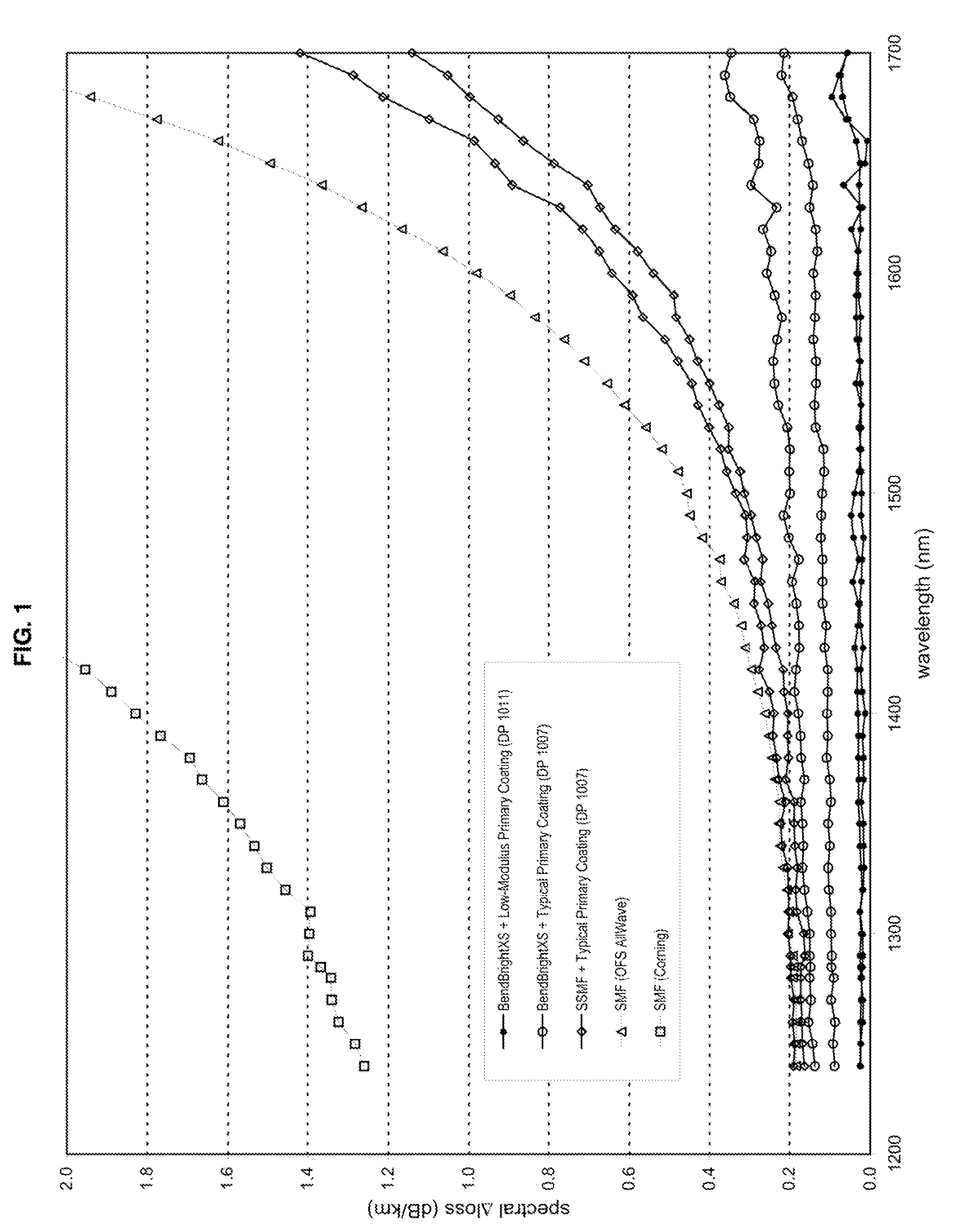

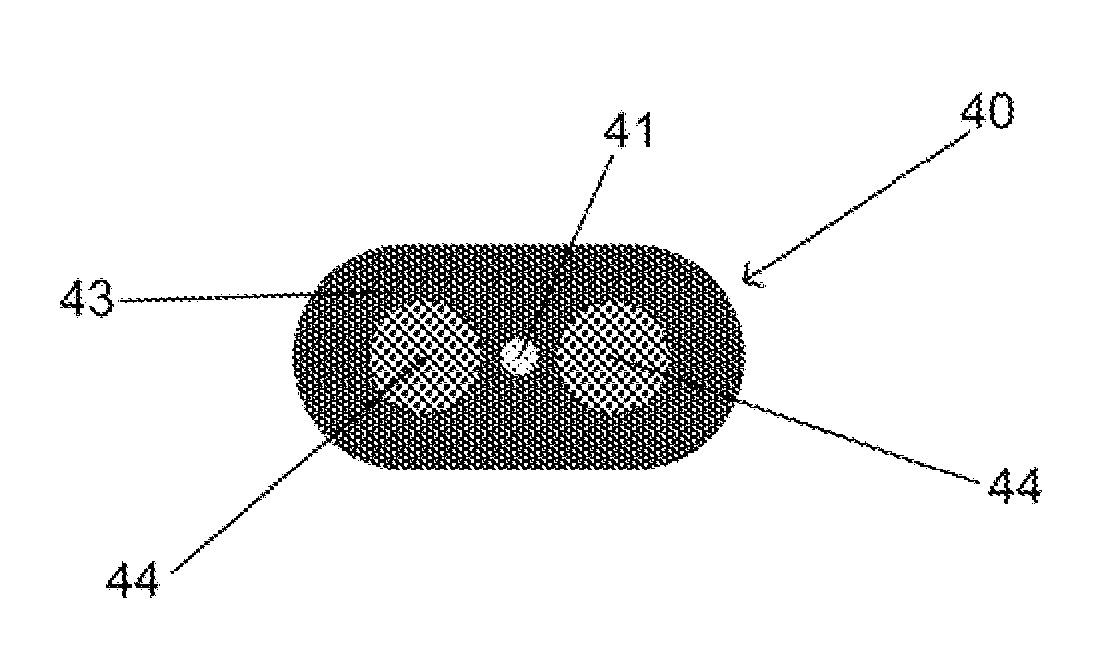

Fiber optic cables with strength members and methods of making the same

A fiber optic cable and method of manufacturing the same include at least one optical fiber component and at least one strength member disposed adjacent to said at least one optical fiber component. The at least one strength member includes a yarn and a jacket generally surrounding said at least one optical fiber component and said at least one strength member. The yarn includes a coating system having a percentage by weight, based on the dry weight of said yarn, of about 2.0% or less. Other embodiments can include a delta attenuation of about 0.3 dB or less over the range of about 0% to about 1.0% of optical fiber strain, a peak cable core pull-out force of about 1 newton or less, or a space disposed between a cable core and the jacket.

Owner:CORNING OPTICAL COMM LLC

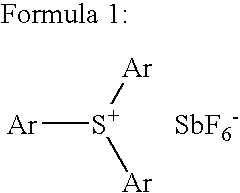

Method of forming a photoresist element

InactiveUS20060257785A1Nanostructure manufacturePhotosensitive material auxillary/base layersCoating systemMetallurgy

A method of forming a photoresist element comprising the steps of: preparing a hot melt photoresist mixture; applying the photoimageable hot melt composition to a film substrate using a slot die coating system; cooling the hot melt sufficiently to prevent flow; and applying a protective cover film to the opposite surface of the partially cooled composition, thereby forming a photoresist element.

Owner:MICROCHEM CORP

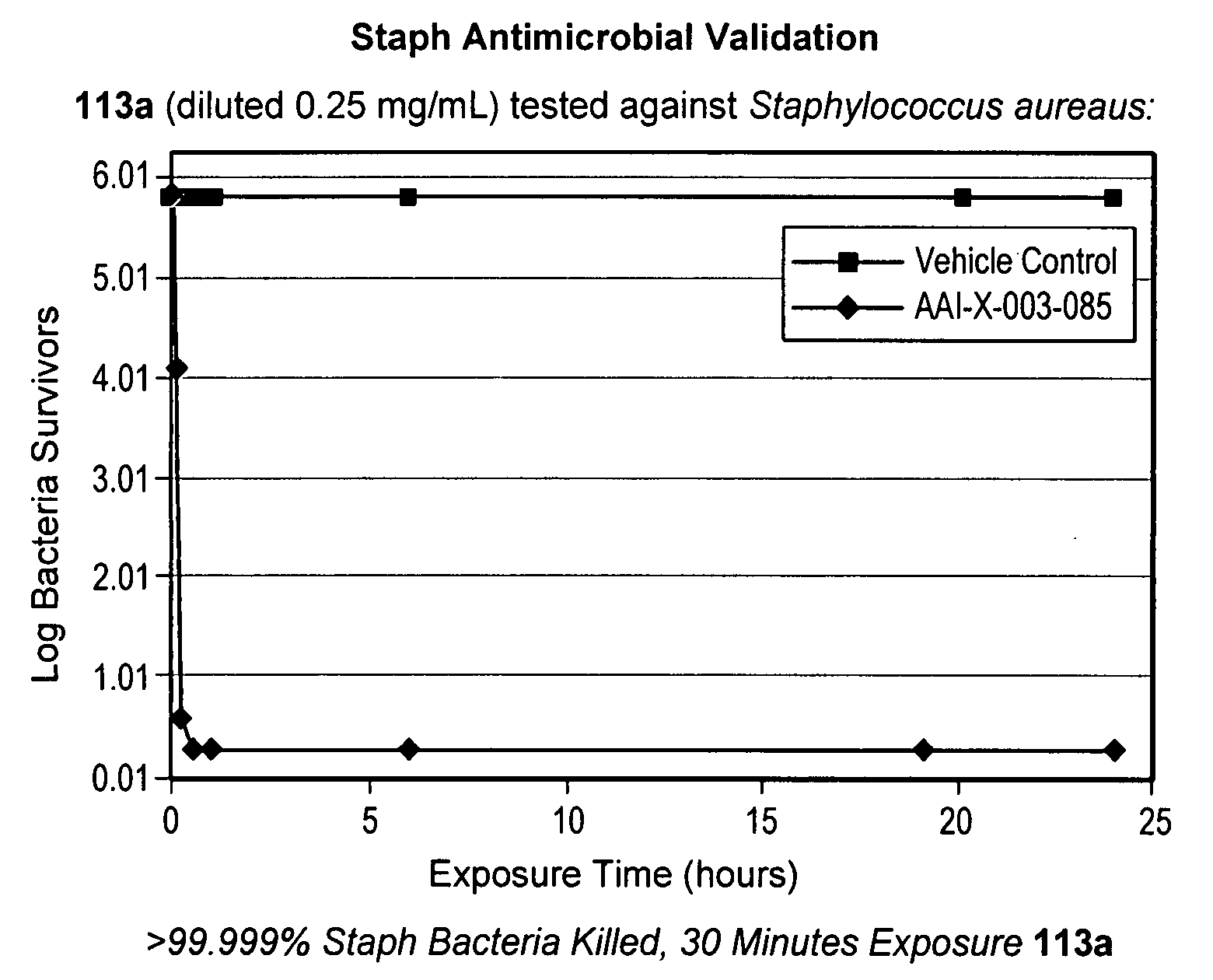

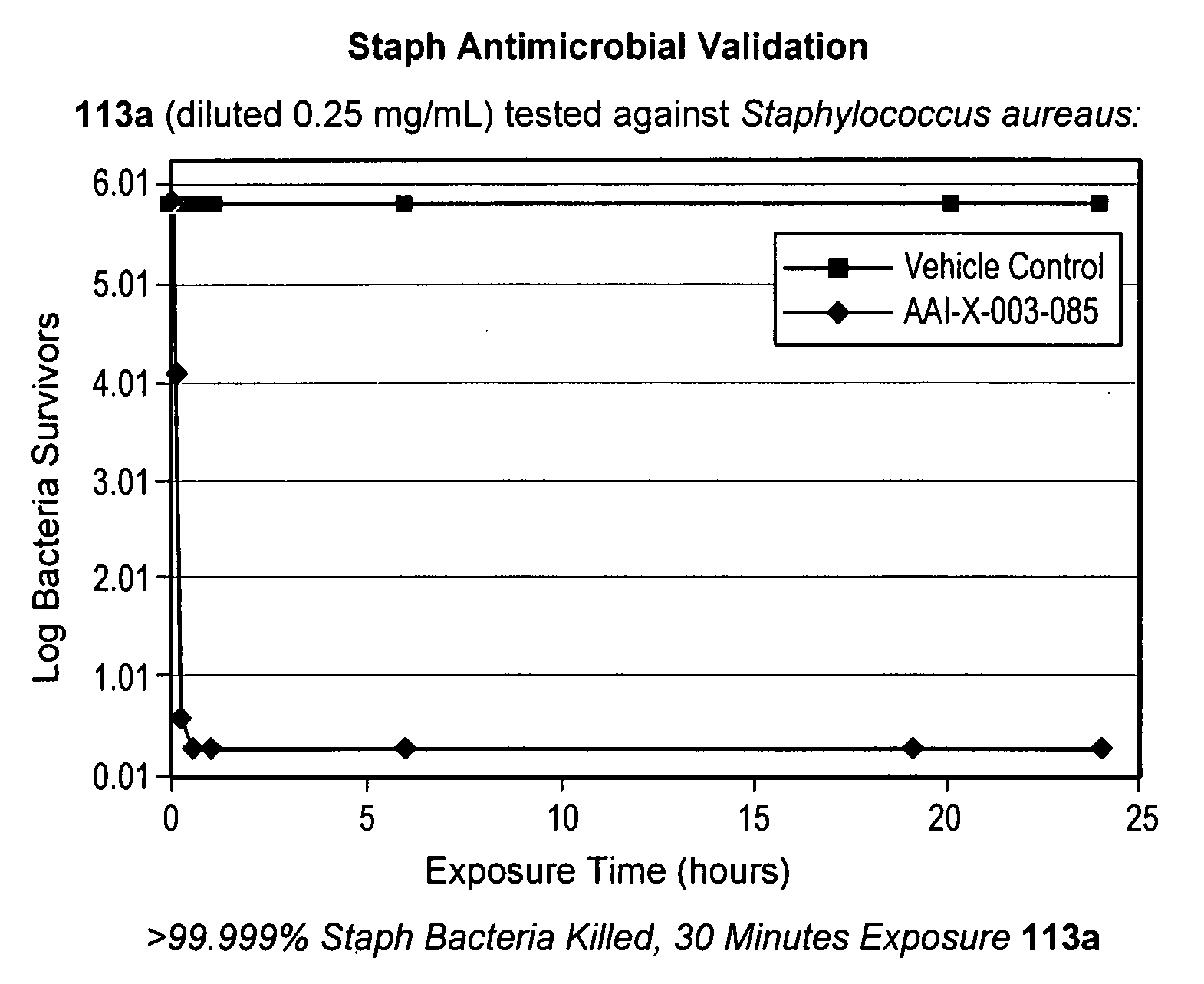

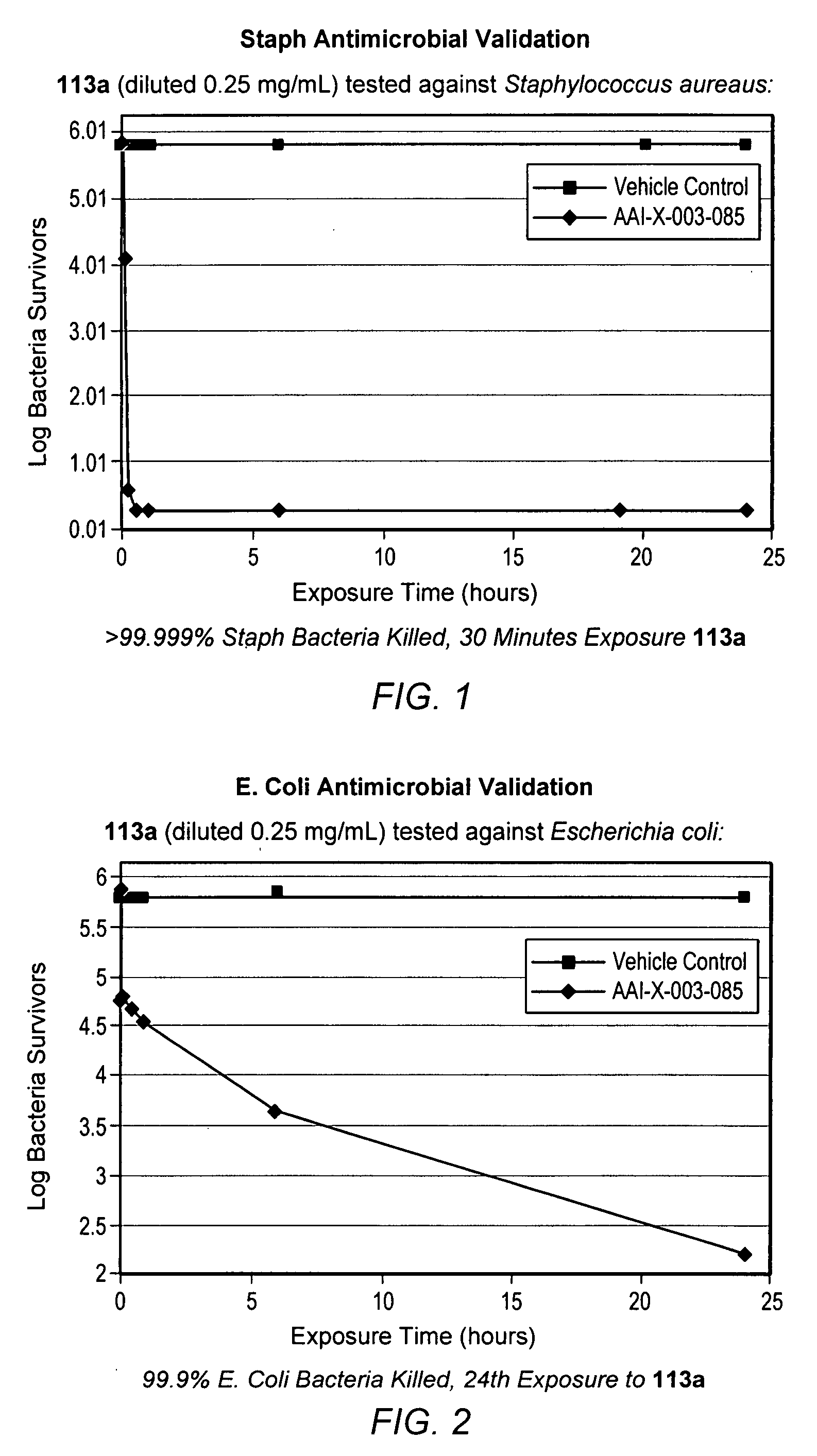

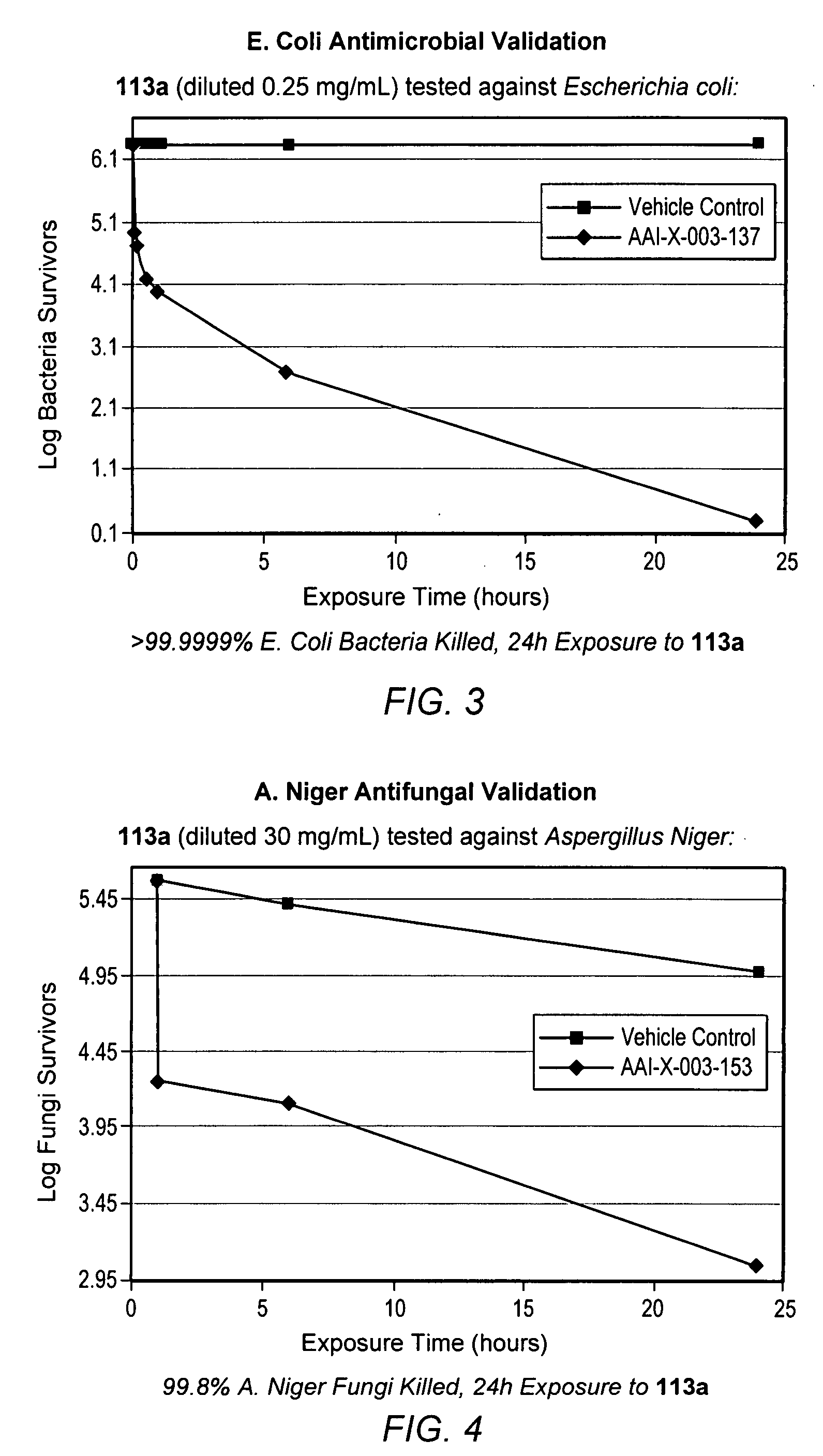

Methods and systems for coating a medical device

ActiveUS20080020127A1High activityImprove solubilityCosmetic preparationsMaterial nanotechnologyPolycyclic compoundAmmonium compounds

A coating system and method are described. In some embodiments, a system may include a composition. The composition may include one or more bridged polycyclic compounds. At least one of the bridged polycyclic compounds may include at least two cyclic groups, and at least two of the cyclic groups may include quaternary ammonium moieties. In some embodiments, a method may include applying a coating to a surface of a medical device. The coating may be antimicrobial. A coating may include antimicrobial bridged polycyclic compounds. Bridged polycyclic compounds may include quaternary ammonium compounds. Bridged polycyclic compounds based coating systems may impart self-cleaning properties to a surface.

Owner:ALLACCEM

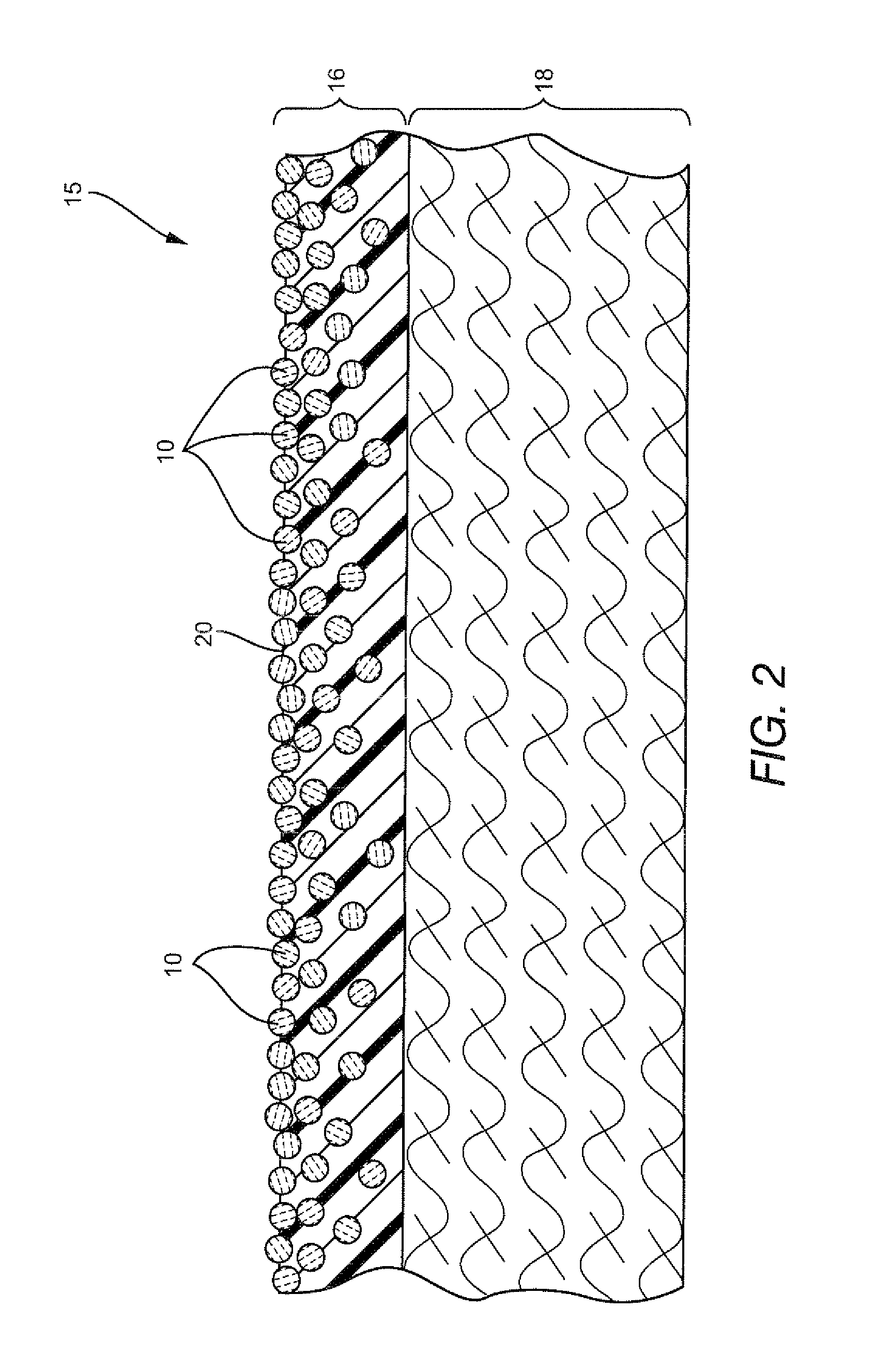

Optical-Fiber Loose Tube Cables

ActiveUS20100092140A1Improve protectionEasily matedGlass optical fibreFibre mechanical structuresGlass fiberFiber

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness.The improved coating system provides optical fibers that are useful in buffer tubes and cables having relatively high filling coefficients and fiber counts.

Owner:DRAKA COMTEQ BV

Bisphenol a and aromatic glycidyl ether-free coatings

ActiveUS20070036903A1Good metal substrateGood inter-coat adhesionLiquid surface applicatorsSynthetic resin layered productsPolyesterMeth-

Disclosed are Bisphenol A (BPA), Bisphenol F, Bisphenol A diglycidyl ether (BADGE), and Bisphenol F diglycidyl ether (BFDGE)-free coating compositions for metal substrates including an under-coat composition containing a polyester (co)polymer, and an under-coat cross-linker; and an over-coat composition containing a poly(vinyl chloride) (co)polymer dispersed in a substantially nonaqueous carrier liquid, an over-coat cross-linker, and a functional (meth)acrylic (co)polymer. Also provided is a method of coating a metal substrate using the BPA, BPF, BADGE and BFDGE-free coating system to produce a hardened protective coating useful in fabricating metal storage containers. The coated substrate is particularly useful in fabricating multi-part foodstuffs storage containers with “easy-open” end closures.

Owner:SWIMC LLC

ADSS Cables with High-Performance Optical Fiber

ActiveUS20100092138A1Improve protectionEasily matedGlass optical fibreFibre mechanical structuresGlass fiberCoating system

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness.The improved coating system provides optical fibers that are useful in all-dielectric self-supporting (ADSS) cables.

Owner:DRAKA COMTEQ BV

Reduced-Diameter Ribbon Cables with High-Performance Optical Fiber

ActiveUS20100135625A1Improve protectionEasily matedGlass optical fibreFibre mechanical structuresGlass fiberFiber

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness. The secondary coating provides improved ribbon characteristics for structures that are robust, yet easily entered (i.e., separated and stripped).The optional dual coating is specifically balanced for superior heat stripping in fiber ribbons, with virtually no residue left behind on the glass. This facilitates fast splicing and terminations. The improved coating system provides optical fibers that offer significant advantages for deployment in most, if not all, fiber-to-the-premises (FTTx) systems.

Owner:DRAKA COMTEQ BV

Reduced-Diameter, Easy-Access Loose Tube Cable

ActiveUS20100092139A1Improve protectionEasily matedGlass optical fibreOptical fibre with multilayer core/claddingLow modulusCoating system

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness.The improved coating system provides optical fibers that are useful in relatively thin-walled, low-modulus buffer tubes (i.e., “flextubes”) that can be readily accessed without special tools.

Owner:DRAKA COMTEQ BV

Reduced-Size Flat Drop Cable

ActiveUS20100135624A1Improve protectionEasily matedGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberCoating system

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness.The improved coating system provides optical fibers that are useful in reduced-size drop cables.

Owner:DRAKA COMTEQ BV

Functional coatings and designs for medical implants

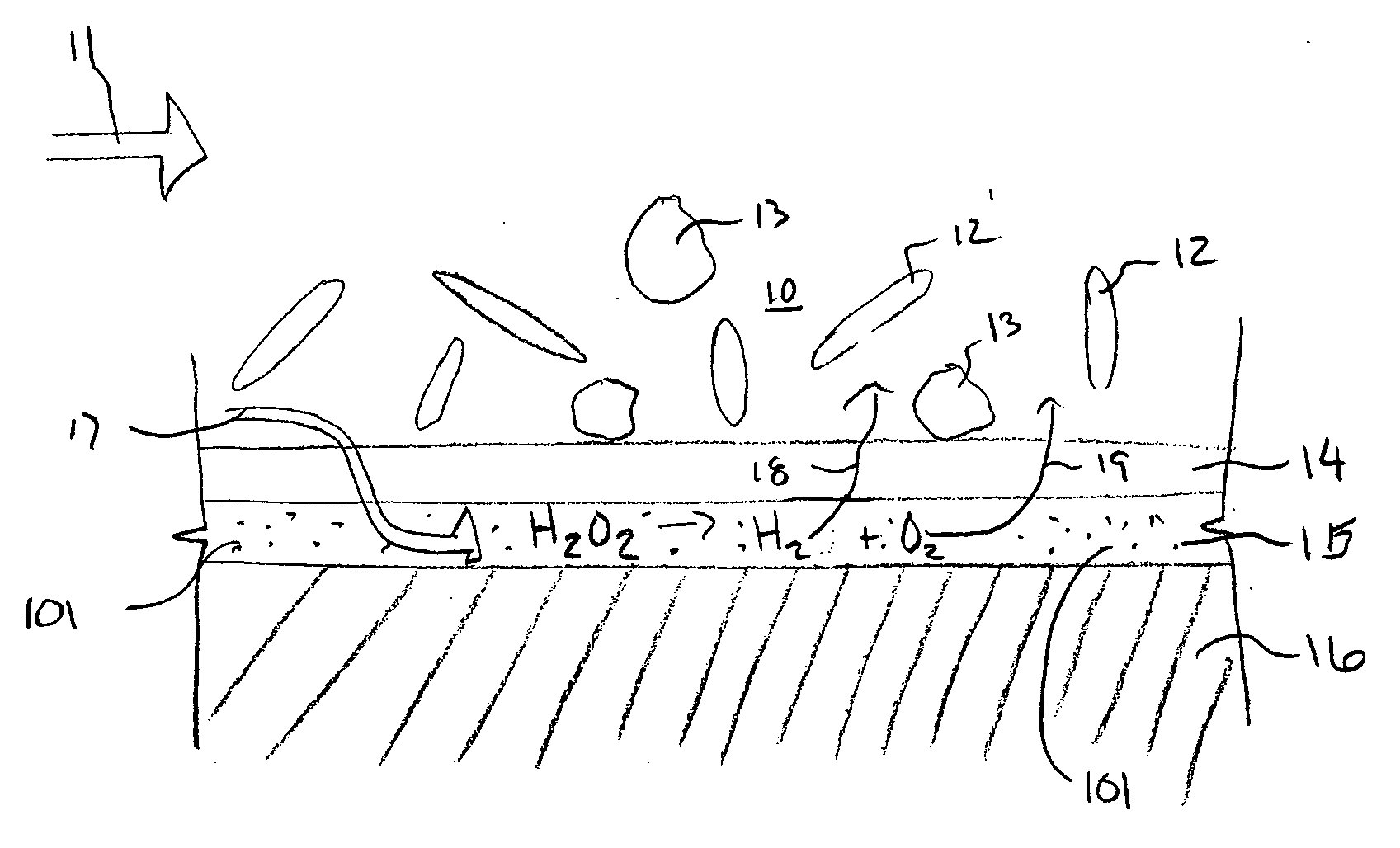

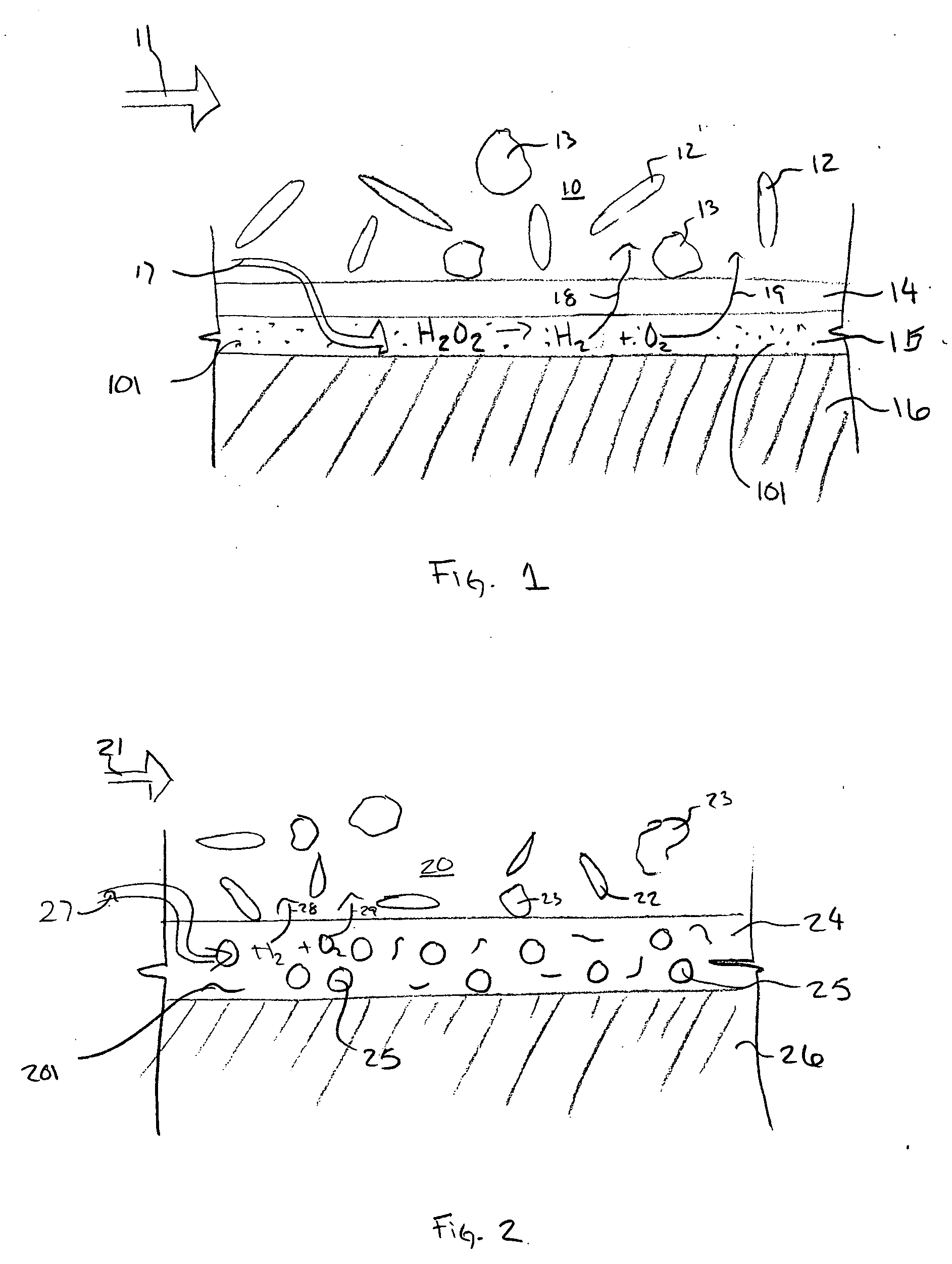

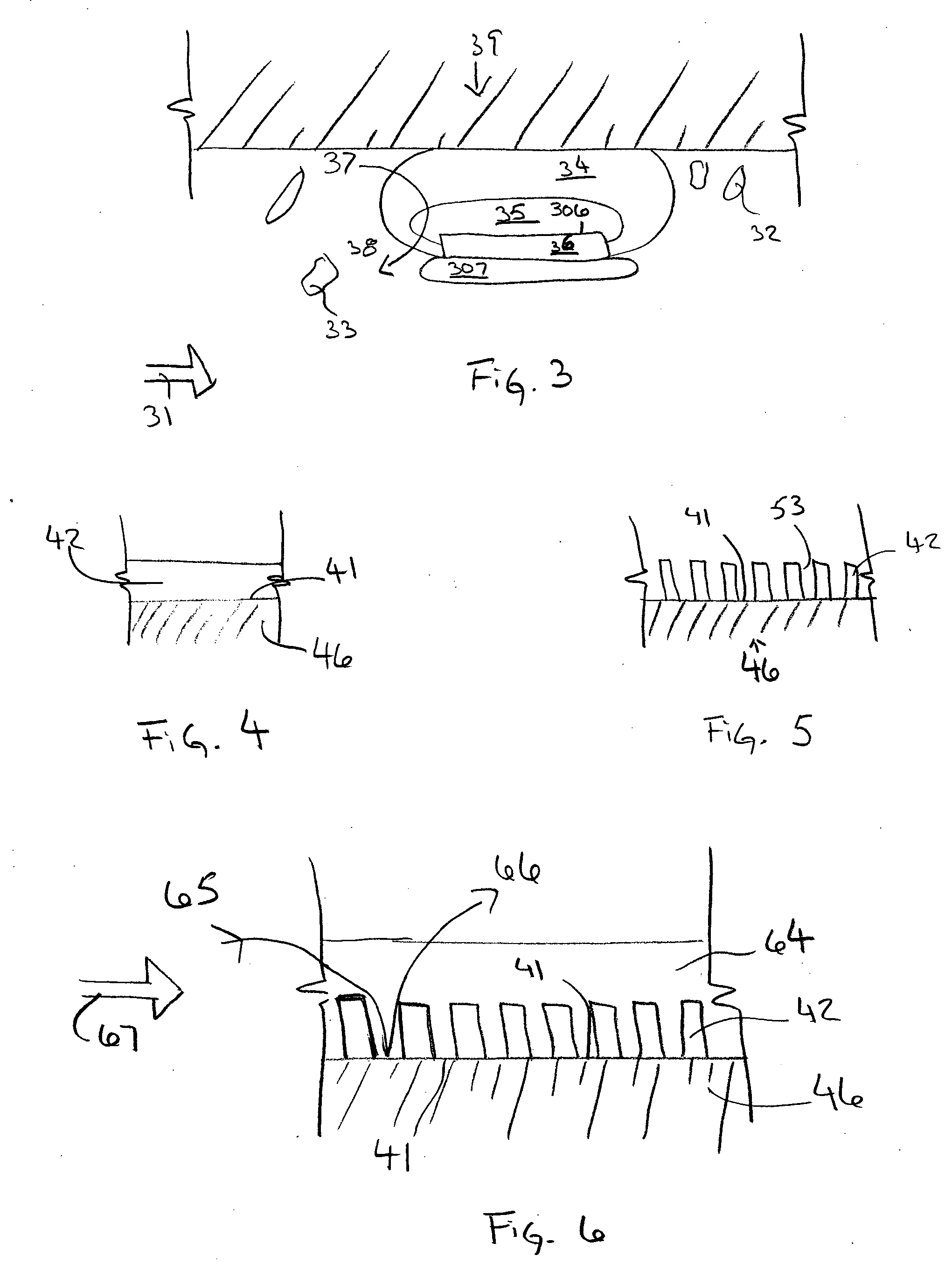

InactiveUS20050159805A1Function increaseFunctionality can be affectedStentsSurgeryHydrogen peroxide breakdownHydrogen

The present invention regards an implant that may be uniquely shaped to enhance its functionality and that may also be coated with a coating system that affects its functionality. In one embodiment the implant may have a first surface that is covered with a filter material, the filter material being in contact with a catalyst that promotes the decomposition of Hydrogen Peroxide into Hydrogen and Oxygen. In this and other embodiments, this filter material may be made from ceramic materials and may be meso-porous. In another embodiment, the implant may or may not be coated with this system and may have at least one strut with a tapered cross-section, the cross-section becoming smaller in area when moving from a reference point on the inside of the implant to the outside of the implant.

Owner:BOSTON SCI SCIMED INC

Single-Fiber Drop Cables for MDU Deployments

ActiveUS20100135623A1Improve protectionEasily matedGlass optical fibreFibre mechanical structuresGlass fiberCoating system

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness.The improved coating system provides optical fibers that offer significant advantages to single-fiber drop cables, such as those employed for Multiple Dwelling Unit (MDU) applications.

Owner:DRAKA COMTEQ BV

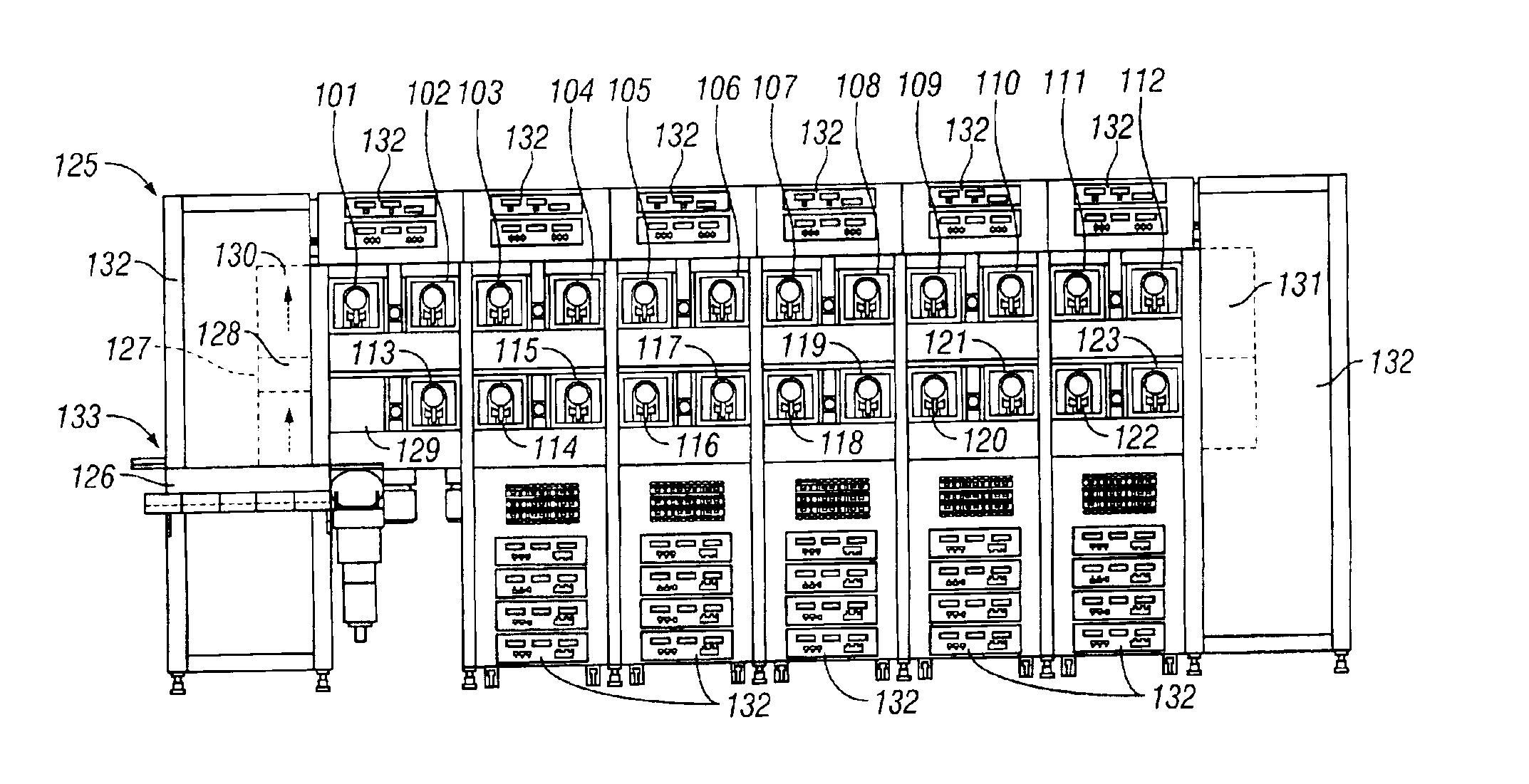

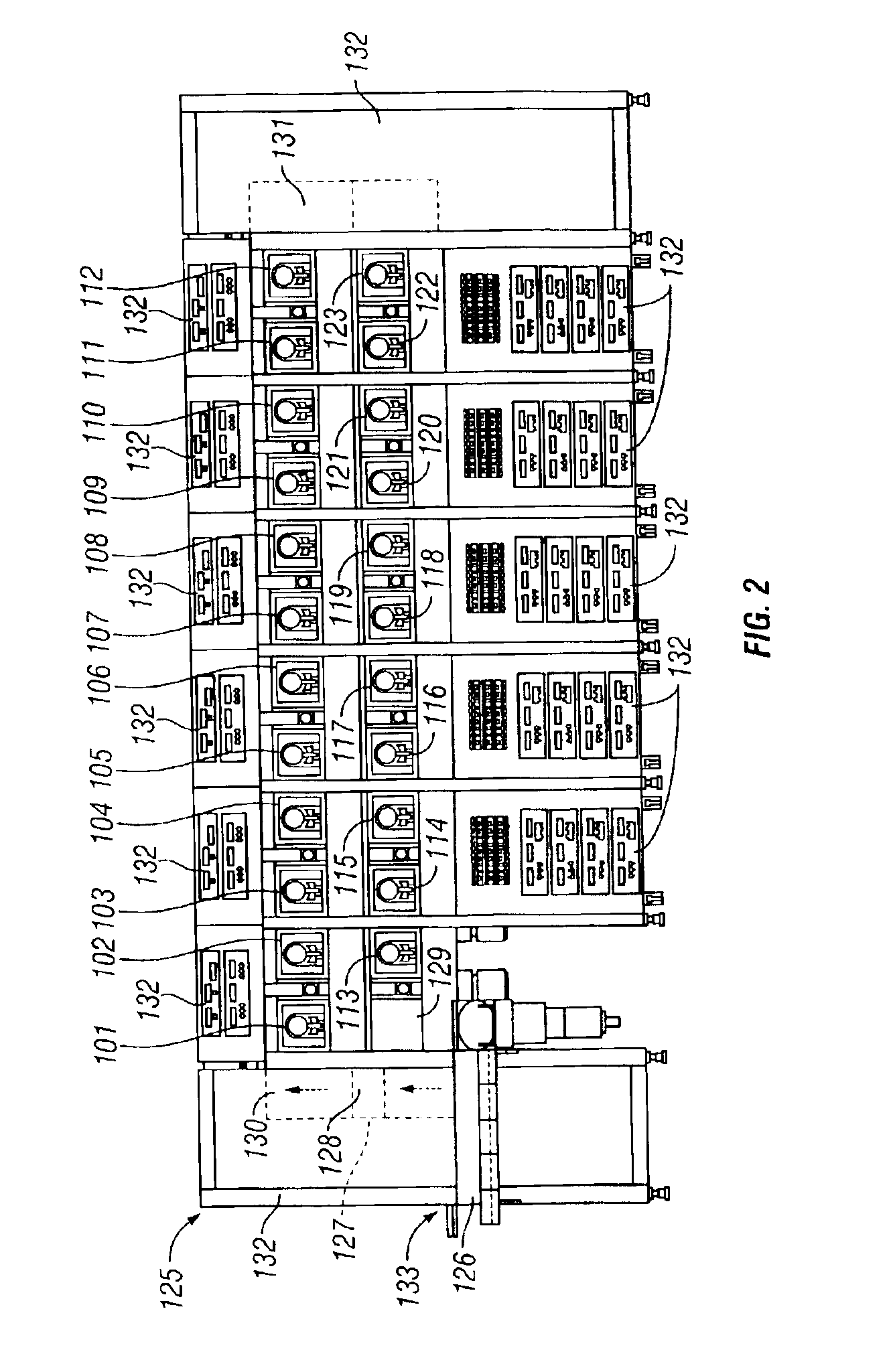

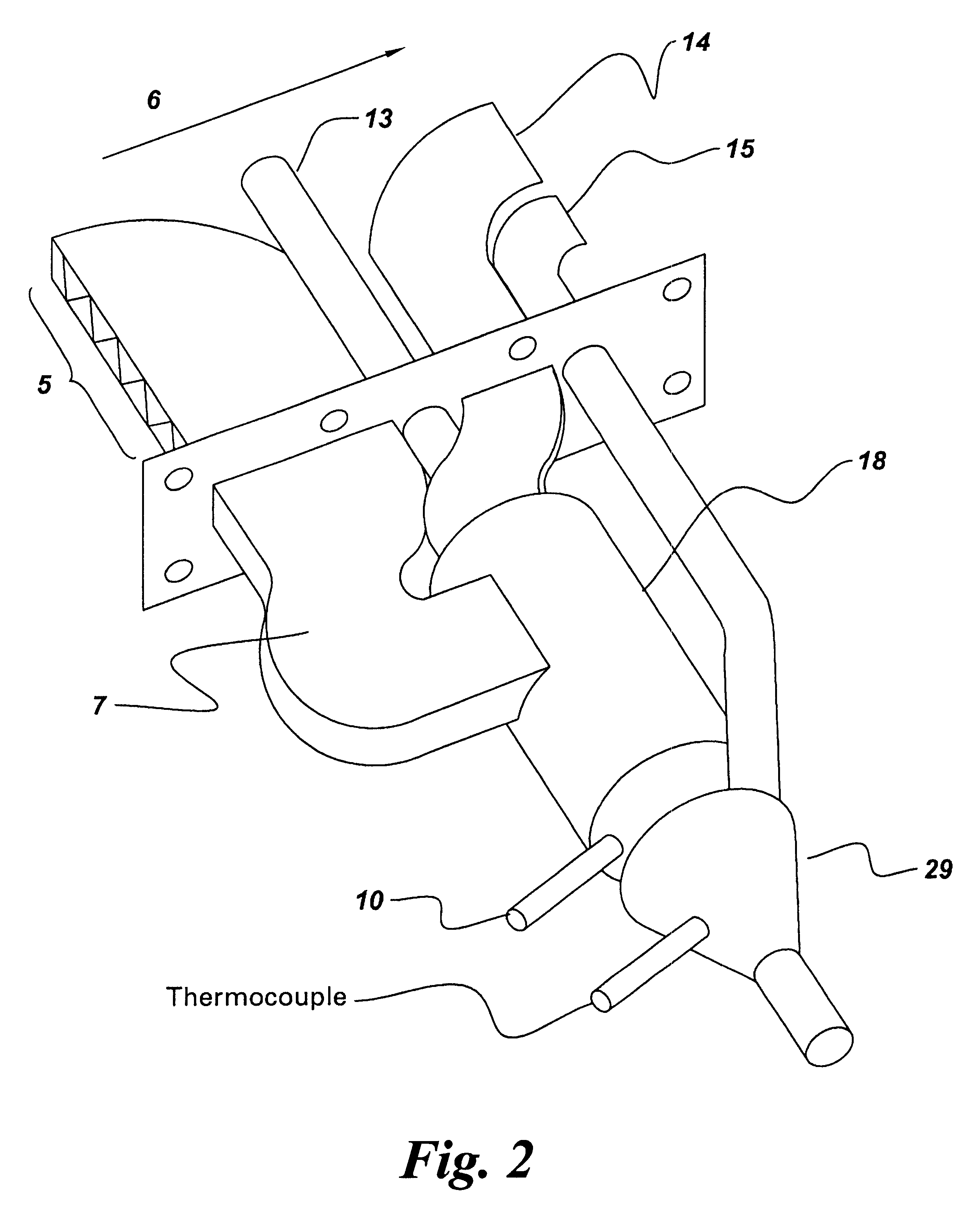

Disk coating system

InactiveUS6919001B2Improve throughputSmall footprintVacuum evaporation coatingSemiconductor/solid-state device manufacturingCoating systemEngineering

There is described a disk processing and manufacturing equipment in which the processing chambers are stacked on top of each other and in which the disks move through the system on disk carriers which are adjustable to take disks of varying sizes. The disks enter the system through a load zone and are then installed into disk carriers. They move in the carriers sequentially through processing chambers at one level and then move to the other level in a lift or elevator. At this other level, the disks again move sequentially through the system on that level and then exit at an unload zone.

Owner:INTEVAC

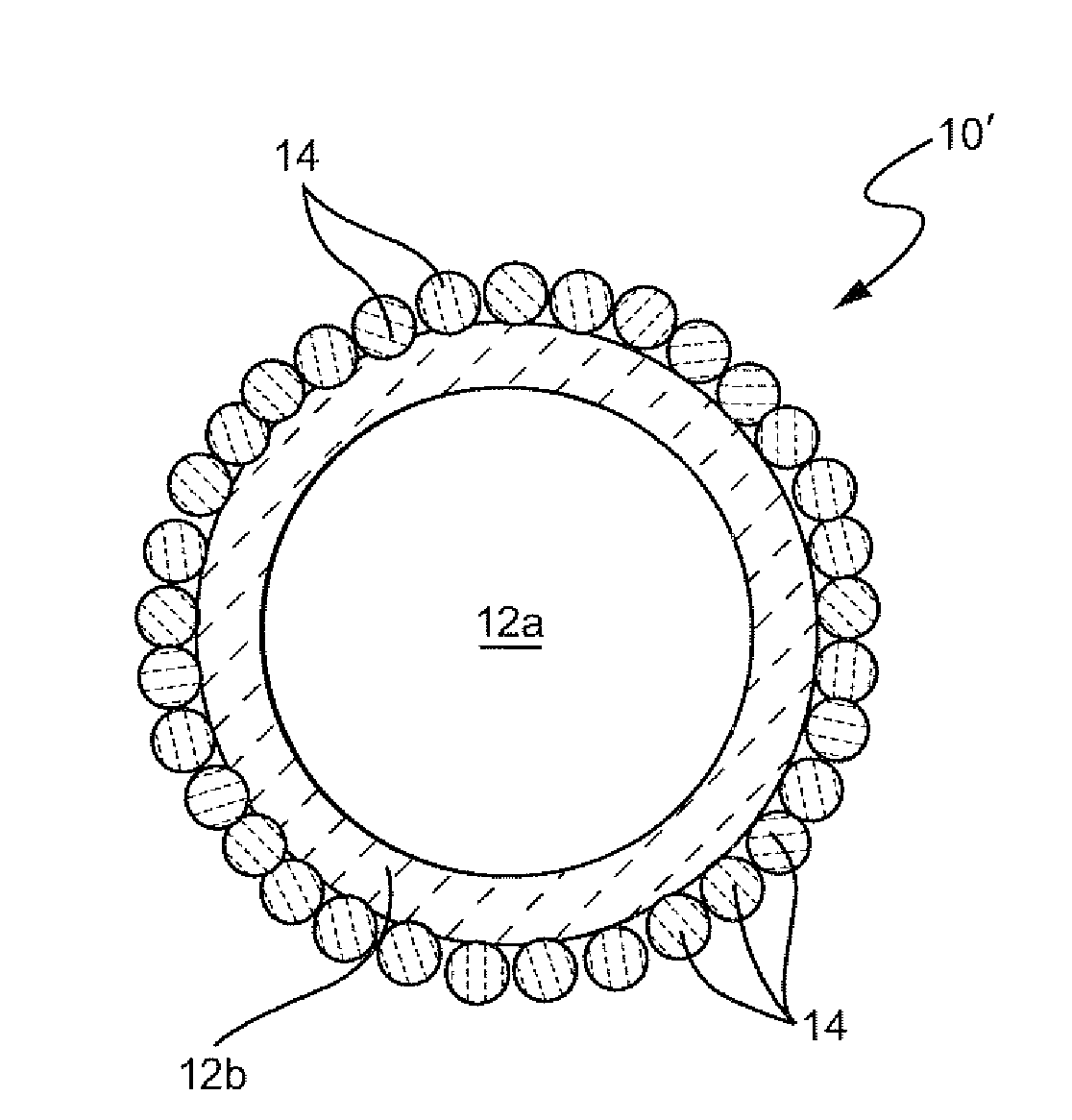

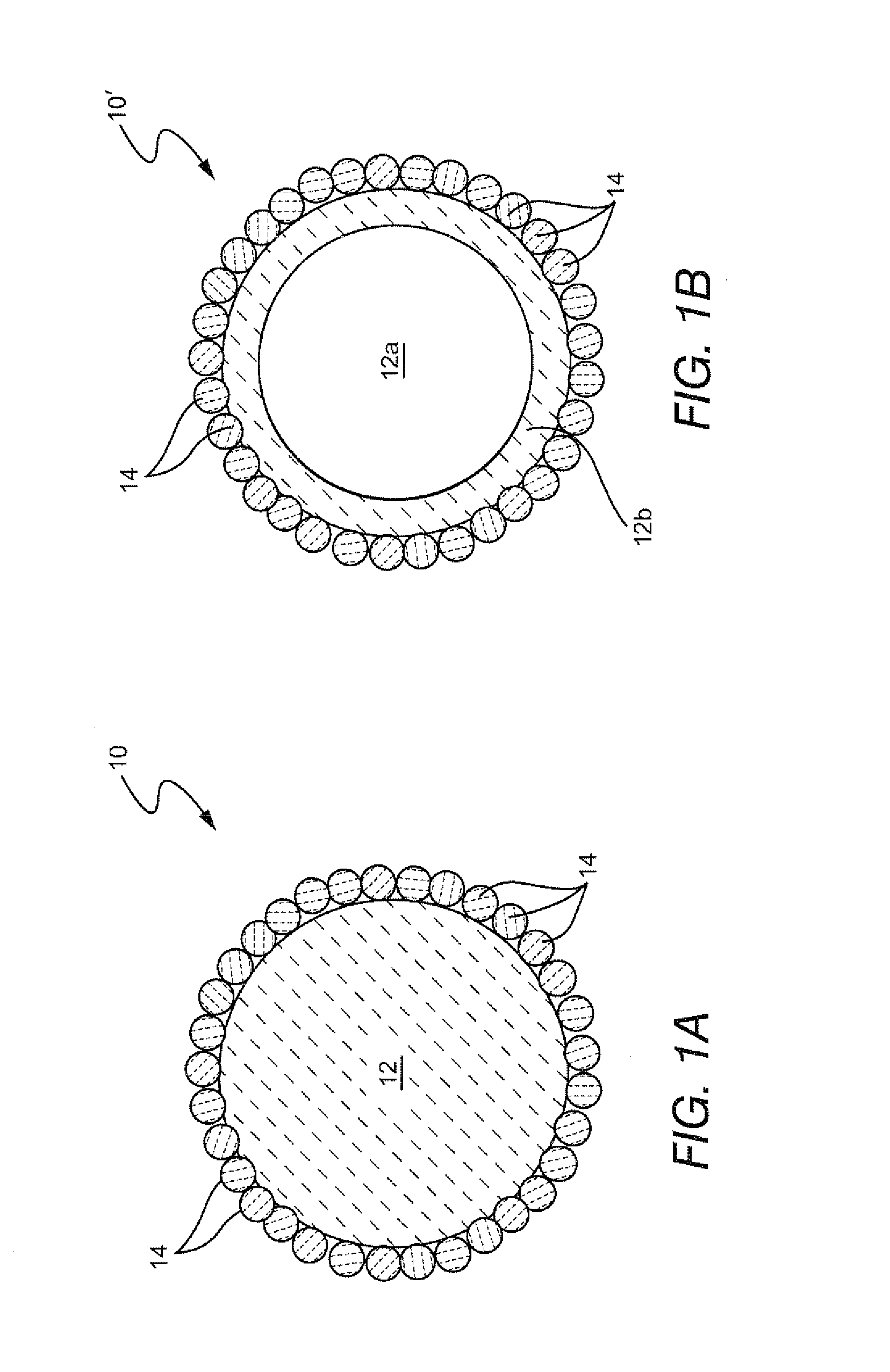

Additive particles having superhydrophobic characteristics and coatings and methods of making and using the same

InactiveUS20090298369A1Non-macromolecular adhesive additivesLiquid repellent fibresCoating systemSilanes

Additive particles may be employed in sufficient amounts to impart superhydrophobicity to a coating system in which the additive particles are incorporated. The additive particles include carrier microparticles and a dense plurality of nanoparticles adhered to the surfaces of the carrier microparticles (e.g., preferably by electrostatic deposition or covalent bonding). The additive particles are advantageously incorporated into a coating material (e.g., a polymeric material) in amounts sufficient to render a substrate surface superhydrophobic when coated with the coating material. The substrate may be rigid (e.g., glass, ceramic or metal) or flexible (e.g., a polymeric film or sheet or a fabric). In some preferred embodiments, both the microparticle and nanoparticles are formed of silica and are surface treated with a hydrophobic treatment so as to impart superhydrophobic properties thereto. Especially preferred are particles treated with silicone fluid comprised of a polysiloxane and / or a perfluoro silane having between 1 and 40 carbon atoms.

Owner:LUNA INNOVATIONS

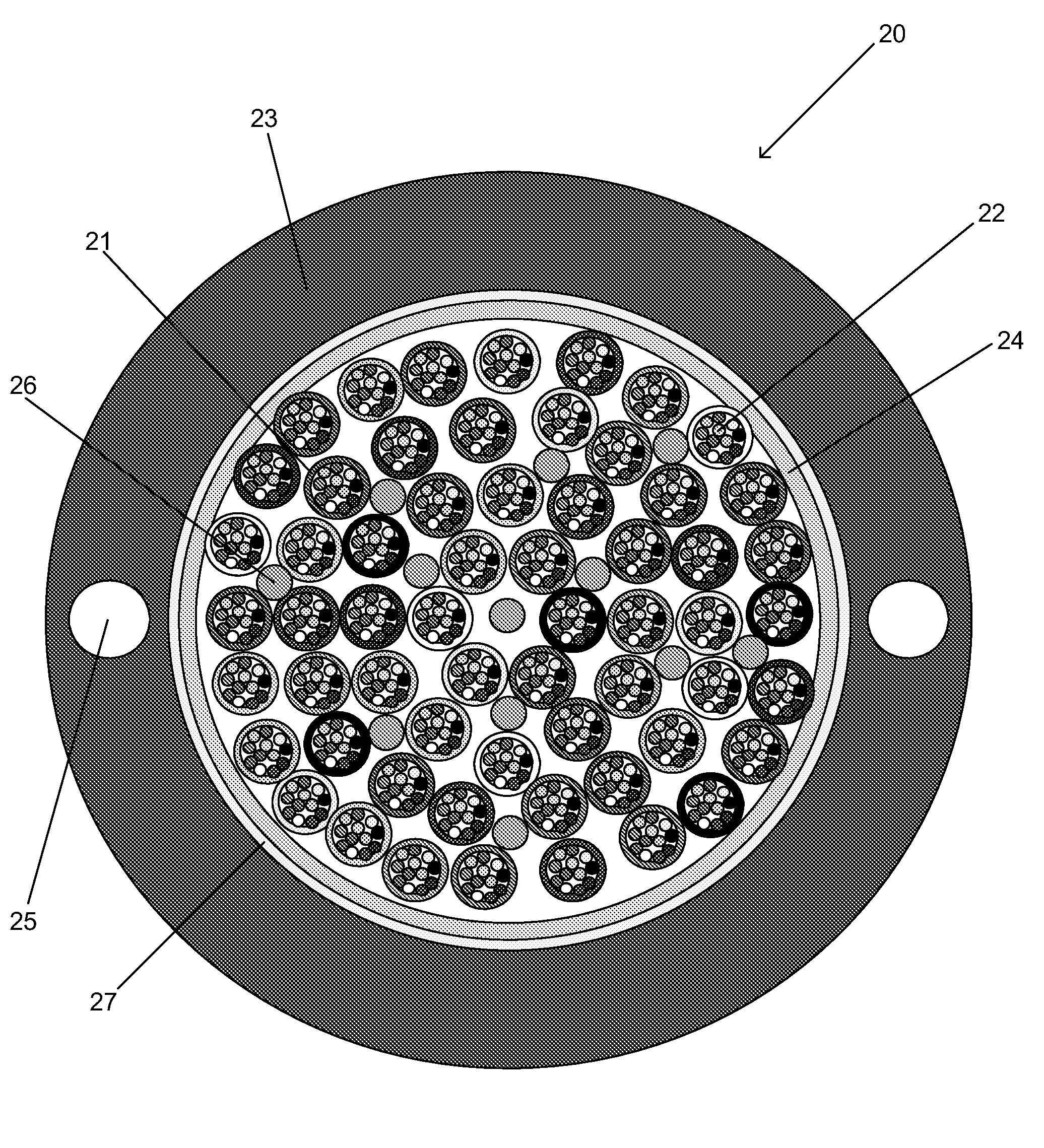

High-Fiber-Density Optical-Fiber Cable

ActiveUS20110069932A1Improve protectionGlass optical fibreOptical fibre with multilayer core/claddingUltrasound attenuationGlass fiber

Disclosed is an improved optical fiber possessing a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness. The secondary coating provides improved ribbon characteristics for structures that are robust, yet easily entered (i.e., separated and stripped).The optical fibers in accordance in the present invention may be incorporated into a reduced-diameter optical-fiber cable that possesses a high fiber count and a high cable fiber density. The high-fiber-density optical-fiber cable, which is suitable for deployments in ducts, is capable of achieving outstanding attenuation performance when subjected to temperature variations of between about −40° C. and 70° C.

Owner:DRAKA COMTEQ BV

Coating system exhibiting cool dark color

A layered coating composition for use in producing a cool dark coating composition. The coating system includes an IR reflecting layer, having IR-reflective pigments in a resinous binder. A radiation absorbing layer is coated onto the IR reflecting layer. The radiation absorbing layer includes nano-sized pigments dispersed in a resinous binder.

Owner:PPG IND OHIO INC

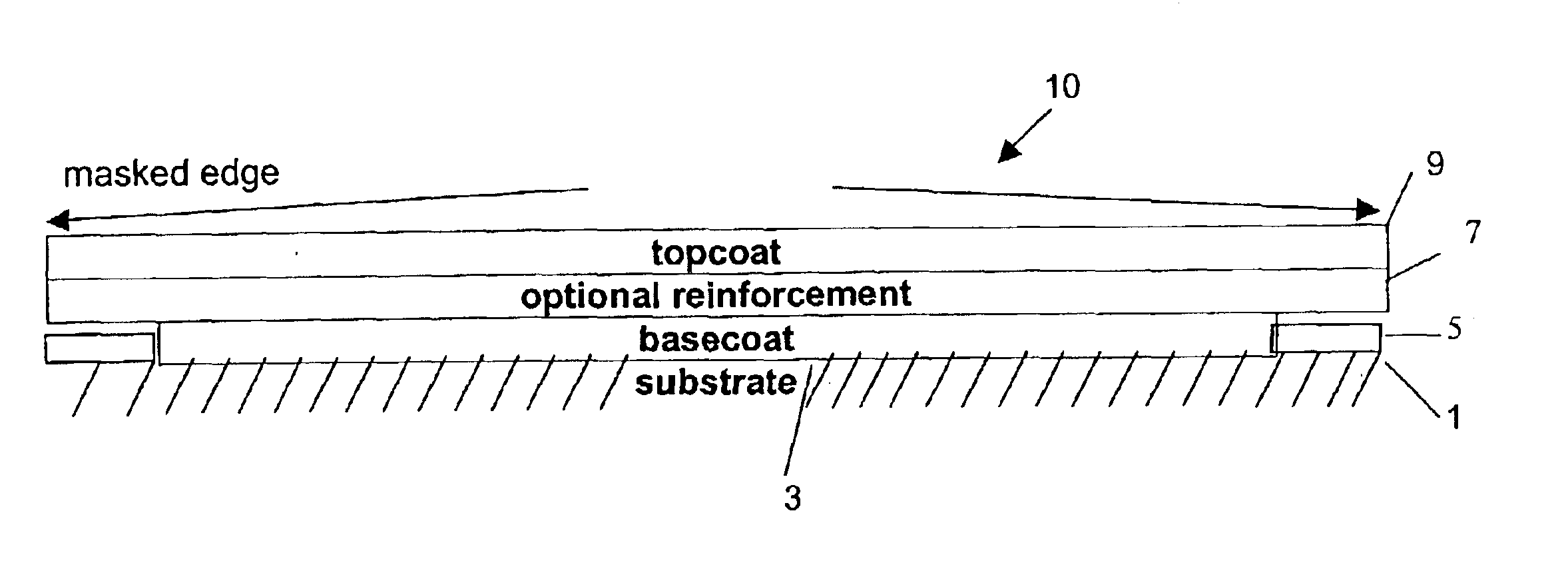

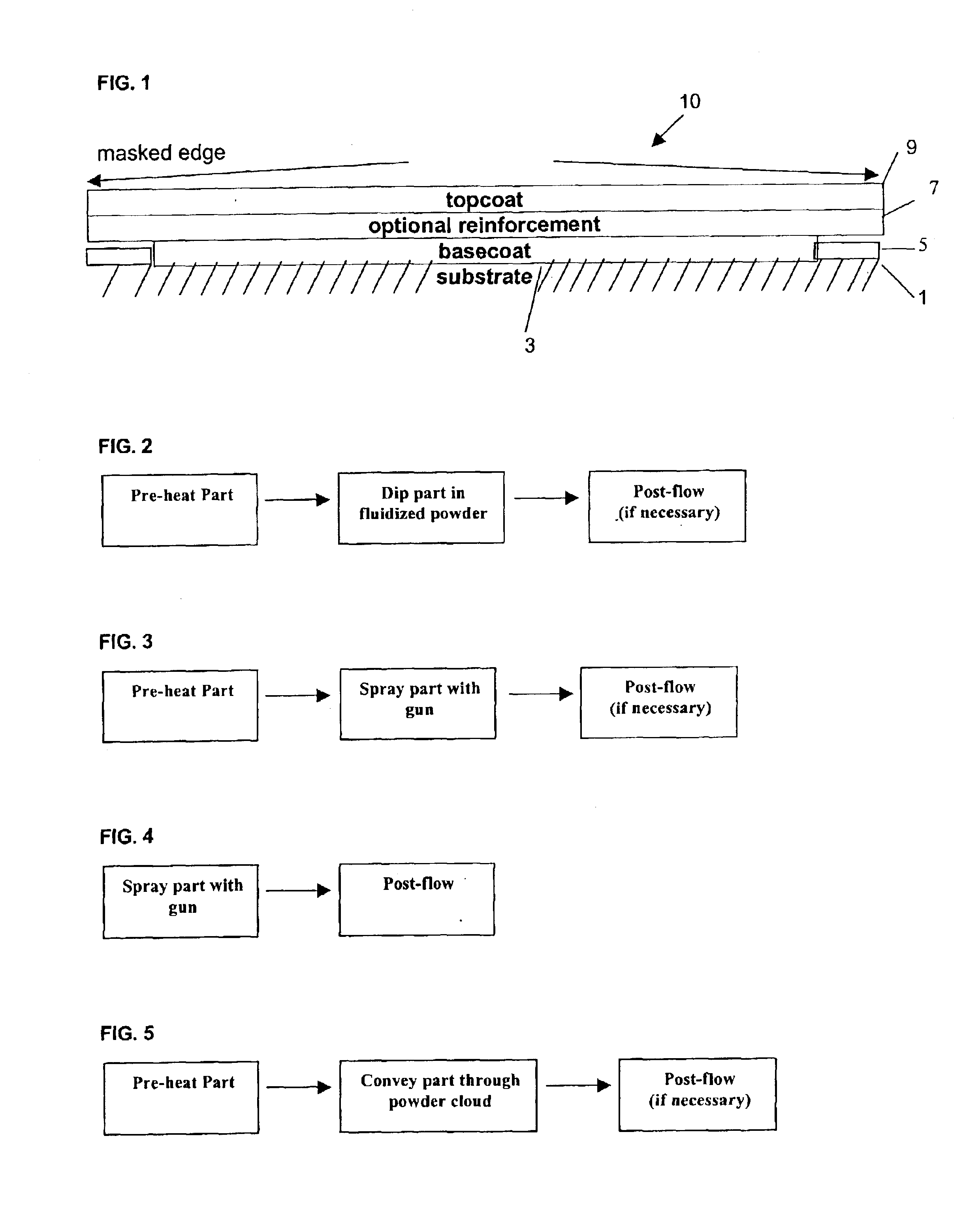

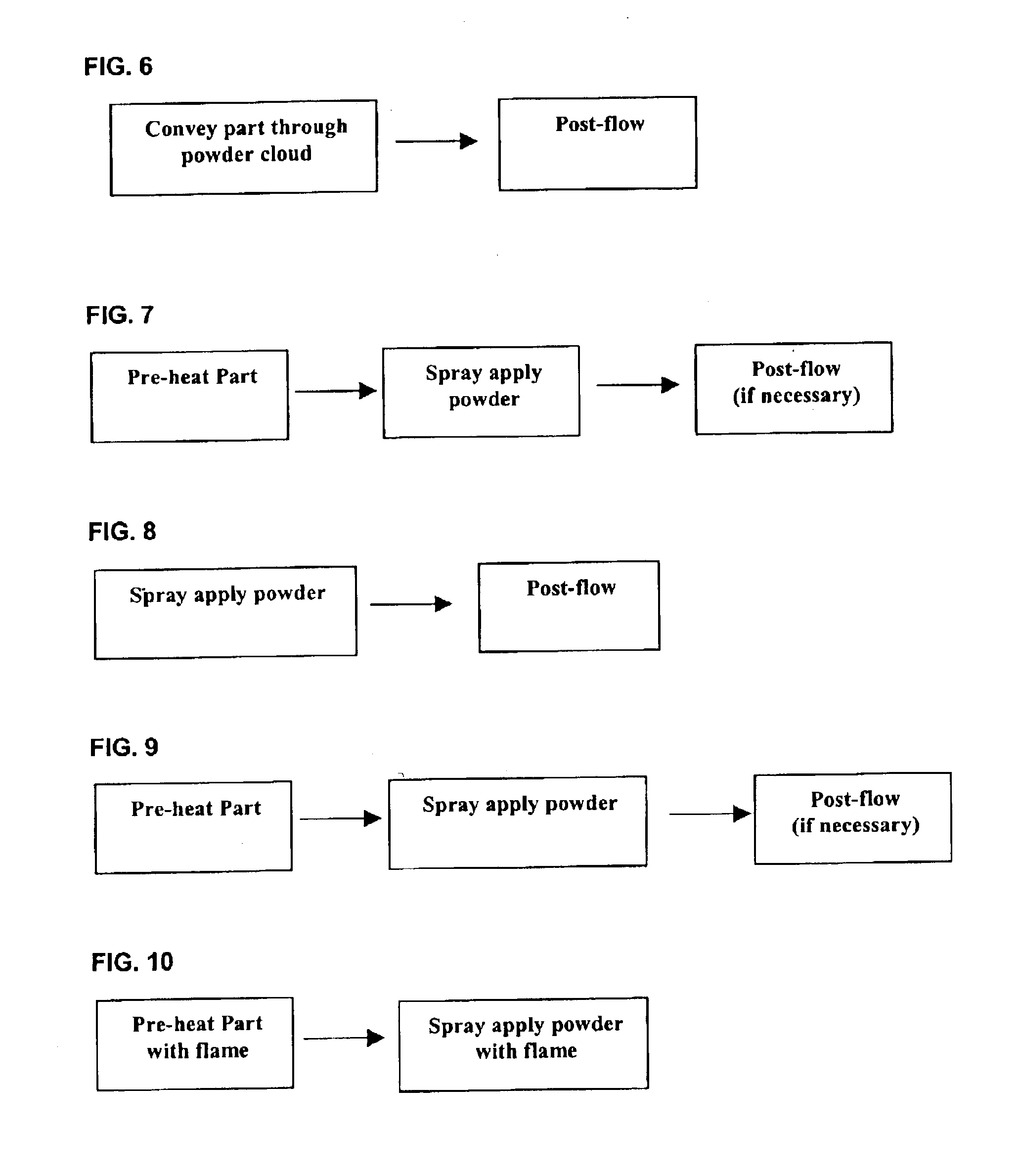

Coating system for a porous substrate using an asphalt-containing thermosetting basecoat composition and a thermoplastic top coat composition

InactiveUS6849338B2Reduce viscosity of compositionIncreasing imperfectionSynthetic resin layered productsPretreated surfacesPorous substrateCross-link

A coating system comprises a basecoat of an thermosetting asphalt extended, chemically cross linked-urethane / epoxy hybrid basecoat resting on a substrate, preferably a porous substrate such as concrete or wood that off-gas when coated with a thermoplastic material; and a thermoplastic powder coating topcoat overlying at least the base coat. The thermosetting basecoat composition consisting essentially of, in weight percent based on final formulation, and between 10 and 90% of a petroleum asphalt; between 10 and 90%, of a hydroxy-terminated homopolymer; and between 0.1 and 30% of a functional epoxy reactive diluent for reducing the viscosity of the composition; and further up to 5% of a surfactant for improving surface imperfections, up to 5% of an anti-oxidant; and up to 25% of a thickening agent.

Owner:PACIFIC NORTHWEST COATINGS

Microbend-Resistant Optical Fiber

ActiveUS20100290781A1Improve protectionGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberCoating system

Disclosed is an improved, single-mode optical fiber possessing a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness. The secondary coating provides improved ribbon characteristics for structures that are robust, yet easily entered (i.e., separated and stripped).The optional dual coating is specifically balanced for superior heat stripping in fiber ribbons, with virtually no residue left behind on the glass. This facilitates fast splicing and terminations. The improved coating system provides optical fibers that offer significant advantages for deployment in most, if not all, fiber-to-the-premises (FTTx) systems.

Owner:DRAKA COMTEQ BV

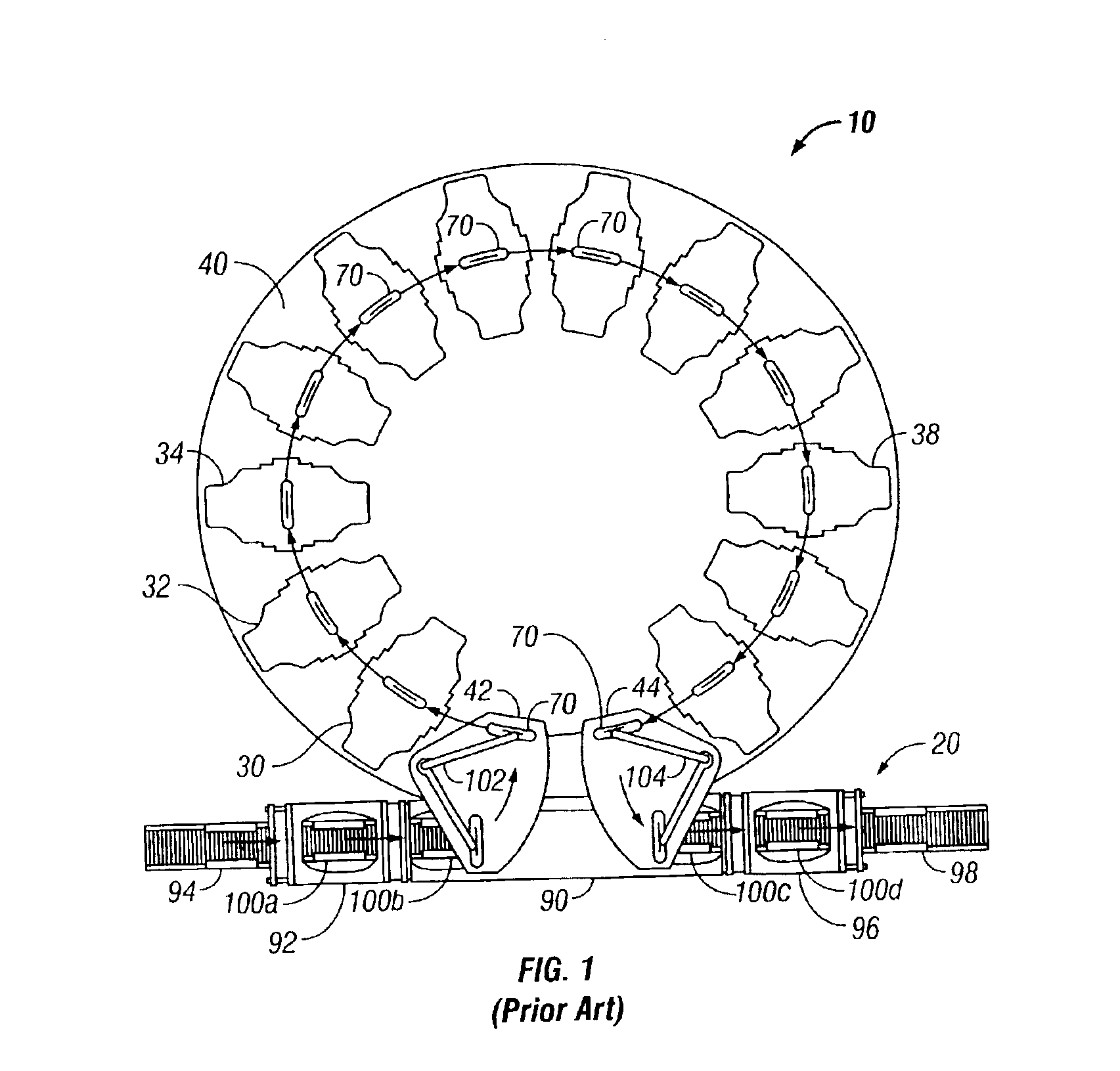

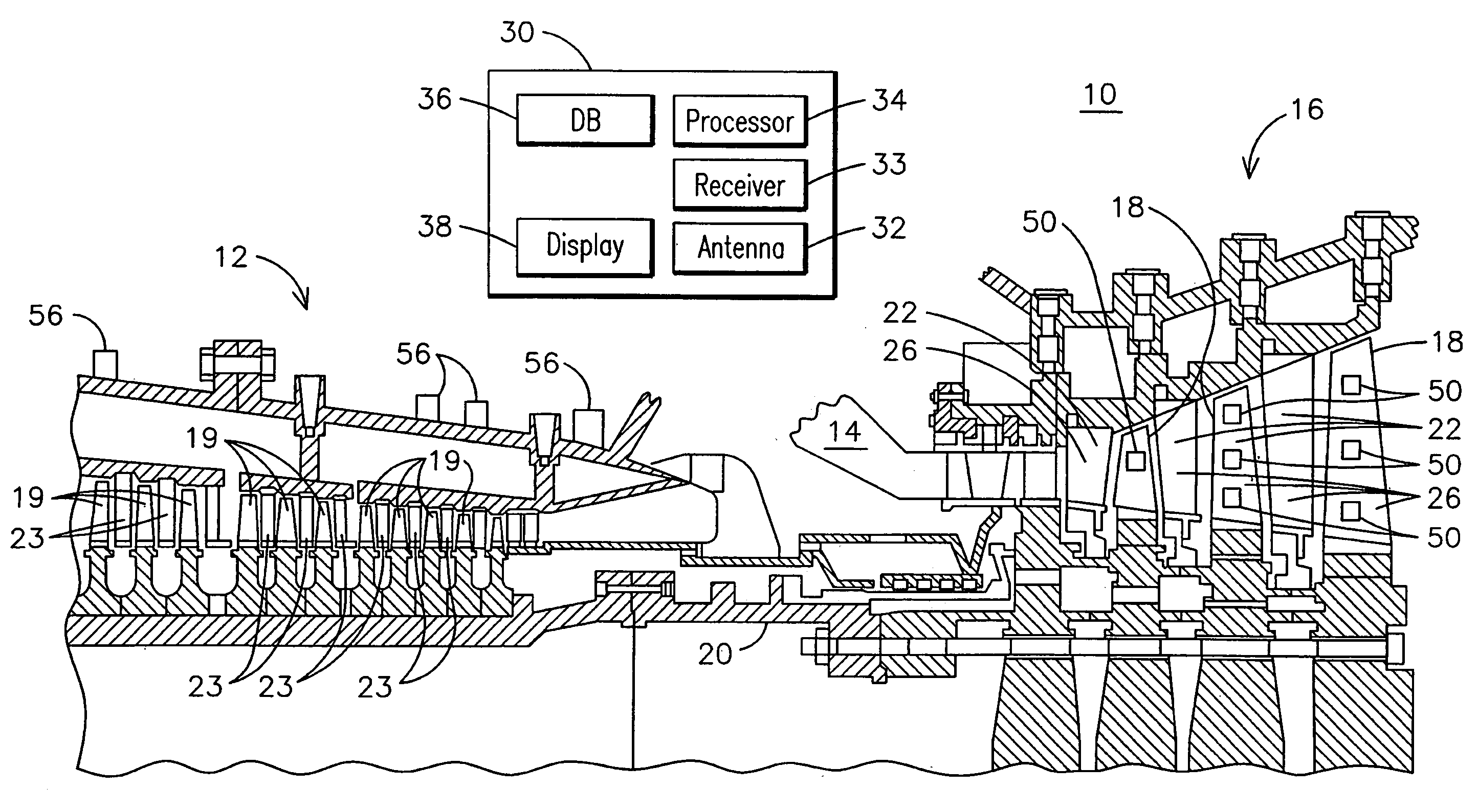

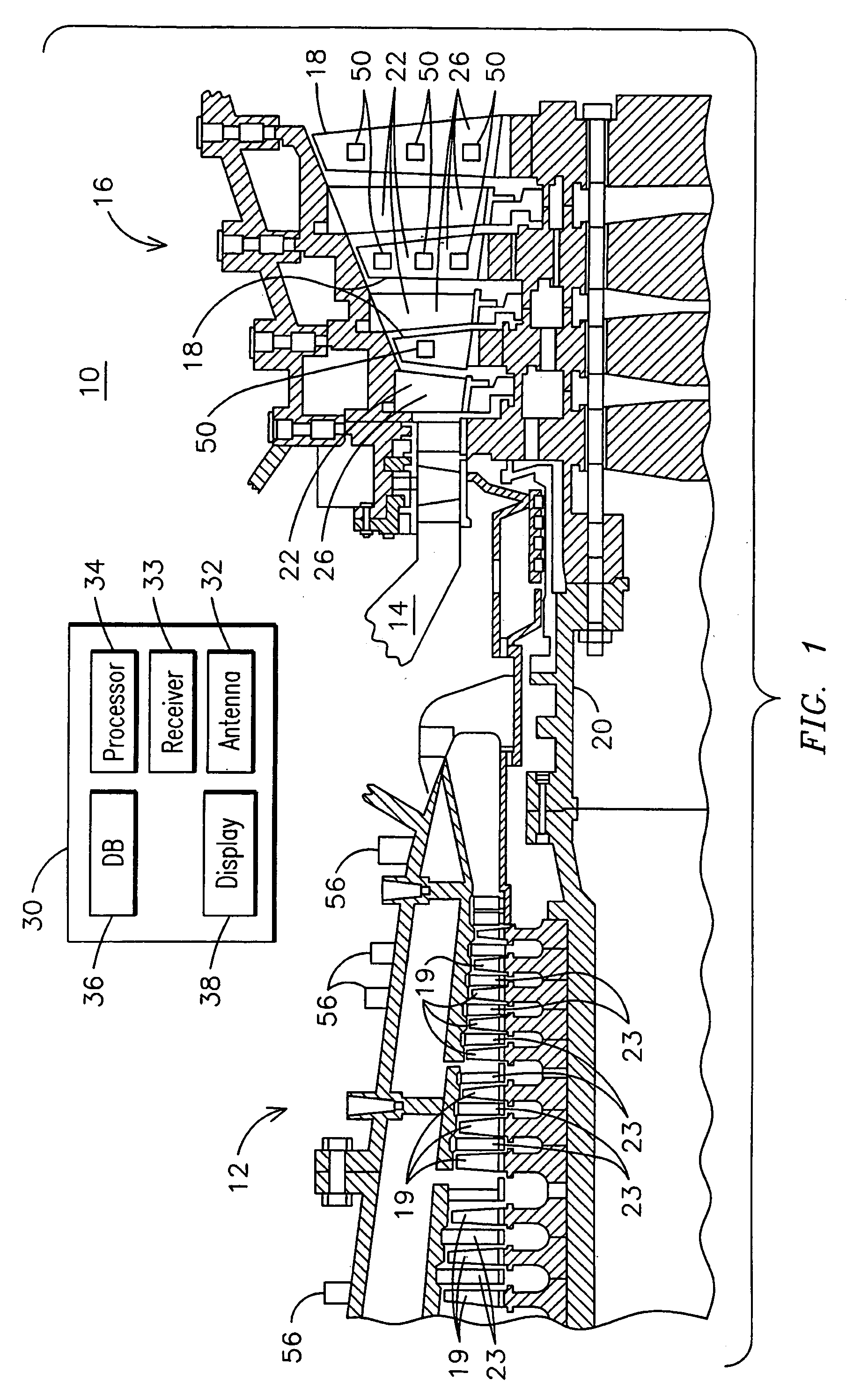

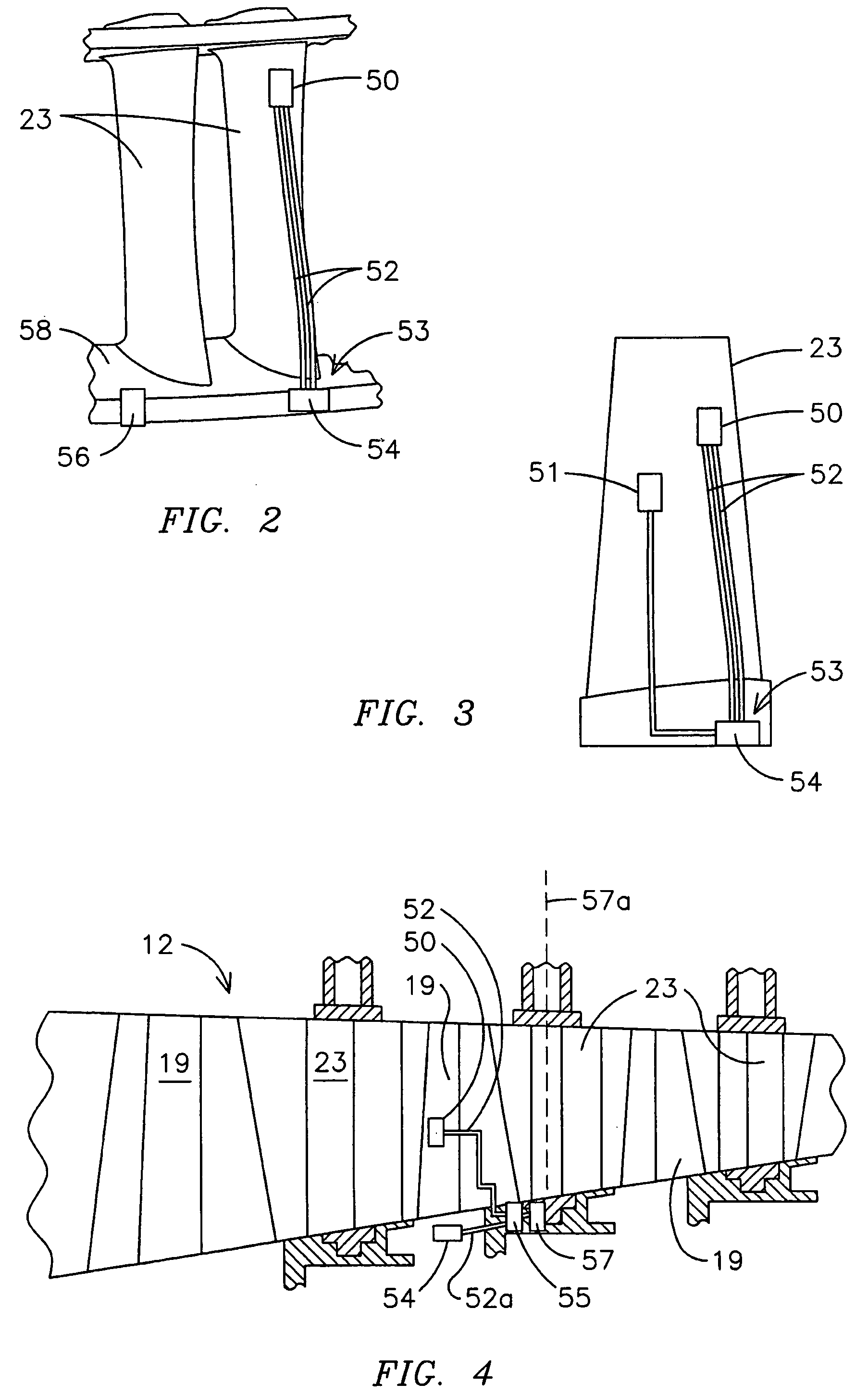

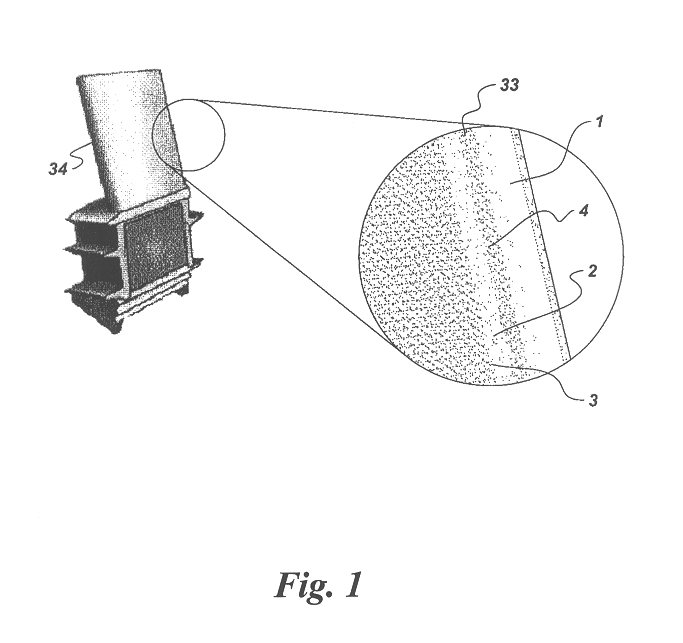

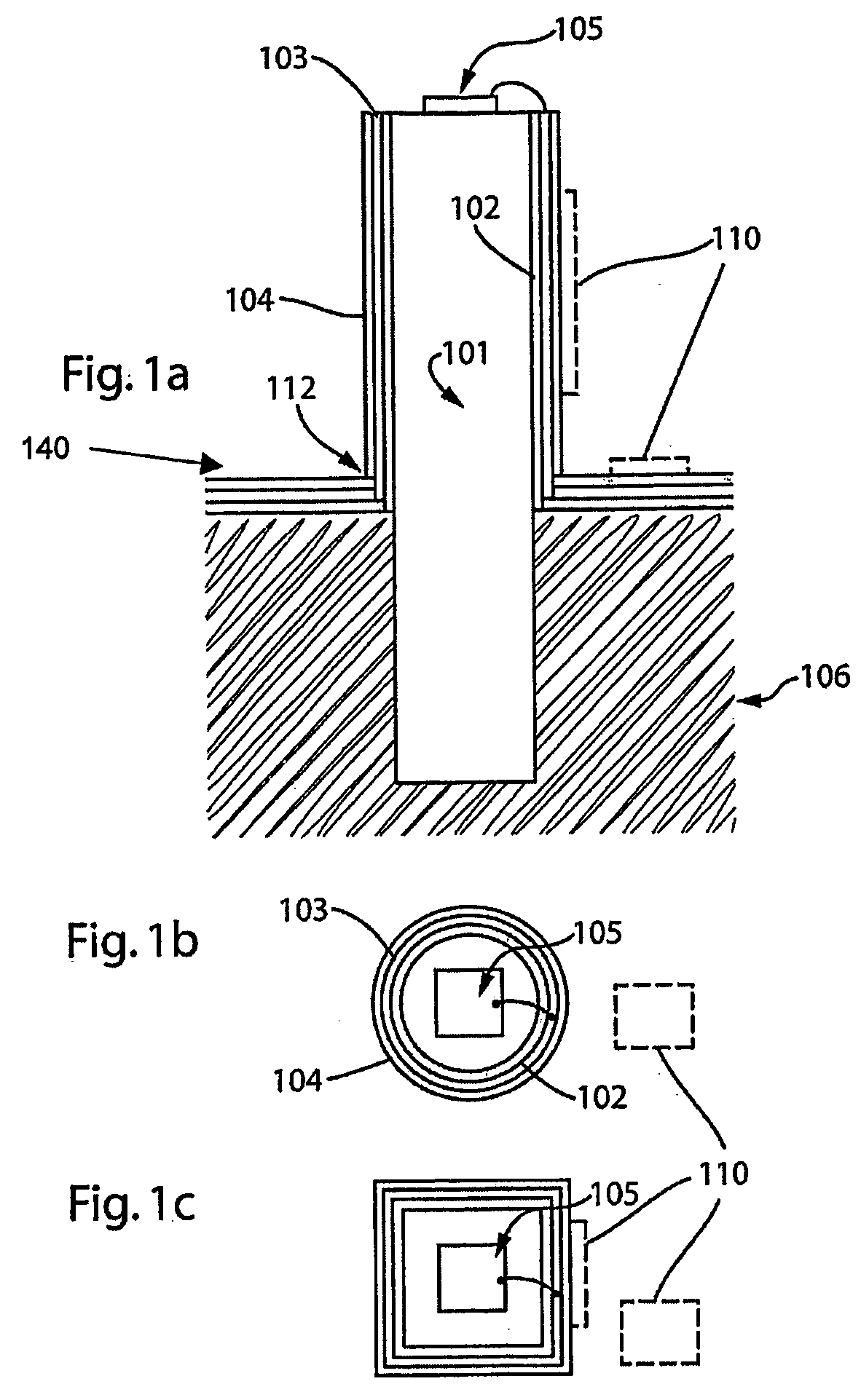

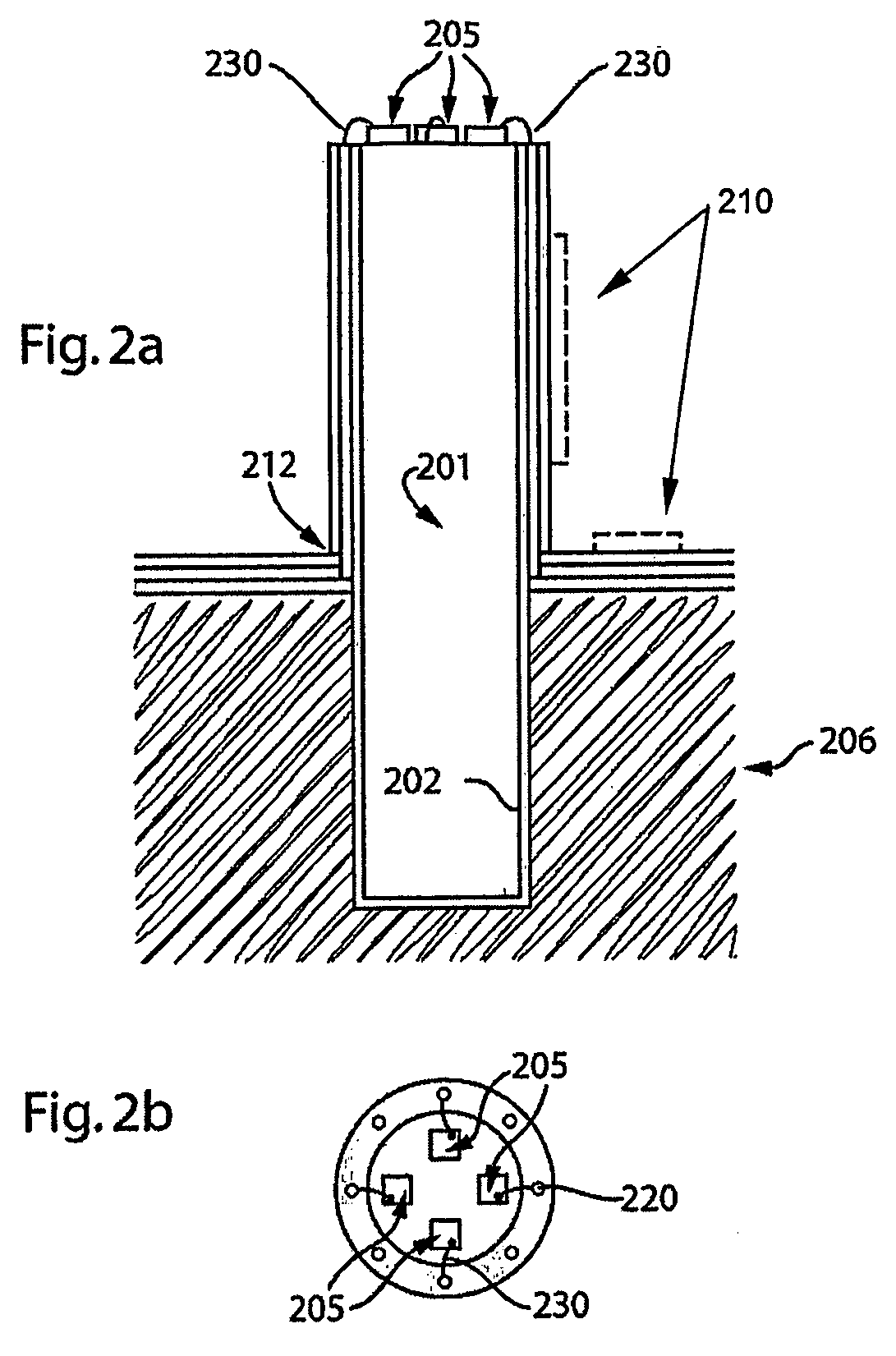

Apparatus and method of detecting wear in an abradable coating system

A component for use in a combustion turbine (10) is provided that includes a substrate (212) and an abradable coating system (216) deposited on the substrate (212). A planar proximity sensor (250) may be deposited beneath a surface of the abradable coating system (216) having circuitry (252) configured to detect intrusion of an object (282) into the abradable coating system (216). A least one connector (52) may be provided in electrical communication with the planar proximity sensor (250) for routing a data signal from the planar proximity sensor (250) to a termination location (59). A plurality of trenches (142) may be formed at respective different depths below the surface of the abradable coating system (216) with a planar proximity sensor (250) deposited within each of the plurality of trenches (142). A processing module (34) may be programmed for receiving data from the planar proximity sensor (250) and calculating a clearance between a row of blades (18,19) within a combustion turbine and the planar proximity sensor (250). The processing module (34) may control a clearance between the row of blades (18) and a ring segment (284) based on data received from the planar proximity sensors (250).

Owner:SIEMENS ENERGY INC

Dual-curing coating and preparation method thereof

InactiveCN102181192ACuring shrinkage is smallIncrease crosslink densityCoatingsInformation layerCoating system

The invention discloses a dual-curing coating. The coating contains ultraviolet curing resin monomers, a low polymer, a photo-initiator, polymer resins, an adjuvant and an organic solvent. In the invention, the dual-curing coating is prepared by synergistic copolymerization of an ultraviolet curing coating system and a solvent-based polymer system. The preparation method of the coating comprises the following steps: firstly thermocuring, and then processing information layers and photocuring at the same time; or firstly photocuring, then processing the information layers, and finally heating with an oven or infrared-heating for further cross-linking curing. Therefore, the dual-curing coating has better comprehensive performances such as fast curing speed, small film-coating cure shrinkage and high crosslinking density so as to achieve the characteristics of chemical corrosion resistance, strong wear resistance, strong high temperature resistance, excellent flexibitity, excellent adhesive force and the like; and the coating can be used for laser anti-counterfeit marks of plastics, cosmetic preparations, ceramic materials, glass, paper, leather, wooden products and metal products as well as production of pigment preparations and the like.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

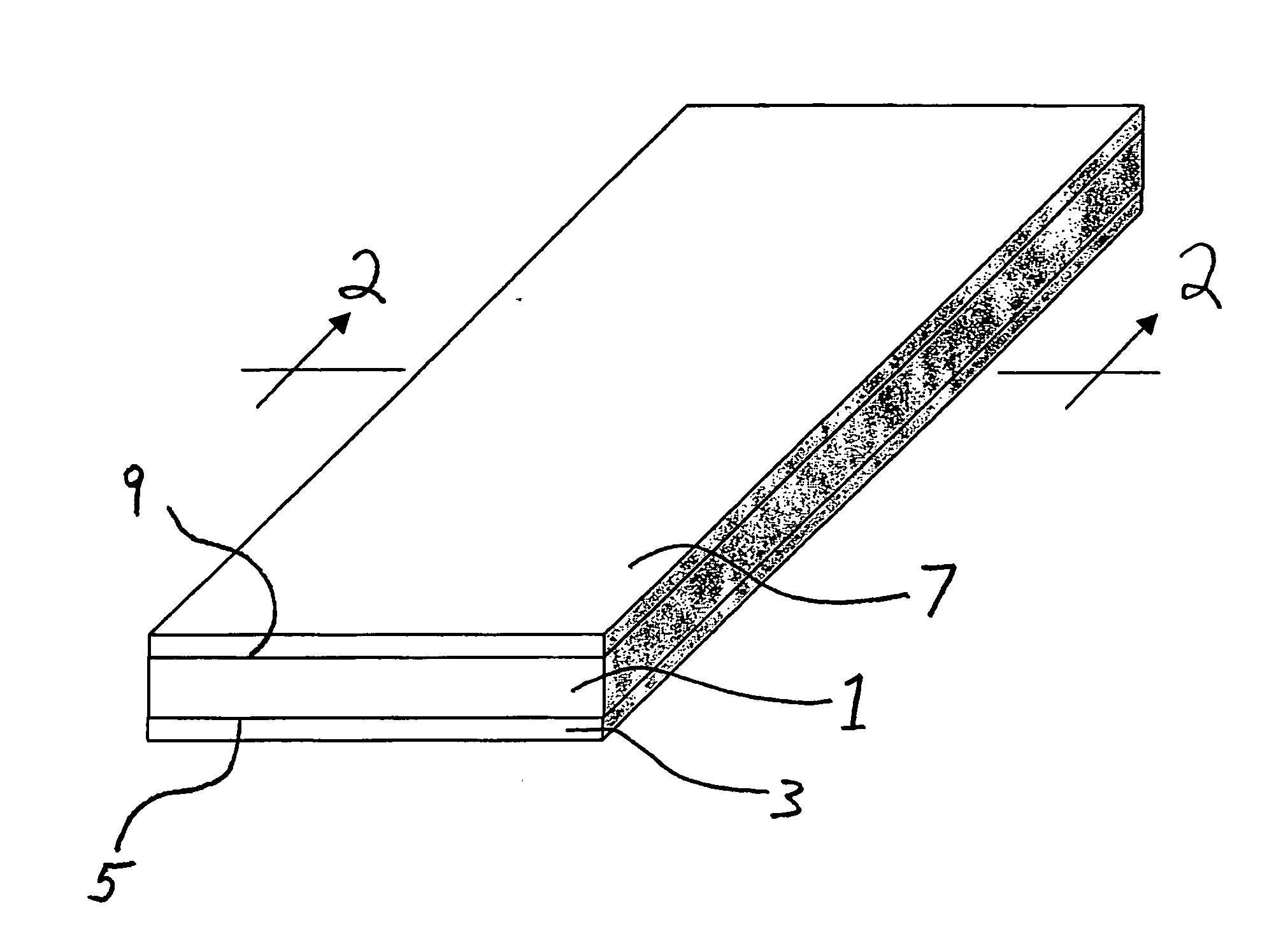

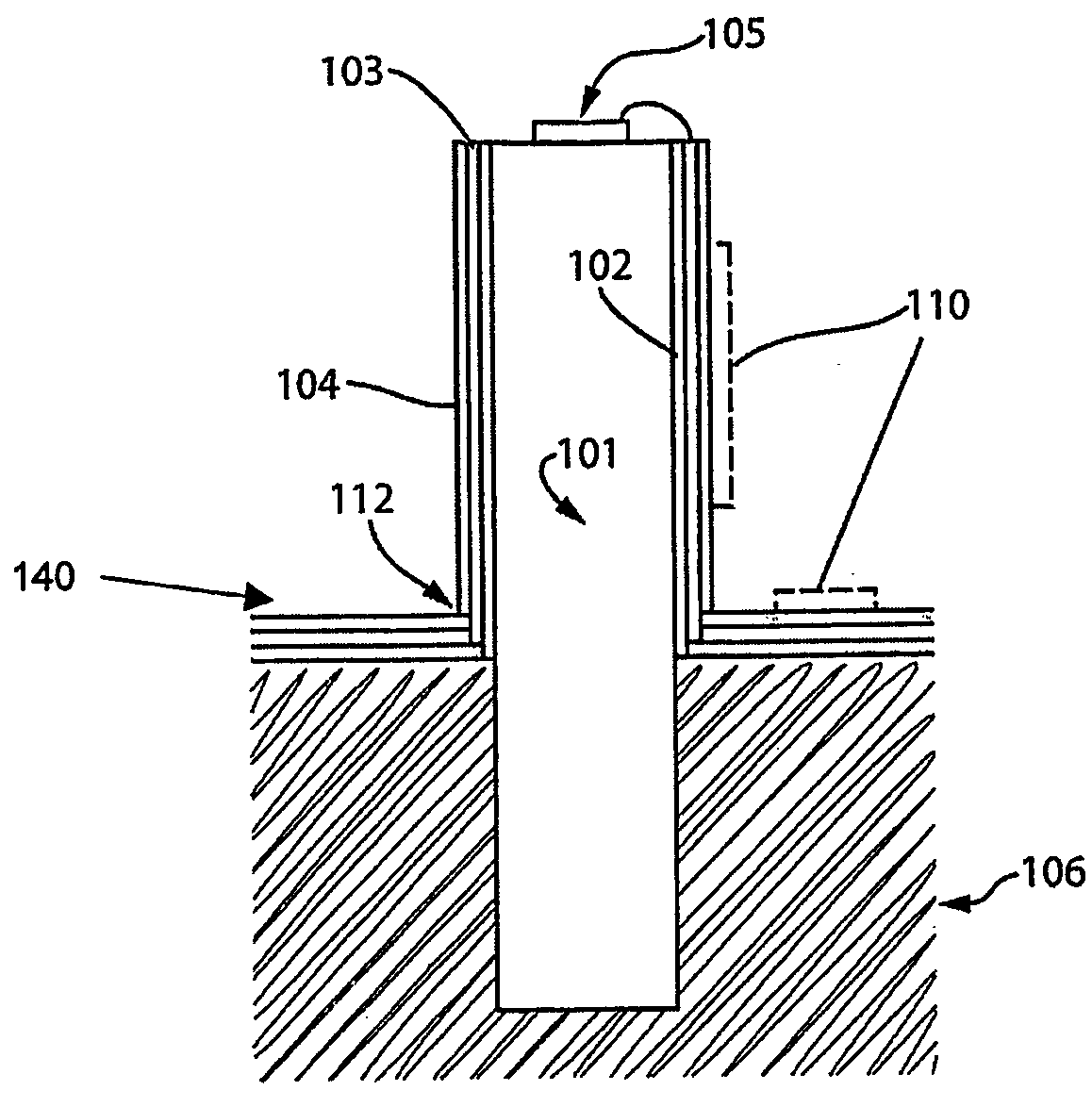

Coating system for sag resistant formaldehyde-free fibrous panels

ActiveUS20070055012A1Low costMaintain resistanceConstruction materialSynthetic resin layered productsFiberHydrophilic coating

A coating system on a fibrous substrate, such as a fibrous ceiling panel, having a first surface and a second surface. A first coating is disposed on the first surface of the substrate and includes a first binder and a first filler material. A second coating may be disposed on the second surface of the substrate. The second coating includes a second binder and a second filler material. The first coating and the second coating expand at different rates in the presence of humidity in order to help prevent sagging of the substrate in presence of humidity. The first coating is preferably a hydrophobic coating having a large particle size, high elastic modulus filler material. The second coating is preferably a hydrophilic coating having a lower concentration of high elastic modulus material and a polymer having a hydrophilic moiety.

Owner:AWI LICENSING

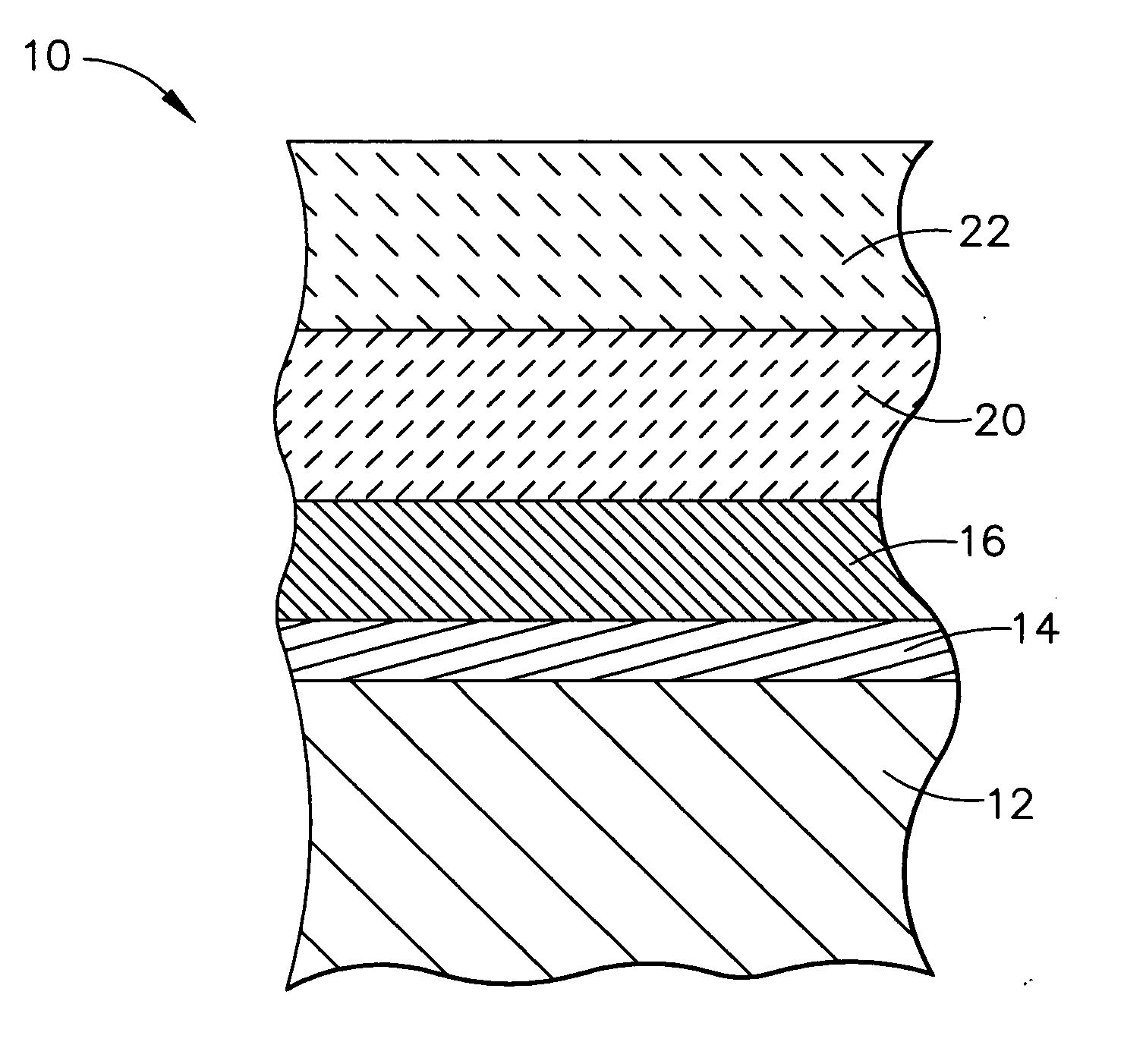

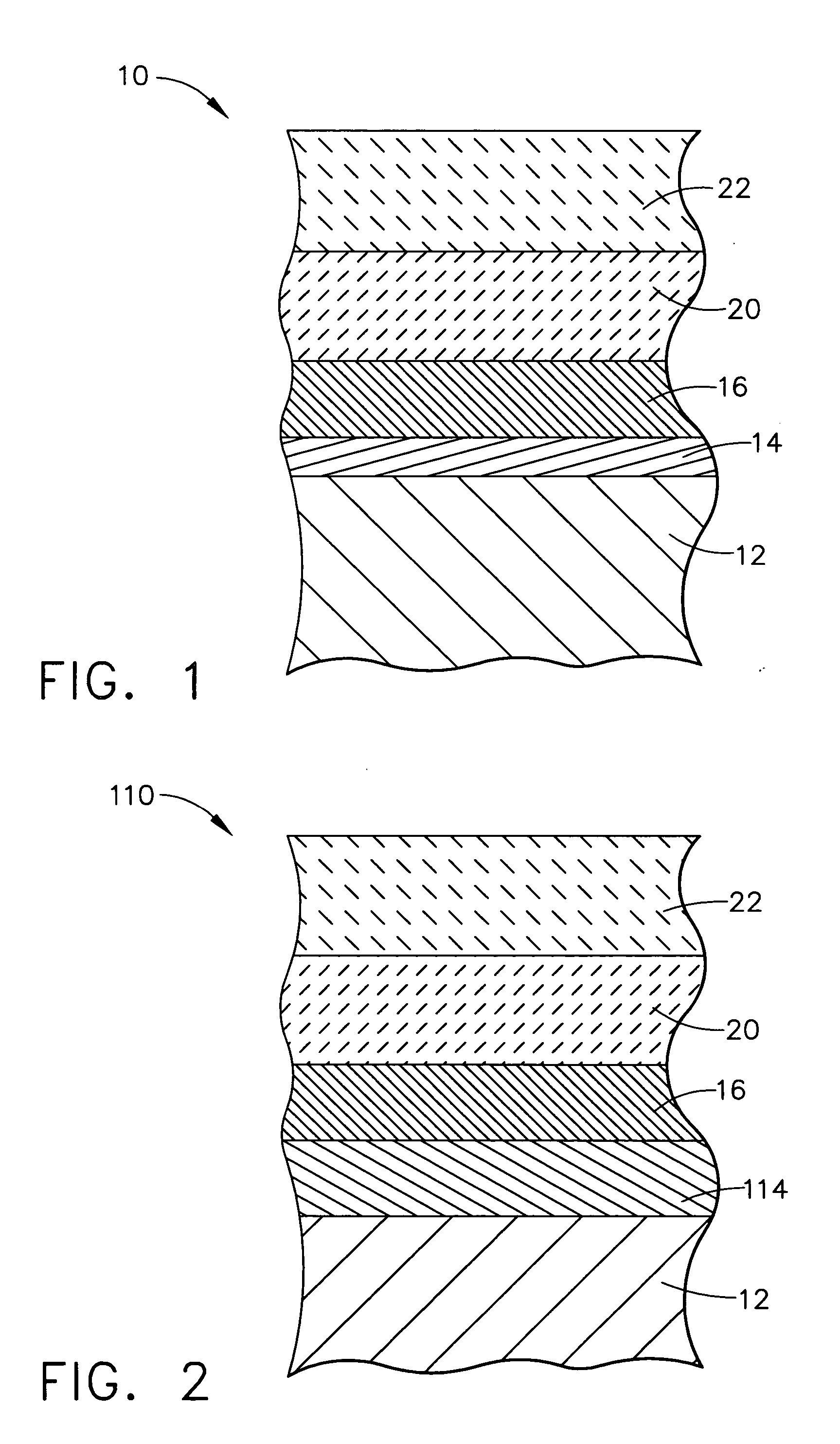

Thermal/environmental barrier coating system for silicon-containing materials

ActiveUS20060280963A1Prolong lifeImprove protectionFireproof paintsBlade accessoriesAluminateCoating system

A coating system for Si-containing materials, particularly those for articles exposed to high temperatures. The coating system exhibits improved resistance to corrosion from sea salt and CMAS as a result of using aluminate compounds to protect silicate-containing layers of the coating system. The coating system includes an environmental barrier coating, a thermal barrier coating overlying the environmental barrier coating and formed of a thermal-insulating material, and a transition layer between the environmental barrier coating and thermal barrier coating, wherein the transition layer contains at least one aluminate compound and / or alumina.

Owner:GENERAL ELECTRIC CO

Smart coating system with chemical taggants for coating condition assessment

InactiveUS6644917B2Improving subsequent up-timeAccurately indicatedPropellersReaction enginesCoating systemGas turbines

A on-line method is provided for detecting wear and / or damage to gas turbine parts. Preferred embodiments of the invention provide a gas turbine comprising parts with smart coatings and collection and detection means to measure wear and erosion of gas turbine parts. In other preferred embodiments, smart coatings are provided comprising chemical taggants that can be collected and detected downstream, thus providing an on-line or in situ evaluation technology for wear and damage to gas turbine parts.

Owner:GENERAL ELECTRIC CO

Thermally and Electrically Conductive Apparatus

ActiveUS20080239675A1Semiconductor/solid-state device detailsLighting heating/cooling arrangementsElectric forceCoating system

The present invention provides a thermally and electrically conductive apparatus that can provide both thermal conductivity and electrical conductivity for one or more electronic devices connected thereto. The apparatus comprises a thermally conductive element that is in thermal contact with one or more electronic devices and optionally in contact with a heat dissipation system. A portion of the thermally conductive element is surrounded by a multilayer coating system comprising two or more layers. The multilayer coating system includes alternating electrically insulating and electrically conductive layers in order to provide paths for the supply of electric current to the one or more electronic devices. A conductive layer of the multilayer coating system may be selectively patterned to connect to one or more electronic devices. In this manner, the combination of an electronic circuit carrier and a thermally conductive element can unify thermal conductivity with the provision of power and / or communication into a single integrated unit for use with electronic devices.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

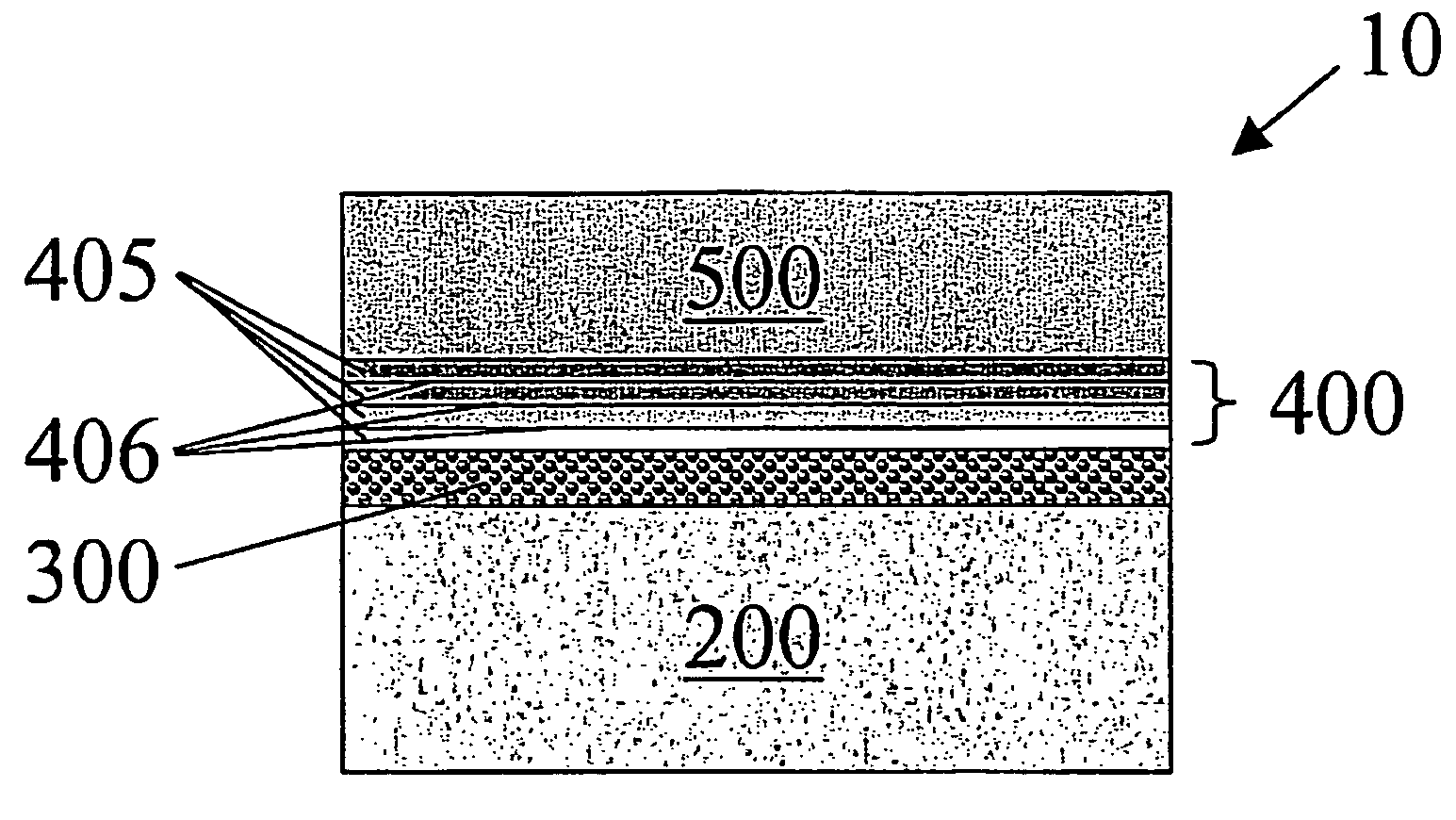

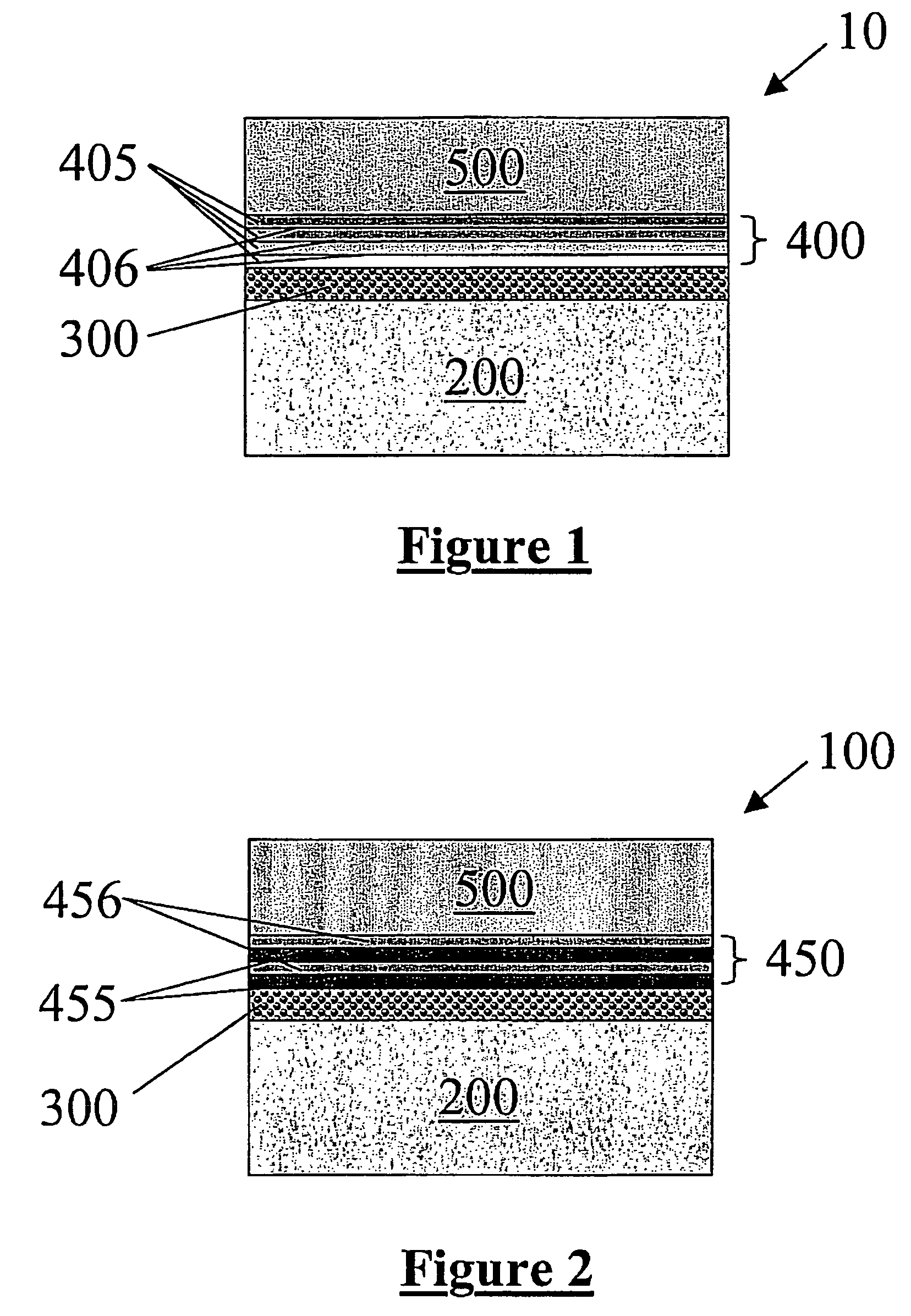

Multifunctionally graded environmental barrier coatings for silicon-base ceramic components

InactiveUS7740960B1Low thermal conductivityIncrease flow ratePropellersReaction enginesCombustionWater vapor

A multilayered coating system consisting of a multicomponent zirconia-base or hafnia-base oxide top layer, an interlayer comprised of a plurality of sublayers and a bond coat layer is provided. The multilayered coating system of the present invention, with an interlayer comprised of a plurality of sublayers, provides a protective coating solution for silicon-base ceramic components exposed to very high temperatures and / or high gas flow velocity water vapor combustion environments. The plurality of sublayers affords for a multitude of interfaces that aid in phonon scattering within the coating system and thereby reduces its thermal conductivity. Furthermore, the plurality of interlayer sublayers afford a strain tolerant buffer between the top layer and substrate and thereby accommodate the thermal expansion mismatch between the oxide top layer (coefficient of thermal expansion (CTE) up to ˜8-10×10−6 m / m-C) and the silicon-base ceramic substrate (CTE≈4-5×10−6 m / m-C).

Owner:ARMY US SEC THE

Methods and systems for preparing an antimicrobial composition

ActiveUS20080021212A1High activityImprove solubilityMaterial nanotechnologyBiocidePolycyclic compoundAmmonium compounds

A coating system and method are described. In some embodiments, a system may include a composition. The composition may include one or more bridged polycyclic compounds. At least one of the bridged polycyclic compounds may include at least two cyclic groups, and at least two of the cyclic groups may include quaternary ammonium moieties. In some embodiments, a method may include applying an antimicrobial composition to a surface. The coating may be antimicrobial. A coating may include antimicrobial bridged polycyclic compounds. Bridged polycyclic compounds may include quaternary ammonium compounds. Bridged polycyclic compounds based coating systems may impart self-cleaning properties to a surface.

Owner:ALLACCEM

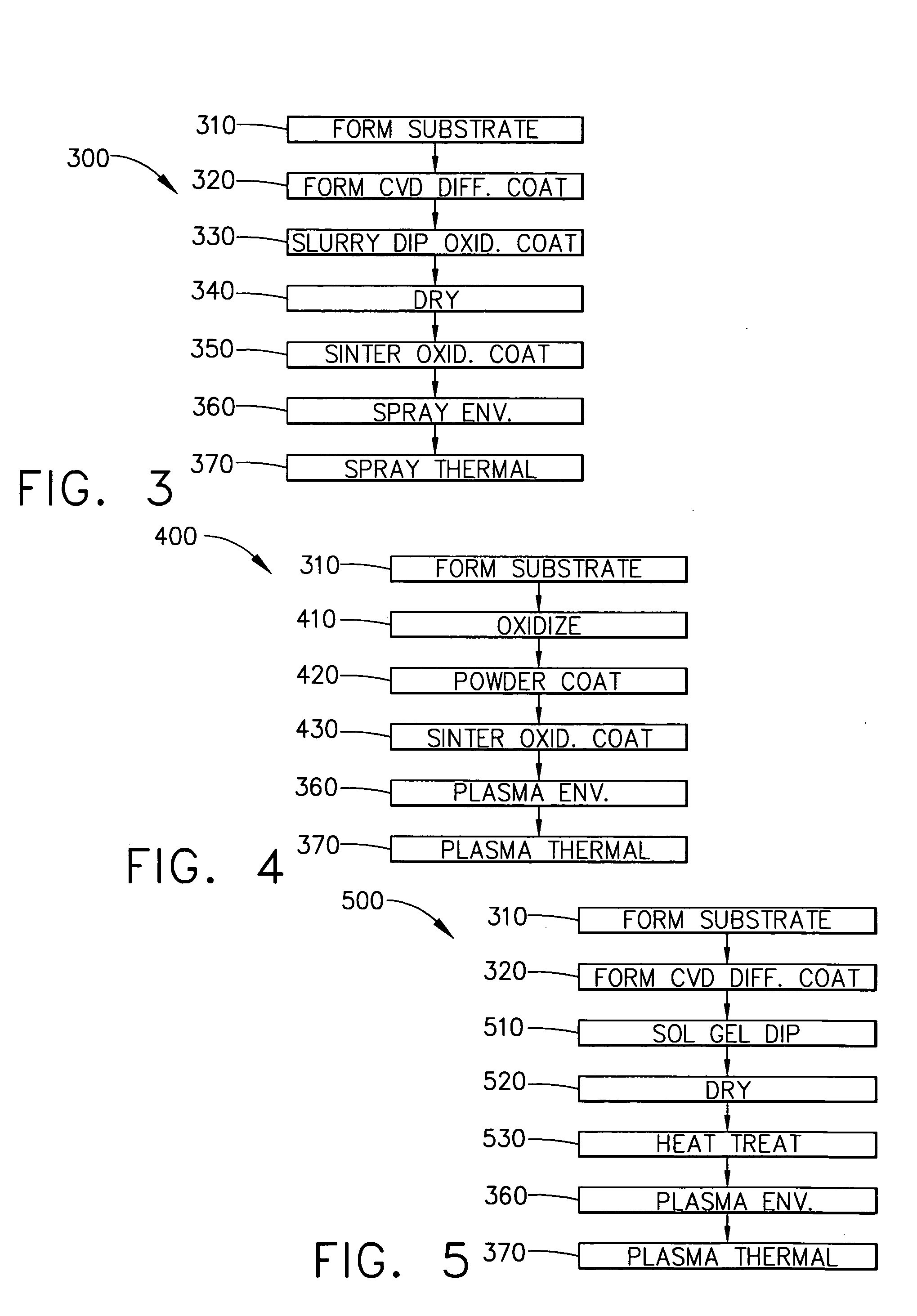

Oxidation barrier coatings for silicon based ceramics

ActiveUS20050112381A1Avoid Explosion HazardsContinuous combustion chamberBlade accessoriesElectron beam physical vapor depositionGas phase

A protective barrier coating system including a diffusion barrier coating and an oxidation barrier coating and method for use in protecting silicon-based ceramic turbine engine components. A complete barrier coating system includes a thermal barrier coating of stabilized zirconia and an environmental barrier coating of an alloyed tantalum oxide. The oxidation barrier coating includes a layer of metallic silicates formed on a substrate of silicon nitride or silicon carbide to be protected. The oxidation barrier coating can include silicates of scandium, ytterbia or yttrium. The oxidation barrier coating may also include an inner layer of Si2ON2 between the diffusion barrier and the metallic silicate layer. The oxidation barrier coating can be applied to the substrate by spraying, slurry dipping and sintering, by a sol-gel process followed by sintering, by plasma spray, or by electron beam-physical vapor deposition. The diffusion layer of essentially pure Si3N4 can be applied to the substrate to prevent the migration of damaging cations from the protective layers to the substrate and is preferably formed by chemical vapor deposition. A method for protecting silicon based substrates can comprise a step of forming an oxidation barrier coating on a substrate, where a step of forming the oxidation barrier includes a step of sintering the oxidation barrier and substrate in a wet gas containing hydrogen.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com