Patents

Literature

962 results about "Extender" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An extender, also known as a filler, in printing ink technology is a white transparent, or semi-transparent, component whose purpose is to reduce the cost of the ink, by increasing the area covered by a given weight of pigment. They generally have little colouring power.

Composition of a thermaly insulating coating system

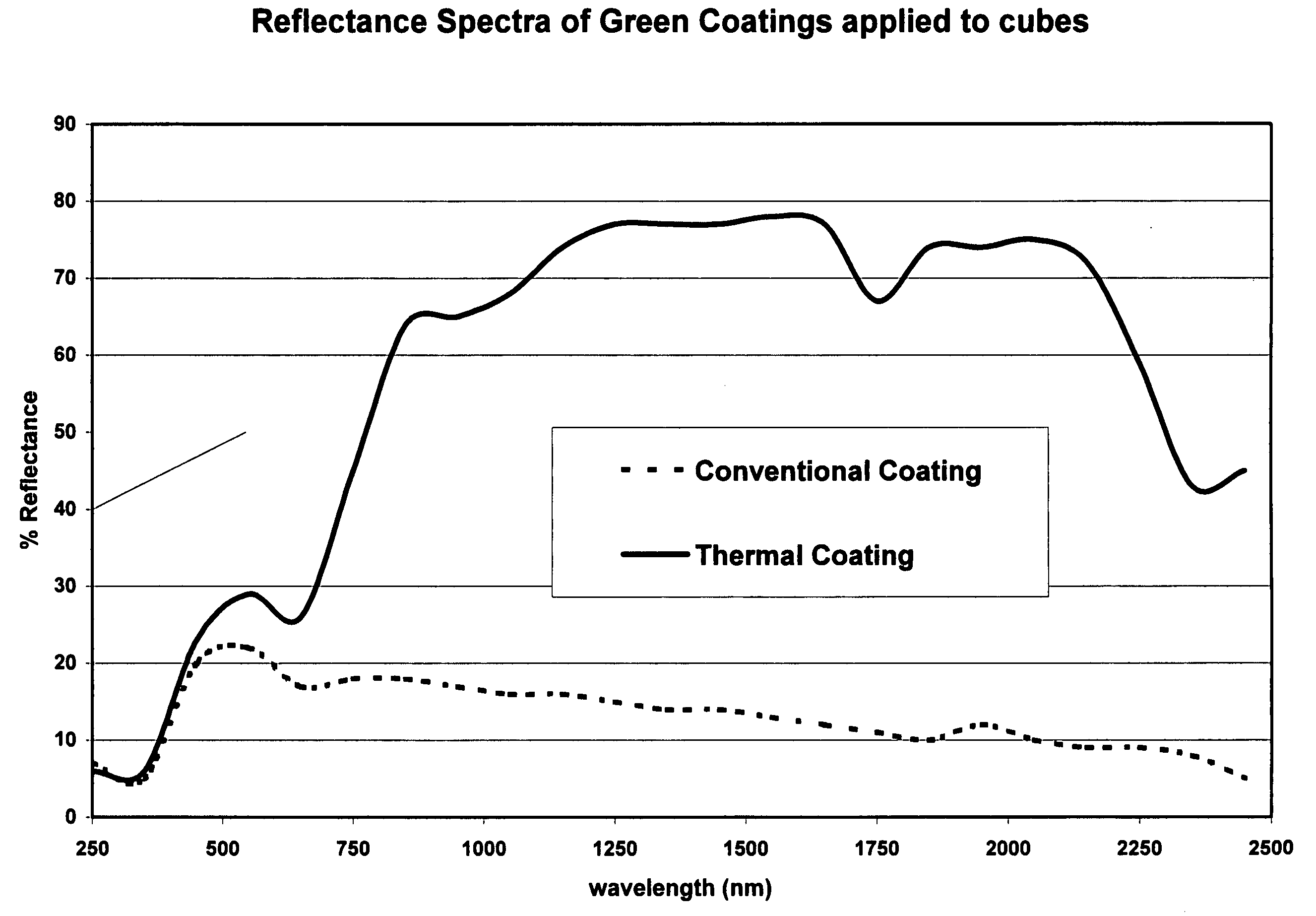

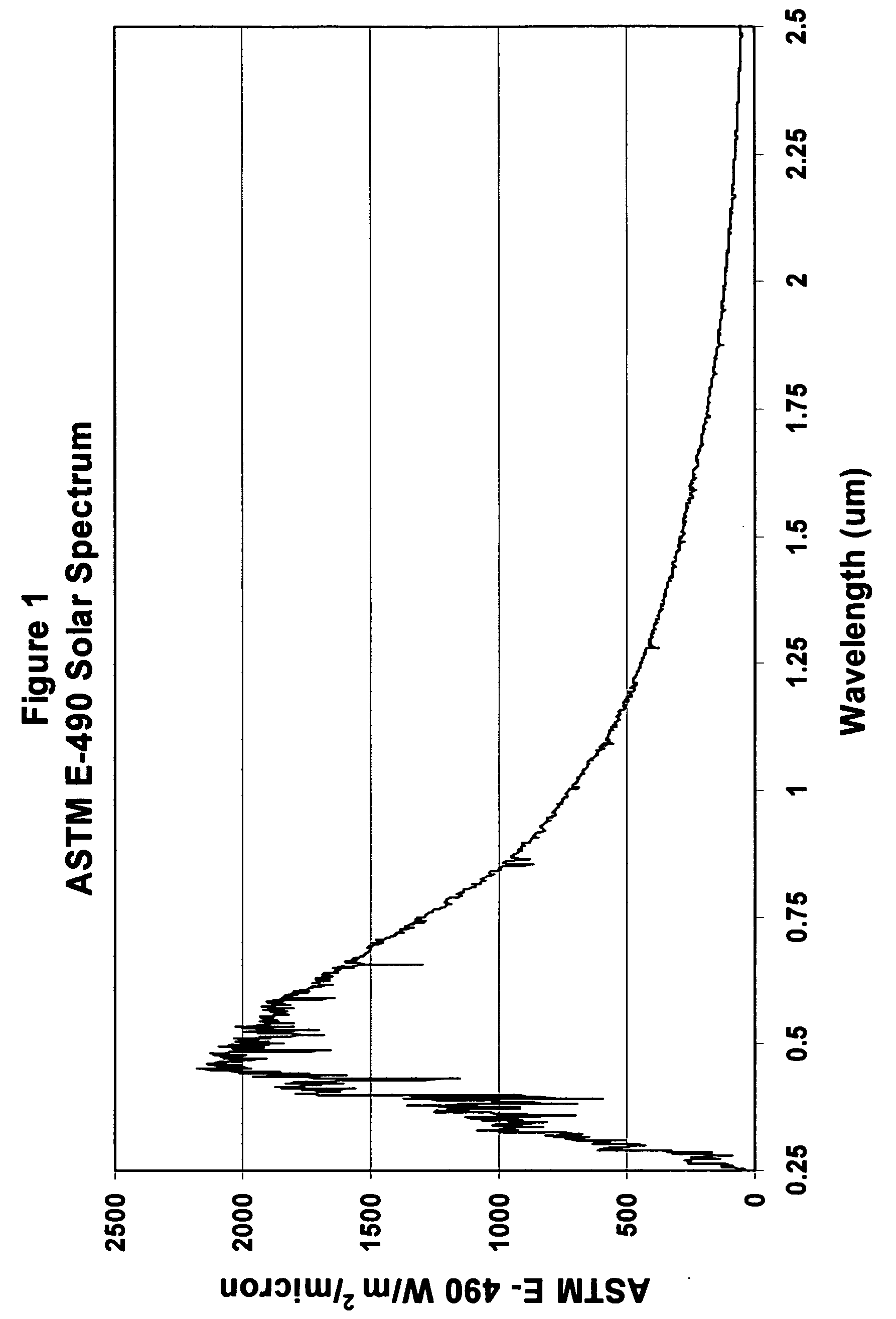

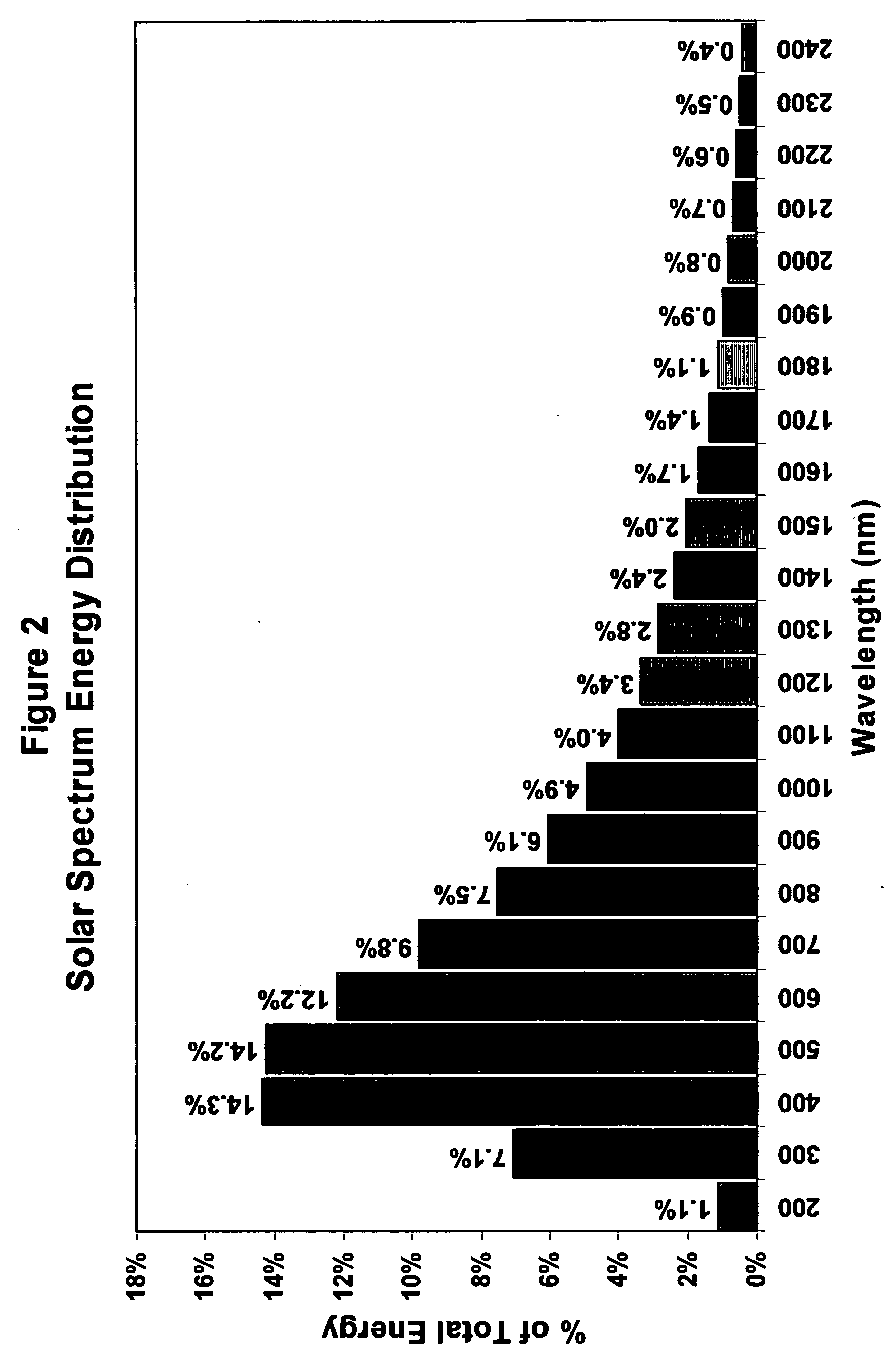

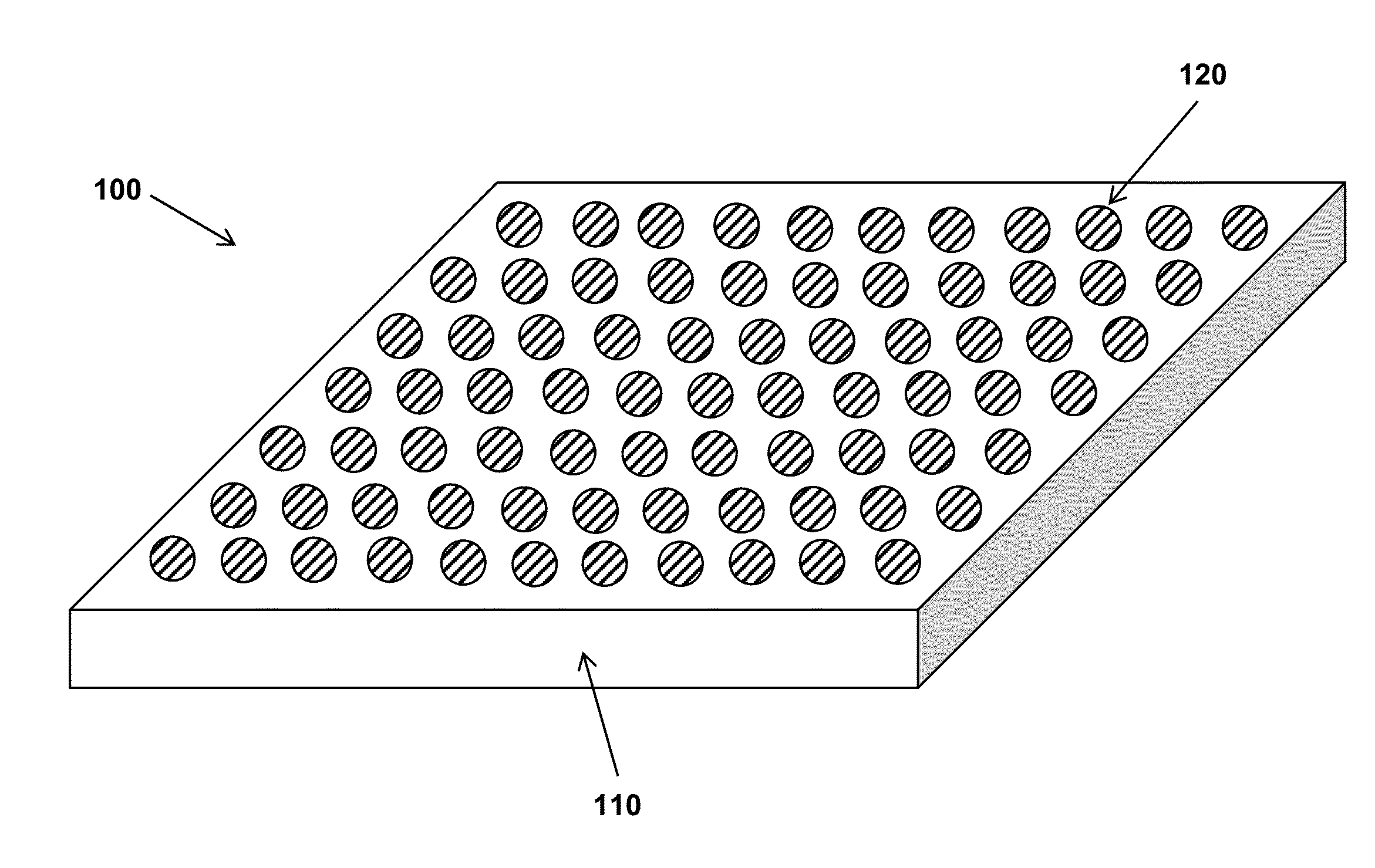

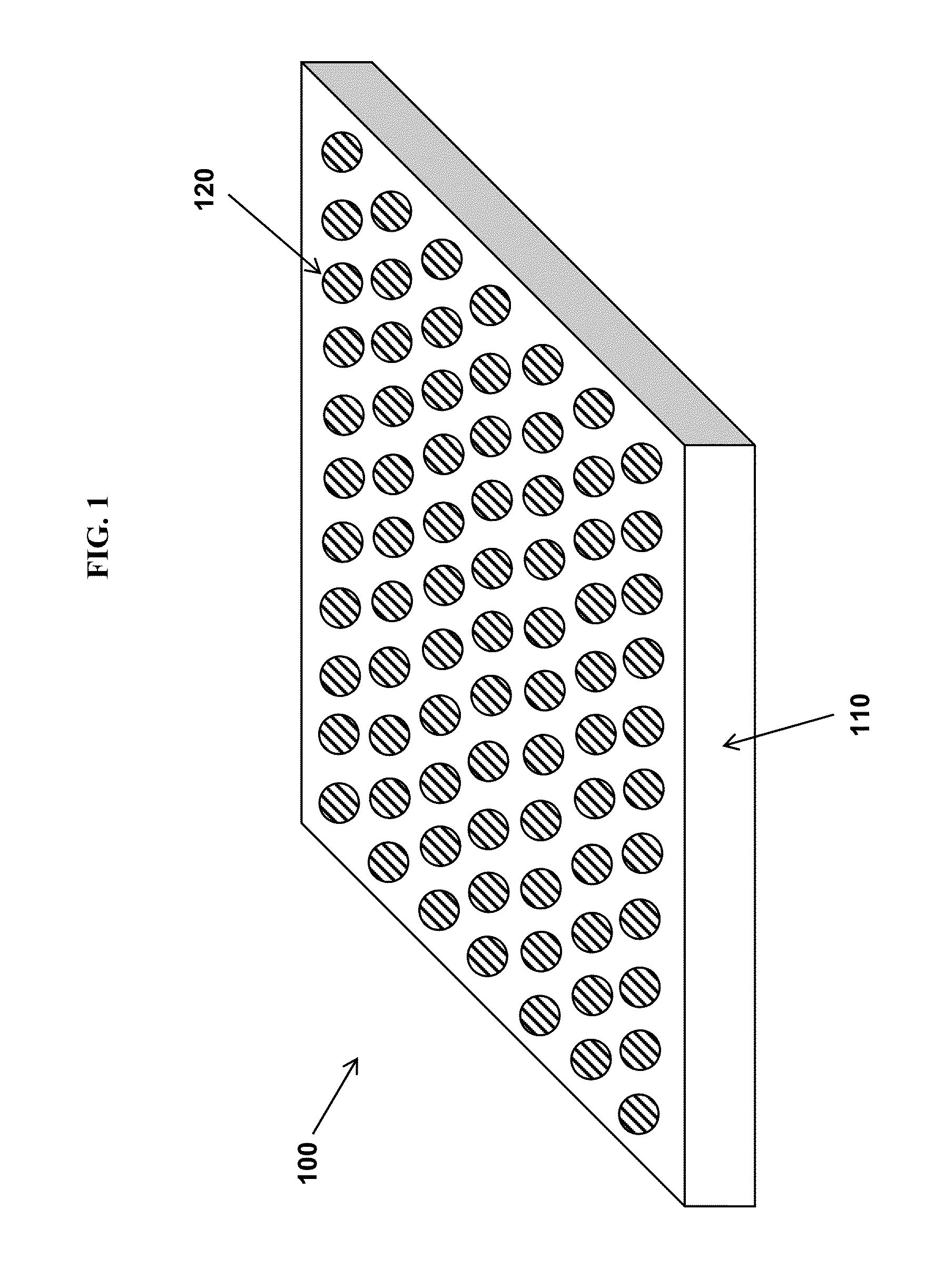

InactiveUS20050126441A1High infrared reflectivityLow thermal conductivityPigmenting treatmentCeramic layered productsCoating systemSolar spectra

A composition for a Coating System (paint) which forms an insulating material being designed to both reflect infrared radiation and have reduced thermal conductivity. The coating system may be either a single Thermal Coating or may be a Thermal Coating used in combination with a Thermal Primer. The Thermal Coating is formulated using conventional techniques and a resin used in paint manufacture, but utilizes primary pigments and extender mineral pigments which preferentially reflect in the infra red area of the solar spectrum. A method of characterizing particulate materials for their infra red reflectivity is described, which provides a means for preferential selection of particulate additives based on their relative visible light and infrared reflectivity. Additionally the incorporation of hollow micro-spheres is desired to reduce thermal conductivity. The Thermal Primer is designed to provide adhesion between the Thermal Coating and the substrate on which it is applied and uses conventional techniques to achieve those properties. However it has been found advantageous to incorporate hollow micro-spheres with low thermal conductivity, such as glass, ceramic or polymeric micro-spheres and / or an extender pigment with low thermal conductivity such as calcined clay to further reduce heat flow through the Coating System.

Owner:ANTHONY DAVID SKELHORN

Degradable polymer filmcoated controlled release fertilizer, preparation thereof and special filmcoated material

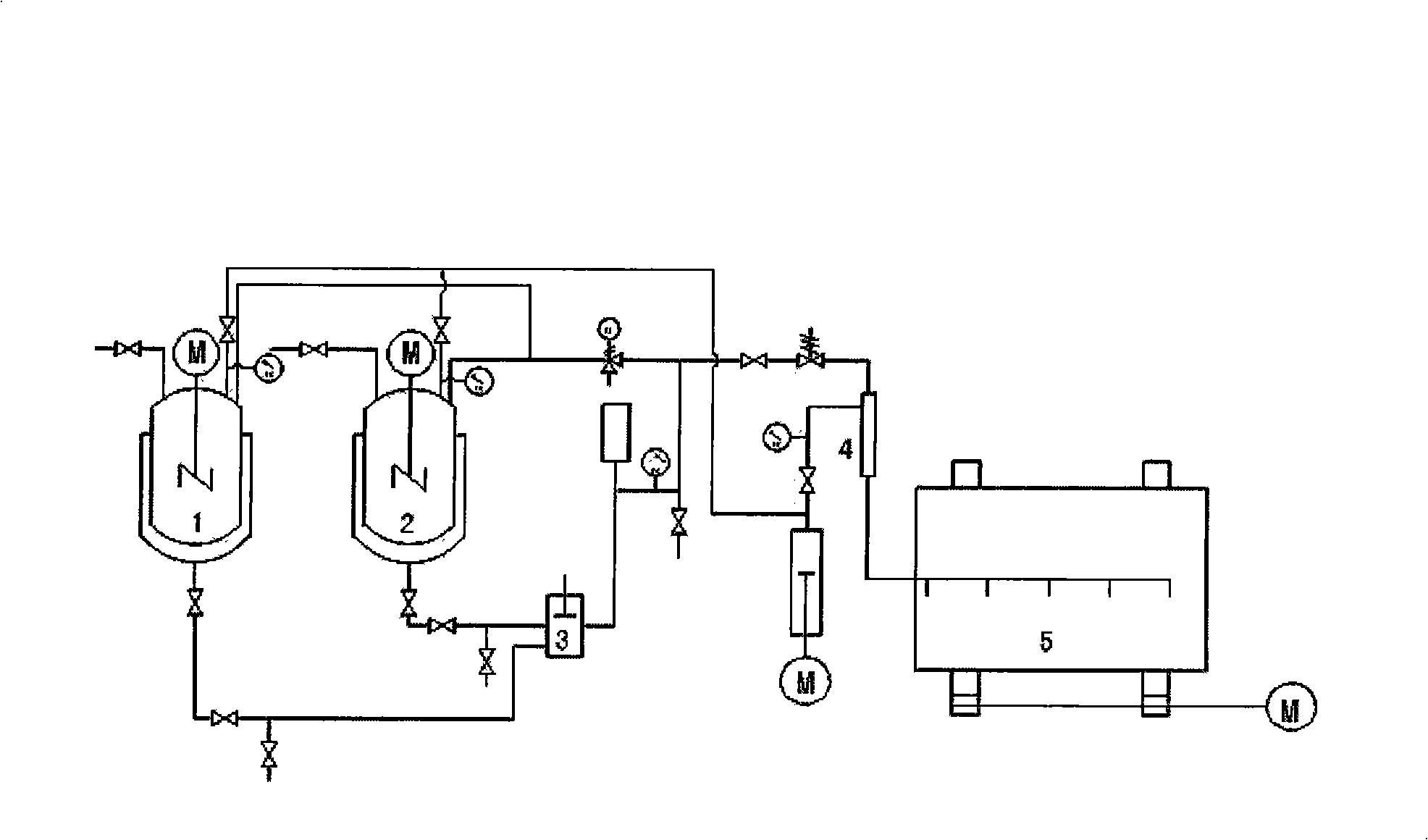

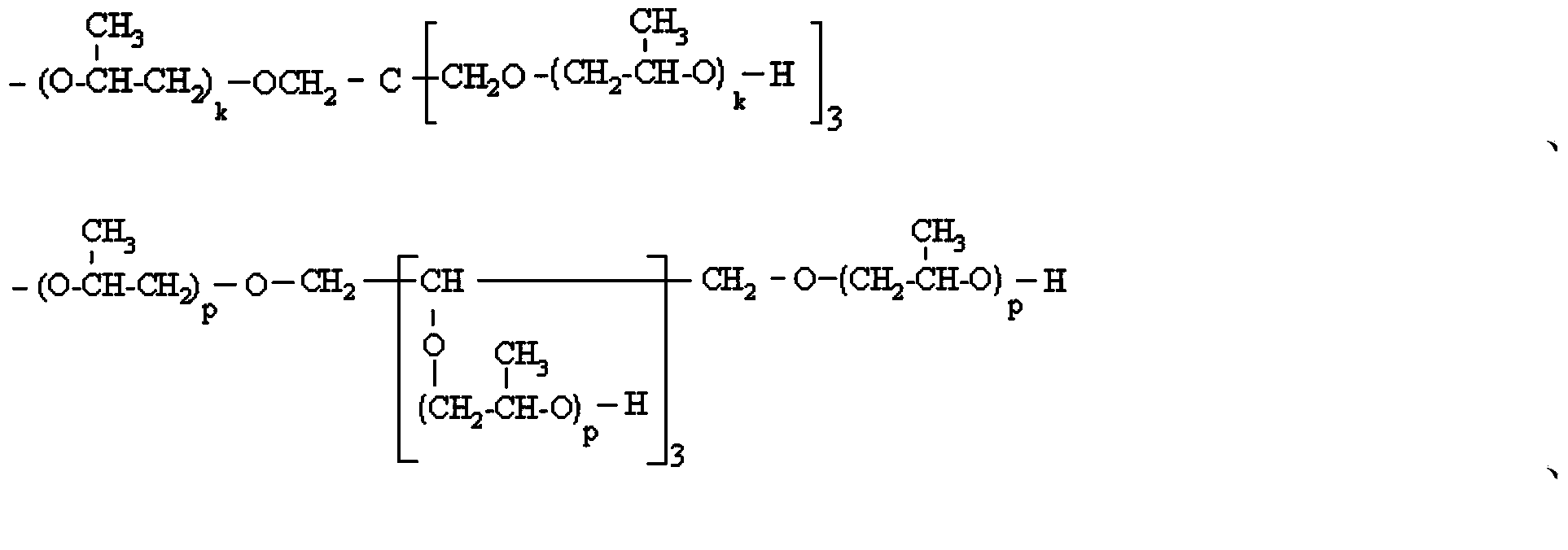

ActiveCN101323545AHas the ability to degradeAchieve friendlyFertilizer mixturesControl releasePolyol

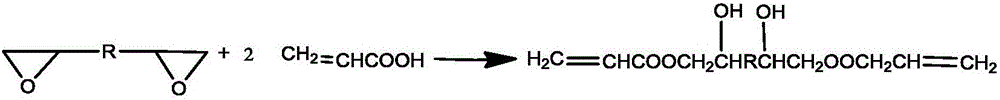

The invention discloses a polymer coated released fertilizer and a preparation method thereof and a special coating material thereof. The coating material comprises isocyanate, polyol, degradable functional monomer, an aid agent of coating and a chain extender, wherein, the mol ratio between the isocyano group in the isocyanate and the hydroxyl group in the polyol is 1:2 to 2:1 and the mass of the degradable functional monomer is 1 percent to 20 percent of the mass of the coating material. The coated released fertilizer provided by the invention consists of a core and a karyotheca, wherein, the core is granule fertilizer and the karyotheca is prepared from the coating material, and the mass of the karyotheca is 2 percent to 10 percent of the mass of the core. The coating material has good film forming and water resisting performance and can be degraded in nature. The hardness and the elasticity of the material can be adjusted by changing the mixure ratio of the coating material so as to prepare released fertilizers with different releasing periods.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

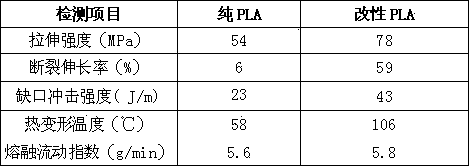

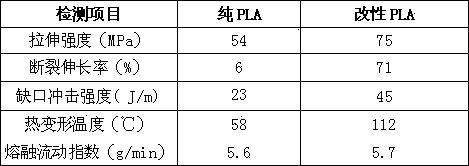

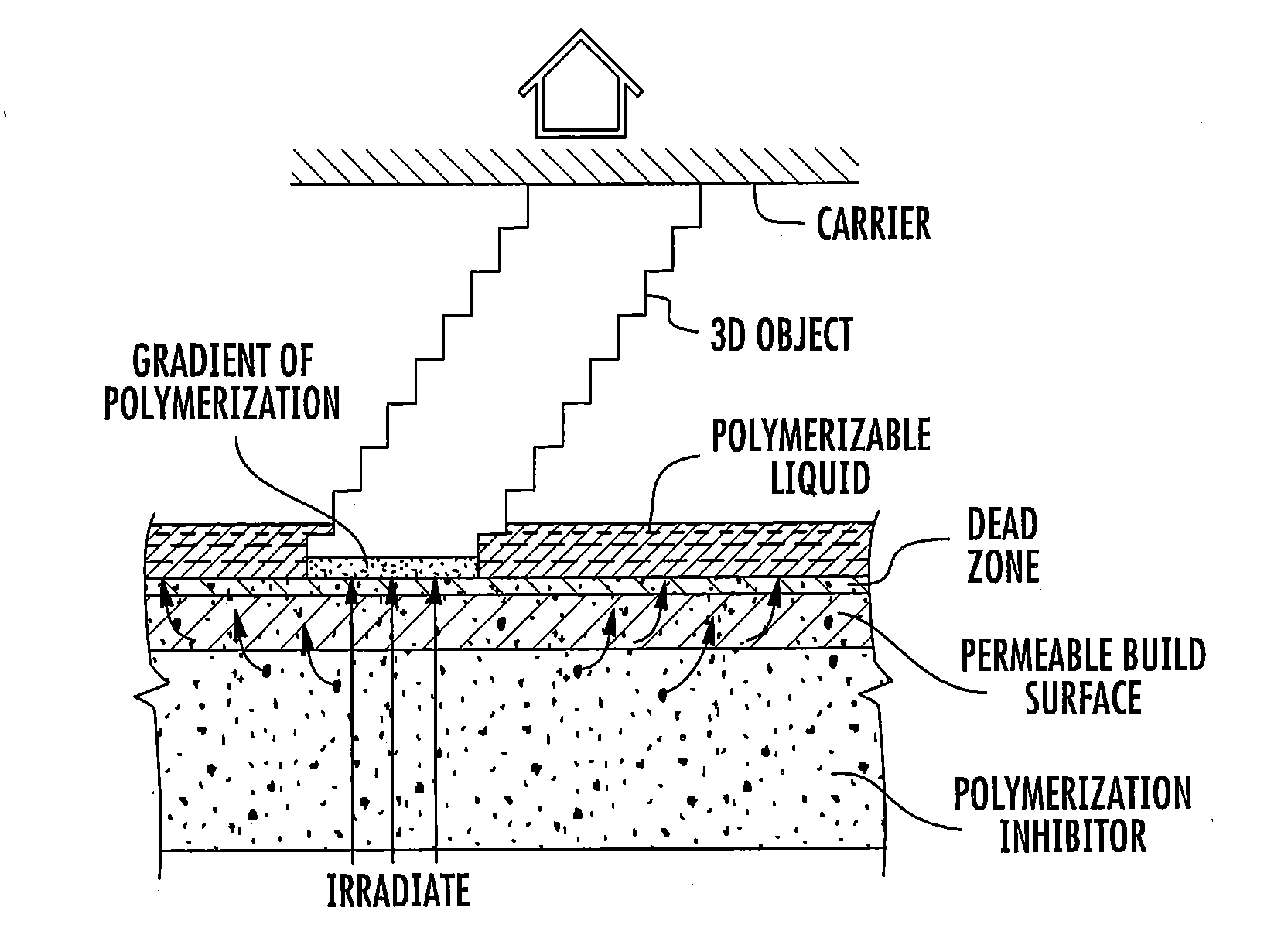

3D printing modified polylactic acid material and preparation method thereof

InactiveCN103467950AIncrease profitSelf-performance has not declinedMonocomponent polyesters artificial filamentArtifical filament manufactureHeat deflection temperaturePolymer science

A 3D printing modified polylactic acid material comprises, by weight, 70-85 parts of polylactic acid, 1-5 parts of chain extenders, 1-5 parts of cross-linking agents, 0.5-1 part of nucleating agents, 5-10 parts of polymers with low molecular weights, 5-10 parts of flexibilizers, 1-5 parts of fortifiers and 0.3-0.8 part of antioxidants. According to the 3D printing modified polylactic acid material, a low-temperature smashing hybrid reaction technology is utilized, modified processing is carried out on polylactic acid, toughness, impact strength and the heat distortion temperature for the polylactic acid are improved to a large extent, and the polylactic acid can have wider application prospects in 3D printing materials.

Owner:佛山市斯太克科技有限公司

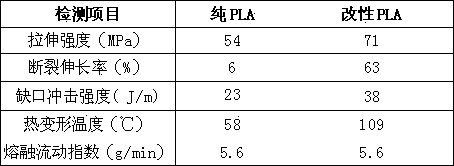

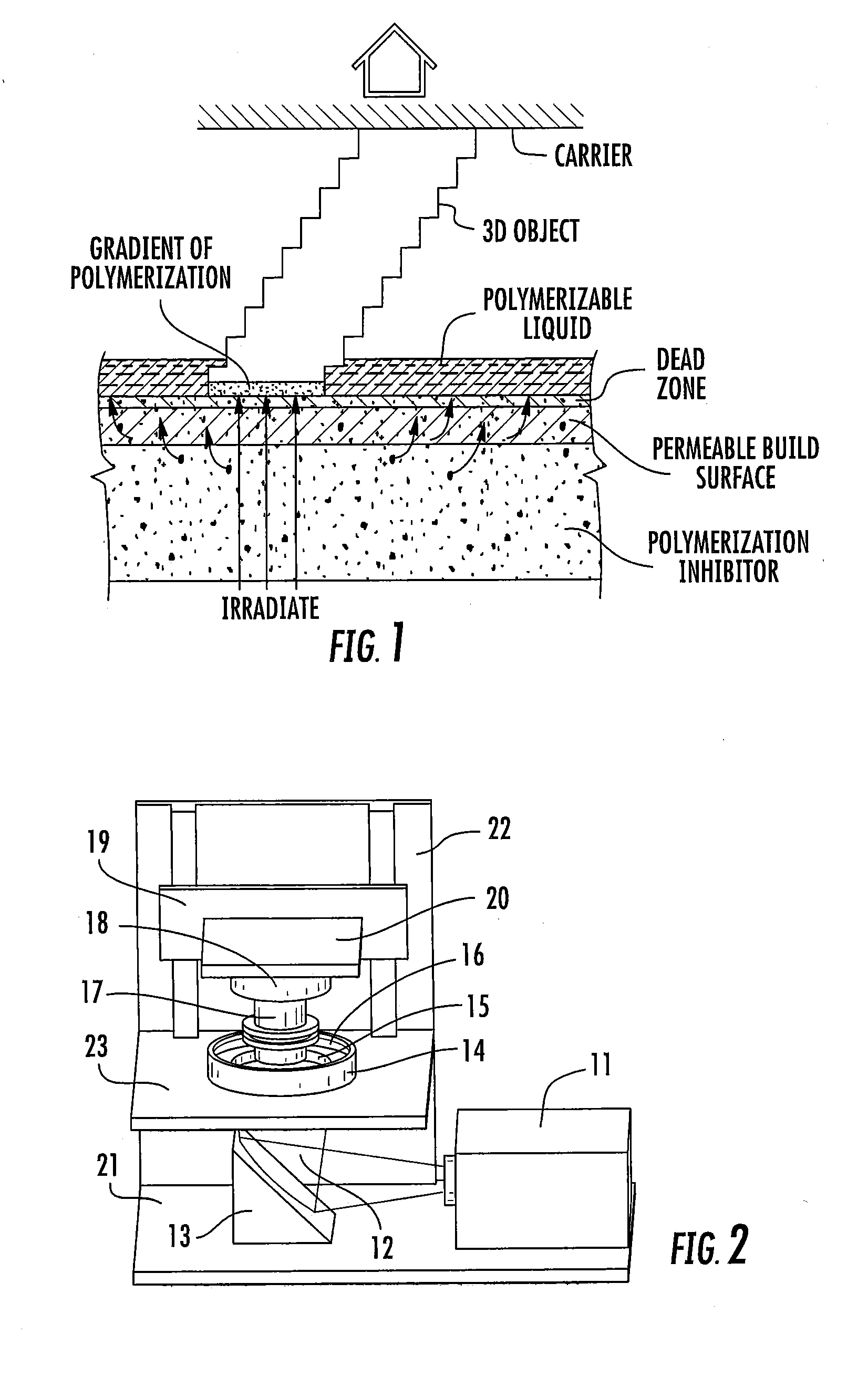

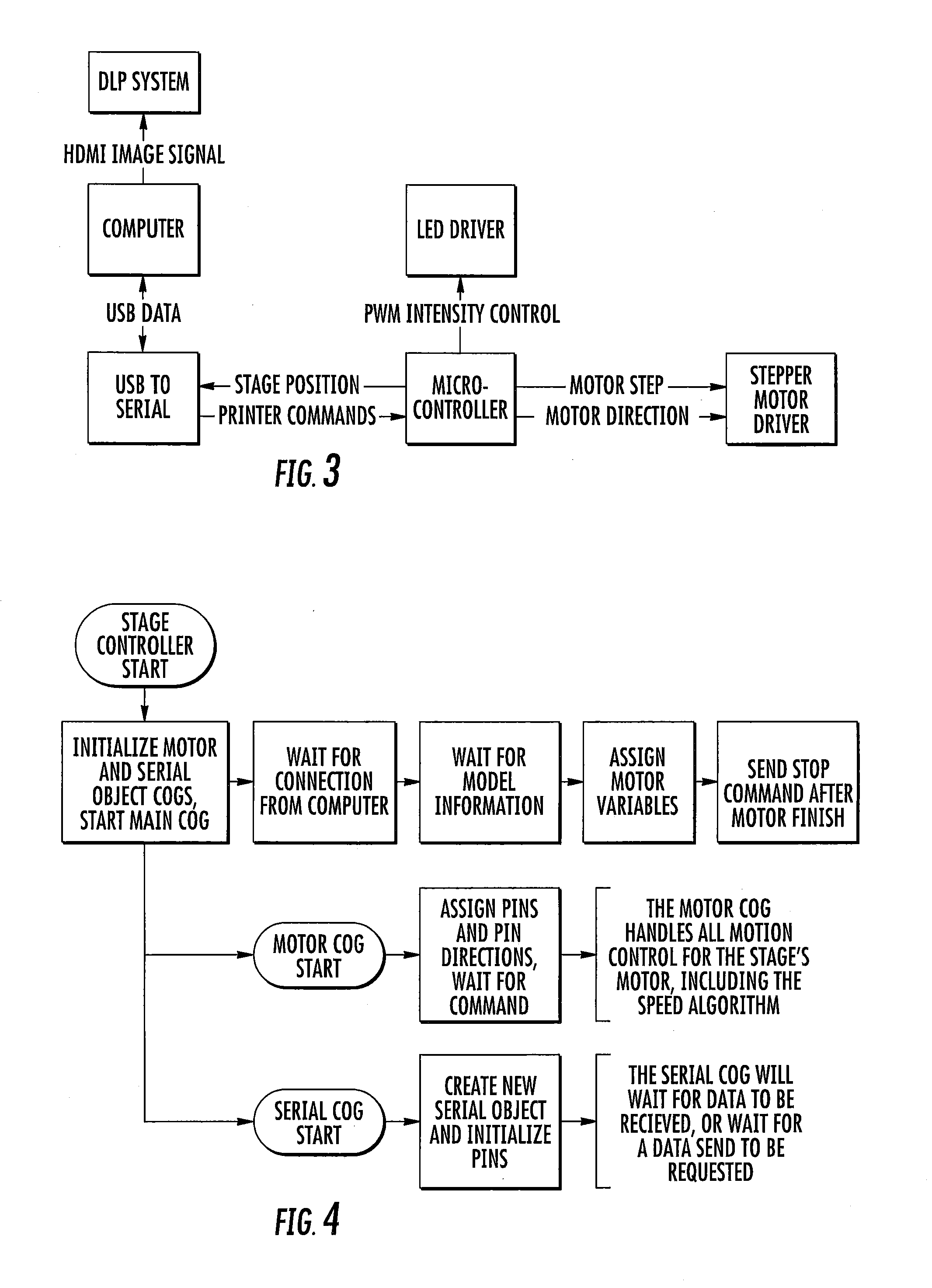

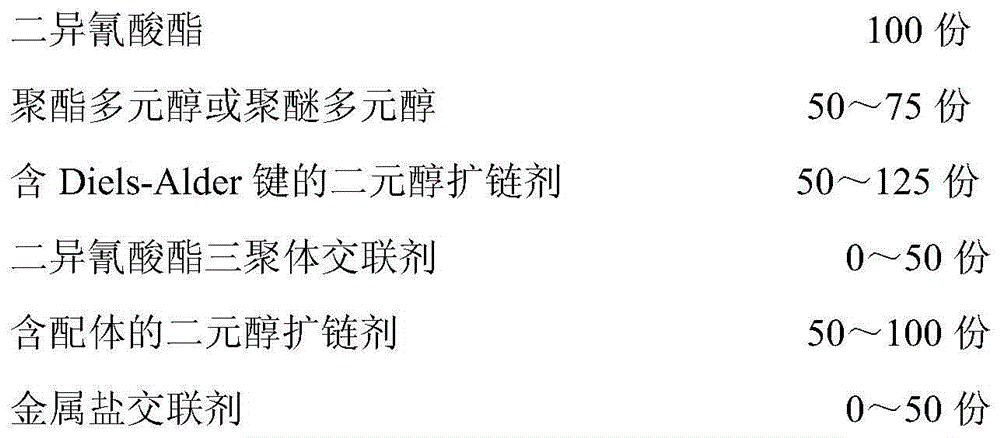

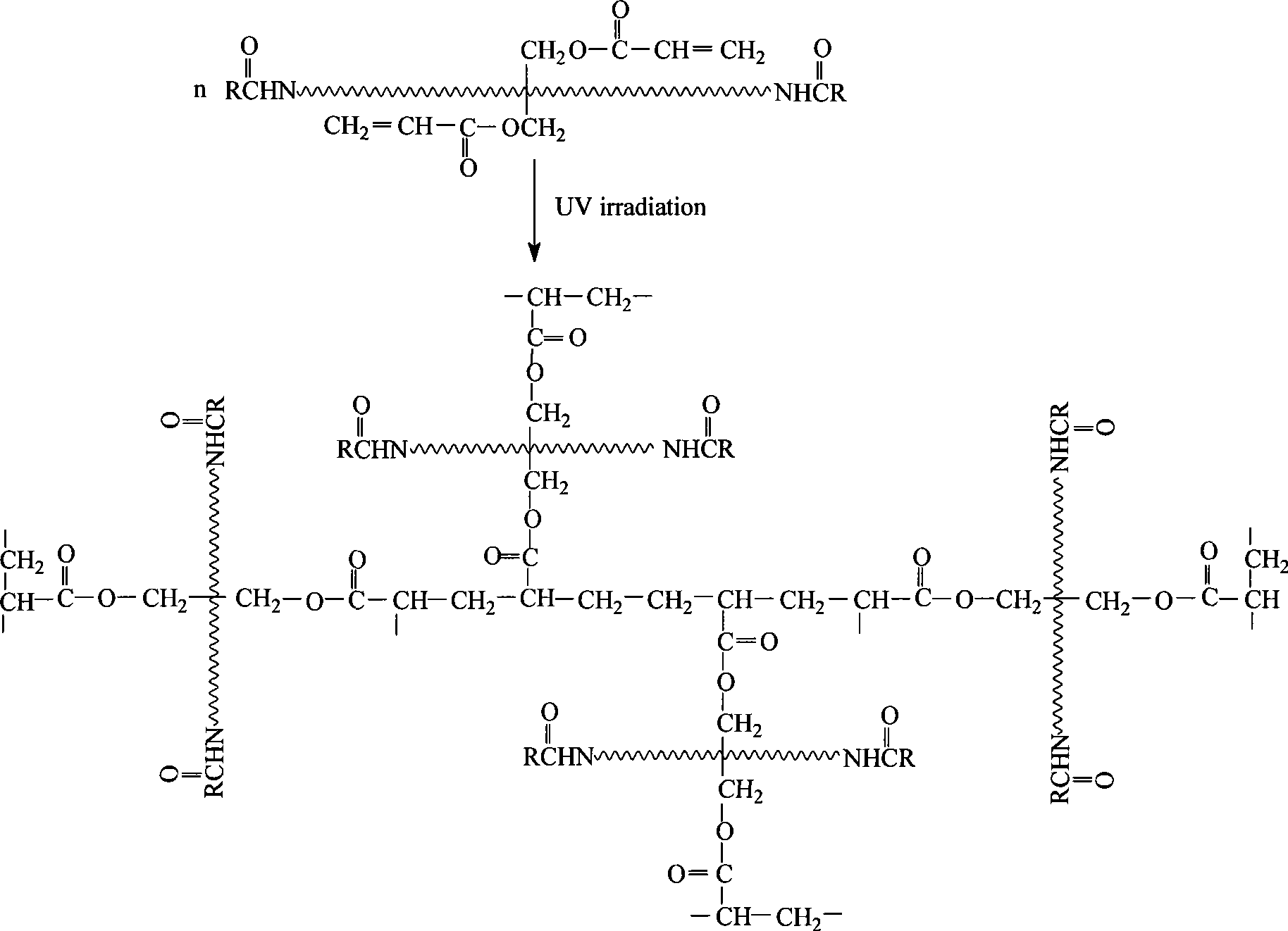

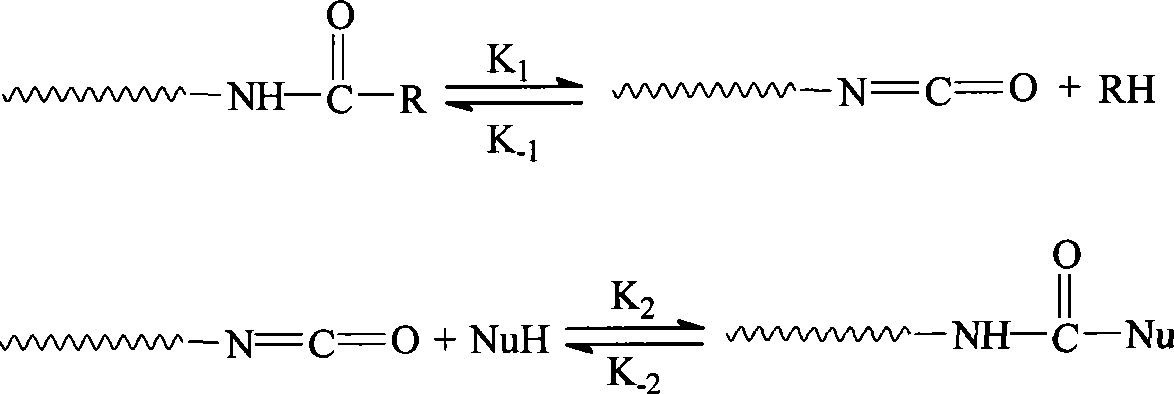

Methods of producing polyurethane three-dimensional objects from materials having multiple mechanisms of hardening

ActiveUS20160137838A1Increased formationEnhance or speed the refilling of the build regionManufacturing enclosuresOptical articlesEndcappingPolymer science

A method of forming a three-dimensional object of polyurethane, polyurea, or copolymer thereof is carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid, the polymerizable liquid including at least one of: (i) a blocked or reactive blocked prepolymer, (ii) a blocked or reactive blocked diisocyanate, or (iii) a blocked or reactive blocked diisocyanate chain extender; (c) irradiating the build region with light through the optically transparent member to form a solid blocked polymer scaffold and advancing the carrier away from the build surface to form a three-dimensional intermediate having the same shape as, or a shape to be imparted to, the three-dimensional object, with the intermediate containing the chain extender; and then (d) heating or microwave irradiating the three-dimensional intermediate sufficiently to form from the three-dimensional intermediate the three-dimensional object of polyurethane, polyurea, or copolymer thereof.

Owner:CARBON INC

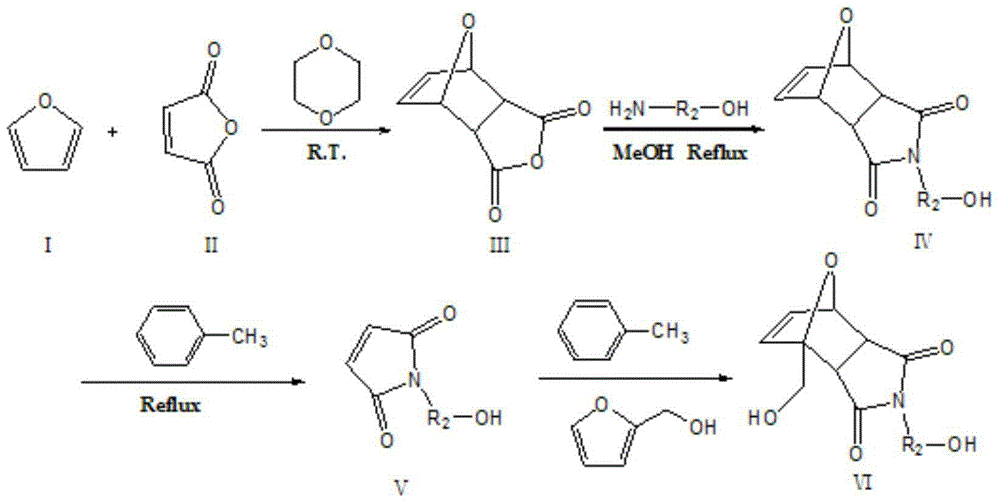

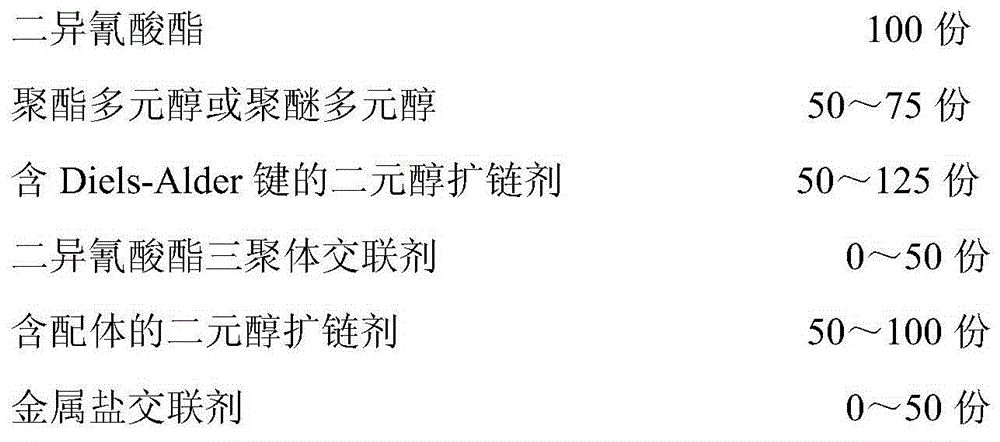

Dynamic bond-containing polyurethane material for 3D printing and its preparation method and use

ActiveCN104961881ALow viscosity3D printing process facilitatesAdditive manufacturing apparatusOrganic chemistryPolyesterAlcohol

Owner:SICHUAN UNIV

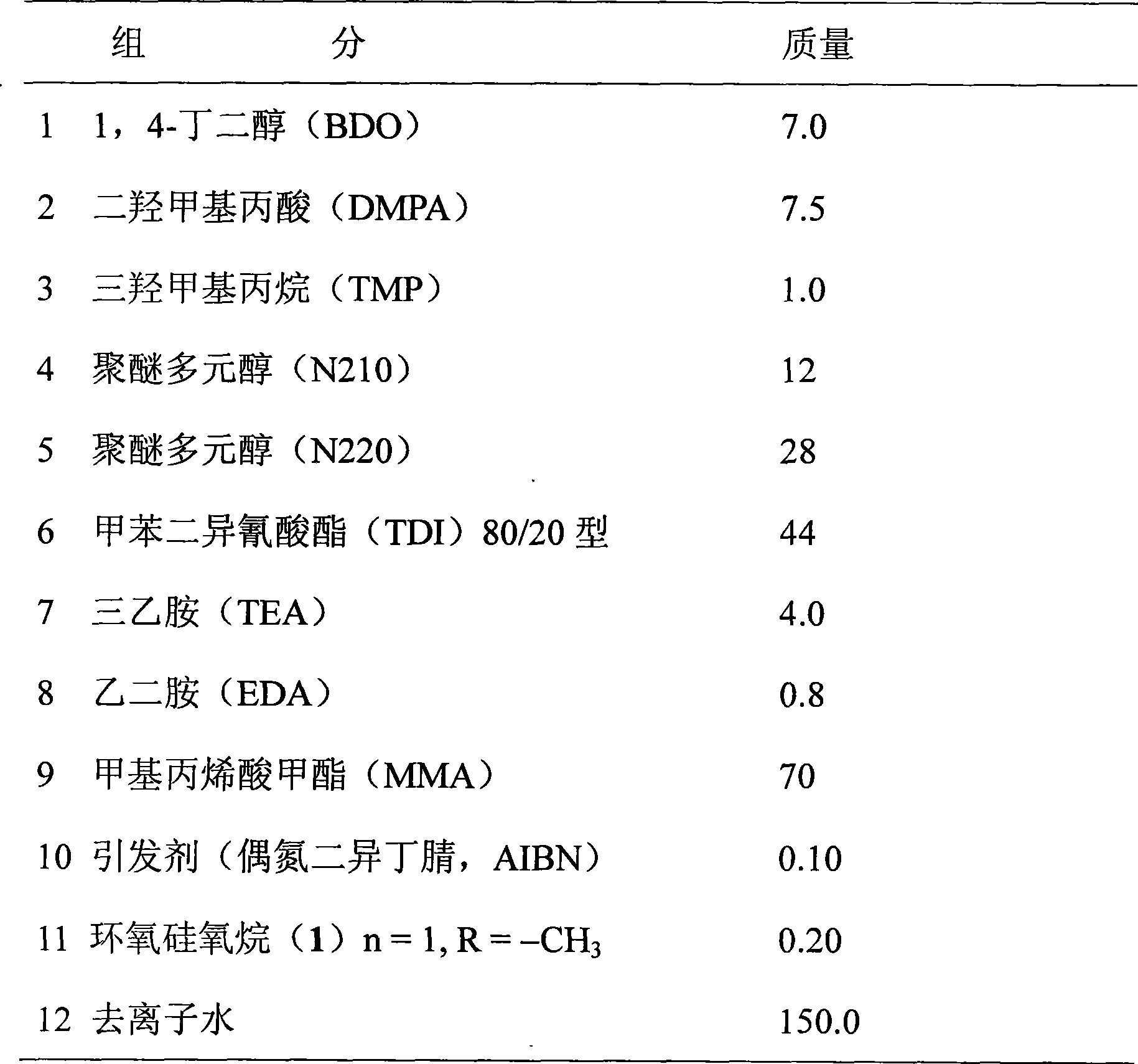

High solid content latent curing polyurethane acroleic acid hybrid emulsion

InactiveCN101481451AHigh solid contentHigh glossPolyurea/polyurethane coatingsPolyesterPolymer science

The invention relates to a method for preparing a high solid content latent cured polyurethane acrylic acid heterozygous latex and an application thereof. The preparation method comprises the following steps: pre-polymerizing polyester polyalcohol, hydrophilic chain extender and diisocyanate monomer to obtain the polyurethane prepolymer containing a hydrophilic group (carboxyl or sulfo group) and a terminal NCO group; then, neutralizing the polymer into salt and dispersing the salt in water to prepare the polyurethane water dispersoid; finally, using the dispersoid as macro molecular emulsifying agent and reactant to emulsify and disperse the acrylic ester monomer, initiating the polymerization by heating, dropping initiator to perform the latex polymerization, and regulating the pH of the latex by adding a latent curing agent to obtain the high solid content latent cured polyurethane acrylic acid heterozygous latex. The high solid content latent cured polyurethane acrylic acid heterozygous latex has a solid content of above 45%; the storage of the high solid content latent cured polyurethane acrylic acid heterozygous latex is stable; and high hardness film coating can be formed at the room temperature. Compared with acrylic acid latex and polyurethane latex, the high solid content latent cured polyurethane acrylic acid heterozygous latex has better film forming performance, water resistance, alcohol resistance, pollution resistance, dry / wet cleaning resistance and chemical solvent resistance, as well as high hardness.

Owner:SOUTH CHINA UNIV OF TECH

Sealed UV curable aqueous polyurethane resin and preparation method thereof

InactiveCN101381446AGood storage stabilityHigh hardnessPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsSide chainAdhesive

The invention discloses closed type ultraviolet light solidifying waterborne polyurethane resin and a method for preparing the same. The polyurethane resin and the method are characterized in that the double bond of acrylic ester is introduced to the side chain of the polyurethane by utilizing a chain extender mode, and an end NCO group is sealed and protected by a sealer; and the side chain of a molecular chain of the obtained product has the double bond of an acrylic ester group, wherein the double bond is capable of ultraviolet light solidifying, and the end of a molecular main chain of the product has an unsealable sealer group. The polyurethane resin has the advantages of good storage stability and high hardness after solidification, and further improves the solidifying degree and the adhesive force of a solidifying film and is applied to the coating of workpiece shadow areas, thicker coatings and three-dimensional parts which are hard to penetrate by ultraviolet light. Because the resin coating film is subjected to triple solidification of natural drying solidification, ultraviolet solidification and unsealing-hot solidification, the resin coating film has the advantages of high solidifying degree, high hardness and high adhesive force of base materials. The product of the invention is obviously environmental friendly, and can be widely applied in fields of thick coatings of various base materials and an adhesive.

Owner:UNIV OF SCI & TECH OF CHINA +1

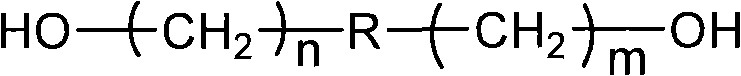

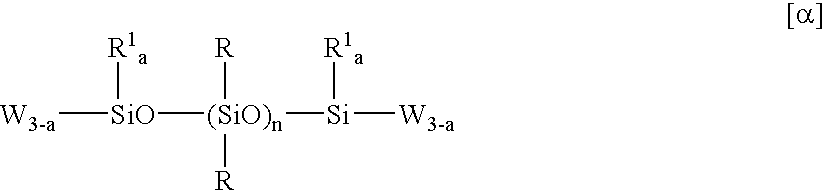

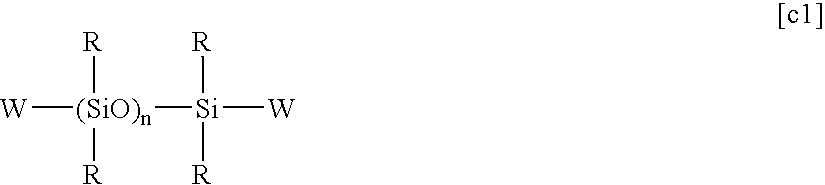

Low-friction fluorinated coatings

Low-friction fluorinated coatings are disclosed herein. A preferred low-friction material contains a low-surface-energy fluoropolymer having a surface energy between about 5 mJ / m2 to about 50 mJ / m2, and a hygroscopic material that is covalently connected to the fluoropolymer in a triblock copolymer, such as PEG-PFPE-PEG. The material forms a lubricating surface layer in the presence of humidity. An exemplary copolymer comprises fluoropolymers with average molecular weight from 500 g / mol to 20,000 g / mol, wherein the fluoropolymers are (α,ω)-hydroxyl-terminated and / or (α,ω)-amine-terminated, and wherein the fluoropolymers are present in the triblock structure T-(CH2—CH2—O)—CH2—CF2—O—(CF2—CF2—O)m(CF2—O)n—CF2—CH2—(O—CH2—CH2)p-T where T is a hydroxyl or amine terminal group, p=1 to 50, m=1 to 100, and n=1 to 100. The copolymer also contains isocyanate species and polyol or polyamine chain extenders or crosslinkers possessing a functionality of preferably 3 or greater. These durable, solvent-resistant, and transparent coatings reduce insect debris following impact.

Owner:HRL LAB

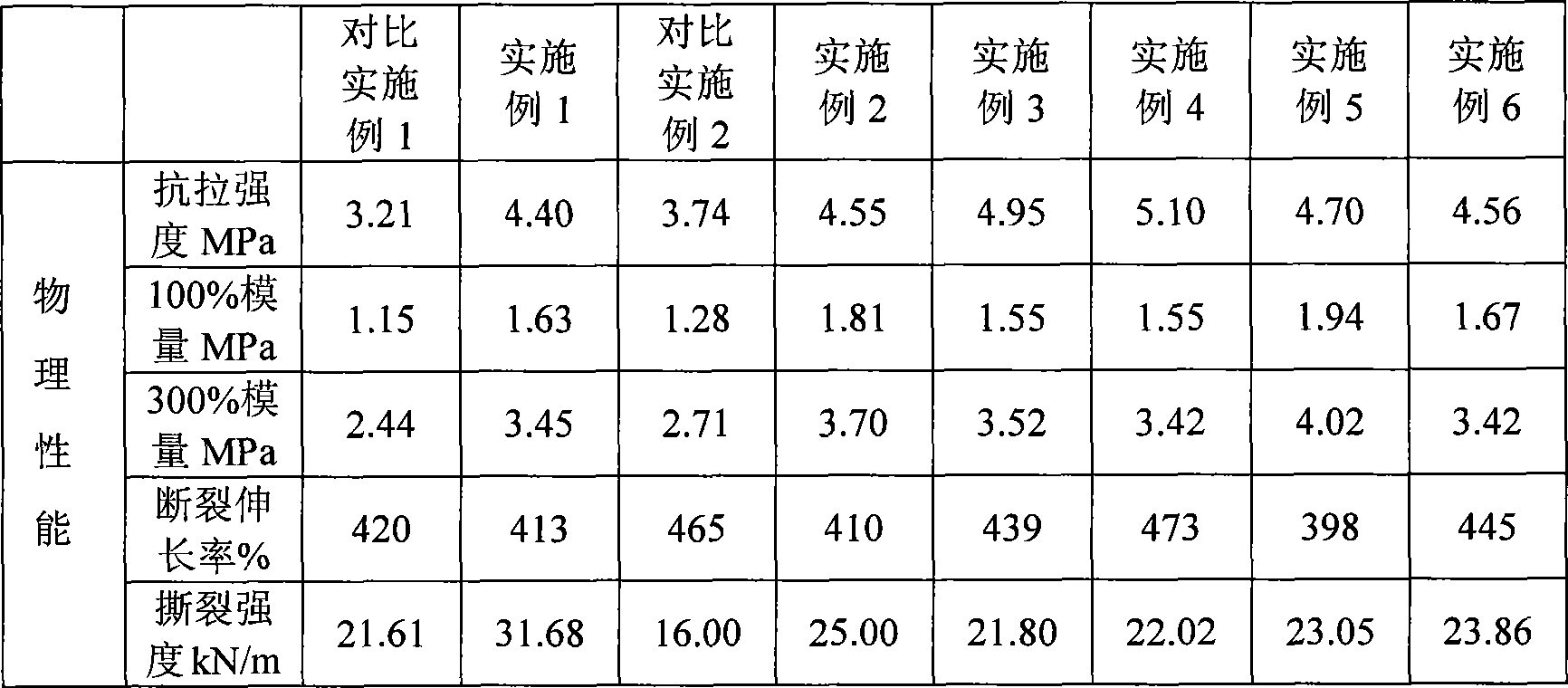

High performance nano polyurethane micropore elastomer composite material and preparation thereof

ActiveCN101486834AImprove mechanical propertiesHigh tensile strengthFoaming agentPolyether polyurethane

The invention discloses a high-performance nanometer polyurethane microcellular elastomer composite material and a preparation method thereof. Organic montmorillonite is added into polyether glycol I, heated and stirred, thus obtaining stably dispersed colloidal fluid; then polyether glycol II, an alcohols chain-extender, a foaming agent, a foam stabilizer and a catalyst are added, fully and evenly mixed, thus obtaining component A. B component is a performed polymer prepared by the reaction of the polyether glycol I, vulcabond or polyisocyanates at the temperature between 60 and 90 DEG C, with NCO percentage controlled between 17 and 26 percent by weight. The components A and B are mixed at high speed according to the weight mixture ratio that A:B equals to 0.5:1 to 3:1 by using a casting machine and at the temperature of 30-55 DEG C, and injected into a mould for injection moulding, consequently, the high-performance nanometer polyurethane microcellular elastomer composite material is obtained. With low cost, the invention improves a plurality of mechanical properties of a polyether polyurethane microcellular elastomer, such as the tensile strength, modulus and tear strength and the like, and broadens the application field of materials. The composite material can be used as shoe parts, bottom materials, bearing tires or shock absorption buffering materials, and the like. With a bi-component system and a casting moulding technology adopted simultaneously, the invention is simple and can be easily controlled, thus bringing convenience to production promotion.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

Transparent high-elasticity thermoplastic polyurethane and method of producing the same

The invention relates to a transparent, high-elasticity and thermoplastic polyurethane and a preparation method thereof. The formula thereof by weight is as follows: 70 portions to 90 portions of polyether polyol, 3 portions to 20 portions of small molecular chain extender, 10 portions to 30 portions of diisocyanate, 0.1 portion to 0.5 portion of catalyst, 0 portion to 1.0 portion of antioxidant, 0 portion to 1.0 portion of yellowing resistant agent and 0 portion to 20 portions of other filler. An extruder method is adopted for production. The products can be applied to transparent shoulder straps, clothes, documentation material for shoes and the like.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Two component spray polyurea waterproof paint and preparation method and construction method of same

ActiveCN101531861AImprove aging resistanceStable structureAntifouling/underwater paintsPaints with biocidesElastomerPolyol

The invention relates to a two component spray polyurea waterproof paint and a preparation method and a construction method of the same. The waterproof paint comprises a component A and a component B, wherein by weight portion, the raw material system of the component A comprises 40 to 60 portions of polyisocyanates, 30 to 45 portions of polyether polyols, 5 to 15 portions of hydroxy silicone oil; and the raw material system of the component B comprises 35 to 60 portions of amino terminated polyethers, 20 to 45 portions of amine chain extenders and 5 to 20 portions of amino silicone oil. Waterproof materials made of the waterproof paint have the combined high performance of a polyurea elastomer and an organosilicon material, high overall physical properties, excellent color retention and ultraviolet radiation resistance, can be used in waterproofing work exposed in atmospheric environment, and are particularly applicable to waterproof coatings of roads and bridges on a passenger special line. The preparation method of the waterproof paint has the advantages of simple process and environmental protection. The construction method of the waterproof paint can allow the paint to moisten and penetrate into substrate materials effectively from the surfaces of the substrate materials, so that the waterproof coatings have better appearance.

Owner:中建材苏州防水研究院有限公司

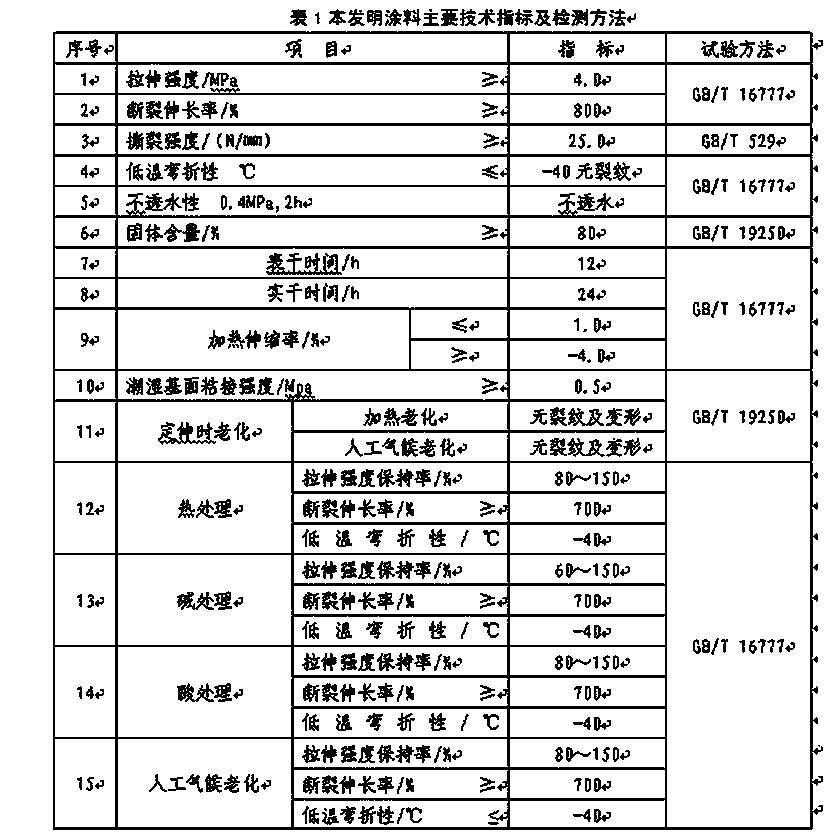

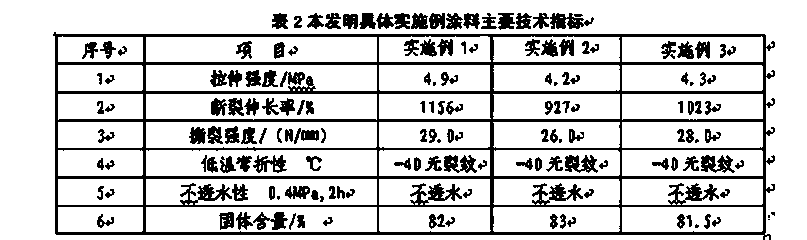

Structural flame retardant type spray coating material of polyurethane elastomer and construction method

InactiveCN1563234ANo addedFast curingPolyurea/polyurethane coatingsPolyurethane elastomerSpray coating

A fire-resisting and spraying type of polyurethane elastomer consists of A composition being semi-prepolymer prepared from low functional degree of polyisocyanic acid ester and polyether-polyalcohol as well as B composition prepared from amine chain extender, fire resisting polyether and end azyl polyether. The application method includes mixing the two compositions uniformly, sending the mixture to spraying gun by material conveying tube, increasing pressure to spray mixture on object surface for forming fire resisting type of sprayed polyurethane and polyether elastomer material instantly.

Owner:JIANGSU CHEM RES INST

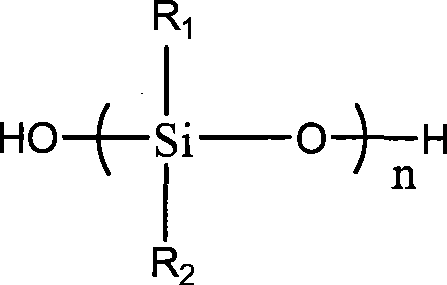

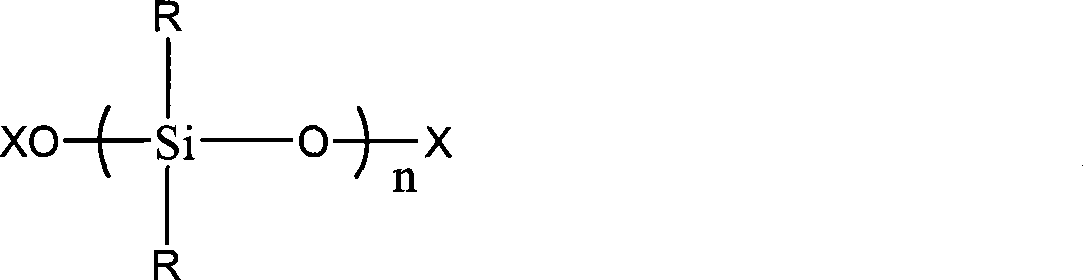

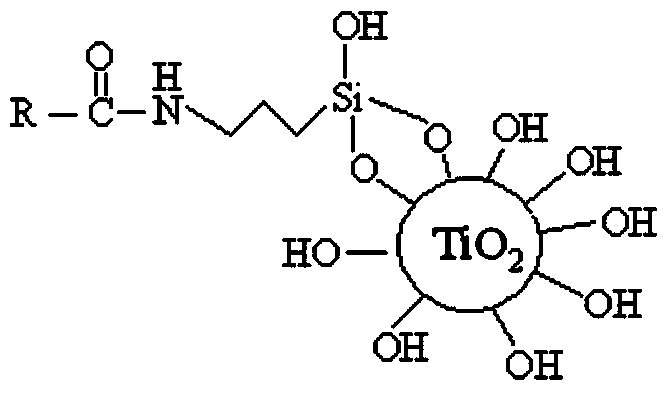

Water-based polyurethane paint containing polyether glycol/nano TiO2 hybrid material

ActiveCN104403548AGood thermal propertiesImprove mechanical propertiesPolyurea/polyurethane coatingsWater basedOrganometallic catalysis

The invention belongs to the technical field of water-based polyurethane paints, and discloses a water-based polyurethane paint containing a polyether glycol / nano TiO2 hybrid material, and a preparation method and application thereof. The paint comprises the following components in parts by mass: 25-75 parts of polyether glycol / nano titanium dioxide hybrid material, 15-65 parts of diisocyanate, 100 parts of polyether glycol, 8-16 parts of polyhydroxy-carboxylic acid, 0.05-0.5 part of organo-metallic catalyst, 0.5-10 parts of crosslinking agent, 6.2-12.4 parts of neutralizer, 1-8 parts of chain extender and 0.2-2.0 parts of defoaming agent. The paint enhances the compatibility between the nano titanium dioxide and polyurethane base, has the advantages of favorable thermal properties, favorable mechanical properties, favorable wear resistance and excellent ultraviolet resistance, and can be widely used in the fields of architectural paints, automobile paints, wood paints, electrodeposition paints, paper conditioning paints, glass fiber paints, electrophoretic paints and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Composite material for 3D printing and preparation method thereof

The invention relates to a 3D printing material and a preparation method thereof, and in particular, relates to a composite material for 3D printing and a preparation method thereof. Specifically, the invention provides a composition comprising: 1) a polyester copolymer prepared by copolymerizing the following components: i) substituted or unsubstituted aliphatic or alicyclic polybasic acid, ii) substituted or unsubstituted aliphatic or alicyclic polyol, and iii) substituted or unsubstituted aromatic polybasic acid; 2) a chain extender; and 3) inorganic particles.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-performance water-based polyurethane dispersoid and application thereof

ActiveCN101265318AImprove water resistanceImprove alcohol resistancePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsWater basedAdhesive

The invention discloses a high-performance aqueous polyurethane dispersion, which adopts polyurethane prepolymer liquid, chain extender, neutralizer and water for preparation; the polyurethane prepolymer liquid adopts polymer polyol containing a cyclic structure with the weight percentage of 2 to 80 percent as the main raw material and polyisocyanate for preparation. The polymer polyol of the polyurethane prepolymer liquid which is prepared by screening contains 2 to 80 percent cyclic structure, the aqueous polyurethane dispersion film forming substance can not be whitened by being soaked in the water for 24 hours and being soaked in liquor with 50 degrees for 2 hours, the hardness is not lower than H, the heat-resistant temperature is not lower than 65 DEG C, the water-resistant performance, the alcohol-resistant performance, the heat-resistant performance and the hardness are completely improved, and the novel high-performance aqueous polyurethane dispersion can be used as an aqueous paint base material and a waterproof adhesive.

Owner:海聚高分子材料科技(广州)有限公司

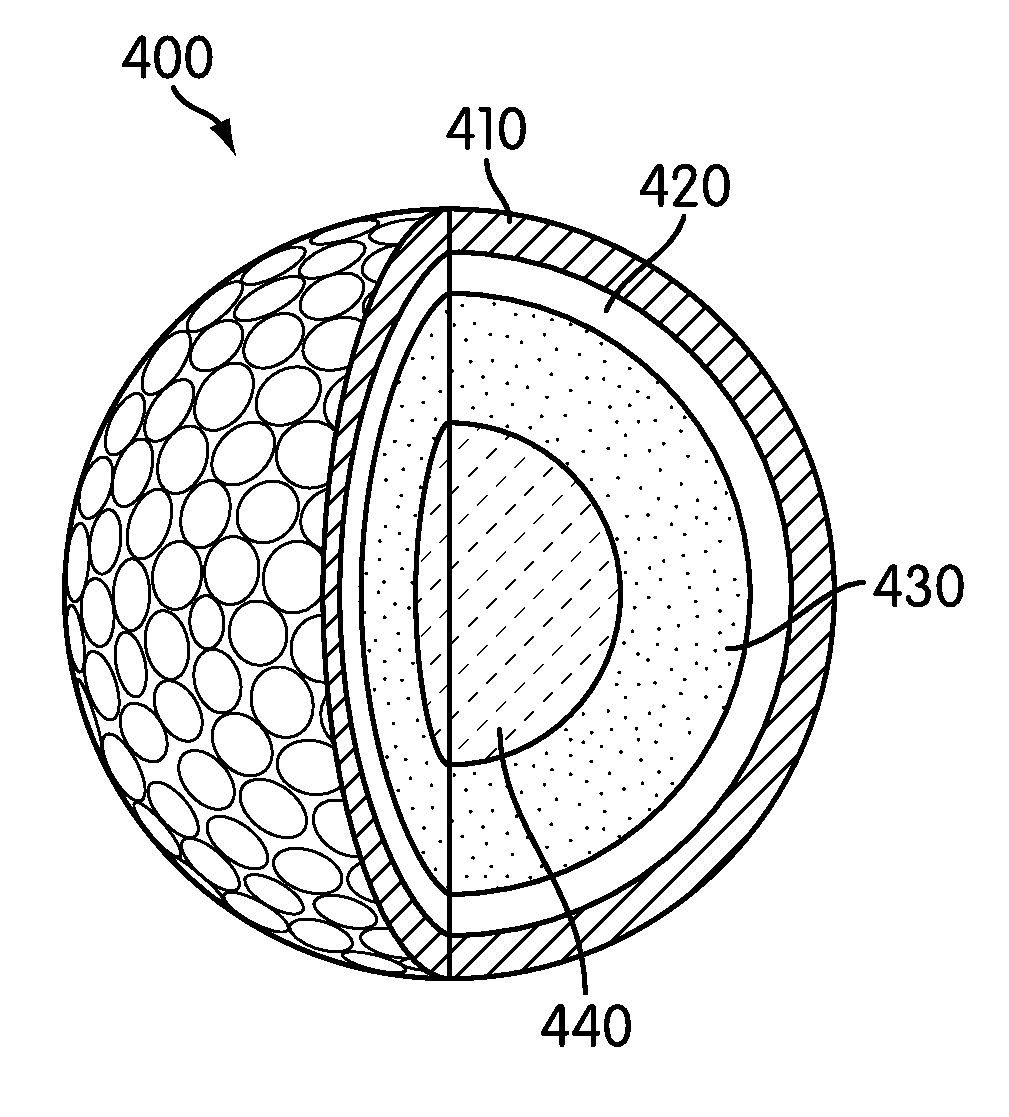

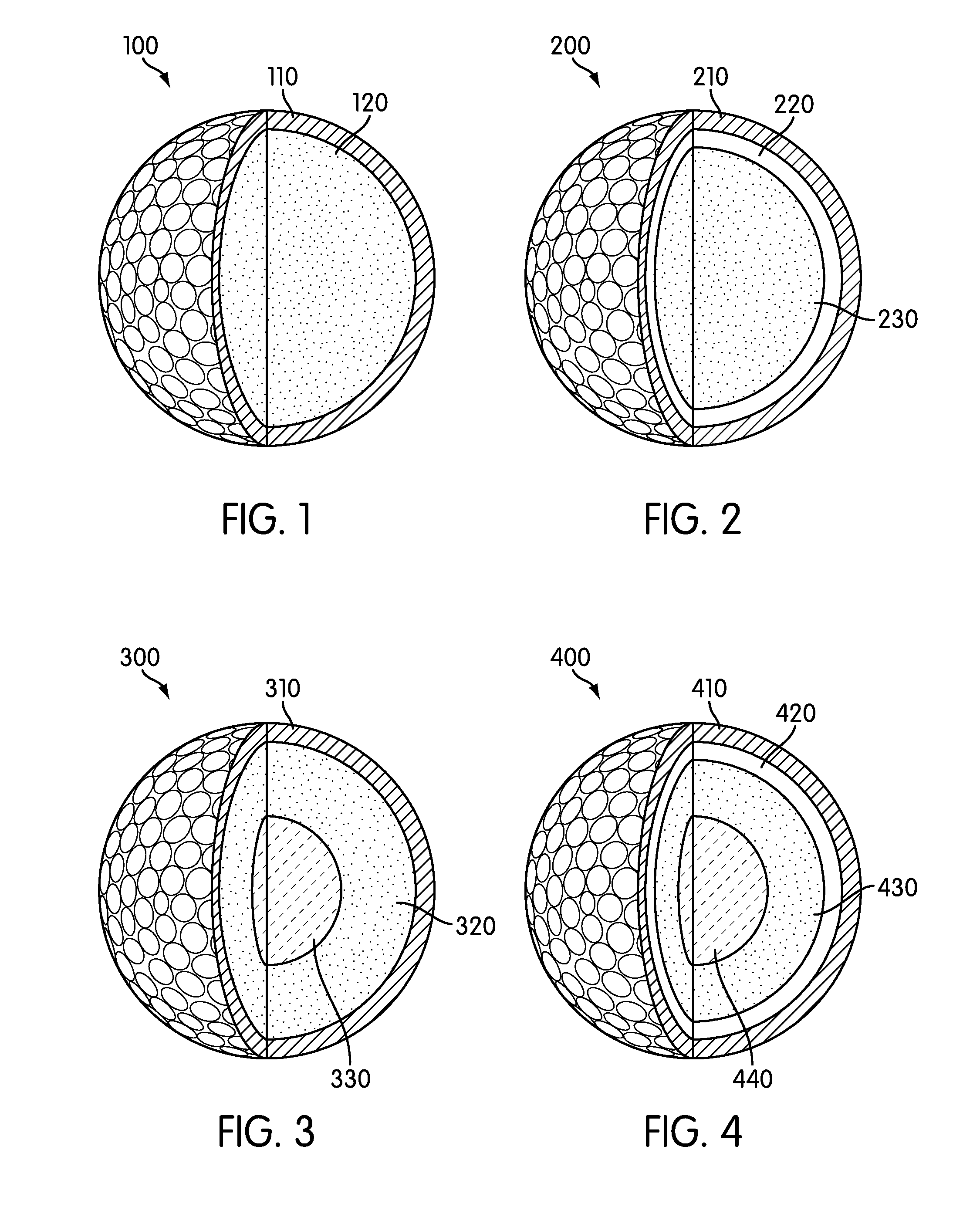

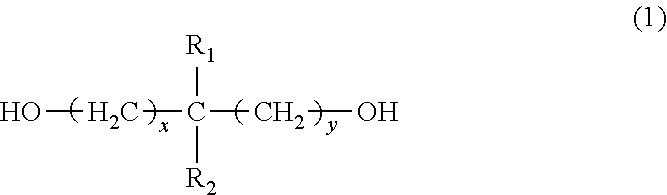

Golf Balls Including A Crosslinked Thermoplastic Polyurethane Cover Layer Having Improved Scuff Resistance

This disclosure relates to golf balls having a cover layer made from a crosslinked thermoplastic polyurethane elastomer. The crosslinked thermoplastic polyurethane elastomer includes crosslinks located in the hard segments, where the crosslinks being the reaction product of unsaturated bonds located in the hard segments catalyzed by a free radical initiator. The crosslinks may be formed from an unsaturated diol as a chain extender. The unsaturated diol may be trimethylolpropane monoallylether (TMPME). The cover layer may have certain properties, such as a desirable flexural modulus value and a desirable Shore D hardness value, that further contribute to the golf ball having a high degree of scuff resistance.

Owner:NIKE INC +1

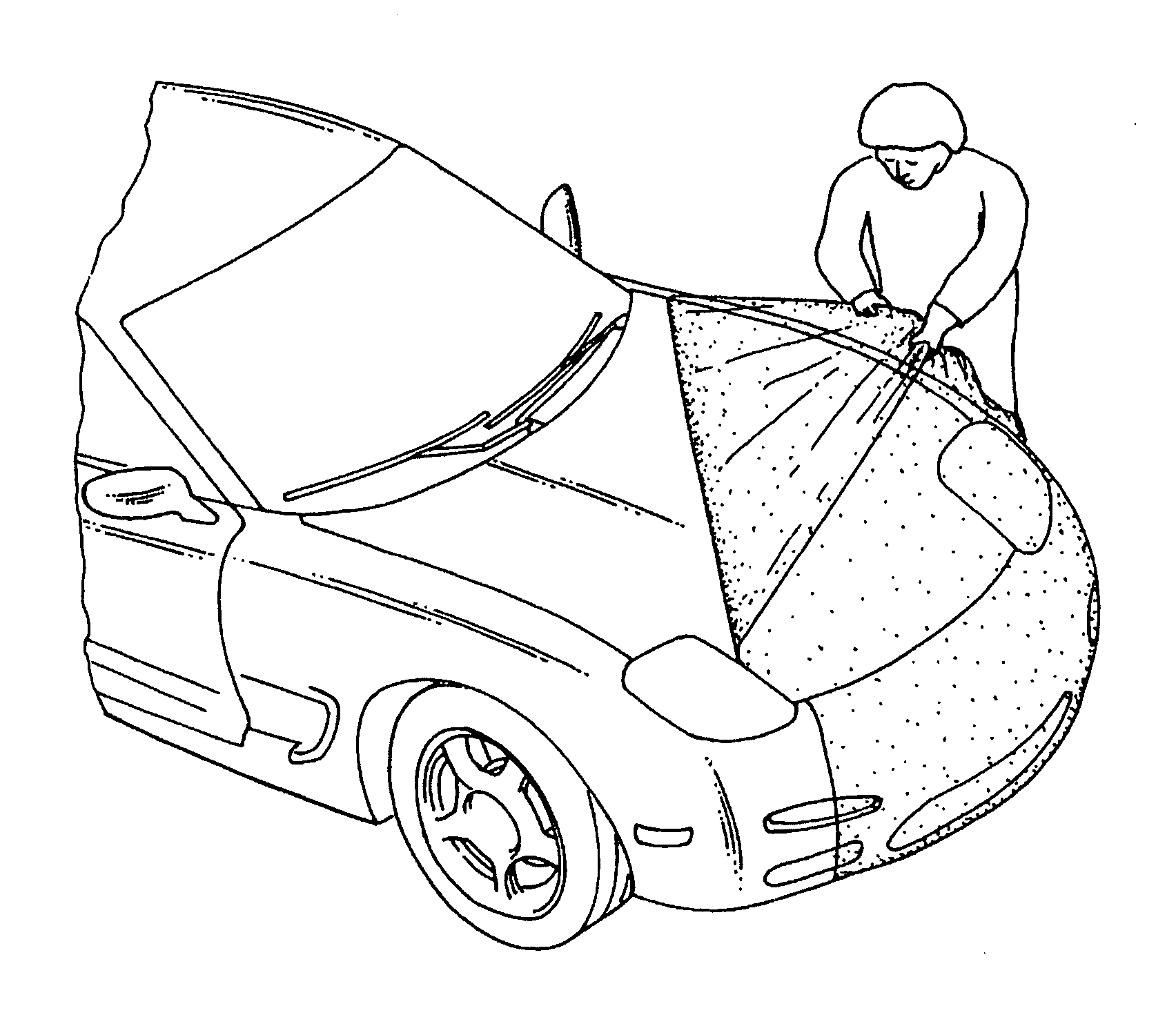

Peel-off coating compositions

ActiveUS20100167075A1High strengthAvoid lack of toughnessNon-fibrous pulp additionAlkaline-earth metal silicatesEmulsionWater resistant

Methods and compositions are provided for protecting exterior surfaces of automobiles and other products, or components of products, against abrasion, abrasive dust, water, acid rain, etc. The methods involve applying to a surface a protective coating composition comprising a polyvinyl butyrate emulsion and a relatively inert extender. The emulsion is dried to form a water-resistant protective coating that can be removed from the underlying surface by peeling when no longer desired.

Owner:CAL WEST SPECIALTY COATINGS

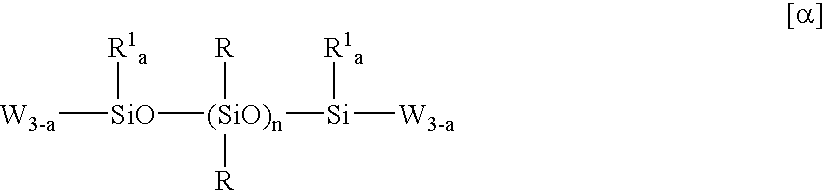

Tei Coat for Organopolysiloxane Antifouling Coat, Composite Coats, and Ships and Underwater Structures Covered with the Composite Coats

InactiveUS20090042042A1Big burden to solveWell formedAntifouling/underwater paintsSynthetic resin layered productsEpoxyBond properties

Disclosed is a tie coat which is formed on a surface of a base or an undercoating film prior to formation of an organopolysiloxane-based antifouling coating film and is formed from a moisture-curing organopolysiloxane-based composition comprising (b1) organopolysiloxane having condensing functional groups at both ends of a molecule and / or (b2) a curing composition formed by subjecting the component (b1) and an extender pigment selected from the group consisting of silica, calcium carbonate, talc, mica, clay, kaolin and barium sulfate to contact treatment with heating or without heating. Also disclosed is a composite coating film wherein on a surface of the above tie coat is formed a finish coat formed from a three-pack type organopolysiloxane-based curing composition comprising (c1) a main agent comprising the component (b1), (c2) a curing agent component comprising tetraalkoxysilicate or its condensate and (c3) a curing accelerator component comprising a metallic compound. Further disclosed is a composite coating film wherein an epoxy-based sealer coat, the tie coat and the finish coat are formed in this order on a surface of an old antifouling coating film (G). There is provided by the invention a tie coat capable of forming a composite coating film having excellent interlaminar bond property. The composite coating film is favorably formed on a surface of a base, an undercoating film, an old antifouling coating film or the like, has excellent interlaminar bond strength and antifouling property and is preferably used for coating outer surfaces of ships, submerged parts of marine structures, water supply / drainage channels of atomic power plant, etc.

Owner:CHUGOKU MARINE PAINTS

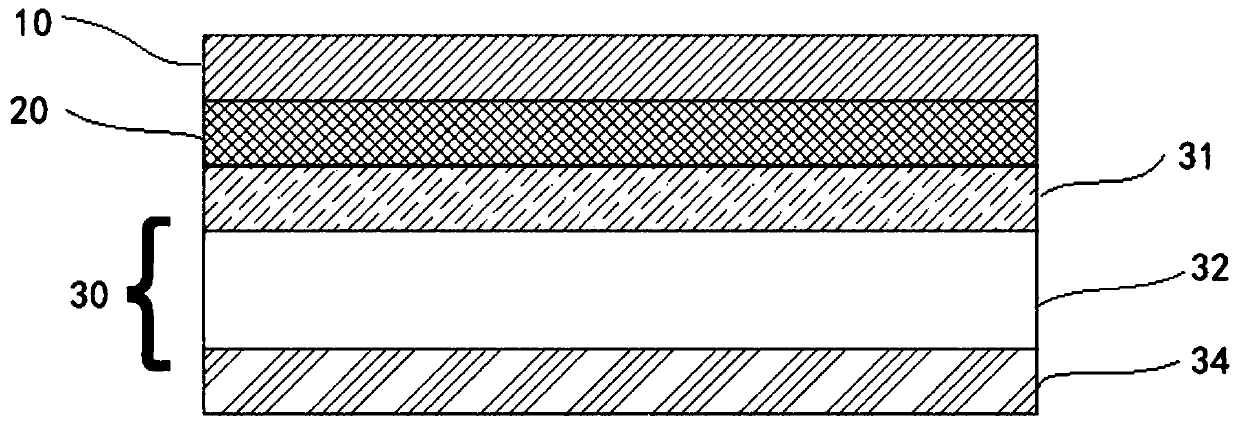

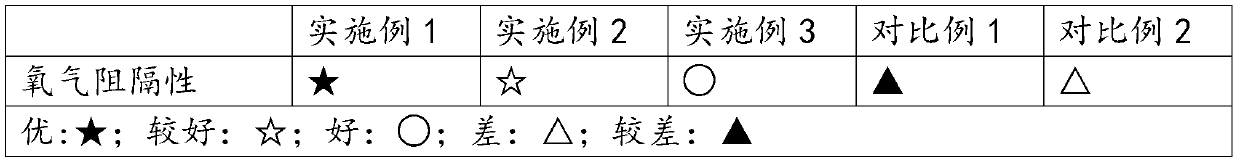

Coated high-barrier biaxially stretched polylactic acid film and preparation method thereof

ActiveCN110774713ASimple processImprove performanceSynthetic resin layered productsPolyurea/polyurethane coatingsPolymer scienceBoPET

The invention relates to a coated high-barrier biaxially stretched polylactic acid film and a preparation method thereof. The coated high-barrier biaxial tensile polylactic acid film structurally comprises a high-barrier coating, a bottom coating and a substrate layer from inside to outside in sequence, wherein the substrate layer is composed of three layers of a co-extruded biaxially stretched PLA (polylactic acid) film, namely a layer A, a layer B and a layer C; the layer A and the layer C comprise the following components in parts by mass: 68-93.2 parts of PLA, 5-20 parts of a toughening agent, 1-3 parts of a compatibilizer, 0.2-1 part of a chain extender, 0.2-1 part of an antioxidant, 0.5-3 parts of an antistatic agent, 0-1 part of an open agent and 0-1 part of a smoothening agent; thelayer B comprises the following components in parts by mass: 76-93.8 parts of PLA, 5-20 parts of a toughened resin, 1-3 parts of a compatibilizer and 0.2-1 part of a chain extender; and the high barrier coating is a water-resistant modified PVA coating. Production procedures are simple, green and environmental protection materials are used, and the film is excellent in performance, and still hasa good barrier effect in case of a very thin high-barrier coating.

Owner:中仑新材料股份有限公司 +1

Special spray polyurea elastic coating for protecting hydraulic structure and preparation method and application method thereof

The invention discloses special spray polyurea elastic coating for protecting a hydraulic structure. The special spray polyurea elastic coating is two-component elastic coating subjected to field spray moulding and composed of a component A and a component B, wherein the component A consists of semi-prepolymer and 0-10 parts of diluent, wherein the semi-prepolymer is obtained by the reaction between 30-60 parts of polyisocyanate and 30-50 parts of polyether polyol all by weight; and the component B consists of 35-65 parts of amino-terminated polyether, 25-40 parts of liquid amine chain extender, 0-20 parts of pigment and 0-8 parts of assistant all by weight. In the special spray polyurea elastic coating for protecting a hydraulic structure, disclosed by the invention, the two components are quickly mixed and sprayed to the substrate surface by the spraying equipment, and quickly react to solidify into an elastic and tough coating. The coating has the functions of high anti-permeability, high strength, high elongation, water prevention, corrosion prevention, abrasion resistance, solvent resistance and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

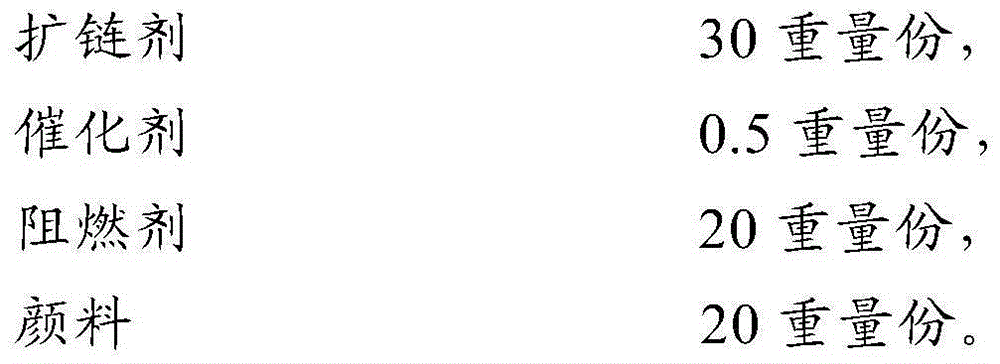

Bi-component polyurethane waterproof coating and preparation method thereof

InactiveCN105038565AImprove flame retardant performanceImprove stabilityPolyurea/polyurethane coatingsPolyolFire retardant

The invention discloses a bi-component polyurethane waterproof coating and a preparation method thereof. The coating comprises a component A and a component B, wherein a raw material formula for preparing the component A comprises aliphatic isocyanate and flame-retardant polyether polyol; a raw material formula for preparing the component B comprises a chain extender and a catalyst. The flame-retardant polyether polyol in the raw material formula for preparing the coating has flame retardance, so that a prepolymer formed by the flame-retardant polyether polyol and the aliphatic isocyanate has flame retardance, and then the bi-component polyurethane waterproof coating has flame retardance; because the prepolymer formed by the flame-retardant polyether polyol and the aliphatic isocyanate in the component A has flame retardance, the coating can achieve the same flame-retardant effect without a flame retardant in the component B, and then a phenomenon of separation of the flame retardant added in the component B is avoided or reduced, so that the flame retardance and stability of the coating are improved, the film-forming effect of the coating is good, and the storage time is long.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Latent-curing single-component color polyurethane waterproofing paint and preparation method thereof

ActiveCN103740260AHigh elongation at breakImprove impermeabilityPolyurea/polyurethane coatingsPolymer scienceChlorinated paraffins

The invention relates to the technical field of polyurethane waterproofing paint, and provides latent-curing single-component color polyurethane waterproofing paint. The latent-curing single-component color polyurethane waterproofing paint comprises the following components by weight: 18-22 parts of polyether 2000, 5-7 parts of polyether 330N, 18-22 parts of chlorinated paraffin, 28-32 parts of powder, 0.8-1.2 parts of dispersing agent, 6-10 parts of MDI-50, 0.8-1.2 parts of catalyst, 3-5 parts of latent curing agent, 3-5 parts of chain extender, and 6-8 parts of solvent. The latent-curing single-component color polyurethane waterproofing paint has such advantages as high strength, good toughness, good flexibility, low-temperature resistance, strong adhesive power with the basal plane, good adaptability, wide application field, convenience for construction and low dependency on the operation proficiency. The latent-curing single-component color polyurethane waterproofing paint not only satisfies the application field of the original single-component polyurethane waterproofing paint, but also can be suitable for the waterproofing requirements in such special fields as larger-deformation areas and low-temperature areas, so that the latent-curing single-component color polyurethane waterproofing paint has strong adaptability and strong market competitive advantages, and meets the higher and higher requirements of the market to the products.

Owner:郑家玉

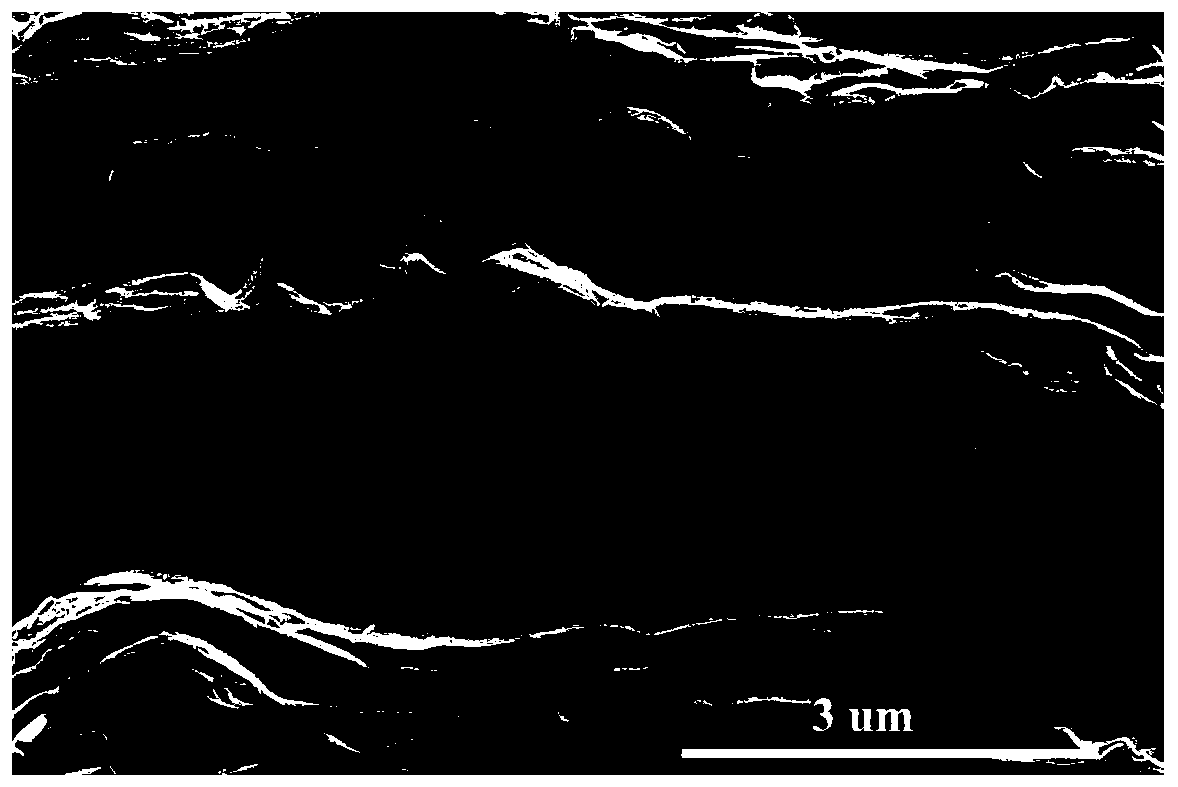

Waterborne polyurethane-MXene electromagnetic shielding bionic nanocomposite material film and preparation method

The invention relates to a waterborne polyurethane-MXene electromagnetic shielding bionic nanocomposite film and a preparation method. Through pre prepolymeriztion reaction of polytetrahydrofuran gl and diisocyanate and chain extension by a hydrophilic chain extender, then a neutralizing agent is added, subsequently, deionized water is added for emulsification dispersion to obtain a waterborne polyurethane emulsion; waterborne polyurethane and MXene are prepared into water dispersion liquid, MXene is added to the waterborne polyurethane under stirring, continuous stirring is carried out to enable waterborne polyurethane macromolecules to be fully and uniformly adsorbed on MXene nanosheets. And waterborne polyurethane-MXene composite dispersion liquid is obtained; and a series of nanocomposite films are prepared by a vacuum filtration method, a solvent evaporation method or a coating method. The prepared nanocomposite thin films have ordered "brick-wall" structures in a bionic shell layer shape on the micro and nano scales, the mechanical properties are excellent, the flexibility is good, the electromagnetic shielding effectiveness is excellent, preparation methods are diverse, thethickness is controllable, and application is wide.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

UV-curable elastic polyurethane acrylate emulsion and synthesis method thereof

InactiveCN104558499ASelf-emulsifyingGood flexibilityInksPolyurea/polyurethane coatingsPolyesterEndcapping

The invention discloses UV-curable elastic polyurethane acrylate emulsion and a synthesis method thereof. The synthesis method of the UV-curable elastic polyurethane acrylate emulsion comprises the following steps: carrying out reaction on polyester glycol or polyether glycol, carboxylic acid-containing glycol and diisocyanate to generate a prepolymer, adding an optimized micromolecular chain extender for carrying out chain extension, then adding hydroxy-containing acrylate for carrying out blocking reaction, diluting by virtue of an organic solvent, neutralizing and salifying by adopting organic amine, finally adding deionized water for carrying out hydration, and adding a photoinitiator to obtain the UV-curable elastic polyurethane acrylate emulsion. The UV-curable elastic polyurethane acrylate emulsion is polyurethane blocked by acrylate, and a molecular chain of the UV-curable elastic polyurethane acrylate emulsion is provided with hydrophilic negative ions and double bonds, so that the UV-curable elastic polyurethane acrylate emulsion has self-emulsifying property and photocuring activity; and a cured film formed by carrying out photocuring on the synthesized elastic polyurethane acrylate emulsion has excellent mechanical properties, tensile strength is 21MPa, and elongation is 350%, so that the elastic polyurethane acrylate emulsion can serve as matrix resin of water-based ink and waterborne UV-curable elastic paint.

Owner:HUNAN SUIFENG NEW MATERIAL & TECH DEV

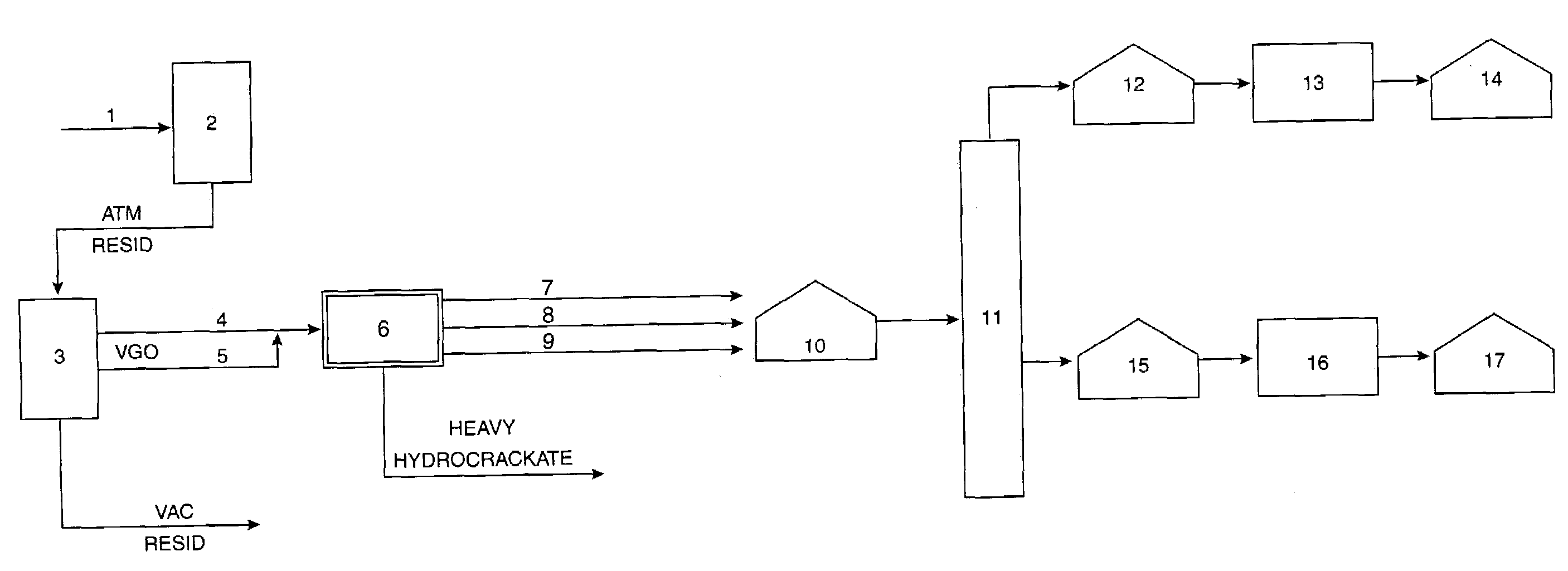

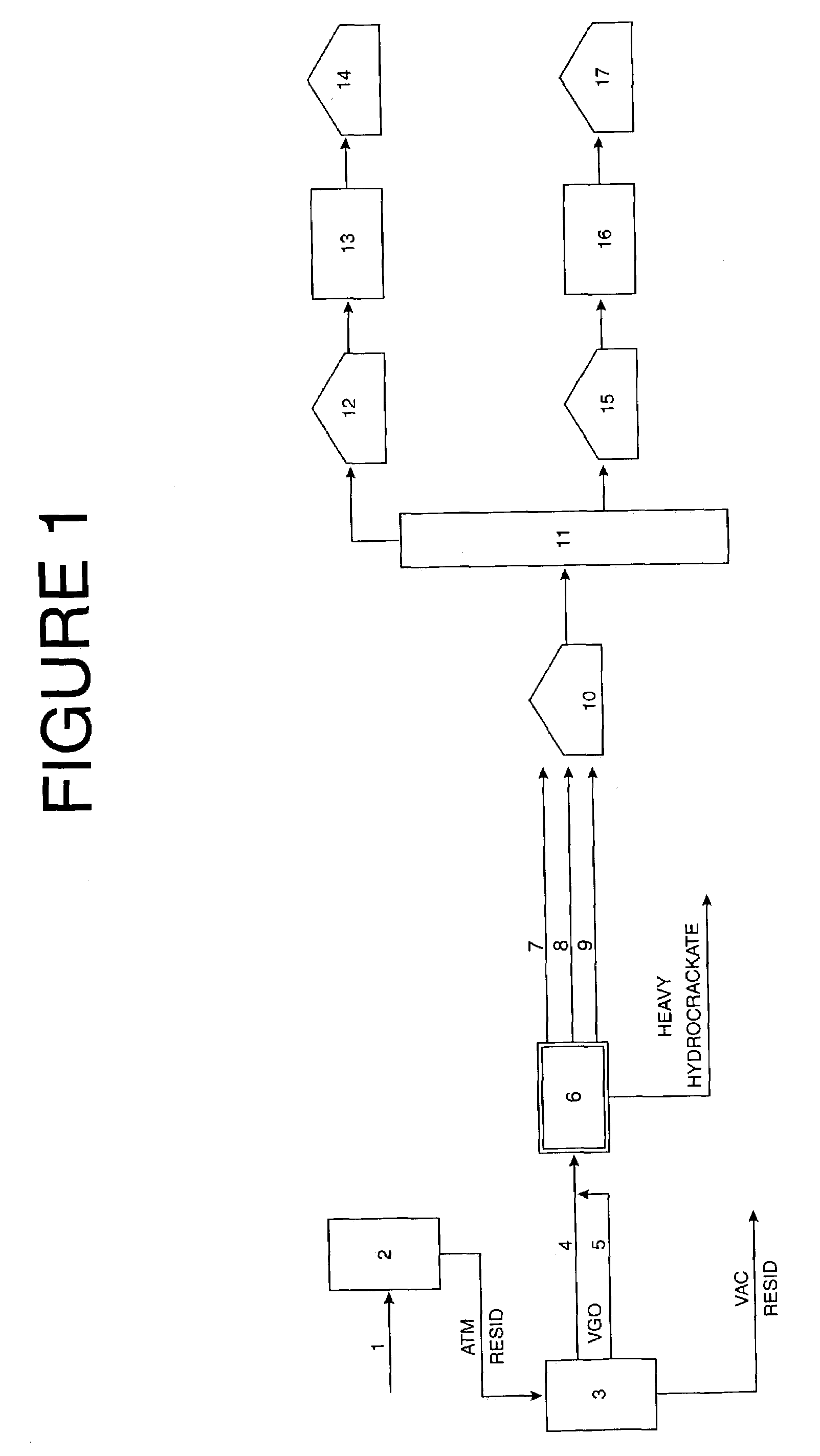

Process for the production of hydrocarbon fluids

ActiveUS7311814B2Low sulphur levelPoint become highSilicon organic compoundsPhysical/chemical process catalystsSolventMetal working

Hydrocarbon fluids are produced by hydrocracking a vacuum gas oil stream, fractionating and / or hydrogenating the hydrocracked vacuum gas oil. The fluids typically have ASTM D86 boiling point ranges within the range 100° C. to 400° C. the range being no more than 75° C., they also have a naphthenic content greater than 60%, the naphthenics containing polycyclic materials, an aromatic content below 2% and an aniline point below 100° C. The fluids are particularly useful as solvents, for printing inks, drilling fluids, metal working fluids and as silicone extenders.

Owner:EXXONMOBIL CHEM PAT INC +1

Sulfonic acid type waterborne polyurethane-acrylate self extinction resin and preparation method and application thereof

The invention discloses a sulfonic acid type waterborne polyurethane-acrylate self extinction resin, the resin is prepared through the reaction of the components of A, prepolymer of diisocyanate sealing side, B, a component of the prepolymer dissolving and diluting the diisocyanate sealing side, C, small molecule amine chain extender, and D, radical initiator. The resin combines the excellent properties of polyurethane and acrylic acid, can achieve excellent adhesion force on the base materials of ABS, PC, PVC, PET and the like, and can achieve excellent hand sweat resistant property, and through adding a cross-linking agent the resin can achieve the excellent properties of alcohol rub resistance, and solvent resistance and the like, the resin can be applied in the fields of leather finish, wood plastic, paper printing, printing ink, printing coating, packaging coating, and matt nail polish and the like.

Owner:WANHUA CHEM GRP CO LTD

Anti-fingerprint TPU protective film for 3D curved screen and preparation method of anti-fingerprint TPU protective film

PendingCN111484810AGood optical performanceImprove smoothnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterColloidal silica

The invention discloses an anti-fingerprint TPU protective film for a 3D curved screen. The protective film comprises a low-viscosity protective film, an anti-fingerprint UV hardening coating, an optical hard TPU resin film layer, an optical-grade high-viscosity silica gel pressure-sensitive adhesive layer and a fluorine element release film which are attached from top to bottom; the anti-fingerprint UV hardening coating is formed by coating an anti-fingerprint UV hardening coating; the optical hard TPU resin film layer is formed by coating optical hard TPU glue, the optical-grade high-viscosity silica gel pressure-sensitive adhesive layer is formed by coating an optical-grade high-viscosity silica gel pressure-sensitive adhesive; the anti-fingerprint UV hardening coating is prepared fromthe following components: UV prepolymer resin, an acrylate reactive diluent, a photoinitiator, a slipping aid and a first solvent, the optical-grade hard TPU glue is formed by polymerizing polyisocyanate, polyester polyol and a chain extender in a second solvent under the action of a first catalyst; the optical-grade high-viscosity silica gel pressure-sensitive adhesive is composed of silica gel resin, a cross-linking agent, an anchoring agent and a second catalyst. The anti-fingerprint TPU protective film for a 3D curved screen has the properties of fingerprint resistance, scratch resistance,difficulty in bursting and good fitting property of the curved screen.

Owner:GUANGDONG BANGGU FILM COATING INNOVATION ACAD CO LTD

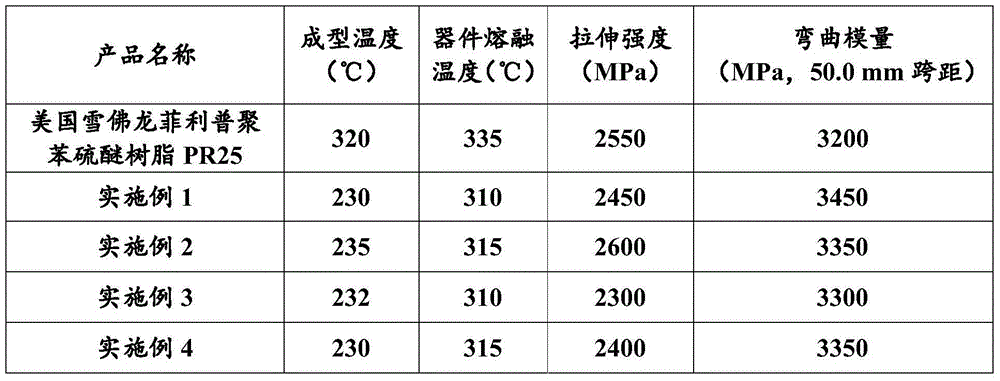

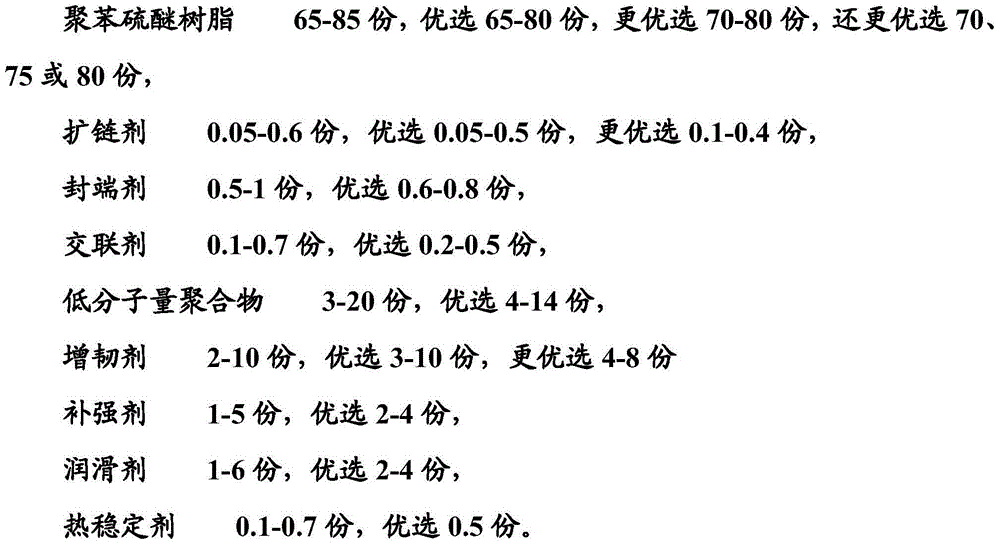

Modified polyphenylene sulfide resin suitable for 3D printing as well as preparation method and application of modified polyphenylene sulfide resin

ActiveCN104650587AIncrease profitImprove toughnessAdditive manufacturing apparatusDevice formToughness

The invention discloses modified polyphenylene sulfide resin suitable for 3D printing. The modified polyphenylene sulfide resin is a combination of the following components in parts by weight: 65-85 parts of polyphenylene sulfide resin, 0.05-0.6 part of a chain extender, 0.5-1 part of an end capping agent, 0.1-0.7 part of a crosslinking agent, 3-20 parts of low-molecular-weight polymer, 2-10 parts of a toughening agent, 1-5 parts of a reinforcing agent, 1-6 parts of a lubricating agent and 0.1-0.7 part of a heat stabilizer. The polyphenylene sulfide resin is modified by adopting the simple processes of mixing materials and extruding, and the processing temperature of the modified polyphenylene sulfide resin is reduced greatly. The melting temperature of the device formed by printing by adopting the modified polyphenylene sulfide resin is not reduced significantly, and the toughness is improved, and thus the polyphenylene sulfide resin can be widely applied to the field of 3D printing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Anti-sticking and wear resistant polyurea coating and its preparation method

ActiveCN102492357ASolve the adhesionSolve corrosivePolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention relates to an anti-sticking and wear resistant polyurea coating and its preparation method. The coating is prepared by blending of component A and component B. Specifically, the component A is synthesized by the following raw materials by weight: 90-120 parts of isocyanate, 40-60 parts of polyether polyol and 20-30 parts of fluorocarbon diol; and the component B is prepared by the following raw materials by weight: 500-800 parts of polyether amine, 400-600 parts of organosilicon diamine, 300-400 parts of high activity polyether polyol, 400-500 parts of an amino chain extender, 80-100 parts of an amino cross-linking agent, 100-150 parts of a high boiling point diluent, 5-10 parts of a composite catalyst, 400-600 parts of composite nano-metal oxide surface active materials, 600-800 parts of a filling material, and 40-60 parts of a pigment. The invention also includes a preparation method of the anti-sticking and wear resistant polyurea coating. A coating layer obtained by spraying of the anti-sticking and wear resistant polyurea coating in the invention has strong adhesion, and has good adhesion resistance, wear resistance, corrosion resistance, as well as impact resistance. Therefore, the anti-sticking and wear resistant polyurea coating of the invention is especially suitable for spraying on the lining surface of a heavy transport dump truck.

Owner:湘江涂料科技有限公司

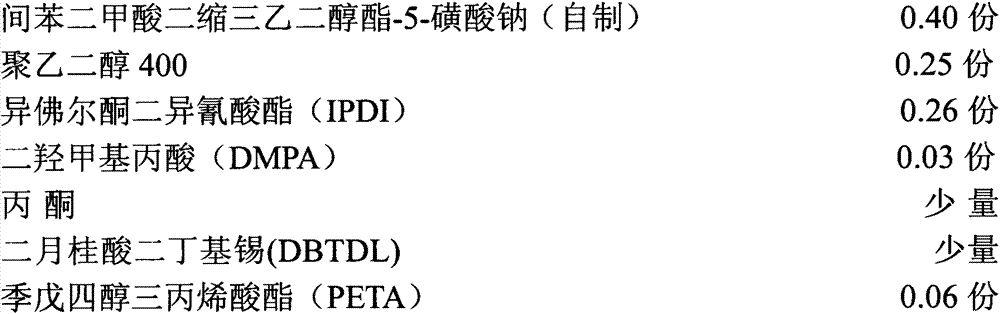

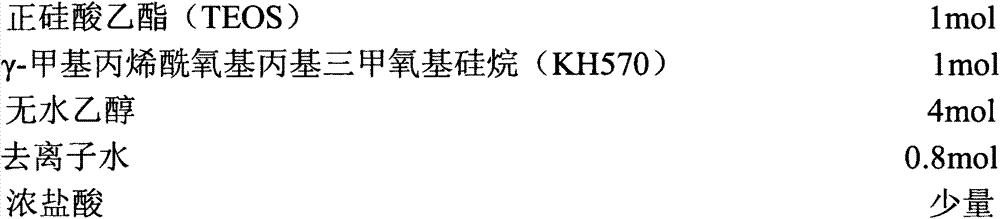

Preparation method for antifogging thin film coating with high light transmission

ActiveCN103709927APolyurea/polyurethane coatingsPigment treatment with organosilicon compoundsSolventDibutyltin dilaurate

Provided is a preparation method for an antifogging thin film coating with high light transmission. M-phthalic acid triethylene glycol ester-5-sodium sulfonate (self made), polyethylene glycol 400, isophorone diisocyanate and pentaerythritol triacrylate are employed as main raw materials, dibutyltin dilaurate is employed as a catalyst, dimethylolpropionic acid is employed as a chain extender, acetone is employed as a solvent, and hydrophilic UV prepolymers are prepared; ethyl orthosilicate is employed as a precursor, gamma-methacryloxy propyl trimethoxysilane is employed as a modifier, a sol-gel method is employed, and uniform and stable modified SiO2 sol is prepared; the hydrophilic UV prepolymers and the modified SiO2 sol are subjected to hybridization through a UV curing way, and a thin film coating is obtained. The prepared thin film coating has good hardness and adhesive force, water resistance and high light transmission and good antifogging effects, and can be used for antifog of surfaces of glass and eyeglass. The preparation technology of the thin film coating accords with green environmental protection concepts, curing and film forming are fast, and comprehensive performances are good. The antifogging thin film coating has good market prospect and is suitable for popularization and application.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com