Composite material for 3D printing and preparation method thereof

A composite material and composition technology, applied in the field of 3D printing materials and their preparation, can solve the problems of high brittleness, poor heat resistance, low molecular weight, etc. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The tensile strength and impact strength heat distortion temperature of the homopolymer obtained according to the preparation method provided by the present invention are respectively measured according to ISO527 and ISO180 test standards.

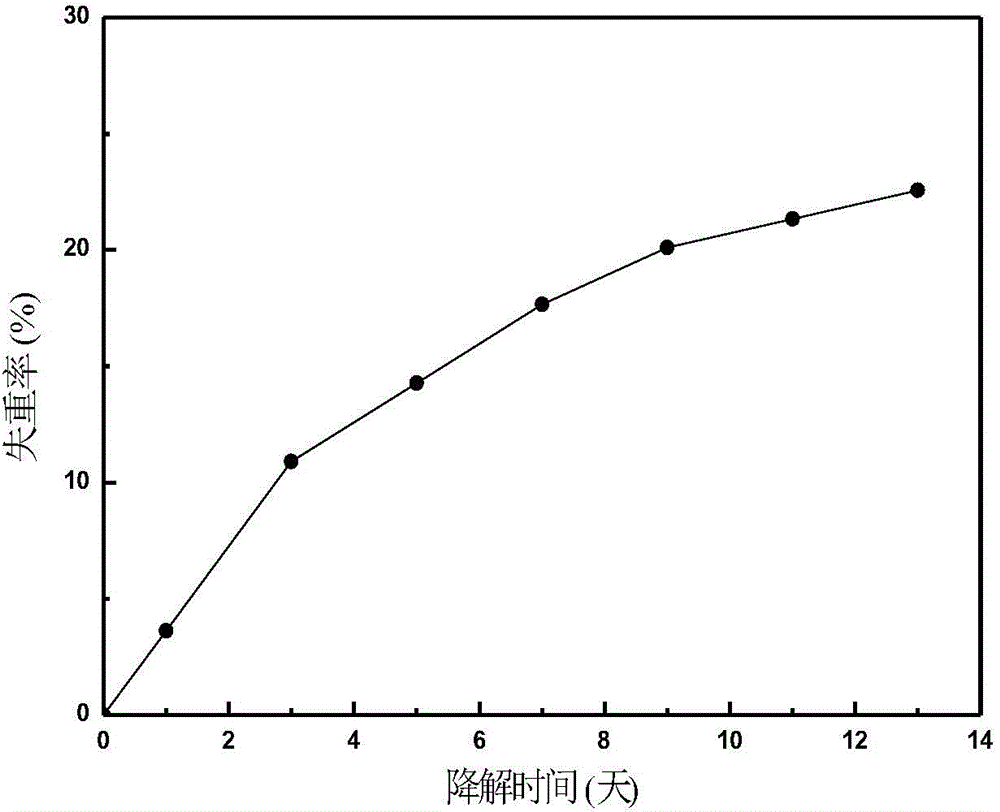

[0055] 3. Biodegradation performance test

[0056] The biodegradability of the block copolymer prepared by the present invention is measured with Pseudomonas sp. enzyme, and the membrane sample (10 * 10 * 0.1mm) of polymer is immersed in the phosphate buffer solution (pH=6.86) that contains the enzyme of 1mg, places In a water bath at 45°C, take out the samples regularly at 45°C and dry them for 3 hours, then weigh them and measure them. The amount of degradation of the sample is [100(W 0 -W t )] / W 0 calculate. Change the buffer solution every 24 hours.

Embodiment 1

[0059] 1) Preparation of hydroxyl-terminated aliphatic and aromatic copolyesters

[0060] At room temperature, 2500 g of succinic acid, terephthalic acid, 1,4-butanediol, and ethylene glycol were added in a molar ratio of 0.95:0.05:2.8:0.2 into a 5 L reaction kettle replaced by high-purity nitrogen. At the same time, the reactor is equipped with a high-purity nitrogen inlet, a mechanical stirrer, and a condenser. The above reaction system was controlled at 170°C, stirred and reacted with nitrogen gas until the water yield reached 95% of the theoretical water yield, then the temperature was raised to 230°C, the pressure was slowly lowered to 50 Pa, and then polycondensed for 10 hours. A copolyester having a number average molecular weight of 1,000 was obtained.

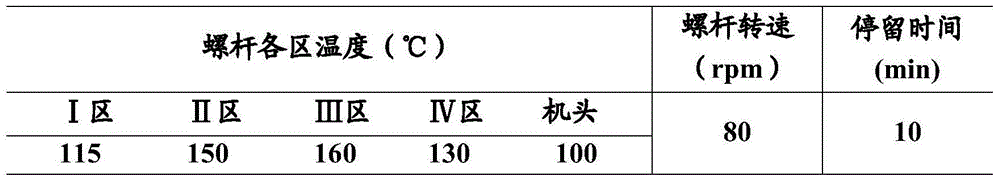

[0061] 2) Preparation of aliphatic and aromatic copolyester composites

[0062] The copolyester obtained in the above step 1) was dried at 100° C. for 3 hours. A total of 2000g of copolyester and MDI according to th...

Embodiment 2

[0064] 1) Preparation of hydroxyl-terminated aliphatic and aromatic copolyesters

[0065] At room temperature, first add succinic acid, terephthalic acid, 1,4-butanediol at a molar ratio of 0.05:0.95:1.6, a total of 2500g, 0.75g of butyl titanate, and 79102.5g of antioxidant to the high-purity nitrogen replacement in a 5L reactor. At the same time, the reactor is equipped with a high-purity nitrogen inlet, a mechanical stirrer, and a condenser. Control the above reaction system at 180°C, stir the reaction with nitrogen gas until the water yield reaches 90% of the theoretical water yield, then add 2.5g of butyl titanate to raise the temperature to 250°C, slowly reduce the pressure to 200Pa, and polycondense for 1 hour . A copolyester is obtained with a number average molecular weight of 5×10 4 .

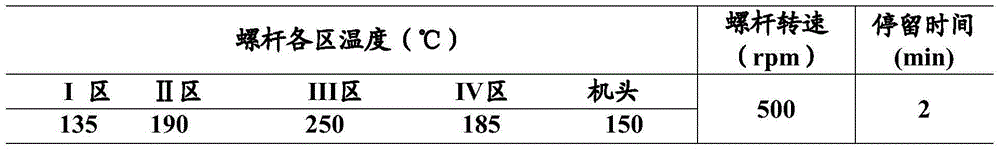

[0066] 2) Preparation of aliphatic and aromatic copolyester composites

[0067] The copolyester obtained in step 1), HDI according to the molar ratio of 1:1.1 total 2375g, nano-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com