Patents

Literature

3777 results about "Sulfite salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

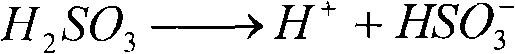

Sodium sulfite (sodium sulphite) is a soluble sodium salt of sulfurous acid (sulfite) with the chemical formula Na2SO3. It is a product of sulfur dioxide scrubbing, a part of the flue-gas desulfurization process.

Water-soluble film

ActiveUS20090291282A1Good water solubilitySynthetic resin layered productsInksPolymer sciencePolyvinyl alcohol

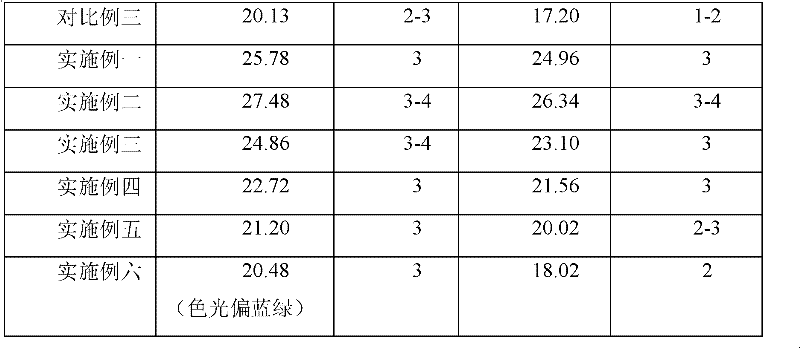

The present invention relates to a water-soluble film, which is a polyvinyl alcohol film comprising a polyvinyl alcohol resin (A), wherein the water-soluble film has a time for dissolution in water at 20° C. of not more than 60 seconds in terms of a film thickness of 76 μm, a b-value of the film is not more than 0.5, and a b-value of the film after leaving at 80° C. for 72 hr is not more than 1.0, preferably a water-soluble film comprising: a polyvinyl alcohol resin (A); at least two kinds of plasticizers (B); and a sulfite salt (C), wherein the content of the plasticizer (B) based on 100 parts by weight of the polyvinyl alcohol resin (A) is 5 to 50 parts by weight and the content ratio of the sulfite salt (C) to the plasticizer (B) (C / B: weight ratio) is more than 0.02 and not more than 0.35. According to the invention, there is provided a water-soluble film comprising a PVA resin as a main component, wherein the film is less likely to cause coloration at the time of film formation and coloration with time even upon contact with a chemical.

Owner:MITSUBISHI CHEM CORP

Copper plating solution and method for copper plating

InactiveCN1514889AImprove bindingReduce adverse effectsLiquid/solution decomposition chemical coatingPermanent magnet manufactureAcetic acidEthylenediamine

A copper plating solution which comprises 0.03 mol / L to 0.5 mol / L of copper sulfate, 0.05 mol / L to 0.7 mol / L of ethylenetetraacetic acid and 0.02 mol / L to 0.3 mol / L of a sulfite salt, and has a pH adjusted to 5.0 to 8.5; and a method for copper plating which comprises using the copper plating solution. The method for copper plating allows a copper plating film being uniform and excellent in adhesion to be formed with stability on the surface of an article to be plated.

Owner:HITACHI METALS LTD

Temperature-resistant salt-resistant efficient gel, and preparation and use thereof

InactiveCN101475667AImprove solubilityGood viscosity increasing effectDrilling compositionSulfite saltAging resistance

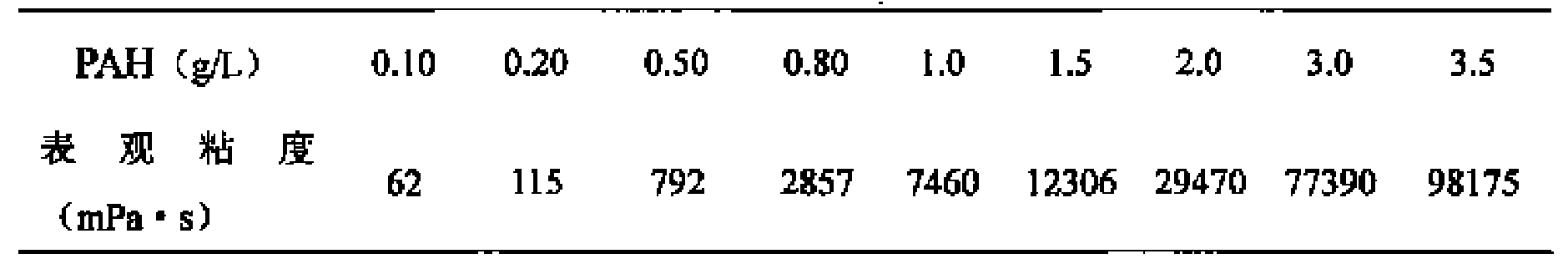

The invention discloses a temperature resistant salt tolerant high efficiency gel and a preparation method and application thereof. The preparation method is characterized in that the preparation method comprises the following steps: preparing a comb-shaped associated copolymer PAH containing macromonomers and functional hydrophobic monomers into an aqueous solution having the concentration of 0.1 to 4g / L, the crosslinking agent concentration of 0.01 to 1.0g / L, the surfactant concentration of 0.01 to 8mmol / L and the sodium sulfite thermal stabilizer concentration of 0.005 to 1.0g / L; adding the aqueous solution into a mixing container with a stirring device; stirring the aqueous solution evenly at the room temperature; regulating the pH value of the solution to be equal to between 4 and 11, and obtaining a temperature resistant salt tolerant high efficiency gel polymer solution system used for tertiary oil recovery and scavenge, displacement modification, profile modification or water shutoff. The polymer solution system has micro-crosslinking to form the gel during the flowage inside the oil reservoir. The gel has good elasticity, not easy dehydration, stable gelling performance, and excellent tackification, temperature resistance, salt tolerance, shearing resistance and ageing resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method of preparing taurine

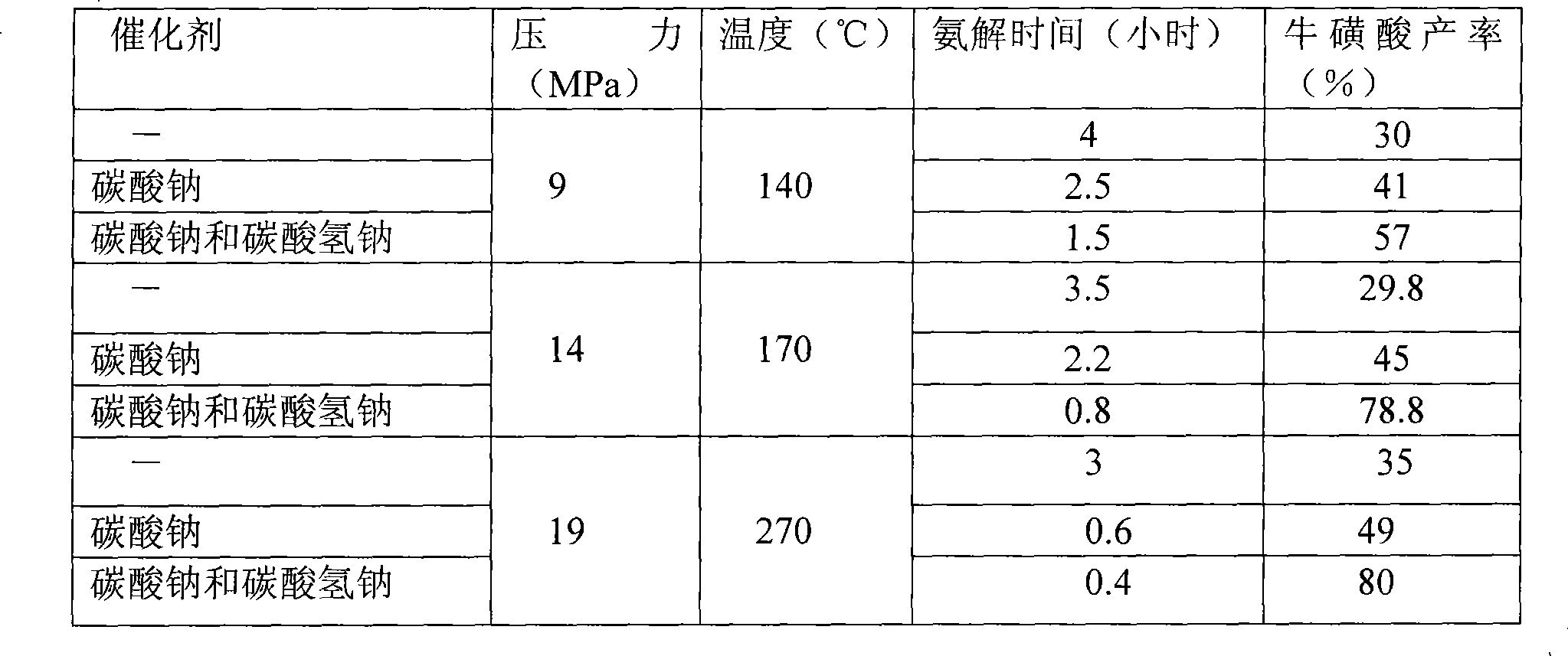

The invention relates to method for preparing taurine, comprising the following steps: (1) reacting epoxy ethane with sodium sulfite under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at temperature between 75 and 85 DEG C to obtain hydroxyethyl sodium sulfonate; (2) carrying out ammonolysis reaction on the hydroxyethyl sodium sulfonate and liquid ammonia under 14 to 21MPa and at temperature between 160 and 280 DEG C to obtain ammonolysis solution containing sodium taurate; (3) introducing the ammonolysis solution into a single flash evaporator for primary flash evaporating at a temperature between 160 and 200 DEG C and under 1.3 to 2.0MPa; introducing the flash evaporated liquid into a secondary flash evaporating and falling film evaporator, using the primary flash vapor as a heating medium to carry out flash evaporating and falling film evaporating on the primary flash evaporated liquid in the secondary flash evaporating and falling film evaporator at a temperature between 110 and 140 DEG C and at 0.1 to 0.6MPa; evaporating and concentrating the flash evaporated liquid subjected to secondary flash evaporating and falling film evaporating with flash vapor and steam as heating media in a multi-effect flash evaporating and falling film evaporator; and (4) neutralizing the sodium taurate by sulphuric acid to obtain the taurine. The method for preparing the taurine has the advantages of short time, high yield and low cost, and is easy for industrialized production. In addition, by primary flash evaporating and secondary flash evaporating processes, almost all the ammonia and 40% to 60% of water in the flash evaporated liquid can be removed, thus having double effects of removing ammonia and condensing.

Owner:王代龙 +1

Acrylic amide modified polymer micro-crosslinking gel and preparation thereof

InactiveCN101475691AImprove solubilityGood viscosity increasing effectDrilling compositionPolymer scienceSulfite salt

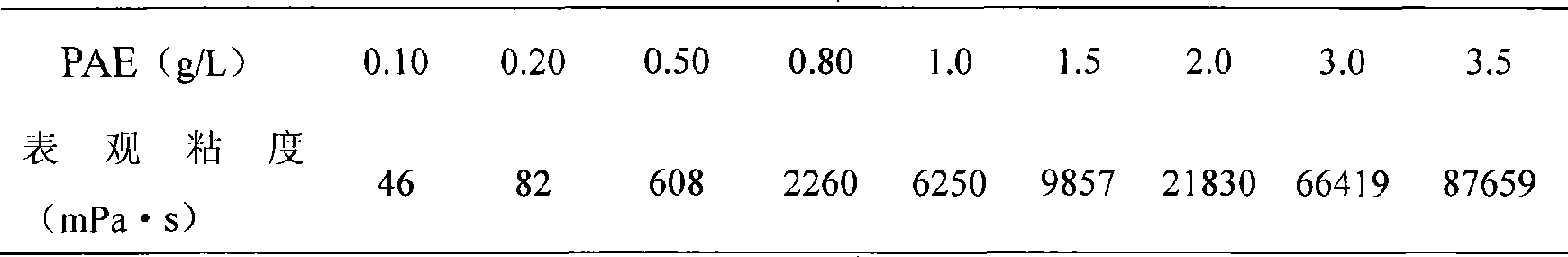

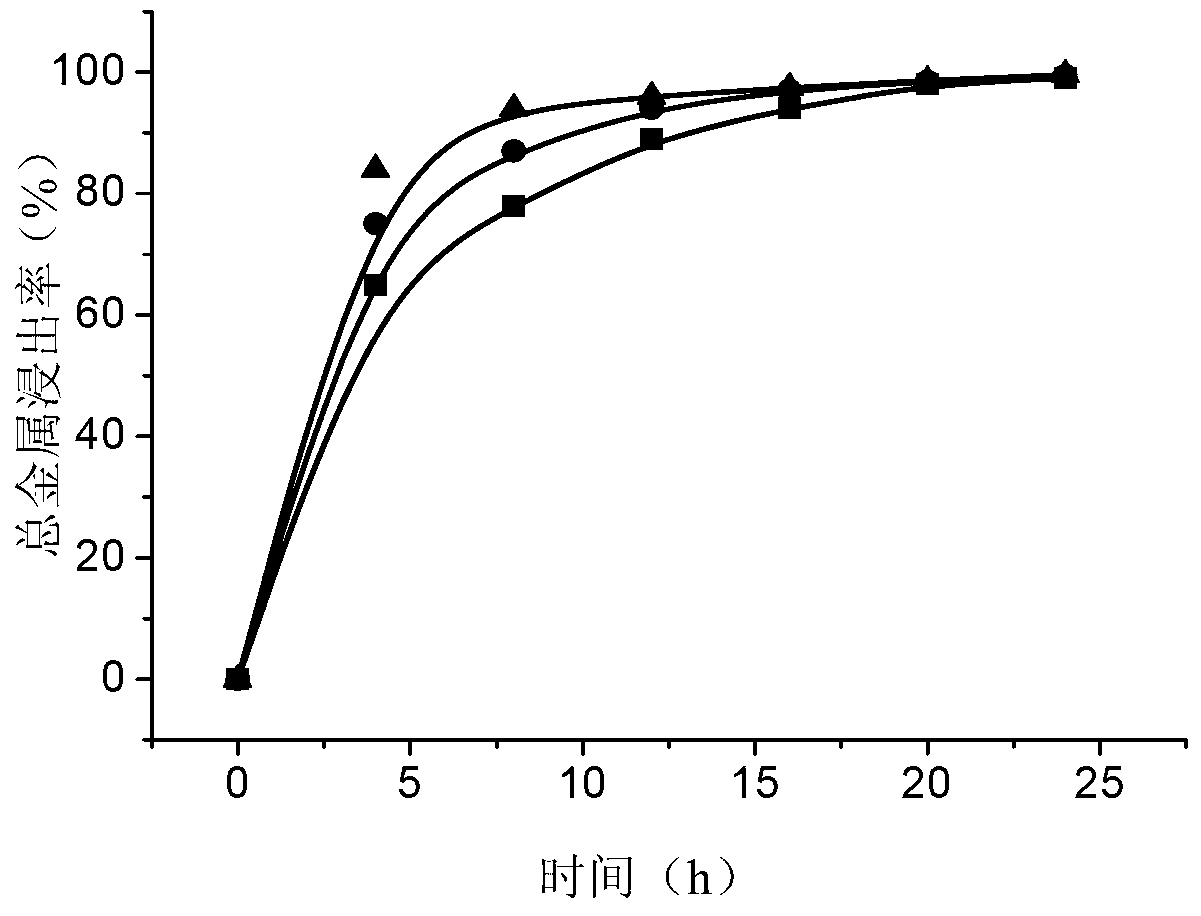

The invention discloses acrylamide modified polymer micro-crosslinking gel and a preparation method thereof. The preparation method is characterized in that the method comprises the following steps that: acrylamide modified polymer PAE containing functional macro monomer is prepared into an aqueous solution with the concentration between 0.1 and 4g / L, the concentration of crosslinking agent between 0.01 and 1.0g / L, the concentration of surface active agent between 0.01 and 8mmol / L and the concentration of heat stabilizer sodium sulfite between 0.005 and 1.0g / L; the aqueous solution is added in a mixing container with a stirring device and is stirred evenly at room temperature; the pH value of the solution is adjusted between 4 and 11 to prepare a polymer solution system of the acrylamide modified polymer micro-crosslinking gel used for tertiary oil recovery and displacement, oil displacement modification, profile modification or water plugging; and the polymer solution system undergoes micro crosslinking during flowing inside an oil layer to form the gel. The acrylamide modified polymer micro-crosslinking gel has ideal elasticity, difficult dehydration, stable performance and excellent performances on tackifying, temperature resistance, salt resistance, shearing resistance and ageing resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Compound decarburization solution for recovering carbon dioxide in gas mixture

ActiveCN101091864APromote absorptionIncrease desorptionProductsCarbon compoundsChemical industryAbsorption capacity

The invention belongs to the gas separation technology area, it relates to a decarbonization solution which recycles or removes the carbon dioxide gas from the mixed gas which contains carbon dioxide, said invention specially relates to an ethoxyl ethylenediamine decarbonization solution. Its characteristic lies in: the invention has designed a new compound decarbonization solution which is composed of the main absorption component, the aid absorption component, the activation component, the corrosion inhibitor, the oxidation inhibitor and the water. Among, the main absorption component is AEE, the aid absorption component is AMP, MDEA and TEA, the activation component is MEA, DEA and PZ, the corrosion inhibitor is vitriol sour sodium, the oxidation inhibitor is the sodium sulfite and the cupric acetate. The effect and the profit of the invention are that it can be used in recycling many kinds of chemical industry reaction exhaust, the carbon dioxide of the combustion flue gas and the mixed gas, may also used in removing the carbon dioxide of town gas, the natural gas and so on, the merit of the decarbonization fluid is that the absorption capacity is big, purification is high, desorption rate is big, regeneration energy consumption is low.

Owner:DALIAN UNIV OF TECH

Comprehensive recycling method of waste and old lithium-ion battery

ActiveCN103326088ANo pollution in the processReduce pollutionWaste accumulators reclaimingProcess efficiency improvementSulfite saltEngineering

The invention provides a comprehensive recycling method of a waste and old lithium-ion battery, and relates to the lithium-ion battery. The method comprises the following steps of: performing explosion-proof magnetic smashing and atomized spraying smashing on the waste and old lithium-ion battery, thereby separating an outer shell and a battery material; carbonizing and roasting in a constant-temperature roaster at high temperature and under negative pressure, thereby removing an isolated membrane and a cathode; recycling the outer shell and an anode material in a grading manner by using a centrifugal disintegrator, thereby separating the outer shell and the anode material containing nickel and cobalt; leaching out by adding sodium sulfite into H2SO4 at the normal pressure by utilizing the characteristics of the anode material; regulating the pH value by adding carbonate into an leaching liquid; preliminarily removing Ca and Mg by adding a fluoride salt; extracting and removing impurities by using P2O4, thereby removing the impurities such as Fe, Cu, Zn, Ca, Mg and the like; performing selective extraction for cobalt-nickel separation by using P507, thereby obtaining a high-purity nickel sulfate solution and a high-purity cobalt sulfate solution in which the content of the Fe, the Cu, the Zn, the Ca and the Mg is respectively less than or equal to 2.0mg / L. The method is efficient, simple and convenient and low in production cost, and has wide applicability and a high additional value.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

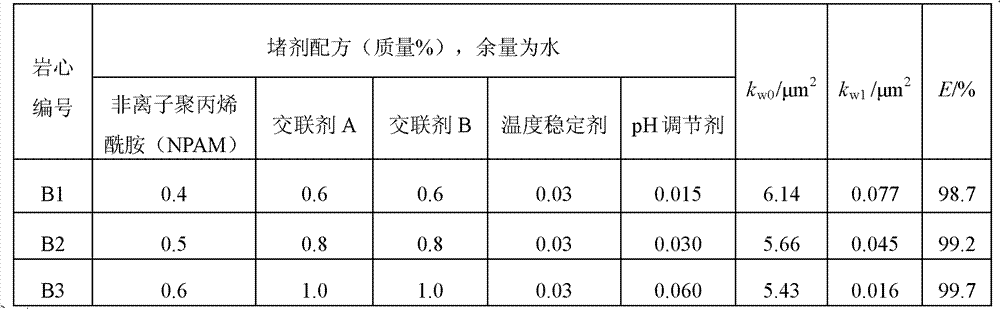

Gel plugging agent for deep profile control of higher temperature oil reservoir and preparation method of gel plugging agent

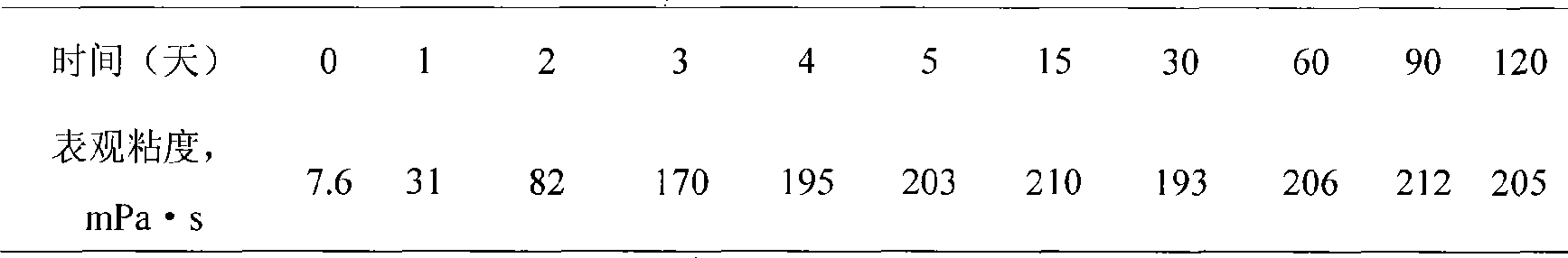

ActiveCN102807849AImprove temperature resistanceGelation time is shortDrilling compositionSodium bicarbonateCross-link

The invention relates to a gel plugging agent for deep profile control of a higher temperature oil reservoir, and a preparation method of the gel plugging agent. The gel plugging agent comprises 0.3-0.8 percent of nonionic polyacrylamide, 0.6-1.3 percent of a cross-linking agent A, 0.45-1.44 percent of a cross-linking agent B, 0.02-0.04 percent of a temperature stabilizer and 0.01-0.08 percent of a pH value regulator, wherein the cross-linking agent A is methenamine; the cross-ling agent B is hydroquinone or resorcinol; the temperature stabilizer is sodium thiosulfate, sodium bisulfite or sodium sulfite; and the pH regulator is sodium hydroxide, potassium hydroxide, sodium carbonate or sodium bicarbonate. The gel plugging agent disclosed by the invention has strong temperature resisting performance and can be used for the profile control operation of the high temperature oil reservoir with 100-160DEG C; the gel plugging agent has the characteristics of high strength after being gelatinized, stronger plugging capability for the stratum and favorable thermal stability; and in addition, after the gel plugging agent is stood at the temperature of 130 DEG C for 90 days, the strength change is little and gel breaking and hydration are avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

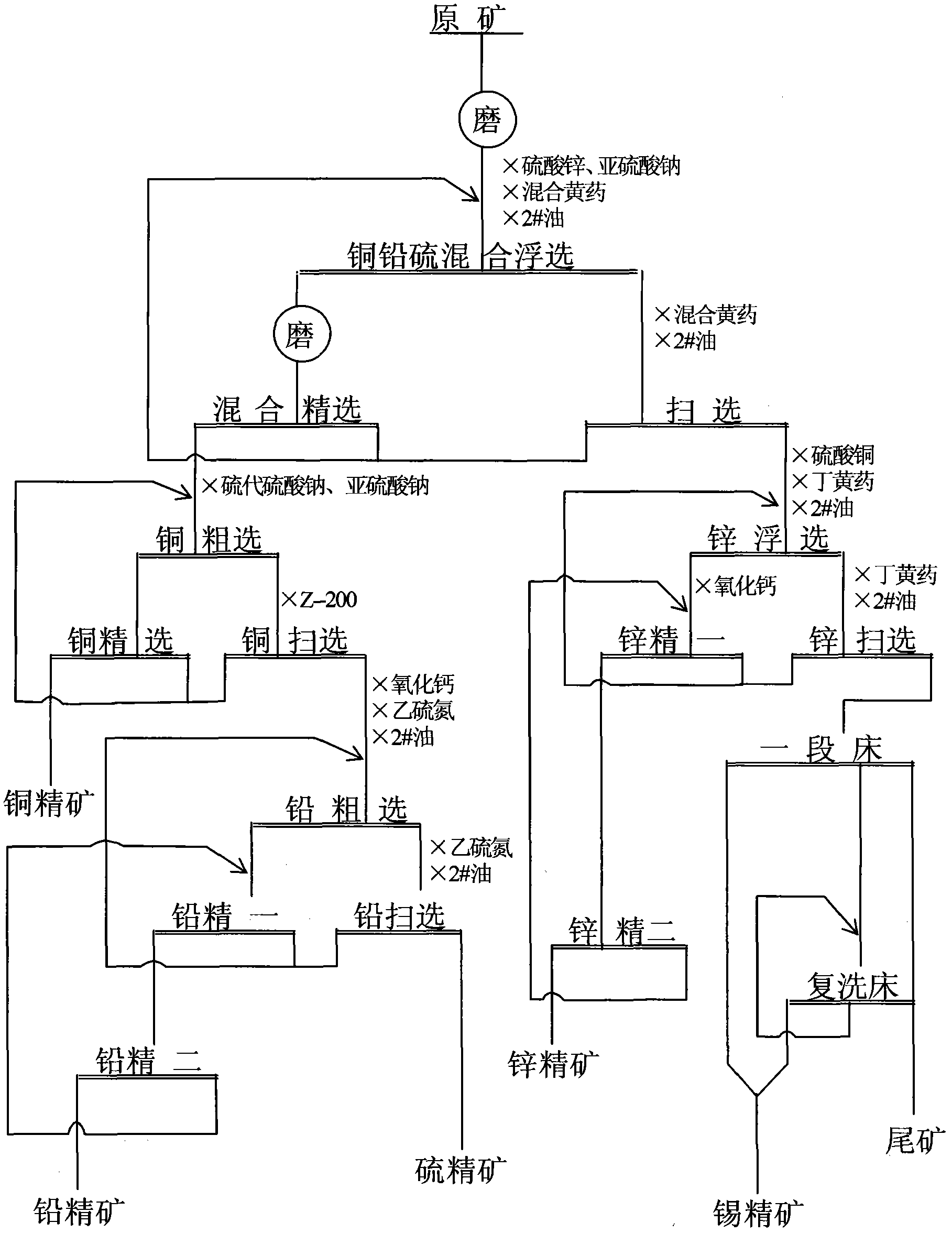

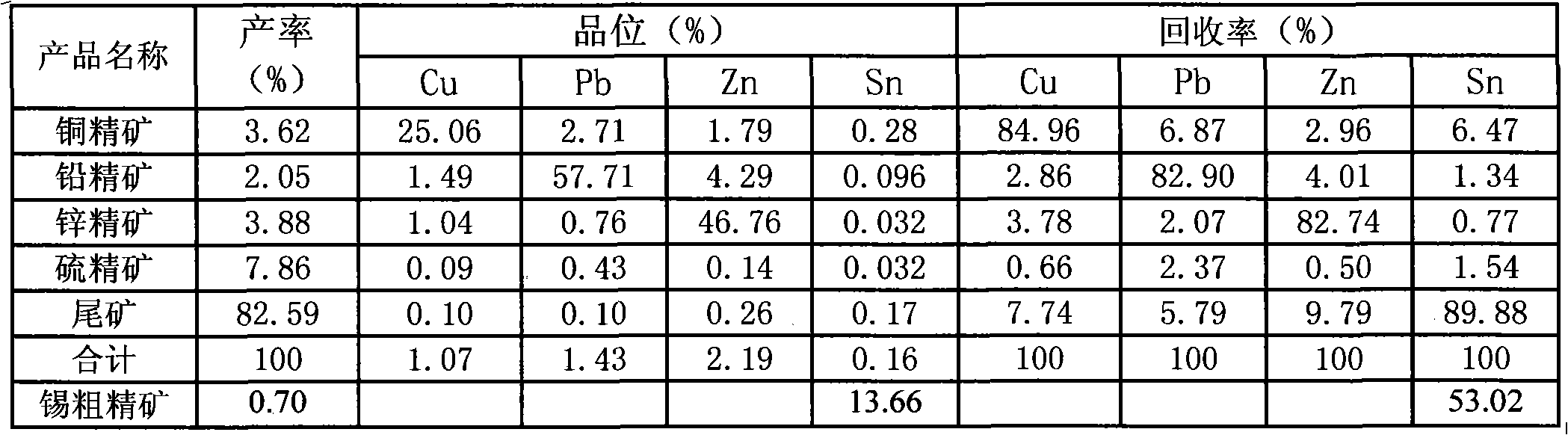

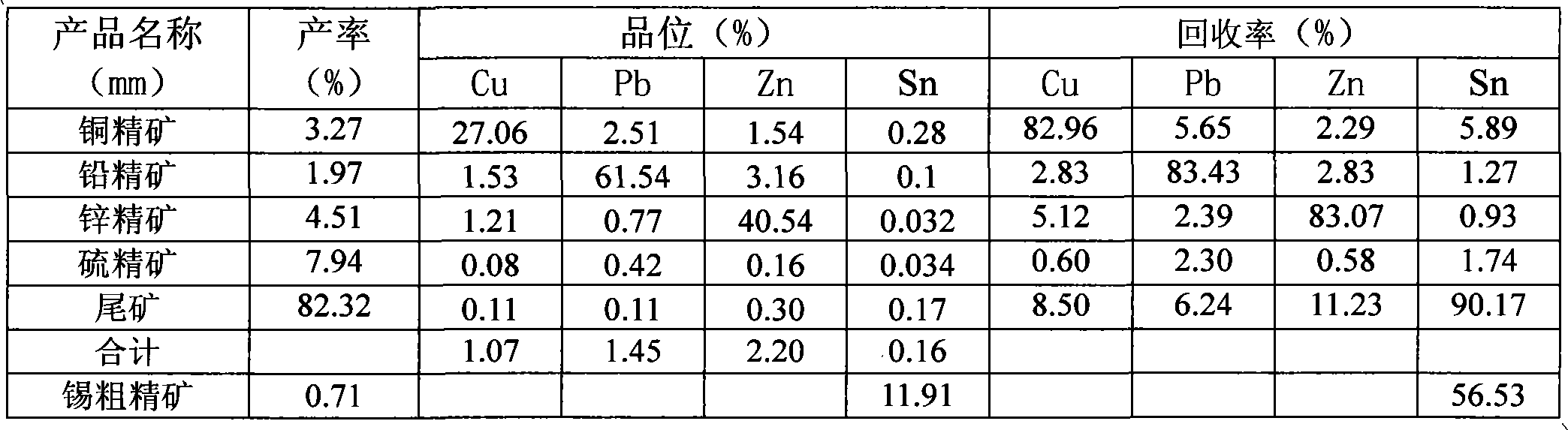

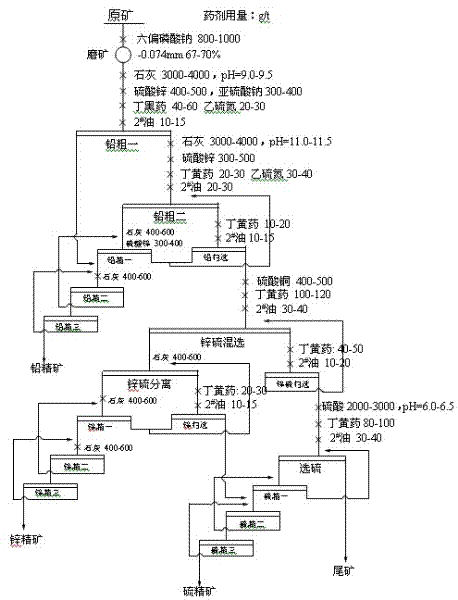

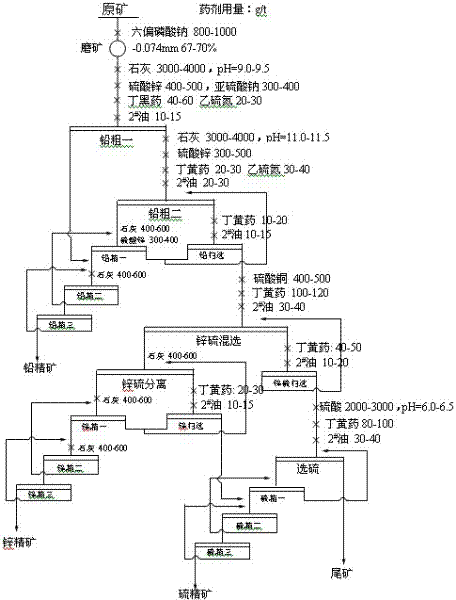

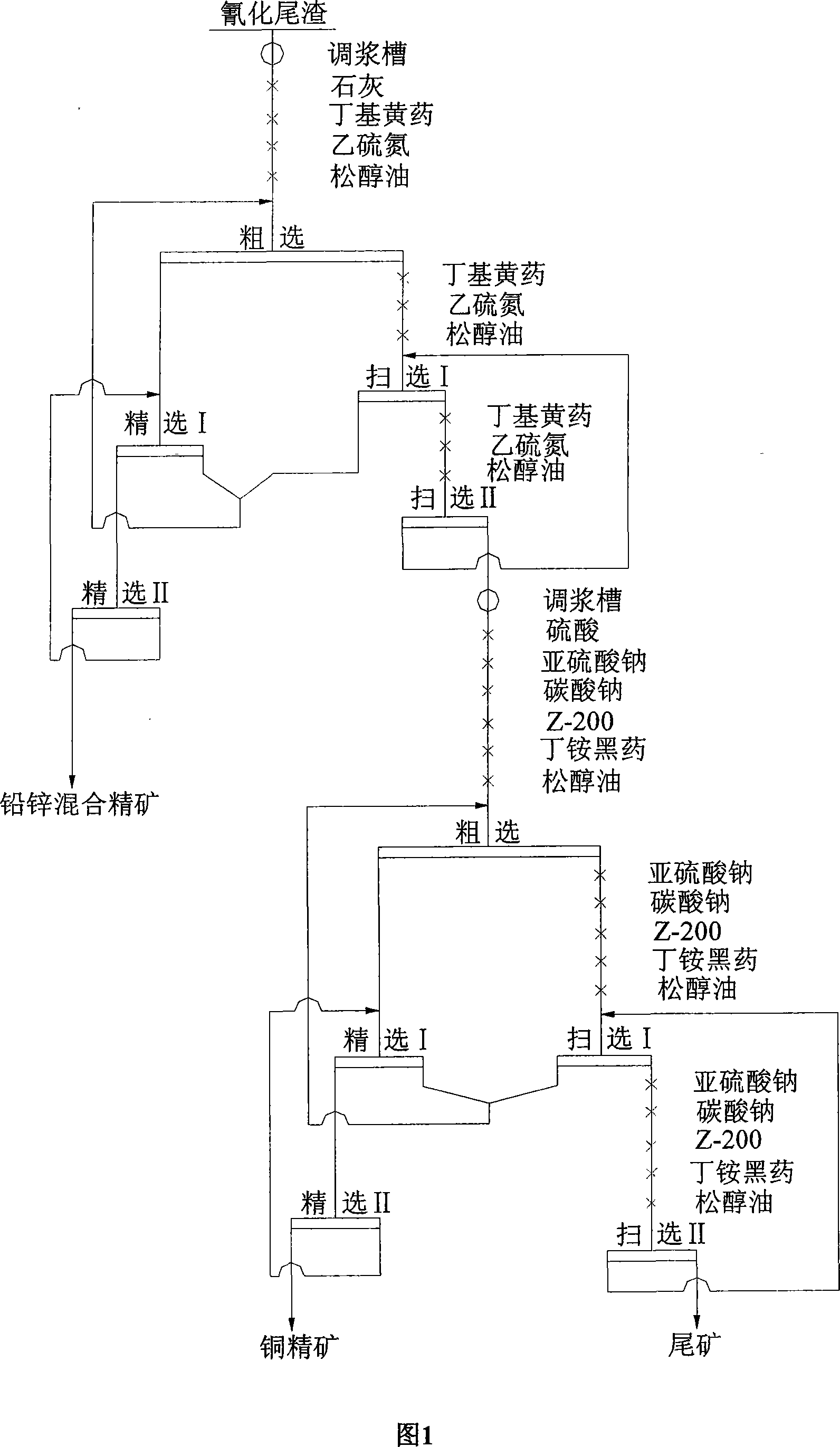

Benification combined method of polymetallic sulphide ore containing copper, lead, zinc and tin

The invention relates to a beneficiation method, in particular to a beneficiation method for separating the polymetallic sulphide ore containing copper, lead, zinc and tin. The method comprises the following steps: (1) carrying out ore grinding on the raw ore before carrying out bulk flotation on copper, lead and sulphur, using diethyl mixed with xanthate as collecting agent of copper and lead mineral, using zinc sulphate and sodium sulfite as inhibitor of zinc mineral; (2) carrying out phase-2 ore grinding and selection; (3) separating copper, lead and sulphur, using sodium sulfite and sodium thiosulfate as the inhibitor of the lead and sulphur mineral, using Z-200 as collecting agent for separation and scavenging and then carrying out lead flotation after the separation and scavenging; (4) carrying out zin flotation on the bulk flotation tailings; and (5) finally, carrying out reselection on the zinc flotation tailings to recover tin. The metalliferous mineral of the invention has the advantages of good separating effect, high metal recovery rate, more complete comprehensive recovery of useful minerals, low cost of medicament, simple method, easy operation and energy conservation.

Owner:云南锡业研究院有限公司研究设计院

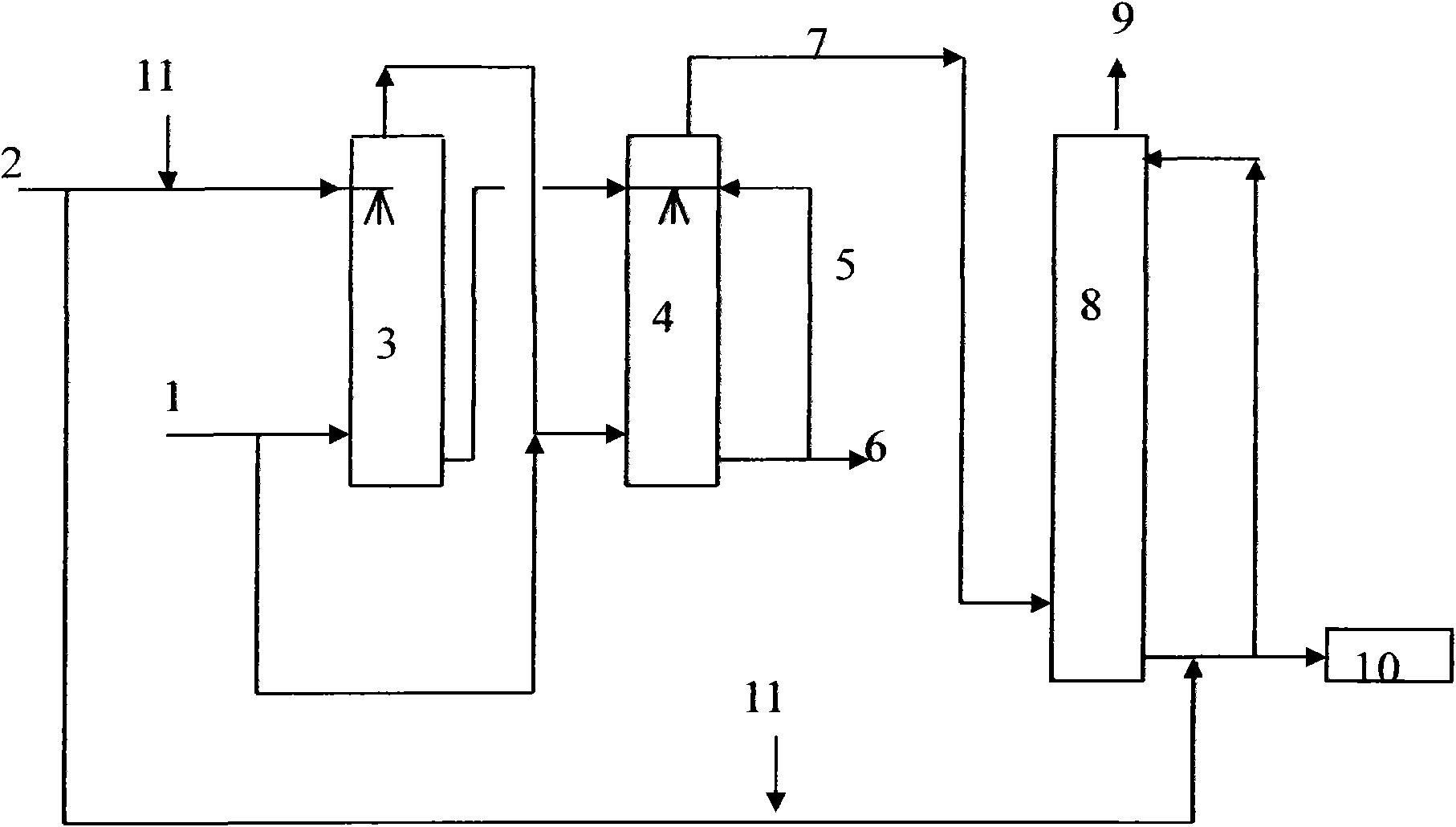

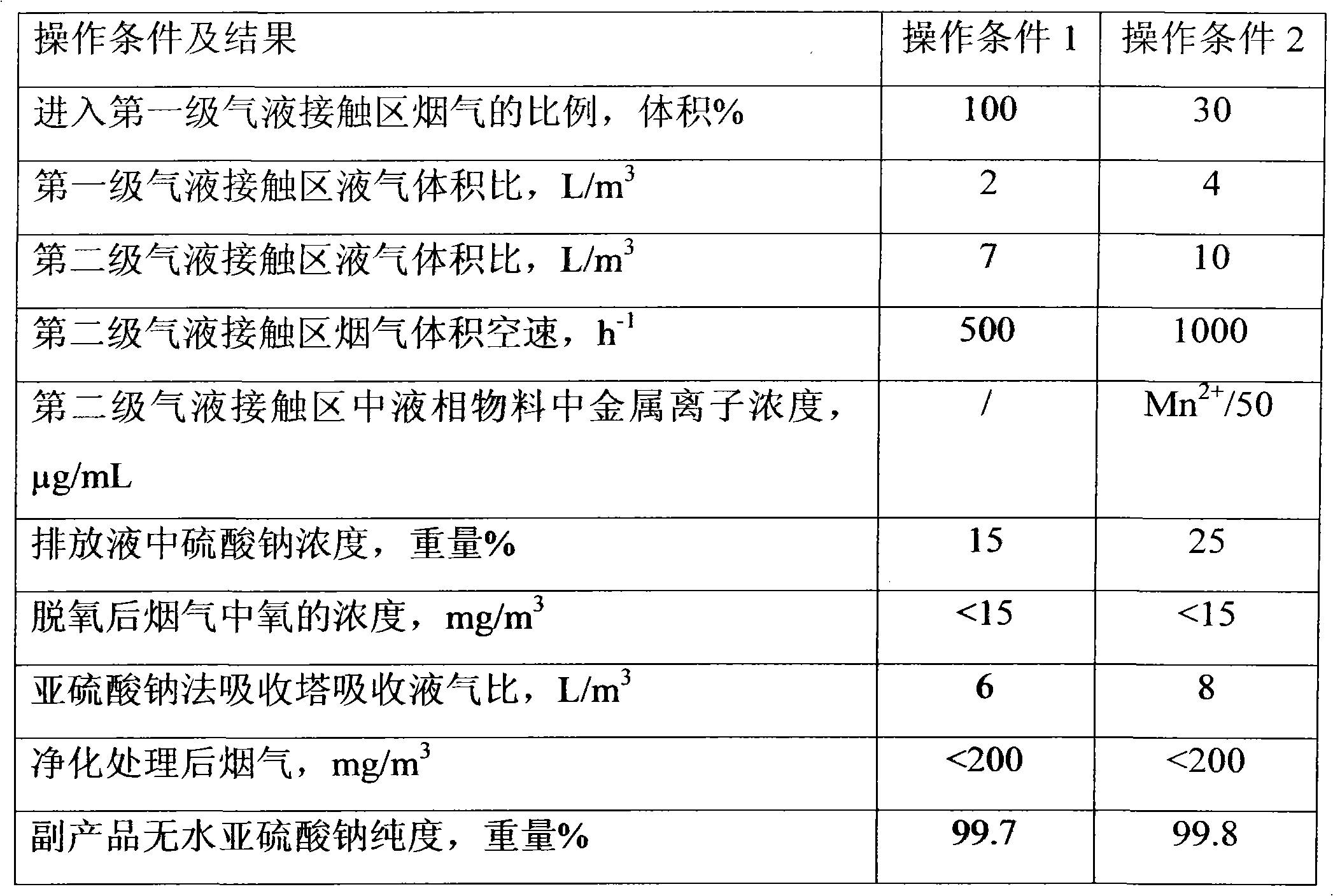

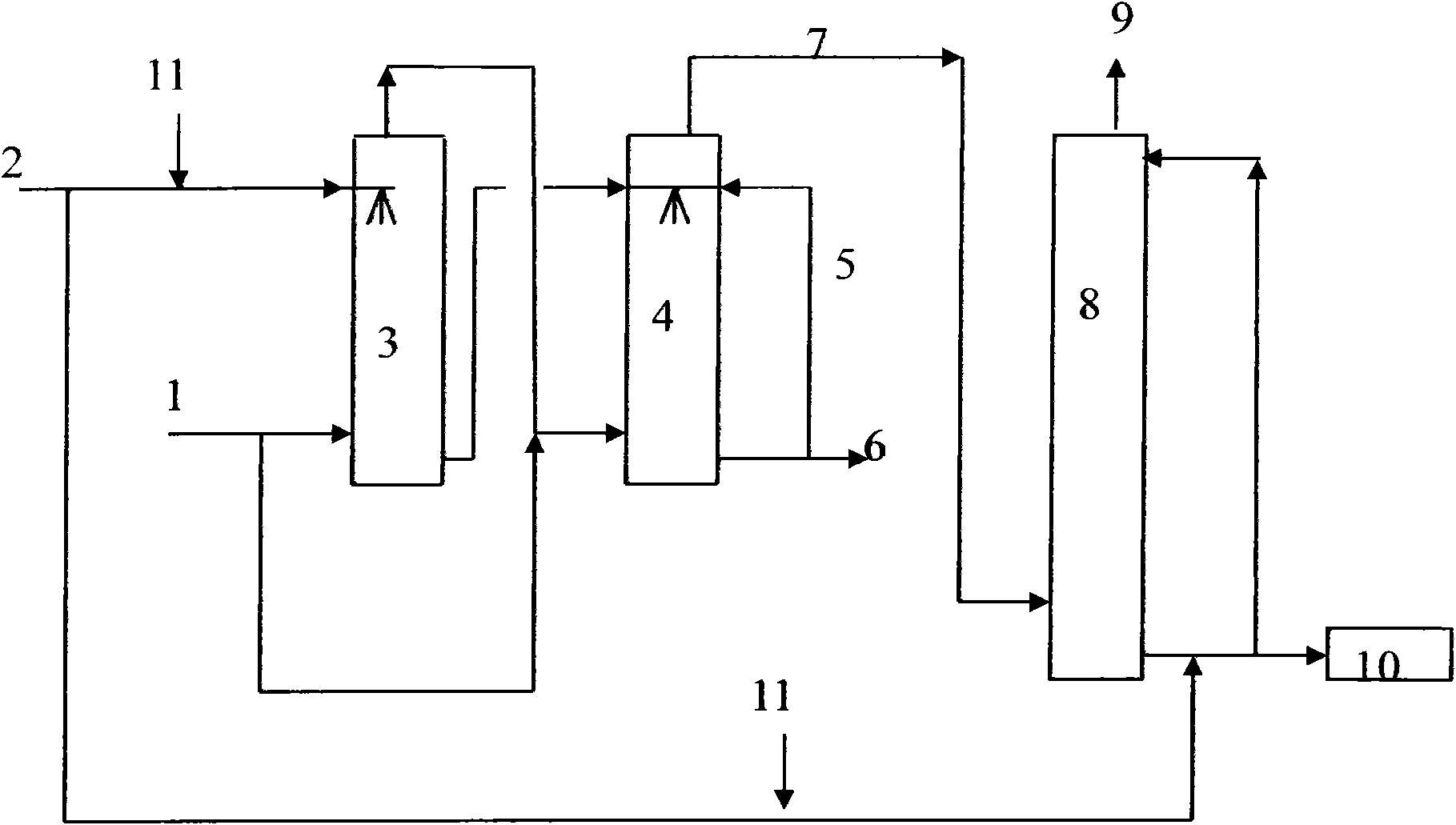

Method for desulfurizing high-concentration flue gas

ActiveCN102049186AIncrease valueLow recovery rateDispersed particle separationHigh concentrationSulfite salt

The invention discloses a method for desulfurizing high-concentration flue gas. The high-concentration flue gas is desulfurized through a sodium sulfite method, and meanwhile, the sodium sulfite is recovered as a by-product, wherein the flue gas needs to be deoxidized before being desulfurized through the sodium sulfite method. In the method for desulfurizing high-concentration flue gas disclosedby the invention, by deoxidizing the flue gas through an appropriate pretreatment process, the purity of the by-product sodium sulfite produced by the subsequent flue gas desulfurization process of the sodium sulfite method can be obviously improved, and the value of the by-product is improved, thereby obviously improving the comprehensive economic benefits. The pretreatment process of the flue gas is performed by using the sulfite and / or the hydrosulfite produced by the reaction of SO2 contained in the flue gas and alkali to react with oxygen without using any other deoxidizer. The method disclosed by the invention has simple production process and is easy to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

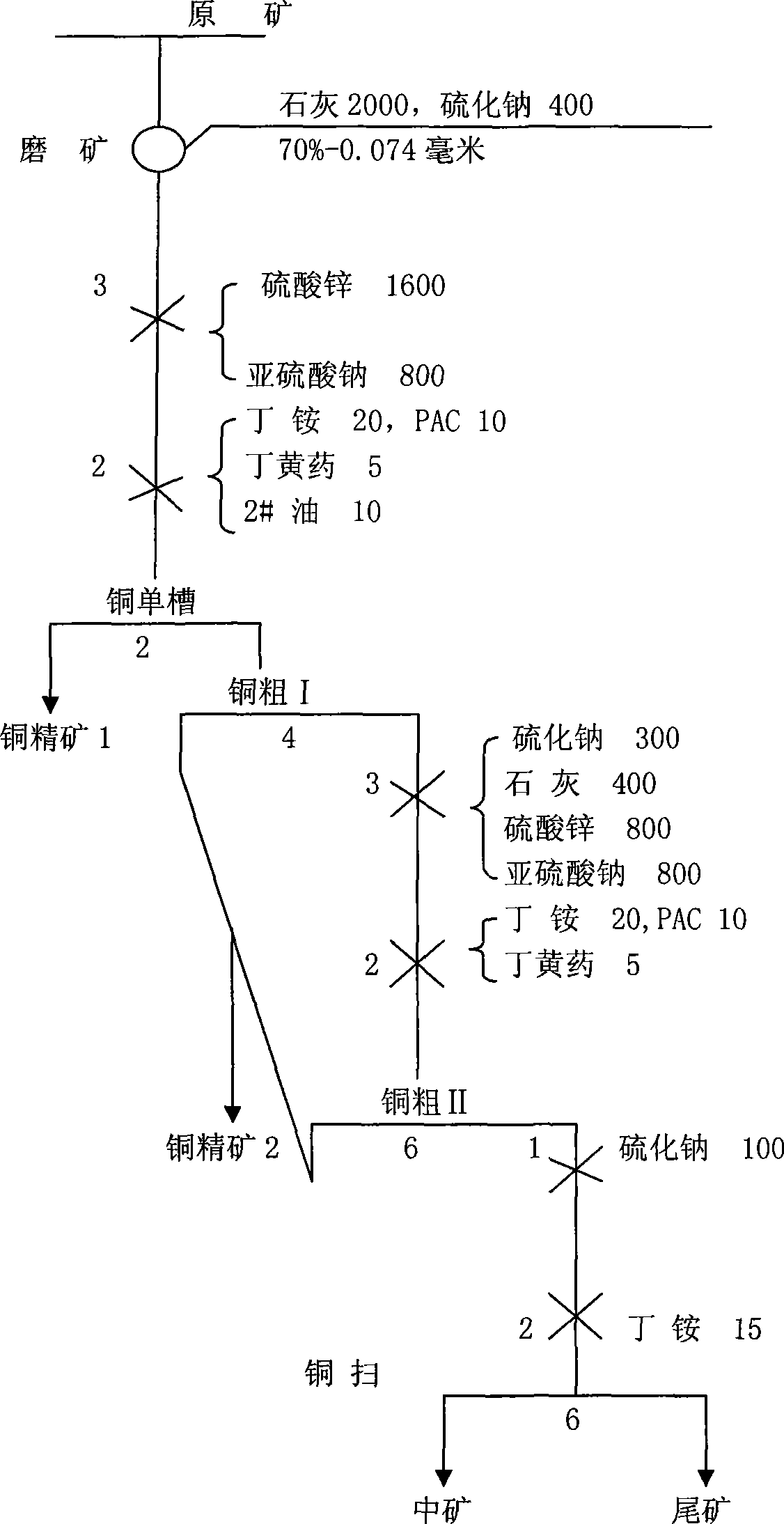

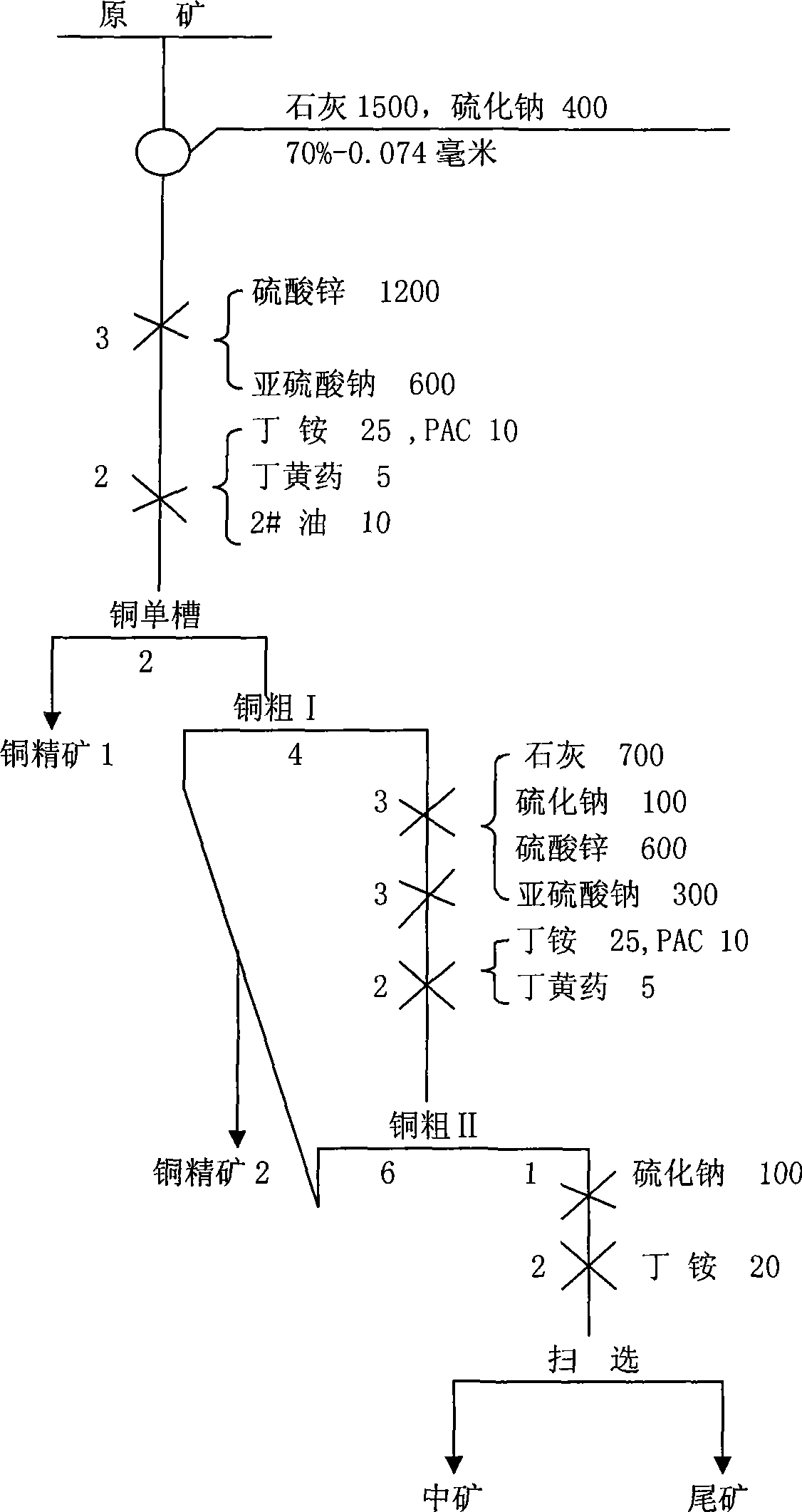

Copper-zinc separation beneficiation method

InactiveCN101428250ARaise the gradeRealize zinc suppression and floating copperFlotationSulfite saltSulfate

The invention relates to a copper-zinc separation beneficiation method which comprises the following steps: (1) primary grinding, that is, adopting a combined depressant comprising lime, sodium sulfide, zinc sulfate, and sodium sulfite under the condition that the size and the content of grinding particles are respectively -0.074 mm and 65 to 70 percent; (2) copper rough concentrates regrinding and concentration, that is, selecting out high-quality copper concentrates which contain high-grade copper and silver, but low zinc by adopting single groove speed flotation method and continually using the combined depressant constituted by lime, sodium sulfide, zinc sulfate, and sodium sulfite, so as to realize the zinc depressing and copper flotation; (3) zinc-sulfur separation, that is, using butyl xanthate as a collecting agent to float zinc, obtaining zinc-sulphur bulk concentrate, conducting pulp conditioning by adding lime so as to depress sulfur and float copper and obtain zinc concentrates and partial sulfur concentrates, conducting the iso-flotation on the tailings and further adding the butyl xanthate to conduct flotation and obtain partial sulfur concentrate. The invention has the advantages of adopting the processes of ore blending, primary grinding, copper rough concentrates regrinding and concentration, and zinc-sulphur iso-flotation technological process, thereby better solving the problem that the copper concentrates contain too much zinc or the copper content in the zinc concentrates is over standard.

Owner:杭州建铜集团有限公司

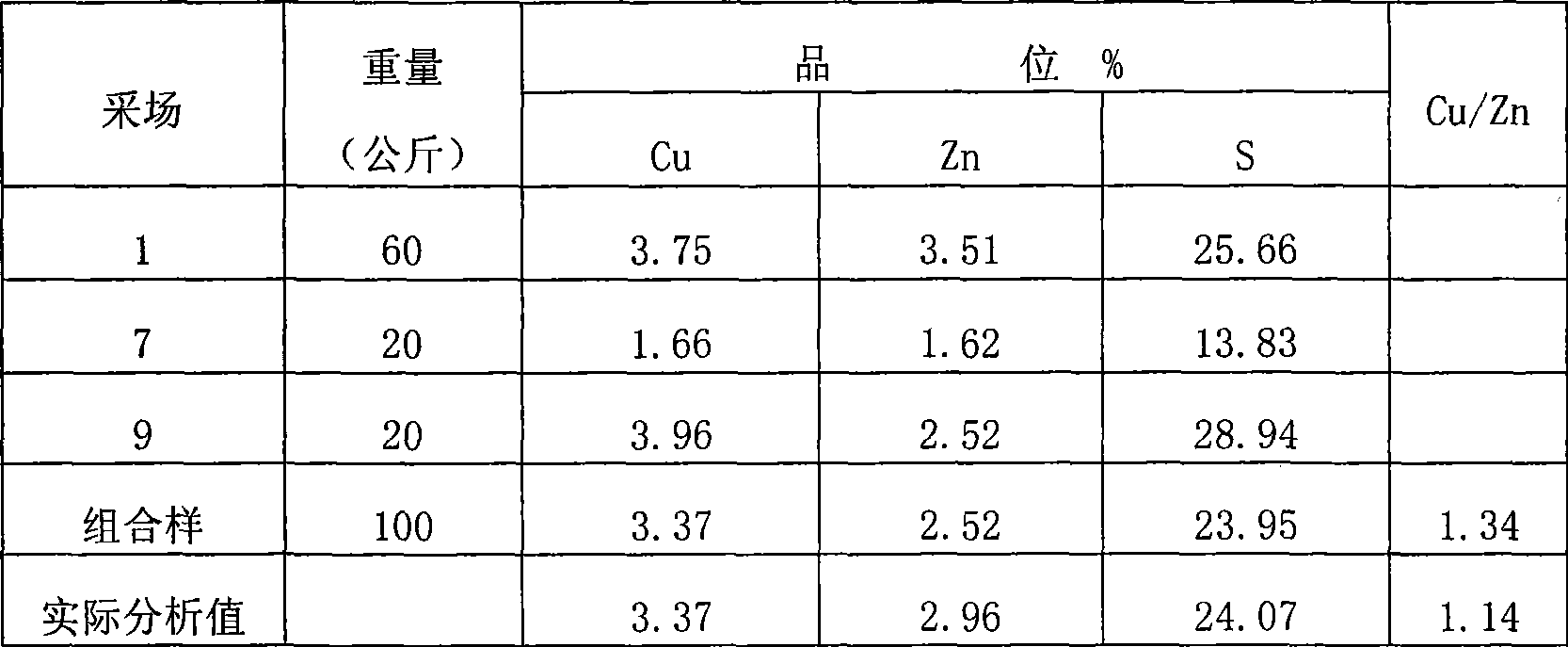

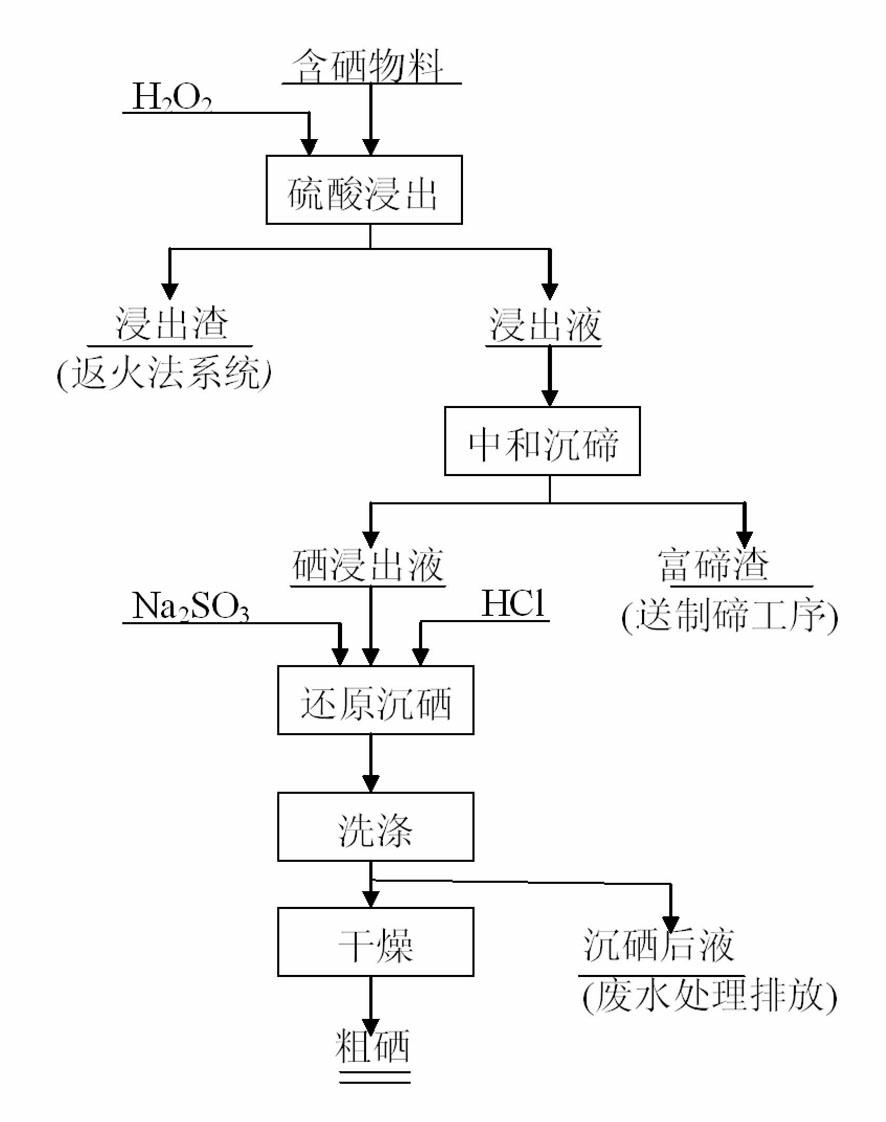

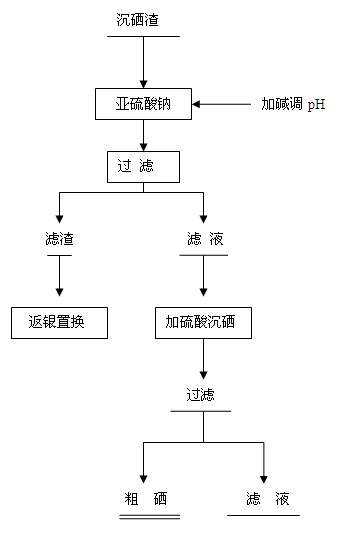

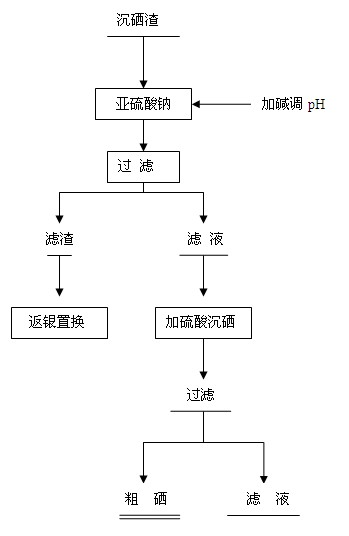

Process for separating and recovering selenium from selenium-containing material

The invention relates to a process for separating and recovering selenium from a selenium-containing material. The process comprises the following steps: dissolving the selenium-containing material into a sulfuric acid solution, adding 10% H2O2 into the mixture, filtering and separating to get leachate and residue containing silver, lead, copper and other valuable metals; separating the selenium from tellurium in the oxidation leachate by using sodium hydroxide; and acidifying the selenium leachate with hydrochloric acid, adding sodium sulfite to reduce the settled selenium, washing and drying to get crude selenium with the grade of not lower than 90%. The crude selenium which is separated by the process is higher in purity and can be directly refined, so that the process flow of recovering selenium is shortened, the recovery rate of selenium is improved, the production cost is reduced and the energy is saved; and the sodium sulfite is used for substituting sulfur dioxide to perform reduction, the control is easy and the environmental pollution is further reduced. The process has very important significance in both aspects of recovering resources and protecting an environment.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

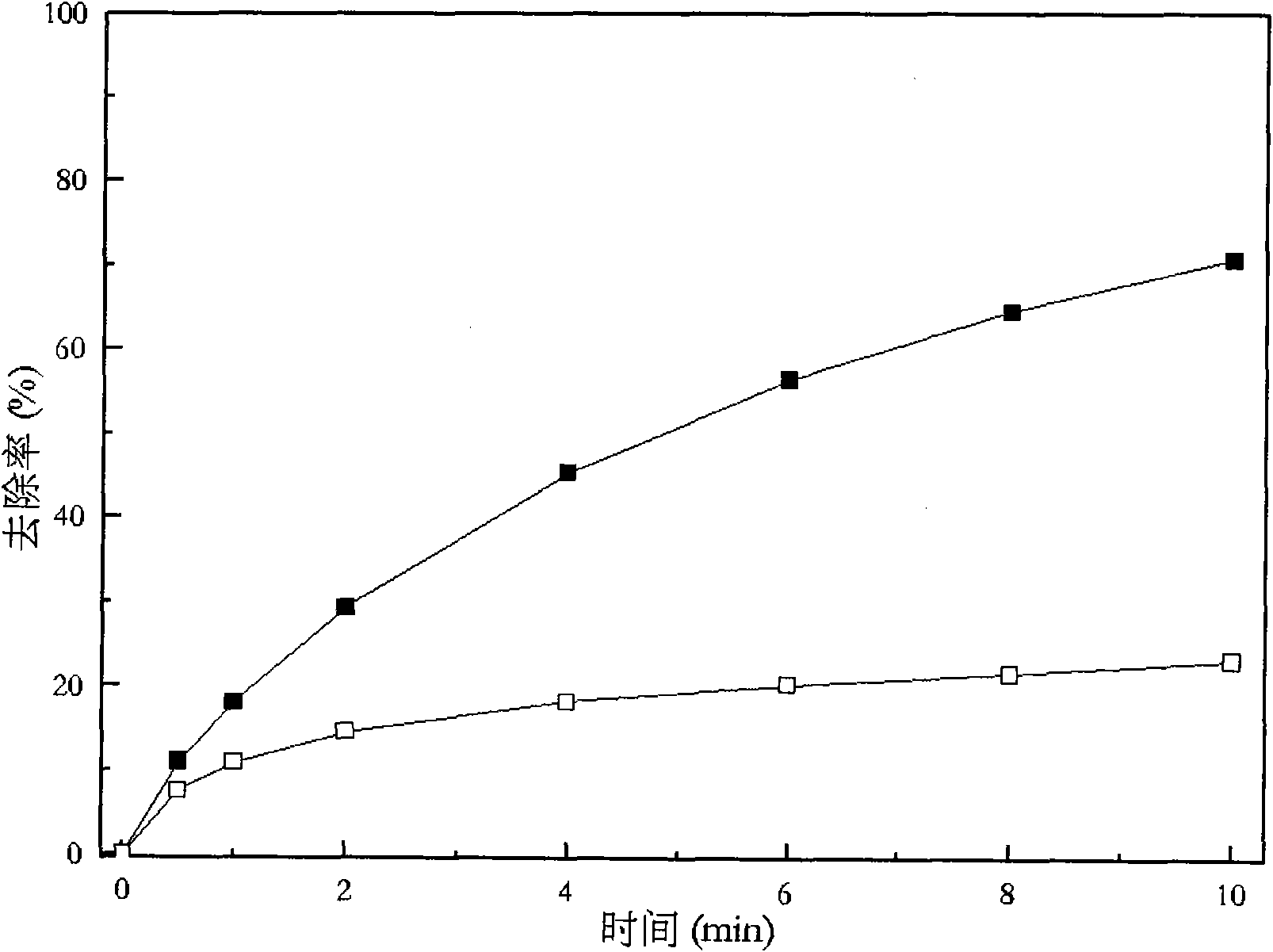

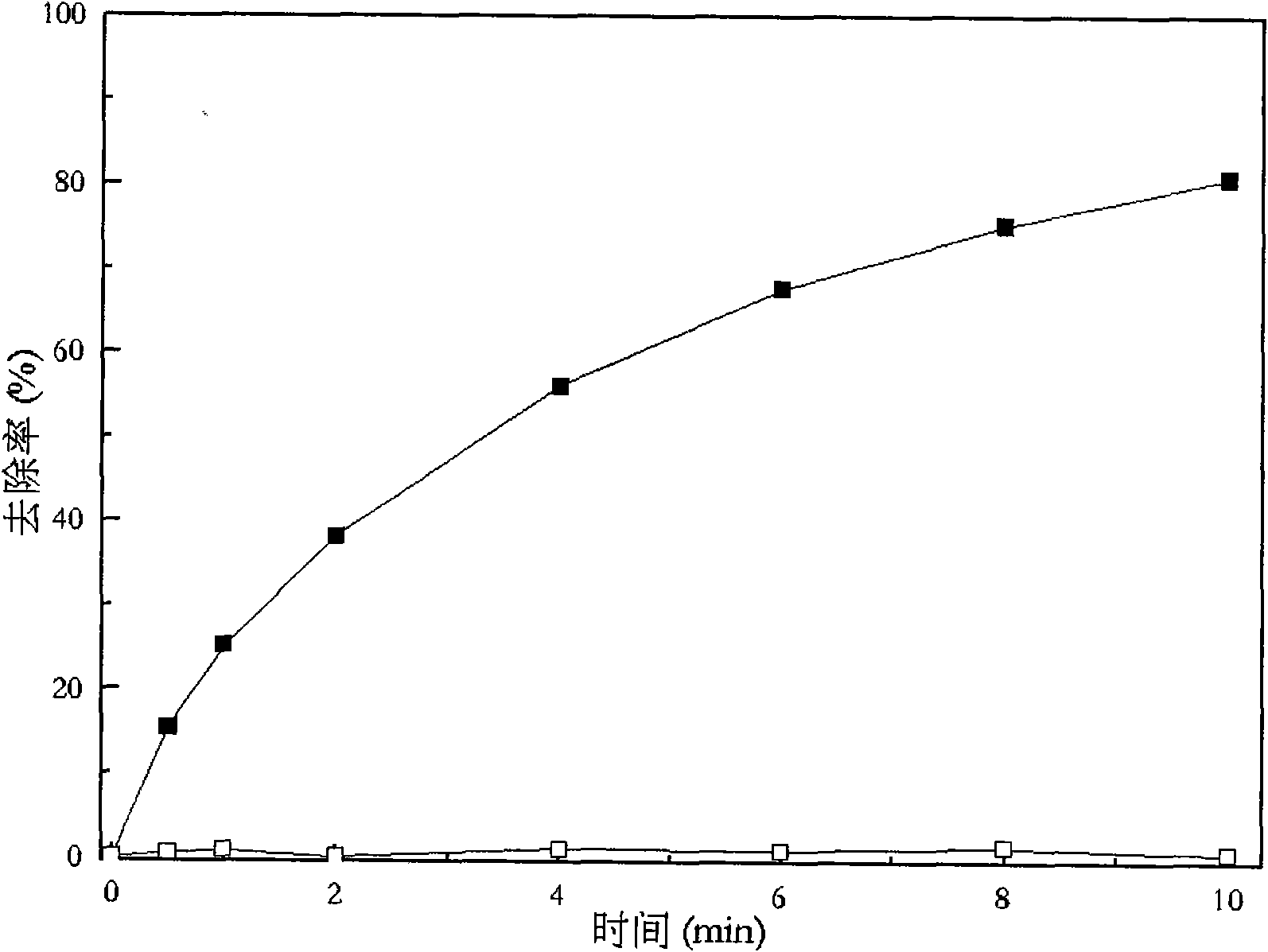

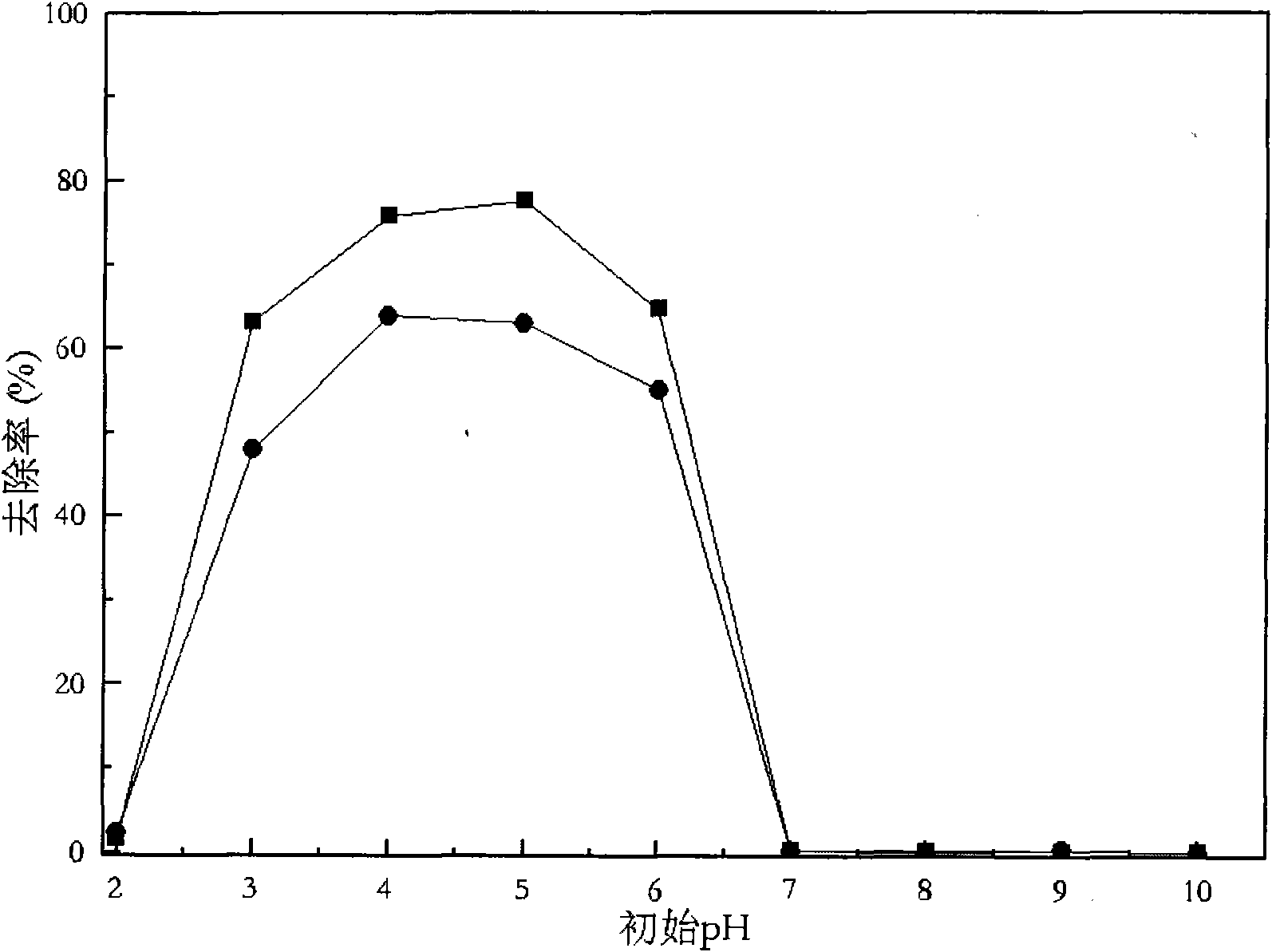

Fenton and Fenton-like system fortifier and using method thereof

ActiveCN101792205AReduce dosageEasy to useWater treatment parameter controlWater treatment compoundsSulfite saltHydrazine compound

The invention provides a Fenton and Fenton-like system fortifier and a using method thereof, which relate to a water treating fortifier and a using method thereof and overcomes the defects that the pH value of the Fenton and Fenton-like system reaction water body is limited, the adding amount of Fe<2+> is overhigh in the Fenton reaction, and the reaction speed is low in Fenton-like reaction. The fortifier is selected from ascorbic acid, sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine, hydroxyl-ammonium perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, carbohydrazide, ethanolamine, a hydroxylamine solution or N,N,N',N'-tetra substituted phenylenediamines. The using method has the following steps of: adding the Fenton and Fenton-like system fortifier, fortificated chemicals and peroxide into the treated water body; and then, uniformly stirring to react. The fortifier can accelerate the reaction of water treatment and decrease the using amount of the fortificated chemicals.

Owner:HARBIN INST OF TECH

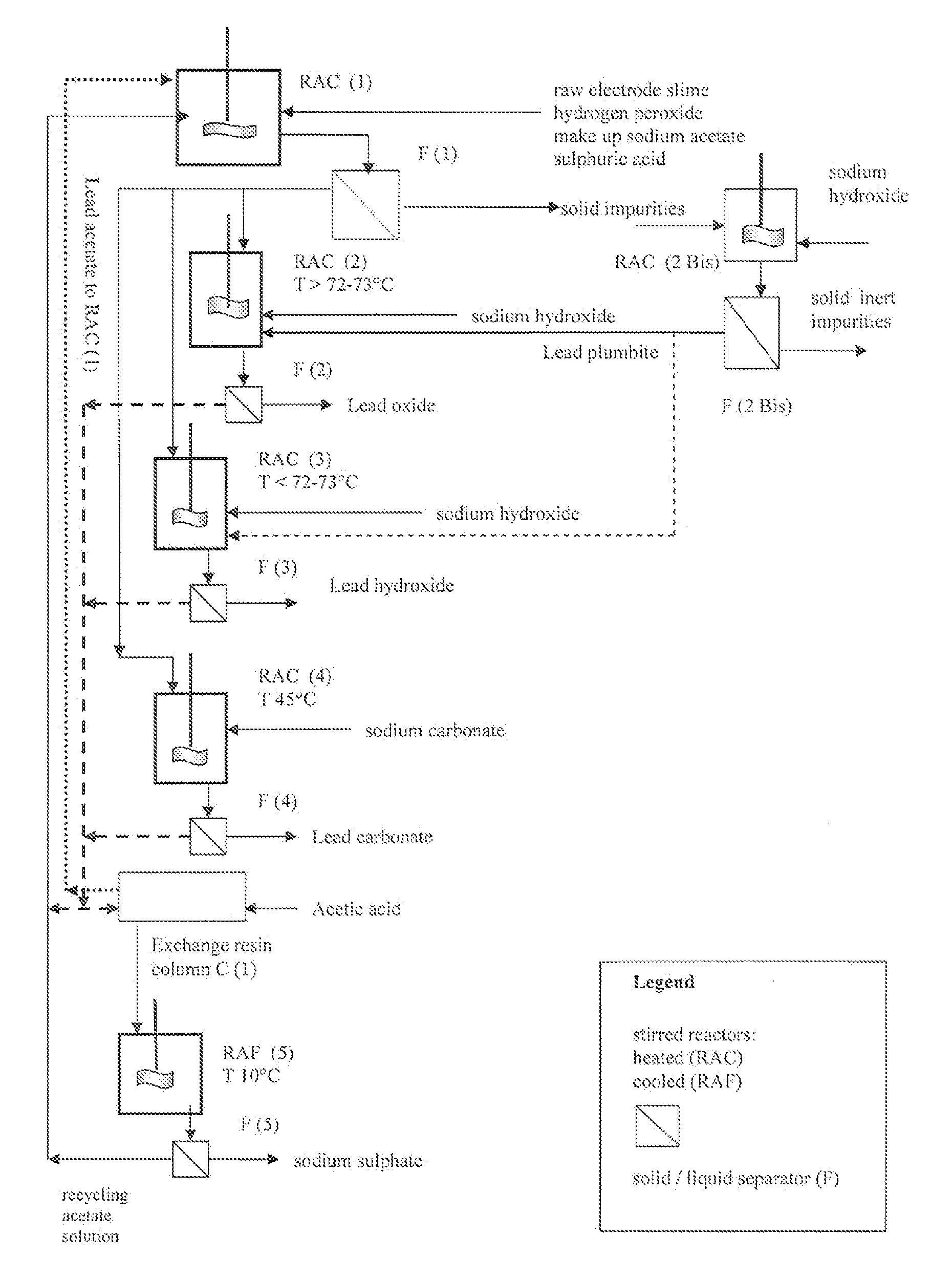

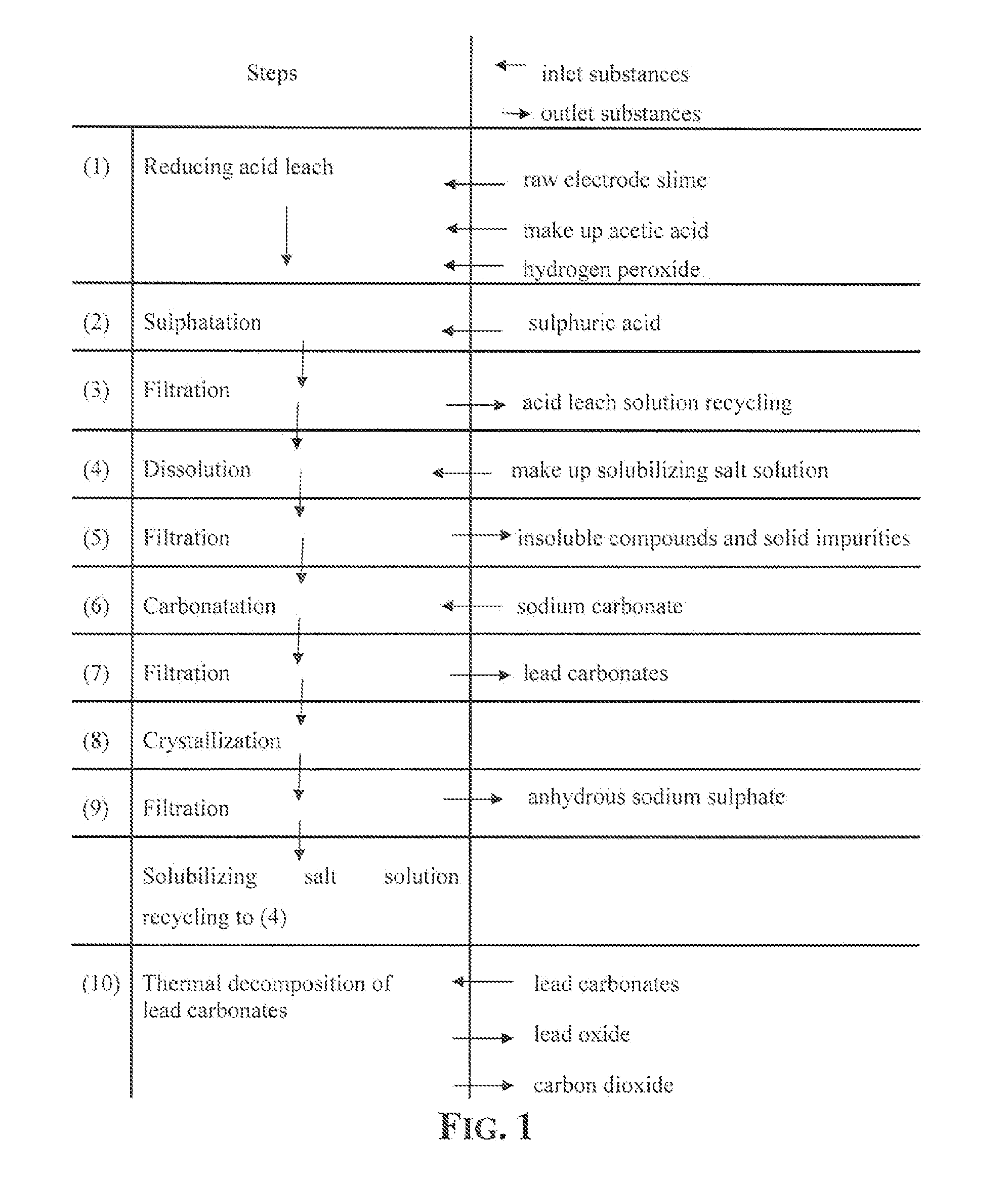

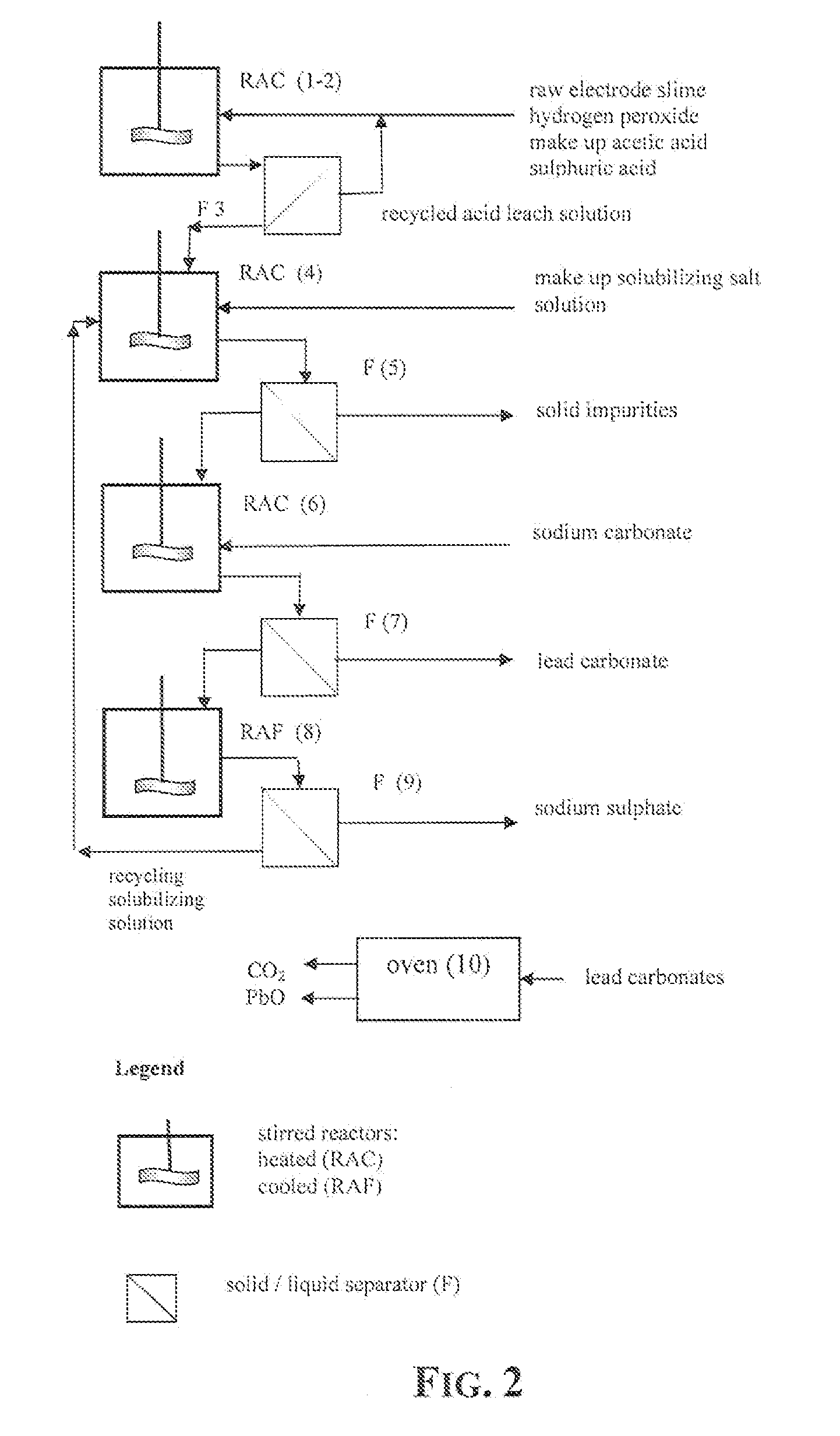

Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

An outstandingly low environmental impact wet process recovers the lead content of an electrode slime and / or of lead minerals in the valuable form of high purity lead oxide or compound convertible to highly pure lead oxide by heat treatment in oven at relatively low temperature, perfectly suited for making active electrode pastes of new batteries or other uses. The process basically comprises the following treatments:a) suspending the impure lead containing material in an aqueous bath containing at least a lead oxide dissolving acid;b) reducing any insoluble lead dioxide to lead oxide by introducing in the suspension either hydrogen peroxide, a sulphite or sulphurous anhydride;c) converting all dissolved lead oxide to lead sulphate in the aqueous bath;d) obtaining a solution of lead sulphate obtained in an aqueous solution containing an acetate salt;e) precipitating and separating a purified lead compound in the form of either carbonate / oxycarbonate or of oxide / or hydroxide by adding to said acetate salt solution a carbonate salt or a hydroxide of the same cation of said acetate salt, respectively.Exemplary flow sheets according to several alternative embodiments and related processing plant diagrams are disclosed.

Owner:MILLBROOK LEAD RECYCLING TECH

Technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity

The invention discloses a technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity. During grading of the lead and zinc sulfide ores, sodium hexametahposphate is taken as a dispersion agent and directly added into a ball mill, the ores are ground till the ores with the size of 0.074mm account for 67%-70%, lime is taken as an adjusting agent, zinc sulfate and sodium sulfite are taken as inhibitors, dithiophosphate BA and diethyldithiocarbamate are taken as collectors, and selective flotation of part of lead minerals with good floatability can be performed under low alkalinity; then xanthate and the diethyldithiocarbamate are taken as collectors, and the flotation of the lead minerals is further performed under high alkalinity; copper sulfate is added in lead flotation tailings for activation, butyl xanthate is further taken as the collector for flotation of zinc blende and part of pyrite, and zinc-sulfur separation flotation is further performed on zinc-sulfur mixed concentrate; and sulfuric acid is added in zinc flotation tailings for activation, and the xanthate is taken as the collector for flotation of the remaining pyrite. By adopting the technology, the lead-silver recovery rate can be improved, the using amount of lime and sulfuric acid can be reduced, the circulating amount of middlings can be reduced, the ore dressing cost can be reduced and the grade of the concentrate can be improved.

Owner:KUNMING UNIV OF SCI & TECH

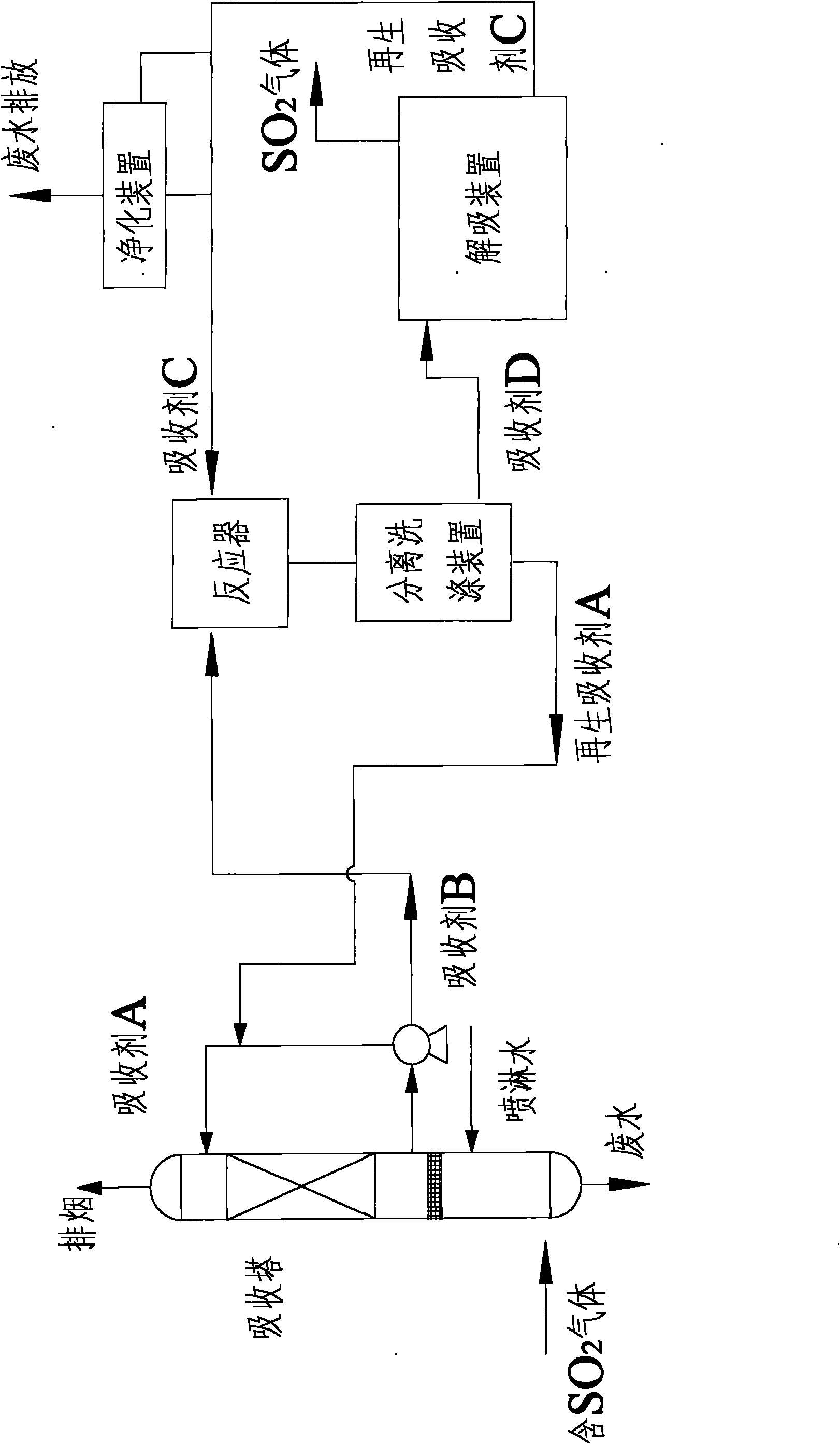

Method for removing and reclaiming sulfur dioxide from gas by low power consumption renewable absorbent

InactiveCN101920159AReduce oxidationReduce lossesSulfur compoundsDispersed particle separationHigh concentrationRecovery method

The invention relates to a method for removing and reclaiming sulfur dioxide from a mixed gas by a renewable absorbent, which is characterized by comprising the following steps: adopting an absorbent to contact with a gas containing sulfur dioxide, and removing the sulfur dioxide in the gas, wherein the absorbent comprises the components as follows by mass concentration: 10-30% of inorganic base and / or complex salt thereof and / or sulfite thereof, 0.02-0.2% of antioxidant and water; after absorbing the sulfur dioxide, reacting a solution containing the sulfur dioxide with another organic amine absorbent, and transferring the sulfur dioxide in the organic amine absorbent, thereby obtaining a renewable absorbent for removing the sulfur dioxide in air current repeatedly, wherein the organic amine absorbent comprises the following components by mass concentration: 30-98% of organic amine, 0.0-0.2% of antioxidant and water; and desorbing the organic amine absorbent containing the sulfur dioxide to obtain a high concentration sulfur dioxide gas and a renewable organic amine absorbent. The method for absorbing and reclaiming the sulfur dioxide proposed by the invention can realize cycled regeneration and utilization of the absorbent, and has no secondary pollution in the use process, low power consumption and low operation cost.

Owner:北京金源化学集团有限公司

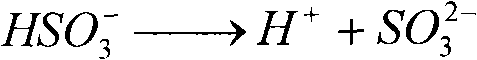

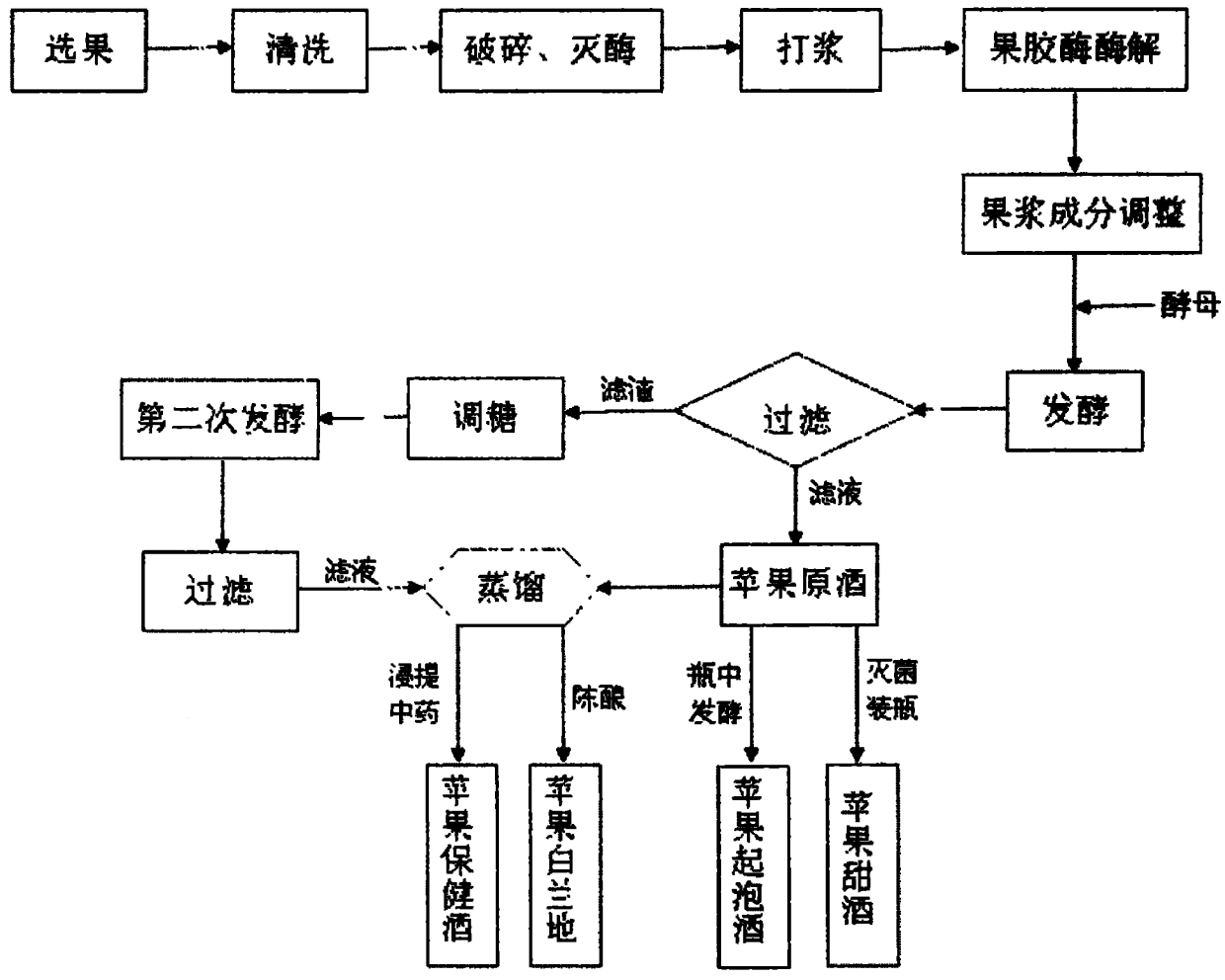

Brewing process of apple unblended wine and preparation method of apple unblended series wine

InactiveCN102021102AAids in synthesisRegulate functional activityAlcoholic beverage preparationMicroorganism based processesAntioxidantSulfite salt

The invention discloses a brewing process of apple unblended wine and a preparation method of apple unblended series wine. The brewing process of the apple unblended wine comprises the following steps of: selecting various apples as raw materials and mixing according to the proportion to use; during fermentation, fermenting full apples without adding sodium sulfite and other antioxidants; and after fermenting for enzymolysis, adding complex peptide so as to improve the brewing efficiency and enhance the nutrition of the apple unblended wine. Compared with the traditional brewing process, the brewing process of the apple unblended wine has the advantages of high brewing efficiency, production cost saving, and the like. In addition, a series of apple wine products can be developed on the basis of high-quality apple unblended wine produced by the process, including apple sweet wine, apple foaming wine, apple brandy, apple heath-care wine and the like.

Owner:陈栋梁

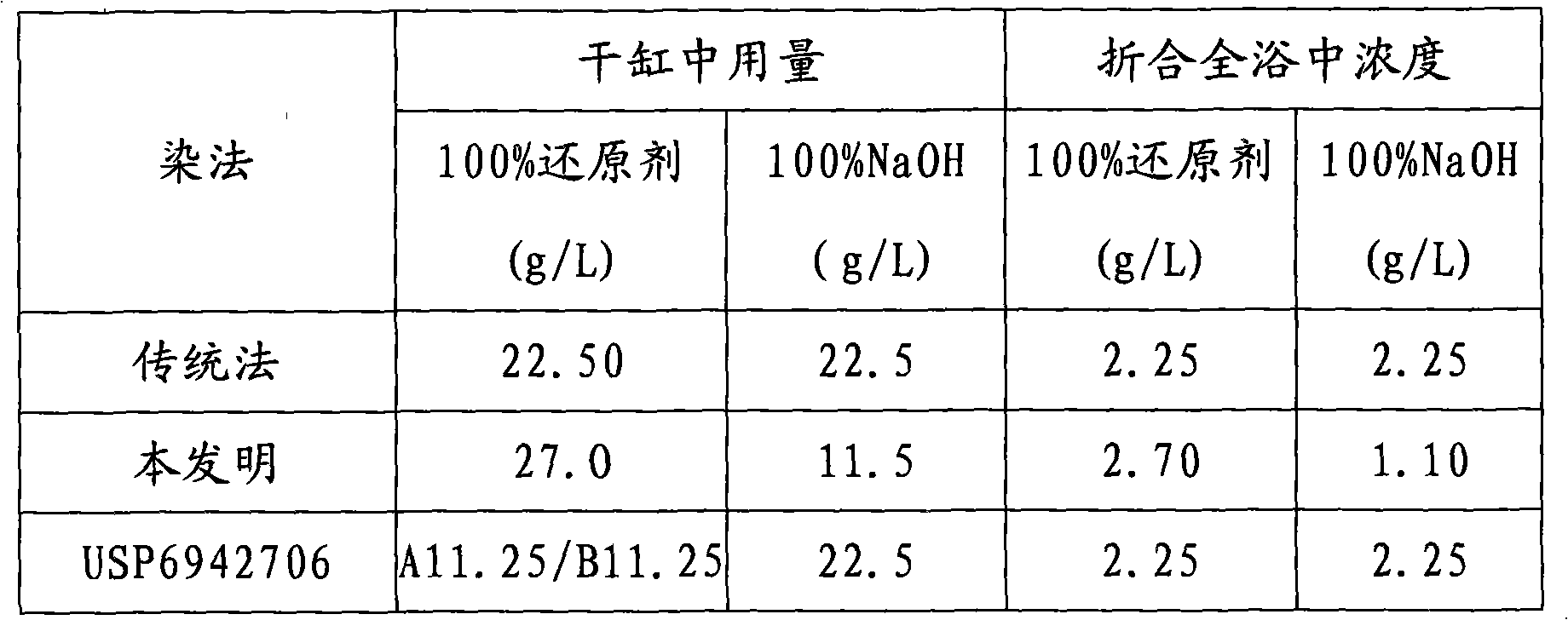

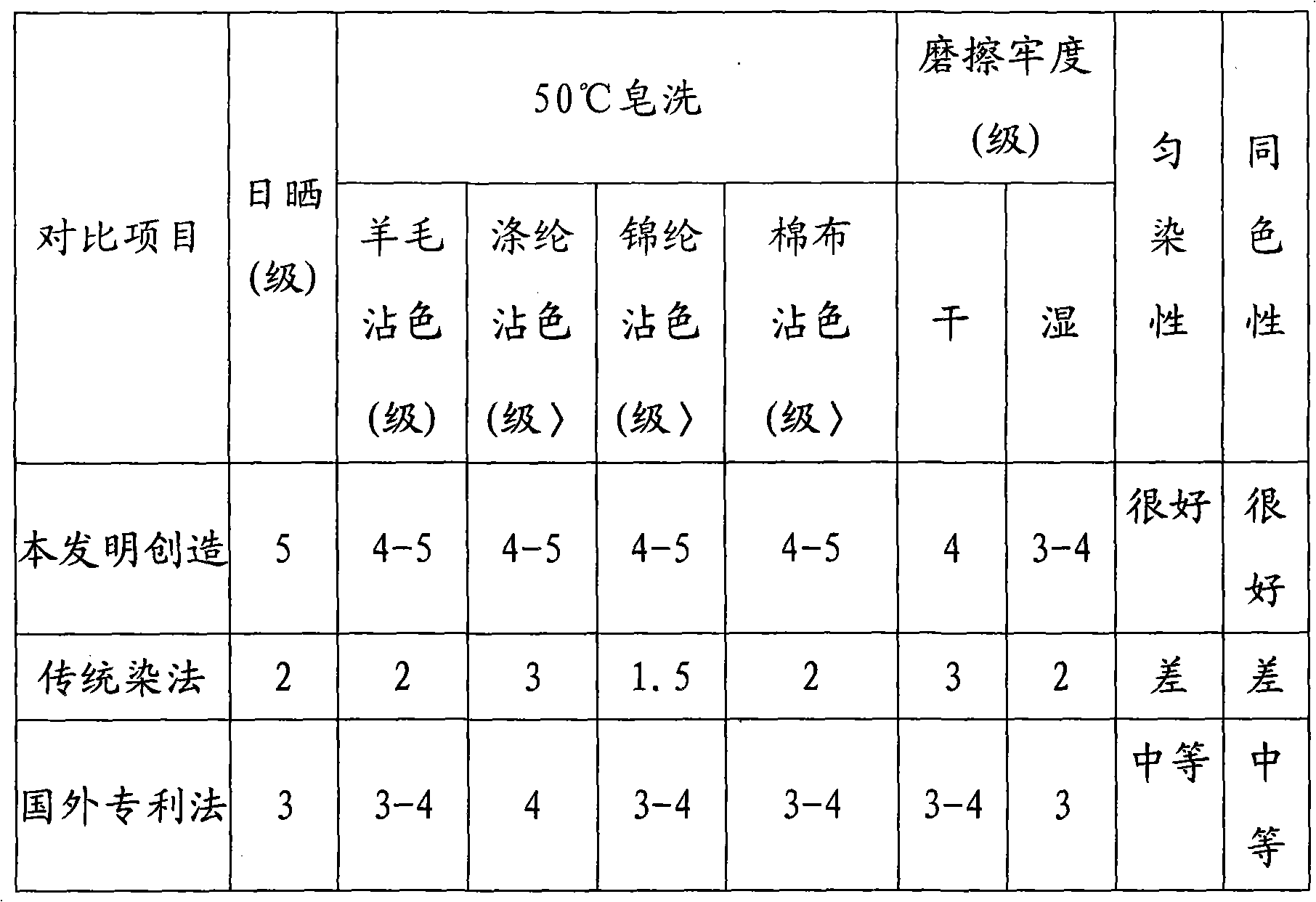

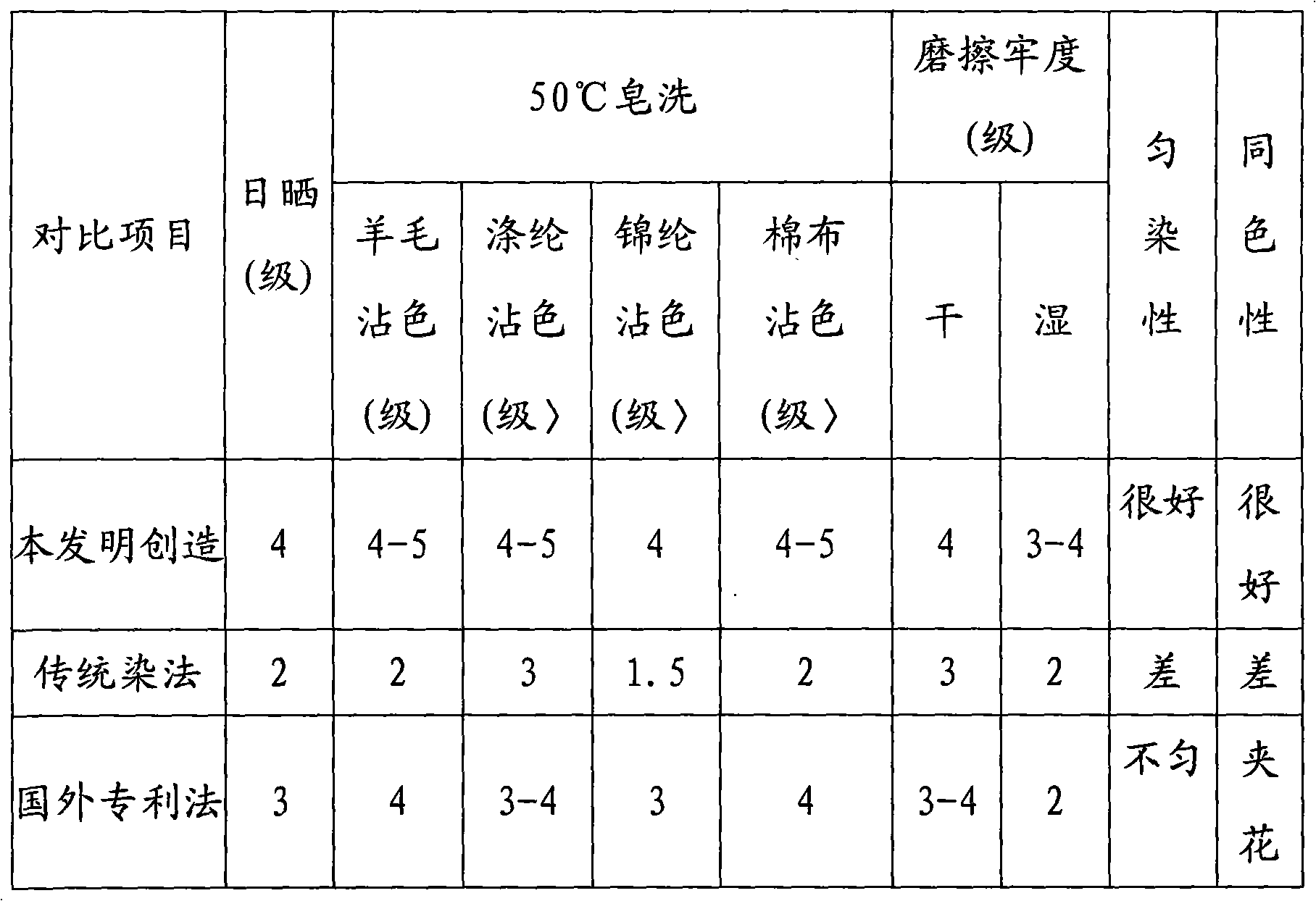

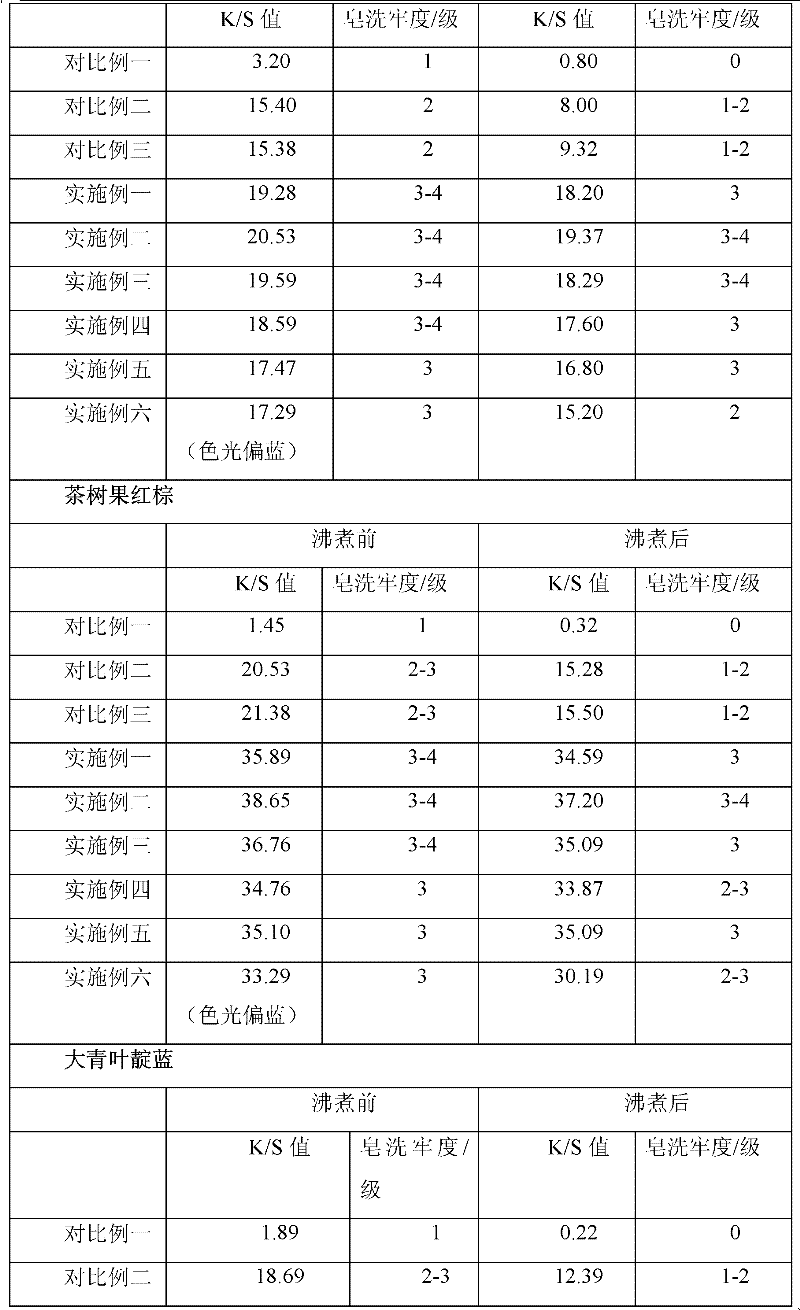

Dye compound reducing agent and method of using the same

The invention discloses a composite reducing agent for dye, comprising the following compositions in weight portion: 8 to 20 portions of vat powder, 5 to 40 portions of thiourea dioxide, and 5 to 15 portions of sodium sulfite. The invention also discloses a method for dyeing by the reducing agent, comprising the following steps that: a reducing agent and sodium hydrate are used for reducing the dye by a vatting method; the weight ratio of a reducing solution to the dye is 37.5: 0.8 to 2.0 and the mixture is for later use; a leveling agent and the fiber penetrating swelling agent are added to dye or a buffering agent is added to adjust the pH value and is dyed by vat acid, the temperature is reduced and the mixture is washed; the mixture is subjected to oxidization to develop color, fixing, reducing temperature and washing; the fresh water bath is performed, the dye composite reducing agent is reduced and washed, and the temperature is reduced and the fiber penetrating swelling agent is produced. The composite reducing agent for the dye is a special reducing agent used for reducing the dye, a sulfur dye, a perylene dye and a leuco body, and improves the stability of the leuco body, color yield percentage, the color reproducibility, the color fixation and the color evenness degree, meanwhile, the dye composite reducing agent avoids the harm of formaldehyde on the environment and the human body.

Owner:SHANGHAI TEXTILE GRP DETECTION STANDARD CO LTD

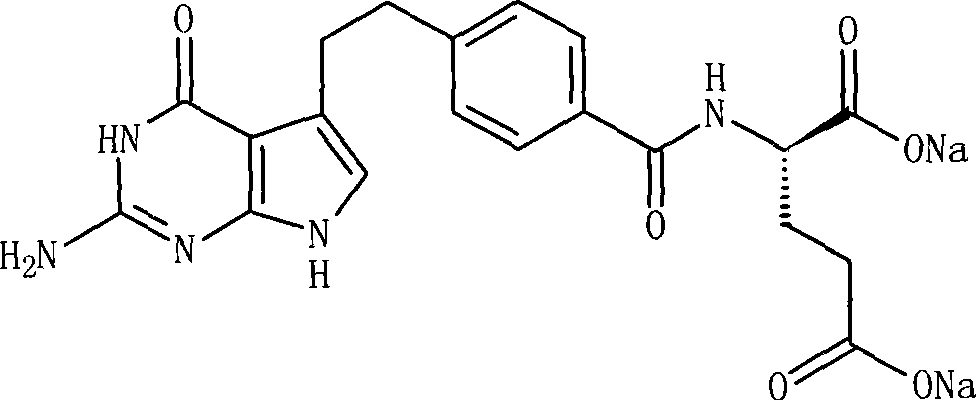

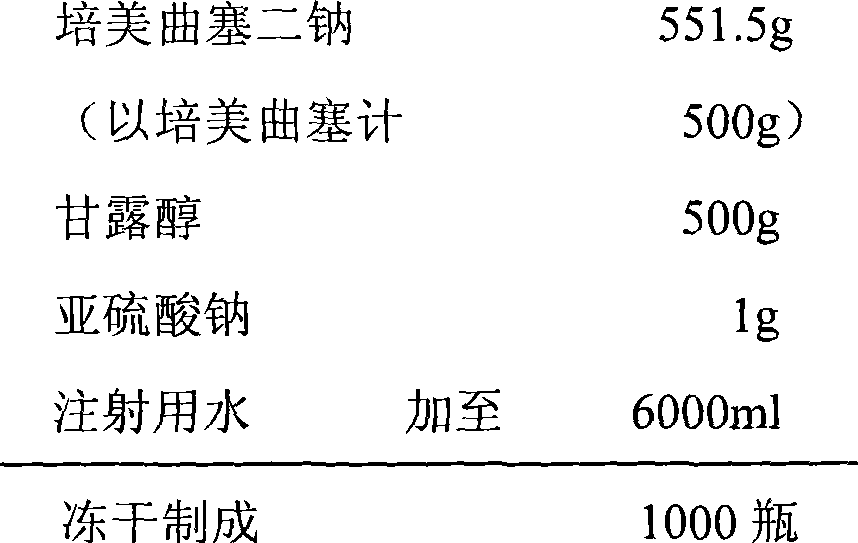

Pemetrexed disodium freeze-dried injection and preparation method thereof

ActiveCN101411710AImprove stabilityLow content of related substancesPowder deliveryOrganic active ingredientsMANNITOL/SORBITOLSulfite salt

The invention relates to a pemetrexed disodium lyophilized powder injection, which consists of pemetrexed disodium, mannitol and sodium sulfite in the following weight portions: 50 portions of the pemetrexed disodium, 10 to 50 portions of mannitol, and 0.1 to 1 portions of sodium sulfite; and the pH value of the pemetrexed disodium lyophilized powder injection is between 7.0 and 8.0. The process for preparing the pemetrexed disodium lyophilized powder injection comprises the following steps: placing the mannitol in a sterile chamber; adding 80 percent of water for injection into the sterile chamber to dissolve the mannitol; adding the sodium sulfite to the mixture after the water for injection is cooled to a temperature of between 15 and 25 DEG C, and evenly stirring the solution for dissolving the sodium sulfite; then, adding the pemetrexed disodium into the solution, and stirring the solution to completely dissolve the pemetrexed disodium and evenly mixing the pemetrexed disodium, and adjusting the pH value of the solution to between 7.0 and 8.0; decarbidizing; after an intermediate compound passes examination, carrying out volume fixing, filtering, filling, partially stopping, traying, lyophilizing, nitrogen aerating, stopping and unboxing, sealing by a plastic-aluminum combined cap, and packaging after passes quality inspection to obtain the pemetrexed disodium lyophilized powder injection. The invention has the advantages of simple preparation process, convenience and practicality, good repeatability and low production cost, and can realize industrial large-scale production easily.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Method for dyeing cotton fibers by using natural dye

The invention relates to a method for dyeing cotton fibers by using a natural dye, comprising the following steps of: 1) boiling the cotton fibers and drying the cotton fibers for later use; 2) modifying the cotton fibers; 3) dyeing the cotton fibers; and 4) fixing the color of the cotton fibers, wherein the dosage of a color fixing agent is 1-5% of the mass of the cotton fibers, the temperature of color fixation is 50-85 DEG C, the color fixing agent is added to the cotton fibers obtained in step 3), the time of color fixation is 20-50 min, drying is performed after water washing, and the color fixing agent can be one or two of sodium chloride, sodium sulfite, citric acid and aluminum potassium sulfate dodecahydrate. The food-grade fixing agent is selected in the method; therefore, the troubles caused by synthetic dyes and heavy metals for the health of human are solved, and the fastness of the cotton fibers can be enhanced; as a result, the dyed cotton fibers are natural and soft in color and have no harm to the human body and the environment.

Owner:CHANGZHOU MYSUN BIOLOGICAL MATERIALS

Manufacture of hydrofluoroalkanesulfonic acids

InactiveUS20060276671A1Simplifies recoveryEliminates solventSulfonic acids salts preparationSulfonic acid preparationOleumChemistry

A process for manufacture of hydrofluoroalkanesulfonic acid with at least one hydrogen bonded to the carbon atom adjacent to the carbon atom bonded to the sulfonic acid group comprising: contacting a fluoroolefin with sulfite in an aqueous solution adjusted to about pH 4 to pH 12; removing water from the solution to form a solid; directly treating the solid with oleum; and distilling the hydrofluoroalkanesulfonic acid therefrom. Also a process for manufacture of potassium hydrofluoroalkanesulfonate in high purity is described.

Owner:THE CHEMOURS CO FC LLC

Nitrogen foam fracturing fluid for coal bed methane and preparation method of nitrogen foam fracturing fluid

The invention relates to a nitrogen foam fracturing fluid for coal bed methane and a preparation method of the nitrogen foam fracturing fluid. The nitrogen foam fracturing fluid comprises a gas phase and a fluid phase, the gas phase is nitrogen, the fluid phase is an aqueous solution which contains 0.20-0.50 wt.% of a foaming agent, 0.4-1.0 wt. % of a foam stabilizer and 0.10-0.30 wt.% of a gel breaker, the volume ratio of the gas phase to the fluid phase is (2-4):1, and corresponding foam mass is 65%-80%; and the foaming agent is a compound system which is composed of sodium dodecyl sulfate and N-(2-hydroxypropyl) perfluor caprylamide according to the mass ratio of (8-10):1, the foam stabilizer is C16-C20 lauryltrimethylammonium chloride, and the gel breaker is a redox system which is composed of ammonium persulfate and sodium sulfite according to the mass ratio of (1.0-2.0):1. A foam generator is used for obtaining the nitrogen foam fracturing fluid. The nitrogen foam fracturing fluid has the advantages of being simple in fluid preparing, small in harm to a coal bed, low in leak-off, small in friction, rapid in flowback speed, high in sand-carrying capability and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Method for inhibiting amine degradation during c02 capture from a gas stream

ActiveUS20090205496A1Induce degradationGas treatmentOther chemical processesHydroxylamineSulfite salt

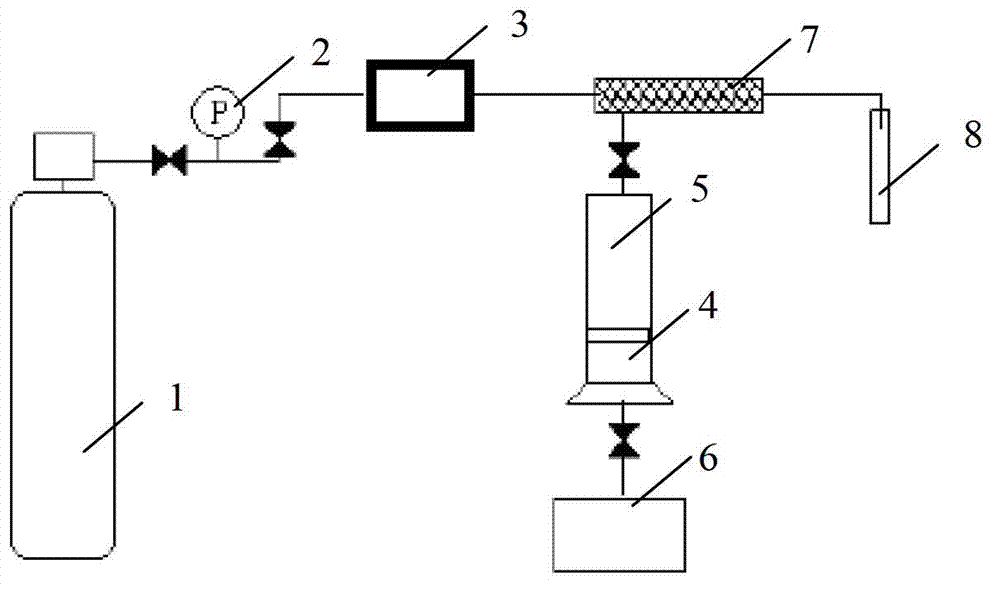

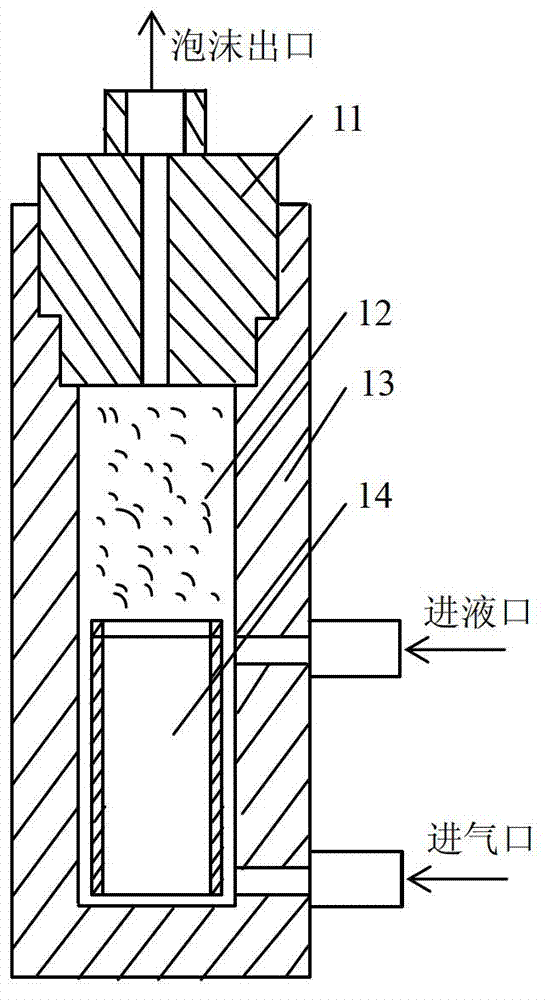

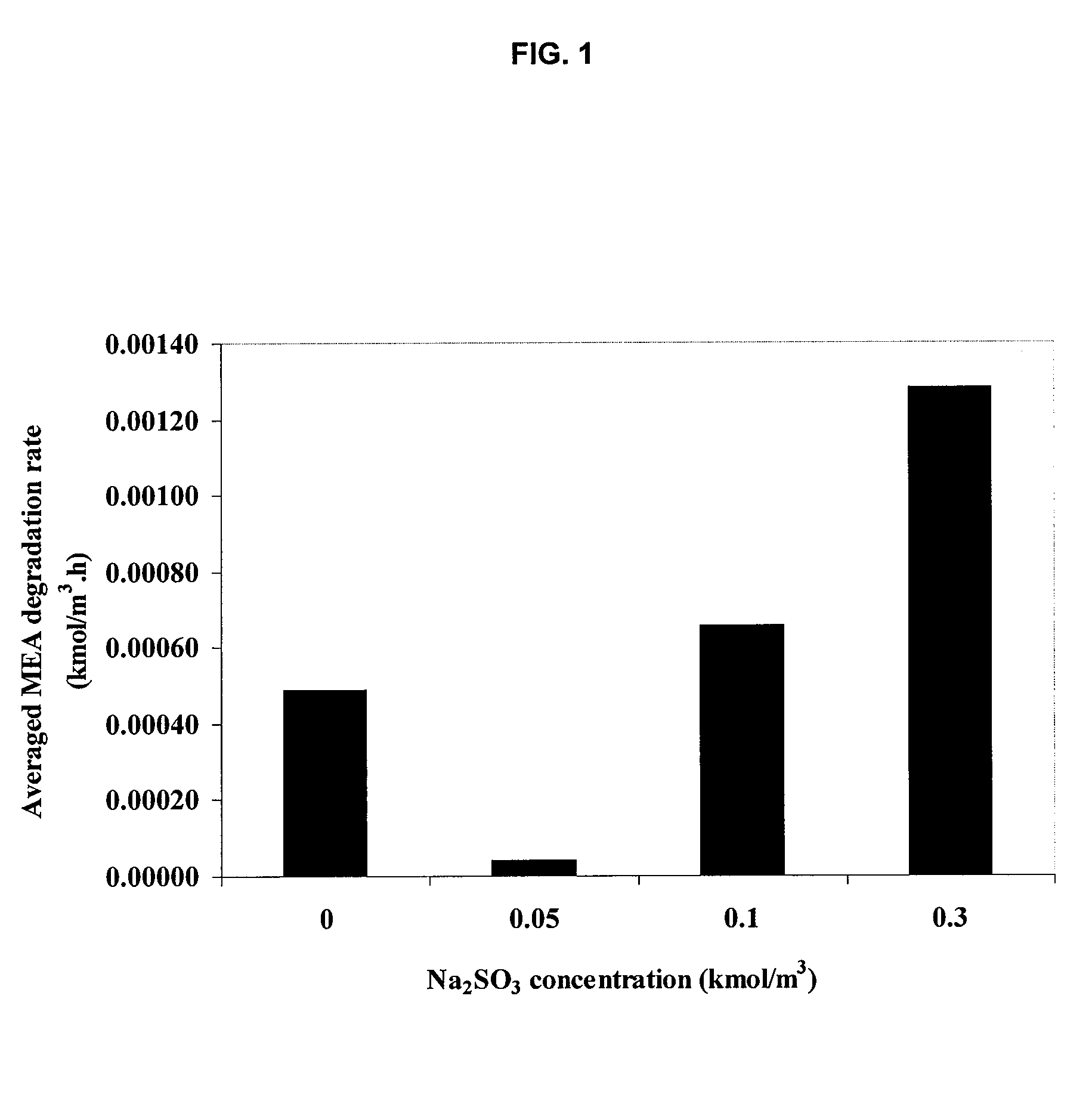

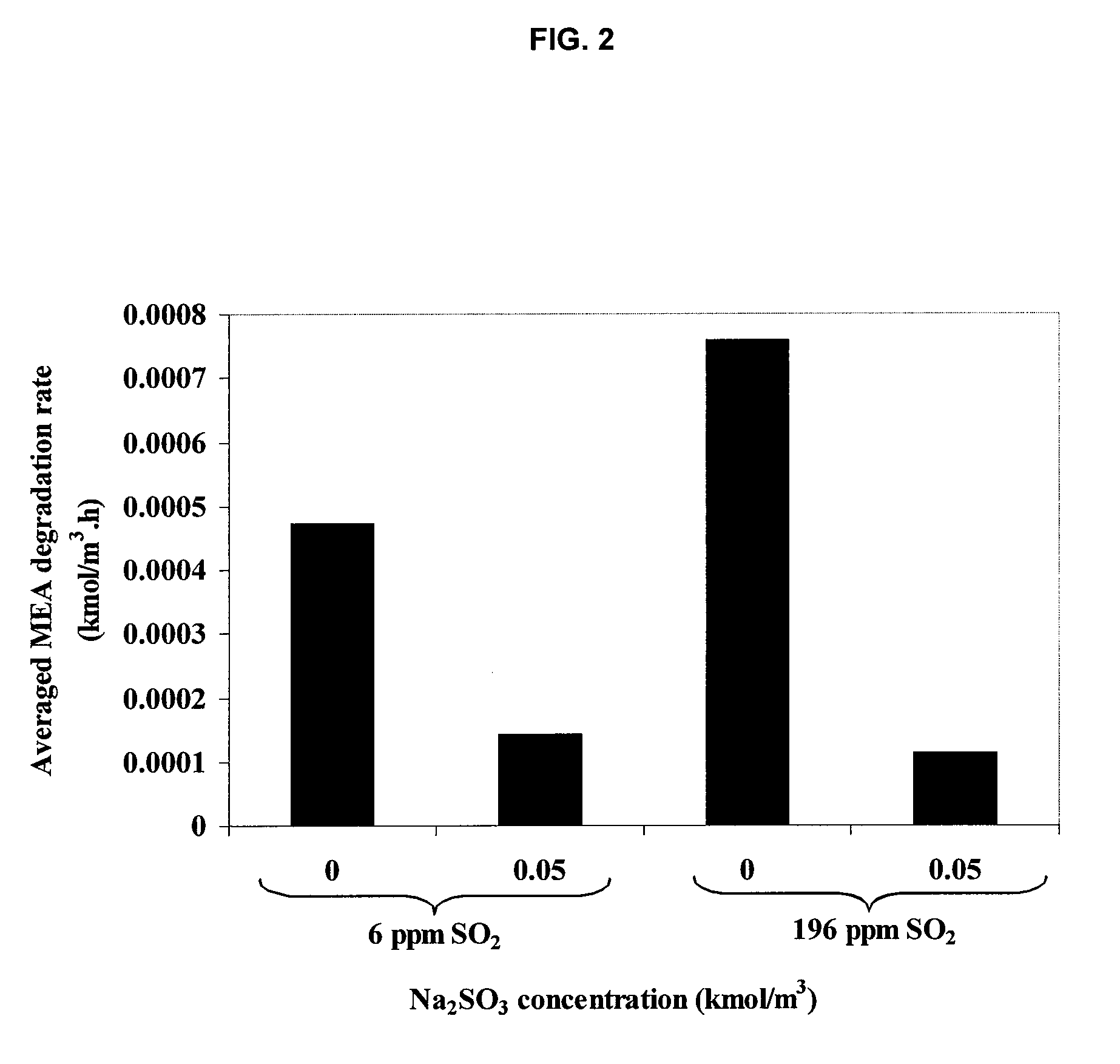

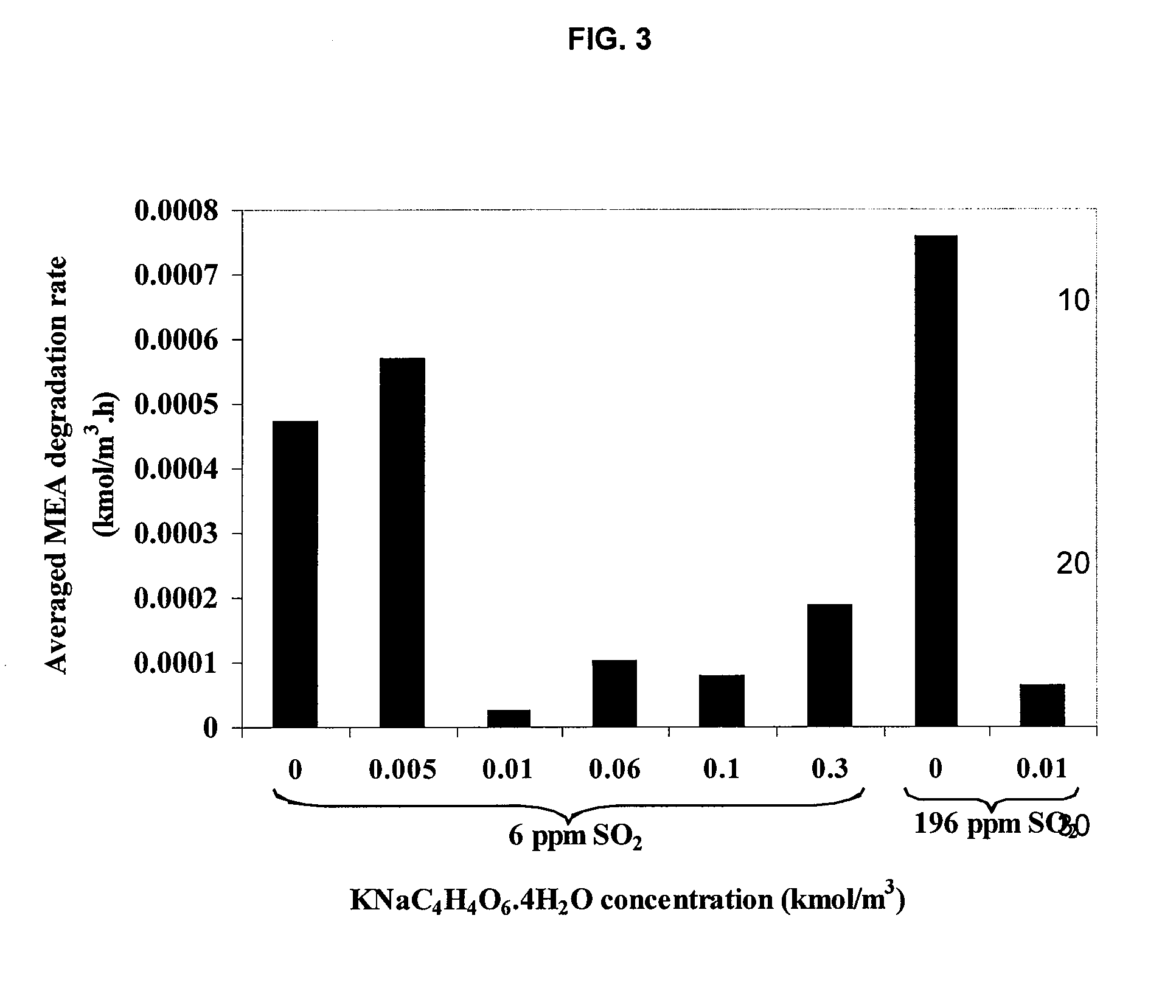

The present application includes a method for inhibiting amine degradation during CO2 capture from flue gas streams. Particularly, the present disclosure relates to a method of inhibiting O2- and / or SO2-induced degradation of amines using sodium sulfite (Na2SO3), potassium sodium tartrate tetrahydrate (KNaC4H4O6.4H2O), ethylenediaminetetraacetic acid (EDTA) or hydroxylamine (NH2OH), or analogs or mixtures thereof during CO2 capture by amines.

Owner:UNIVERSITY OF REGINA

Formaldehyde removing agent

A formaldehyde remover for the aldehyde-contained adhesive and the flyboard is prepared from triethanolamine, sodium dimetasulfite, Na2EDTA, 2,3,4,5,6-pentahydroxy hexyaldehyde and distilled water through proportion and compounding. It has high effect on removing formaldehyde from indoor air.

Owner:陈玉春 +1

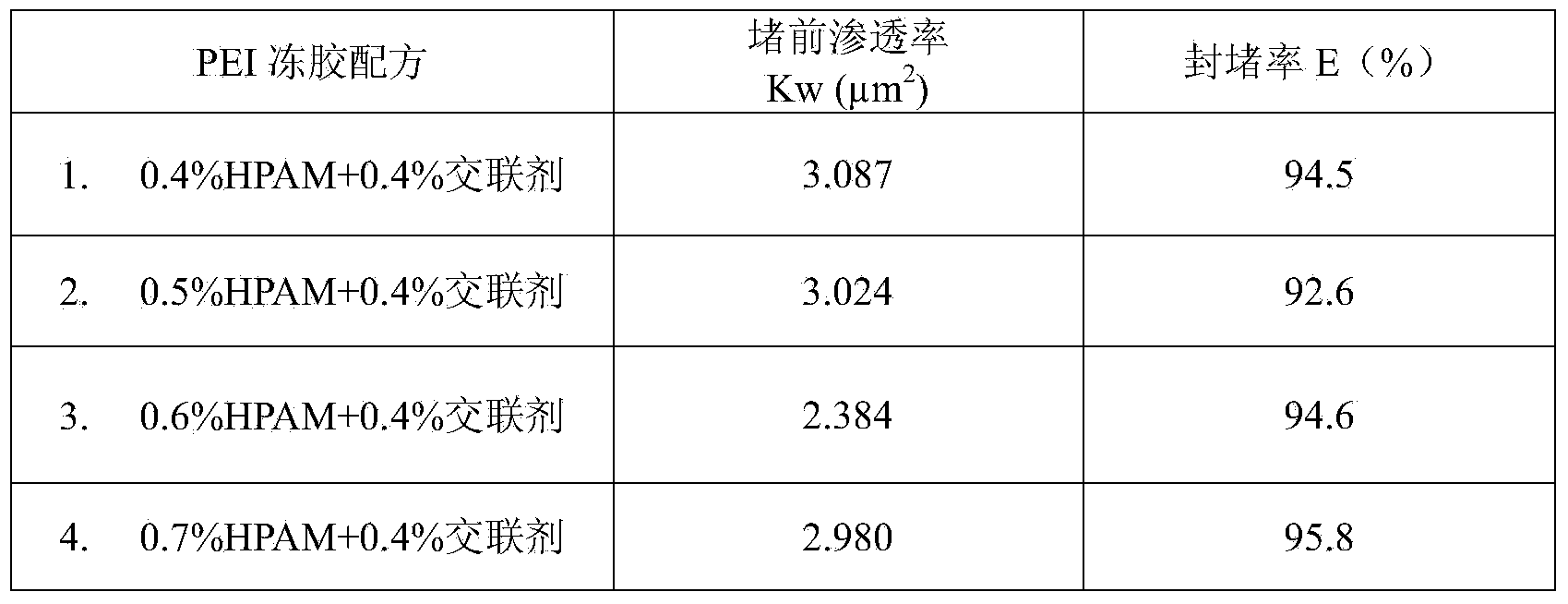

Polyethyleneimine jelly profile-control water-blocking agent

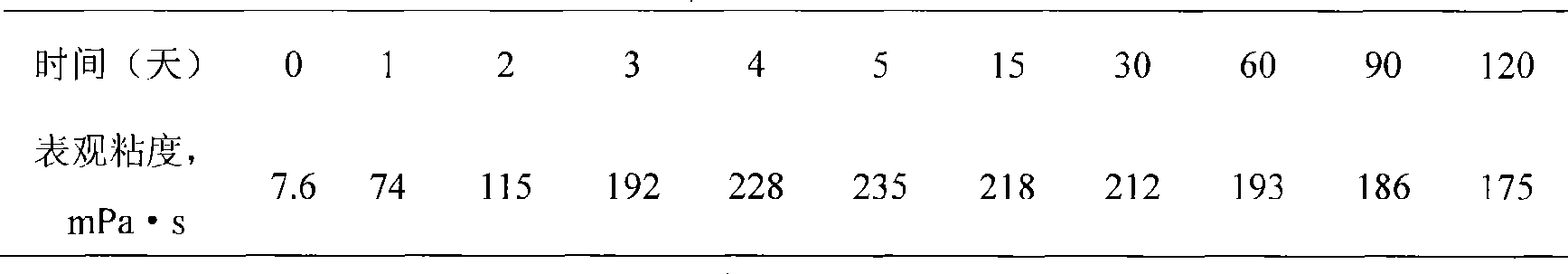

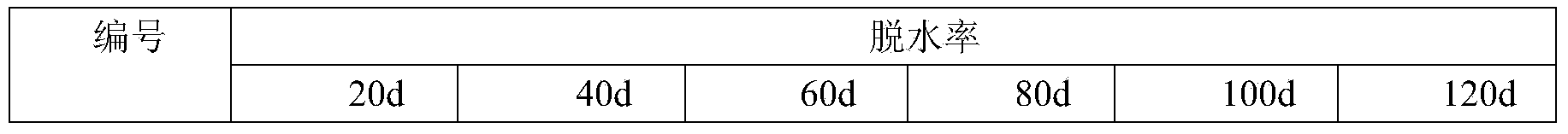

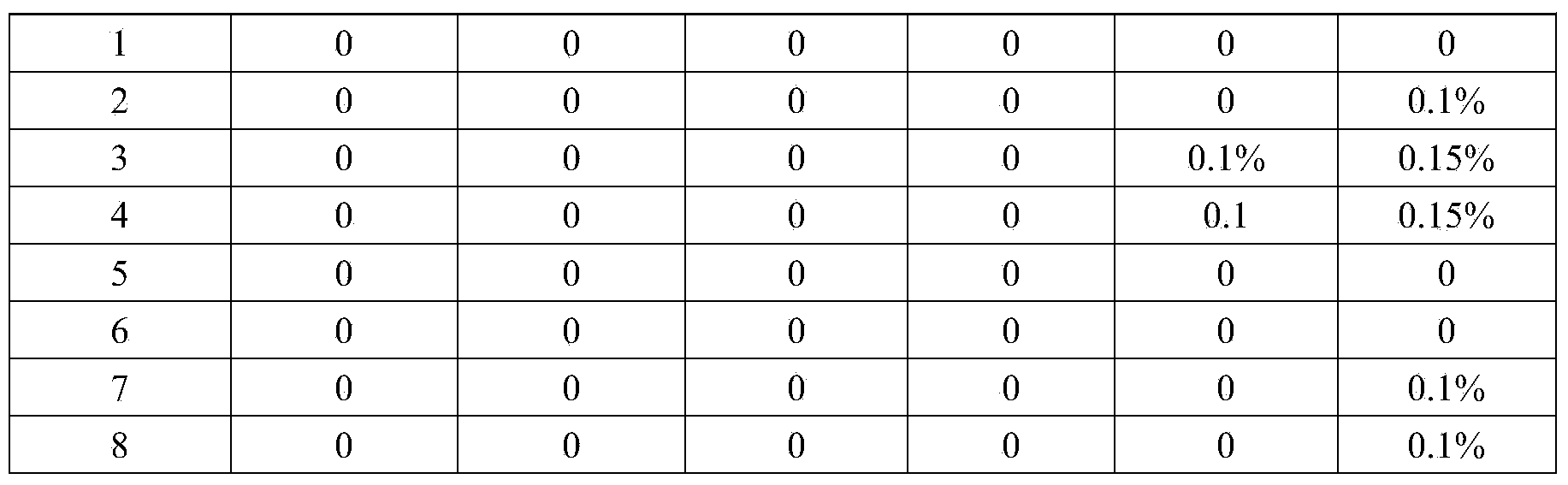

The invention provides a polyethyleneimine jelly profile-control water-blocking agent. The profile-control water-blocking agent is prepared by reacting partially-hydrolyzed polyacrylamide and a cross-linking agent polyethyleneimine. The profile-control water-blocking agent comprises following components by weight: 0.3-0.8% of the partially-hydrolyzed polyacrylamide, 0.2-0.5% of the cross-linking agent polyethyleneimine and 0.3-0.8% of an additive, with the balance being water, wherein the partially-hydrolyzed polyacrylamide adopts anionic polyacrylamide, and the additive is one compound selected from a group of sodium sulfite, sodium bisulfate, and sodium hyposulfite or thiourea, or is a mixture of several compounds selected from the group. The jelly forming time of the profile-control water-blocking agent is adjustable and the jelly has high strength. The profile-control water-blocking agent can block underground water having a temperature lower than 110 DEG C and a NaCl mineralization degree of 50000 mg / L. The profile-control water-blocking agent has good temperature toleration and cannot be dehydrated for 120 days.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Method for using cyaniding barren solution to float, reclaim and cyaniding copper plumbum and zinc in tailings

A method that cyanide barren solution is used for recovering the copper-lead-zinc from cyanide tailing by means of floatation belongs to the field of nonferrous metal separation. The processing procedures of the method are as following: (1) mashing: the cyanide barren solution is added into the cyanide tailing and stirred to ore slurry, the concentration of which is 35 to 40 per cent; (2) lead-zinc preferential flotation: after being stirred, the ore slurry is put into flotation machine and lime, Ethyl thiocarbamate and Sodium n-butyl xanthate synthetic are added in to the ore slurry. The course of once rough floatation, twice scavenging and twice concentration is processed to recover Zinc and Lead; (3) Cu-S separation: after the tailing of lead and zinc bulk flotation is concentrated, the cyanide barren solution is added into the tailing and the tailing is made into the ore slurry with the concentration of 35 to 40 per cent. And then, the ore slurry is put into the floatation machine and sulfate, sodium sulfite, Z-200 and ammonium butyl aerofloat are added into the tailing. The course of once rough floatation, twice scavenging and twice concentration is processed to recover copper. And the tailing can be for sale as sulfur concentrate; (4) Reuse of separation tailing water: the press filtrate of bulk concentrate, the overflow of thickener, the press filtrate of copper concentrate and the press filtrate of the sulfur concentrate return to the buffer slot of the cyanide barren solution to be used for replacement fluid. The invention has the advantages of good flotation effect, high recovery rate of the copper-lead-zinc and zero discharge of waste water and residue.

Owner:UNIV OF SCI & TECH BEIJING

Adsorption absorption reaction type formaldehyde eliminating agent

An adsorption-absorption reaction type formaldehyde removing agent is composed of adsorption-absorption agent (activated carbon, alumina, diatomite, polyamide or water) for adsorbing and absorbing the formaldehyde from indoor air, and reactant (sodium sulfite and ammonium salt or hydroxy amine hydrochloride) for reacting on adsorbed and absorbed formaldehyde to become non-toxic, no-odor and non-pollution substance.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for extracting selenium from selenium-contained material

ActiveCN102086029AHigh purityImprove pass rateElemental selenium/telluriumSulfite saltSodium sulfites

The invention relates to a method for extracting selenium from selenium-deposited residue. The method comprises the following steps of: dissolving selenium-deposited residue to an alkaline sodium sulfite solution, generating water-soluble seleno sodium sulfate through a reaction between elemental selenium and the sodium sulfite solution; fully reacting the seleno sodium sulfate under the acidification of sulfuric acid to obtain a selenium elemental precipitate; and washing and drying to obtain coarse selenium with the purity of about 90 percent. The invention realizes separation of copper, silver and selenium in the selenium residue, and the separated selenium can be directly refined due to higher purity, therefore, the process flow of selenium recovery is shortened, the recovery rate is increased, and the production cost is decreased; the trouble of high copper content of an anode plate in silver electrolysis in the gold and silver refining process is solved and the pass rate of primary silver powder electrolysis is increased. The invention can be applied to recovering and extracting selenium from materials, such as selenium-contained residue generated in the technical process by using a wet method for treatment or selenium-contained acid mud generated in the production process of the copper anode slime by using a pyrogenic method for treatment and can also be applied to the production of high-purity selenium products by directly purifying a coarse selenium raw material.

Owner:JINCHUAN GROUP LIMITED

Composite decarbonizing solution for gathering carbon dioxide in mixed gas

InactiveCN101612509AReduce consumptionDispersed particle separationChemical reactionAbsorption capacity

The invention discloses a composite decarbonizing solution for gathering carbon dioxide in mixed gas, belonging to the technical field of gas separation. The composite decarbonizing solution is characterized by consisting of main absorption components including MEA and AEE, auxiliary absorption components including AHPD, AMP, TEA and MDEA, active components including PZ, HEPZ, AEP and DEA, sodium vanadate as an inhibiter, sodium sulfite and copper acetate as antioxidant, and a mixed solvent including NMP, polyethylene glycol and propylene carbonate and water. Because the mixed solvent is used for the composite decarbonizing liquid, on the one hand, the absorption capacity, the purification degree and the desorption rate are improved, and the reaction temperature range is enlarged, and on the other hand, regeneration energy consumption is greatly improved. The invention has the advantages that the composite decarbonizing solution is used for gathering carbon dioxide in various kinds of chemical reaction tail gas, burning stack gas and natural mixed gas and eliminating carbon oxide in city gas, natural gas, and the like, and has social benefit and economic benefit.

Owner:DALIAN UNIV OF TECH

Controllable expanded plugging agent

InactiveCN102146280AReduce penetrationReduce processing timeDrilling compositionParaffin waxSulfite salt

The invention relates to a controllable expanded plugging agent used for drilling plugging operation of an oil and gas field. The controllable expanded plugging agent has the characteristics of expansion controllability, deformability, adaptivity and the like. A technical scheme of the invention is that the ingredients and contents of raw materials used for preparing the plugging agent are as follow: 120 g of water, 7-12 g of acrylic acid, 18-23 g of acrylic amine, 3-6 g of ultrathin CaCO3 (Calcium Carbonate), 12-20 g of neutralizer, 0.05-1 g of crosslinking agent, 0.4-0.8 g of initiators, 3-7 g of emulsifier and 35-45 g of paraffin wax; a preparation method of the plugging agent comprises the steps of putting 120 g of water into a reaction tank; adding the acrylic acid and the acrylic amine at the same time of stirring; dropping the neutralizer NaOH (Sodium Hydroxide) after the solution is dissolved and regulating the pH value of the solution to be 9-11; then adding the ultrathin CaCO3, the crosslinking agent NMBH (Novel Microemulation-based Hydrogel) and initiators Na2SO3 (Sodium Sulfite) and (NH4)S2O8 (Ammonium Persulfate); stirring to react for 50-150 minutes at 40-60 DEG C soas to obtain a sample; heating the paraffin wax to a liquid state; adding the sample into the paraffin wax; adding Span 80; and uniformly stirring, drying and grinding to obtain the product. The product of the invention, which is a multifunctional plugging agent with a controllable expansion speed, is used for the drilling plugging operation of the oil and gas field.

Owner:XINJIANG GRAND OILFIELD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com