Patents

Literature

859 results about "Falling film evaporator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A falling film evaporator is an industrial device to concentrate solutions, especially with heat sensitive components. The evaporator is a special type of heat exchanger.

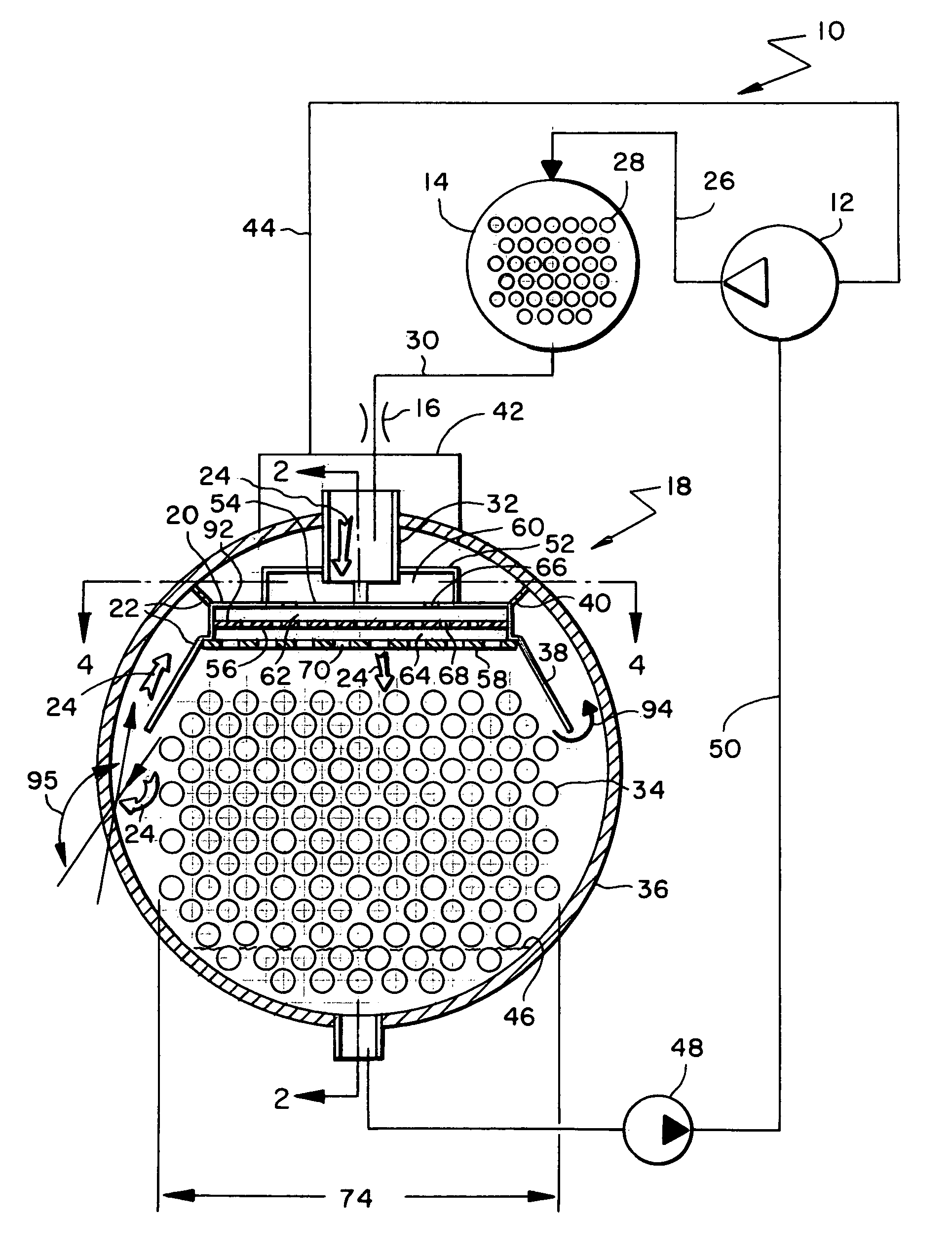

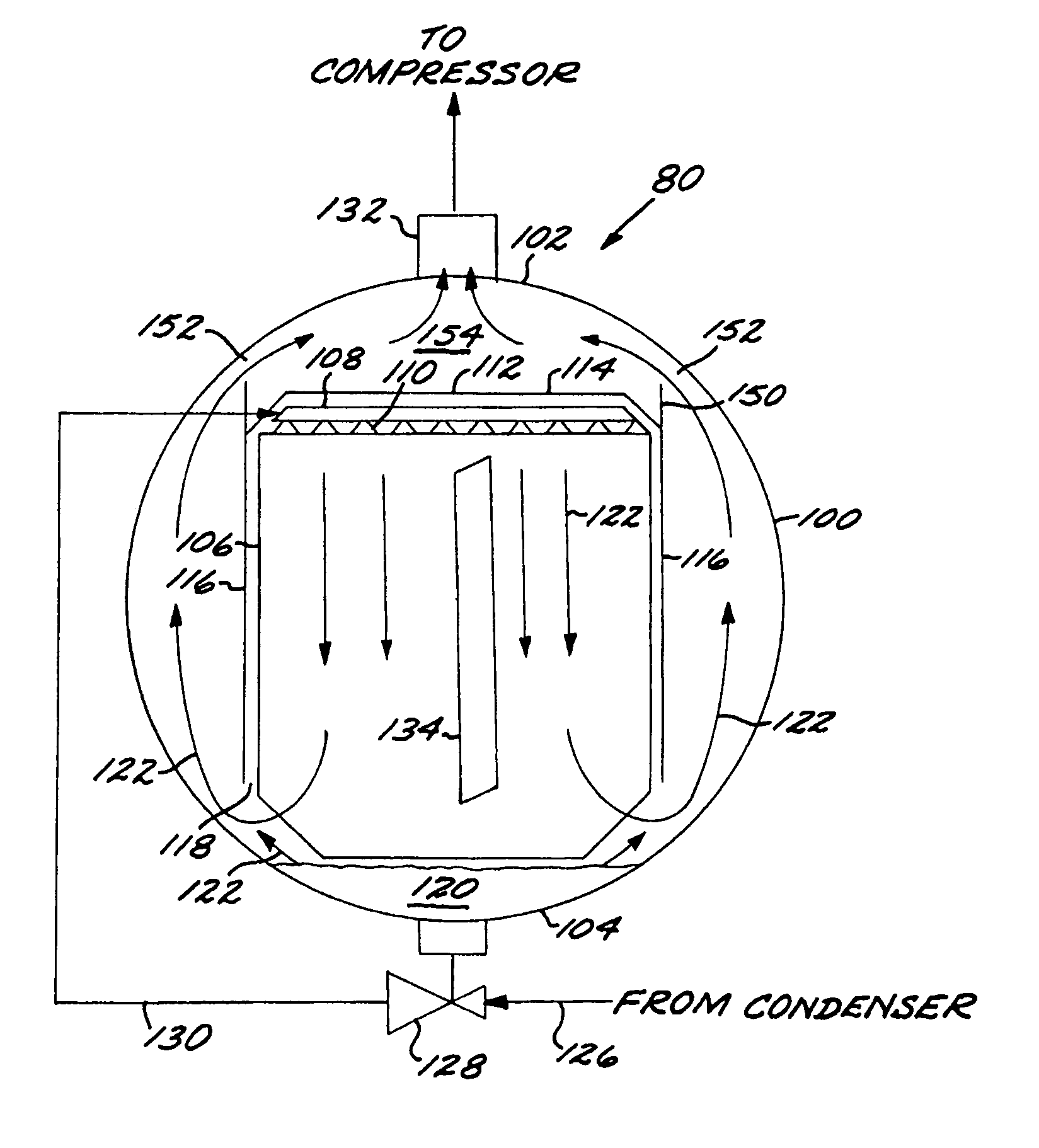

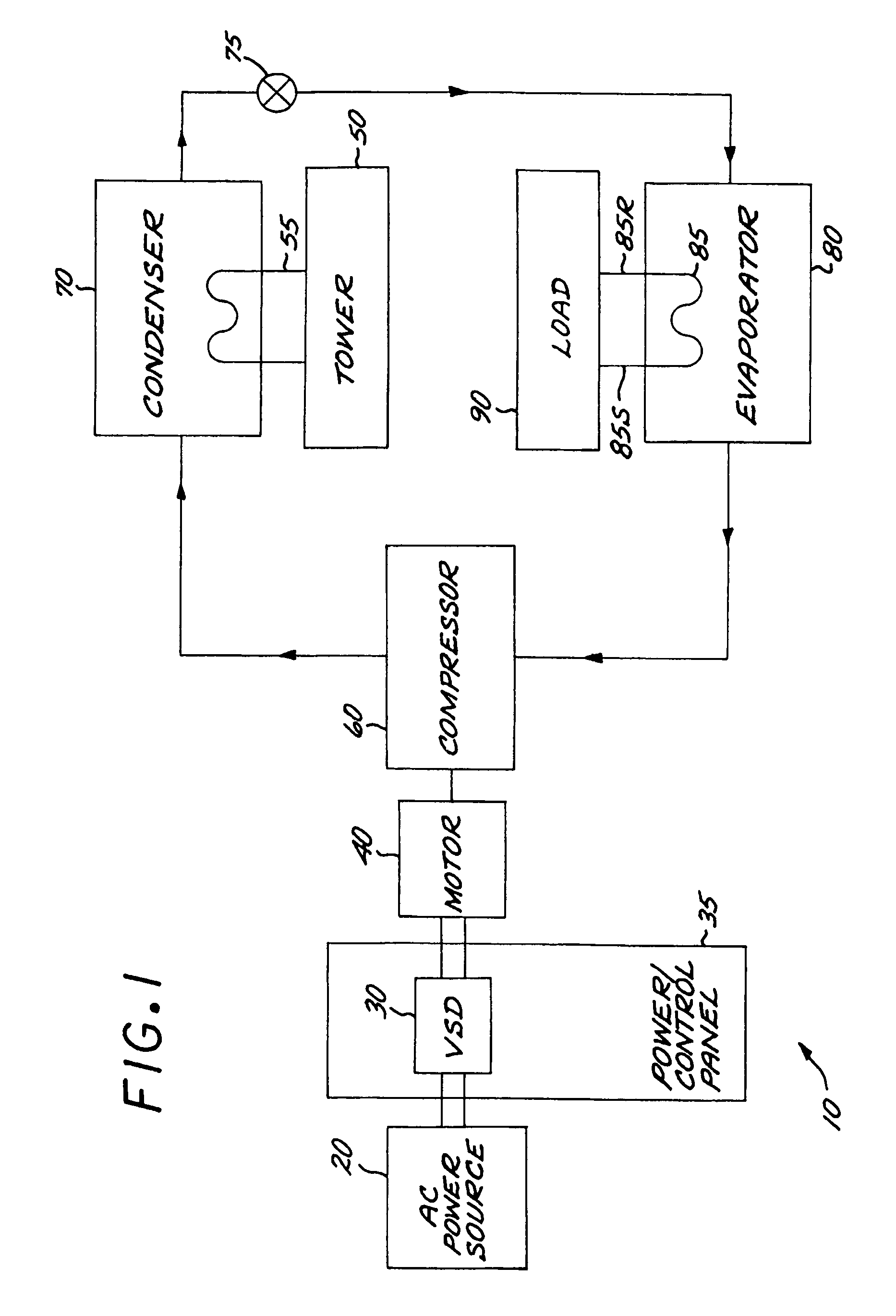

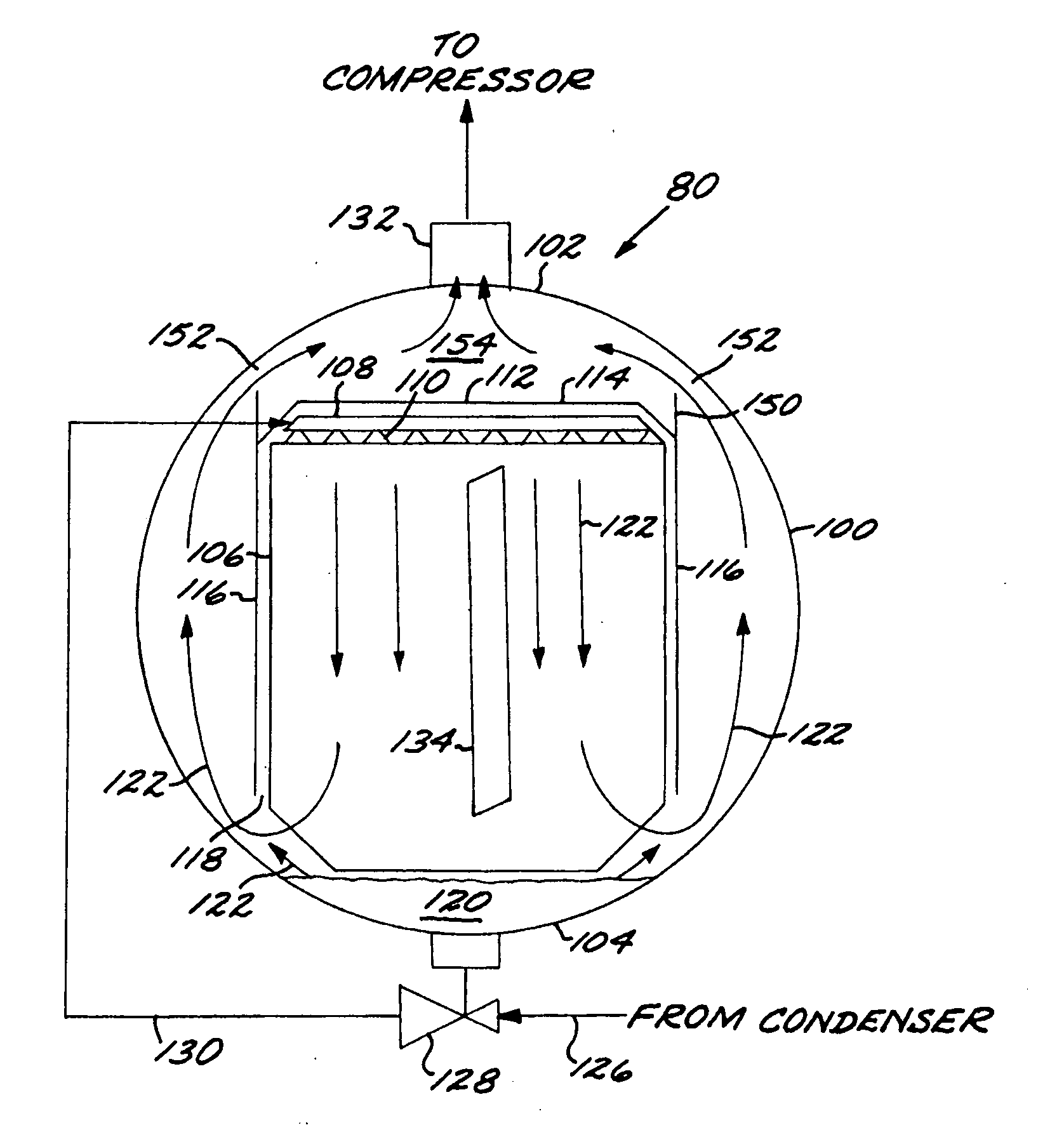

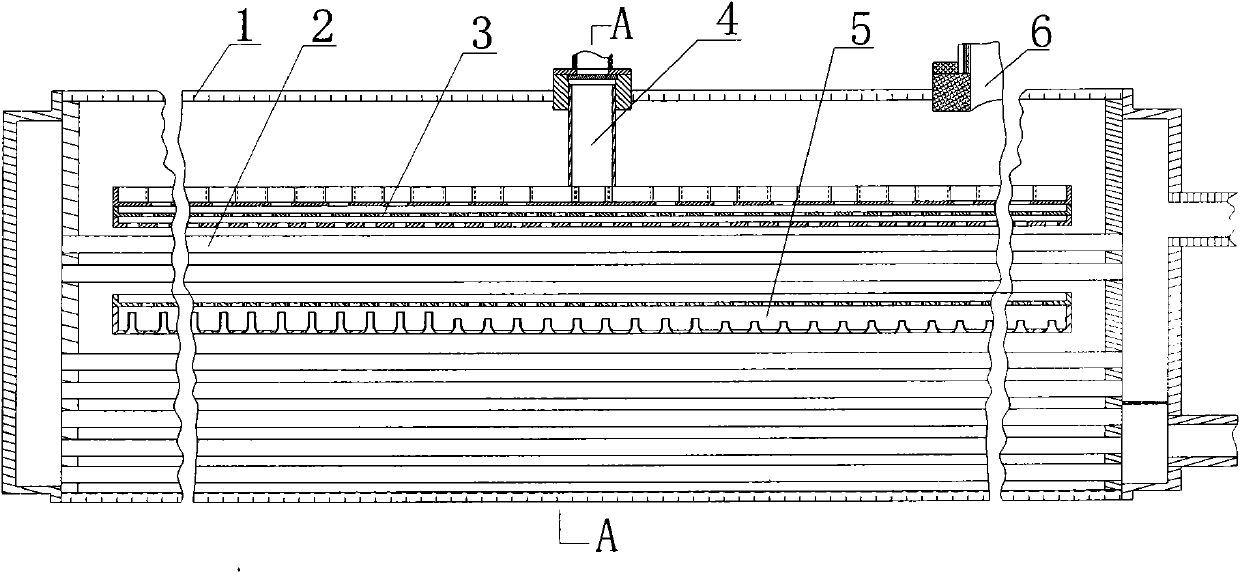

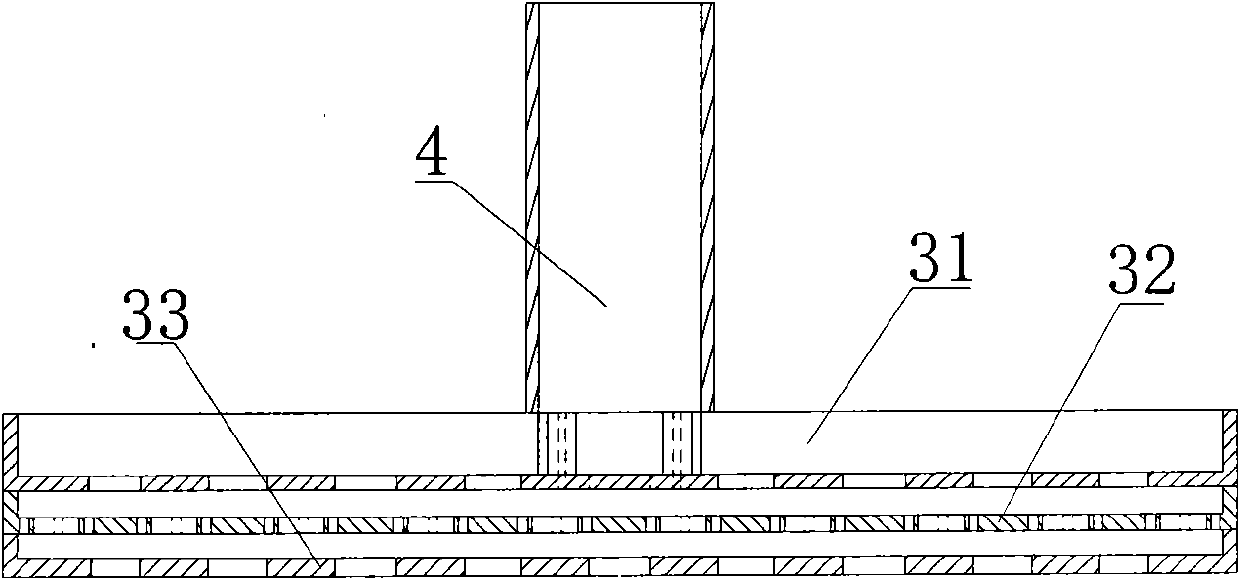

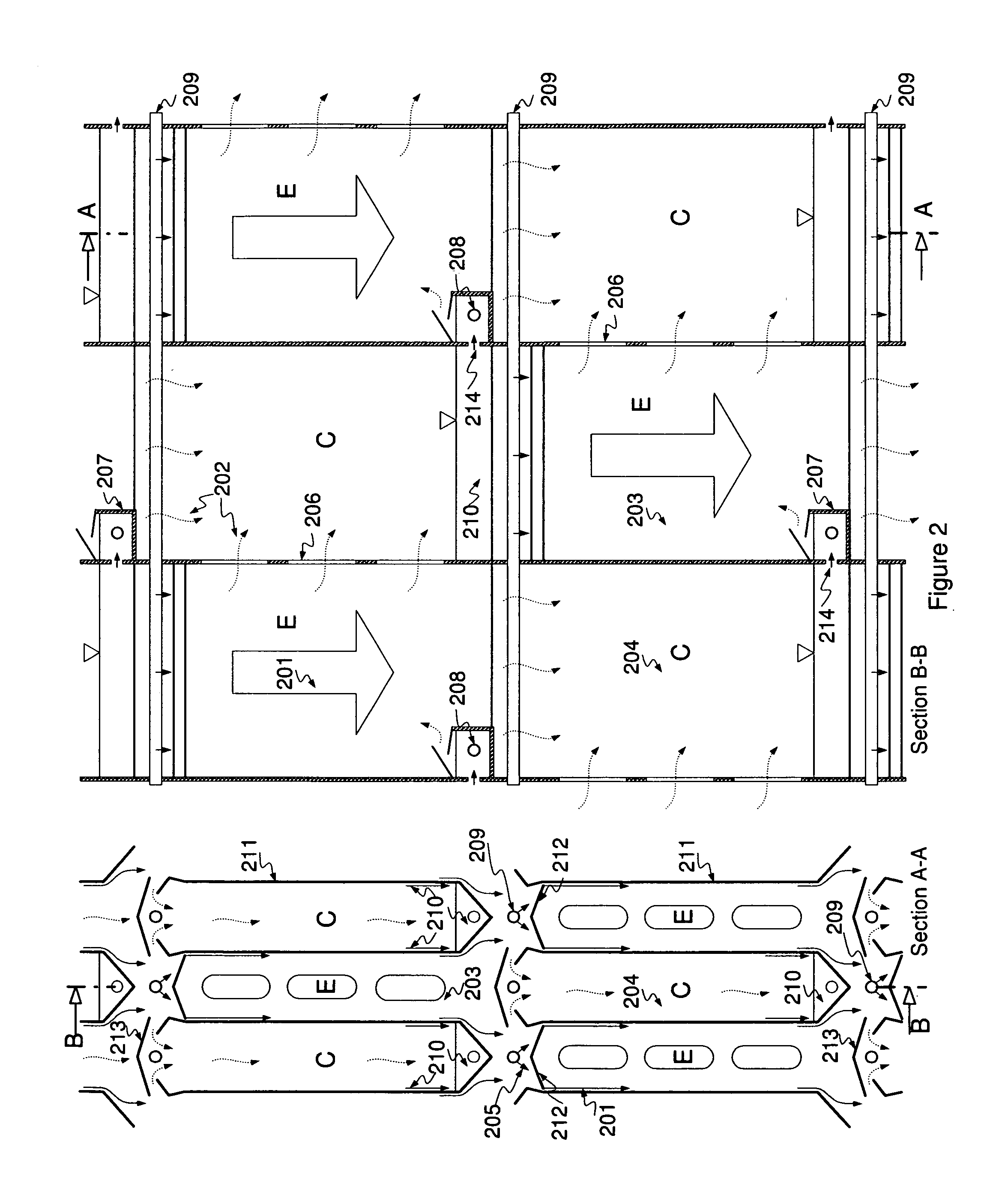

Flow distributor and baffle system for a falling film evaporator

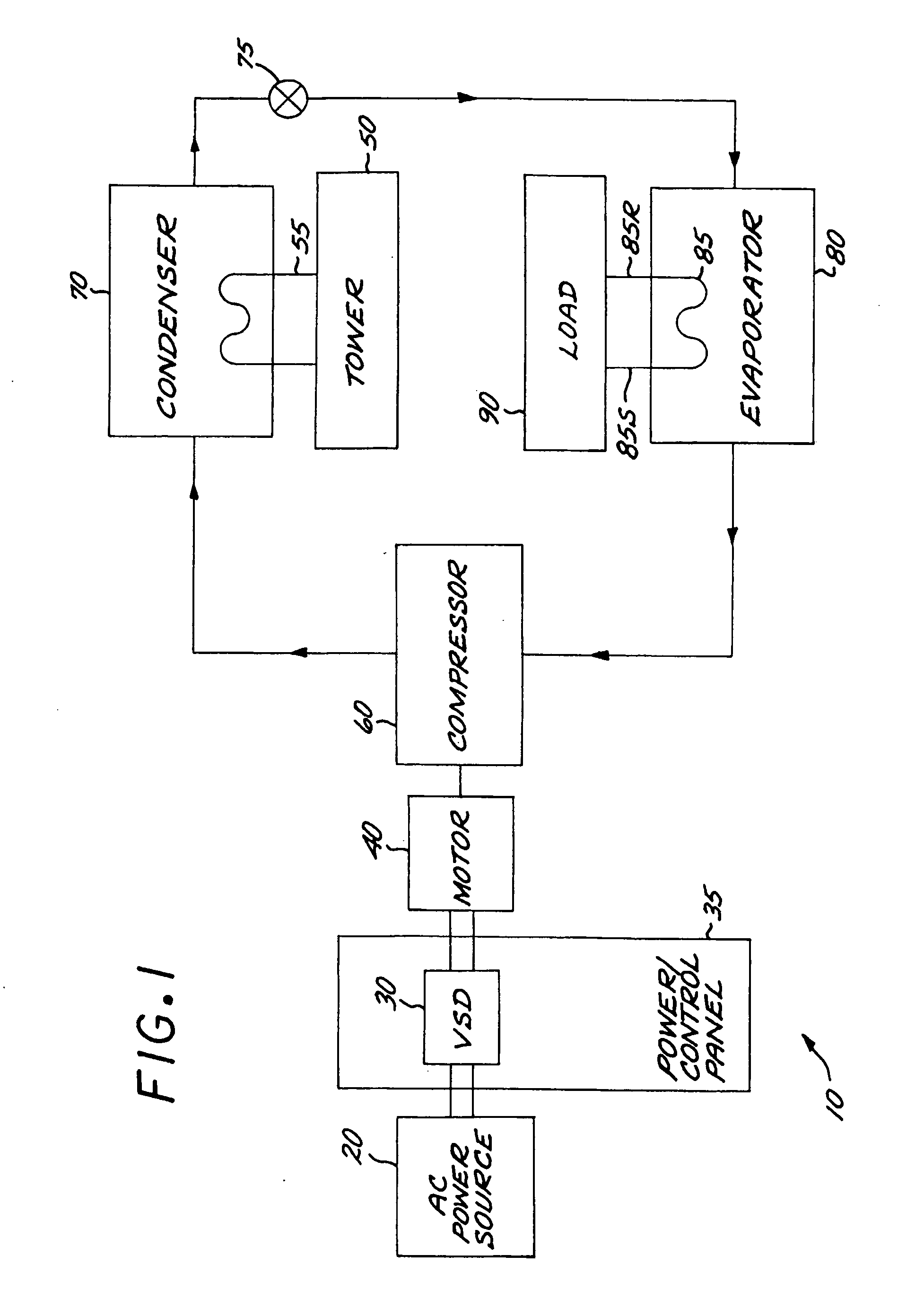

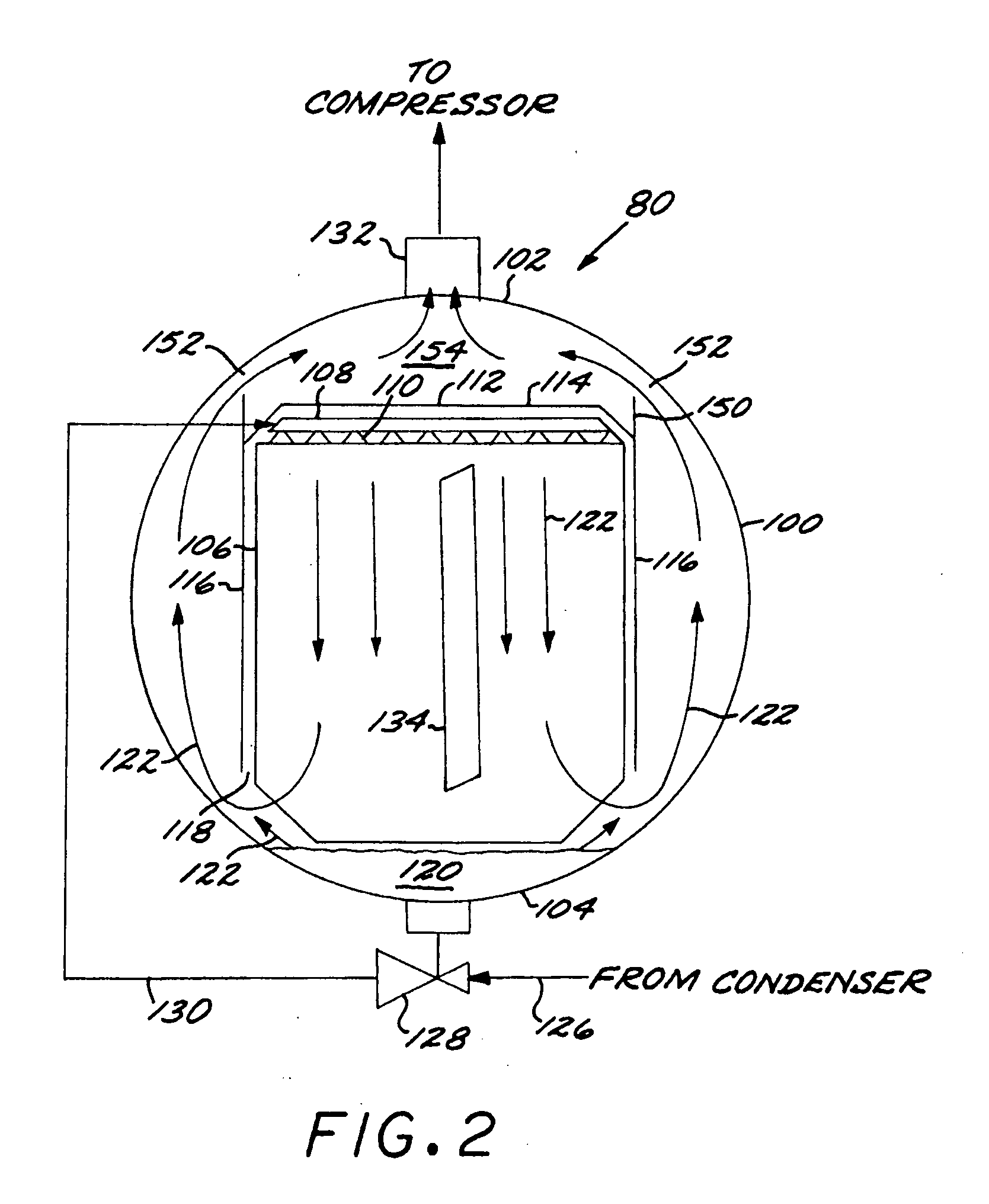

ActiveUS6868695B1Even flow distributionEasy to separateMilk preservationEvaporators/condensersEngineeringRefrigerant

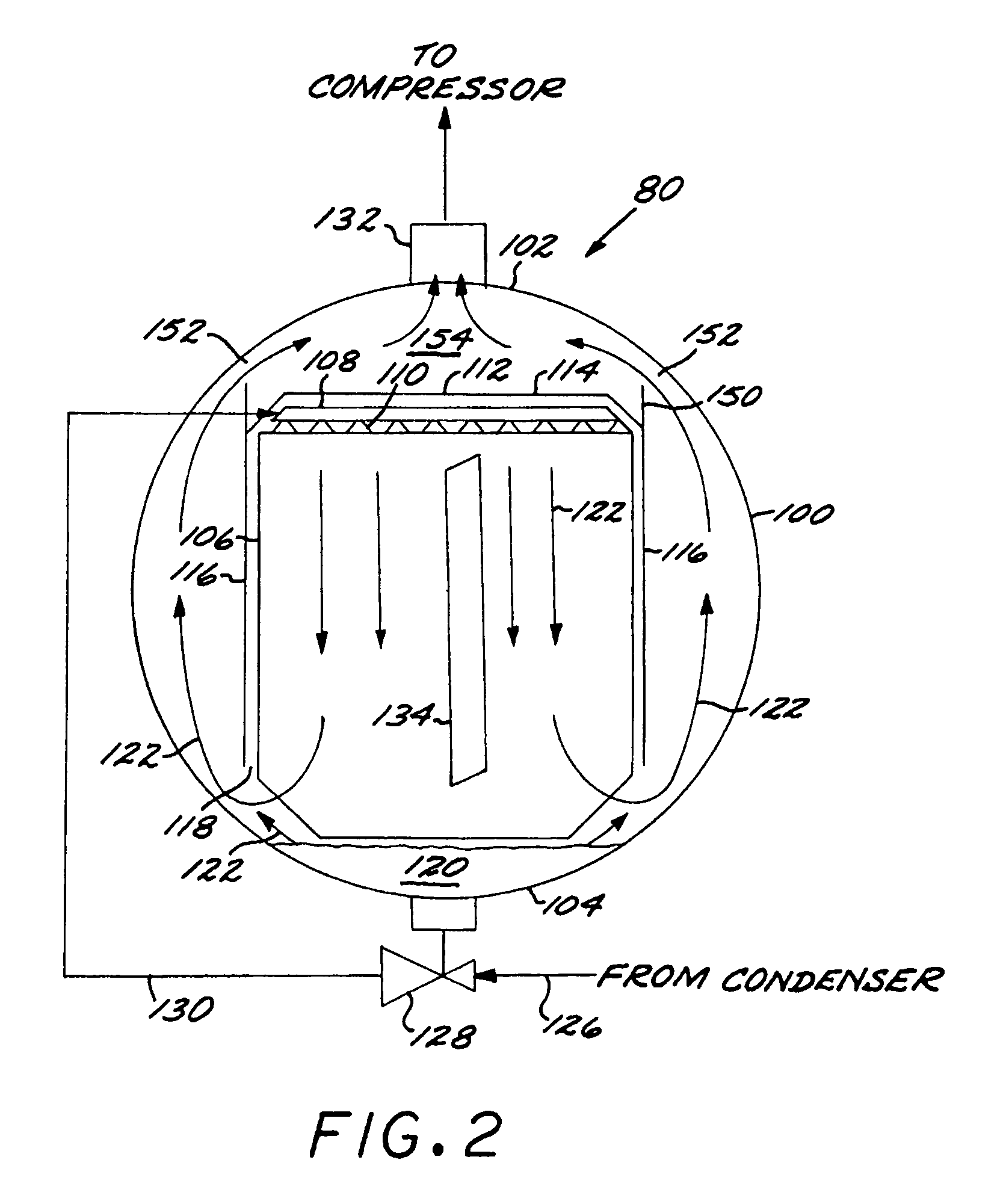

A falling film evaporator includes a flow distributor for uniformly distributing a two-phase refrigerant mixture across a tube bundle. The flow distributor includes a stack of at least three perforated plates each of which are separated by nearly full-width, full-length gaps or chambers. The flow distributor may also include a suction baffle and / or a distributor baffle. The distributor baffle extends downward to provide a hairpin turn past which refrigerant travels before exiting the evaporator. This directional change helps separate liquid from a primarily gaseous refrigerant stream. The suction baffle has various size openings to ensure that the flow rate of refrigerant through the hairpin turn is generally uniform and is maintained low enough to ensure liquid disentrainment over and along the length of the tube bundle within the evaporator.

Owner:TRANE INT INC

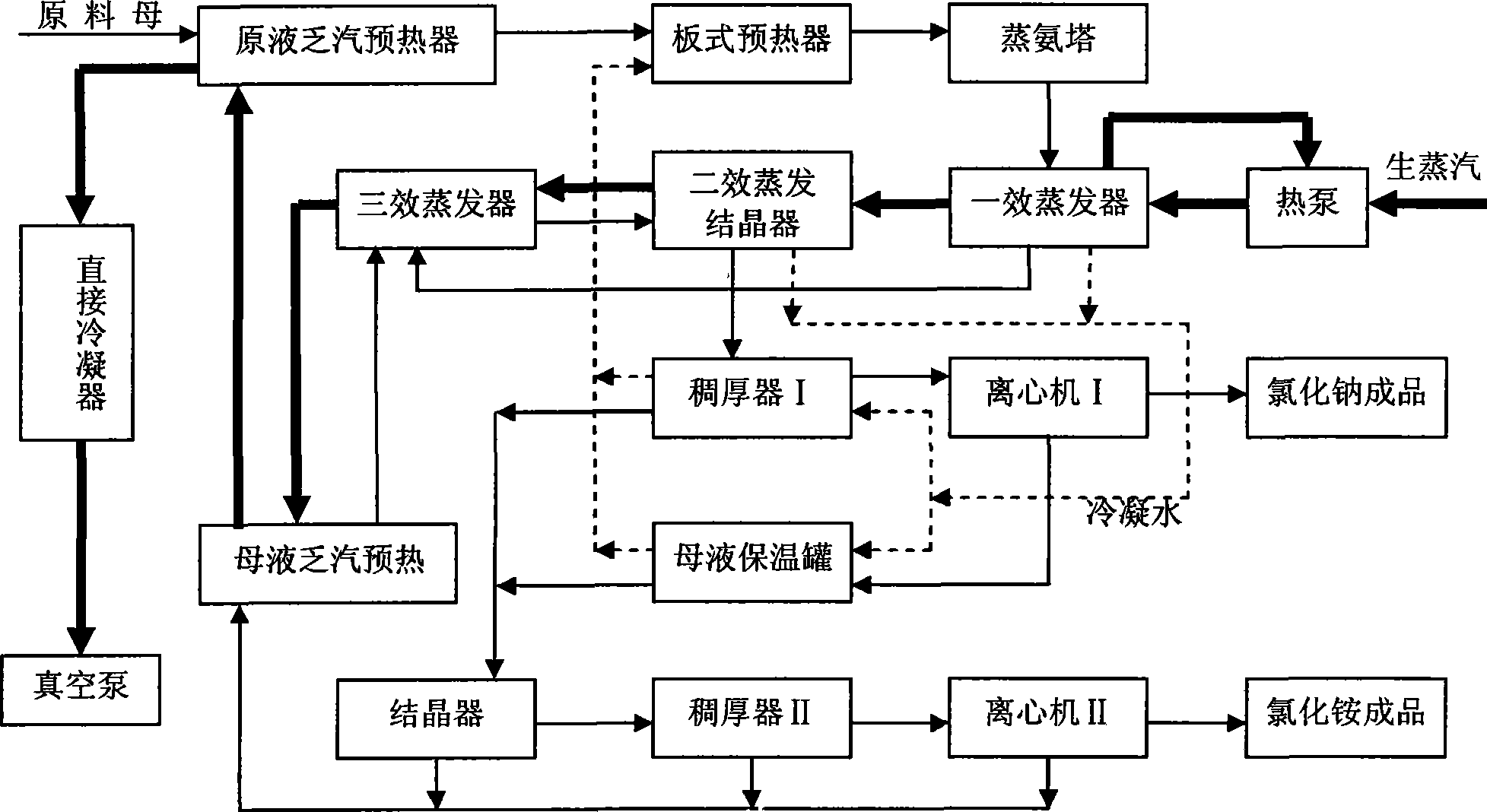

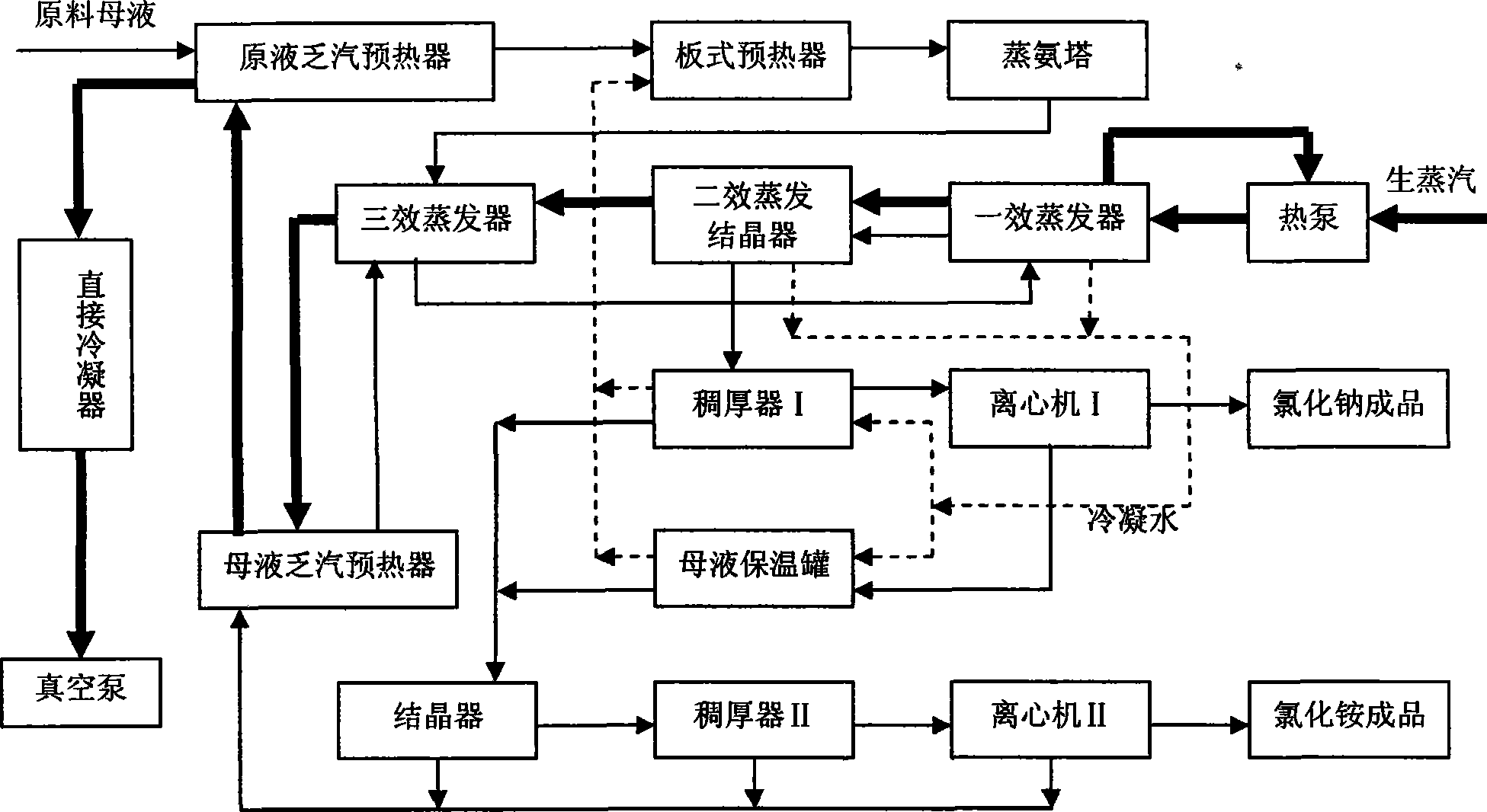

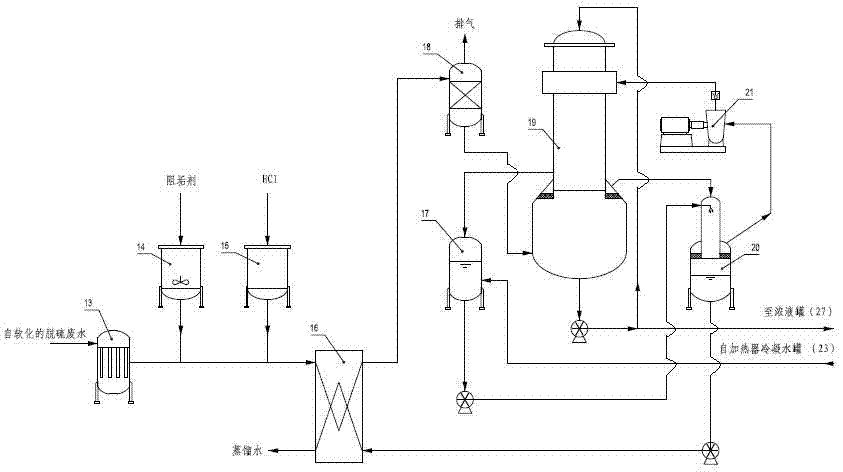

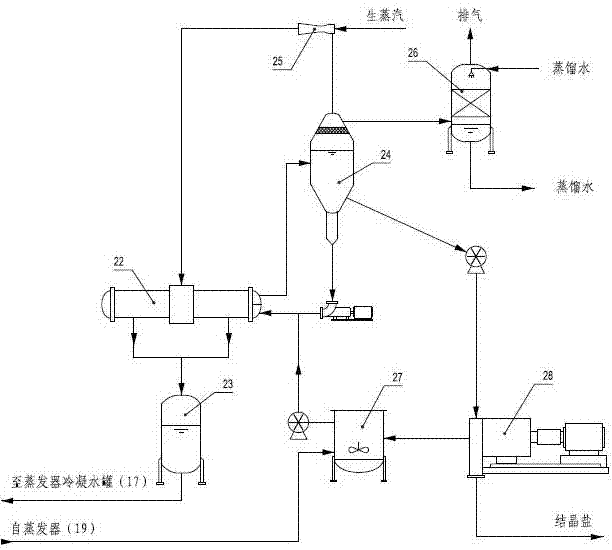

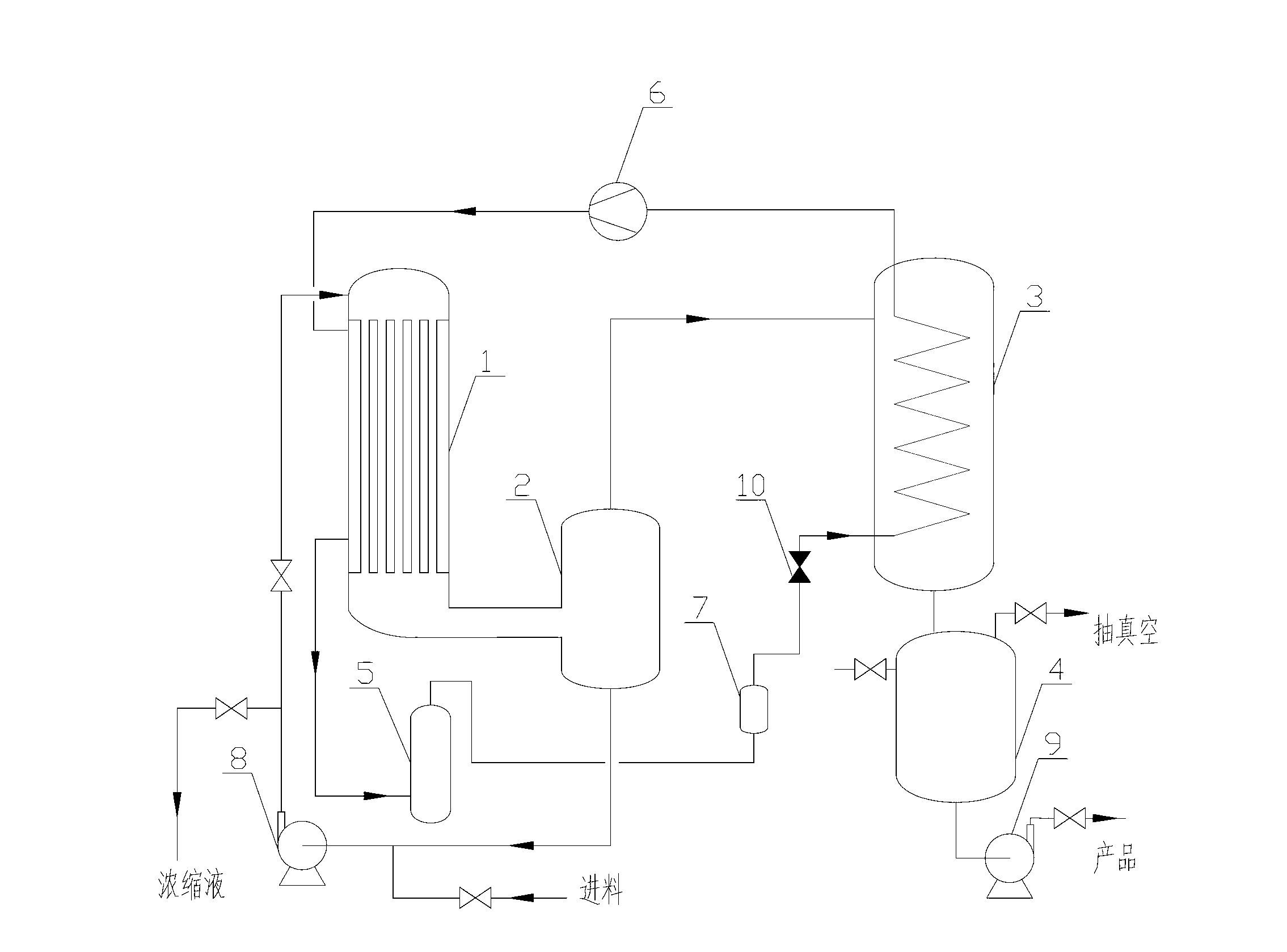

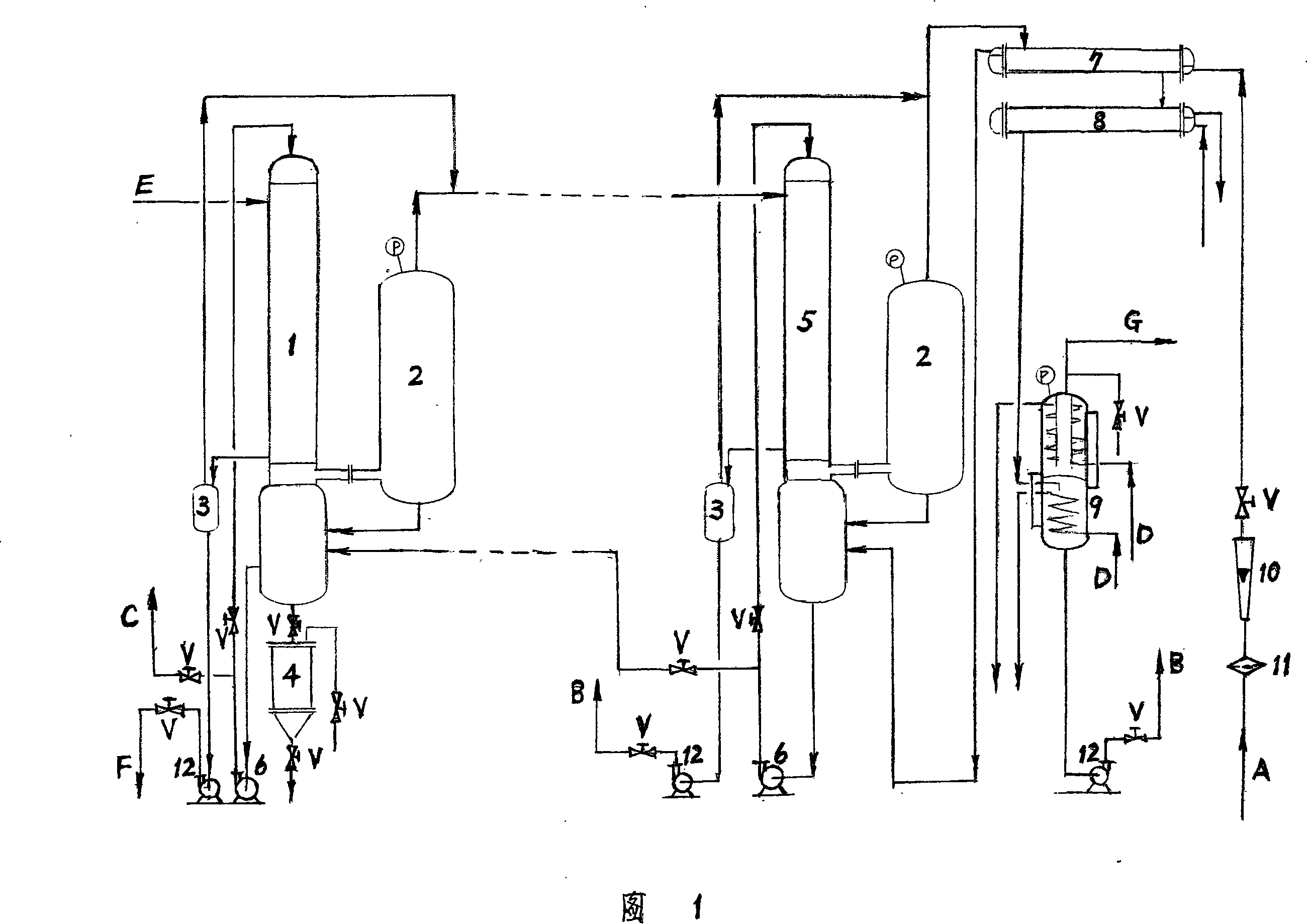

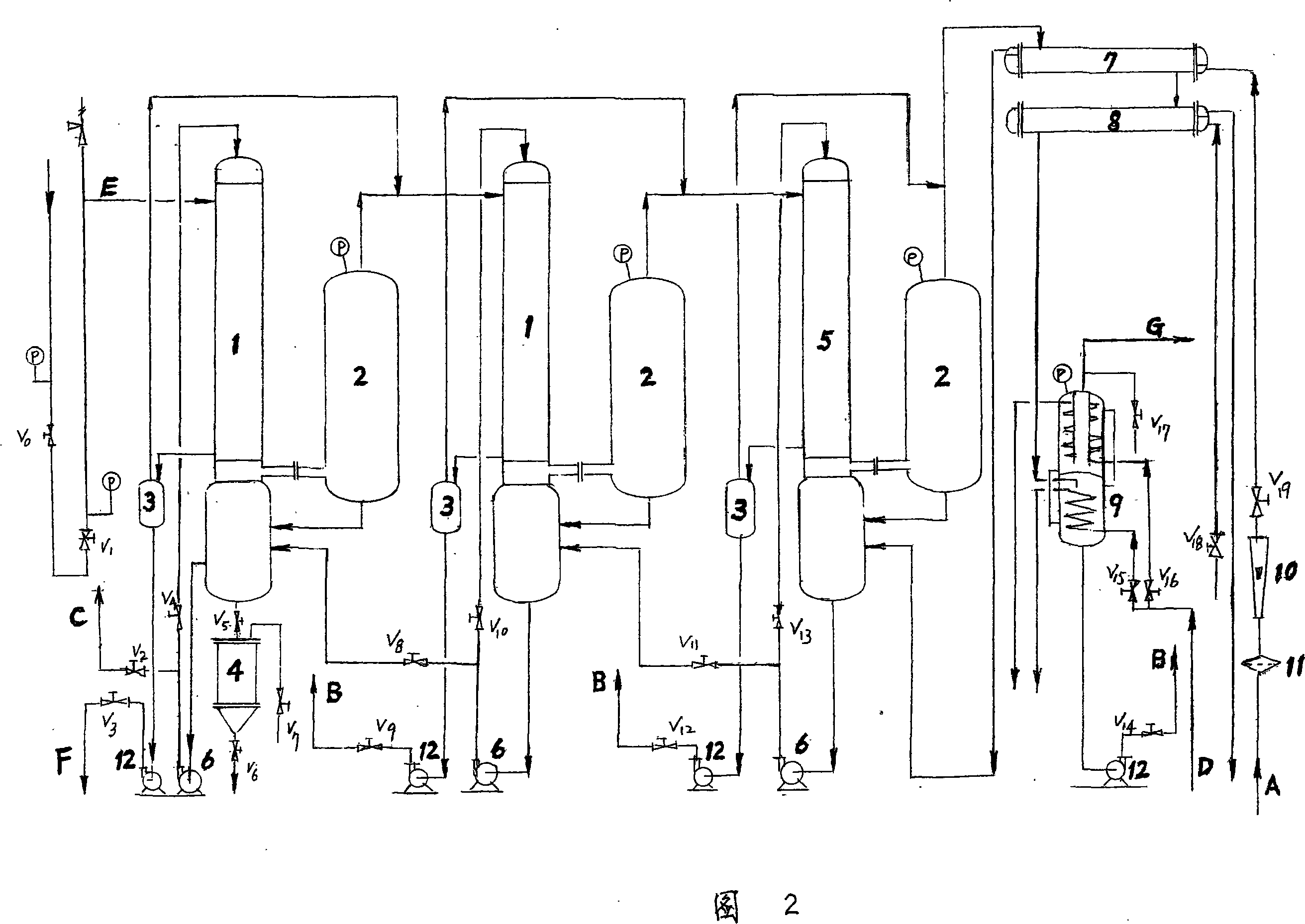

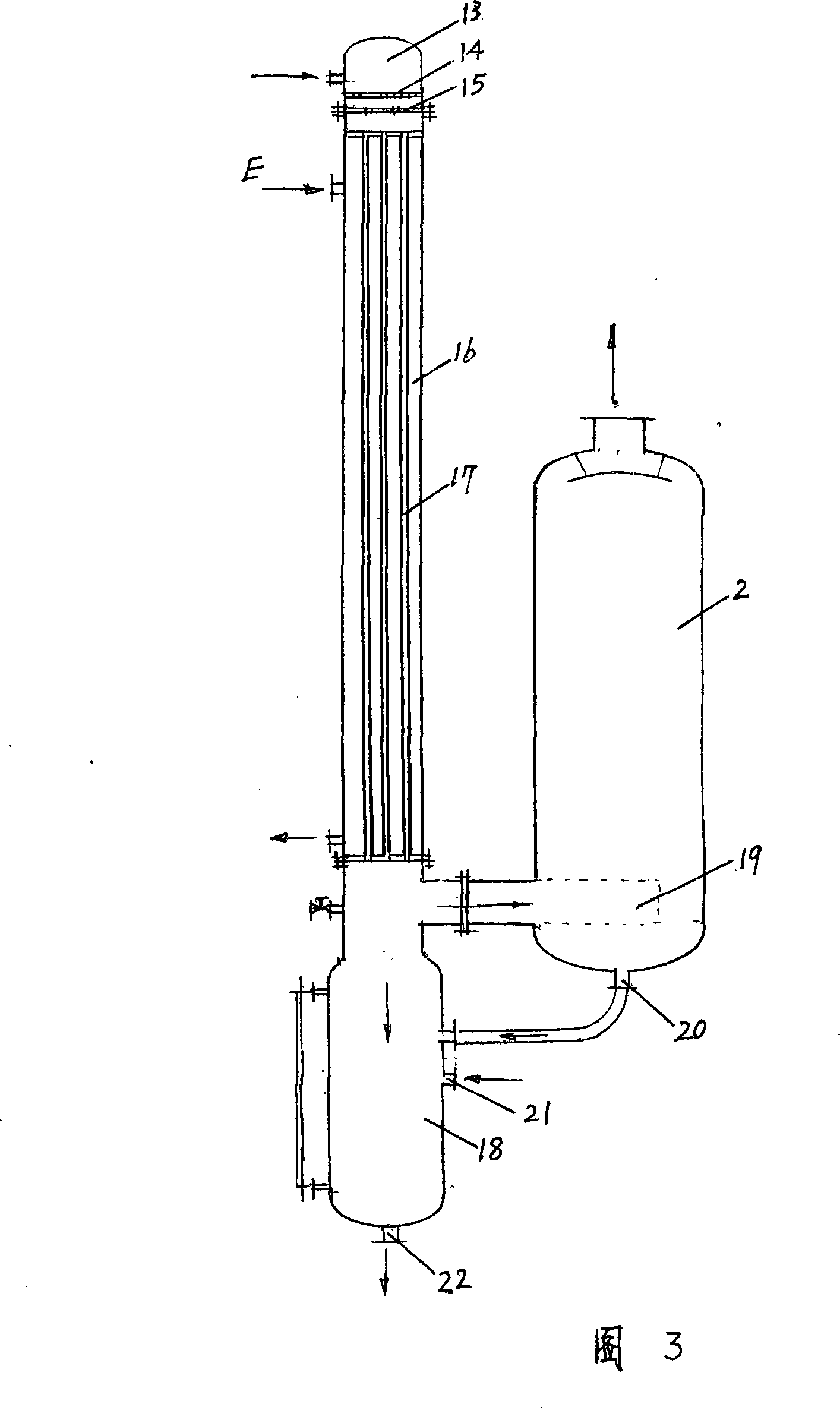

Process method for recovering ammonium chloride and sodium chloride from waste water containing ammonium chloride and sodium chloride

InactiveCN101544437AFully recycleReduce energy consumptionEnergy inputSolution crystallizationSodium bicarbonateDecomposition

The invention relates to a process method for recovering ammonium chloride and sodium chloride from waste water containing the ammonium chloride and the sodium chloride, which produces the ammonium chloride and the sodium chloride by using mother solution which is generated in a process for producing sodium bicarbonate by natural bittern double decomposition reaction and contains the ammonium chloride and the sodium chloride as raw materials. The method adopts ammonium still, evaporation, crystallization and separation process to treat, wherein the evaporation adopts multiple-effect, a heat pump and a vacuum evaporation process, and selects a falling film evaporator and a forced circulation type evaporator to perform triple-effect mixed-flow procedure, so that sodium chloride is crystallized and separated in the evaporation; and the ammonium chloride is crystallized and separated by cooling after the evaporation. The method effectively reduces the operation temperature of the equipment, can repeatedly use secondary steam and condensed water, reduces erosion of the ammonium chloride solution to the equipment, saves the energy, reduces the cost, improves the production efficiency, and reduces environmental pollution.

Owner:HEBEI UNIV OF TECH +1

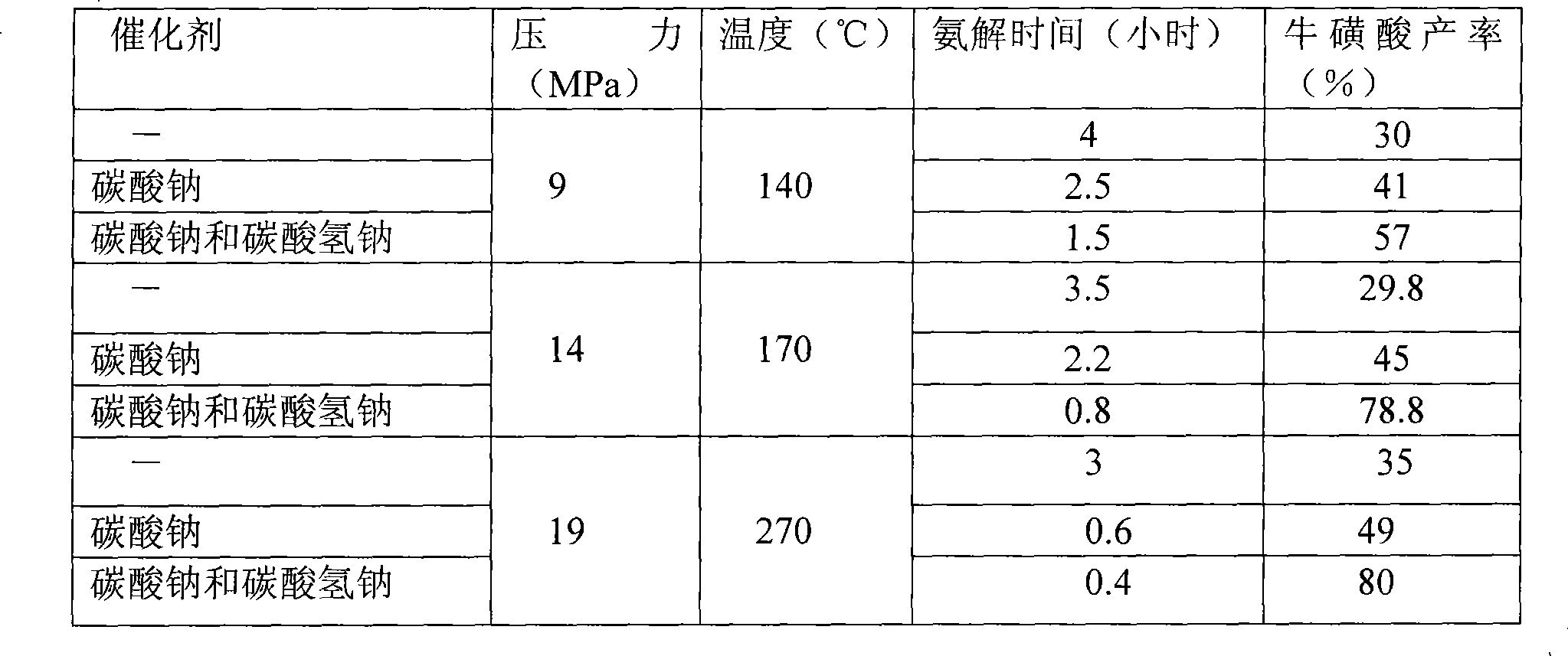

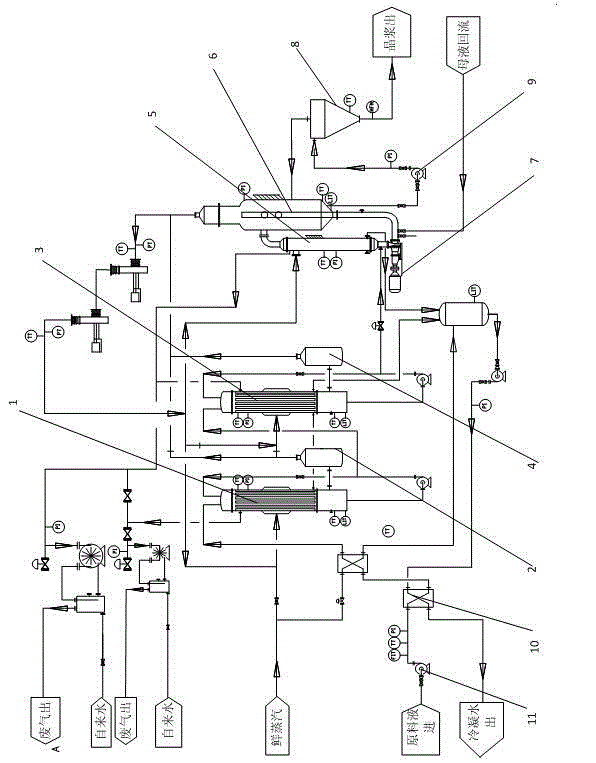

Method of preparing taurine

The invention relates to method for preparing taurine, comprising the following steps: (1) reacting epoxy ethane with sodium sulfite under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at temperature between 75 and 85 DEG C to obtain hydroxyethyl sodium sulfonate; (2) carrying out ammonolysis reaction on the hydroxyethyl sodium sulfonate and liquid ammonia under 14 to 21MPa and at temperature between 160 and 280 DEG C to obtain ammonolysis solution containing sodium taurate; (3) introducing the ammonolysis solution into a single flash evaporator for primary flash evaporating at a temperature between 160 and 200 DEG C and under 1.3 to 2.0MPa; introducing the flash evaporated liquid into a secondary flash evaporating and falling film evaporator, using the primary flash vapor as a heating medium to carry out flash evaporating and falling film evaporating on the primary flash evaporated liquid in the secondary flash evaporating and falling film evaporator at a temperature between 110 and 140 DEG C and at 0.1 to 0.6MPa; evaporating and concentrating the flash evaporated liquid subjected to secondary flash evaporating and falling film evaporating with flash vapor and steam as heating media in a multi-effect flash evaporating and falling film evaporator; and (4) neutralizing the sodium taurate by sulphuric acid to obtain the taurine. The method for preparing the taurine has the advantages of short time, high yield and low cost, and is easy for industrialized production. In addition, by primary flash evaporating and secondary flash evaporating processes, almost all the ammonia and 40% to 60% of water in the flash evaporated liquid can be removed, thus having double effects of removing ammonia and condensing.

Owner:王代龙 +1

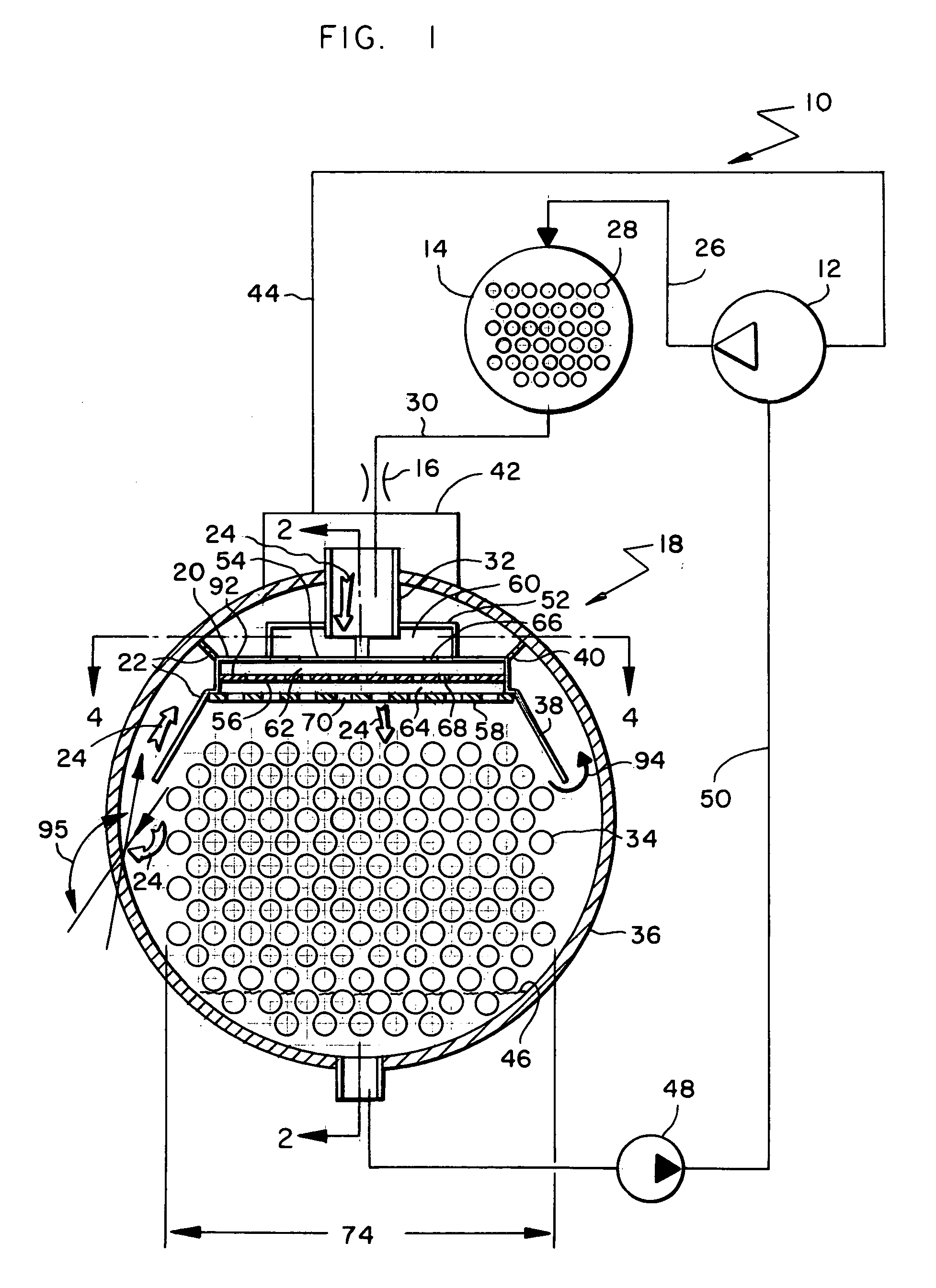

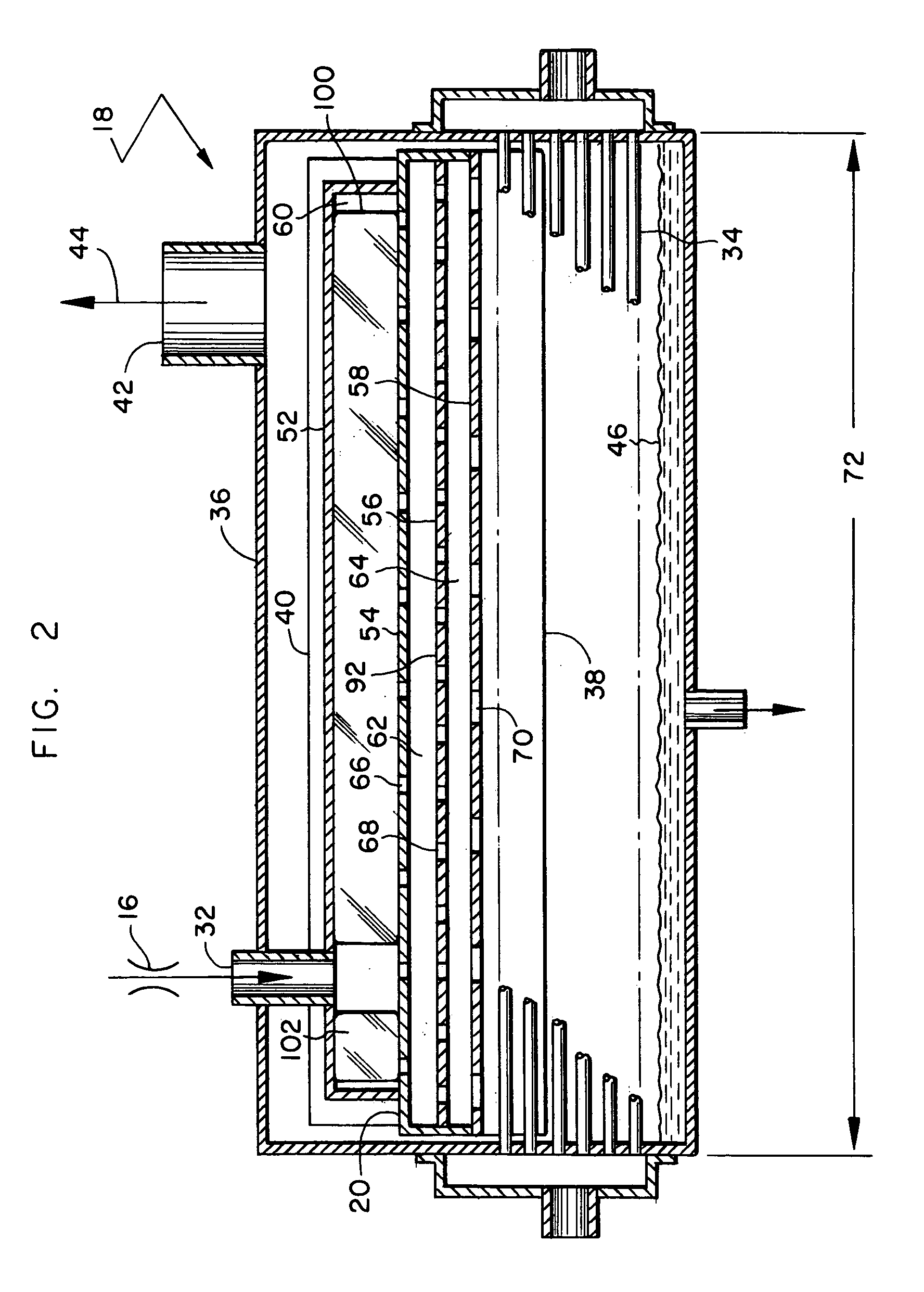

Falling film evaporator

ActiveUS7849710B2Avoid cross flowImprove heat transfer performanceEvaporators/condensersStationary conduit assembliesProcess systemsHandling system

A falling film evaporator is provided for use in a two-phase refrigeration system or process system. The evaporator includes a shell having an upper portion, a lower portion, and a tube bundle having tubes extending substantially horizontally in the shell. A hood is disposed over the tube bundle, the hood having an upper end adjacent the upper portion above the tube bundle, the upper end having opposed substantially parallel walls extending toward the lower portion, the walls terminating at an open end opposite the upper end. Once liquid refrigerant or liquid refrigerant and vapor refrigerant is deposited onto the tube bundle, the substantially parallel walls of the hood substantially prevent cross flow of refrigerant vapor or liquid and vapor between the tubes of the tube bundle.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Method for recycling deoiled water using counterflow falling-film evaporators

ActiveUS20120145386A1High speedReduce chemical consumption requirementFatty/oily/floating substances removal devicesEvaporation with vapour compressionWater useSaline water

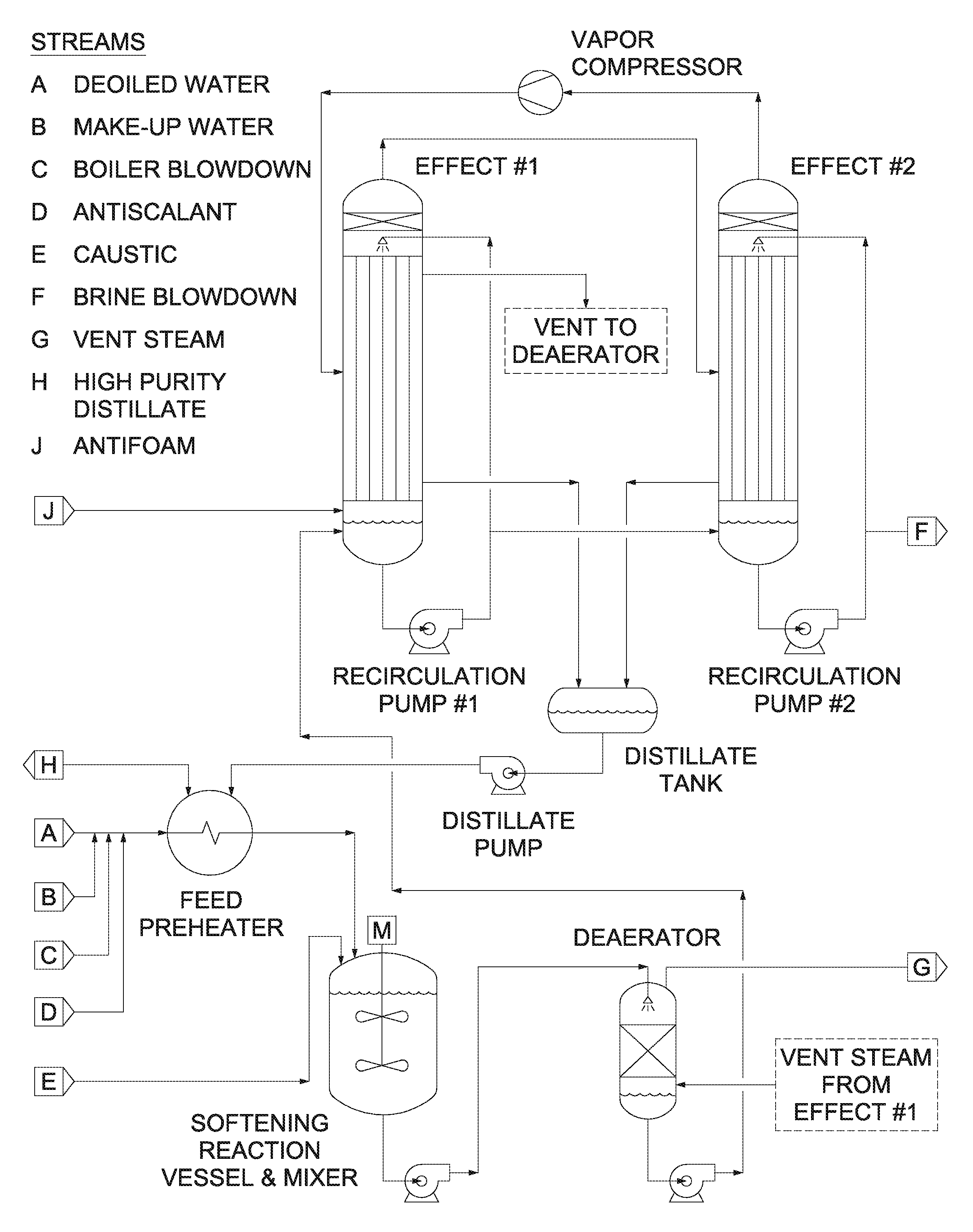

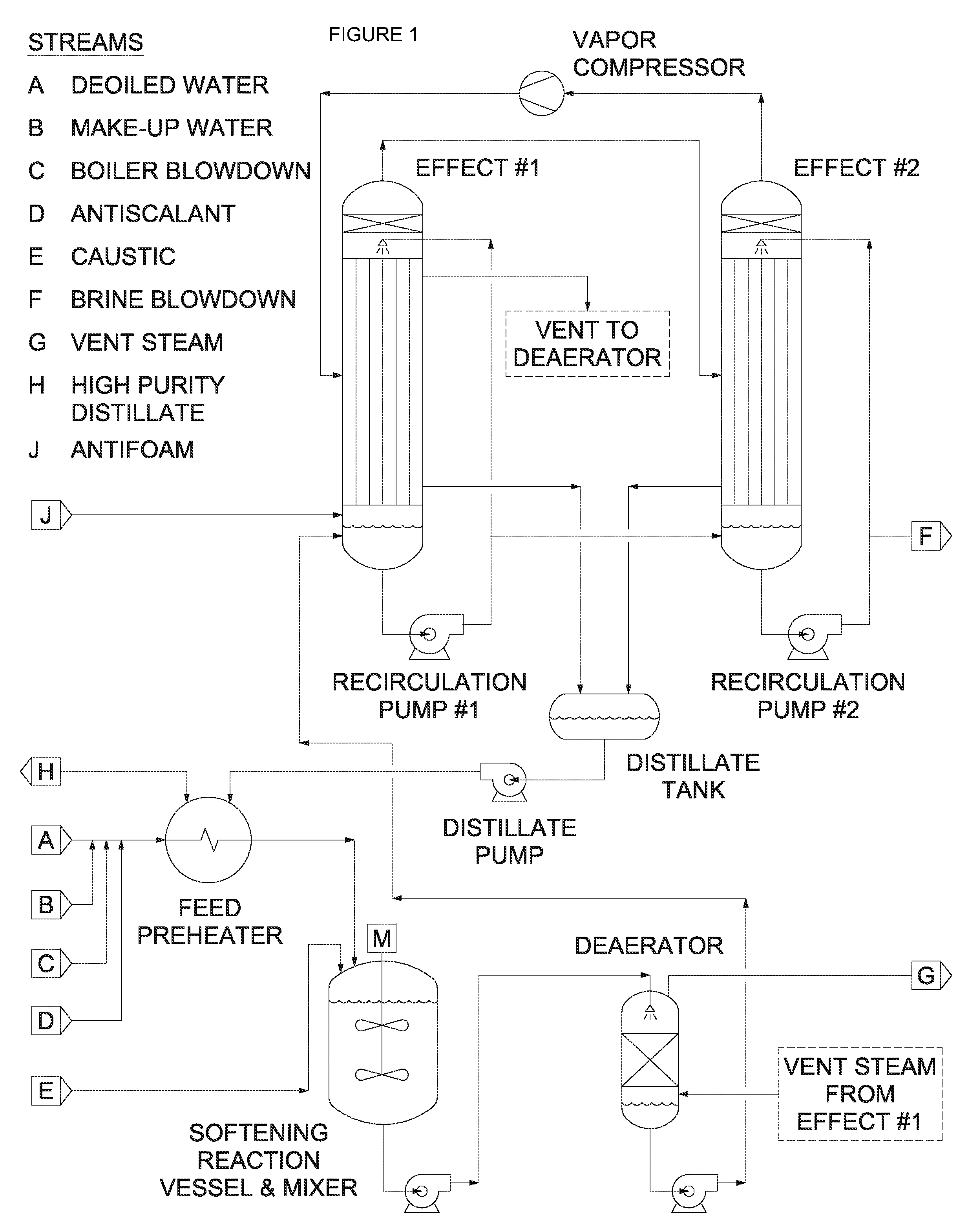

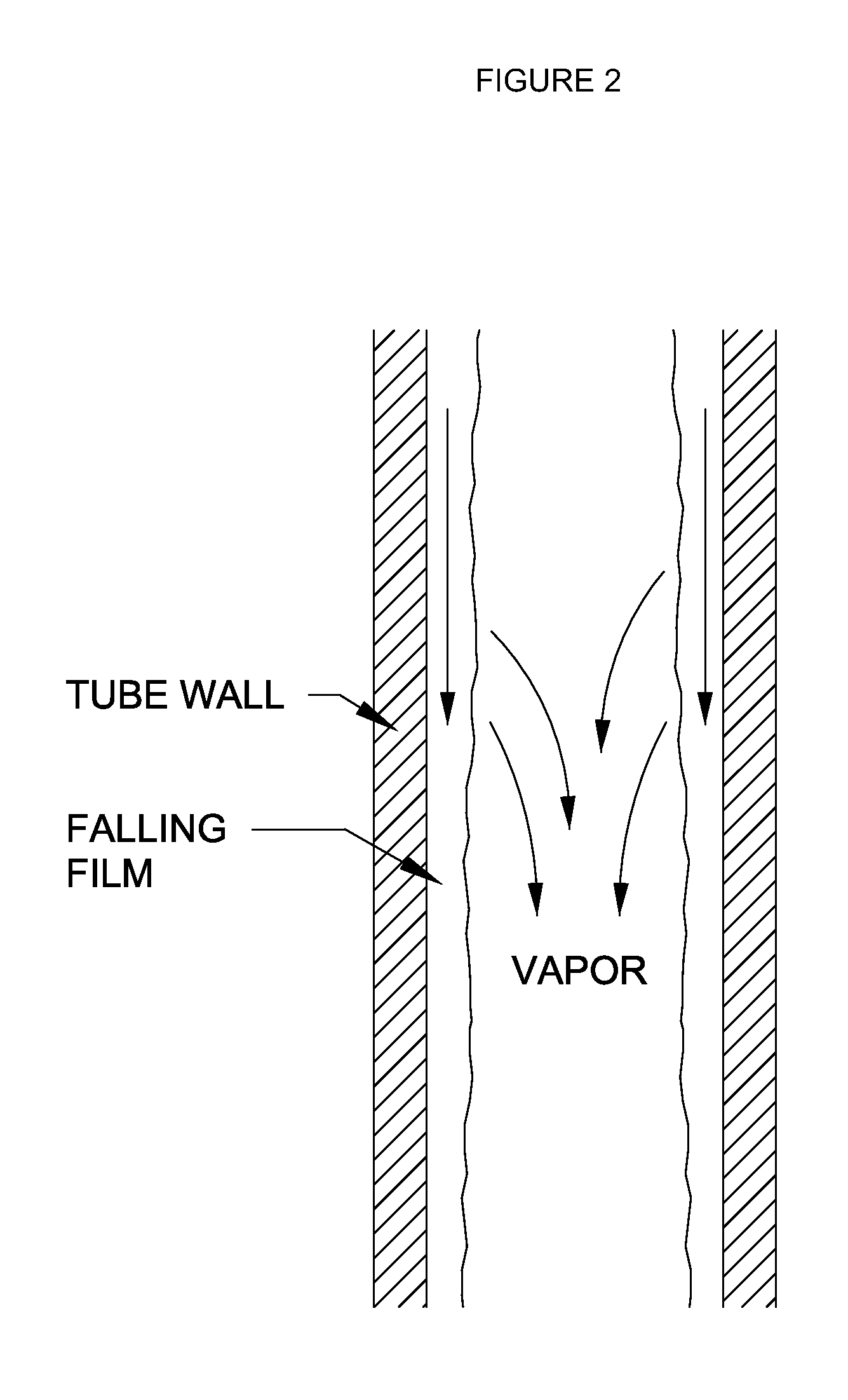

We provide an evaporator technology for treatment of produced water that may be deoiled water. Systems described herein utilize a vertical tube heat exchanger bundle where the brine is distributed in a falling film along the inside of the tube wall. Condensing steam causes a portion of the deoiled water to evaporate; this water vapor travels upward in a counterflow direction relative to the deoiled water. This evaporator technology provides several design advantages over the conventional vertical tube co-current flow evaporators (where the vapor flows downward with the falling film). These advantages include a minimal total installed cost (TIC) as well as offering optimal design features for water chemistry management.

Owner:AQUATECH INT LLC

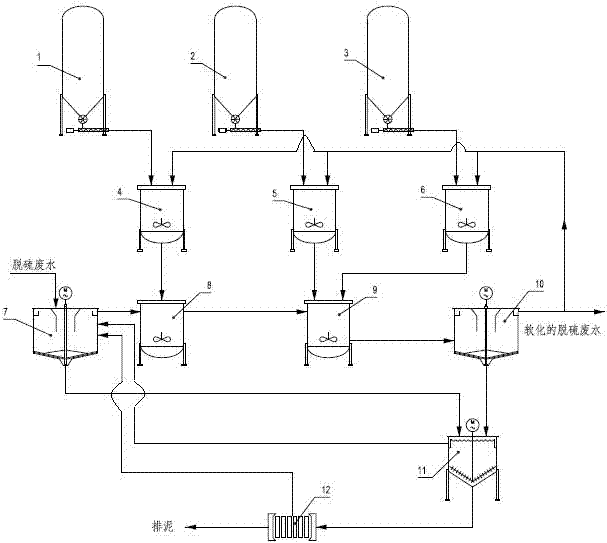

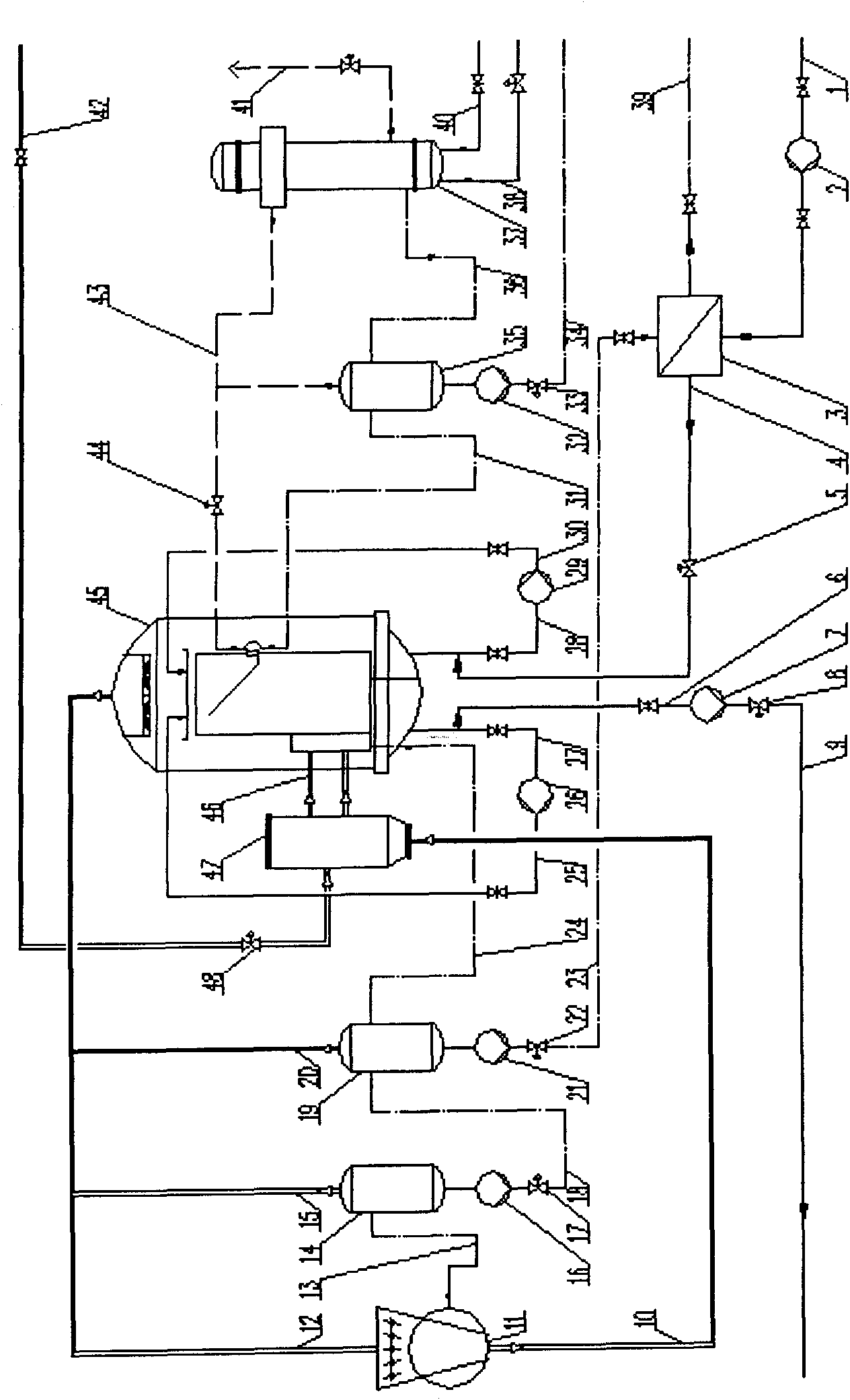

Power plant wastewater zero-discharge treatment technique

ActiveCN104276708AImprove flushing effectRemove supersaturationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationProcess equipmentDegasser

The invention discloses a power plant wastewater zero-discharge treatment technique which comprises a pretreatment process, an evaporative concentration process and an evaporative crystallization process, wherein the pretreatment process equipment comprises a precipitation and concentration tank, a sludge dewatering machine, and a raw water precipitation tank, a primary softening reactor, a secondary softening reactor and a softening precipitation tank which are sequentially connected; the evaporative concentration process equipment comprises an automatic back flush filter, a plate-type preheater, a degasser and a falling film evaporator which are sequentially communicated; and the evaporative crystallization process equipment comprises a concentrated solution tank, a crystallizing heater and a crystallizer which are sequentially communicated. The desulfurization water treatment technique is reasonable in step design and performs the pretreatment, evaporative concentration and evaporative crystallization on the desulfurization wastewater, and the end products are only distilled water and crystalline salt, thereby reducing the discharge of the harmful substances, lowering the energy consumption and implementing the goal of zero discharge of desulfurization wastewater.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

Falling film evaporator

ActiveUS20060080998A1Avoid cross flowImprove heat transfer performanceEvaporators/condensersStationary conduit assembliesProcess systemsRefrigeration

A falling film evaporator is provided for use in a two-phase refrigeration system or process system. The evaporator includes a shell having an upper portion, a lower portion, and a tube bundle having tubes extending substantially horizontally in the shell. A hood is disposed over the tube bundle, the hood having an upper end adjacent the upper portion above the tube bundle, the upper end having opposed substantially parallel walls extending toward the lower portion, the walls terminating at an open end opposite the upper end. Once liquid refrigerant or liquid refrigerant and vapor refrigerant is deposited onto the tube bundle, the substantially parallel walls of the hood substantially prevent cross flow of refrigerant vapor or liquid and vapor between the tubes of the tube bundle.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Heat pump type low-temperature evaporating device and method

InactiveCN102698451AEvaporator accessoriesMultiple-effect evaporationSteam condensationChemical separation

The invention relates to a heat pump type low-temperature evaporating device and method, belonging to the technical fields of chemical separation, energy conservation and emission reduction. The method is characterized in that a solvent is evaporated and condensed in the heating circulation process of a heat-carrying medium, so that the aim that a thermosensitive material liquid is evaporated and concentrated or an organic solvent is recovered at the low temperature can be achieved; the heat pump type low-temperature evaporating device mainly comprises a material liquid evaporator, a gas-liquid separator, a secondary steam condenser, a condensate tank, a heat medium storage tank, a heat medium steam compressor, a filter, a material liquid pump, a condensate pump, a throttling device and a pipeline valve, wherein a single-effect or multi-effect falling-film evaporator is used as the material liquid evaporator. The material liquid evaporating temperature is controlled to be within the range of 25-60 DEG C by adjusting the system vacuum degree; and the system heating capacity is controlled to be matched with the evaporation capacity by adjusting the input power of the compressor at the variable frequency. The heat pump type low-temperature evaporating device and method have the beneficial effects and advantages that the gas emission is reduced, so that the environment is protected, and the energy is saved; and furthermore, the active ingredients of the material liquid can be maintained by low-temperature evaporation, equipment is seldom corroded, and a pipeline is not easily blocked, so that the equipment cost is lowered.

Owner:DALIAN UNIV OF TECH

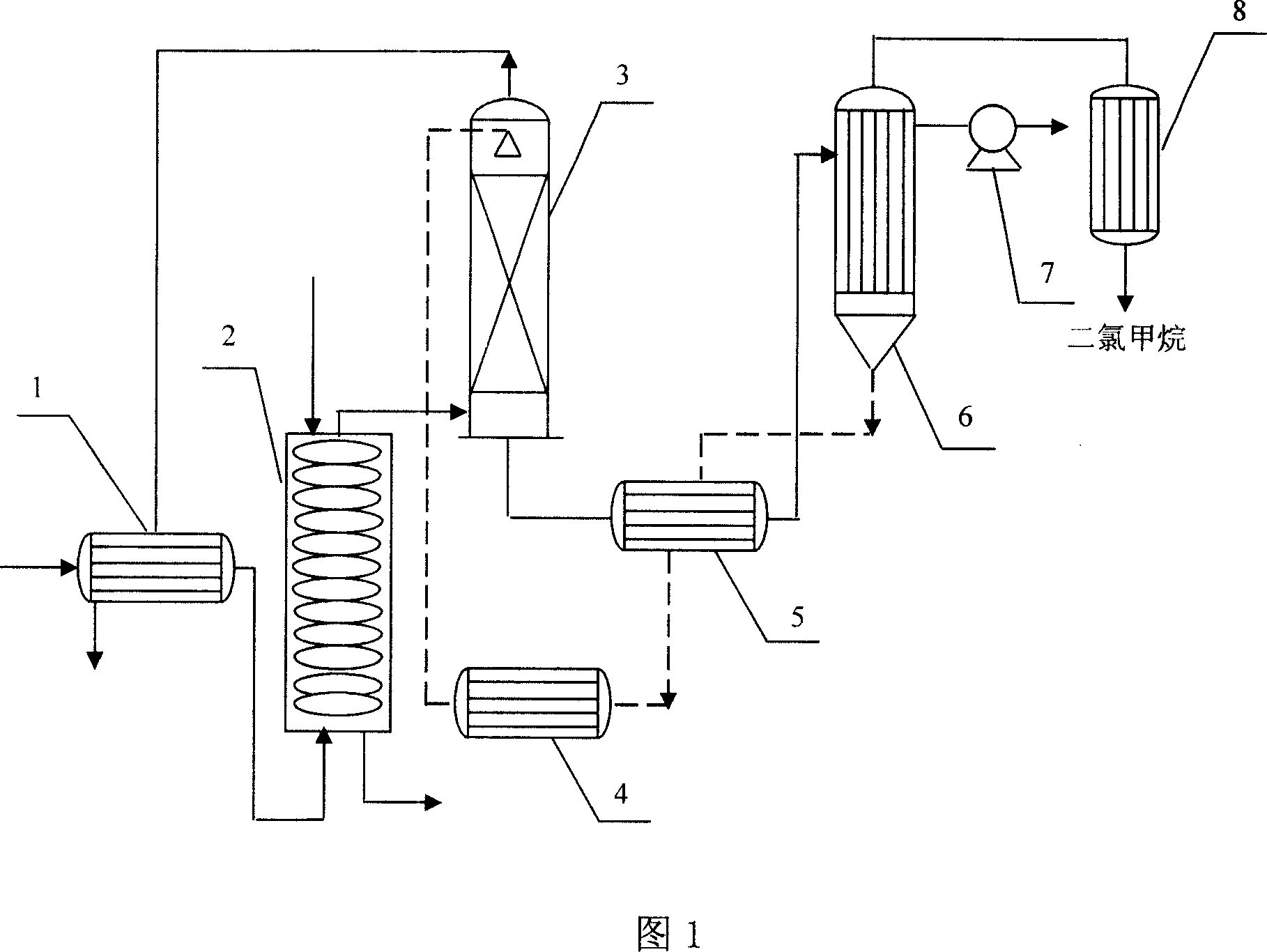

Method for reclaiming methylene chloride from waste gas

InactiveCN1962028ASmall poison spotThe content adapts to a wide rangeDispersed particle separationVapor condensationRecovery methodChloride

The invention relates to a method for recycling carrene of waste gas, wherein the invention uses condense-adsorption method to recycle the carrene of organic waste gas; uses water as cooling medium to condense the waste gas; then uses dimethyl formamide in the stuff adsorption tower as absorber to absorb the carrene; the absorber is analyzed in passive pressure in degrade vaporizer, to regenerate the absorber and form loop-close circulation. The invention has low cost and high efficiency.

Owner:TSINGHUA UNIV

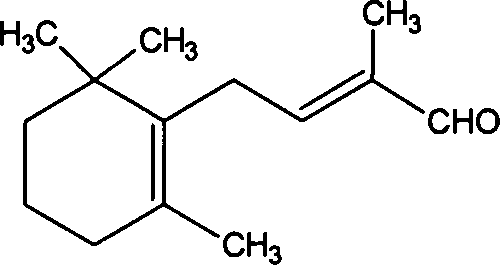

Method and apparatus for purifying vitamin A intermediate mynistic aldehyde

ActiveCN101070277AHigh purityQuality improvementCarbonyl compound separation/purificationPurification methodsVitamin A Alcohol

This invention relates to purification method of intermedium myristic aldehyde and device. The device has set heater, fractionating tower, falling film reboiler, falling film evaporator and condenser. Raw myristic aldehyde outlet of heater connect with fractionating tower inlet; steam outlet of fractionating tower top connect with condenser steam inlet; one way of first condenser condensed fluid outlet connect with reflux liquid inlet of fractionating tower top, the other way outflow low boiler of beta - ionone. Dephlegmation tower bottom outlet respectively connect with falling film reboiler overhead entrance and falling film evaporator overhead entrance; falling film reboiler bottom outlet connect with fractionating tower bottom entrance; one way of falling film evaporator outlet connect with second condenser entrance, the other way is outlet of high boil thing; second condenser outlet is outlet of refine myristic aldehyde. Whil purification first send raw myristic aldehyde to fractionating tower, gain distillate from fractionating tower top. The distillate enter fractionating tower bottom tower kettle, pass through falling film evaporator to remove high boil thing.

Owner:XIAMEN KINGDOMWAY VI TAMIN INC +1

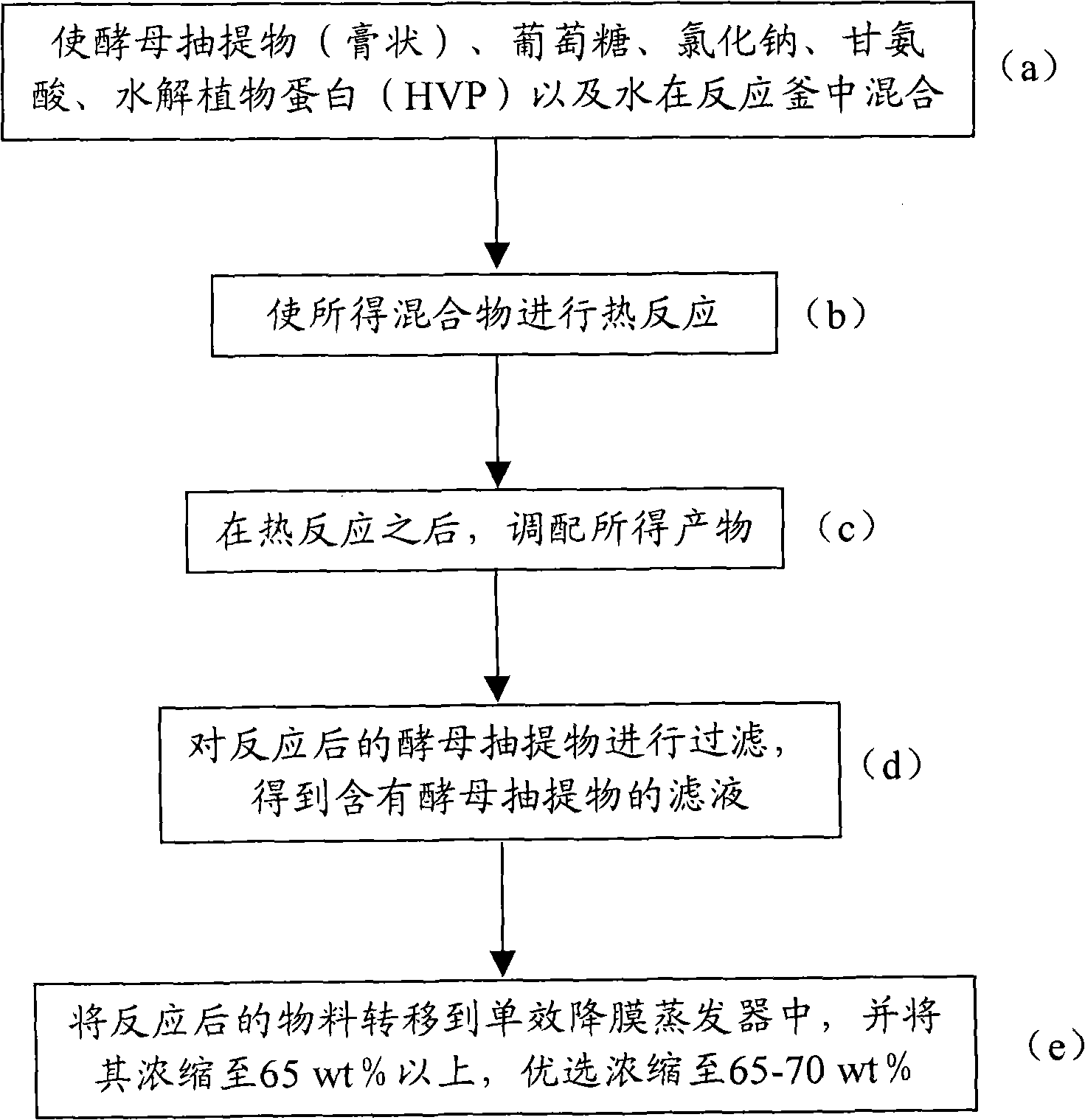

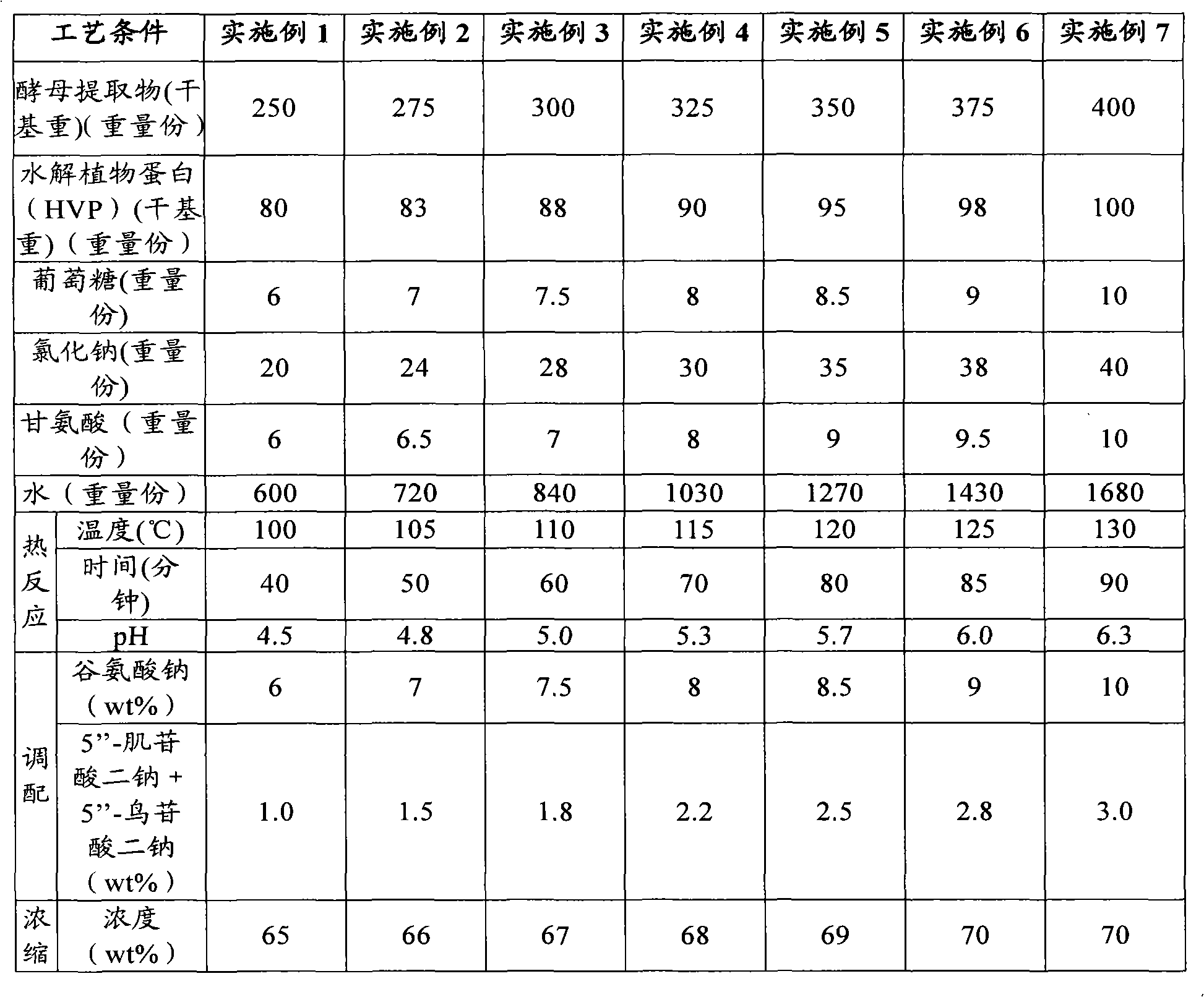

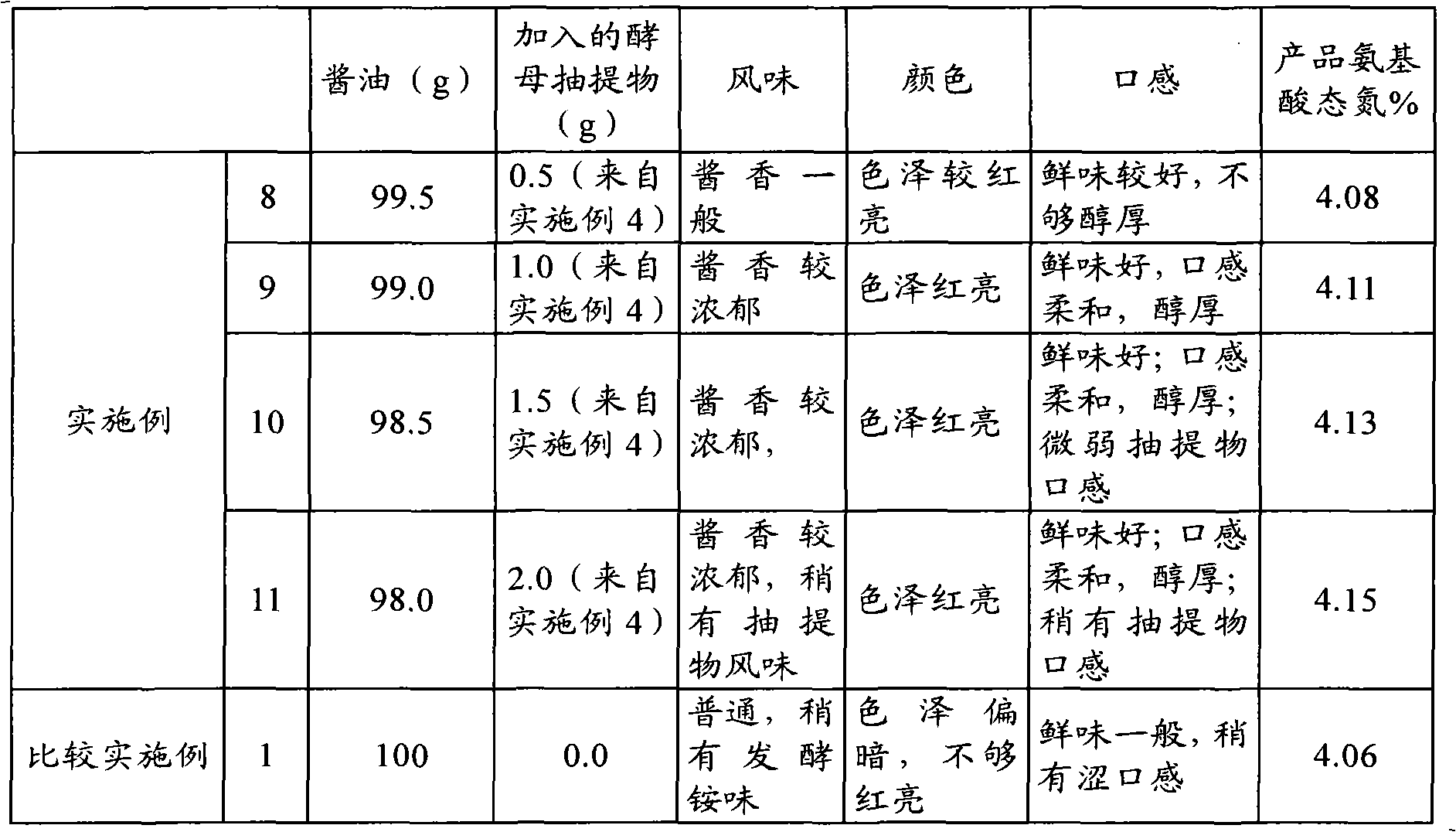

Yeast extract, preparation method and application thereof

InactiveCN101513246AFlavor coordinationTaste balanceFood preparationCaramel FlavorVegetable Proteins

The invention provides a yeast extract, a preparation method and application thereof. The preparation method of the yeast extract comprises the following steps: (a) mixing the yeast extract, glucose, sodium chloride, glycin, hydrolyzed vegetable protein and water in a reaction kettle; (b) performing heat reaction on the mixture in step (a) for 40 to 90 minutes at a temperature of between 100 and 130 DEG C and pH of between 4.5 and 6.3; (c) after the heat reaction, adding 6 to 10 weight percent of sodium glutamate and 1.0 to 3.0 weight percent of disodium inosinate and disodium guanylate into an obtained product for preparation; (d) filtering the yeast extract after the reaction to obtain filtrate containing the yeast extract; and optional (e) transferring materials after the reaction to a single effect falling film evaporator, and concentrating the materials to more than 65 weight percent and preferably concentrating the materials to between 65 and 70 weight percent. The yeast extract prepared by the method has sauce fragrance and caramel like deep bright red color, and a water solution of the yeast extract has transparent bright red color and fresh and salty mouthfeel.

Owner:ANGELYEAST CO LTD

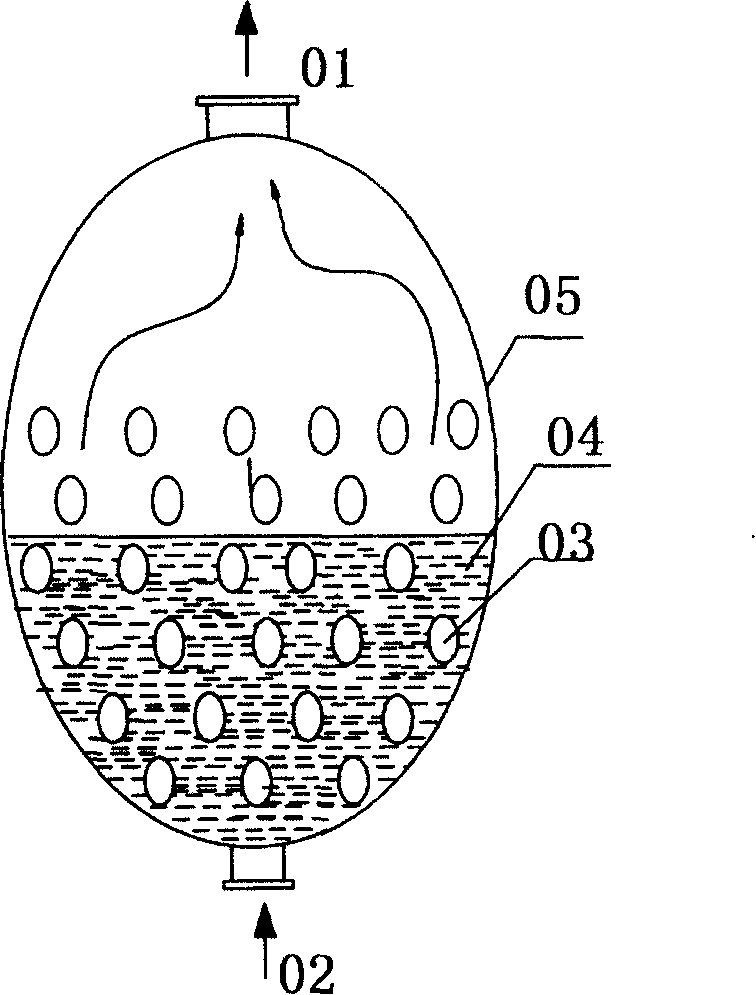

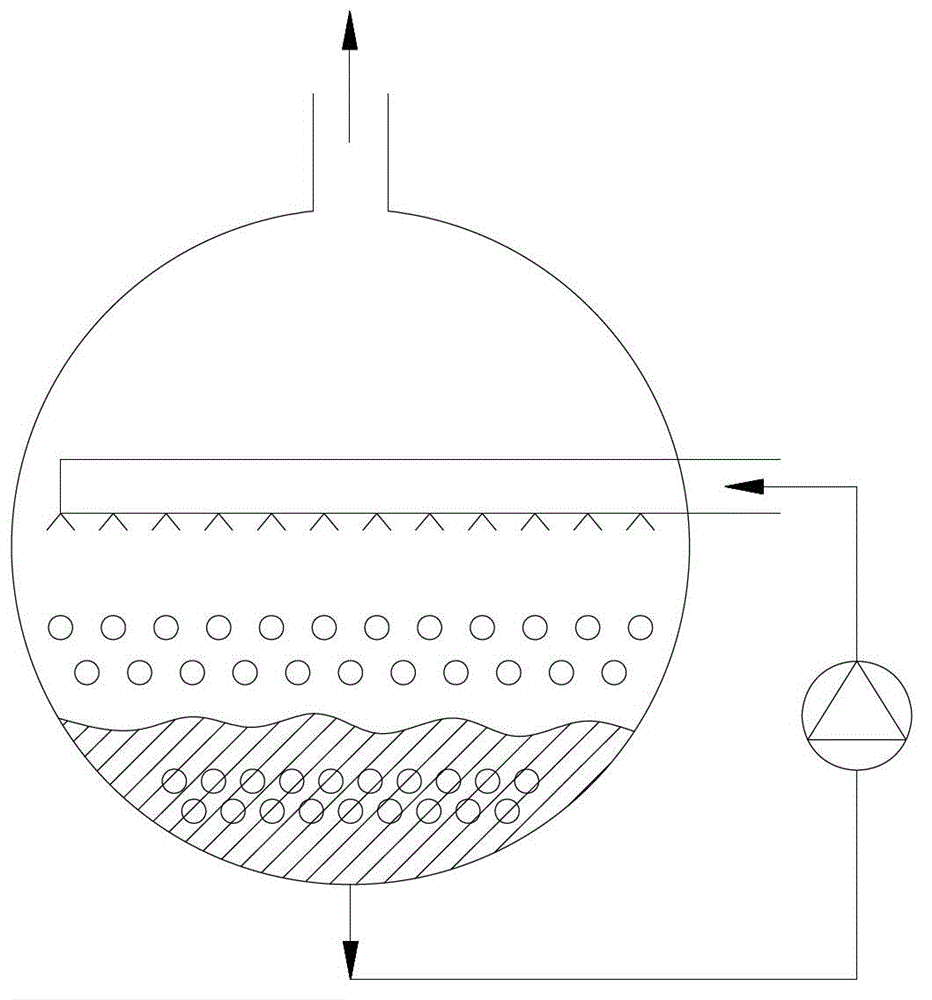

Jet flow circulated sprinkling falling-film evaporator

InactiveCN101191683AReduce heat transfer areaGood value for moneyEvaporators/condensersStationary conduit assembliesJet flowVapor–liquid separator

A fluidic circulation spray falling film evaporator comprises an evaporator shell, a gas outlet arranged on the upper part of the evaporator shell, a heat-exchange tube bundle, a distributor and a gas-liquid separator which are axially distributed in the evaporator shell; the distributor is positioned on the upper part of the heat-exchange tube bundle; the gas-liquid separator is positioned between the distributor and the gas outlet; the invention also comprises a fluidic pump; the high-pressure refrigerant inlet of the fluidic pump is communicated with a condenser; the circulating refrigerant inlet is communicated with the bottom of the evaporator shell; the mixed refrigerant outlet is communicated with the distributor. Compared with the prior art of the pumpless spray falling film type evaporator, the invention can reduce the heat-exchange area of the evaporator by 10 percent around. Compared with the prior art of the pump spray falling film type evaporator, the invention consumes no circulation pump power, therefore, the invention is a spray falling film type evaporator technology with high performance-cost ratio.

Owner:SHANGHAI MARITIME UNIVERSITY

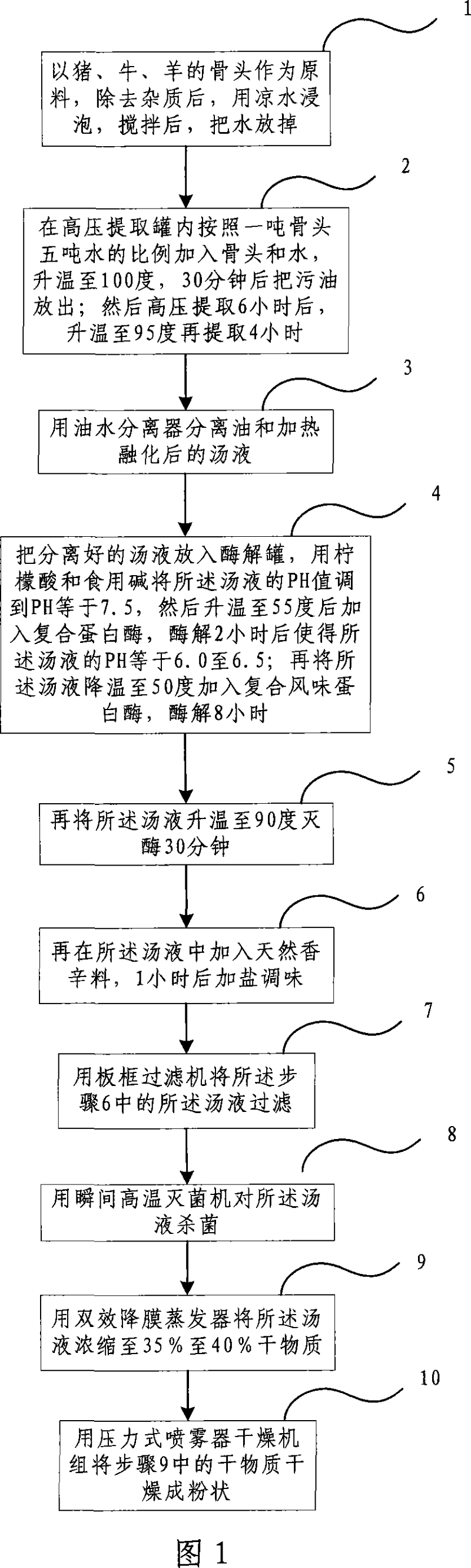

Preparing process of extracting bone collagen from pig, cattle and sheep bone

InactiveCN101033481ARestore elasticityAvoid forksFermentationProtein foodstuffs working-upFlavorEnzymatic hydrolysis

The invention relates to a method for extracting bone collagen protein from bone of pig, cow and sheep, including: It removes the impurities of the bone. And then it warms up and extracts the bone under high-pressure in the high-pressure extraction tank. And then it separates the oil and melting soup by using oil-water separator. And then it transfers the separated liquid into the enzymolysis can for enzymatic hydrolysis. And then it cools the liquid to 50 deg.C, and then adds liquid complex flavor protease to enzymolysis for eight hours. And then it warms the liquid up to 90 deg.C, and it eliminate enzyme for 30 minutes. And then it adds natural spice and salt. And then it filters the liquid. And then it sterilizes the liquid with a high-temperature sterilization machine. And then it condenses the liquid to dry materials by using double-effect falling film evaporator. And then it dries the dry materials into power by using pressure-type sprayer.

Owner:庞小战

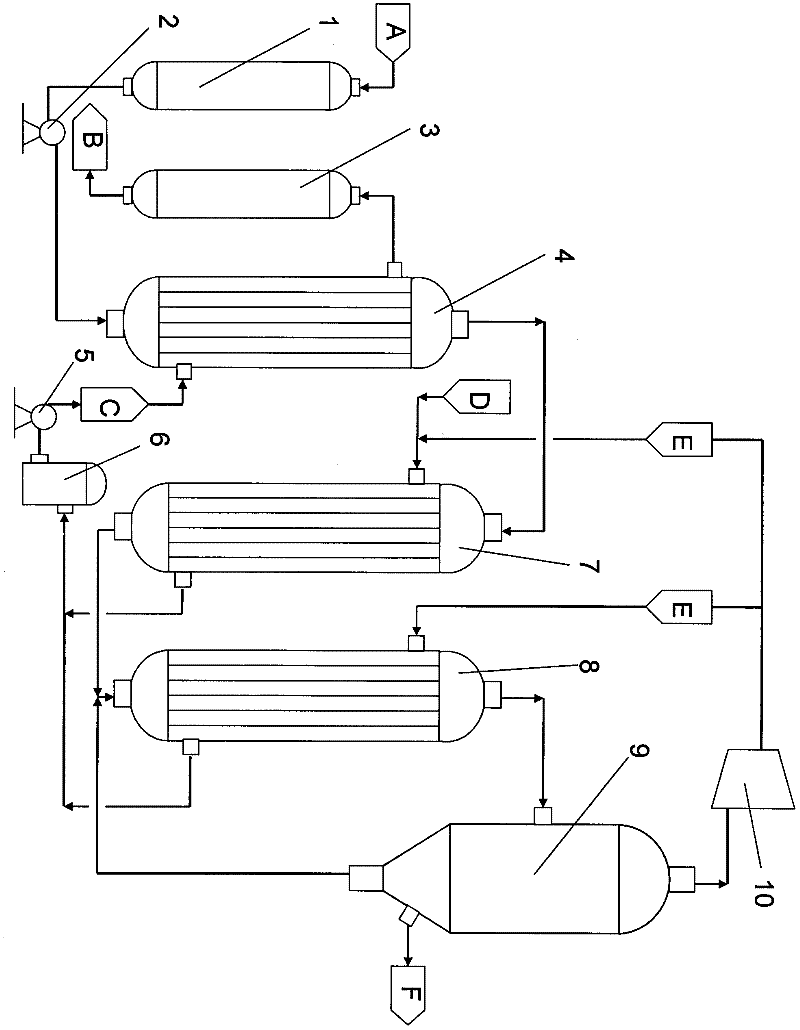

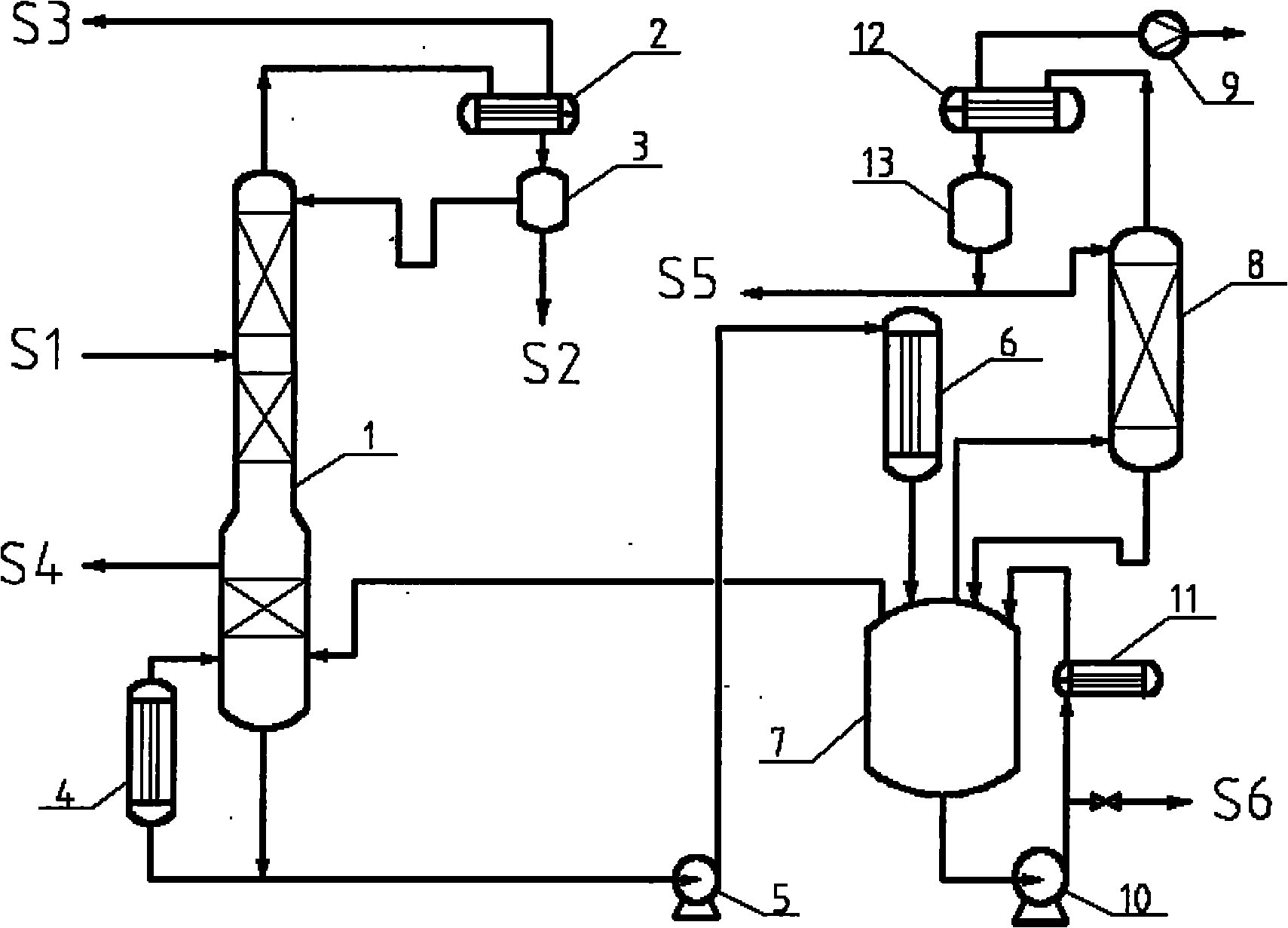

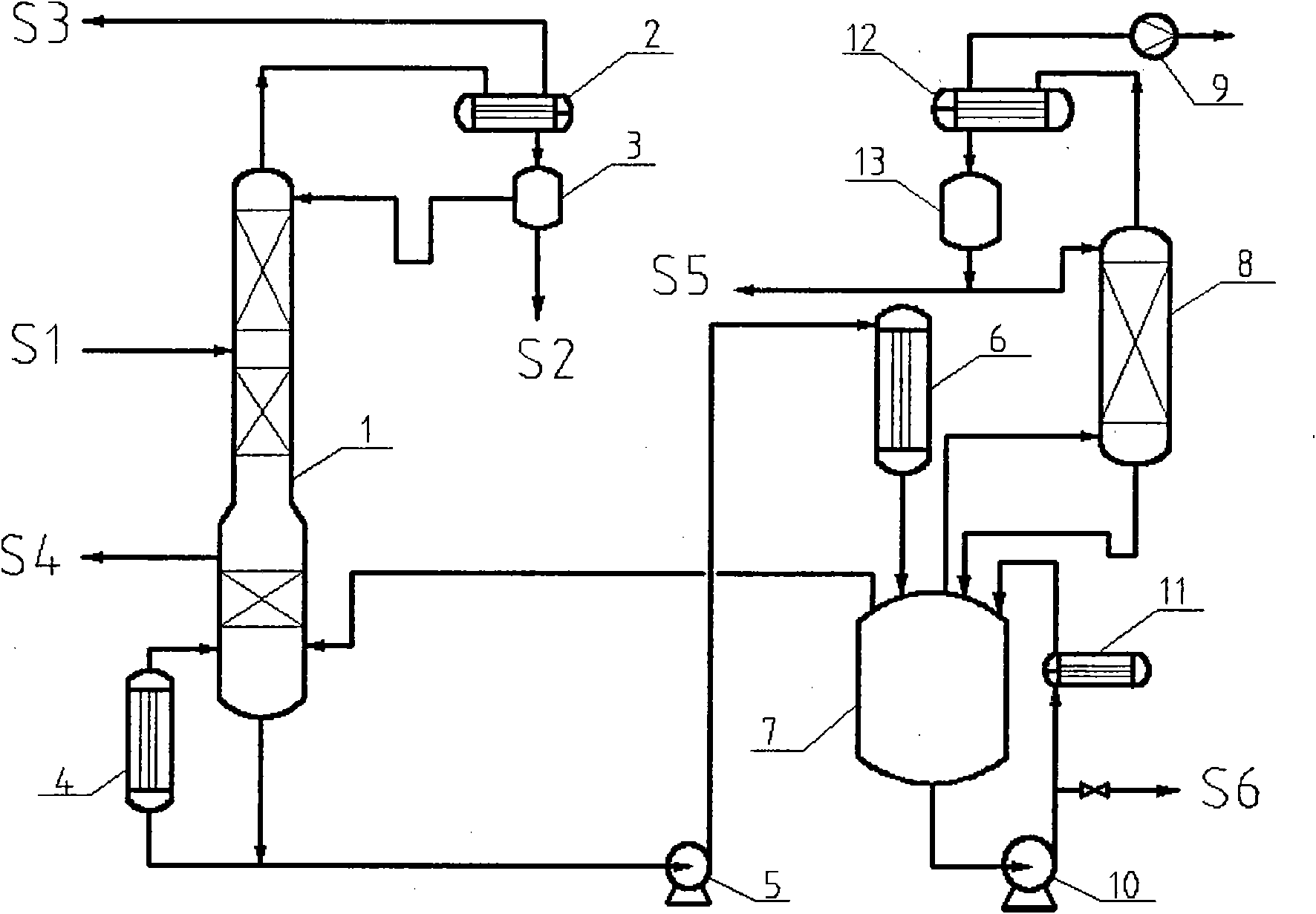

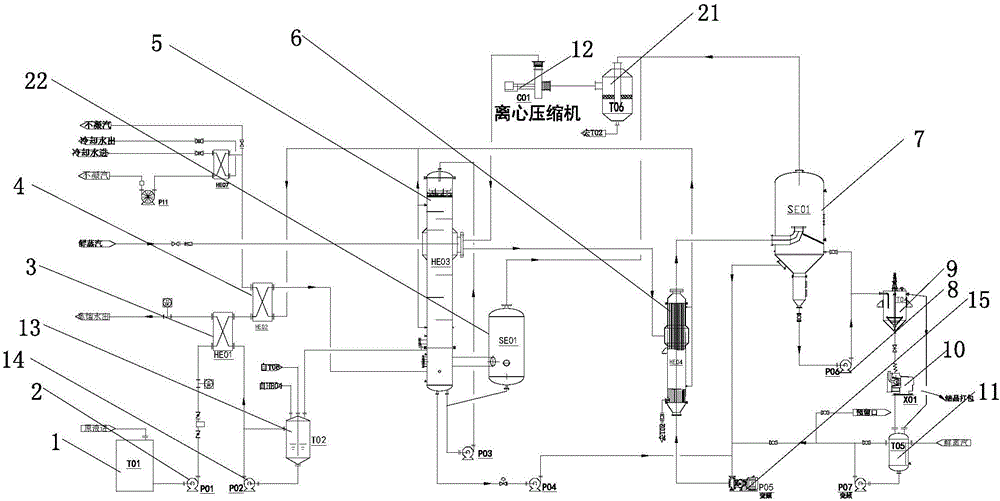

Energy-saving evaporating process and equipment for L-phenylalanine brine solution

ActiveCN102343162ASmall volumeEnergy saving processEvaporator accessoriesMultiple-effect evaporationVapor liquidHeat balance

The invention relates to an energy-saving evaporating process and equipment for a L-phenylalanine brine solution, belonging to the technical field of efficient energy saving and environmental protection. The process comprises the following steps of: preheating a 1 percent concentration of feed solution to 50-60 DEG C with a preheater 4; making the preheated feed solution enter the tube pass and shell pass of a falling film evaporator 7 and a climbing film evaporator 8 for secondary vapor heat exchange at 78-80 DEG C, heating to 70 DEG C, and evaporating in a way of combining a falling film with a climbing film to generate secondary vapor and a concentrated solution; making the secondary vapor and the concentrated solution enter a separator 9 for vapor-liquid separation; making the separated secondary vapor enter a centrifugal compressor 10 for compressing and increasing caloric content, heating to 78-80 DEG C for serving as a heating source of the evaporators 7 and 8, and heating and evaporating the feed solution; discharging the concentrated solution of which the concentration is controlled at 3 percent from the separator 9, and returning the concentrated solution of which the concentration does not reach 3 percent to the climbing film evaporator 8 for continually evaporating and concentrating. The system has the advantages of self-heat balance, small using amount of live vapor, low running cost, high efficiency and saving in energy.

Owner:想莱(常州)节能科技有限公司

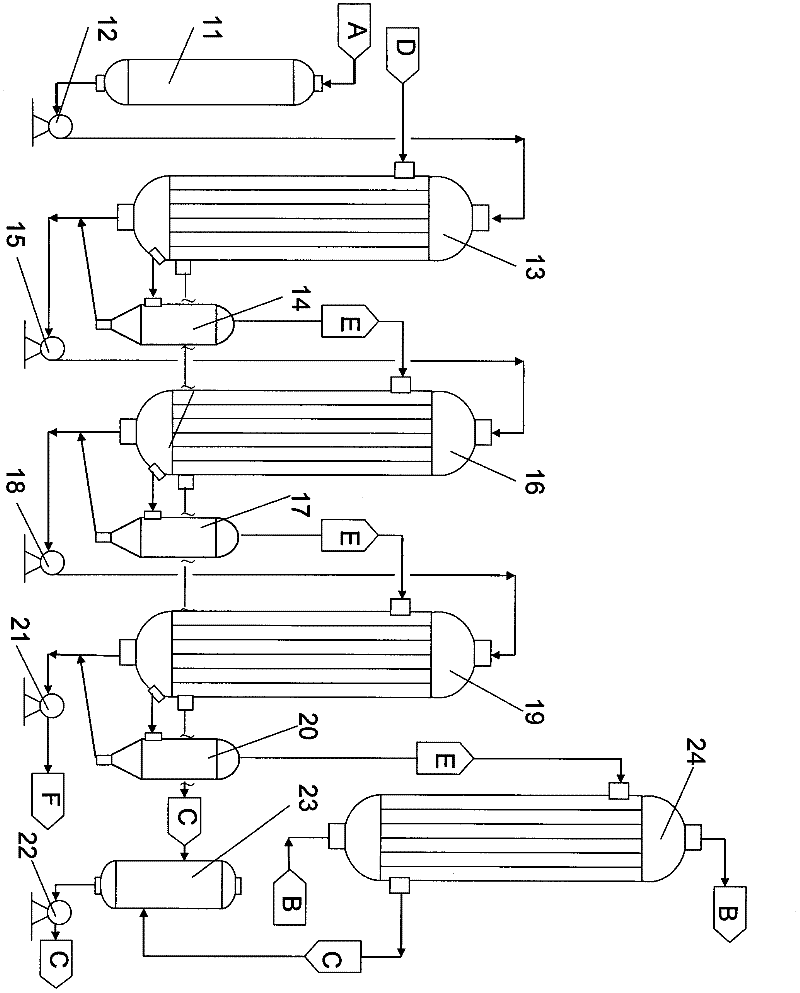

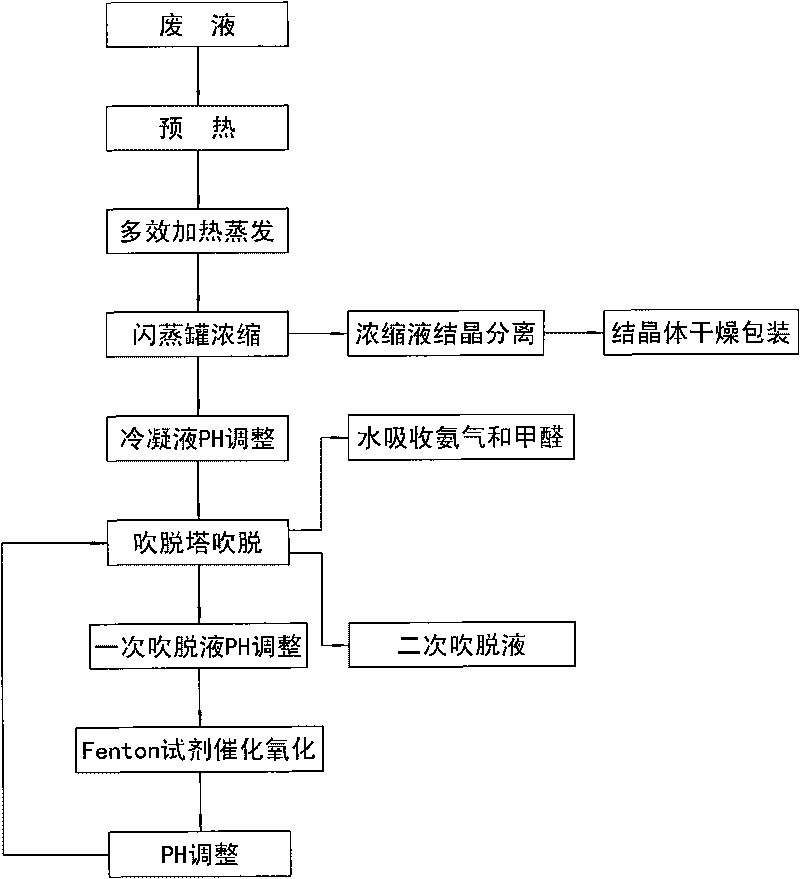

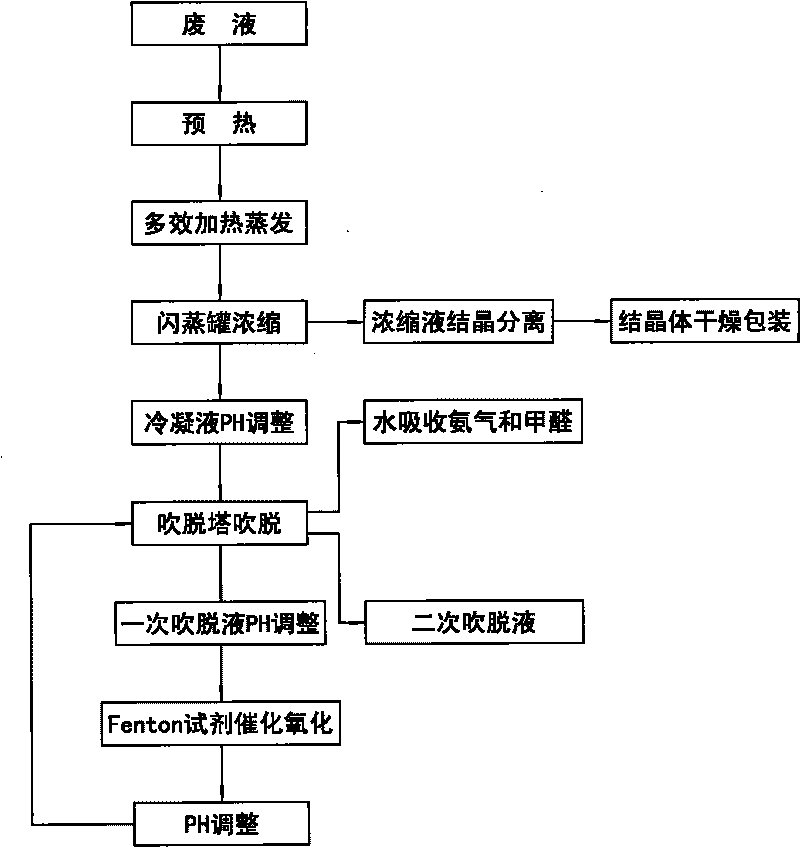

Method for treating wastewater from preparation of glycine by chloroacetic acid ammonolysis process

InactiveCN101717165AReduce energy consumptionReduce corrosionWater contaminantsMultistage water/sewage treatmentLiquid wasteFenton reagent

The invention discloses a method for treating wastewater from the preparation of glycine by the chloroacetic acid ammonolysis process, comprising the following steps: throwing waste liquid into a multi-effect falling film vacuum evaporation system, preheating the waste liquid in the multi-effect falling film vacuum evaporation system, heating and evaporating the waste liquid with a multi-effect falling film evaporator, putting the waste liquid in a flashing pot, concentrating the waste liquid until achieving the ammonium chloride concentration of 35-45%, crystallizing the concentrated solution with a crystallizer at normal temperature, drying and packaging the crystalline solid, adjusting the pH value of condensate which is generated by the multi-effect falling film vacuum evaporation system to 10-11 with NaOH, stripping the condensate in a stripping tower, absorbing methanol and ammonia which are generated from stripping with water, adjusting the pH value of primary stripping solution to 2-4 with dilute sulfuric acid, catalyzing and oxidizing the primary stripping solution with Fenton reagent at 30-40 DEG C, adjusting the pH value of the catalyzed and oxidized primary stripping solution to 10-11 with dilute sulfuric acid, throwing the primary stripping solution into the stripping tower, stripping the primary stripping solution for the second time in the stripping tower, absorbing methanol and ammonia which are generated from the primary stripping solution stripping with water, and discharging secondary stripping solution.

Owner:DALIAN FISHERIES UNIVERSITY

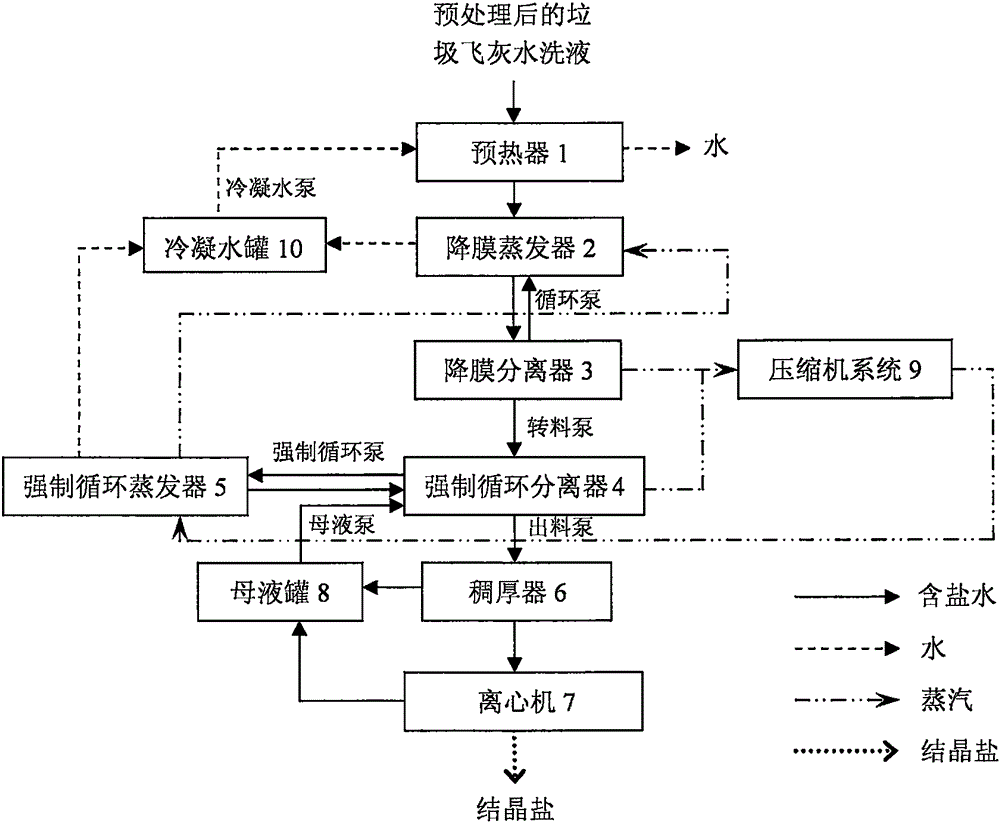

Garbage fly ash water washing liquid evaporation desalination system and method

InactiveCN105016555AInnovativeImprove energy savingMultistage water/sewage treatmentDesalinationEnvironmental engineering

The invention discloses a garbage fly ash water washing liquid evaporation desalination system and method. The system comprises two individual evaporative concentration and evaporation crystallization units. A compressor provides desired heat energy for the units and keeps heat energy balance. The evaporative concentration unit comprises a preheater, a falling film evaporator and a falling film separator. Through garbage fly ash water washing liquid pre-heating and repeated evaporation, the material is concentrated. The evaporation crystallization unit comprises a forced circulation separator and a forced circulation evaporator. Through further evaporation of the concentrate, the material is in a saturated or oversaturated state and salt crystals are precipitated. Through settlement condensation adopting a thickener and separation adopting a centrifuge, the salt in the garbage fly ash water washing liquid can be separated finally. The system adapts to the garbage fly ash water washing liquid characteristics of complex components and high salt content, has the characteristics of large evaporation capability, operation stability and smooth desalination and guarantees large scale stable treatment on the garbage fly ash water washing liquid.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Circulation evaporator

InactiveCN101811743ANon-deterministicLower evaporation temperatureWater/sewage treatment by heatingPapermakingSewage

The invention discloses an evaporator for performing innocent treatment on sewage in industries of papermaking and the like. In an existing device, a secondary steam pipe is connected to an inlet of a compressor; an outlet of the compressor is connected with a steam inlet of a steady head tank; the other steam inlet pipe of the steady head tank is connected with a fresh steam pipe of a boiler; a steam outlet of the steady head tank is connected with a falling-film evaporator which is at least provided with one circulating pipe connected with a circulating pump; an outlet of a stripper plant of the falling-film evaporator is communicated with a non-condensable air pipe and a heavily-polluted condensate water outlet pipe which is communicated with a water inlet of a heavily-polluted condensate water tank; a water outlet of the heavily-polluted condensate water tank is communicated with a heavily-polluted condensate water delivery pipe; and a condensation water outlet pipe of a condenser is communicated with the water inlet of the heavily-polluted condensate water tank.

Owner:兰州节能环保工程有限责任公司 +1

Refining and reclaiming technology of tail gas absorption solvent in production of toluene diisocyanate

InactiveCN101870666AContinuous and stable feedingContinuous and stable dischargeDispersed particle separationDistillation purification/separationToluene diisocyanateGas phase

The invention relates to a refining and reclaiming technology of a tail gas absorption solvent in the production of toluene diisocyanate (TDI). The solvent containing little phosgene, toluene diisocyanate and di-Et-1,3-benzenedicarboxylate (DEIP) performs two-stage refinement in an atmospheric refining tower and a vacuum refining tower, and a falling-film evaporator and a storage tank are arranged between the two towers. The overhead non-condensable gas phase of the atmospheric refining tower is returned to a phosgene absorption tower to recycle phosgene, the refined solvent is drawn from theside of the atmospheric refining tower, the temperature of the tower bottom is controlled to be 3-8 DEG C higher than the boiling point of the solvent, the discharged material of the tower bottom enters the falling-film evaporator, the evaporating temperature is 20-30 DEG C higher than the boiling point of the solvent, the unevaporated material enters the storage tank for storage, the material inthe storage tank performs batch vacuum rectification under the absolute pressure of 0.1-0.25bar, and the unevaporated residual material enters the residue evaporator of a TDI device to recycle TDI and DEIP. By using the solvent refining technology provided by the invention, the useful components in the solvent can be completely recycled, and the technology has the advantages of simple and stable operation and lower cost and energy consumption.

Owner:QINGDAO UNIV OF SCI & TECH +1

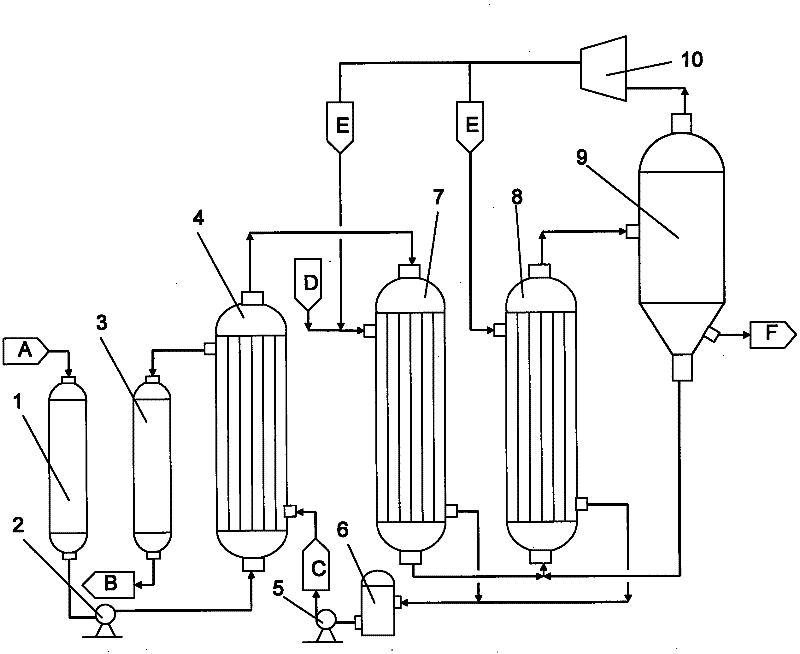

Phenol-acetone wastewater evaporation desalting pretreatment process

ActiveCN104192927AReduce entrainmentIncrease productivityGeneral water supply conservationNature of treatment waterTarWastewater

The invention relates to a phenol-acetone wastewater evaporation desalting pretreatment process. A process that a falling film evaporator and an OSLO evaporation crystallizer are combined is adopted, cross flow operation is adopted, and a solution is treated according to the following steps: preheating a raw material liquid through a condensate water preheater, passing through a two-effect falling film evaporator, passing through a three-effect falling film evaporator, passing through a four-effect film evaporator, passing through a one-effect OSLO evaporation crystallizer, discharging out concentrated crystal slurry, performing solid-liquid separation, feeding the mother liquid back to the one-effect OSLO evaporation crystallizer for further evaporation, and recycling the solid. The process is reasonable in design, and due to selection of process procedures and equipment, the problems that a phenol-acetone wastewater evaporation desalting device is instable in operation and tubes are blocked by tar are solved, and the production efficiency is improved.

Owner:青岛国标环保有限公司

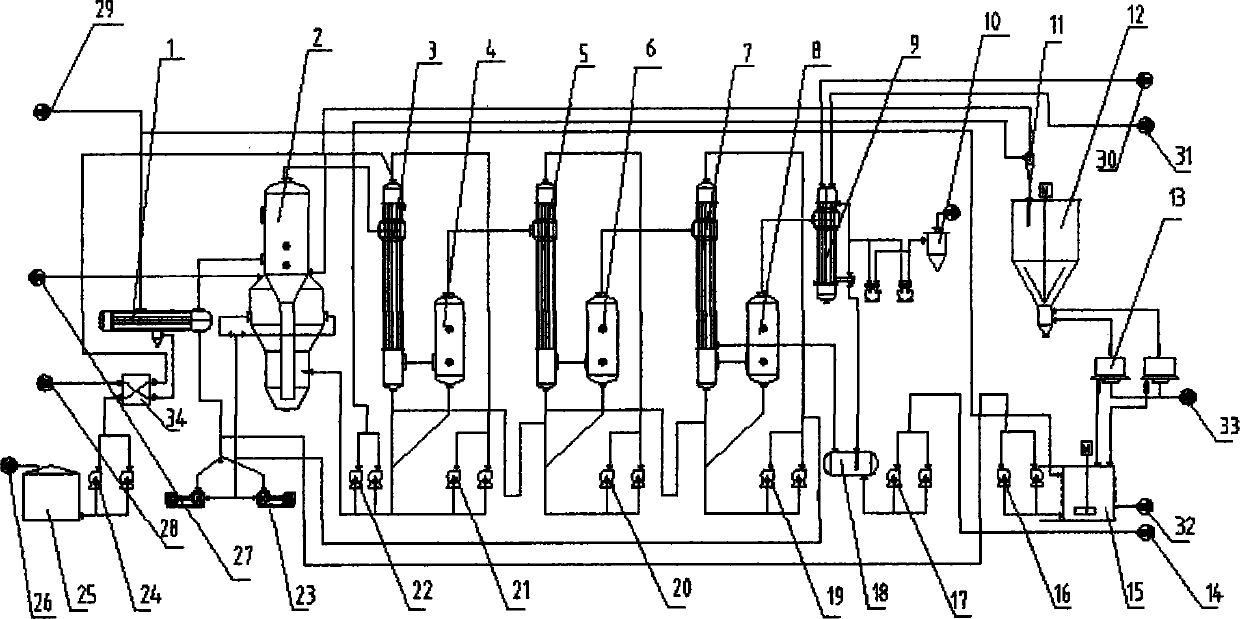

Pleietrepie counter current falling film evaporator of organic solvent recycle

InactiveCN101229449AControl circulation volumePromote circulationMultiple-effect evaporationSteam condensationGas phase

The invention provides a multiple effective reflux falling film evaporation system used for recycling organic solvent. The invention is mainly used for recycling the solvent in water solution of the organic solvent during the concentration production process of plant extractions in food industry and biopharmaceutical industry. The invention adopts falling film evaporators with high heat transmission coefficient and small terminal temperature difference to form the multiple effective evaporation system. Each evaporator is provided with a solution circulating pump which increases down-flow quantity in a heat transfer tube and avoids dry wall of a heat transfer surface and enhances heat transferring, thus having great evaporation ability and high efficiency. The condensate of each evaporator enters into a corresponding condensate tank respectively and is discharged by the pump and recycled. A gas-phase communicating pipe is arranged between the condensate tank and a gas-liquid separator, which guarantees the discharge of noncondensable gas under vacuum operation condition, thus being beneficial for improving condensing and heat transferring efficiency. The invention is a new technique, new technology and new device used in concentration process of the extractions of the organic solvent and used for recycling solvent, which has high recycling rate, little energy consumption and convenient operation and can use a vacuum low temperature evaporation concentration production device in continuous and intermittent production operation.

Owner:DALIAN UNIV OF TECH

High-salt high-concentration cellulose ether waste water treatment system

ActiveCN104829026ALow running costHigh solid contentMultistage water/sewage treatmentWater/sewage treatment by heatingHigh concentrationWater treatment system

The invention provides a high-salt high-concentration cellulose ether waste water treatment system and relates to the field of waste water treatment. The system is less in energy consumption and is high in waste water treatment efficiency. The high-salt high-concentration cellulose ether waste water treatment system includes, in a successively connecting manner, a first-effect falling-film evaporator, a second-effect falling-film evaporator and a third-effect forced circulating evaporator, wherein the first-effect falling-film evaporator performs first-effect evaporation on a waste water material being heated primarily to generate a concentrated liquid and a secondary steam; the second-effect falling-film evaporator, with the secondary steam as a heat source, continuously evaporates and concentrates the concentrated liquid to generate a concentrated liquid; and the concentrated liquid is fed into the third-effect forced circulating evaporator for being crystallized therein.

Owner:湖州展望天明药业有限公司

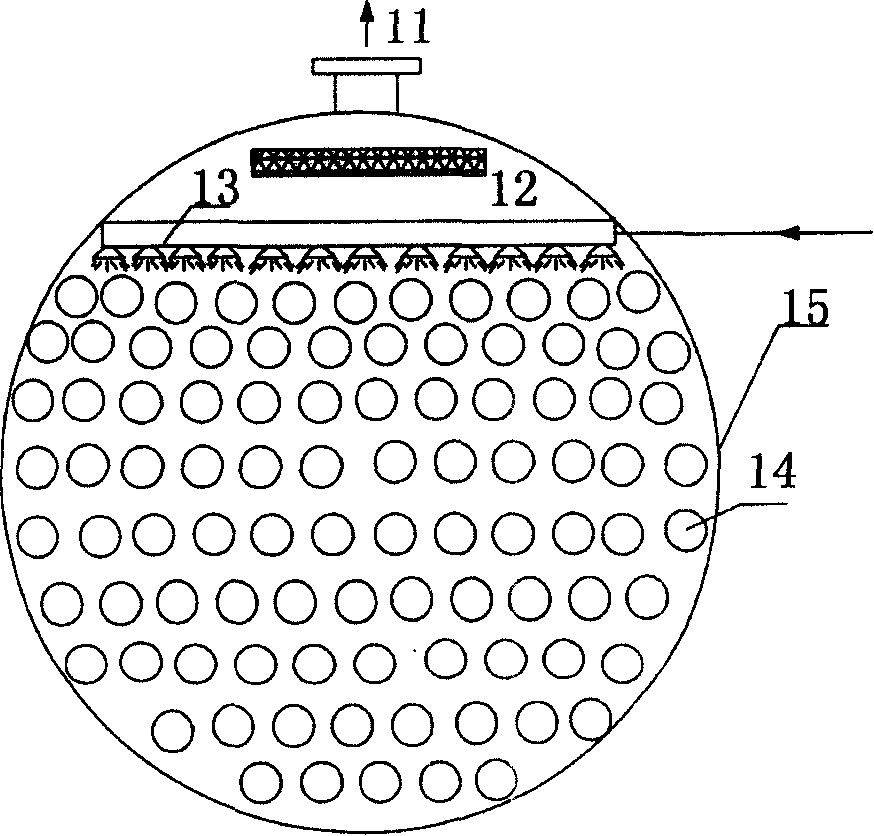

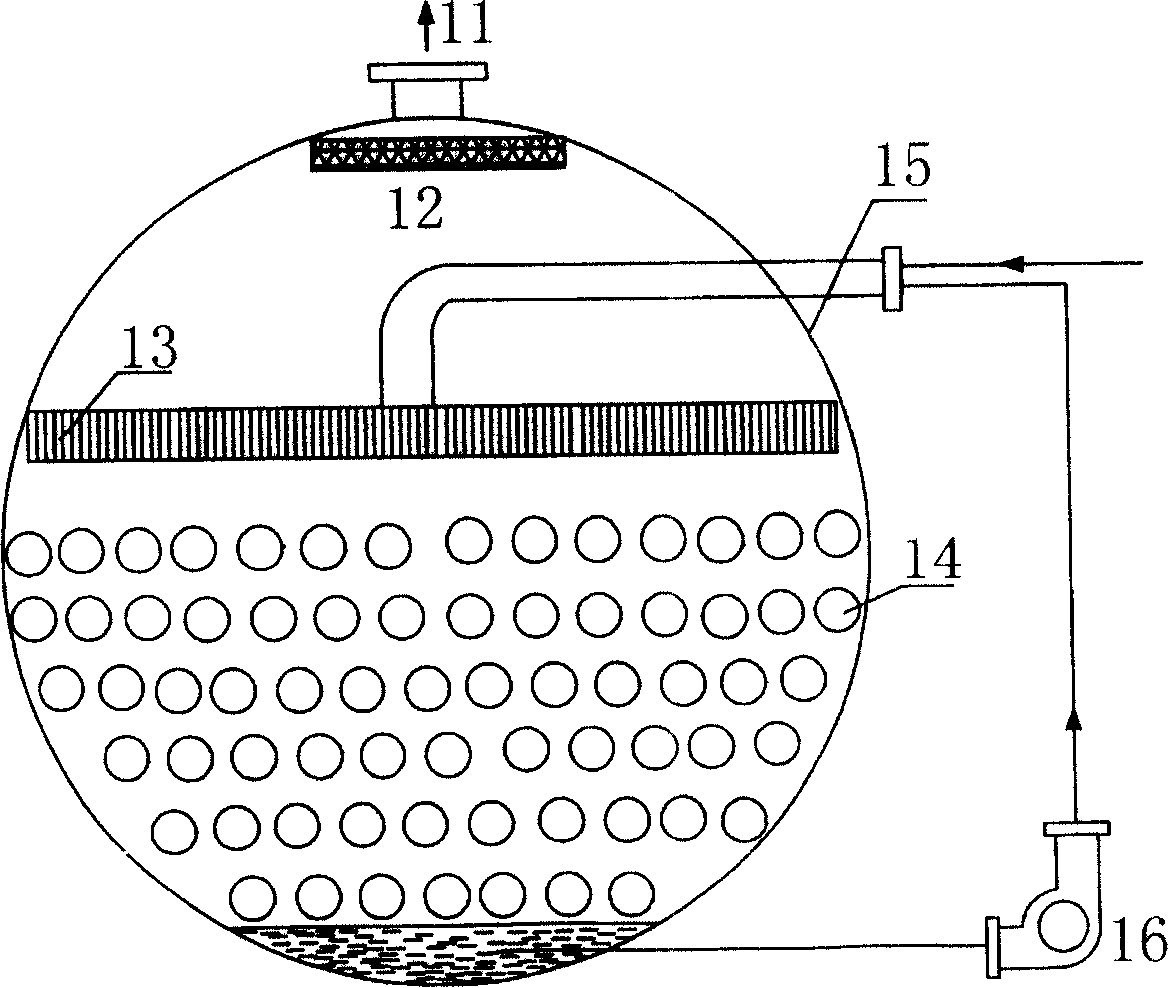

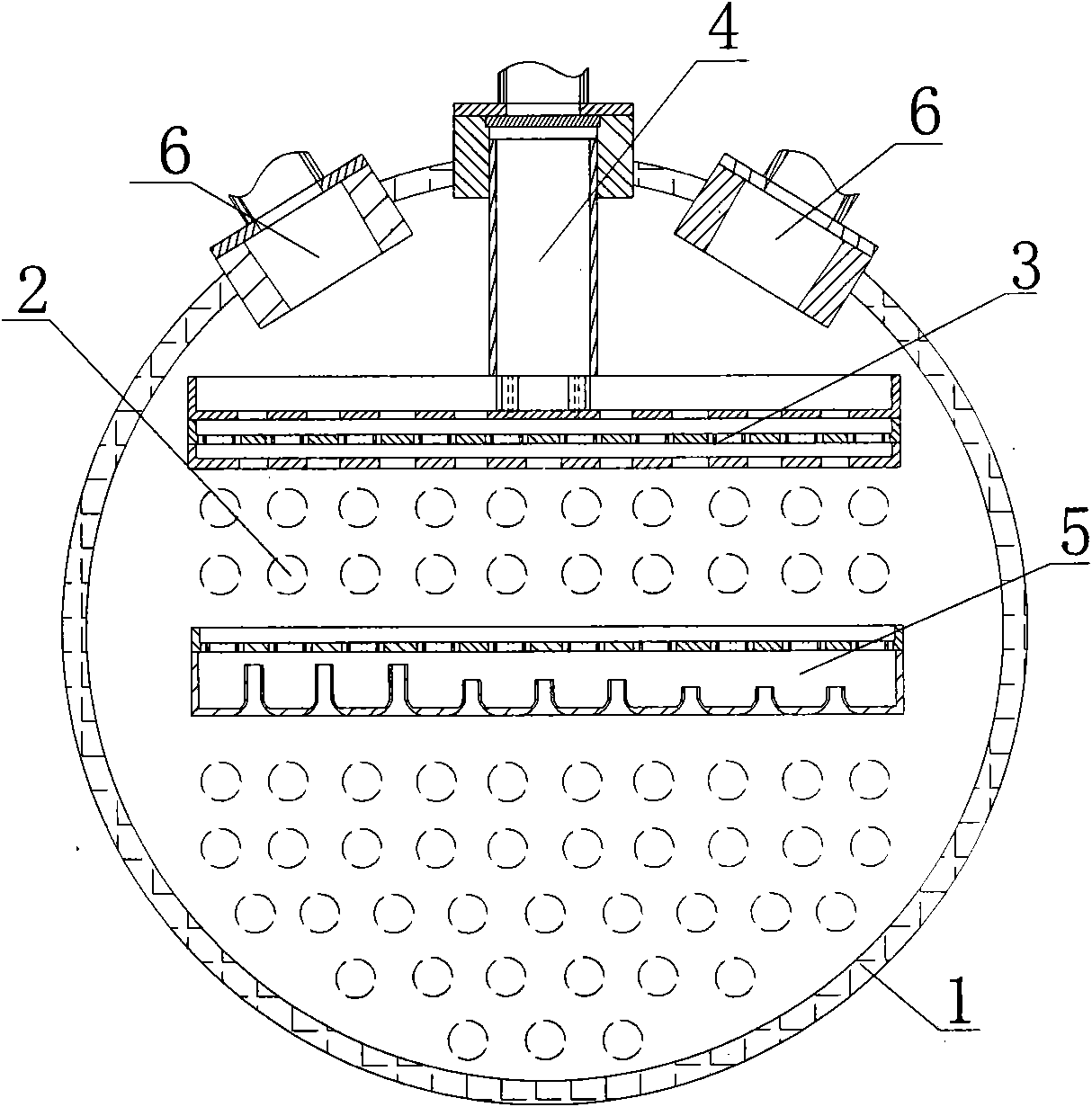

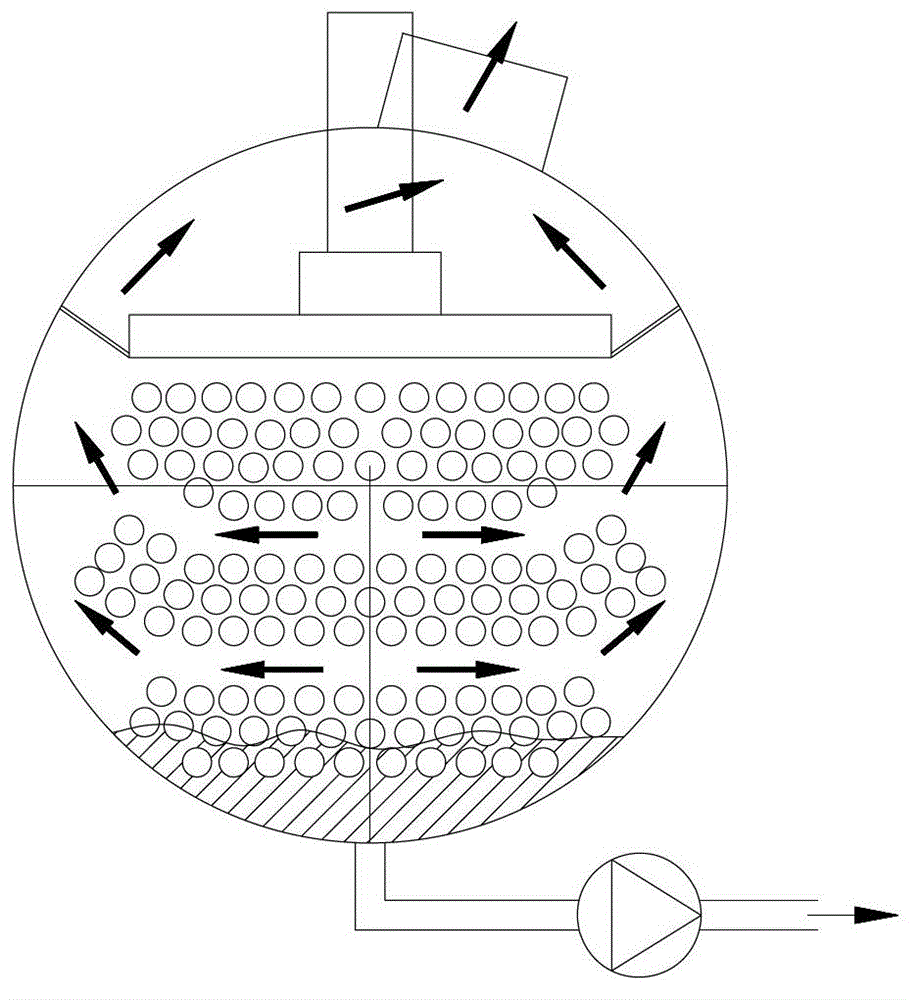

Falling film evaporator with gas-liquid separating and membrane-distributing functions

InactiveCN102000437AEvenly distributedAvoid heat transferEvaporator accessoriesEvaporators with horizontal tubesGas phaseEngineering

The invention discloses a falling film evaporator with gas-liquid separating and membrane-distributing functions, which comprises at least two layers of film distributors with a gas-liquid separation function, wherein the first layer of film distributor is connected with a refrigerant inlet pipe, the second layer of film distributor is positioned below the first layer of film distributor, and at least one group of exhaust pipes are arranged between the second layer of film distributor and the first layer of film distributor. The invention has the advantages that: at least two layers of film distributors are arranged in the horizontal pipe falling film evaporator, a refrigerant is firstly subjected to effective gas-liquid separation and uniformly distributed on the outer walls of the exhaust pipes in the evaporator, thus the influence on heat exchange due to the gas phase in the refrigerant can be avoided, phenomena of local aggregation and local dryness due to nonuniform distribution of the refrigerant in the exhaust pipes can be effectively avoided, the heat exchange efficiency is effectively increased, and the purpose of saving energy is achieved.

Owner:GUANGDONG UNIV OF TECH

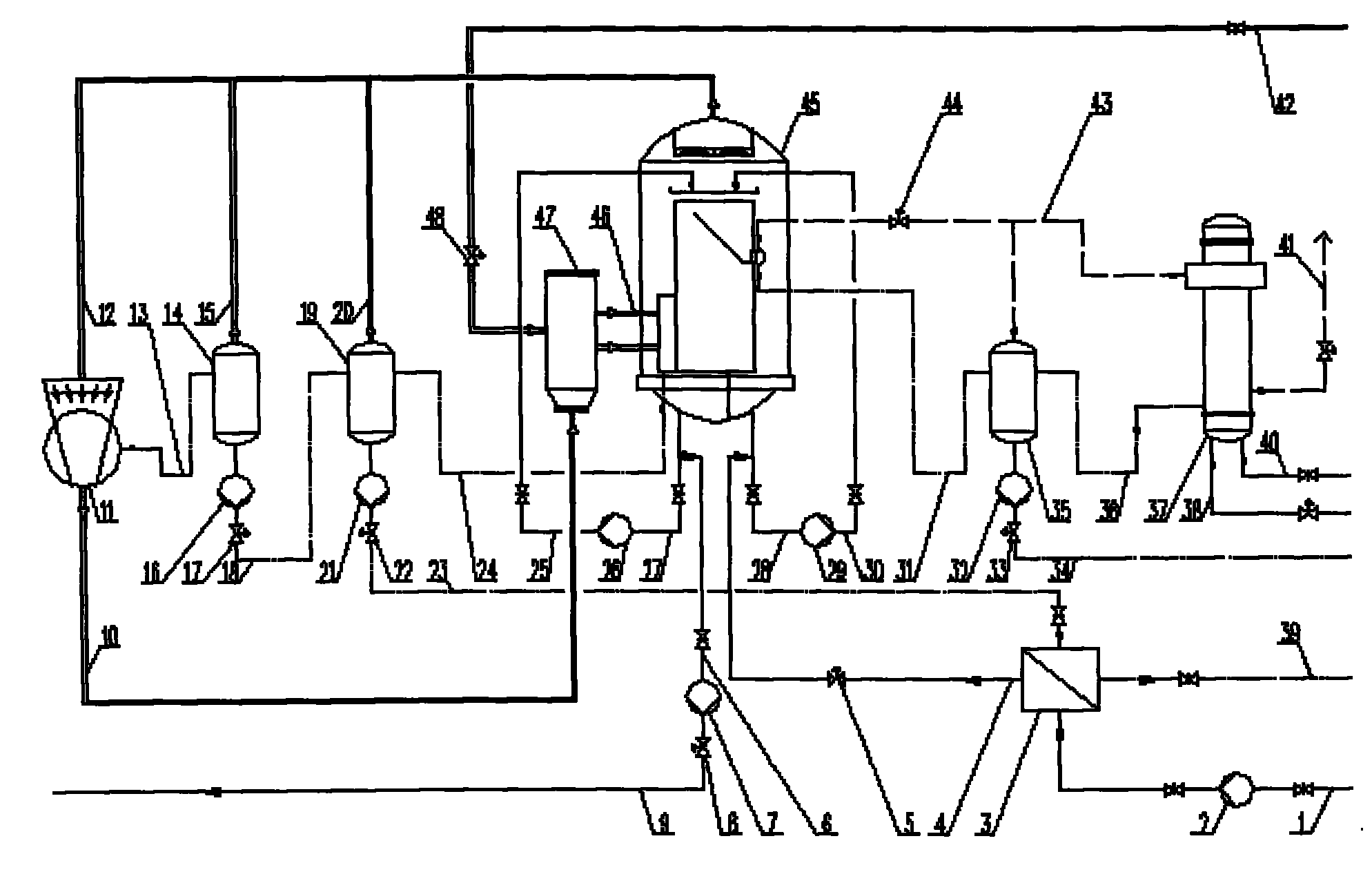

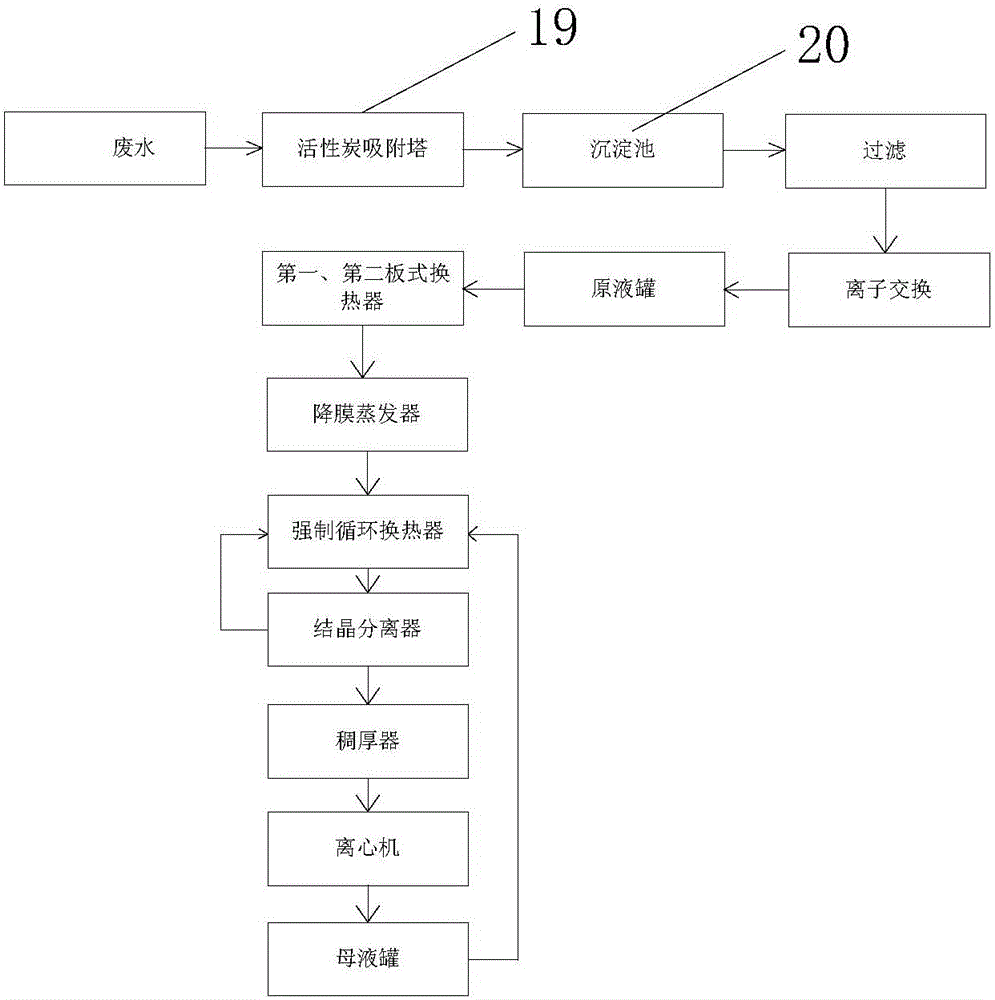

Treatment process and device of electroplating wastewater

ActiveCN105836951AExtended service lifeWater/sewage treatment by centrifugal separationSpecific water treatment objectivesTreatment effectCirculator pump

The invention relates to the technical field of sewage treatment equipment, in particular to a treatment process and device of electroplating wastewater. The treatment device comprises a stock solution tank, a feeding pump, a first plate heat exchanger, a second plate heat exchanger, a falling film evaporator, a falling film separator, a forced circulation heat exchanger, a crystallization segregator, a discharging pump, a thickener, a centrifuge and a mother liquor tank which are successively communicated, wherein the falling film separator and the top end of the crystallization segregator are communicated with the falling film evaporator through a centrifugal compressor; the falling film evaporator and the forced circulation heat exchanger are further communicated with a distilled water tank, and the distilled water tank is communicated with the first plate heat exchanger through a distilled water pump; the falling film separator, the falling film evaporator and the crystallization separator are all communicated with the input end of a forced circulation pump, and the output end of the forced circulation pump is communicated with the forced circulation heat exchanger. Therefore, the treatment process and device disclosed by the invention are low in production cost, and high in treatment effect.

Owner:JIANGSU RUISHENGHUA ENERGY TECH CO LTD

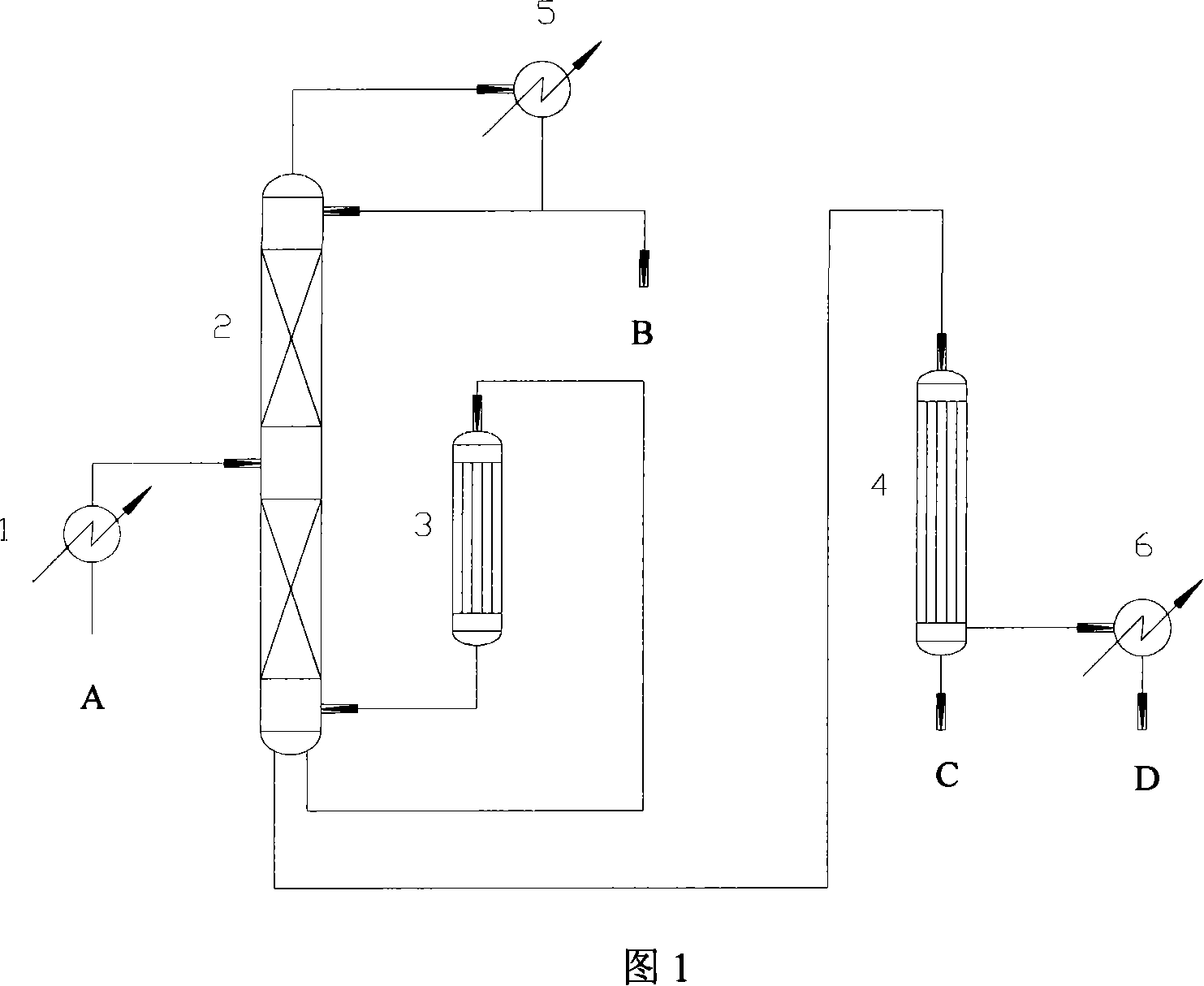

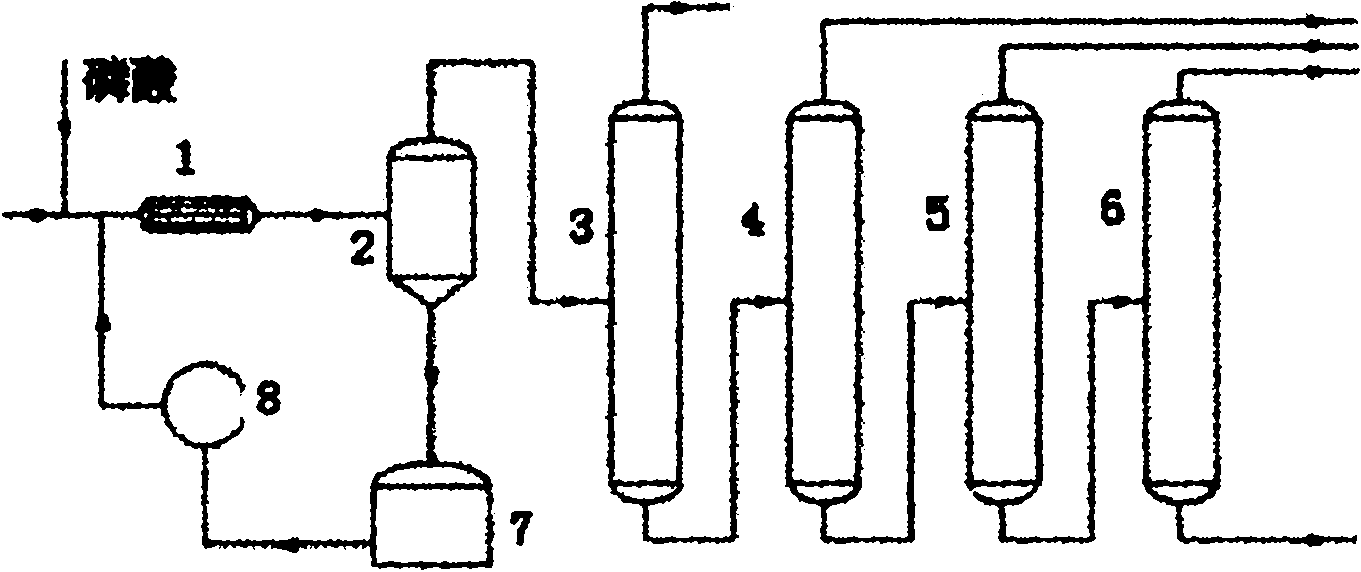

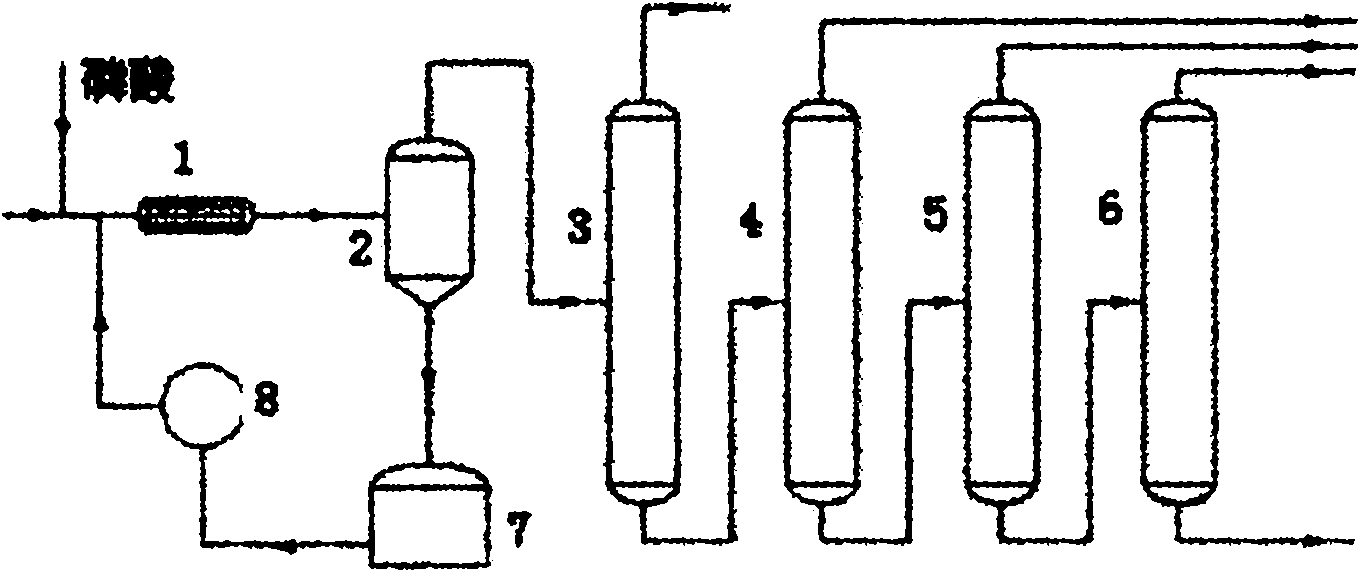

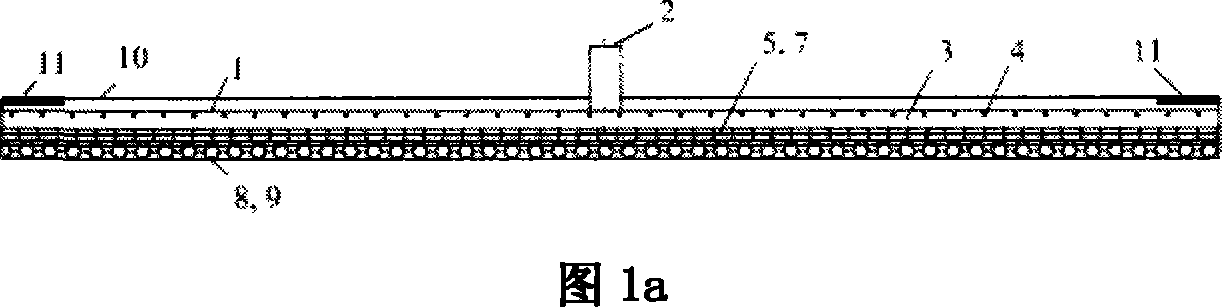

Method and device for recovering polyethylene glycol raffinate byproduct from ethylene glycol process

InactiveCN102010294AImprove film formationReduce corrosionEther separation/purificationMultistage water/sewage treatmentAlcoholPolyethylene glycol

The invention relates to a method and a device for recovering a polyethylene glycol raffinate byproduct form an ethylene glycol process. The method comprises the following steps of: (1) adding phosphoric acid into the polyethylene glycol raffinate, controlling the pH value to be between 7 and 9, conveying the mixture to a preheater (1), and preheating; (2) allowing a preheated material to enter a scraper falling-film evaporator (2), discharging a material at the bottom of the evaporator into an intermediate tank (3), and allowing the material to enter the preheater (1) through a centrifugal separator (8); (3) conveying the mixture of water and alcohol on the top of the falling-film evaporator to a dehydration rectifying tower (3); (4) conveying a mixed alcohol material at the bottom of the tower to an ethylene glycol separating tower (4); (5) conveying the material at the bottom of the tower to a diethylene glycol separating tower (5); and (6) conveying the material at the bottom to a triethylene glycol separating tower (6), and collecting products on the top and bottom of the tower respectively. The method is simple, efficient and low in energy consumption, and is suitable for industrial application; and by the method, the utilization rate of the raffinate produced by ethylene glycol is improved.

Owner:NINGBO POLYTECHNIC +1

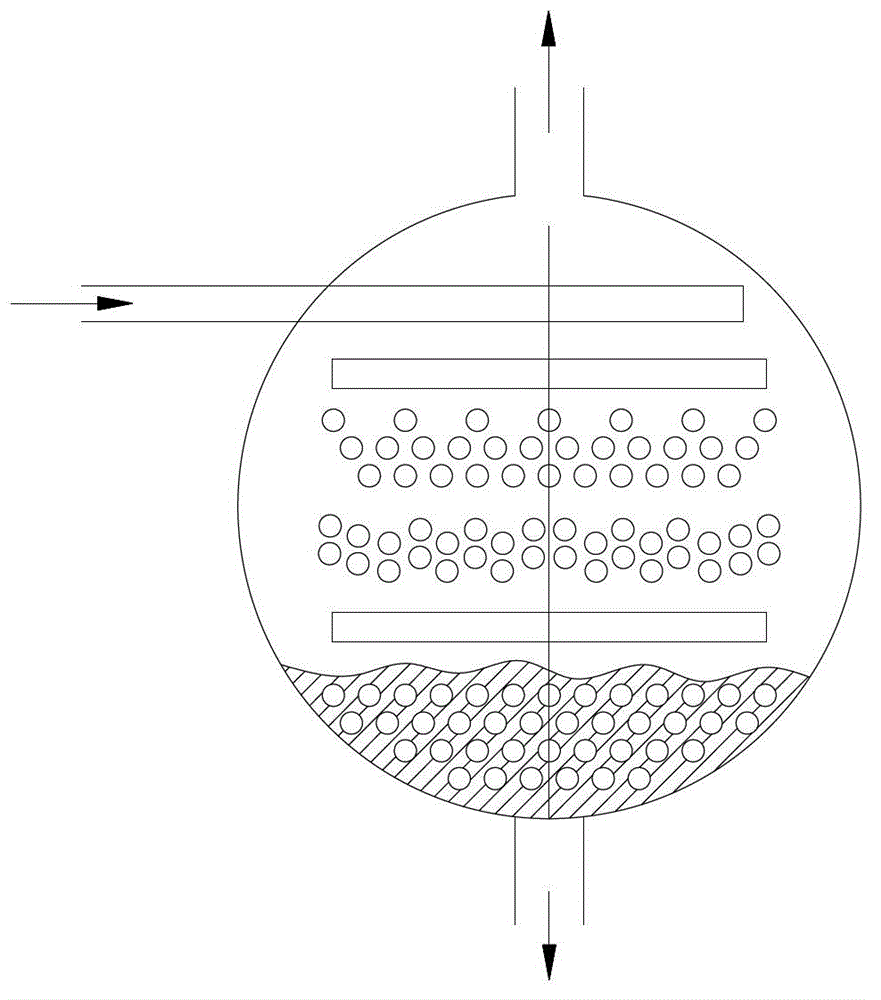

Full-falling-film evaporator and water chilling unit

The invention provides a full-falling-film evaporator and a water chilling unit, being applicable to the technical field of refrigeration air conditioners. The full-falling-film evaporator comprises an evaporator shell formed by an evaporator barrel and a tube sheet, wherein the evaporator shell is internally provided with a plurality of falling-film evaporating pipes, pipe bundles formed by the plurality of falling-film evaporating pipes are supported by at least one pipe support plate, at least two distributing plates are arranged between the pipe bundles, the distributing plates divide the pipe bundles into a plurality of pipe bundle layers, a gas-liquid two-phase distributor is arranged between the pipe bundle layer at the uppermost layer and the barrel, the top of the barrel is provided with a gas-liquid two-phase refrigerating medium inlet pipe and a gaseous refrigerating medium air-return pipe, and the bottom of the barrel is provided with at least one refrigeration oil return pipe. According to the full-falling-film evaporator and the water chilling unit which are disclosed by the invention, the full-falling-film evaporation is truly achieved, the heat transfer coefficient is enhanced, and the refrigerant charge is reduced, therefore the purpose of energy saving and environmental protection are achieved.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP

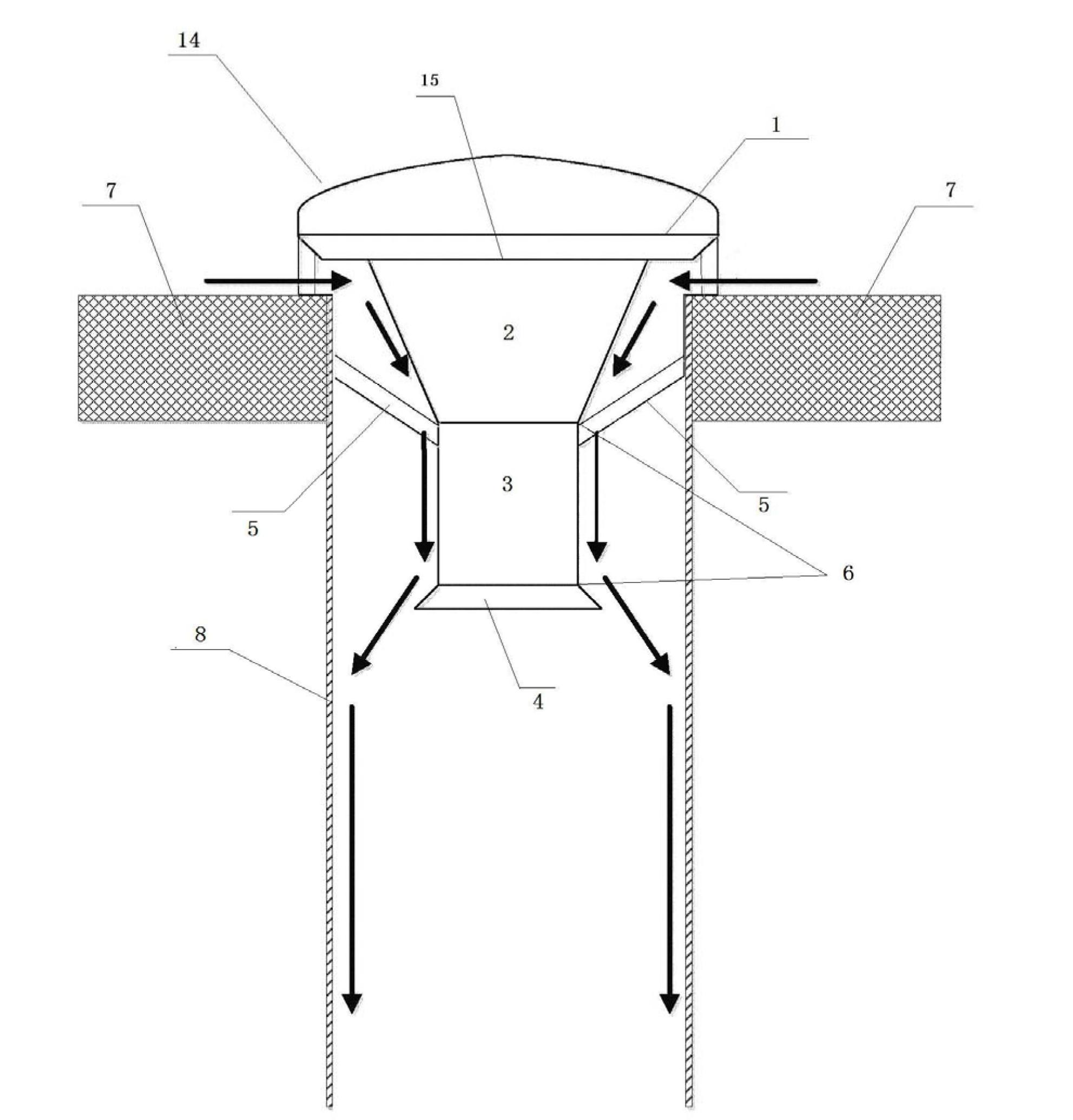

Liquid distributor and vertical tube falling film evaporator comprising same

ActiveCN102657948AReduce areaReduce depositionEvaporator accessoriesEvaporators with vertical tubesVertical tubeEngineering

The invention discloses a liquid distributor and a vertical tube falling film evaporator comprising the same. The liquid distributor mainly comprises a flow-guiding body and a support component, wherein the surrounding of a main body of the flow-guiding body is a concave surface, and the basal area of a top cover of the flow-guiding body is larger than the area of a tube mouth of a heat exchange tube of the vertical tube falling film evaporator; and the flow-guiding body is movably or fixedly supported in a corresponding position of the upper part in the heat exchange tube of the vertical tube falling film evaporator through the support component, so that a certain gap exists between the undersurface edge of the top cover of the flow-guiding body and the upper surface of a tube plate of the vertical tube falling film evaporator to form an intake channel. The vertical tube falling film evaporator comprises the liquid distributor. According to the structure of the flow-guiding body of the liquid distributor, on one hand, the area of a low-speed liquid area is reduced, therefore the deposition of suspended solids can be reduced; and on the other hand, the inner wall of the heat exchange tube forms smooth liquid flow with few bubbles and a uniform liquid film is easier to form.

Owner:JIANGSU SUNPOWER TECH

Multi effect distiller with falling film evaporator and condenser cells

InactiveUS20120055776A1General water supply conservationSeawater treatmentVertical planeDistillation

Multi Effect Distiller (MED) with vertical flat-plate, falling-film heat transfer mechanism. A multitude of alternatively arranged or “checkered”, rectangular shaped evaporator and condenser cells form one layer between two vertical flat plate walls. Multitude of layers—each comprised of alternating evaporator and condenser cells—form the block-shaped MED unit. The evaporator and condenser cells are against each other, sharing common vertical heat transfer walls. The simultaneous propagation of multi effect distillation occurs in two dimensions along the longitudinal vertical plane of the heat exchanger. One end of the distiller is heated, while the other end is cooled.

Owner:FEHER PETER

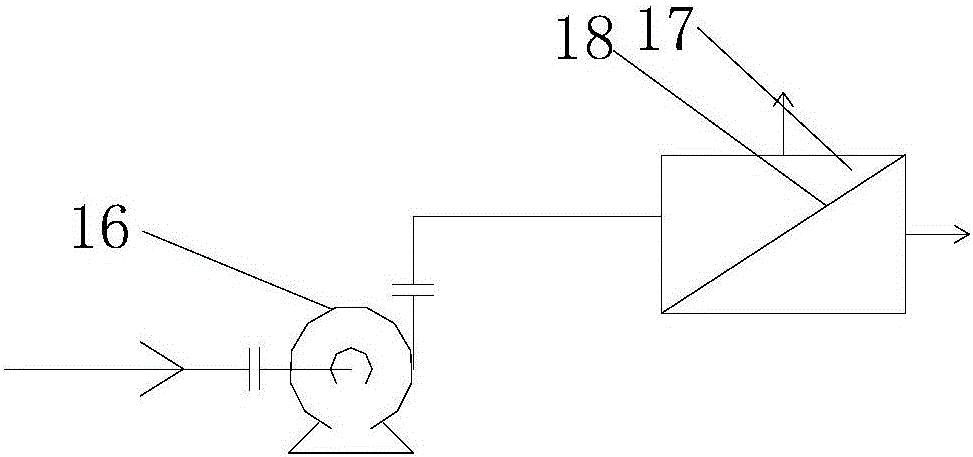

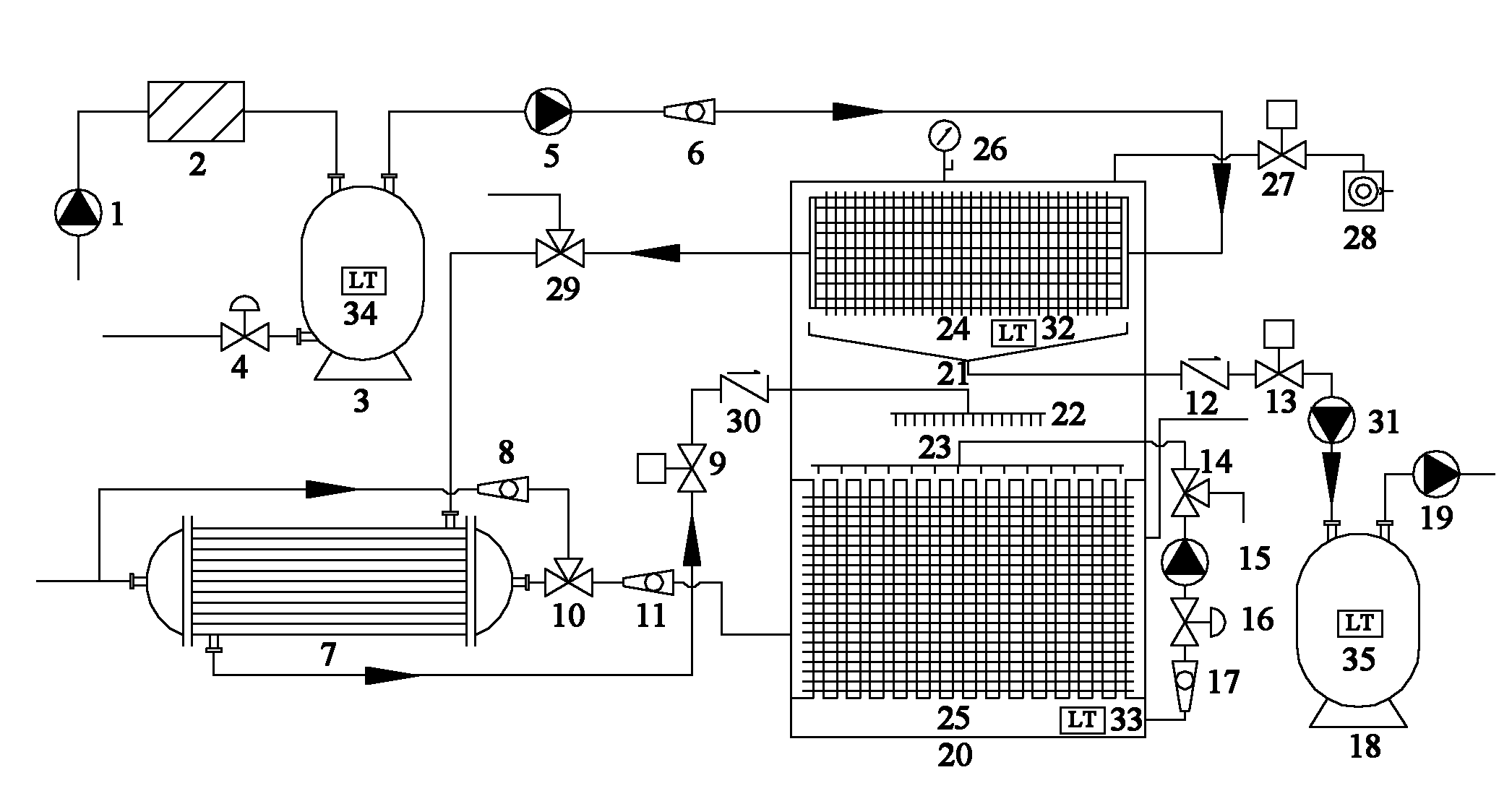

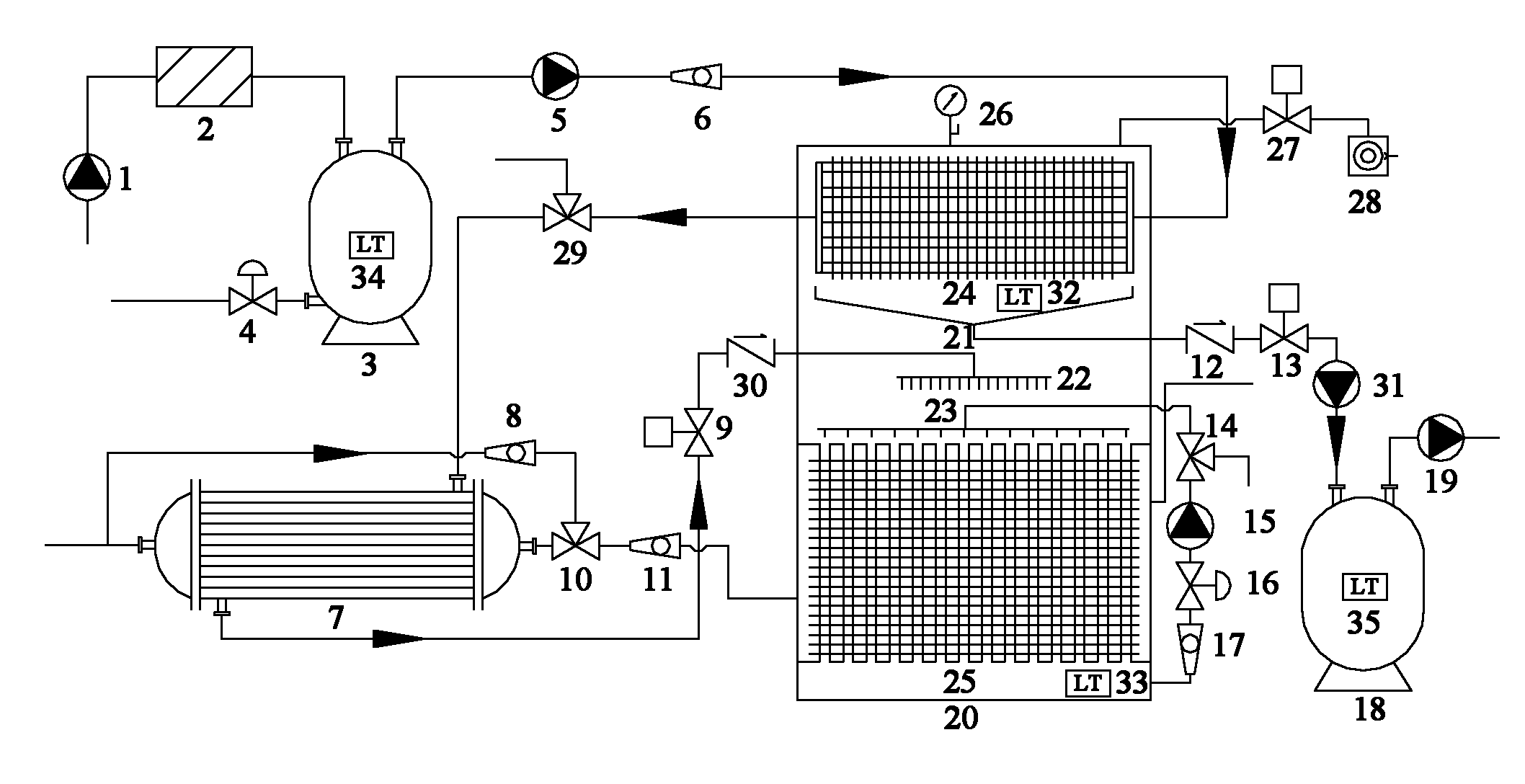

Device for desalinating seawater by utilizing residual heat of tail gas exhausted by diesel engine

InactiveCN102092808AStable temperatureStabilize Freshwater ProductionGeneral water supply conservationSeawater treatmentControllabilityDiesel engine

The invention relates to an efficient seawater desalinization device for a ship, in particular to a device for desalinating seawater by utilizing the residual heat of tail gas exhausted by a diesel engine. The seawater is sequentially fed into a seawater pretreatment filter (2) and a seawater storage tank (3) by a No.1 pump (1), and is introduced into a condenser (24) in a desalinator (20) by a No.2 pump (5); a horizontal shell and tube heat exchanger (7) is switched on; the flue gas inlet end and the flue gas outlet end of the heat exchanger (7) are connected with each other through a No.1 three-way valve (10); a falling film evaporator (25) in the desalinator (20) is switched on; the seawater outlet of the heat exchanger (7) is communicated to the desalinator (20) through a one-way valve (30); a spraying device (22) is used for spraying; the falling film evaporator (25) is arranged at the bottom of the spraying device (22); seawater accumulated at the bottom of the desalinator (20) is pumped into a heat exchange tube of which the upper part is connected to a seawater film forming device (23) by a circulating pump (15); high temperature flue gas flows outside the heat exchange tube; and a fresh water accumulating disk (21) on the lower part of the condenser (24) is communicated to a fresh water storage tank (18) through a No.5 pump (31). The residual heat of the flue gas is utilized and the emission of pollutants is reduced; and the device has the characteristics of simple structure, high controllability, energy conservation, environmental friendliness, high efficiency and the like.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Refrigerant distributor of compression refrigeration falling-film evaporator

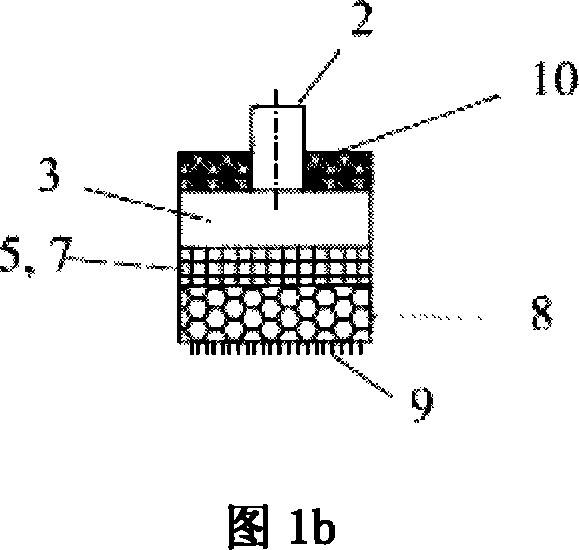

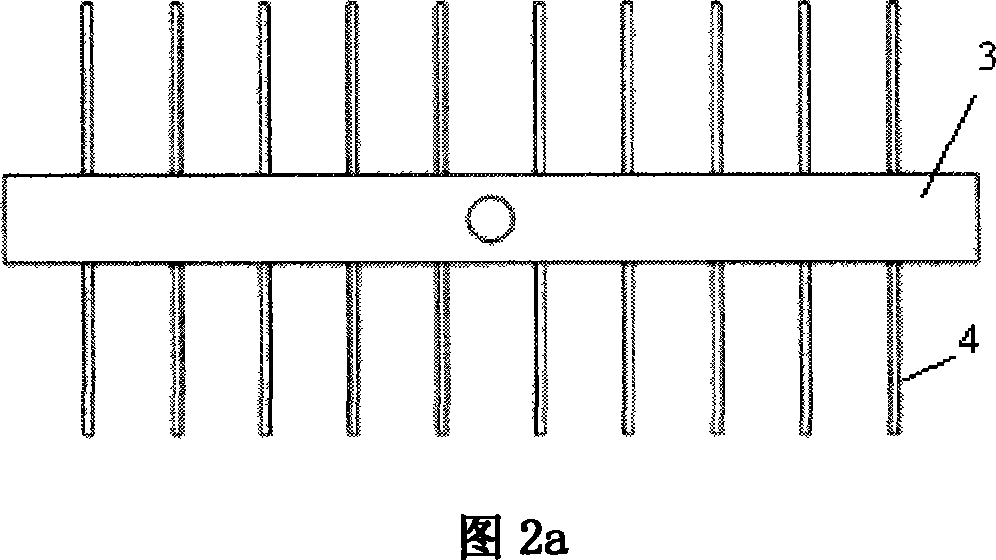

InactiveCN101050899AReduce chargeReduce in quantityEvaporators/condensersRefrigerant distributionVapor–liquid separator

A refrigerant distributor of evaporator in compression-refrigeration falling film type is prepared for connecting refrigerant inlet to refrigerant longitudinal tensile distribution tube being connected with refrigerant horizontal tensile capillary tube, setting a row of small holes at bottom of each said capillary tube, setting porous material layer under said distribution tube and said capillary tube, arranging steel plate mesh under porous material layer and porous plate under steel plate mesh then arranging a flow guide silk screen under porous plate.

Owner:SHANGHAI JIAO TONG UNIV +1

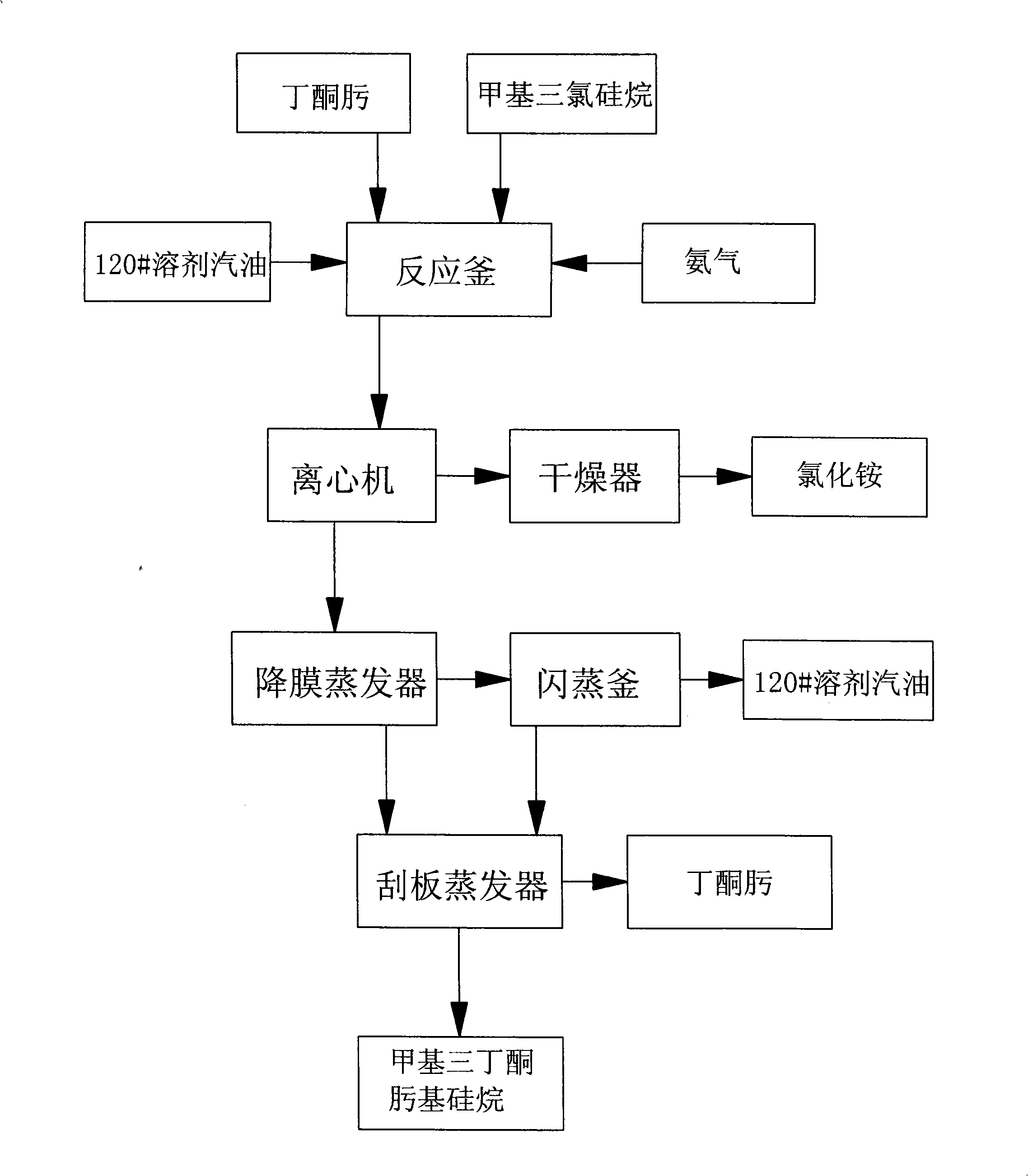

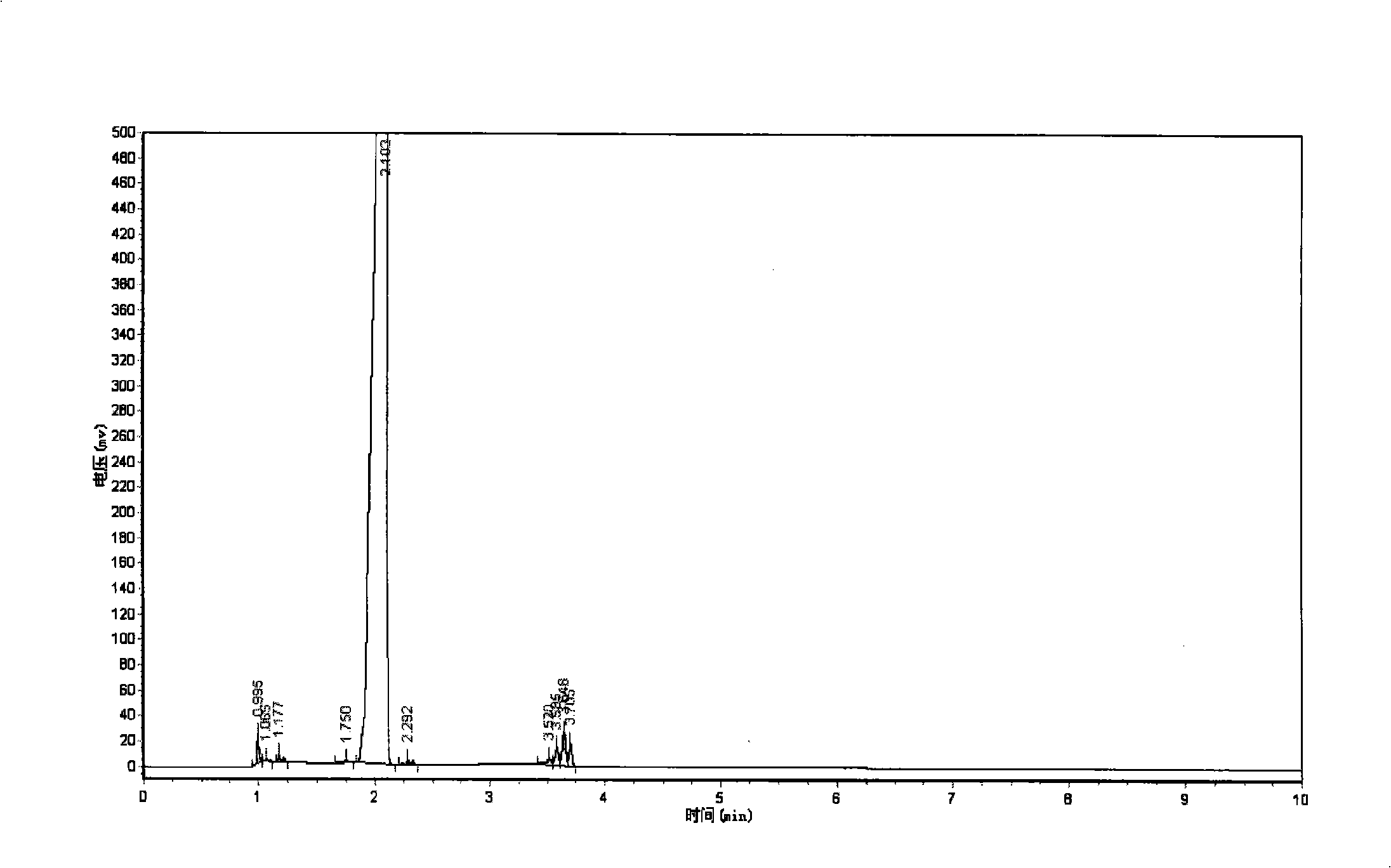

Preparation of methyl tributanoximo silane

ActiveCN101348498AImprove solubilityGood volatilization effectGroup 4/14 element organic compoundsSilanesDistillation

The invention provides a method for preparing methyltris(methylethylketoxime)silane. The method comprises the following steps that: a. methyl trichlorosilane, butanone oxime, alkaline air and 120#solvent naphtha are simultaneously pumped in a reaction kettle by a measuring pump and reacted for 30m under the normal pressure and at a temperature of between 35 to 40 DEG C, and reactants are picked up and filtered by a centrifuge so as to obtain a filtrate and ammonium chloride deposit; b. the filtrate passes through a falling-film evaporator to distill off 120#solvent naphtha, and the coarse product of methyltris(methylethylketoxime)silane is obtained; c. the coarse product of methyltris(methylethylketoxime)silane is put in a scraper evaporator for distillation, the remained butanone oxime is distilled off, and the refined product is obtained. The process of the invention has the characteristics of big productivity, low energy consumption, simple control and greenness and environmental protection, etc.; moreover, the product yield is 95 percent, the effective content of the product is high, and the content of methyltris(methylethylketoxime)silane is more than 96 percent.

Owner:湖北新蓝天新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com