Treatment process and device of electroplating wastewater

A technology for electroplating wastewater and treatment process, which is applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment and other directions, which can solve the problems of inability to remove salt in water, high investment and unstable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

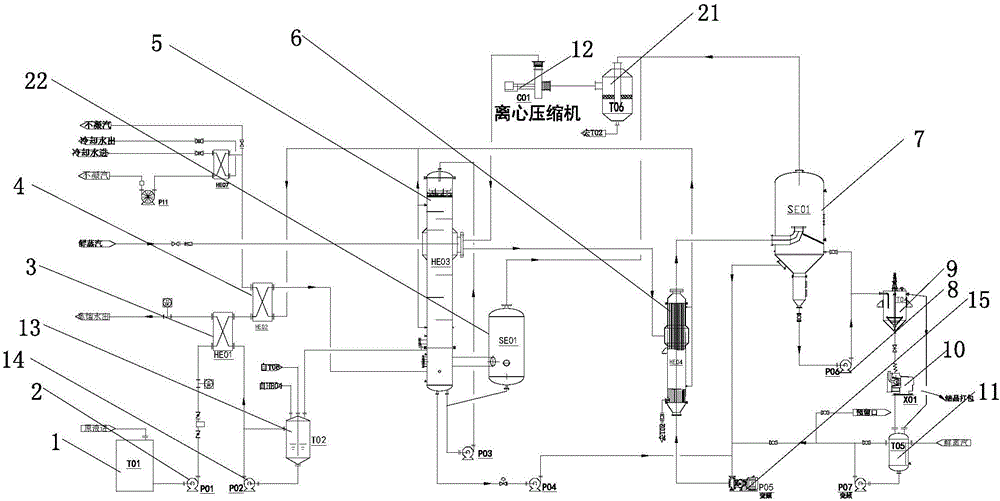

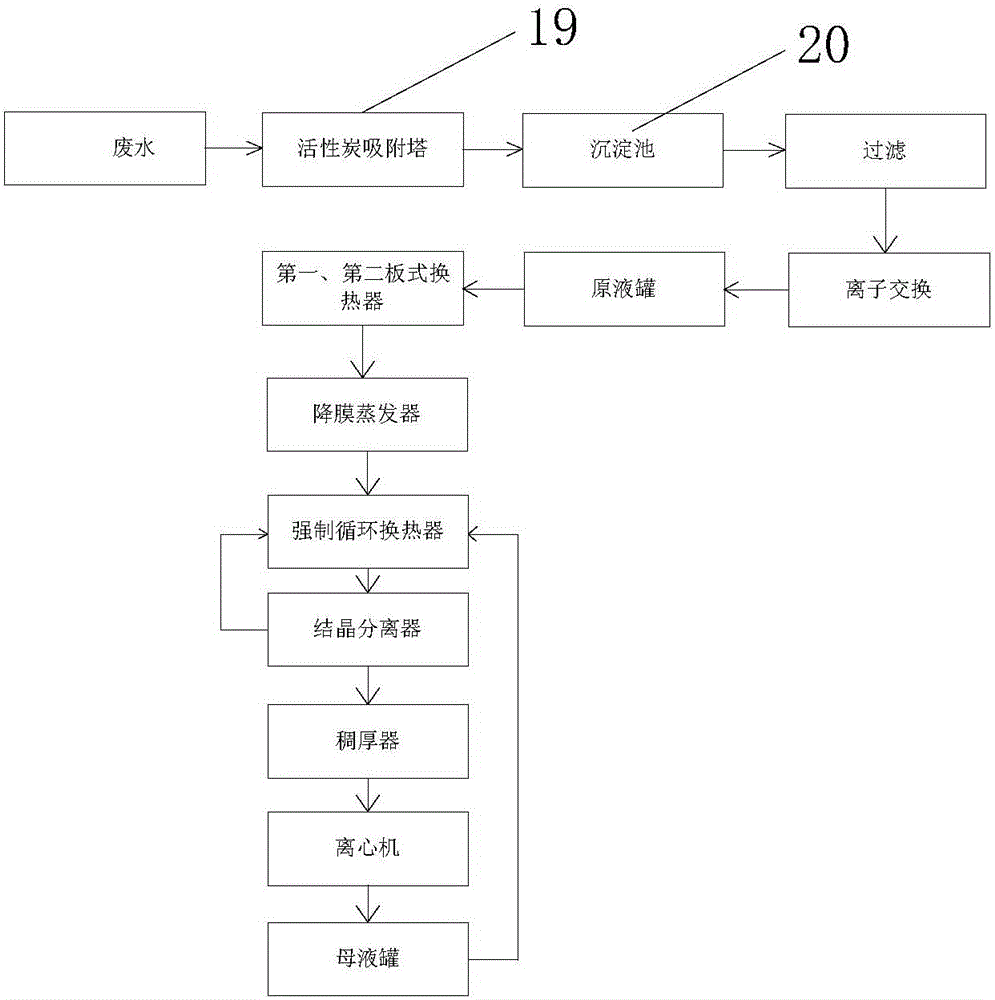

[0030] A kind of electroplating wastewater treatment process, is characterized in that, comprises the following steps:

[0031] Step 1: The original solution passes through the activated carbon adsorption tower to reduce COD and remove Cr 6+ ;

[0032] Step 2: The raw liquid passing through the activated carbon adsorption tower flows into the sedimentation tank, and chemical agents are added to remove cyanide and chromium;

[0033] Step 3: filtering the precipitated stock solution;

[0034] Step 4: Perform ion exchange on the filtered wastewater, and store the ion-exchanged material in the stock solution tank;

[0035] Step 5: The material in the raw liquid tank is driven into the first and second plate heat exchangers by the feed pump for heat exchange;

[0036] Step 6: After heat exchange, the material reaches the evaporation temperature and is put into the falling film evaporator for evaporation and concentration;

[0037] Step 7: After evaporation and concentration, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com