Patents

Literature

6196 results about "Liquid tank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A liquid tank can contain one of any of 26 liquids at one time (i.e. liquids cannot be mixed in a tank). The liquids are Water, Lava, Milk, Mushroom Soup, Rabbit Stew, Experience and all the potions and tier two potions.

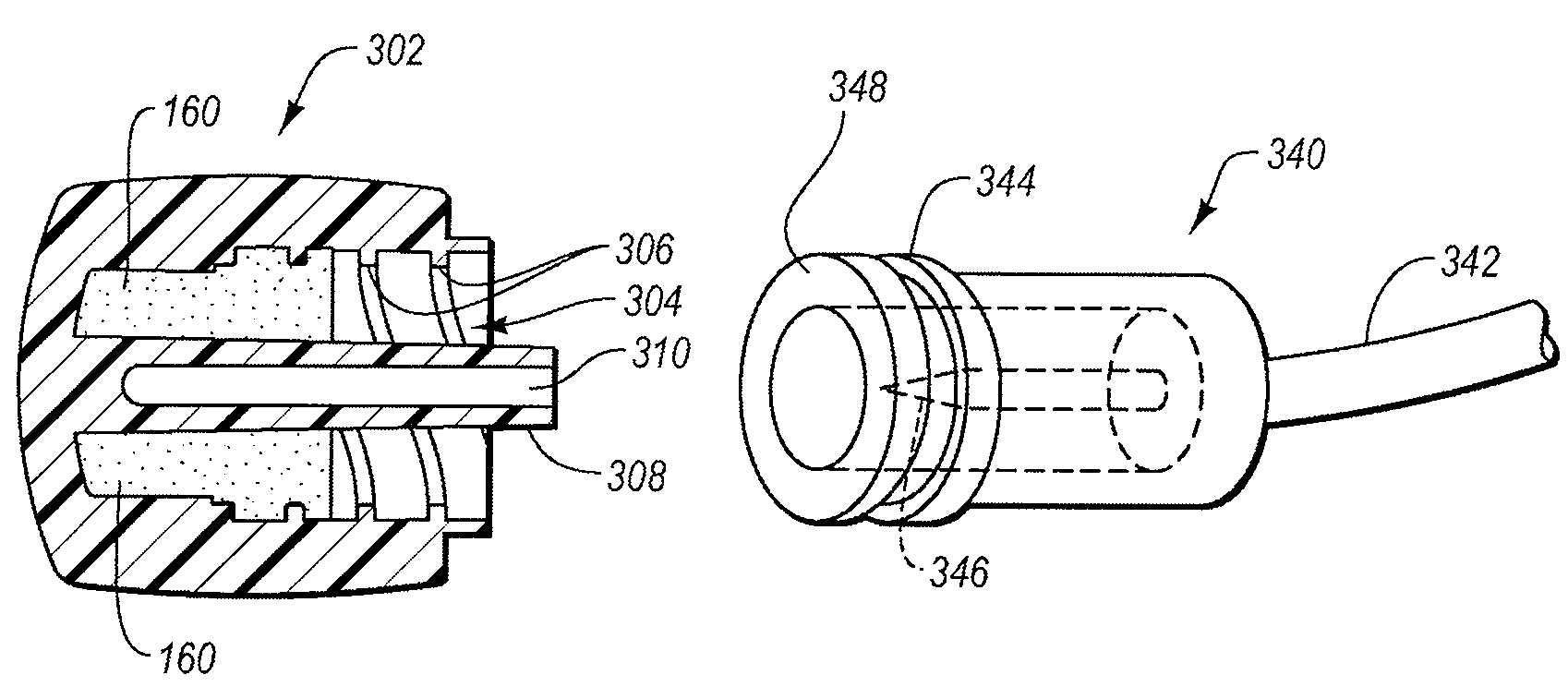

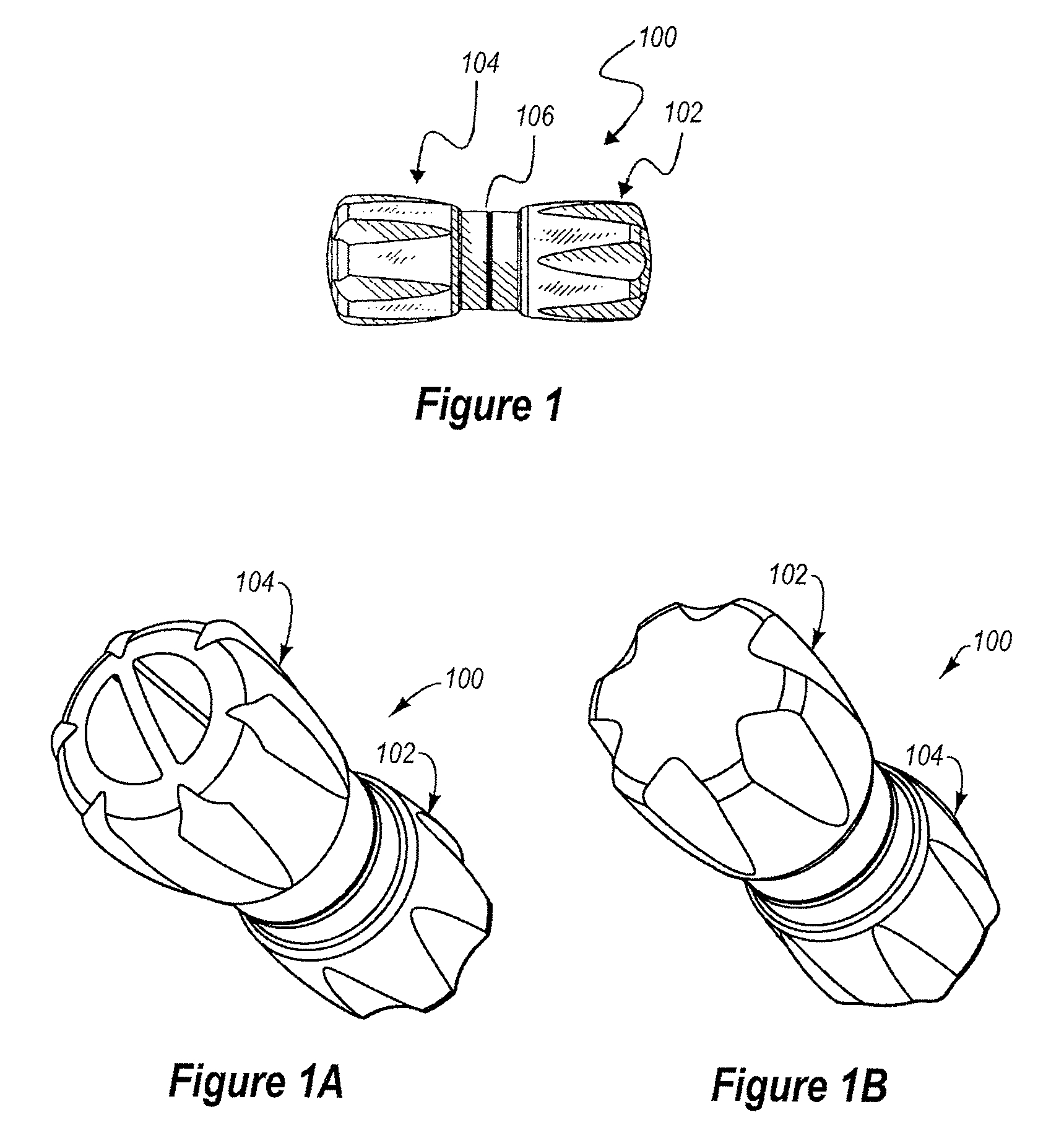

Sterility-protecting caps with fluid reservoir for separated connectors

A pair of nestable caps are disclosed, each of the caps being sized and shaped to provide a protective union about a separated medical connector. The pair comprises a male cap and a female cap, each of which is configured to be adjoined to a complimentary cap to form a nested pair. The nested pair is sealed until separated for use, thereby maintaining sterility of the internal surfaces of the nested pair. One of the caps may have a fluid chamber joined thereto filled with medicine or antiseptic. The cap can have a channel extending therethrough to provide fluid communication between the fluid chamber and a fluid pathway. The fluid chamber can be adapted to diffuse the fluid into the fluid pathway over time, or the fluid chamber can be adapted to dispense the fluid out of the fluid chamber without reflux.

Owner:MERIT MEDICAL SYST INC

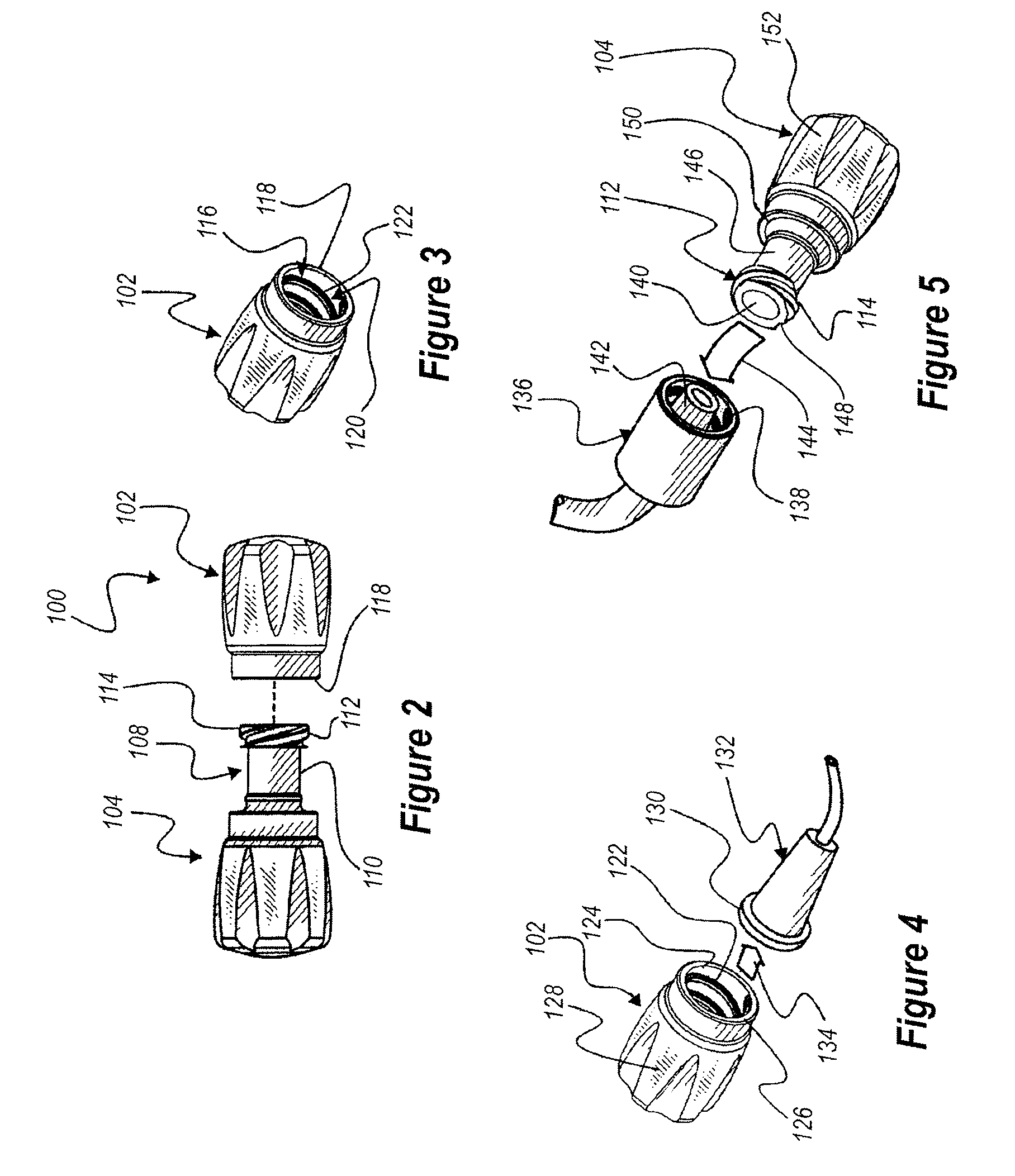

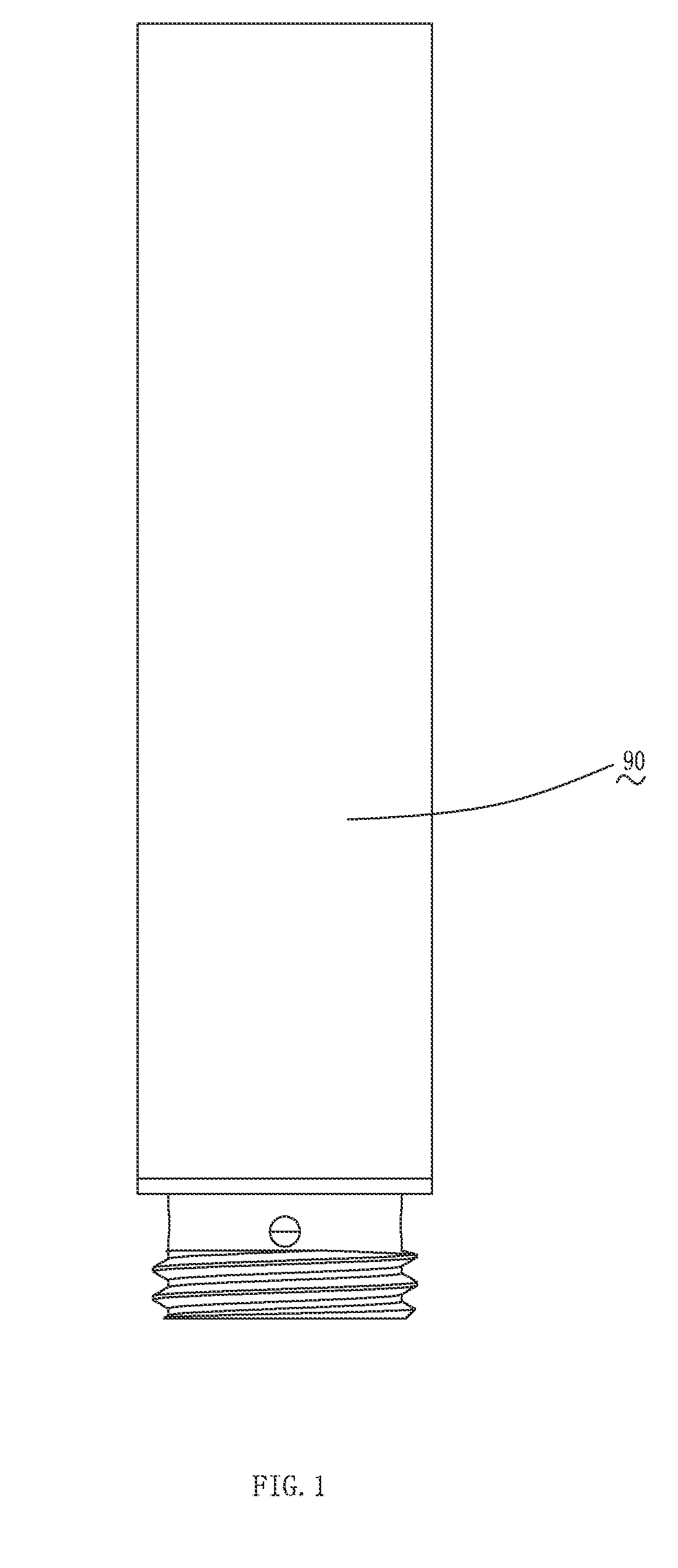

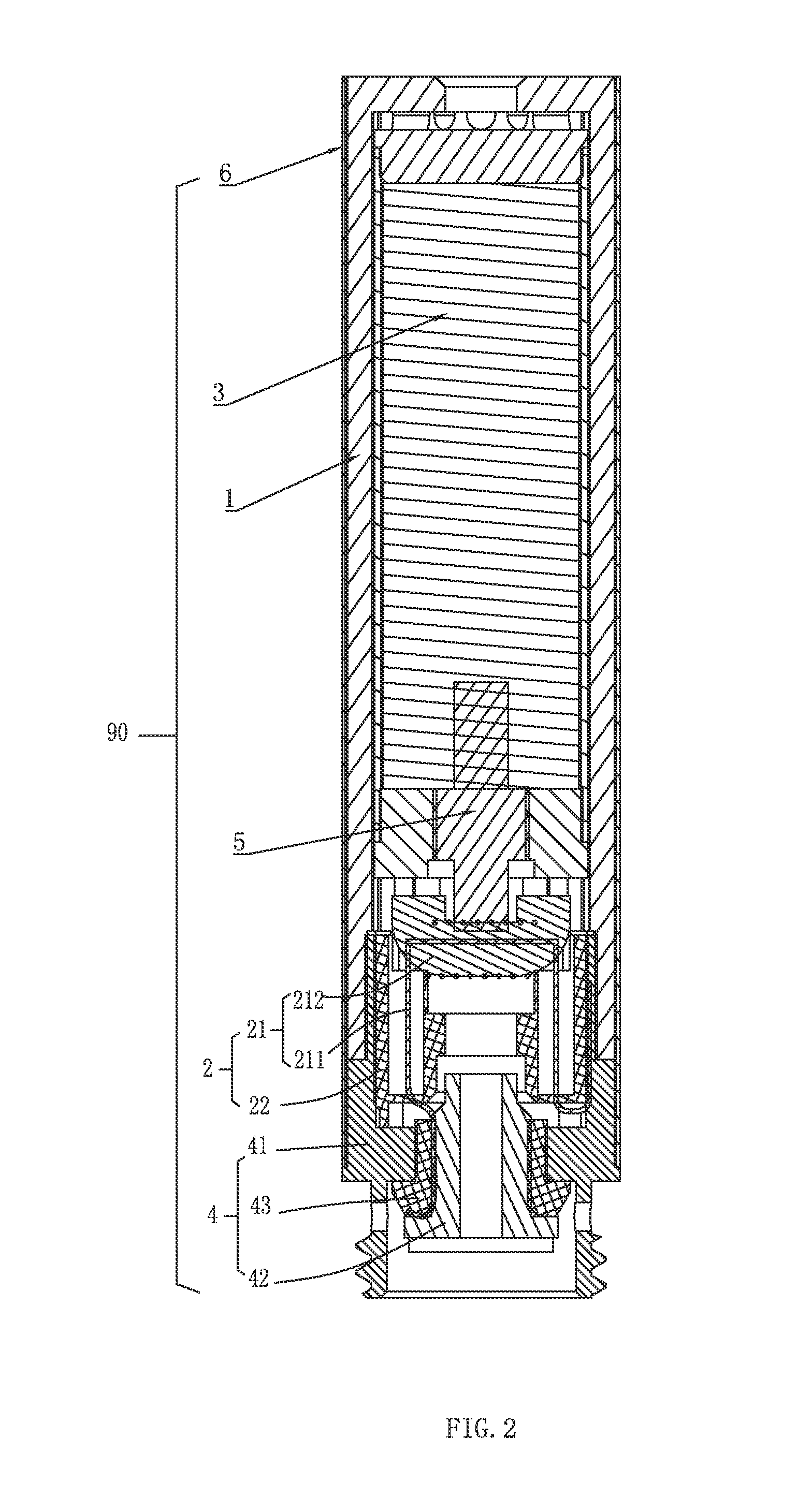

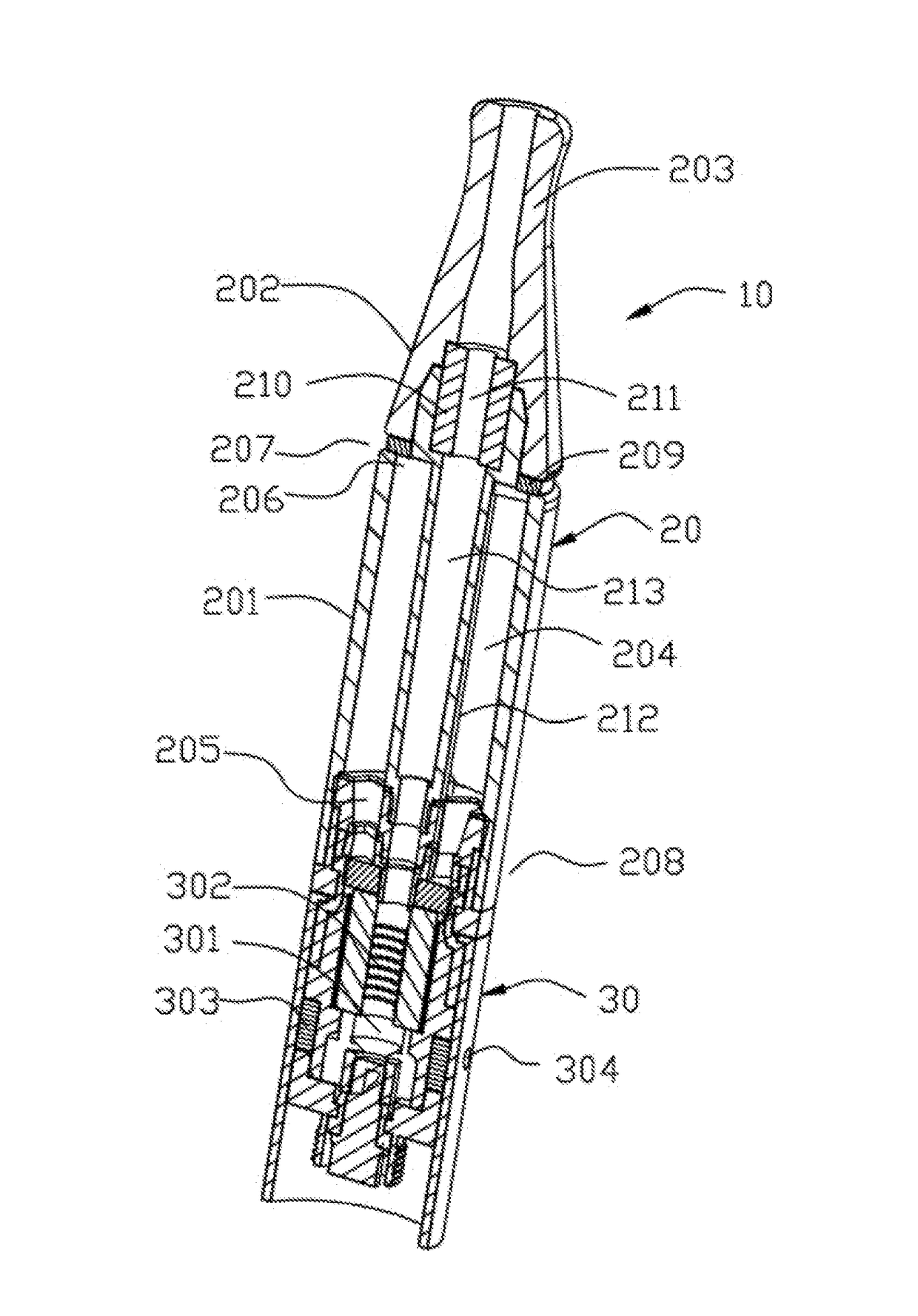

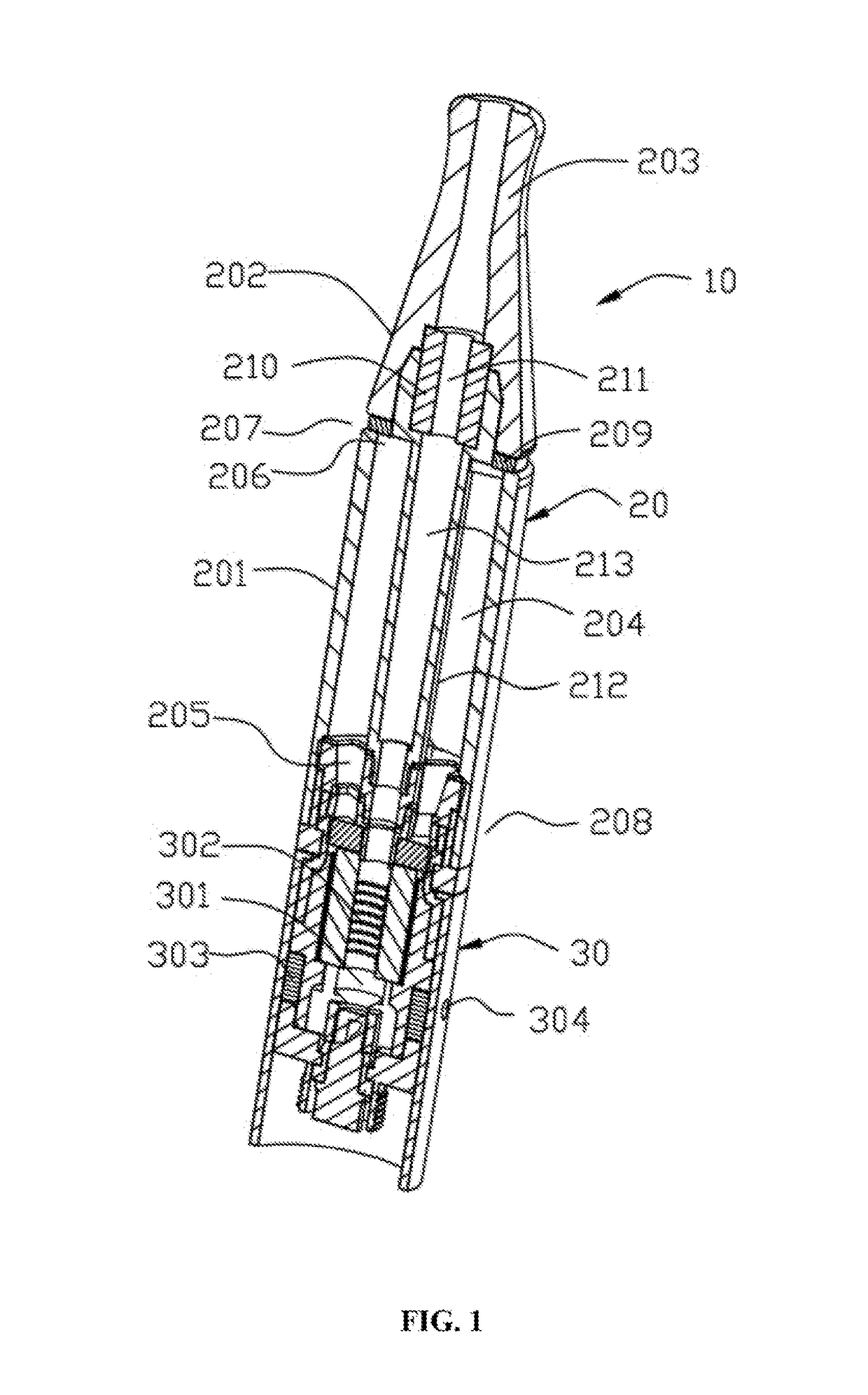

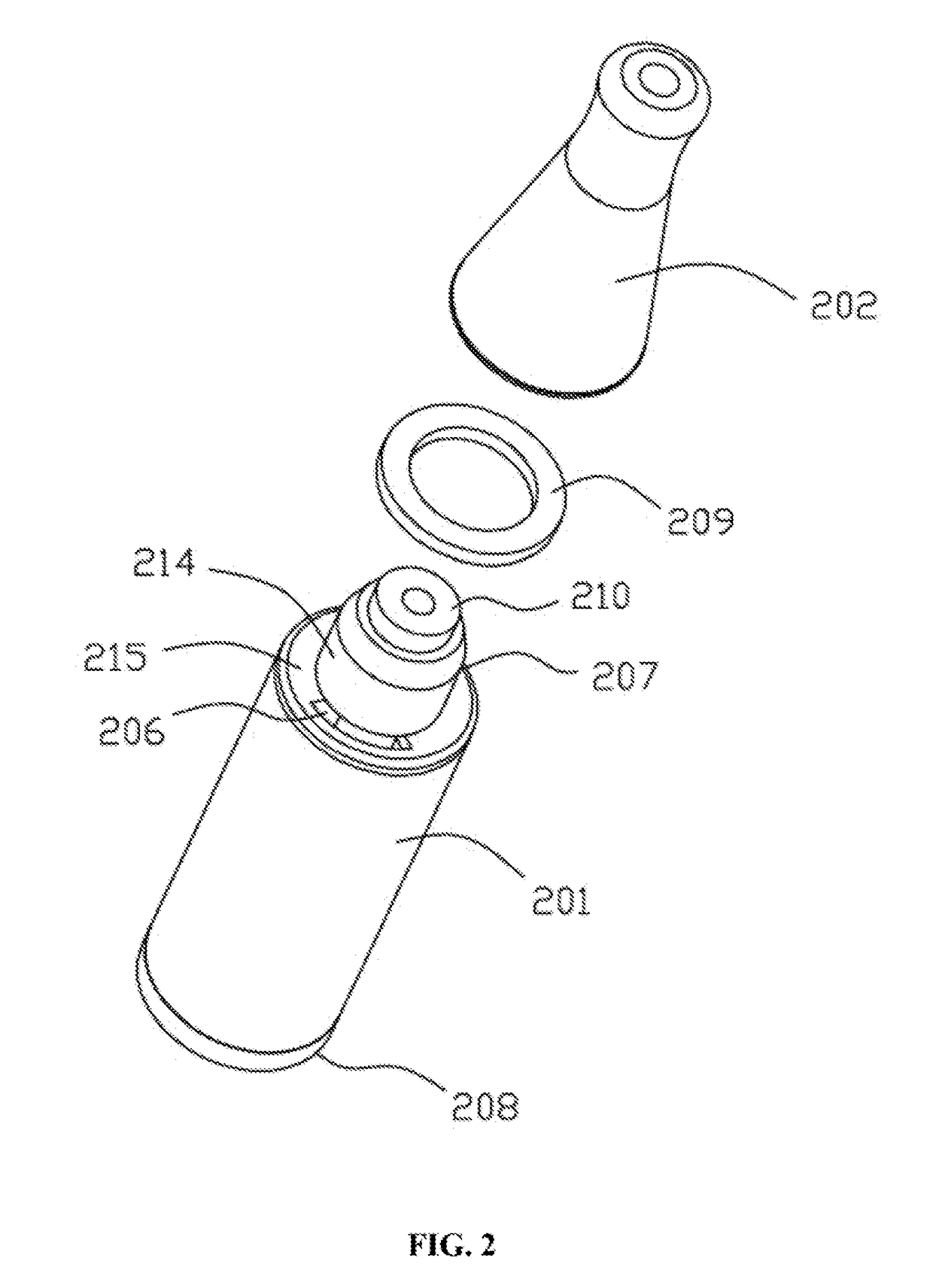

Electronic Cigarette and Soft Absorption Stem Thereof

InactiveUS20140182610A1Compact internal structureUnique smoke pathTobacco pipesTobacco devicesElectronic cigaretteSoft materials

A soft absorption stem for an electronic cigarette is provided, comprising a sleeve, a cigar liquid tank disposed inside the sleeve, an atomization device and a liquid guiding component. The sleeve is made of soft material; a plurality of venting slots is extended axially from one end of the sleeve to the other end thereof and disposed on an inner wall of the sleeve; the sleeve includes a mouthpiece end and a connection end; a suction hole communicating with the venting slots is provided on the mouthpiece end; smoke produced by atomization of the atomization device flows out of the sleeve from the venting slots across the suction hole. The electronic cigarette makes the user more comfortable when holding the sleeve in hand and containing in mouth, having more compact internal construction, having unique smoke path, and having increased cigar liquid storage capacity.

Owner:HUIZHOU KIMREE TECH

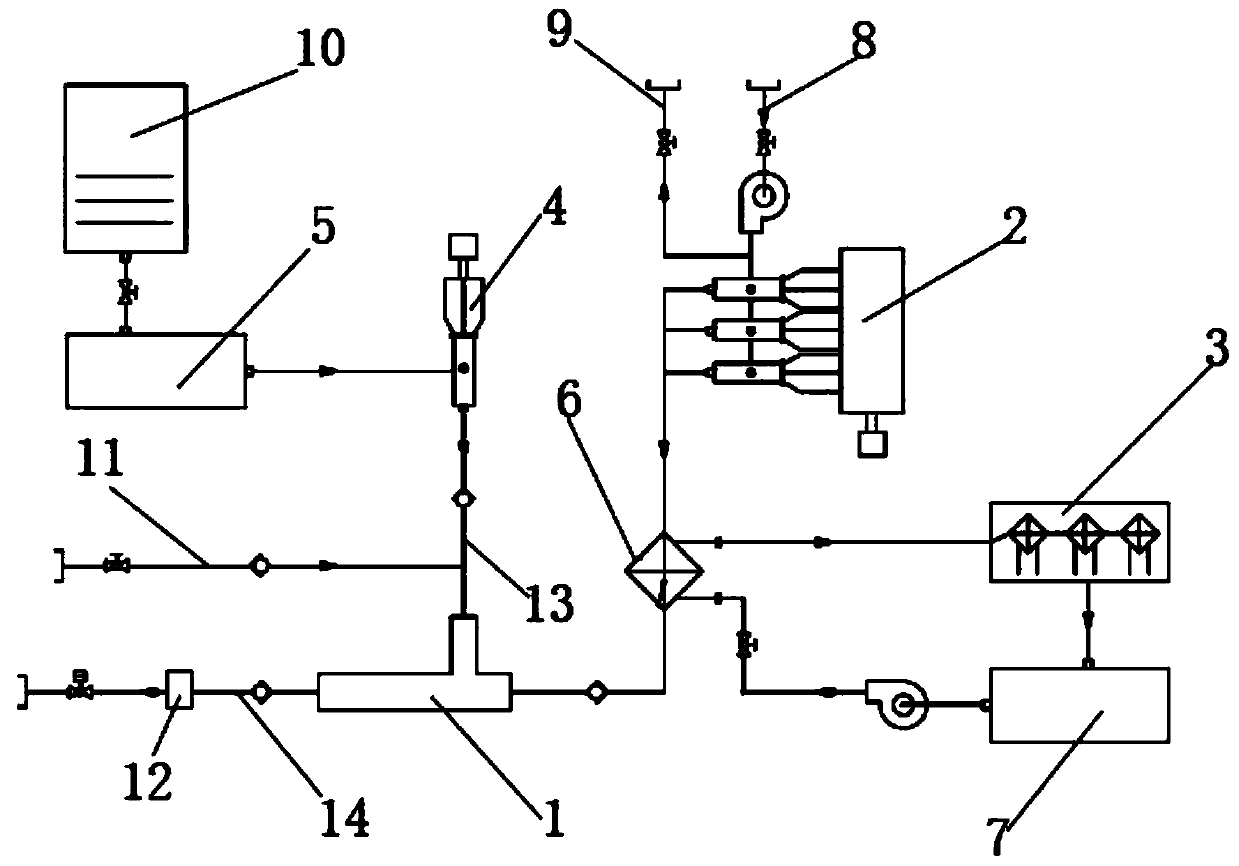

Device and method for preparing nitrogen foam cement

InactiveCN111206901ALow densityReduce energy consumptionSealing/packingHigh pressure waterNitrogen gas

The invention discloses a device and method for preparing nitrogen foam cement. The preparing device comprises a foam cement producer, a liquid nitrogen evaporator, a liquid nitrogen plunger pump, a foam liquid plunger pump, a foam liquid tank, a heat exchange system, a liquid nitrogen pipeline, a high-pressure cement paste pipeline, a first pipeline, a foam cement discharge pipeline and a densitydetecting device. The heat generated by a power unit, a hydraulic system and other devices in a nitrogen foam well fixing device is recovered through the heat exchange system, the recovered heat is used as a heat source of the liquid nitrogen evaporator, energy conservation and environment protection are realized, the energy utilization rate is high, and equipment input is low. Liquid nitrogen and foam liquid are pressurized through a high-pressure liquid nitrogen plunger pump and a high-pressure foam liquid plunger pump, the mixing uniformity is increased, and the density of foam cement is reduced. The density of the foam cement is detected in real time through the density detecting device, the flow of the liquid nitrogen and / or foam liquid is adjusted according to the density, and the density is simply controlled. By arranging a clear water tank, after operation ends, the equipment and pipelines are flushed, and the service life is polonged.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

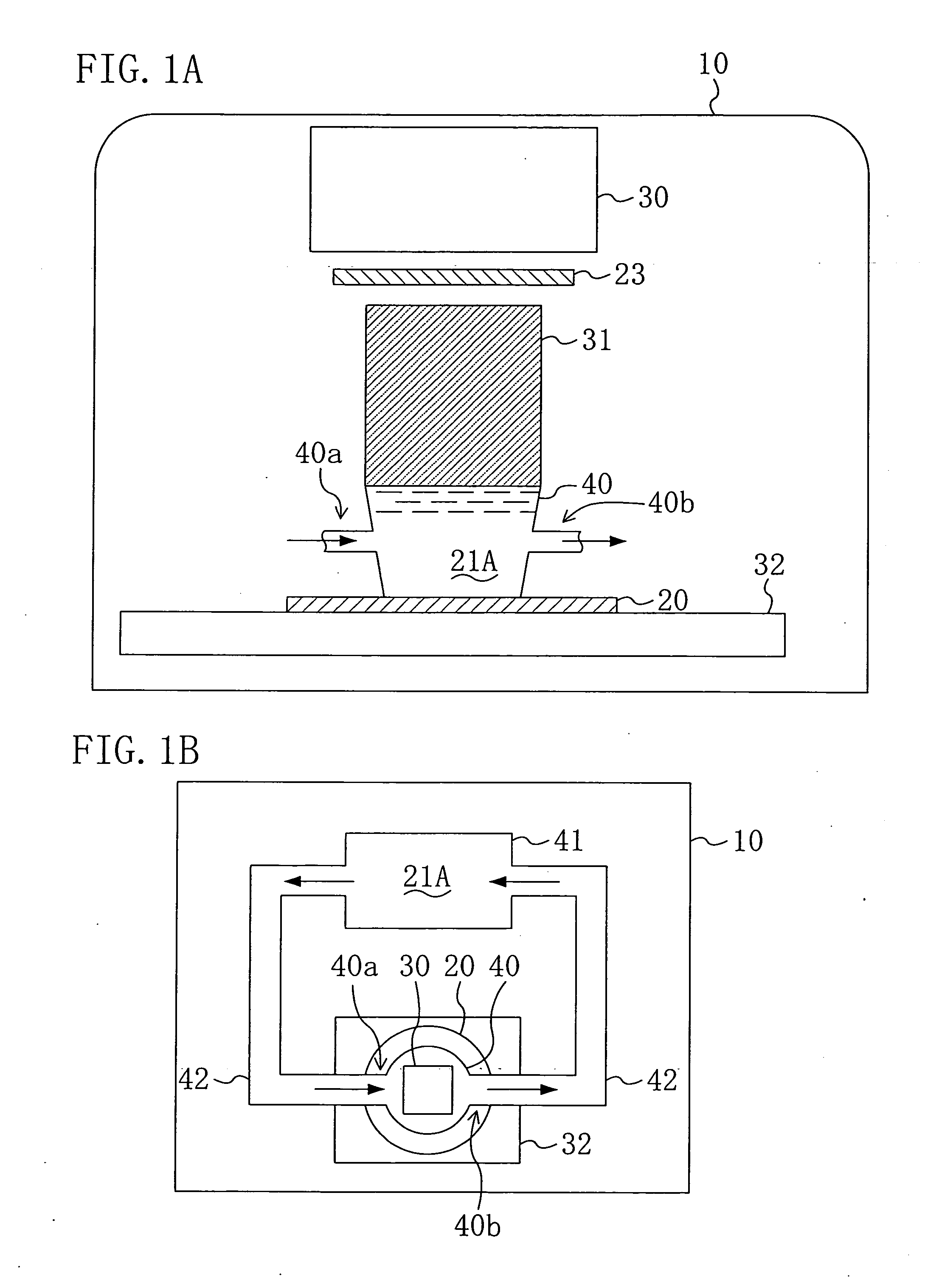

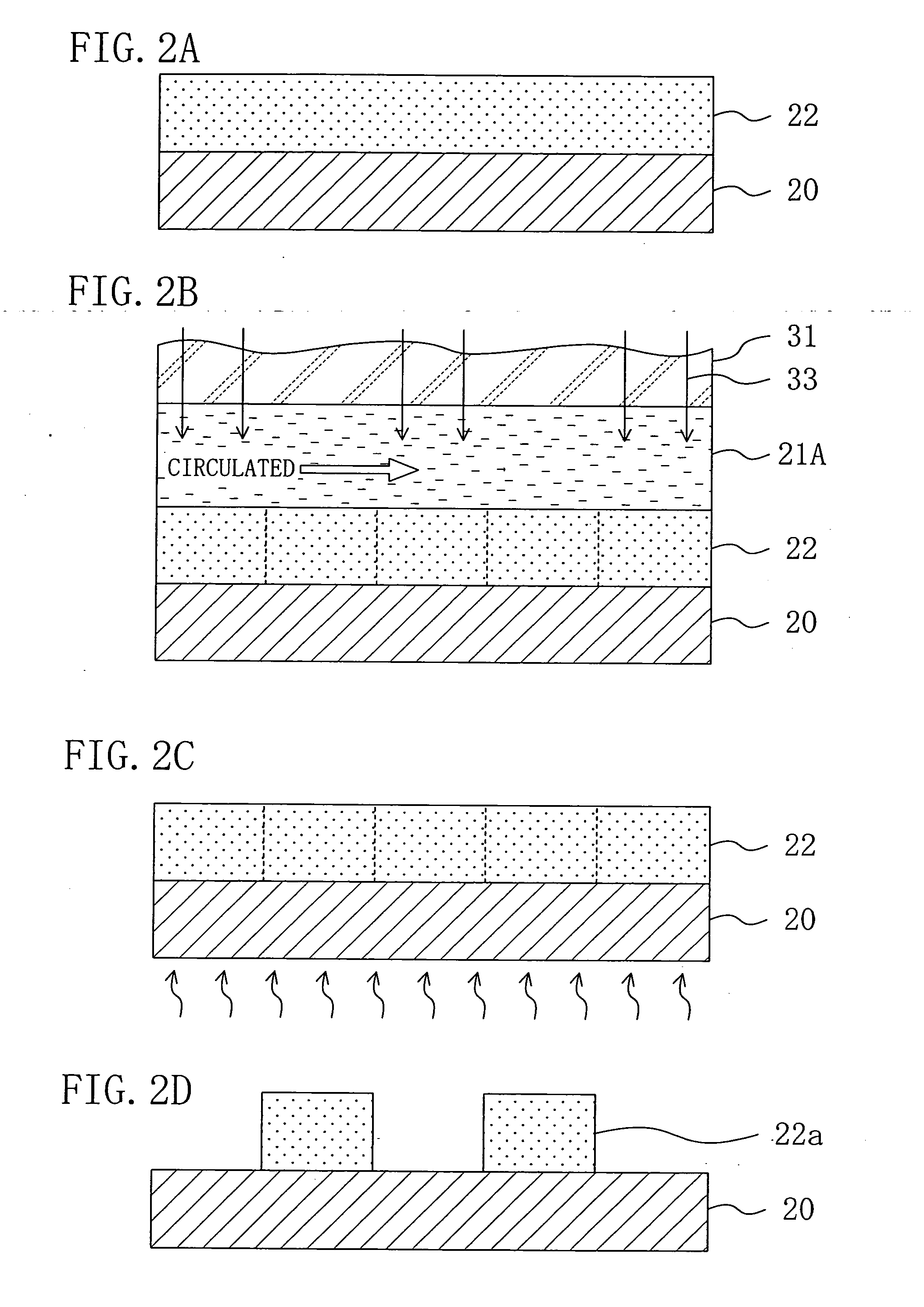

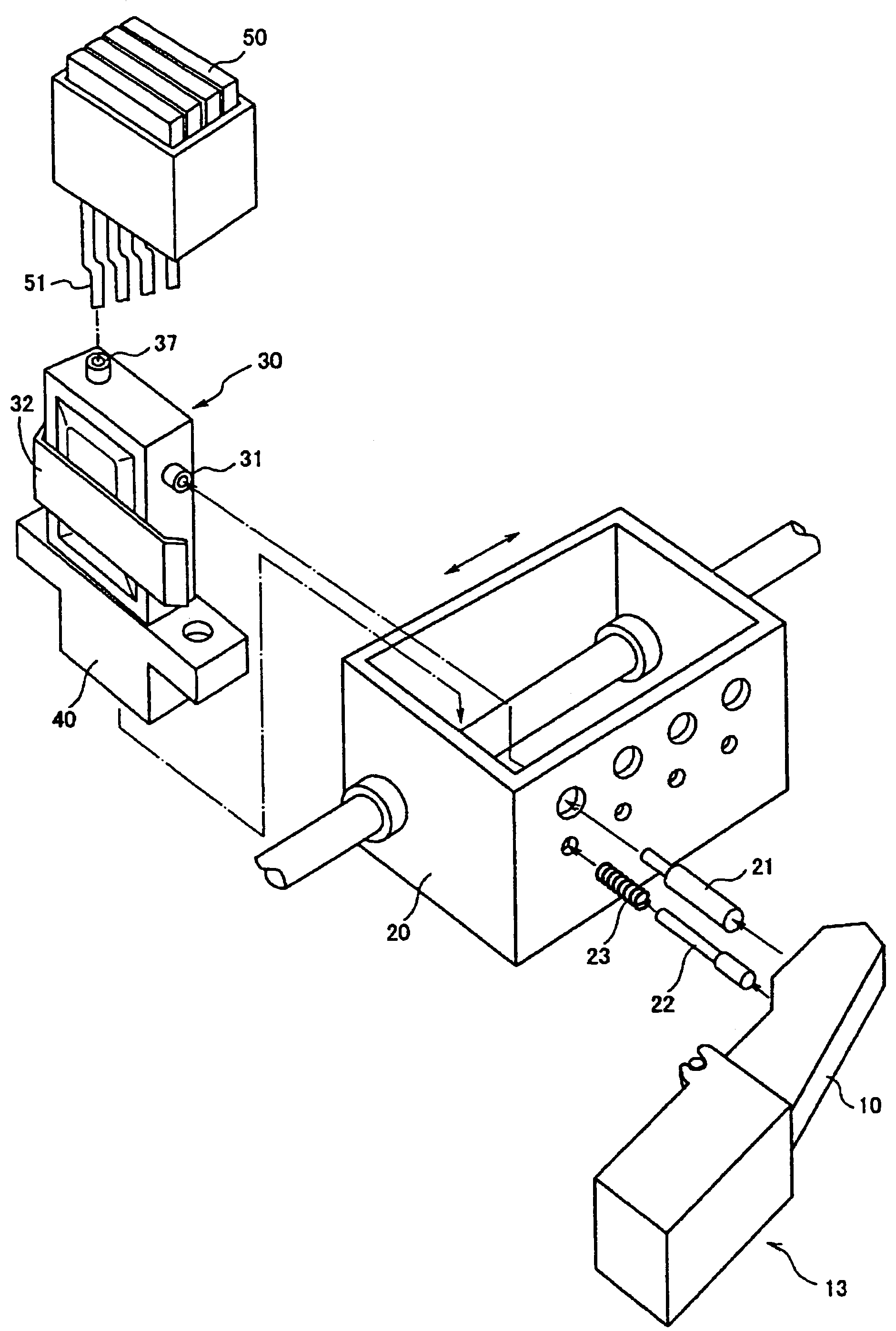

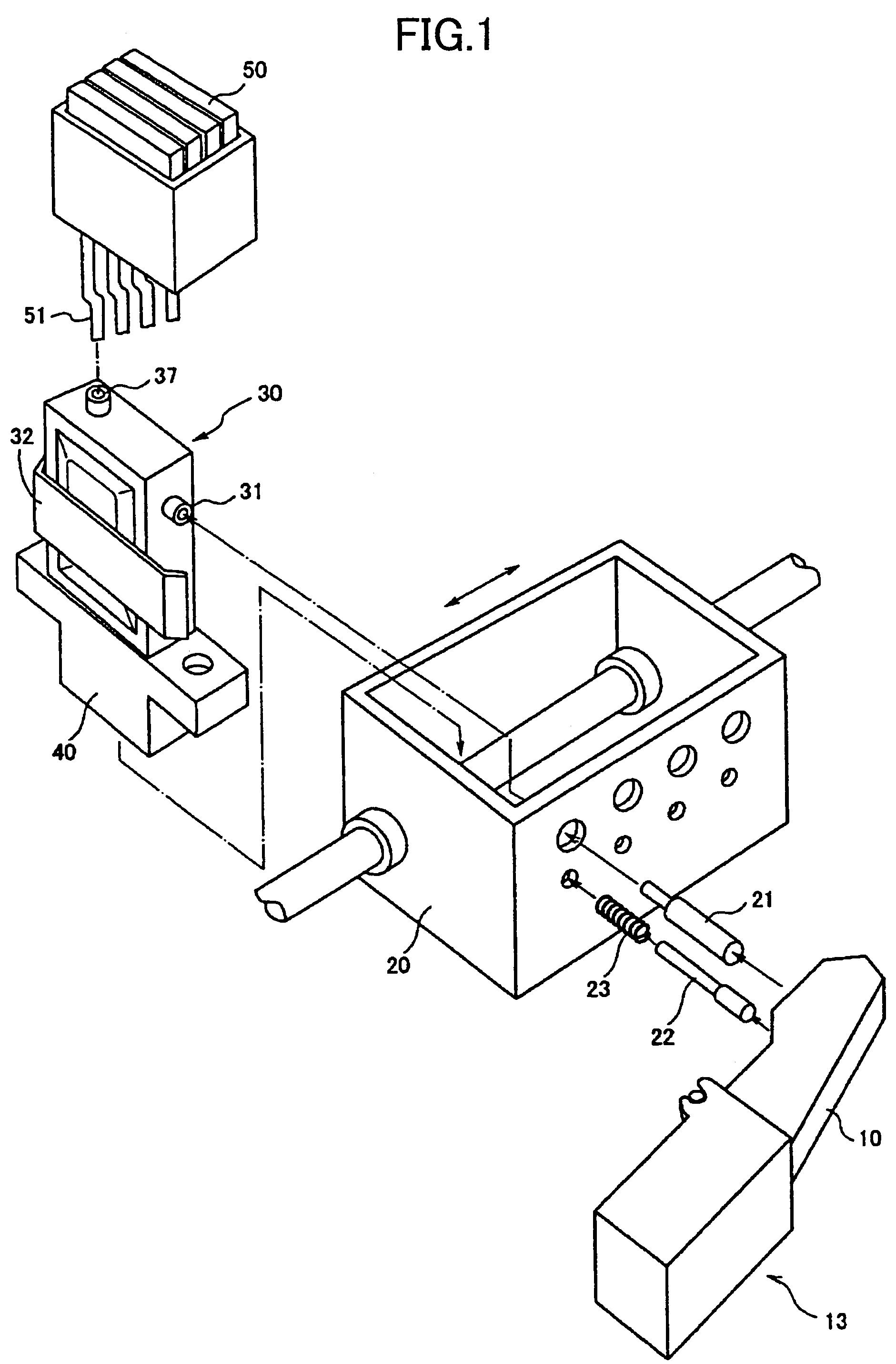

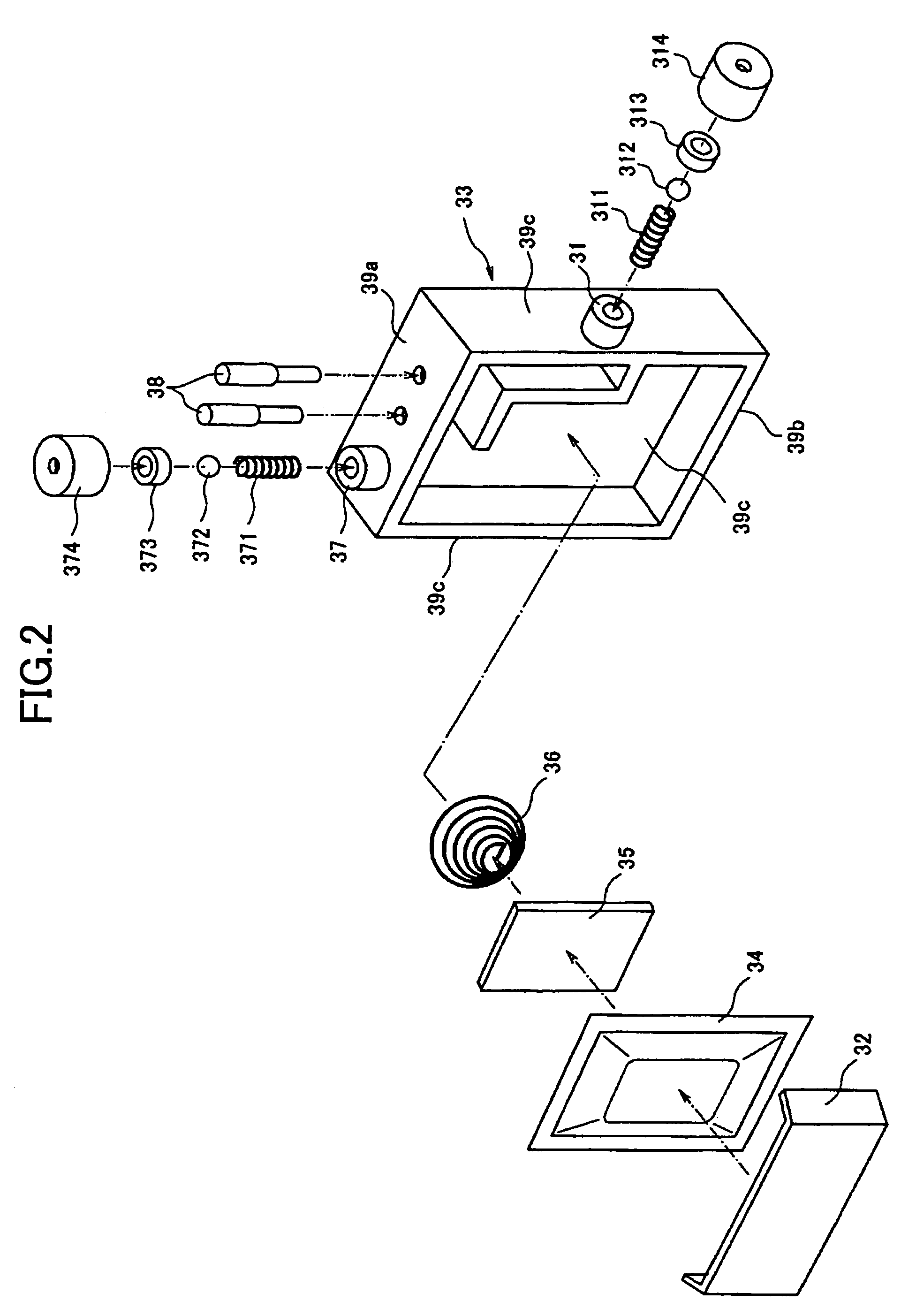

Exposure system and pattern formation method using the same

InactiveUS20050136361A1Good body shapeAbnormal exposureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistEngineering

An exposure system includes a liquid supply section for supplying an immersion liquid onto a resist film formed on a substrate; and an exposure section for irradiating the resist film with exposing light through a mask with the immersion liquid provided on the resist film. The liquid supply section includes an immersion liquid tank for circulating the immersion liquid during exposure.

Owner:RPX CORP

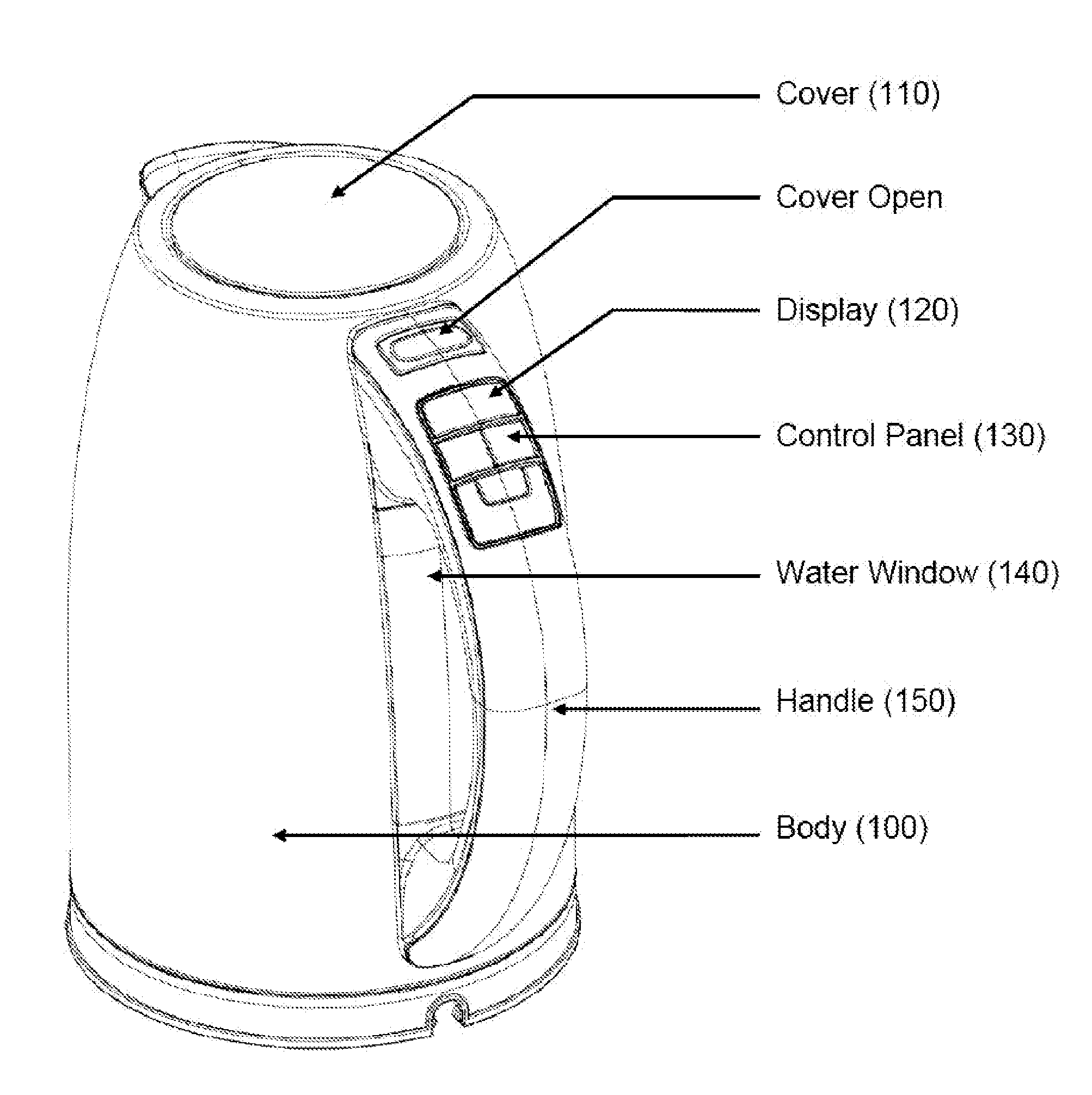

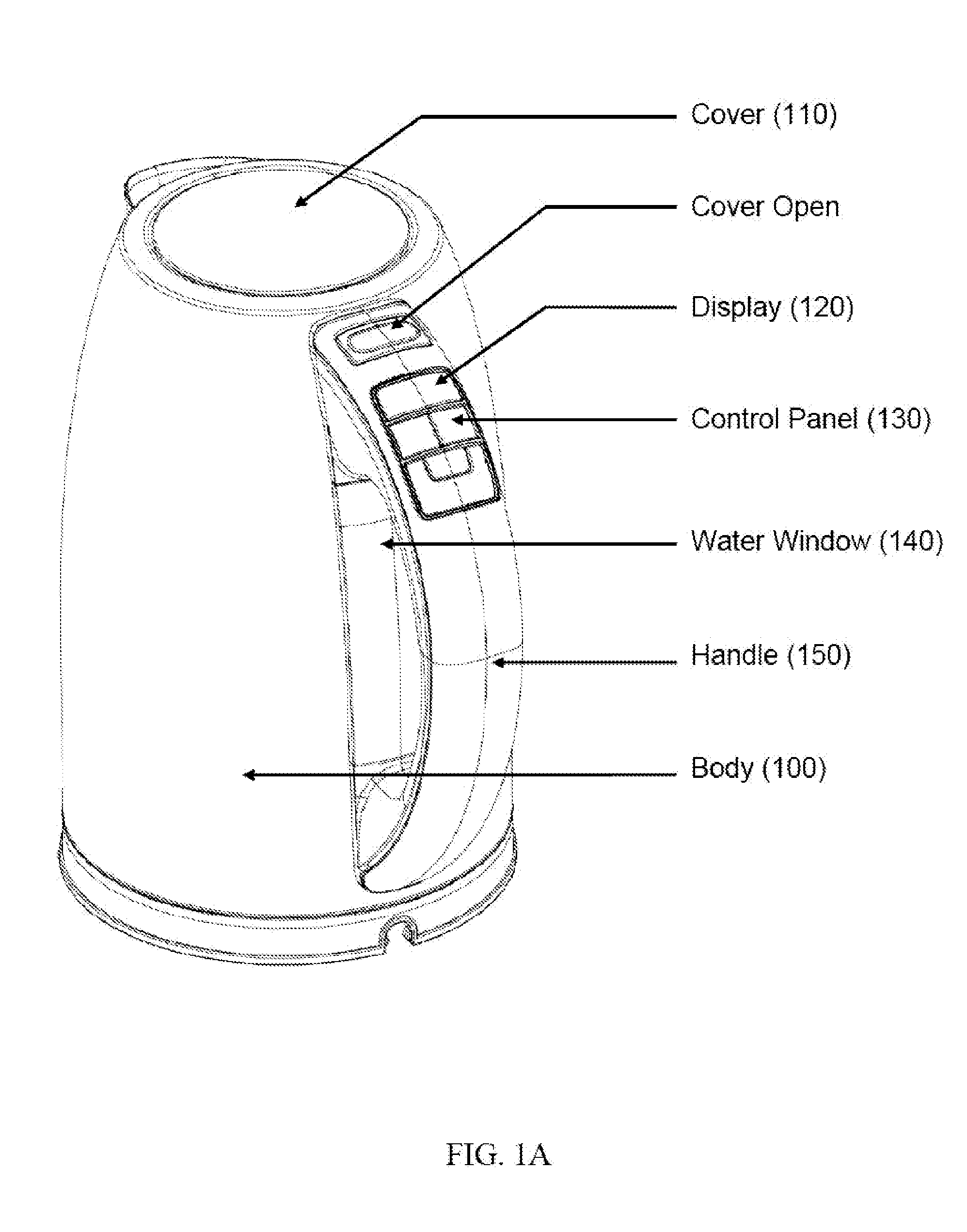

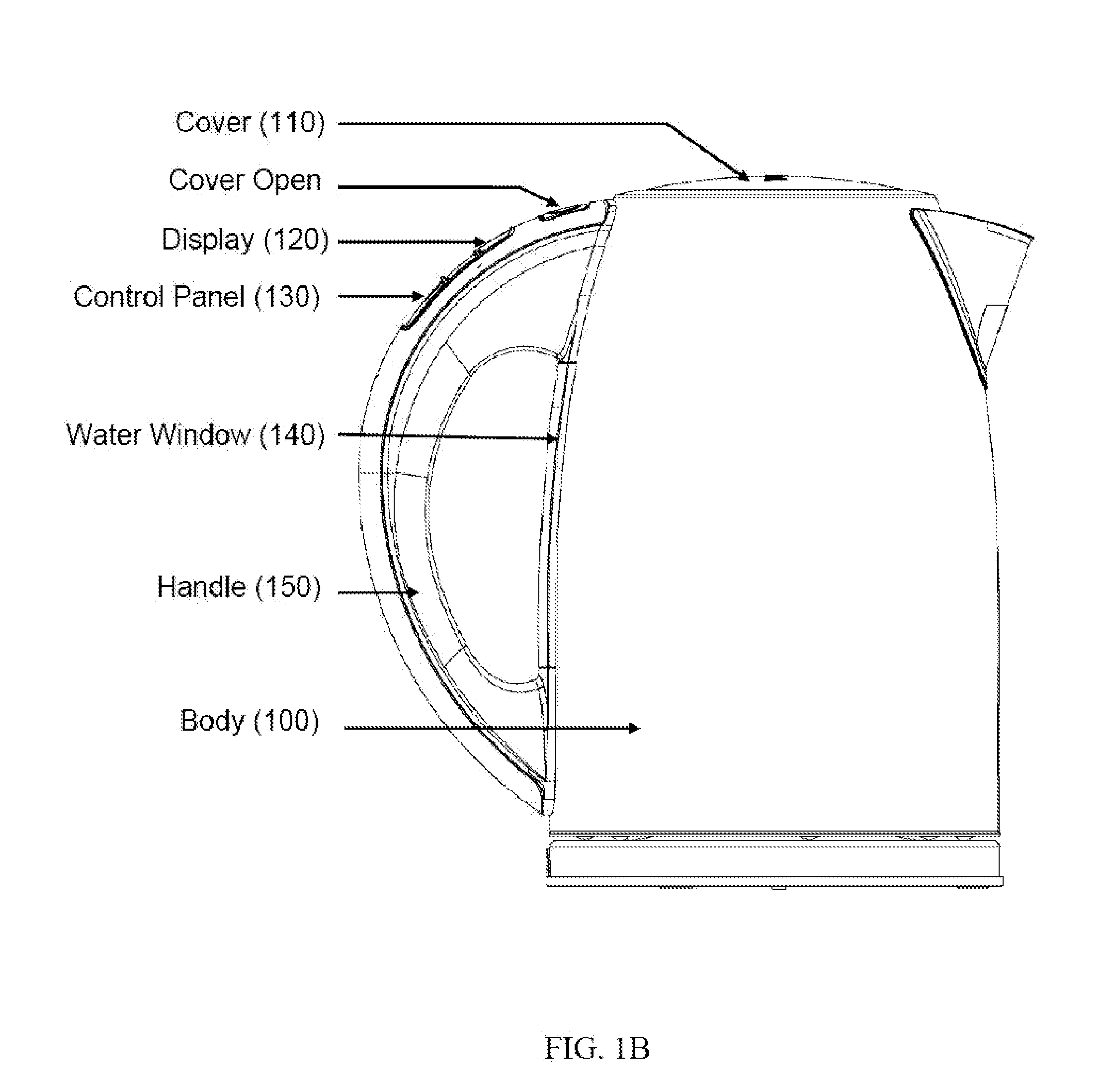

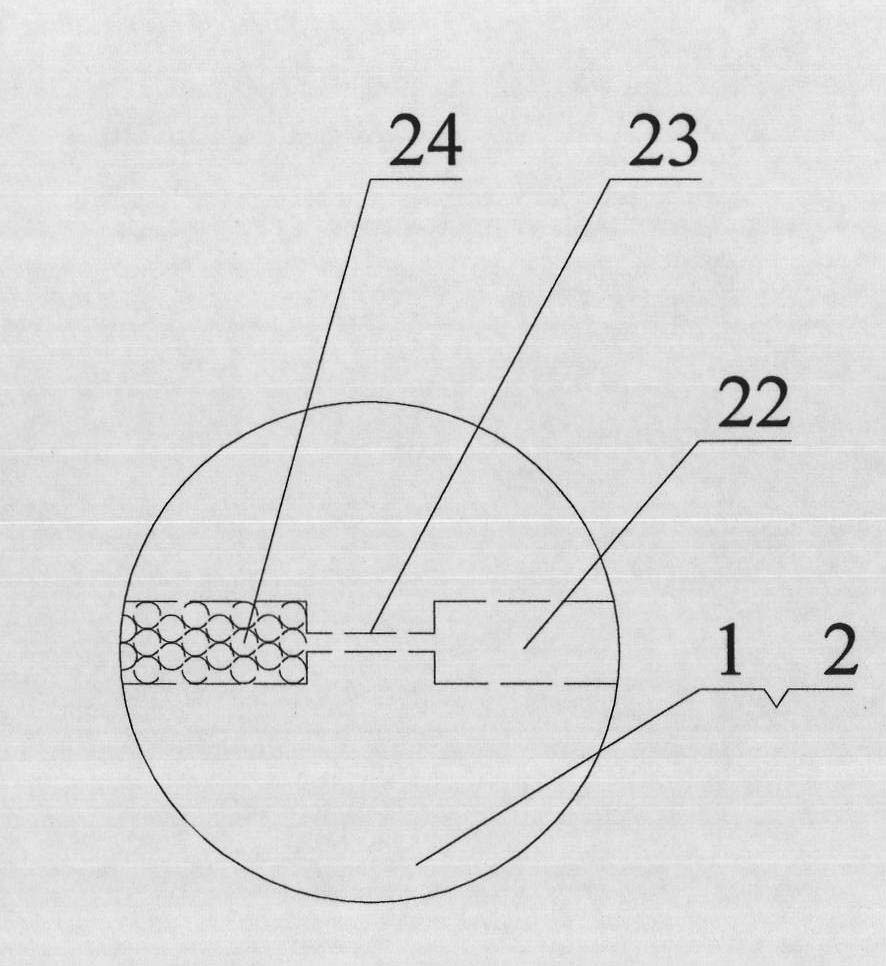

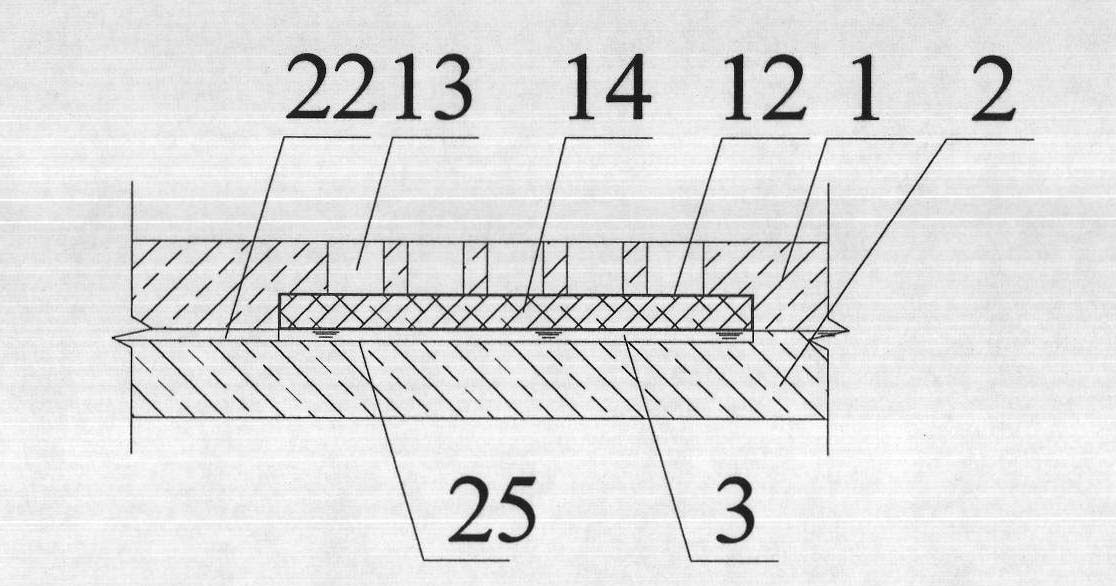

Non-contact liquid level sensing system for household electric appliances

A non-contact liquid level sensing system for an electric appliance is provided. The electric appliance includes a liquid container for containing liquid. The non-contact liquid level sensing system includes a micro-controller and a plurality of sensors vertically aligned and mounted to the inside of the liquid container. The micron-controller includes a non-volatile memory for storing data. Each of the sensors includes a circuit board, a sensor pad made of a conductive material mounted on the circuit board, and a cover plate made of a dielectric material covering and being in direct contact with the sensor pad. The micro-controller is electrically connected with the sensors, and configured to measure the capacitance between the sensor pad of each sensor and a reference electric potential, and to determine a liquid level in the liquid tank based on the measured capacitance and the data stored in the non-volatile memory of the micro-controller.

Owner:LI WING CHUNG

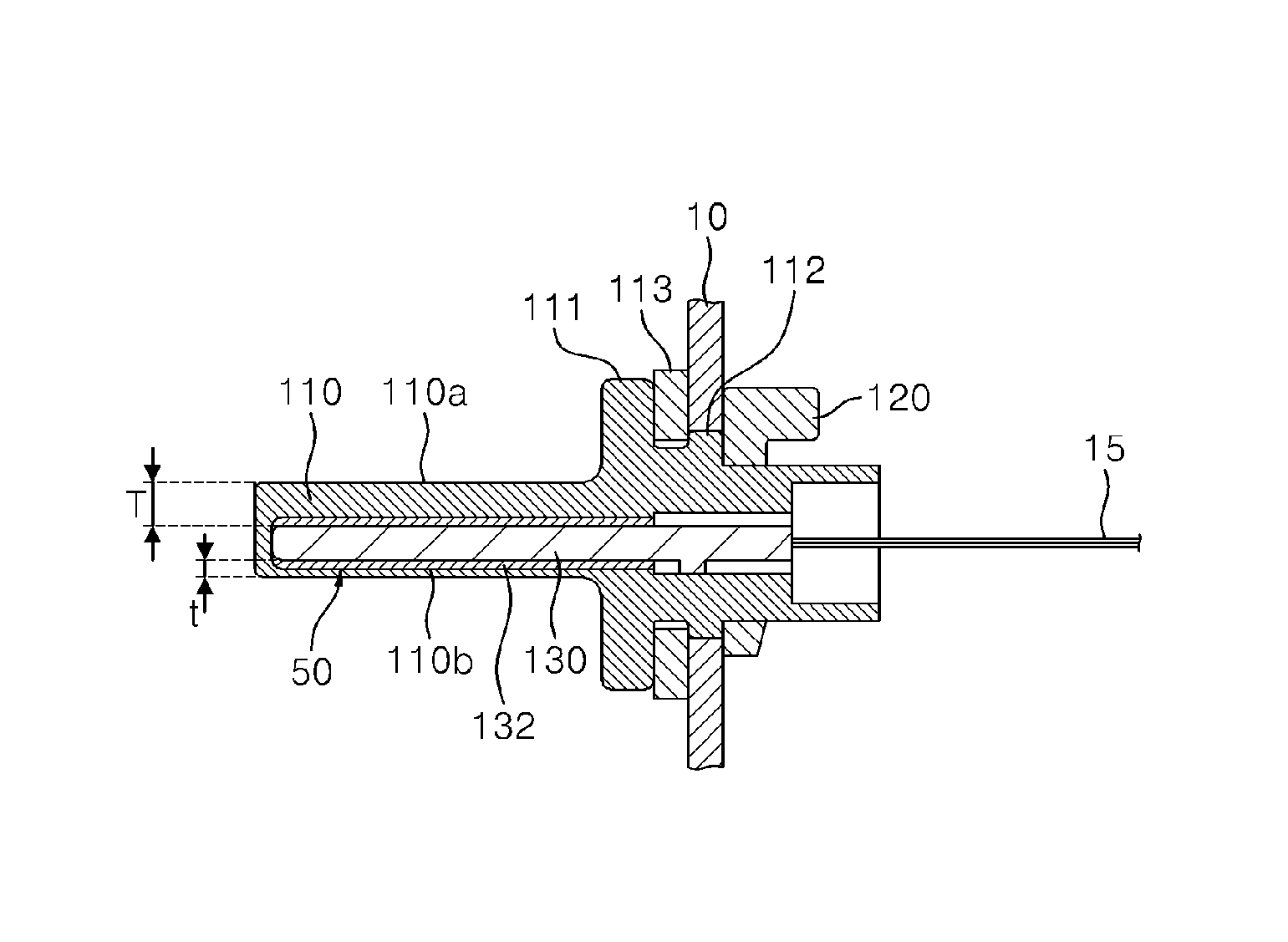

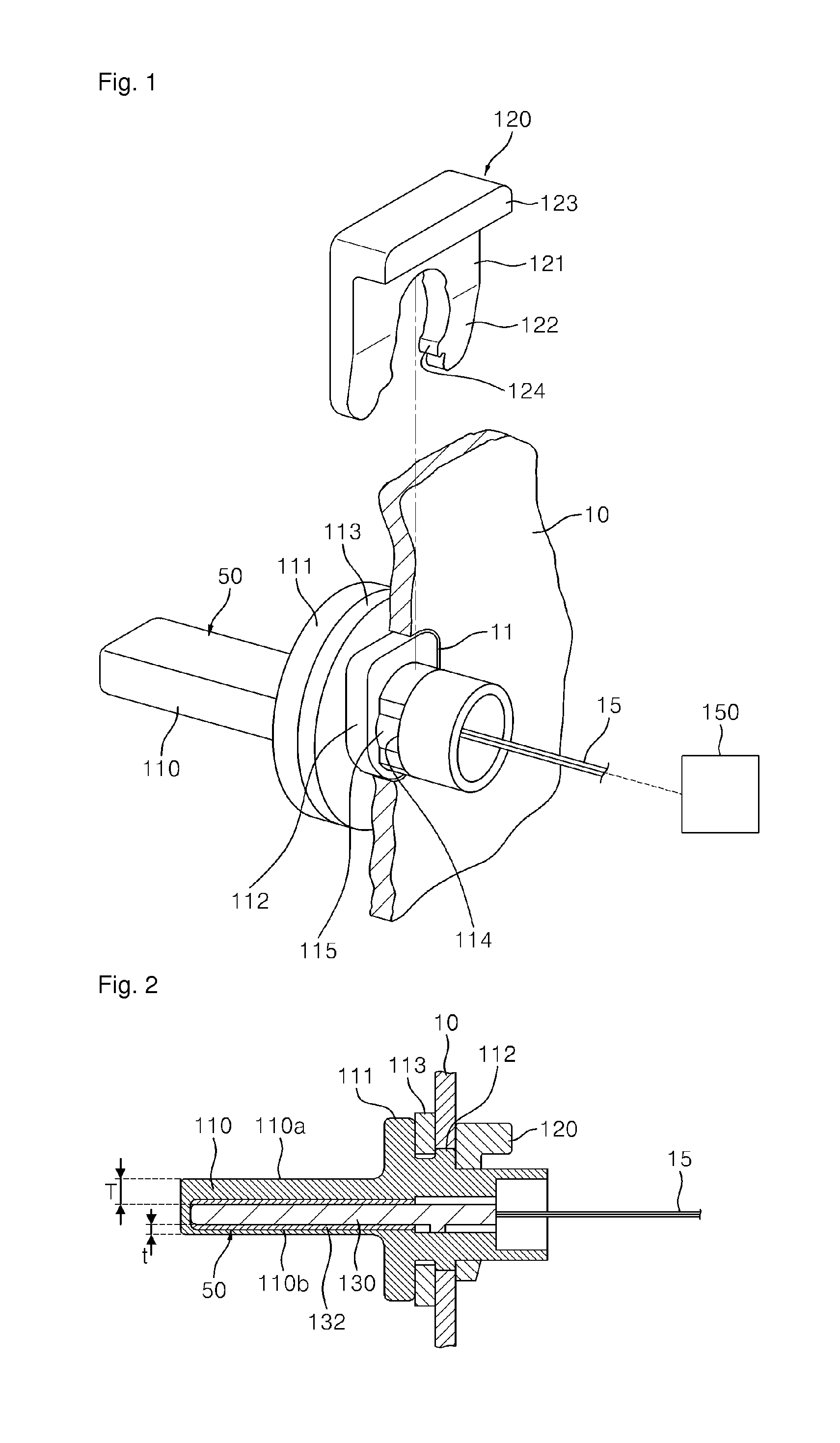

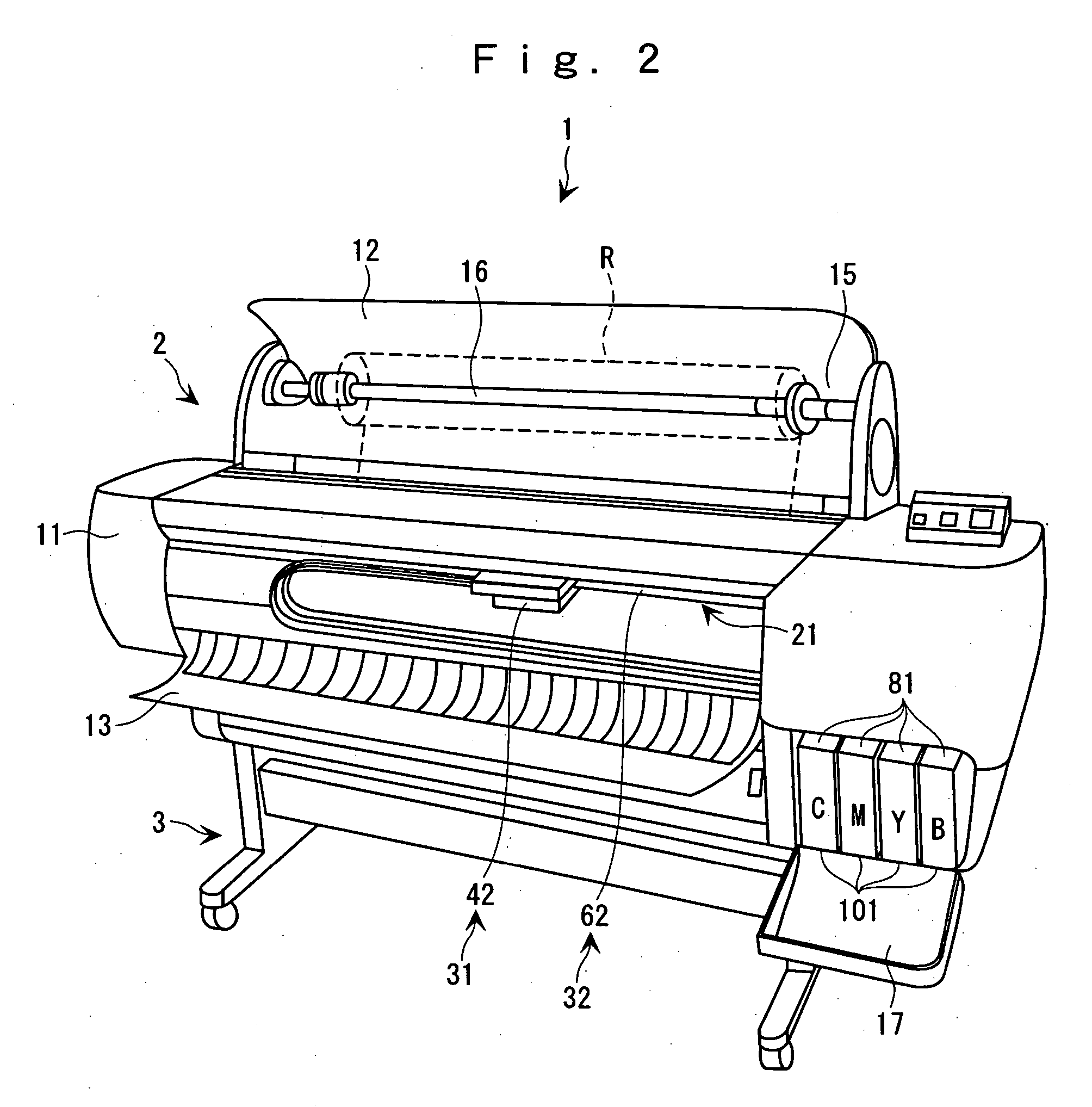

Pressure adjustment mechanism, liquid tank, liquid providing device, ink cartridge, and inkjet printing apparatus

Owner:RICOH KK

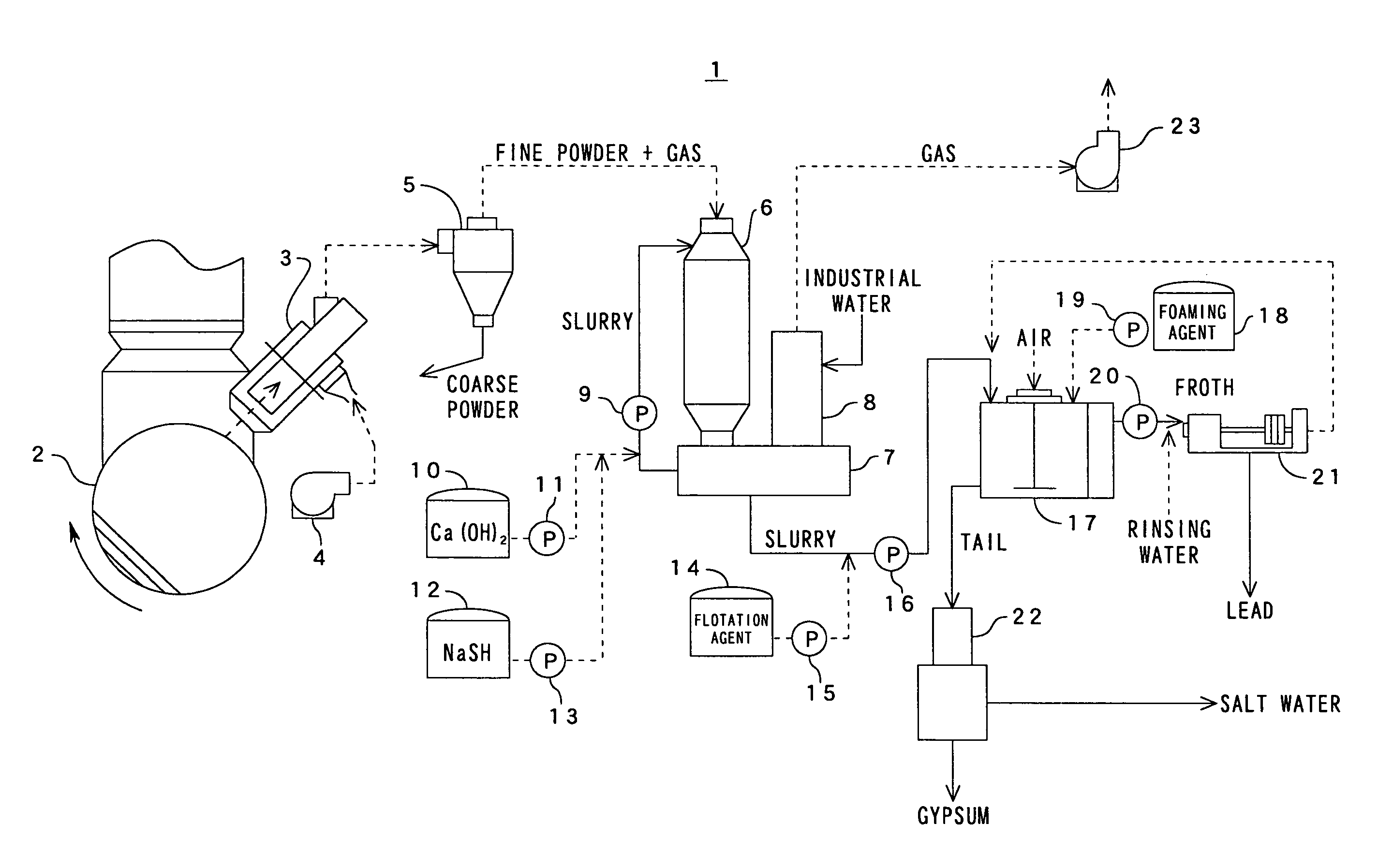

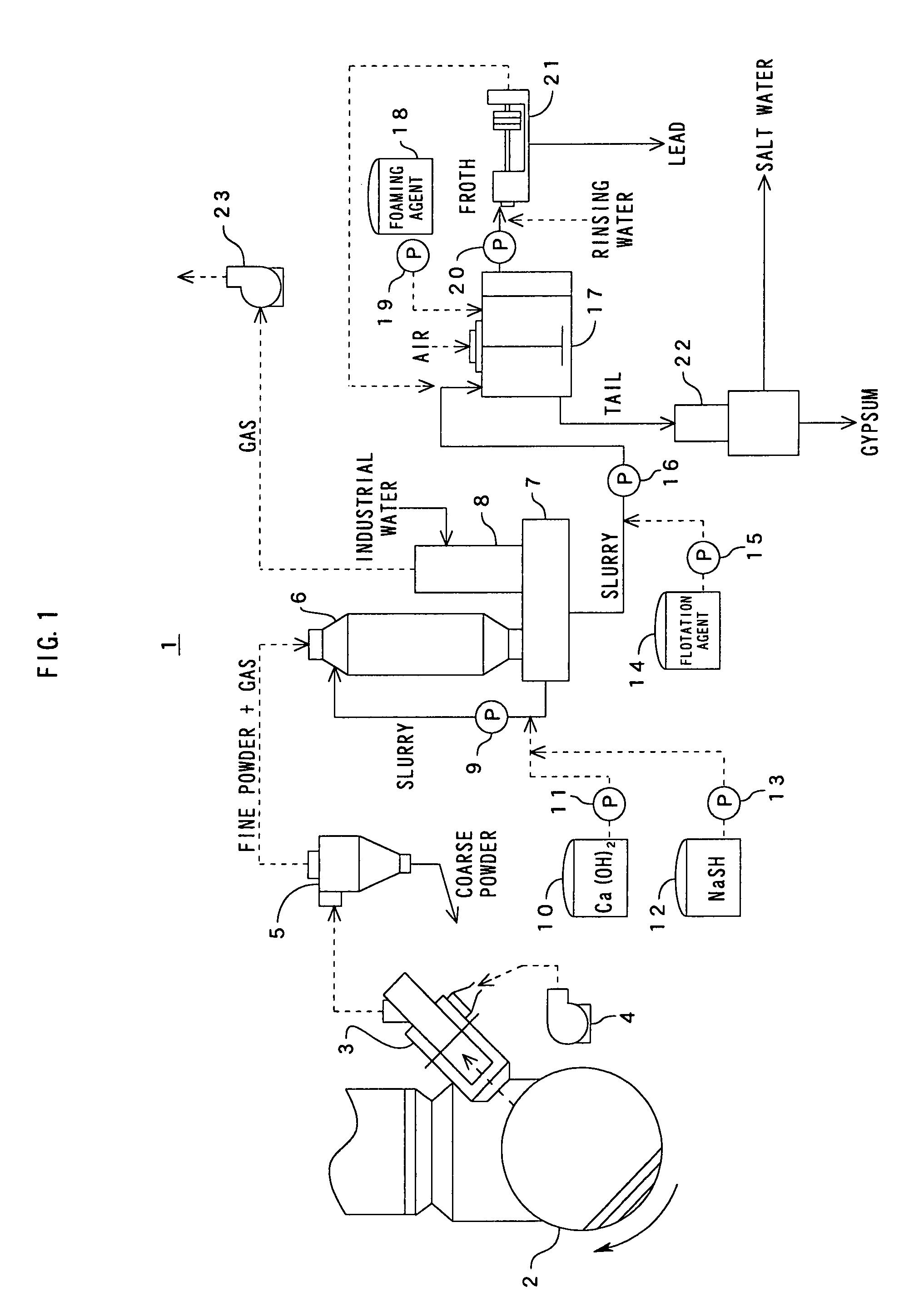

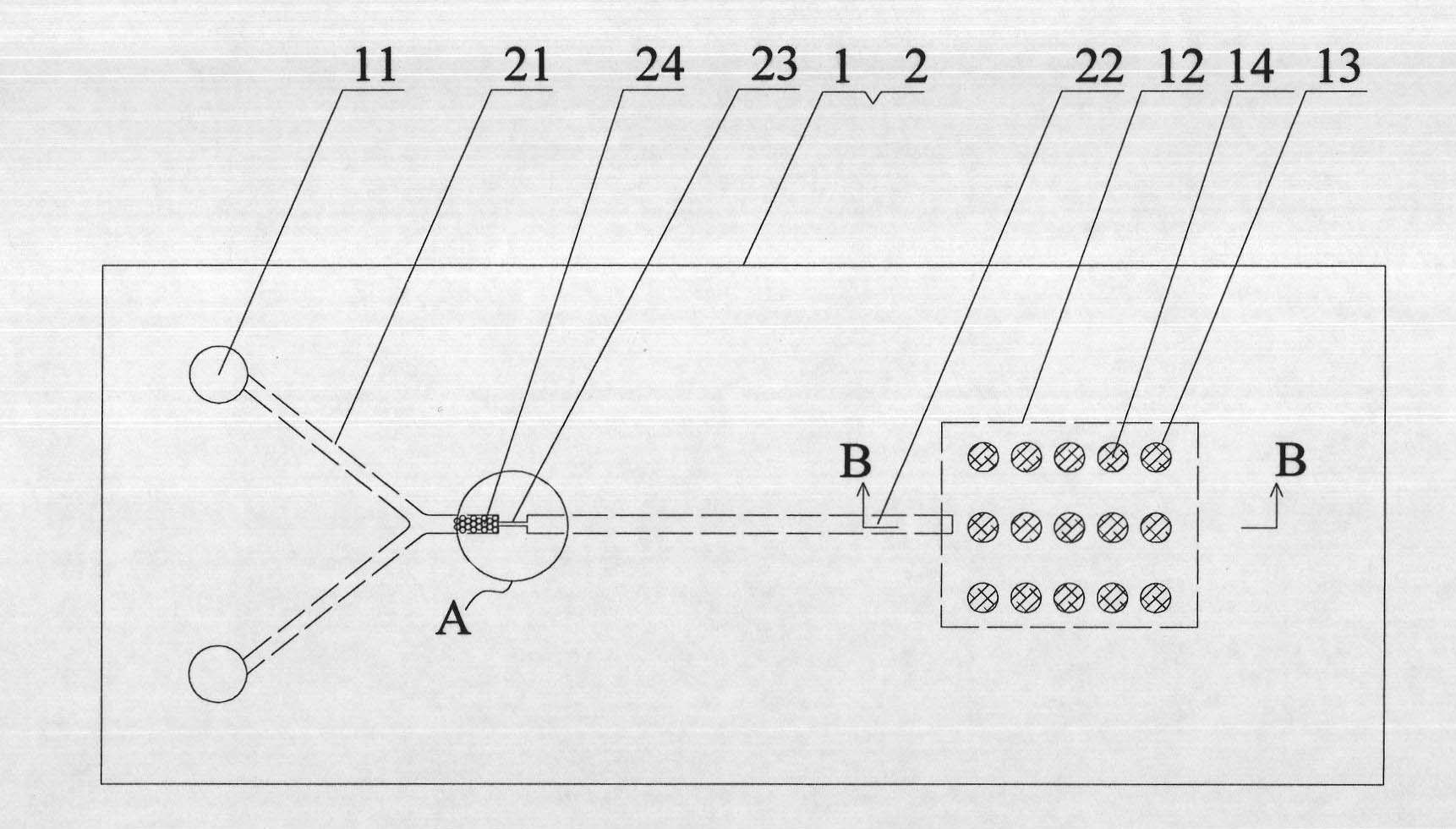

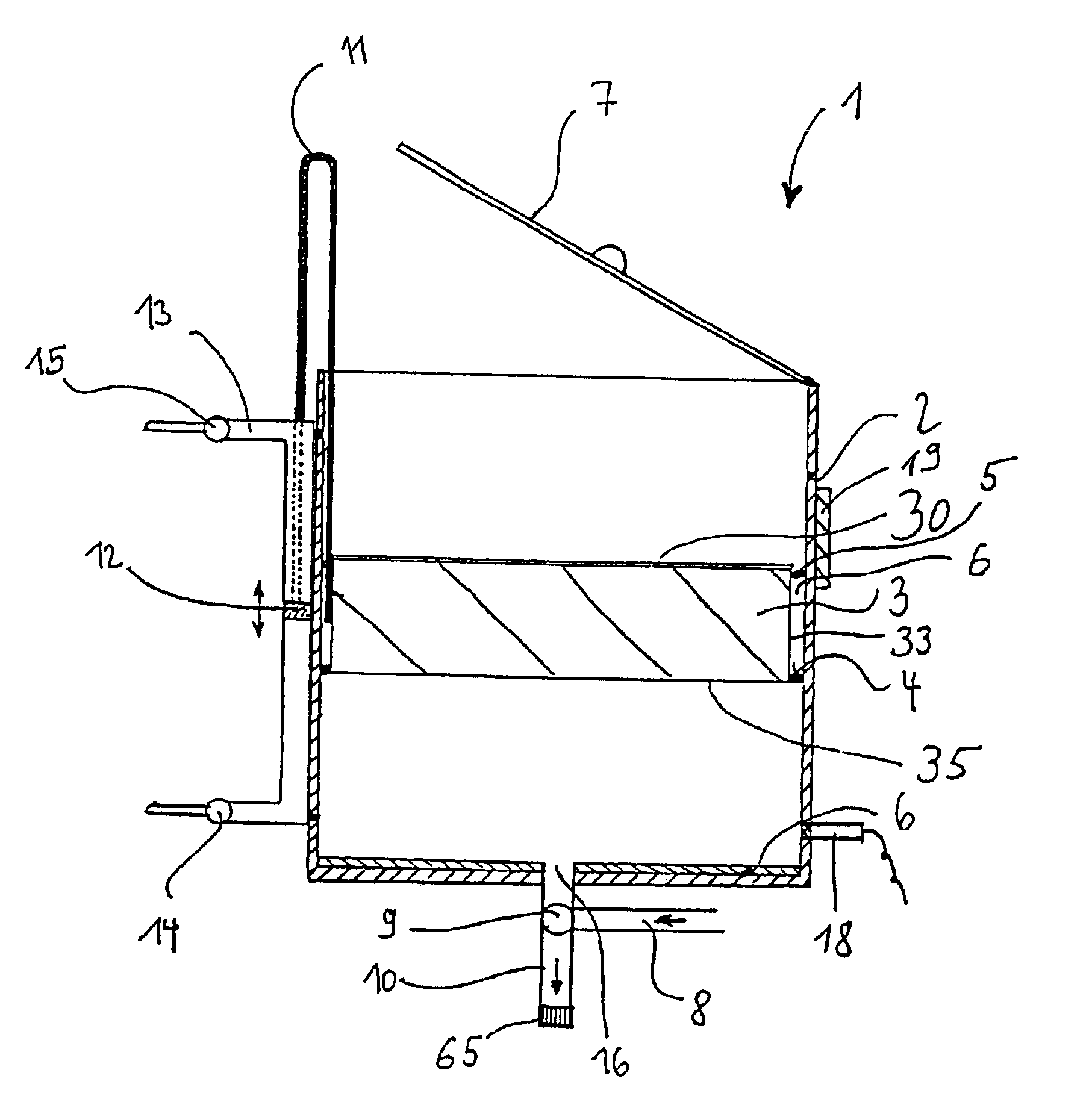

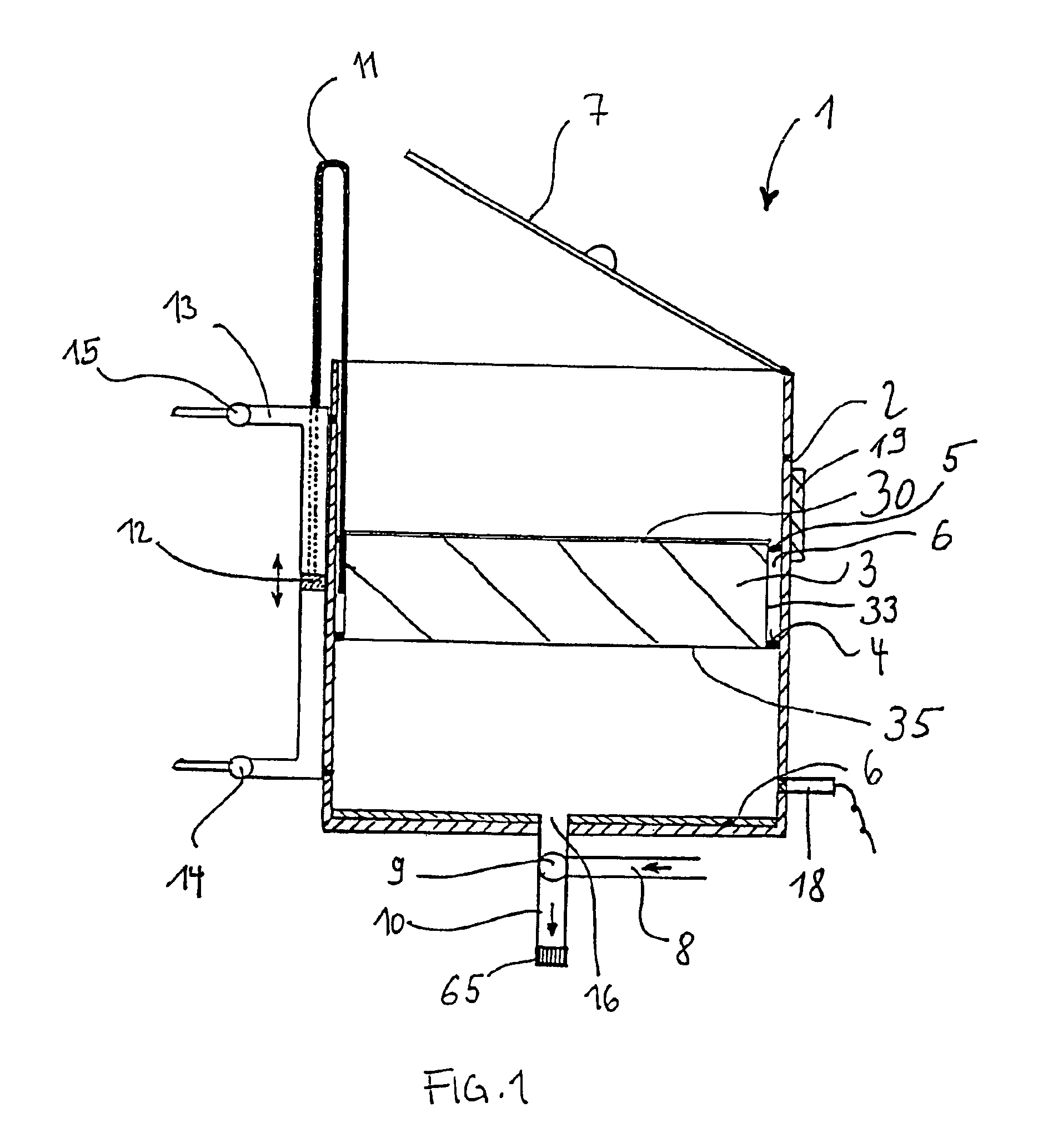

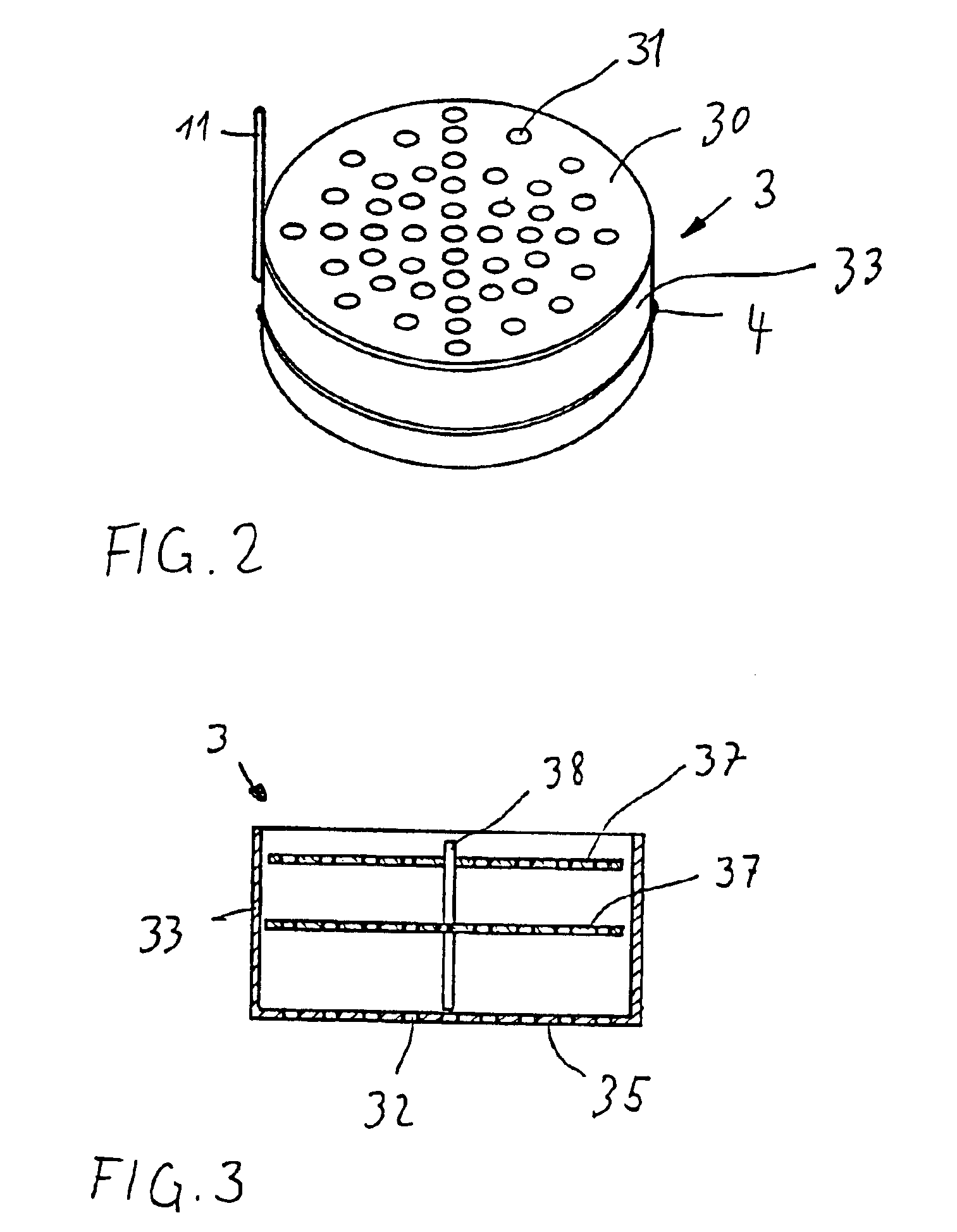

System and method for treating dust contained in extracted cement kiln combustion gas

InactiveUS7789944B2Effectively remove dustLow facility requirementsCombination devicesUsing liquid separation agentCycloneSlurry

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising: a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a classifier 5 for separating coarse powder from dust contained in the combustion gas extracted by the probe 3; a wet dust collector 6 for collecting dust from the extracted gas containing fine powder discharged from the classifier 5; and devices 12, 13 for feeding sulfurizing agent for sulfurizing lead contained in the kiln exhaust gas to the wet dust collector 6, and others. From the sulfurizing-agent feeders 12, 13 are preferably added the sulfurizing agents to a circulation liquid tank 7 or a pump 9 for circulating slurry. The slurry obtained by the wet dust collector 6 is separated into froth including lead and tail side slurry including gypsum by a flotation facility 14, 17, 18.

Owner:TAIHEIYO CEMENT CORP

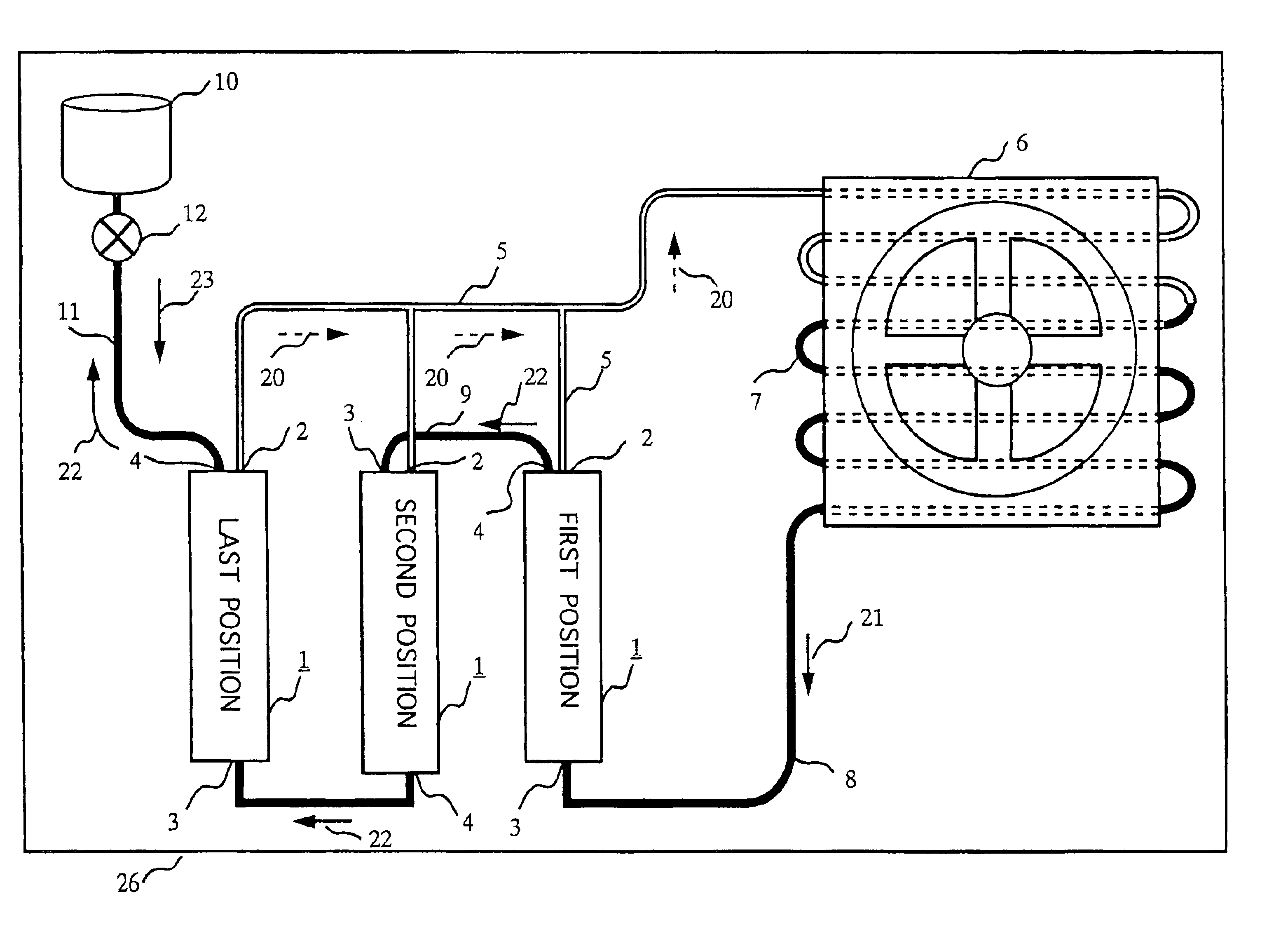

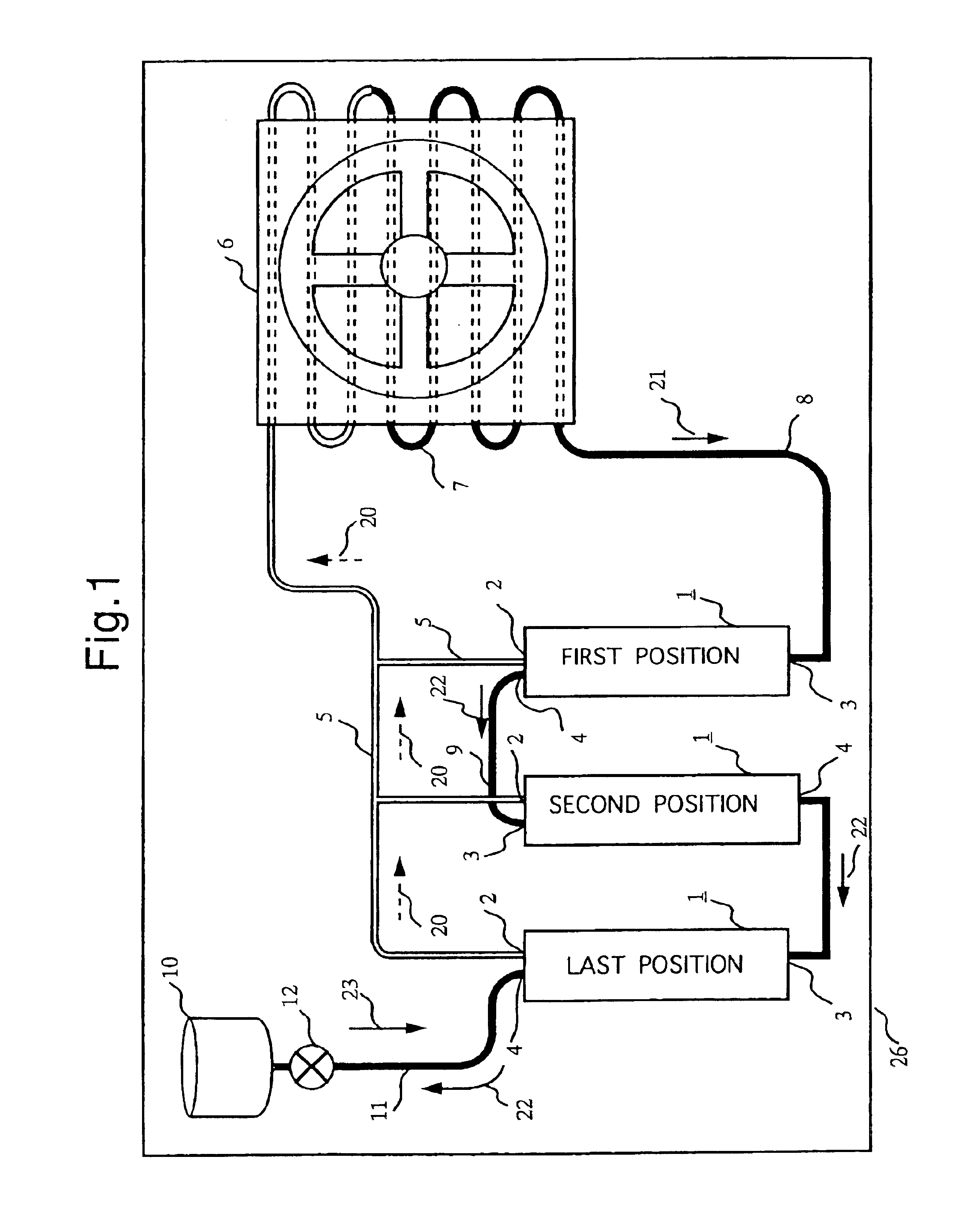

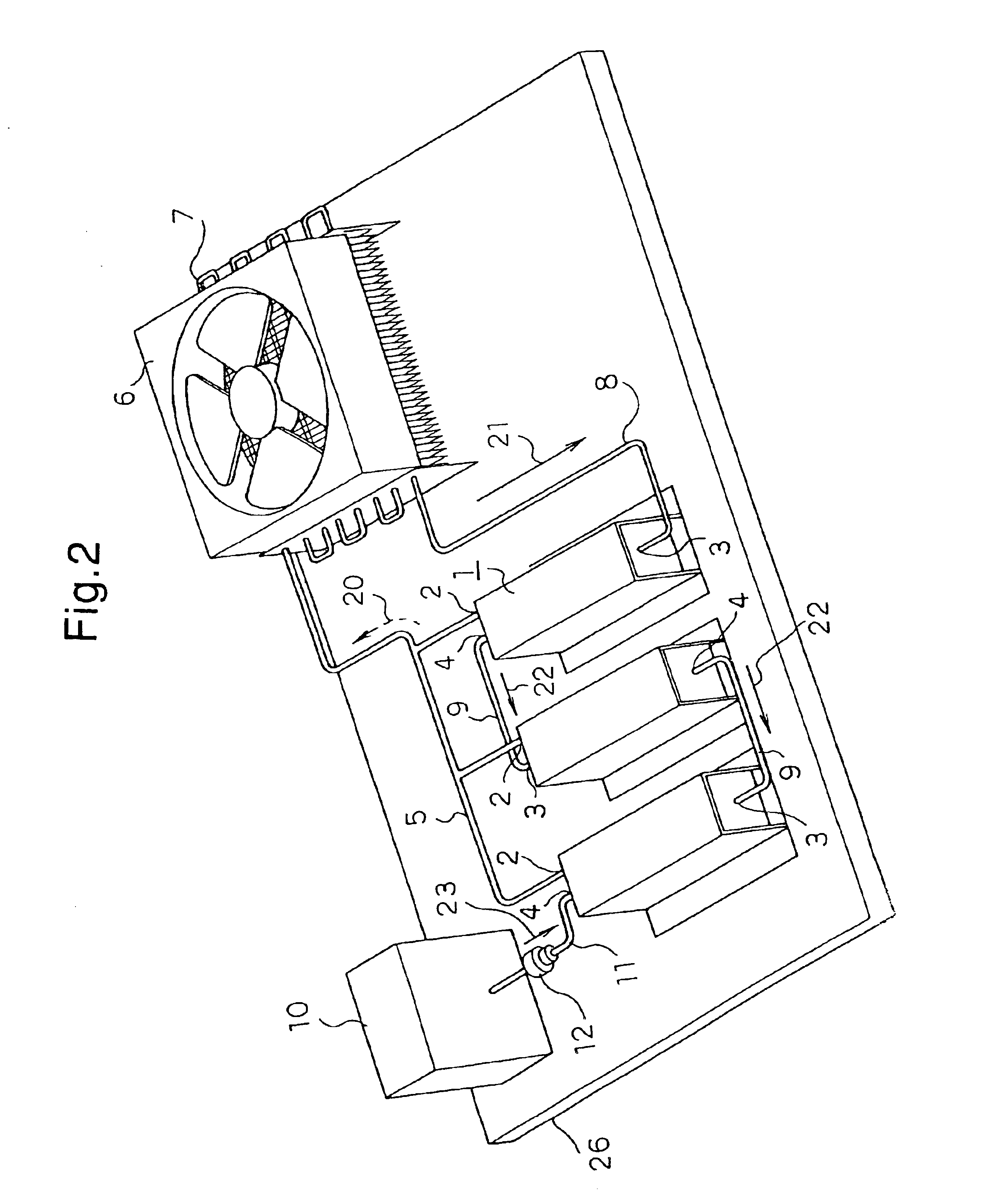

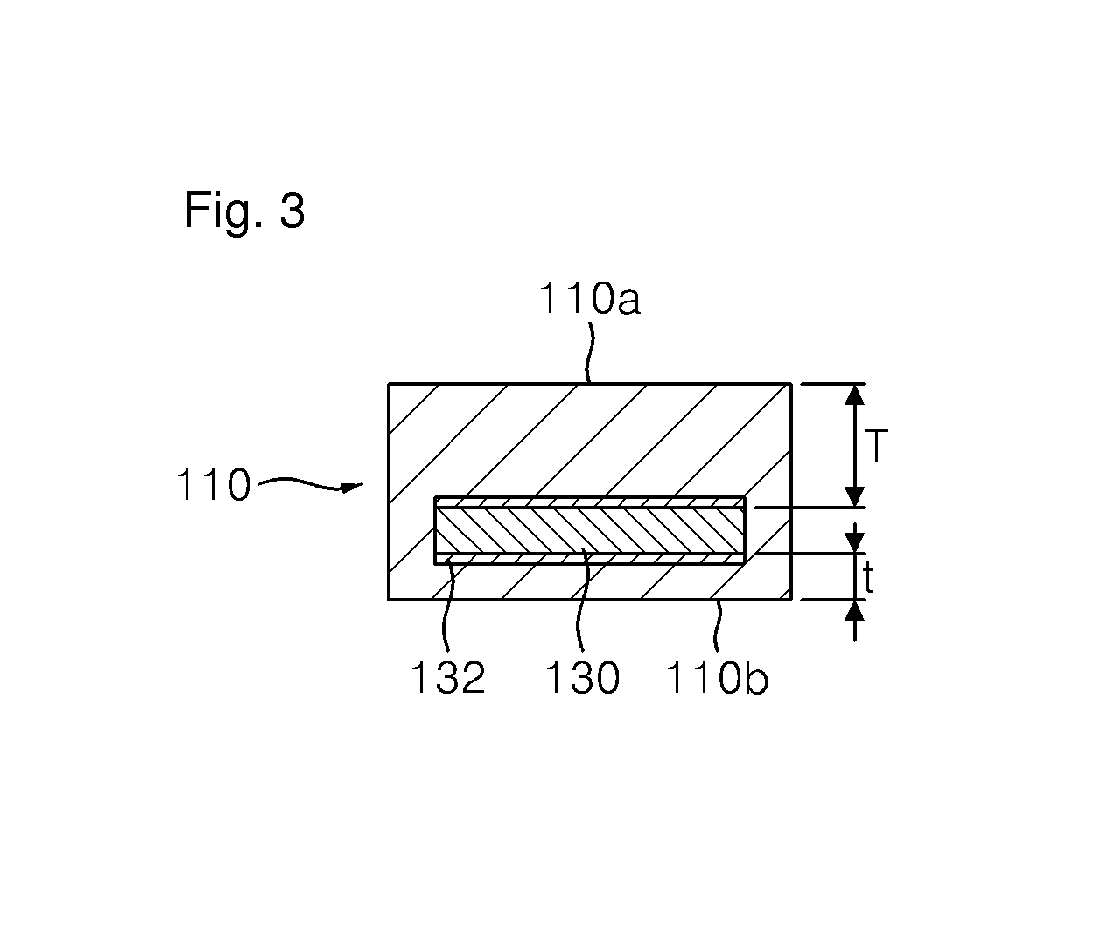

Evaporator, a heat absorber, a thermal transport system and a thermal transport method

InactiveUS6840304B1Air-treating devicesEnergy recuperation in distillationThermal transportLiquid tank

The conventional thermal transport system has disadvantages of the configuration being complex, large, heavyweight and expensive. In the present invention, a plurality of evaporators are connected in series via the liquid flow line, the evaporator of the first position is connected to the condenser via the liquid supply line, the evaporator of the last position is connected to the reservoir tanks for adjusting the amount of the liquid. The liquid amount measuring sensor is installed to measure the amount of the liquid in the liquid reservoir of the evaporator. Based on the measured result of the liquid amount measuring sensor, the control valve operates so as to supply the liquid accommodated in the reservoir tanks to each evaporator.

Owner:MITSUBISHI ELECTRIC CORP

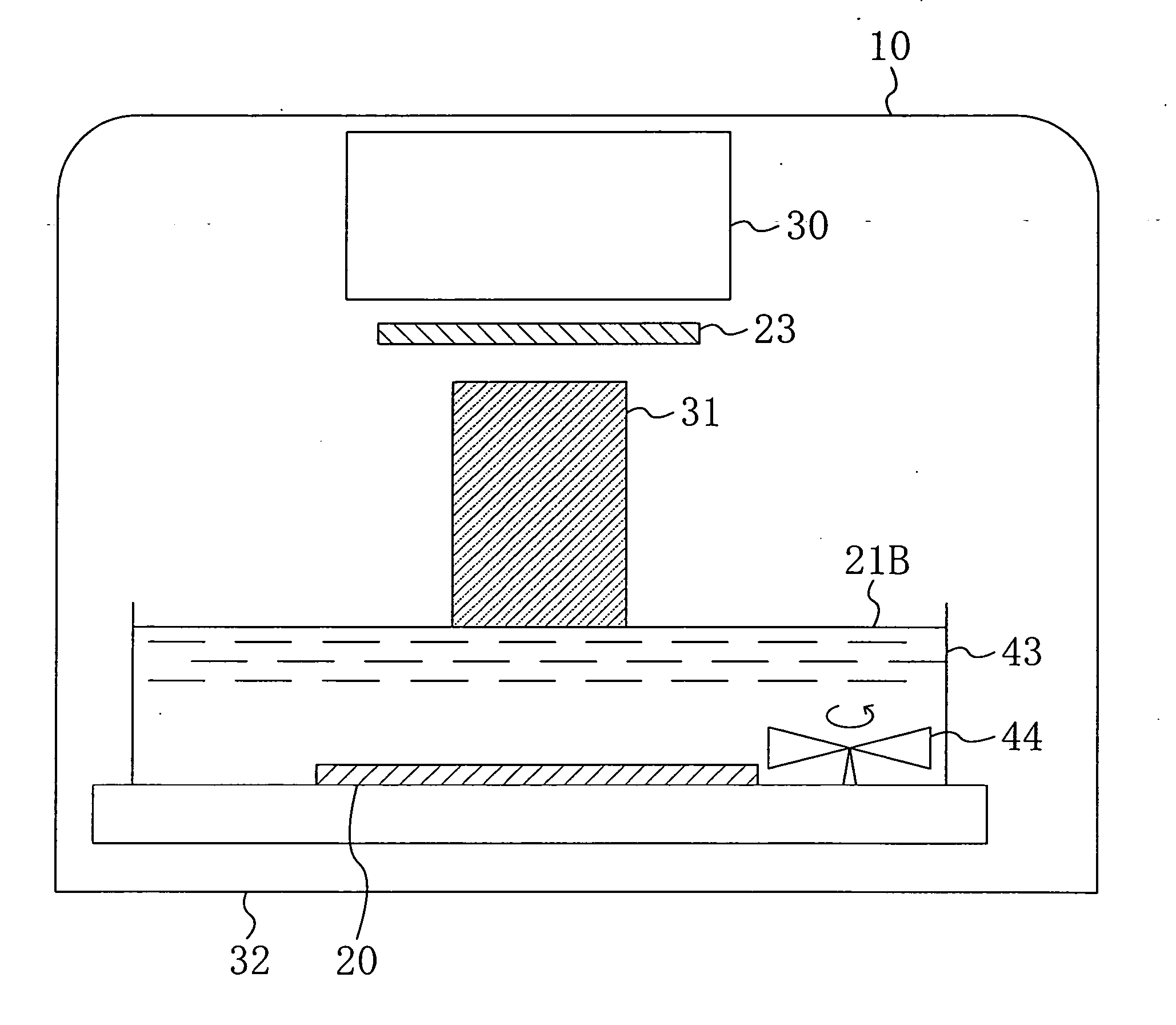

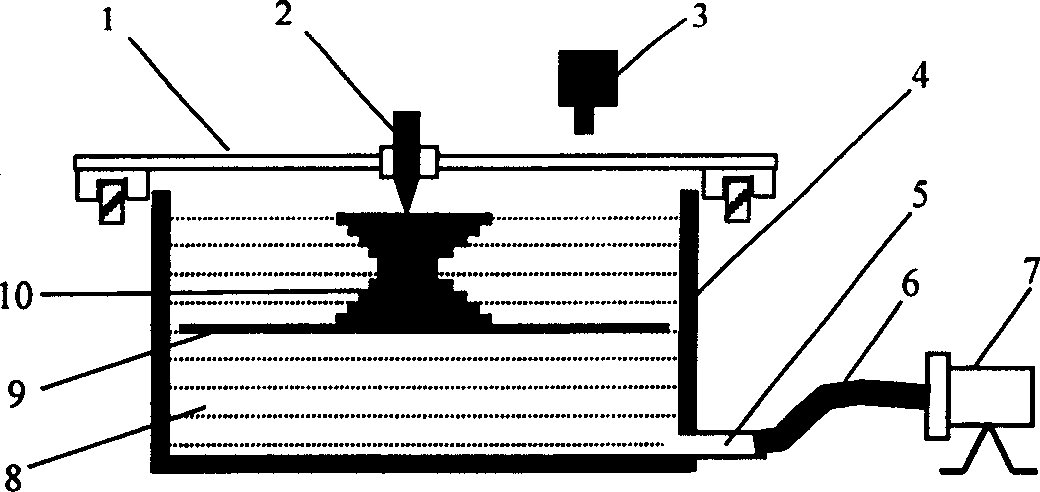

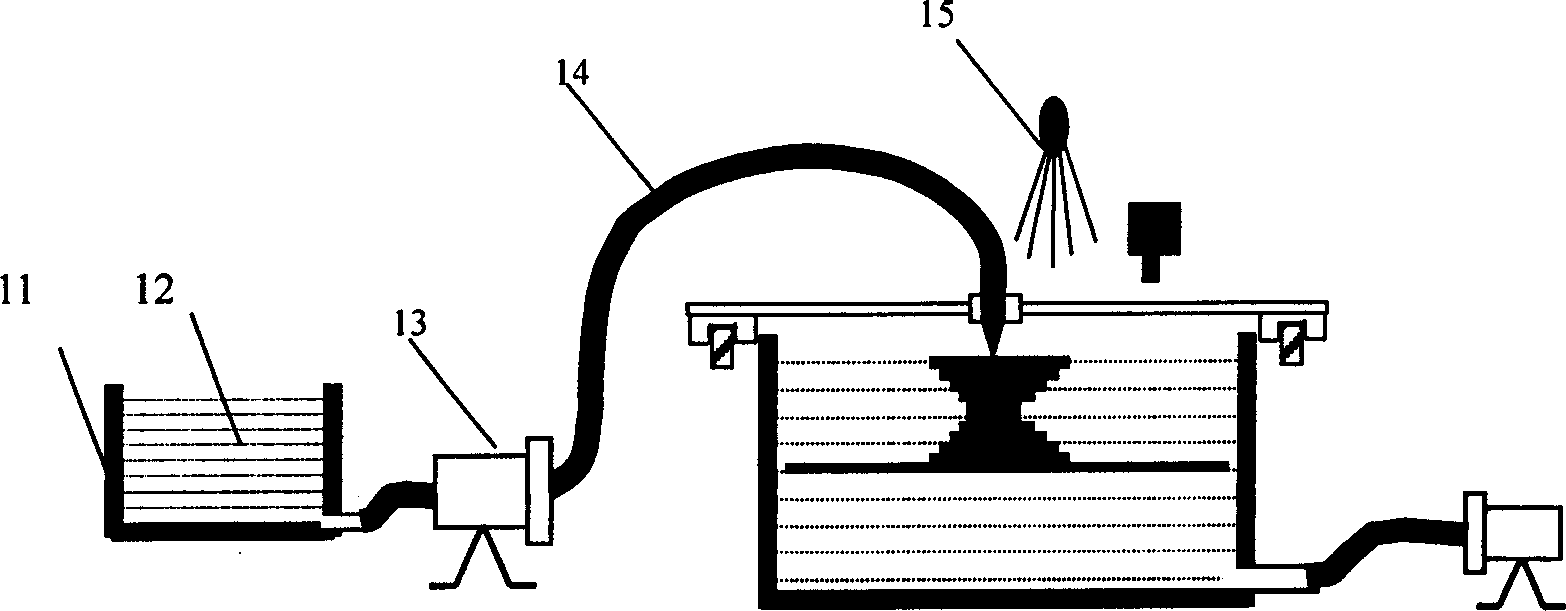

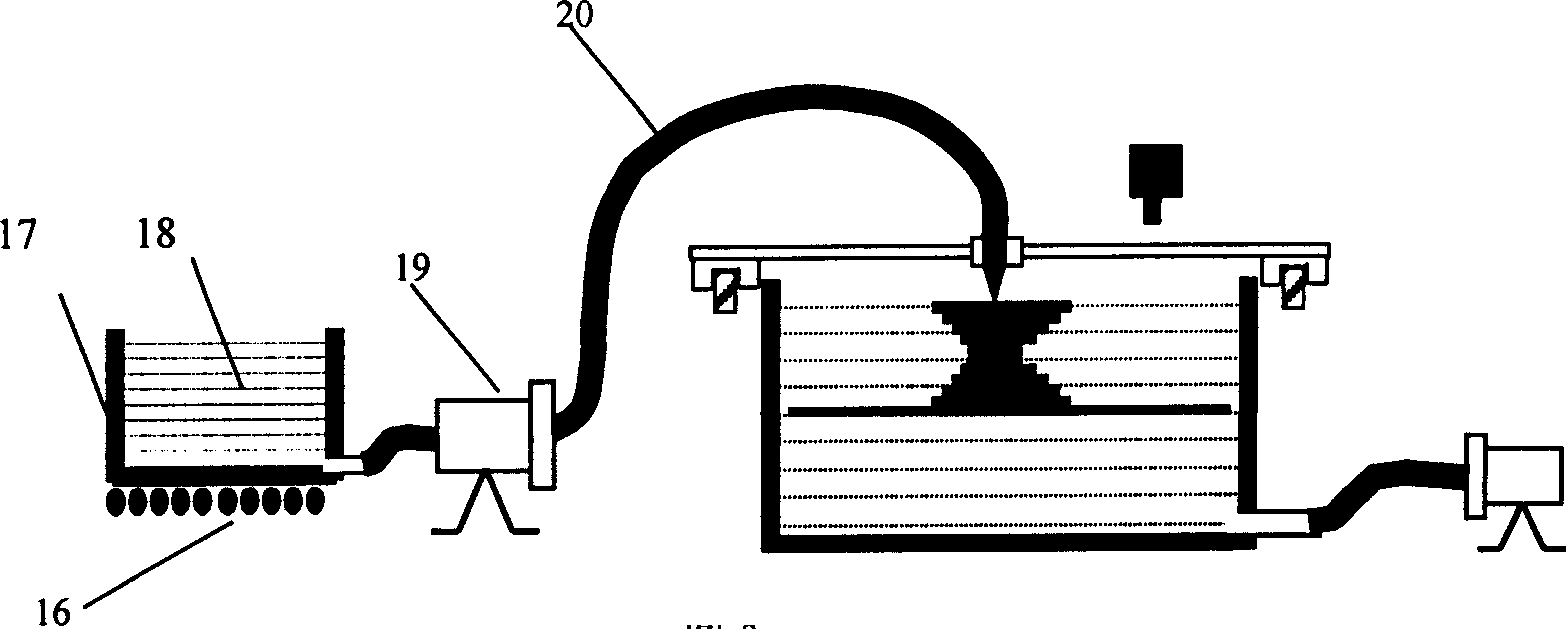

Three-dimensional printing formation unit and method

InactiveCN1739946AEasy to makeIncrease profitCoatingsSpecial data processing applicationsLiquid tankEngineering

The three-dimensional printing formation unit includes one X-Y work bench and one elevating platform. The X-Y work bench has lower liquid tank with bottom liquid support medium, and upper nozzle with downward spout, over liquid level sensor. The lower liquid tank has liquid support material and bottom flow guide hole, the elevating platform is located inside the liquid support material, and the flow guide hole is connected via duct with pump. The three-dimensional printing formation method includes spraying the forming material via the nozzle, forming on the liquid support material surface and based on the cross section data, curing the forming material on the surface of the support material to form one layer of the part, lowering the work bench for one layer of thickness for the painting of the next layer, and adhering the adjacent layer to form three-dimensional body. The present invention has the advantages of no need of special support structure, simple part making process, high material utilization, etc.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

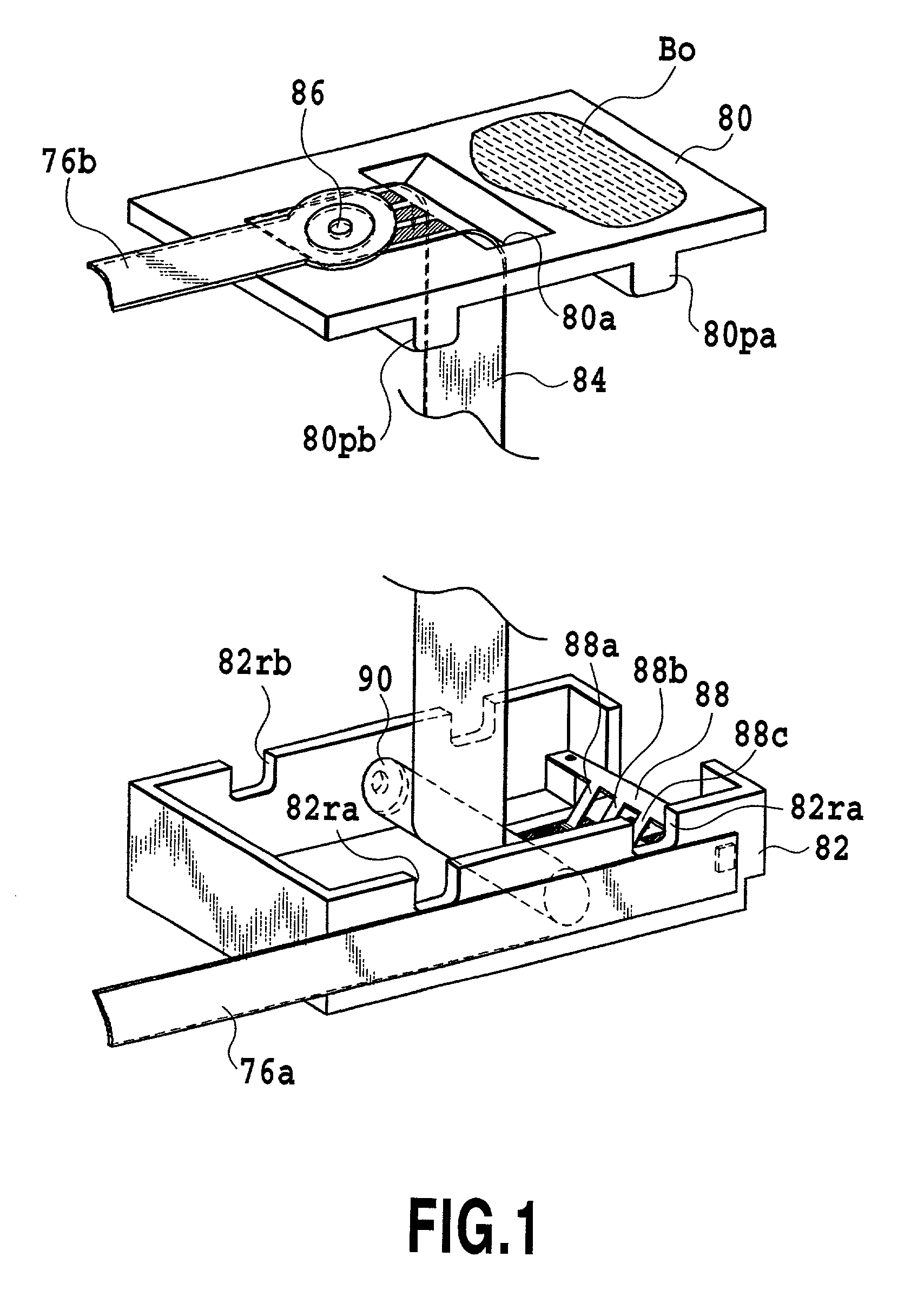

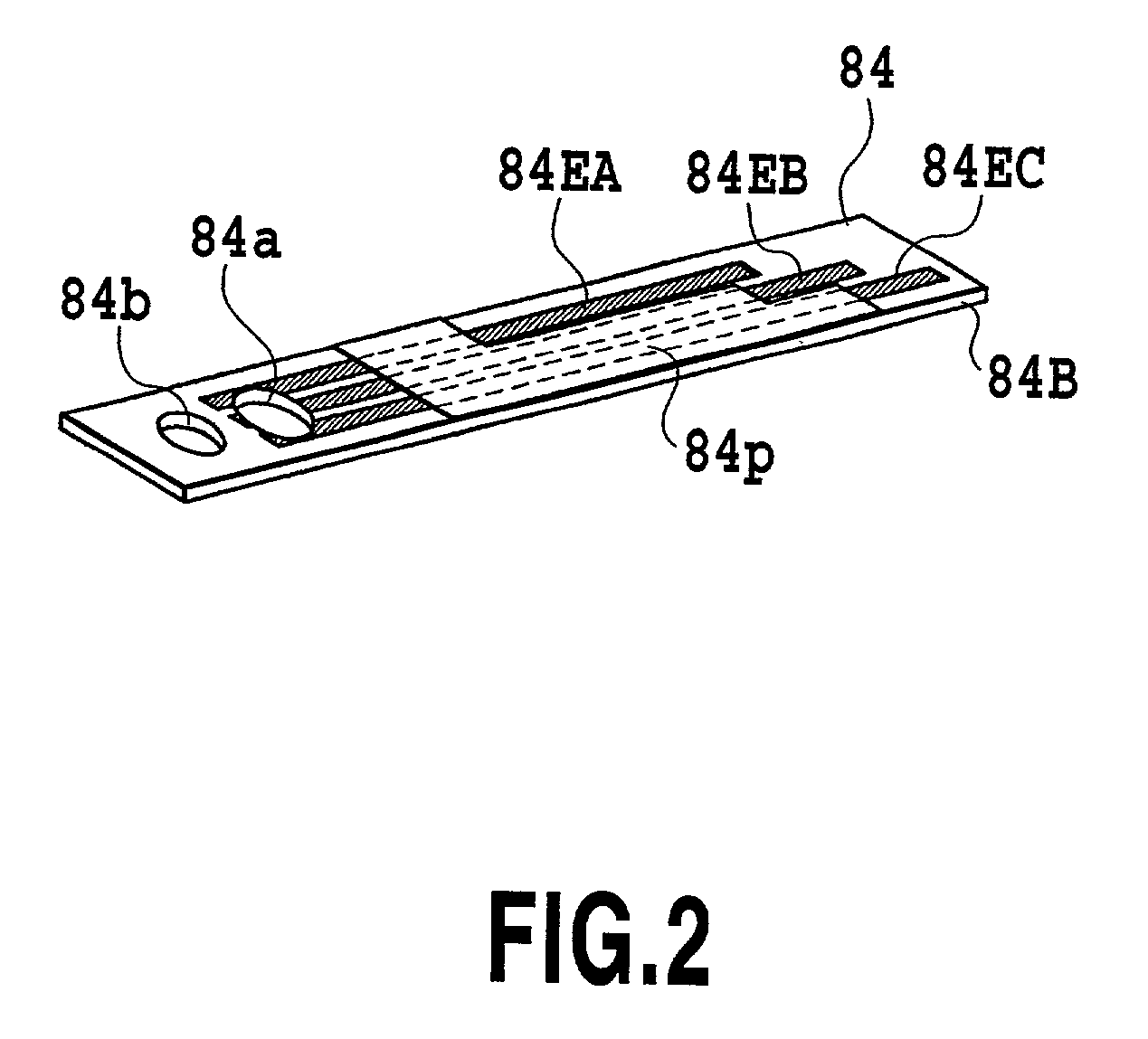

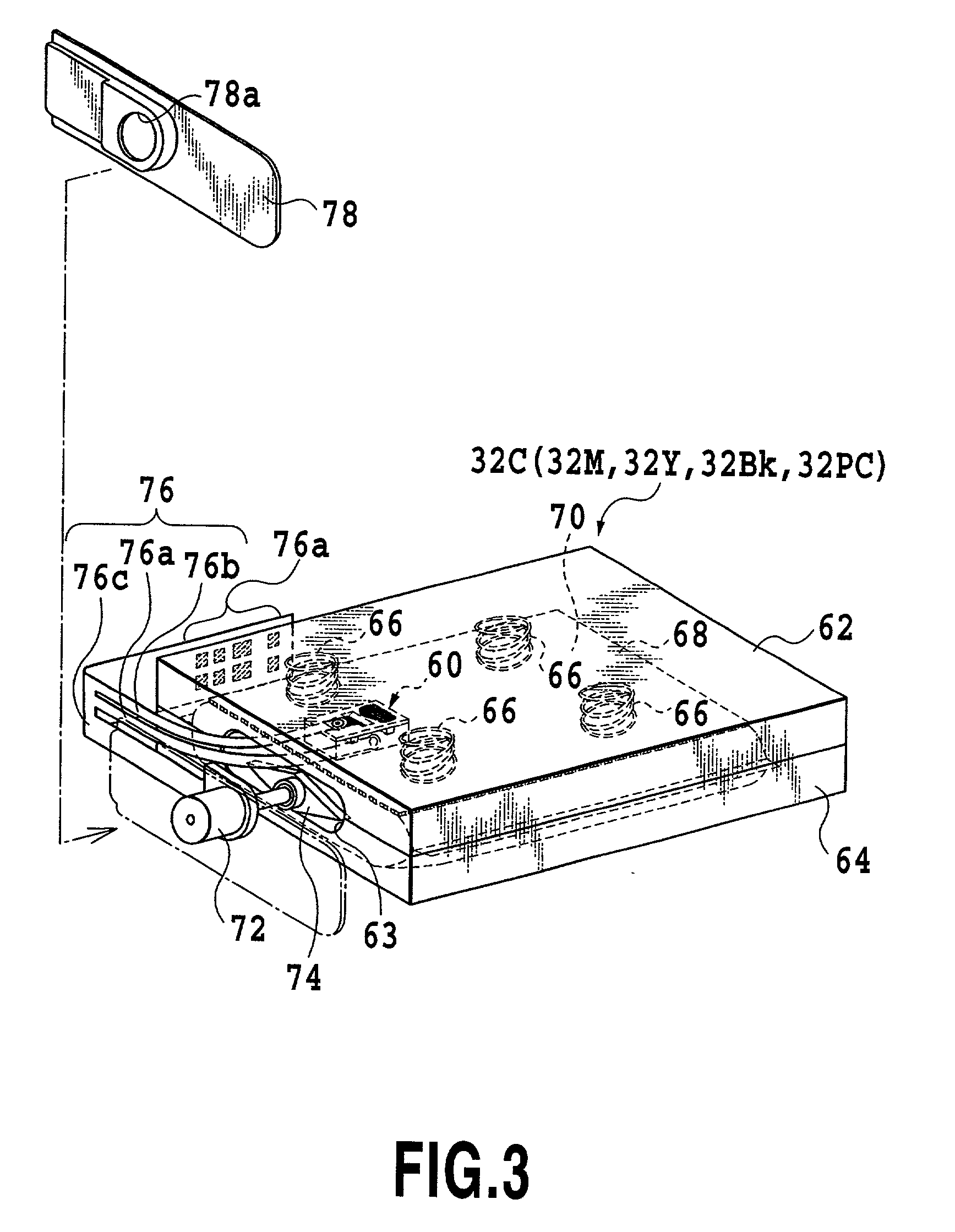

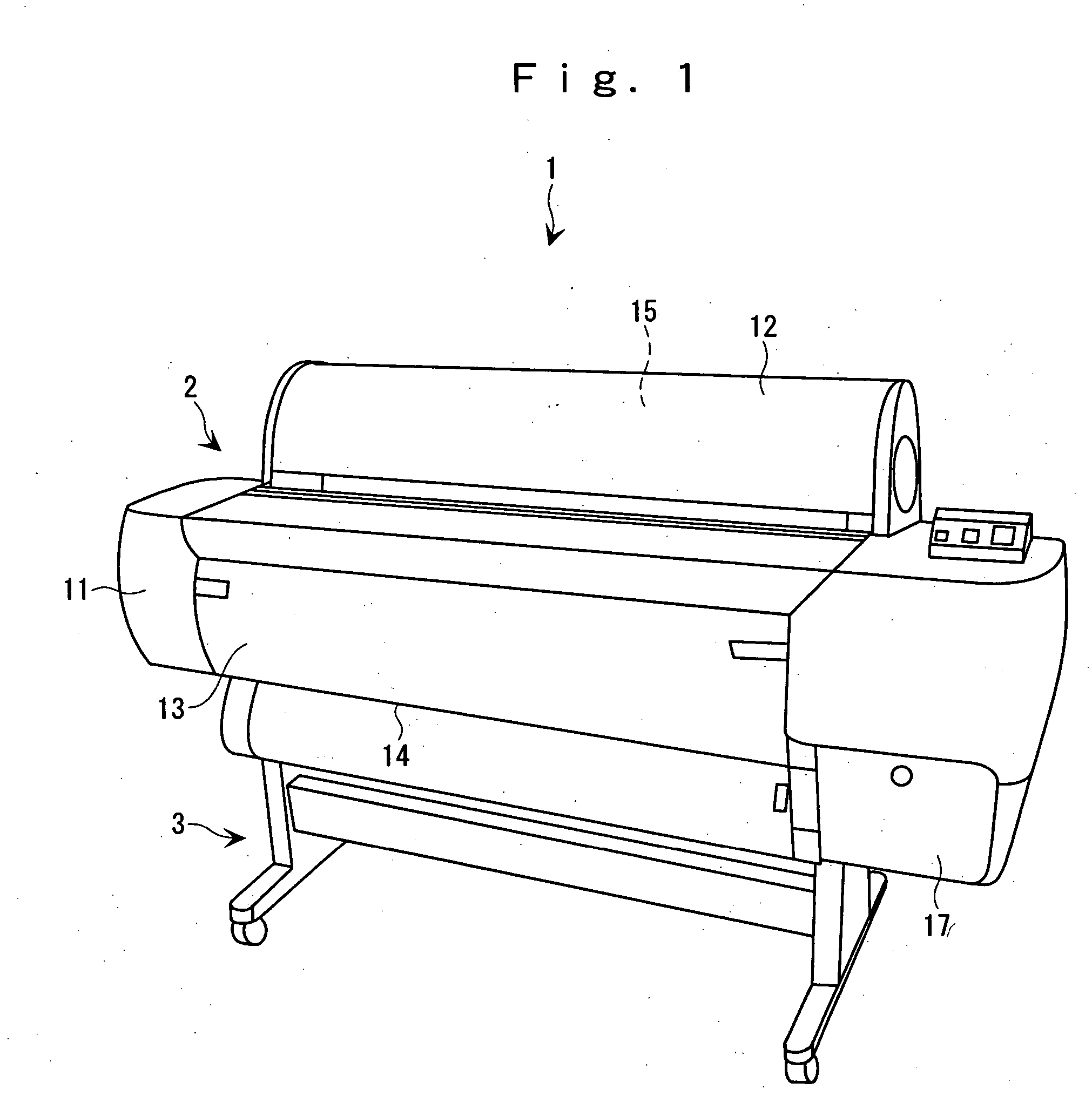

Print liquid tank and printing apparatus having the same

An ink consumption detection unit 60 includes the contact tape 84, whose one end is secured to the tank case 62 side and the other end to the flexible ink bag 68 side, and the contact electrode member 88 secured to the ink bag 68 side and placed in contact with the contact tape 84. As the ink in the ink bag 68 is consumed, the contact electrode member 88 is moved. When the contact electrode member 88 comes into contact with a plurality of contact electrodes 84EA, 84EB, 84EC representing ink consumptions in stages, the ink consumption detection unit 60 successively issues detection signals representing the ink consumptions.

Owner:CANON KK

Liquid ejection apparatus and liquid tank

The liquid ejection apparatus comprises: a liquid ejection unit which ejects a liquid; a liquid storage unit which stores the liquid to be supplied to the liquid ejection unit; a plurality of flow passages through which the liquid flows; and a switching unit which holds a removable filter to trap foreign matter and switches a position of the filter so that the filter is connected to each of the plurality of flow passages in succession.

Owner:FUJIFILM CORP

Water level sensing apparatus

ActiveUS8667840B2Increase intervalLess clean upMachines/enginesLubrication indication devicesCapacitanceBody contact

There is provided a water level sensing apparatus including: a body disposed to be exposed within a liquid tank and having an accommodating space therein; and a capacitance detecting unit accommodated in the accommodating space of the body, wherein the capacitance detecting unit compares an upper side capacitance value and a lower side capacitance value and turns on or off an output signal. Because a changeable reference that the capacitance values of a reference surface and a detected surface of the body are simultaneously changed is used, even if the body comes in contact with moisture or debris, the reference surface and the detected surface are equally affected by the moisture or debris, thus reducing the occurrence of malfunction.

Owner:WOONGJIN COWAY

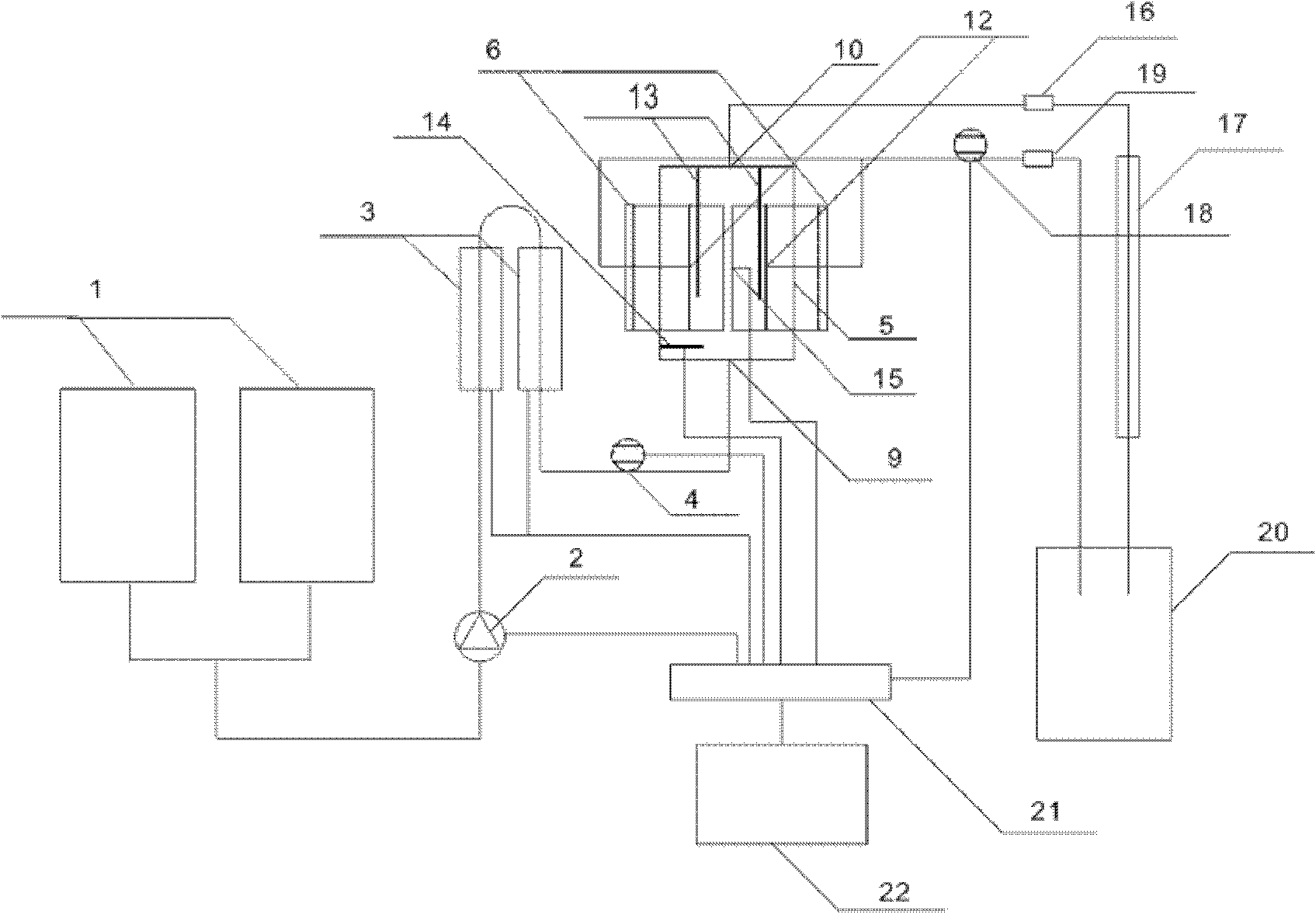

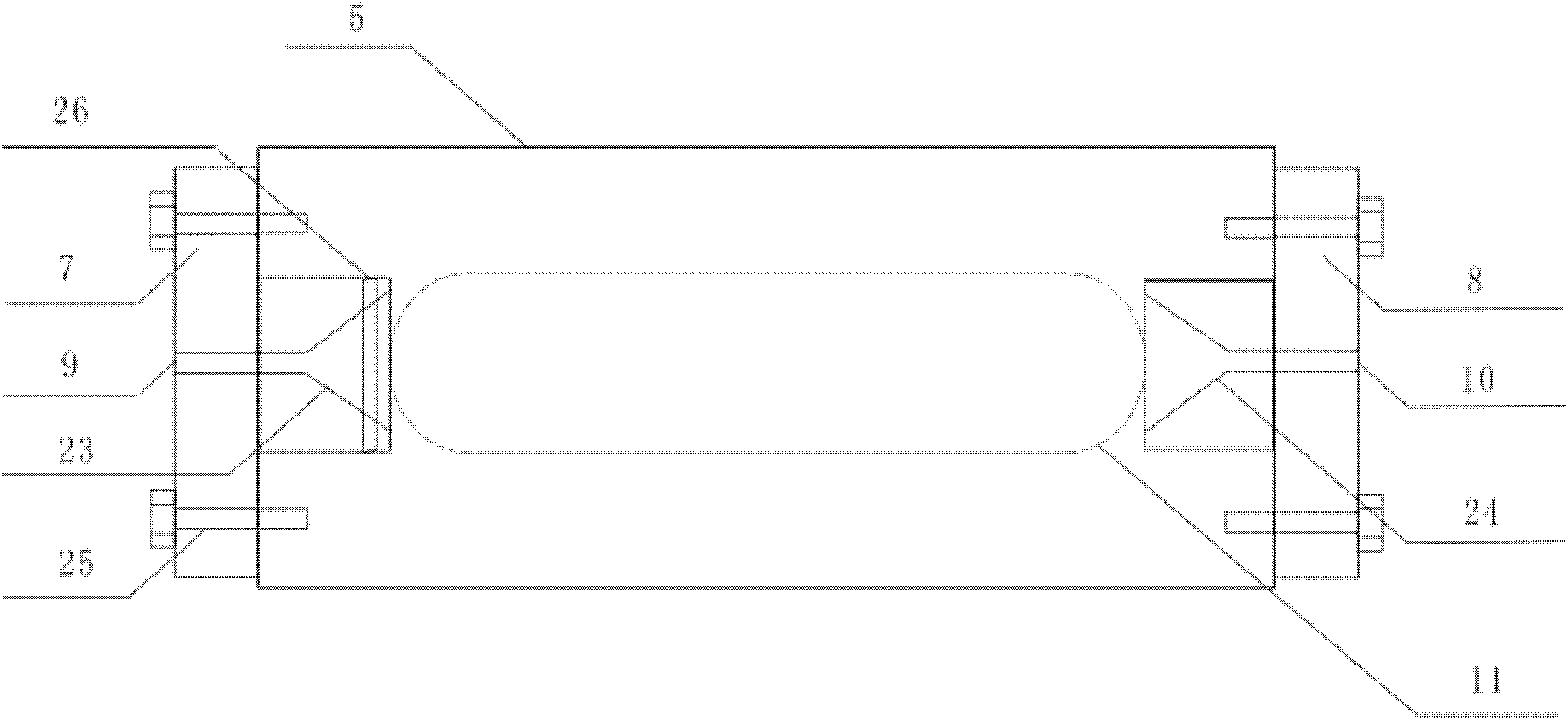

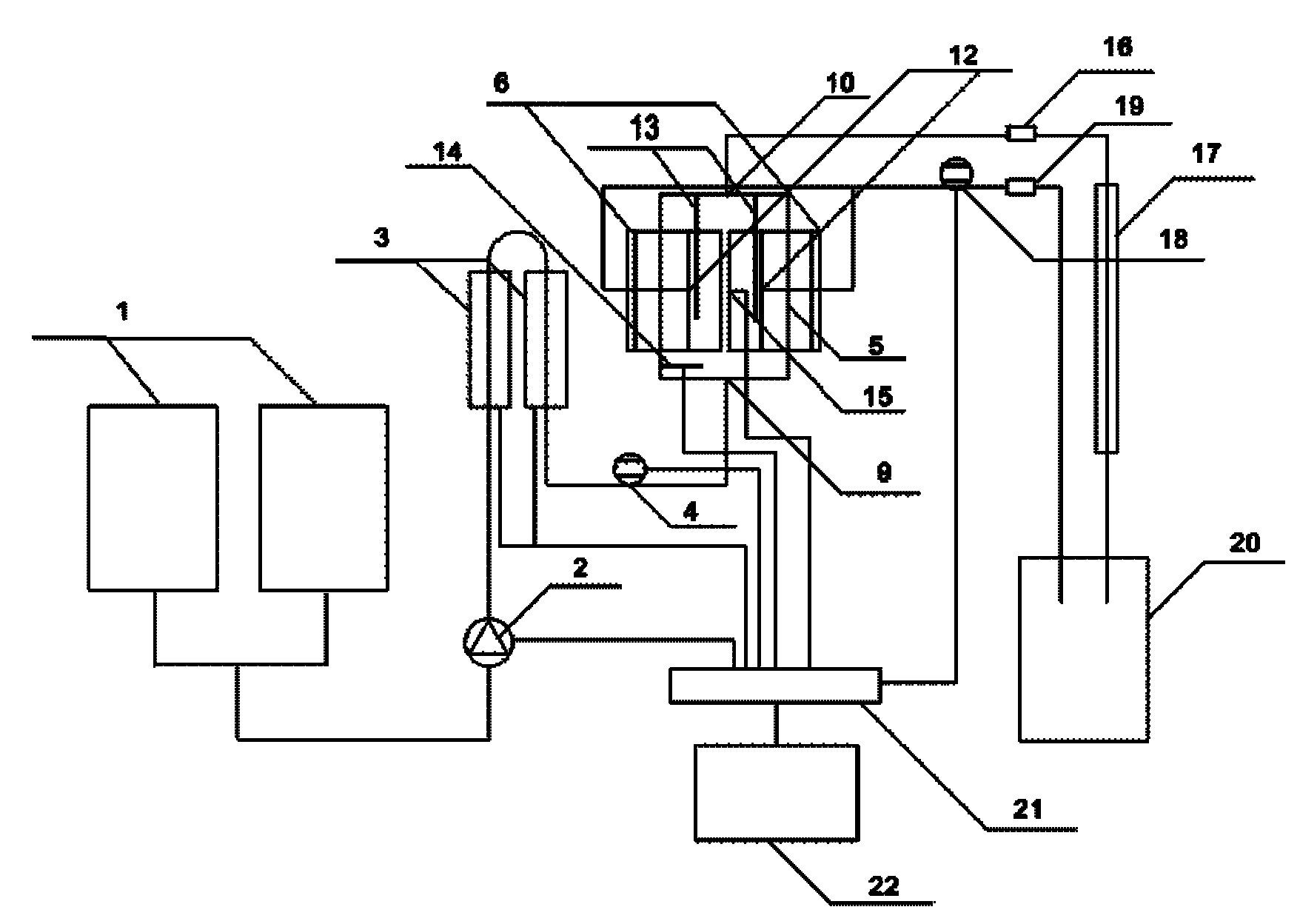

Test device and method for simulating acid etching crack flow guide capability

InactiveCN101864949AMonitor pressure in real timeMonitor temperature in real timeFluid removalAcid etchingWater storage tank

The invention relates to a test device and a method for simulating acid etching crack flow guide capability. The test device consists of a liquid storage tank, a diaphragm pump, a pipeline electric heating sleeve, a flow meter, a flat plate clamping device, a pressure return valve, a condensing pipe, a waste liquid tank, a data collection and control panel and the like, wherein the inner side of the clamping device is provided with a temperature sensor and a pressure sensor, both ends of the lamping device are provided with small liquid inlet holes and small liquid outlet holes, the inside of the clamping device is provided with a liquid inlet piston and a liquid outlet piston, a rock core chamber is arranged between the liquid inlet piston and the liquid outlet piston, the clamping device is connected with a pressure machine, and the diaphragm pump, the pipeline electric heating sleeve, the flow meter, the temperature sensor and the pressure sensor are all connected with the data collection and control panel and a computer. The test method comprises the following steps; cutting the rock into rock core samples conforming to the standard flow guide chamber, and sealing and curing the rock core samples; placing the rock core samples into the rock core chamber; adopting a gasket for simulating the crack width; sequentially opening a clear water storage tank and an acid liquid storage tank; starting the computer, and inputting experiment parameters; and calculating the flow guide capability of the acid etching cracks of the rock core samples. The invention can simulate the real conditions of the underground acid etching crack forms, and can meet the requirements of the acid etching crack flow guide capability test under different environment conditions.

Owner:SOUTHWEST PETROLEUM UNIV

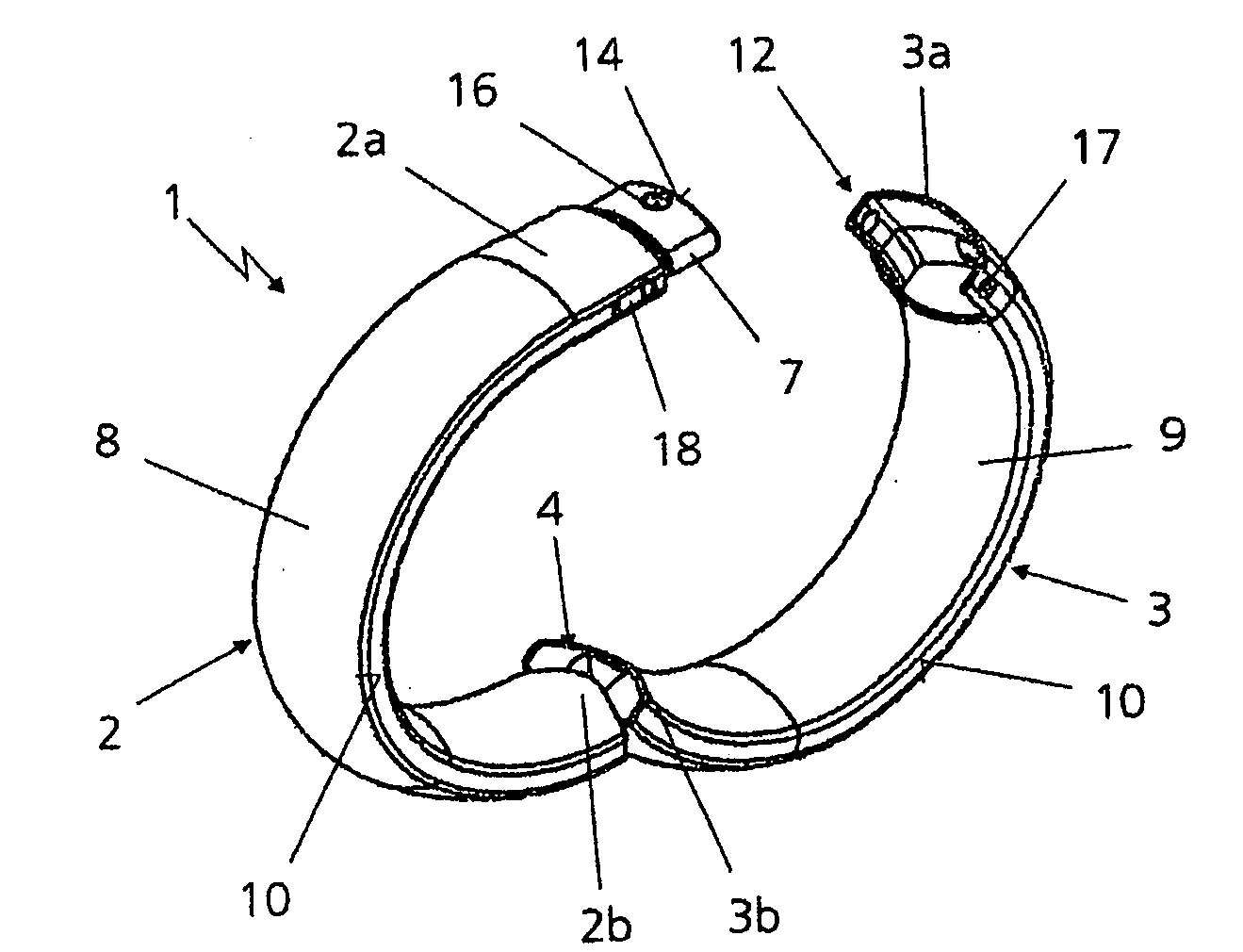

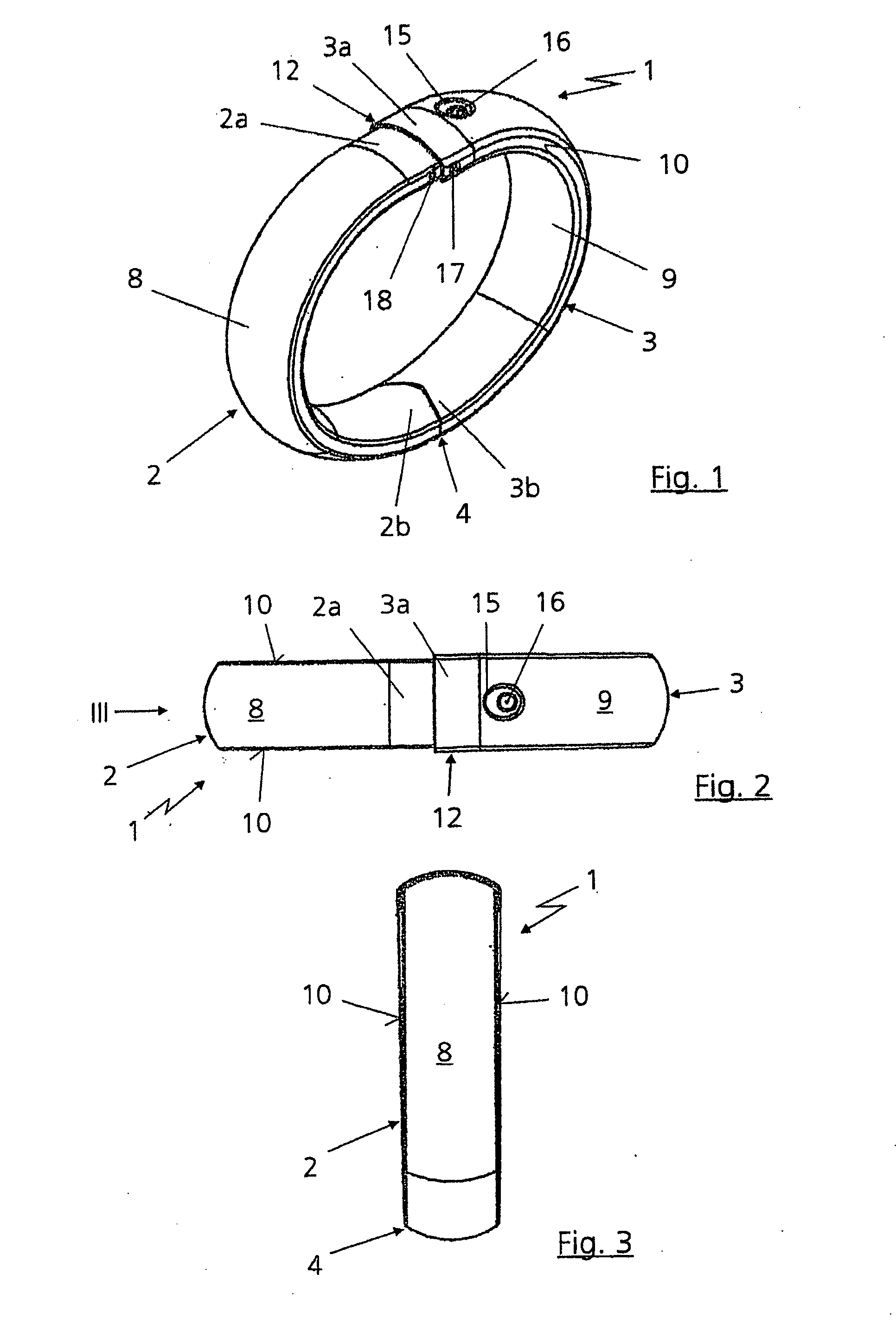

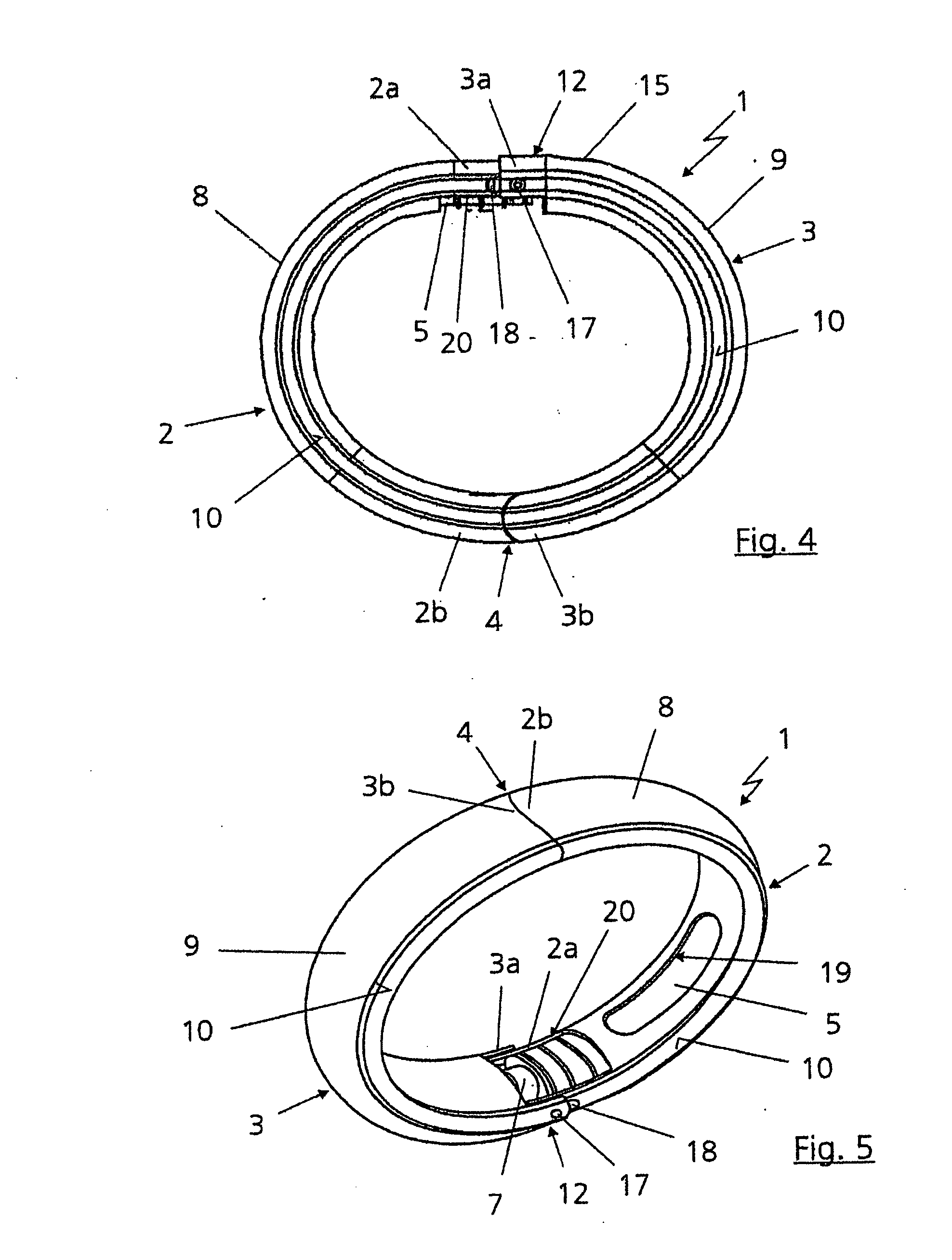

Bangle

InactiveUS20080236195A1Easy to operateMeet precise requirementsBraceletsWrist-watch strapsLiquid tankEngineering

The invention relates to a bangle comprising an annular-shaped cover which is formed, essentially, of two curved tubes. The tubes are connected together on one of the tube ends by a hinge and comprises a liquid tank. One tube is embodied in such a manner that it receives the liquid tank, and a spraying head of the liquid tank protrudes into a tube end of the adjacent tube. The two tubes can be displaced in relation to each other in the region of the tube end thereof which is oriented away from the hinge.

Owner:WOEBKE KLAUS

Micro fluid control chip and preparation method and application thereof

InactiveCN101817495AReduce volumeVolume stabilityPrecision positioning equipmentSolid-state devicesFluid controlVolumetric Mass Density

The invention belongs to the technical field of micro fluid control, particularly disclosing a micro fluid control chip and a preparation method and application thereof. One side of the chip is provided with a plurality of sample introduction holes, each sample introduction hole is communicated with a sample introduction runner; after meeting, each sample introduction runner is communicated with a main runner; the main runner is provided with a narrow runner; a micro-sphere of which the size is 0.5-1.5 mm is filled in front of the inlet of the narrow runner; the outlet of the main runner is communicated to a waste liquid tank arranged at the other side of the chip. The preparation method mainly comprises: firstly preparing a PDMS substrate; then, preparing a PDMS cover plate with an upper groove; sticking the substrate onto the cover plate to obtain a semi-finished product of the chip; carrying out modified treatment on each runner in the semi-finished product of the chip; finally, putting the micro-sphere in, controlling the charge quantity, and finishing production. The micro fluid control chip of the invention has high solution mixing efficiency, stable solution flow rate, small volume, convenient carrying and relatively simple manufacturing; when being used for detecting the density of triphosadenine, the micro fluid control chip has the advantages of high sensitivity, favourable detection effect and the like and can not be affected by environment humidity.

Owner:HUNAN UNIV

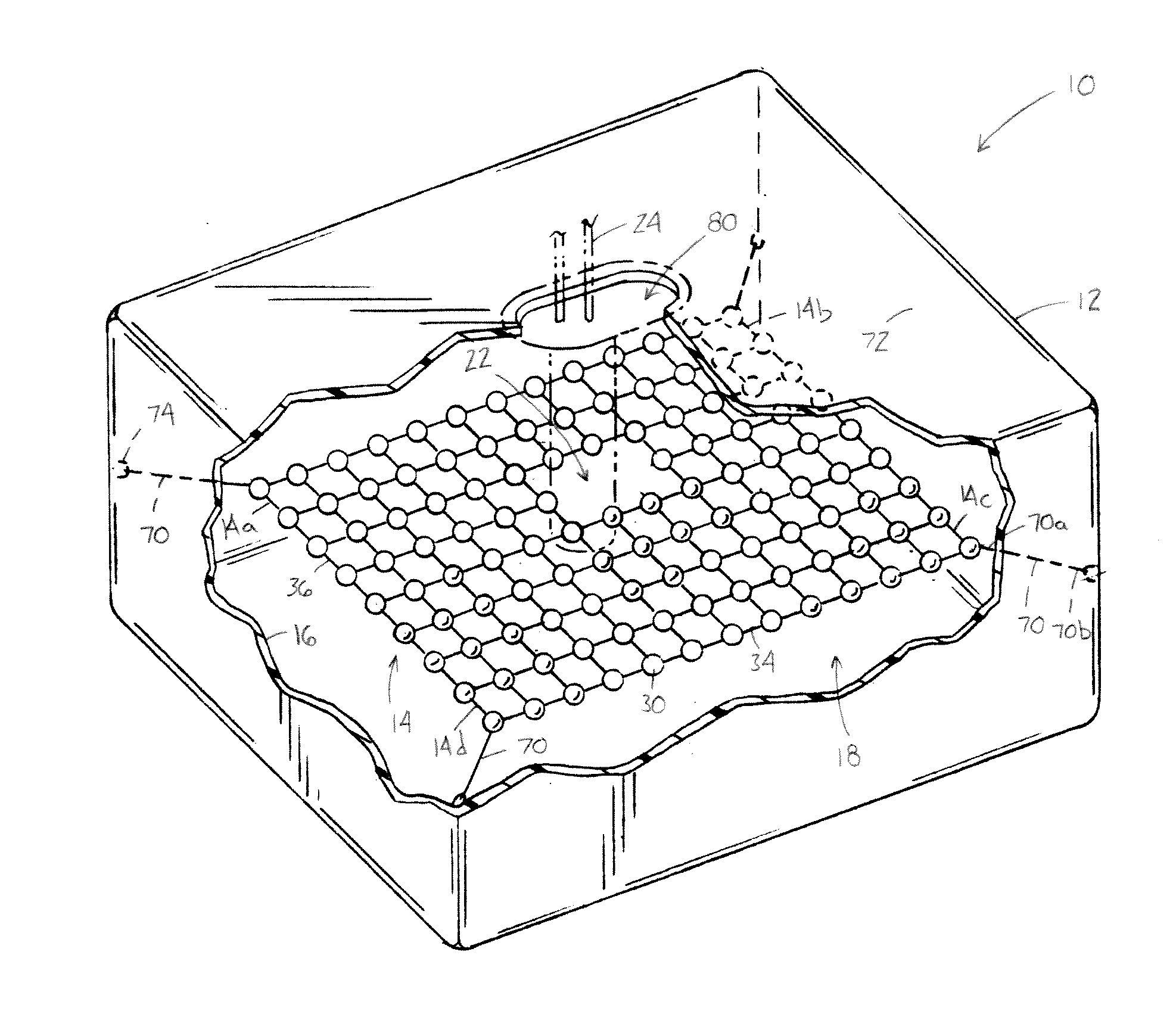

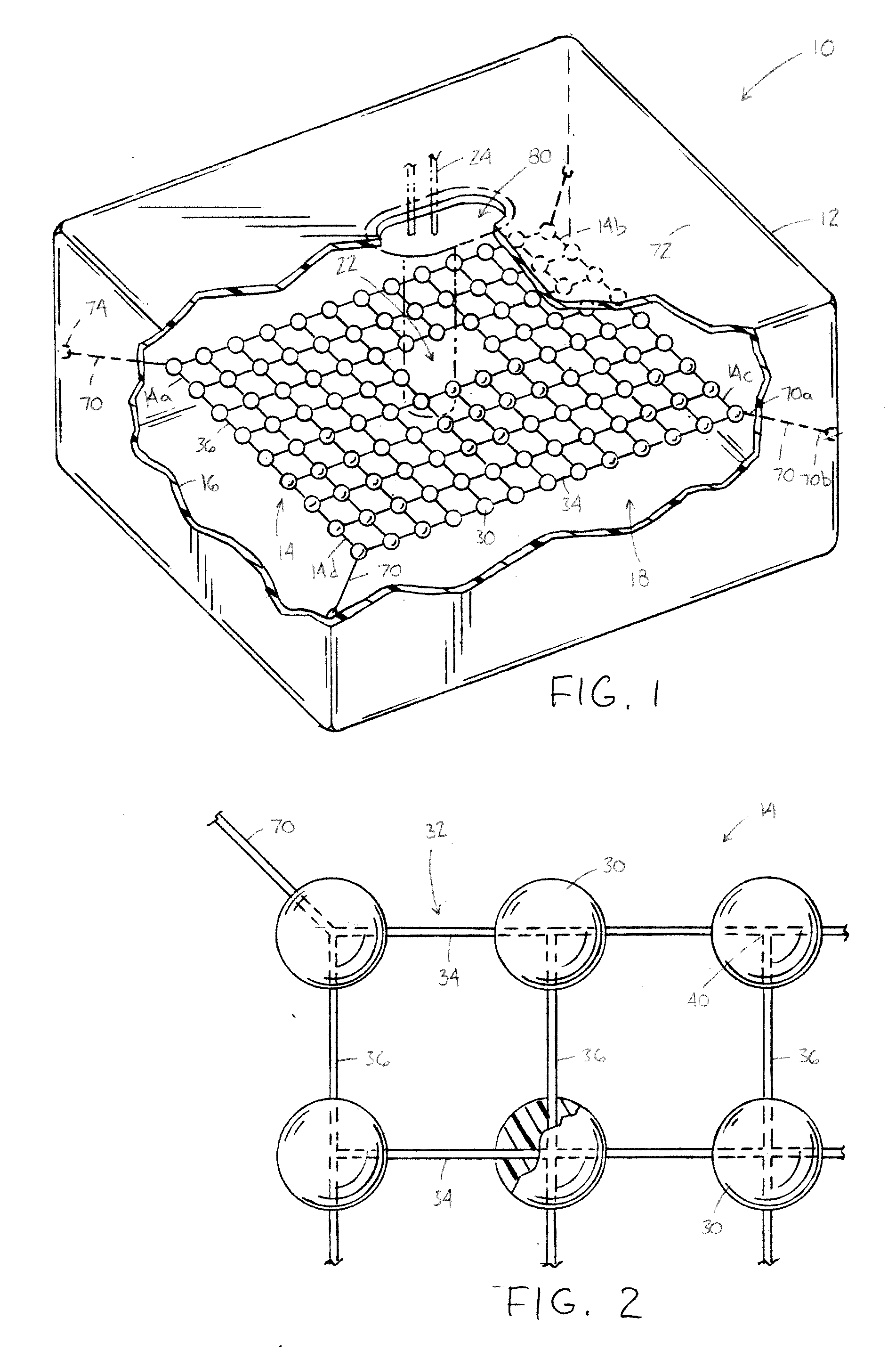

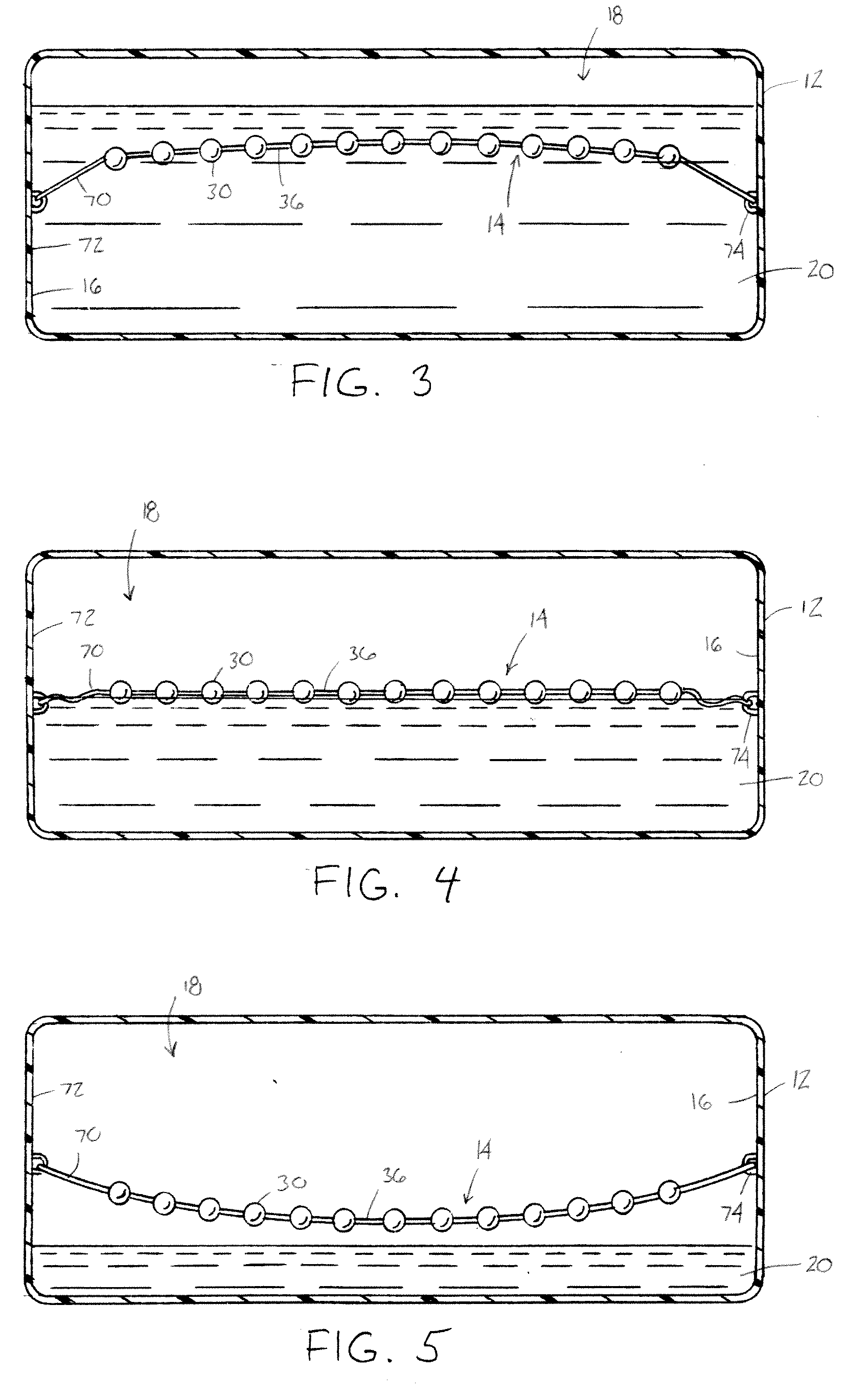

Floating Absorber Assembly for Reduced Fuel Slosh Noise

InactiveUS20090078705A1Reduce noiseMitigate surface wave propagationLarge containersItem transportation vehiclesEngineeringLiquid tank

A liquid tank assembly for a motor vehicle includes a tank and an absorber assembly. The tank has an inner surface defining a cavity for receiving a liquid substance. The absorber assembly is disposed within the cavity for dampening liquid sloshing noises. The absorber assembly includes a plurality of connected dampener elements. End sections of the absorber assembly are attached to the inner surface of the tank. The absorber assembly is configured to float on a surface of the liquid when a volume of liquid within the tank is between a first critical volume and a second, lower critical volume. The absorber assembly is generally submerged when a volume of liquid within the tank is a generally greater than the first critical volume. The absorber assembly is generally suspended within the cavity when a volume of liquid within the tank is a generally lower than the second critical volume.

Owner:HONDA MOTOR CO LTD

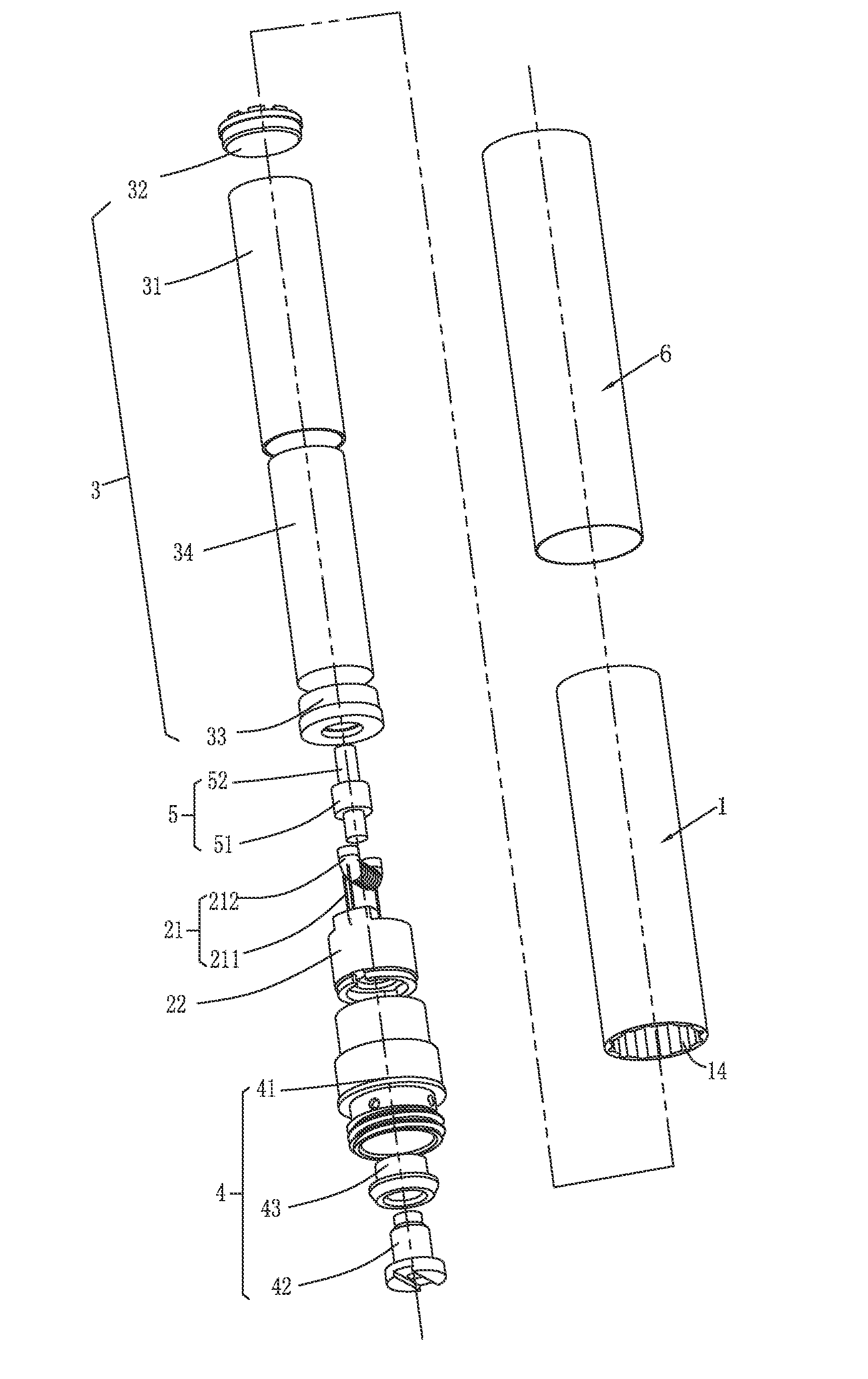

Liquid tank, atomizer and electronic cigarette having same

An exemplary liquid tank for an atomizer includes a bottom part, a liquid outlet, a first air inlet, a first porous liquid blocking element, and a top part. The bottom part has a first end and an opposite second end, and defines a liquid chamber for containing tobacco liquid. The liquid outlet is defined in the second end. The first air inlet is defined in the first end, so that external air can enter the liquid chamber via the first air inlet. The first porous liquid blocking element covers the first air inlet. The first porous liquid blocking element is capable of preventing the tobacco liquid in the liquid chamber from flowing out via the first air inlet, and allows air to pass through. The top part is detachably connected to the first end. The top part and the bottom part cooperatively clamp the first liquid blocking element therebetween.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Treatment liquid for ink jet, treatment liquid tank for ink jet, ink set for ink jet, ink tank for ink jet, ink jet recording method, and ink jet recording apparatus

The invention provides a treatment liquid for ink jet, which includes at least an organic acid having a pKa value of 4.5 or less, a nonionic substance, and water, wherein: (I) the treatment liquid has a pH value of 1.5 to 5.5, (II) the nonionic substance has a weight-average molecular weight of 300 or more but less than 5,000, and (III) a difference in solubility parameter (SP value) between a fundamental skeleton part of the organic acid excluding its acid group and the nonionic substance is 0.01 to 0.75.

Owner:FUJIFILM BUSINESS INNOVATION CORP

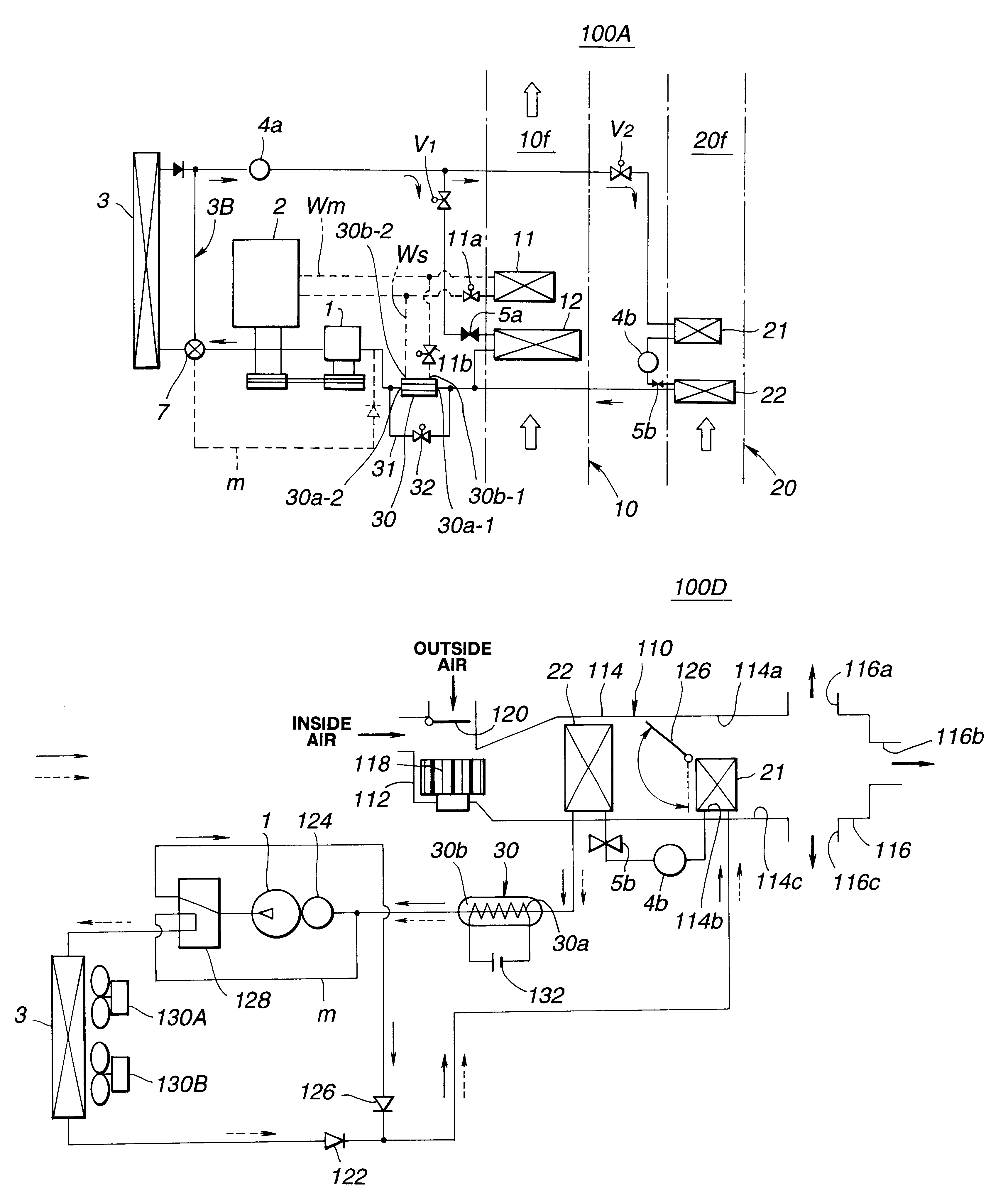

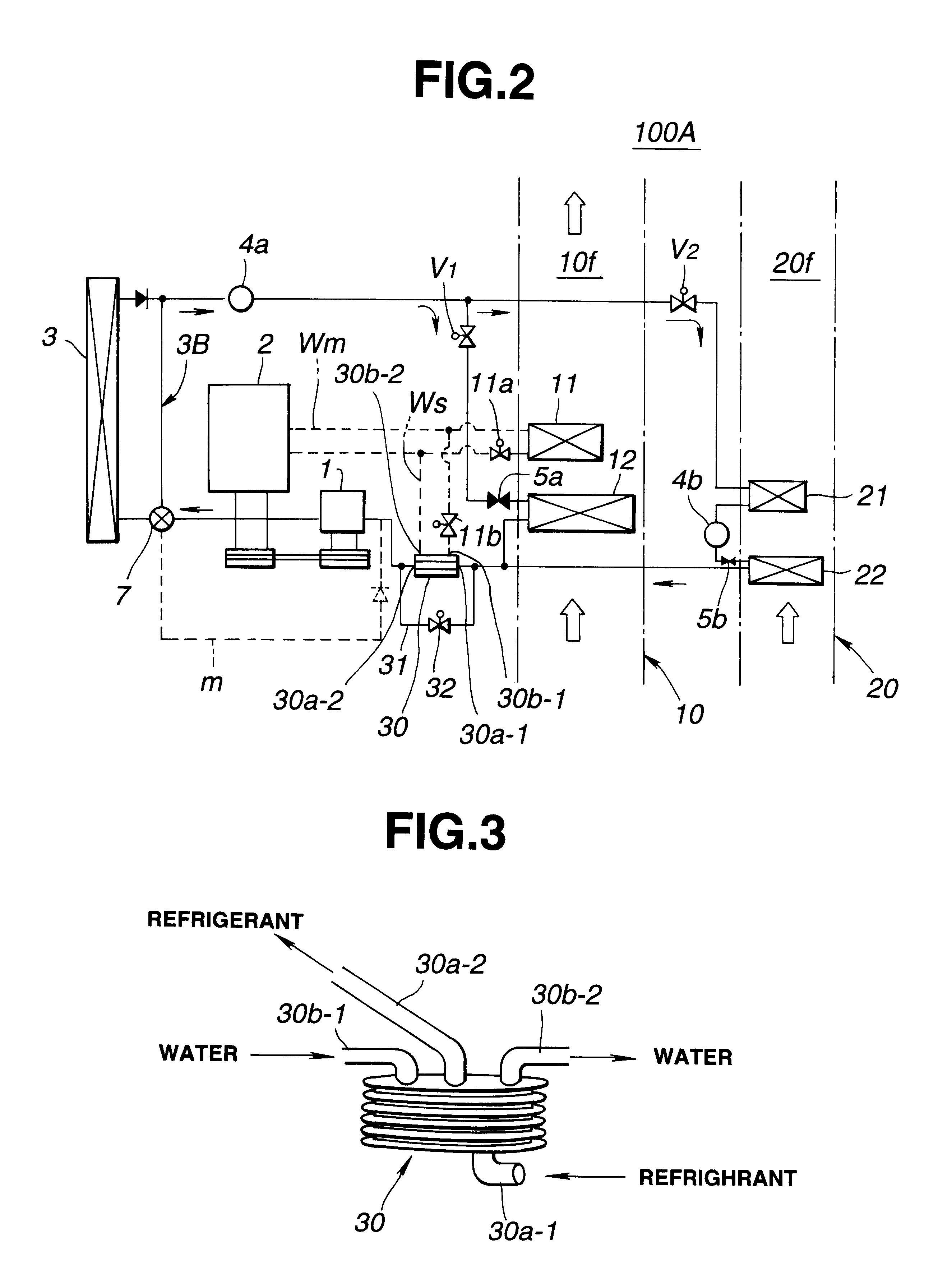

Automotive air conditioning system

An air conditioning system for a vehicle has a first cycle including a compressor, a first condenser, a second condenser, a liquid tank, an expansion valve and an evaporator which are connected through pipes to form a first refrigerant circulation circuit through which a refrigerant flows from an outlet of the compressor to an inlet of the compressor while changing the phase. The first cycle causes the evaporator to act as a cooler when operated. The system further has a second cycle including the compressor, the second condenser, the liquid tank, the evaporator and the evaporator which are connected through pipes to form a second refrigerant circulation circuit through which the refrigerant flows from the outlet of the compressor to the inlet of the compressor while changing the phase. The second cycle causes the condenser to act as a heater and the evaporator to act as a cooler when operated. The first and second cycles are switched by switch means. The system further has an air duct case having an air flow passage in which the second condenser and the evaporator are installed. The air flow passage is connected at its downstream part to a passenger room of the vehicle. The air conditioning system further comprises heater means for heating a returning refrigerant which, under operation of the second cycle, flows in the pipe extending from an outlet of the evaporator to the inlet of the compressor.

Owner:CALSONIC KANSEI CORP

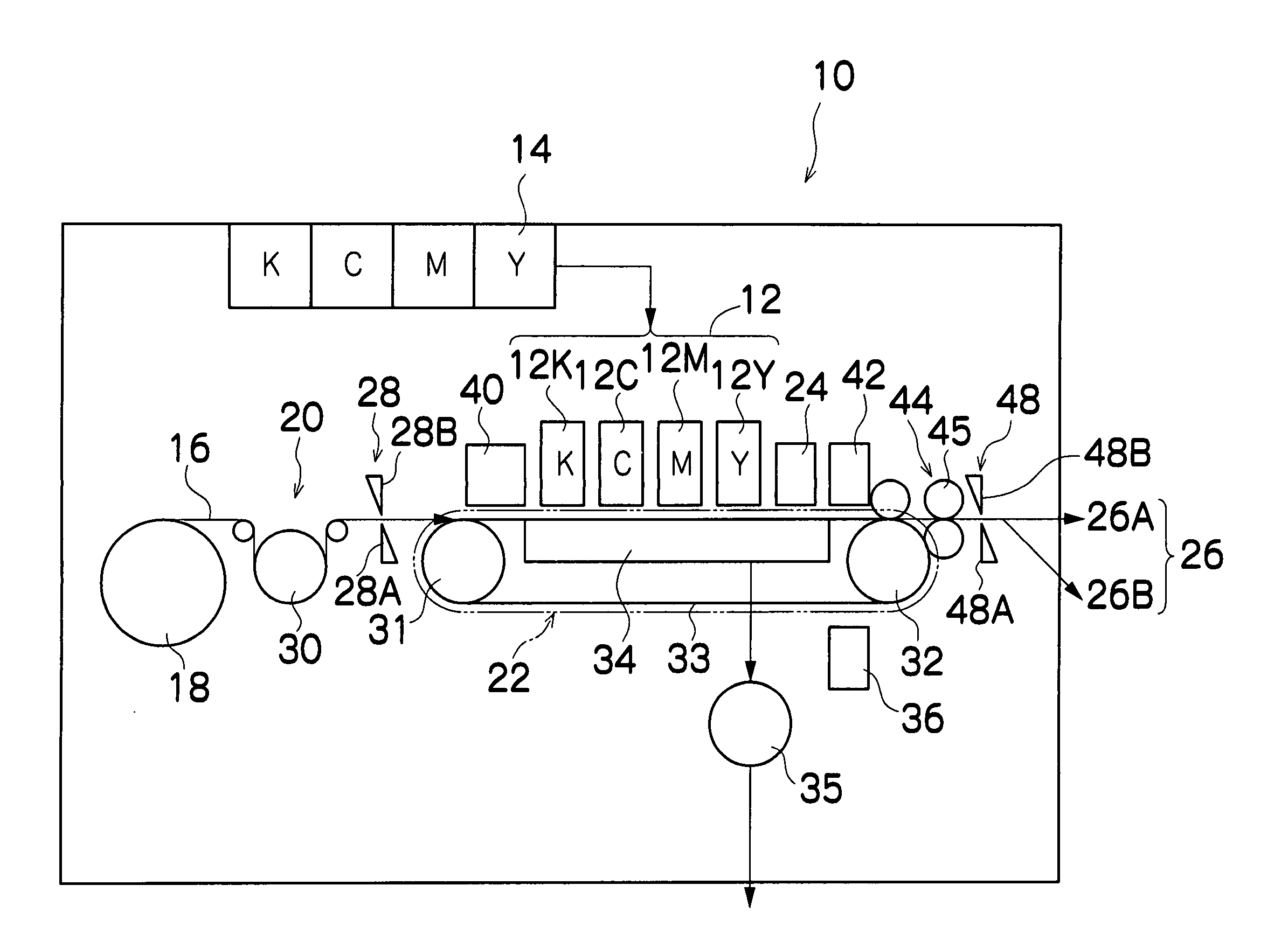

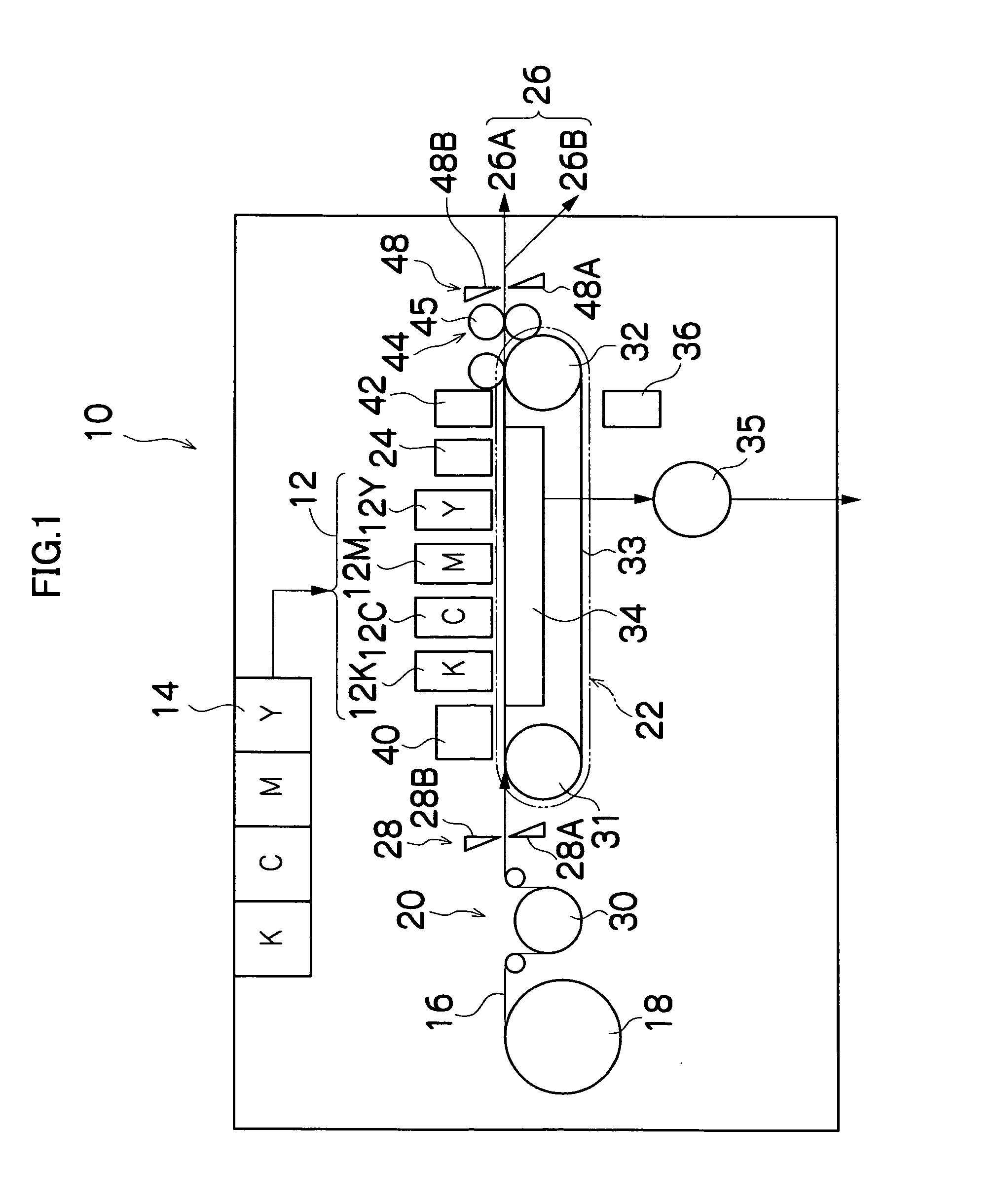

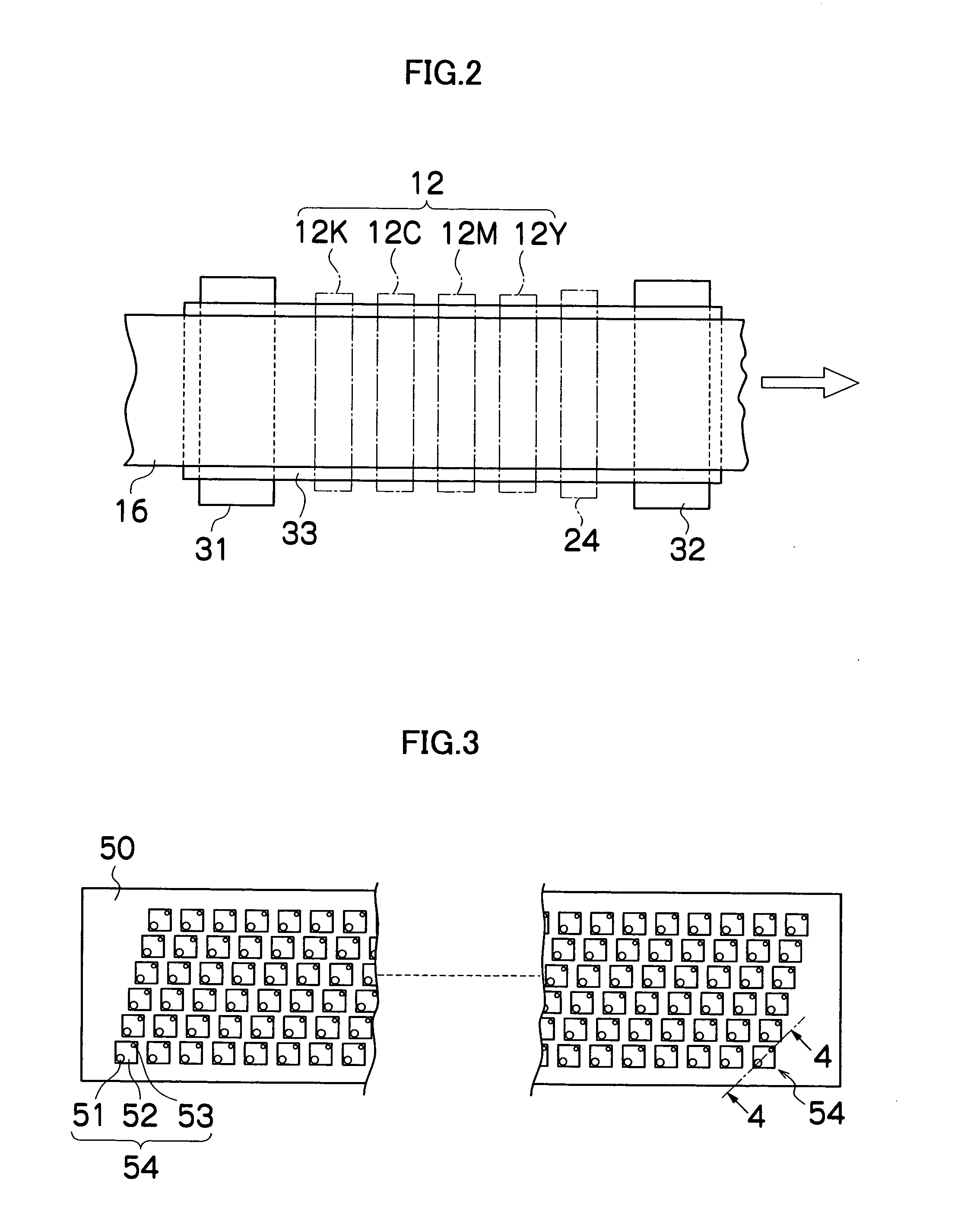

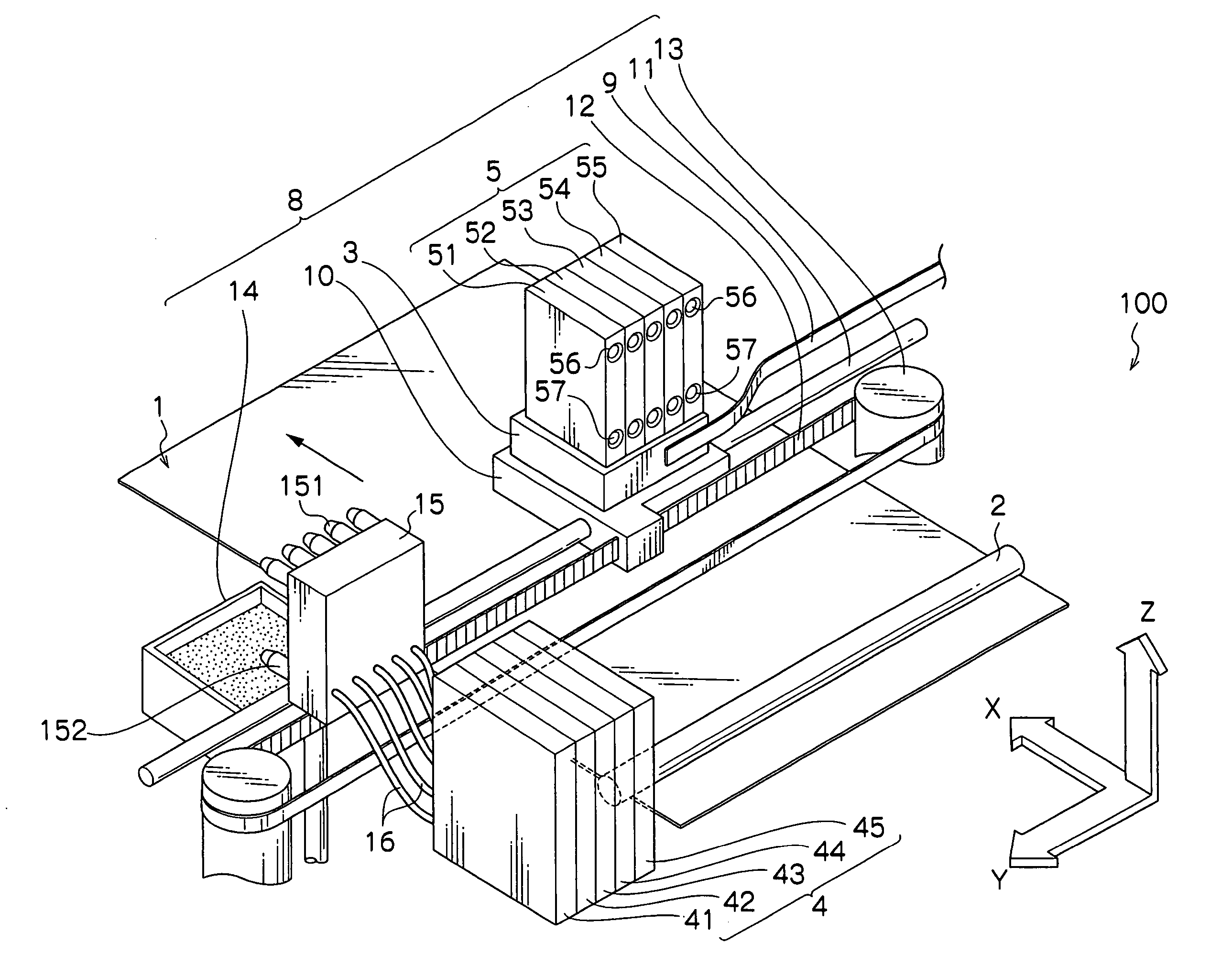

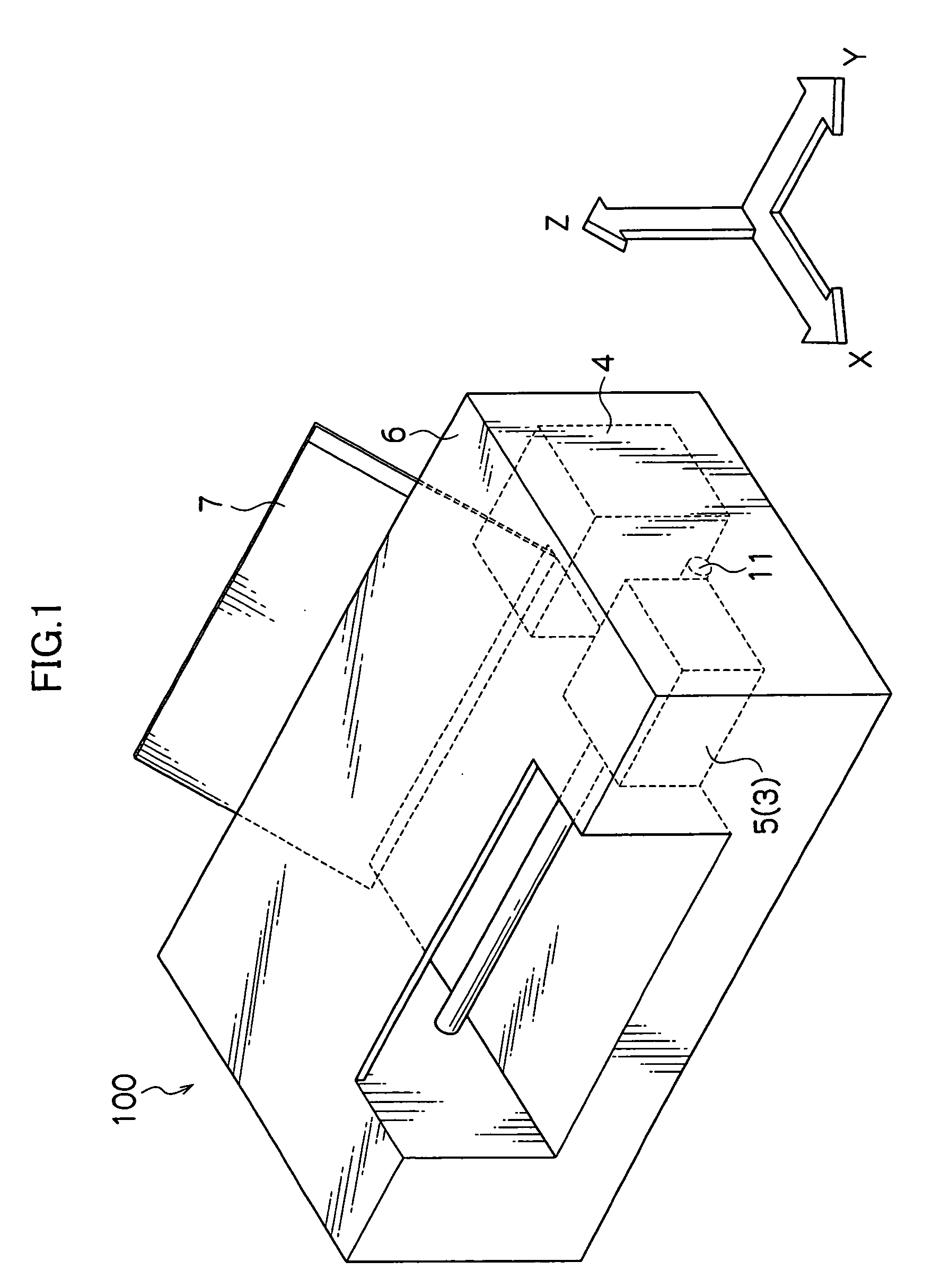

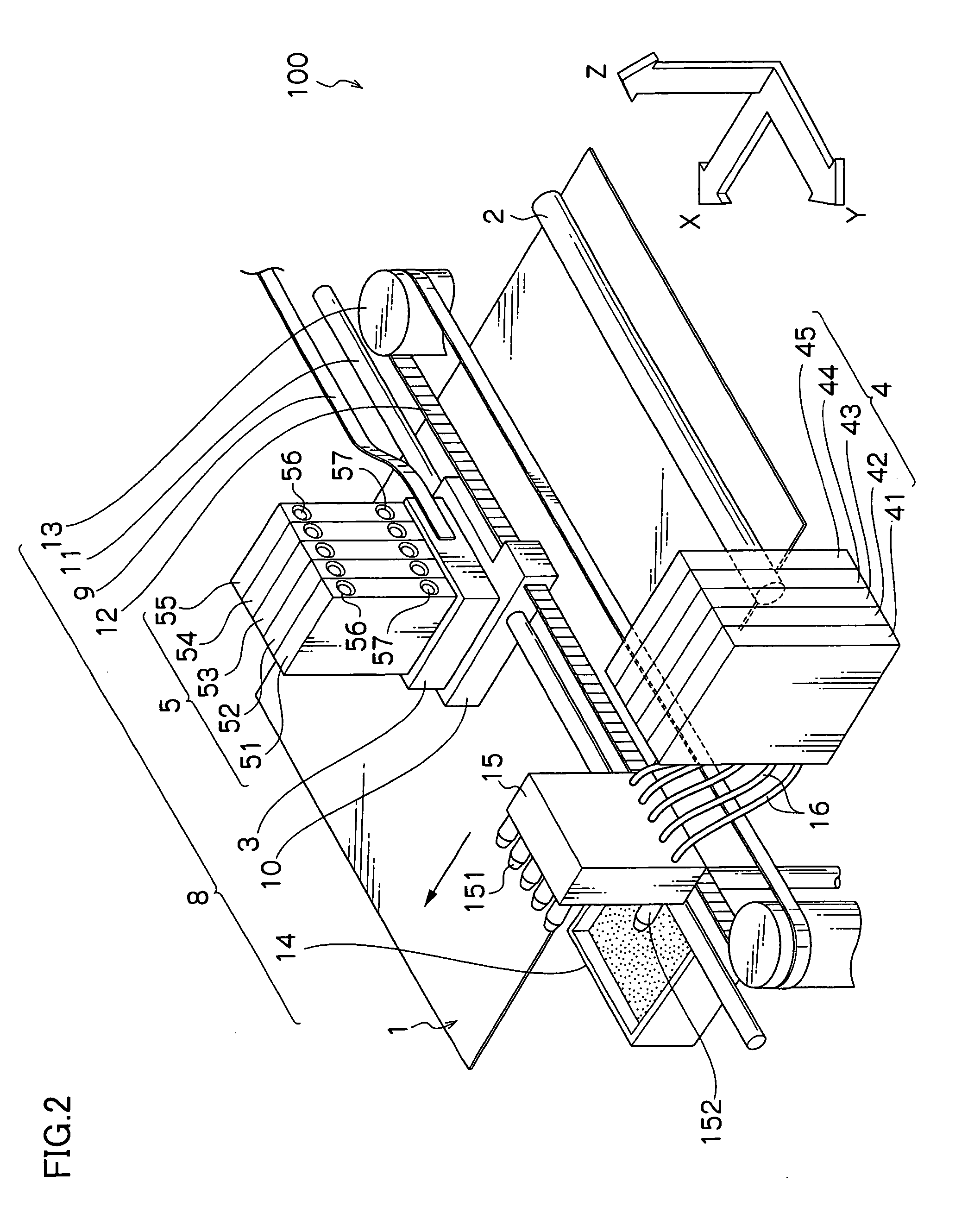

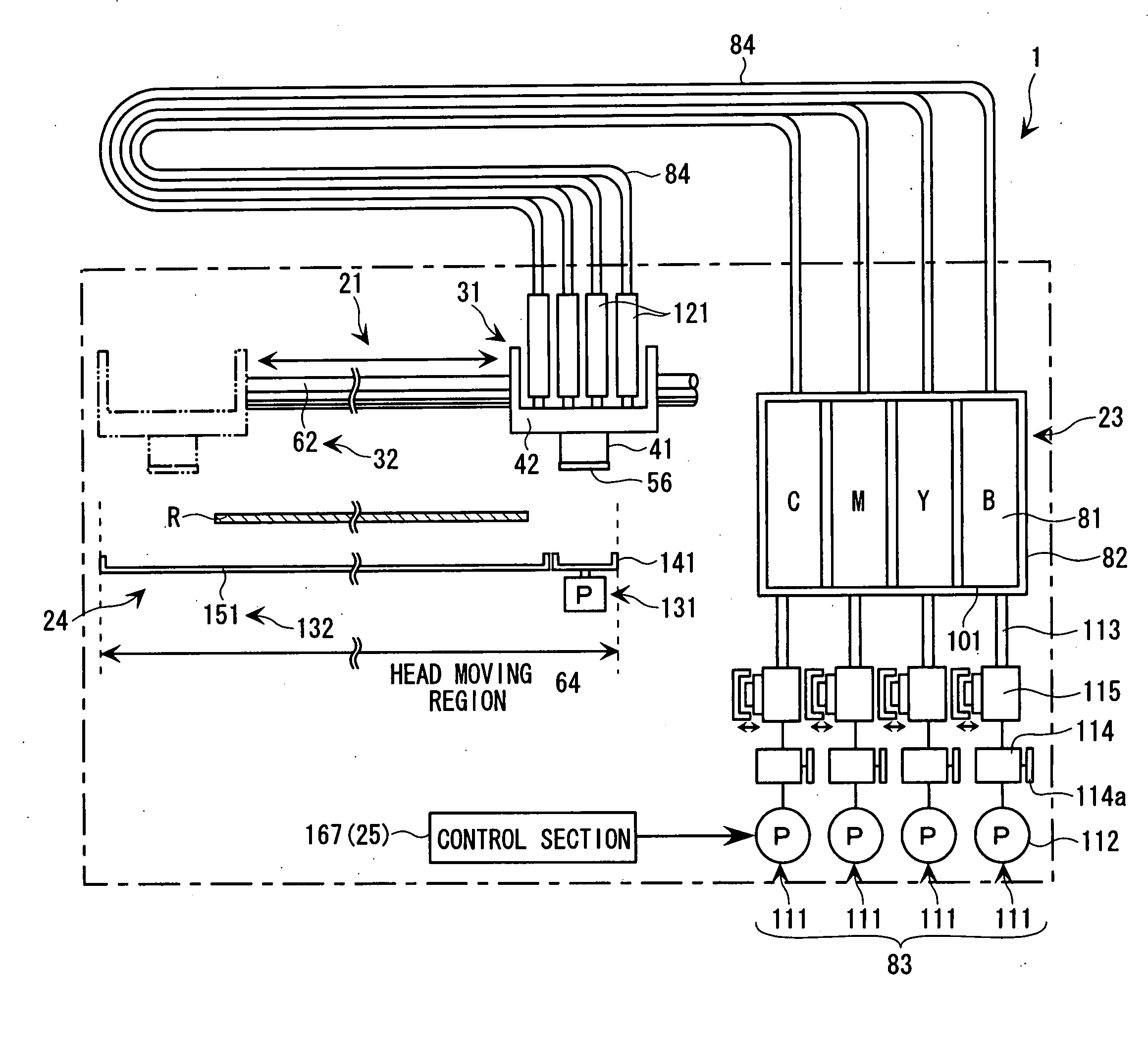

Method of controlling functional liquid supply apparatus, functional liquid supply apparatus, liquid droplet ejection apparatus, method of manufacturing electro-optical device, electro-optical device, and electronic device

InactiveUS20060181583A1Variations in pressureAccurate operationOther printing apparatusEngineeringLiquid tank

Owner:SEIKO EPSON CORP

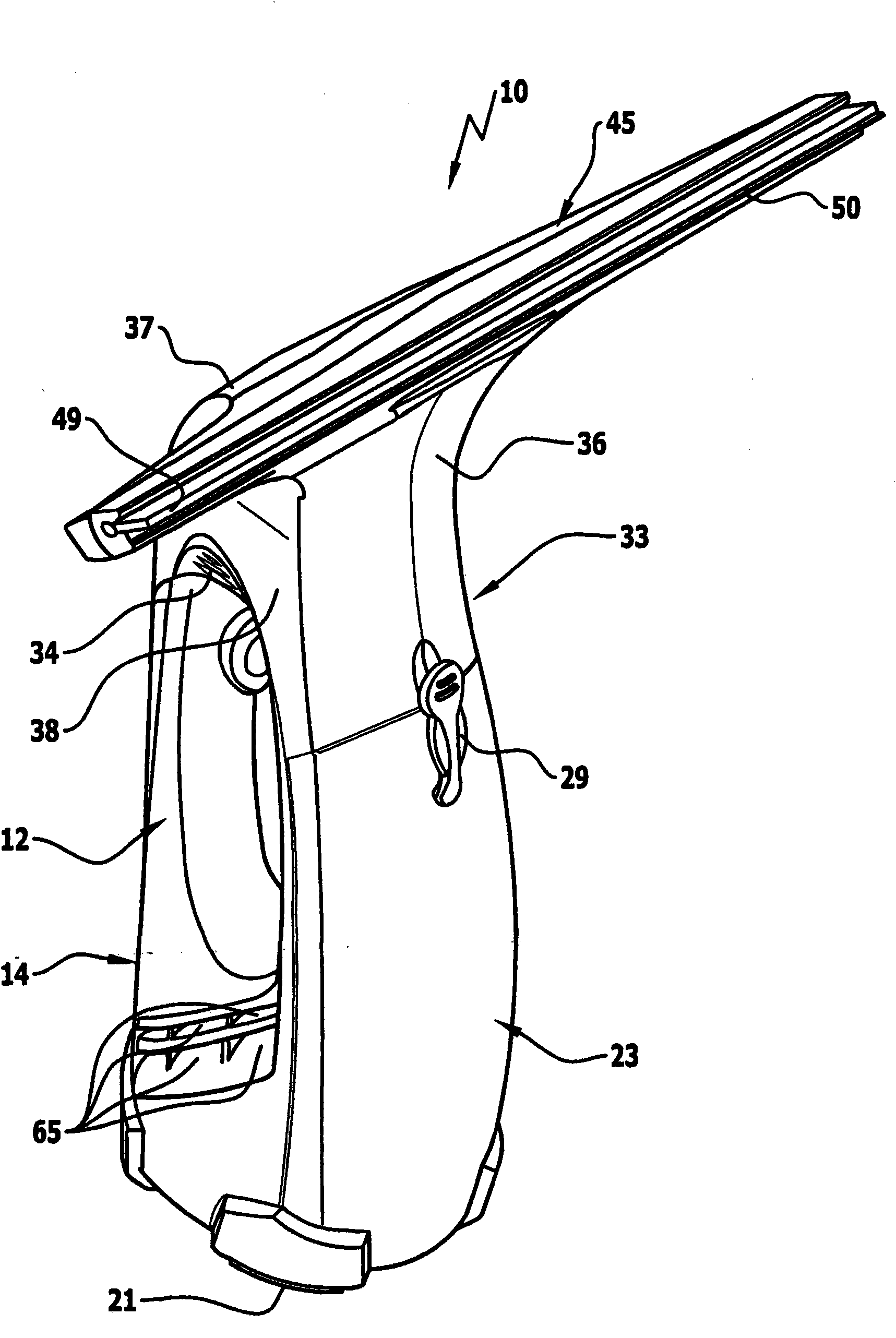

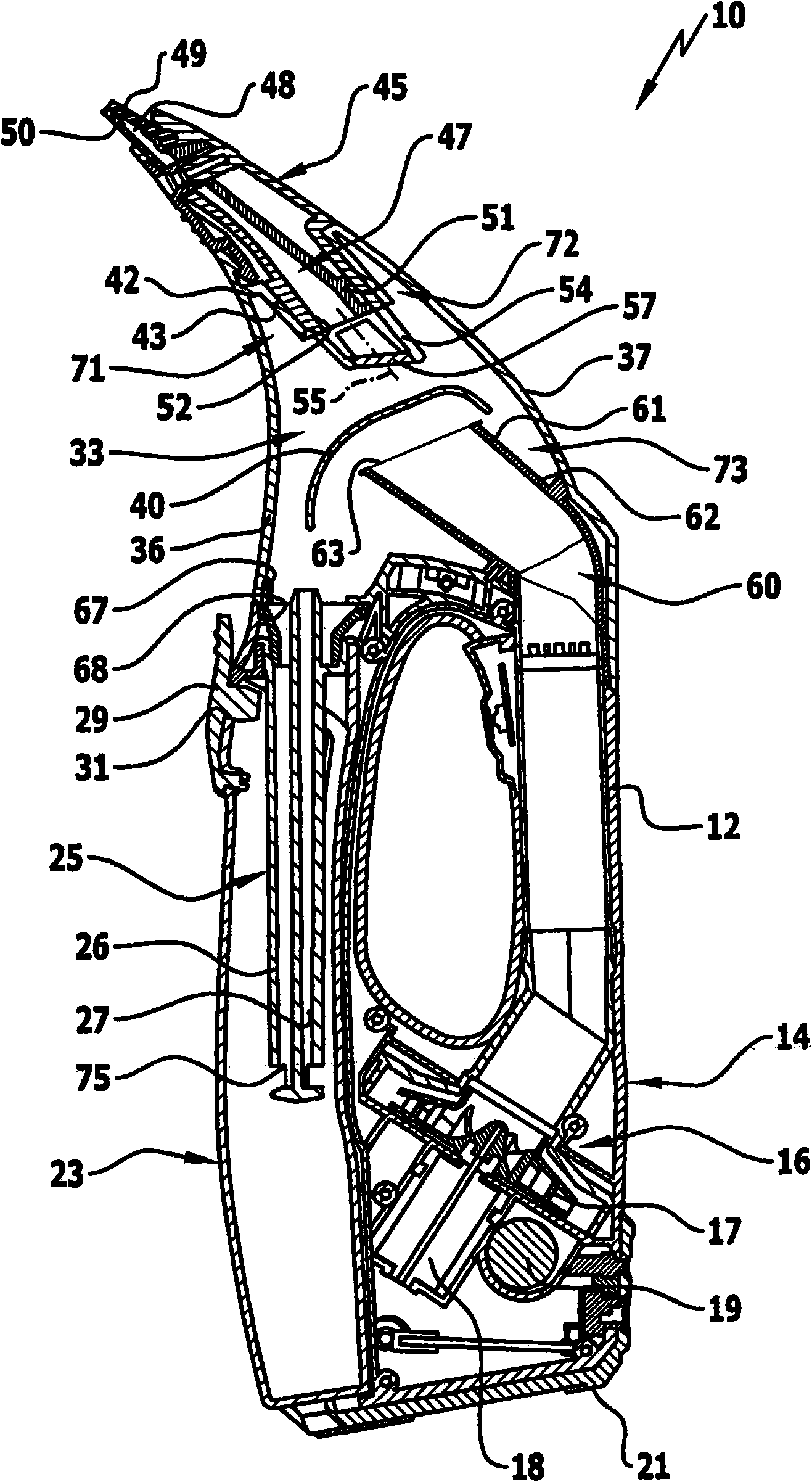

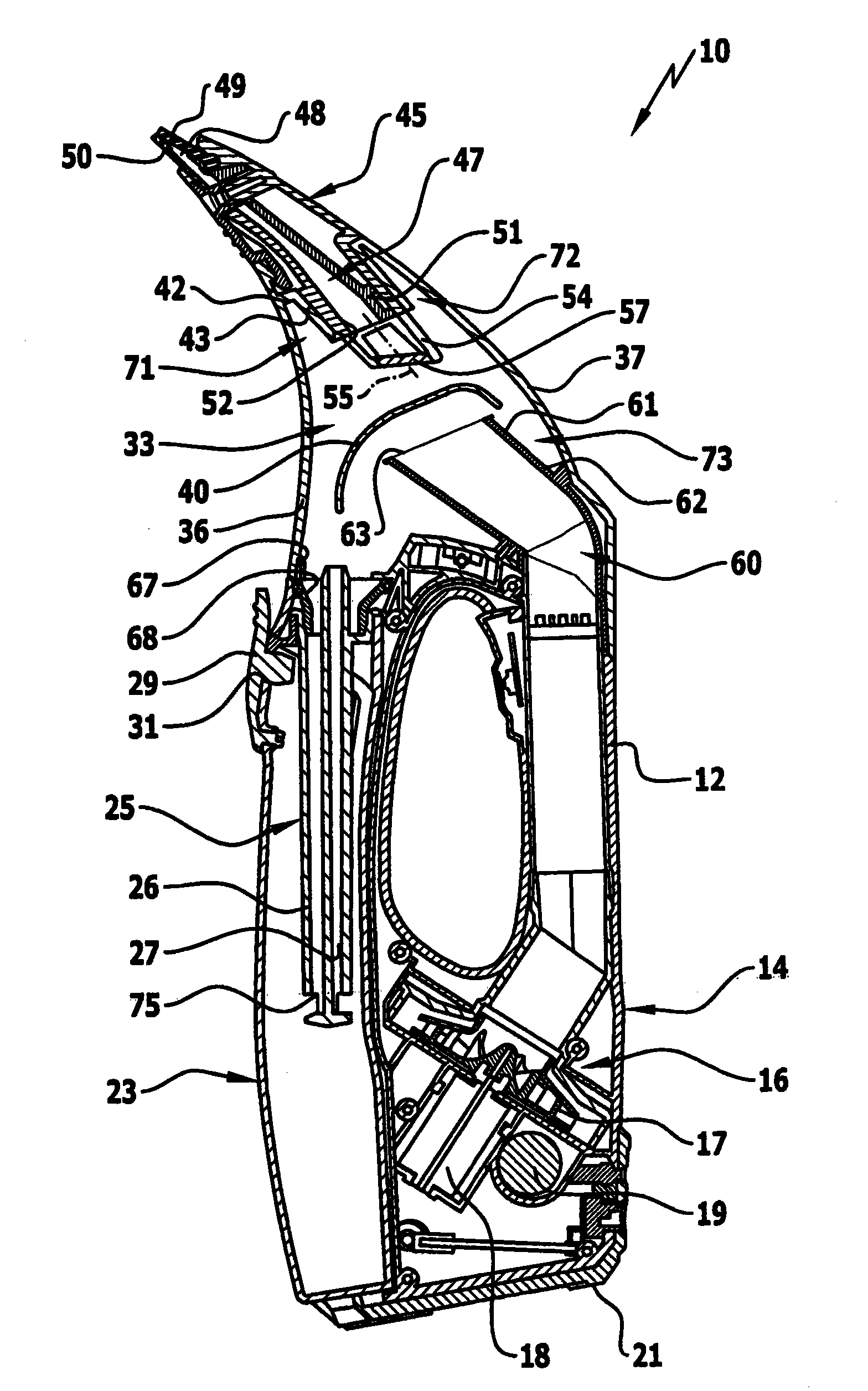

Portable hard surface vacuum

InactiveCN101909499AEasy to separateReduce flow lossCarpet cleanersFloor cleanersLiquid tankLow stress

The invention relates to a portable hard surface vacuum (10) comprising a suction nozzle (45) and a suction unit (16), which is in fluid connection with the suction nozzle, for vacuuming a liquid-air mixture from a hard surface, and comprising a separating device (40, 57) for separating liquid from the liquid-air mixture and comprising a waste liquid tank (23) for receiving the separated liquid. In order to refine the hard surface vacuum in such a way that a constant suction flow is provided, regardless of the fill level of the waste liquid tank, and such that operation in an arbitrary orientation in relation to the vertical position can be carried out, a separating chamber (33) is arranged between the suction nozzle and the suction unit, said chamber housing the separating unit and being in fluid connection via a suction line (47) to the suction port (48) of the suction nozzle and in fluid connection to the suction unit via a suction line (60), and said chamber being connected via an outlet opening (67) to the waste liquid tank, wherein the port regions (51, 61) of the suction (47) and vacuum line within the separating chamber are surrounded at least partially by intermediate storage regions (71, 72, 73) for separated liquid in the circumferential direction.

Owner:ALFRED KARCHER GMBH & CO KG

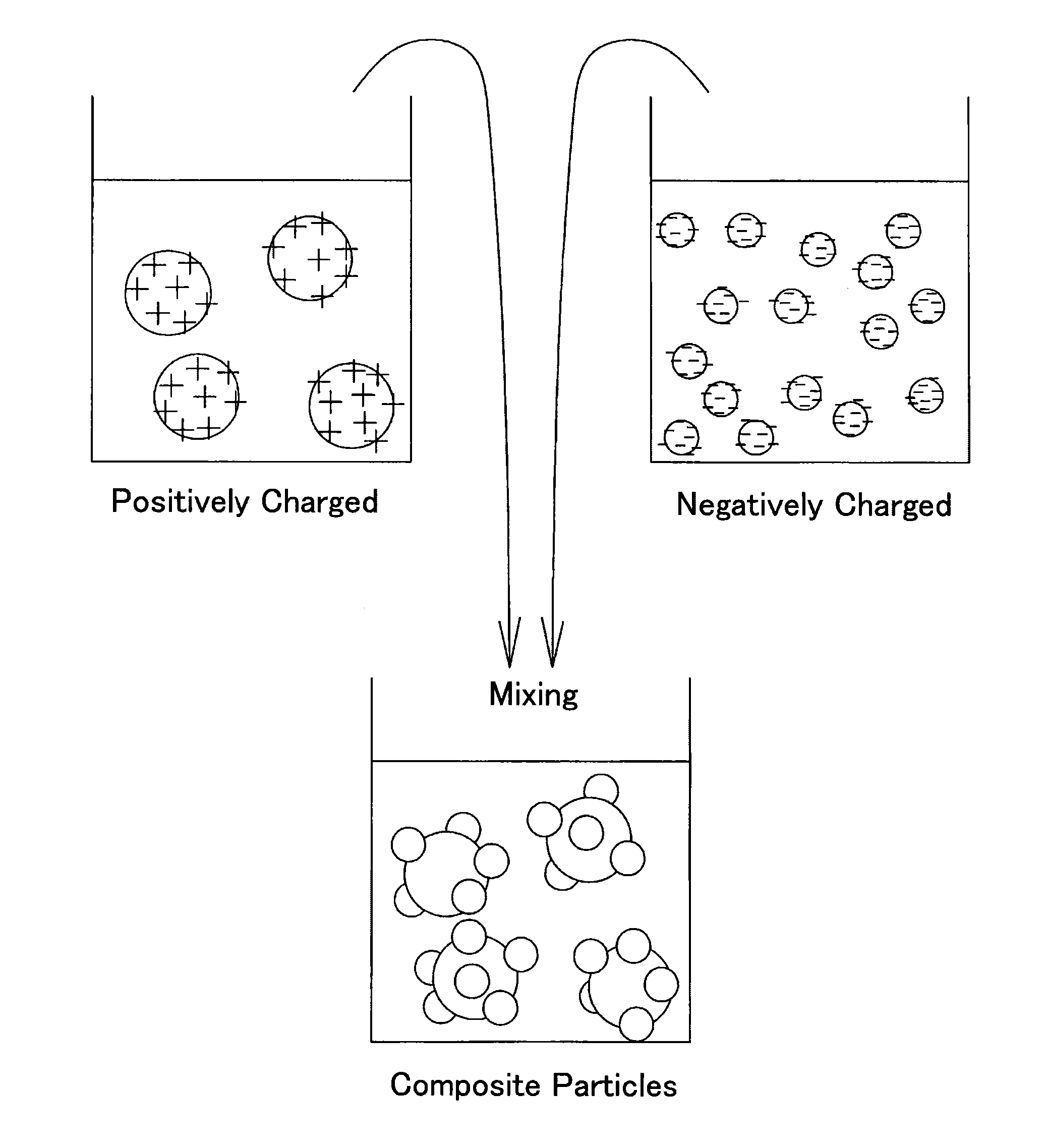

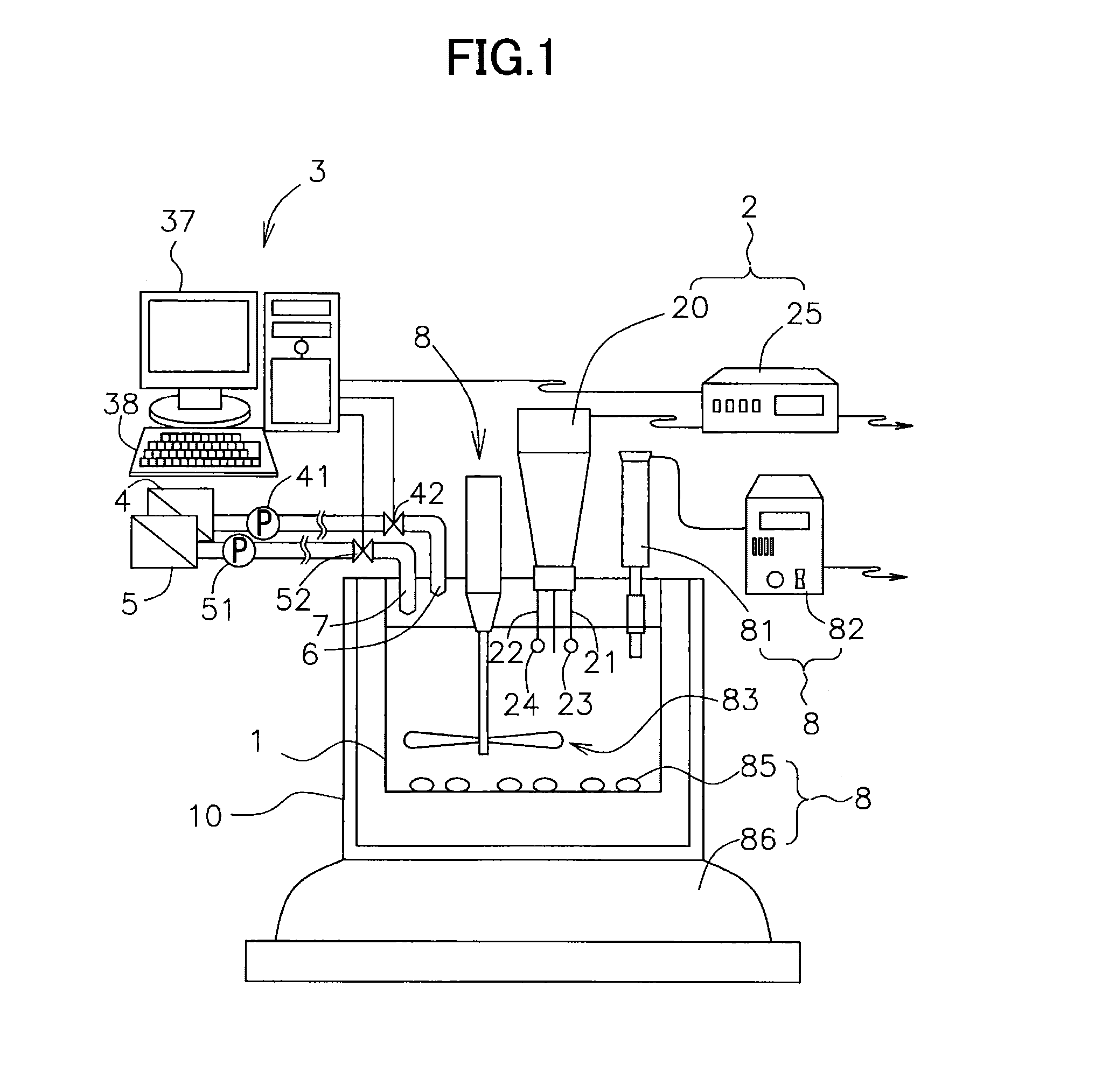

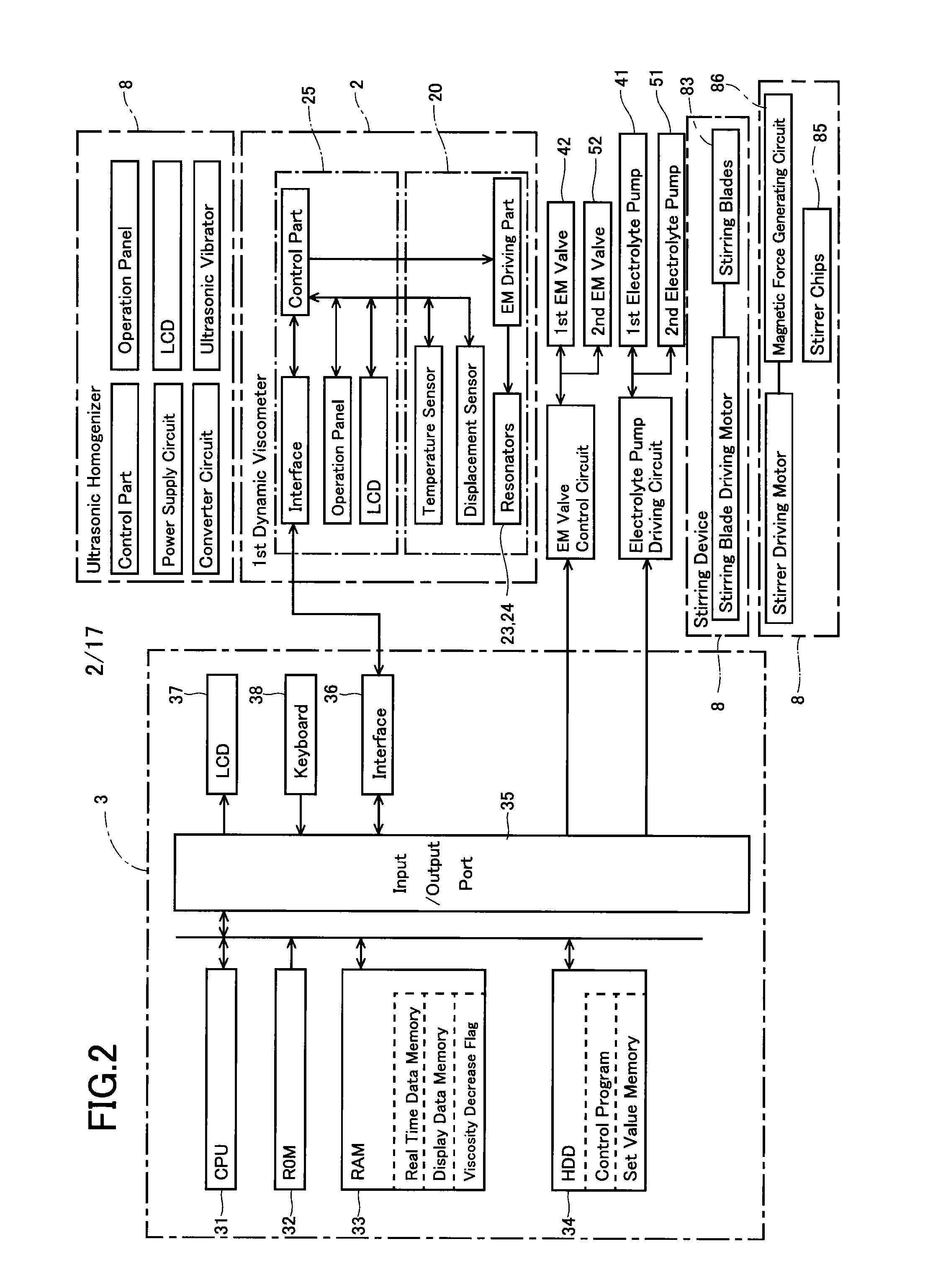

Device and process for producing composite particles

InactiveUS20150190840A1Simple processGuaranteed to workLiquid surface applicatorsGranulation in stationary drums/troughsPolymer electrolytesEngineering

A device and process for producing composite particles capable of adding a control agent for controlling a surface charge of particles such as a polymer electrolyte without being in excess or short. The production device includes a reservoir tank holding liquid containing either a first group or a second group of particles; a dispersion state measuring mechanism measuring a dispersion state of the particles in the liquid held in the reservoir tank; a dispersion state storage storing the dispersion state measured by the dispersion state measuring mechanism when a control agent for controlling a surface charge of the particles contained in the liquid in the reservoir tank is added into the reservoir tank; and an information output outputting information indicating that the dispersion state of the particles in the liquid in the reservoir tank is a desired state, based on the dispersion state stored in the dispersion state storage.

Owner:TOYOHASHI UNIVERSITY OF TECHNOLOGY

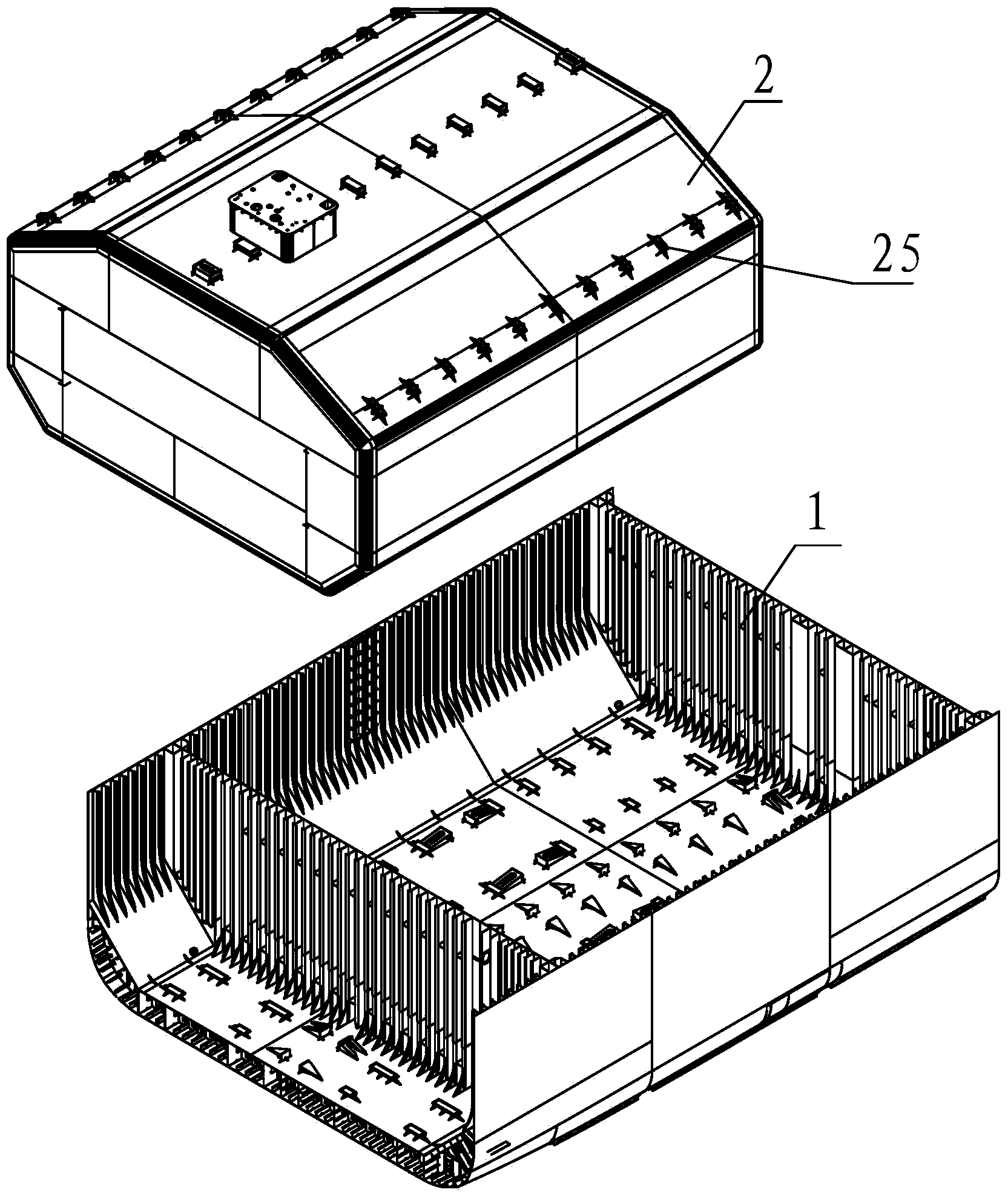

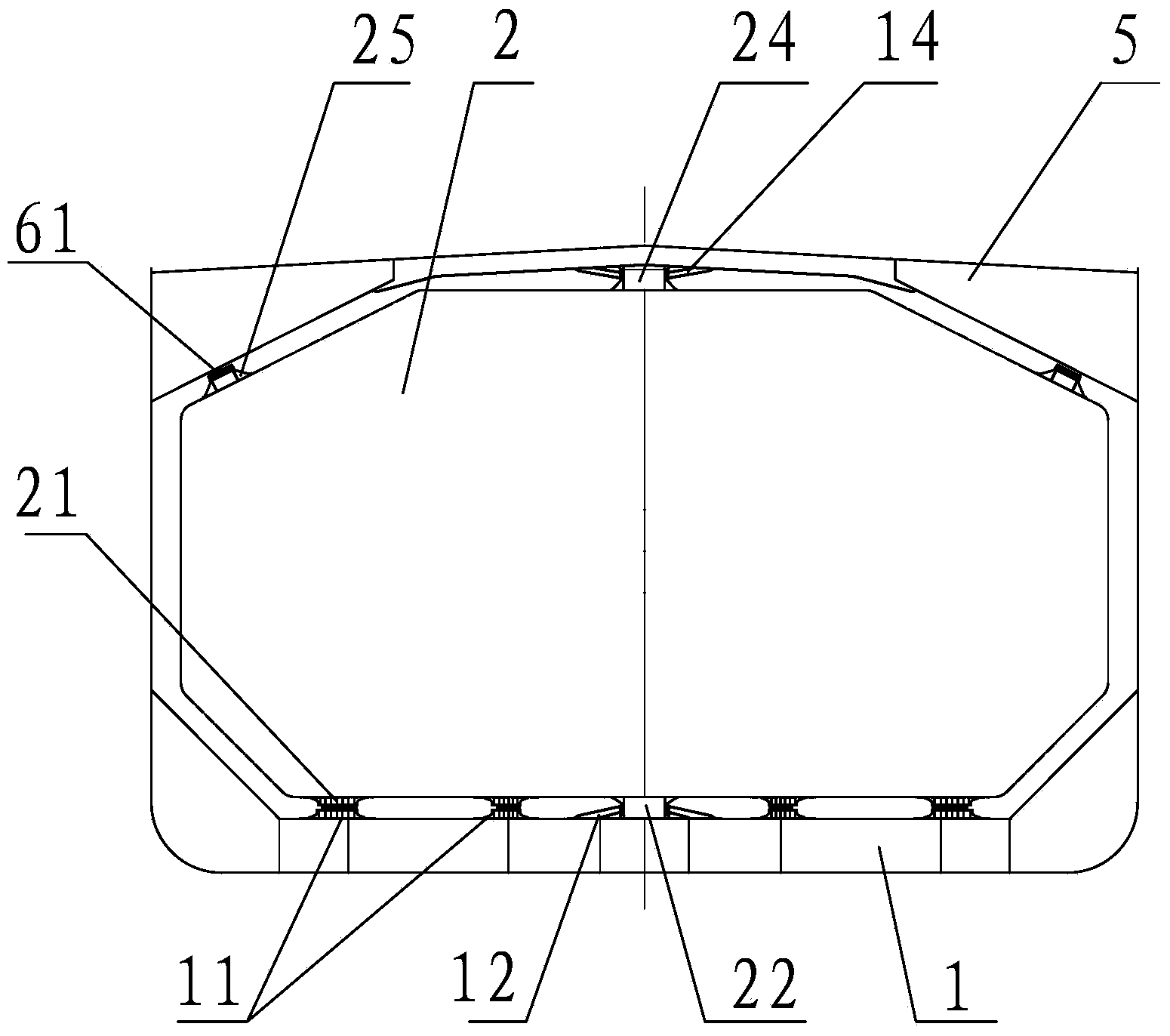

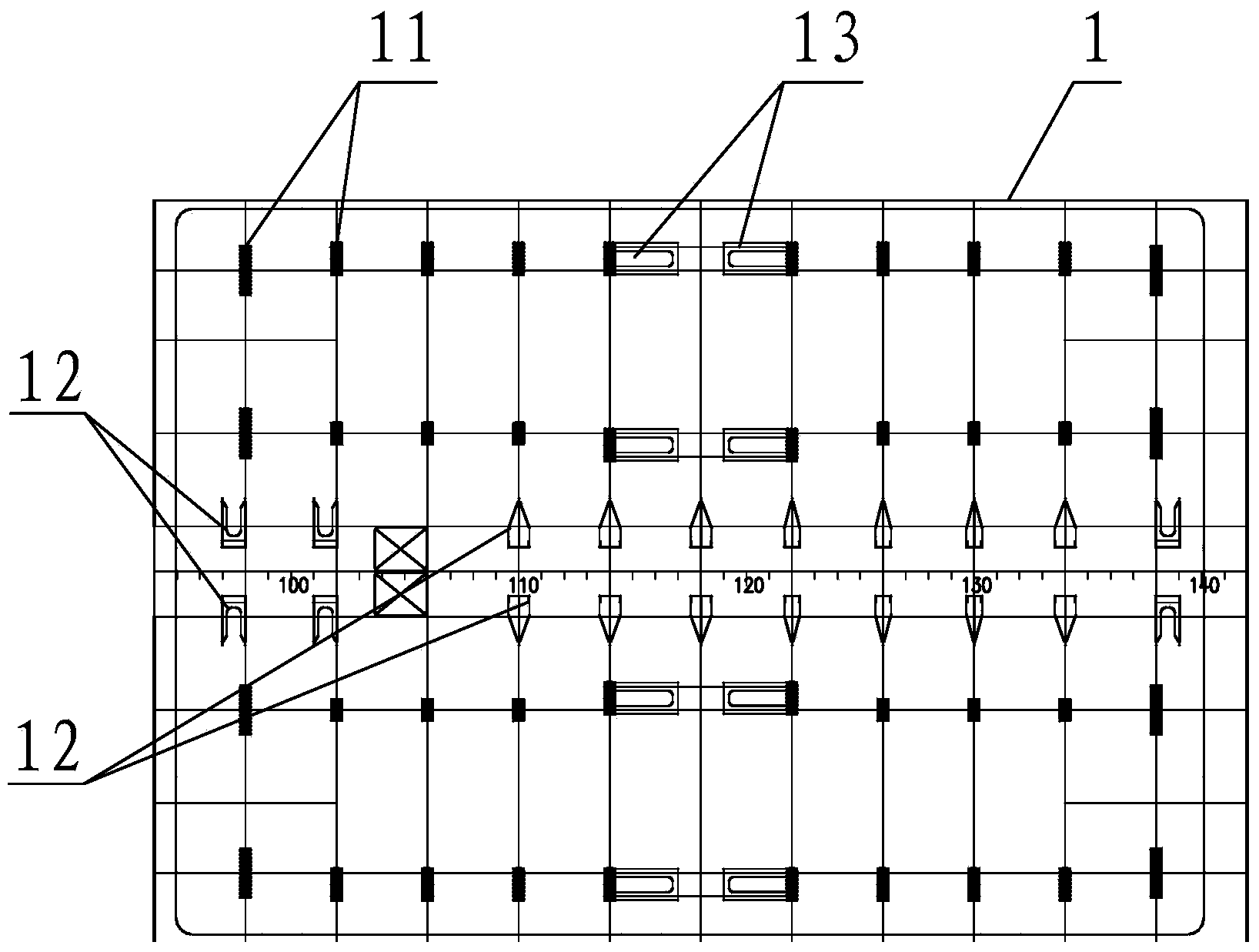

Installing structure of liquid tank of large liquefied gas carrier and installation locating method of liquid tank

ActiveCN103832543ALow equipment requirementsSimple and fast operationHull interior subdivisionLarge containersCollections dataLiquid tank

The invention provides an installing structure of a liquid tank of a large liquefied gas carrier and an installation locating method of the liquid tank. According to the installing structure of the liquid tank of the large liquefied gas carrier, a liquid tank cabin of the large liquefied gas carrier is mainly provided with a bottom perpendicular supporting base, a bottom transverse-shake preventing support, a top transverse-shake preventing support and a bottom longitudinal-shake preventing support, wherein the bottom perpendicular supporting base is used for supporting a whole liquid tank, the bottom transverse-shake preventing support and the top transverse-shake preventing support are used for preventing the liquid tank from transversely shaking relative to a hull, and the bottom longitudinal-shake preventing support is used for preventing the liquid tank from longitudinally shaking relative to the hull. In the actual working process of installing the liquid tank in the liquid tank cabin, according to the installation locating method of the liquid tank, the data collection step, the three-dimensional simulation step, the epoxy resin thickness calculation step, the locating datum line assignment step, the supporting positioning step and the like are carried out in sequence, and finally the liquid tank is installed in the liquid tank cabin. By the adoption of the installation locating method of the liquid tank, installation locating work of the liquid tank can be rapidly and accurately accomplished, the utilization rate of tools is high, the using time of a crane is short, and the construction cost of an enterprise is greatly reduced.

Owner:JIANGNAN SHIPYARD GRP CO LTD

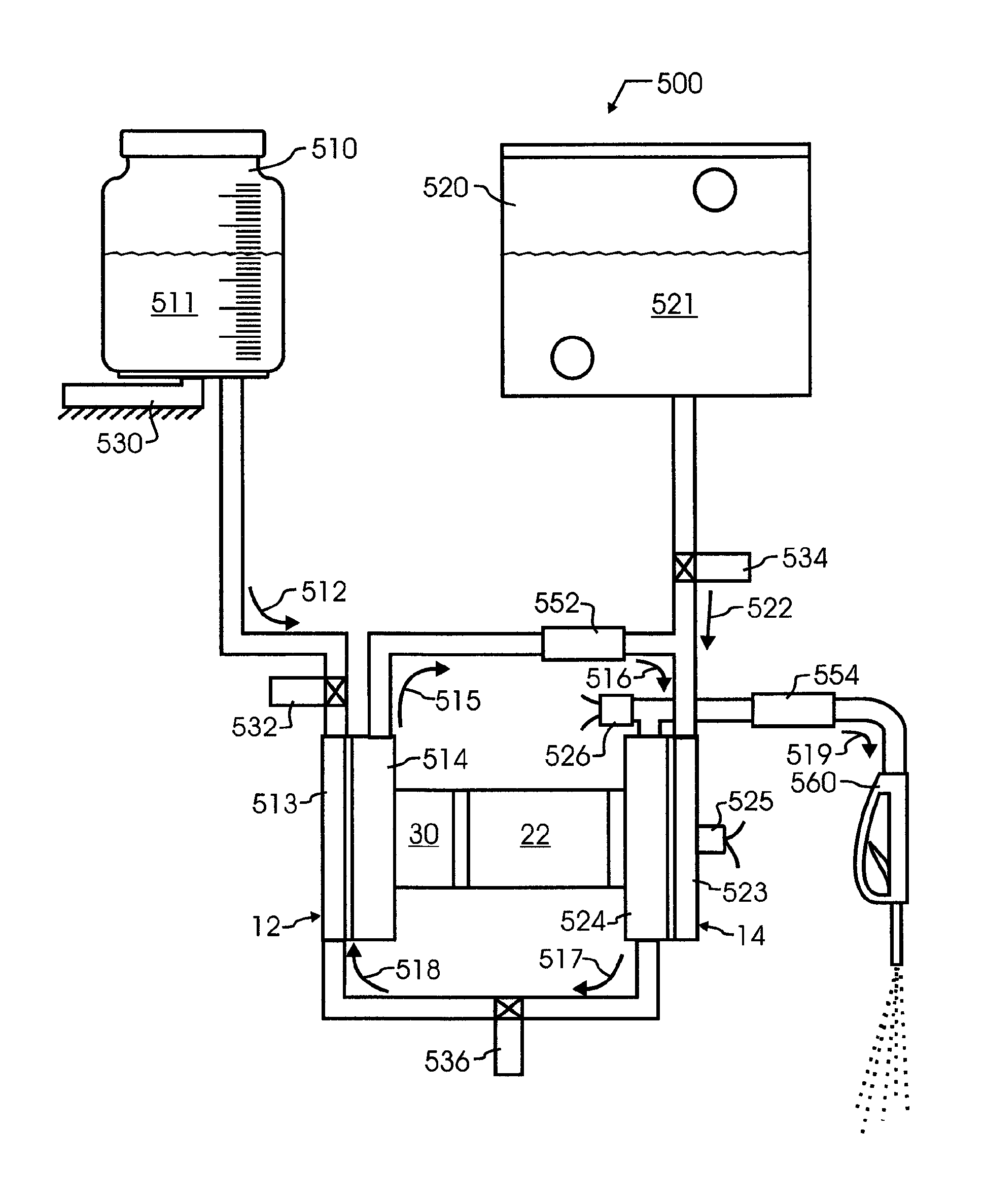

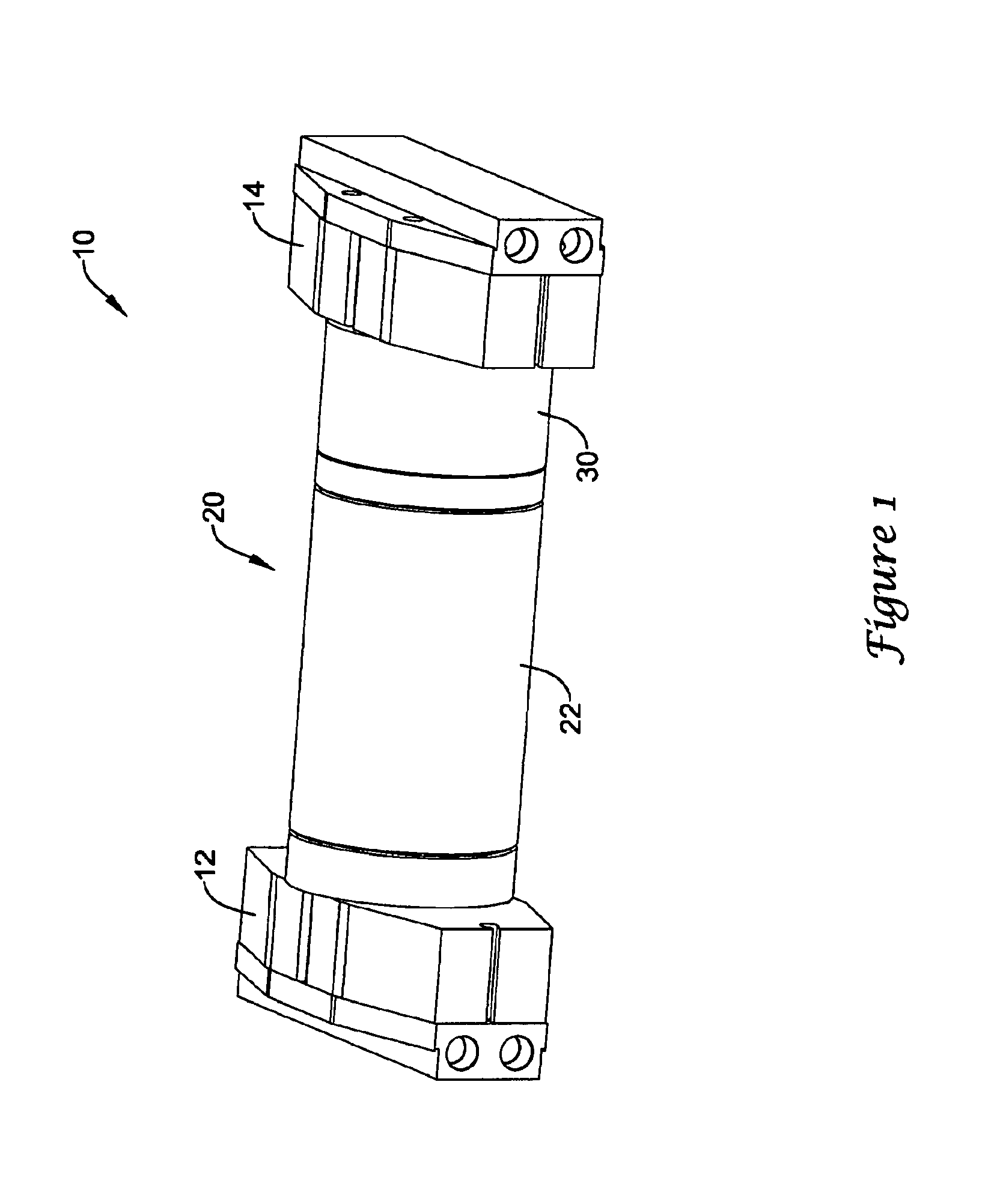

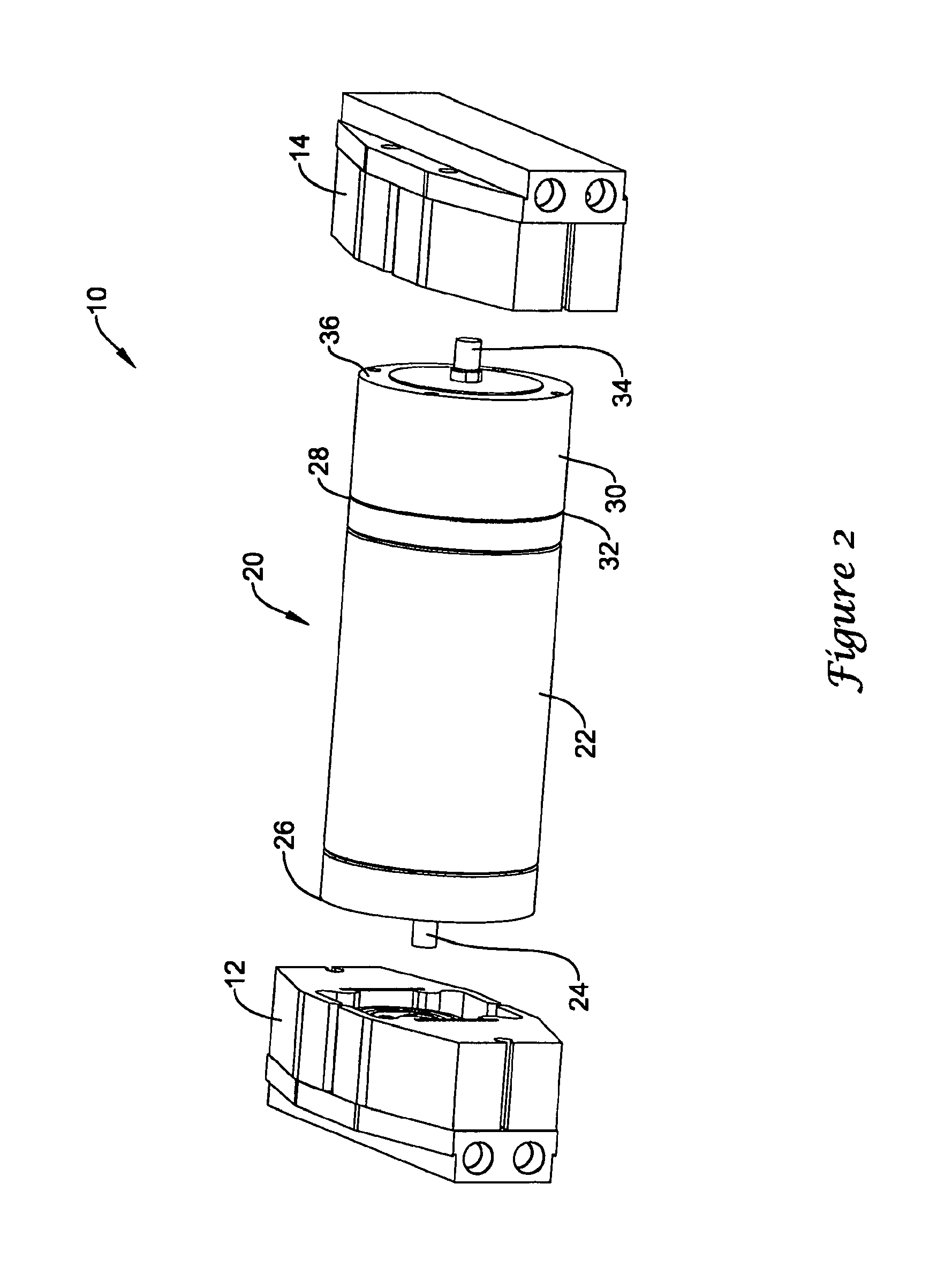

Proportioning pump, control systems and applicator apparatus

ActiveUS9316216B1Positive displacement pump componentsTransportation and packagingControl systemFixed ratio

An absolute proportioning pumping system includes an electric motor assembly powering a first pump at a first flow rate and powering a second pump at a second flow rate. A proportioned fluid output includes a first fluid pumped by the first pump and a second fluid pumped by the second pump. The pumping system provides a desired ratio of the first fluid to the second fluid at the proportioned fluid output, relatively independently of pressure and flow rate at the output. In accord with further embodiments, a pump and motor assembly is mounted to and generally surrounded by a liquid tank. The pump and motor assembly may include a pair of fixed ratio outputs driven from a common motor, or may include a single variable output pump either slaved to a master pump or controlled through a timed bypass valve to control output flow rate.

Owner:PUMPTEC

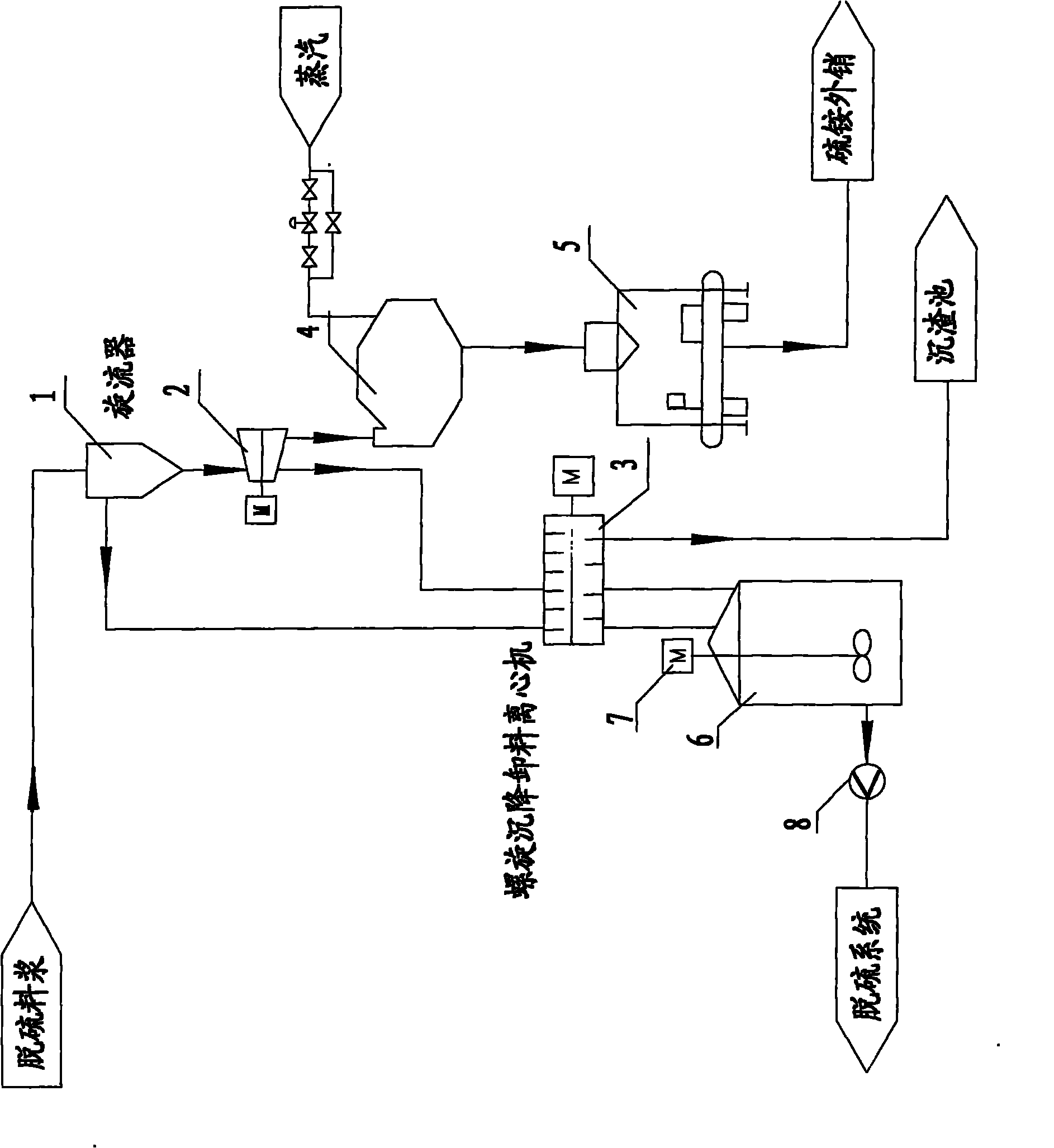

Process for removing smoke dust by wet ammonia flue gas desulphurization and device thereof

ActiveCN101972592AEfficient removalReduce processingDispersed particle separationAmmonia compoundsSulfateFlue gas

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

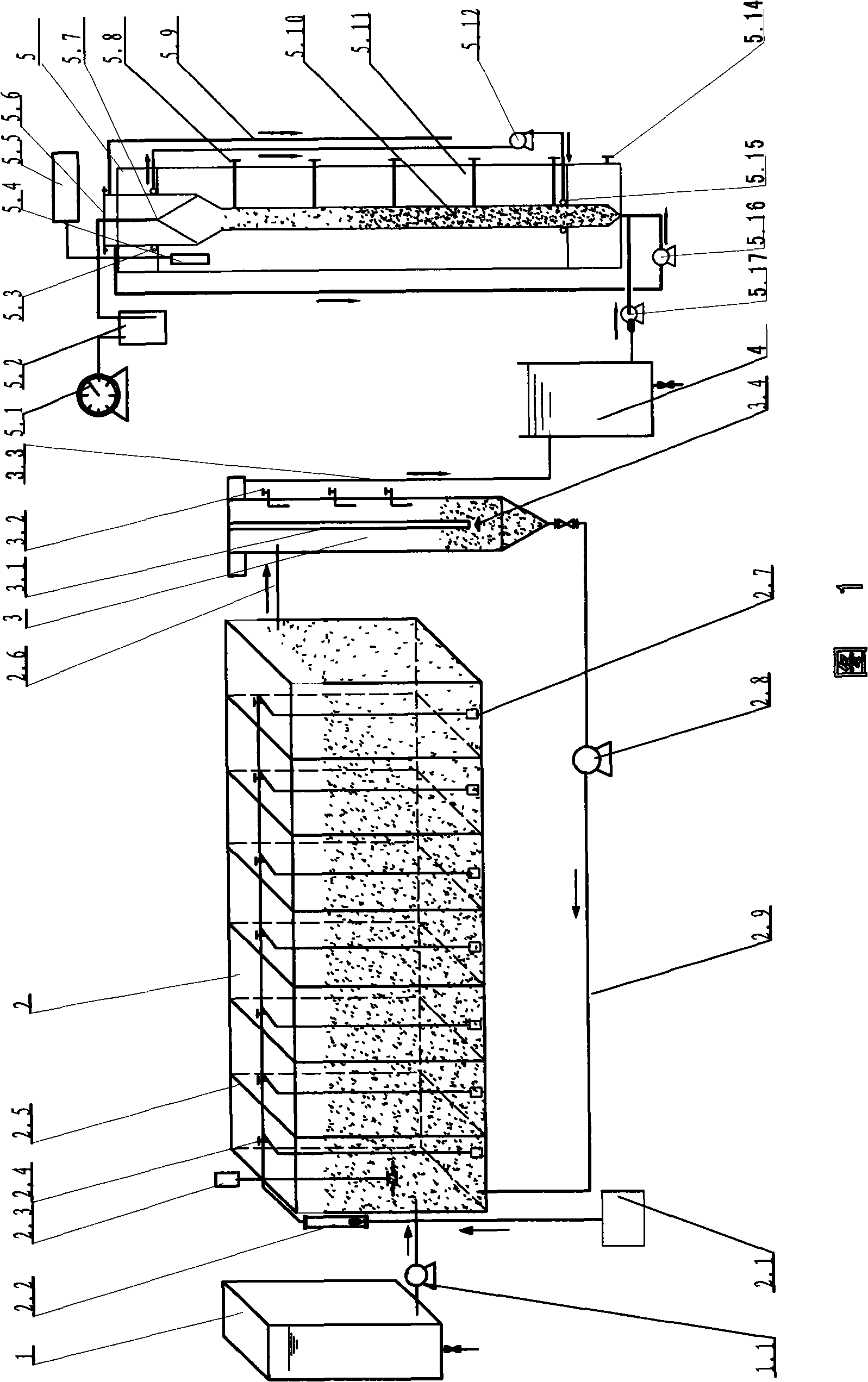

Combined denitrification apparatus and method by shortcut nitrification and anaerobic ammonium oxidation of sludge-digestion liquid

ActiveCN101289264AImprove nitrogen and phosphorus removal efficiencyLow construction costTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater bathsSludge

The invention discloses a device for autotrophic nitrogen removal by combining A / O shortcut nitrification of sludge digestion liquid and anaerobic ammonium oxidation of granular sludge and a method thereof. The device of the invention comprises a digestion liquid tank, an A / O shortcut nitrification tank, a sedimentation tank, a middle water tank, an anaerobic ammonium oxidation tank, wherein, the digestion liquid tank is communicated with a first cancellus as an anoxic zone of the A / O shortcut nitrification tank by the inlet pump of the A / O shortcut nitrification tank; the sedimentation tank the upper part of which is communicated with the middle water tank by a water pipe is provided with a central pipe and the anaerobic ammonium oxidation tank is provided with a water bath sleeve and a granular sludge bed. In addition, the method of the invention comprises the following steps of starting the A / O shortcut nitrification tank; starting the anaerobic ammonium oxidation tank of the granular sludge; operating an autotrophic biological nitrogen removal system in series after the starting of the A / O shortcut nitrification tank and the anaerobic ammonium oxidation tank is respectively completed. The device and the method of the invention are applicable to the shortcut nitrification and the nitrogen removal of the sludge digestion liquid in a sewage treatment plant and have the advantages of advanced technology, simple structure of the device, convenient operation and good treatment effect of water purification.

Owner:BEIJING DRAINAGE GRP CO LTD

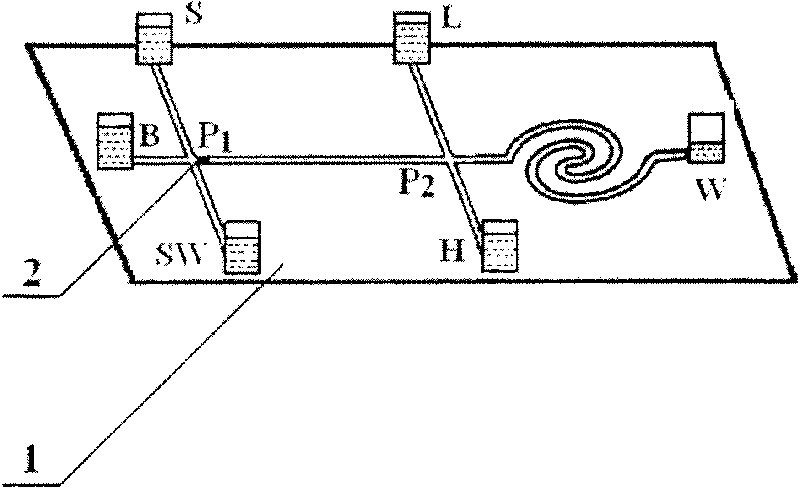

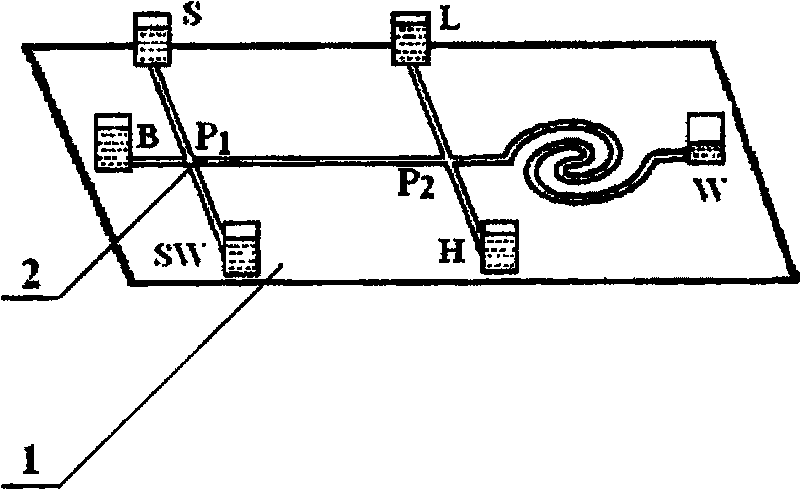

Microfluidic chip for capillary electrophoresis separation and chemiluminescence detection

InactiveCN101692047AImprove separation efficiencyHigh sensitivityChemiluminescene/bioluminescenceDispersed particle separationCapillary electrophoresisElectrophoresis

The invention discloses a microfluidic assay chip integrated capillary electrophoresis separation with chemiluminescence detection. The microfluidic chip consists of a buffer solution storage tank, a sample liquid storage tank, a sample waste liquid tank, a waste liquid tank, a sheath flow storage tank, a sample introduction channel, a separation channel, a sheath flow channel and a detection channel. A terminal of the separation channel and a starting point of the detection channel are communicated with the sheath flow channel. A chemiluminescence reagent enters the detection channel through the sheath flow channel; and when compositions to be assayed after the capillary electrophoresis separation of the chip meets the chemiluminescence reagent at a connecting point of the separation channel and the detection channel, the compositions are mixed with chemiluminescence reagent in the detection channel and then undergo luminous reaction. The inside of the separation channel is provided with a microporous plug to prevent the chemiluminescence reagent from flowing backwards into the separation channel under the driving of pressure difference so as not to influence electrophoresis separation. The microfluidic assay chip has the characteristics of high separation efficiency, high detection sensitivity, simple structure, small volume, light weight, convenient operation and the like, and is ideal to prepare a portable micro total separation system.

Owner:ZHEJIANG UNIV

Preparation device and bag for infusible beverages and method for the preparation of the same

InactiveUS6915733B1Quickly and with optimum developmentIncreased exploitationBeverage vesselsFood preparationInfusion timeLiquid tank

This invention is a device for the production of beverages made by the addition of water as described, in particular brewed hot beverages, such as soups etc., and in particular tea or coffee, whereby the invention comprises a liquid tank and a movable screen basket which holds the material used for the infusion, whereby the gap between the screen basket and the inside wall of the tank in the direction of movement of the screen basket is such that when the screen basket is moved, essentially the entire volume liquid in the tank flows into the screen basket with the aim of achieving a targeted flow of liquid through and around the material which is being infused. A process is provided for the production of beverages made by the addition of water,in particular brewed hot beverages, or soups etc., whereby the quantity of liquid in the tank is measured before the production process begins, the liquid in the tank is heated or cooled to a set temperature and the appropriate brewing or infusion time is calculated dependent on the measured quantity and / or temperature of the liquid and / or the nature of the beverage being produced.

Owner:LANGBAUER WERNER

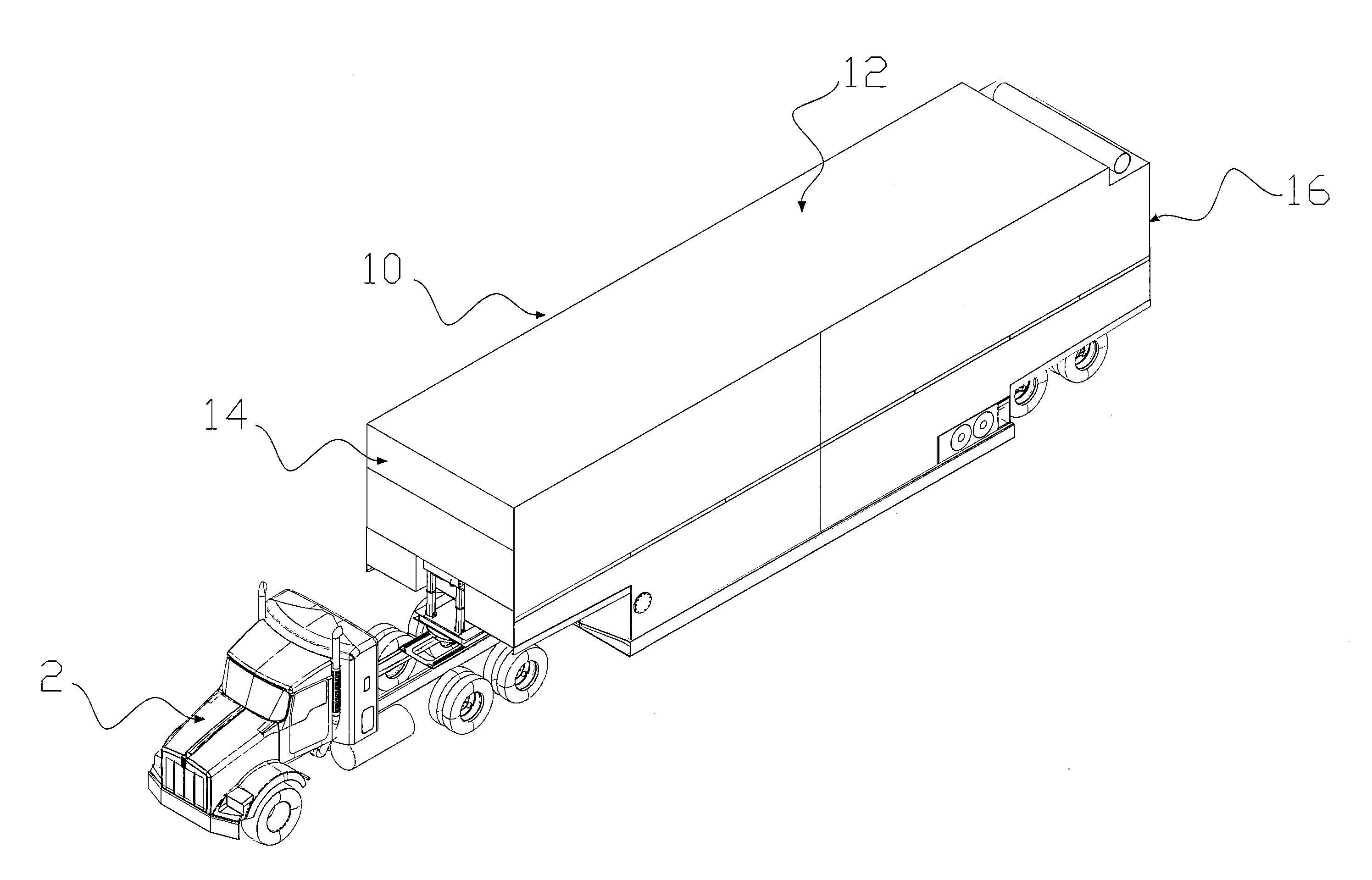

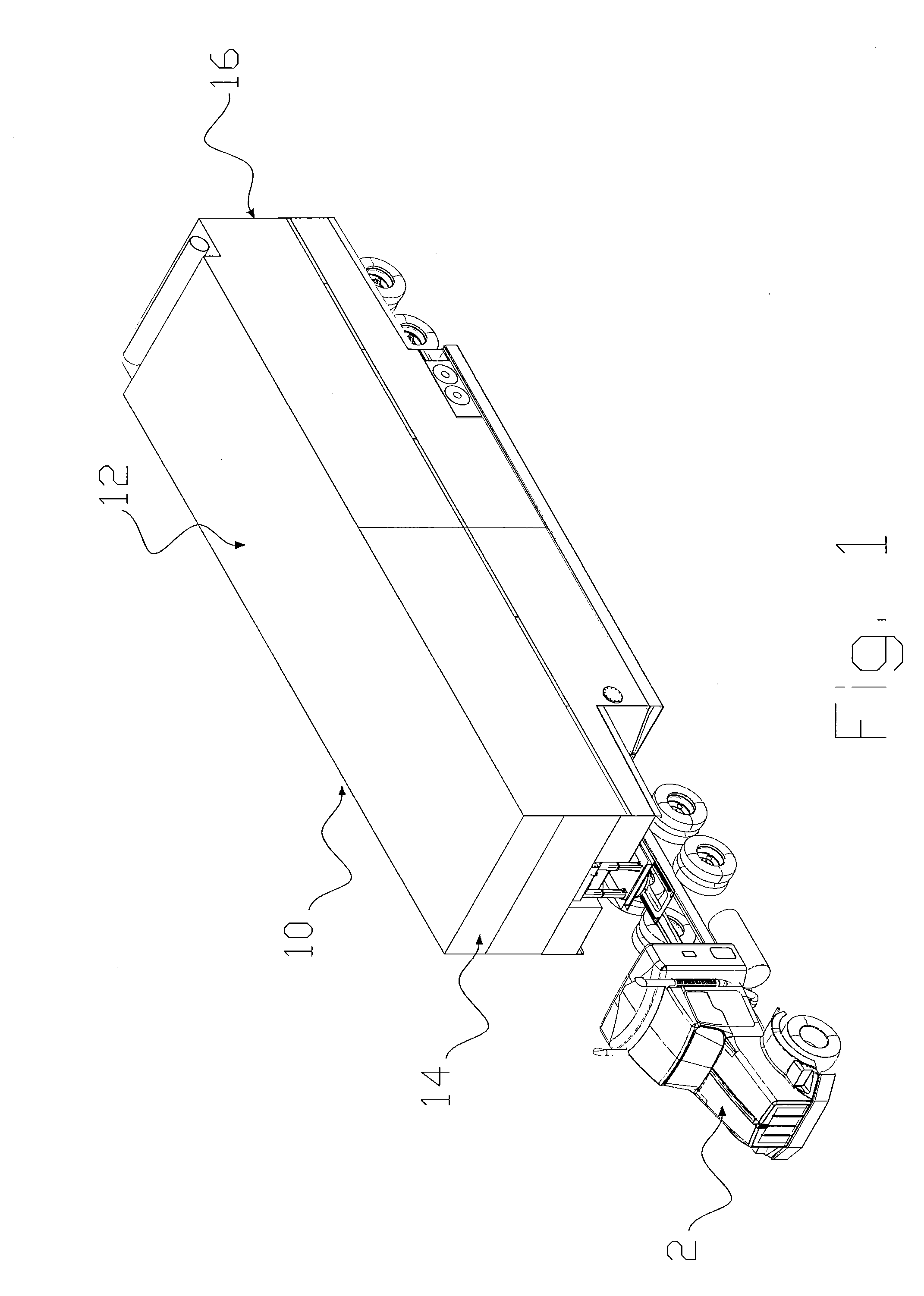

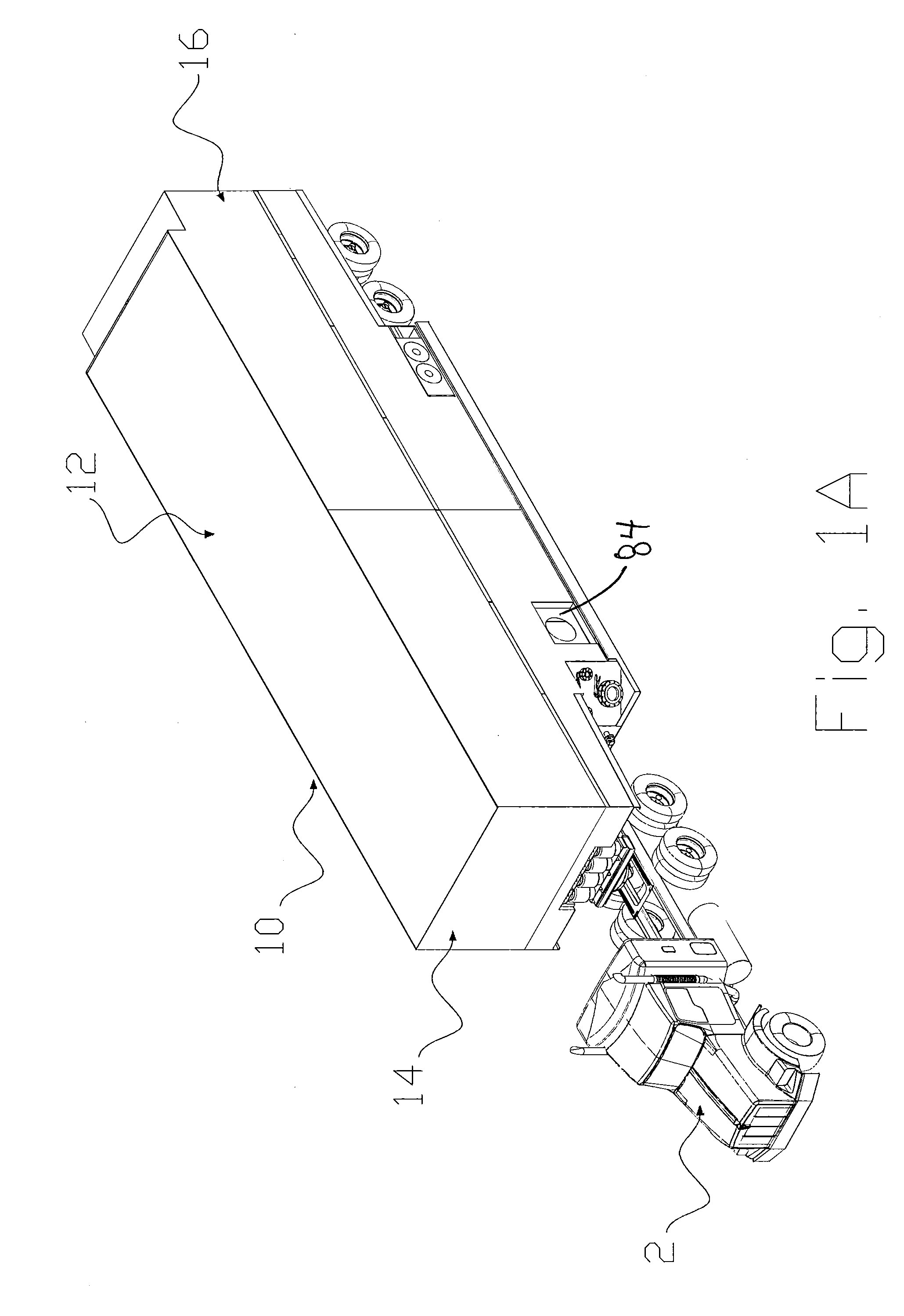

Mobile fluid storage tank

InactiveUS20150115589A1Maximizing lengthMaximizing widthValve arrangementsTank vehiclesLiquid tankStorage tank

Owner:THIESSEN LONNY

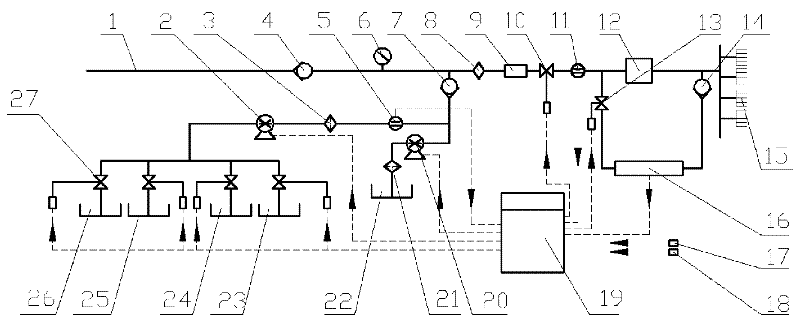

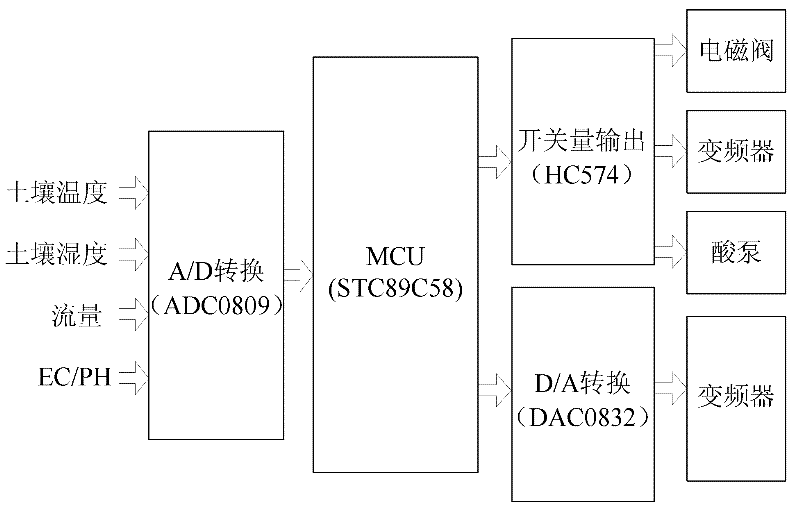

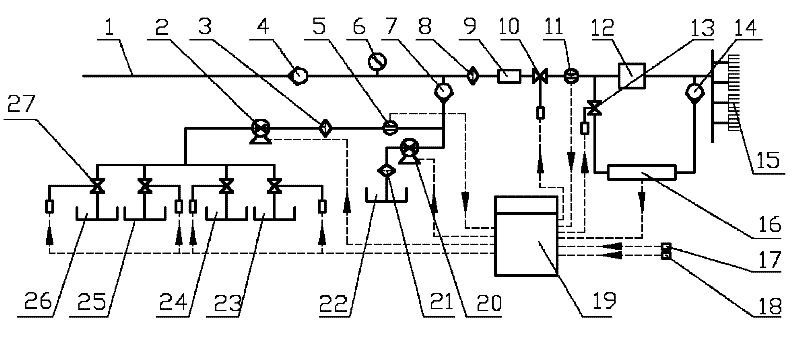

Automatic precise controller for water fertilizer

InactiveCN102163043ARealize precision irrigationGuarantee unimpededProgramme controlComputer controlControl systemAgricultural engineering

The invention provides an automatic precise controller for water fertilizer, comprising a fertilizer liquid tank and an acid liquid tank which are communicated with a main water pipe; a fertilizer filling pump and a fertilizer liquid flowmeter are sequentially installed on a fertilizer liquid pipe; an acid liquid pump is installed on an acid liquid pipe; a fertilizer mixer, a fertilizer mixer outlet electromagnetic valve, a fertilizer mixer outlet flowmeter and a pressure difference valve are sequentially arranged on the main water pipe on the rear end of the joint of the fertilizer liquid pipe, acid liquid pipe and the main water pipe; the tail end of the main water pipe, namely the outlet of the pressure difference valve is connected with a partition filling pipe; a PH meter and an EC meter are connected in parallel on both ends of the pressure difference valve; and the fertilizer filling pump, the fertilizer liquid flowmeter, the acid liquid pump, the fertilizer mixer outlet electromagnetic valve, the fertilizer mixer outlet flowmeter, the PH meter, the EC meter, and a temperature sensor and a humidity sensor arranged in the soil are respectively connected with a control cabinet. During the fertilizing process, non-manual operation can be completely realized by inputting corresponding parameters; a control system can automatically detect the flow of the fertilizer path and automatically switch the electromagnetic valve so as to irrigate with different fertilizer ratios.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com