Patents

Literature

442results about "Granulation in stationary drums/troughs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

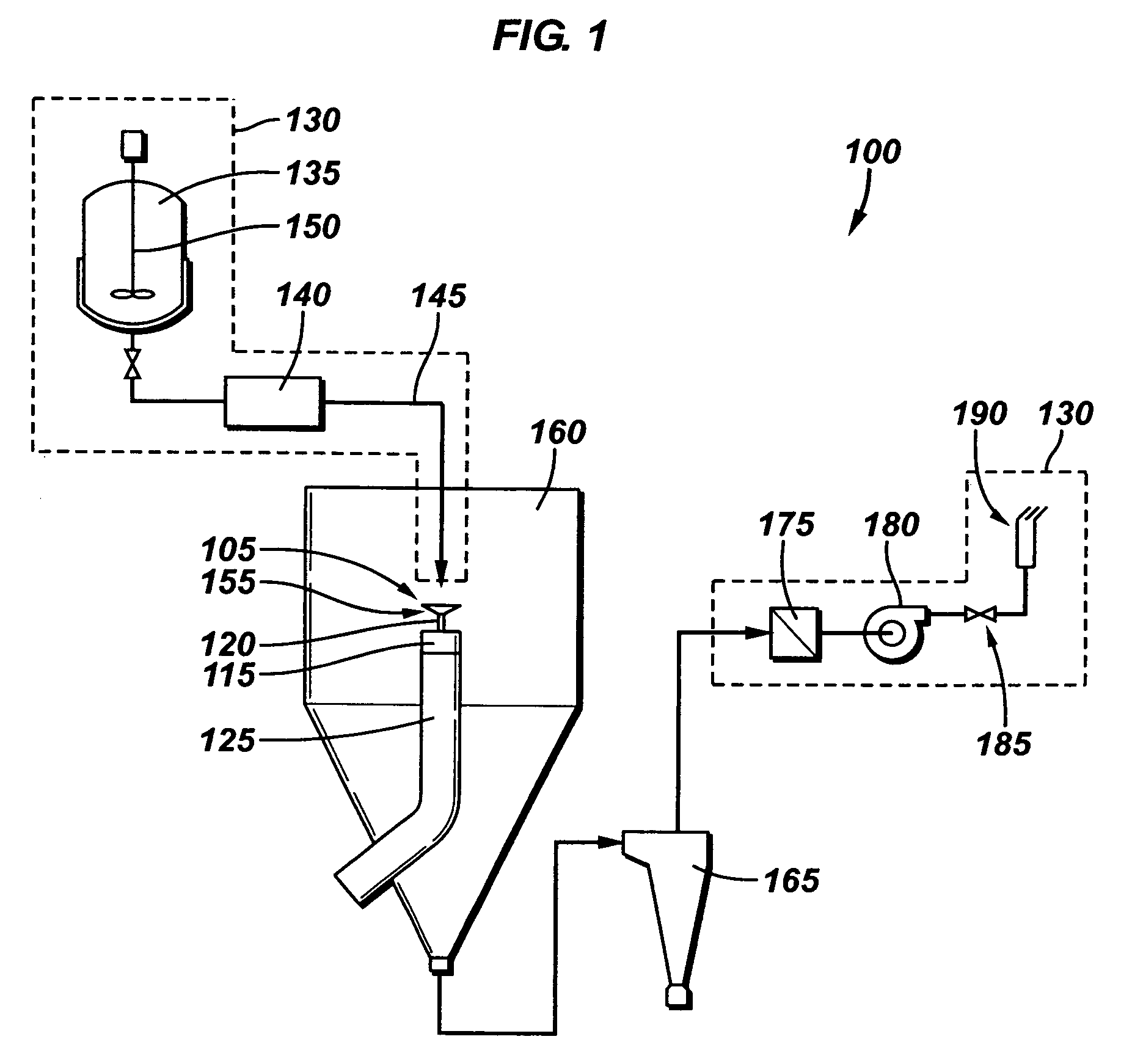

Apparatus for preparing biodegradable microparticle formulations containing pharmaceutically active agents

ActiveUS7261529B2Auxillary shaping apparatusGranulation in stationary drums/troughsRotational axisActive agent

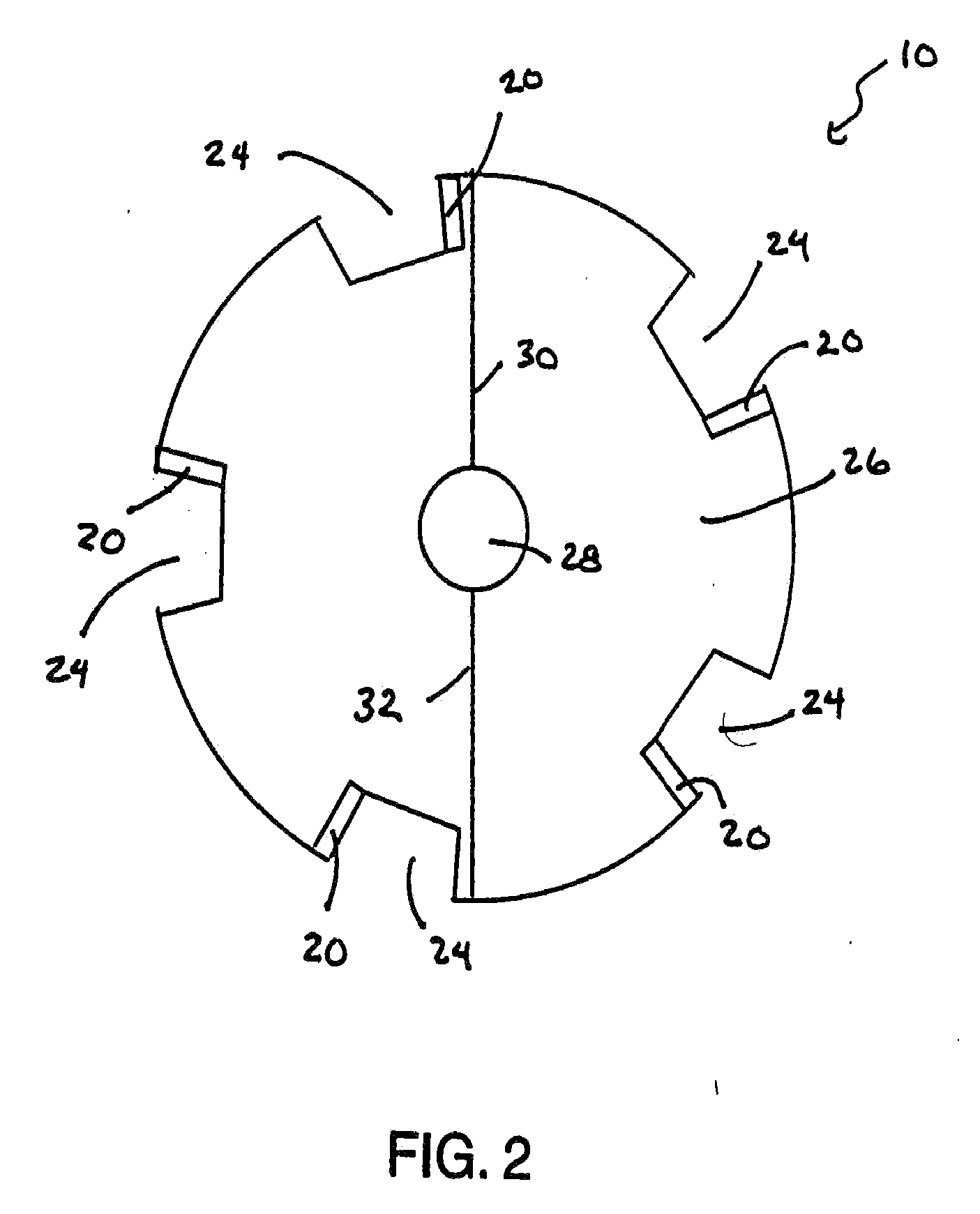

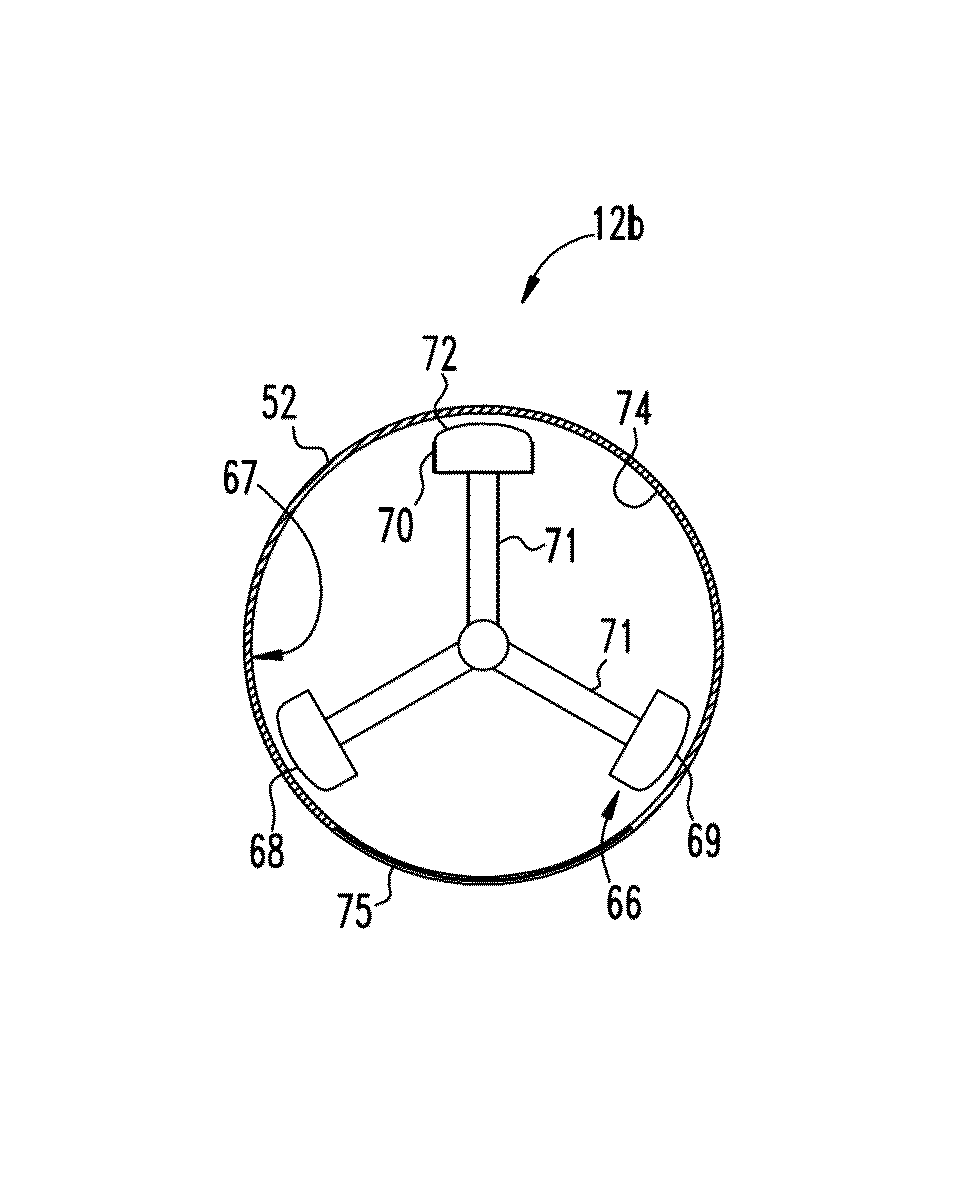

This invention is directed to an apparatus and method for producing microparticles comprising pharmacologically active agents and biodegradable polymers. The apparatus includes a spinning disk containing a reservoir in the center thereof and a flat inclined surface. The apparatus optionally includes serrations and / or a flat surface beneath the periphery of the disk that is parallel to the rotational axis of the disk. The invention is also directed to a method for producing microparticles containing pharmacologically active agents, using the spinning disk apparatus. Formulations containing ophthalmically active agents are provided. Formulations exhibiting zero order release rates are also described.

Owner:ALCON INC +1

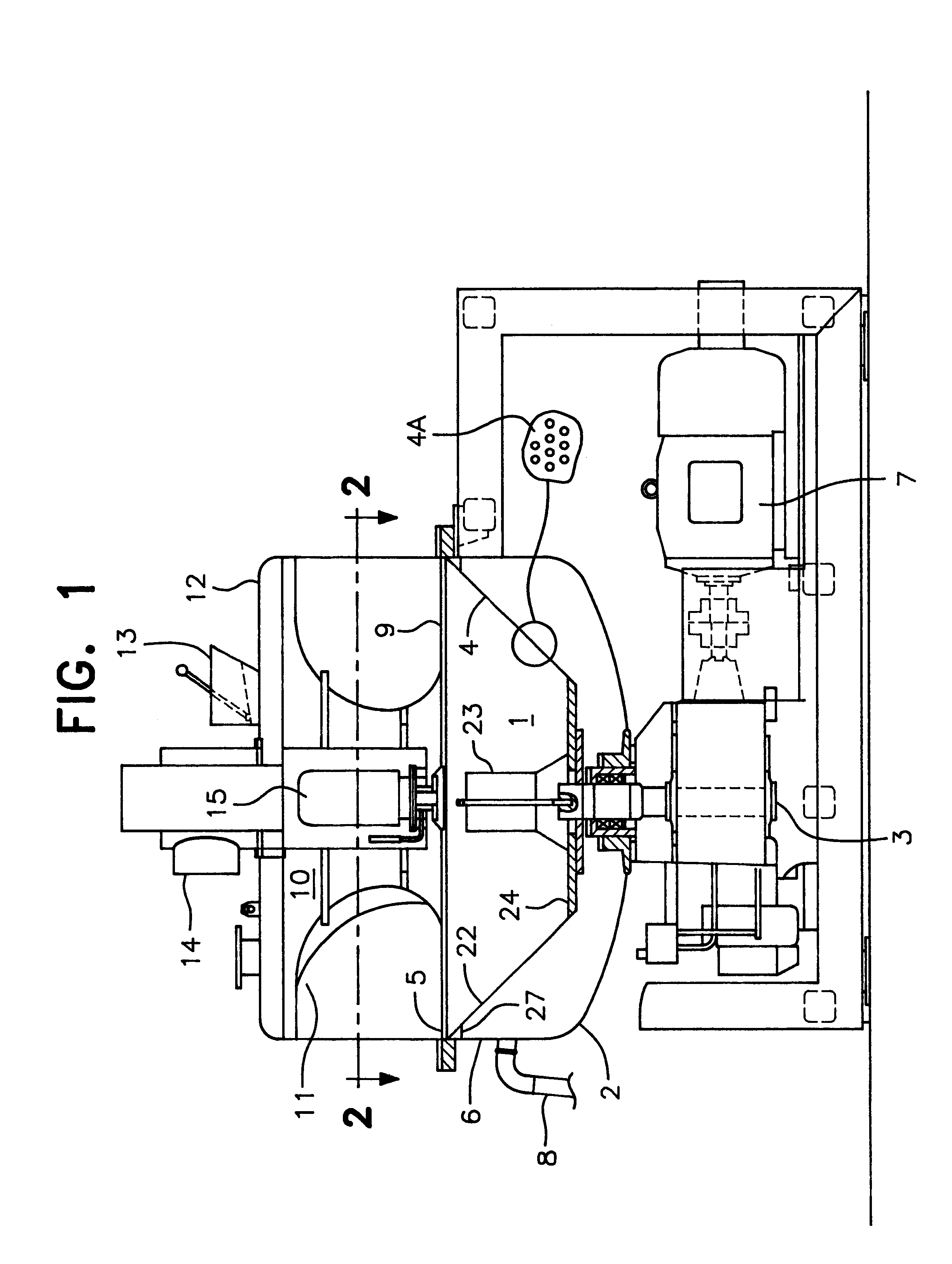

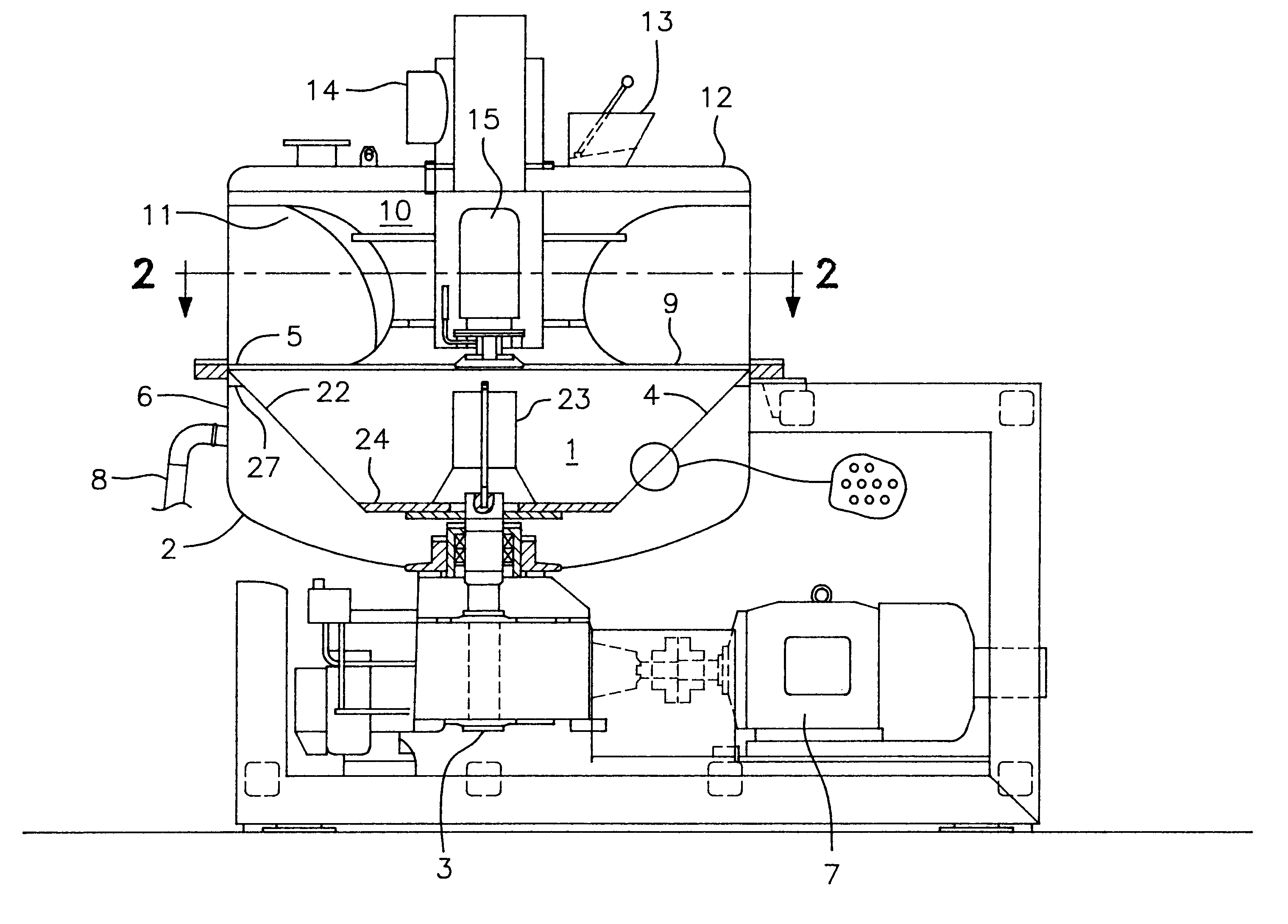

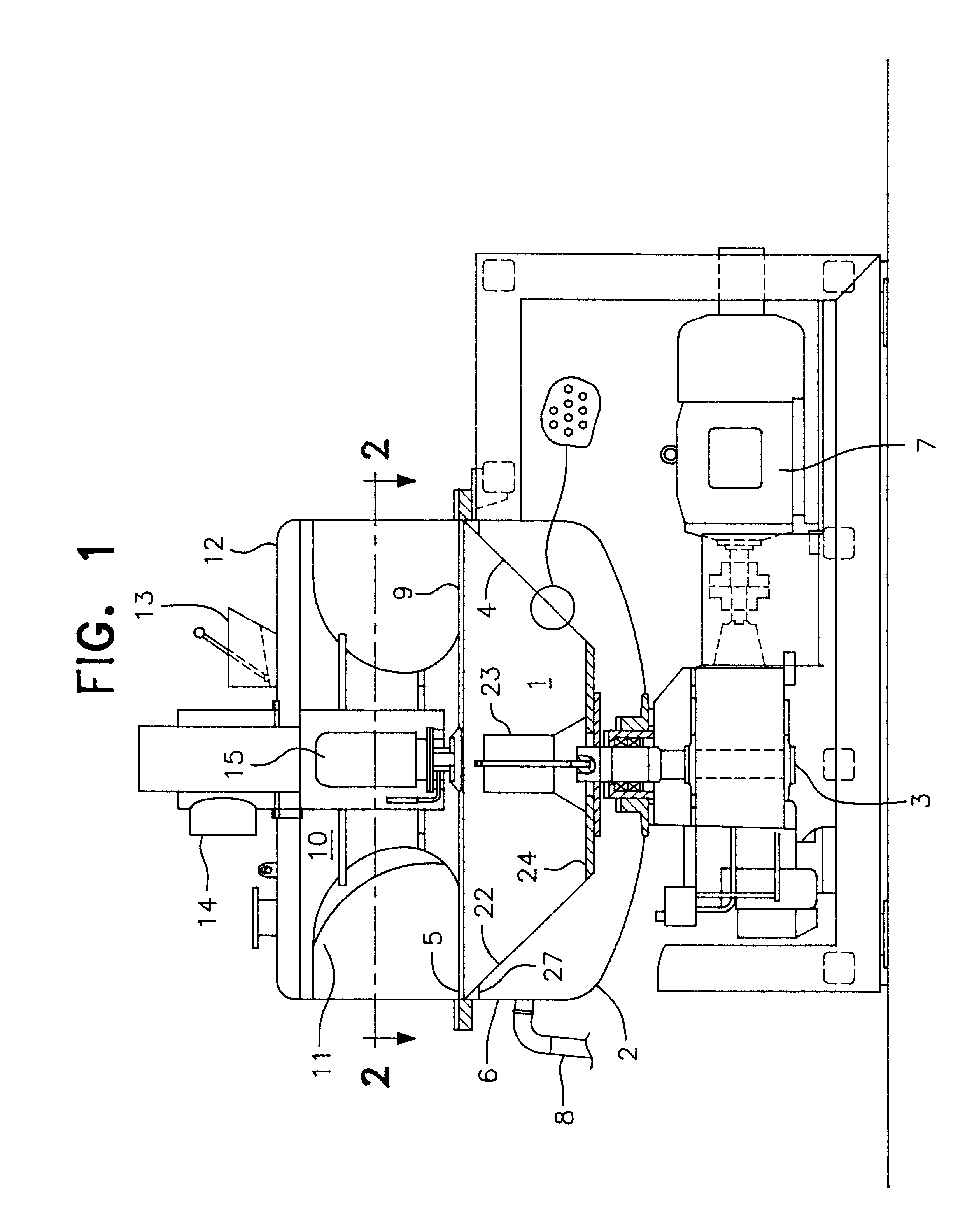

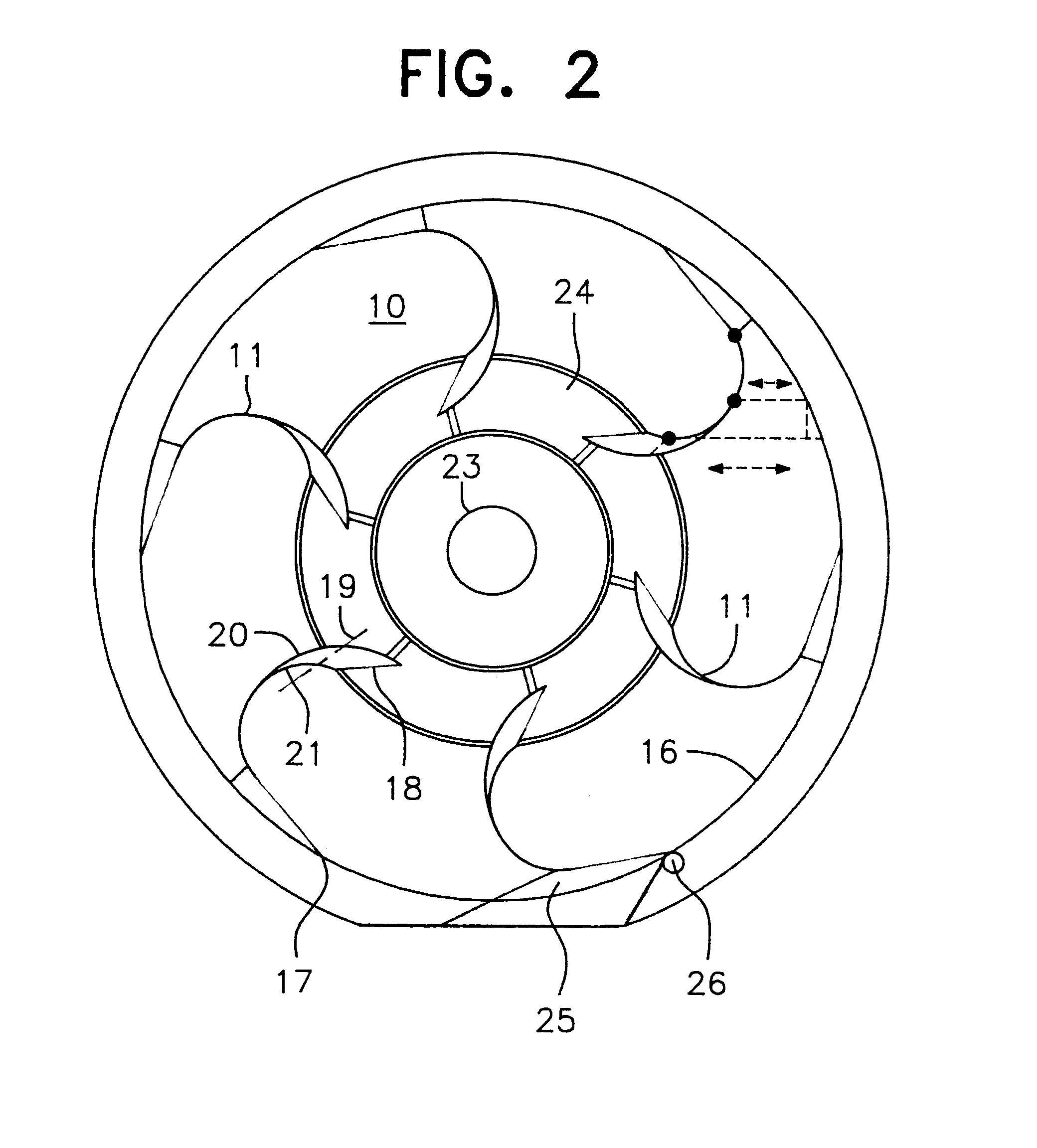

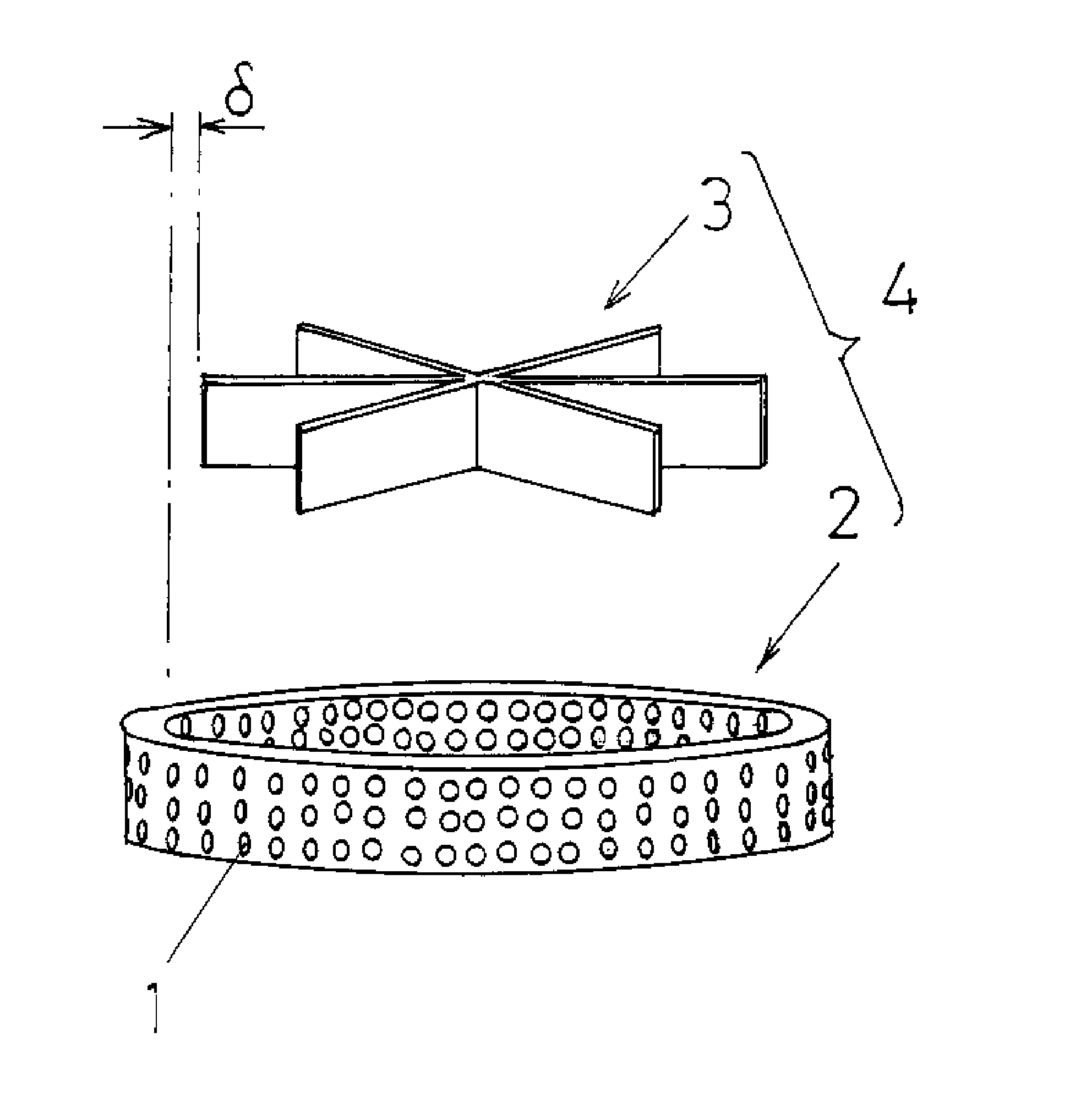

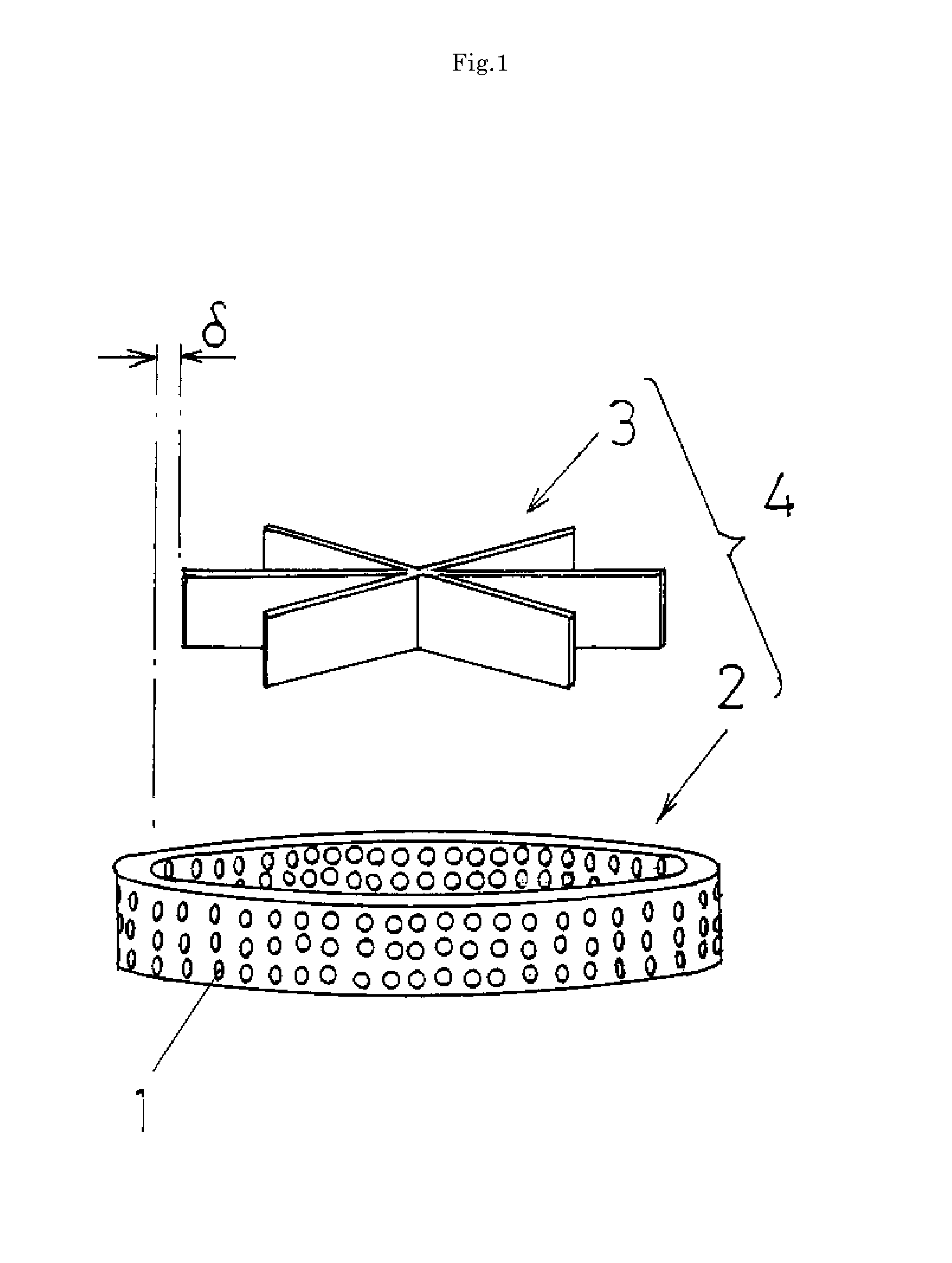

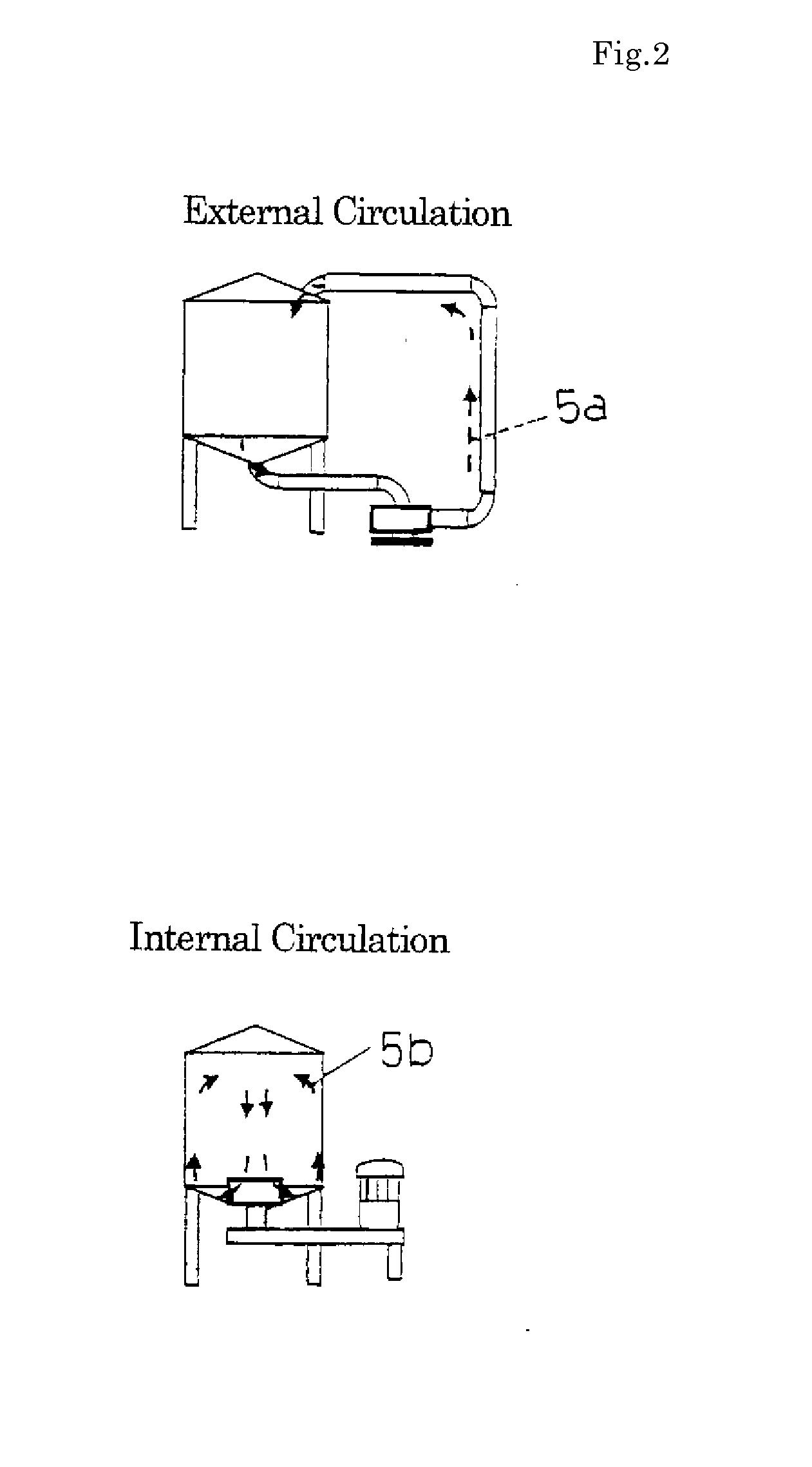

Device for producing a pourable product with a guide vane therein

InactiveUS6354728B1Avoid loadRotating receptacle mixersLiquid surface applicatorsEngineeringMechanical engineering

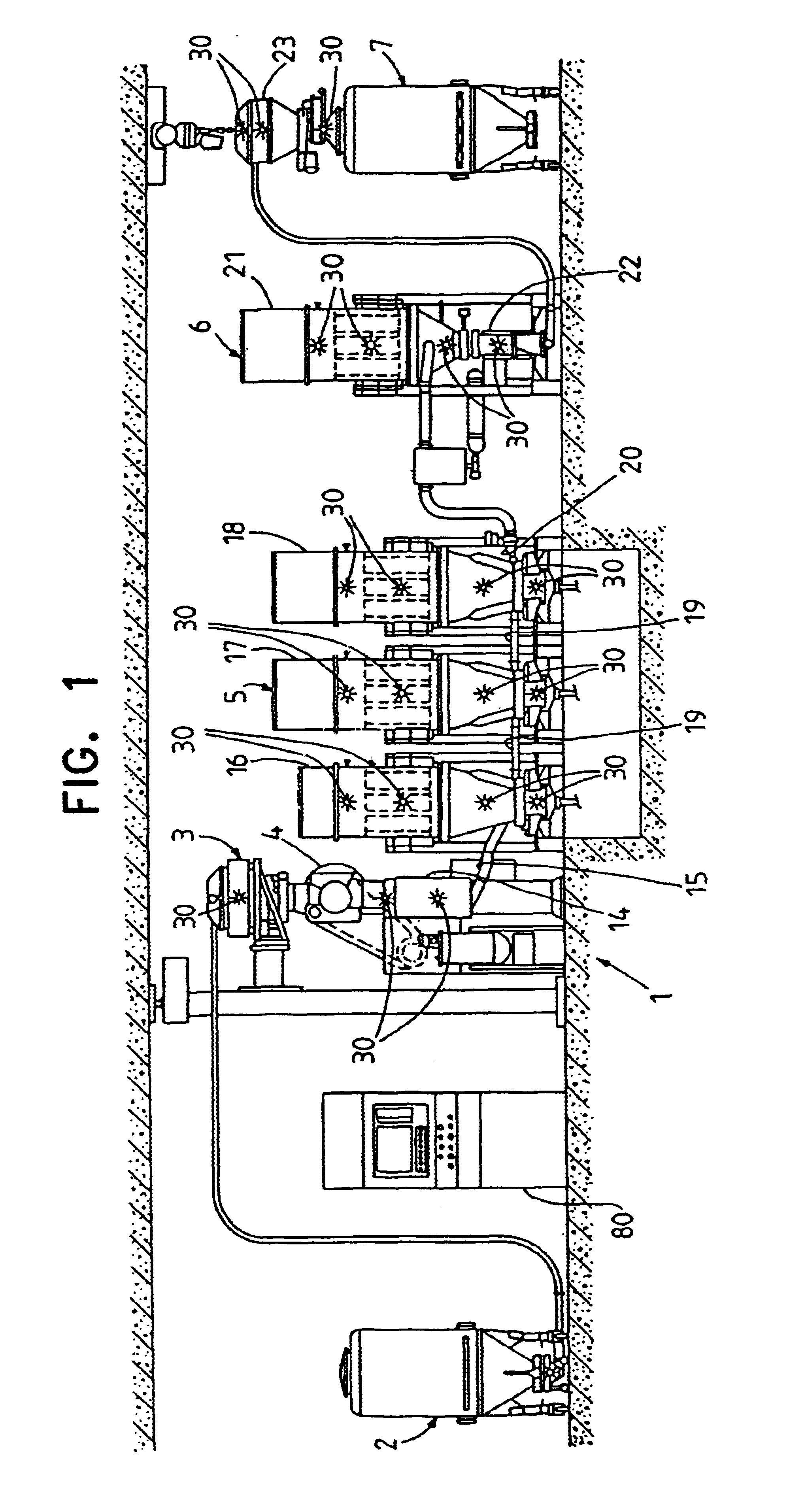

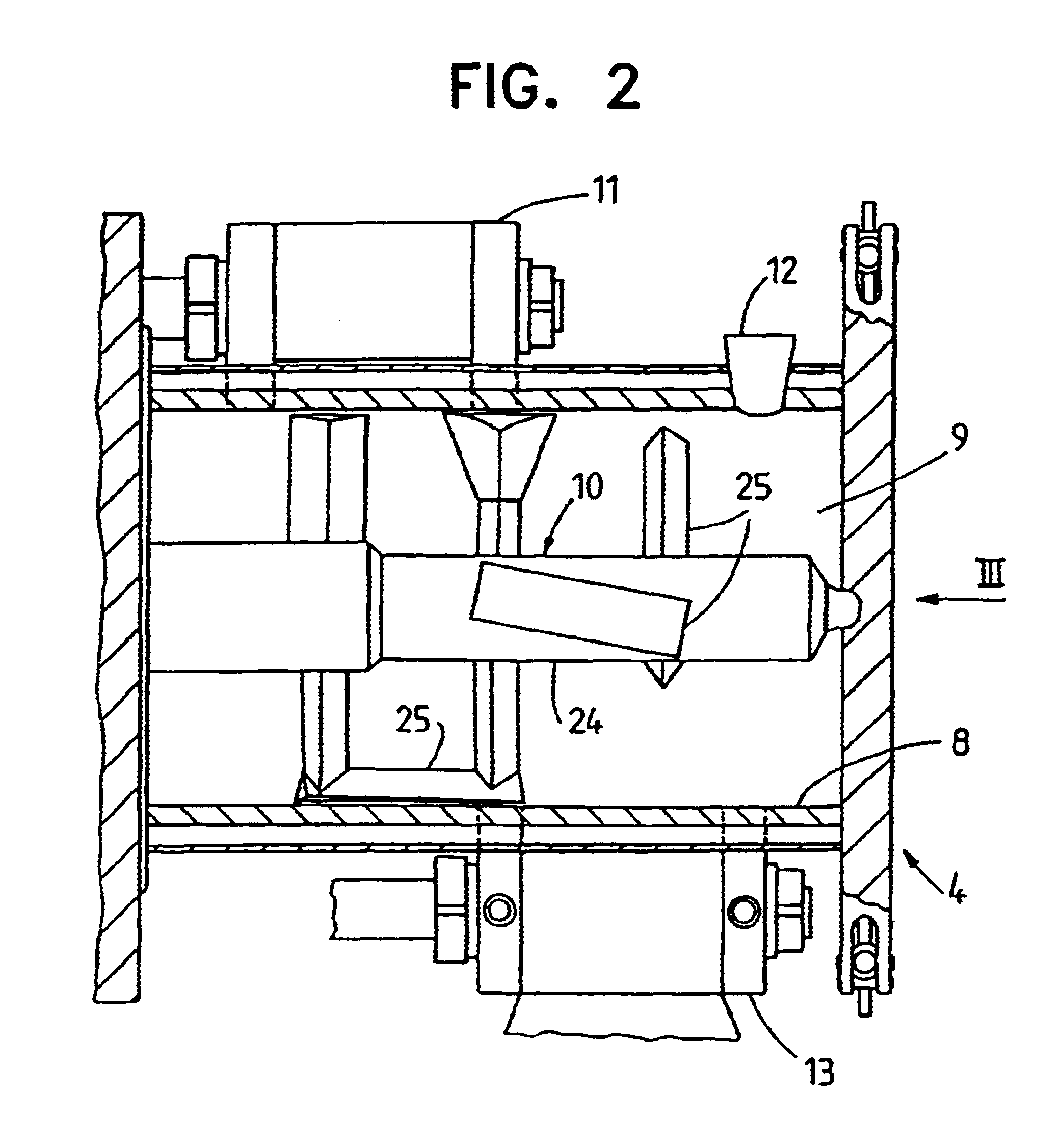

Device for producing a pourable product with a guide vane therein and method for using the device. The device includes a rotor chamber in which a rotor is arranged with a vertical rotor axis. The rotor has, at least in its radially outer third, the shape of a conical shell. Guide vanes for circulating starting materials or the product are arranged statically on an inner wall of the rotor chamber above the plane of the upper edge of the rotor. The guide vanes have, in cross section to the rotor axis, essentially the shape of a segment of a circle or spiral. The inner ends of the guide vanes lie approximately in the middle part of the rotor radius. The conical shell may have at least partially sheet-like gas passages in the form of perforations or screens. The device is used for producing pourable products.

Owner:REINER NOWAK +2

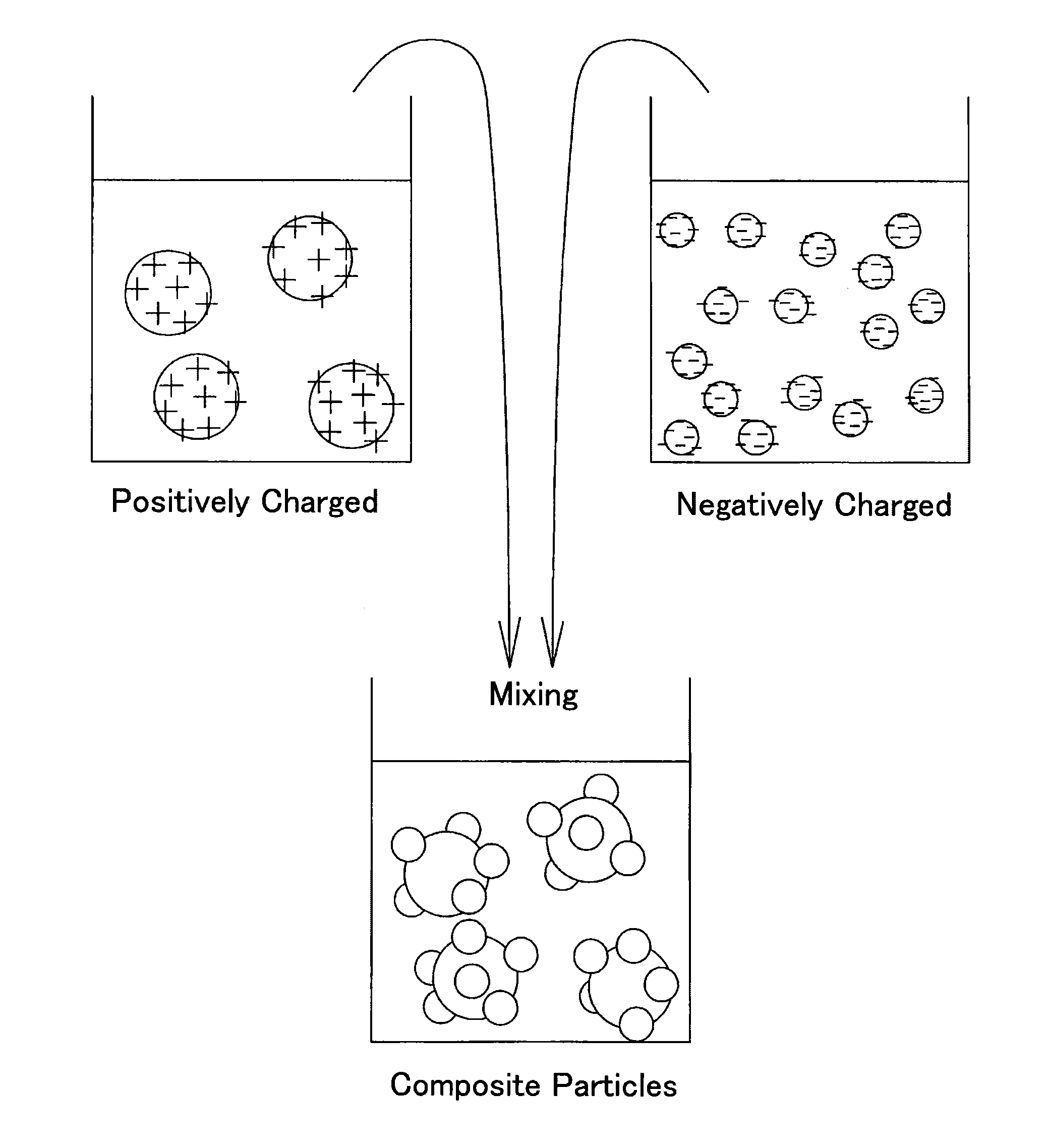

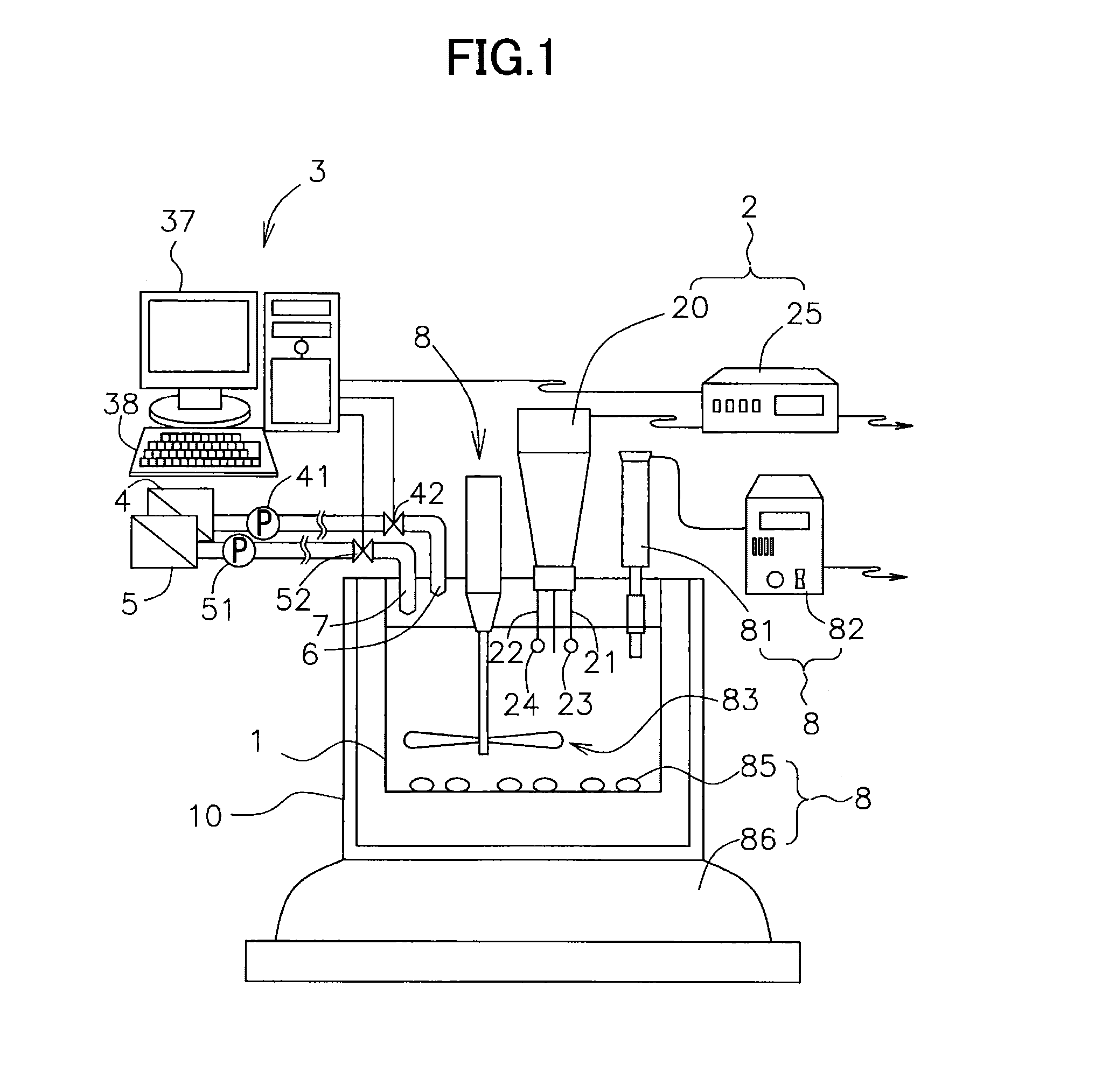

Device and process for producing composite particles

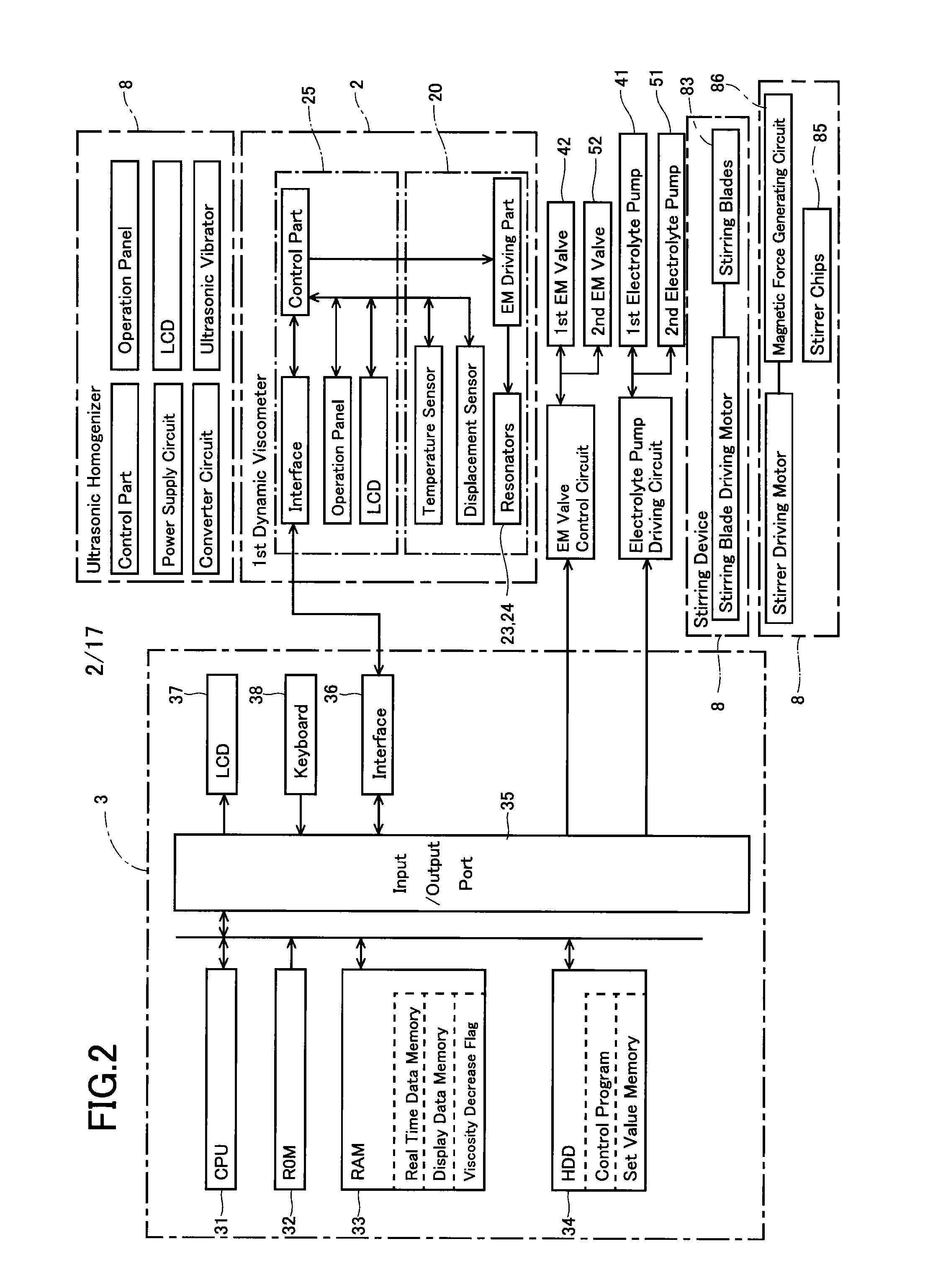

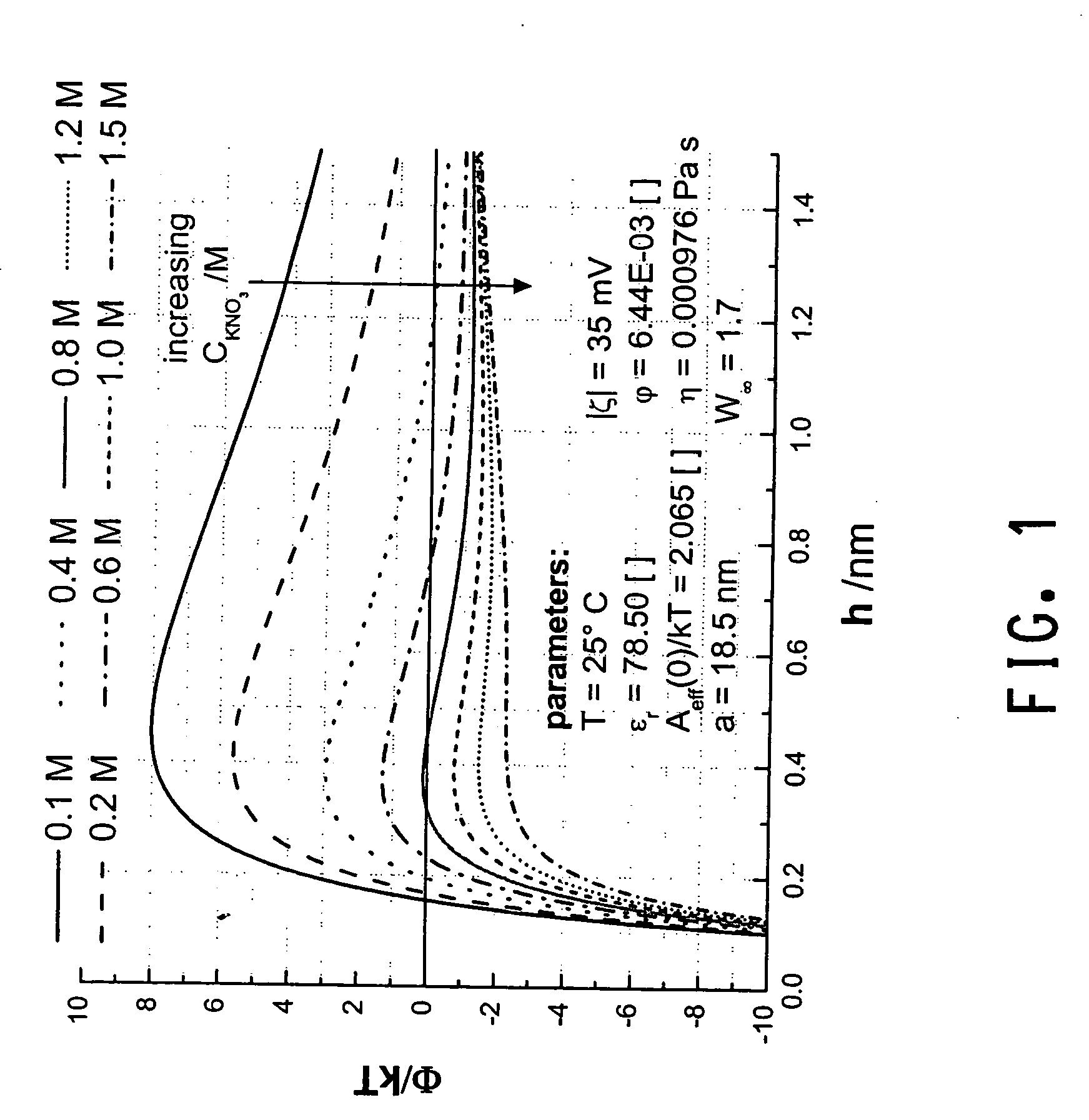

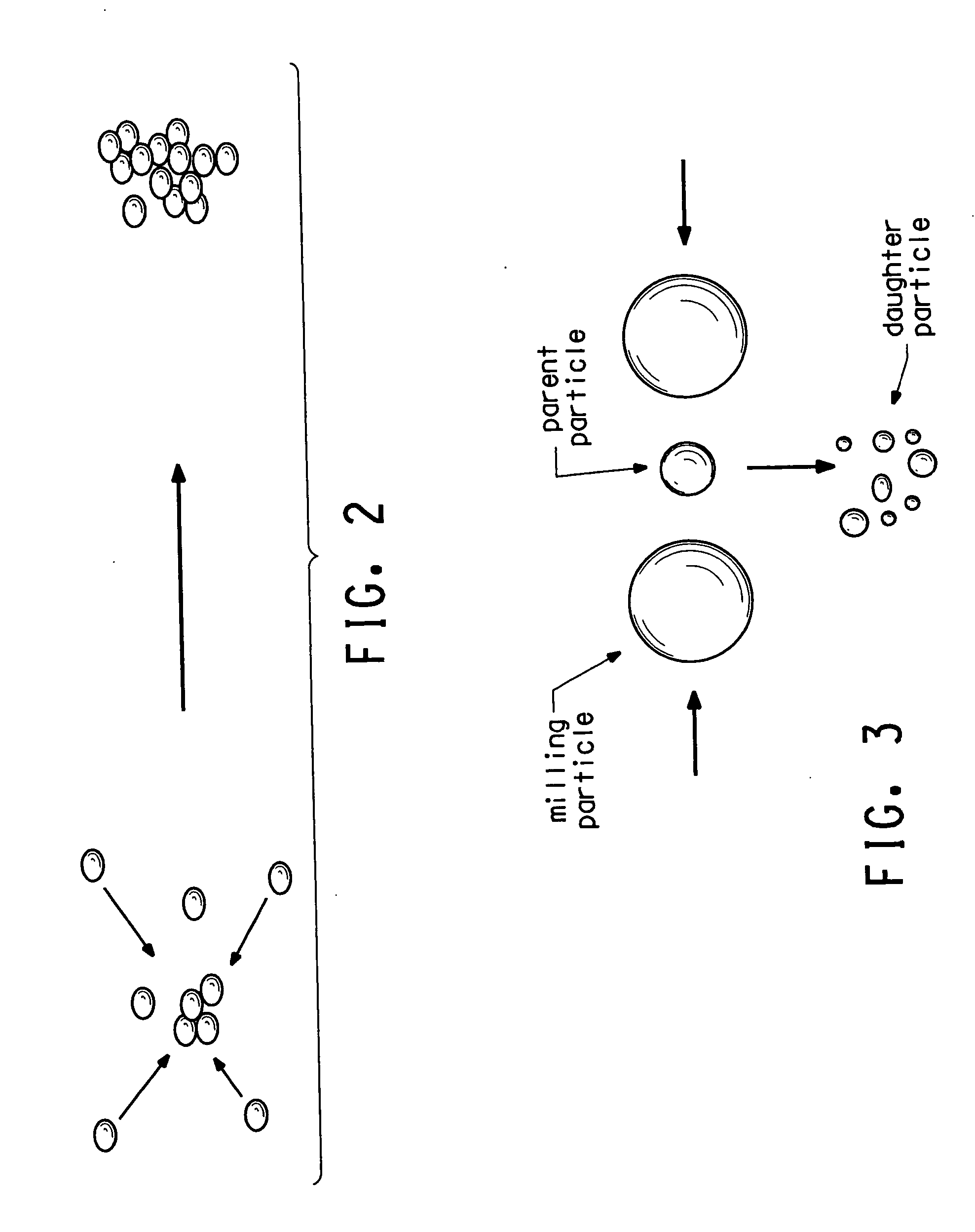

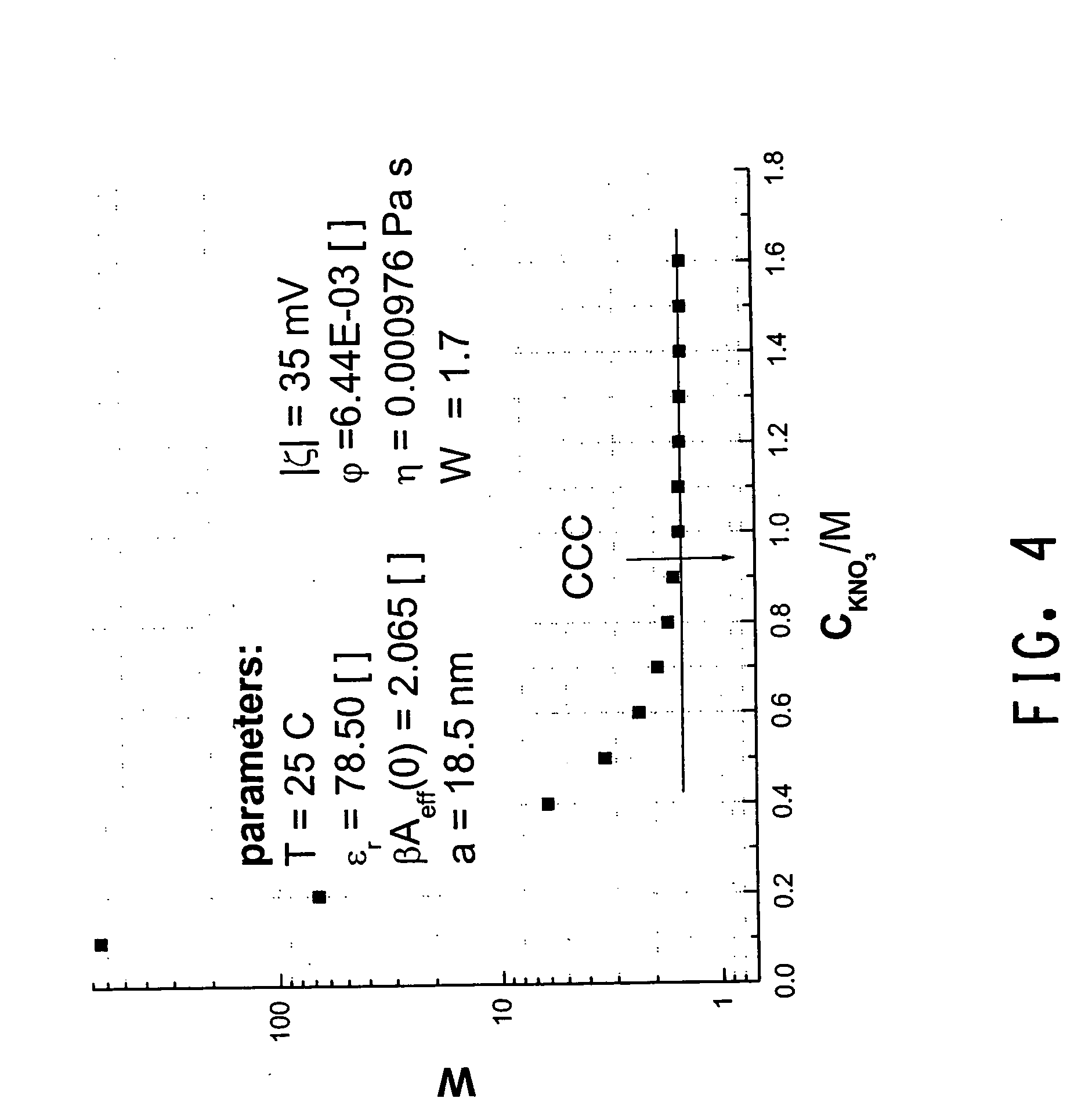

InactiveUS20150190840A1Simple processGuaranteed to workLiquid surface applicatorsGranulation in stationary drums/troughsPolymer electrolytesEngineering

A device and process for producing composite particles capable of adding a control agent for controlling a surface charge of particles such as a polymer electrolyte without being in excess or short. The production device includes a reservoir tank holding liquid containing either a first group or a second group of particles; a dispersion state measuring mechanism measuring a dispersion state of the particles in the liquid held in the reservoir tank; a dispersion state storage storing the dispersion state measured by the dispersion state measuring mechanism when a control agent for controlling a surface charge of the particles contained in the liquid in the reservoir tank is added into the reservoir tank; and an information output outputting information indicating that the dispersion state of the particles in the liquid in the reservoir tank is a desired state, based on the dispersion state stored in the dispersion state storage.

Owner:TOYOHASHI UNIVERSITY OF TECHNOLOGY

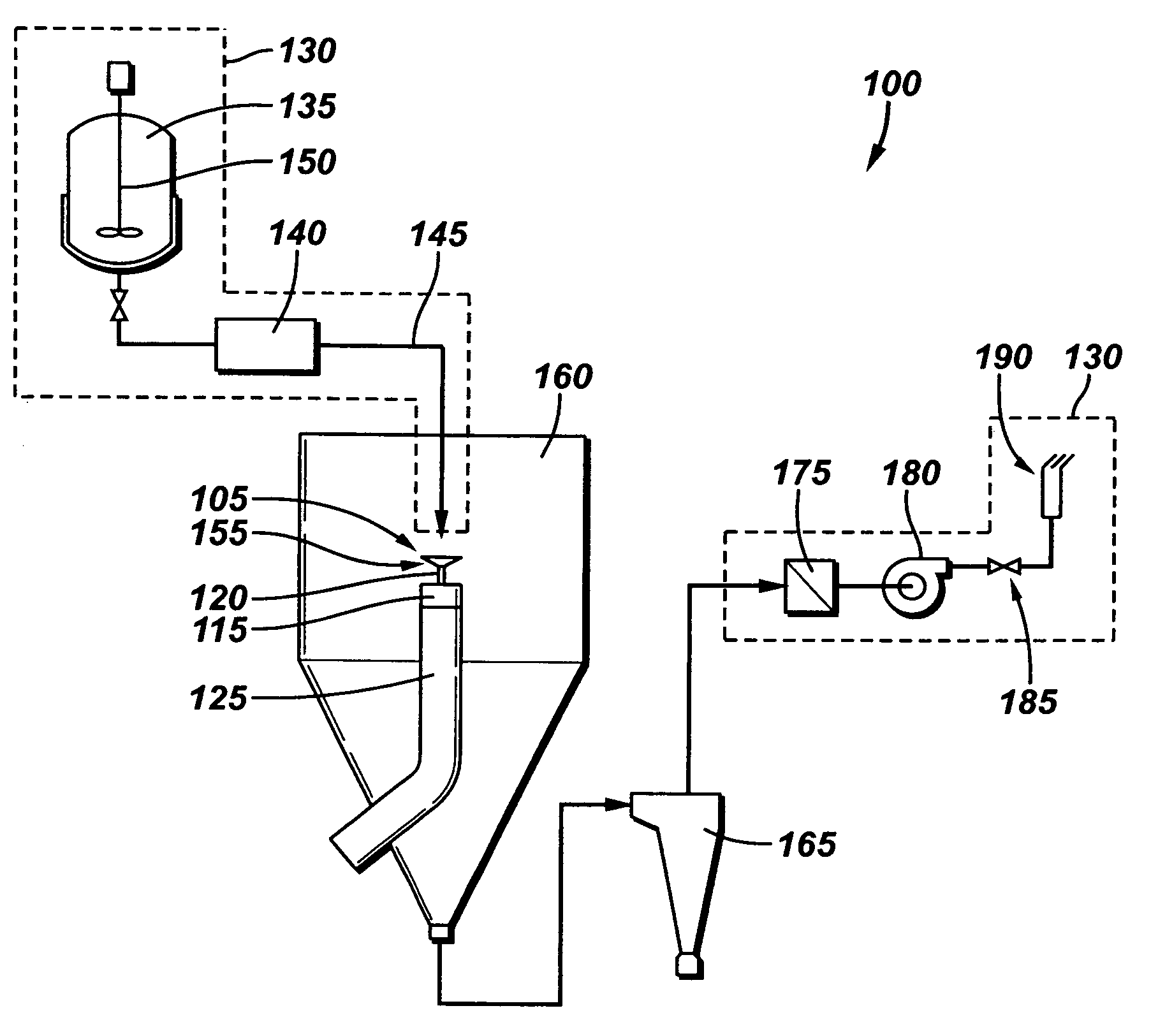

Method and apparatus for producing dry particles

Owner:CIVITAS THERAPEUTICS

Device and method for drying pourable products

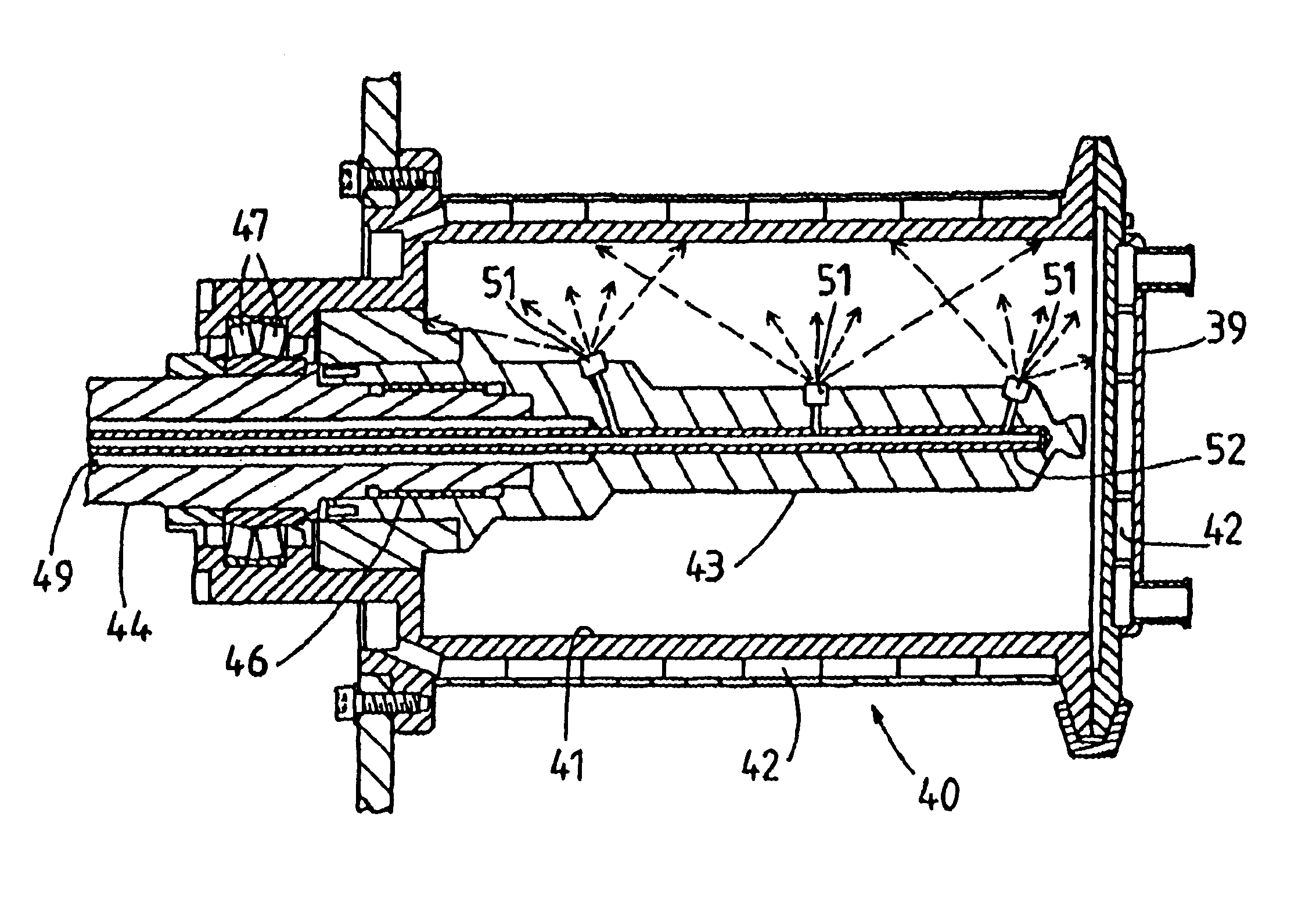

Device and method for drying a pourable products. The device includes a rotor chamber in which a rotor is arranged with a vertical rotor axis. The rotor has a central horizontal surface and, at least in its radially outer third, a conical shell which is inclined to the axis of rotation by 20° to 70°, in such a way that the end face of the conical shell has the largest diameter and is located at the top. The conical shell has, at least partially, sheet-like gas passages in the form of perforations or screens. The method for drying pourable products provides for dry gas to be fed in a sheet like manner to the products to be dried during the radially peripheral circulation of the products without the products being swirled up and being exposed to unacceptable compressive, concussive and / or frictional loads.

Owner:GLATT SYSTTECHN +2

Production of nanoparticles, especially nanoparticle composites, from powder agglomerates

The invention relates to a method for producing particulate composite materials. According to the method, solid inorganic or organic particle agglomerates or particle aggregates that are provided in a dry state, particularly in powder form, are first reduced in size in the gas phase or in a gaseous carrier medium in the presence of organic matrix particles by applying energy. The obtained comminuted particles are dispersed into the organic matrix particles, especially embedded thereinto and / or attached thereto. The composite materials produced in said manner can be used in many different ways and are suitable in particular for use in a large variety of plastic materials, coating materials, paints, and lacquers, especially coating powders, to modify properties during use in the corresponding products and similar.

Owner:BYK CHEM GMBH

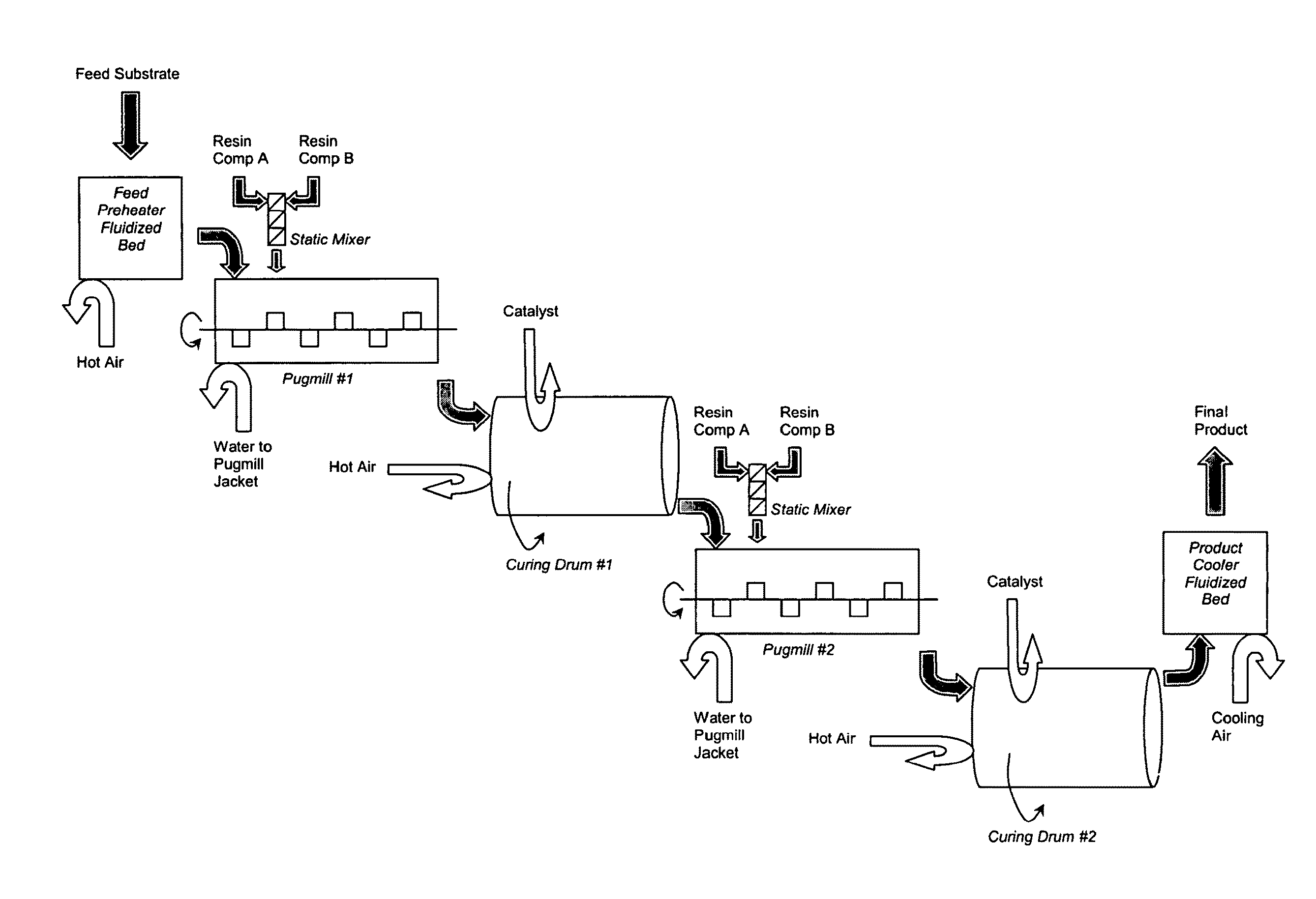

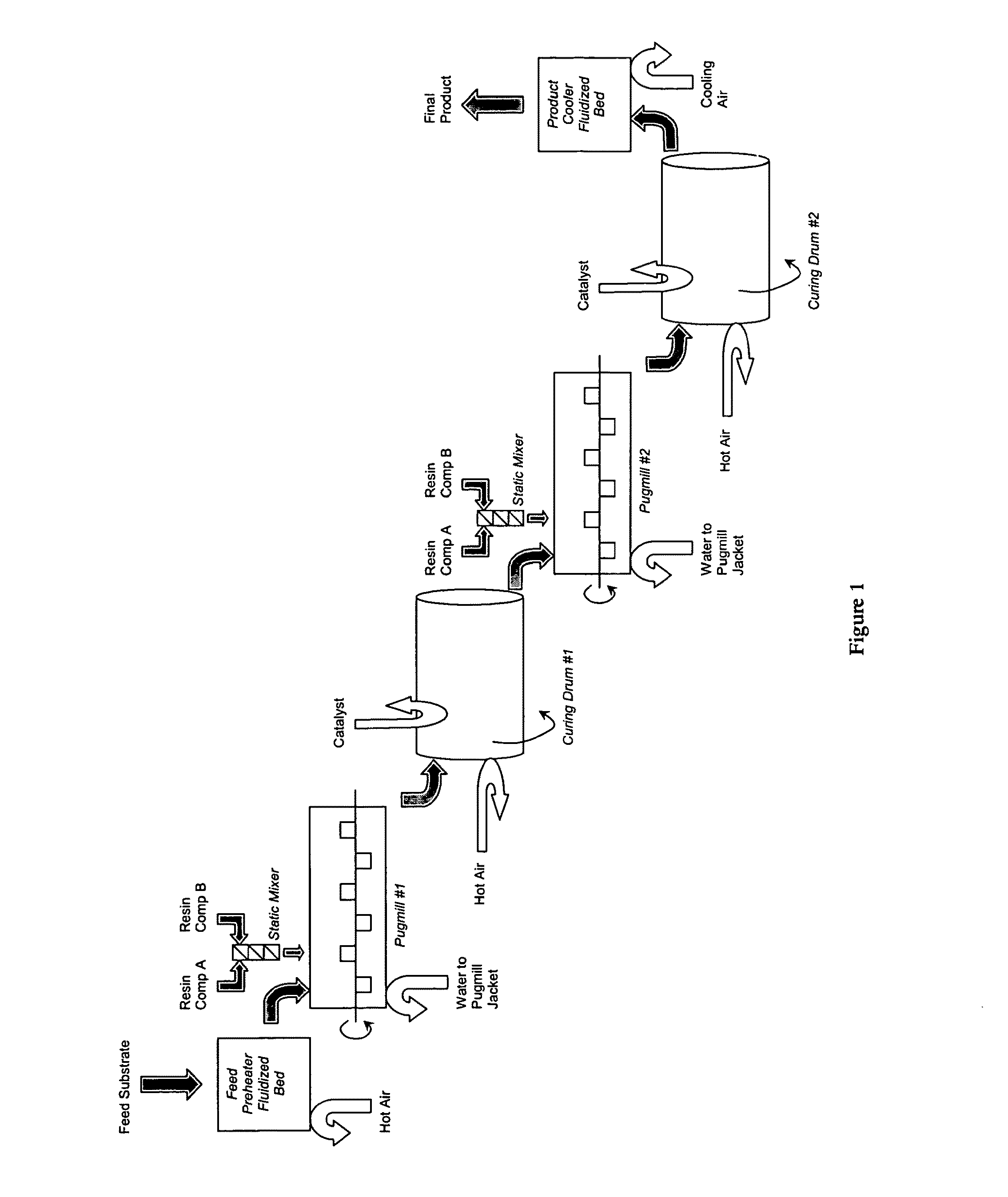

Methods and systems for coating granular substrates

ActiveUS20140033779A1Easy to controlReduce the possibilityBiocideRotating receptacle mixersEngineeringCoating

Owner:EVERRIS INT

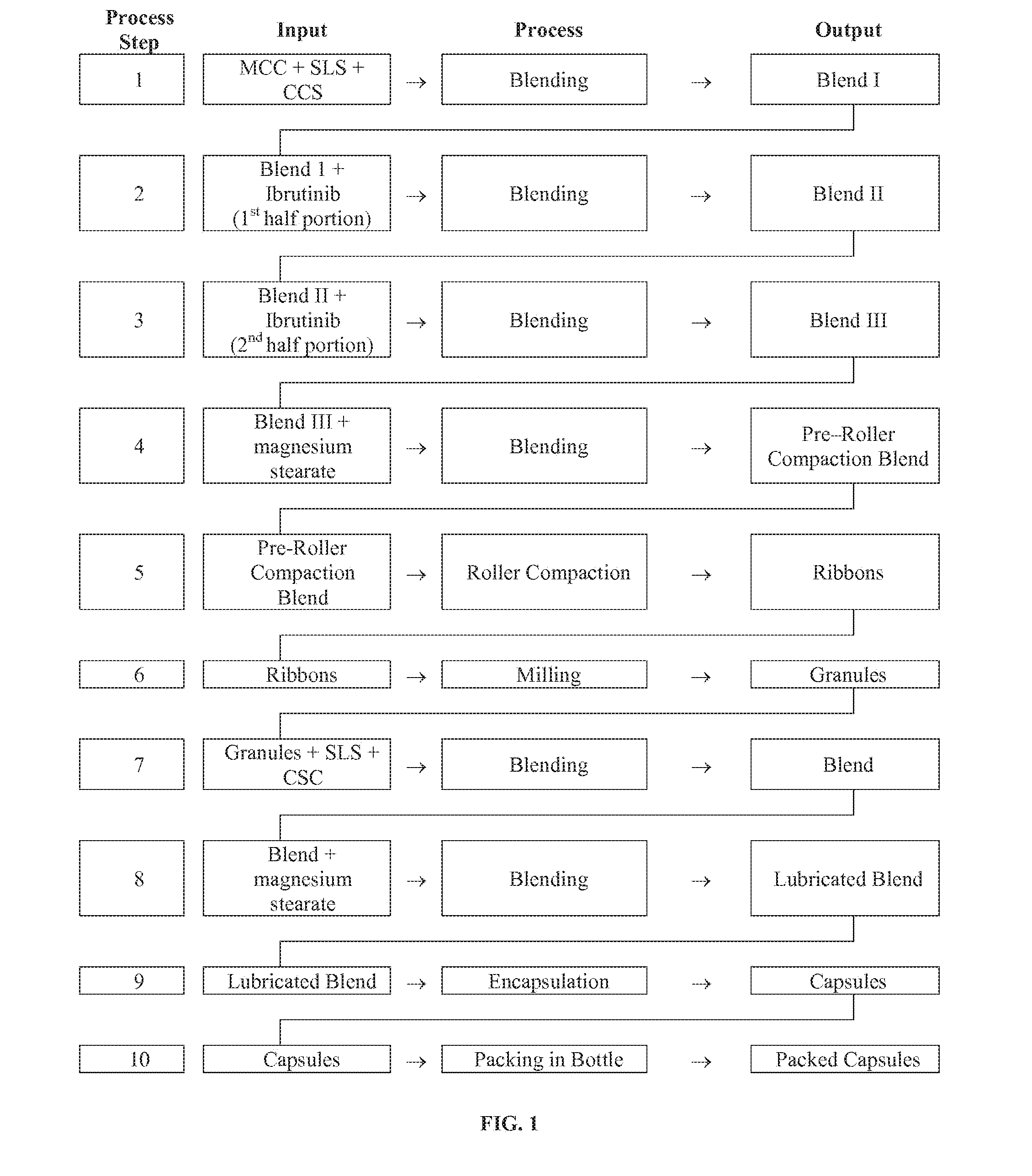

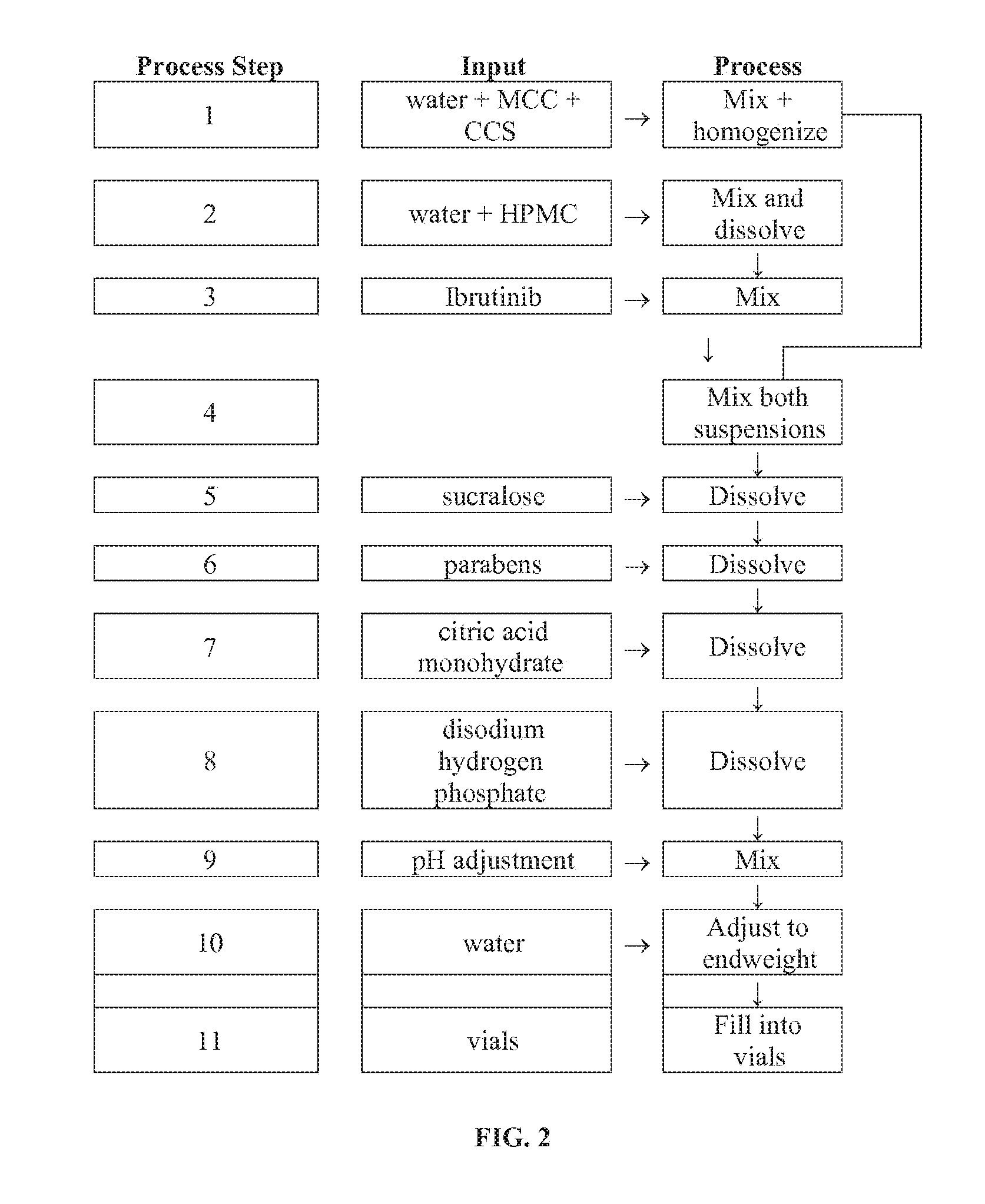

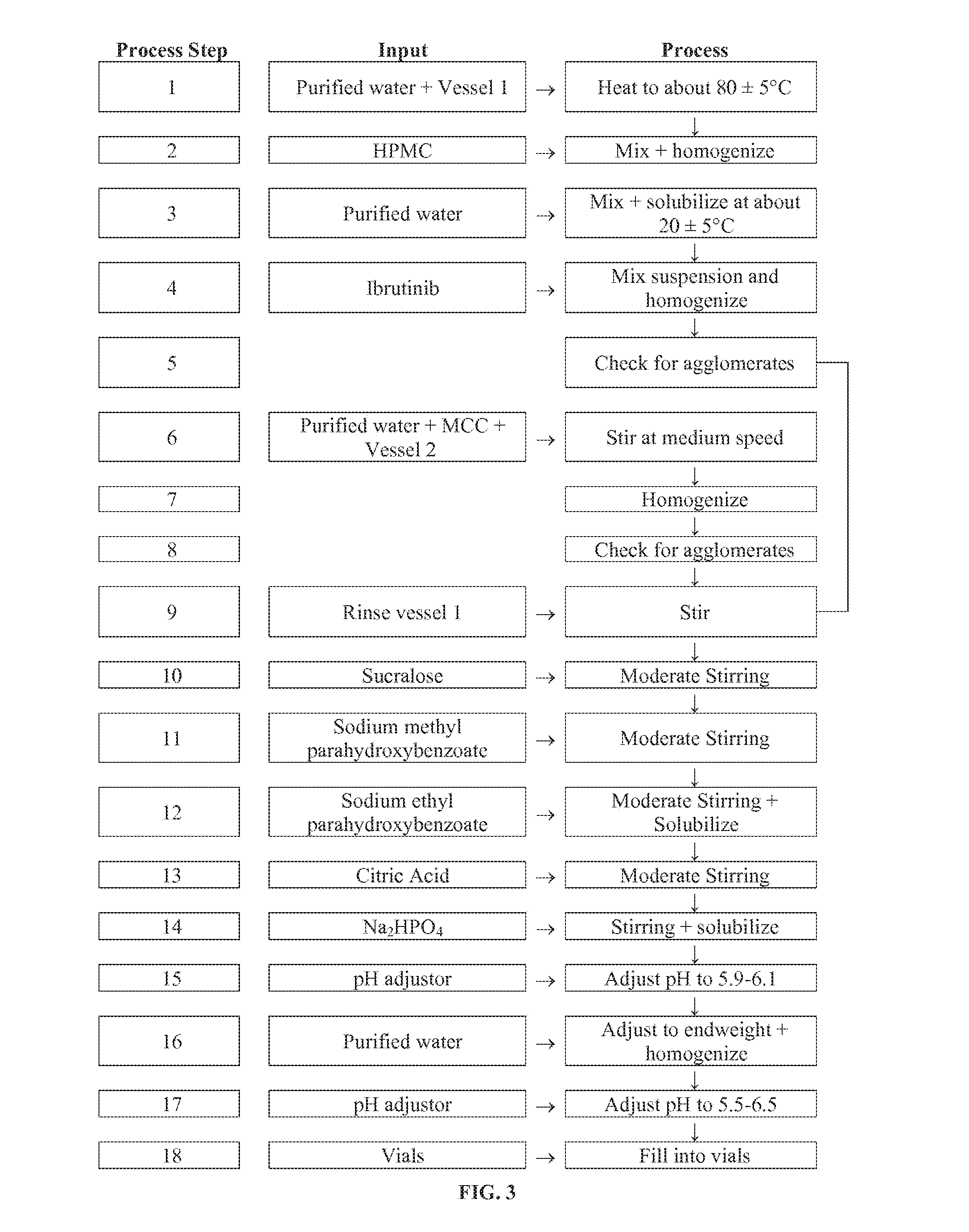

Compositions Containing Ibrutinib

InactiveUS20160287594A1Easy to sprinkleOrganic active ingredientsInorganic non-active ingredientsWaldenstrom macroglobulinemiaMetabolite

Discussed herein are pharmaceutical compositions containing Ibrutinib and processes for preparing them. The compositions may be utilized in the treatment of a variety of conditions including, without limitation, B-cell proliferative disorders such as non-Hodgkin lymphoma (diffuse large B cell lymphoma, follicular lymphoma, mantle cell lymphoma or burkitt lymphoma), Waldenstrom macroglobulinemia, plasma cell myeloma, chronic lymphocytic leukemia, lymphoma, or leukemia. These compositions are designed for oral ingestion. The compositions are contained within a capsule such as a standard or sprinkle or in a liquid formulation such as a suspension. In one embodiment, the pharmaceutical composition contains Ibrutinib, a salt, prodrug, or metabolite thereof, microcrystalline cellulose, croscarmellose sodium, sodium lauryl sulfate, and magnesium stearate. In another embodiment, the pharmaceutical composition contains Ibrutinib, a salt, prodrug, or metabolite thereof, microcrystalline cellulose, carboxymethylcellulose sodium, hydroxypropylmethylcellulose, citric acid monohydrate, disodium hydrogen phosphate, sucralose, sodium methyl parahydroxybenzoate, sodium ethyl parahydroxybenzoate, concentrated hydrochloric acid, sodium hydroxide, and water.

Owner:JANSSEN PHARMA NV

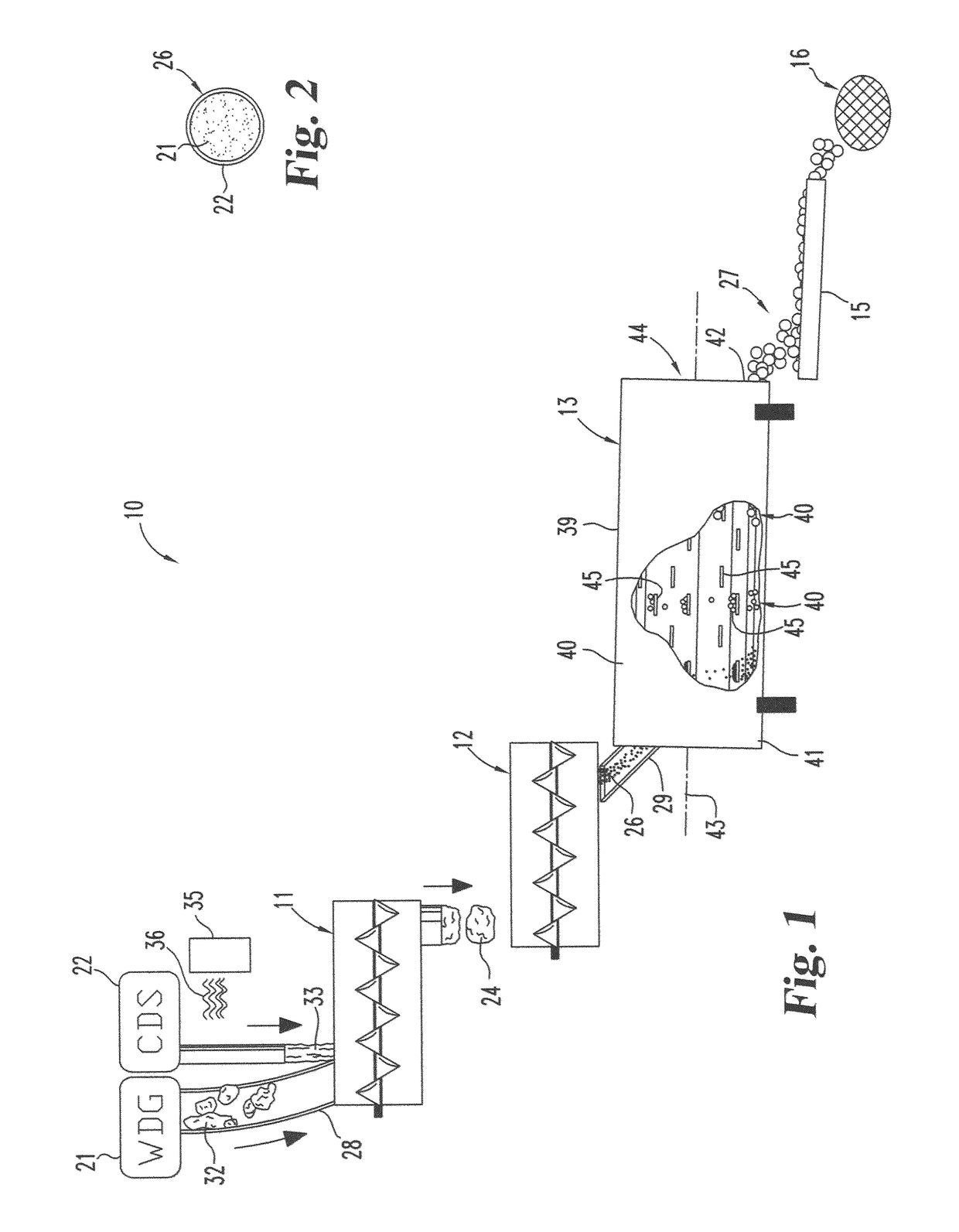

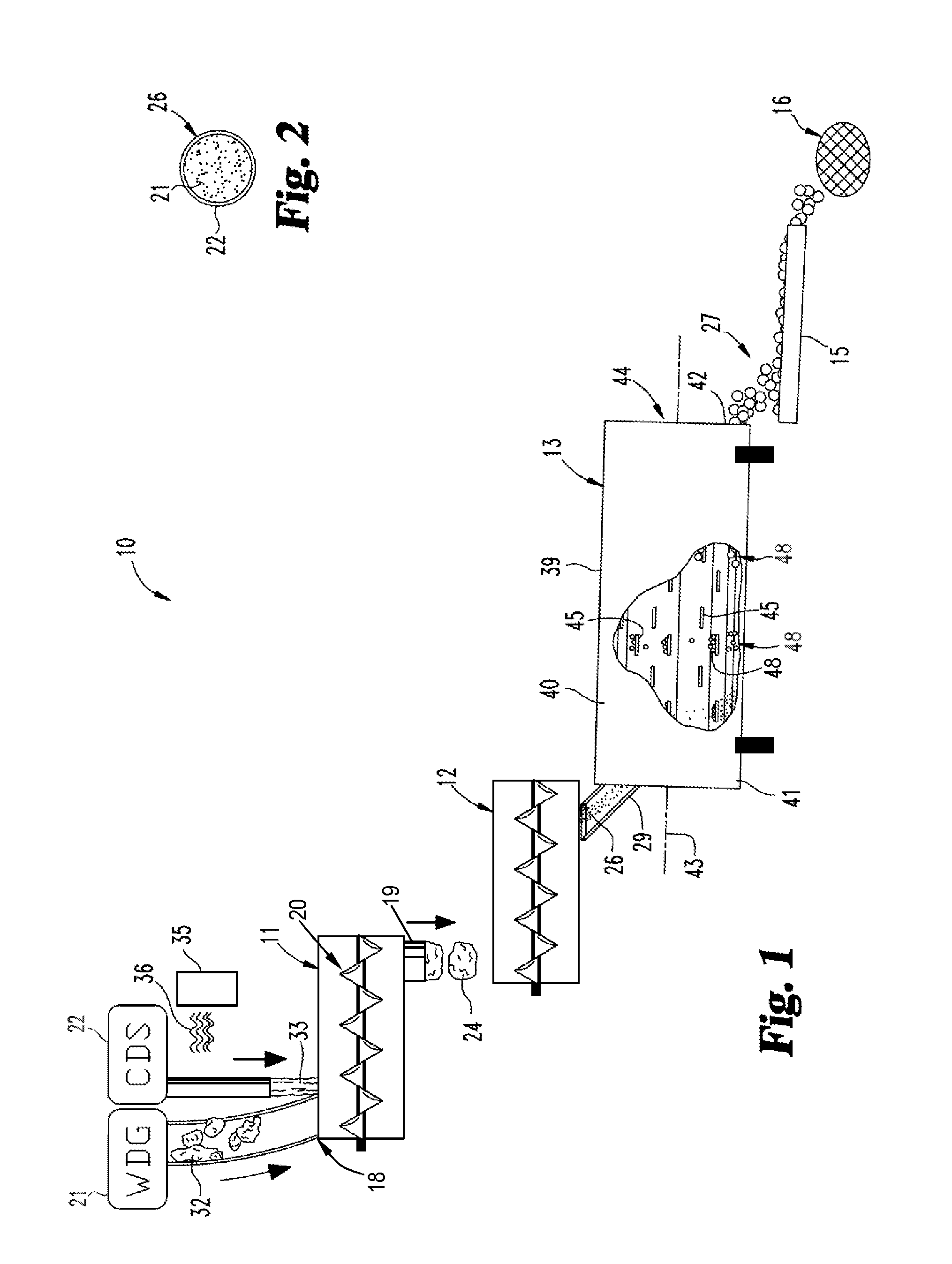

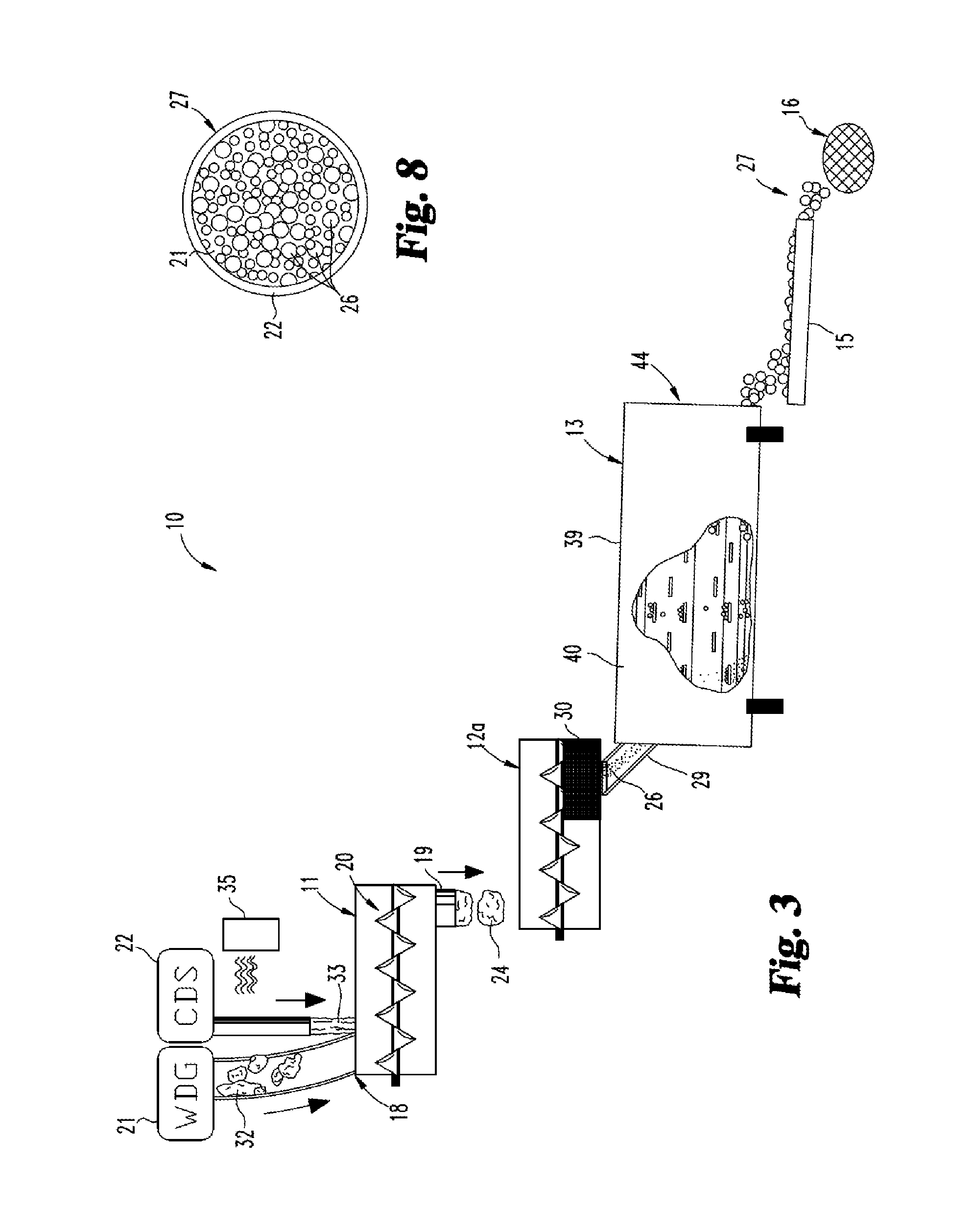

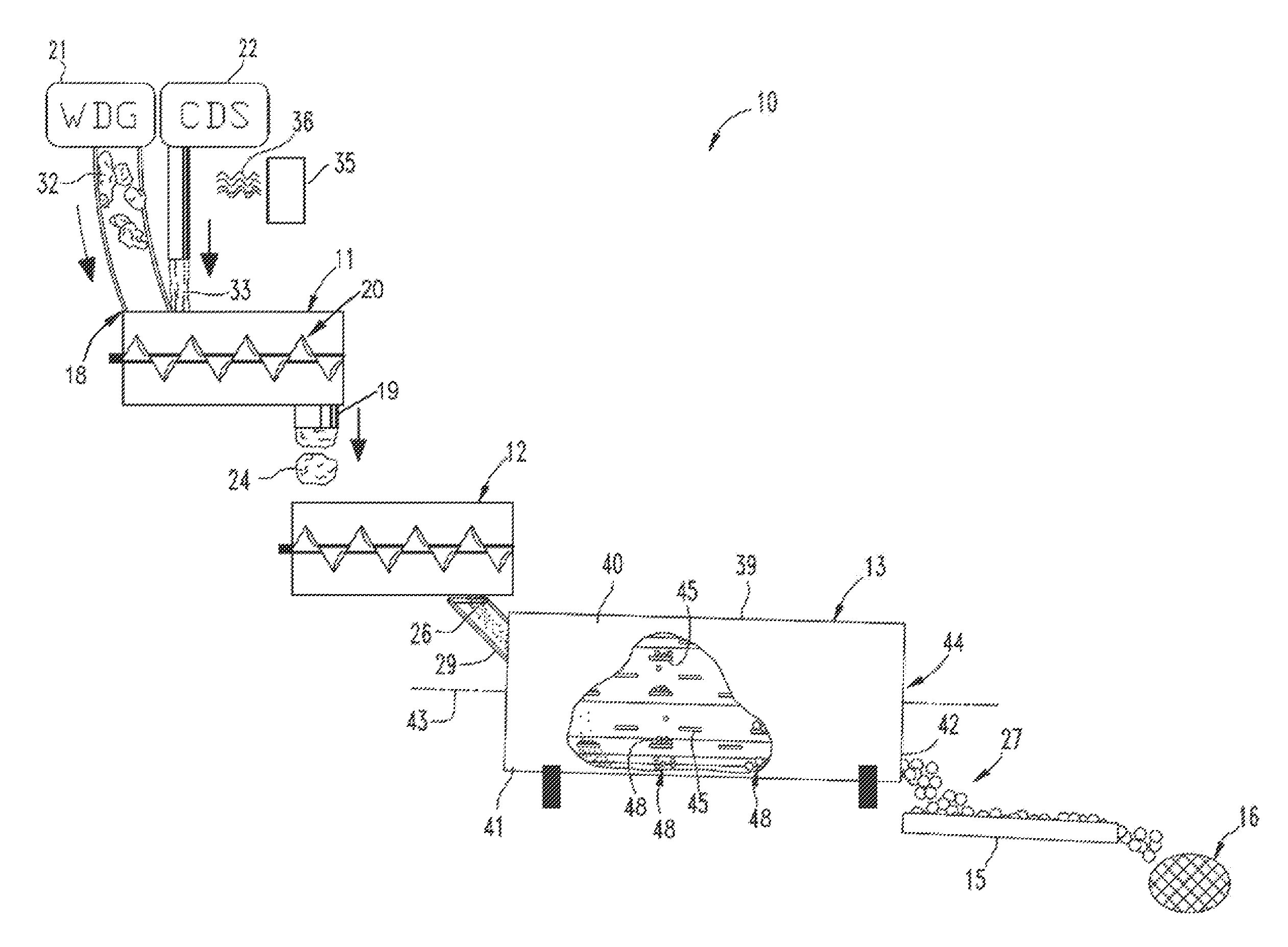

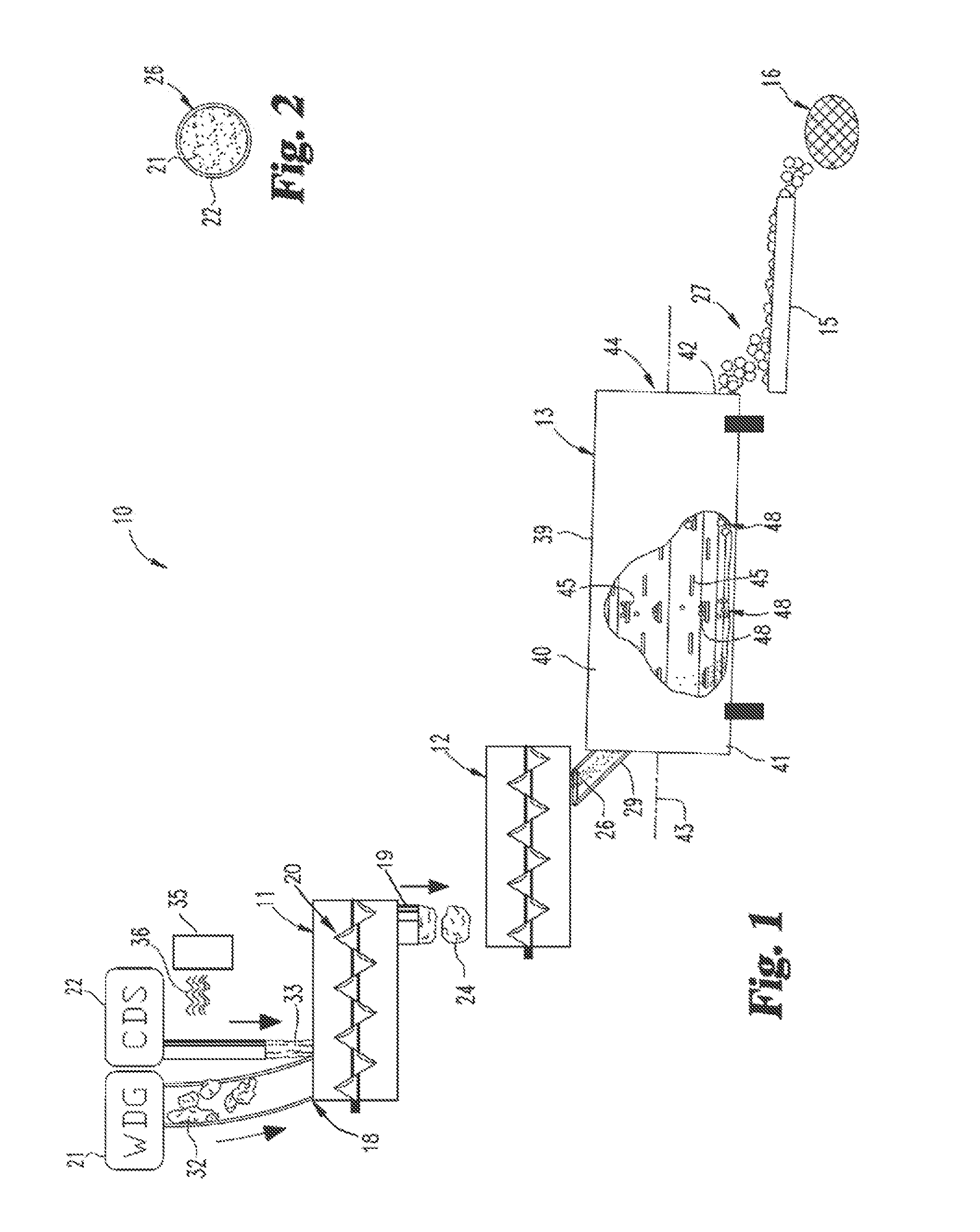

Method and apparatus for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a cavity for receiving a coproduct of a wet biomass process and a binder and being operable to premix the coproduct and binder to produce a substantially homogeneous DDGS mixture; a high shear mixer having a receptacle for receiving the DDGS mixture and being operable to shear mix the mixture and produce very small DDGS particles; and, an agglomerator having an interior chamber sized and configured to receive and transform the DDGS particles into substantially spherical DDGS pellets.

Owner:PURDUE RES FOUND INC

Production of nanoparticles, especially nanoparticle composites, from powder agglomerates

The invention relates to a method for producing particulate composite materials. According to the method, solid inorganic or organic particle agglomerates or particle aggregates that are provided in a dry state, particularly in powder form, are first reduced in size in the gas phase or in a gaseous carrier medium in the presence of organic matrix particles by applying energy. The obtained comminuted particles are dispersed into the organic matrix particles, especially embedded thereinto and / or attached thereto. The composite materials produced in said manner can be used in many different ways and are suitable in particular for use in a large variety of plastic materials, coating materials, paints, and lacquers, especially coating powders, to modify properties during use in the corresponding products and similar.

Owner:BYK CHEM GMBH

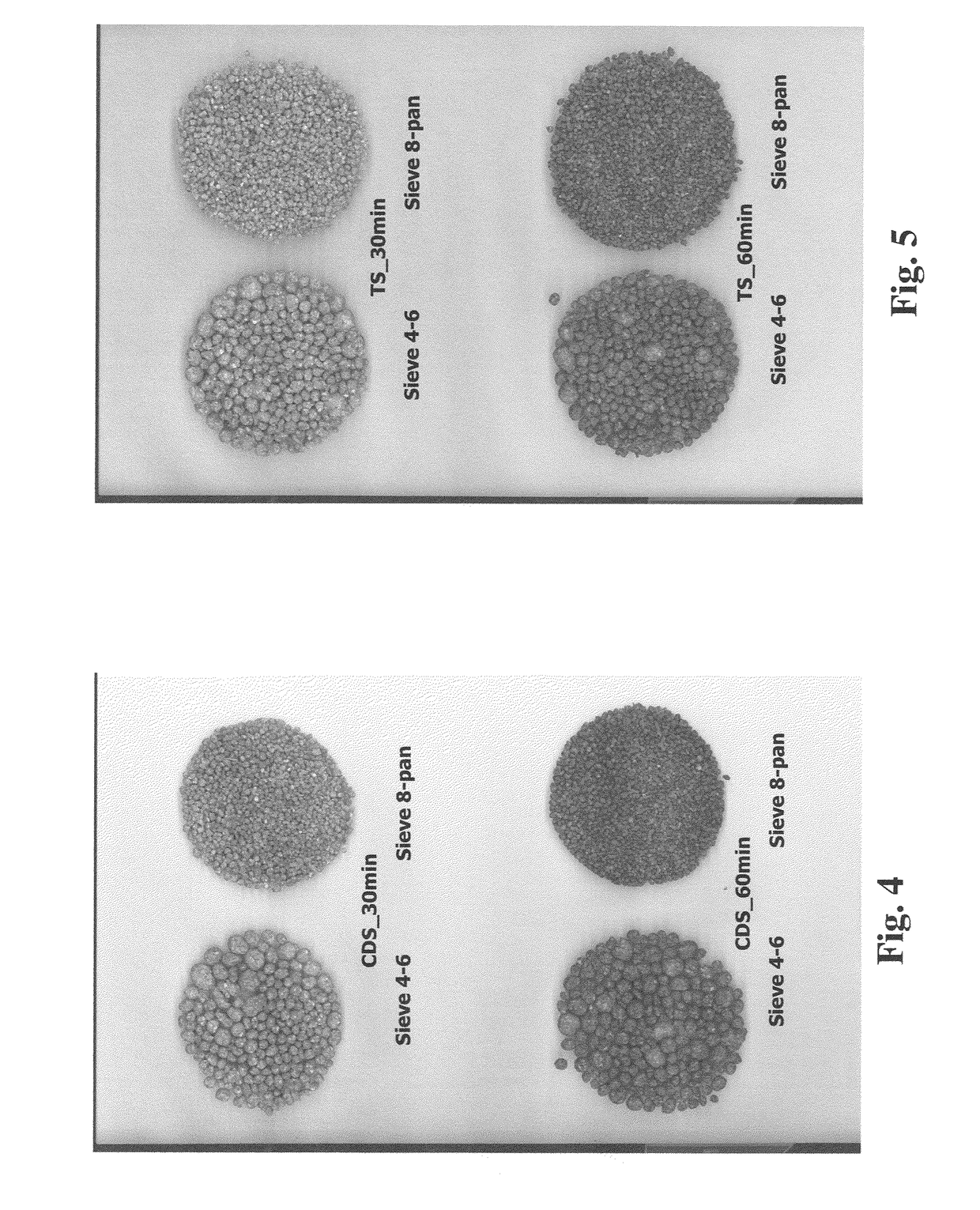

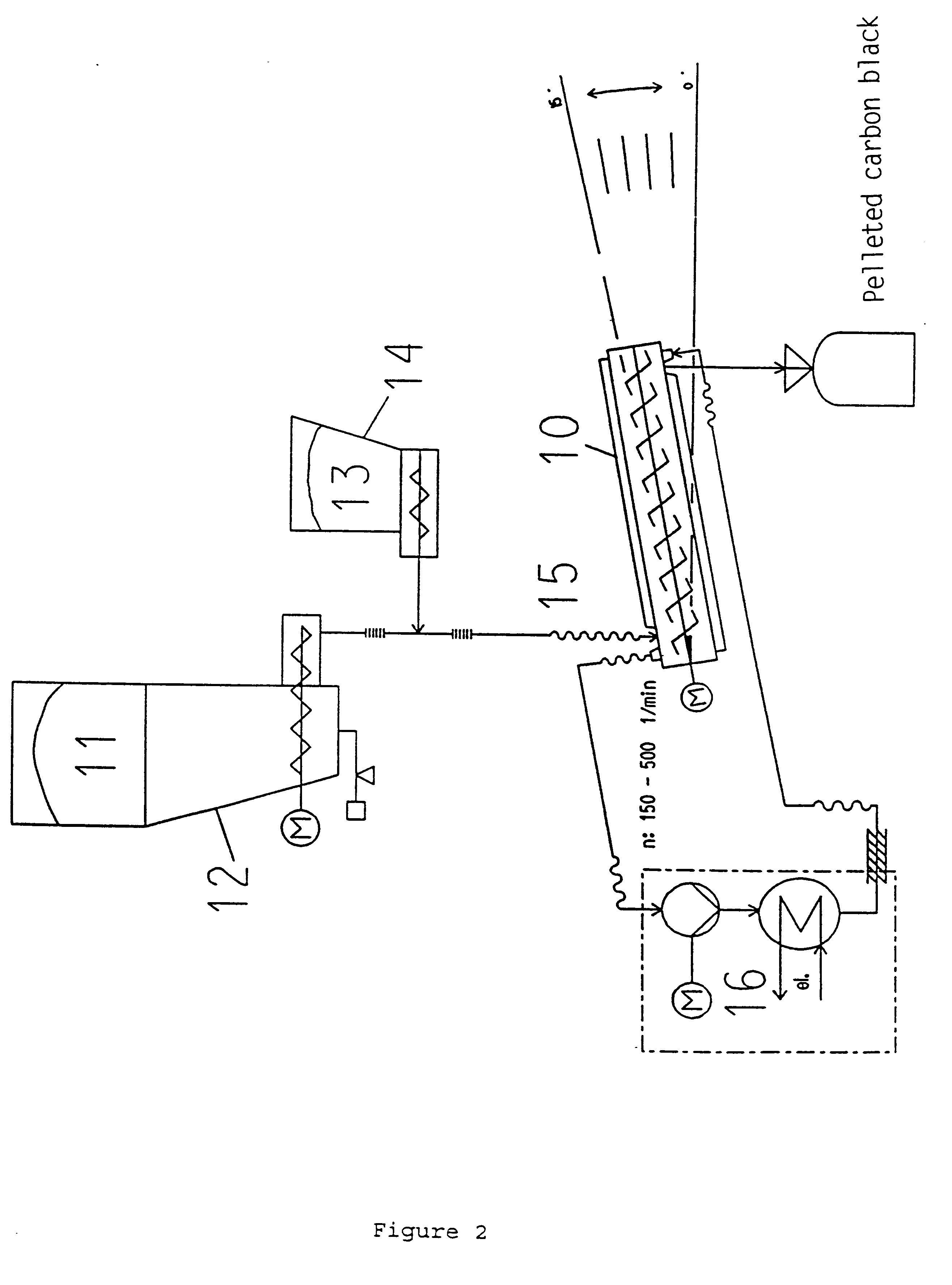

Process for continuous dry granulation of powered carbon black

A process for continuous dry granulation of powdered carbon black. Granulation is performed with the assistance of a granulator. As a result, for comparable sized equipment, the carbon black throughput can be increased several times as compared with pelletizing drums used in the conventional manner.

Owner:DEGUSSA AG

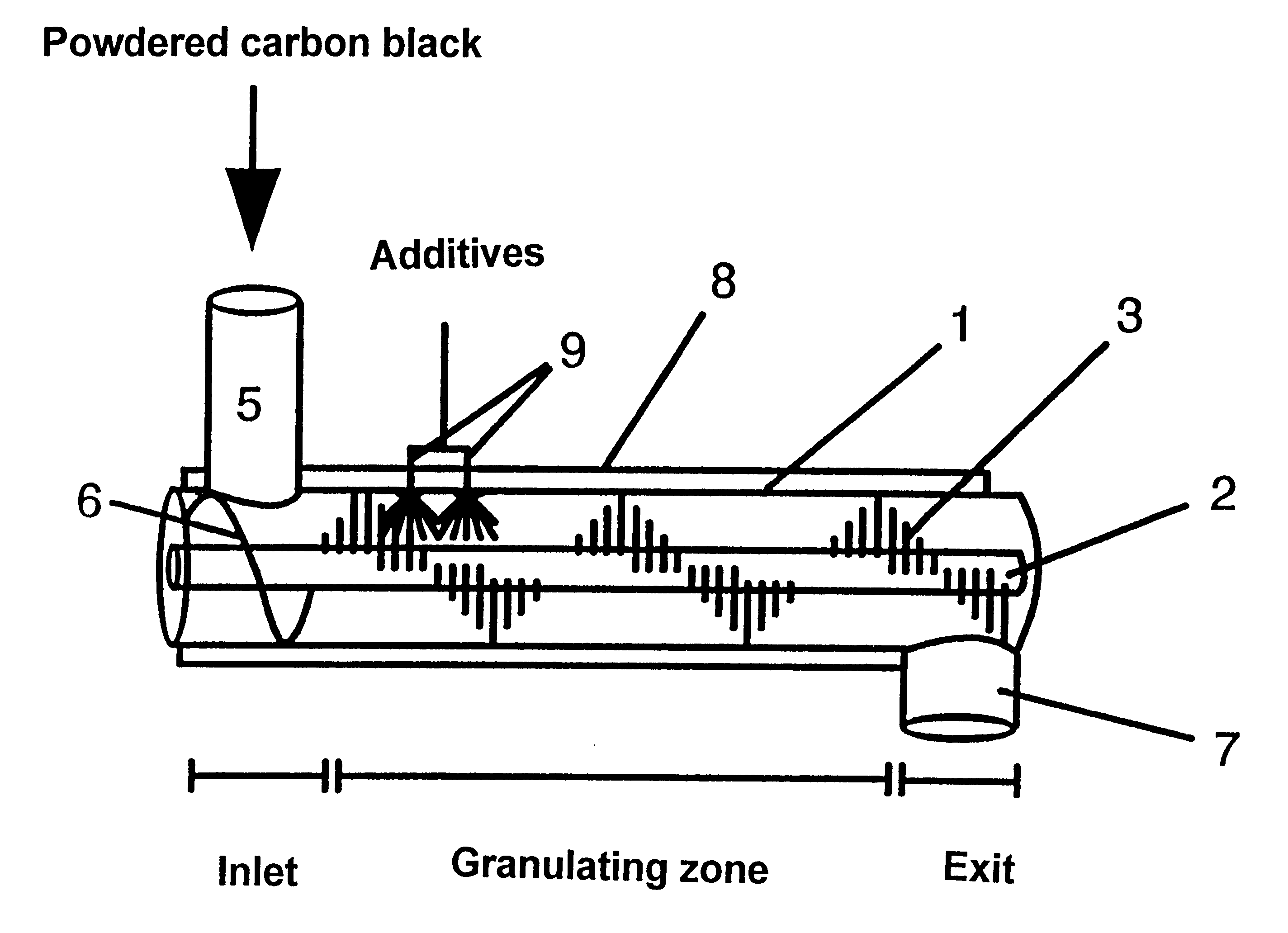

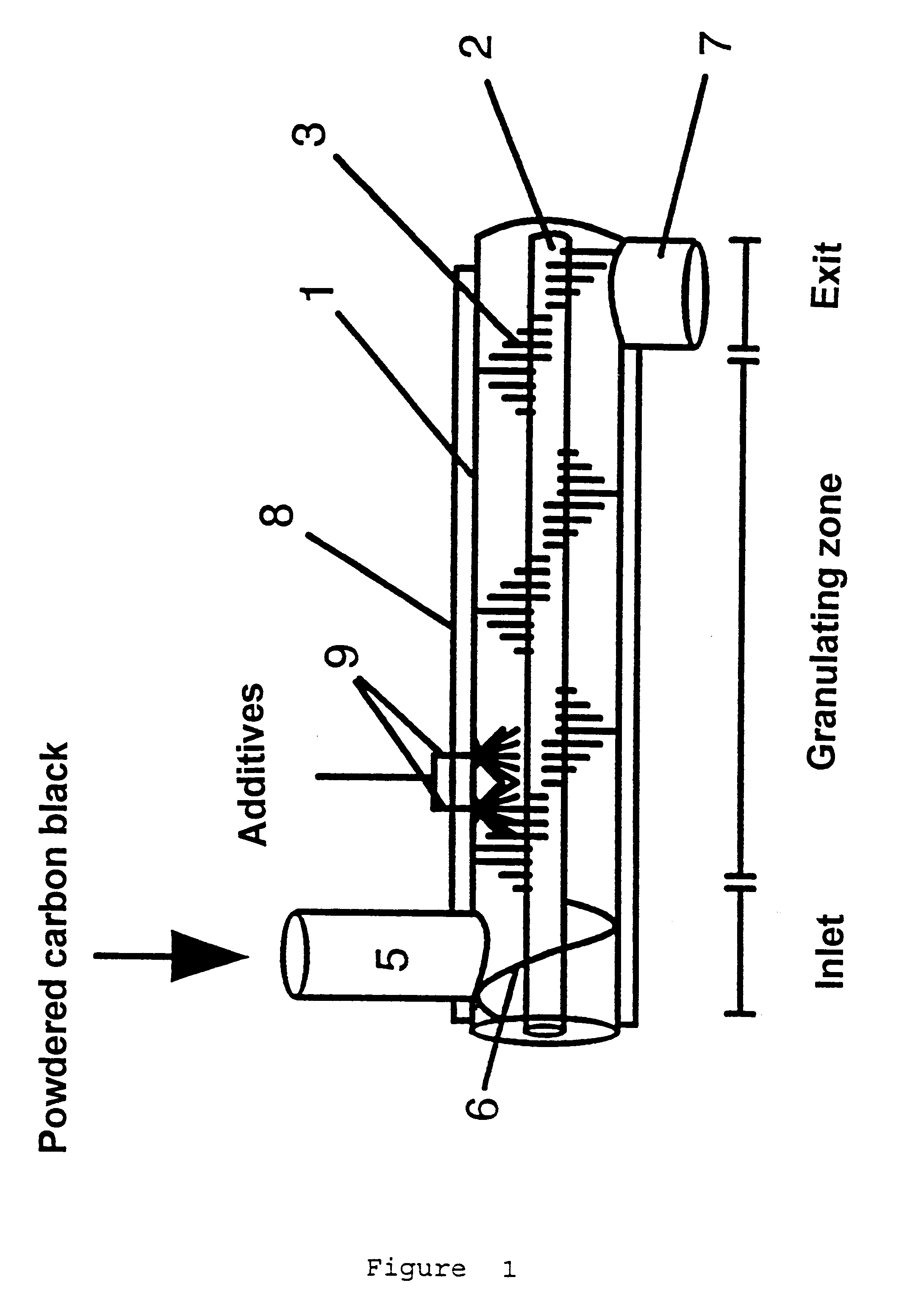

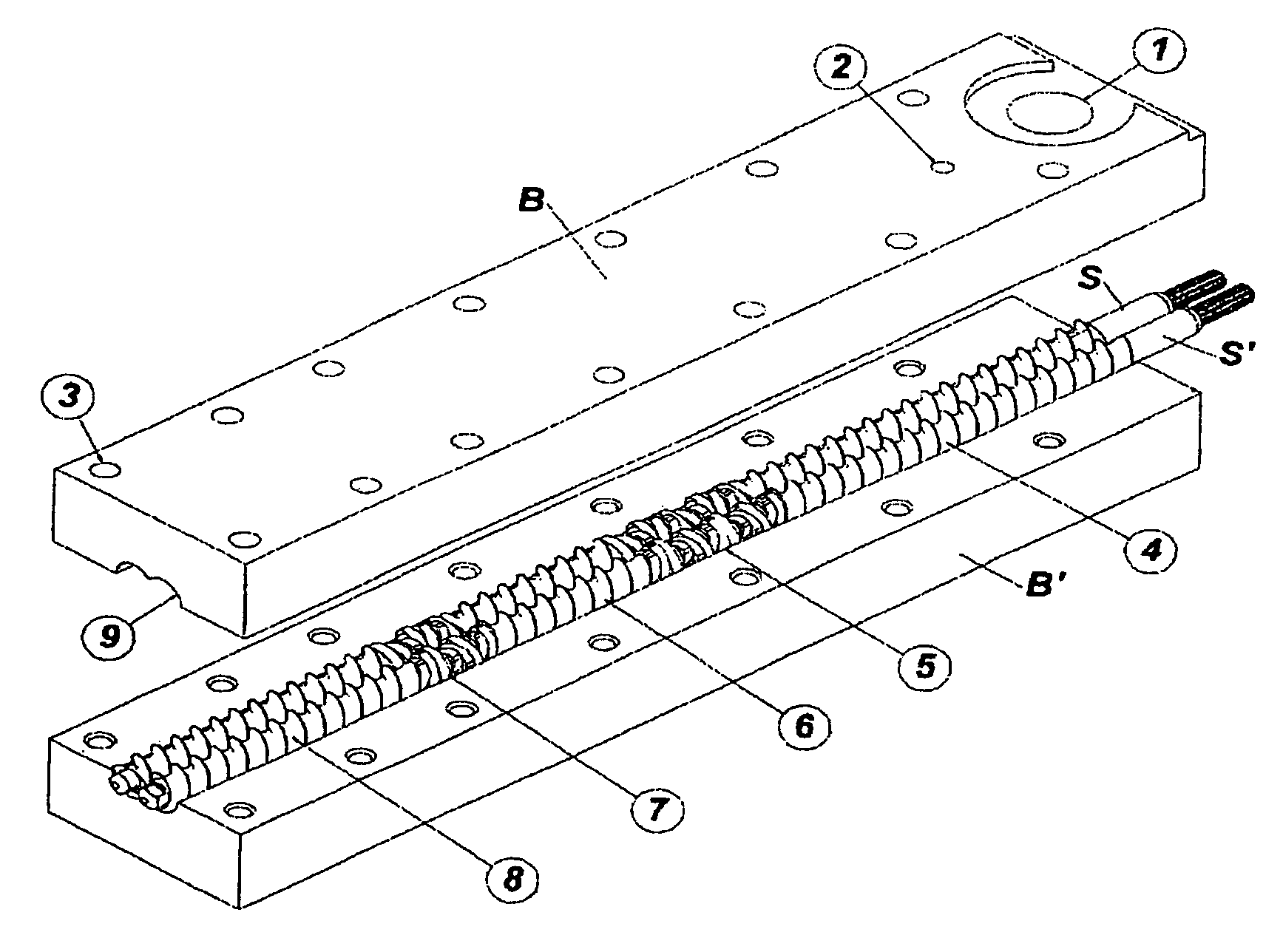

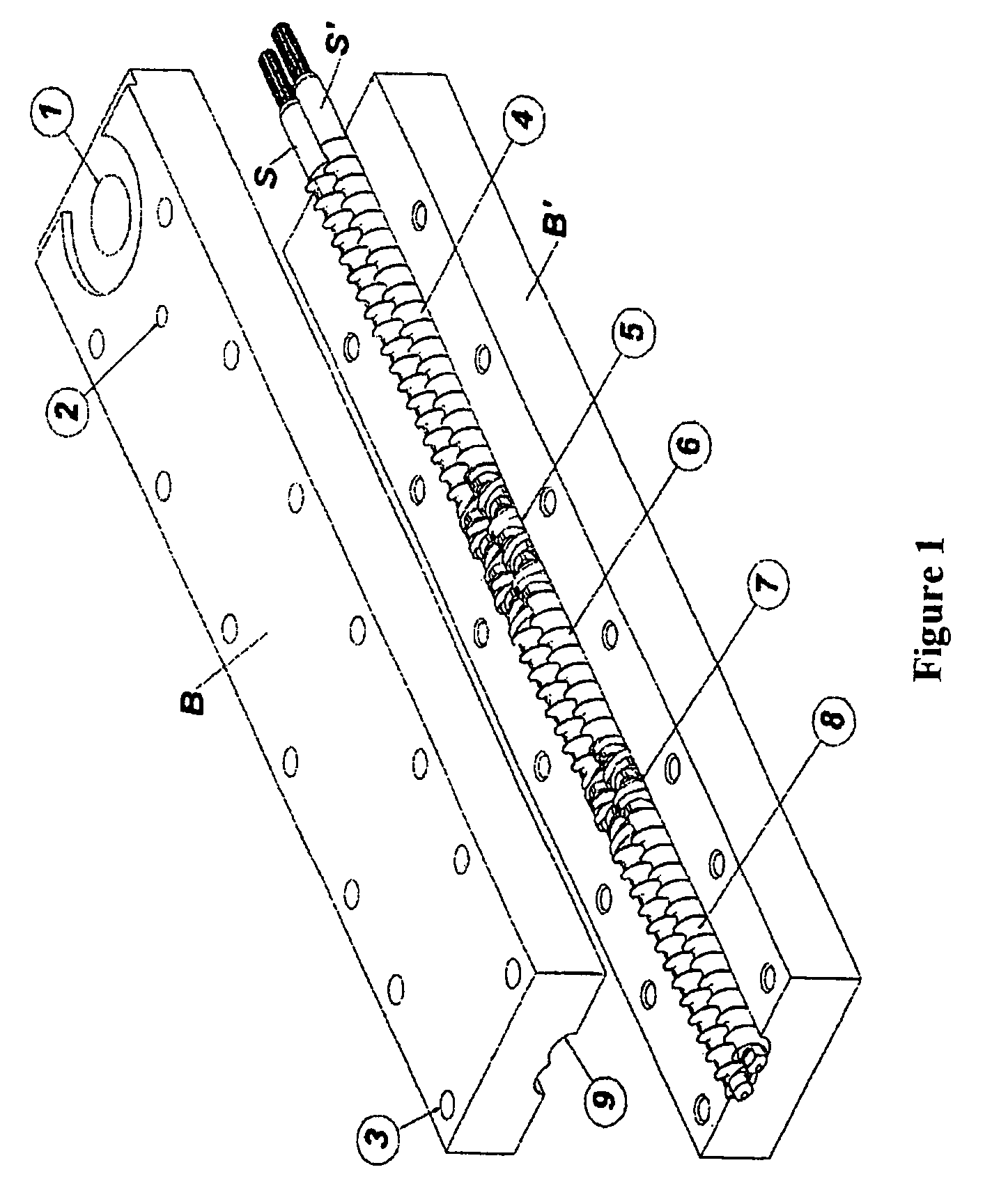

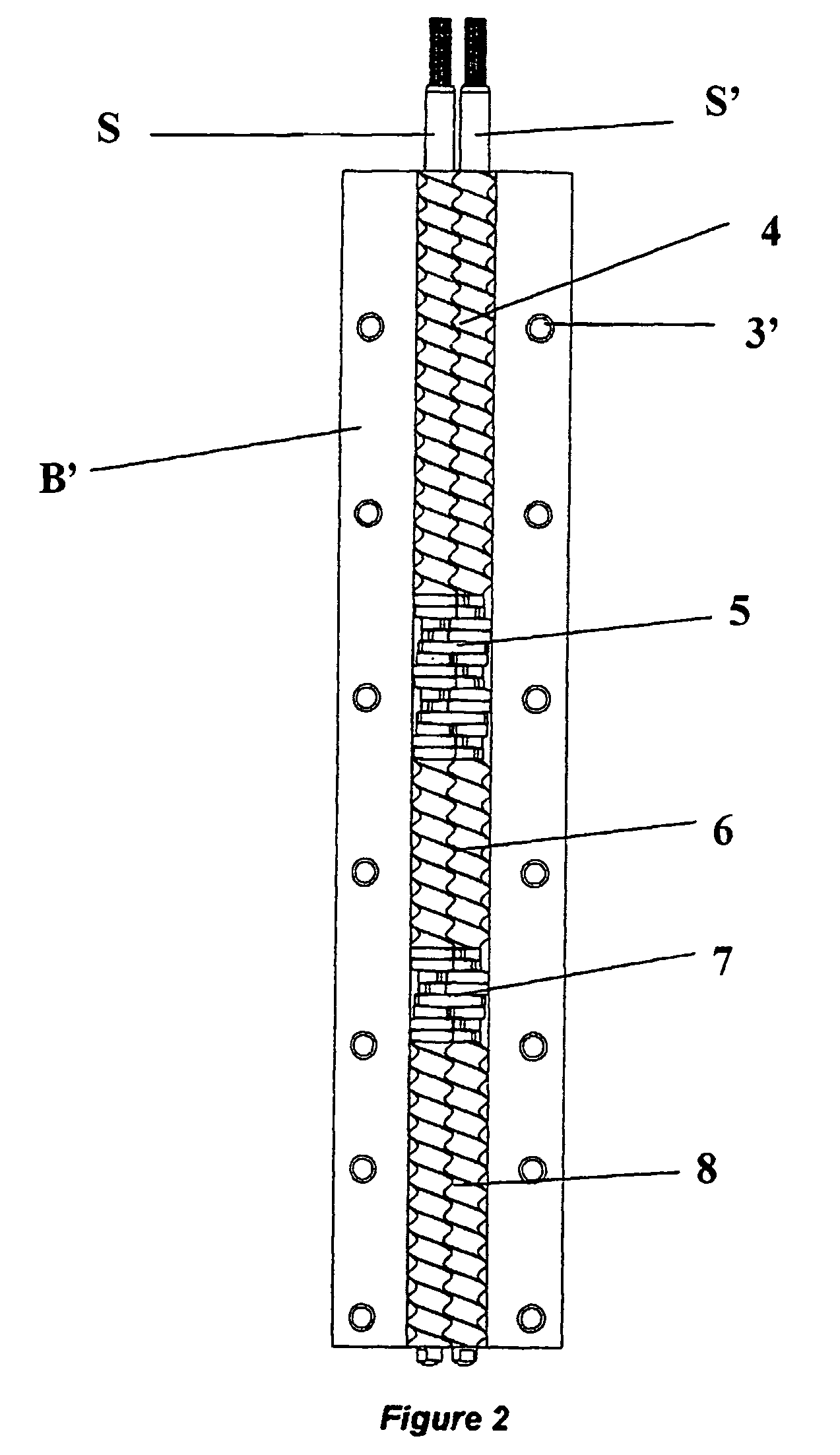

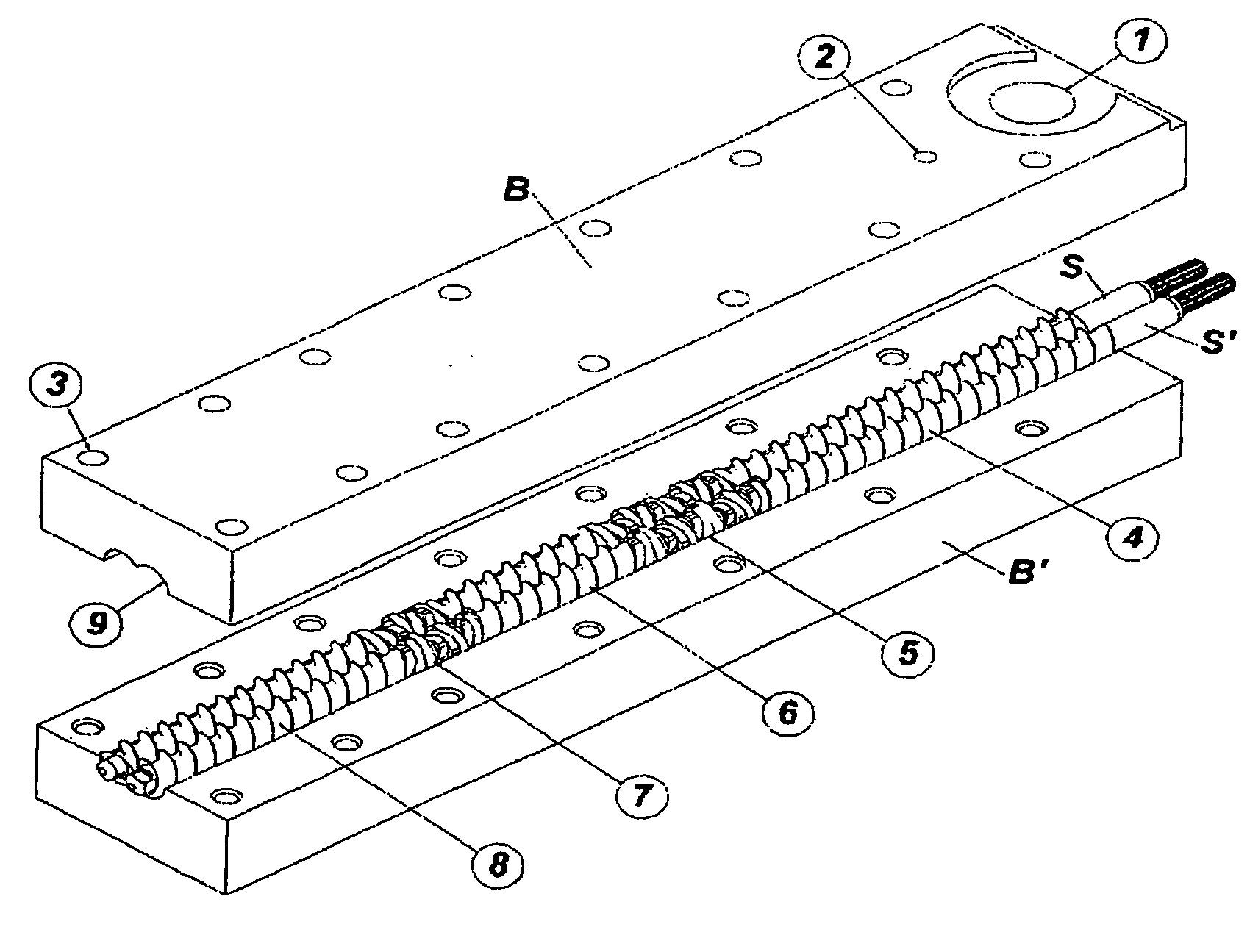

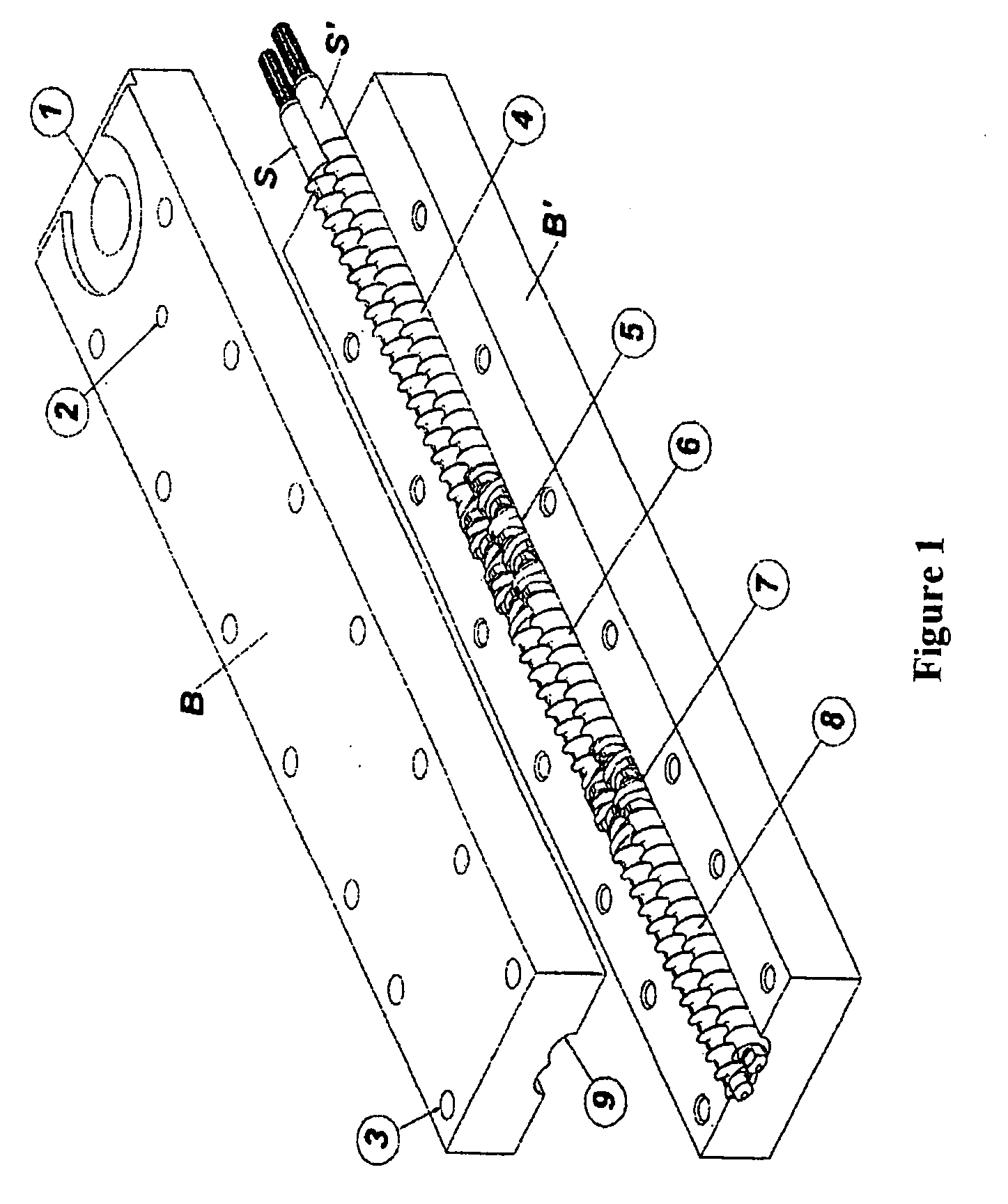

Process and apparatus for continuous wet granulation of powder material

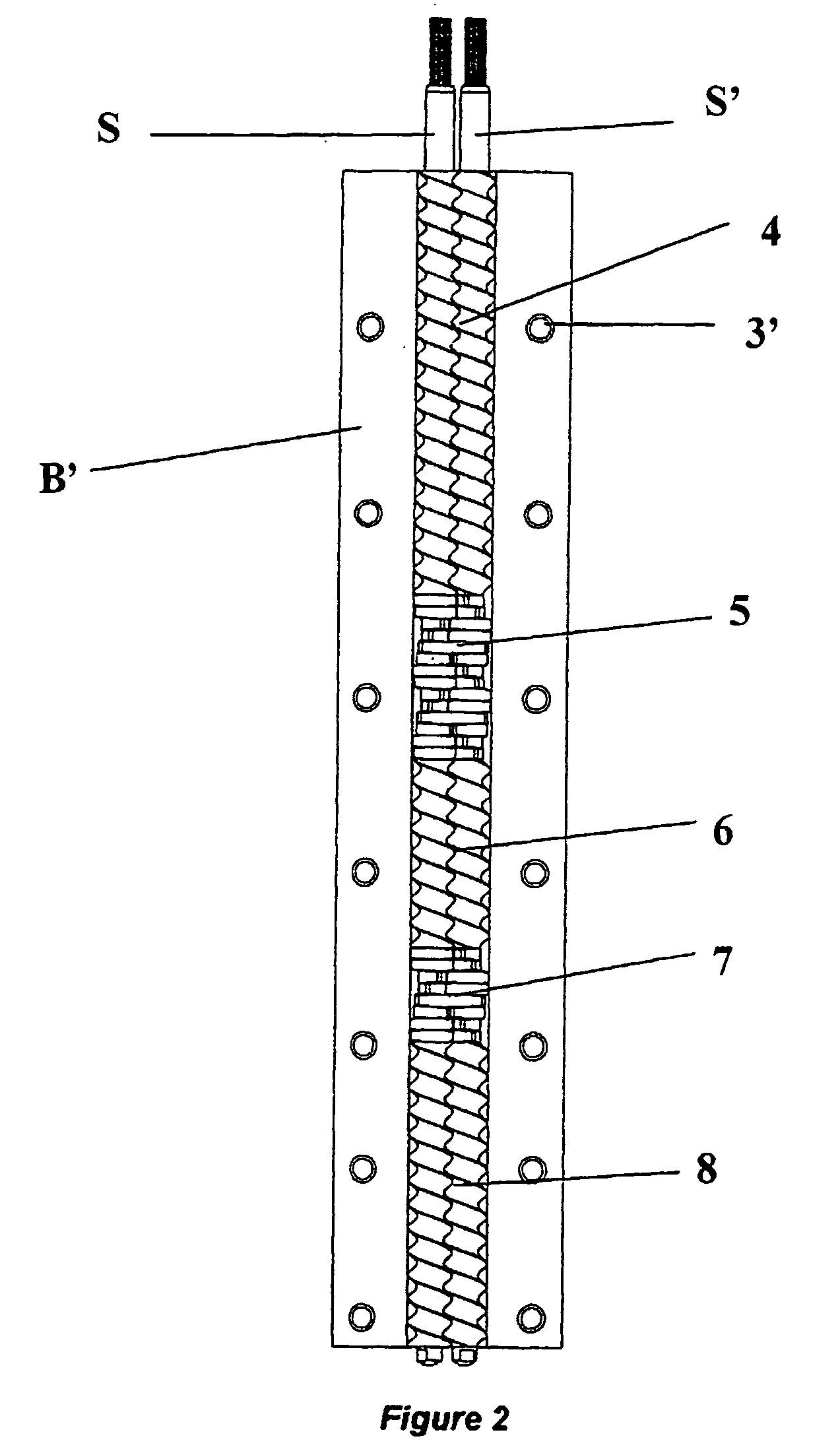

ActiveUS7910030B2Simple processQuantity minimizationRotary stirring mixersFrozen sweetsEngineeringActive ingredient

An apparatus for wet granulating a powder material comprises: —a barrel having a granulation chamber and being provided with a first inlet (1) for receiving said powder material and for supplying it to said granulation chamber and with a second inlet (2) for receiving a granulating liquid and for supplying it to said granulation chamber, said granulation having an aperture (9) for discharge of granules from said barrel, and —a transporting means (S) for advancing said powder material toward the end of said granulation chamber while granulating it with the aid of said granulating liquid, said transporting means (S) comprising a first transport zone (4) at its rear end, an agglomeration zone (5) downstream from the first transport zone (4) and a second transport zone (8) at its front end, said first inlet (1) and said second inlet (2) being positioned above the first transport zone (4), wherein said aperture (9) has a shape tightly fitting the terminal portion of the transporting means (S) for directly discharging said granules from the granulation chamber. The apparatus is useful for continuously wet granulating biologically-active ingredient formulations, chemicals, detergents and foodstuffs.

Owner:UNIV GENT

Prilling method

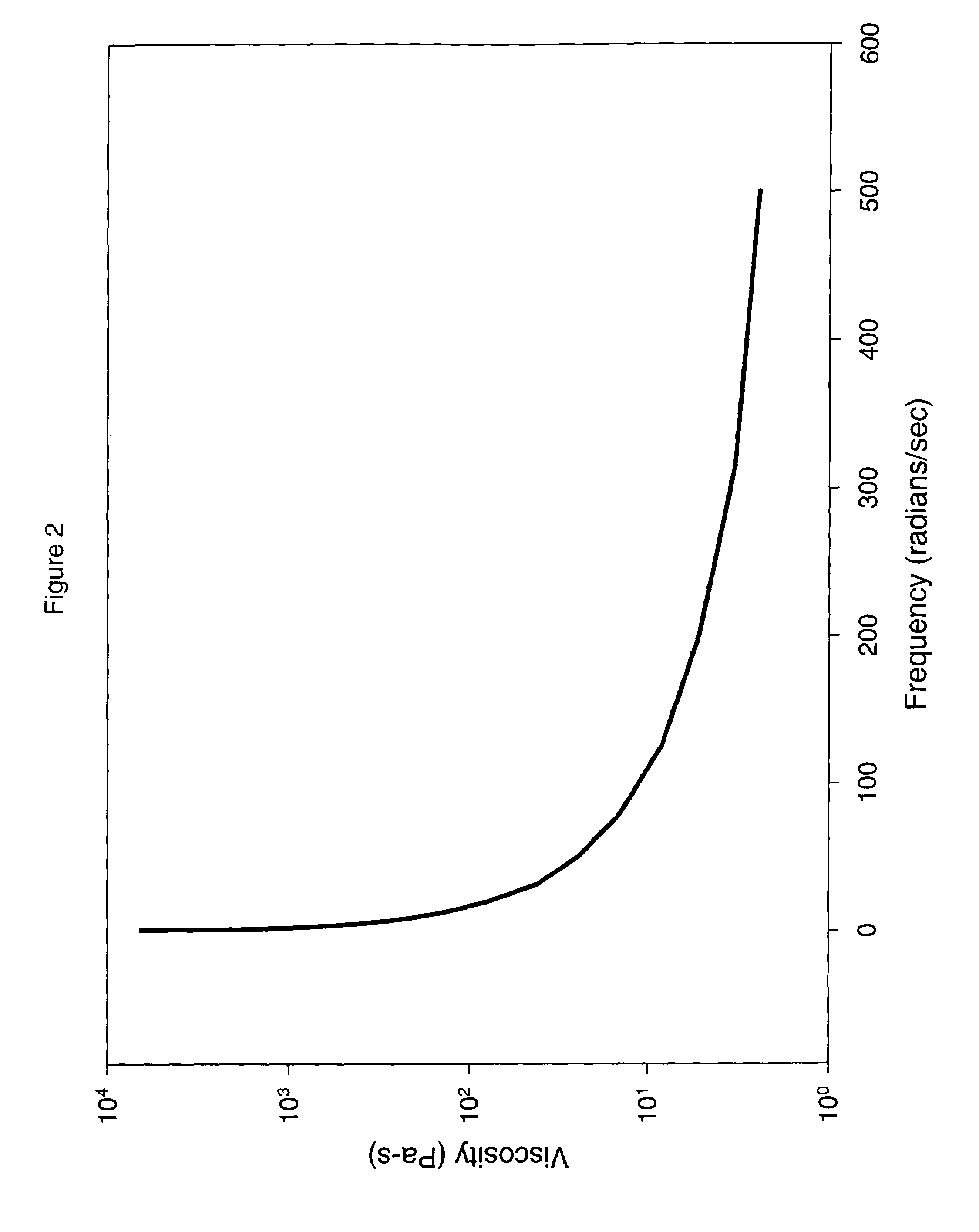

A prilling method comprising the steps of: providing a molten first component, mixing at least a second component with the molten first component, reacting the components to form a shear-thinnable mixture; and prilling the shear-thinnable mixture wherein the prilling comprises mechanically agitating in the prill head to shear thin the shear-thinnable mixture sufficiently to permit prilling. The inventive method can be used to produce fertilizer product comprising ammonium sulfate nitrate.

Owner:ADVANSIX RESINS & CHEM LLC

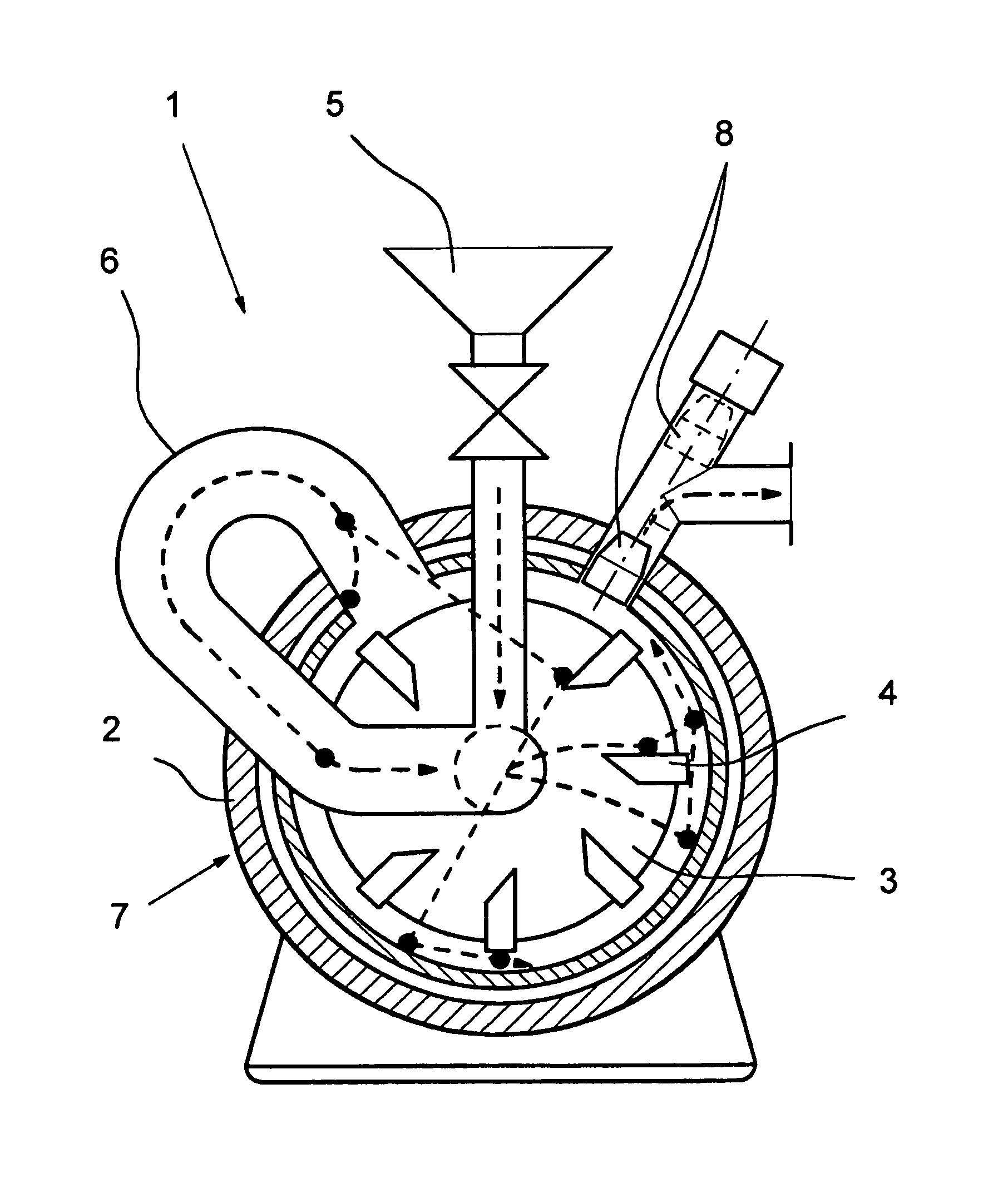

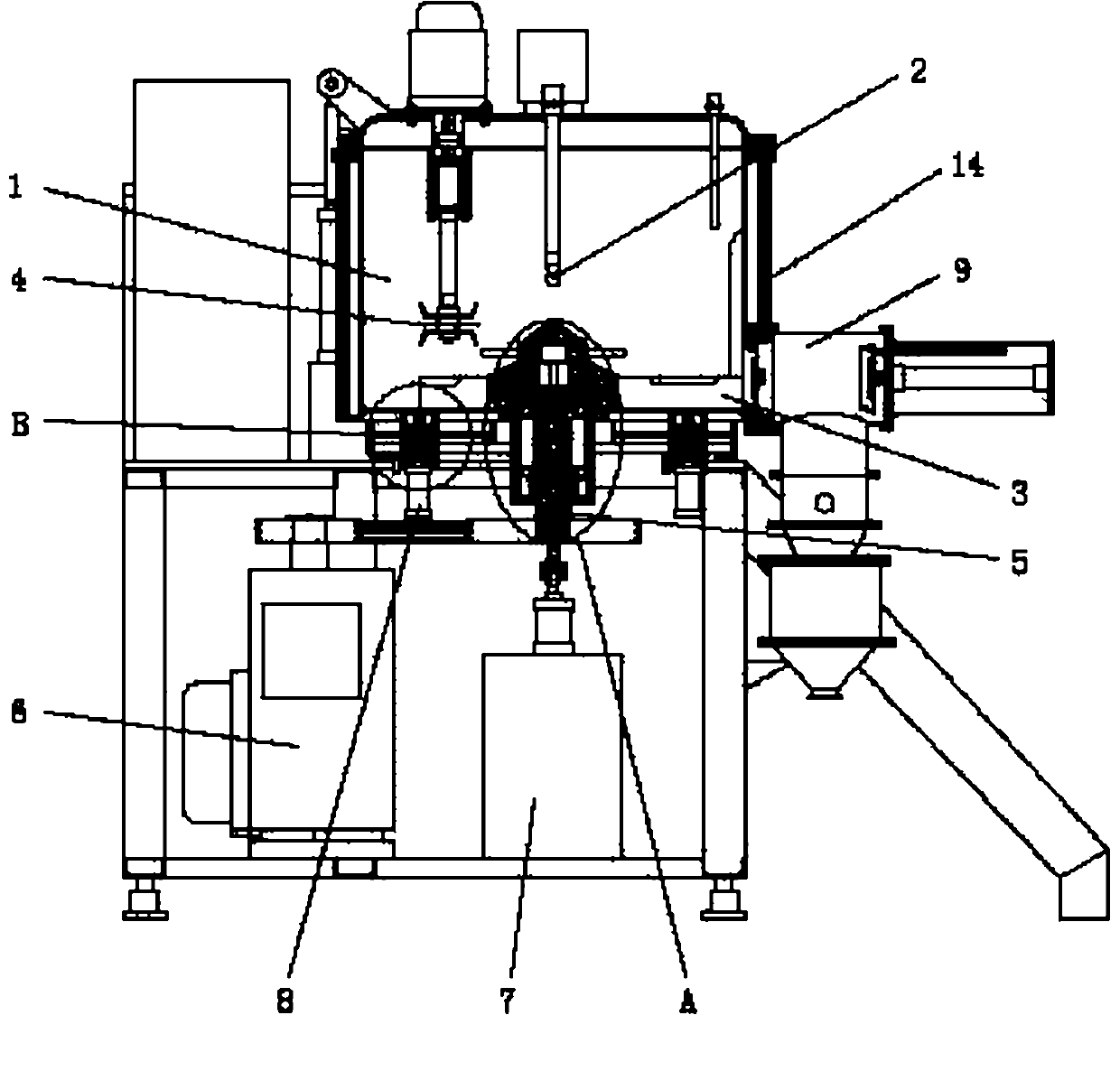

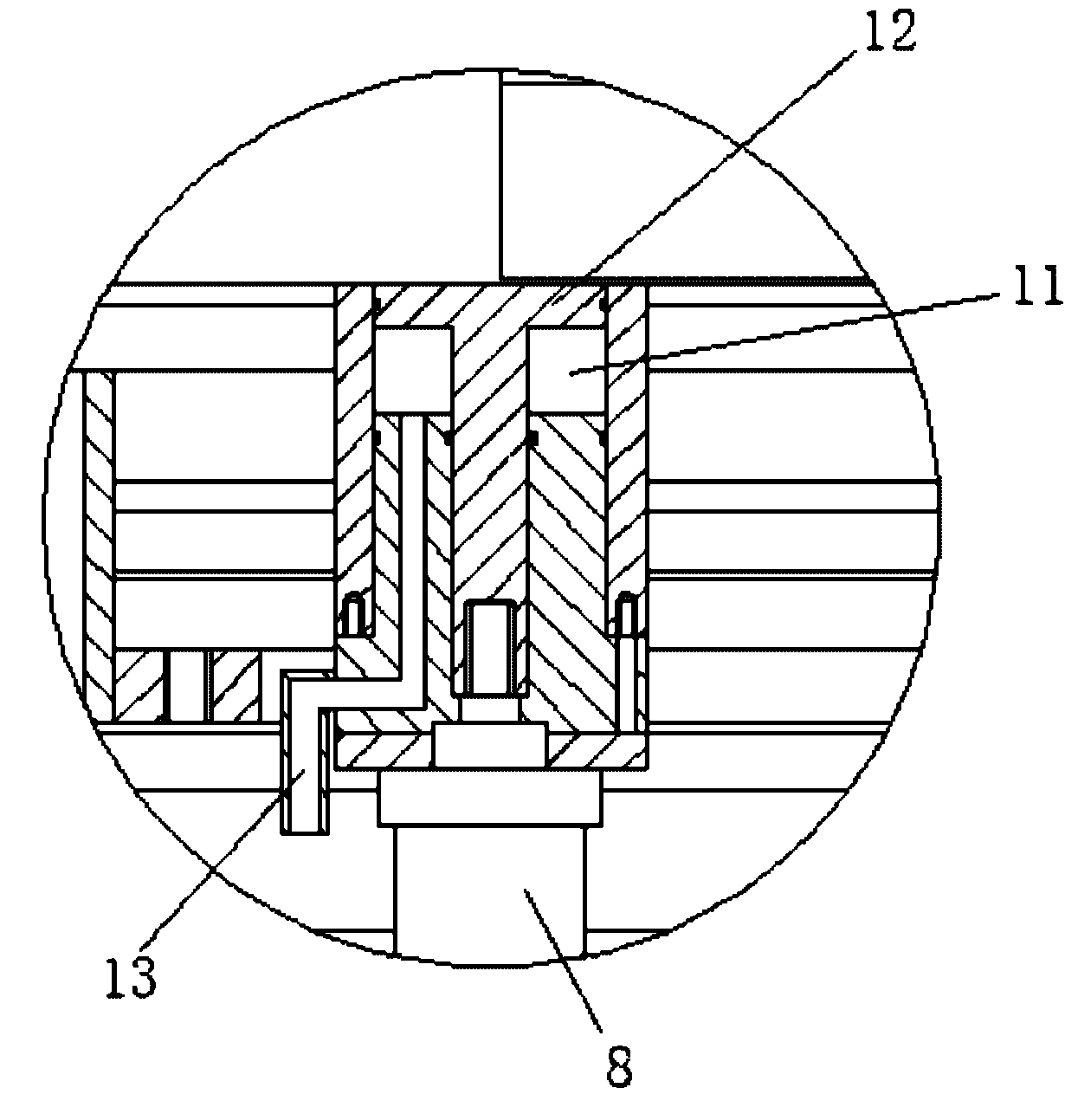

Wet mixing pelletizer having tangent stirring blade

ActiveCN1651130AWell mixedQuality improvementGranulation in stationary drums/troughsPulp and paper industryRaw material

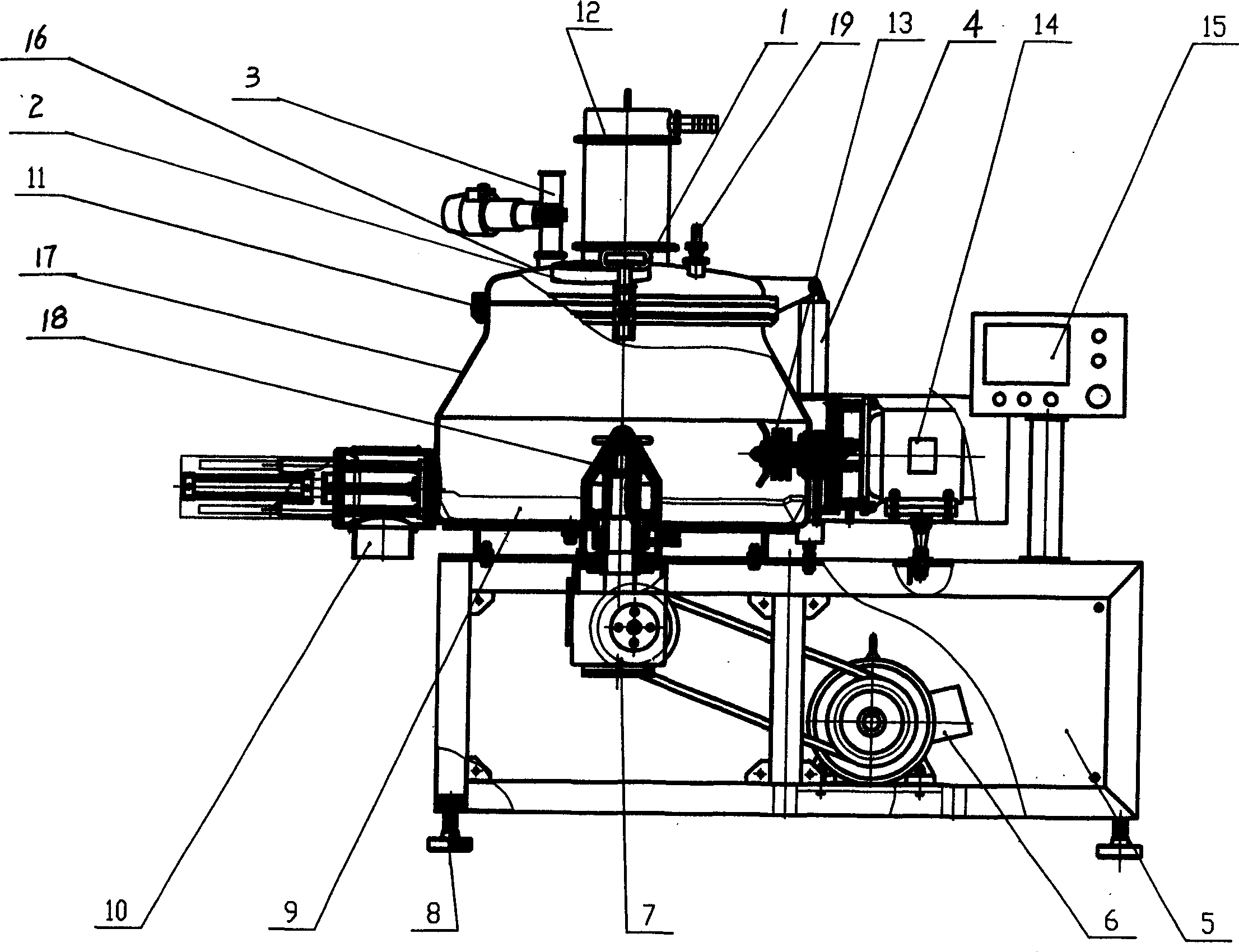

A wet mixing pelletizer with tangent stirring paddles is composed of machine base, raw material bin, stirring unit consisting of driver and stirring paddles, pelletizing unit comprising driver and pelletizing blade, spray gun unit, discharging valve, sealing unit, feeder and operating panel.

Owner:ZHEJIANG CANAAN TECH

Process and apparatus for continuous wet granulation of power material

ActiveUS20060006258A1Quantity minimizationMinimize durationRotary stirring mixersFrozen sweetsEngineeringExtremity Part

An apparatus for wet granulating a powder material comprises:—a barrel having a granulation chamber and being provided with a first inlet (1) for receiving said powder material and for supplying it to said granulation chamber and with a second inlet (2) for receiving a granulating liquid and for supplying it to said granulation chamber, said granulation having an aperture (9) for discharge of granules from said barrel, and—a transporting means (S) for advancing said powder material toward the end of said granulation chamber while granulating it with the aid of said granulating liquid, said transporting means (S) comprising a first transport zone (4) at its rear end, an agglomeration zone (5) downstream from the first transport zone (4) and a second transport zone (8) at its front end, said first inlet (1) and said second inlet (2) being positioned above the first transport zone (4), wherein said aperture (9) has a shape tightly fitting the terminal portion of the transporting means (S) for directly discharging said granules from the granulation chamber. The apparatus is useful for continuously wet granulating biologically-active ingredient formulations, chemicals, detergents and foodstuffs.

Owner:UNIV GENT

Dedusting dry powder recycling process

InactiveCN101224363ASimplify the recycling processNo spreading problemHuman health protectionDispersed particle filtrationDusting powdersMaterial scattering

The invention relates to a dust-removal dry powder recycling process. The process procedure consists of dust-removal ash hoppers, dust powder transferring devices, exhaust collecting cavities, wet ball machines and sealed transferring devices of each dust removal points of smelters or ironworks. The process includes three steps: dusts removing-transferring, dusts collecting and wet ball transferring, i.e. a set of dust powder air-transferring device is arranged below the dust-removal ash hopper of the dust catcher; compressed air is adopted for transferring the dust through a sealed transferring device into the dust collecting cavity far away, and then a ration feeding machine is adopted for transferring the dust to the wet ball machine; after wetting and balling by the wet ball machine, the finished small balls are finally transferred to a storing bin through a sealed transferring device as recycled materials for application. The invention adopts the novel dust disposal process of dust-removal dry powders to simplify the process procedure; a sealed state is guaranteed before wetting and balling and during the transferring process so as to avoid dust rising and material scattering; the recycling treatment is simple, thus saving investigation and manpower, and being environment-protective.

Owner:BAOSTEEL ENG & TECH GRP

Deicer mixing method

ActiveUS20090011125A1Efficient coatingAvoid lostLiquid surface applicatorsGranule coatingCakingScrew conveyor

An apparatus for applying a liquid coating to a deicer composition, methods of applying a liquid coating to a deicer composition, and solid deicer compositions that have been coated using the apparatus or method of the invention are disclosed. The apparatus includes a screw conveyor that has a housing, at least one screw with a plurality of flights, an inlet for uncoated deicer, an inlet for a liquid coating composition, and an outlet for deicer coated with the liquid coating composition. The screws contain protrusions or tabs that extend from the surrounding surface of the screw. These protrusions or tabs aid in the mixing of the solid deicer and the liquid coating composition in order to provide a well-mixed deicer that resists caking while avoiding losing the coating composition to leaching.

Owner:CARGILL INC

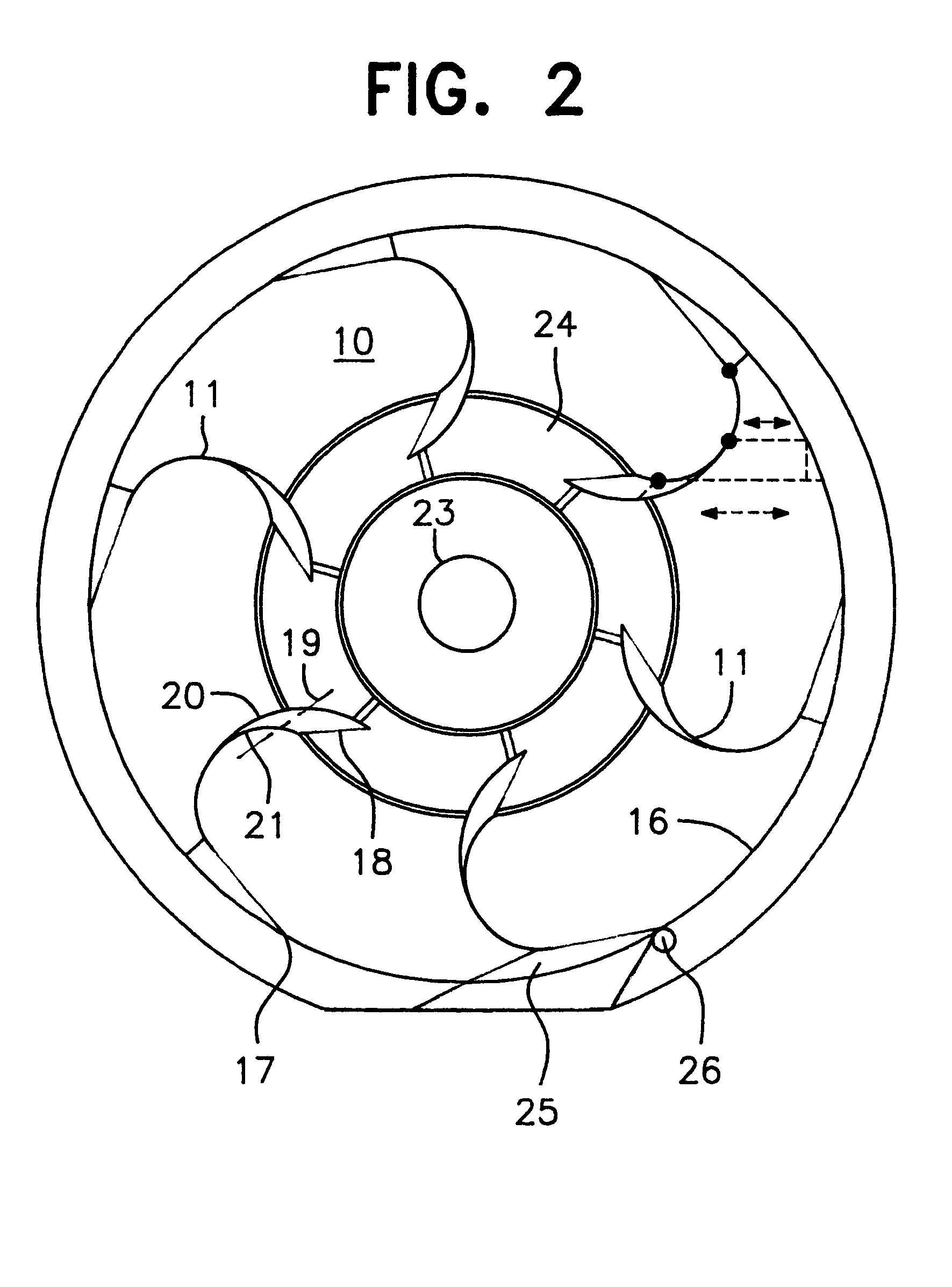

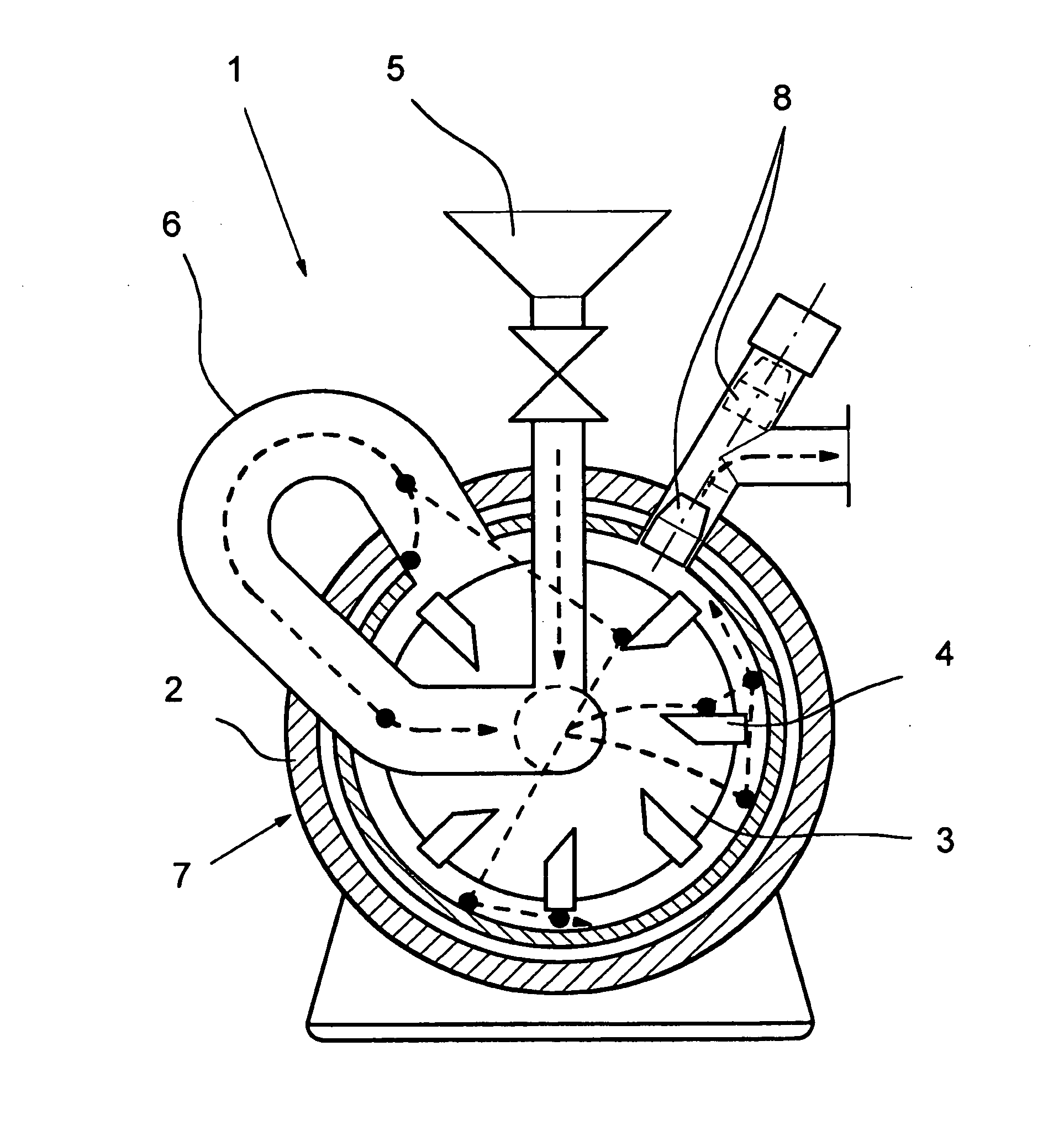

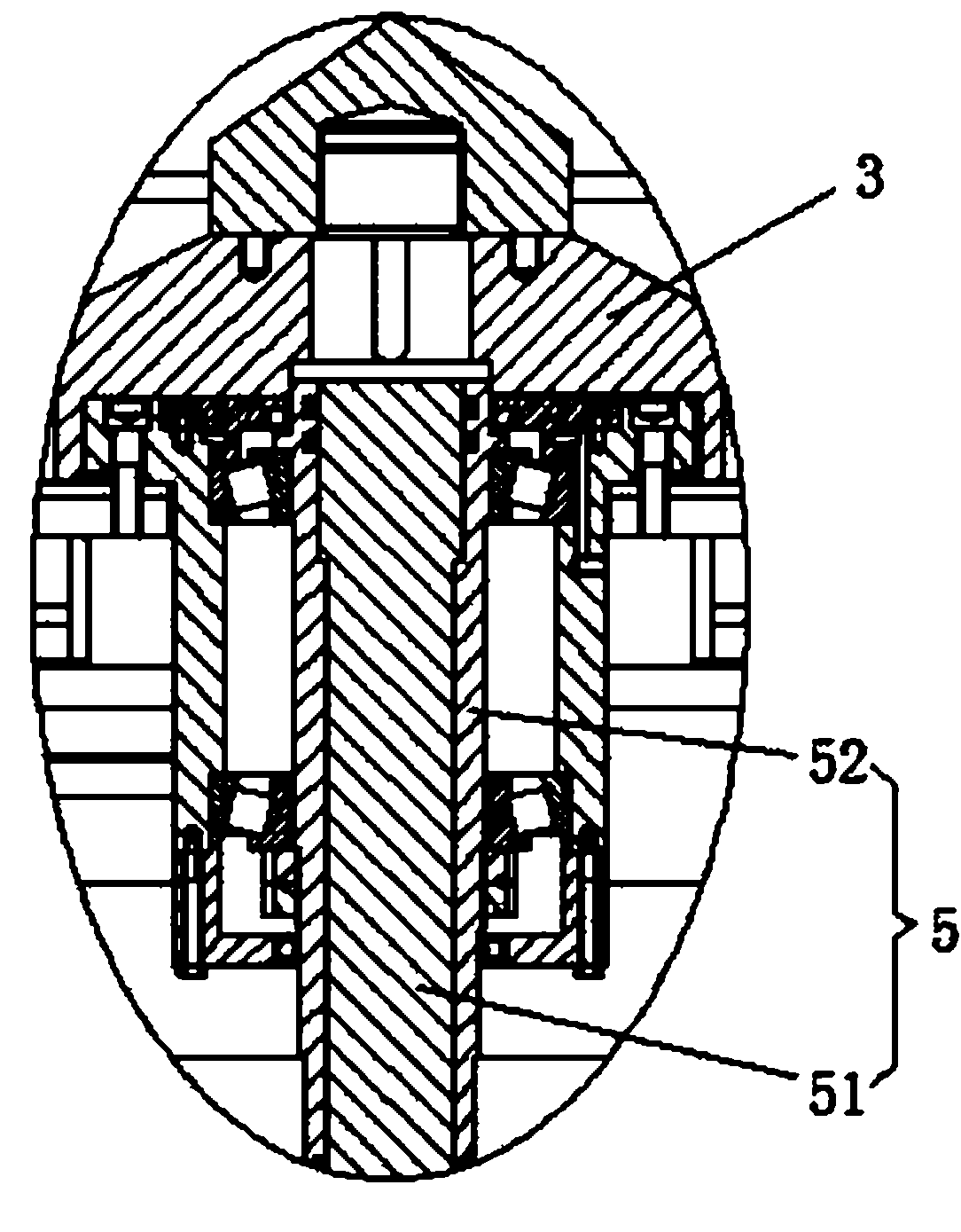

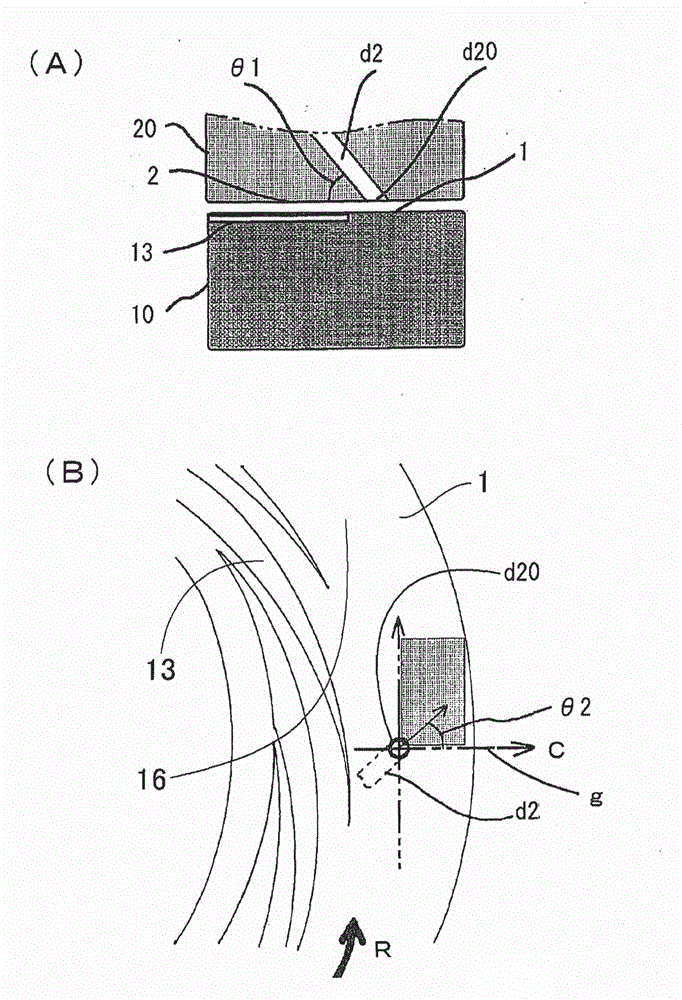

Method of manufacturing chemical-containing composite particles

InactiveUS20050191357A1Easy to useFine surfacePowder deliveryOrganic active ingredientsNanoparticleCompound (substance)

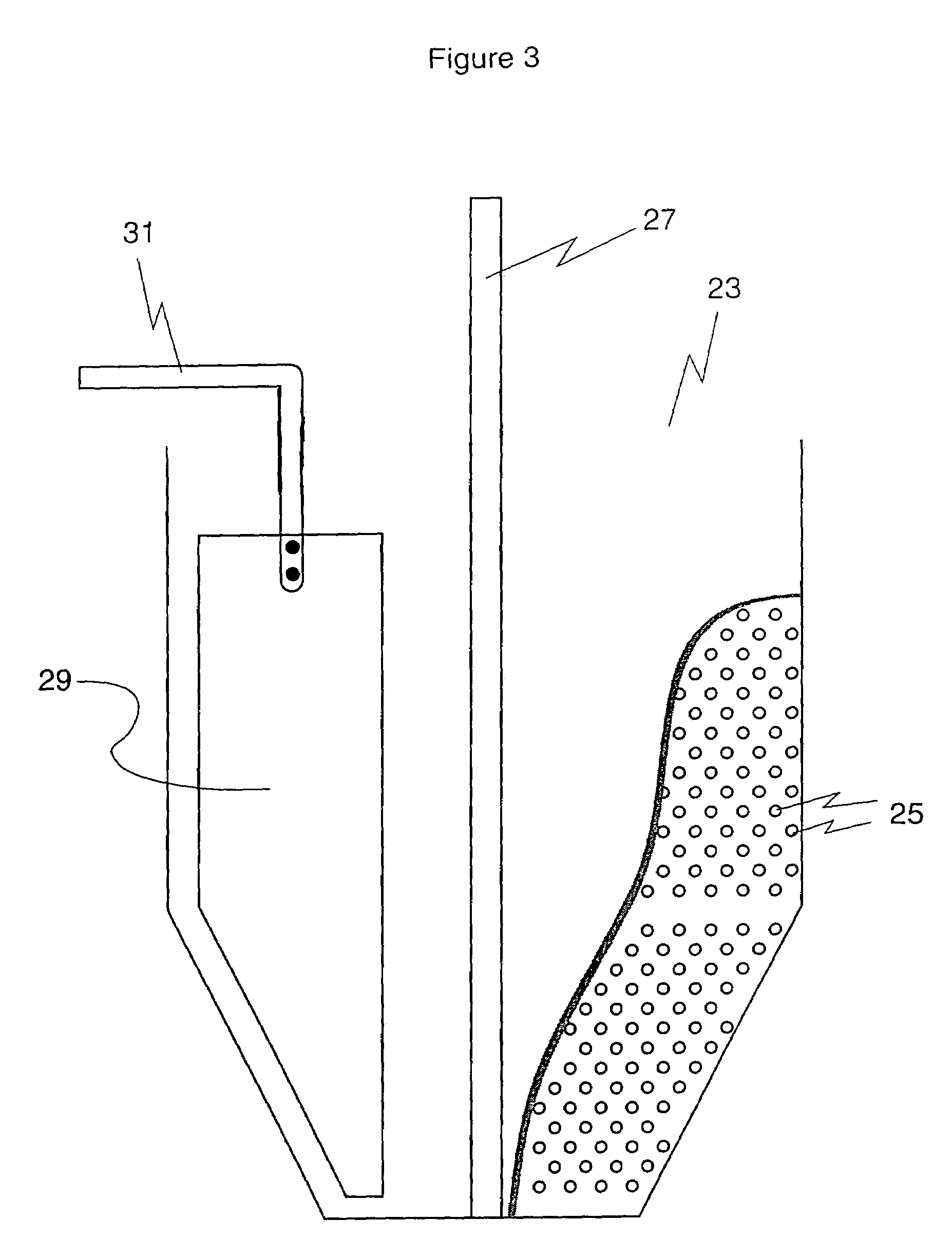

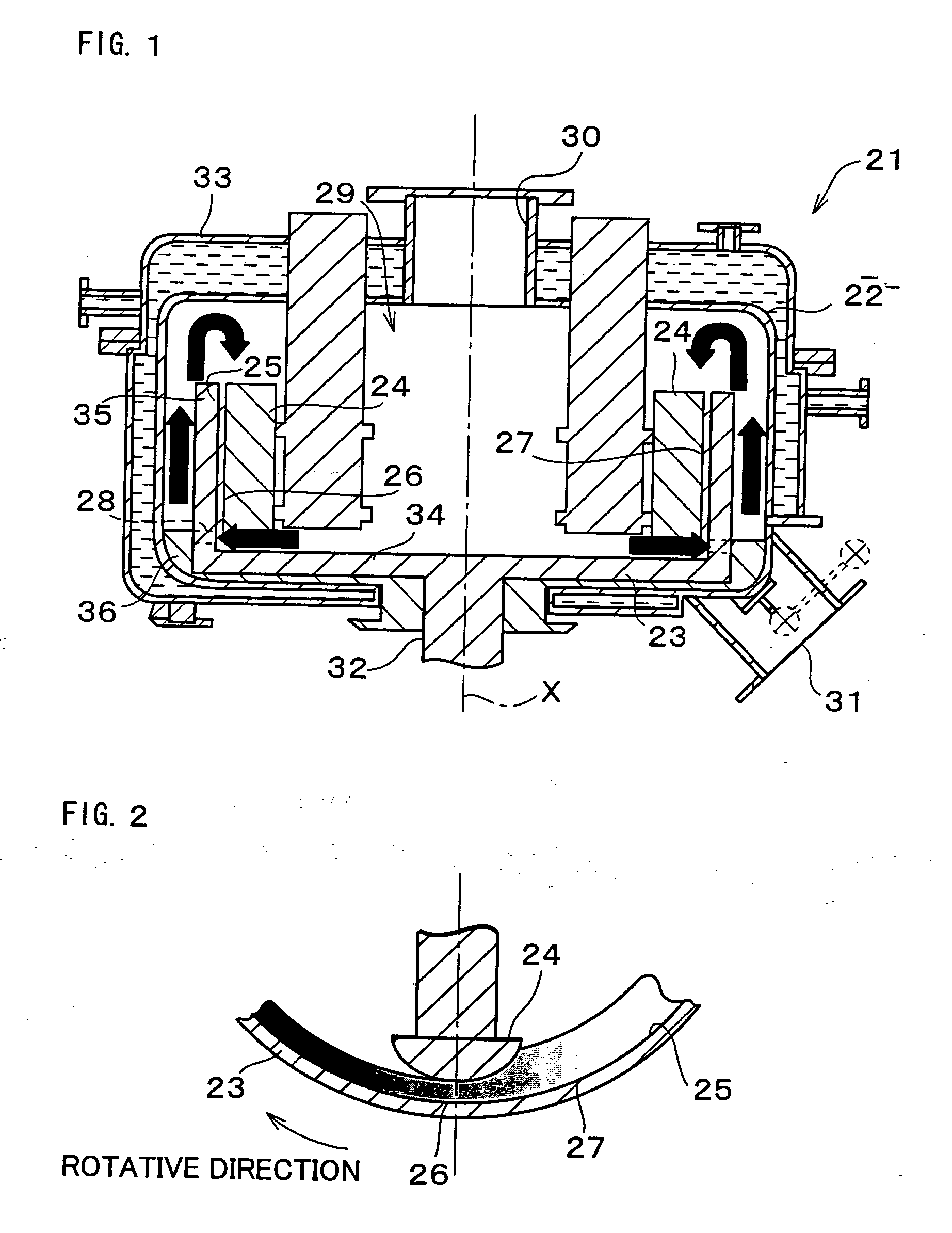

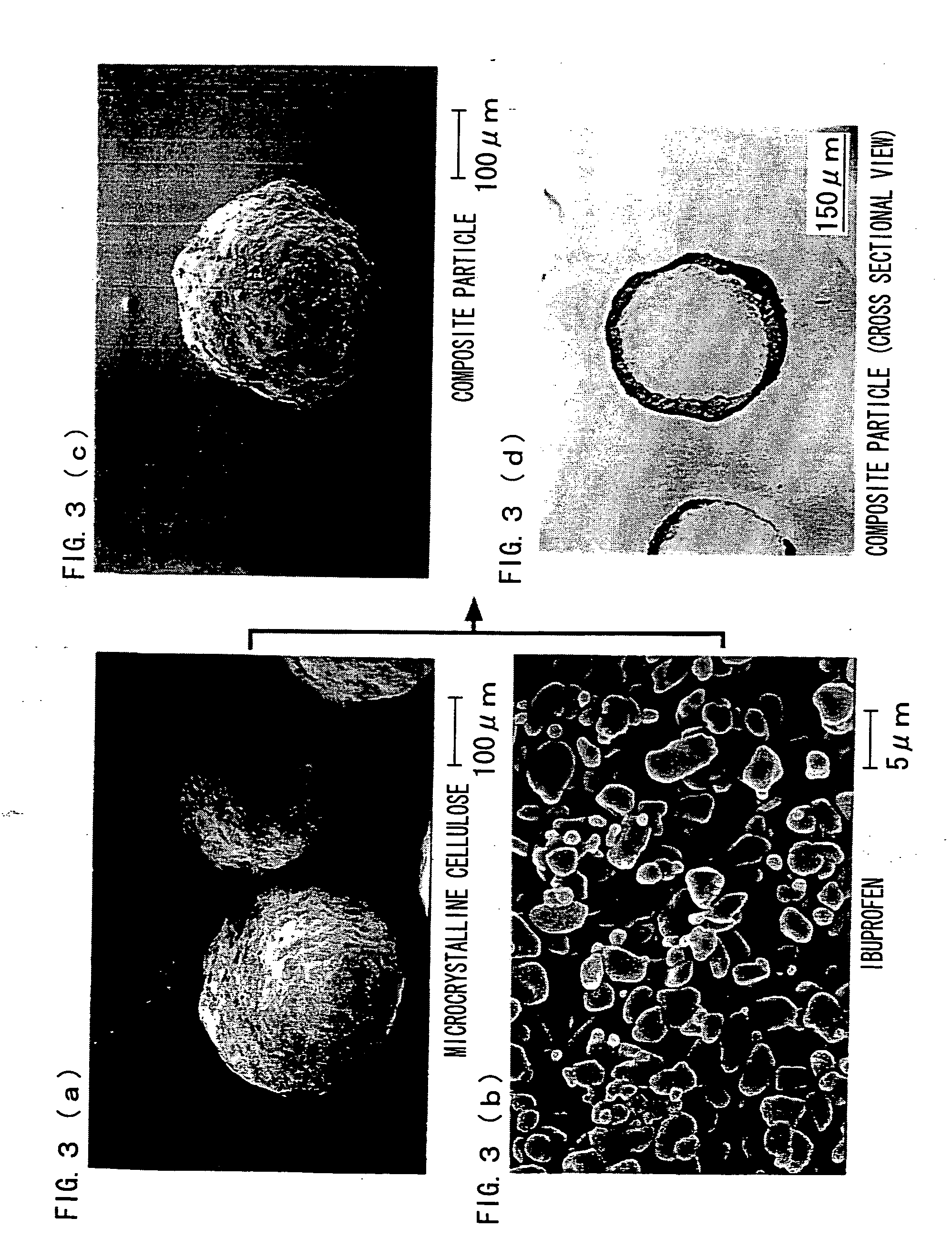

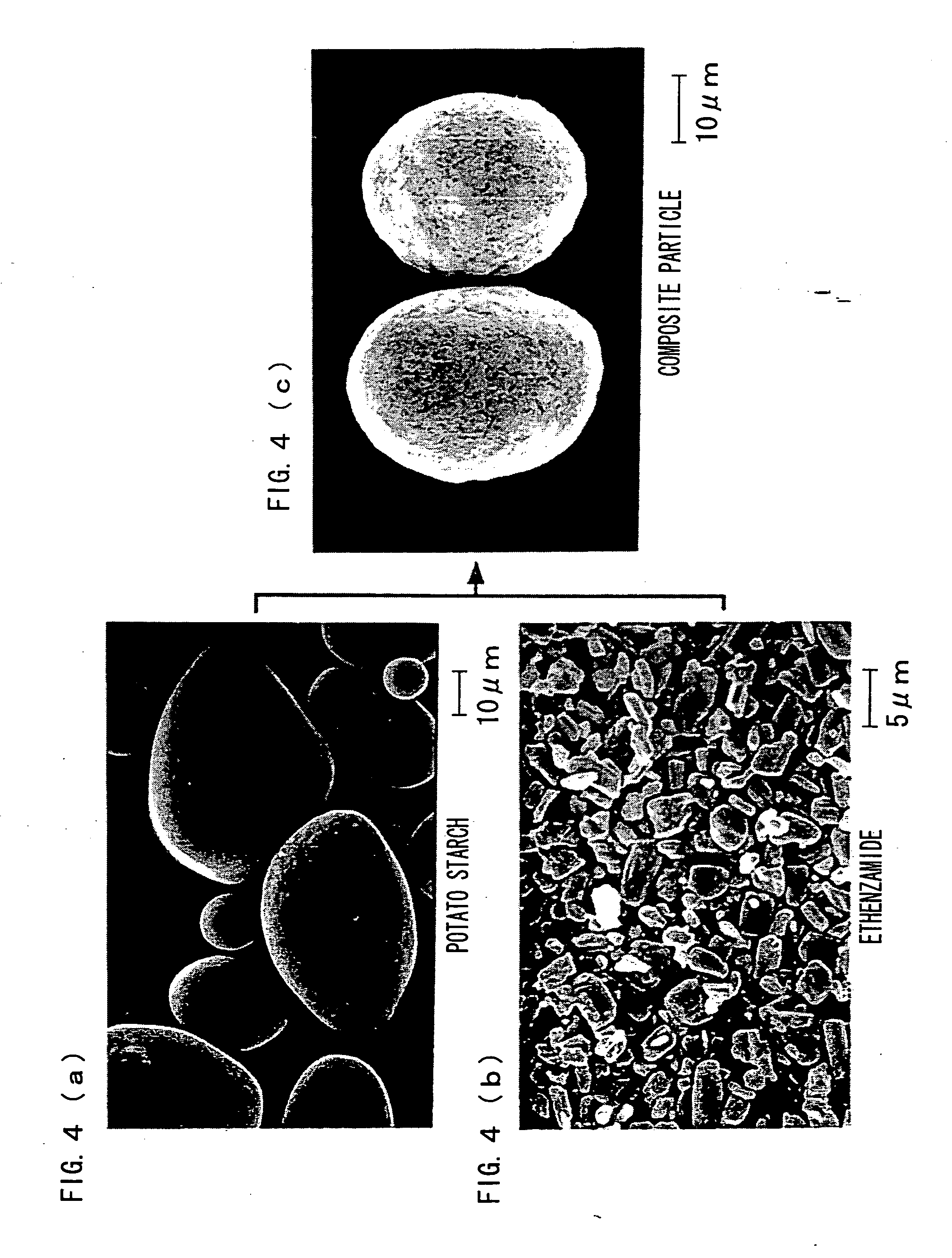

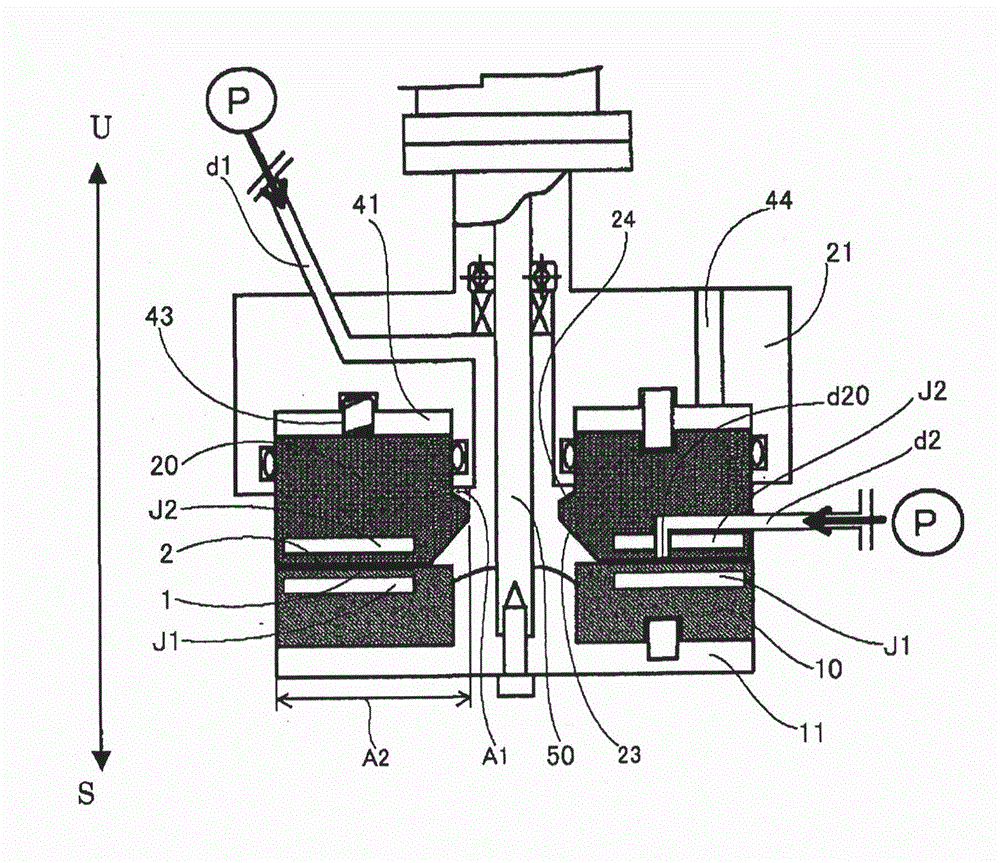

A strong pressure and a strong shearing force are exerted to a mixture, constituted of two kinds or more of powder materials including a drug powder, while causing the mixture to pass between a press section (26) of a press head (24) and a receiving surface (25) of a cylindrical rotator (23), thereby combining the drug powder with the other powder material. For example, at least one of a drug and a biocompatible polymer is made into a nano particle whose average particle diameter is less than 1000 nm, and the nano particle is made into a composite in accordance with a dry mechanical particle combining method, so as to form a polymer nano composite particle. Thus, it is possible to produce a composite particle, which contains a drug under a stable condition, in a short time, and it is possible to remarkably improve its handling property without losing advantages of the nano particle. As a result, it is possible to favorably apply the foregoing technique to DDS of a powdery drug taken into the body through the lung or a similar drug.

Owner:HOSOKAWA MICRON CORP

Designed particle agglomeration

InactiveUS20050106310A1Pigmenting treatmentGranulation in stationary drums/troughsMaterials scienceAgglomerate

Owner:EI DU PONT DE NEMOURS & CO

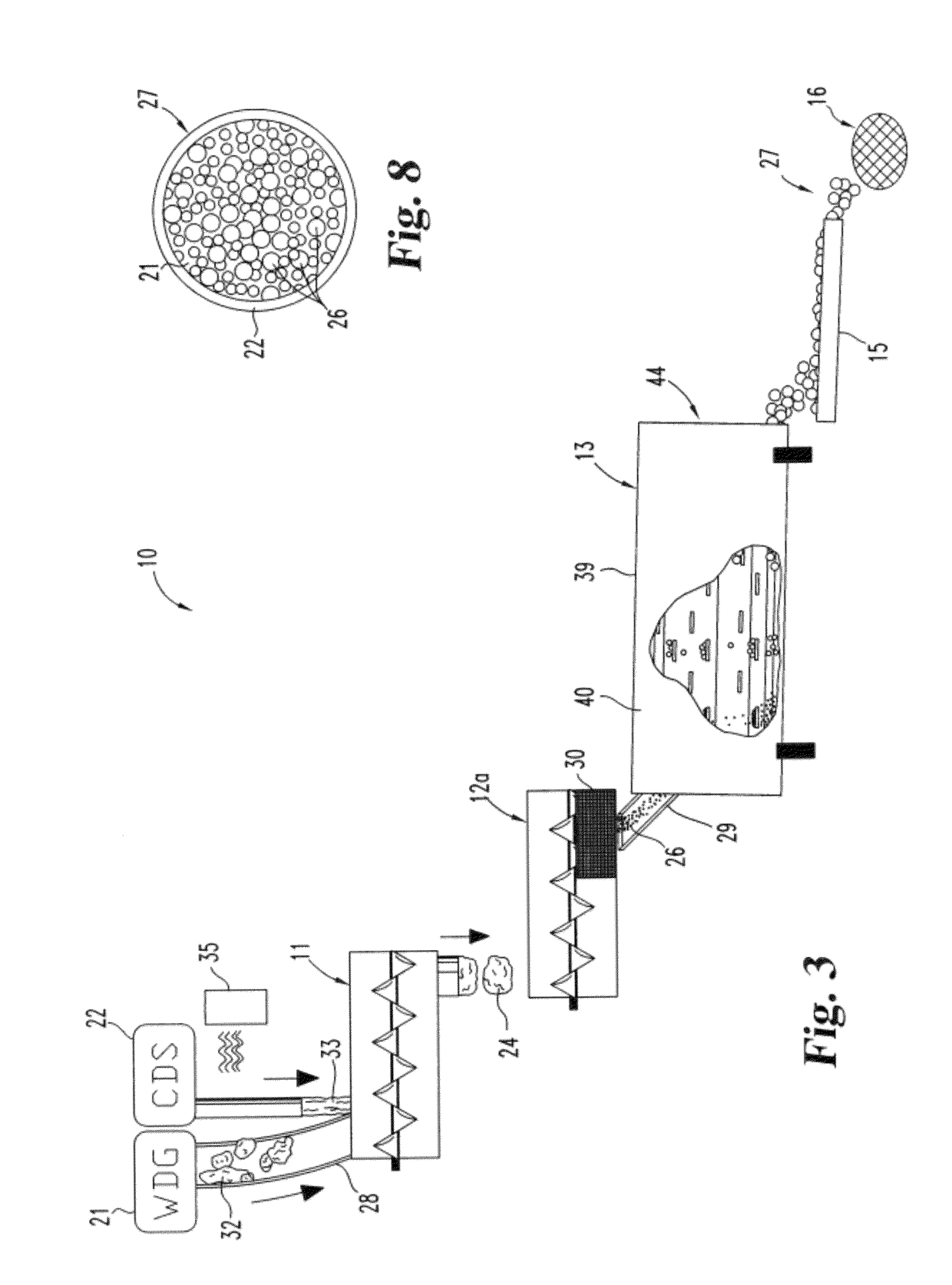

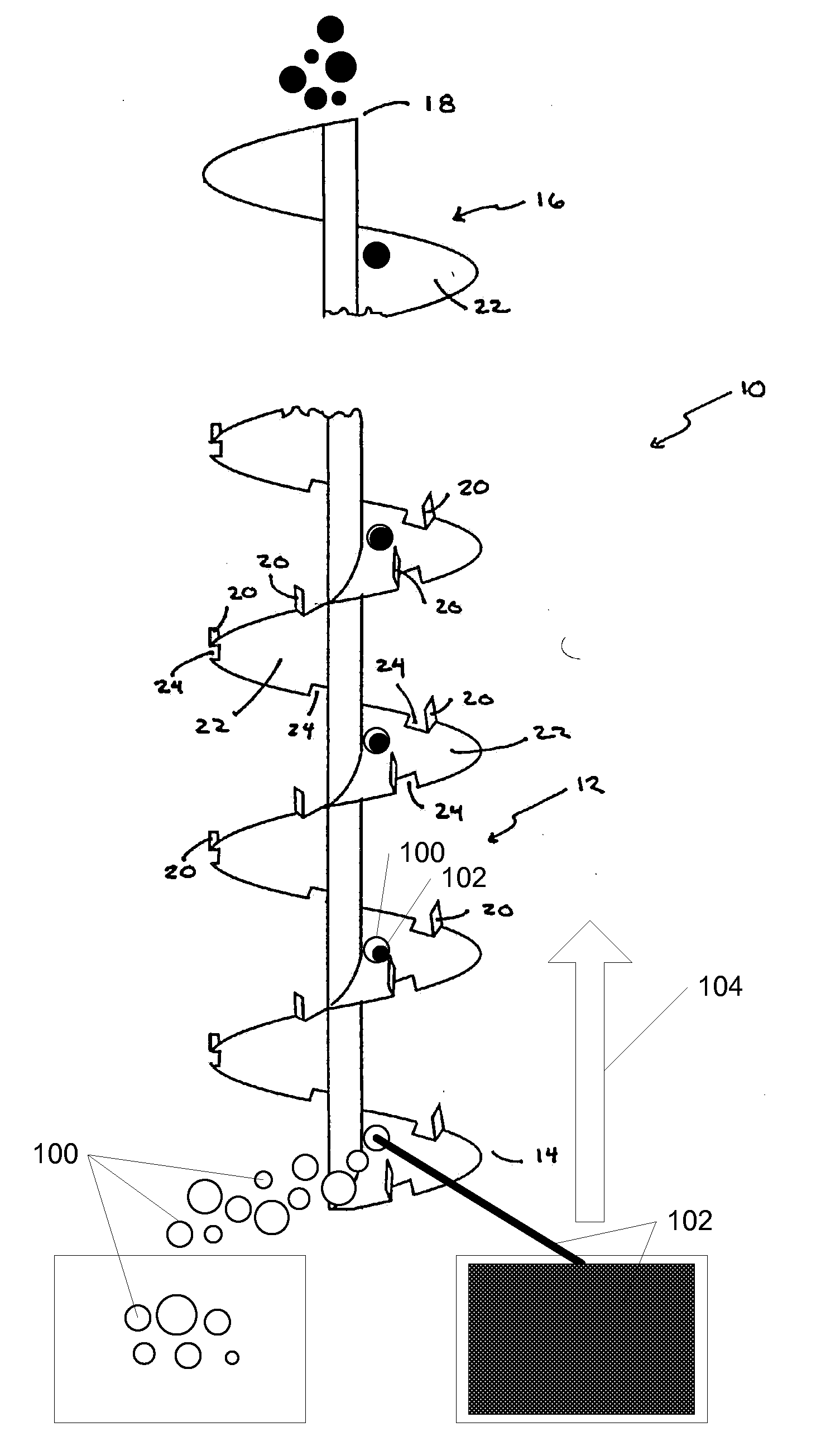

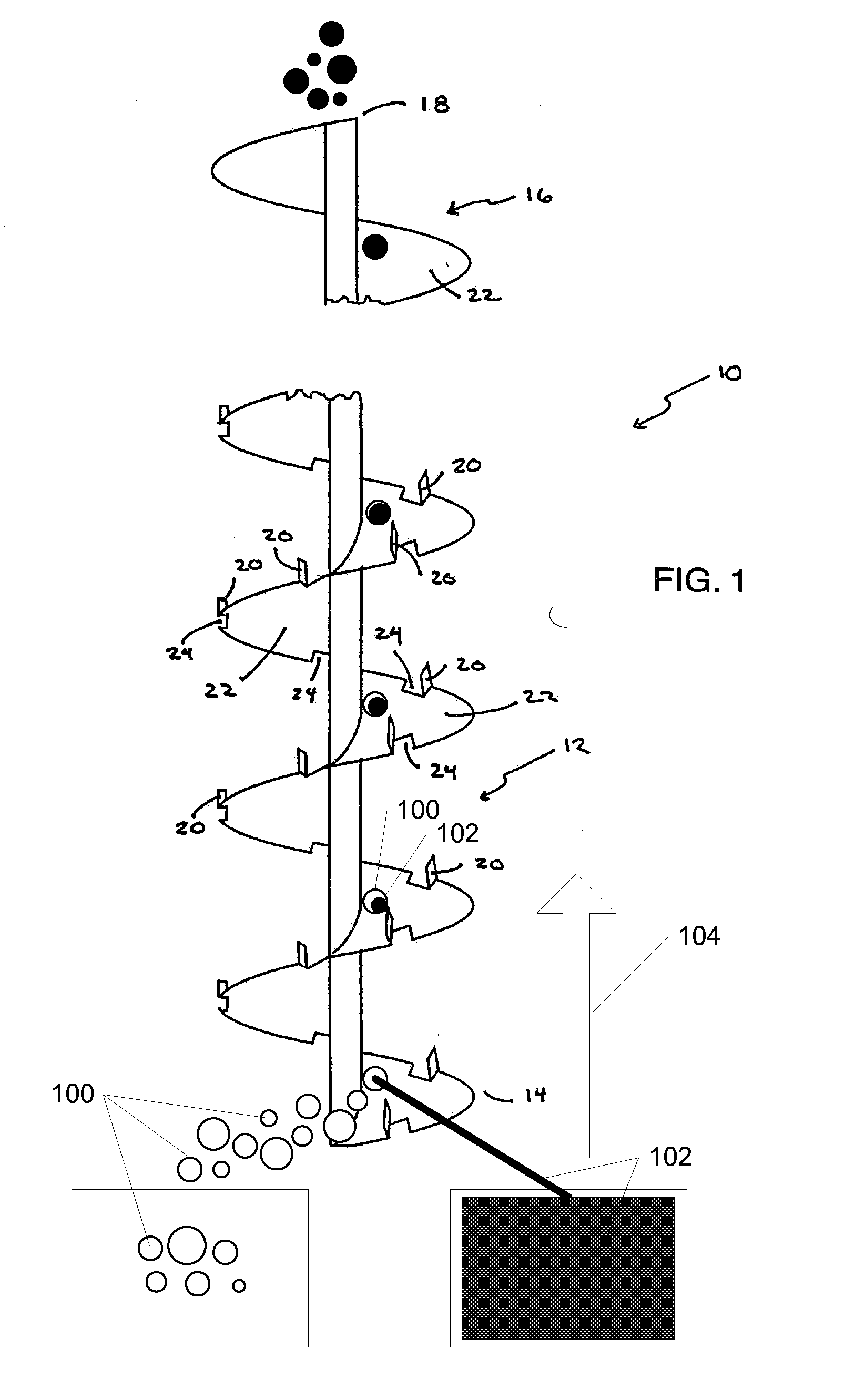

Apparatus and method for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a first inlet, a first outlet, a cavity configured for receiving a wet coproduct and a binder through the first inlet, and a stirring apparatus within the cavity for premixing the wet coproduct and binder into a substantially homogeneous mixture; a high shear mixer having a housing, a drive apparatus and a high shear apparatus, the housing defining an opening, the drive apparatus being within the housing and for forcing the substantially homogeneous mixture from the premixer into the high shear apparatus, and the high shear apparatus including a rotor, a stator and a screen covering the opening and being for shear mixing the mixture including forcing the mixture through the screen and out of the housing in the form of nucleation enhanced particles; and an agglomerator having an interior chamber sized and configured to receive the nucleation enhanced particles from the high shear mixer and for transforming the nucleation enhanced particles into substantially spherical biomass pellets.

Owner:PURDUE RES FOUND INC

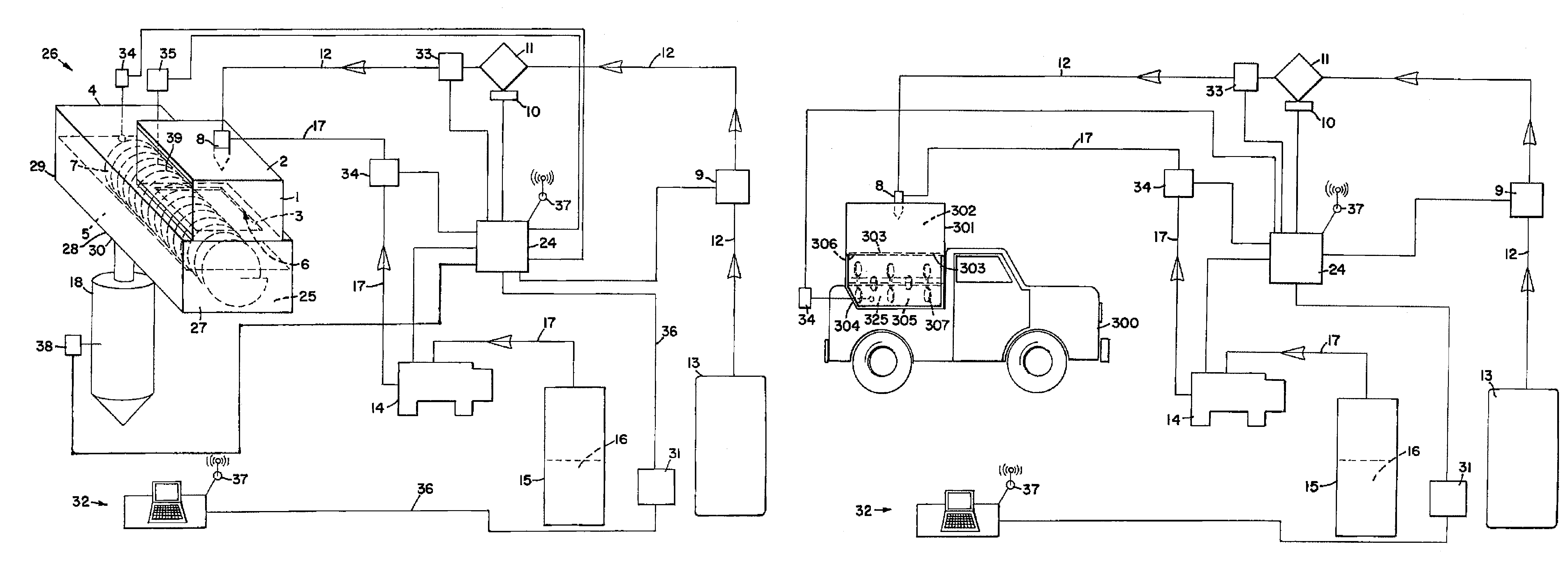

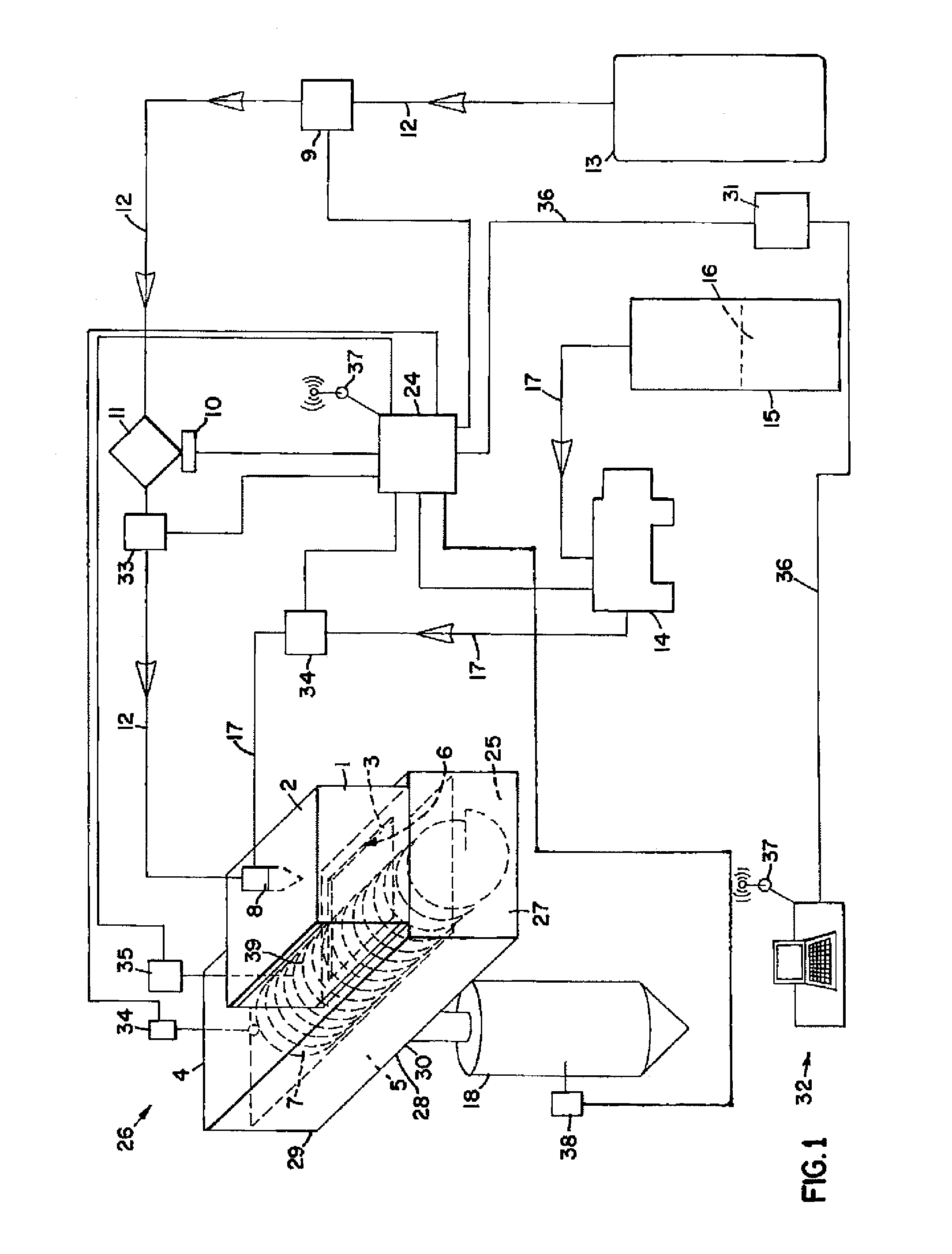

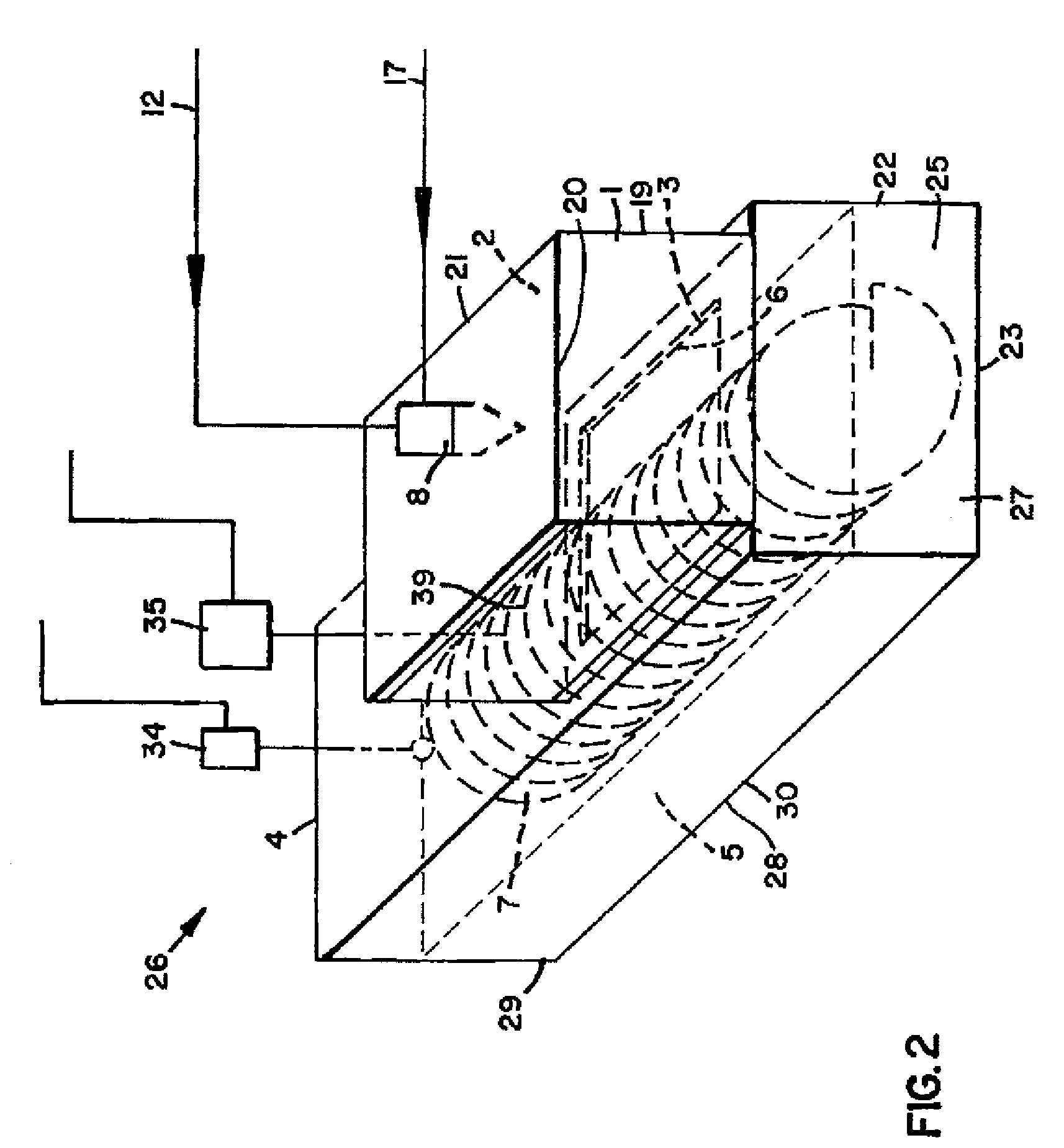

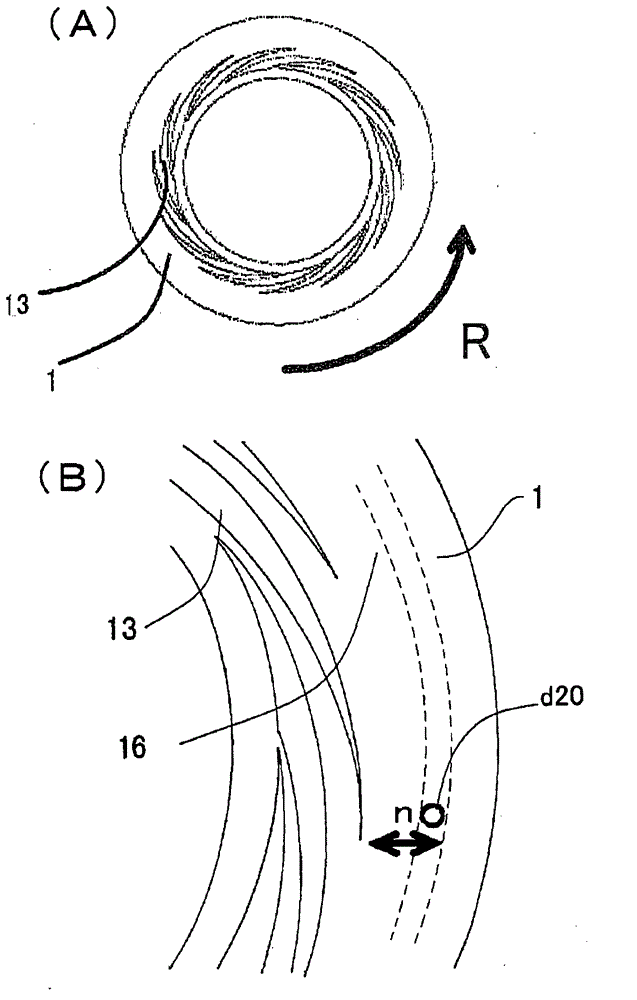

Particle size breakup device and its performance estimation method and scale up method

Herein is disclosed a comprehensive mixer performance estimation method that can be applied to the mixers of the rotor-stator type having various configurations and circulation systems.Specifically, the performance estimation method for the mixers of the rotor-stator type includes the steps of: obtaining the homogenization index: H.I. for each of the mixers, measuring the size of each of the mixers, the power requirements and flow rates during the running time of each of the mixers, estimating the magnitude (smallness or greatness) of the configuration dependent term value of each of the mixer as a whole which is specific to each of the mixers, and estimating the performance of each of mixers accordingly.

Owner:MEIJI CO LTD

System and method for applying an additive to a material stream

The present disclosure is generally directed to systems and methods for applying liquid feed additives to a feed composition. In one embodiment, the system has a spray housing defining a spray chamber located adjacent a mix housing carrying a material composition. The mix housing defines a mix chamber, which contains an actuating device, such as an auger, that moves the material stream through the mix chamber. The mix chamber and spray chamber are in fluid communication. A spray nozzle is coupled to the spray housing and in fluid communication with an air source and liquid additive tank. The spray nozzle sprays a fog of air and liquid additive through the spray chamber and into the mix chamber, which gets deposited on the passing feed stream.

Owner:SARTEC

Apparatus and method for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a first inlet, a first outlet, a cavity configured for receiving a wet coproduct and a binder through the first inlet, and a stirring apparatus within the cavity for premixing the wet coproduct and binder into a substantially homogeneous mixture; a high shear mixer having a housing, a drive apparatus and a high shear apparatus, the housing defining an opening, the drive apparatus being within the housing and for forcing the substantially homogeneous mixture from the premixer into the high shear apparatus, and the high shear apparatus including a rotor, a stator and a screen covering the opening and being for shear mixing the mixture including forcing the mixture through the screen and out of the housing in the form of nucleation enhanced particles; and an agglomerator having an interior chamber sized and configured to receive the nucleation enhanced particles from the high shear mixer and for transforming the nucleation enhanced particles into substantially spherical biomass pellets.

Owner:PURDUE RES FOUND INC

Wet granulation machine

InactiveCN102198381AEasy to cleanImprove efficiencyGranulation in stationary drums/troughsEngineeringDrive motor

The invention relates to a wet granulation machine, which comprises a granulation tower, a cleaning nozzle disposed inside the granulation tower, a stirring paddle, a granulation knife and a discharging mechanism disposed at the side of the granulation tower, wherein the stirring paddle is connected through shafts with a driving motor outside the granulation tower. The wet granulation machine provided by the invention is characterized in that the shafts are double-sleeve shafts possessing a mandrel fixedly connected with the center of the stirring paddle and a sleeve shaft connected with the driving motor. The mandrel cross section and the cross section of the sleeve shaft bore are profiles fitting with each other. The mandrel slides up and down and is disposed inside the sleeve shaft. The upper end of the mandrel is connected with the stirring paddle and the lower end of the mandrel extends the sleeve shaft which is connected with a cylinder. The bottom of the granulation tower is evenly provided with 2 to 8 cleaning holes. Each cleaning hole is internally provided with a sealing cover and a water inlet pipe, wherein the sealing cover can slide up and down. The lower end of each sealing cover is correspondingly connected with a small cylinder. Since the bottom of the granulation tower is provided with cleaning holes, the cleaning for the granulation operation is realized. The stirring paddle is provided with a vertical paddle, so that most materials on the inner wall of the granulation tower can be scraped off. The discharging mechanism can be rapidly opened and is convenient to clean and novel in design.

Owner:CHANGZHOU YIBU DRYING EQUIP

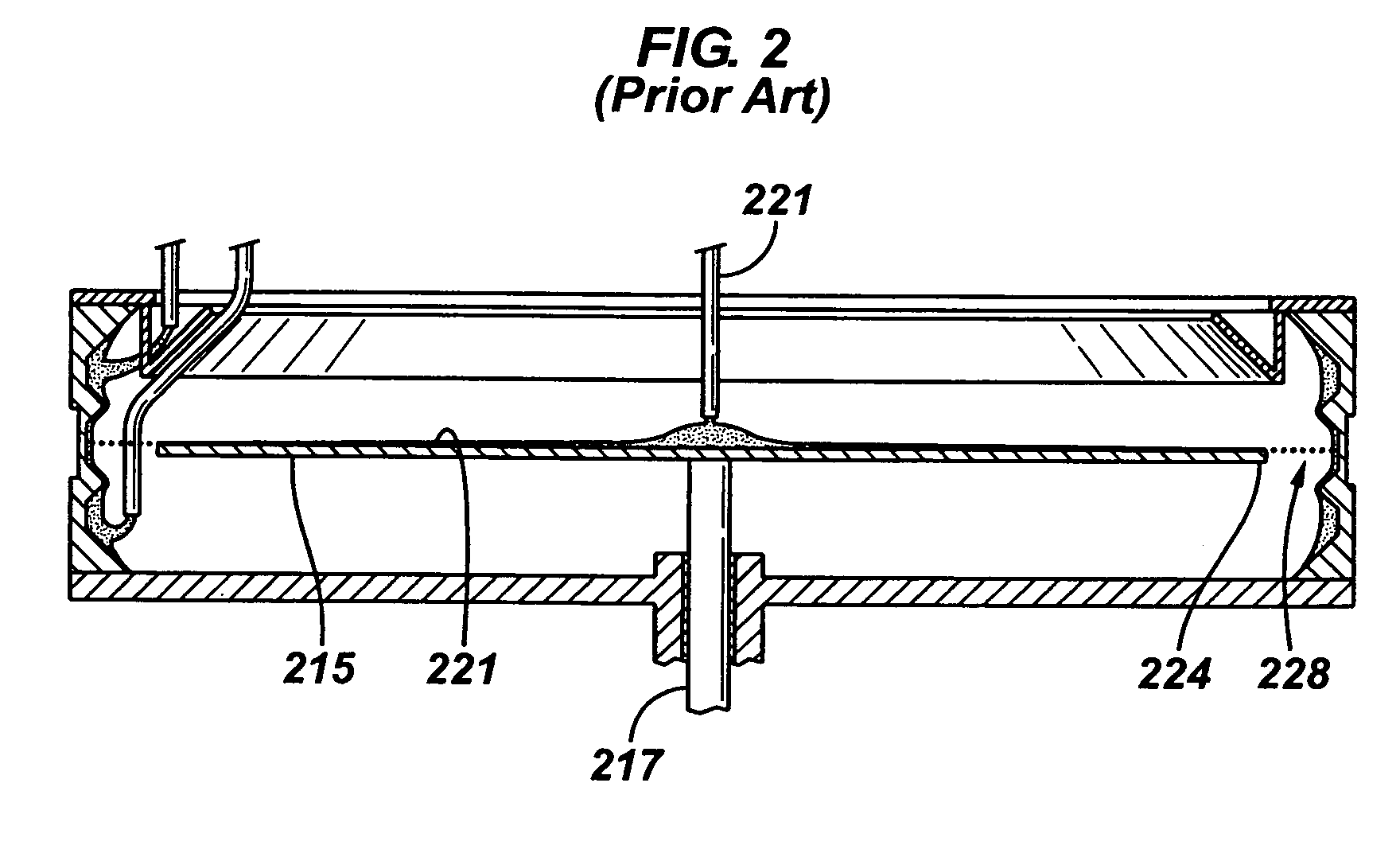

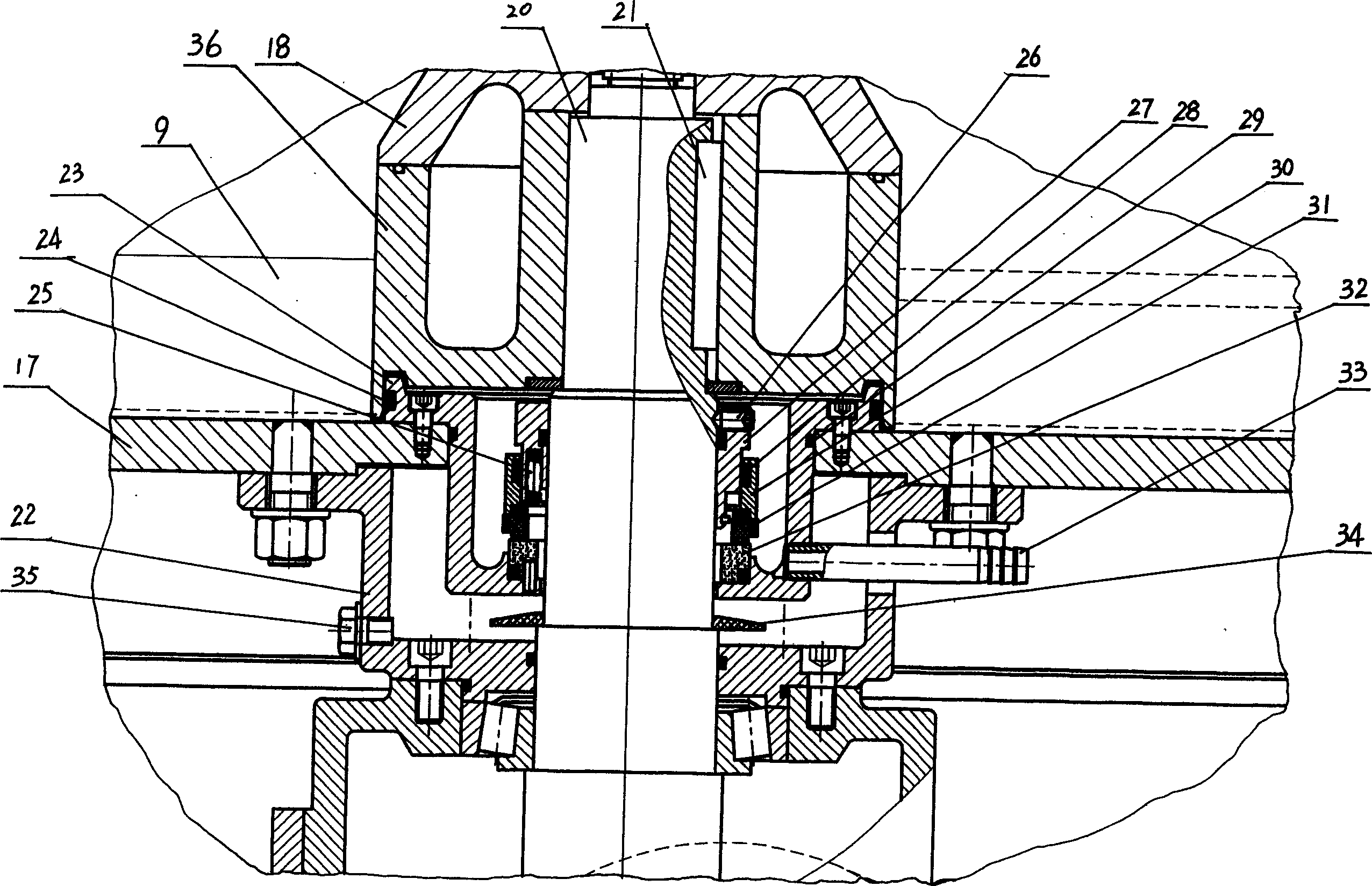

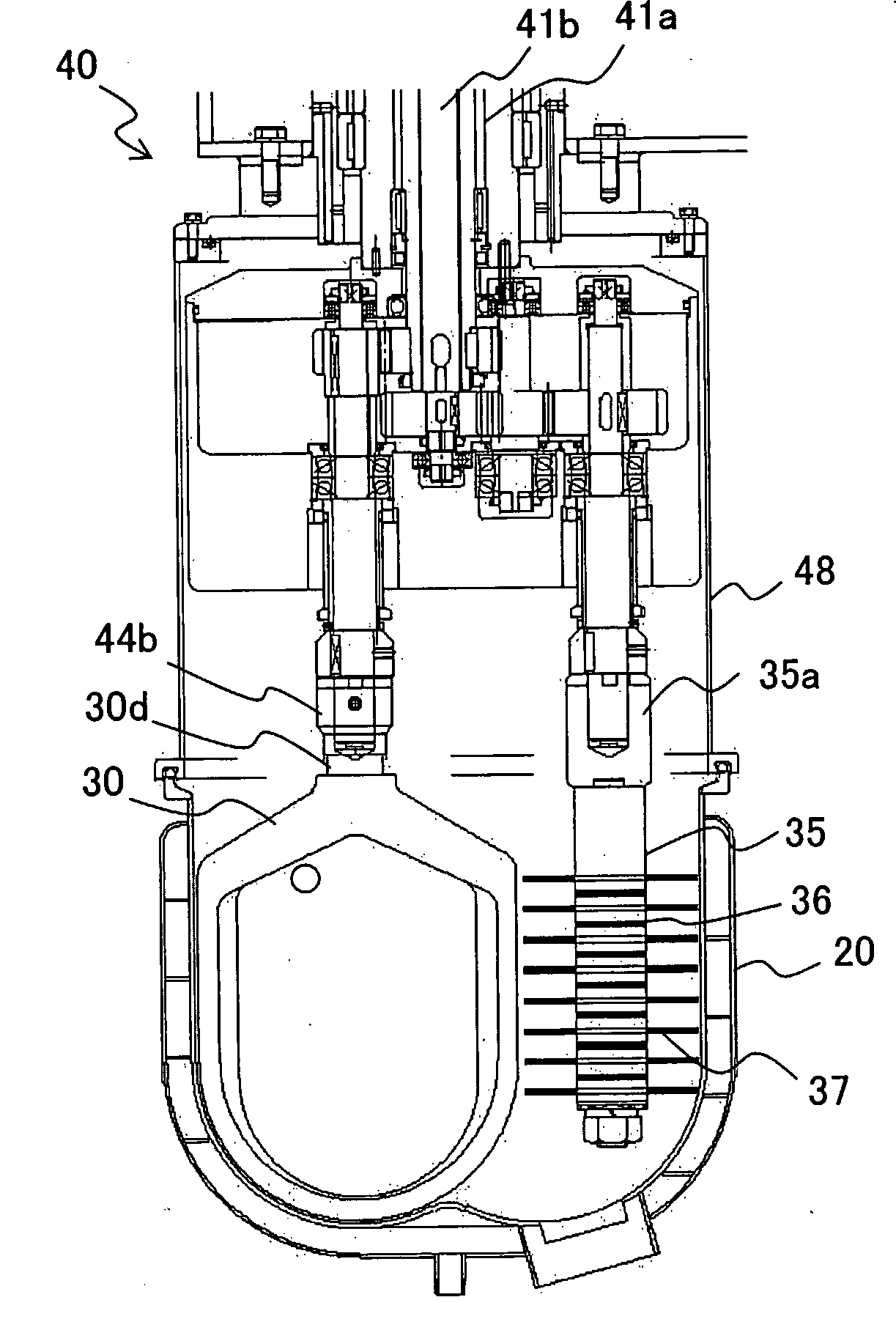

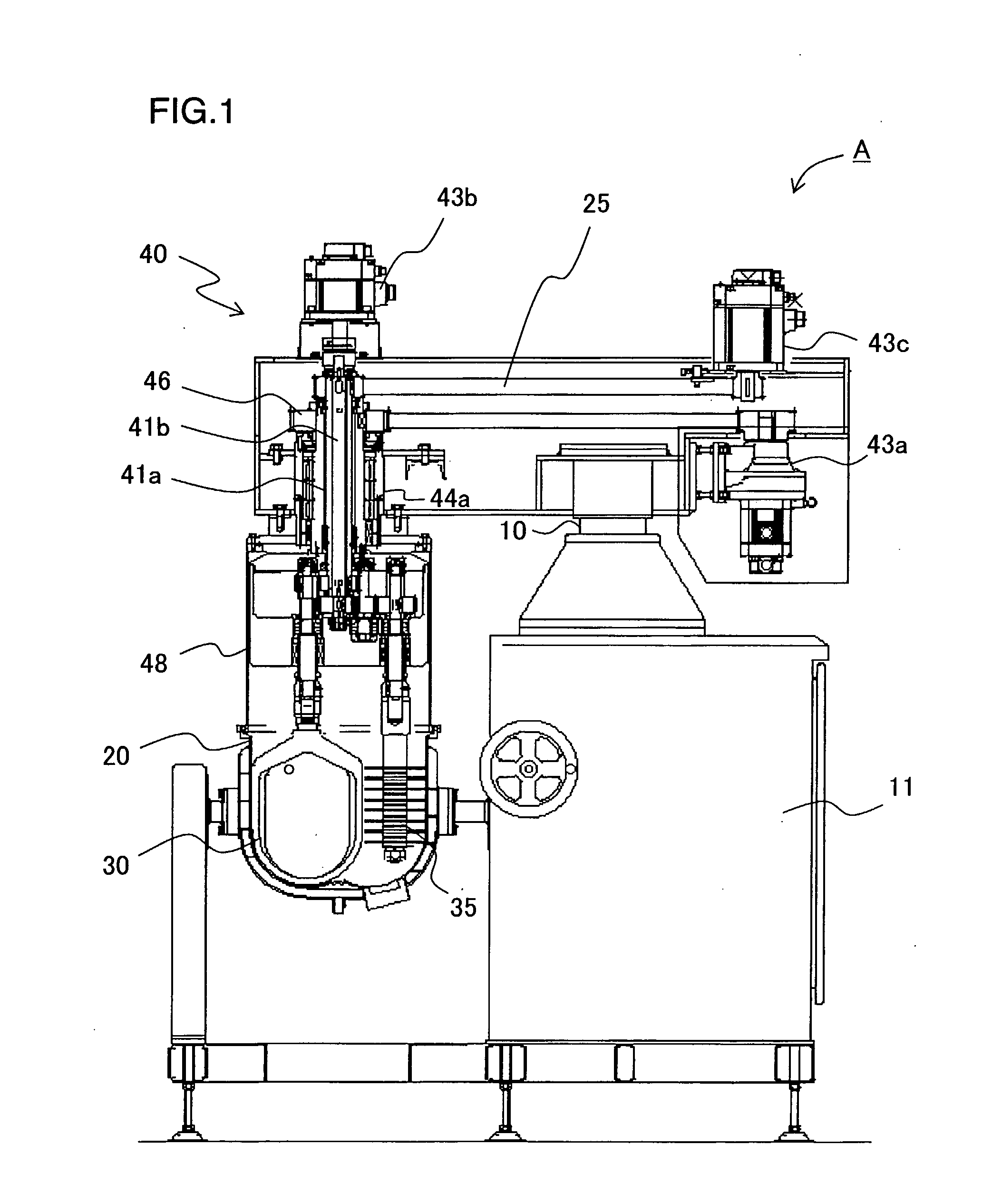

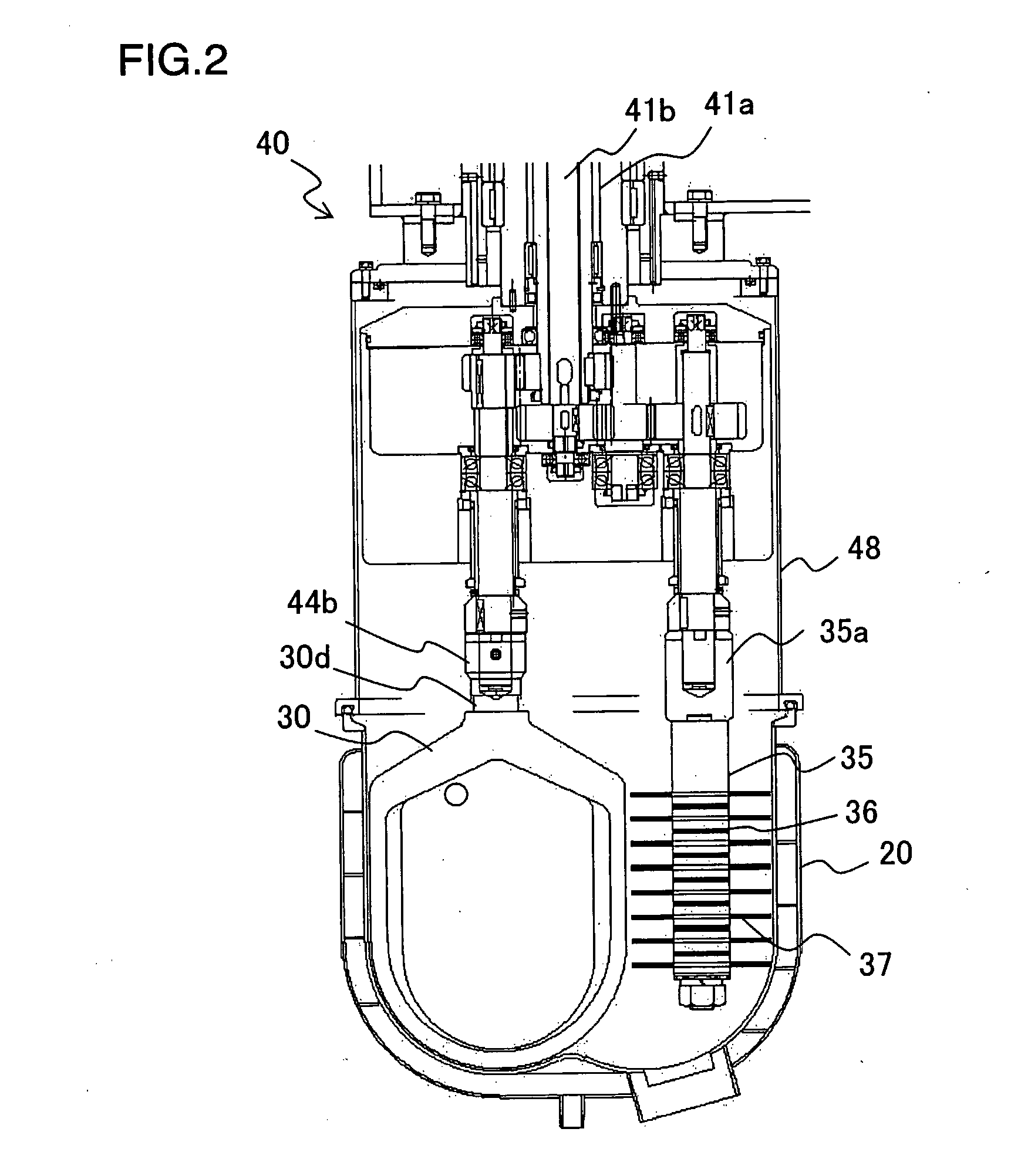

Kneading and granulating machine

ActiveUS20090135666A1Small sizeReduce manufacturing costRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

A kneading and granulating machine comprises: a container containing a material to be kneaded; a kneading member, which moves along the inner wall surface of the container and revolves and spins at the same time within the container; and a crushing blade, which revolves and spins at the same time within the container to shear the material to be kneaded in the container. The kneading member comprises a blade having a shape corresponding to the inner wall surface of the container, which enables kneading the material to be kneaded between itself and the inner wall surface of the container.

Owner:SHINAGAWA INDSSHO +2

Quasi-continuous treatment of particulate materials with cleansing nozzle system

The multicell apparatus according to the invention is suitable for batchwise and in particular quasi-continuous operation, i.e. for the continuous processing of batches in rapid succession, for example for the preparation of readily free-flowing granules which are suitable for filling in capsules or sachets. The apparatus is in particular a multifunctional system which combines the process steps of batch introduction, metering, mixing / granulation, drying, product cooling and product collection with one another in a very compact design. The individual batches are conveyed inside the apparatus through a product path which is hermetically sealed from the outside and in which an internal pressure lower than the ambient pressure may additionally prevail at least in sections. This, together with the cleaning nozzles connected to a central cleaning system, permits contamination-free operation both with aqueous and with organic starting materials.

Owner:GLATT MASCHINEN UND APPARATEBAU AG

Method for manufacturing metal microparticles

ActiveCN104411429ACheap and stableLow costTransportation and packagingMetal-working apparatusMicroparticleSULFATE ION

Provided is a method for manufacturing metal microparticles in which the ratio of crystallite diameter to the particle diameter of the metal microparticles is controlled. At least two types of process fluid are used, including a metal fluid in which a metal or a metal compound is dissolved in a solvent, and a reducing agent fluid which includes a reducing agent. Sulfate ions are included in one or both of the metal fluid and the reducing agent fluid. The process fluid is mixed in a fluid thin film formed between at least two processing surfaces, at least one of which rotates relative to the other, and which are disposed facing each other and capable of approaching and separating from each other, and metal microparticles are precipitated. The present invention is characterized in that at this time, the ratio (d / D) of the crystallite diameter (d) of the metal microparticles to the particle diameter (D) of the metal microparticles is controlled by controlling the mole ratio of metal and sulfate ions in the mixed process fluid.

Owner:M TECHN

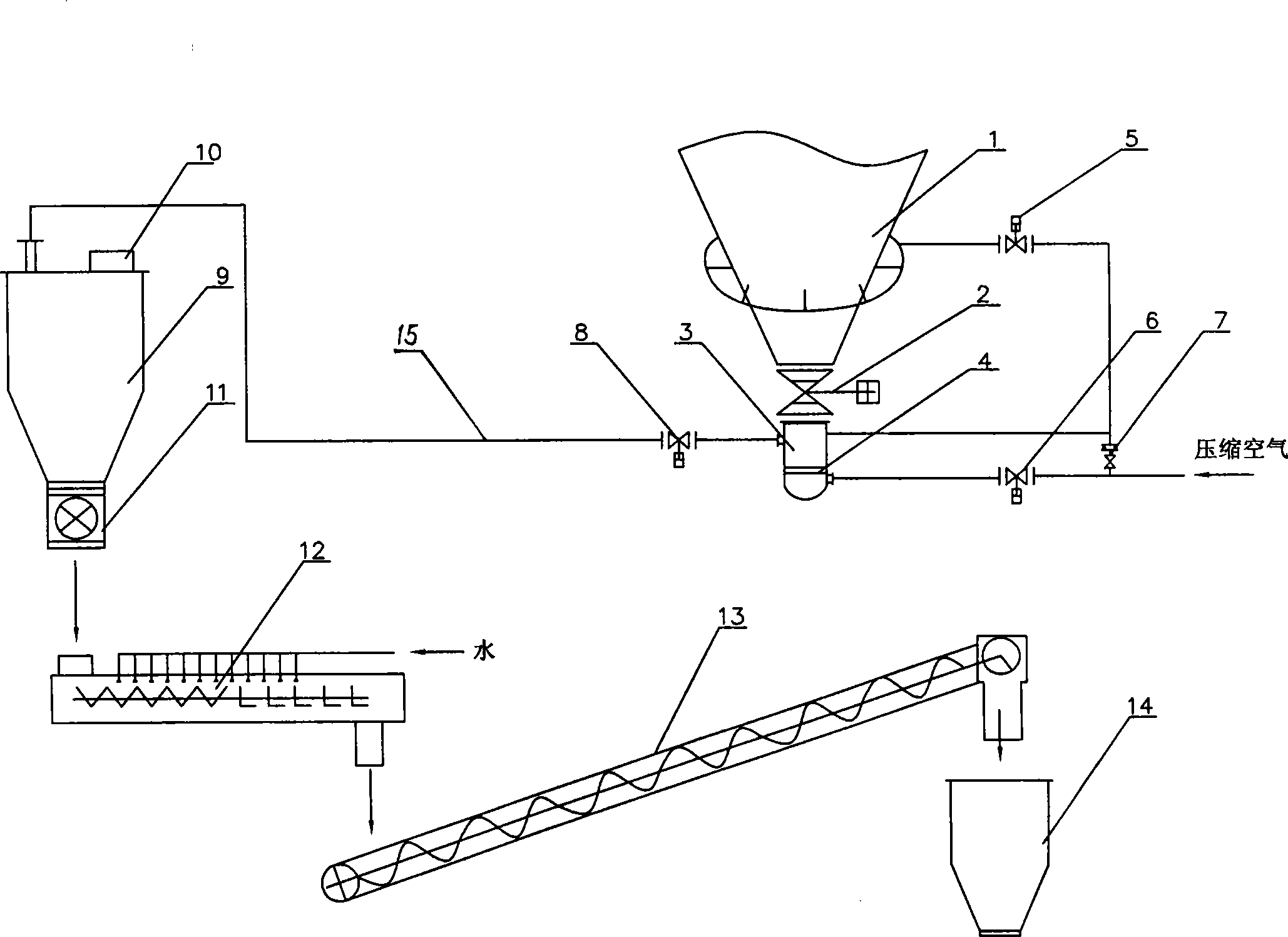

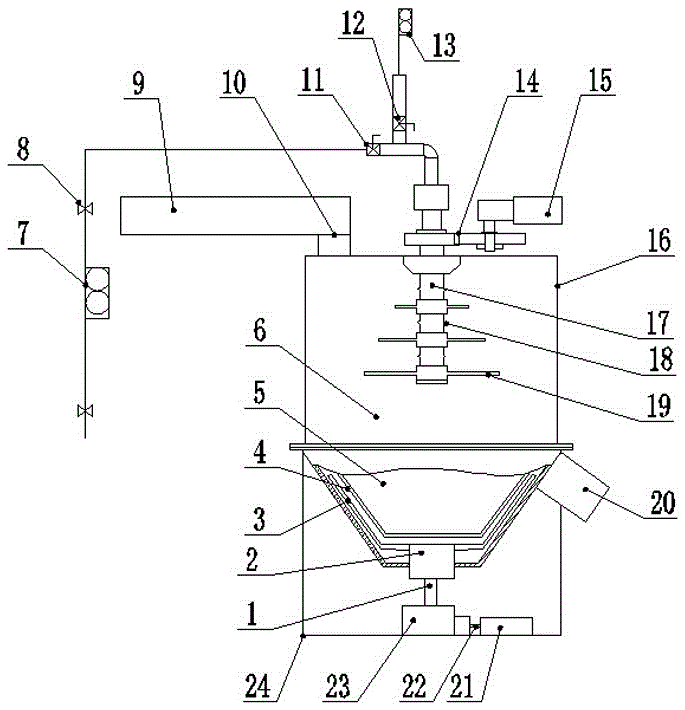

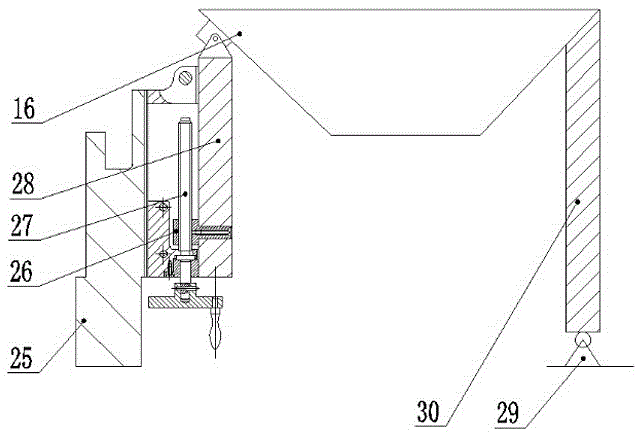

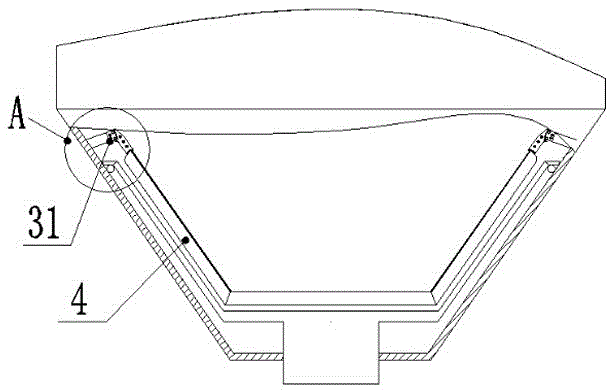

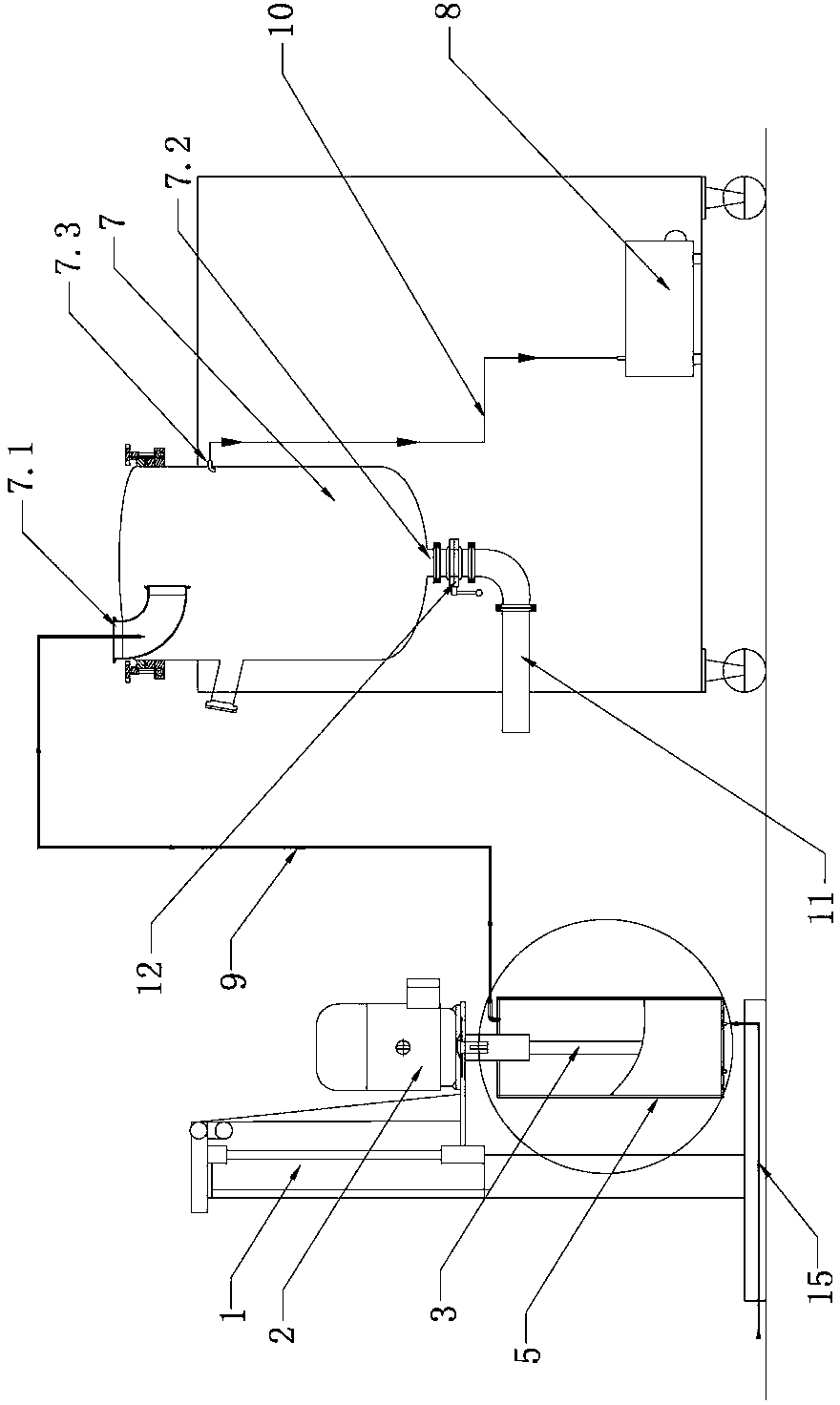

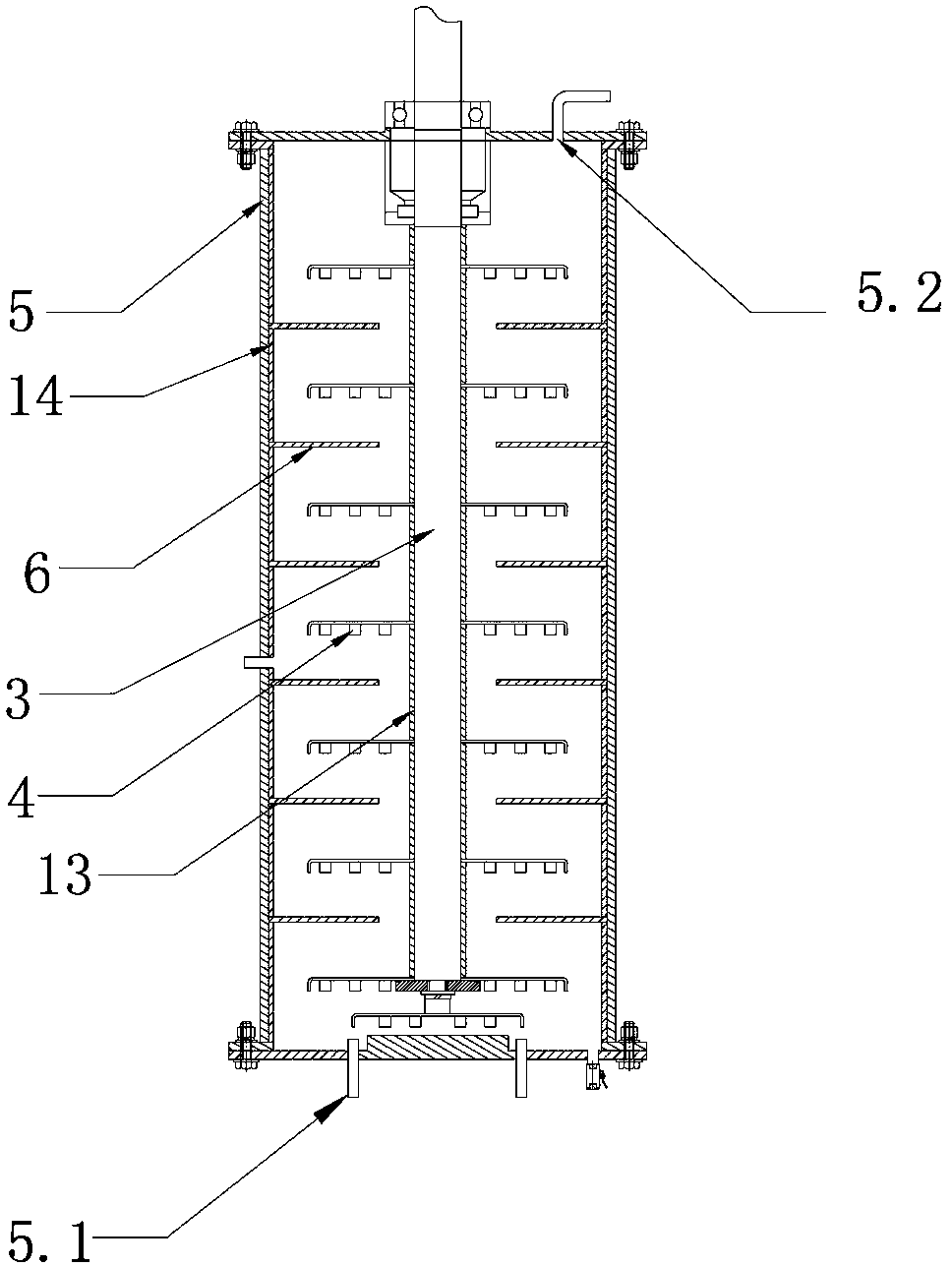

Continuous prilling machine applied to ceramic powder and prilling technology thereof

PendingCN105536644ASmooth feedingContinuous granulationGranulation in stationary drums/troughsFeed devicesSpray nozzleEngineering

The invention relates to a continuous prilling machine applied to ceramic powder and a prilling technology thereof. The continuous prilling machine comprises a prilling tank, and the prilling tank is installed on an adjustable base; a nucleating chamber is formed in the upper portion of the prilling tank, a stirring shaft is arranged in the nucleating chamber, a plurality of sets of stirring teeth are arranged on the stirring shaft in the axial direction of the stirring shaft, atomizing nozzles are further arranged on the stirring shaft, and the atomizing nozzles and the stirring teeth are alternately arranged in the axial direction of the stirring shaft; a water delivering pipe is connected to the atomizing nozzles, and a water atomizing controlling valve and an anti-blocking device are arranged on the water delivering pipe. The continuous prilling machine further comprises a continuous feeding device jointed with a feeding opening of the prilling tank; a prilling chamber is formed in the lower portion of the prilling tank, a rotating device is arranged in the prilling chamber, a rotating disc is arranged on the rotating device, and a discharging opening is formed in a tank body of the prilling tank; a scraping plate is installed on the inner side wall of the prilling tank, and the rotating disc is located between the scraping plate and the tank body of the prilling tank. By means of the continuous prilling machine, continuous prilling can be achieved, and efficiency is high; the moisture content of particles is controllable, and control accuracy is high; energy consumption is low, the structure is compact, and cost is low.

Owner:SHANDONG ECON ENERGY SAVING TECH

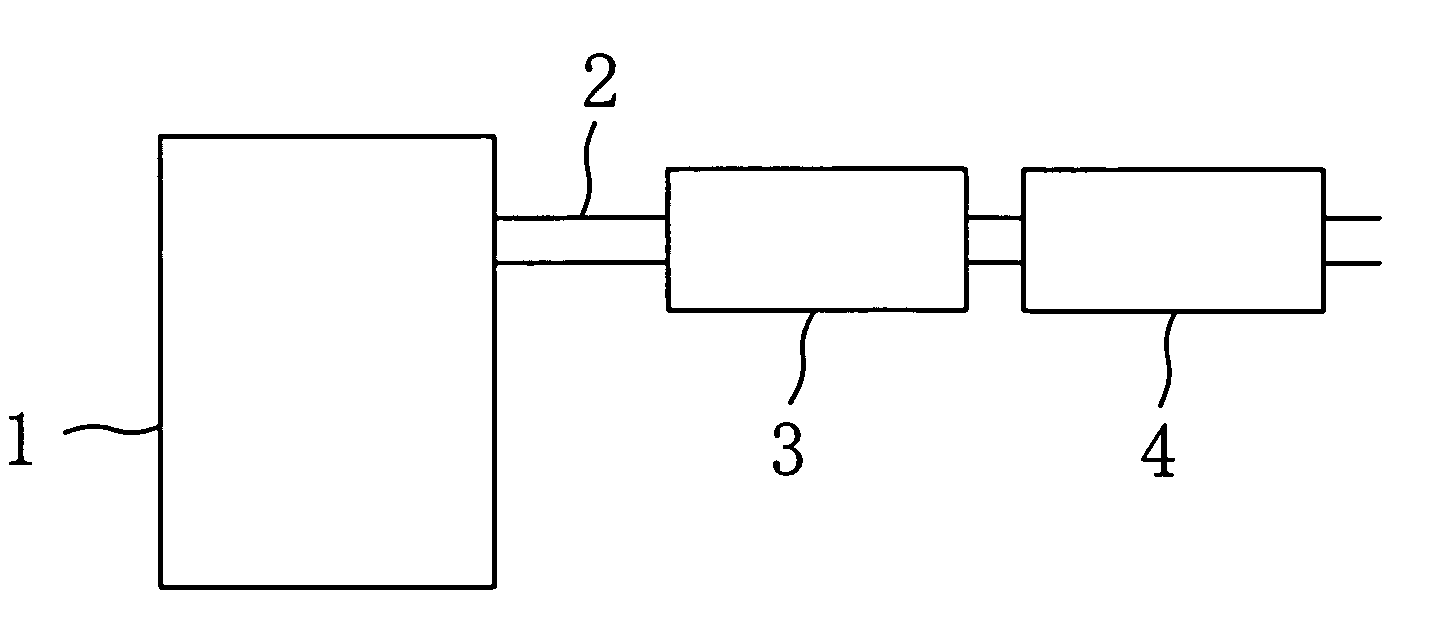

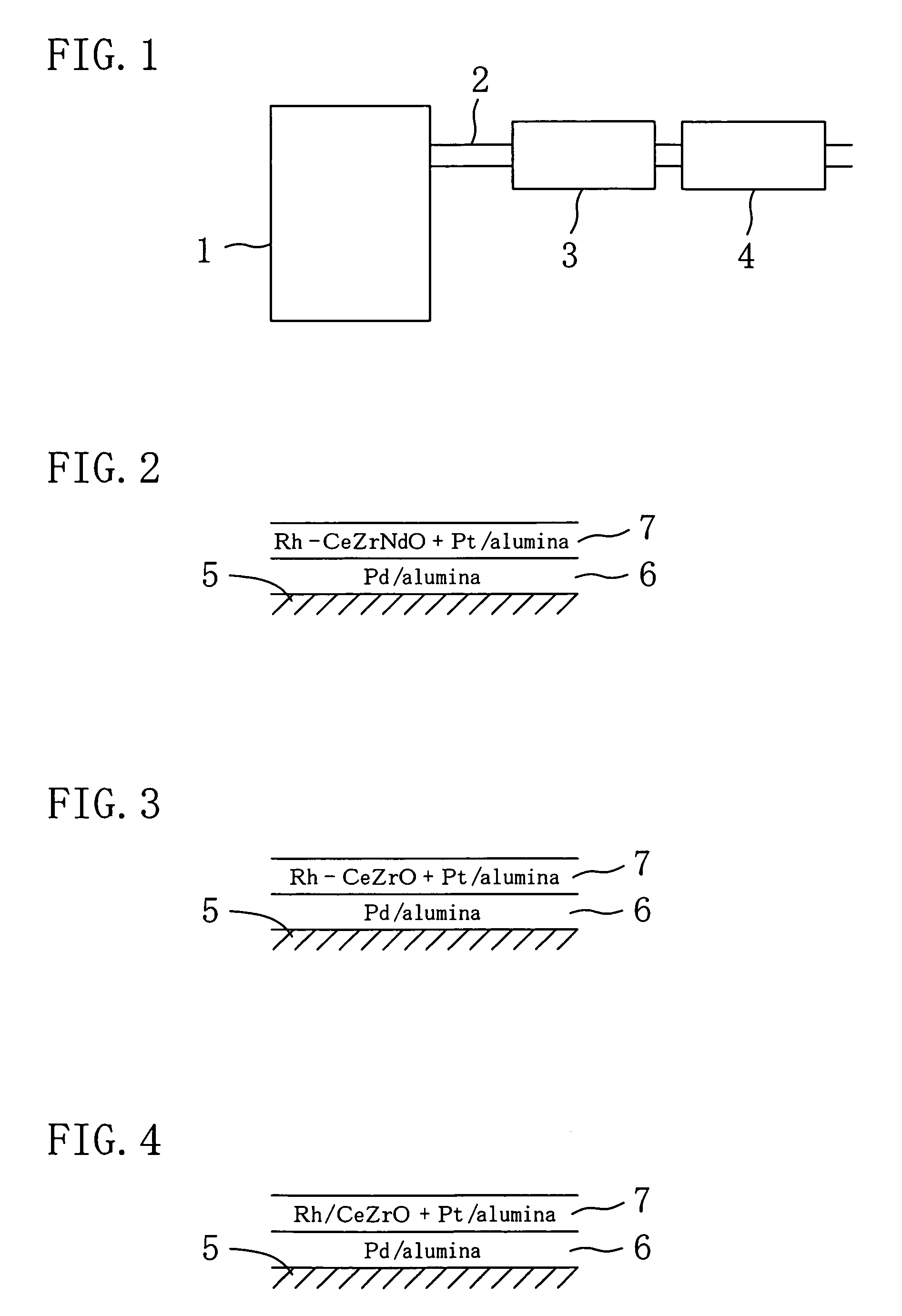

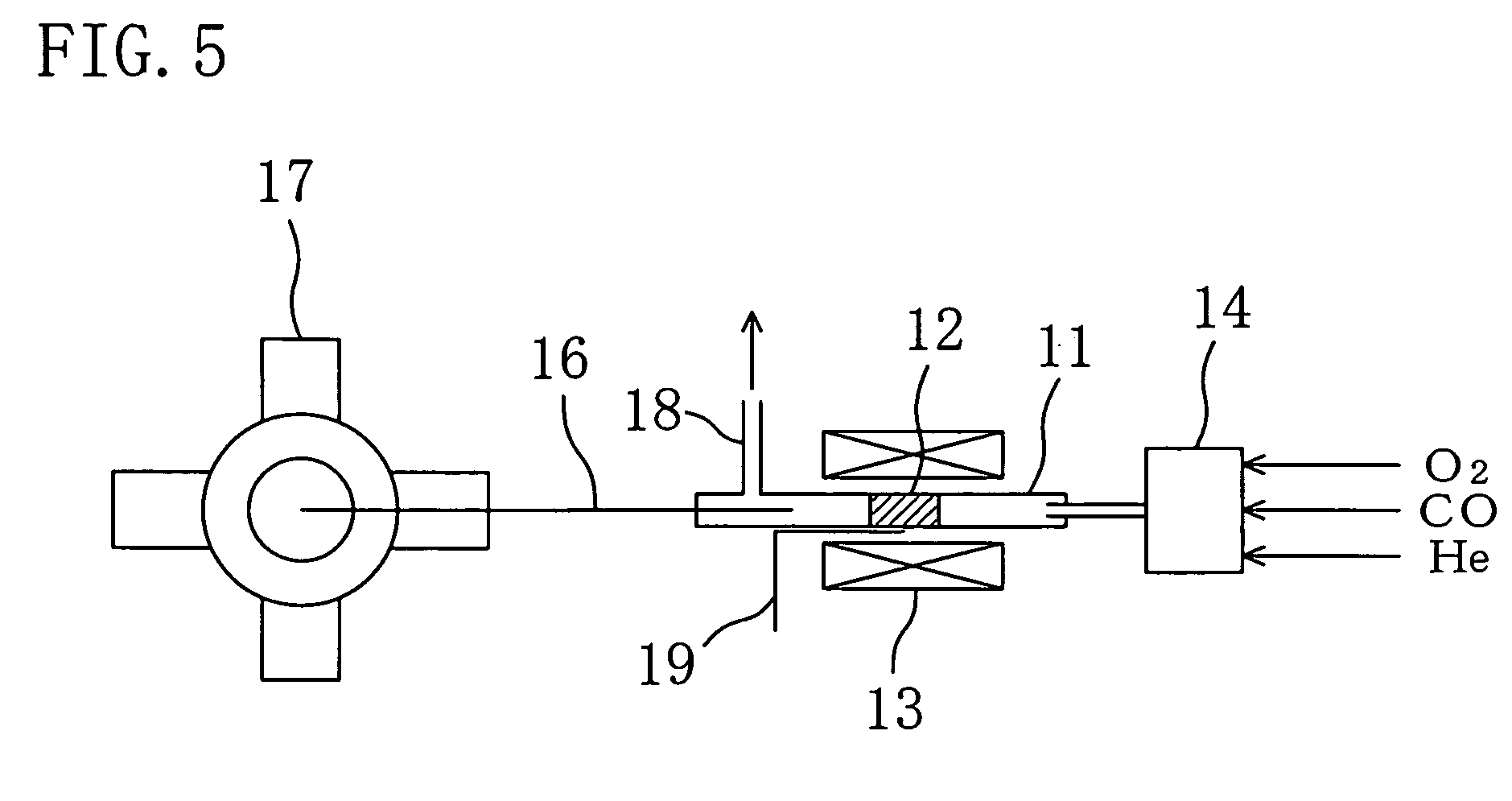

Exhaust gas catalytic converter

InactiveUS7344683B2Improve performanceConverter decreaseCombination devicesInternal combustion piston enginesMixed oxideHeat resistance

The present invention is intended to ensure the improvement in catalytic performance of an exhaust gas catalytic converter, which is an essential performance thereof, ensure the thermal resistance thereof and downsize the converter, i.e., improve the arrangeability thereof. The exhaust gas catalytic converter has an upstream catalyst and a downstream catalyst which are arranged in upstream and downstream sides of an engine exhaust passage through which exhaust gas flows. Each of the upstream catalyst and the downstream catalyst contains an oxygen storage component. The oxygen storage component in the upstream catalyst has a structure in which Rh atoms are placed at or between crystal lattice points of a mixed oxide containing Ce and Zr and has a larger amount of oxygen storage than the oxygen storage component in the downstream catalyst under the same temperature conditions.

Owner:MAZDA MOTOR CORP

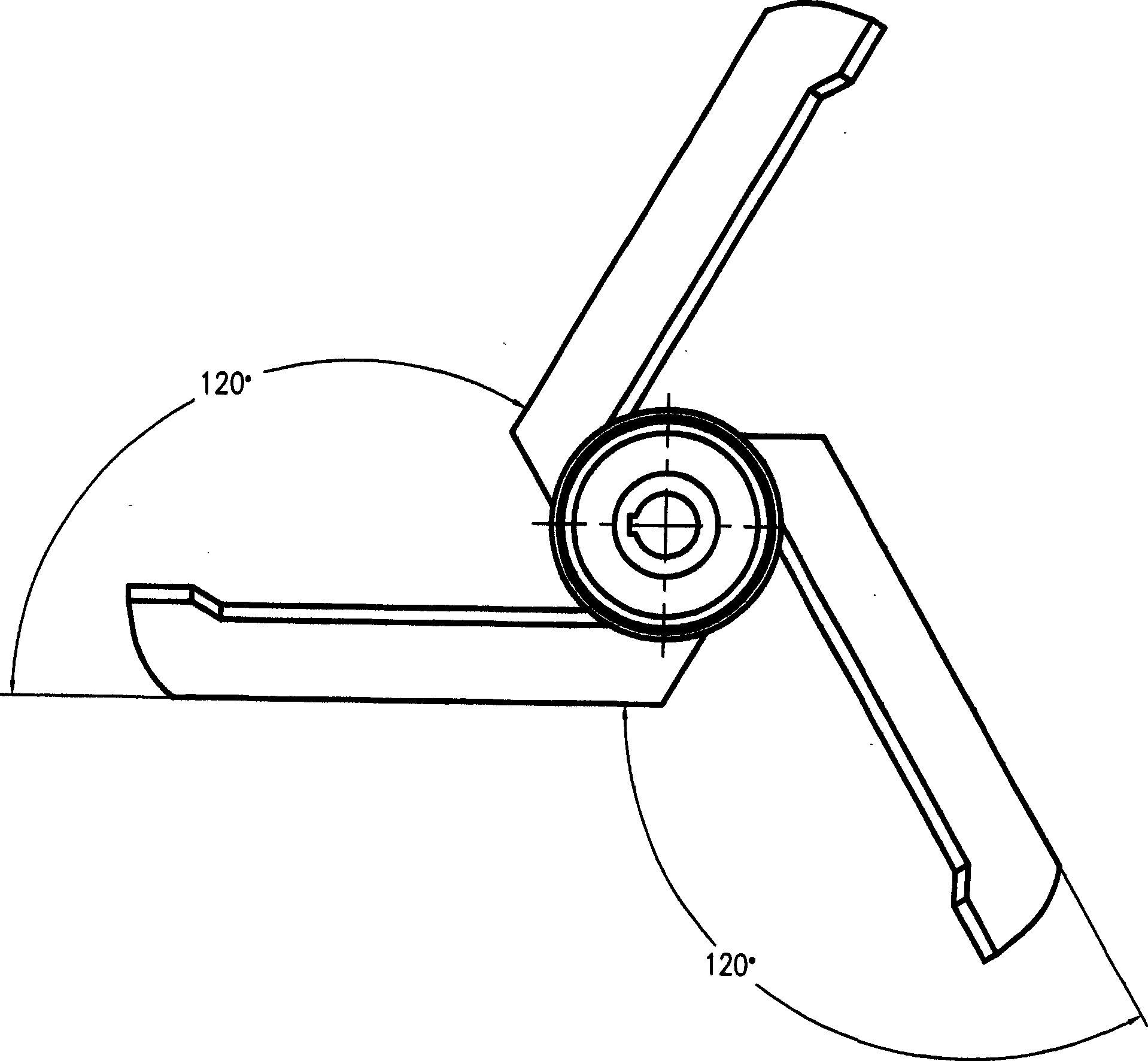

Flaky colorful coating particle granulator

ActiveCN103212341AUniform sizeImprove stabilityGranulation in stationary drums/troughsElectric machineryEngineering

The invention relates to a flaky colorful coating particle granulator which comprises a rack, a motor, a rotary shaft and dispersion discs. The flaky colorful coating particle granulator is characterized by also comprising a material cylinder, annular flow guide plates, a hopper, a vacuum pump, a material conveying pipe, an air ventilation pipe, a material discharge pipe and a butterfly valve, wherein the material cylinder is installed on the rack; the motor is installed on the rack on the upper end of the material cylinder; one end of the rotary shaft is connected with the motor, and the other end of the rotary shaft extends into the material cylinder; the rotary shaft extending into the material cylinder is provided with a plurality of dispersion discs; the inner wall of the material cylinder between two adjacent dispersion discs is provided with one annular flow guide plate; the annular flow guide plates respectively extend towards the direction of the rotary shaft between two adjacent dispersion discs; the upper end of the material cylinder is communicated with the upper end of the hopper in a sealed mode, and the lower end of the material cylinder is communicated with the material discharge pipe through the butterfly valve; the vacuum pump is communicated with a suction port of the hopper through the air ventilation pipe. The flaky colorful coating particle granulator provided by the invention has the advantages that flaky colorful coating granules can be produced in large batch; the production efficiency of the flaky colorful coating granules is high; and the stability is good.

Owner:JIANGYIN XIONGWEI CHEM MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com