Patents

Literature

122 results about "Polymixiiformes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

At present they are classified in their own order Polymixiiformes, but as Nelson says, "few groups have been shifted back and forth as frequently as this one". For instance, they have previously been classified as belonging to the Beryciformes. They are of little economic importance. They are ...

Water-based ink for ink-jet recording

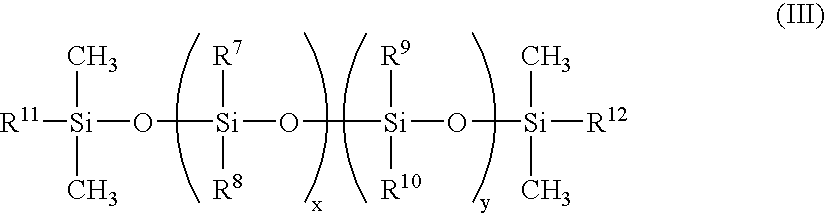

A water-based ink for inkjet printing comprising a water dispersion of vinyl polymer particles prepared by containing a pigment in a vinyl polymer prepared by copolymerizing a monomer mixture comprising (a) a salt-forming group-containing monomer, (b) a macromer, and (c) a monomer copolymerizable with the salt-forming group-containing monomer and the macromer; and a process for preparing a water-based ink for inkjet printing comprising a water dispersion of vinyl polymer particles prepared by containing a pigment in a vinyl polymer, comprising dissolving in an organic solvent a vinyl polymer prepared by copolymerizing a monomer mixture comprising (a) a salt-forming group-containing monomer, (b) a macromer, and (c) a monomer copolymerizable with the salt-forming group-containing monomer and the macromer; adding a pigment to the resulting solution; pre-kneading the mixture; thereafter adding a neutralizing agent and water and kneading the mixture, to give an oil-in-water dispersion; and distilling off the organic solvent from the resulting kneaded product.

Owner:KAO CORP

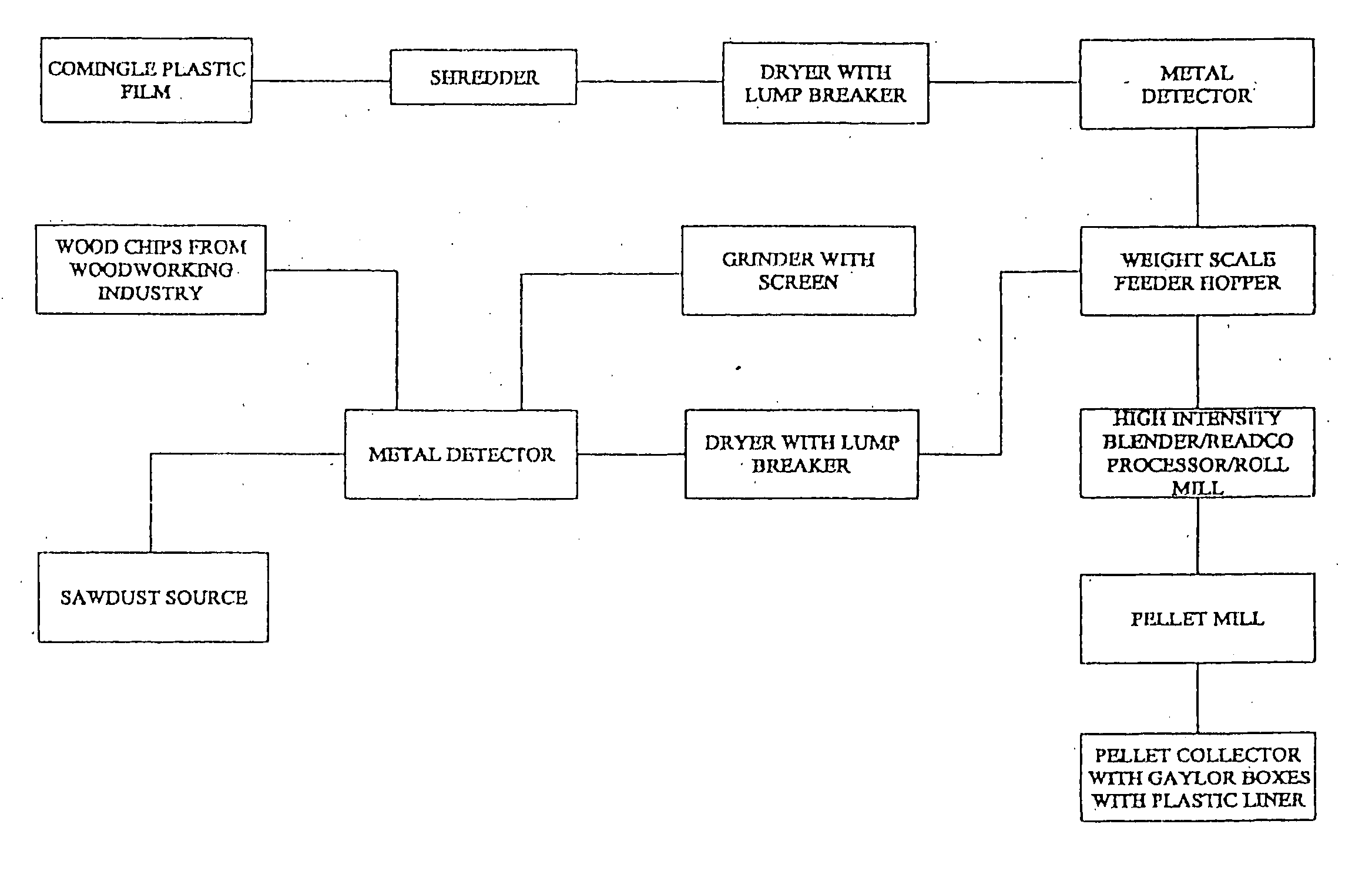

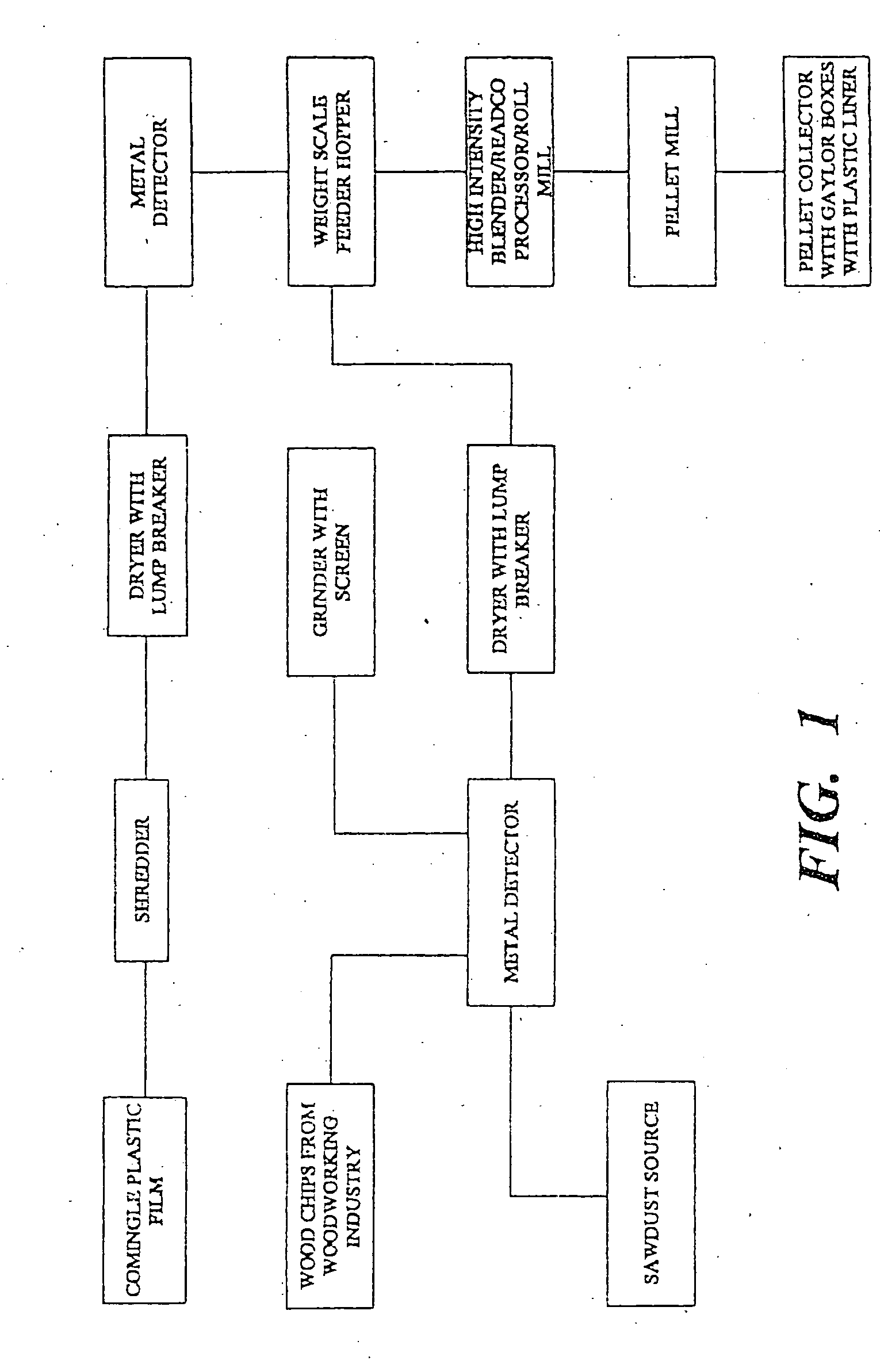

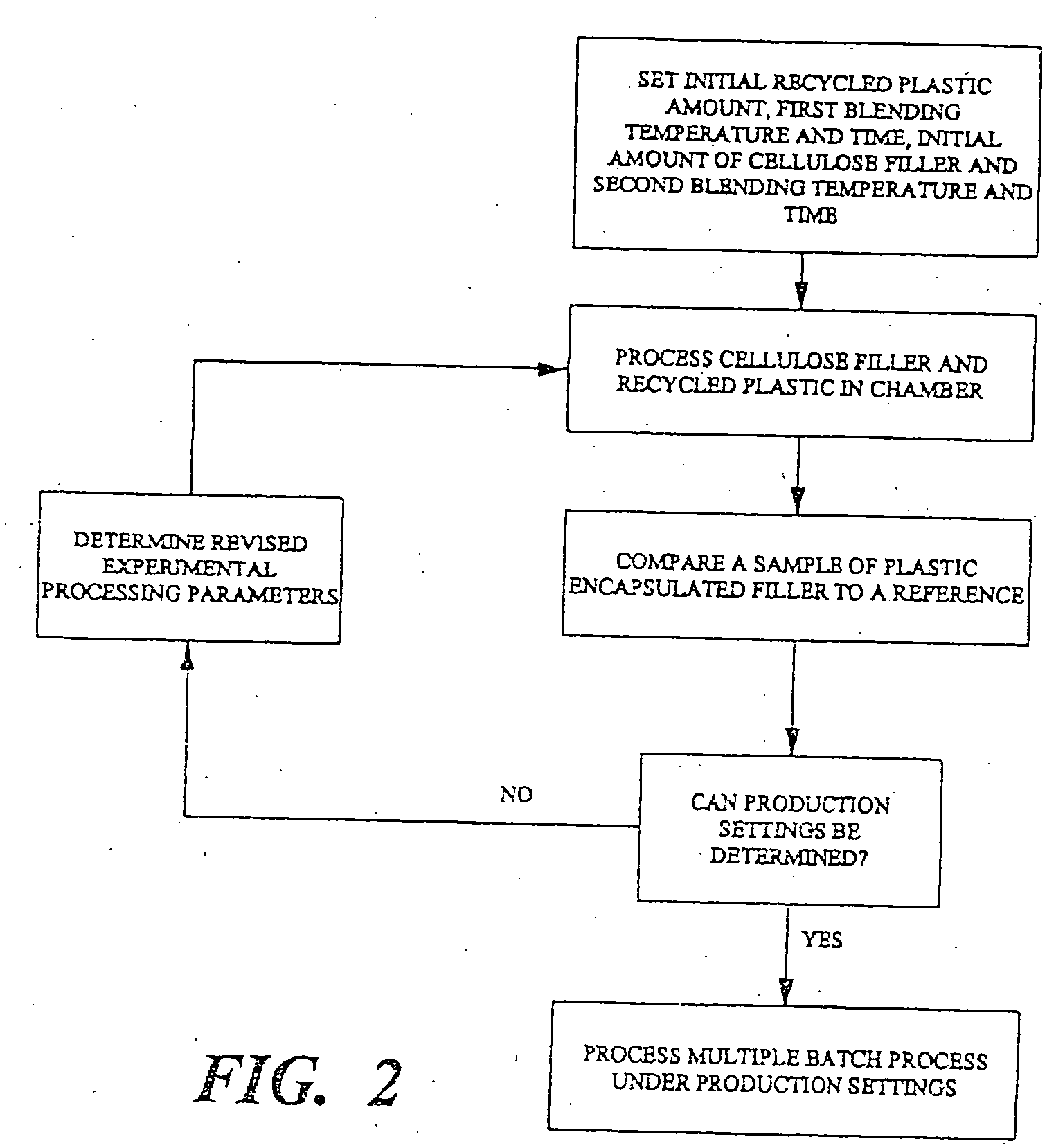

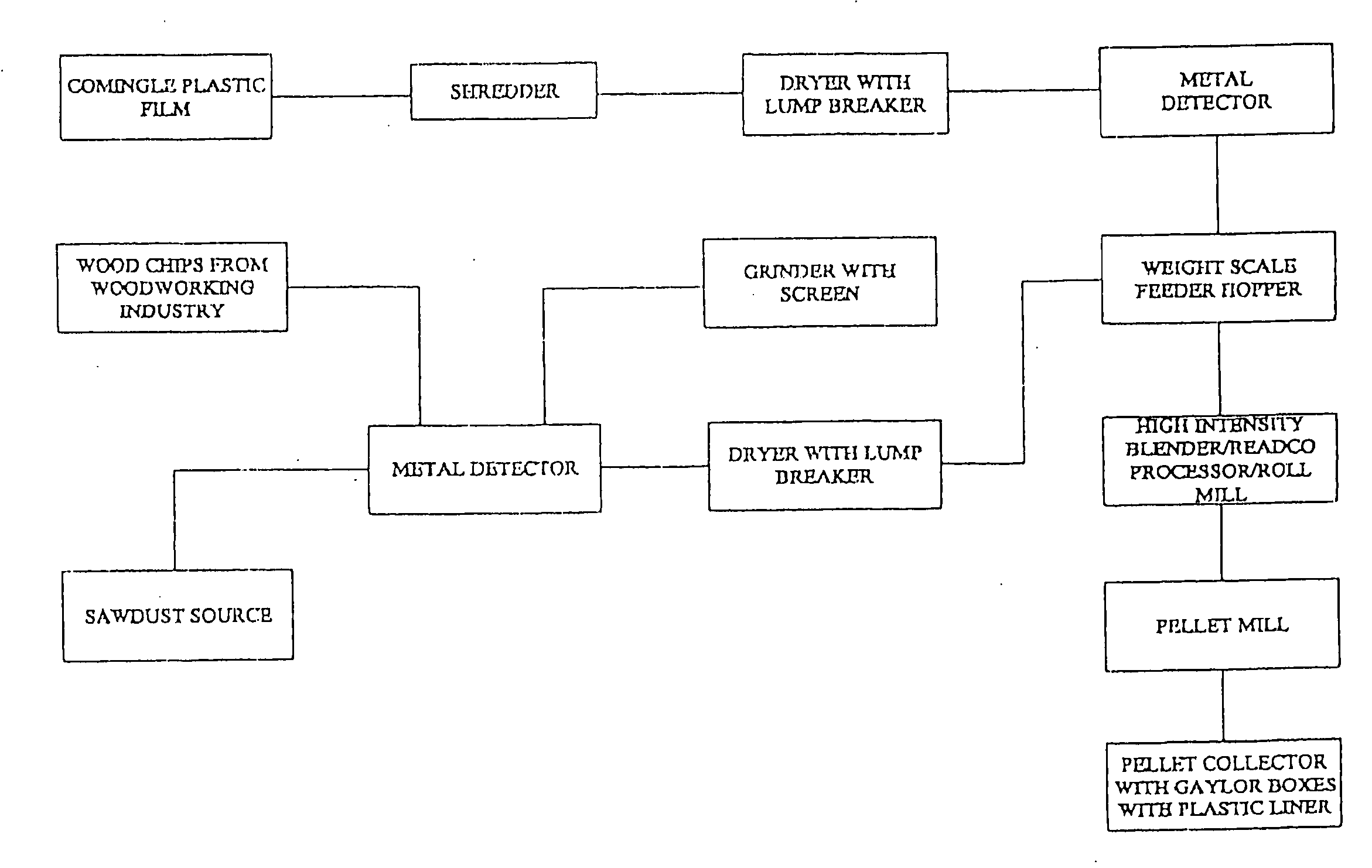

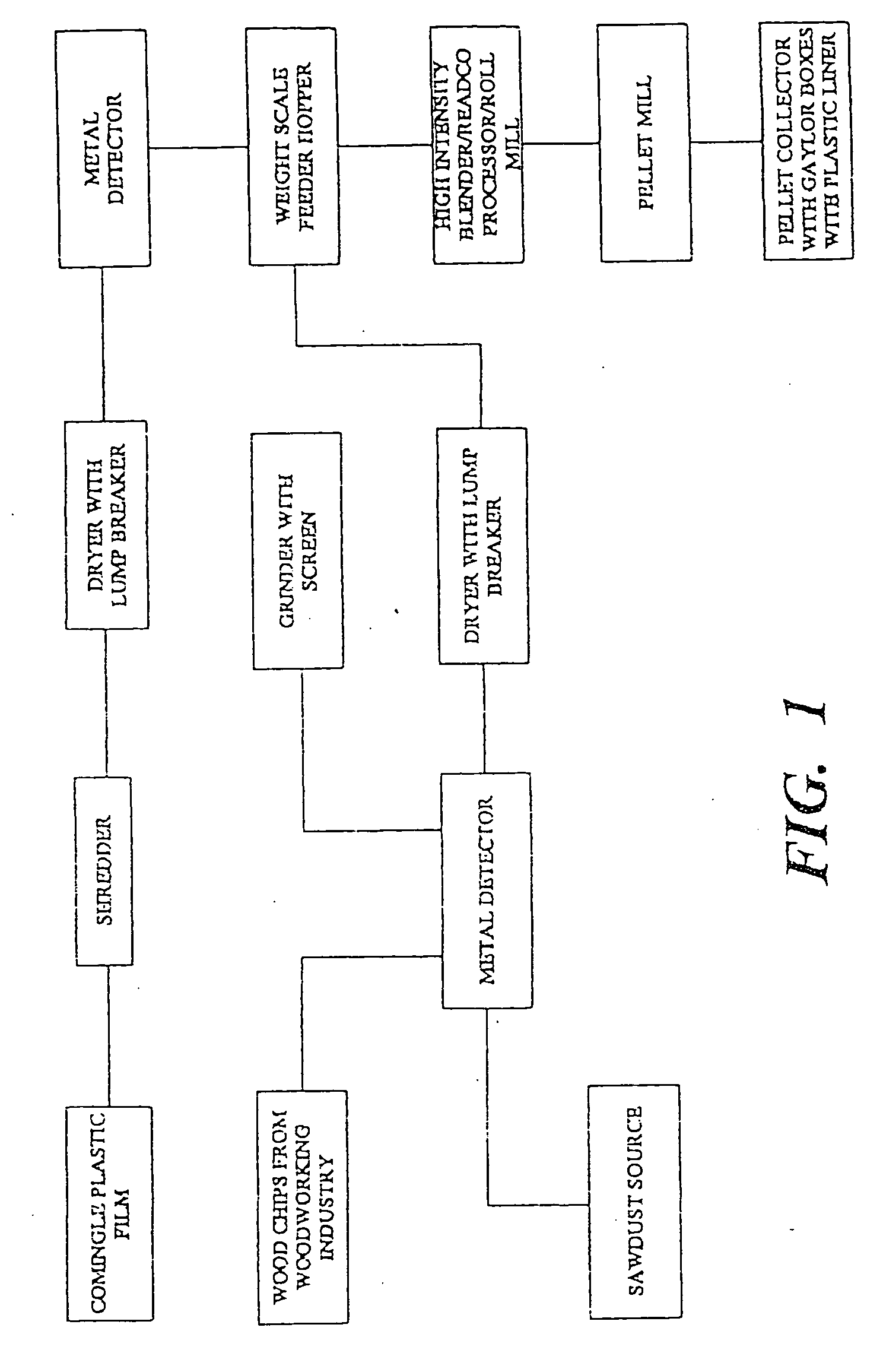

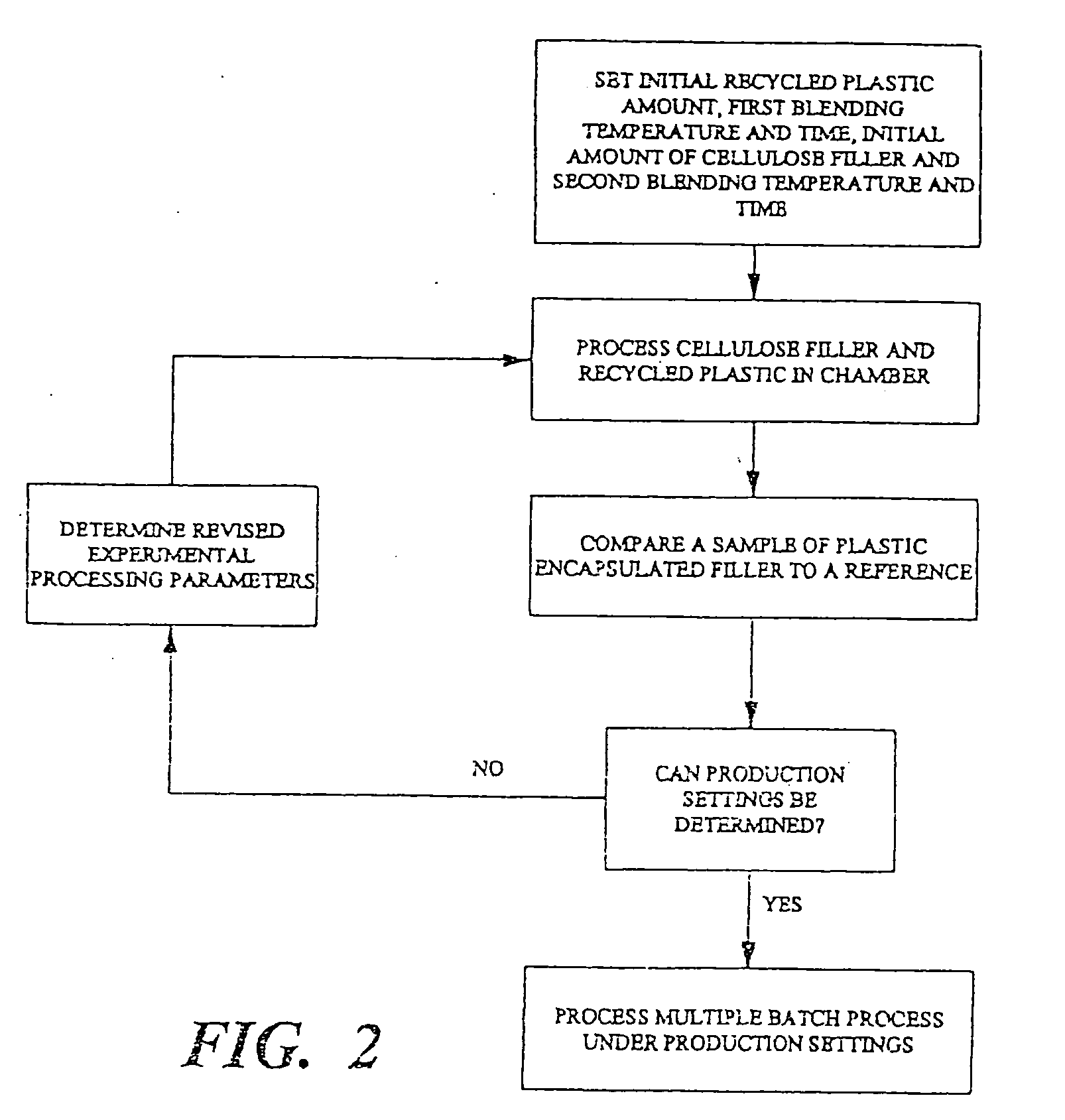

Process for making modified cellulosic filler from recycled plastic waste and forming wood substitute articles

InactiveUS20060006564A1Reduce the possibilityLower melting and softening temperaturePlastic recyclingWood working apparatusThermoplasticPolyvinyl chloride

A low cost process of making modified cellulosic materials by melt blending with at least 30% recycled and commingled plastic waste stream at higher temperature and pressure where at least 70% of plastics melts and encapsulate the filler. The plastic encapsulated filler can be used as a feed stock for continuous or discontinuous process of compression, extrusion, coextrusion and injection molded structural (e.g. profiles, stake, panel) and non-structural (e.g. sheet, thin-board) articles by mixing with a thermoplastic (e.g. polyethylene, polypropylene, polyvinyl chloride, polystyrene) or a hybrid mixture of said thermoplastics, bonding agents, plastic processing additives, impact modifiers, colorant and with / without a lightner.

Owner:MALDAS DEBESH +1

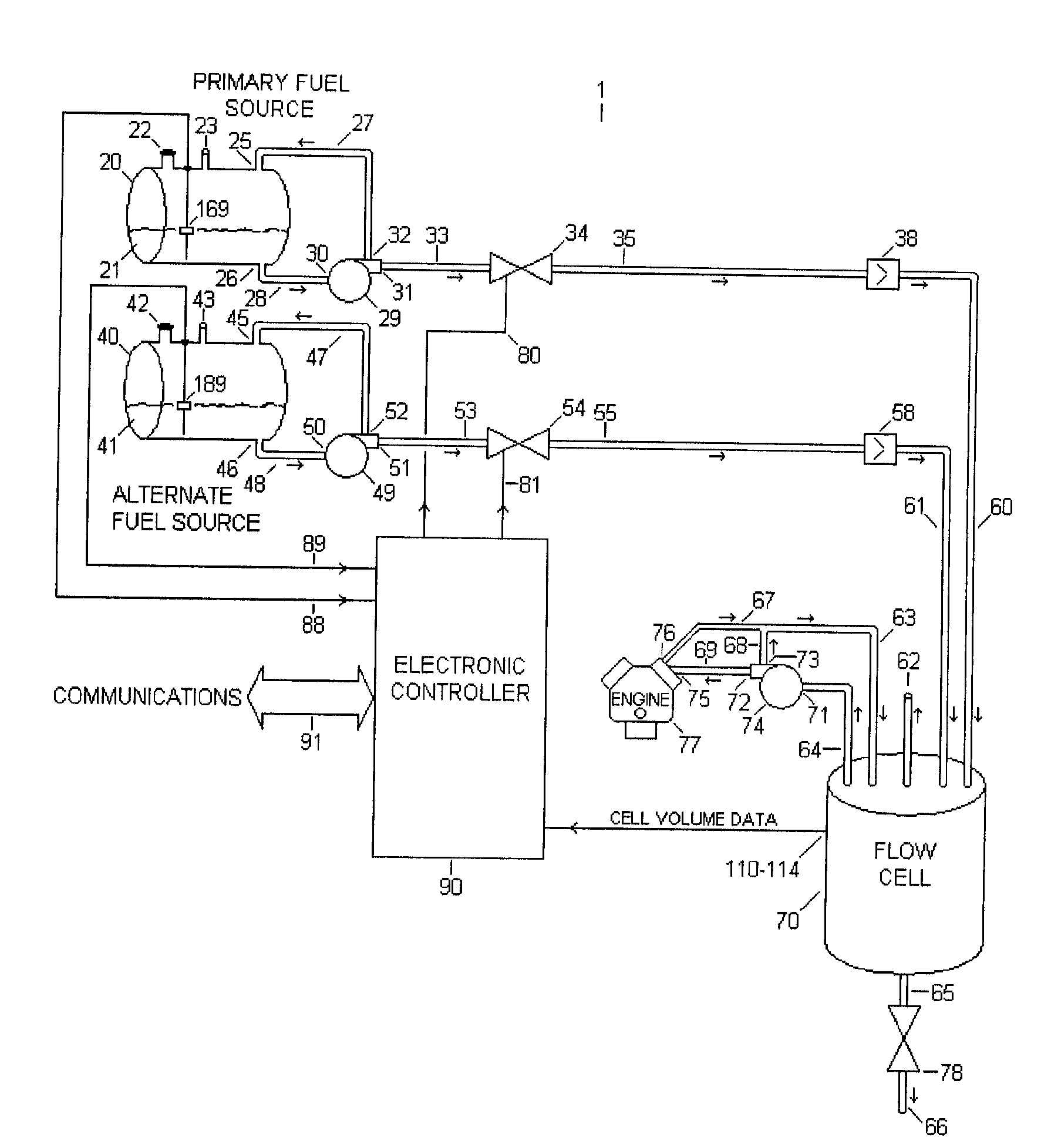

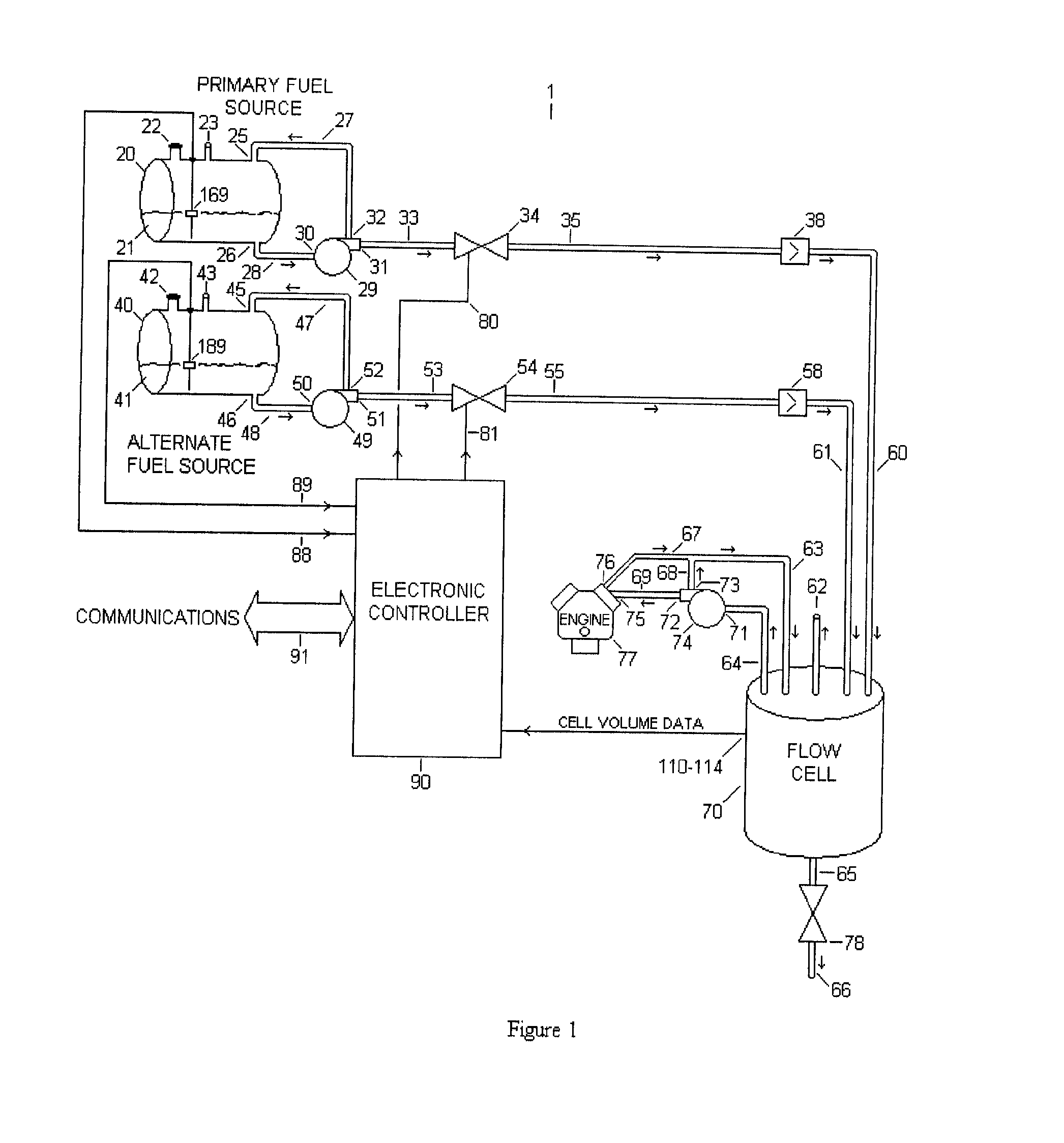

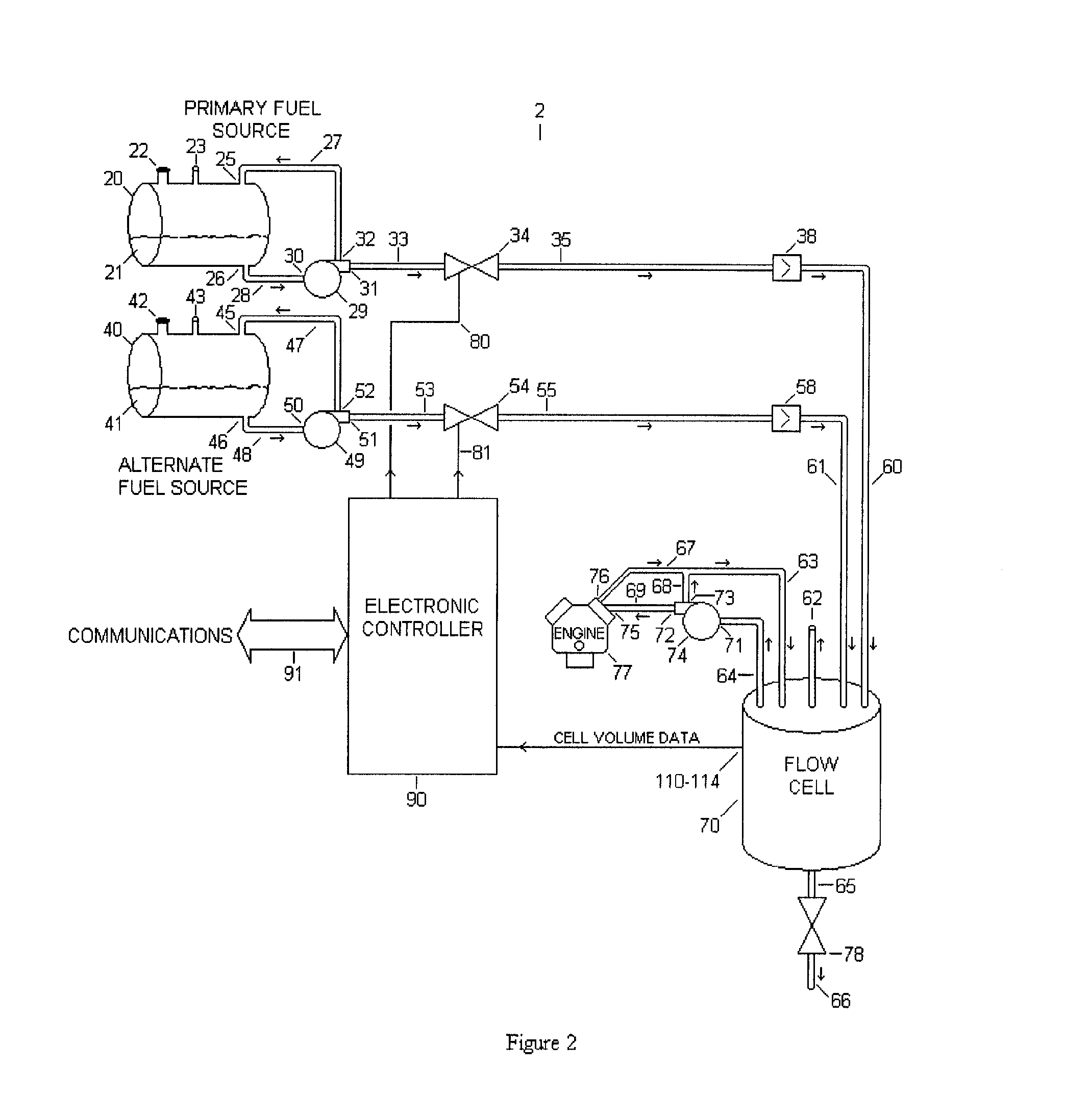

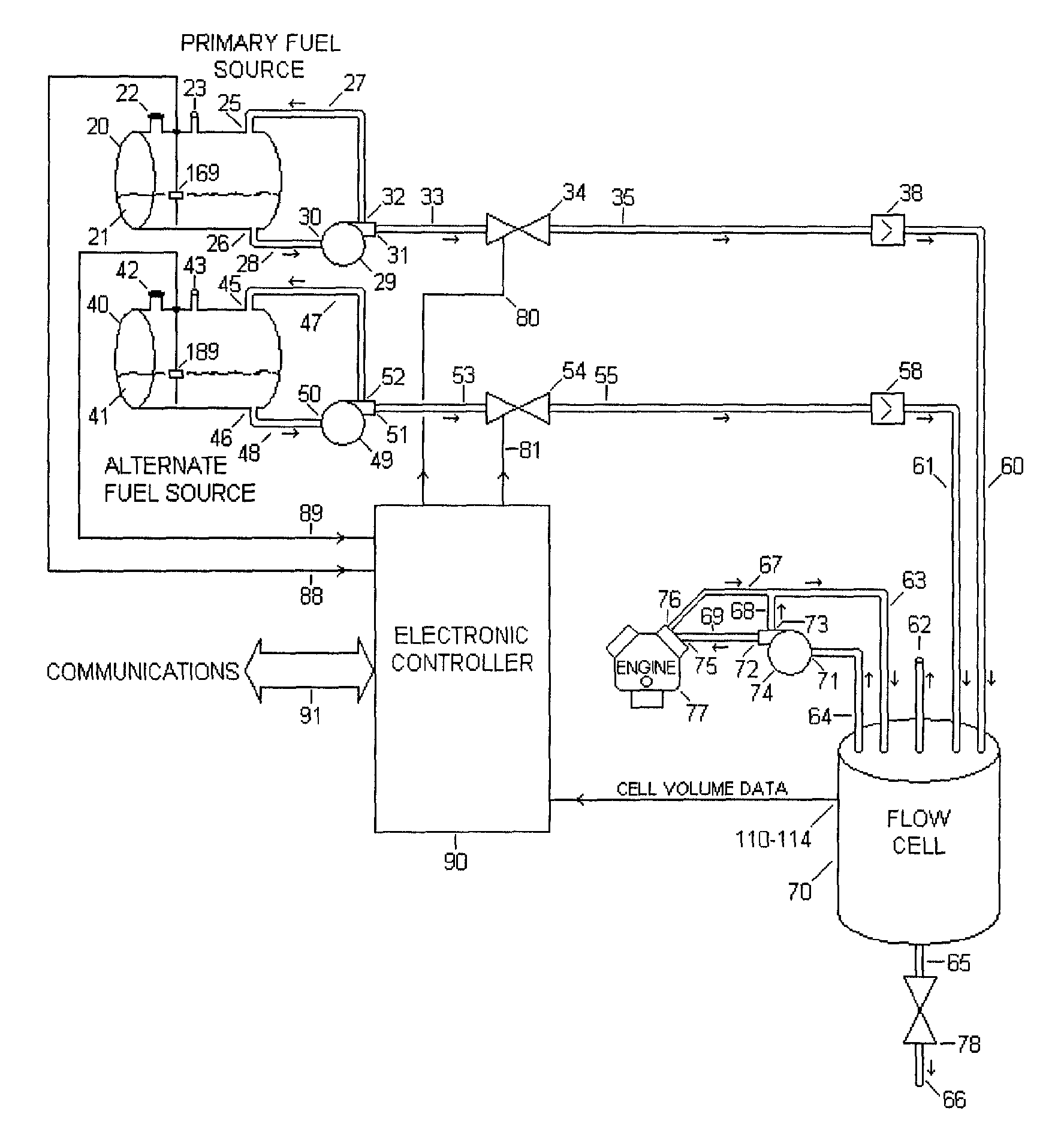

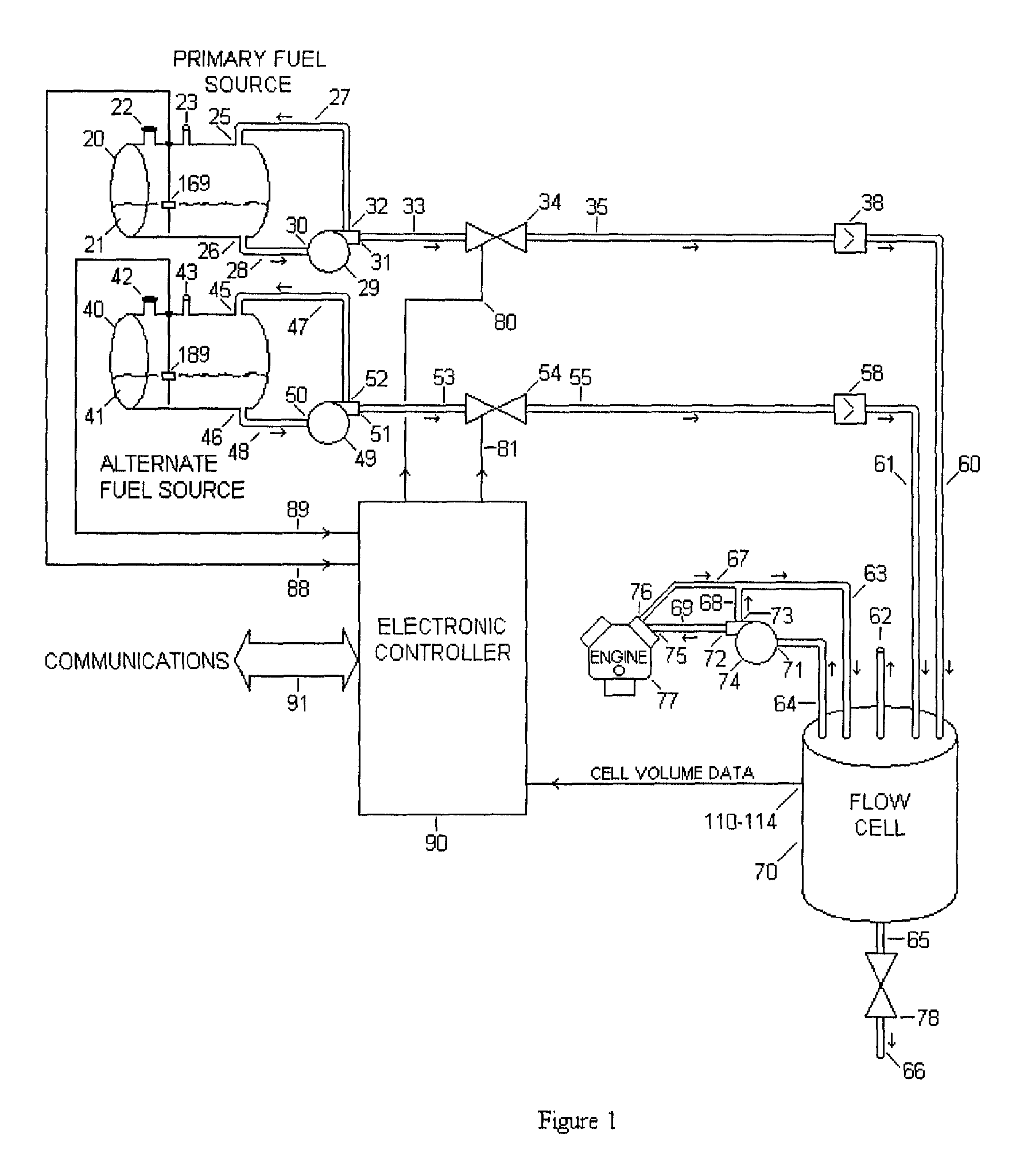

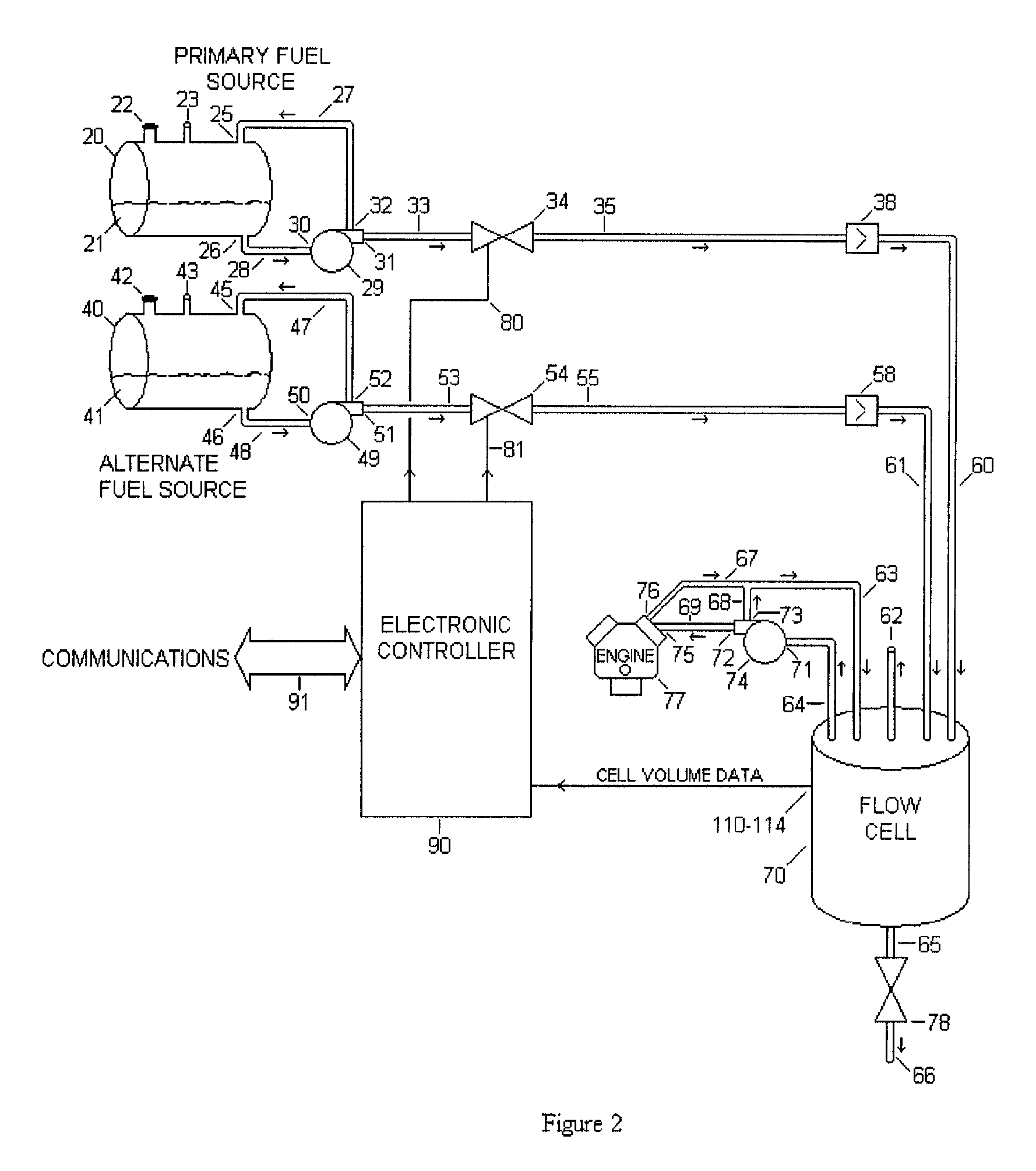

Alternate fuel blending system and associated method

ActiveUS20080262701A1Discounts/incentivesInternal combustion piston enginesAlternative fuelsControl system

A fuel control system for controlling the use of primary fuel and alternate fuel in an internal combustion engine without cross-contamination of fuel types. Cross-contamination of fuel types may eliminate the ability to receive certain benefits or financial incentives associated with use of alternate fuel, including but not limited to RINs, credits, and subsidies. In one embodiment, primary and / or alternate fuel are controllably delivered from sources to a flow cell. If blending is desired, both primary and alternate fuels are delivered to the flow cell. The engine is fed with the resulting primary fuel, alternate fuel, or blended mixture of fuel from the flow cell. The flow cell contains a bypass inlet port adapted to receive excess fuel not consumed by the engine in lieu of the excess fuel being returned to the primary and / or alternate fuel sources. In this manner, cross-contamination of the fuel sources can be avoided.

Owner:GILBARCO

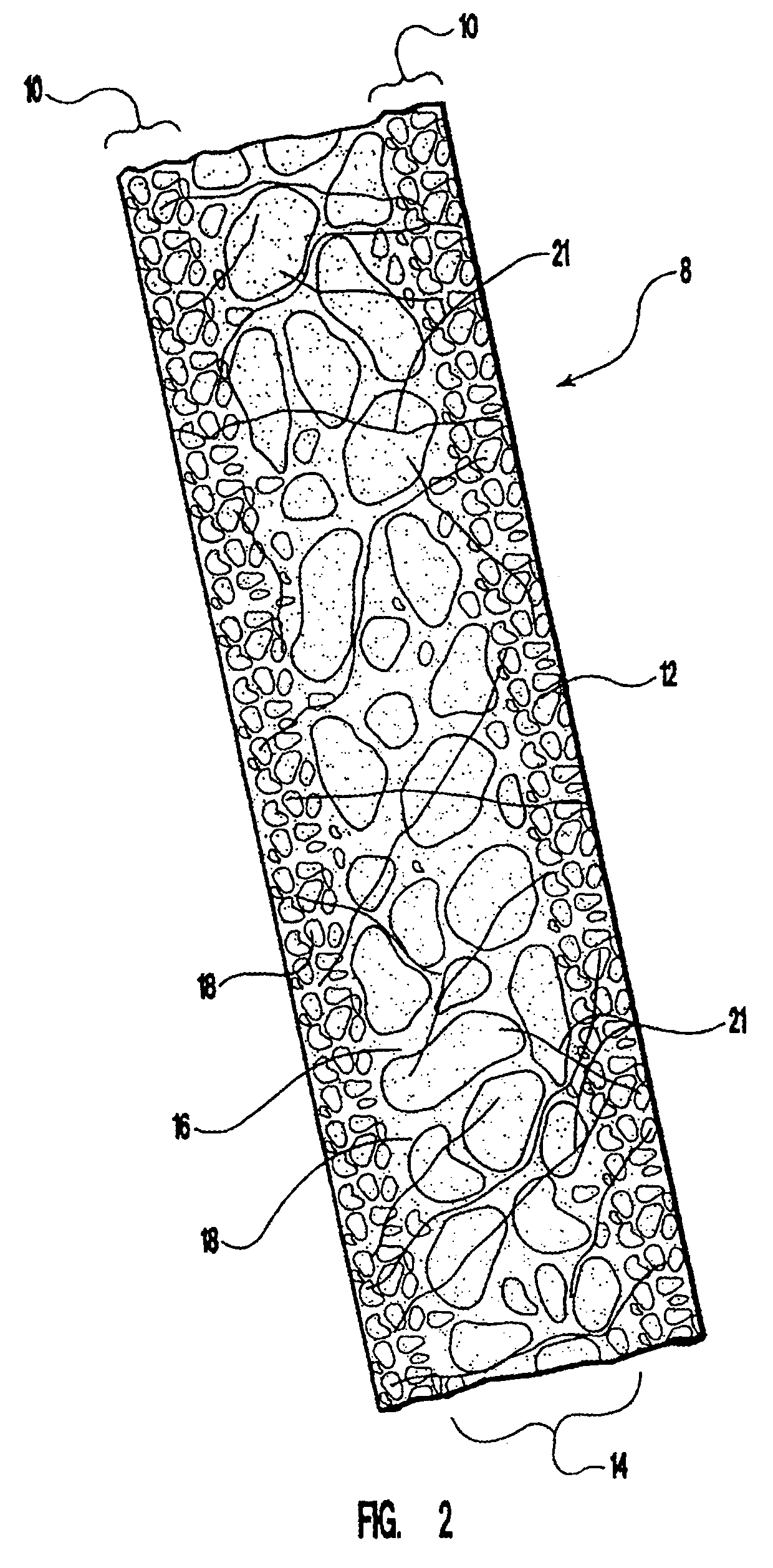

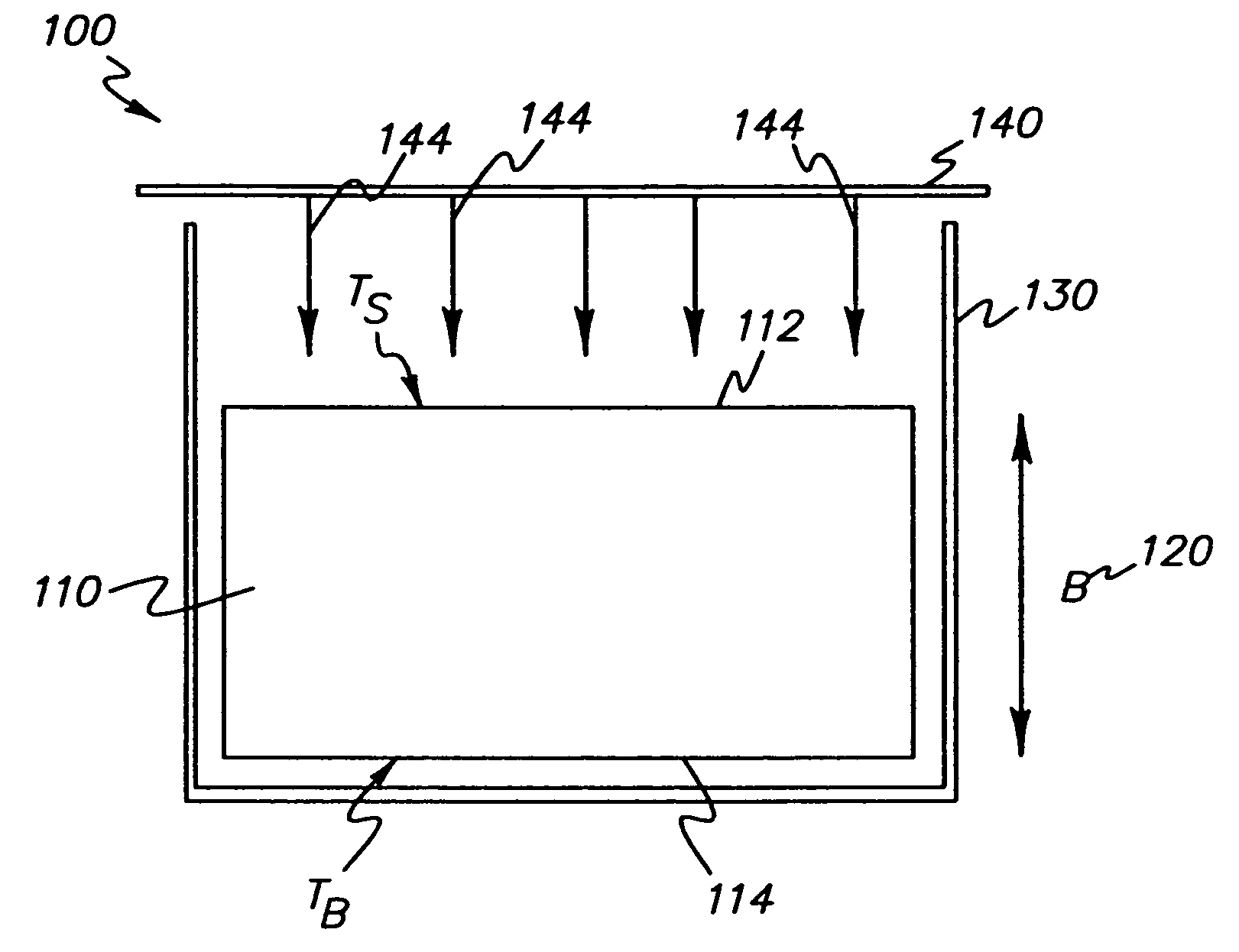

Compositions for manufacturing fiber-reinforced, starch-bound articles having a foamed cellular matrix

InactiveUSRE39339E1Avoid lack of toughnessHigh strengthClosure lidsSolid waste managementPolymer sciencePaperboard

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a fiber-reinforced, starch-bound cellular matrix. Suitable mixtures used to form the articles are prepared by first preparing a viscous preblended mixture comprising water, a gelatinized starch-based binder, and fibers having an average length greater than about 2 mm. The highly viscous preblended mixture effectively transfers the shearing forces of the mixer to the fibers. The final moldable mixture is then prepared by mixing into the preblended mixture the remaining starch-based binder, water, and other desired admixtures, e.g., mold-releasing agents, inorganic filler rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The moldable mixtures are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled foamed structural matrix. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic-based materials and have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

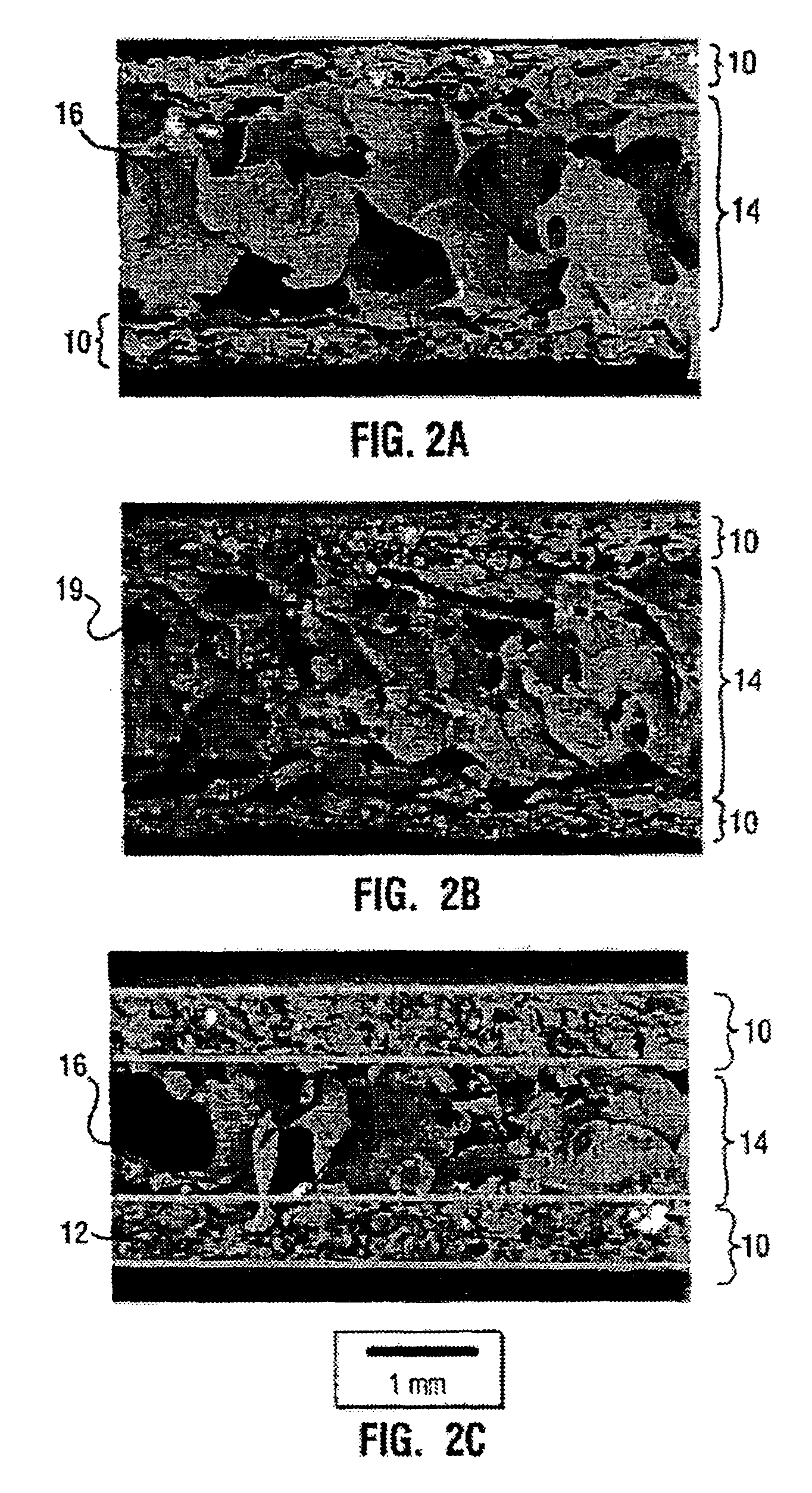

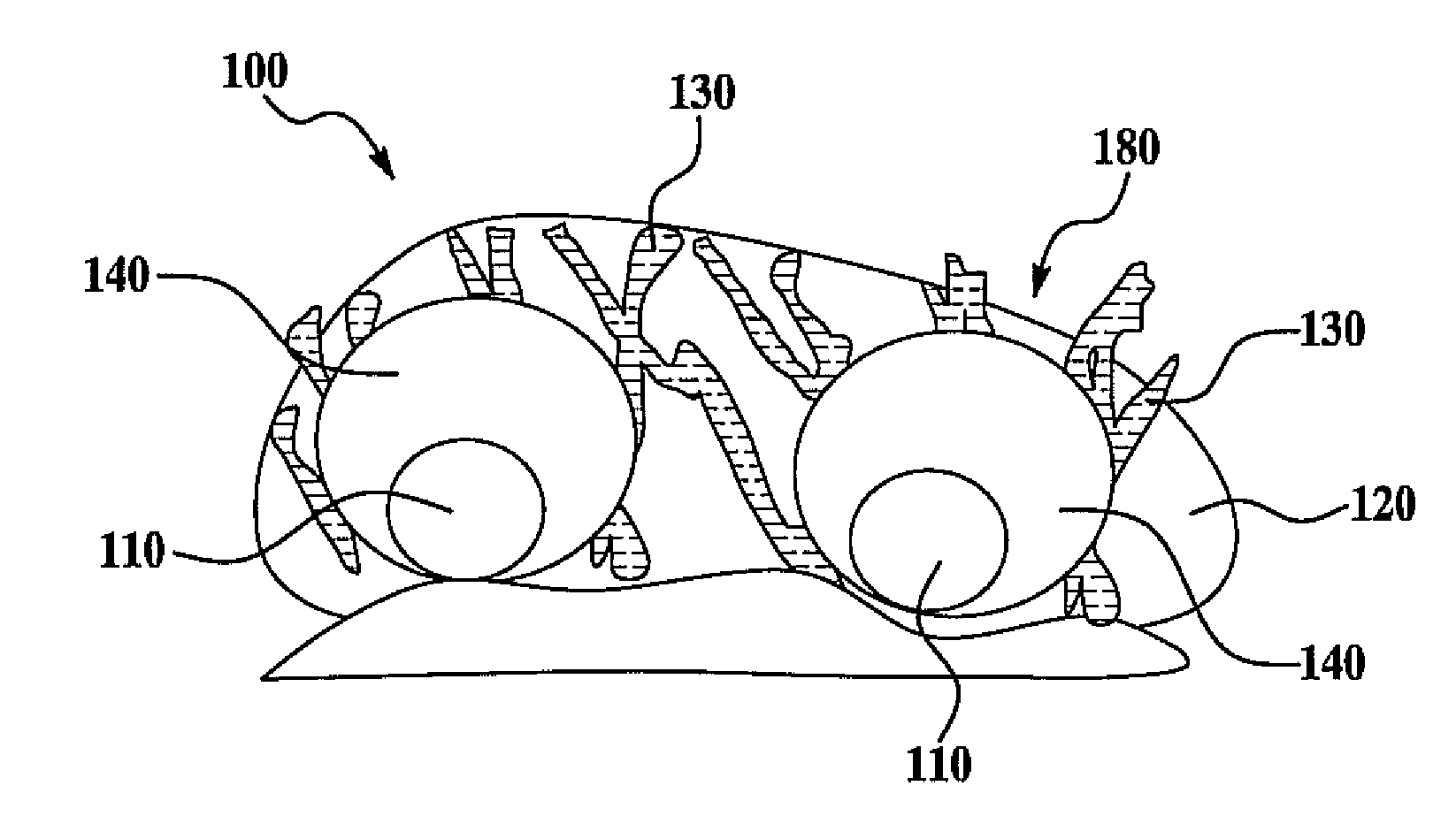

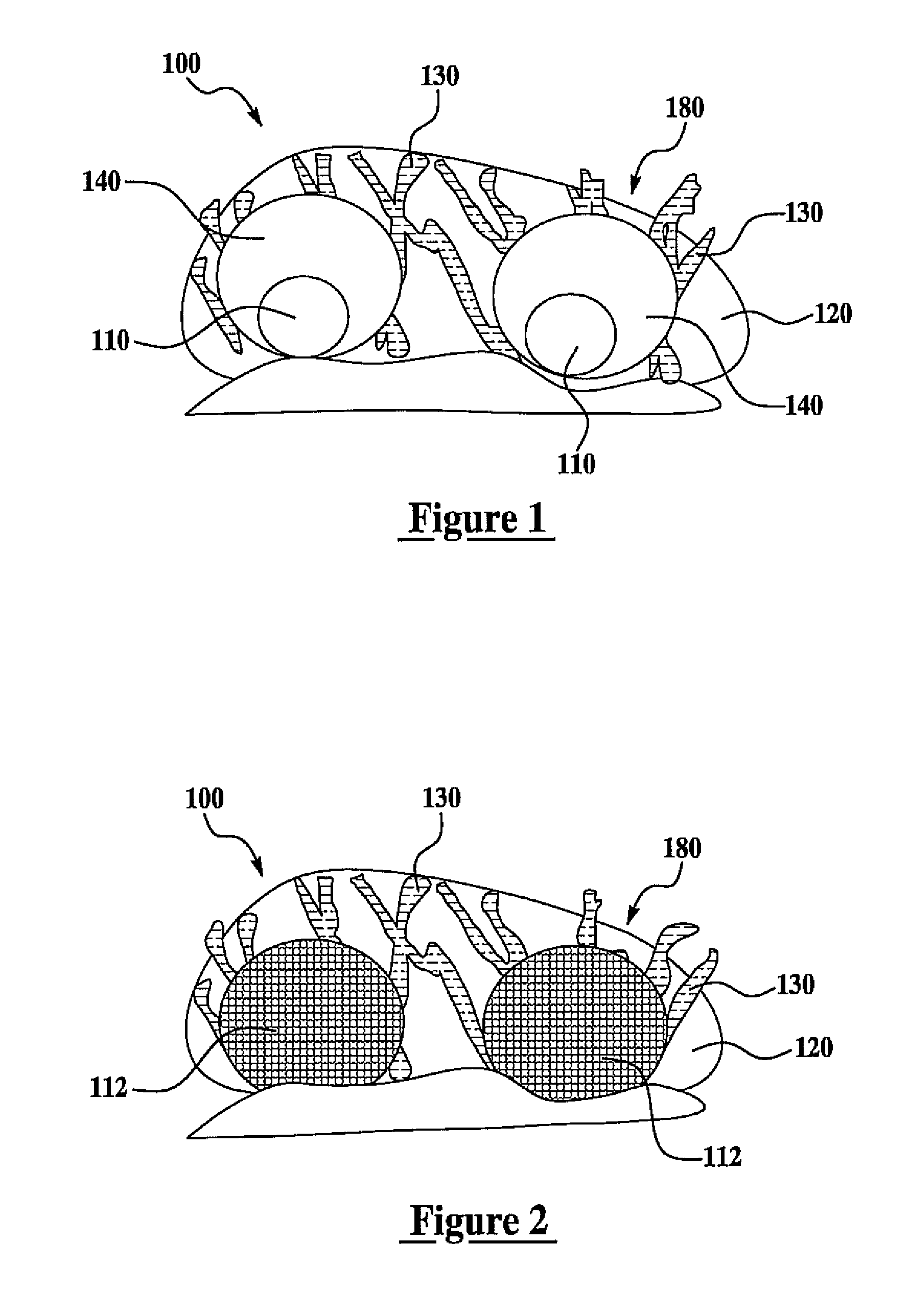

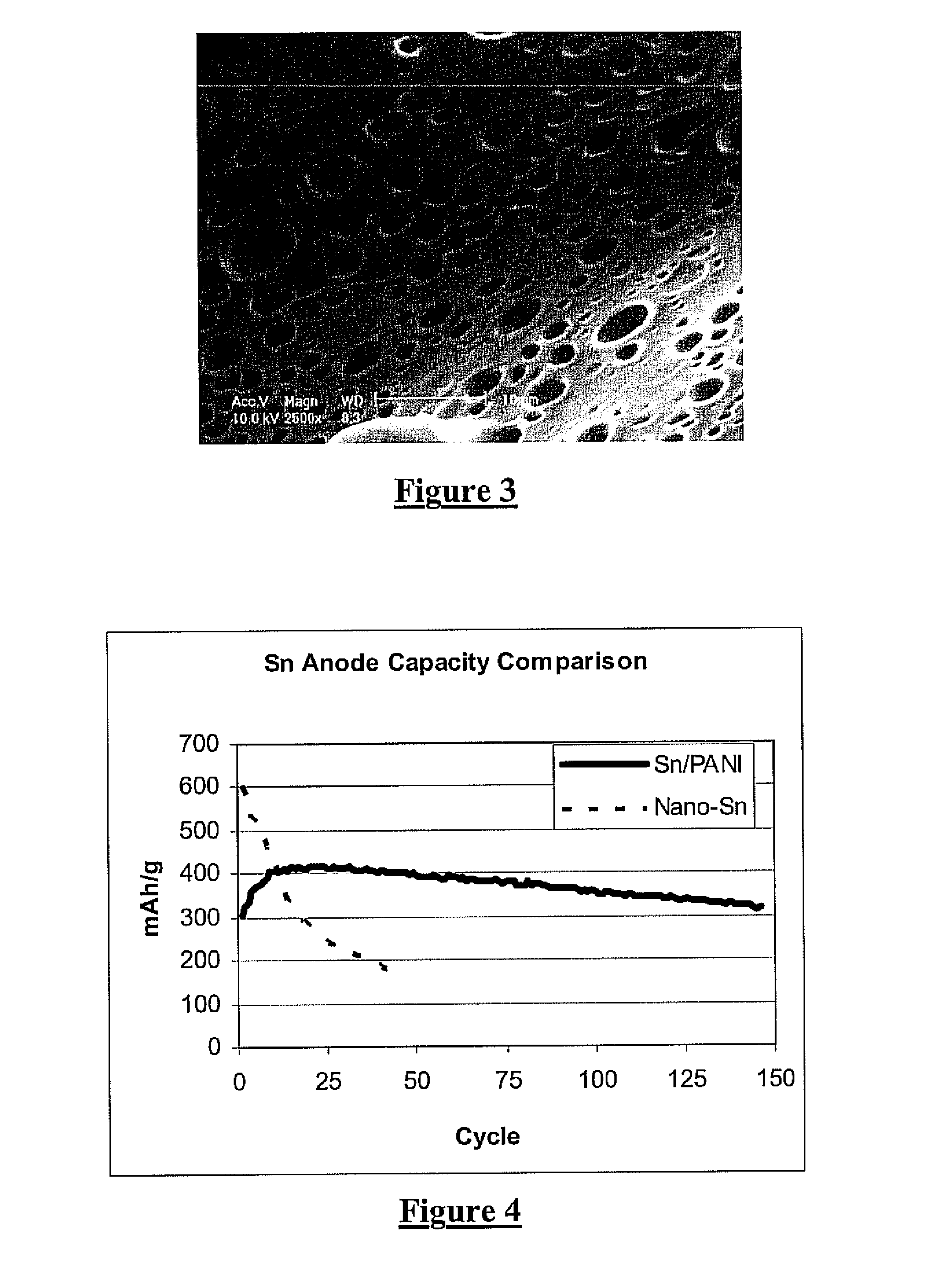

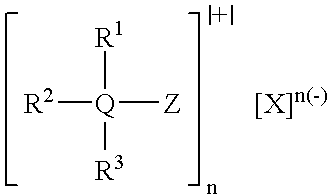

High performance anode material for lithium-ion battery

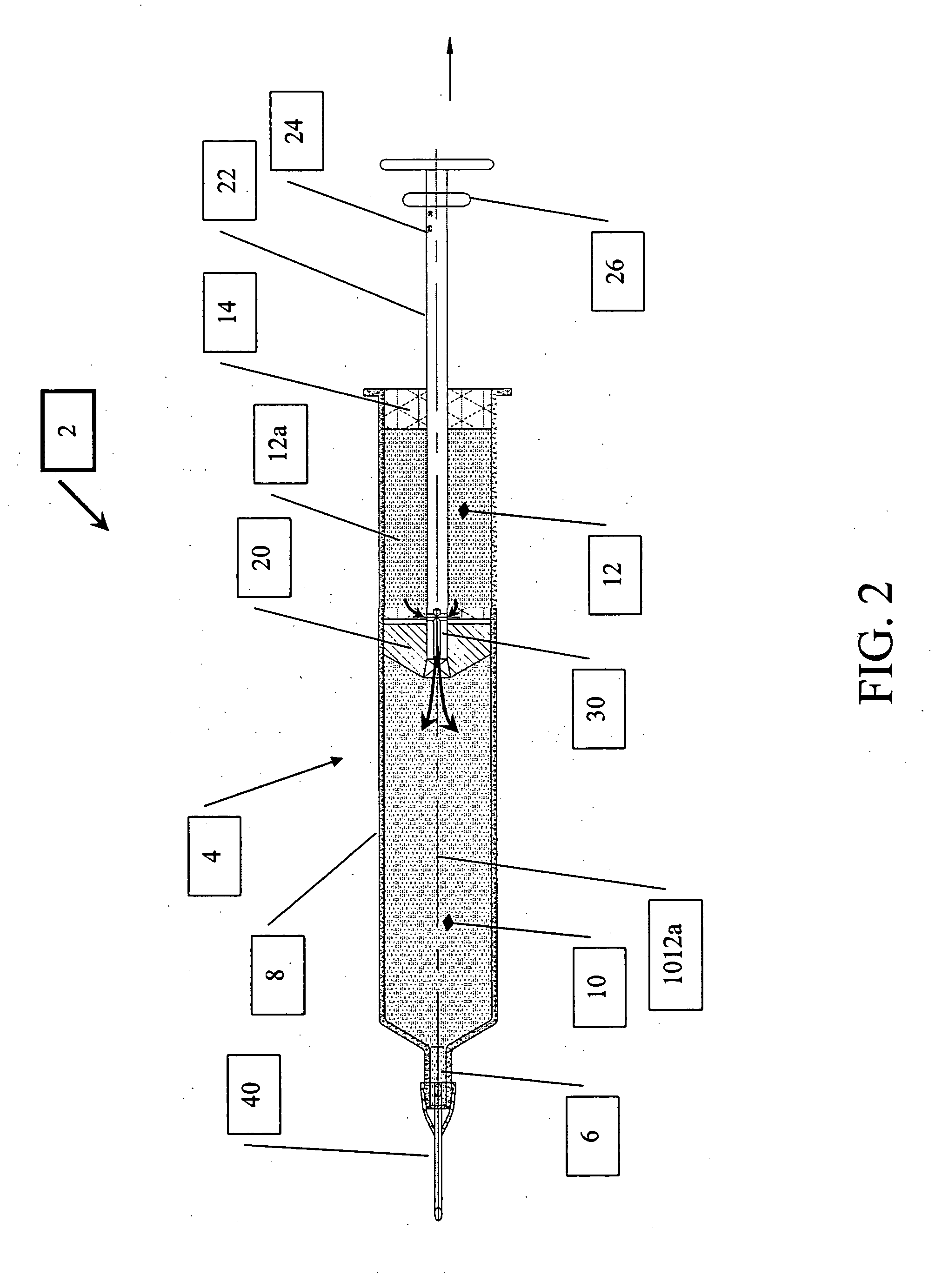

An anode material with lithium-alloying particles contained within a porous support matrix is provided. The porous support matrix preferably has a porosity of between 5 and 80% afforded by porosity channels and expansion accommodation pores, and is electrically conductive. More preferably the support matrix has a porosity of between 10 and 50%. The support matrix is made from an organic polymer, an inorganic ceramic or a hybrid mixture of organic polymer and inorganic ceramic. The organic polymer support matrix and can be made from a rod-coil polymer, a hyperbranched polymer, UV cross-linked polymer, heat cross-linked polymer or combination thereof. An inorganic ceramic support matrix can be made from at least one group IV-VI transition metal compound, with the compound being a nitride, carbide, oxide or combination thereof. The lithium-alloying particles are preferably nanoparticles with a mean linear dimension of between 5 and 500 nanometers, and more preferably have a mean linear dimension of between 5 and 50 nanometers.

Owner:TOYOTA MOTOR CO LTD +1

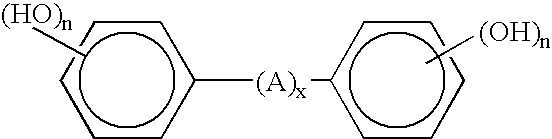

Composition and Process for Increasing the Dry Strength of a Paper Product

A dry strength additive composition generally includes an anionic and / or amphoteric polyacrylamide having a molecular weight of less than 1,000,000 Daltons, wherein the amphoteric polyacrylamide has a net negative charge; a cationic and / or amphoteric starch; and a cationic non-starch polymer having a charge density greater than 1 milliequivalent per gram (meq / g) at a pH of 3. The components defining the composition can be added to a pulp suspension sequentially or as a pre-blended mixture.

Owner:KEMIRA OY

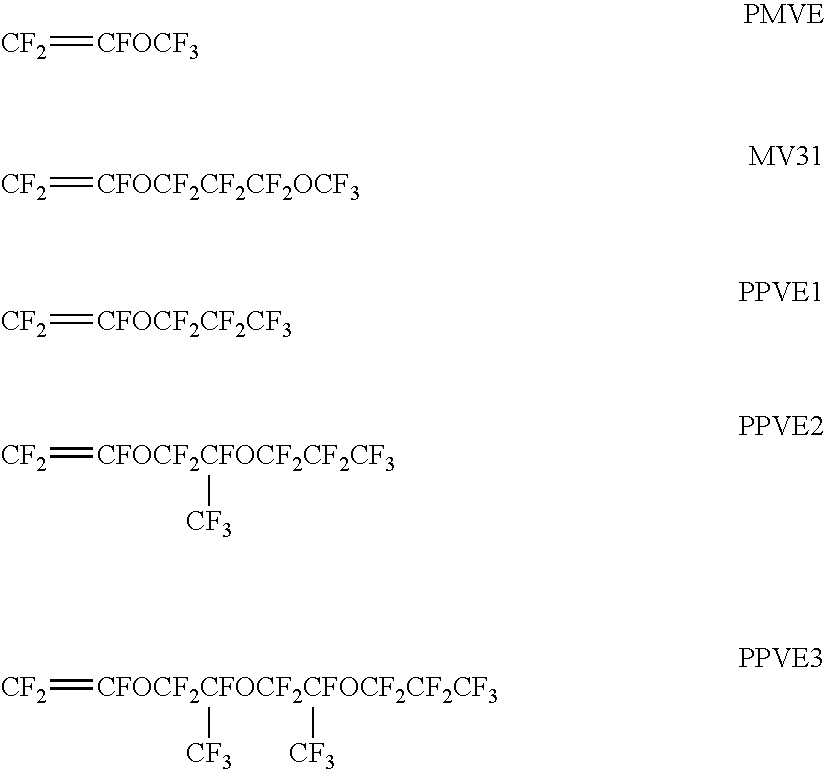

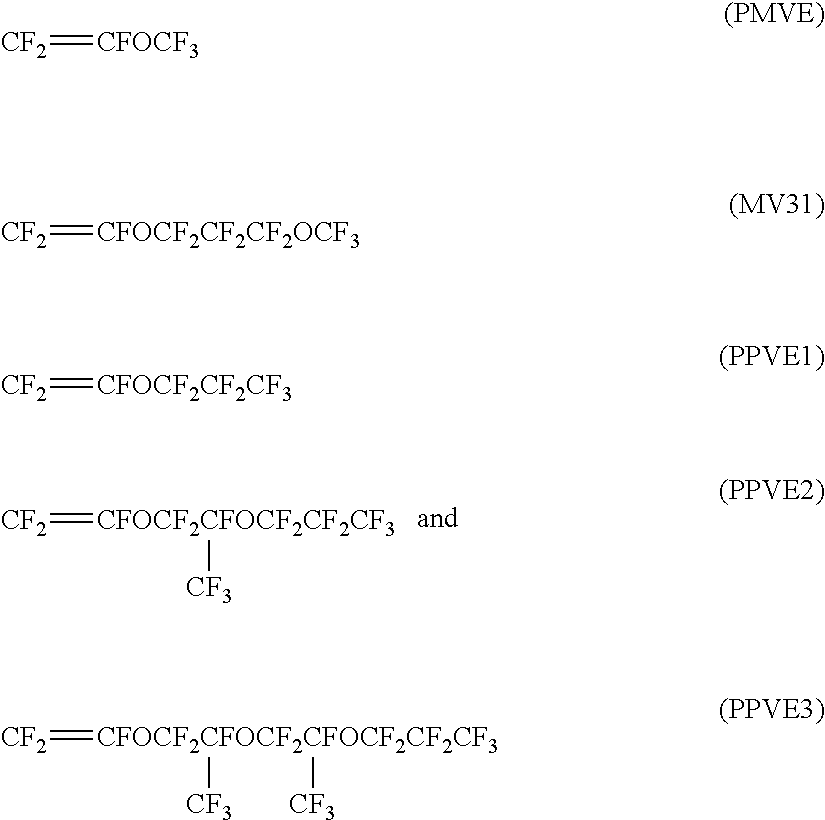

Elastomeric compositions containing fluoropolymer blends

Processable rubber compositions contain a vulcanized fluorocarbon elastomer dispersed in a thermoplastic matrix comprising a fully fluorinated polymer and a partially fluorinated polymer. The processing temperature is below the melting point of the fully fluorinated polymer. The compositions are made by combining a curative, uncured fluorocarbon elastomer, a fully fluorinated thermoplastic, and a partially fluorinated thermoplastic material, and heating the mixture at a temperature and for a time sufficient to effect vulcanization of the elastomeric material, while mechanical energy is applied to mix the mixture during the heating step. Shaped articles such as seals, gaskets, O-rings, and hoses may be readily formed from the rubber compositions according to conventional thermoplastic processes such as blow molding, injection molding, and extrusion.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

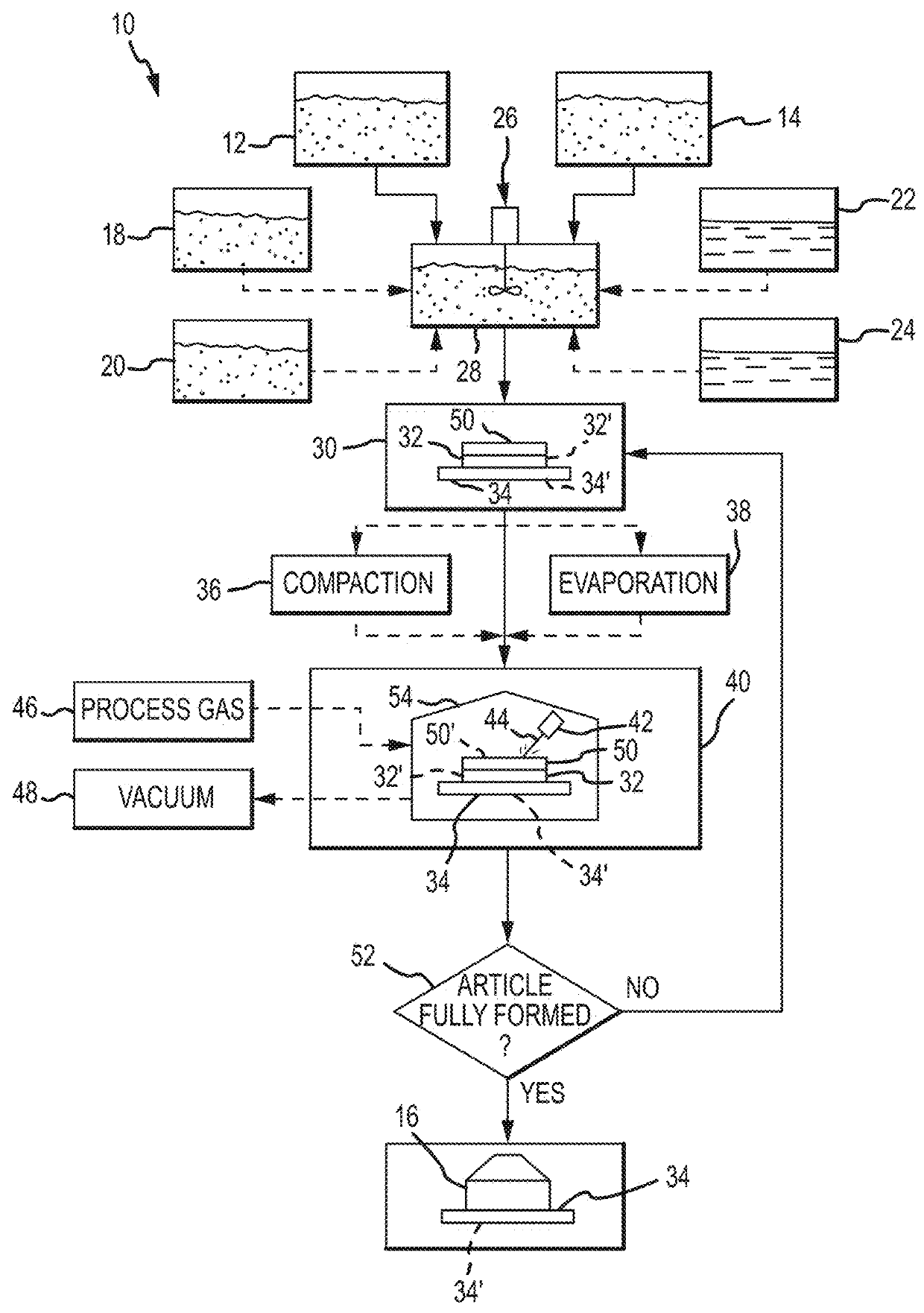

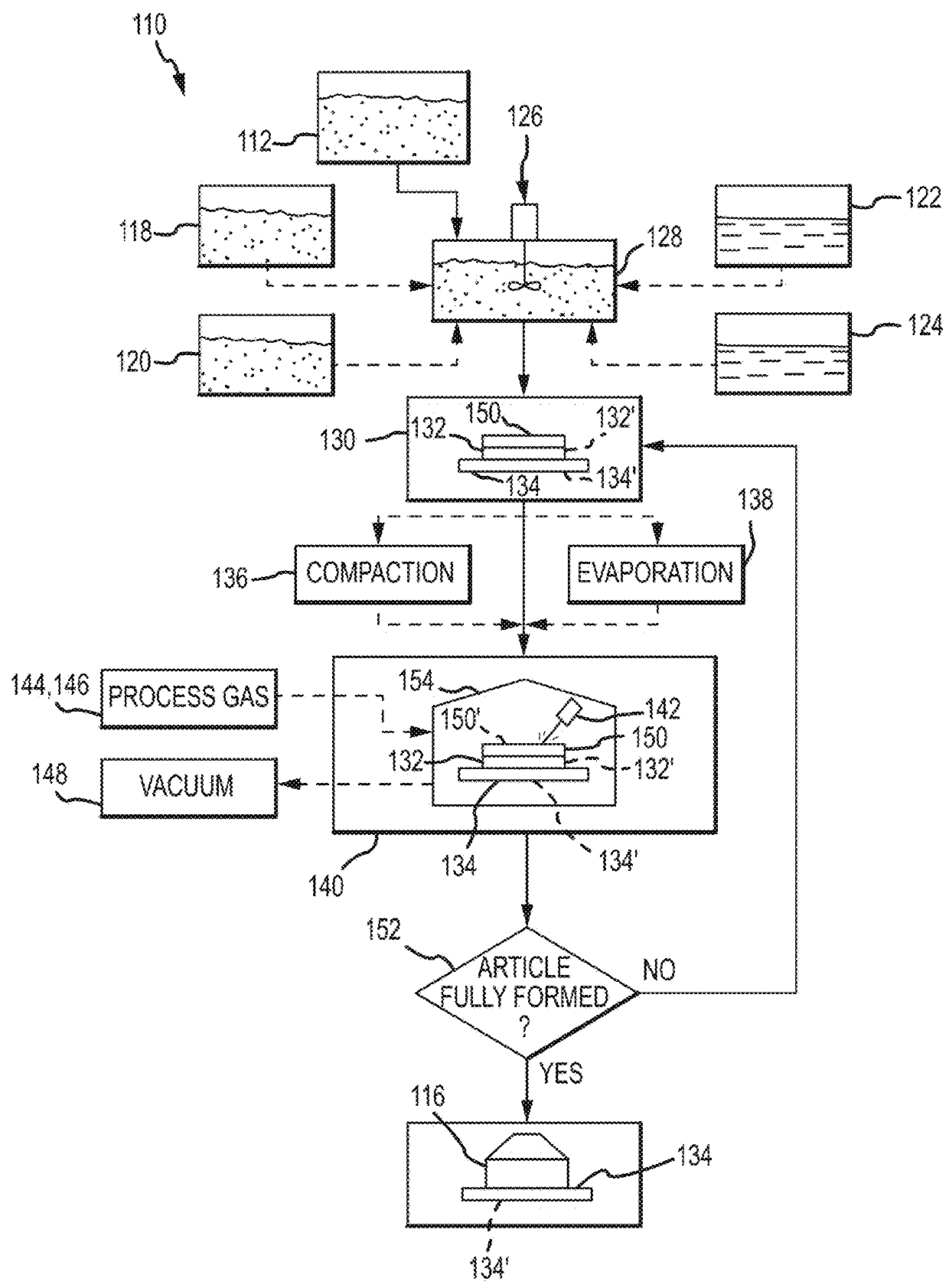

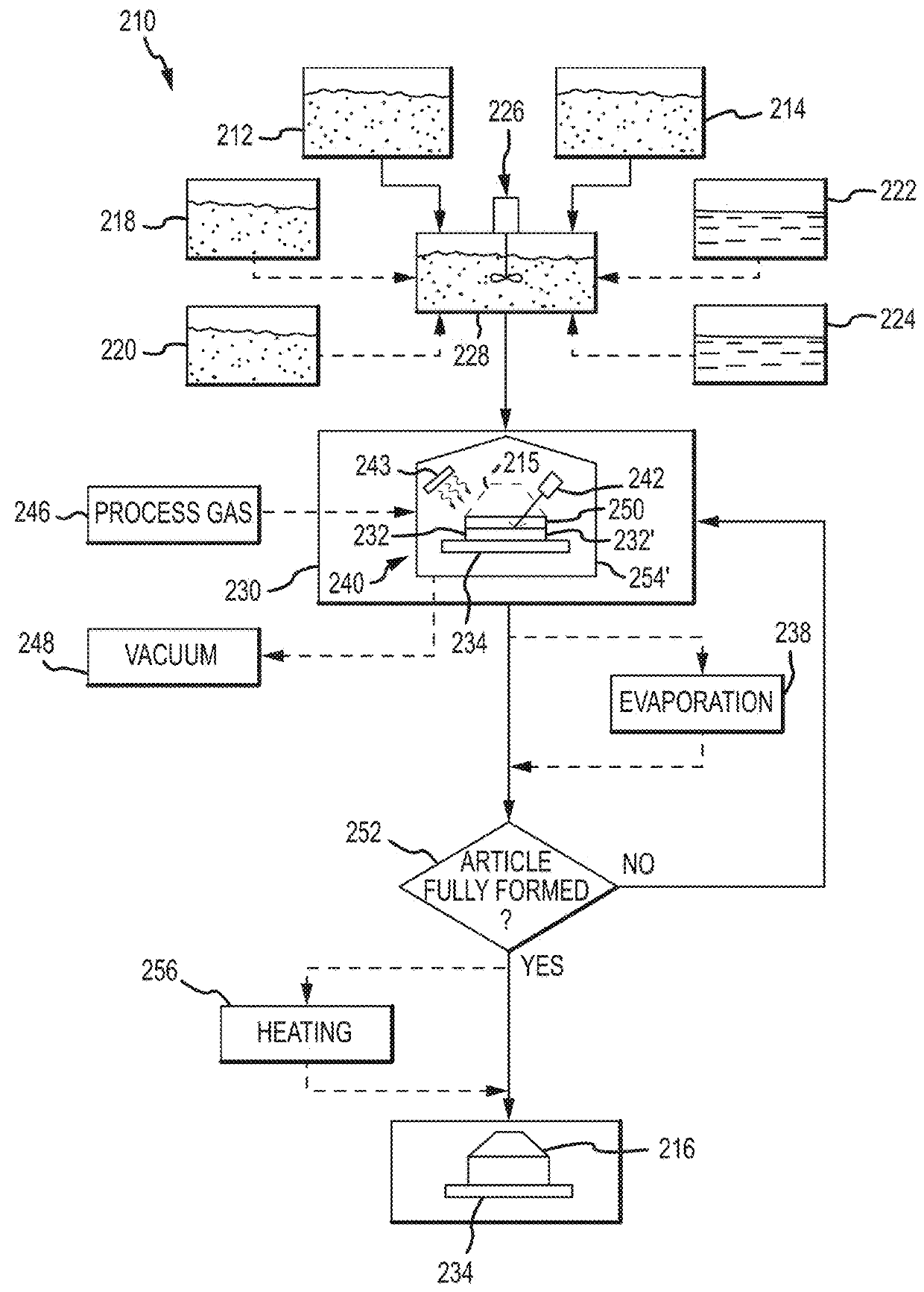

Additive manufacturing of metal alloys and metal alloy matrix composites

ActiveUS20180161874A1High strengthPrevent partial lowAdditive manufacturing apparatusTitanium carbideMetal alloyNucleation

An additive manufacturing method of producing a metal alloy article may involve: Providing a supply of a metal alloy in powder form; providing a supply of a nucleant material, the nucleant material lowering the nucleation energy required to crystallize the metal alloy; blending the supply of metal alloy powder and nucleant material to form a blended mixture; forming the blended mixture into a first layer; subjecting at least a portion of the first layer to energy sufficient to raise the temperature of the first layer to at least the liquidus temperature of the metal alloy; allowing at least a portion of the first layer to cool to a temperature sufficient to allow the metal alloy to recrystallize; forming a second layer of the blended mixture on the first layer; and repeating the subjecting and allowing steps on the second layer to form an additional portion of the metal alloy article.

Owner:ELEMENTUM 3D INC

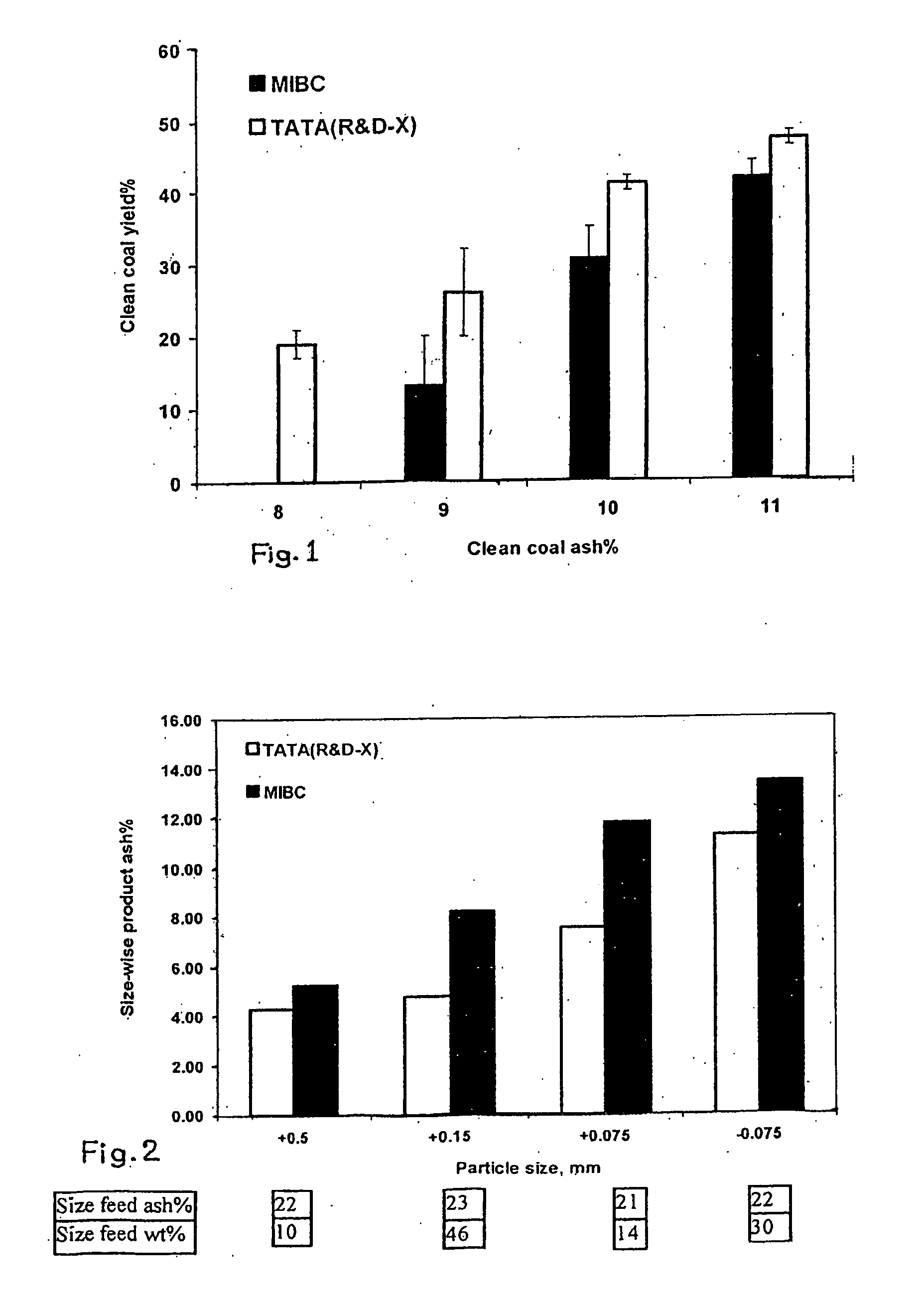

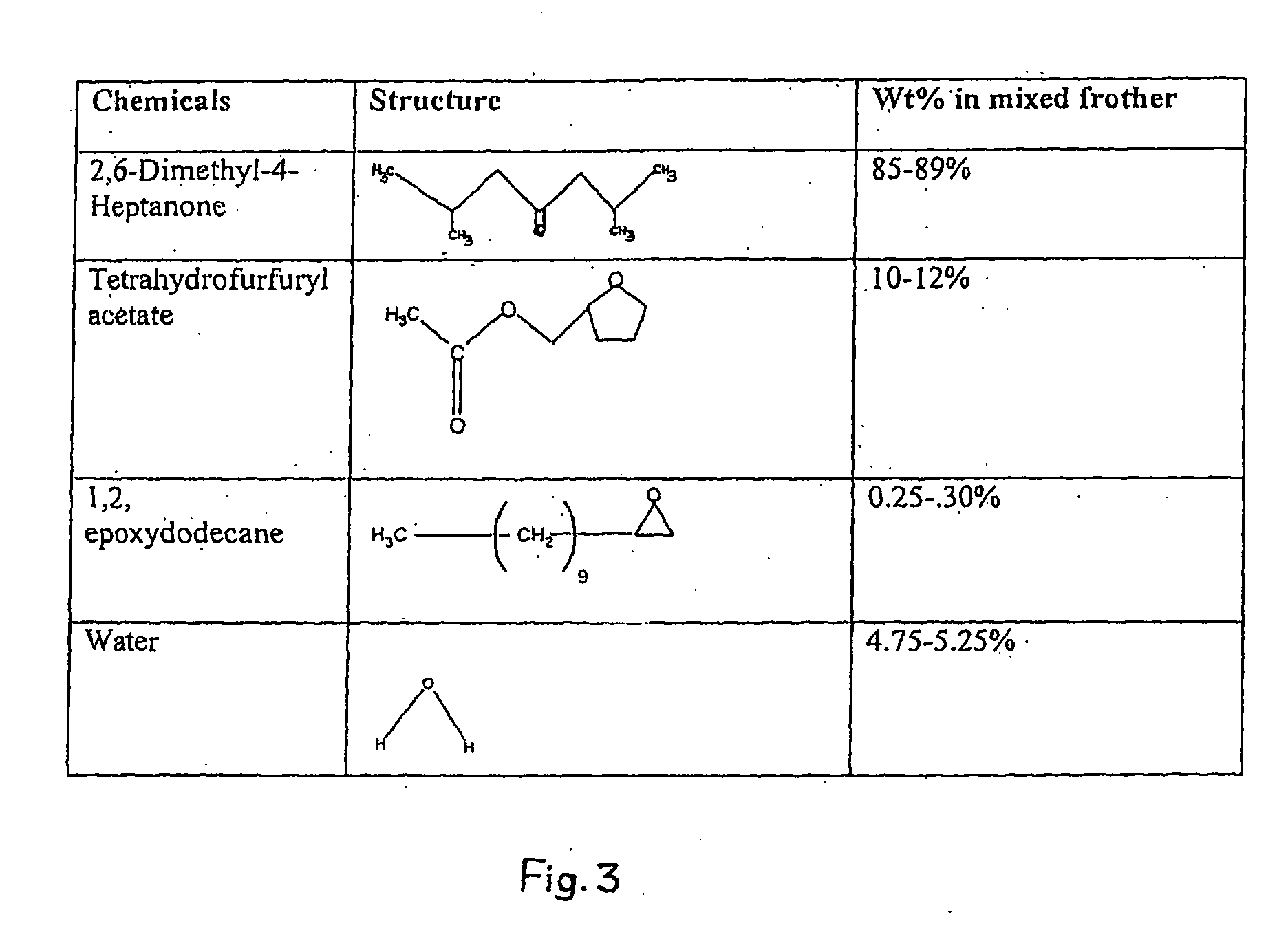

Blended frother for producing low ash content clean coal through flotation

An improved frothing agent adaptable to froth flotation process to enhance coal selectivity for separation and efficiency of the forth flotation process comprises:-A blended mixture ofKetone (2,6 Dimethl-4-Heptanone)85-89%(Wr %)Ester molecule(Tetrahydrofurfuryl acetate)10-12%(Wt %)Epoxide conditioner (1,2-Epoxydodecane)0.25-0.30%(Wt %)Water4.75-5.25%(Wt %)

Owner:TATA STEEL

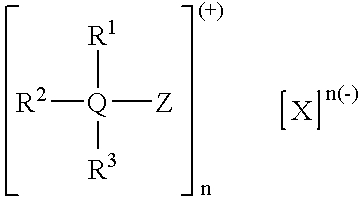

Process for producing an emulsion

InactiveUS7495031B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsInorganic saltsEmulsion

A process for producing an emulsion, including adding a mixture (1) comprising a water-soluble inorganic salt (a) and / or an aqueous solution containing (a) to a mixture (2) containing a surfactant (b), a surfactant-emulsifying agent (c) for emulsifying the surfactant (b), and a hydrophilic powder (d), and mixing mixtures (1) and (2) to emulsify the surfactant (b), wherein water-soluble inorganic salt (a) may be a carbonate, surfactant (b) may be an anionic surfactant and / or a nonionic surfactant, surfactant-emulsifying agent (c) may be a water-soluble polymer, and hydrophilic powder (d) may be an inorganic chelating agent.

Owner:KAO CORP

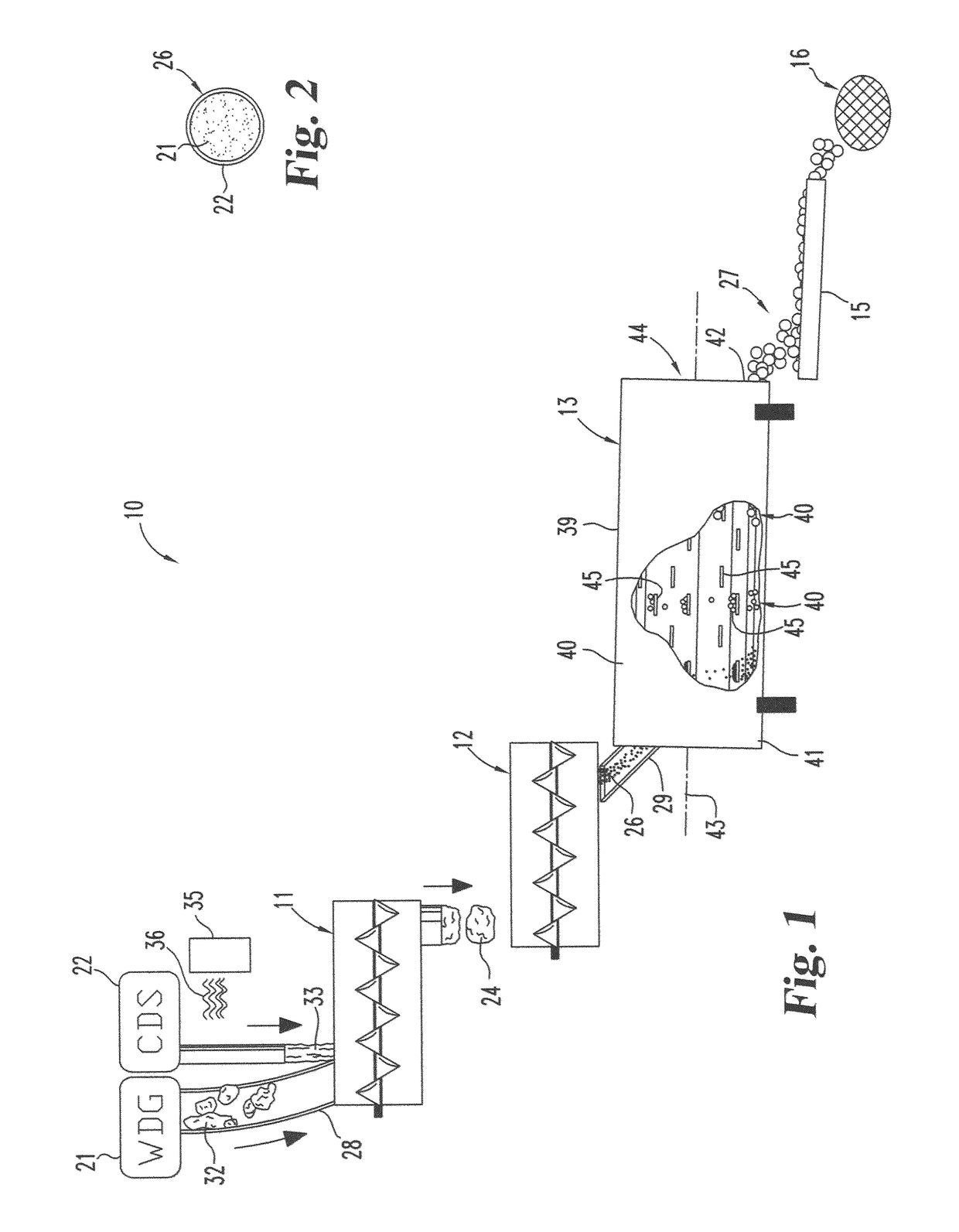

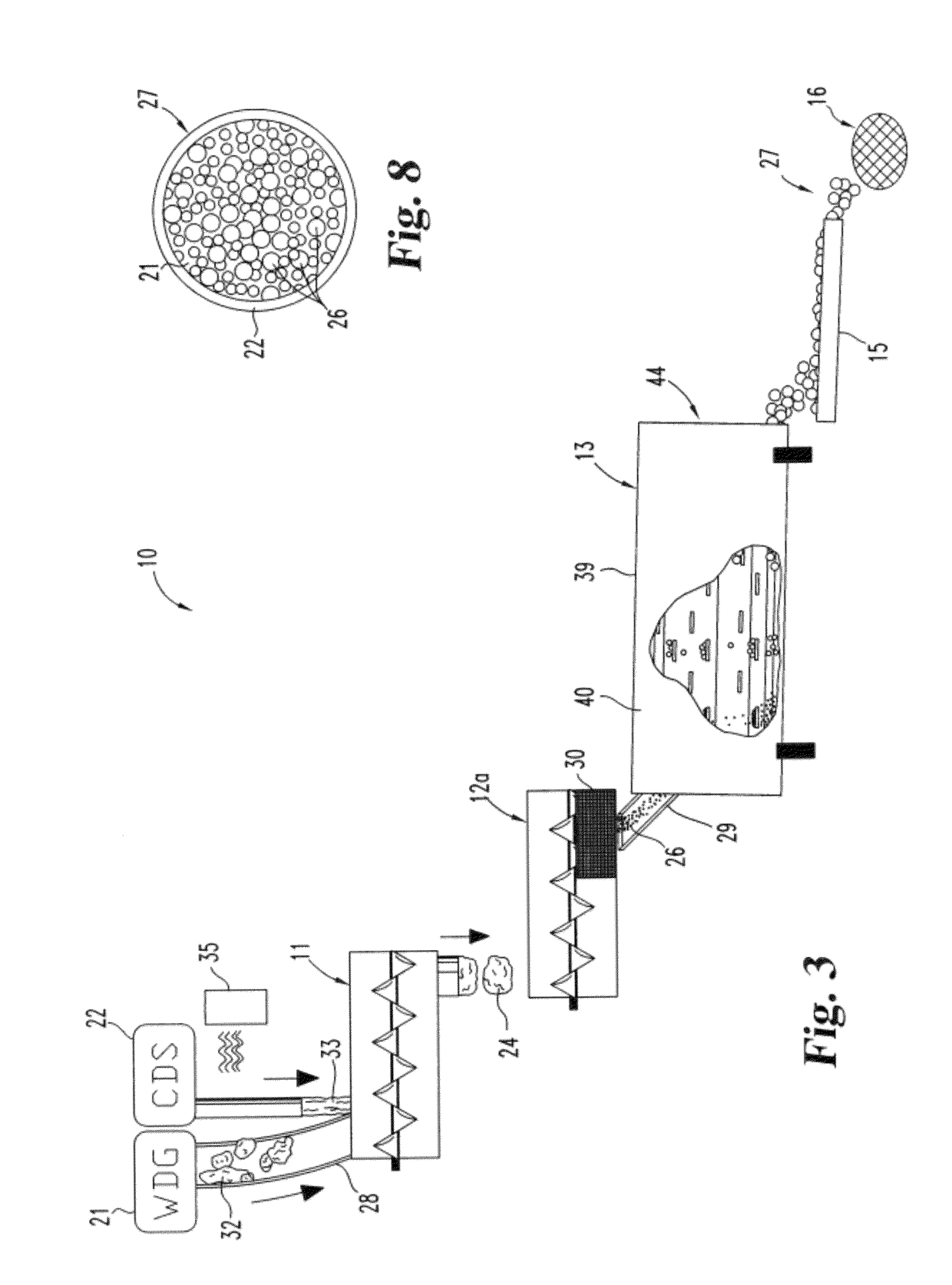

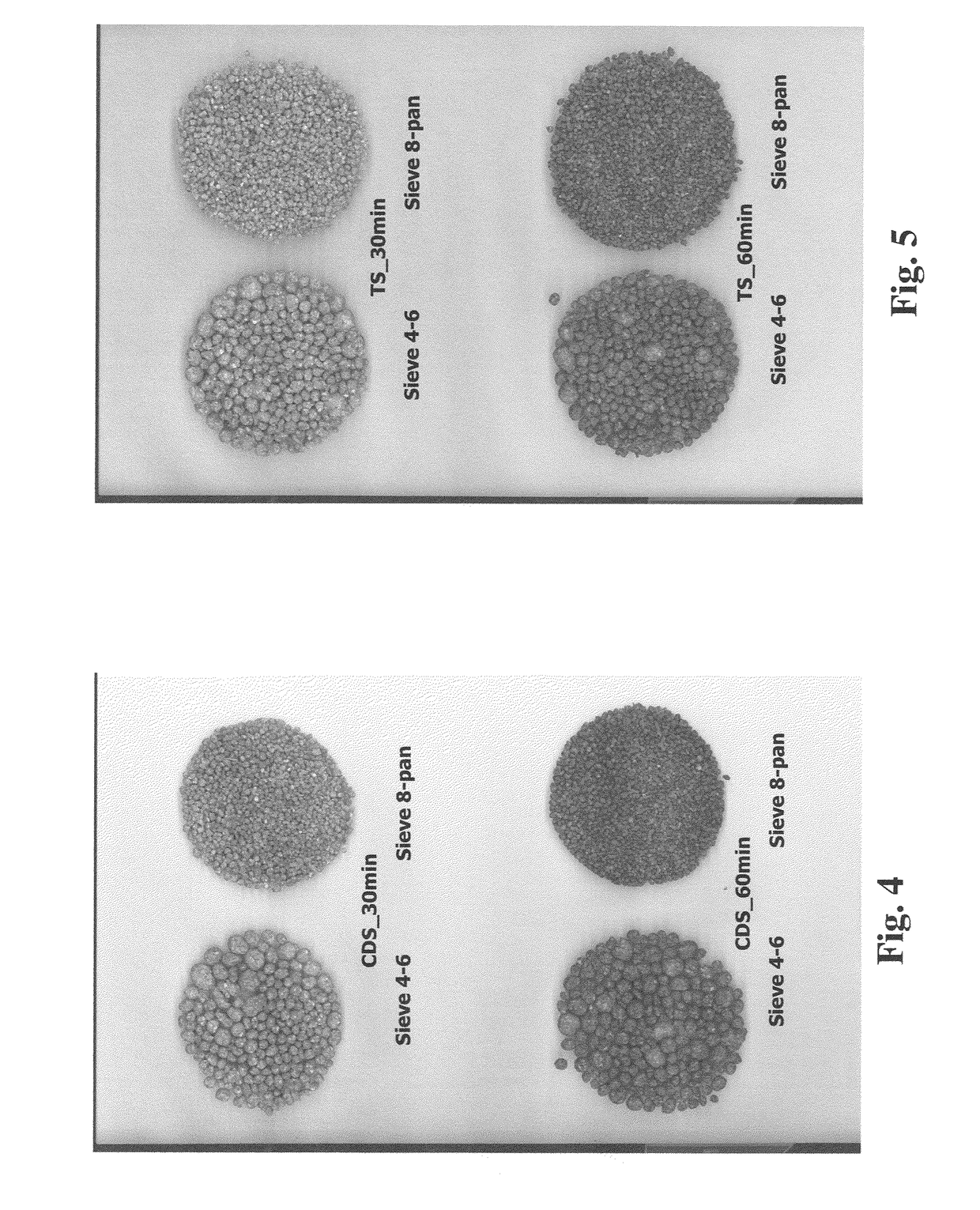

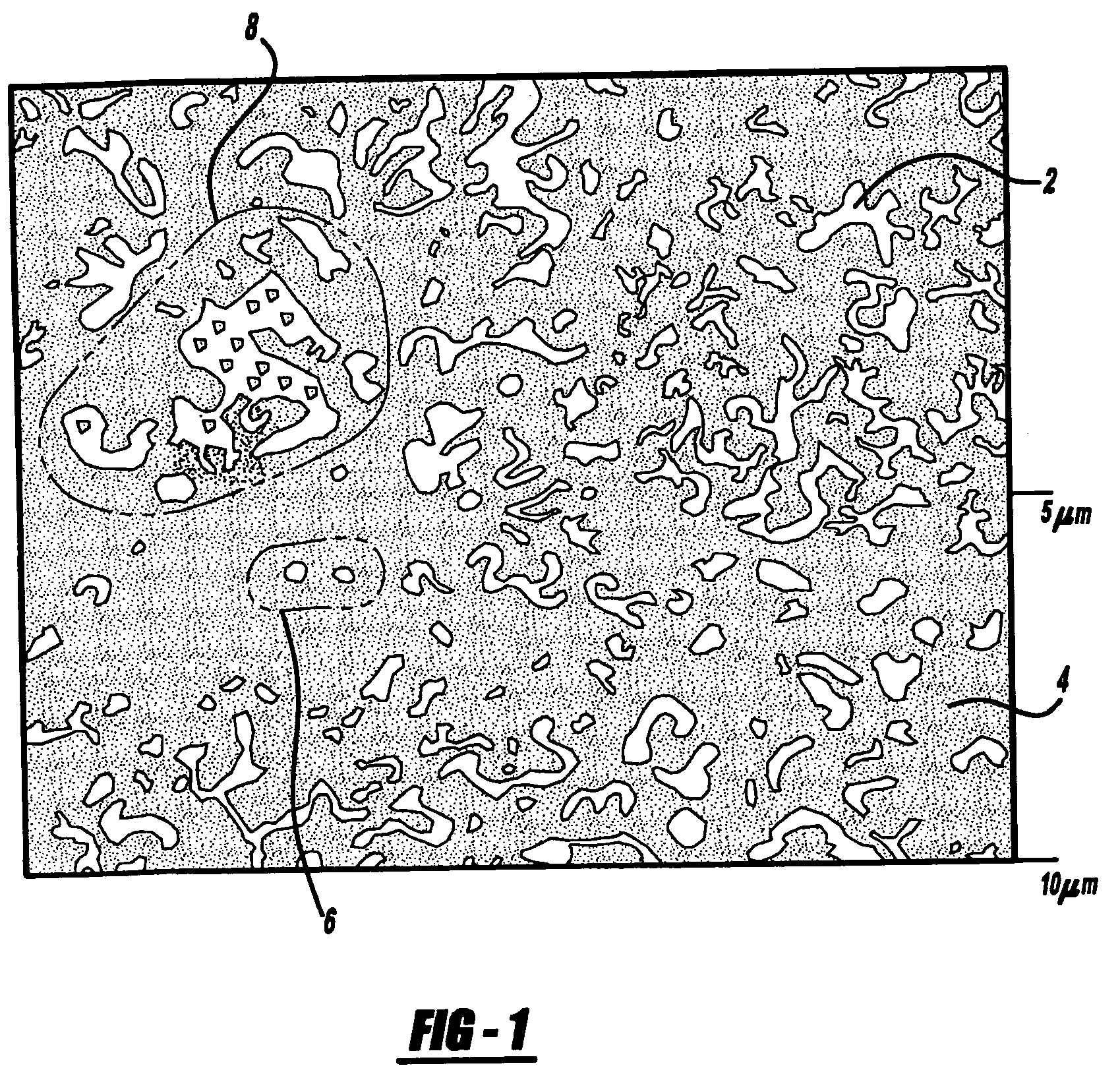

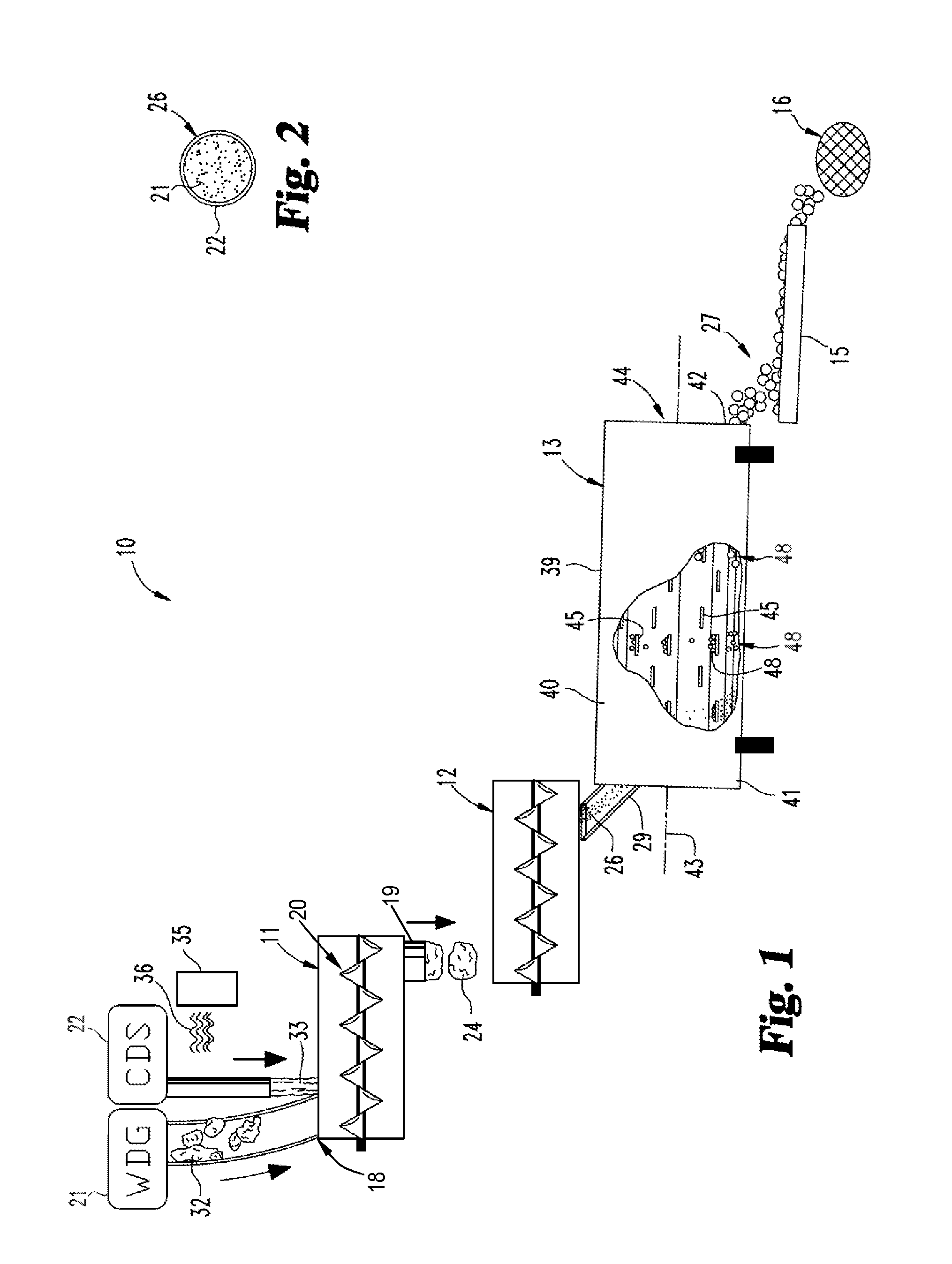

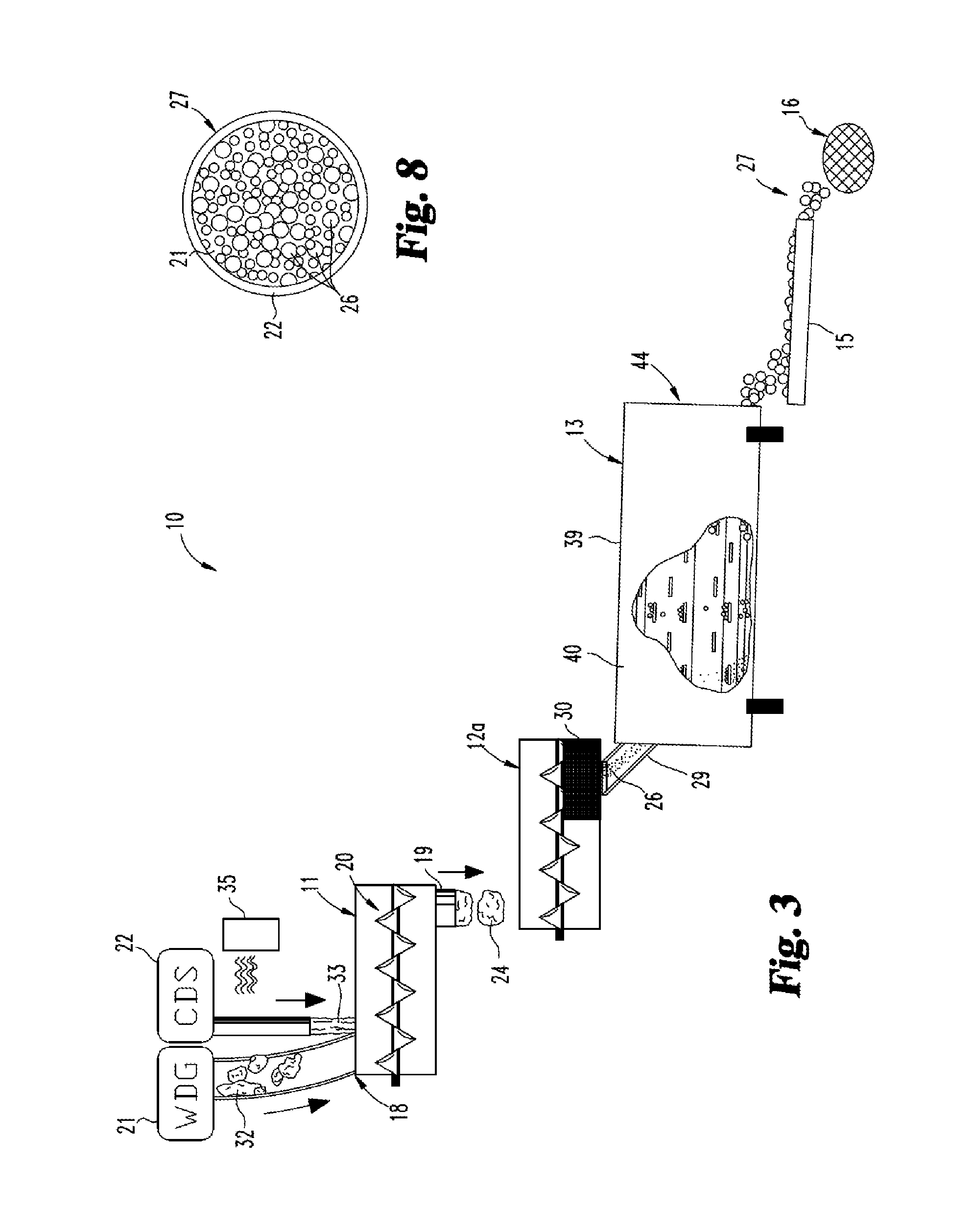

Method and apparatus for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a cavity for receiving a coproduct of a wet biomass process and a binder and being operable to premix the coproduct and binder to produce a substantially homogeneous DDGS mixture; a high shear mixer having a receptacle for receiving the DDGS mixture and being operable to shear mix the mixture and produce very small DDGS particles; and, an agglomerator having an interior chamber sized and configured to receive and transform the DDGS particles into substantially spherical DDGS pellets.

Owner:PURDUE RES FOUND INC

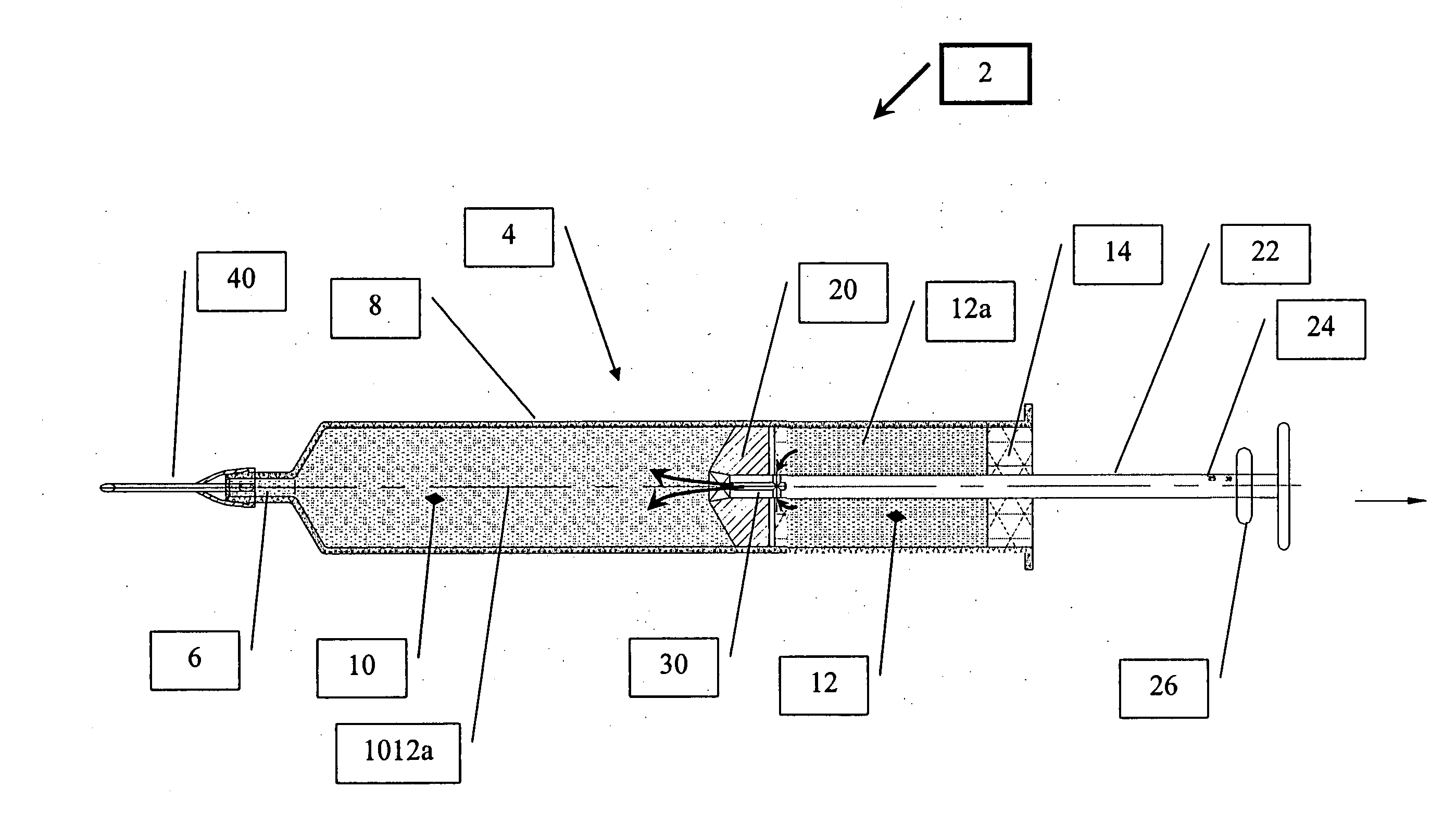

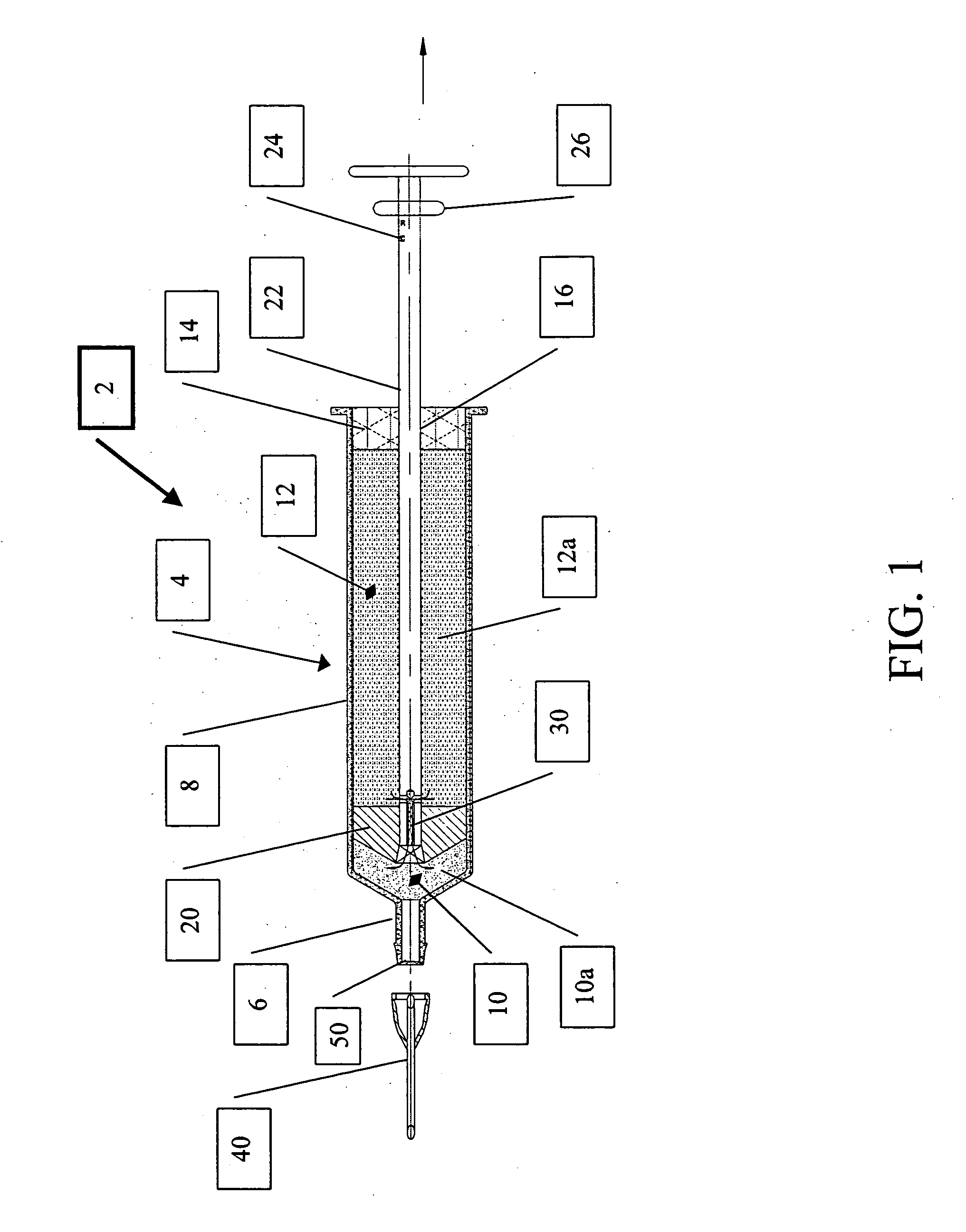

Alternate fuel blending system and associated method

ActiveUS7841317B2Discounts/incentivesInternal combustion piston enginesAlternative fuelsControl system

A fuel control system for controlling the use of primary fuel and alternate fuel in an internal combustion engine without cross-contamination of fuel types. Cross-contamination of fuel types may eliminate the ability to receive certain benefits or financial incentives associated with use of alternate fuel, including but not limited to RINs, credits, and subsidies. In one embodiment, primary and / or alternate fuel are controllably delivered from sources to a flow cell. If blending is desired, both primary and alternate fuels are delivered to the flow cell. The engine is fed with the resulting primary fuel, alternate fuel, or blended mixture of fuel from the flow cell. The flow cell contains a bypass inlet port adapted to receive excess fuel not consumed by the engine in lieu of the excess fuel being returned to the primary and / or alternate fuel sources. In this manner, cross-contamination of the fuel sources can be avoided.

Owner:GILBARCO

Dynamic vulcanization of fluorocarbon elastomers containing peroxide cure sites

Processable rubber compositions contain a vulcanized elastomeric material dispersed in a matrix of a thermoplastic polymeric material. The vulcanized elastomeric material is a peroxide cure polymeric material containing repeating units derived from fluorine-containing monomers and at least one peroxide cure site monomer. In one embodiment the matrix forms a continuous phase and the vulcanized elastomeric material is in the form of particles forming a non-continuous phase. The compositions are made by combining a radical curing system, a fluorocarbon elastomer material, and a fluoroplastic material, and heating the mixture at a temperature and for a time sufficient to effect vulcanization of the elastomeric material, while mechanical energy is applied to mix the mixture during the heating step. Shaped articles may be readily formed from the rubber compositions according to conventional thermoplastic processes such as blow molding, injection molding, and extrusion. Examples of useful articles include seals, gaskets, O-rings, and hoses.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

Water-conserving urinal block and holder

InactiveUS7921479B2Reducing and eliminating use of waterUrinalsLavatory sanitoryWater basedPolymixiiformes

Owner:HUNTER JAY D

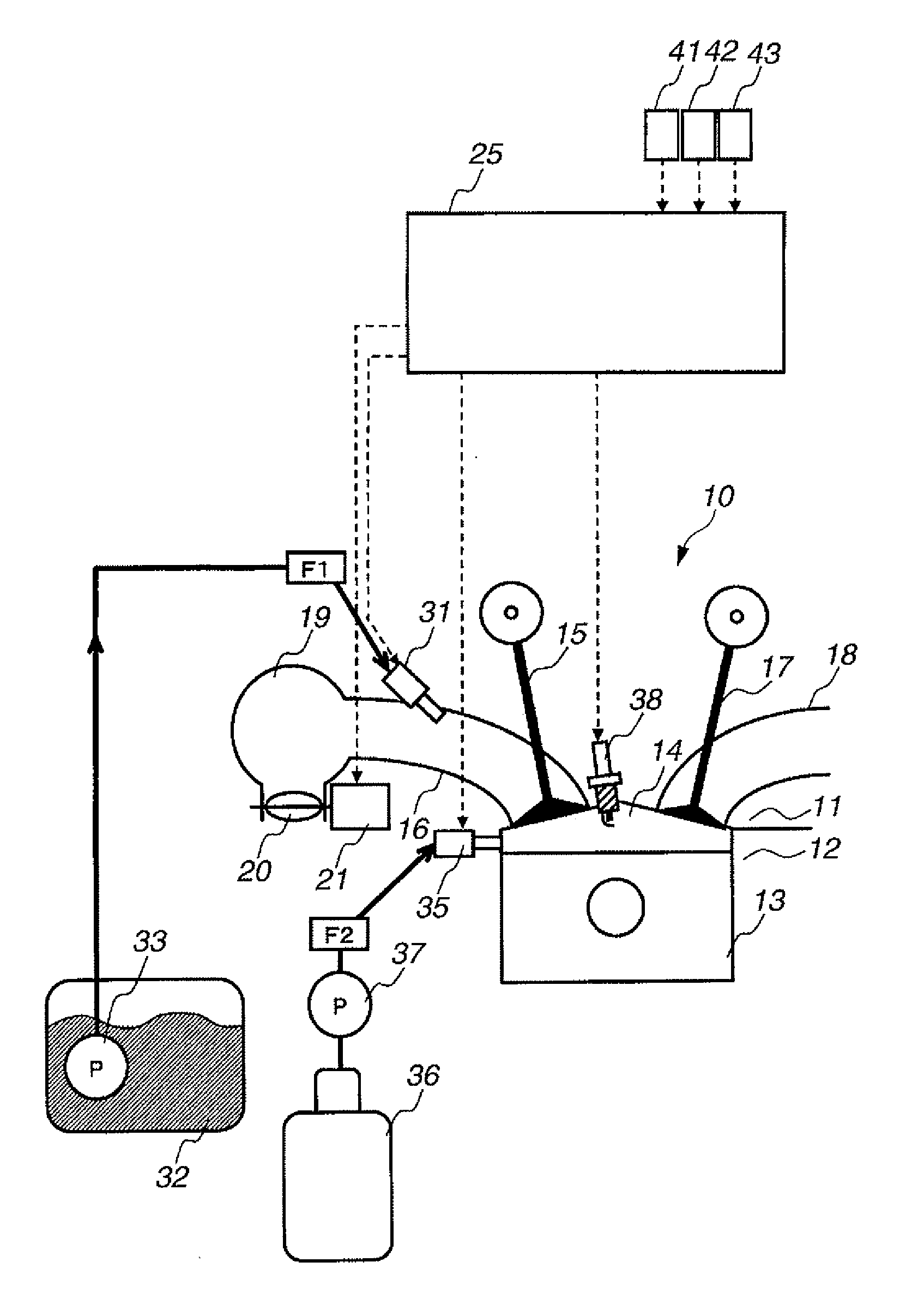

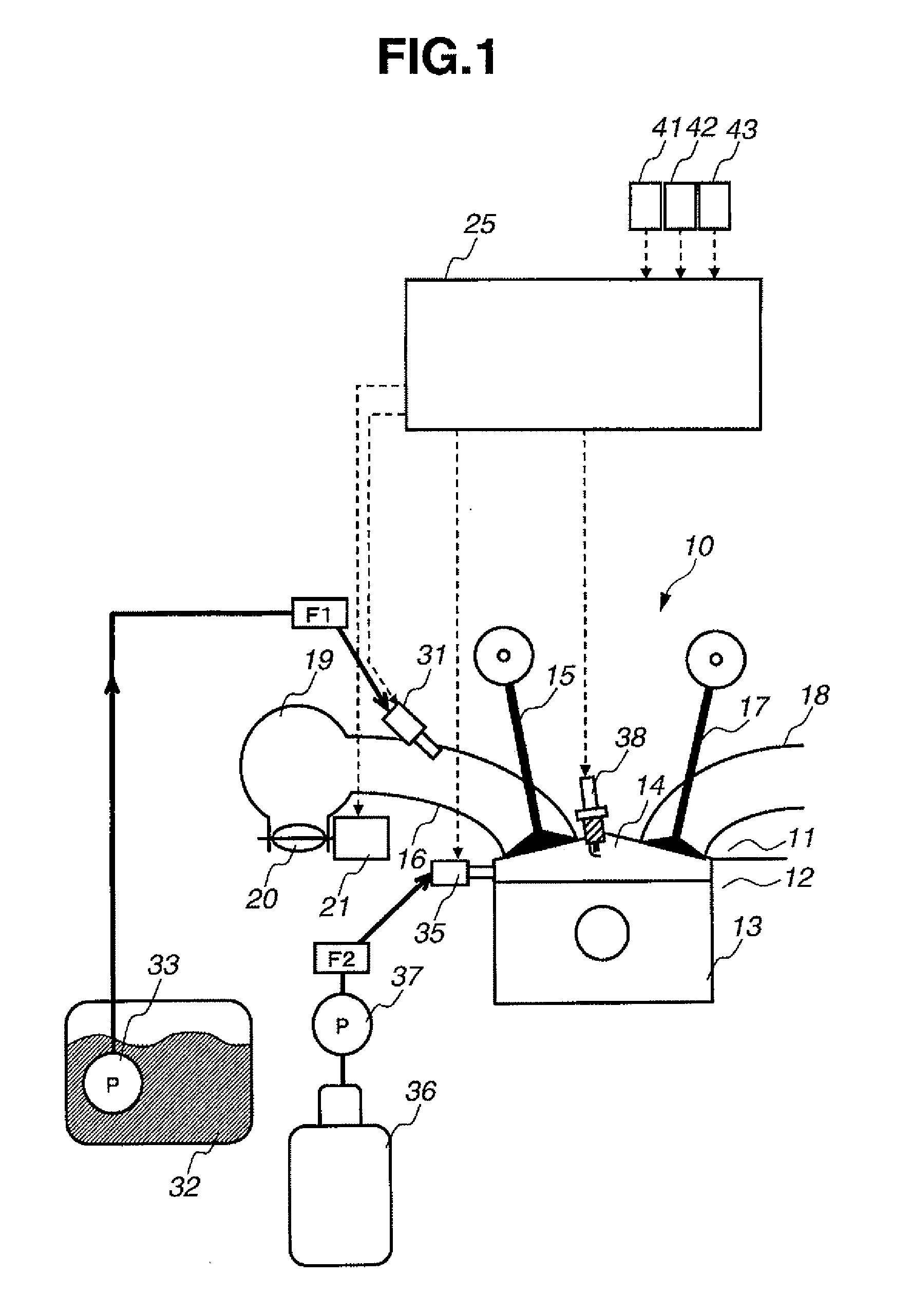

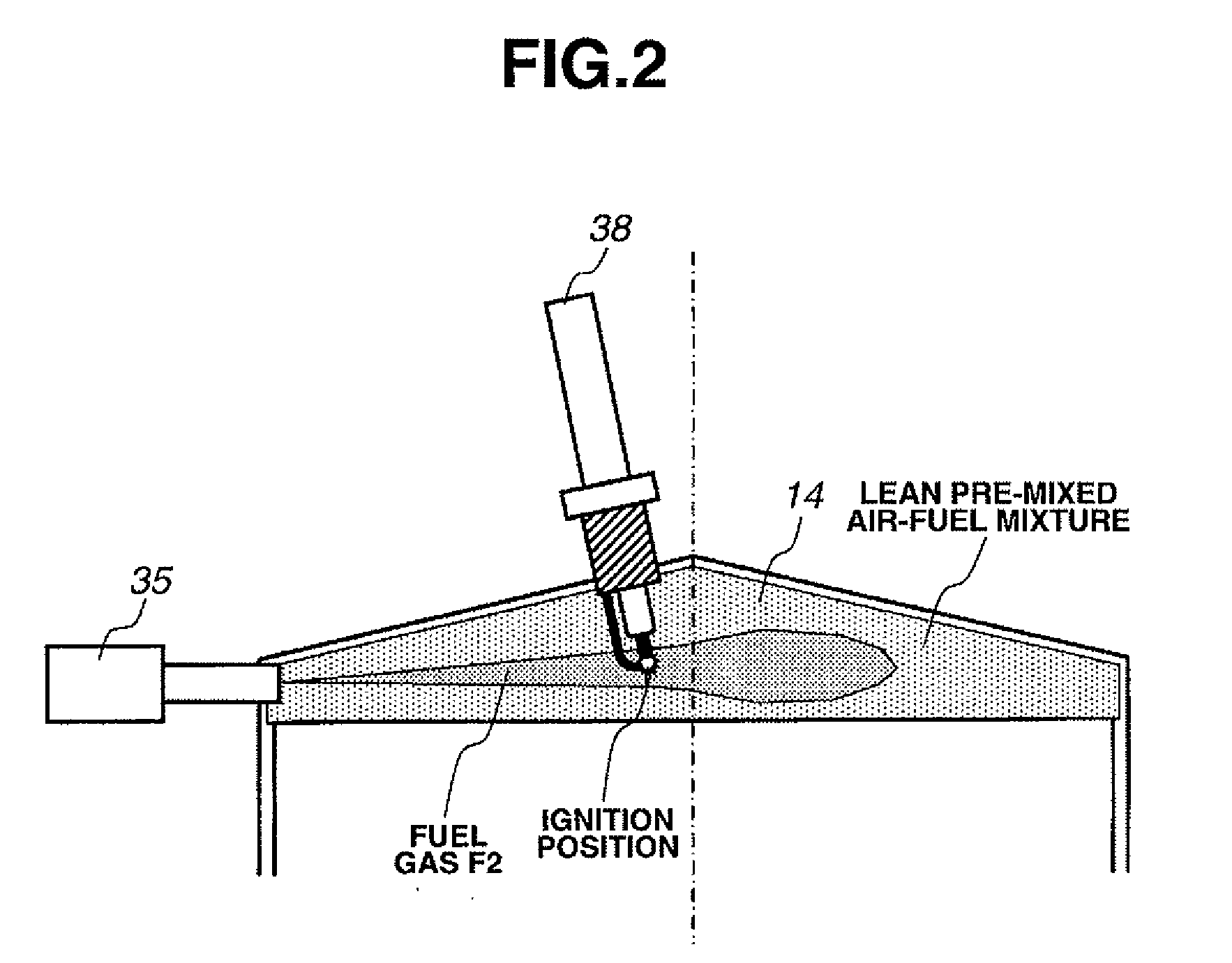

Internal combustion engine and combustion method of the same

InactiveUS20080257304A1Strong turbulent flowStrong flowValve arrangementsElectrical controlCombustion chamberTop dead center

An internal combustion engine, including a premixed mixture formation device that forms a premixed mixture of fuel and air in a combustion chamber, a fuel gas supply device that injects fuel gas directly into the combustion chamber, and an ignition device that ignites the fuel gas. The fuel gas supply device is configured to inject the fuel gas into the premixed mixture near a top dead center of a compression stroke such that a spray of the fuel gas passes through a firing position of the ignition device, to produce the spray of the fuel gas in a predetermined area substantially extending from one end of a cylinder bore to the other end as viewed in a cylinder-bore direction defined by a centerline of the cylinder bore. The ignition device is configured to directly ignite the spray of the fuel gas and to ignite and burn the premixed mixture by way of flame propagation along the spray of the fuel gas.

Owner:NISSAN MOTOR CO LTD

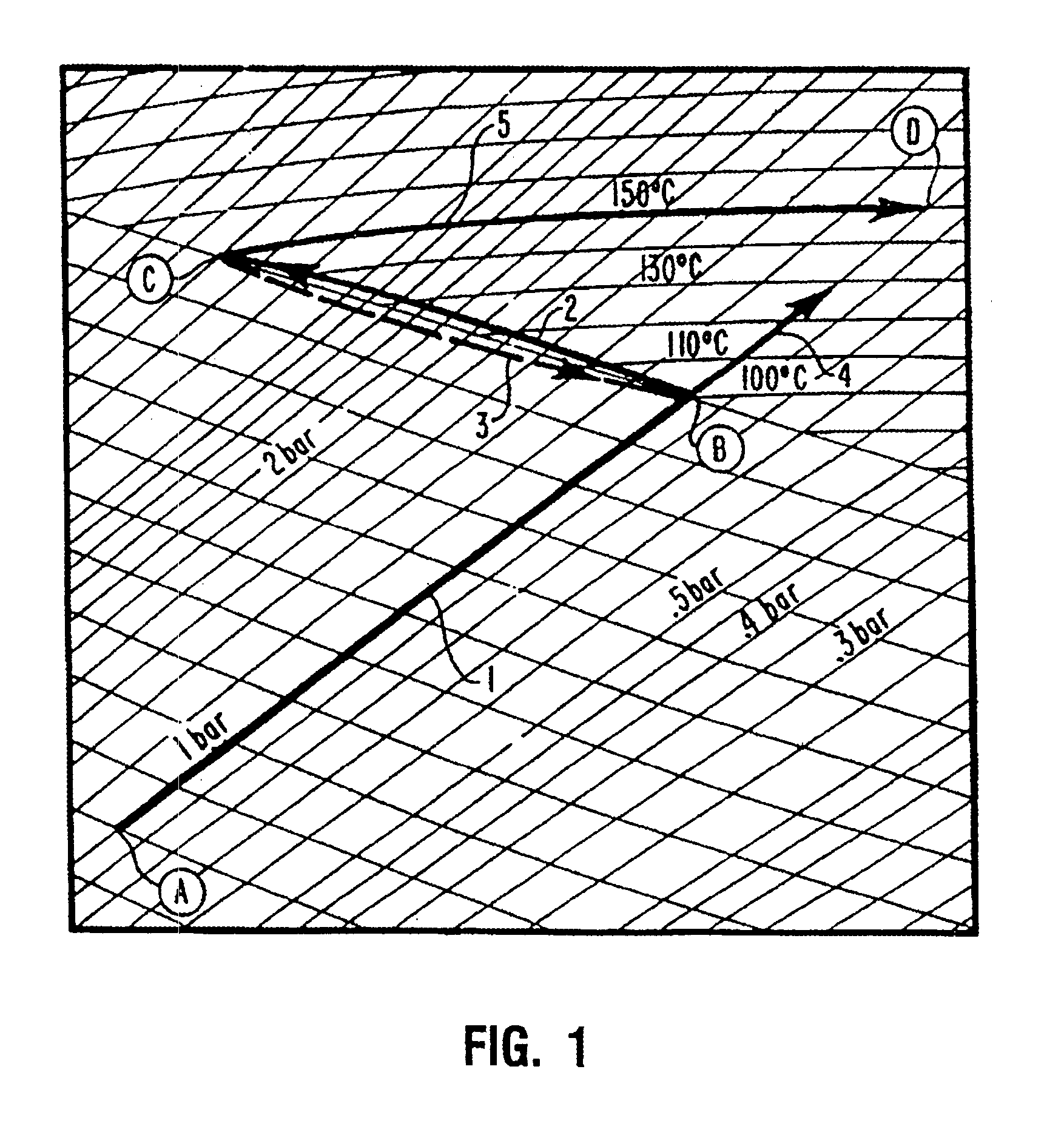

Memorial created for cremation remains and processes for making same

ActiveUS20050071964A1Eliminate cracksSolid waste disposalTransportation and packagingParticulatesFaceting

A memorial for deceased humans or animals in which the cremated residue or ash is blended or mixed with particulate glass, the mixture being heated to form a liquid pool of glass with the cremation residue or ash dispersed, infused and / or absorbed therein, the molten glass and ash being removed from the heat source after a suitable time period and transferred to a mold in the shape of the memorial, the mold allowed to cool until the memorial sets, the memorial then removed from the mold and reheated in an annealing oven at a suitable temperature for a suitable time so as to eliminate possible cracking and scoring, the memorial once removed from the annealing oven can be further cut, polished, faceted, engraved or the like. The initial mixture of particulate glass and cremation residue and ash can be further combined with a coloring agent if so desired before heating or before transfer to the memorial mold.

Owner:VOGEL HAROLD C +1

Process for making modified cellulosic filler from recycled plastic waste and forming wood substitute articles

InactiveUS20070007682A1Lower melting and softening temperatureImprove compatibilityPlastic recyclingWood working apparatusThermoplasticPolyvinyl chloride

A low cost process of making modified cellulosic materials by melt blending with at least 30% recycled and commingled plastic waste stream at higher temperature and pressure where at least 70% of plastics melts and encapsulate the filler. The plastic encapsulated filler can be used as a feed stock for continuous or discontinuous process of compression, extrusion, coextrusion and injection molded structural (e.g. profiles, stake, panel) and non-structural (e.g. sheet, thin-board) articles by mixing with a thermoplastic (e.g. polyethylene, polypropylene, polyvinyl chloride, polystyrene) or a hybrid mixture of said thermoplastics, bonding agents, plastic processing additives, impact modifiers, colorant and with / without a lightner.

Owner:MALDAS DEBESH +1

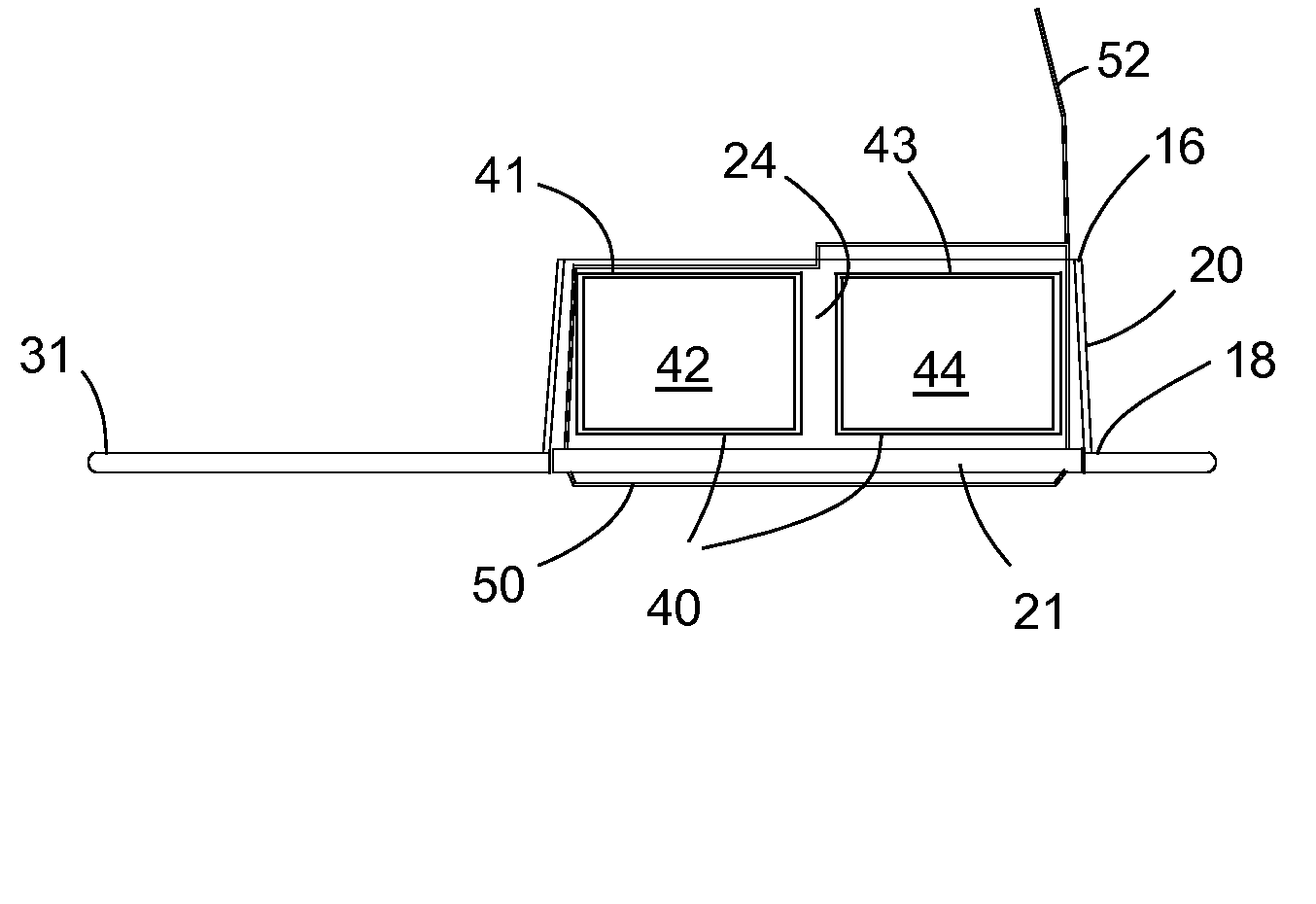

Multi-chamber mixing ampoule

InactiveUS20070185438A1Simple designLimited amountMedical devicesIntravenous devicesAxial displacementInterior space

The present invention provides a multi-compartment ampoule for the storage of the separated components of a multiple component mixture and then mixing them together in a single ampoule. The ampoule housing has a proximal dispensing end. The distal end of the ampoule housing is sealed by an end plug configured with an axial through bore. A portion of an axially displaceable plunger element passes thorough the axial through bore and extends into the interior volume and is fixedly attached to an axially displaceable piston element slideablely deployed within the ampoule housing so as to sealingly divide the interior volume into at least first and second storage regions that are pre-filled with the separate components that will be mixed together just prior to use. Axial displacement of the plunger element, and thereby the piston element, in a first direction discharges a first component of the mixture from the distal storage region through a one-way flow configuration into the proximal storage region. After the two components are in a single storage region, they may be thoroughly mixed together. Once the components are mixed, dispensing of the mixture may be by any number of methods. The mixture may be dispensed as if from a standard ampoule, wherein the needle of a syringe is inserted through the sealing membrane and the prescribed amount of the mixture is drawn out. Alternatively, the ampoule may be inserted into an injection device, such as an injection pen for example, in a manner similar to a standard ampoule. The additional features of a needle cannula configured for attachment directly to the proximal dispensing end of the ampoule housing and graduated markings on the shaft of the plunger that are indicative of volume dispensation combined with the basic ampoule provides an embodiment that can store the separated components of the mixture before use, provide a way of mixing the components together in the same ampoule and that can be used as the syringe to dispense the mixture directly into the patient.

Owner:HAIMI SHLOMO +1

Dynamic vulcanization of fluorocarbon elastomers

Owner:FREUDENBERG NOK GEN PARTNERSHIP

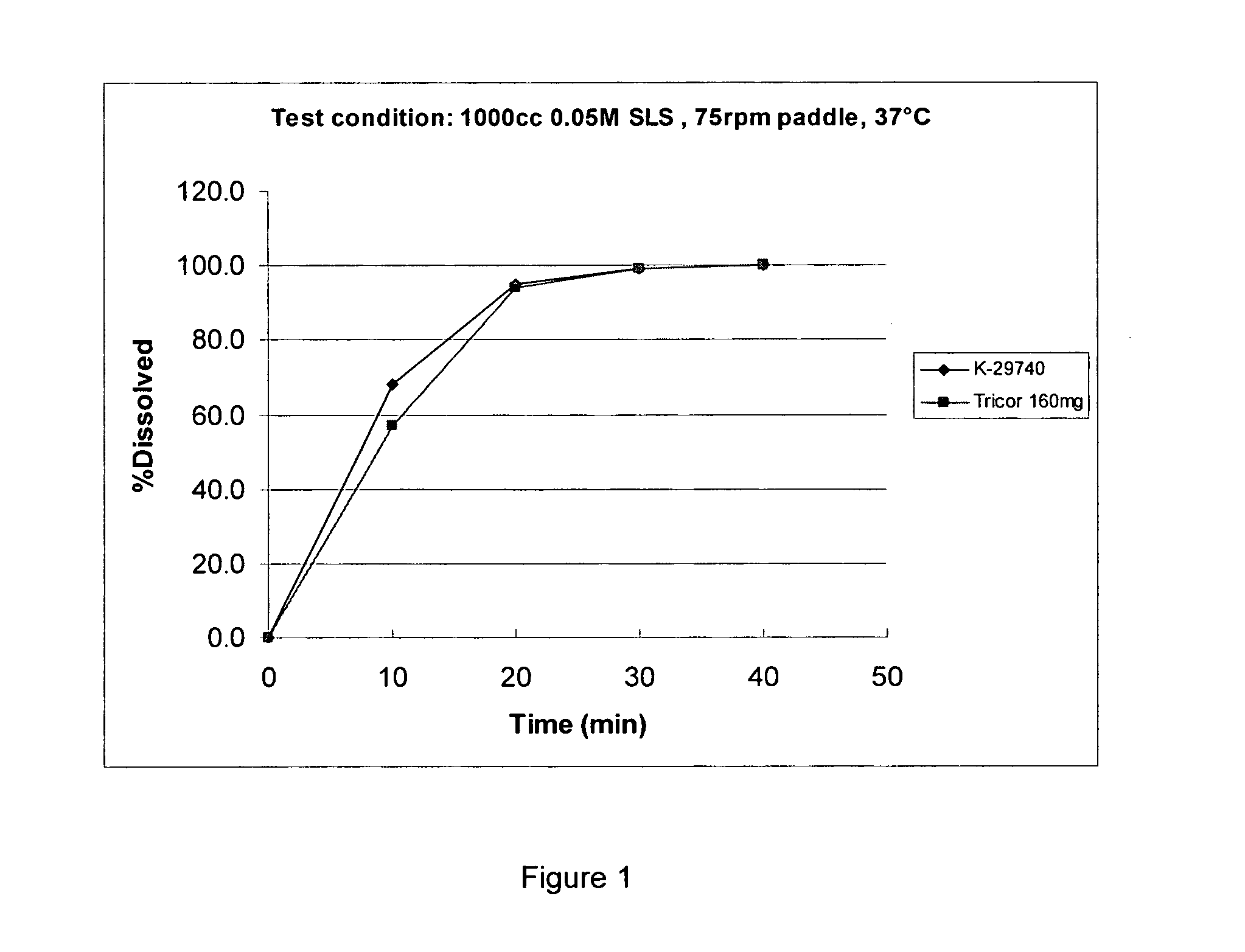

Novel granulation process

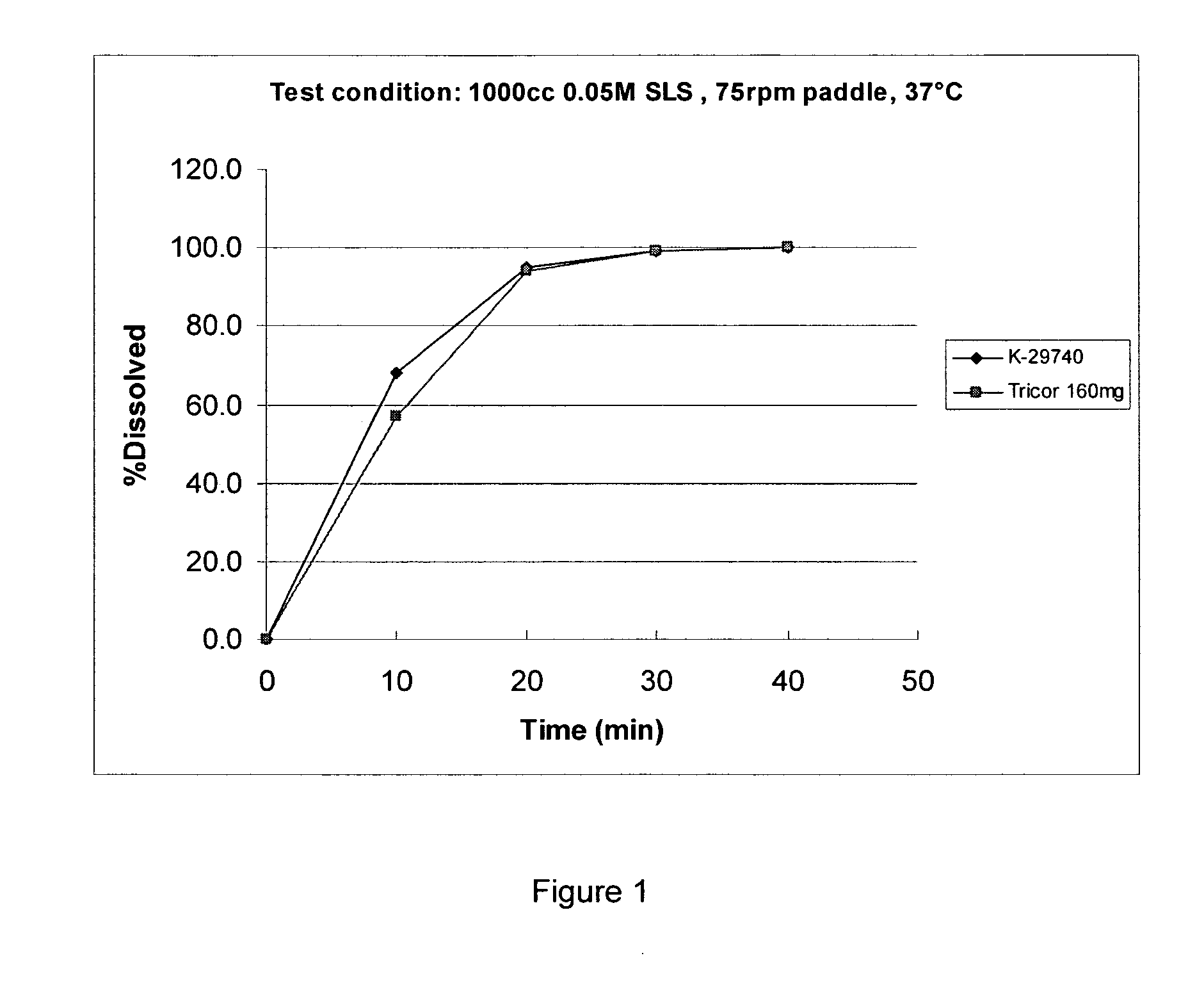

One of the objects of the invention relates to a pharmaceutical composition in the form of a granulate, wherein the granulates comprises an active pharmaceutical ingredient (API) having a poor water solubility intimately associated with at least one pharmaceutically acceptable sugar, and optionally or preferably at least one pharmaceutically acceptable excipient other than the at least one pharmaceutically acceptable sugar, wherein the active pharmaceutically ingredient has a water solubility less than about 20 mg / ml. The at least one pharmaceutically acceptable excipient other than the at least one pharmaceutically acceptable sugar is selected from the group consisting of disintegrants, wetting agents, diluents, binders, lubricants, glidants, coloring agents and flavoring agents. The at least one pharmaceutically acceptable sugar is preferably selected from pyranosyl pyranoses, such as lactose. Another object of the invention relates to a process for preparing a pharmaceutical granulate, comprising (a) combining an API having poor water solubility with a solution comprising at least one pharmaceutically acceptable sugar, for example a pyranosyl pyranose such as lactose, and a solvent, and optionally at least one pharmaceutically acceptable excipient other than the at least one pharmaceutically acceptable sugar to form a combined mixture; (b) drying the combined mixture of step (a); and (c) comminuting the product of step (b) to obtain the granulate.

Owner:TEVA PHARM USA INC

Fluorocarbon rubber with enhanced low temperature properties

Processable rubber compositions containing a vulcanized elastomeric material dispersed in a matrix of a thermoplastic polymeric material. The vulcanized elastomeric material is a peroxide cure polymeric material containing repeating units derived from fluorine-containing monomers and at least one peroxide cure site monomer. In one embodiment the matrix forms a continuous phase and the vulcanized elastomeric material is in the form of particles forming a non-continuous phase. The compositions are made by combining a radical curing system, a fluorocarbon elastomer material, and a fluoroplastic material, and heating the mixture at a temperature and for a time sufficient to effect vulcanization of the elastomeric material, while mechanical energy is applied to mix the mixture during the heating step. Shaped articles may be readily formed from the rubber compositions according to conventional thermoplastic processes such as blow molding, injection molding, and extrusion. Examples of useful articles include seals, gaskets, O-rings, and hoses.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

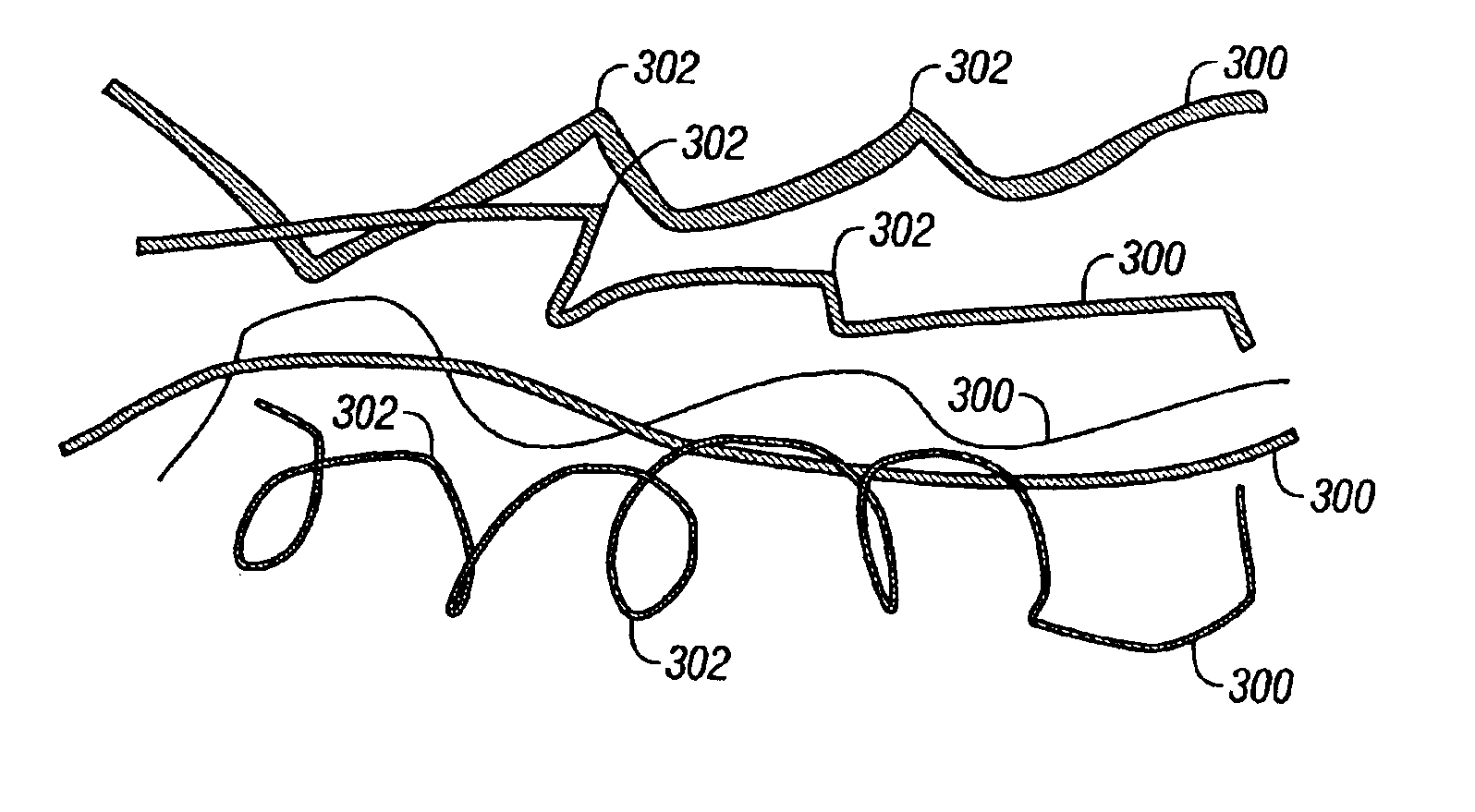

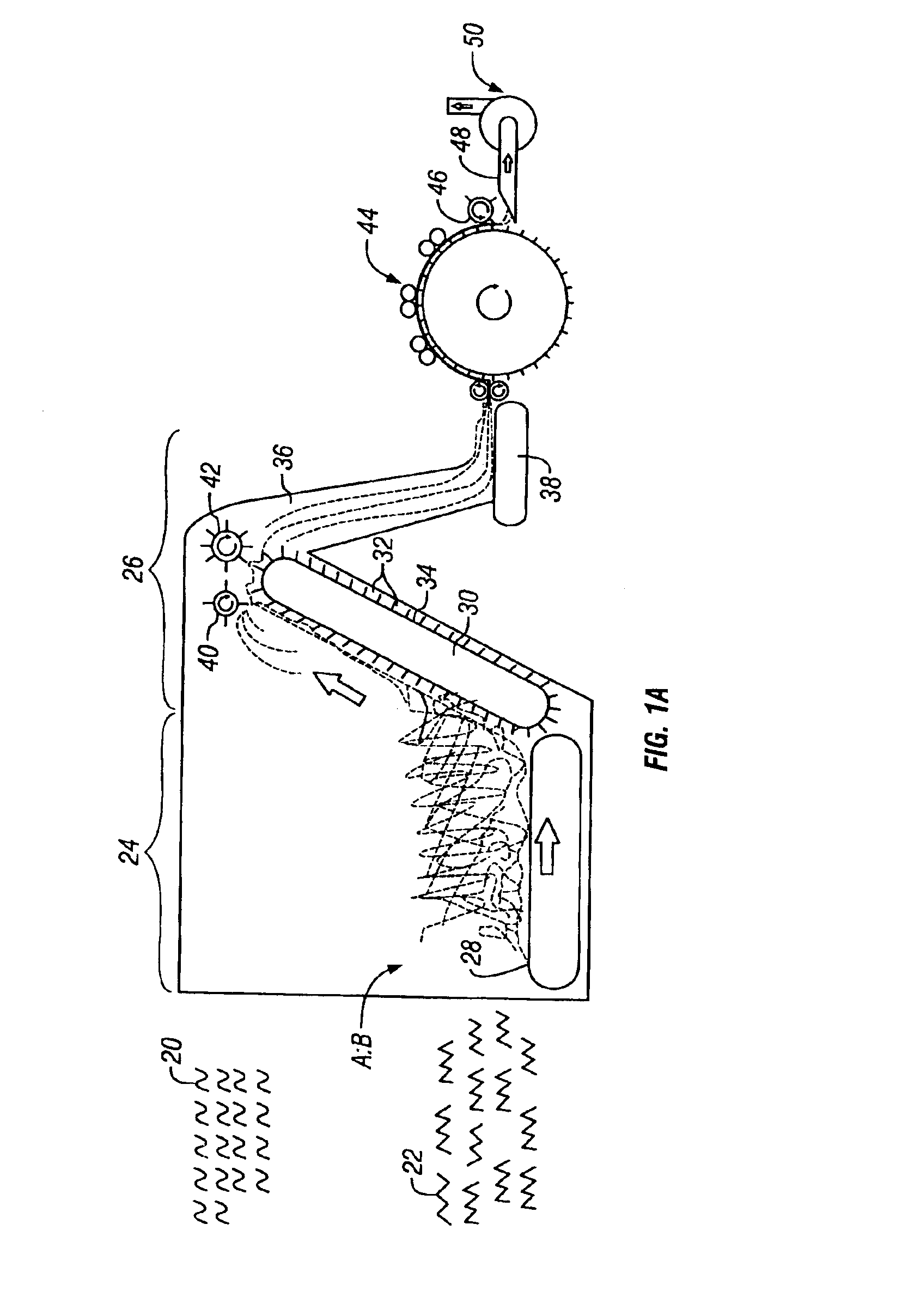

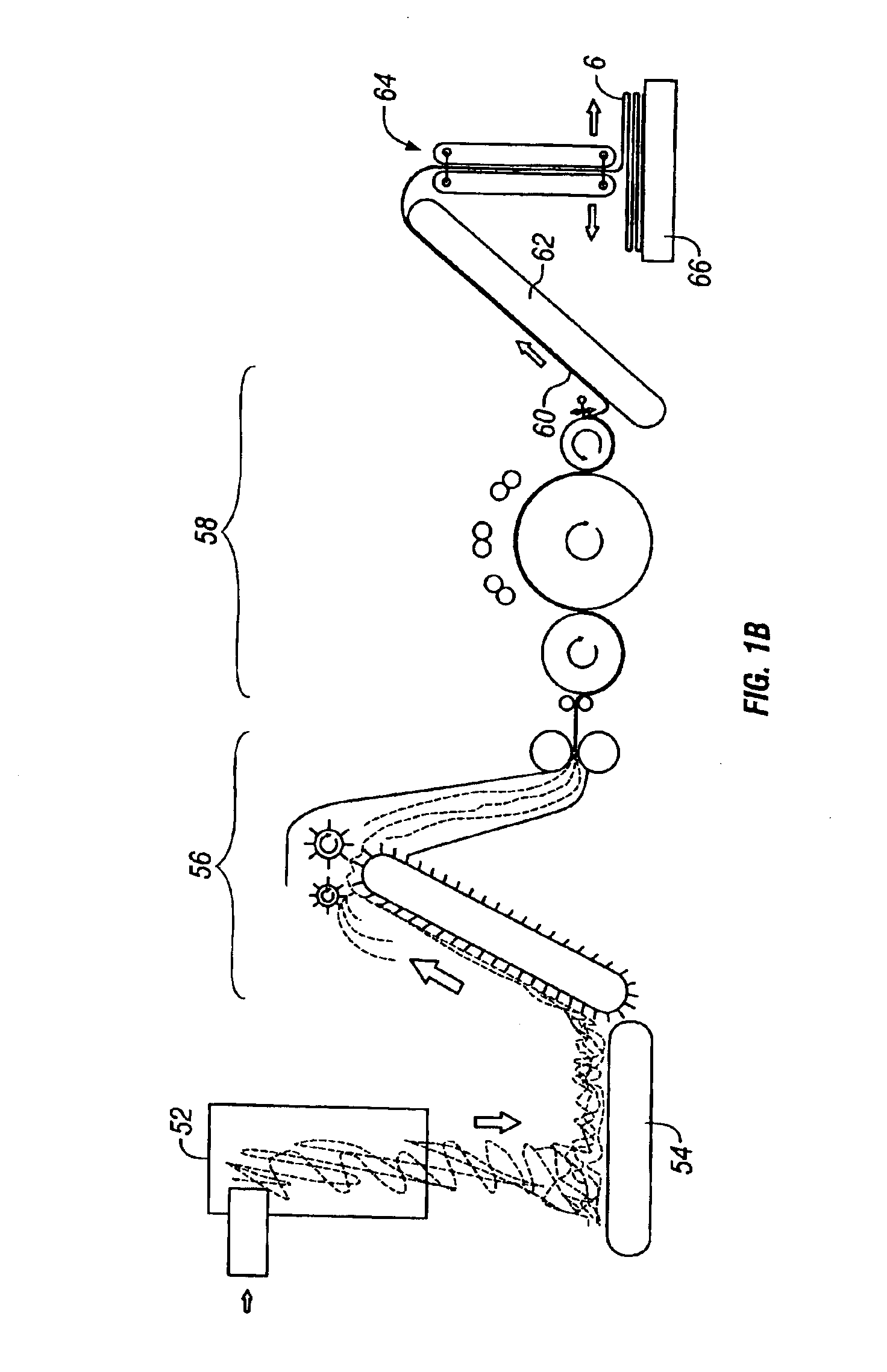

Composite nonwoven fabric and method for making same

A composite nonwoven fabric comprising multiple layers of a web formed from a blended mixture of metal fibers and nonmetal fibers is provided. The metal fibers preferably have a rough outer surface with irregular shaped cross-sections that vary along their length. The fibers of adjacent layers of the web material are interengaged in a needlepunching step. The composite nonwoven fabrics of the invention, which have very good isotropic strength. In a preferred embodiment, the composite nonwoven fabric is employed as a floor buffing pad for use with an electric floor buffing apparatus.

Owner:GLOBAL MATERIAL TECH

Novel pharmaceutical granulate

One of the objects of the invention relates to a pharmaceutical composition in the form of a granulate, wherein the granulates comprises an active pharmaceutical ingredient (API) having a poor water solubility intimately associated with at least one pharmaceutically acceptable sugar, and optionally or preferably at least one pharmaceutically acceptable excipient other than the at least one pharmaceutically acceptable sugar, wherein the active pharmaceutically ingredient has a water solubility less than about 20 mg / ml. The at least one pharmaceutically acceptable excipient other than the at least one pharmaceutically acceptable sugar is selected from the group consisting of disintegrants, wetting agents, diluents, binders, lubricants, glidants, coloring agents and flavoring agents. The at least one pharmaceutically acceptable sugar is preferably selected from pyranosyl pyranoses, such as lactose. Another object of the invention relates to a process for preparing a pharmaceutical granulate, comprising (a) combining an API having poor water solubility with a solution comprising at least one pharmaceutically acceptable sugar, for example a pyranosyl pyranose such as lactose, and a solvent, and optionally at least one pharmaceutically acceptable excipient other than the at least one pharmaceutically acceptable sugar to form a combined mixture; (b) drying the combined mixture of step (a); and (c) comminuting the product of step (b) to obtain the granulate.

Owner:TEVA PHARM USA INC

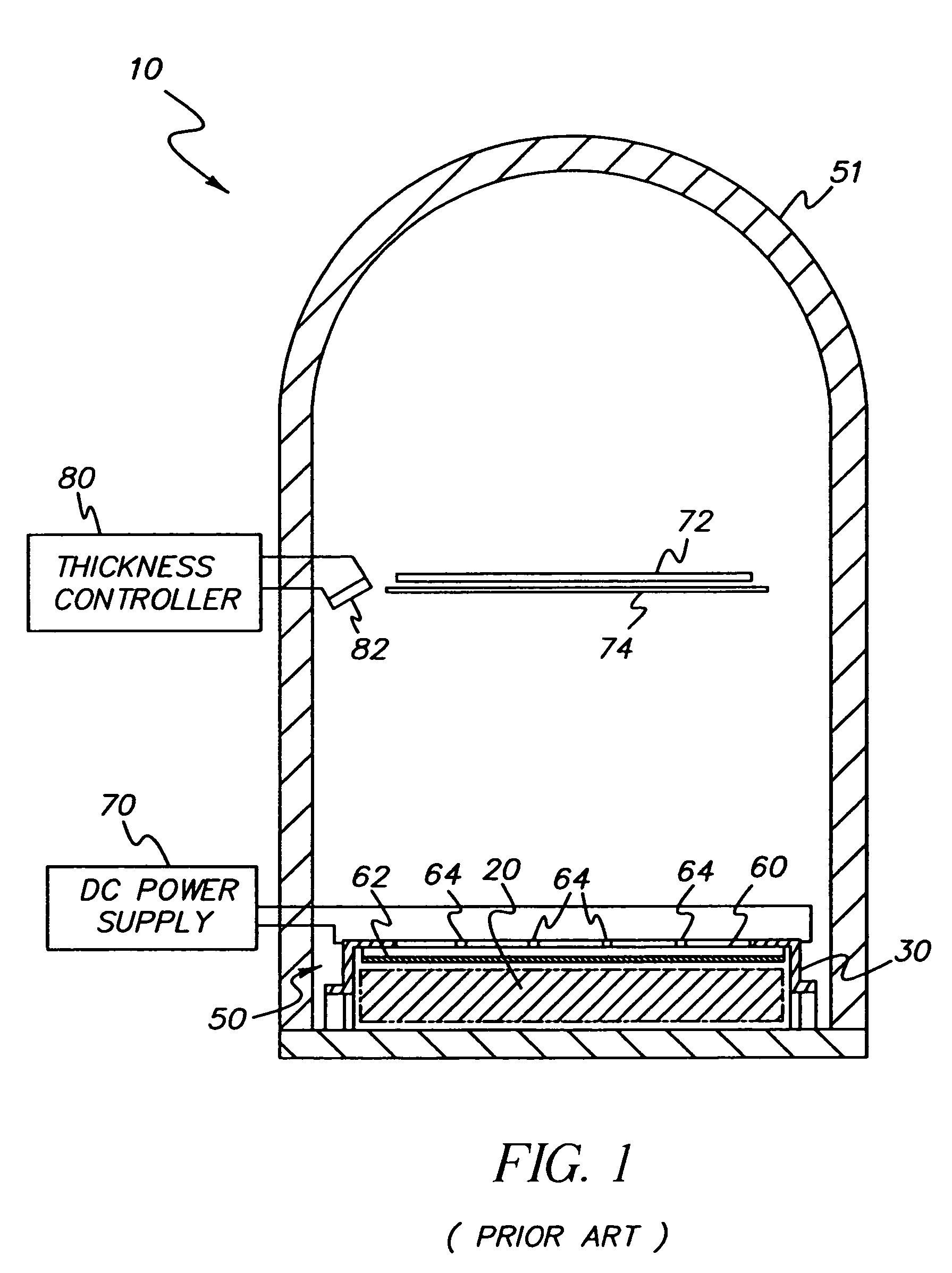

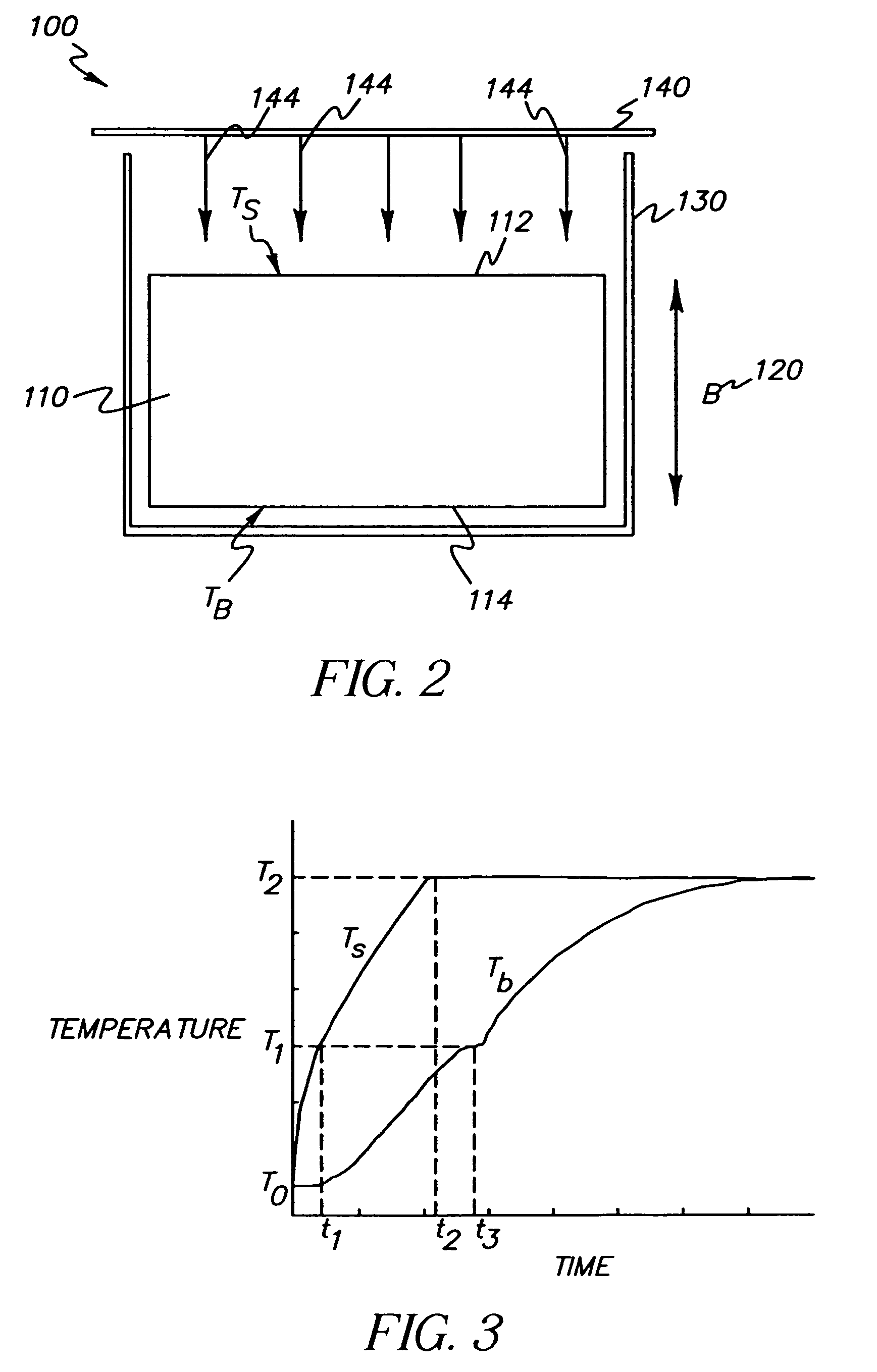

Organic materials for an evaporation source

ActiveUS7252859B2Efficient preparationVacuum evaporation coatingSolid-state devicesOrganic layerEvaporation

A method of using a compacted pellet having uniform blended mixture with at least first and second different organic components that sublime at temperatures T1 and T2 respectively, wherein T1 represents the temperature of the first organic material with the lowest sublimation temperature and T2 represents the temperature of the second organic material with the highest sublimation temperature, to form an organic layer having a uniform blended mixture of the organic components, includes providing a compacted pellet, having a top and bottom surface, into a boat having an open top surface wherein the compacted pellet conforms to the interior of the boat; and applying heat to the top of the compacted pellet to cause the deposition of a uniform blended mixture of the organic components to form an organic layer.

Owner:GLOBAL OLED TECH

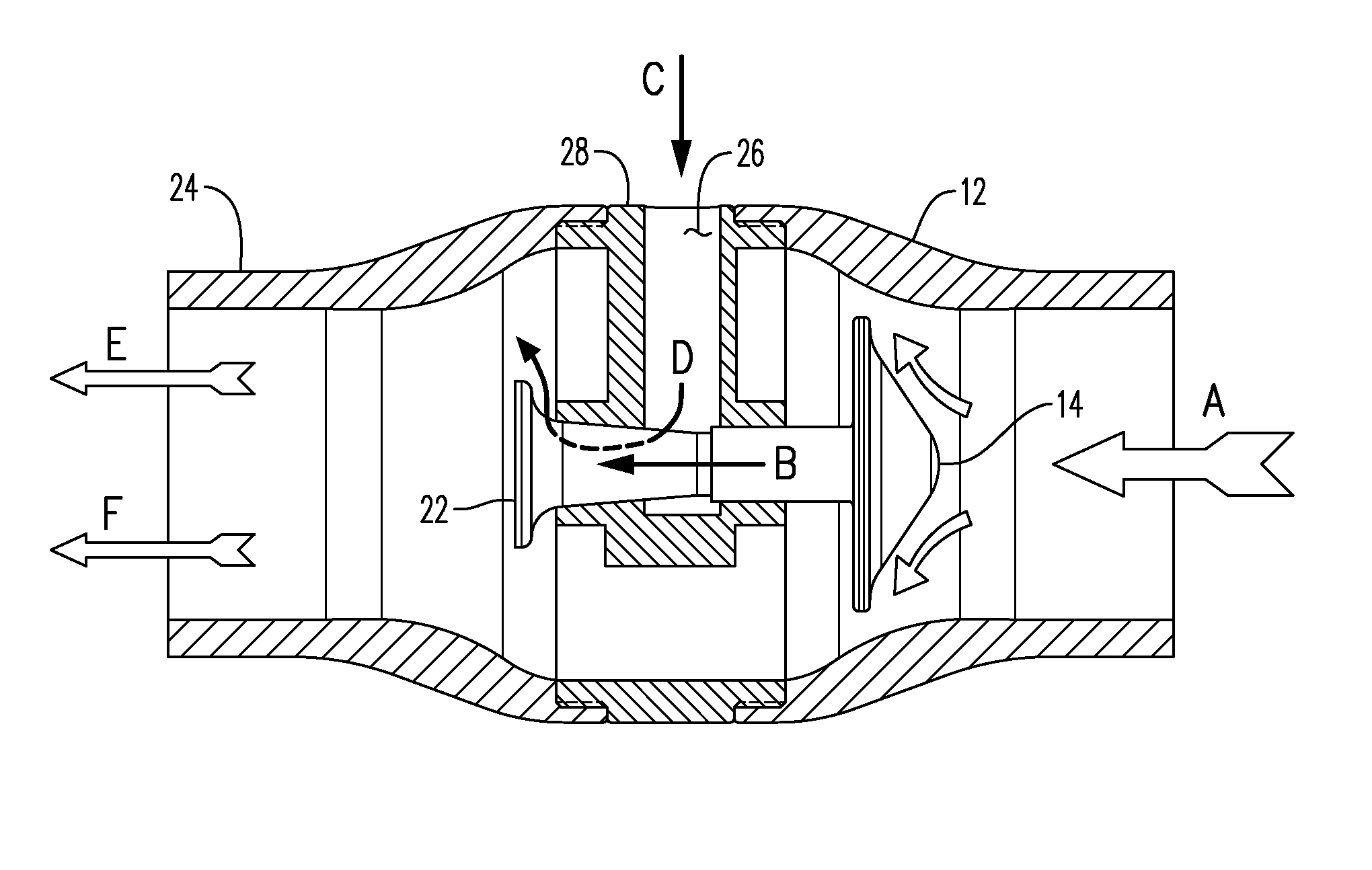

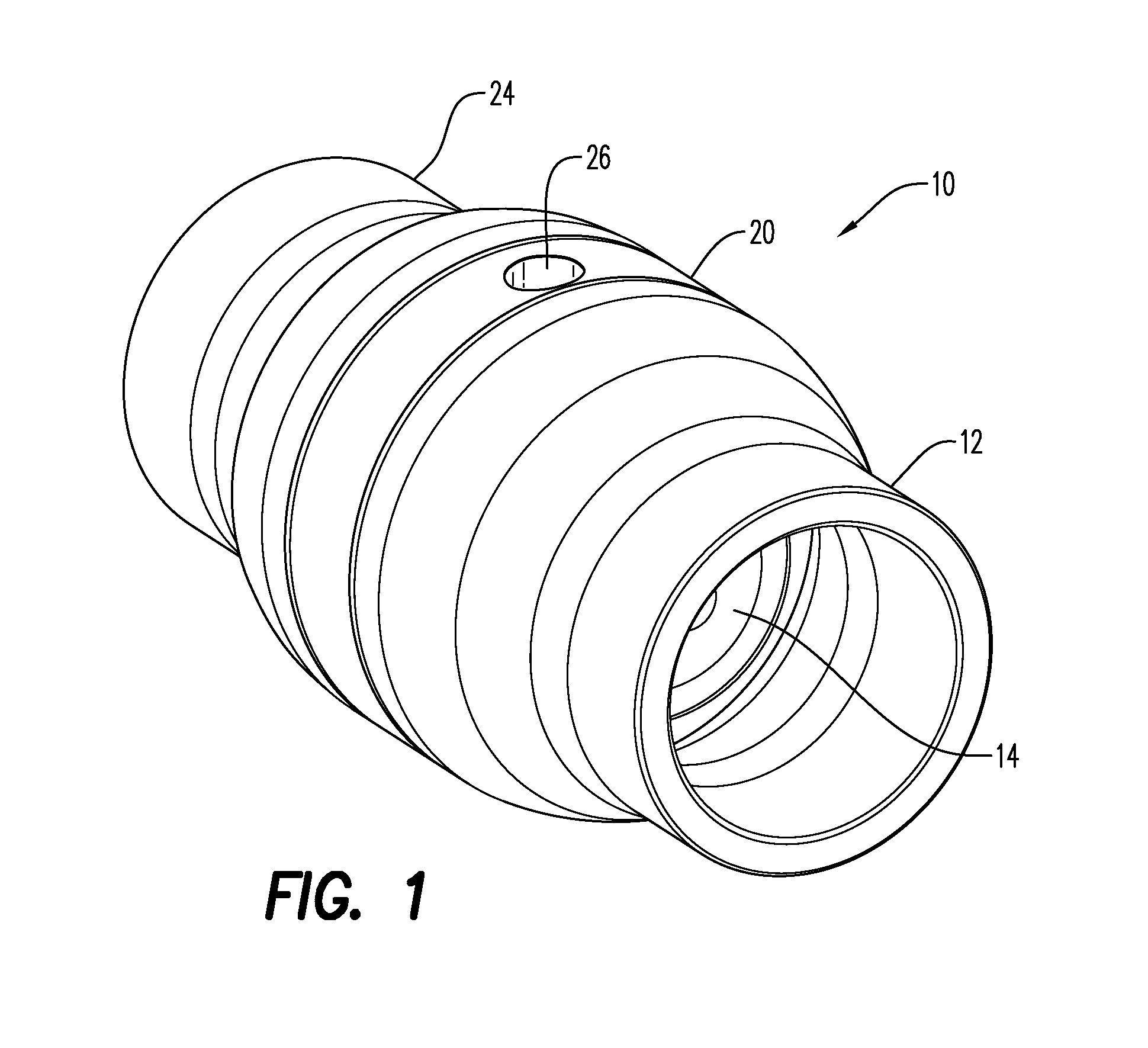

Secondary Fuel Premixing Controller for an Air Intake Manifold of a Combustion Engine

InactiveUS20110226218A1Reduce fuel consumptionSignificant loss of engine powerInternal combustion piston enginesNon-fuel substance addition to fuelCombustionEngineering

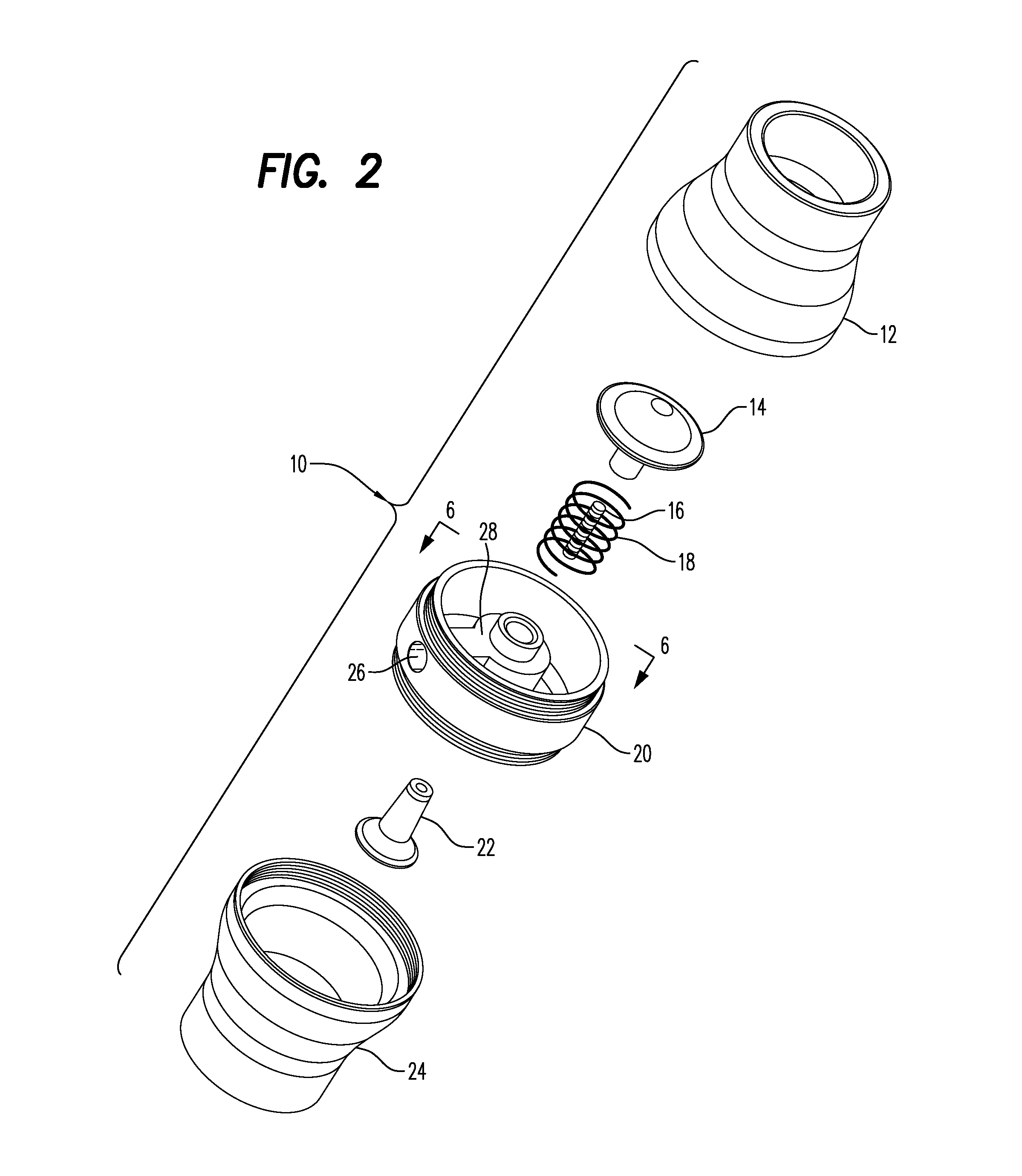

A secondary fuel premixing controller for introducing a secondary fuel into an air intake manifold of a primary fuel combustion engine. The controller includes a hollow housing having an air inlet, a main controller body, and an air / secondary fuel mixing outlet connected together in central alignment one to another. The air inlet introduces incoming air into the controller while the air / fuel mixing outlet discharges a blended mixture of secondary fuel and air into an air intake manifold of the running engine. The main controller body includes a secondary fuel manifold positioned centrally within an interior of the controller which supports for axial movement an air pressure valve positioned proximate to the air inlet and a secondary fuel / air blender connected thereto. The secondary fuel manifold also has a secondary fuel inlet formed therethrough connectable at an outer end thereof to a source of secondary fuel, an inner end positioned for sealing engagement with the secondary fuel / air blender. The air pressure valve and secondary fuel / air blender are biased to close and seal the inner end of secondary fuel inlet when the engine is stopped and to open the inner end responsive to engine intake air intake through the controller when the engine is running.

Owner:VONGSATEANCHAI SUPOJ +3

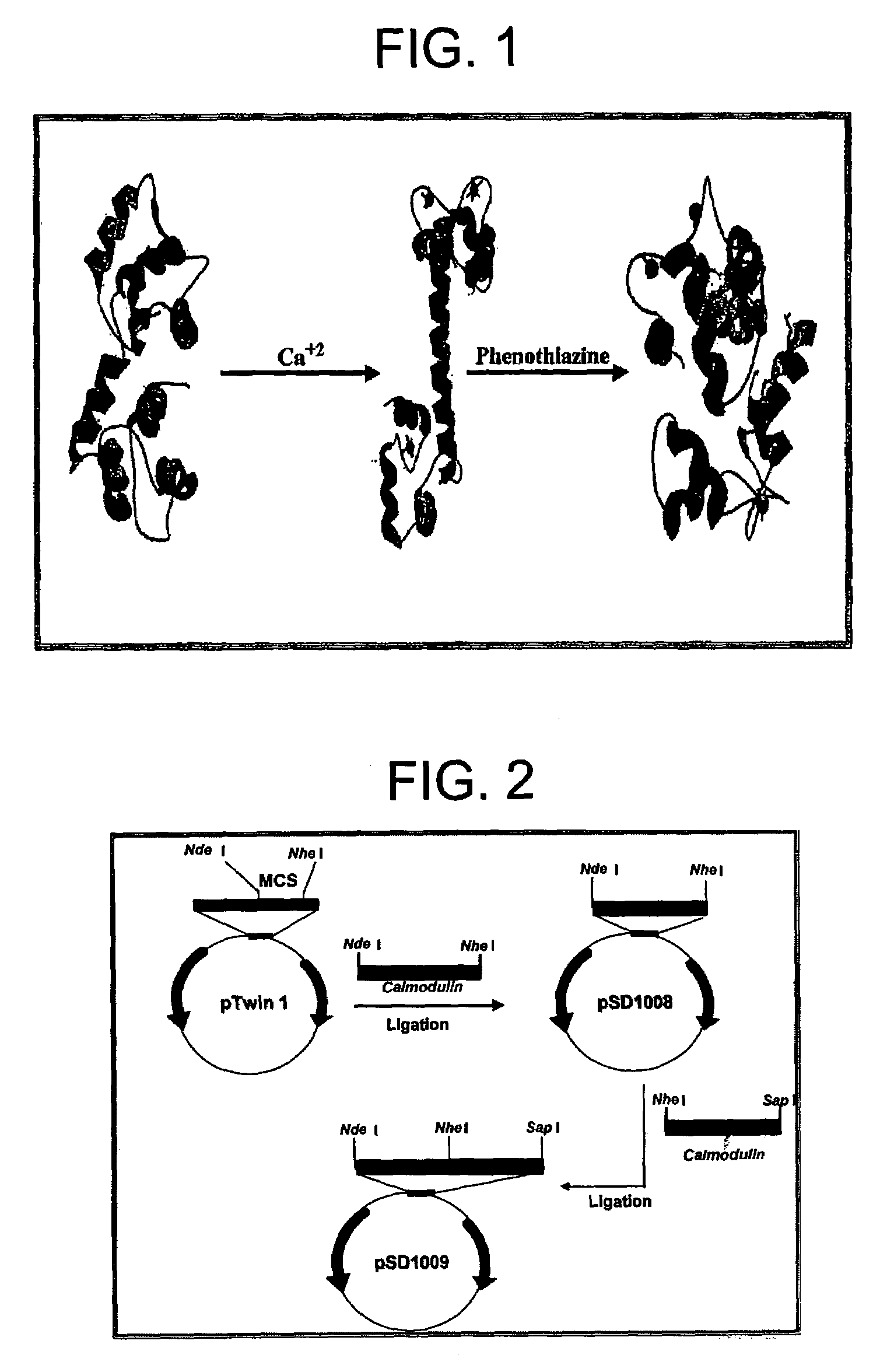

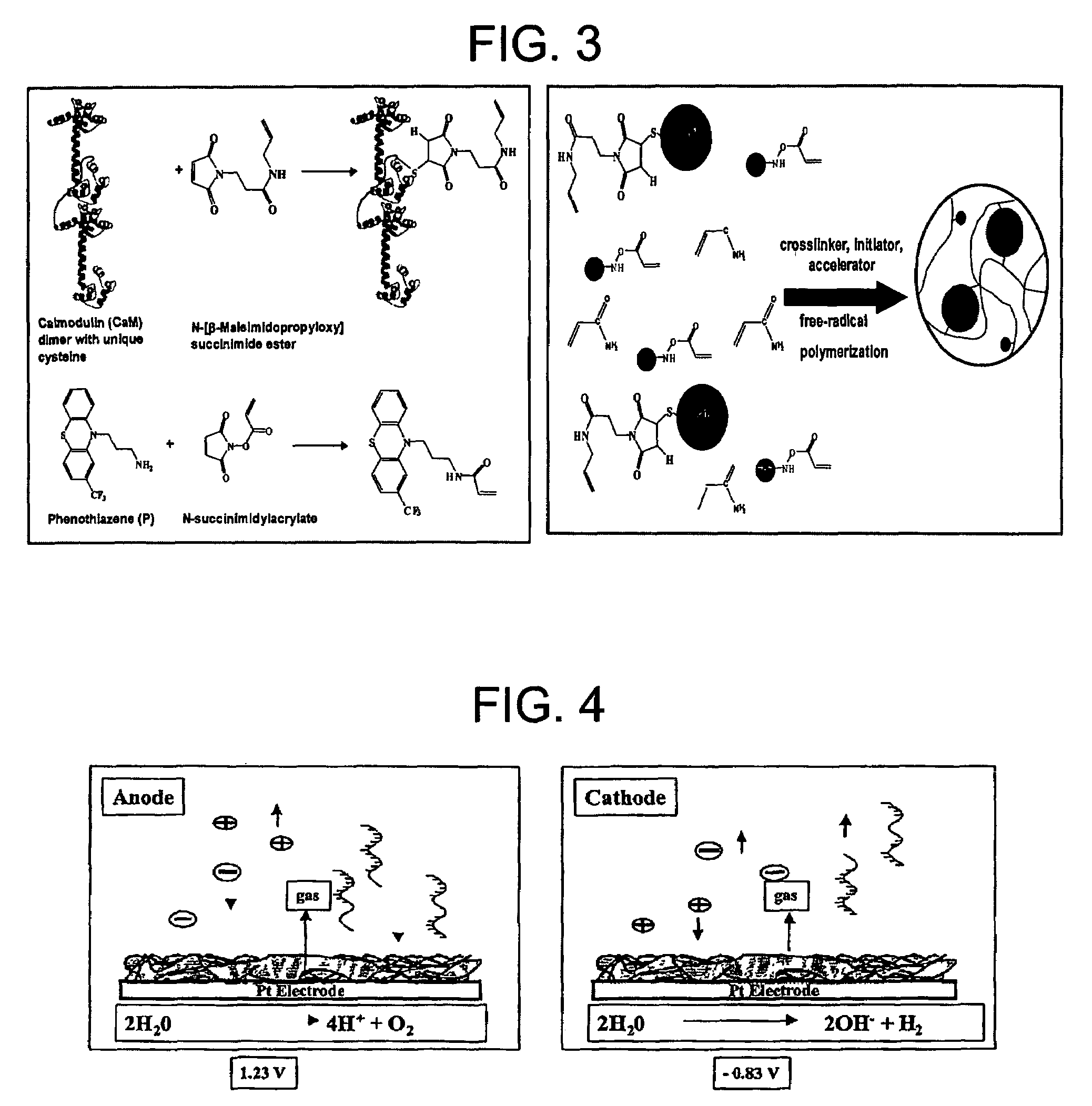

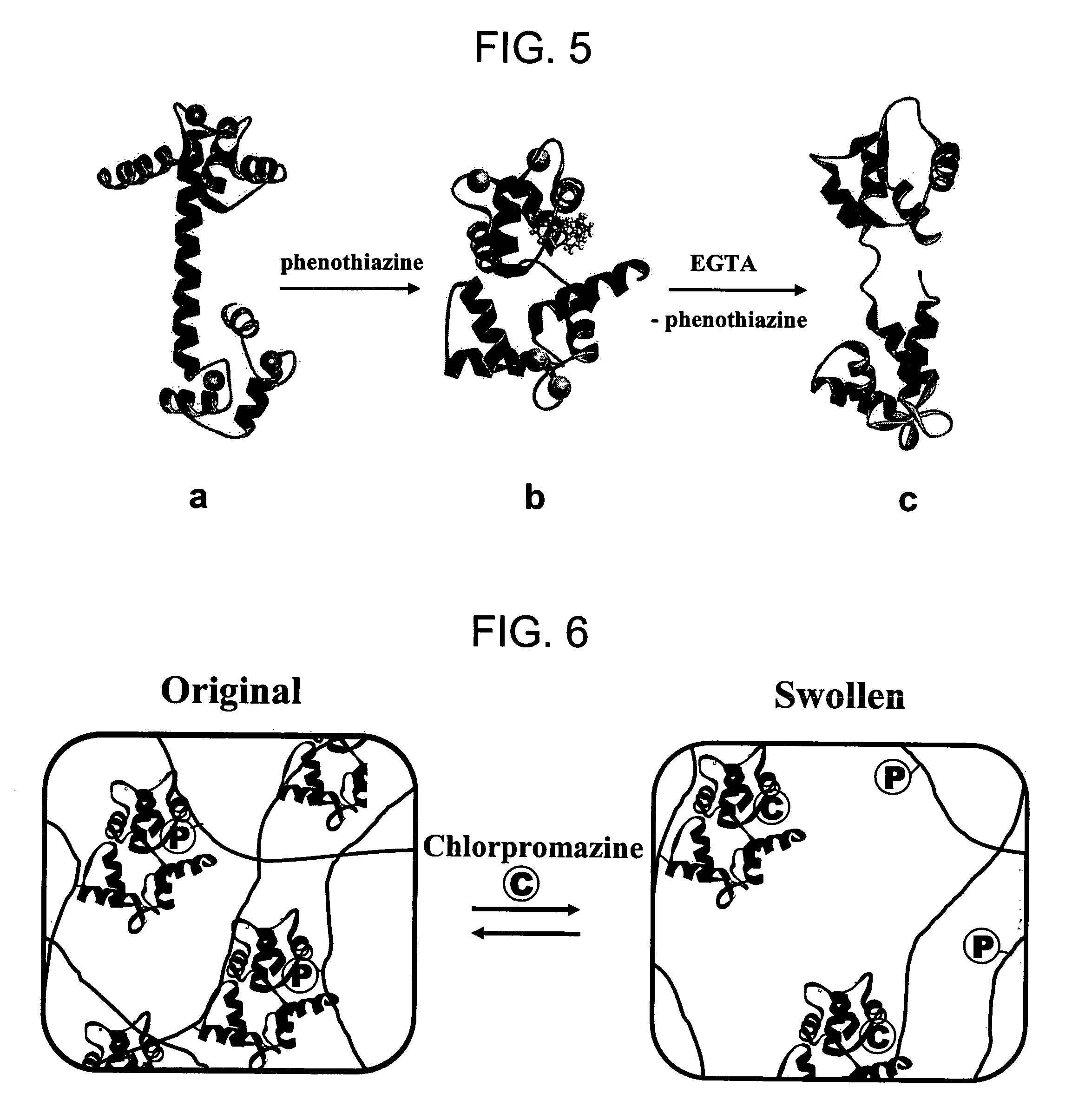

Stimuli-responsive hydrogel microdomes integrated with genetically engineered proteins for high-throughput screening of pharmaceuticals

InactiveUS7625951B2Good choiceBioreactor/fermenter combinationsBiological substance pretreatmentsStimuli responsiveAnalyte

A hydrogel microdome that can swell in response to a stimuli or target molecule is formed by polymerizing a mixture comprising a monomer capable of forming a hydrogel with a biopolymer. An array of hydrogel microdomes can be formed on a substrate by microspotting the mixture and polymerizing. The array can be used for high-throughput screening of analytes as well as for use as an actuator and biosensor using the swelling property of the hydrogel.

Owner:UNIV OF KENTUCKY RES FOUND

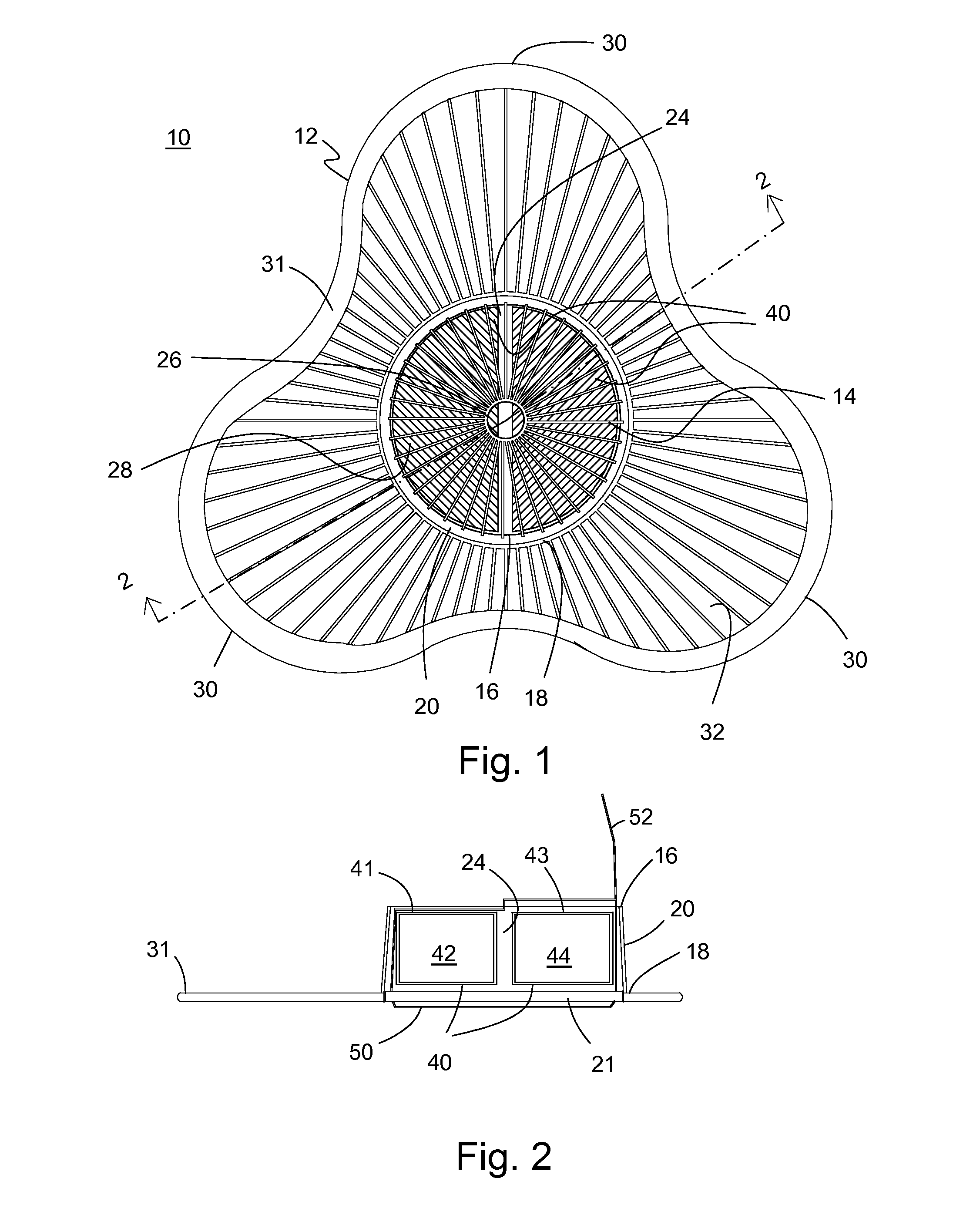

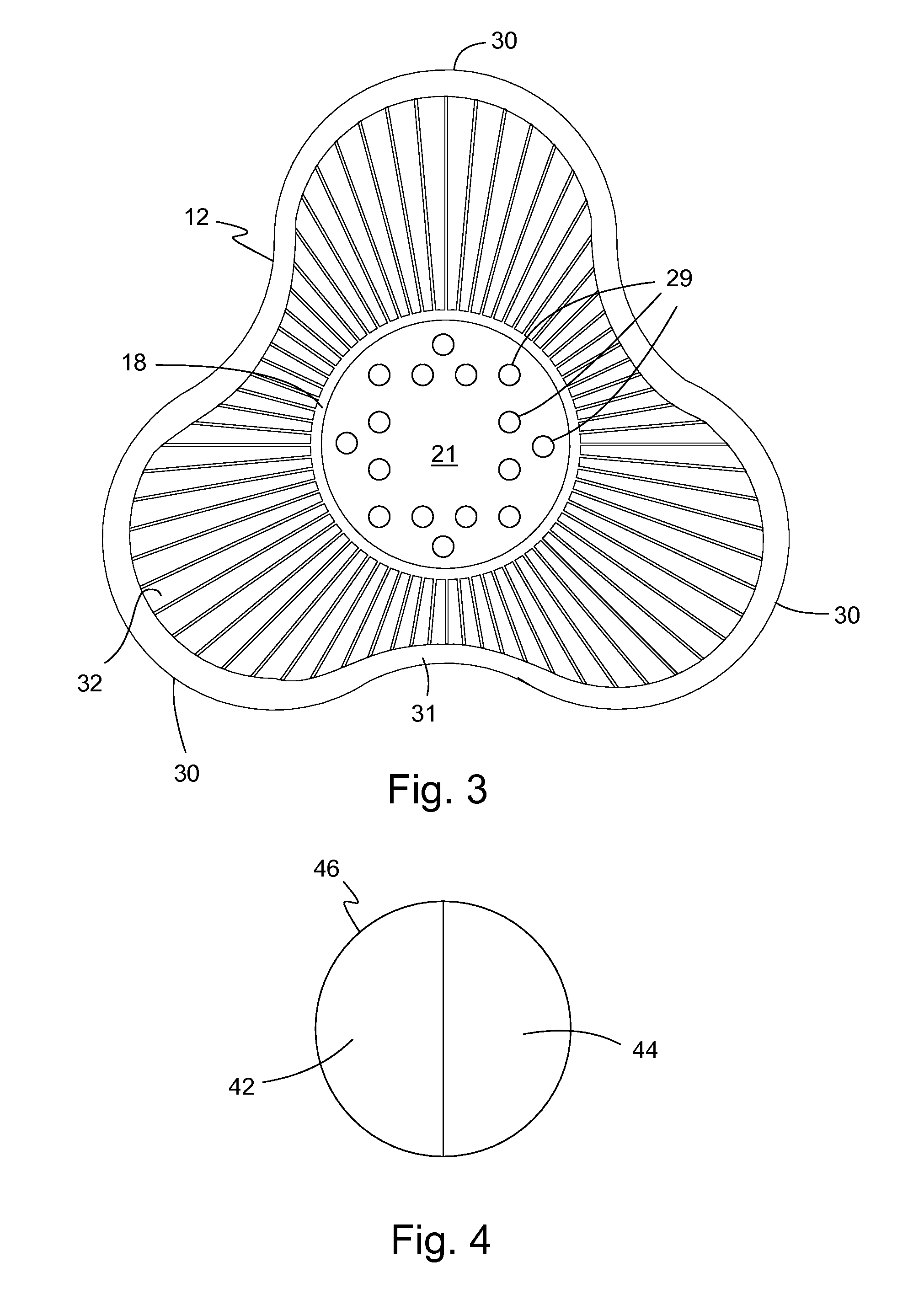

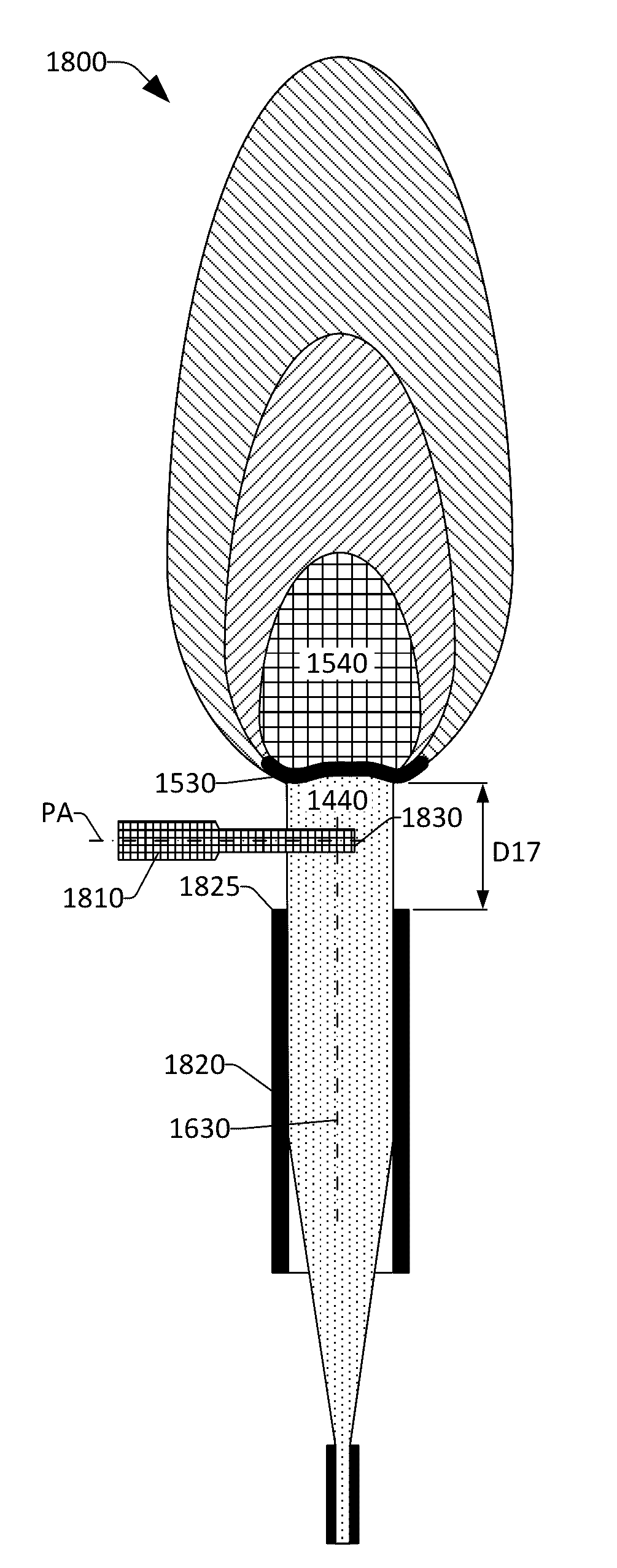

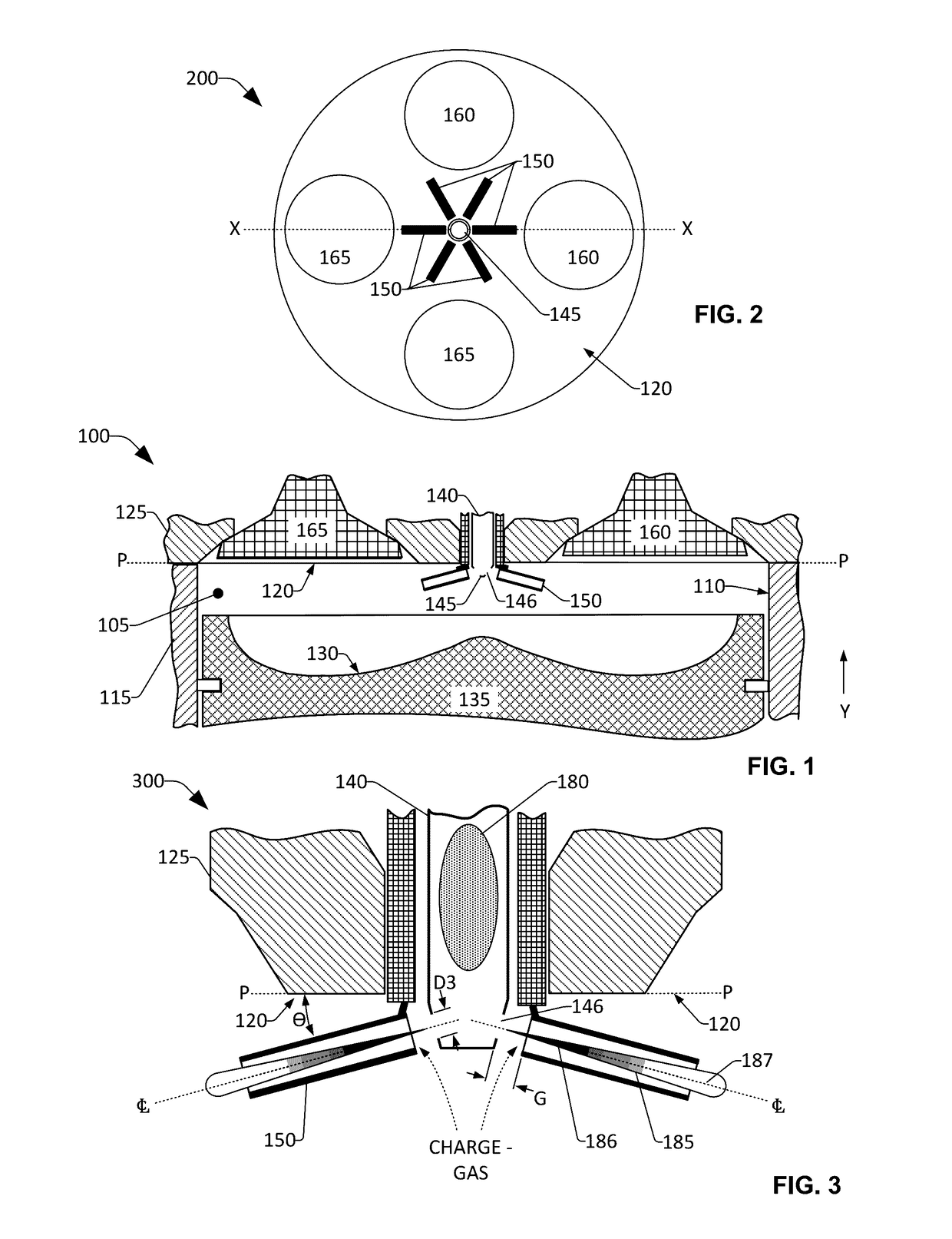

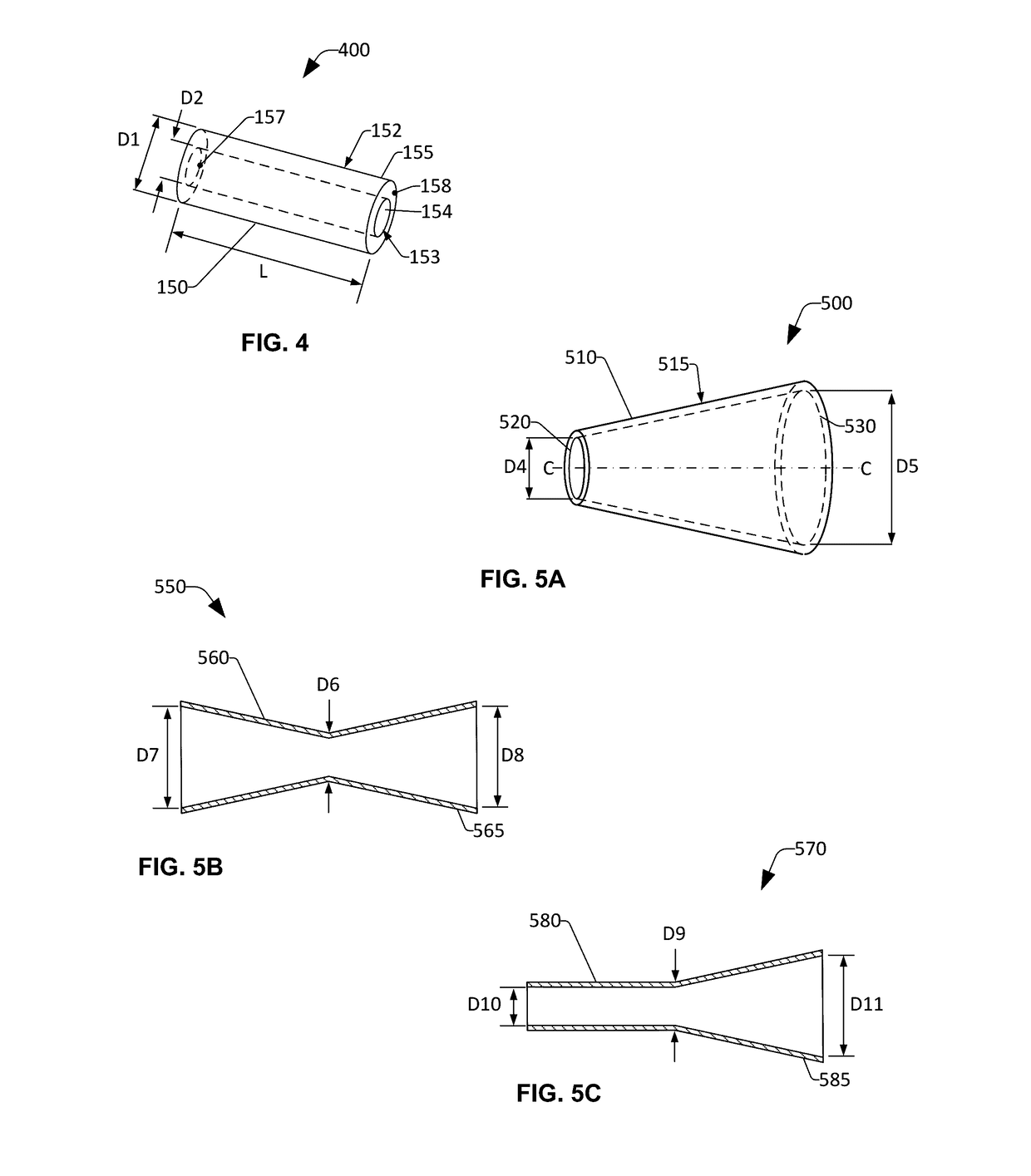

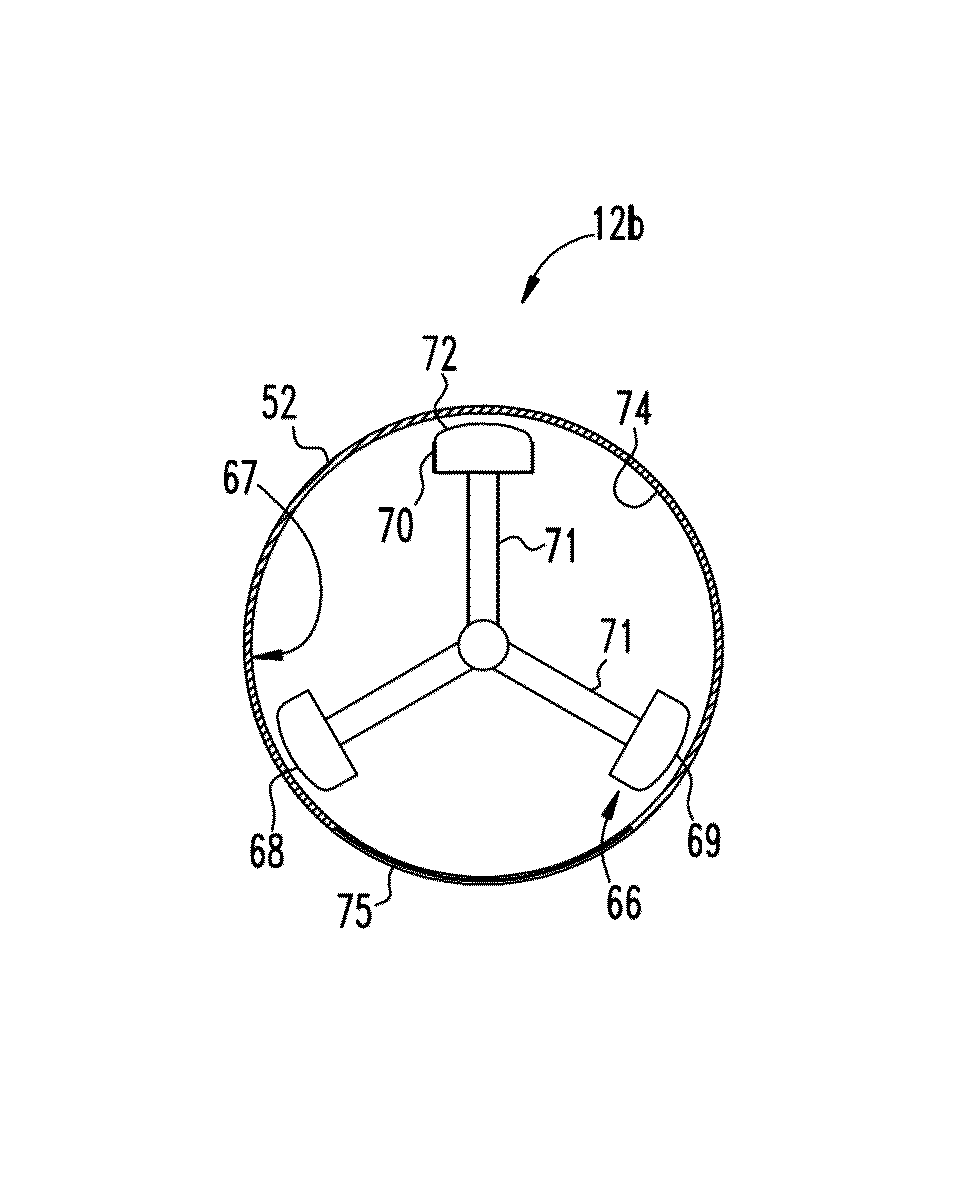

Ducted fuel injection with ignition assist

ActiveUS20170114763A1Increase ignition delayWell mixedInternal combustion piston enginesFuel injection apparatusCombustion chamberSoot

Various technologies presented herein relate to enhancing mixing inside a combustion chamber to form one or more locally premixed mixtures comprising fuel and charge-gas to enable minimal, or no, generation of soot and / or other undesired emissions during ignition and subsequent combustion of the locally premixed mixtures. To enable sufficient mixing of the fuel and charge-gas, a jet of fuel can be directed to pass through a bore of a duct causing charge-gas to be drawn into the bore creating turbulence to mix the fuel and the drawn charge-gas. The duct can be located proximate to an opening in a tip of a fuel injector. An ignition assist component can be located downstream of the duct to facilitate ignition of the fuel / charge-gas mixture.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Apparatus and method for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a first inlet, a first outlet, a cavity configured for receiving a wet coproduct and a binder through the first inlet, and a stirring apparatus within the cavity for premixing the wet coproduct and binder into a substantially homogeneous mixture; a high shear mixer having a housing, a drive apparatus and a high shear apparatus, the housing defining an opening, the drive apparatus being within the housing and for forcing the substantially homogeneous mixture from the premixer into the high shear apparatus, and the high shear apparatus including a rotor, a stator and a screen covering the opening and being for shear mixing the mixture including forcing the mixture through the screen and out of the housing in the form of nucleation enhanced particles; and an agglomerator having an interior chamber sized and configured to receive the nucleation enhanced particles from the high shear mixer and for transforming the nucleation enhanced particles into substantially spherical biomass pellets.

Owner:PURDUE RES FOUND INC

Rectal plug and method of introducing same into a slaughtered animal

InactiveUSRE36994E1Easy to useNot lose viscosityAnimal stomach clearanceSurgeryFood gradePolymixiiformes

Fecal leakage and contamination from the vent opening of an animal carcass during slaughtering and processing is eliminated by injecting a highly viscous material comprising a mixture of food grade constituents through the vent opening so as to create a self-adhering plug in the lower colon and rectum of the animal. The plug material preferably comprises a blended mixture of water, gum, modified food starch and a preservative whose viscosity is in the range of from about 220,000 centipoise to 480,000 centipoise. Being formed from food grade constituents, the offal can safely be harvested and used in animal feed as a by-product of the meat processing operation.

Owner:STARCHTECH

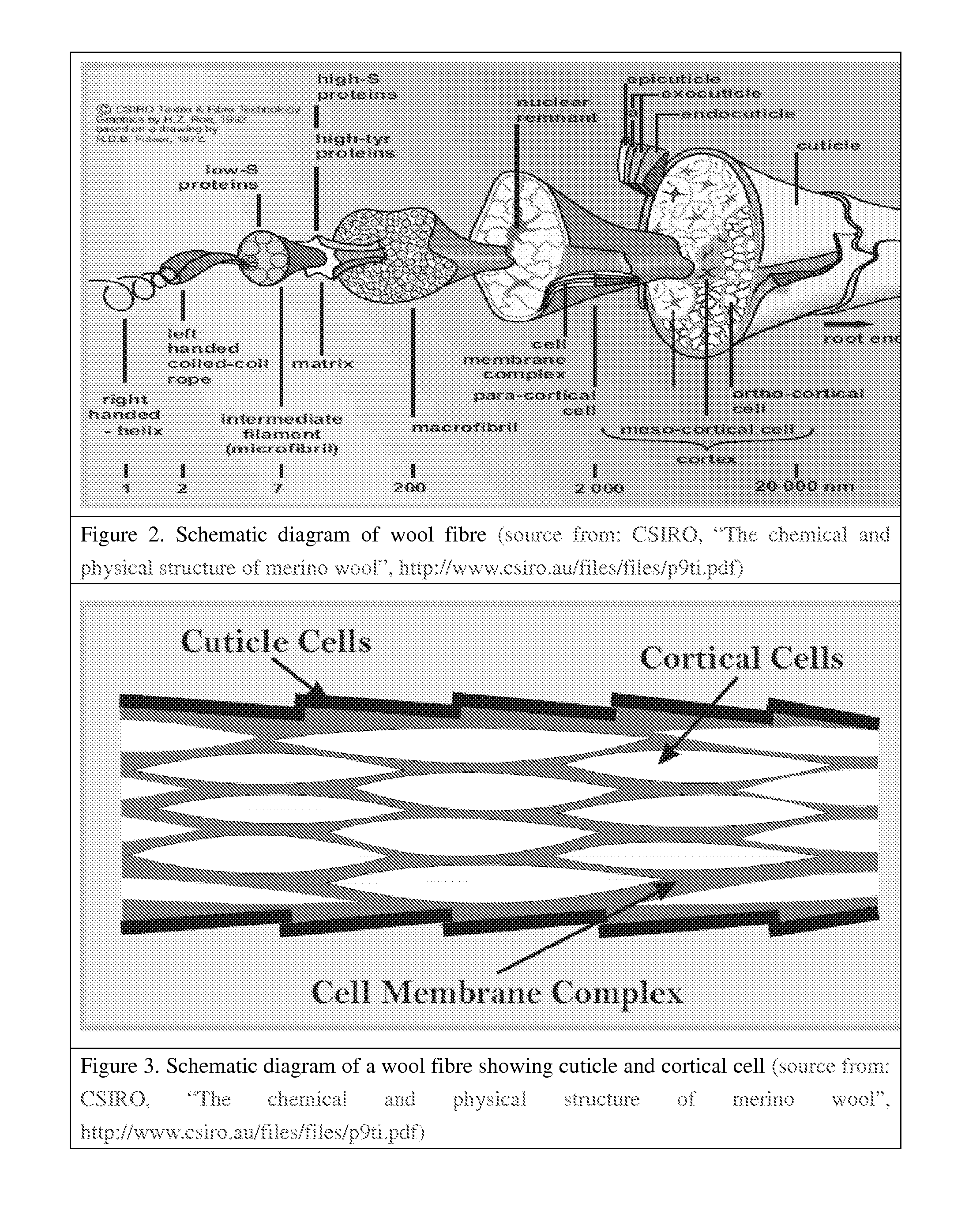

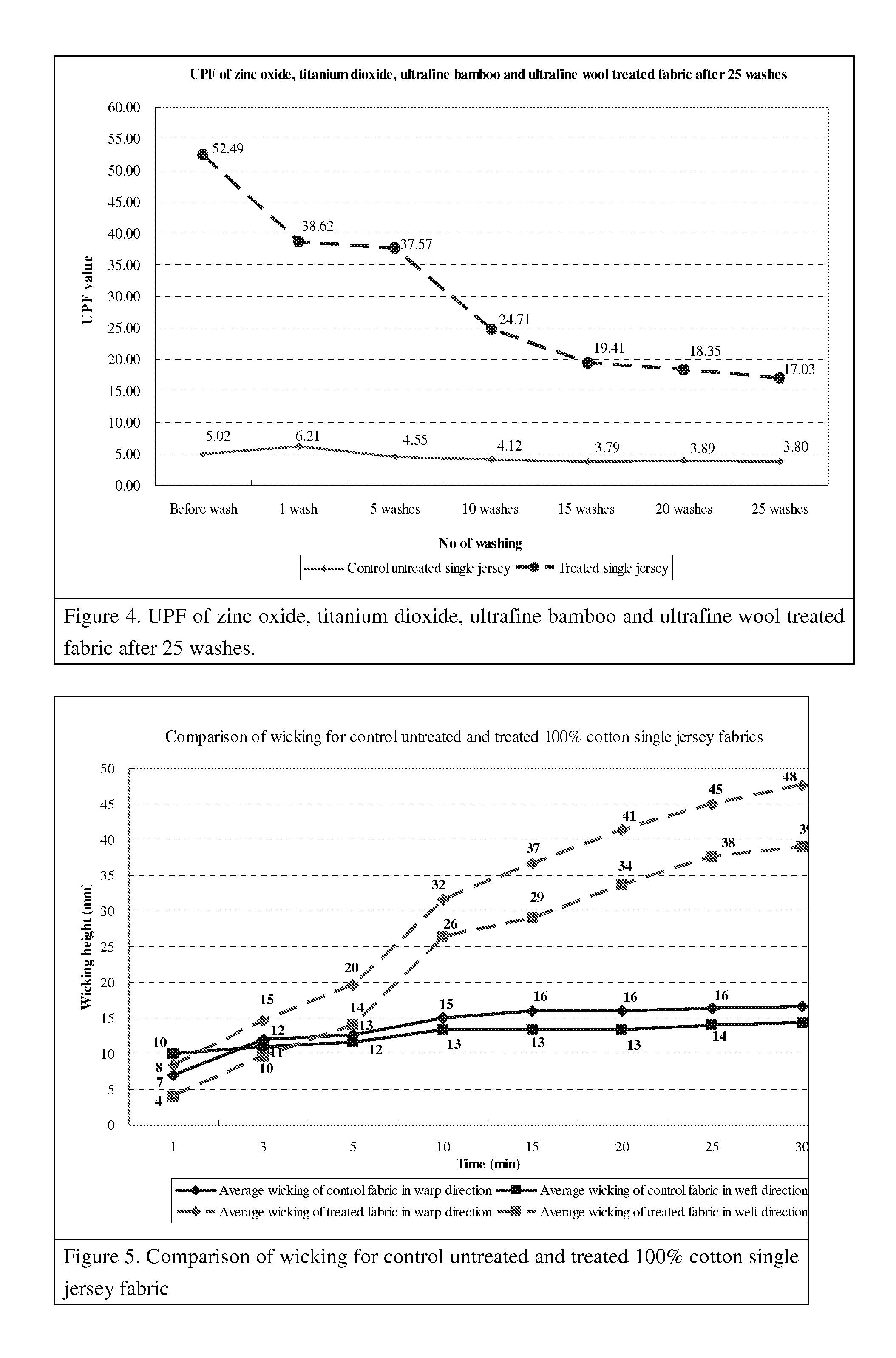

Preparation for application onto a cellulosic fabric or textile material and textile articles comprising same

InactiveUS20110272619A1Increased durabilityGood moisture management propertyLight resistant fibresFiberCellulose

A preparation for application onto a cellulosic fabric or textile material includes a blended mixture of wool particles or wool powder, and a binding agent. The functional additive is carried by the wool particles. The wool particles or wool powder is preferably of macrofibril size or below. Such a preparation exhibits exceptional functional additive-carrying and retention ability which enhances the durability of functional enhancements of a cellulosic fabric material. In another embodiment, the preparation includes a mixture of powdered bamboo fibre, carrier agents, and binding agents. Preferably, the non-charcoal fibrous bamboo powder is nano-sized having an ultrafine particle size, e.g., 1 μm or below. Fabric materials treated with ultrafine bamboo fibre powder have good moisture management properties.

Owner:STERLING PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com