Patents

Literature

487results about "Titanium carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mxene nanosheet and manufacturing method thereof

ActiveUS20170088429A1Material nanotechnologyNitrogen-metal/silicon/boron binary compoundsIodideInorganic compound

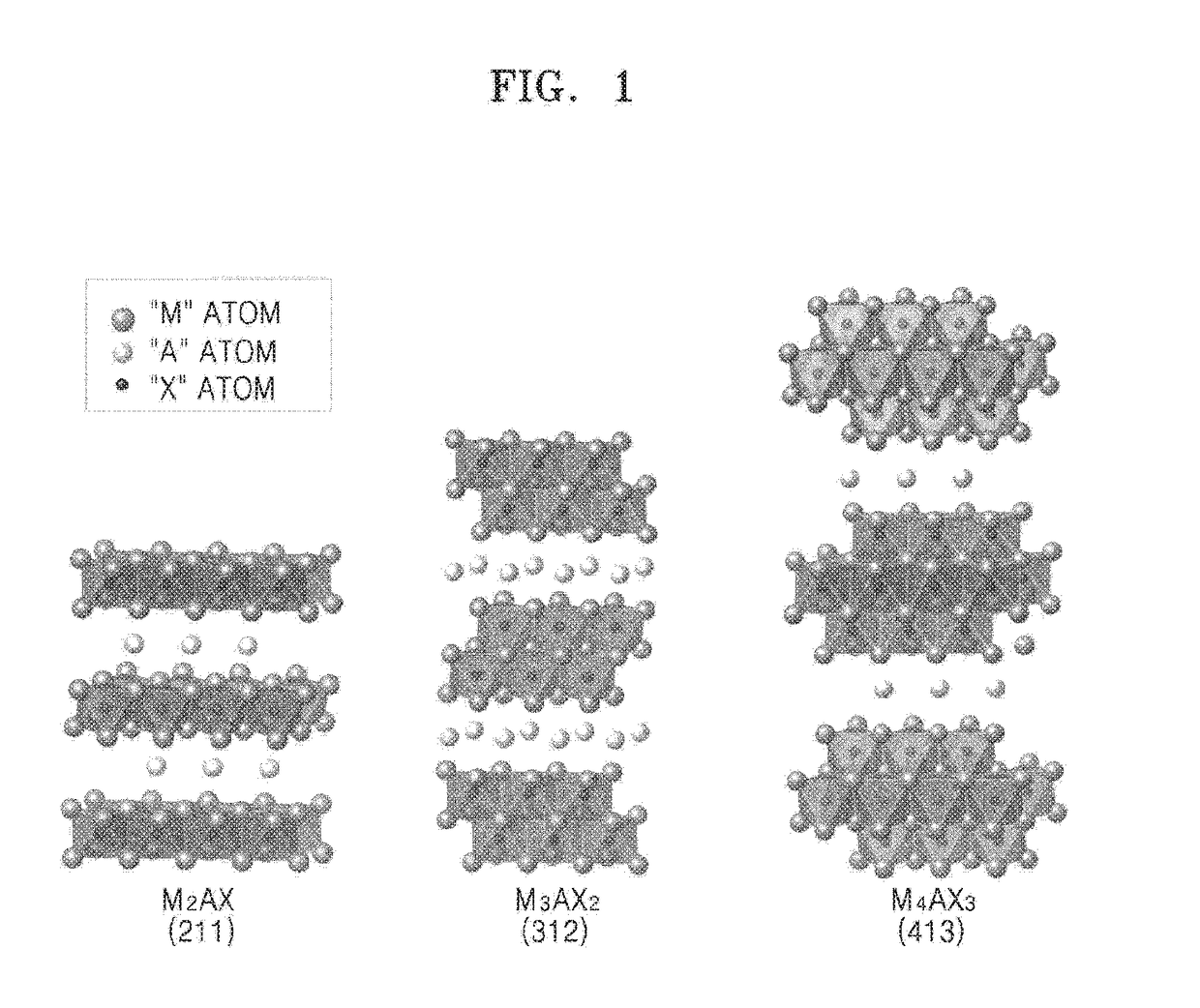

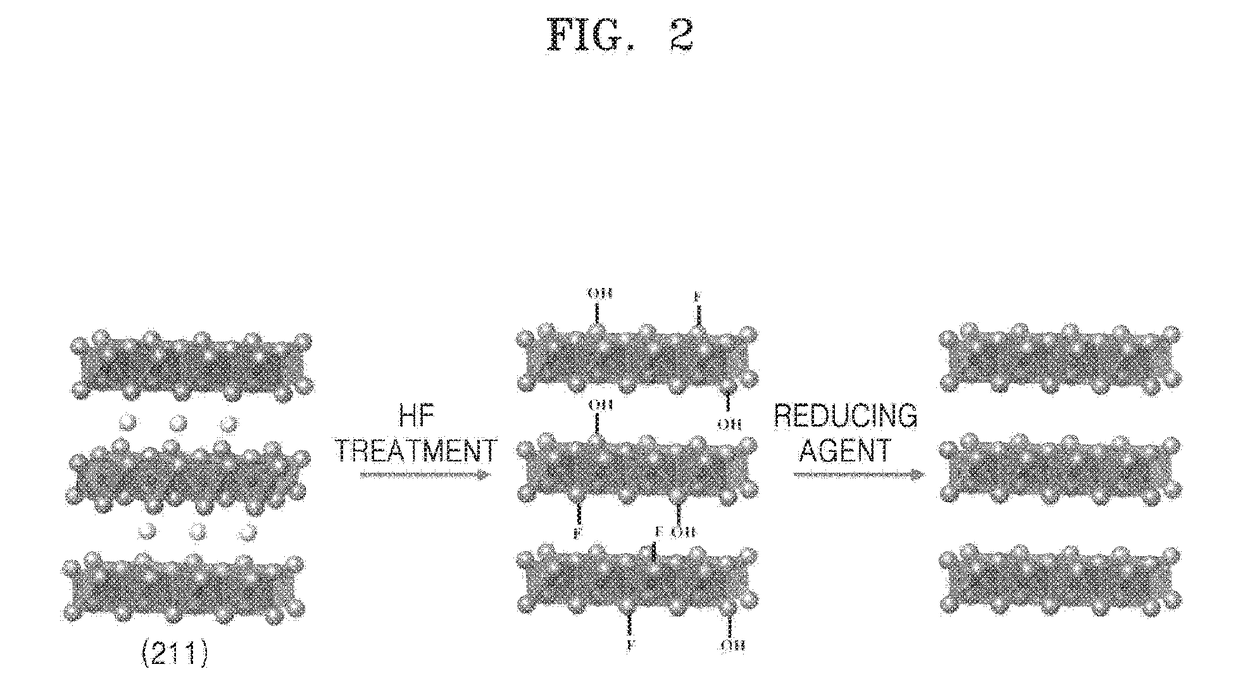

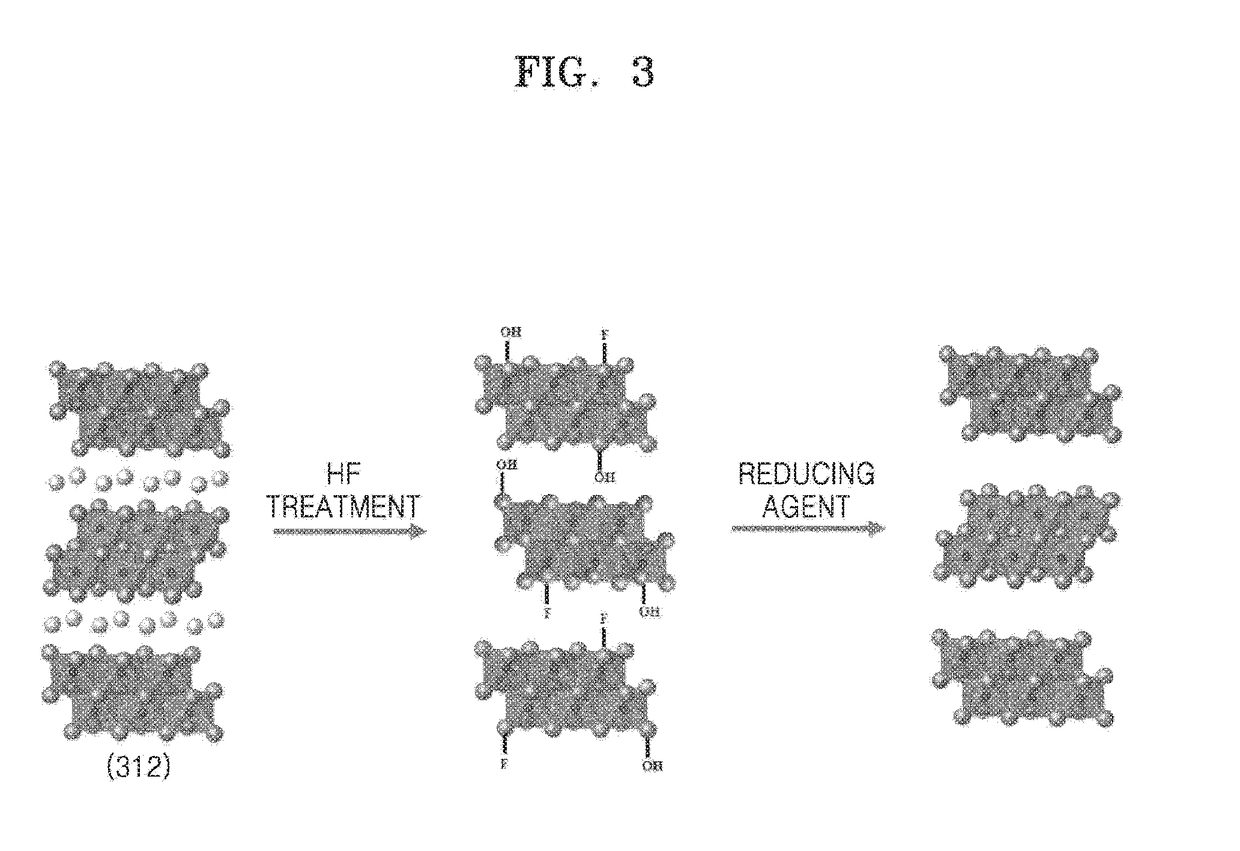

A method of manufacturing a MXene nanosheet includes removing an A atomic layer from an inorganic compound having a formula of Mn+1AXn to form a nanosheet, the nanosheet having a formula of Mn+1XnTs, and reducing the nanosheet having a formula of Mn+1XnTsto form an MXene nanosheet, the MXene nanosheet having a formula of Mn+1Xn, wherein M is at least one of Group 3 transition metal, Group 4 transition metal, Group 5 transition metal, and Group 6 transition metal, A is at least one of a Group 12 element, Group 13 element, Group 14 element, Group 15 element and Group 16 element, X is one of carbon (C), nitrogen (N) and a combination thereof, Ts is one of oxide (O), epoxide, hydroxide (OH), alkoxide having 1-5 carbon atoms, fluoride (F), chloride (Cl), bromide (Br), iodide (I), and a combination thereof, and n is one of 1, 2 and 3.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV +1

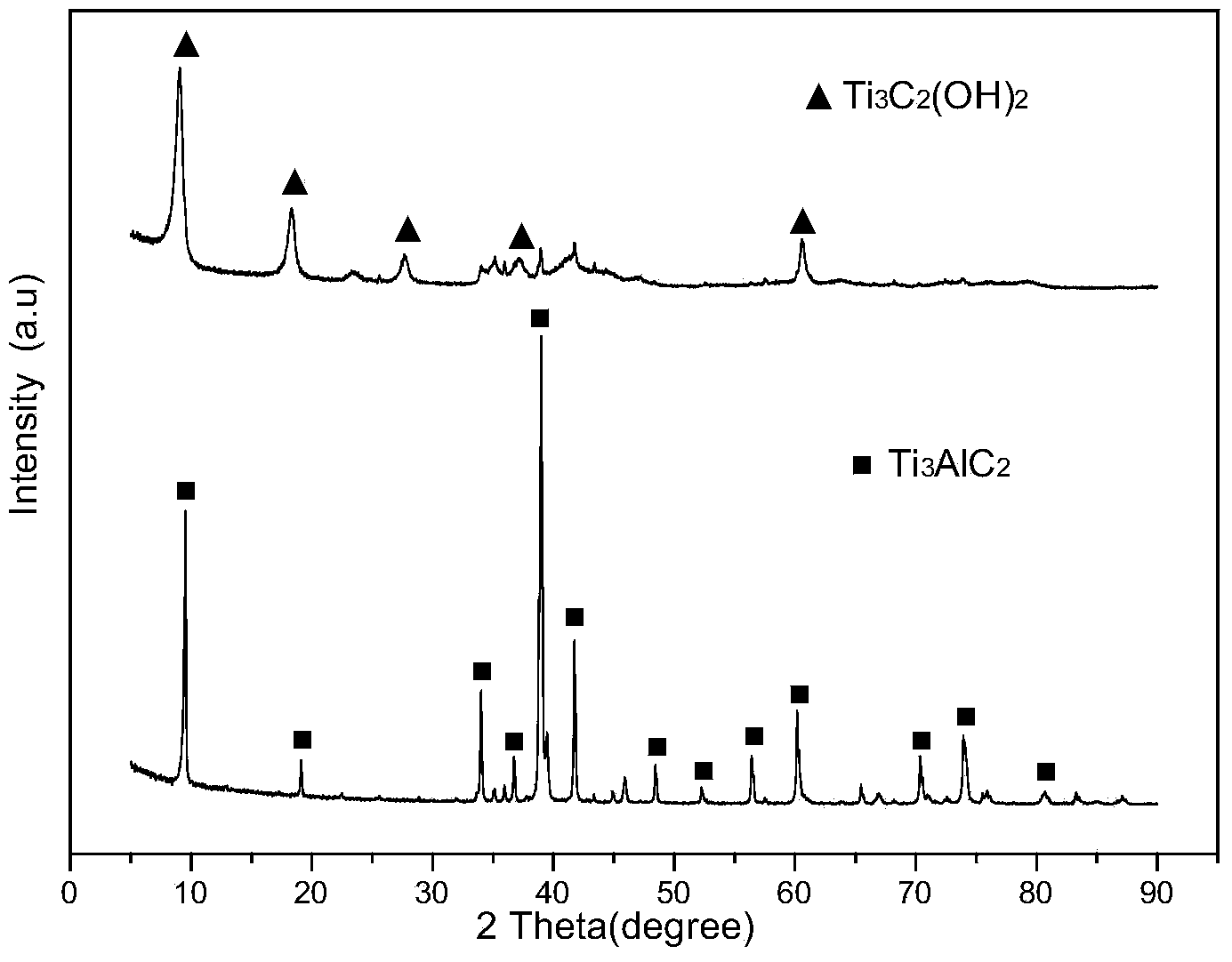

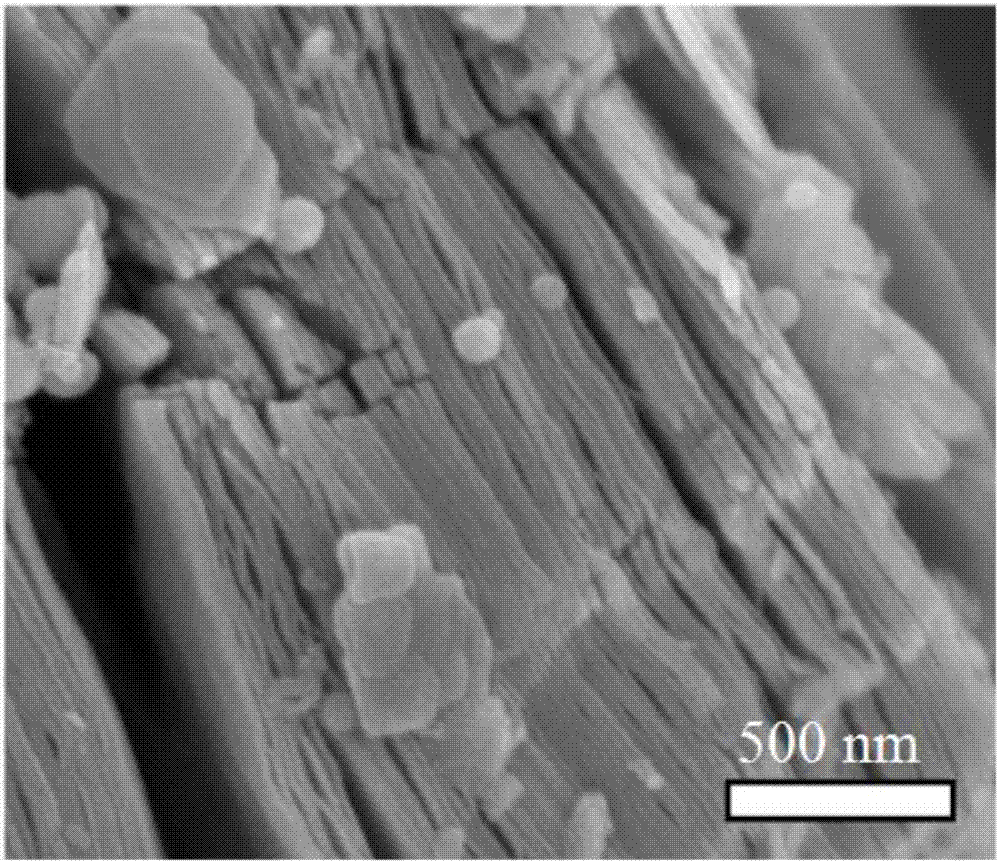

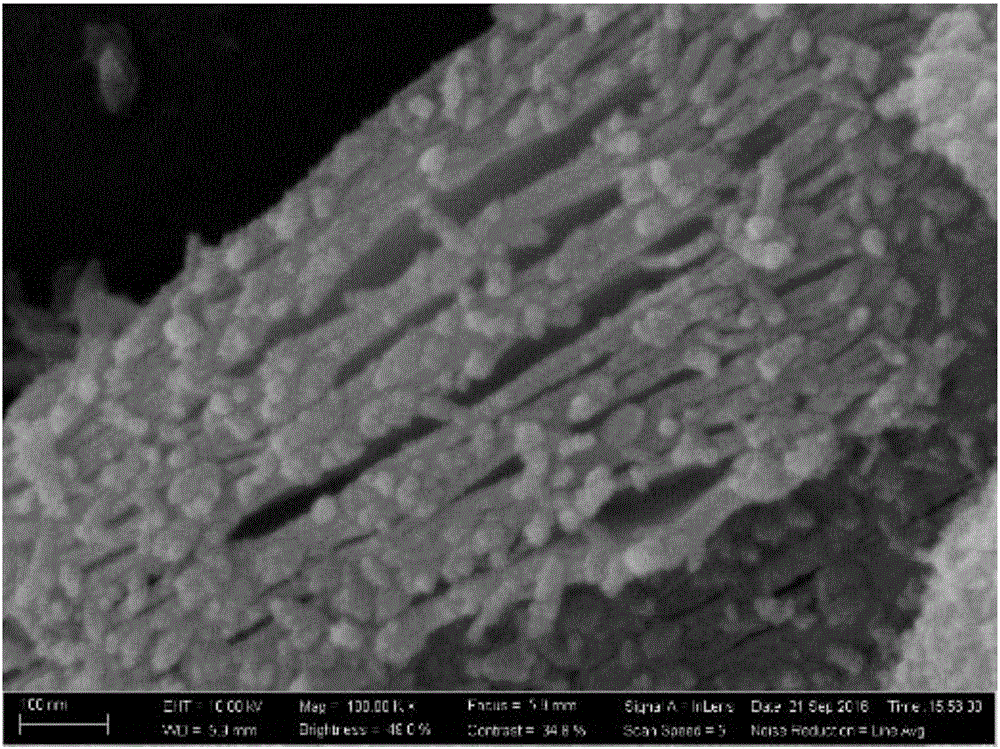

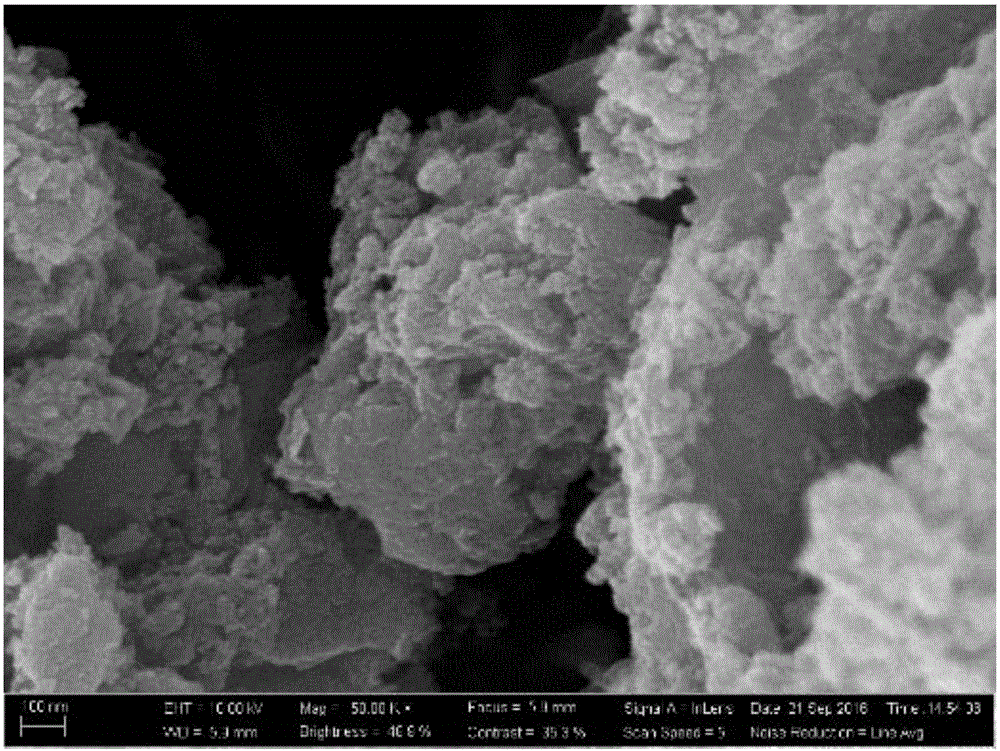

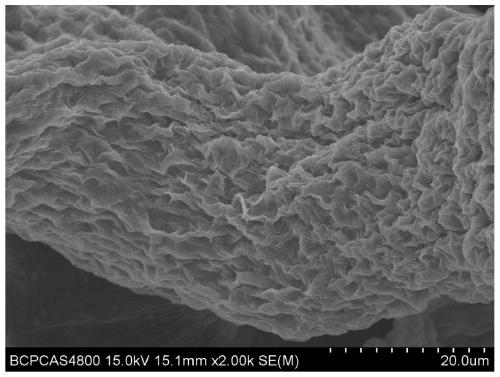

Method for preparing graphene-like two-dimensional laminar titanium carbide nanoplate

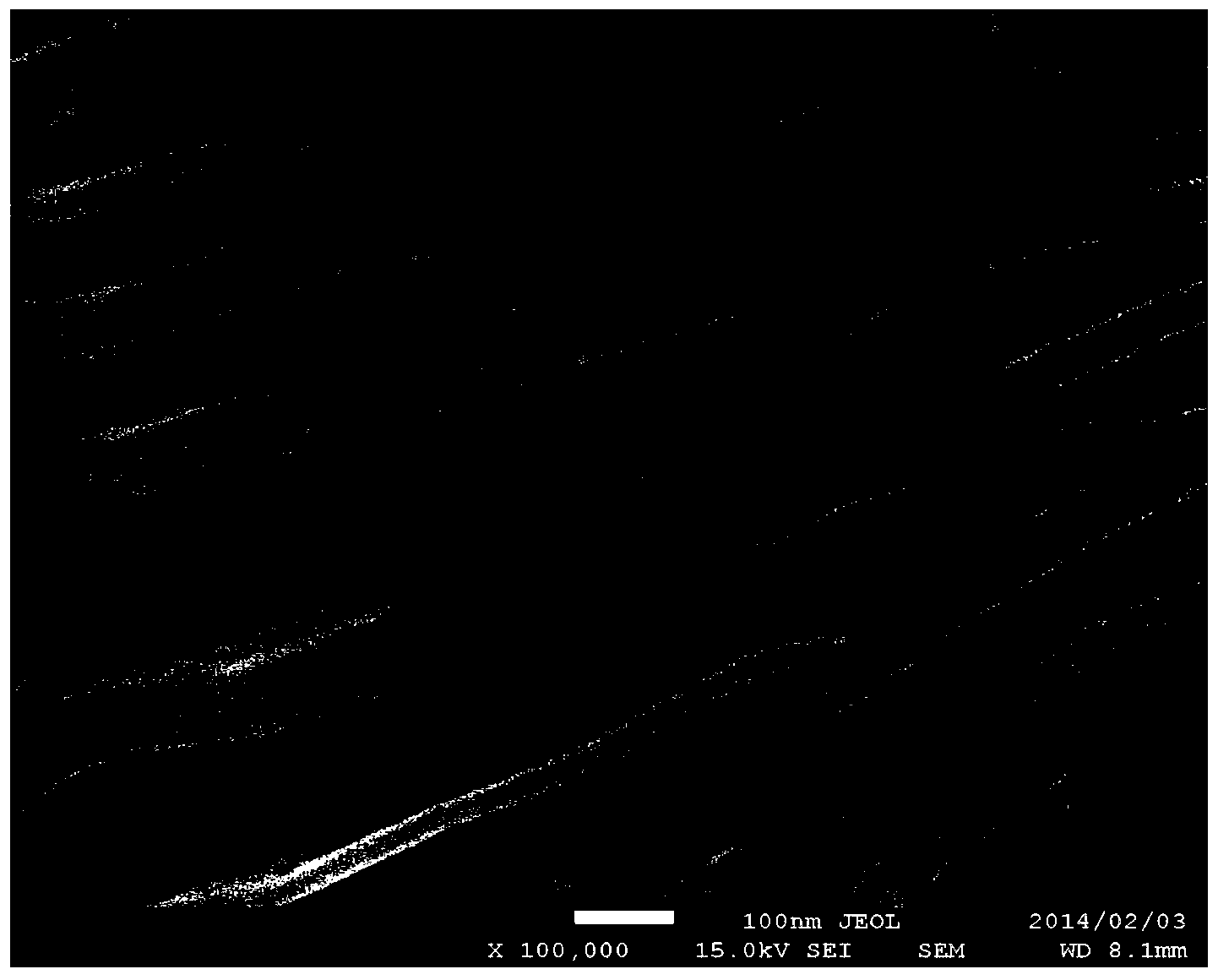

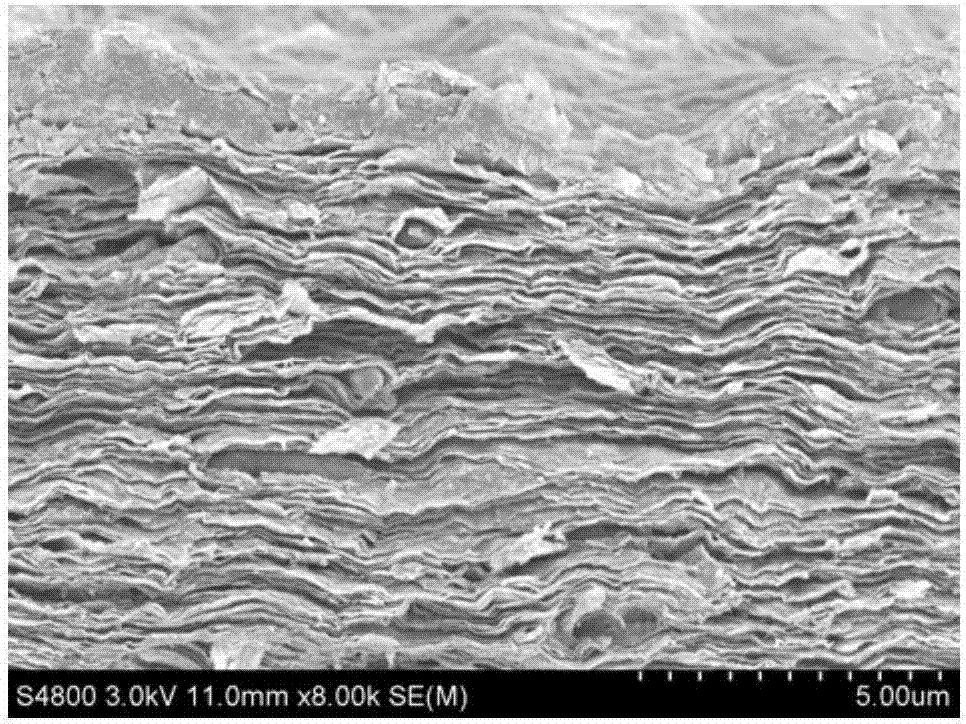

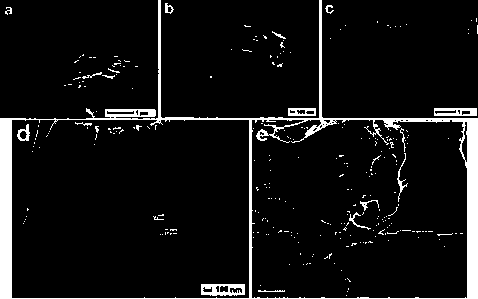

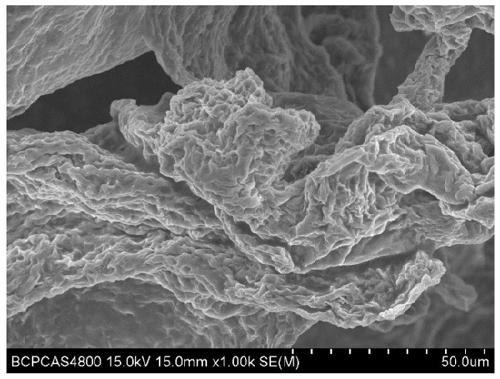

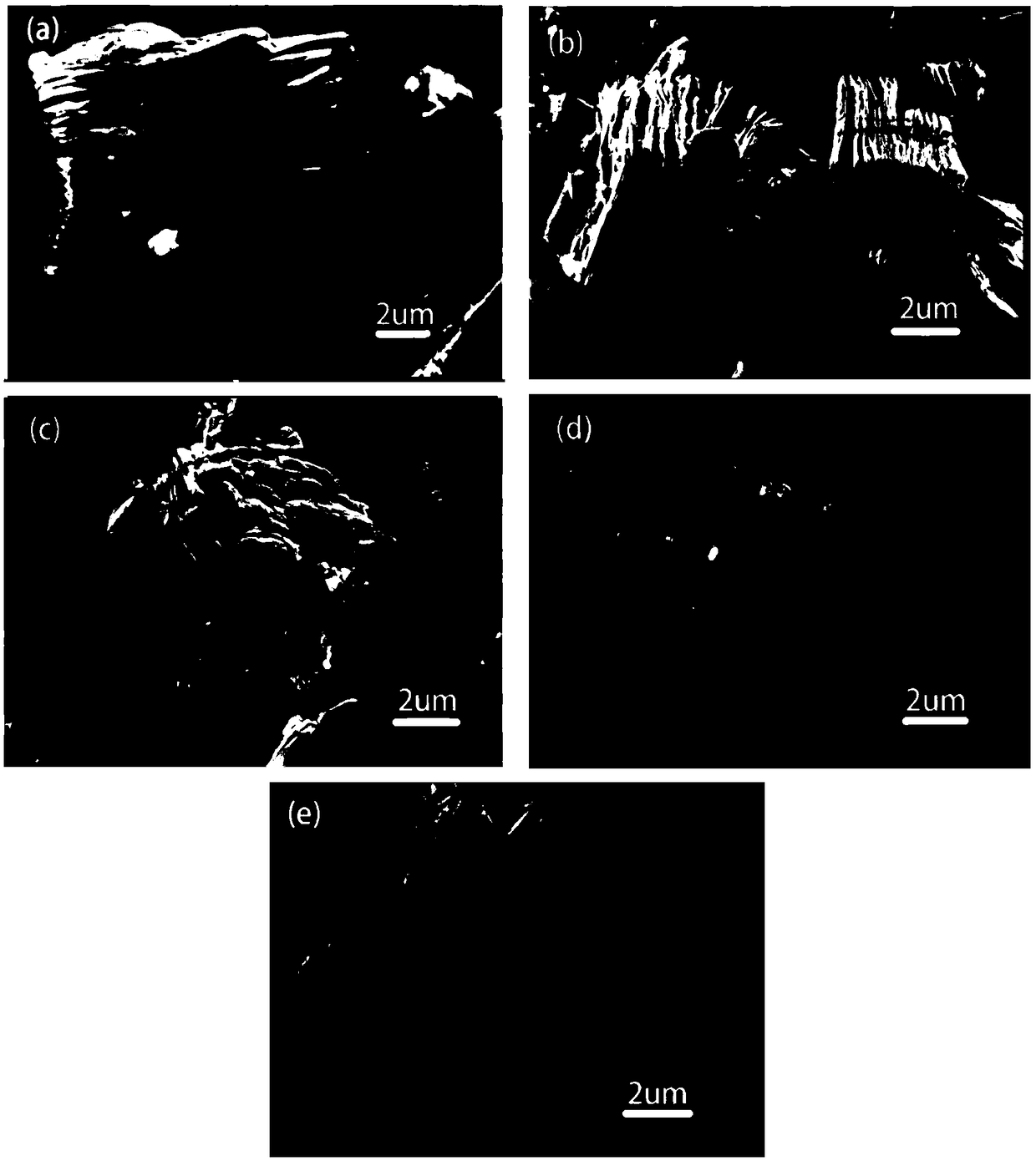

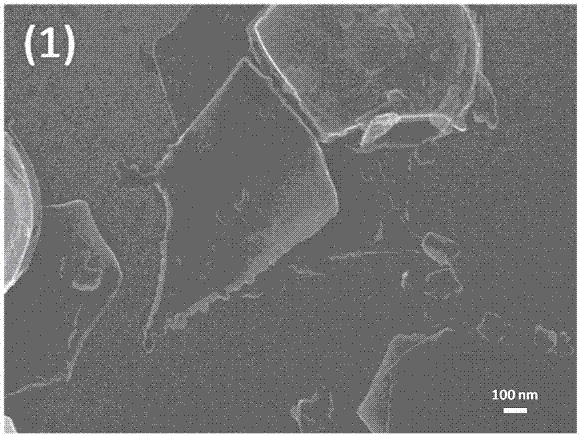

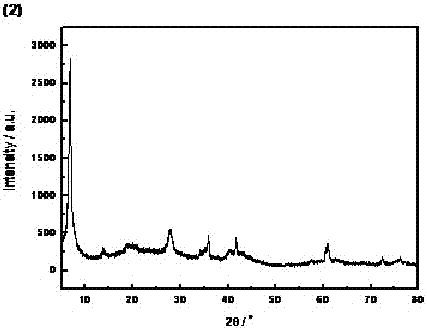

InactiveCN104016345AHigh purityHigh crystallinityMaterial nanotechnologyTitanium carbideSem micrographsCrystallinity

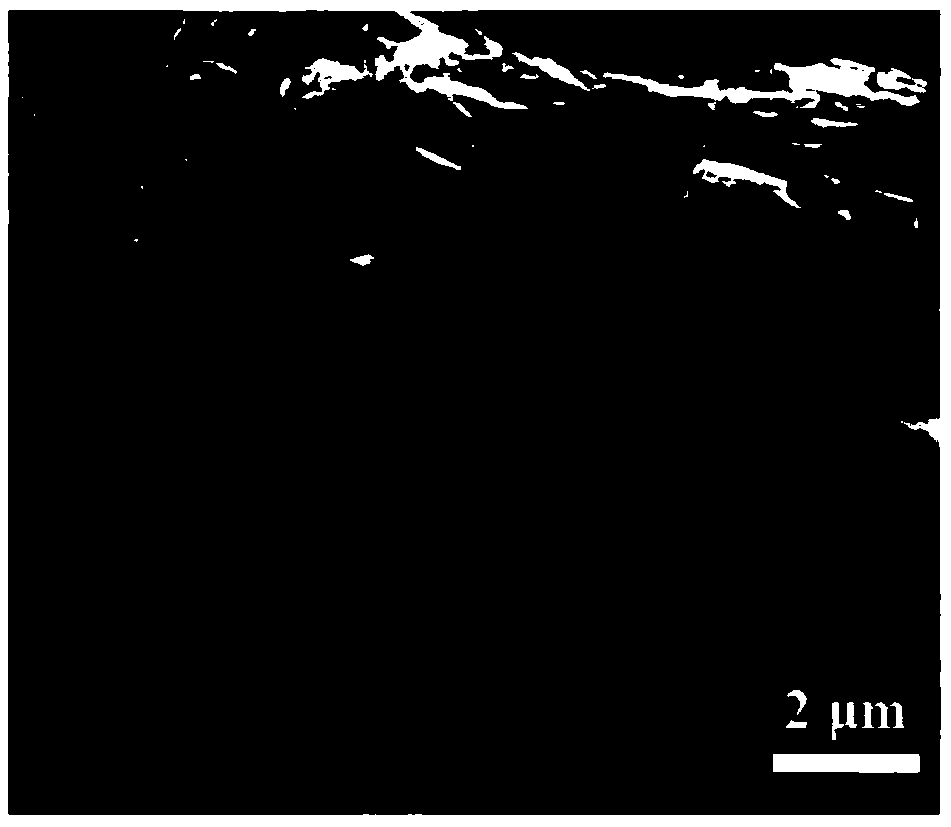

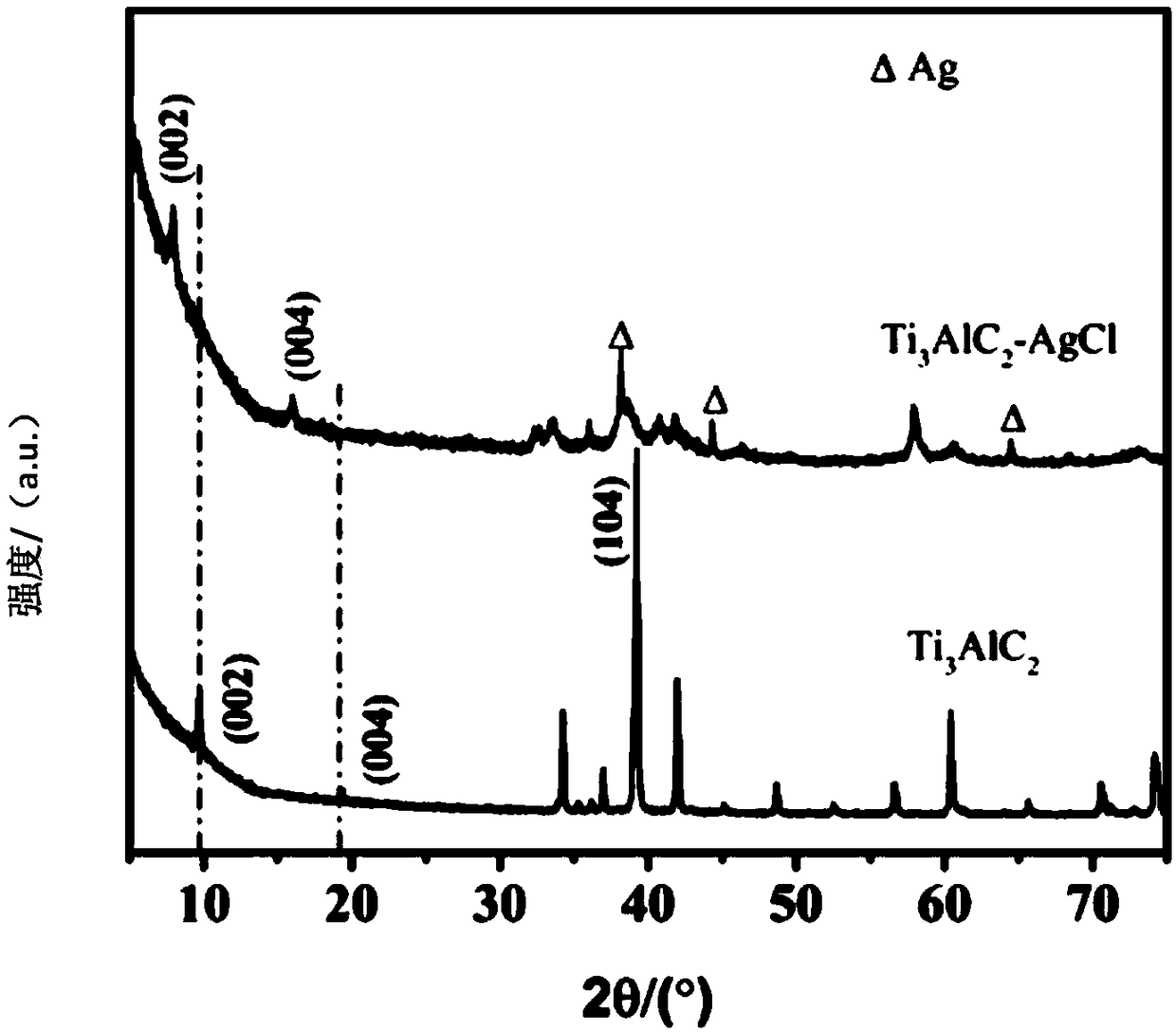

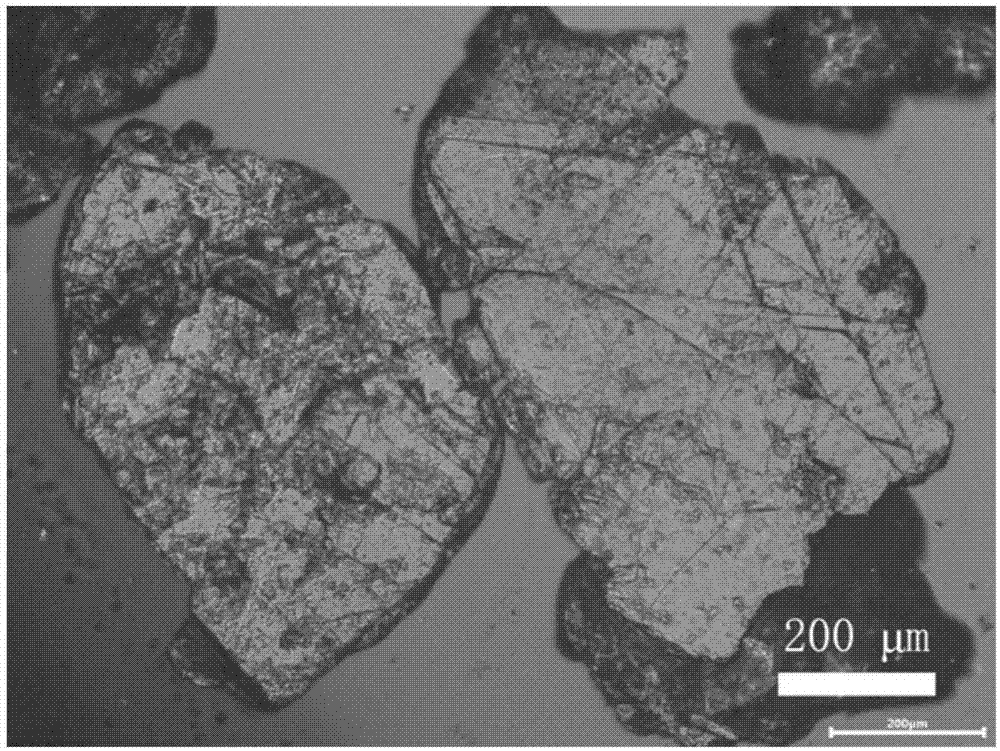

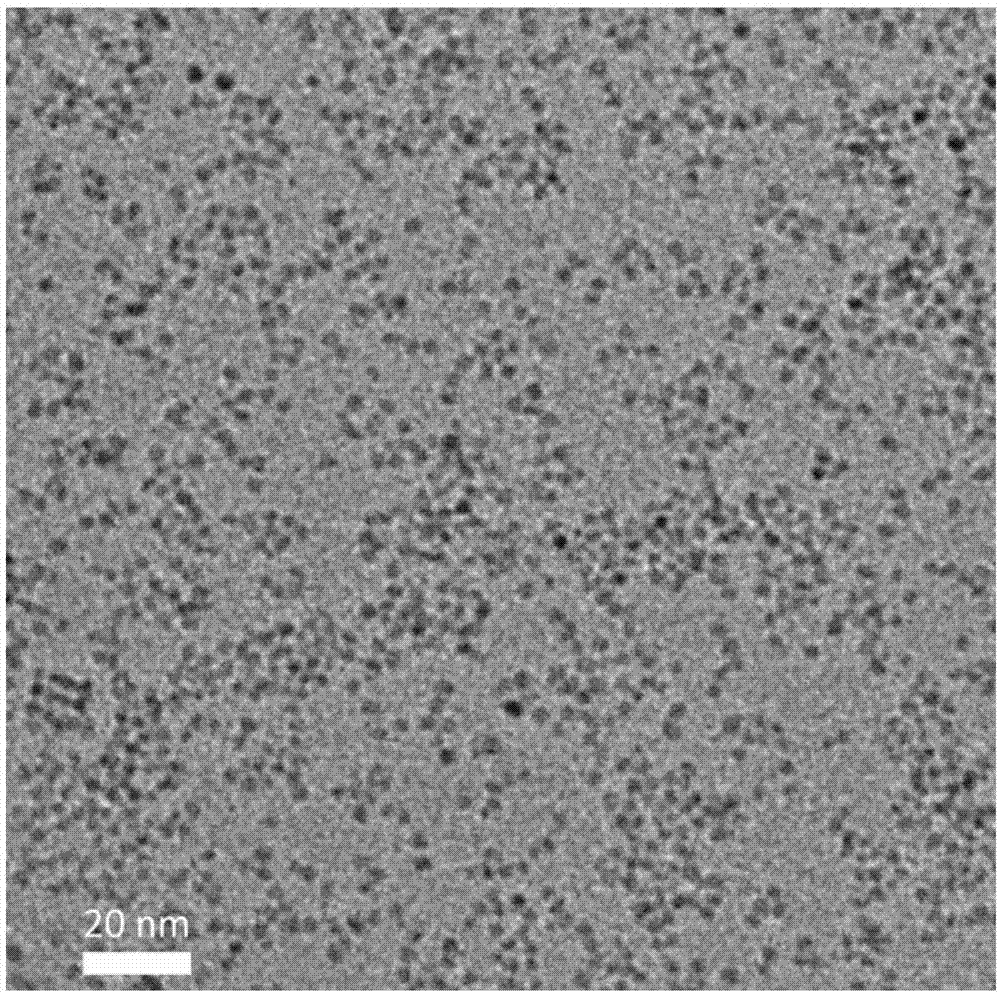

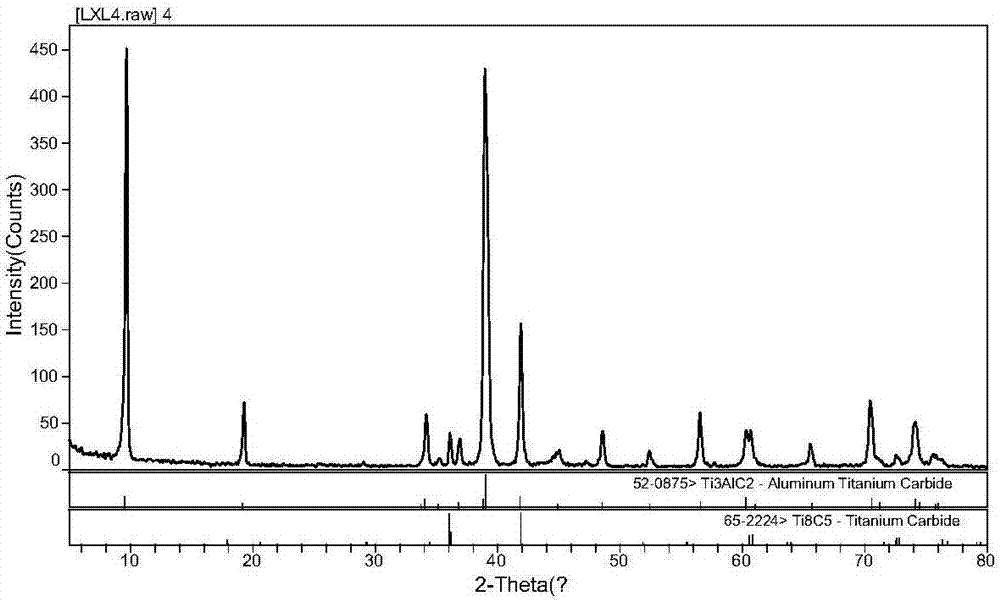

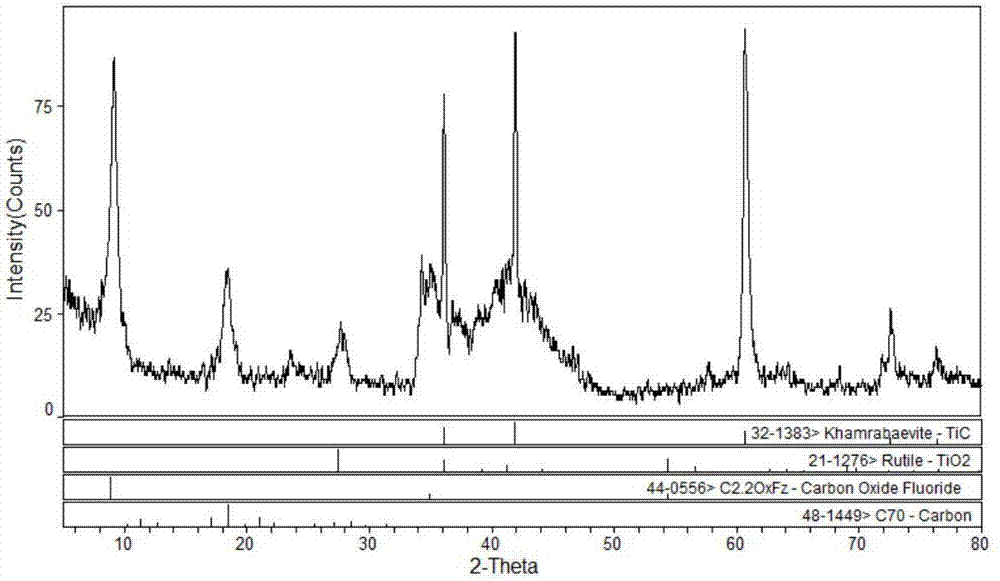

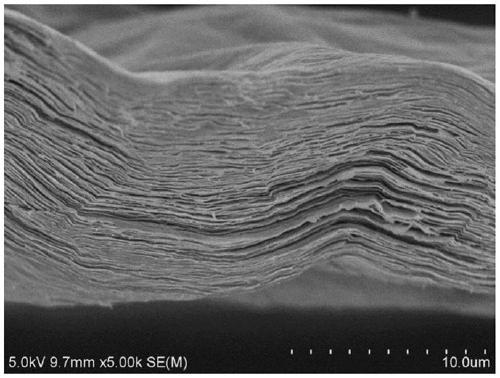

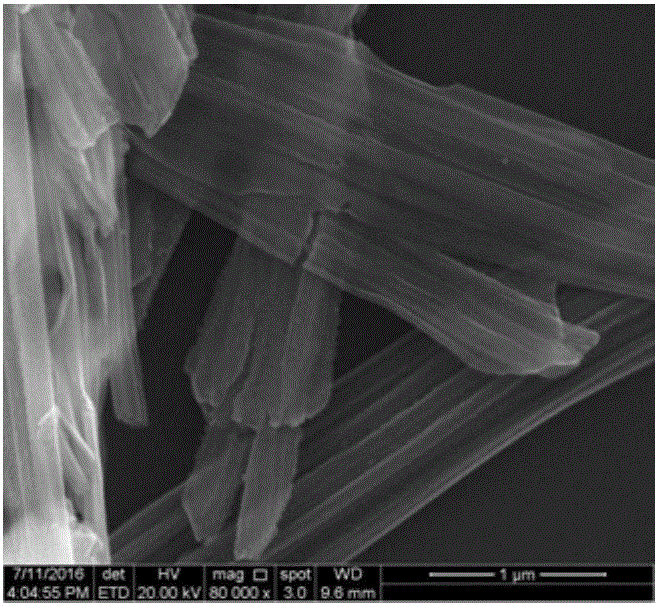

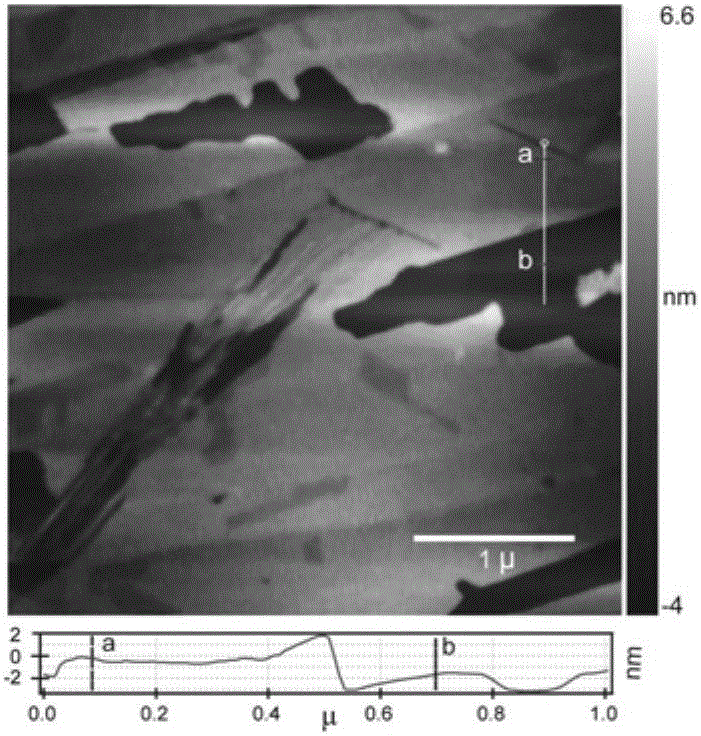

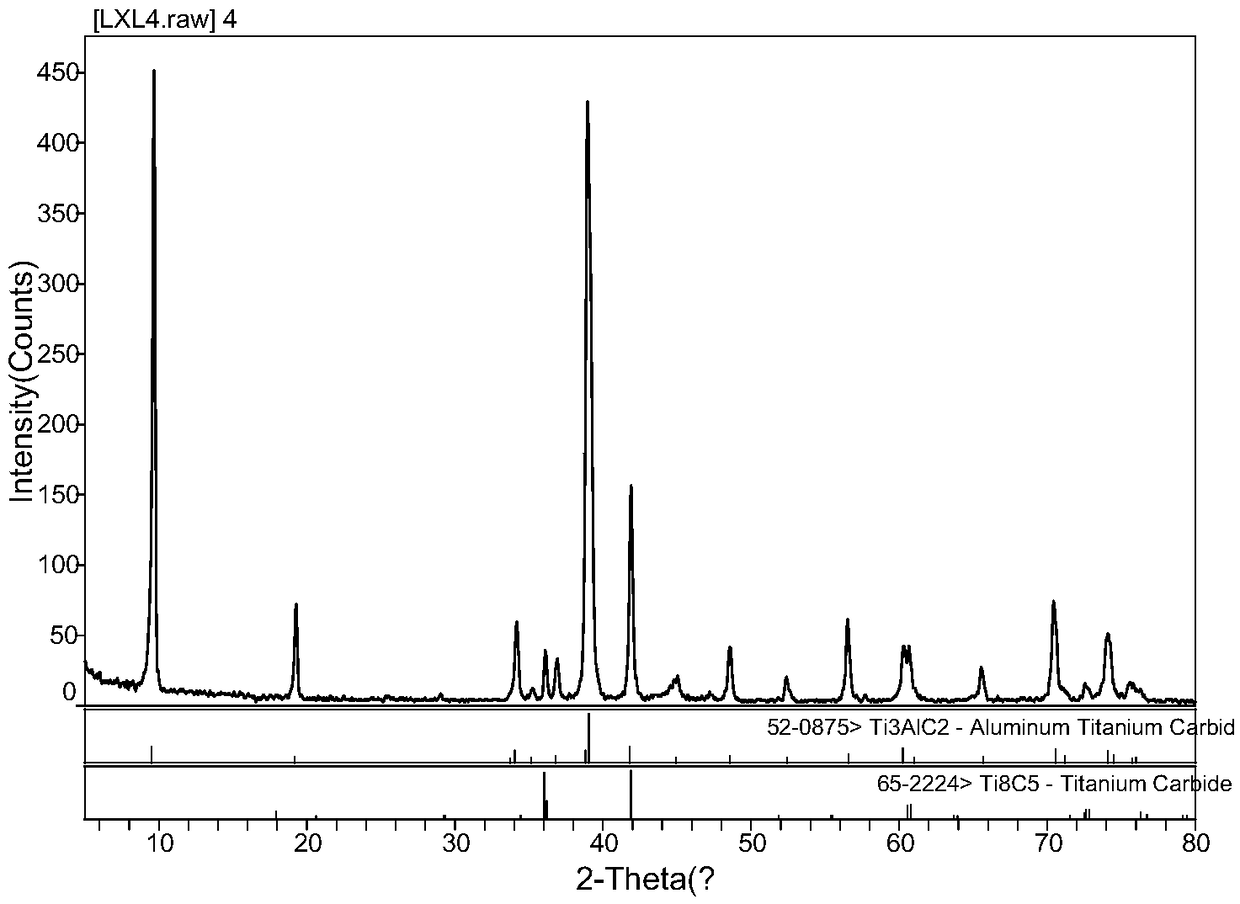

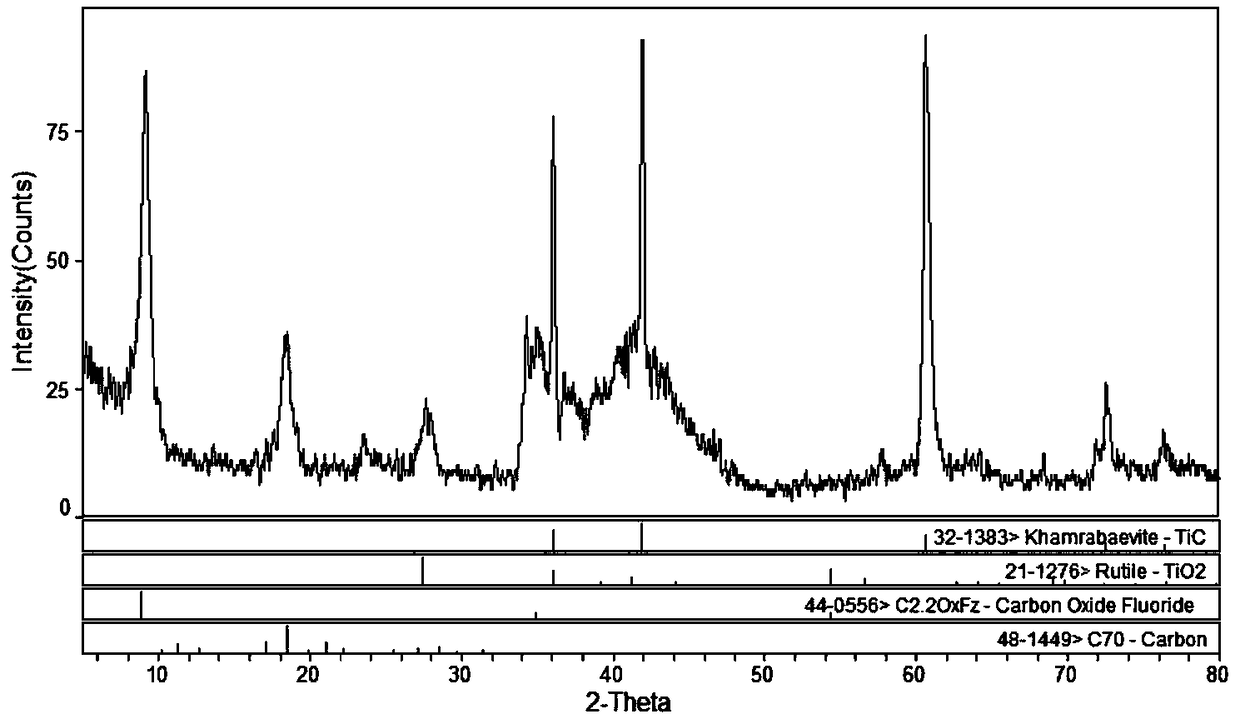

The invention discloses a method for preparing a graphene-like two-dimensional laminar titanium carbide nanoplate. The method comprises the following steps: preparing Ti3AlC2 powder by an in-situ hot-pressing solid-liquid reaction; preparing two-dimensional titanium carbide by a chemical liquid phase reaction; performing vacuum calcination post-treatment, and the like. The method can be used for preparing a Ti3AlC2 precursor with excellent crystallinity and high purity under simple process flow, stable process parameters, controllable process, high efficiency, low cost, short time and low pressure; the information that the transverse size of the two dimensional Ti3AlC2 nanoplate prepared by the method can be 5-10 microns, the average thickness of a single layer is about 10-20 nanometers can be found from an SEM picture, the inter-laminar spacing is remarkably enlarged after calcination treatment, and the laminar surface is regular and smooth.

Owner:HOHAI UNIV

Physical forms of MXene materials exhibiting novel electrical and optical characteristics

ActiveCN107001051ANitrogen-metal/silicon/boron binary compoundsTitanium carbideElectrical conductorOptical property

Owner:DREXEL UNIV

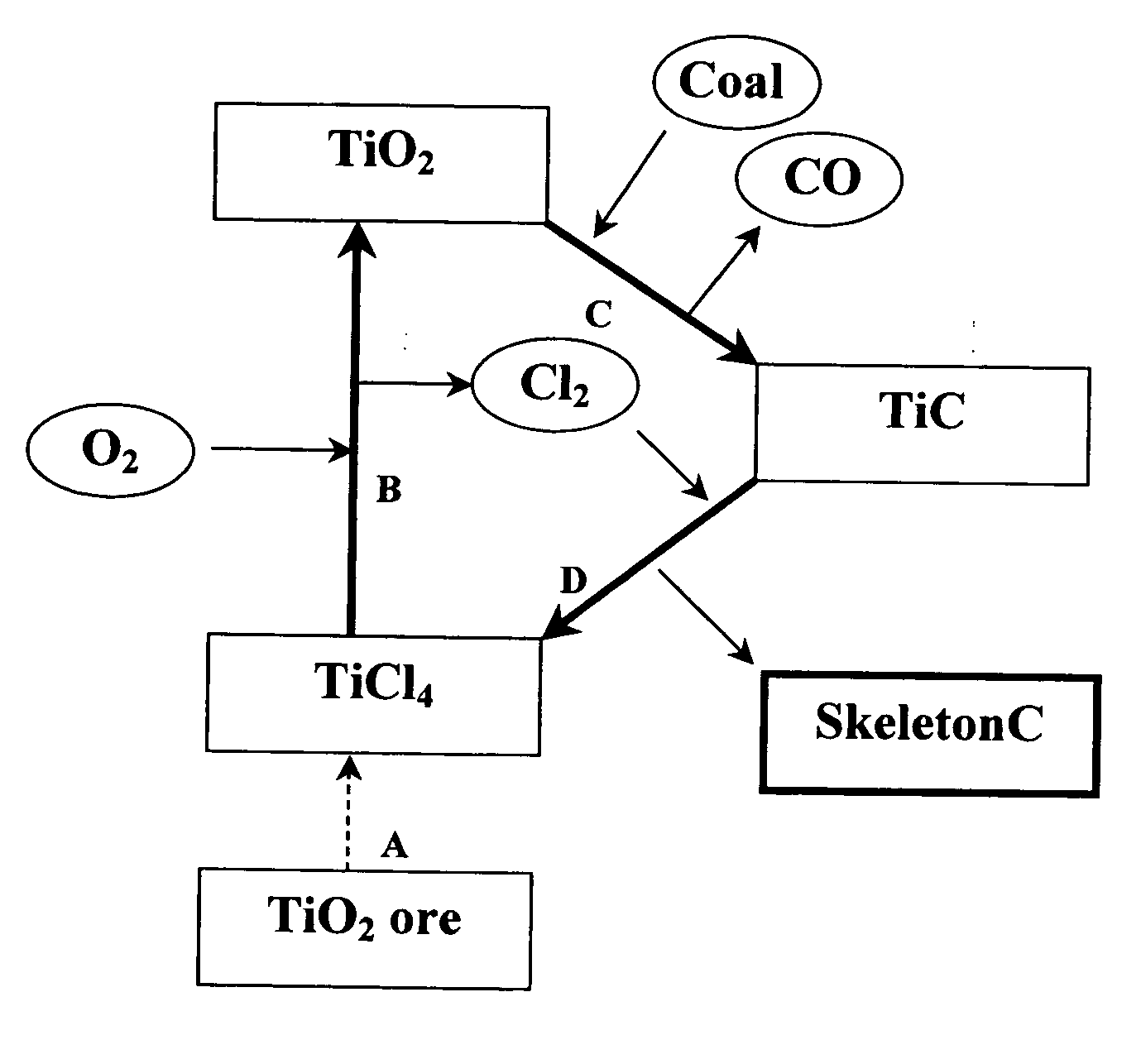

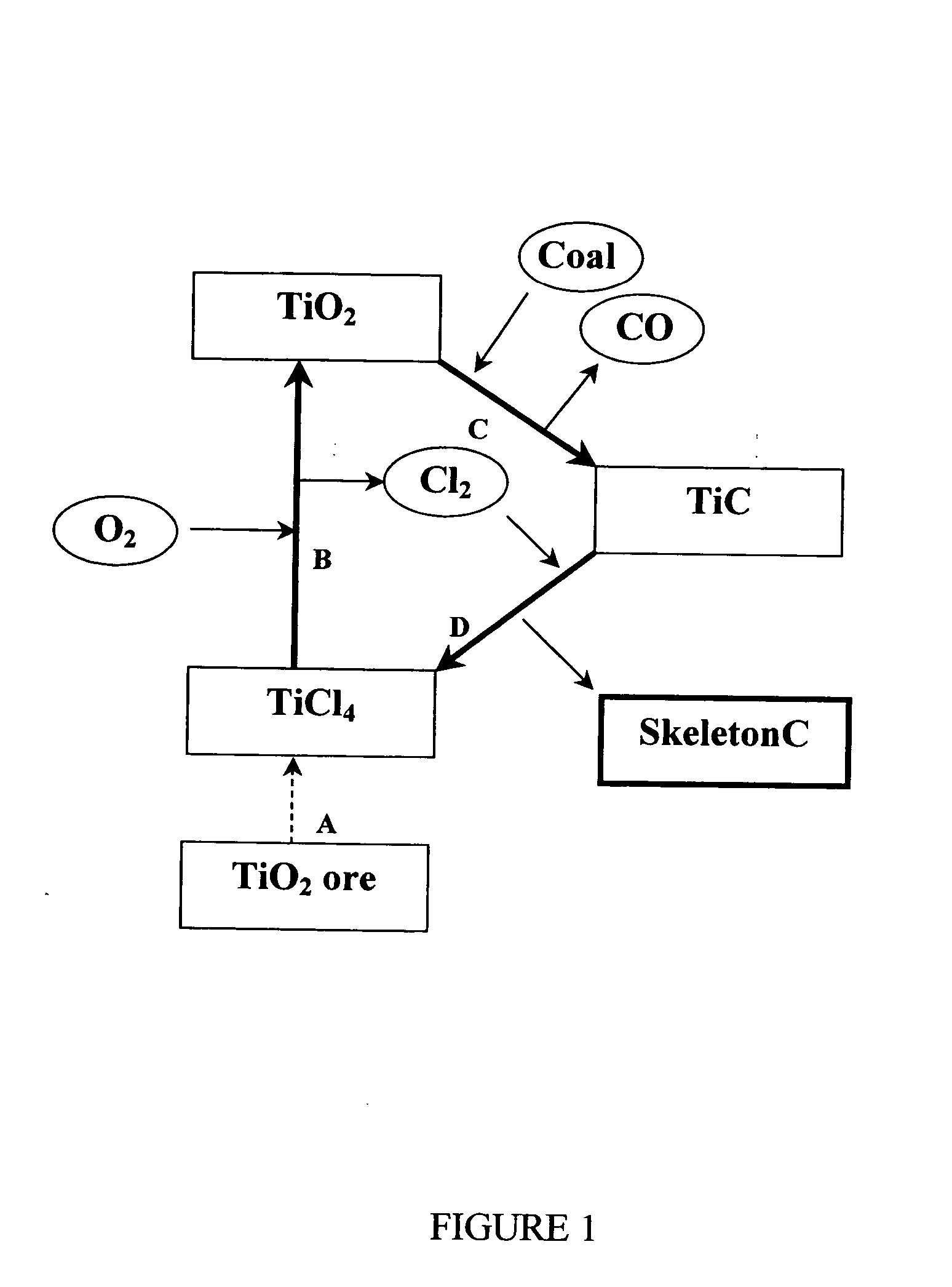

Method for manufacturing the nanoporous skeletonC material

InactiveUS20060251565A1Noticeable economic benefit in productionWaste minimizationTitanium carbideCarbon preparation/purificationMetal chlorideCarbide

A method to produce the nanostructured carbon material comprising the steps of synthesis of metal or metalloid oxide (STAGE B) from respective metal or metalloid chloride, synthesis of metal or metalloid carbide (STAGE C) from respective metal or metalloid oxide and synthesis of metal or metalloid chloride (STAGE D) from the solid product wherein the metal or metalloid carbide in STAGE C is synthesized from the respective metal or metalloid oxide produced in STAGE B.

Owner:CARBON EE OU

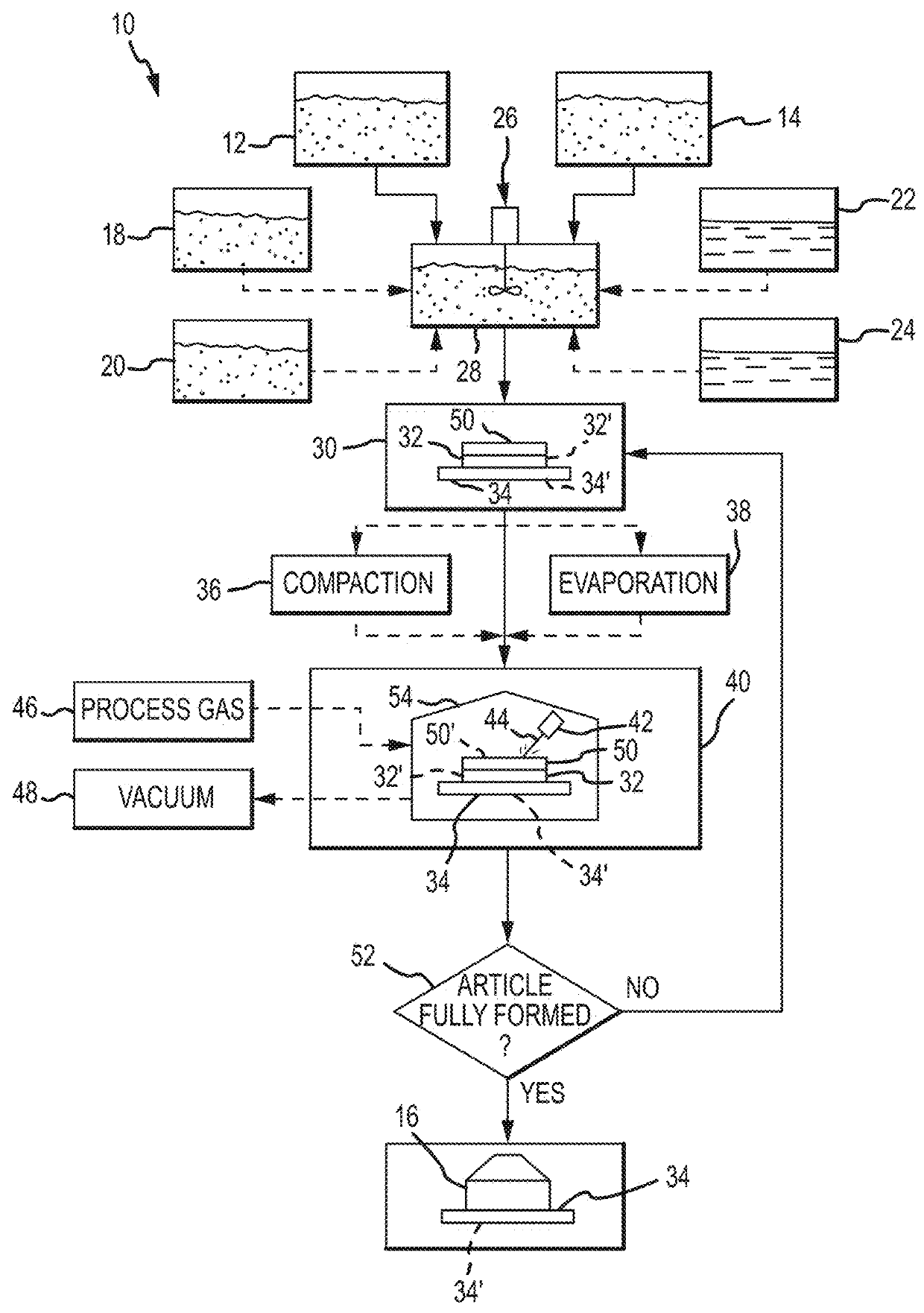

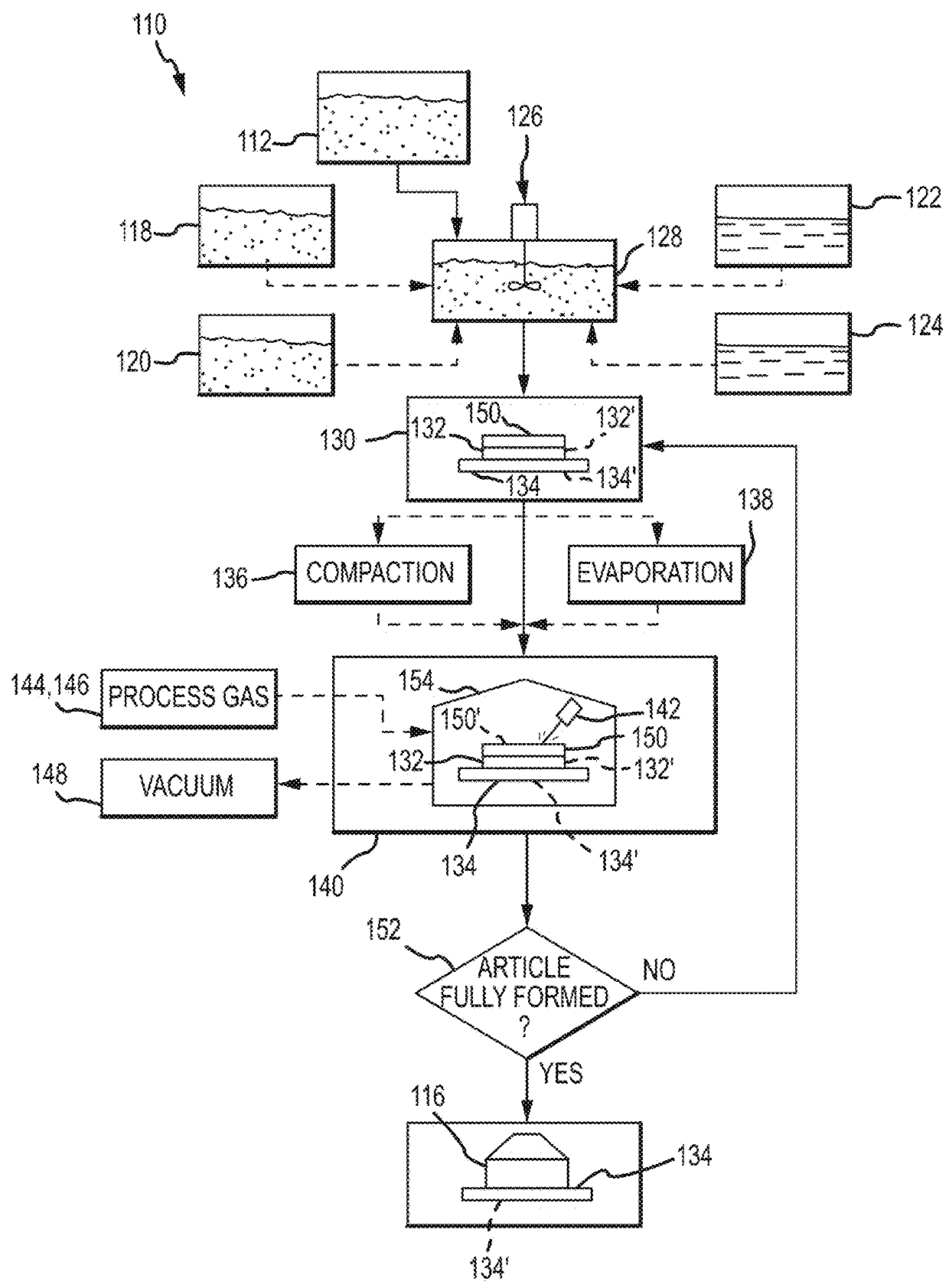

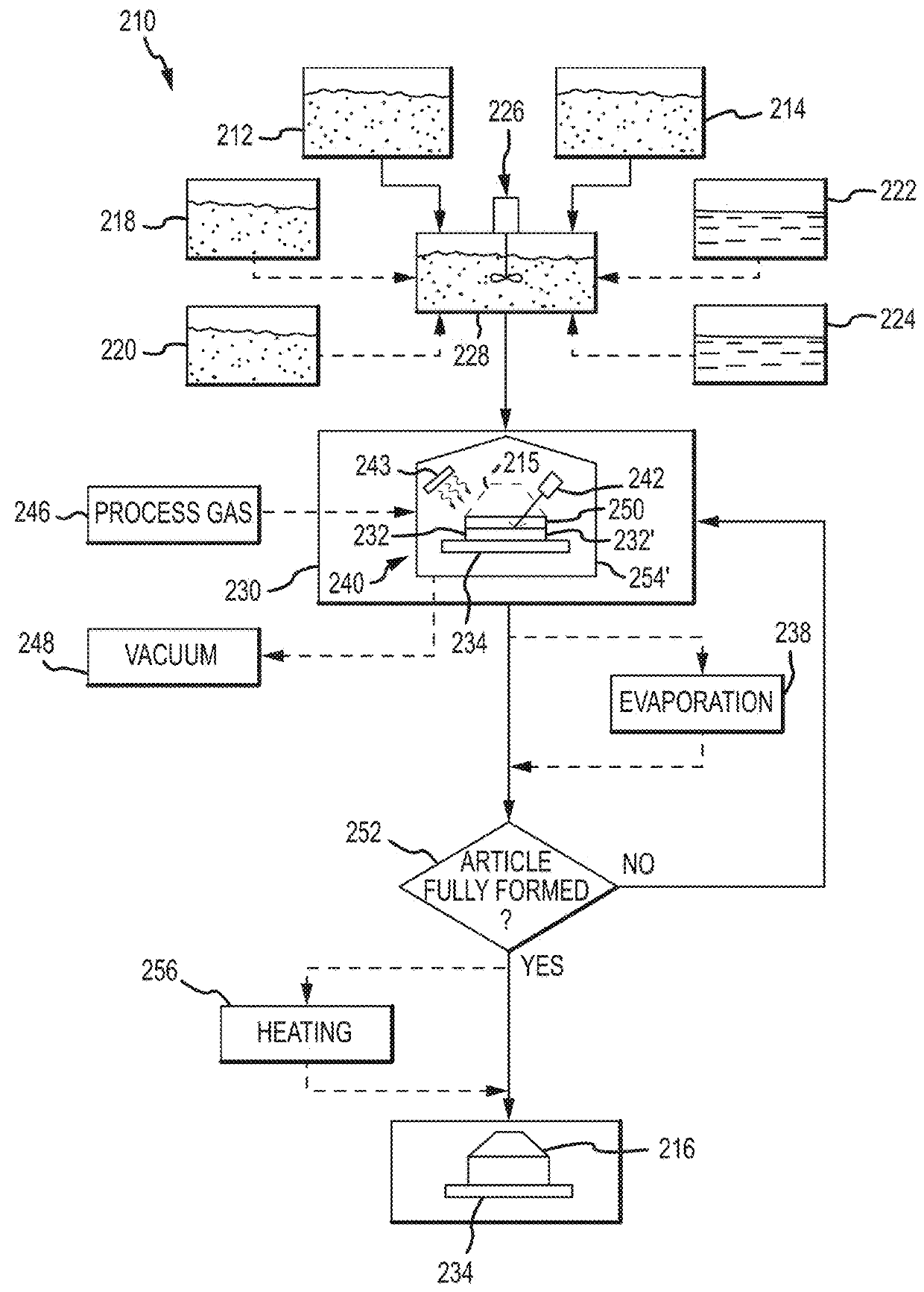

Additive manufacturing of metal alloys and metal alloy matrix composites

ActiveUS20180161874A1High strengthPrevent partial lowAdditive manufacturing apparatusTitanium carbideMetal alloyNucleation

An additive manufacturing method of producing a metal alloy article may involve: Providing a supply of a metal alloy in powder form; providing a supply of a nucleant material, the nucleant material lowering the nucleation energy required to crystallize the metal alloy; blending the supply of metal alloy powder and nucleant material to form a blended mixture; forming the blended mixture into a first layer; subjecting at least a portion of the first layer to energy sufficient to raise the temperature of the first layer to at least the liquidus temperature of the metal alloy; allowing at least a portion of the first layer to cool to a temperature sufficient to allow the metal alloy to recrystallize; forming a second layer of the blended mixture on the first layer; and repeating the subjecting and allowing steps on the second layer to form an additional portion of the metal alloy article.

Owner:ELEMENTUM 3D INC

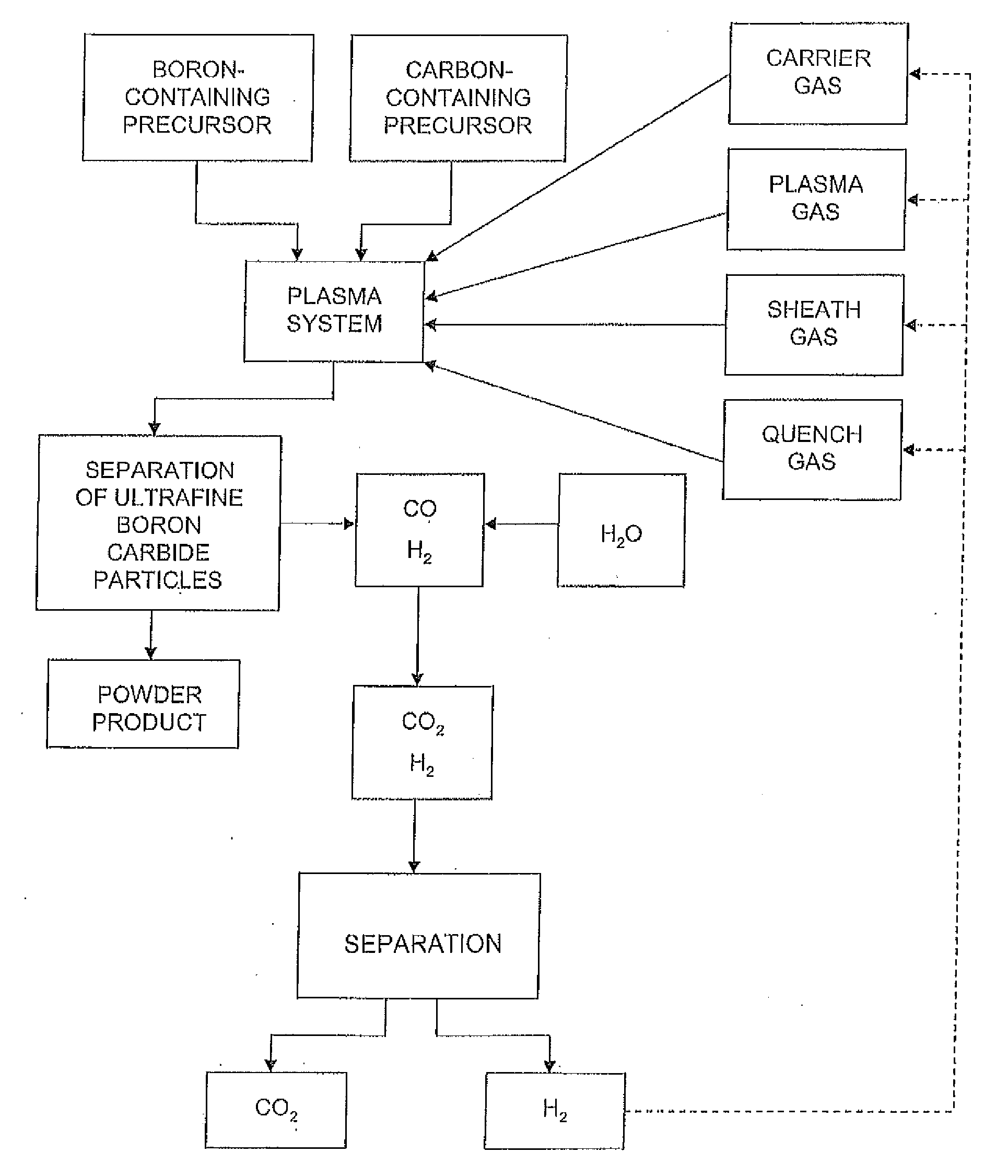

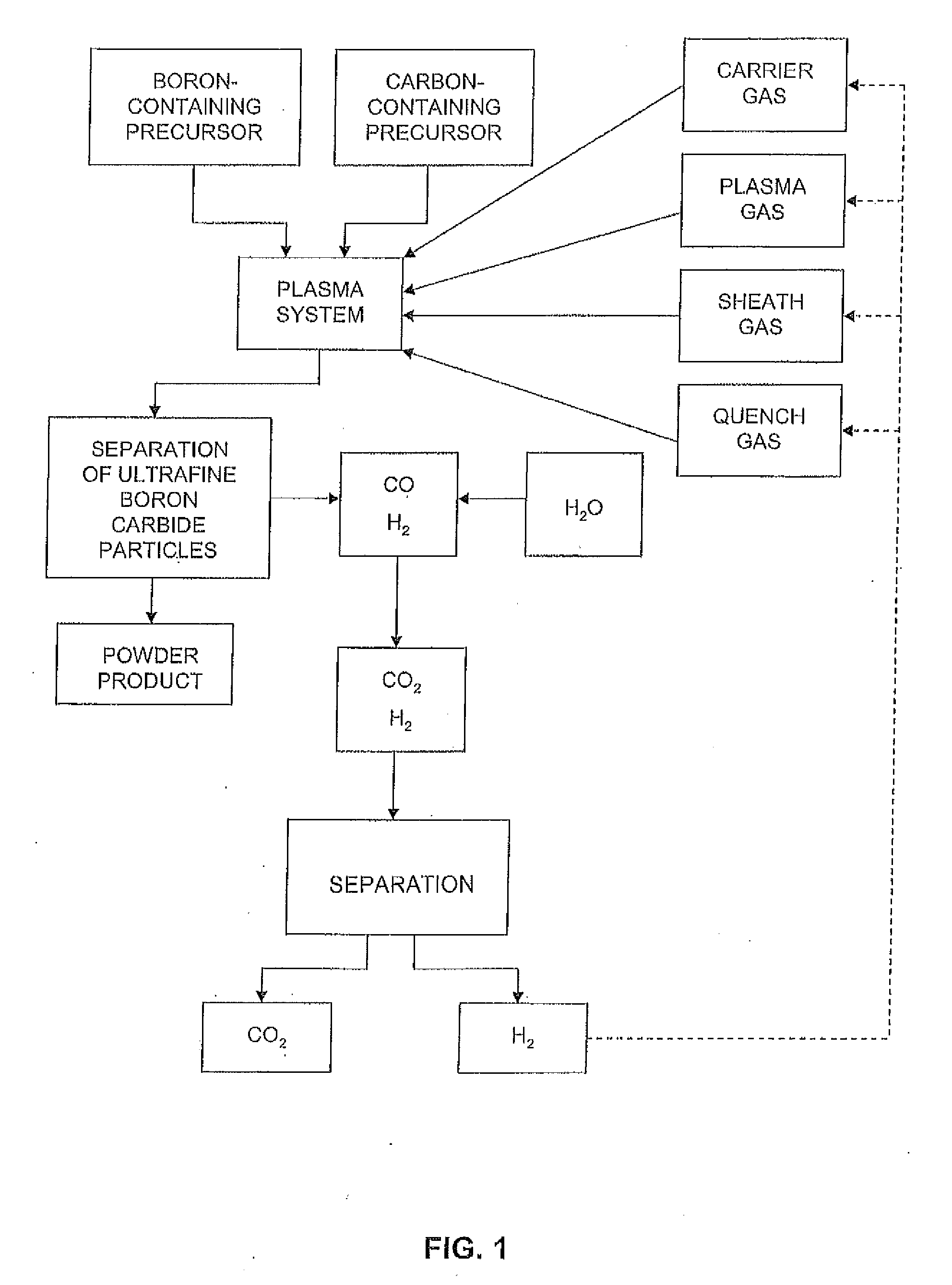

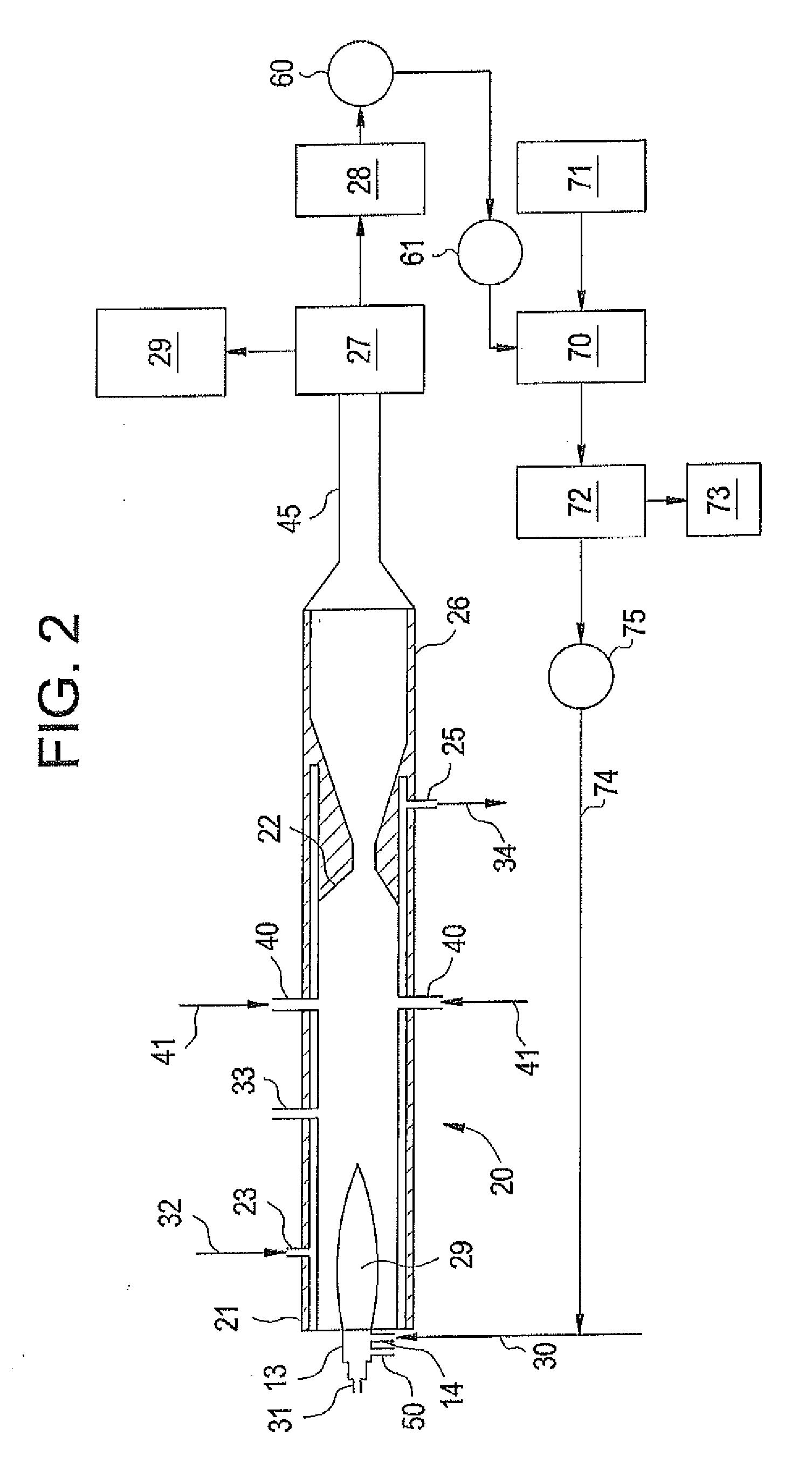

Methods for the production of ultrafine metal carbide particles and hydrogen

A method for producing ultrafine metal carbide particles and hydrogen is disclosed. The method includes introducing a metal-containing precursor and a carbon-containing precursor into a thermal reaction chamber, heating the precursors in the thermal reaction chamber to form the ultrafine metal carbide particles from the precursors and to form carbon monoxide and hydrogen, collecting the ultrafine doped metal carbide particles, converting at least a portion of the carbon monoxide to carbon dioxide and generating additional hydrogen, and recovering at least a portion of the hydrogen.

Owner:PPG IND OHIO INC

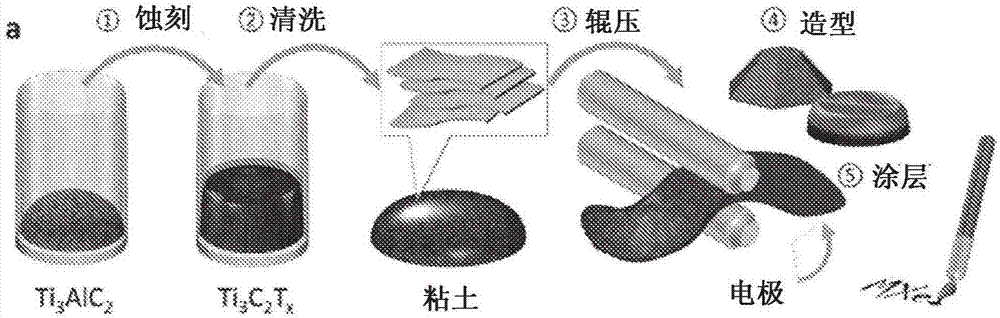

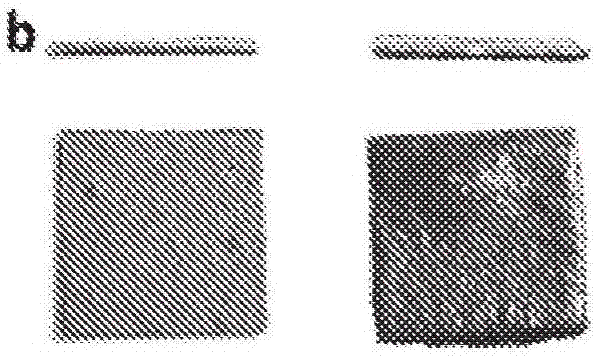

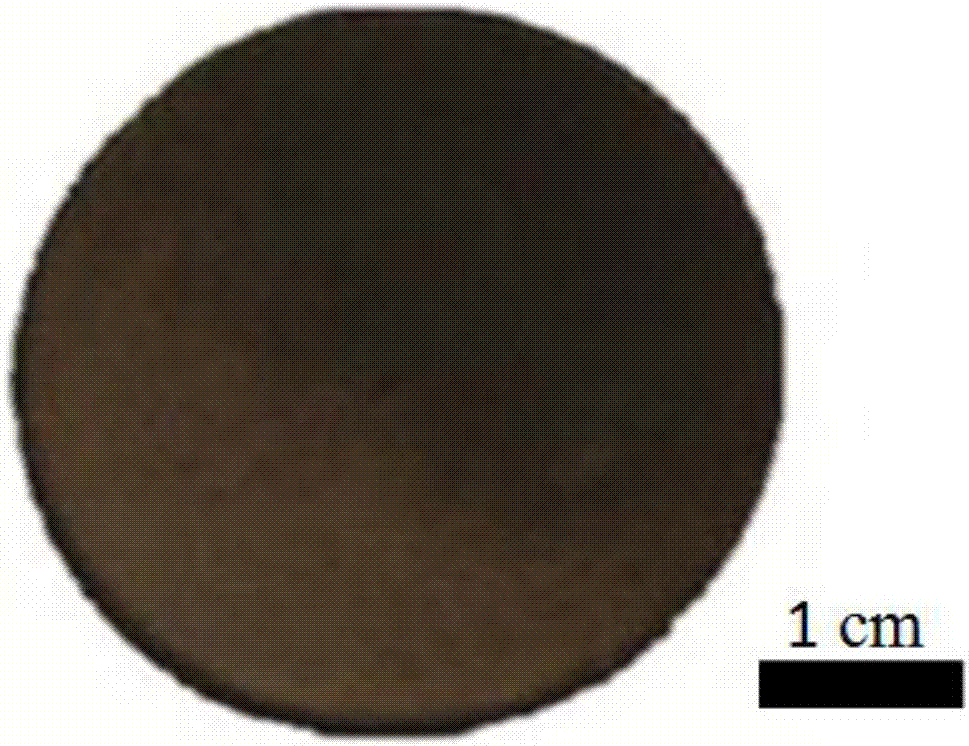

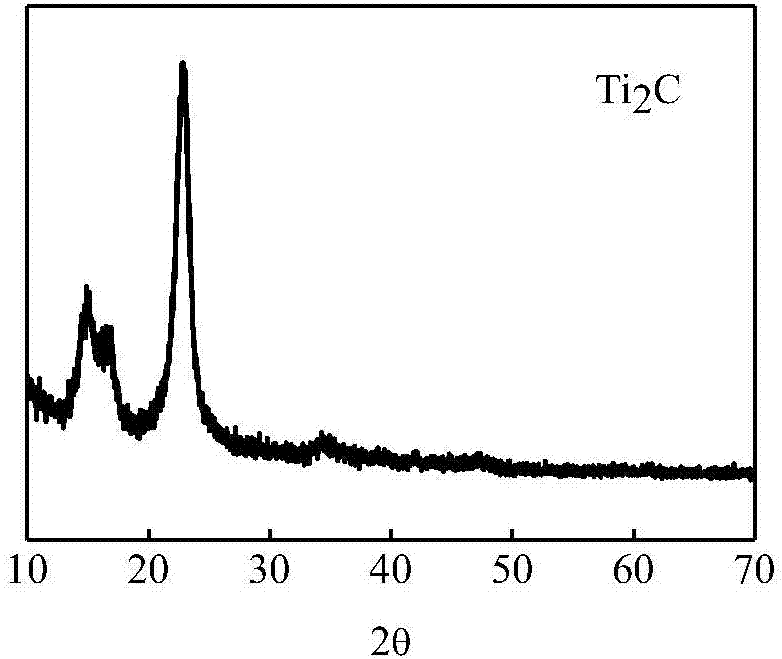

Preparation method of Ti2CMXene-based battery electrode material

InactiveCN107161999ALarge specific surface areaImprove conductivityHybrid capacitor electrodesCell electrodesDiffusion resistanceFilm material

The invention discloses a preparation method of a Ti2CMXene-based battery electrode material. A Ti2CMXene film material is prepared. Through intercalation and exfoliation, the interlayer spacing is enlarged, and the material has a high specific surface area, good conductivity, good cycling stability and rate capability. Meanwhile, the MXene material which is intercalated has low ion diffusion resistance, low open-circuit voltage and high storage capacity, so that the MXene material is quite suitable for being applied to an electrode material of an energy storage apparatus such as a lithium battery and a supercapacitor. The preparation method disclosed by the invention is simple in process and low in cost and does not generate exhaust gas and exhaust liquids polluting the environment. The Ti2C film material prepared by the preparation method is good in conductivity and large in specific surface area. As the electrode material, the Ti2C film material has good cycling stability and rate capability. The specific capacity of the prepared battery is greatly enhanced compared with that of the battery prepared from a conventional material.

Owner:SHENZHEN UNIV

Preparation method of surface organic modified titanium carbide nanosheet

PendingCN108557822ALess corrosiveImprove operational safetyTitanium carbideNanotechnologyHeat stabilityHigh surface

The invention relates to a preparation method of a surface organic modified titanium carbide nanosheet, belonging to the technical field of preparation of nano materials. The preparation method comprises the following steps: etching an aluminum atom layer in titanium aluminum carbide by virtue of a mixed solution of lithium fluoride and hydrochloric acid so as to prepare titanium carbide precipitates, re-dispersing the titanium carbide precipitates into water, carrying out ultrasonic treatment and centrifugation so as to remove precipitates, and extracting supernatant liquid, so as to obtain titanium carbide nanosheet suspension liquid; and finally adding a surfactant water solution to react, so as to obtain the surface organic modified titanium carbide nanosheet. Compared with a method for etching titanium aluminum carbide by virtue of hydrofluoric acid, the method for preparing titanium carbide by etching the aluminum atom layer in titanium aluminum carbide by virtue of the mixed solution of lithium fluoride and hydrochloric acid has the advantages that the corrosivity is reduced, and the operation safety is improved; and the surface organic modified titanium carbide nanosheet prepared by virtue of the preparation method has relatively high surface activity and heat stability, has good compatibility with high-molecular materials and can be uniformly dispersed into the high-molecular materials, so that the mechanical properties, flame retardance and thermal properties of the high-molecular materials are improved.

Owner:HEFEI UNIV

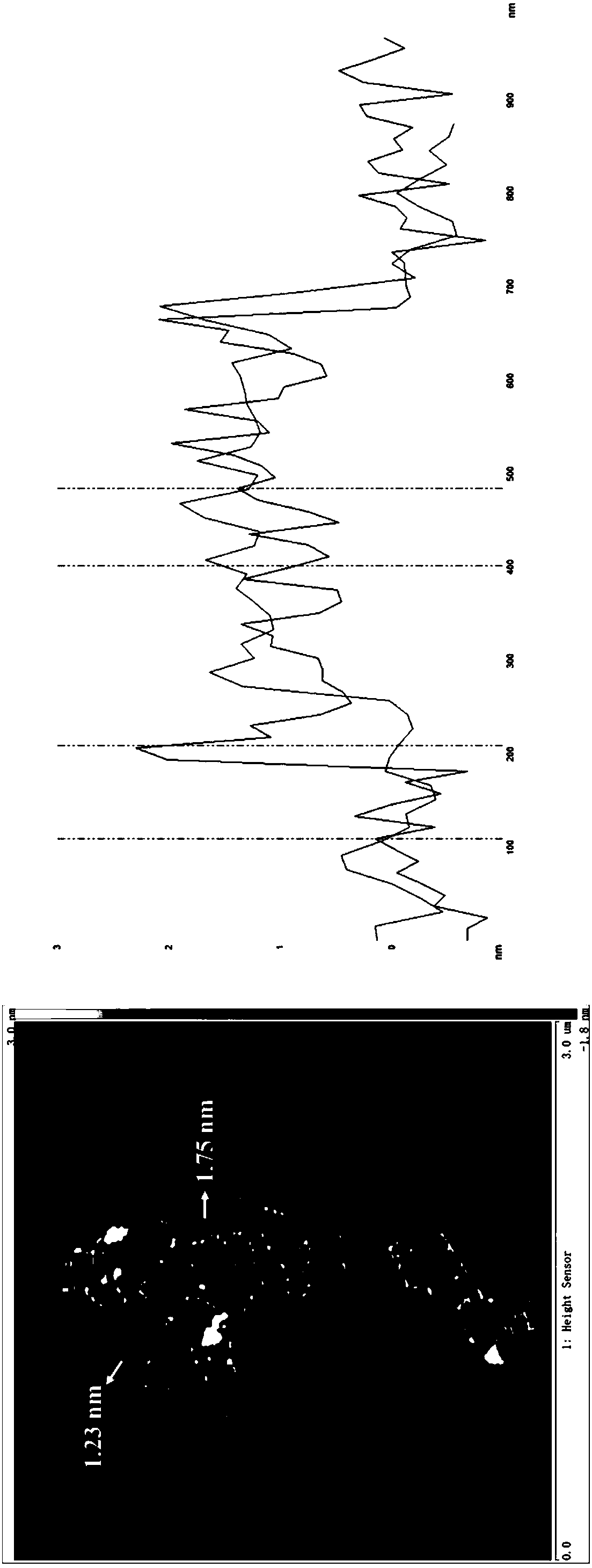

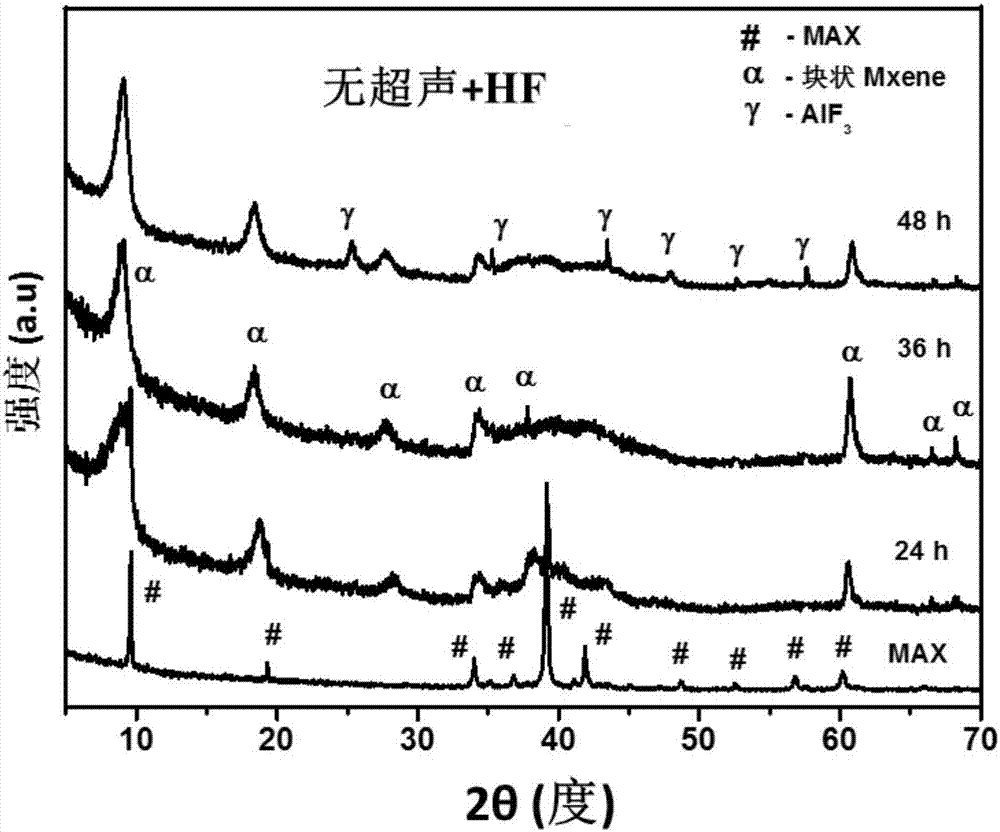

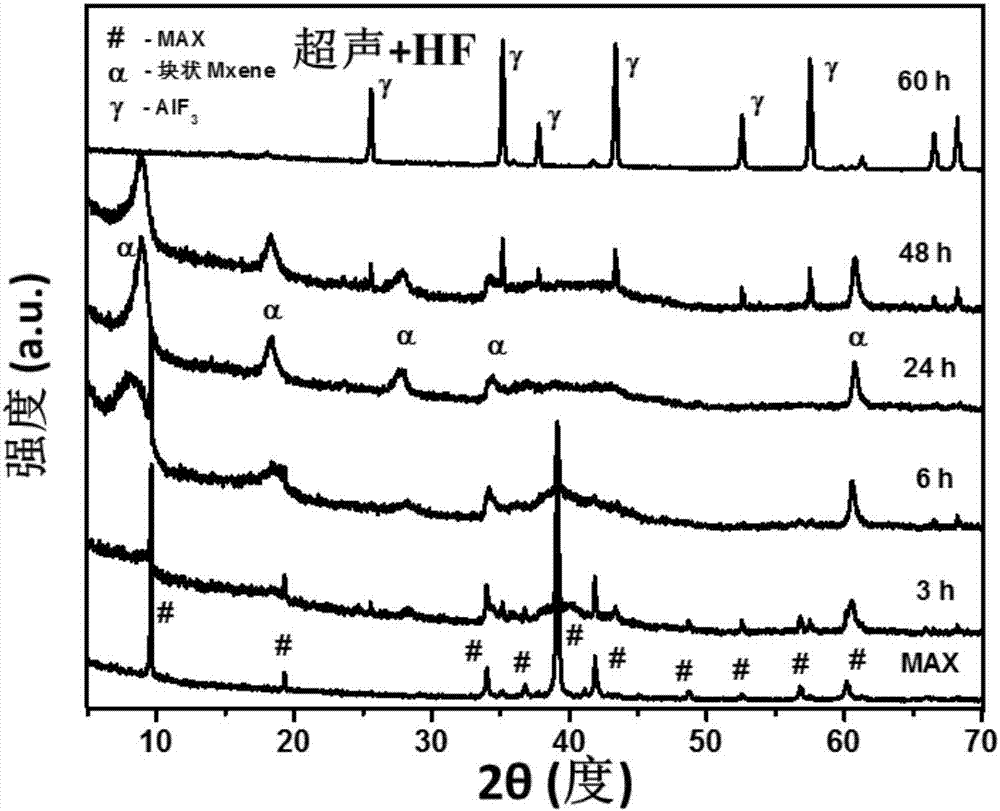

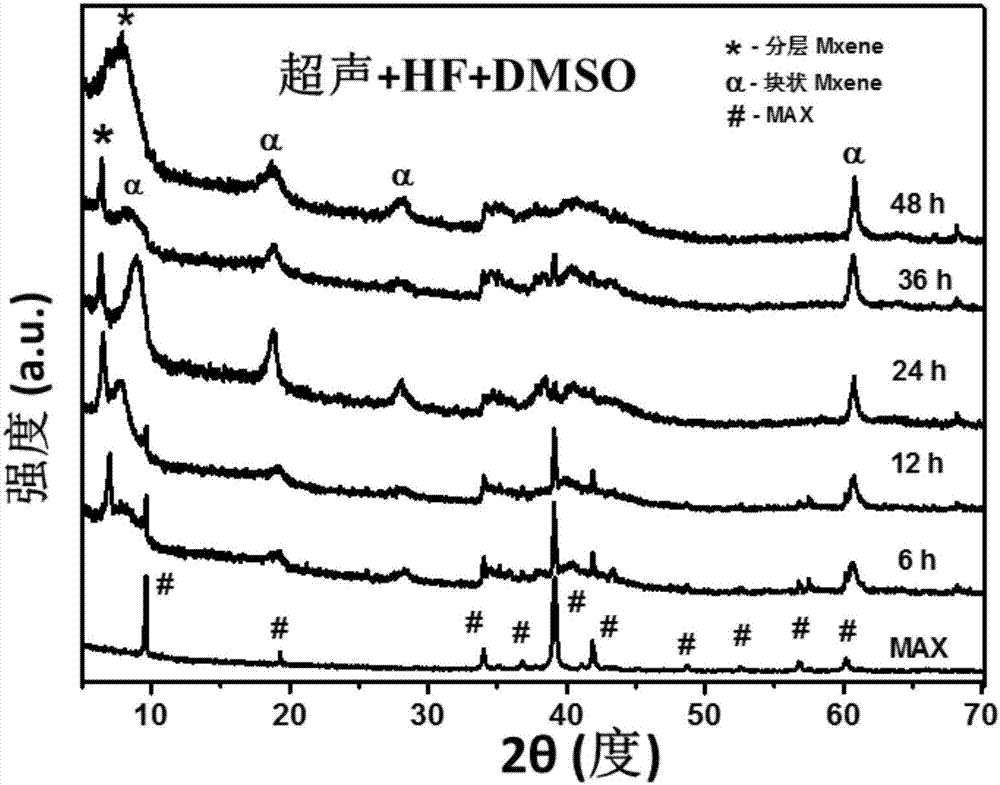

Ultrasound-assistant preparation method of layered Mxene-Ti3C2

The invention relates to an ultrasound-assistant preparation method of layered Mxene-Ti3C2. The method comprises the following steps: (1) Ti3AlC2-MAX phase ceramic powder and an HF solution are mixed, and then dimethyl sulfoxide is added in order to obtain mixed liquor; (2) ultrasonic treatment of the mixed liquor is carried out, and after ultrasonic treatment is completed, a stirring reaction is carried out in an oil bath condition; ultrasonic treatment and the stirring reaction are alternatively and repeatedly carried out, and after the reaction ends, a middle solution is obtained; (3) washing and centrifugation of the middle solution are carried out by using deionized water till pH of supernatant is equal to 5-6; ethanol is used continuously in order to carry out washing and centrifugation, a sediment is obtained, drying treatment is carried out, and layered Mxene-Ti3C2 is obtained. Preparation and layering of Mxene-Ti3C2 are realized simultaneously.

Owner:ZHEJIANG UNIV

MXene-polyaniline composite material and preparation method thereof

ActiveCN106750277ASolve the technical problem of poor microwave absorption performance of MXeneTitanium carbidePolyaniline compositeSOLUTION/DROPS

The invention provides an MXene-polyaniline composite material and a preparation method thereof, relates to a preparation method of the MXene-polyaniline composite material and aims to solve the technical problem of poor wave absorbing performance of the conventional two-dimensional transition metal carbide MXene. The MXene-polyaniline composite material comprises laminated two-dimensional transition metal carbide and a polyaniline shell coating the surface of the two-dimensional transition metal carbide. The preparation method comprises the following steps: aniline is added to water and stirred, an aniline / water dispersion liquid is obtained, the pH value is regulated to 1.5-2, and a hydrochloride solution of aniline is obtained; the hydrochloride solution of aniline is added to the water dispersion liquid of the two-dimensional transition metal carbide and is stirred and mixed at a low temperature, and an MXene-aniline mixed solution is obtained; an ammonium persulfate solution is added dropwise to the MXene-aniline mixed solution, the mixture is subjected to a stirring reaction at a low temperature, a product is washed and dried, and the MXene-polyaniline composite material is obtained. The MXene-polyaniline composite material can be applied to the field of wave absorption.

Owner:HARBIN INST OF TECH

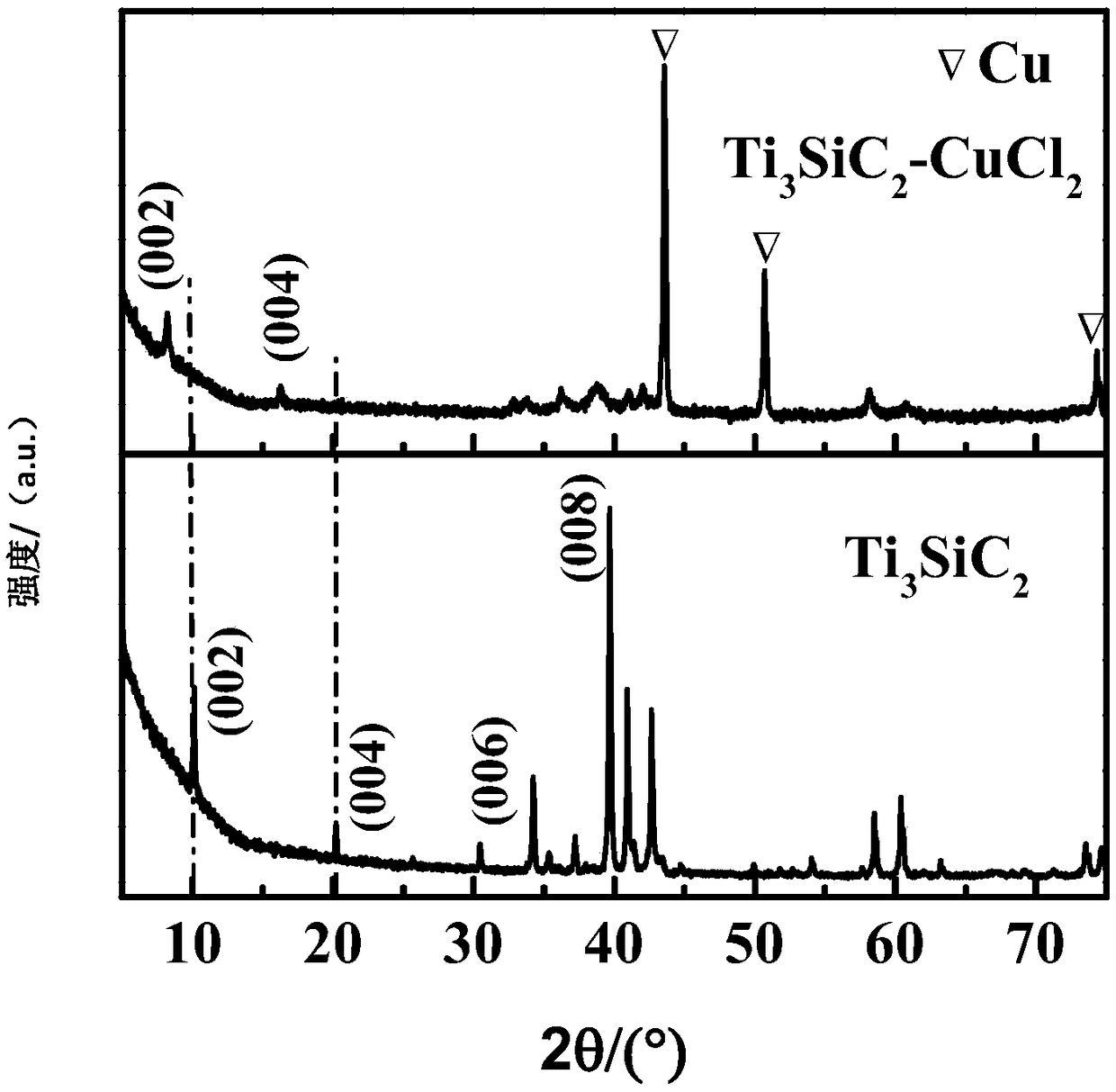

Composite material of sub-group metals compounded with MXenes and preparation method and application of composite material

ActiveCN108793166ARealize the structureRealize functionTitanium carbideMetal/metal-oxides/metal-hydroxide catalystsInorganic saltsMolten salt

The invention discloses a composite material of sub-group metals compounded with MXenes and a preparation method of the composite material. The composite material of sub-group metals compounded with MXenes is prepared from MXenes materials and sub-group metals, wherein the surfaces of the MXenes materials are coated with the sub-group metals in situ, and the sub-group metals are also distributed among layers of the MXenes materials. The preparation method comprises the following steps: grinding precursor Mn+1AXn-phase materials, sub-group metal salts and inorganic salts for 5-60min by adoptinga molten salt method, enabling the obtained mixture to react for 1-48h at 300-800 DEG C in inert atmosphere, and then, performing post-treatment to obtain the composite material of the sub-group metals compounded with the MXenes. The composite material disclosed by the invention has the advantages of adjustable and uniform components, low cost, environmental protection, high efficiency and the like, and has application prospects in the fields of electrode materials for electrochemical energy storage, wave absorption materials, electromagnetic shielding materials, catalysts and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

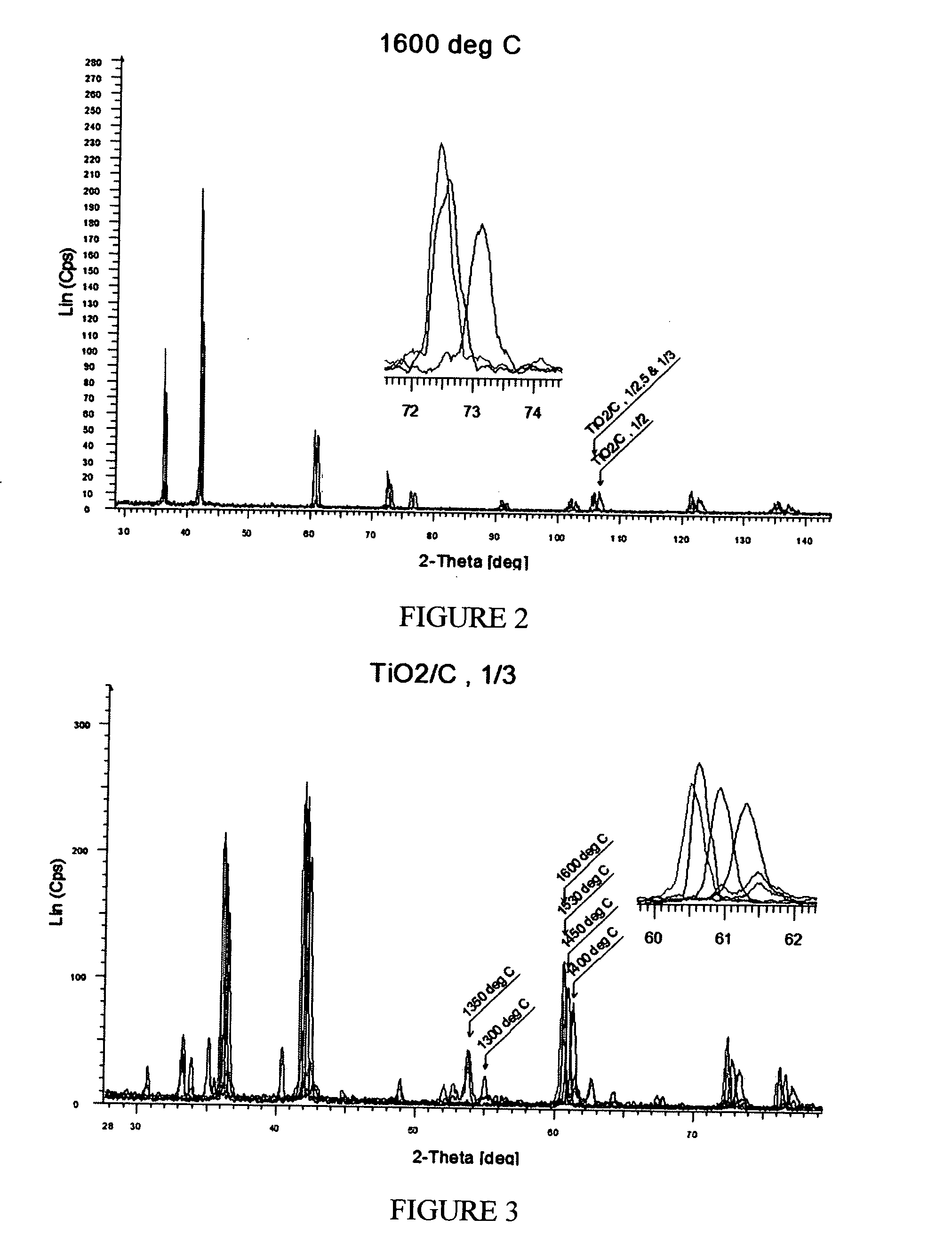

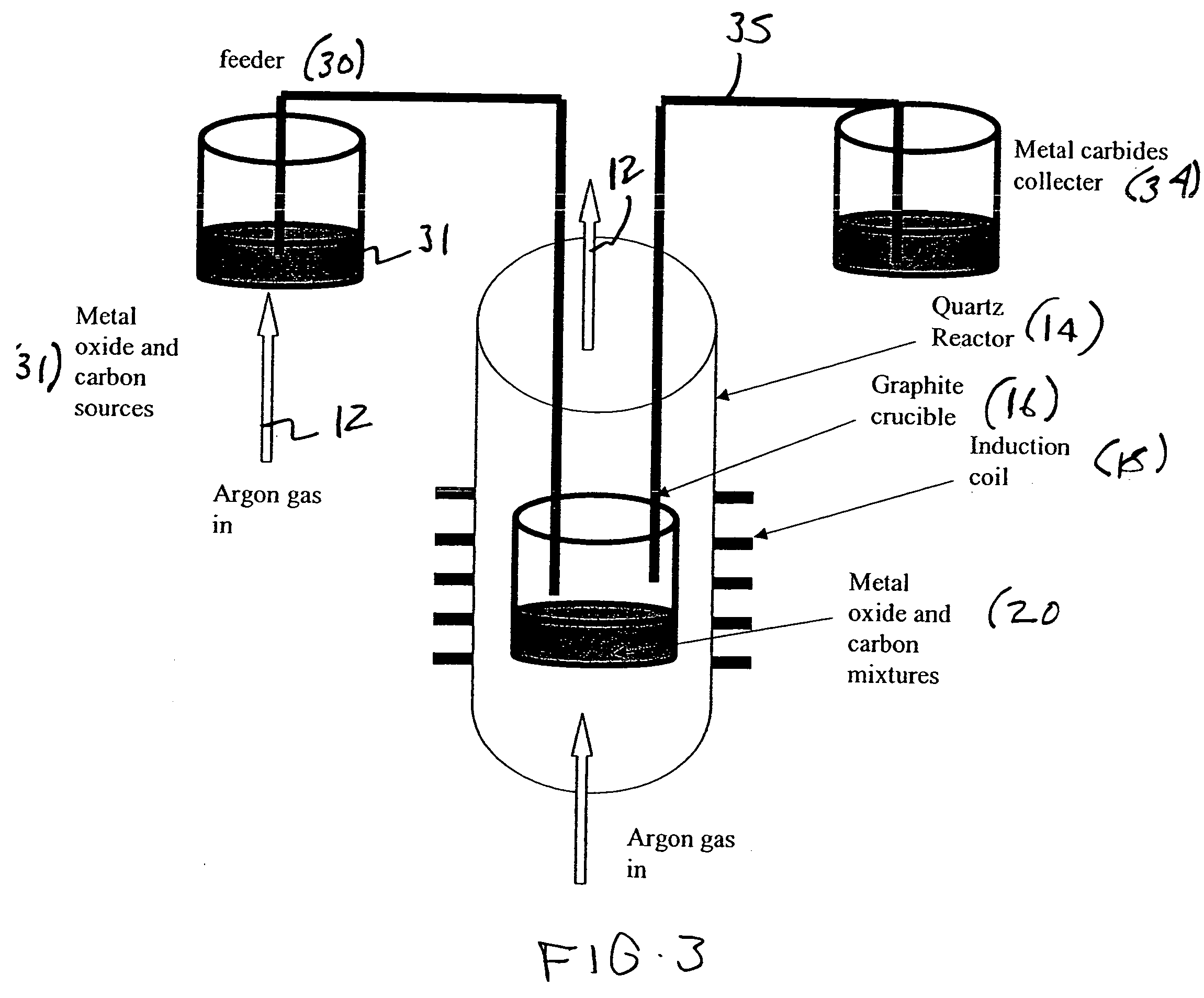

Metal carbides and process for producing same

InactiveUS20060051281A1Minimize stress concentrationIncreased tortuosityMaterial nanotechnologyInorganic material artificial filamentsQuantum wellCarbide

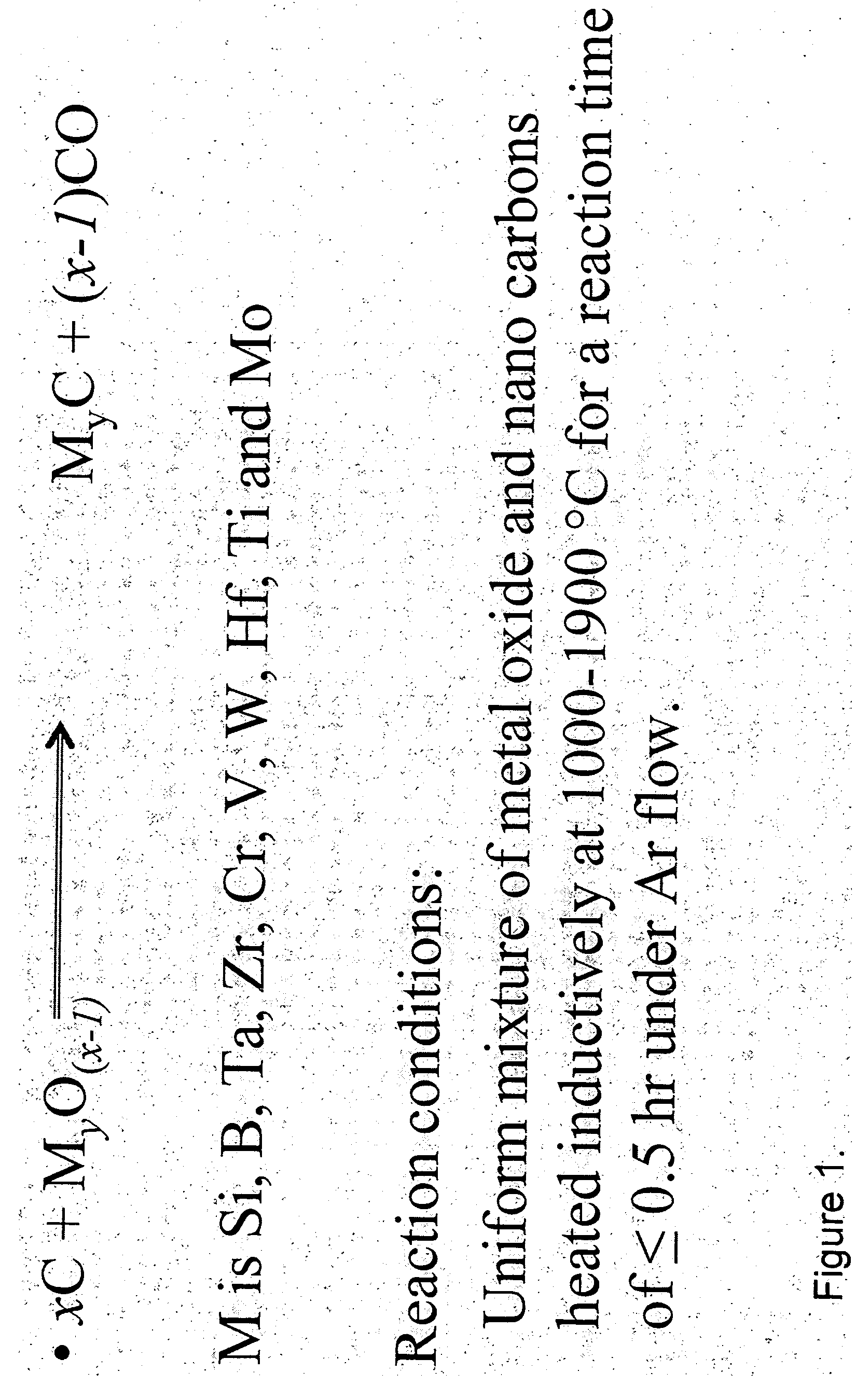

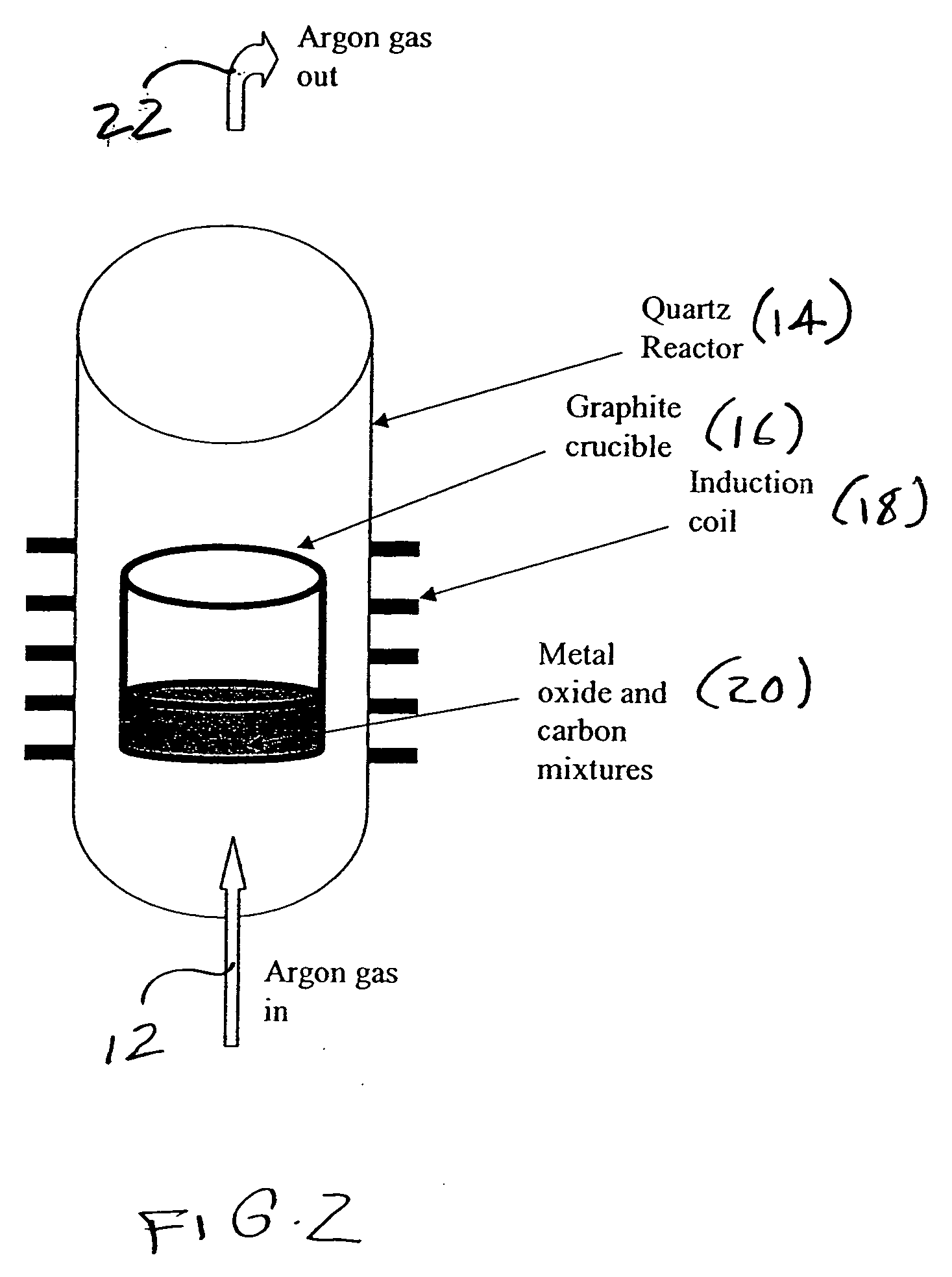

A metal carbide composition and a process for synthesizing metal carbides, through a single step process, wherein oxides of different metals, including, but not limited to Si, Ti, W, Hf, Zr, V, Cr, Ta, B, Nb, Al, Mn, Ni, Fe, Co, and Mo were physically mixed with spherical or filamentateous nano structured carbon, and inductively heated to a certain temperature range (900-1900° C.) where the metal oxide reacts with carbon to form different metal carbides. The process retains the original morphology of the starting carbon precursor in the resultant metal carbides. This method also produces highly crystalline metal nano-carbides. The metal carbide products would have applications in high temperature thermoelectric devices, quantum wells, optoelectronic devices, semi-conductors, body armour, vehicle armour, catalysts, and as discontinuous reinforced agents in metal such as aluminum and other alloys.

Owner:COLUMBIAN CHEM CO

Composite nanostructure based on three-dimensional porous transition metal carbide Ti3C2MXene and general preparation method thereof

InactiveCN110589786AFix production issuesSolve application problemsTitanium carbideNickel oxides/hydroxidesChemical reactionMetal-organic framework

The invention discloses a composite nanostructure based on a three-dimensional porous transition metal carbide Ti3C2MXene and a general preparation method thereof, and belongs to the field of nanomaterials. The three-dimensional composite structure is composed of a three-dimensional porous Mxene-supported inorganic nanostructure, and has a honeycomb hierarchical porous structure. A precursor of atwo-dimensional transition metal carbide and a metal-organic framework compound is subjected to high-temperature pyrolysis or a chemical reaction in an inert or reactive atmosphere to prepare the composite nanostructure with a controllable size. According to the composite nanostructure, stacking of MXene itself is inhibited, an active surface area, porosity, and ion permeability of MXene are increased, and thereby a surface interface of MXene is efficiently used. At the same time, introduction of the metal-organic framework compound realizes uniform and stable compounding of the three-dimensional porous MXene and an inorganic nanomaterial, the fundamental difficult problem that plagues exerting and application of inorganic nanomaterial performance is solved, and the composite nanostructurehas wide application prospects in the fields such as catalysis, energy, photo-electricity, space technology, and military industry.

Owner:DALIAN UNIV OF TECH

Two-dimensional material quantum sheet and preparation method thereof

The invention belongs to the technical field of inorganic nanometer material preparation, and relates to a two-dimensional material quantum sheet and a preparation method thereof. Through the process, inorganic matters with the proper particle diameter are firstly used as auxiliary agents for ball milling; then, solvents are added for ultrasonic processing; finally, suction filtration is performed; filter liquid is centrifuged. The uniform and stable dispersion liquid of the two-dimensional material quantum sheet is obtained; the sheet layer dimension of the quantum sheet is between 1nm and 20 nm; the layer number is one to ten. Compared with the existing method, the method has the advantages that the resources are wide; the operation is simple and convenient, and the like. The prepared quantum sheet maintains the intrinsic property; the defects are few; the yield is very high; the two-dimensional material quantum sheet is hopeful to realize the mass production.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for preparing laminated MXenes material from ternary MAX materials

ActiveCN107117616AHigh degree of peelingIncrease contactMaterial nanotechnologyTitanium carbideLiquid temperatureOperability

The invention provides a method for preparing a laminated MXenes material from ternary MAX materials. Corrosion liquid is added into a pressure container; then, ternary MAX material powder is added into the corrosion liquid; the pressure container is sealed; through external gas pressure, a corrosion environment with the pressure higher than the atmospheric pressure is formed in the pressure container; corrosion is performed under the stirring condition at the corrosion liquid temperature of 4 to 60 DEG C; after the corrosion, the pressure is fast relieved; washing and drying are performed; the laminated MXenes materials are obtained. The method has the advantages that simplicity is realized; the operability is high; the realization result is good; the Mxenes material with good microtopography and high peeling degree can be obtained.

Owner:SHAANXI UNIV OF SCI & TECH

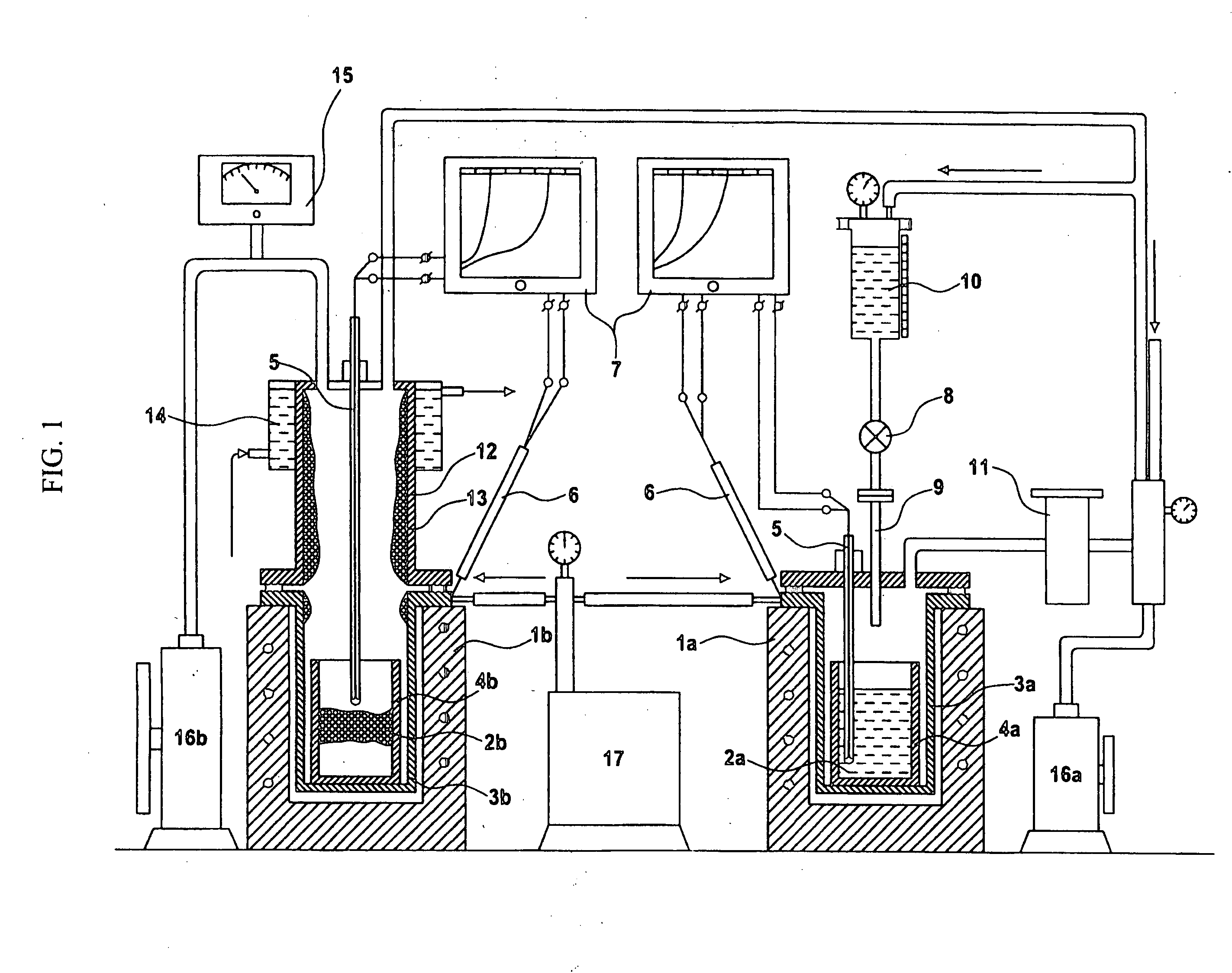

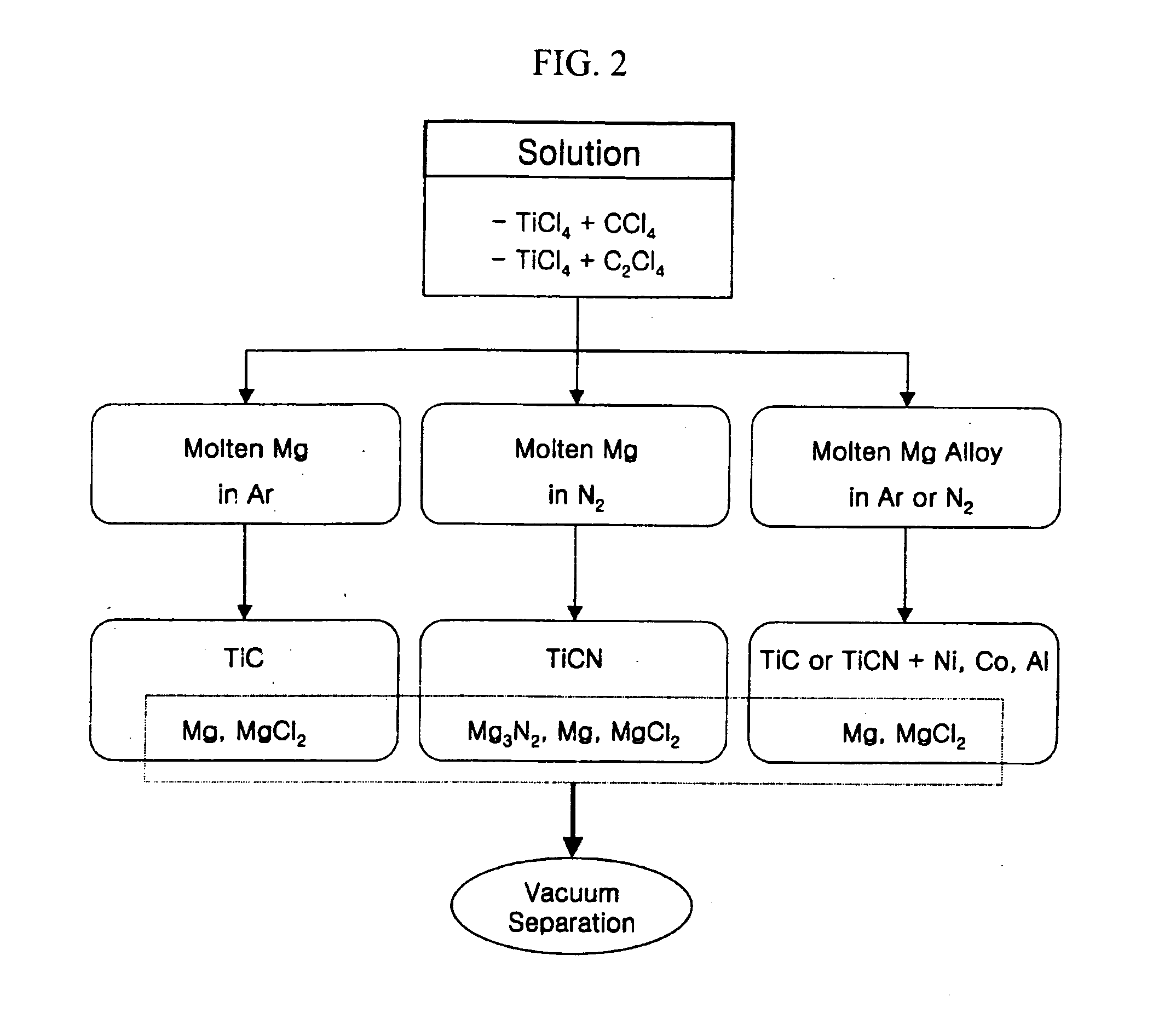

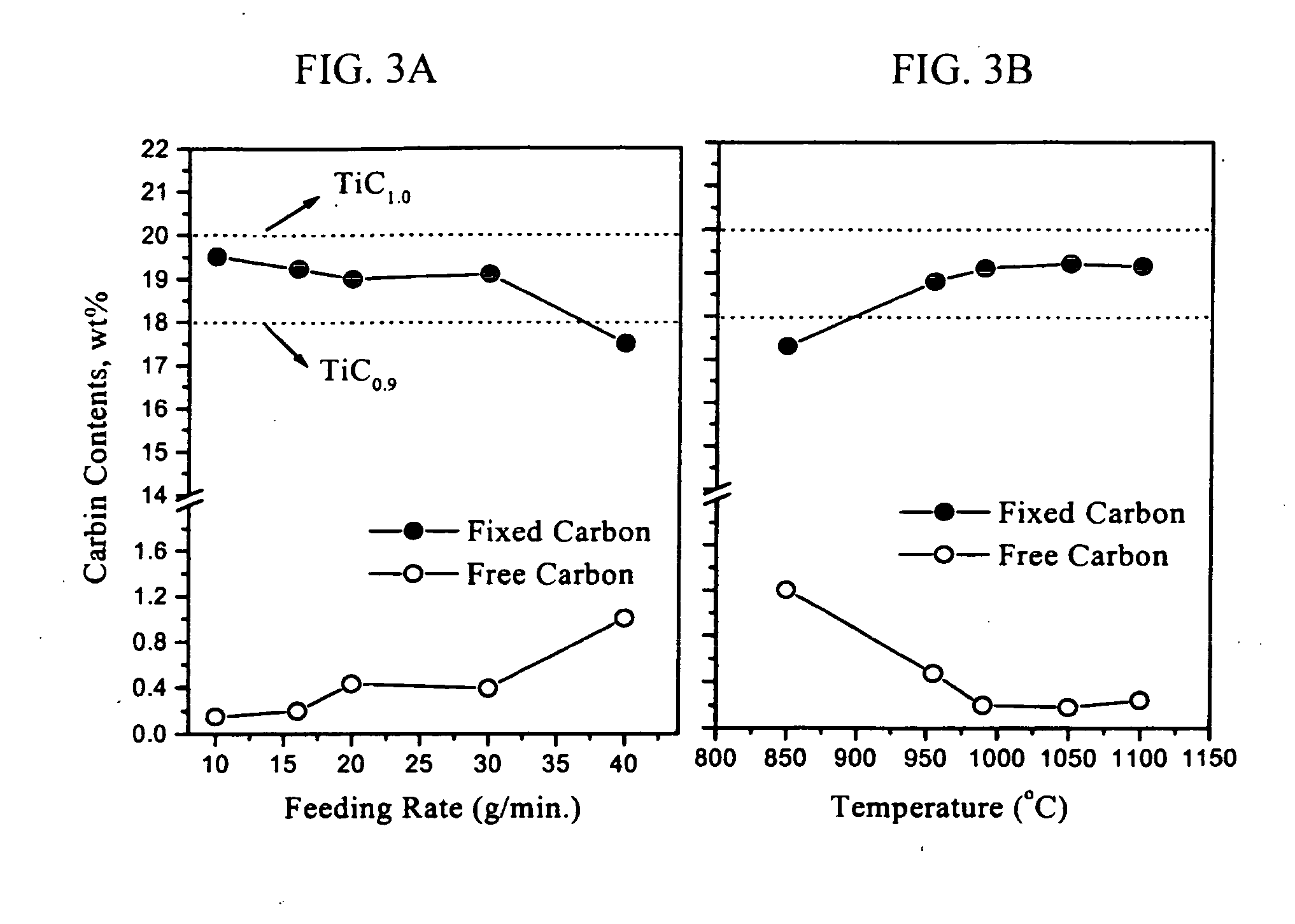

Method for manufacturing nanophase TiC-based composite powders by metallothermic reduction

Disclosed herein is a method for economically manufacturing high quality TiC powder, TiCN powder or ultrafine nanophase TiC+Ni (Co, Al) and TiCN+Ni (Co, Al) composite powders by means of metallothermic reduction. The method comprises the steps of preparing a starting solution of titanium tetrachloride (TiCl4) in a carbon chloride, feeding the starting solution into a closed container containing molten magnesium (Mg) under inert atmosphere, vacuum-separating unreacted liquid-phase Mg and magnesium chloride (MgCl2) remaining after reduction of magnesium from the closed container, and collecting a TiC compound from the closed container. TiC powder, TiCN powder or ultrafine nanophase TiC+Ni (Co, Al) and TiCN+Ni (Co, Al) composite powders having a particle size of a few tens nm can be manufactured in a simpler manner using economically advantageous starting materials such as titanium tetrachloride and carbon chlorides.

Owner:KOREA INST OF MASCH & MATERIALS

Preparation method of material similar to graphene

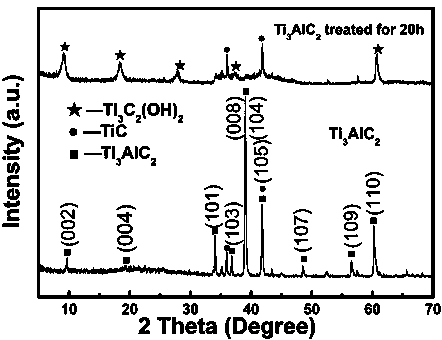

InactiveCN103641119ASimple preparation processLow costTitanium carbideCentrifugationPhysical chemistry

The invention discloses a method for preparing a material similar to graphene by selectively etching Ti3AlC2. The method comprises the following steps: sieving Ti3AlC2 with a 100-200-mesh sieve, putting Ti3AlC2 into a hydrofluoric acid liquid under magnetic stirring or ultrasonic dispersion to react for 20 hours, repeatedly cleaning a reaction product with ethanol and distilled water, then carrying out ultrasonic dispersion for 1-6 hours, and then carrying out centrifugation or suction filtration and drying the collected product at 50 DEG C for 1-2 hours. The method is low in cost, simple in process and convenient to operate and is suitable to be popularized in industrial production.

Owner:JIANGSU UNIV

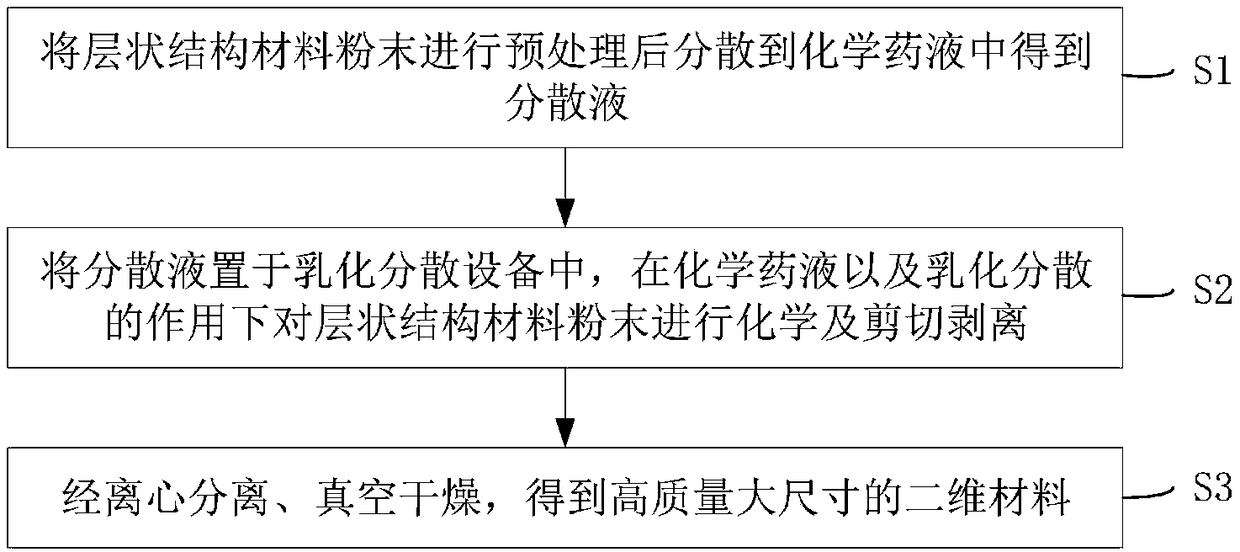

High-quality and large-size two-dimensional material and preparation method thereof

ActiveCN108793140AIncrease tangential speedImprove stripping efficiencyNitrogen compoundsTitanium carbidePre treatmentLarge size

The invention discloses a high-quality and large-size two-dimensional material and a preparation method thereof. The preparation method of the high-quality and large-size two-dimensional material comprises the following steps: S1, after pre-treating lamellar structure material powder, dispersing in chemical drug liquid, so as to obtain a dispersion solution; S2, putting the dispersion solution into emulsifying and dispersing equipment, and carrying out chemical and shearing peeling on the lamellar structure material powder under the action of the chemical drug liquid and emulsification and dispersion; S3, carrying out centrifugal separation and vacuum drying to obtain the high-quality and large-size two-dimensional material. The high-quality and large-size two-dimensional material and thepreparation method thereof, provided by the invention, have the advantages of simplicity and rapidness, high peeling efficiency and capability of realizing continuous scale production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

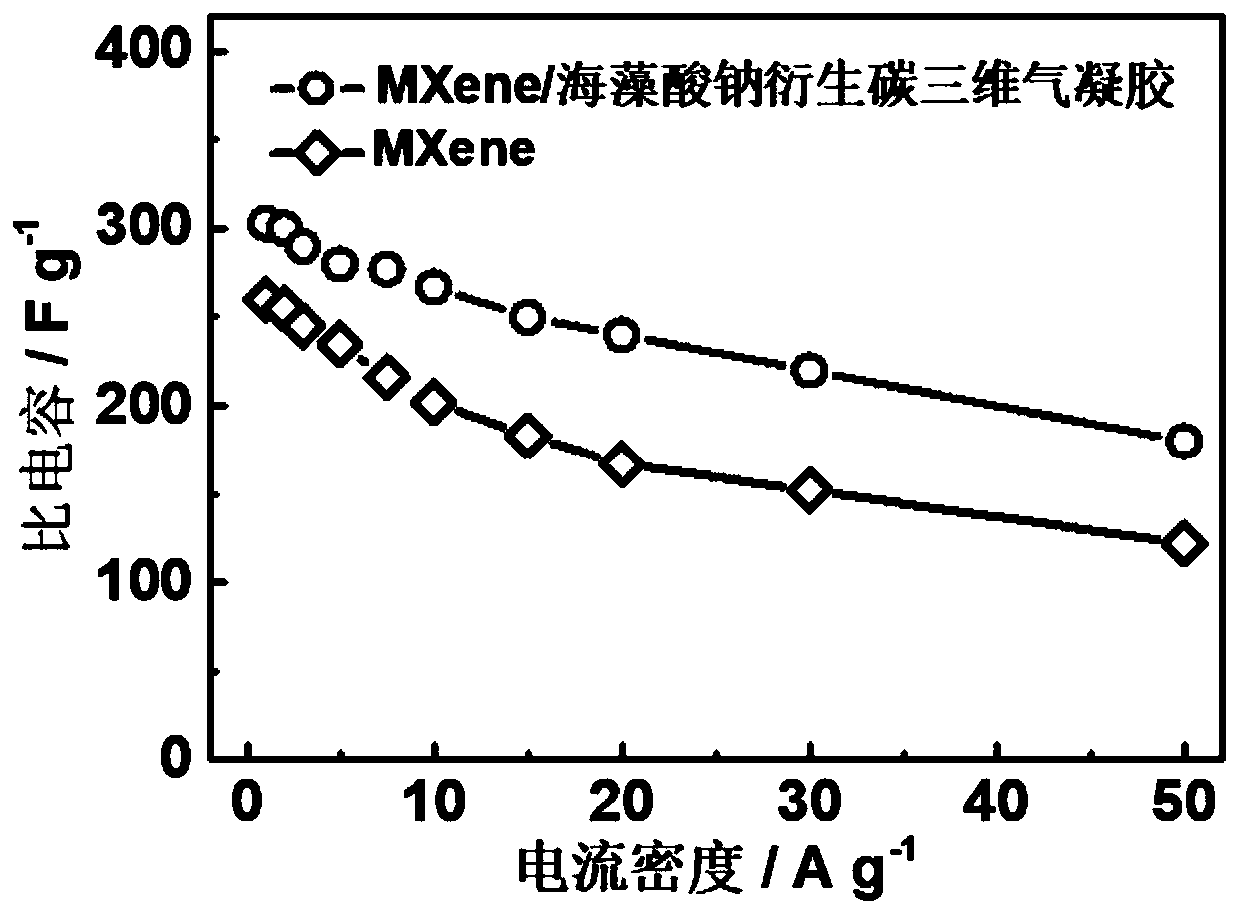

MXene/sodium alginate derived carbon three-dimensional aerogel as well as preparation method and application thereof

ActiveCN111422873AAvoid stackingImprove electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesFluid phaseSupercapacitor

The invention provides MXene / sodium alginate derived carbon three-dimensional aerogel as well as a preparation method and application thereof. The preparation method of the MXene / sodium alginate derived carbon three-dimensional aerogel, provided by the invention, comprises the following steps: carrying out liquid-phase mixing on an MXene dispersion liquid and a sodium alginate aqueous solution toobtain an MXene / sodium alginate mixed solution; adding a calcium chloride solution into the MXene / sodium alginate mixed solution, and gelatinizing sodium alginate to obtain MXene / sodium alginate hydrogel; carbonizing sodium alginate through high-temperature treatment, and then washing with 1-3mol / L hydrochloric acid and deionized water to obtain the MXene / sodium alginate derived carbon three-dimensional aerogel material. The MXene / sodium alginate derived carbon three-dimensional aerogel material provided by the invention has good electrochemical performance when used in the field of supercapacitors.

Owner:BEIJING UNIV OF CHEM TECH

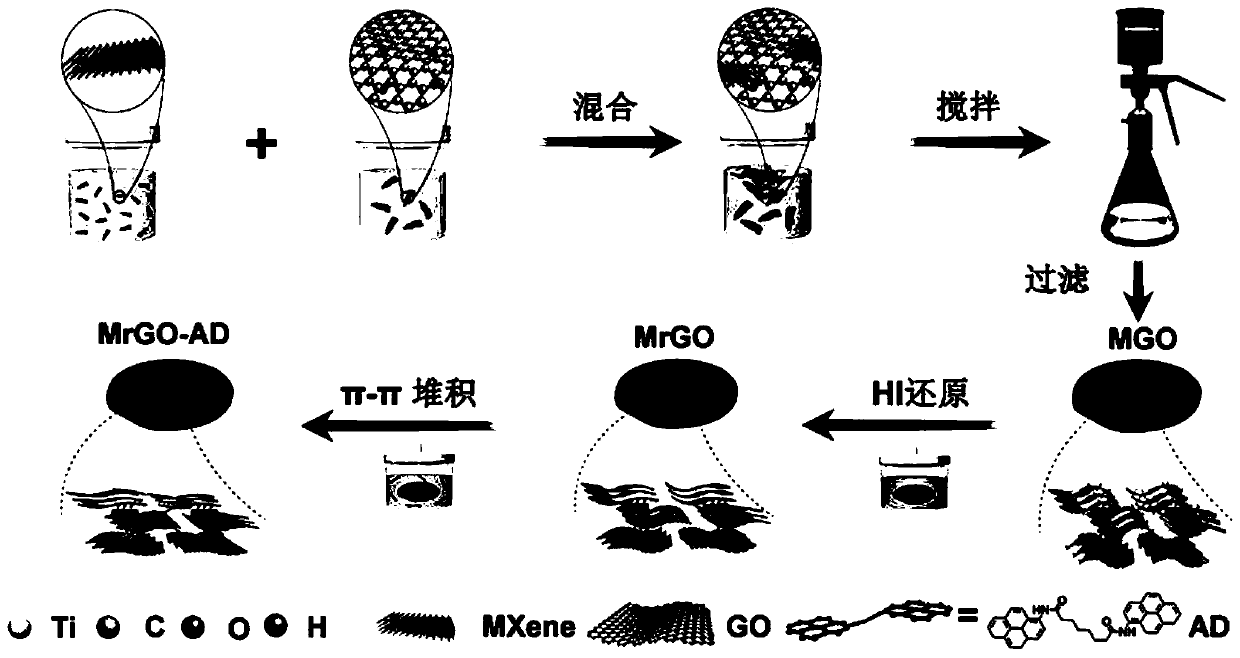

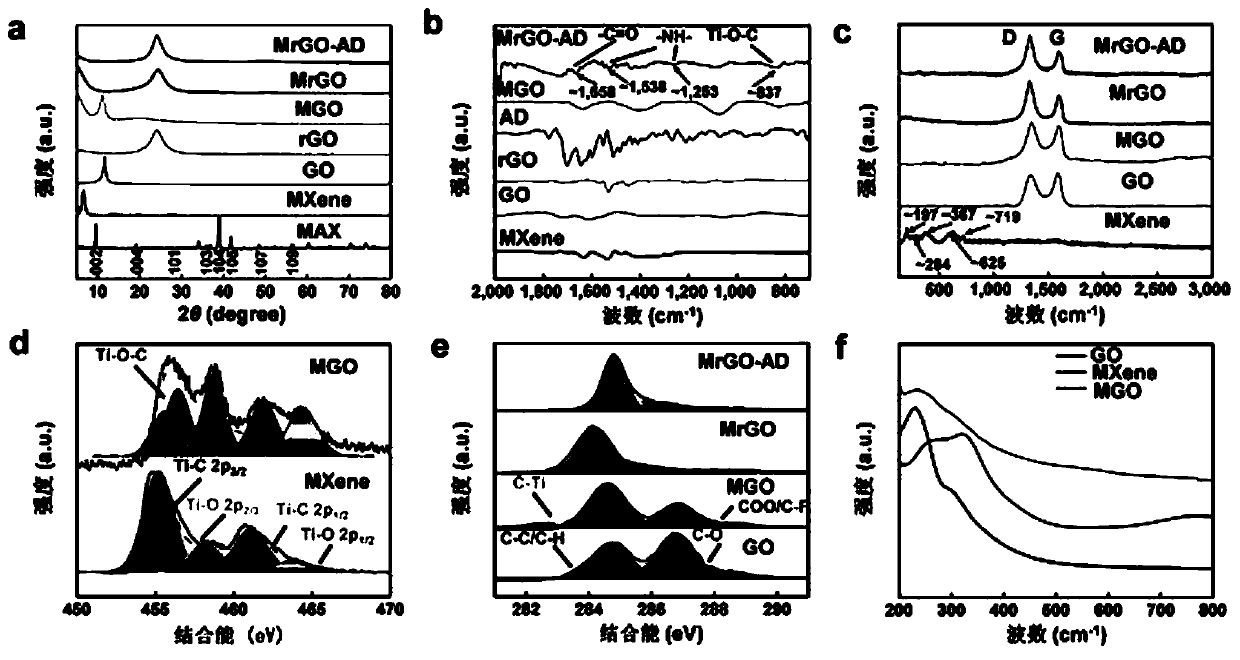

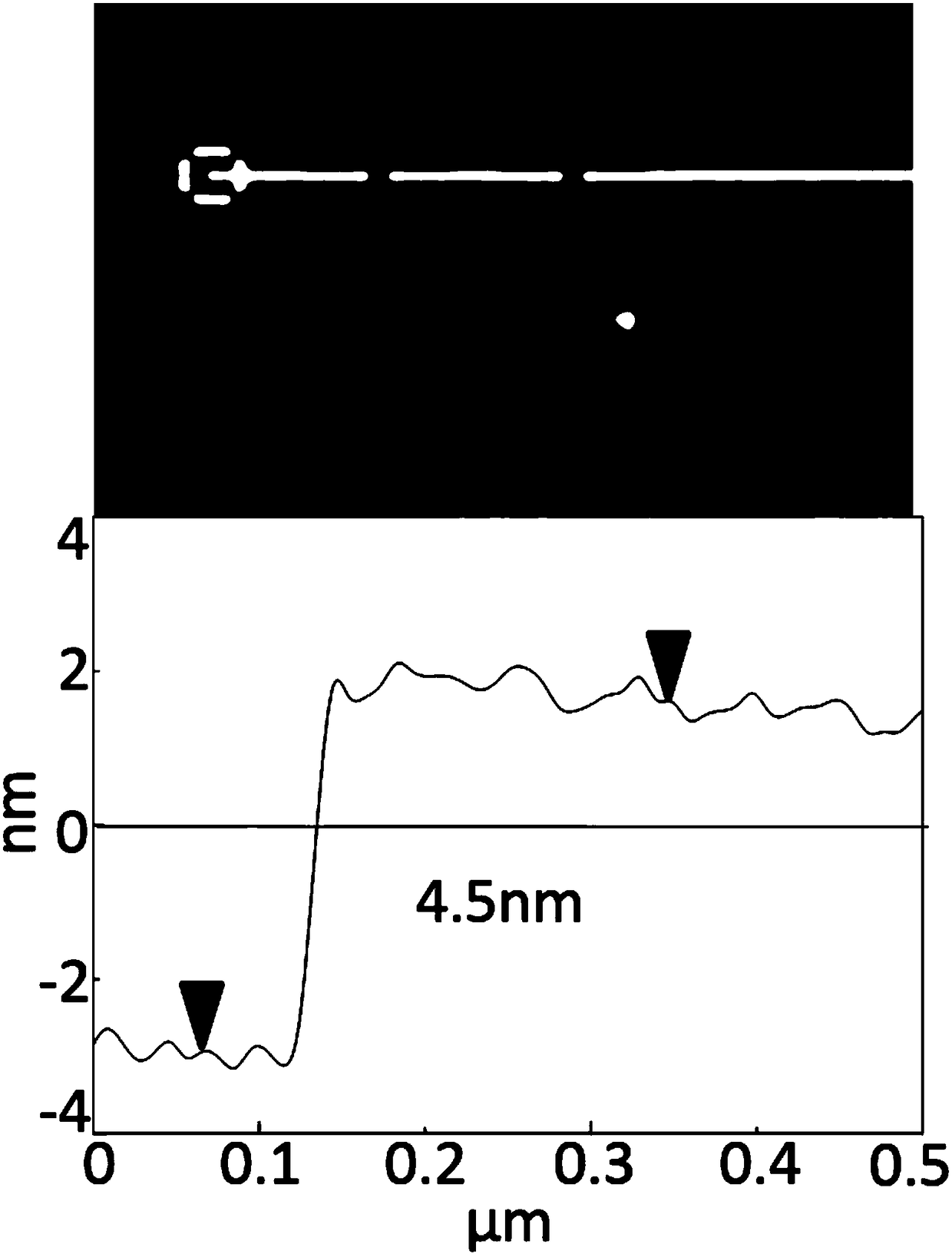

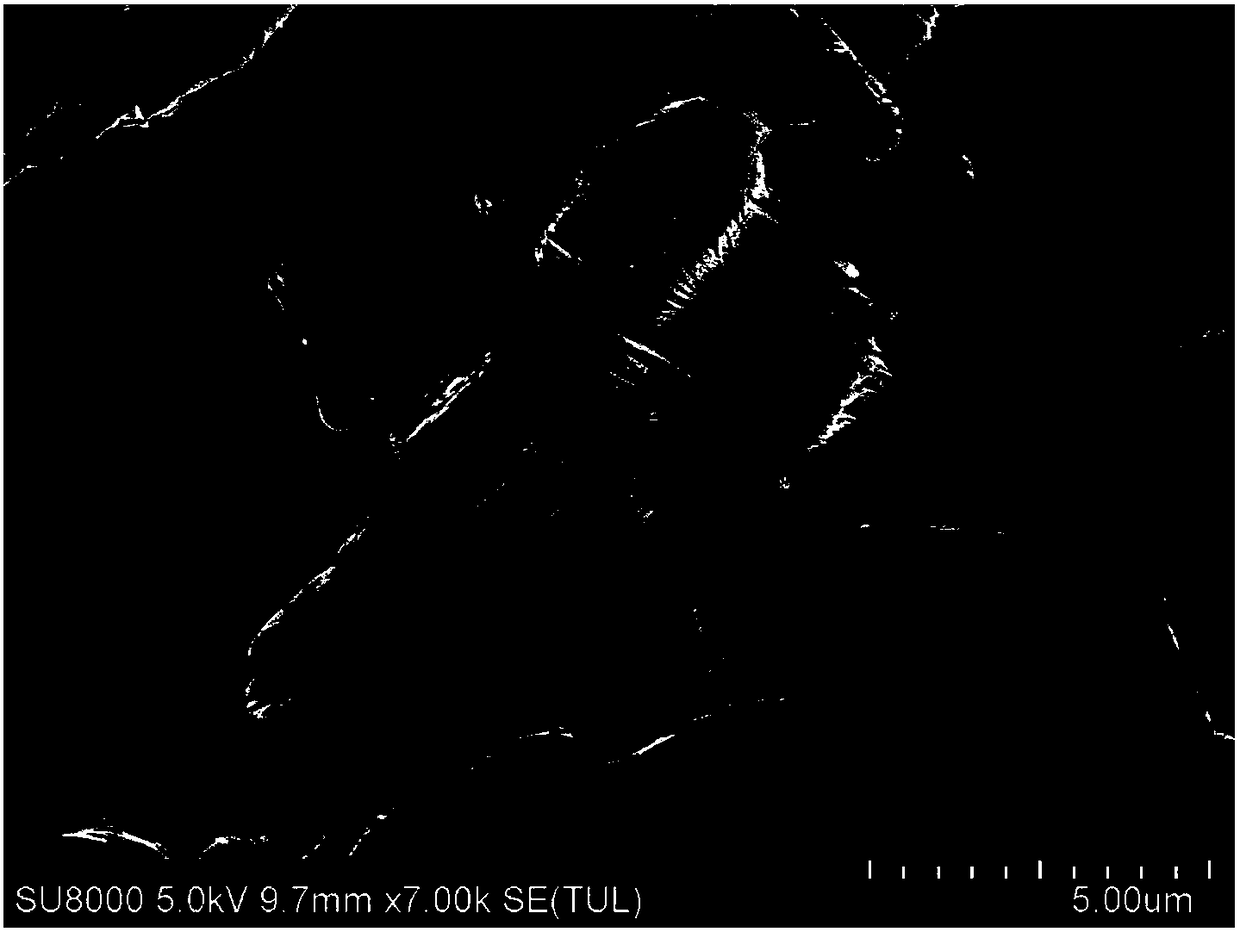

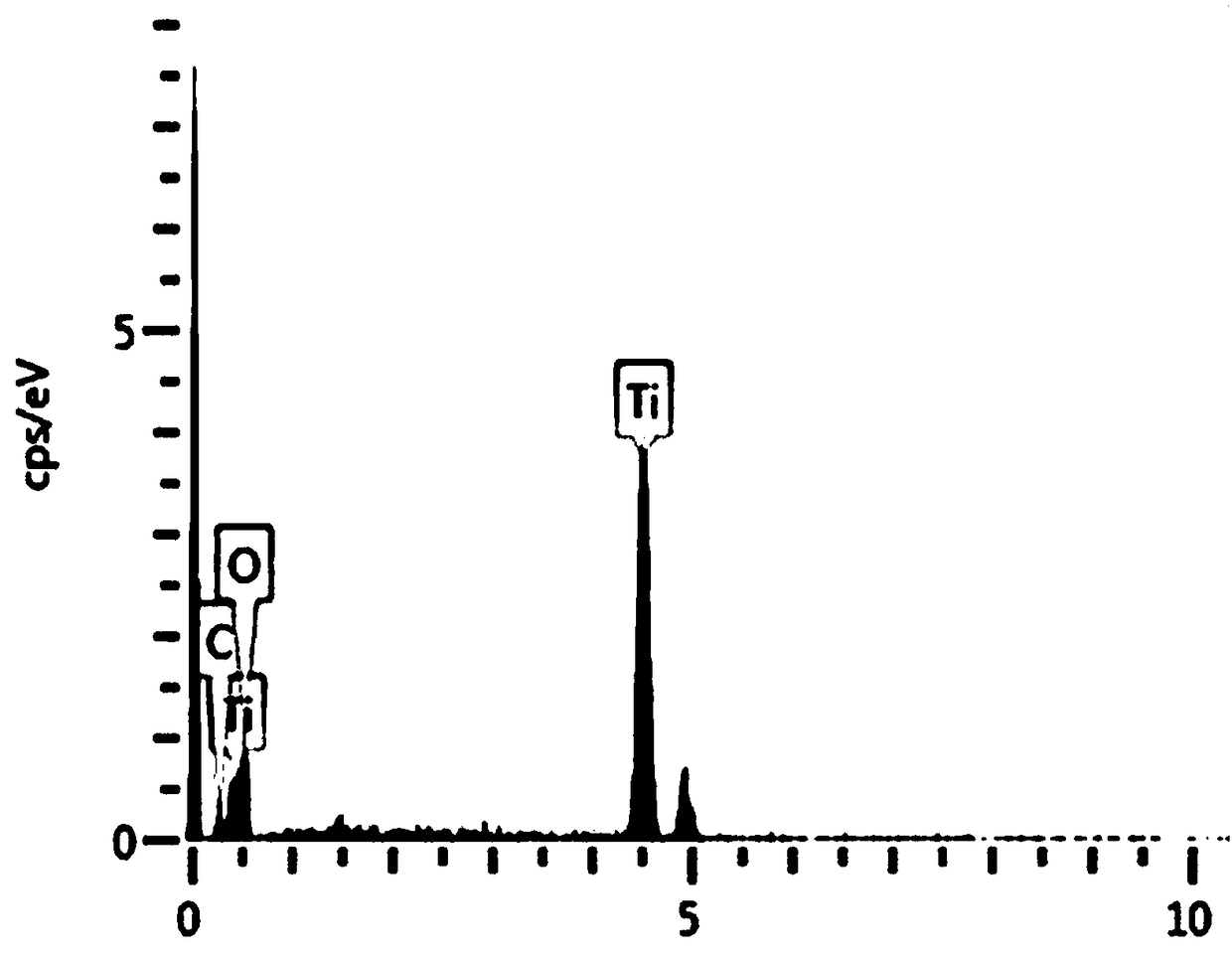

Preparation method of titanium carbide MXene functionalized graphene nanocomposite film and application thereof

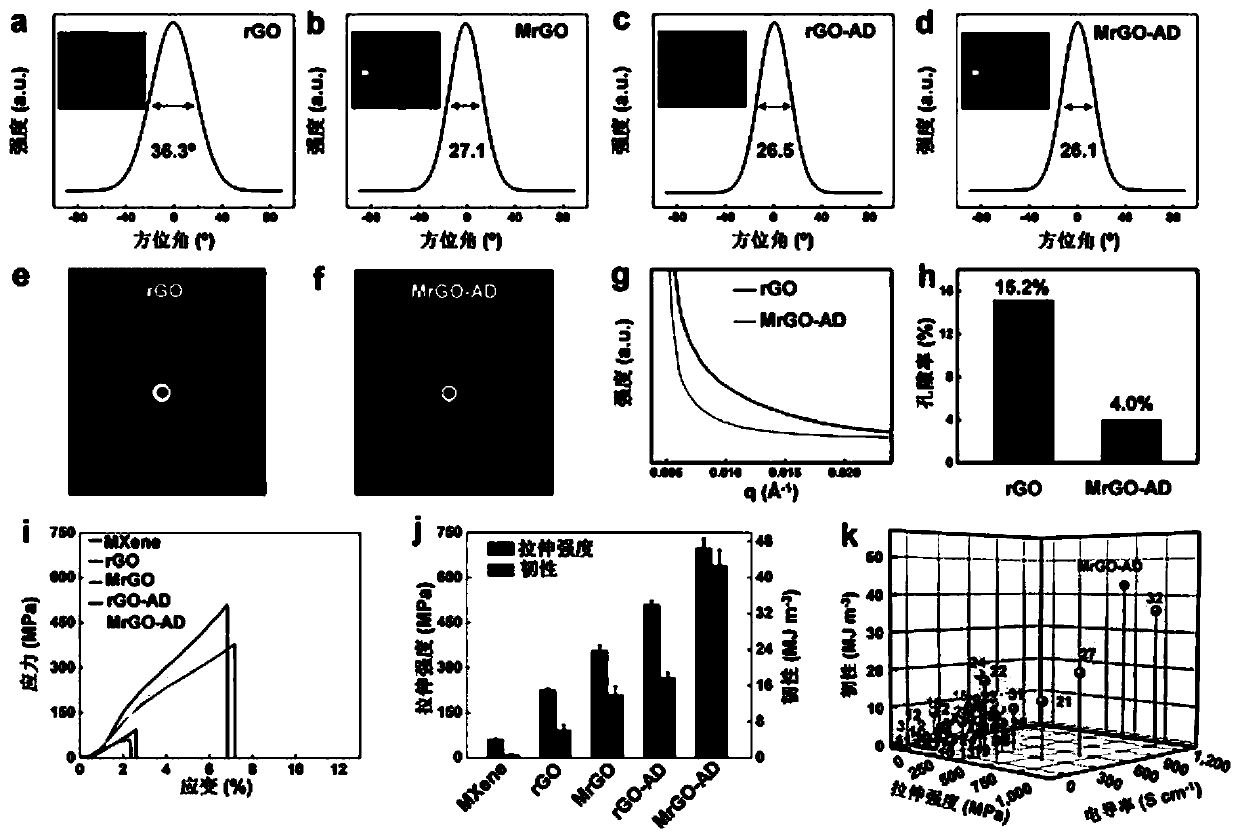

ActiveCN111252768AHigh mechanical strengthImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesGraphene nanocompositesTitanium carbide

The invention relates to a preparation method of a titanium carbide MXene functionalized graphene nanocomposite film and an application thereof. However, the preparation of the graphene nanocompositefilm with high strength and high conductivity is always a challenge. In order to solve the problem, hydrophilic and high-conductivity MXene nanosheets are adopted, Ti-O-C covalent bonds are used for functionalizing graphene oxide, then chemical crosslinking is conducted through organic molecules, and the super-toughness MXene functionalized graphene nanocomposite film is prepared. The introduced MXene nanosheet and organic molecules not only reduce the porosity of the graphene film, but also improve the orientation degree of the graphene nanosheet. Therefore, due to the interface synergistic effect, the prepared graphene nano composite material film has ultrahigh toughness of 42.7 MJ m<-3> and high conductivity of 1329.0 S cm<-1>. Based on the super-toughness and high-conductivity MXene functionalized graphene nanocomposite film, a flexible supercapacitor assembled by the MXene functionalized graphene nanocomposite film shows high volume energy density and excellent flexibility.

Owner:BEIHANG UNIV

Titanium carbide powder and preparation method thereof

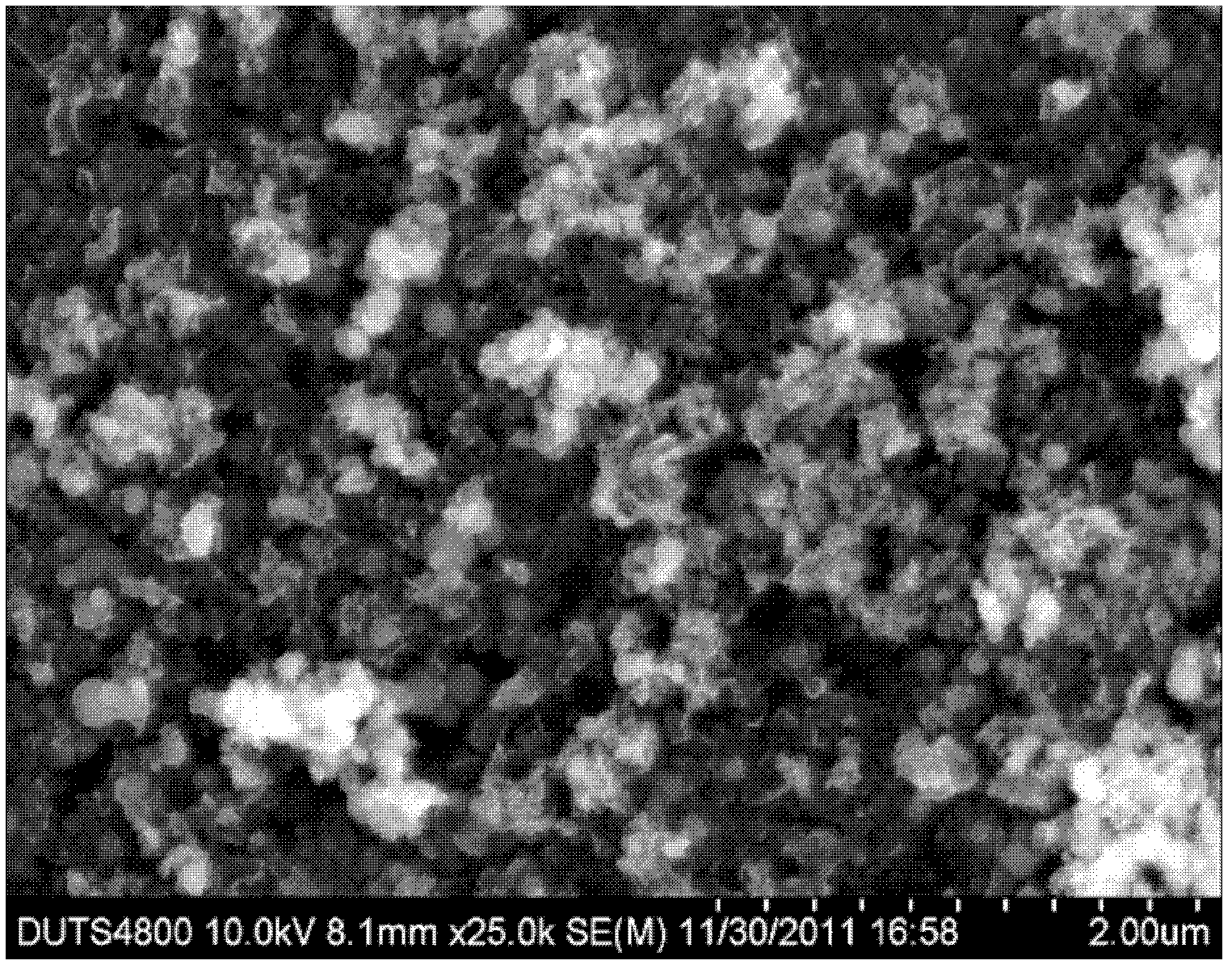

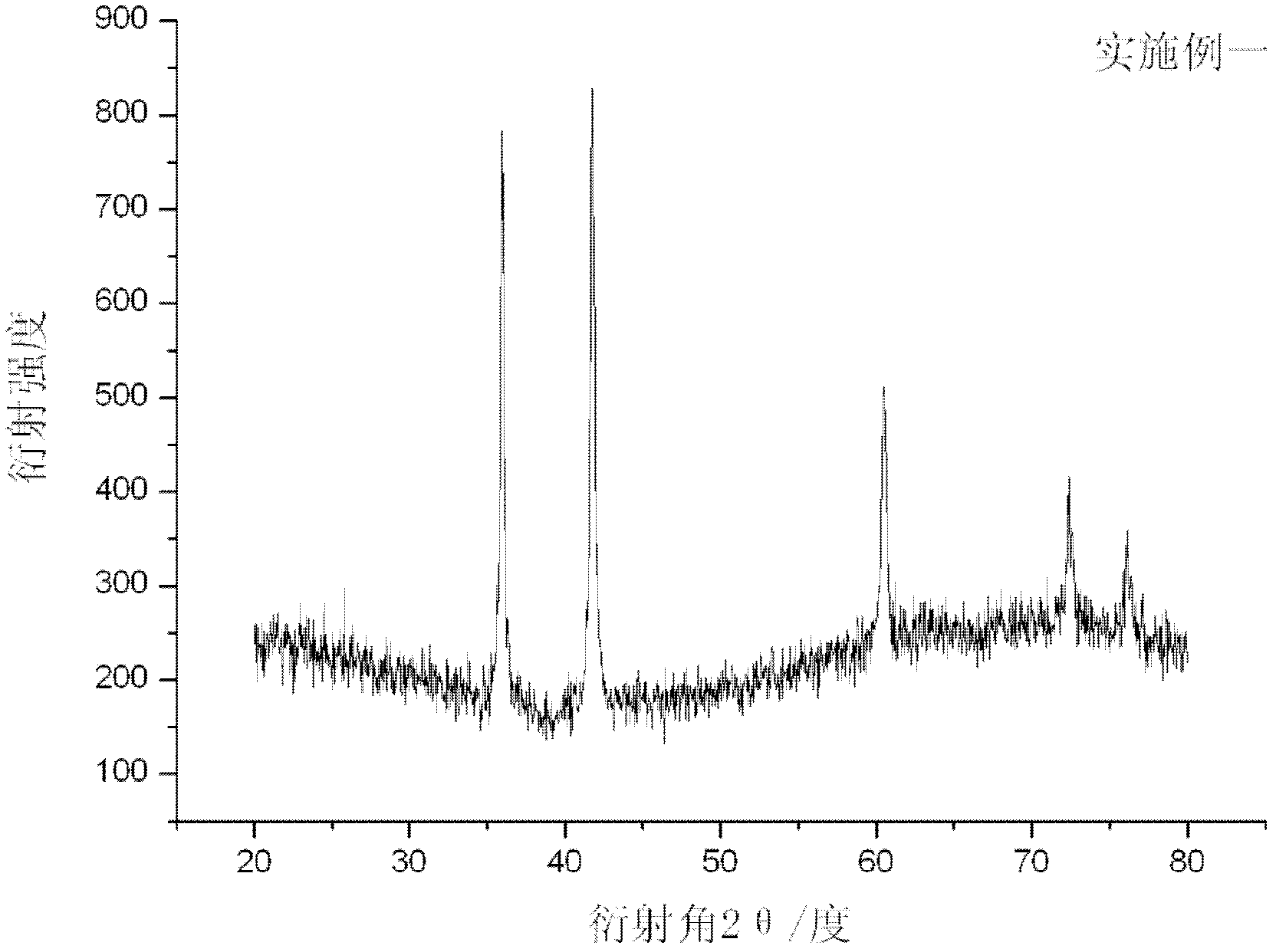

InactiveCN102491328AControl reaction processLow reaction temperatureTitanium carbideAluminium powderReaction temperature

The invention specifically relates to titanium carbide powder and a preparation method thereof. According to a technical scheme, the preparation method comprises the following steps of: uniformly mixing 10-25 percent by weight of aluminum powder or magnesium powder, 0.5-2 percent of amorphous graphite powder or carbon black, 5-20 percent by weight of titanium dioxide and 60-80 percent by weight of a halide of lithium serving as raw materials; putting the uniformly-mixed raw materials into a tubular electric furnace, raising the temperature to 900-1,100 DEG C at the temperature raising rate of 2-8 DEG C per minute under the atmosphere of argon, and preserving heat for 1-5 hours; putting an obtained product into hydrochloric acid of which the concentration is 2-4 mol / L for soaking for 3-6 hours, filtering, and cleaning with deionized water till the pH value of a cleaning solution is 7.0; and drying at the temperature of 110 DEG C for 10-24 hours to obtain titanium carbide powder. The method has the characteristics of low reaction temperature, simple process, controllable synthesis process, low production cost, and the like; and the prepared titanium carbide powder has the characteristics of high crystallization, high product purity, freeness from an impure phase and powder particle size of 100-400 nanometers.

Owner:WUHAN UNIV OF SCI & TECH

Metal-based composite material as well as preparation method and application thereof

ActiveCN108275683ACoated evenlyUniform covering thicknessElectrolytic coatingsNitrogen-metal/silicon/boron binary compoundsMetal matrix compositeStructural formula

The invention relates to a metal-based composite material which comprises a metal substrate and an MXene material membrane layer, wherein the MXene material membrane layer is arranged on the bottom surface of the metal substrate in a wrapping layer and is of a structural formula Mn+1Xn(Ts); an MXene material is prepared by removing A from a compound of a structural formula Mn+1AXn; in the formula,M, A and X are respectively three different elements; n is a positive integer; Ts is an end sealing group on the surface of the MXene material. The surface of the metal-based composite material provided by the invention is uniformly wrapped with the MXene material membrane layer, the number of sheet layers of the MXene material is only 1-15, the wrapping thickness is smaller than 250 nm, the thickness is uniform, the wrapped surface is smooth and flat, surface defects can be avoided, and the corrosion velocity of the obtained metal-based composite material is very low, that is, is only about0.06% of that of a conventional metal substrate; the invention further discloses a novel method for preparing the metal-based composite material, and by adopting the method, no complex instrument equipment is needed, and the metal-based composite material can be conveniently and rapidly prepared.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

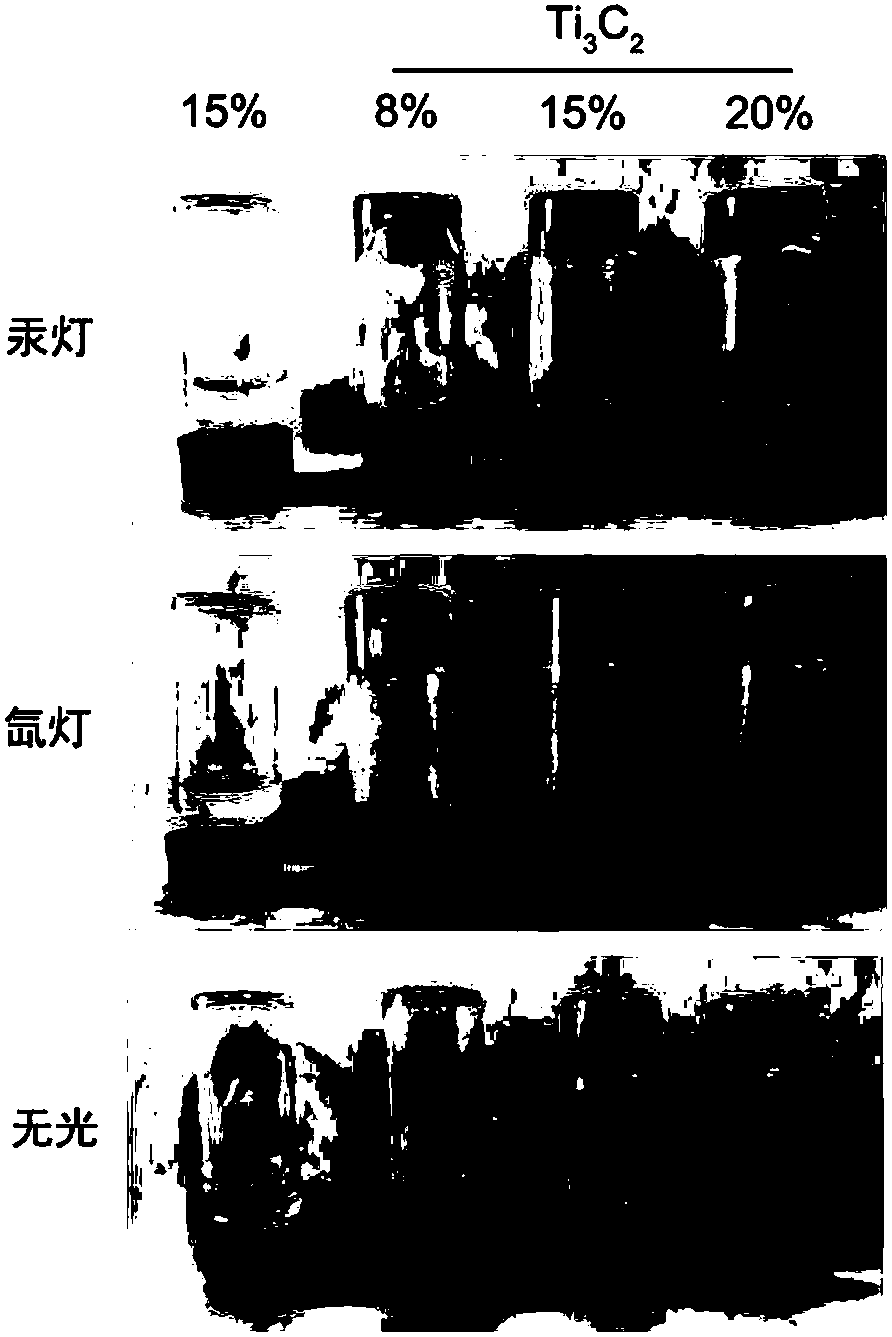

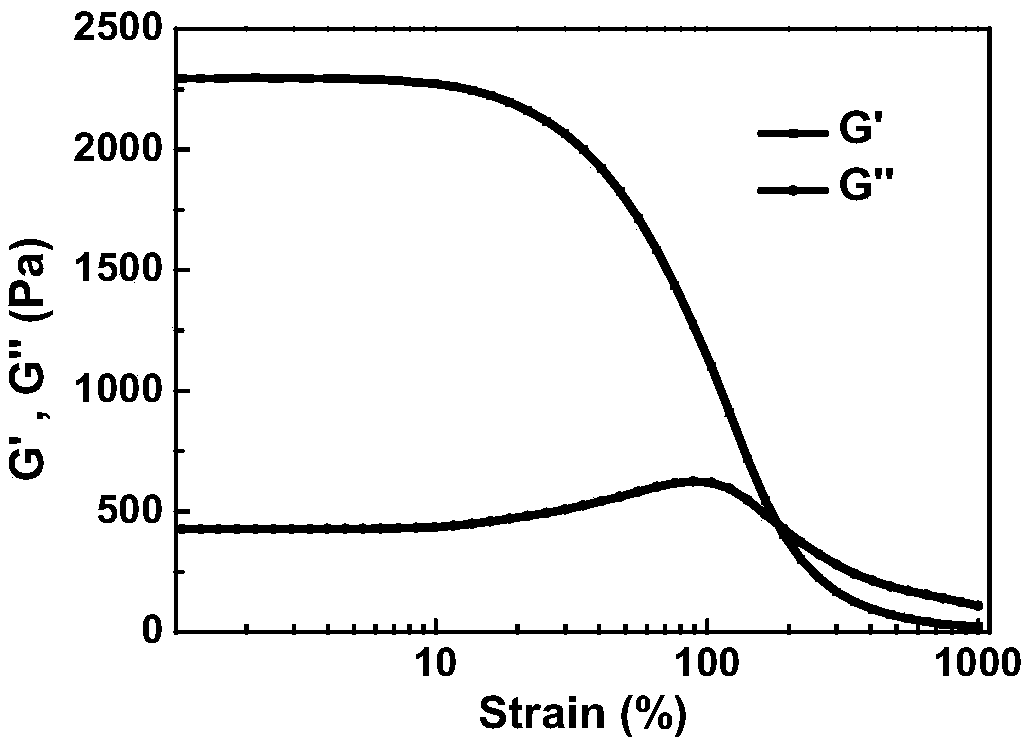

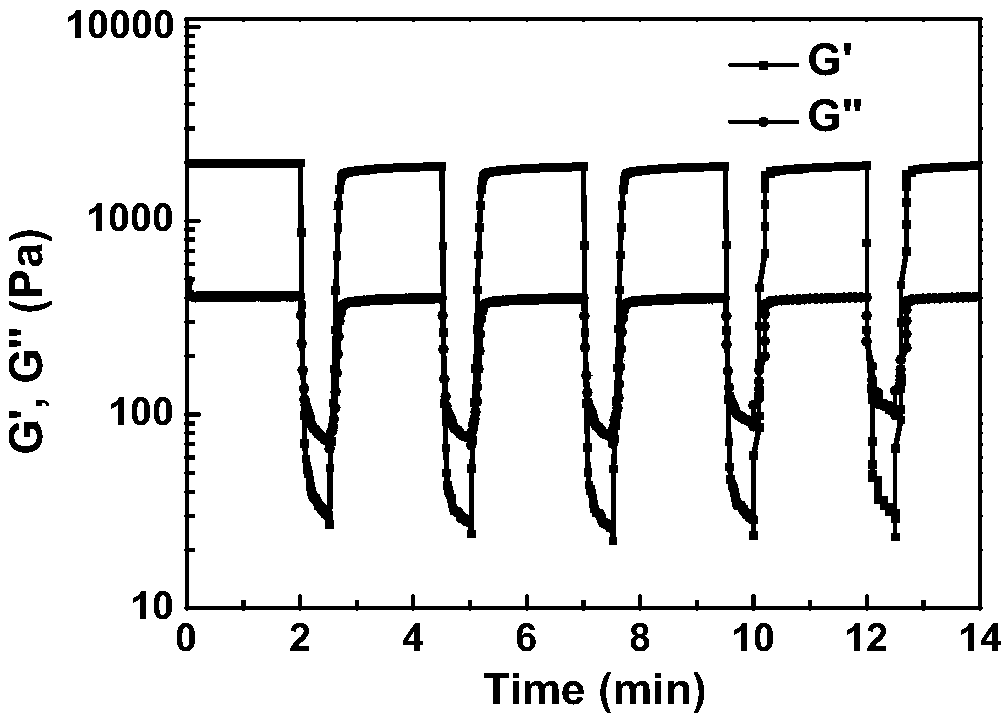

Polymer hydrogel based on cross-linking of two-dimensional titanium carbide layered compound and preparation method and application of polymer hydrogel

InactiveCN108440696AGood mechanical propertiesImprove self-healing abilityMaterial nanotechnologyTitanium carbidePolymer sciencePolymer network

The invention belongs to the field of organic / inorganic nano composite hydrogel, and particularly discloses a preparation method of polymer hydrogel based on cross-linking of a two-dimensional titanium carbide layered compound. The method comprises the step of: with Ti3C2 nanosheets as a cross-linking agent and acrylic compounds and / or acrylamide compounds as monomers, performing a polymerizationreaction so as to obtain the polymer hydrogel. The invention also discloses the polymer hydrogel prepared by using the preparation method and application of the polymer hydrogel as a thermo-sensitivephase-change and / or near-infrared photothermal conversion material. According to the preparation method, the obtained polymer network structure is in situ doped with the Ti3C2 nanosheets which participate in the polymerization reaction through a physical and chemical crosslinking mode, not only can novel photoelectric characteristics be given to the polymer hydrogel, but also excellent mechanicalproperties, such as self-healing performance and high toughness, can be achieved.

Owner:CENT SOUTH UNIV

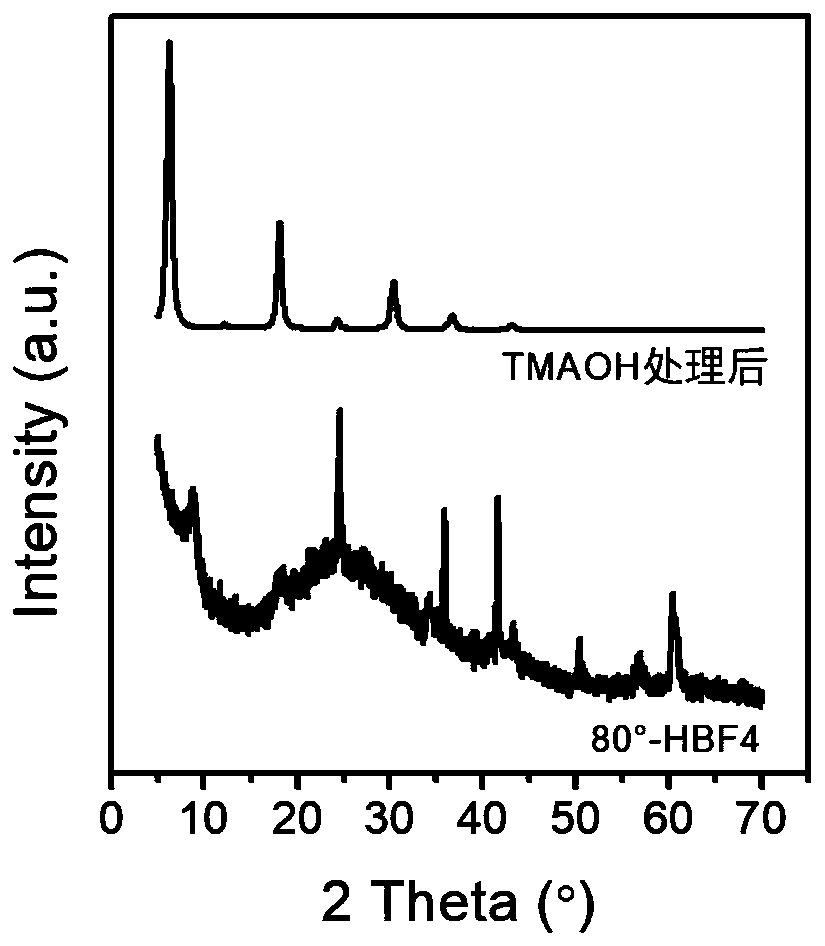

Two-dimensional transition metal carbonitride as well as preparation method and application thereof

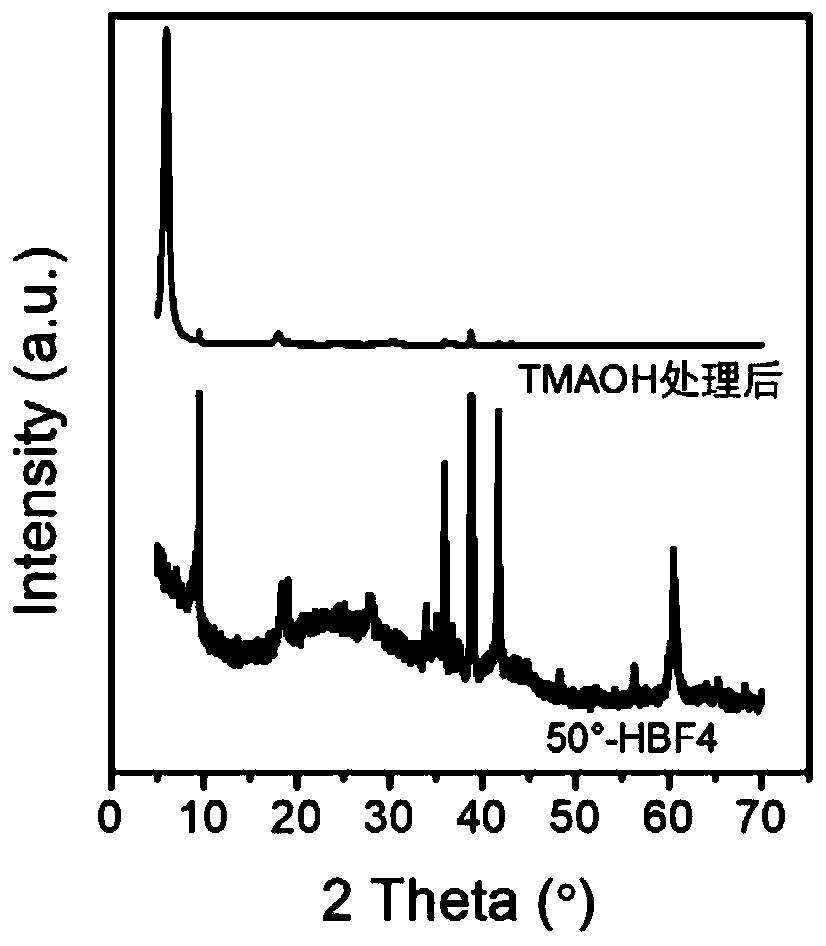

ActiveCN111498850AEasy to filmHigh specific capacitanceNitrogen compoundsTitanium carbideEtchingFluoroboric acid

The invention discloses a two-dimensional transition metal carbonitride and a preparation method and application thereof, and belongs to the technical field of two-dimensional materials. The method comprises the following steps: adding an MAX phase material into a fluoroboric acid aqueous solution for normal-pressure etching; then washing and adding the MXene into an aqueous solution of tetraalkylammonium hydroxide for post-treatment, then washing a treatment product to obtain a two-dimensional transition metal carbonitride (MXene) material; and dispersing the material into water through handcranking, oscillation, stirring, high-speed dispersion or ultrasonic dispersion to form a stable dispersion liquid. According to the method, without use of hydrofluoric acid, the method is safer and more environmentally friendly compared with hydrofluoric acid etching; and the obtained MXene material has good application in the fields of supercapacitors, lithium ion batteries, electromagnetic shielding and electro-catalysis.

Owner:JIANGNAN UNIV

Method for preparing titanium carbide nanometer particles and composite materials thereof by direct current arc method

A method for preparing titanium carbide nanometer particles and composite materials thereof by a direct current arc method belongs to the field of nanometer material preparation technology and application. The method is characterized by including steps of using automatically controlled direct-current arc plasma equipment; utilizing a bulk metal titanium raw material as an anode and a graphite bar as a cathode; leading in mixed gases including carbonic reaction gas, inert gas and active gas which are in certain proportion; and obtaining the titanium carbide nanometer particles and the composite materials thereof after evaporating the bulk metal raw material. The method has the advantages that a preparation process is simple, the kind of nanometer powder materials can be produced on a large scale, size distribution is uniform, purity is high, and accordingly the method can be applied to the fields of electrochemical electrodes and wear-resistant coating materials.

Owner:DALIAN UNIV OF TECH

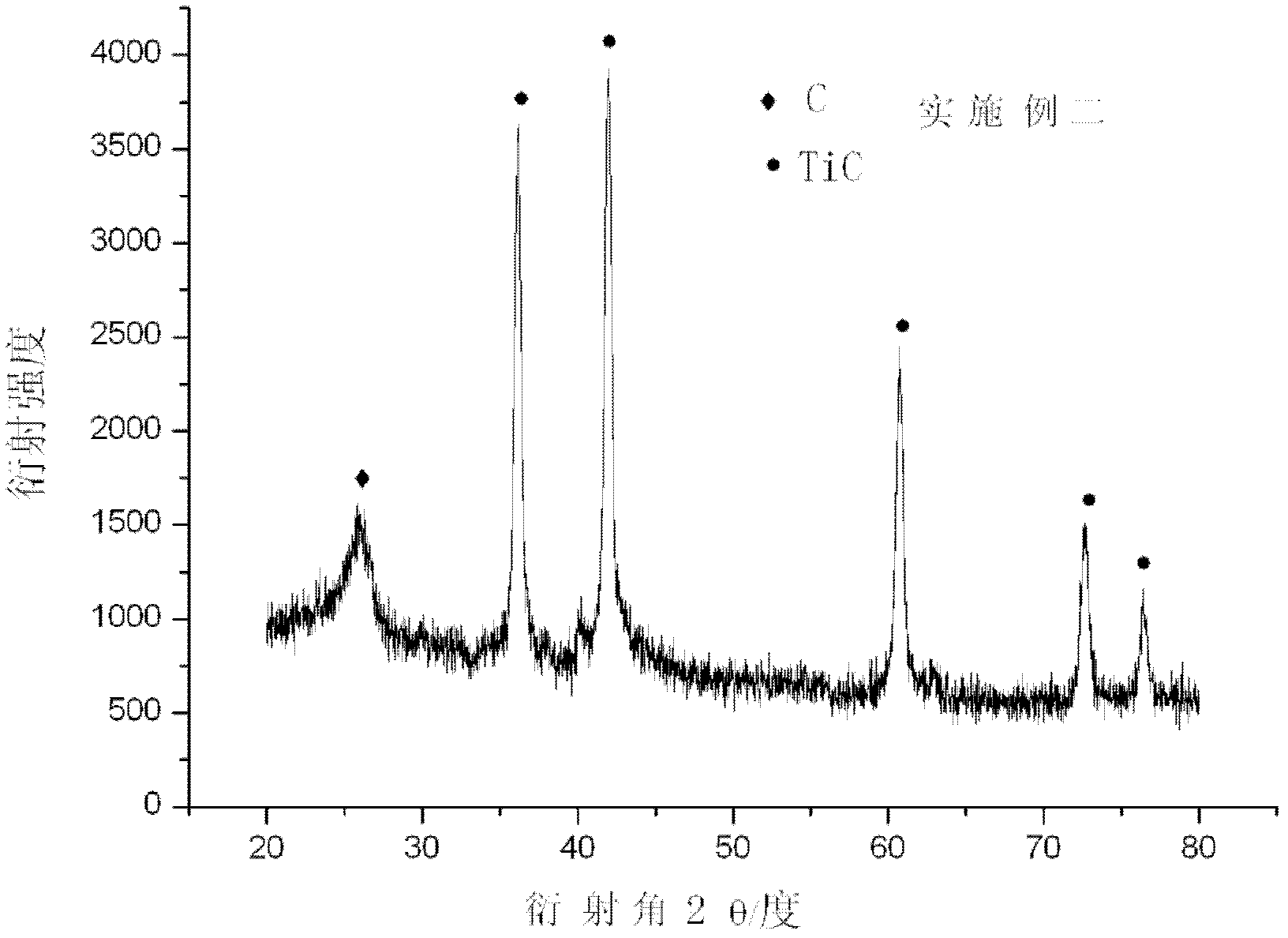

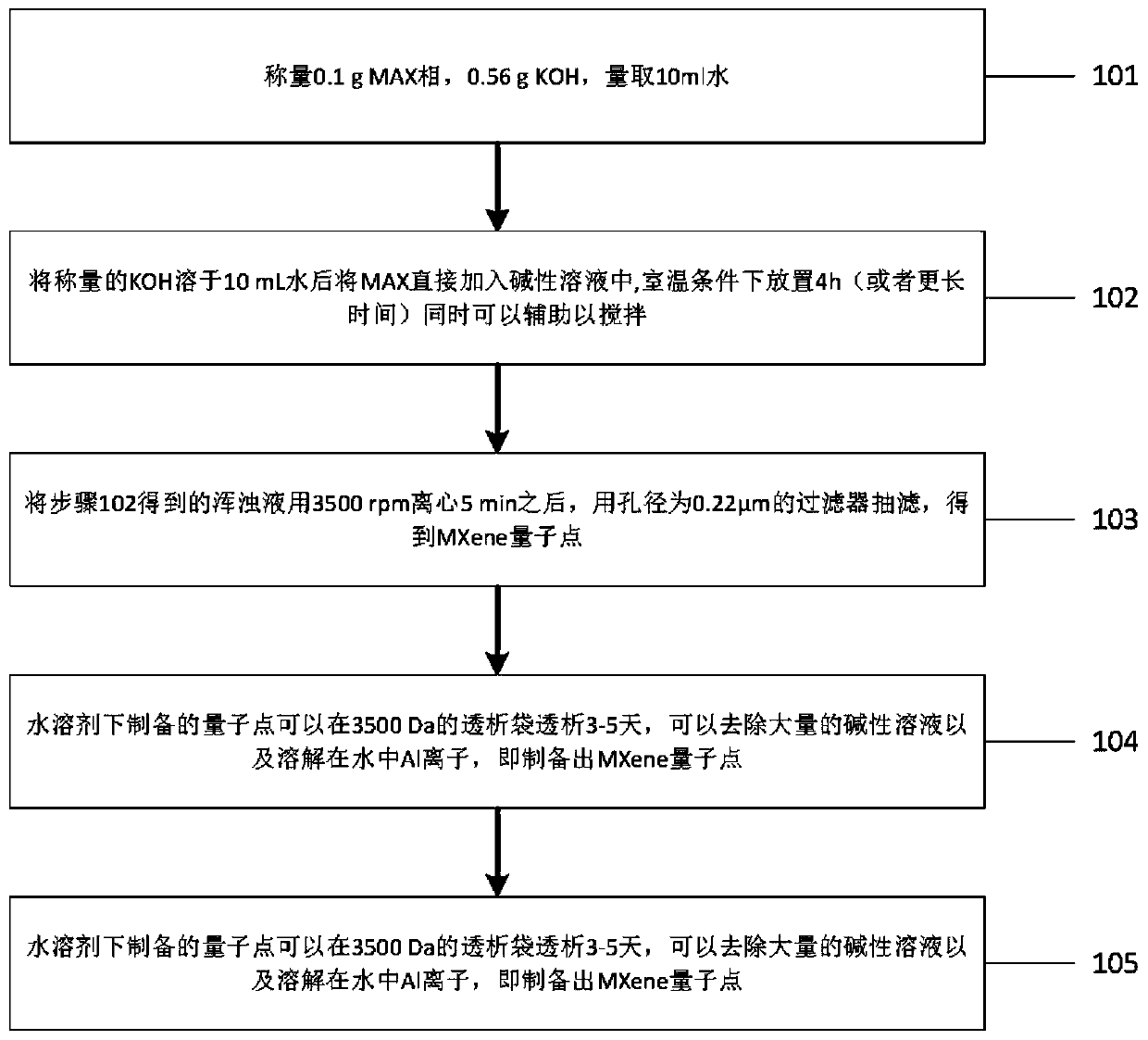

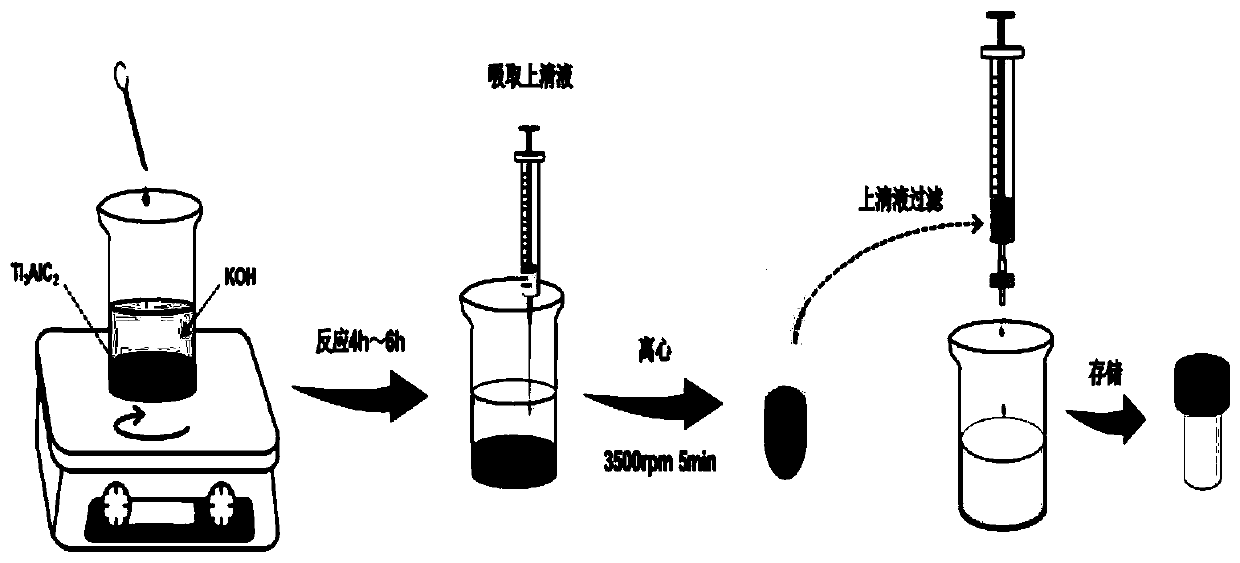

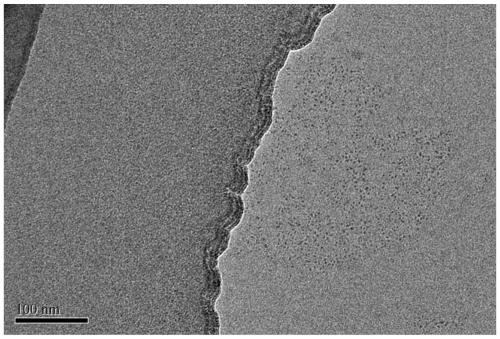

Method for preparing MXene quantum dot by etching with alkali liquor

ActiveCN110371979ASave raw materialsLow costNitrogen compoundsTitanium carbideOrganic solventSemiconductor materials

The invention relates to a method for preparing a MXene quantum dot by etching with an alkali liquor, belonging to the field of semiconductor materials. The method comprises the following steps: weighing a MAX phase, an alkaline compound and water for subsequent usage; dissolving the alkaline compound into the water so as to form an alkaline solution; adding the MAX phase into the alkaline solution, and placing an obtained solution under the condition of a room temperature so as to form a turbid solution; centrifuging the turbid solution obtained in the step 3, and carrying out vacuum filtering through a filter so as to obtain a MXene quantum dot containing alkaline solution; dialyzing the MXene quantum dot containing alkaline solution so as to remove alkaline ions and metal ions in the solution; and mixing an organic solvent with the MAX phase under stirring so as to prepare the MXene quantum dot. The method provided by the invention has the advantages of simple preparation process, environmental friendliness, low cost, less time consumption and applicability to large-scale production; meanwhile, the MXene quantum dot is proved to have universality to a MAX material.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of two-dimensional transition metal carbide or nitride

InactiveCN106744733AMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsTransition metal carbidesCarbide

The invention relates to a preparation method of two-dimensional transition metal carbide or nitride. The preparation method comprises the following steps: uniformly mixing metal carbide or metal nitride with strong alkali to obtain a mixture, wherein the metal carbide or the metal nitride is selected from at least one in the group consisting of Ti2AlC, Ti3AlC2, Ti3SiC2, Ti4SiC3, Ti2AlN, V2AlC, V3AlC2, V4AlC3, V4SiC3, Nb2AlC, Nb4AlC3, Nb4SiC3, Ta2AlC, Ta3AlC2 and Ta3SiC2; the strong alkali is selected from at least one in the group consisting of KOH, RbOH and CsOH; washing the mixture by use of deionized water to obtain a single-layer dispersed two-dimensional transition metal carbide or nitride colloidal solution. The preparation method disclosed by the invention is an environmental-friendly and pollution-free method for obtaining a single-layer two-dimensional nanometer lamella.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing laminar MXenes material by utilizing ternary MAX material

ActiveCN108793167AAccelerated corrosionGood microscopic appearanceMaterial nanotechnologyTitanium carbideStrong acidsMetal

The invention provides a method for preparing a laminar MXenes material by utilizing a ternary MAX material. The method comprises the following steps: taking strong acid or strong alkali as corrosionliquid and putting the corrosion liquid into a reaction container; putting MAX powder into the corrosion liquid; then adding soluble mixed salt while stirring; continuously corroding for 0.5 to 48h; then centrifuging and separating; washing and drying to obtain the laminar MXenes material. According to the method provided by the invention, the soluble mixed salt of metal with metal activity whichis weaker than that of layer-A metal is added into the corrosion liquid by utilizing a galvanic battery principle, so that the soluble mixed salt is reduced by the layer-A metal to obtain the metal with the metal activity which is weaker than that of the layer-A metal; the metal is combined with the layer-A metal to form a corroded couple; reaction is promoted to be carried out rightward and the corrosion of the layer-A metal is accelerated, so that a single-layer two-dimensional nano material which is completely peeled and corroded is obtained. The method is simple and has strong operabilityand a good realization result; the MXenes material, which has a relatively high peeling degree and a relatively good microcosmic shape, can be obtained.

Owner:SHAANXI UNIV OF SCI & TECH

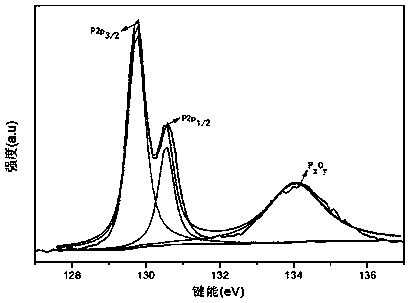

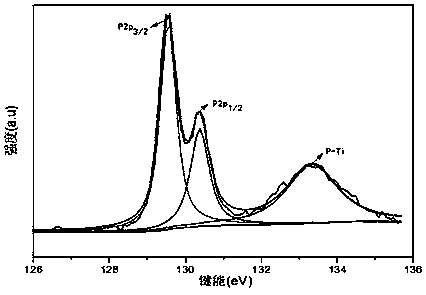

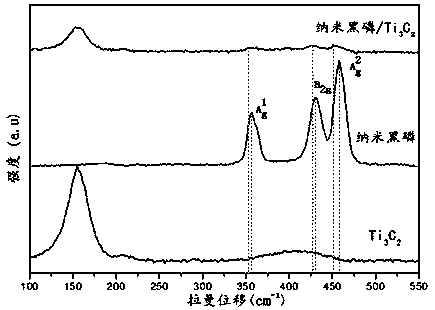

Method for stabilizing nanometer black phosphorus

InactiveCN108383092AFix stability issuesSolve structural instabilityTitanium carbideTungsten/molybdenum carbideBlack phosphorusSolvent

The invention discloses a method for stabilizing nanometer black phosphorous. The method comprises the following steps: under inert gas shielding, mixing MXene powder and nanometer black phosphorous powder in the mass ratio of (1: 6) to (6: 1), adding the mixture into a solvent for blending, then carrying out separation, and drying the separated materials so as to obtain a nanometer black phosphorous / MXene composite material. Aiming at the disadvantage that the nanometer black phosphorous is easy to oxidize and unstable in structure, the problem can be solved by compounding the nanometer blackphosphorous and MXene, the nanometer black phosphorous and the MXene are presented in a coordination bond (P-Ti) manner, and the single nanometer black phosphorous is stabilized preferably; the method disclosed by the invention is simple in operation, mild in preparation condition, green, environmentally-friendly and low in cost, and the obtained high-stability nanometer black phosphorous can bewidely applied to the fields of energy storages, photoelectrocatalysis, flame retardance and the like.

Owner:KUNMING UNIV OF SCI & TECH

Electrochemical synthesis method of two-dimensional titanium carbide nanosheet

InactiveCN107381576AEfficient preparationNo need for ultrasonic strippingMaterial nanotechnologyTitanium carbideElectrochemical responseSynthesis methods

The invention discloses an electrochemical synthesis method of a two-dimensional titanium carbide nanosheet. The ultrathin two-dimensional titanium carbide nanosheet can be directly prepared from an anode material through an electrochemical reaction on an anode at certain voltage with Ti3SiC2, Ti3AlC2, TiAlC or other materials as an anode and a water solution containing F<-> and SO4<2-> as electrolyte. The two-dimensional nanosheet can be independently used and can be combined with other materials for use, can serve as an electrode material to be used in a lithium ion battery and a supercapacitor and can also be used for the field of electronics and the like.

Owner:ANYANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com