Patents

Literature

67 results about "Motor tics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tic is a sudden, repetitive, nonrhythmic motor movement or vocalization involving discrete muscle groups. Tics can be invisible to the observer, such as abdominal tensing or toe crunching. Common motor and phonic tics are, respectively, eye blinking and throat clearing.

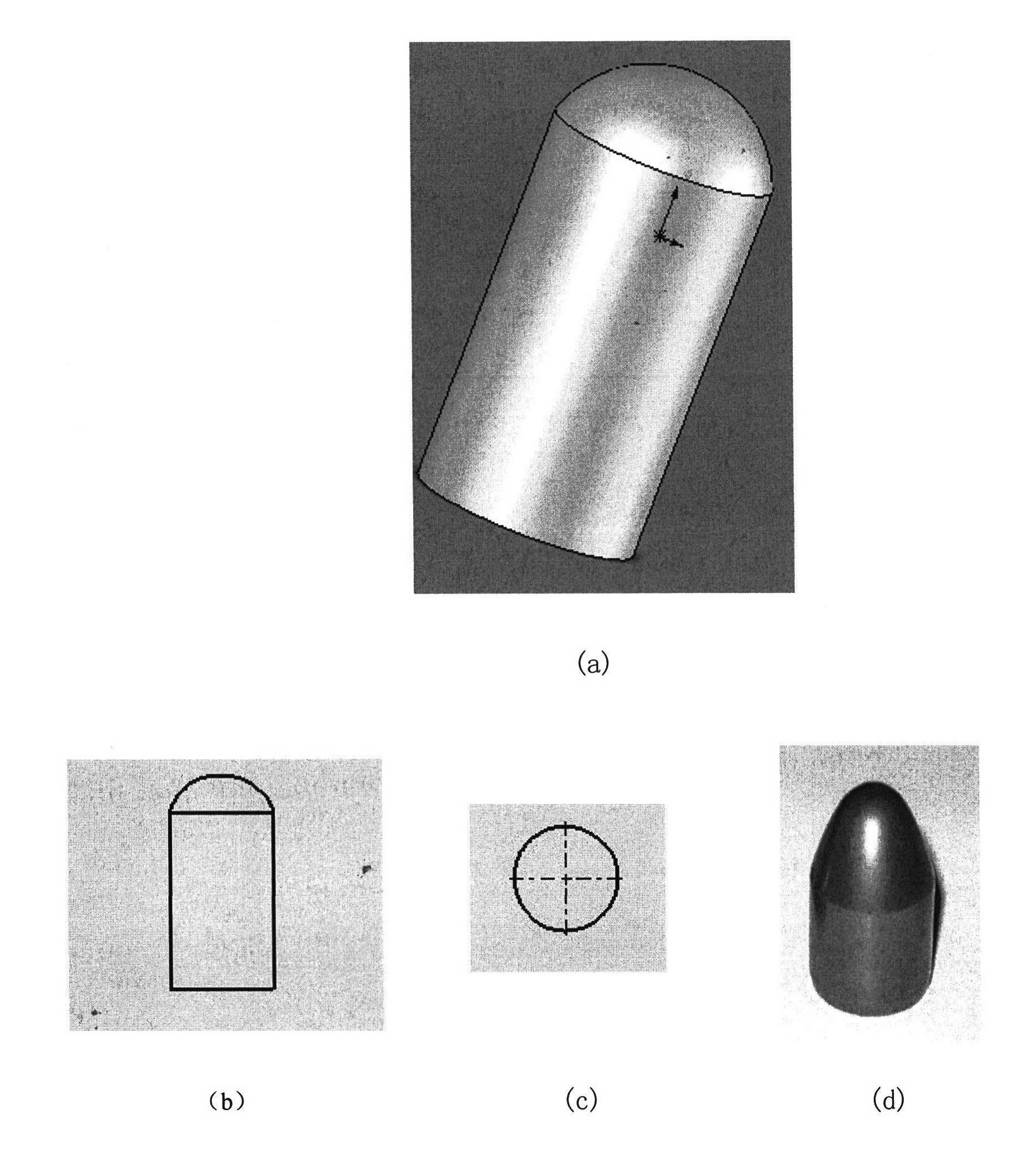

Inserted tooth hammer of crushing machine and preparation method thereof

The invention relates to an inserted tooth hammer of a crushing machine and a preparation method thereof and belongs to the fields of high technology engineering materials and application thereof. The inserted tooth hammer of the crushing machine consists of ball teeth and a hammer base body and is formed by virtue of high temperature imbedding, wherein the ball teeth are novel high-hardness high-strength anti-abrasive composite metal ceramic comprising one or more of WC, TiN or TiC based composite metal ceramic; the hammer base body is middle-low carbon steel or alloy steel with high hardness and strength and good toughness; the inserted tooth hammer of the crushing machine structurally comprises multiple cylindrical ball teeth with spherical crowns, the multiple cylindrical ball teeth are imbedded at the front end of the hammer base body, a cylinder is buried in a steel body, the spherical crowns are exposed out of the steel body, and a distance is reserved between the ball teeth. The preparation method of the inserted tooth hammer of the crushing machine successively comprises the following steps of: pre-preparing composite metal ceramic ball teeth; smelting hammer base body alloy steel; imbedding the ball teeth; and demoulding. The inserted tooth hammer of the crushing machine has the characteristics of good abrasive resistance, long service life, raw material economization and low cost.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

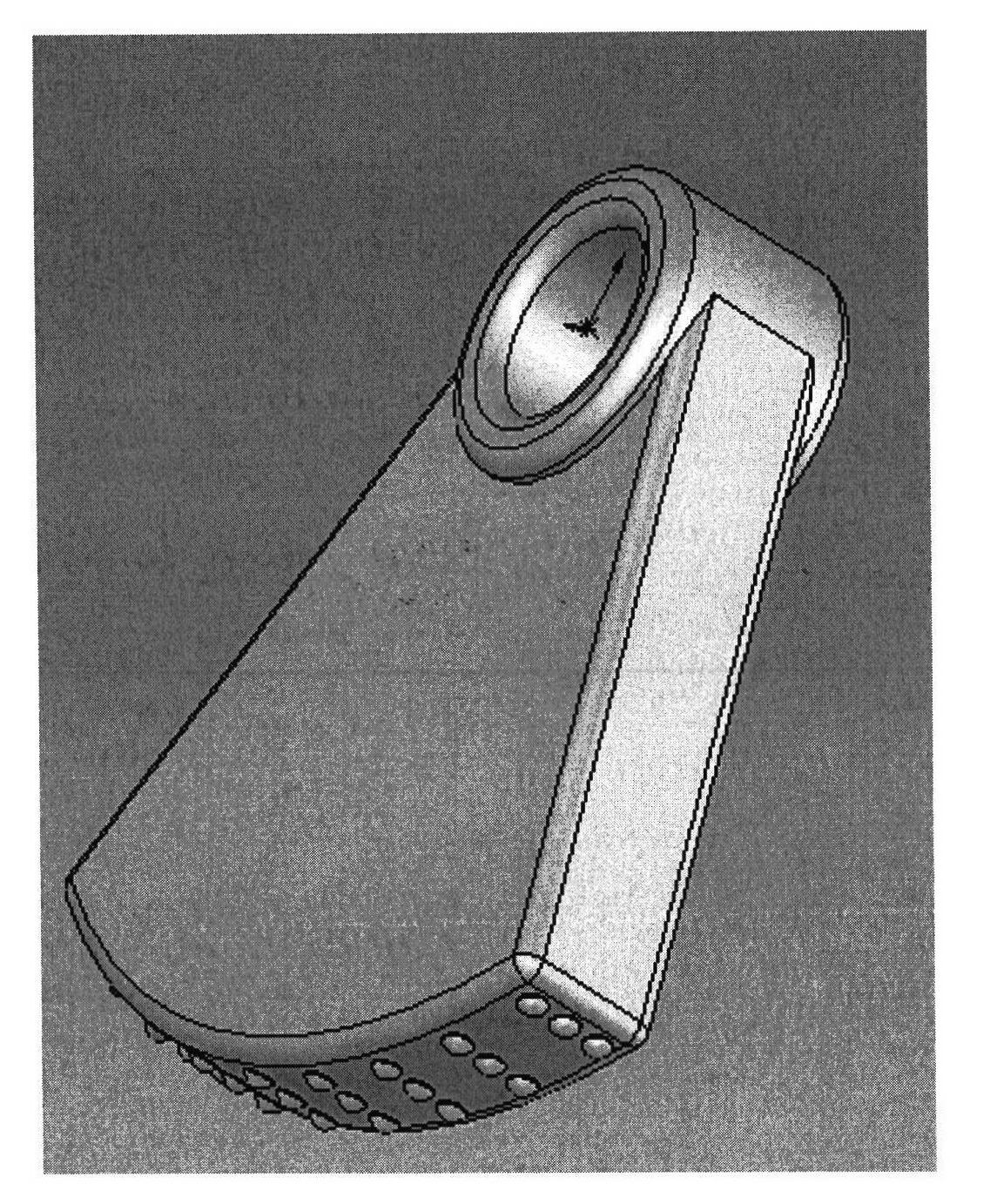

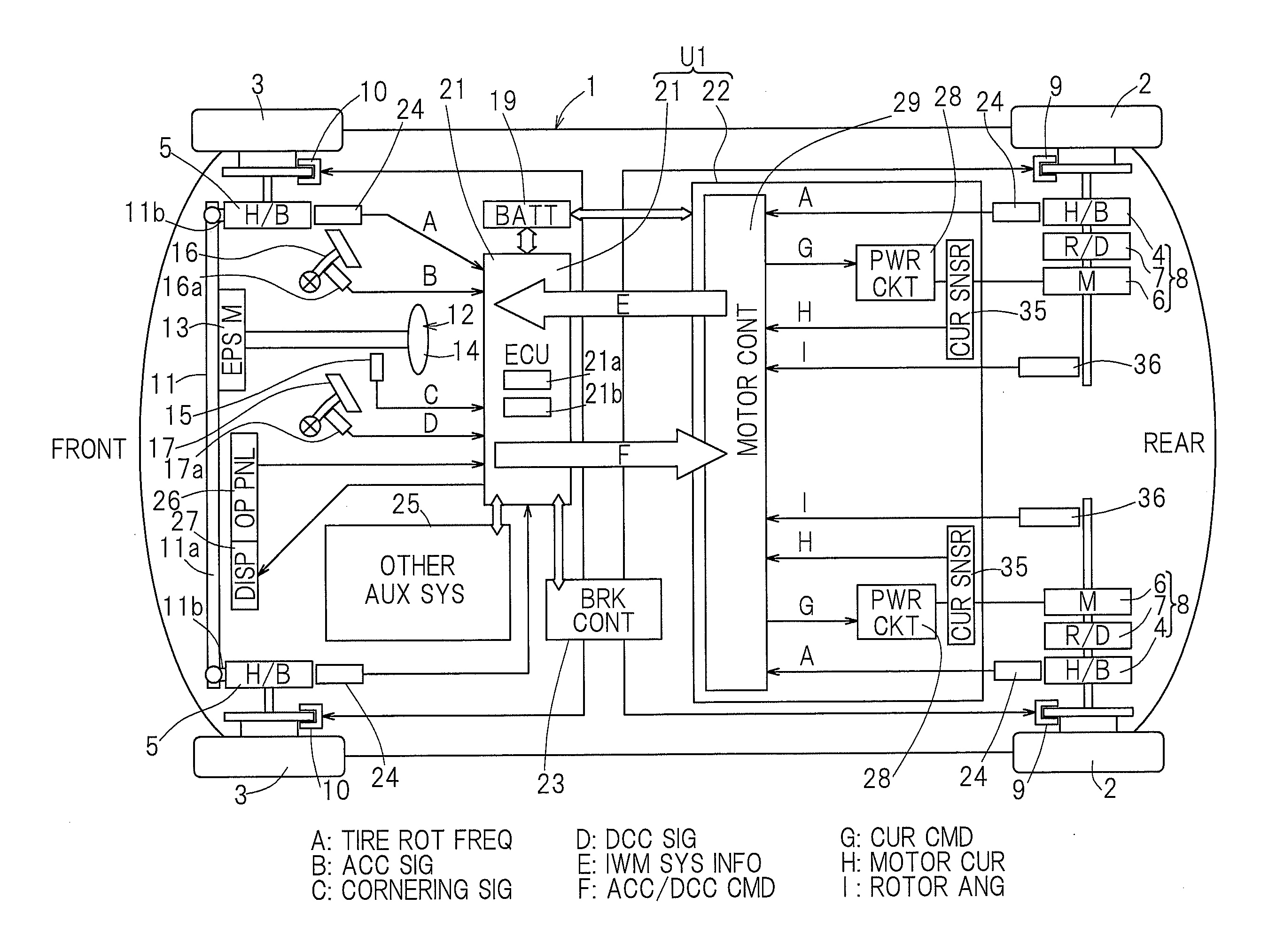

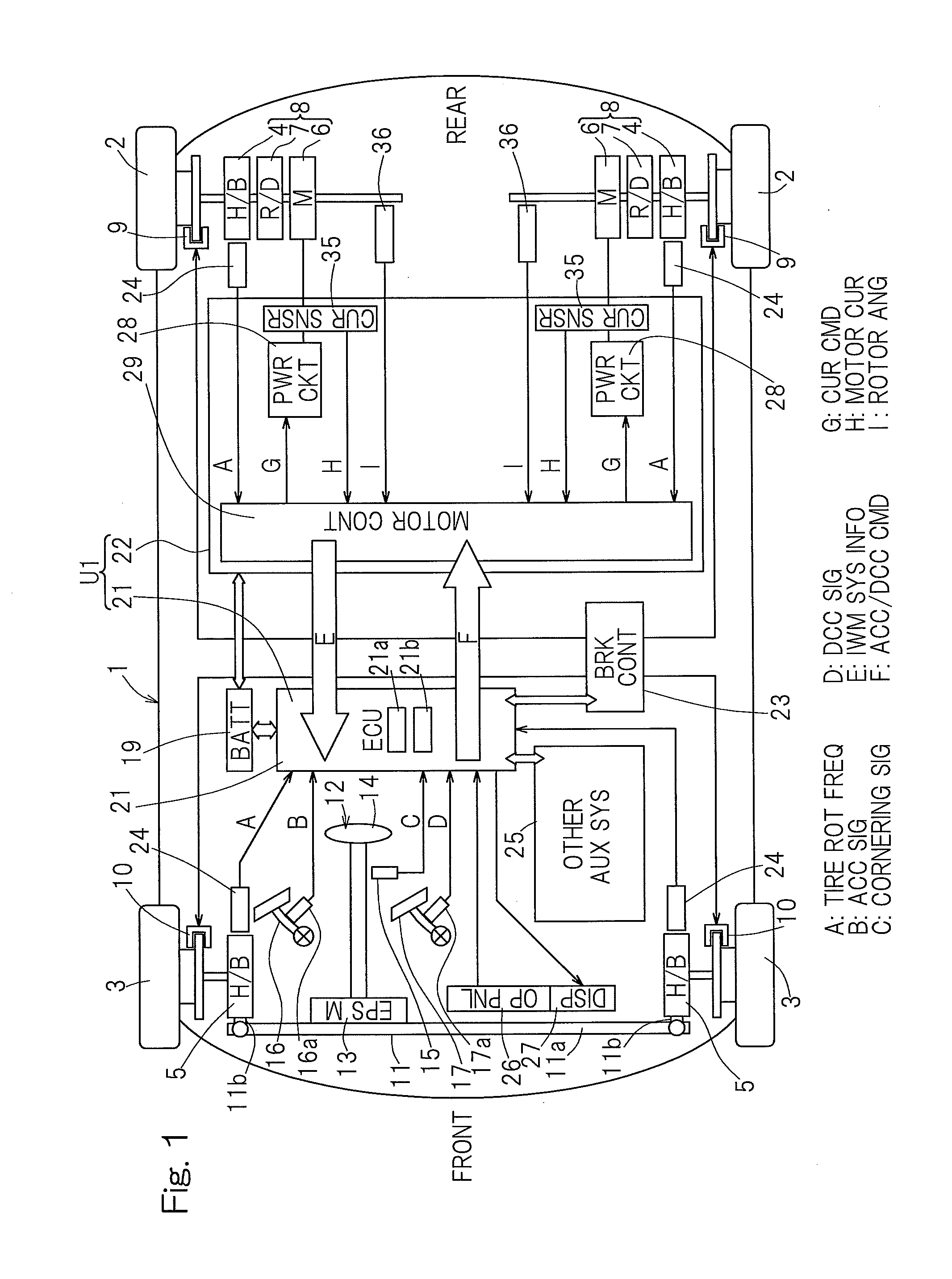

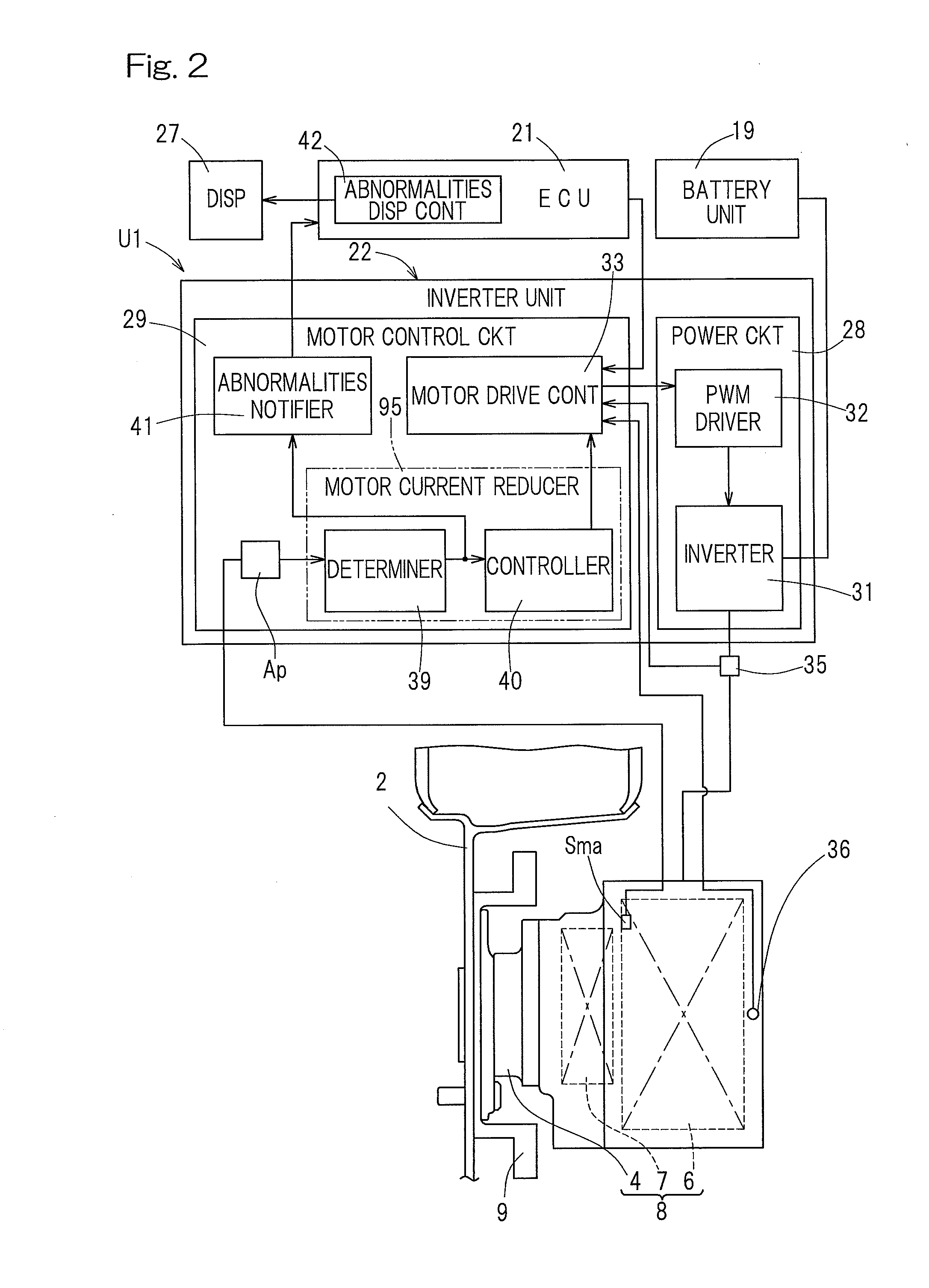

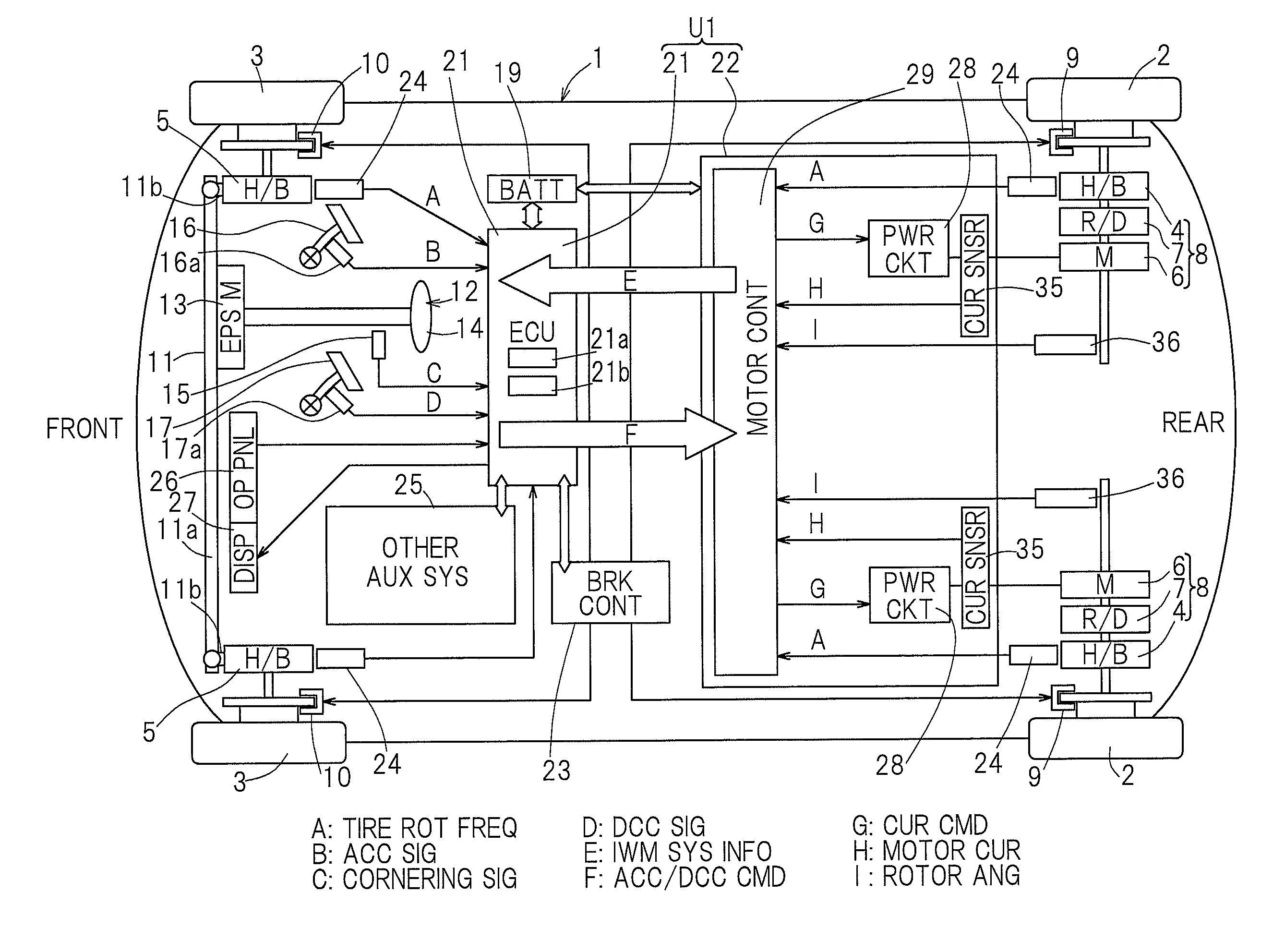

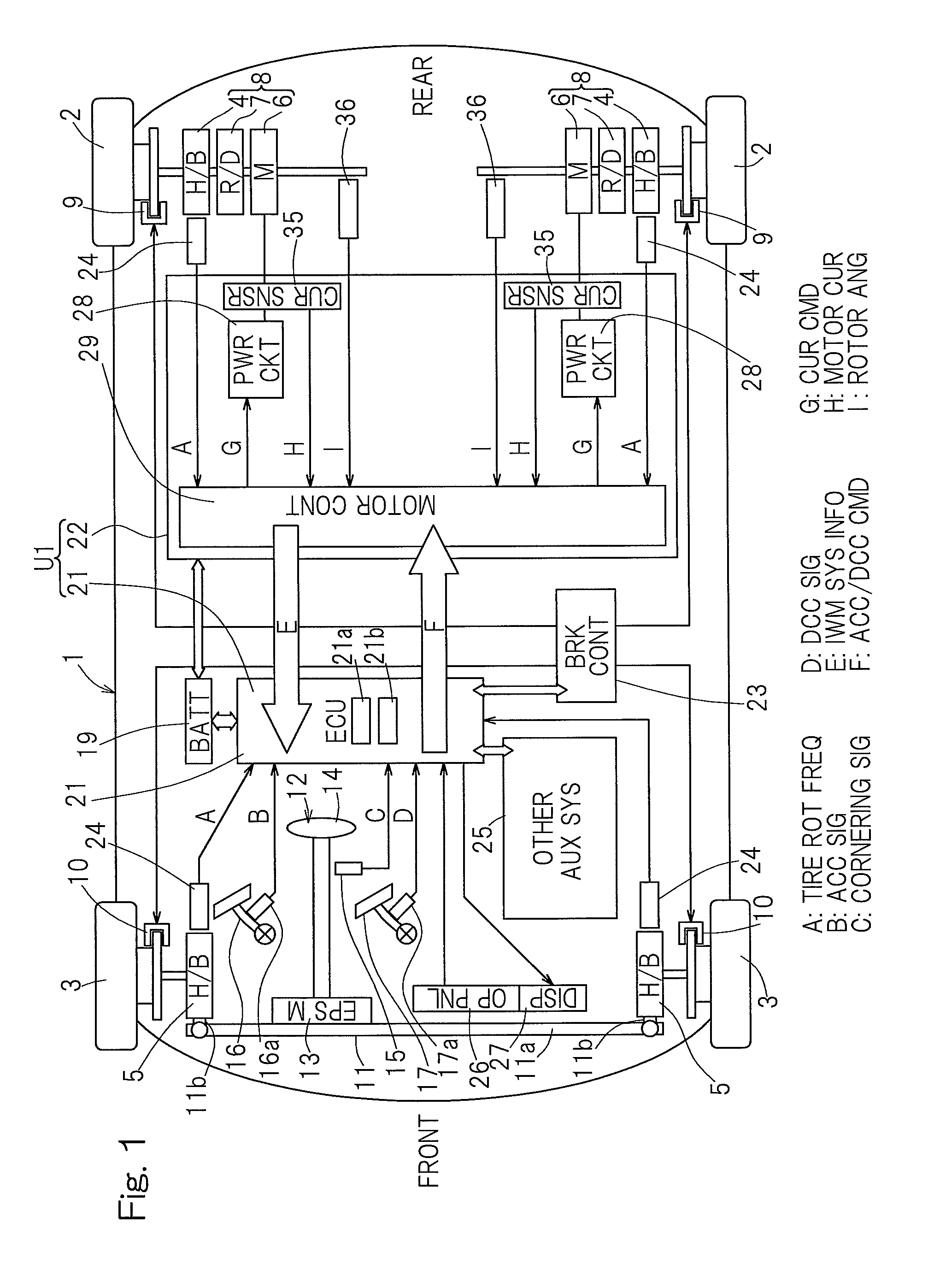

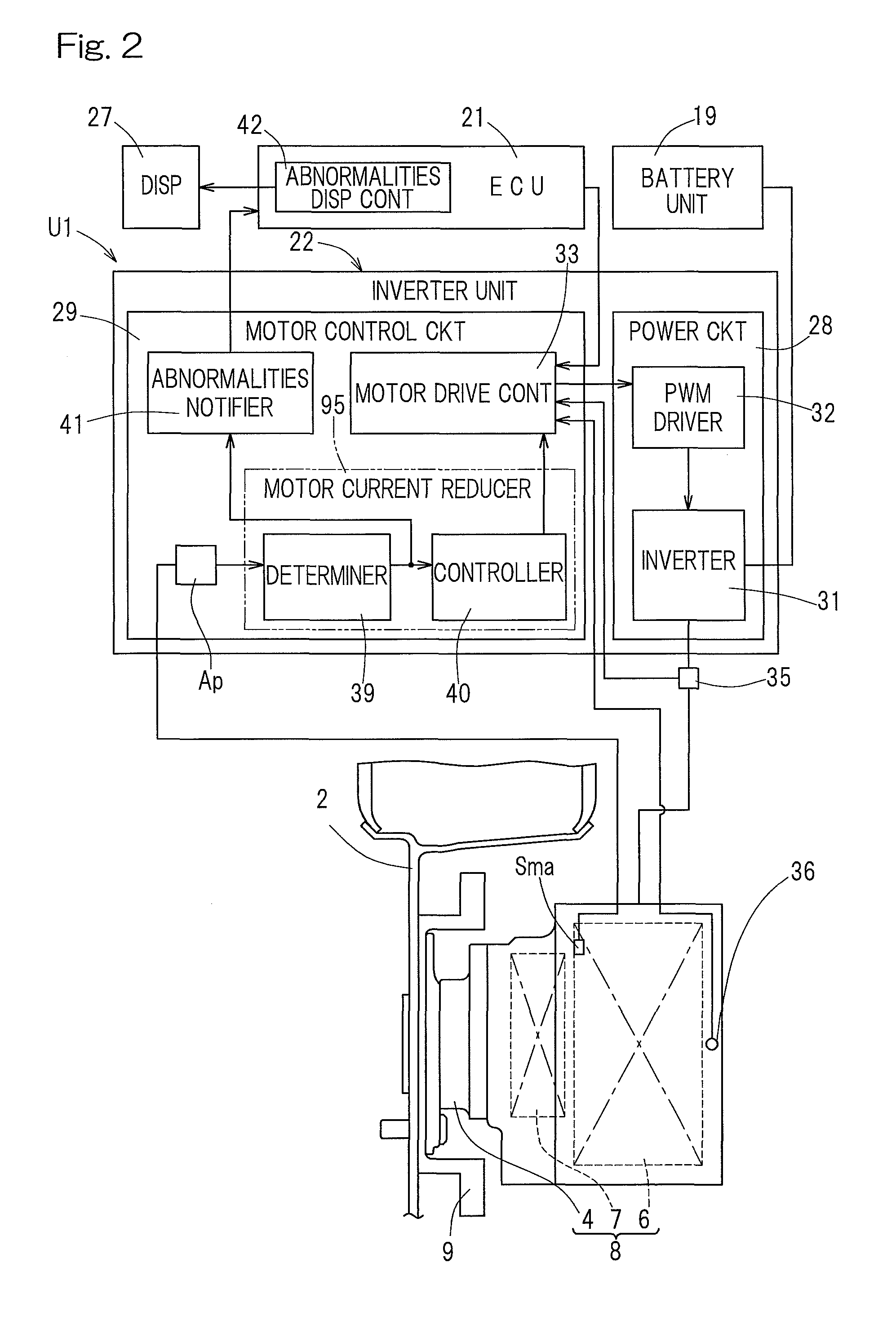

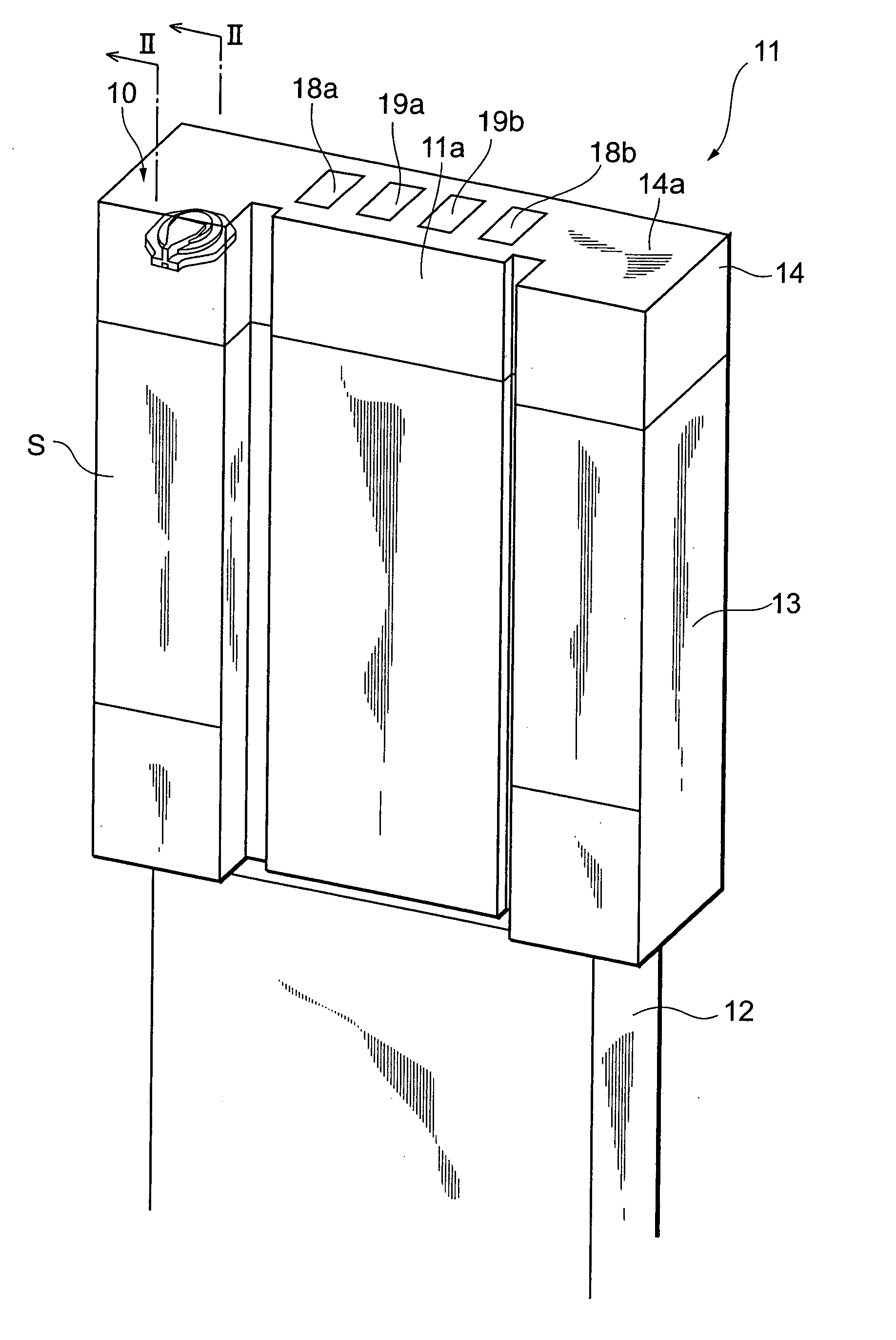

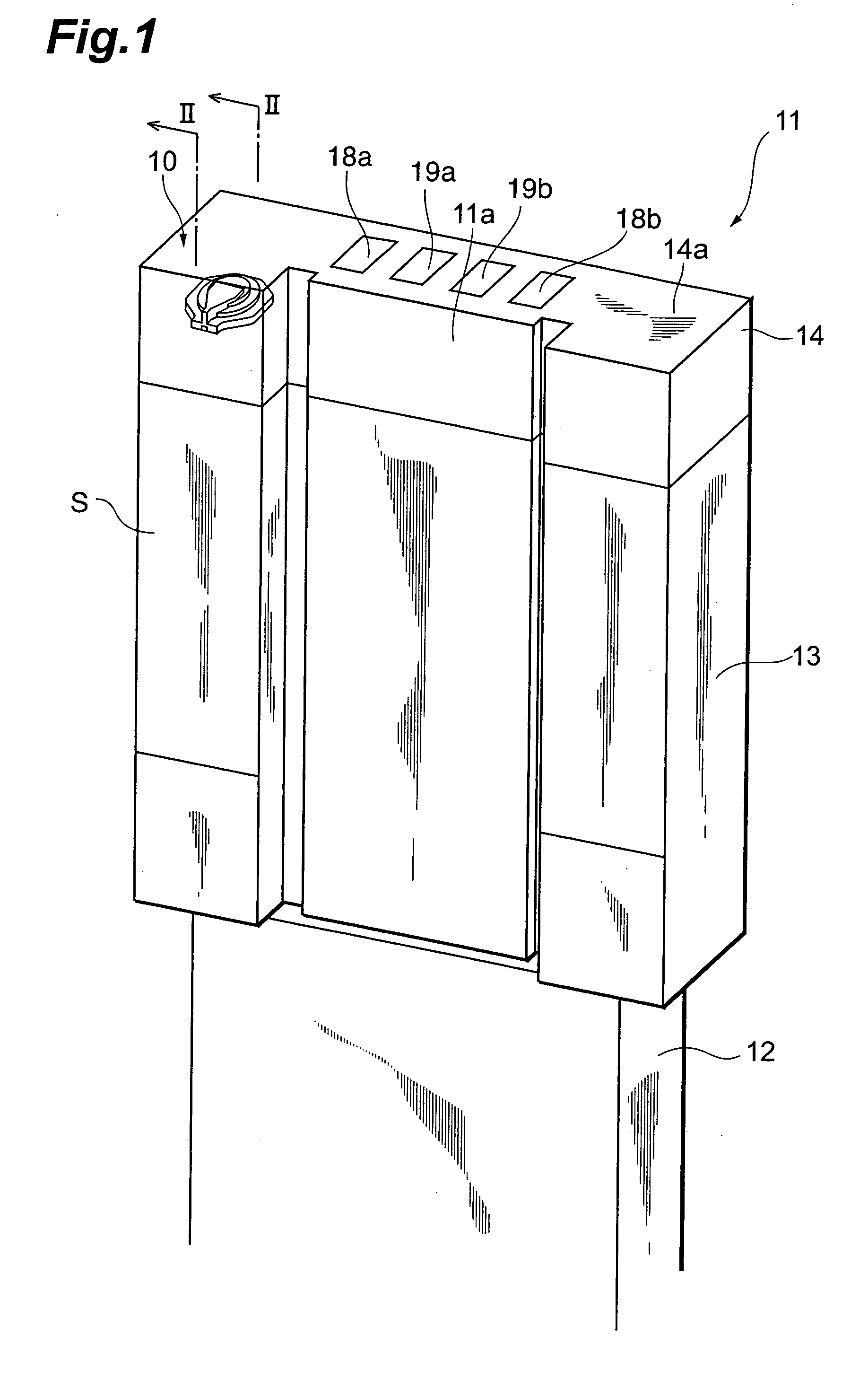

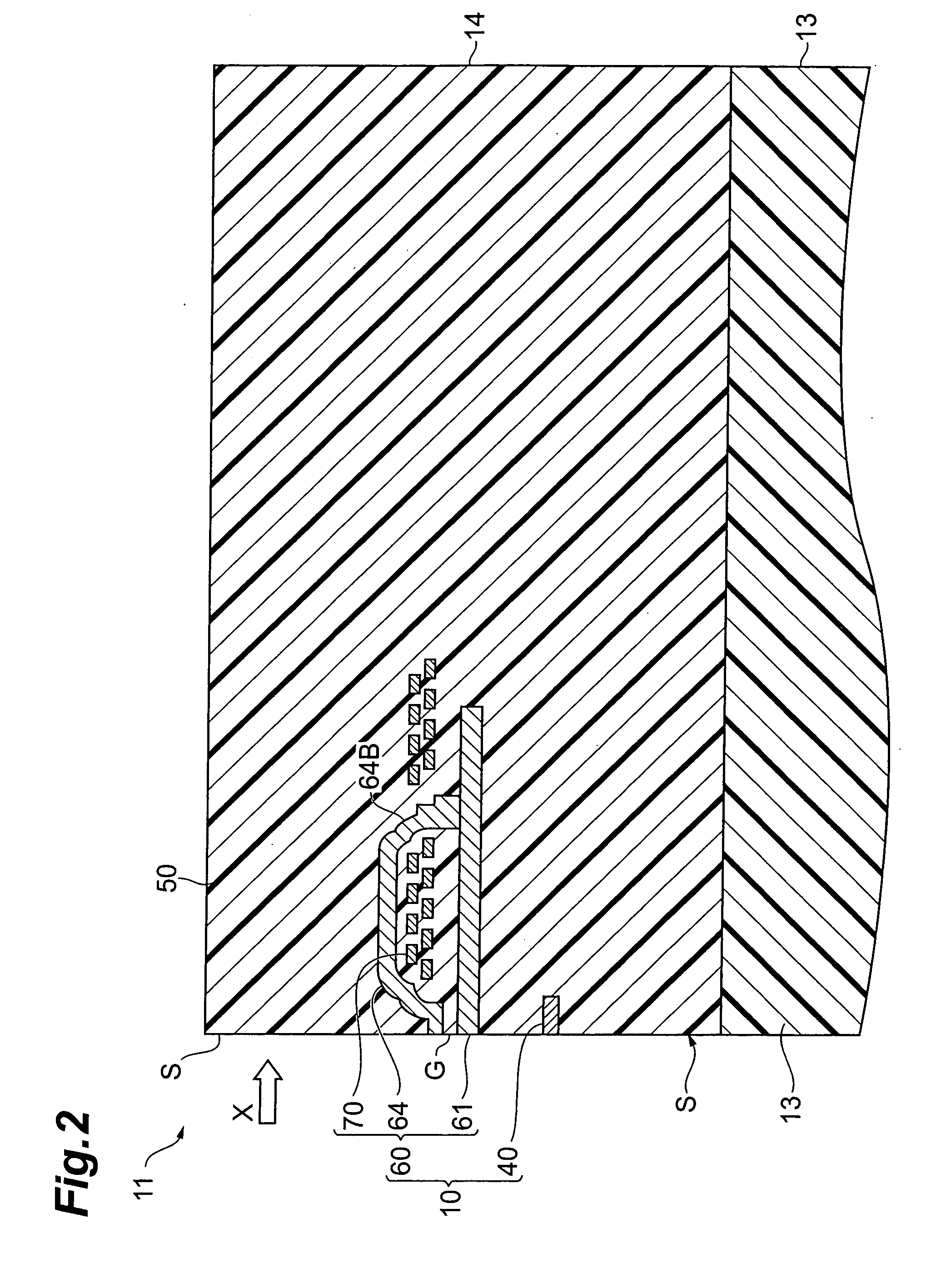

Electric automobile

InactiveUS20130320747A1Increase temperatureIncrease torqueDC motor speed/torque controlTemperatue controlPower inverterMotor tics

An electric vehicle includes a motor unit to drive a wheel. The electric vehicle also includes a control system that controls the motor unit. The control system includes an inverter. The electric vehicle also includes a temperature sensor to sense temperature Tmc of the motor coils of the motor unit or a temperature sensor to sense temperature Tic of the inverter. The electric vehicle also includes a limiter to, if the temperature Tmc sensed by the sensor exceeds a motor coils temperature threshold, reduce a motor current of the unit until a derivative dTmc / dt of the sensed temperature Tmc with time t drops to zero or below, or to, if the temperature Tic sensed by the sensor exceeds an inverter temperature threshold, limit a current command to the inverter until a derivative dTic / dt of the sensed temperature Tic with time t drops to zero or below.

Owner:NTN CORP

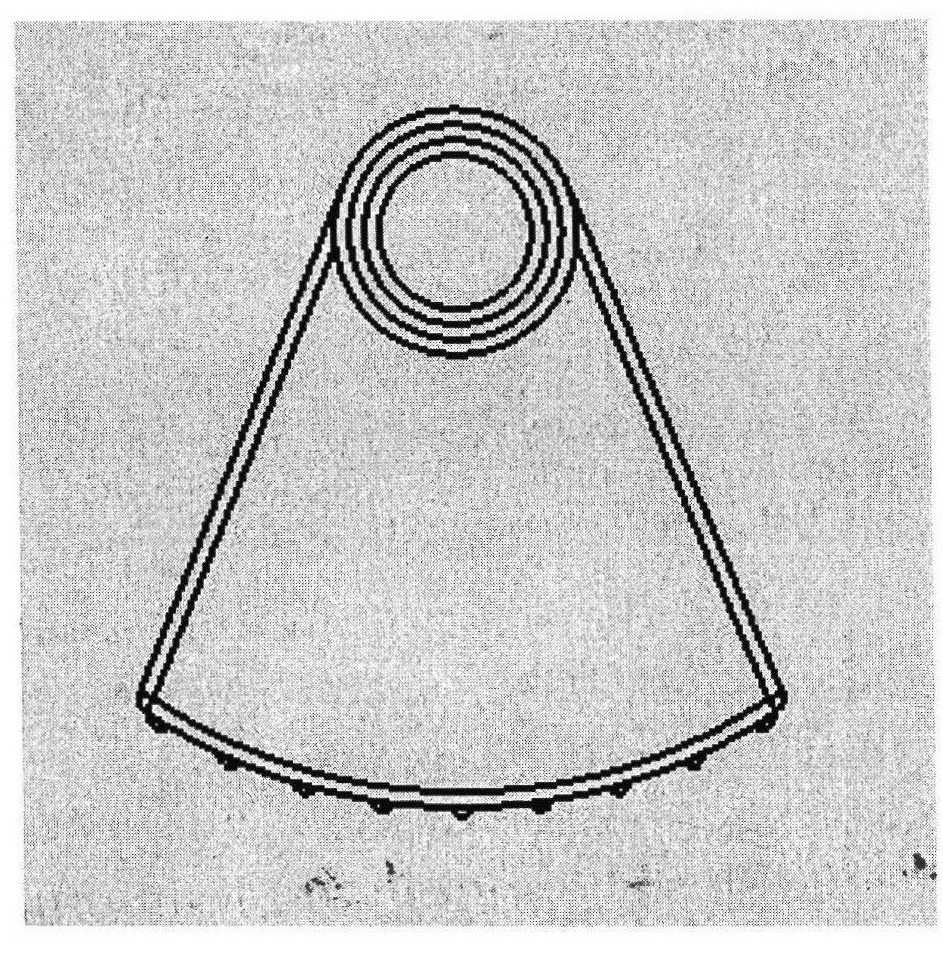

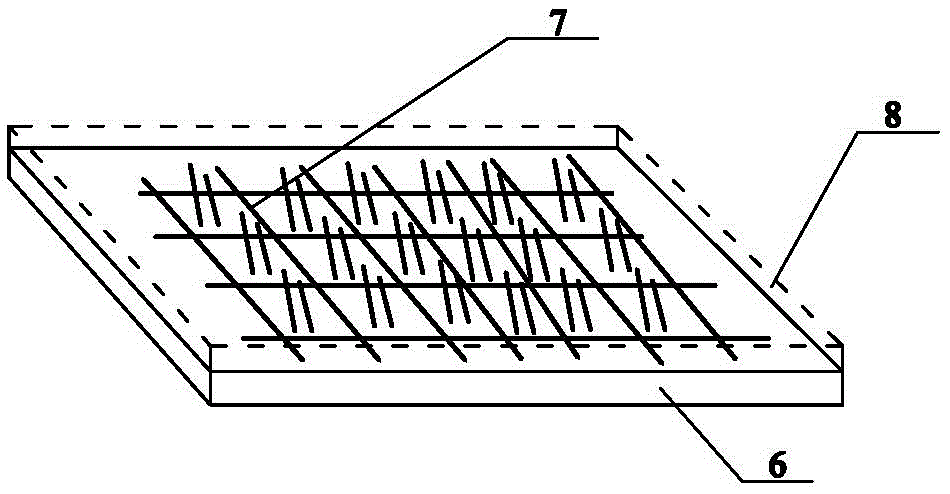

Composite materials and methods for making same

InactiveUS8128861B1Suppress unwanted by-product chemical reactionsAmeliorate the tendency of molten siliconCeramic shaping apparatusArmour platesMotor ticsHigh pressure

Current top performing SAPI systems are B4C-containing (hot pressed B4C or reaction bonded B4C). These systems will not function well versus future WC / Co threats due to the inability of B4C to withstand high pressure impacts. New approaches will be needed for next generation SAPI ceramics. Three related concepts are disclosed herein, each of which will lead to improved reaction bonded ceramics for next generation SAPI applications. The first concept aims to reactively heat treat reaction bonded B4C, causing. SiC and SiB6 to form at the expense of B4C. The second approach will add Ti to the system, thus allowing TiC and TiB2 to form at the expense of B4C. Finally, the third concept will evaluate the use of finer particle sizes, thus improving the static properties of the ceramics (with the aim of enhancing multi-hit performance). In all cases, preliminary work has been conducted to demonstrate the viability of the concepts. This will lead to a new family of advanced armor ceramics. These new armor ceramics will allow the modern soldier to be better protected versus next generation, high level threats (e.g., high pressure WC / Co projectiles) with a more ergonomic package (lower weight, less bulk). Further, the results disclosed herein will yield improvement versus the current tool steel threats.

Owner:M CUBED TECH

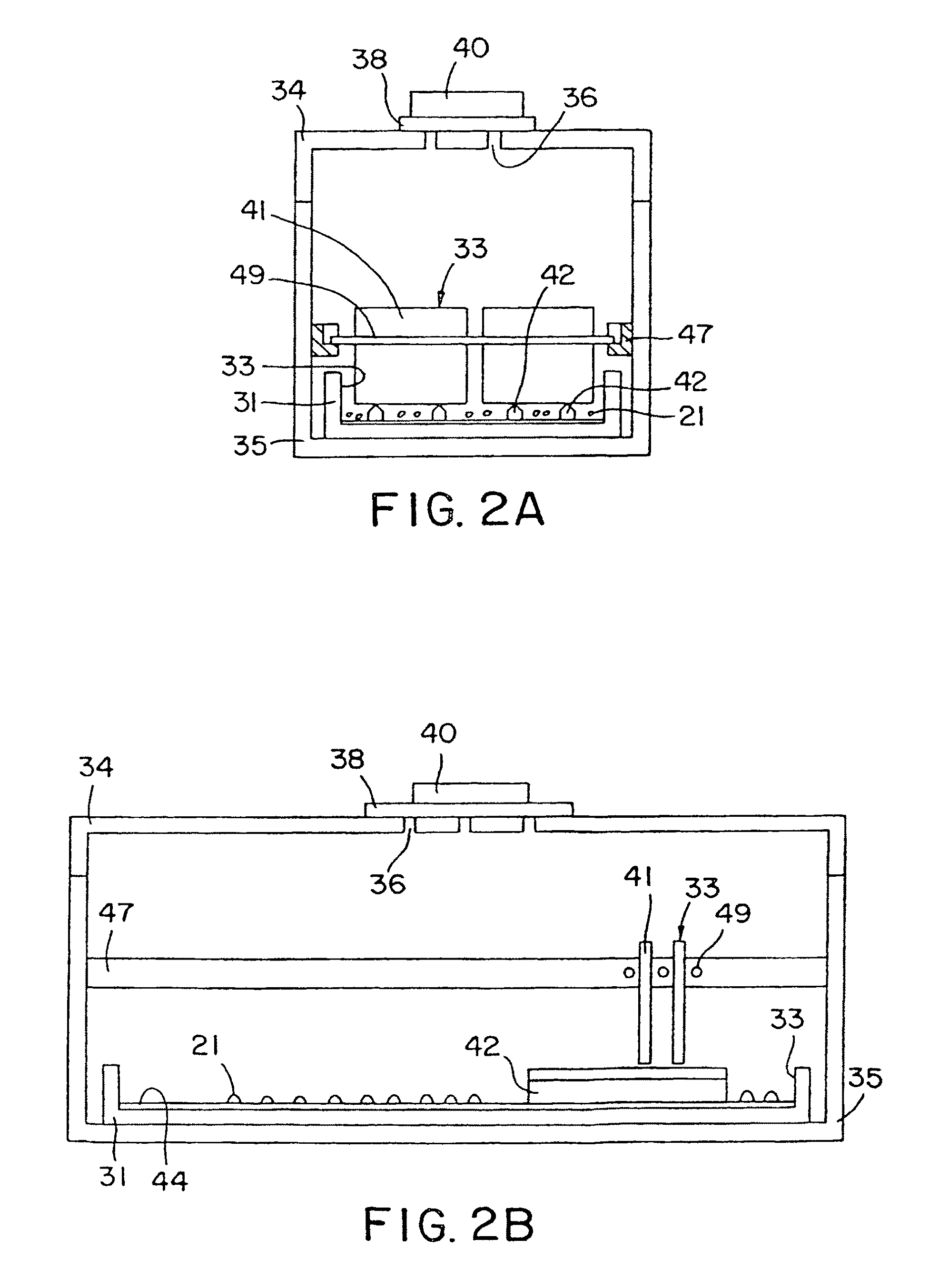

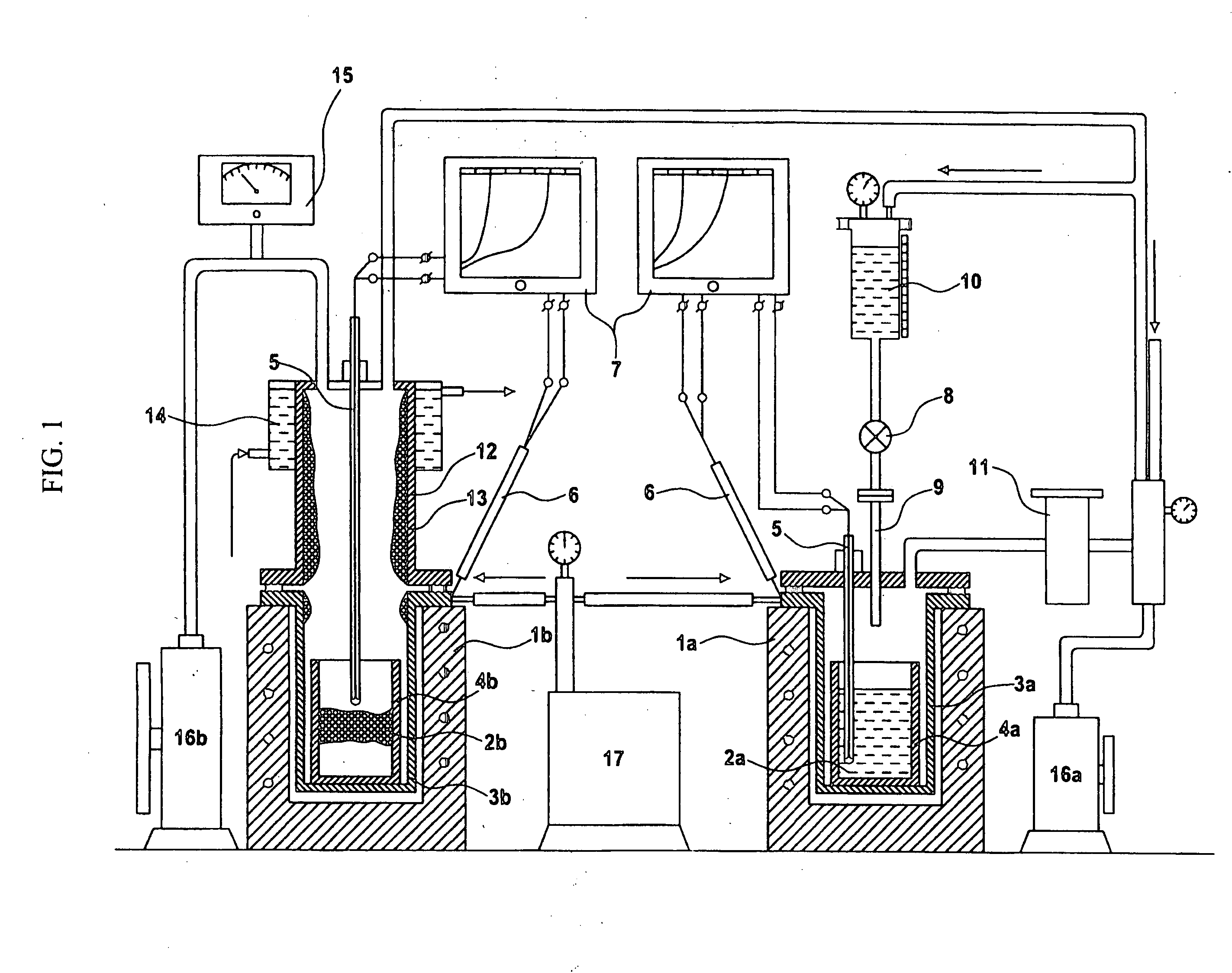

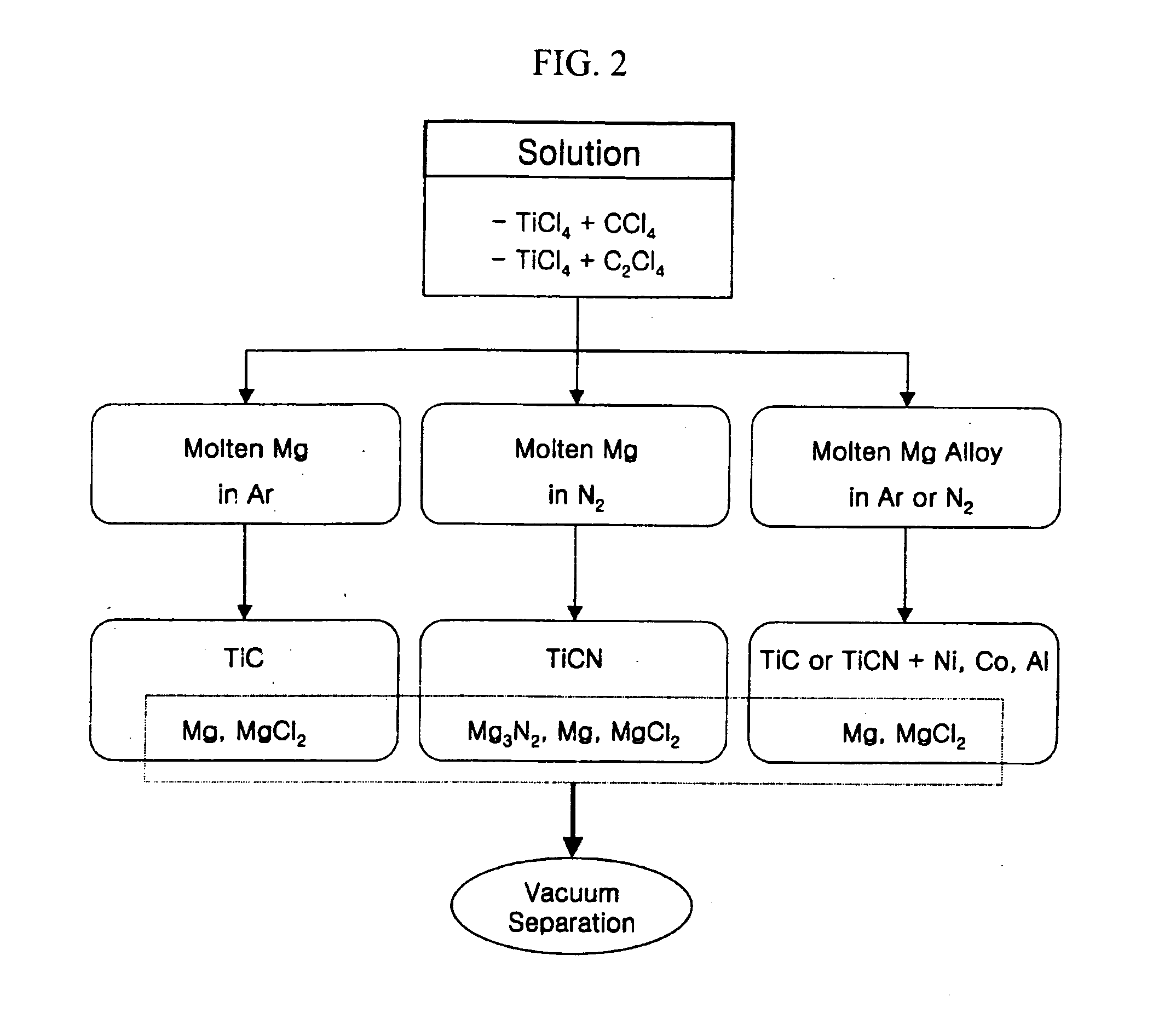

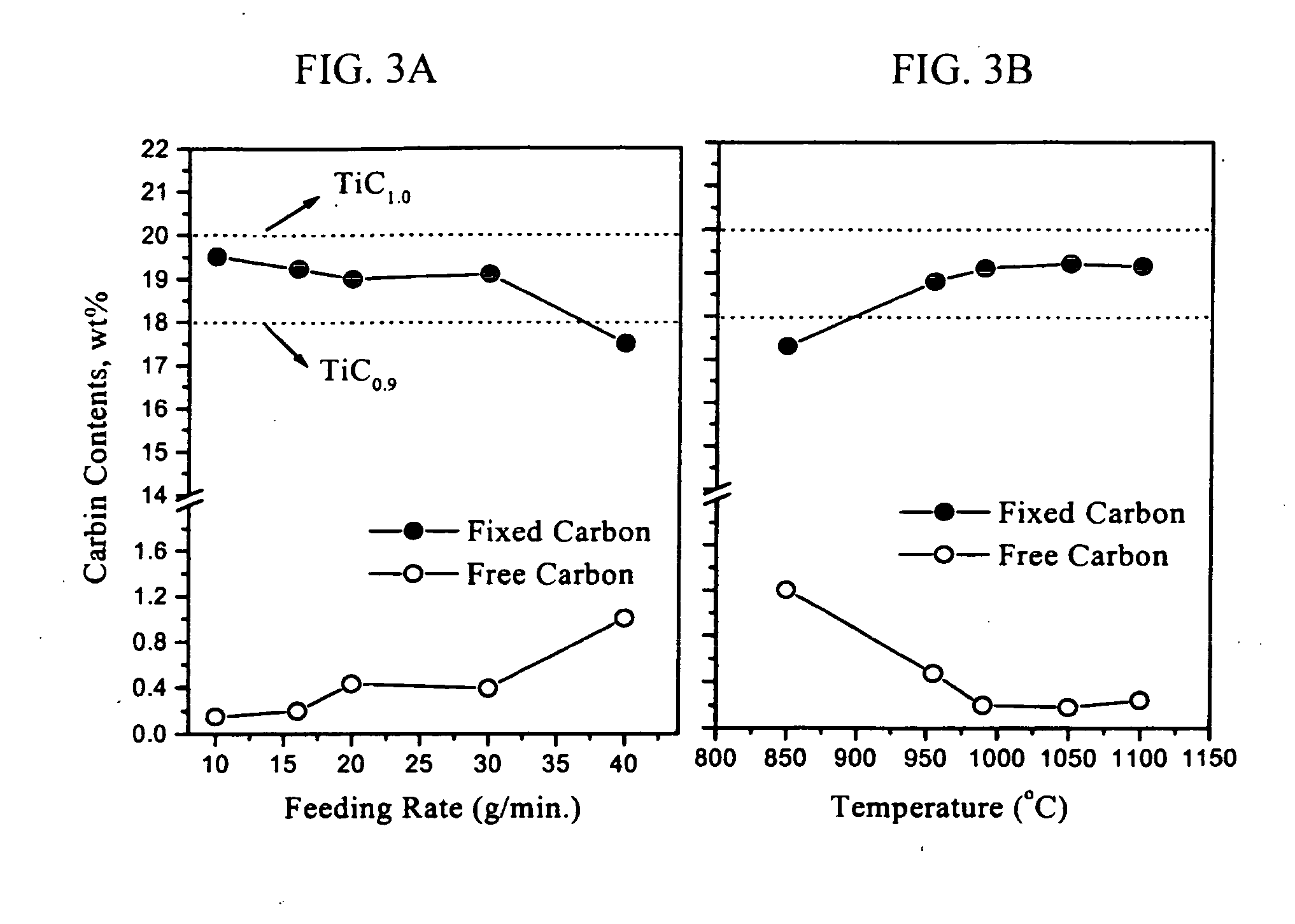

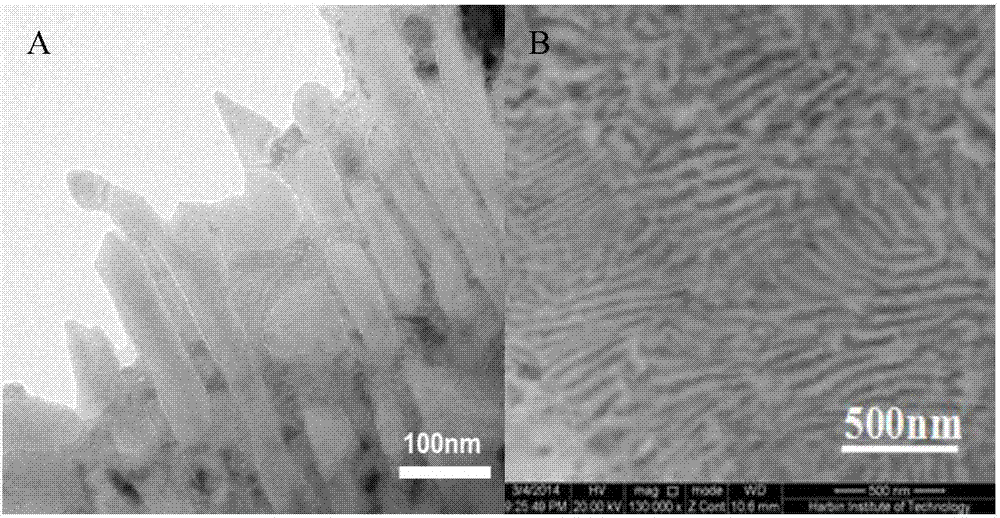

Method for manufacturing nanophase TiC-based composite powders by metallothermic reduction

Disclosed herein is a method for economically manufacturing high quality TiC powder, TiCN powder or ultrafine nanophase TiC+Ni (Co, Al) and TiCN+Ni (Co, Al) composite powders by means of metallothermic reduction. The method comprises the steps of preparing a starting solution of titanium tetrachloride (TiCl4) in a carbon chloride, feeding the starting solution into a closed container containing molten magnesium (Mg) under inert atmosphere, vacuum-separating unreacted liquid-phase Mg and magnesium chloride (MgCl2) remaining after reduction of magnesium from the closed container, and collecting a TiC compound from the closed container. TiC powder, TiCN powder or ultrafine nanophase TiC+Ni (Co, Al) and TiCN+Ni (Co, Al) composite powders having a particle size of a few tens nm can be manufactured in a simpler manner using economically advantageous starting materials such as titanium tetrachloride and carbon chlorides.

Owner:KOREA INST OF MASCH & MATERIALS

Brake pad material for high-speed railway passenger train and preparing method thereof

ActiveCN107460362ASolve the hardnessPoor ability to solve deformationTransportation and packagingMetal-working apparatusAdhesiveManganese

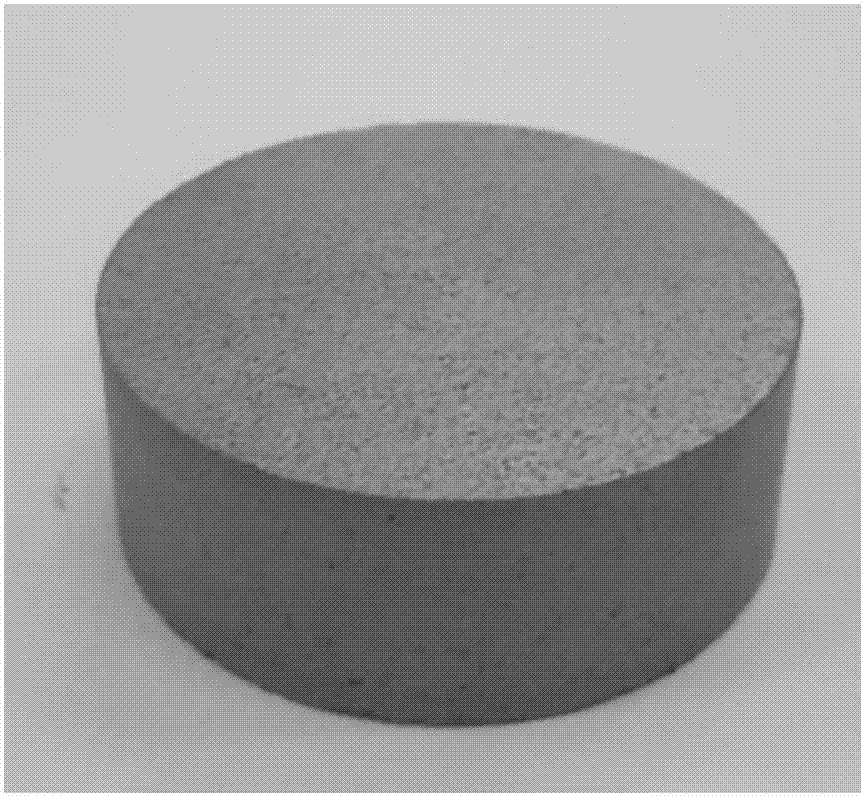

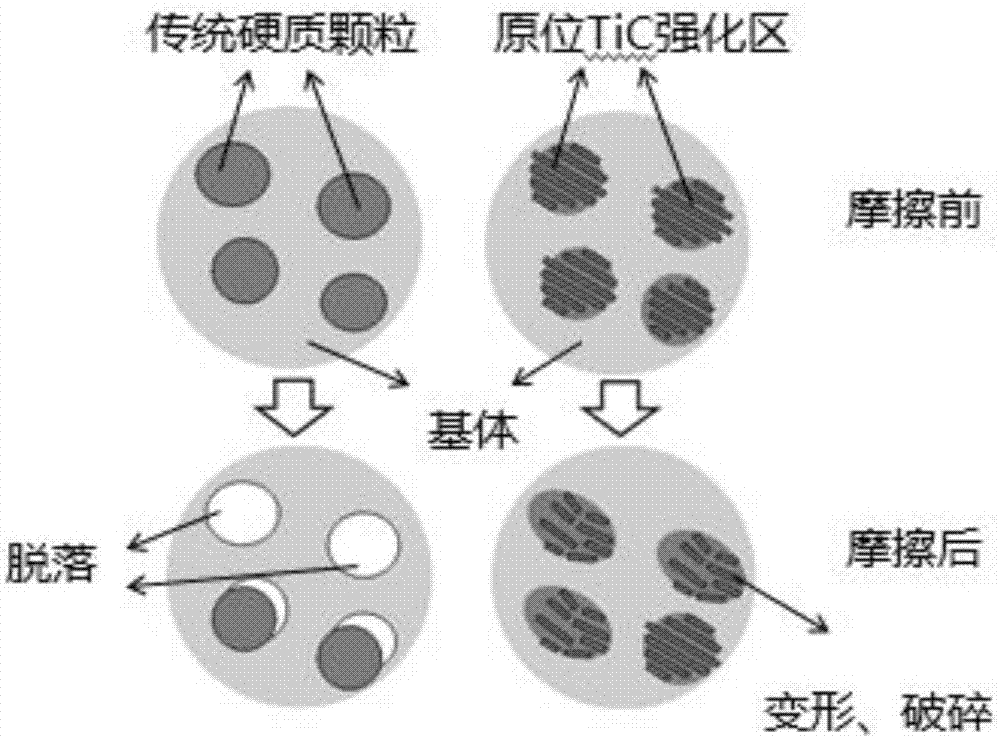

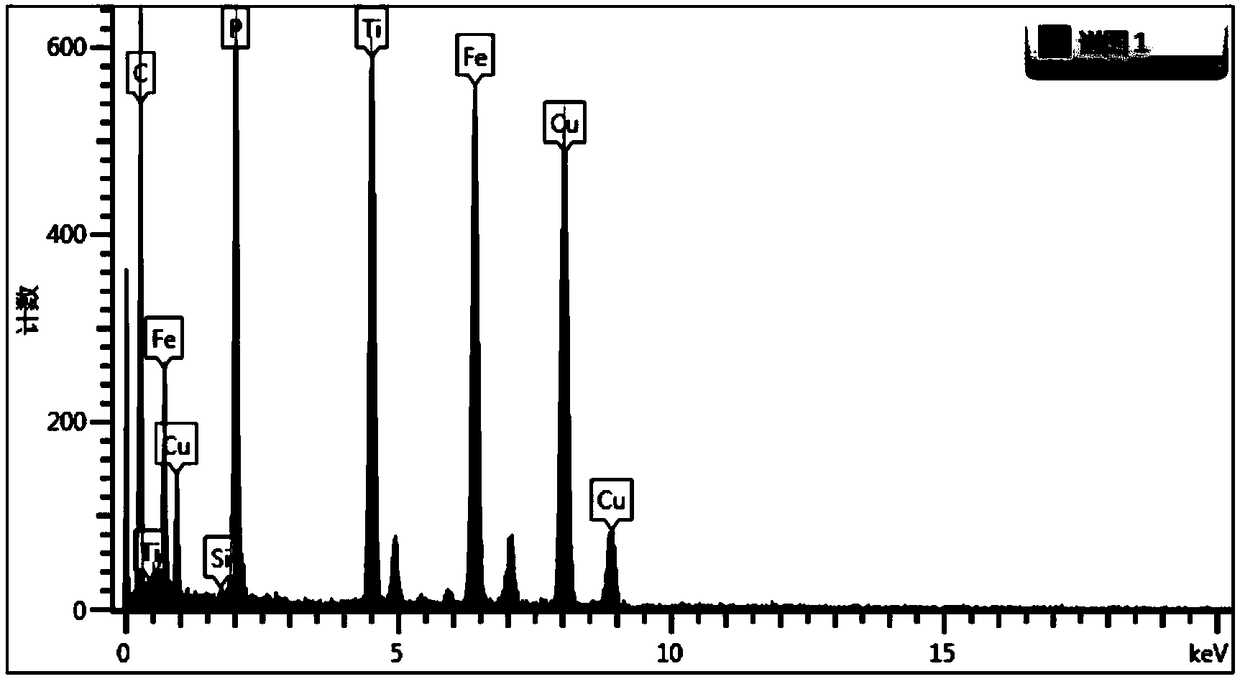

The invention discloses a brake pad material for a high-speed railway passenger train and a preparing method thereof and belongs to the technical field of powder metallurgy friction materials. The brake pad material is prepared by the following steps: after drying and sieving powdery raw materials, feeding the raw materials into a mixer, and spraying an adhesive; after mixing the materials, placing the materials in a steel mould, and carrying out pressing; and then, carrying out sintering at a reduction atmosphere, and then, carrying out heat treatment in a reduction atmosphere, wherein the powdery raw materials comprise copper powder, iron powder, Ti2AlC powder, chromium powder, nickel powder, manganese powder, silicon dioxide, graphite, boron nitride and molybdenum disulfate. The invention further provides the preparing method of the brake pad material. In the invention, in-situ TiC obtained through the Ti2AlC is used as a main friction component, the material of an in-situ nanometer TiC layered framework is prepared, the copper is accordingly used as a matrix, a small quantity of other metals is added, the content of lubricating components, such as the graphite, is regulated, and a novel material with a great brake effect and a low wear rate is finally obtained. The material is suitable for being used as the brake pad material for the high-speed railway passenger train.

Owner:哈尔滨新干线轨道交通科技有限公司

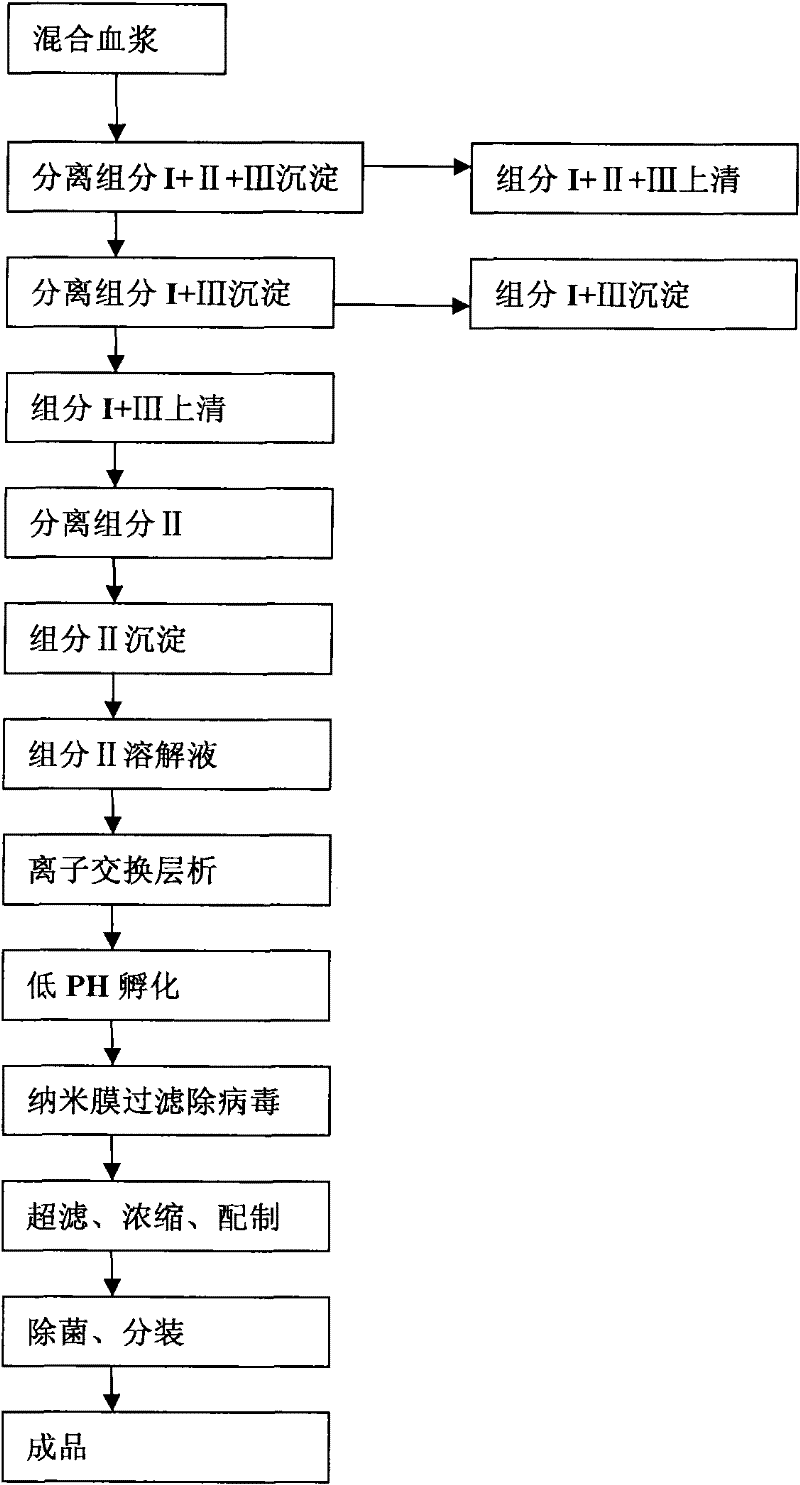

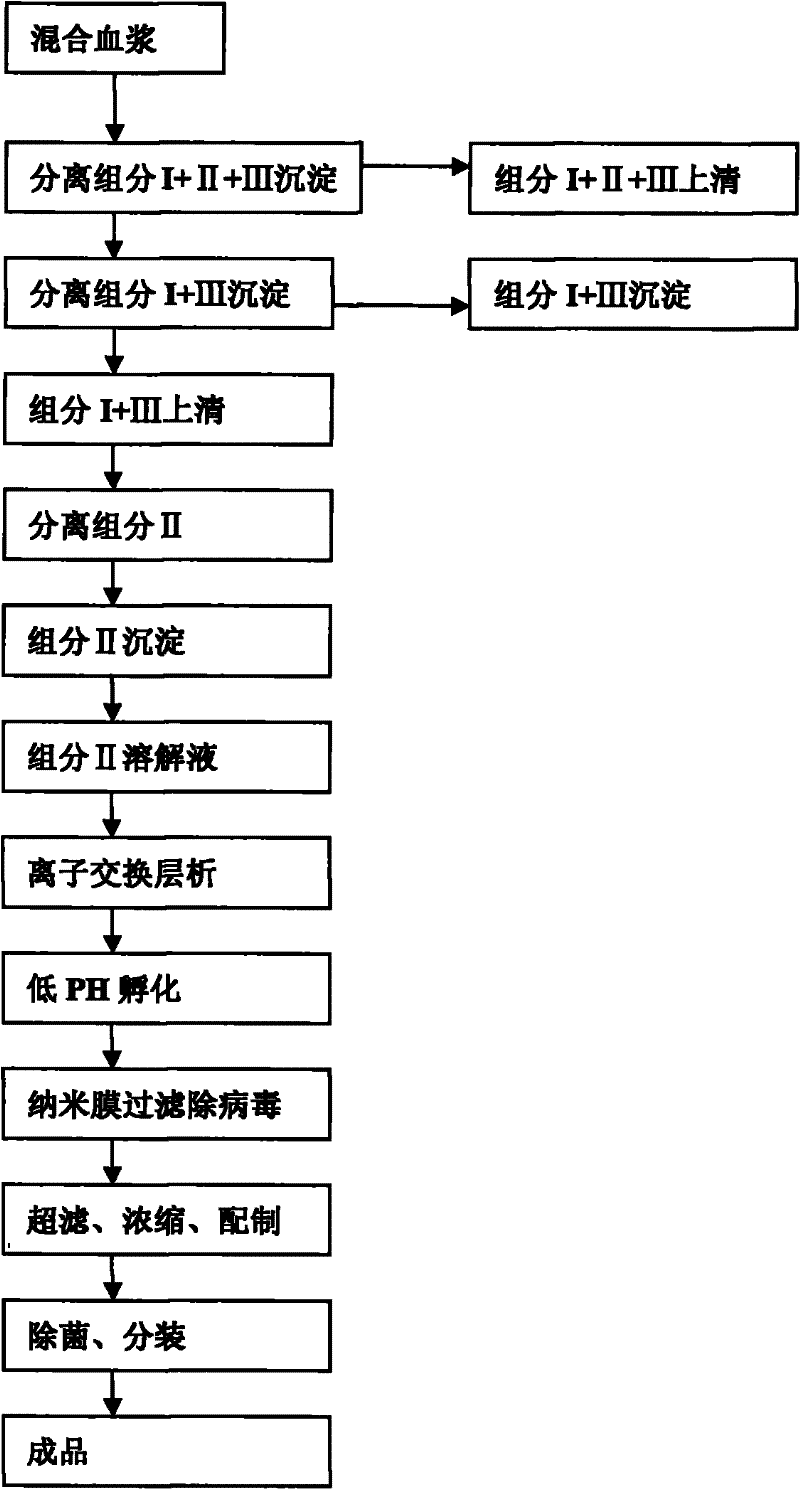

Method for extracting human TIG (Tetanus Immune Globulin) based on chromatography

ActiveCN102178952AHigh purityHigh yieldAntibacterial agentsImmunoglobulins against bacteriaWhole blood productActive matter

The invention belongs to the field of blood products in biological products, in particular relates to a method for extracting human TIG (Tetanus Immune Globulin) based on chromatography. The method comprises the following three steps: 1, primary separation; 2, purification by chromatography; and 3, virus inactivation. When the chromatography process provided by the invention is used for further purifying products, the purity of the products is improved greatly, the purity of human TIC in the products can be improved to above 98%, which is not only far higher than the standard specified in Chinese Pharmacopoeia version 2010, but also higher than the standard specified in European Pharmacopoeia; in addition, the contents of other impurities causing anaphylactic reaction are reduced greatly, for instance, two major anaphylactic substances, namely anticomplement active substance (ACA) and depressor substance (PKA), are both reduced remarkably. Two different virus inactivation processes, namely low-pH incubation and nano-film filtering, are adopted in the invention and can be used for effectively inactivating and removing both lipid-enveloped viruses and non lipid-enveloped viruses.

Owner:哈尔滨派斯菲科生物制药有限公司

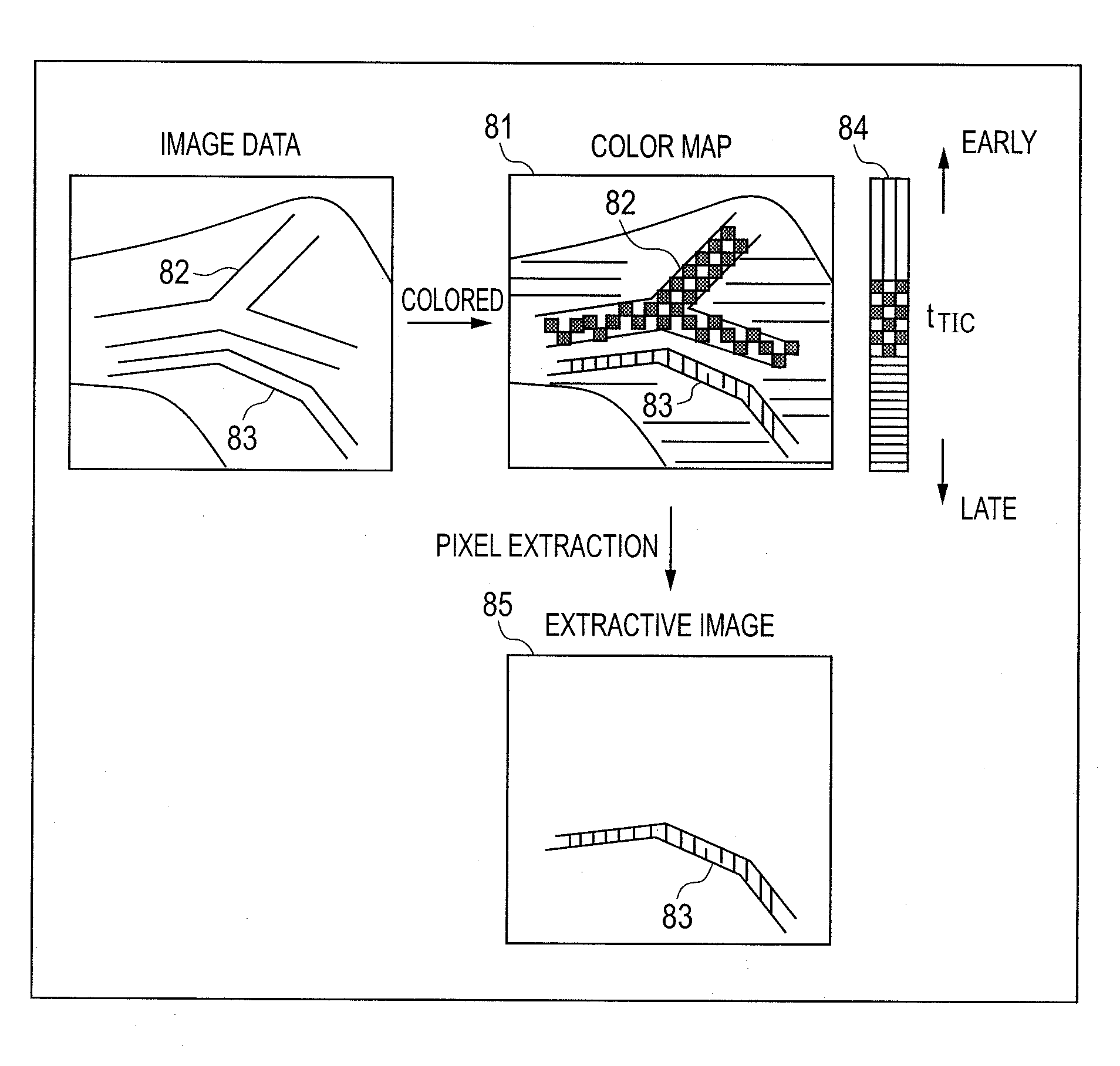

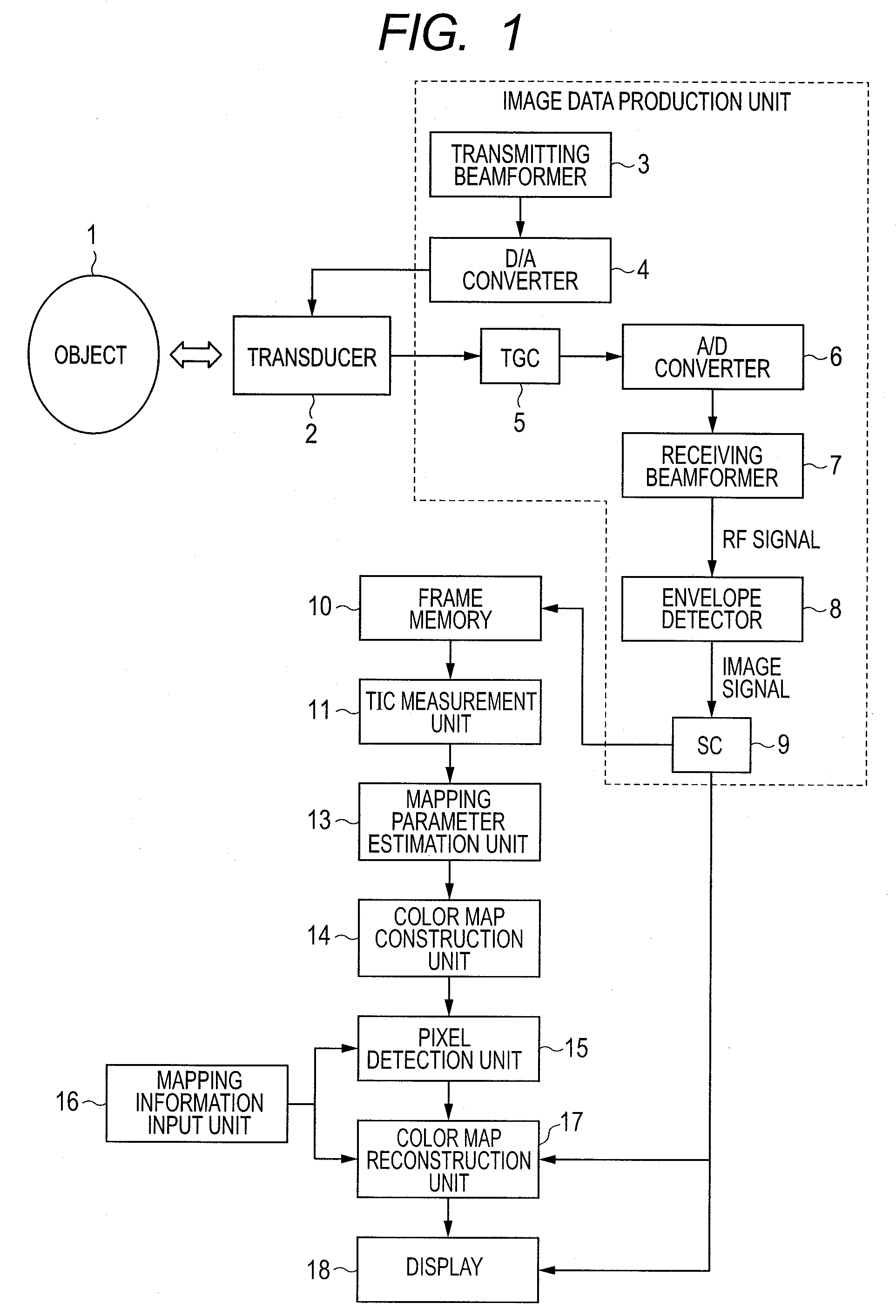

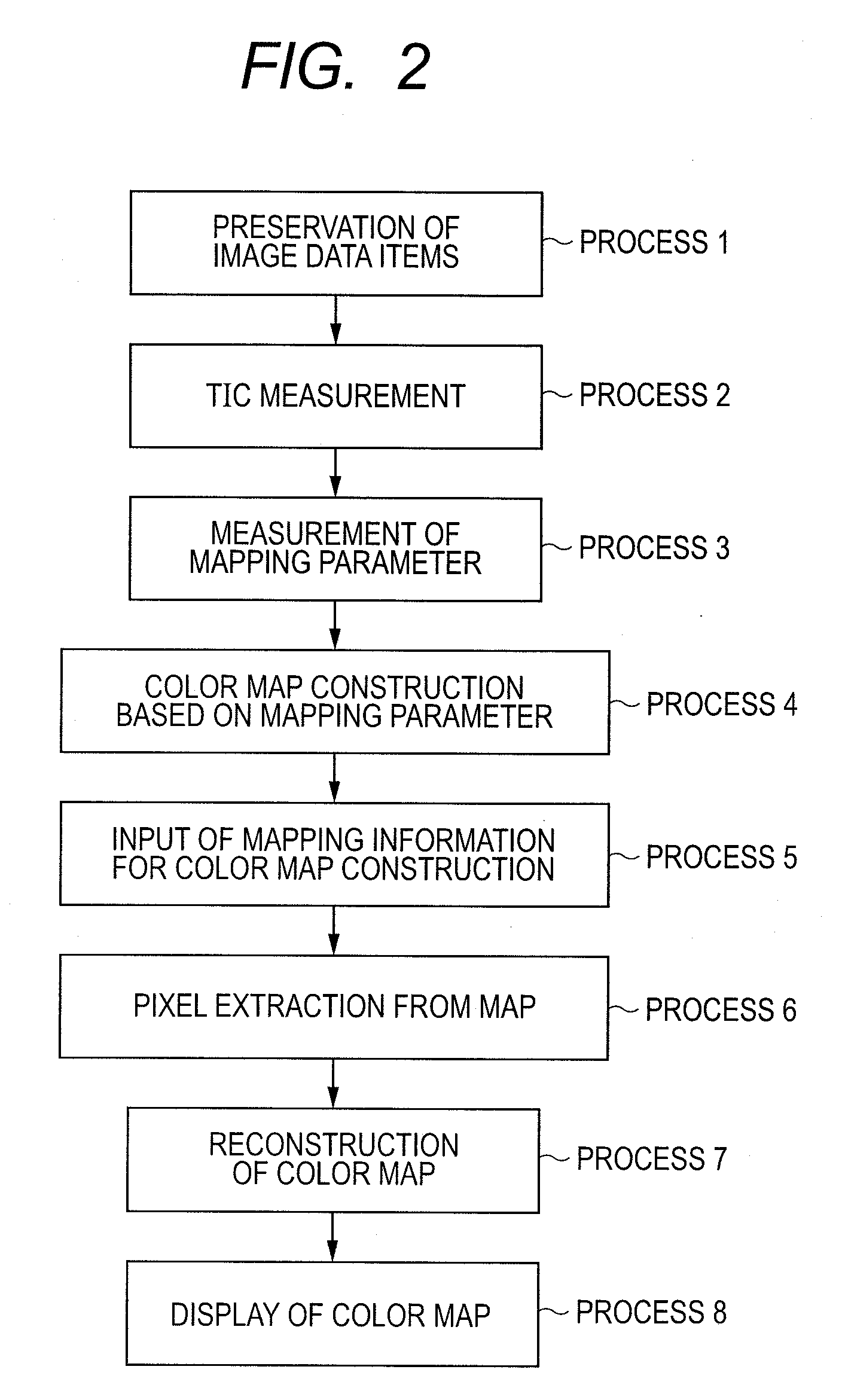

Ultrasonic imaging apparatus

ActiveUS20110075904A1Wave based measurement systemsBlood flow measurement devicesBiological bodyScan conversion

Provided is an ultrasonic imaging apparatus including: a time-gain controller (TGC) that compensates an amplitude fading occurring in the process of propagation inside a living body; a scan converter (SC) that constructs image data; a TIC measurement unit that measures a TIC of each pixel; an evaluation index input unit that inputs an index for evaluating hemodynamics on the basis of a TIC; a mapping parameter estimation unit that estimates a mapping parameter comparable to an evaluation index; a TIC image construction unit that constructs a two-dimensional image on the basis of the mapping parameter; and a pixel detection unit that extracts a region corresponding to a color map from a TIC image, and utilizing a TIC measured with each pixel so as to measure a difference in hemodynamics.

Owner:FUJIFILM HEALTHCARE CORP

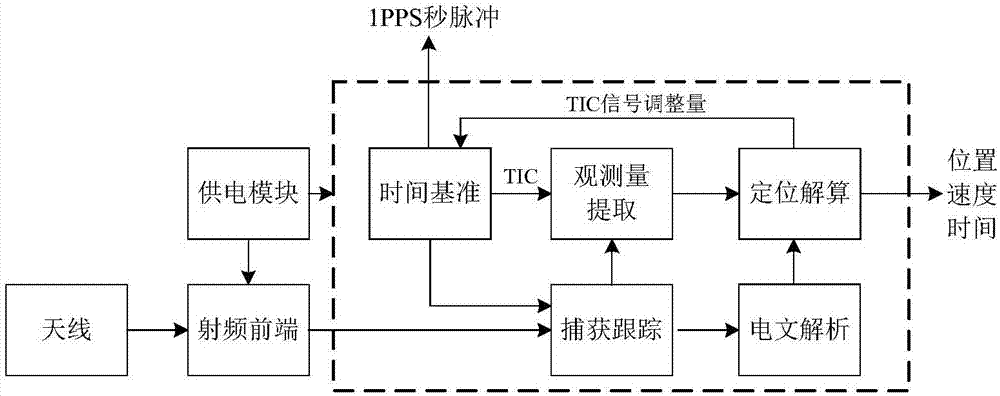

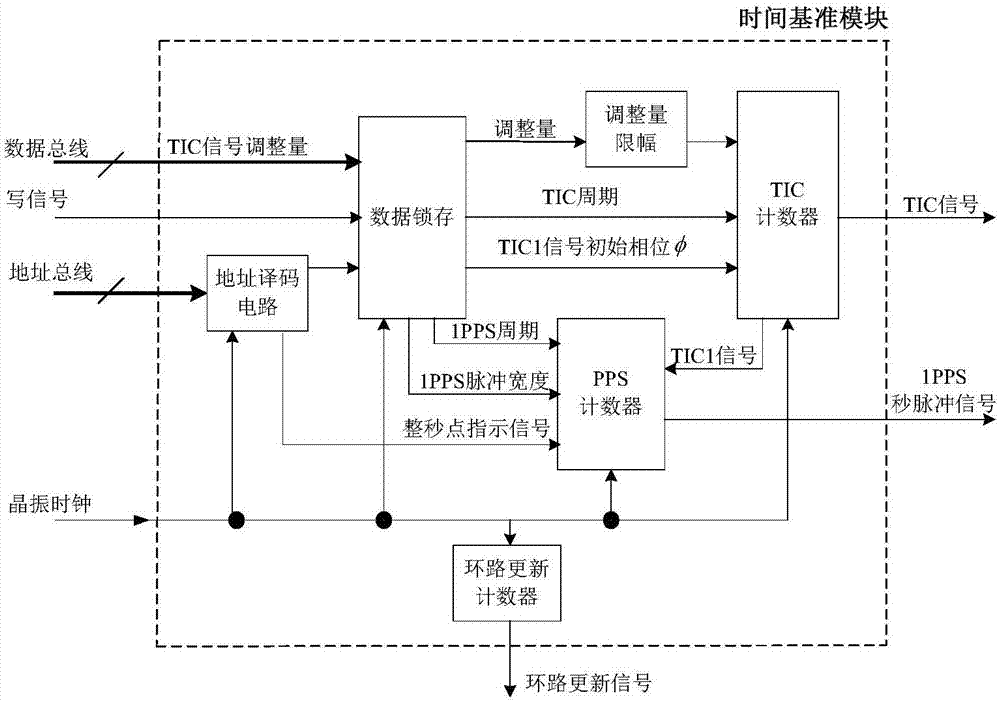

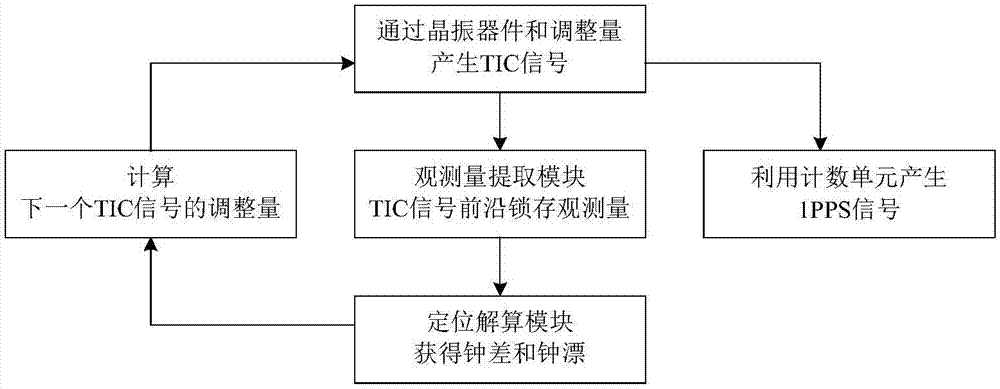

Method and device for generating second pulse of satellite navigation receiver

ActiveCN108008424AHigh time accuracyFlexible modificationSatellite radio beaconingClock driftDistance correction

The invention discloses a method and a device for generating a second pulse of a satellite navigation receiver. The method includes the following steps: generating a rough timing signal TIC through afrequency reference device such as a crystal oscillator; latching the pseudo code phase, carrier Doppler value and other observables of a satellite signal at the leading edge of the TIC signal; carrying out positioning calculation according to the satellite position, pseudo distance correction and other parameters in a navigation message to obtain the position, speed, clock difference and clock drift; calculating the adjustment amount of next TIC signal cycle by using the clock difference and the clock drift value; and finally, adjusting the TIC signal, and generating an accurate 1PPS second pulse signal. The problem that large deviation is caused as the existing satellite navigation receiver generates a second pulse according to the clock difference only is solved. The defect that the method for generating a second pulse under stable control of a phase locked loop needs a large amount of computation is overcome.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

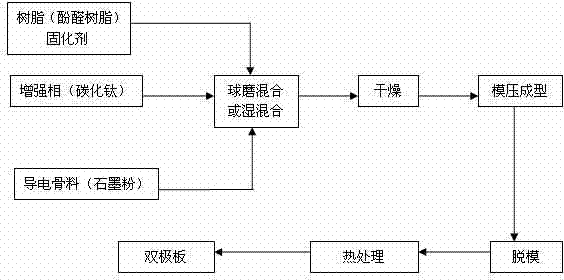

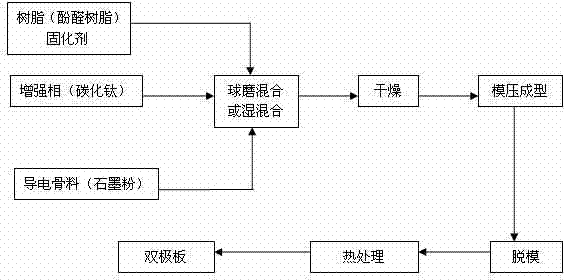

Composite bipolar plate for proton exchange membrane fuel cell and production method thereof

InactiveCN102244271AImprove conductivityImprove thermal conductivityFinal product manufactureCell electrodesHeat conductingTitanium carbide

The invention discloses a composite bipolar plate for a proton exchange membrane fuel cell and a production method thereof. The composite bipolar plate comprises phenolic resin, titanium carbide, graphite and a curing agent. In the invention, graphite powder, modified phenolic resin and titanium carbide powder are selected. Titanium carbide (TiC) belongs to face-centered cubic lattices, has high melting point, good heat conducting property, high hardness, good chemical stability and good high-temperature oxidation resistance, can not react with acid at normal temperature and has strong corrosion resistance and high conductivity (higher than pure graphite). The mechanical properties, the conductivity and the heat conducting property of the phenolic resin / graphite composite bipolar plate can be greatly improved, and the prepared bipolar plate not only has higher conductivity and heat conductivity, but also has higher strength and hydrogen corrosion resistance.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH

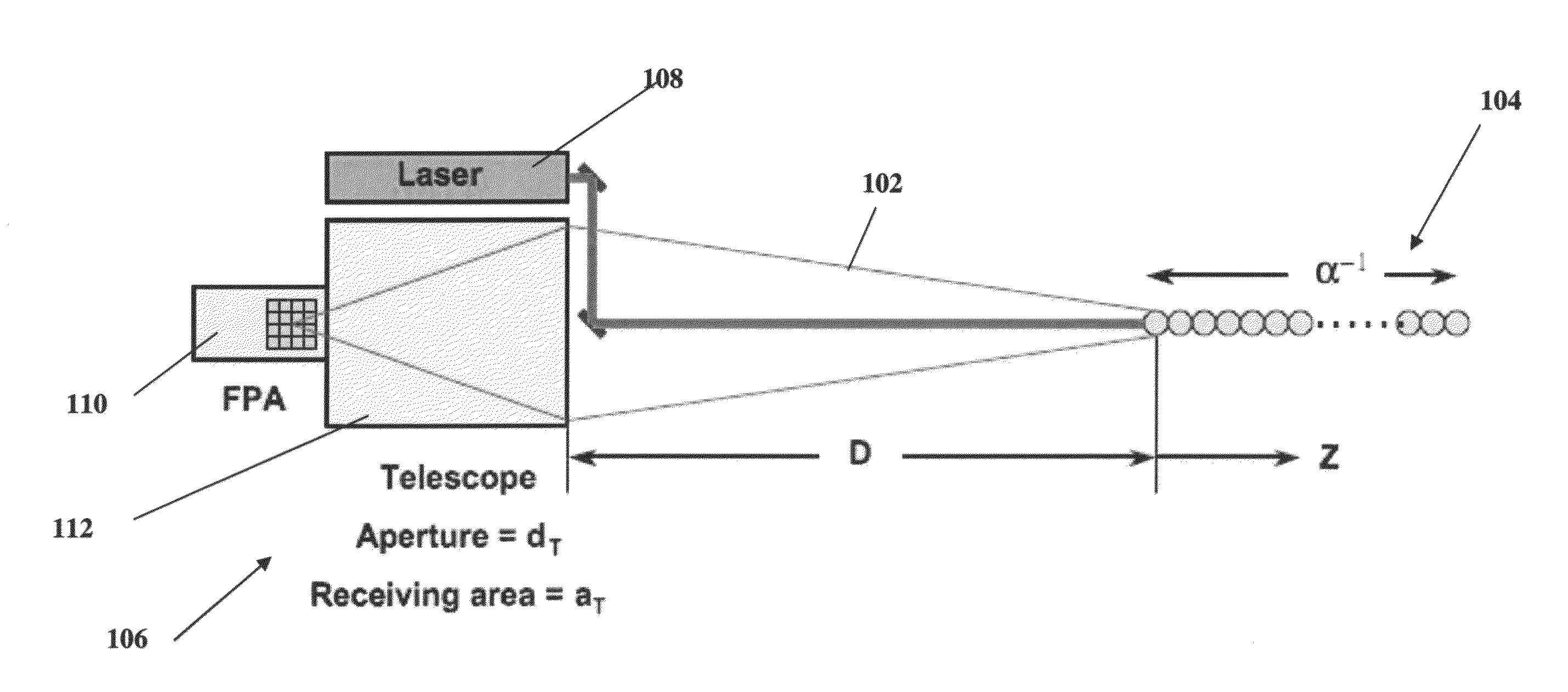

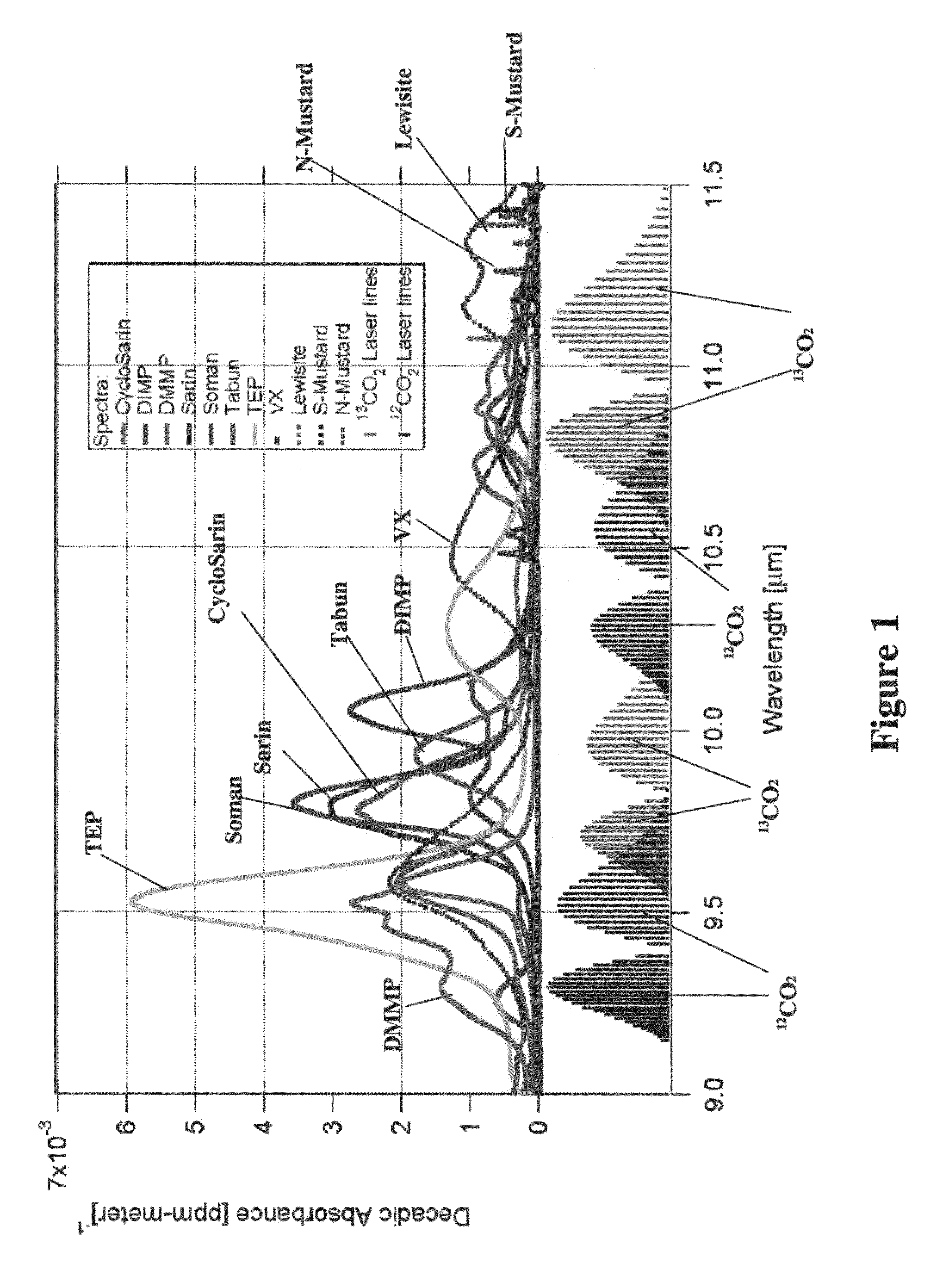

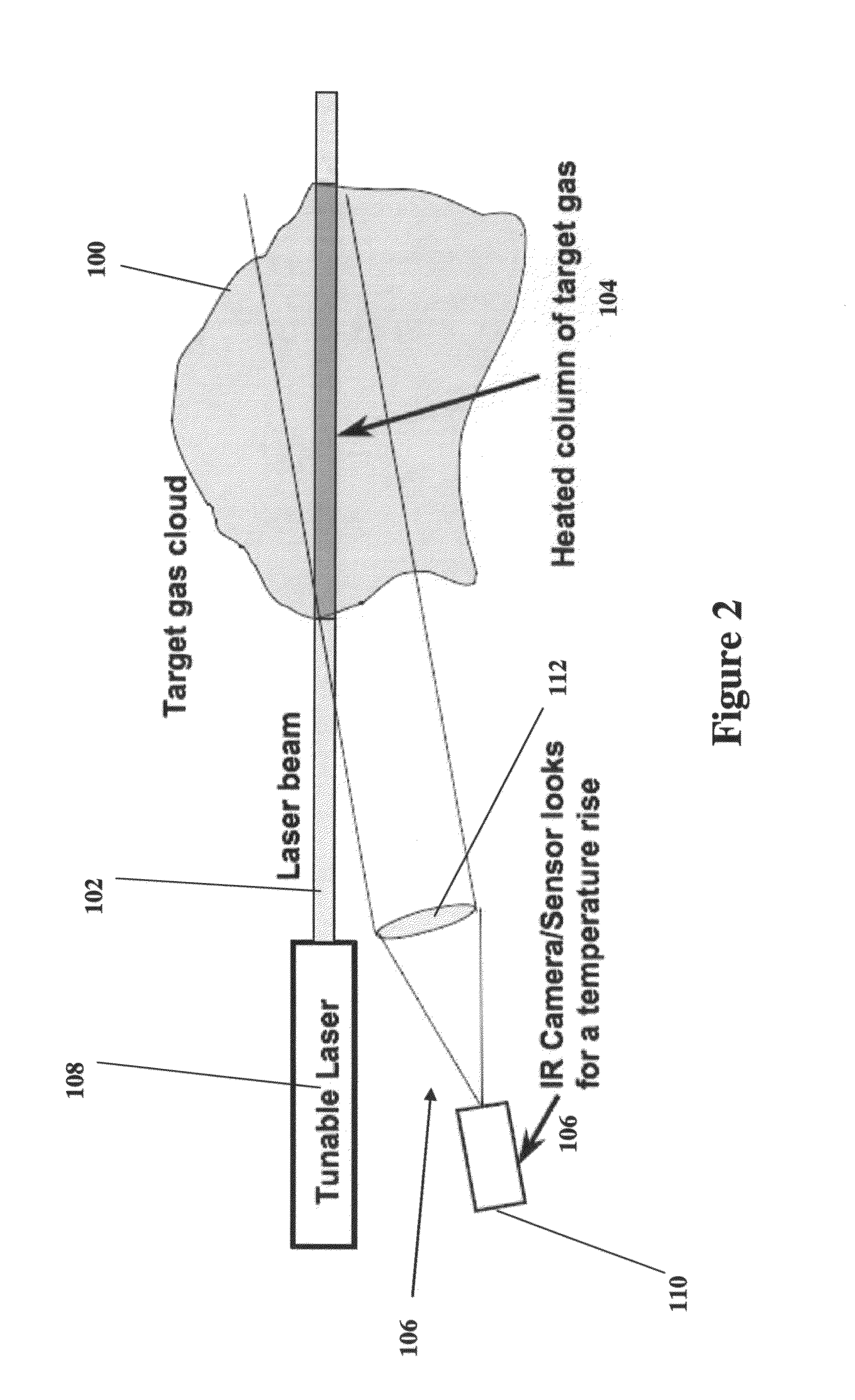

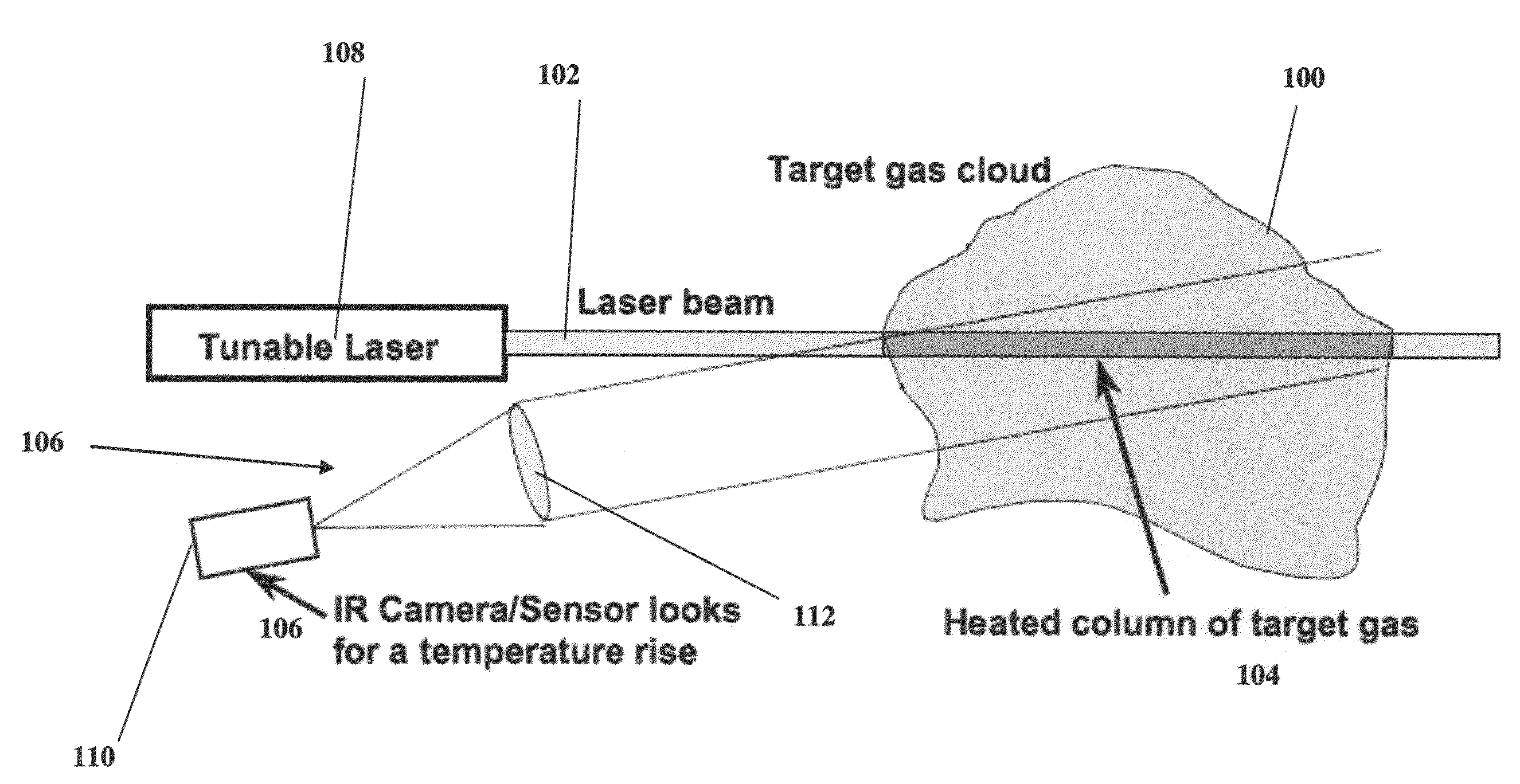

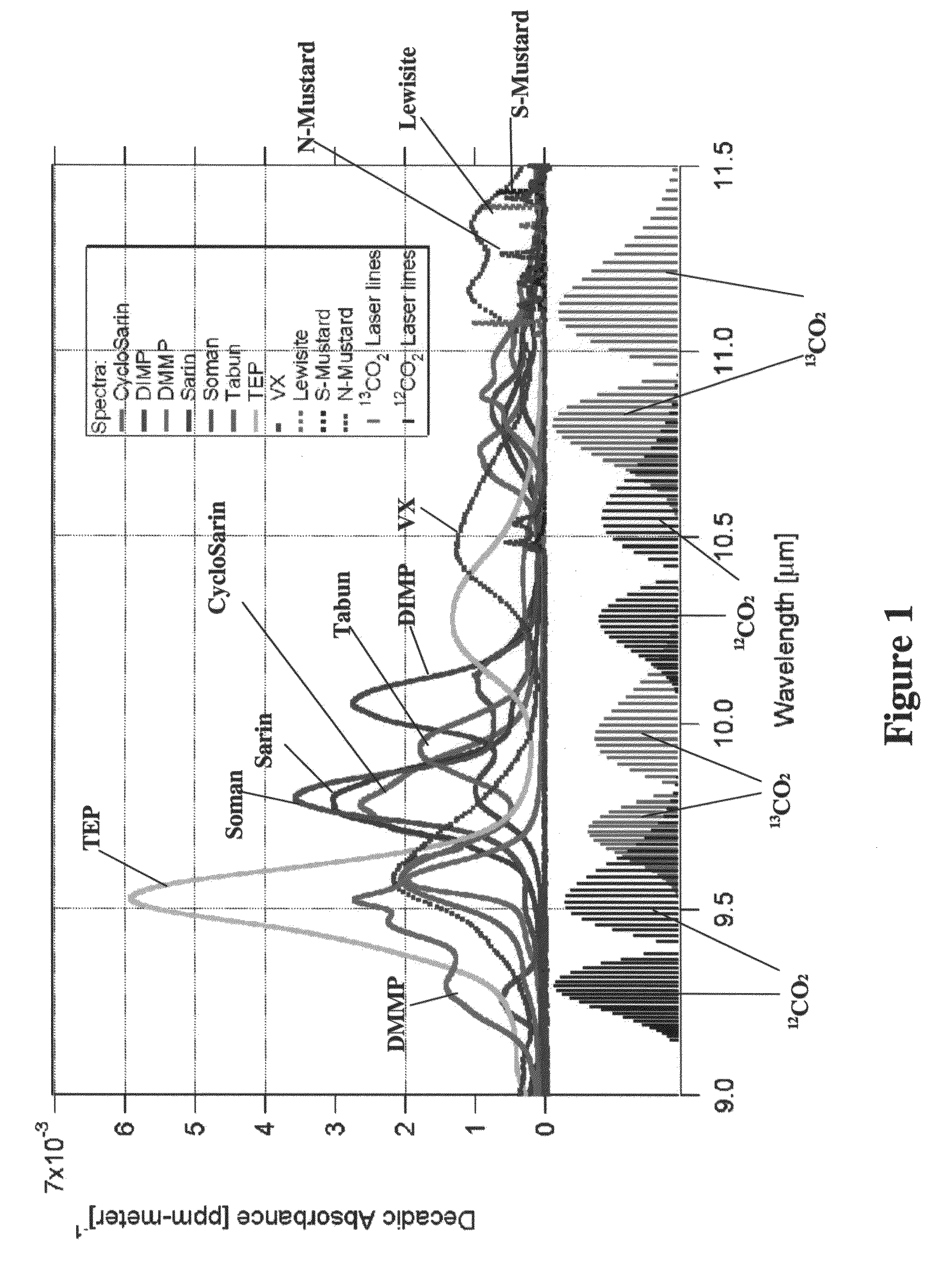

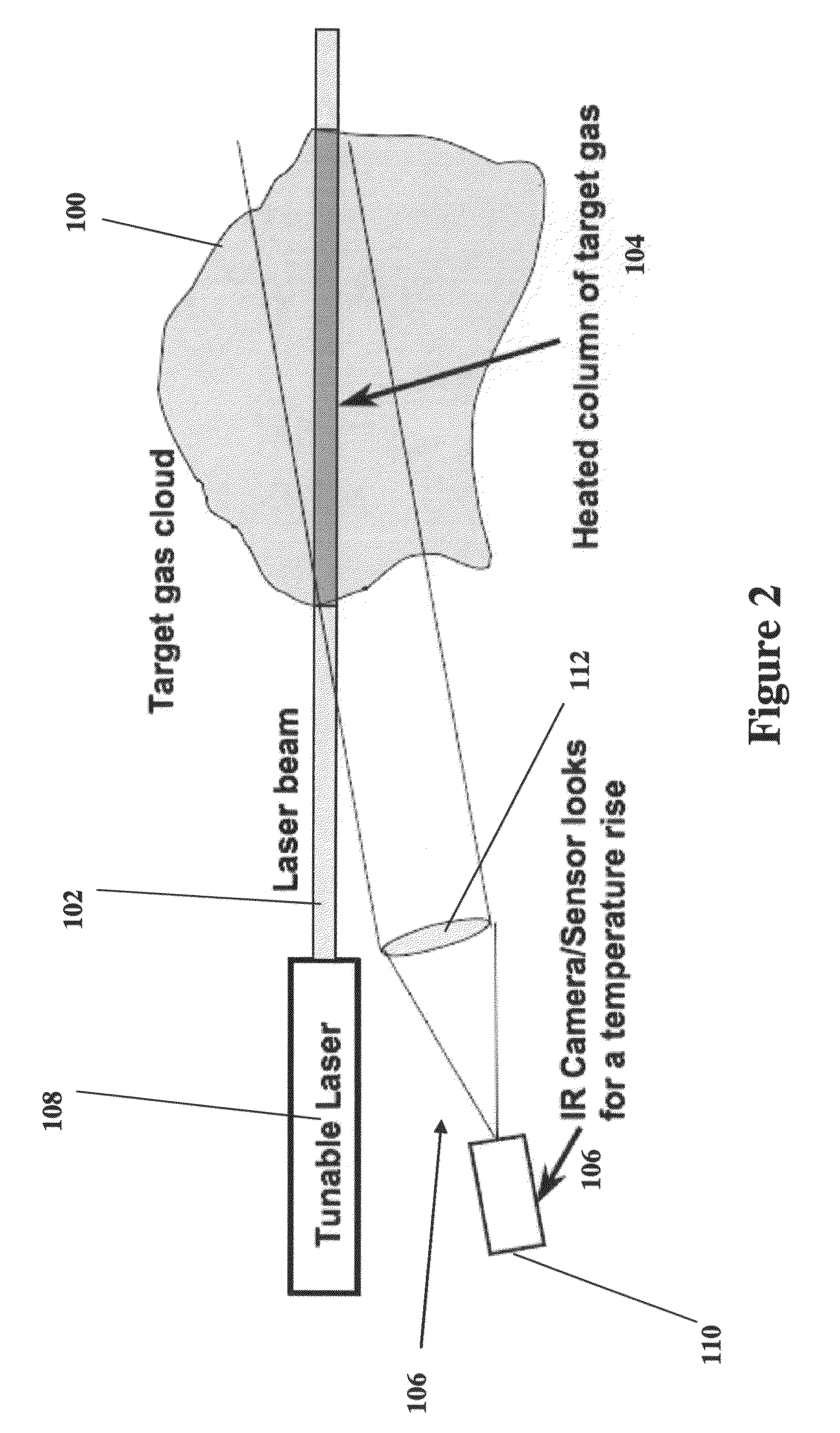

Remote optothermal sensor (rose) standoff detection of CWAs, explosives vapors and TICs

ActiveUS20120153156A1Radiation pyrometryInvestigating moving fluids/granular solidsMotor ticsSignal-to-noise ratio (imaging)

A system and method for standoff detection of explosives, CWAs and TICs using optical techniques. Preliminary analysis indicates detection of TNT at a distance of 0.5 km with a signal-to-noise ratio exceeding 10,000. The optical / thermal techniques apparently permit unambiguous detection of the target molecules even the presence of commonly encountered interferents. The technique, named Remote Optothermal Sensor (ROSE), has the potential for standoff detection at distances greater than one (1) kilometer.

Owner:DAYLIGHT SOLUTIONS

Remote optothermal sensor (ROSE) standoff detection of CWAs, explosives vapors and TICs

ActiveUS8247775B2Radiation pyrometryInvestigating moving fluids/granular solidsMotor ticsSignal-to-noise ratio (imaging)

A system and method for standoff detection of explosives, CWAs and TICs using optical techniques. Preliminary analysis indicates detection of TNT at a distance of 0.5 km with a signal-to-noise ratio exceeding 10,000. The optical / thermal techniques apparently permit unambiguous detection of the target molecules even the presence of commonly encountered interferents. The technique, named Remote Optothermal Sensor (ROSE), has the potential for standoff detection at distances greater than one (1) kilometer.

Owner:DAYLIGHT SOLUTIONS

Electric automobile

InactiveUS8950528B2Increase temperatureIncrease torqueHybrid vehiclesDC motor speed/torque controlPower inverterMotor tics

An electric vehicle includes a motor unit to drive a wheel. The electric vehicle also includes a control system that controls the motor unit. The control system includes an inverter. The electric vehicle also includes a temperature sensor to sense temperature Tmc of the motor coils of the motor unit or a temperature sensor to sense temperature Tic of the inverter. The electric vehicle also includes a limiter to, if the temperature Tmc sensed by the sensor exceeds a motor coils temperature threshold, reduce a motor current of the unit until a derivative dTmc / dt of the sensed temperature Tmc with time t drops to zero or below, or to, if the temperature Tic sensed by the sensor exceeds an inverter temperature threshold, limit a current command to the inverter until a derivative dTic / dt of the sensed temperature Tic with time t drops to zero or below.

Owner:NTN CORP

Tungsten carbide roll collar formula

InactiveCN101994051AOptimize raw material compositionImprove the ratio of ingredientsMotor ticsRolling mill

The invention discloses a tungsten carbide roll collar formula being capable of effectively solving the problems of low combination property and low rolling amount of the traditional tungsten carbide roll collar. The tungsten carbide roll collar formula comprises the following components in weight percentage: 93-98 percent of WC, 1.5-5 percent of Co, 0-4 percent of Ni, 0.2-0.3 percent of TiC, 0.2-0.3 percent of CrC, 0.05-0.3 percent of VC and 0.05-0.1 percent of Y. The invention has the advantages that the raw material composition and the component proportion of a tungsten carbide roll are improved so that the tungsten carbide roll has the internal condition formed by an internal organization structure meeting the service performance requirement, and moreover, the roll collar has small abrasion loss, smooth surface and long service period, cannot be broken and has low roll replacing frequency, and thus, the roll replacing work load is reduced, the cost is reduced, the operating rate of a rolling mill and the product quality are improved and the inherent quality and the surface quality of produced wire rod products are ensured.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

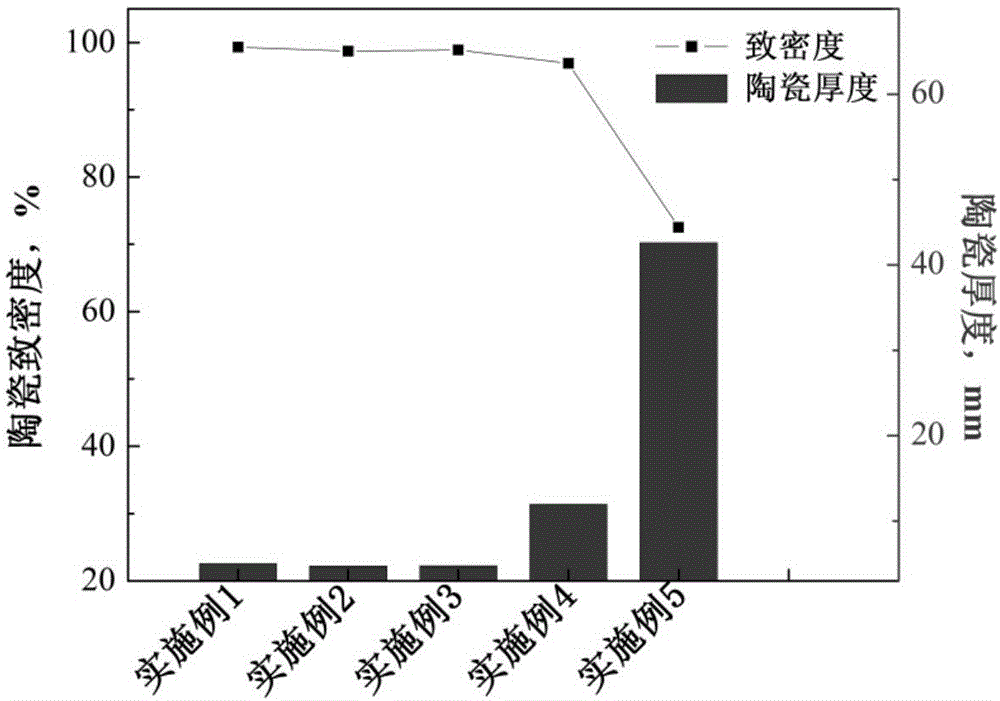

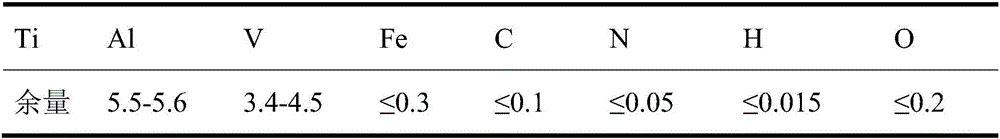

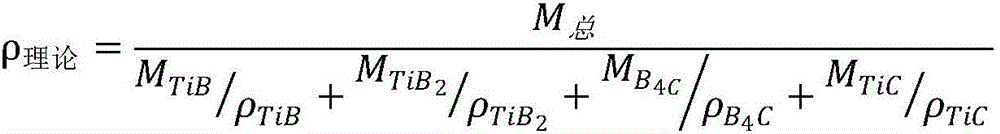

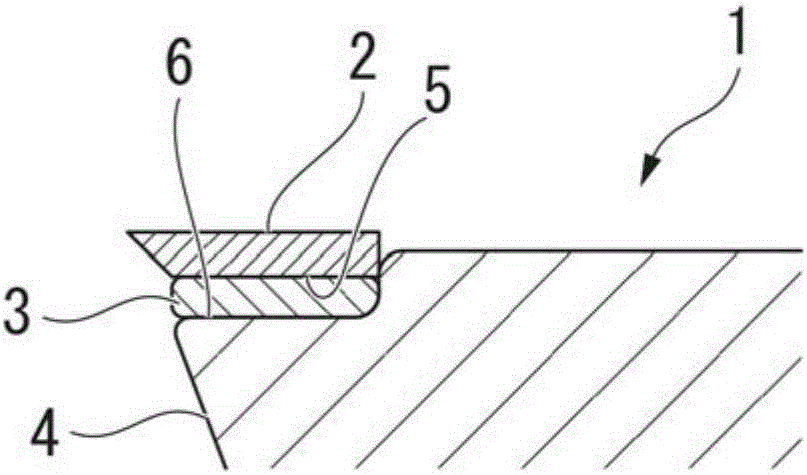

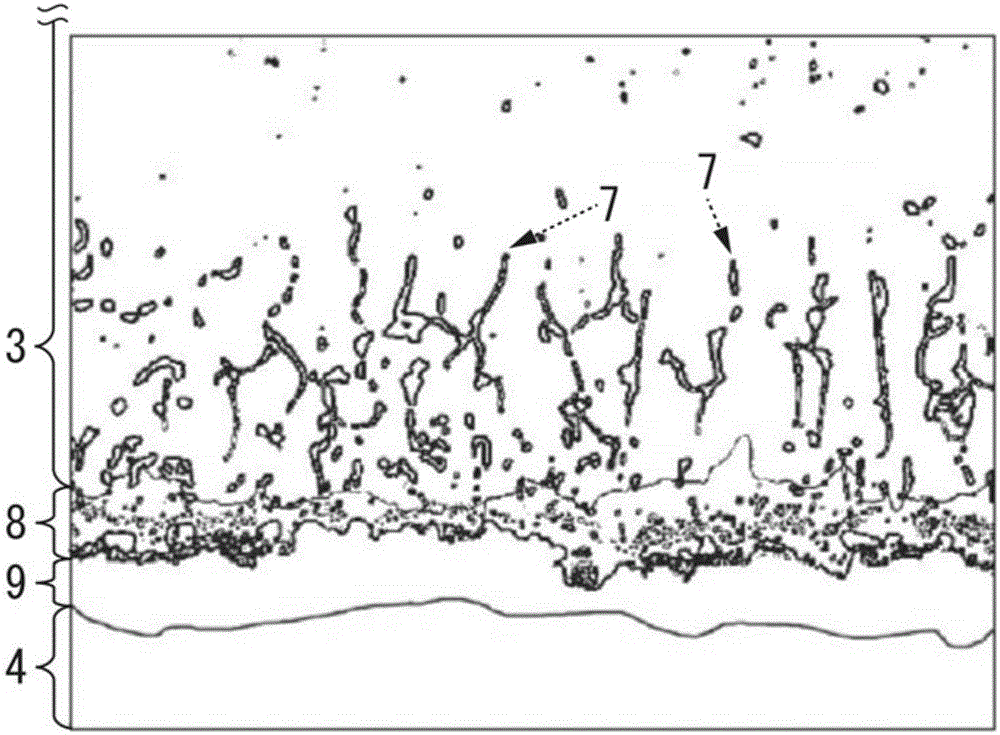

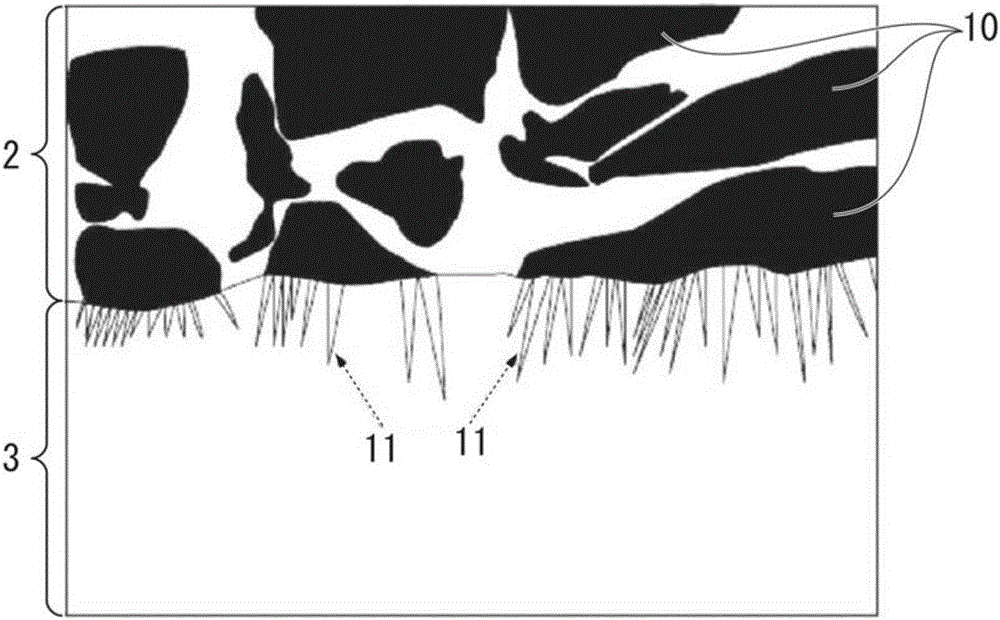

Fast preparation method of TiB-TiC-TiB2-B4C composite ceramic

The invention discloses a fast preparation method of TiB-TiC-TiB2-B4C composite ceramic, and belongs to the field of functional protection materials. The method is characterized in that TC4 powder and TiB2 powder are added into a ball milling tank; ball milling media are added; ball milling is performed, so that the mixture is uniformly mixed; drying is performed; mixed powder is obtained; the mixed powder is subjected to sintering treatment by a discharging plasma sintering system; the TiB-TiC-TiB2-B4C composite ceramic is obtained. The TiB-TiC-TiB2-B4C composite ceramic prepared by the method has the advantages that the density is high; the hardness is high; the intensity is high; the comprehensive performance is good; the TiB-TiC-TiB2-B4C composite ceramic can be applied to the field of protection materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Composite member and cutting tool

ActiveCN106457415AImprove joint strengthExcellent machinabilityTransportation and packagingMilling cuttersMotor ticsBoron nitride

Owner:MITSUBISHI MATERIALS CORP

Piezoelectric material and preparation method thereof

ActiveCN102701739AImprove piezoelectric performanceLower Qm valuePiezoelectric/electrostrictive/magnetostrictive devicesElectricitySonar

The invention relates to a piezoelectric material and a preparation method thereof. The chemical constitution of the piezoelectric material is shown as follows: Pb1-x-yMe1xMe2y[(Ni1 / 3Nb2 / 3a.Zrb.Tic)O3, wherein Me1 and Me2 are independently selected from one of or combination of at least two of Ba, Ca, Sr, Mg and La; x and y are equal to 0.02 to 0.1; a is 0.1 to 0.7; b is 0.1 to 0.6; c is 0.1 to 0.8; and a, b and c are equal to 1. The piezoelectric material has the advantages of high piezoelectric coefficient and low mechanical quality factor, has other excellent performance and can be widely applied in the fields of high-sensitivity flowmeter sensors, piezoelectric loudspeakers, brakes, micro-positioning systems, hydroacoustic engineering, passive sonar and the like.

Owner:WUXI ZHONGKE ULTRASONIC TECH

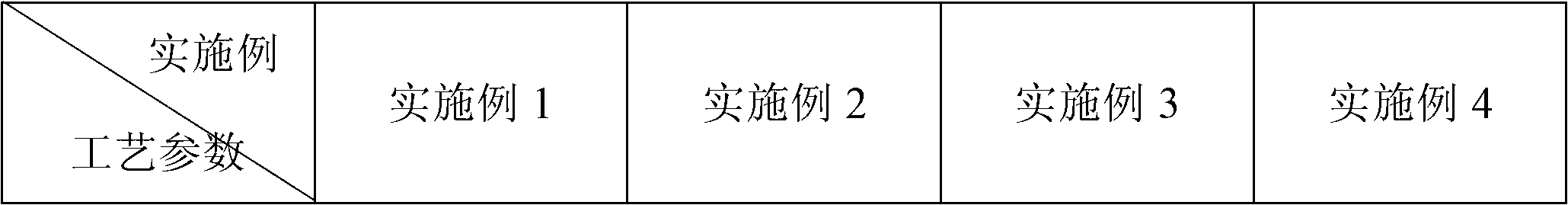

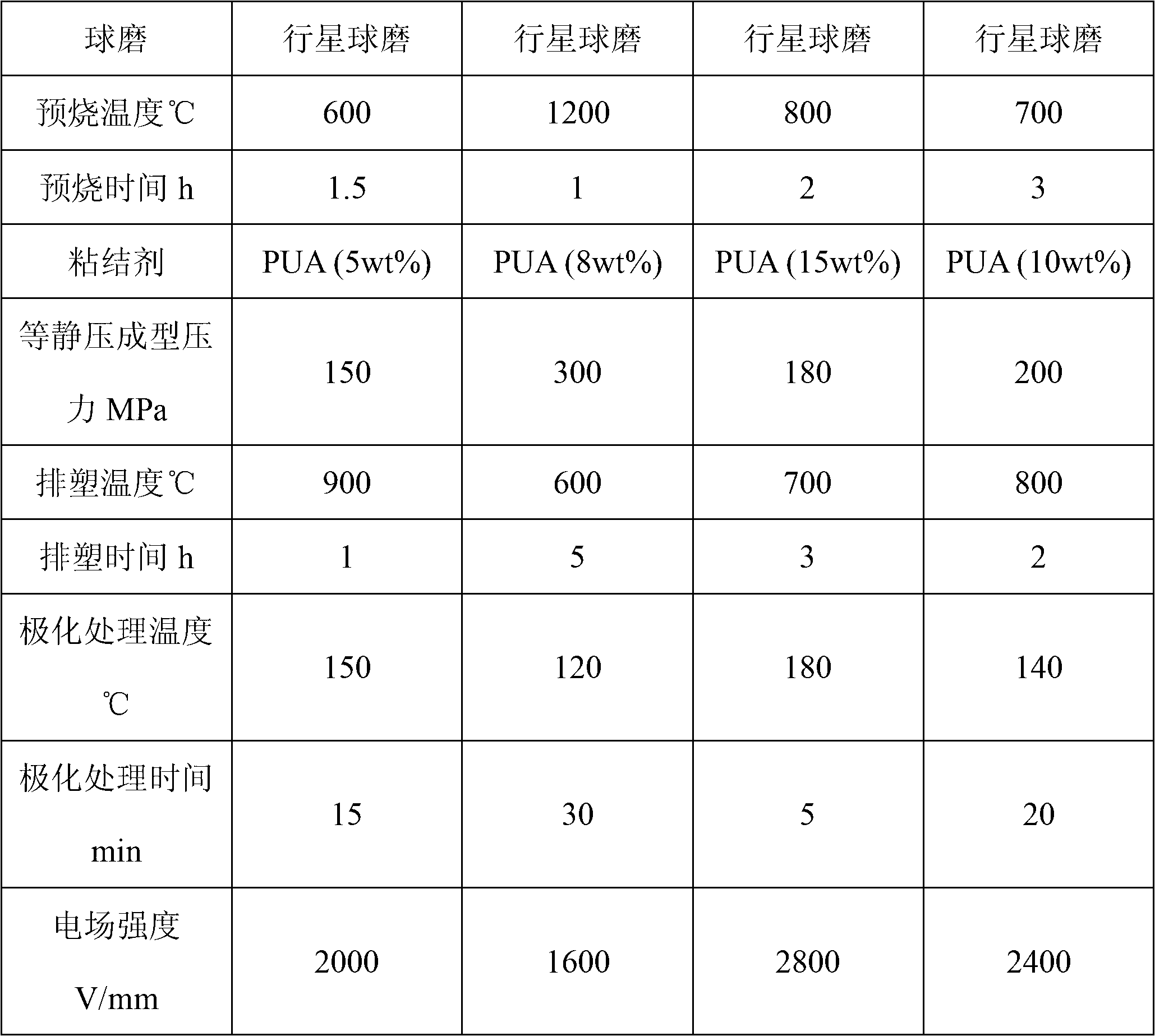

W-WC-TiC-Hf-Co alloy rod and preparation method thereof

The invention discloses a W-WC-TiC-Hf-Co alloy rod and a preparation method thereof, and relates to the technical field of alloy materials. The W-WC-TiC-Hf-Co alloy rod is prepared from the following raw materials in percentage by mass: 1 to 5 percent of WC, 2 to 8 percent of TiC, 1 to 5 percent of Hf, 1 to 5 percent of Co and the balance of W and unavoidable impurities; the preparation method of the W-WC-TiC-Hf-Co alloy rod comprises the following steps: (1) uniformly mixing tungsten powder, tungsten carbide powder, titanium carbide powder, hafnium powder and cobalt powder by adopting a wet ball milling method, and performing vacuum drying to obtain mixed powder; (2) performing vacuum sintering to obtain a sintering body; (3) smelting 2 to 5 times by electron beams to obtain an ingot; (4) performing thermal extruding to obtain a semi-finished rod blank; (5) performing thermal extruding to obtain an alloy rod. The W-WC-TiC-Hf-Co alloy rod disclosed by the invention has high hardness, high strength and excellent comprehensive mechanical properties, and has wide application prospect in aerospace field, national defence industry, electronic information, energy resources and the like.

Owner:XIAN HUASHAN METAL PROD CO LTD

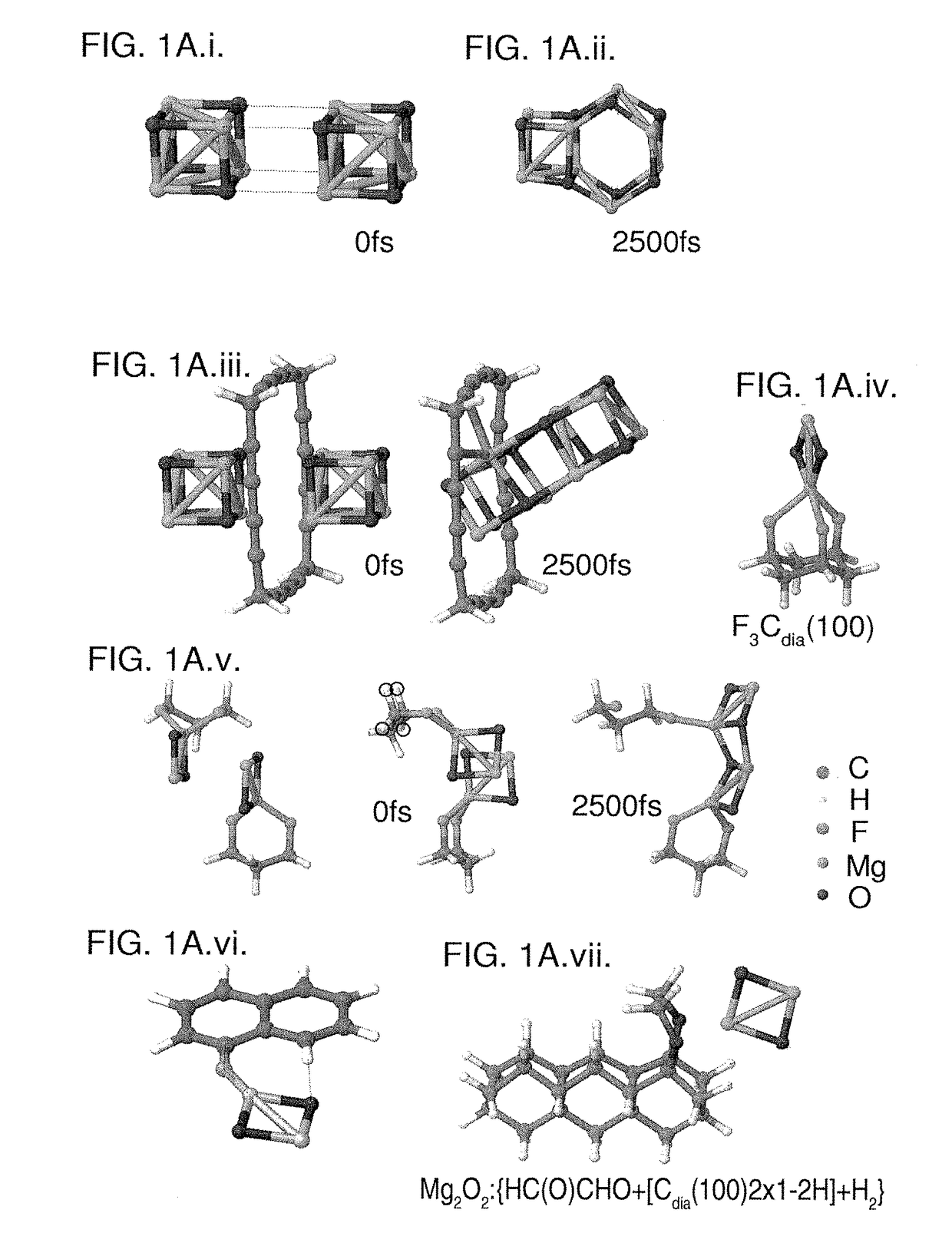

Convergent nanofabrication and nanoassembly methods, means and applications thereof, products and systems therefrom including methods and means for conversion of pollutants to useful products

ActiveUS10106401B1Improve energy efficiencyAvoid wastingSpecific nanostructure formationMaterial nanotechnologyInformation processingNanostructure

Convergent nanofabrication and nanoassembly methods are disclosed. Molecules and / or nanostructures are bound to supported binding tools and manipulated to bond together in desired locations and orientations to yield desired precise structures. Methods for precise fabrication of materials including diamond, graphene, nanotube, β-SiC (and precise modifications thereof, e.g. color centers for quantum computation and information processing and storage), halite structured materials including MgO, MgS, TiC, VN, ScN, precisely Mn doped ScN, NbN, HfC, TaC, HfxTayC, and metals, and graphenoid structures for photovoltaic devices are disclosed. Systems disclosed performing these methods can fabricate systems with similar capabilities, enabling allo- or self-replication, and have capabilities including: conversion and storage of energy; obtainment and processing of matter from abundant environmental sources including on other planets and fabrication of desired articles using same; converting wind power (esp. high altitude wind) to electricity with concurrent capture of CO2 and conversion thereof to useful feedstocks e.g. by reaction with CH4 from oceanic methane clathrates; growth of algae crops including food. Fabrication of arbitrarily long carbon nanotubes enable construction of orbital elevators.

Owner:RABANI ELI MICHAEL

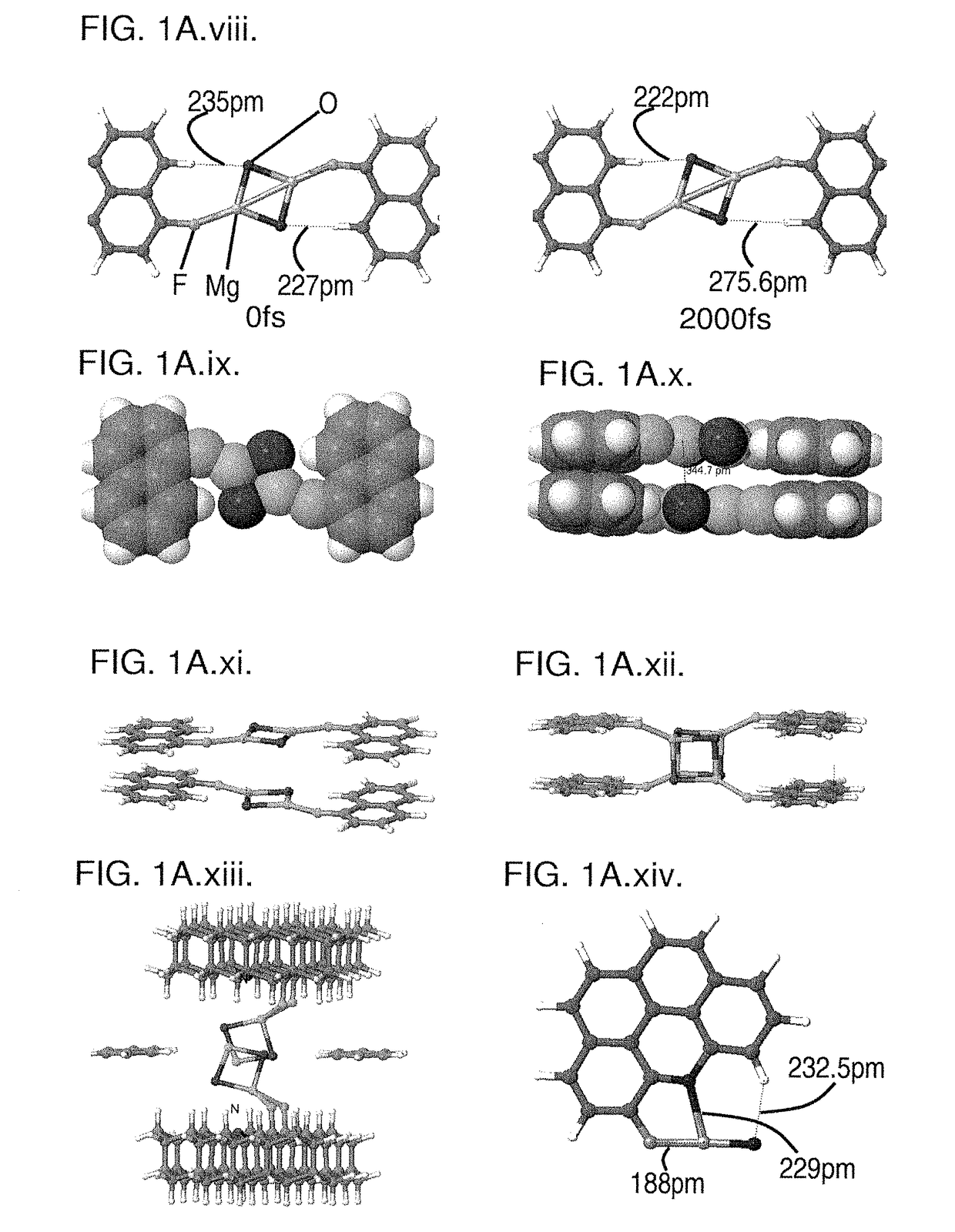

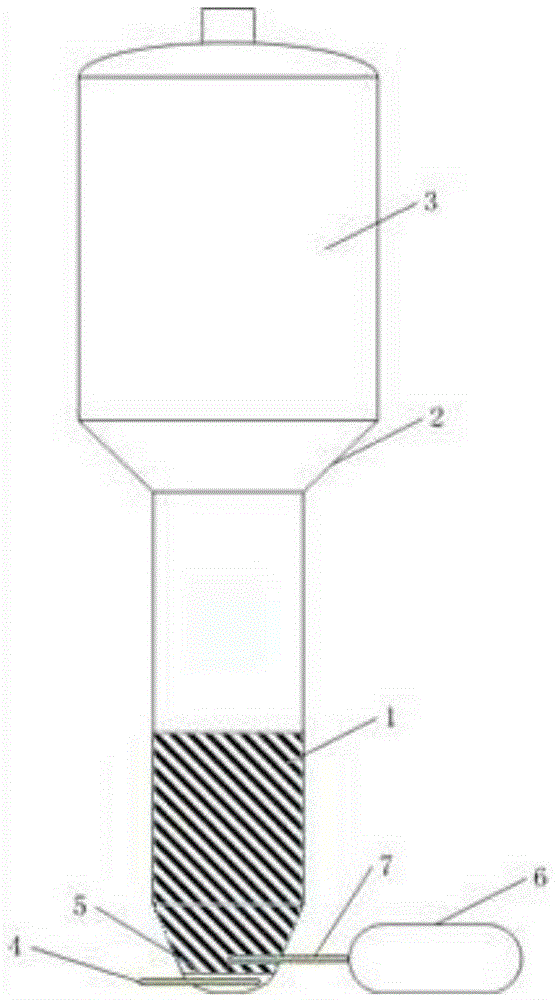

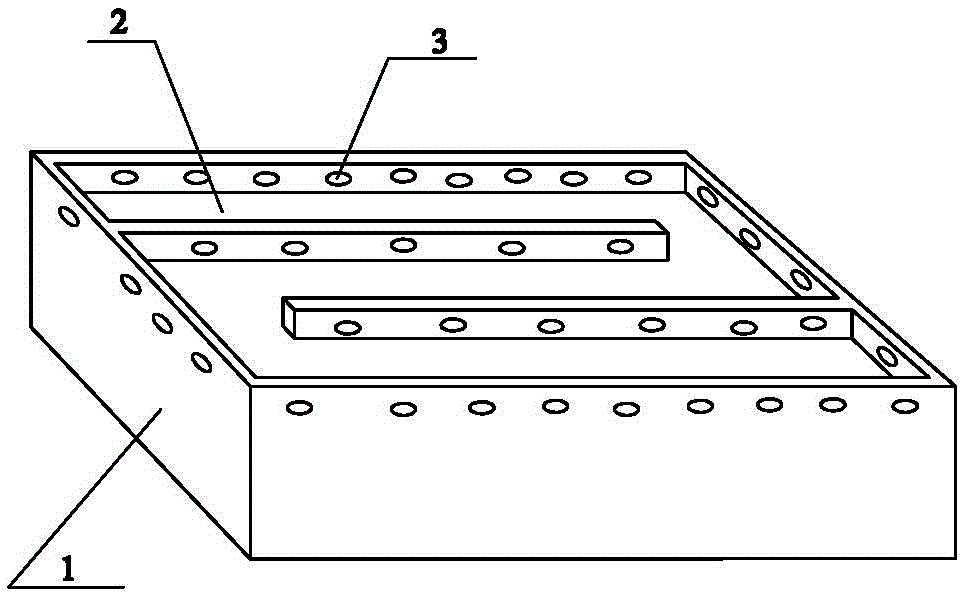

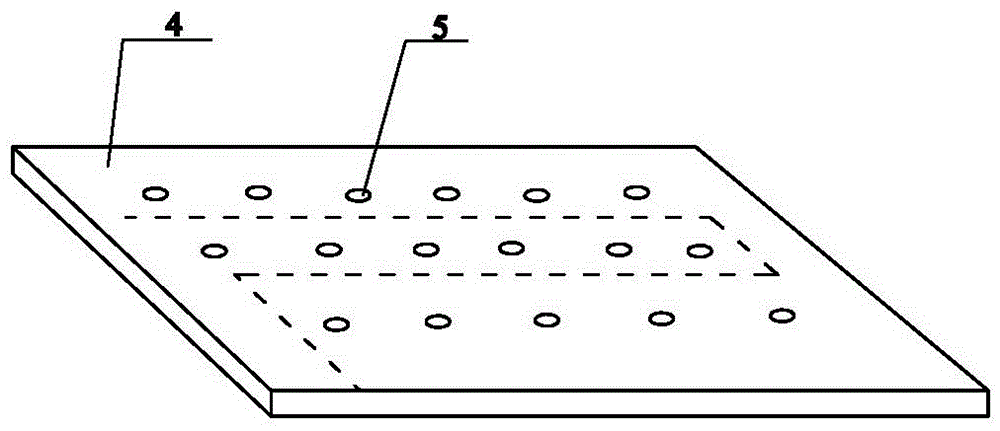

Low temperature boiling chlorination furnace and temperature-controllable low-temperature boiling chlorination process

InactiveCN105271381AAdjust and control the reaction temperatureEasy dischargeTitanium tetrachlorideMotor ticsSlag

The present invention discloses a low temperature boiling chlorination furnace and a temperature-controllable low-temperature boiling chlorination process. The temperature of a reaction zone of the low temperature boiling chlorination furnace can be controlled within a predetermined temperature range by introduction of liquid TiCl4 to the bottom of the reaction zone of the low temperature boiling chlorination furnace in the process of chlorination of carbonization slag containing TiC in the low temperature boiling chlorination furnace to obtain titanium tetrachloride. The temperature of the reaction zone of the low temperature boiling chlorination furnace can be effectively controlled within a suitable range by the device and the method, and mean while the amount of N2 is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

TiC/TiB2/Al/Cu electrical contact material as well as preparation method and application thereof

ActiveCN103981418AImprove the lubrication effectImprove conductivityNon-metal conductorsMetal/alloy conductorsTitanium carbideContact resistance

The invention discloses a TiC / TiB2 / Al / Cu electrical contact material and a preparation method thereof, and belongs to the field of materials. The TiC / TiB2 / Al / Cu electrical contact material is prepared from the following raw materials in parts by weight: 28-40 parts of titanium carbide, 10-20 parts of titanium boride, 10-22 parts of aluminum, 20-54 parts of copper and 1-3 parts of bonding agents, wherein the bonding agents are graphite powder and / or organic solvents. The TiC / TiB2 / Al / Cu electrical contact material is obtained through the following steps: uniformly mixing the raw materials, and then carrying out compression moulding at the pressure of 10-20 MPa; and then keeping temperature under a vacuum condition at 700-1100 DEG C for 3-6 hours. The TiC / TiB2 / Al / Cu electrical contact material disclosed by the invention reduces the content of the Cu, increases the content of strengthening phase titanium carbide and titanium boride, improves the wetting property of the titanium carbide and the copper and has the advantages of high density, low contact resistance, good welding resistance, high rigidity, bending strength and suitability for industrial large-scale production application.

Owner:威海区域创新中心有限责任公司

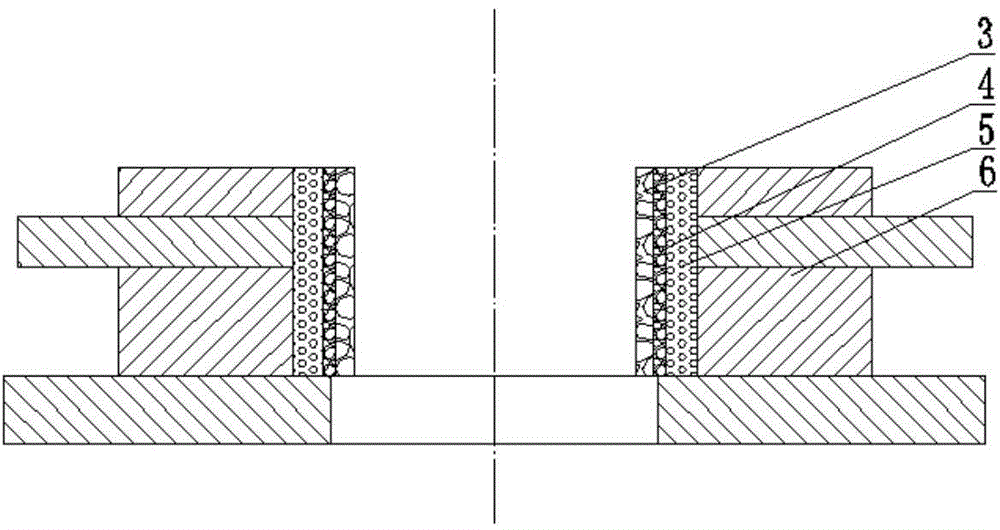

Cold punched die and manufacturing method thereof

ActiveCN104525716AGood chemical stabilityImprove wear resistanceShaping toolsMotor ticsCarbide coating

The invention aims at providing a cold punched die. The surface of a station punched position of the die is provided with carbide coatings, and a manufacturing method for obtaining the cold punched die is provided. According to the cold punched die, the upper surface and the lower surface of the station punched position are provided with the carbide coatings; a pseudo-single crystal TiC compact ceramic layer, a micrometer TiC ceramic layer and a composite layer of the TiC and a base body are sequentially distributed in a gradient manner from outside to inside, and are exerted on the surface of carbon steel. Through the base body and a titanium composite body which are obtained through casting, an outer carbon source is introduced externally, heating and heat preservation are carried out, and therefore a carbide coating is formed on the surface of the base body; the carbide coating is in metallurgical bonding with the base body, and the bonding force is large; the problem that existing hard particles and the metal base body are bonded in a non-metallurgical manner, the bonding force is weak, and the particles are prone to falling off is solved; and the wear-resisting performance of the station punched surface of the cold punched die is greatly improved.

Owner:XIAN UNIV OF TECH

Method for preparing Cf/TiC-TiB2 surface modified layer through utilizing friction stir processing

ActiveCN106480451AImprove fatigue resistanceImprove wear resistanceMetallic material coating processesChemical reactionMotor tics

The invention discloses a method for preparing a Cf / TiC-TiB2 surface modified layer through utilizing friction stir processing, and particularly discloses a method for forming the Cf / TiC-TiB2 surface modified layer through utilizing high temperature generated during the friction stir processing process to promote chemical reaction of Ti, B4C and Cf. According to the method, the abrasion resistance and corrosion resistance of materials for cutters and large area materials for ships, automobiles and planes are greatly improved, the fatigue resistance of the materials is greatly improved, the preparation technology is simple and convenient, the technology is applicable to large batch production, and the production cost for preparing the materials is greatly reduced.

Owner:HUANGSHAN UNIV

Sintered body for magnetic head slider, magnetic head slider, and method of producing sintered body for magnetic head slider

InactiveUS20070127159A1Sufficient surface smoothnessReduce level differenceRecord information storageFluid-dynamic spacing of headsMotor ticsCarbide

A sintered body for a magnetic head slider has at least one of TiC and XC, a carbide containing Ti and X, Al2O3, and free carbon, contains 25 to 160 parts by volume of all the carbides including at least one of TiC and XC, and the carbide containing Ti and X, based on 100 parts by volume of Al203, and contains 1 to 15 parts by volume of free carbon, based on 100 parts by volume of a total of Al2O3 and all the carbides (where X is at least one element selected from the group consisting of Ta, W, Mo, Nb, Zr, V, and Cr).

Owner:TDK CORPARATION

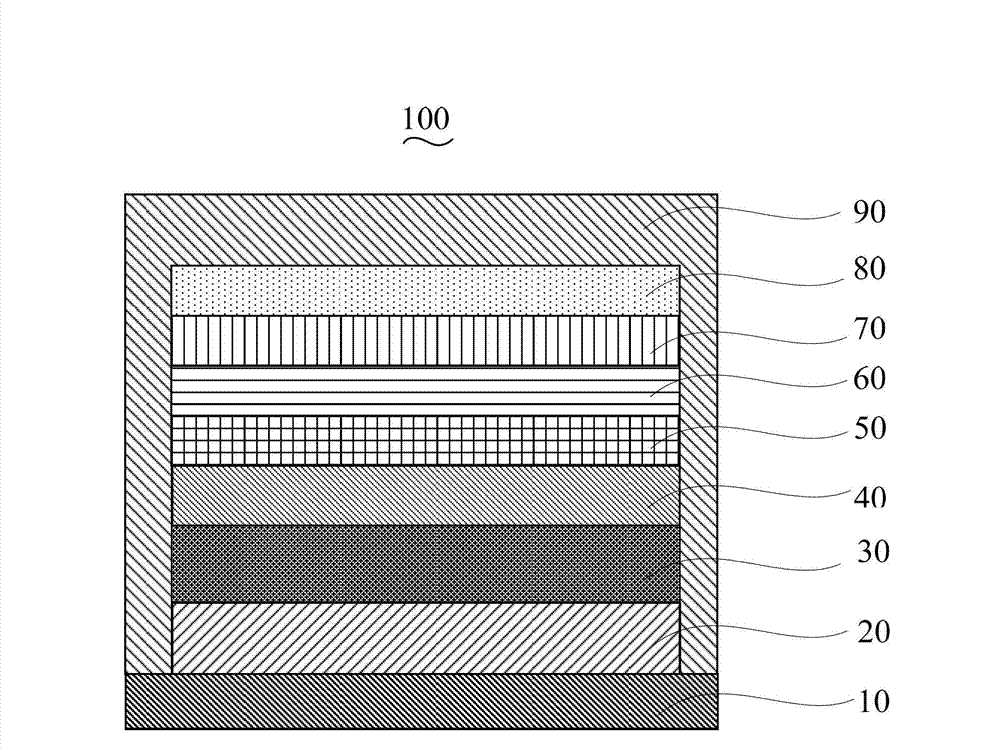

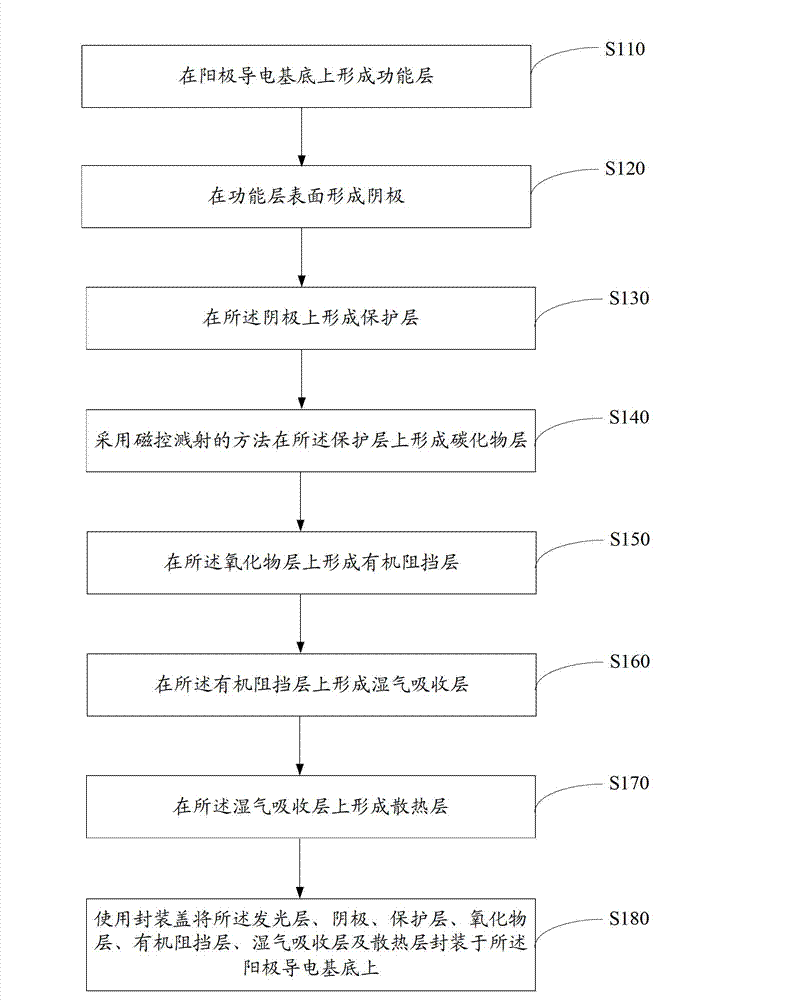

Organic electroluminescent device and preparation method thereof

InactiveCN103594650ASolution to short lifeAvoid destructionSolid-state devicesSemiconductor/solid-state device manufacturingMotor ticsCarbide

The invention relates to an organic electroluminescent device, comprising an anode conductive substrate, a luminescent layer, a cathode, a protective layer, a carbide layer, an organic barrier layer, a moisture absorption layer and a heat dissipation layer which are sequentially laminated, wherein the carbide layer is made of at least one of SiC, WC, TaC, BC, TiC and HfC; and the organic barrier layer is made of at least one of polytetrafluoroethylene, methacrylic resin and cycloaliphatic epoxy resin. The organic electroluminescent device further comprises a package cover, wherein the package cover packages the luminescent layer, the cathode, the protective layer, the carbide layer, the organic barrier layer, the moisture absorption layer and the heat dissipation layer on the anode conductive substrate. The organic electroluminescent device is long in service life. The invention further provides a preparation method of the organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Pneumatic actuator piston material and preparation method thereof

InactiveCN110066947AImprove hardness performanceImprove corrosion resistanceMotor ticsThermal expansion

The invention relates to a pneumatic actuator piston material and a preparation method thereof. The piston material comprises, by weight, 0.57% of Fe, 1.65% of Cu, 0.85% of Mg, 0.18% of Mn, 1.55% of Ni, 1.9% of Zn, 0.55% of B2O3, 1.85% of SiO2, 2.0% of TiC, 0.6% of Pt, 0.45% of Ti, 0.45% of Pb and the balance Al. The preparation method of the pneumatic actuator piston comprises the steps of blankforming, blank pretreatment, die pretreatment, forging, forming and polishing treatment. According to the pneumatic actuator piston material and the preparation method thereof, the excellent hardnessperformance, good corrosion resistance, low thermal expansion coefficient, low friction coefficient and high abrasion resistance are achieved, and the characteristics of good mechanical properties, reliable quality and long service life are also achieved.

Owner:WUXI CHENGTIANNUO ACTUATOR MFG CO LTD

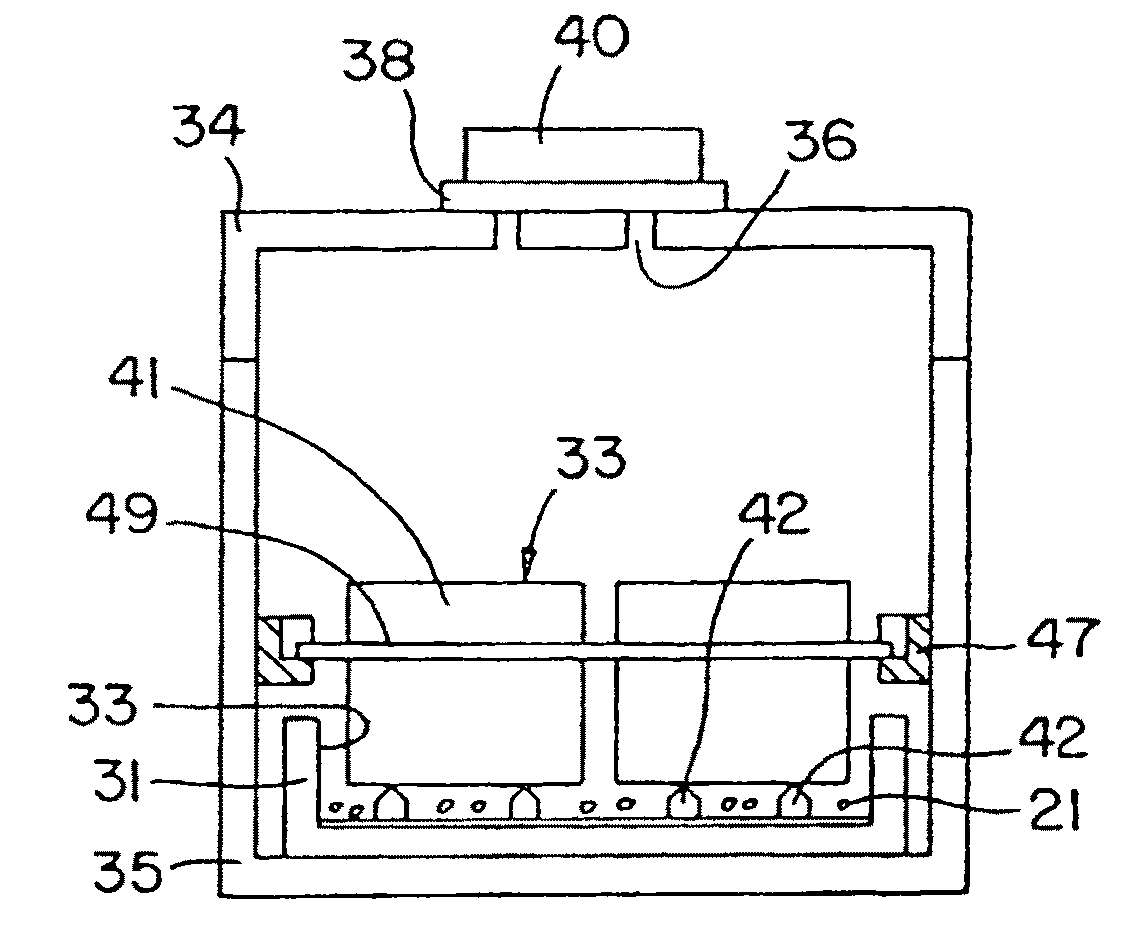

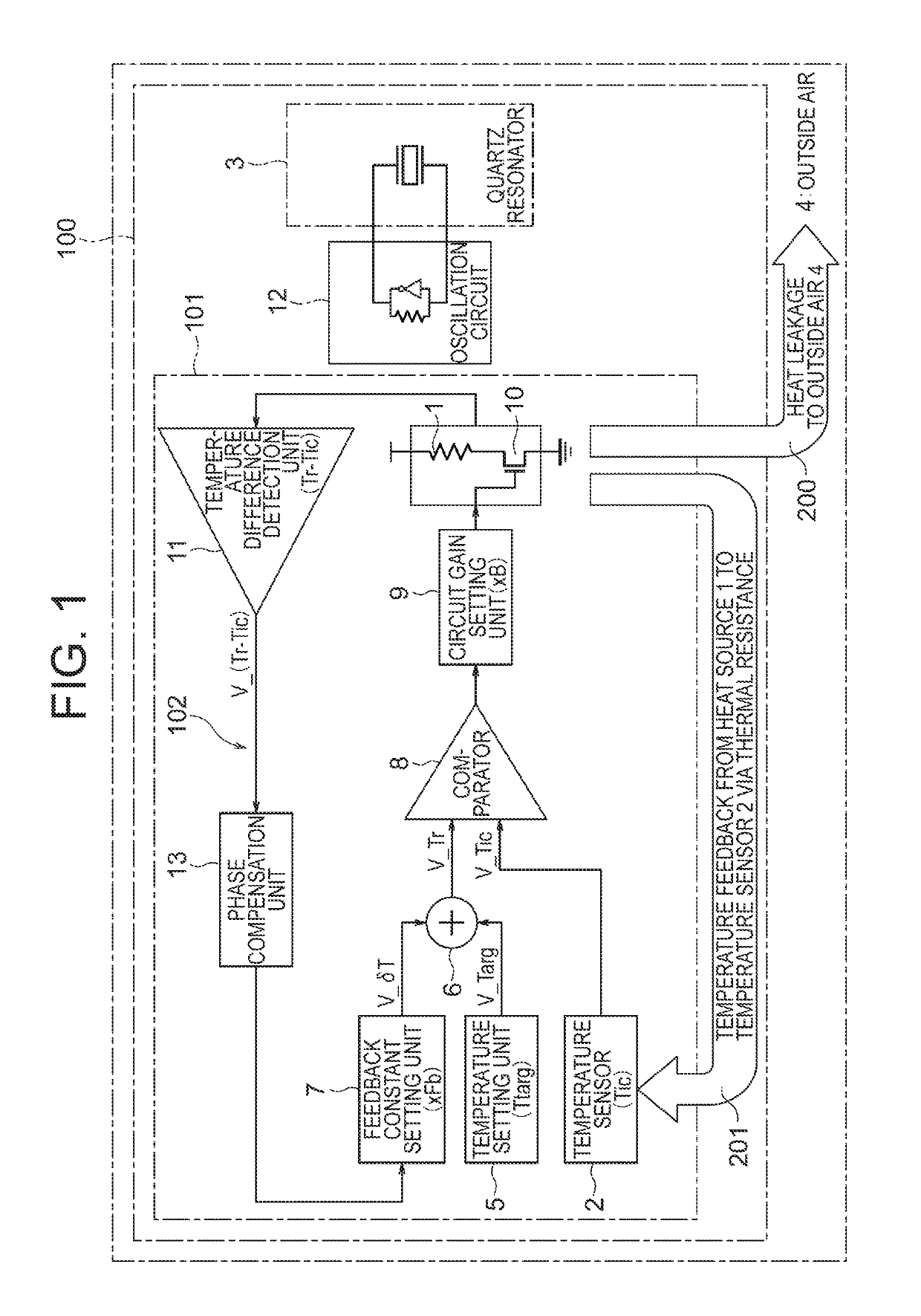

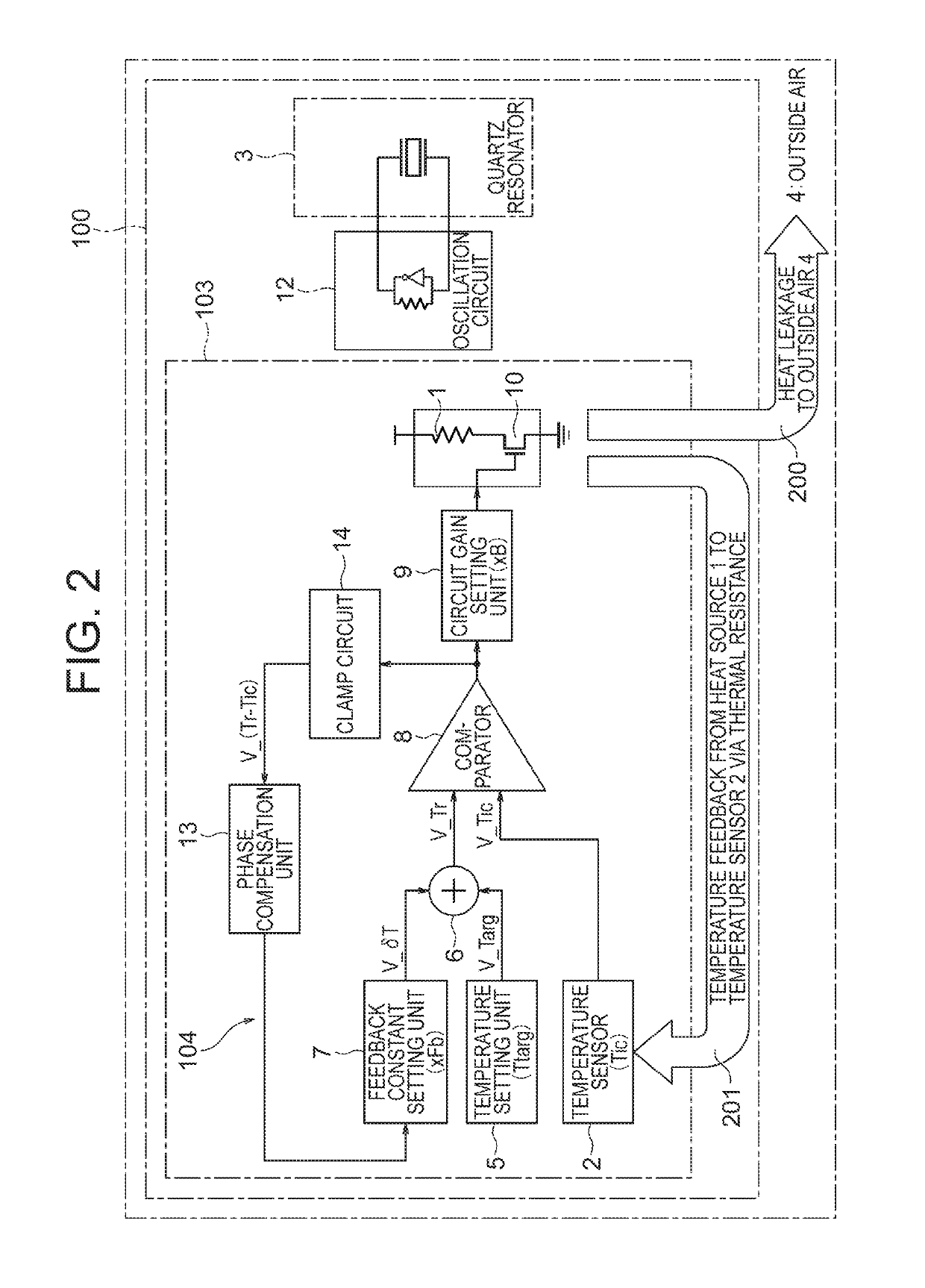

Thermostatic Oven Type Electronic Instrument

ActiveUS20190222173A1Stable temperatureHighly accurate frequencyMultiple input and output pulse circuitsImpedence networksMotor ticsControl system

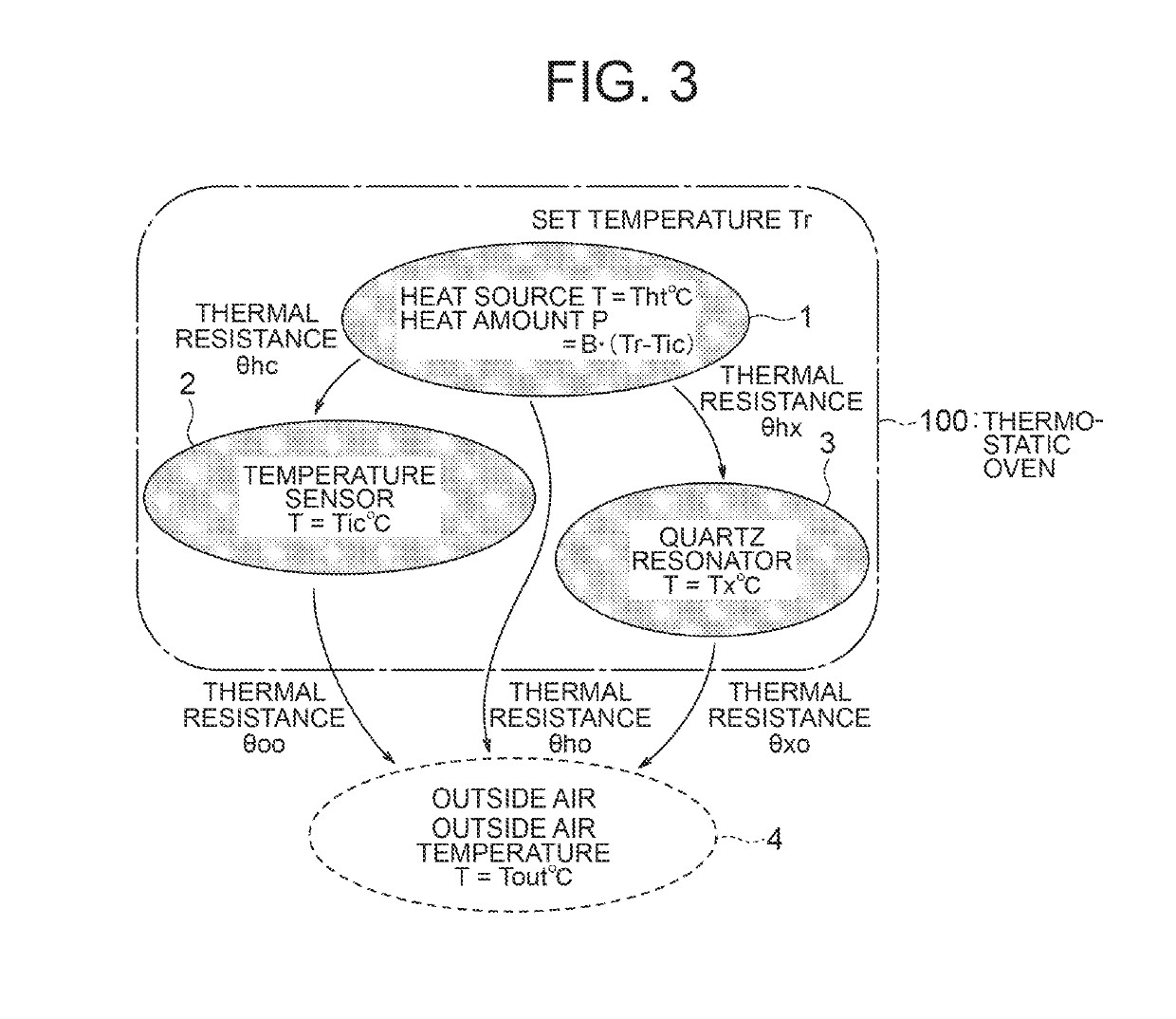

To provide an oven controlled crystal oscillator which can keep constant the temperature of a quartz resonator housed within a thermostatic oven, thereby ensuring stable operation of the quartz resonator. An oven controlled crystal oscillator has a control system for exercising control so that the temperature of a quartz resonator becomes a target temperature Ttarg of a predetermined fixed value. The quartz resonator is housed within a thermostatic oven which is configured to compare a set temperature Tr and a measured temperature Tic based on an outside air temperature measured by a temperature sensor and which is controlled so that a difference between both temperatures is narrowed. The quartz resonator has characteristics influenced by an environmental temperature. The control system adds a predetermined feedback amount δT to the target temperature Ttarg of the fixed value to generate a new set temperature Tr for comparison with the measured temperature Tic so that when the measured temperature Tic lowers, the set temperature Tr becomes high, or when the measured temperature Tic rises, the set temperature Tr becomes low.

Owner:INTERCHIP

Analysis device

ActiveUS20190170712A1Reduce the burden onExclude influenceComponent separationMotor ticsLiquid chromatography mass spectroscopy

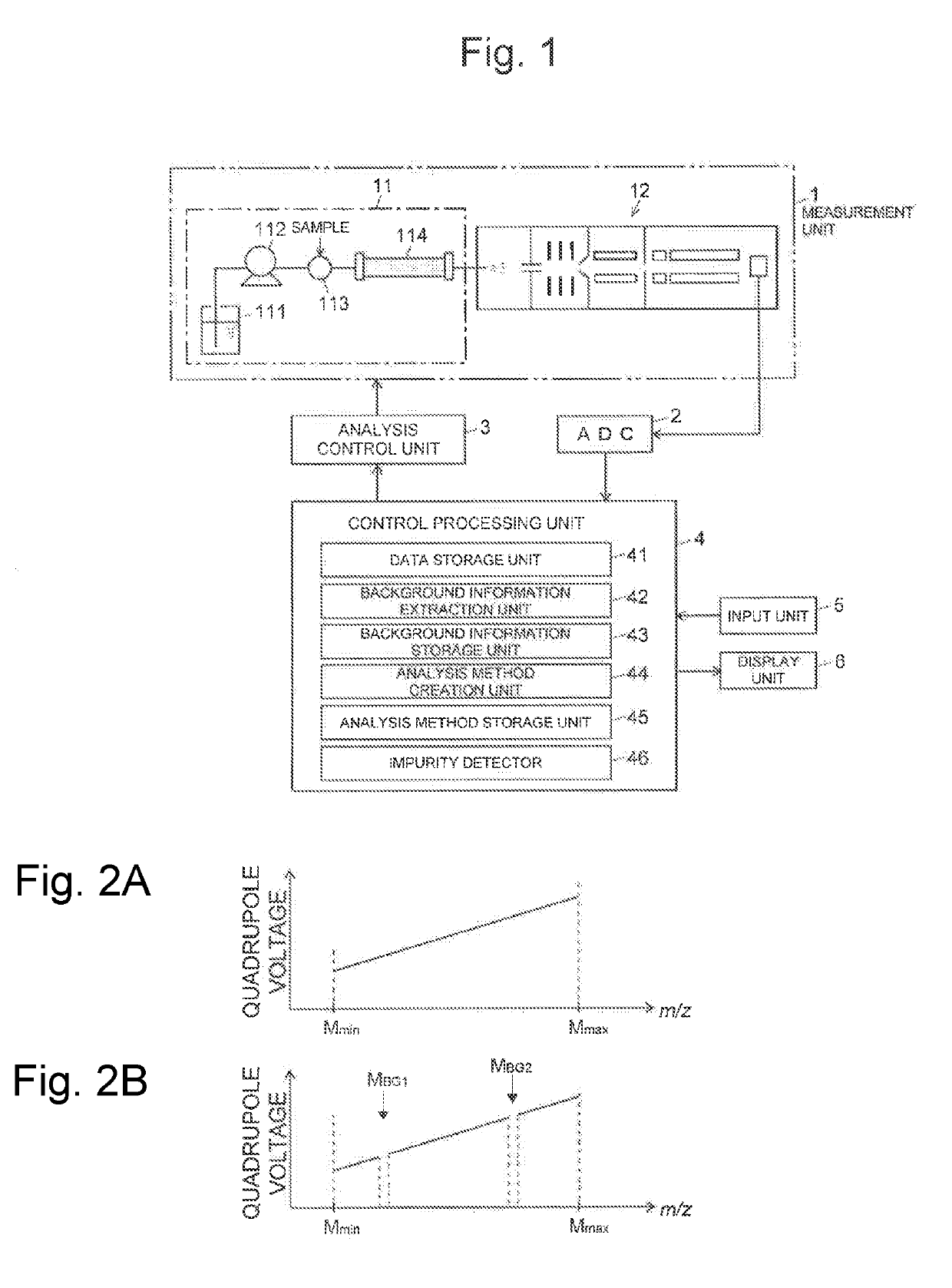

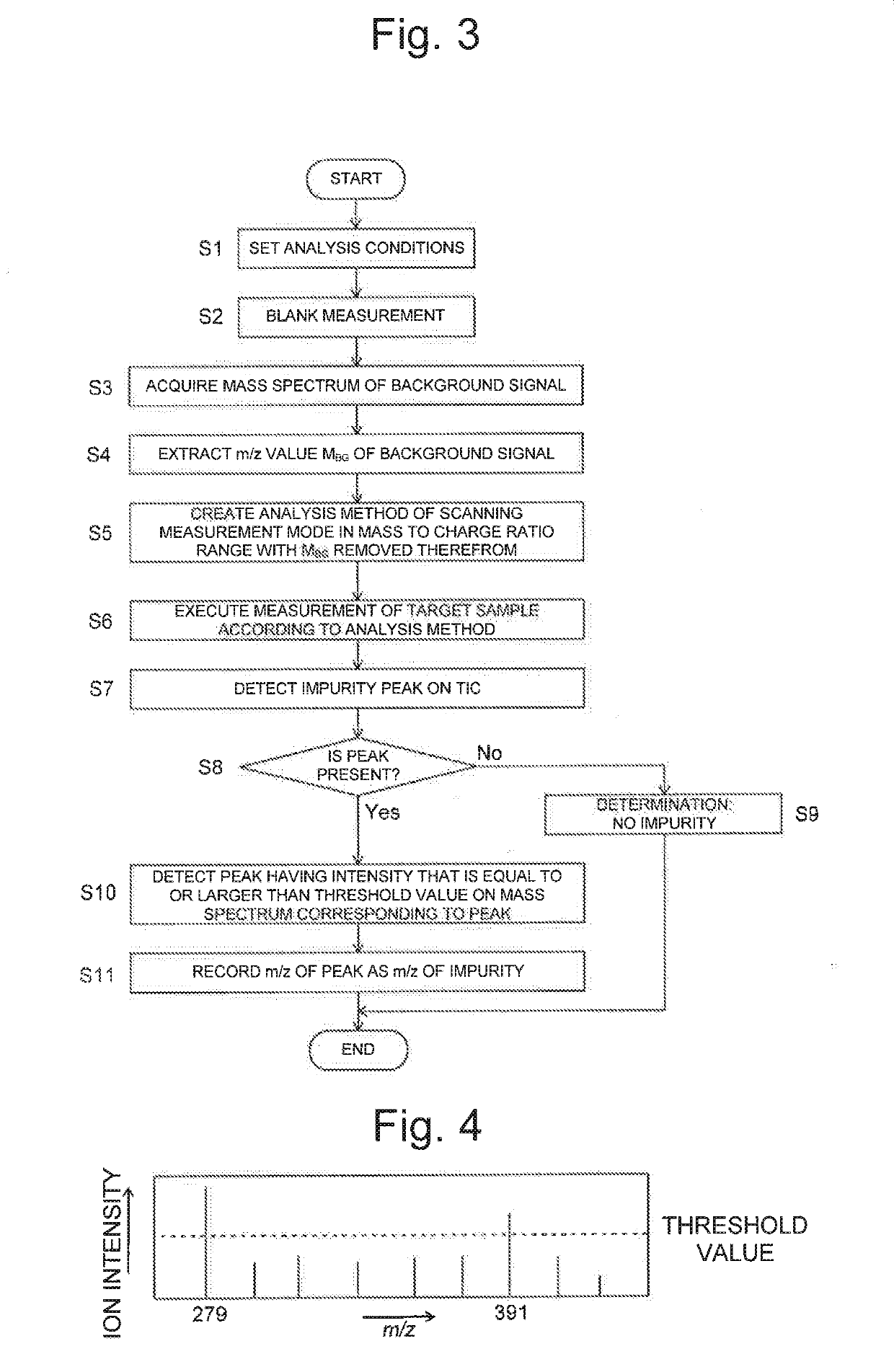

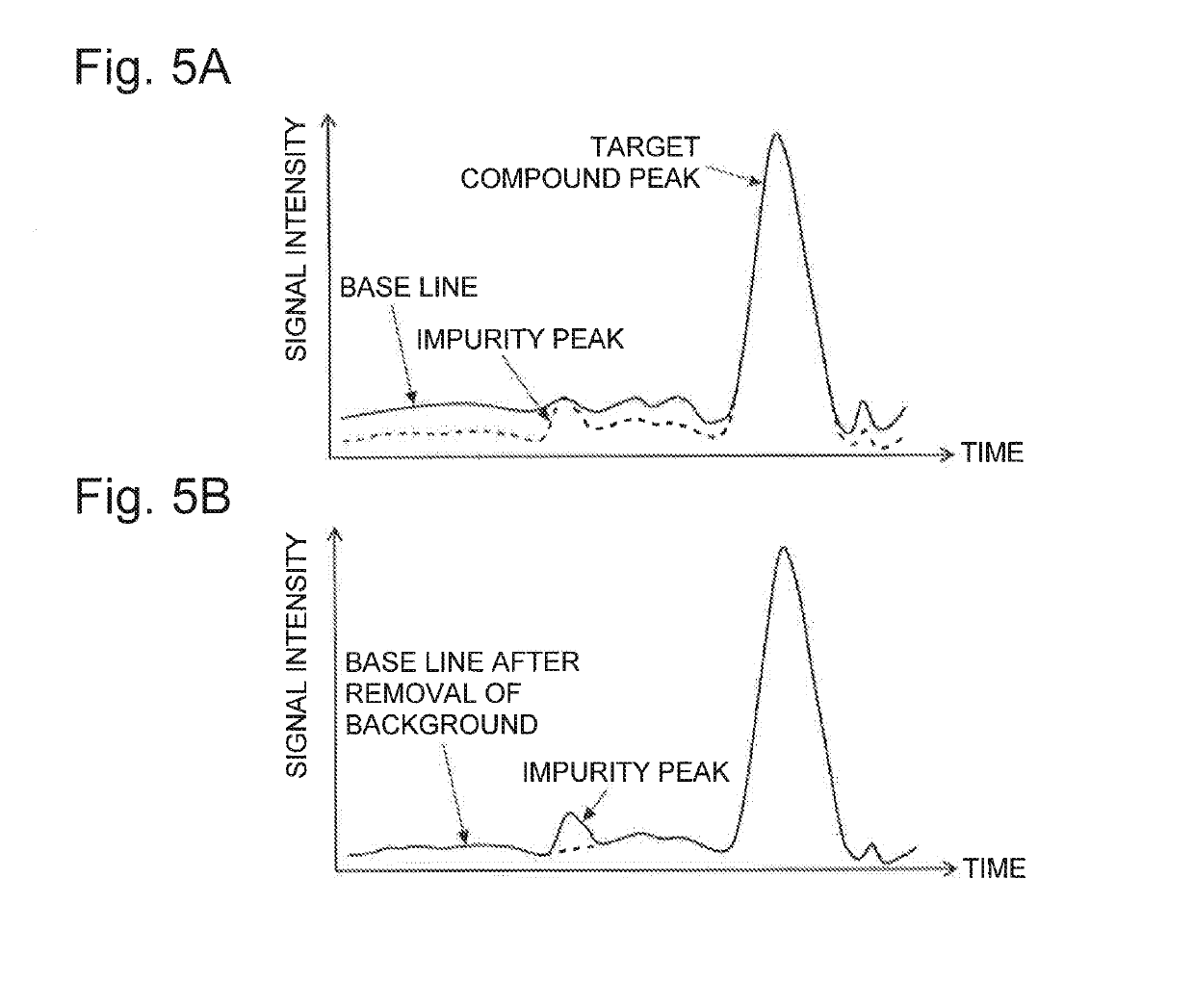

The detection of minute amounts of components that have been undetectable due to an influence of a mobile phase or reagents or the like added to the mobile phase is realized in LC-MS. At the outset, blank measurement is executed, and an m / z value MBG of a background signal derived from a mobile phase or the like is extracted on a mass spectrum obtained by the blank measurement (S2-S4). An analysis method is then created that executes scanning measurement in a plurality of divided m / z ranges in which the m / z value MBG of the background signal has been excluded from a predetermined m / z range. An LC / MS analysis of the target sample is executed according to the analysis method (S5-S6). When a total ion chromatogram (TIC) is created from data obtained by the LC / MS analysis, influence of the background signal hardly appears in the TIC, and the base line is lowered.

Owner:SHIMADZU CORP

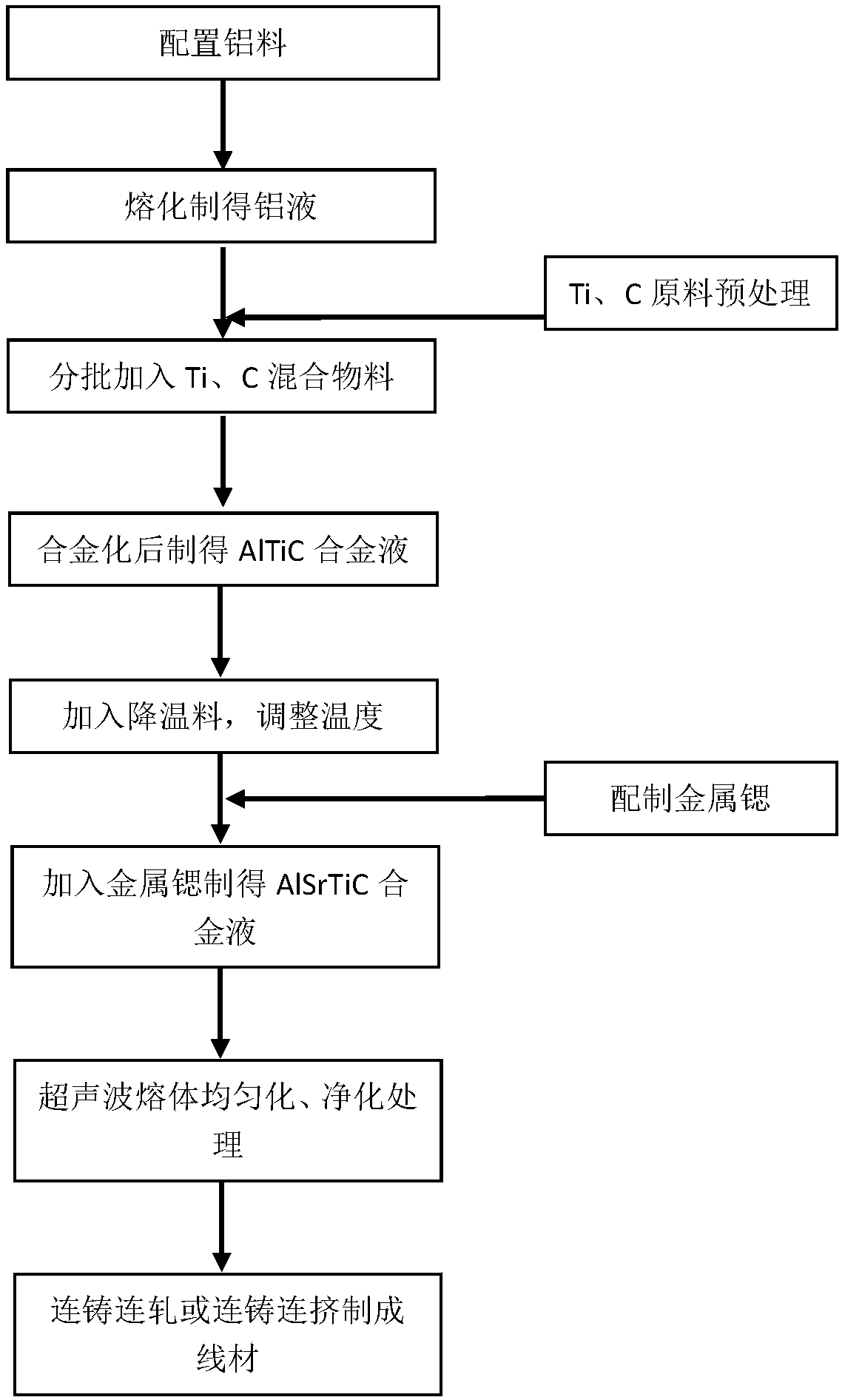

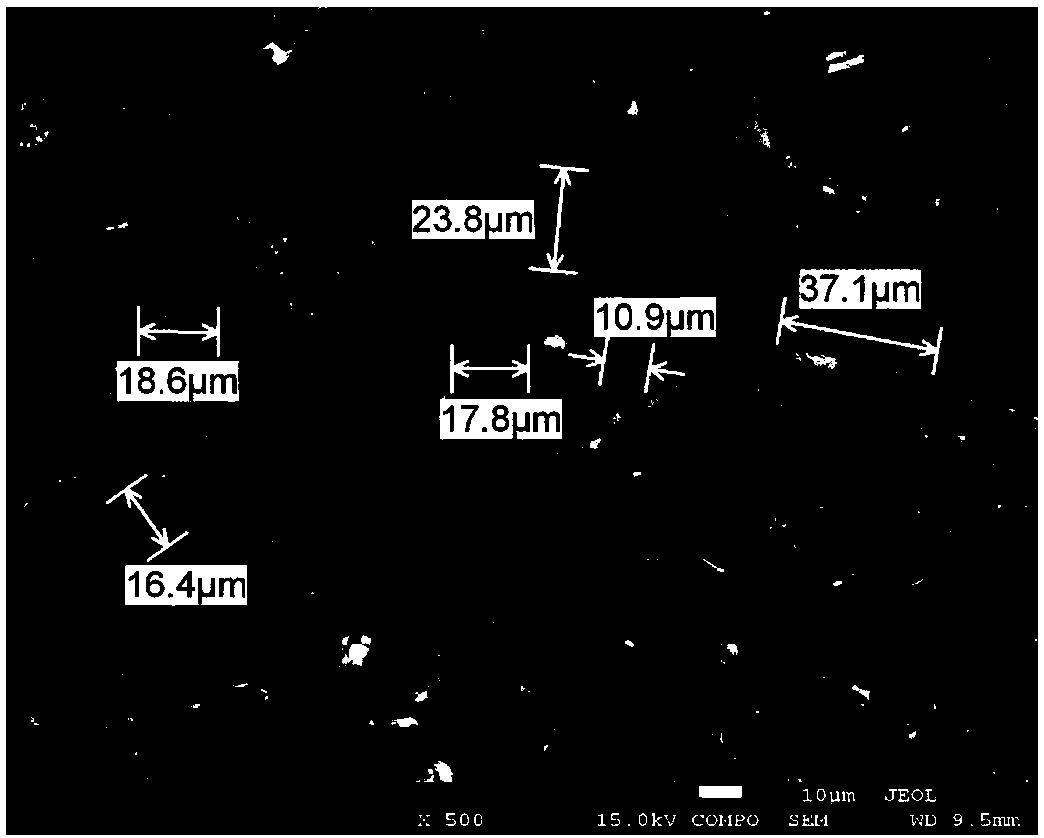

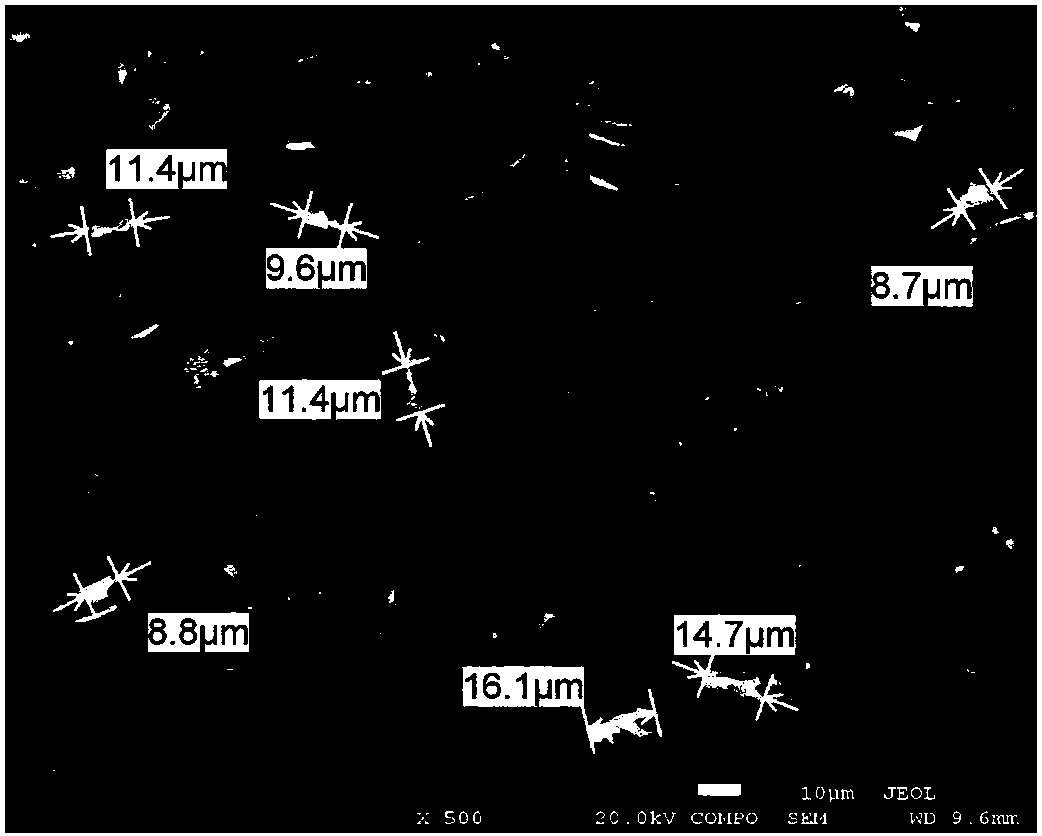

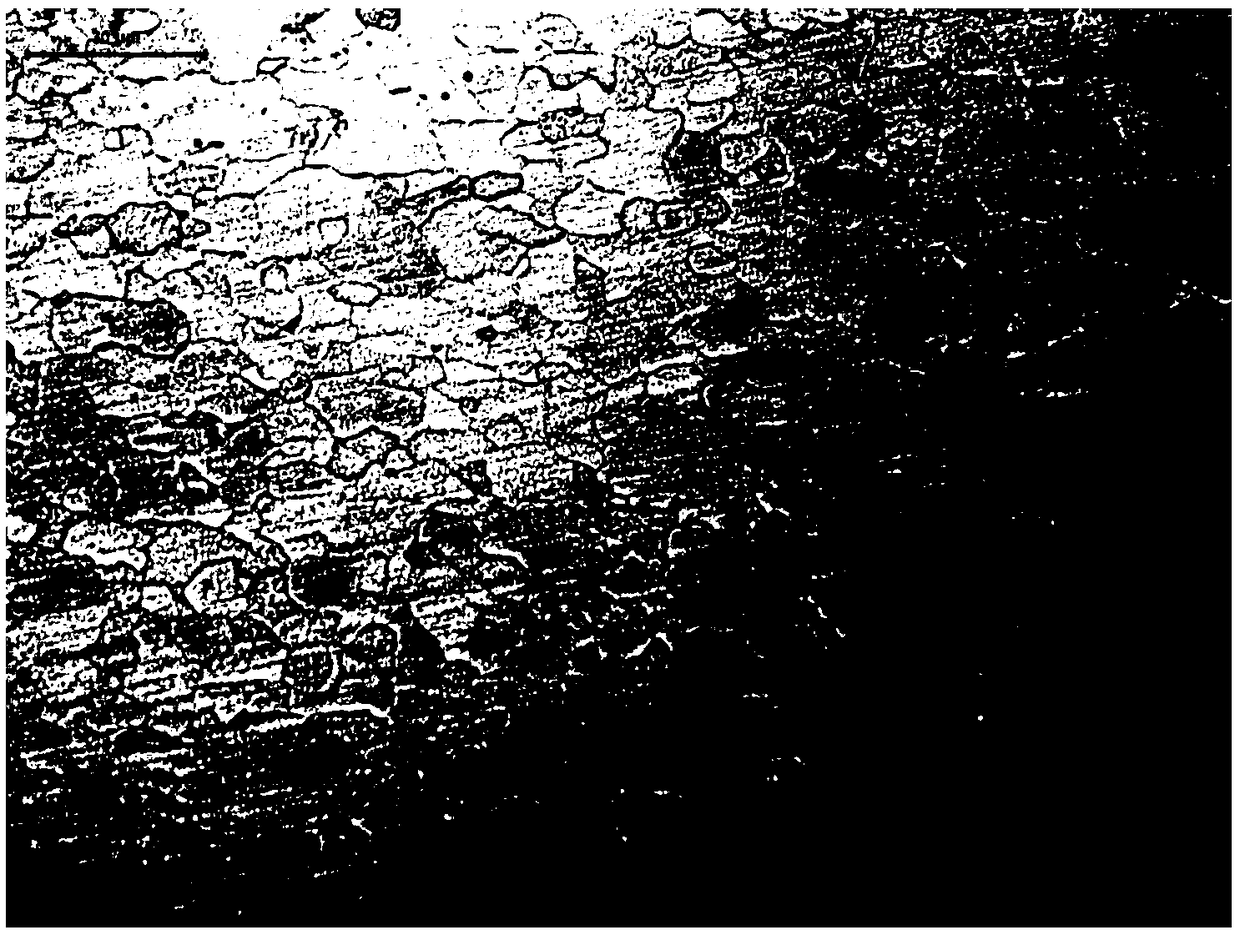

Manufacturing method of combined refining and modifying agent

The invention relates to a manufacturing method of a combined refining and modifying agent. A preparation process comprises the steps that titanium and carbon are mixed at a certain proportion; aftercommercially pure aluminum is added into an alloy furnace and heated to be completely molten and the temperature is increased to a certain value, the mixture of titanium and carbon is added into the to-be-alloyed aluminum melt in the alloy furnace in batches through a bell jar; prepared to-be-cooled aluminum ingots are added into the melt in the alloy furnace to be cooled; metal strontium is addedinto the melt through the bell jar; drossing is carried out after alloying is carried out for a certain period; an alloy solution is transferred to a heat preservation furnace for degassing and refining; the melt flows into a degassing tank through a flow channel and undergoes online continuous homogenization treatment through ultrasonic waves; and finally the melt is cast into ingots or extrudedinto wires. The ingredients of Sr, Ti and C of an Al-Sr-Ti-C product obtained through the method are stable; in the microscopic structure of the wire products, TiAl3 is evenly distributed in a blockymode, the largest size is smaller than or equal to 100 [mu]m, and the average size is smaller than 50 [mu]m; Al3Sr is distributed in a blocky mode, and the average size is smaller than 30 [mu]m; theaverage size of TiC is smaller than 2 [mu]m; and the elongation is larger than 7% and the tension strength is larger than 120 MPa.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD

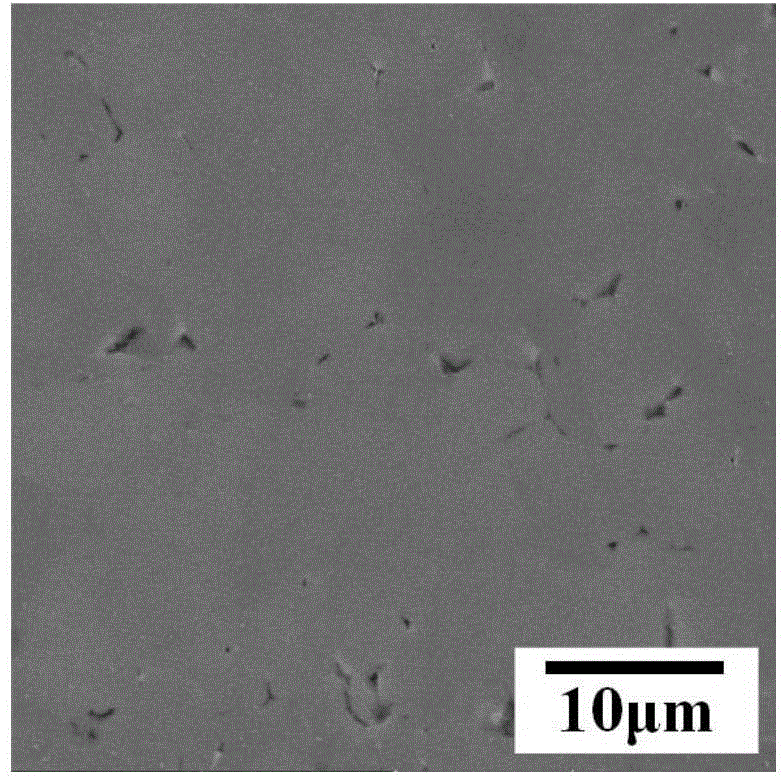

Hot galvanized plate for U-shaped shell of roller washing machine and preparation method thereof

The invention provides a hot galvanized plate for a U-shaped shell of a roller washing machine. A steel plate base body comprises the following chemical components of, by mass, less than or equal to 0.0080% of C, less than or equal to 0.40% of Si, less than or equal to 1.2% of Mn, less than or equal to 0.12% of P, less than 0.015% of S, less than or equal to 0.060% of Alt, 0.05-0.08% of Ti, less than 0.0020% of B, less than 0.0060% of N and the balance of iron and inevitable impurities. The hot galvanized plate has the characteristics of being high in yield strength, high in tensile strength,high in press molding, free of aging, impact-resistant and the like, wherein the yield strength is 260-340 MPa, the tensile strength is 420-500 MPa, the elongation after fracture A80 is greater than or equal to 30%, and then the hot galvanized plate can be used for the U-shaped shell of the roller washing machine and steel for a refrigerator panel. The invention further provides a preparation method of the hot galvanized plate. The preparation method comprises the following steps that 1) iron water is obtained, and continuous casting is carried out to obtain a slab; 2) heating, rough rolling,finish rolling and rolling of hot rolled rolls are carried out; 3) pickling-rolling rolling is carried out; and 4) a hot galvanizing process is carried out. According to the component requirements andprocess control, the galvanized plate meeting the use of the U-shaped shell is obtained, and TiC+FeTiP mixture precipitation phases are dispersedly distributed in a microscopic tissue matrix, so thatit shows that solid solution strengthening of the P is vitrificated.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

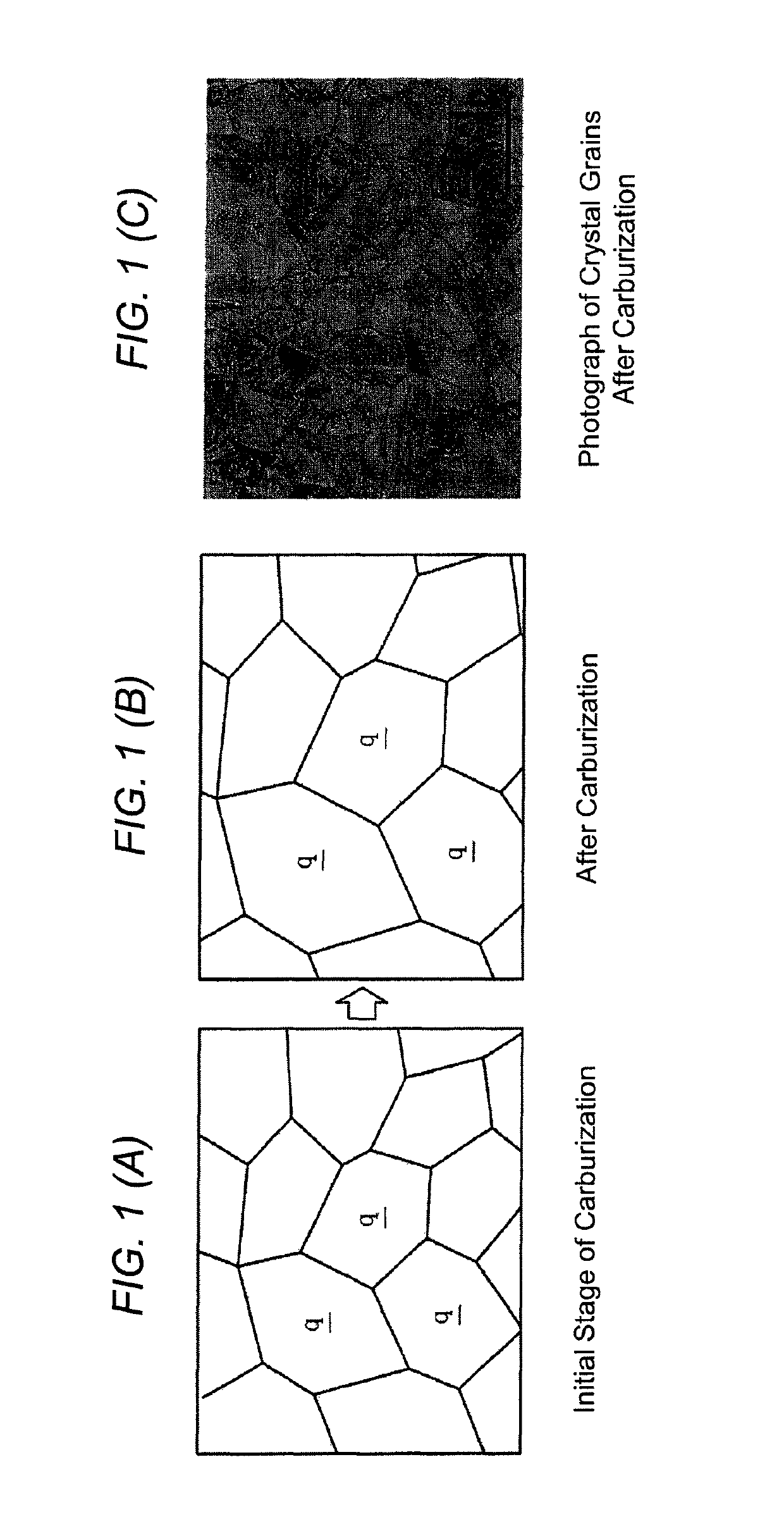

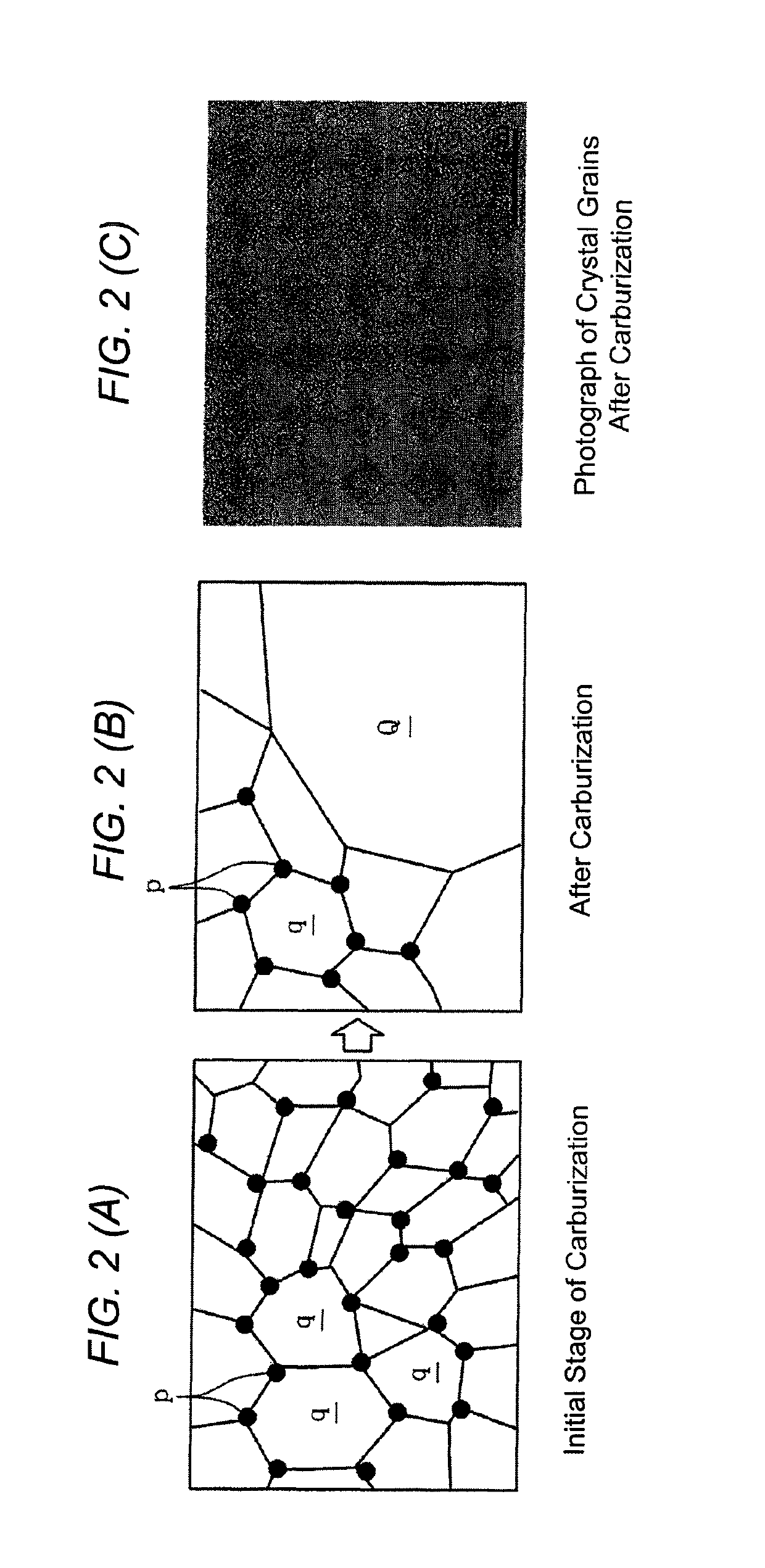

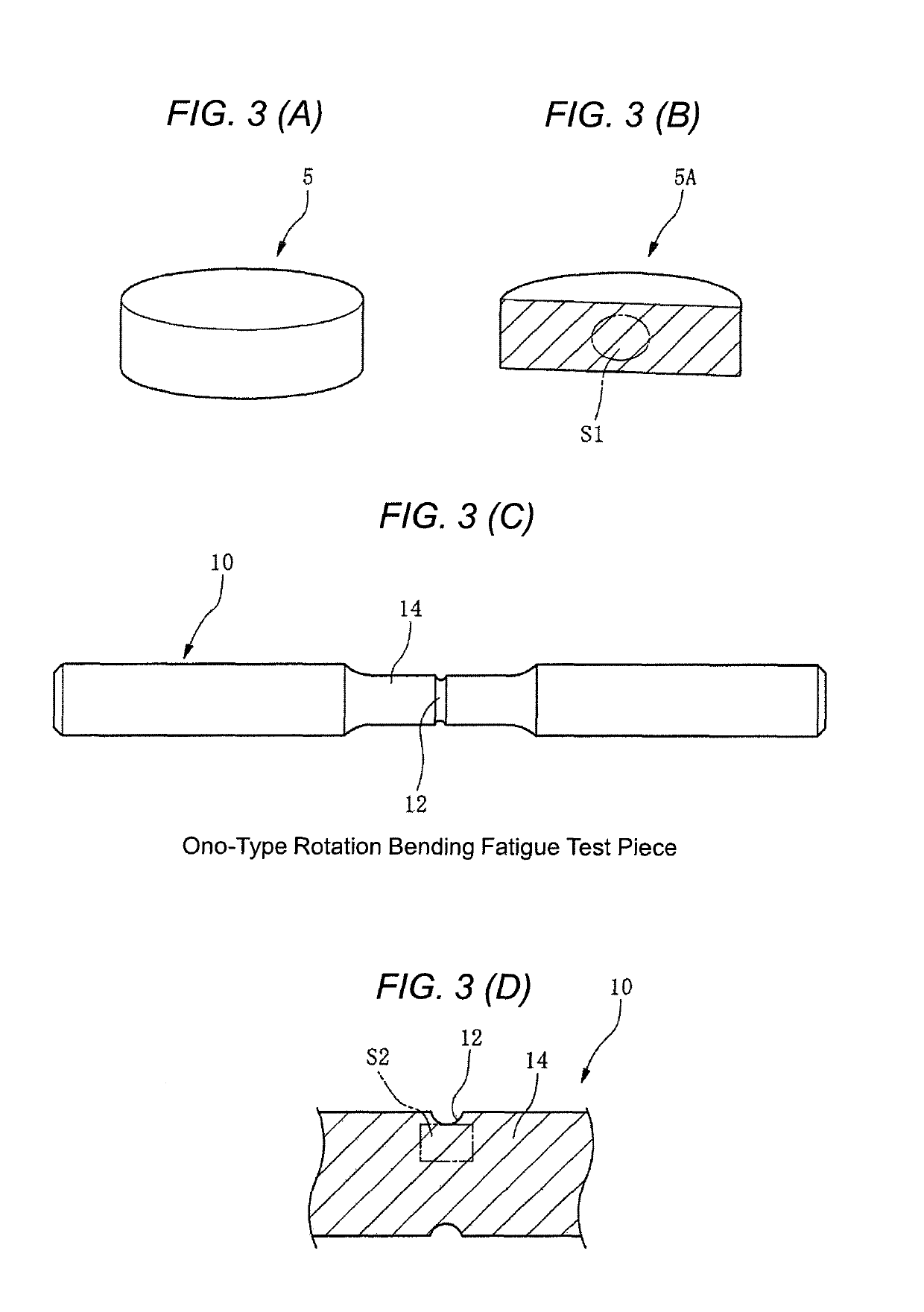

Case hardening steel

ActiveUS10287668B2Inhibition is effectiveMinimizing the crystal grain boundary pinningSolid state diffusion coatingAbnormal grain growthMotor tics

Provided is a case hardening steel which allows effective inhibition of abnormal grain growth during carburizing treatment or the like and makes it possible to solve the problem of abnormal grain growth-induced reduction in characteristics. In the case hardening steel, a total amount of TiC, ZrC and AlN which are precipitate particles contained in 100 g of a steel material after subjecting the case hardening steel to hot rolling is 3.5×10−4 mole or less.

Owner:DAIDO STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com