Patents

Literature

3763 results about "Cermet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cermet is a composite material composed of ceramic (cer) and metal (met) materials. A cermet is ideally designed to have the optimal properties of both a ceramic, such as high temperature resistance and hardness, and those of a metal, such as the ability to undergo plastic deformation. The metal is used as a binder for an oxide, boride, or carbide. Generally, the metallic elements used are nickel, molybdenum, and cobalt. Depending on the physical structure of the material, cermets can also be metal matrix composites, but cermets are usually less than 20% metal by volume.

Tool with a molybdenum sulfide containing coating and method for its production

InactiveUS6528171B1Improve wear resistanceRecord information storageMagnetic recordingMetallic materialsMonolayer

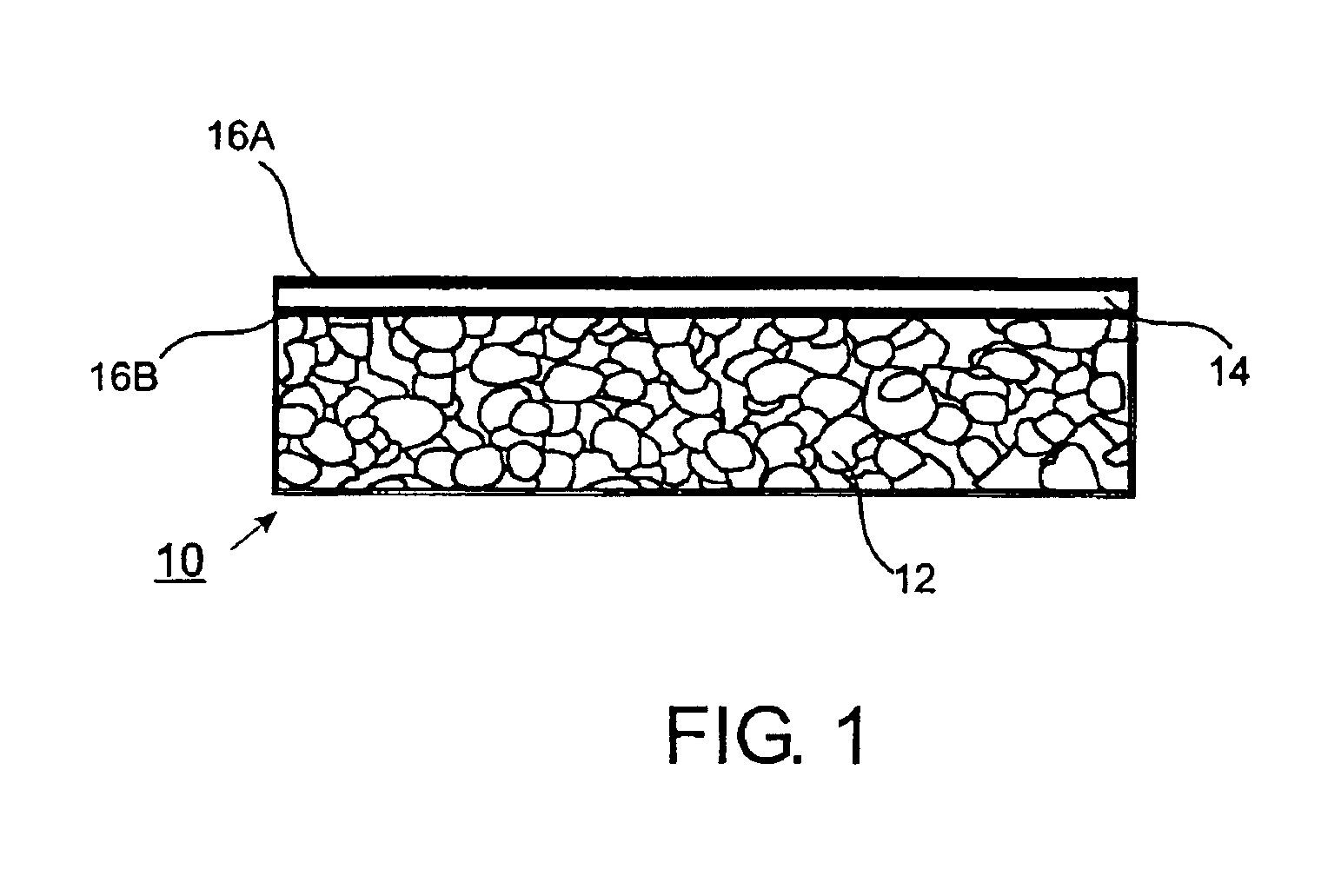

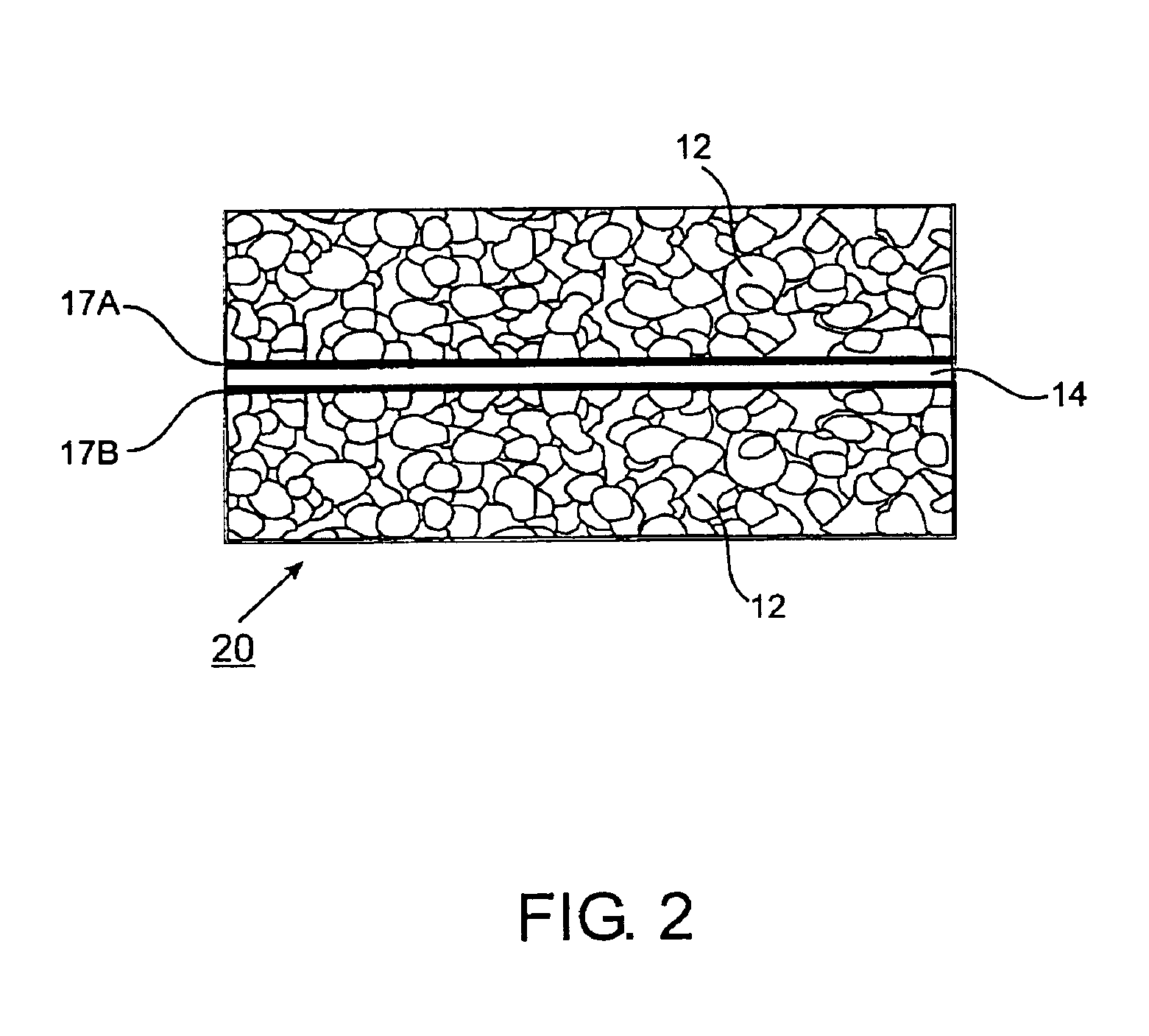

The invention relates to a tool, especially a cutting insert for cutting metallic materials, which consist of a hard metal, cermet ceramics or steel base, especially of a high speed steel base, and at least one layer deposited thereon. The single layer, or in the case of several layers the outer layer or the layer underneath the outer layer, contains molybdenum sulfide. The aim of the invention is to improve the resistance to wear of the friction-reducing, molybdenum sulfide containing layer even at high pressures. To this end, the molybdenum sulfide containing layer consists of an alternating sequence of two layer that are different from one another. The first layer contains 51 to 100% by weight of metallic molybdenum and the second layer contains 21 to 100% by weight of MoS2 which substantially consists of hexagonal crystals that are at least substantially oriented in a plane parallel to the tool surface.

Owner:WIDIA

Nanocoated primary particles and method for their manufacture

InactiveUS6913827B2Granule coatingSemiconductor/solid-state device detailsConformal coatingElectronic packaging

Particles have an ultrathin, conformal coating are made using atomic layer deposition methods. The base particles include ceramic and metallic materials. The coatings can also be ceramic or metal materials that can be deposited in a binary reaction sequence. The coated particles are useful as fillers for electronic packaging applications, for making ceramic or cermet parts, as supported catalysts, as well as other applications.

Owner:UNIV OF COLORADO THE REGENTS OF

Metal-ceramic composite articulation

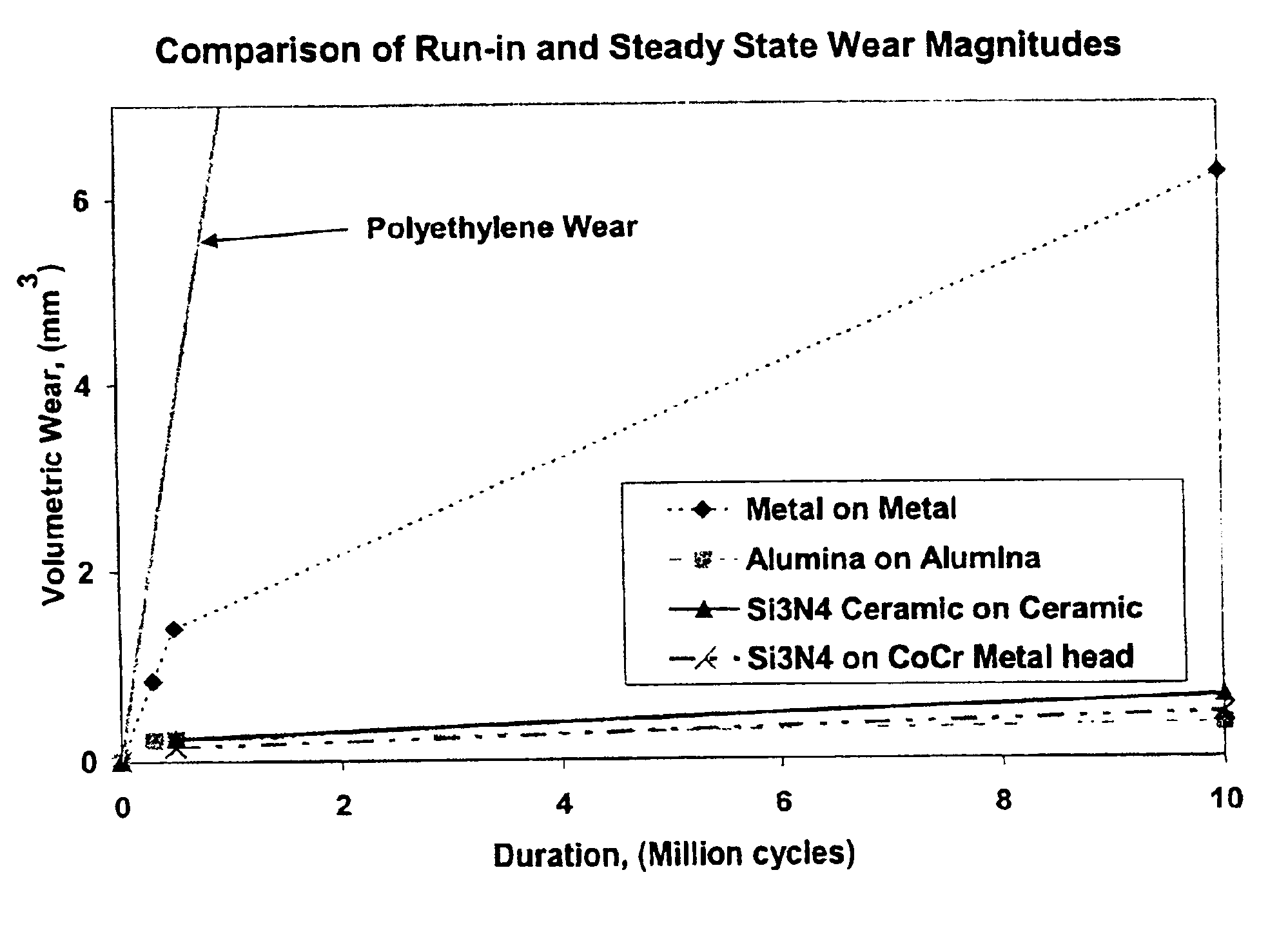

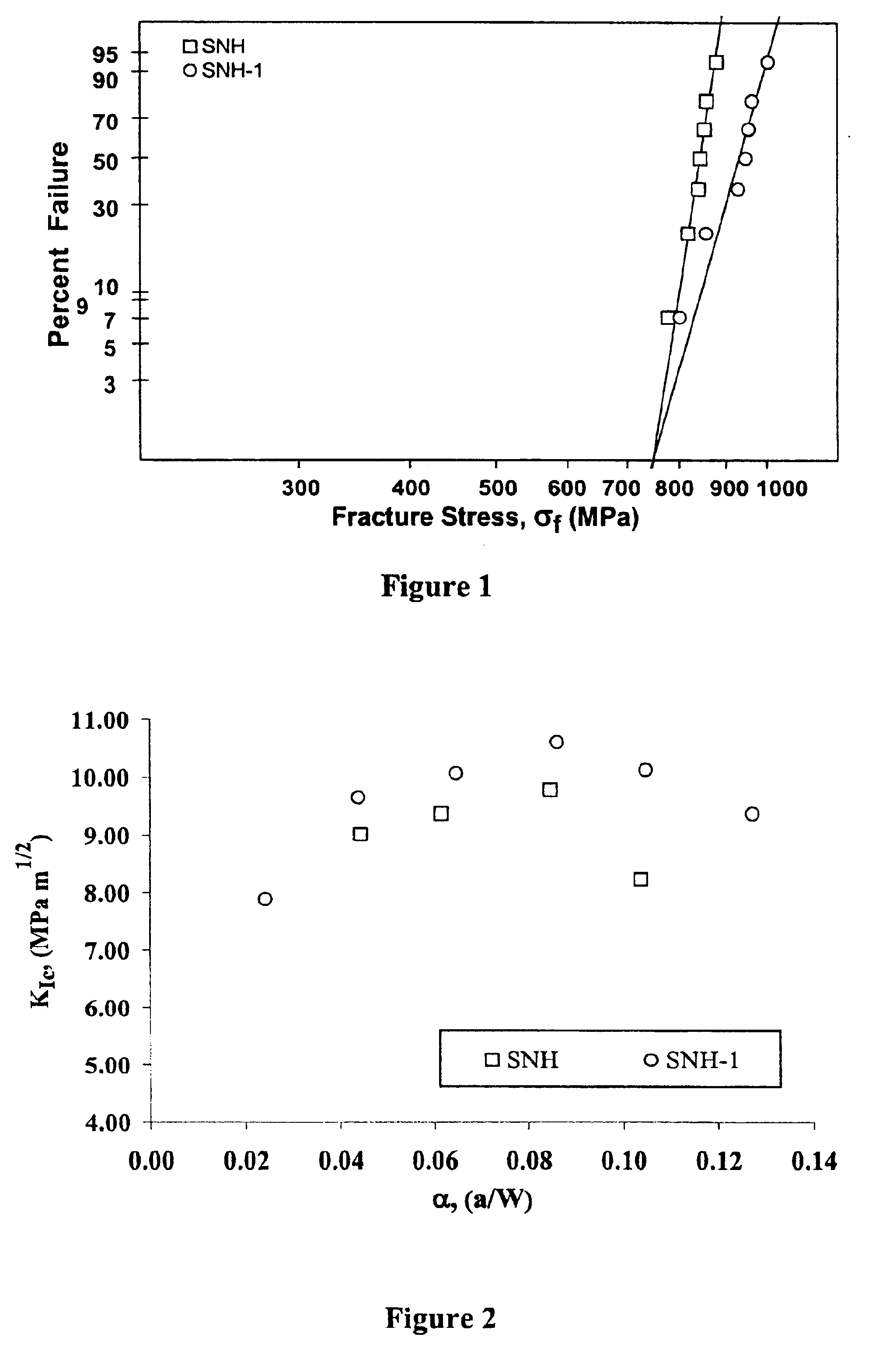

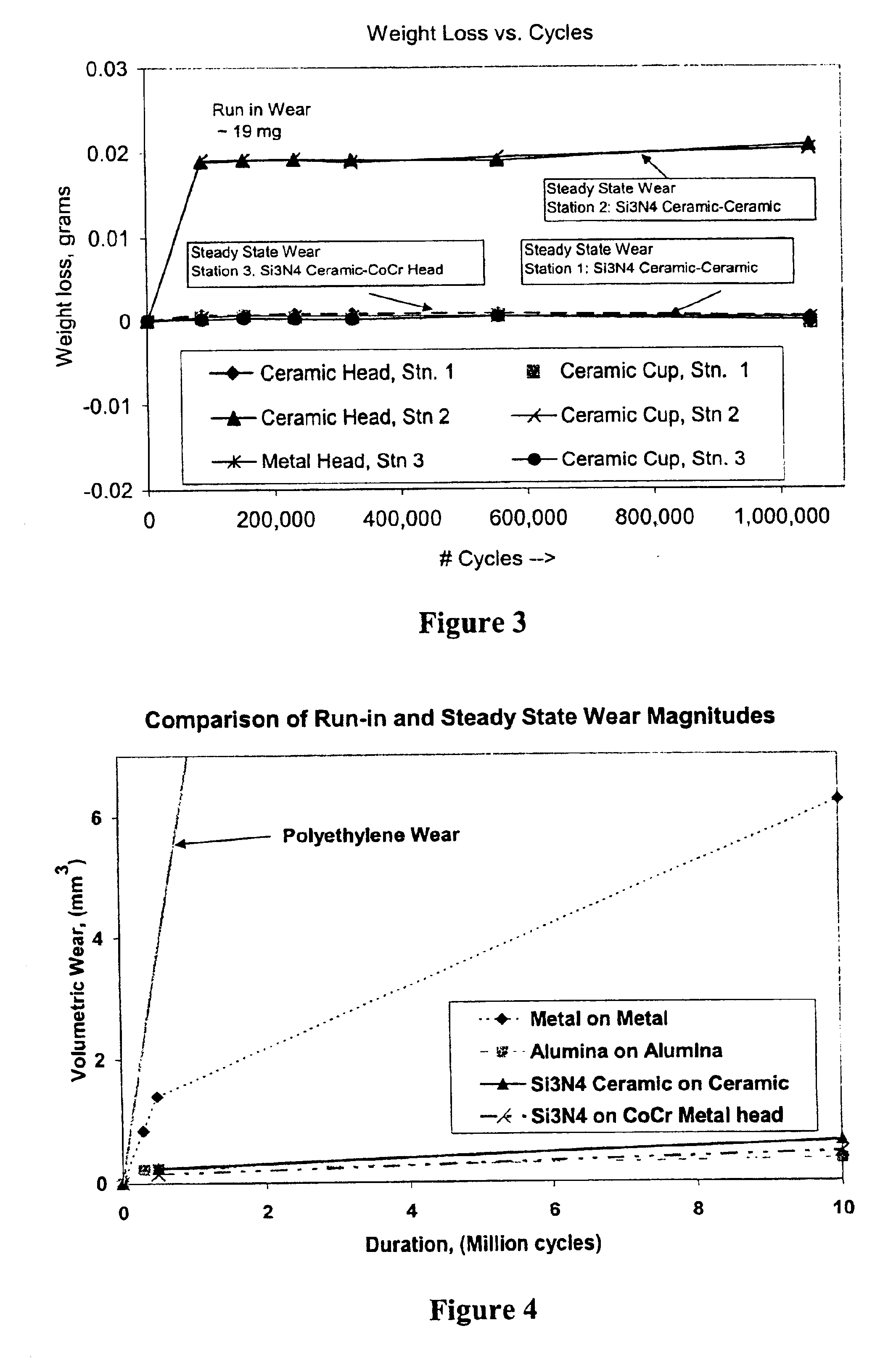

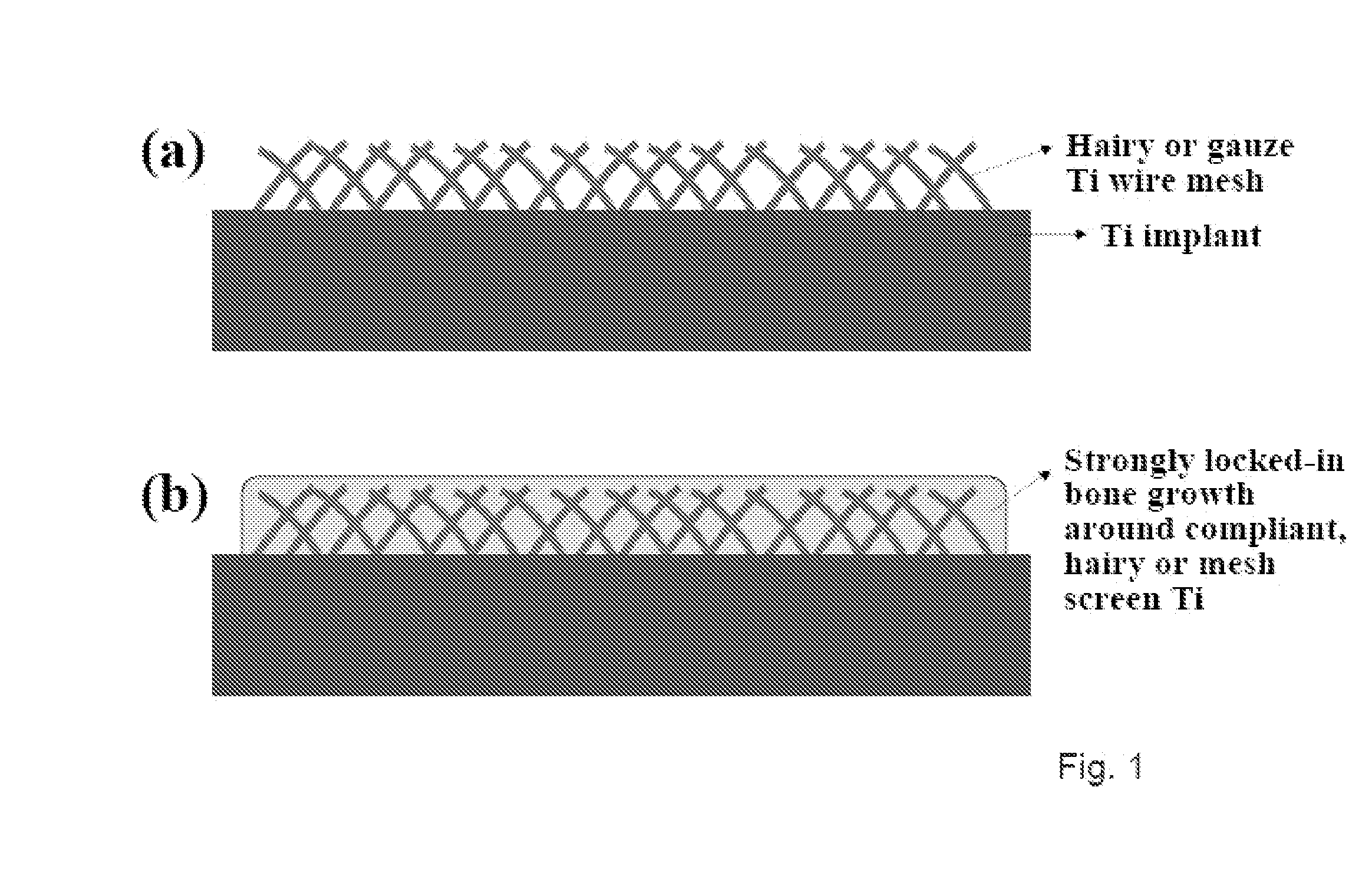

InactiveUS6881229B2Minimal productionImprove flexural strengthBone implantJoint implantsHigh fractureIn vivo

A ceramic-metal composite articulation is provided with substantial elimination of wear debris, wherein a ceramic material is provided with superior mechanical properties tailored for articulating with ceramic articulations having high flexural strength (greater than about 700 MPa), high fracture toughness (greater than about 7 MPa1 / 2) and a high Weibull modulus (greater than about 20), in comparison with presently available bio-ceramics such as alumina or zirconia. The mechanical property enhancement enables ceramic materials with greater reliability and significantly reduced in-vivo fracture risk to be obtained. Preliminary in-vitro wear performance, to several million cycles using established test protocols, of head / cup components in a prosthetic hip joint made from these ceramics also demonstrates the ultra low wear characteristics. These material properties substantially eliminate polyethylene (PE) wear debris mediated implant failures by offering an optimal combination of bio-mechanical safety and reliability with ultra low wear performance.

Owner:SINTX TECH INC

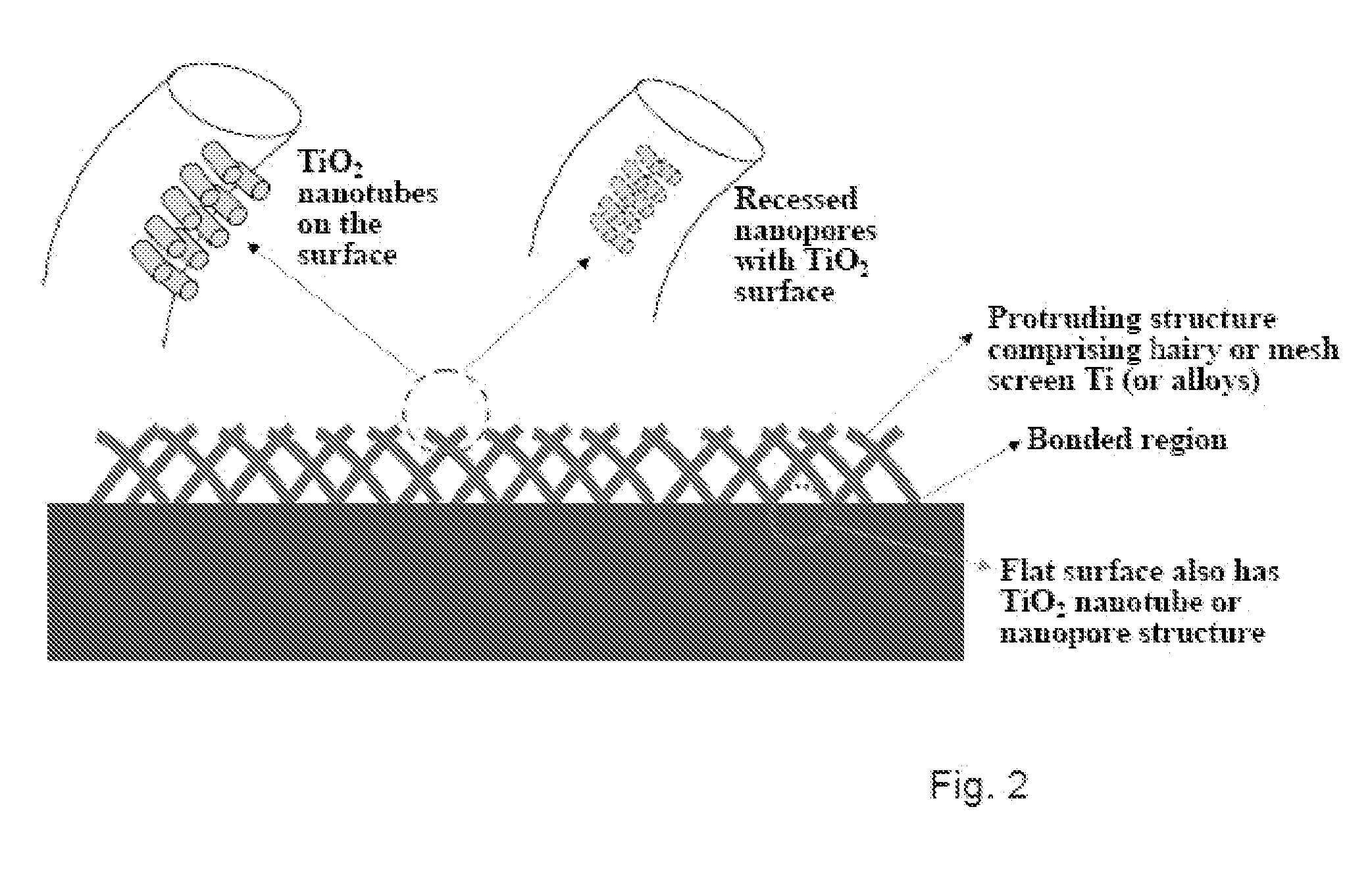

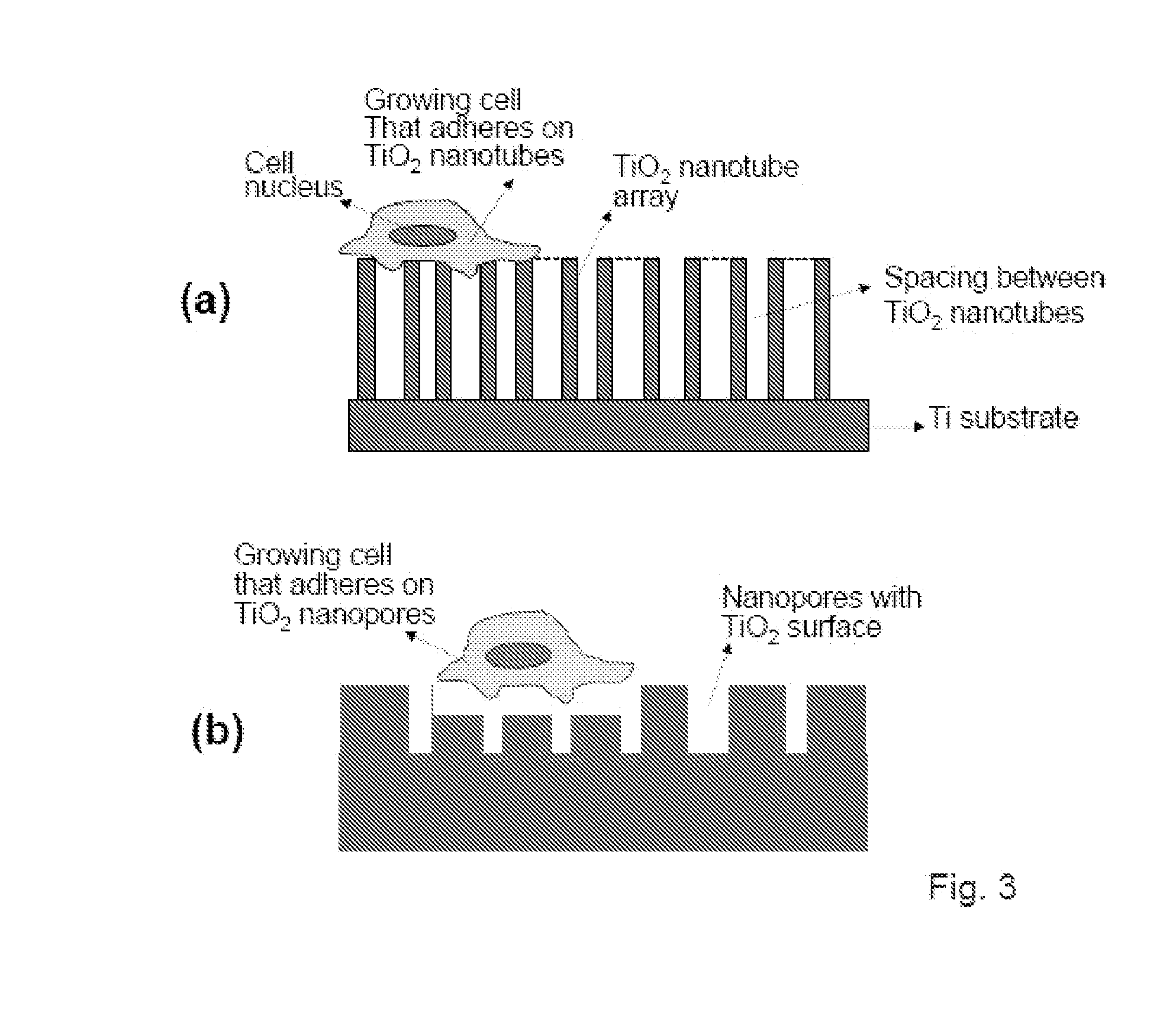

Articles comprising large-surface-area bio-compatible materials and methods for making and using them

ActiveUS20100303722A1Improve cell adhesionAccelerated cell growth characteristicImmobilised enzymesBioreactor/fermenter combinationsCell culture mediaBone growth

The present invention provides articles of manufacture comprising biocompatible nanostructures comprising significantly increased surface area for, e.g., organ, tissue and / or cell growth, e.g., for bone, tooth, kidney or liver growth, and uses thereof, e.g., for in vitro testing of drugs, chemicals or toxins, or as in vivo implants, including their use in making and using artificial tissues and organs, and related, diagnostic, screening, research and development and therapeutic uses, e.g., as drug delivery devices. The present invention provides biocompatible nanostructures with significantly increased surface area, such as with nanotube and nanopore array on the surface of metallic, ceramic, or polymer materials for enhanced cell and bone growth, for in vitro and in vivo testing, cleansing reaction, implants and therapeutics. The present invention provides optically transparent or translucent cell-culturing substrates. The present invention provides biocompatible and cell-growth-enhancing culture substrates comprising elastically compliant protruding nanostructure substrates coated with Ti, TiO2 or related metal and metal oxide films.

Owner:RGT UNIV OF CALIFORNIA

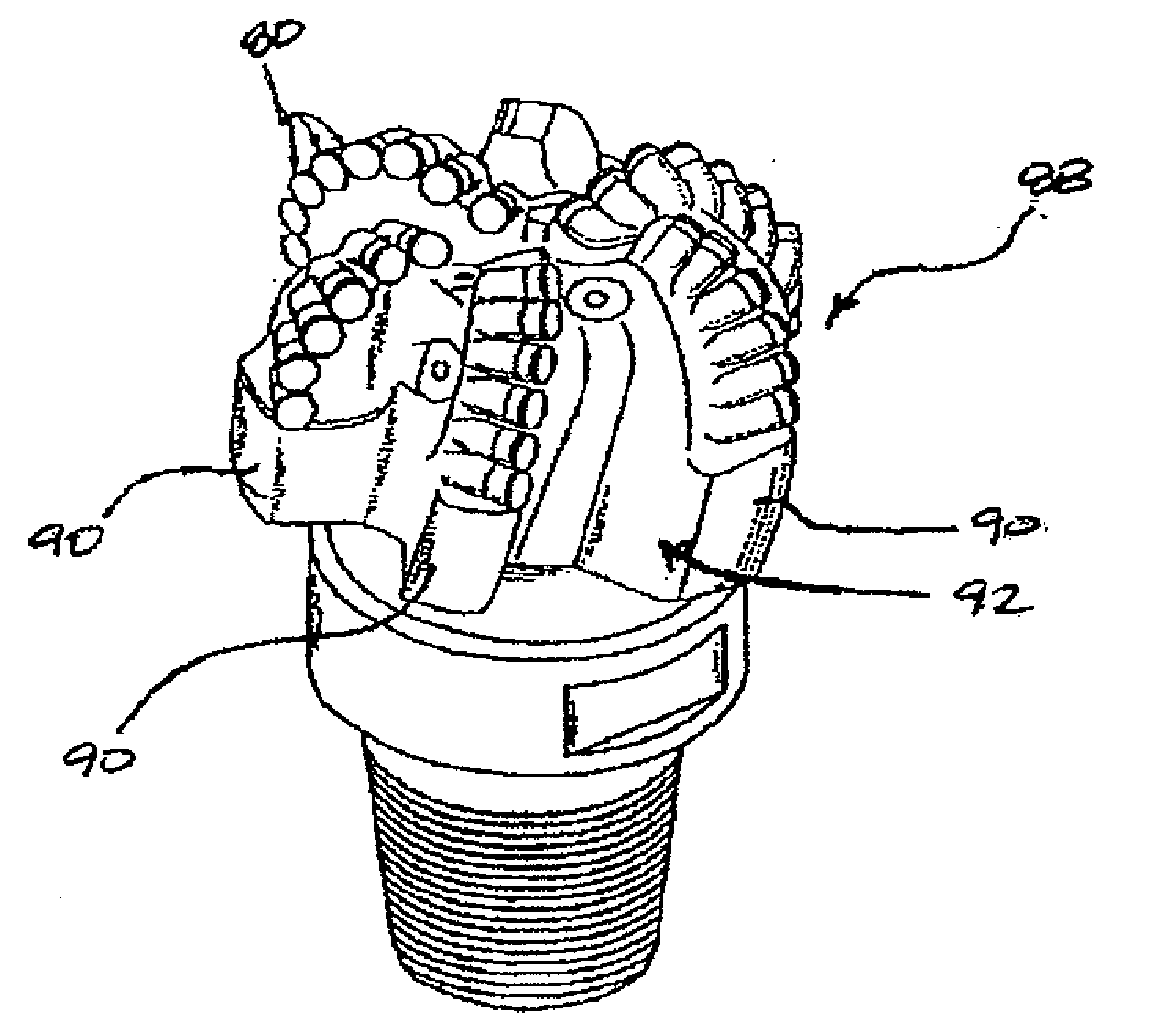

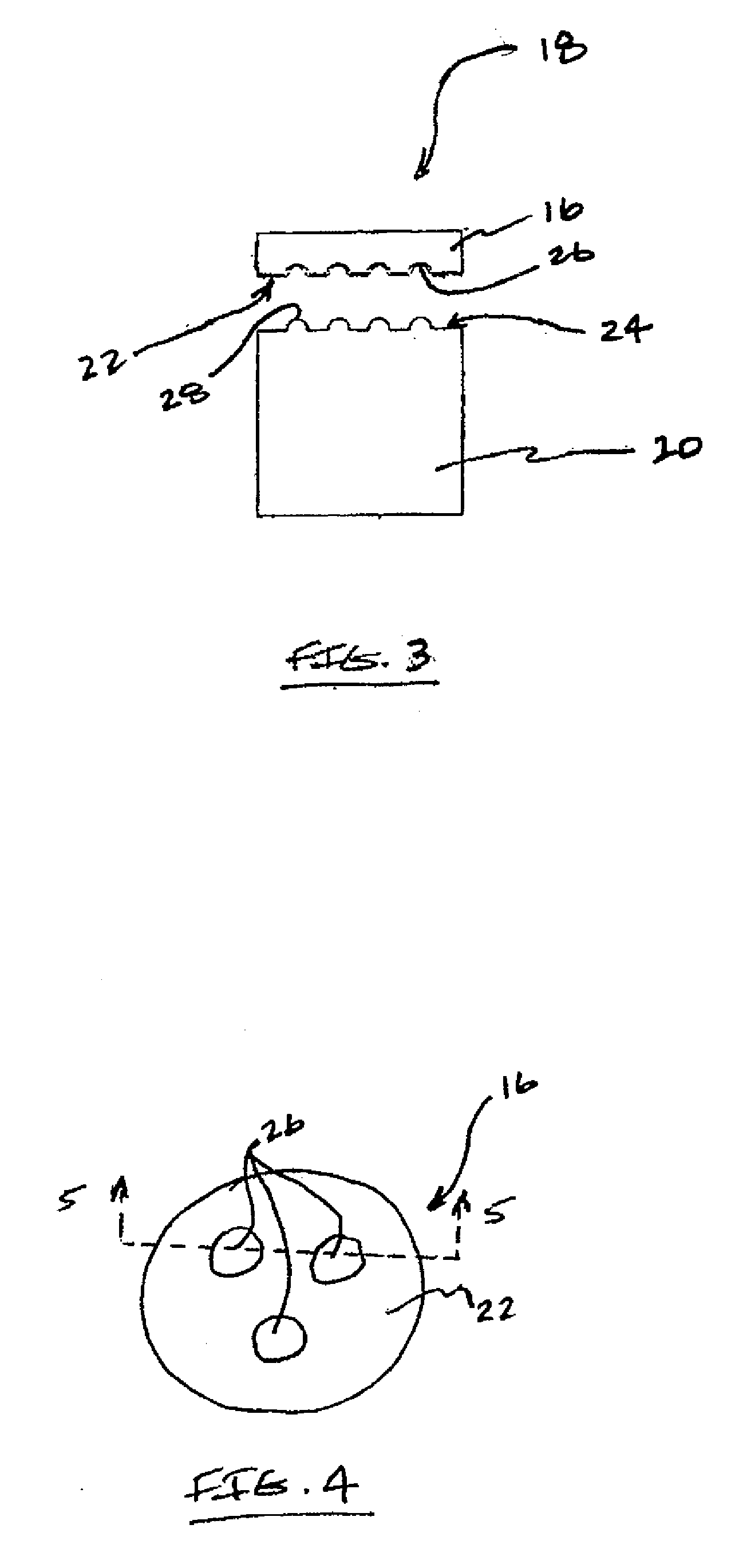

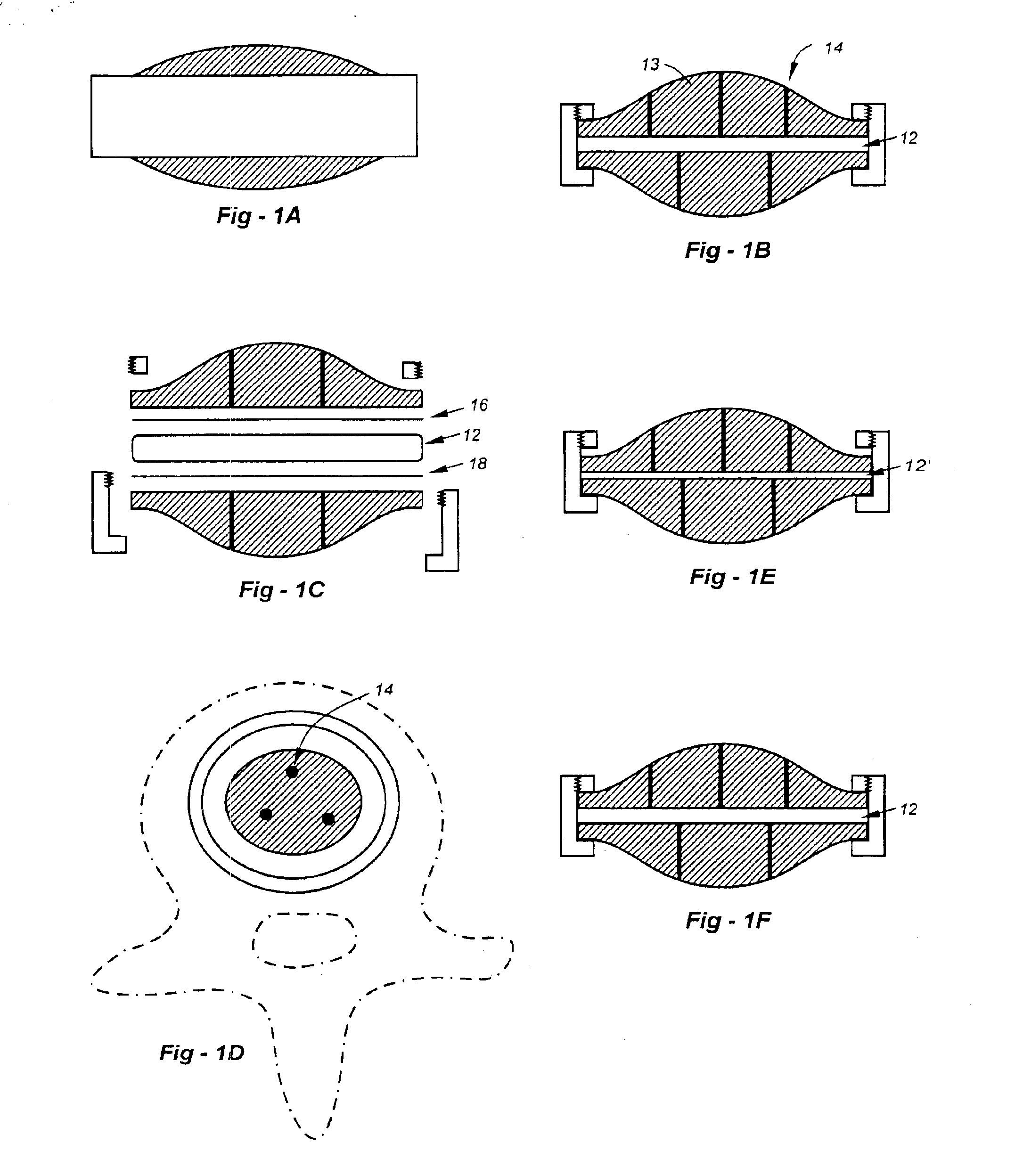

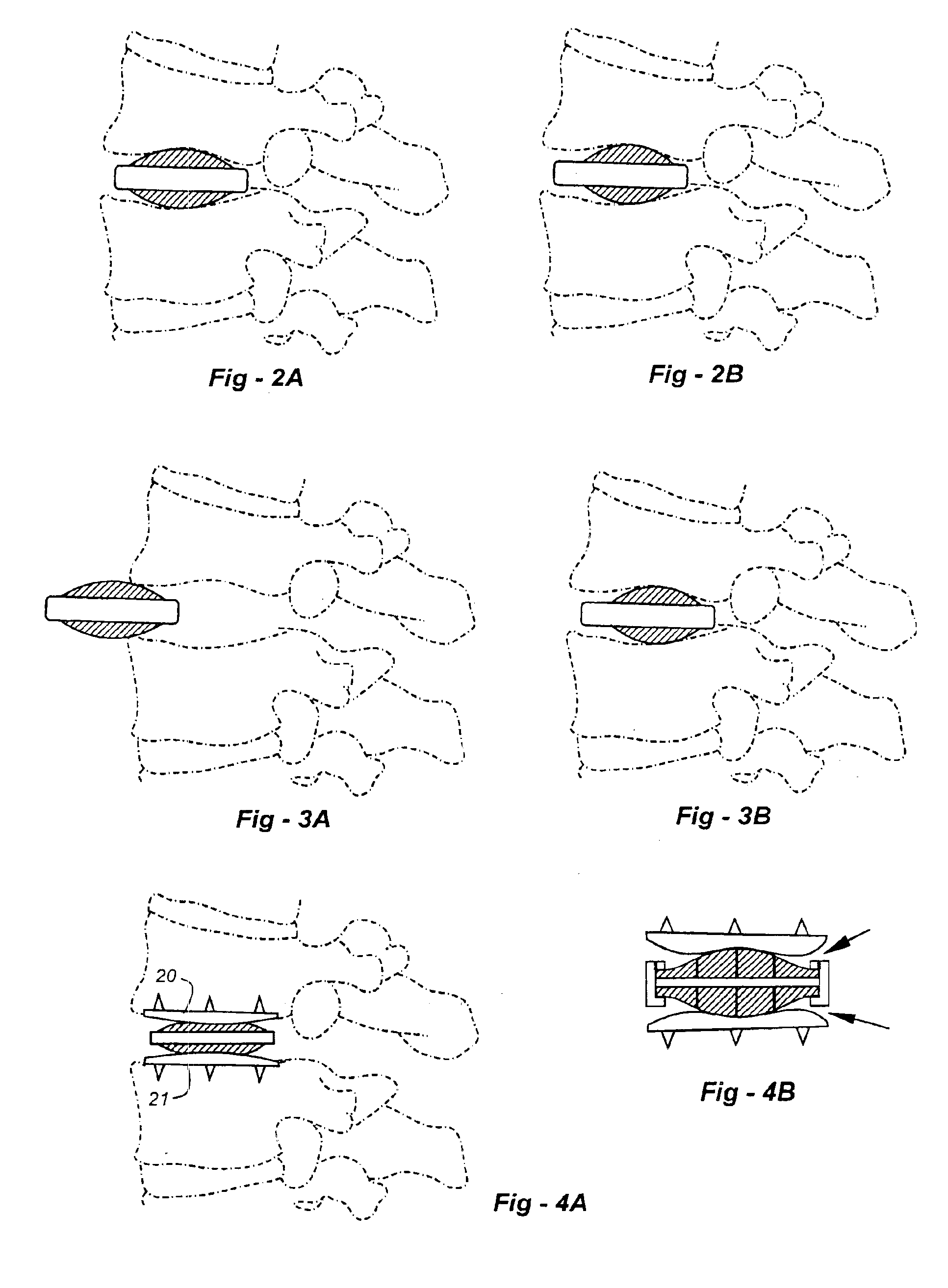

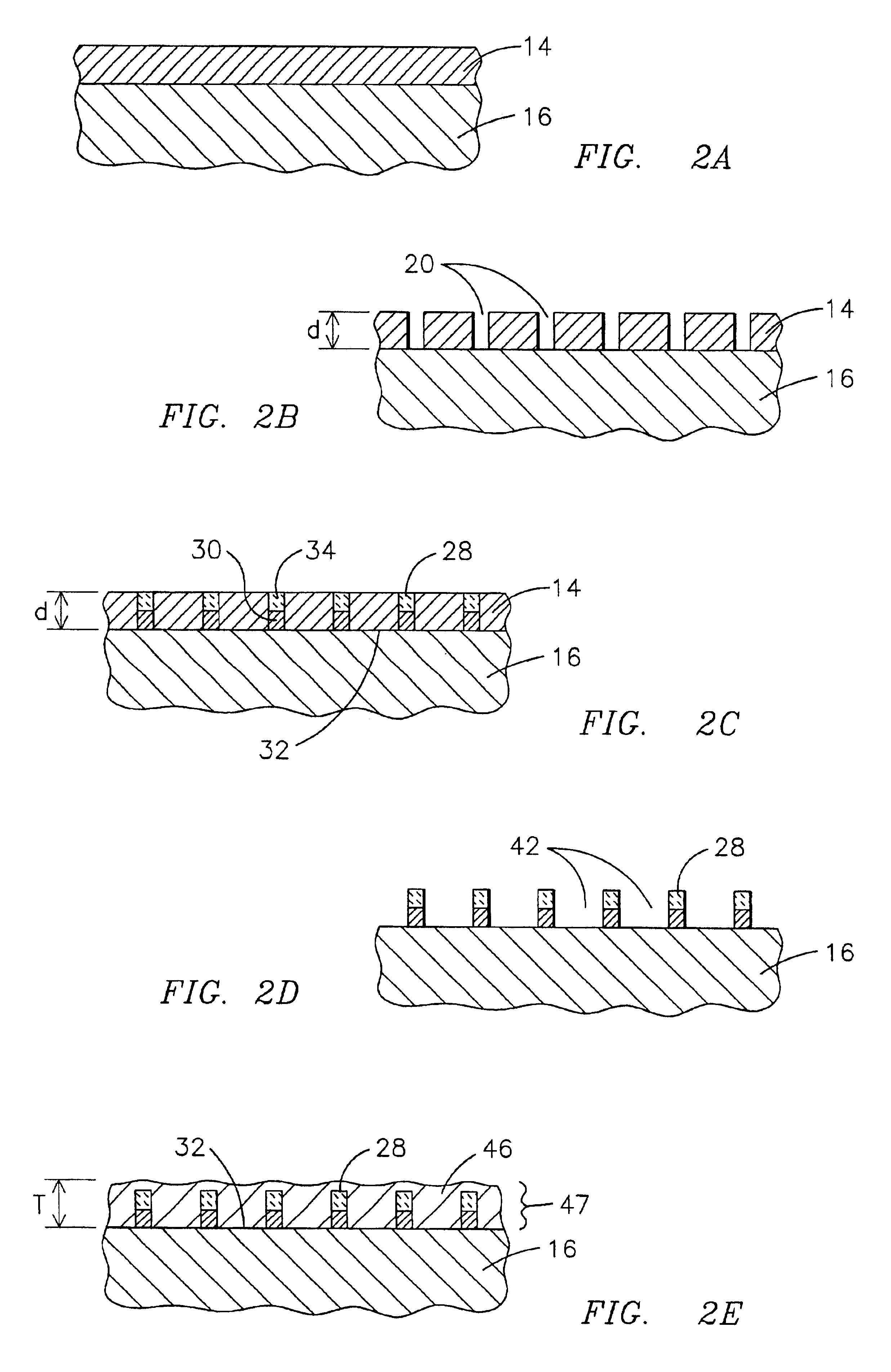

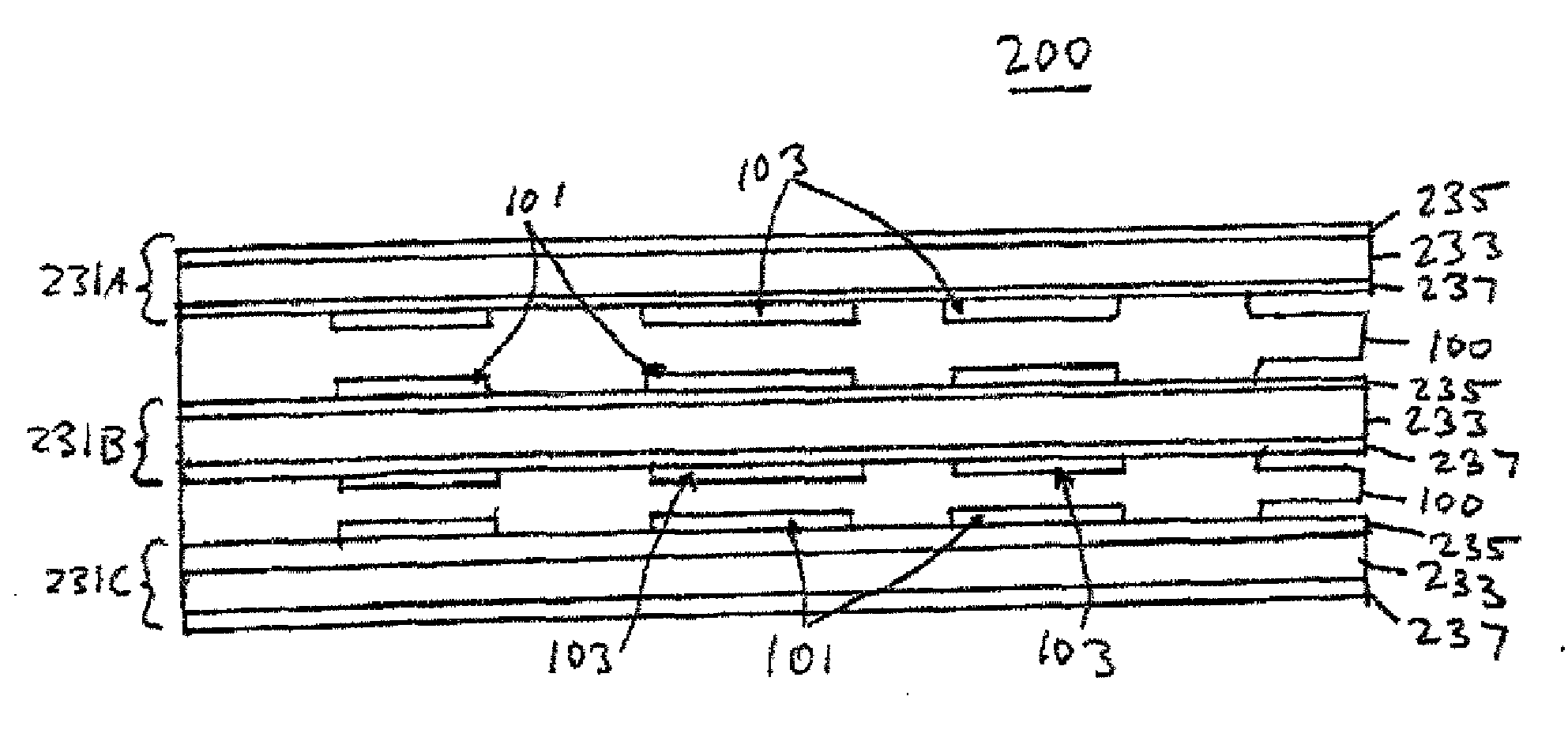

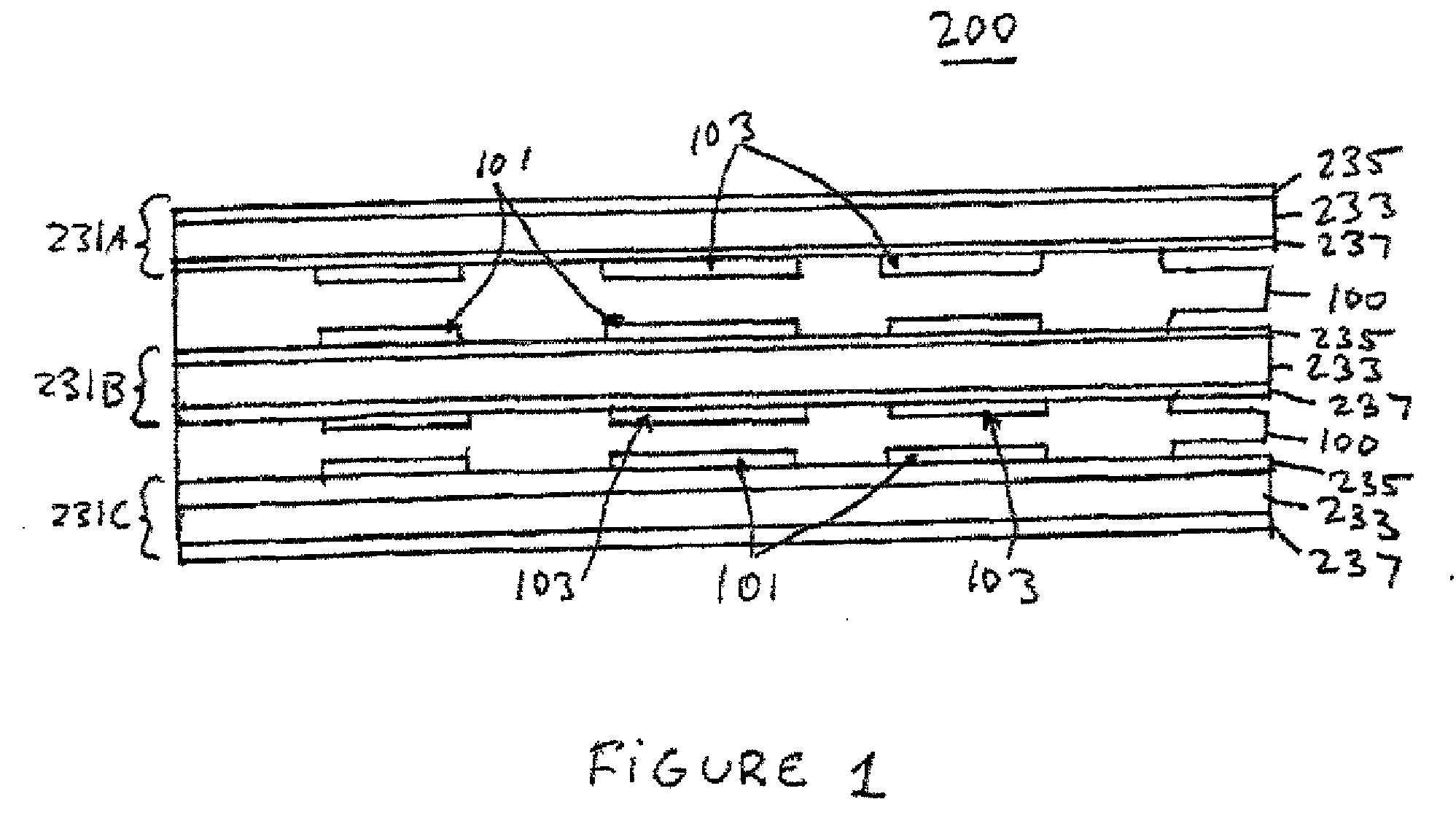

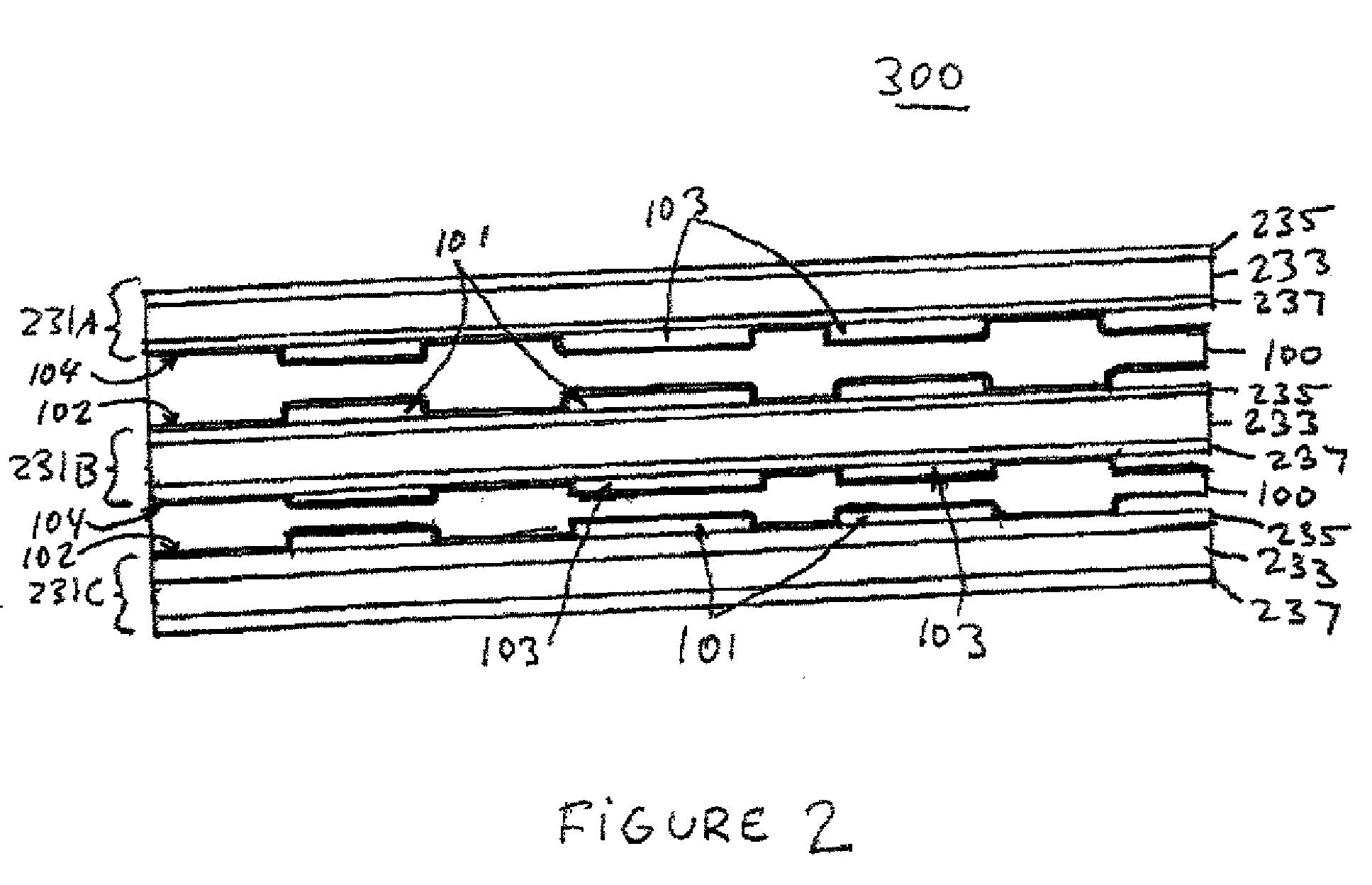

Thermally stable ultra-hard material compact constructions

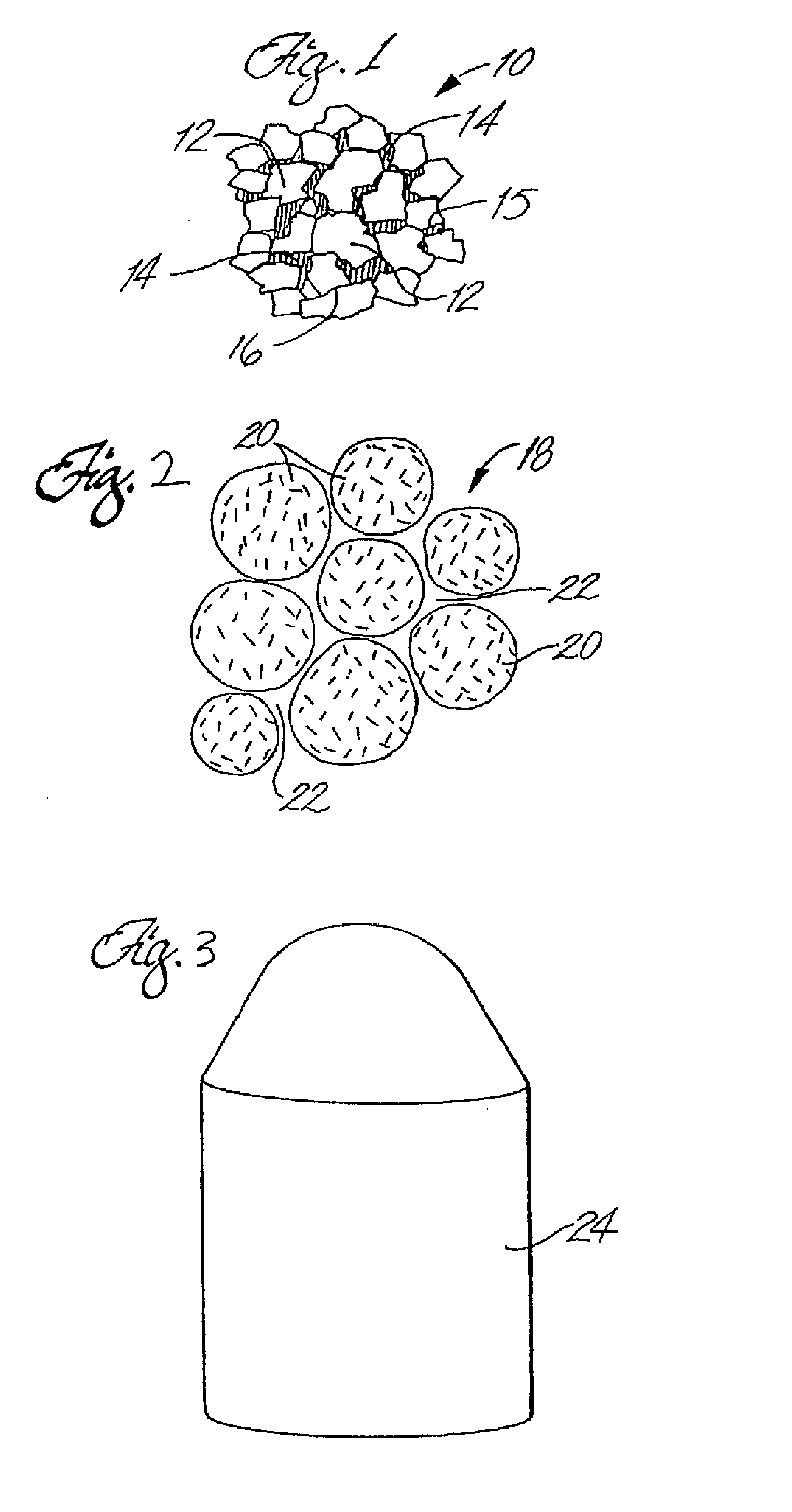

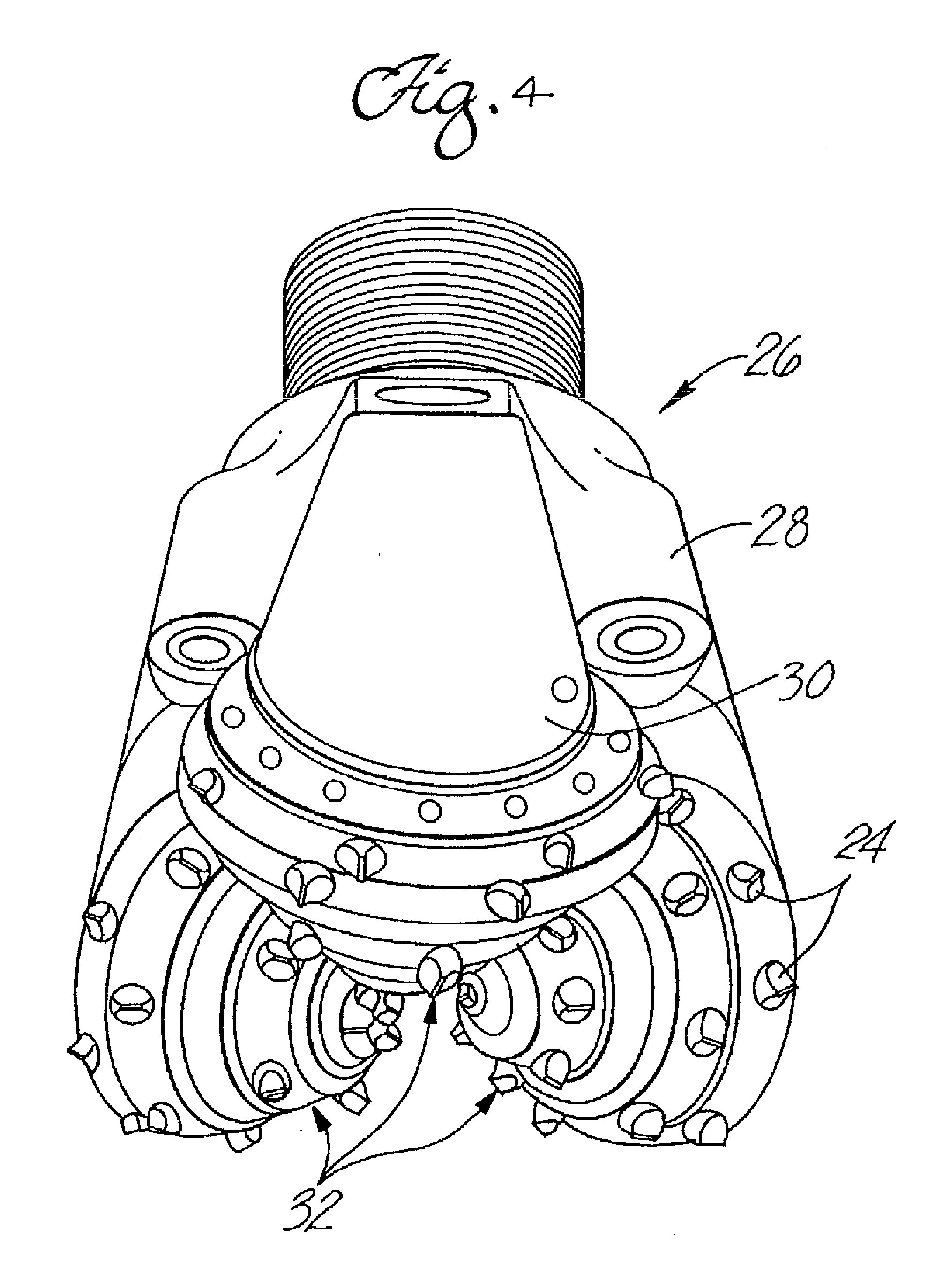

InactiveUS20080142276A1Extend effective lifePigmenting treatmentDrill bitsSuperhard materialPolycrystalline diamond

Thermally stable ultra-hard compact constructions comprise a polycrystalline diamond body substantially free of a catalyst material, and a substrate that is joined thereto. The substrate can be ceramic, metallic, cermet and combinations thereof, and can be joined to the body by a braze material or other material that forms an attachment bond at high pressure / high temperature conditions. The body and substrate are specially formed having complementary interfacing surface features to facilitate providing an improved degree of attachment therebetween. The complementary surface features can in the form of openings and projections, e.g., one of the body or substrate can comprise one or more openings, and the other of the body or substrate can comprise one or more projections, disposed within or extending from respective interfacing surfaces. The complementary surface features operate to resist unwanted delamination between the body and substrate, thereby extending effective service life of the construction.

Owner:SMITH INT INC

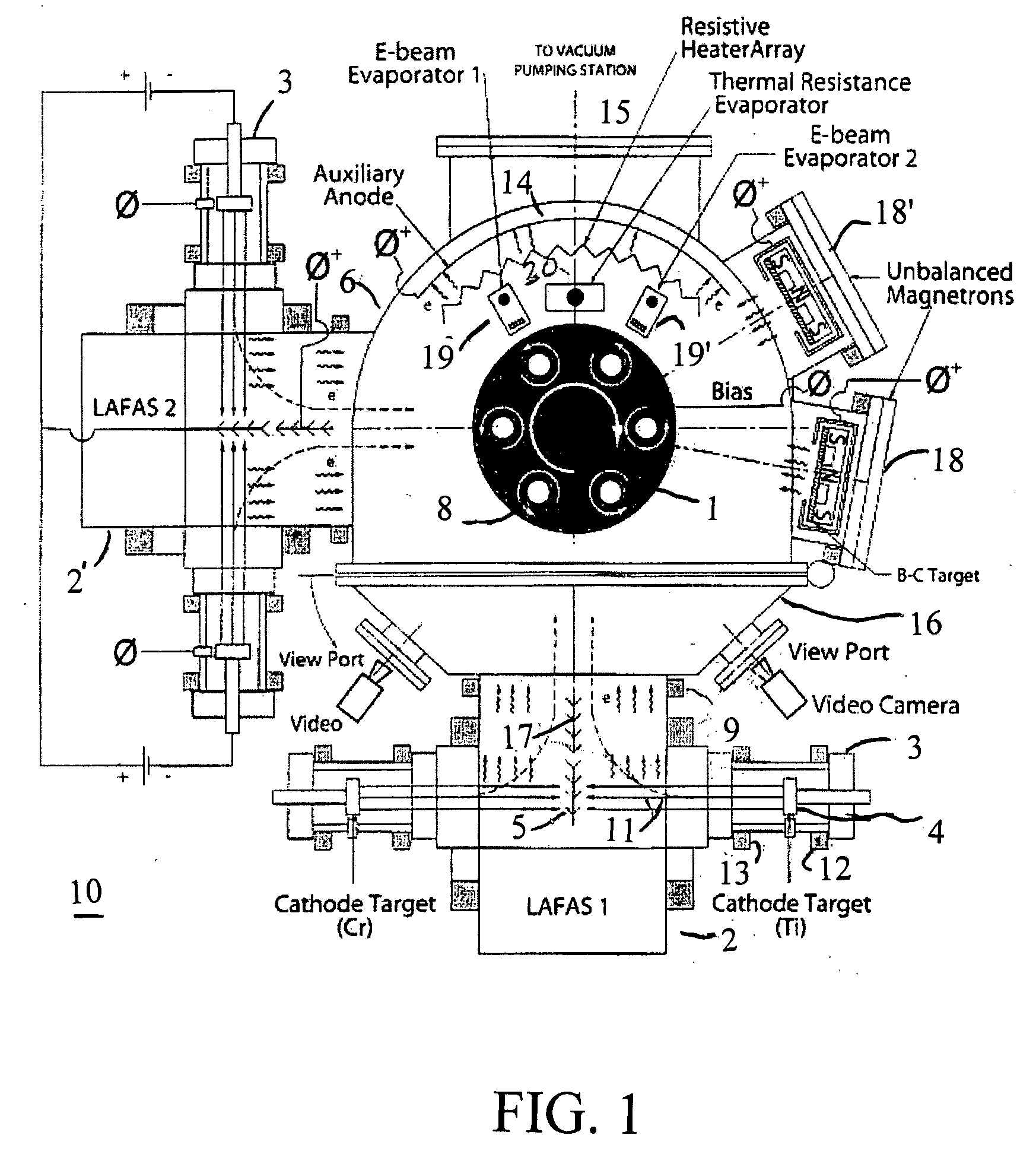

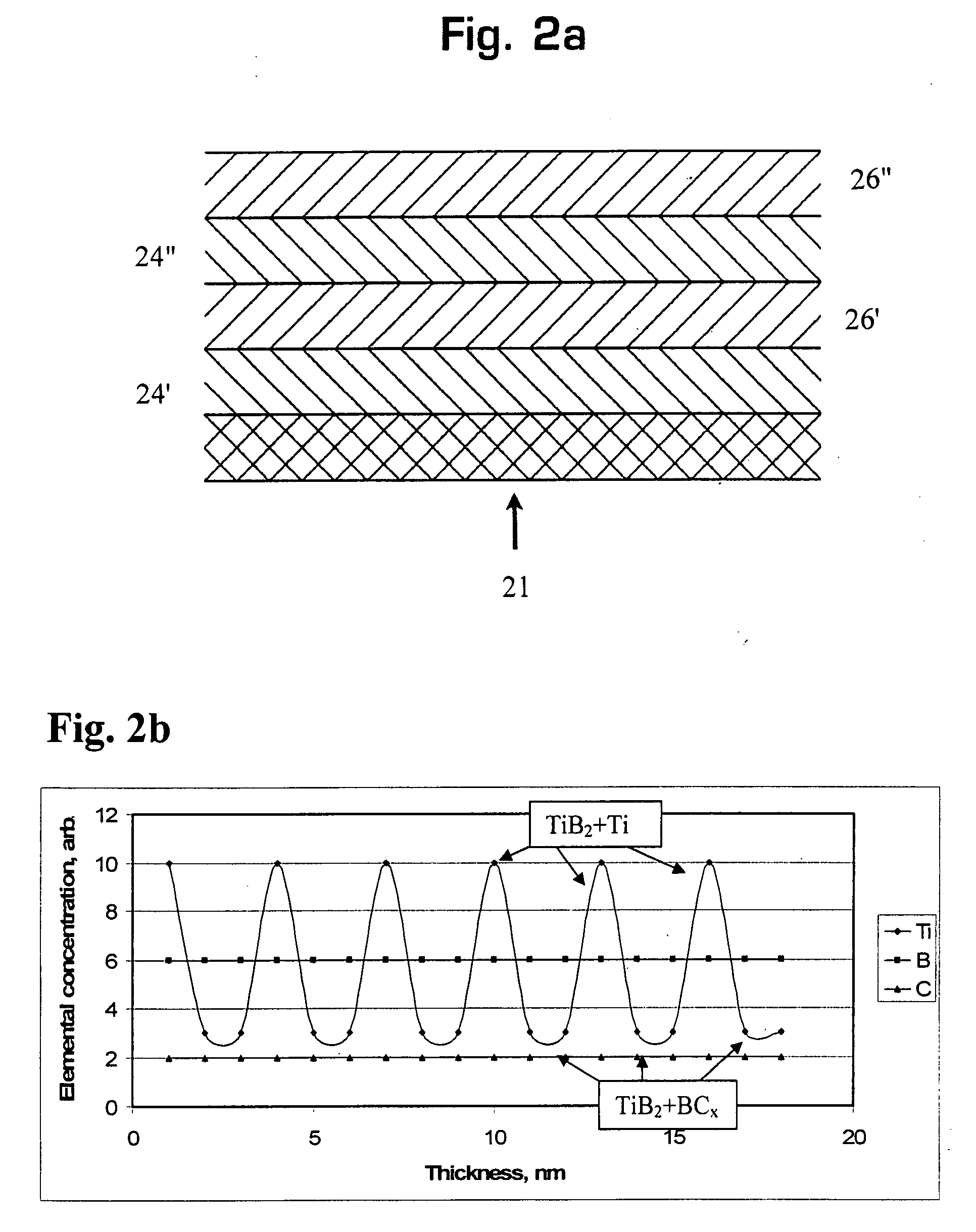

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

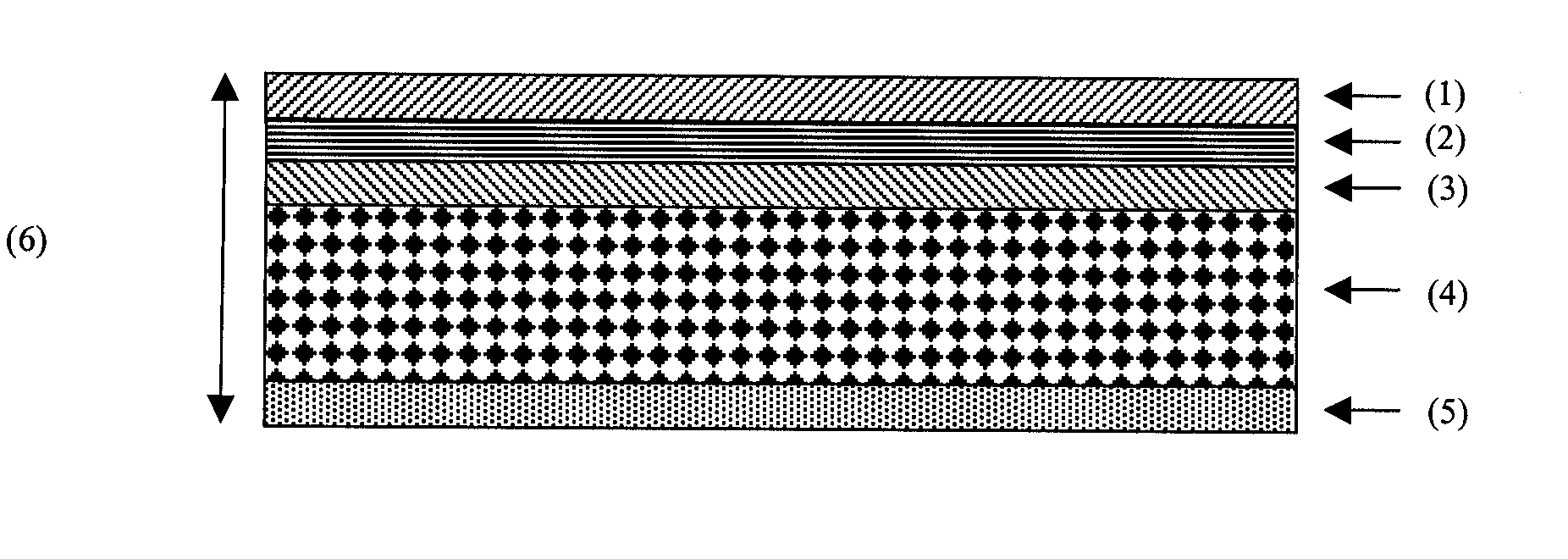

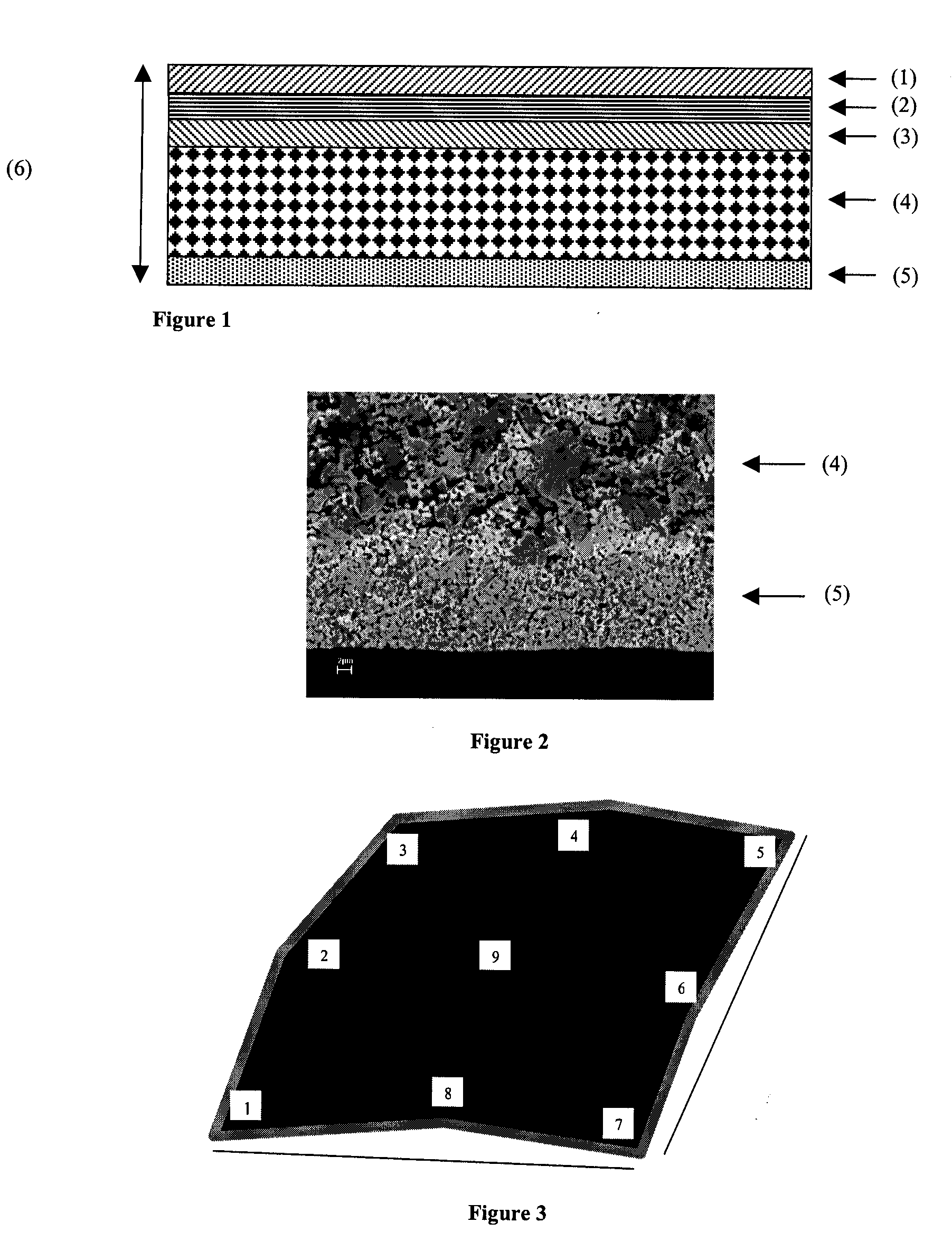

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

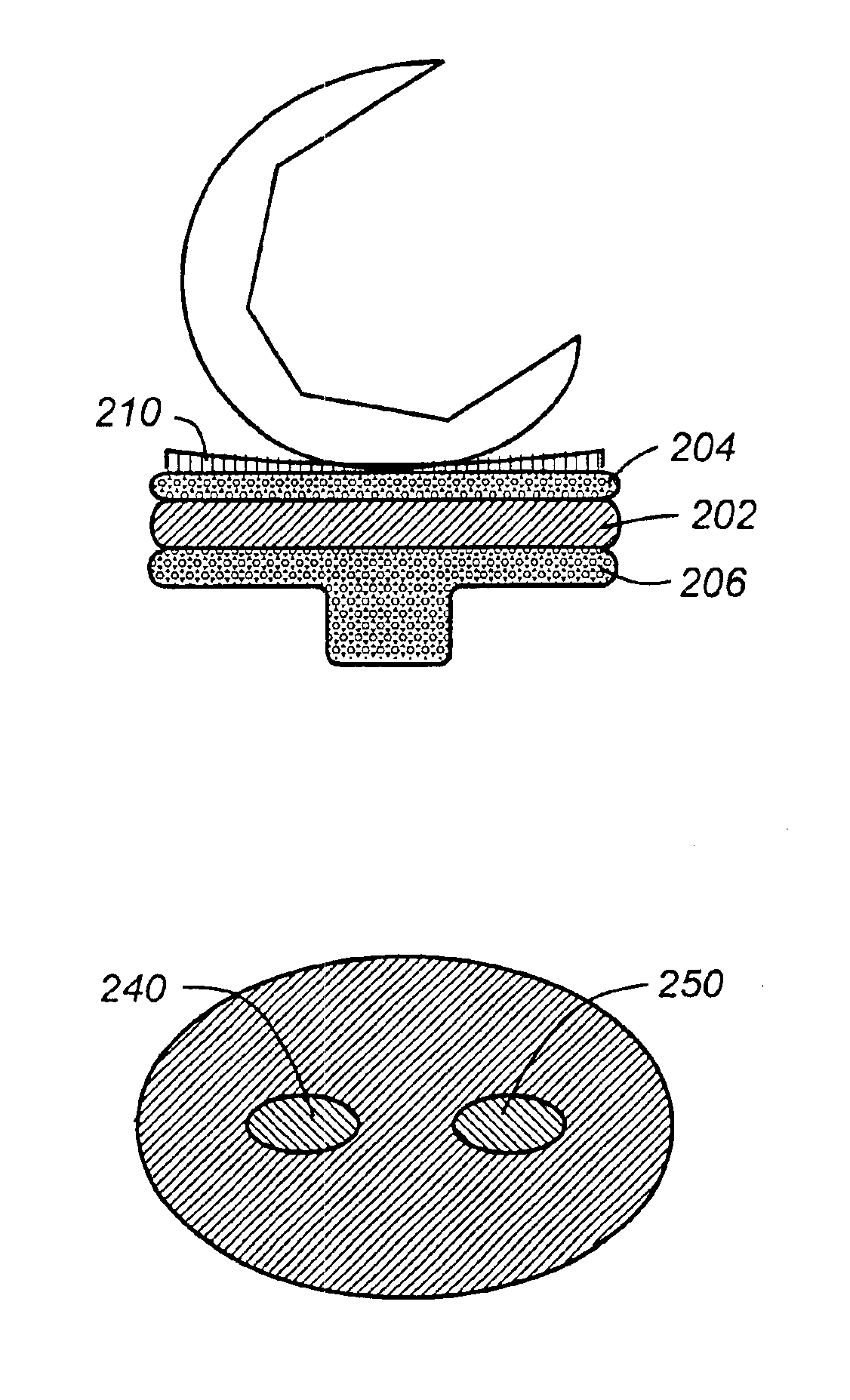

Prosthetic joints with contained compressible resilient members

InactiveUS6875235B2Improve protectionEliminate shear stressInternal osteosythesisJoint implantsElastomerTotal knee replacement

In a total knee replacement (TKR), the use of a cushion element provides better wear characteristics than polyethylene (“poly”) alone. Since a metal-on-metal, metal-on-ceramic, or ceramic-on-ceramic articulating surface has better wear characteristics than metal on poly, the invention essentially provides cushioning for metal / ceramic-on-metal / ceramic joint replacements. It also allows the use of elastomers for their cushioning properties rather than their surface wear and tensile strength characteristics. The contained compressible elements could also be used as a cushion below polyethylene components, polyethylene over metal components, unicondylar knee replacements, patellar components, and prosthetic components for other parts of the body, including the hip, elbow, shoulder, wrist, and ankle.

Owner:ANOVA

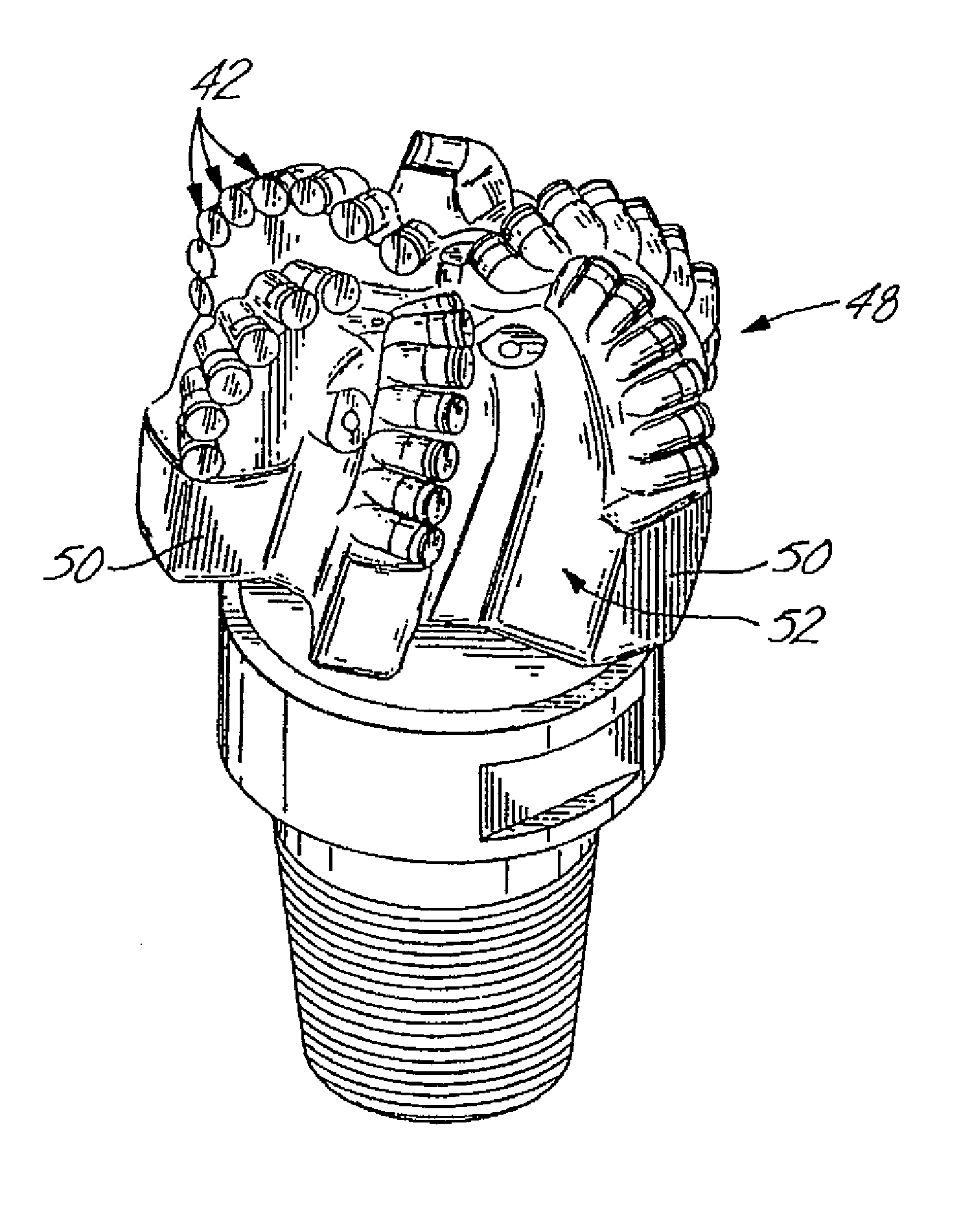

Polycrystalline diamond carbide composites

InactiveUS20070193782A1Improve fracture toughnessEasy to useDrill bitsOther chemical processesPolycrystalline diamondCarbide

Owner:SMITH INT INC

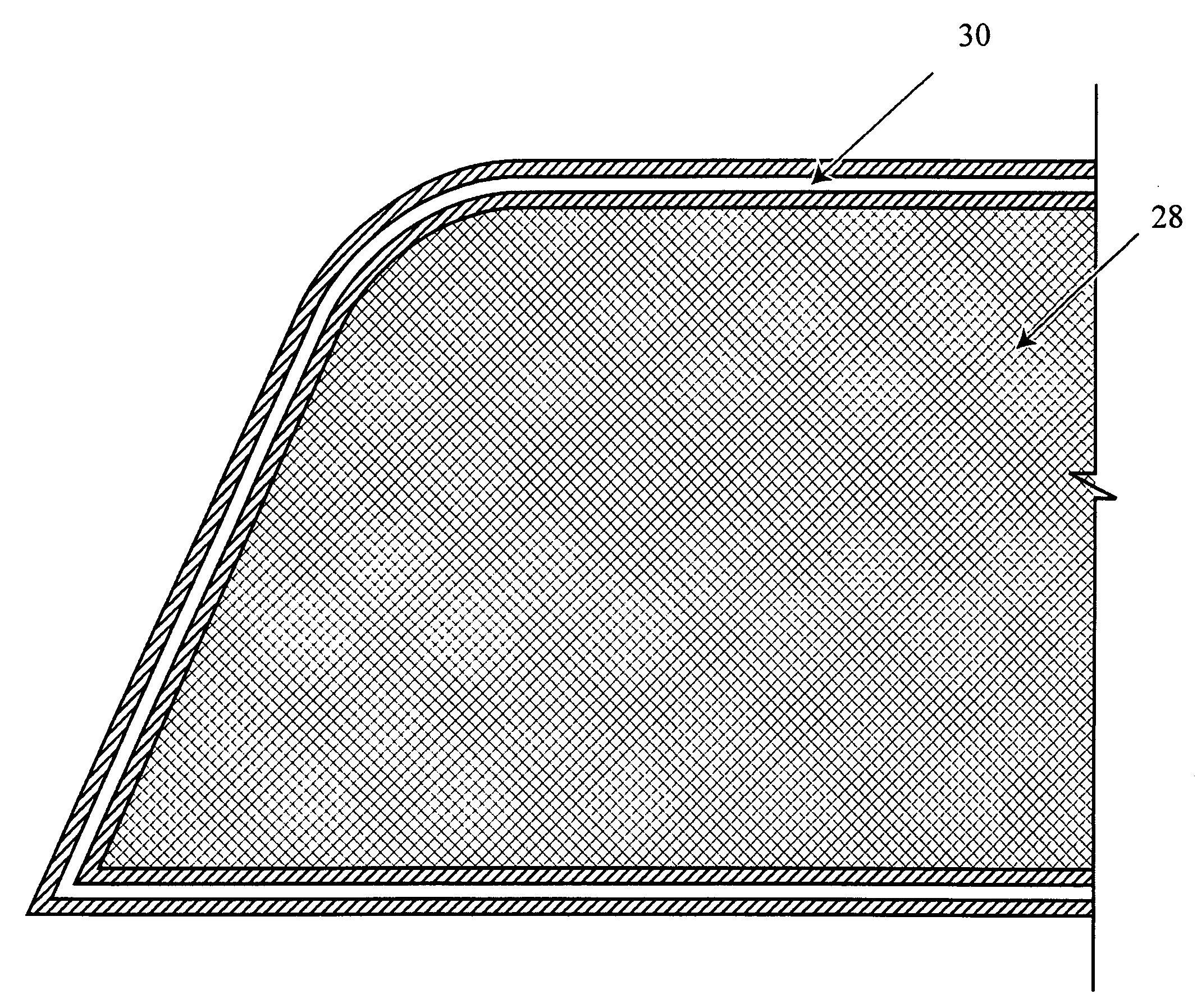

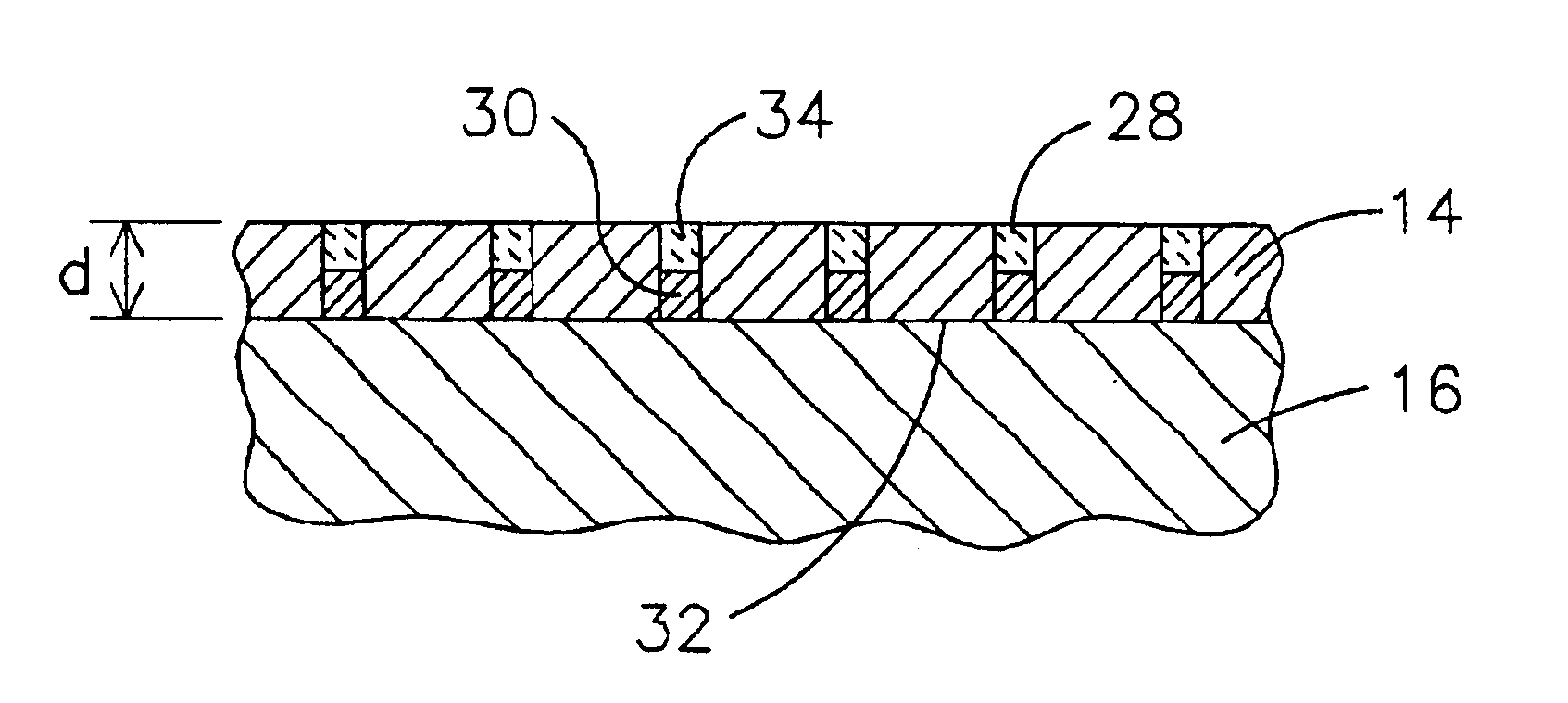

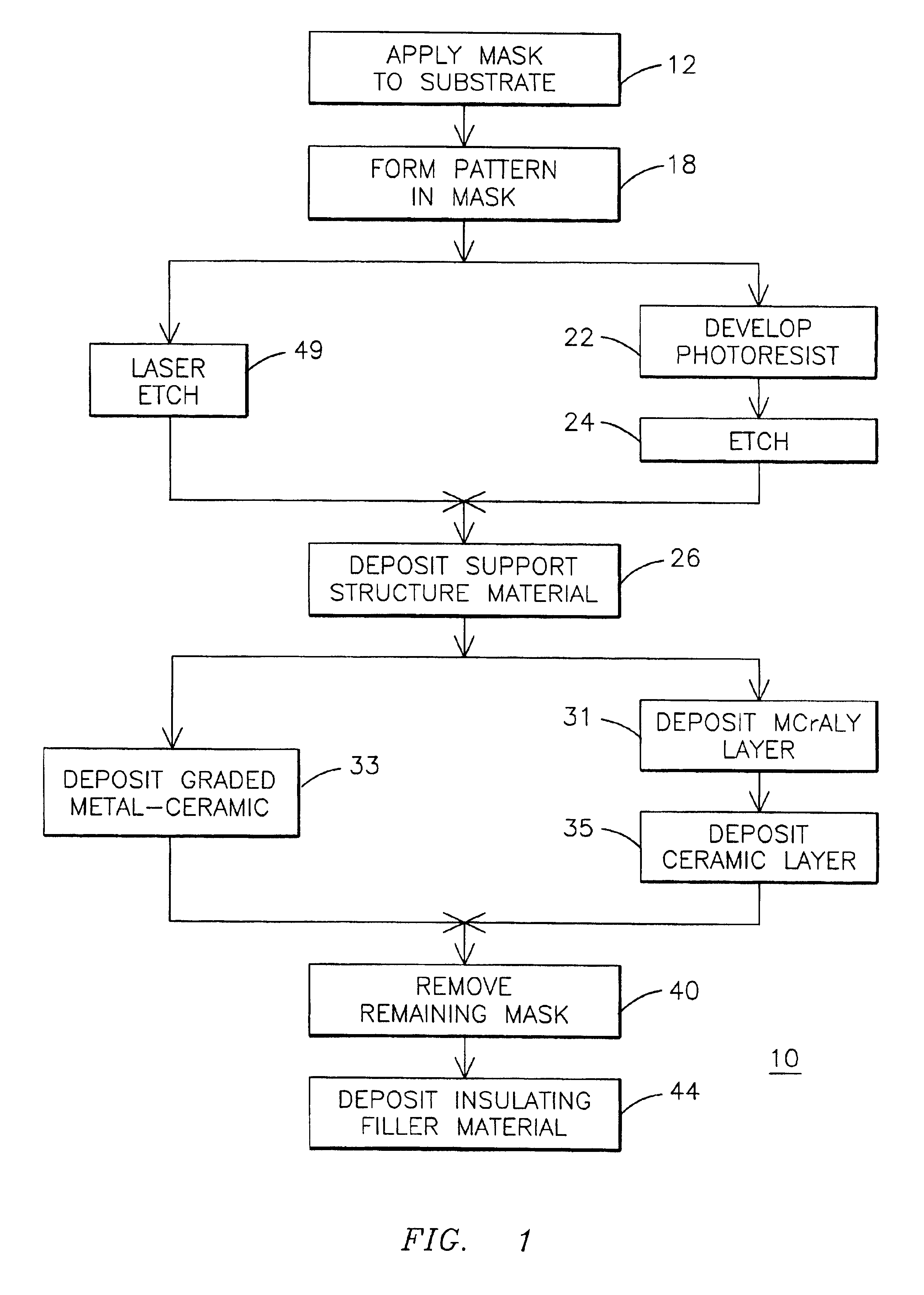

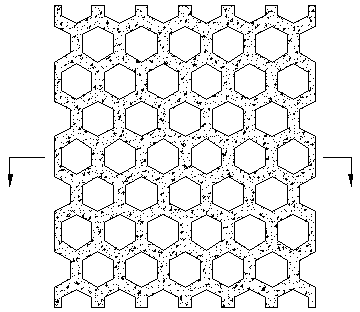

Honeycomb structure thermal barrier coating

InactiveUS6846574B2Minimize heat transfer rateConvenient coatingMolten spray coatingRecord information storageForeign matterLaser etching

A device having an improved thermal barrier coating (46) and a process for manufacturing the same. A support structure (28) for retaining a ceramic insulating material (46) on a substrate (16) is formed by the deposition of a support structure material through a patterned masking material (14). The support structure can define cells into which the ceramic insulating material is deposited following removal of the masking material. The masking material may be patterned by known photolithographic techniques (22,24) or by laser etching (48). The support structure (28) may be a composite metal-ceramic material having either discreet layers (30,34) or a graded composition and may be deposited by an electro-desposition process followed by a heat treatment to form a solid state diffusion bond with the substrate. The ceramic filler material may be deposited (44) by the electrophoretic deposition of ceramic particles coated with a bonding material that is subsequently heated to oxidize and to bond the particles together. The support structure may be provided with included walls in order to improve its resistance to foreign object impact damage.

Owner:SIEMENS ENERGY INC

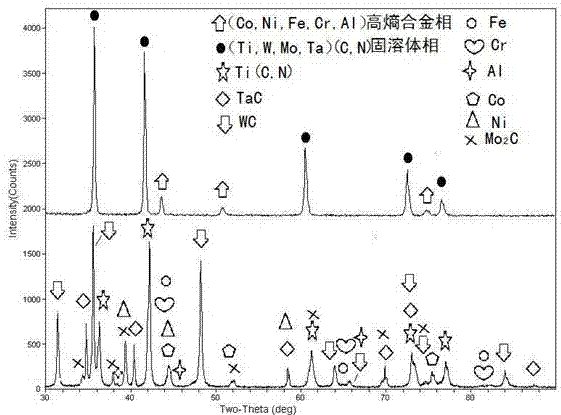

Titanium carbonitride based metal ceramic based on high-entropy alloy binder phase and preparation method of metal ceramic

InactiveCN102787266AImprove corrosion resistanceImprove wear resistanceRare-earth elementHigh entropy alloys

Disclosed is a titanium carbonitride based metal ceramic material based on a high-entropy alloy binder phase. The binder phase of the titanium carbonitride based metal ceramic material is high-entropy alloy, the hard phase of the titanium carbonitride based metal ceramic material is carbonitride solid solution, the high-entropy alloy binder phase includes at least four of ferrum, cobalt, nickel, chromium, aluminum, vanadium, titanium, copper, zirconium, molybdenum, manganese and rare earth elements, and the molar content ratio of each element ranges from 5% to 35%. In a preparation method, the titanium carbonitride based metal ceramic material based on the high-entropy alloy binder phase comprises raw materials including, in weight percent, 3-30% of the high-entropy alloy binder phase, 0-30% of second carbide powder and the balance carbonitride solid solution powder, the carbonitride solid solution powder includes at least one of Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x), the M1 component of the (Ti, M1...) and (Cx, N1-x) includes at least one of W, Mo, Ta, Nb, V, Cr, Zr, Hf, Y and lanthanide, and 0<x<1 in the Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x). The preparation method includes the process steps of (1) ball-milling mixing, (2) forming and (3) low-pressure sintering.

Owner:SICHUAN UNIV

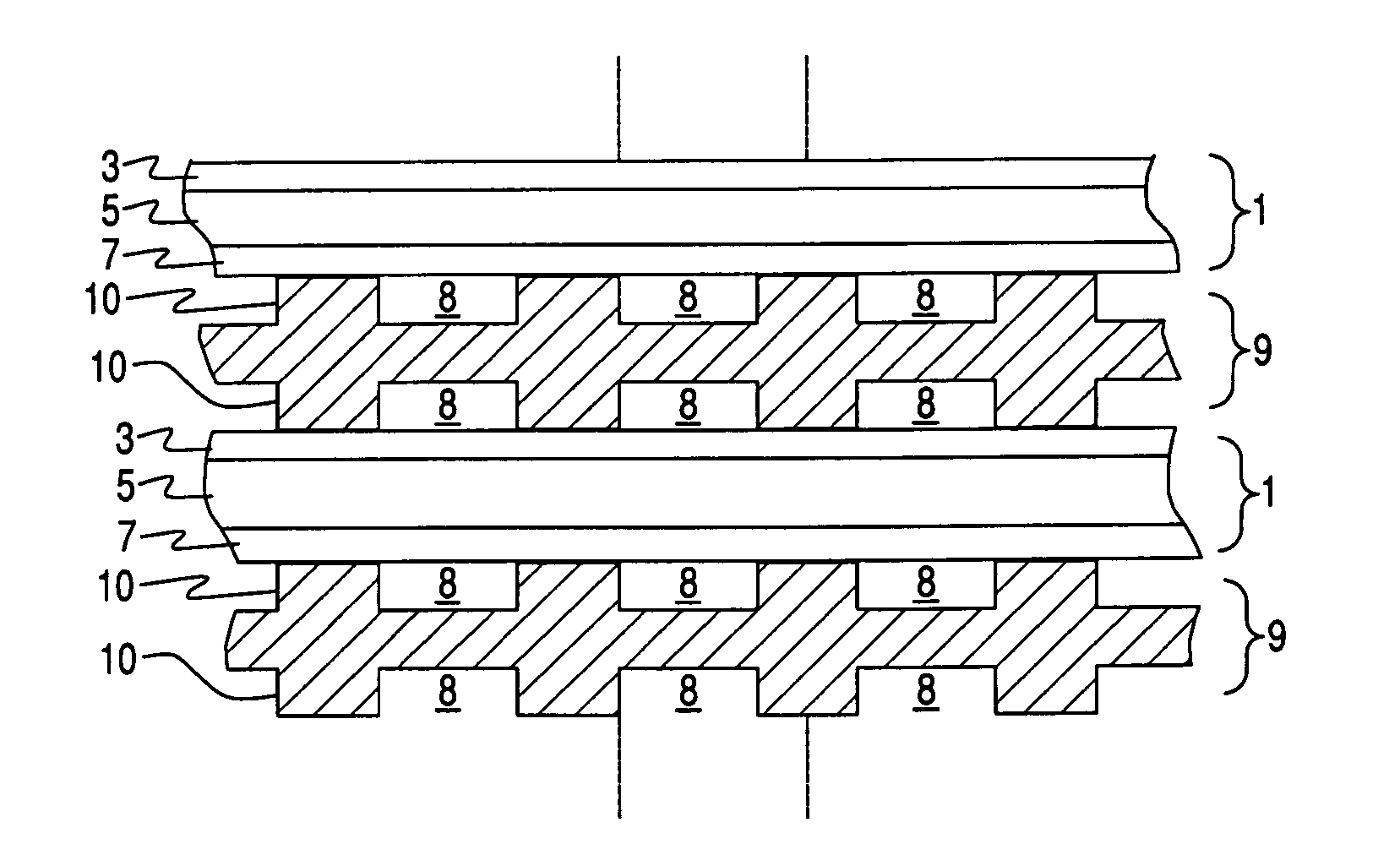

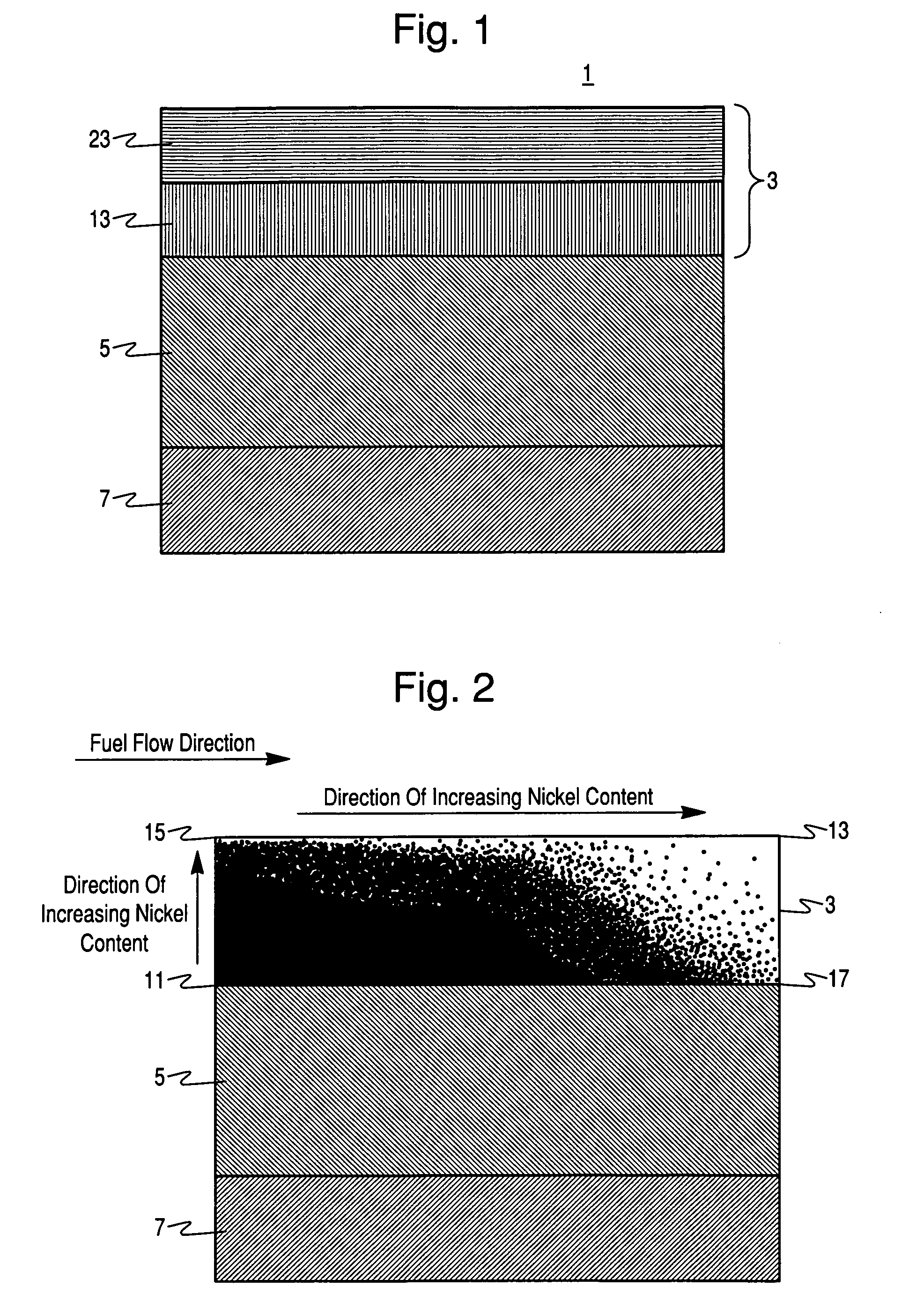

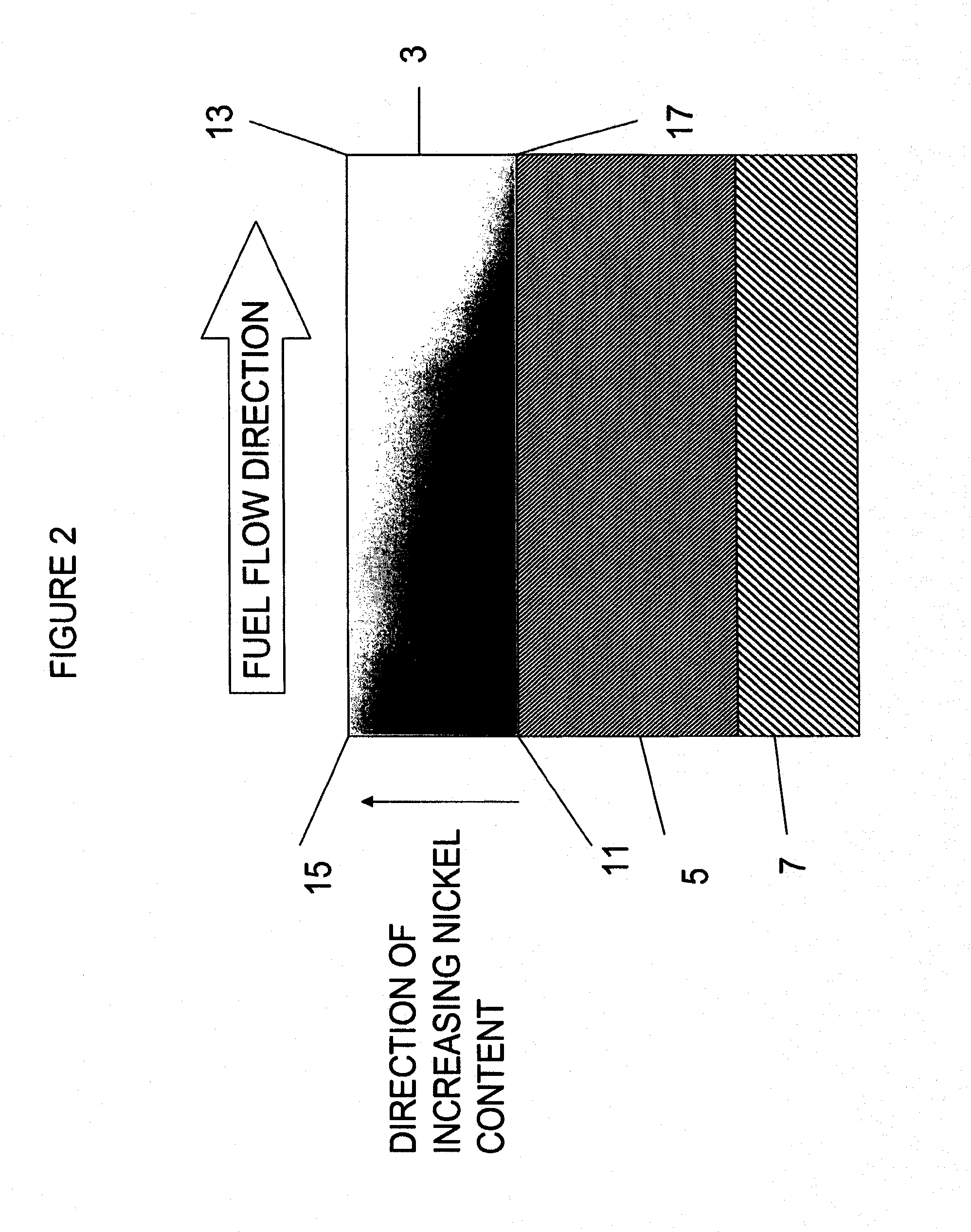

Anode with remarkable stability under conditions of extreme fuel starvation

A solid oxide fuel cell (SOFC) includes a cathode electrode, a solid oxide electrolyte, and an anode electrode having a first portion and a second portion, such that the first portion is located between the electrolyte and the second portion. The anode electrode comprises a cermet comprising a nickel containing phase and a ceramic phase. The first portion of the anode electrode contains a lower porosity and a lower ratio of the nickel containing phase to the ceramic phase than the second portion of the anode electrode.

Owner:BLOOM ENERGY CORP

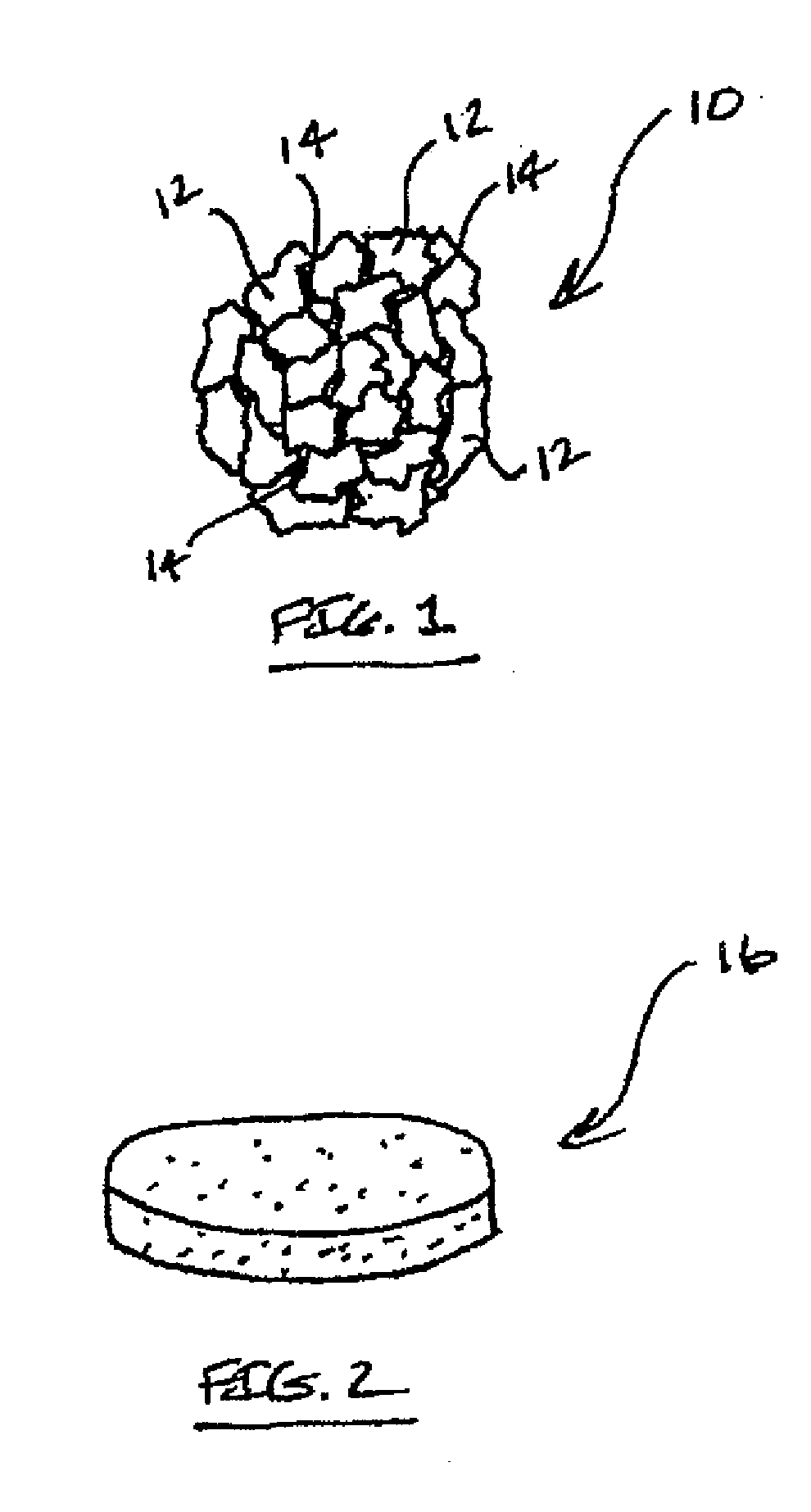

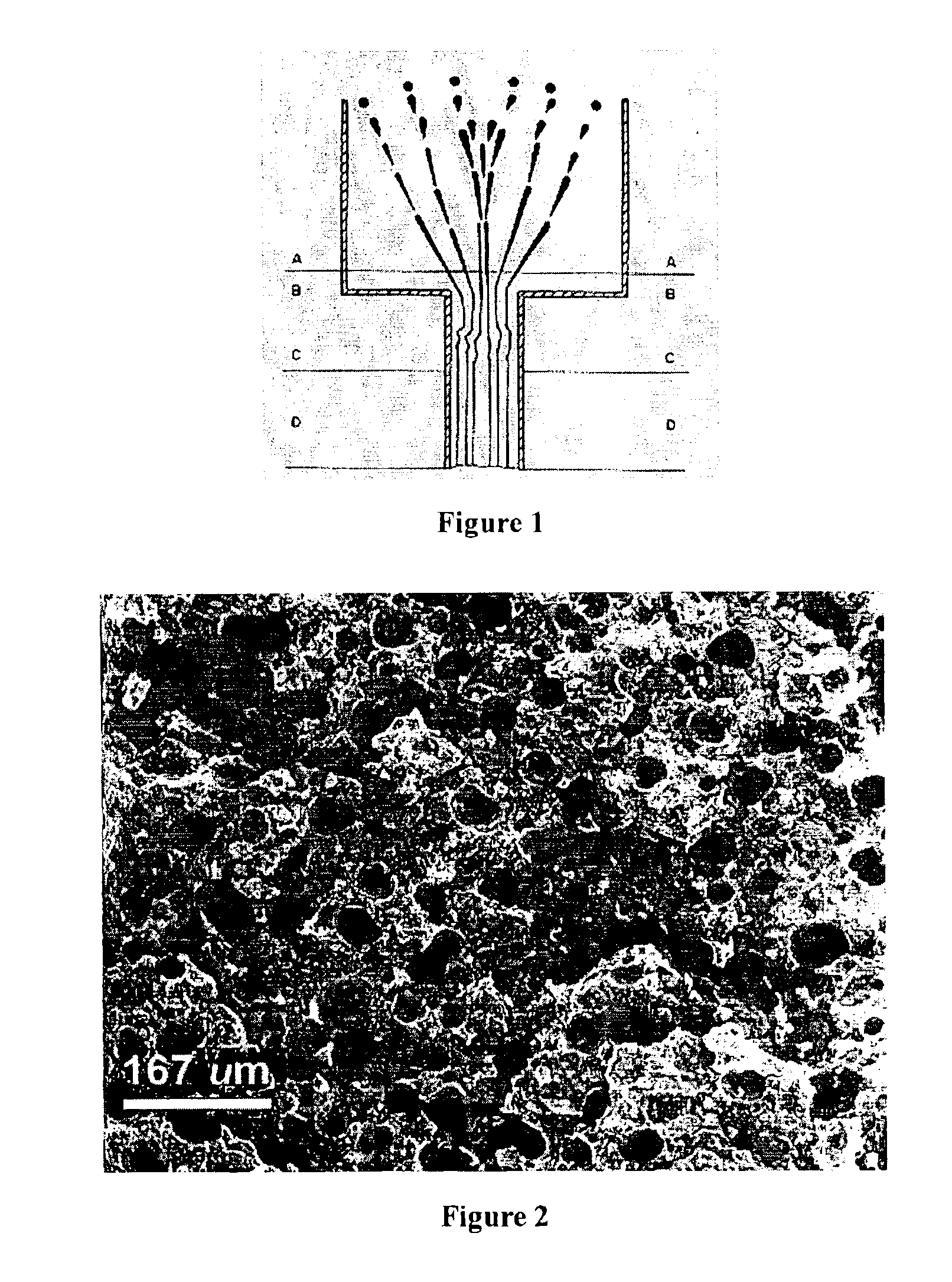

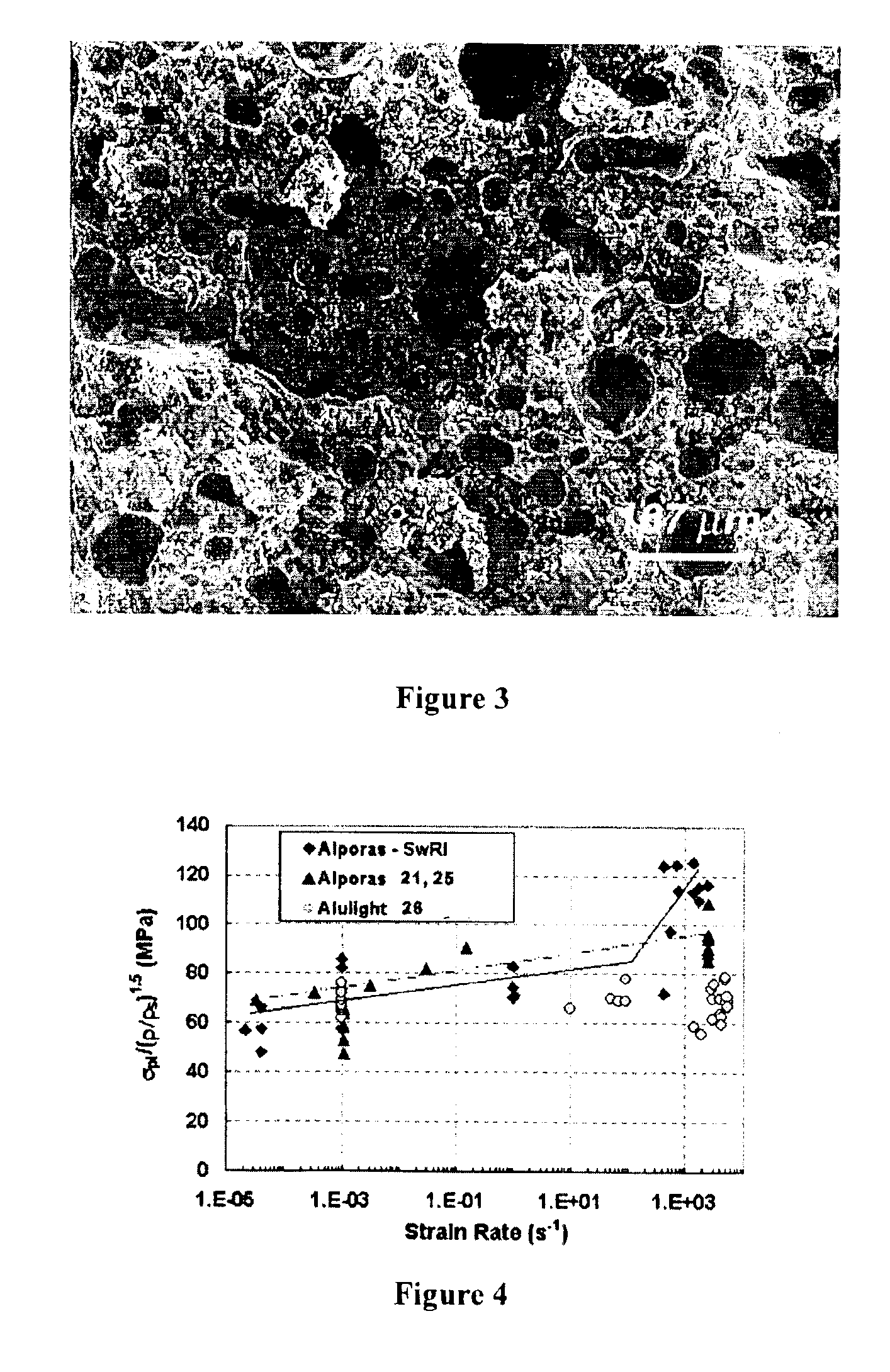

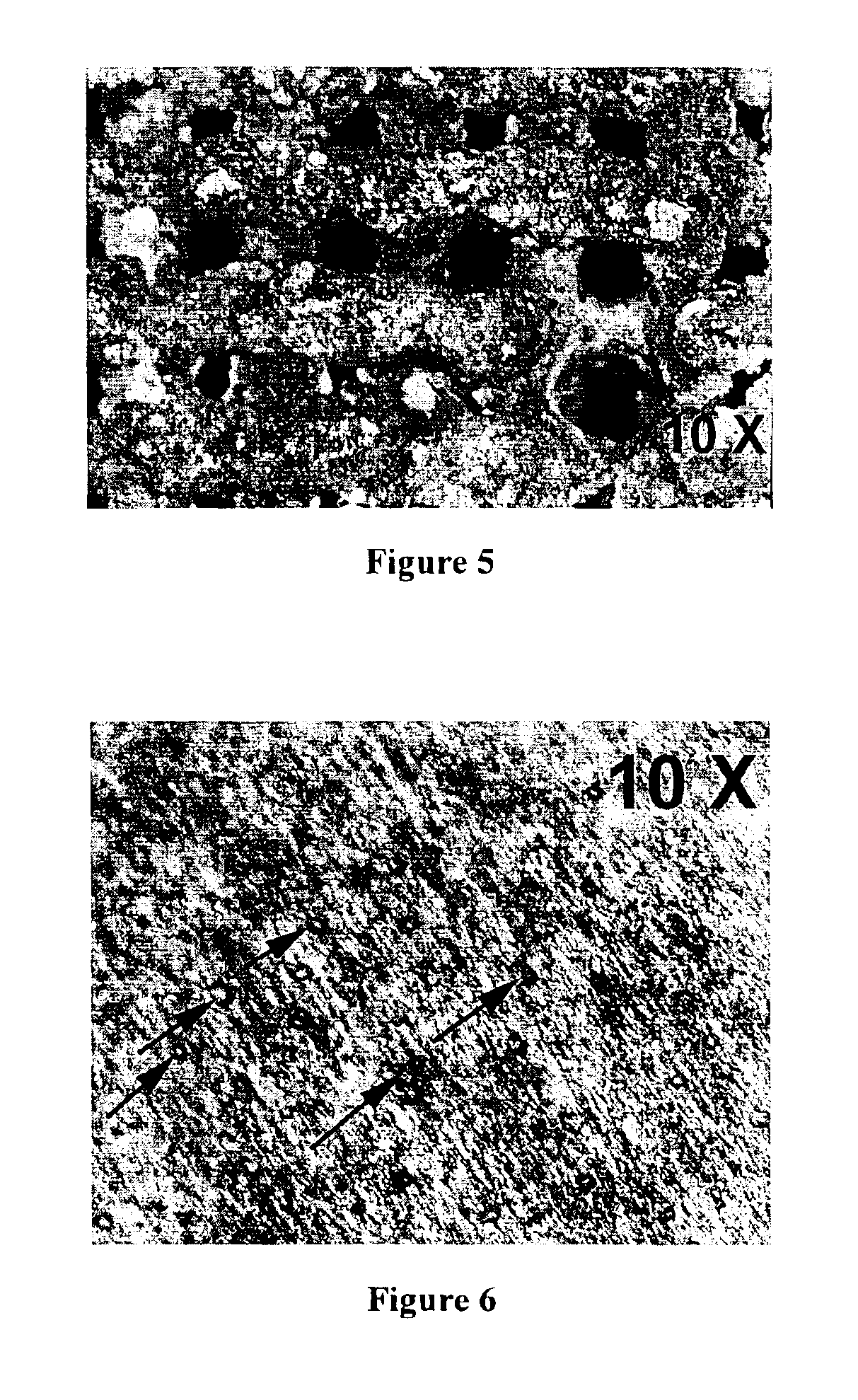

Method for preparation of metallic and ceramic foam products and products made

InactiveUS6852272B2Efficient and cost-effectiveImprove mechanical propertiesAdditive manufacturing apparatusTransportation and packagingEnergy absorptionMechanical property

The present invention relates to the fabrication of low cost, in situ, porous metallic, ceramic and cermet foam structures having improved mechanical properties such as energy absorption and specific stiffness. Methods of fabricating the structures from compositions including ceramic and / or metallic powders are provided. The flowable compositions also include an immiscible phase that results in pores within the final structure. Furthermore, the structures may be shaped to have external porosity, such as with mesh-like structures.

Owner:ADVANCED CERAMICS

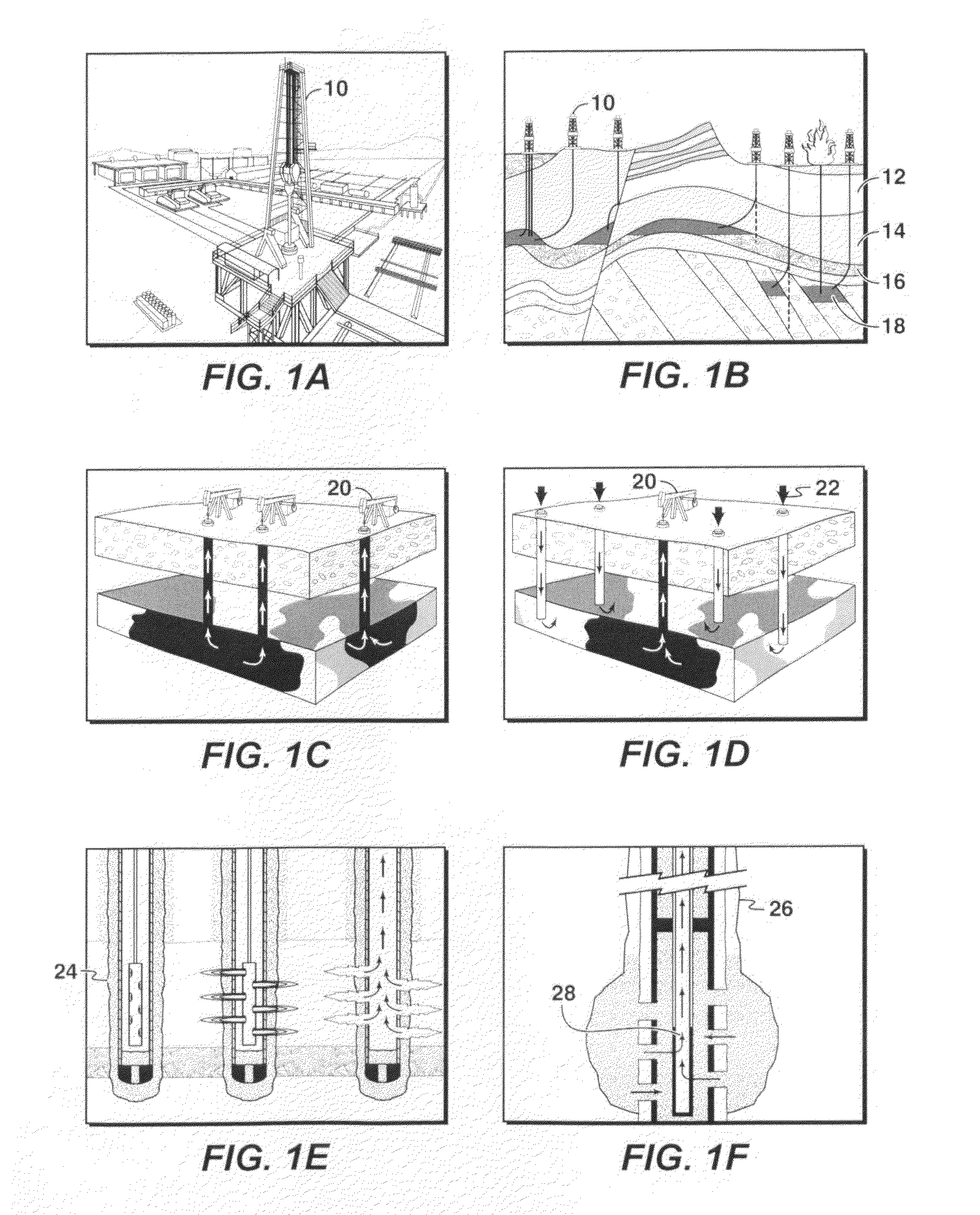

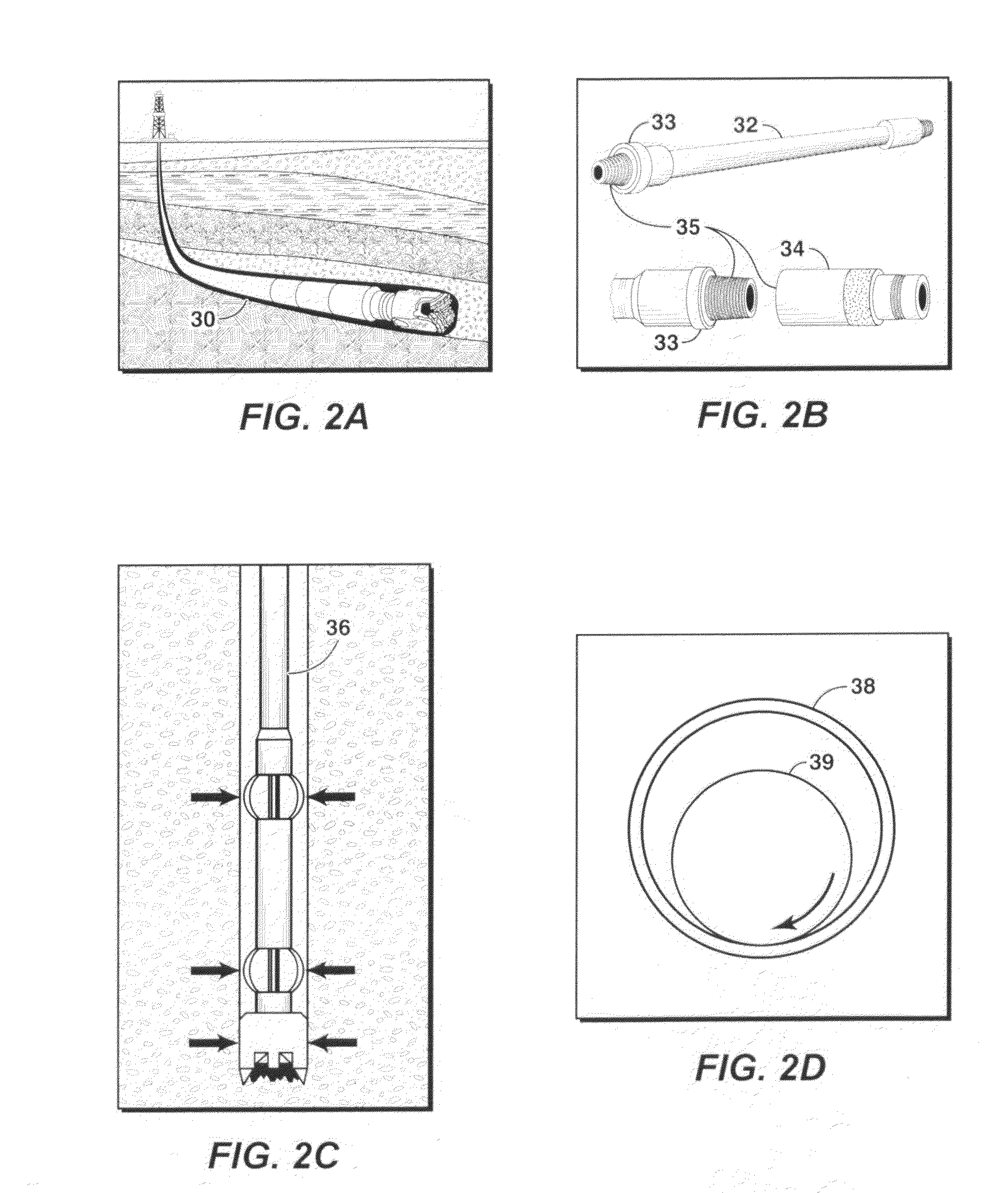

Coated sleeved oil and gas well production devices

Provided are coated sleeved oil and gas well production devices and methods of making and using such coated sleeved devices. In one form, the coated sleeved oil and gas well production device includes an oil and gas well production device including one or more bodies and one or more sleeves proximal to the outer or inner surface of the one or more bodies, and a coating on at least a portion of the inner sleeve surface, outer sleeve surface, or a combination thereof, wherein the coating is chosen from an amorphous alloy, a heat-treated electroless or electro plated based nickel-phosphorous composite with a phosphorous content greater than 12 wt %, graphite, MoS2, WS2, a fullerene based composite, a boride based cermet, a quasicrystalline material, a diamond based material, diamond-like-carbon (DLC), boron nitride, and combinations thereof. The coated sleeved oil and gas well production devices may provide for reduced friction, wear, erosion, corrosion, and deposits for well construction, completion and production of oil and gas.

Owner:EXXONMOBIL UPSTREAM RES CO

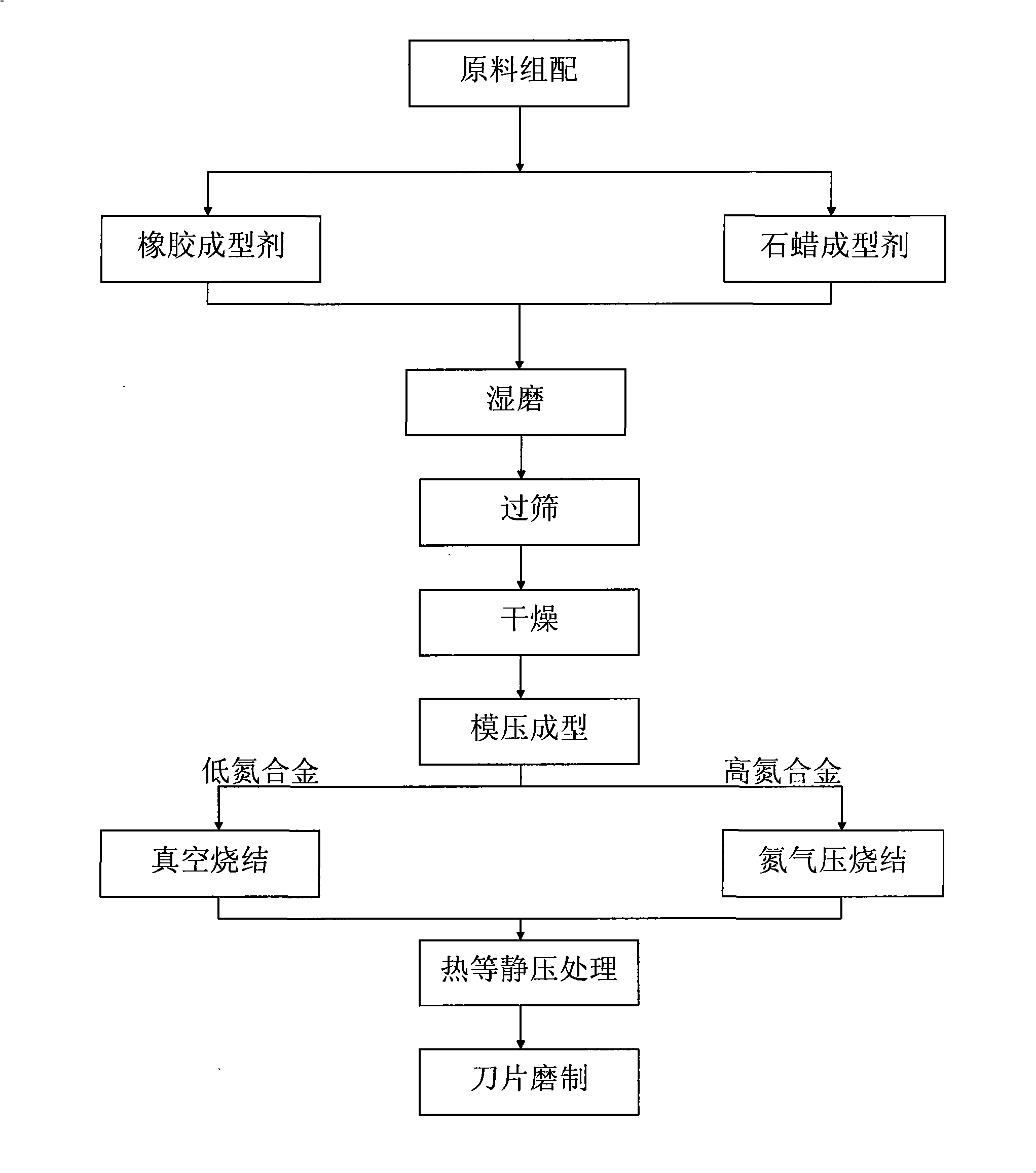

High-wear resistant Ti (C, N)-base ceramet tool bit and preparation thereof

InactiveCN101302595AReliable guarantee of high nitrogen-carbon ratioReliable Guarantee of HardnessLow nitrogenWear resistant

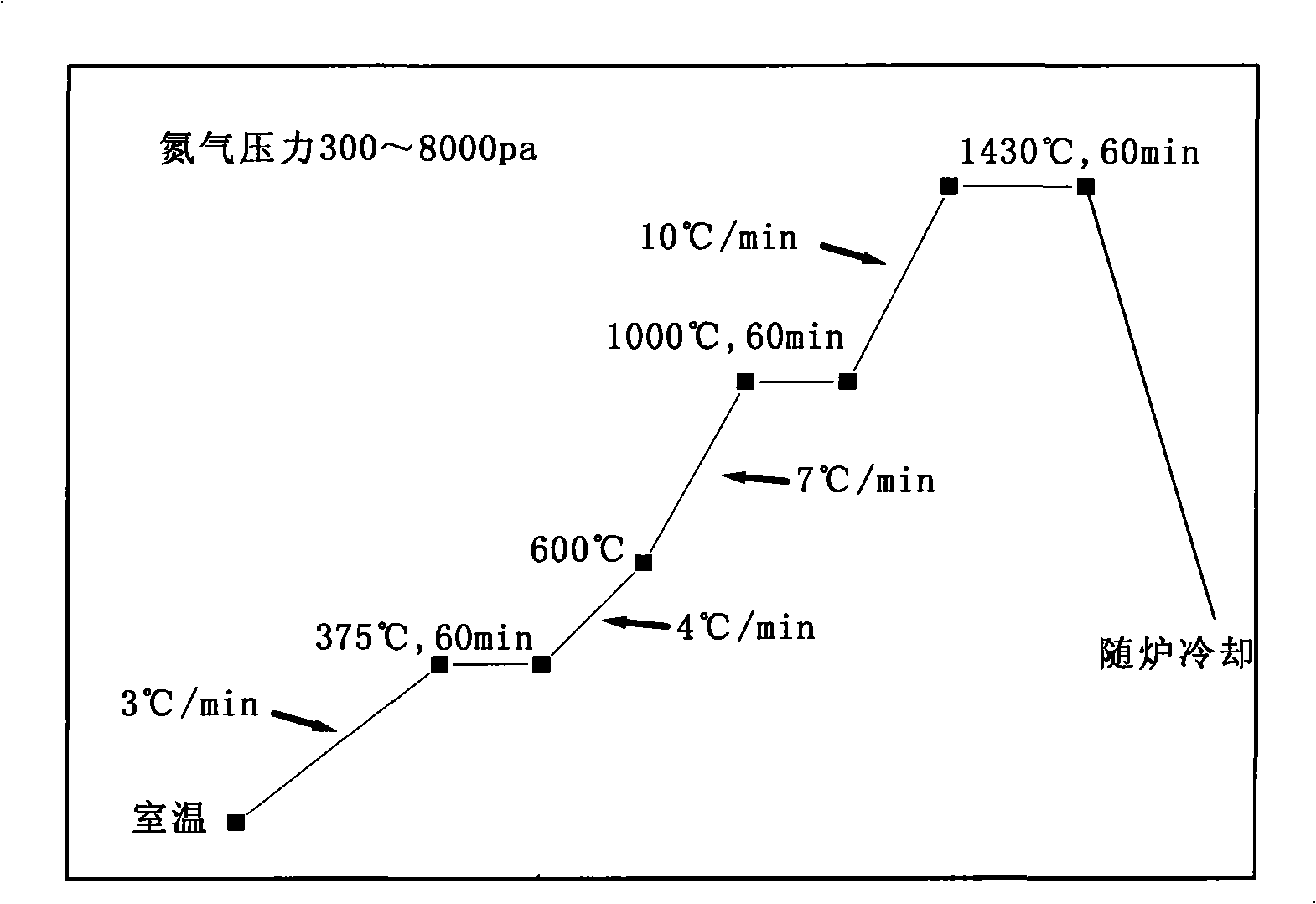

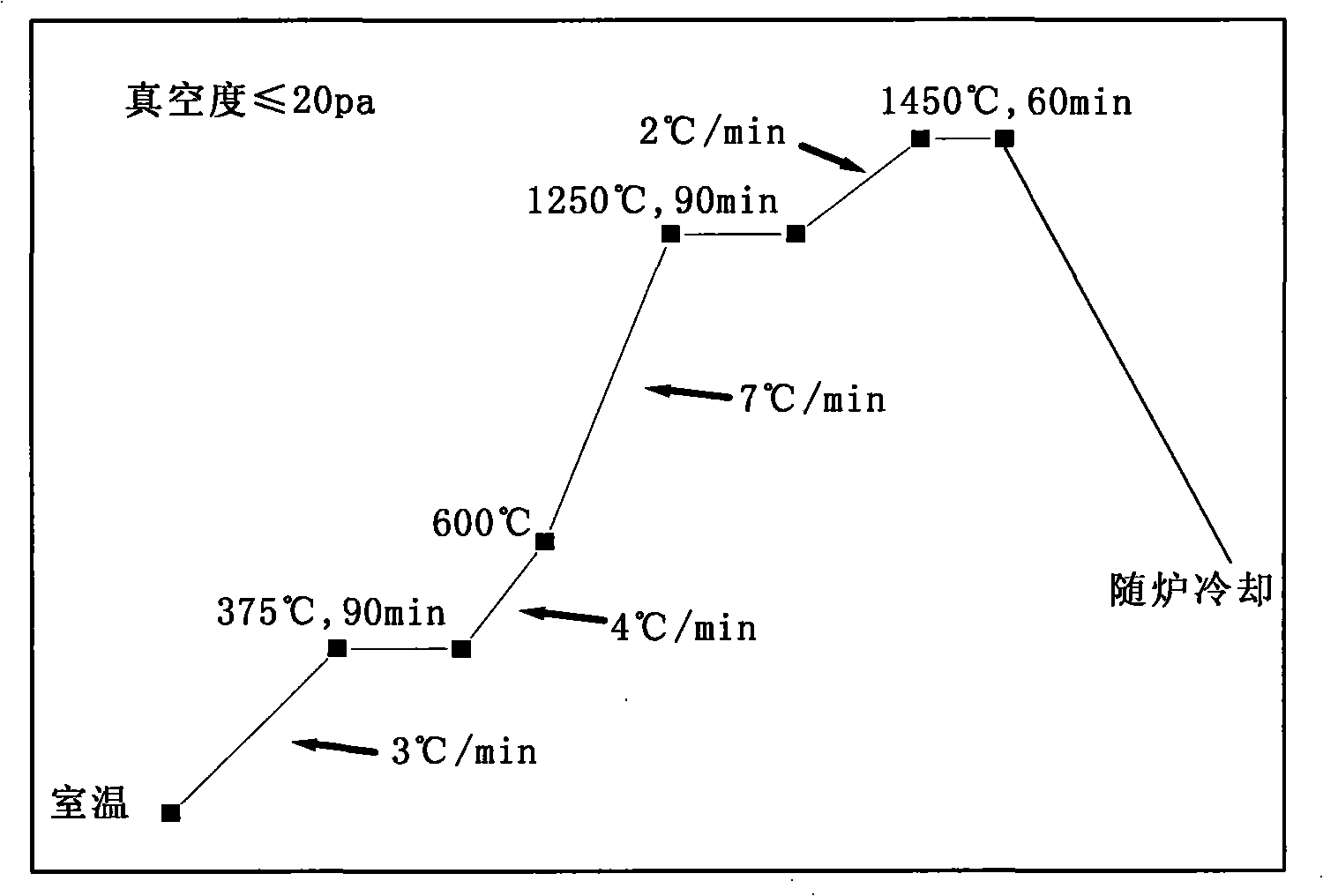

The invention provides a high-abrasion Ti(C, N) based metal ceramic tool and a preparation thereof. The Ti(C, N) based metal ceramic tool uses Ni and Co as a binder phase, is added with at least one carbonitride of Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x as a basic batch, and consists of at least one composition of WC, Mo2C, Co, Ni, ZrC, Cr3C2, VC, TaC and NbC, and the balance being Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x, wherein, an X value for adding the carbonitride of the Ti(C, N) based metal ceramic tool is as follows: X is less than or equal to 0.5 and more than or equal to 0.4, or the X is more than 0.5 and less than or equal to 0.7. The Ti(C, N) based metal ceramic tool is prepared according to the content of nitrogen by nitrogen pressure sintering or vacuum sintering combined with hot isostatic pressing treatment, thereby preventing nitrogen from escaping during the process of sintering high-nitrogen alloy, so that the high-nitrogen-carbon ratio in matrix and material hardness can be reliably guaranteed, and anti-oxidative abrasion property and anti-diffusive abrasion property of the material can be obviously increased through adding slight ZrC, Cr3C2, VC and other carbides into the basic batch; meanwhile, compactability and buckling strength of a low-nitrogen alloy structure can be obviously improved through optimally distributing each composition and content. The Ti(C, N) based metal ceramic tool is widely suitable for high-speed cutting tools of medium-low carbon steel and low alloy steel.

Owner:HUNAN UNIV OF SCI & TECH

Cermet and ceramic interconnects for a solid oxide fuel cell

An interconnect and gas separator for a solid oxide fuel cell includes a cermet material comprising a first conductive phase and a second ceramic phase or a multi-component ceramic material including a first ceramic ionically conductive and electrically non-conductive component and a second ceramic electrically conductive component.

Owner:BLOOM ENERGY CORP

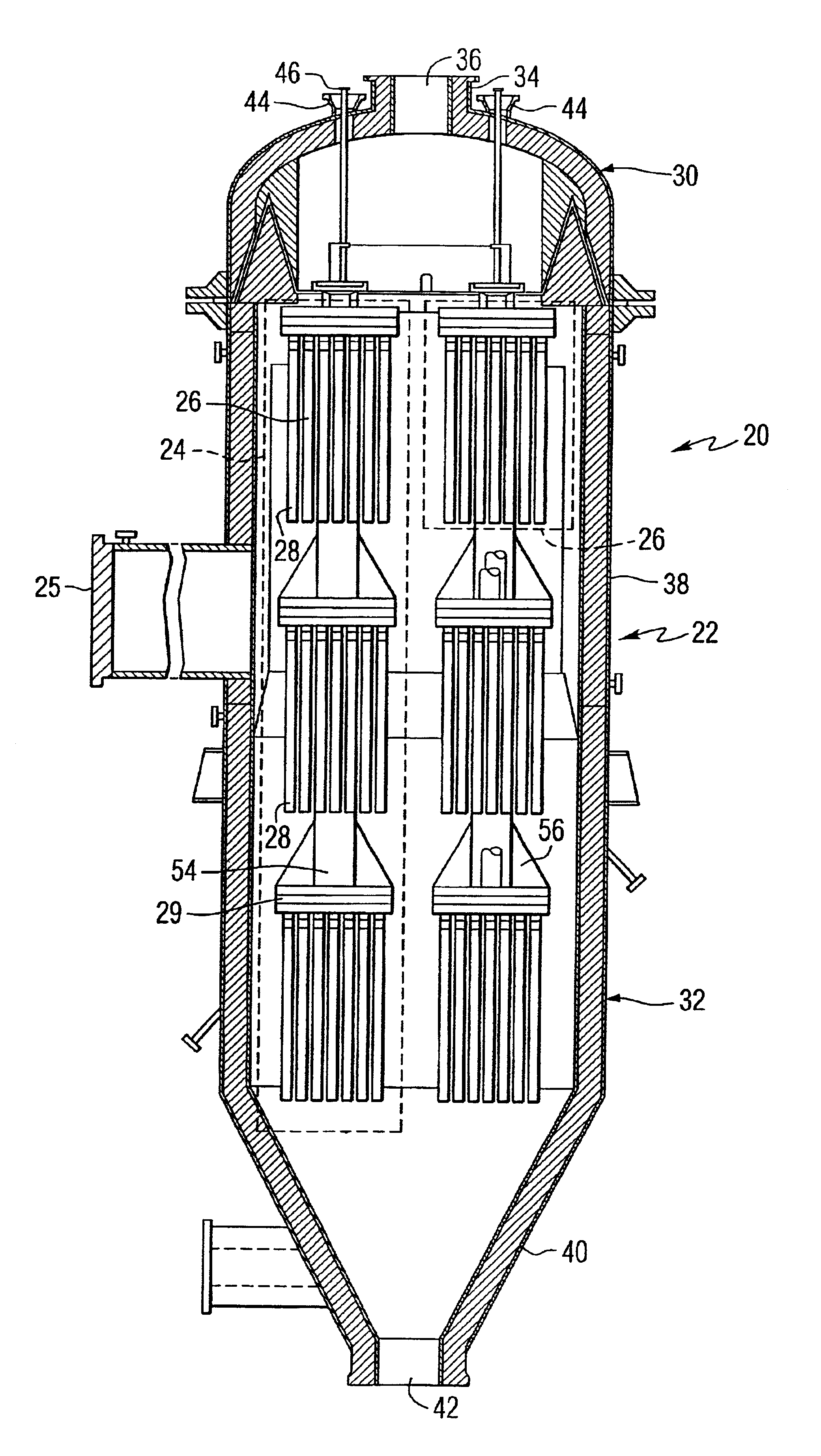

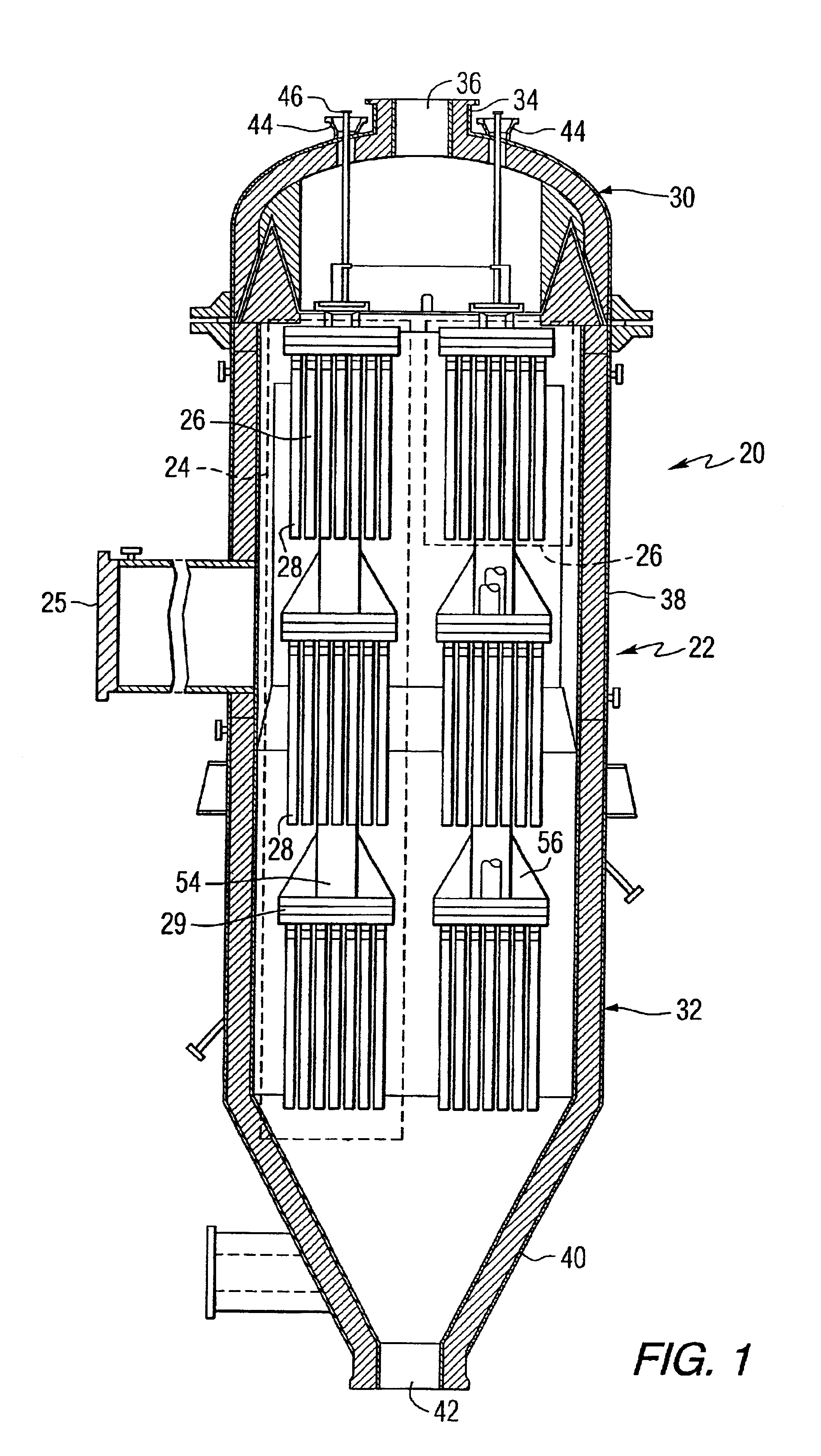

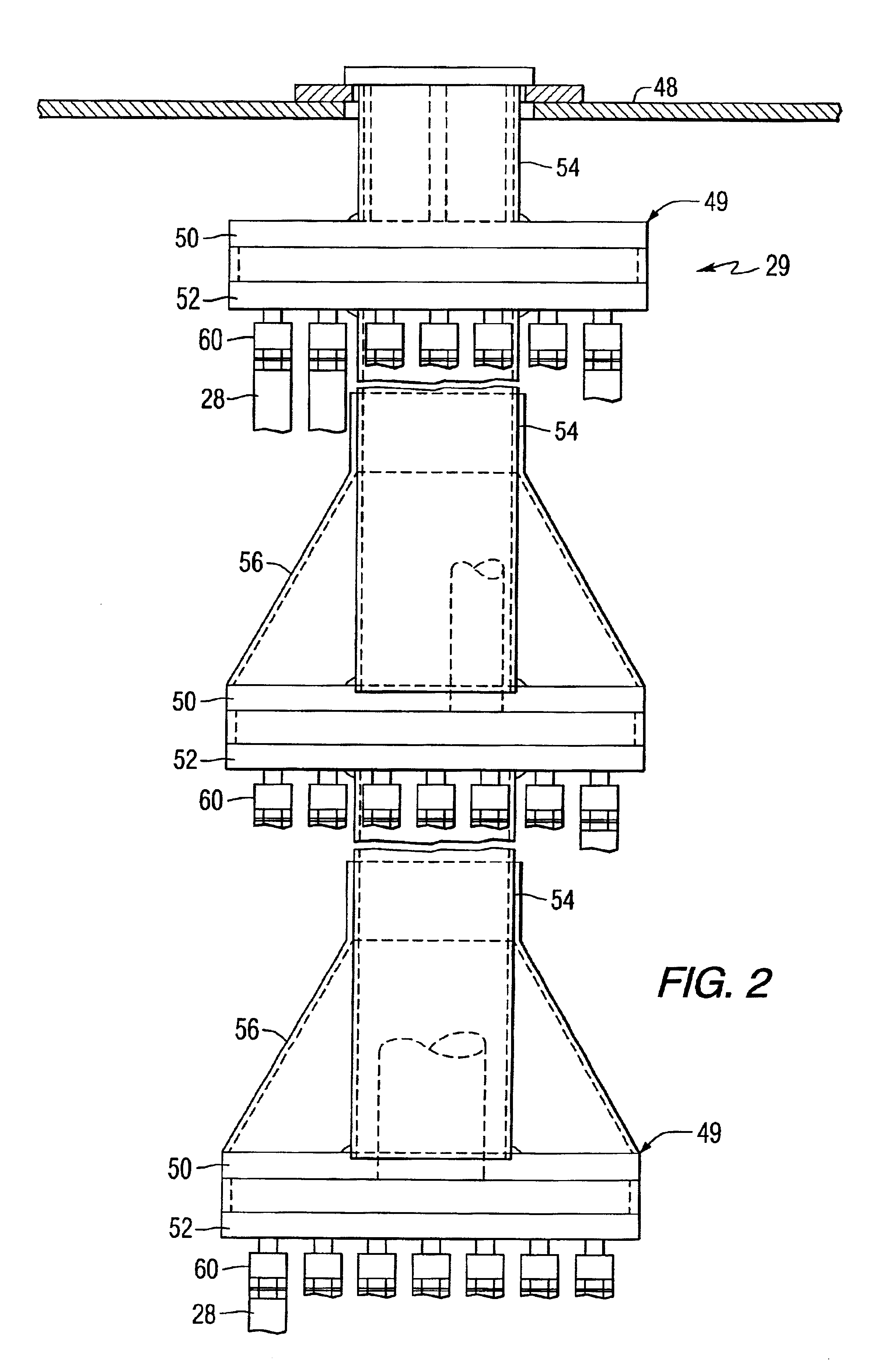

Catalytically enhanced filtration apparatus

A hot gas filtration apparatus includes a vessel, a plurality of filter elements mounted within the vessel and positioned such that hot gas flows through said filter elements, with each of said filter elements having a porous body, and a catalytic layer on surfaces of the porous body. The porous body of the filter element may include one of: a porous ceramic monolithic matrix, a continuous fiber reinforced ceramic composite (CFCC) matrix, a metallic matrix, an intermetallic matrix, a superalloy, and a metal-ceramic composite matrix. When the porous body is a nonoxide ceramic, a metallic matrix, an intermetallic matrix, a superalloy, or a metal-ceramic composite matrix, the invention further includes an oxidative resistant layer coating surfaces within the porous body, and the catalytic layer is on the oxidative resistant layer. A porous particulate removal membrane can be positioned on one or more surfaces of the filter element. The porous membrane can also provide a surface for one or more catalysts. The catalysts on the porous surface of the membrane(s) can be the same as or different from the catalysts on surfaces within the porous body.

Owner:SIEMENS ENERGY INC

Anti-abrasion metal-ceramic composite product and preparation method thereof

The invention provides an anti-abrasion metal-ceramic composite product and a preparation method thereof. The structural performance of the product is improved through at least one type of metallic oxides, metal nitrides or metal borides and intermetallic compounds. Metal-ceramic particle prefabricated parts made of ceramic particles and metal powder, or metal-ceramic particle prefabricated parts made of metal powder and mixtures which are obtained through uniform mixing of ceramic particles and metal powder with auxiliaries are subjected to high-temperature sintering thermal treatment to obtain the product. According to the anti-abrasion metal-ceramic composite product and the preparation method thereof, abrasion resistance of ceramic particles and mechanical performances of metal materials are perfectly combined, so that the hardness and the abrasion resistance of traditional metal materials are greatly improved. Compared with traditional anti-abrasion parts, the service life of metal grinding balls is increased by 1 time to 1.9 times, and the service life of liner plates and hammers is increased by more than 2.5 times, accordingly, a large number of metal materials are saved, and the production efficiency is improved.

Owner:湖北秦鸿新材料有限公司

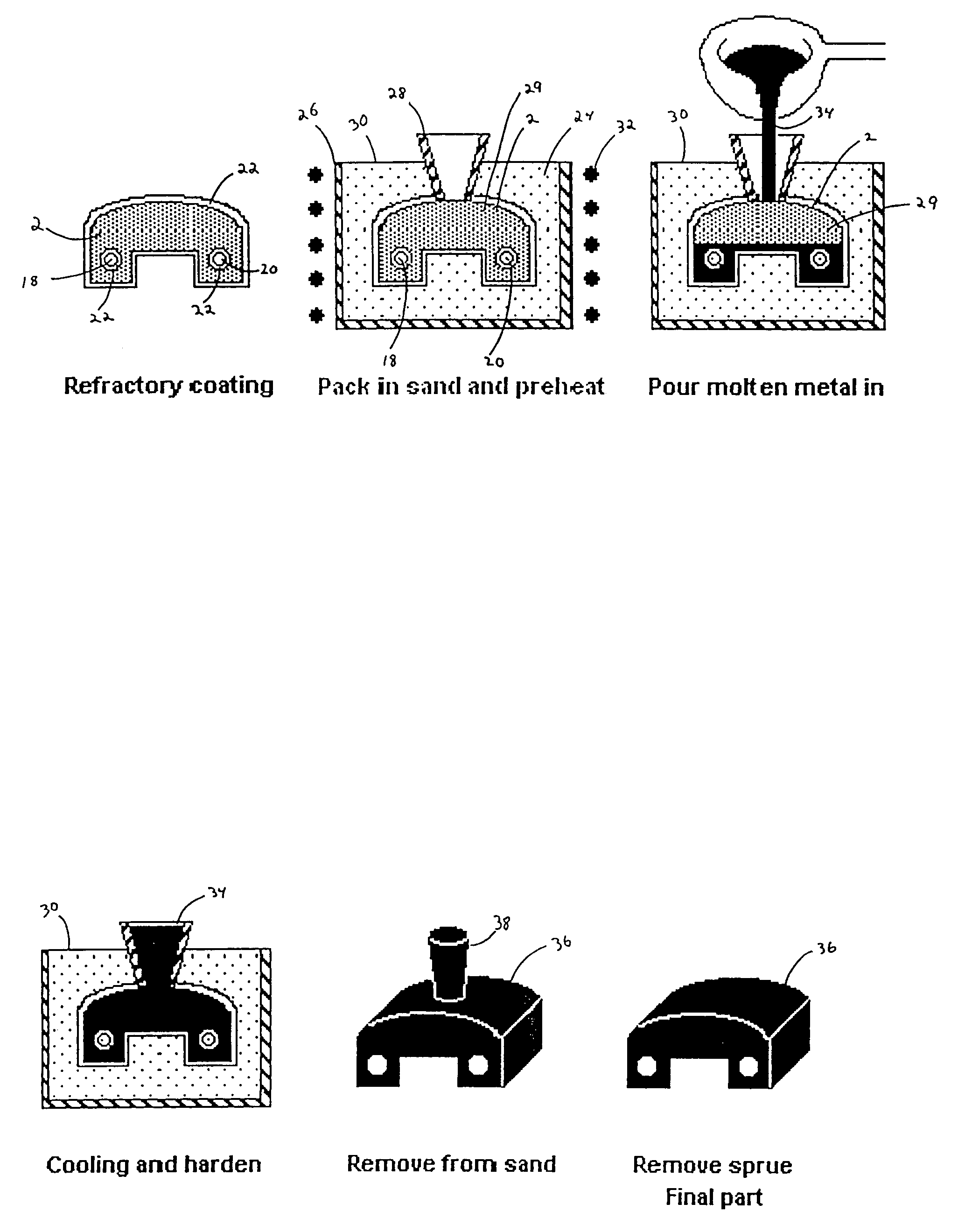

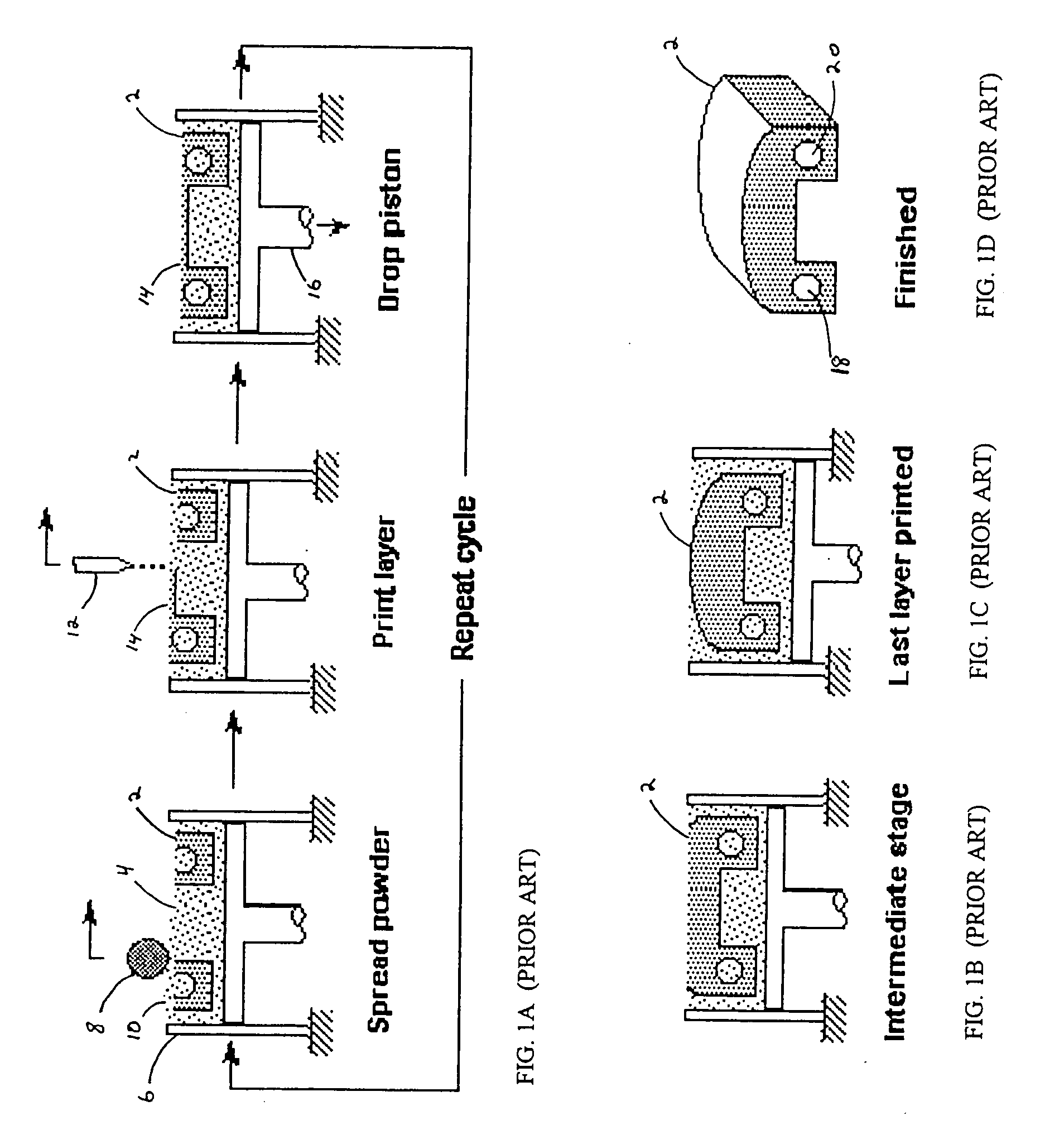

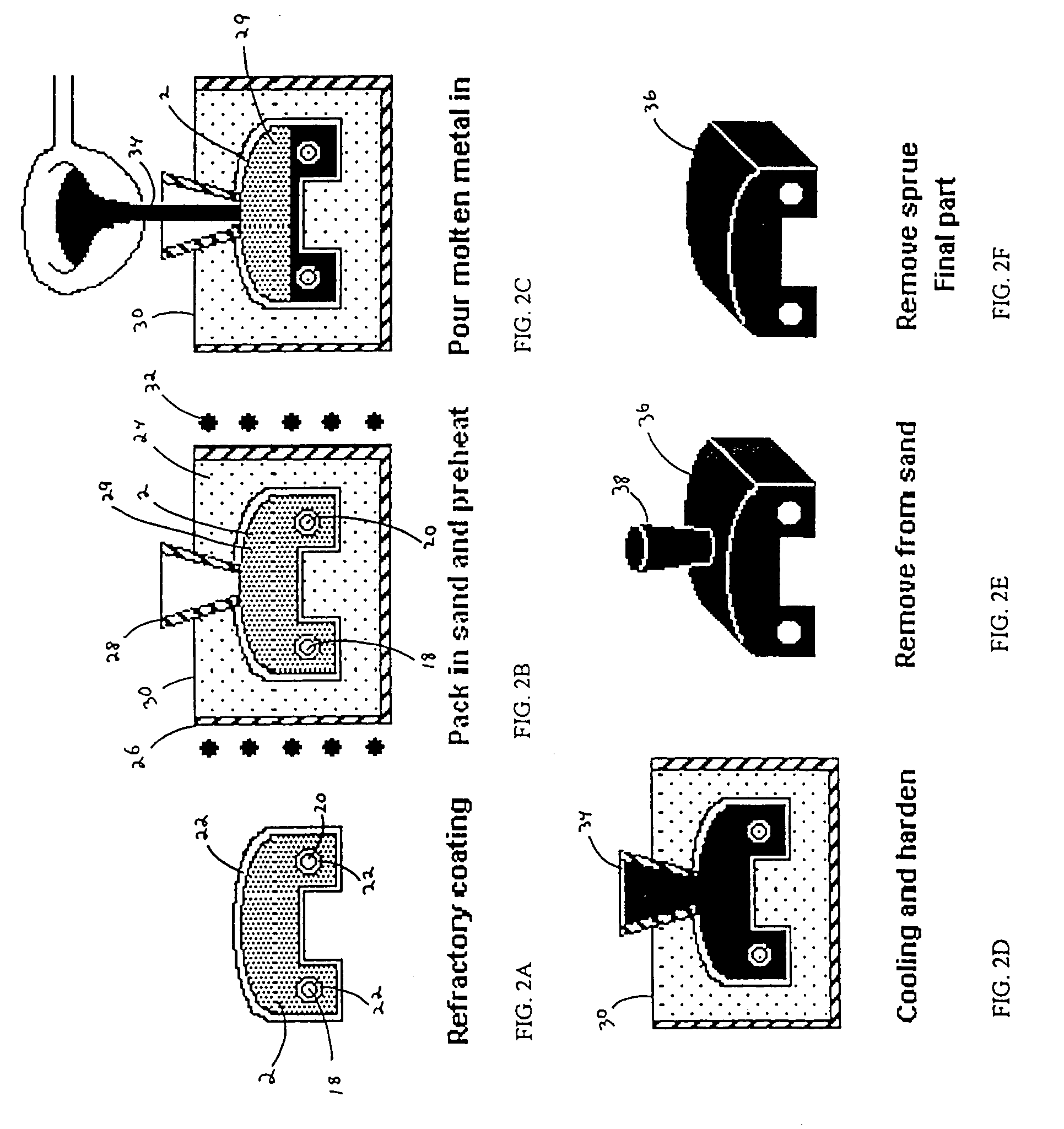

Novel casting process and articles for performing same

ActiveUS20040140078A1Fast technologyShort timeAdditive manufacturing apparatusFoundry mouldsCeramic coatingCasting mold

A method for producing a cast article comprises using a porous powder article as a sacrificial pattern. The porous powder article is preferably made using a rapid prototyping process. The porous powder article is used as a sacrificial pattern for a mold into which a molten metal is cast. Some embodiments include a step of proving the porous powder article with a ceramic coating. Methods of making molds and patterns using a porous powder article are also disclosed. The powder comprising the porous powder article may be a metal, ceramic or cermet. In some embodiments, the powder alloys with the molten casting metal. In some other embodiments, the powder and the casting metal form a composite. Sacrificial casting mold patterns comprising porous powder articles and casting molds comprising such sacrificial patterns are also disclosed.

Owner:THE EX ONE

Hydrogen transport membranes

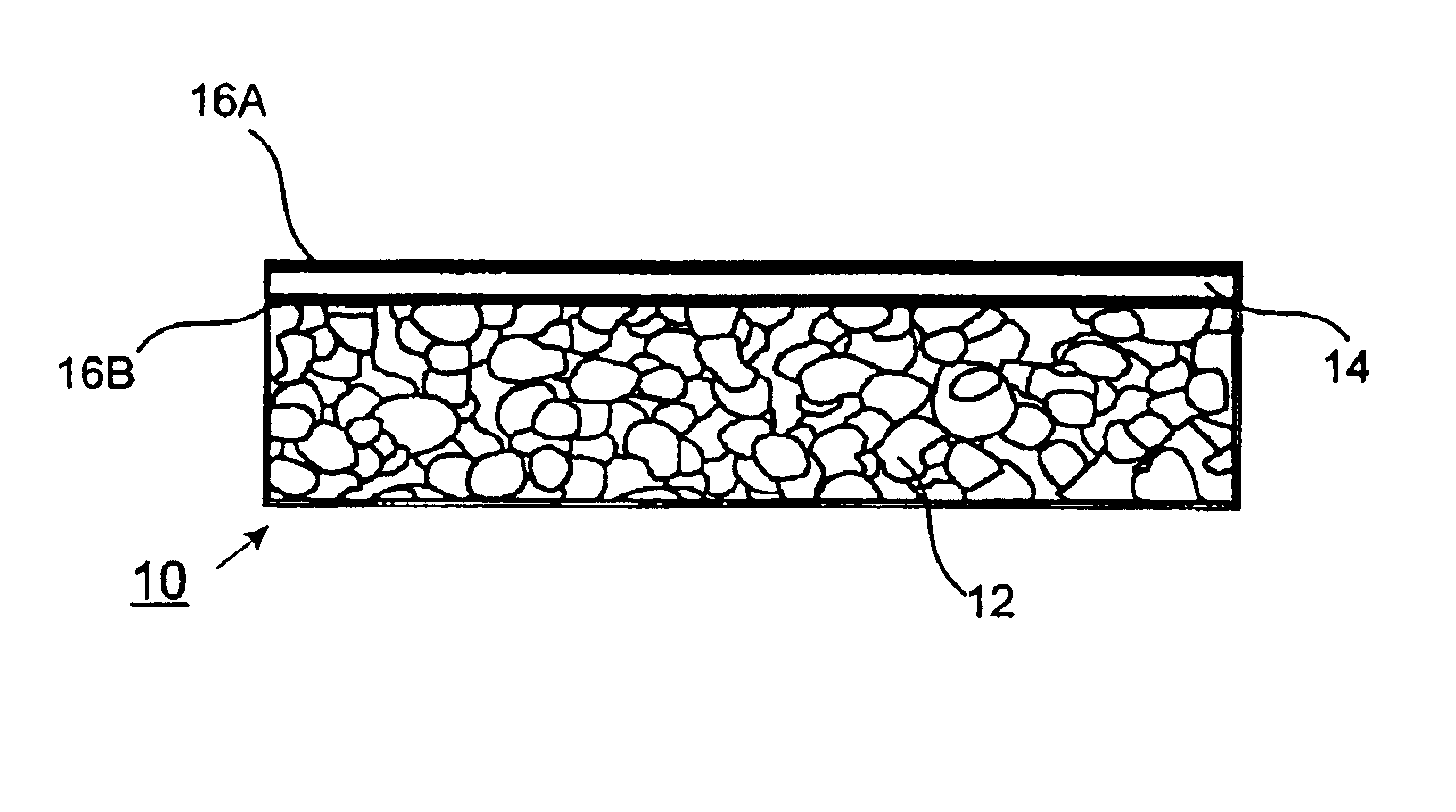

InactiveUS6899744B2Increase ratingsThickness minimizationSemi-permeable membranesMembranesSupport matrixNiobium

Composite hydrogen transport membranes, which are used for extraction of hydrogen from gas mixtures are provided. Methods are described for supporting metals and metal alloys which have high hydrogen permeability, but which are either too thin to be self supporting, too weak to resist differential pressures across the membrane, or which become embrittled by hydrogen. Support materials are chosen to be lattice matched to the metals and metal alloys. Preferred metals with high permeability for hydrogen include vanadium, niobium, tantalum, zirconium, palladium, and alloys thereof. Hydrogen-permeable membranes include those in which the pores of a porous support matrix are blocked by hydrogen-permeable metals and metal alloys, those in which the pores of a porous metal matrix are blocked with materials which make the membrane impervious to gases other than hydrogen, and cermets fabricated by sintering powders of metals with powders of lattice-matched ceramic.

Owner:ELTRON RES

Method for removing printing metal, ceramic product metal, ceramic powder and polymer mixed material and polymer from finished product

The invention discloses a method for removing printing metal, ceramic product metal, mixed material of ceramic powder (as a material component) and a polymer adhesive agent and the polymer adhesive agent from a finished printing product. According to the method, the mixed material comprises components in a volume ratio as follows: 40%-70% of material components and 30%-60% of the polymer adhesive agent which comprises components in a mass ratio of 50%-95% of main materials removed at the lower temperature, 4.5%-46% of auxiliary materials removed at the higher temperature and 0.5%-4% of auxiliaries; the mixed material is subjected to mixing and banburying to obtain filaments, pipes, bars, balls and blocks for printing forming; and the finished product obtained by printing is subjected to molten decomposition, water decomposition or acid catalysis at the lower temperature to remove the main polymer adhesive agent, is subjected to molten decomposition at the higher temperature to remove the auxiliary polymer adhesive agent and the auxiliaries, and is sintered to obtain a target product. The printing material has a wide source, is low in price, reduces the cost greatly and facilitates development of 3D (three-dimensional) manufacture.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

Anode supported sofc with an electrode multifunctional layer

The invention is directed to a fuel cell which is configured to avoid deformation caused by differential shrinking, and which mitigates the damage caused by the introduction of an oxidizing environment in the anode cavity during the operation of the fuel cell. The fuel cell has a cathode, an electrolyte, an anode and a porous multifunctional layer disposed on the anode opposite to the electrolyte. The porous multifunctional layer comprises a cermet which has thermal expansion and shrinkage behaviour substantially similar to the other fuel cell layers.

Owner:VERSA POWER SYST

Composite reinforced wear-resistant part of metal-ceramic prefabricated member and manufacturing method of composite reinforced wear-resistant part

The invention discloses a composite reinforced wear-resistant part of a metal-ceramic prefabricated member and a manufacturing method of the composite reinforced wear-resistant part. The manufacturing method comprises the steps as follows: uniformly mixing ceramic particles with self-fluxing alloy powder to obtain a mixture; filling a mould cavity of a pressing machine with the mixture, pressing by pressure, forming and demoulding, and placing biscuits and gaskets into a drying box for drying; placing the dried biscuits and gaskets into a vacuum furnace for sintering, cooling and discharging to obtain the metal-ceramic composite prefabricated member; carrying out sand blasting on the prefabricated member, and spraying a layer of nickel-based self-fluxing alloy powder onto the surface of the prefabricated member; and placing the processed fabricated member onto the end surface of a cast cavity, and pouring metal liquid formed by smelting metal matrix materials into the bottom of the cast cavity to obtain the composite reinforced wear-resistant part of the metal-ceramic prefabricated member. According to the manufacturing method, the wear resistance and the impact resistance of the composite wear-resistant part are improved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

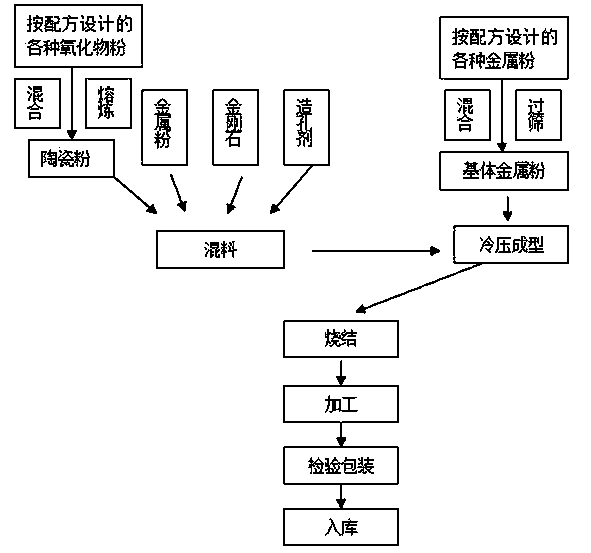

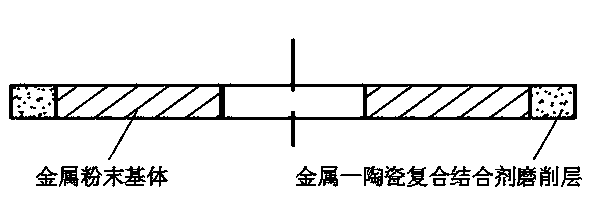

Metal ceramic combination binding agent and combination binding agent diamond wheel

ActiveCN103831740AGood self-sharpeningImprove sharpnessAbrasion apparatusGrinding devicesNumerical controlSilicon dioxide

The invention belongs to the field of diamond wheels and particularly relates to a metal ceramic combination binding agent and a combination binding agent diamond wheel. The metal ceramic combination binding agent is composed of, by weight, 60%-80% of 663 bronze powder and 20%-40% of ceramic powder. The ceramic powder is homemade and composed of, by weight, 45%-60% of silicon dioxide, 20%-30% of boric oxide, 10%-15% of potassium oxide, 5%-10% of magnesium oxide and 2%-5% of calcium oxide. The combination binding agent diamond wheel is composed of, by volume, 25%-40%of diamond abrasive, 55%-75% of combination binding agent and 2%-3% of pore forming agent. When the diamond wheel made of the metal ceramic combination binding agent is applied to a five-axis cnc machine tool, the good sharpness and the good self-sharpening performance of a ceramic binding agent are kept and the advantages of high rigidity and the good shape-maintaining performance of a metal binding agene are obtained. The comprehensive processing efficiency is improved by 100% to 150%.

Owner:江苏赛扬精工科技有限责任公司

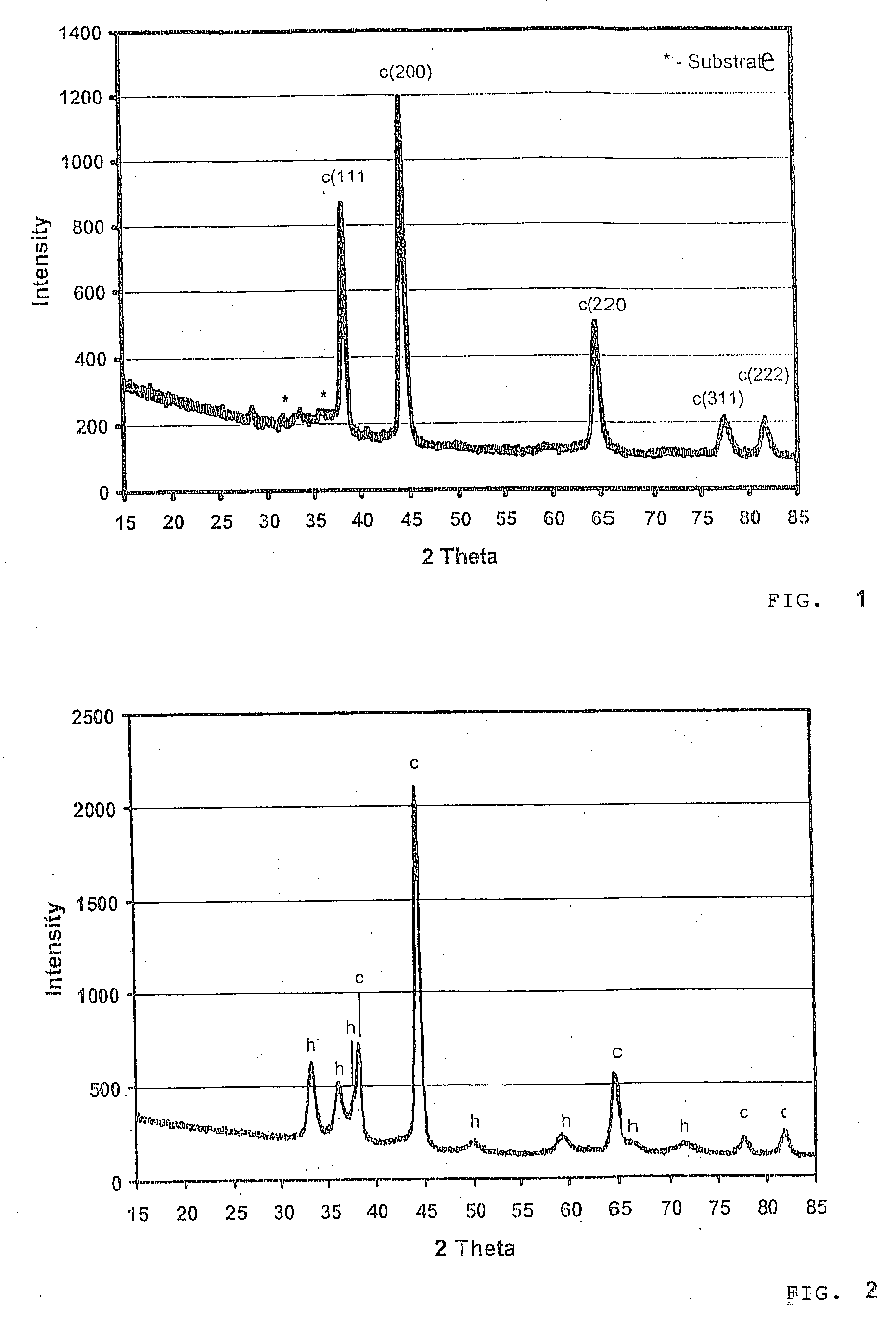

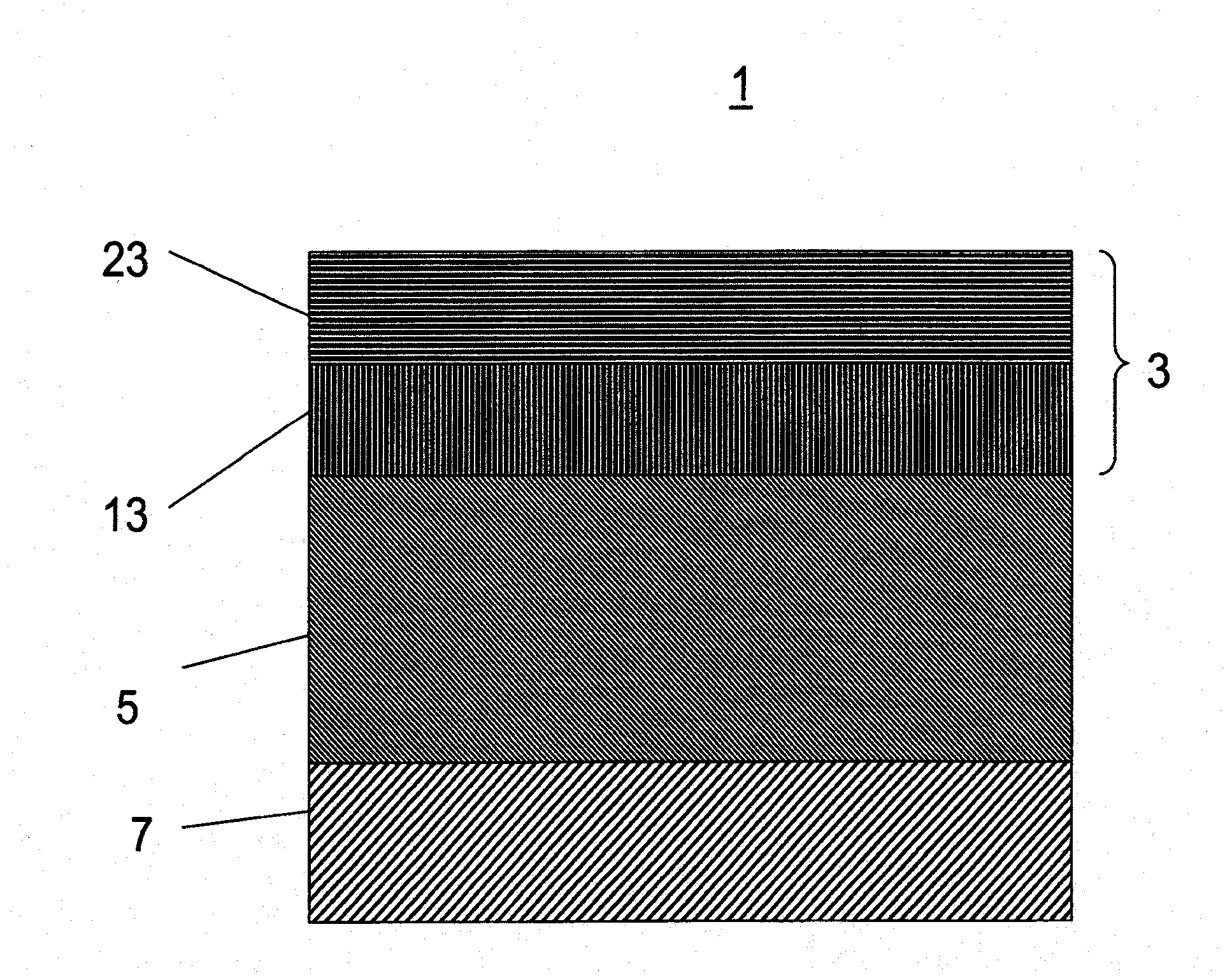

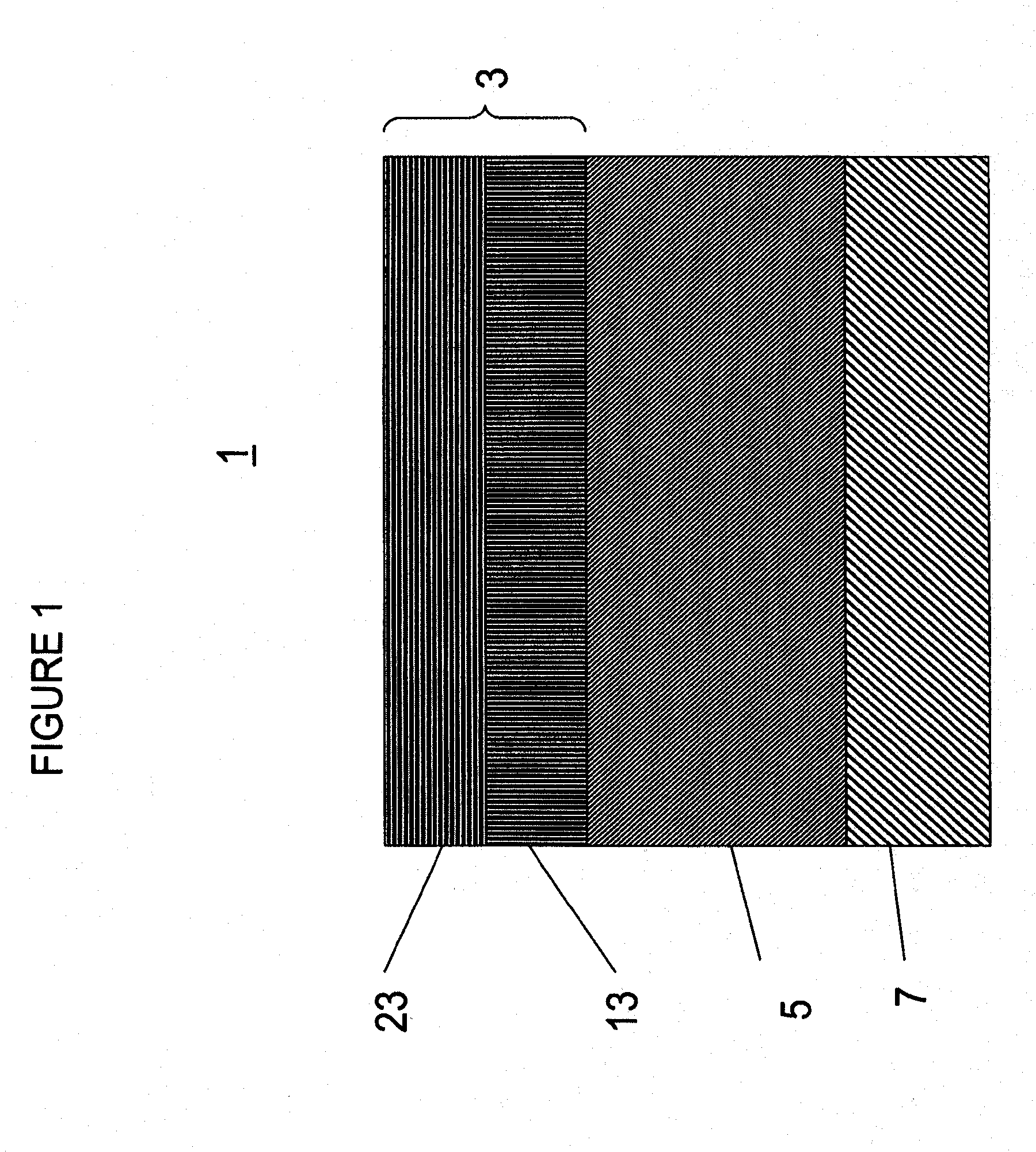

Hard-material-coated bodies and method for their production

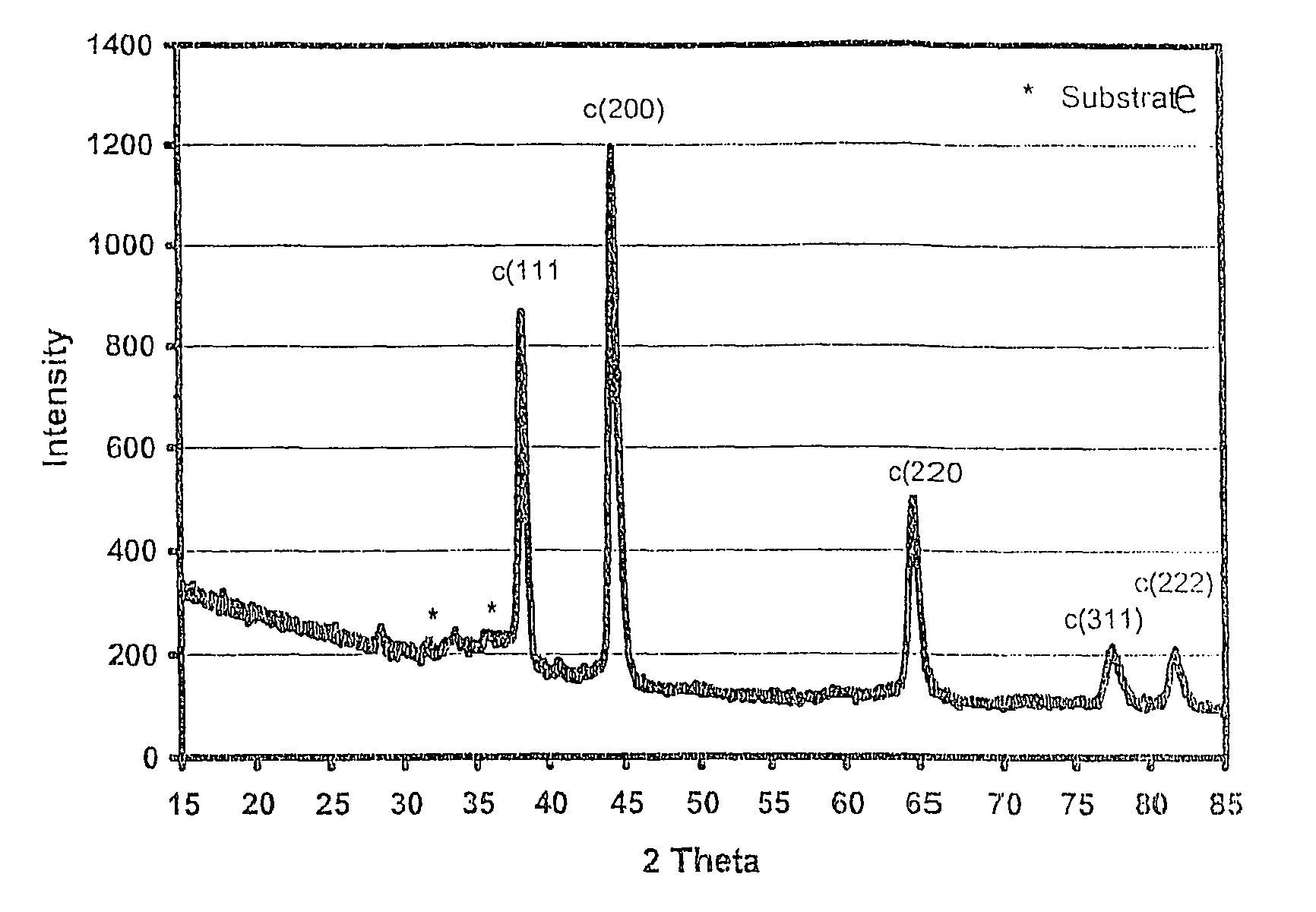

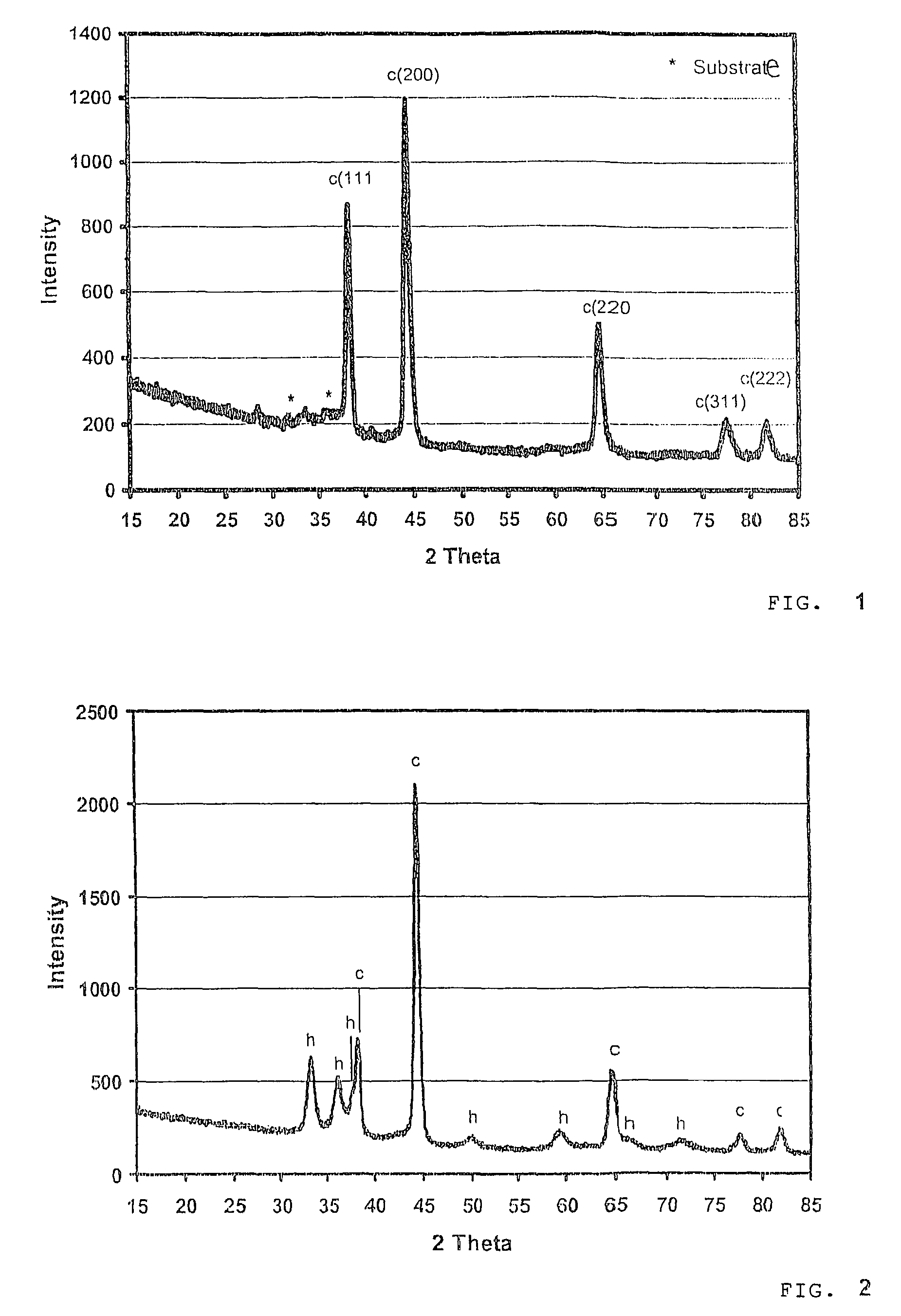

ActiveUS7767320B2Improve the immunityExcellent friction and wear resistanceNatural mineral layered productsChemical vapor deposition coatingLattice constantChemical measurement

The invention relates to hard-coated bodies with a single- or multi-layer system containing at least one Ti1-xAlxN hard layer and a method for production thereof. The aim of the invention is to achieve a significantly improved wear resistance and oxidation resistance for such hard-coated bodies. Said hard-coated bodies are characterised in that the bodies are coated with at least one Ti1-xAlxN hard layer, generated by CVD without plasma stimulation present as a single-phase layer with cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, or as a multi-phase layer, the main phase being Ti1-xAlxN with a cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, with Ti1-xAlxN with a wurtzite structure and / or as TiNx with NaCl structure as further phase. Another feature of said hard layer is that the chlorine content is in the range of only 0.05 to 0.9 atom %. The invention further relates to a method for production of the body, characterised in that the body is coated in a reactor at temperatures from 700° C. to 900° C. by means of CVD without plasma stimulation with titanium halides, aluminium halides and reactive nitrogen compounds as precursors, mixed at elevated temperatures. Said coating can be applied to tools made from steel, hard metals, cermets and ceramics, such as drills, millers and indexable inserts.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

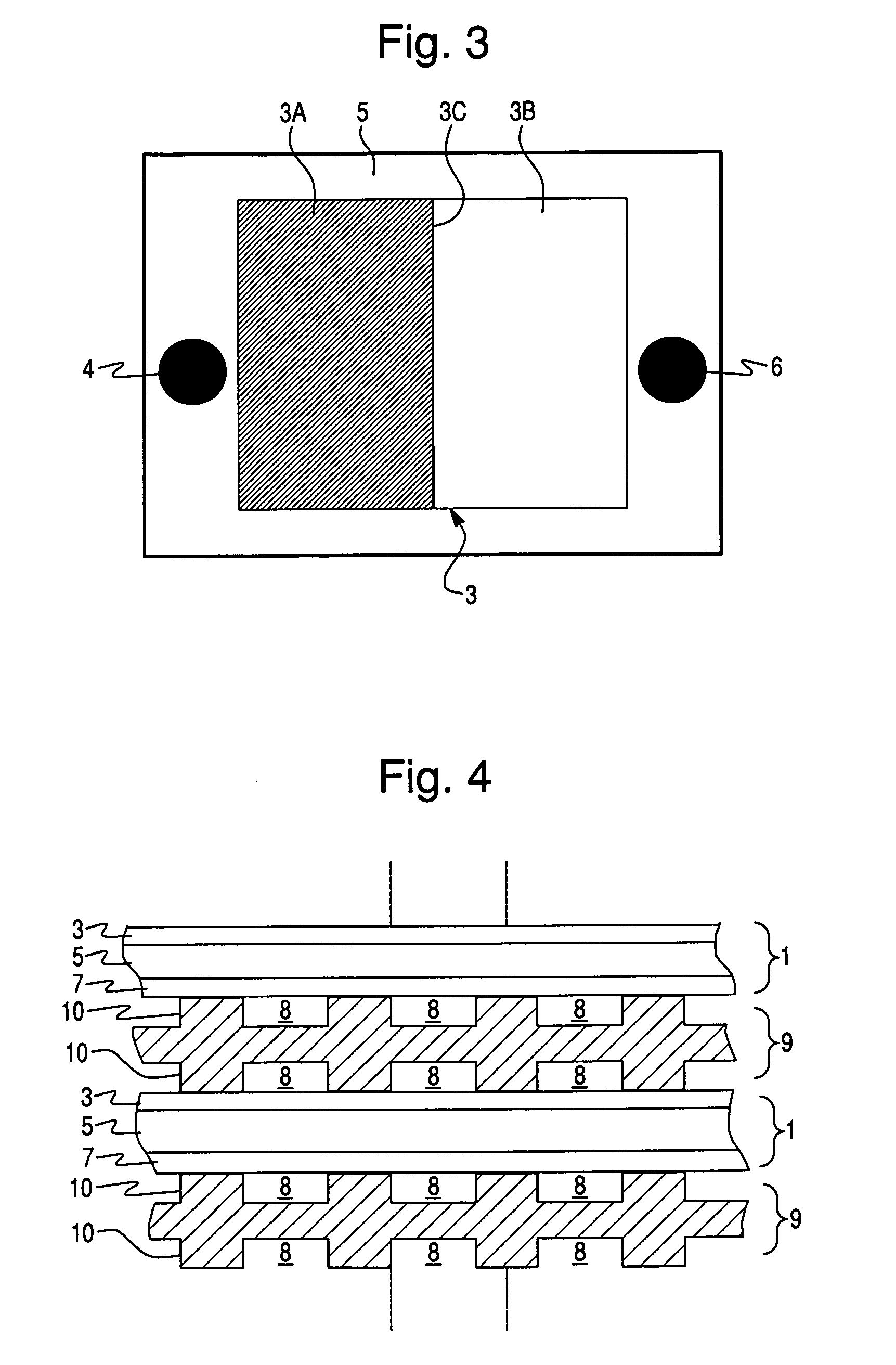

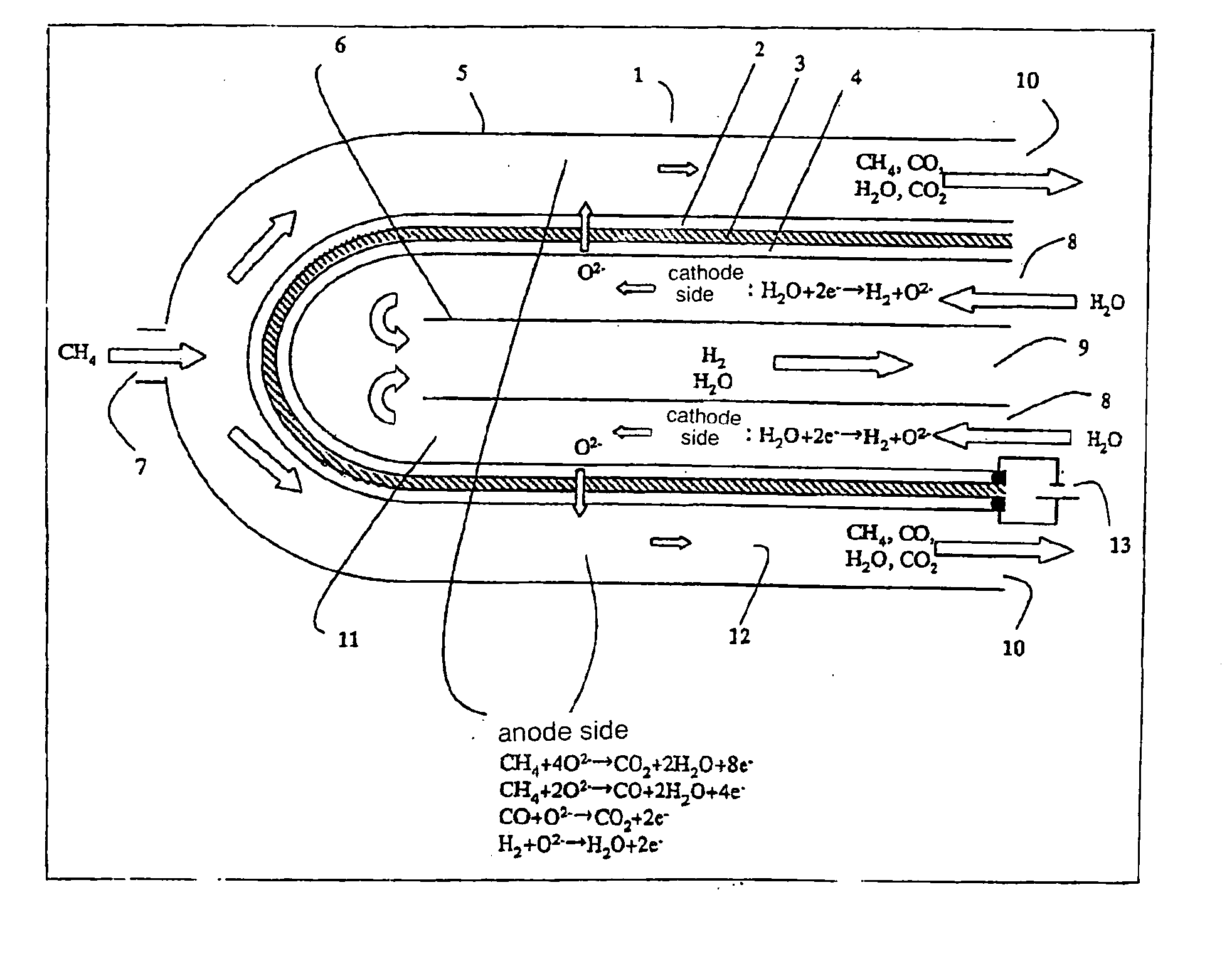

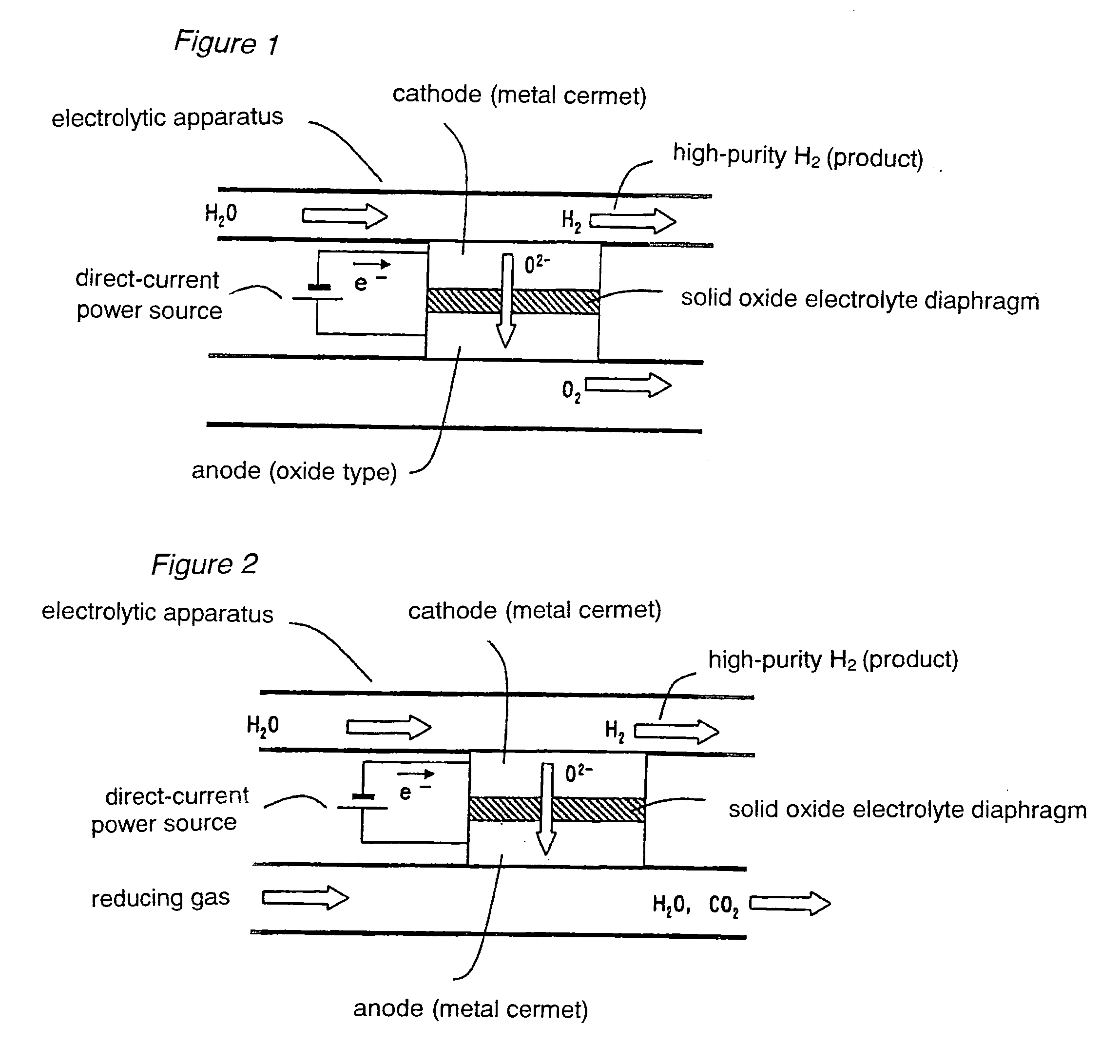

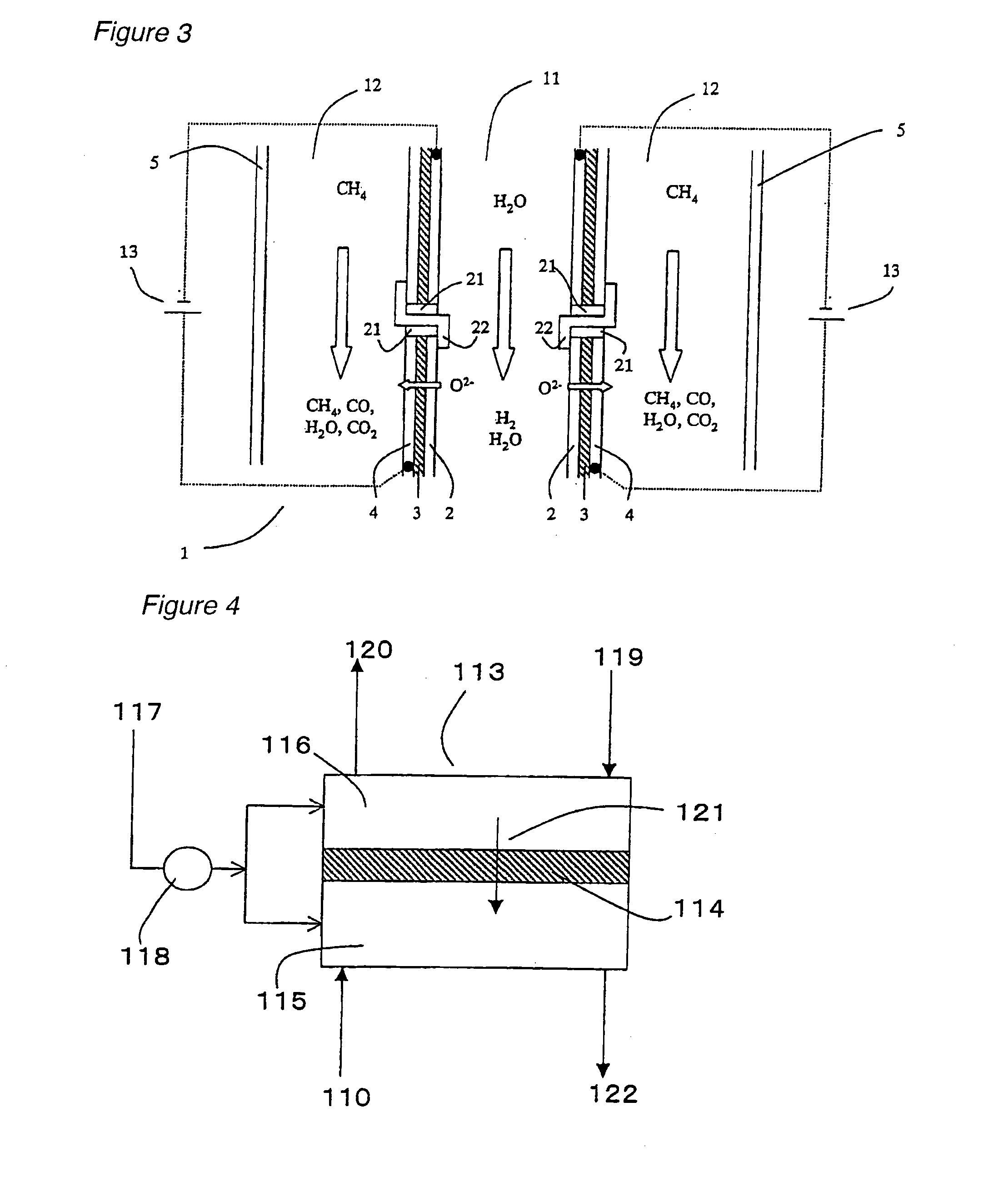

Method and apparatus for producing hydrogen

An electrolyzer structure is provided that is suitable for use in a method that produces hydrogen by steam electrolysis by feeding reducing gas to an anode side and feeding steam to a cathode side of an electrolyzer that is partitioned into the anode side and the cathode side by a diaphragm of solid oxide electrolyte, and feeding power to the anode and cathode of the electrolyzer. One embodiment of the present invention relates to an apparatus that produces hydrogen by high temperature steam electrolysis and that comprises an electrolyzer partitioned into an anode side and a cathode side by a solid oxide electrolyte diaphragm, a conduit that feeds reducing gas to the anode side of the electrolyzer, and a conduit that feeds steam to the cathode of the electrolyzer, in which a metal cermet stable in a reducing atmosphere is used as the material of the anode and the cathode. Another embodiment of the present invention relates to a method of producing hydrogen by high temperature steam electrolysis for reducing electrolysis voltage by feeding steam to a cathode side and feeding hydrocarbon-containing gas to an anode side for reaction with oxygen ion, the cathode side and the anode side being provided in a high temperature steam electrolytic apparatus in which an electrolyzer is partitioned into the anode side and the cathode side using a solid oxide electrolyte as the diaphragm, wherein offgas discharged from the anode side of the electrolytic apparatus is admixed into the hydrocarbon-containing gas that is fed to the anode side of the electrolytic apparatus.

Owner:EBARA CORP +1

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

Coated particles and sunscreen and cosmetic products containing same

InactiveUS20070280895A1Increasing bed volumeEqually distributedCosmetic preparationsToilet preparationsMetallic materialsConformal coating

Particles have an ultrathin, conformal coating are made using atomic layer deposition methods. The base particles include ceramic and metallic materials. The coatings can also be ceramic or metal materials that can be deposited in a binary reaction sequence. The coated particles are useful as fillers for electronic packaging applications, for making ceramic or cermet parts, as supported catalysts, as well as other applications.

Owner:WEIMER ALAN W +1

Hard-Material-Coated Bodies and Method for Their Production

ActiveUS20090123779A1Improve the immunityExcellent friction and wear resistanceNatural mineral layered productsChemical vapor deposition coatingLattice constantChemical measurement

The invention relates to hard-coated bodies with a single- or multi-layer system containing at least one Ti1-xAlxN hard layer and a method for production thereof. The aim of the invention is to achieve a significantly improved wear resistance and oxidation resistance for such hard-coated bodies. Said hard-coated bodies are characterised in that the bodies are coated with at least one Ti1-xAlxN hard layer, generated by CVD without plasma stimulation present as a single-phase layer with cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, or as a multi-phase layer, the main phase being Ti1-xAlxN with a cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, with Ti1-xAlxN with a wurtzite structure and / or as TiNx with NaCl structure as further phase. Another feature of said hard layer is that the chlorine content is in the range of only 0.05 to 0.9 atom %. The invention further relates to a method for production of the body, characterised in that the body is coated in a reactor at temperatures from 700° C. to 900° C. by means of CVD without plasma stimulation with titanium halides, aluminium halides and reactive nitrogen compounds as precursors, mixed at elevated temperatures. Said coating can be applied to tools made from steel, hard metals, cermets and ceramics, such as drills, millers and indexable inserts.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Internal reforming anode for solid oxide fuel cells

A solid oxide fuel cell (SOFC) includes a cathode electrode, a solid oxide electrolyte, and an anode electrode having a first portion and a second portion, such that the first portion is located between the electrolyte and the second portion. The anode electrode comprises a cermet comprising a nickel containing phase and a ceramic phase. The first portion of the anode electrode contains a lower porosity and a lower ratio of the nickel containing phase to the ceramic phase than the second portion of the anode electrode. The nickel containing phase in the second portion of the anode electrode comprises nickel and at least one other metal which has a lower electrocatalytic activity than nickel.

Owner:BLOOM ENERGY CORP

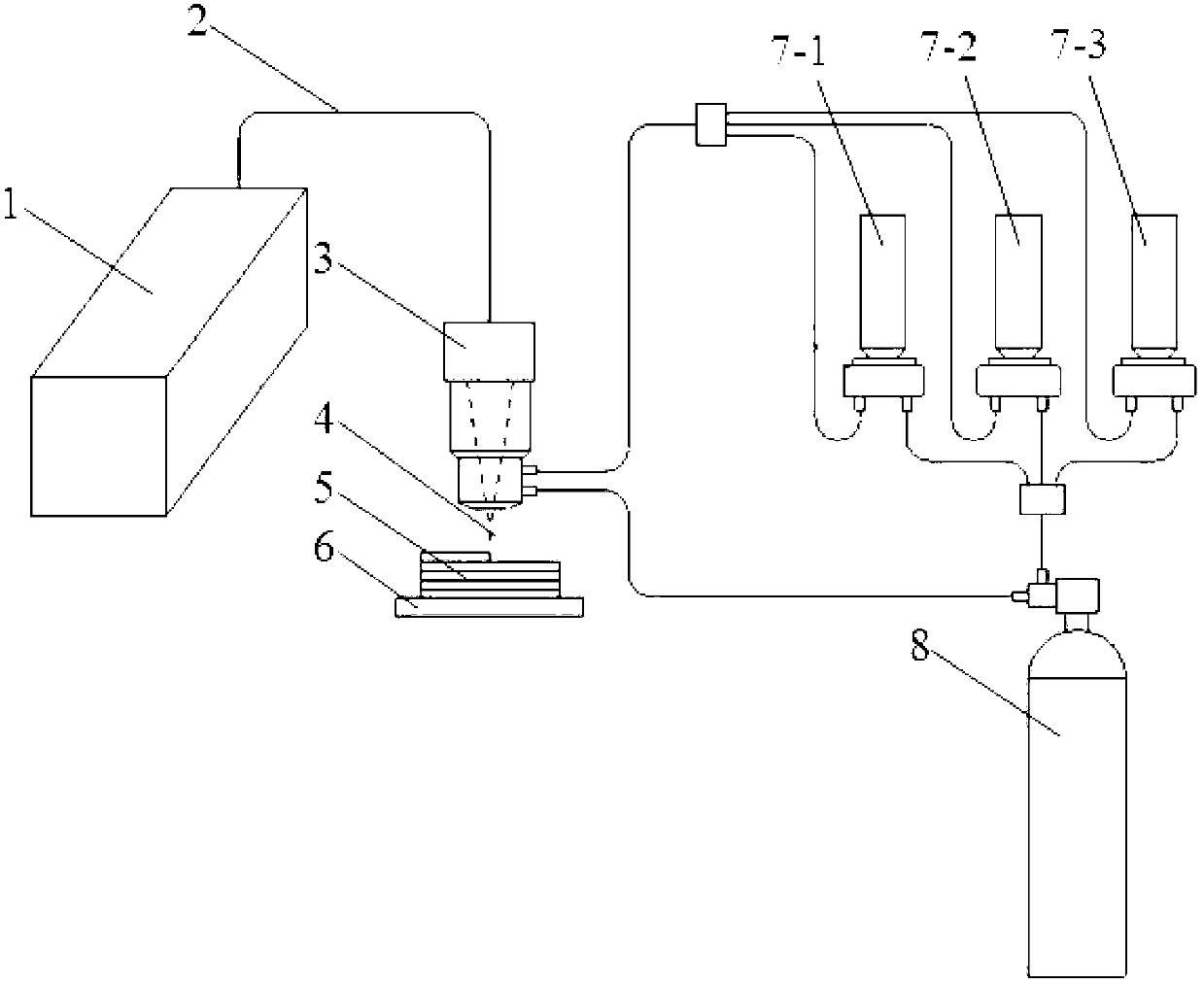

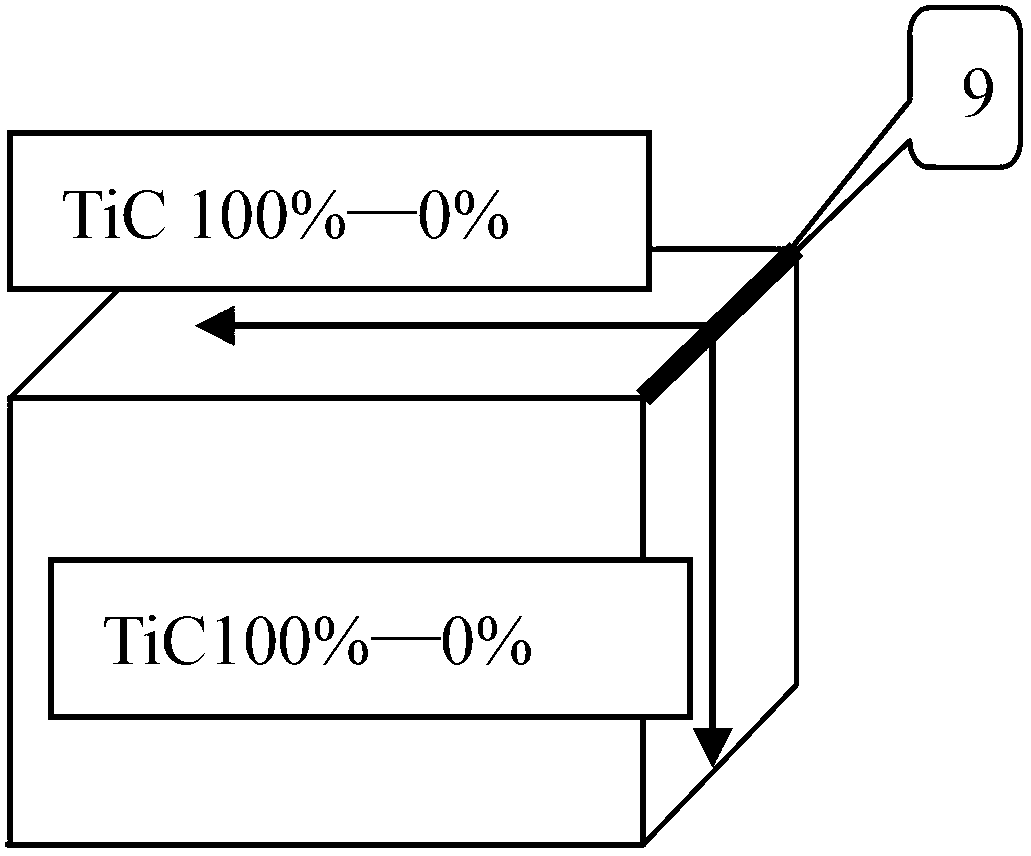

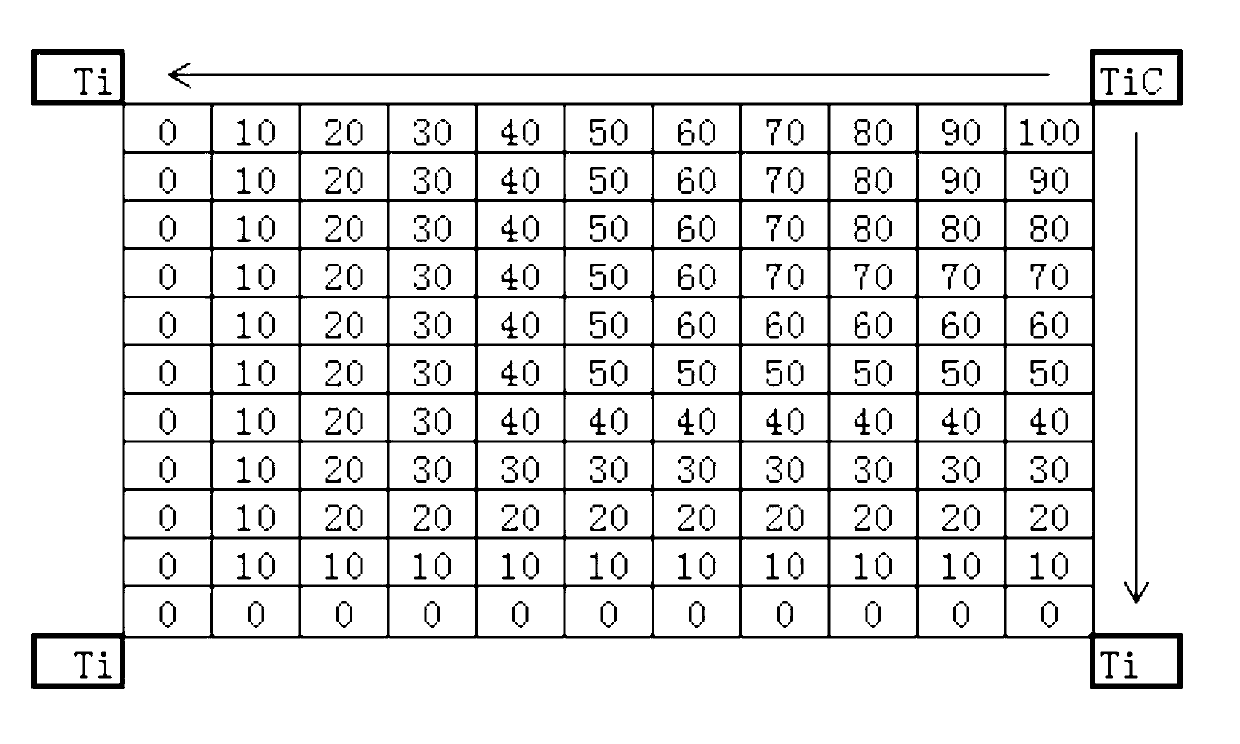

Laser near-net shaping method for metal-ceramic multi-dimensional functionally-graded structural component

The invention discloses a laser near-net shaping method for a metal-ceramic multi-dimensional functionally-graded structural component. According to the laser near-net shaping method for the metal-ceramic multi-dimensional functionally-graded structural component, a laser fast shaping system is used for combining metal powder and ceramic powder, which are used as raw materials and have changeable proportioning rates, to form the multi-dimensional functionally-graded structural component directly. The laser near-net shaping method specifically includes the following steps: firstly, two types or more than two types of metal powder and ceramic powder are dried and respectively placed in different powder barrels of a powder feeding device; secondly, inert gas is used as powder feeding and protecting gas; and lastly, a numerical control program is used for controlling the moving trajectory and the moving speed of a laser machining head and the real-time powder feeding amount of each powder barrel of the powder feeding device, the change of gradients can be realized in a horizontal plane and a vertical plane of a base plate, and therefore the complex multi-dimensional gradient change in the overall space can be realized. On one hand, the laser near-net shaping method for the metal-ceramic multi-dimensional functionally-graded structural component is a direct shaping method, and on the other hand, the laser near-net shaping method is suitable for melting solidification shaping of various high-melting-point materials, and the selection range of the design of functionally-graded materials is expanded.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com