Patents

Literature

413results about "Granule coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

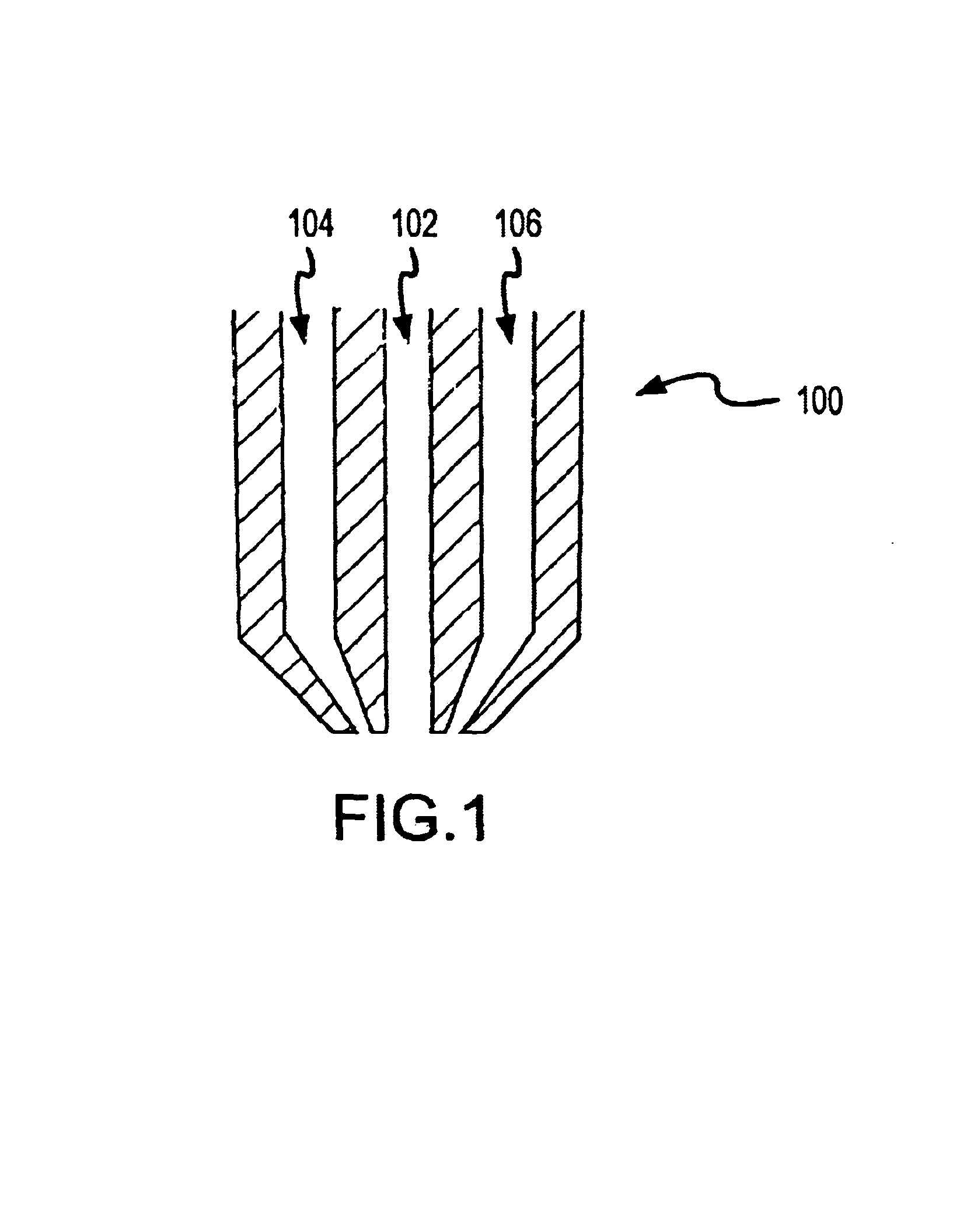

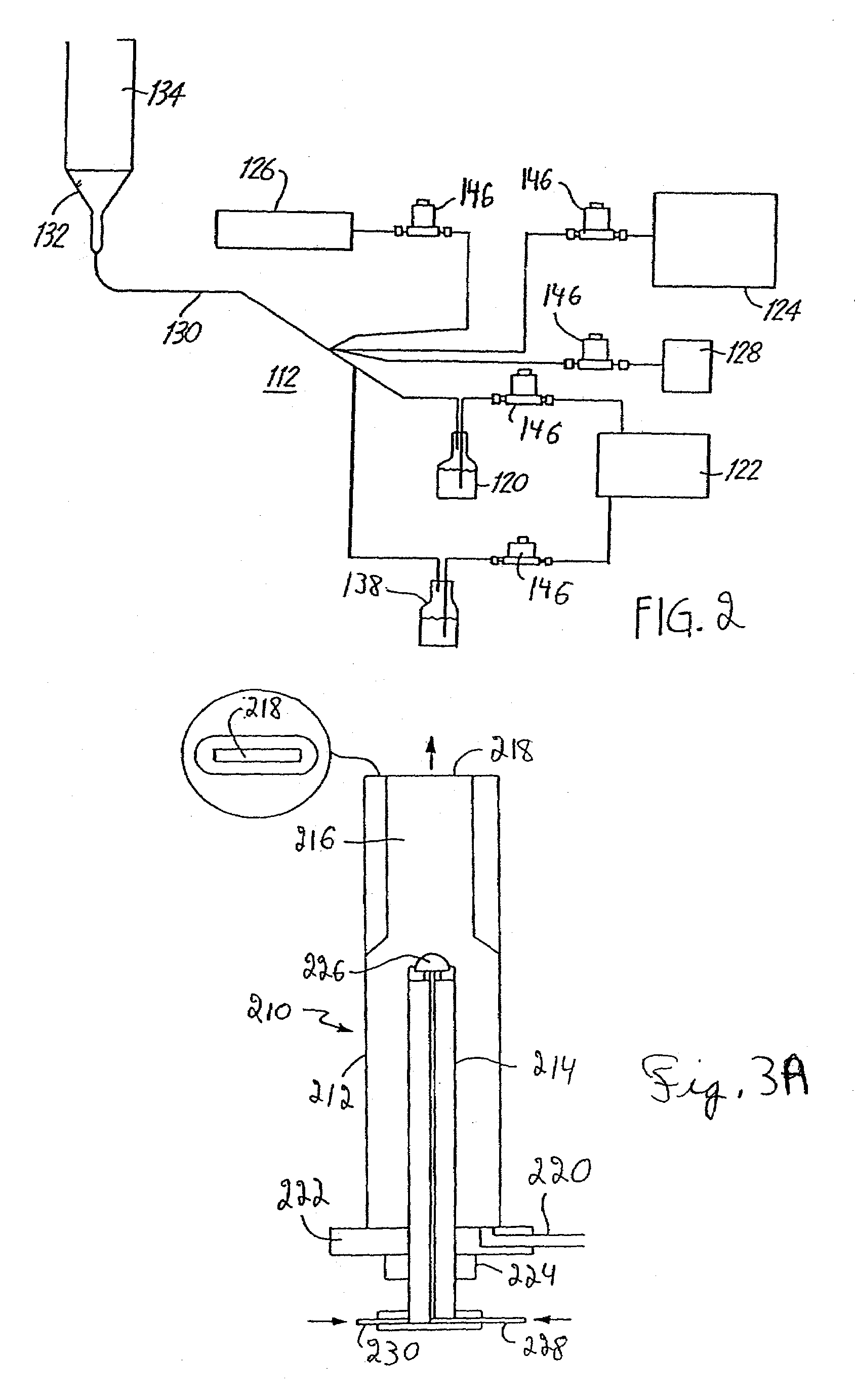

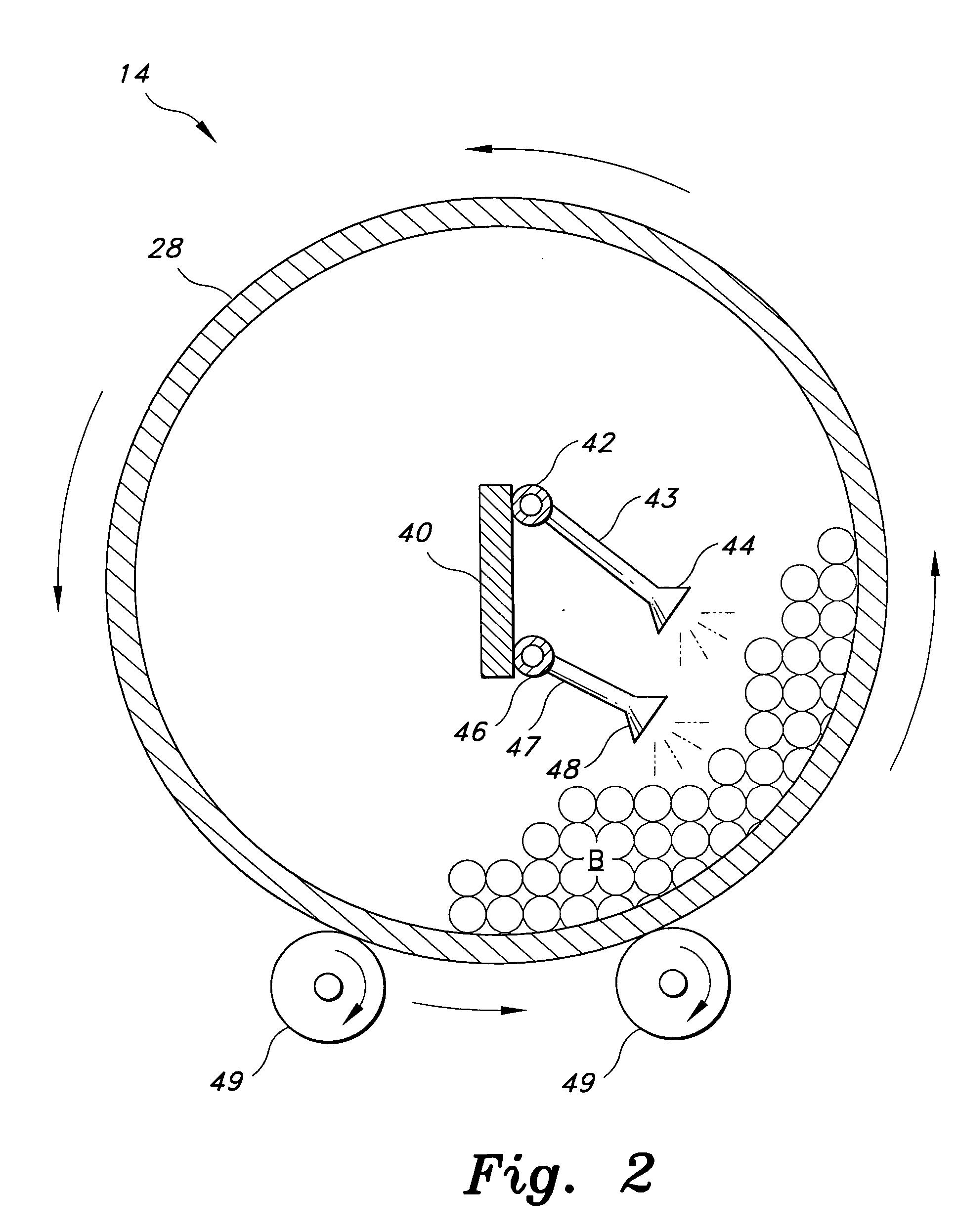

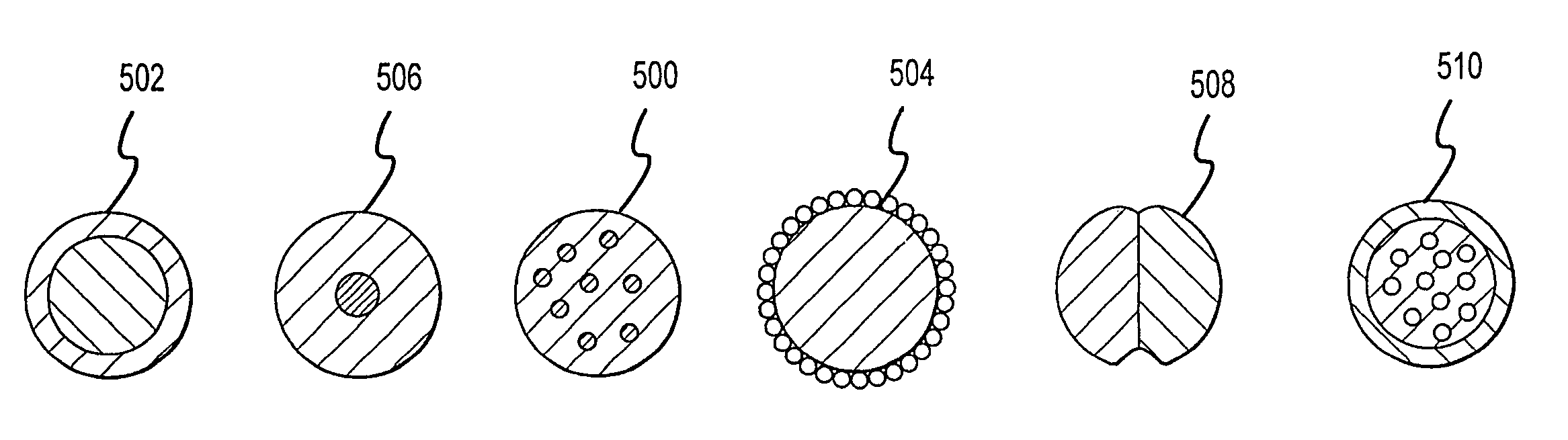

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS6582819B2Low densityEasy to transportGranule coatingPretreated surfacesFiltrationArtificial turf

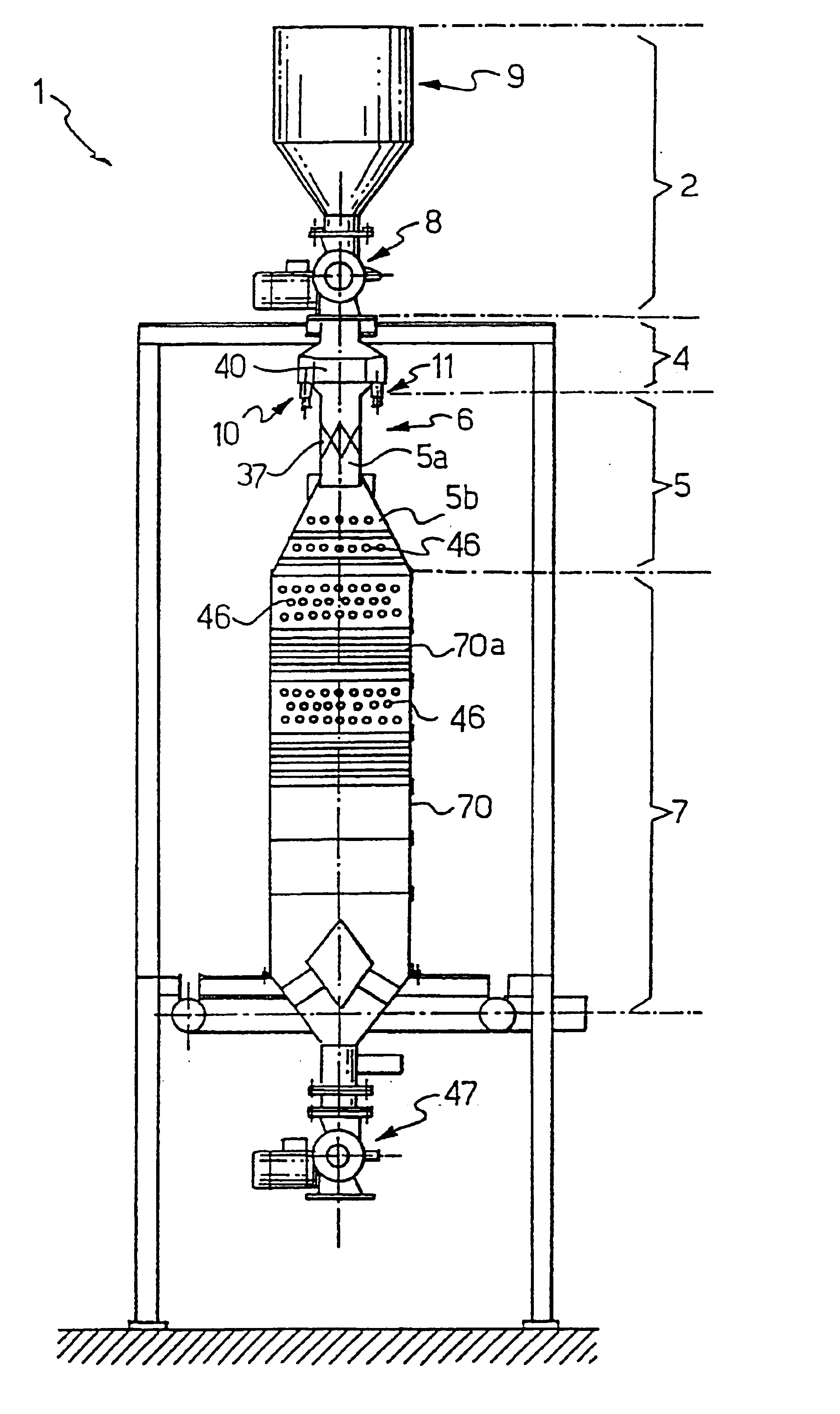

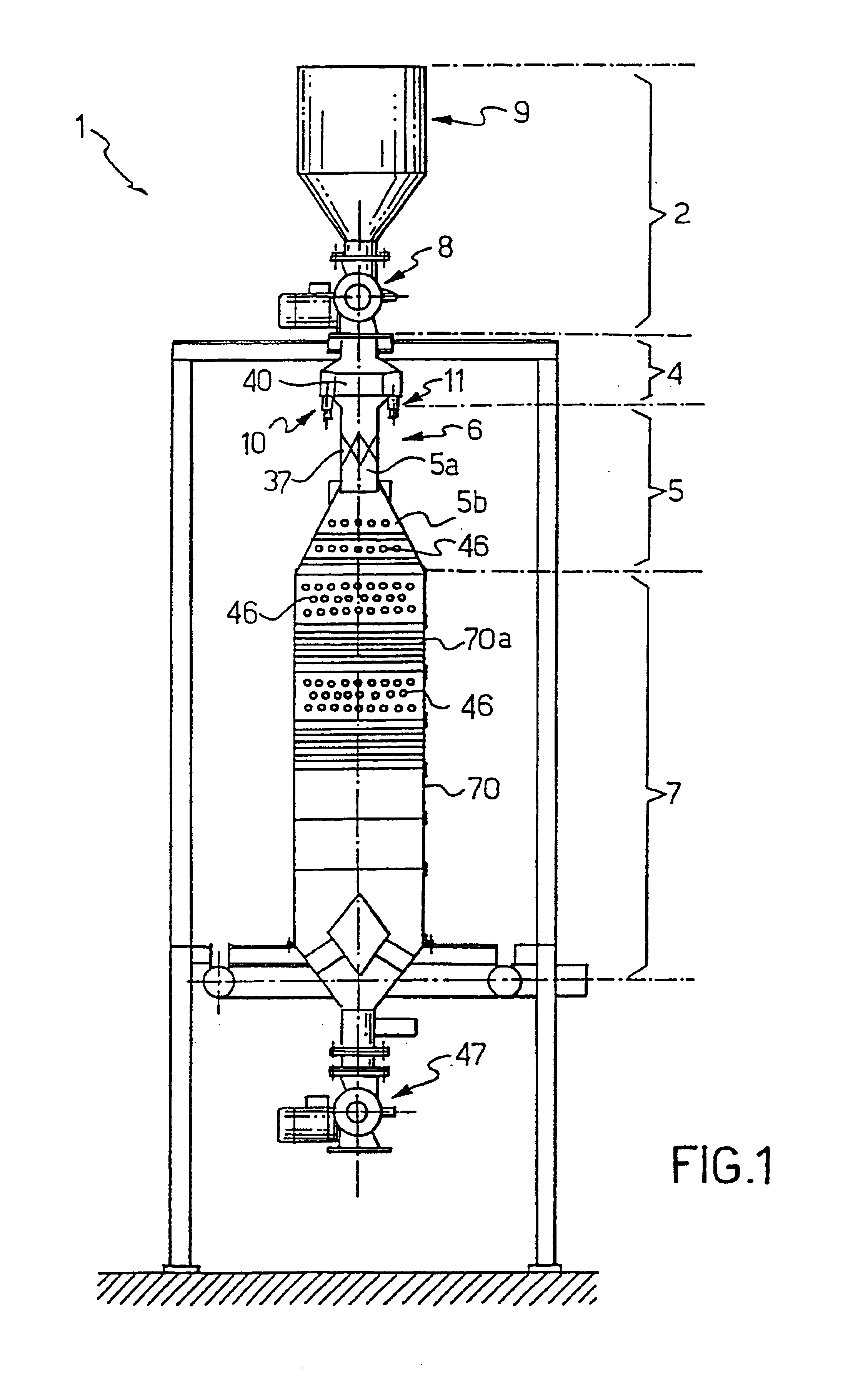

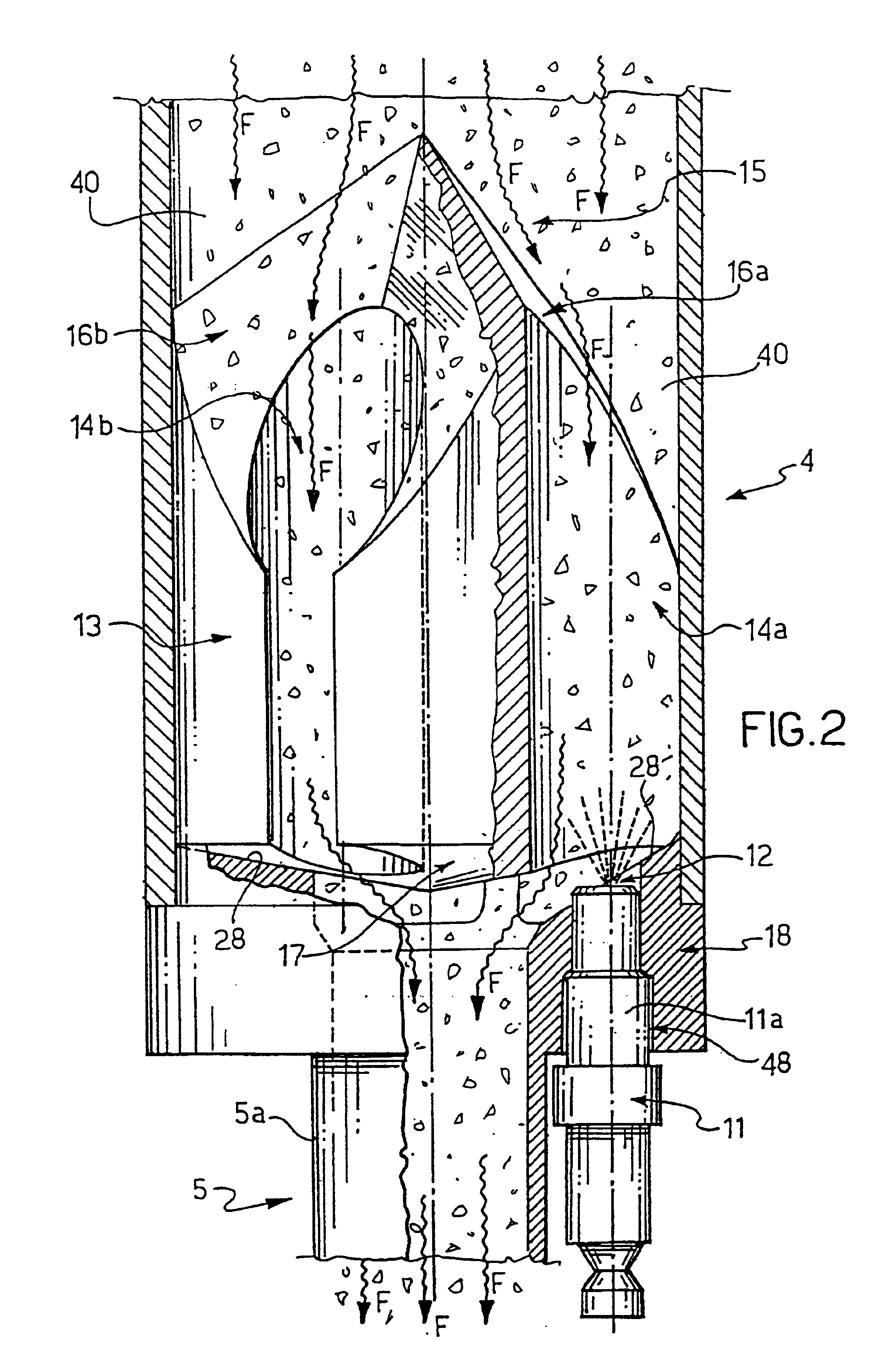

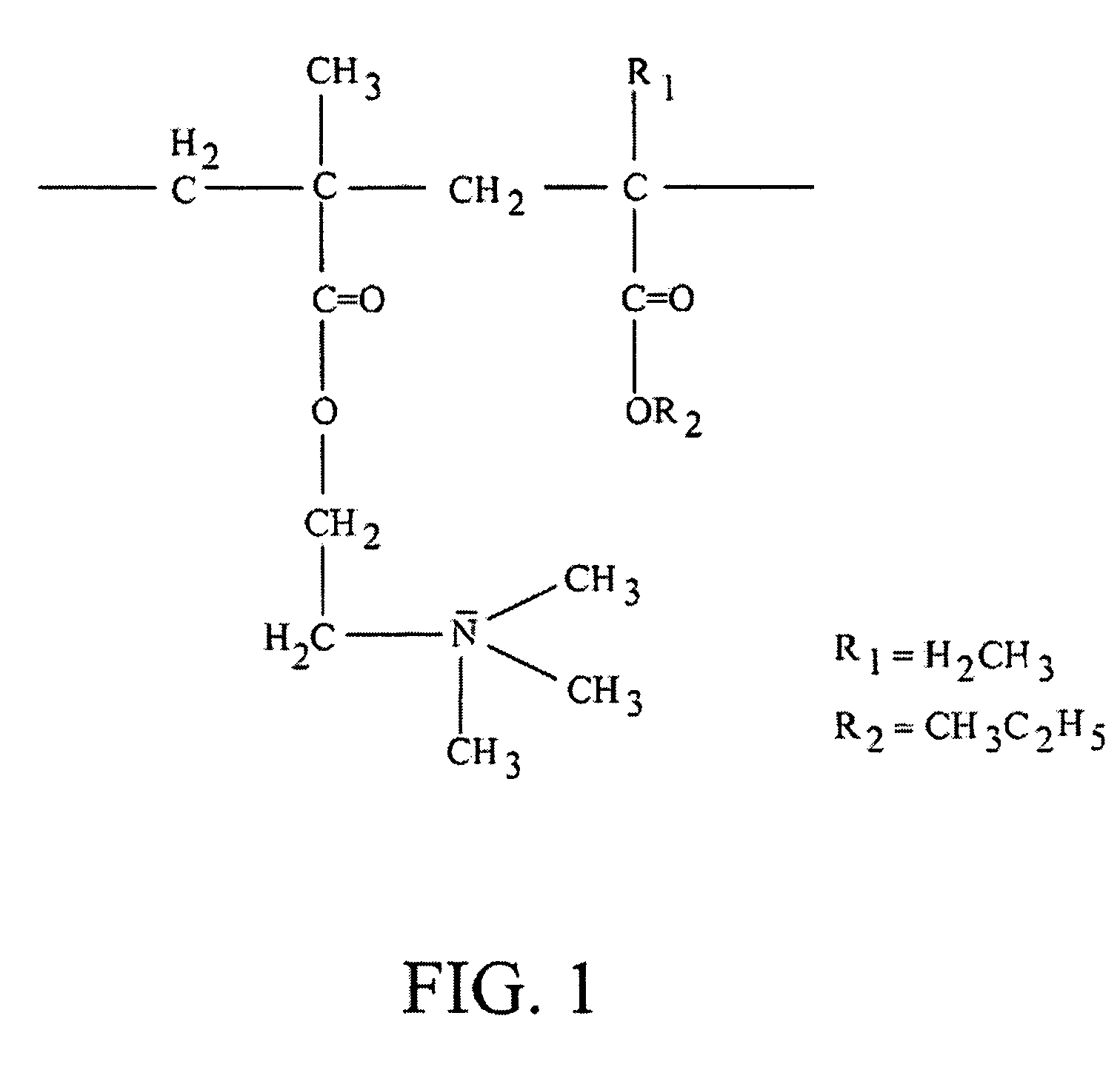

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS20020048676A1Point becomes highImprove interfacial organic-inorganic adhesionPigmenting treatmentDead plant preservationFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

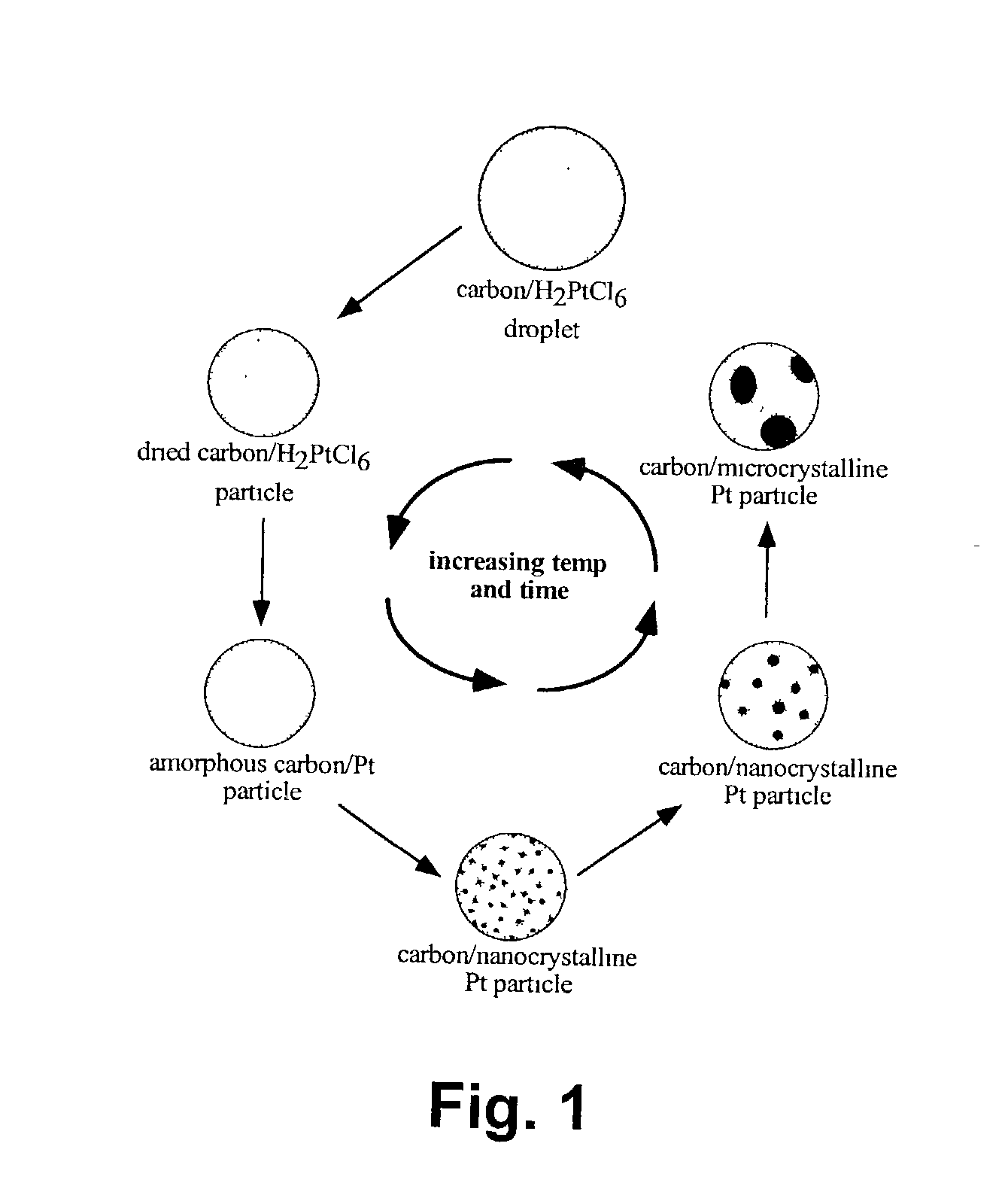

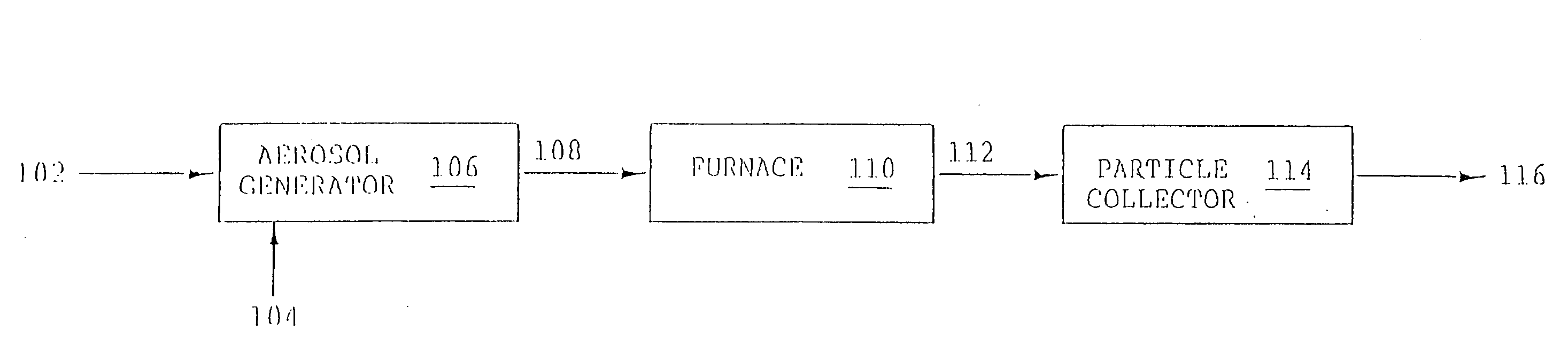

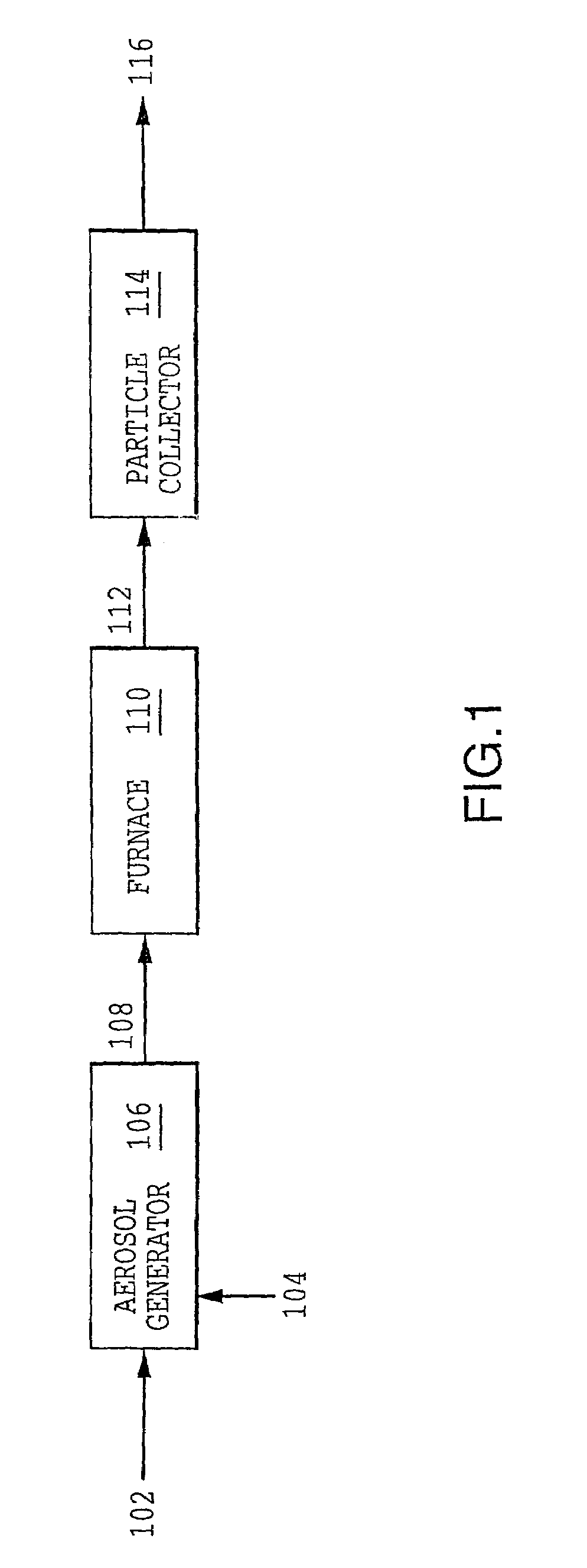

Electrocatalyst powders, methods for producing powders and devices fabricated from same

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

Nanocoated primary particles and method for their manufacture

InactiveUS6913827B2Granule coatingSemiconductor/solid-state device detailsConformal coatingElectronic packaging

Particles have an ultrathin, conformal coating are made using atomic layer deposition methods. The base particles include ceramic and metallic materials. The coatings can also be ceramic or metal materials that can be deposited in a binary reaction sequence. The coated particles are useful as fillers for electronic packaging applications, for making ceramic or cermet parts, as supported catalysts, as well as other applications.

Owner:UNIV OF COLORADO THE REGENTS OF

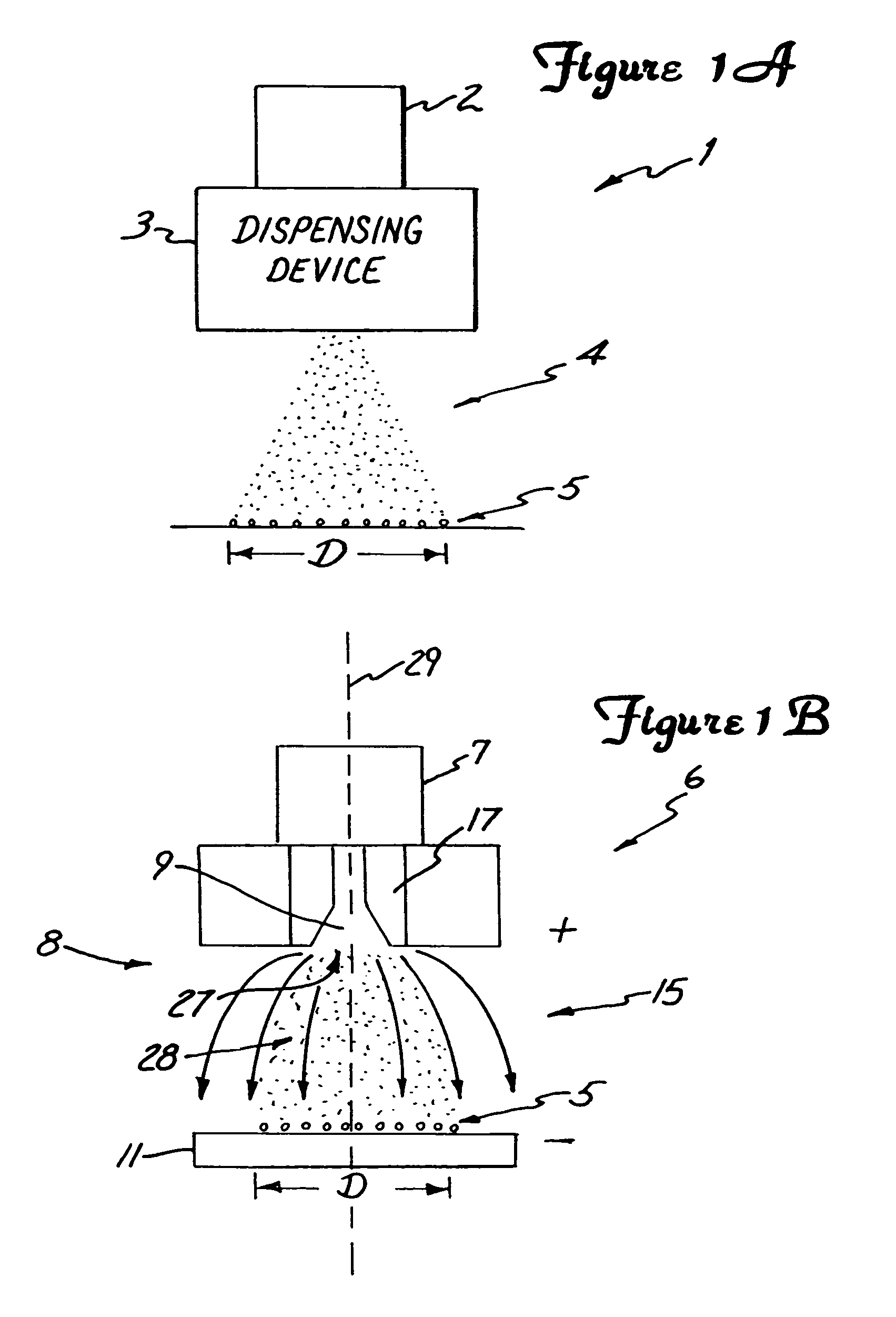

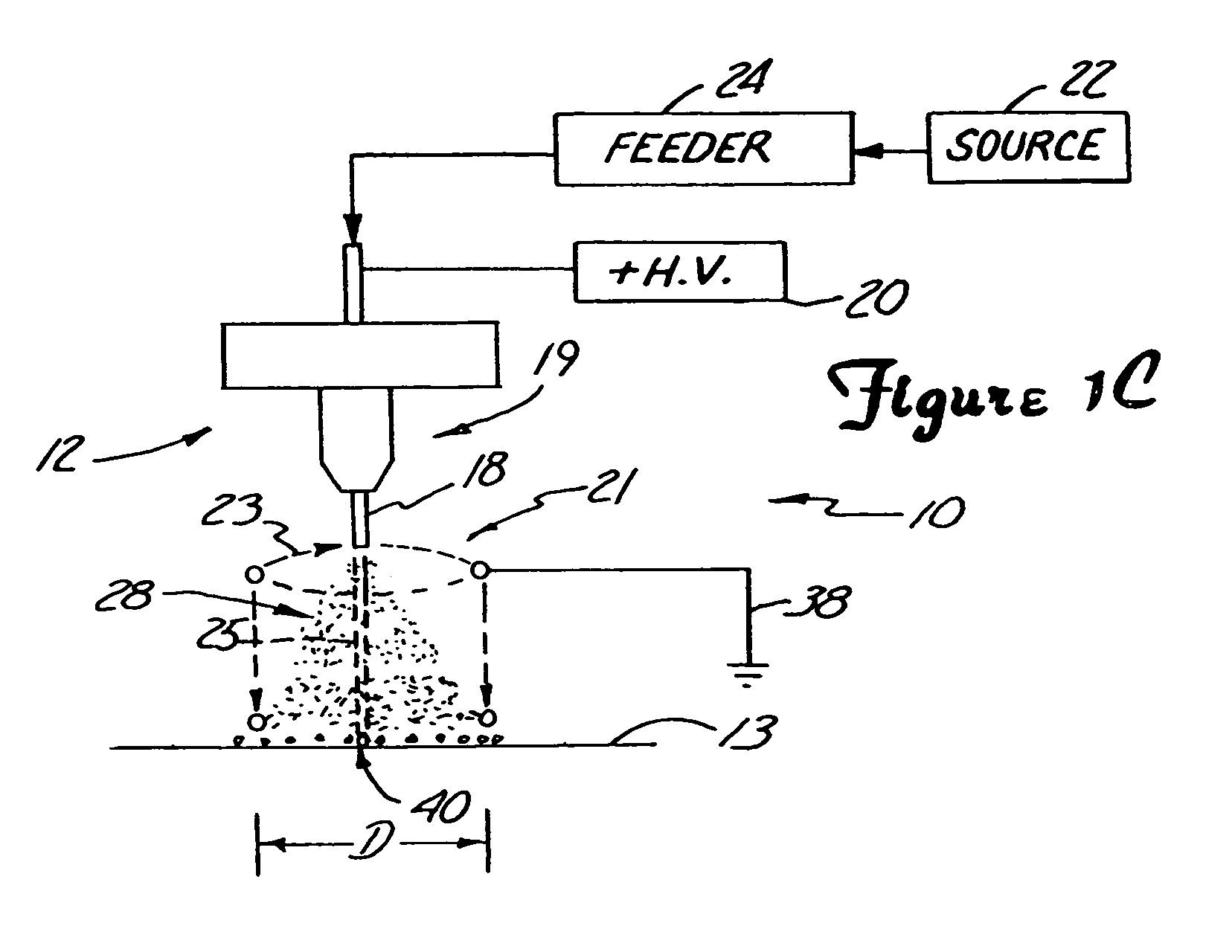

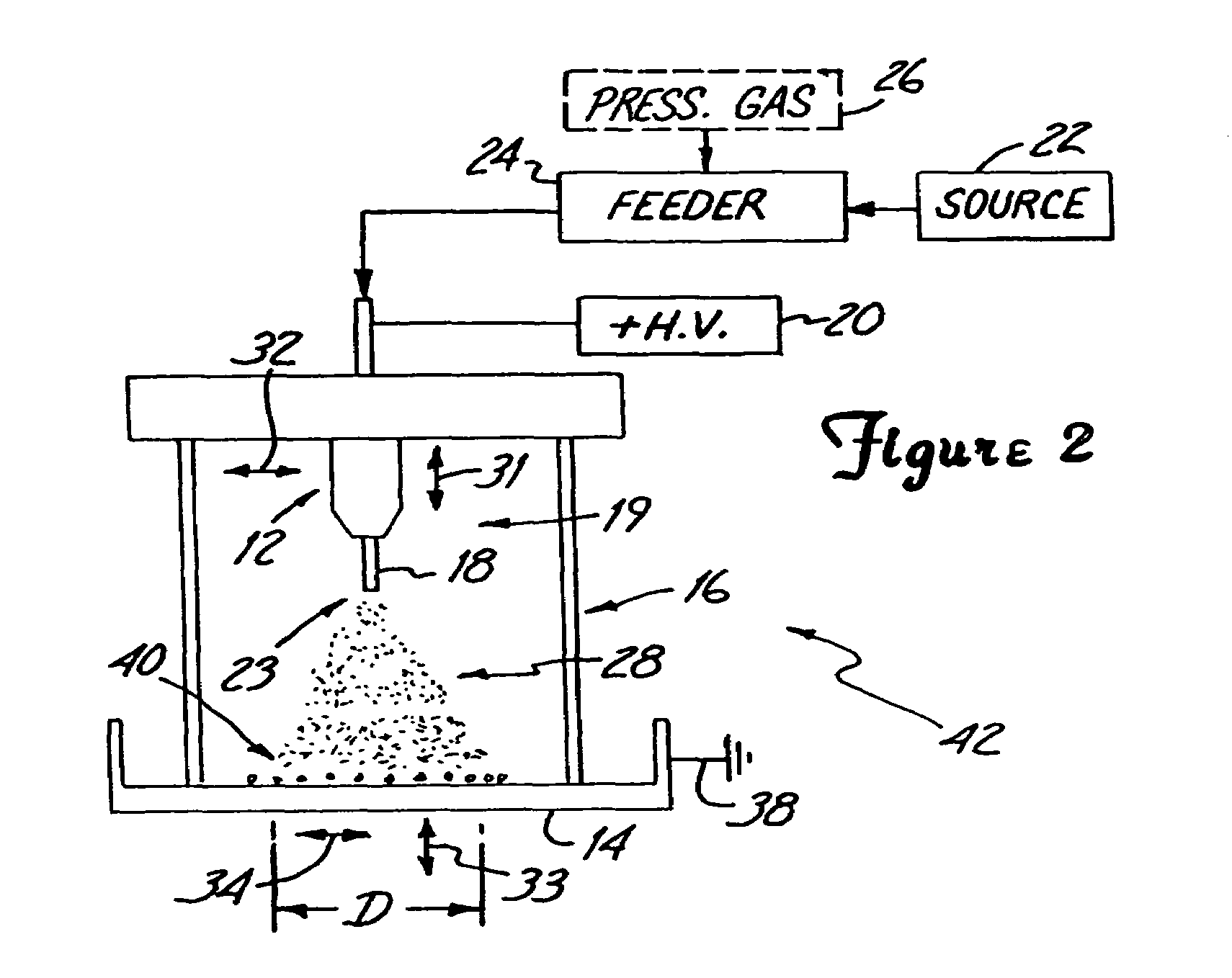

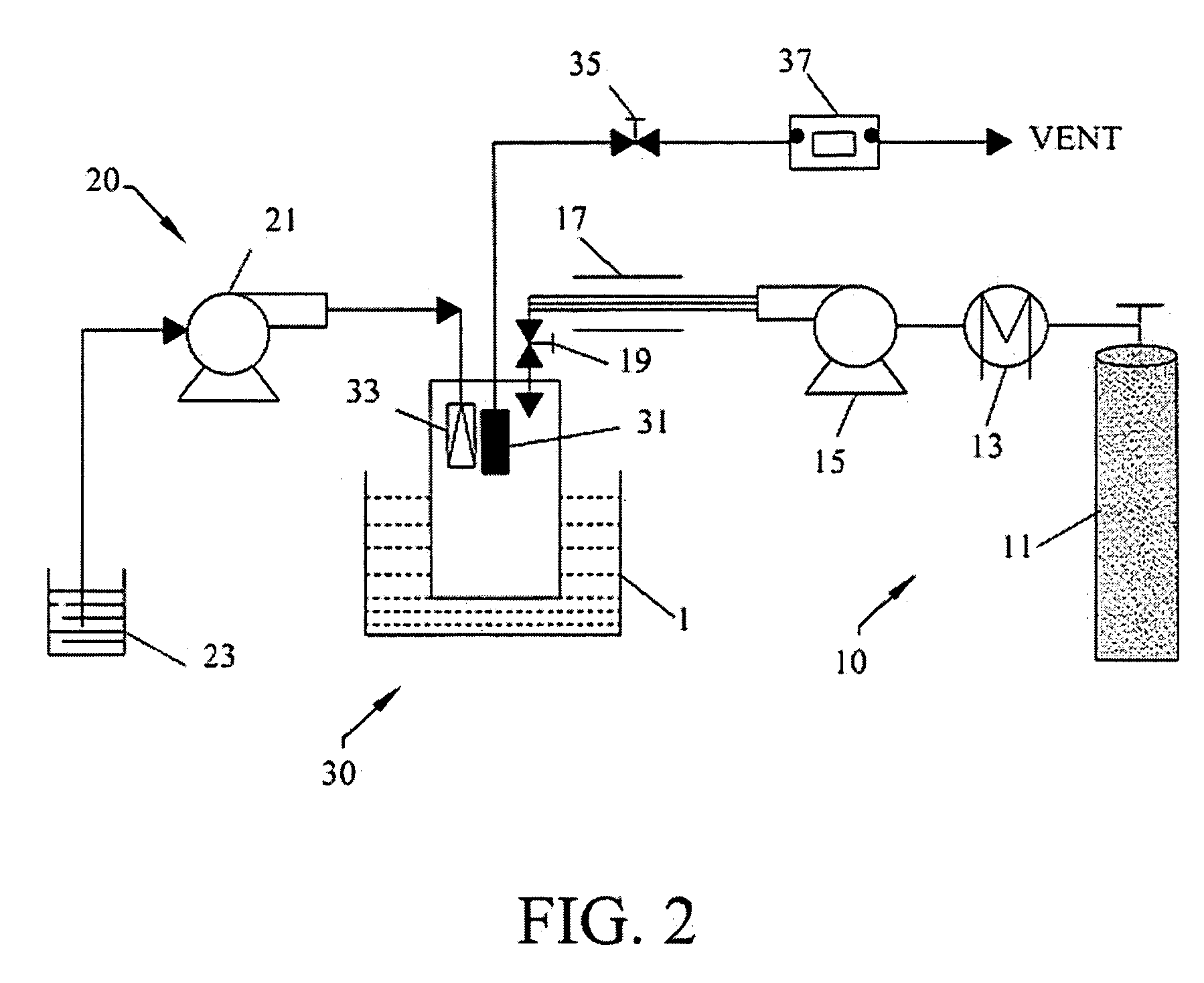

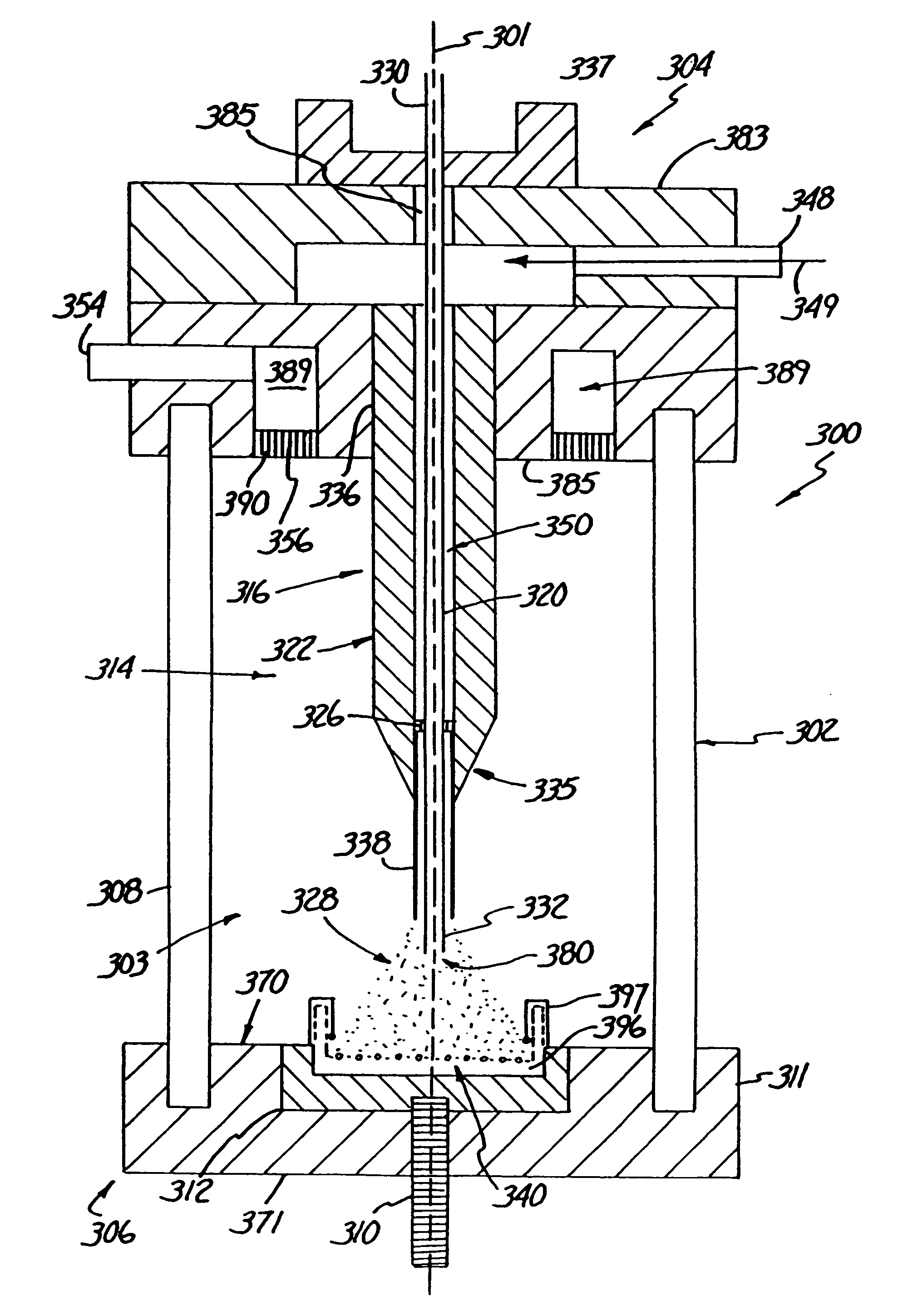

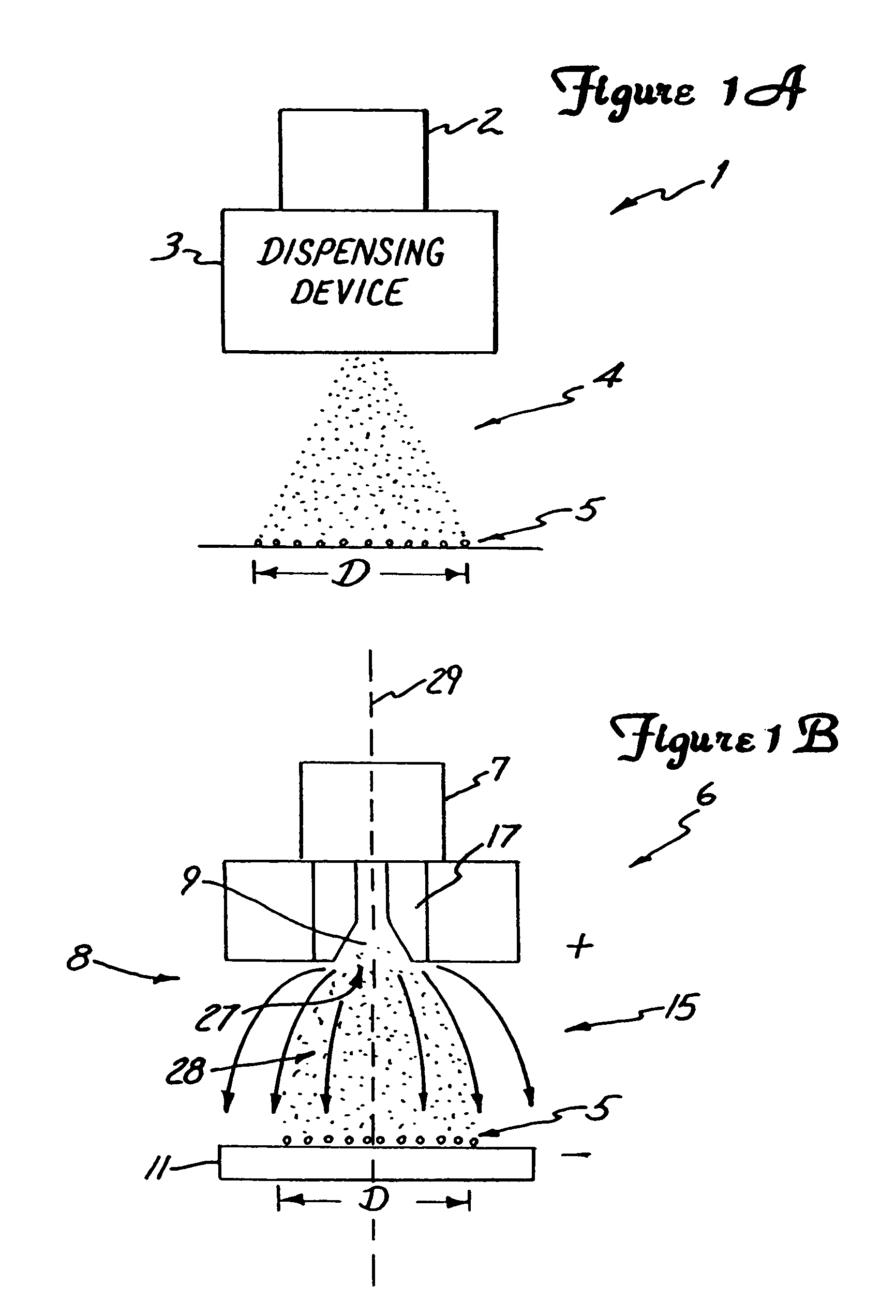

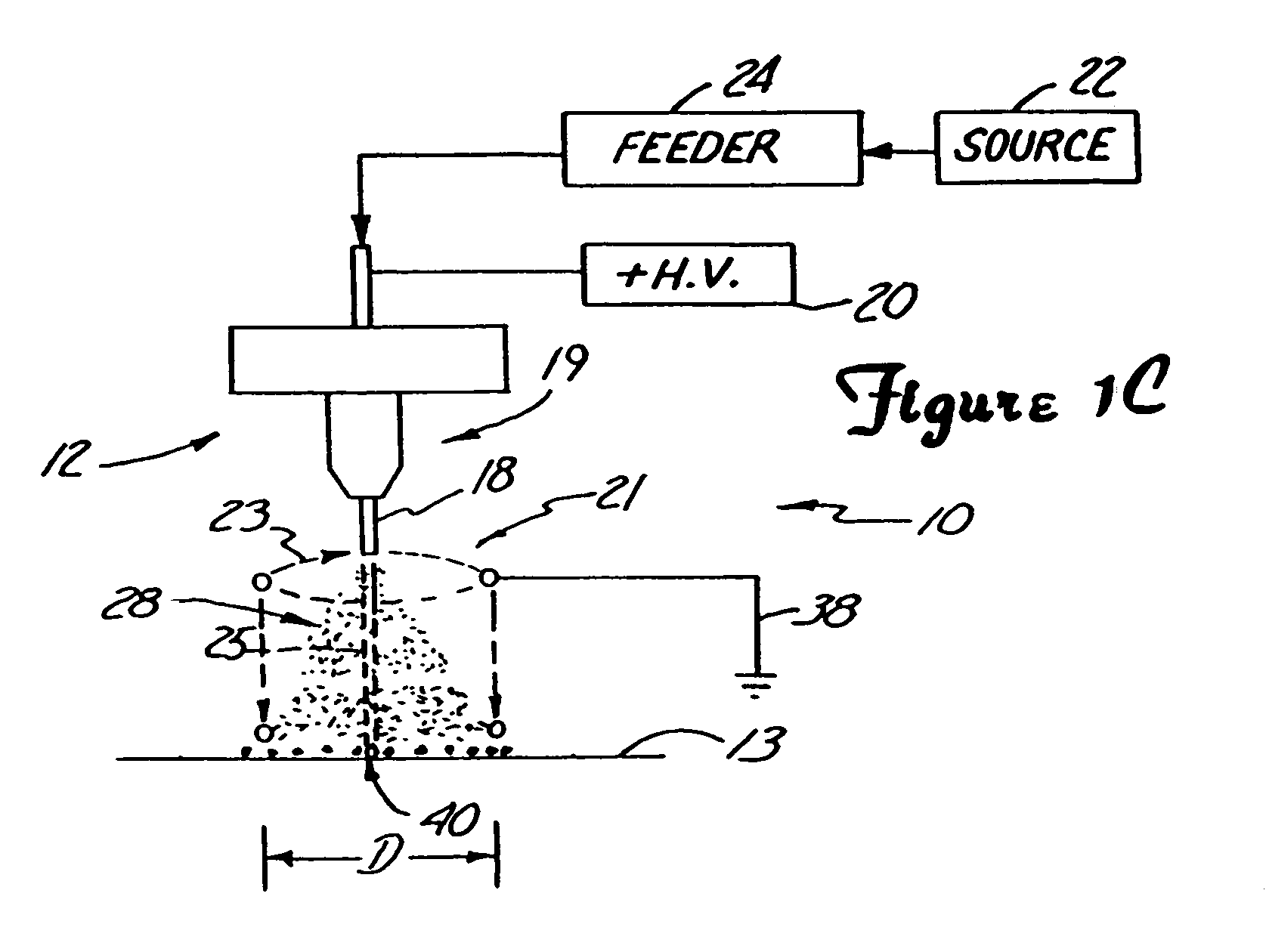

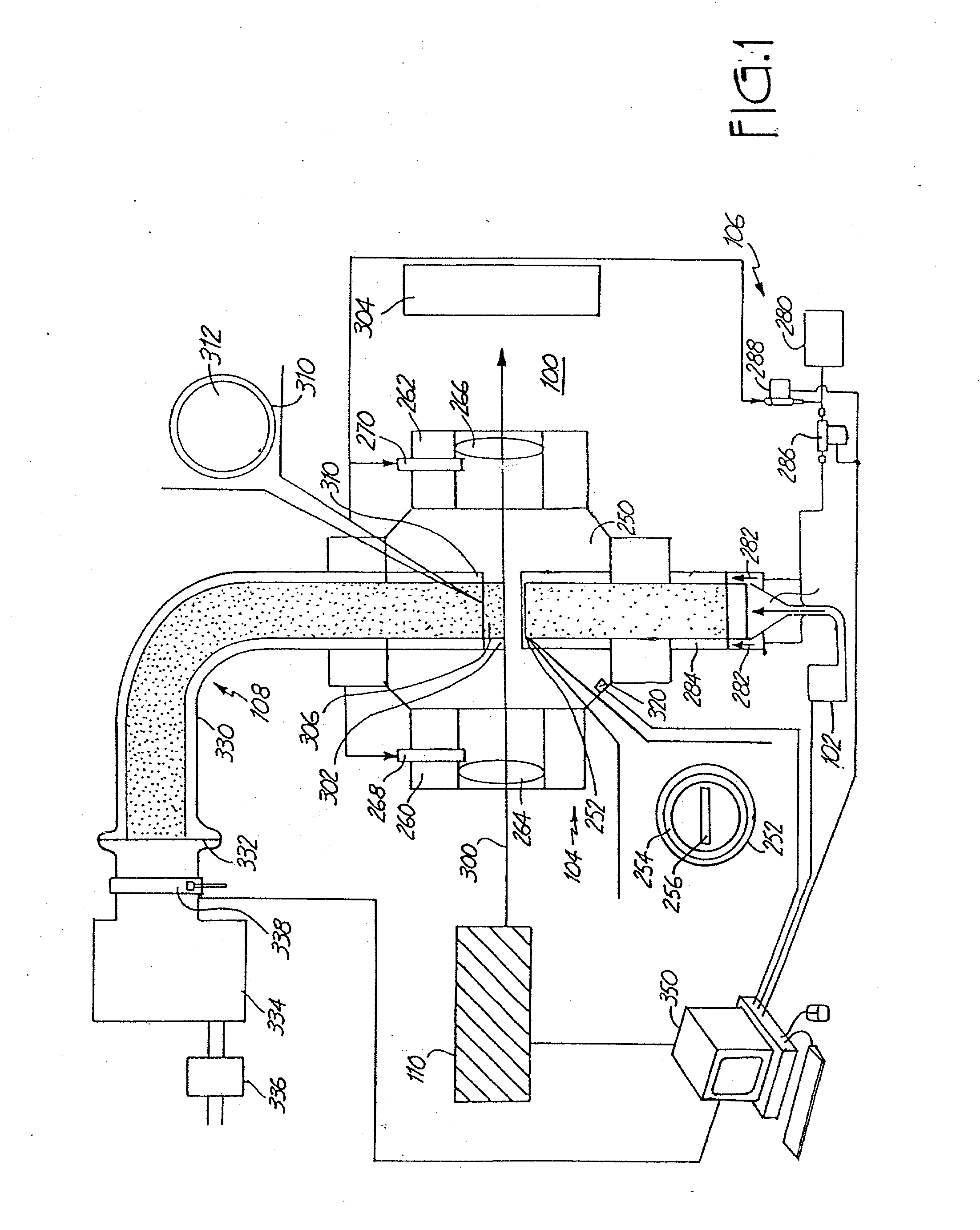

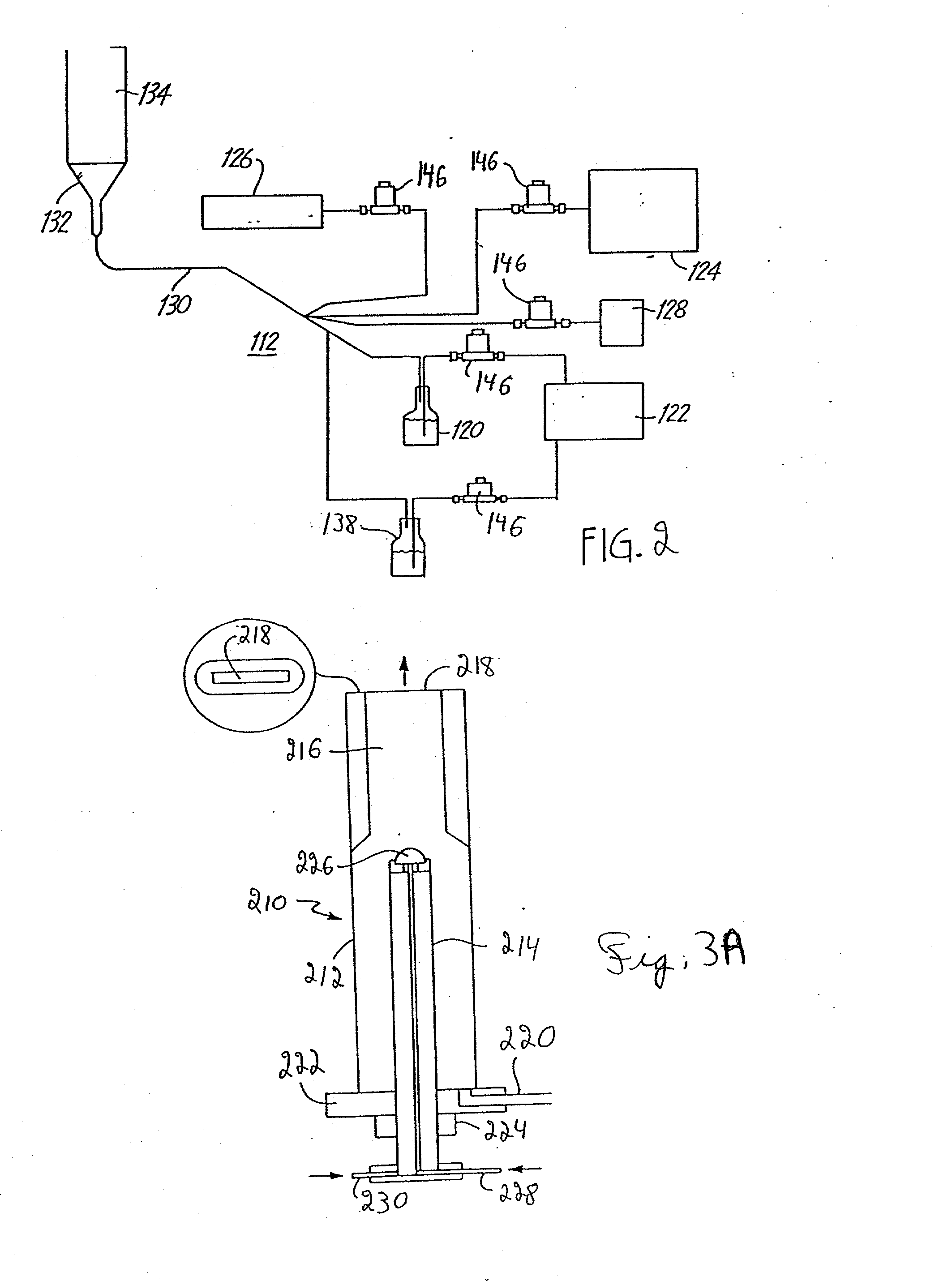

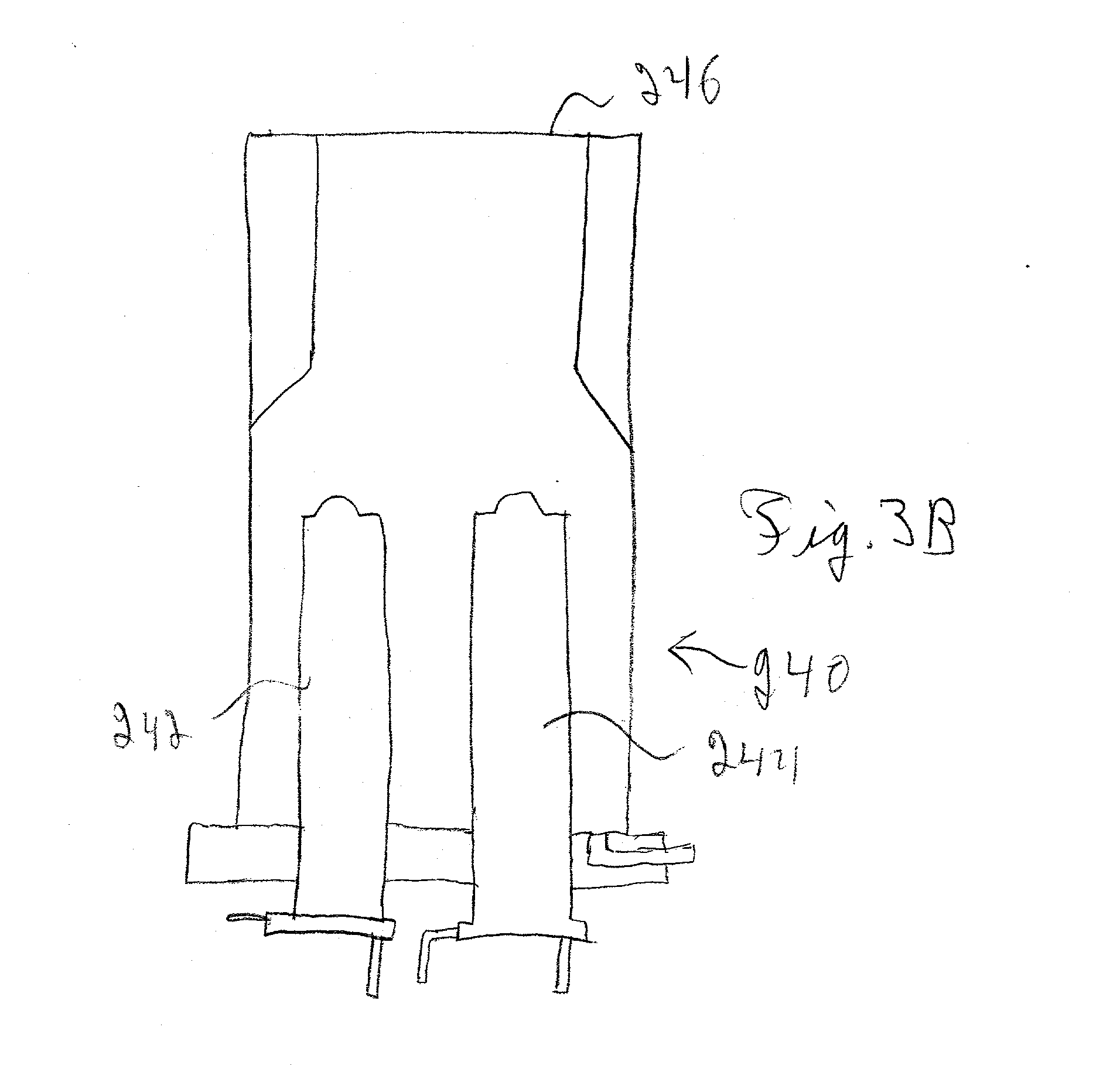

Electrospraying apparatus and method for coating particles

An electrospraying apparatus and / or method is used to coat particles. For example, a flow including at least one liquid suspension may be provided through at least one opening at a spray dispenser end. The flow includes at least particles and a coating material. A spray of microdroplets suspending at least the particles is established forward of the spray dispenser end by creating a nonuniform electrical field between the spray dispenser end and an electrode electrically isolated therefrom. The particles are coated with at least a portion of the coating material as the microdroplet evaporates. For example, the suspension may include biological material particles.

Owner:RGT UNIV OF MINNESOTA

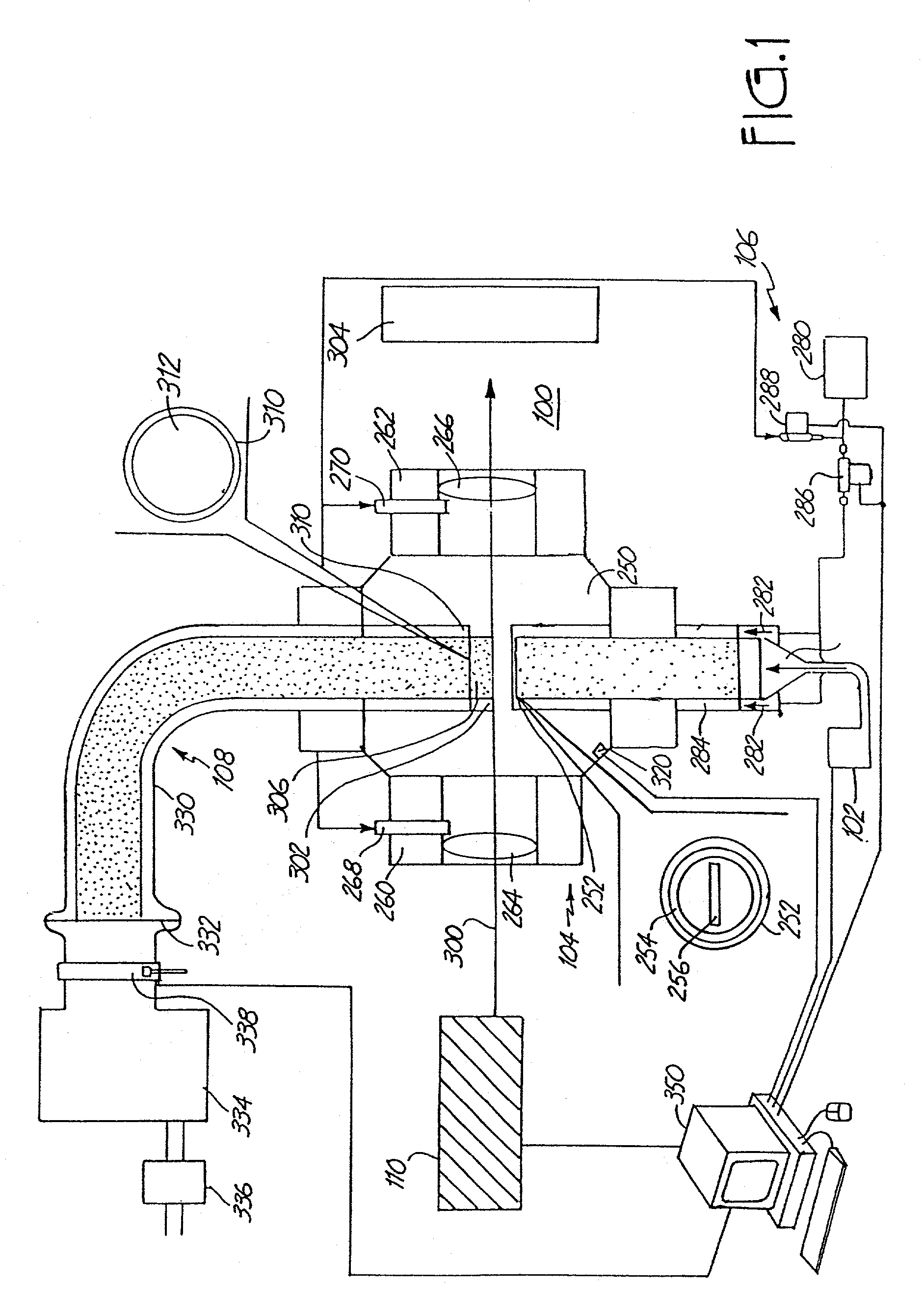

Nanoparticle-based power coatings and corresponding structures

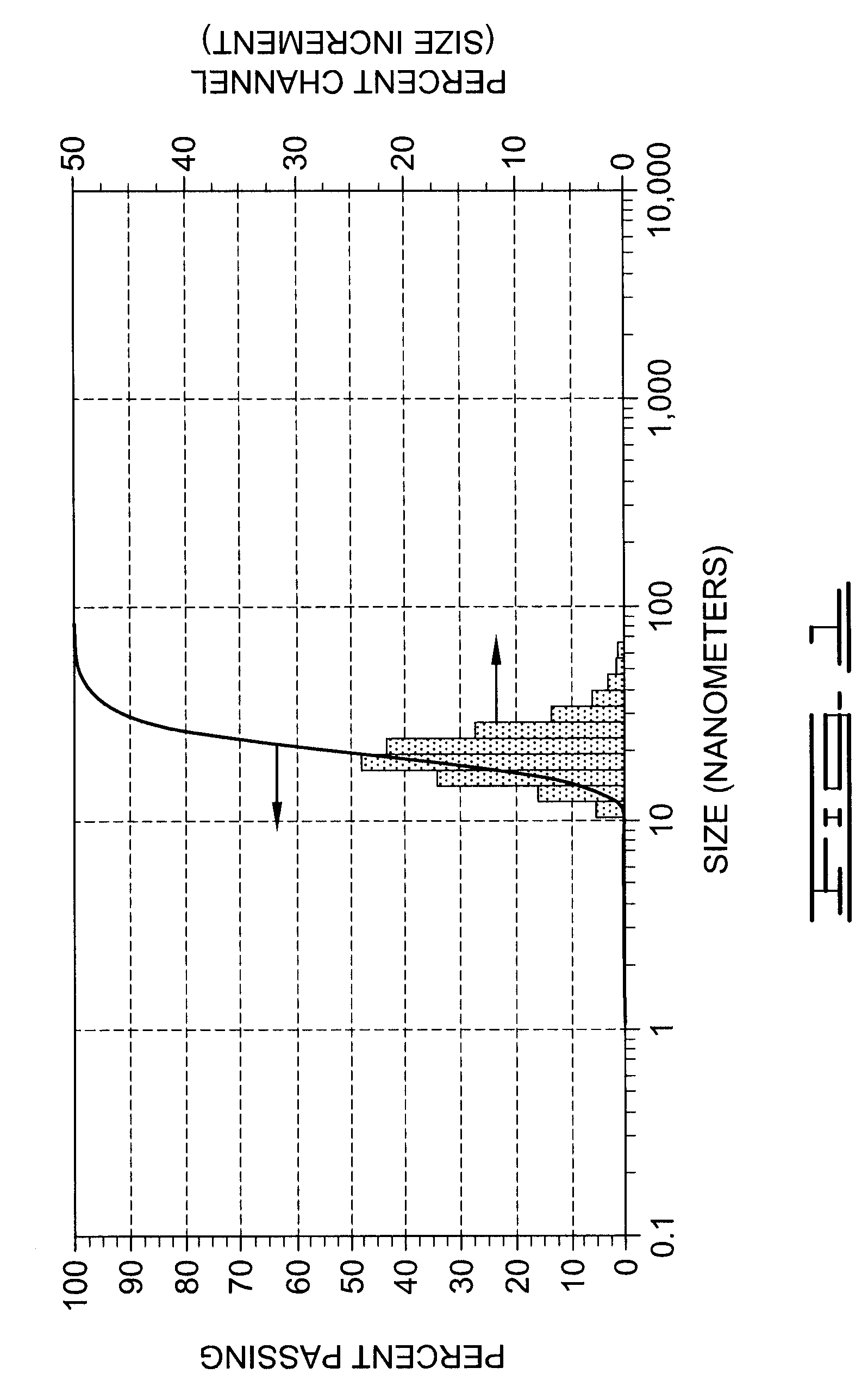

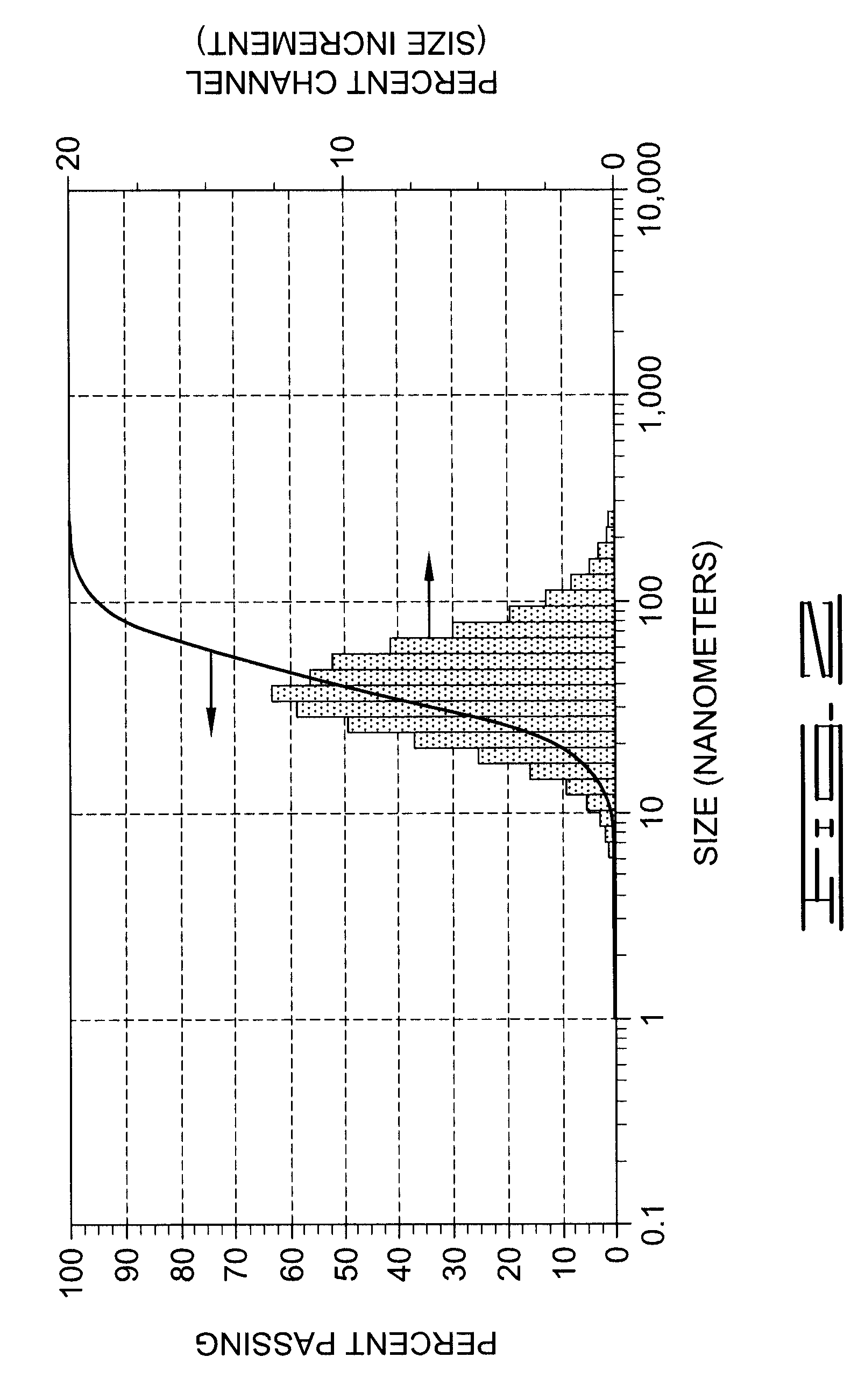

Methods are described that have the capability of producing submicron / nanoscale particles, in some embodiments dispersible, at high production rates. In some embodiments, the methods result in the production of particles with an average diameter less than about 75 nanometers that are produced at a rate of at least about 35 grams per hour. In other embodiments, the particles are highly uniform. These methods can be used to form particle collections and / or powder coatings. Powder coatings and corresponding methods are described based on the deposition of highly uniform submicron / nanoscale particles.

Owner:NANOGRAM

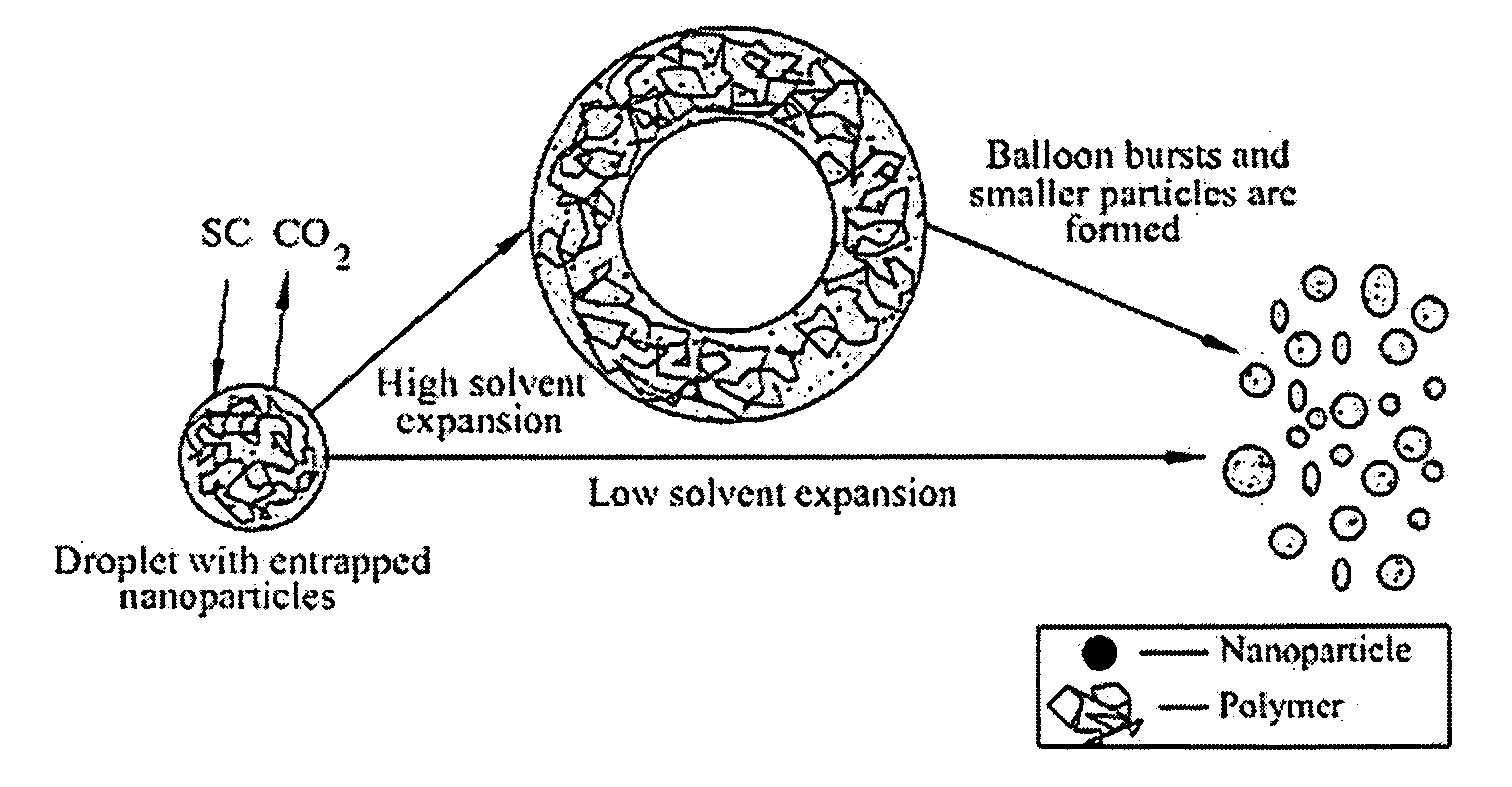

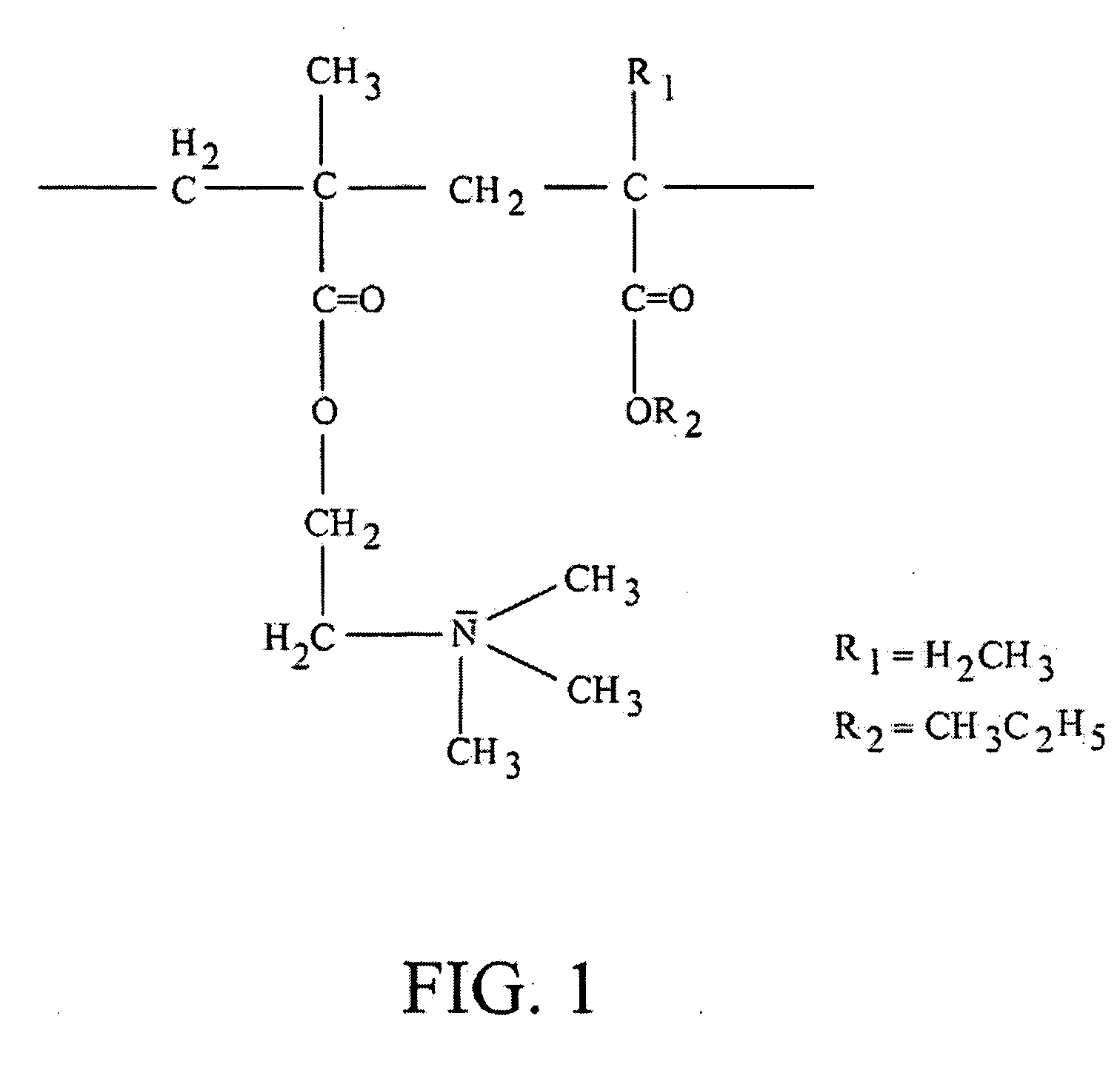

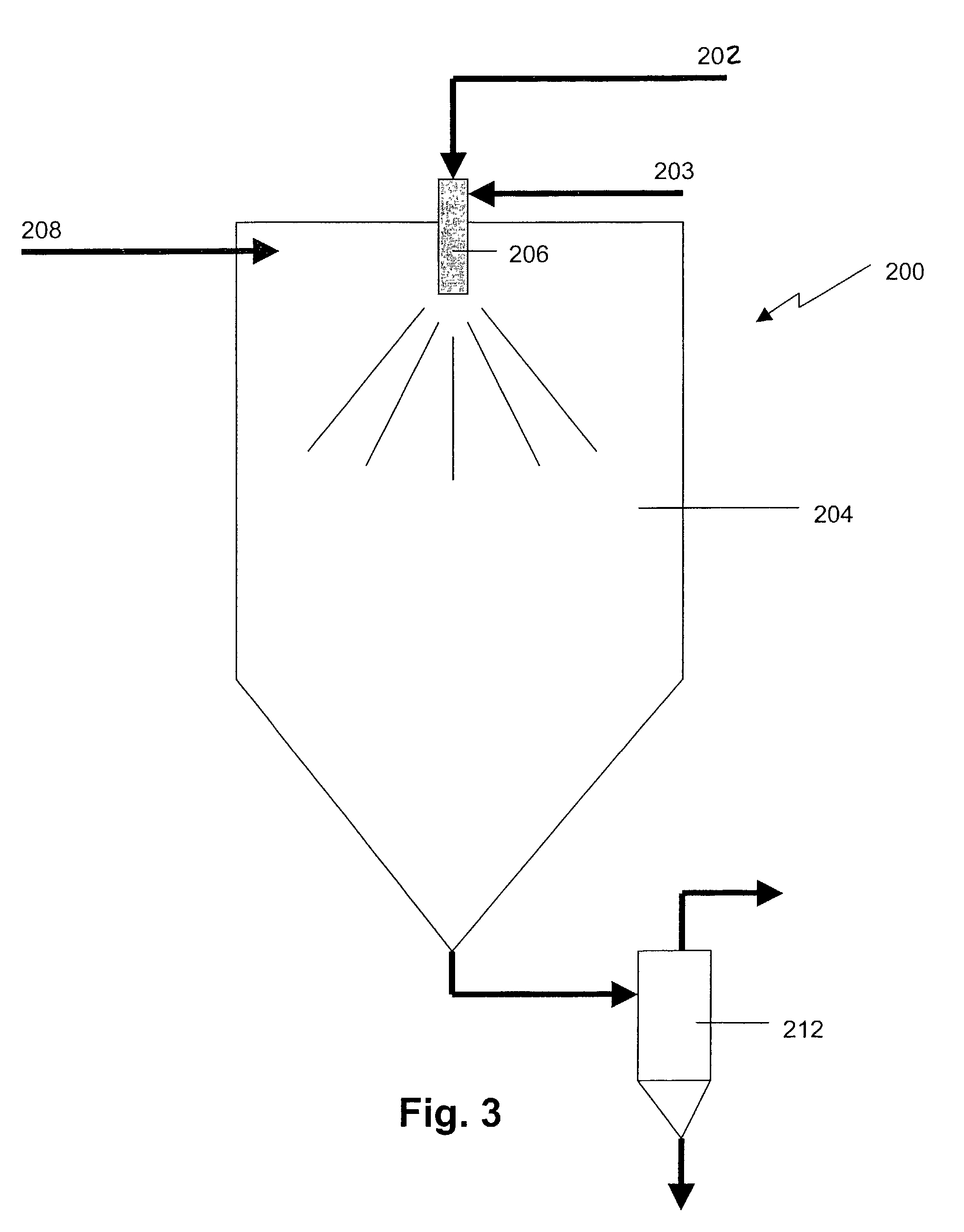

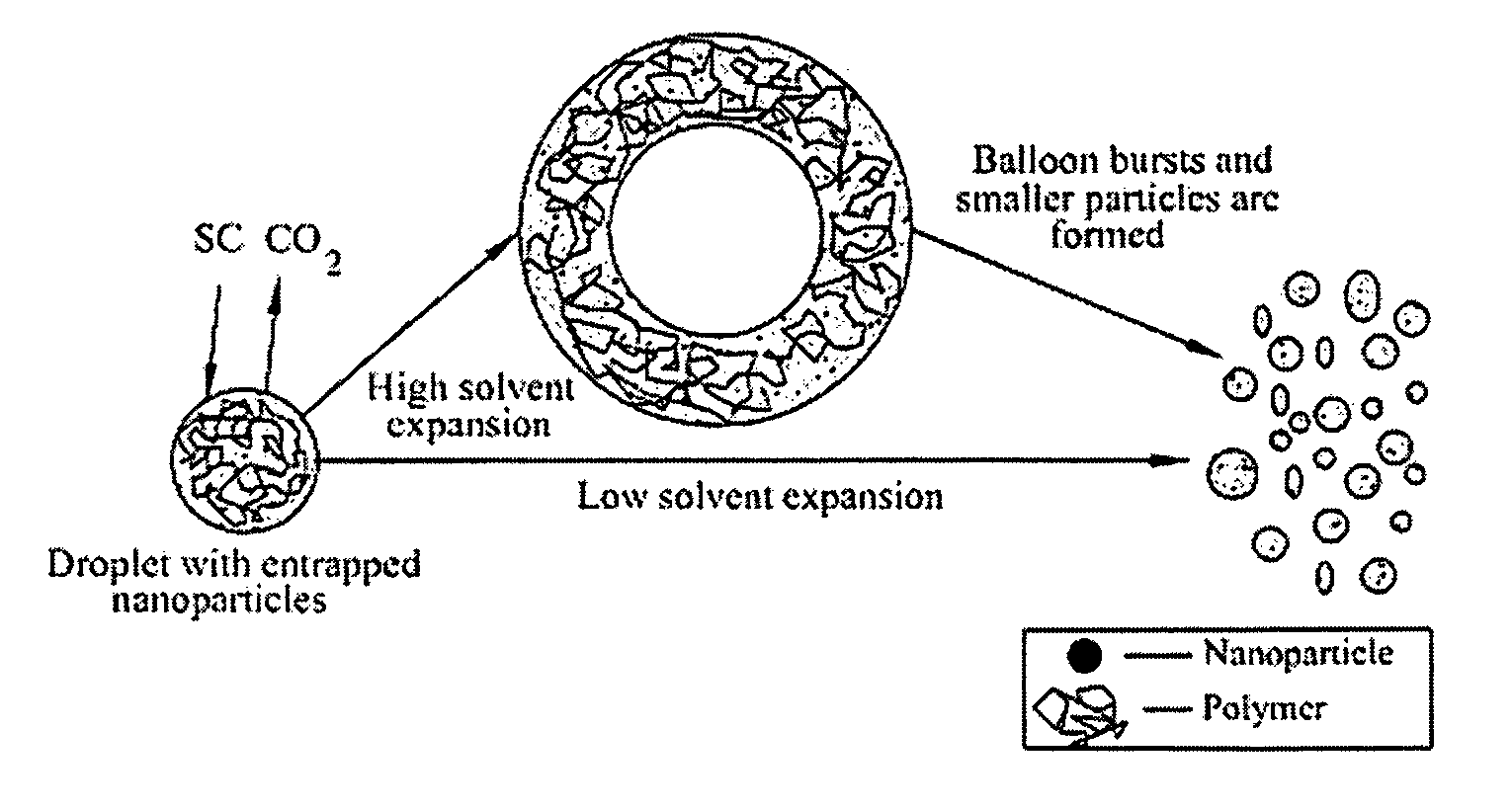

Polymer coating/encapsulation of nanoparticles using a supercritical antisolvent process

InactiveUS20050191491A1Speed up the processGranule coatingPretreated surfacesSolventSupercritical carbon dioxide

A process, method and / or system for preparing polymer-coated nanoparticles and / or other ultrafine particles utilizing a supercritical fluid, e.g., supercritical carbon dioxide (SC CO2), as an antisolvent that may be added to a solution of a polymer and an organic solvent in which insoluble nanoparticles or the like are suspended. The coating process occurs when the supercritical fluid (e.g., SC CO2) and the nanoparticle-containing suspension are combined to cause the suspended nanoparticles to precipitate as coated nanoparticles. Processing parameters for optimizing and / or enhancing the efficacy and / or efficiency of the coating process, method and / or system and for controlling the coating and / or agglomeration of coated particles are also described. The process, method and / or system has wide ranging applicability, e.g., for coating and / or encapsulation of pharmaceuticals, cosmetics, food products, chemicals, agrochemicals, pesticides, polymers, coatings, catalysts and the like.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

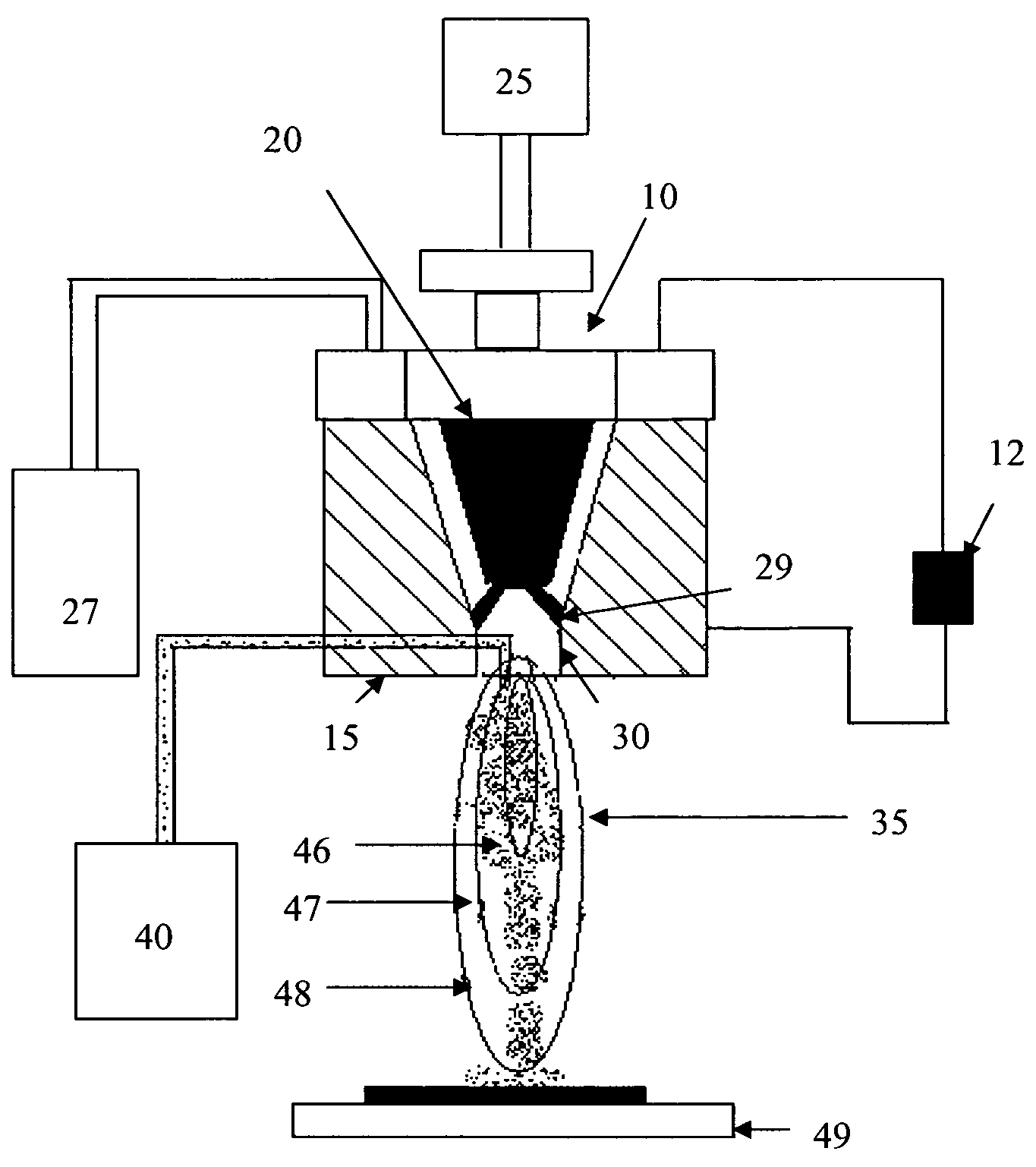

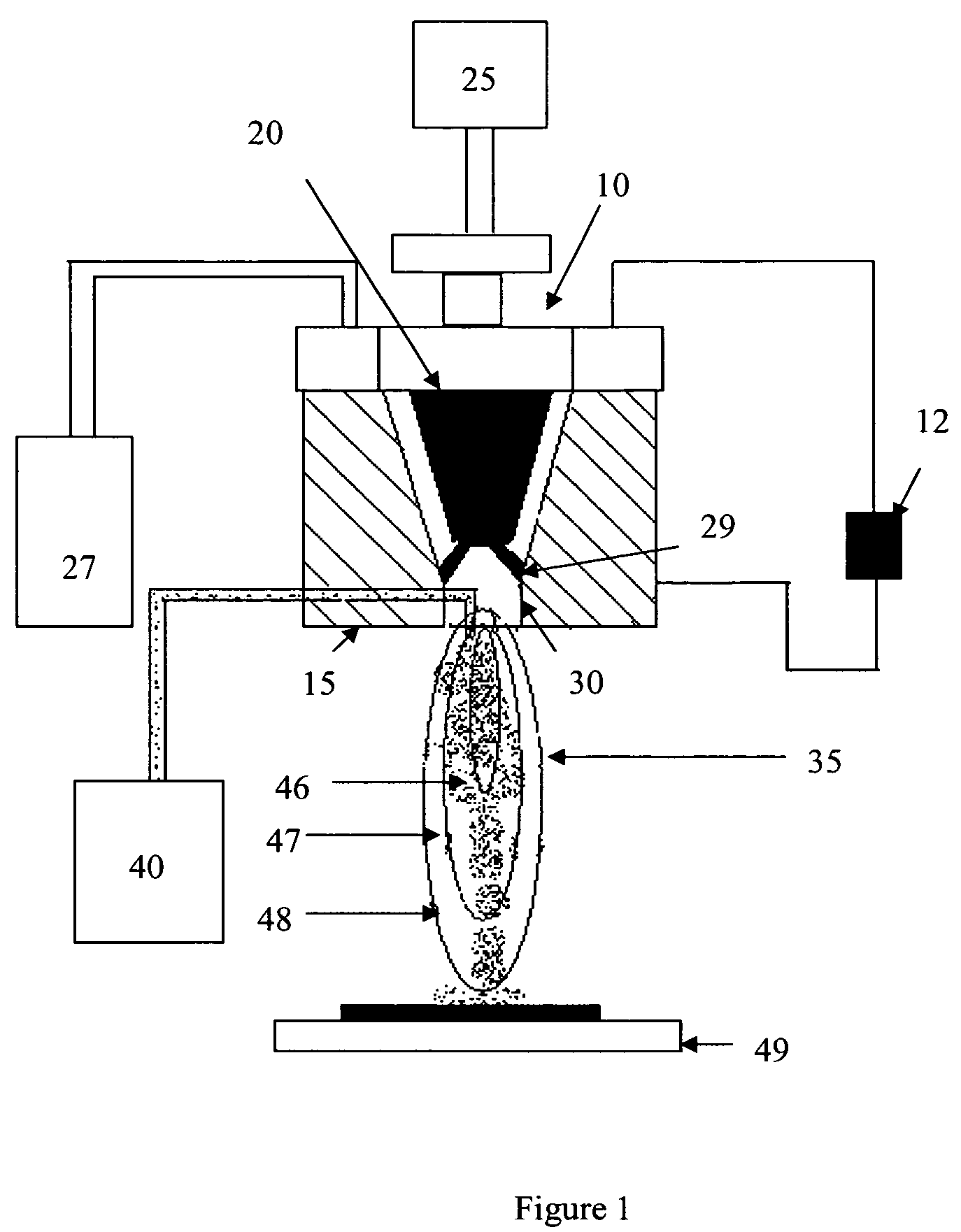

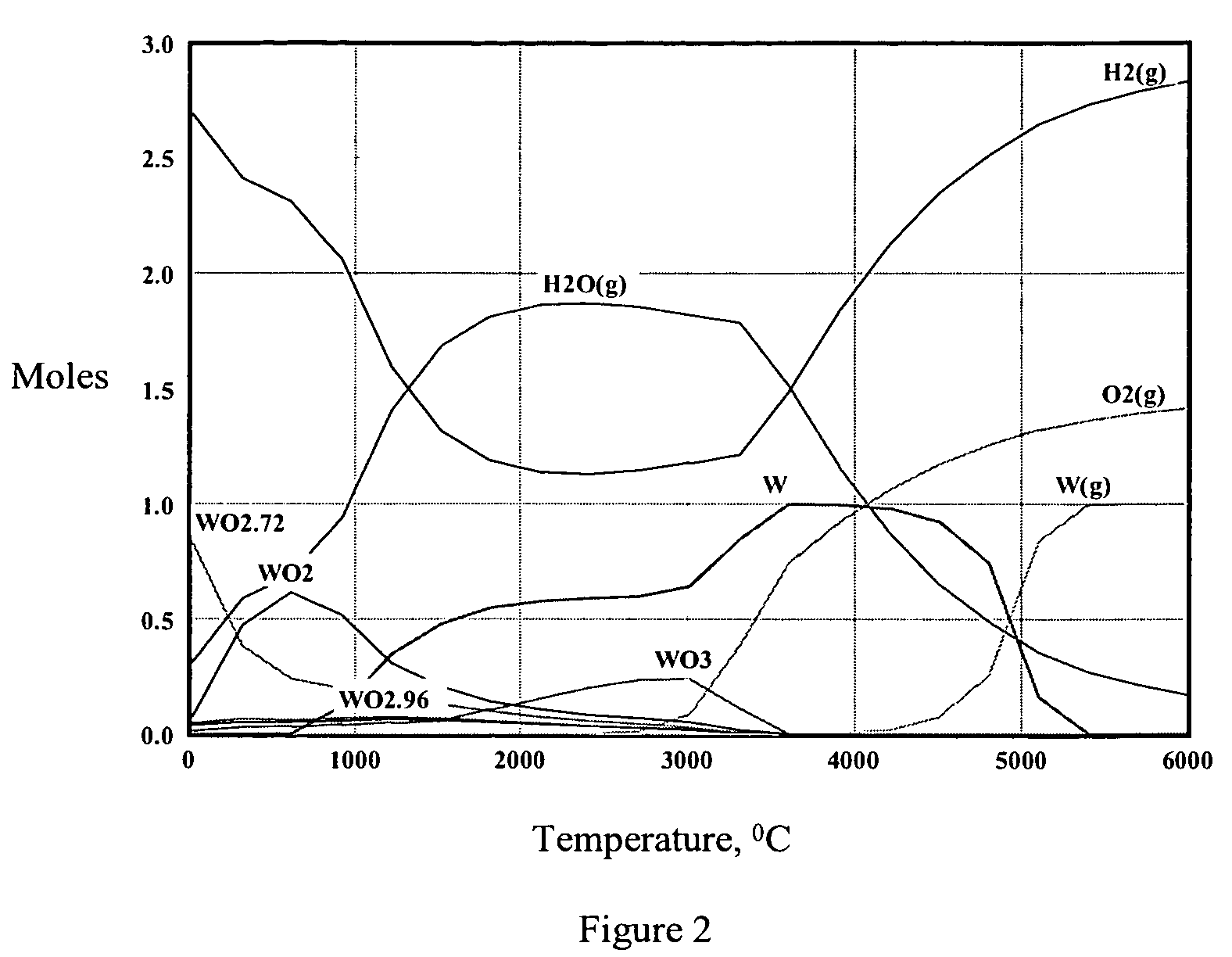

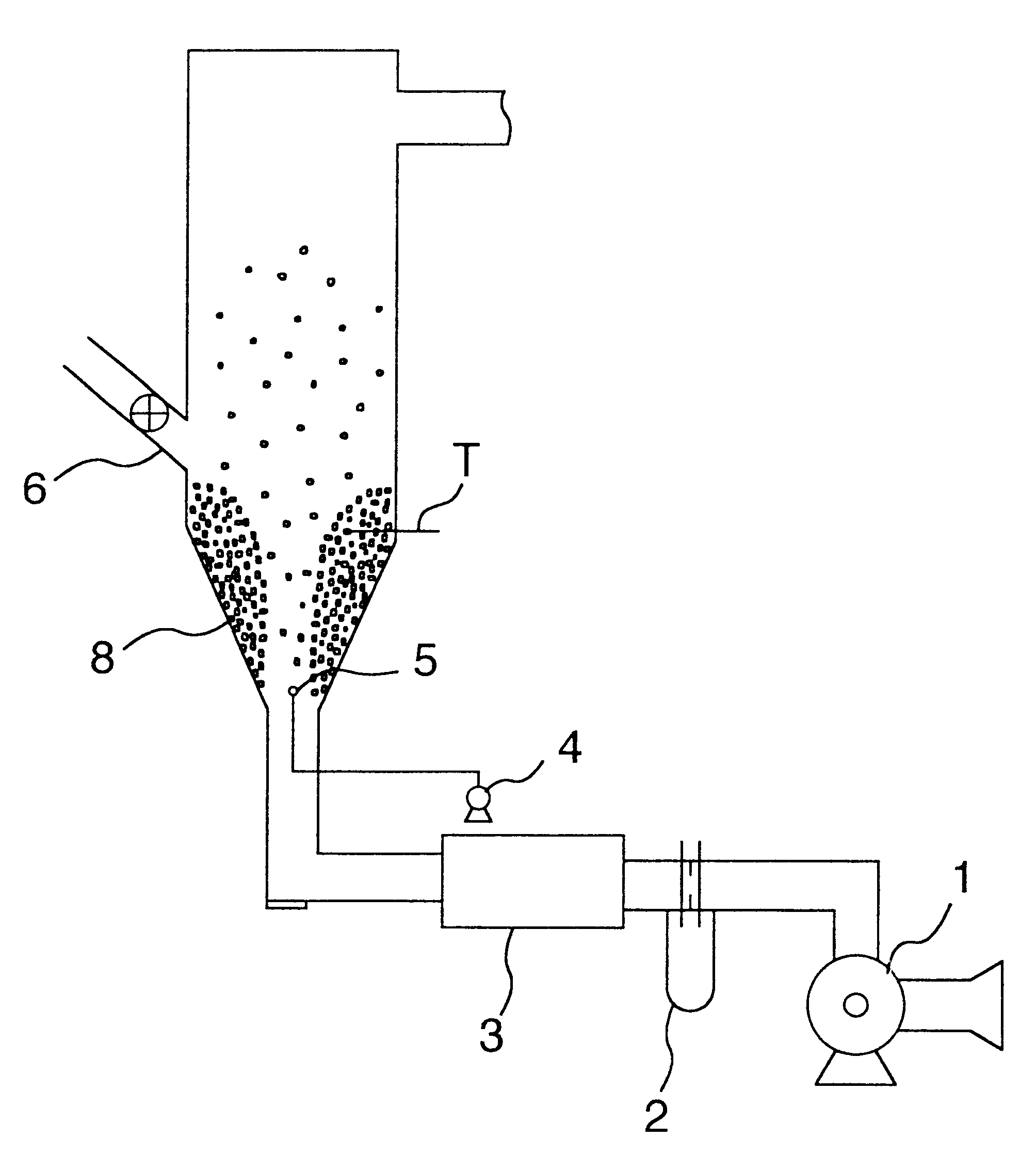

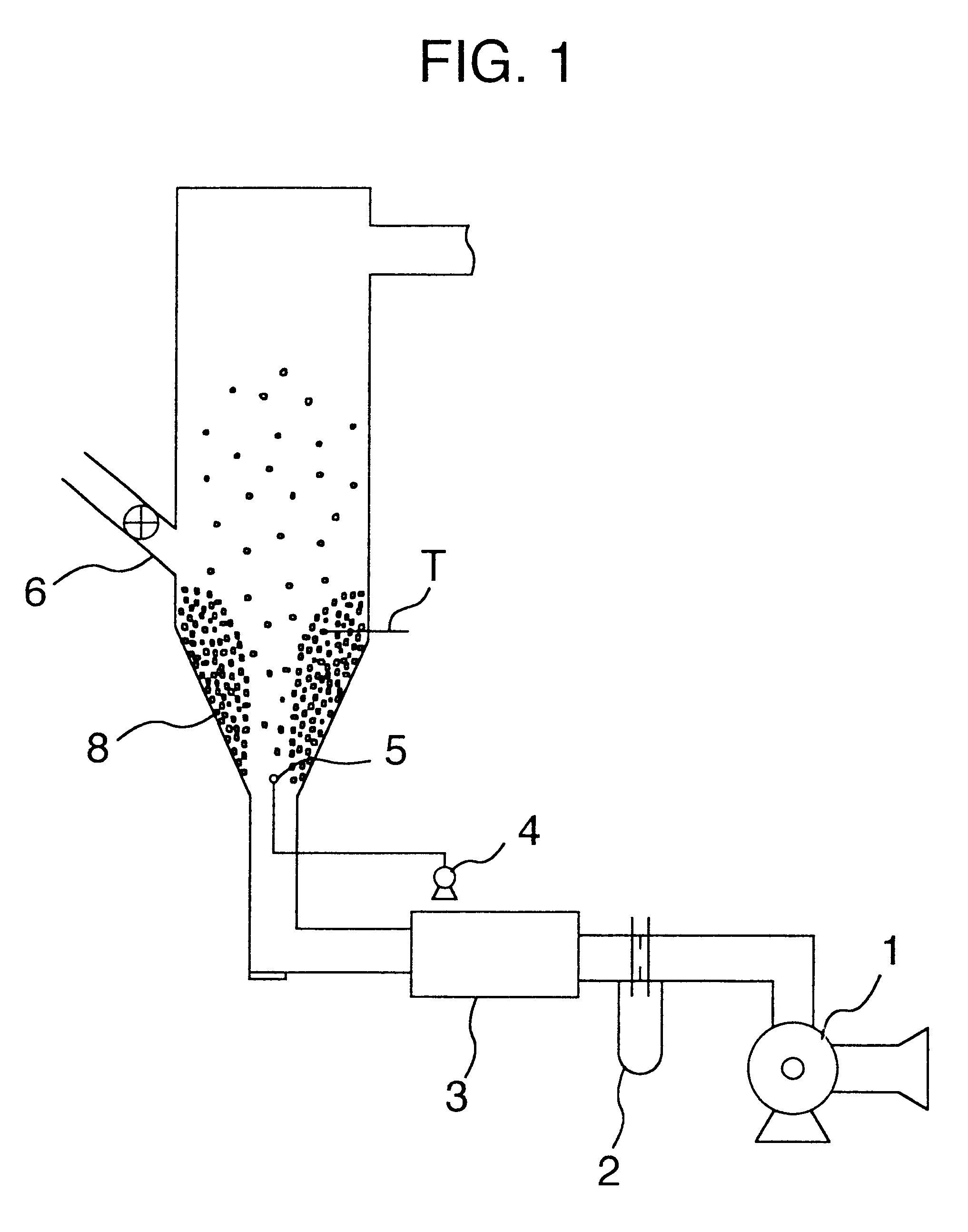

Nano powders, components and coatings by plasma technique

ActiveUS7615097B2Rapid quenching and generationHigh materialLiquid surface applicatorsMolten spray coatingRheniumChemical reaction

Ultra fine and nanometer powders and a method of producing same are provided, preferably refractory metal and ceramic nanopowders. When certain precursors are injected into the plasma flame in a reactor chamber, the materials are heated, melted and vaporized and the chemical reaction is induced in the vapor phase. The vapor phase is quenched rapidly to solid phase to yield the ultra pure, ultra fine and nano product. With this technique, powders have been made 20 nanometers in size in a system capable of a bulk production rate of more than 10 lbs / hr. The process is particularly applicable to tungsten, molybdenum, rhenium, tungsten carbide, molybdenum carbide and other related materials.

Owner:PLASMA PROCESSES

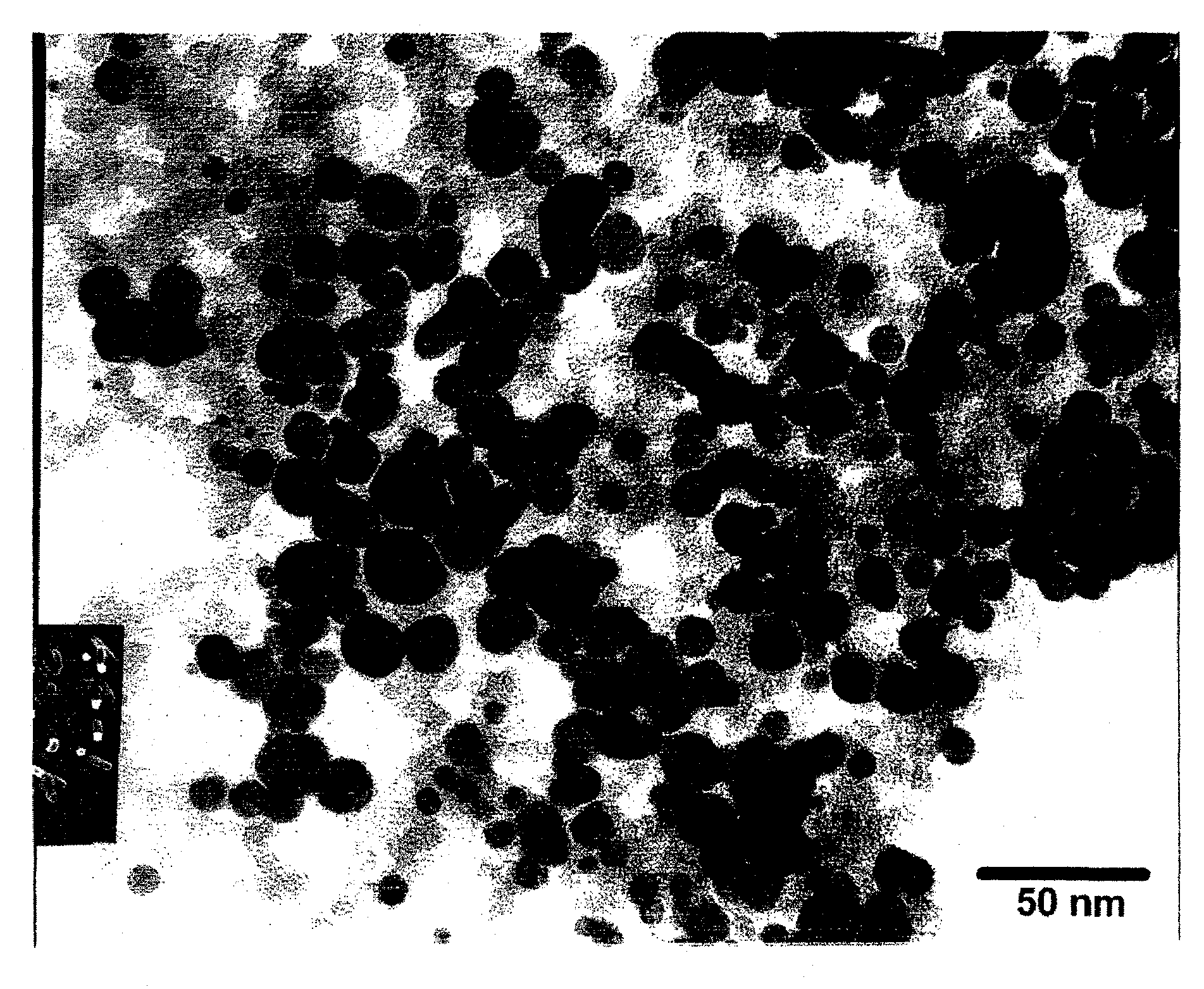

Coated nickel-containing powders, methods and apparatus for producing such powders and devices fabricated from same

InactiveUS20050097988A1High rateIncrease loadMaterial granulation and coatingGranule coatingSpherical morphologySmall particle

Nickel powder batches including coated nickel-containing particles and methods for producing the same. The coated nickel-containing particles having have a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the coated nickel-containing particles.

Owner:CABOT CORP

Granular fertilizer coated with decomposable coating film and process for producing the same

A coated granular fertilizer which comprises a degradable film containing 10% by weight or more of a polyolefin and / or petroleum wax having a weight-average molecular weight of 300-10,000 and an inorganic filler and / or a surface active agent and a granular fertilizer coated with said degradable film.

Owner:JCAM AGRI

Membrane electrode assemblies for use in fuel cells

InactiveUS20030064265A1High purityImprove electrocatalytic activityGranule coatingCell electrodesCarbon compositesFuel cells

Owner:CABOT CORP

Electrospraying method with conductivity control

An electrospraying apparatus and / or method is used to coat particles. For example, a flow including at least one liquid suspension may be provided through at least one opening at a spray dispenser end. The flow includes at least particles and a coating material. A spray of microdroplets suspending at least the particles is established forward of the spray dispenser end by creating a nonuniform electrical field between the spray dispenser end and an electrode electrically isolated therefrom. The particles are coated with at least a portion of the coating material as the microdroplet evaporates. For example, the suspension may include biological material particles.

Owner:RGT UNIV OF MINNESOTA

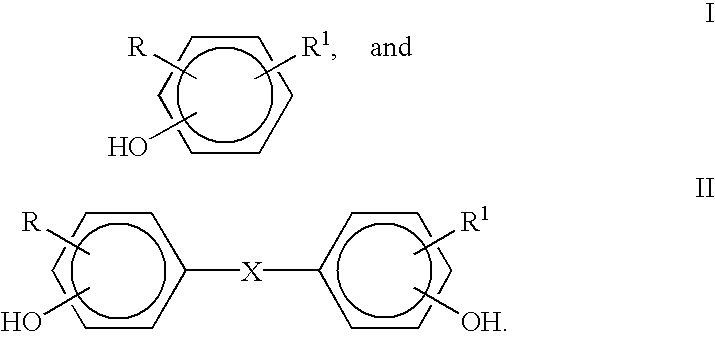

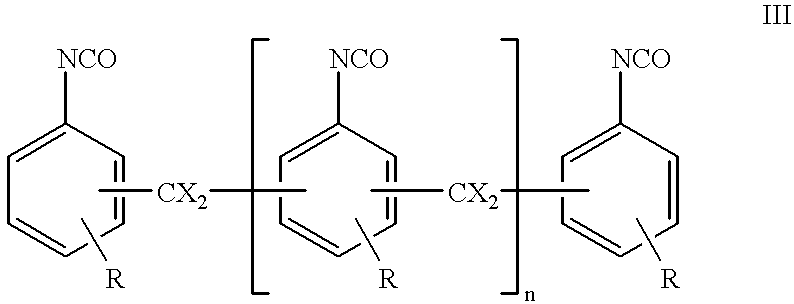

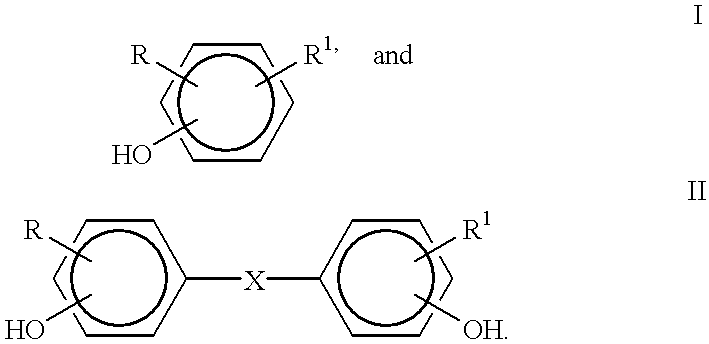

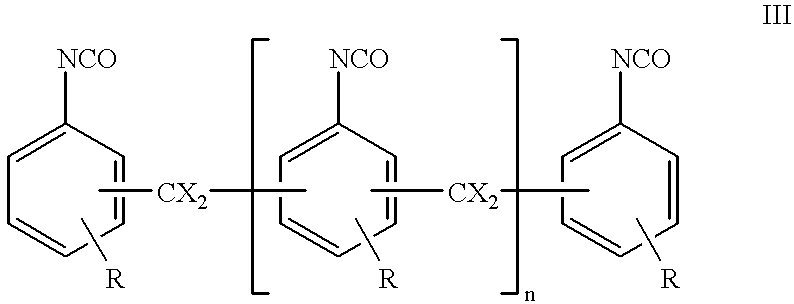

Coating for fertilizer

InactiveUS20050076687A1Maintain reaction temperatureImparts physical strengthBiocideGas treatmentVegetable oilPolymer chemistry

Method and apparatus for coating fertilizer in pellet or other form to impart time-release characteristics and the resulting coated pellet product. The polyurethane coating encapsulates fertilizer particles, forming a hydrophobic coating for slow-release qualities. The urethane polymer coating is formulated with an isocyanate and a combined fluid of a polyether polyol, a methyl ester derivative of plant or vegetable oil, a T-12 curing catalyst, barium sulfate, and an oil-based dye. The barium sulfate imparts physical strength to and enhances color quality of the polyurethane coating, and acts as a detackifier and maintains temperature in the coating reactor. The inventive formulation is effective in the practical polymer coating of sulfate-based or other fertilizer pellets in an inventive time-release fertilizer product. An apparatus is provided for carrying out the coating process.

Owner:WHITTINGTON PATSIE A

Method for coating particles for generative prototyping processes

InactiveUS20060251826A1Good storage stabilityImprove handlingAdditive manufacturing apparatusGranule coatingOrganic fluidMetal

The invention relates to a method for coating particles of a plastic, metal and / or ceramic powder material for producing an adhesive-containing coating material, in particular for producing appropriate particles by compressing a 3D binder. Said coating is applied to fluidised particles in a gaseous phase by means of a coating solution, at least the particles and / or coated particles being exposed to ionised particles. A method for producing bodies or sintered bodies from organic liquid binders by compressing the 3D binder and the use thereof are also disclosed.

Owner:DAIMLER AG

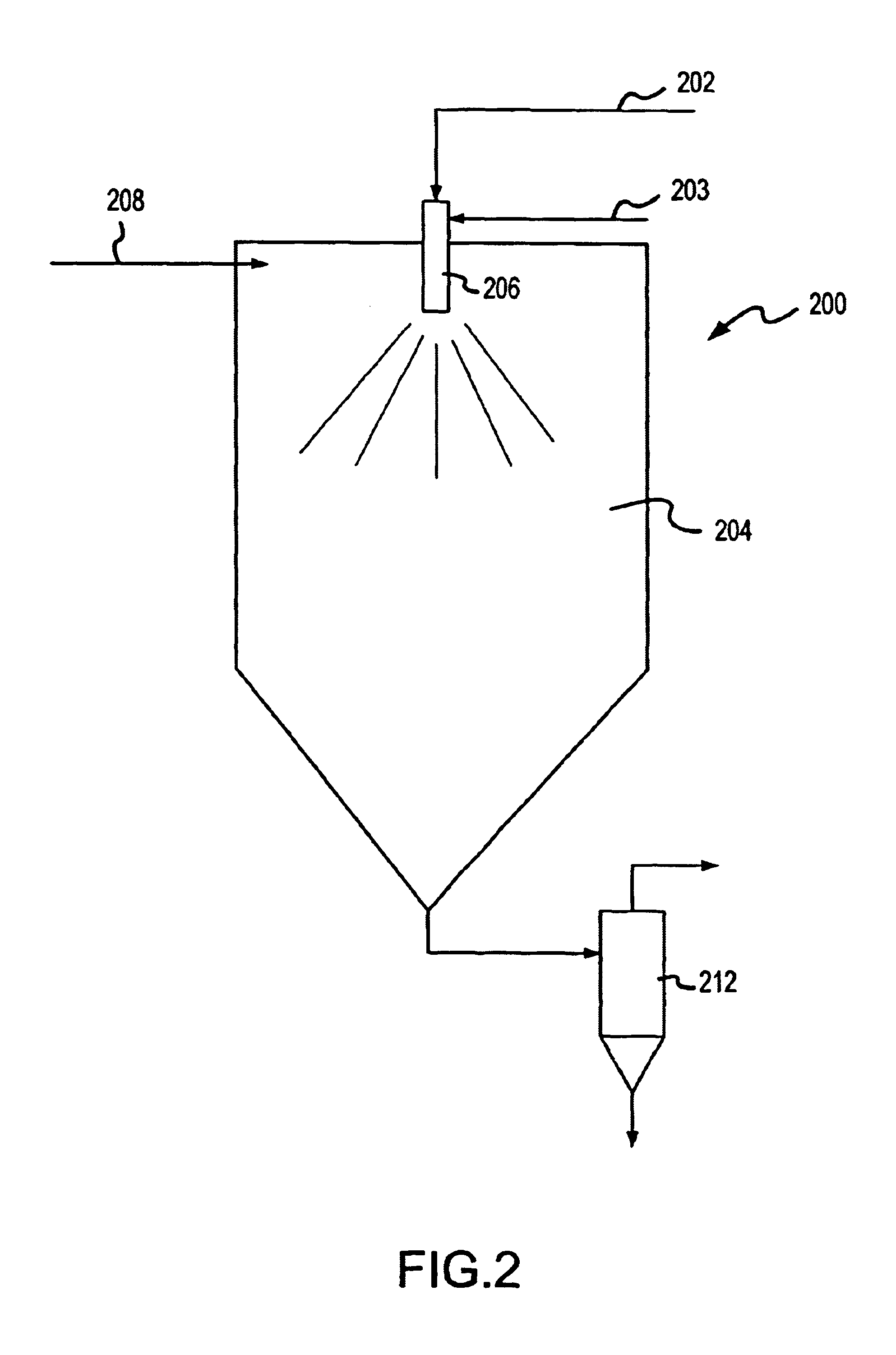

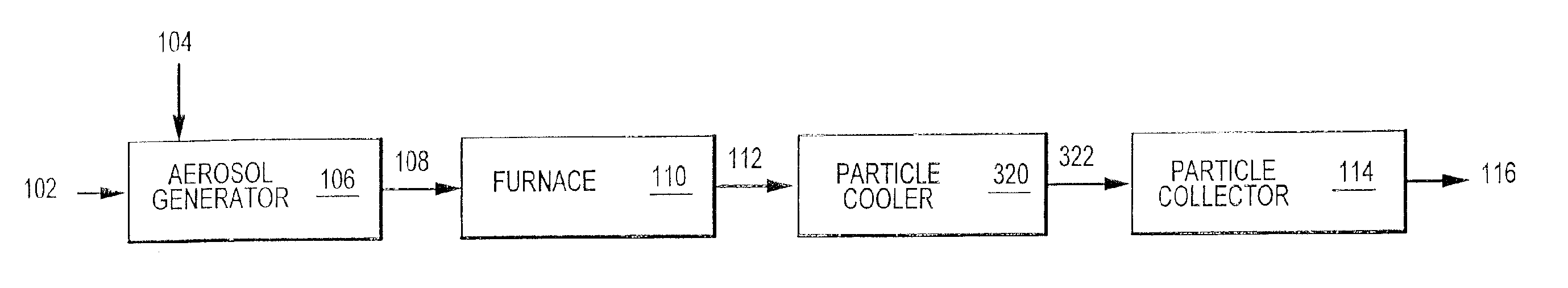

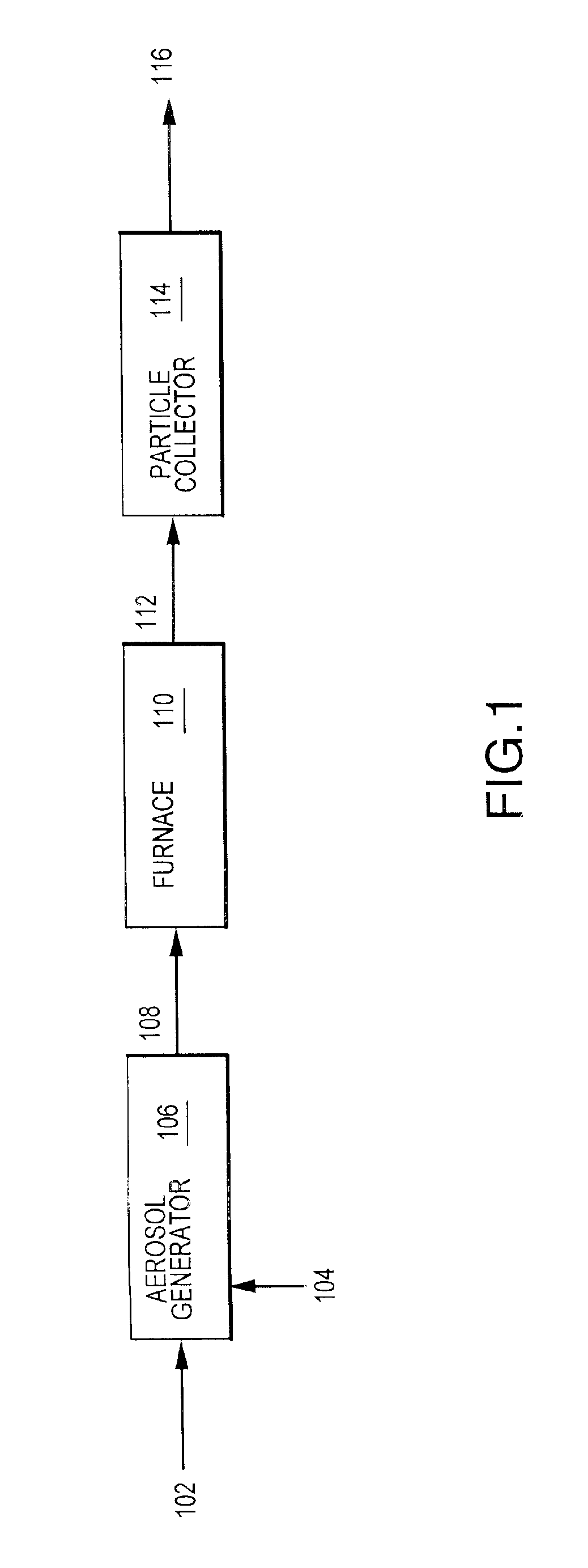

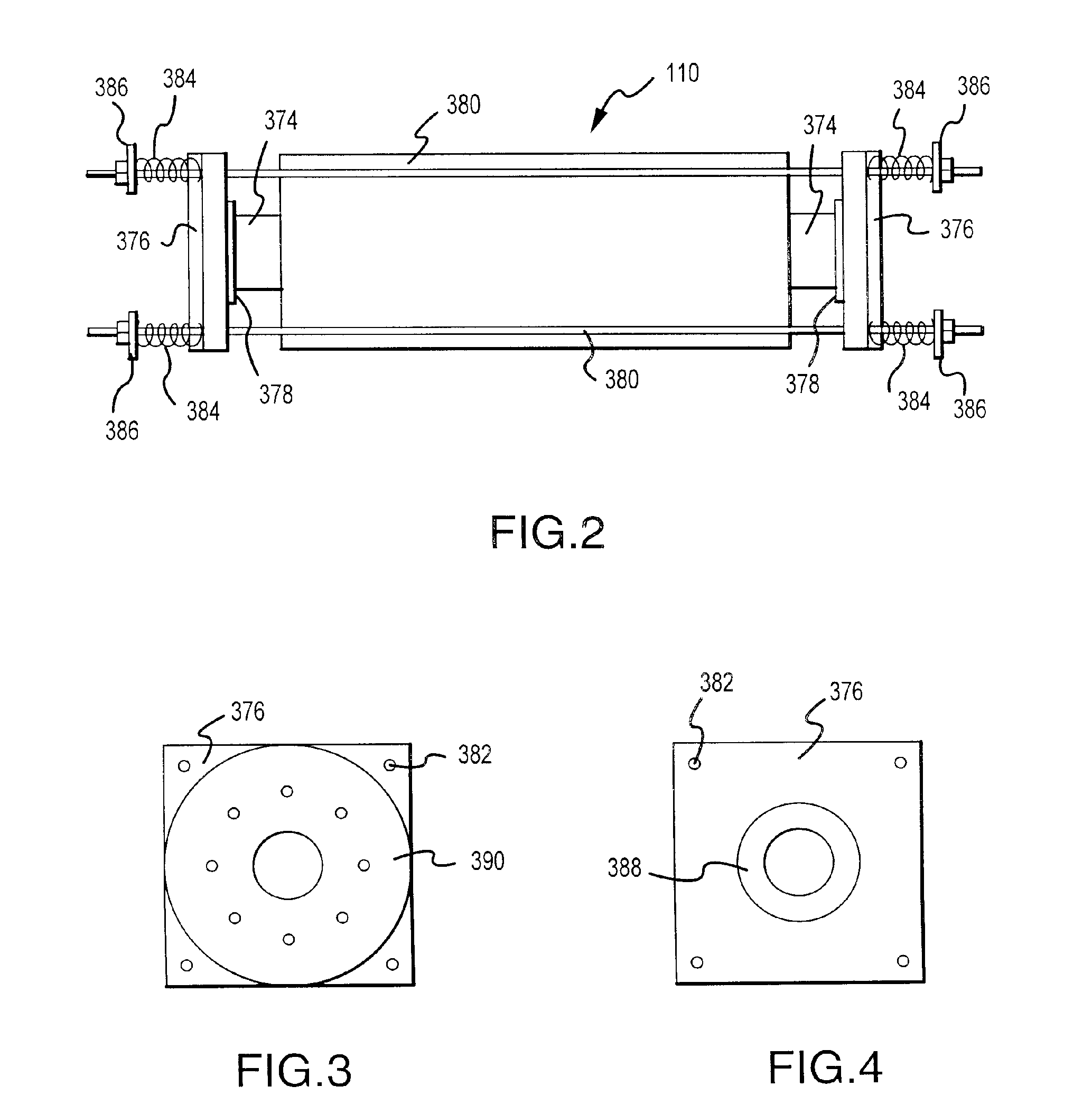

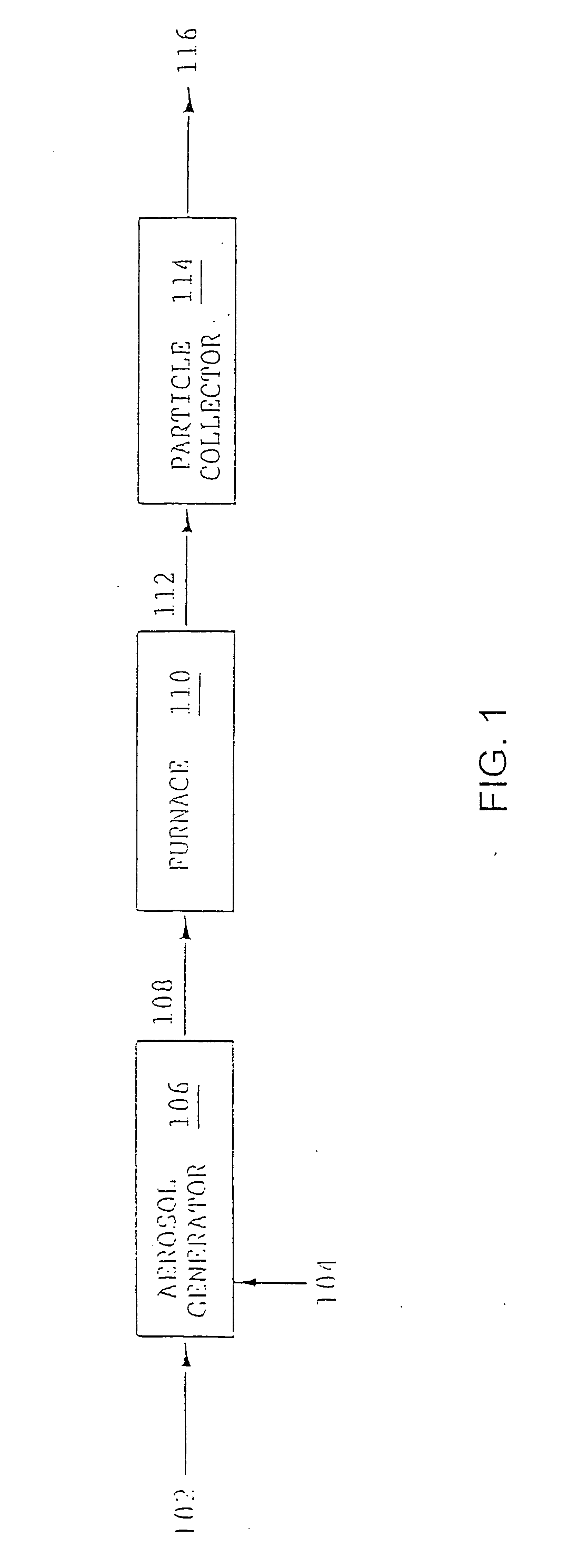

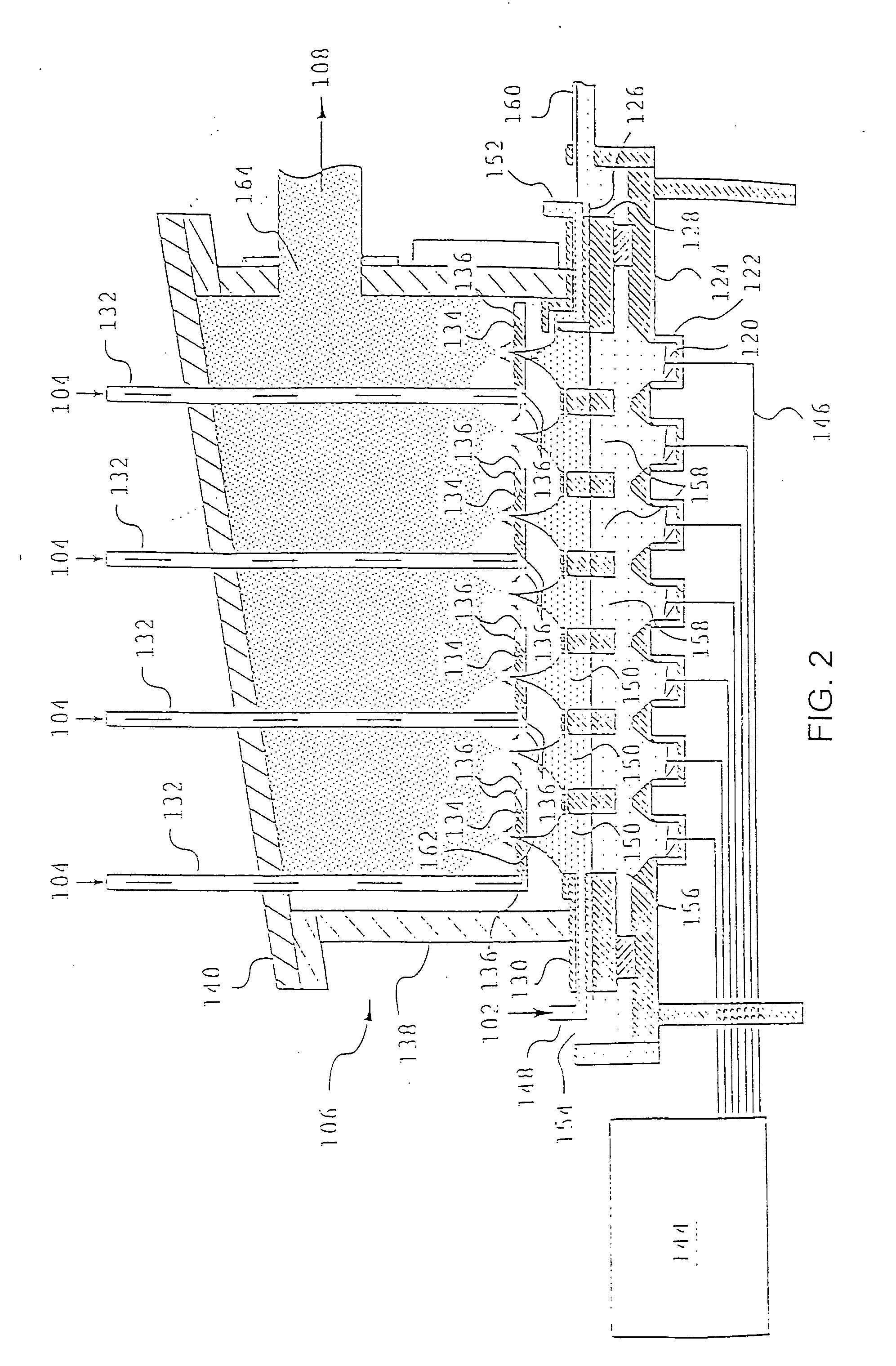

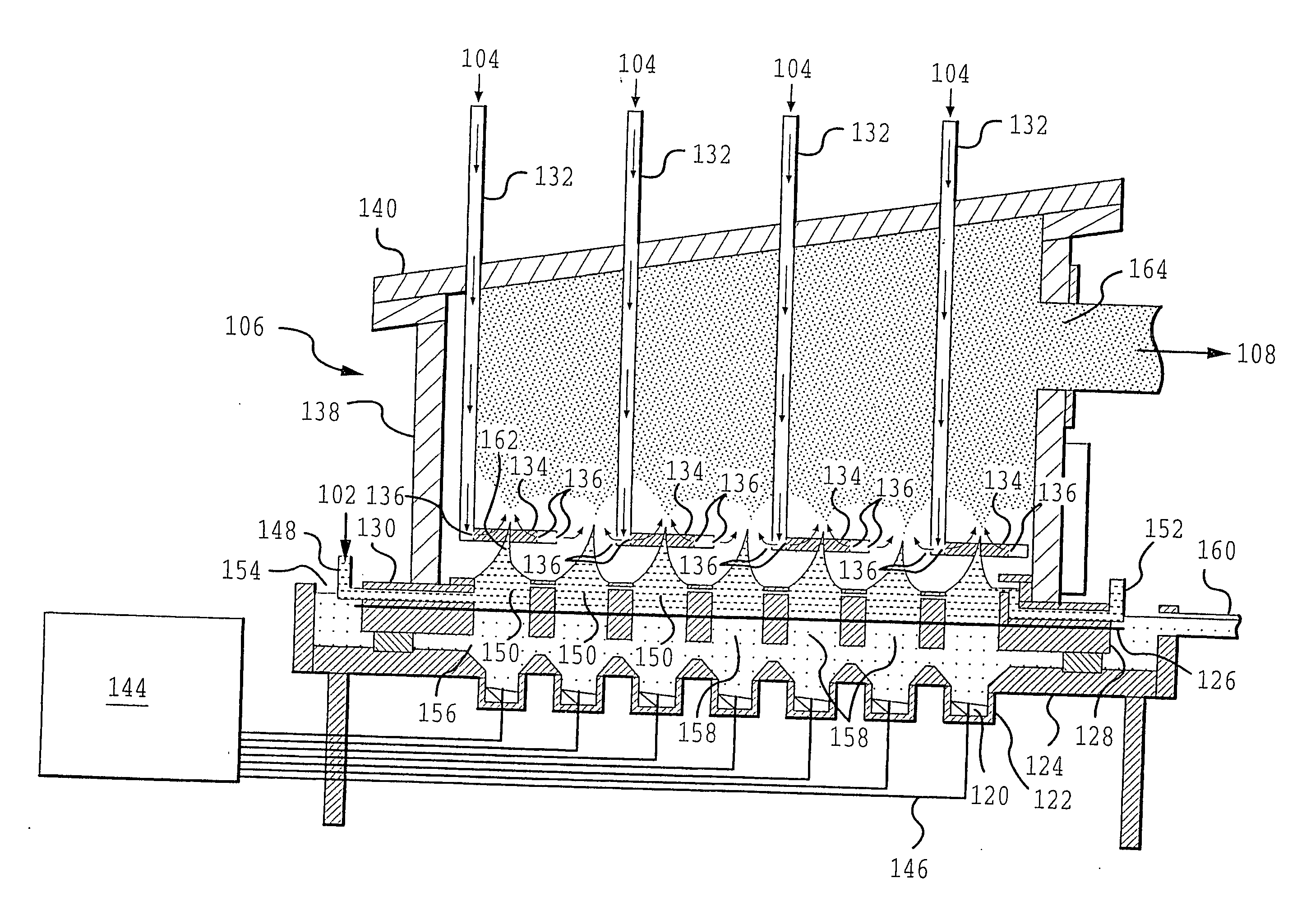

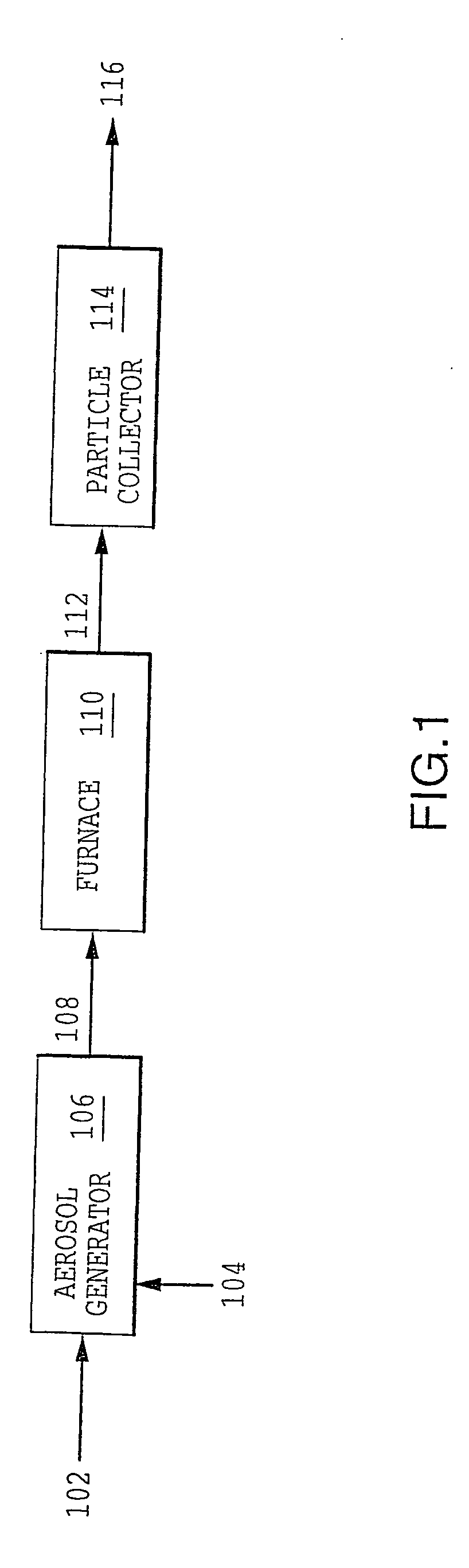

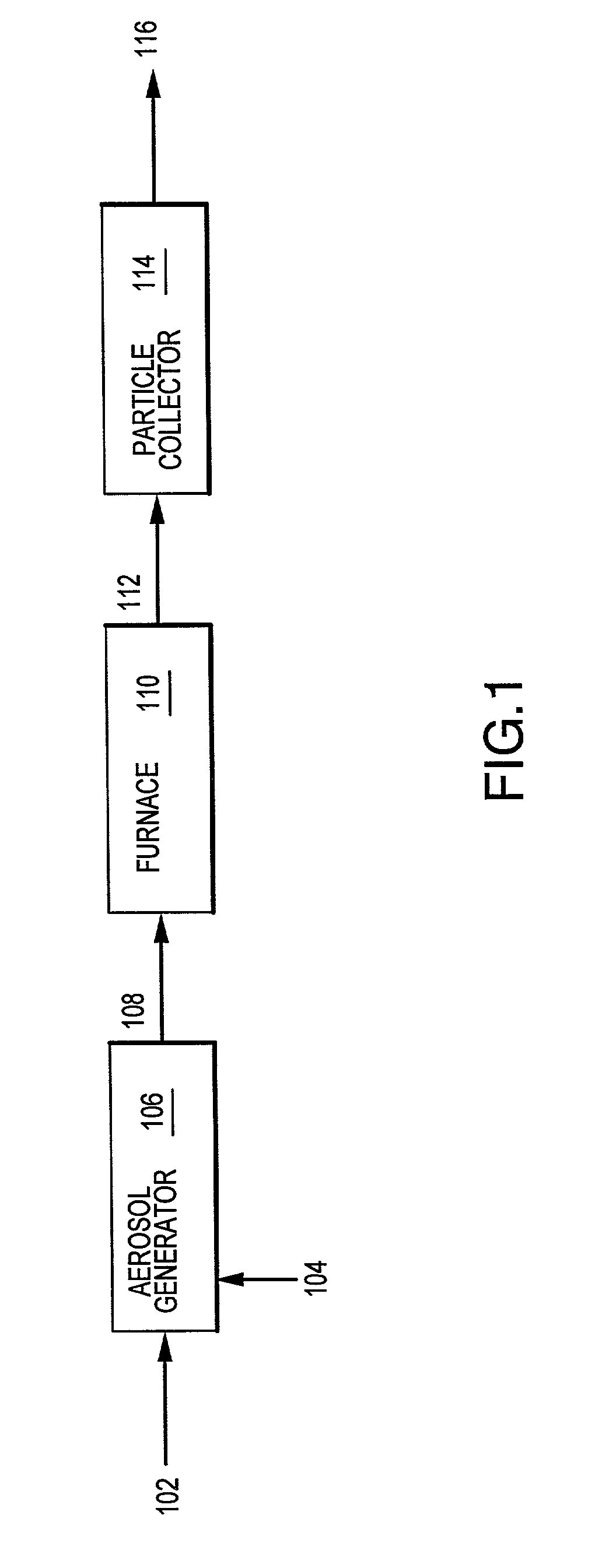

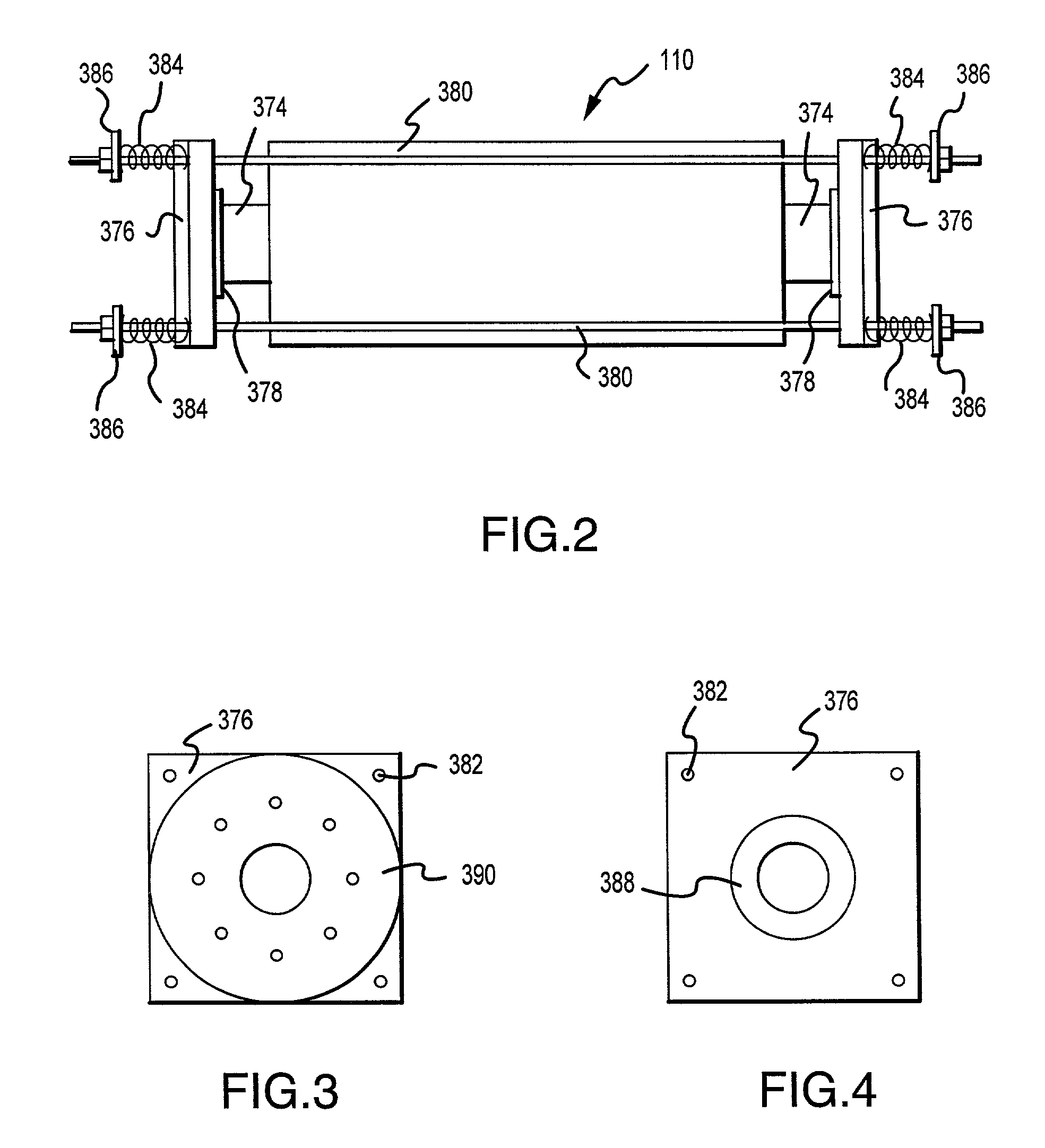

Aerosol method and apparatus, particulate products, and electronic devices made therefrom

Metal-carbon composite powders and methods for producing metal-carbon composite powders. The powders have a well-controlled microstructure and morphology and preferably have a small average particle size. The method includes forming the particles from an aerosol of powder precursors. The invention also includes novel devices and products formed from the composite powders.

Owner:CABOT CORP

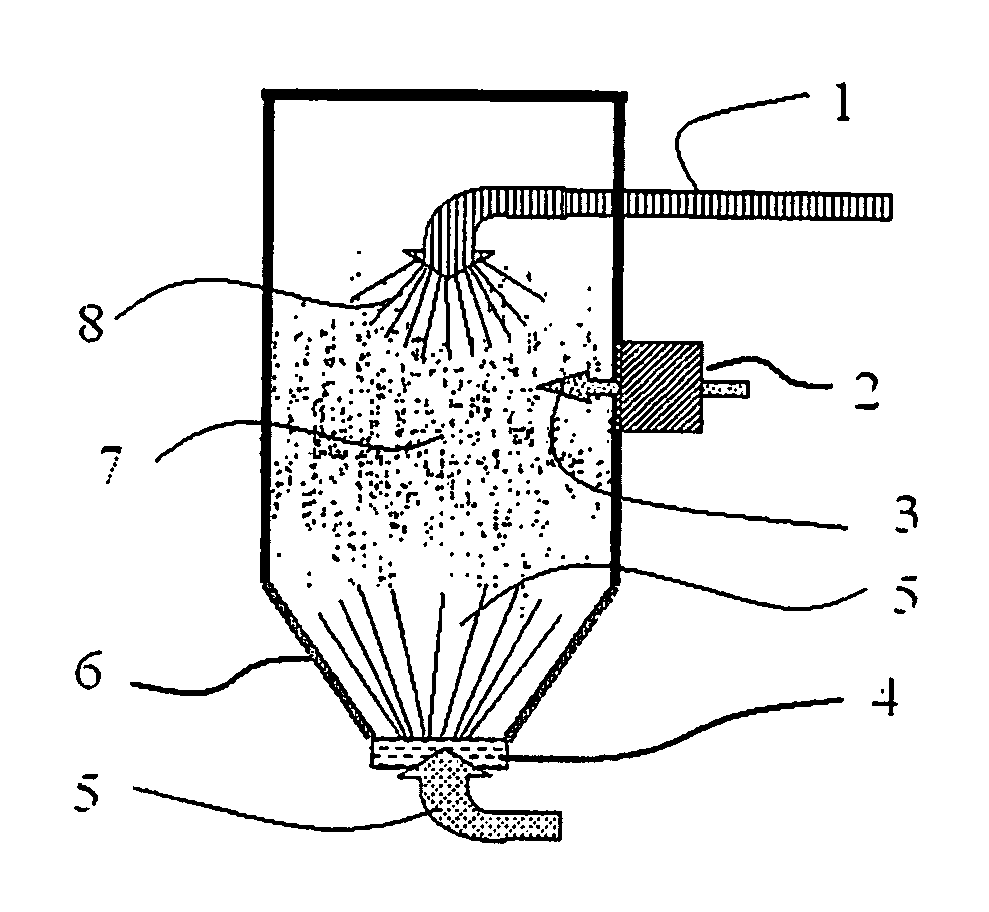

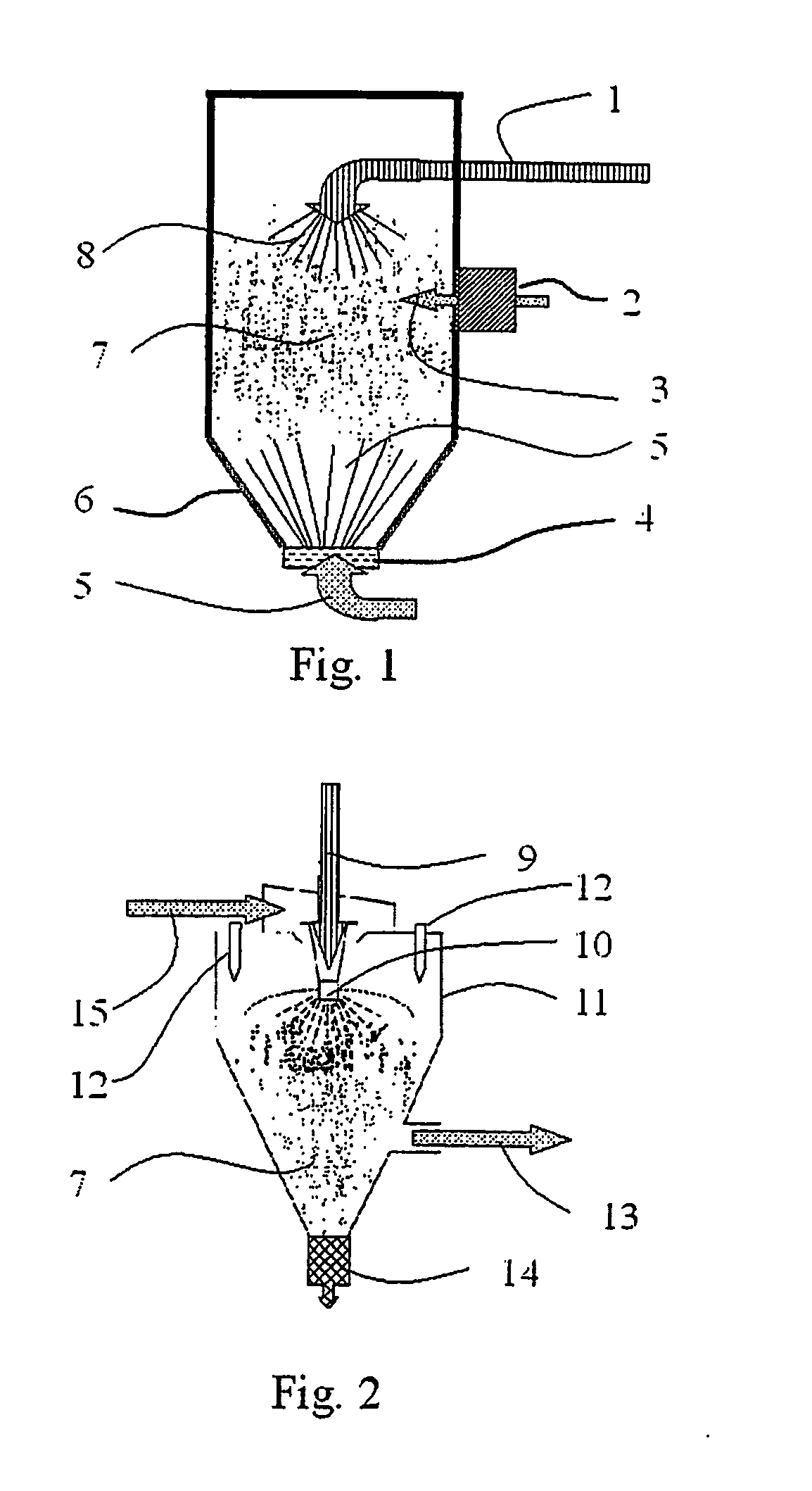

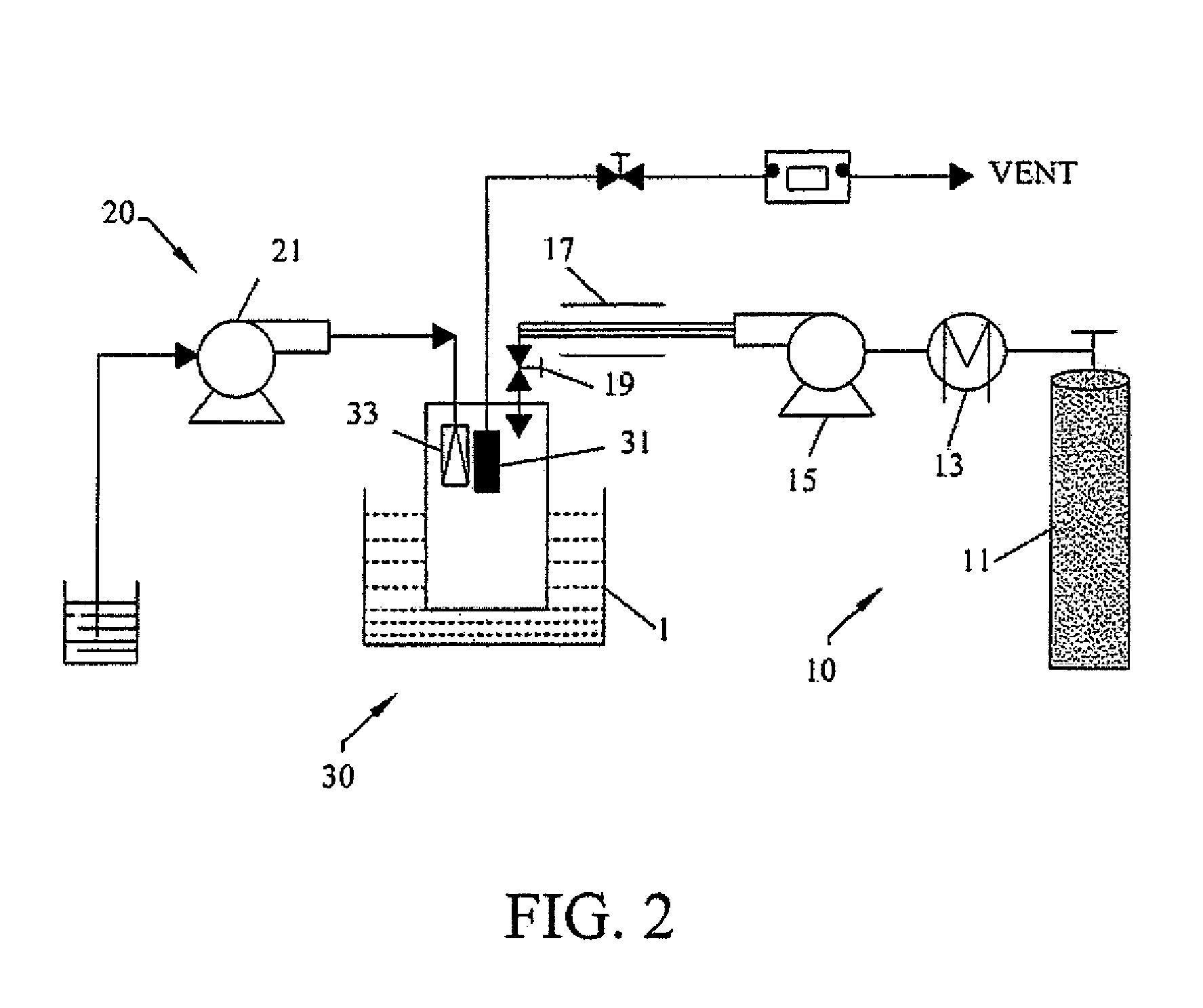

Coated silver-containing particles, method and apparatus of manufacture, and silver-containing devices made therefrom

InactiveUS20050061107A1Increase loadMaterial granulation and coatingGranule coatingPolymer scienceDroplet size

Provided are silver-containing powders and a method and apparatus for manufacturing the silver-containing particles of high quality, of a small size and narrow size distribution. An aerosol is generated from liquid feed and sent to a furnace, where liquid in droplets in the aerosol is vaporized to permit formation of the desired particles, which are then collected in a particle collector. The aerosol generation involves preparation of a high quality aerosol, with a narrow droplet size distribution, with close control over droplet size and with a high droplet loading suitable for commercial applications.

Owner:CABOT CORP

Method and apparatus for introducing in continuous a substance in liquid phase into plastics granules

InactiveUS6878400B2Avoid it happening againWell mixedGranule coatingFlow mixersContinuous flowLiquid phase

A method for continuously introducing a substance in liquid phase into plastics granules comprising: a) feeding a substantially continuous flow of the plastics granules to at least one substantially static spraying chamber, b) spraying the substance in liquid phase onto the plastics granules, c) passing the granules partially or totally coated by the substance in liquid phase by a substantially static mixing means supported in at leas one mixing chamber provided downstream of the spraying chamber, d) submitting the mixed granules to drying for a time sufficient to allow a substantially complete absorption of the substance in liquid phase by the granules.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA +1

Nanoparticle-based power coatings and corresponding structures

Methods are described that have the capability of producing submicron / nanoscale particles, in some embodiments dispersible, at high production rates. In some embodiments, the methods result in the production of particles with an average diameter less than about 75 nanometers that are produced at a rate of at least about 35 grams per hour. In other embodiments, the particles are highly uniform. These methods can be used to form particle collections and / or powder coatings. Powder coatings and corresponding methods are described based on the deposition of highly uniform submicron / nanoscale particles.

Owner:NANOGRAM

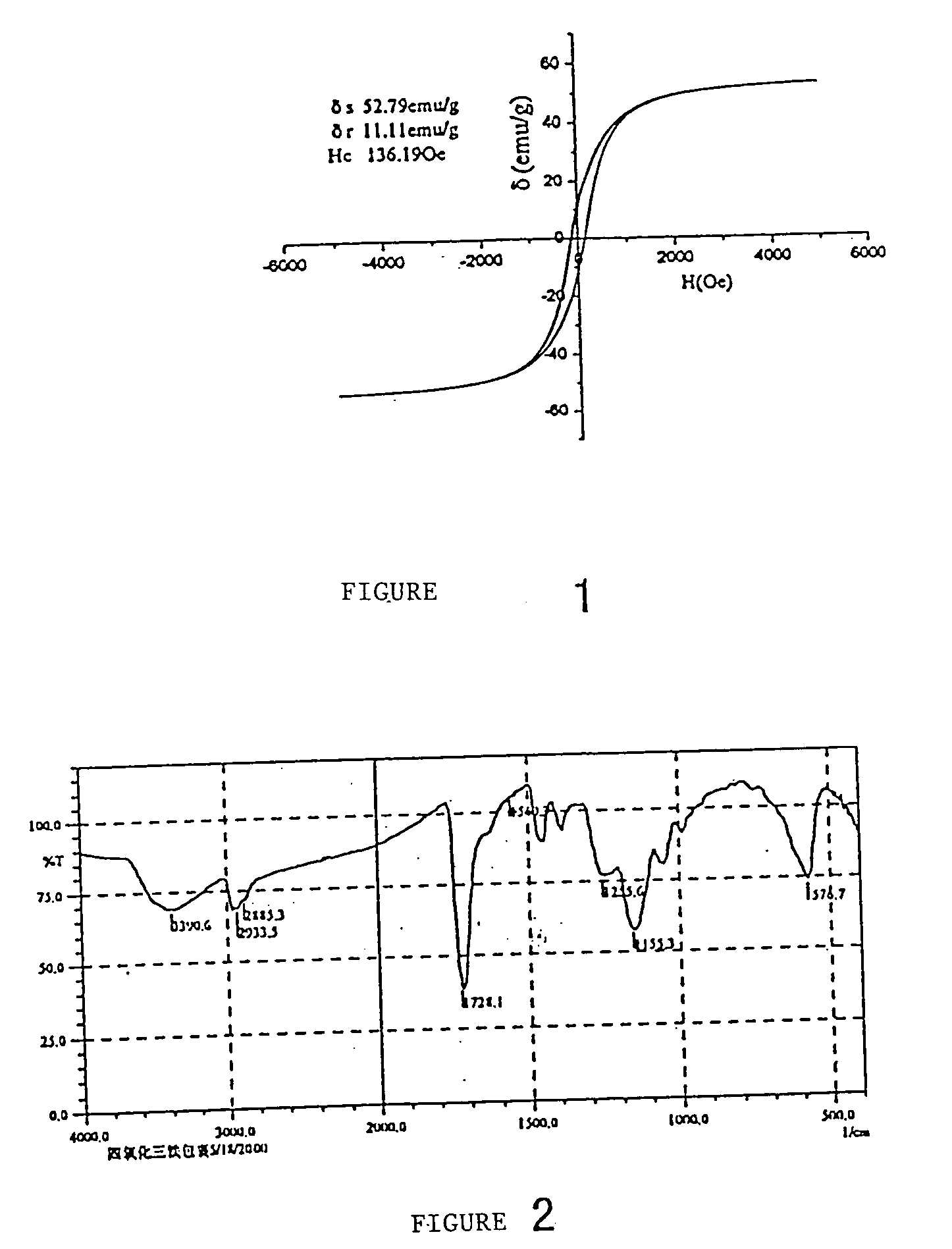

Processes for producing coated magnetic microparticles and uses thereof

This invention relates generally to the field of production of coated magnetizable microparticles and uses thereof. In particular, the invention provides a process for producing coated magnetizable microparticles with active functional groups, which process uses, inter alia, conducting polymerization of said coating monomers on the surface of magnetic particle to form coated magnetizable microparticles with active functional groups in the presence of a coupling agent, coating monomers, a functionalization reagent, a cross-linking agent and an initiator in an organic solvent containing a surfactant. The coated magnetizable microparticles produced according to the present processes and uses of the coated magnetizable microparticles, e.g., in isolating and / or manipulating various moieties are also provided.

Owner:AVIVA BIOSCI

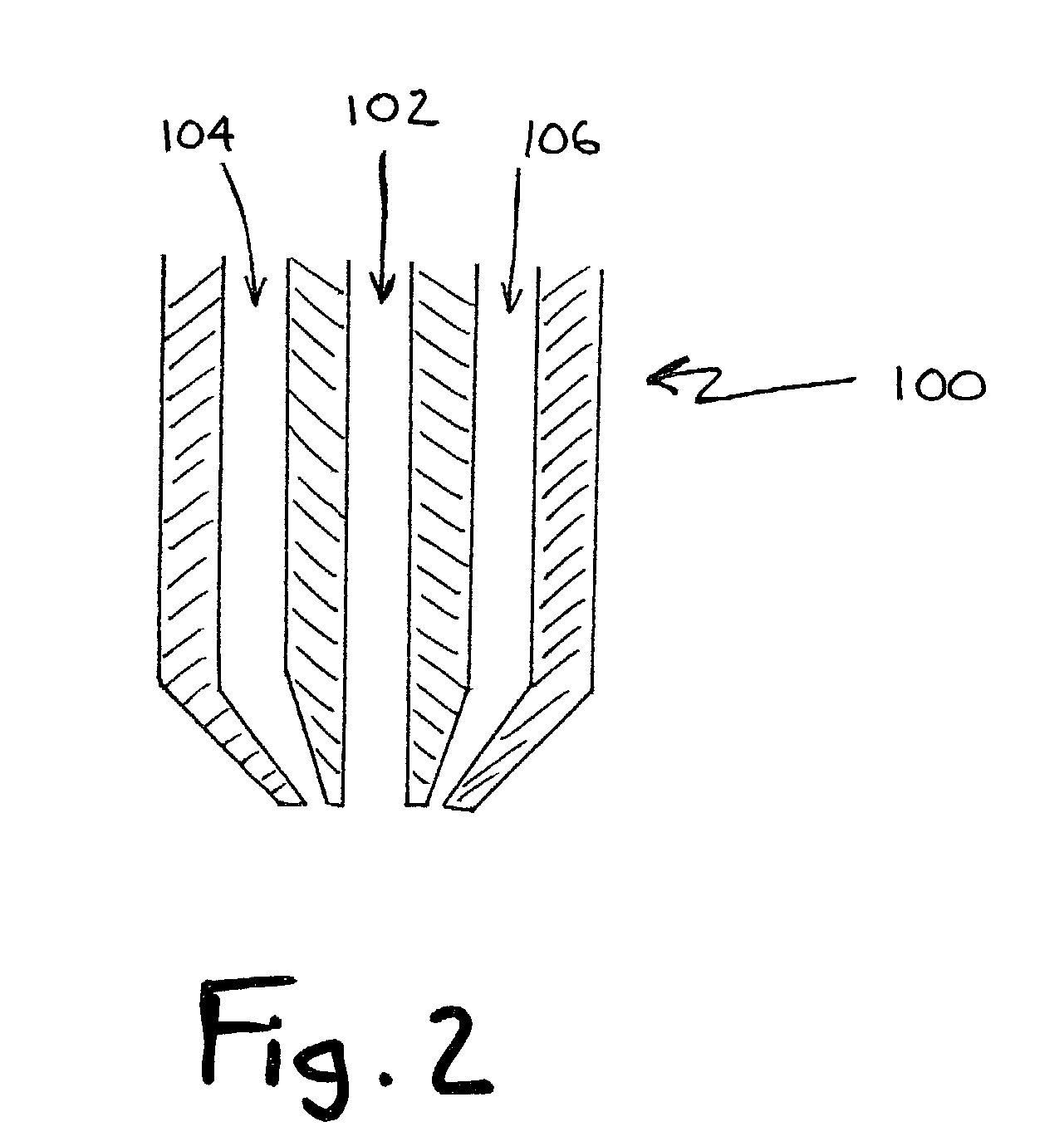

Polyvinyl butyral granular material for 3-D binder printing, production method and uses therefor

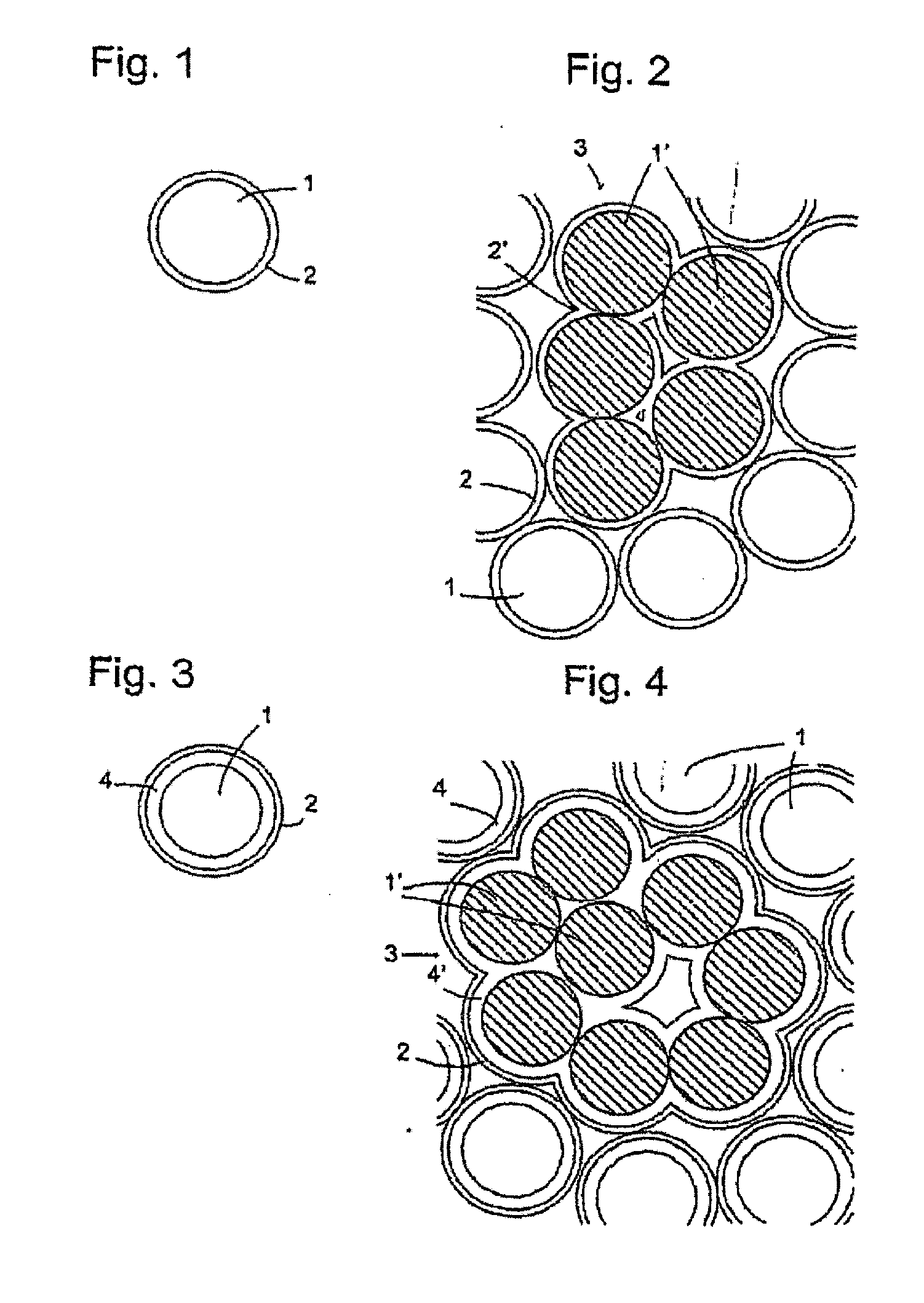

InactiveUS7402330B2Flat surfaceFiner and more detailed structureGranule coatingPretreated surfacesSurface layerMaterials science

The invention relates to a granular material for 3D binder printing, said granular material consisting of particles provided with an externally non-polar surface layer (2). The invention also relates to a method for producing a granular material for 3D binder printing, whereby a surface layer (2) having a non-polar outer side is applied to initial particles (1), and to a method for producing an object consisting of the inventive granular material, according to which a layer of the inventive granular material is applied to a base, and pre-determined regions (3) of said layer are moistened with a binding fluid, said binding fluid being selected from fluids in which a surface layer of the particles of the granular material is soluble. The invention further realties to objects consisting of interconnected particles of the inventive granular material. The invention enables a very precise printing process.

Owner:VOXELJET AG

Single step milling and surface coating process for preparing stable nanodispersions

ActiveUS20090180976A1Good dispersionImprove light resistanceBiocideCosmetic preparationsNanoparticleAqueous medium

A single step milling and surface coating process allows for production of a stable dispersion of surface coated nanoparticles in an efficient manner. The process comprises providing feed particles, providing a coating agent, and generating the stable dispersion of surface coated nanoparticles by milling the feed particles in an aqueous medium containing the coating agent such that the coating agent bonds to surfaces of the feed particles as the feed particles are milled to an average particle size of less than about 100 nm.

Owner:NANOMATERIALES S A DE

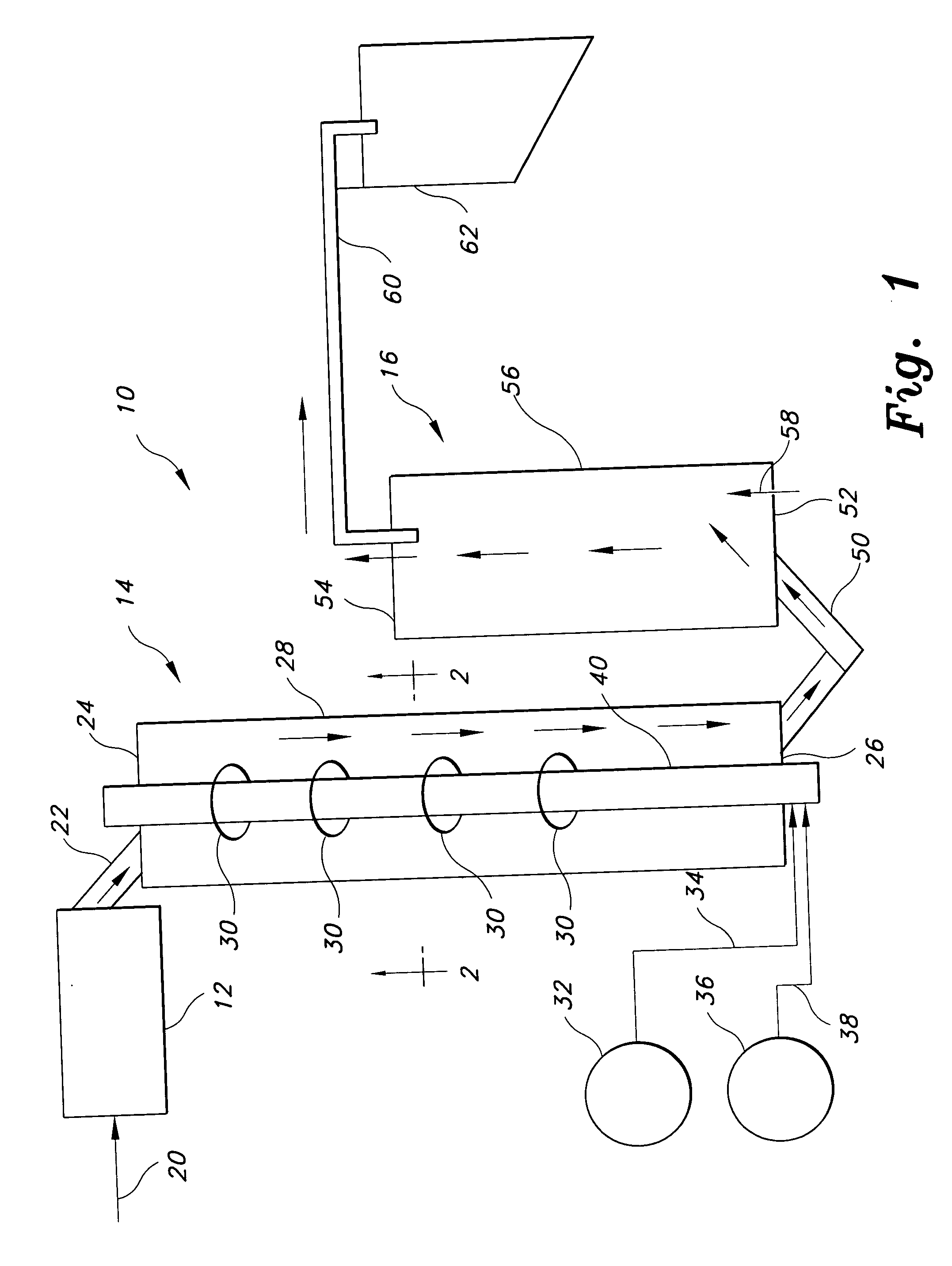

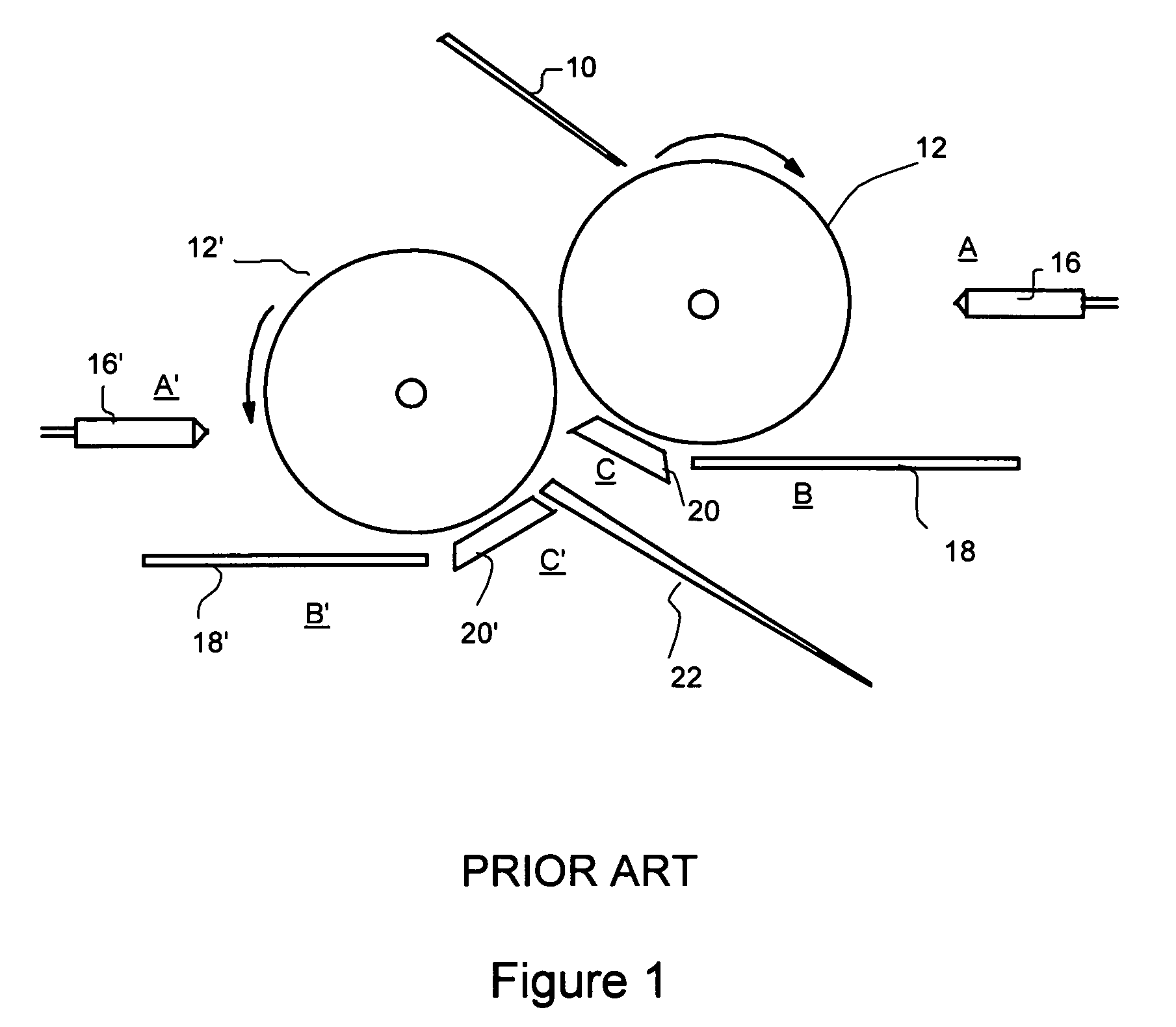

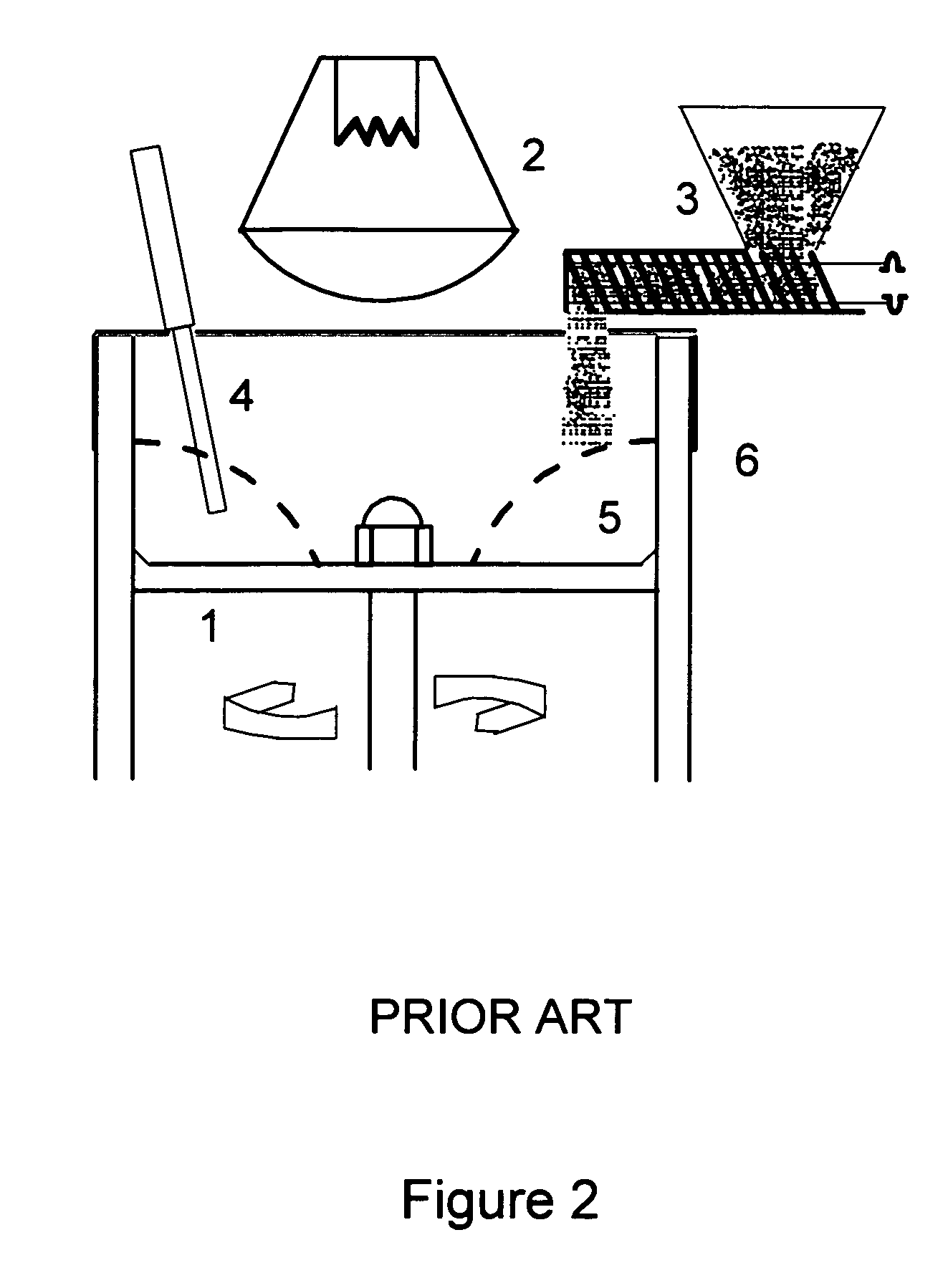

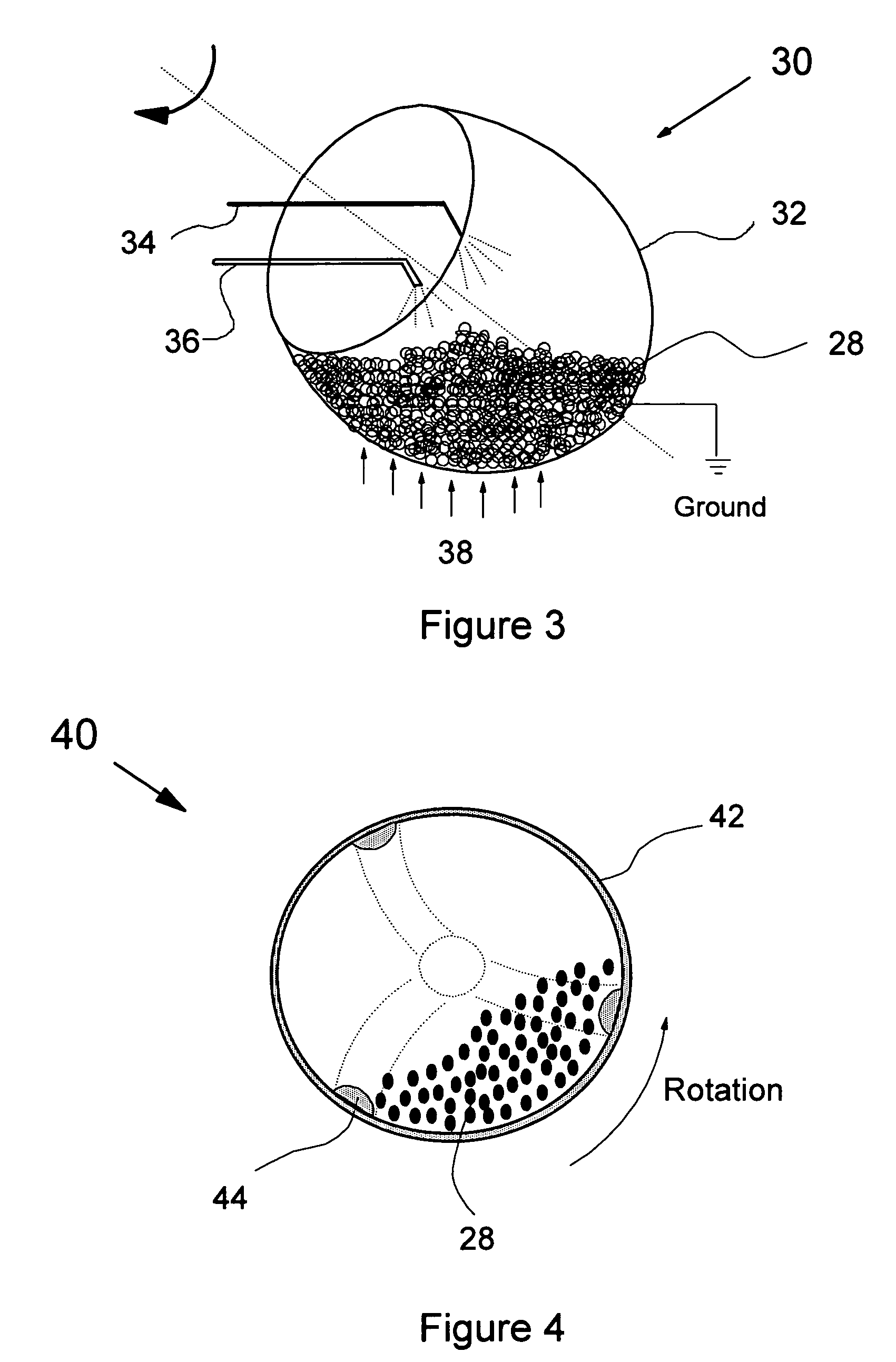

Direct coating solid dosage forms using powdered materials

The present invention provides a method and apparatus for dry coating solid dosage forms. The method includes the steps of placing solid dosage forms in a rotatable, electrically grounded housing, and spraying a film forming polymer powder composition into the housing during rotation thereof to form a polymer coating on the solid dosage forms, the polymer powder composition being sprayed using an electrostatic spray gun, and curing the coated solid dosage forms.

Owner:WESTERN ONTARIO THE UNIV OF +1

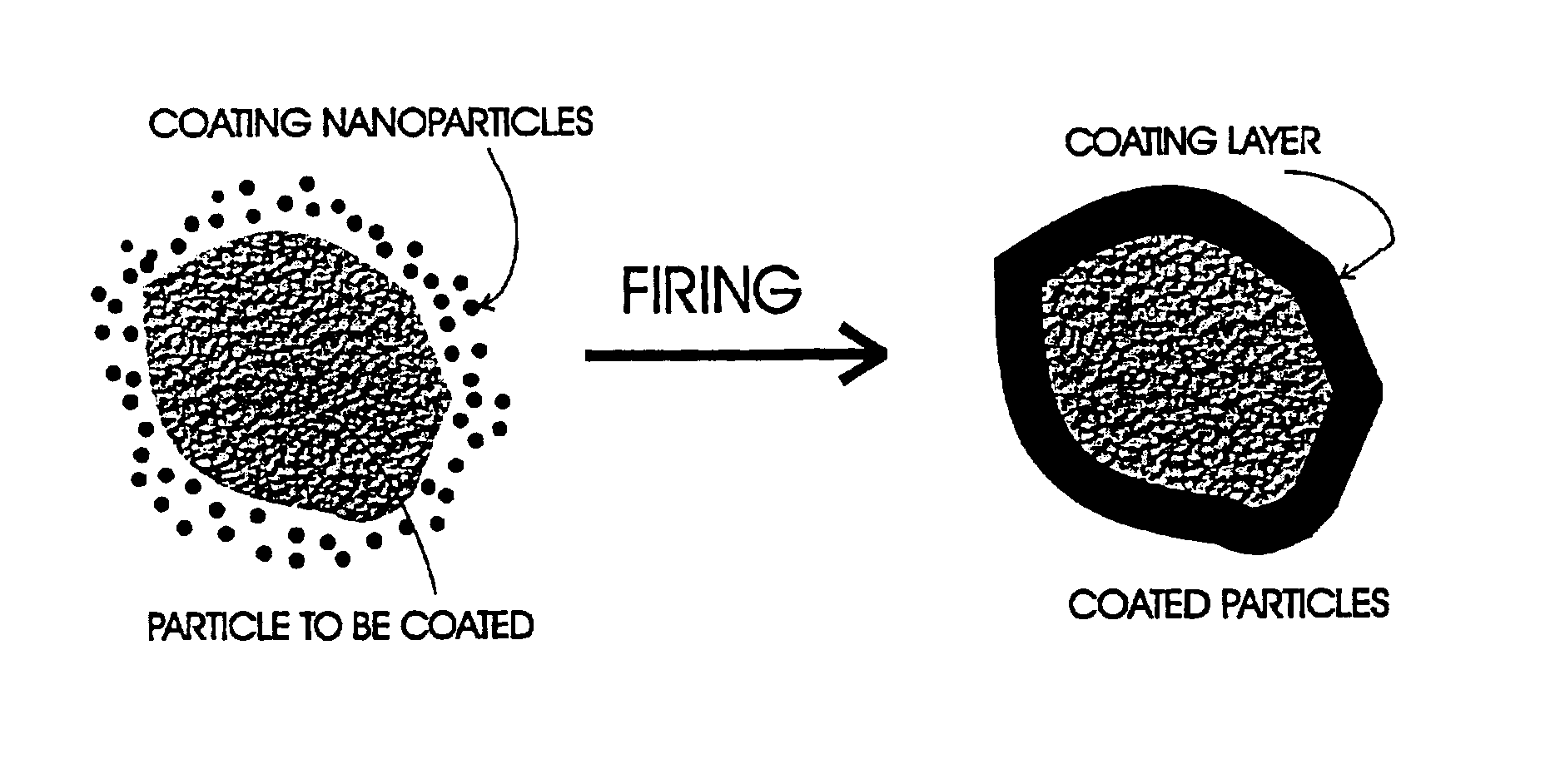

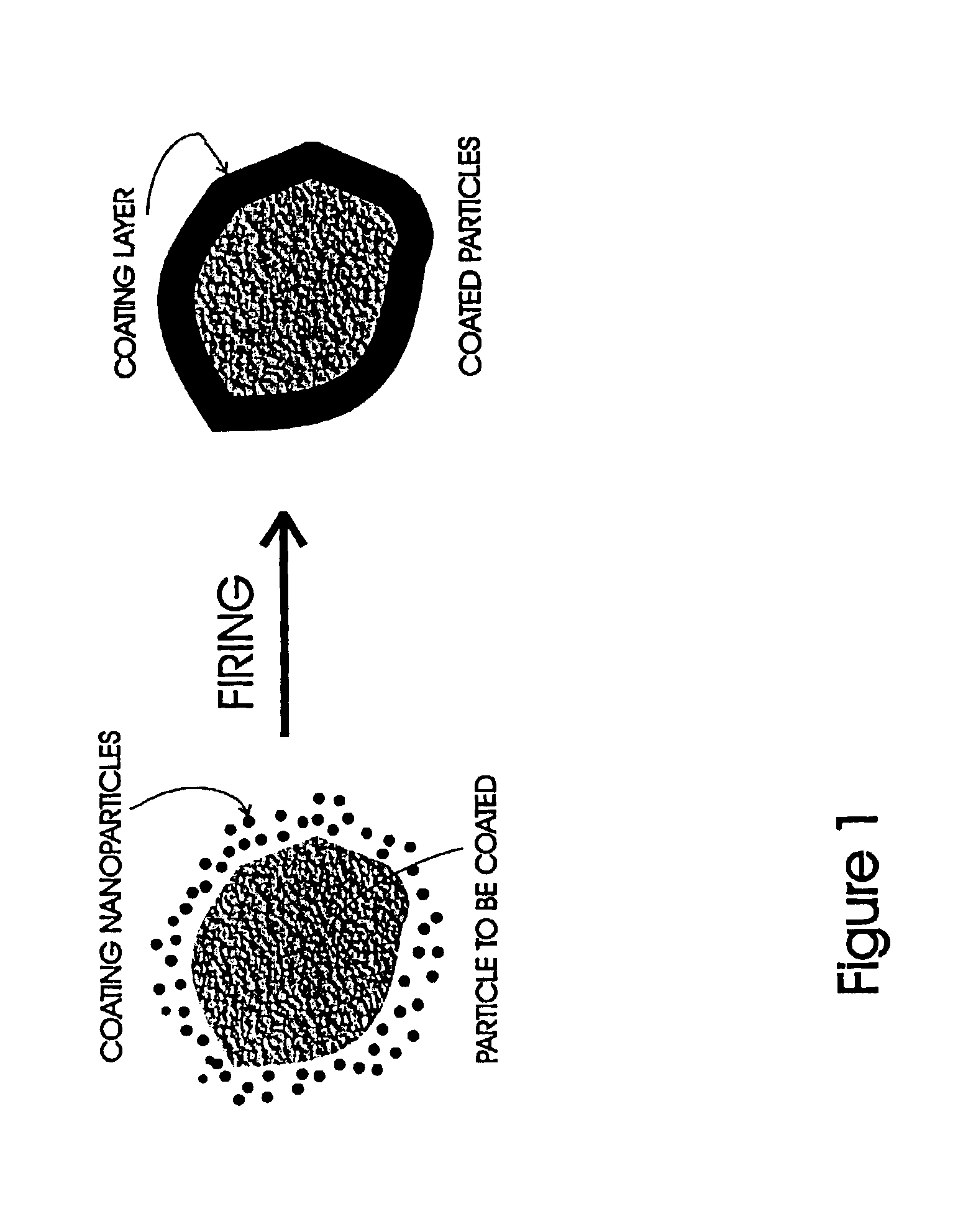

Method of coating micrometer sized inorganic particles

A method for coating moisture sensitive inorganic particles, such as phosphors, comprising mixing the inorganic particles having a particle size of about 1 to 100 micrometers with nanometer-sized coating particles, and firing the mixture to soften or melt the nanometer-sized particles about the inorganic particles, forming a moisture impervious coating. The coated particles are washed to remove excess particles, and dried. Coated moisture sensitive phosphor particles are impervious to moisture.

Owner:SARNOFF CORP

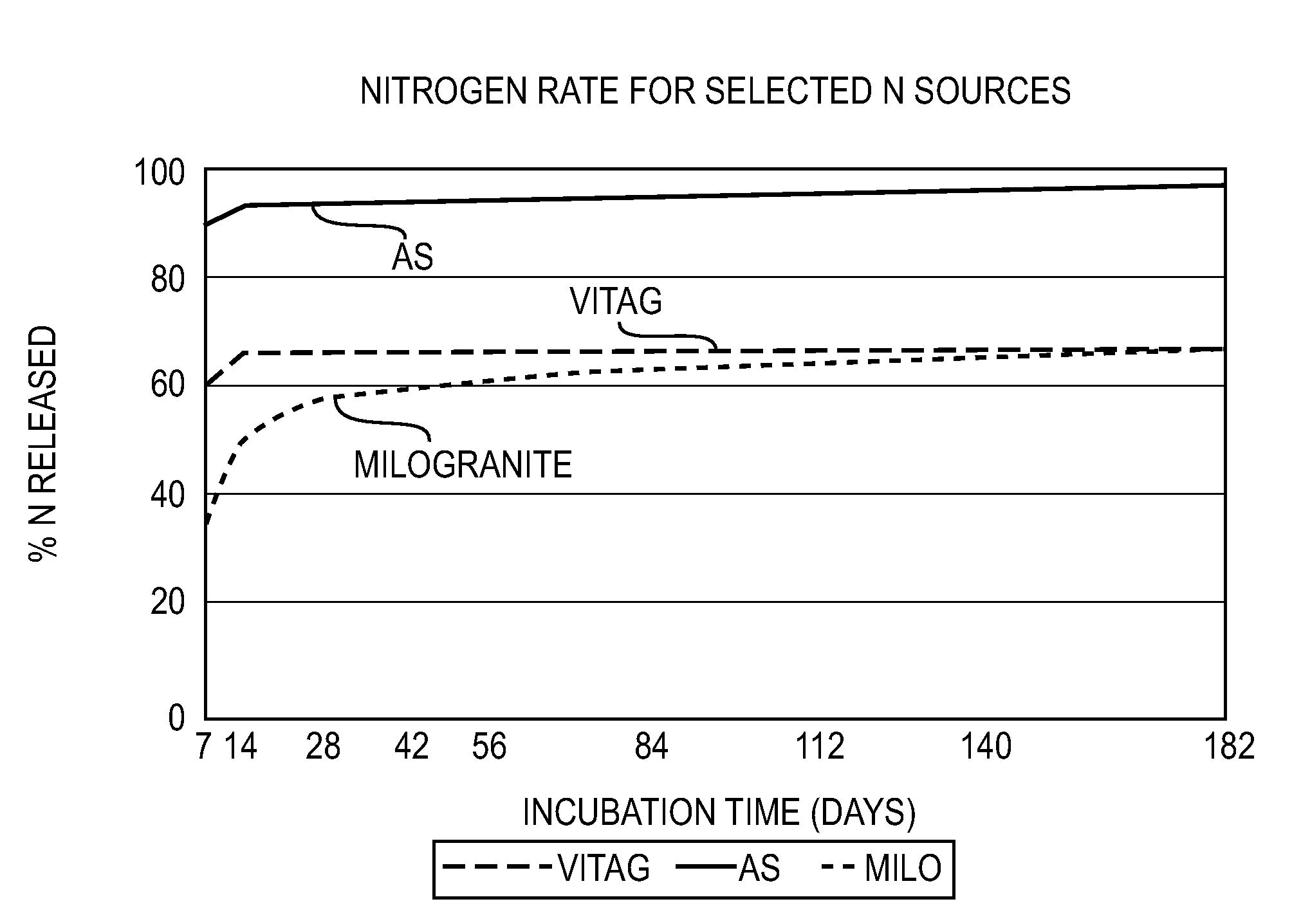

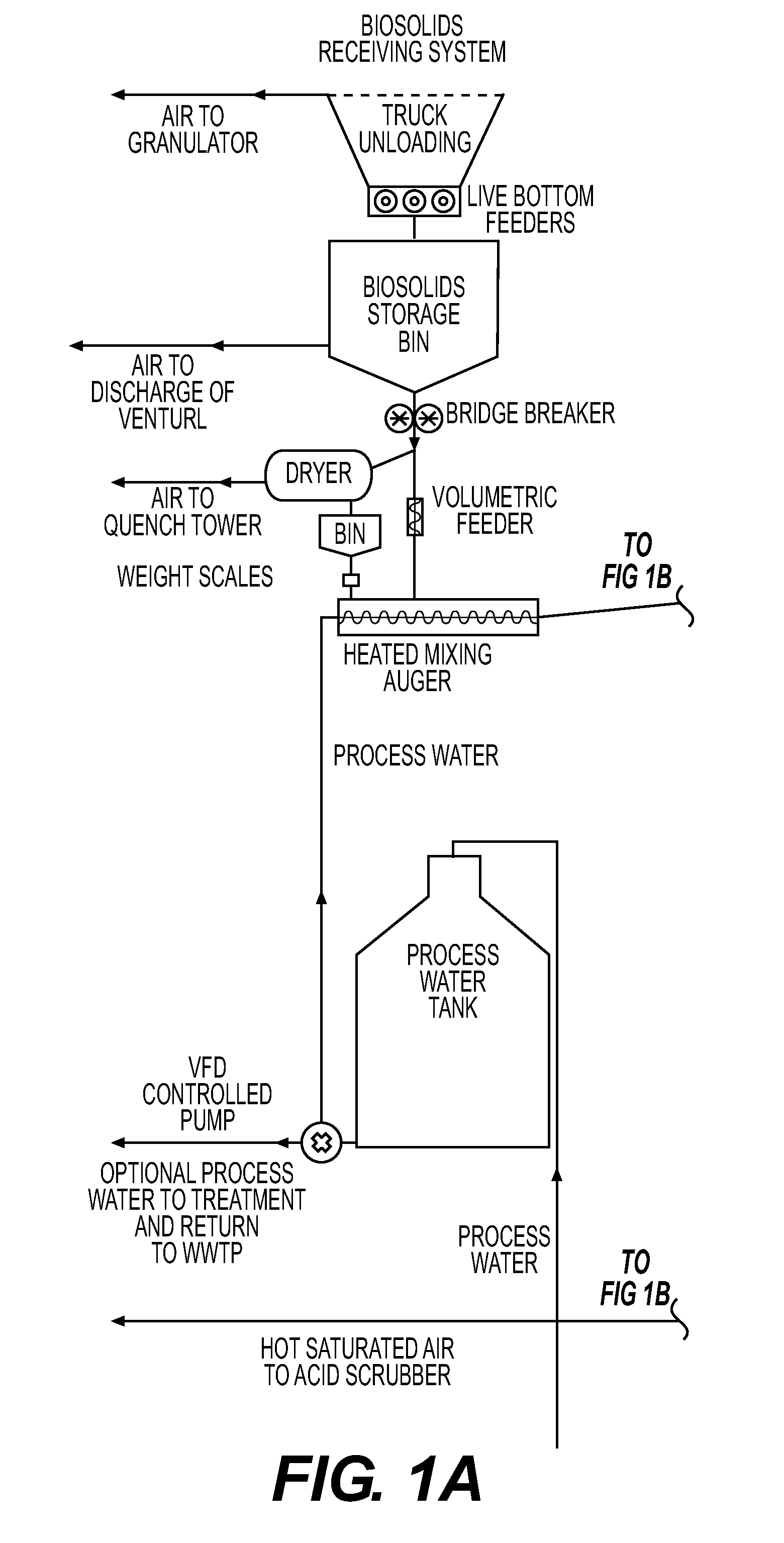

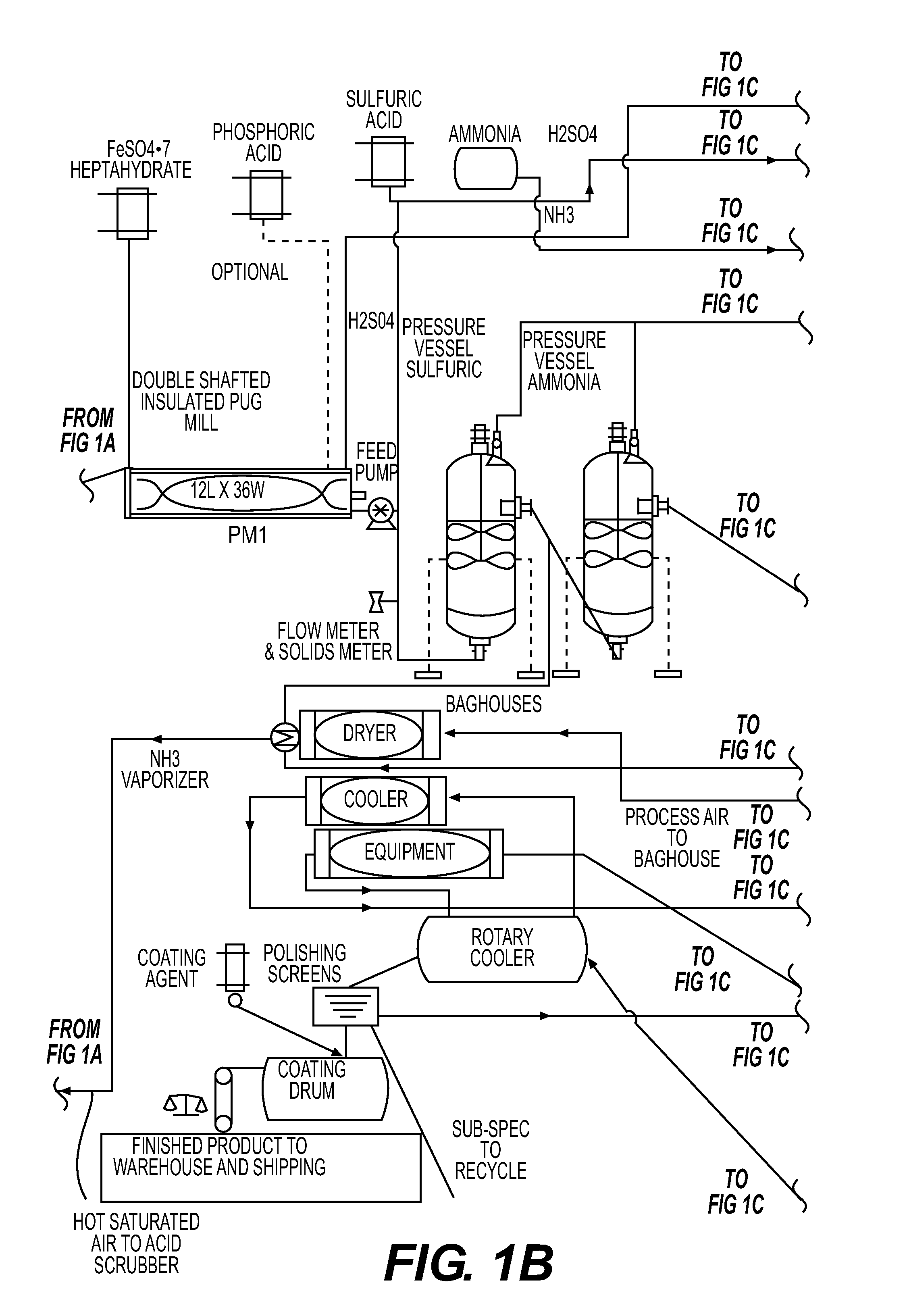

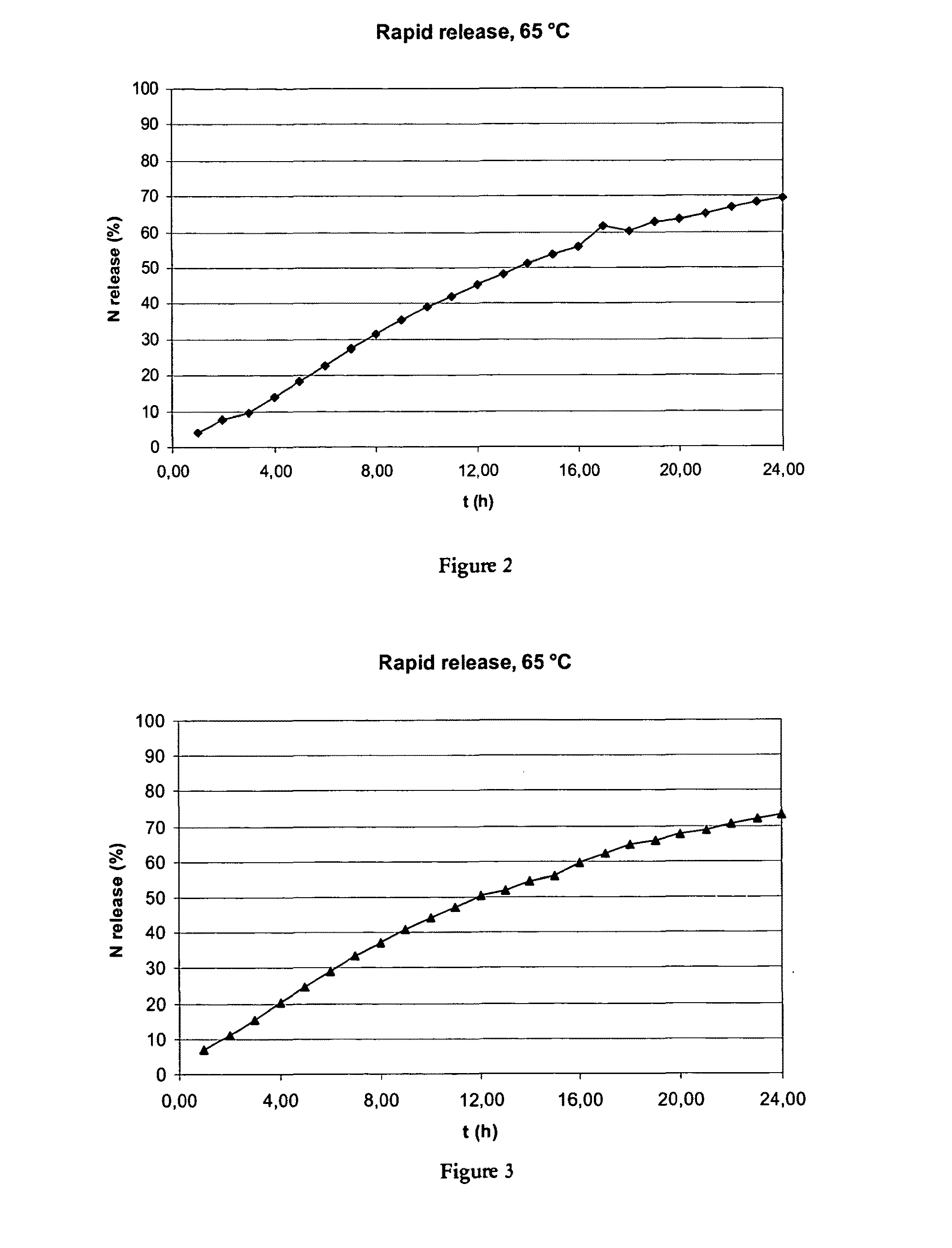

High value organic-enhanced inorganic fertilizers

ActiveUS20120247164A1Increase valueEasy to containCalcareous fertilisersGranule coatingSoil organic matterNitrogen

The invention is directed to manufacture of fertilizer having commercial levels of nitrogen supplemented with organic substances. The process treats organic matter with acid causing hydrolysis of organic polymers after which the mix is injected with nitrogen. The resultant sterilized and liquefied organic matter is disbursed over recycled material for the production of granules. Because the process allows for the controlled addition of acids and ammonia, desired levels of components can be achieved. The process is scalable, odor controlled and safe thereby allowing for the location of biosolid processing facilities in most any location. Further, the fertilizer of the invention provides a dual nitrogen-release profile when applied to crops. After application to soil, fertilizer of the invention releases an immediate bolus of nitrogen, similar to traditional ammonium sulfate, followed by continued slow release of nitrogen typically over a season.

Owner:GENERATE LENDING LLC +1

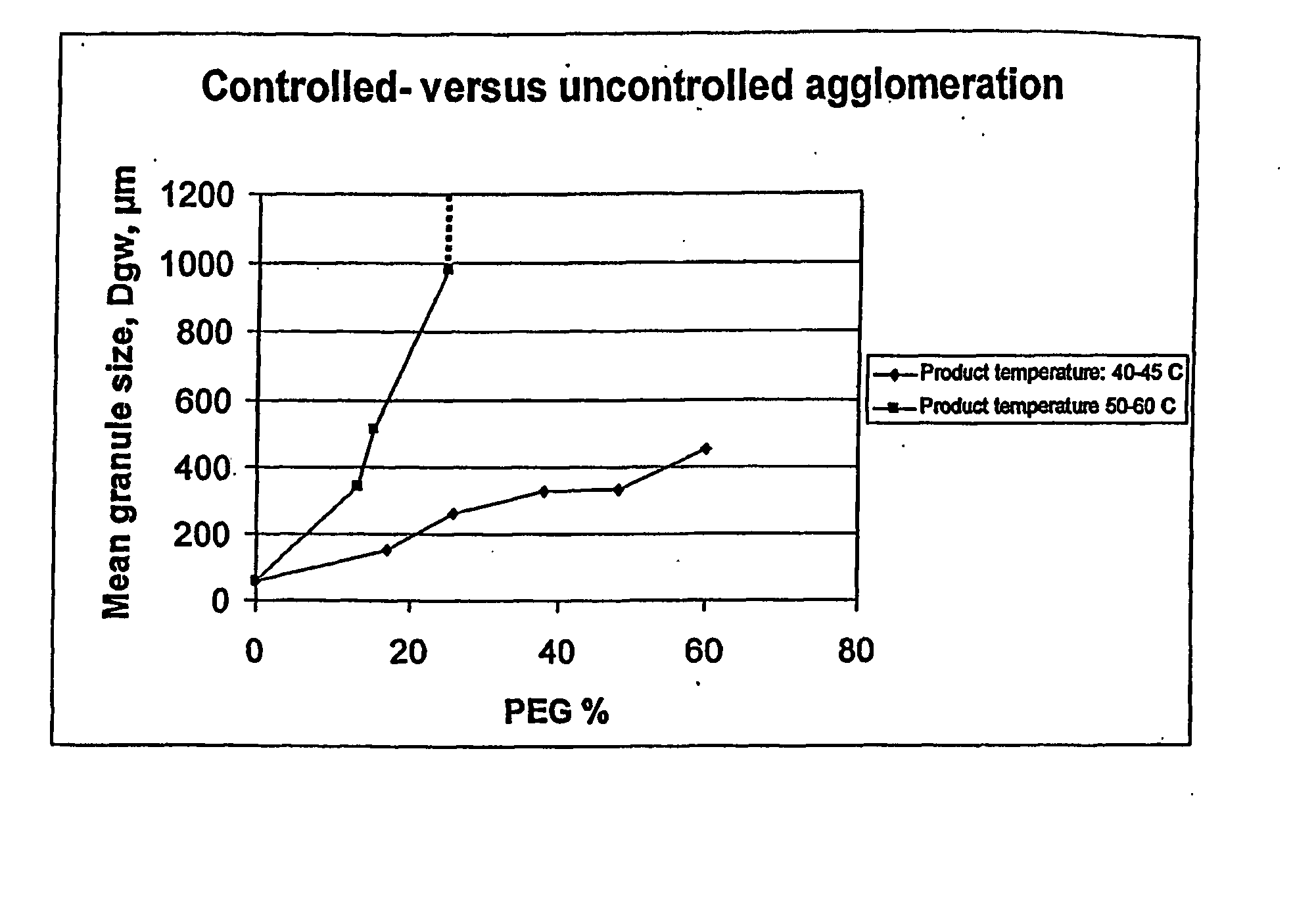

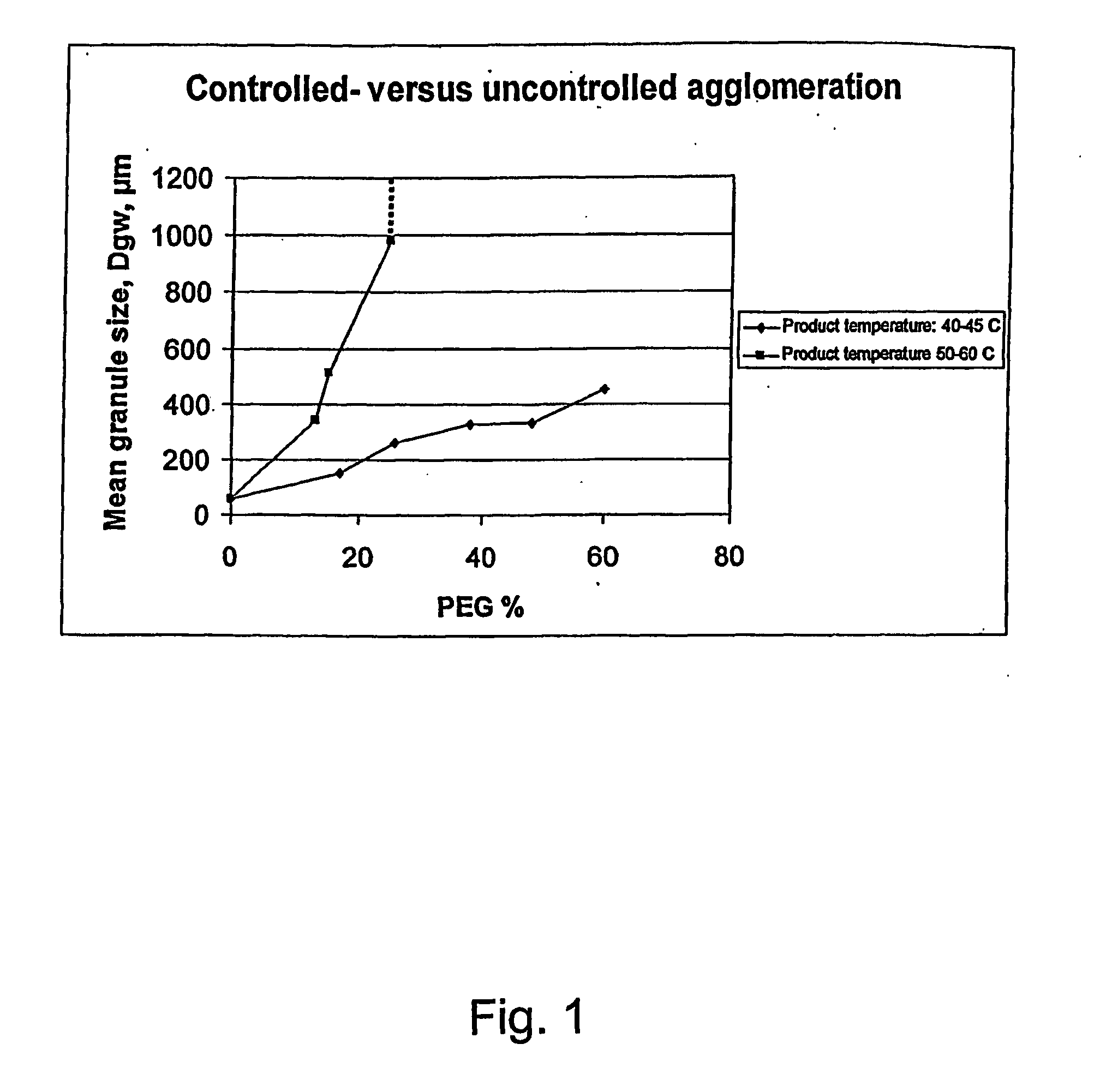

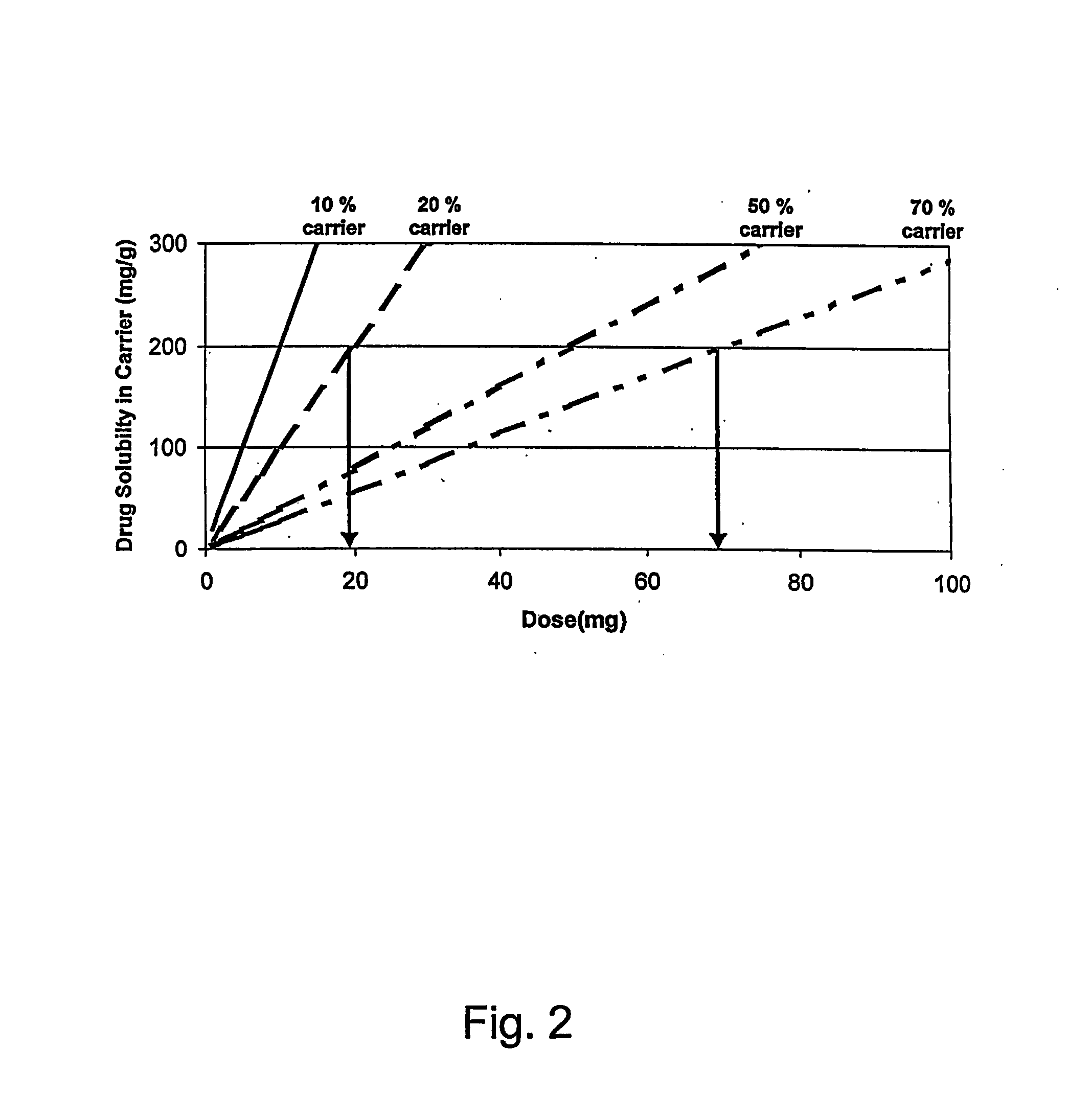

Controlled agglomeration

InactiveUS20070275074A1Improve solubilityLow water solubilityPowder deliveryBiocideSolid massAqueous solubility

A process for the preparation of a particulate material by a controlled agglomeration method, i.e. a method that enables a controlled growth in particle size. The method is especially suitable for use in the preparation of pharmaceutical compositions containing a therapeutically and / or prophylactically active substance which has a relatively low aqueous solubility and / or which is subject to chemical decomposition. The process comprising i) spraying a first composition comprising a carrier, which has a melting point of about 5° C. or more which is present in the first composition in liquid form, on a second composition comprising a material in solid form, the second composition having a temperature of at the most a temperature corresponding to the melting point of the carrier and / or the carrier composition and ii) mixing or others means of mechanical working the second composition onto which the first composition is sprayed to obtain the particulate material.

Owner:VELOXIS PHARM INC

Nickel powders, methods for producing powders and devices fabricated from same

InactiveUS20050262966A1High crystallinityHigh rateGranule coatingCell electrodesSpherical morphologyMetal powder

Nickel powder batches and methods for producing nickel powder batches. The powder batches include particles having a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the nickel metal powders.

Owner:CABOT CORP

Polymer coating/encapsulation of nanoparticles using a supercritical antisolvent process

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Method for making a film from silver-containing particles

InactiveUS7004994B2High rateIncrease loadMaterial granulation and coatingGranule coatingPolymer scienceDroplet size

Provided are silver-containing powders and a method and apparatus for manufacturing the silver-containing particles of high quality, of a small size and narrow size distribution. An aerosol is generated from liquid feed and sent to a furnace, where liquid in droplets in the aerosol is vaporized to permit formation of the desired particles, which are then collected in a particle collector. The aerosol generation involves preparation of a high quality aerosol, with a narrow droplet size distribution, with close control over droplet size and with a high droplet loading suitable for commercial applications.

Owner:CABOT CORP

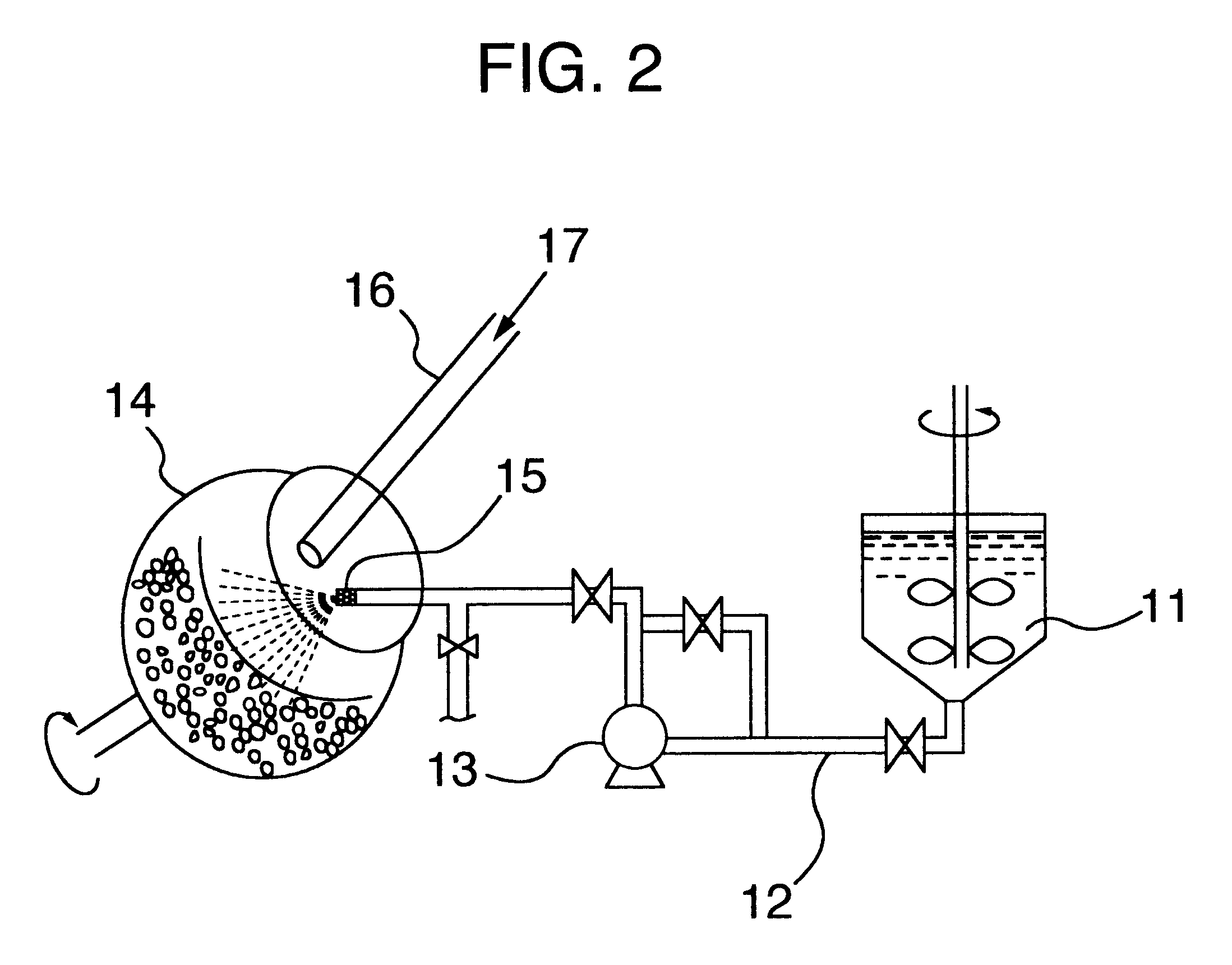

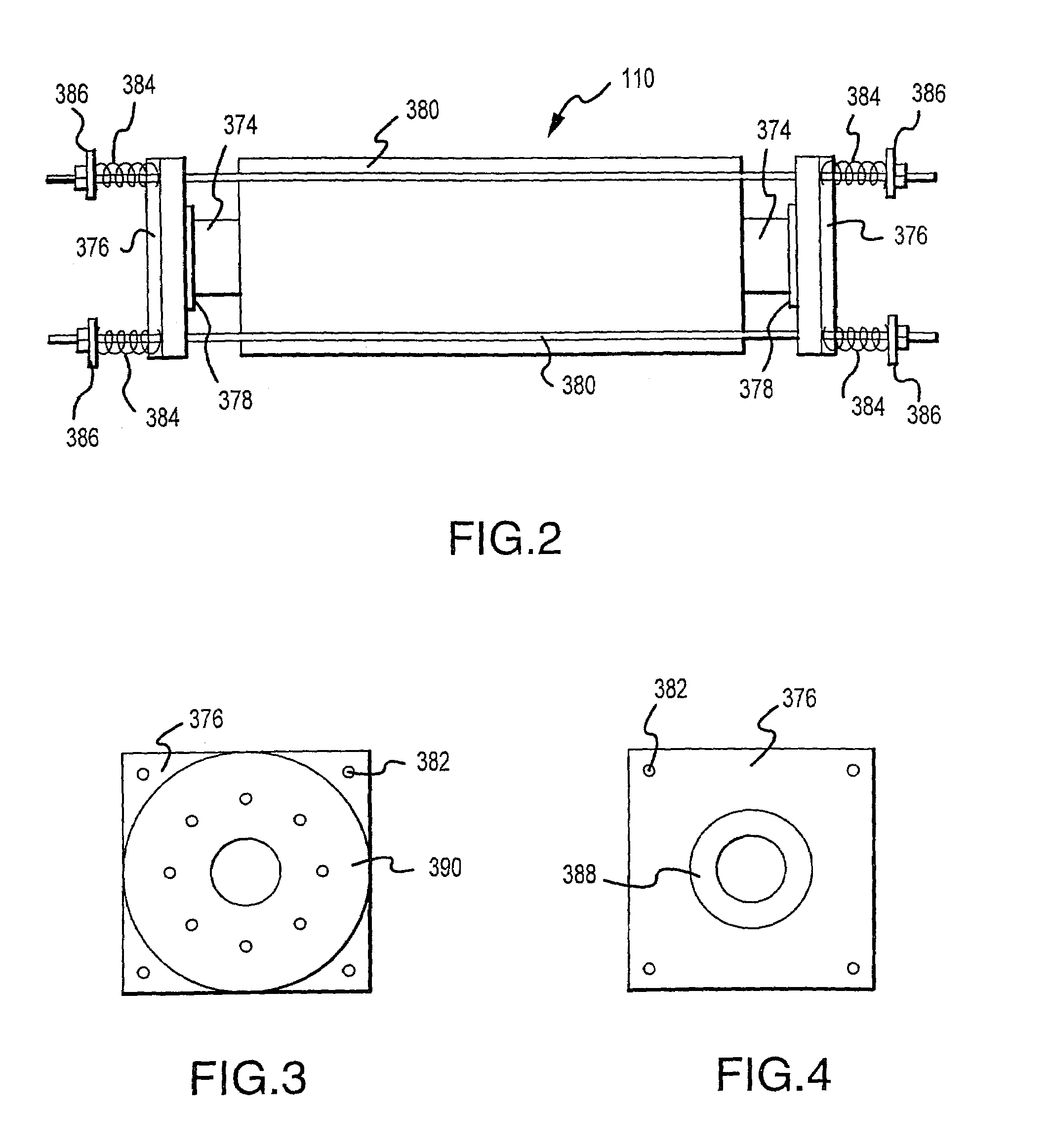

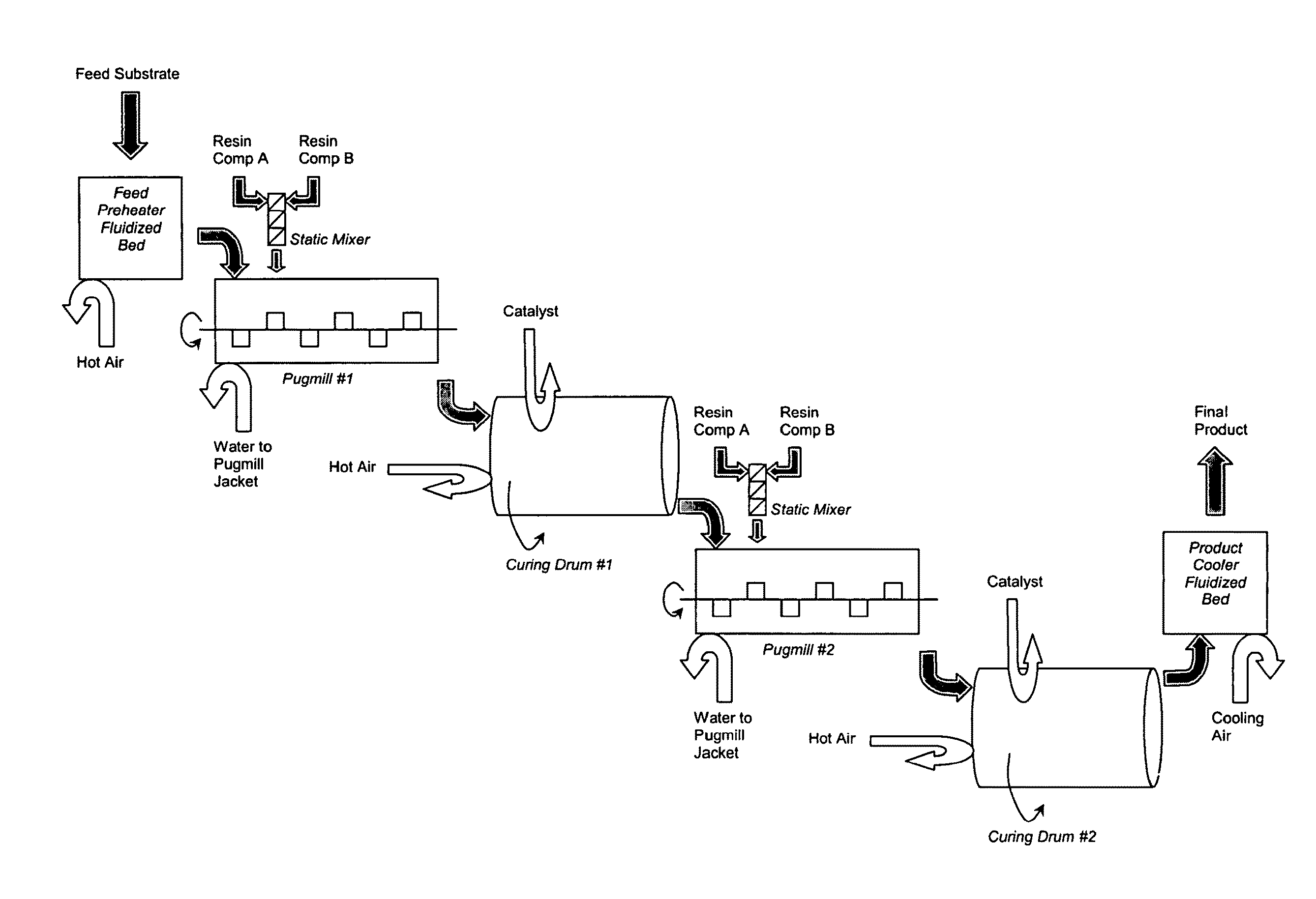

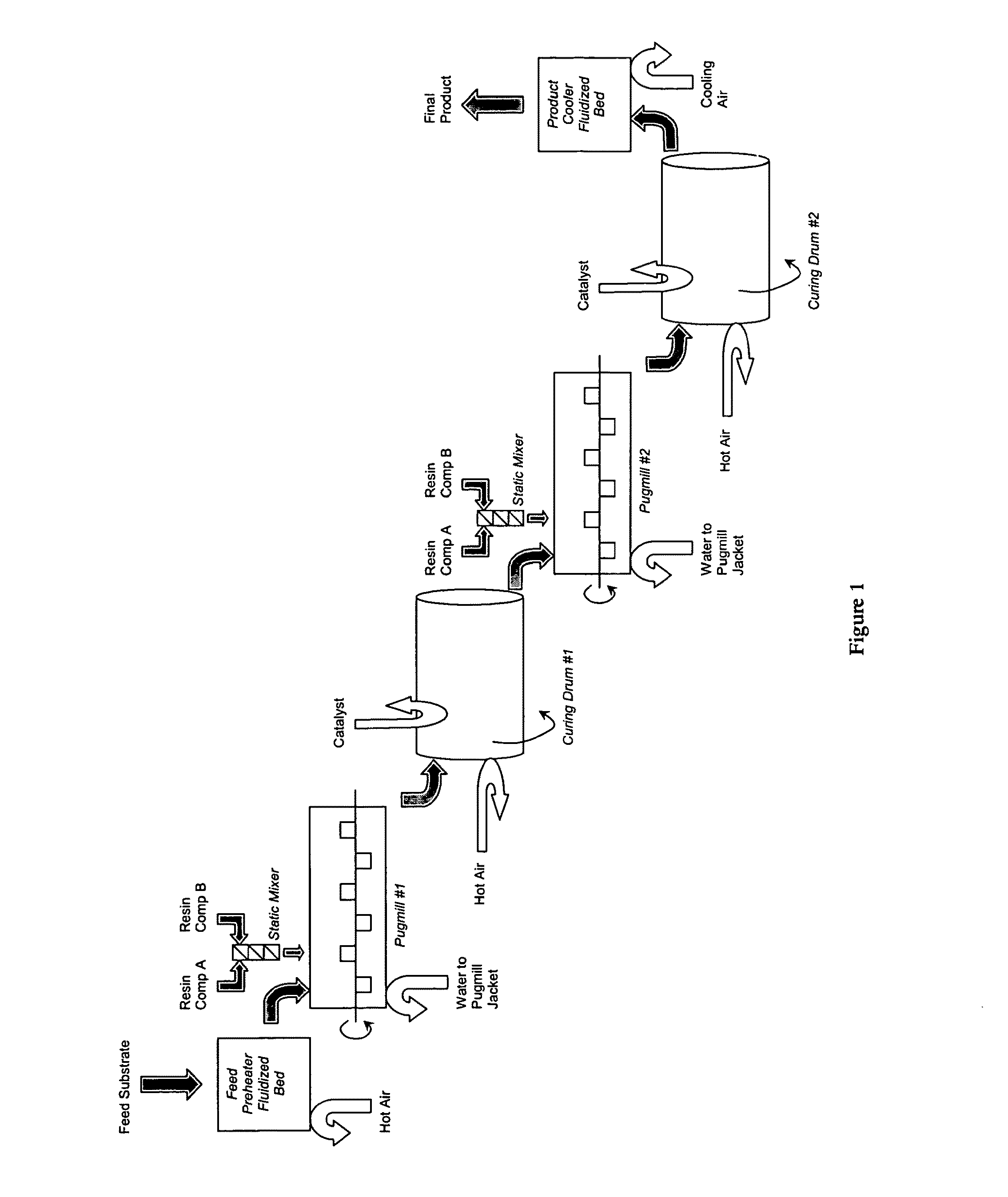

Methods and systems for coating granular substrates

ActiveUS20140033779A1Easy to controlReduce the possibilityBiocideRotating receptacle mixersEngineeringCoating

Owner:EVERRIS INT

Granular material for 3d binder printing, production method and uses therefor

InactiveUS20050276976A1Extended service lifeFlat surfaceGranule coatingPretreated surfacesSurface layerMaterials science

The invention relates to a granular material for 3D binder printing, said granular material consisting of particles provided with an externally non-polar surface layer (2). The invention also relates to a method for producing a granular material for 3D binder printing, whereby a surface layer (2) having a non-polar outer side is applied to initial particles (1), and to a method for producing an object consisting of the inventive granular material, according to which a layer of the inventive granular material is applied to a base, and pre-determined regions (3) of said layer are moistened with a binding fluid, said binding fluid being selected from fluids in which a surface layer of the particles of the granular material is soluble. The invention further realties to objects consisting of interconnected particles of the inventive granular material. The invention enables a very precise printing process.

Owner:VOXELJET AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com