Patents

Literature

2905 results about "Electrocatalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electrocatalyst is a catalyst that participates in electrochemical reactions. Catalyst materials modify and increase the rate of chemical reactions without being consumed in the process. Electrocatalysts are a specific form of catalysts that function at electrode surfaces or may be the electrode surface itself. An electrocatalyst can be heterogeneous such as a platinum surface or nanoparticles, or homogeneous like a coordination complex or enzyme. The electrocatalyst assists in transferring electrons between the electrode and reactants, and/or facilitates an intermediate chemical transformation described by an overall half-reaction.

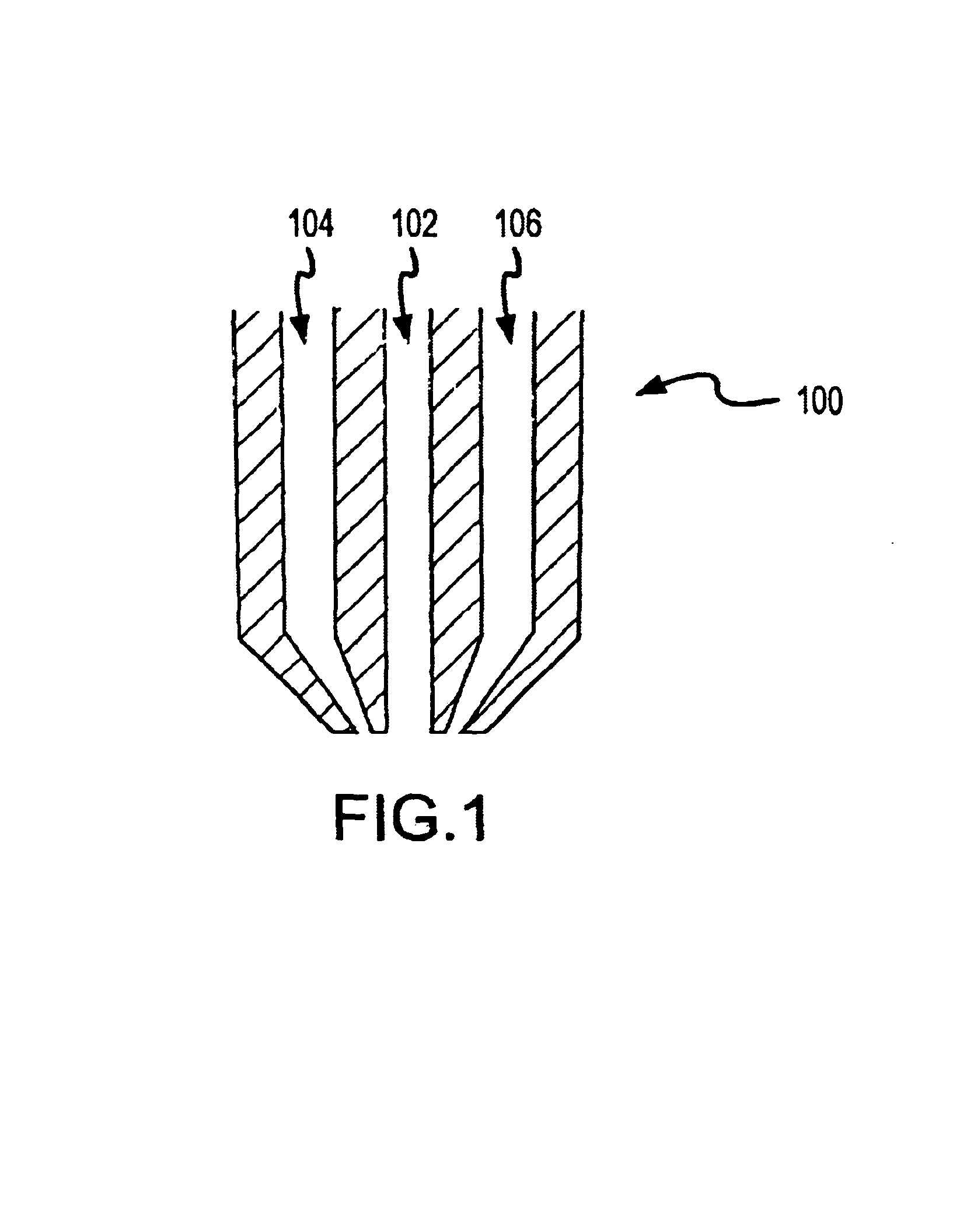

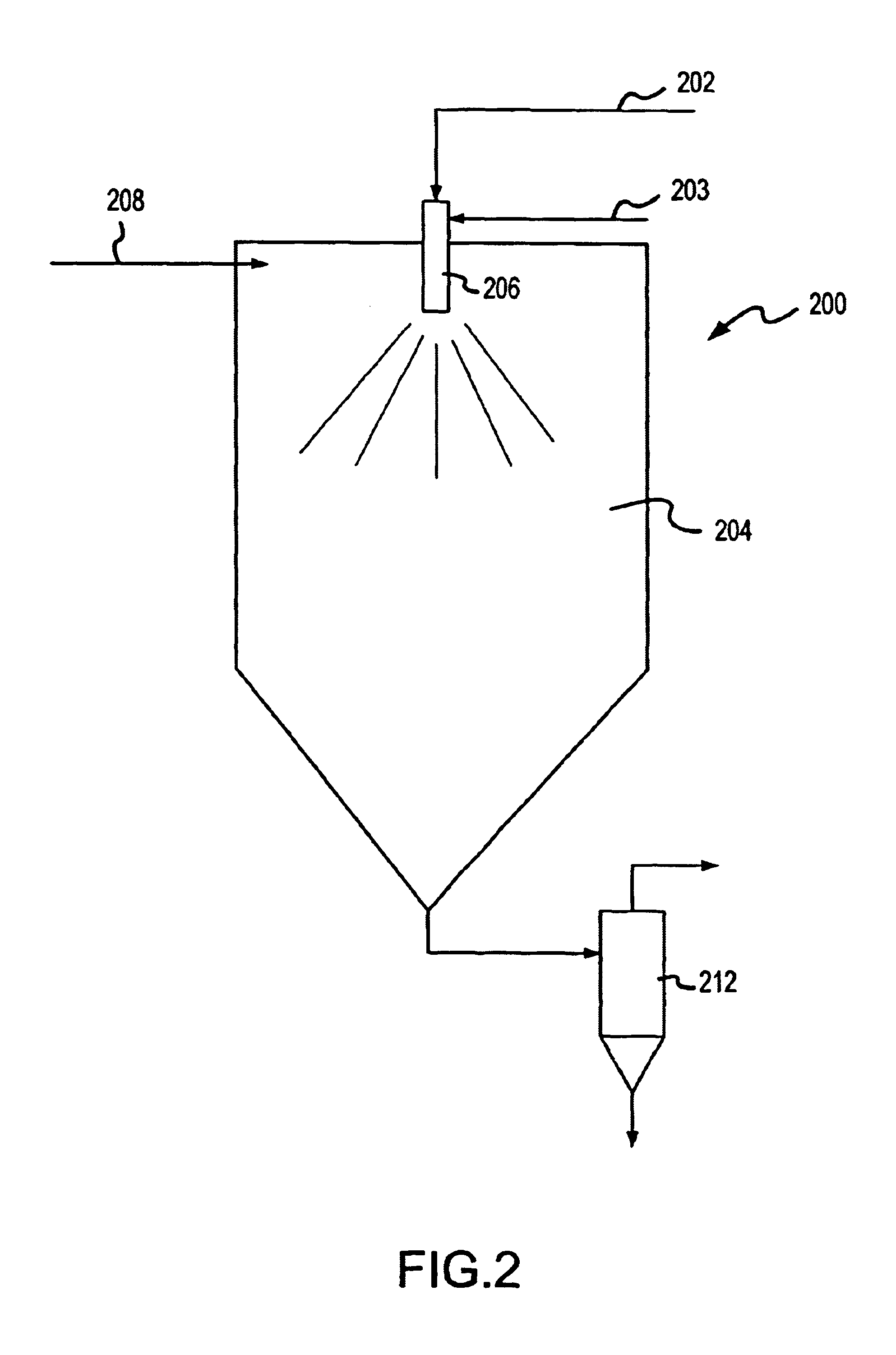

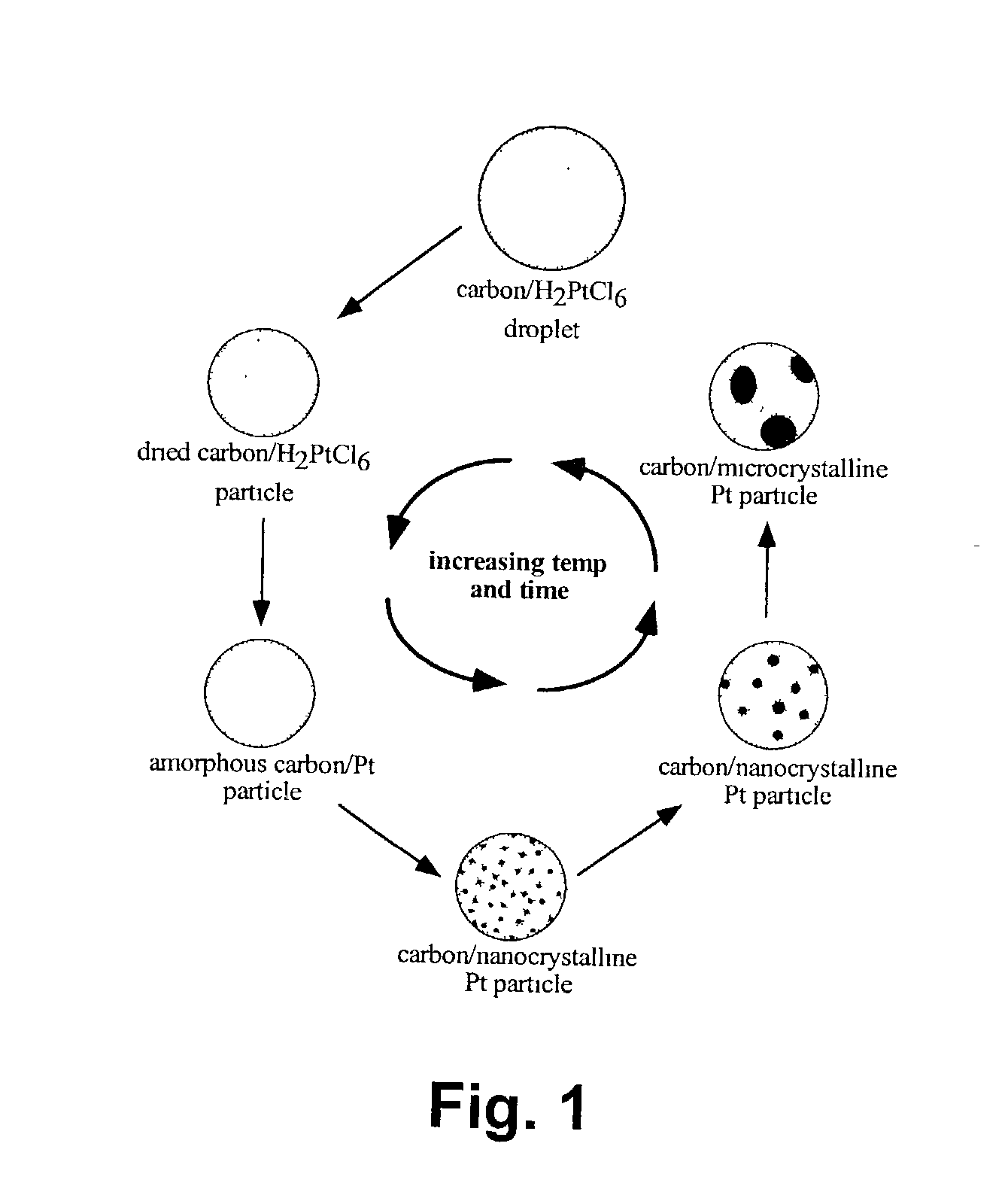

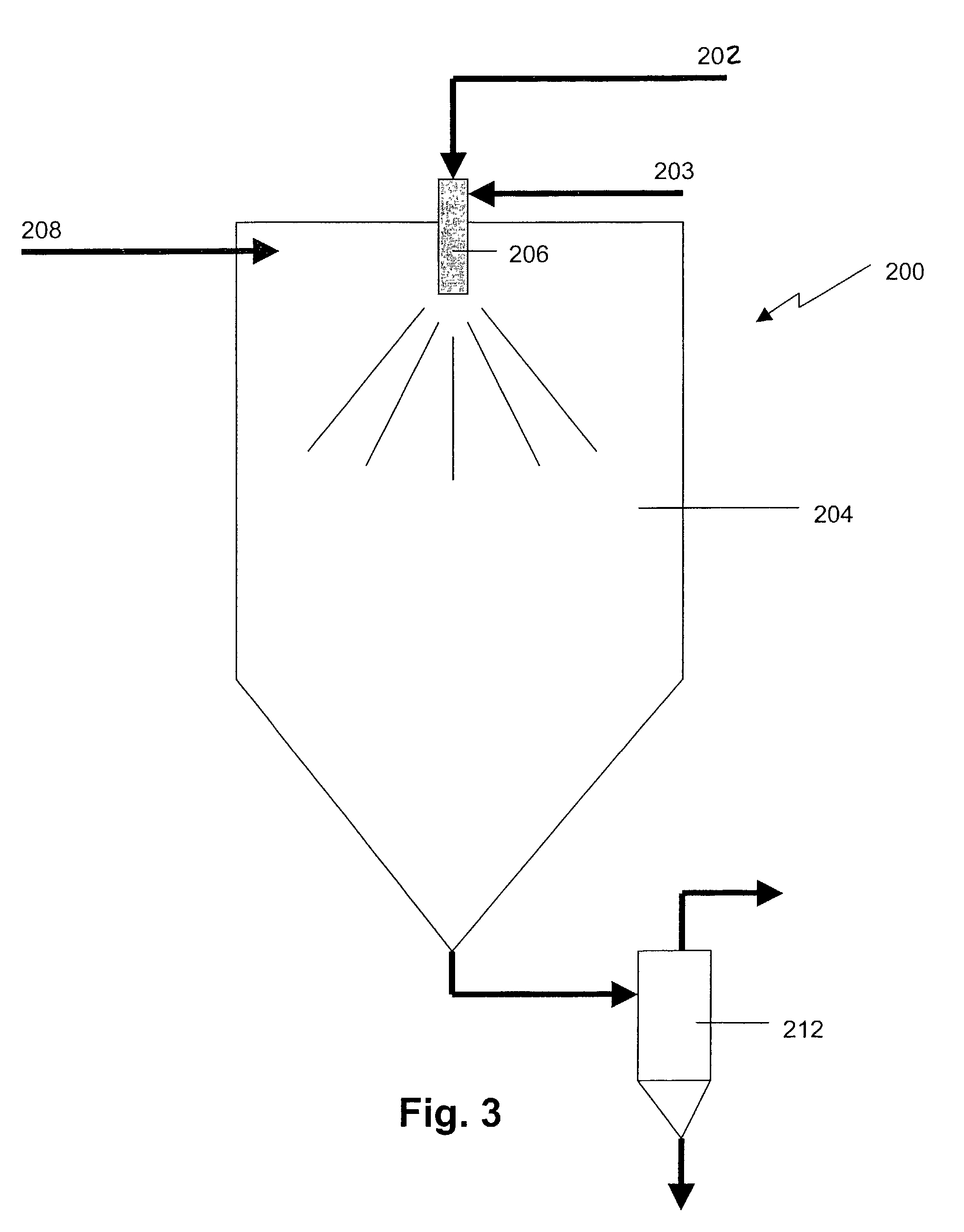

Electrocatalyst powders, methods for producing powders and devices fabricated from same

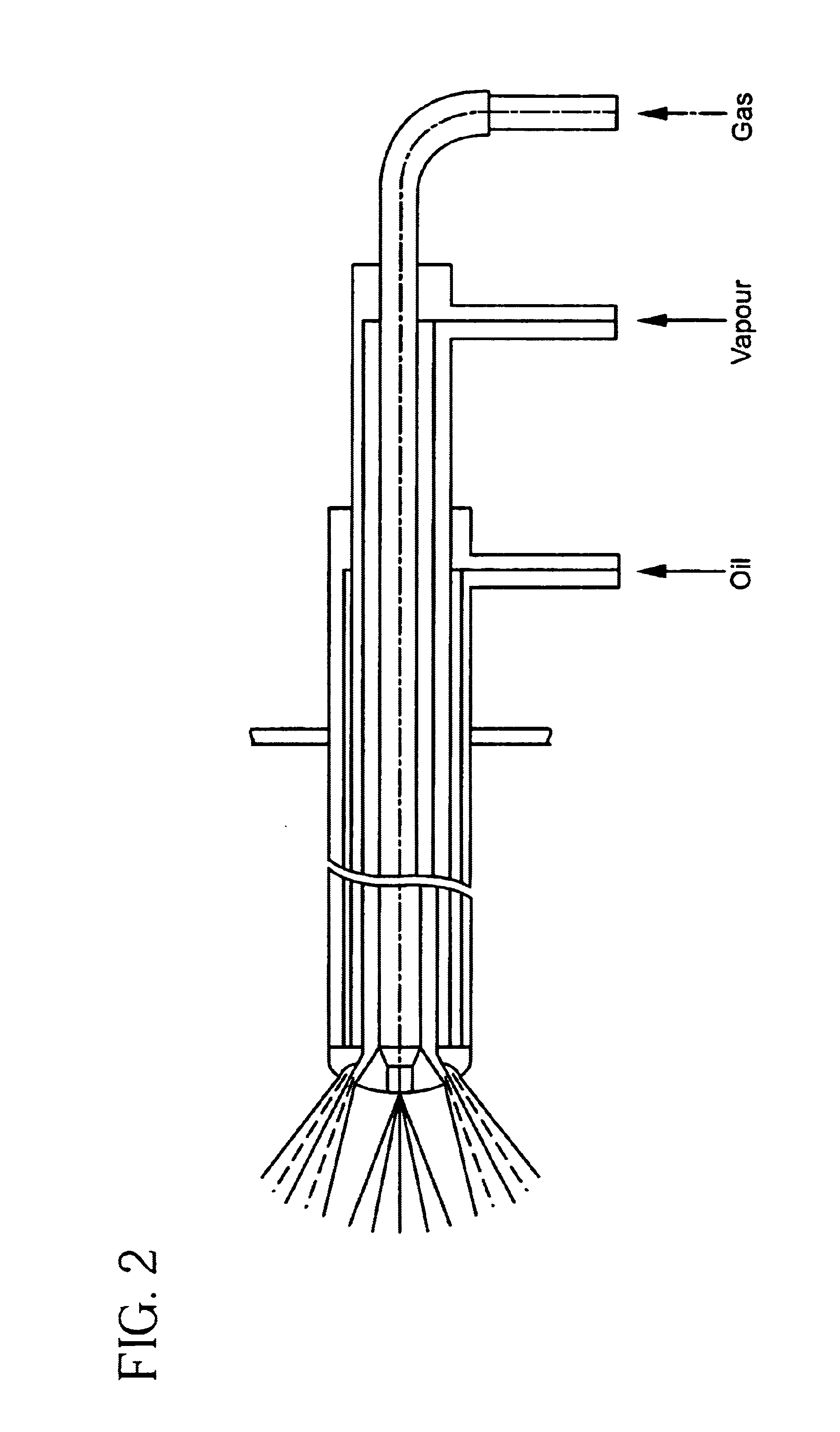

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

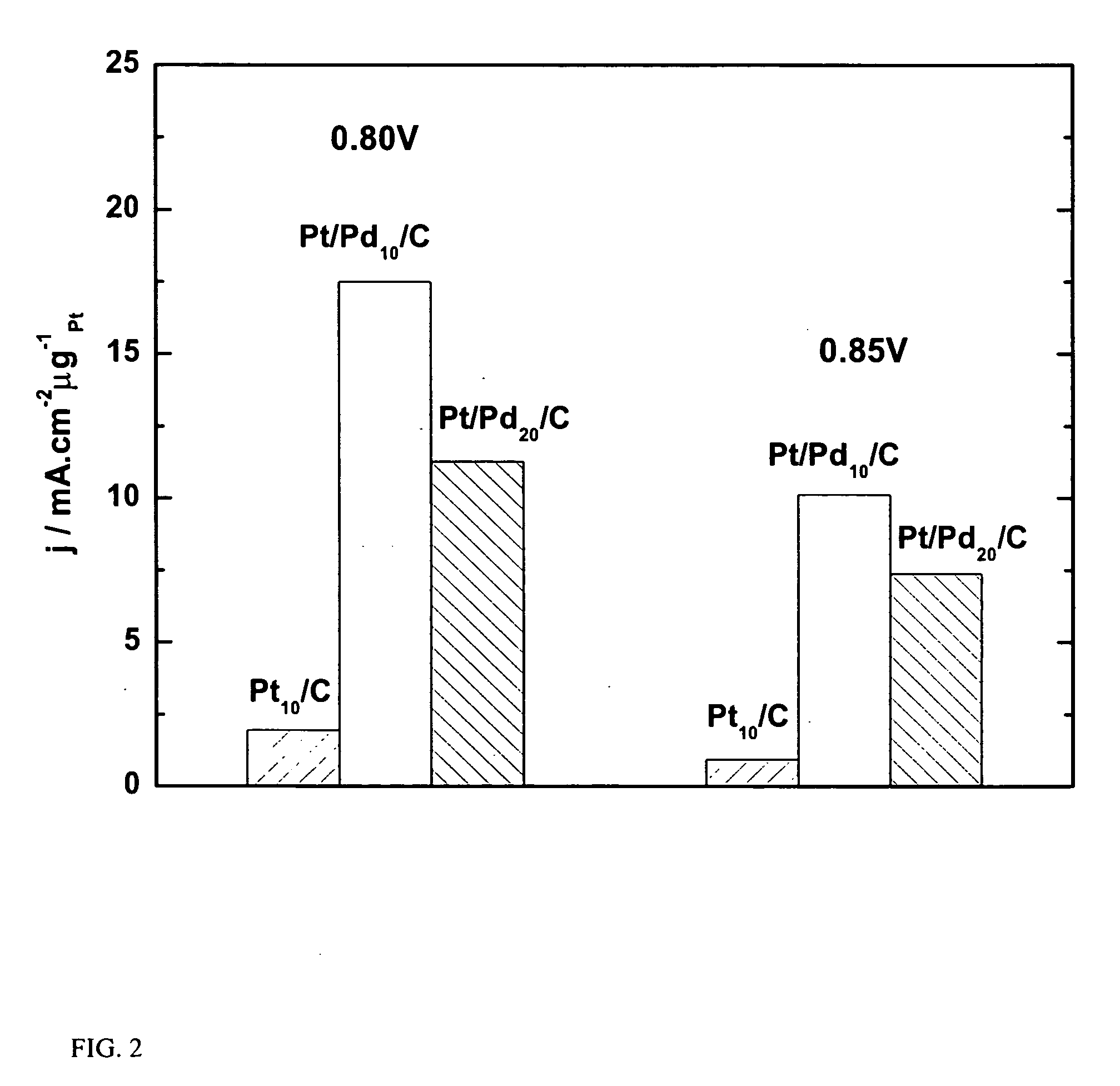

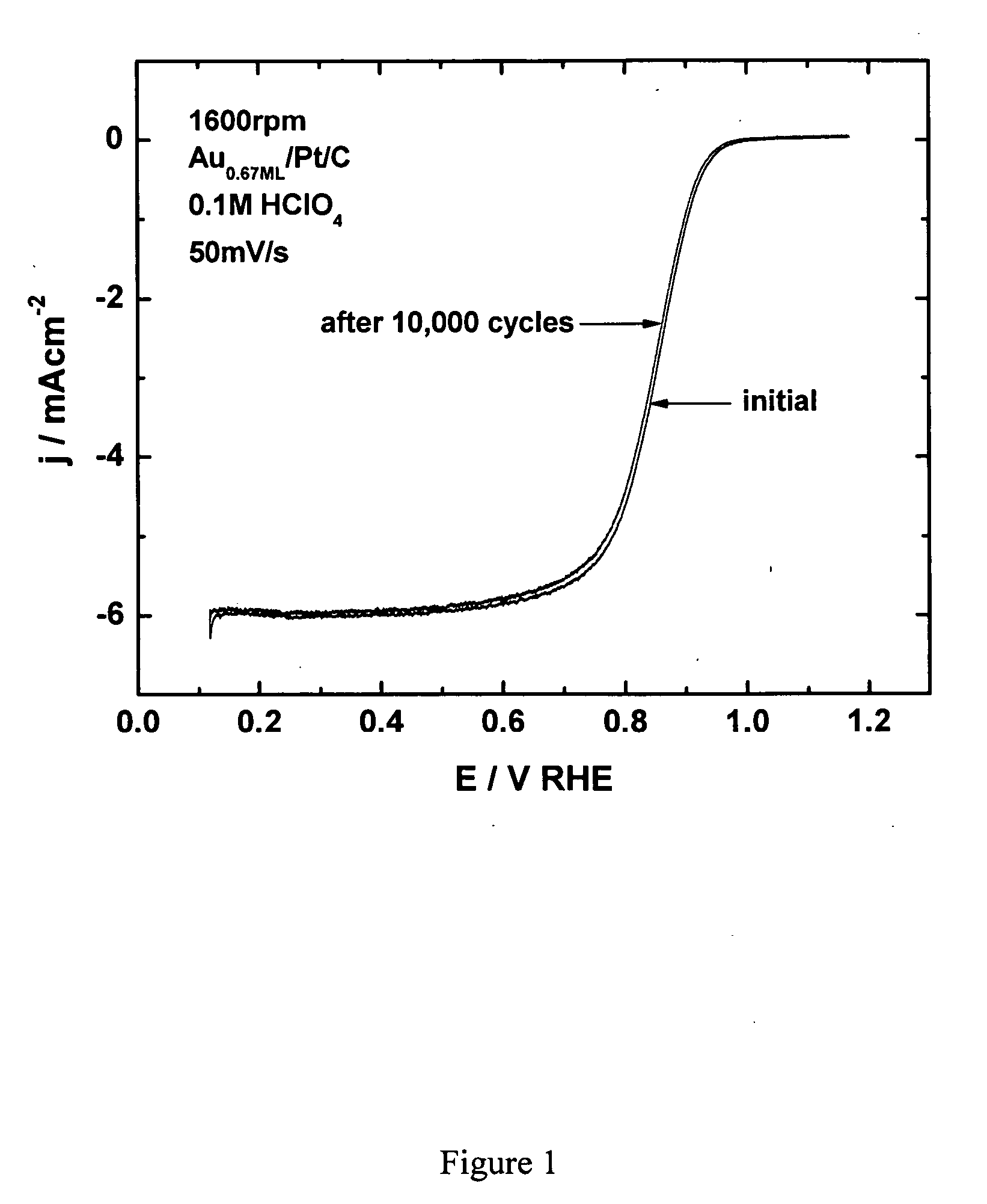

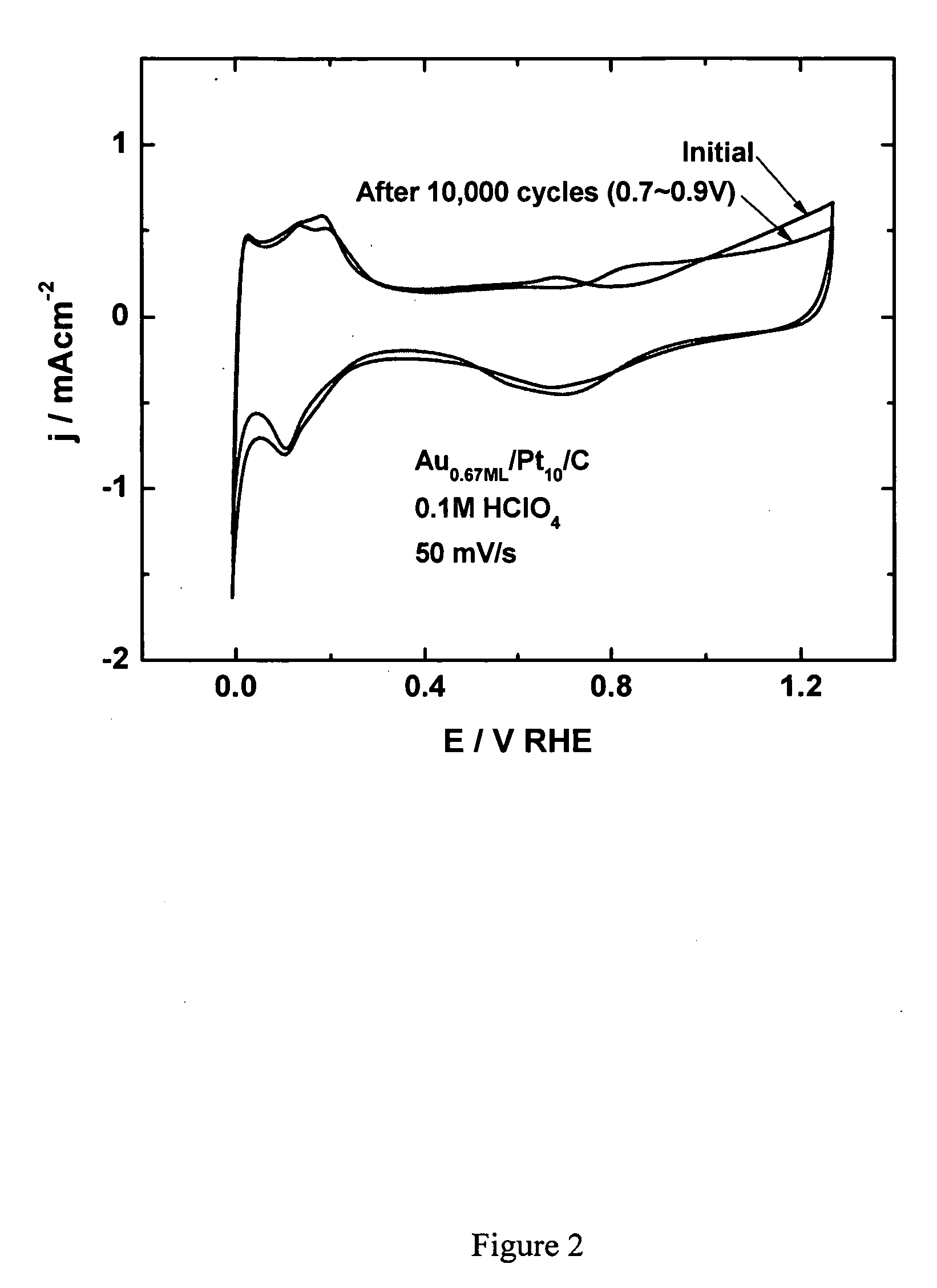

Electrocatalysts having platinum monolayers on palladium, palladium alloy, and gold alloy nanoparticle cores, and uses thereof

ActiveUS20070031722A1Improved oxygen-reducing catalytic activityLow platinum loadingMetal-working apparatusActive material electrodesRheniumGold alloys

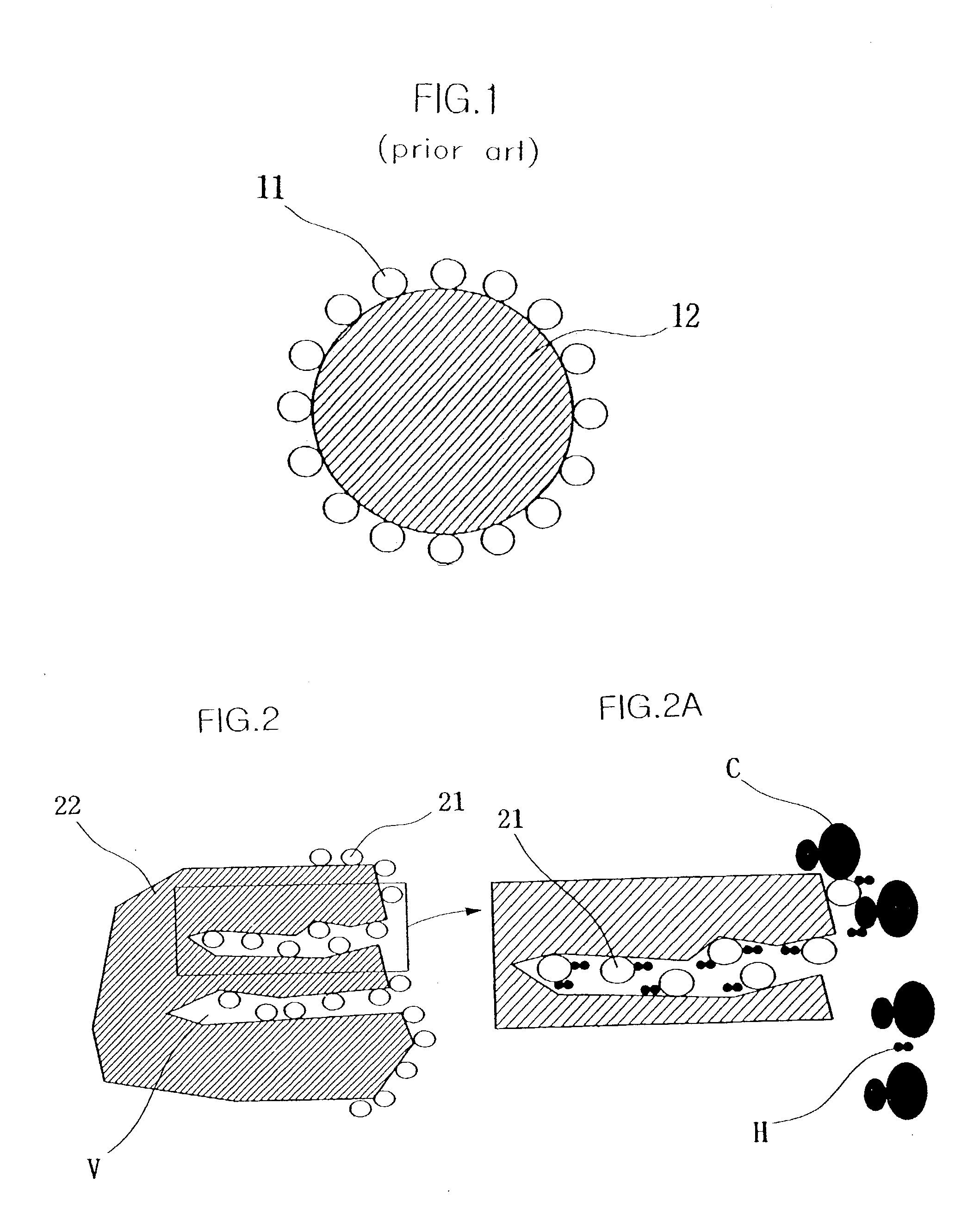

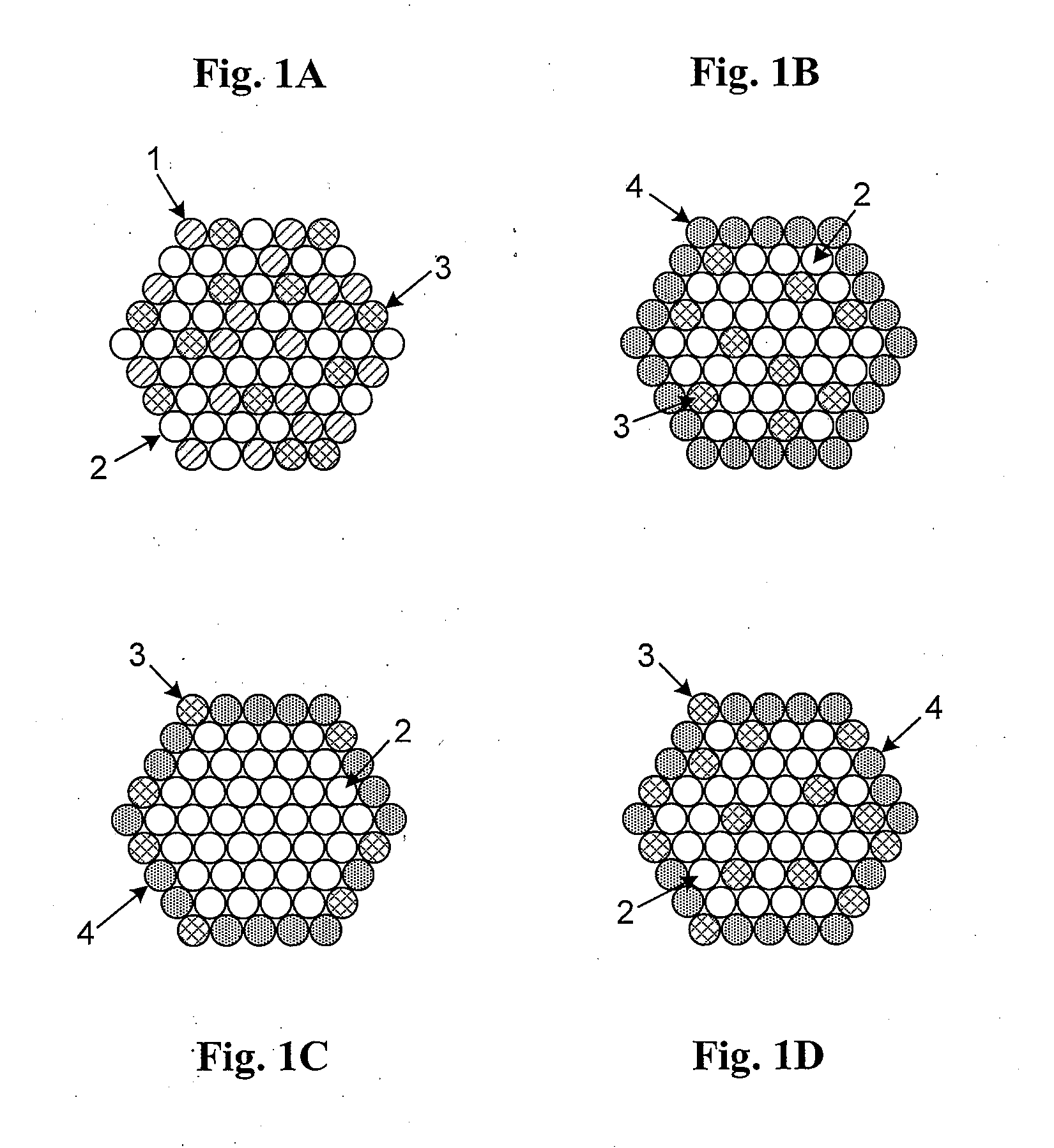

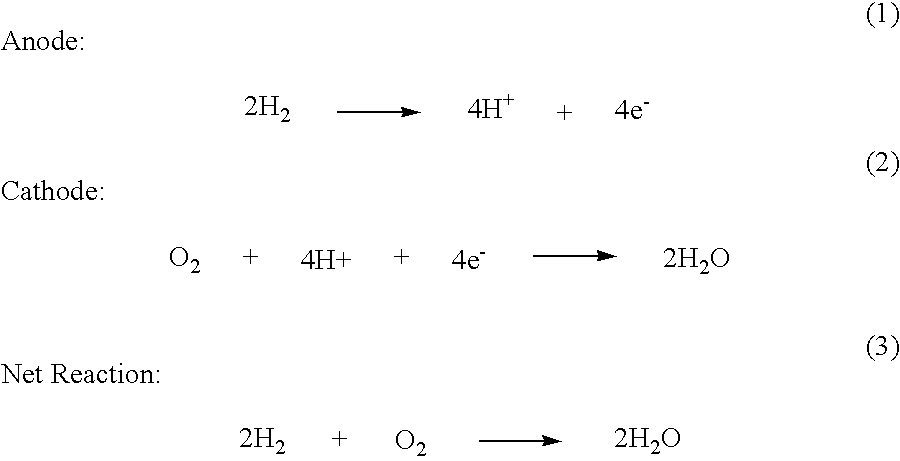

The invention relates to platinum-coated particles useful as fuel cell electrocatalysts. The particles are composed of a noble metal or metal alloy core at least partially encapsulated by an atomically thin surface layer of platinum atoms. The invention particularly relates to such particles having a palladium, palladium alloy, gold alloy, or rhenium alloy core encapsulated by an atomic monolayer of platinum. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

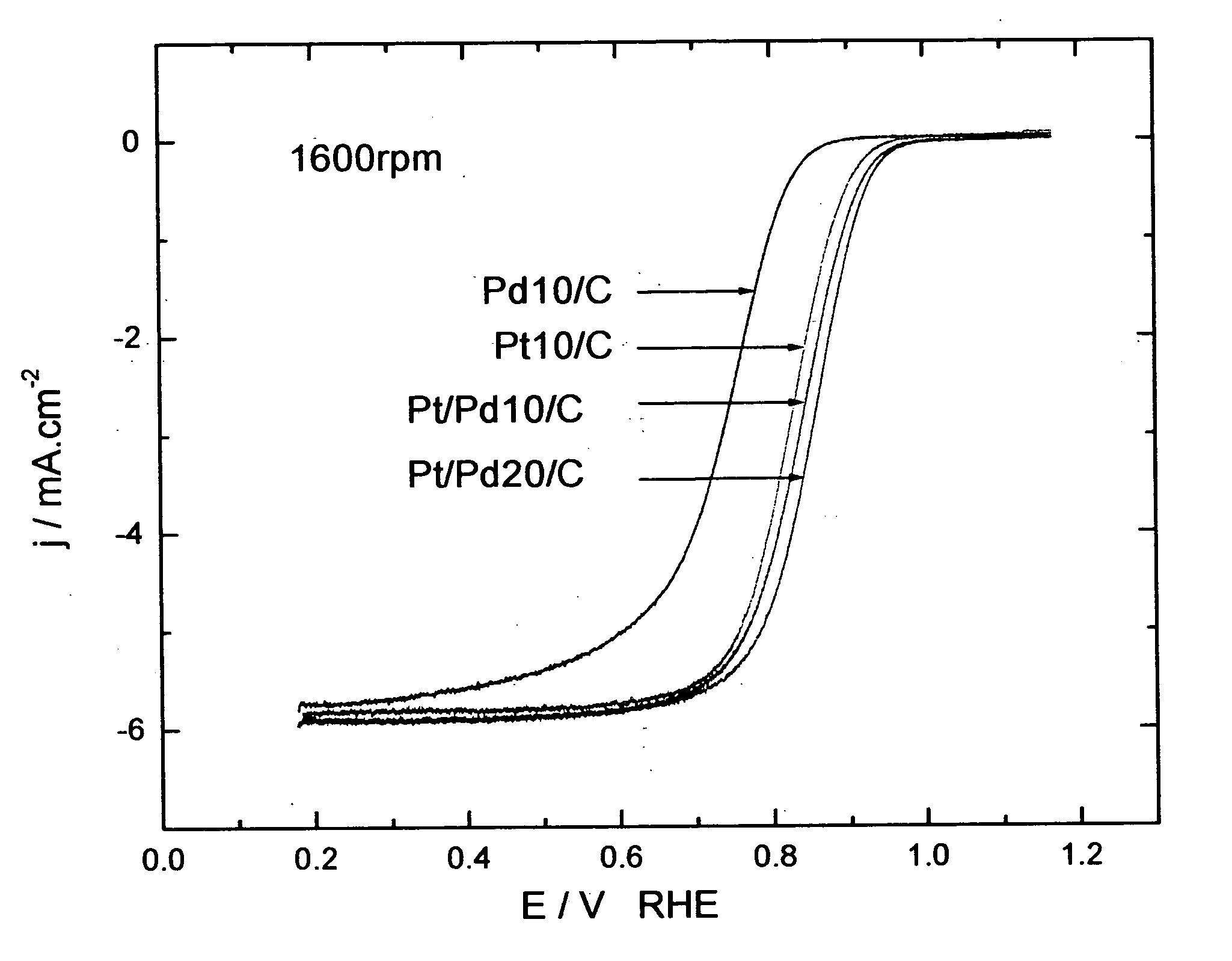

Platinum- and platinum alloy-coated palladium and palladium alloy particles and uses thereof

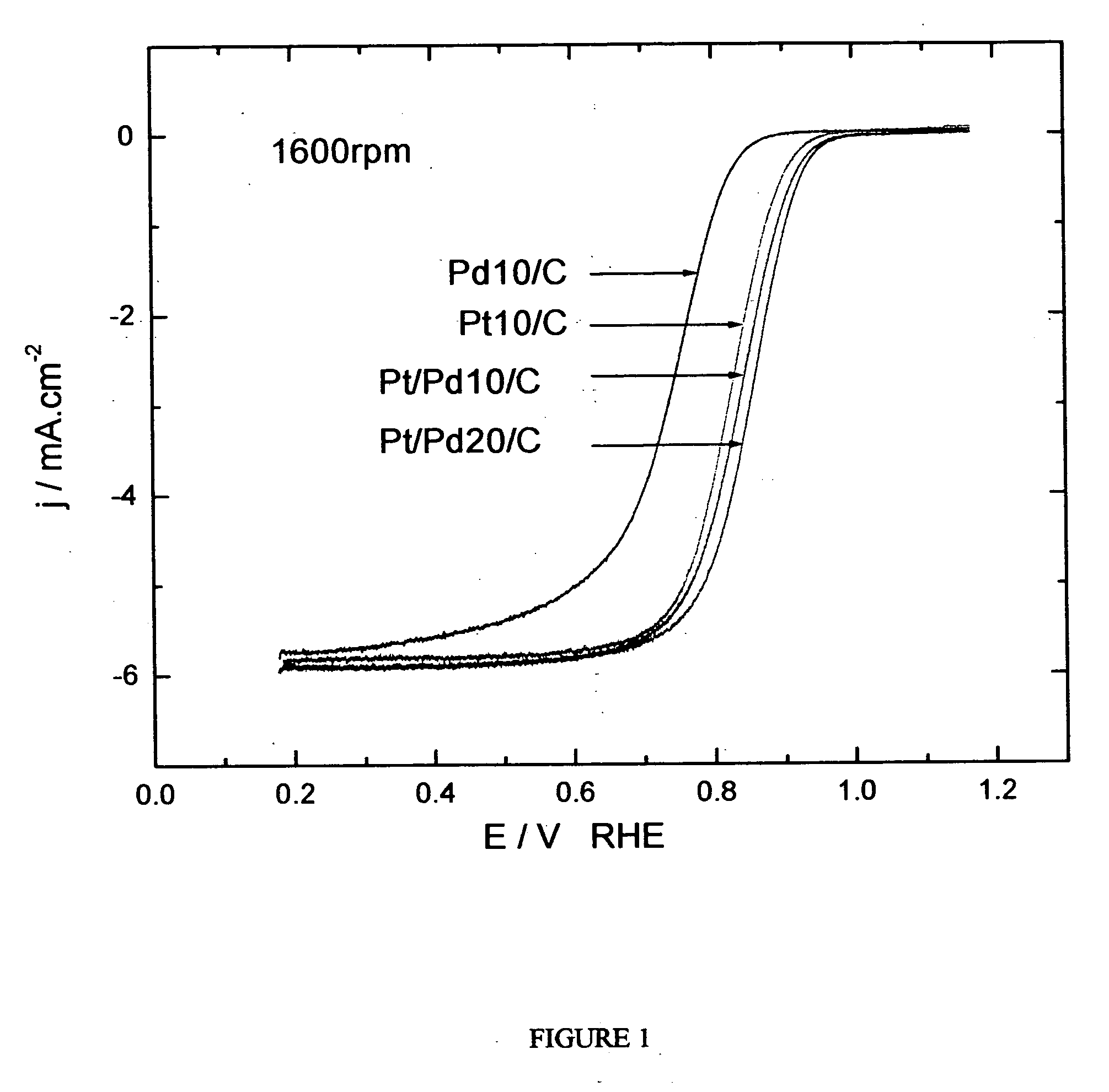

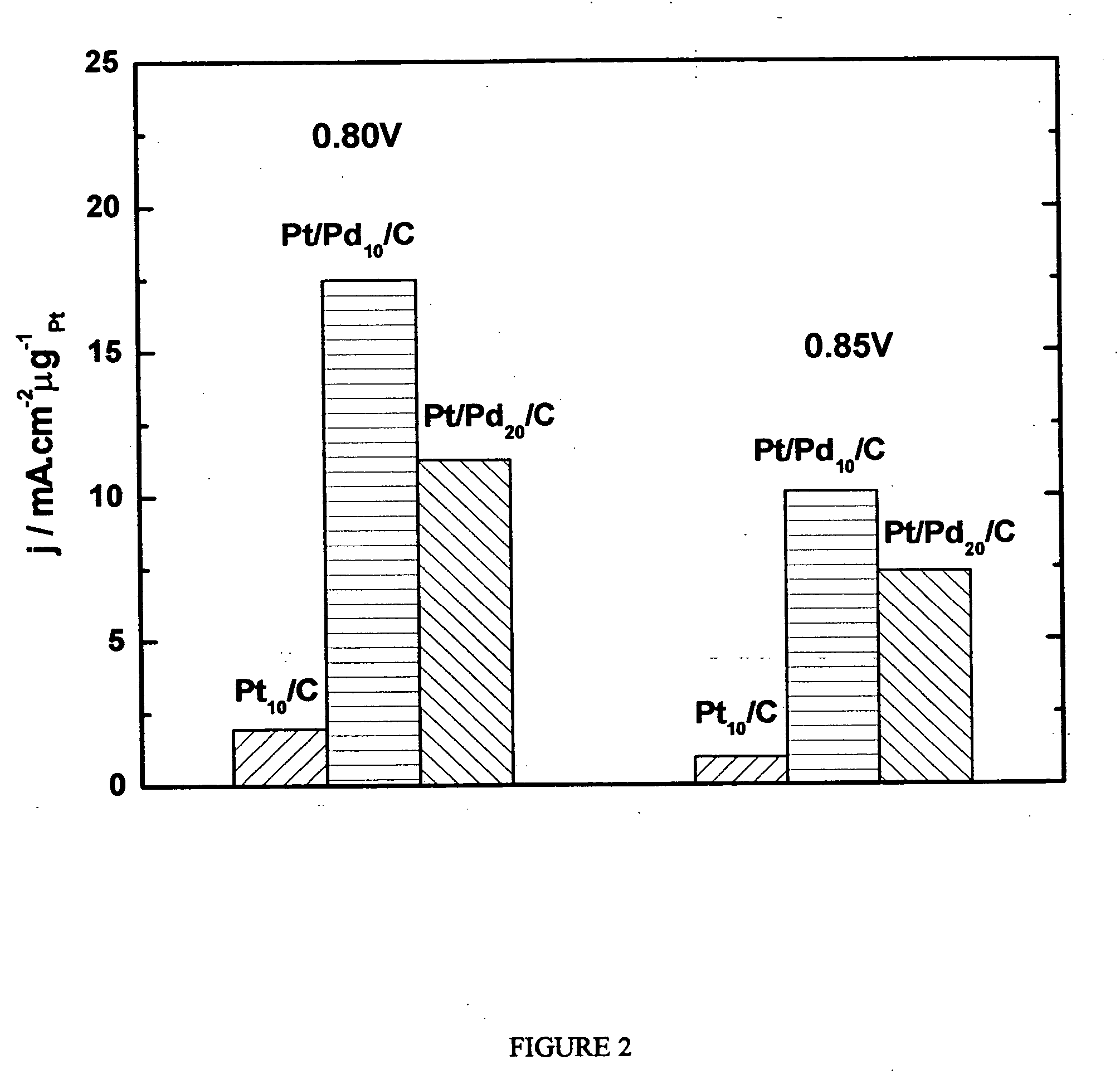

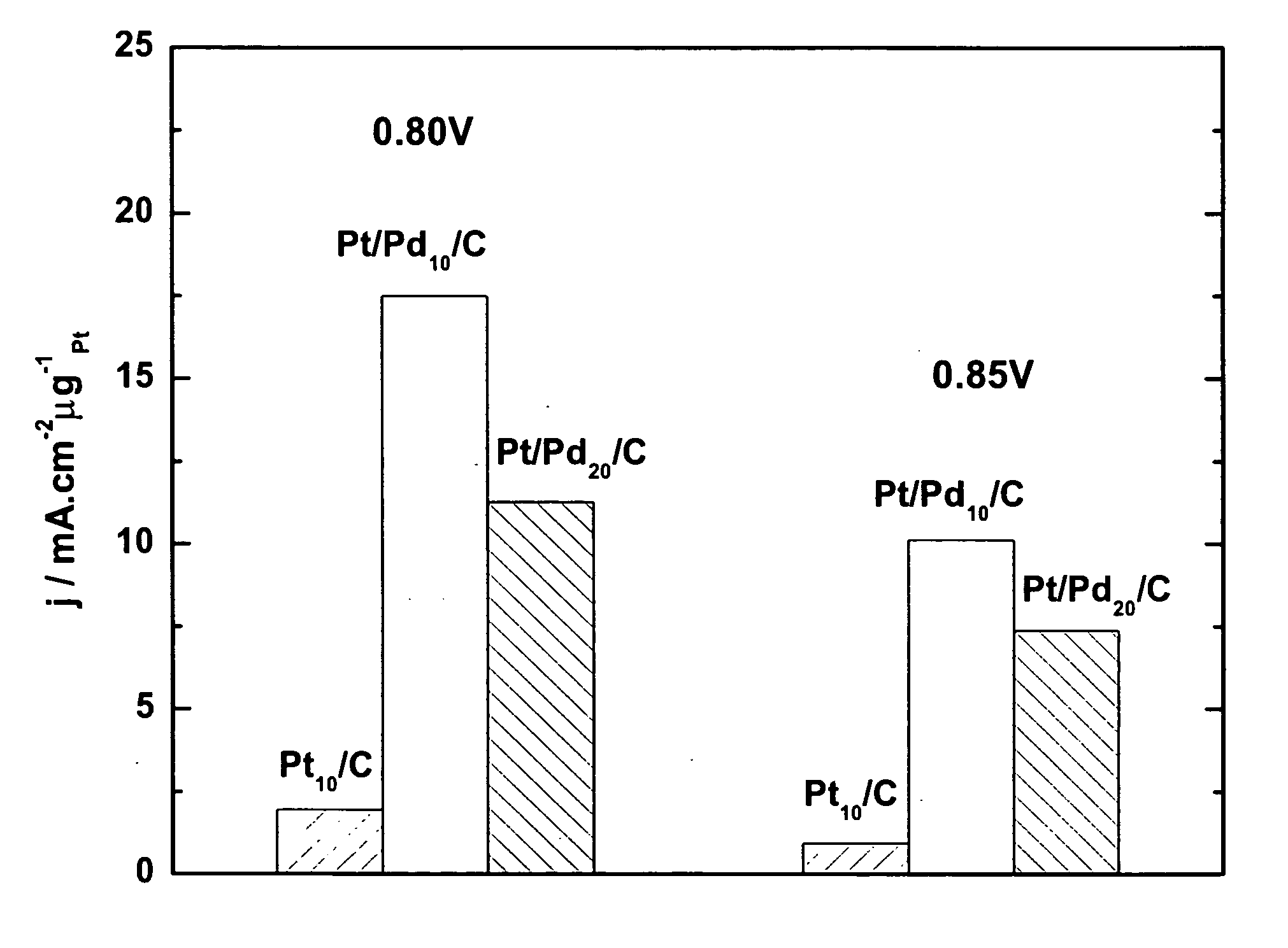

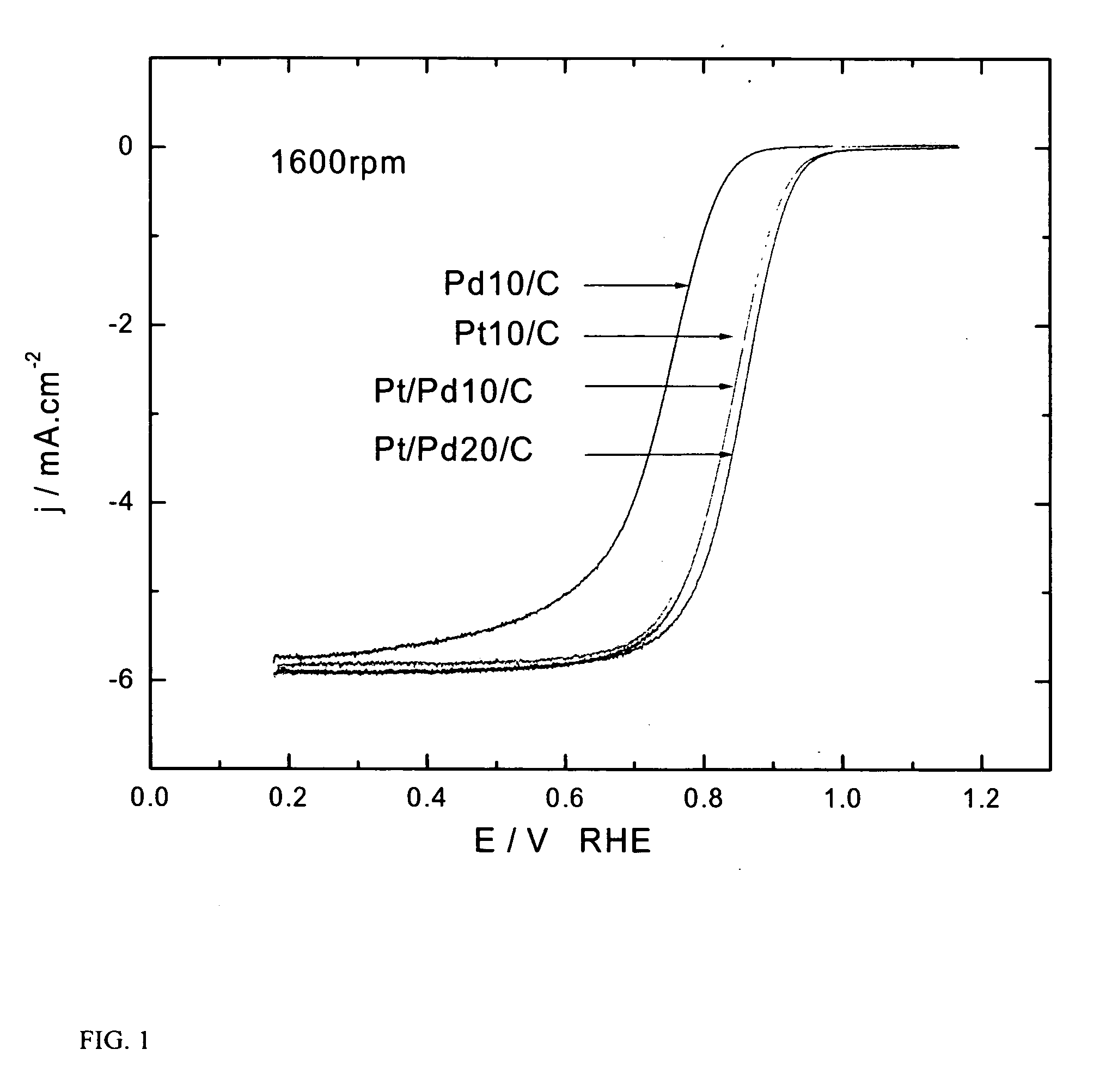

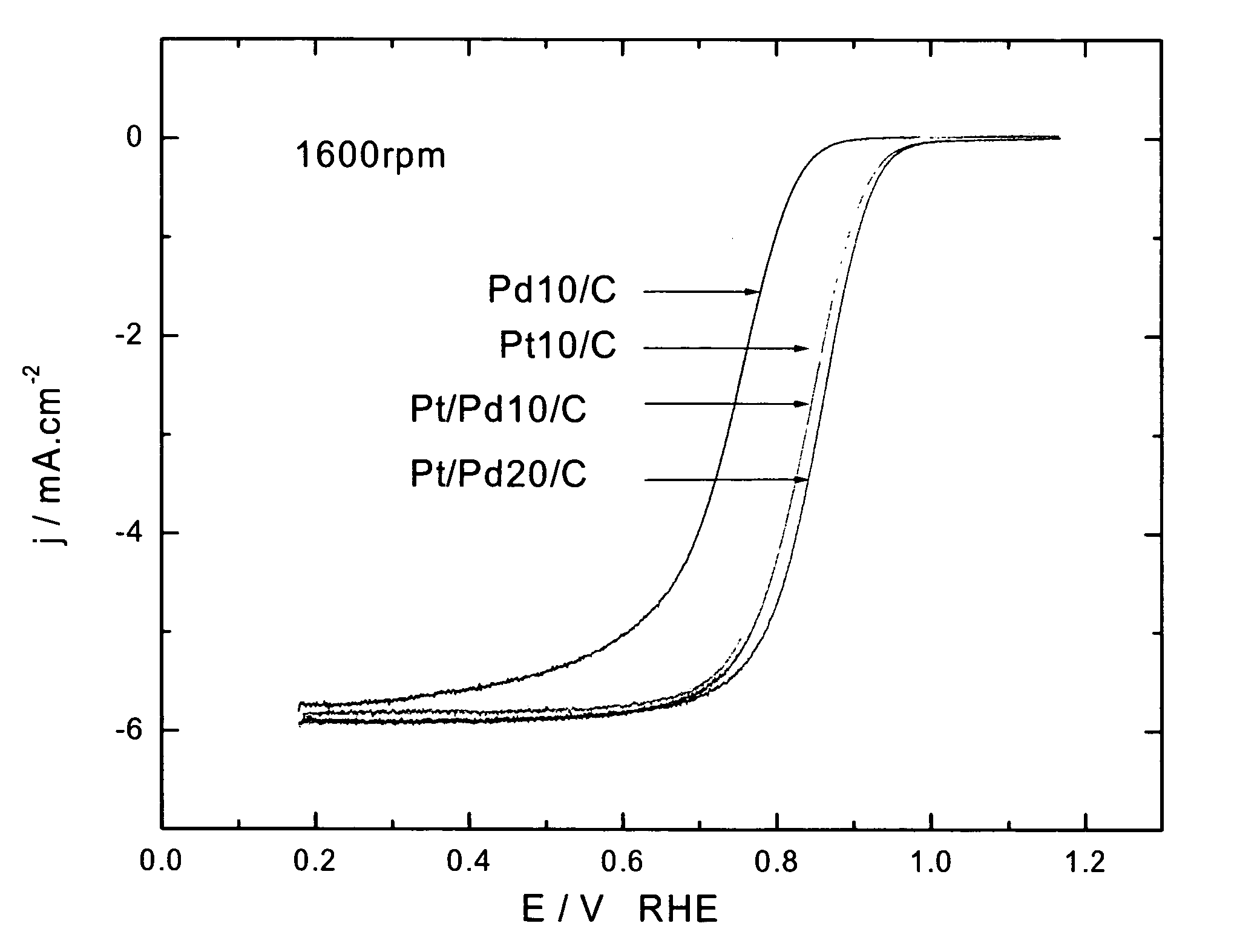

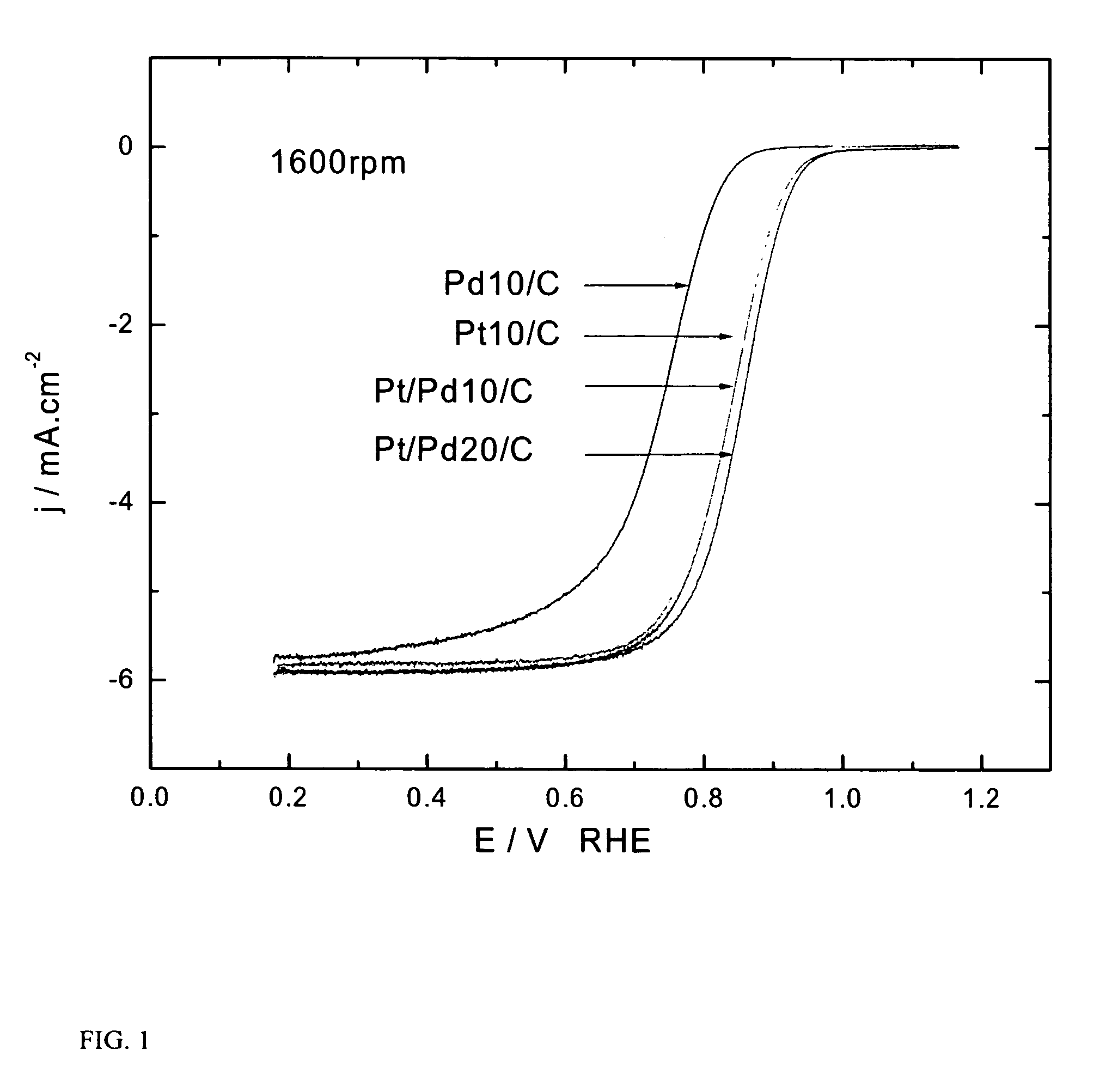

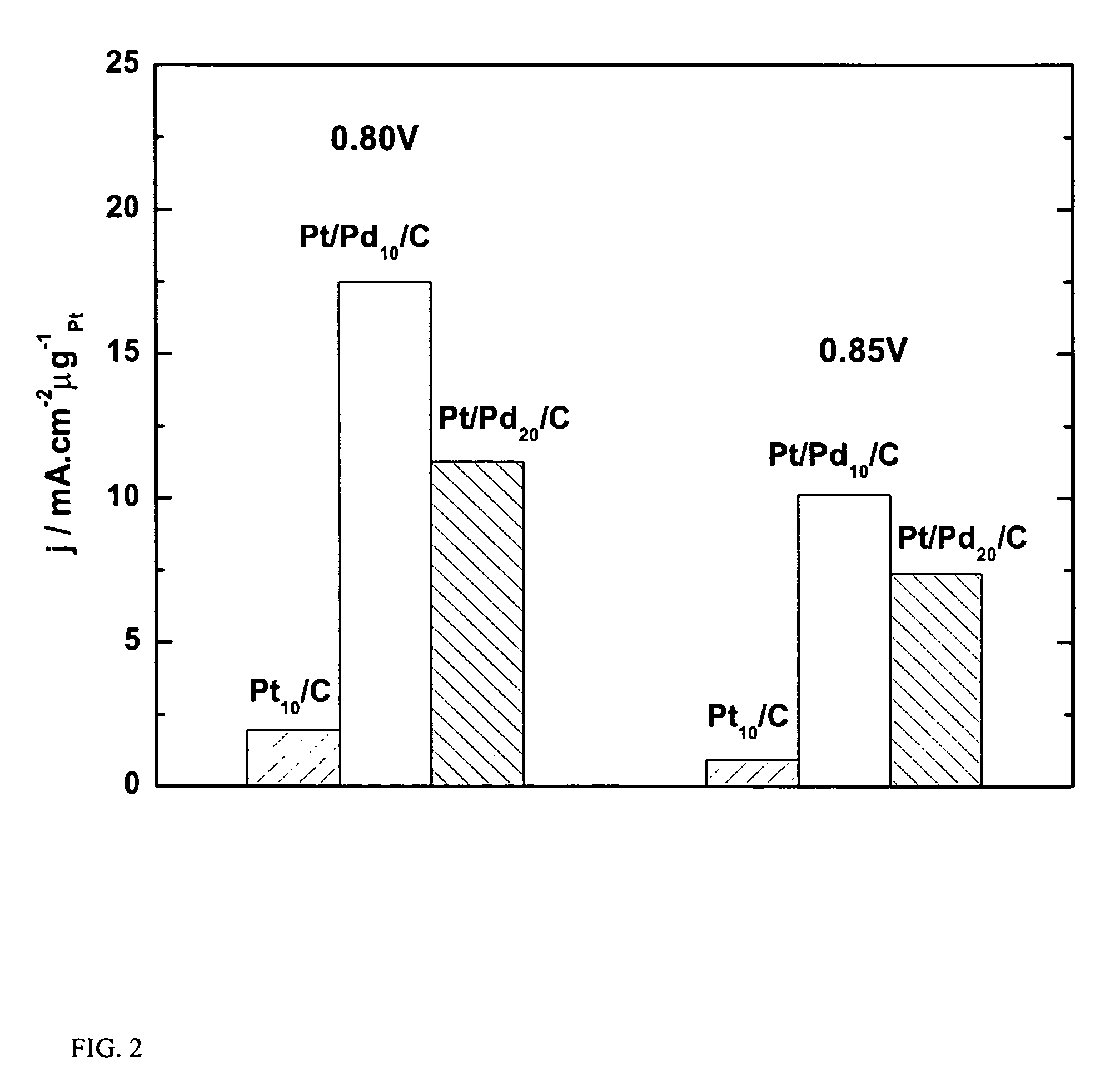

ActiveUS20060135359A1Improved oxygen-reducing catalytic activityLow platinum loadingSynthetic resin layered productsCellulosic plastic layered productsAlloyOxygen

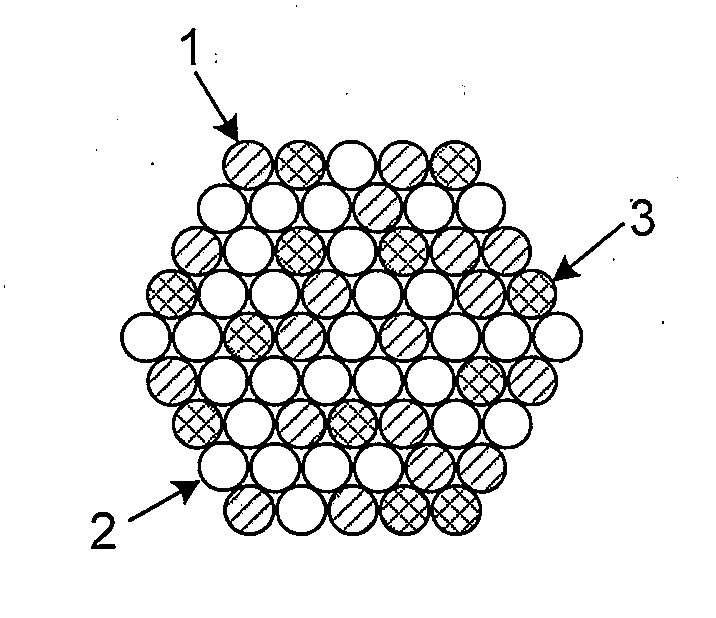

The present invention relates to particle and nanoparticle composites useful as oxygen-reduction electrocatalysts. The particle composites are composed of a palladium or palladium-alloy particle or nanoparticle substrate coated with an atomic submonolayer, monolayer, bilayer, or trilayer of zerovalent platinum atoms. The invention also relates to a catalyst and a fuel cell containing the particle or nanoparticle composites of the invention. The invention additionally includes methods for oxygen reduction and production of electrical energy by using the particle and nanoparticle composites of the invention.

Owner:BROOKHAVEN SCI ASSOCS

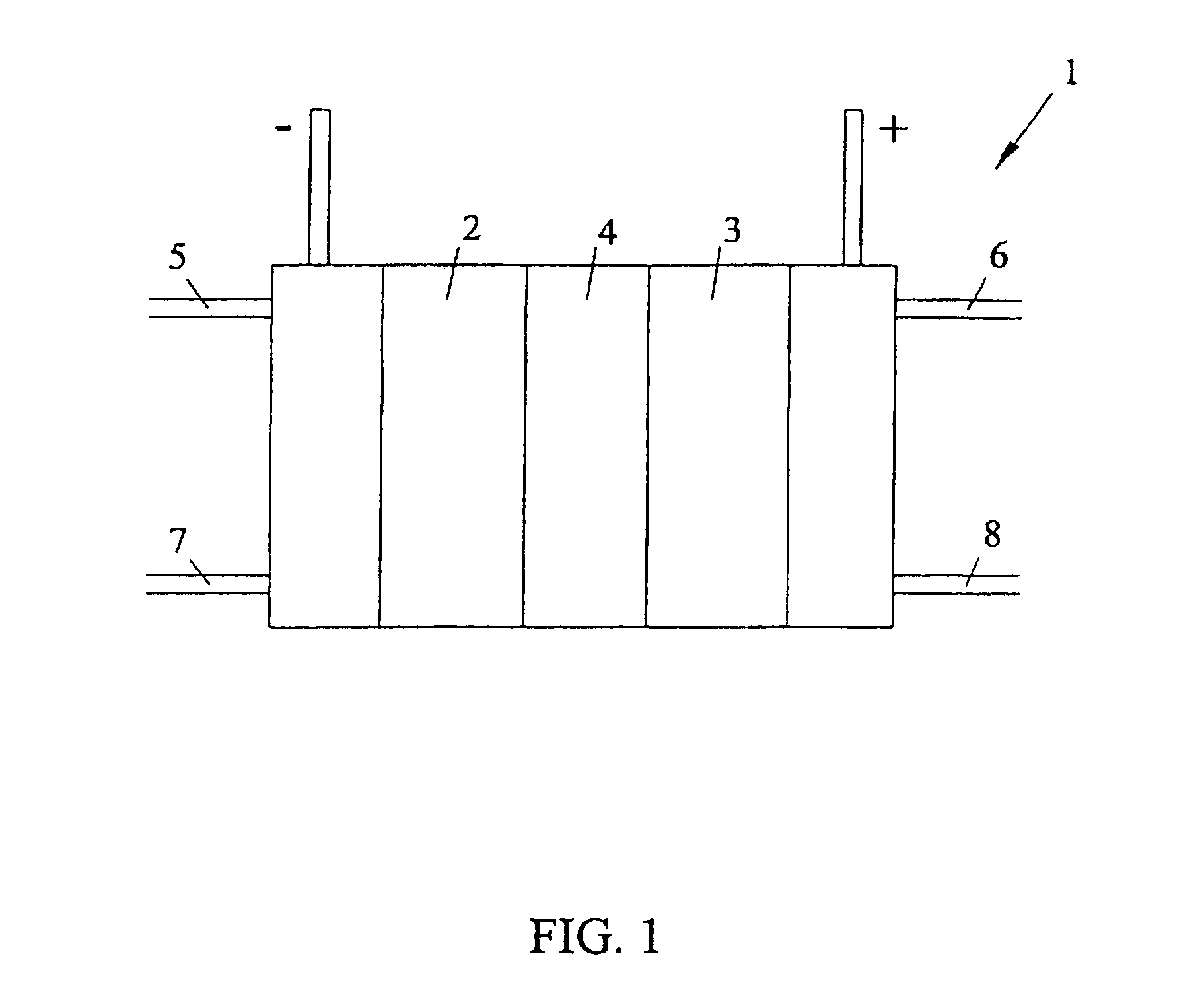

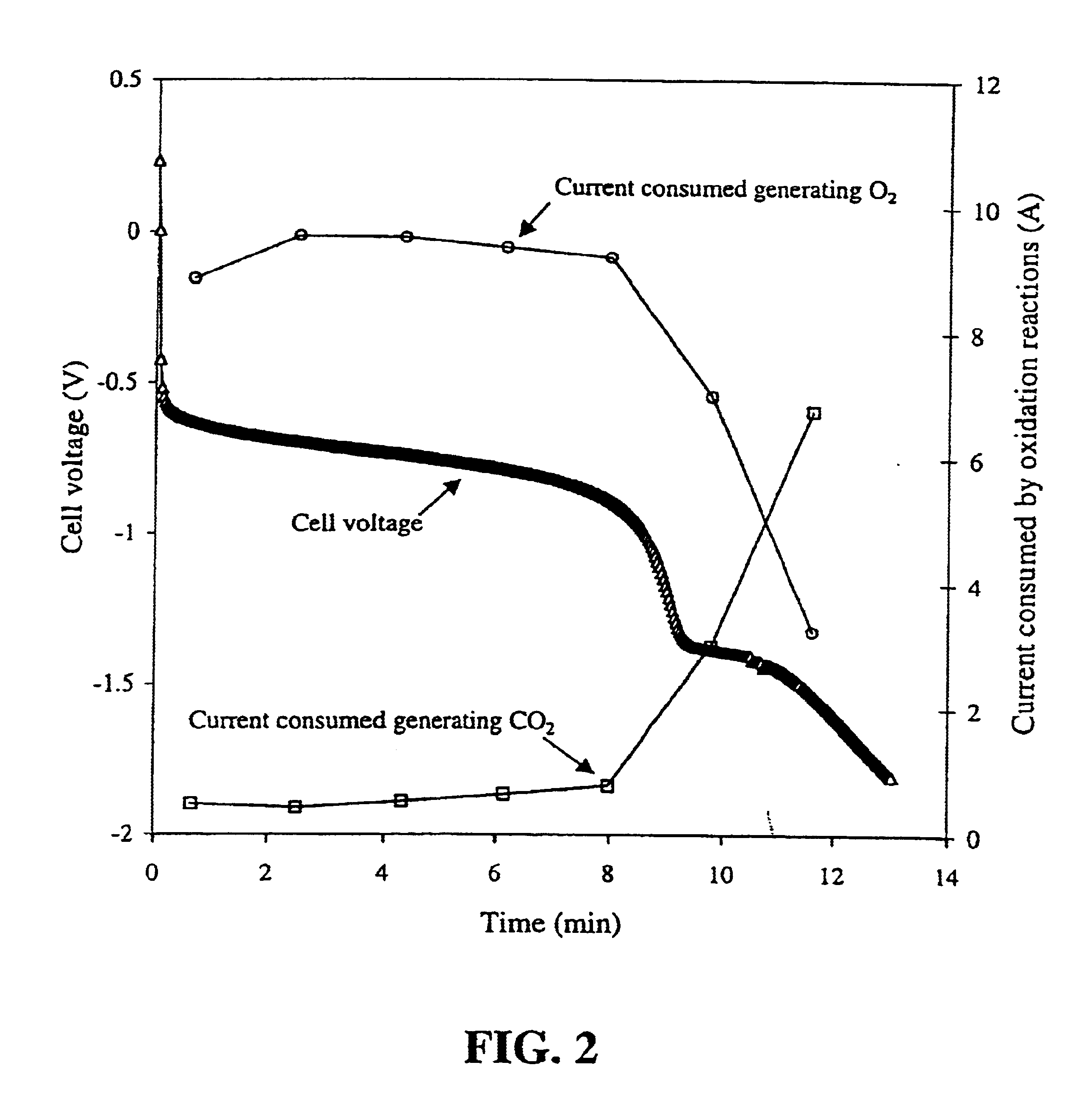

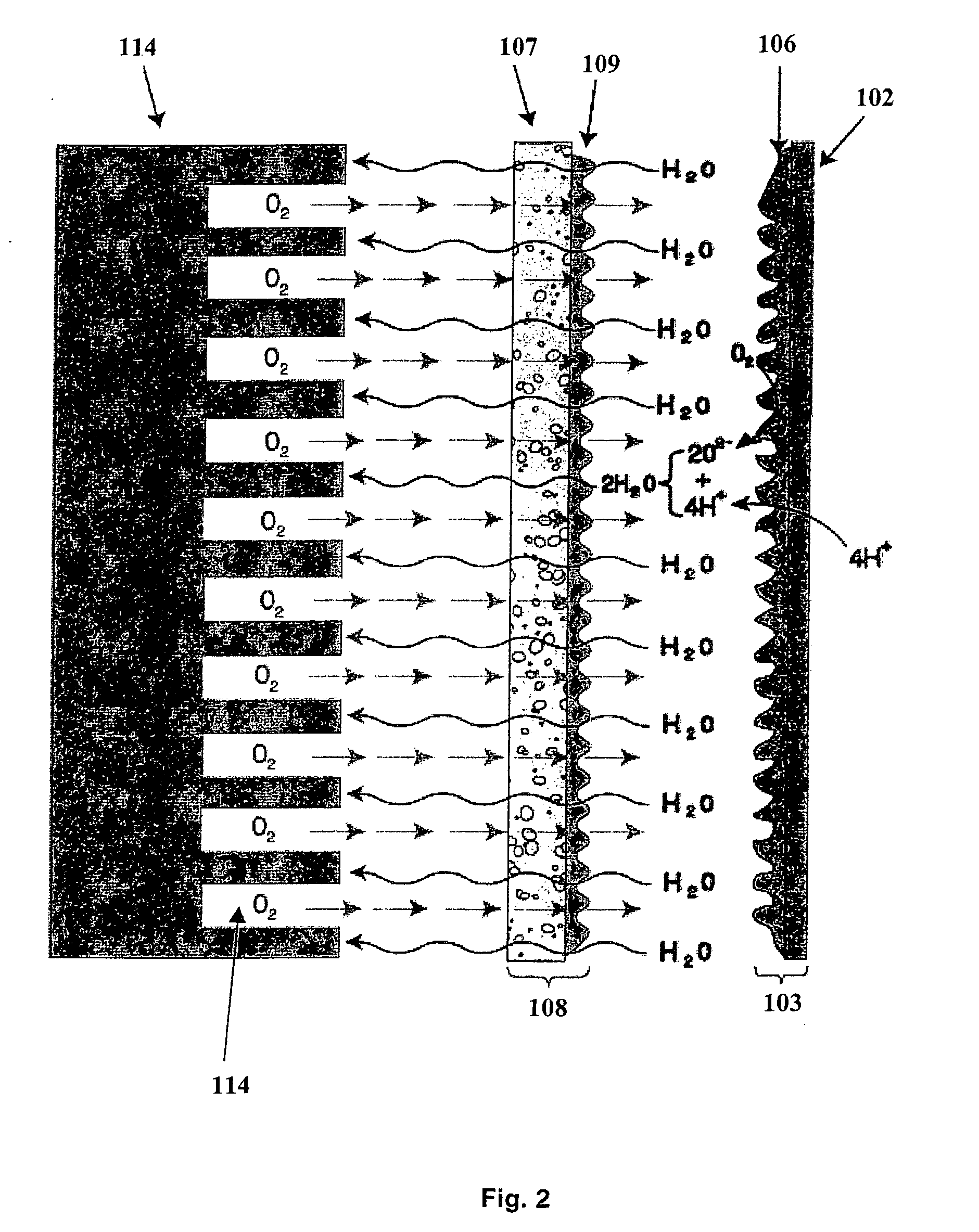

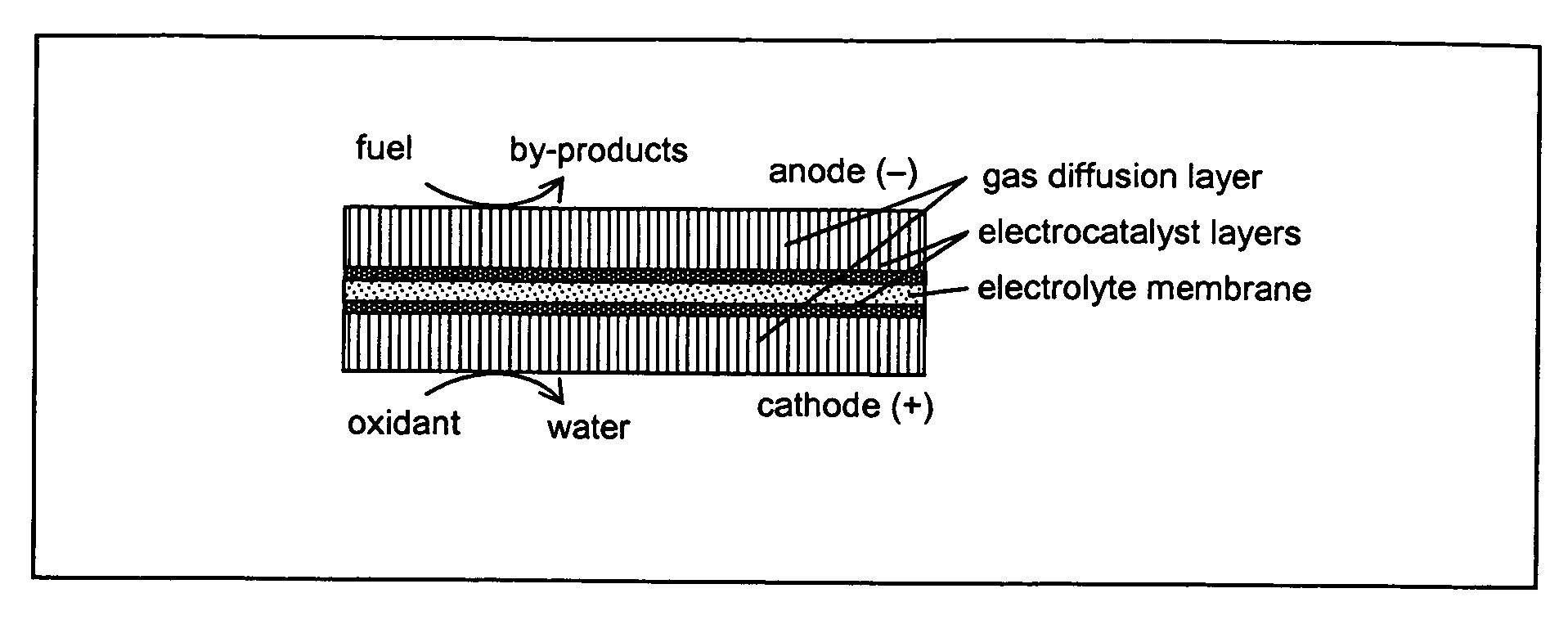

Solid polymer fuel cell with improved voltage reversal tolerance

In a solid polymer fuel cell series, various circumstances can result in the fuel cell being driven into voltage reversal. For instance, cell voltage reversal can occur if that cell receives an inadequate supply of fuel (for example, fuel starvation). In order to pass current during fuel starvation, reactions other than fuel oxidation may take place at the fuel cell anode, including water electrolysis and oxidation of anode components. The latter may result in significant degradation of the anode. Such fuel cells can be made more tolerant to cell reversal by promoting water electrolysis over anode component oxidation at the anode. This can be accomplished by incorporating a catalyst composition at the anode to promote the water electrolysis reaction, in addition to the typical anode electrocatalyst for promoting fuel oxidation.

Owner:BALLARD POWER SYSTEMS +1

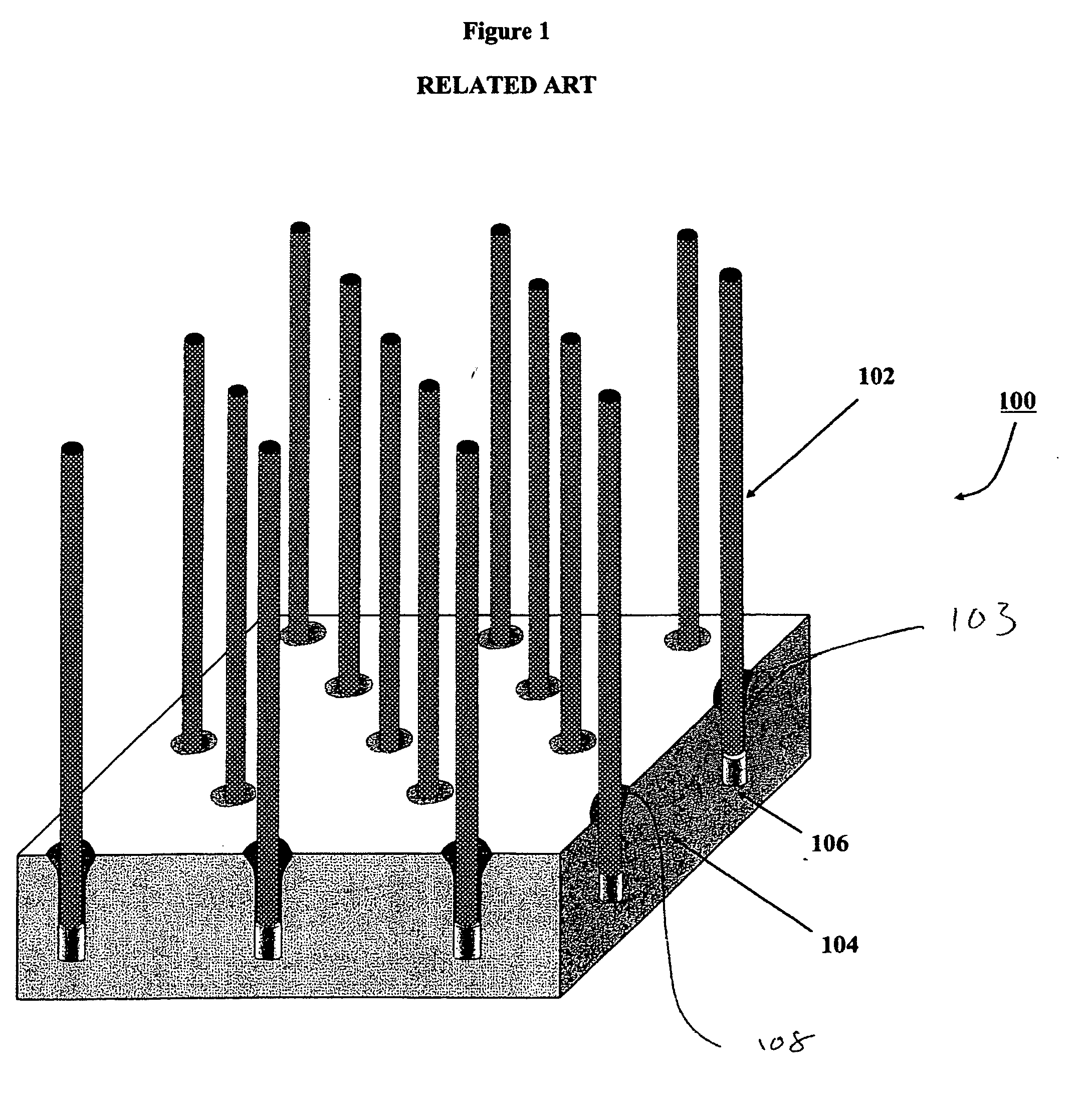

Method for fabrication of porous metal templates and growth of carbon nanotubes and utilization thereof

InactiveUS20050276743A1Large caliberSimple methodAnodisationMaterial nanotechnologyChemical speciesFuel cells

The present invention relates to controlled growth of carbon nanotube (CNT) arrays via chemical vapor deposition (CVD) using novel porous anodic aluminum oxide (AAO) templates, which have been seeded with transition metal catalysts. The resulting CNT bundles may be dense and long and can be used for numerous applications. Further, the porous AAO templates and the CNTs grown thereby, can be functionalized and used for separation of chemical species, hydrogen storage, fuel cell electrocatalyst and gas flow membranes, other catalytic applications, and as a bulk structural material.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION ON BEHALF OF THE UNIV OF NEVADA RENO

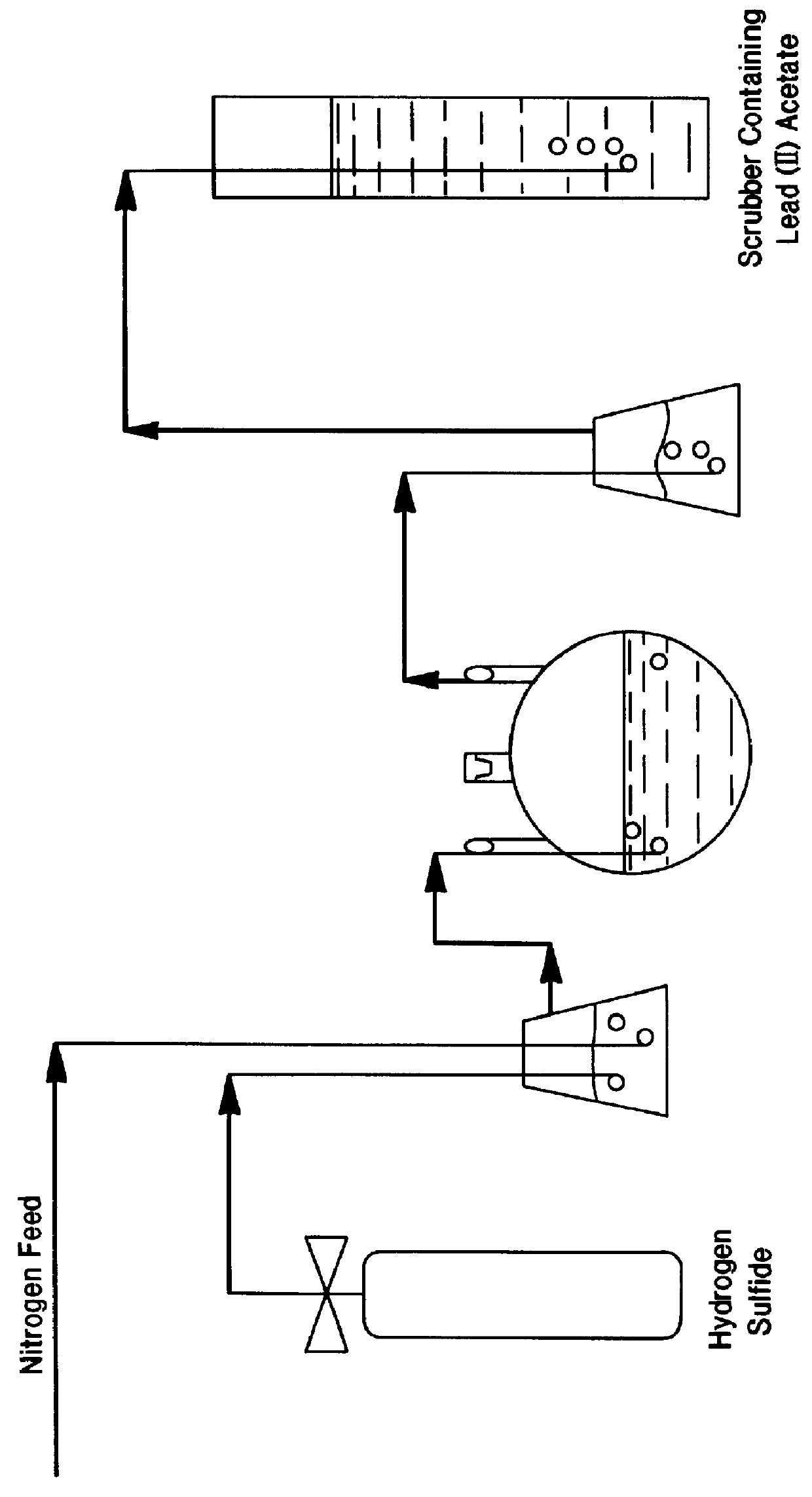

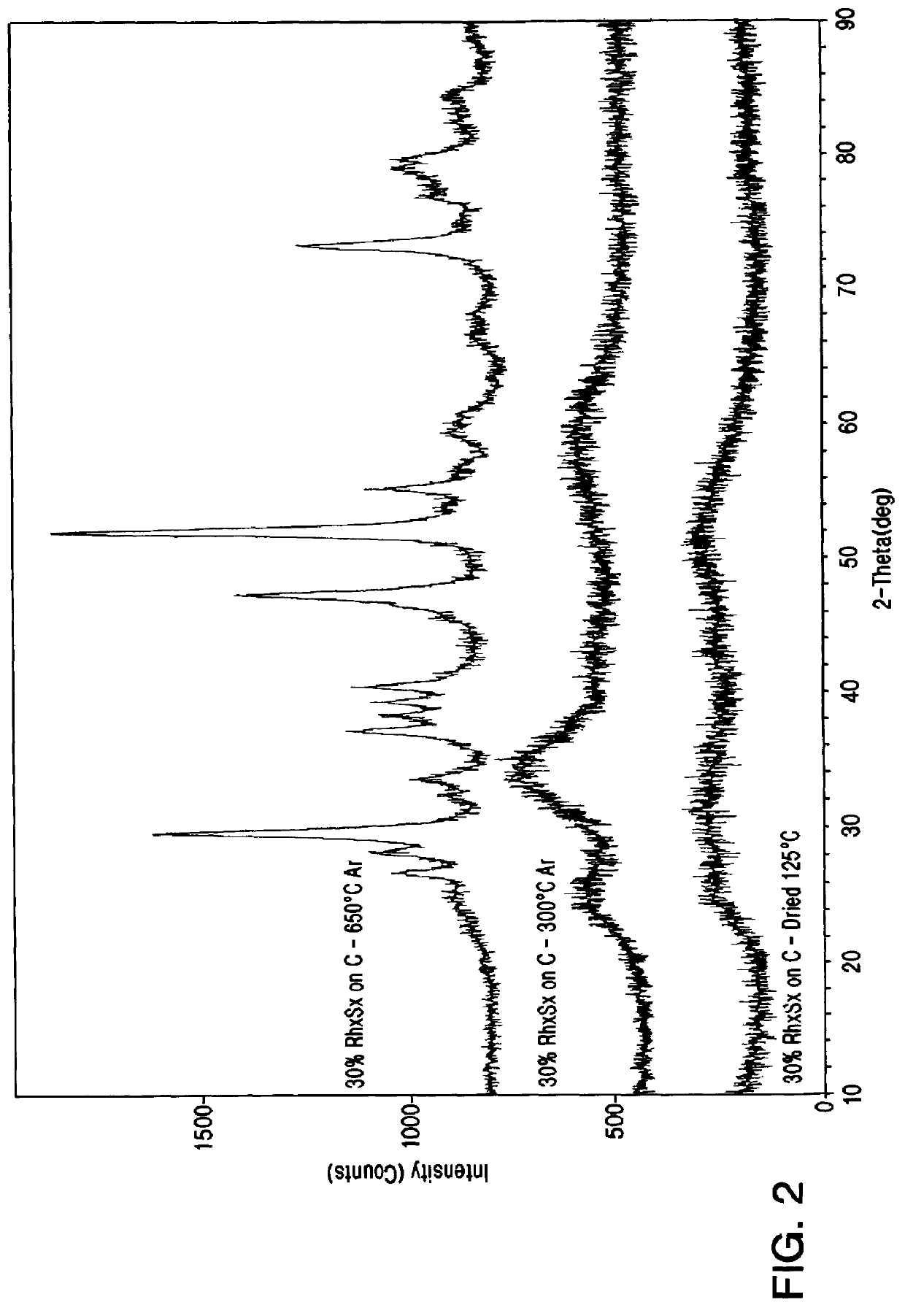

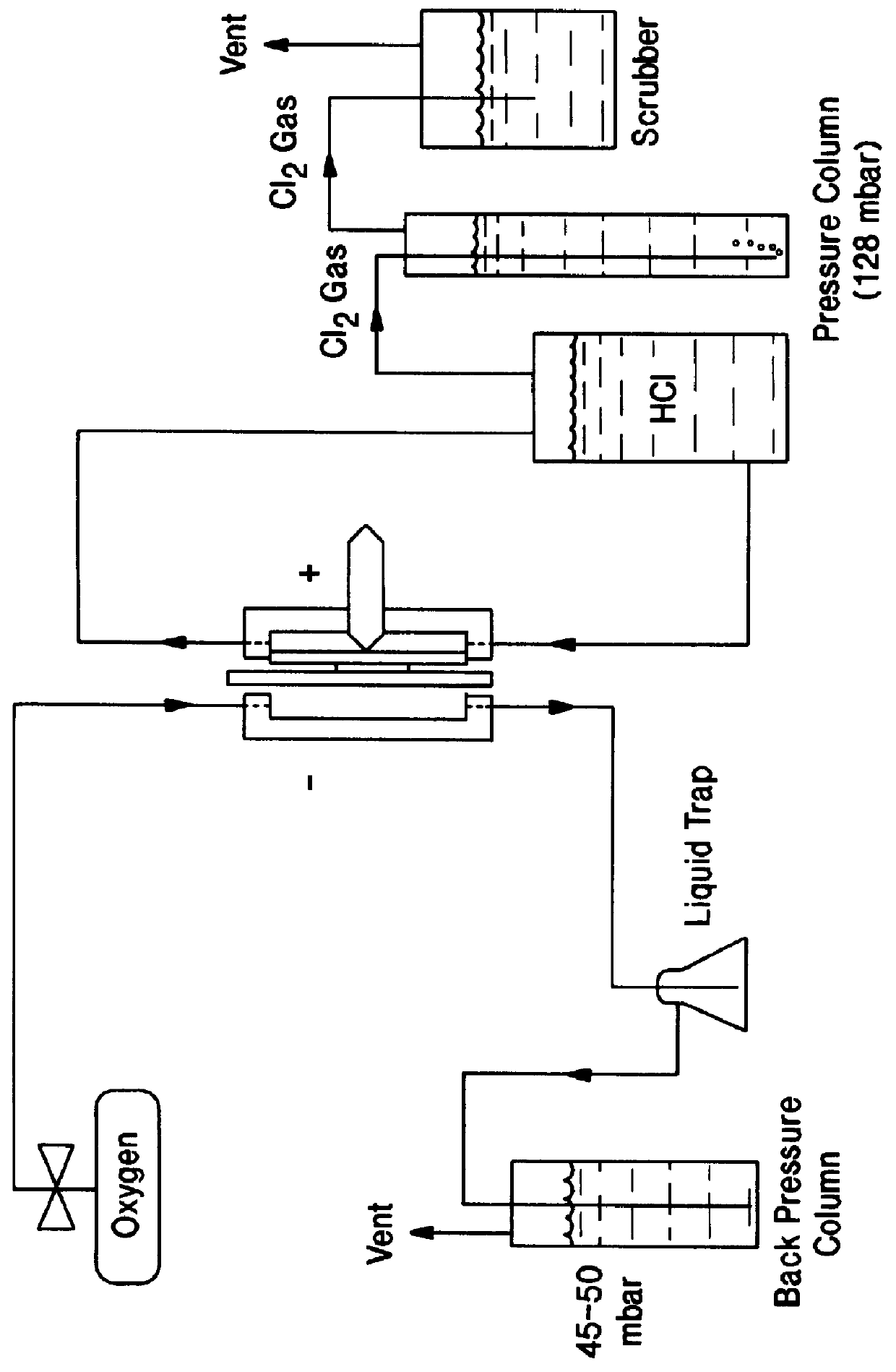

Rhodium electrocatalyst and method of preparation

The invention relates to a novel rhodium sulfide catalyst for the reduction of oxygen in industrial electrolyzers. The catalyst is highly resistant towards corrosion and poisoning by organic species, thus resulting particularly suitable for use in aqueous hydrochloric acid electrolysis, when technical grade acid containing organic contaminants is employed.

Owner:DE NORA SPA

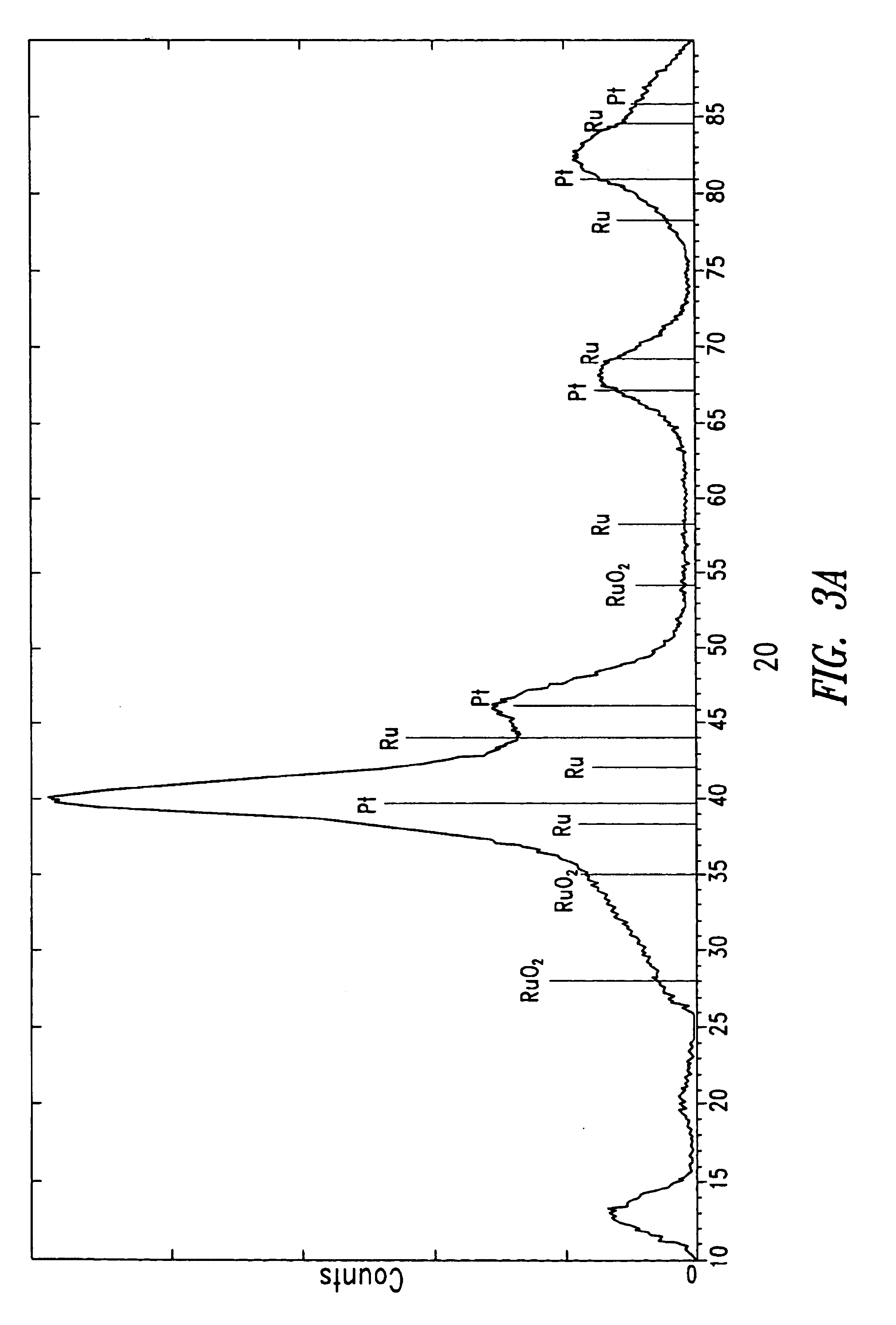

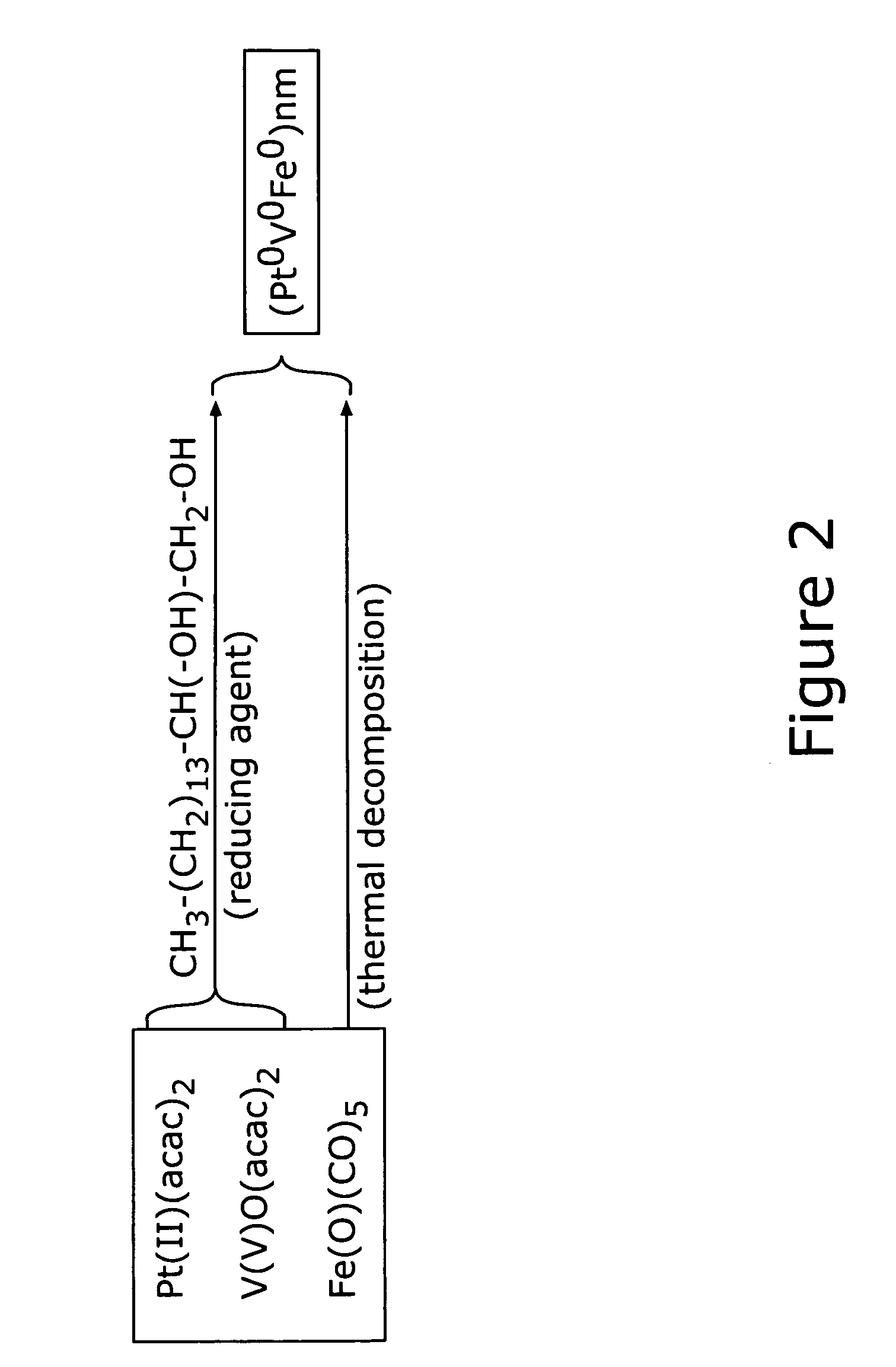

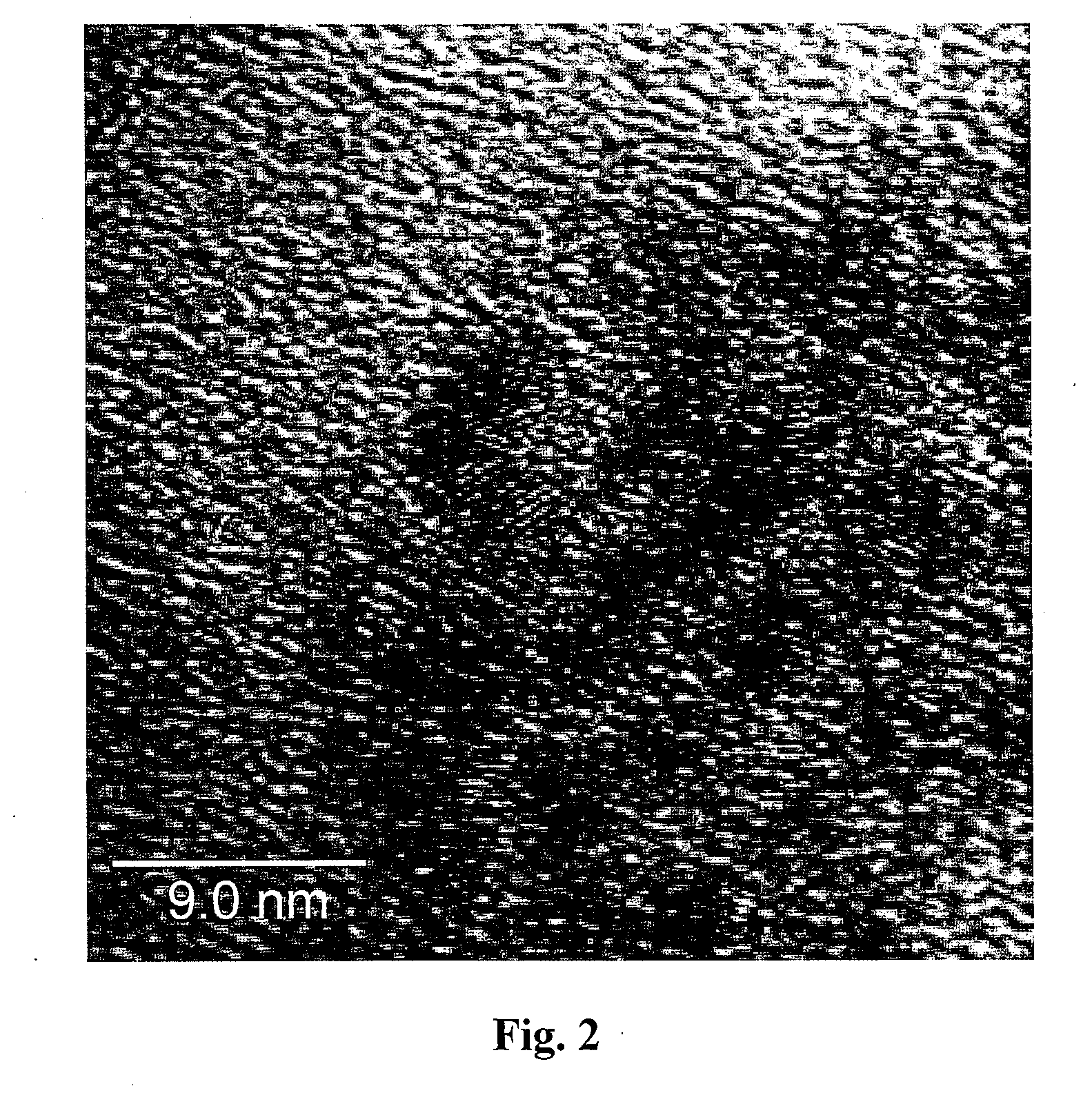

Core-shell synthesis of carbon-supported alloy nanoparticle catalysts

InactiveUS7053021B1Good monodispersityEfficient activationMaterial nanotechnologyTransportation and packagingFuel cellsBiological activation

There is provided a method of preparing carbon supported, ternary alloy composition core-shell PtVFe nanoparticles for use as fuel cell electrocatalysts. These catalysts have been found particularly useful for oxygen reduction reactions. The alloy nanoparticles can be assembled on carbon supports which then may undergo subsequent activation and / or calcination treatments. The method, combined with new synthetic feed and processing conditions, provides core-shell PtVFe alloy nanoparticles of 1–3 nm size. The catalyst-produced high monodispersity, controlled composition are highly dispersed, and have a uniform distribution. Finally, the correlation of the preparation and treatment parameters to the ORR catalytic activities of the prepared nanoparticles is described. The catalysts exhibit ORR in the range of 2 to 4 times more than a standard Pt / carbon catalyst.

Owner:HONDA MOTOR CO LTD +1

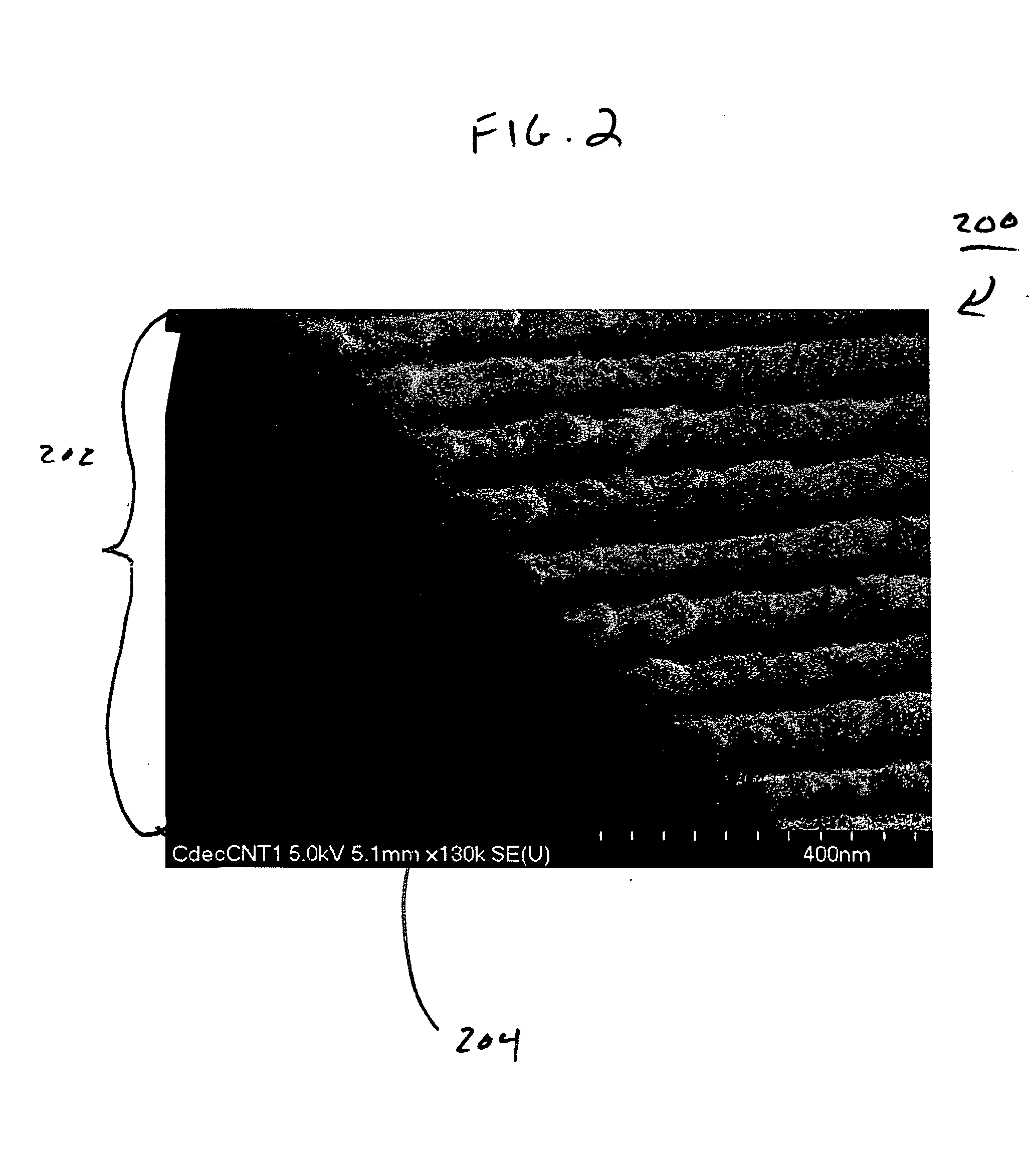

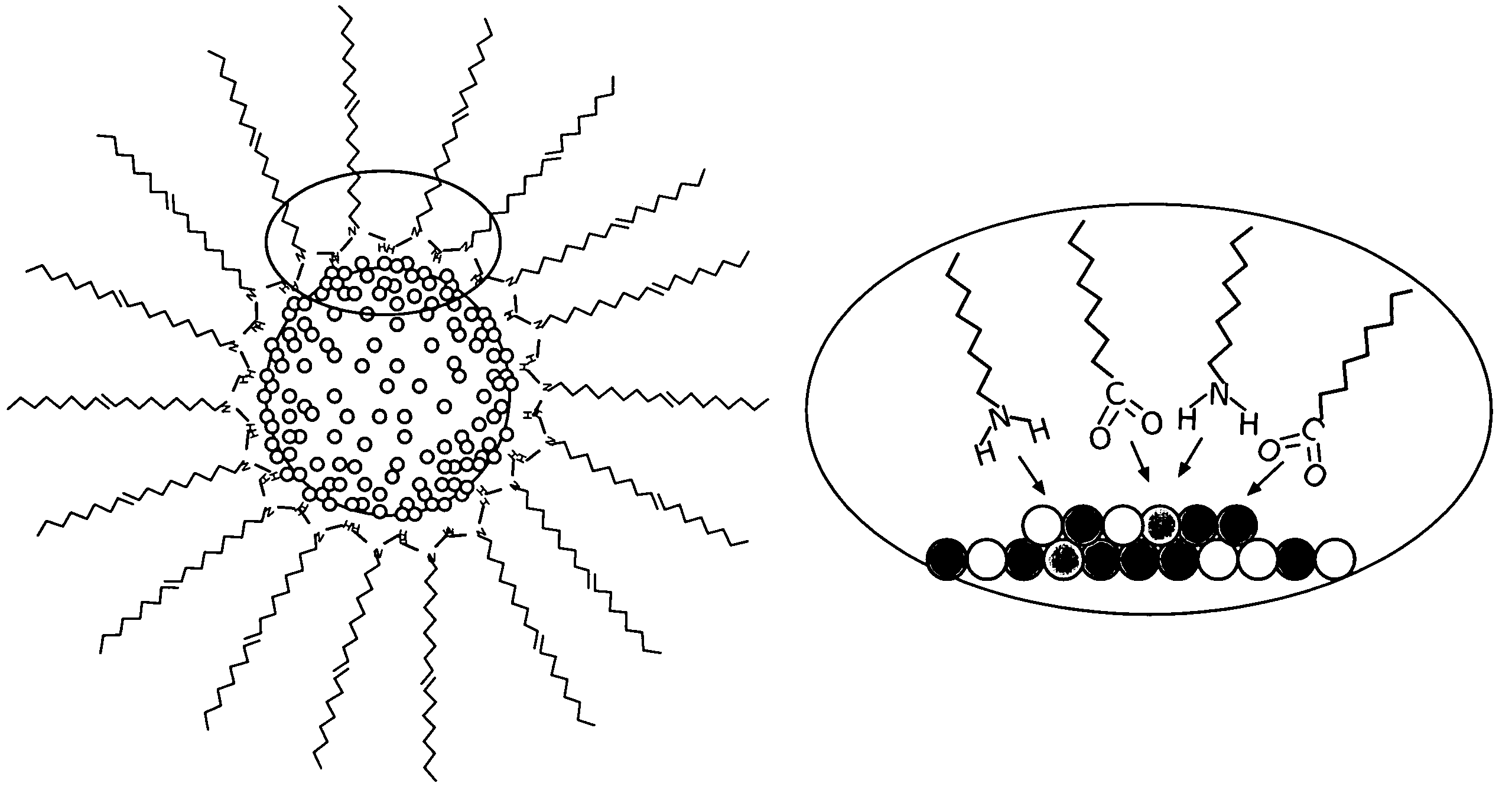

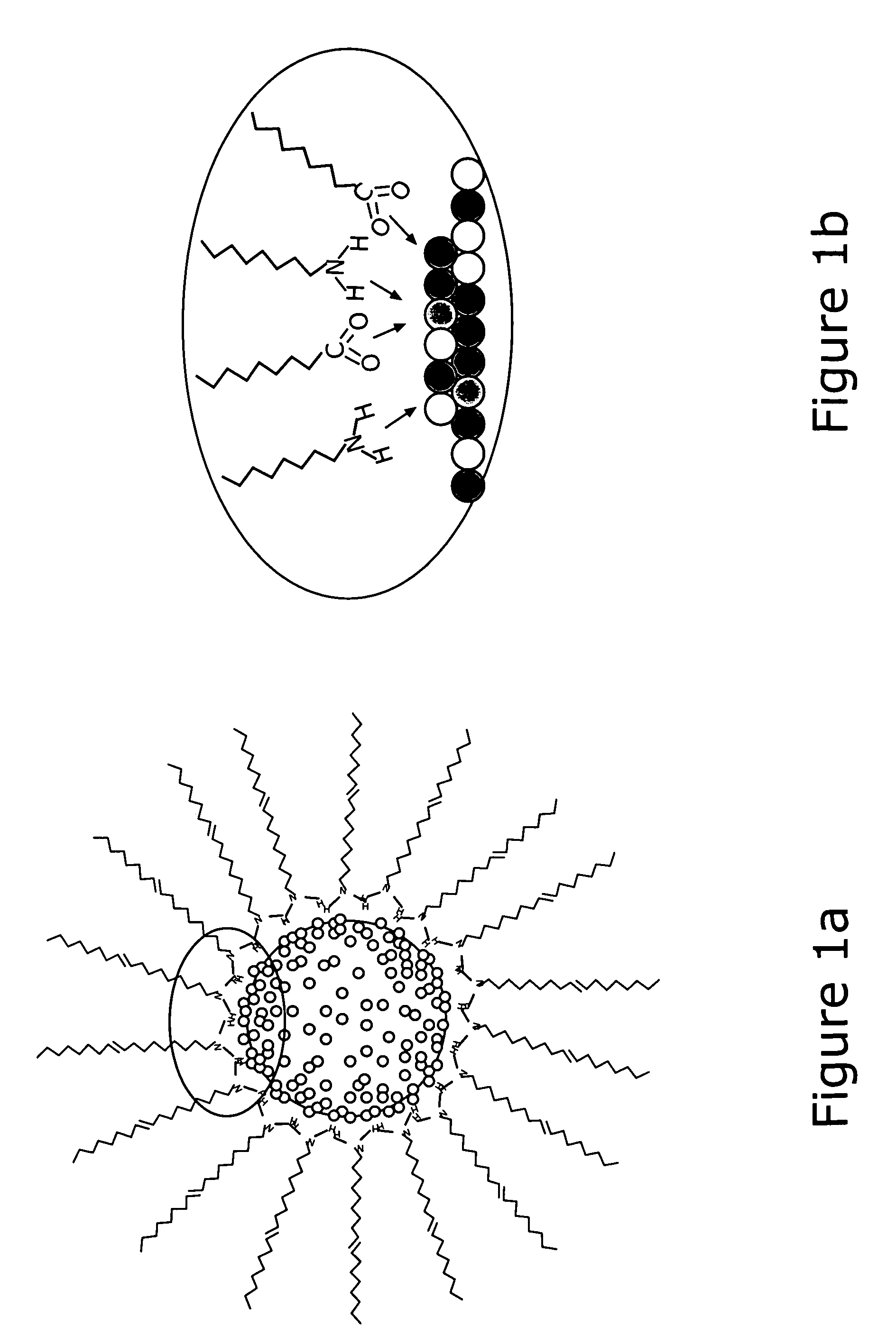

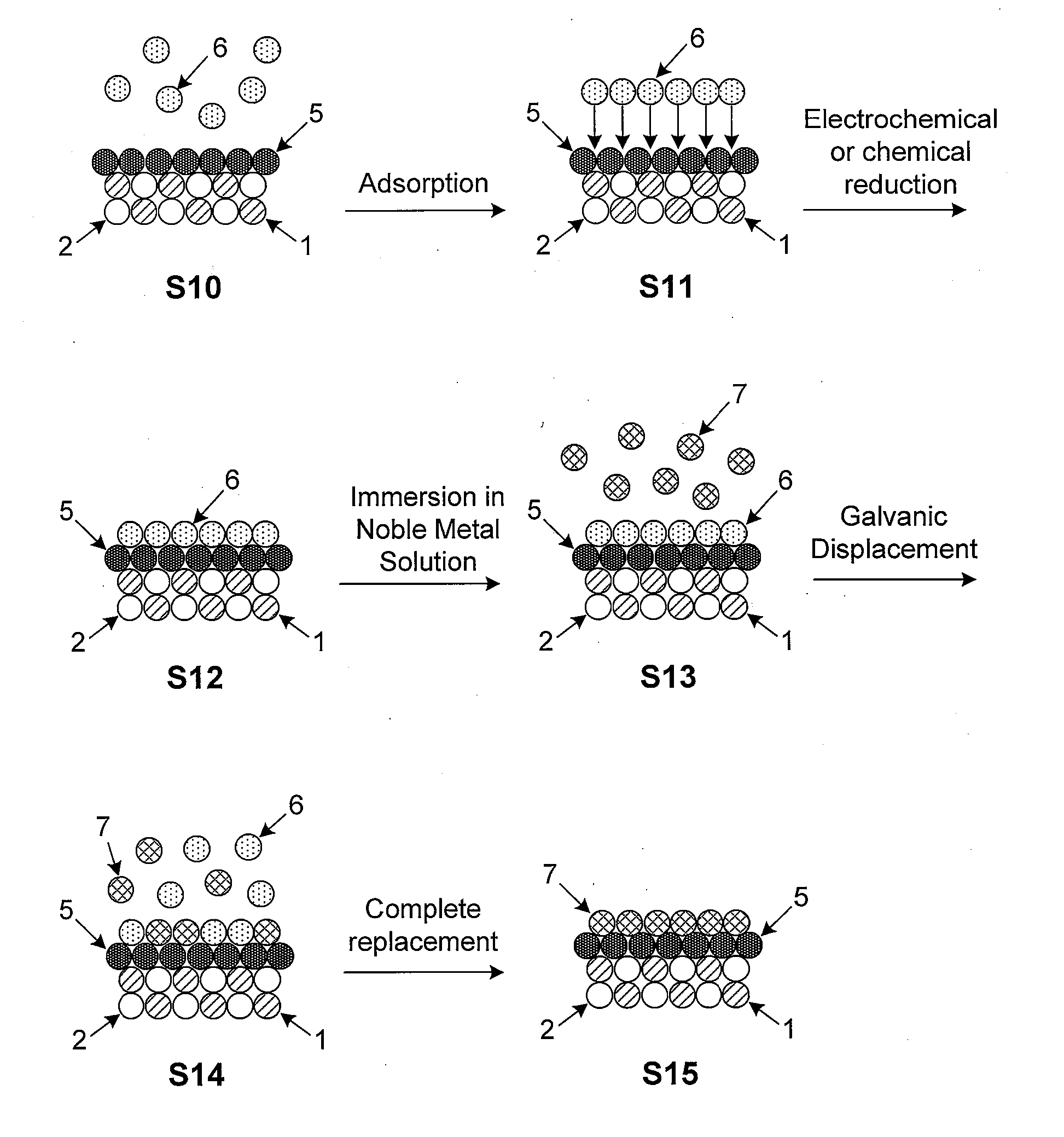

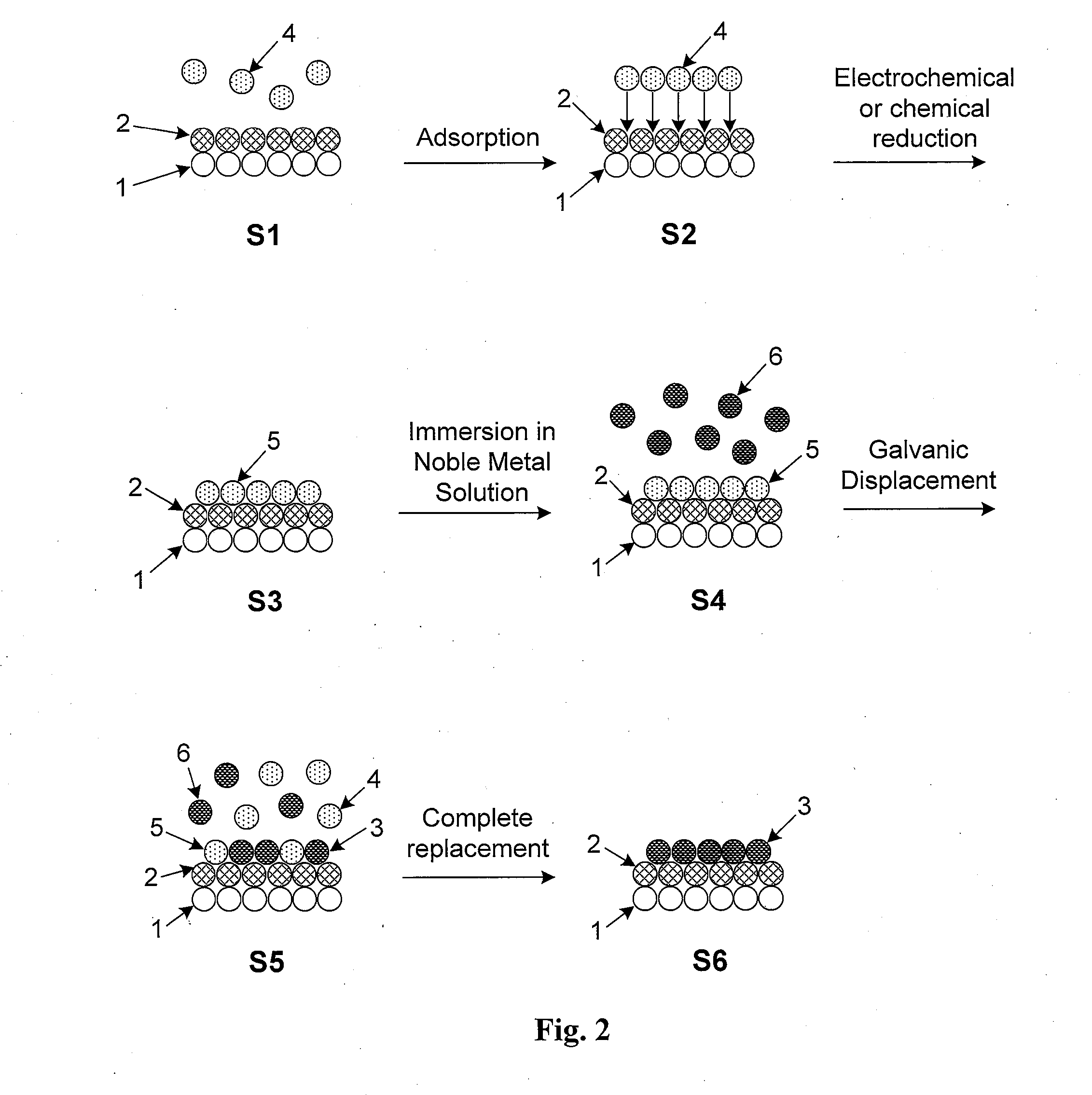

Platinum-Based Electrocatalysts Synthesized by Depositing Contiguous Adlayers on Carbon Nanostructures

InactiveUS20100177462A1High catalytic activityImprove stabilityMaterial nanotechnologyCarbon compoundsNanostructurePt element

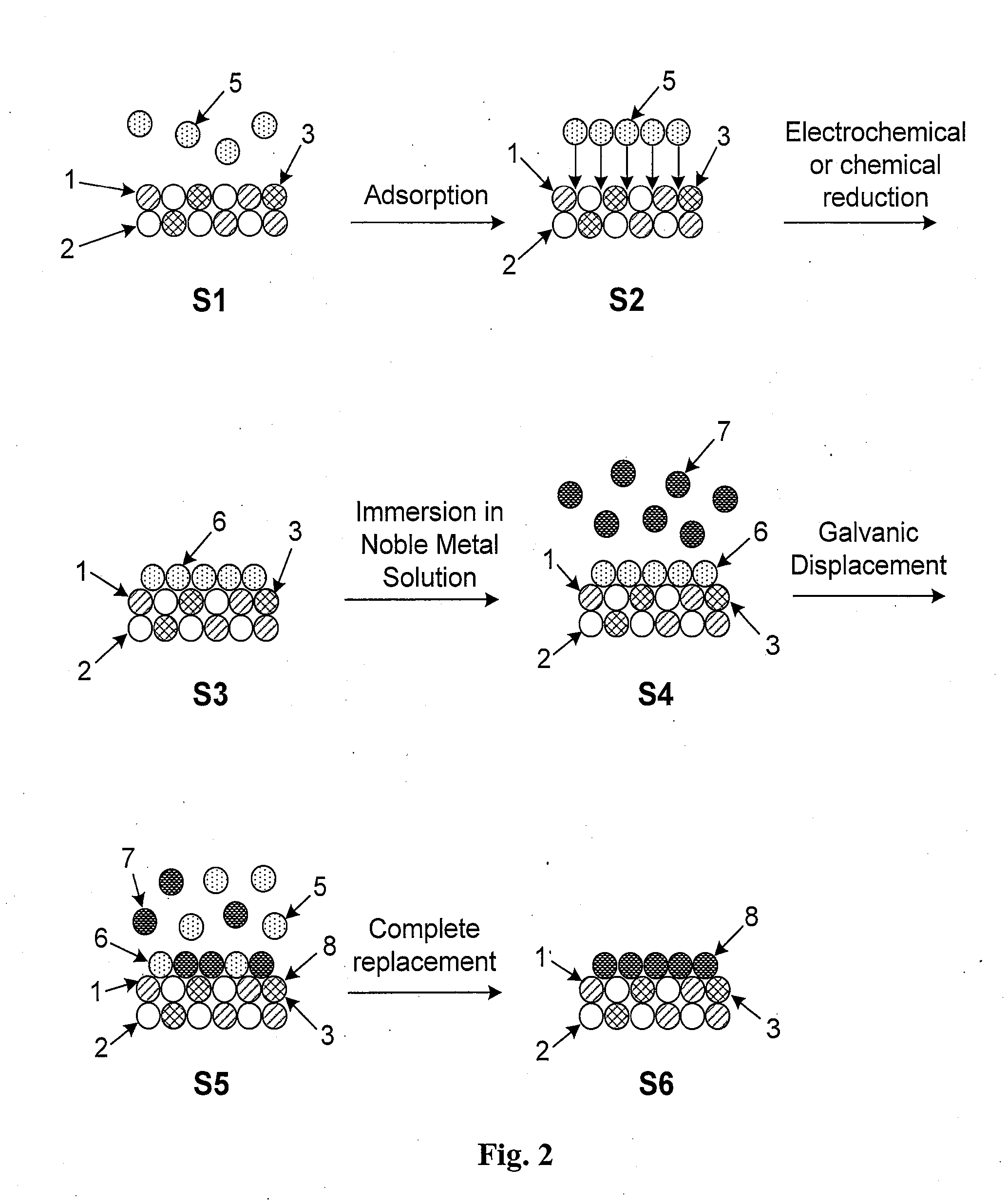

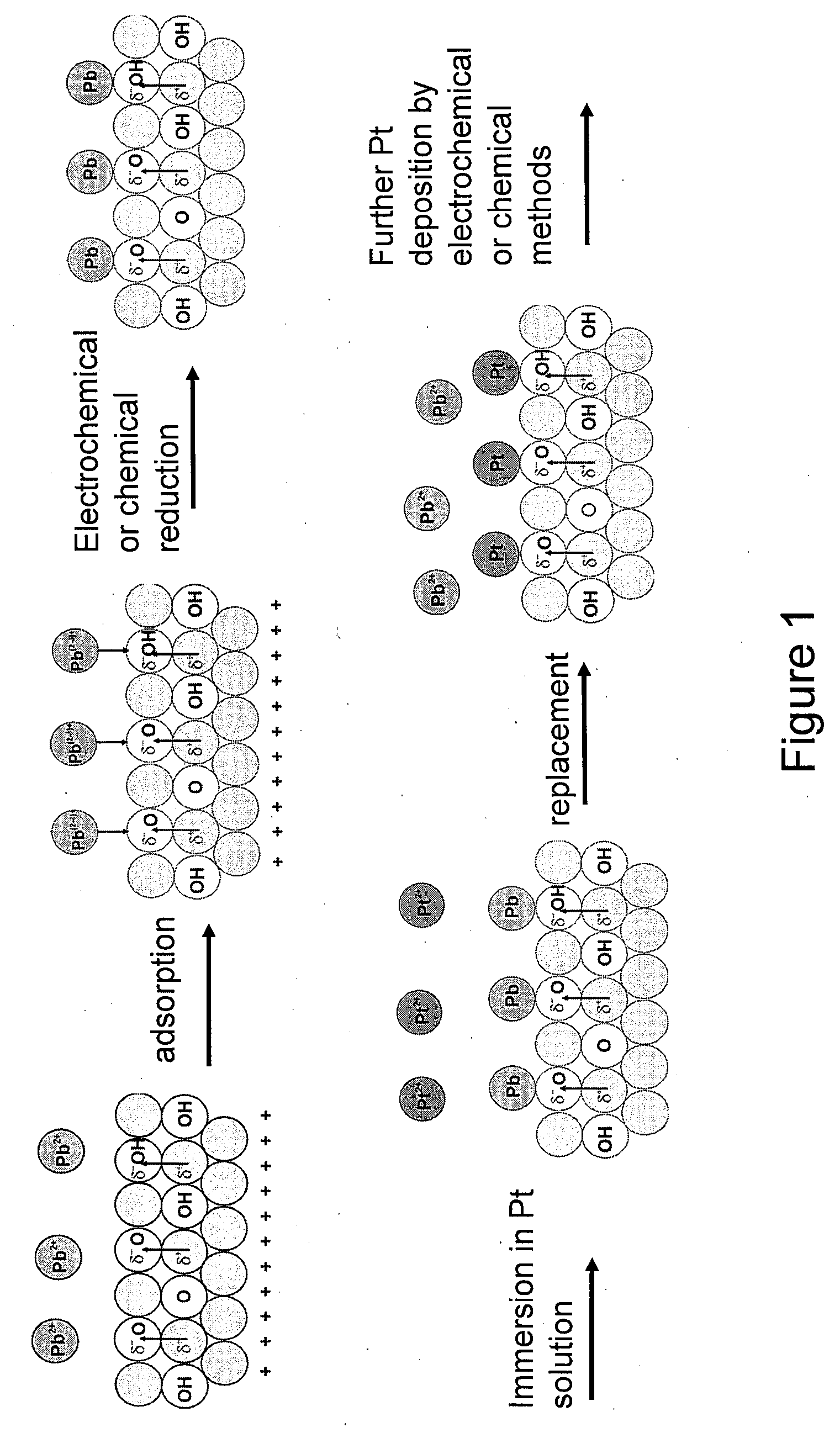

High-surface-area carbon nanostructures coated with a smooth and conformal submonolayer-to-multilayer thin metal films and their method of manufacture are described. The preferred manufacturing process involves the initial oxidation of the carbon nanostructures followed by immersion in a solution with the desired pH to create negative surface dipoles. The nanostructures are subsequently immersed in an alkaline solution containing non-noble metal ions which adsorb at surface reaction sites. The metal ions are then reduced via chemical or electrical means and the nanostructures are exposed to a solution containing a salt of one or more noble metals which replace adsorbed non-noble surface metal atoms by galvanic displacement. Subsequent film growth may be performed via the initial quasi-underpotential deposition of a non-noble metal followed by immersion in a solution comprising a more noble metal. The resulting coated nanostructures may be used, for example, as high-performance electrodes in supercapacitors, batteries, or other electric storage devices.

Owner:BROOKHAVEN SCI ASSOCS

Electrocatalysts having gold monolayers on platinum nanoparticle cores, and uses thereof

InactiveUS20070026292A1Maintain efficiencyReduce loadMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPlatinumFuel cells

The invention relates to gold-coated particles useful as fuel cell electrocatalysts. The particles are composed of an electrocatalytically active core at least partially encapsulated by an outer shell of gold or gold alloy. The invention more particularly relates to such particles having a noble metal-containing core, and more particularly, a platinum or platinum alloy core. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

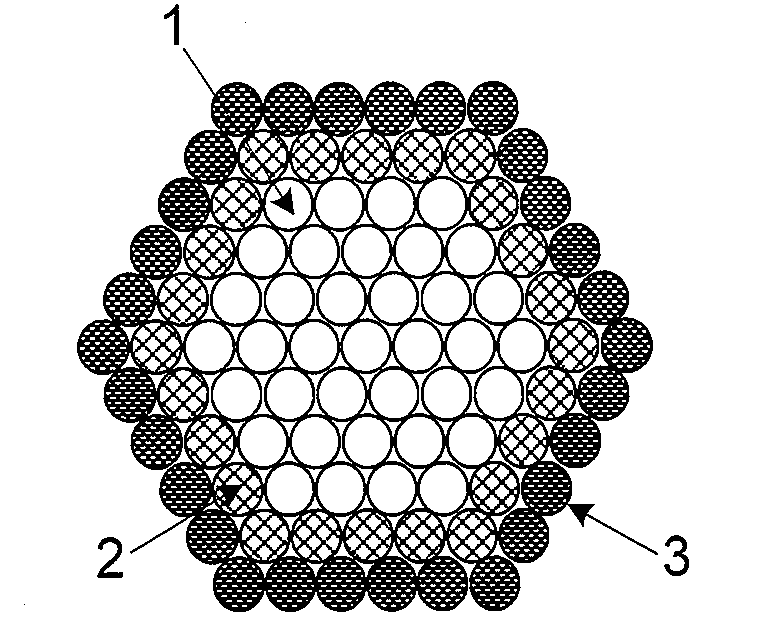

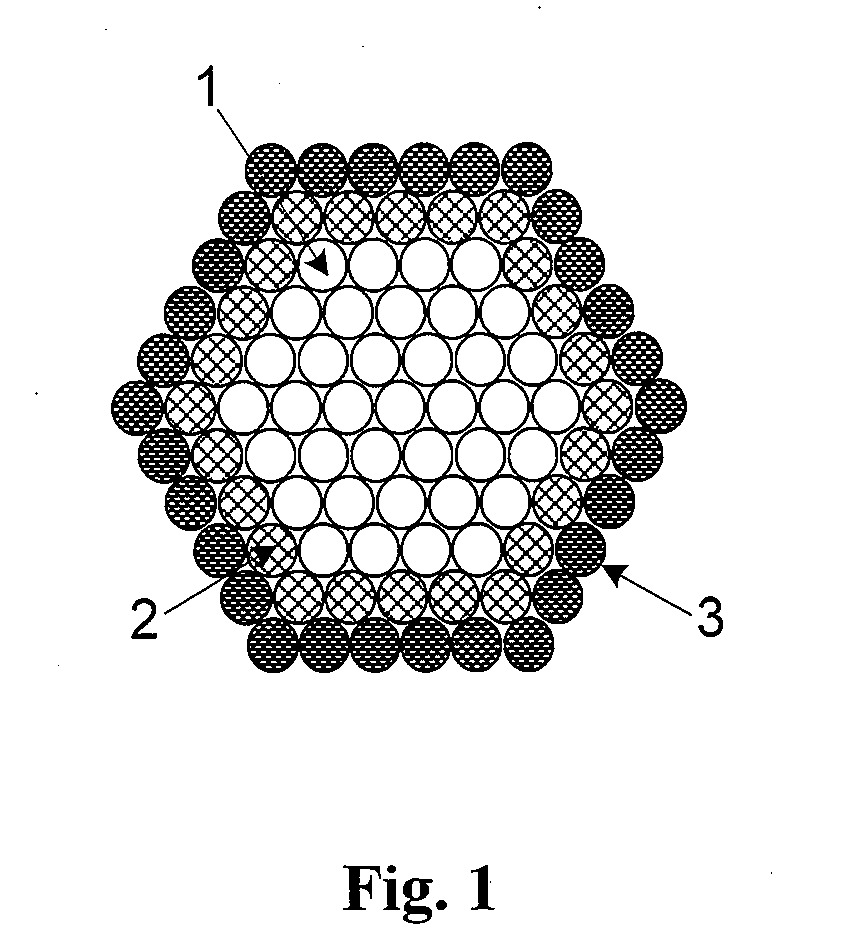

Core / shell-type catalyst particles comprising metal or ceramic core materials and methods for their preparation

ActiveUS20100092841A1High specific activityLow precious metal contentMaterial nanotechnologyCell electrodesFuel cellsAlloy

The invention is directed to core / shell type catalyst particles comprising a Mcore / Mshell structure with Mcore=inner particle core and Mshell=outer particle shell, wherein the medium diameter of the catalyst particle (dcore+shell) is in the range of 20 to 100 nm, 5 preferably in the range of 20 to 50 nm. The thickness of the outer shell (tshell) is about 5 to 20% of the diamet the inner particle core of said catalyst particle, preferably comprising at least 3 atomic layers. The inner particle core (Mcore) of the particles comprises metal or ceramic materials, whereas the material of the outer shell (Mshell) comprises precious metals and / or alloys thereof. The core / shell type catalyst particles are preferably supported on suitable support materials such as carbon black and can be used as electrocatalysts for fuel cells and for other catalytic applications.

Owner:UMICORE AG & CO KG

Modified carbon products, their use in electrocatalysts and electrode layers and similar devices and methods relating to the same

Electrodes and electrocatalyst layers incorporating modified carbon products. The modified carbon products may advantageously enhance the properties of an electrode or electrode layer, leading to more efficiency within the a fuel cell or similar device.

Owner:CABOT CORP

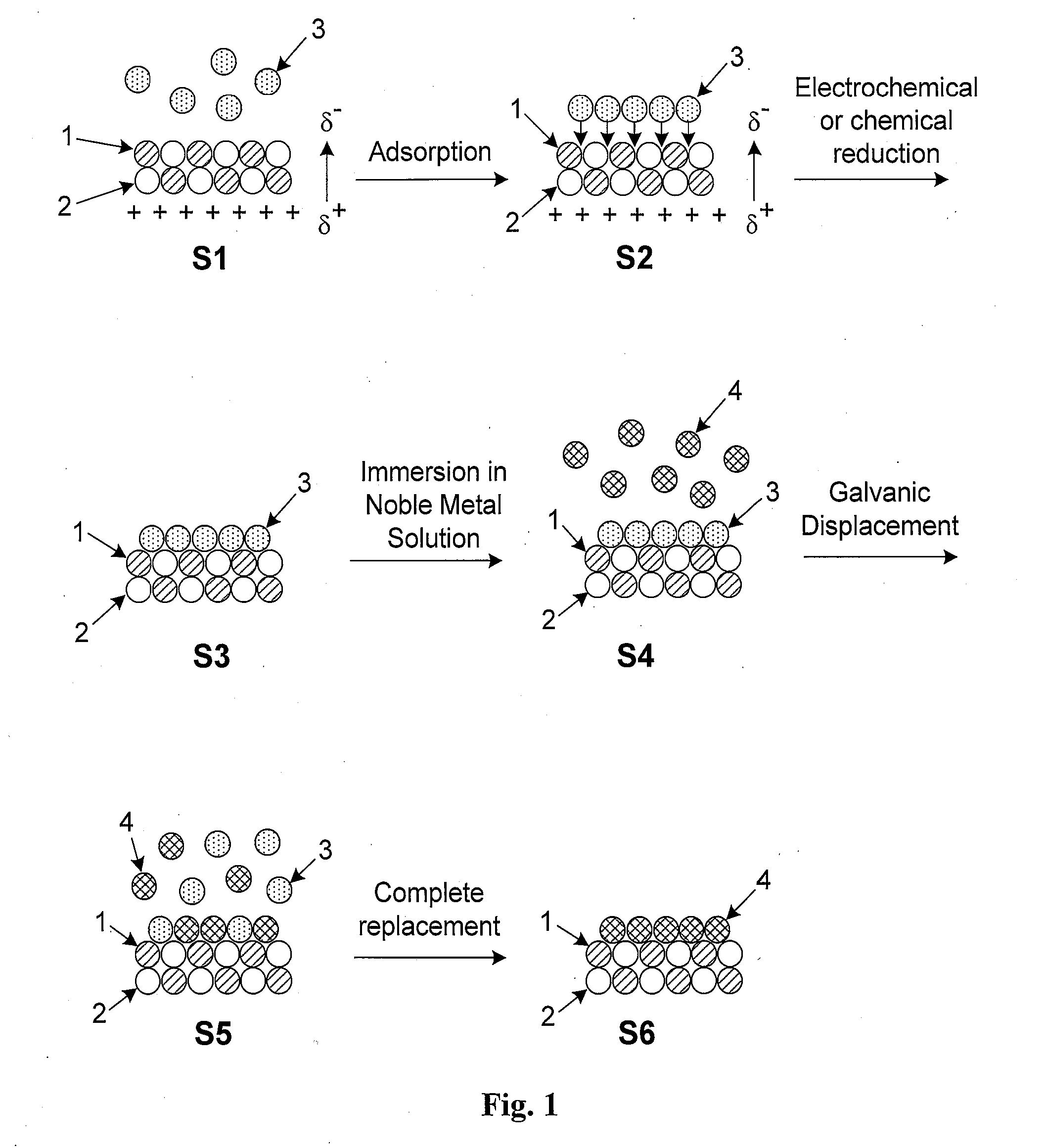

Platinum-Coated Non-Noble Metal-Noble Metal Core-Shell Electrocatalysts

InactiveUS20100197490A1Minimal loadingEfficiently formedMaterial nanotechnologyCell electrodesAlloyPt element

Core-shell particles encapsulated by a thin film of a catalytically active metal are described. The particles are preferably nanoparticles comprising a non-noble core with a noble metal shell which preferably do not include Pt. The non-noble metal-noble metal core-shell nanoparticles are encapsulated by a catalytically active metal which is preferably Pt. The core-shell nanoparticles are preferably formed by prolonged elevated-temperature annealing of nanoparticle alloys in an inert environment. This causes the noble metal component to surface segregate and form an atomically thin shell. The Pt overlayer is formed by a process involving the underpotential deposition of a monolayer of a non-noble metal followed by immersion in a solution comprising a Pt salt. A thin Pt layer forms via the galvanic displacement of non-noble surface atoms by more noble Pt atoms in the salt. The overall process is a robust and cost-efficient method for forming Pt-coated non-noble metal-noble metal core-shell nanoparticles.

Owner:BROOKHAVEN SCI ASSOCS

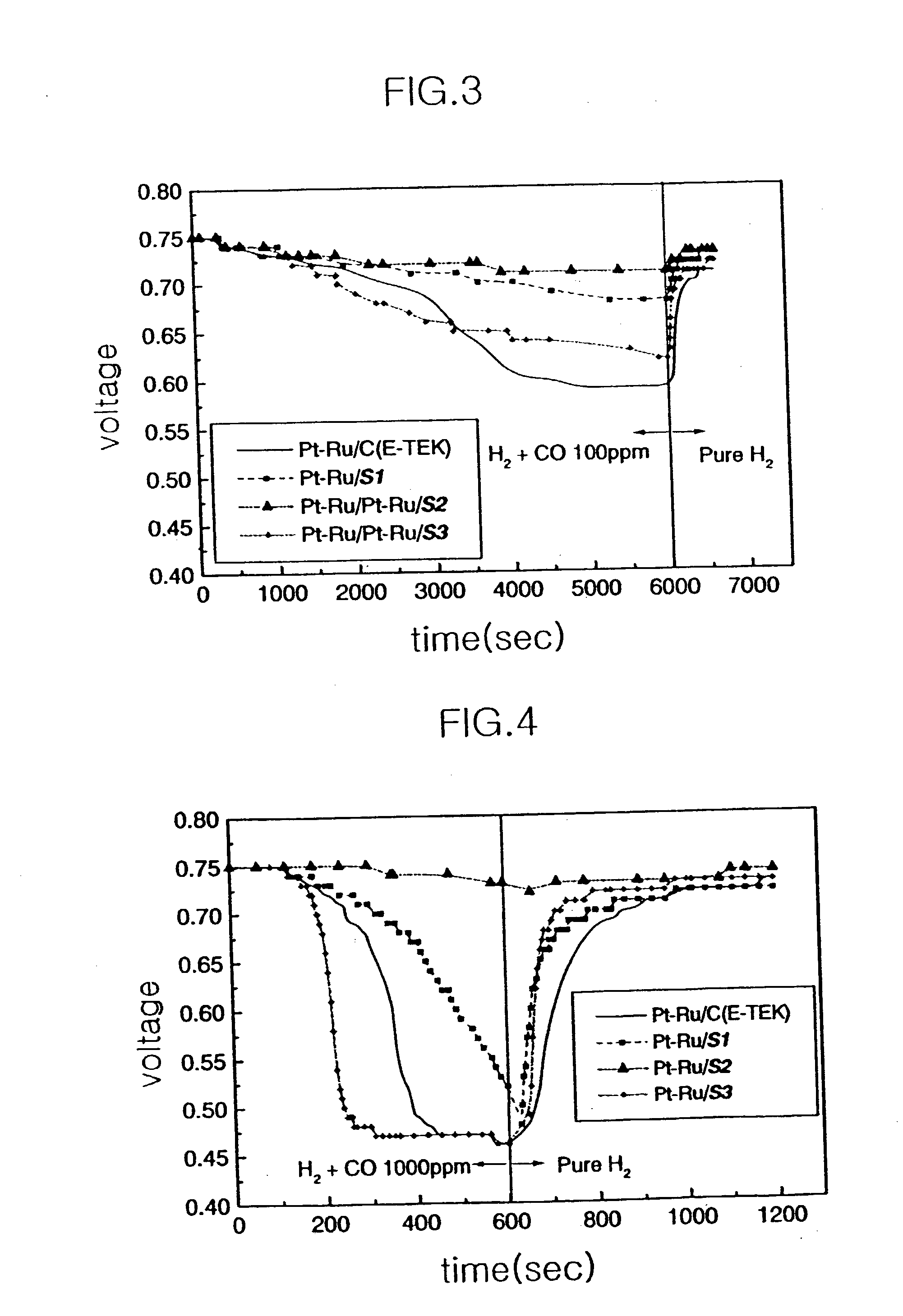

Electrocatalyst for fuel cells using support body resistant to carbon monoxide poisoning

InactiveUS20040248730A1Cell electrodesMetal/metal-oxides/metal-hydroxide catalystsPorous carbonPt element

Disclosed is an electrocatalyst for fuel cells, in which a porous carbon material including pores having a diameter smaller than a kinetic diameter of carbon monoxide is used as a support body and contact probability between an activated metal and carbon monoxide is decreased, thereby preventing fuel cell performance from being degraded by carbon monoxide. The electrocatalyst is obtained by adsorbing 10-80 parts by weight of an activated metal to 20-90 parts by weight of a porous support body, characterized in that the porous support body has a total surface area of 200-2,500 m<2> / g including an outer surface thereof and an inner surface of pores thereof, and has a plurality of pores penetrating into an interior of the support body with an average diameter of 2-15 nm and a total volume of 0.4-2.0 m<3> / g, and the activated metal is alloyed with 20-95 at % of platinum and 5-80 at % of one metal selected from among Ru, Sn, Os, Rh, Ir, Pd, V, Cr, Co, Ni, Fe and Mn. As for such an electrocatalyst, carbon monoxide does not fundamentally come in contact with the activated metal adsorbed to the inner surface of the pores of the support body, thereby minimizing degradation of fuel cell performance, thus overcoming fuel-feeding problems.

Owner:KOREA INST OF ENERGY RES

Electrocatalyst for fuel cells

Electrocatalyst which are formed of a carbon support, which is a carbon black with an H content of >4000 ppm and, as the catalytically active component, platinum or bi- or multi-metallically doped or alloyed platinum. The electrocatalysts are prepared by deposition of noble metals on the carbon black surface. They can be used for the production of fuel cells.

Owner:SAMSUNG ELECTRONICS CO LTD +2

High Stability, Self-Protecting Electrocatalyst Particles

InactiveUS20100216632A1Avoid corrosionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCore shell nanoparticlesAlloy

High-stability, self-protecting particles encapsulated by a thin film of a catalytically active noble metal are described. The particles are preferably nanoparticles comprising a passivating element having at least one metal selected from the group consisting of columns IVB, VB, VIB, and VIIB of the periodic table. The nanoparticle is preferably encapsulated by a Pt shell and may be either a nanoparticle alloy or a core-shell nanoparticle. The nanoparticle alloys preferably have a core comprised of a passivating component alloyed with at least one other transition metal. The core-shell nanoparticles comprise a core of a non-noble metal surrounded by a shell of a noble metal. The material constituting the core, shell, or both the core and shell may be alloyed with one or more passivating elements. The self-protecting particles are ideal for use in corrosive environments where they exhibit improved stability compared to conventional electrocatalyst particles.

Owner:BROOKHAVEN SCI ASSOCS

Electrocatalyst for oxygen reduction with reduced platinum oxidation and dissolution rates

InactiveUS20060263675A1Low platinum loadingImprove stabilityMaterial nanotechnologyConductive materialOxide compositeDissolution

The invention relates to platinum-metal oxide composite particles and their use as electrocatalysts in oxygen-reducing cathodes and fuel cells. The invention particularly relates to methods for preventing the oxidation of the platinum electrocatalyst in the cathodes of fuel cells by use of these platinum-metal oxide composite particles. The invention additionally relates to methods for producing electrical energy by supplying such a fuel cell with an oxidant, such as oxygen, and a fuel source, such as hydrogen.

Owner:BROOKHAVEN SCI ASSOCS

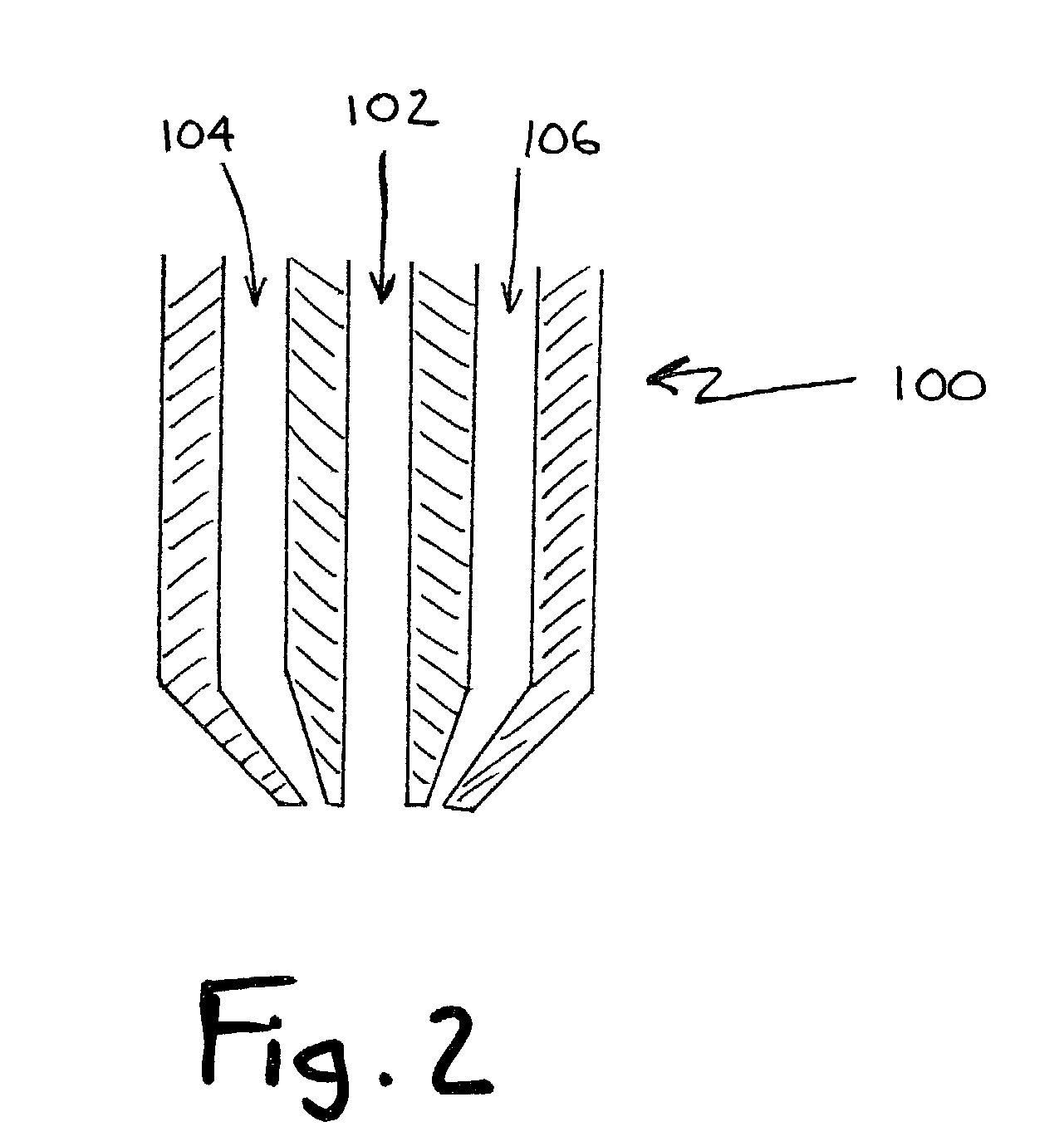

Membrane electrode assemblies for use in fuel cells

InactiveUS20030064265A1High purityImprove electrocatalytic activityGranule coatingCell electrodesCarbon compositesFuel cells

Owner:CABOT CORP

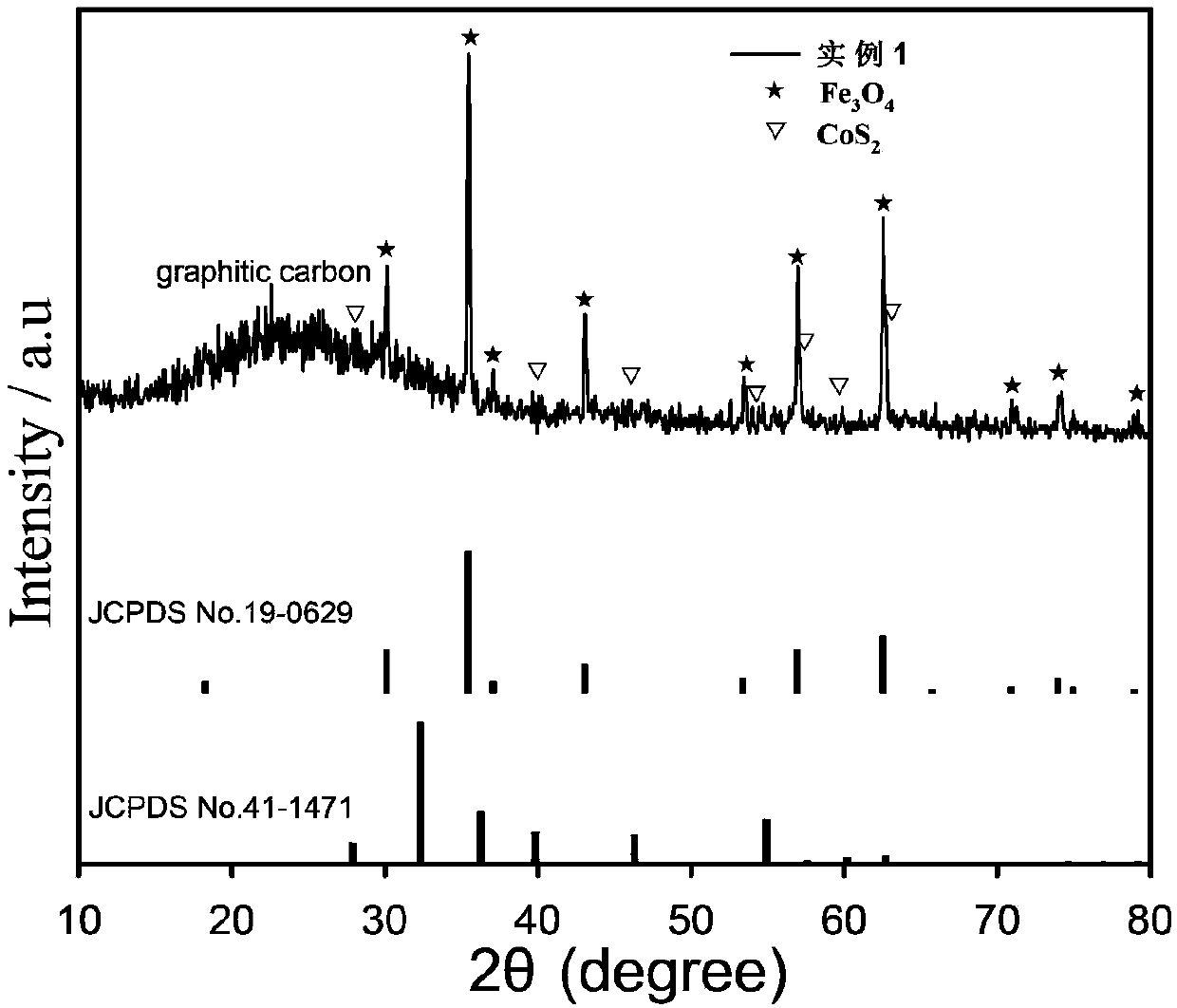

Nano carbon doped electrocatalyst for fuel cell, and application of nano carbon doped electrocatalyst

InactiveCN103050714AChange the microstructureChange Edge Face DefectsPhysical/chemical process catalystsCell electrodesMicrowave radiometryHigh heat

The invention relates to a nano carbon doped electrocatalyst for a fuel cell, and application of the nano carbon doped electrocatalyst. The electrocatalyst is prepared by adopting the steps of: complexing a nitrogen-containing and / or boron-containing organic precursor and a transition metal salt to form a composite; adding nano carbon as a carrier, and heating and reacting a mixture by adopting a microwave radiation method; and after the reaction is complete, filtering and drying, placing a product obtained after the reaction in an inert atmosphere and / or reducing atmosphere, and treating at a high temperature of 500-1500 DEG C to obtain the nano carbon doped electrocatalyst. The nano carbon doped electrocatalyst is very low in cost, high in activity and stability and excellent in anti-poisoning capacity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

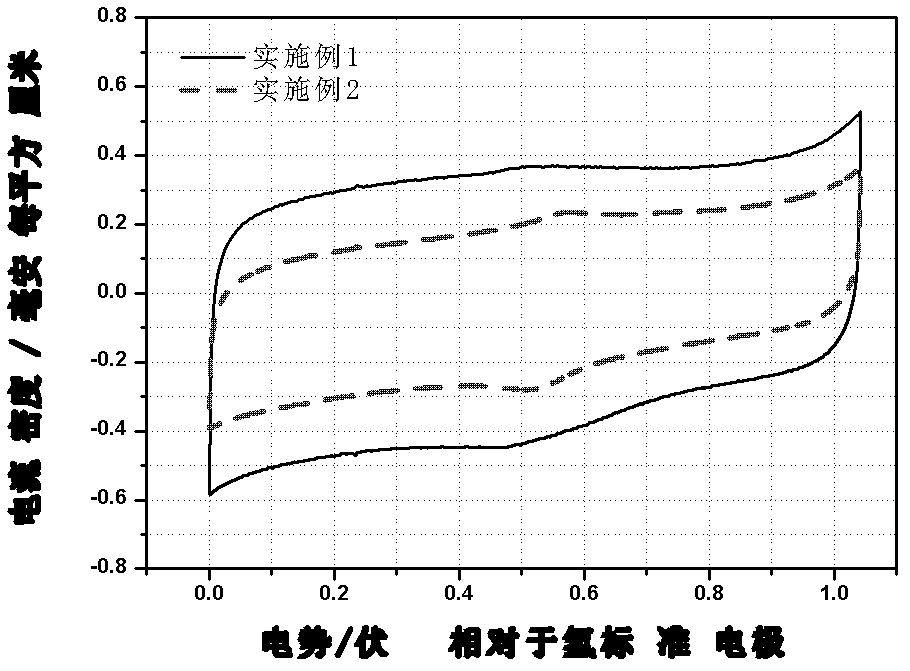

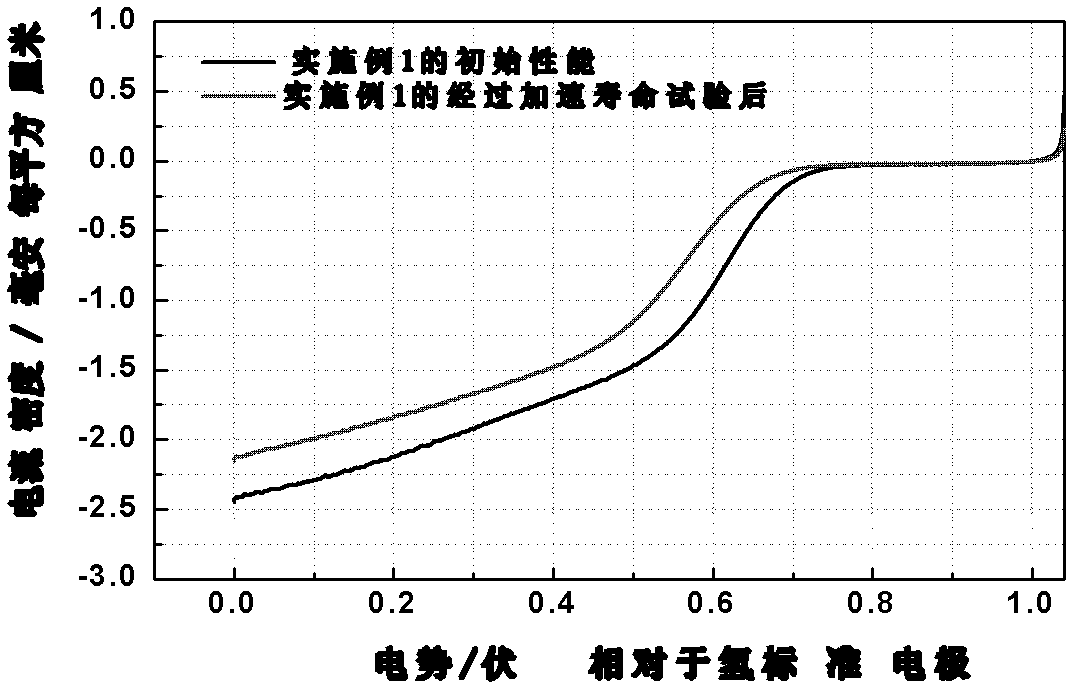

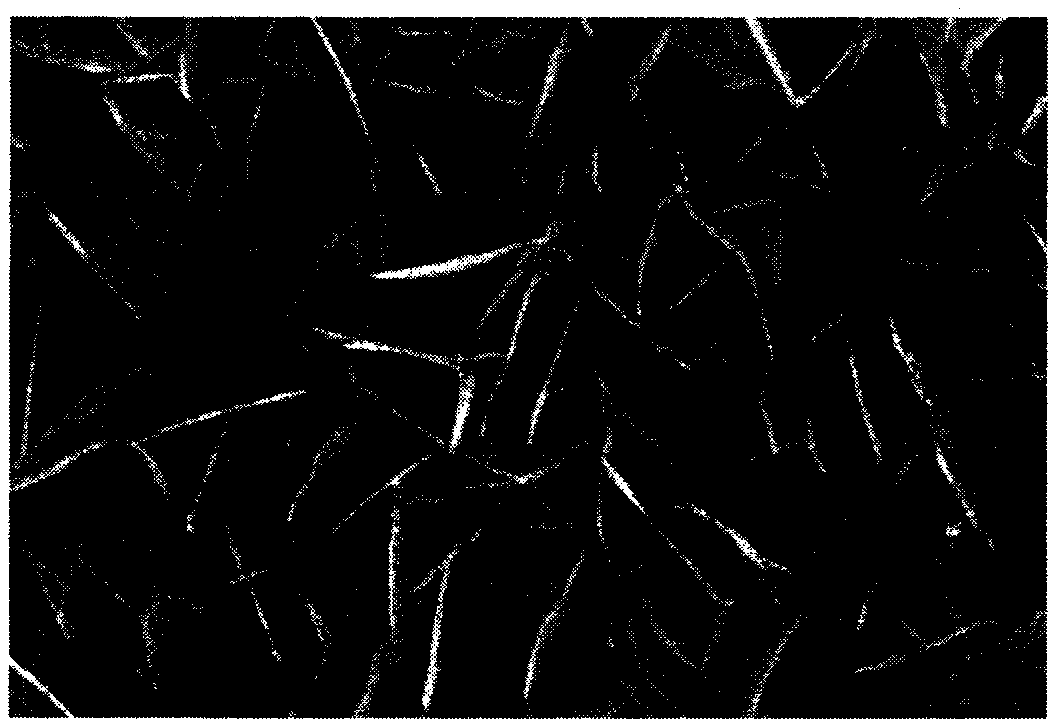

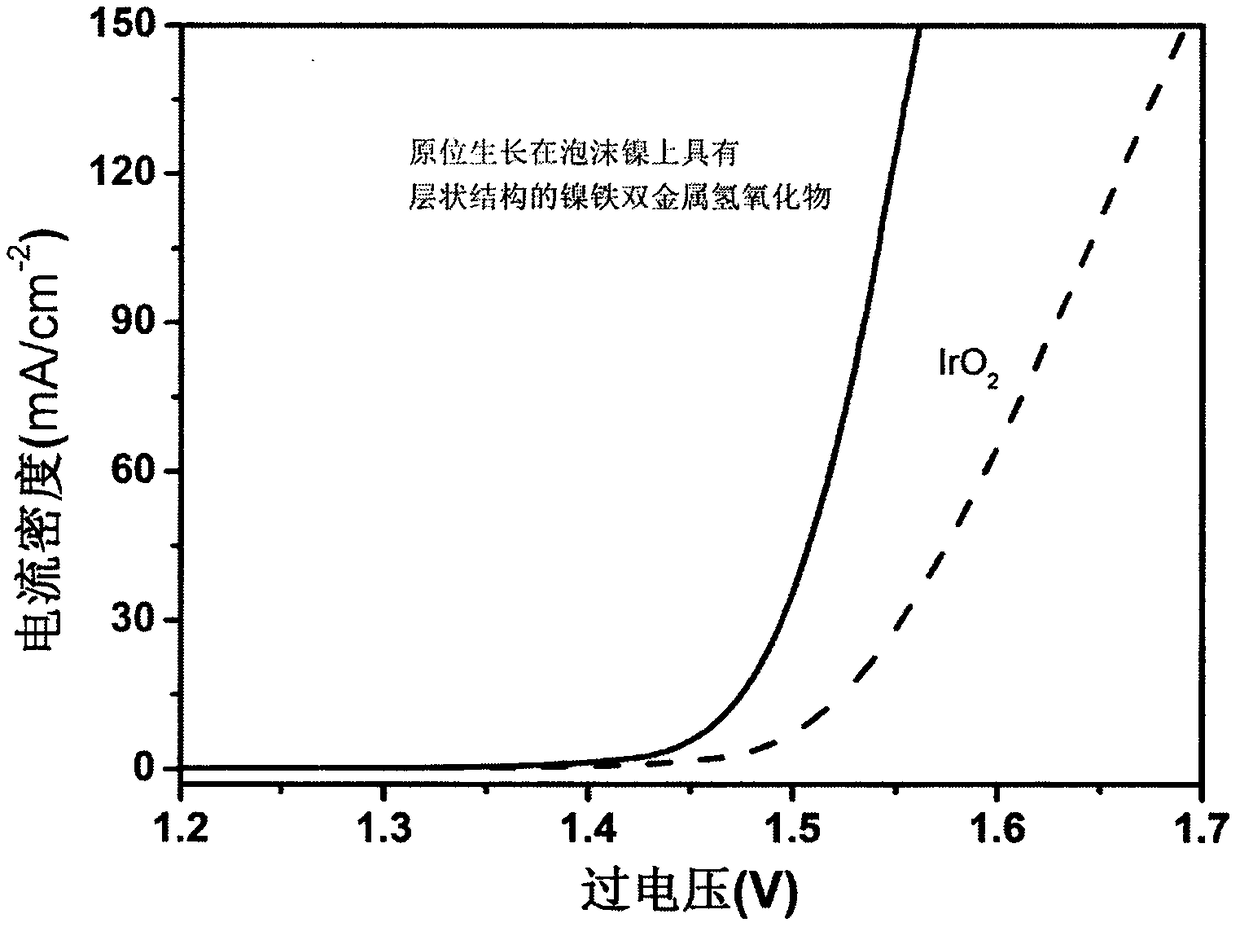

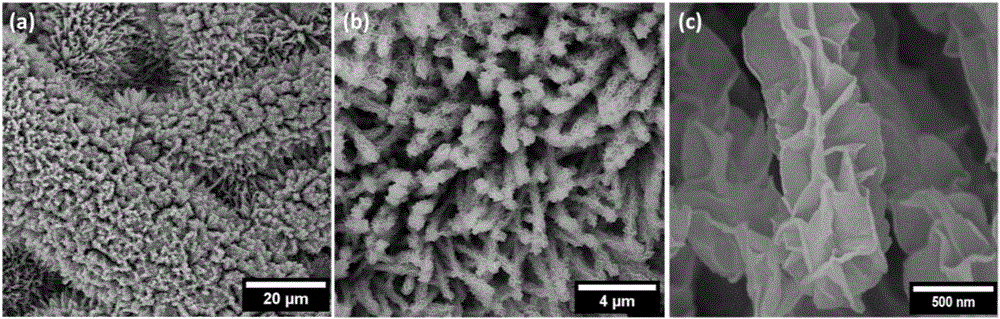

Preparation method of ferro-nickel bi-metal hydroxide of sheet structure on foamed nickel through in-situ growth

InactiveCN108283926AImprove performanceHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectrolysisOxygen

The invention discloses a preparation method of a ferro-nickel bi-metal hydroxide of a sheet structure on foamed nickel through in-situ growth, and belongs to the field of electrochemistry. Nickel nitrate hexahydrate, iron nitrate nonahydrate, urea, ammonium fluoride and foamed nickel are adopted as main raw materials, and an electrocatalyst through water electrolysis oxygen production is successfully prepared. The sheet structure of the catalyst supplies abundant active sites, due to existence of substrate foamed nickel, the electrical conductivity is enhanced, and when the hydroxide is adopted as the electro-catalysis oxygen production catalyst, the excellent catalysis activity is shown. The activity of a traditional non-noble metal material under an oxygen evolution reaction (OER) in analkaline electrolyte is not ideal. Accordingly, the OER catalysis performance of the non-noble metal material under the alkaline condition is improved, and the method is of great significance in solving the fossil fuel energy crisis. Nickel and iron earth reserve volumes are quite abundant, the OER catalytic performance of the ferro-nickel bi-metal hydroxide of the sheet structure under the alkaline condition is excellent, and the hydroxide is a catalytic material with the wide prospect.

Owner:QINGDAO UNIV

Core / shell-type catalyst particles and methods for their preparation

ActiveUS20100086832A1High mass activityLow precious metal contentMaterial nanotechnologyCell electrodesFuel cellsHigh specific activity

The invention discloses core / shell type catalyst particles comprising a Mcore / Mshell structure with Mcore=inner particle core and Mshell=outer particle shell, wherein the medium diameter of the catalyst particle (dcore+shell) is in the range of 20 to 100 nm, preferably in the range of 20 to 50 nm. The thickness of the outer shell (tshell) is about 5 to 20% of the diameter of the inner particle core of said catalyst particle, preferably comprising at least 3 atomic layers. The core / shell type catalyst particles, particularly the particles comprising a Pt-based shell, reveal a high specific activity. The catalyst particles are preferably supported on suitable support materials such as carbon black and are used as electrocatalysts for fuel cells.

Owner:UMICORE AG & CO KG

Photocatalytic Deposition of Metals and Compositions Comprising the Same

InactiveUS20080241640A1Improve performanceMaterial nanotechnologyMolecular sieve catalystsMetal alloyNanocomposite

A photocatalytic metal deposition process and a resulting nanocomposite are described. The nanocomposite includes an electrically conducting carbonaceous material, a photoactive metal oxide and a metal. Metals for deposition include noble metals, metal alloys and other transition metals in which the metal is laid down precisely and in a predetermined fashion on one or more surfaces of a composite. Deposition provides a high performance electrocatalyst for a number of suitable applications.

Owner:SID RICHARDSON CARBON CO +1

Platinum- and platinum alloy-coated palladium and palladium alloy particles and uses thereof

ActiveUS7691780B2High catalytic activityReduce loadSynthetic resin layered productsCellulosic plastic layered productsAlloyOxygen

The present invention relates to particle and nanoparticle composites useful as oxygen-reduction electrocatalysts. The particle composites are composed of a palladium or palladium-alloy particle or nanoparticle substrate coated with an atomic submonolayer, monolayer, bilayer, or trilayer of zerovalent platinum atoms. The invention also relates to a catalyst and a fuel cell containing the particle or nanoparticle composites of the invention. The invention additionally includes methods for oxygen reduction and production of electrical energy by using the particle and nanoparticle composites of the invention.

Owner:BROOKHAVEN SCI ASSOCS

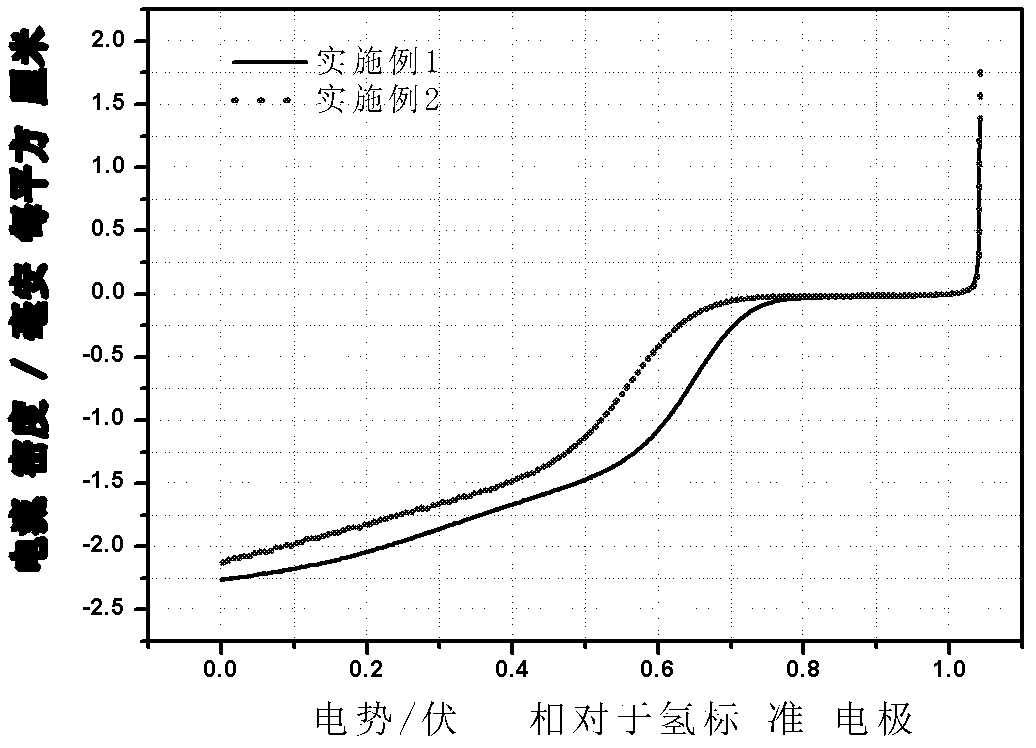

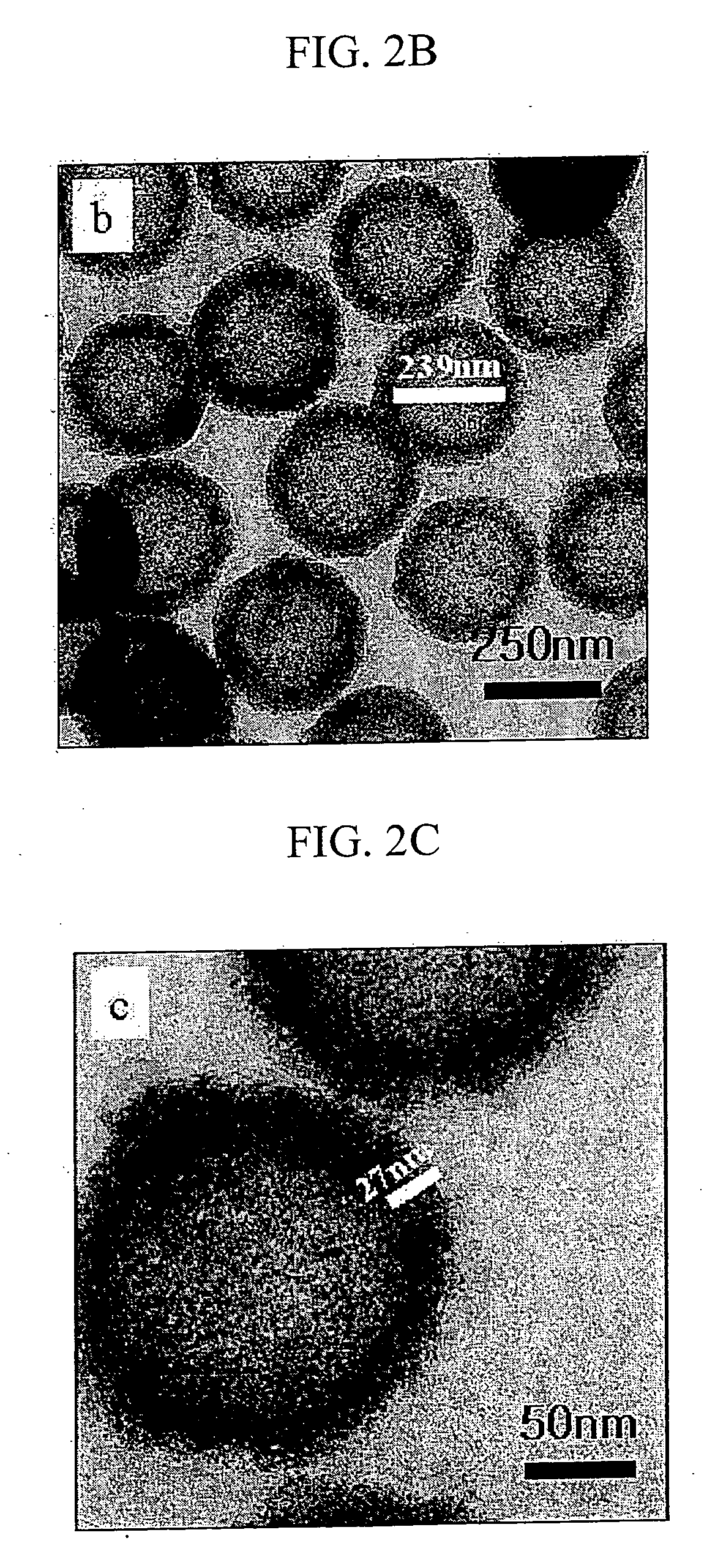

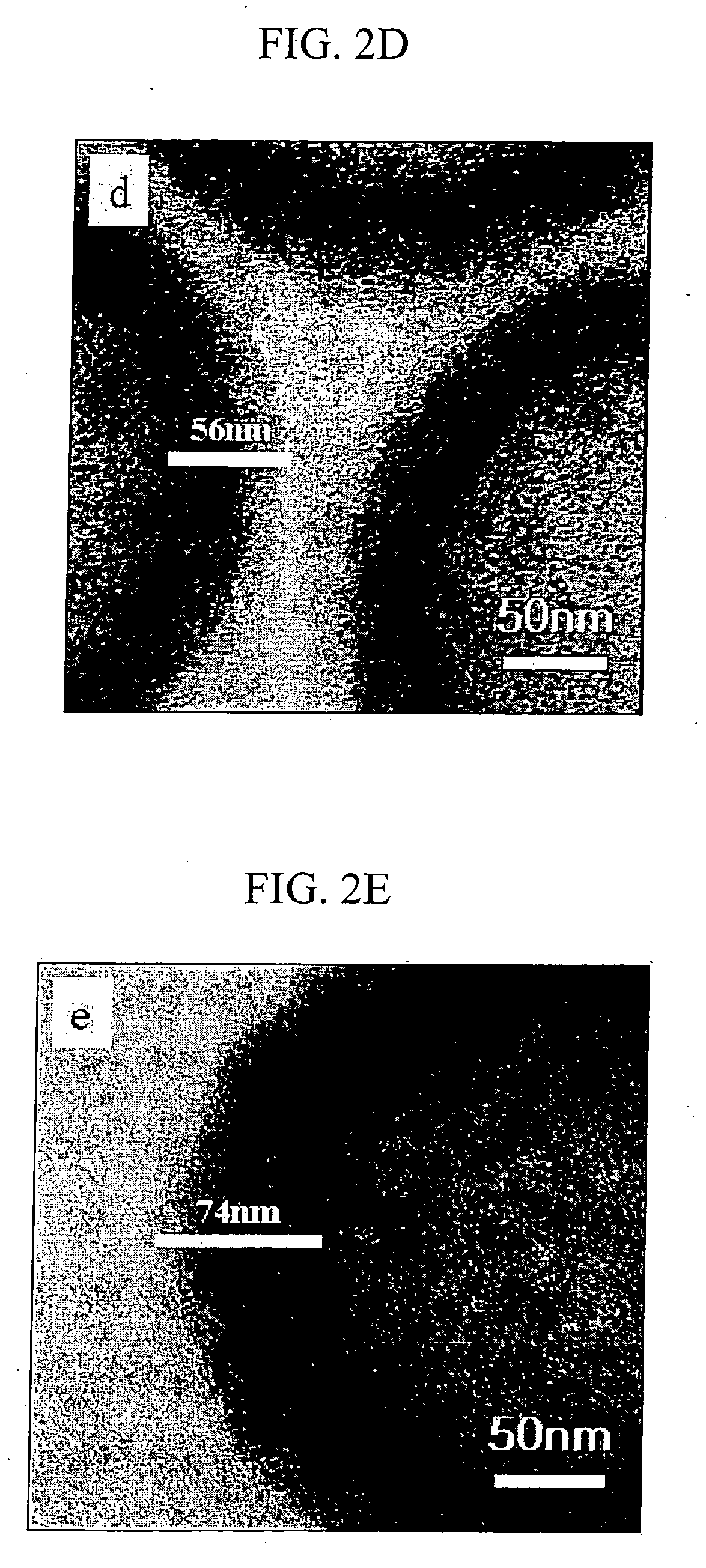

HCMS carbon capsule, electrocatalysts for fuel cell supported by HCMS carbon capsule, and method of preparing the same

The present invention provides a bimodal porous carbon capsule with a hollow core and a mesoporous shell structure, which can be employed as an electrocatalyst support for a fuel cell; electrocatalysts for the fuel cell using the bimodal porous carbon capsule, and a method of preparing the same. The electrocatalyst according to the present invention has higher catalysis activity as compared with the Pt—Ru or Pt catalyst supported by the conventional carbon black, so that the performance of the fuel cell is enhanced, and it can be easily prepared in an aqueous solution state. According to the present invention, the porous carbon support employed as the support for the catalyst has excellent conductivity and a high surface area, so that the loaded catalyst can be prepared with a smaller amount than that of the conventional carbon black. Further, metal particles having an extremely fine size of 2˜3 nm are uniformly distributed on the support, so that the area of an active site at which catalysis reaction is performed is increased, thereby increasing the catalyst activity with respect to the oxidation reaction of the fuel such as methanol, ethanol, hydrogen, etc. Also, a fine pore of a porous carbon support secures a fuel dispersing passage, so that the fuel including alcohol such as methanol, ethanol or the like, hydrogen, etc. can be easily transferred and dispersed, thereby efficiently performing its oxidation-reduction reaction. On the other hand, an air electrode can efficiently function as the catalyst due to the same principle.

Owner:HANNAM UNIV

Synthesis of Metal-Metal Oxide Catalysts and Electrocatalysts Using a Metal Cation Adsorption/Reduction and Adatom Replacement by More Noble Ones

InactiveUS20070264189A1Improve stabilityReducing and preventing oxidationCell electrodesGold compoundsHydrogenFuel cells

The invention relates to platinum-metal oxide composite particles and their use as electrocatalysts in oxygen-reducing cathodes and fuel cells. The invention particularly relates to methods for preventing the oxidation of the platinum electrocatalyst in the cathodes of fuel cells by use of these platinum-metal oxide composite particles. The invention additionally relates to methods for producing electrical energy by supplying such a fuel cell with an oxidant, such as oxygen, and a fuel source, such as hydrogen. The invention also relates to methods of making the metal-metal oxide composites.

Owner:BROOKHAVEN SCI ASSOCS

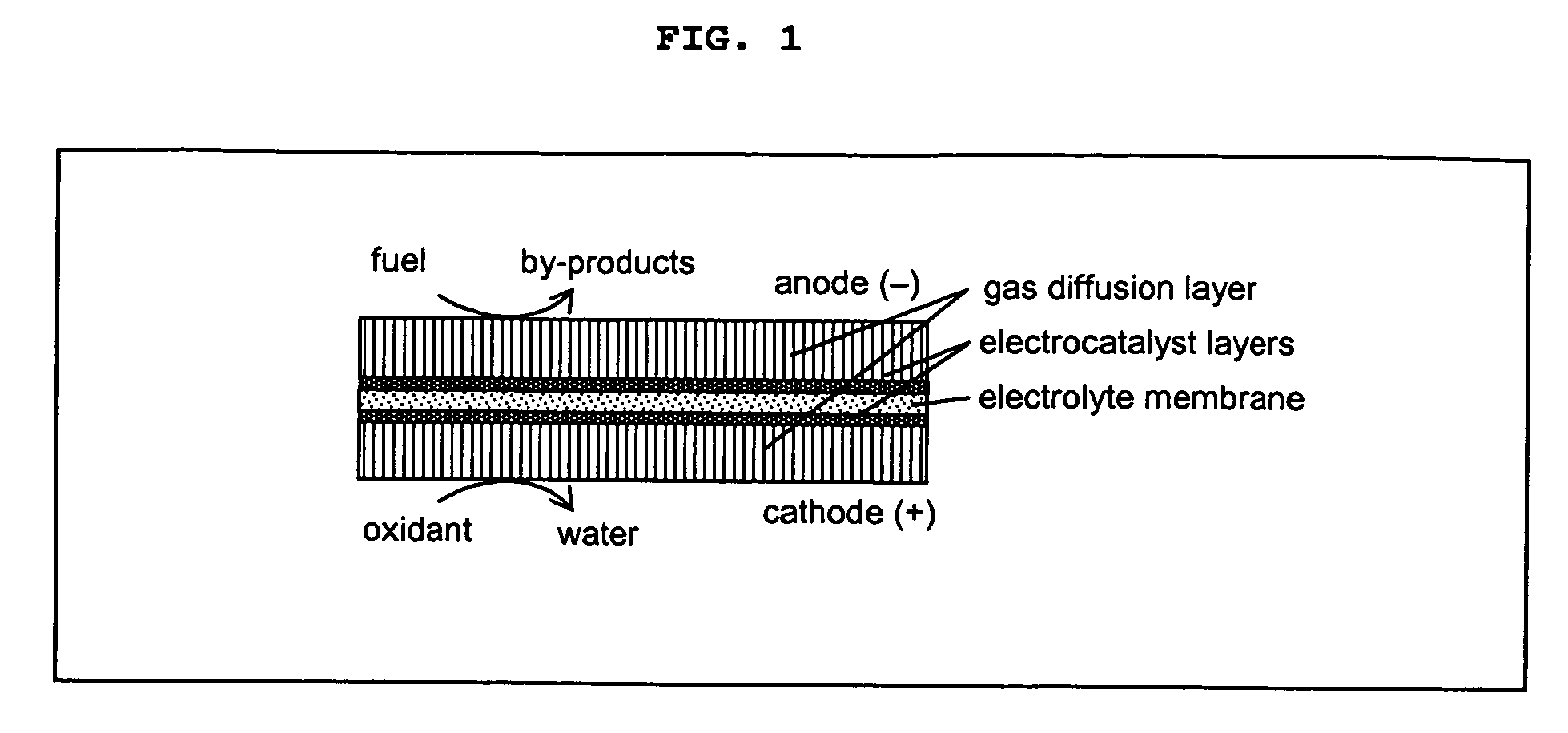

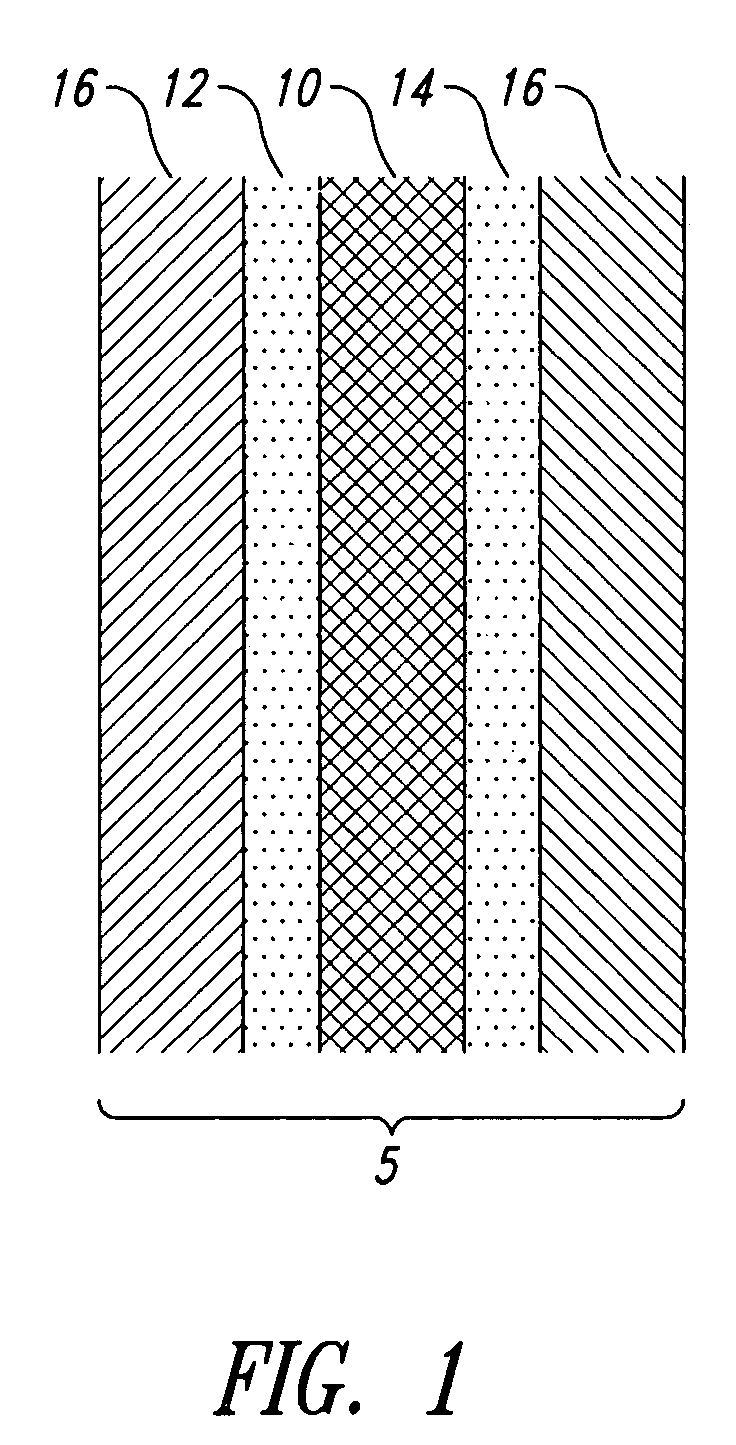

Processing techniques for the fabrication of solid acid fuel cell membrane electrode assemblies

ActiveUS20060014068A1Improve proton conductivityMaterial nanotechnologyElectrolyte holding meansFuel cellsSolid acid

Processes, techniques, and compositions used to fabricate high performance solid acid fuel cell membrane electrode assemblies are disclosed. The techniques include preparing the solid acid electrolyte material, depositing the electrolyte membrane, depositing the electrocatalyst layer, preparing the electrodes, fabricating the gas seals, and constructing the membrane electrode assembly.

Owner:CALIFORNIA INST OF TECH

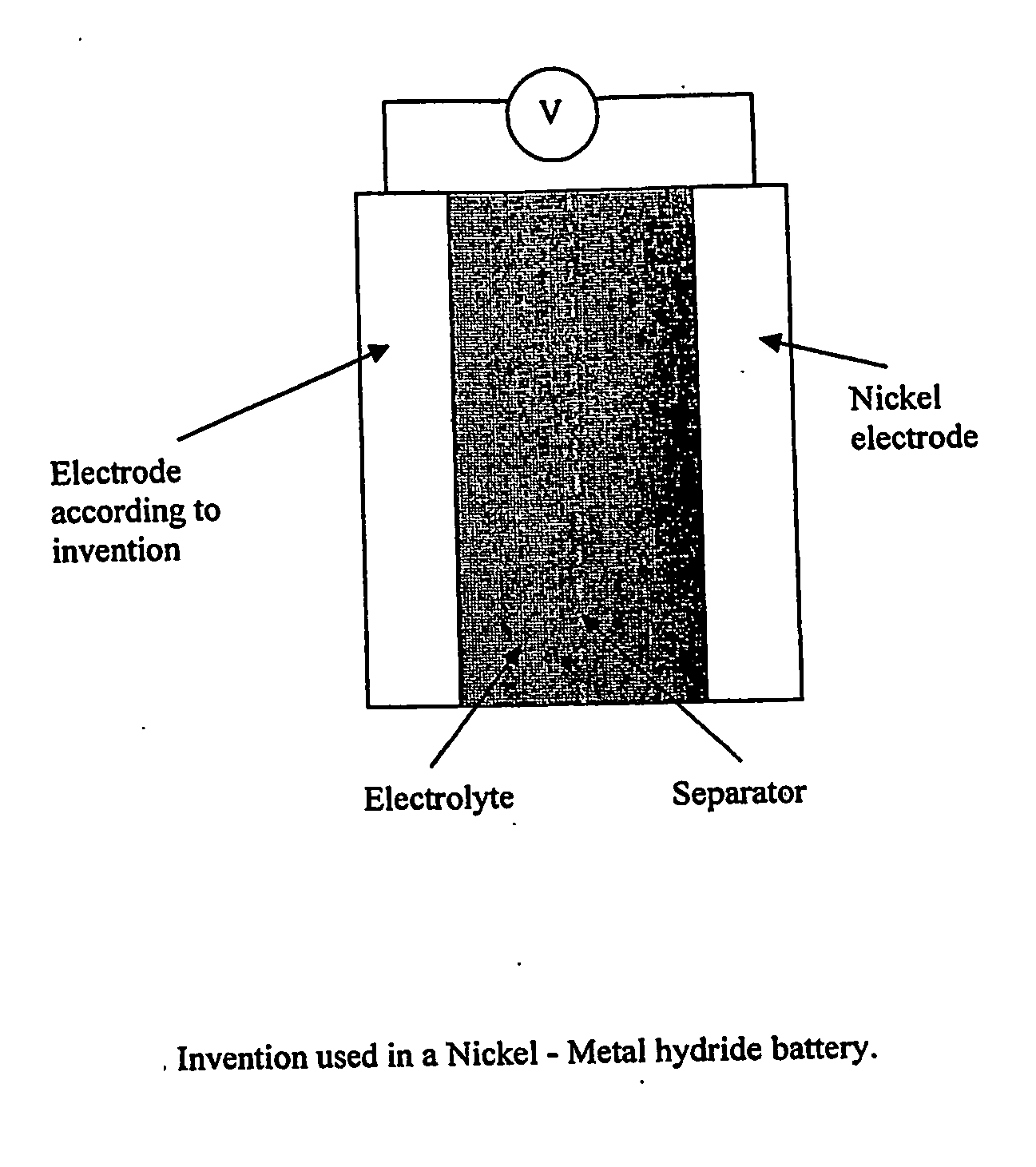

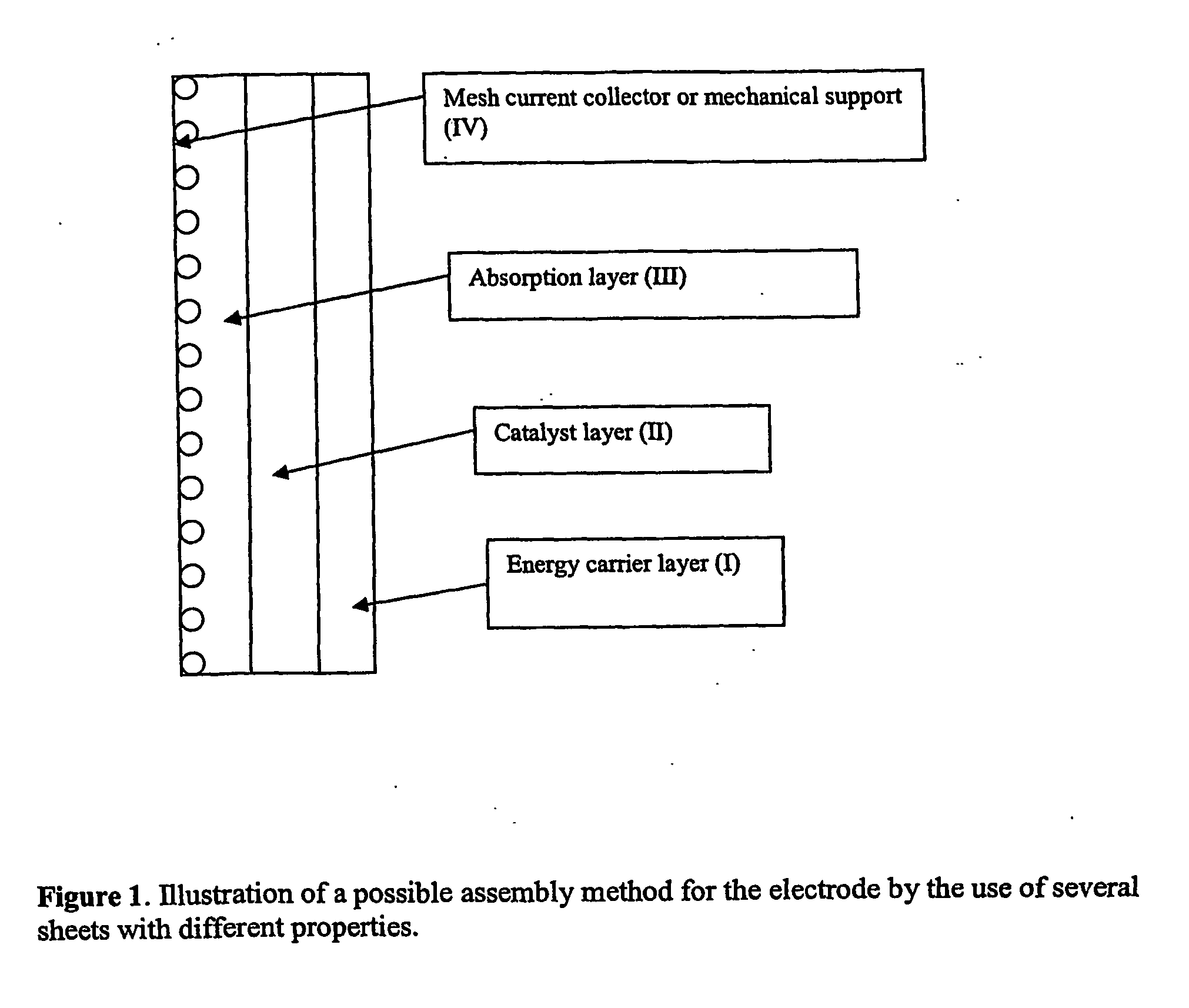

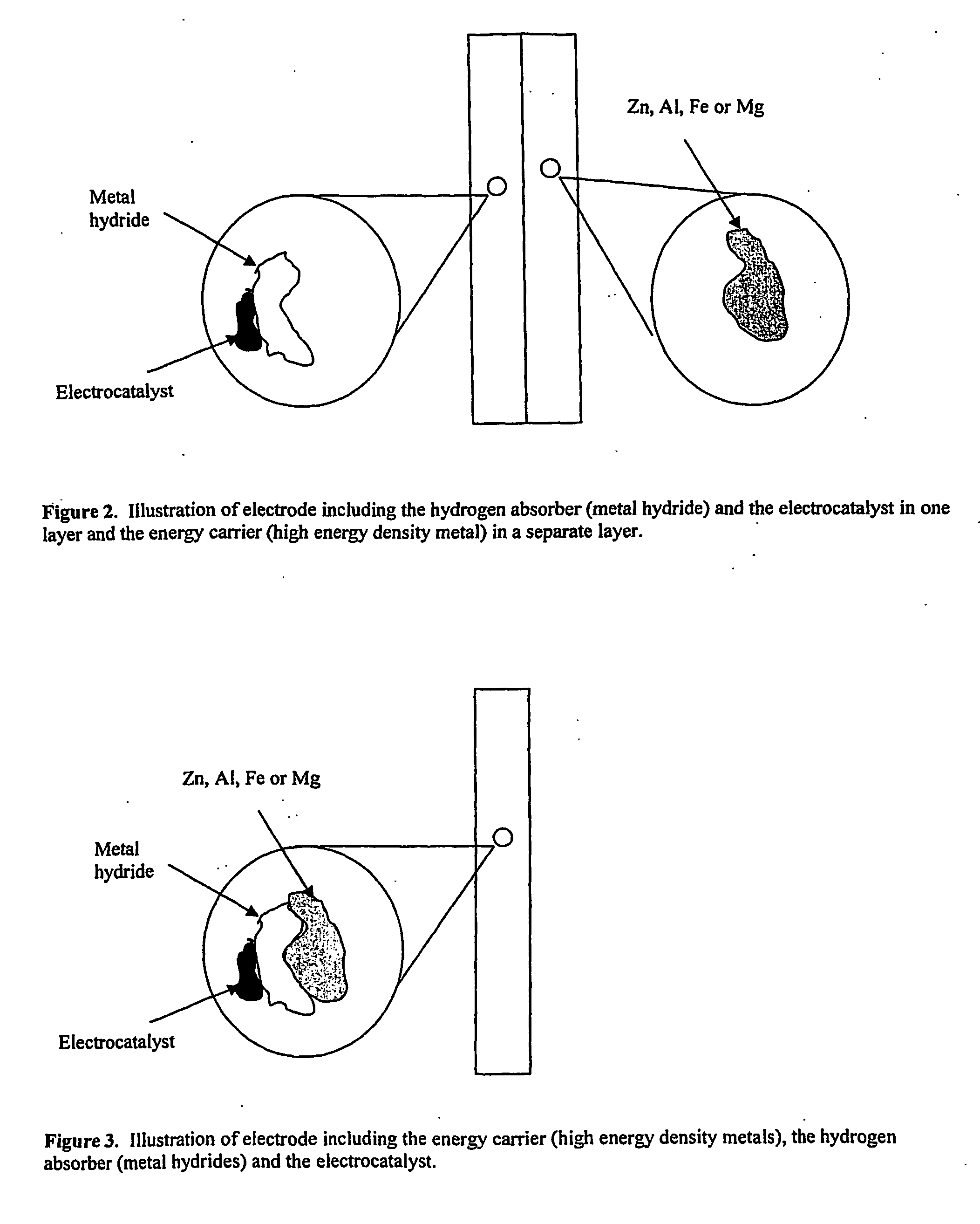

Electrode, method of its production, metal-air fuel cell and metal hydride cell

InactiveUS20070077491A1Improve energy efficiencyHigh energy capacityElectrode rolling/calenderingHydrogenFuel cellsReaction rate

The invention described concerns an anode electrode comprising a hydrogen storage material / alloy and a high energy density metal. In addition a hydrogen electrocatalyst may be added to increase the hydrogen reaction rate. The high energy density metal is selected from a group consisting of Al, Zn, Mg and Fe, or from a combination of these metals. A method of production of an electrode comprising a hydrogen storage alloy and a high energy density metal is also described. The method comprises sintering or binding a high energy density metal powder and / or hydrogen storage alloy into at least one thin street, and calendaring or pressing said sheet forming the electrode. The anode electrode may be used in metal hydride batteries and metal air fuel cells.

Owner:REVOLT TECH LTD

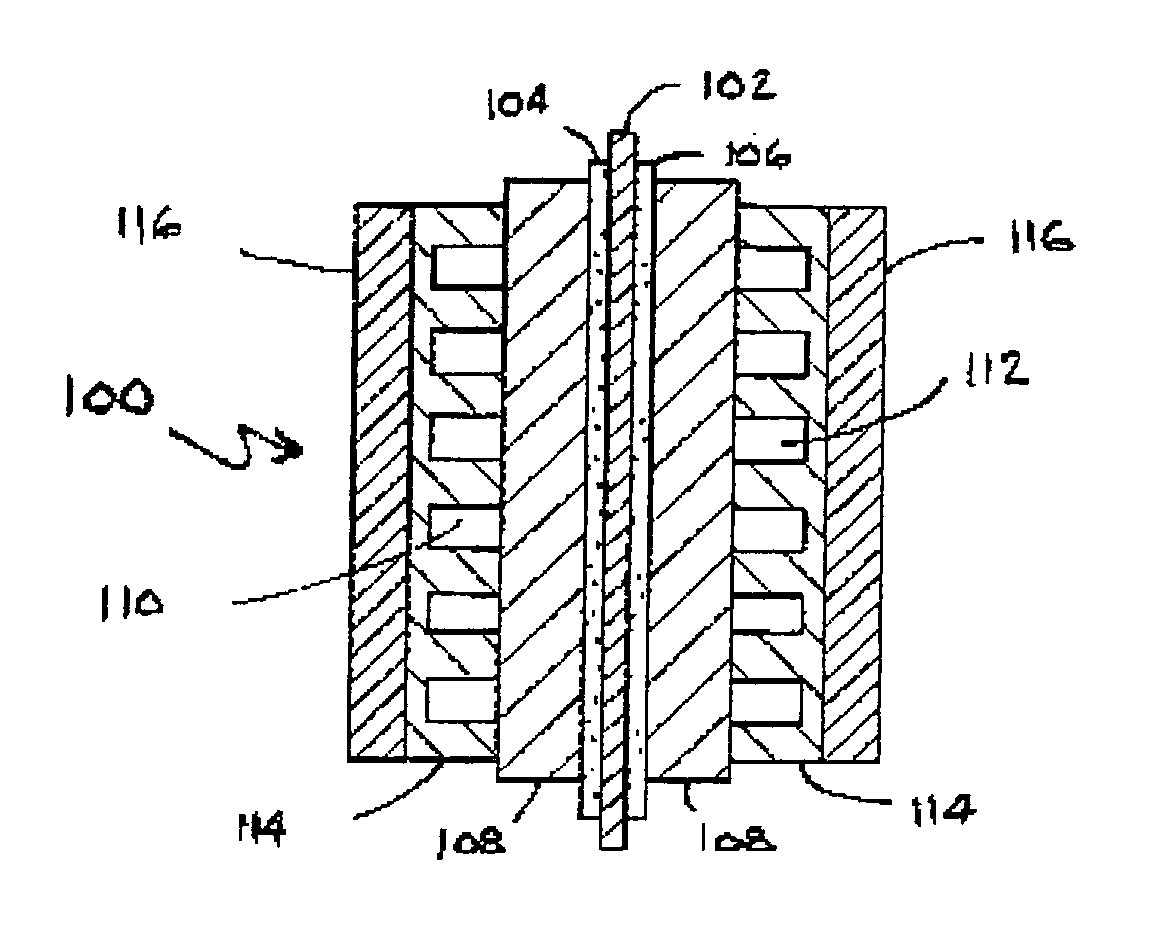

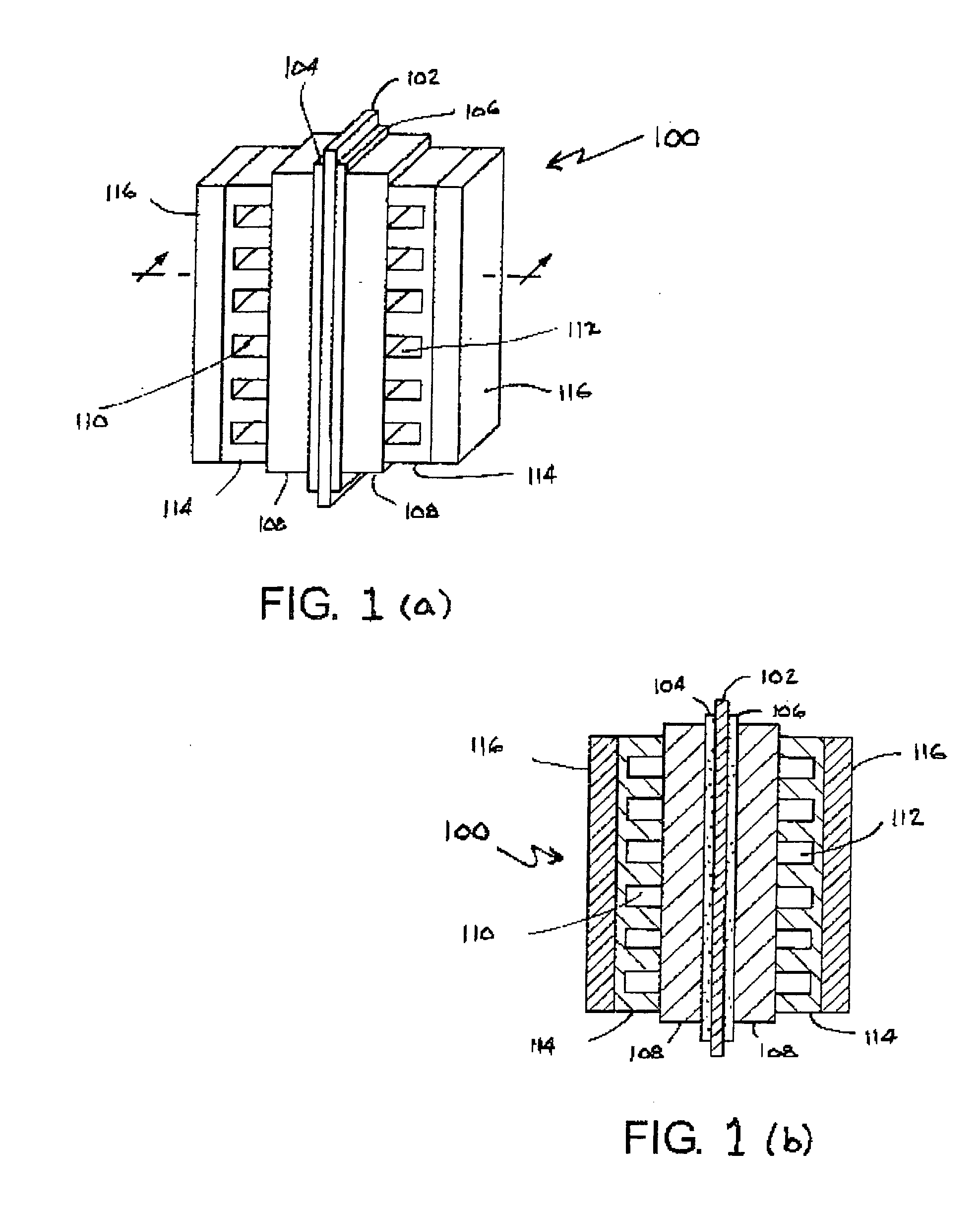

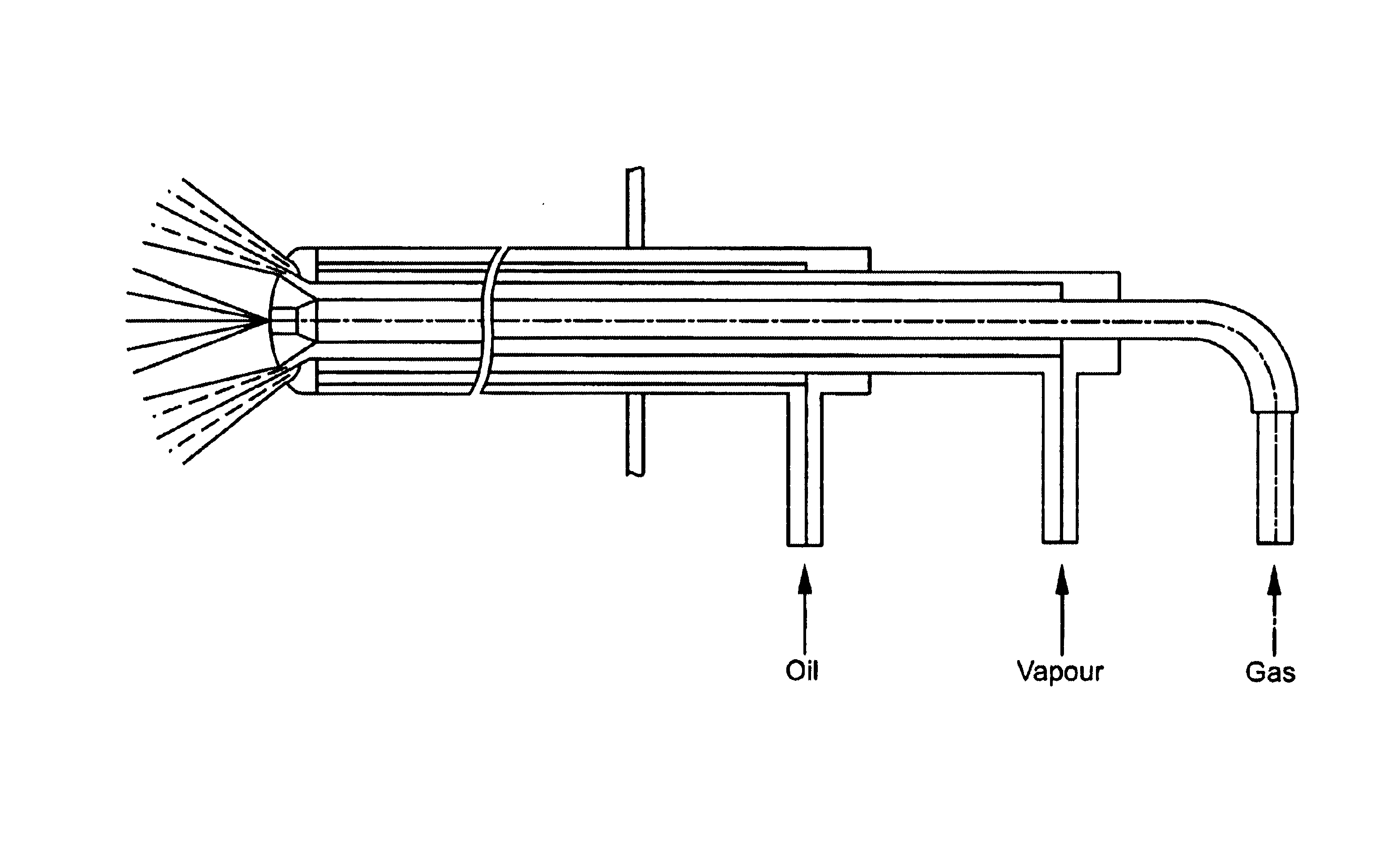

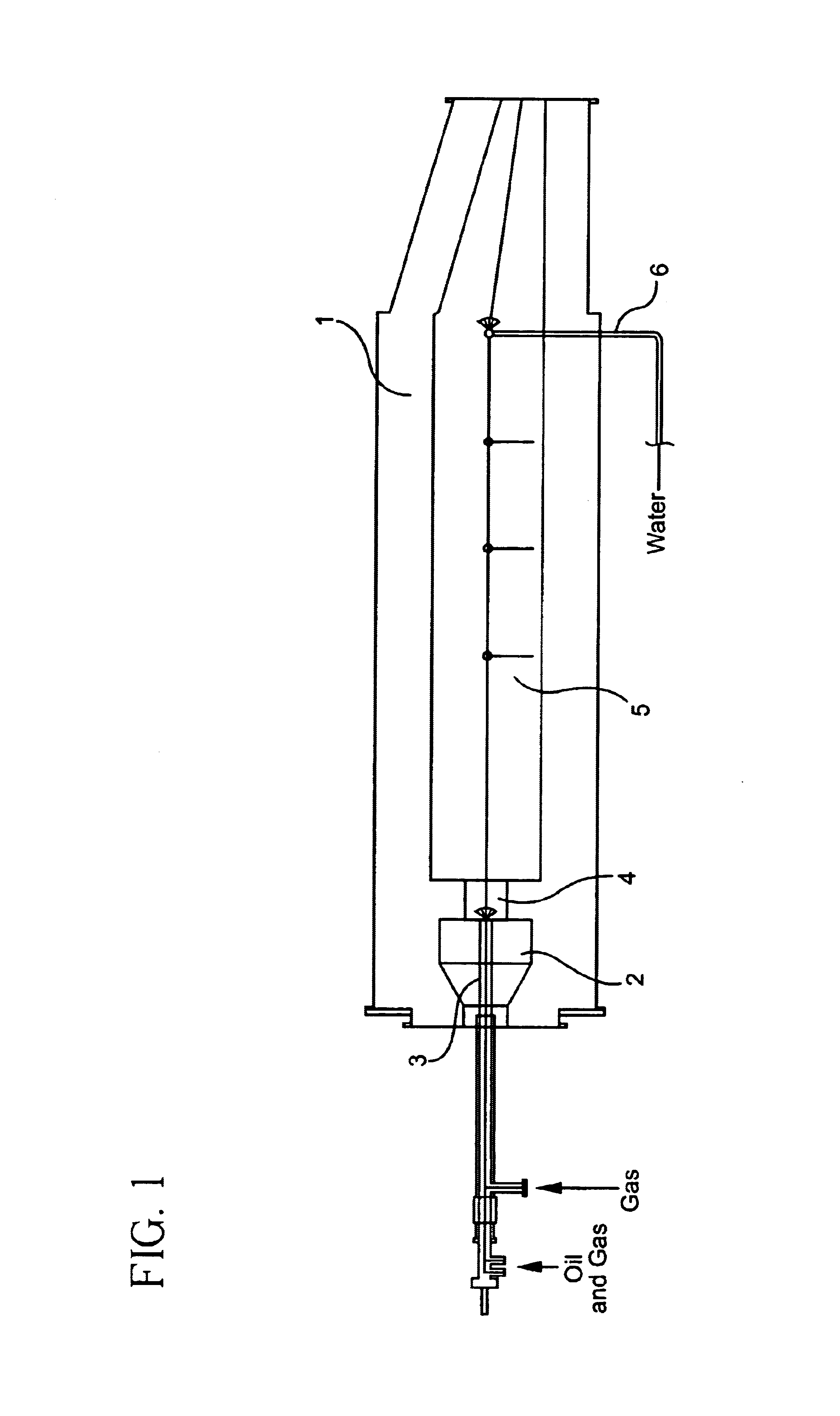

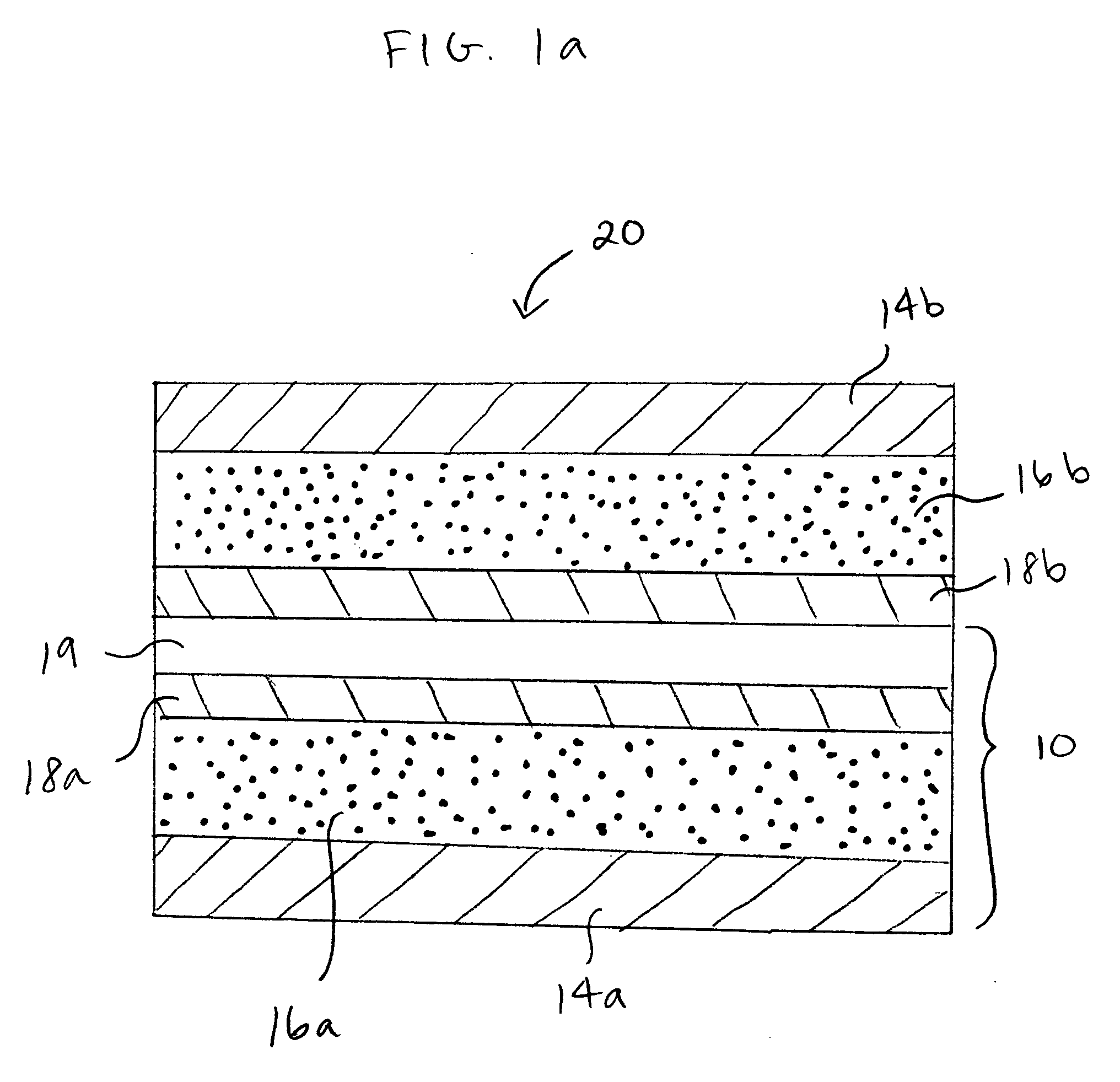

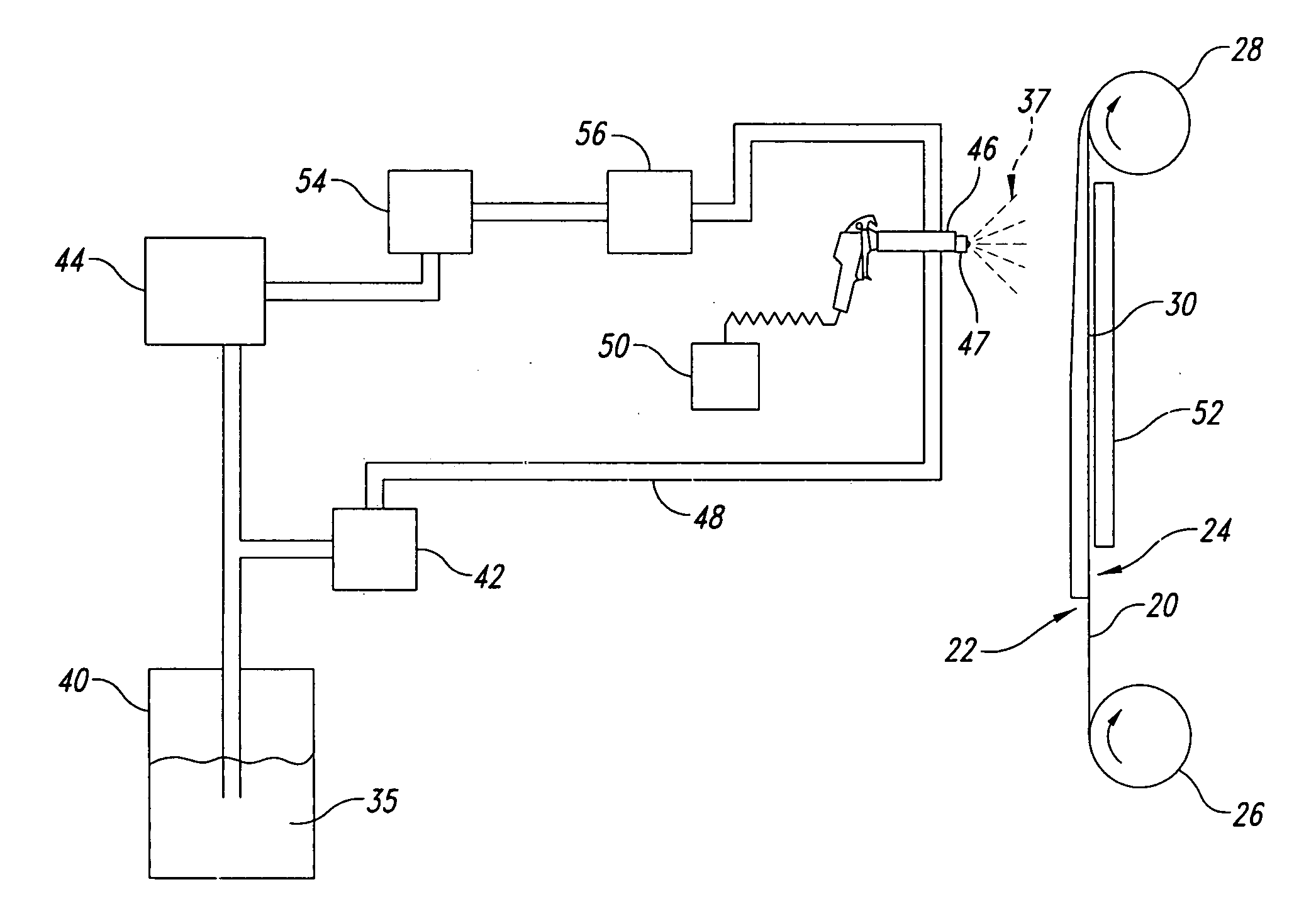

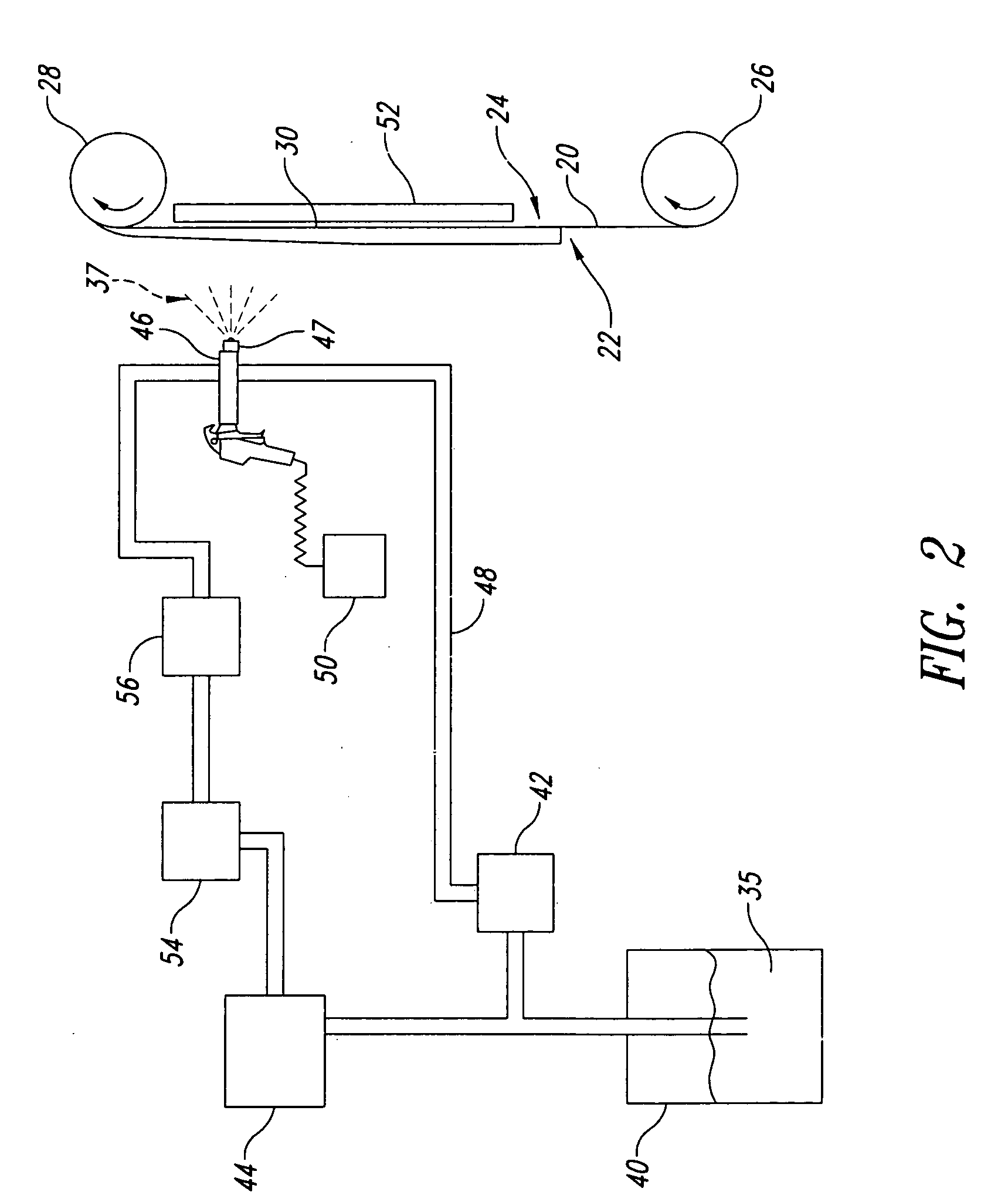

Method and apparatus for electrostatically coating an ion-exchange membrane or fluid diffusion layer with a catalyst layer

A method and apparatus for coating an ion-exchange membrane or fluid diffusion layer with a catalyst layer for use in an electrochemical fuel cell is disclosed, the method comprising the steps of electrostatically charging a catalyst slurry to yield an electrostatically-charged catalyst slurry, and applying the electrostatically-charged catalyst slurry onto a first surface of the ion-exchange membrane or fluid diffusion layer to form a first catalyst layer on the first surface.

Owner:BALLARD POWER SYSTEMS

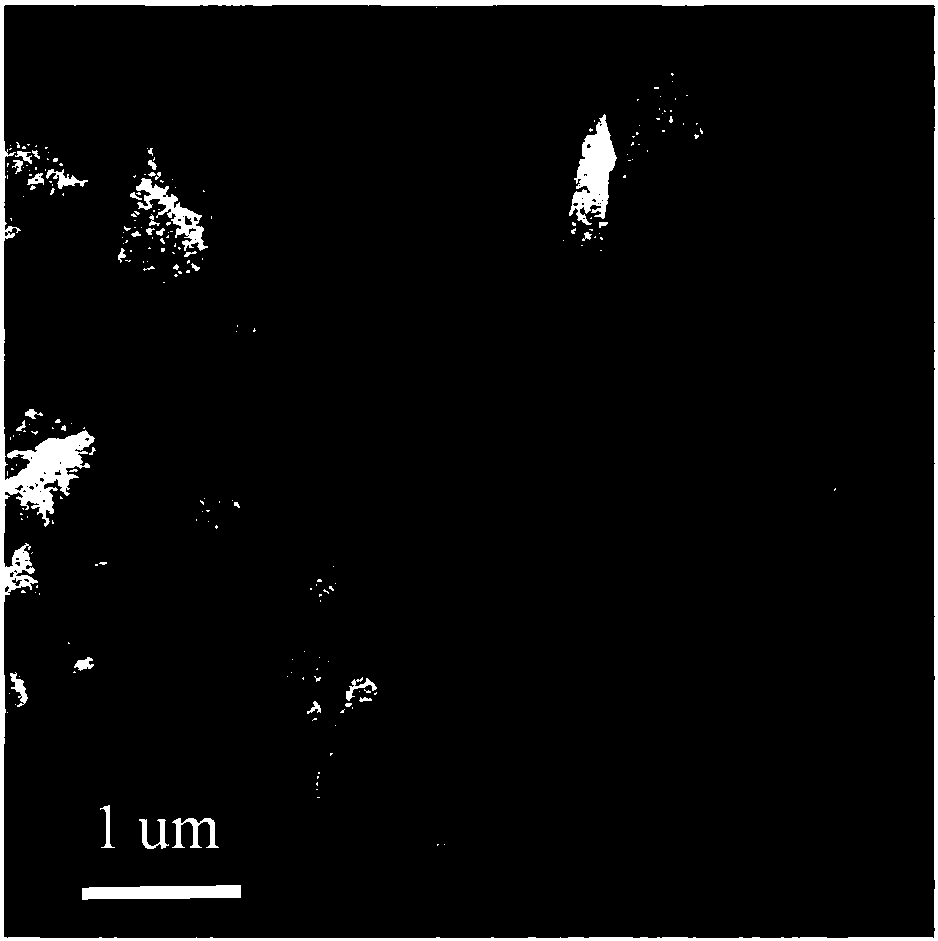

Carbon based bimetallic composite material, preparation and application thereof

ActiveCN107803207AExcellent OER catalytic performanceImprove performancePhysical/chemical process catalystsElectrodesSulfideOxygen evolution

The invention discloses a carbon based bimetallic composite material. The composite material includes a carbon based shell, the inner surface of the carbon based shell is compounded with a sulfide ofa transition metal A, and the outer surface is compounded with an oxide of a transition metal B. The transition metal A and the transition metal B are selected from different metals. The invention also discloses a preparation method of the carbon based bimetallic composite material, and the method includes: subjecting a mixed solution salt containing a salt of the transition metal A, a salt of thetransition metal B, an organic ligand and alcohol to hydrothermal reaction at 60-180DEG C so as to obtain bimetallic MOF; and mixing the obtained bimetallic MOF with sublimed sulfur, then conductingroasting in a protective atmosphere at 300-800DEG C, thus obtaining the carbon based bimetallic composite material. In addition, the invention also includes application of the composite material as anOER electrocatalyst. The invention provides an electrocatalyst with a brand-new structure. The material has excellent OER catalytic performance. Under an electric current density of 10mA / cm<2>, the oxygen evolution potential is close to 0.55V, and under an overpotential of 320mV, the TOF can reach 34.7s<-1>.

Owner:CENT SOUTH UNIV

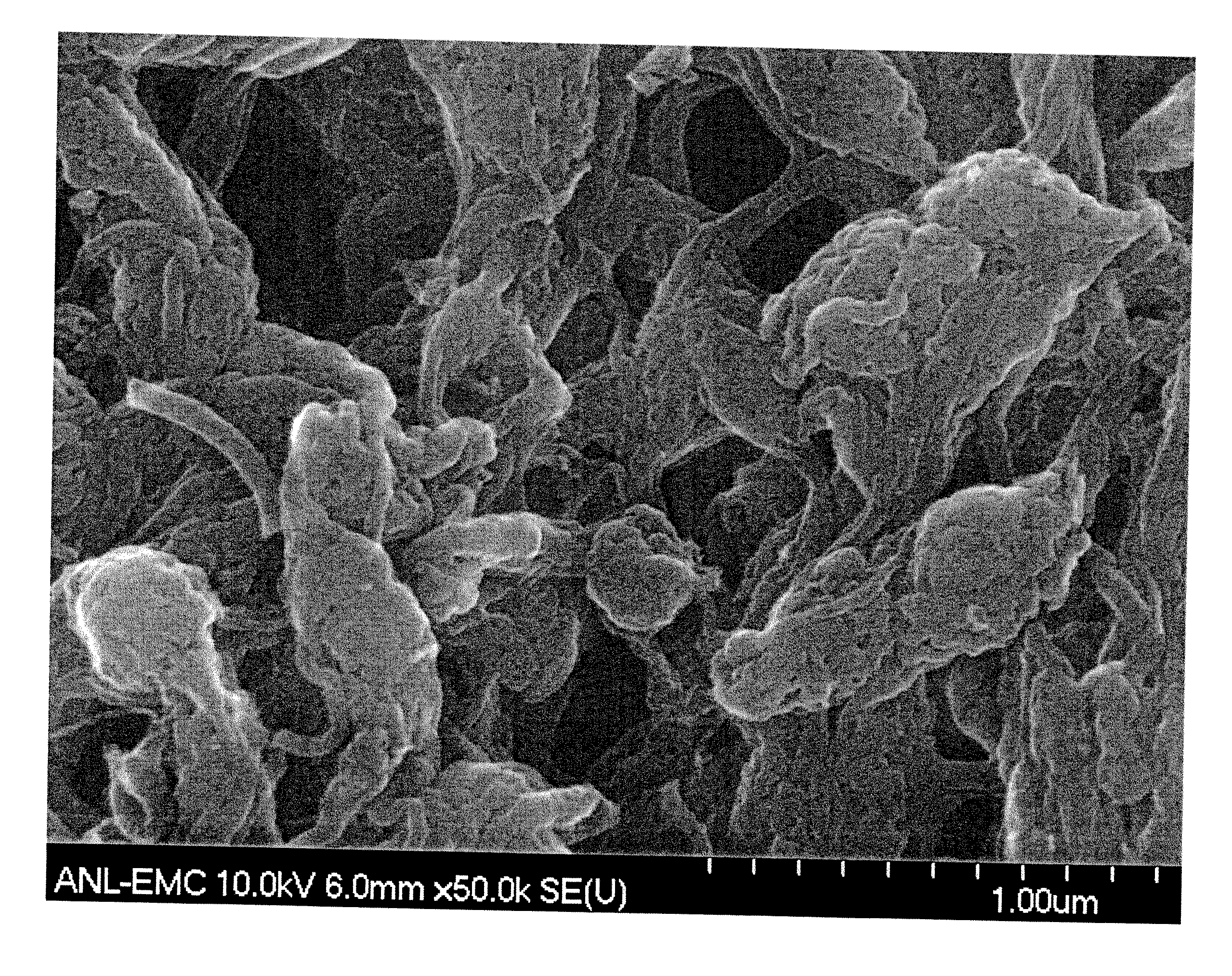

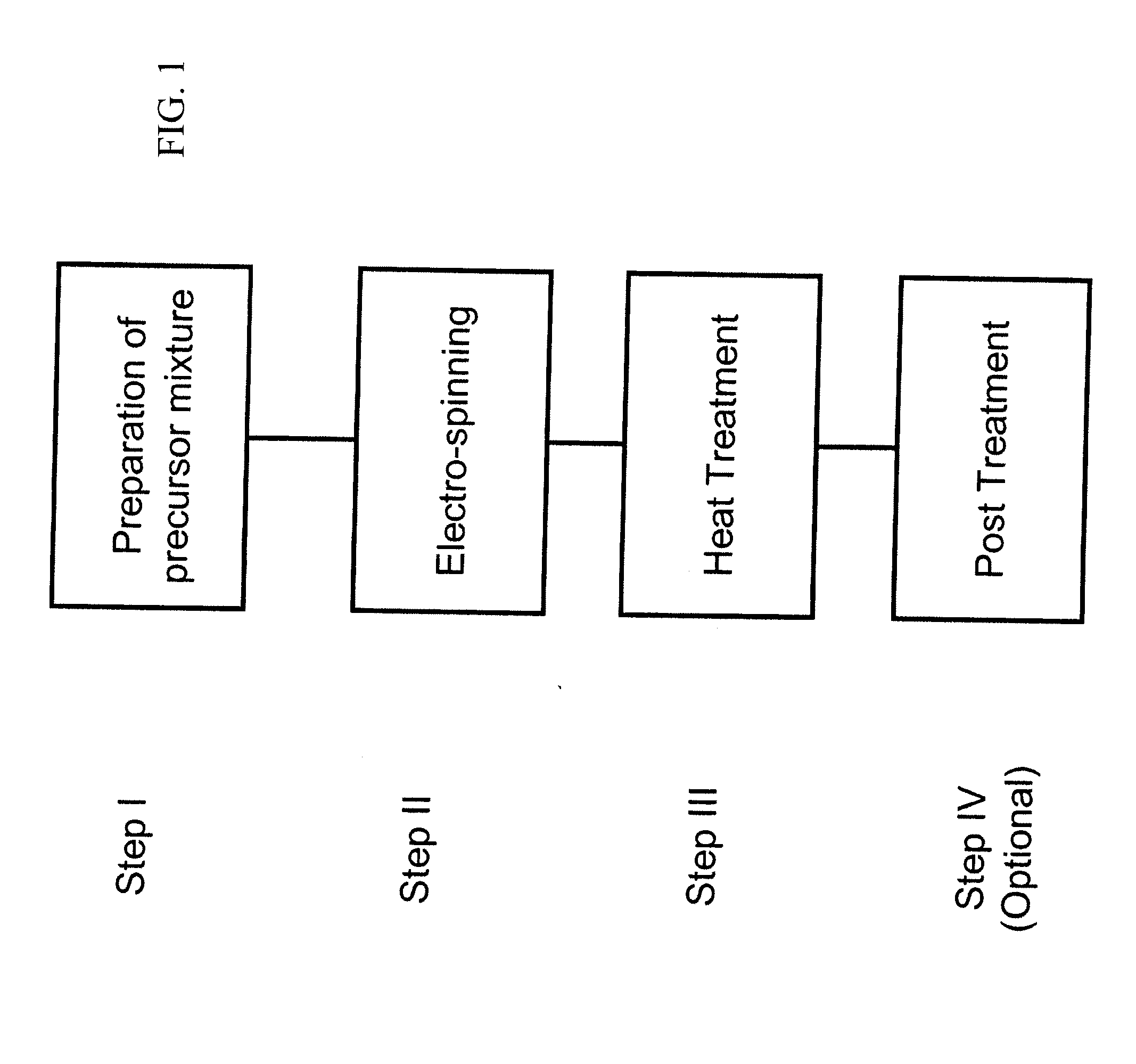

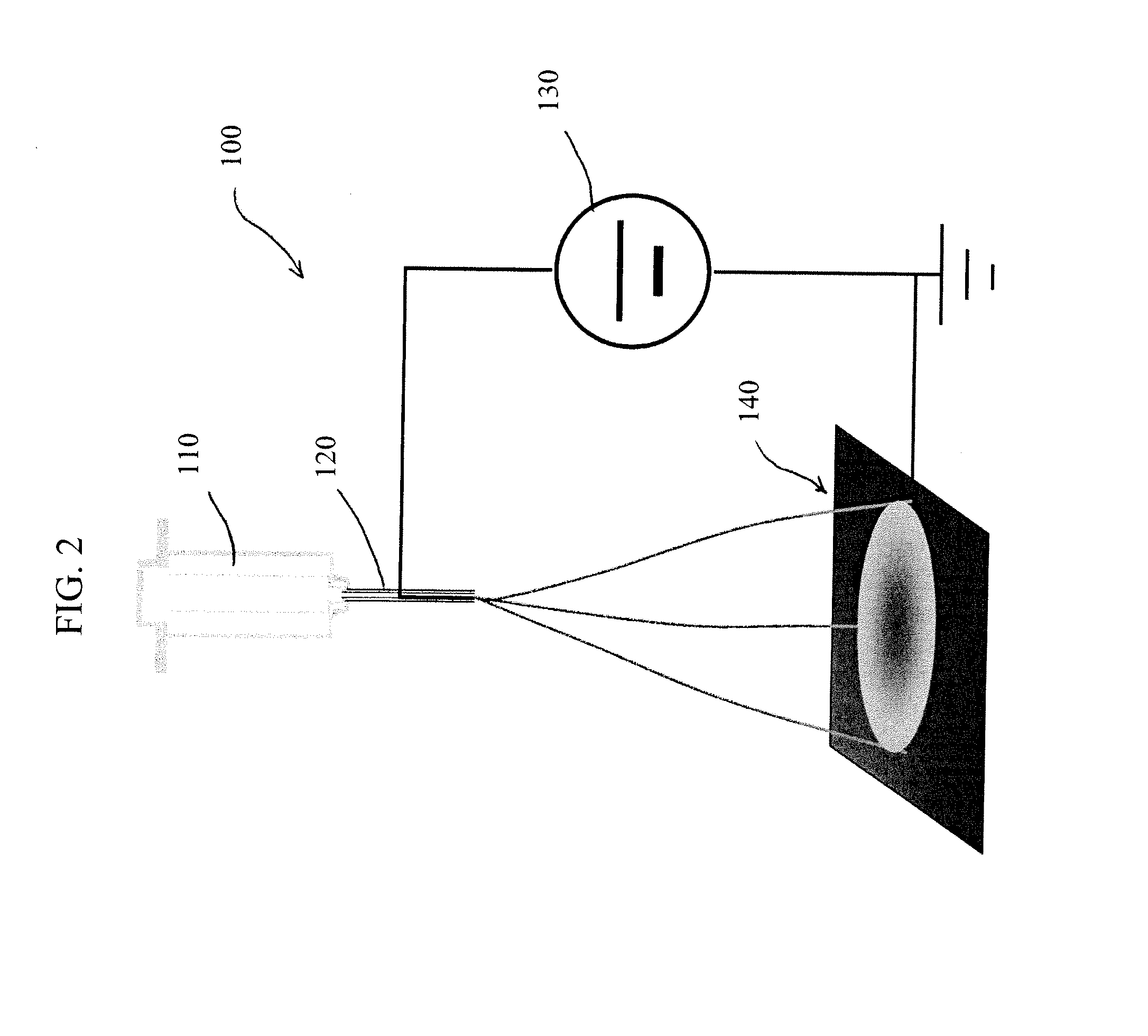

Nanofibrous electrocatalysts

ActiveUS20140093790A1Promoting mass transportImproves thermalMaterial nanotechnologyFuel and secondary cellsNanofiberMetal

A nanofibrous catalyst and method of manufacture. A precursor solution of a transition metal based material is formed into a plurality of interconnected nanofibers by electro-spinning the precursor solution with the nanofibers converted to a catalytically active material by a heat treatment. Selected subsequent treatments can enhance catalytic activity.

Owner:UCHICAGO ARGONNE LLC

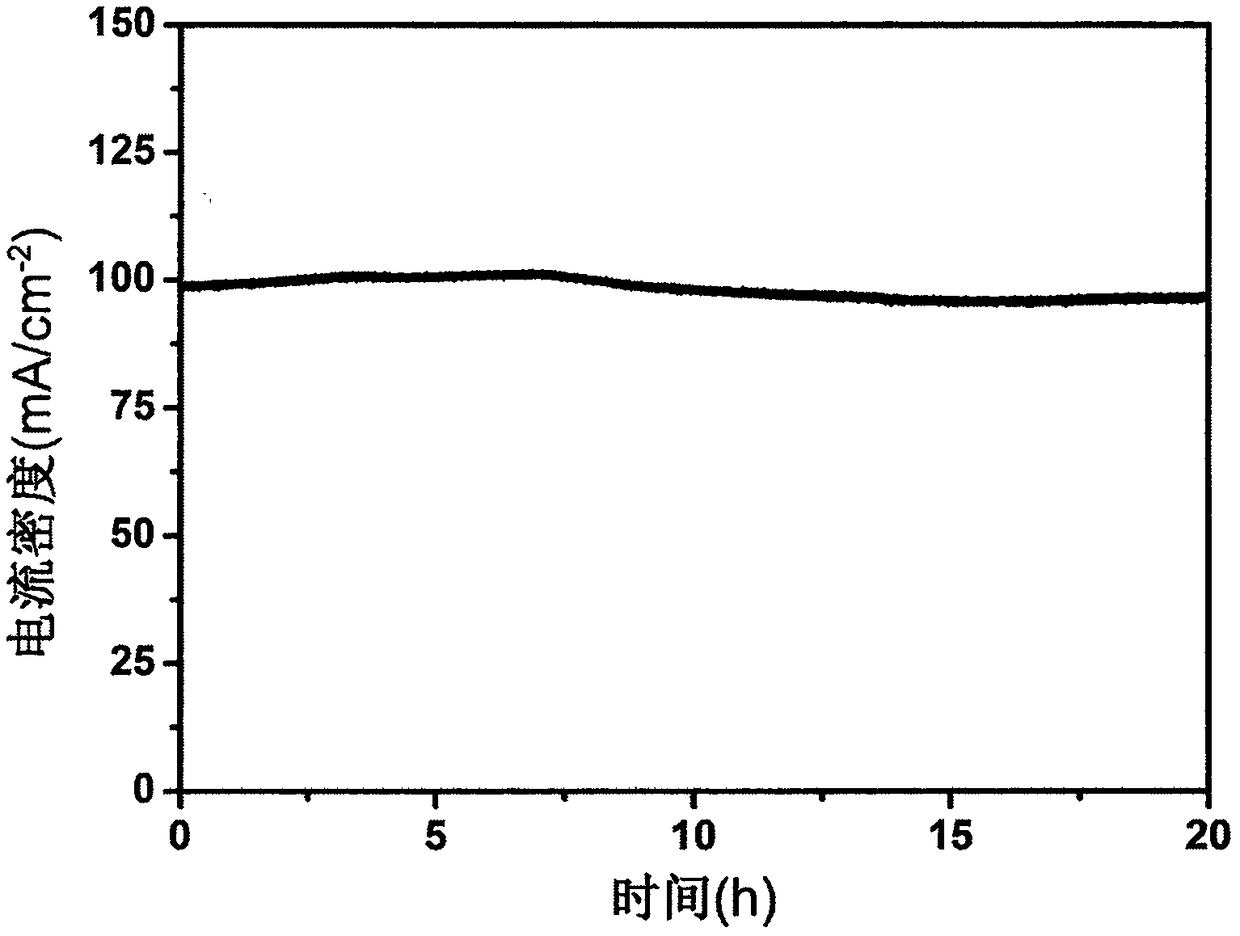

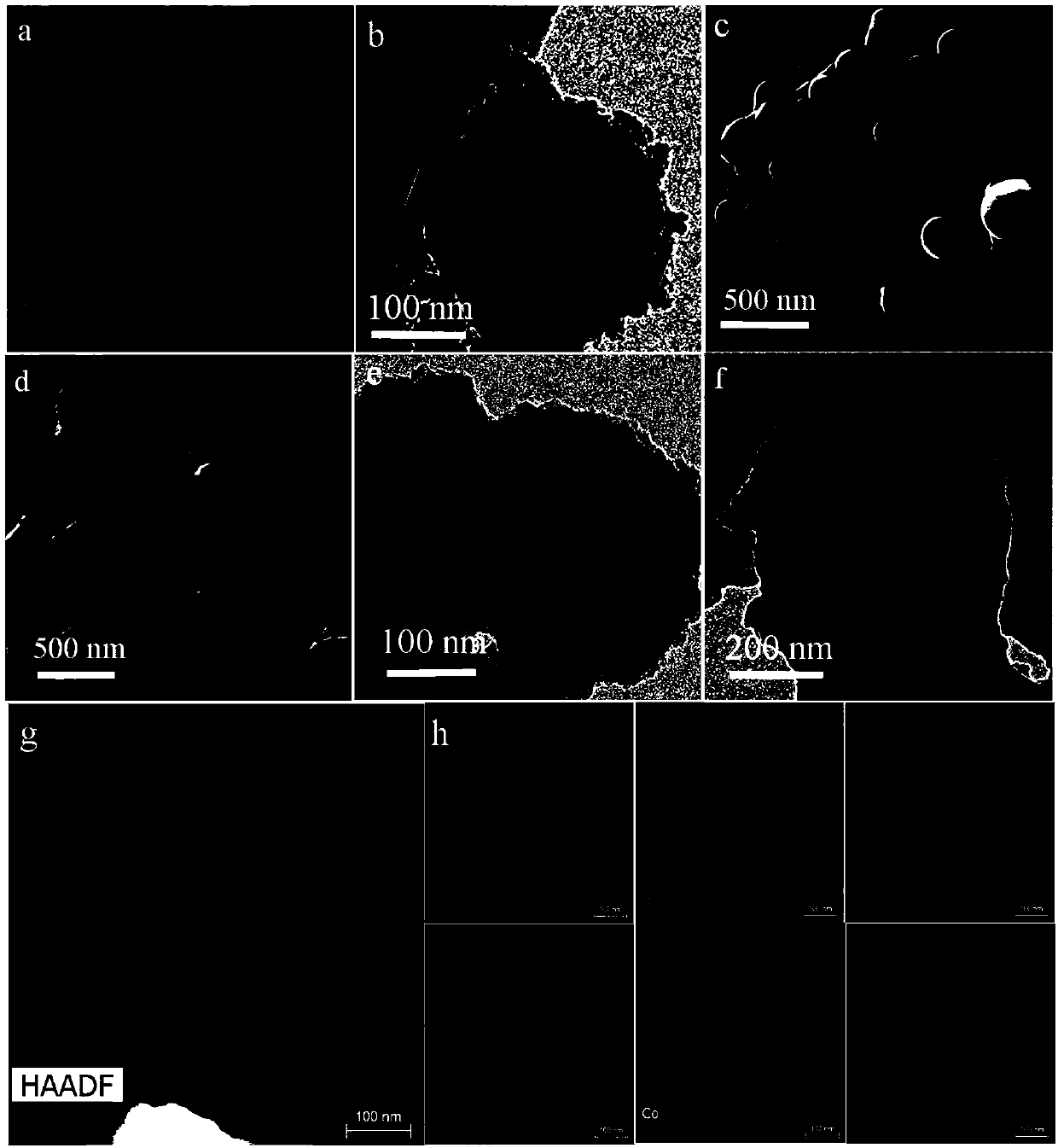

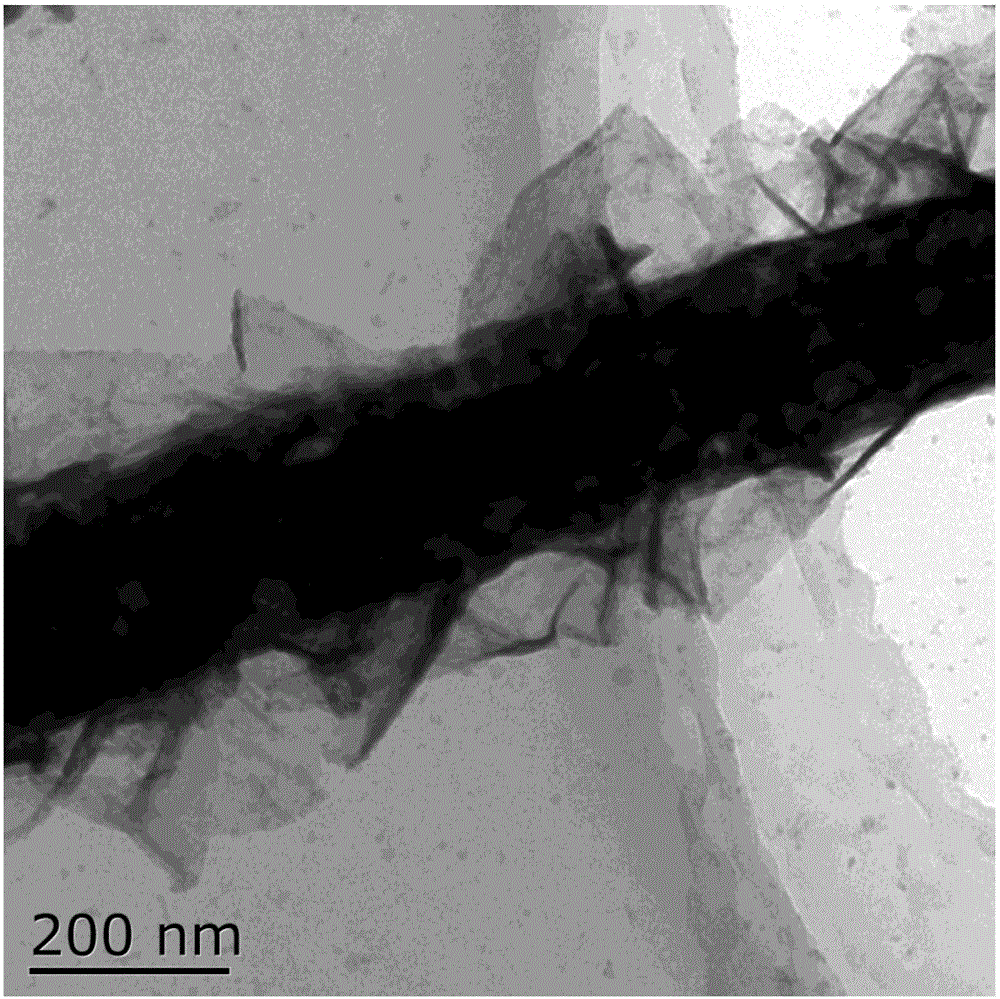

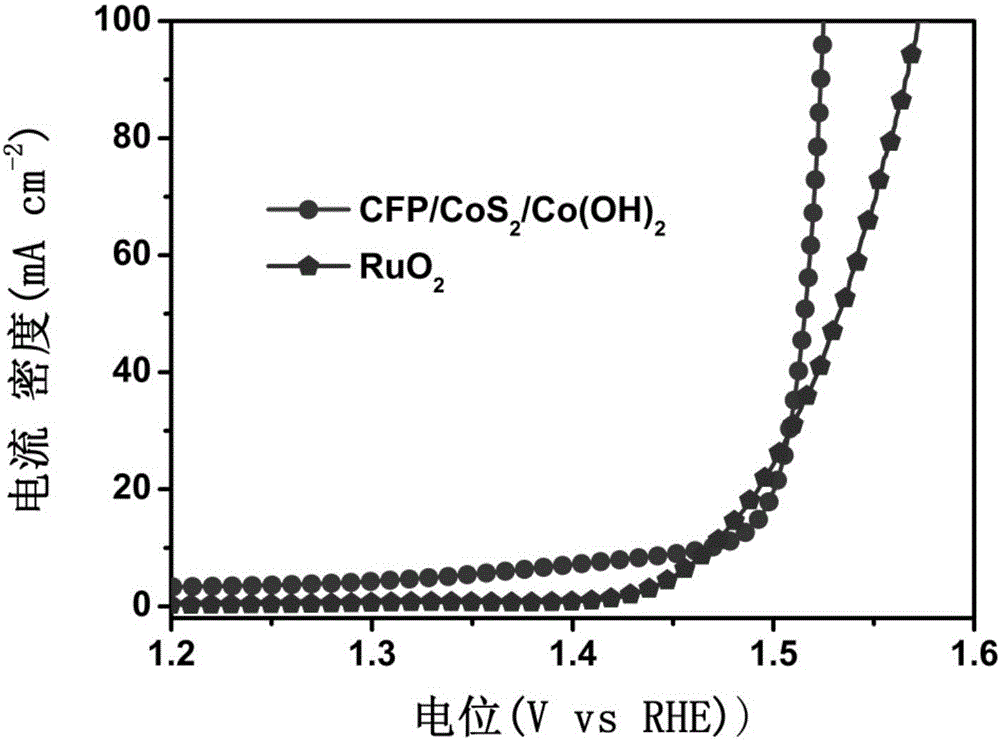

Electrocatalyst with cobalt-based multi-stage nano-composite structure for oxygen production by electrolysis of water and preparation method of electrocatalyst

InactiveCN106011926ALow costEasy to operateCobalt sulfidesElectrolytic inorganic material coatingFiberCarbon fibers

The invention provides an electrocatalyst with a cobalt-based multi-stage nano-composite structure for oxygen production by electrolysis of water and a preparation method of the electrocatalyst. The preparation method comprises the following steps: dissolving cobalt nitrate hexahydrate, urea and ammonium fluoride in deionized water to obtain a precursor solution; transferring the precursor solution into a hydrothermal reactor; adding carbon fiber paper; enabling basic cobalt carbonate nanowires to grow on the carbon fiber paper through solvothermal reaction; after finish of reaction, naturally cooling; then taking out a product; washing and drying to obtain a carbon fiver paper loaded basic cobalt carbonate nanowire composite structure; by taking powdered sulfur as the raw material, preparing a carbon fiber paper loaded cobalt sulfide nanowire composite structure through low-temperature sulfuration reaction under the condition of an inert gas; and finally, electroplating the surface of the carbon fiber paper loaded cobalt sulfide nanowire composite structure with a layer of cobalt hydroxide nanosheets by use of the electrochemical deposition method so as to obtain the electrocatalyst with the cobalt-based multi-stage nano-composite structure for oxygen production by electrolysis of water. As the sulfide and the hydroxide of transition metal cobalt are adopted as the catalyst, in comparison with noble metals, the cost of the catalyst is lowered.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com