Preparation method of ferro-nickel bi-metal hydroxide of sheet structure on foamed nickel through in-situ growth

An in-situ growth, hydroxide technology, applied in the field of electrocatalysis, can solve the problems of low reserves, high price of precious metal catalysts, hindering the commercialization process of electrolyzed water, etc., and achieve the effect of good stability and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Weigh 1.163g of nickel nitrate hexahydrate, 0.1616g of ferric nitrate nonahydrate, 1.2g of urea, and 0.296g of ammonium fluoride and dissolve them in 80mL of deionized water. Processed under the effect of a magnetic stirrer for 30 minutes to obtain a homogeneous solution;

[0021] 2) Cut out 1cm*5cm foam nickel, wash in acetone, ethanol and distilled water for 30 minutes;

[0022] 3) Transfer the solution configured in step 1 to a 100ml high-pressure reactor, then insert the washed nickel foam vertically into the solution, and put the reactor into a 120-degree oven to react for 12 hours;

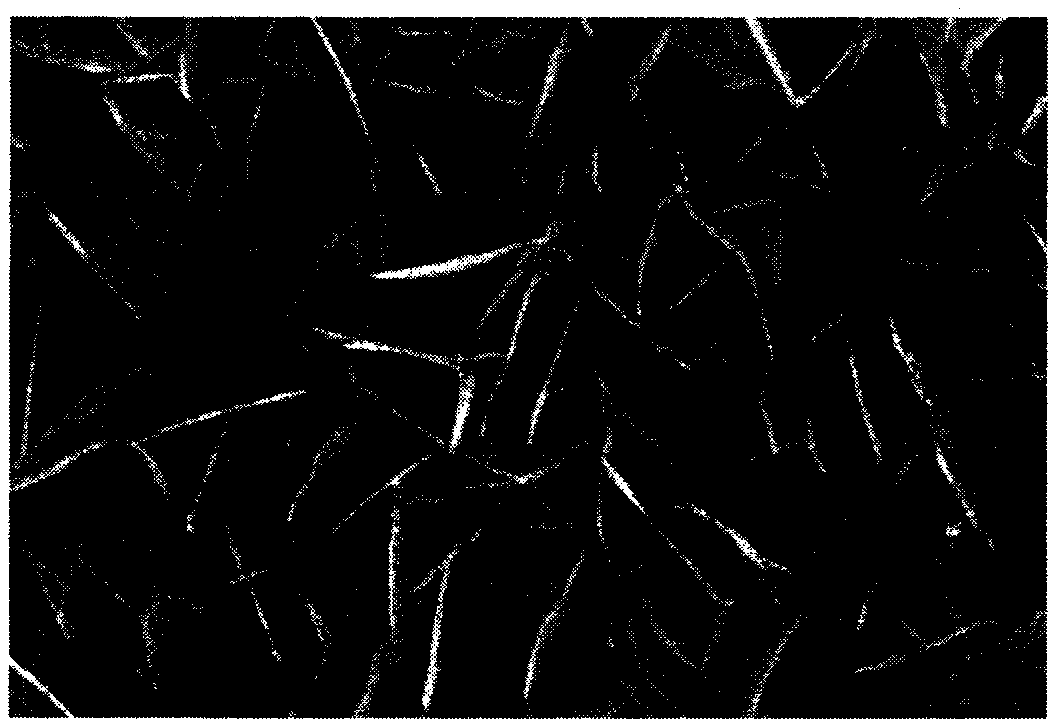

[0023] 4) After the reaction kettle is cooled to room temperature, take out the foamed nickel. At this time, the foamed nickel changes from silver to yellow-green, ultrasonically wash with ethanol and distilled water, and dry to obtain the in-situ growth on the foamed nickel with a flaky structure. Double metal hydroxide;

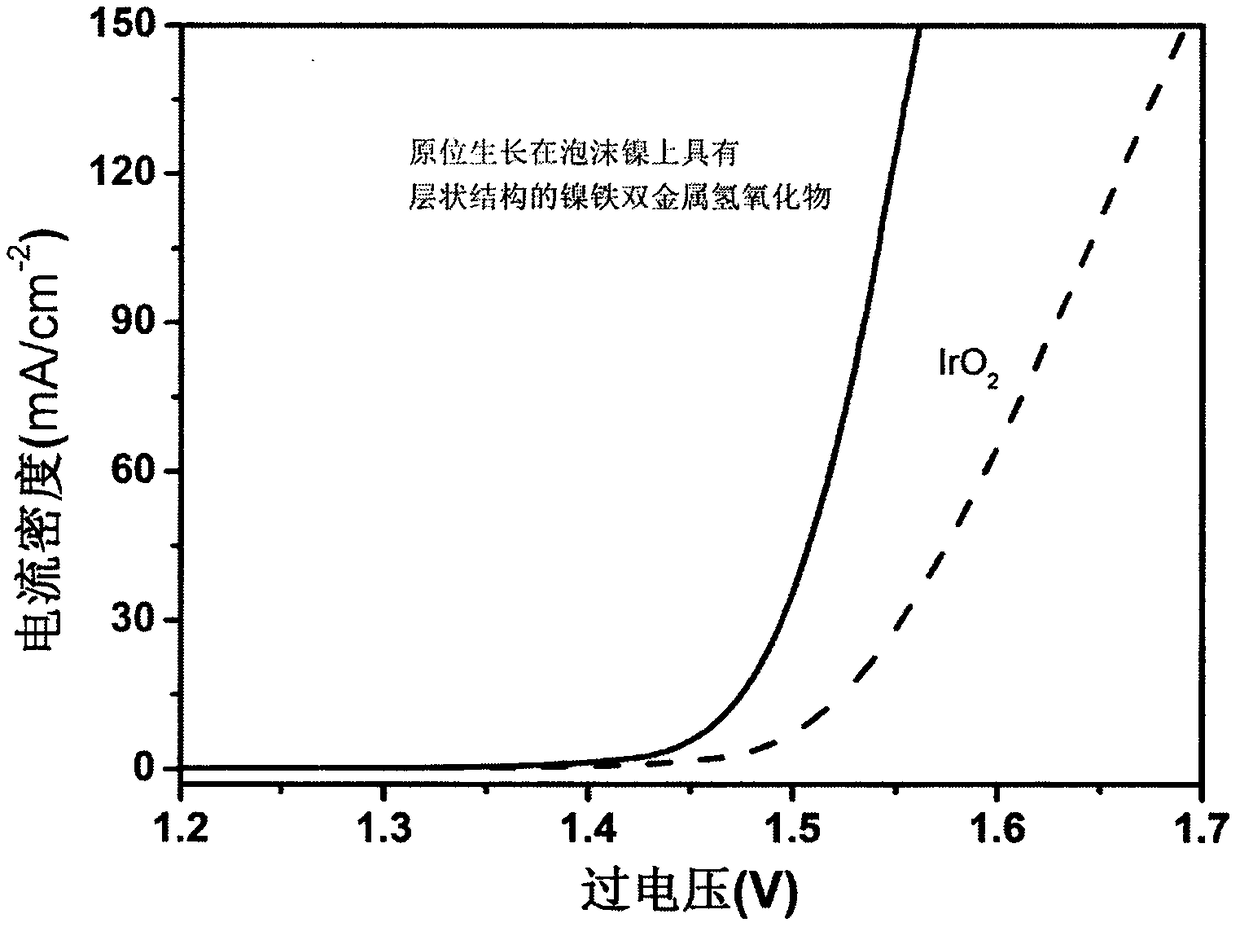

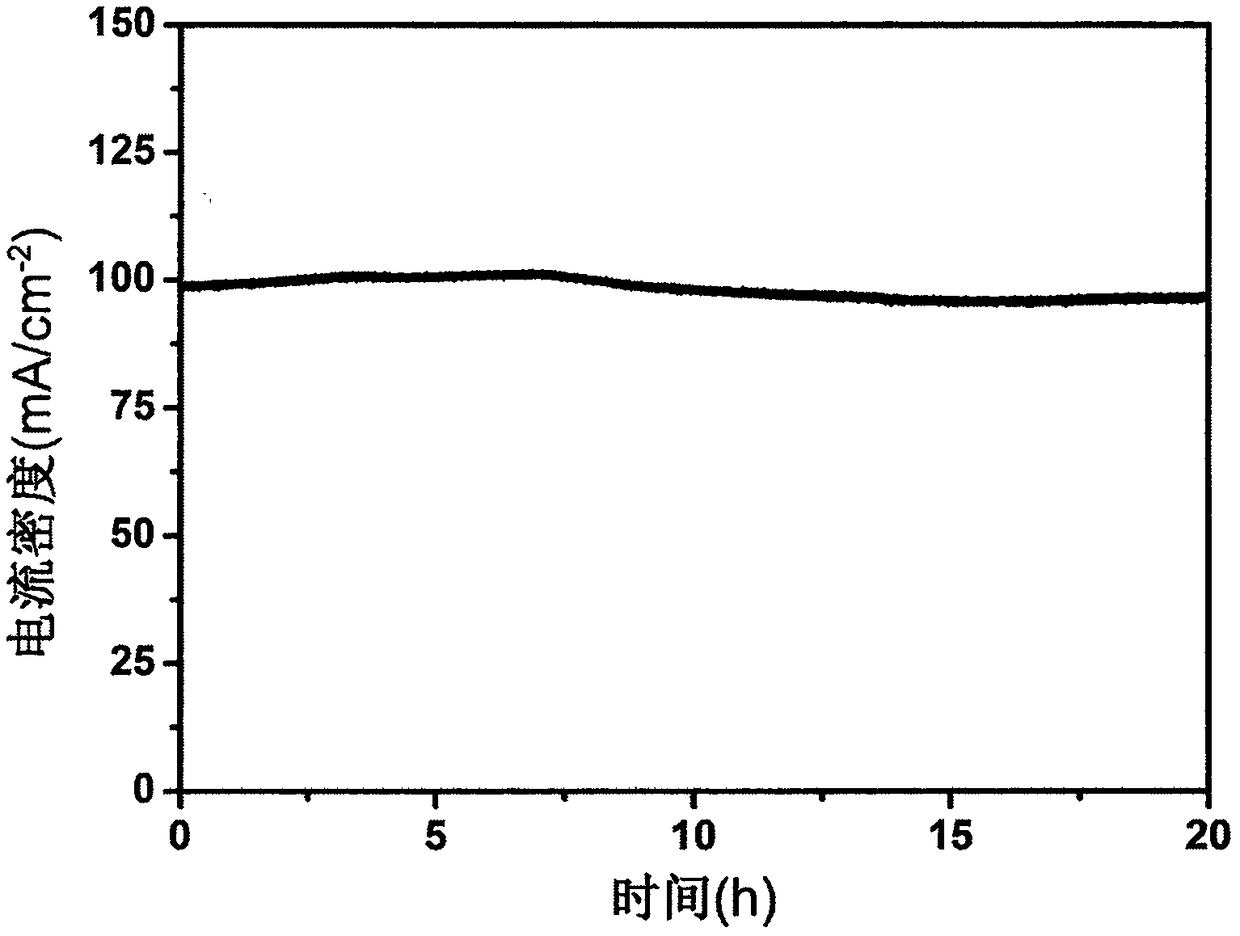

[0024] 5) The OER catalytic activity of the above produc...

Embodiment 2

[0026] 1) Weigh 1.018g of nickel nitrate hexahydrate, 0.3232g of ferric nitrate nonahydrate, 1.2g of urea, and 0.296g of ammonium fluoride and dissolve them in 80mL of deionized water. Processed under the effect of a magnetic stirrer for 30 minutes to obtain a homogeneous solution;

[0027] 2) Cut out 1cm*5cm foam nickel, wash in acetone, ethanol and distilled water for 30 minutes;

[0028] 3) Transfer the solution configured in step 1 to a 100ml high-pressure reactor, then insert the washed nickel foam vertically into the solution, and put the reactor into a 120-degree oven to react for 12 hours;

[0029] 4) After the reaction kettle is cooled to room temperature, take out the foamed nickel. At this time, the foamed nickel changes from silver to yellow-green, ultrasonically wash with ethanol and distilled water, and dry to obtain the nickel-iron with a flaky structure grown on the foamed nickel in situ. Double metal hydroxide;

[0030] 5) The OER catalytic activity of the a...

Embodiment 3

[0032] 1) Weigh 1.163g of nickel nitrate hexahydrate, 0.4848g of ferric nitrate nonahydrate, 1.2g of urea, and 0.296g of ammonium fluoride and dissolve them in 80mL of deionized water. Processed under the effect of a magnetic stirrer for 30 minutes to obtain a homogeneous solution;

[0033] 2) Cut out 1cm*5cm foam nickel, wash in acetone, ethanol and distilled water for 30 minutes;

[0034] 3) Transfer the solution configured in step 1 to a 100ml high-pressure reactor, then insert the washed nickel foam vertically into the solution, and put the reactor into a 120-degree oven to react for 12 hours;

[0035] 4) After the reaction kettle is cooled to room temperature, take out the foamed nickel. At this time, the foamed nickel changes from silver to yellow-green, ultrasonically wash with ethanol and distilled water, and dry to obtain the nickel-iron with a flaky structure grown on the foamed nickel in situ. Double metal hydroxide;

[0036] 5) The OER catalytic activity of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com