Patents

Literature

927 results about "Nickel nitrate hexahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel nitrate is the inorganic compound Ni(NO3)2 or any hydrate thereof. The anhydrous form is not commonly encountered, thus "nickel nitrate" usually refers to nickel(II) nitrate hexahydrate.

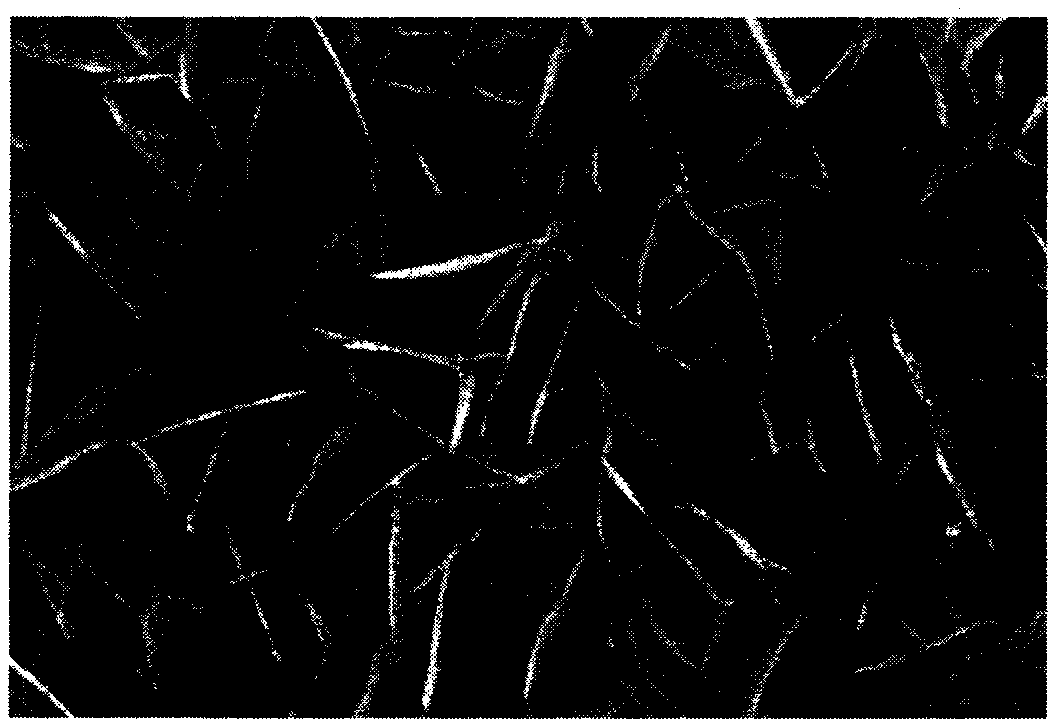

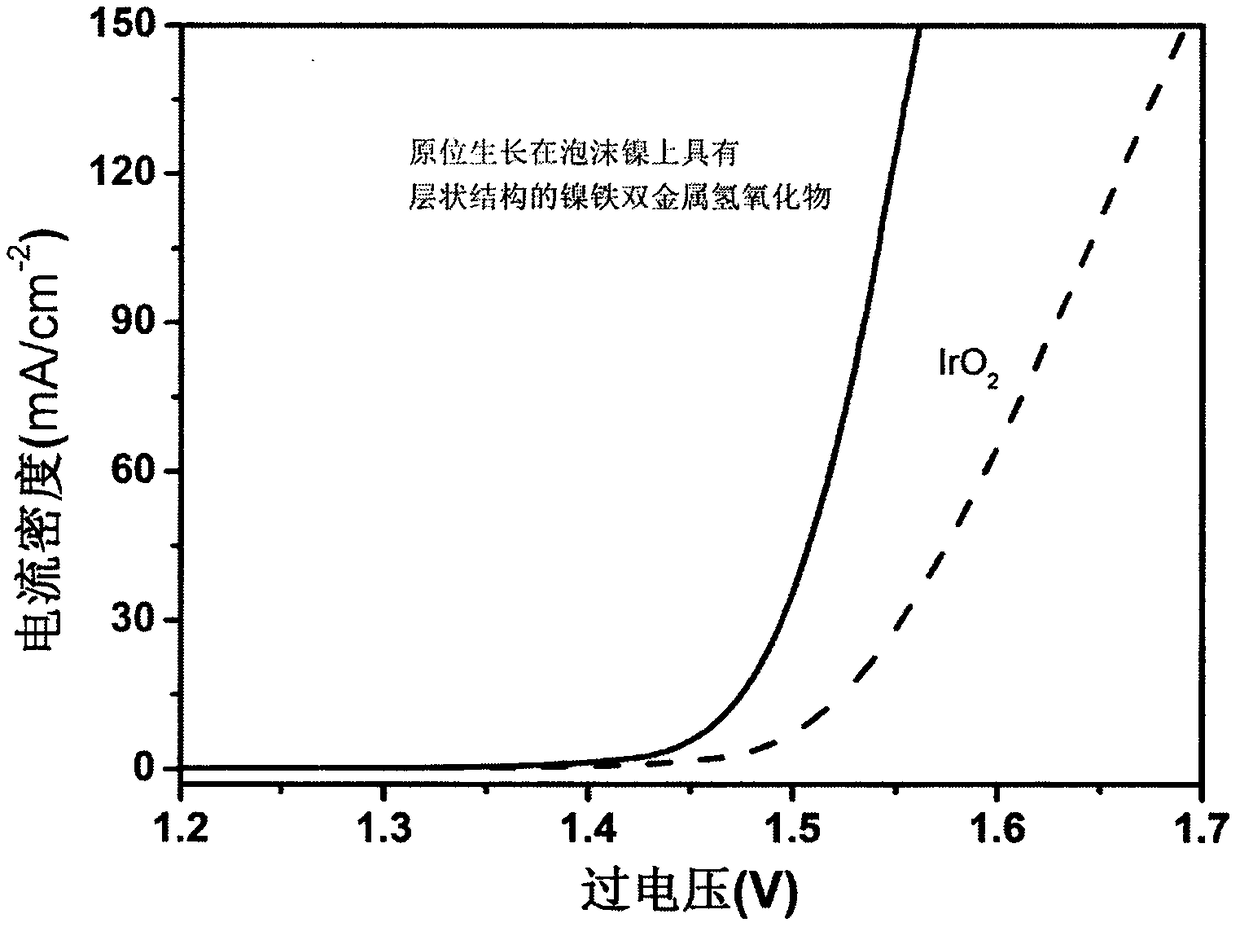

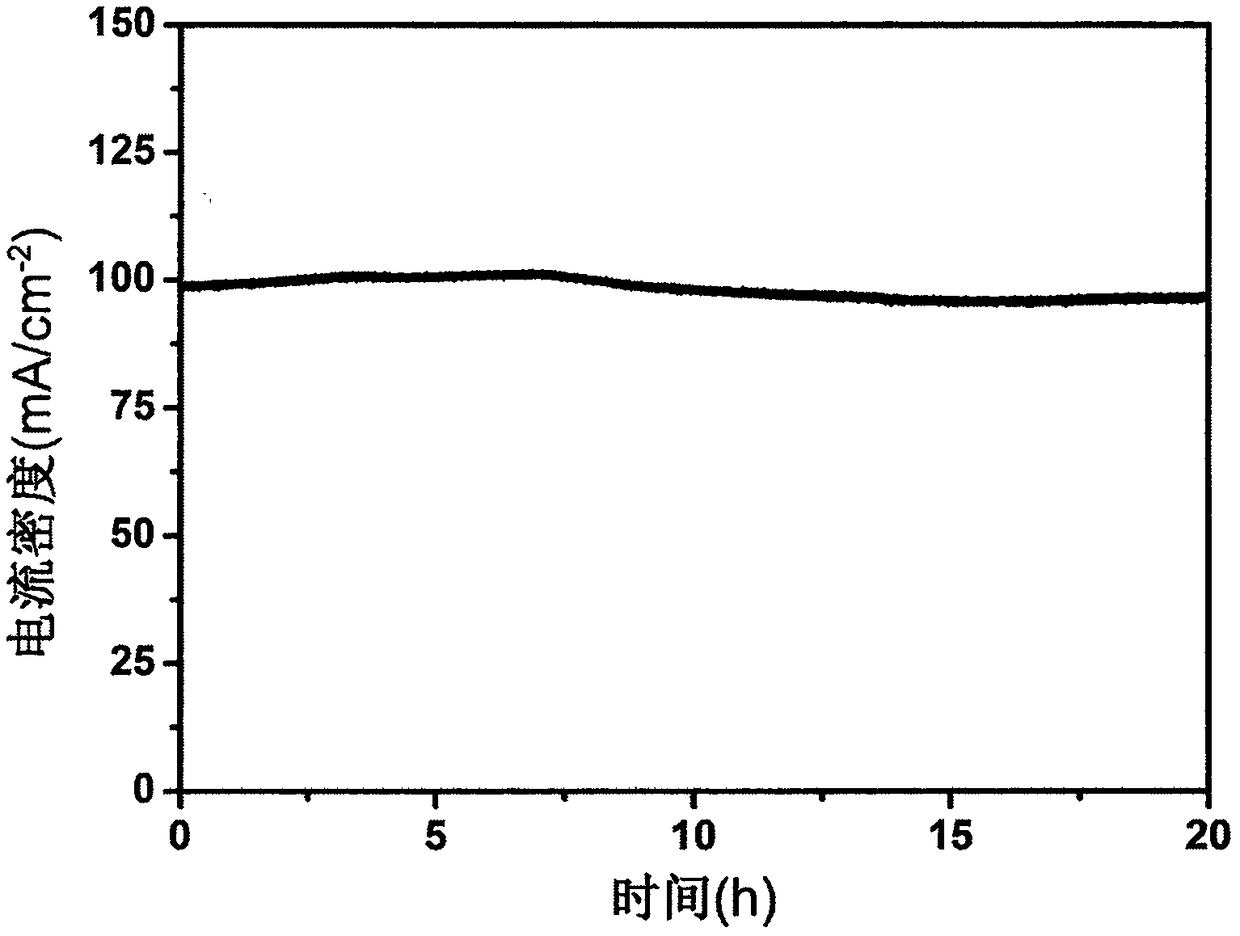

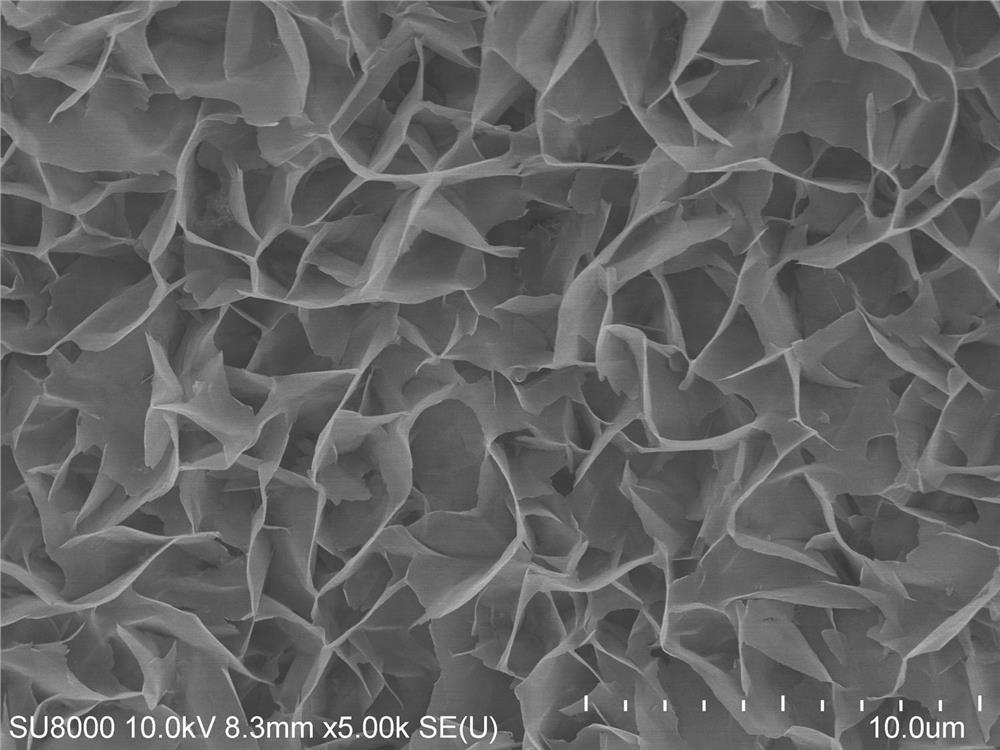

Preparation method of ferro-nickel bi-metal hydroxide of sheet structure on foamed nickel through in-situ growth

InactiveCN108283926AImprove performanceHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectrolysisOxygen

The invention discloses a preparation method of a ferro-nickel bi-metal hydroxide of a sheet structure on foamed nickel through in-situ growth, and belongs to the field of electrochemistry. Nickel nitrate hexahydrate, iron nitrate nonahydrate, urea, ammonium fluoride and foamed nickel are adopted as main raw materials, and an electrocatalyst through water electrolysis oxygen production is successfully prepared. The sheet structure of the catalyst supplies abundant active sites, due to existence of substrate foamed nickel, the electrical conductivity is enhanced, and when the hydroxide is adopted as the electro-catalysis oxygen production catalyst, the excellent catalysis activity is shown. The activity of a traditional non-noble metal material under an oxygen evolution reaction (OER) in analkaline electrolyte is not ideal. Accordingly, the OER catalysis performance of the non-noble metal material under the alkaline condition is improved, and the method is of great significance in solving the fossil fuel energy crisis. Nickel and iron earth reserve volumes are quite abundant, the OER catalytic performance of the ferro-nickel bi-metal hydroxide of the sheet structure under the alkaline condition is excellent, and the hydroxide is a catalytic material with the wide prospect.

Owner:QINGDAO UNIV

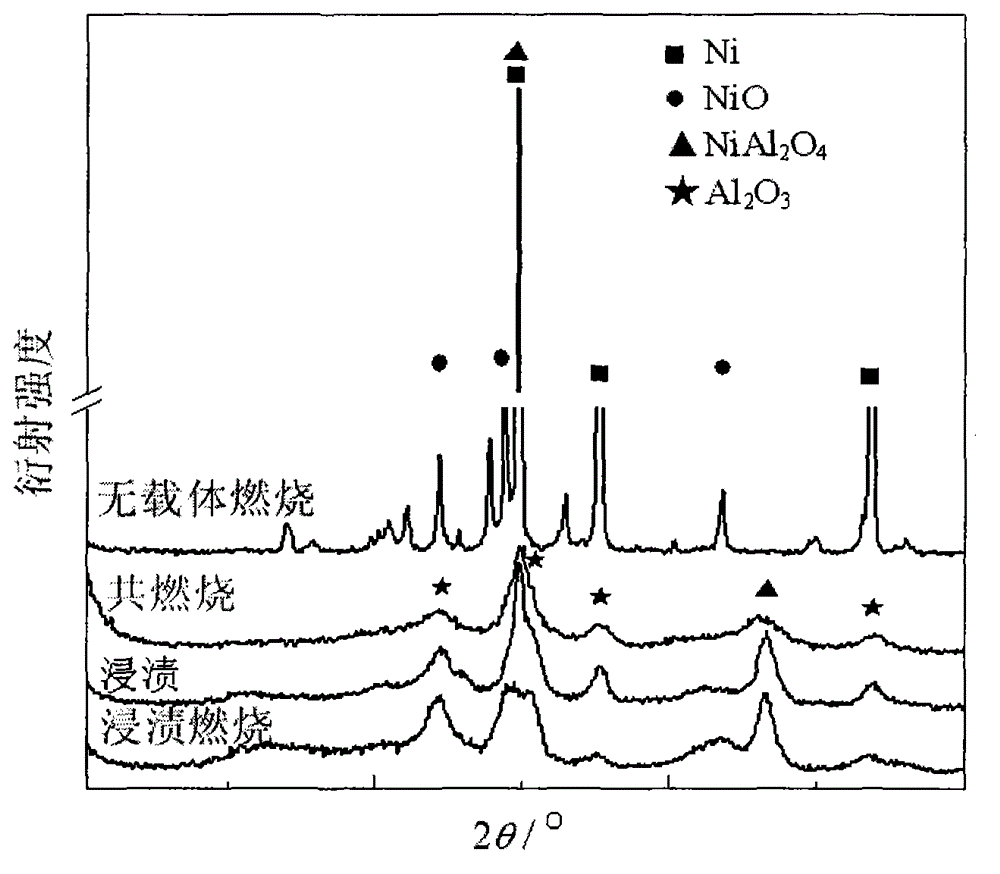

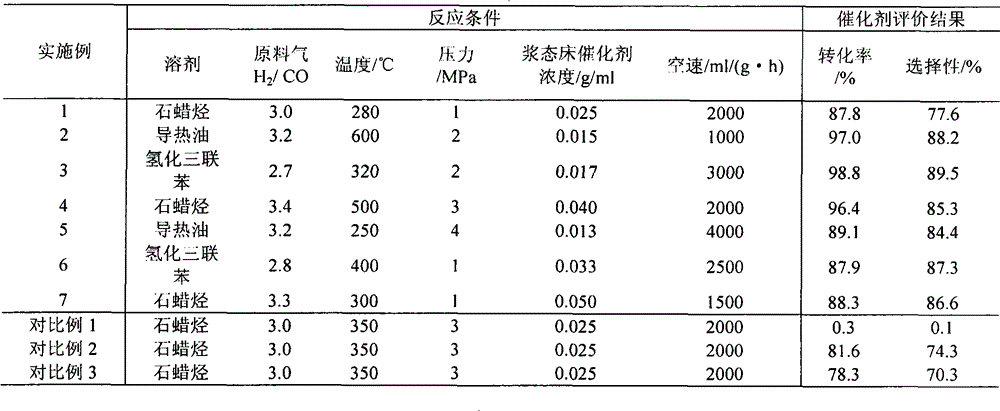

Loaded type nickel-based catalyst used for slurry bed methanation, and preparation method and application thereof

InactiveCN102872874AGood dispersionIncrease the number of active centersGaseous fuelsCatalyst activation/preparationWater bathsNitrate

The invention relates to a loaded type nickel-based catalyst used for slurry bed methanation, and a preparation method and an application thereof. The loaded type nickel-based catalyst is composed of, by weight, 10-40 wt% of NiO, 56-90 wt% of a carrier and 0-4 wt% of an auxiliary agent. The loaded type nickel-based catalyst is prepared by the steps of preparing a soluble salt solution of 0.5-1.3 g / mL nicdel nitrate and the auxiliary agent; adding a catalyst carrier and a soluble organic fuel to the salt solution in sequence; impregnating for 6-24 h while stirring; heating the solution for concentration in a water bath with a temperature of 60-90 DEG C after finishing the impregnation, or heating for igniting the solution at a temperature of 300-700 DEG C directly; collecting the combustion residue powder, grinding the powder and granulating, and reducing for 2-6 h with a reducing gas on a fixed bed at a temperature of 500-700 DEG C. The loaded type nickel-based catalyst has a slurry bed methanation process, and has the advantages of good and stable catalytic performance, and can be used for large-scale industrialization.

Owner:TAIYUAN UNIV OF TECH +1

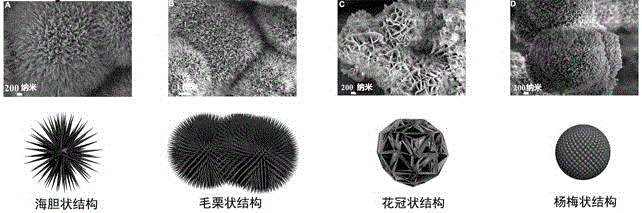

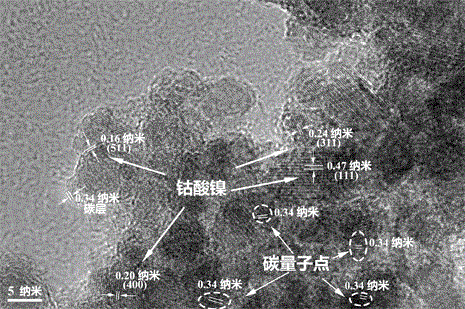

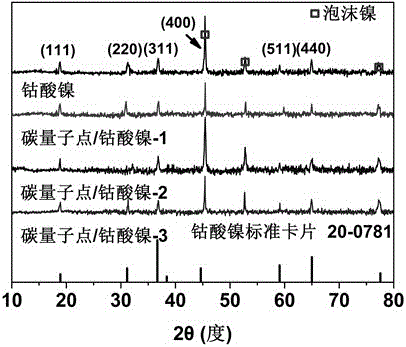

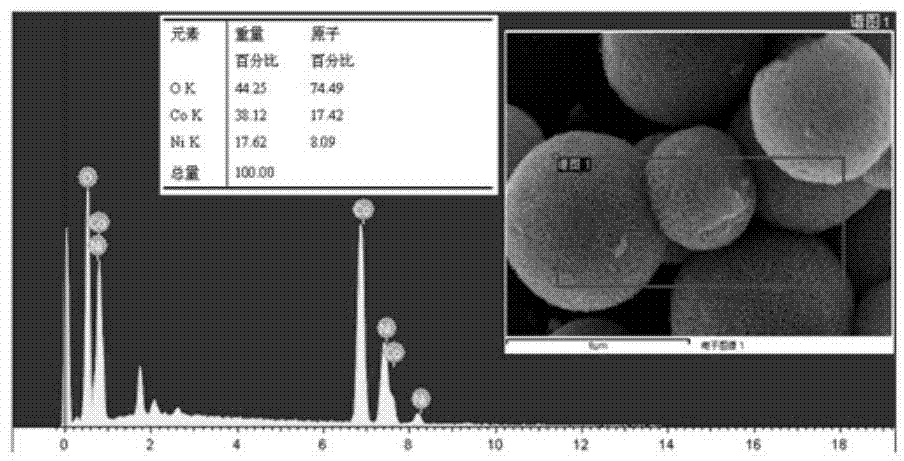

Morphology-controlled carbon quantum dot/nickel cobaltate composite electrode material and preparation method

ActiveCN105914353AEasy to prepareIncrease capacityMaterial nanotechnologyCell electrodesHydration reactionMaterials science

The invention belongs to the technical field of nanometer materials, and particularly relates to a morphology-controlled carbon quantum dot / nickel cobaltate composite electrode material and a preparation method. The preparation method specifically comprises the following steps of (1) dissolving carbon quantum dot powder, nickel nitrate hexahydrate, cobalt nitrate hexahydrate and urea into a mixed solvent of water and ethanol, mixing, putting into a polytetrafluoroethylene-lined reaction kettle, adding foam nickel, sealing, heating to react, cooling, taking out foam nickel, flushing and drying; (2) performing heat treatment on the dried foam nickel, so as to obtain the carbon quantum dot / nickel cobaltate composite electrode material using the foam nickel as a substrate. The preparation method has the advantages that by adjusting the feeding amount of carbon quantum dots, different morphologies of the composite material, such as urchin shape, corolla shape and waxberry shape are formed on the micro structure; the preparation method is simple, the implementing is easy, and the cost is low; the chemical and physical property of obtained material is stable, and the application prospect is good in the fields of electrochemical energy storage and catalyzing.

Owner:FUDAN UNIV

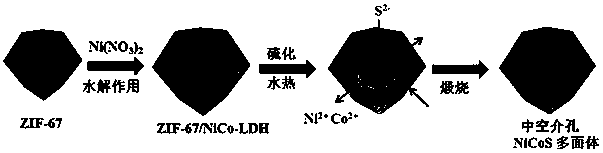

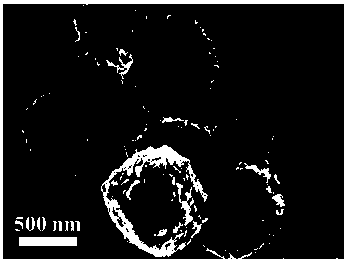

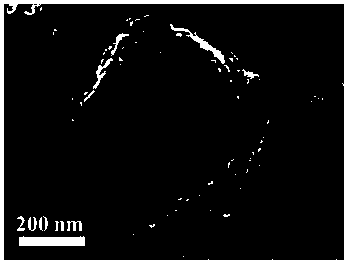

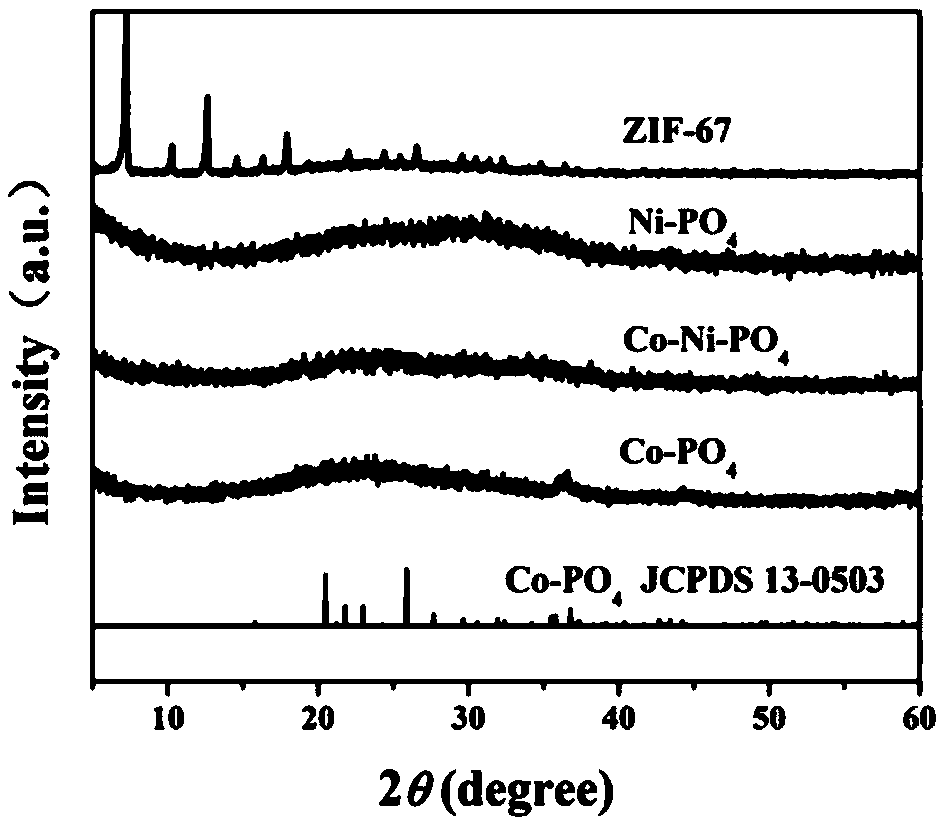

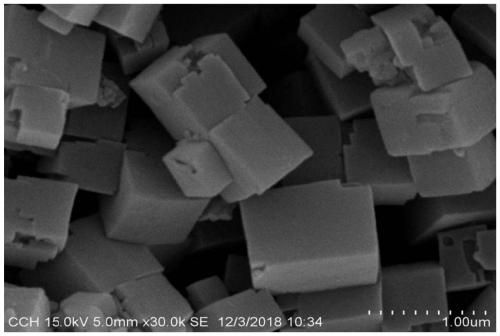

Preparation method and application of hollow mesoporous structure NiCoS polyhedron

InactiveCN107740135ALarge specific surface areaEasy to passElectrode shape/formsEnvironmental resistanceClean energy

The invention provides a preparation method and application of a hollow mesoporous structure NiCoS polyhedron, and belongs to the technical field of clean energy preparation. The preparation method comprises the following steps that 1, divalent cobalt salt and 2-methylimidazole are dissolved in a methanol solution and then subjected to still standing, and ZIF-67 is obtained; 2, the ZIF-67 and nickel nitrate are mixed and stirred and then subjected to centrifugation and vacuum drying, and a middle body ZIF-67 / NiCo-LDH is obtained; and 3, the middle body is dispersed in an ethanol solution, thenthioacetamide is added for stirring, a mixed solution is placed in a reaction kettle for hydrothermal reaction, precipitation obtained after reaction is subjected to centrifugal washing and vacuum drying and then calcined in the protective atmosphere, and the hollow mesoporous structure NiCoS polyhedron is obtained. The preparation method of the hollow mesoporous structure NiCoS polyhedron has the advantages that the method is simple, going green and environmentally friendly, low in cost and easy to operate and control, and the preparation method is suitable for industrialized continuous large-scale production; and a raw material involved in the preparation method is environmentally friendly, low in price and excellent in performance, and large-scale application is expected to achieve.

Owner:HARBIN INST OF TECH

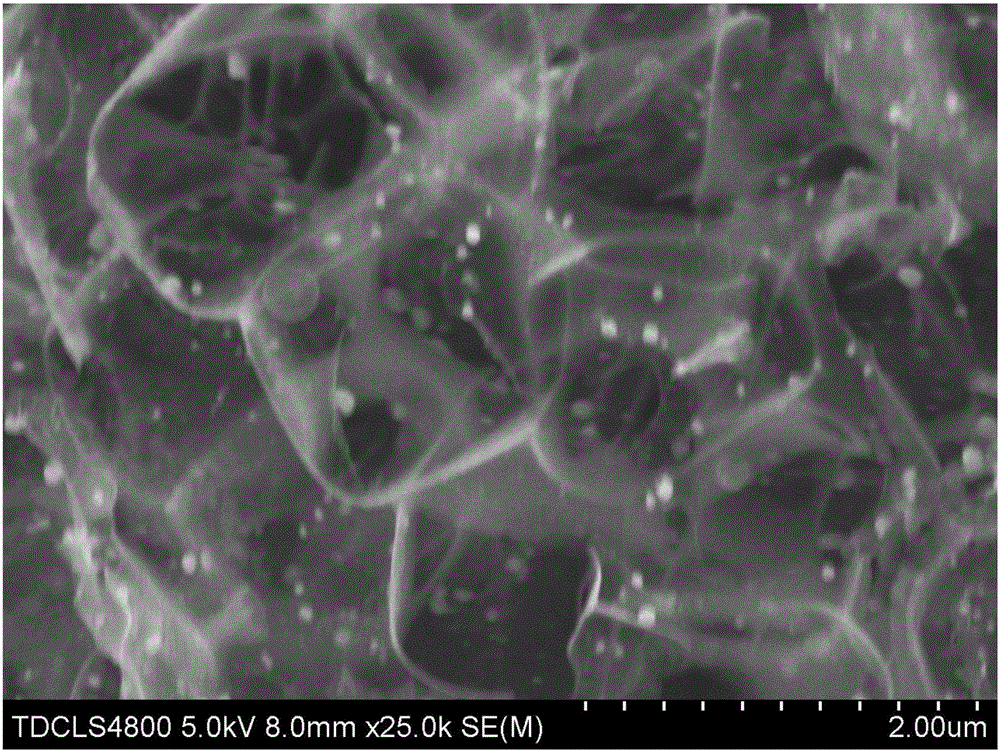

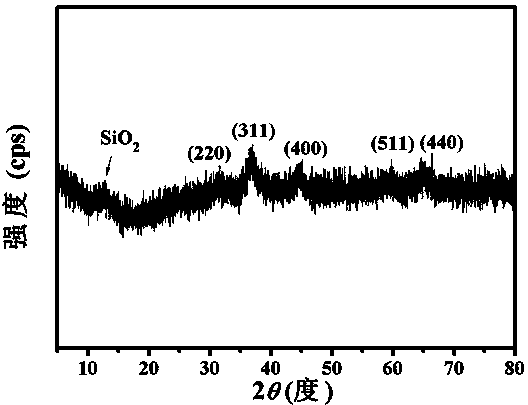

Foamed nickel-loaded iron-cobalt-nickel metal nano-catalyst and preparation method and application thereof

ActiveCN111495417AHigh catalytic activityImprove catalytic stabilityPhysical/chemical process catalystsElectrodesPtru catalystEngineering

The invention discloses a foamed nickel-loaded iron-cobalt-nickel metal nano-catalyst and a preparation method and application thereof. The method comprises the following steps: cutting foamed nickel,washing and drying for later use; dissolving three metal salts of cobalt nitrate, ferrous nitrate and nickel nitrate, ammonium fluoride and urea into deionized water; performing stirring to obtain ahydrothermal solution; then adding the pretreated foamed nickel and the prepared hydrothermal solution into a high-pressure reaction kettle, vertically putting the foamed nickel into the bottom of thehigh-pressure reaction kettle after the foamed nickel is inserted into a polytetrafluoroethylene base, fastening the high-pressure reaction kettle, putting the high-pressure reaction kettle into a blast drying oven, carrying out first-step hydrothermal treatment, performing cooling to room temperature, performing washing and drying to obtain an intermediate product; and putting the prepared precursor into a reaction kettle, carrying out a second-step hydrothermal reaction, performing cooling to room temperature, and performing washing and drying. The preparation method provided by the invention has good economy and environmental protection property, and the prepared product has excellent electro-catalytic oxygen evolution performance, high strength and good stability, and can be applied to the field of water electrolysis oxygen evolution.

Owner:YANCHENG INST OF TECH

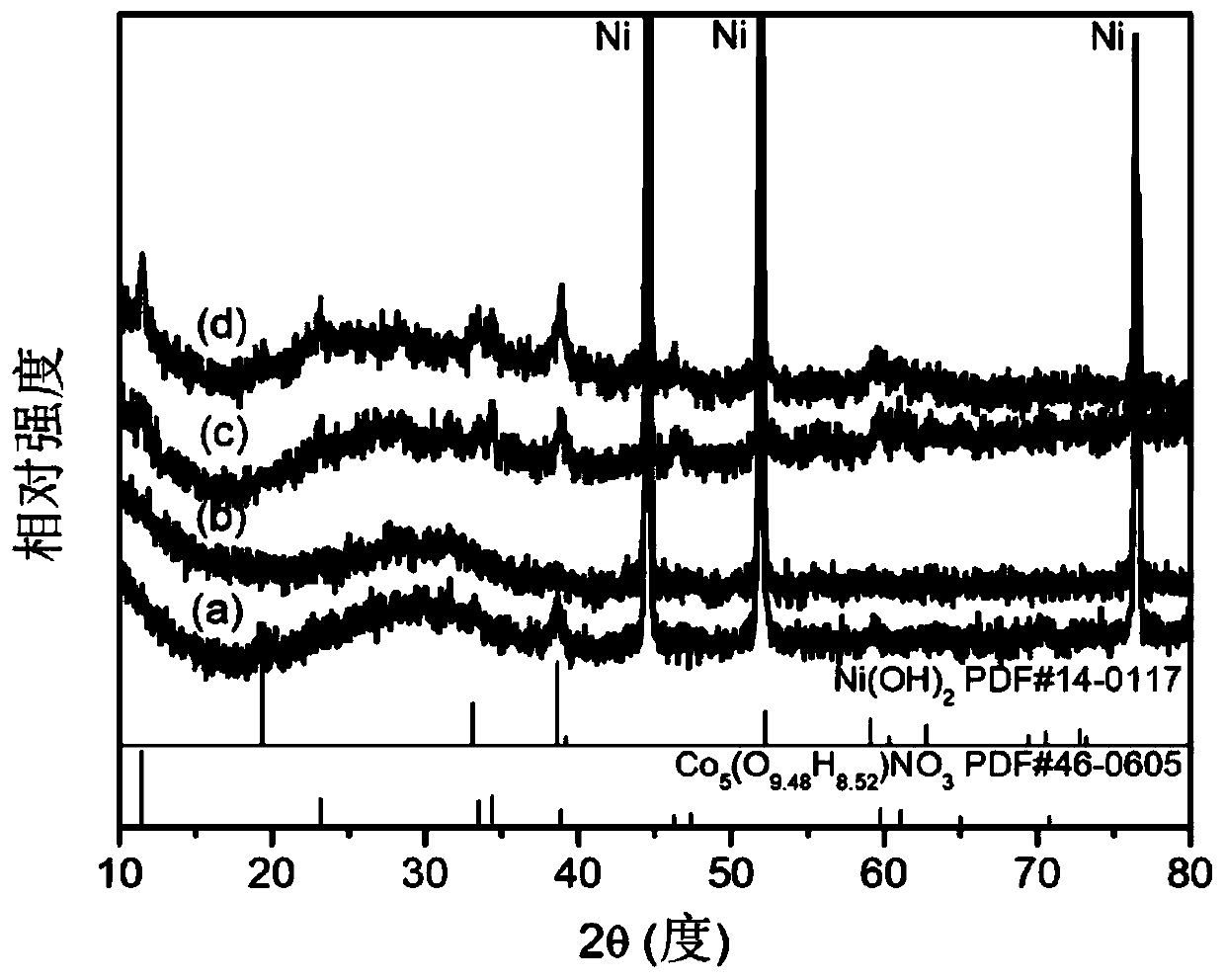

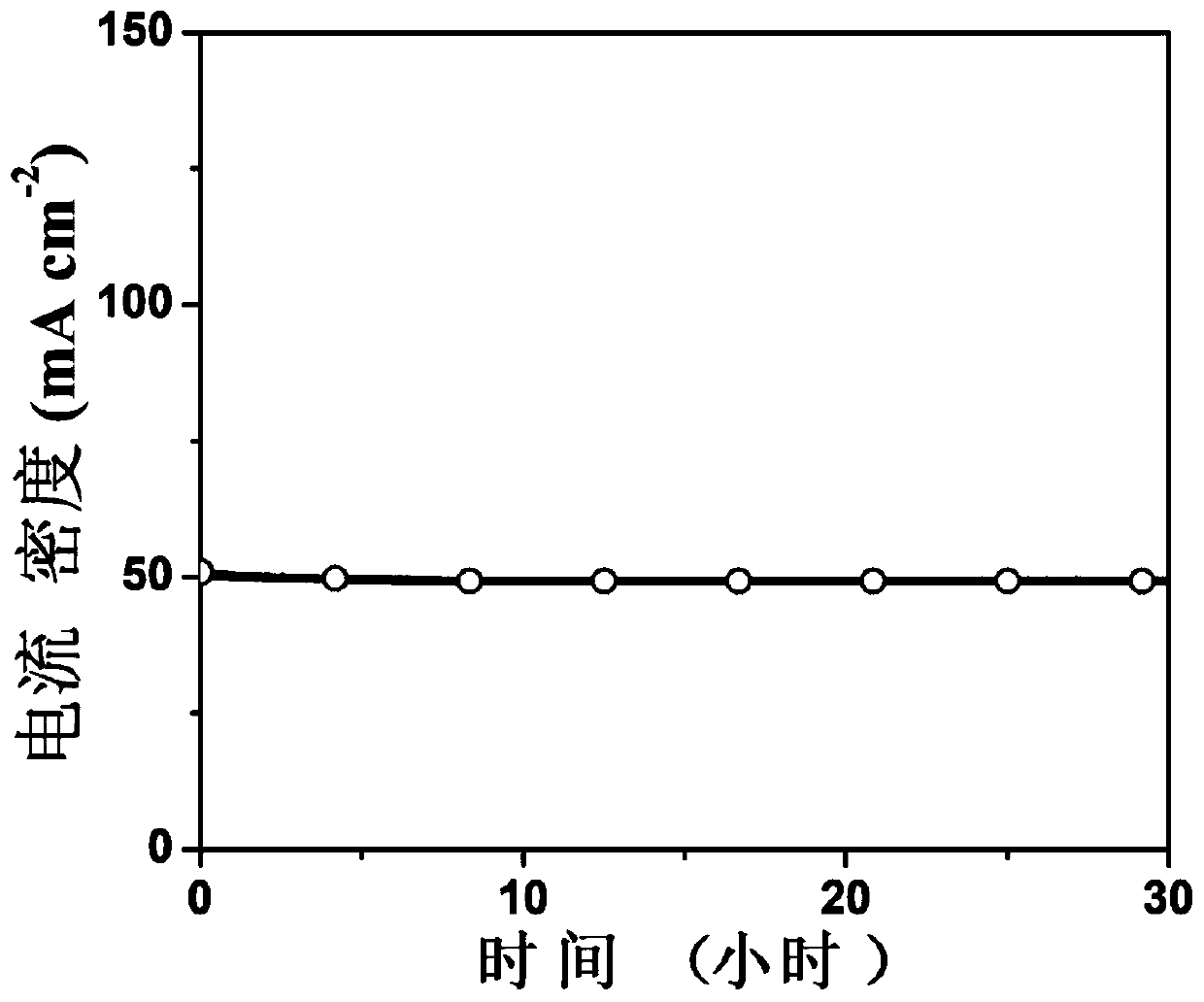

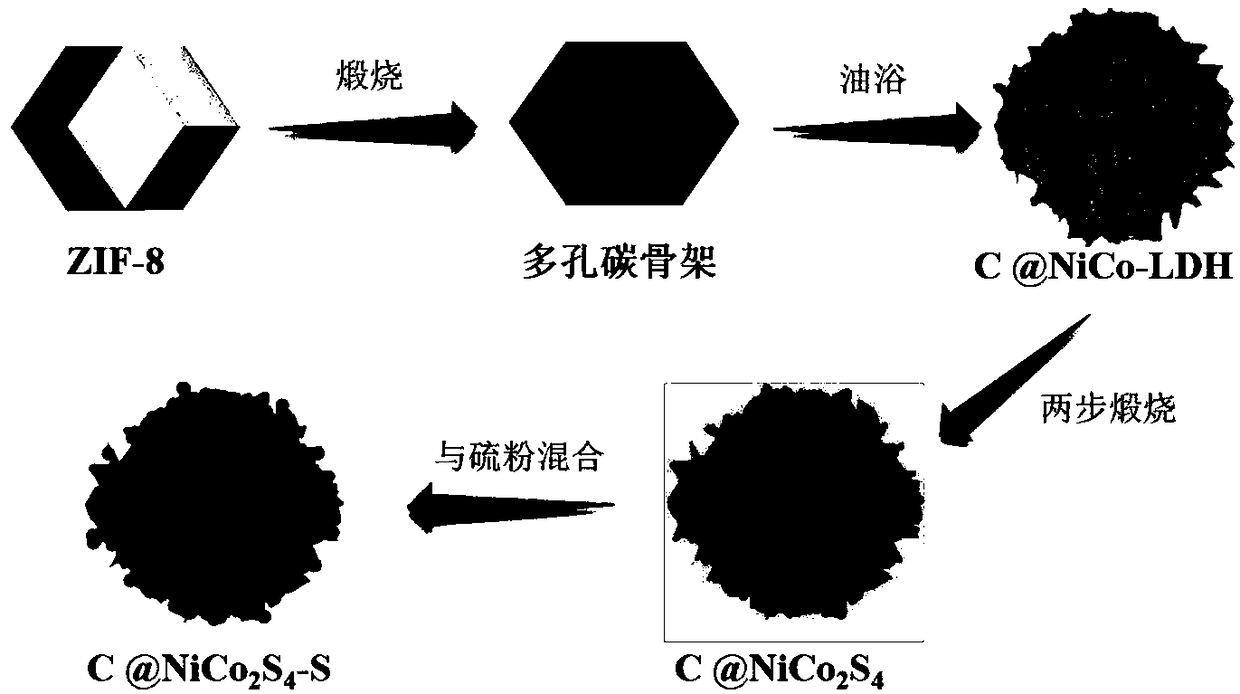

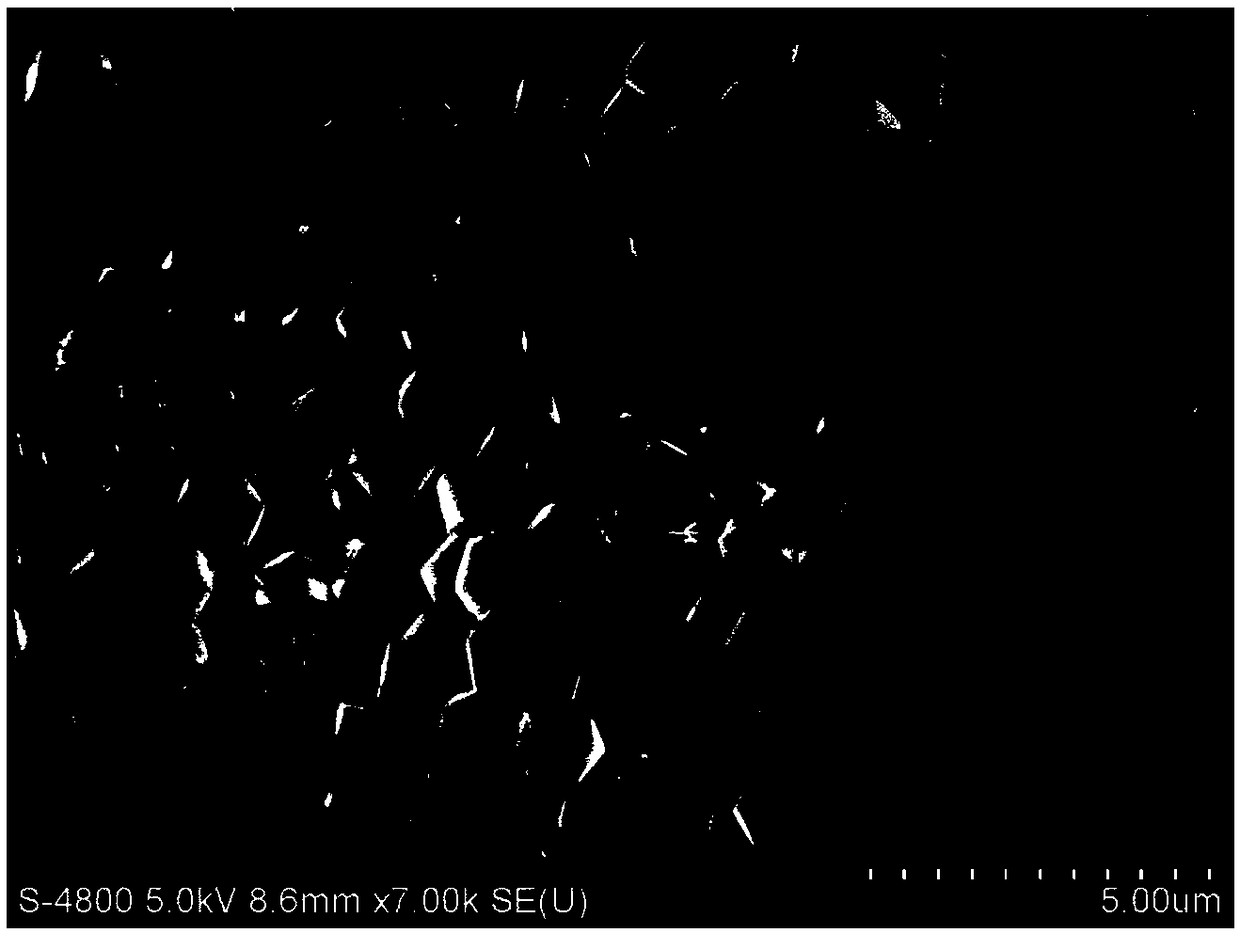

Preparation method of NiCo2S4-coated porous carbon skeleton for positive electrode material of lithium-sulphur battery

ActiveCN109378449AFacilitated DiffusionImprove conductivityCell electrodesLi-accumulatorsPorous carbonHexamethylenetetramine

The invention relates to a preparation method of a NiCo2S4-coated porous carbon skeleton for a positive electrode material of a lithium-sulphur battery. The preparation method comprises the followingsteps: preparing a nitrogen-doped porous carbon skeleton; preparing a C@NiCo-LDH composite material: adding the nitrogen-doped porous carbon skeleton prepared in the last step, cobalt nitrate hexahydrate, nickel nitrate hexahydrate, urotropin and sodium citrate according to the molar ratio of (10-15): (60-120): (30-60):30:10 into deionized water, after stirring uniformly, carrying out oil bathingat a temperature of 70-90 DEG C, carrying out condensation and returning for 3-6 hours, centrifuging reaction products using the deionized water and alcohol, drying to obtain the NiCo-LDH-coated porous composite material which is marked as C@NiCo-LDH; preparing the C@NiCo2S4 composite material; and loading sulfur on the C@NiCo2S4 composite material.

Owner:TIANJIN UNIV

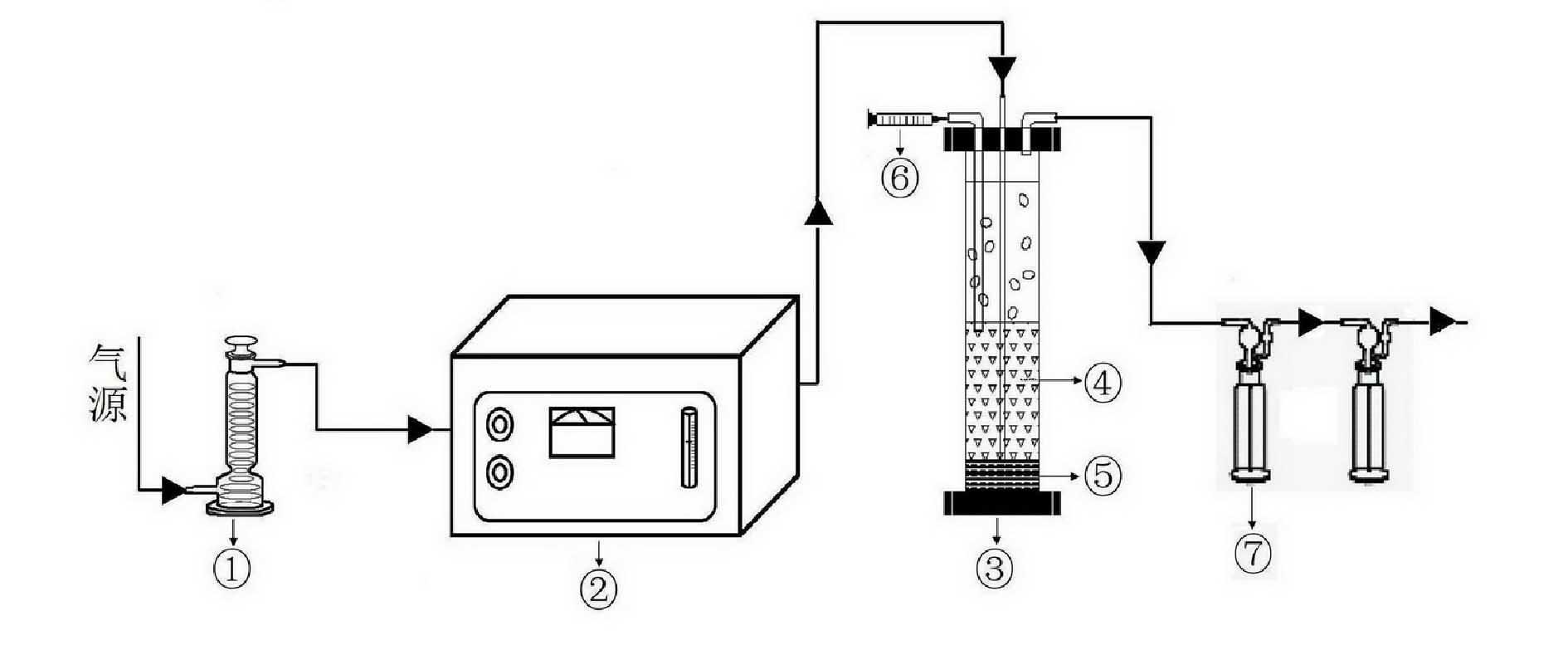

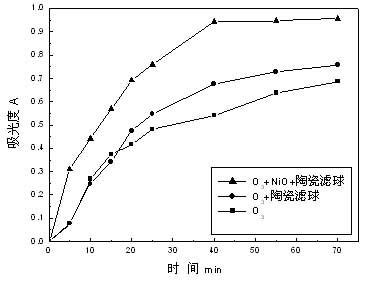

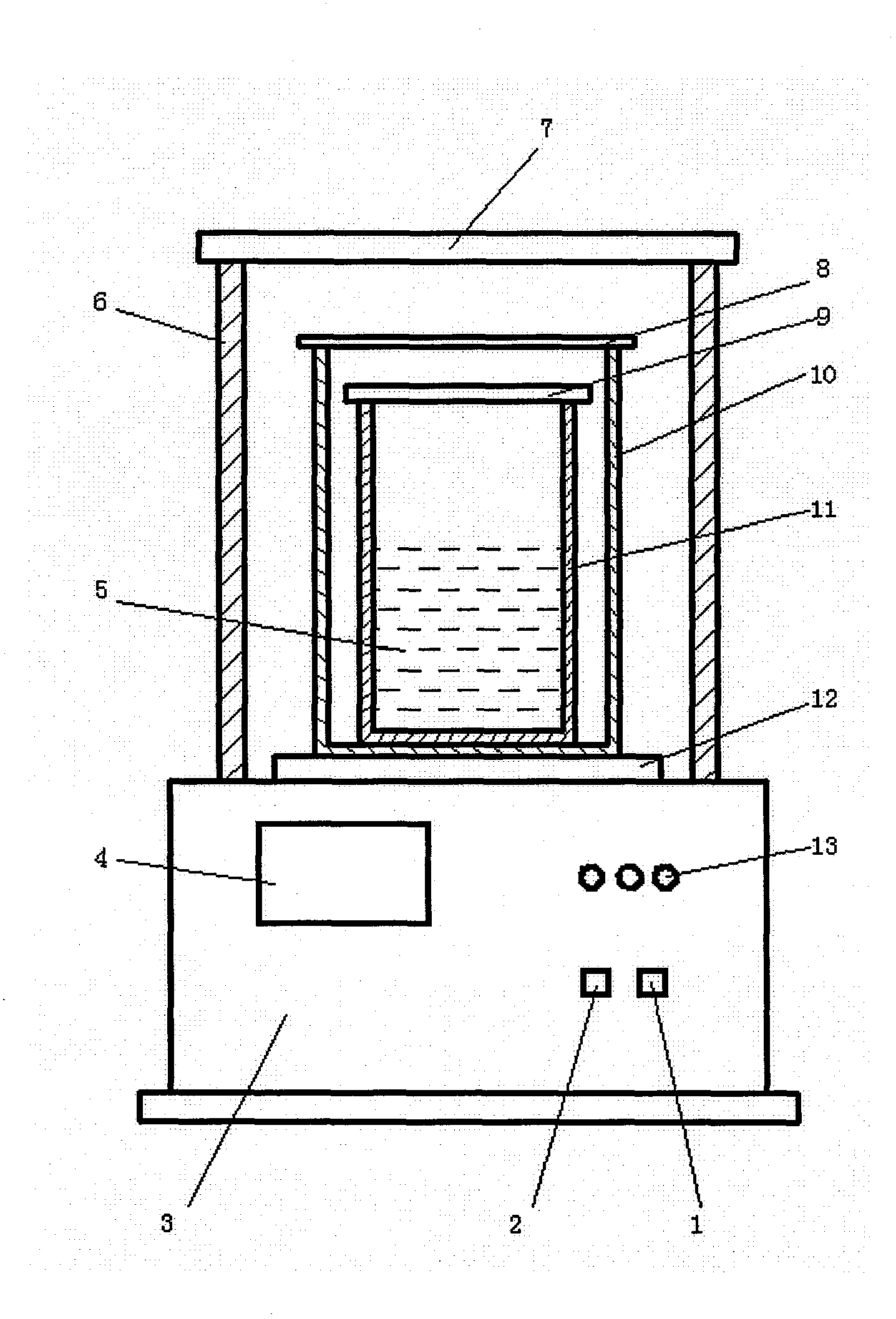

Preparation method of load-type metallic oxide ozone catalytic oxidation catalyst

InactiveCN102626629AHigh catalytic activityIncreased rate of catalytic degradationWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The invention relates to a preparation method of a catalyst, in particular to a preparation method of a load-type metallic oxide ozone catalytic oxidation catalyst, which is characterized by comprising the following steps of (1) selecting ceramic filter bulbs to serve as a carrier, washing through deionized water, soaking for 24h by using diluted hydrochloric acid, and washing through the deionized water to effluent neuter for stoving; (2) dipping for 24h in nickel nitrate solution with the concentration of 0.1-1.0mol / L and drying; (3) roasting for 5h in a muffle furnace at 500 DEG C to obtain roasting objects; and (4) washing through the deionized water and stoving to obtain the load-type metallic oxide ozone catalytic oxidation catalyst. The preparation method is simple, low in cost, capable of greatly improving oxidation rate and efficiency of ozone on organic pollutant, good in product stability and capable of repeatedly using, and having important significant on application and dissemination of catalytic ozonation techniques.

Owner:WUHAN UNIV OF TECH

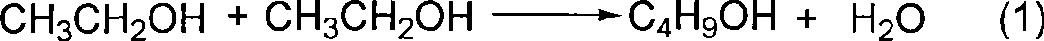

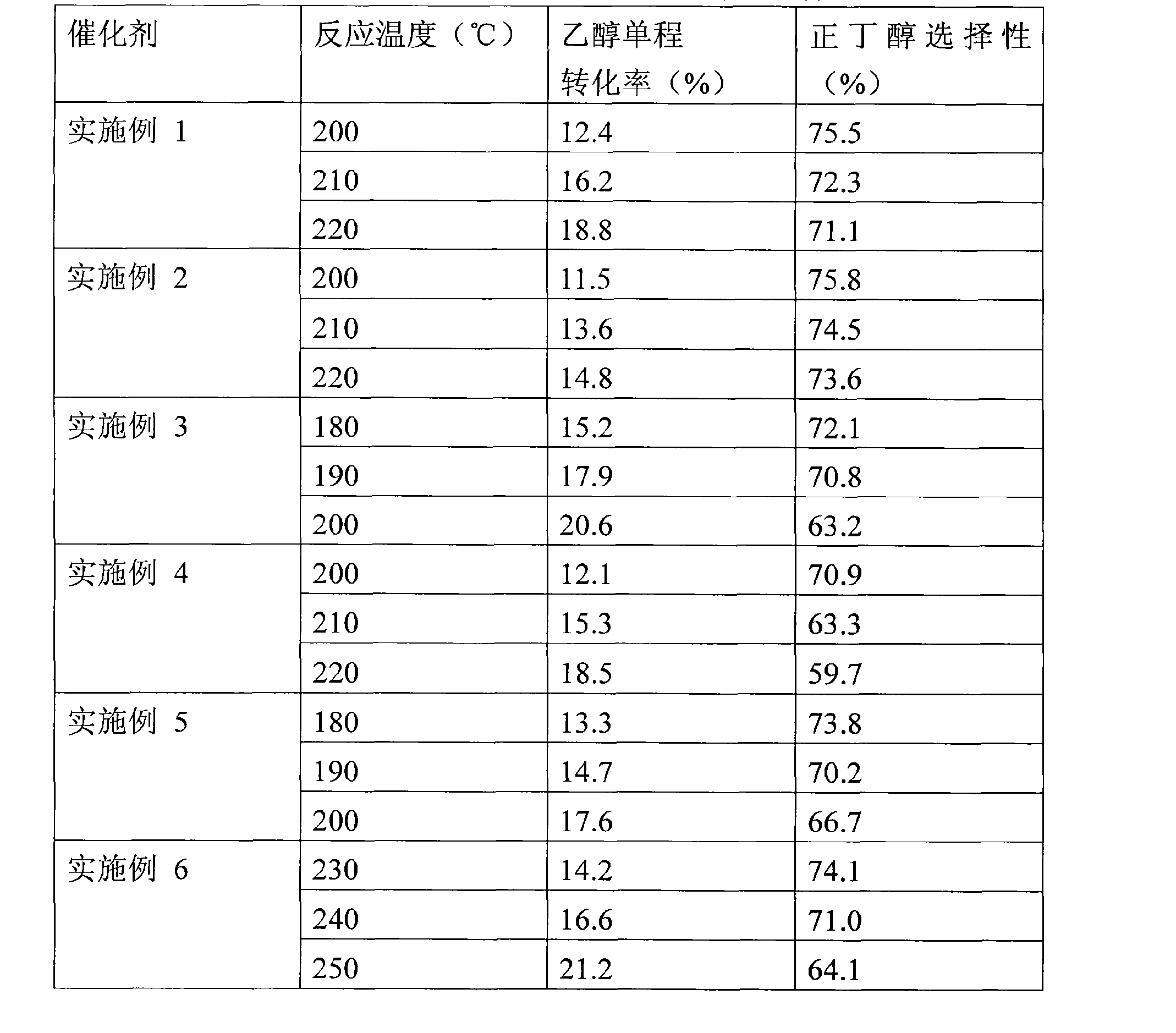

Bi-component supported catalyst of ethanol condensed n-butanol and a method of preparing thereof

InactiveCN101530802ASimple methodLow costOrganic compound preparationHydroxy compound preparationPotassium fluorideGram

The invention discloses a bi-component supported catalyst of ethanol condensed n-butanol and a method of preparing thereof. The main active ingredients of the catalyst are as follows by weight percentage content: 2%-10% nickel, 0.5%-9% cocatalyst MgO or KF. The preparing method comprises the steps of: directly dipping 30-50 grams of granulose gamma-Al2O3 into nickel acetate or nickel nitrate aqueous solution with consistency being 0.5-1.0 mol / L, dipping for 2 to 4 days, occasionally stirring, evaporating, drying under 130 degrees centigrade, then dipping into magnesium nitrate or potassium fluoride aqueous solution with consistency being 0.1-1.0 mol / L for 2 to 3 days, evaporating, drying under 130 degrees centigrade to prepare the bi-component supported catalyst of ethanol condensed n-butanol. The method of preparing bi-component supported catalyst in the invention is simple and has low cost; the catalytic activity is higher than that of the single component nickel supported catalyst; the selectivity of the n-butanol in the products can achieve above 70% and has wildly industrialized application prospect.

Owner:ZHEJIANG UNIV

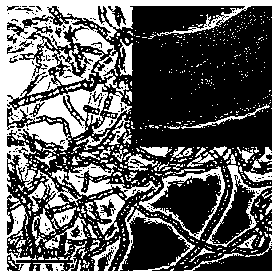

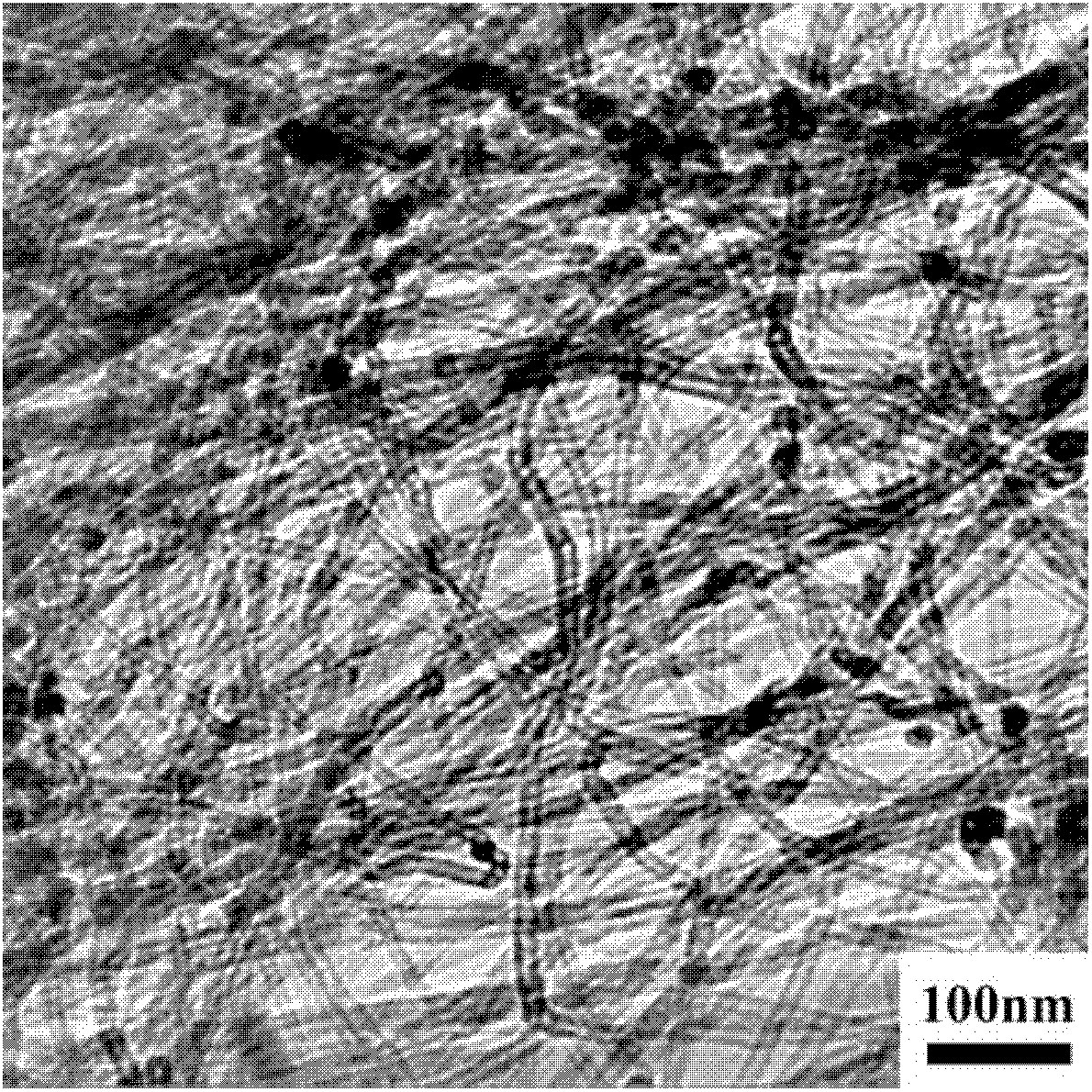

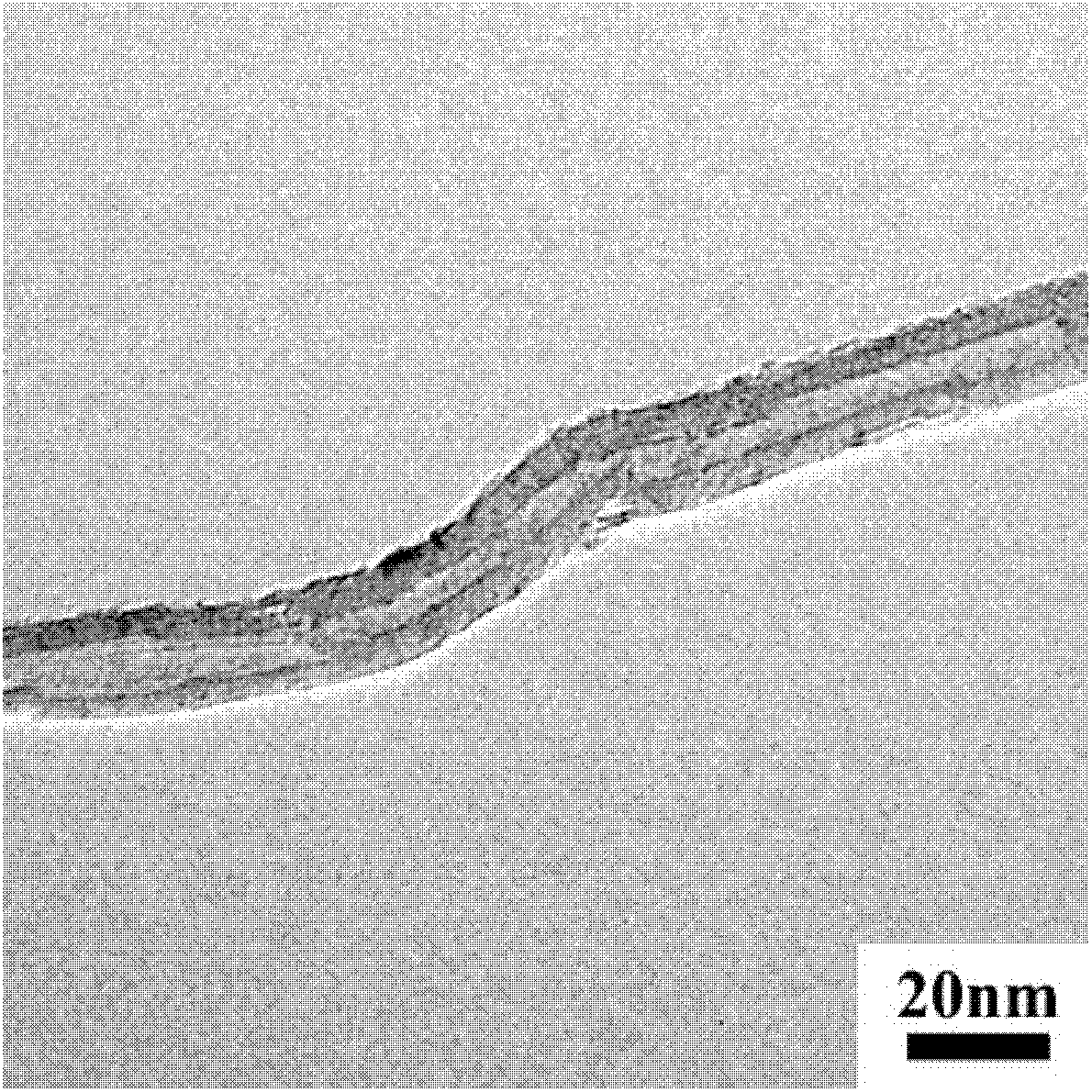

Vapor depositing in-situ reaction process for preparing carbon nanotube reinforced copper-base composite material

InactiveCN1888103ASolve the problem of fragmentationExcellent electrical performanceChemical vapor deposition coatingGas phaseCarbon nanotube

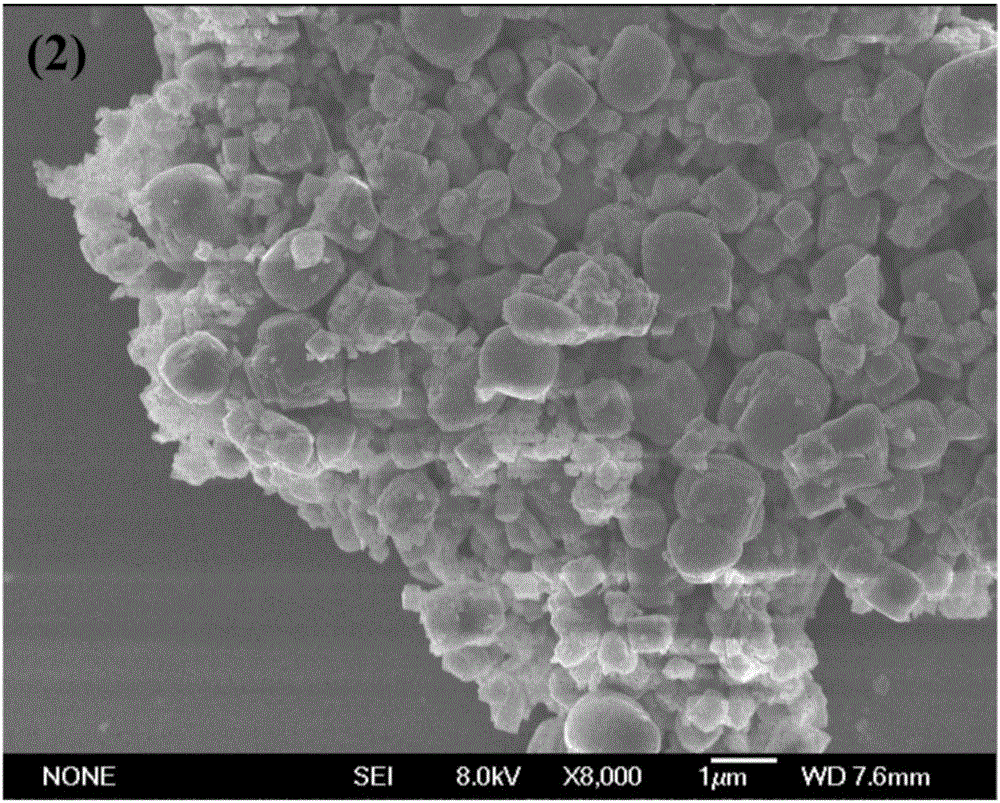

The present invention is preparation process of carbon nanotube reinforced copper-base composite material with high strength and high conductivity, and belongs to the field of copper-base composite material preparing technology. The preparation process includes the following steps: adding nickel nitrate hexahydrate, yttrium nitrate hexahydrate and ethanol soaked copper powder in certain weight proportion into distilled water to obtain nickel nitrate solution; dropping sodium hydroxide solution to the nickel nitrate solution to produce neutralizing reaction obtaining ternary Ni(OH)2 / Y(OH)3 / Cu colloid; washing, filtering, drying, grinding and calcining to obtain Ni / Y / Cu catalyst precursor; setting the precursor into reaction furnace, introducing H2 to reduce, and introducing N2 and reaction gas for catalytic cracking reaction to obtain composite carbon nanotube / Cu powder; initially pressing the composite powder, sintering and re-pressing to obtain carbon nanotube in-situ reinforced copper-base composite material.

Owner:TIANJIN UNIV

Shell metal stamping part surface treatment technique

InactiveCN104404491AImprove antioxidant capacityImprove corrosion resistanceMetallic material coating processesWorking fluidPhytic acid

The invention discloses a shell metal stamping part surface treatment technique which comprises the following steps: 1) mixing 65 parts by mass of ethanedioic acid, 7 parts by mass of zinc nitrate, 5 parts by mass of sodium molybdate, 2.3 parts by mass of nickel nitrate, 2 parts by mass of coconut diethanol amide, 3 parts by mass of phytic acid and 2 parts by mass of dodecyl trimethyl ammonium sulfate, and reacting at 115 DEG C for 3 hours to obtain a metal surface treating agent; 2) mixing 17 parts by mass of metal surface treating agent and 136 parts by mass of water to obtain a surface treatment working fluid; and 3) heating the surface treatment working fluid to 54 DEG C, and putting the metal stamping part in the surface treatment working fluid to perform surface treatment for 27 minutes. The surface treatment technique can enhance the oxidation resistance and corrosion resistance of the metal stamping part.

Owner:常熟市宏福塑料金属制品有限公司

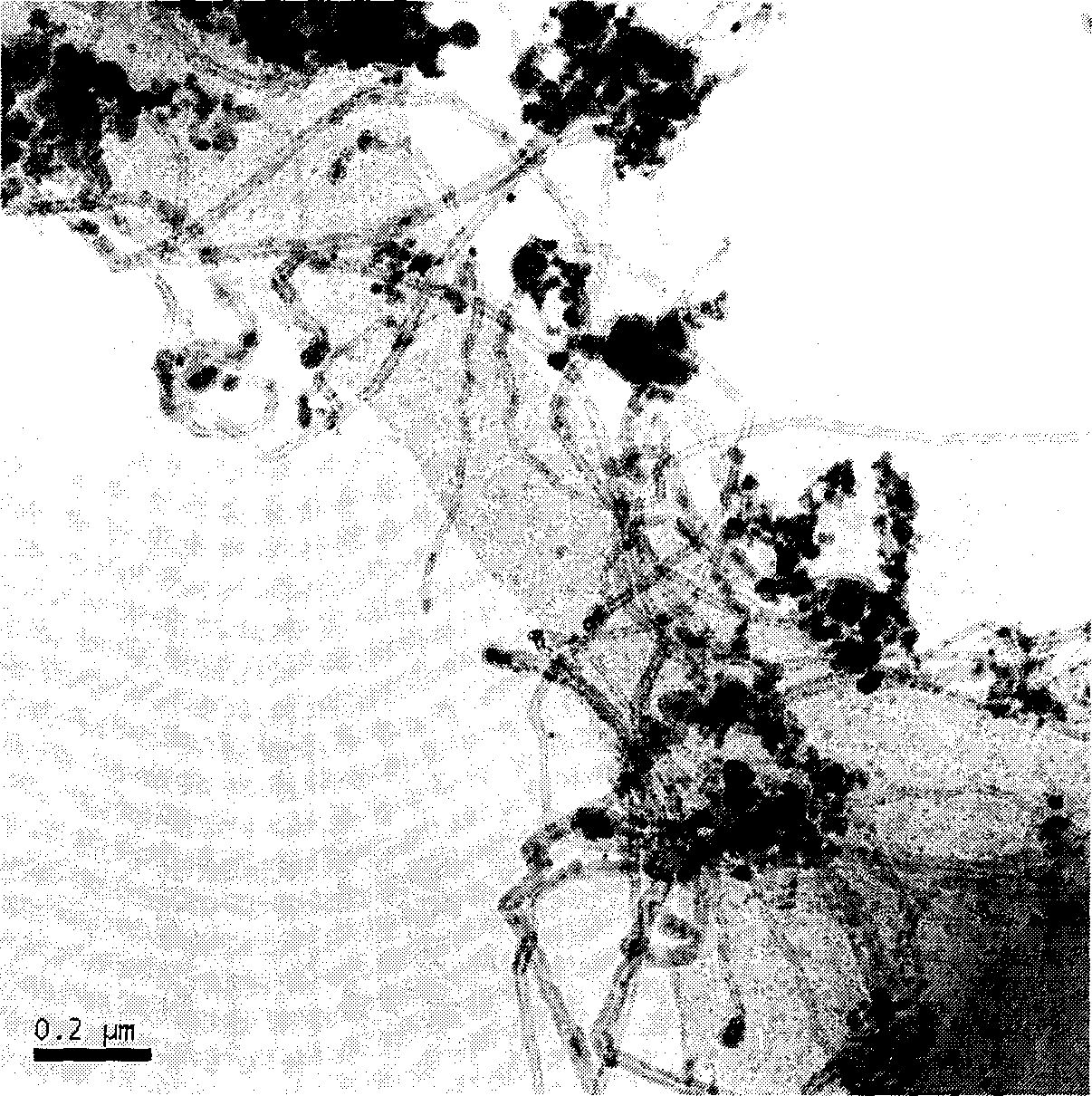

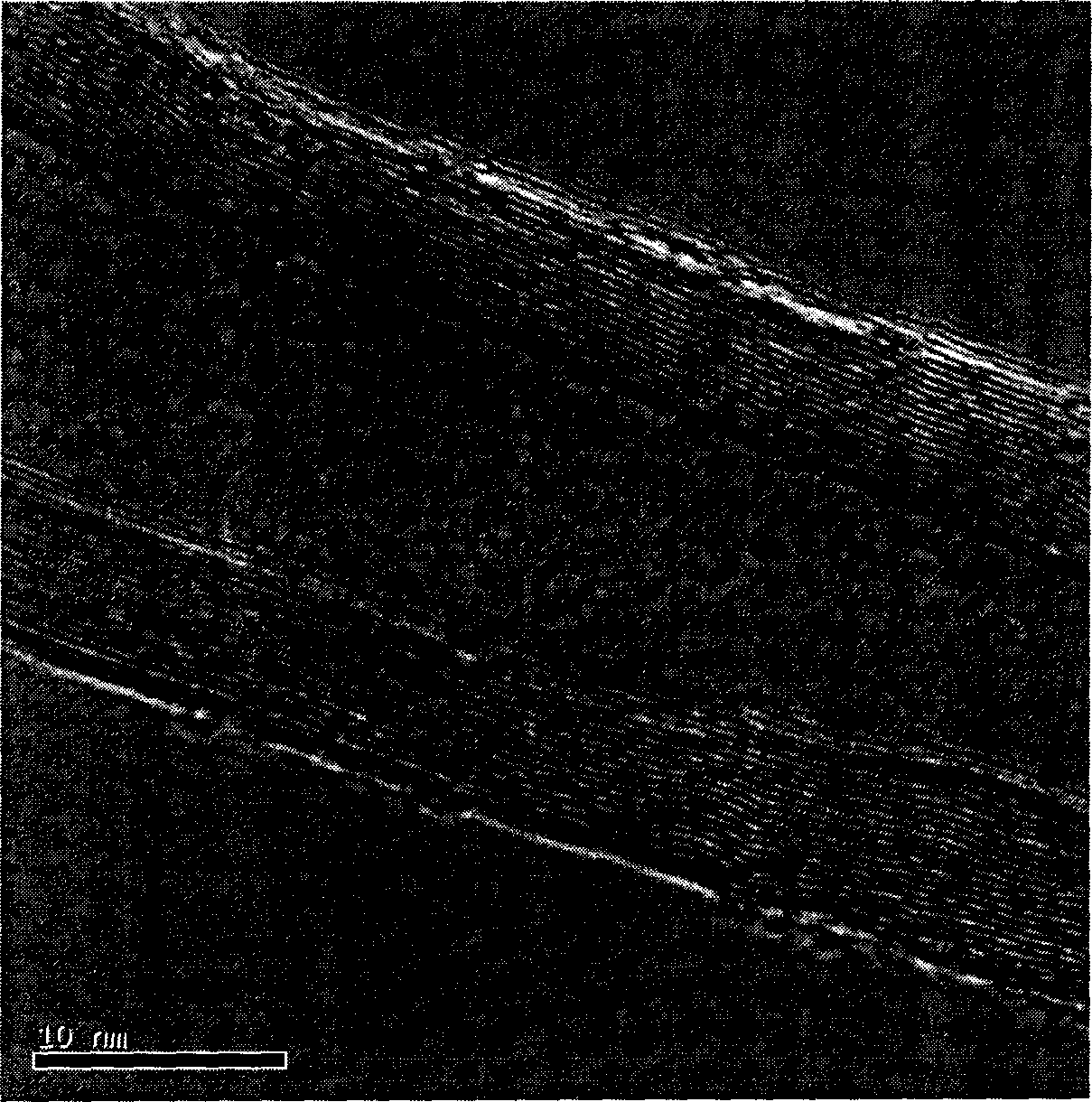

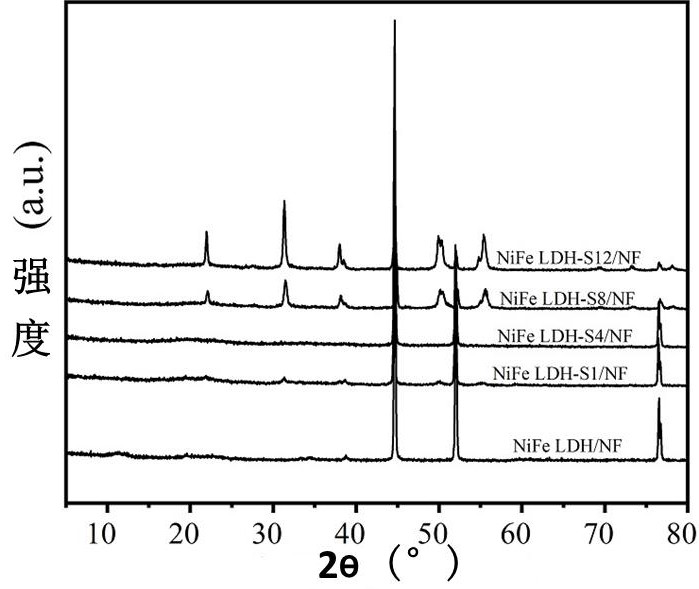

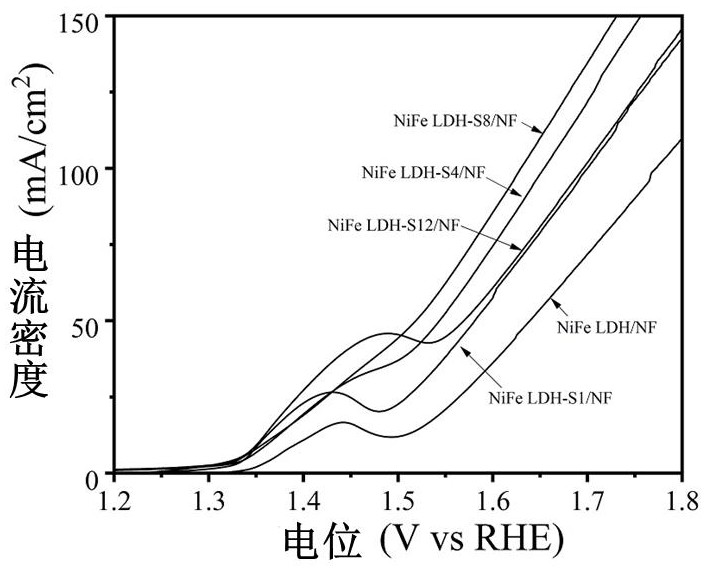

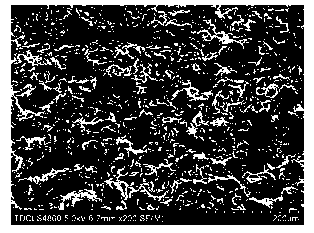

Preparation method of self-supporting ferronickel layered double hydroxide sulfide electrocatalyst

PendingCN112023946AHigh catalytic activityImprove conductivityMaterial nanotechnologyCatalyst activation/preparationHydration reactionPtru catalyst

The invention provides a preparation method of a self-supporting ferronickel layered double hydroxide sulfide electrocatalyst. The preparation method comprises the steps of pretreating original foamednickel to obtain purified foamed nickel; dissolving nickel nitrate hexahydrate, iron nitrate nonahydrate and urea into deionized water according to a preset proportion to obtain a mixed solution, wherein the concentration of cations in the mixed solution is 40-45 mmol / L, and the concentration of urea in the mixed solution is 130-150 mmol / L; carrying out primary hydrothermal reaction on the mixedsolution to obtain NiFe LDH / NF; putting the NiFe LDH / NF into a thioacetamide solution, and carrying out a secondary hydrothermal reaction to obtain NiFe LDH-Sx / NF, wherein x is any number from 1 to 8.According to the preparation method of the self-supporting ferronickel layered double hydroxide sulfide electrocatalyst provided by the invention, the electrocatalyst shows excellent oxygen evolutionreaction catalytic activity under an alkaline condition, a ferronickel double hydroxide nanosheet structure directly growing on foamed nickel is beneficial to electron transfer, the catalytic surfacearea is increased, and the catalytic active sites are improved, so that diffusion of oxygen evolution reaction is facilitated.

Owner:HENAN NORMAL UNIV

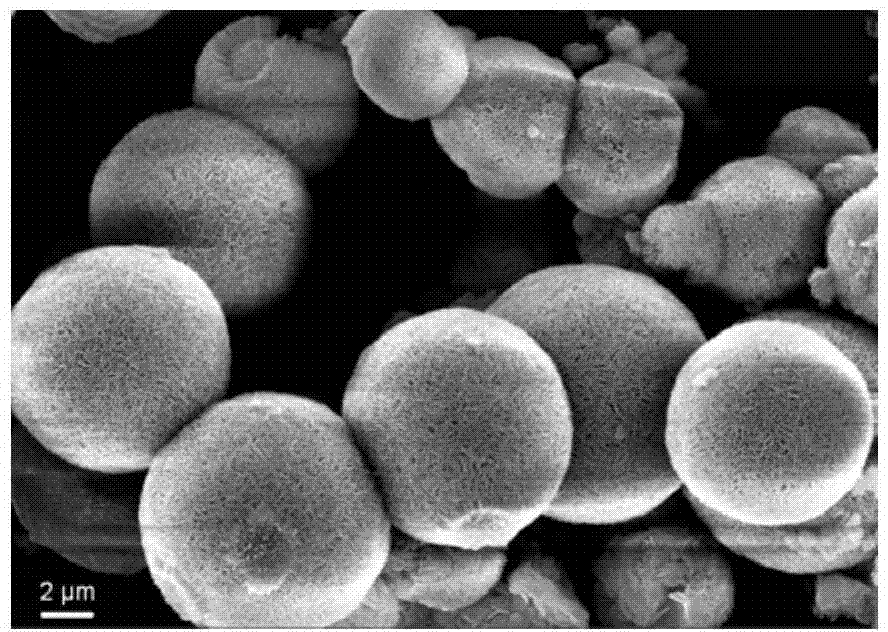

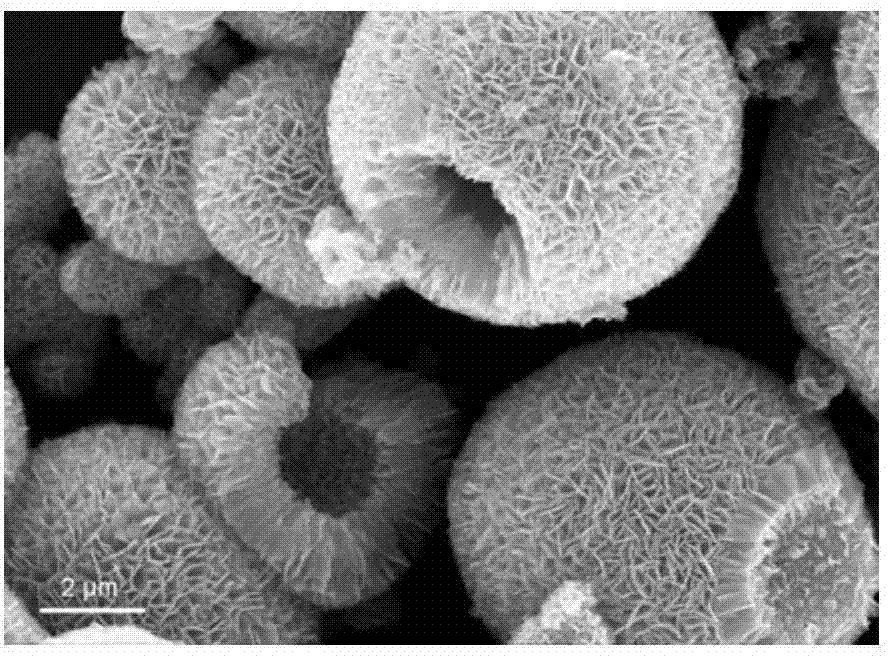

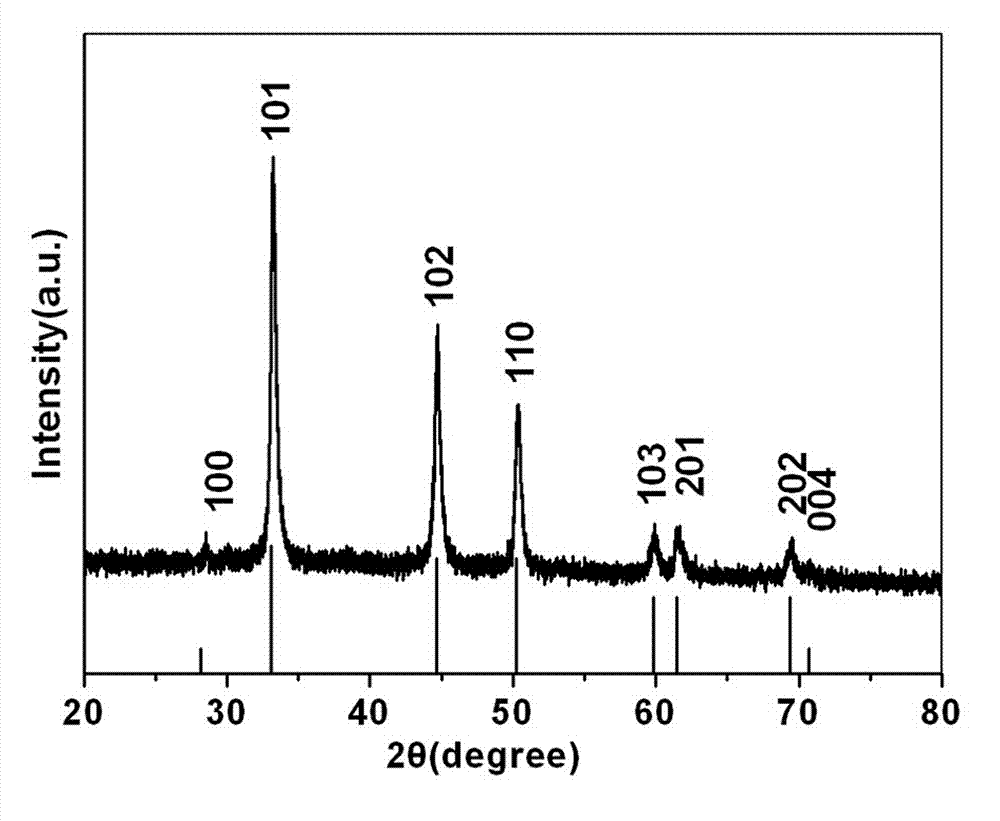

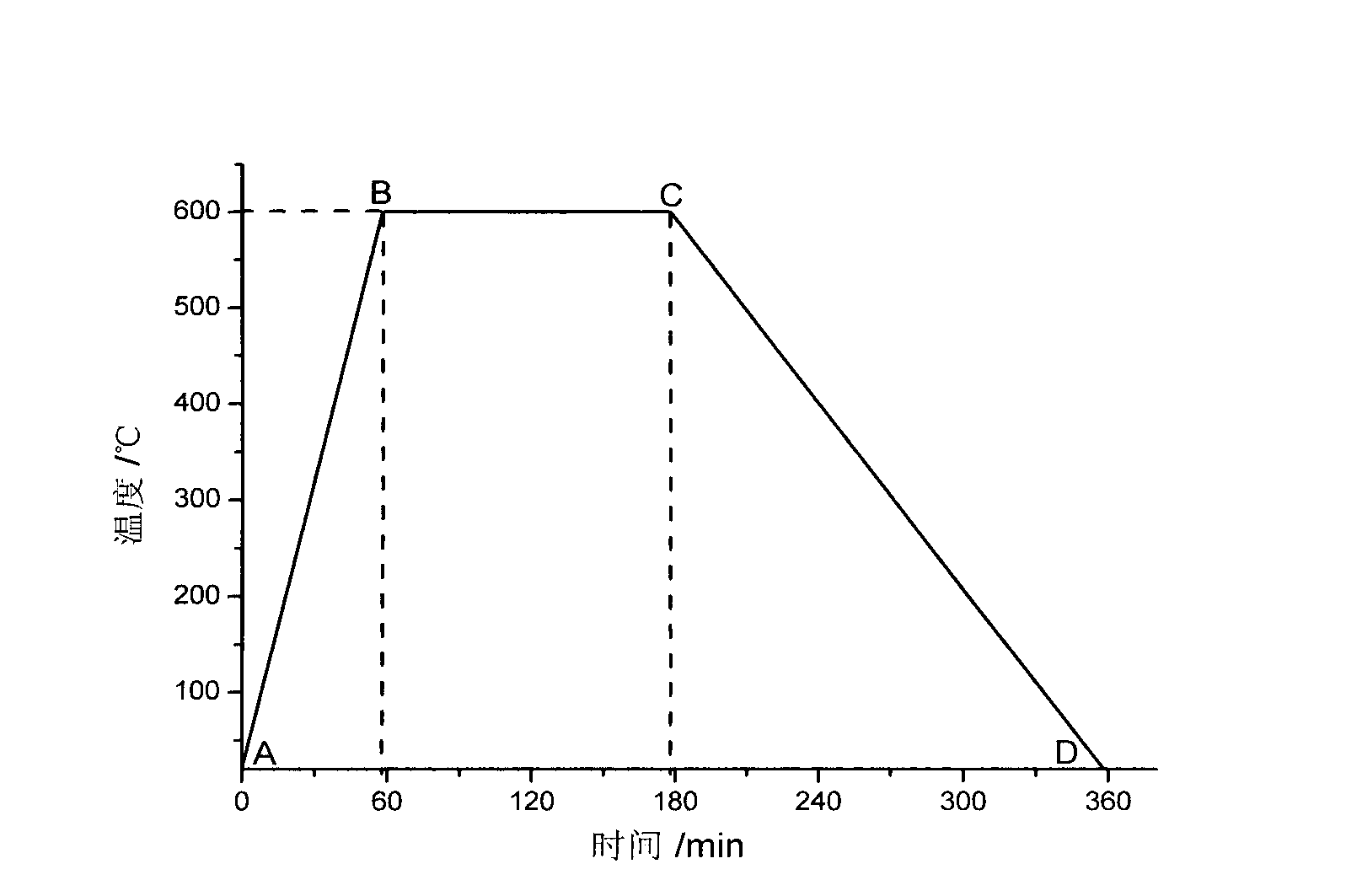

Preparation method of three-dimensional flower-shaped nickel cobaltate nano-sheet mesoporous microspheres

InactiveCN104773764AEasy to operateGood experimental reproducibilityMaterial nanotechnologyNickel compoundsAir atmosphereNano catalyst

The invention relates to a preparation method of three-dimensional flower-shaped nickel cobaltate nano-sheet mesoporous microspheres, and relates to the technical field of multi-level structured nano-grade catalyst materials. First, nickel nitrate hexahydrate and cobalt nitrate hexahydrate are adopted as a nickel source and a cobalt source, a deionized water-isopropanol mixed phase with a proper proportion is adopted as a solvent, methanol is adopted as a reactant, and no additional base precipitating agent is adopted; a three-dimensional flower-shaped nano-sheet microsphere precursor is prepared in a Ni<2+>-Co<2+>-NH3-NH4<+>-SG<n->-H2O-IPA-CH3OH system (SG<n-> is CO3<2-> or HCOO<->); the temperature is increased to 300-400 DEG C in an air atmosphere with a speed of 1 DEG C / min, and the precursor is calcined for 2-3h, such that the three-dimensional flower-shaped nickel cobaltate nano-sheet mesoporous microspheres are obtained. According to the invention, co-precipitation of the formulated cobalt and nickel in the raw materials is realized. The prepared three-dimensional flower-shaped nickel cobaltate nano-sheet mesoporous microspheres are spinel cubic phases with high purity, and are formed by ultrathin nano-sheet self-assembly. The microspheres comprise rich mesopores, and have a large specific surface area. The method has the advantages of simple operation, appropriate conditions and easy control.

Owner:BEIJING UNIV OF CHEM TECH

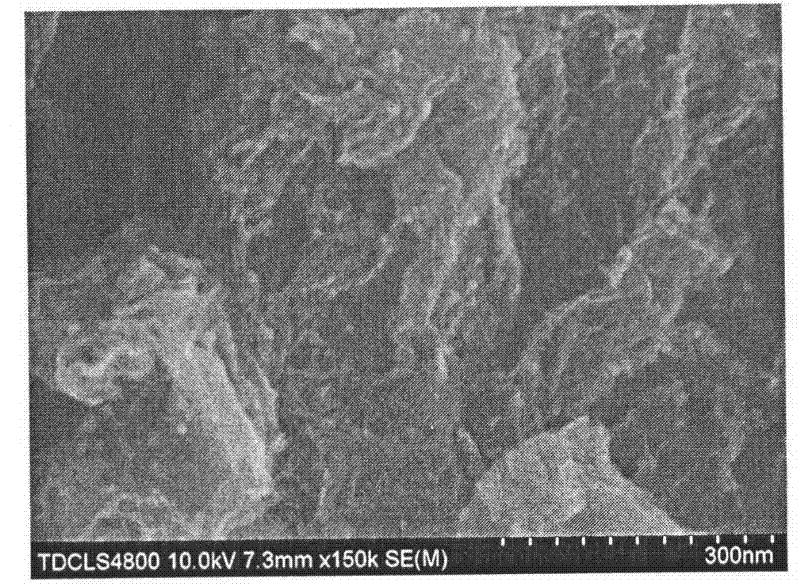

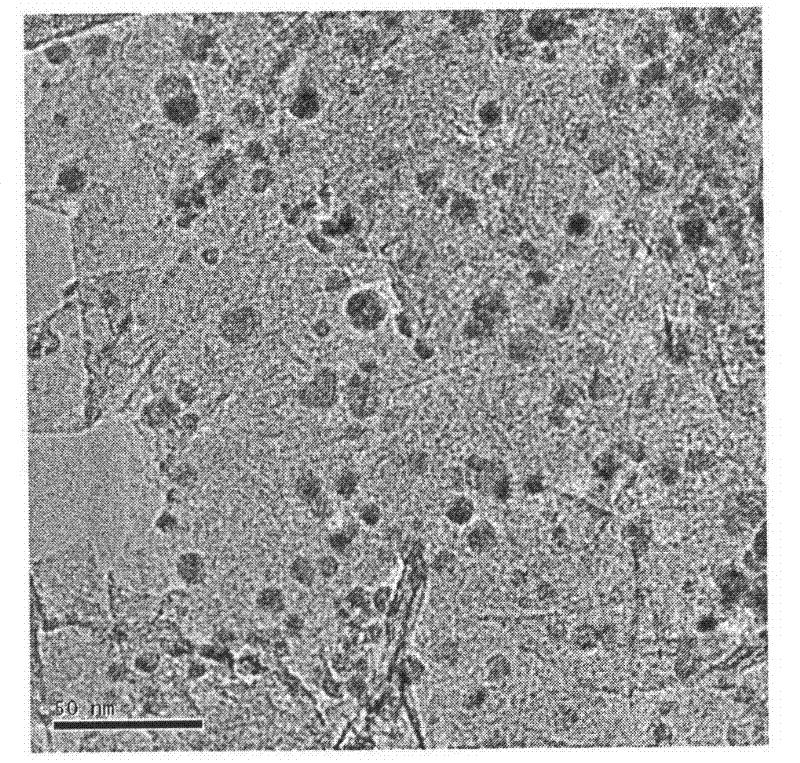

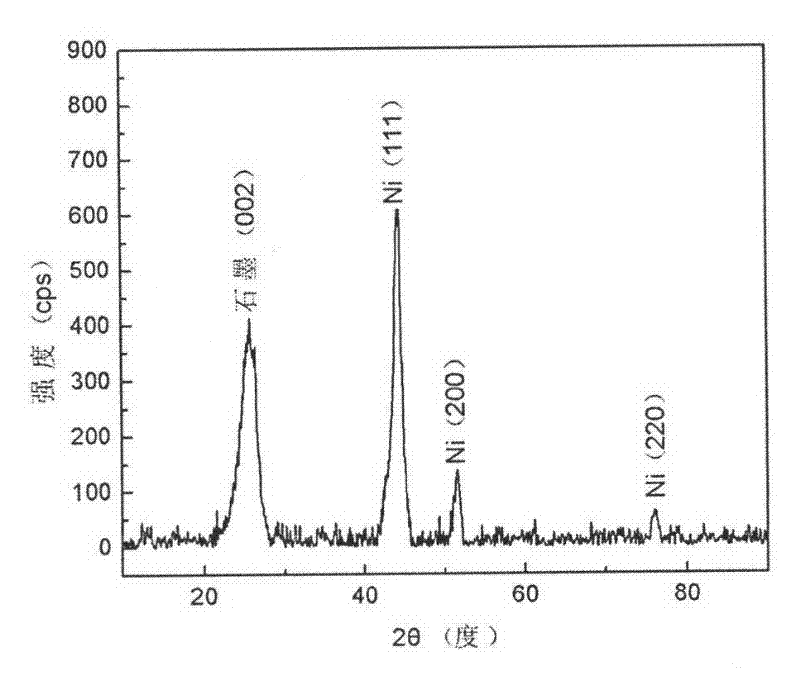

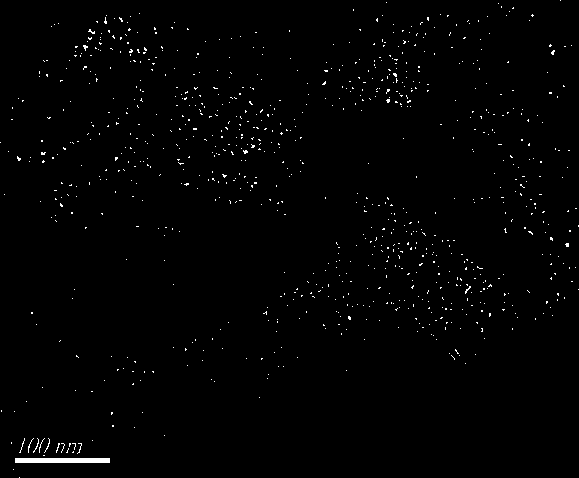

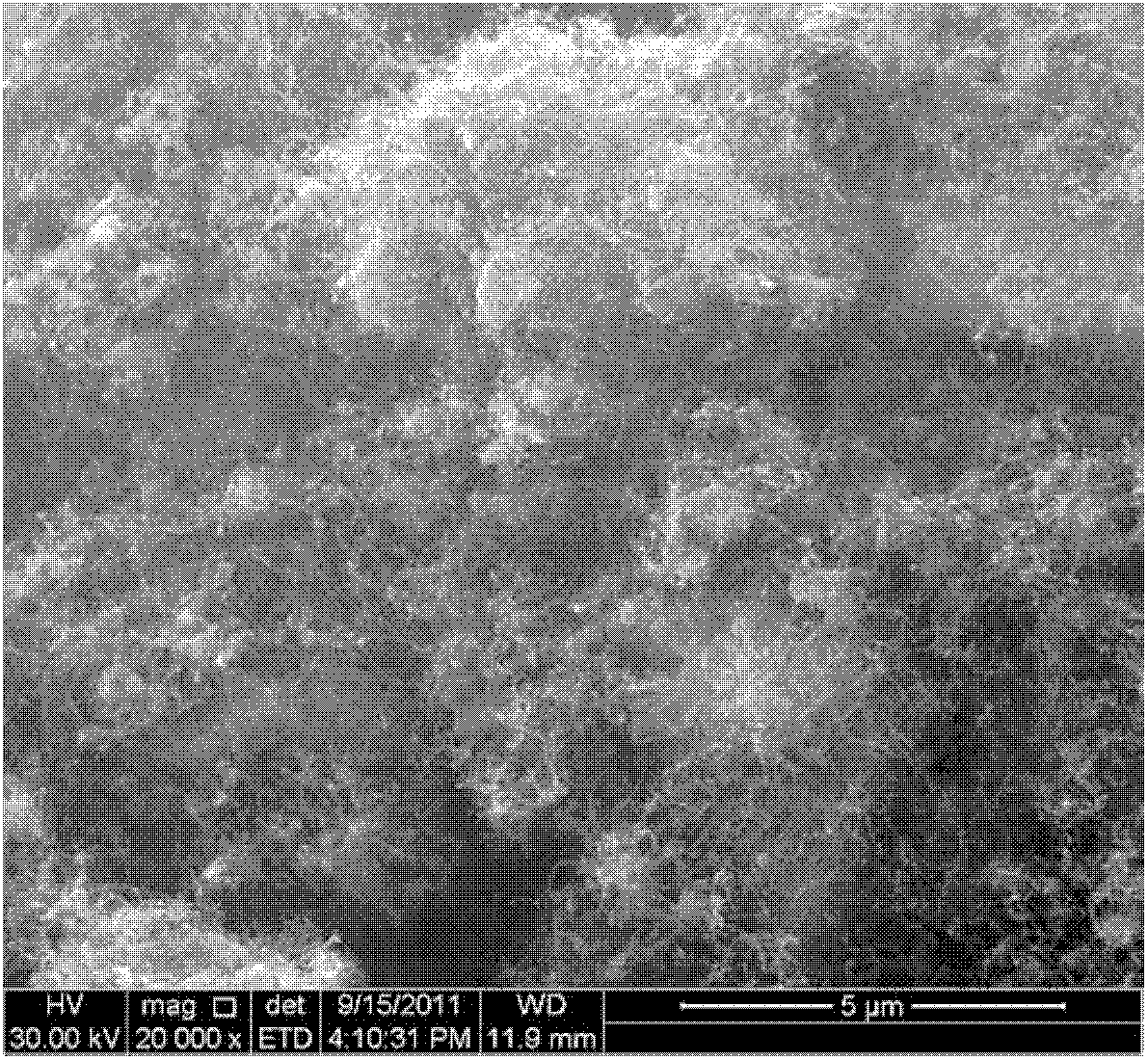

Nano-nickel catalyst loaded on grapheme and preparation method thereof

InactiveCN102350357AReduced activityExtended service lifeMetal/metal-oxides/metal-hydroxide catalystsNickel catalystHigh intensity

The invention discloses a nano-nickel catalyst loaded on grapheme and a preparation method thereof. The catalyst adopts grapheme as a carrier, which is loaded with 1 mass percent-10 mass percent of nickel particles with a particle size of 5-10nm. The preparation method comprises the steps of: preparing the purchased or self-made grapheme into an ethanol solution, preparing a precursor of grapheme-loaded nickel oxide with an ethanol solution of nickel nitrate hexahydrate and an ethanol solution of grapheme, reducing the precursor so as to obtain the nano-nickel catalyst loaded on grapheme. Grapheme with high strength, big specific surface area and stable structure is taken as the catalyst carrier, and the catalyst has high activity, long service life. Also nickel particles loaded on grapheme have a small size and centralized size distribution ranging from 5 to 10nm. And nickel nano-particles are uniformly dispersed on the grapheme carrier. The preparation method provided in the invention has the advantages of simple preparation process, easy operation, low cost, and less pollution.

Owner:TIANJIN UNIV

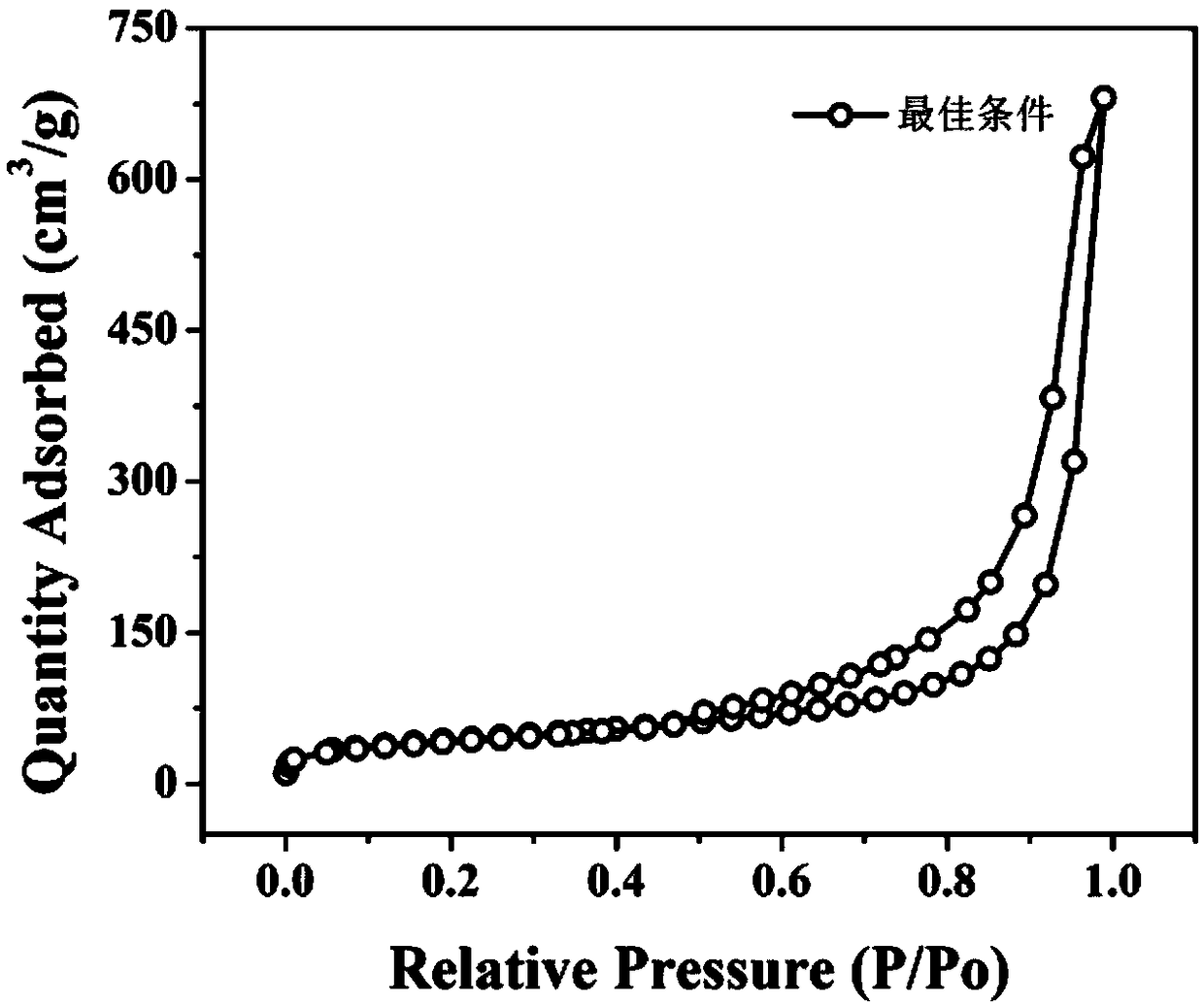

Bimetallic nano-phosphate based on metal-organic framework and preparation method and application thereof

InactiveCN109354698AImprove Capacitive PerformanceLarge specific surface areaHybrid capacitor electrodesCapacitancePhosphate

The invention provides a preparation method of bimetallic nano-phosphate based on a metal-organic framework, which comprises the following steps of: using cobalt nitrate and 2-methylimidazole as raw materials to prepare a metal-organic framework, and then using another nitrate, that is, nickel nitrate to treat the metal-organic framework to form a layered double hydroxide on the metal-organic framework to maintain the morphology of the metal-organic framework, to achieve a conformal transformation, and to obtain a precursor. According to the bimetallic nano-phosphate based on the metal-organicframework and the preparation method and the application thereof, the obtained precursor is etched by using phosphate, and a hollow core shell structure formed increases the specific surface area ofthe material and the capacitance performance is high accordingly. The preparation method of the bimetallic nano-phosphate based on the metal-organic framework has the advantages that the raw materialsare cheap and easy to obtain, the operation is simple, the high energy consumption is avoided, and the bimetallic nano-phosphate obtained has high capacitance performance and can be used for preparation of capacitor elements.

Owner:QINGDAO UNIV OF SCI & TECH

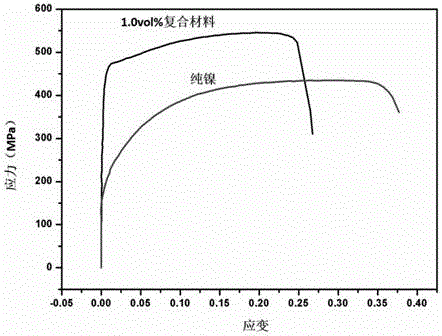

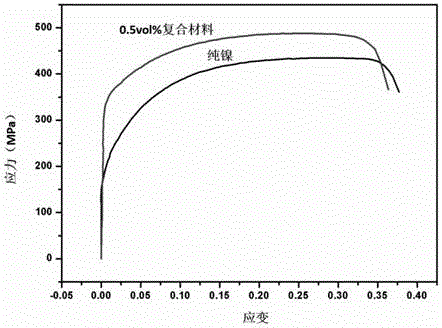

Preparation method for synthesizing three-dimensional graphene reinforced nickel-based composite material in situ

The invention discloses a preparation method for synthesizing a three-dimensional graphene reinforced nickel-based composite material in situ. The preparation method comprises the following steps of: taking glucose or citric acid as a carbon source, taking nickel nitrate hexahydrate as a nickel source, and combining a soluble salt template NaCl to co-mix and dissolve into a deionized water solution, thereby obtaining a light green uniform solution; performing freeze-drying and grinding treatment to obtain powder; putting the powder into a constant-temperature region of a high-temperature tubular furnace to synthesize to obtain mixed powder of sodium chloride-three-dimensional graphene loaded nickel; washing the mixed powder until sodium chloride is completely removed, and performing drying treatment to obtain nano nickel modified three-dimensional graphene powder; and uniformly coating nano nickel modified three-dimensional graphene composite powder with basic nickel nitrate to obtain composite powder of three-dimensional graphene nickel powder.

Owner:TIANJIN UNIV

Solid catalyst for propylene manufacture with propane oxo-dehydrogenation and method for producing the same

InactiveCN101219389AMild reaction conditionsImprove catalytic performancePhysical/chemical process catalystsHydrocarbonsAlkaline earth metalDehydrogenation

The invention relates to a solid catalyst used for the preparation of propylene through the oxidation-dehydrogen of propane and a preparation method thereof, providing a solid catalyst that can create moderate reaction condition and good catalytic performance for the preparation of propylene through the oxidation-dehydrogen of propane and the preparation method of the catalyst. The catalyst comprises a main material and an additive, the main material is phosphor-molybdic heteropolyacid alkali metal salt- nickel oxide compound material or phosphor-molybdic heteropolyacid alkaline earth metal- nickel oxide compound material. The preparation method is that: citric acid is prepared into a water solution, added with an alkali metal carbonate or alkaline earth metal carbonate solution, nickel nitrated hexahydrate, and a H3PMo12O40 solution till the mixture is gelatinous, and dried to obtain a foamy solid; the foamy solid is ground, roasted and pelletized. The preparation method may also be that: citric acid is prepared into a water solution, added with nickel nitrate hexahydrate, stirred till the mixture is gelatinous, and dried to obtain a foamy solid; the foamy solid is ground and roasted to acquire a nano nickel oxide, then nano nickel oxide is added into a H3PMo12O40 solution, stirred while the alkali metal carbonate solution or alkaline earth metal carbonate solution is added, and evaporated till dryness, ground, roasted and pelletized.

Owner:XIAMEN UNIV

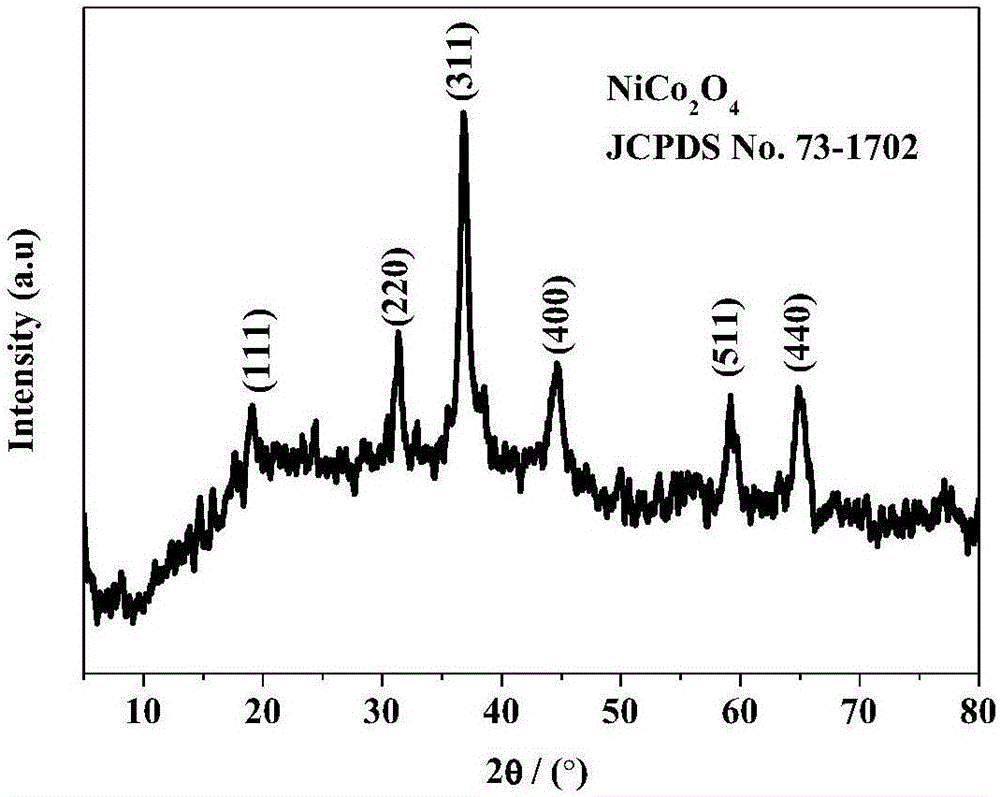

Method for manufacturing porous flaky NiCo2O4 and grapheme composite capacitive material

ActiveCN104240972AHigh specific capacitanceImprove electrochemical stabilityHybrid/EDL manufactureAir atmosphereCapacitance

The invention relates to a method for manufacturing a porous flaky NiCo2O4 and grapheme composite capacitive material, and belongs to the field of nano composite material manufacturing. According to the method, a graphite oxide, cobalt nitrate and nickel nitrate are dissolved in deionized water in an ultrasonic mode and stirred, a certain amount of hexamethylene tetramine is added, a reflux reaction is carried out for 3-4 hours at the temperature of 90 DEG C, sediments are collected, the collected sediments are calcined in an air atmosphere for 2 hours at the temperature of 330 DEG C, and the porous flaky NiCo2O4 and grapheme nano composite material is obtained. In the manufactured porous flaky NiCo2O4 and grapheme composite capacitive material, porous flaky NiCo2O4 is completely attached to the surface of a grapheme piece. By means of the composite structure, conductivity of the material is improved, and the contact area of the material and an electrolyte solution is greatly improved, so that the composite material has high specific capacitance and good electrochemical stability and can be possibly used as a super-capacitor electrode material.

Owner:江阴智产汇知识产权运营有限公司

Method for preparing multi-shape controllable nano nikel-cobalt spinel oxide

The invention relates to a method for preparing multi-shape controllable nano nikel-cobalt spinel oxide. The method includes the steps that nickel nitrate and cobalt nitrate are dissolved in anhydrous ethanol according to the cobalt-nickel atom ratio to form a solution A; oleylamine is dispersed in an ethanol solution to form a solution B, and the solution B and the solution A are mixed to obtain a mixed solution; the mixed solution is fully and evenly stirred and moved into a dynamic reaction kettle, H2 is replaced in a sealed mode, pressure intensity of H2 is adjusted to 6-15 bar after replacement, and a steel cylinder air outlet valve is closed; the stirring speed of the dynamic reaction kettle is adjusted to 400 r / min, temperature is set to be 150 DEG C, and reaction is carried out for 10 h; a product is cleaned through ethanol and other nonpolar solvents respectively, centrifugal separation is carried out, and a sediment precursor is obtained through drying at the temperature of 60 DEG C; the temperature of the obtained sediment precursor rises in an air atmosphere at the speed of 10 DEG C / min, and the sediment precursor is heated to 200-400 DEG C and kept warm. According to the method, procedures are few, materials are easy to get and low in price, the procedures are safe, nikel-cobalt spinel oxide of different shapes can be obtained by changing a small condition in the procedures, and accordingly preparing of the controllable nano nikel-cobalt spinel oxide is achieved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

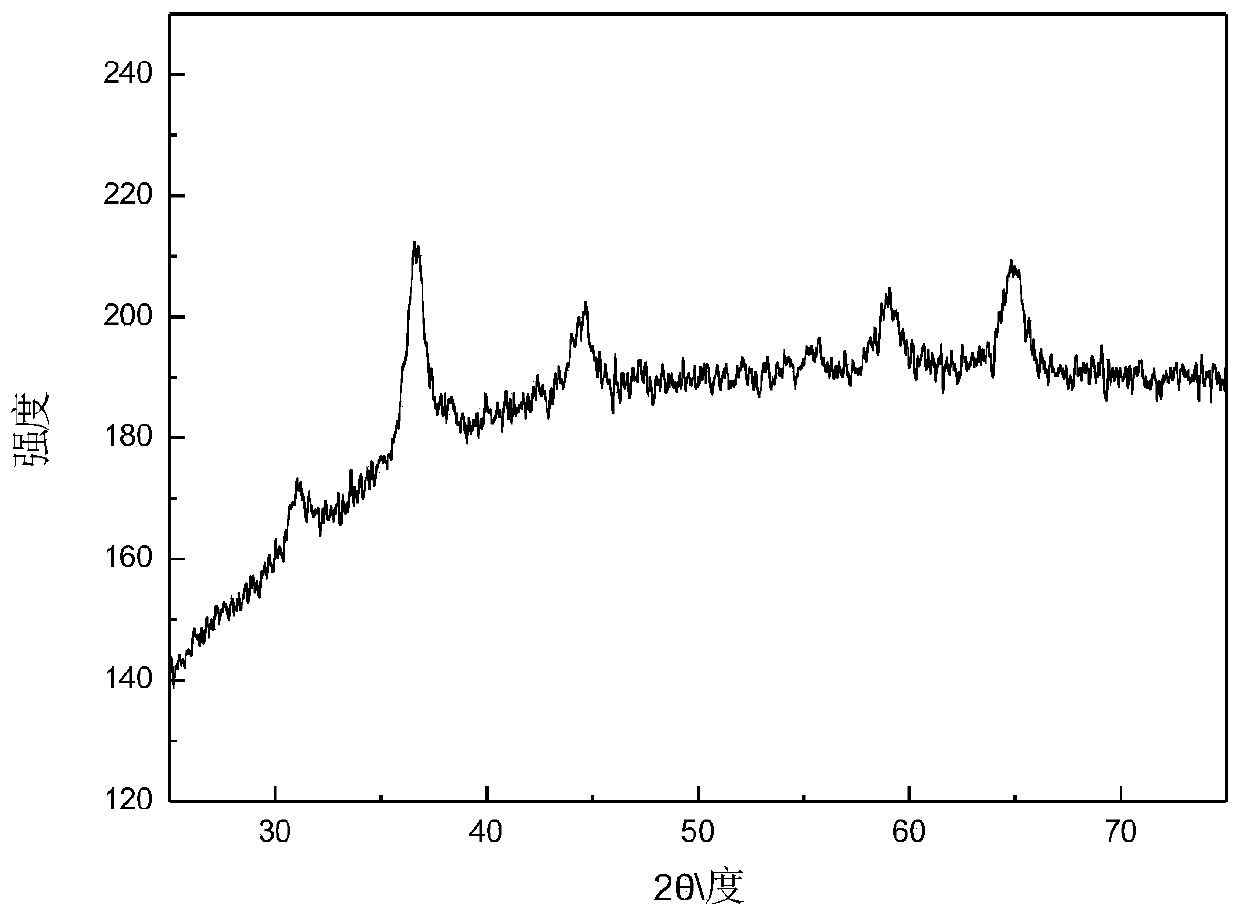

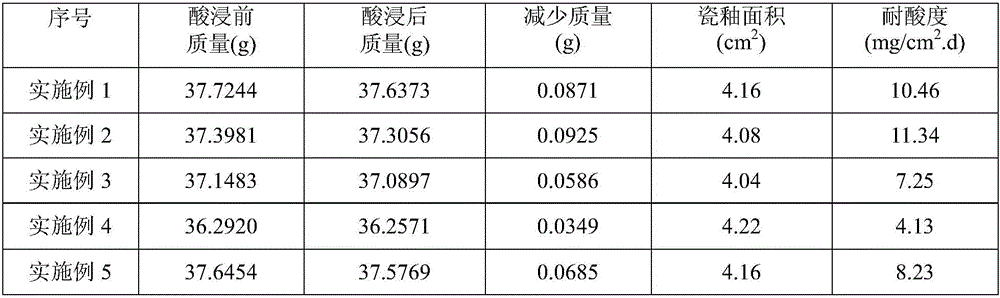

Enamel glaze material, enamel slurry, and preparation method and application thereof

The invention specifically relates to an enamel glaze material, an enamel slurry, and a preparation method and an application thereof. The invention relates to the technical field of enamel materials. The invention aims at solving a technical problem of providing an enamel glaze material. The enamel glaze material is prepared by uniformly mixing the following raw materials, by weight: 40-45 parts of quartz sand, 9.5-10 parts of feldspar powder, 24-26 parts of borax, 2.5-3 parts of cryolite, 5.5-7.5 parts of sodium nitrate, 3.5-4 parts of lithium carbonate, 3.5-4.5 parts of fluorite powder, 2-4 parts of calcium carbonate, 3-4 parts of cobalt nitrate, 0.8-1.2 parts of nickel nitrate, 2-2.2 parts of manganese oxide, and 3.4-3.8 parts of zirconium dioxide. The enamel glaze material can be combined well with glass powder to produce the enamel slurry. The enamel slurry can be coated on the surface of a metal substrate to form an enamel coating. The coating has the advantages of smooth glaze surface, good gloss, no bubble, and no scaling. The coating can be firmly combined with a carbon steel substrate, and has good acid resistance.

Owner:PANZHIHUA UNIV

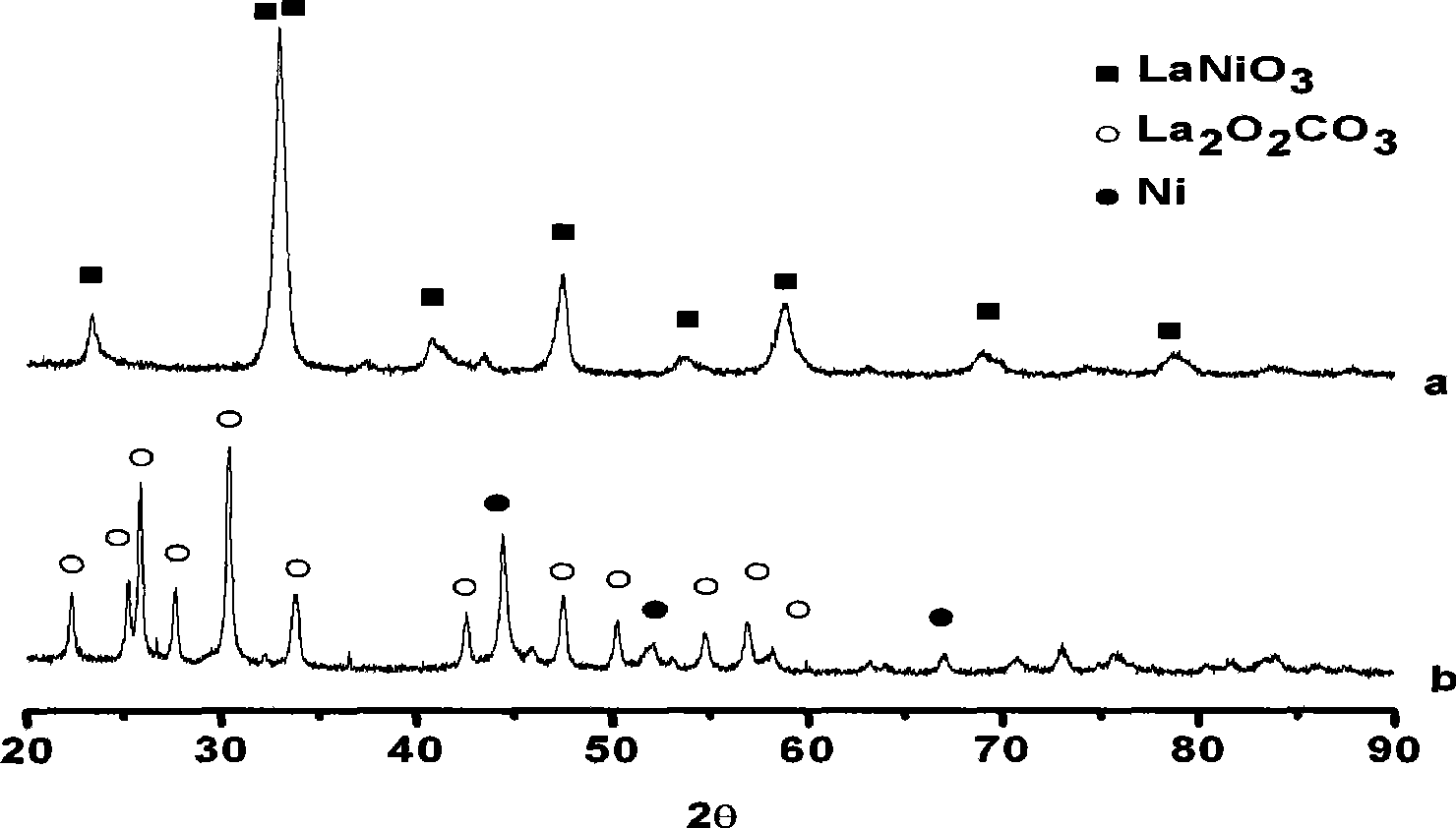

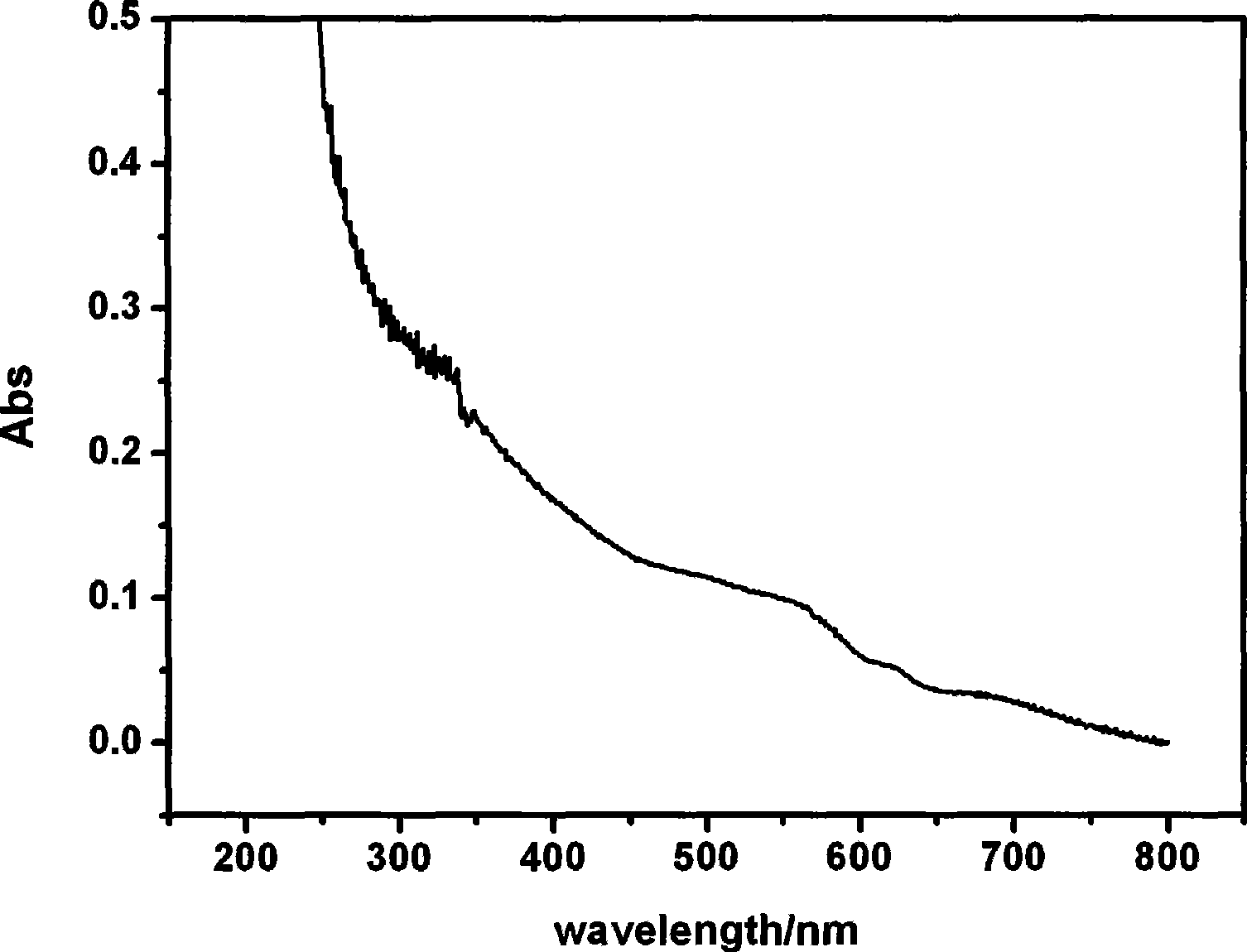

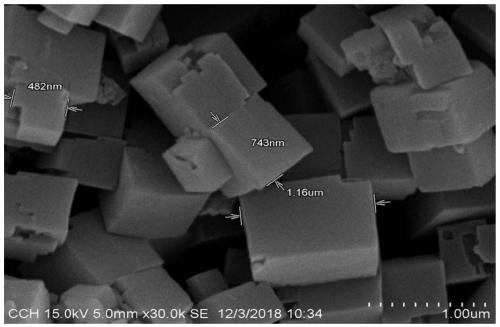

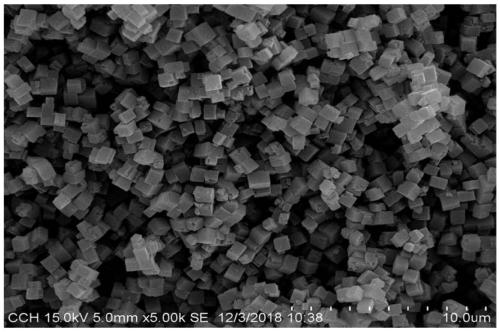

Photocatalyst and its preparing process

InactiveCN101428223AHigh hydrogen production rateMetal/metal-oxides/metal-hydroxide catalystsDecompositionFixed bed

The invention provides a photocatalyst and a preparation method thereof, and particularly relates to a reducing catalyst for hydrogen production via water decomposition and carbon dioxide reduction at the same time under visible light photocatalysis and a preparation method thereof. The invention provides a photocatalyst for photocatalytic reduction of carbon dioxide to organic matters and simultaneously hydrogen production via water decomposition under sunlight. The photocatalyst is Ni / La2O2CO3. The preparation method comprises the following steps: preparing a lanthanum nitrate solution and a nickel nitrate solution respectively, synthesizing LaNiO3 by the conventional complexation method, that is, mixing the lanthanum nitrate solution, the nickel nitrate solution and citric acid and allowing reactions under infrared radiation to form a gel, pre-calcining and calcining the gel to obtain perovskite LaNiO3, and activating the perovskite LaNiO3 in a fixed bed reactor to obtain the finial Ni / La2O2CO3.

Owner:XIAMEN UNIV

Preparation method of catalyst for ammoxidation of caprolactam

ActiveCN110404582AEasy to prepareLow costMolecular sieve catalystsCarboxylic acid nitrile preparationFixed bedCaprolactam

The invention discloses a preparation method of a catalyst for ammoxidation of caprolactam. According to the method, a phosphorus-aluminum molecular sieve is taken as a carrier, a certain amount of active components of magnesium nitrate, aluminum nitrate and nickel nitrate are carried through a dipping method at a certain temperature, an ammoniation dehydration catalyst is obtained after drying, forming and roasting, the catalyst is packed in a fixed bed, and the caprolactam and ammonia gas are subjected to a reaction at 420-500 DEG C under 0-1 mpa. The preparation method of the obtained catalyst is simple, the conversion rate of the caprolactam is greater than 80%, and the selectivity of 6-aminocapronitrile is greater than 99%.

Owner:CHINA CATALYST HLDG CO LTD

Preparation method of foamy copper/carbon nanophase composite negative electrode material for lithium ion battery

InactiveCN103000906AQuality improvementHigh purityElectrode carriers/collectorsPtru catalystComposite electrode

The invention discloses a preparation method of a foamy copper / carbon nanophase composite negative electrode material for a lithium ion battery. The method comprises the steps that the foamy copper is obtained through the processes of mixing NaCl particles and electrolytic copper powder, briquetting the mixture into blanks, sintering the blanks, dissolving out the NaCl particles and reducing under the protection of hydrogen; the foamy copper loaded with a catalyst precursor is obtained by immersing the foamy copper in a catalyst solution prepared by nickel nitrate, yttrium nitrate or cobalt nitrate and calcining the foamy copper loaded with the catalyst; and the foamy copper / carbon nanophase composite electrode material is obtained via reduction of the foamy copper loaded with a catalyst precursor and growth in acetylene. The method is advantageous in that foamy copper with controllable porosity and aperture is employed as a current collector; and carbon nanophase with different morphologies which has good quality and high purity is grown on the foamy copper current collector directly by controlling doping and growing processes of the catalyst. The method is simple in preparation process, and is easy to realize and popularize. The composite negative electrode material has low preparation cost and good electrochemical performance.

Owner:TIANJIN UNIV

Preparation method of three-dimensional mesoporous NiCo2O4/nitrogen-doped graphene composite electrode material

InactiveCN106169384AGood size controlMild reaction conditionsMaterial nanotechnologyHybrid capacitor electrodesAir atmosphereFiltration

The invention provides a preparation method of a three-dimensional mesoporous NiCo2O4 / nitrogen-doped graphene composite electrode material. The preparation method comprises the following steps: step 1, implementing ultrasonic dispersion on graphene oxide in an acetonitrile system to obtain a uniform graphene oxide solution A; step 2, transferring the solution A to a polytetrafluoroethylene hydrothermal reactor to implement constant-temperature thermal reaction, and completing the reaction to obtain mixed liquid B; step 3, implementing extraction filtration, washing and drying on the mixed liquid B to obtain a product C; step 4, implementing uniform ultrasonic dispersion on the product C, cobalt nitrate hexahydrate, nickel nitrate hexahydrate and hexamethylenetetramine to obtain mixed liquid D; step 5, transferring the mixed liquid D to the polytetrafluoroethylene hydrothermal reactor to implement constant-temperature thermal reaction, and filtering and washing the liquid to obtain a nickel cobaltate precursor E; and step 6, putting the precursor E into a tubular furnace, and implementing calcination at an air atmosphere to obtain a reaction product namely the three-dimensional mesoporous NiCo2O4 / nitrogen-doped graphene composite electrode material. The preparation method provided by the invention is mild in reaction condition, easy to control, low in cost, and simple and convenient in process and procedure.

Owner:JIANGSU UNIV

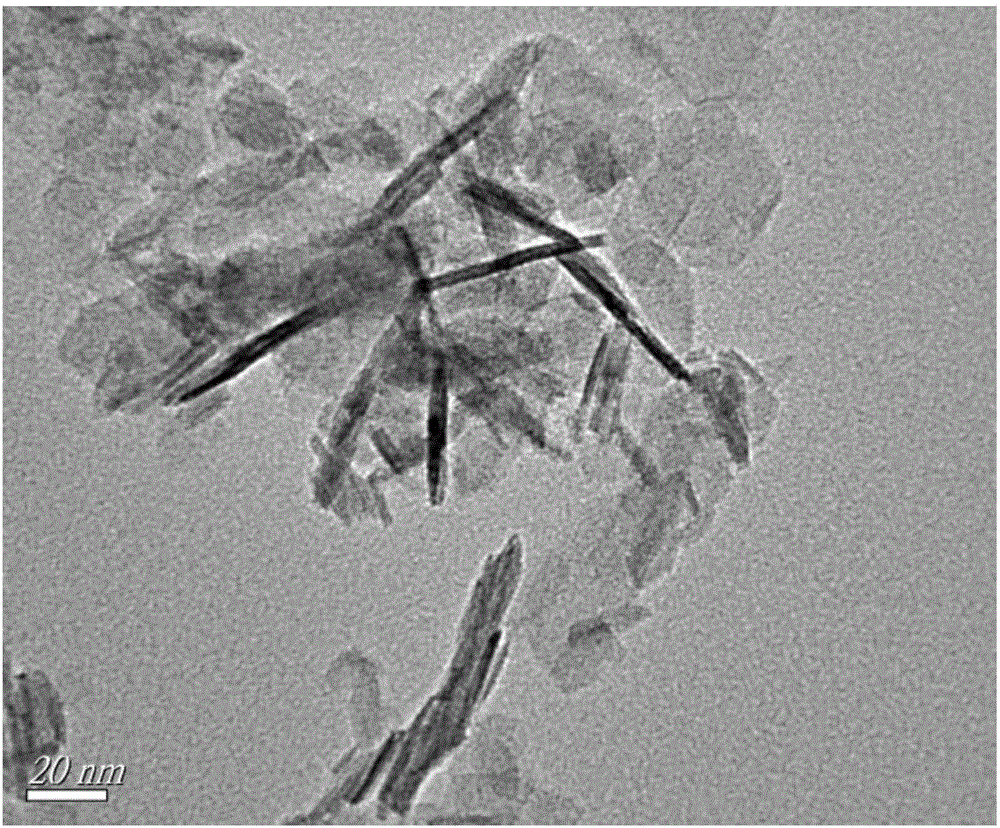

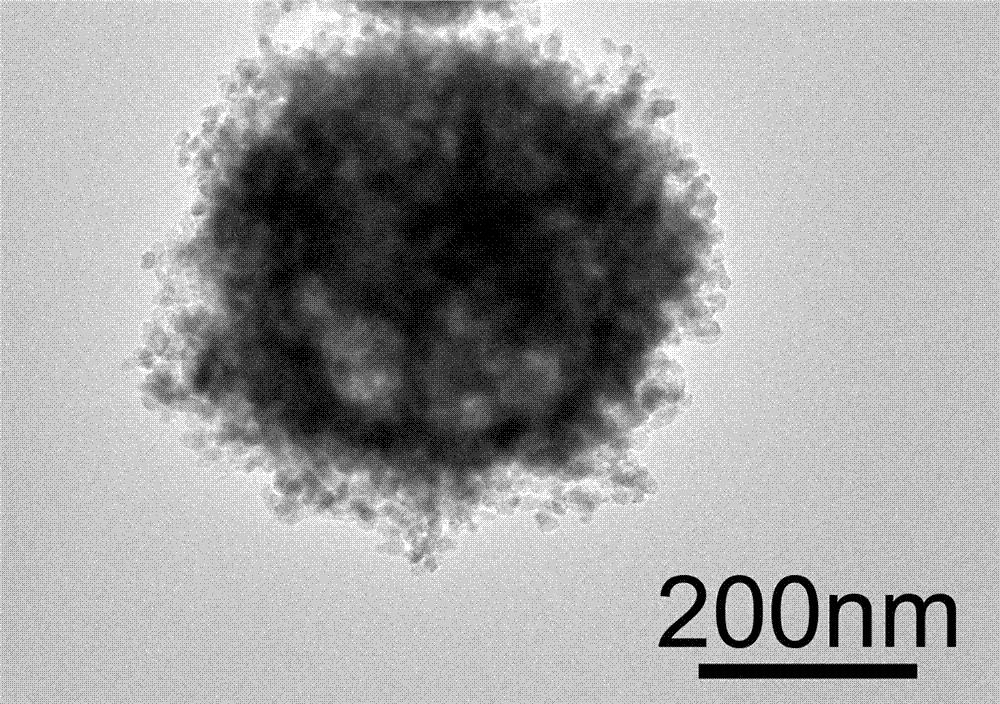

Preparation method of porous nickel selenide hollow nanospheres

ActiveCN102874773AGood chemical stabilityMeets friendly requirementsMaterial nanotechnologyBinary selenium/tellurium compoundsEngineeringSelenium Oxide

The invention belongs to the technical field of nanometer material, relates to a synthetic method for preparing porous hollow nanospheres with uniform appearance through a hydrothermal process, and particularly relates to a preparation method of porous nickel selenide hollow nanospheres. The preparation method comprises the steps as follows: positioning selenium dioxide and nickel nitrate into alkaline aqueous solution of ammonia water; and preparing the porous hollow nanospheres through the hydrothermal process under the reduction effect of hydrazine hydrate. The nickel selenide hollow nanospheres prepared by the preparation method provided by the invention have the diameter of 300 to 400nm, and are formed by self-assembling 30 to 50nm of porous nickel selenide. The preparation method provided by the invention is simple in technology, and high in repeatability; and the used nickel source and selenium source are the inorganic compounds, low in cost, easy to obtain, low in cost, and meets the environment-friendly requirement; the method can be conducted without pre-processing such as ageing and roasting; the resultant temperature is low, therefore, the energy consumption and the reacting cost are reduced; and the mass production can be conveniently conducted.

Owner:指南者品牌管理(苏州)有限公司

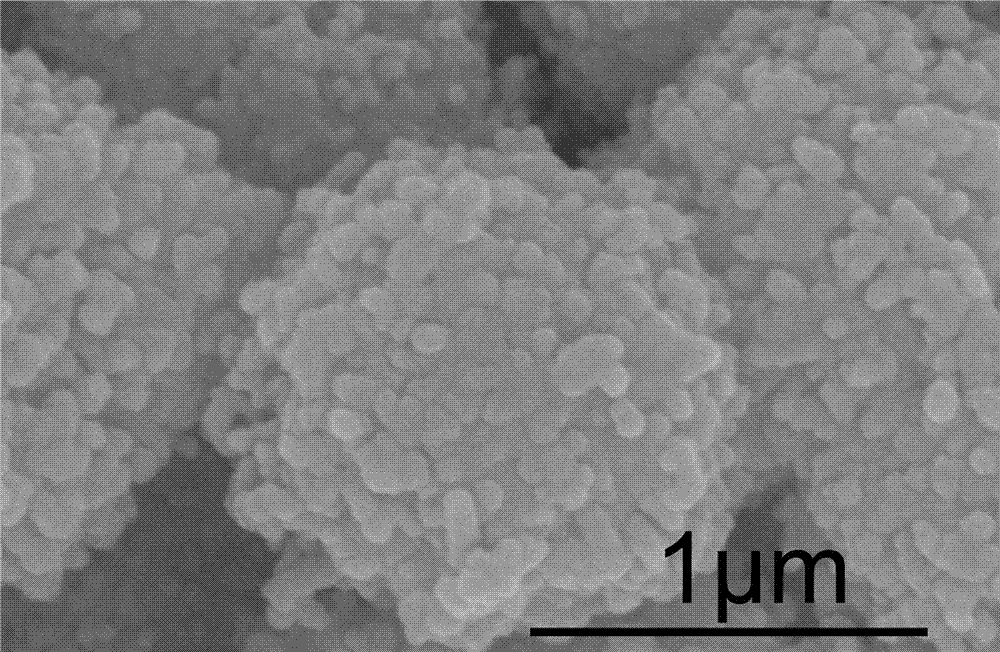

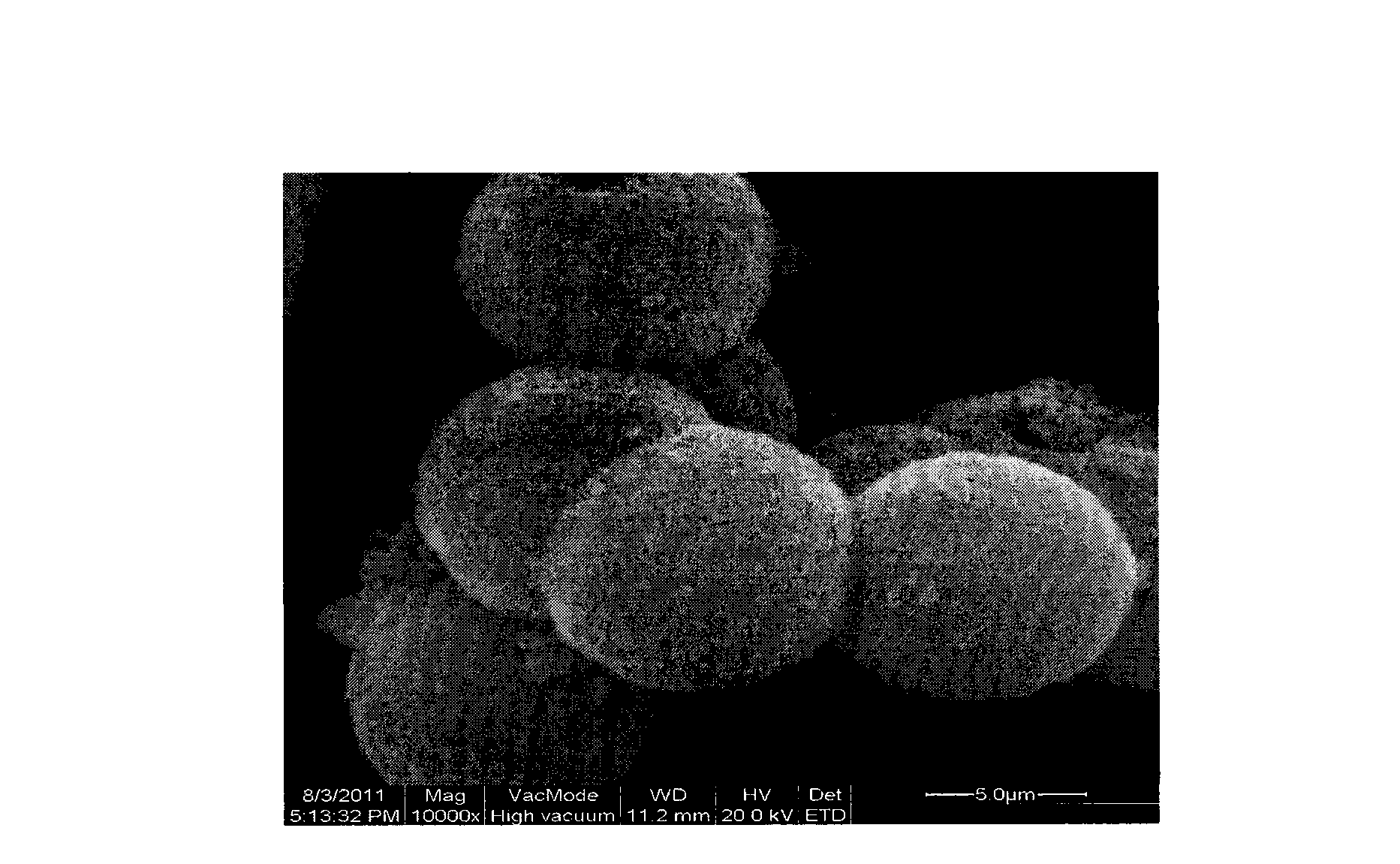

Method for preparing large-specific-surface-area porous nickel oxide microspheres

The invention discloses a method for preparing large-specific-surface-area porous nickel oxide microspheres. The method comprises the following steps of: preparing and synthesizing a mixed solution by taking nickel nitrate and urine as raw materials, taking hexadecyl trimethyl ammonium bromide as a surfactant, taking absolute ethanol and deionized water as washing agents and refining raw materials; heating in a reaction kettle for preparing hydrogen nickel carbonate; and washing, performing suction filtration, drying in vacuum, and baking to obtain large-specific-surface-area porous nickel oxide microspheres. The preparation method has the advantages of advanced process, short process flow, small using amount of raw materials, detailed and accurate data, high product yield which can be up to 95 percent and high product purity, which can be up to 98.5 percent; the specific surface area of the product, i.e., nickel oxide microspheres is 748.25m<2> / g, microsphere particles are less than or equal to 10 mum, irregular hexagonal nano-sheets are distributed on the surfaces of the microspheres and are less than or equal to 40 nanometers in diameter, and the microspheres can be matched with a plurality of chemical substances; and the method is very ideal method for preparing large-specific-surface-area porous nickel oxide microspheres.

Owner:TAIYUAN UNIV OF TECH

Pole lug aluminum strip surface treatment passivation solution

The invention discloses a pole lug aluminum strip surface treatment passivation solution. The pole lug aluminum strip surface treatment passivation solution comprises chromium trioxide, nickel nitrate hexahydrate, a pickling agent, a film formation accelerant and water. By means of the pole lug aluminum strip surface treatment passivation solution, the passivation film compactness and the salt mist can be improved, and the bonding performance between a film and pole lug glue can be improved.

Owner:MAIKAIMEN ELECTRONICS TECH SHANGHAI

Preparation method of capacitor electrode material beta-NiMoO4 and super capacitor

ActiveCN105244182AIncrease surface areaImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention discloses a preparation method of a capacitor electrode material beta-NiMoO4. The method comprises the following steps: (1) adding sodium molybdate dehydrate and nickel nitrate hexahydrate to ultrapure water, adding ammonium hydroxide to adjust pH to be 7-8, and stirring and mixing the ammonium hydroxide until the solution is clear; (2) putting plain carbon cloth and / or a carbon fiber into an air-tight reaction container, and adding the mixed solution prepared in the step (1) for sealing; (3) heating the air-tight reaction container prepared in the step (2) in thermostatically controlled heating equipment, and growing a beta-NiMoO4 nanowire on the carbon cloth; and (4) cooling the air-tight reaction container in the step (3) to a room temperature, taking out the carbon cloth, cleaning and drying the carbon cloth, and then burning the carbon cloth in the air to obtain the carbon cloth or carbon fiber with the beta-NiMoO4 nanowire. The invention further discloses an application of the capacitor electrode material in the super capacitor. The capacitor electrode material is relatively few in controllable parameters, low in cost, mild in reaction condition, high in conductivity, good in capacitance characteristics, high energy density and power density, and relatively long in cycle lifetime.

Owner:CHONGQING UNIV

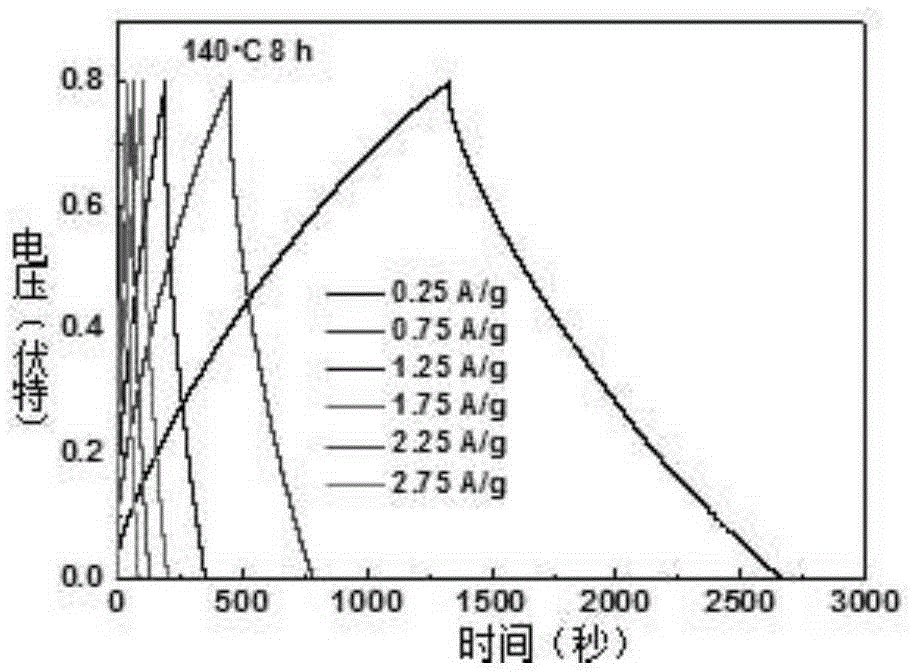

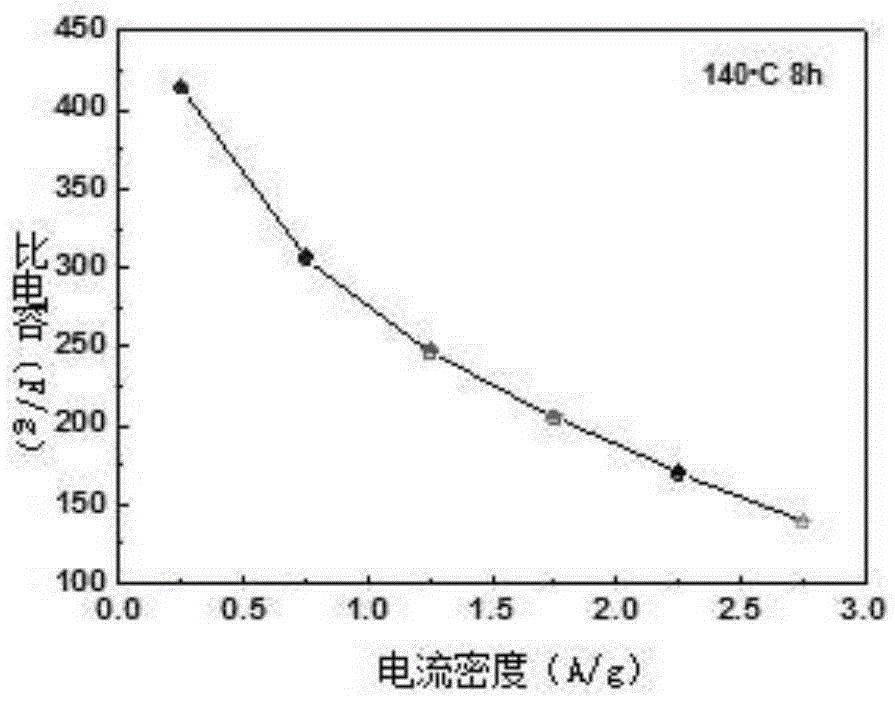

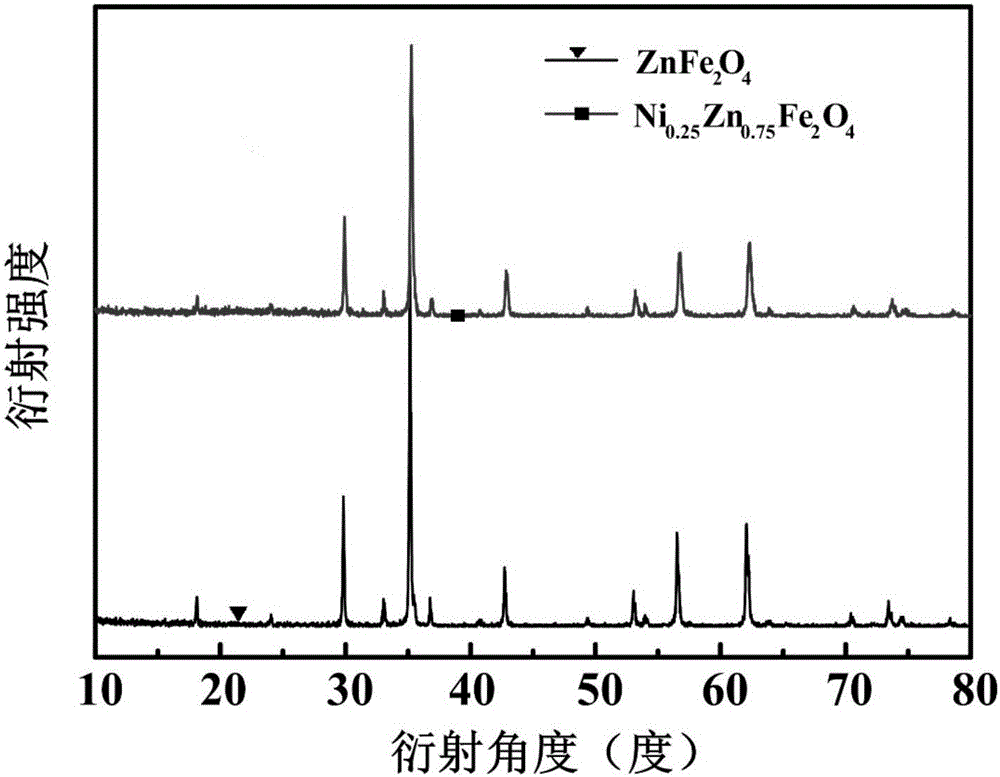

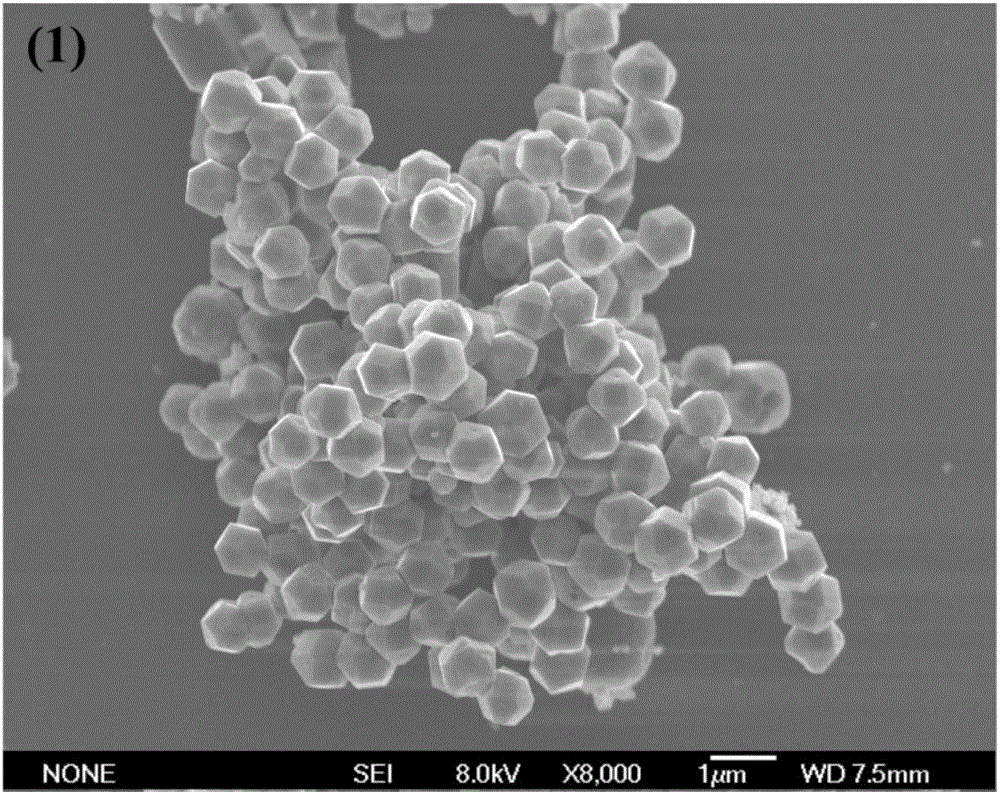

Method for improving electrochemical performance of zinc ferrite by doping nickel element and application

ActiveCN105958032AWide variety of sourcesThe synthesis method is simpleMaterial nanotechnologyCell electrodesCharge dischargeElectrochemistry

The invention discloses a method for improving charge-discharge cycling capacity of zinc ferrite by doping nickel element and application, and relates to the field of lithium ion battery anode composite material preparation. The method comprises the following steps: forming a ternary metallic oxide by doping the nickel element in zinc ferrite, selecting and using, and mixing and stirring nickel nitrate hexahydrate, zinc nitrate hexahydrate, ferrous sulfate septihydrate, urea and ammonium fluoride according to a certain molar mass ratio to form a uniform mixed solution; and carrying out hydro-thermal synthesis and calcinations to obtain NixZn1-xFe2O4(x being greater than 0 and smaller than 1) metallic oxide. According to the method, the NixZn1-xFe2O4(x being greater than 0 and smaller than 1) metallic oxide with excellent electrochemical performance can be prepared; and moreover, the synthetic method is relatively simple, low in energy consumption, good in controllability, high in yield and low in cost, and is applicable for large-scale production. The invention also discloses application of the NixZn1-xFe2O4(x being greater than 0 and smaller than 1) metallic oxide, the NixZn1-xFe2O4(x being greater than 0 and smaller than 1) metallic oxide is used for lithium ion battery anode materials, and the metallic oxide has the characteristics of high charging and discharging specific capacity and high cycling stability.

Owner:JILIN UNIV

Method for preparing carbon nano tube enhanced titanium-base compound material by in-suit reaction

The invention relates to a method for preparing a carbon nano tube enhanced titanium-base compound material by in-suit reaction in order to solve the problems of low uniform dispersion and low structural completeness of a carbon nano tube in the conventional method for preparing the carbon nano tube enhanced titanium-base compound material and pollution to the titanium-base material caused by reaction of a carbon group and a titanium base body. The method comprises the following steps of: adding nickel nitrate hexahydrate and TiH2 powder into an ethanol solution, stirring and evaporating to obtain Ni-TiH2 compound powder; paving the Ni-TiH2 compound powder in a quartz boat, putting the quartz boat into deposition equipment, feeding H2, raising temperature, feeding CH4, and after the deposition is finished, stopping feeding the CH4 so as to obtain carbon nano tube / TiH2 compound power; pressing the carbon nano tube / TiH2 compound power into a block body, sintering, and re-pressing to obtain the carbon nano tube enhanced titanium-base compound material. Carbon nano tubes in the compound material are uniform to disperse and cannot be aggregated; the compound material is high in purity and has a complete structure; and reaction between the titanium and the defected carbon nano tube can be avoided.

Owner:HARBIN INST OF TECH

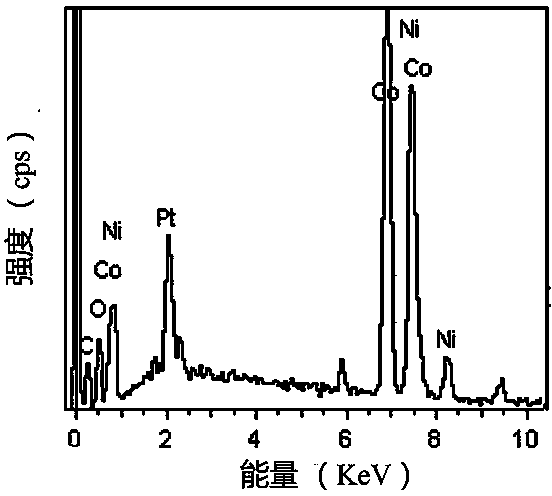

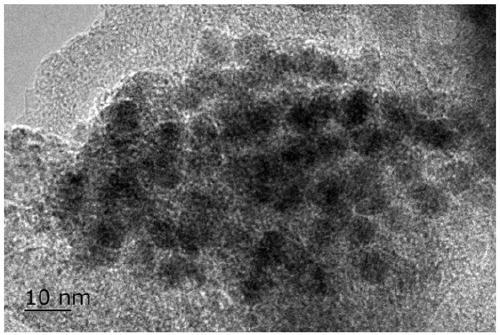

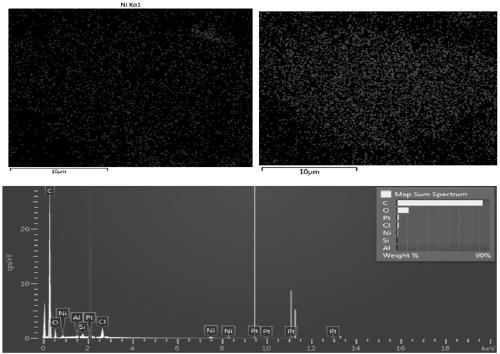

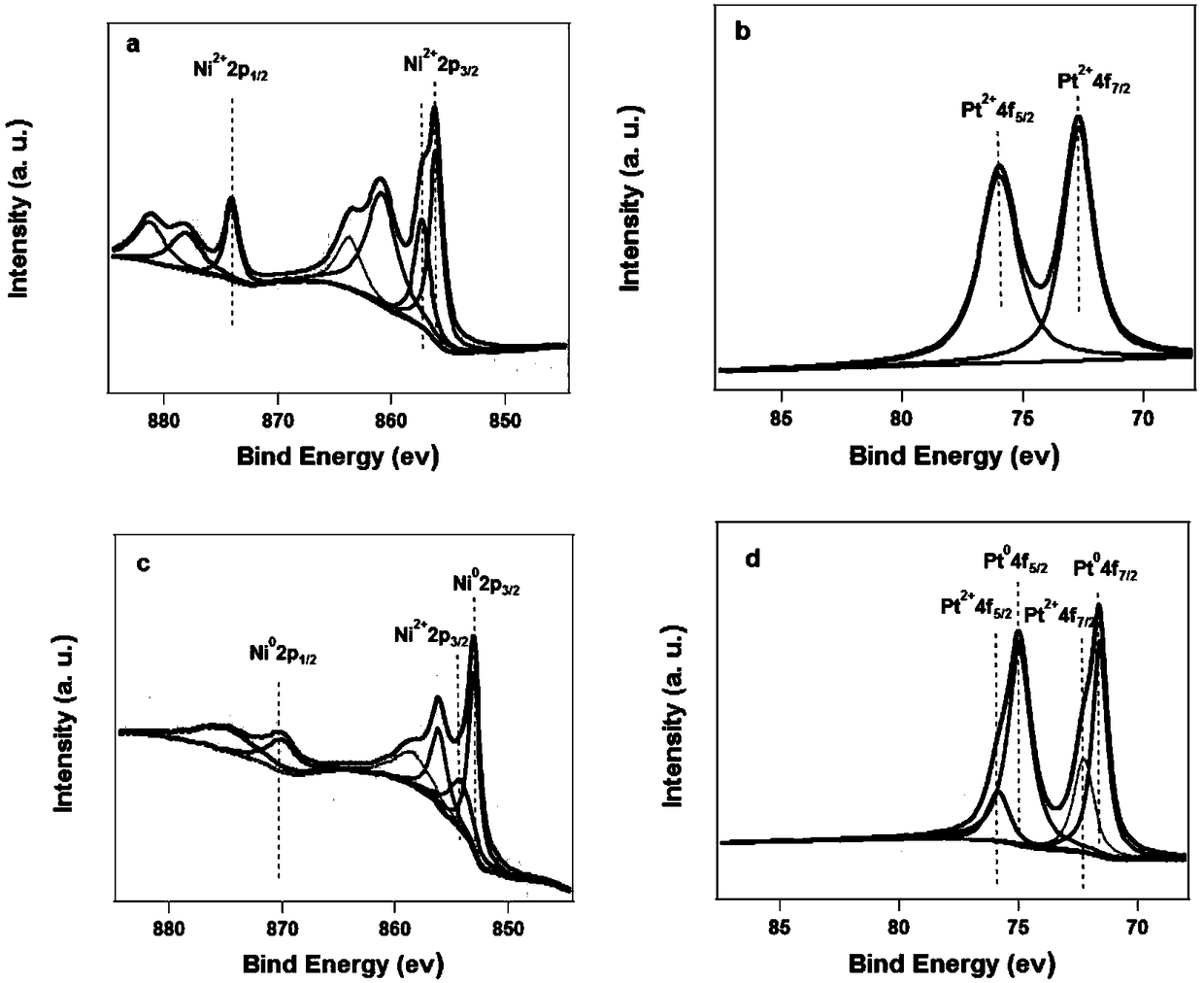

PtNi/C bimetallic catalyst and preparation method thereof

ActiveCN109225254AReduce manufacturing costSolve the problems of poor selectivity, easy carbon deposition and deactivationOrganic chemistryCatalyst activation/preparationActivated carbonNitrate

The invention provides a PtNi / C bimetallic catalyst and a preparation method thereof. The preparation method comprises the following steps: (1) adding pretreated activated carbon into a nitric acid solution, heating to a temperature of 75-85 DEG C, uniformly stirring, filtering and washing the activated carbon until the pH value is 7, and drying the washed activated carbon; (2) adding the activated carbon into deionized water, sequentially adding chloroplatinic acid and nickel nitrate to be uniformly stirred so as to obtain a catalyst precursor solution, centrifuging the catalyst precursor solution, and drying to obtain a catalyst precursor; (3) reducing the catalyst precursor in a hydrogen atmosphere of 400 DEG C for 2 hours, thereby obtaining the PtNi / C bimetallic catalyst. The bimetallic catalyst provided by the invention has large specific surface area and high reaction activity, and is capable of catalyzing selective hydrogenation of furfural in an aqueous phase at a normal temperature, the reaction efficiency is greatly improved, the reactive energy consumption is reduced, aqueous phase catalysis is realized, and the bimetallic catalyst has excellent economic value and environmental protection significance.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com