Preparation method for synthesizing three-dimensional graphene reinforced nickel-based composite material in situ

A composite material and in-situ synthesis technology, which is applied in the field of in-situ synthesis of three-dimensional graphene-reinforced nickel-based composite materials, and achieves the effects of good dispersion, simple reaction process and controllable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

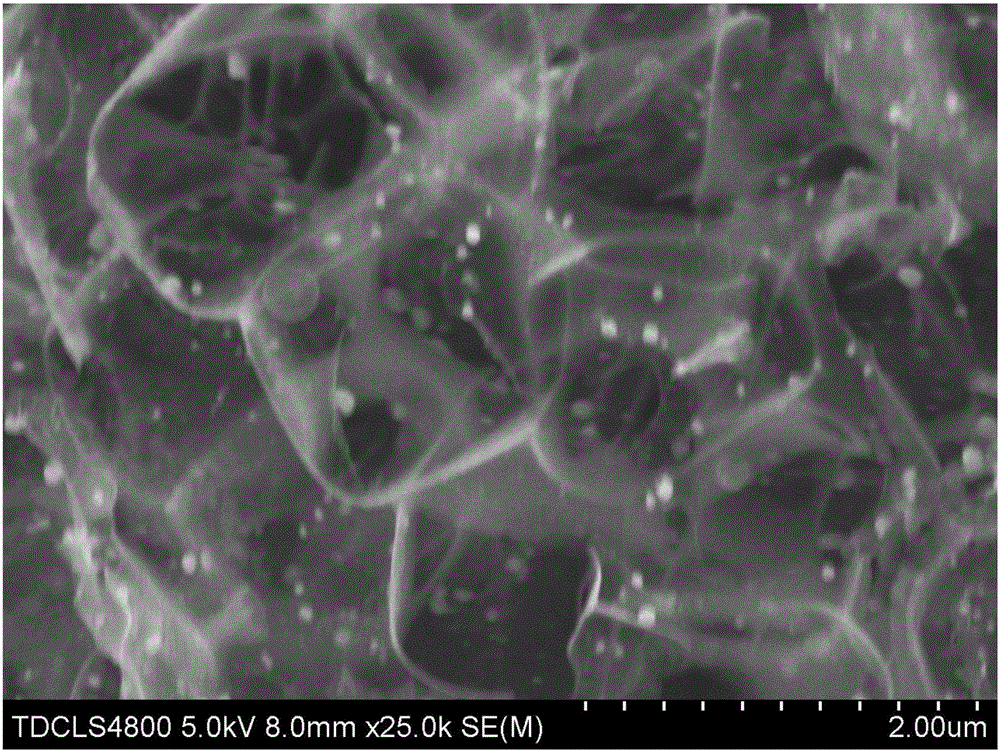

[0024] Weigh 1.000g of glucose, 0.431g of nickel nitrate hexahydrate and 21.535g of sodium chloride, mix them and dissolve them in 80ml of deionized water, stir and dissolve with a magnetic stirrer at a stirring speed of 250r / min to form a solution, and mix well A light green solution was obtained. Put the mixed solution in the refrigerator for 12 hours to freeze, and then place it in a freeze dryer at -50°C for 24 hours under vacuum to freeze-dry to obtain a three-dimensional graphene precursor mixture. Grind the mixture and pass through a 100-mesh sieve, take 10g of composite powder and spread it on the corundum ark, place the corundum ark in the constant temperature zone of the high-temperature tube furnace, and pass the air in the argon exhaust pipe at a rate of 100ml / min, and switch after 20min To a mixture of argon and hydrogen at a ratio of 4:1, the tube furnace is heated to 750°C at a heating rate of 5°C / min, kept for 2 hours, and then cooled to room temperature at a c...

Embodiment 2

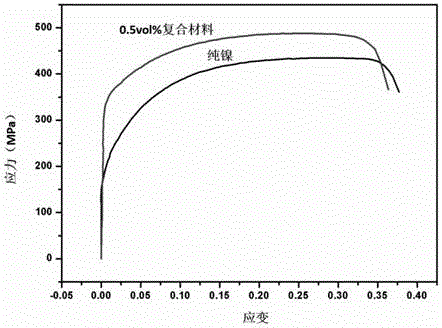

[0026]Weigh 1.000g of glucose, 0.431g of nickel nitrate hexahydrate and 21.535g of sodium chloride, mix them and dissolve them in 80ml of deionized water, stir and dissolve with a magnetic stirrer at a stirring speed of 250r / min to form a solution, and mix well A light green solution was obtained. Put the mixed solution in the refrigerator for 12 hours to freeze, and then place it in a freeze dryer at -50°C for 24 hours under vacuum to freeze-dry to obtain a three-dimensional graphene precursor mixture. Grind the mixture and pass through a 100-mesh sieve, take 10g of composite powder and spread it on the corundum ark, place the corundum ark in the constant temperature zone of the high-temperature tube furnace, and pass the air in the argon exhaust pipe at a rate of 100ml / min, and switch after 20min To a mixture of argon and hydrogen at a ratio of 4:1, the tube furnace is heated to 750°C at a heating rate of 5°C / min, kept for 2 hours, and then cooled to room temperature at a co...

Embodiment 3

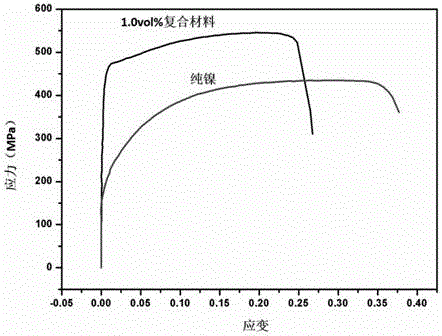

[0028] Weigh 1.000g of glucose, 0.431g of nickel nitrate hexahydrate and 21.535g of sodium chloride, mix them and dissolve them in 80ml of deionized water, stir and dissolve with a magnetic stirrer at a stirring speed of 250r / min to form a solution, and mix well A light green solution was obtained. Put the mixed solution in the refrigerator for 12 hours to freeze, and then place it in a freeze dryer at -50°C for 24 hours under vacuum to freeze-dry to obtain a three-dimensional graphene precursor mixture. Grind the mixture and pass through a 100-mesh sieve, take 10g of composite powder and spread it on the corundum ark, place the corundum ark in the constant temperature zone of the high-temperature tube furnace, and pass the air in the argon exhaust pipe at a rate of 100ml / min, and switch after 20min To a mixture of argon and hydrogen at a ratio of 4:1, the tube furnace is heated to 750°C at a heating rate of 5°C / min, kept for 2 hours, and then cooled to room temperature at a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com