Patents

Literature

35354 results about "Graphene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

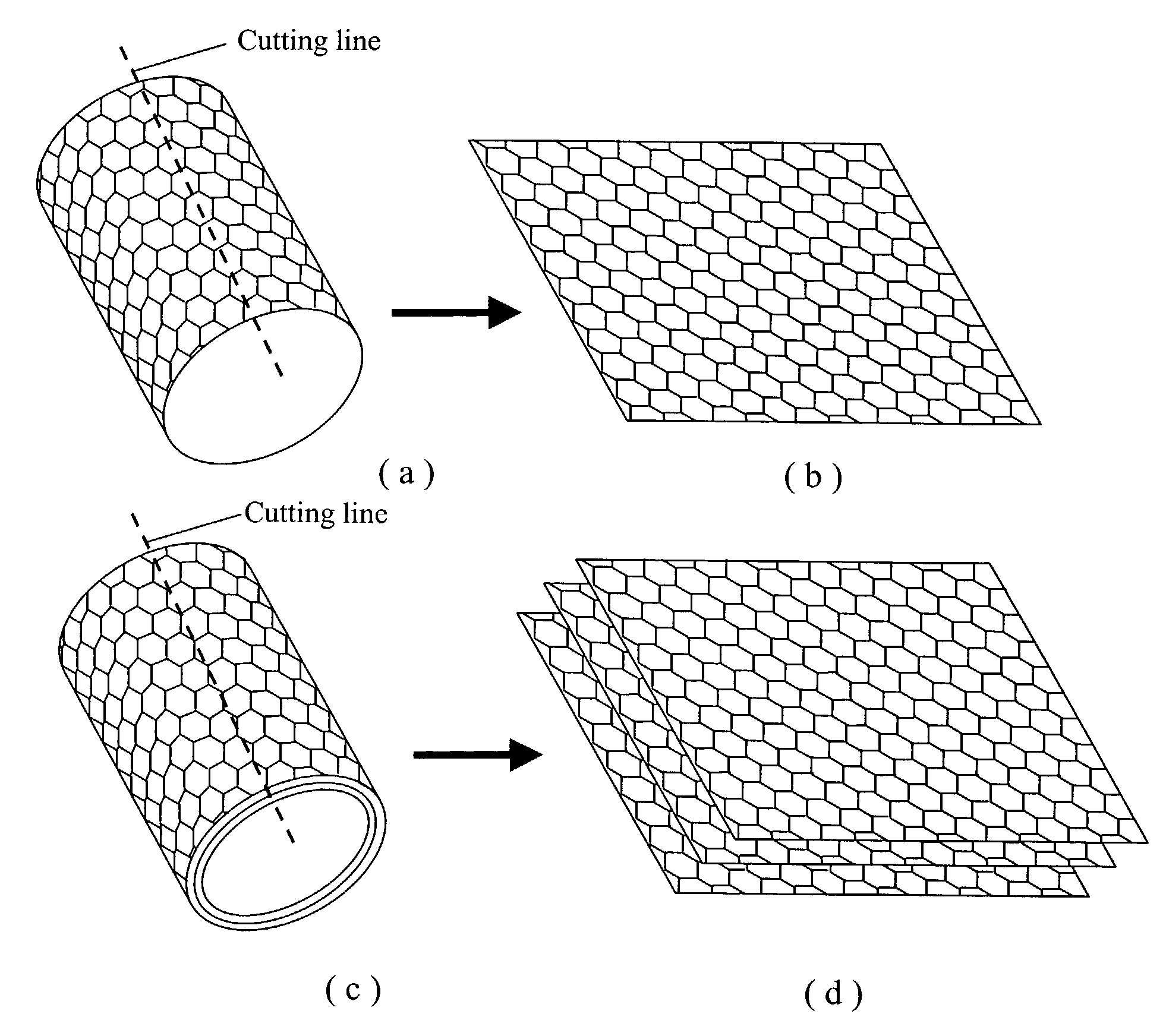

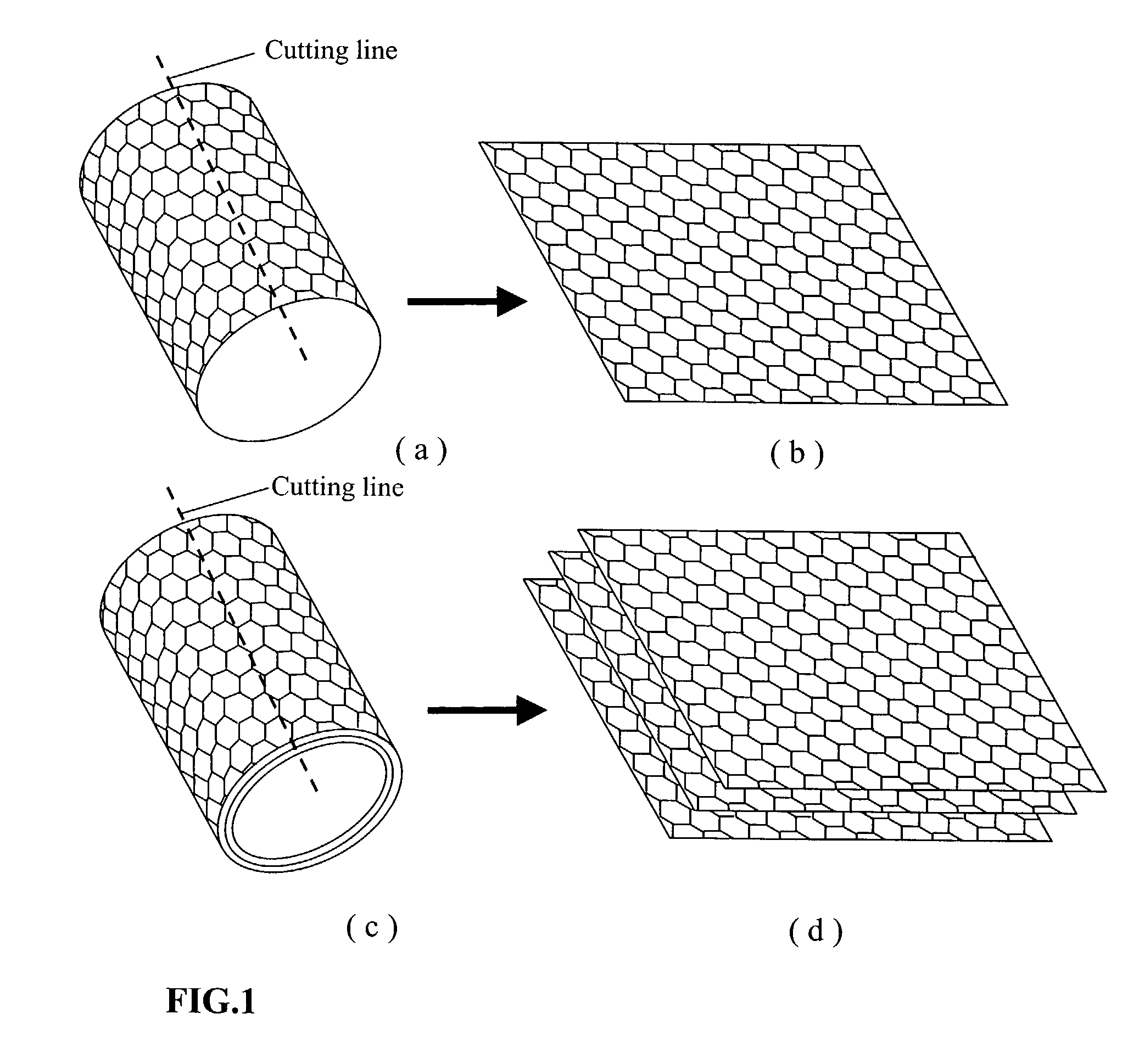

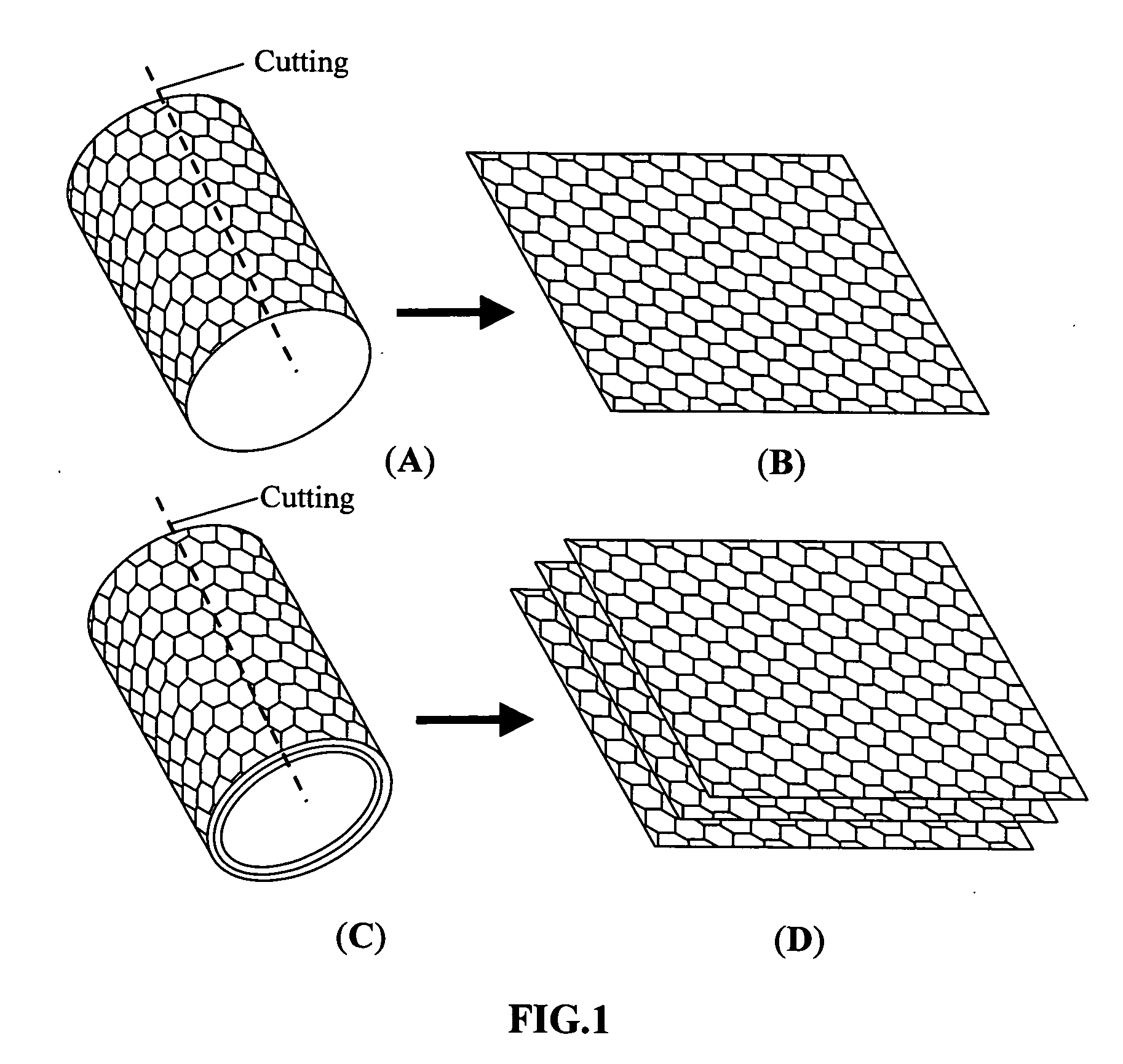

Graphene (/ˈɡræfiːn/) is an allotrope of carbon in the form of a single layer of atoms in a two-dimensional hexagonal lattice in which one atom forms each vertex. It is the basic structural element of other allotropes, including graphite, charcoal, carbon nanotubes and fullerenes. It can also be considered as an indefinitely large aromatic molecule, the ultimate case of the family of flat polycyclic aromatic hydrocarbons.

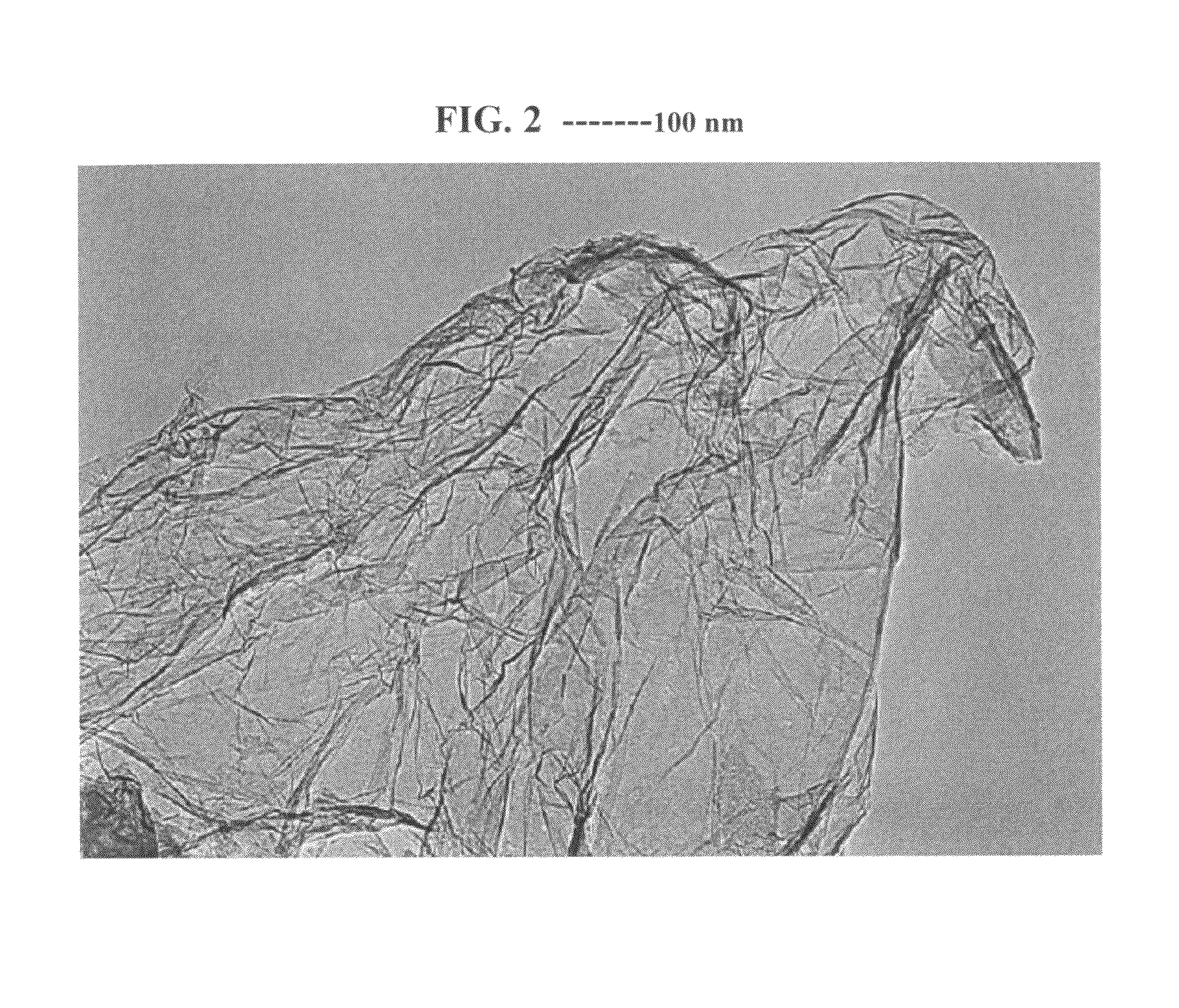

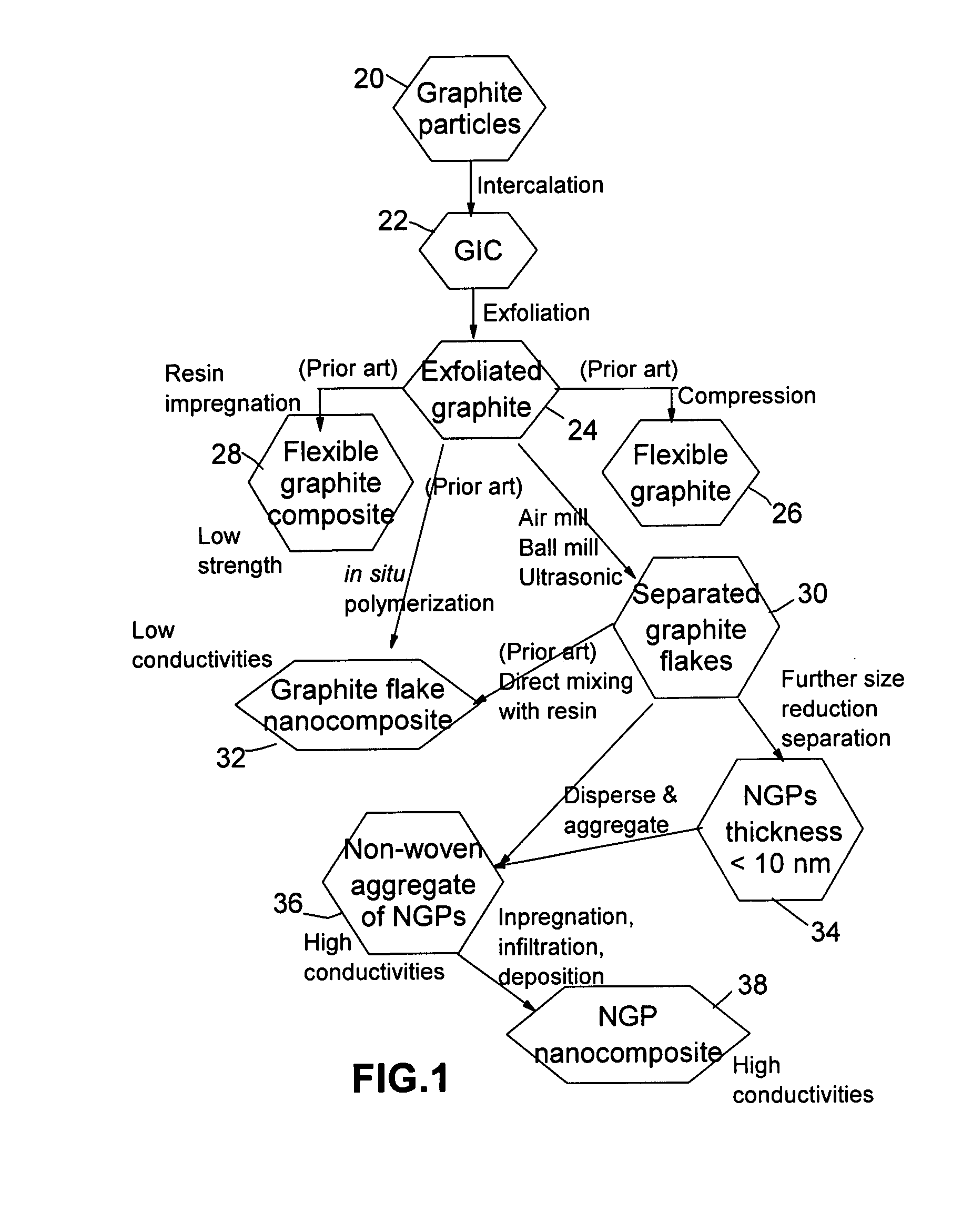

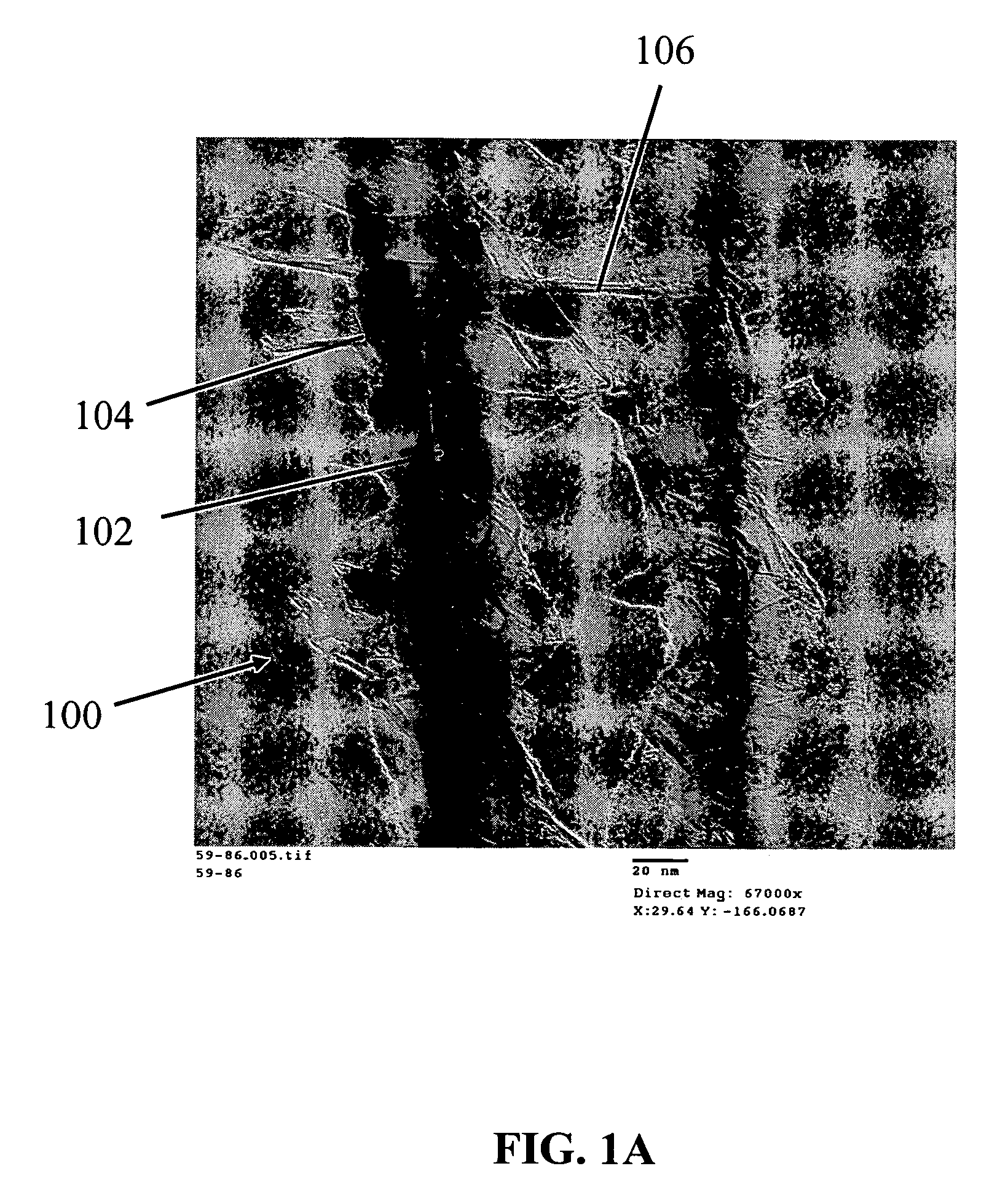

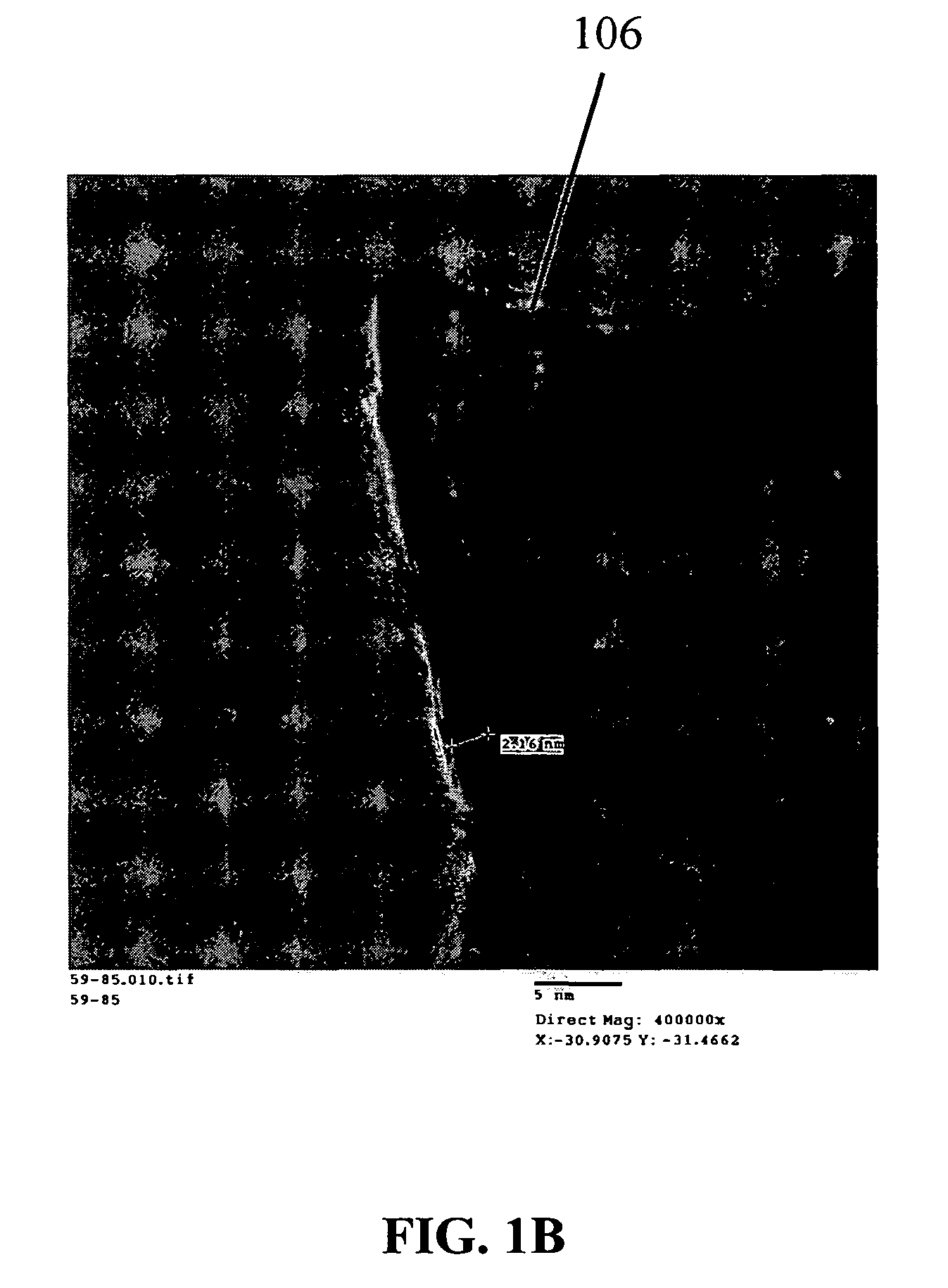

Nano-scaled graphene plates

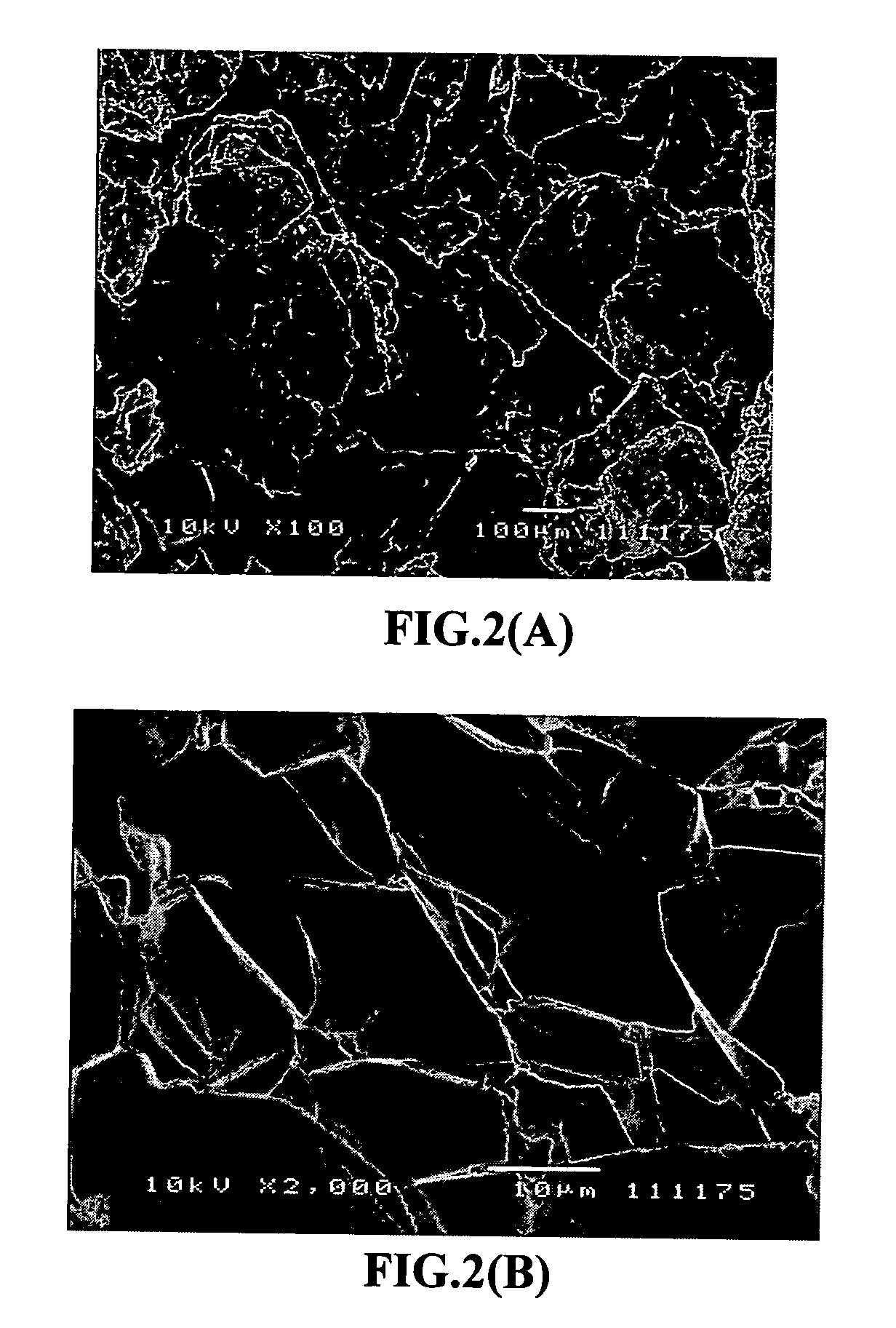

A nano-scaled graphene plate material and a process for producing this material. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:GLOBAL GRAPHENE GRP INC

Process for producing nano-scaled graphene plates

InactiveUS20050271574A1Faster and cost-effective processHighly cost-effectiveMaterial nanotechnologyGraphiteGrapheneGraphite particle

A process for producing nano-scaled graphene plates with each plate comprising a sheet of graphite plane or multiple sheets of graphite plane with the graphite plane comprising a two-dimensional hexagonal structure of carbon atoms. The process includes the primary steps of: (a) providing a powder of fine graphite particles comprising graphite crystallites with each crystallite comprising one sheet or normally a multiplicity of sheets of graphite plane bonded together; (b) exfoliating the graphite crystallites to form exfoliated graphite particles, which are characterized by having at least two graphite planes being either partially or fully separated from each other; and (c) subjecting the exfoliated graphite particles to a mechanical attrition treatment to further reduce at least one dimension of the particles to a nanometer scale, <100 nm, for producing the nano-scaled graphene plates.

Owner:GLOBAL GRAPHENE GRP INC

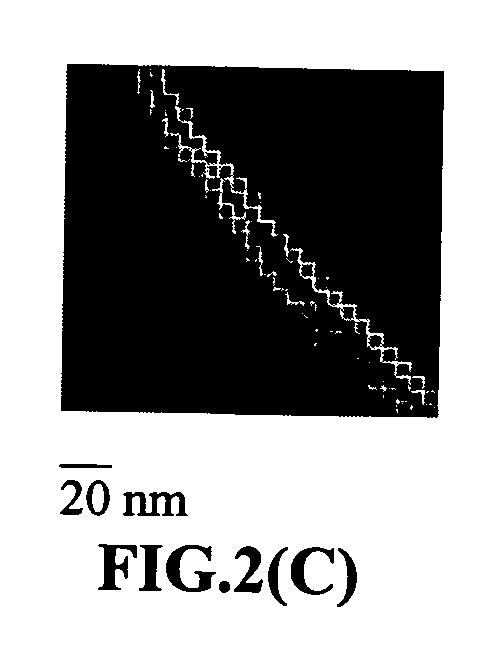

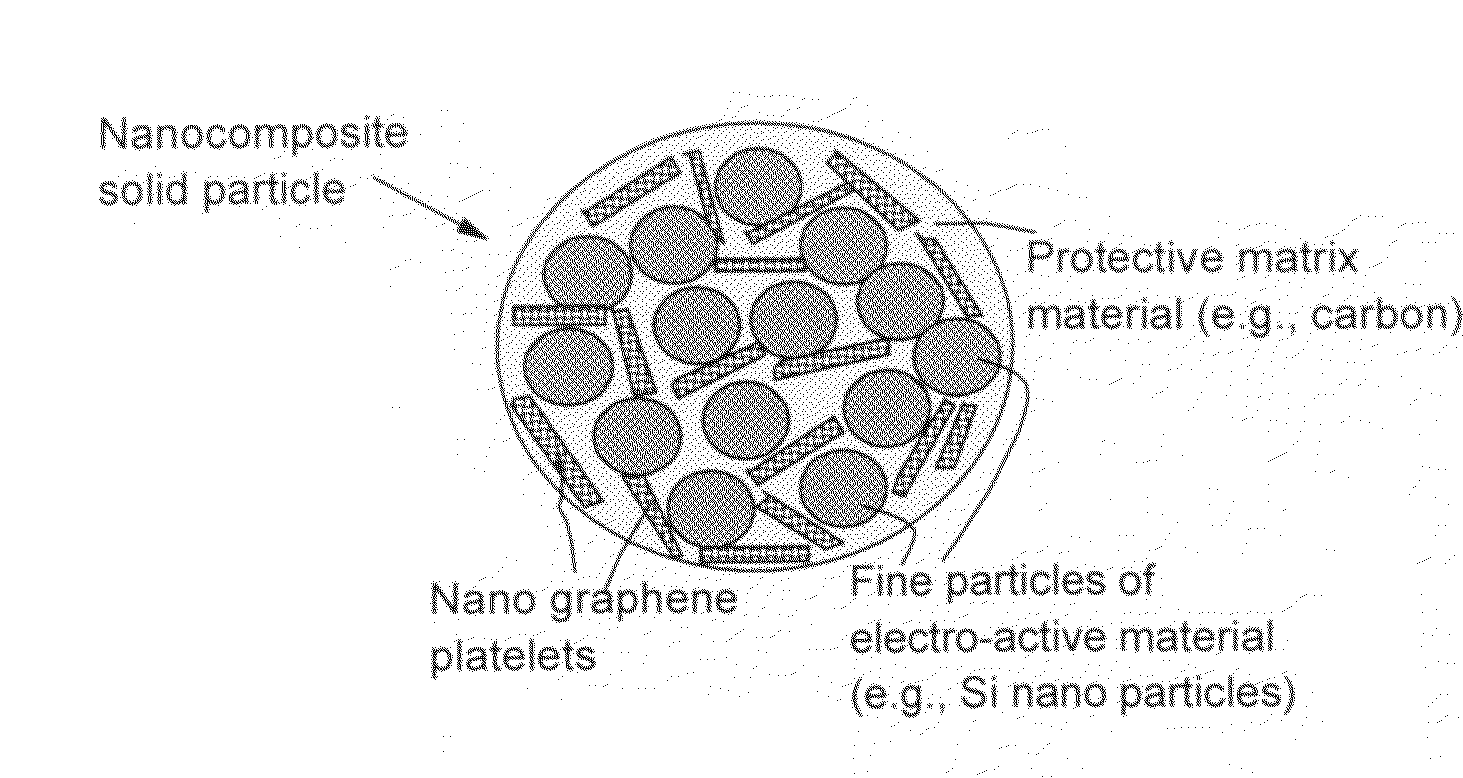

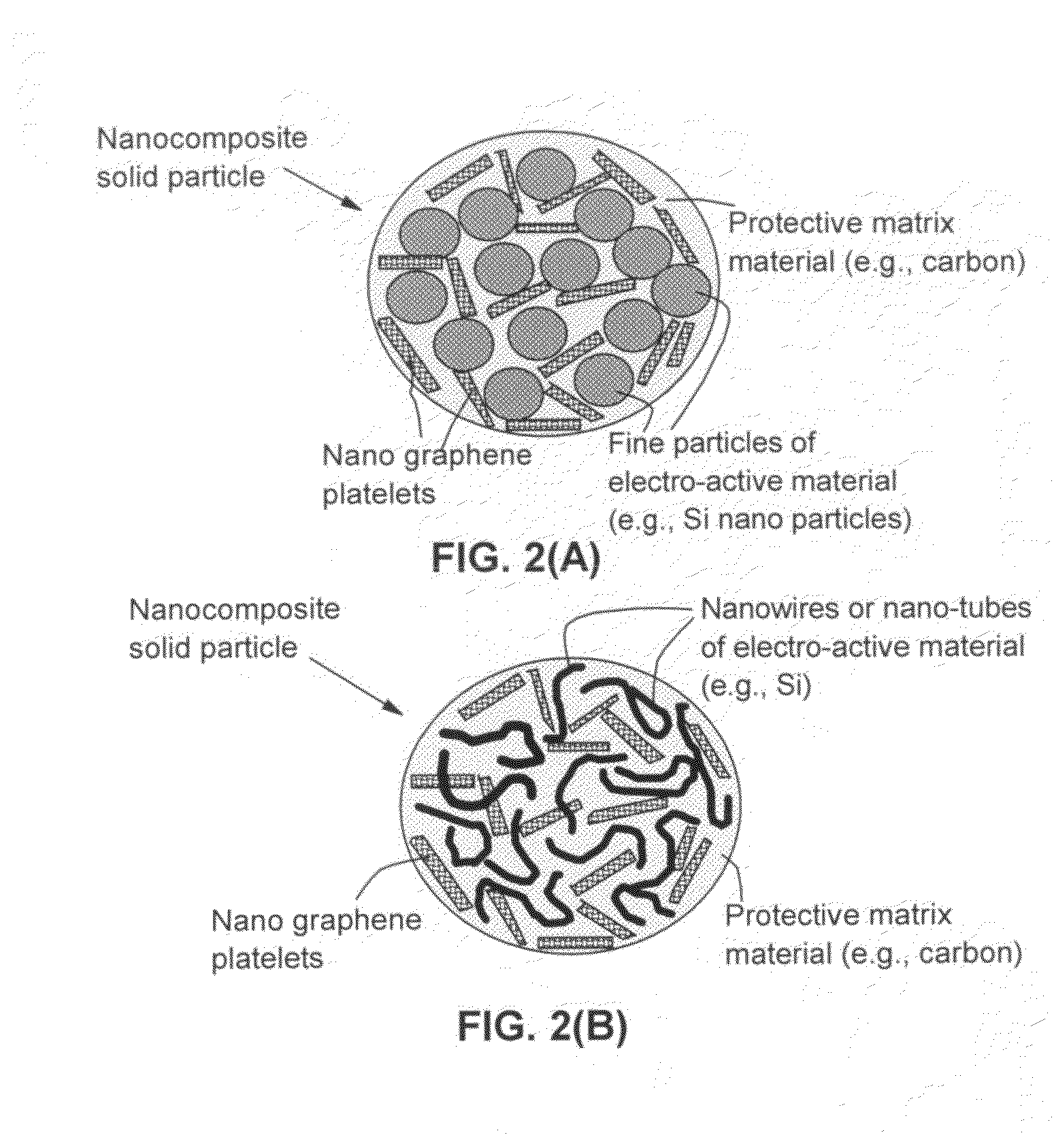

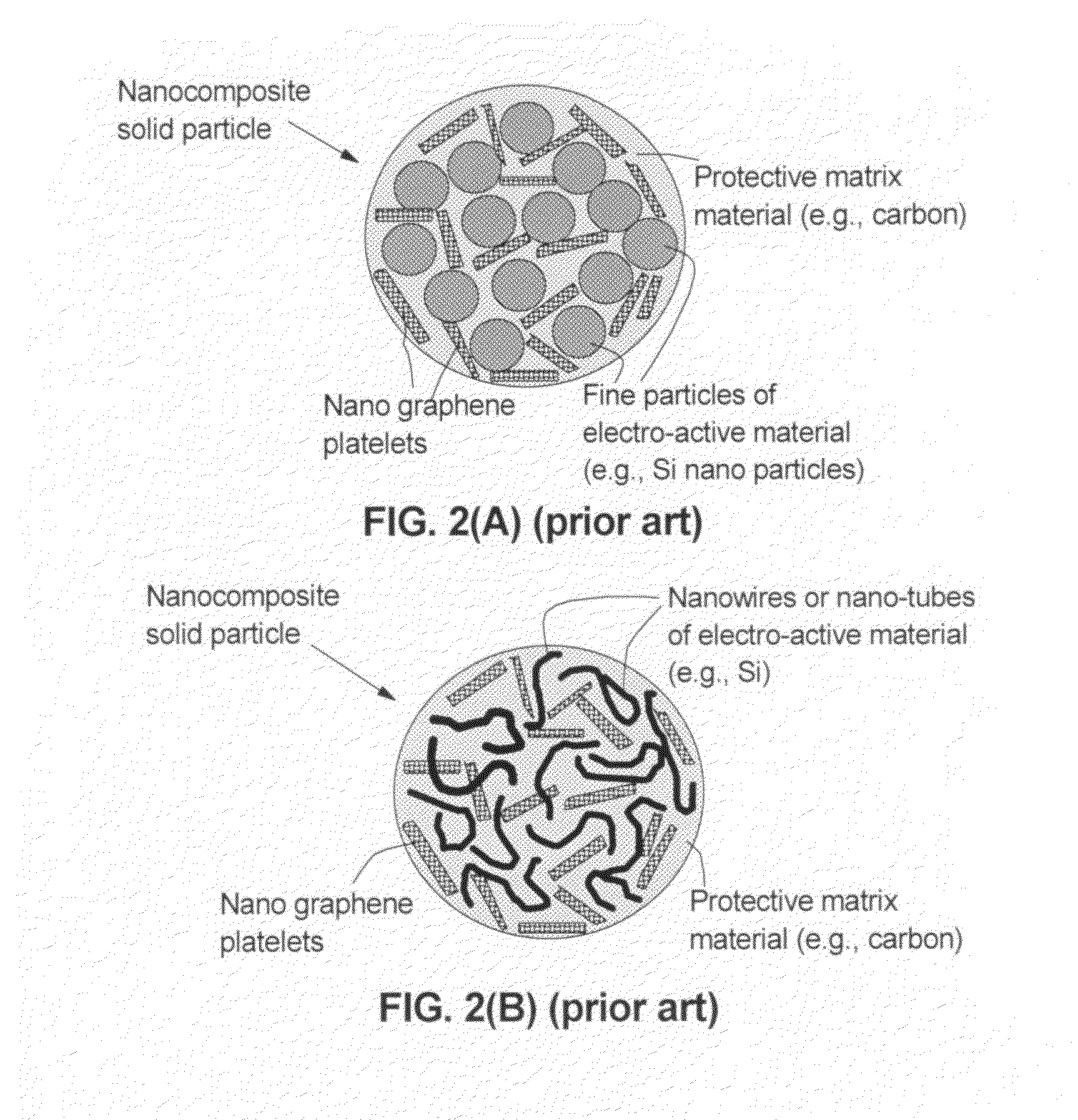

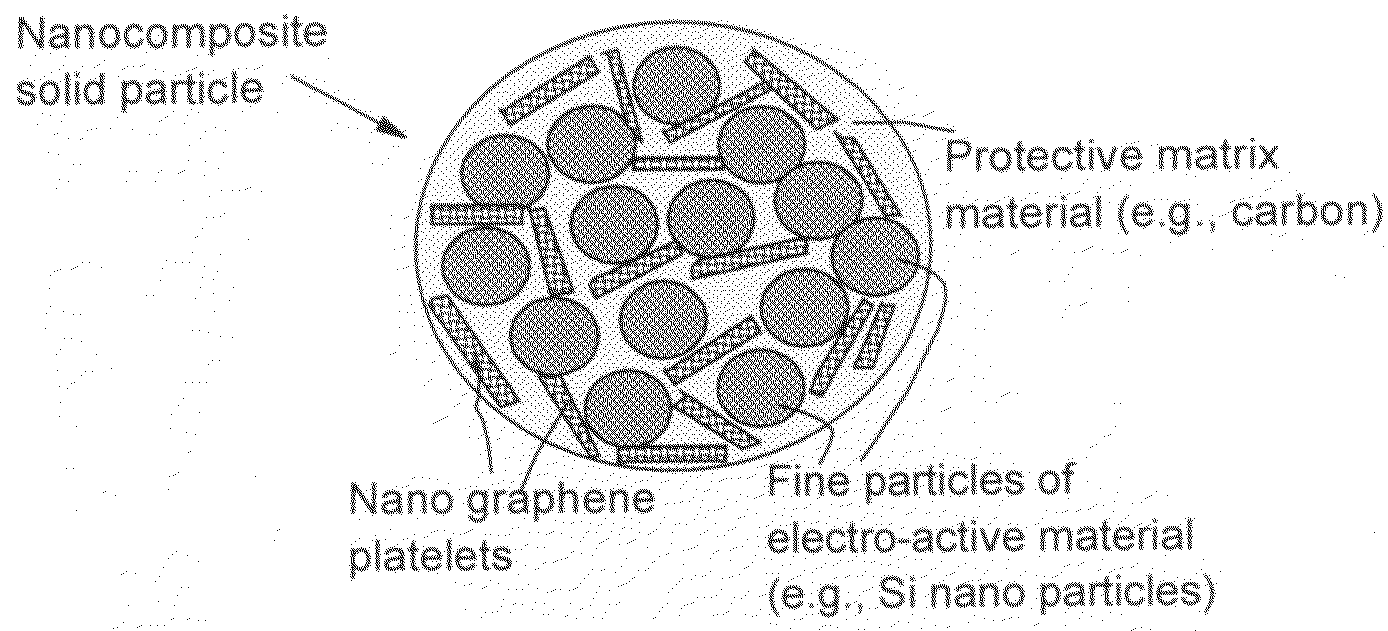

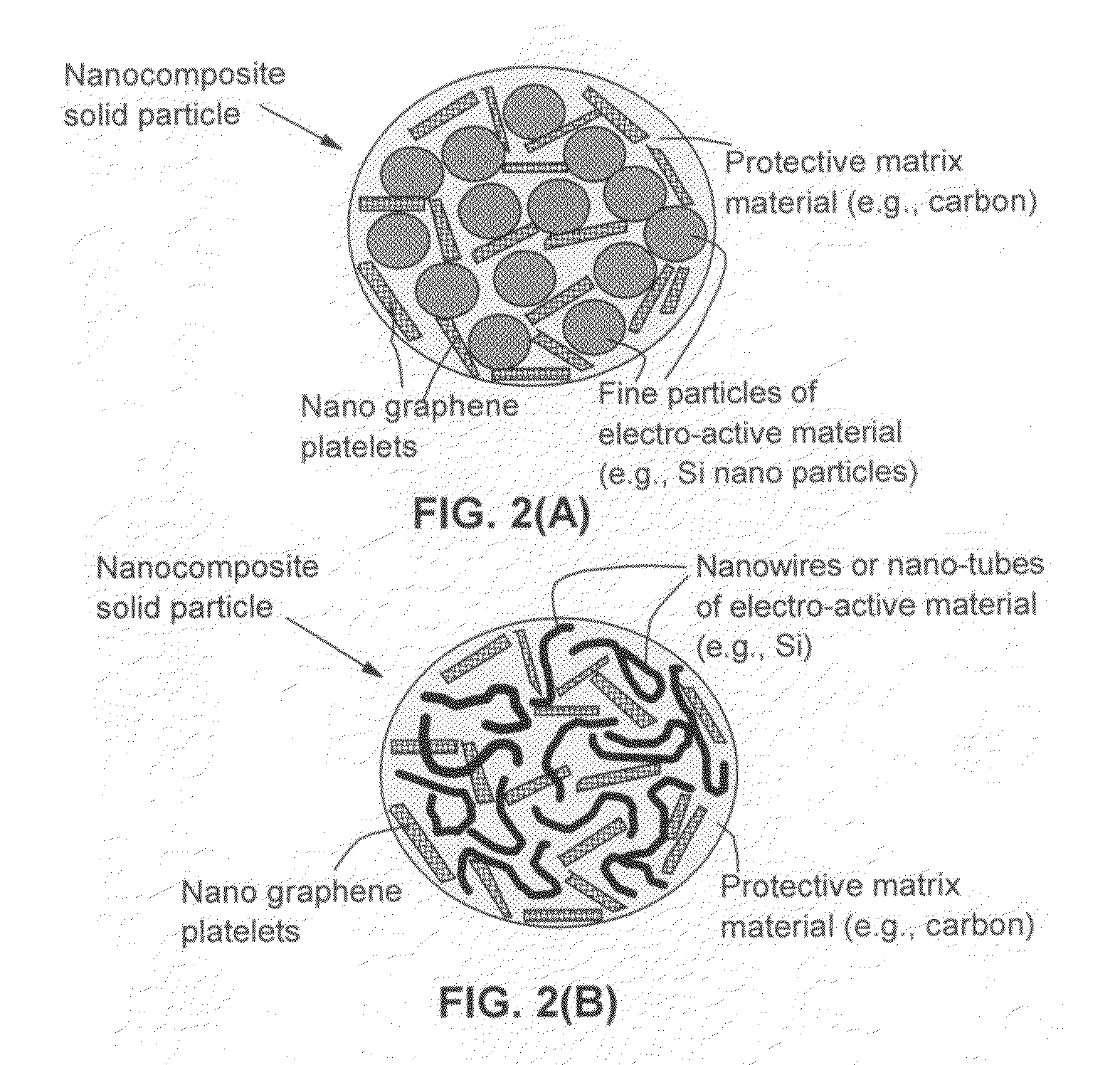

Nano graphene reinforced nanocomposite particles for lithium battery electrodes

ActiveUS20100143798A1Increase stiffnessHigh strengthActive material electrodesSecondary cellsLithium metalNanocomposite

A solid nanocomposite particle composition for lithium metal or lithium ion battery electrode applications. The composition comprises: (A) an electrode active material in a form of fine particles, rods, wires, fibers, or tubes with a dimension smaller than 1 μm; (B) nano graphene platelets (NGPs); and (C) a protective matrix material reinforced by the NGPs; wherein the graphene platelets and the electrode active material are dispersed in the matrix material and the NGPs occupy a weight fraction wg of 1% to 90% of the total nanocomposite weight, the electrode active material occupies a weight fraction wa of 1% to 90% of the total nanocomposite weight, and the matrix material occupies a weight fraction wm of at least 2% of the total nanocomposite weight with wg+wa+wm=1. For a lithium ion battery anode application, the matrix material is preferably amorphous carbon, polymeric carbon, or meso-phase carbon. Such a solid nanocomposite composition provides a high anode capacity and good cycling stability. For a cathode application, the resulting lithium metal or lithium ion battery exhibits an exceptionally high cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

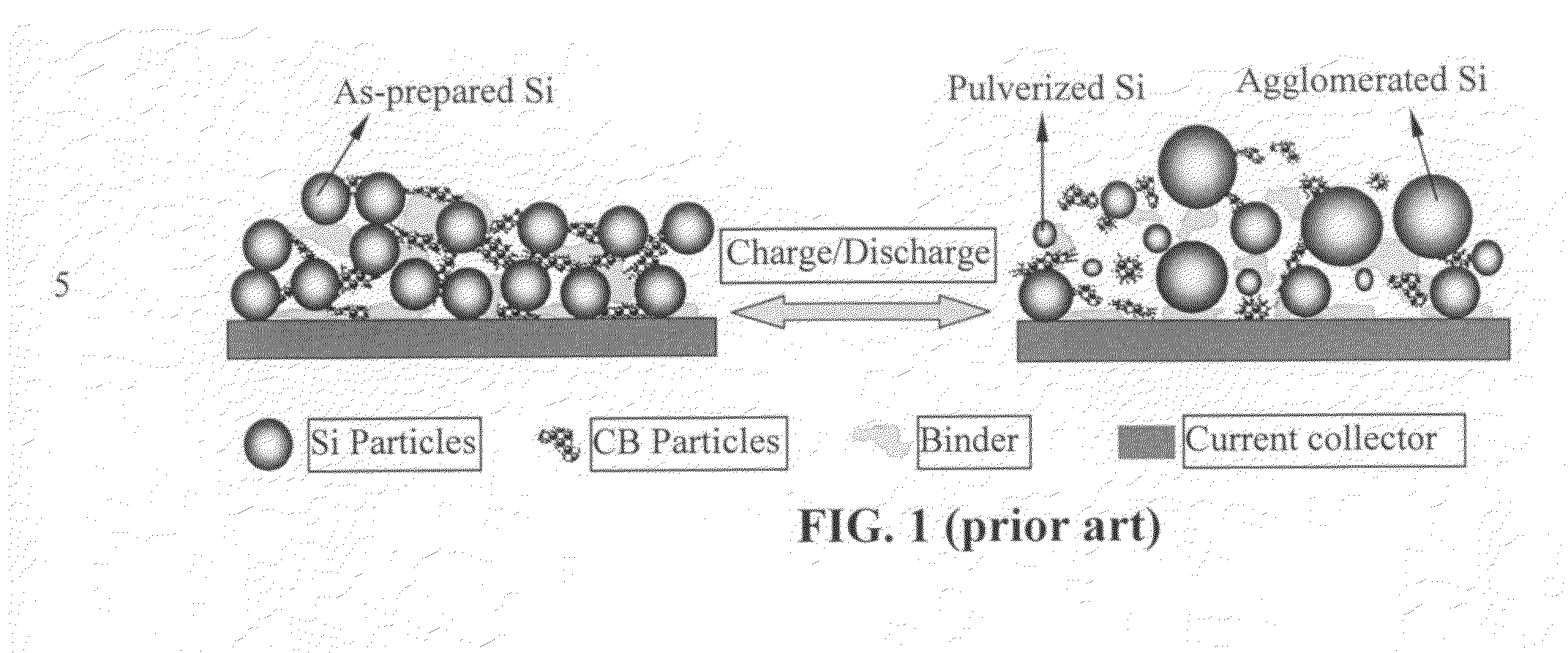

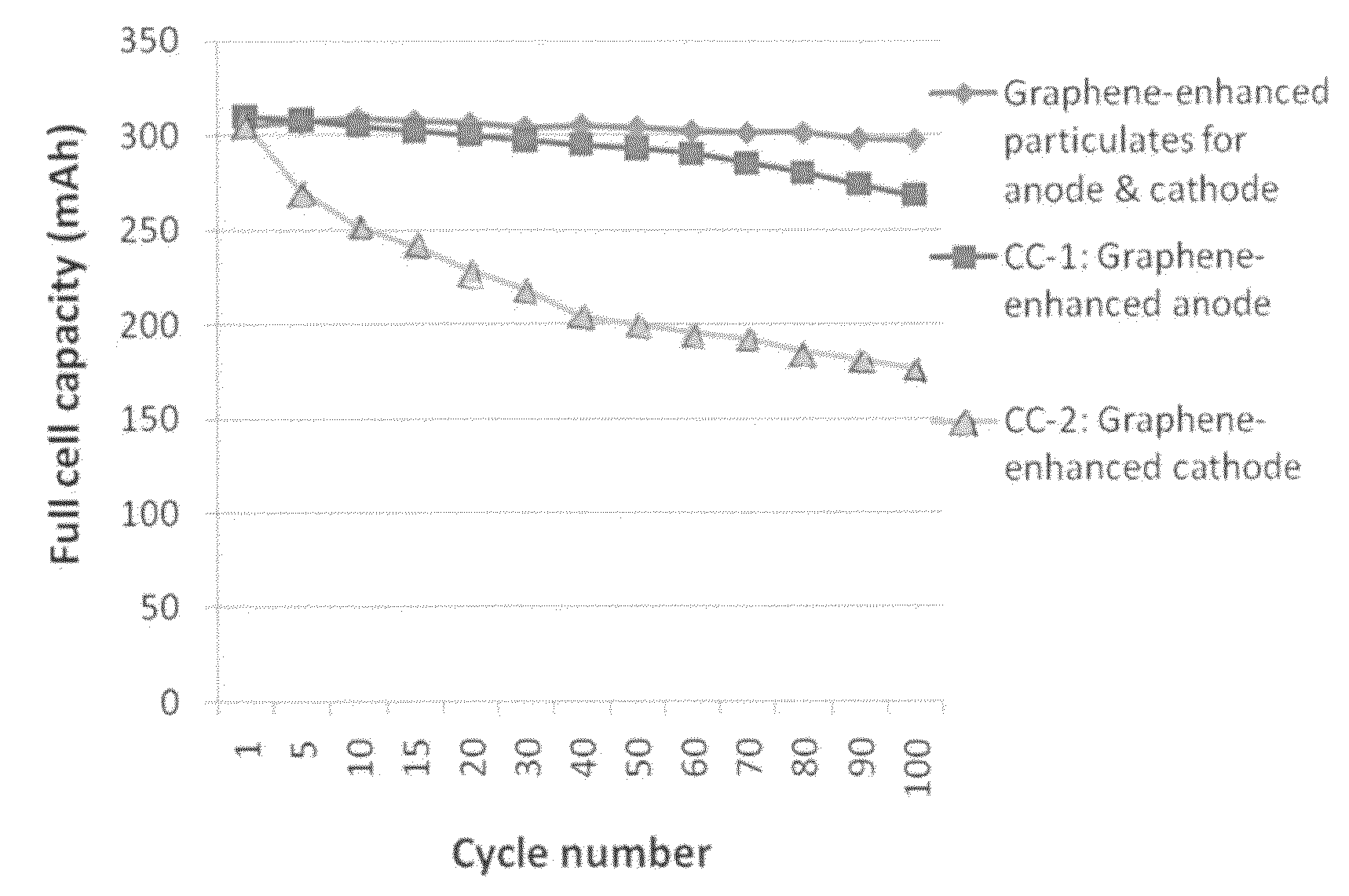

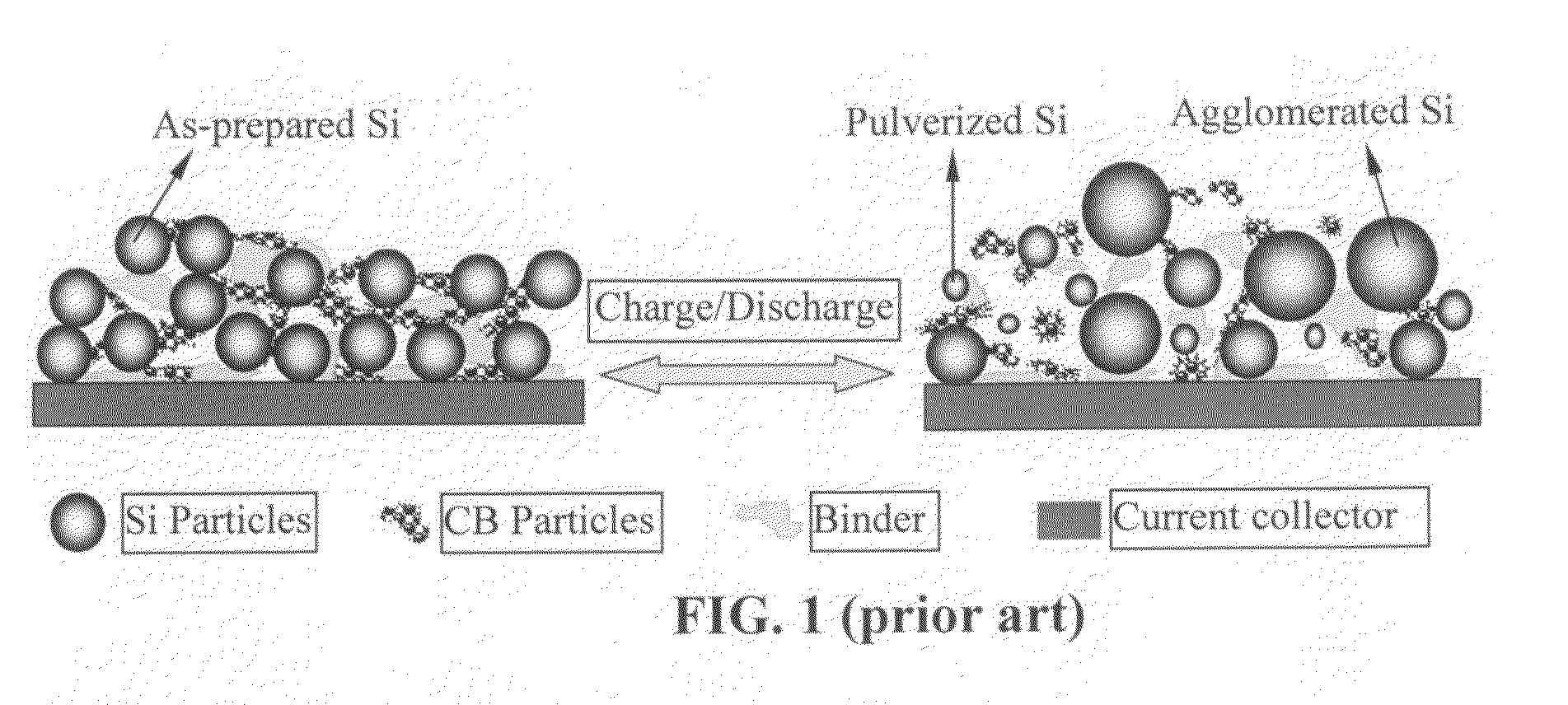

Graphene-enhanced anode particulates for lithium ion batteries

ActiveUS20120064409A1Enhanced Li-ion insertionIncrease capacityNon-metal conductorsMaterial nanotechnologyParticulatesMicroparticle

A nano graphene-enhanced particulate for use as a lithium-ion battery anode active material, wherein the particulate is formed of a single sheet of graphene or a plurality of graphene sheets and a plurality of fine anode active material particles with a size smaller than 10 μm. The graphene sheets and the particles are mutually bonded or agglomerated into the particulate with at least a graphene sheet embracing the anode active material particles. The amount of graphene is at least 0.01% by weight and the amount of the anode active material is at least 0.1% by weight, all based on the total weight of the particulate. A lithium-ion battery having an anode containing these graphene-enhanced particulates exhibits a stable charge and discharge cycling response, a high specific capacity per unit mass, a high first-cycle efficiency, a high capacity per electrode volume, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Process for producing nano graphene reinforced composite particles for lithium battery electrodes

ActiveUS20100176337A1Increase stiffnessHigh strengthCell electrodesLi-accumulatorsFiberLithium metal

Owner:SAMSUNG ELECTRONICS CO LTD

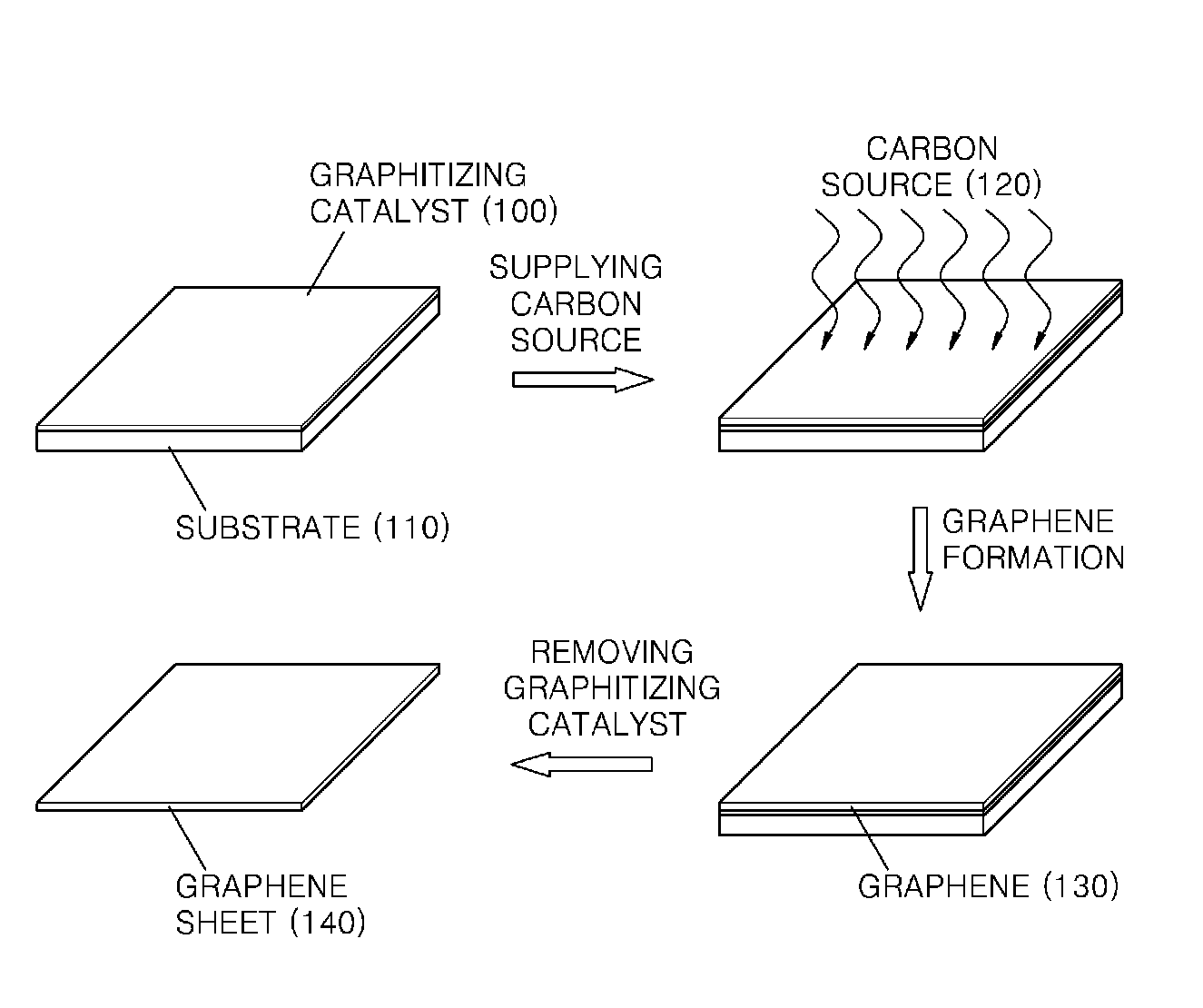

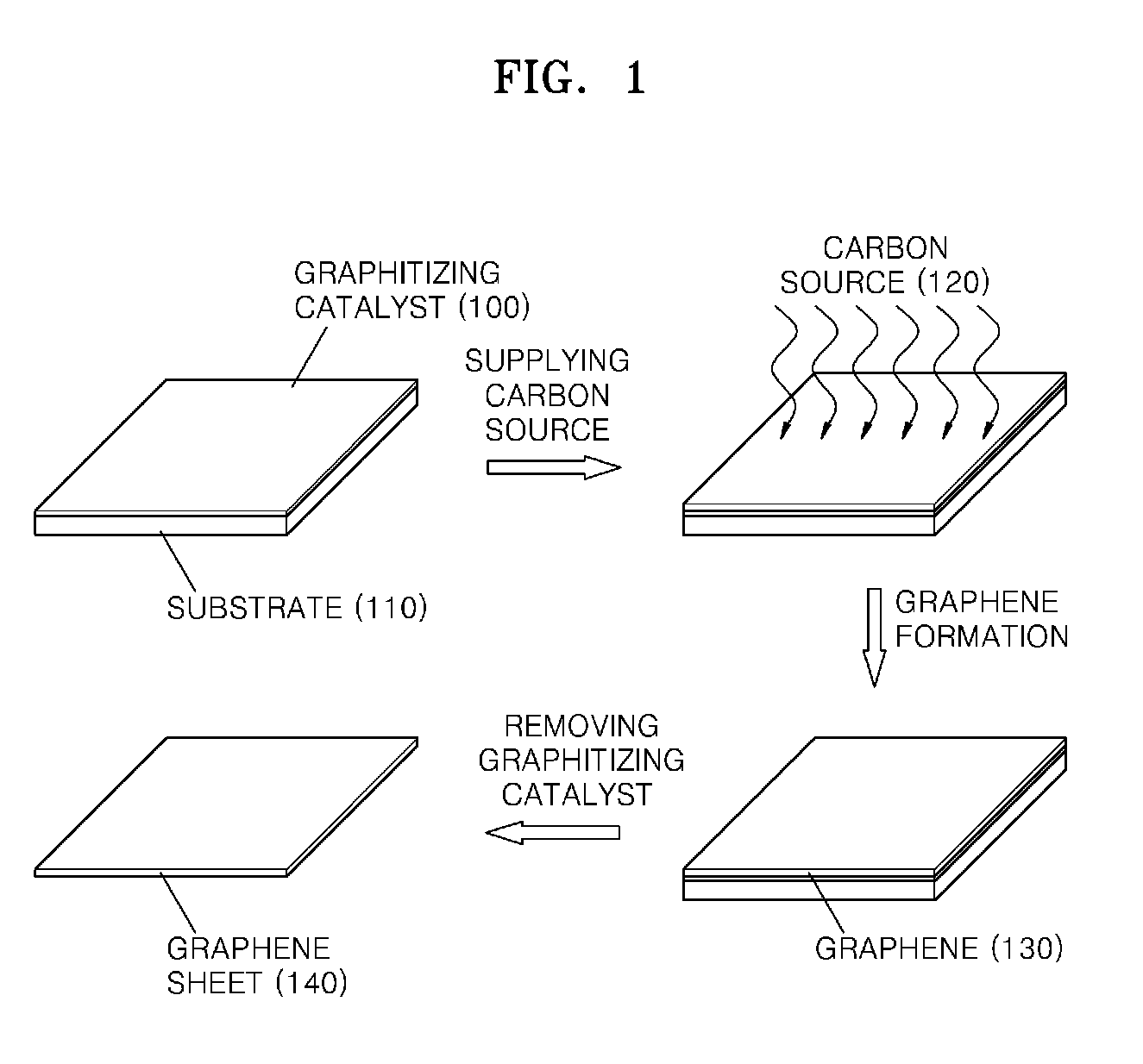

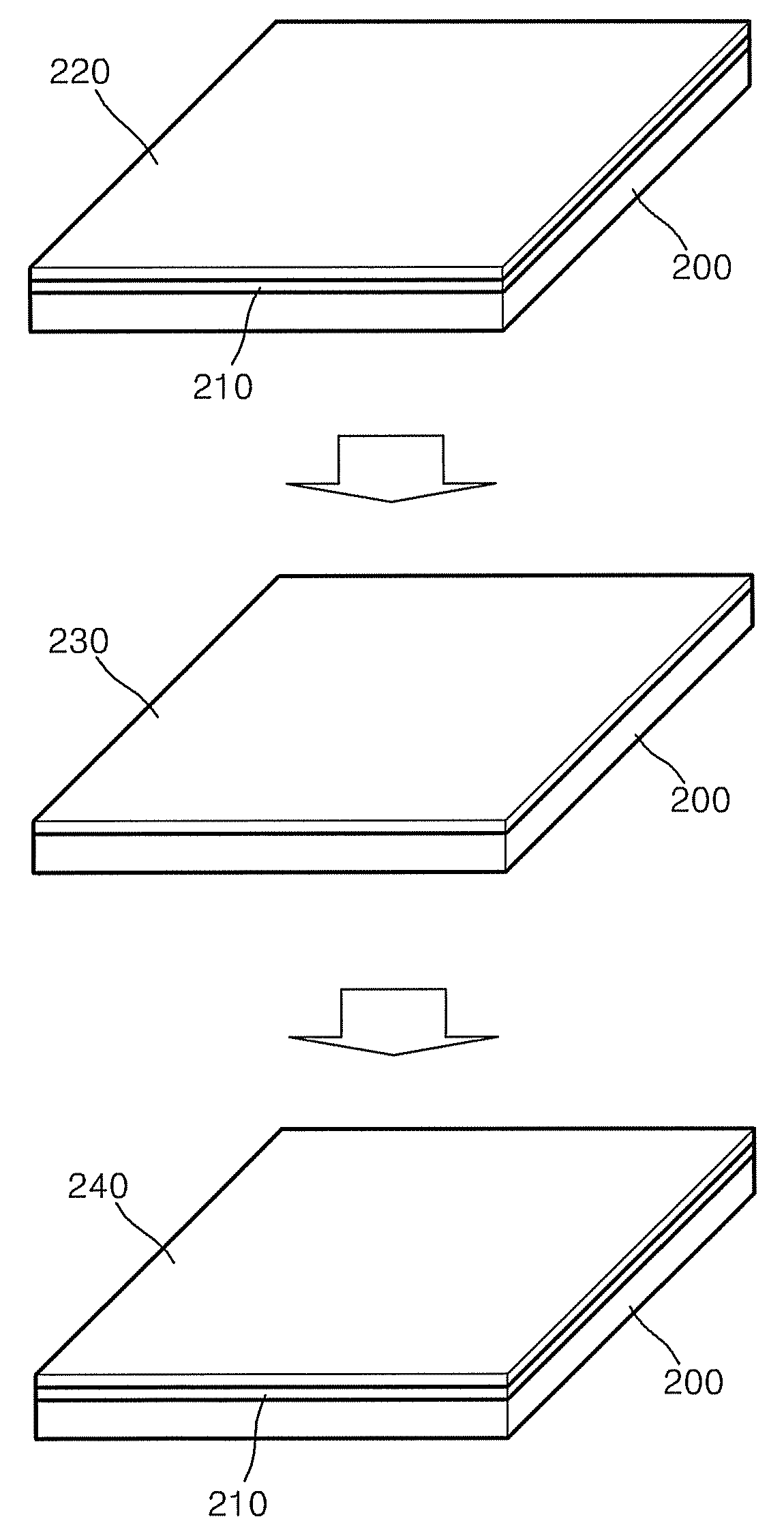

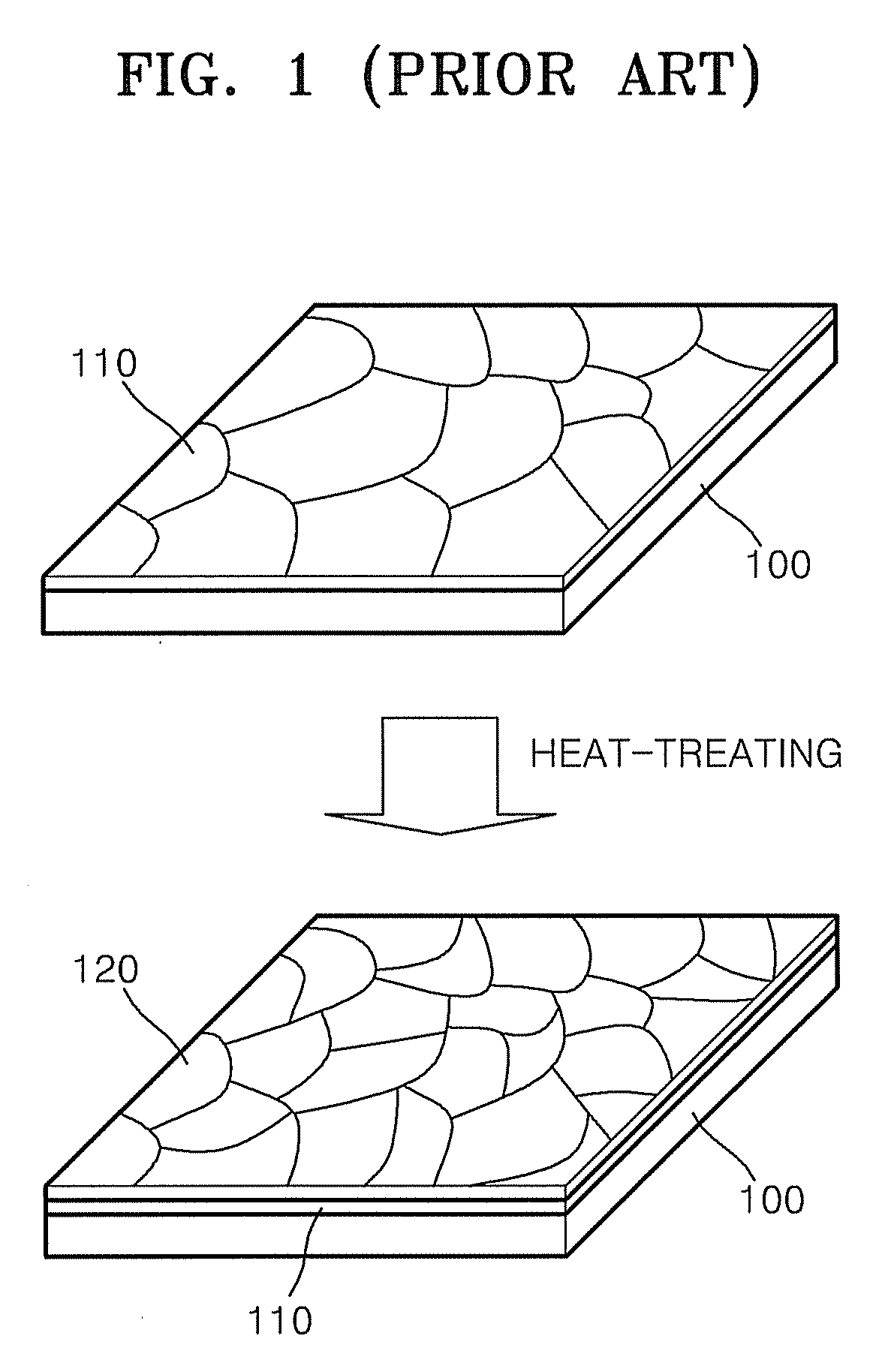

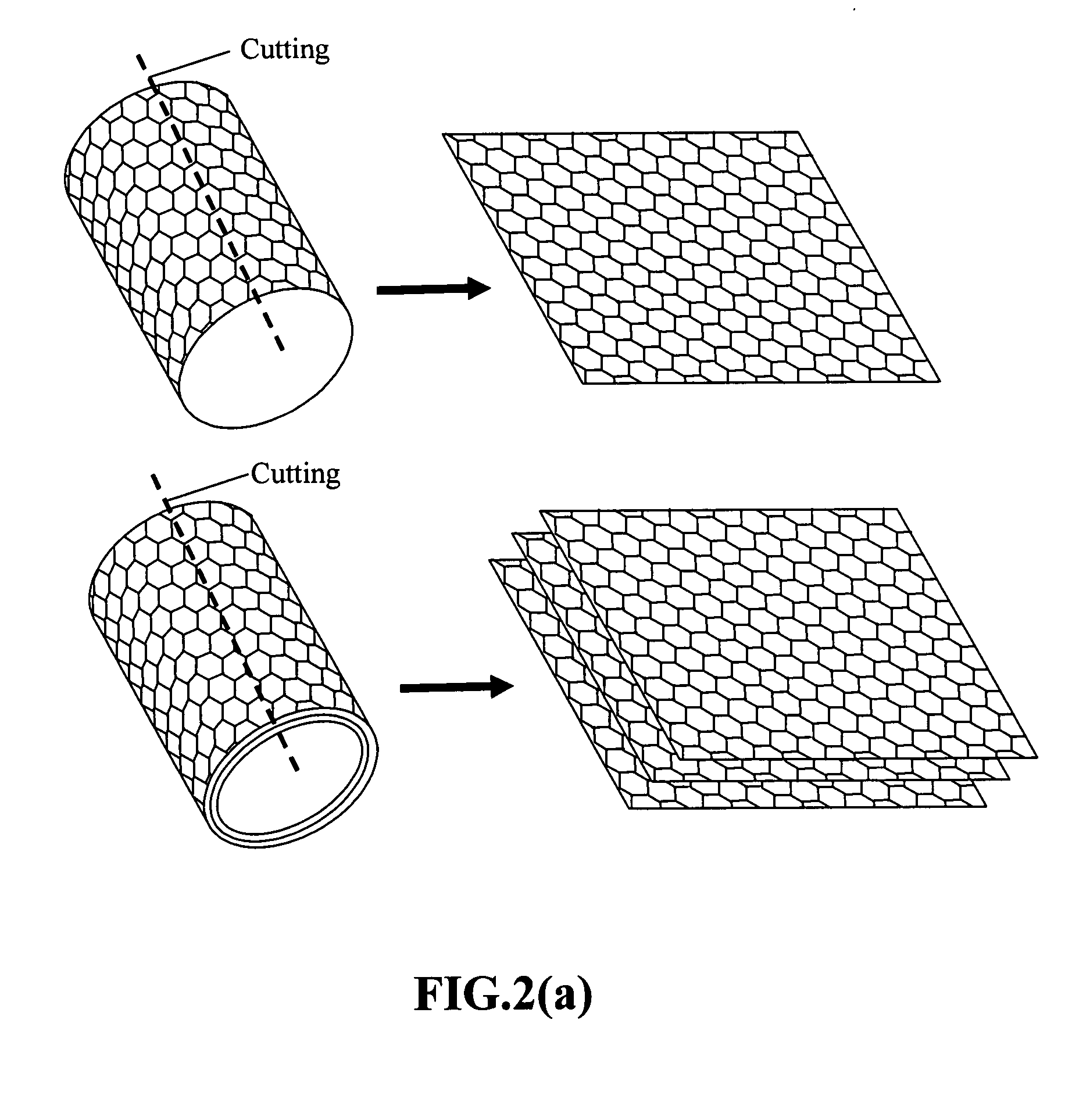

Graphene sheet and method of preparing the same

An economical method of preparing a large-sized graphene sheet having a desired thickness includes forming a film, the film comprising a graphitizing catalyst; heat-treating a gaseous carbon source in the presence of the graphitizing catalyst to form graphene; and cooling the graphene to form a graphene sheet. A graphene sheet prepared according to the disclosed method is also described.

Owner:SAMSUNG ELECTRONICS CO LTD

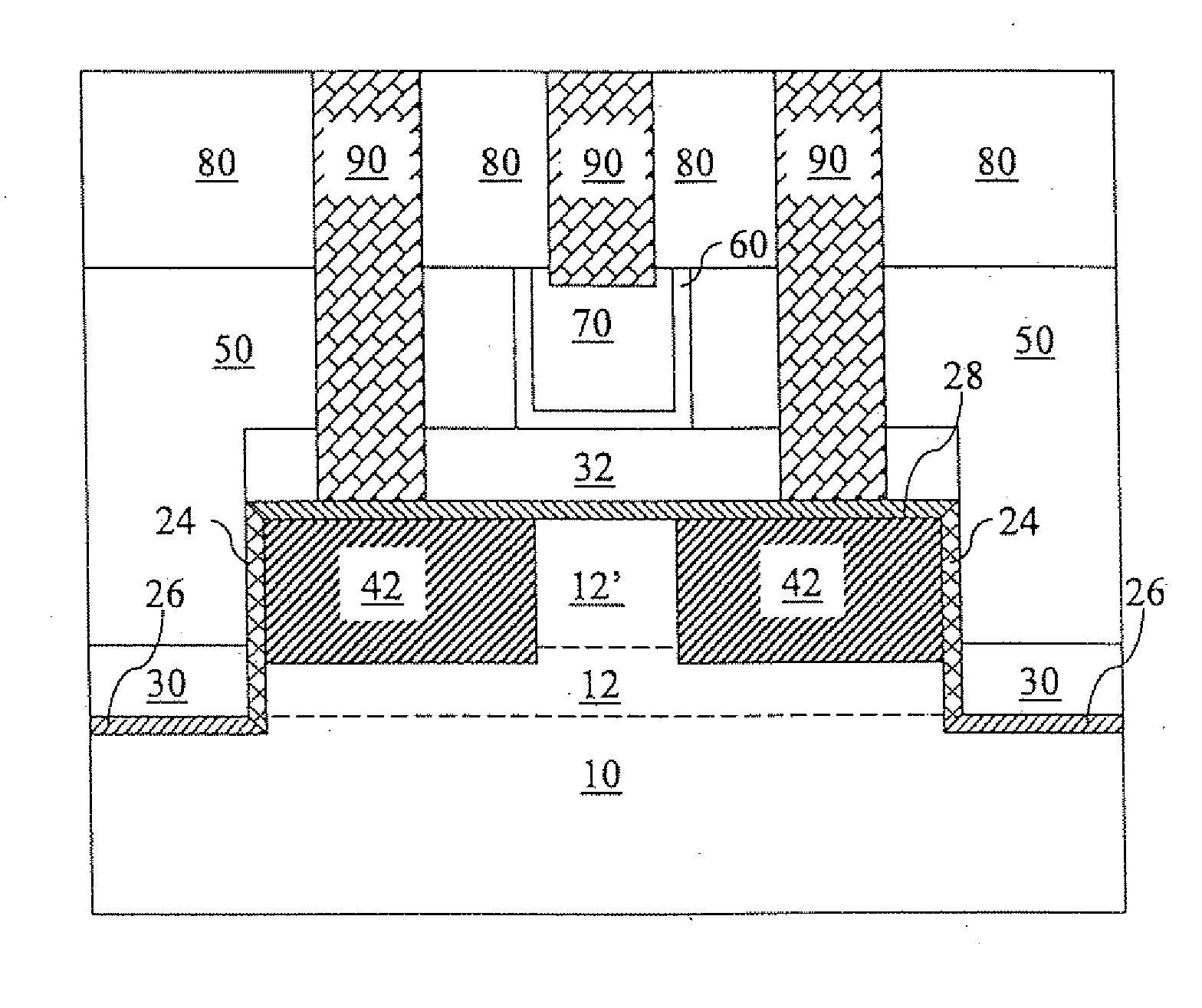

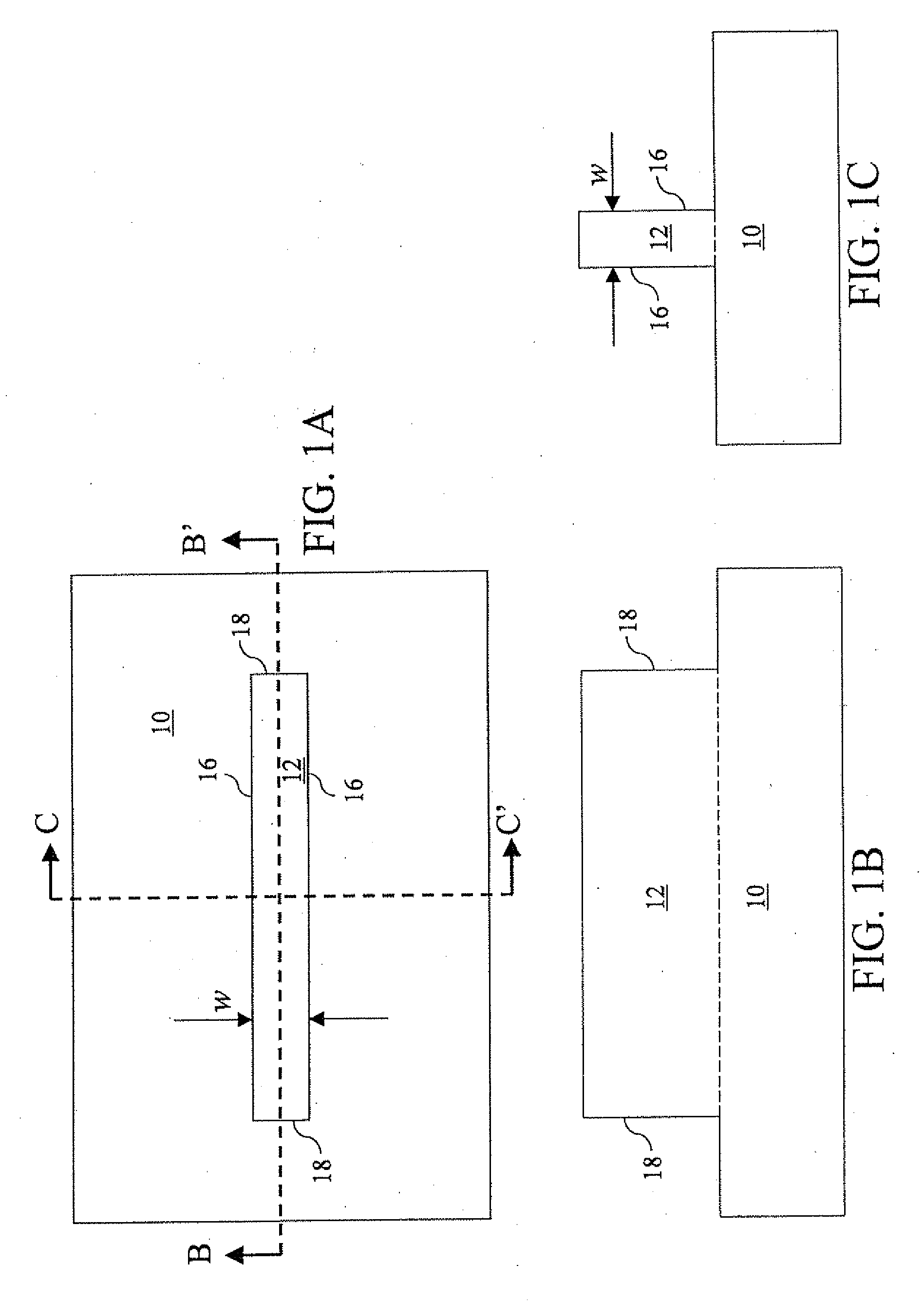

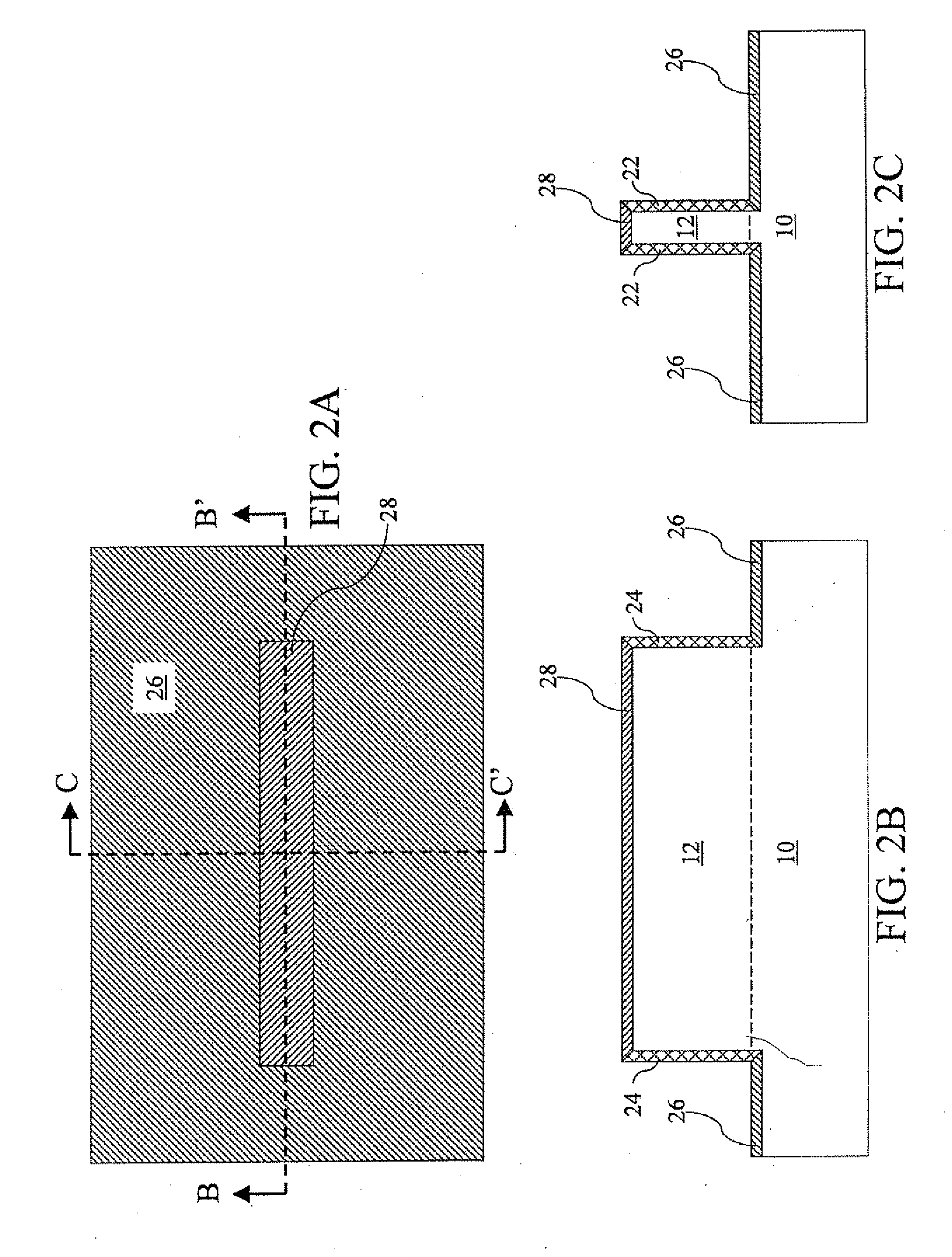

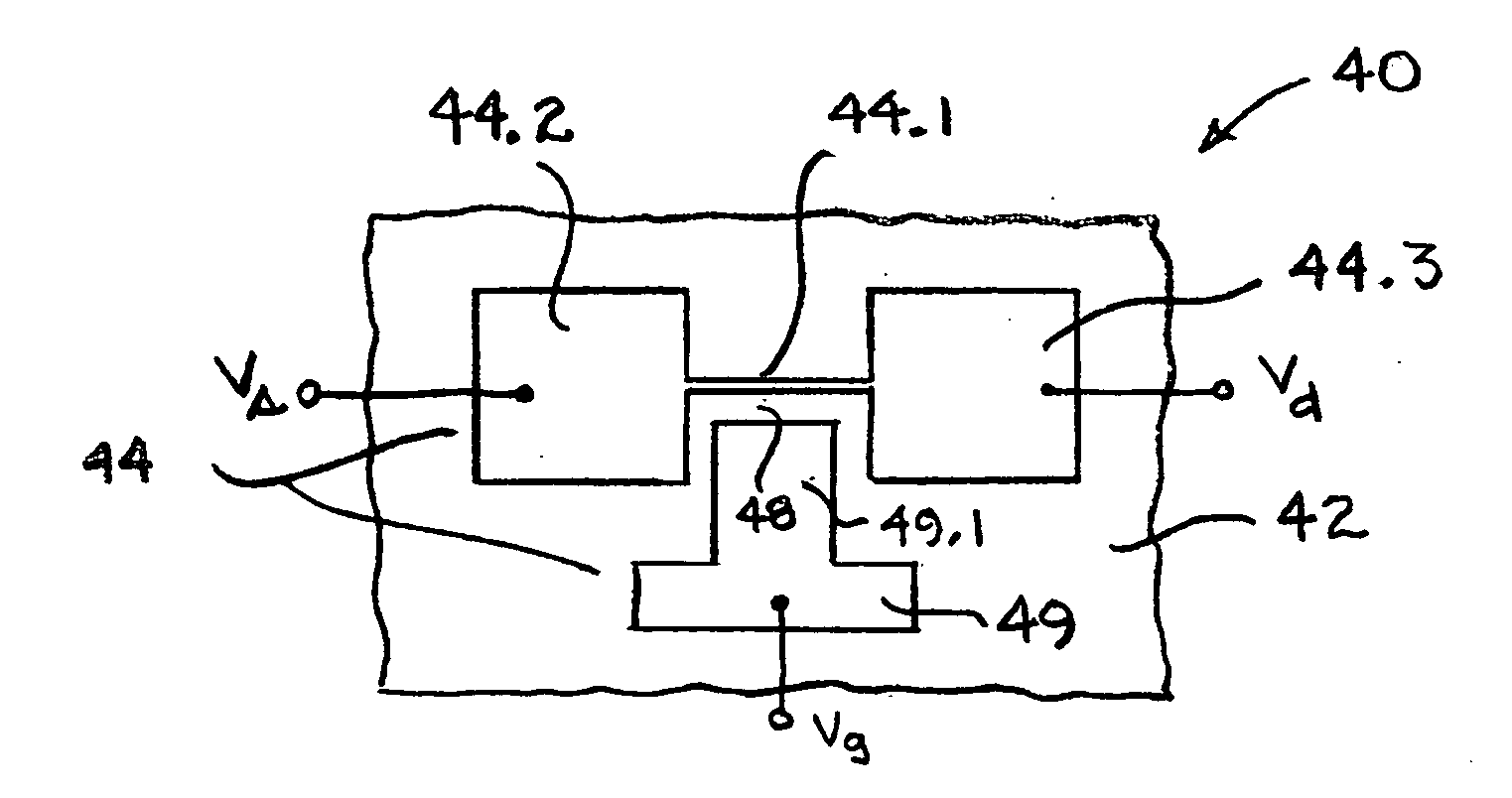

Graphene-based transistor

ActiveUS20090020764A1Semiconductor/solid-state device manufacturingSemiconductor devicesDopantGate dielectric

A graphene layer is formed on a surface of a silicon carbide substrate. A dummy gate structure is formed over the fin, in the trench, or on a portion of the planar graphene layer to implant dopants into source and drain regions. The dummy gate structure is thereafter removed to provide an opening over the channel of the transistor. Threshold voltage adjustment implantation may be performed to form a threshold voltage implant region directly beneath the channel, which comprises the graphene layer. A gate dielectric is deposited over a channel portion of the graphene layer. After an optional spacer formation, a gate conductor is formed by deposition and planarization. The resulting graphene-based field effect transistor has a high carrier mobility due to the graphene layer in the channel, low contact resistance to the source and drain region, and optimized threshold voltage and leakage due to the threshold voltage implant region.

Owner:GLOBALFOUNDRIES US INC

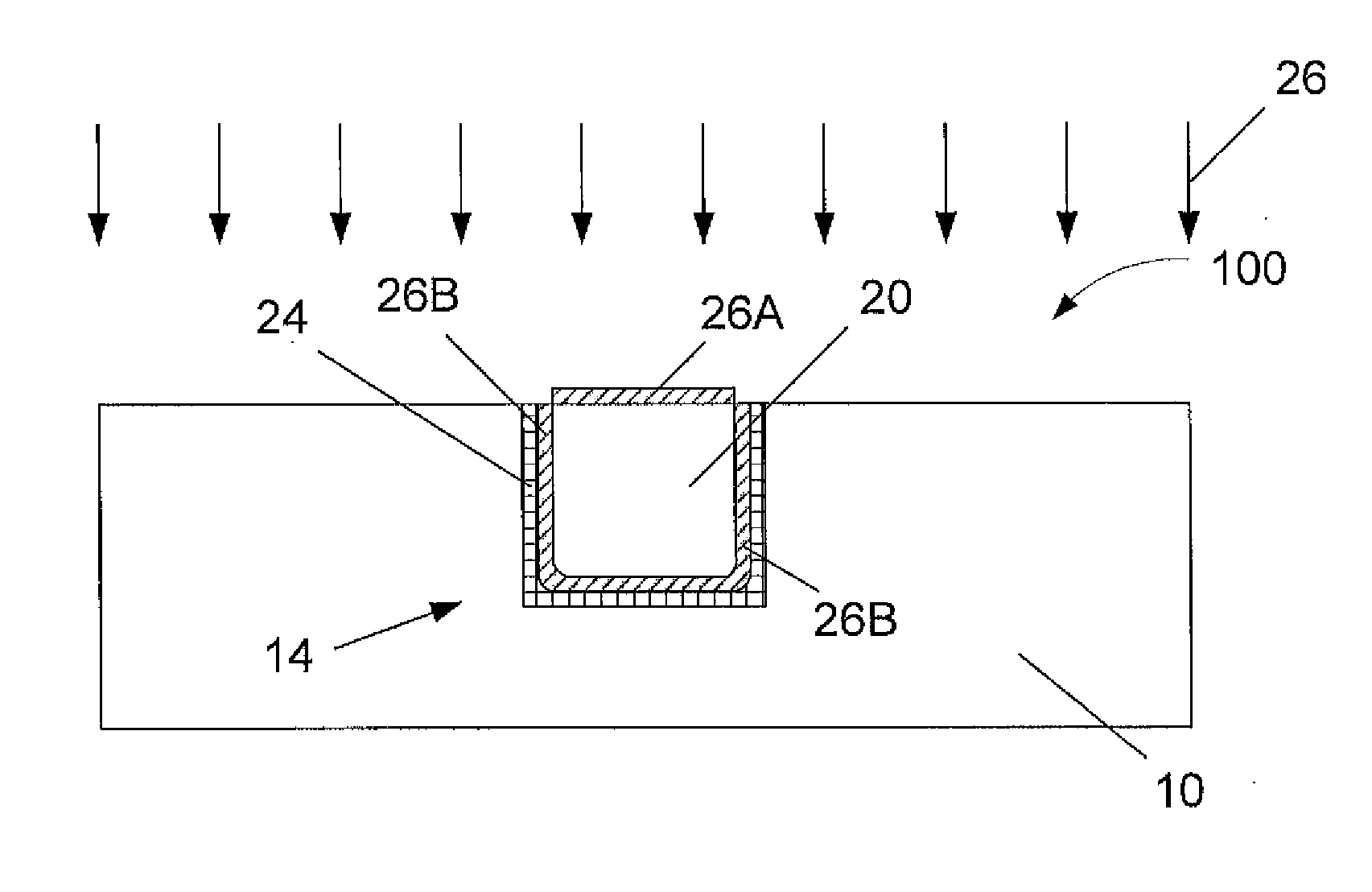

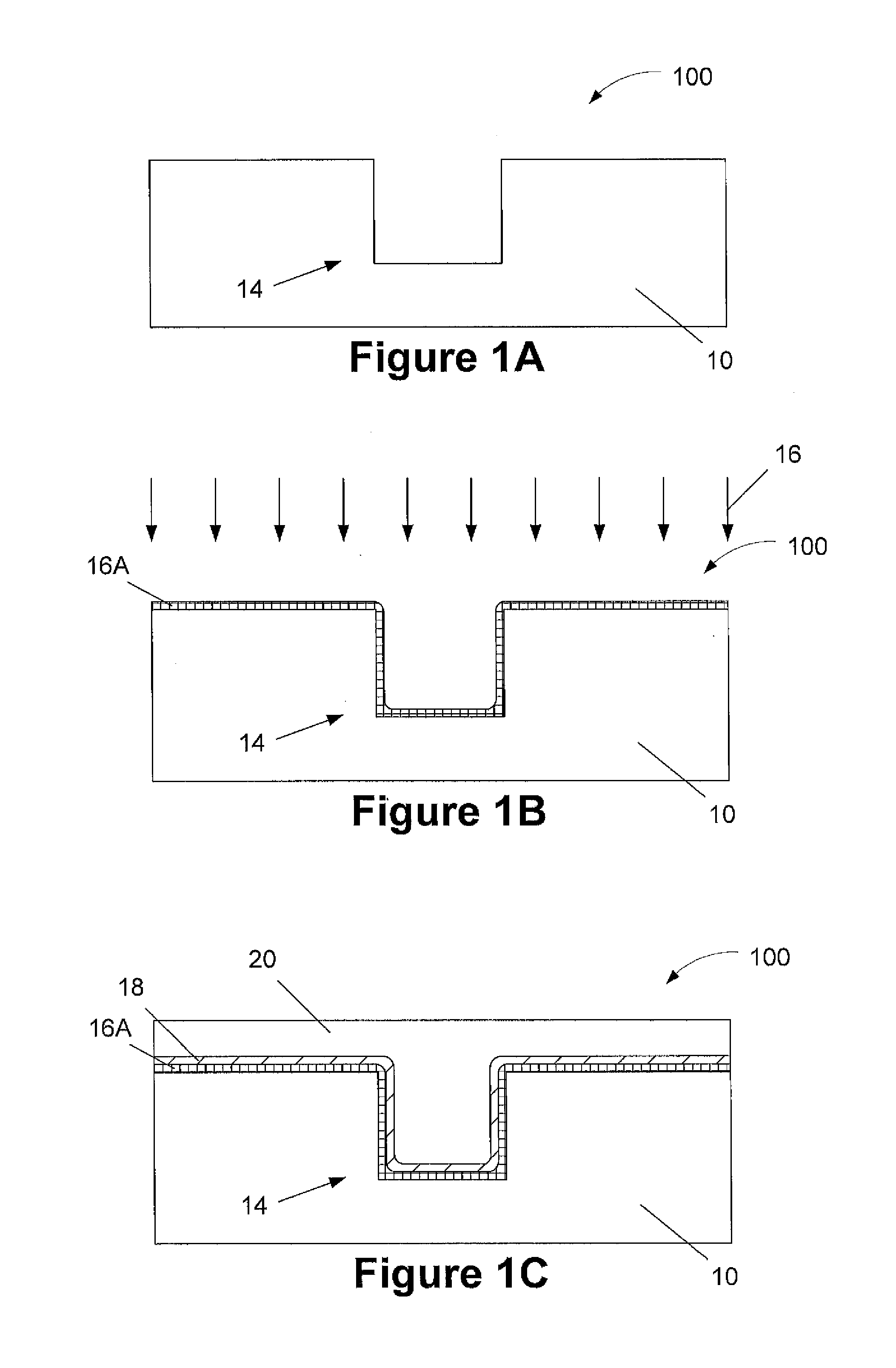

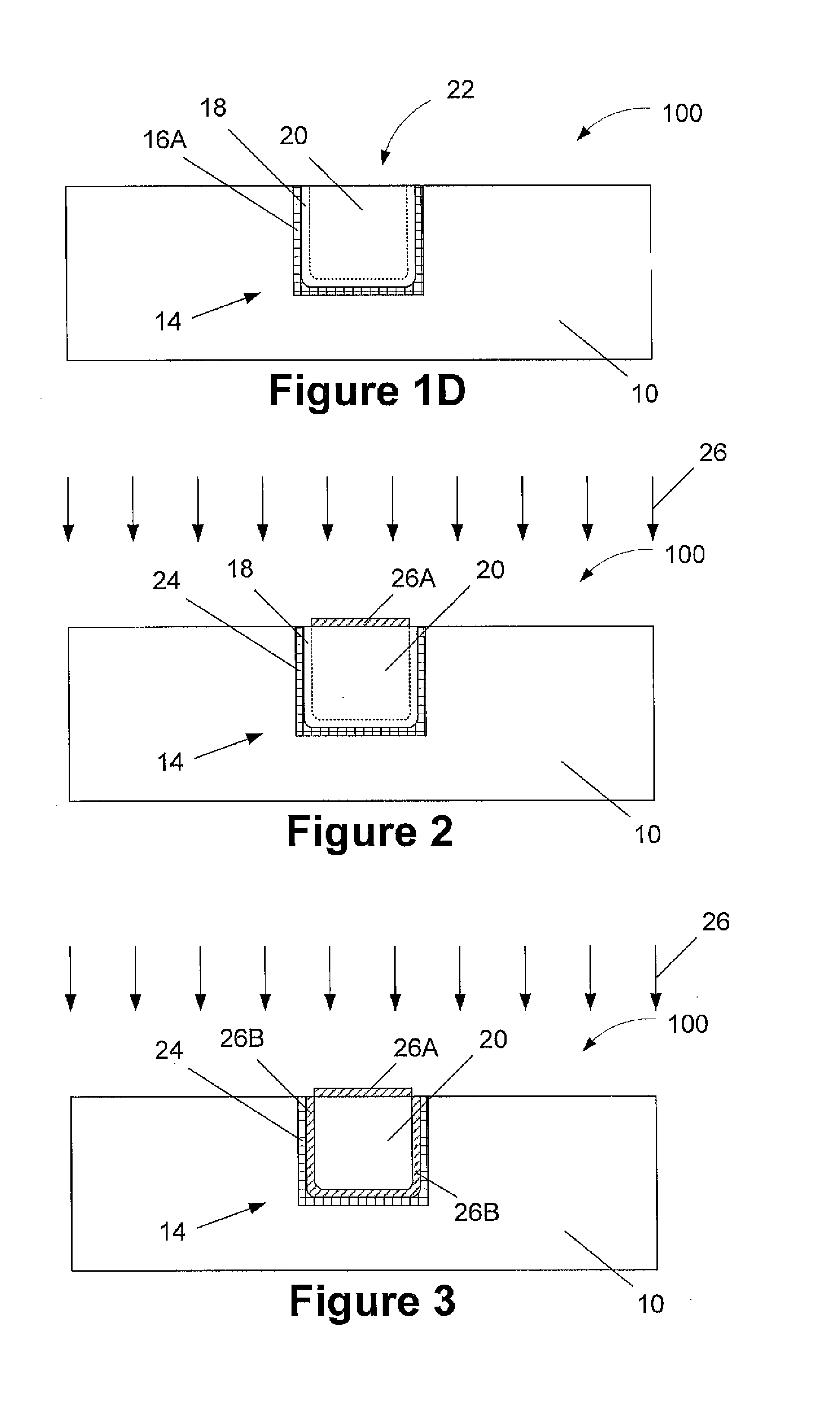

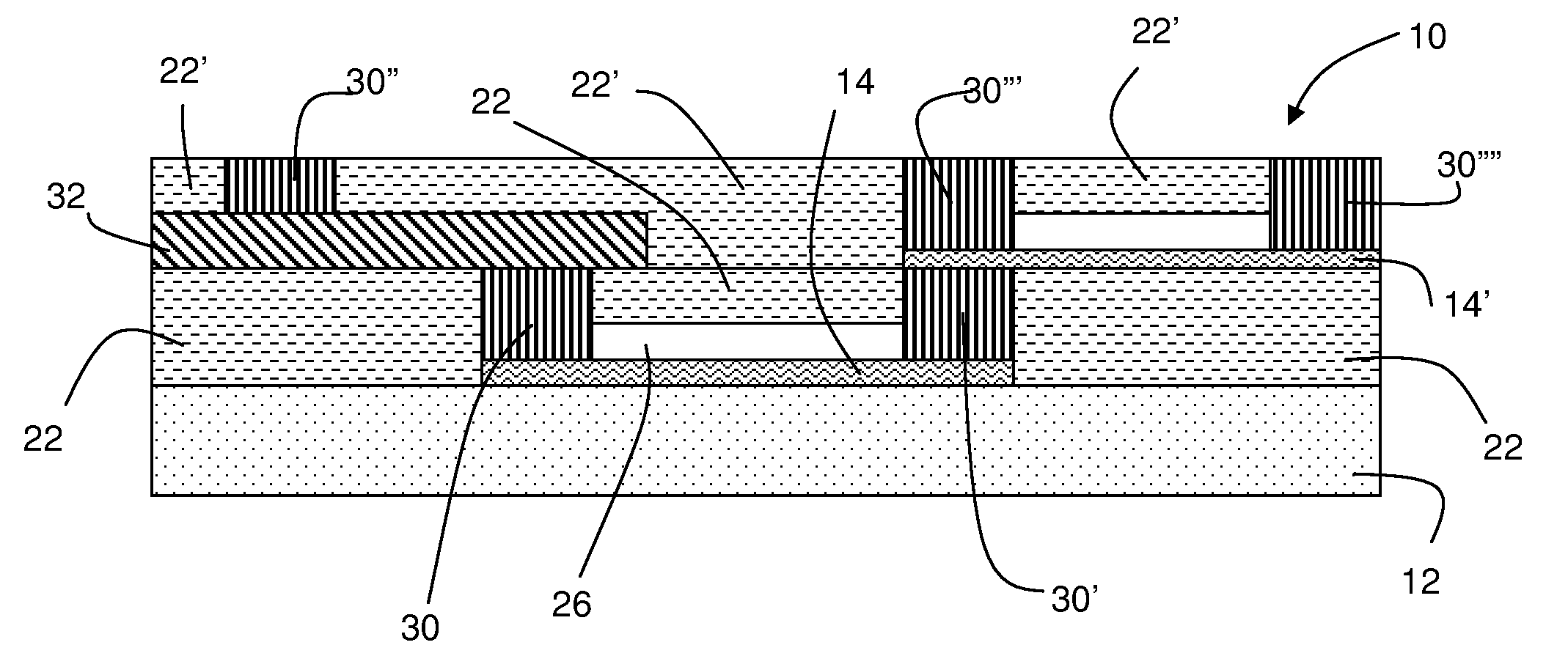

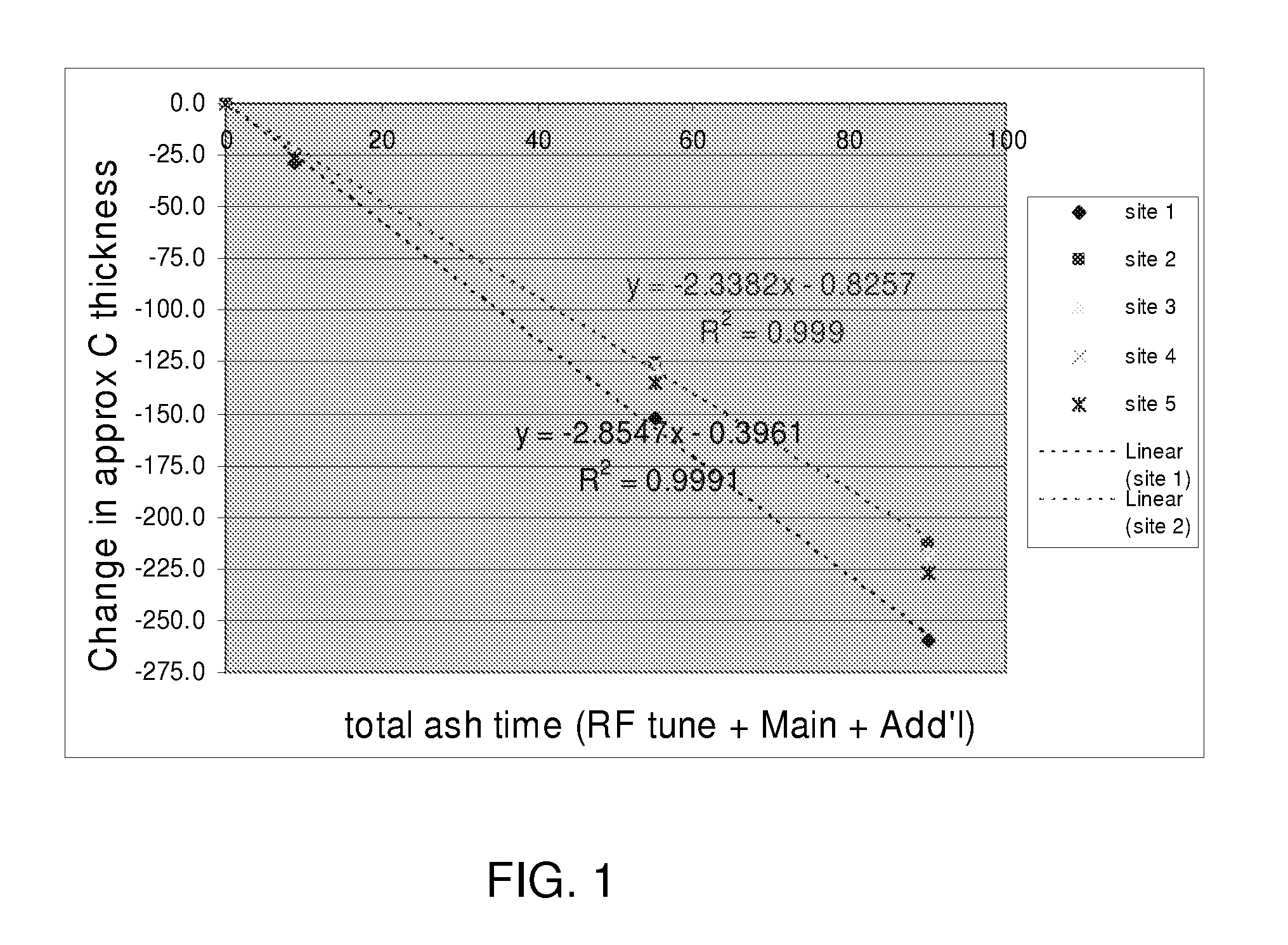

Methods of forming graphene liners and/or cap layers on copper-based conductive structures

InactiveUS20140145332A1Well formedSemiconductor/solid-state device detailsSolid-state devicesCompound (substance)Optoelectronics

One illustrative method disclosed herein includes forming a trench / via in a layer of insulating material, forming a graphene liner layer in at least the trench / via, forming a copper-based seed layer on the graphene liner layer, depositing a bulk copper-based material on the copper-based seed layer so as to overfill the trench / via, and performing at least one chemical mechanical polishing process to remove at least excess amounts of the bulk copper-based material and the copper-based seed layer positioned outside of the trench / via to thereby define a copper-based conductive structure with a graphene liner layer positioned between the copper-based conductive structure and the layer of insulating material.

Owner:GLOBALFOUNDRIES INC

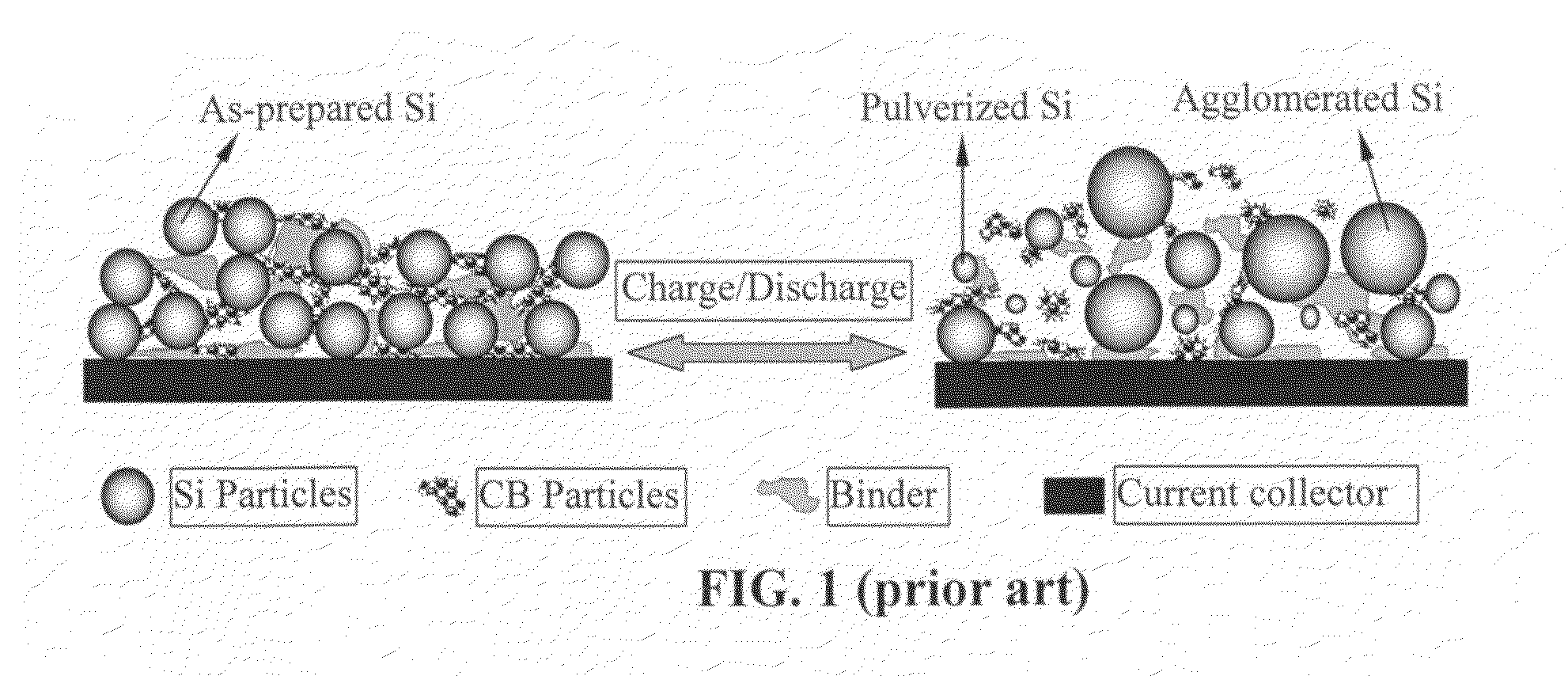

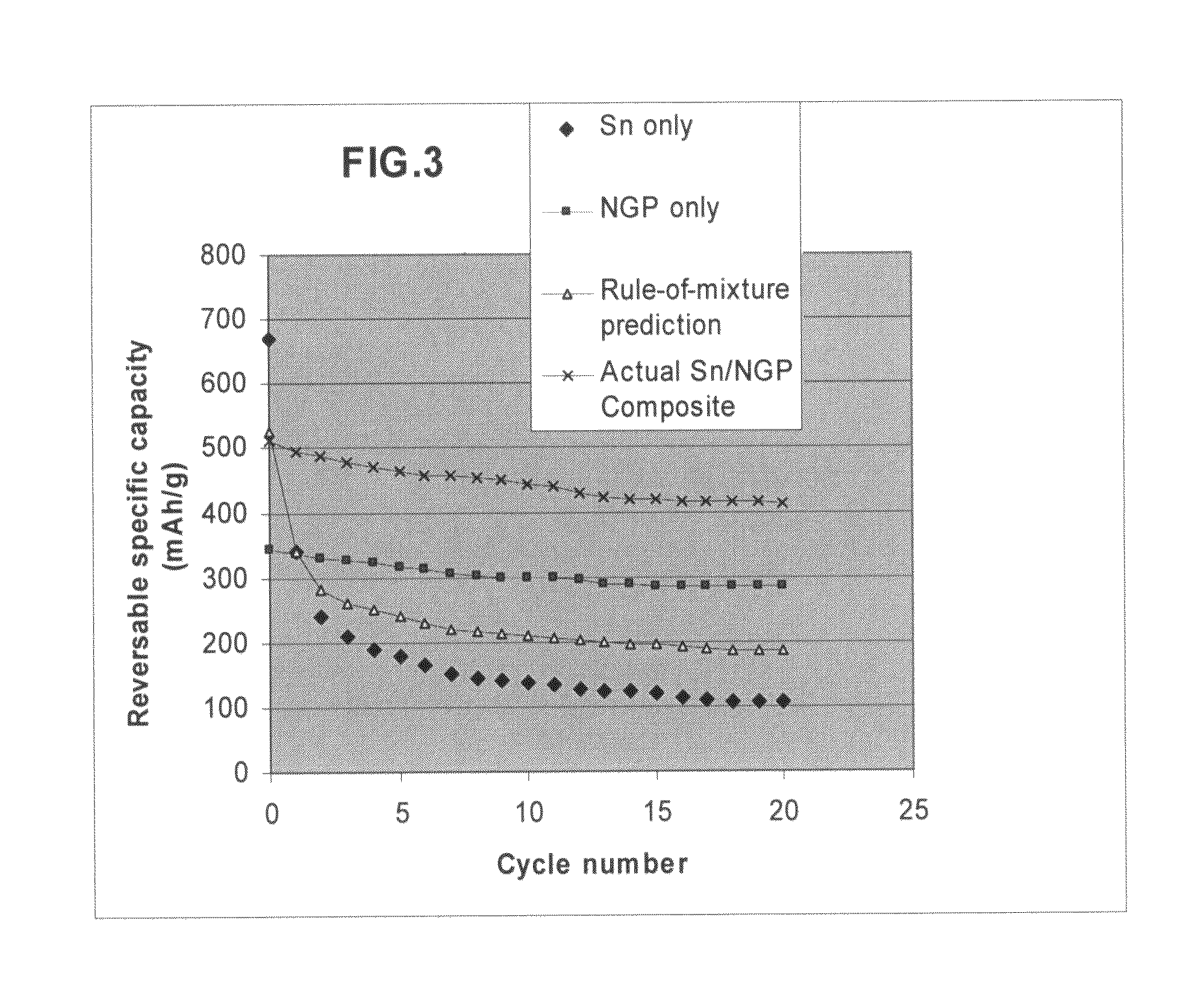

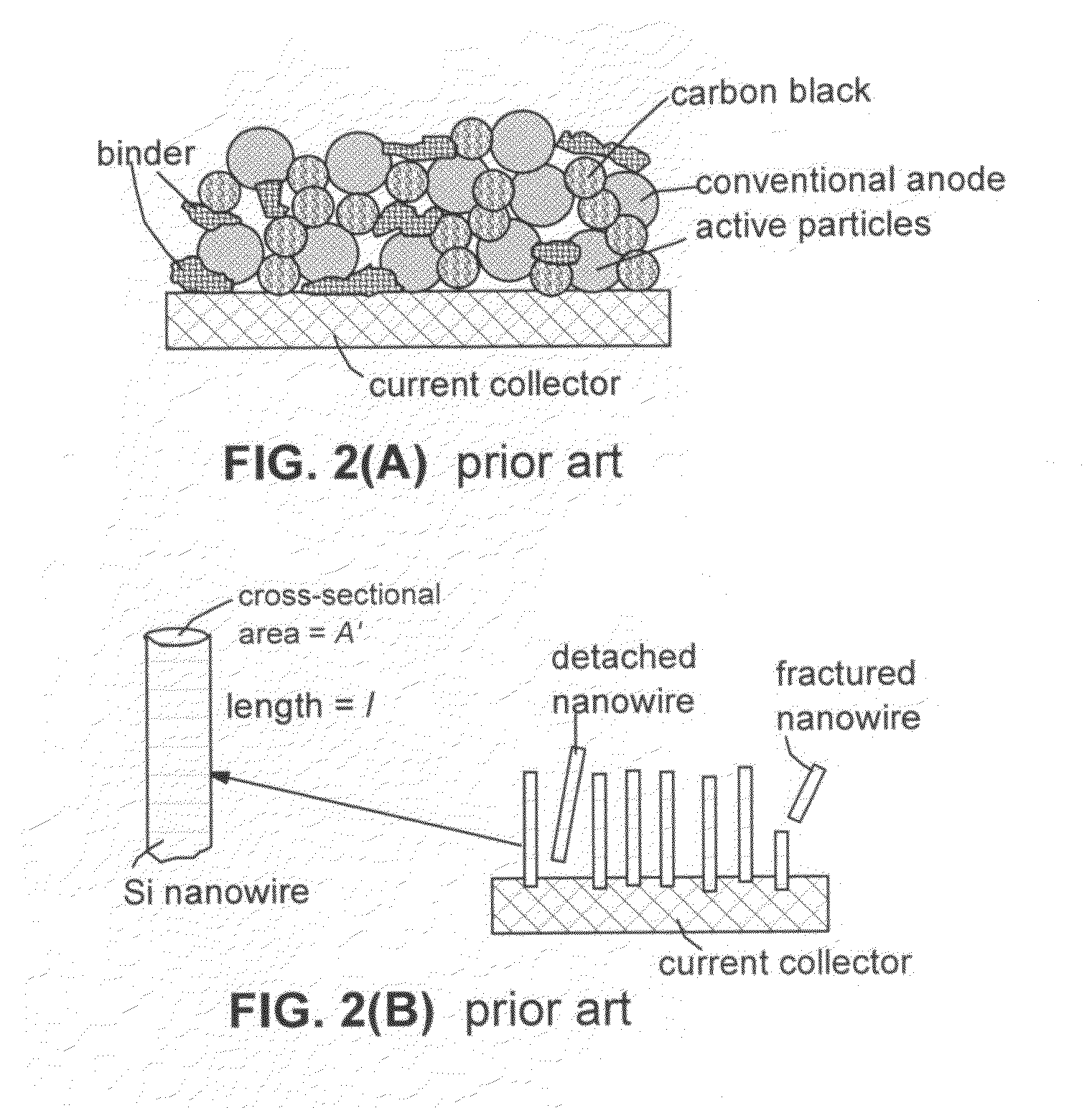

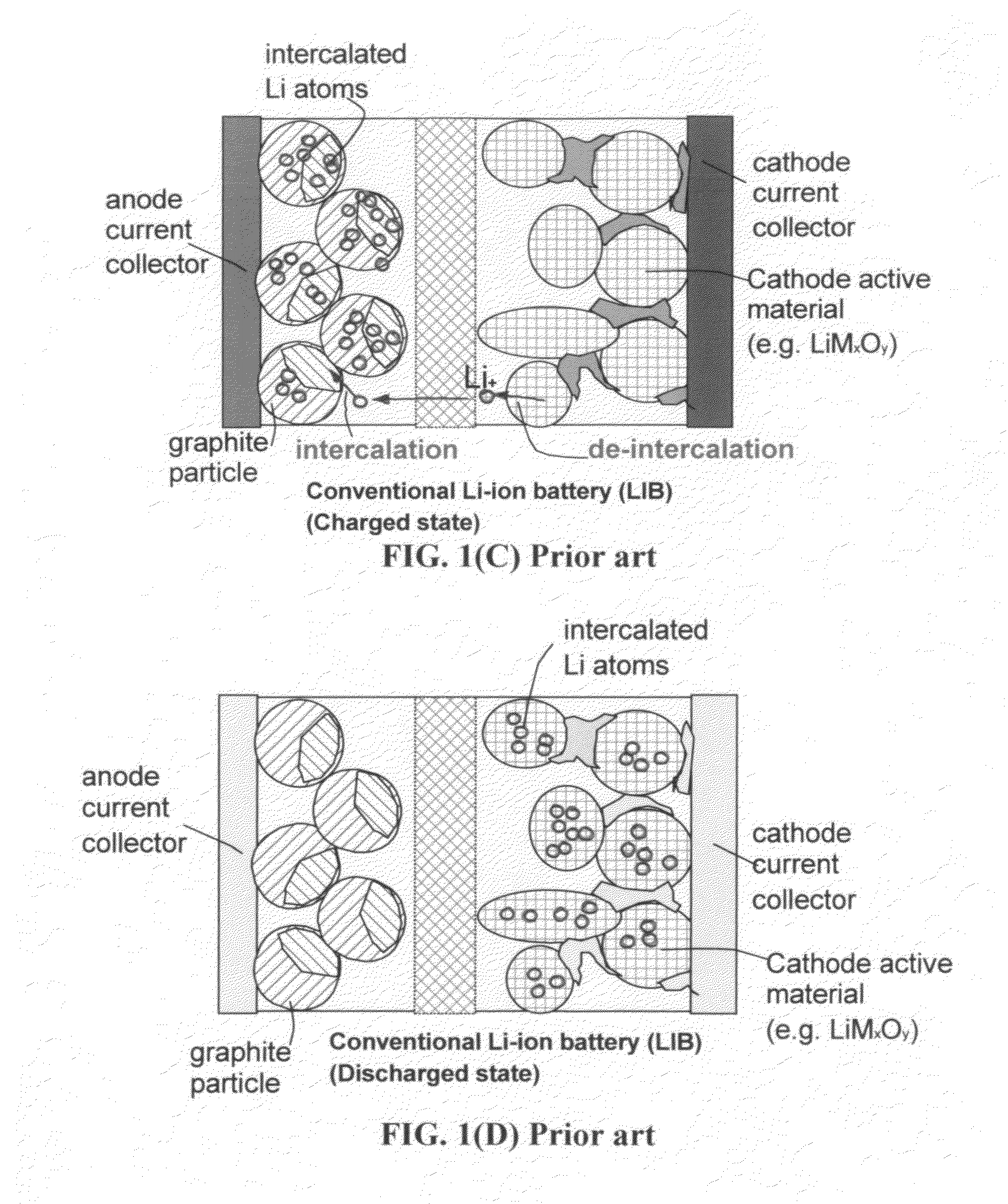

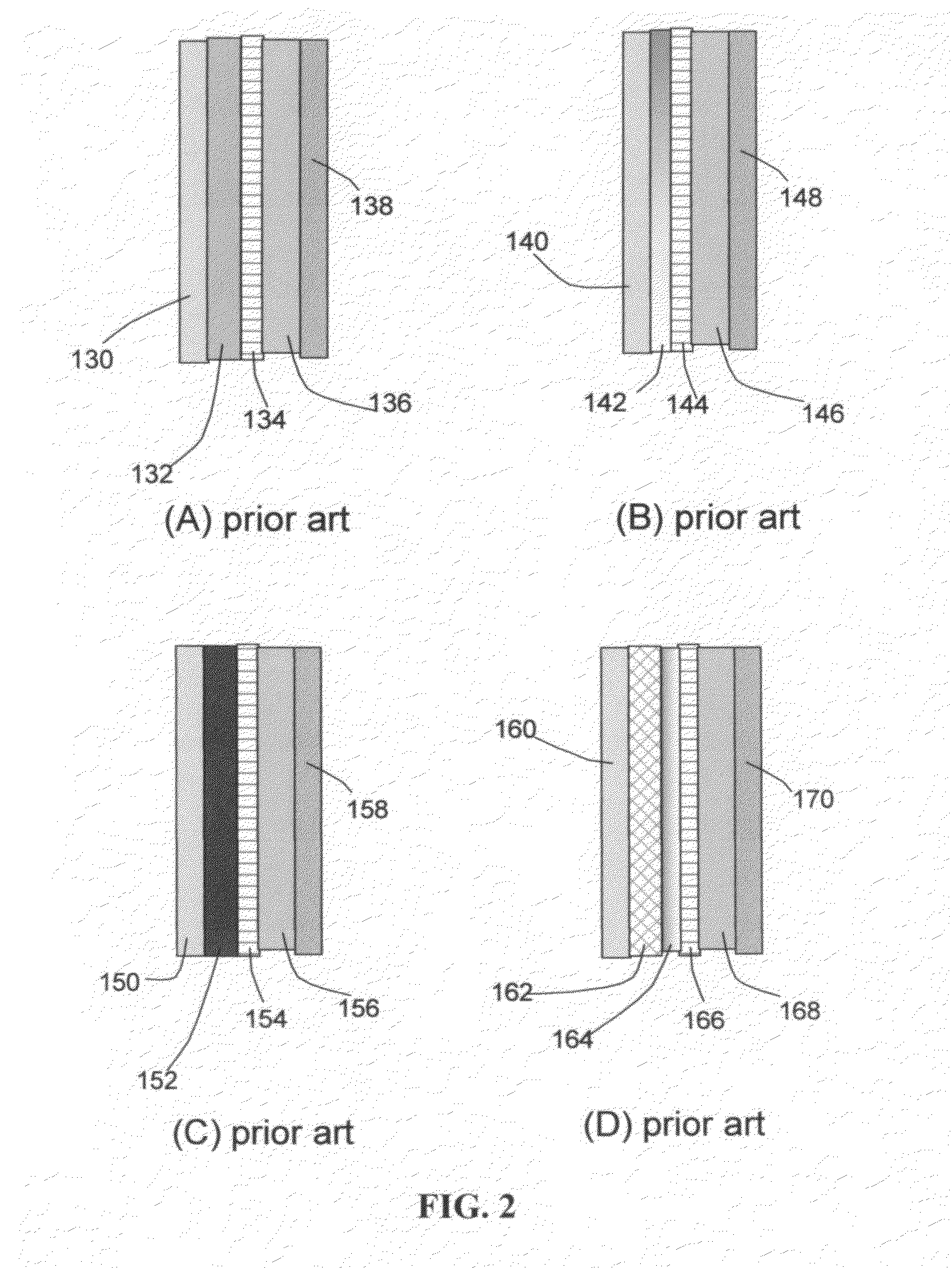

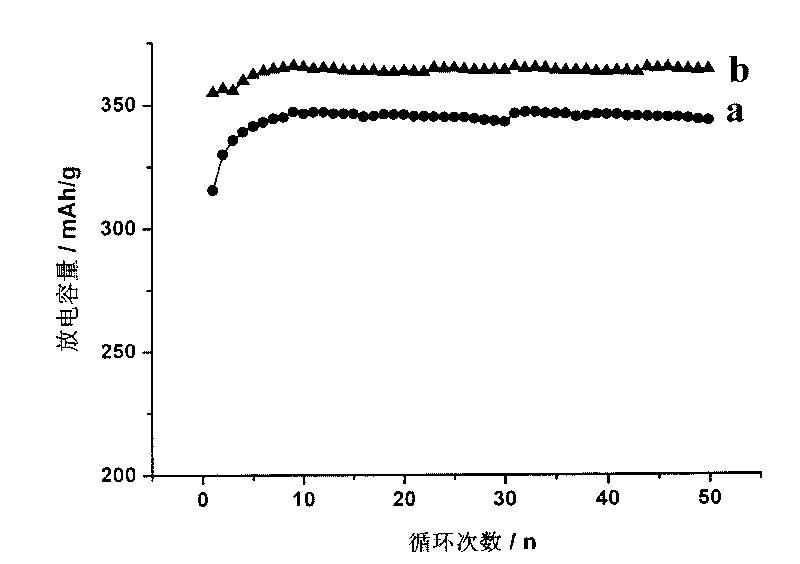

Nano graphene platelet-base composite anode compositions for lithium ion batteries

ActiveUS7745047B2Improve conductivityLower internal resistanceAlkaline accumulatorsElectrolytic capacitorsGraphiteGraphene

The present invention provides a nano-scaled graphene platelet-based composite material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing lithium ions; and (b) a plurality of nano-scaled graphene platelets (NGPs), wherein a platelet comprises a graphene sheet or a stack of graphene sheets having a platelet thickness less than 100 nm; wherein at least one of the particles or coating is physically attached or chemically bonded to at least one of the graphene platelets and the amount of platelets is in the range of 2% to 90% by weight and the amount of particles or coating in the range of 98% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

Conductive graphene polymer binder for electrochemical cell electrodes

The present invention provides an electrically conductive electrode comprising particles of an electroactive material and a conductive graphene polymer binder that bonds multiple particles of the electroactive material together, wherein the binder is in an amount of from 0.01% to 90% by weight based on the total electrode weight. Also provided are (a) a precursor solution or suspension to the graphene polymer binder for the electrode; (b) a paste containing electroactive particles and a graphene polymer dispersed in a liquid; (c) a method of producing the electrode from the precursor paste; and (d) an electrochemical cell (a battery or supercapacitor) containing such an electrode.

Owner:GLOBAL GRAPHENE GRP INC

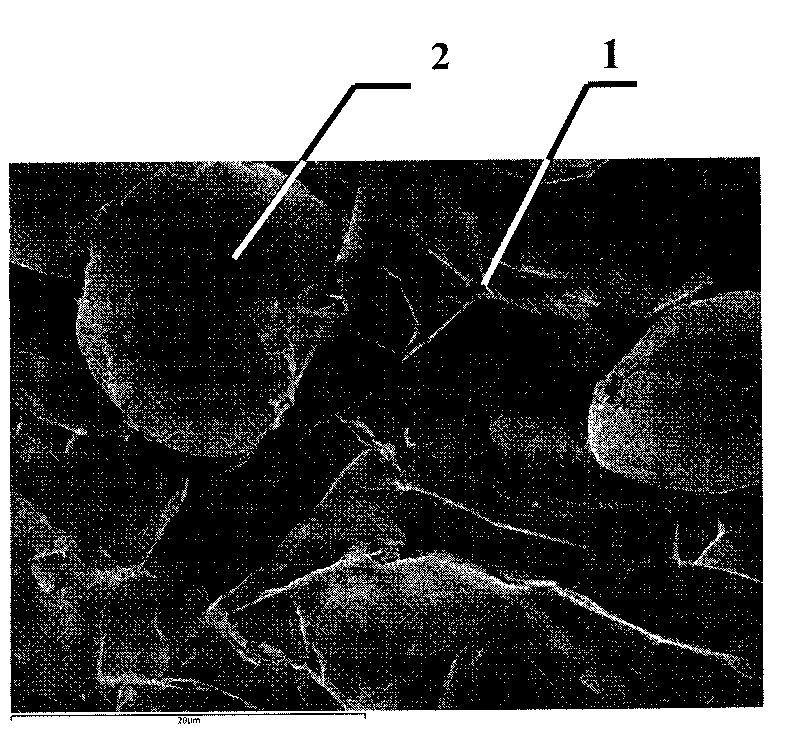

Carbon/silicon/carbon nano composite structure cathode material and preparation method thereof

The invention discloses a carbon / silicon / carbon nano composite structure cathode material and a preparation method thereof, belonging to the technical field of electrochemical power supply technologies. The cathode material consists of a carbon-based conductive substrate, nano silicon and a nano carbon coating layer, wherein the nano silicon is uniformly distributed on the carbon-based conductive substrate; the nano carbon coating layer is arranged on the surface of the nano silicon; the carbon-based conductive substrate is porous carbon, a carbon nanotube or graphene; the nano silicon exists in the state of nanoparticles or nano films; the weight percentage of the nano silicon in the cathode material is 10-90 percent; and the thickness of the nano carbon coating layer is 0.1-10 nanometers. The preparation method comprises the following steps of: depositing nano silicon on the carbon substrate in a reaction space in oxygen-free atmosphere by adopting a chemical vapor deposition process; and coating nano carbon on the surface of the nano silicon by adopting the chemical vapor deposition process. In the obtained carbon / silicon / carbon composite cathode material, the volume change of a silicon electrode material is controlled effectively in the charging and discharging processes, the electrode structure is kept complete, the circulation volume is large, the circulation service life is long, and the electrochemical performance is high.

Owner:TSINGHUA UNIV

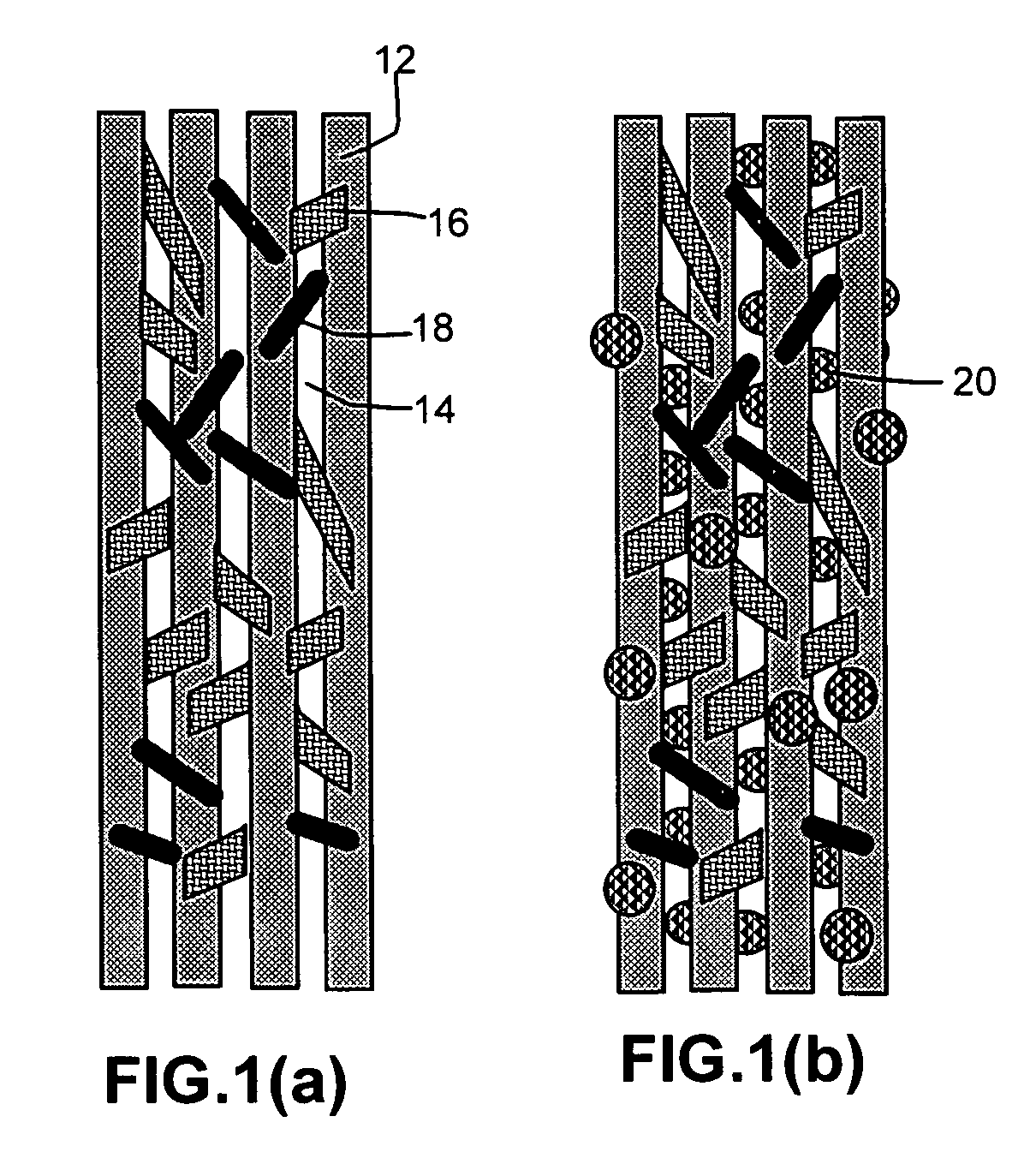

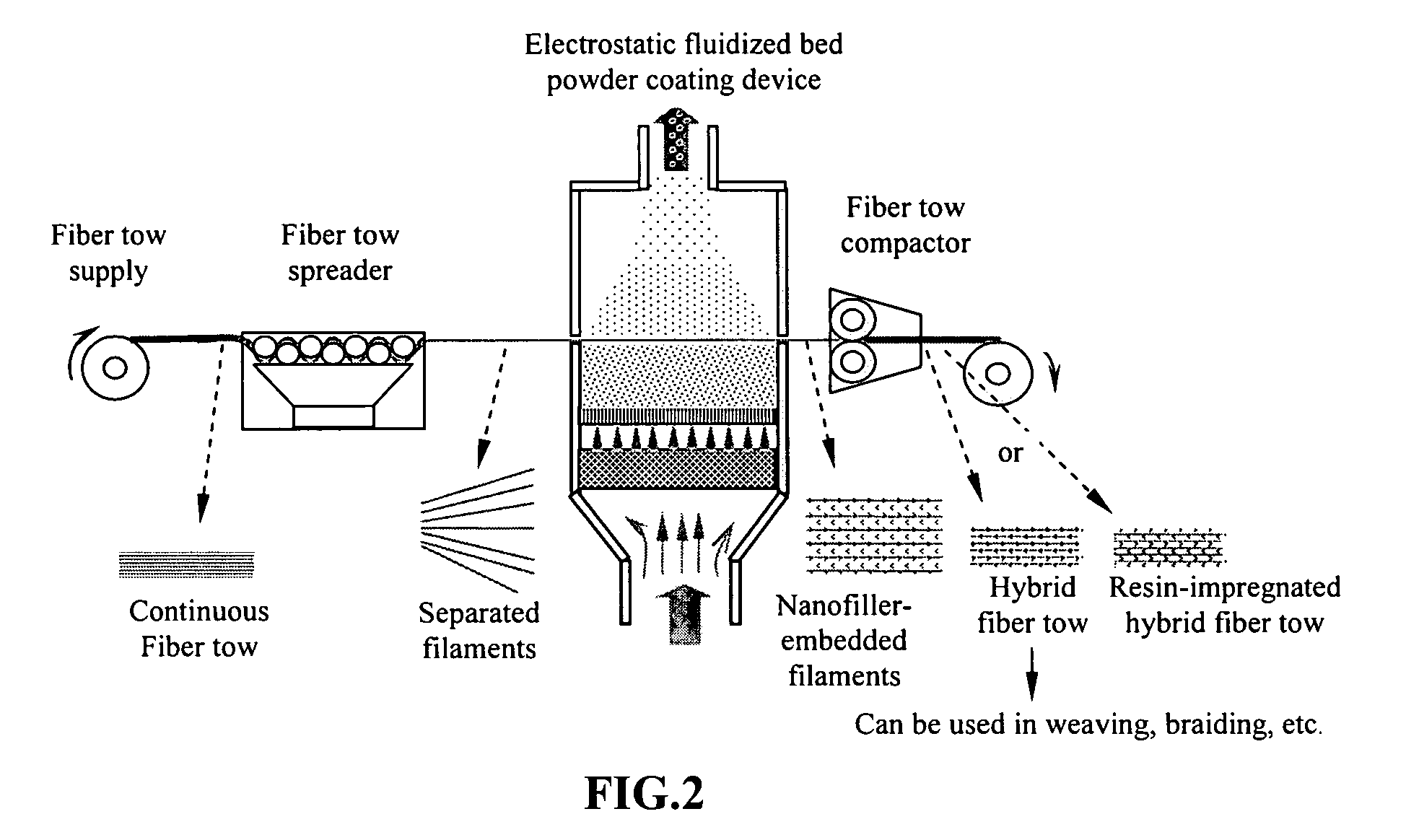

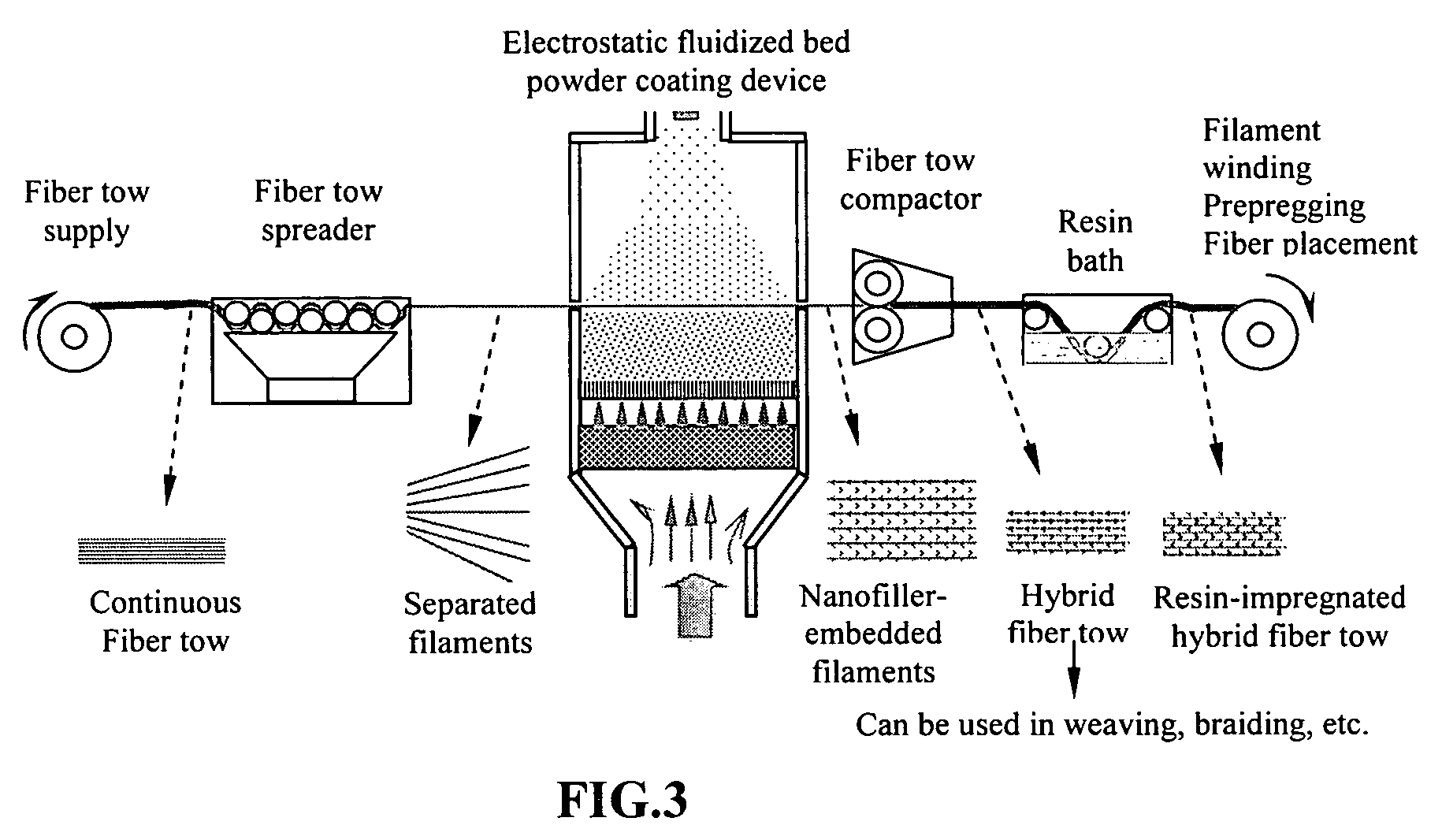

Hybrid fiber tows containning both nano-fillers and continuous fibers, hybrid composites, and their production processes

Disclosed is a hybrid fiber tow that comprises multiple continuous filaments and nanoscale fillers embedded in the interstitial spaces between continuous filaments. Nanoscale fillers may be selected from a nanoscale graphene plate, non-graphite platelet, carbon nano-tube, nano-rod, carbon nano-fiber, non-carbon nano-fiber, or a combination thereof. Also disclosed are a hybrid fiber tow impregnated with a matrix material and a composite structure fabricated from a hybrid fiber tow. The composite exhibits improved physical properties (e.g., thermal conductivity) in a direction transverse to the continuous fiber axis. A roll-to-roll process for producing a continuous fiber tow or matrix-impregnated fiber tow and an automated process for producing composite structures containing both continuous filaments and nanoscale fillers are also provided.

Owner:NANOTEK INSTR

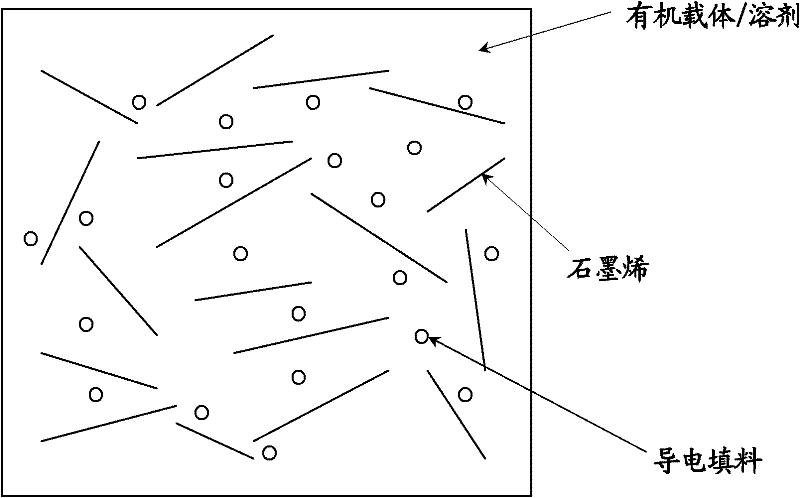

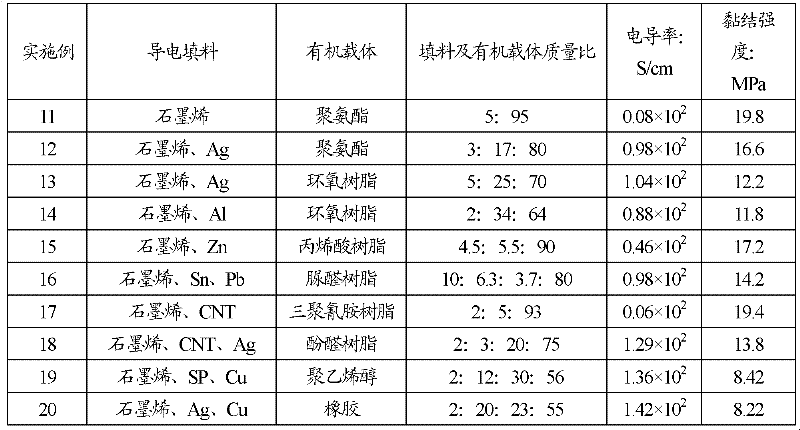

General electronic paste based on graphene filler

ActiveCN102254584AImprove conductivityConductivity regulationNon-conductive material with dispersed conductive materialNano structuringConductive coating

The invention discloses general electronic paste based on graphene filler. The electronic paste contains graphene-containing conductive filler, an organic carrier, a solvent and an auxiliary agent. Because the graphene has good electronic conductivity and a unique two-dimensional laminar nano structure, the graphene forms a conductive network in the organic carrier more easily, and the electric conductivity of the electronic paste is improved by adding the graphene. Further, the conductive filler also contains a conductive material with relatively high electric conductivity, so that the electric conductivity of the electronic paste is further improved. Because the graphene and the conductive material are compounded to form the conductive filler, the electronic paste has good electric conductivity. The electronic paste can obtain a relatively wide electric conductivity range by changing the category of the conductive material mixed with the graphene and adjusting the relative proportion of the graphene to the conductive material of different category. The electric conductivity of the electronic paste is 1*10<-3>S / cm to 1*10<3>S / cm. The paste can be widely applied, and can be particularly used as a conductive coating or adhesive.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

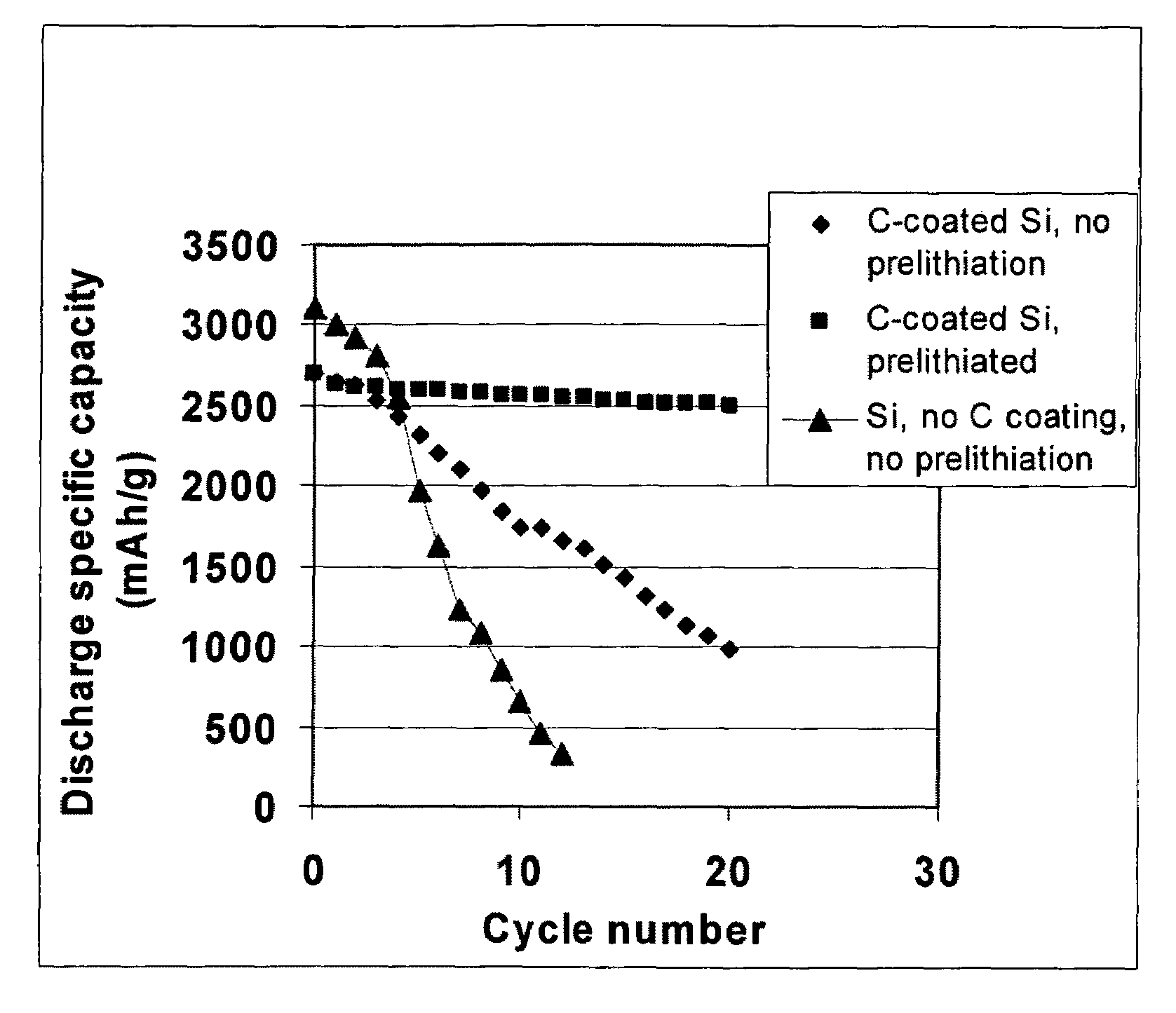

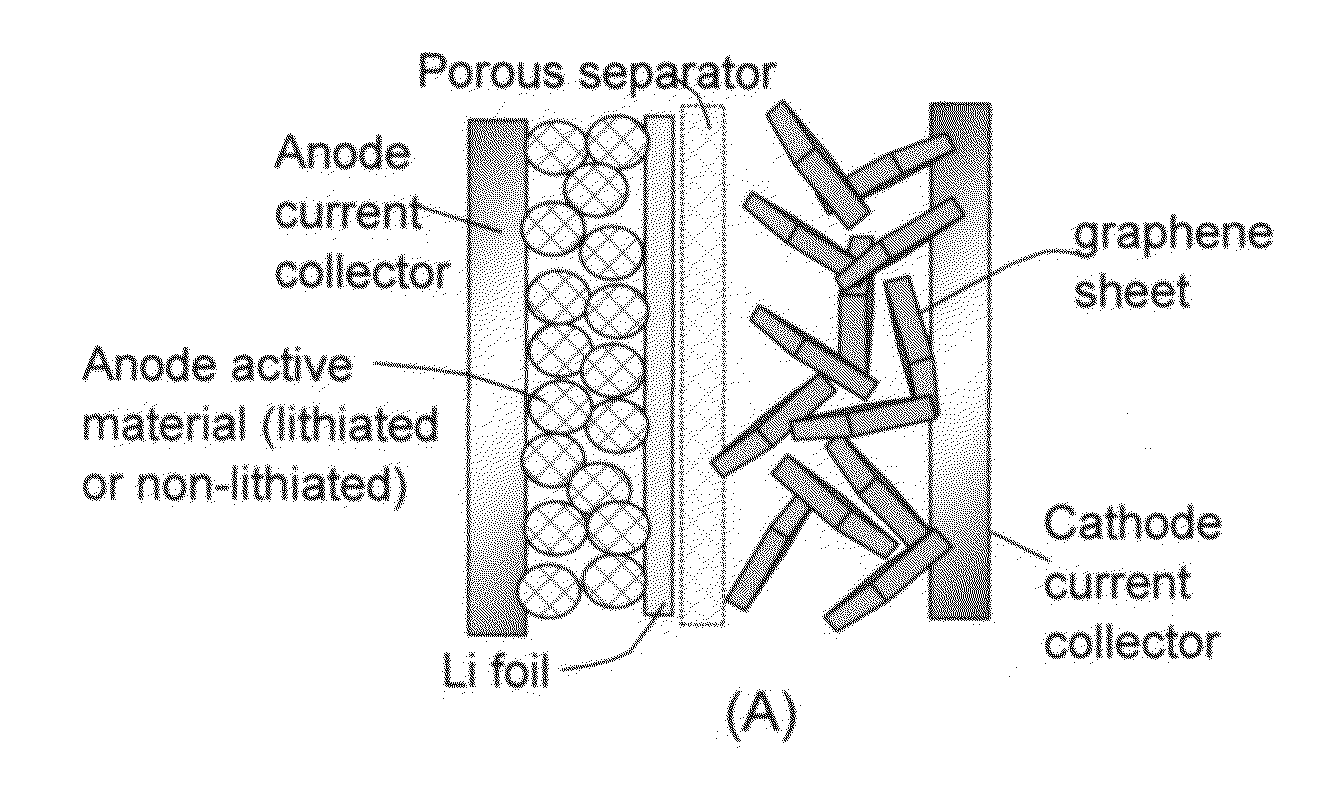

Secondary lithium ion battery containing a prelithiated anode

ActiveUS20100173198A1High specific capacityLong charge-discharge cycle lifeSecondary cellsActive material electrodesCharge dischargeGraphene

The present invention provides a lithium ion battery that exhibits a significantly improved specific capacity and much longer charge-discharge cycle life. In one preferred embodiment, the battery comprises an anode active material that has been prelithiated and pre-pulverized. This anode may be prepared with a method that comprises (a) providing an anode active material (preferably in the form of fine powder or thin film); (b) intercalating or absorbing a desired amount of lithium into the anode active material to produce a prelithiated anode active material; (c) comminuting the prelithiated anode active material into fine particles with an average size less than 10 μm (preferably <1 μm and most preferably <200 nm); and (d) combining multiple fine particles of the prelithiated anode active material with a conductive additive and / or a binder material to form the anode. Preferably, the prelithiated particles are protected by a lithium ion-conducting matrix or coating material. Further preferably, the matrix material is reinforced with nano graphene platelets.

Owner:GLOBAL GRAPHENE GRP INC

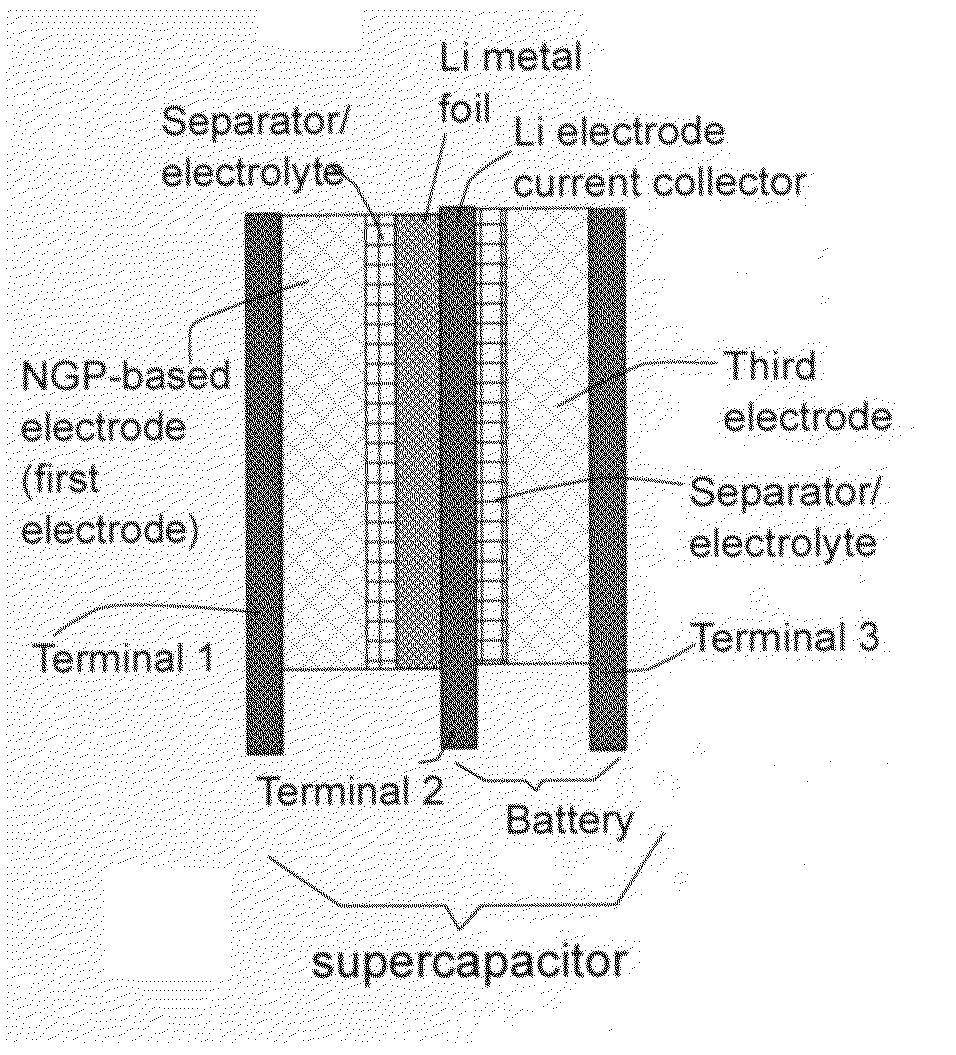

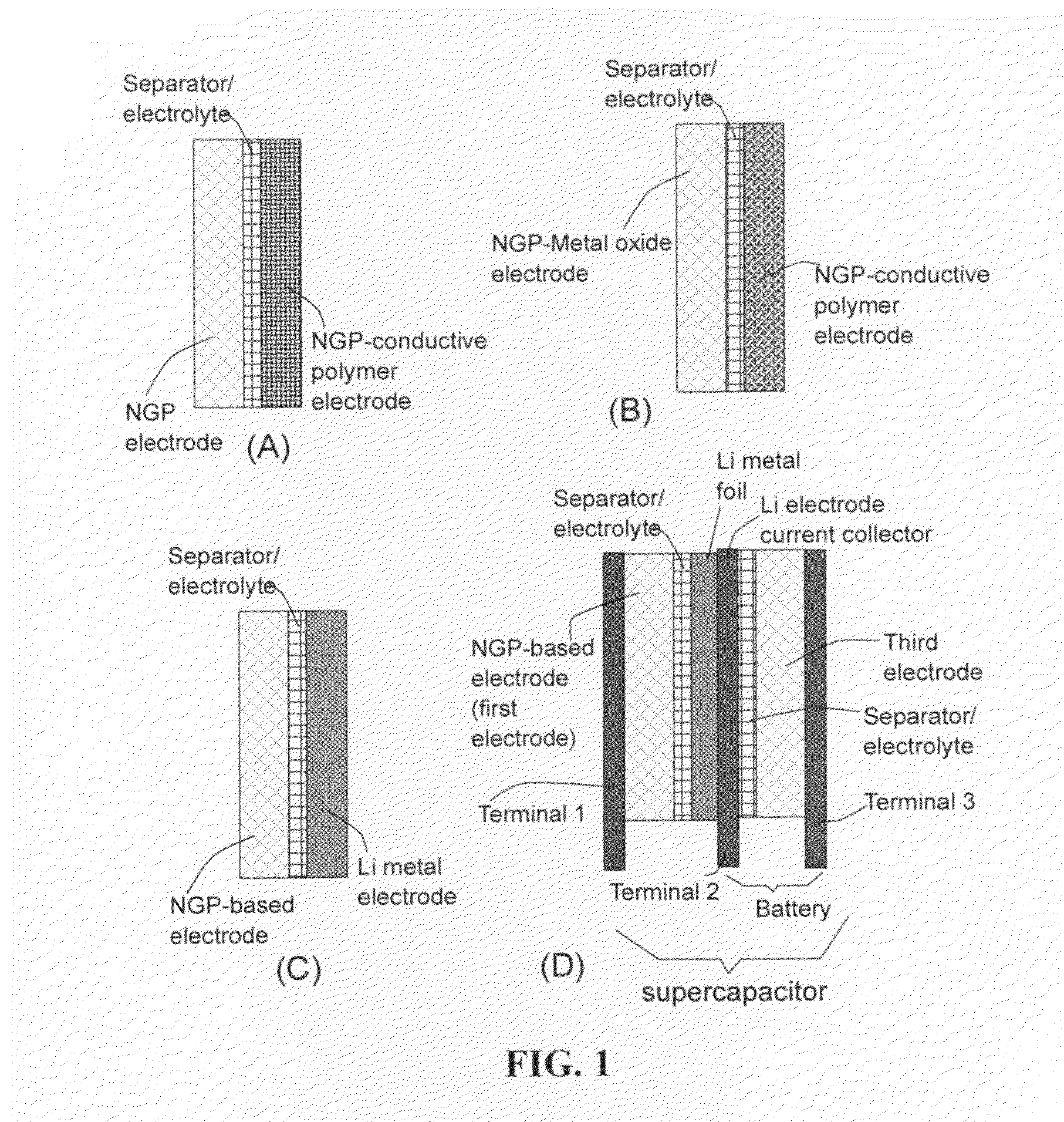

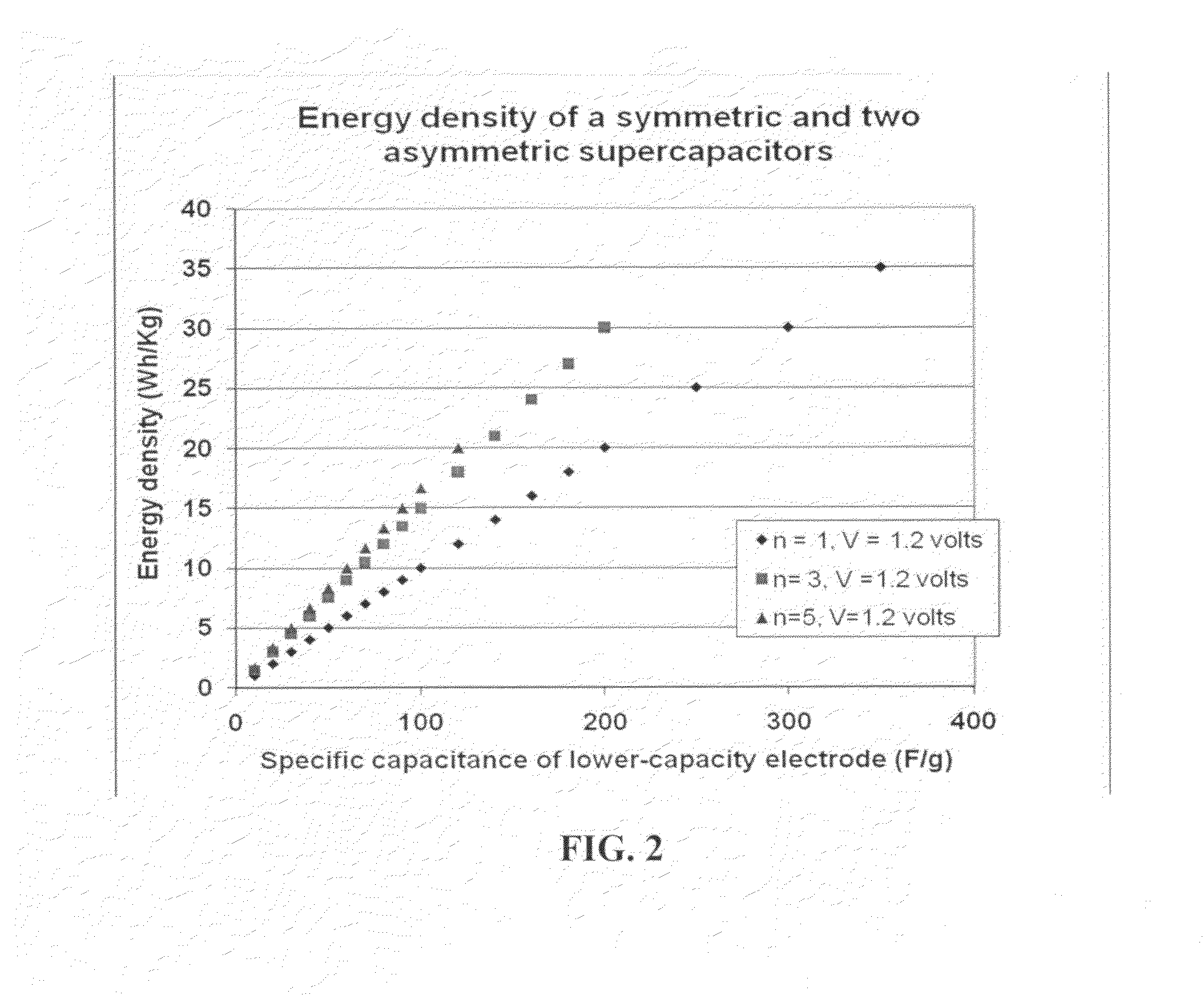

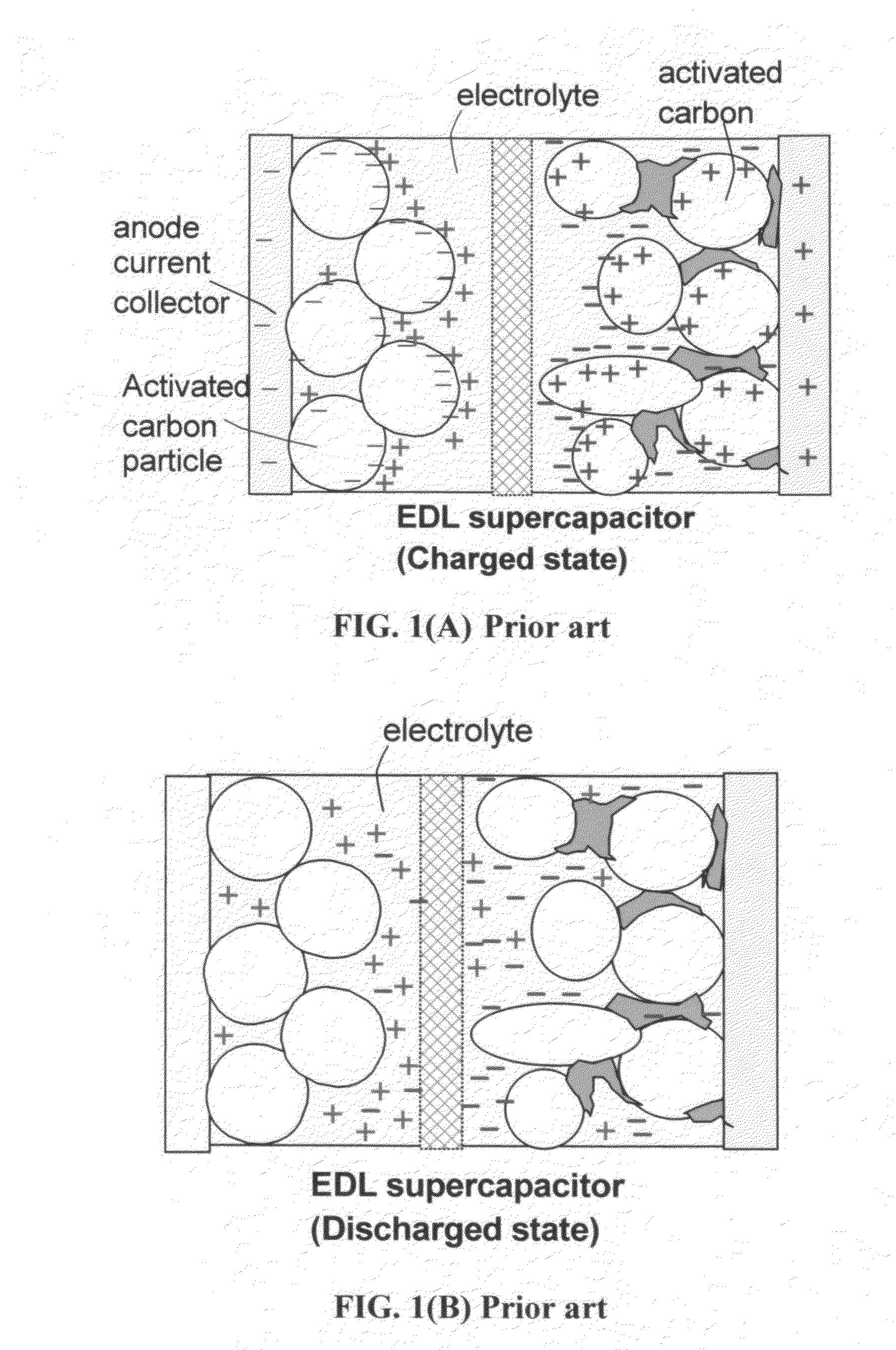

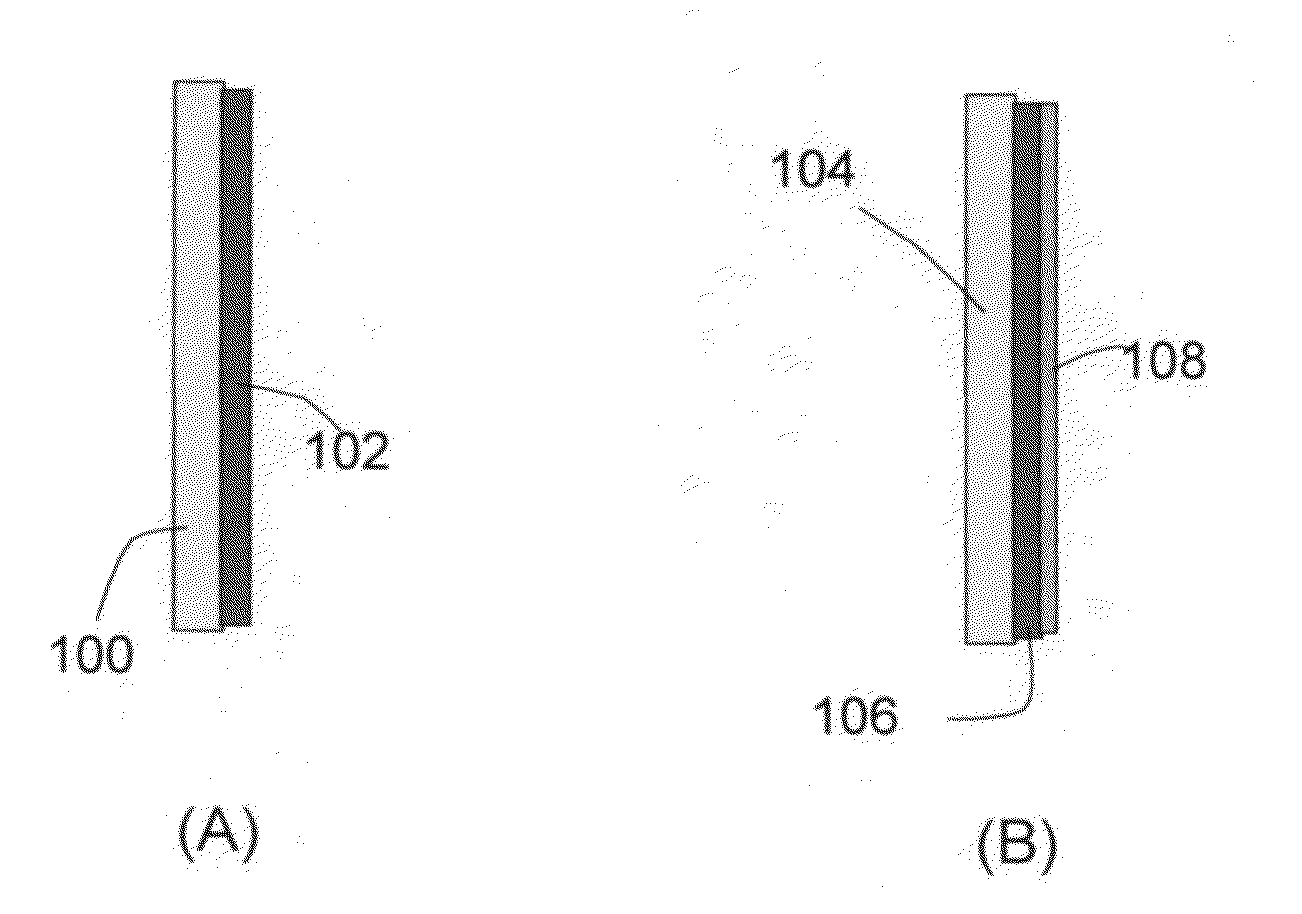

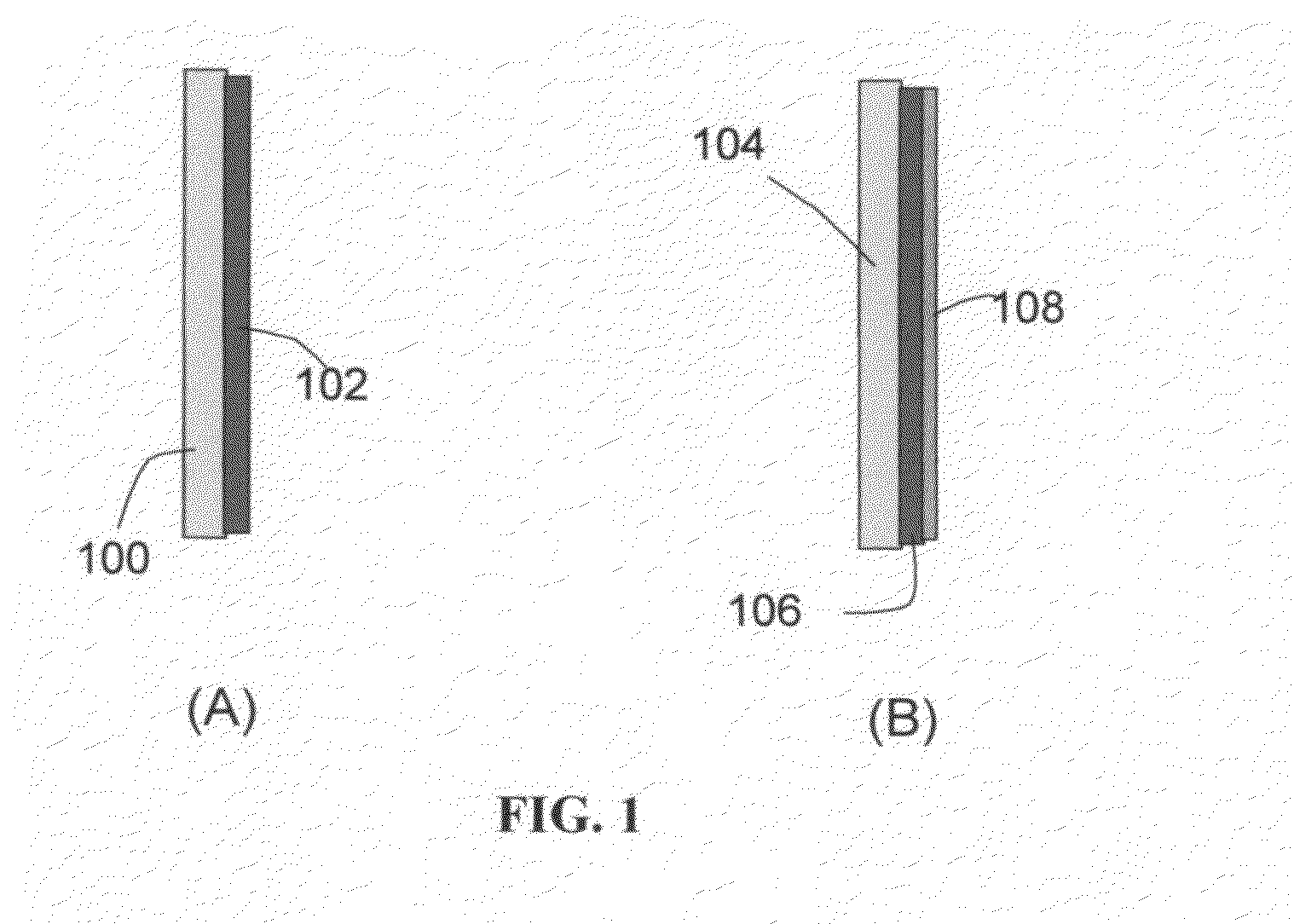

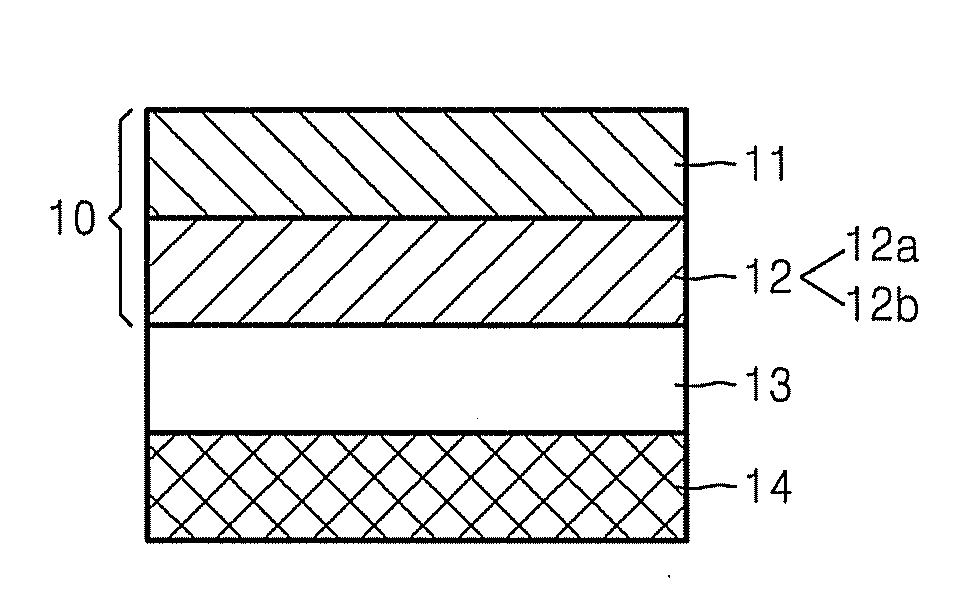

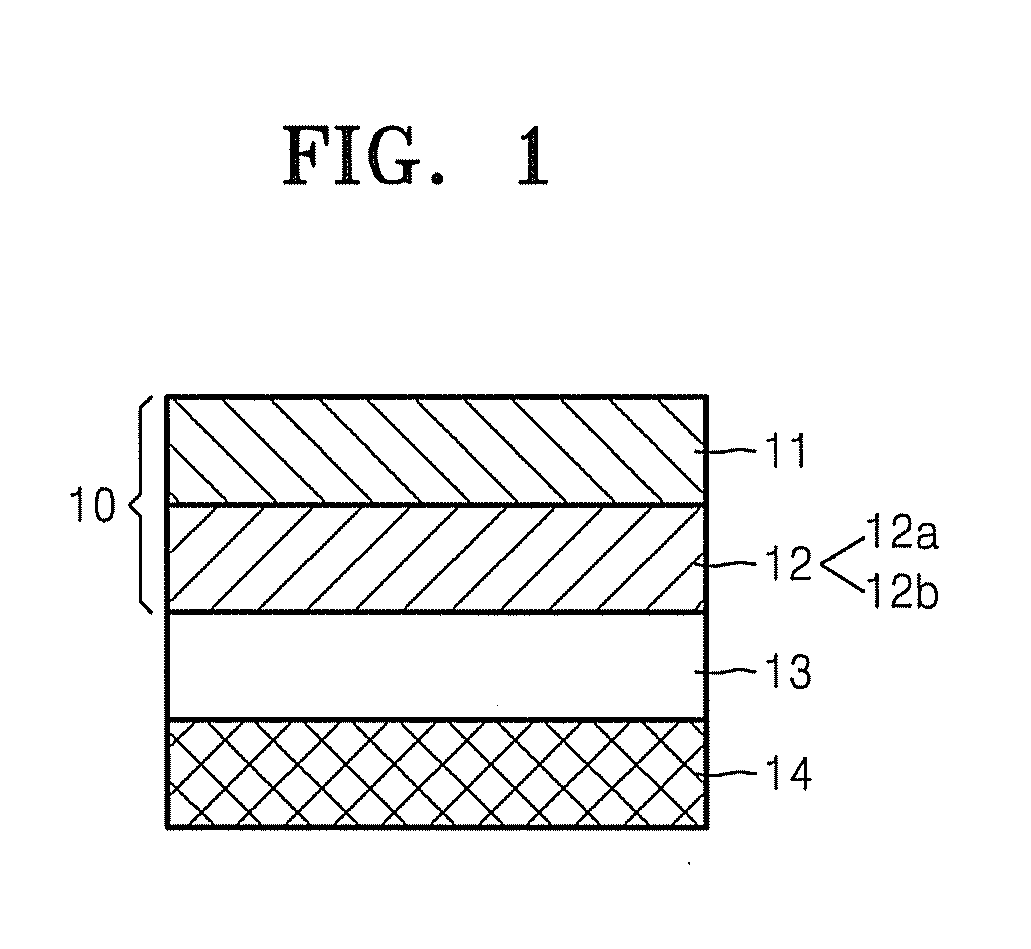

Flexible asymmetric electrochemical cells using nano graphene platelet as an electrode material

InactiveUS20110183180A1Excellent specific capacitanceLarge specific surface areaElectrochemical generatorsHybrid capacitor separatorsPlateletGraphene

A flexible, asymmetric electrochemical cell comprising: (A) A sheet of graphene paper as first electrode comprising nano graphene platelets having a platelet thickness less than 1 nm, wherein the first electrode has electrolyte-accessible pores; (B) A thin-film or paper-like first separator and electrolyte; and (C) A thin-film or paper-like second electrode which is different in composition than the first electrode; wherein the separator is sandwiched between the first and second electrode to form a flexible laminate configuration. The asymmetric supercapacitor cells with different NGP-based electrodes exhibit an exceptionally high capacitance, specific energy, and stable and long cycle life.

Owner:NANOTEK INSTR GRP LLC

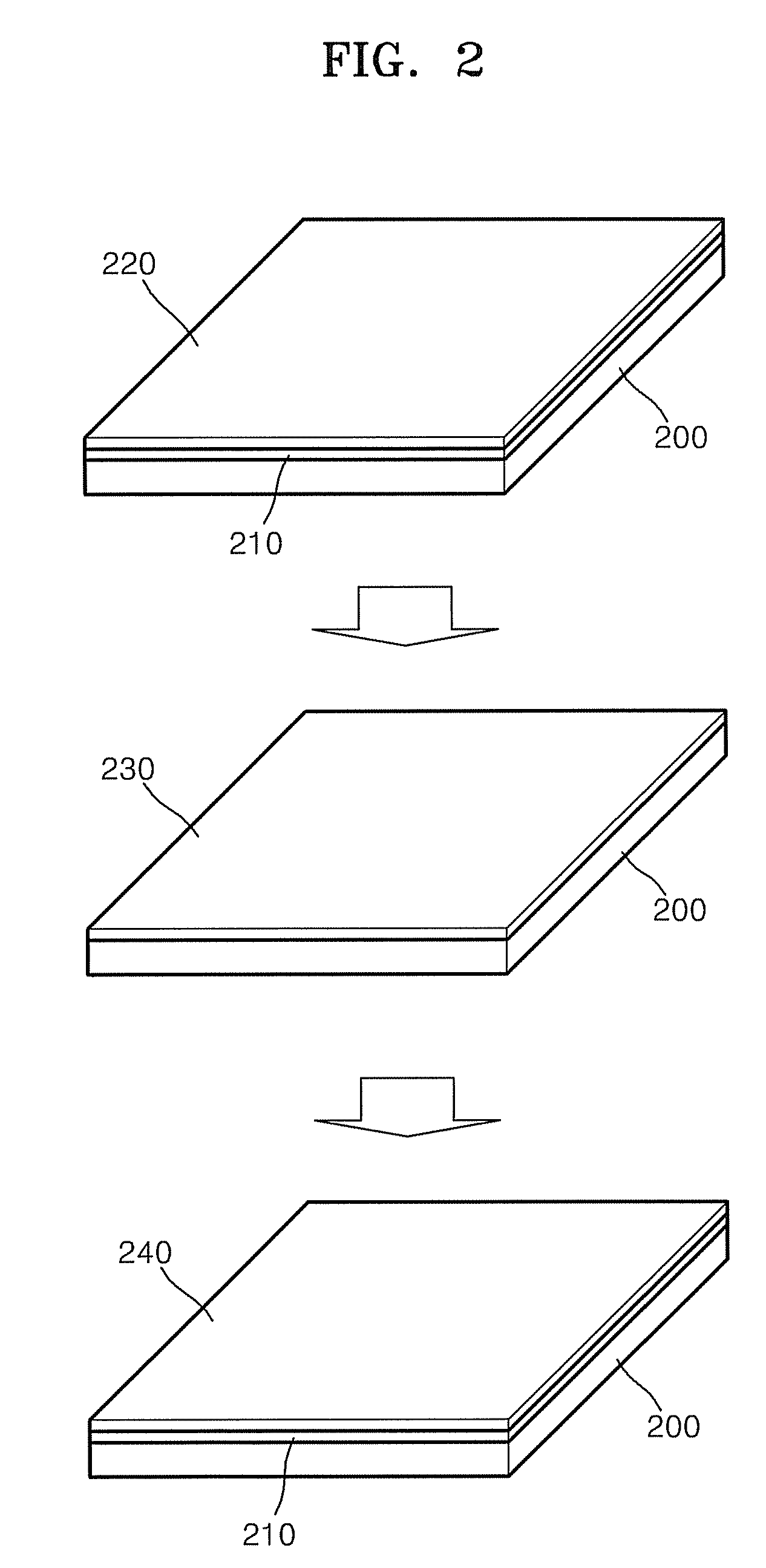

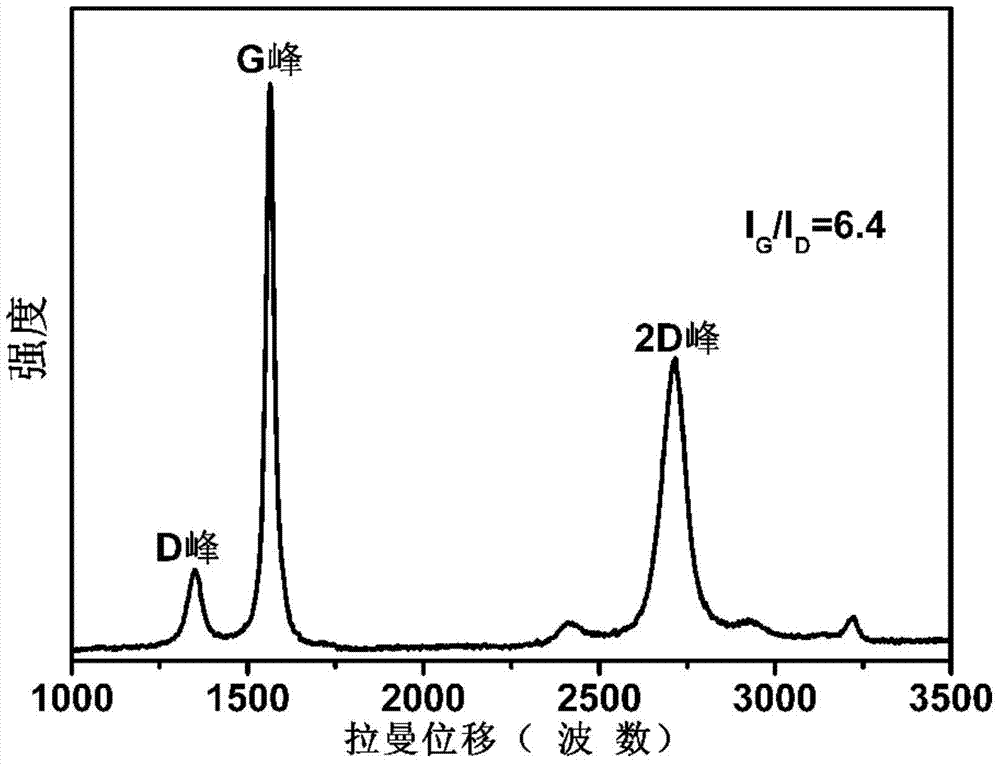

Single crystalline graphene sheet and process of preparing the same

A single-crystal graphene sheet includes a polycyclic aromatic molecule wherein a plurality of carbon atoms are covalently bound to each other, the single-crystal graphene sheet comprising between about 1 layer to about 300 layers; and wherein a peak ratio of a Raman D band intensity to a Raman G band intensity is equal to or less than 0.2. Also described is a method for preparing a single-crystal graphene sheet, the method includes forming a catalyst layer, which includes a single-crystal graphitizing metal catalyst sheet; disposing a carbonaceous material on the catalyst layer; and heat-treating the catalyst layer and the carbonaceous material in at least one of an inert atmosphere and a reducing atmosphere. Also described is a transparent electrode including a single-crystal graphene sheet.

Owner:SAMSUNG ELECTRONICS CO LTD

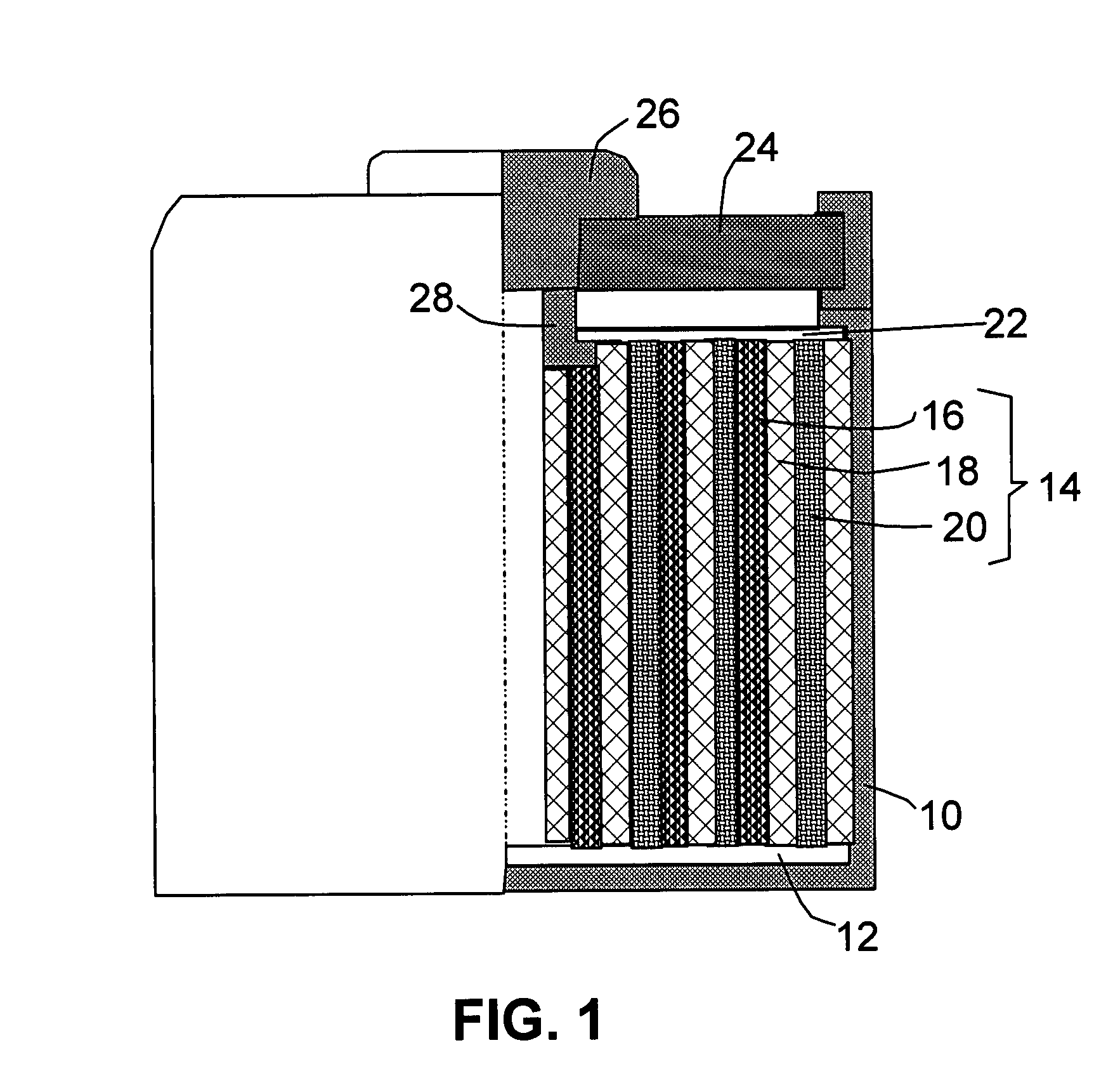

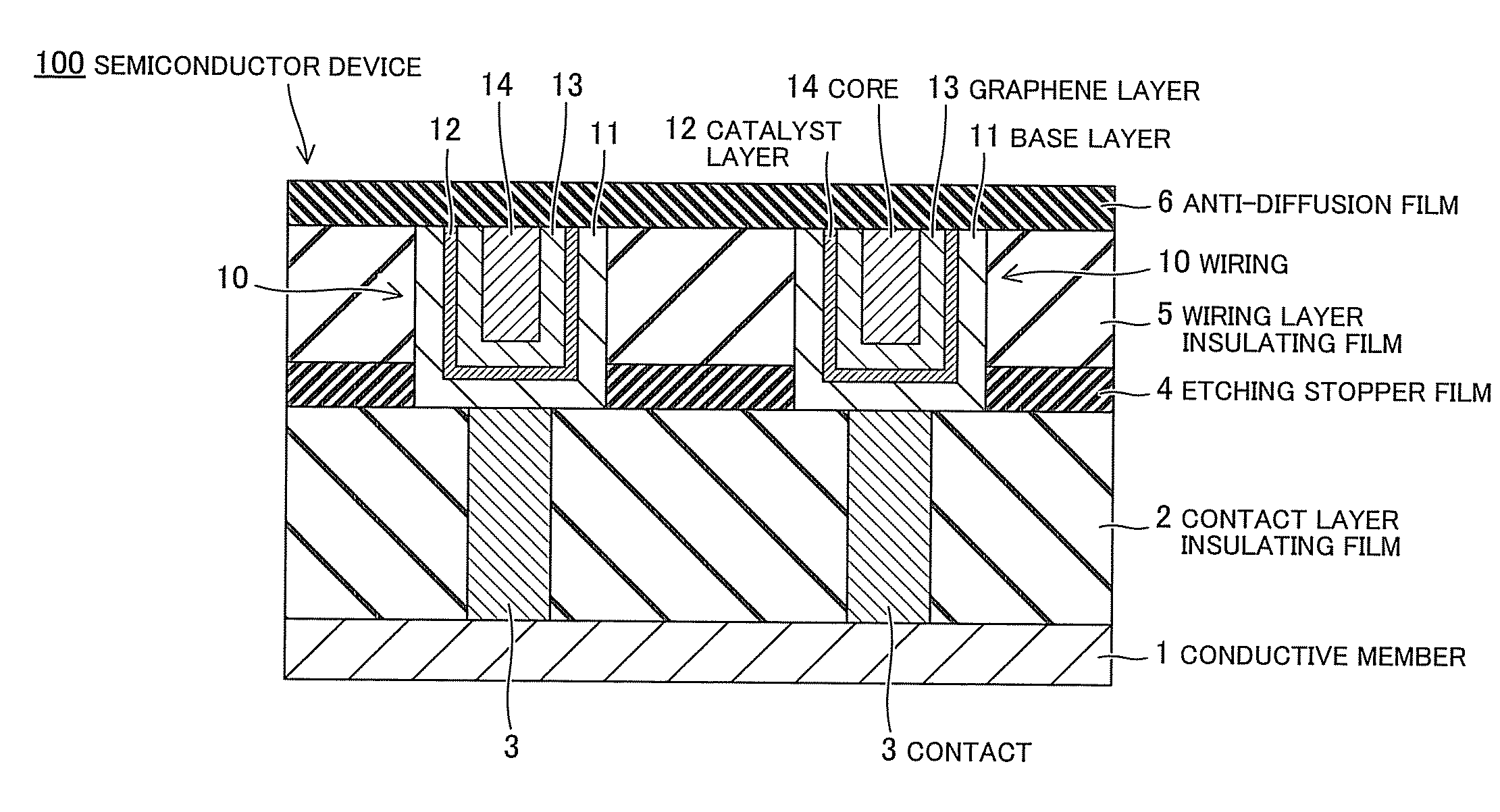

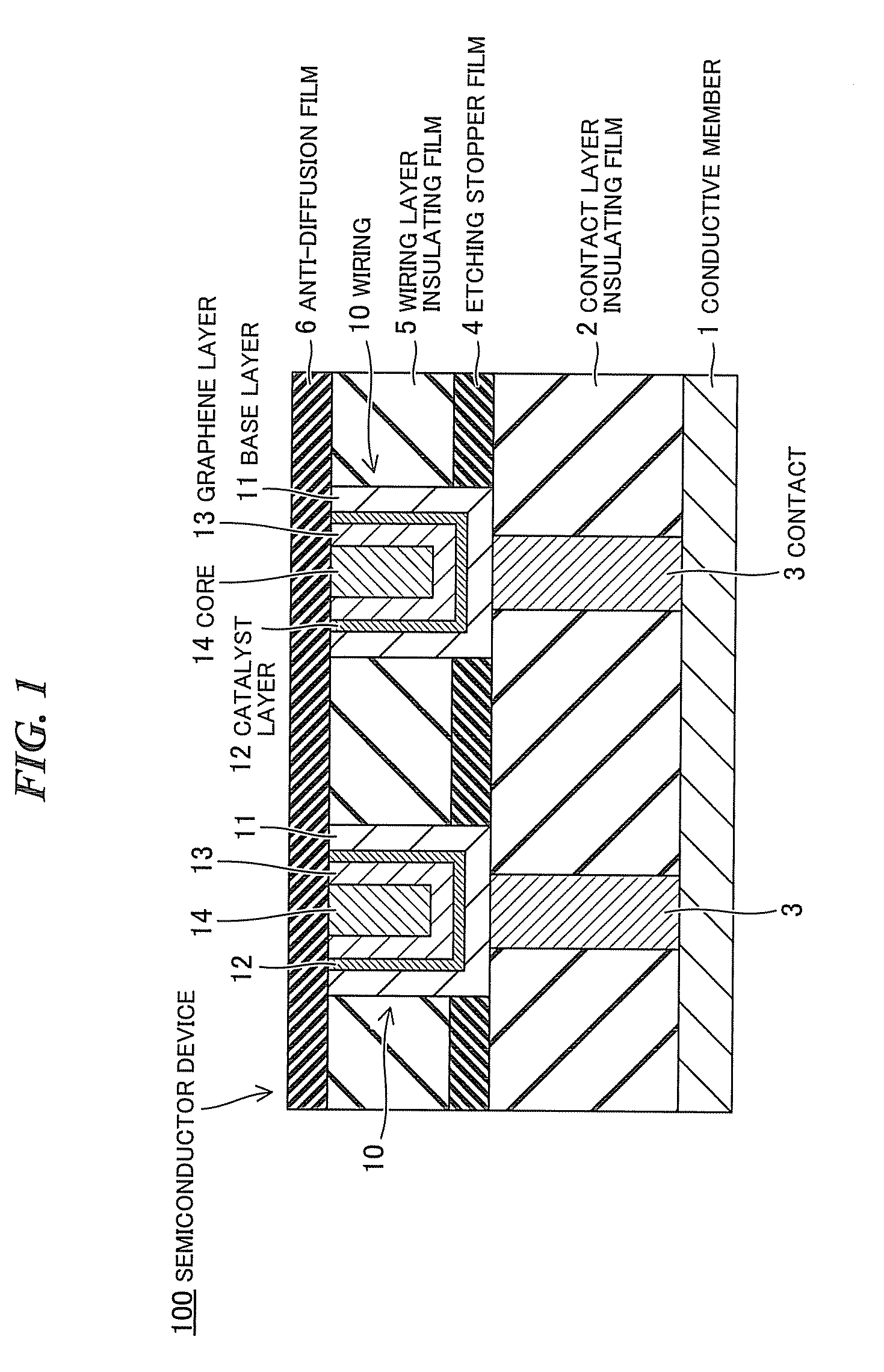

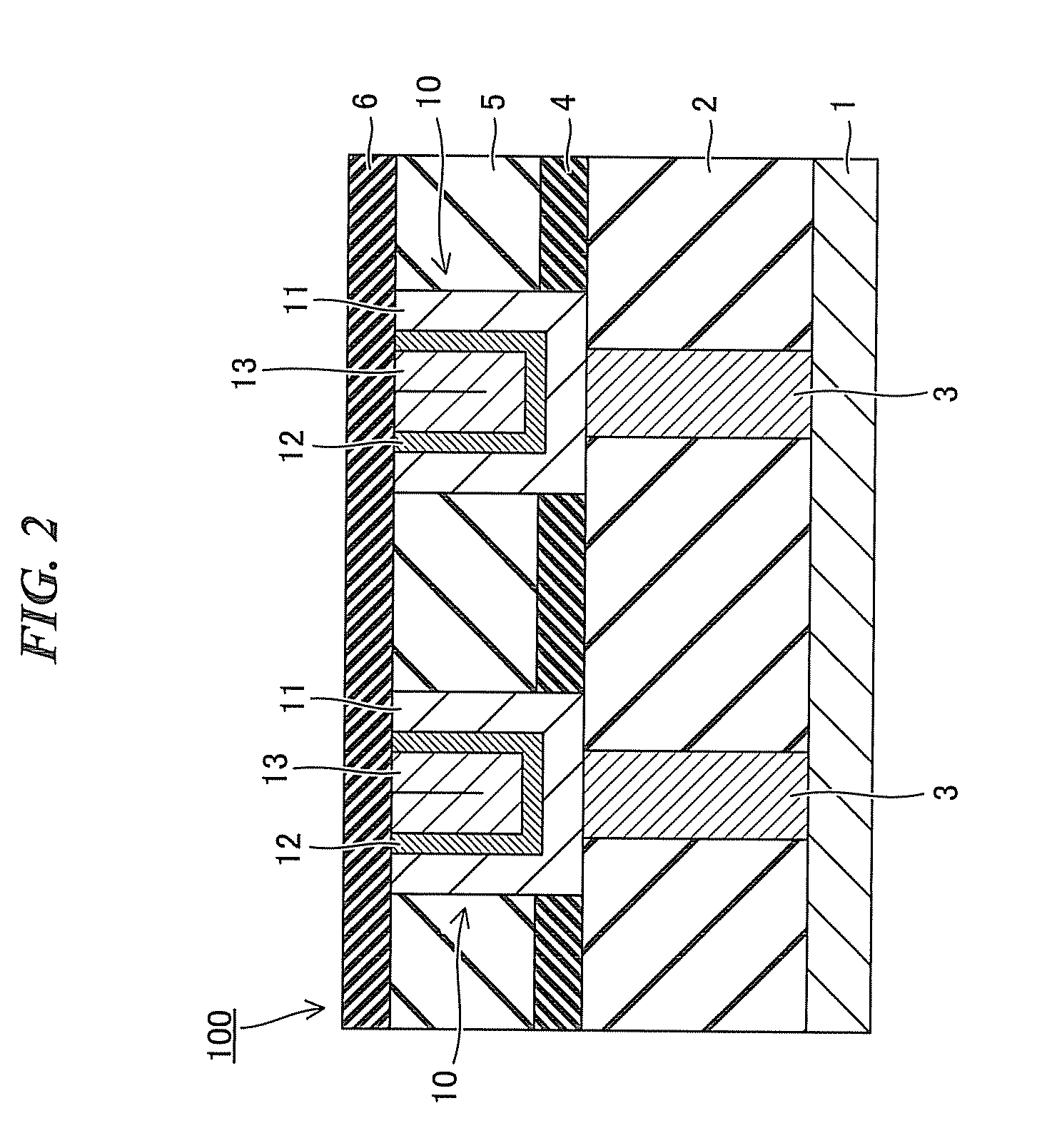

Semiconductor device

ActiveUS20110006425A1Semiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceGraphene

A semiconductor device according to one embodiment includes: a semiconductor substrate; an insulating film provided on the semiconductor substrate and containing a wiring trench; a first catalyst layer provided directly or via another member on side and bottom surfaces of the wiring trench; and a first graphene layer provided in the wiring trench so as to be along the side and bottom surface of the wiring trench, the first graphene layer being provided on the first catalyst layer so as to be in contact with the first catalyst layer.

Owner:KK TOSHIBA

Lithium-ion cell having a high-capacity anode and a high-capacity cathode

ActiveUS20130224603A1Easy dischargeImprove power densityMaterial nanotechnologyHybrid capacitor electrodesLithiumHigh energy

A lithium-ion cell comprising: (A) a cathode comprising graphene as the cathode active material having a surface area to capture and store lithium thereon and wherein said graphene cathode is meso-porous having a specific surface area greater than 100 m2 / g; (B) an anode comprising an anode active material for inserting and extracting lithium, wherein the anode active material is mixed with a conductive additive and / or a resin binder to form a porous electrode structure, or coated onto a current collector in a coating or thin film form; (C) a porous separator disposed between the anode and the cathode; (D) a lithium-containing electrolyte in physical contact with the two electrodes; and (E) a lithium source disposed in at least one of the two electrodes when the cell is made. This new Li-ion cell exhibits an unprecedentedly high energy density.

Owner:GLOBAL GRAPHENE GRP INC

Prelithiated current collector and secondary lithium cells containing same

ActiveUS20130045427A1Reduce capacityMaterial nanotechnologyHybrid capacitorsLithium metalLithium sulfur

The present invention provides a battery or supercapacitor current collector which is prelithiated. The prelithiated current collector comprises: (a) an electrically conductive substrate having two opposed primary surfaces, and (b) a mixture layer of carbon (and / or other stabilizing element, such as B, Al, Ga, In, C, Si, Ge, Sn, Pb, As, Sb, Bi, Te, or a combination thereof) and lithium or lithium alloy coated on at least one of the primary surfaces, wherein lithium element is present in an amount of 1% to 99% by weight of the mixture layer. This current collector serves as an effective and safe lithium source for a wide variety of electrochemical energy storage cells, including the rechargeable lithium cell (e.g. lithium-metal, lithium-ion, lithium-sulfur, lithium-air, lithium-graphene, lithium-carbon, and lithium-carbon nanotube cell) and the lithium ion based supercapacitor cell (e.g, symmetric ultracapacitor, asymmetric ultracapacitor, hybrid supercapacitor-battery, or lithium-ion capacitor).

Owner:GLOBAL GRAPHENE GRP INC

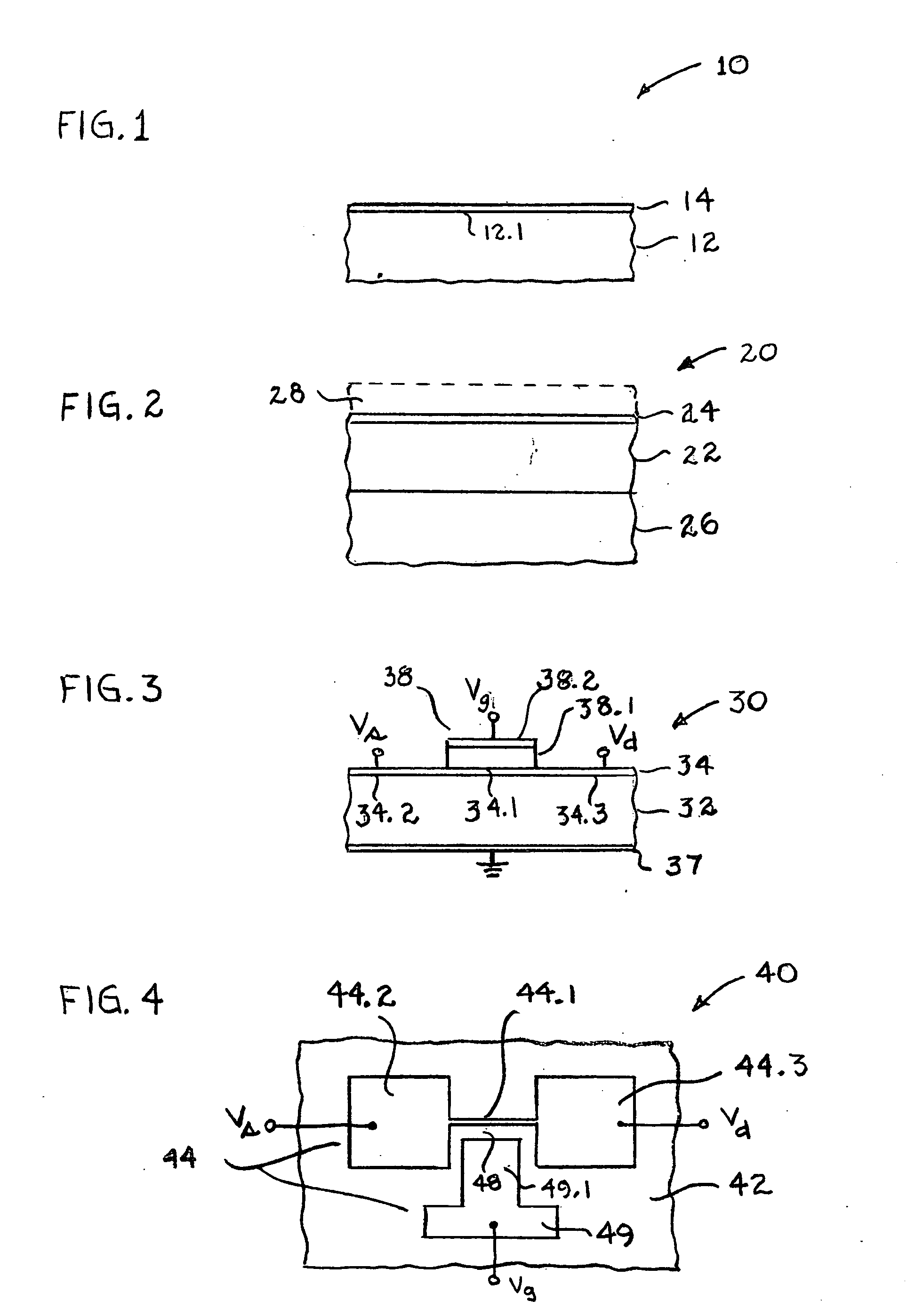

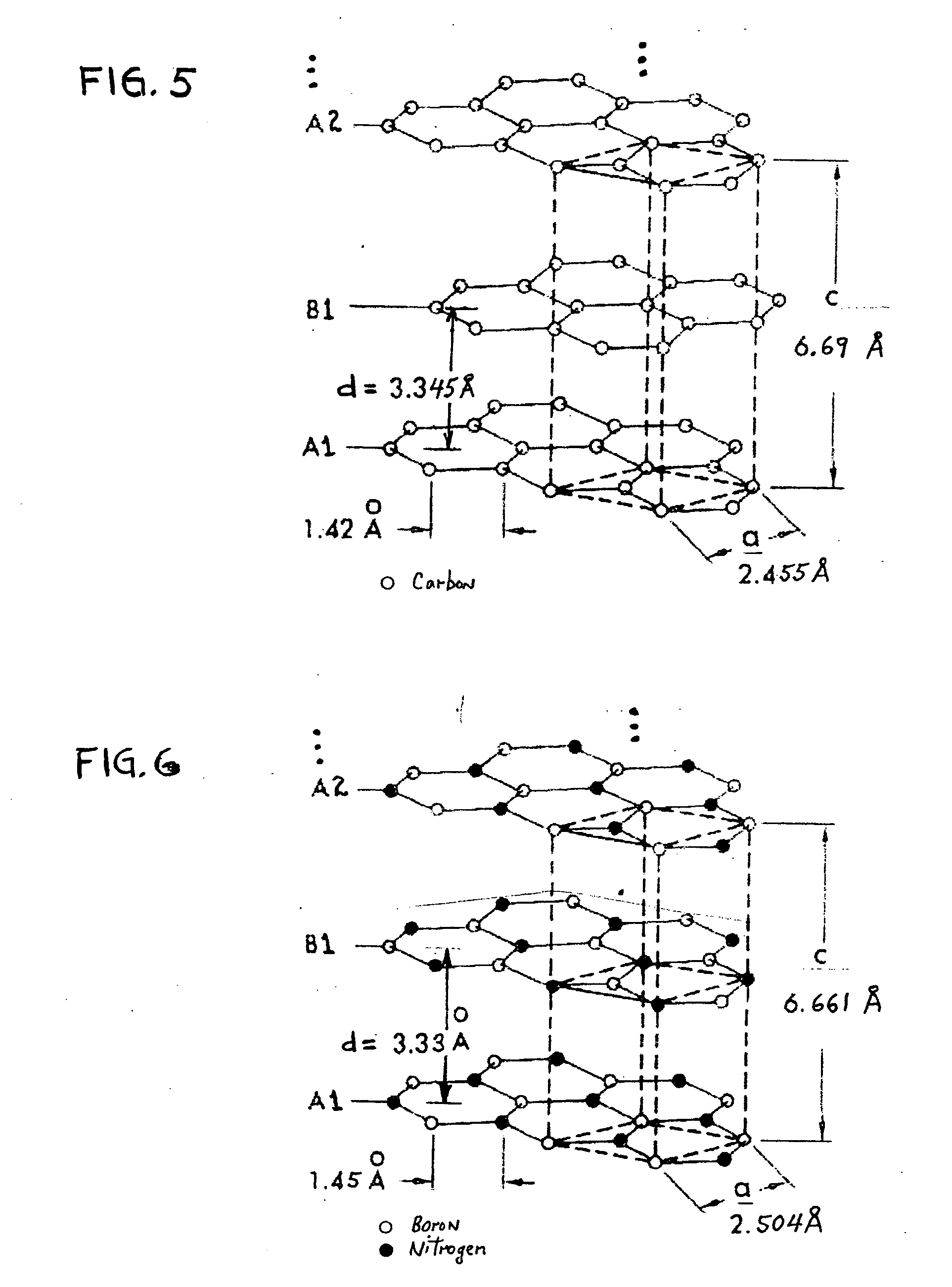

Devices including graphene layers epitaxially grown on single crystal substrates

ActiveUS20070187694A1Semiconductor/solid-state device manufacturingSemiconductor devicesSingle crystal substrateGraphite

An electronic device comprises a body including a single crystal region on a major surface of the body. The single crystal region has a hexagonal crystal lattice that is substantially lattice-matched to graphene, and a at least one epitaxial layer of graphene is disposed on the single crystal region. In a currently preferred embodiment, the single crystal region comprises multilayered hexagonal BN. A method of making such an electronic device comprises the steps of: (a) providing a body including a single crystal region on a major surface of the body. The single crystal region has a hexagonal crystal lattice that is substantially lattice-matched to graphene, and (b) epitaxially forming a at least one graphene layer on that region. In a currently preferred embodiment, step (a) further includes the steps of (a1) providing a single crystal substrate of graphite and (a2) epitaxially forming multilayered single crystal hexagonal BN on the substrate. The hexagonal BN layer has a surface region substantially lattice-matched to graphene, and step (b) includes epitaxially forming at least one graphene layer on the surface region of the hexagonal BN layer. Applications to FETs are described.

Owner:ALCATEL-LUCENT USA INC +1

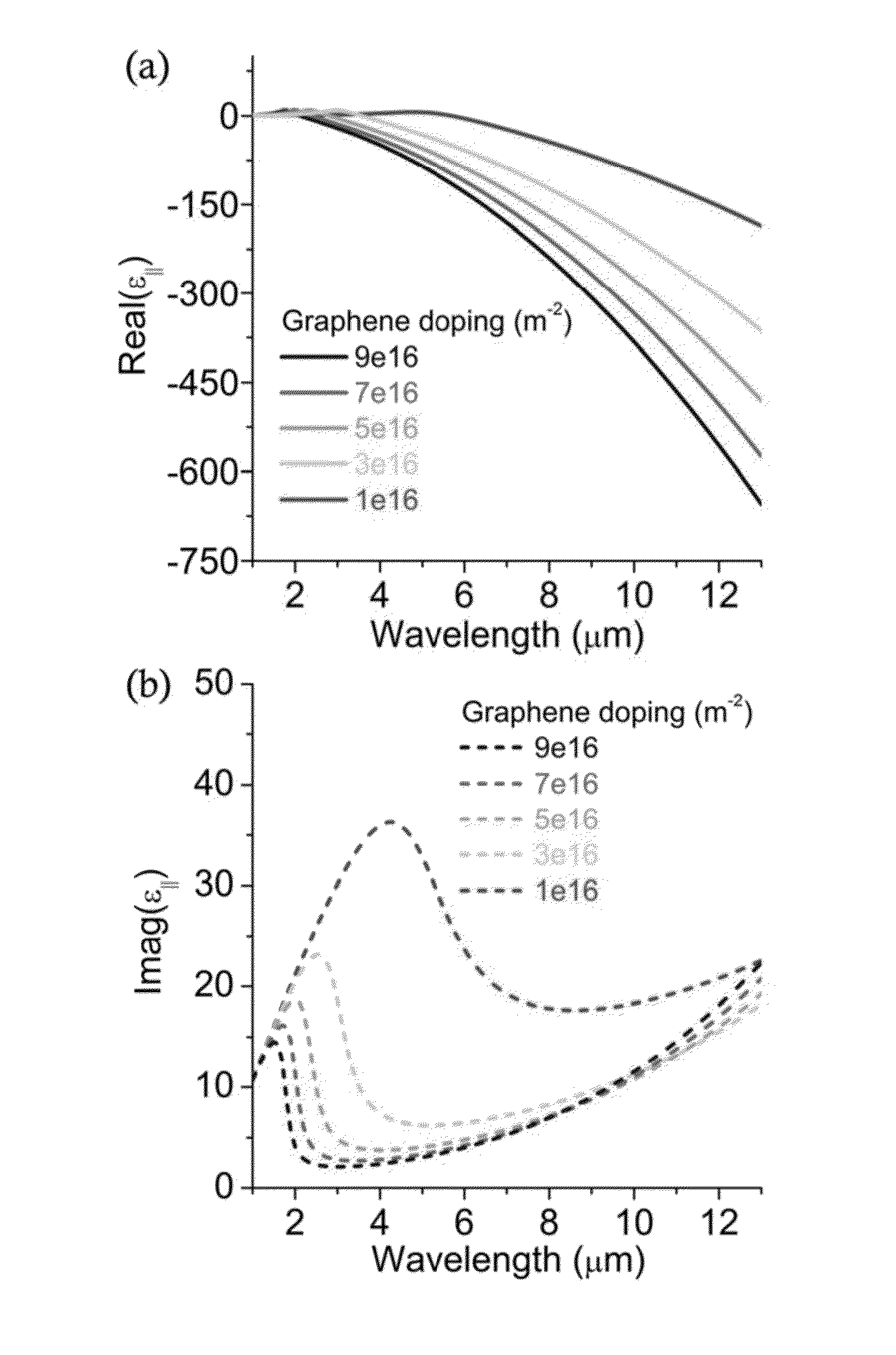

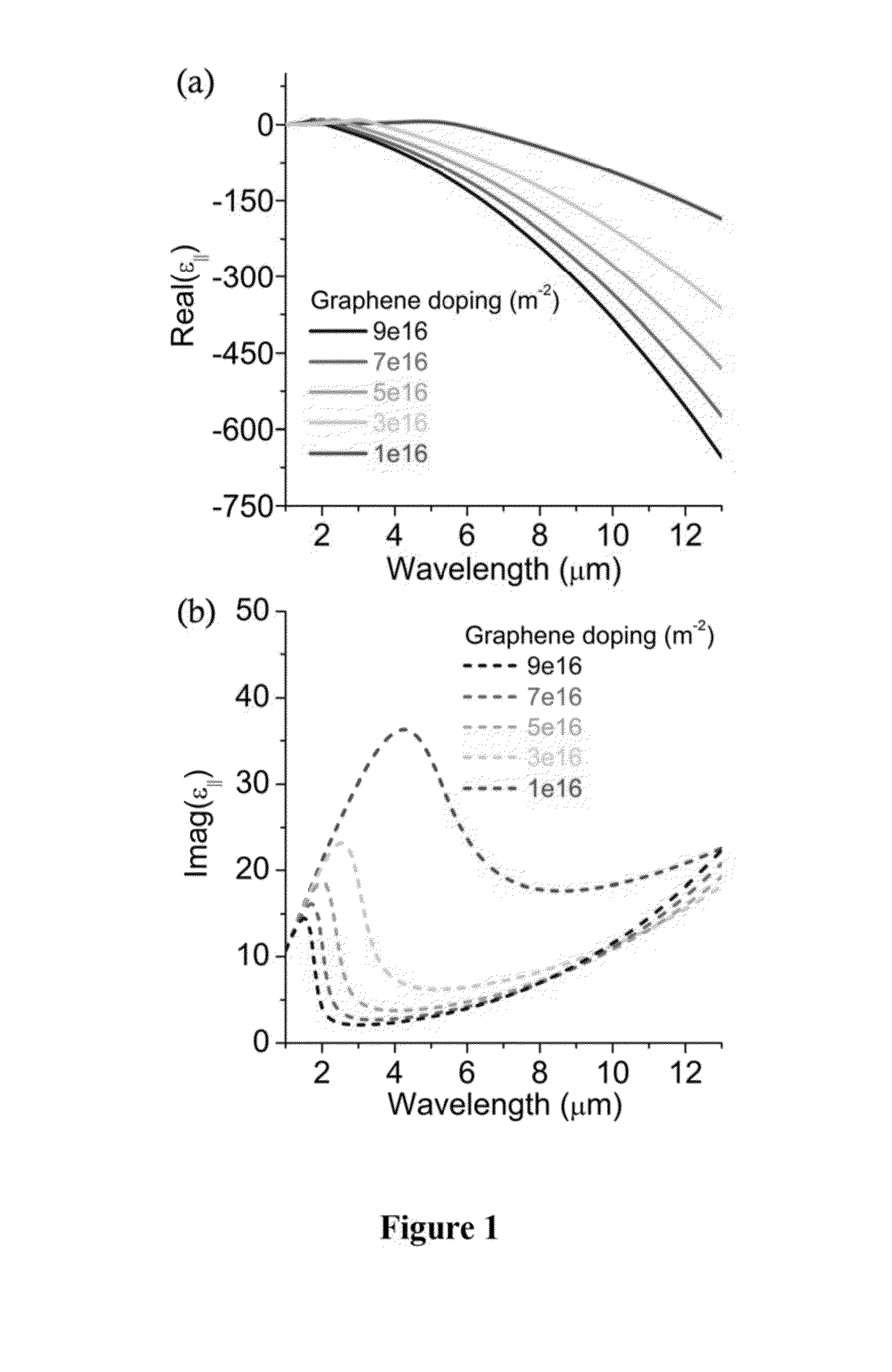

System, method and computer-accessible medium for depth of field imaging for three-dimensional sensing utilizing a spatial light modulator microscope arrangement

ActiveUS20150369660A1Efficiently modulate the intensity, phase, and/or polarization of incident radiationSolid-state devicesRadiating elements structural formsElectrical conductorPlanar antennas

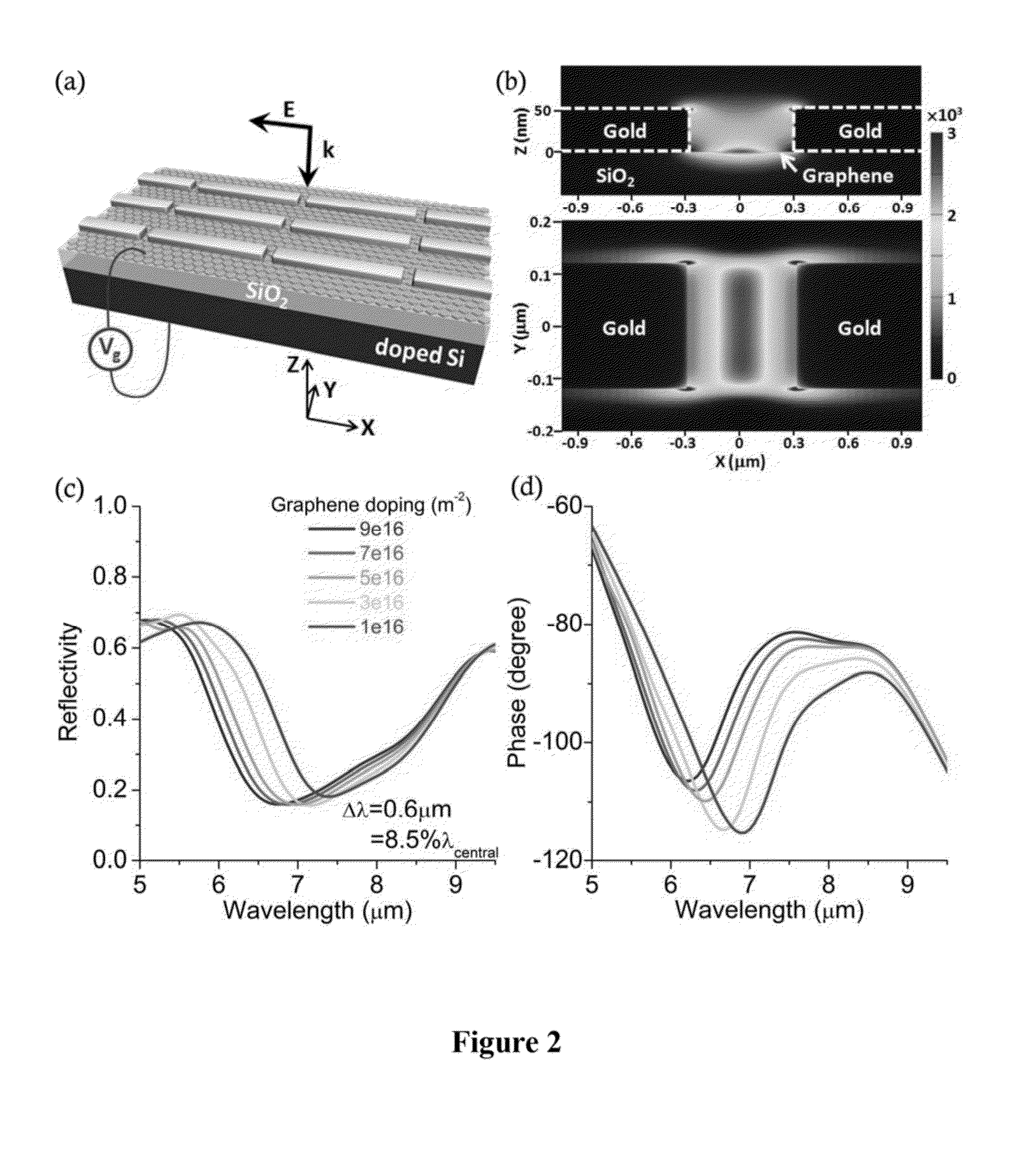

Exemplary embodiment can utilize the properties of tunable thin-film, material (e.g., graphene) to efficiently modulate the intensity, phase, and / or polarization of transmitted and / or reflected radiation, including mid-infrared (“mid-IR”) radiation. Exemplary embodiments include planar antennas comprising tunable thin-film material sections and metallic sections disposed in contact with the tunable thin-film material sections, each metallic section having a gap with at least one dimension related to a wavelength of the radiation, which in some embodiments may be less than the wavelength. The metallic layer may comprise rods arrange in one or more shapes, or one or more apertures of one or more shapes. Embodiments of the antenna may also comprise a substrate, which may be a semiconductor or conductor in various embodiments. Embodiments also include systems, computer-implemented methods, devices, and computer-readable media for effectuating desired modulation of incident radiation by, e.g., varying the doping level of the tunable thin-film material.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

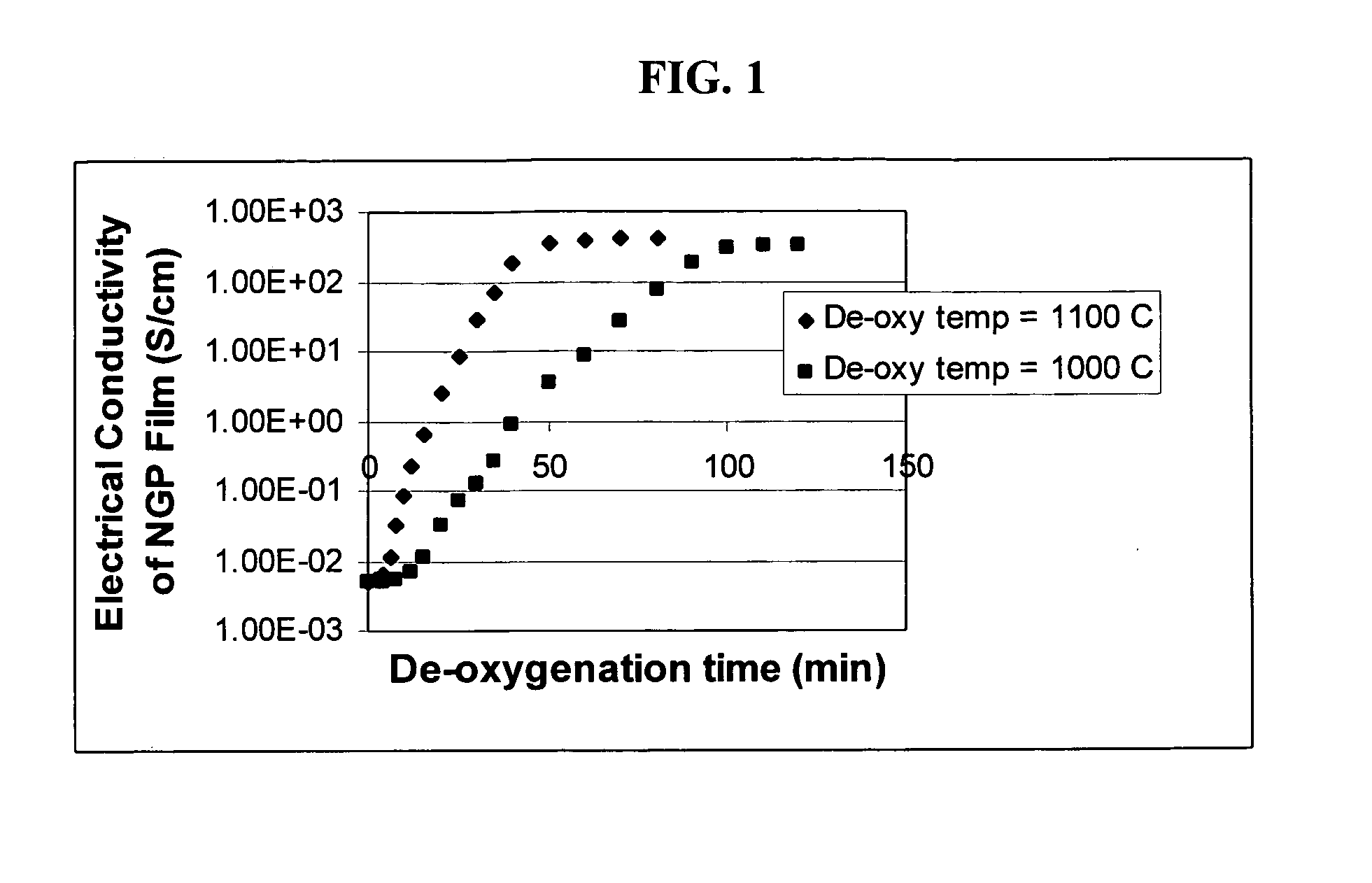

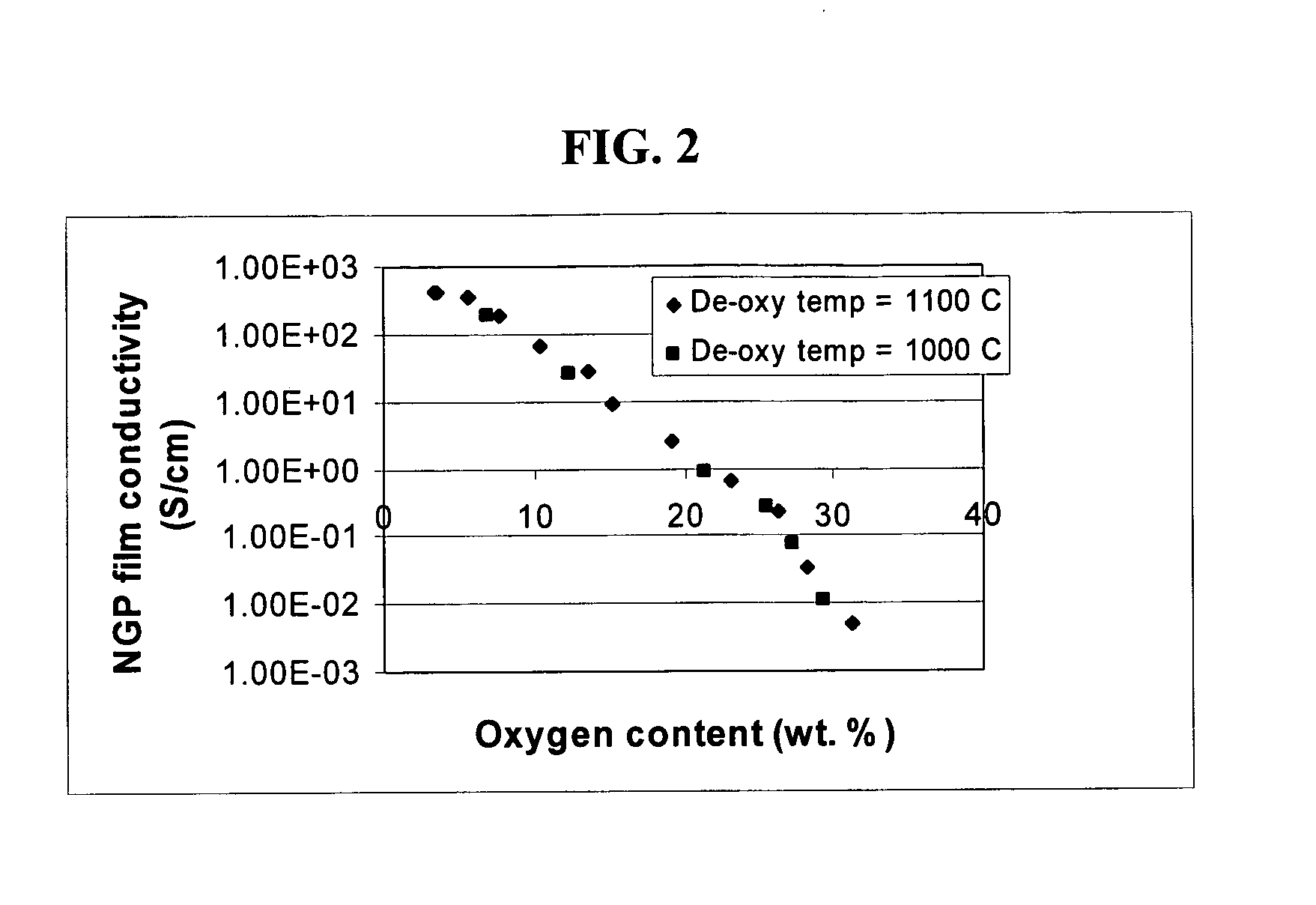

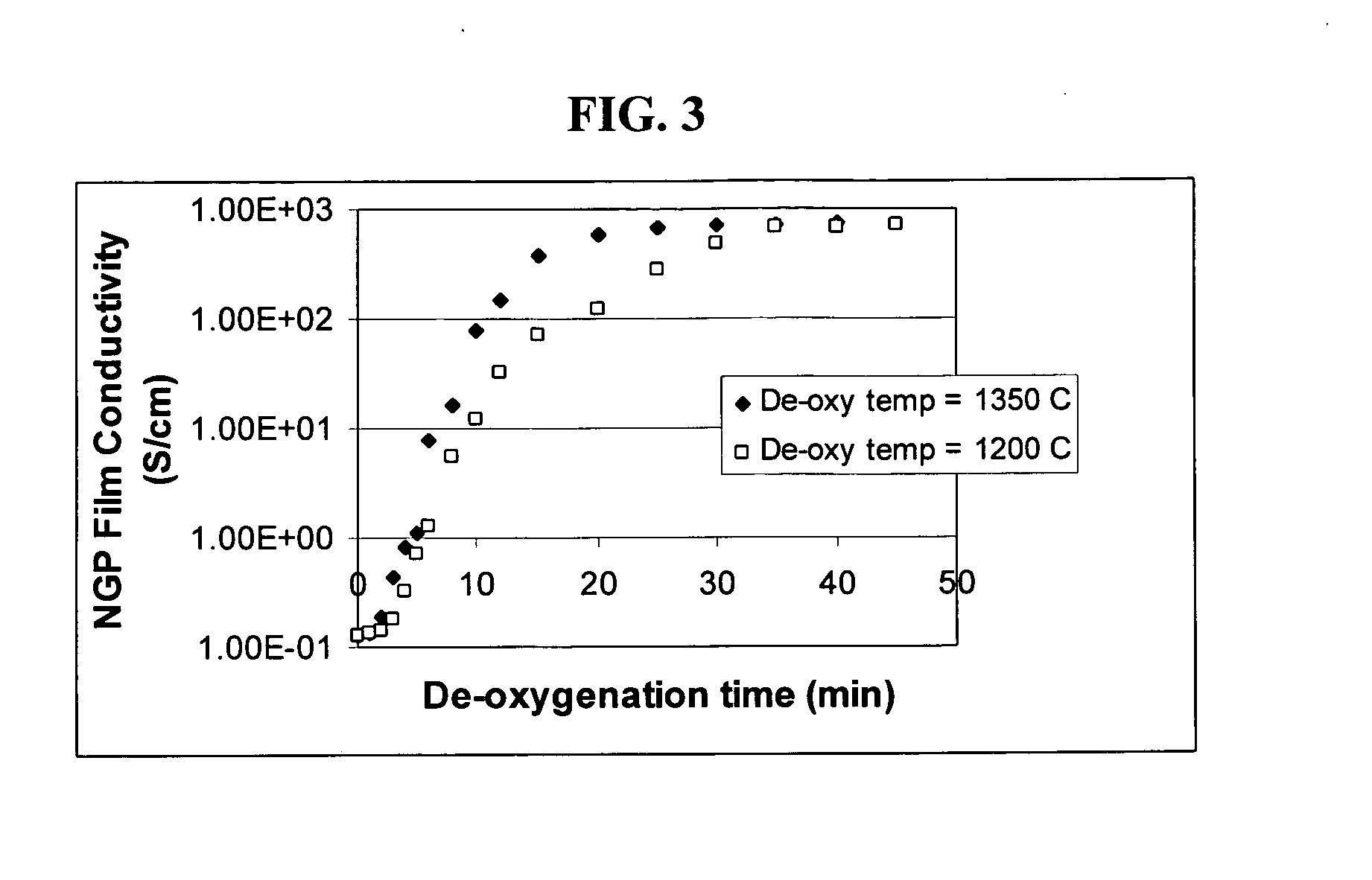

Nano-scaled graphene plate films and articles

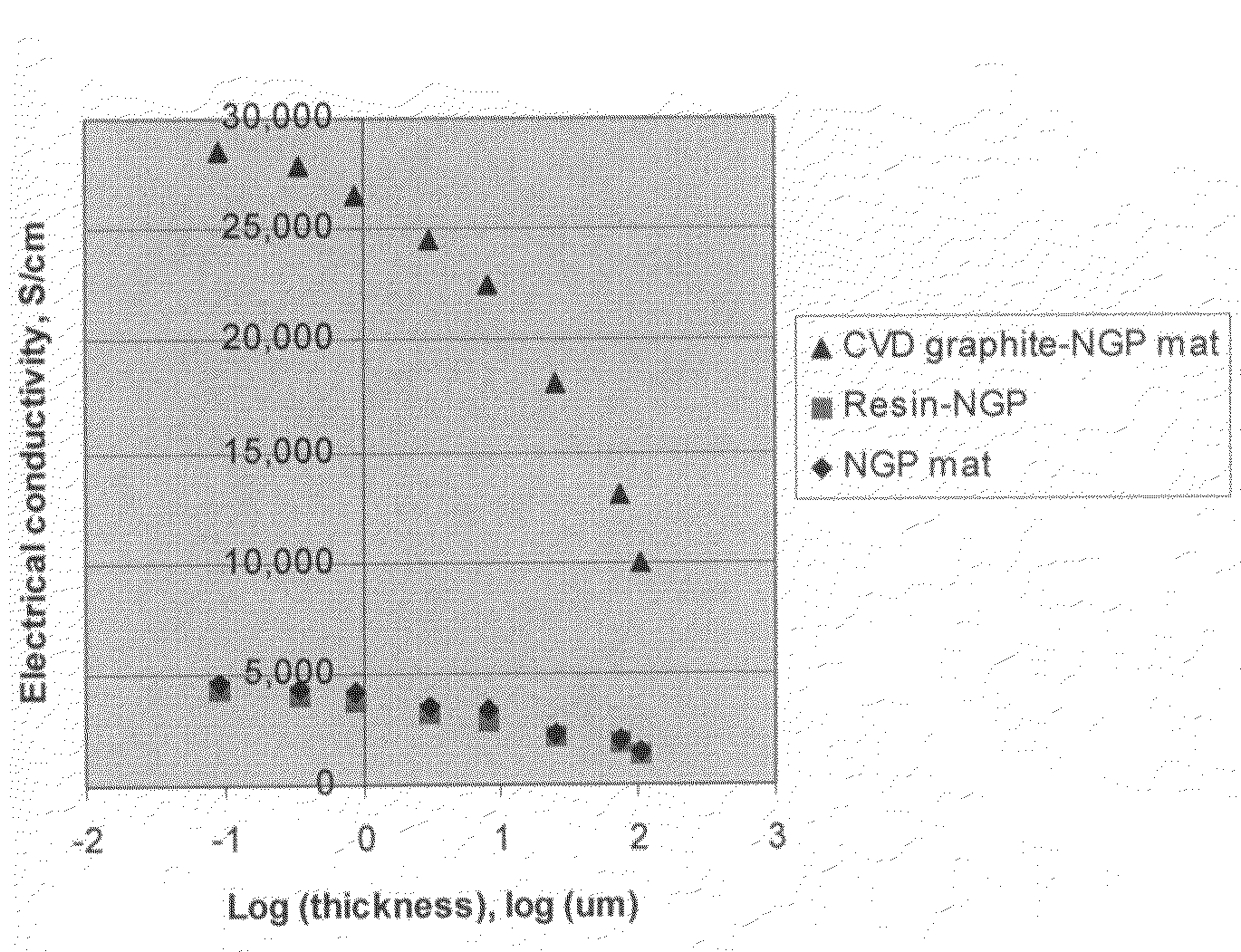

ActiveUS20080248275A1Improve thermal conductivityNon-metal conductorsMaterial nanotechnologyLightning strikePlatelet

Disclosed is a nano-scaled graphene article comprising a non-woven aggregate of nano-scaled graphene platelets wherein each of the platelets comprises a graphene sheet or multiple graphene sheets and the platelets have a thickness no greater than 100 nm (preferably smaller than 10 nm) and platelets contact other platelets to define a plurality of conductive pathways along the article. The article has an exceptional thermal conductivity (typically greater than 500 Wm−1K−1) and excellent electrical conductivity (typically greater than 1,000 S / cm). Thin-film articles of the present invention can be used for thermal management in micro-electronic devices and for current-dissipating on an aircraft skin against lightning strikes.

Owner:GLOBAL GRAPHENE GRP INC

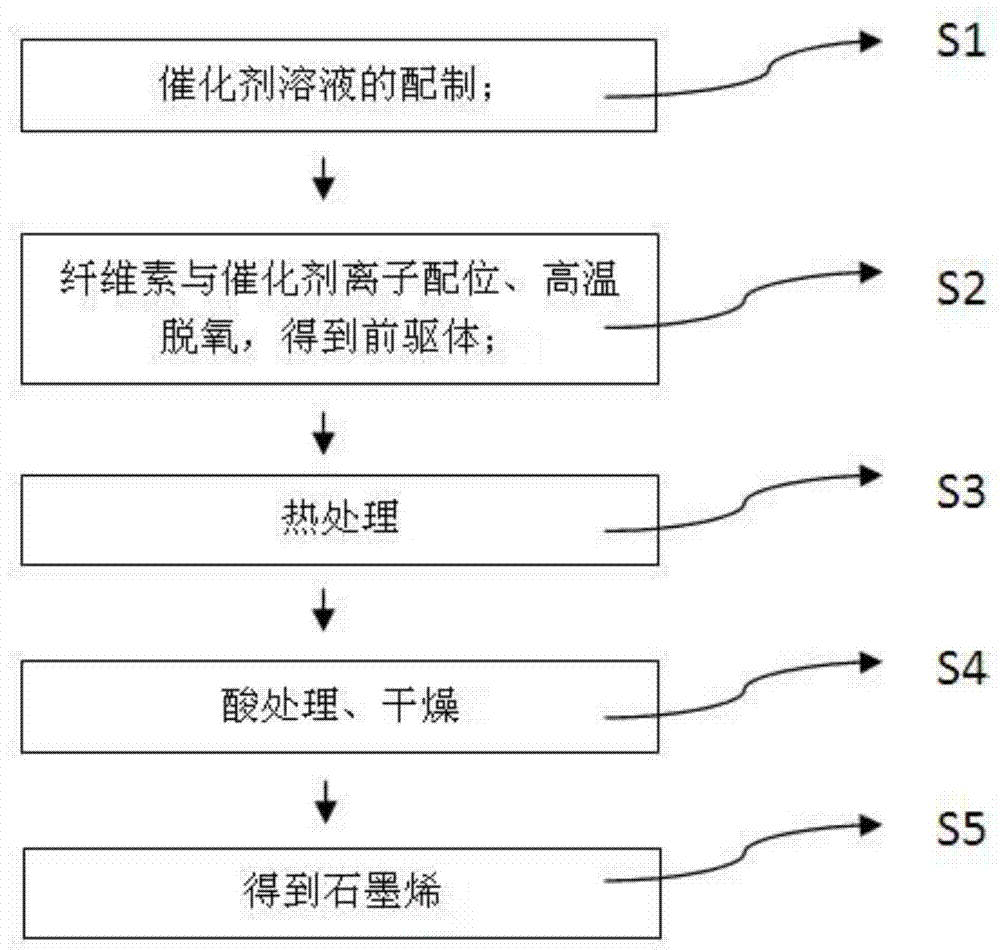

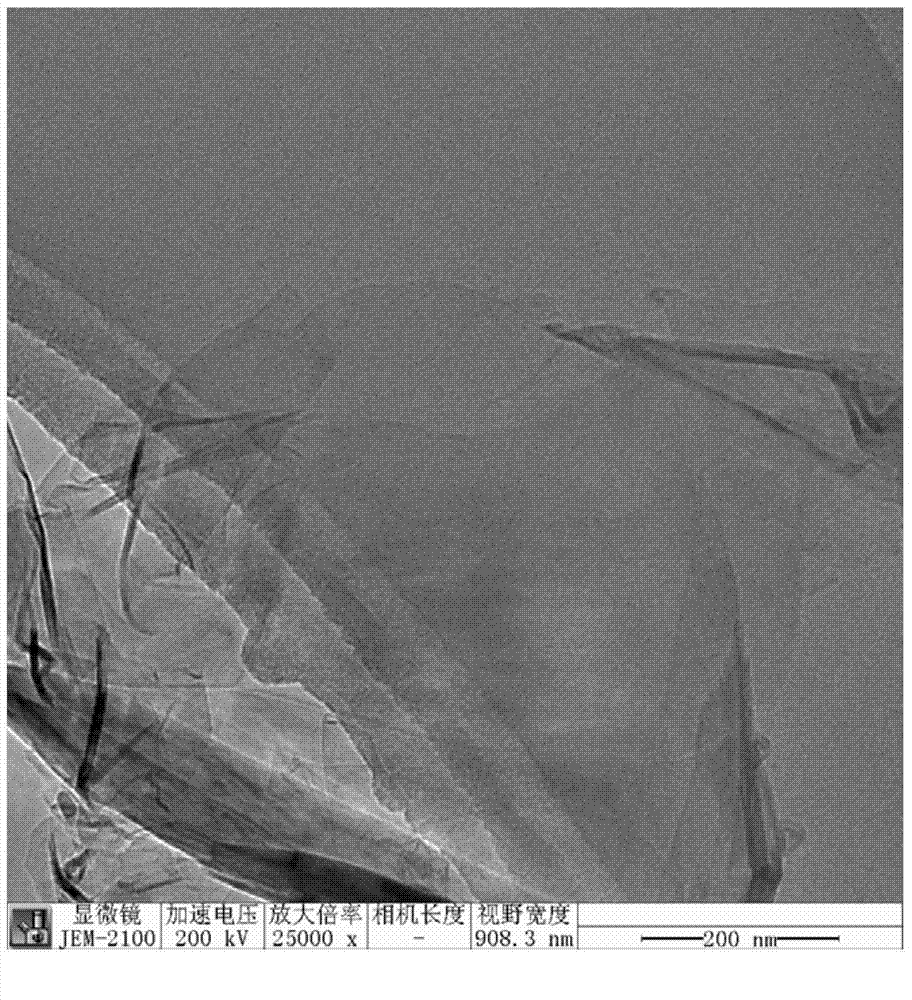

Method for preparing biomass graphene employing cellulose as raw material

ActiveCN104724699AUniform sizeIncrease productionPhysical/chemical process catalystsGrapheneCellulosePolymer science

The invention provides a preparation method of graphene, and particularly relates to a method for preparing biomass graphene employing cellulose as a raw material. The specific preparation method comprises the following steps: 1, preparing a catalyst solution; 2, carrying out ionic coordination and high-temperature deoxidization on cellulose and a catalyst, so as to obtain a precursor; 3, carrying out thermal treatment; 4, carrying out acid treatment, and drying to obtain the graphene, wherein the prepared graphene is uniform in morphology, has a single-layer or multi-layer two-dimensional layered structure; the dimension is 0.5-2 microns; and the electrical conductivity is 25,000-45,000S / m. The preparation method is simple in preparation technology, low in cost, high in yield, high in production safety, and controllable in product dimension and physical property; industrialized production can be realized; the graphene prepared by the method can be applied to electrode materials of super capacitors and lithium ion batteries, and can also be added to resin and rubber as an additive; and the physical property of the material can be improved.

Owner:HEILONGJIANG UNIV +1

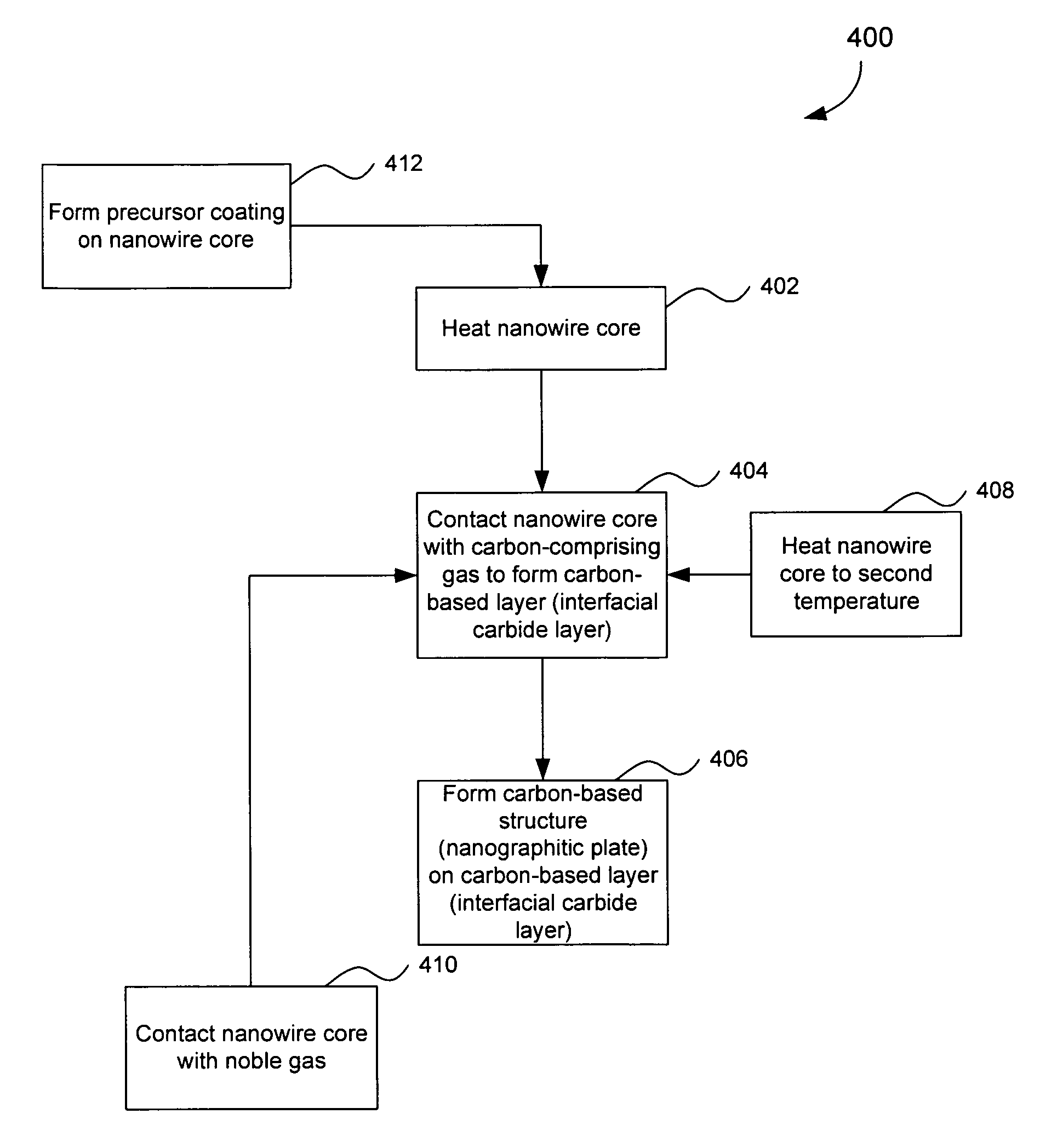

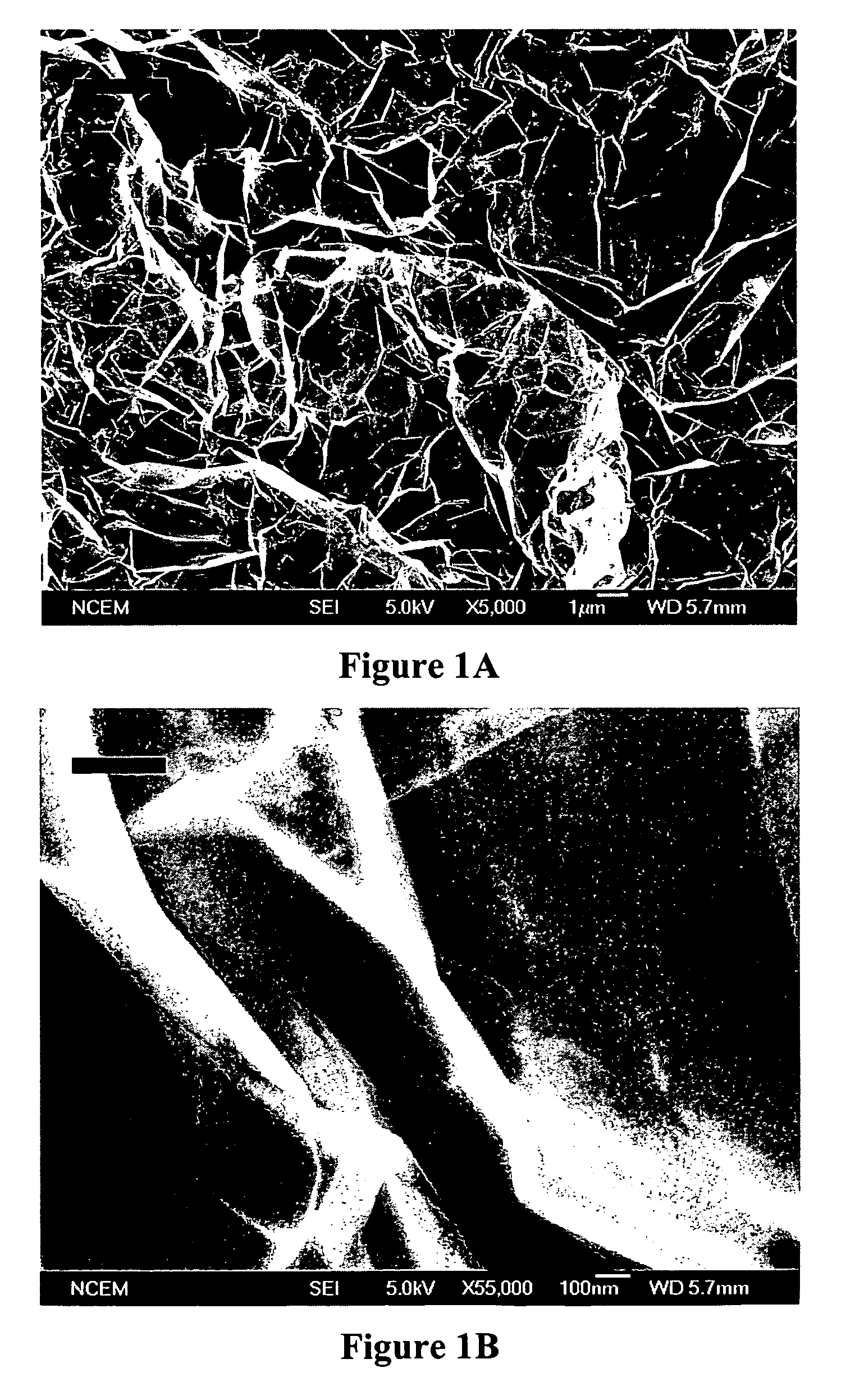

Nanowire structures comprising carbon

ActiveUS7939218B2High rateLow costElectric discharge heatingFuel cells groupingField emission deviceNanowire

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

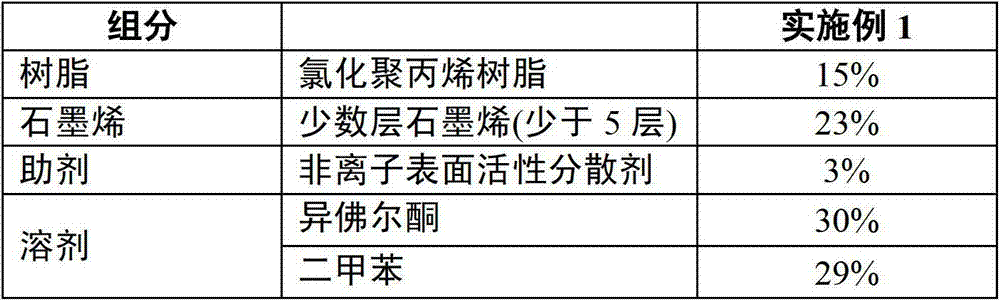

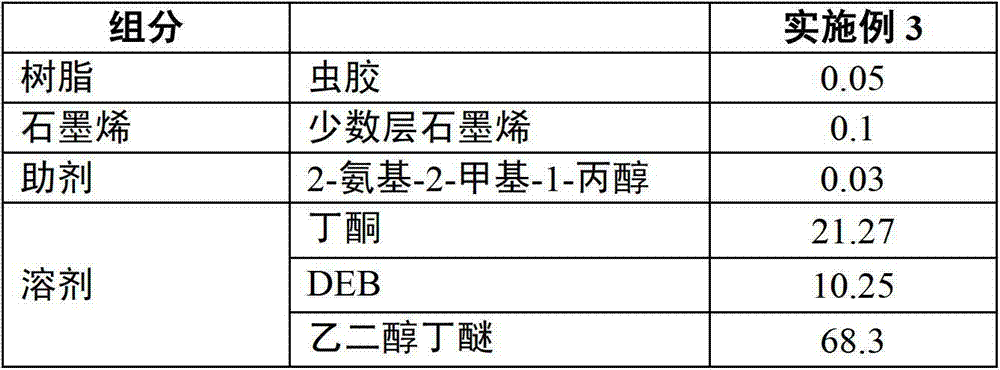

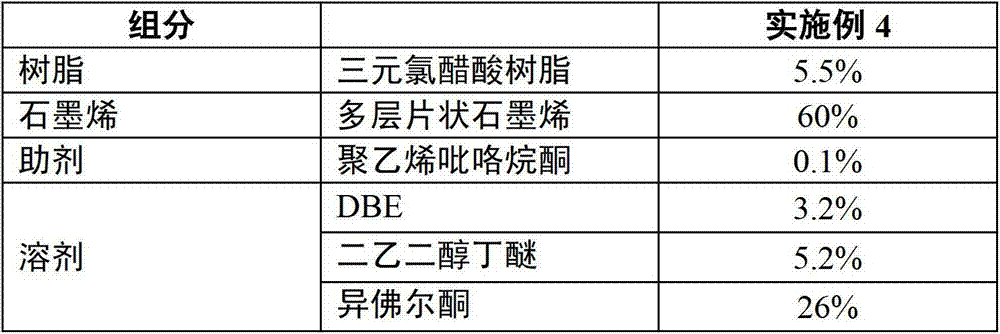

Graphene conductive ink and preparation method thereof

ActiveCN103113786AImprove thermal conductivityImprove mechanical propertiesInksConductive materialsSolvent

The invention relates to graphene conductive ink comprising the following components by weight percent: 0.01-25% of resin, 0.1-95% of graphene, 0.1-30.0% of assistant, and 5.0-99.79% of solvent. The two-dimensional conductive material graphene is used for the conductive ink; the graphene with special ratio is adopted as a conductive phase; the resin is taken as a binder; the assistant and the solvent are used for assisting; the prepared ink is good in anti-sedimentation property, and adjustable in viscosity and rheological behavior, and can be used for flexibly printing on the surfaces of a plurality of substrates; and the ink is stable in mechanical property, stable in electrical properties, oxidation resistance, acid resistance, alkali resistance and resistance to a chemical solvent after being cured.

Owner:SUZHOU NIUJIAN NEW MATERIAL

Reduced graphene oxide doped with dopant, thin layer and transparent electrode

InactiveUS20090146111A1Improve electrical performanceMaterial nanotechnologyNon-metal conductorsDopantDisplay device

Disclosed herein is a reduced graphene oxide doped with a dopant, and a thin layer, a transparent electrode, a display device and a solar cell including the reduced graphene oxide. The reduced graphene oxide doped with a dopant includes an organic dopant and / or an inorganic dopant.

Owner:SAMSUNG ELECTRONICS CO LTD

Mass production of carbon nanostructures

InactiveUS20060121279A1Improve mechanical stabilityPigmenting treatmentMaterial nanotechnologyGraphiteGraphene

Carbon nanostructures are mass produced from graphite. In particularly preferred aspects, graphene is thermo-chemically derived from graphite and used in numerous compositions. In further preferred aspects, the graphene is re-shaped to form other nanostructures, including nanofractals, optionally branched open-ended SWNT, nanoloops, and nanoonions.

Owner:PETRIK VIKTOR I

Electronics including graphene-based hybrid structures

InactiveUS20160284811A1High carrier mobilityRobustTransistorSemiconductor/solid-state device manufacturingSchottky barrierSemiconductor materials

Device are described that include a semiconductor material layer and at least one graphene-based electrode disposed over a portion of the semiconductor material layer, such that the at least one graphene-based electrode forms an overlap region with the semiconductor material layer. The device includes a means for providing charge carriers in the at least one graphene-based electrode proximate to the overlap region, to reduce a difference between a work function of the at least one graphene-based electrode and an electron affinity of the semiconductor material layer, to reduce a Schottky barrier height between the semiconductor material layer and the at least one graphene-based electrode.

Owner:MASSACHUSETTS INST OF TECH

Electrode plate for lithium ion battery and manufacturing method thereof

InactiveCN101710619AChange the conductive contact interfaceImprove conductivityCell electrodesAdhesiveEngineering

The invention discloses an electrode plate for a lithium ion battery and a manufacturing method thereof, and particularly relates to the electrode plate for the lithium ion battery taking multi-layer graphene as a conductive agent and a manufacturing method thereof. The electrode plate of the invention consists of a positive electrode or negative electrode active substance, the conductive agent and an adhesive. The method comprises the steps of: using the positive electrode or negative electrode active substance, the conductive agent and the adhesive as raw materials to obtain electrode slurry through stirring and dispersing, and then obtaining the electrode plate through coating, drying and tabletting. The conductive agent adopted by the invention has the advantages of high dispersivity, high electric conductivity, good filling effect and the like; and the method has the advantages of simplicity, low production cost and convenient popularization and application. The method can remarkably improve the electric conductivity, electrochemical capacity and enhance charge-discharge capability of electrode materials by multiples, so the method can be widely applied to the preparation of electrode plates of lithium ion batteries.

Owner:CHONGQING UNIV

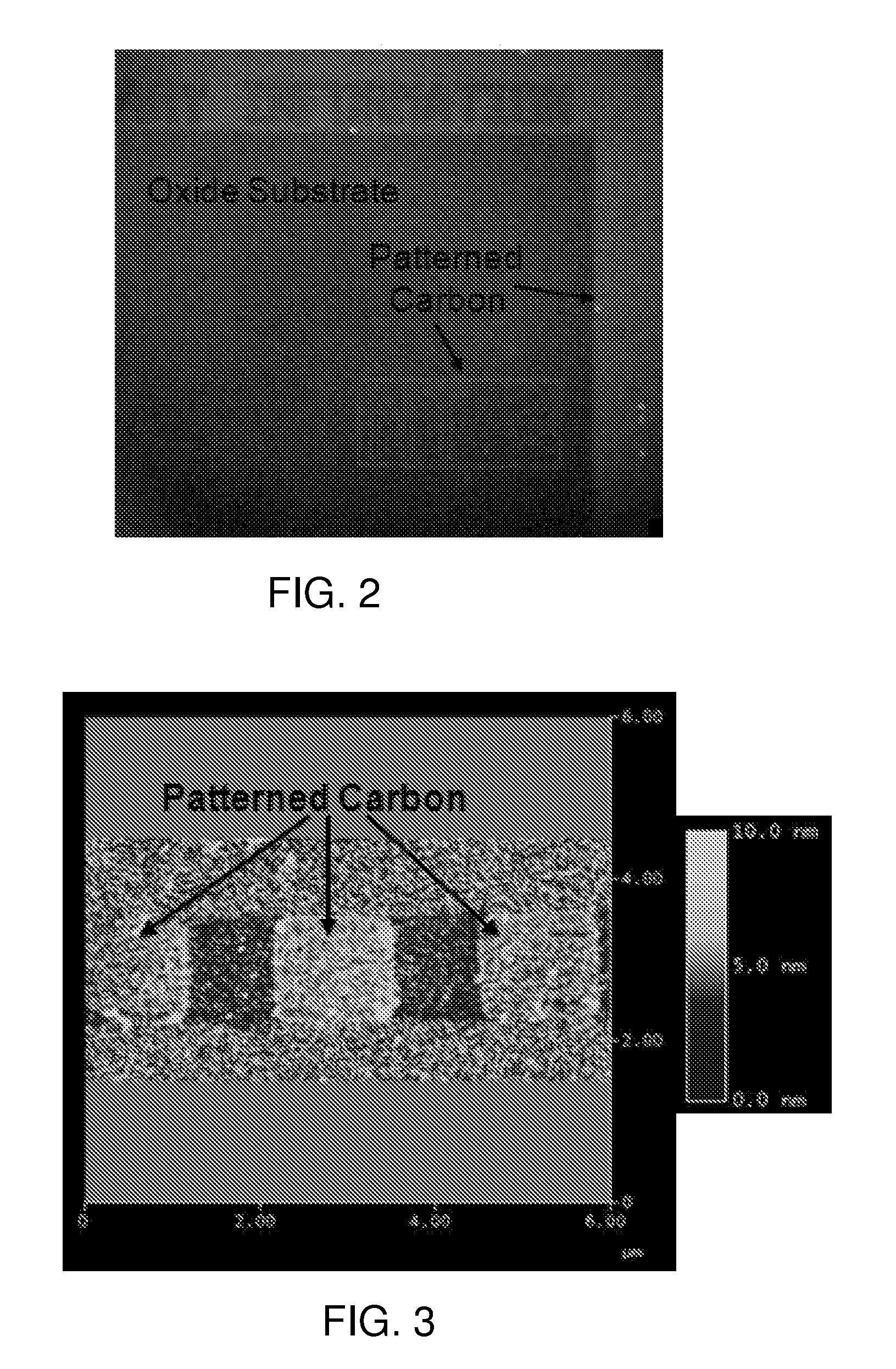

Graphene Nanoelectric Device Fabrication

Embodiments of the present invention provide methods for fabricating graphene nanoelectronic devices with semiconductor compatible processes, which allow wafer scale fabrication of graphene nanoelectronic devices. Embodiments of the present invention also provide methods for passivating graphene nanoelectronic devices, which enable stacking of multiple graphene devices and the creation of high density graphene based circuits. Other embodiments provide methods for producing devices with graphene layer segments having multiple thicknesses.

Owner:LOCKHEED MARTIN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com