Patents

Literature

382 results about "Unit mass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The standard International System of Units (SI) unit of mass is the kilogram (kg). The kilogram is 1000 grams (g), first defined in 1795 as one cubic decimeter of water at the melting point of ice.

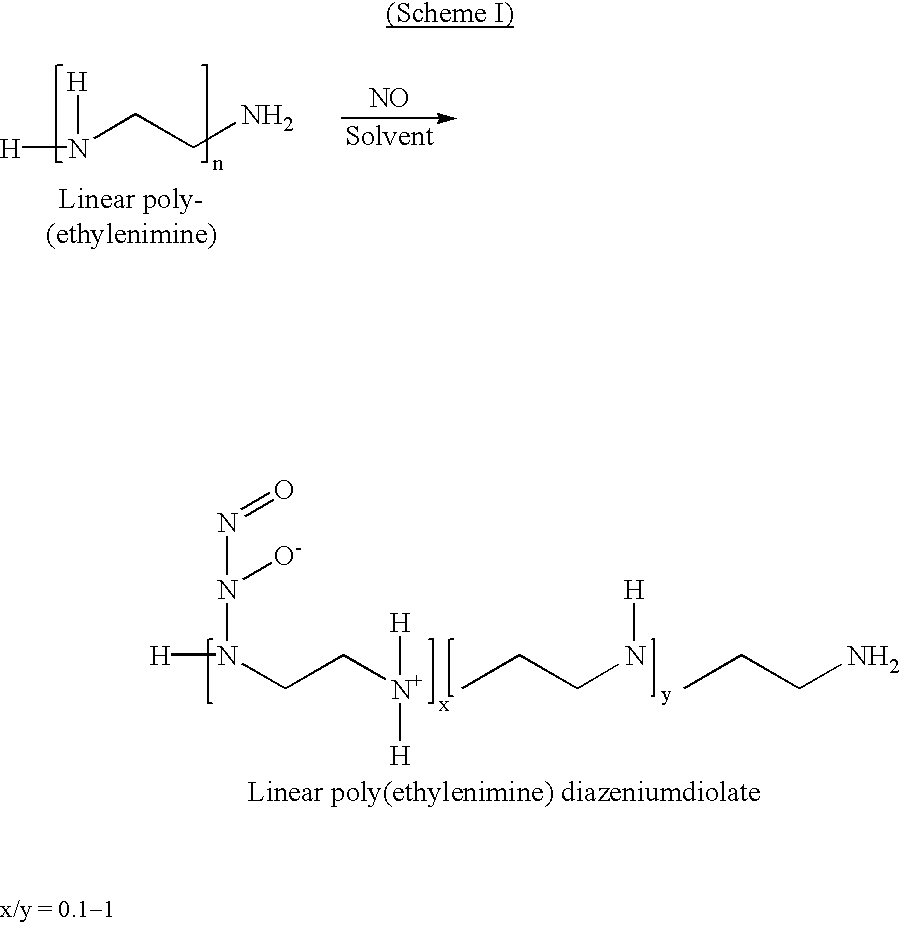

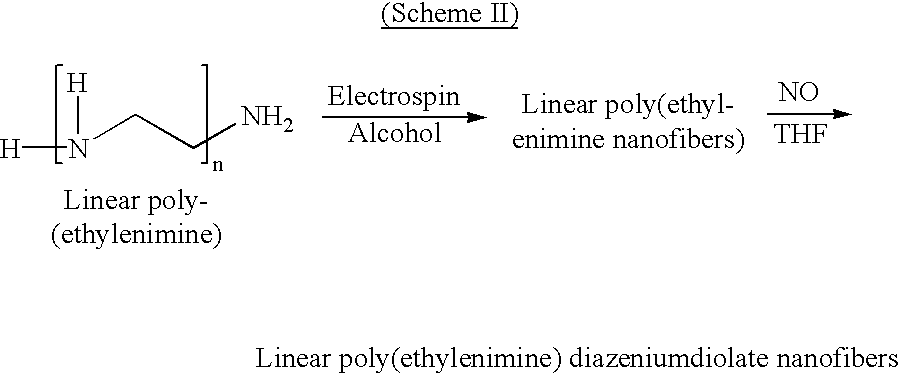

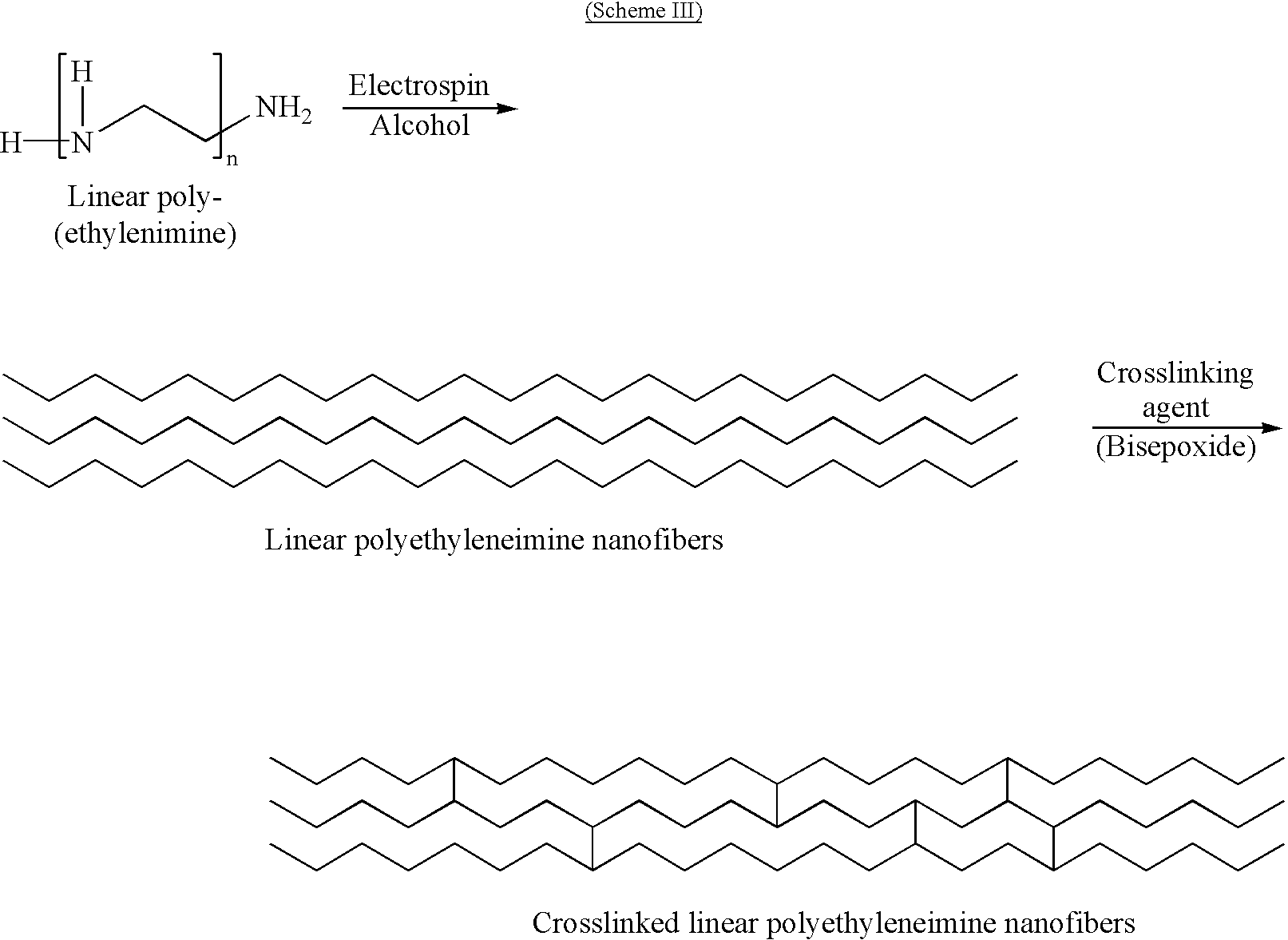

Nitric oxide-modified linear poly(ethylenimine) fibers and uses thereof

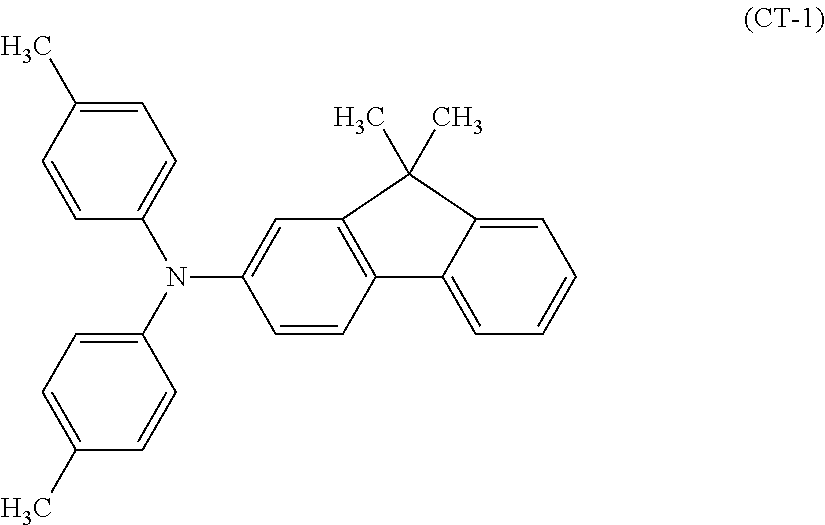

A novel coating for medical devices provides nitric oxide delivery using nanofibers of linear poly(ethylenimine)diazeniumdiolate. Linear poly(ethylenimine)diazeniumdiolate releases nitric oxide (NO) in a controlled manner to tissues and organs to aid the healing process and to prevent injury to tissues at risk of injury. Electrospun nano-fibers of linear poly(ethylenimine) diazeniumdiolate deliver therapeutic levels of NO to the tissues surrounding a medical device while minimizing the alteration of the properties of the device. A nanofiber coating, because of the small size and large surface area per unit mass of the nanofibers, provides a much larger surface area per unit mass while minimizing changes in other properties of the device.

Owner:AKRON THE UNIV OF

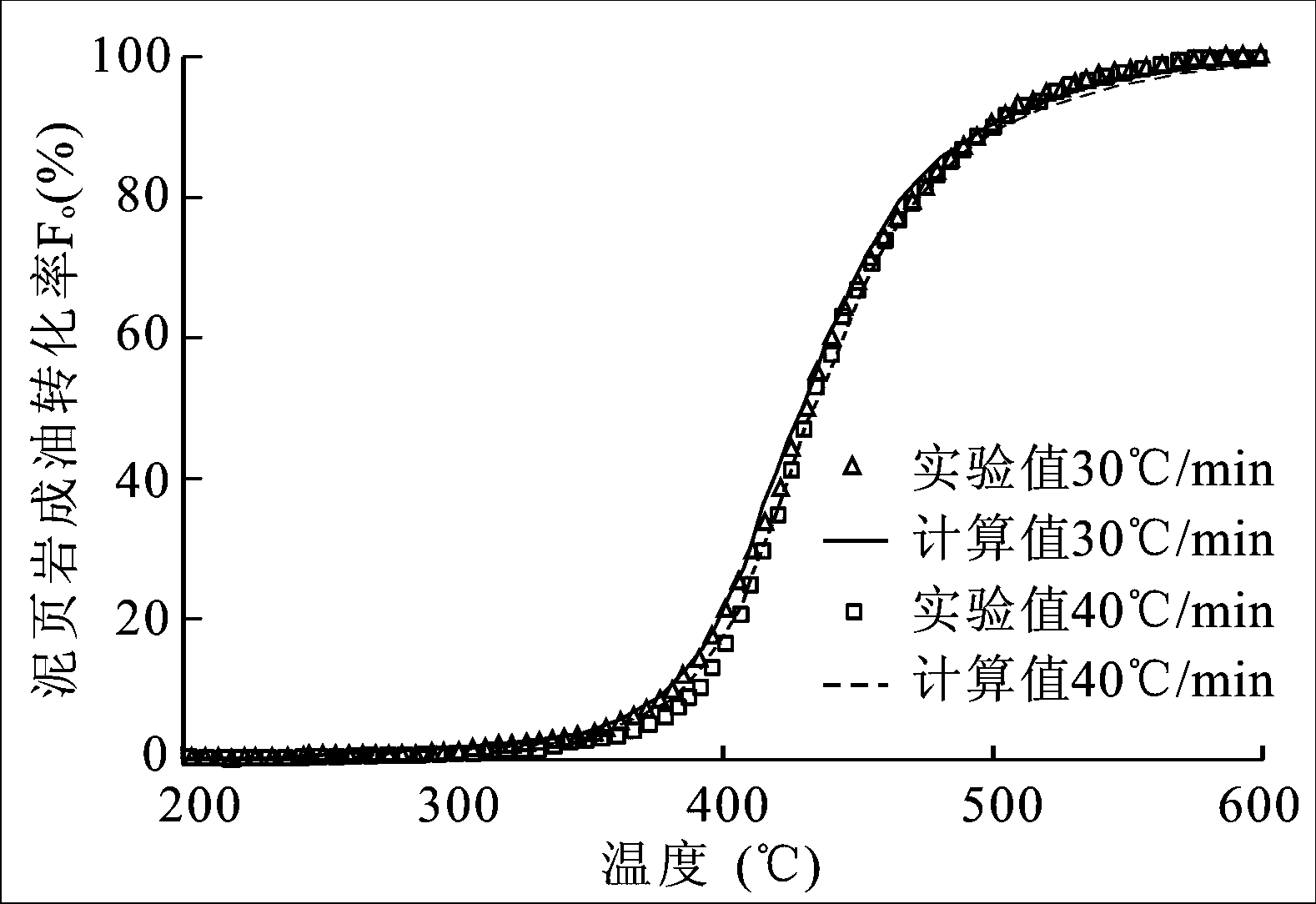

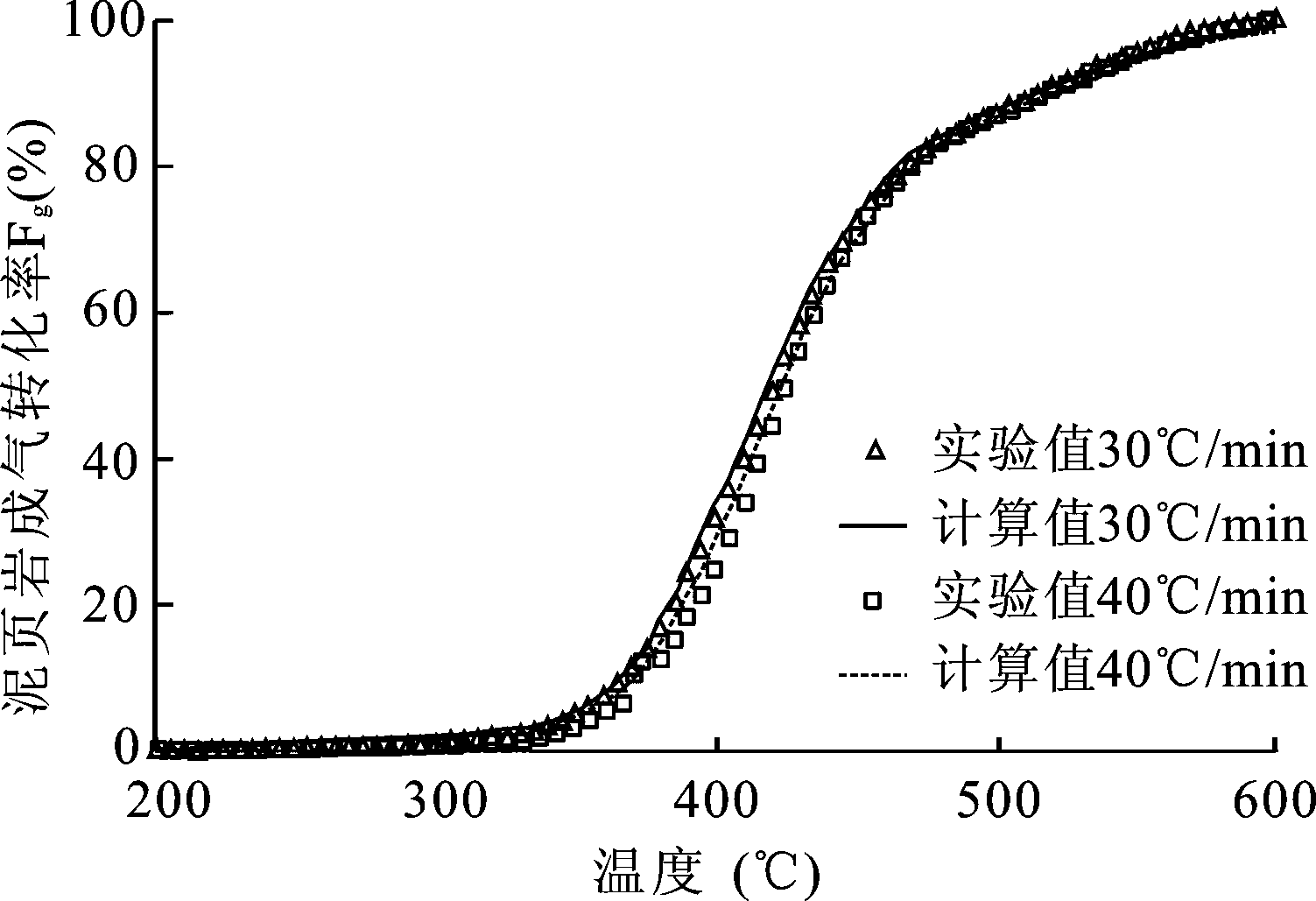

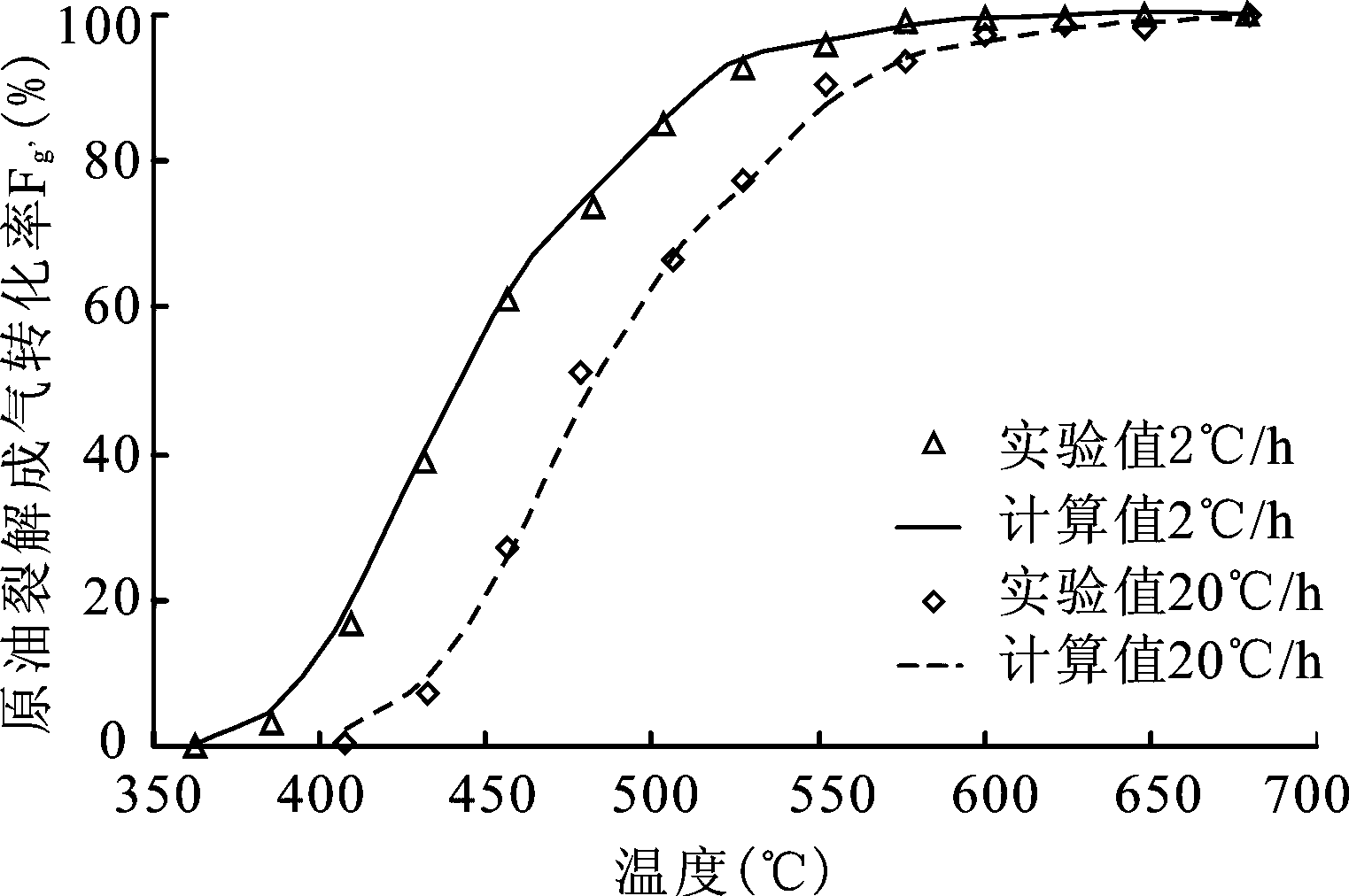

Method for evaluating porosity of mud shale at objective layer segment

InactiveCN103822866ARealize evaluationEasy to operatePermeability/surface area analysisElectron micrographsUnit mass

The invention relates to a method for evaluating the porosity of mud shale at an objective layer segment, and belongs to the technical field of exploration and development of petroleum, geology and mining industry. The method can be used for evaluating the total porosity, the organic porosity and the inorganic porosity of the mud shale at the objective layer segment in a shale gas well. The method comprises the following steps: (1) determining the mass of various ingredients in a mud shale sample skeleton in unit mass at each depth point of the objective layer segment and the density of each dried sample block body and calculating the total porosity of the mud shale in all the depth points via the combination of the actual density of various minerals; (2) calculating the organic porosity (Phi organic') formed by the hydrocarbon generation of the mud shale at the objective layer segment by utilizing chemical kinetics; (3) seeking a solution of the organic porosity (Phi organic) according to scanning electron micrographs of multiple argon ion polishing samples in the same depth point; (4) calibrating the organic porosity (Phi organic') calculated according to the chemical kinetics by utilizing the organic porosity (Phi organic); and (5) seeking a solution of the inorganic porosity by utilizing a difference value of the total porosity and the calibrated organic porosity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

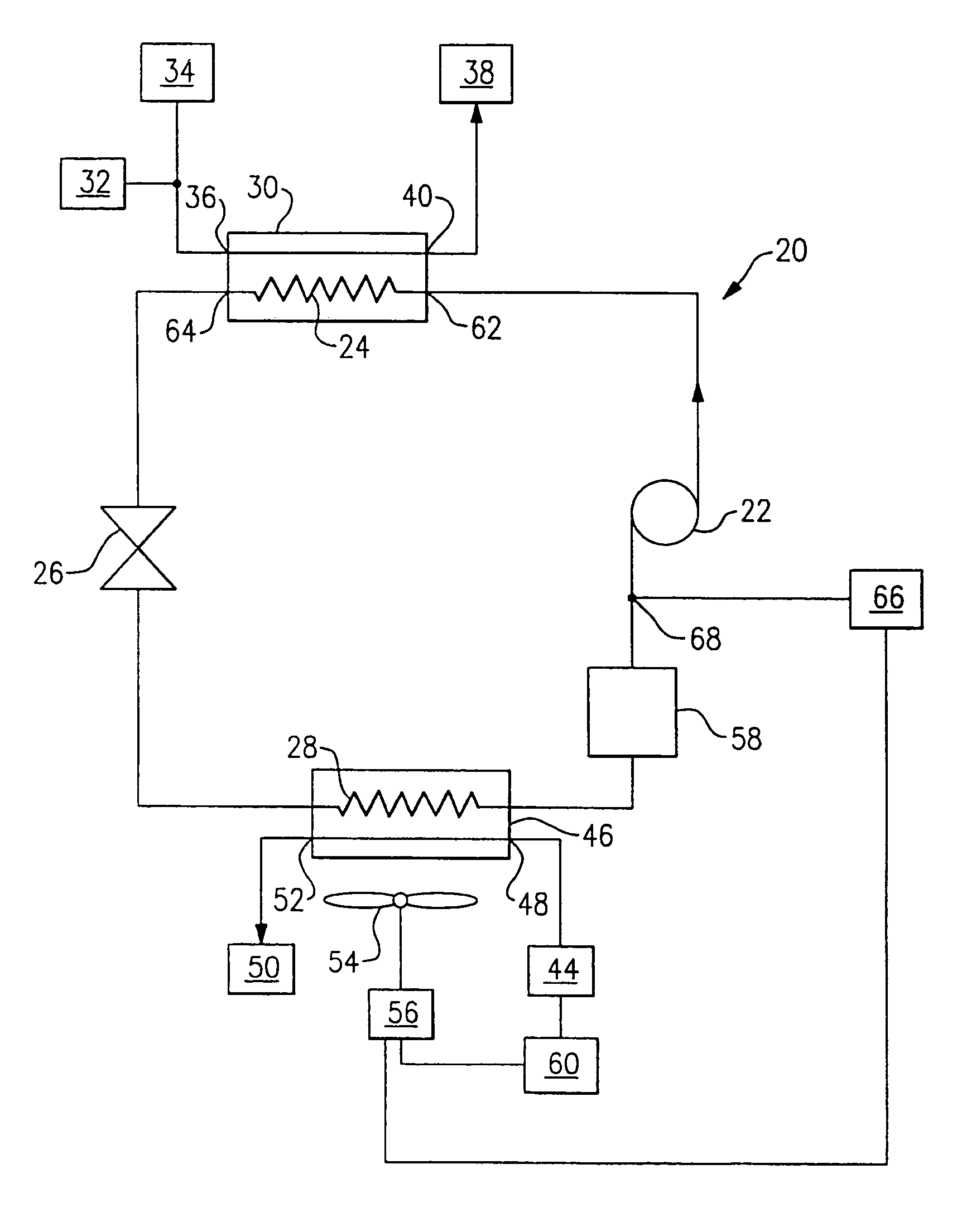

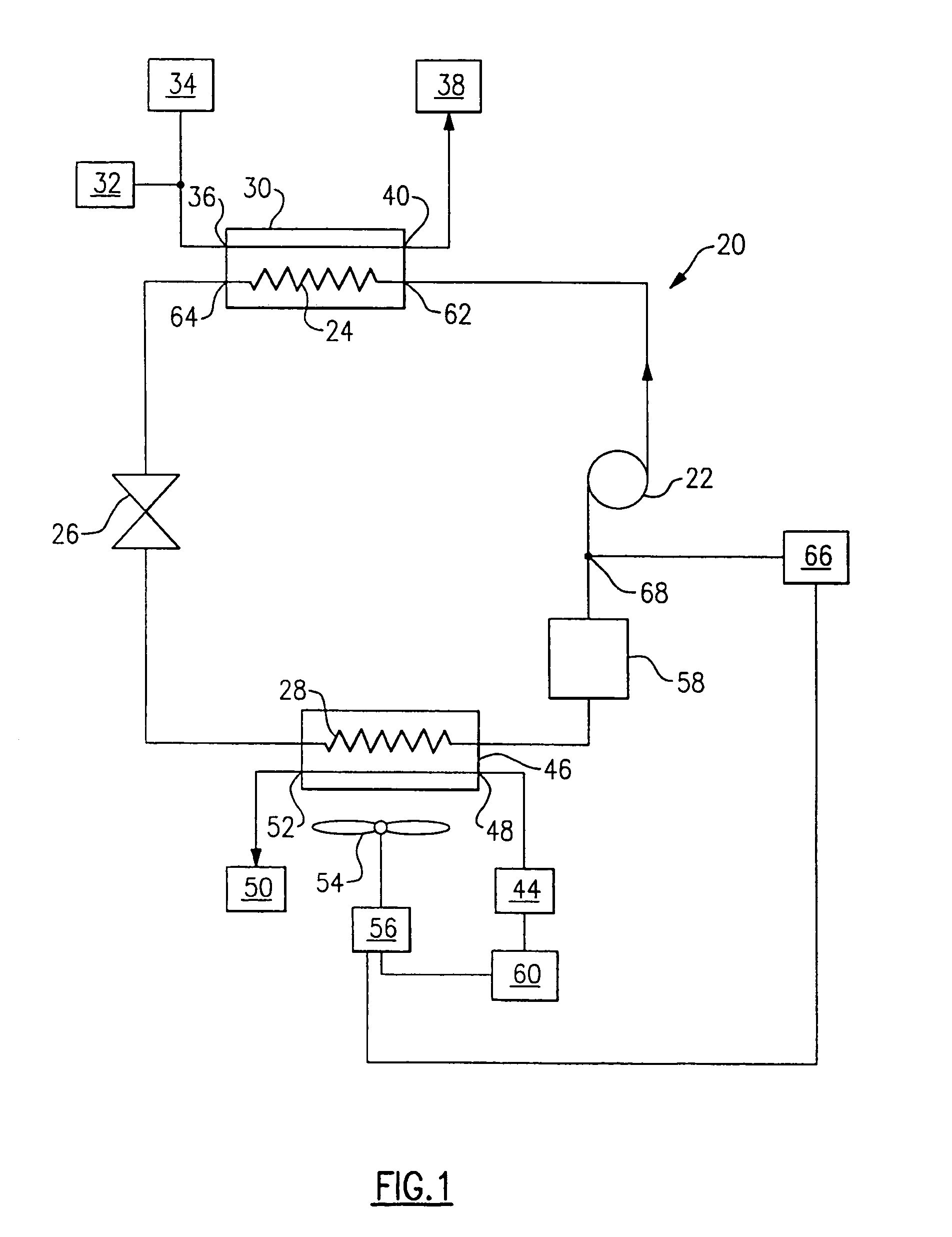

Refrigeration system having variable speed fan

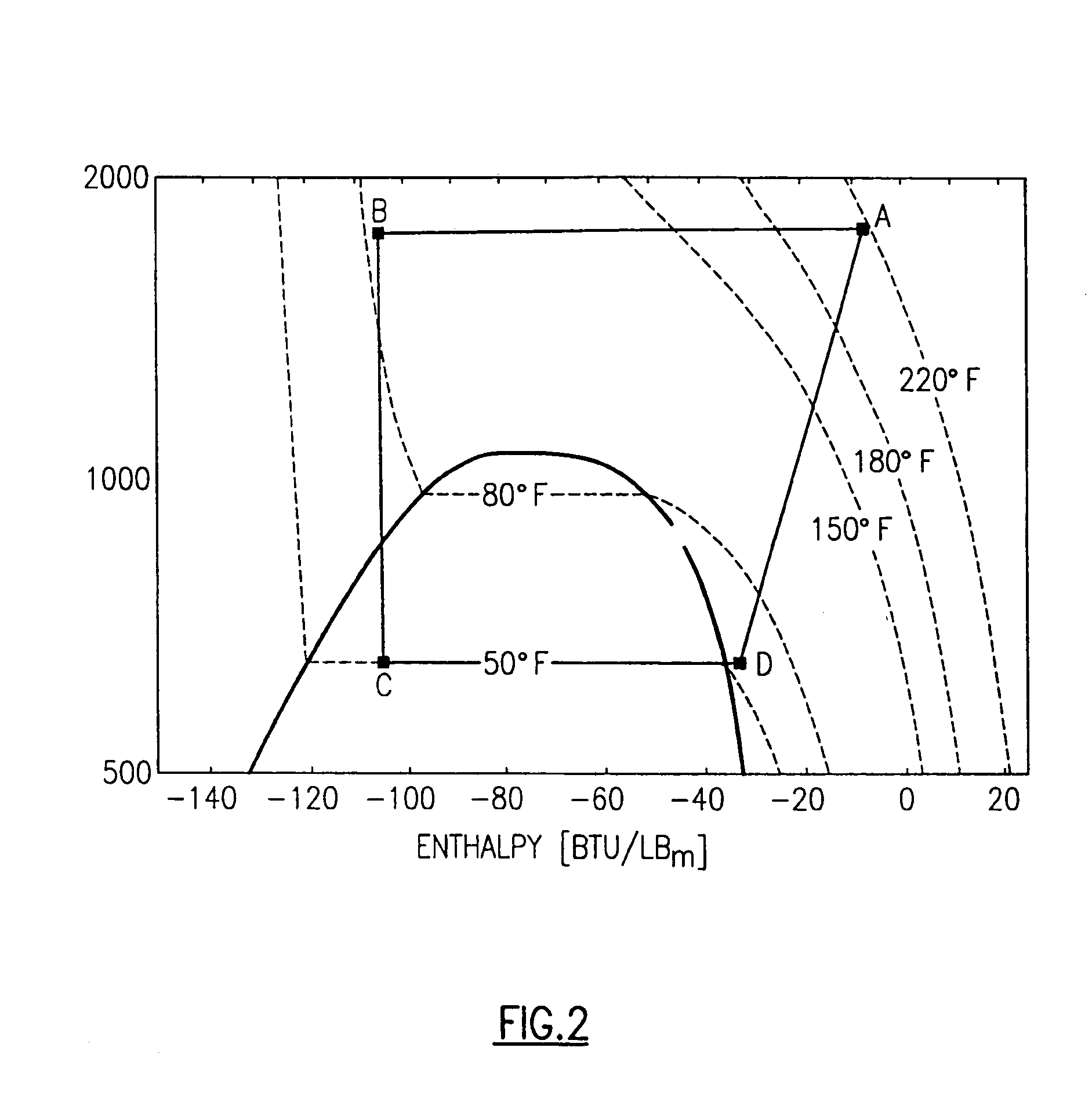

InactiveUS6968708B2Improve the coefficient of performanceIncreasing refrigerant mass flow rateCompression machines with non-reversible cycleEvaporators/condensersUnit massGas cooler

A transcritical refrigeration system includes a compressor, a gas cooler, an expansion device, and an evaporator. Refrigerant is circulated though the closed circuit system. Preferably, carbon dioxide is used as the refrigerant. A fan moves outdoor air that exchanges heat with the refrigerant across the evaporator. The speed of the fan is regulated to regulate the evaporator pressure and to adapt the evaporator to different environmental conditions to achieve the optimal coefficient of performance. During high ambient conditions, the fan speed is decreased, decreasing the refrigerant mass flowrate in the system. The energy exchange per unit mass of the refrigerant in the gas cooler increases and the work of the fan decreases, increasing the coefficient of performance of the system. During low ambient conditions, the mass flowrate of the system is low and there is more heat transfer thermal resistance on the refrigerant side at the evaporator. The speed of the fan is lowered to decrease the work of the fan. Therefore, the coefficient of performance increases.

Owner:CARRIER CORP

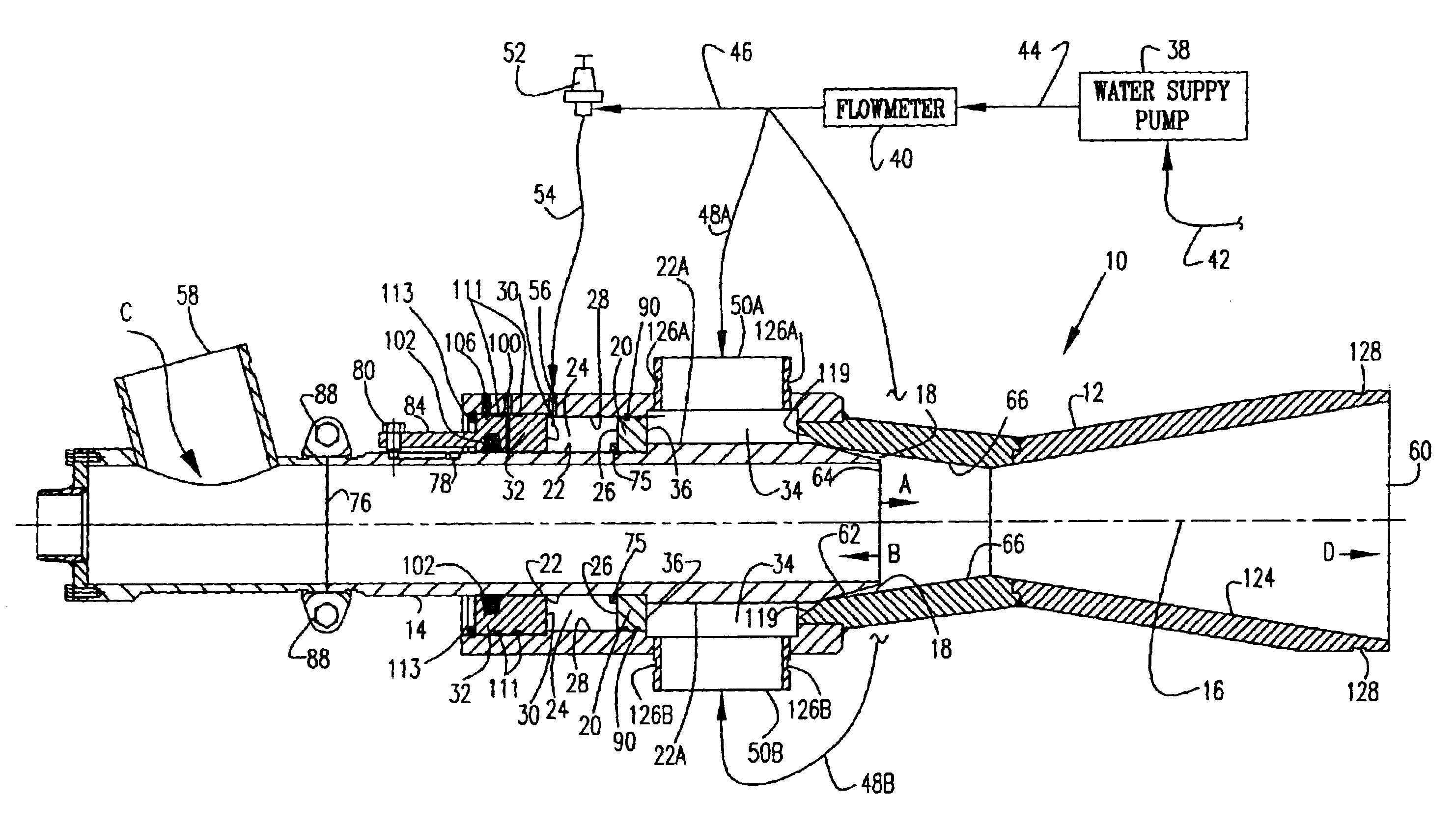

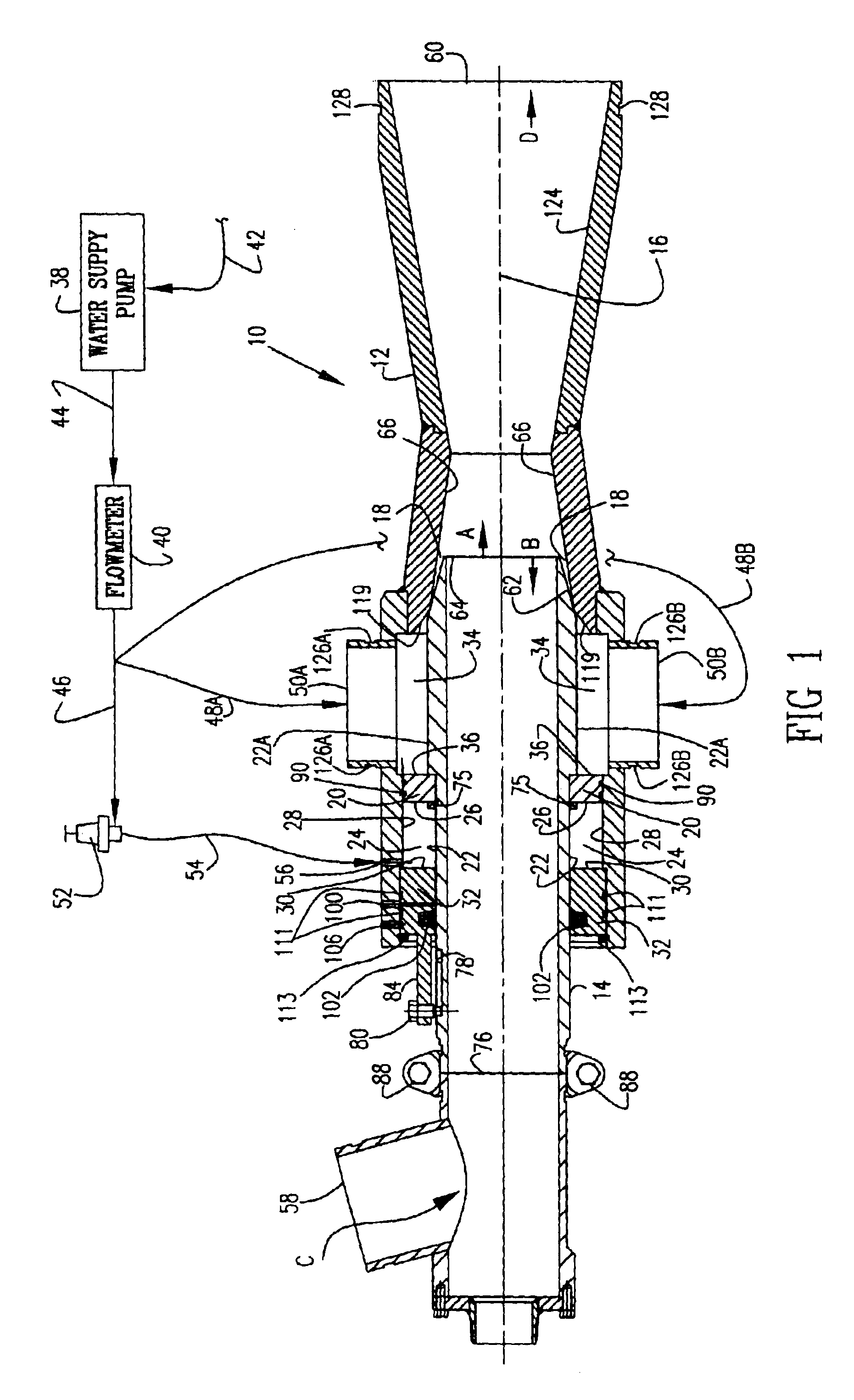

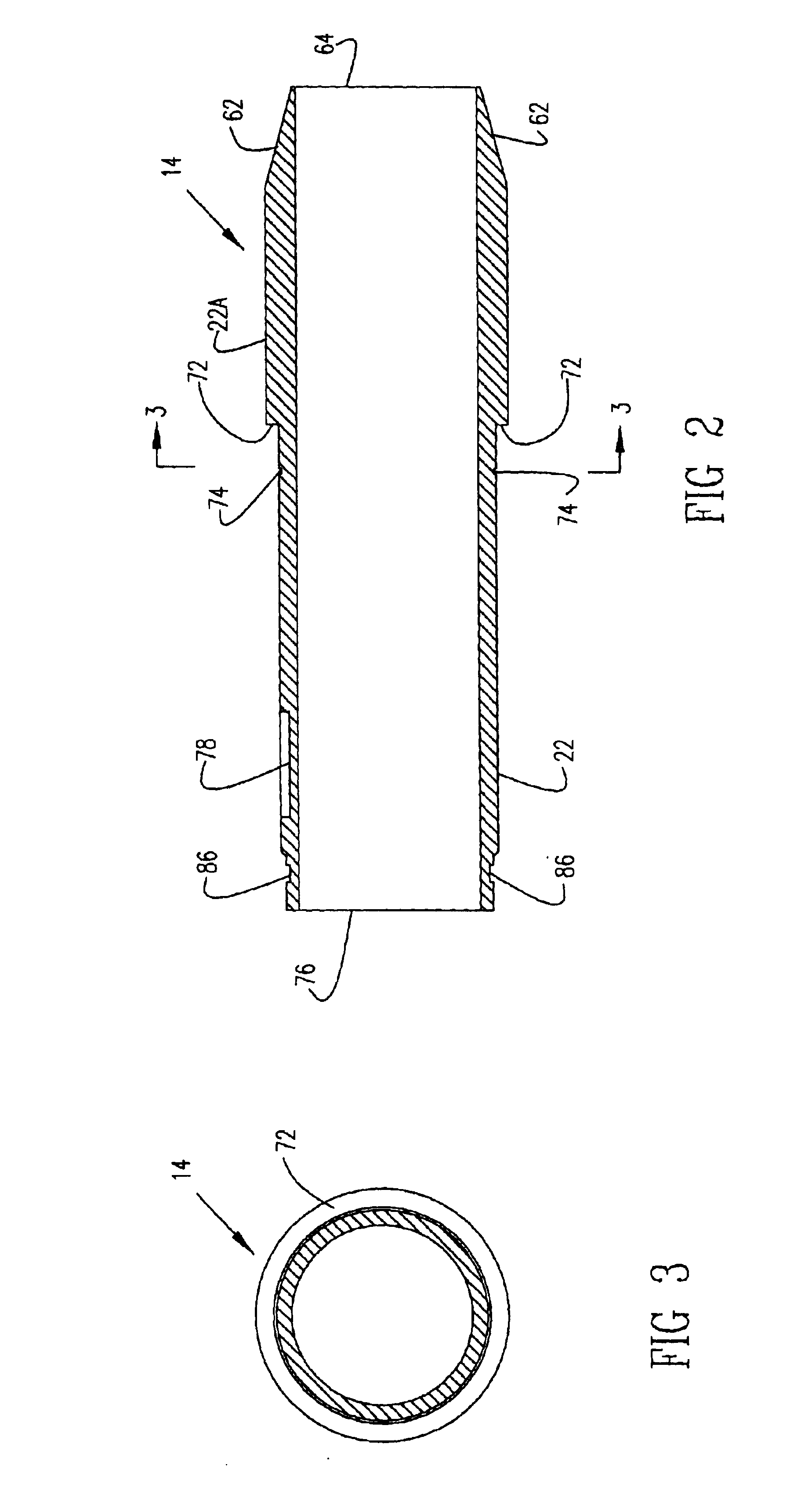

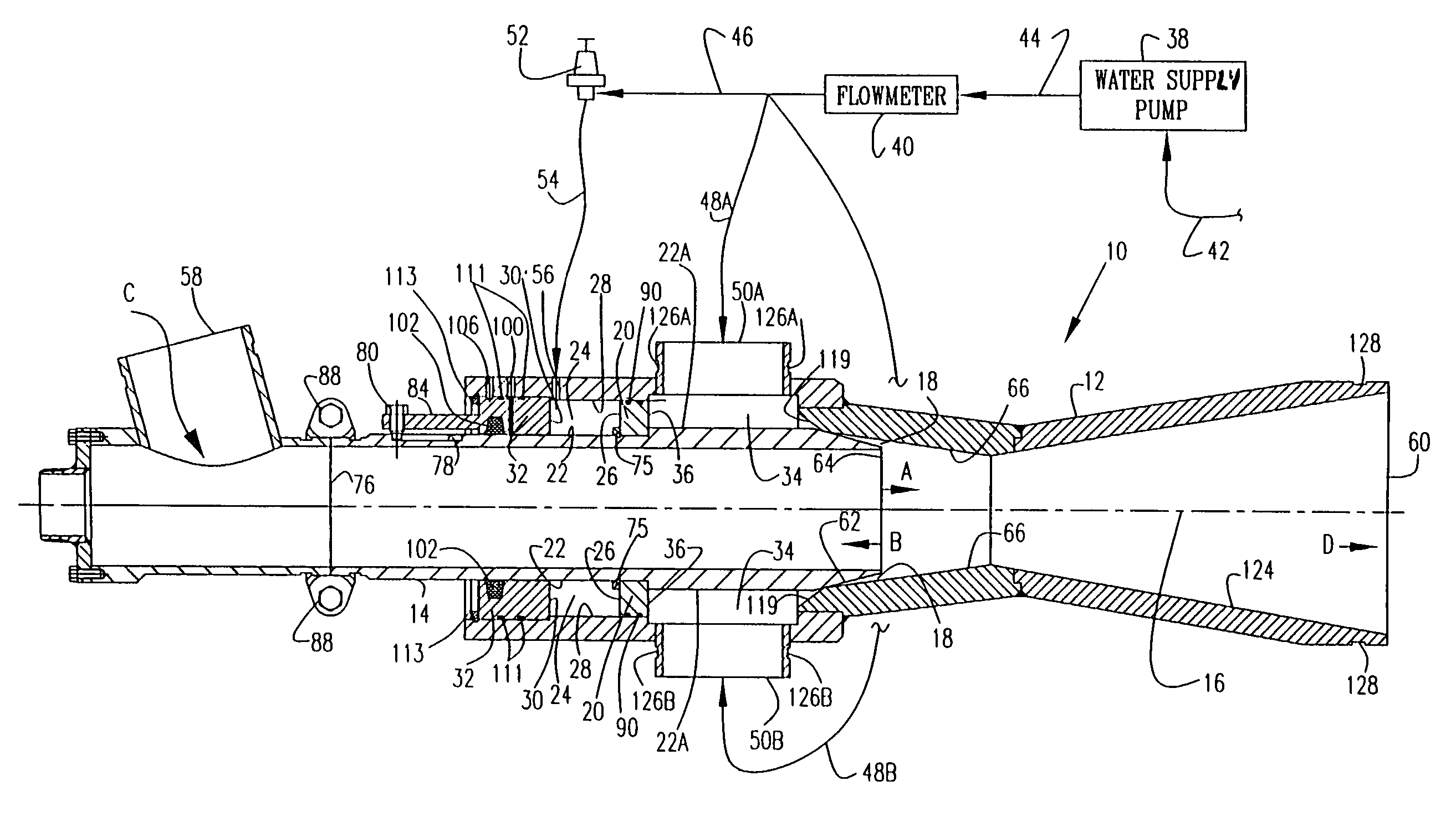

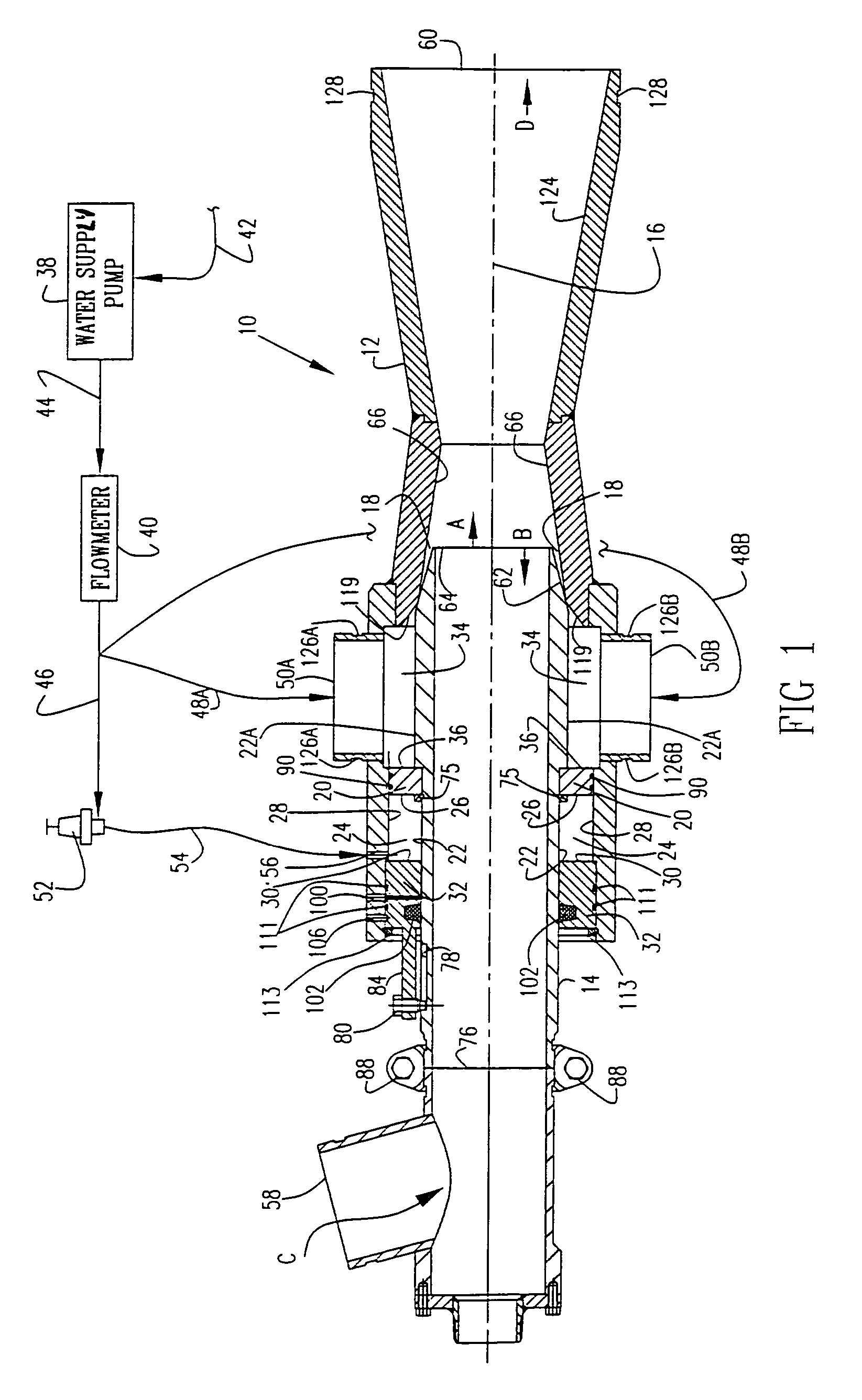

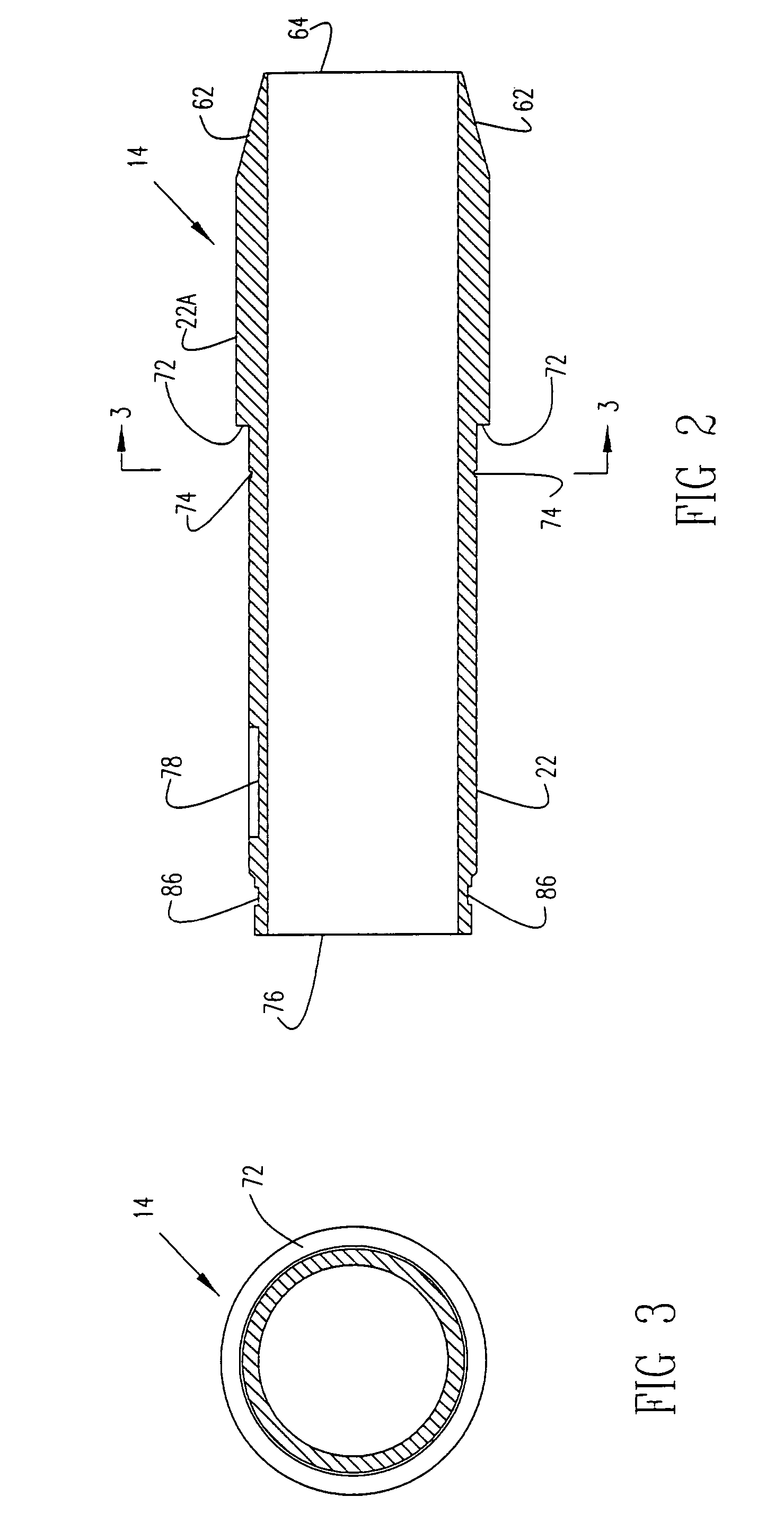

Automatically adjusting annular jet mixer

InactiveUS6802638B2Small sizeReduce pressureControlling ratio of multiple fluid flowsFlow mixersUnit massFracturing fluid

An automatically adjusting jet mixer used in mixing fracturing fluid gel for gas and oil wells. The mixer has an inner nozzle and an attached piston that move axially within the mixer's housing to change the size of the nozzle opening thorough which mix water enters the mixer. One side of the piston has an upstream area and an opposite side has a downstream area. The downstream area is connected to the mix water supply pump and the upstream area is connected to the outlet of a pressure regulator that maintains a constant pressure in the upstream area. The piston and the nozzle move via hydraulic pressure exerted on the piston in proportion to the change in pressure in the downstream area to a position that will maintain a constant mixing jet pressure, thus providing constant specific mixing energy, i.e. constant energy per unit mass of fluid.

Owner:SERVA CORP

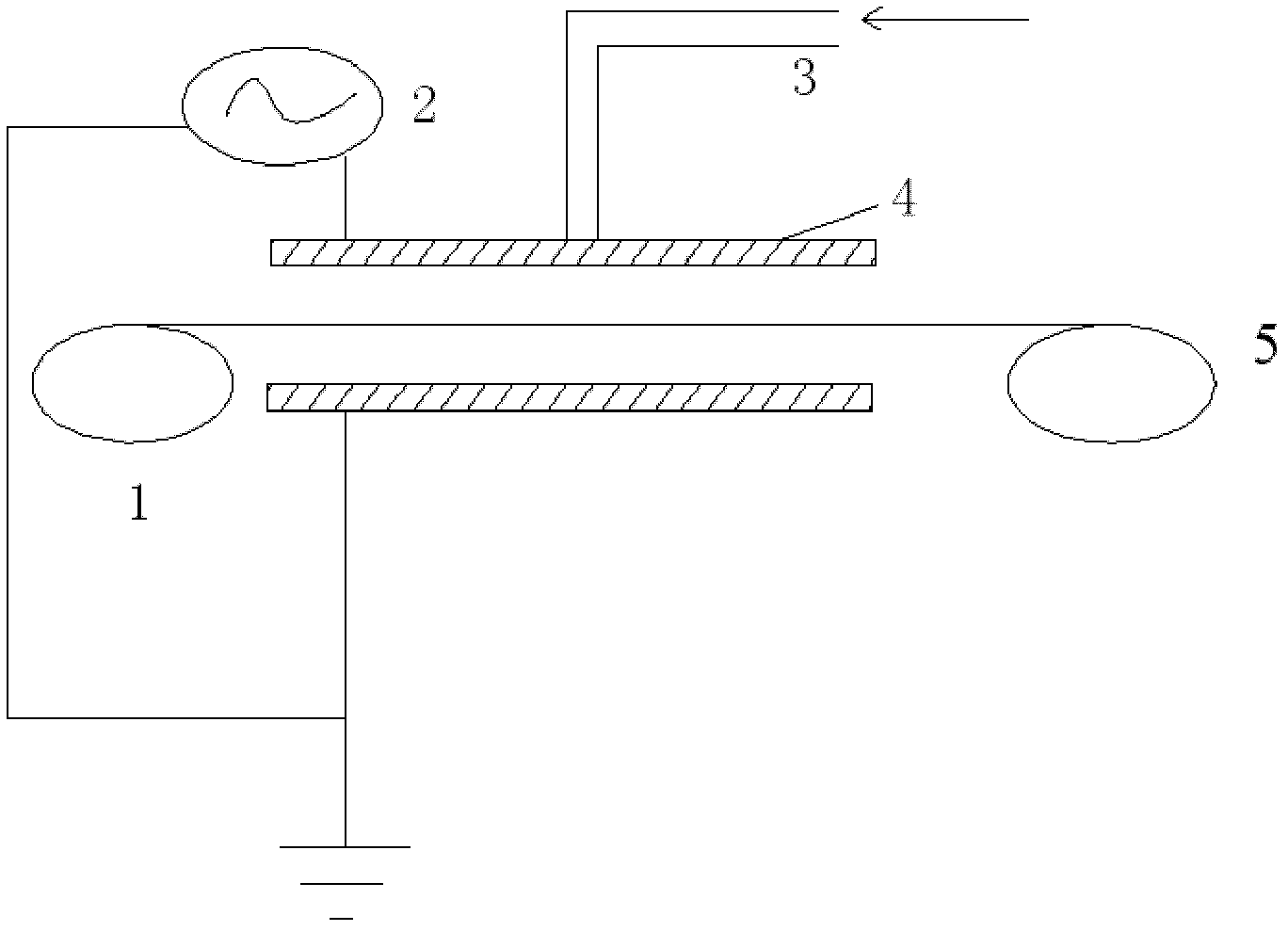

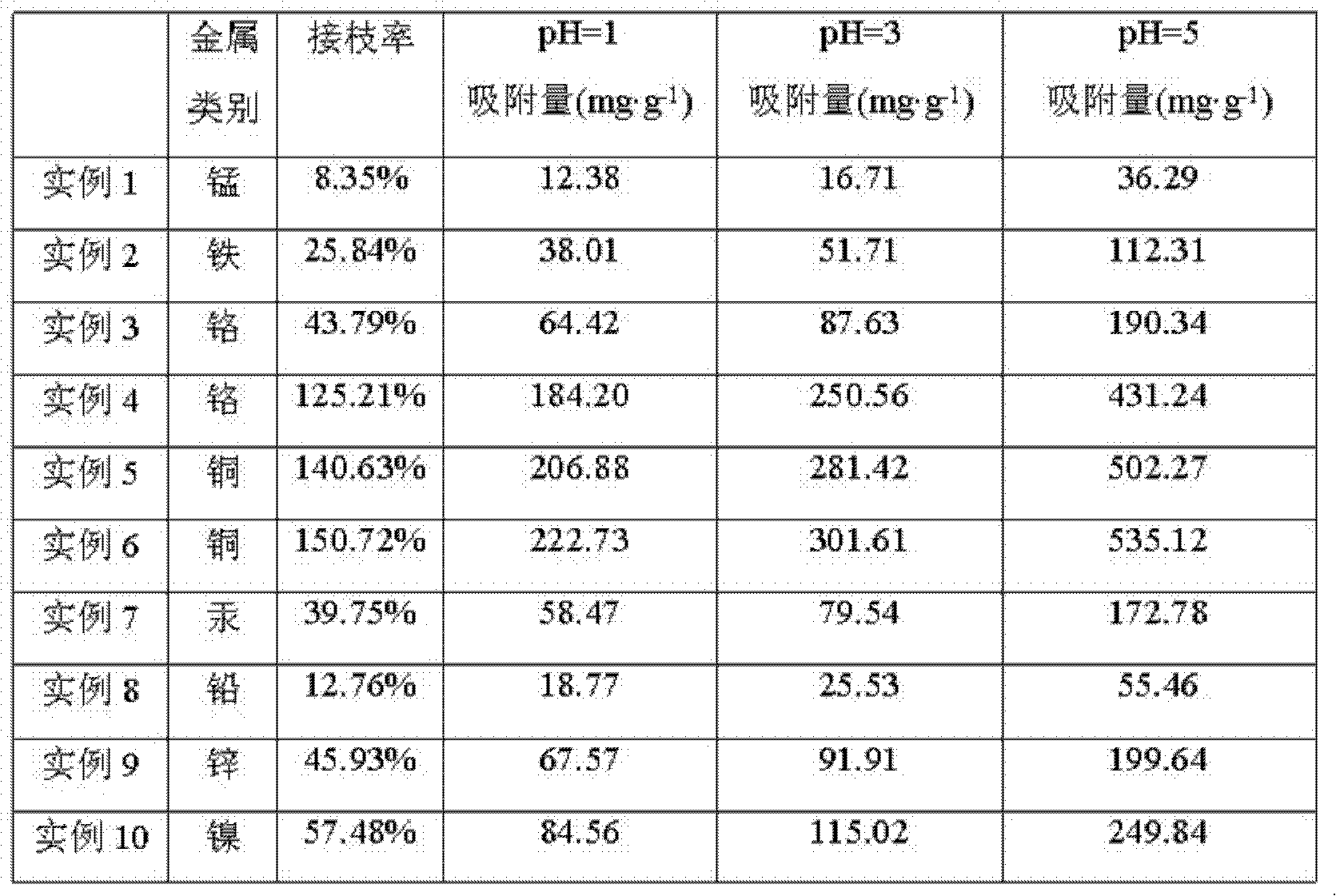

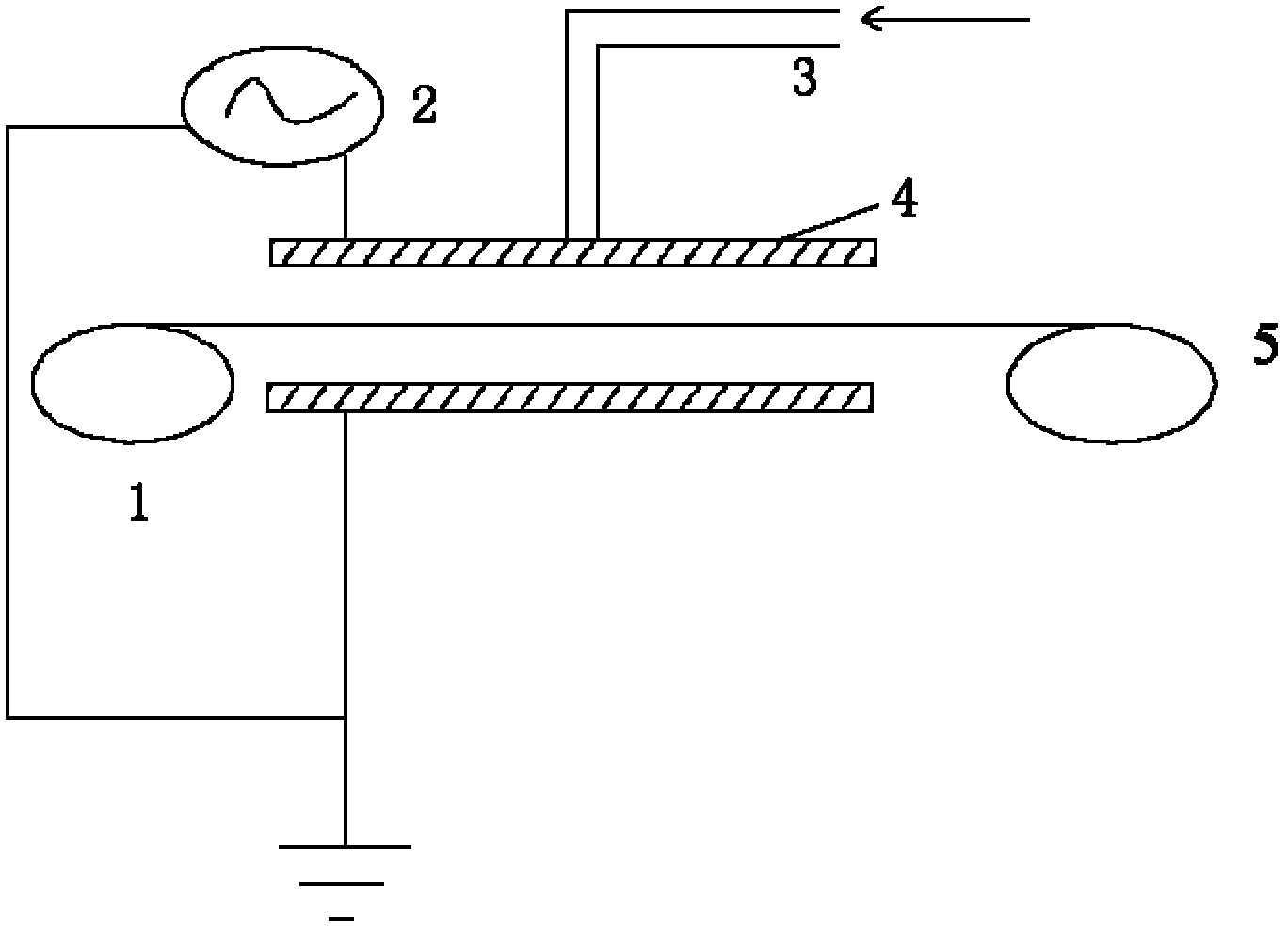

Preparation method of modified polymer film material for effectively removing trace heavy metal ions in water body

ActiveCN102634054AImprove mechanical propertiesFlexible designSemi-permeable membranesOther chemical processesUnit massTherapeutic effect

The invention discloses a preparation method of a modified polymer film material for effectively removing trace heavy metal ions in a water body, which comprises the following steps: 1) carrying out plasma treatment on a polymer film; 2) respectively preparing an initiator solution, a monomer solution, a buffer solution, an activating solution and a polyethylene polyamine water solution; 3) immerging the polymer film in the initiator solution, and carrying out surface activation by ultraviolet irradiation; 4) putting the polymer film into the monomer solution to carry out grafting reaction under ultraviolet irradiation; 5) activating the polymer film in the activating solution; and 6) putting the activated film into a polyethylene polyamine water solution to carry out coupling reaction, thereby preparing the modified film material capable of removing trace heavy metal ions in a water body. In the polymer film modifying process, carboxyl and amino groups are introduced to carry out hydrophilization and endow the modified film with complexing capacity, thereby removing the trace heavy metal ions. The invention has the advantages of simple technique, favorable treatment effect, wide application range, low cost, high unit mass adsorption capacity, time saving, high efficiency and energy saving.

Owner:NINGBO SHUIYI FILM TECH DEV CO LTD

Automatically adjusting annular jet mixer

InactiveUS7029165B2Small sizeReduce pressureControlling ratio of multiple fluid flowsFlow mixersUnit massFracturing fluid

An automatically adjusting jet mixer used in mixing fracturing fluid gel for gas and oil wells. The mixer has an inner nozzle and an attached piston that move axially within the mixer's housing to change the size of the nozzle opening thorough which mix water enters the mixer. One side of the piston has a pressure regulated area and an opposite side has an upstream area. The upstream area is connected to the mix water supply pump and the pressure regulated area is connected to the outlet of a pressure regulator that maintains a constant pressure in the pressure regulated area. The piston and the nozzle move via hydraulic pressure exerted on the piston in proportion to the change in pressure in the upstream area to a position that will maintain a constant mixing jet pressure, thus providing constant specific mixing energy, i.e. constant energy per unit mass of fluid.

Owner:SERVA CORP

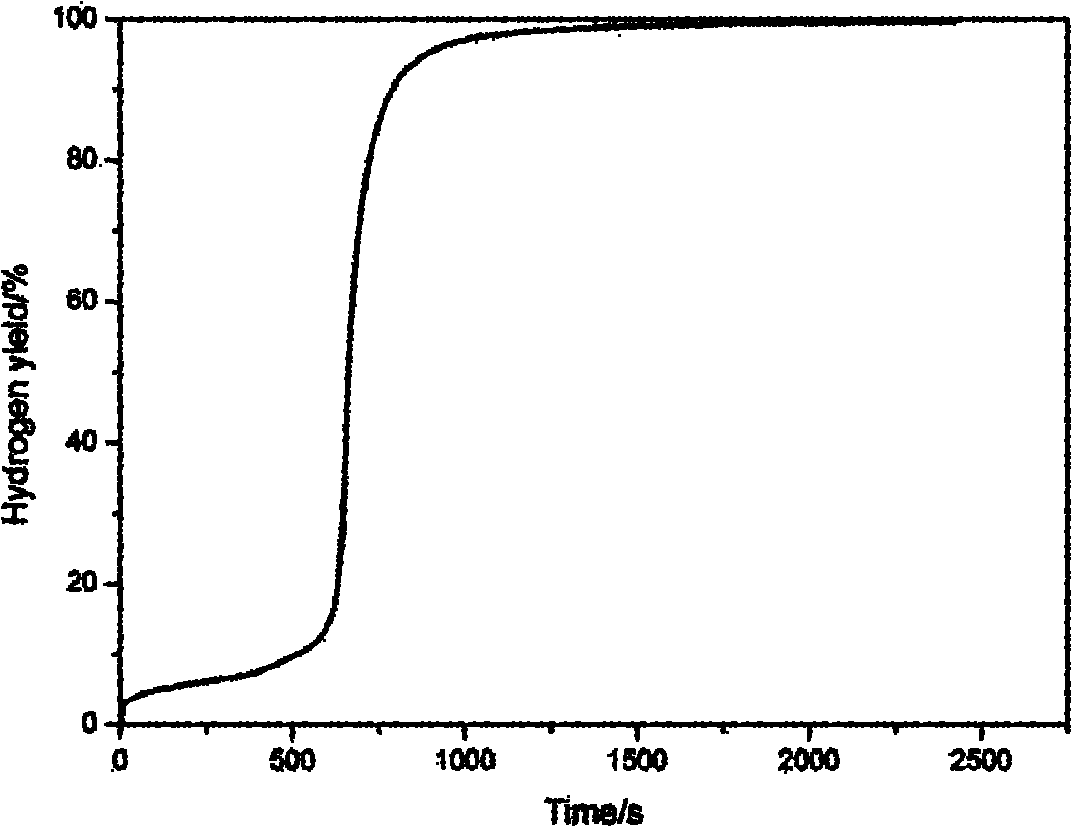

Hydrogen production method by hydrolysis of aluminum-calcium alloy

The invention provides a hydrogen production method by hydrolysis of an aluminum-calcium alloy, wherein, aluminum and calcium in different mass percentages are taken as raw materials, and salt is taken as an activating agent. The obtained aluminum-calcium alloy can react with aqueous solution at different initial temperatures to produce hydrogen rapidly. In addition, hydrogen production rate and yield can be adjusted by changing the percentage of components in the alloy. The aluminum-calcium alloy can inhibit generation of an inertia alumina membrane on a surface, greatly improve the hydrogen production rate of the alloy per unit mass and lower hydrogen production cost.

Owner:CENT SOUTH UNIV

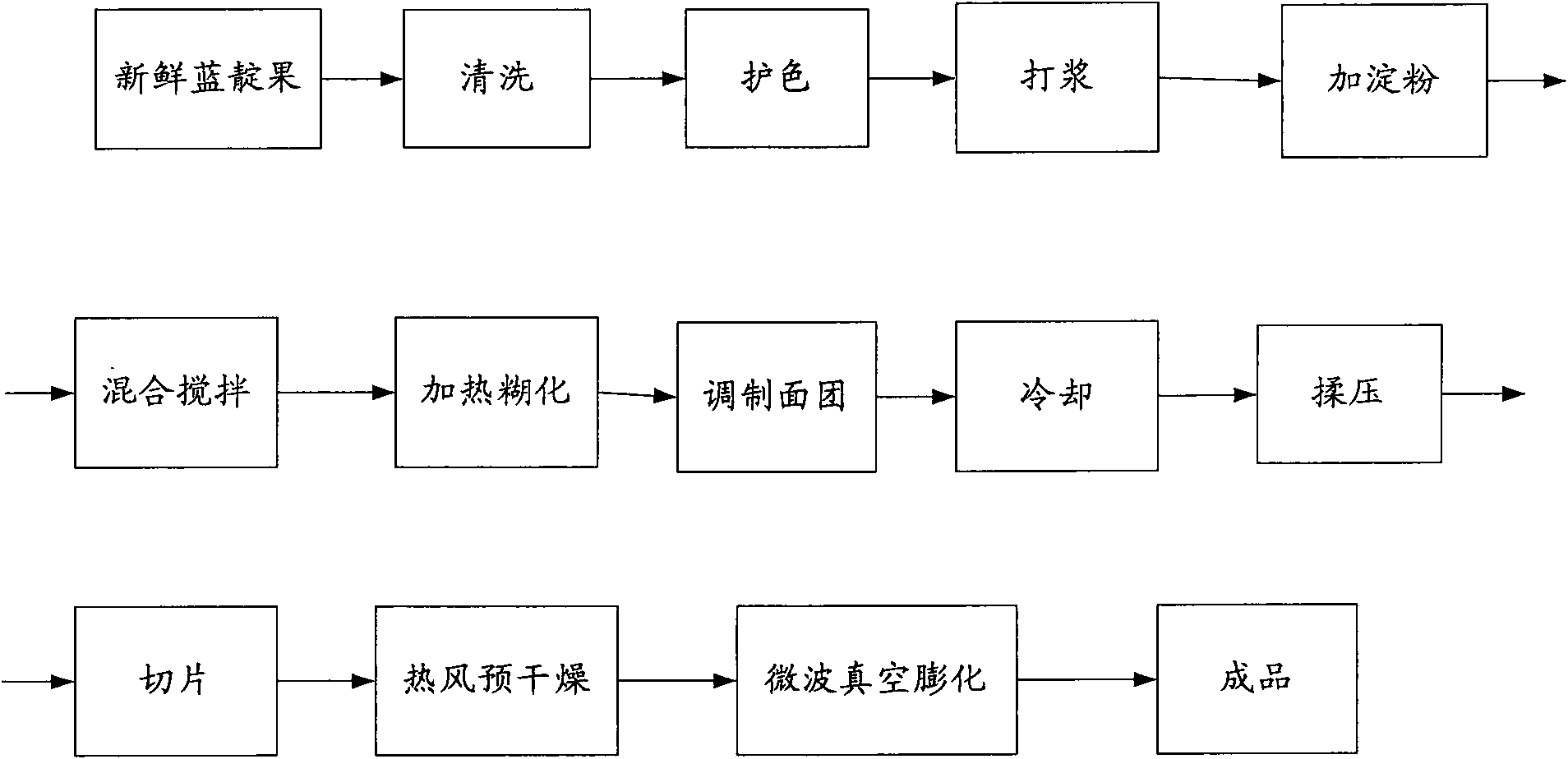

Technology of microwave vacuum extrusion of lonicera edulis chip

The invention relates to a processing method of lonicera edulis, in particular to a processing method which adopts microwave vacuum technology for the extrusion of lonicera edulis chip, belonging to the field of food processing. The technical process is as follows: cleaning fresh lonicera edulis, cleaning, protecting color, pulping, adding starch, mixing, stirring, heating, pasting, preparing dough, cooling, kneading, slicking, predrying by hot wind, vacuum pulping by microwave, and obtaining a finished product. The condition for vacuum pulping by microwave is as follows: after predrying, initial moisture content is 25-45%, vacuum degree is 70-90 kPa, unit mass microwave power is 10-30 W / g, and microwave output power is 2-5 kW. The lonicera edulis which is puffed by microwave in vacuum has high comprehensive quality, is favourable for storing nutrition constituents and greatly saves energy consumption.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

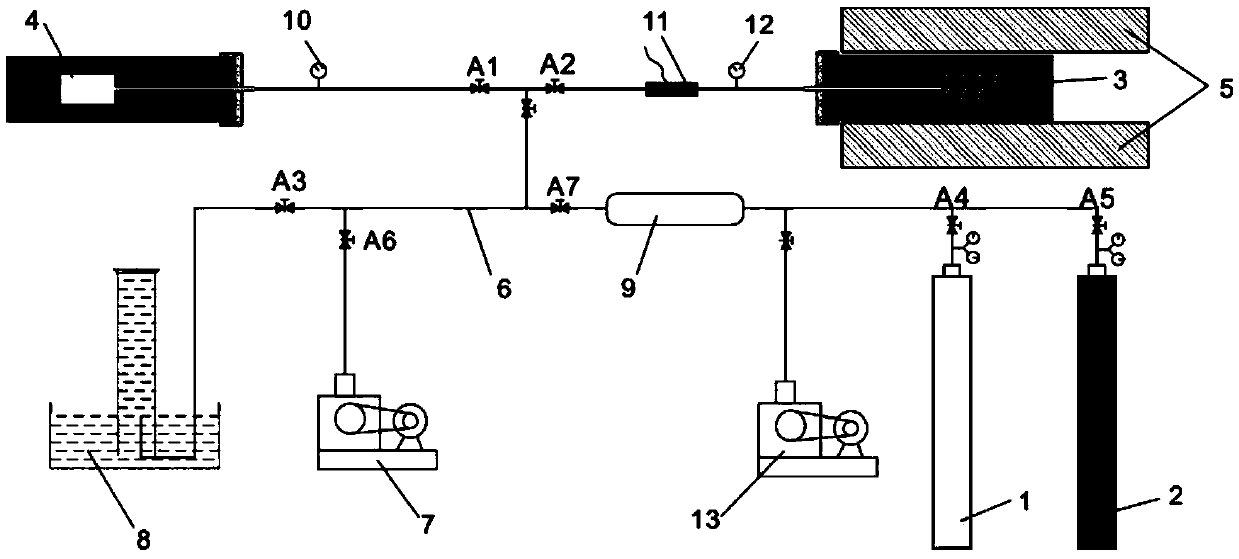

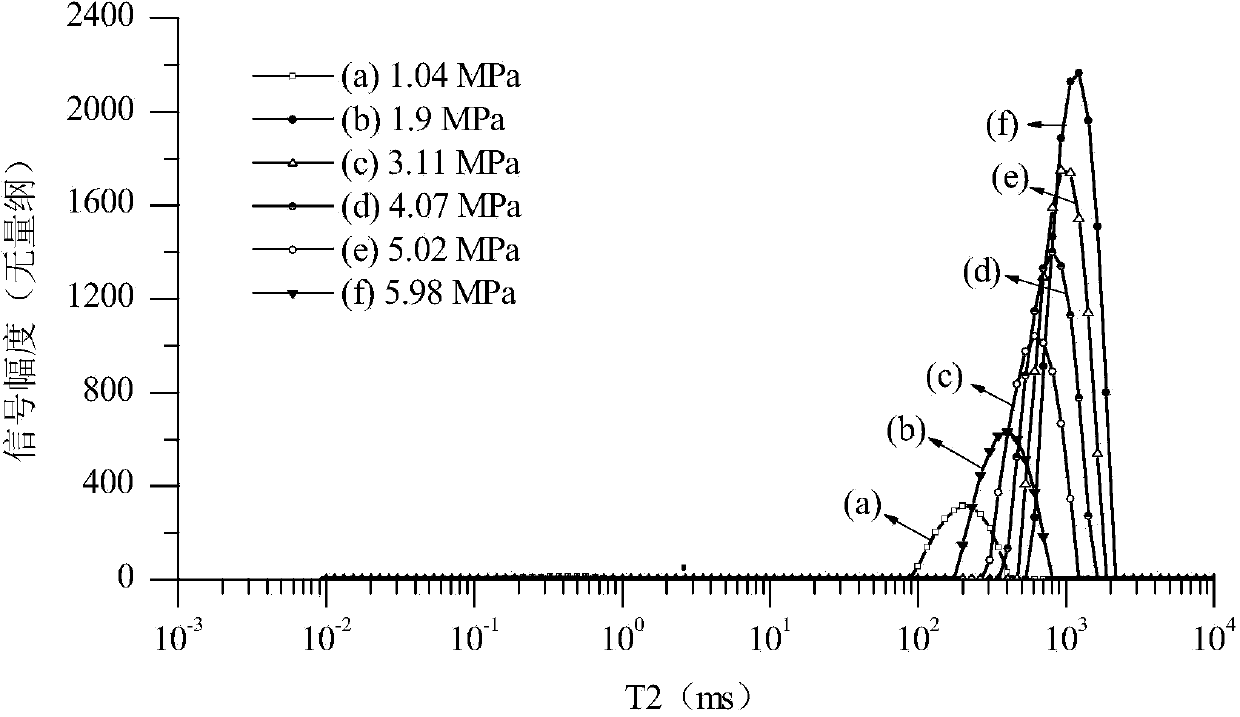

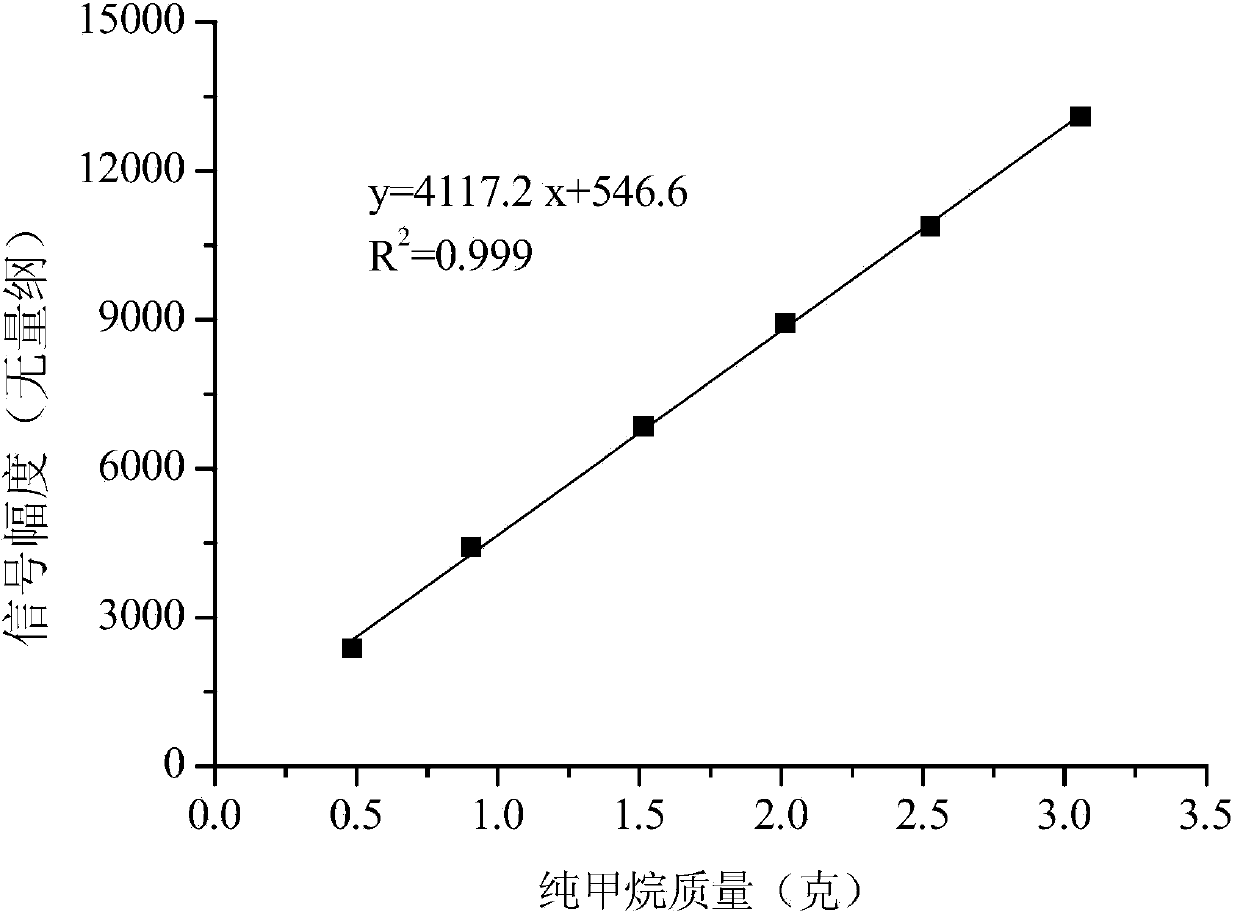

Method for measuring coal sample methane adsorbing capacity through low-field nuclear magnetic resonance

ActiveCN103424421AShort measurement timeHigh speedAnalysis using nuclear magnetic resonanceUnit massLow field nuclear magnetic resonance

The invention discloses a method for measuring coal sample methane adsorbing capacity through low-field nuclear magnetic resonance. According to the method, selected measuring parameters are used for carrying out low-field nuclear magnetic resonance measurement on powder coal samples after methane adsorption balance under set pressure, the nuclear magnetism T2 spectrum of methane in the coal samples is obtained, then signal amplitude integrals of the first spectrum peak (in the range of 0.1-4ms spectrum) on the left of the T2 spectrum are substituted to a hydrogen content index reticle equation of methane under the standard condition built through an experiment, the standard condition size of methane adsorbed by the coal samples is obtained, and therefore the methane adsorbing capacity of unit mass of coal under the set pressure is obtained. According to the method, the scale relation of methane mass and nuclear magnetic resonance 1H nuclear signals is built, the quantitative assay of methane adsorbing capacity under the same temperature and different pressures is achieved, and the novel method can be used for measuring coal methane absorbing capacity in a real-time, home-position and dynamic mode.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

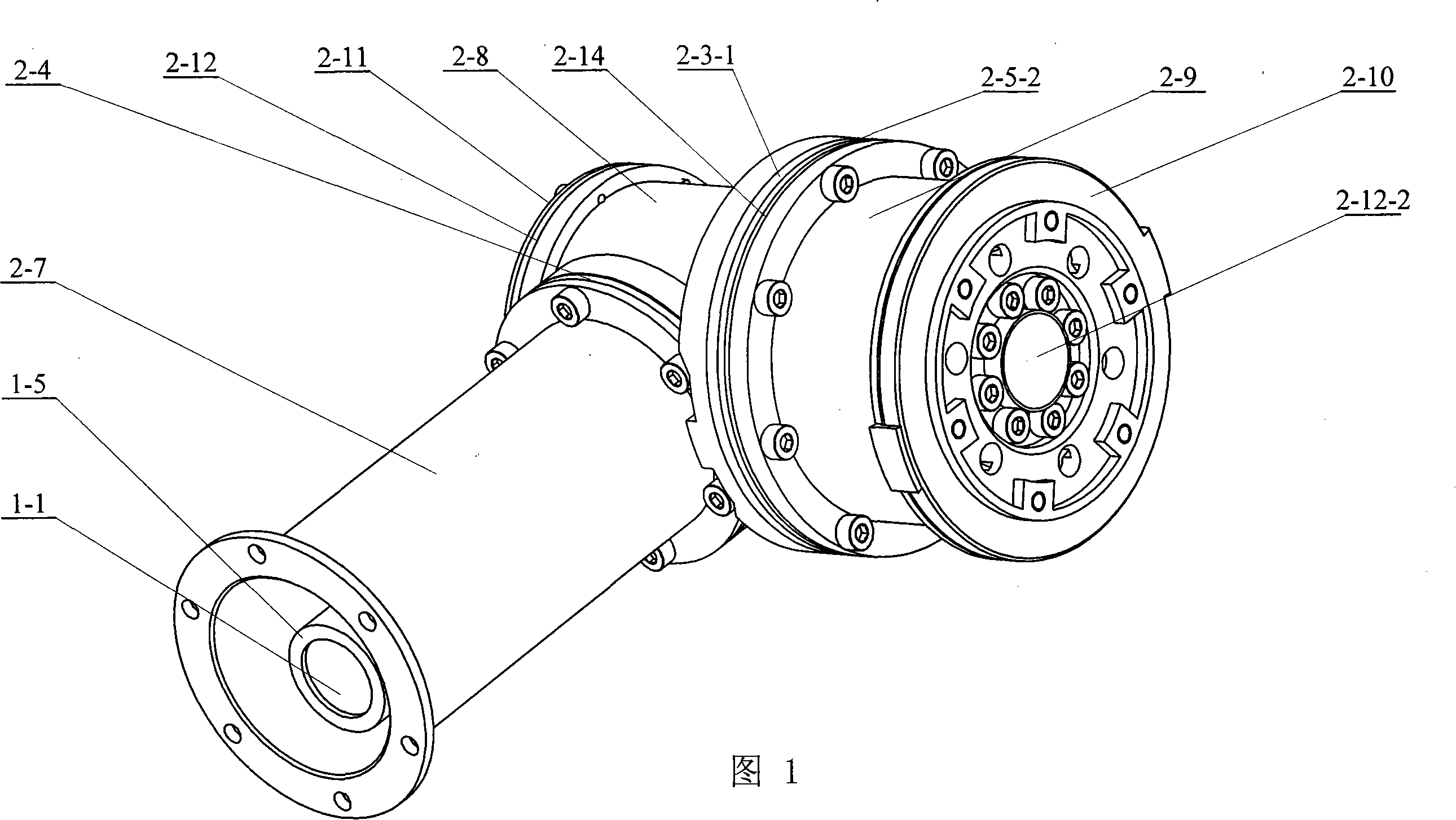

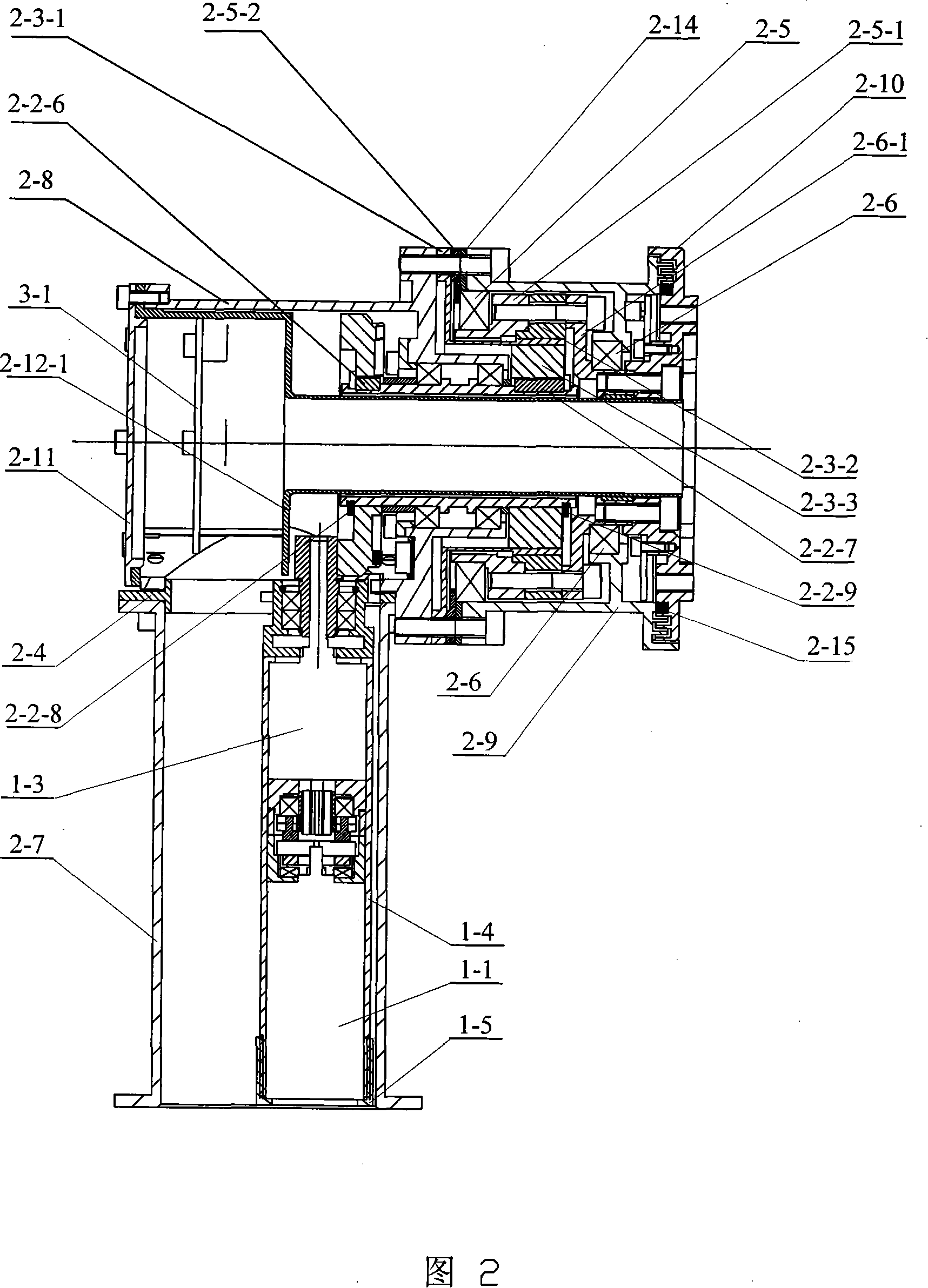

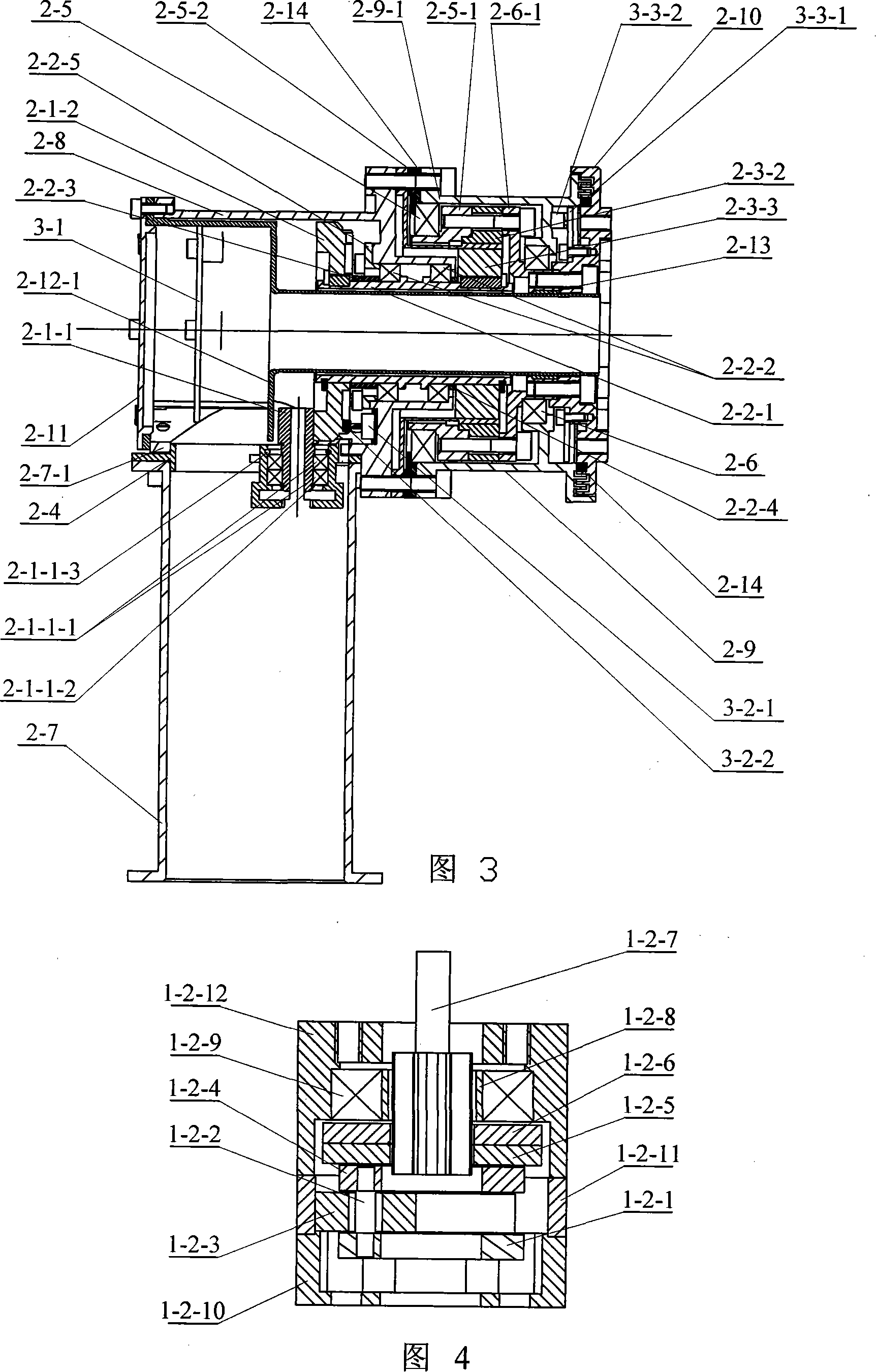

Spacing mechanical arm perpendicular style modularization joint

The invention provides a vertical modular joint for space manipulator, relating to a modular joint for space manipulator. The invention aims to solve the problems with the prior space manipulator which is big in mass, size and power consumption but small in output torque of unit mass. A driving device of the invention is connected with a crown / Rolex gear series device, the crown / Rolex gear series device and a wave generator (2-3-3) is connected with a hollow transmission shaft (2-2-1), a rigid wheel (2-3-2) is connected with an inner ring support base (2-6-1) of a thin wall bearing two and the inner ring support base (2-6-1) of the thin wall bearing two is connected with an output flange (2-10). The invention has the advantages of high in integration and reliability, light in mass, small in size, low in power consumption, compact in structure, big in output torque of unit mass, high in position output precision and big in anti-bending rigidity, and is applicable to adapting to the environment of strong space radiation, high vacuum and big temperature difference, which has good maintainability and reliable operation performance.

Owner:HARBIN INST OF TECH

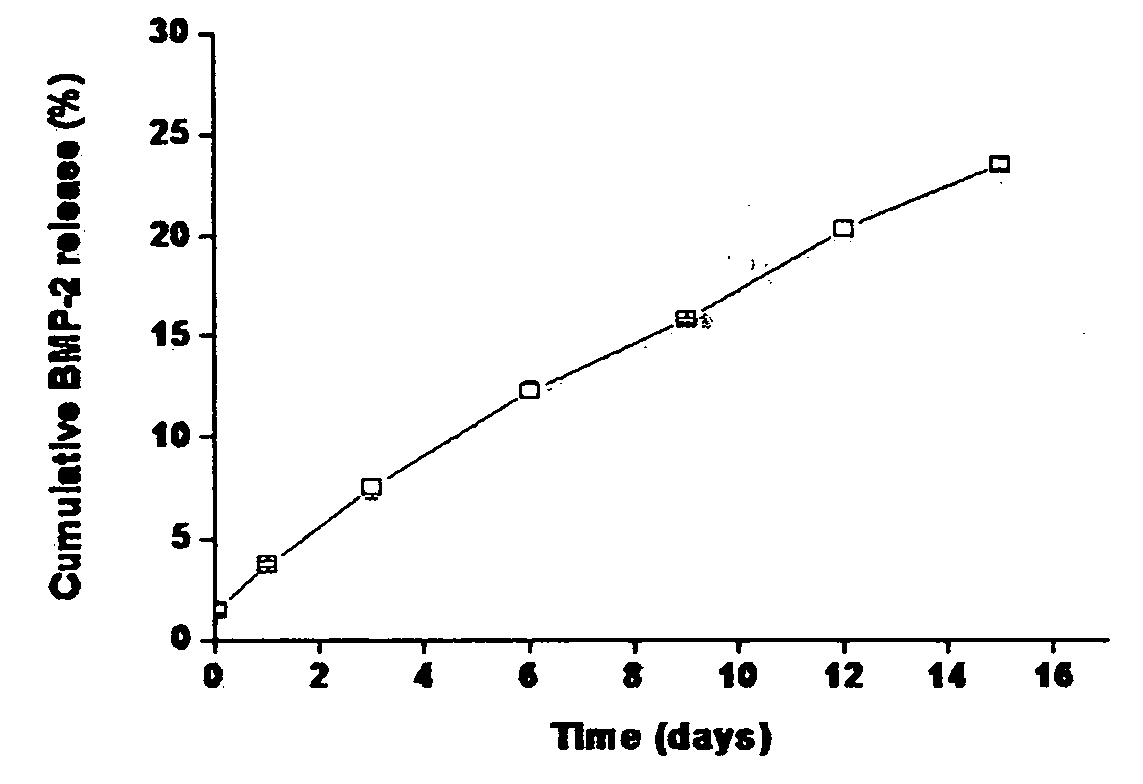

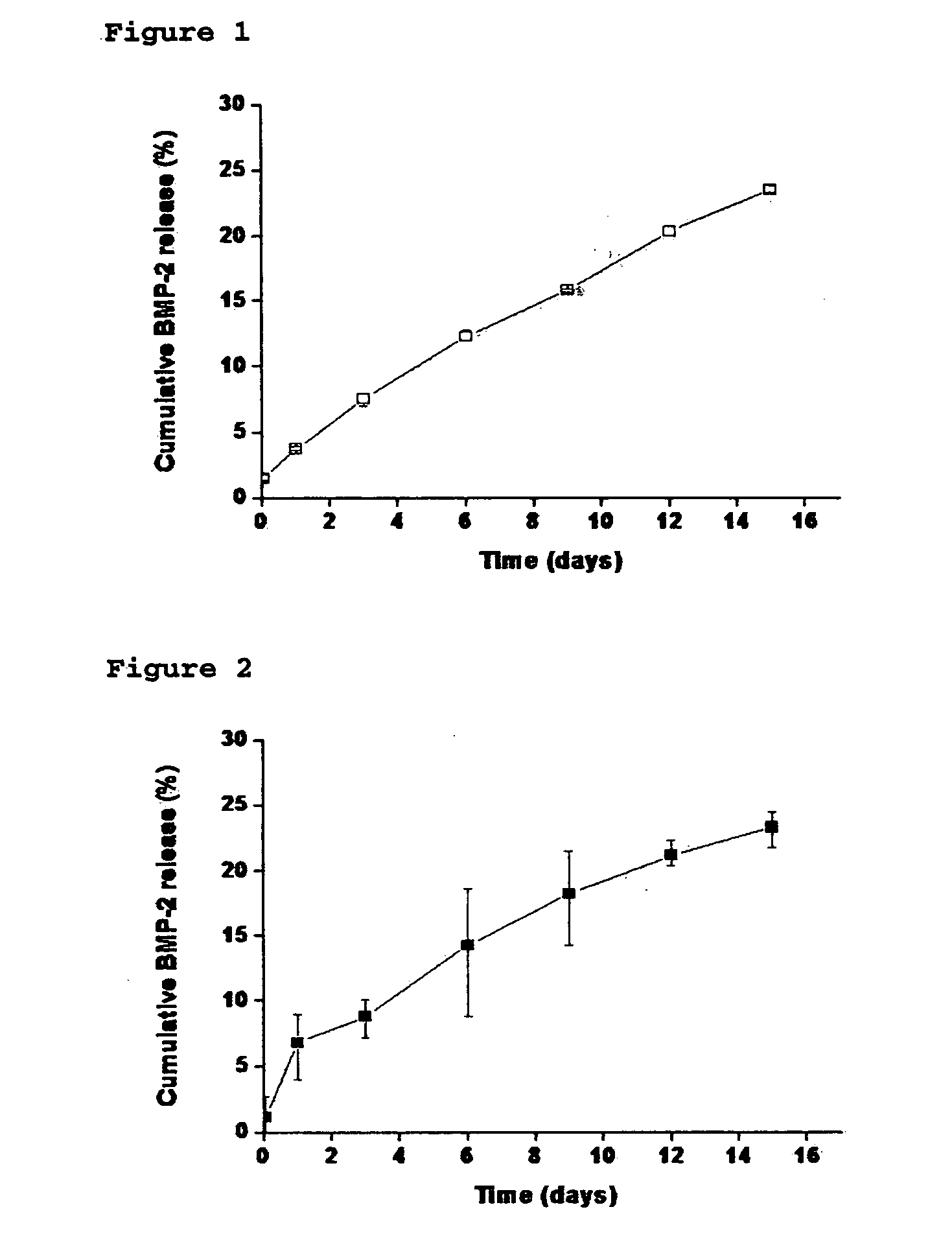

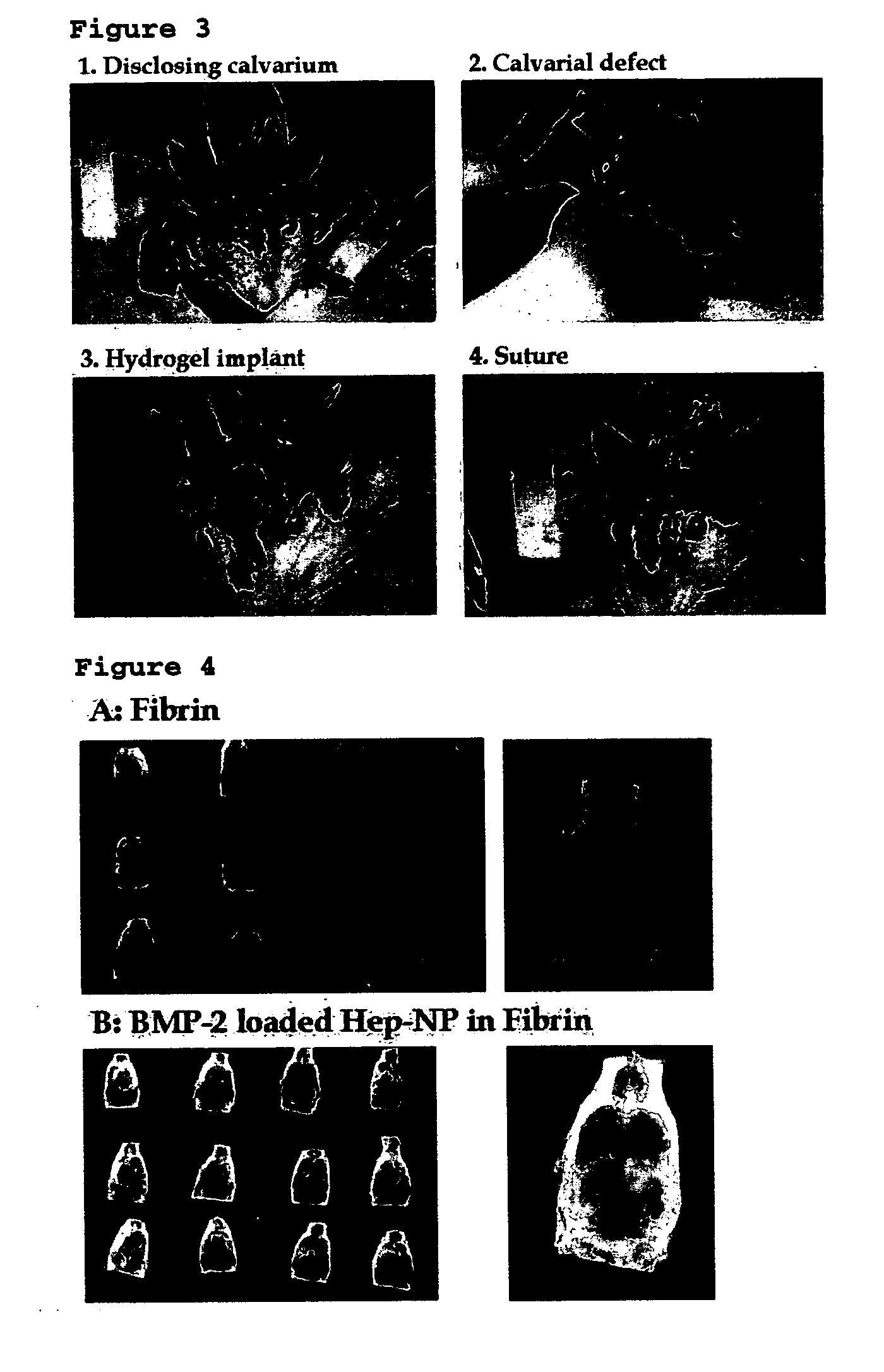

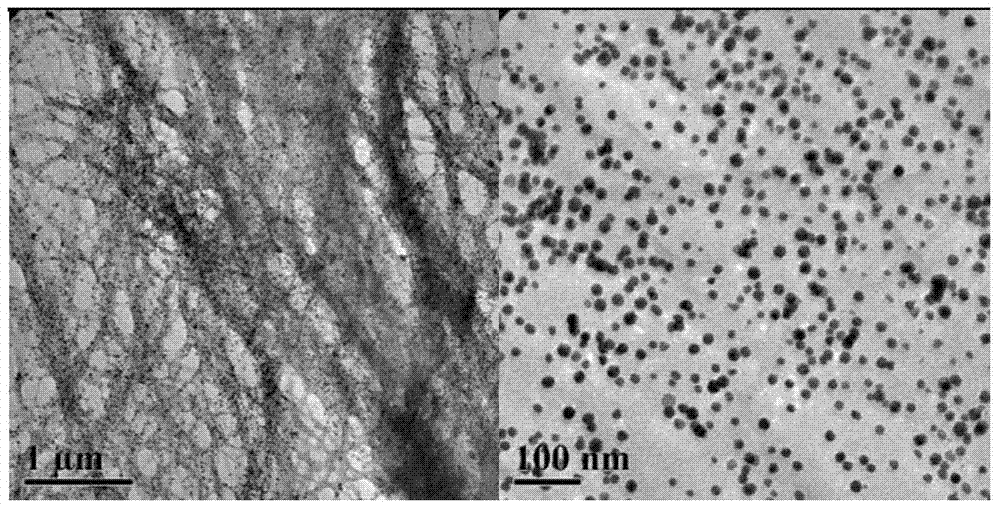

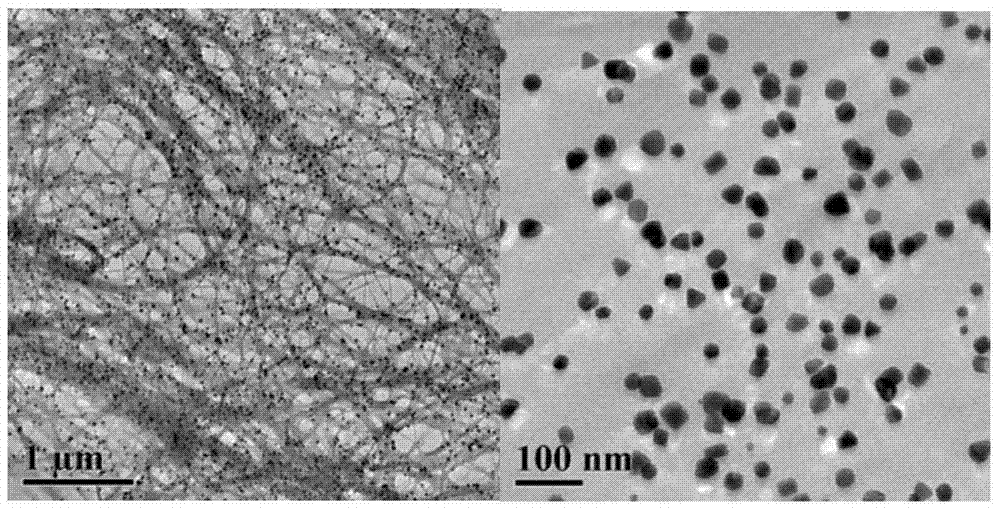

Composite comprising polysaccharide-functionalized nanoparticle and hydrogel matrix, a drug delivery system and a bone defect replacement matrix for sustained release comprising the same, and the preparation method thereof

InactiveUS20070248675A1Powder deliveryPeptide/protein ingredientsFunctionalized nanoparticlesUnit mass

The present invention relates to a nanoparticle-protein-hydrogel composite comprising (1) a polysaccharide-functionalized nanoparticle comprising a core composed of a biodegradable polymer, a hydrogel surface layer composed of a biocompatible polymer emulsifier, and a polysaccharide physically bound to the core and / or the hydrogel layer; (2) a protein forming a specific binding with the polysaccharide; and (3) a hydrogel matrix composed of a biocompatible polymer as a matrix for the nanoparticle. The present also relates to a drug delivery system and a bone defect replacement matrix comprising the composite for sustained release, and the preparation method thereof. Further, the present invention also provides a method for controlling the release rate of a protein drug by changing the content of the polysaccharide in a unit mass of the nanoparticle and / or by changing the content of the nanoparticle in a unit mass of the composite.

Owner:GWANGJU INST OF SCI & TECH

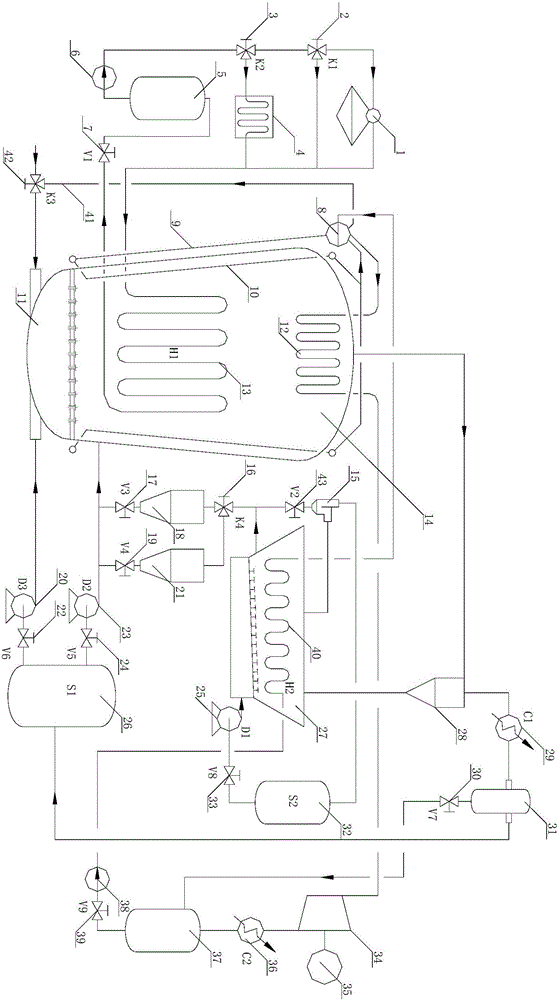

Fluidization calcium-based thermal-chemical high temperature energy storing/releasing system and working method thereof

InactiveCN105737658AEasy accessLow priceHeat storage plantsEnergy storageThermal energyDecomposition

The invention discloses a fluidization calcium-based thermal-chemical high temperature energy storing / releasing system and a working method thereof. The system is characterized in that the storing and releasing of energy are performed by means of a calcium-based thermal-chemical high-temperature reversible reaction through mutual transformation among solar energy, thermal energy and chemical energy. The system mainly comprises an energy input unit, an energy storing unit and an energy output unit. During storing of energy, calcium hydroxide is subjected to an endothermic decomposition reaction under a fluidization condition, and absorbed energy is stored in calcium oxide as a reaction product in a chemical energy form; during releasing of the energy, the calcium oxide and water vapor are subjected to an exothermic reaction under the fluidization condition, and released heat heats water to generate high-temperature high-pressure steam, so that a steam turbine is driven to generate power. The fluidization calcium-based thermal-chemical high temperature energy storing / releasing system has the characteristics of high unit mass energy-storing density, high energy quality, low energy-storing lost, no pollution and the like, can be modularly combined according to energy-storing capacity, and can be applied to fields such as large-scale solar thermal generation and peak-load regulation.

Owner:SOUTH CHINA UNIV OF TECH

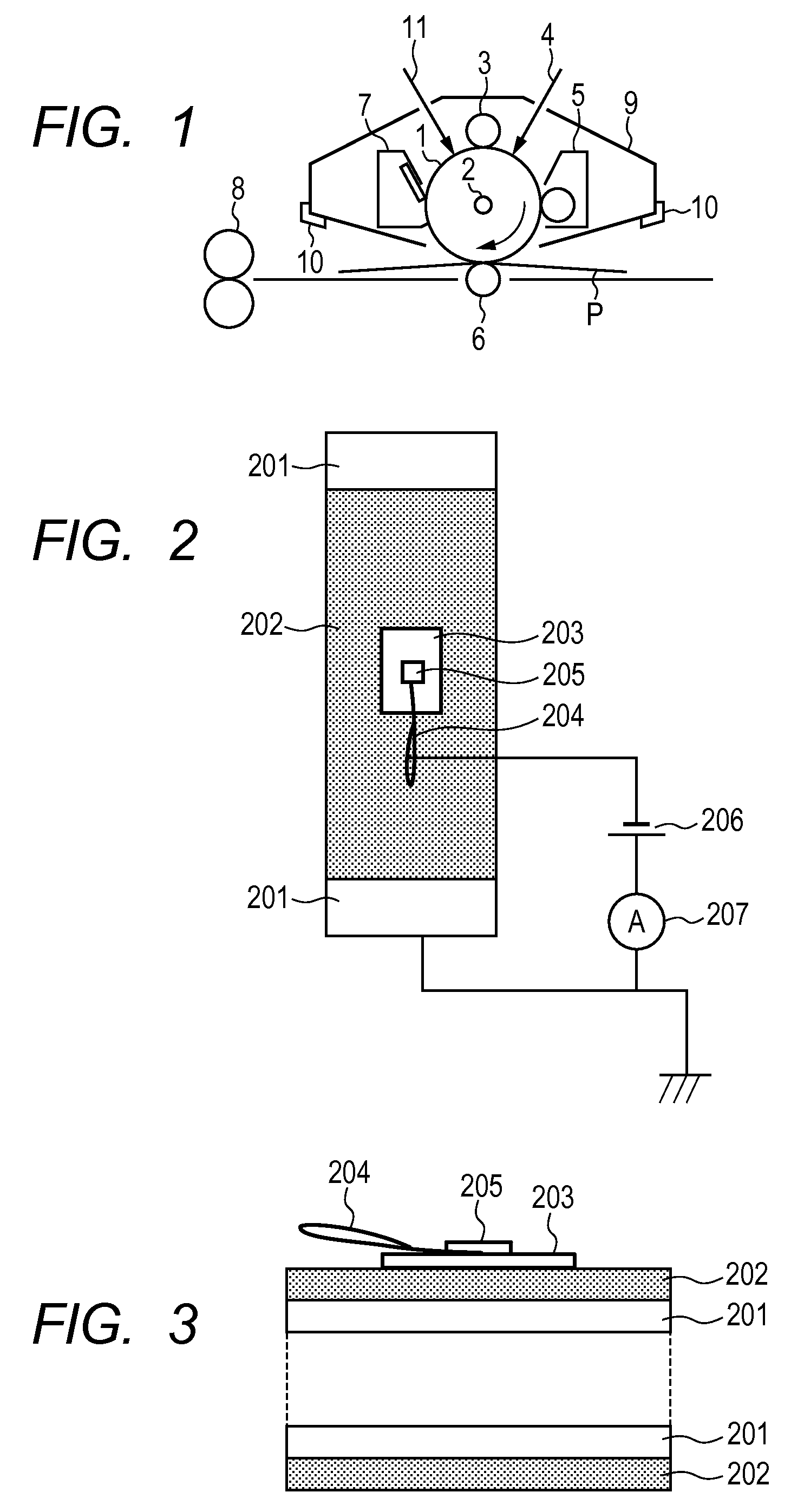

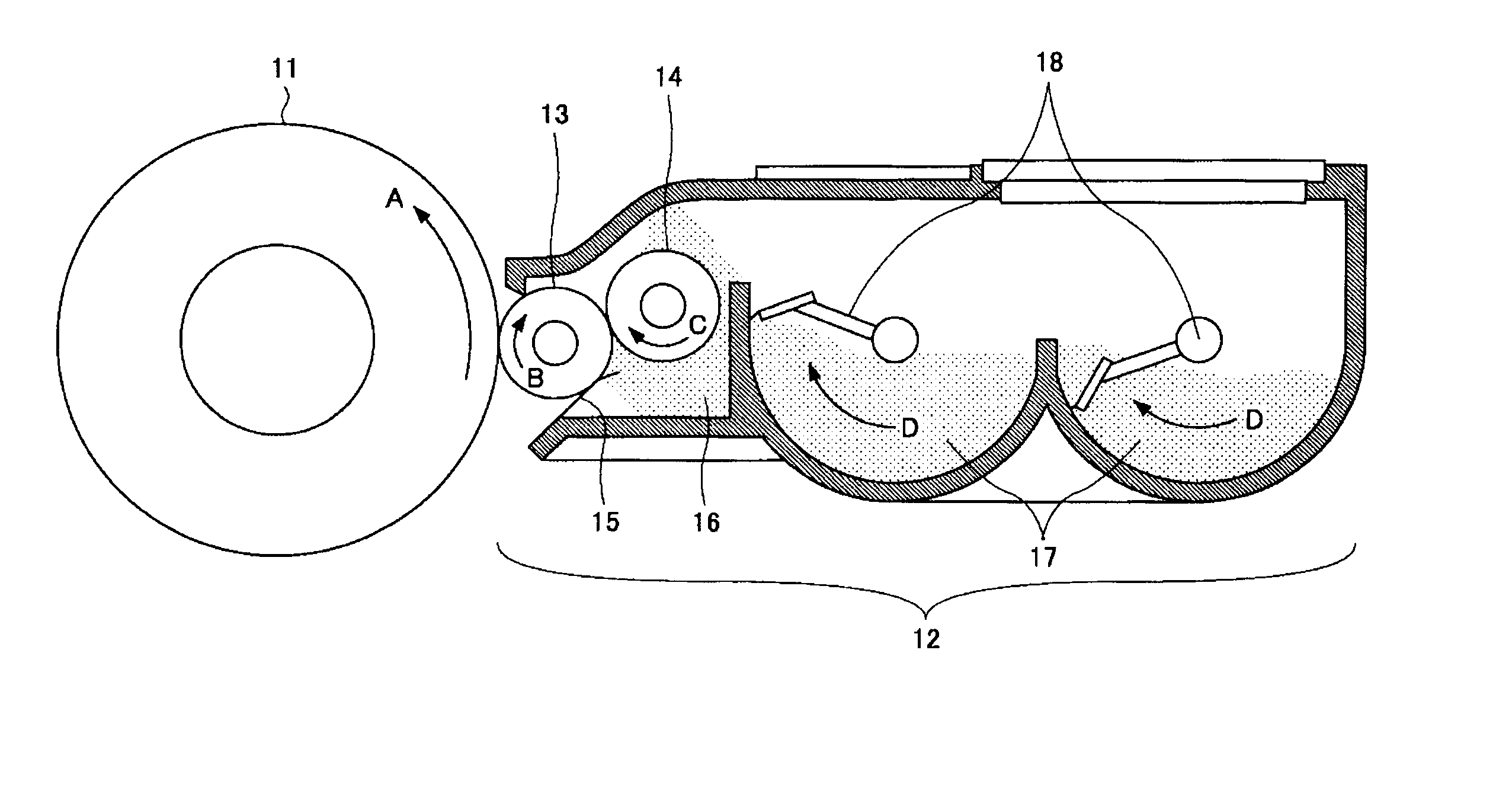

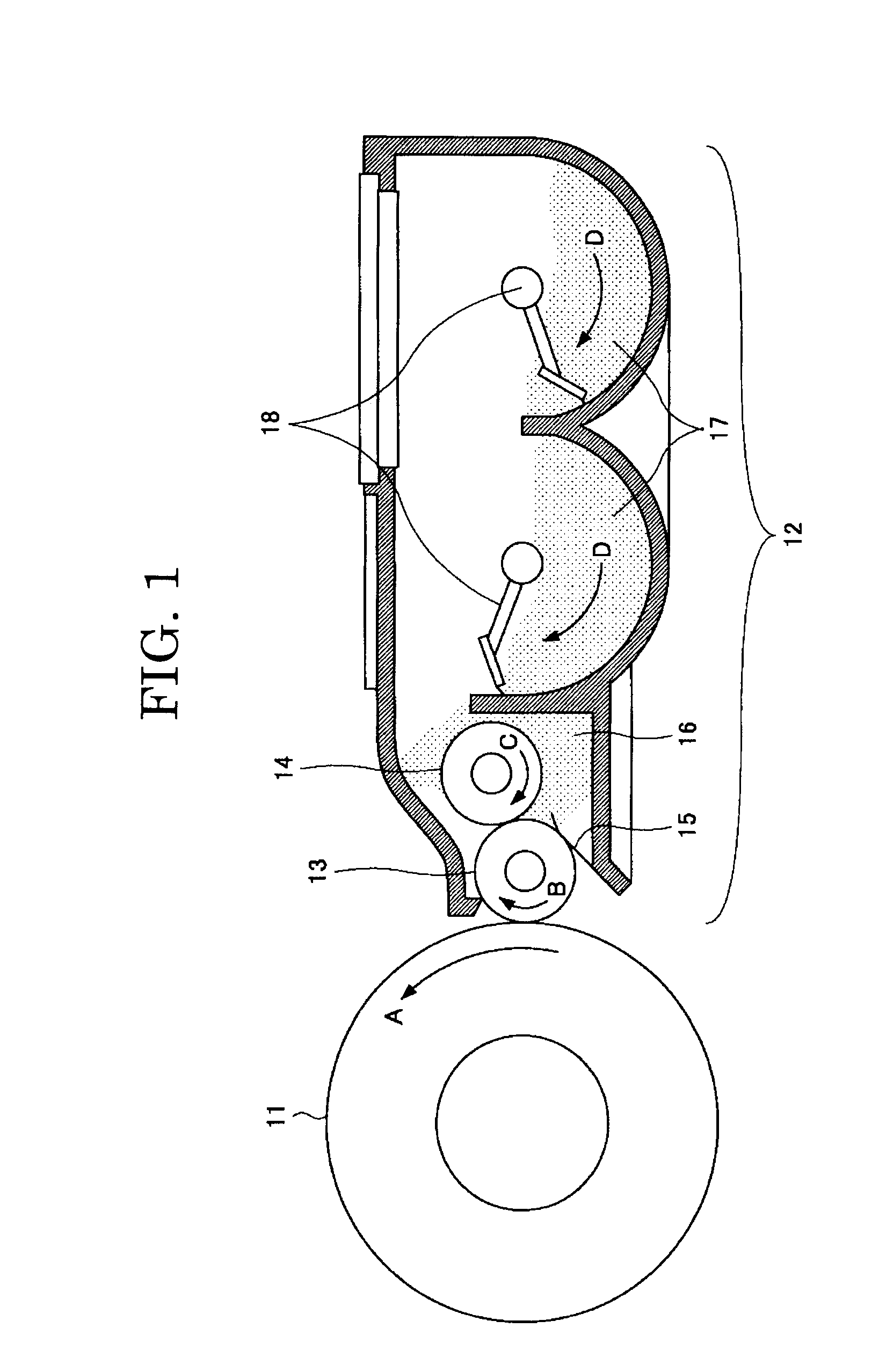

Developing device, image developing method, image forming apparatus, image forming method, and process cartridge

InactiveUS20080063957A1Electrographic process apparatusElectrographic processes using charge patternFistUnit mass

The present invention provides a developing device that allows for maintaining the conveyance amount of a toner within a certain definite range. A developing device 12 of the present invention is provided with a toner conveying unit 13 configured to convey a fist toner and a controlling member 15 configured to control the thickness of a toner layer formed with the first toner conveyed by the toner conveying unit 13, wherein a second toner provided with a charged amount per unit mass that differs from a charged amount per unit mass of the first toner is applied over the surface of the controlling member 15.

Owner:RICOH KK

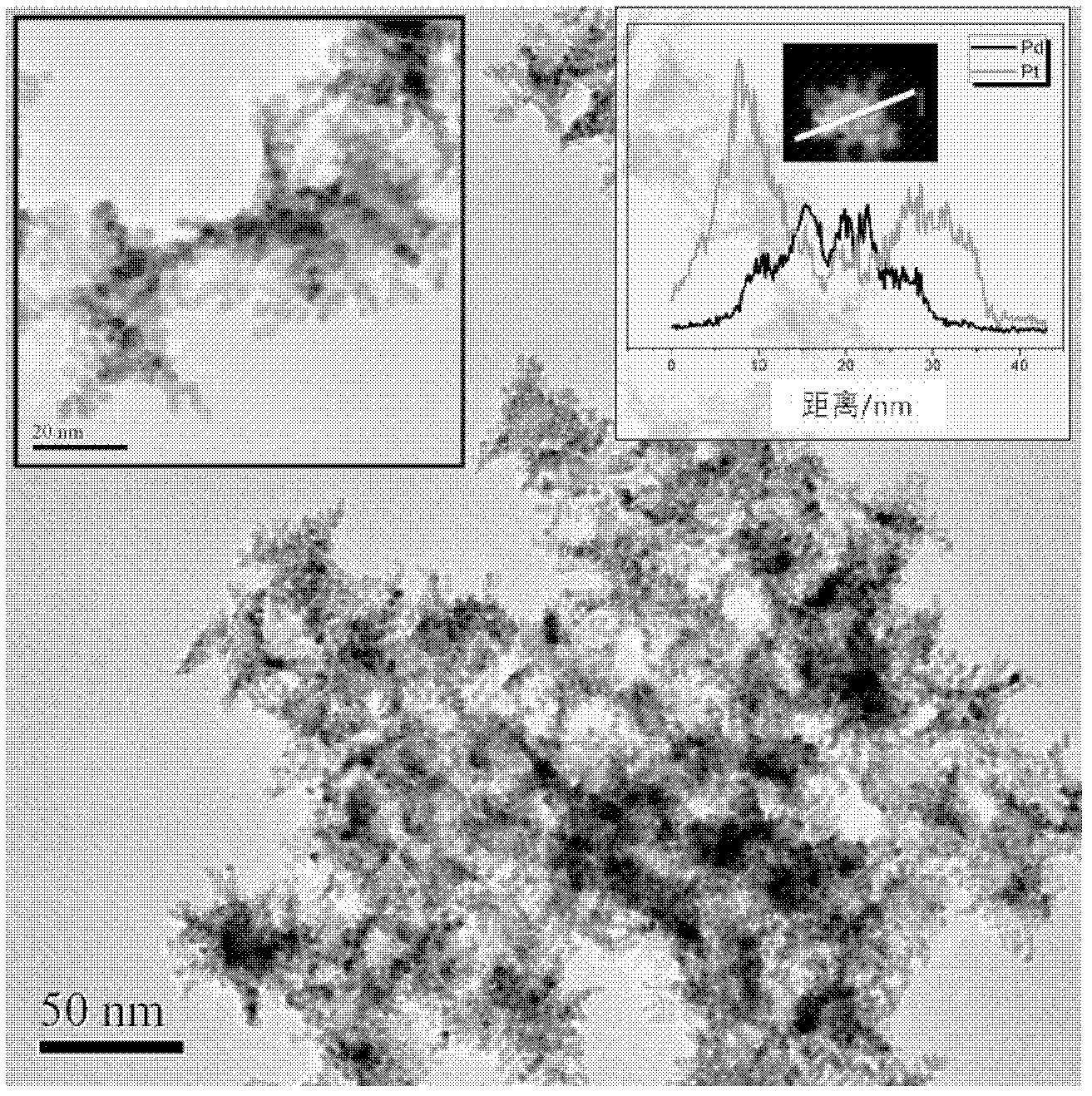

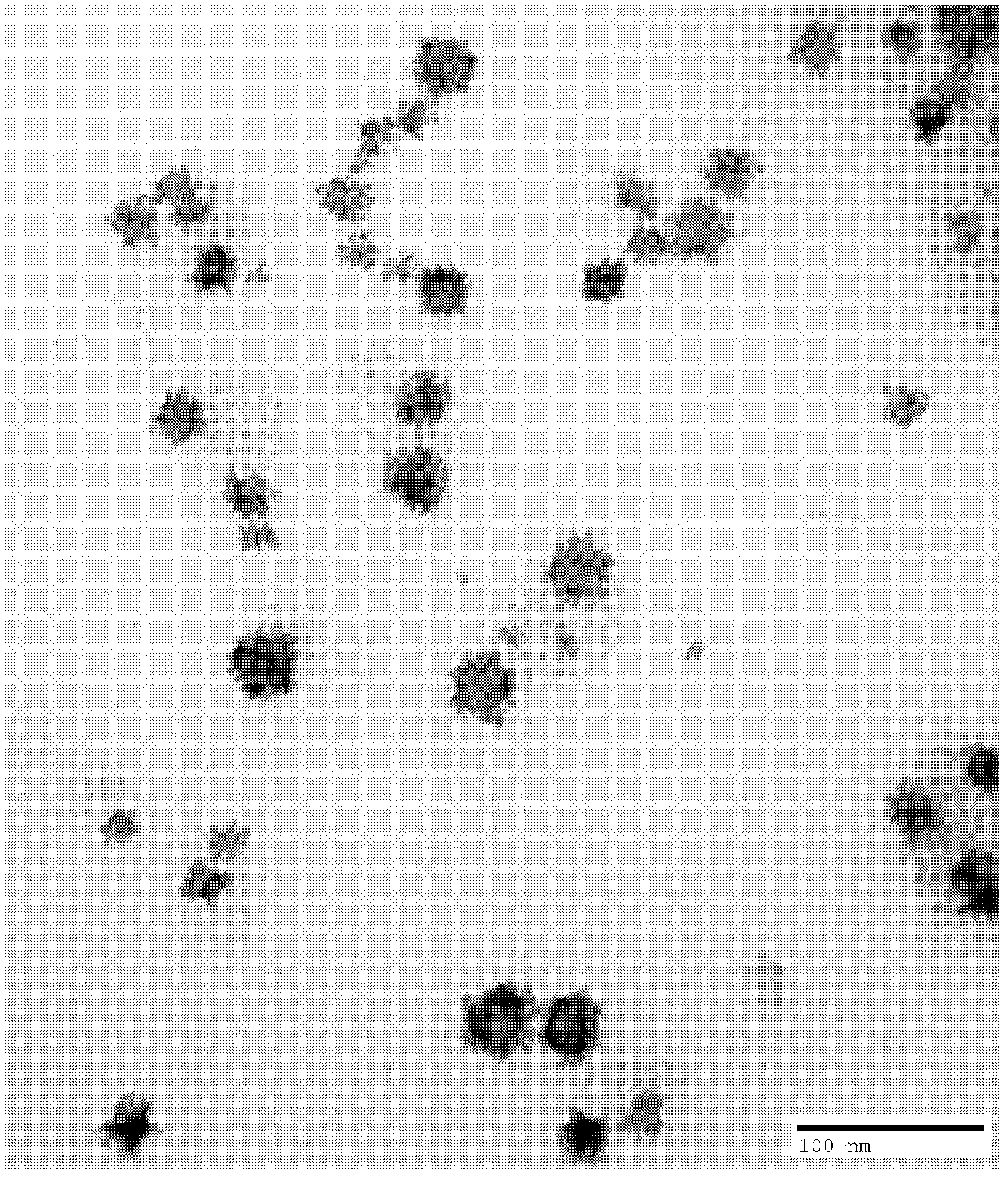

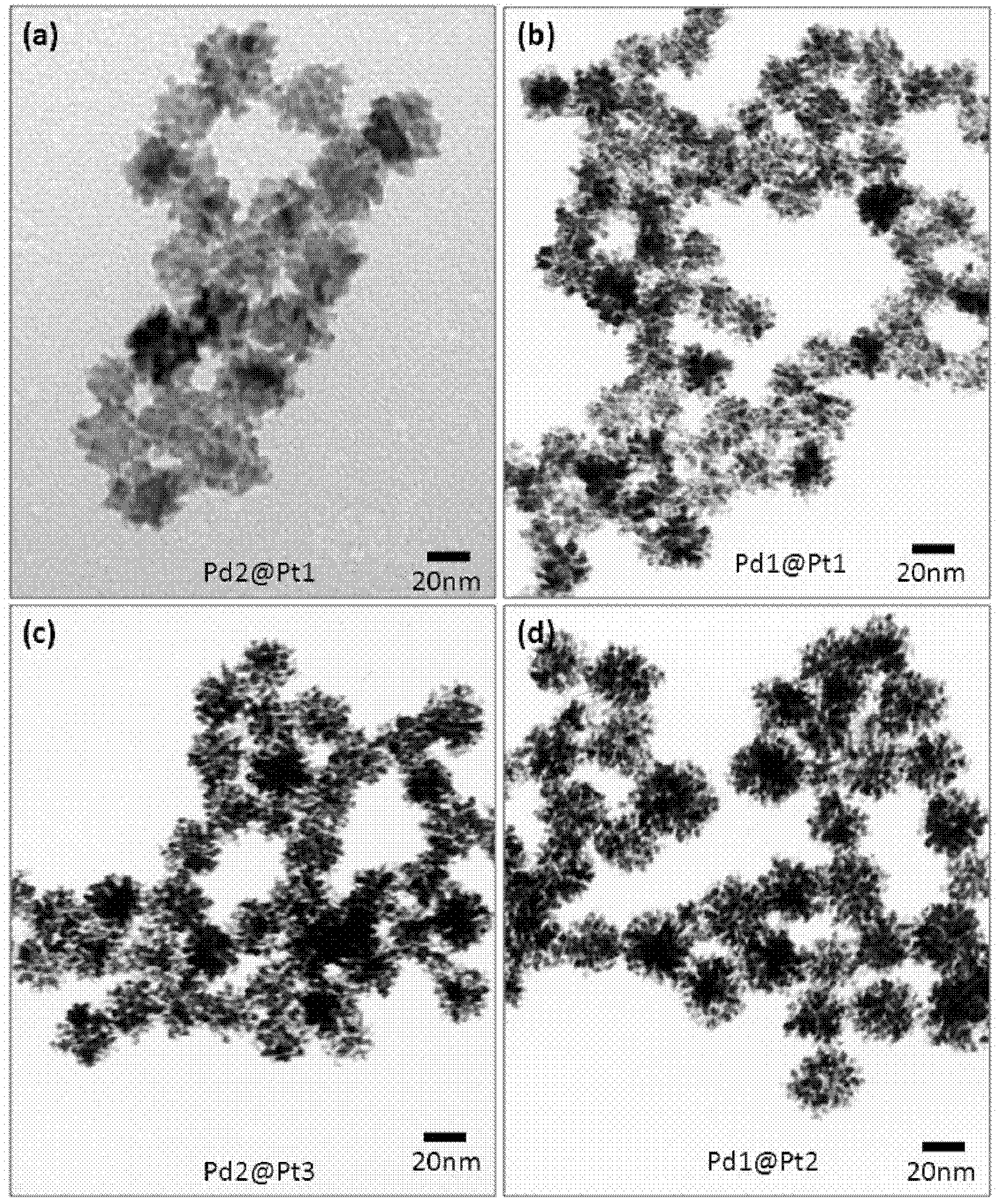

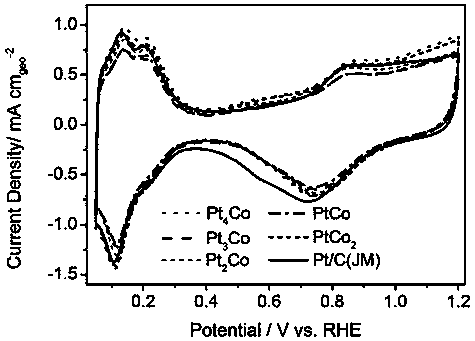

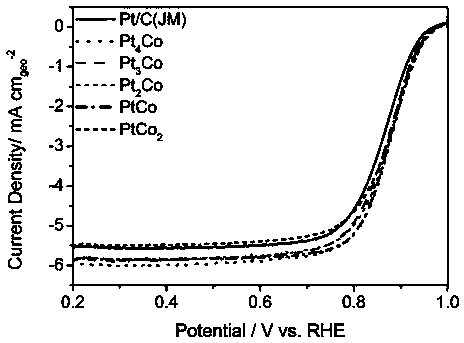

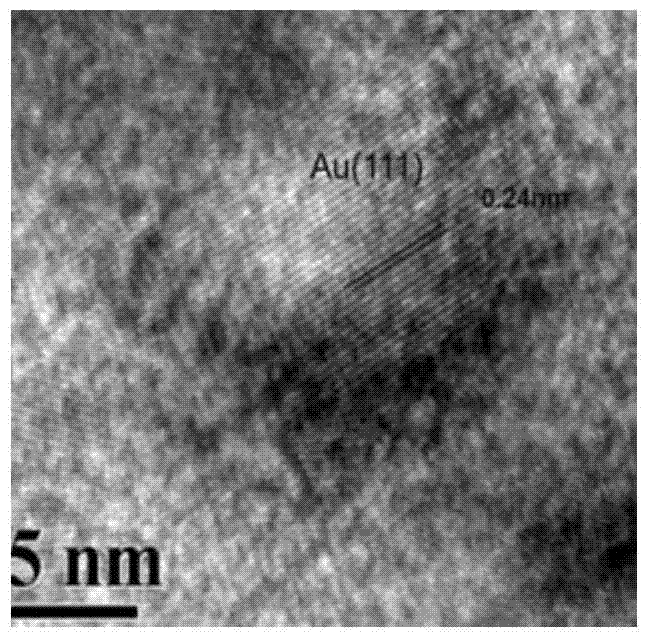

Preparation method of Pd@Pt core-shell structural catalyst for low-temperature fuel cell

InactiveCN103028396AHigh catalytic activity for oxygen reductionAdjust the densityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsUnit massMetal particle

The invention provides a method for preparing core-shell structural nanometer metal particles. Spherical Pd nanoparticles are taken as a core; Pt nanodendrites are taken as a shell; and the nanometer metal particles can be taken as a low-temperature fuel cell catalyst. The preparation method comprises the following steps of: reducing precursors of Pd and Pt with ascorbic acid by taking deionized water as a solvent and taking a segmented copolymer as a protecting agent; and preparing nanoparticles according to different reducing sequences of the ascorbic acid on the Pd and Pt precursors, wherein the Pt shell has a nanometer dendritic crystal structure. A supported catalyst can be obtained by adding a carrier into nanoparticle sol obtained by reacting. The preparation method adopted by the invention has the advantages of easiness, environment friendliness, energy saving and the like. The prepared core-shell structural catalyst shows high area specific activity and unit mass Pt catalytic activity on an oxygen reduction reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

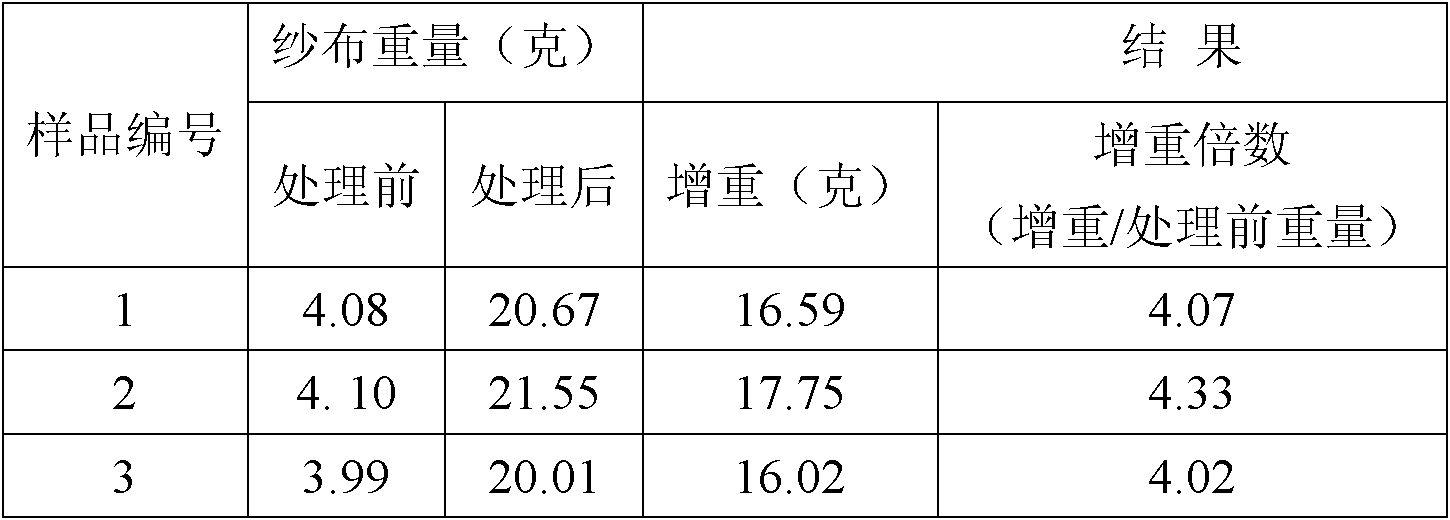

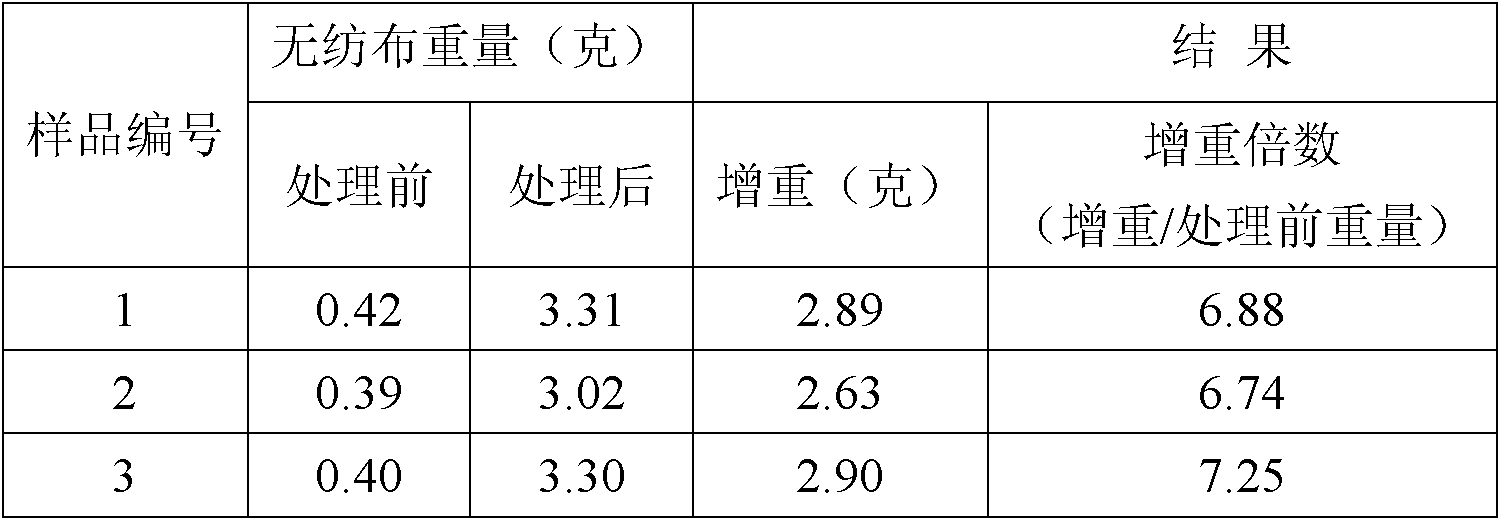

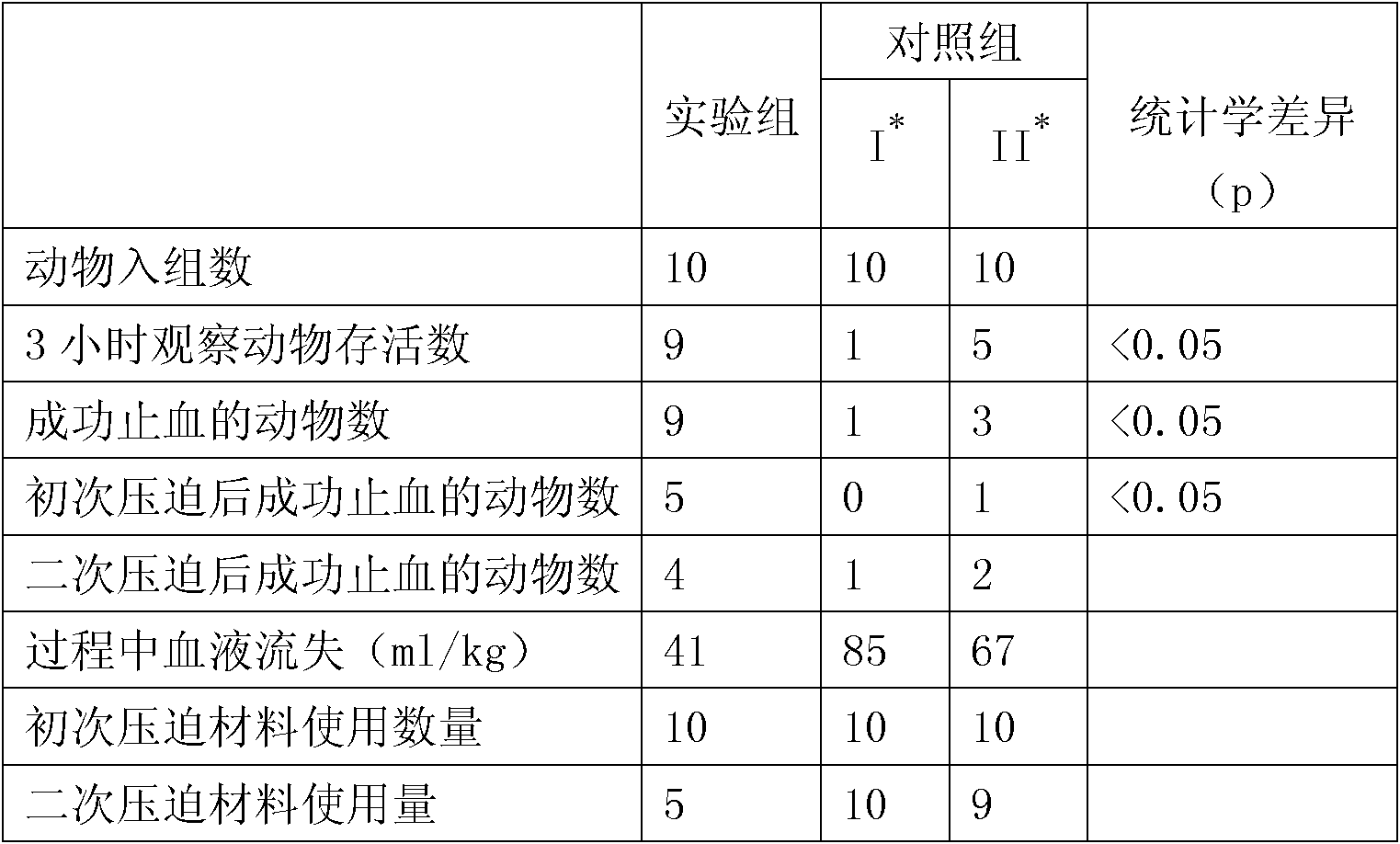

a hemostatic material

InactiveCN102274541AFull and direct contactIncrease surface areaAbsorbent padsBandagesPrillUnit mass

The invention discloses a hemostatic material, which comprises the following raw materials: woven or non-woven fabric as a support matrix, starch as a binder, glycerin as a softener, and inorganic particles, the inorganic particles are silicon At least one of algae earth particles, glass powder, micro silica fume, kaolin clay particles, silicate particles, montmorillonite particles and zeolite particles. The quality of the hemostatic agent on the hemostatic material of the present invention is more than 2-8 times that of the support matrix, thereby improving its effect of promoting blood coagulation; the present invention uses micron-scale or nano-scale inorganic particles, which greatly increases the surface area per unit mass, making The contact with blood is more comprehensive and direct, and accelerates the speed of blood coagulation; it is easy to use and can be used immediately; it is suitable for use in various environments, not only in battlefields, disaster sites, accident sites, but also in emergency vehicles and emergency centers , Surgical ward use.

Owner:天津禹王生物医药科技有限公司

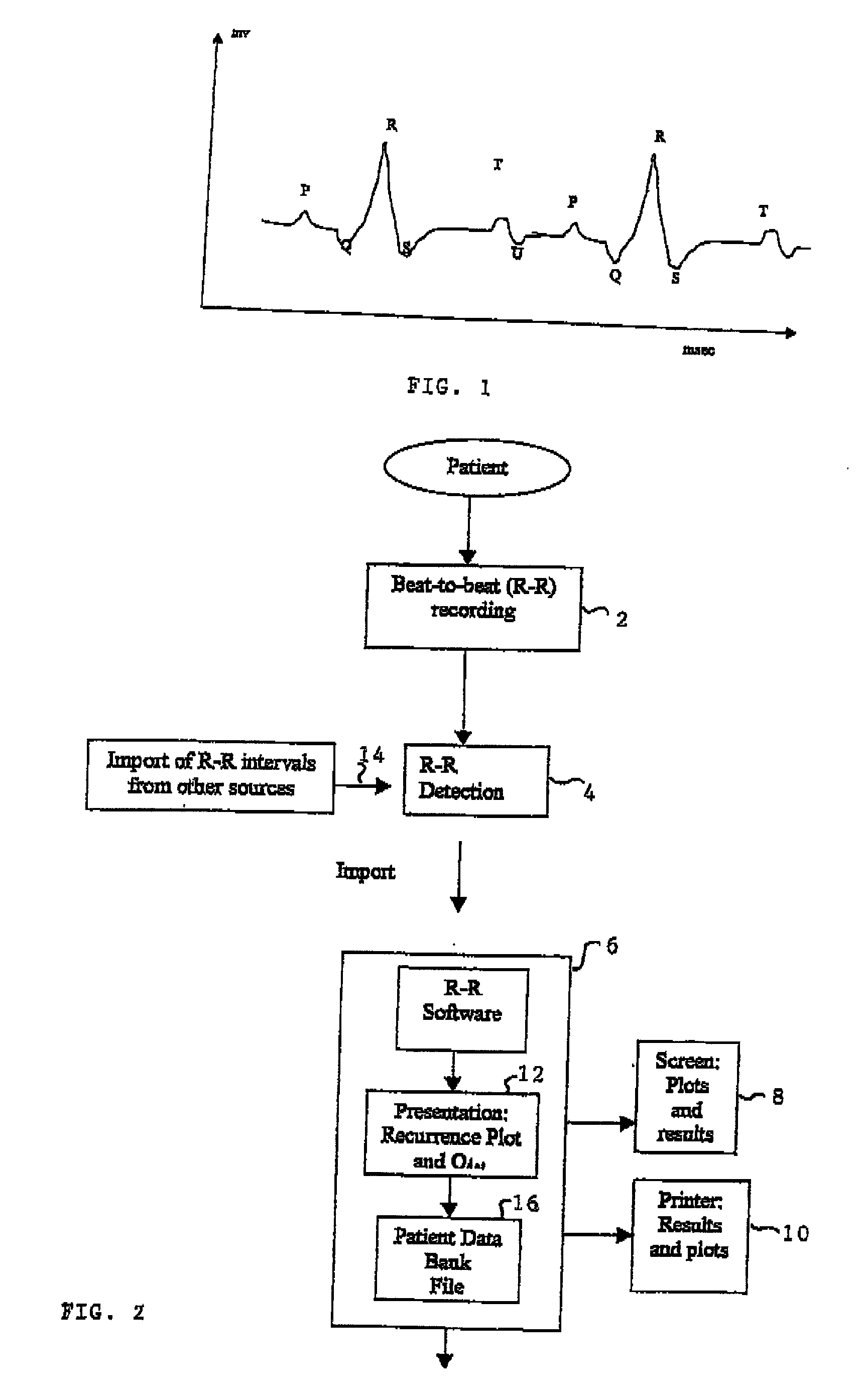

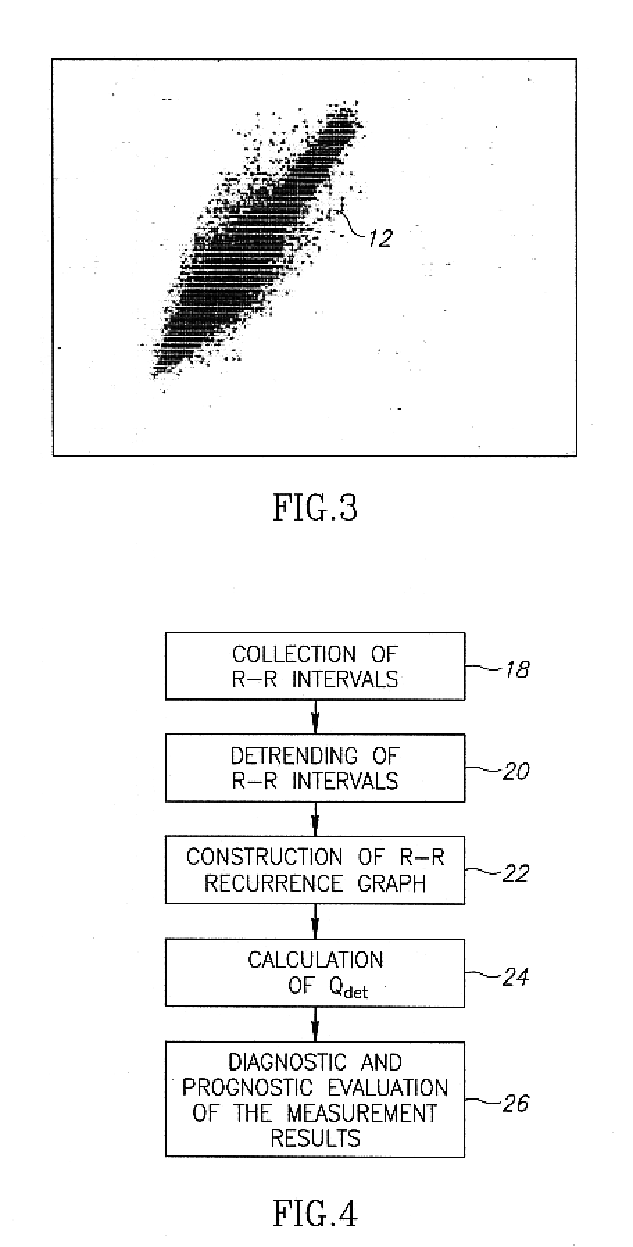

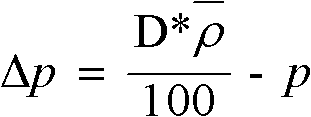

Method and system for measuring heart rate variability

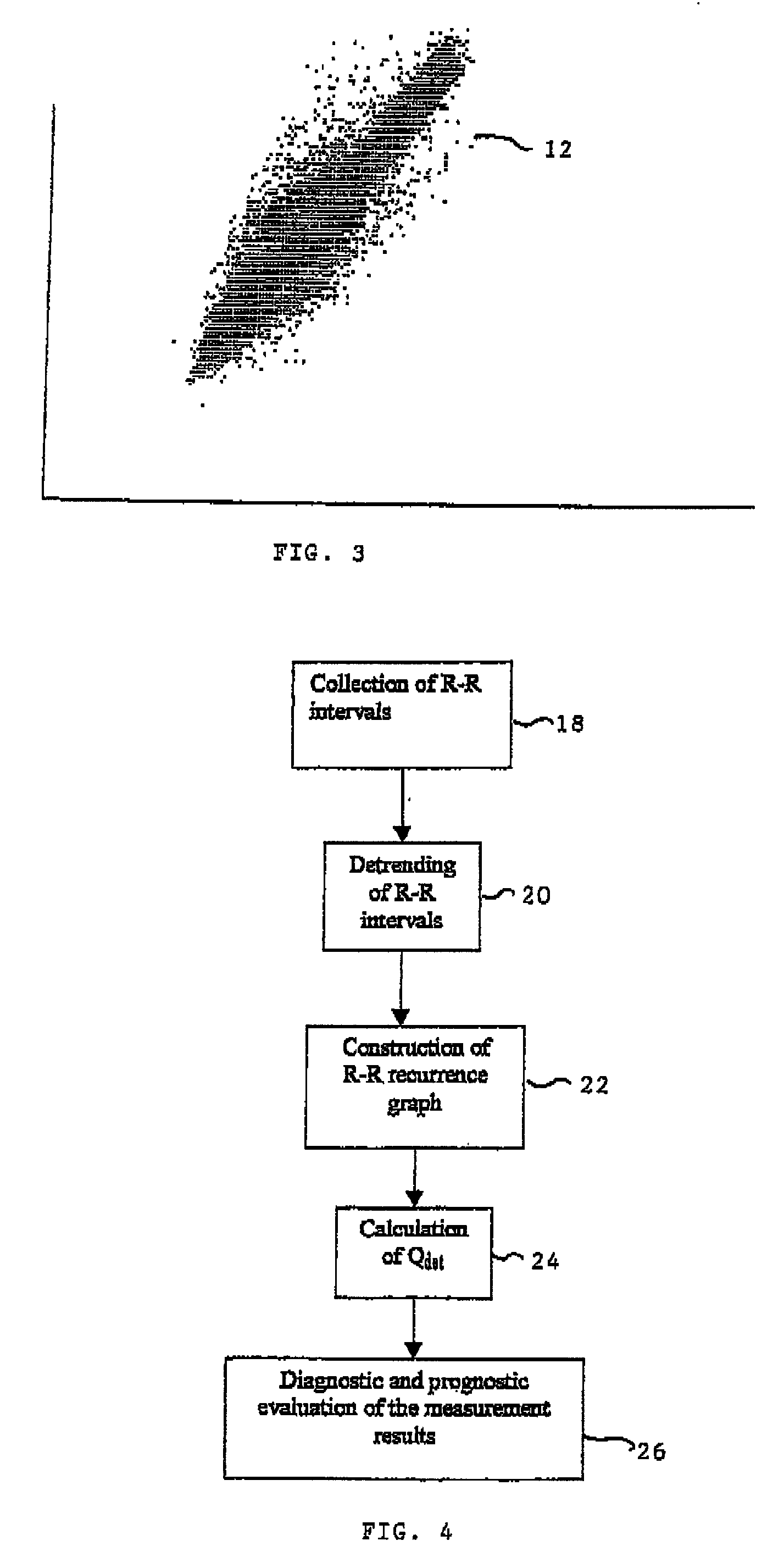

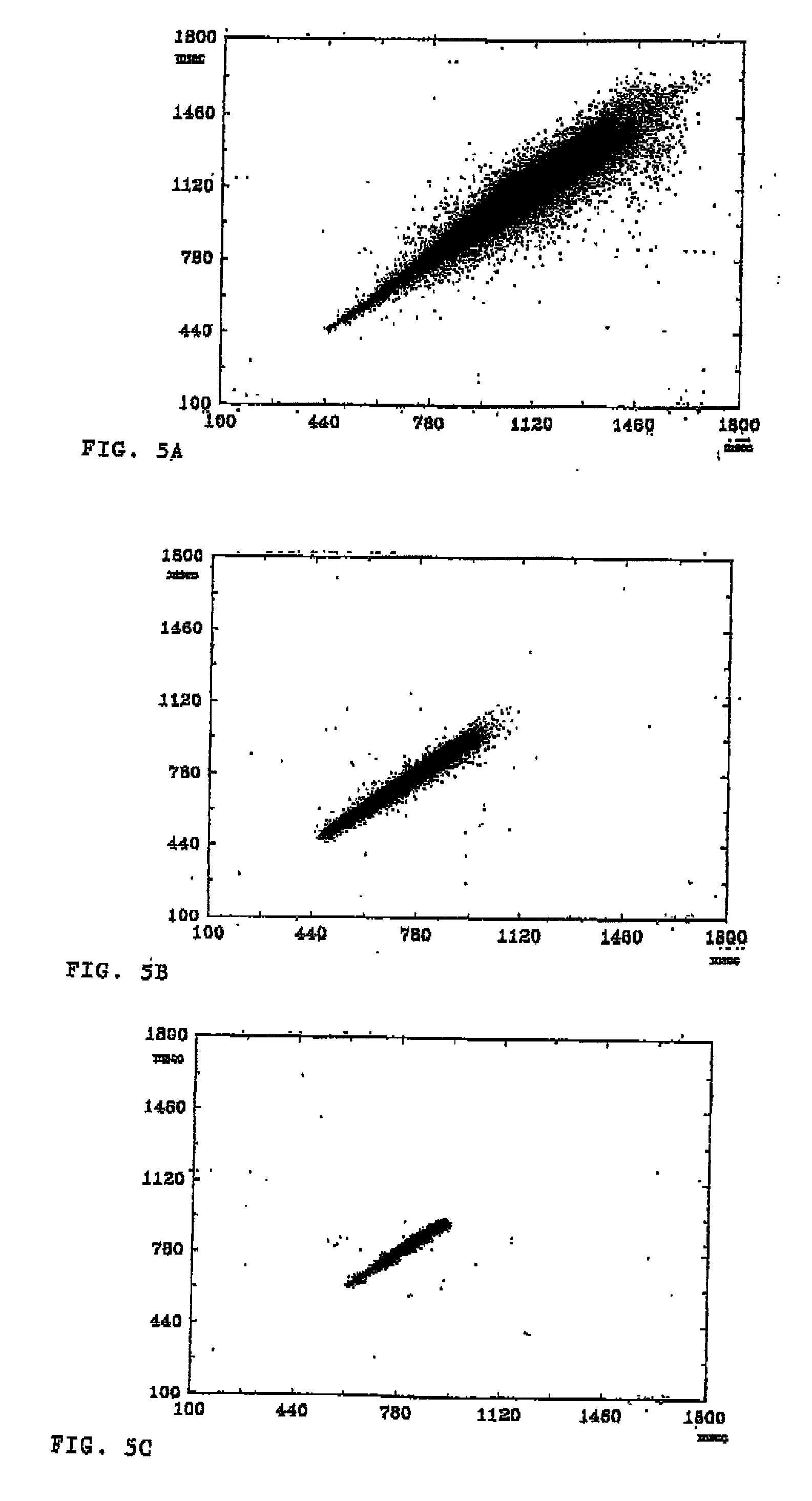

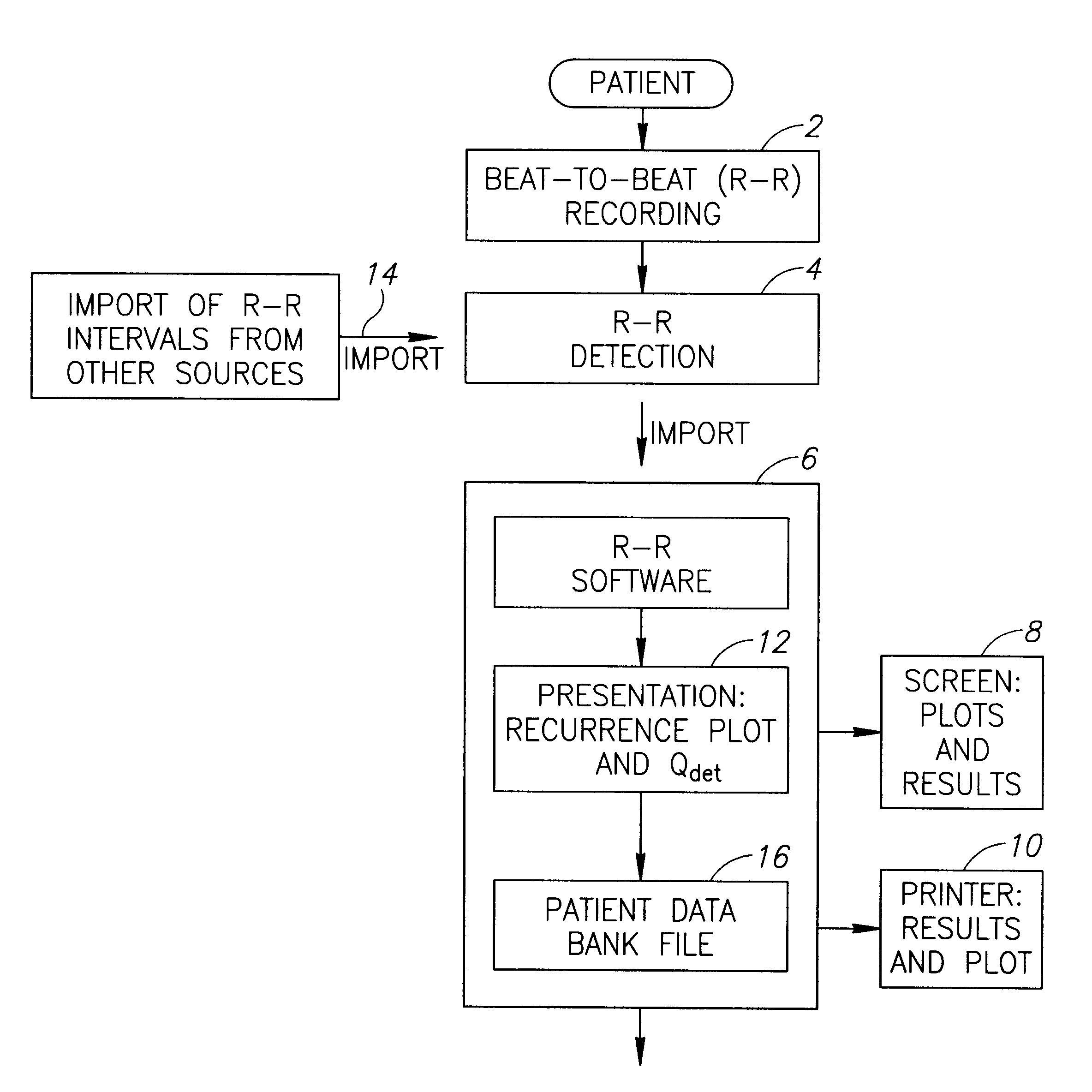

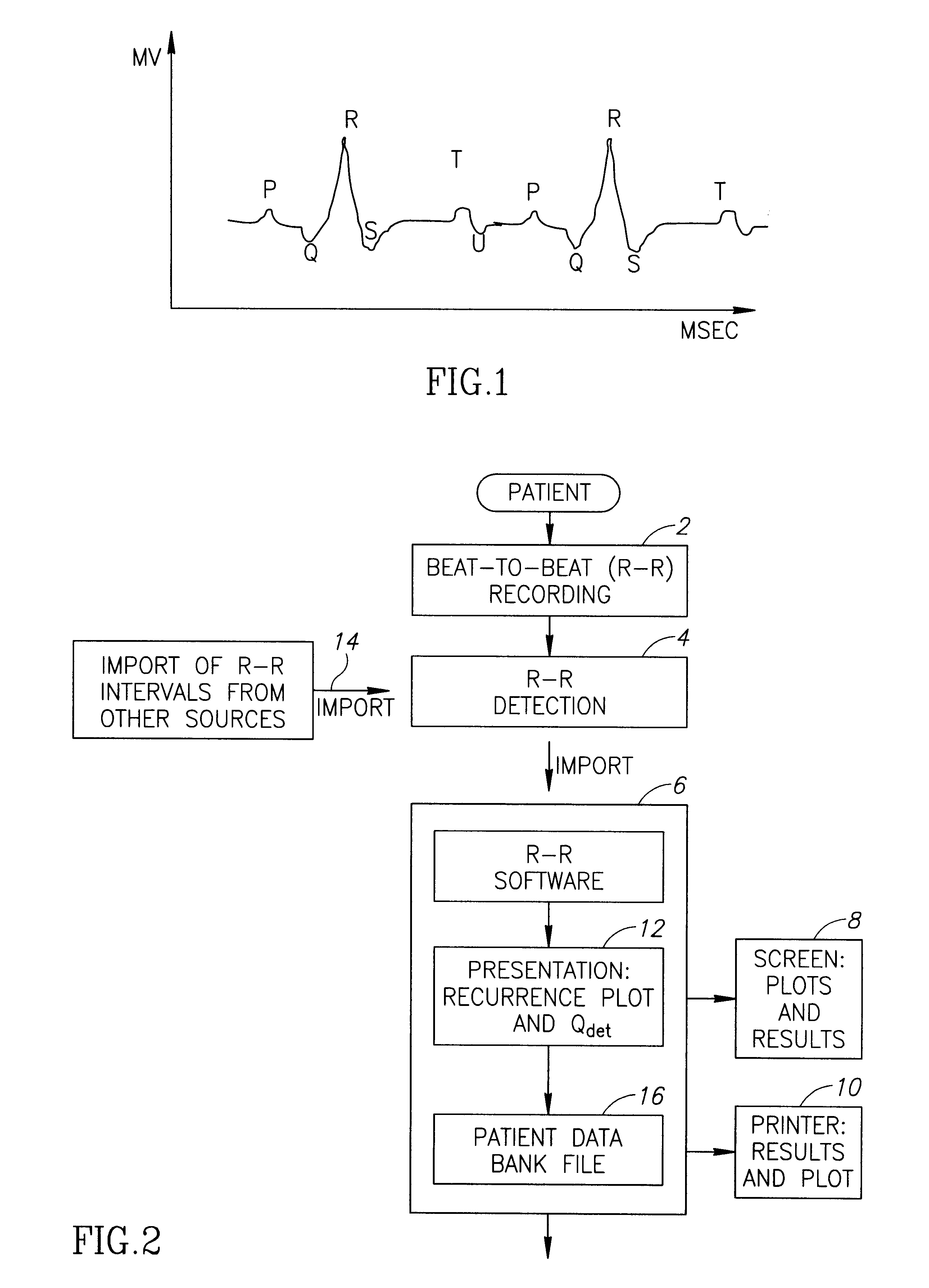

InactiveUS20010008954A1More preciseEasy assessment processDiagnostic recording/measuringSensorsRR intervalUnit mass

A system for measuring heart rate variability (HRV) of a patent comprises: recording means for obtaining and regulating heartbeat-to-heartbeat intervals for a predetermined period of time; processing means for digitizing said intervals, forming a recurrence plot, and assigning a unit mass to each point on the plot representing a measured interval, and calculating the determinant by the expression<paragraph lvl="0"><in-line-formula>Qdet=QxxQyy< / in-line-formula>wherein: Qxx is the quadrupole moment relative to the X axis of the principal coordinate, Qyy is the quadrupole moment relative to the Y axis of the principal coordinate; and Qdet is the product of Qxx and Qyy.

Owner:LEV EL DIAGNOSTICS OF HEART DISEASE

Method and system for measuring heart rate variability

InactiveUS6731974B2More preciseEasy assessment processSensorsMeasuring/recording heart/pulse rateRR intervalUnit mass

A system for measuring heart rate variability (HRV) of a patent comprises:recording means for obtaining and regulating heartbeat-to-heartbeat intervals for a predetermined period of time;processing means for digitizing said intervals, forming a recurrence plot, and assigning a unit mass to each point on the plot representing a measured interval, and calculating the determinant by the expressionwherein:Qxx is the quadrupole moment relative to the X axis of the principal coordinate,Qyy is the quadrupole moment relative to the Y axis of the principal coordinate; andQdet is the product of Qxx and Qyy.

Owner:LEV EL DIAGNOSTICS OF HEART DISEASE

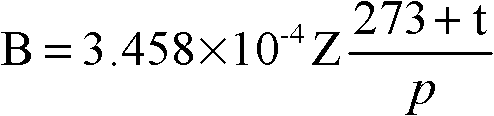

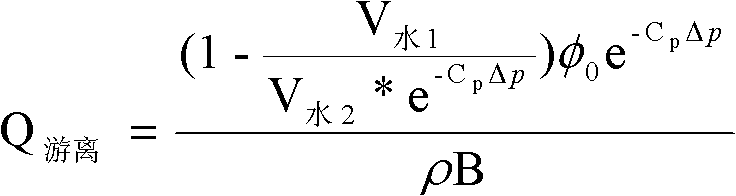

Method for measuring content of free gas in coal bed gas

ActiveCN102565112AAccurate calculationWater resource assessmentAnalysis using nuclear magnetic resonanceUnit massBack calculation

The invention discloses a method for measuring the content of free gas in coal bed gas. By calculating the surface water saturation of a fresh coal core and performing back calculation to obtain water saturation in the stratum state, the volume of the free gas in a coal rock of unit mass is measured. Preferably, the method comprises the following steps of: collecting a sample, namely collecting a cylindrical coal sample which is not polluted by drilling fluid; measuring the volume Vtotal of the coal sample; measuring the volume Vwater1 of initial water; measuring the volume Vwater2 of saturated water; measuring an effective burden pressure delta p and a volume coefficient B; and according to parameter results in the preceding steps, calculating the content of the free gas. By adoption of the method, the content of the free gas can be accurately measured, so a total gas content test result is approximate to an underground true value, and great significance is provided for exploration and development of the coal bed gas.

Owner:PETROCHINA CO LTD

Portable all-solid hydrogen production material as well as preparation method and application thereof

ActiveCN104649225AEven contactIncrease hydrogen productionHydrogen productionUnit massHydrogen fuel cell

The invention belongs to the field of hydrogen production materials, and particularly relates to a portable all-solid hydrogen production material as well as a preparation method and application thereof. The all-solid hydrogen production material comprises a solid matter reacting with water to release hydrogen and a water-containing solid matter in a molar ratio of (1-12): (1-3). Water required for hydrolysis is provided by the water-containing solid for the first time; and the two solids are sufficiently mixed at a hydrogen desorption temperature, so that the hydrogen production matters comes into contact with water molecules more uniformly, then the actual water consumption for hydrolysis is greatly reduced and the hydrogen production quantity of a unit mass material is improved. Meanwhile, the hydrogen production material is all-solid, so additional water is not needed; and the temperature in the hydrogen production process can be controlled, so that the hydrogen production material is more convenient to carry and operate, and the hydrogen source of a hydrogen fuel battery is more compact and smaller.

Owner:苏州清德氢能源科技有限公司

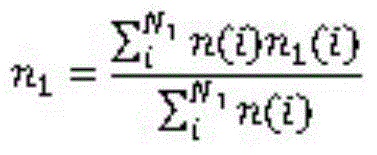

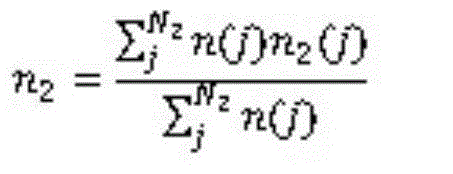

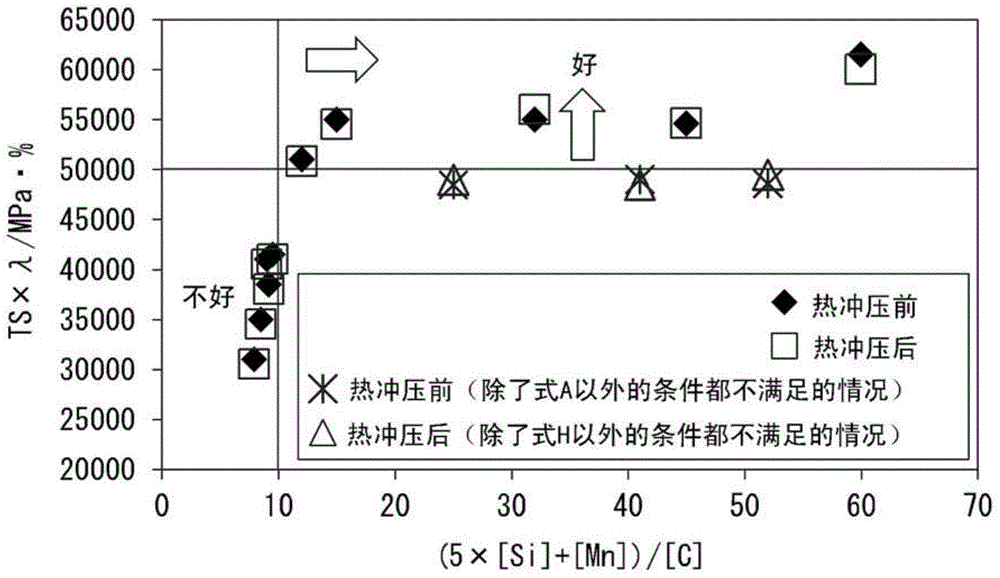

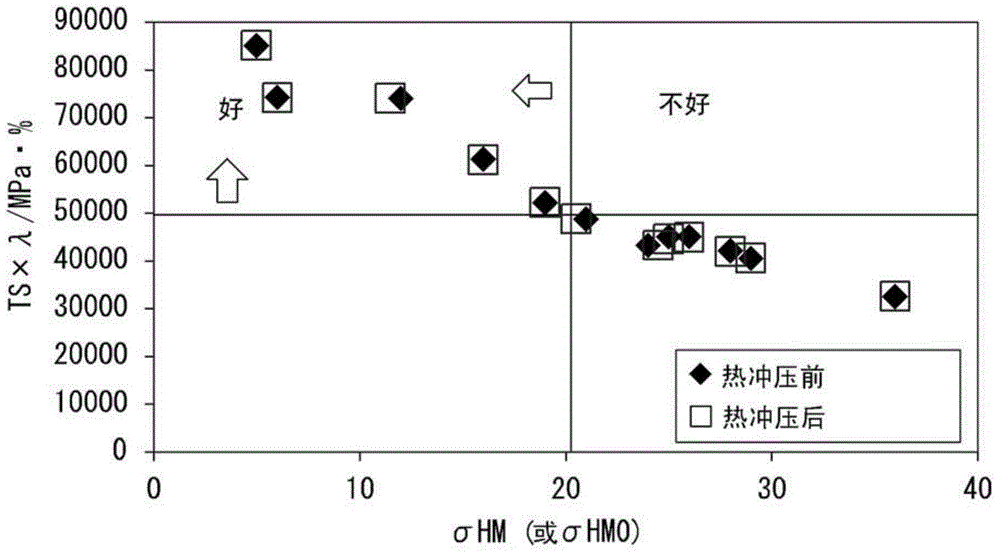

Hot stamp molded article, and method for producing hot stamp molded article

ActiveCN104040011AExcellent hole expandabilityHot-dipping/immersion processesFurnace typesHot stampingUnit mass

When the carbon content, silicon content and manganese content of this hot stamp molded article are expressed as [C], [Si] and [Mn], respectively, in terms of unit mass%, a relationship of (5 × [Si] + [Mn]) / [C] > 11 holds; and the metal structure after hot stamping contains ferrite at 40% to 90% and martensite at 10% to 60% by area ratio, and the sum of the area ratio of ferrite and the area ratio of martensite is at least 60%. Furthermore, the hardness of the martensite, as measured by a nanoindenter, satisfies H2 / H1 < 1.10 and sigmaHM < 20, and TS × lambda, which is the product of the tensile strength (TS) and hole expansion rate (lambda), is at least 50000 MPa.%.

Owner:NIPPON STEEL CORP

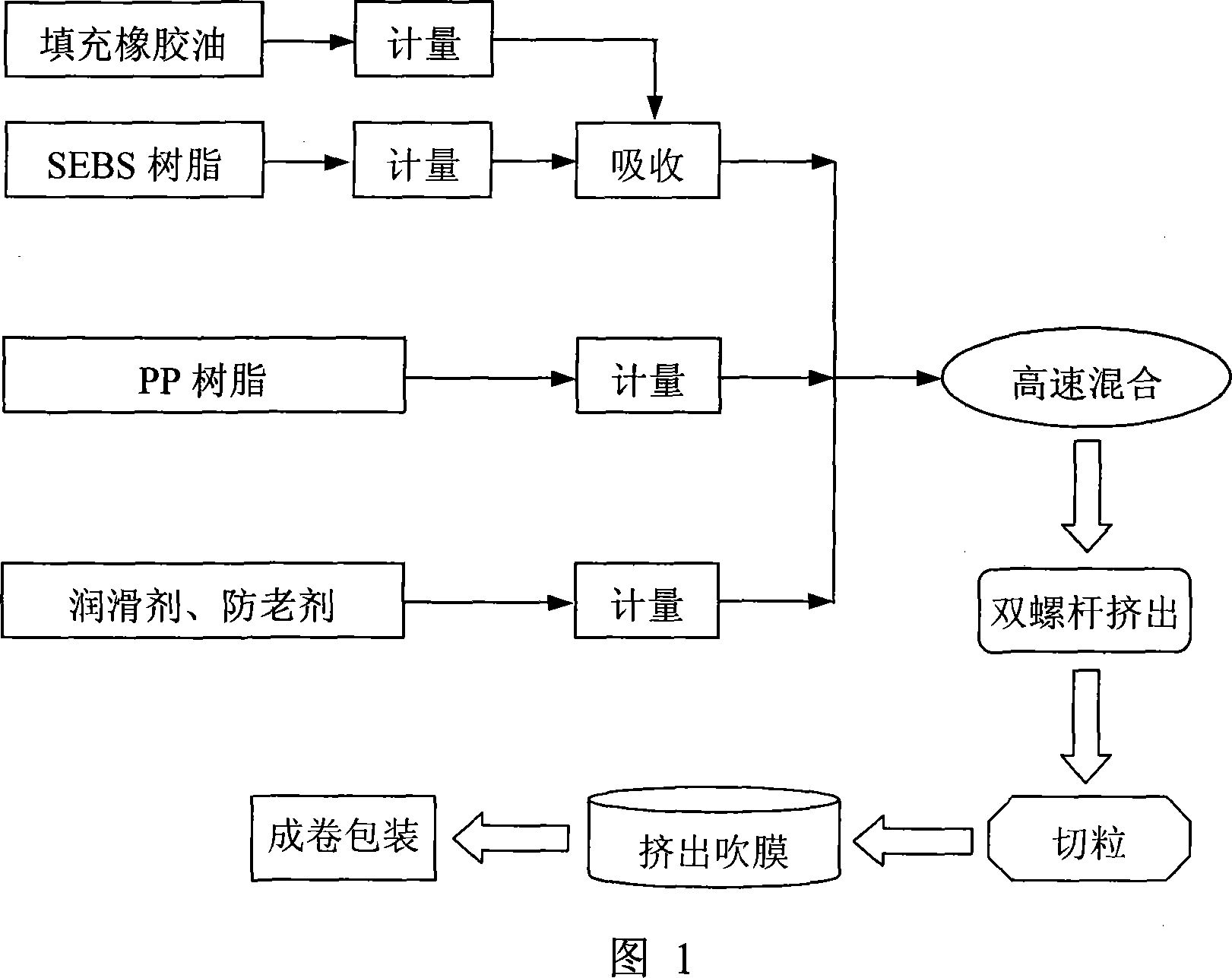

Environment-protective SEBS fresh-preservation film and producing method thereof

The present invention discloses a kind of environmental friendly SEBS fresh-keeping film, and includes the following components with contents of unit mass: SEBS resin 100 units, rubber filling oil 75-125 units, polypropylene 40-115 units, lubricant 0.6-0.8 units, and anti-aging agent 0.4-0.6 units. The present invention also offers a production method of environmental friendly SEBS fresh-keeping film, which includes the following steps: weighting and taking the various components according to their dosages: SEBS resin 100 units, rubber filling oil 75-125 units, polypropylene 40-115 units, lubricant 0.6-0.8 units, and anti-aging agent 0.4-0.6 units; letting SEBS resin to fully absorb rubber filling oil; being even mixed with polypropylene, lubricant, and anti-aging agent, using twin screw extruder to produce particles; finally, using plastic-extruded blower to extrude the shaped fresh-keeping film. The environmental friendly SEBS fresh-keeping film of the present invention has excellent transparence, tackiness, and good mechanical properties, and is health, safe and environmental friendly, which can replace soft PVC fresh-keeping film for foods and packings of other daily-used goods and industrial products.

Owner:SHENZHEN POLYTECHNIC +1

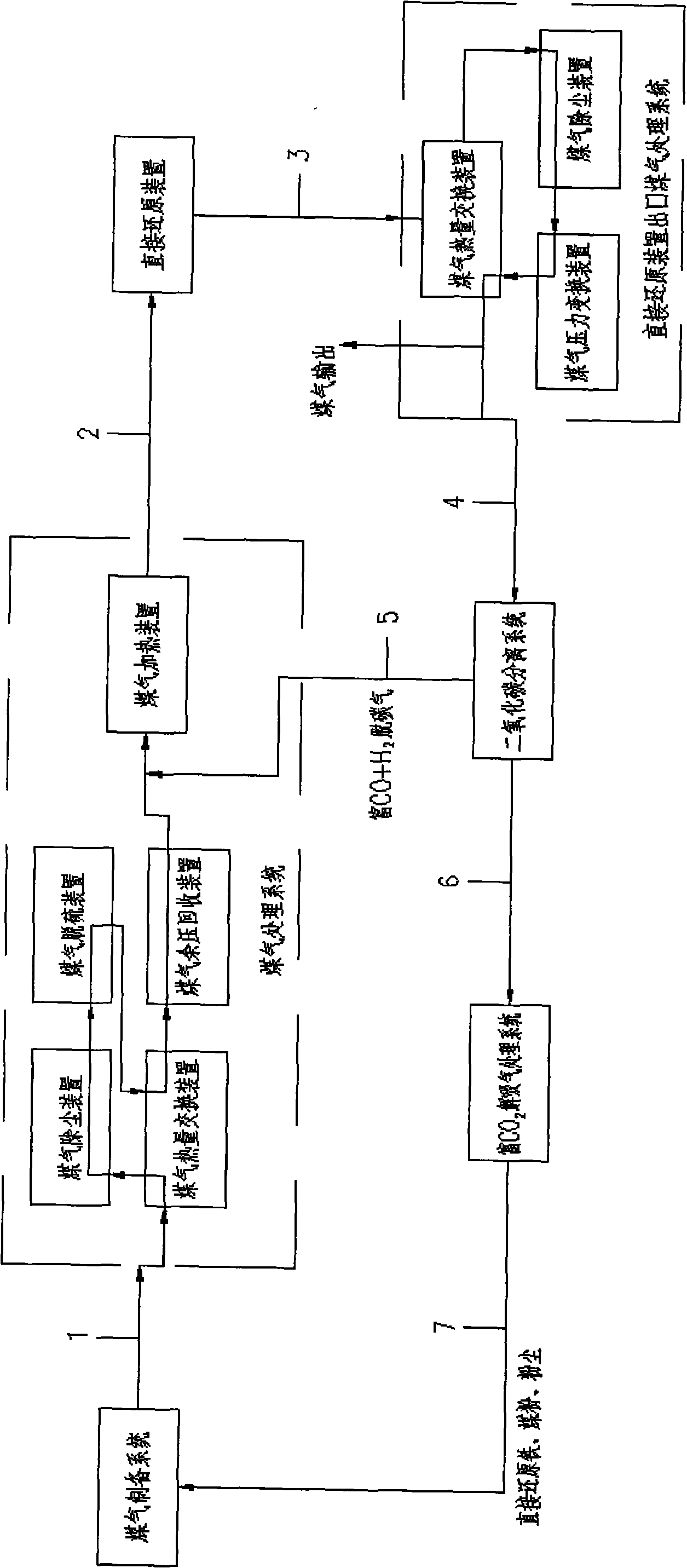

Recycling method of outlet gas in direct reduction process using gas as reducing gas

ActiveCN101638702AReduce displacementEconomical and energy-savingCombustible gas chemical modificationExhaust gas handlingDesorptionHigh carbon

The invention discloses a recycling method of outlet gas in a direct reduction process using gas as reducing gas, in particular to a method for recycling CO2 in outlet gas in a direct reduction process using gas as reducing gas. The method comprises the following treating steps: after outlet gas of a direct reduction device is treated by an outlet gas treating system of the direct reduction device, the outlet gas enters a CO2 separating system for decarburization treatment to obtain CO2 enriched desorption gas and CO+H2 enriched decarburizing gas, wherein after the CO2 enriched desorption gasis treated by a treating system of the CO2 enriched desorption gas, and the CO2 enriched desorption gas is sent back to a gas preparing system or the CO2 enriched desorption gas used as a transport carrier of direct reduction iron, high-carbon carrier or dust is sent back to the gas preparing system. The method achieves the purpose of CO2 emission reduction, also reduces the quantity of consumed coal required by reducing iron ore per unit mass and saves the cost.

Owner:CISDI ENG CO LTD

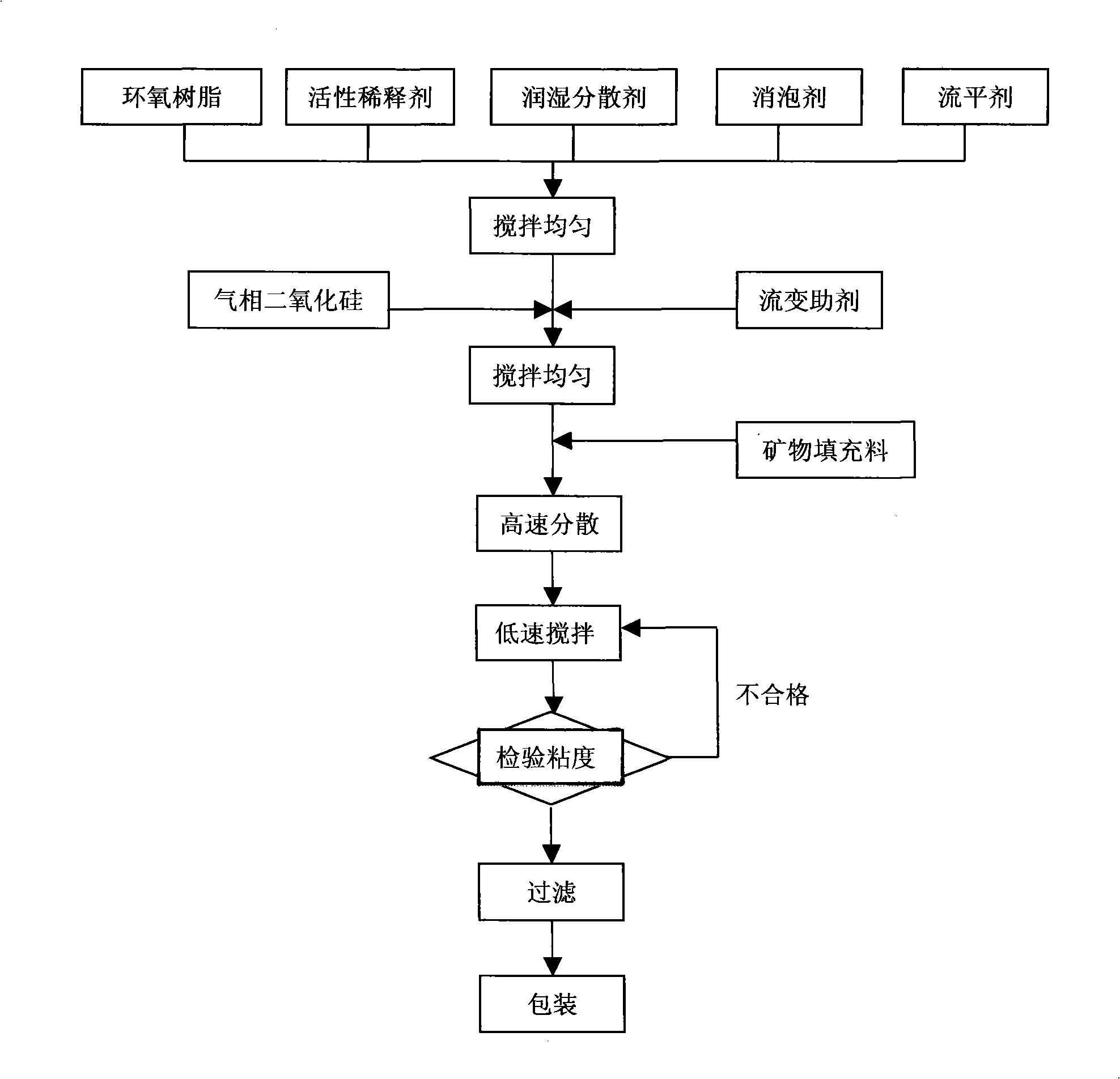

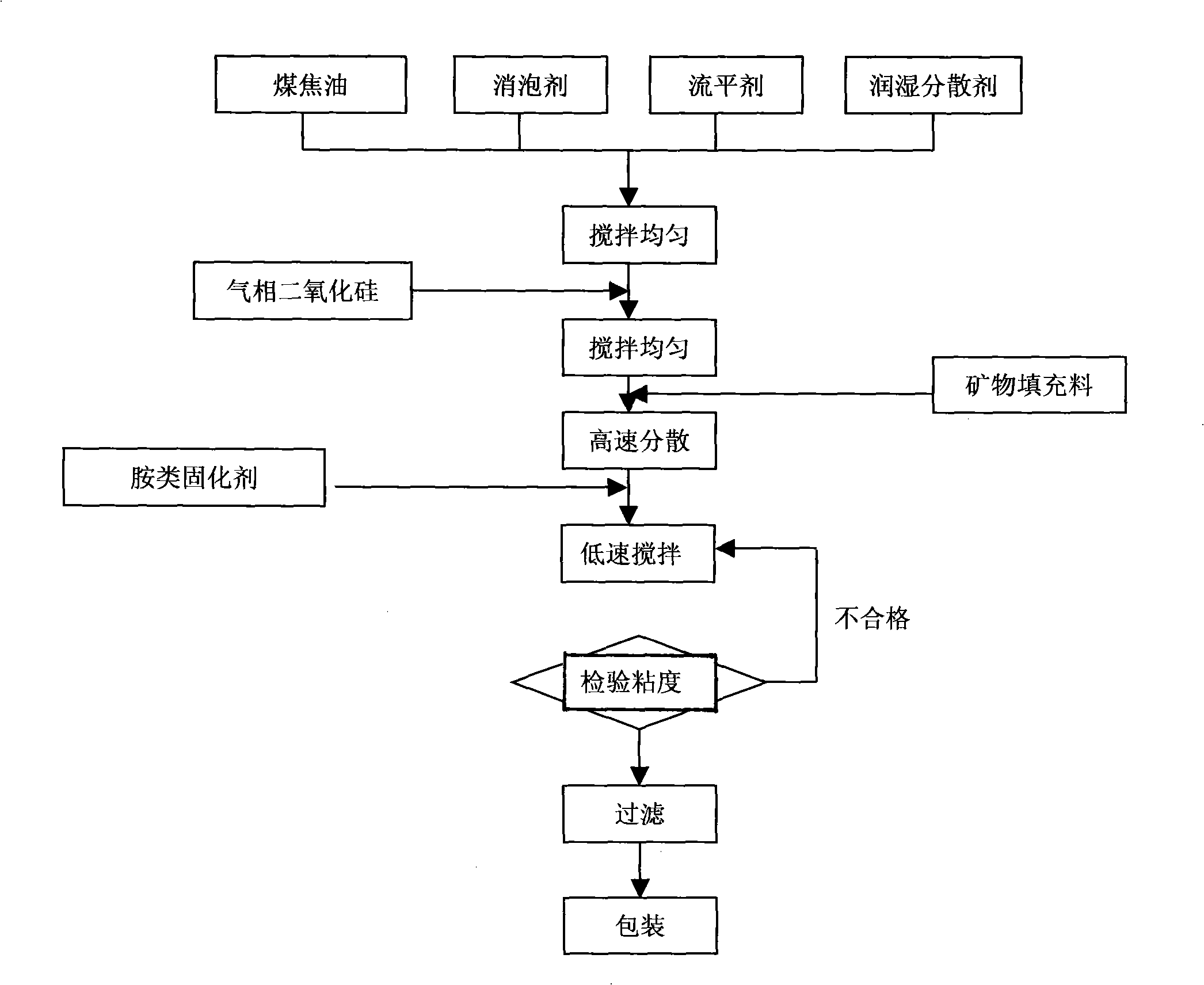

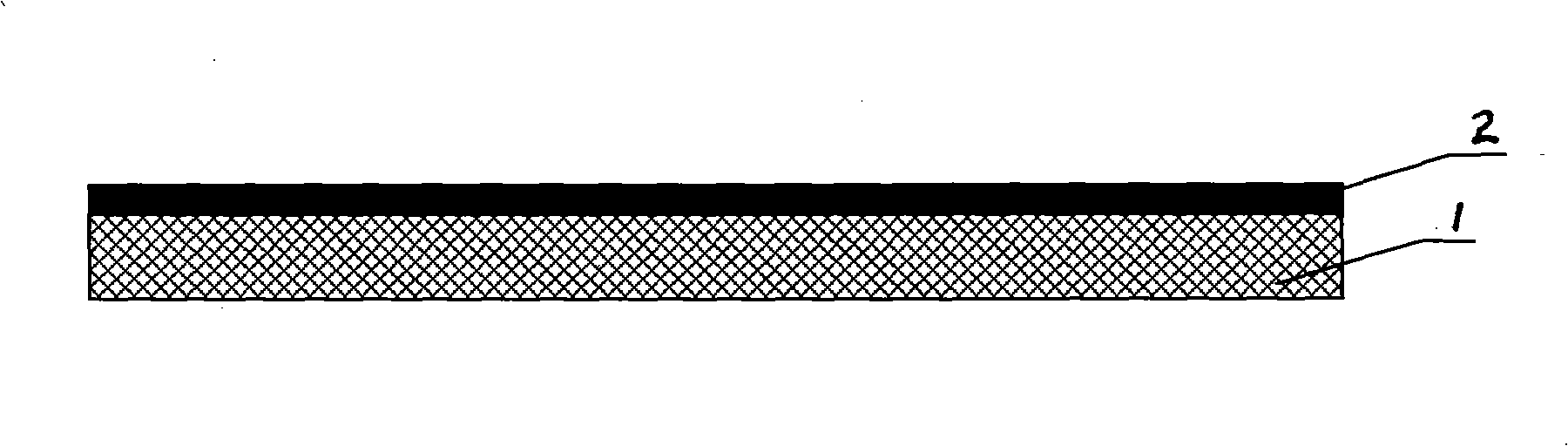

Solvent-free epoxy coal tar heavy duty anticorrosive coating and preparation process thereof

ActiveCN101284969AImprove anti-corrosion performanceGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsUnit massGas phase

The invention relates to solvent-free epoxy coal tar heavy anticorrosive paint and a process for making the same. The solvent-free epoxy coal tar heavy anticorrosive paint relates to the anticorrosive paint technical field and comprises two compositions A and B, wherein the composition A comprises 20 to 50 unit mass of epoxide resin, 10 to 15 unit mass of reactive diluent, 0.5 to 2 unit mass of rheological additive, 0.5 to 2 unit mass of defoaming agent, 0.5 to 2 unit mass of flatting agent, 1 to 3 unit mass of wetting dispersant, 0.5 to 2 unit mass of gas phased silicon dioxide and 36 to 55 unit mass of mineral filling material; the composition B comprises 15 to 20 unit mass of amine curing agent, 25 to 30 unit mass of coal tar, 0.5 to 2 unit mass of defoaming agent, 0.3 to 2 unit mass of flatting agent, 0.5 to 2 unit mass of wetting dispersant, 0.7 to 2 unit mass of gas phased silicon dioxide and 45 to 55 unit mass of mineral filling material.

Owner:XIAMEN SUNRUI SHIP COATING

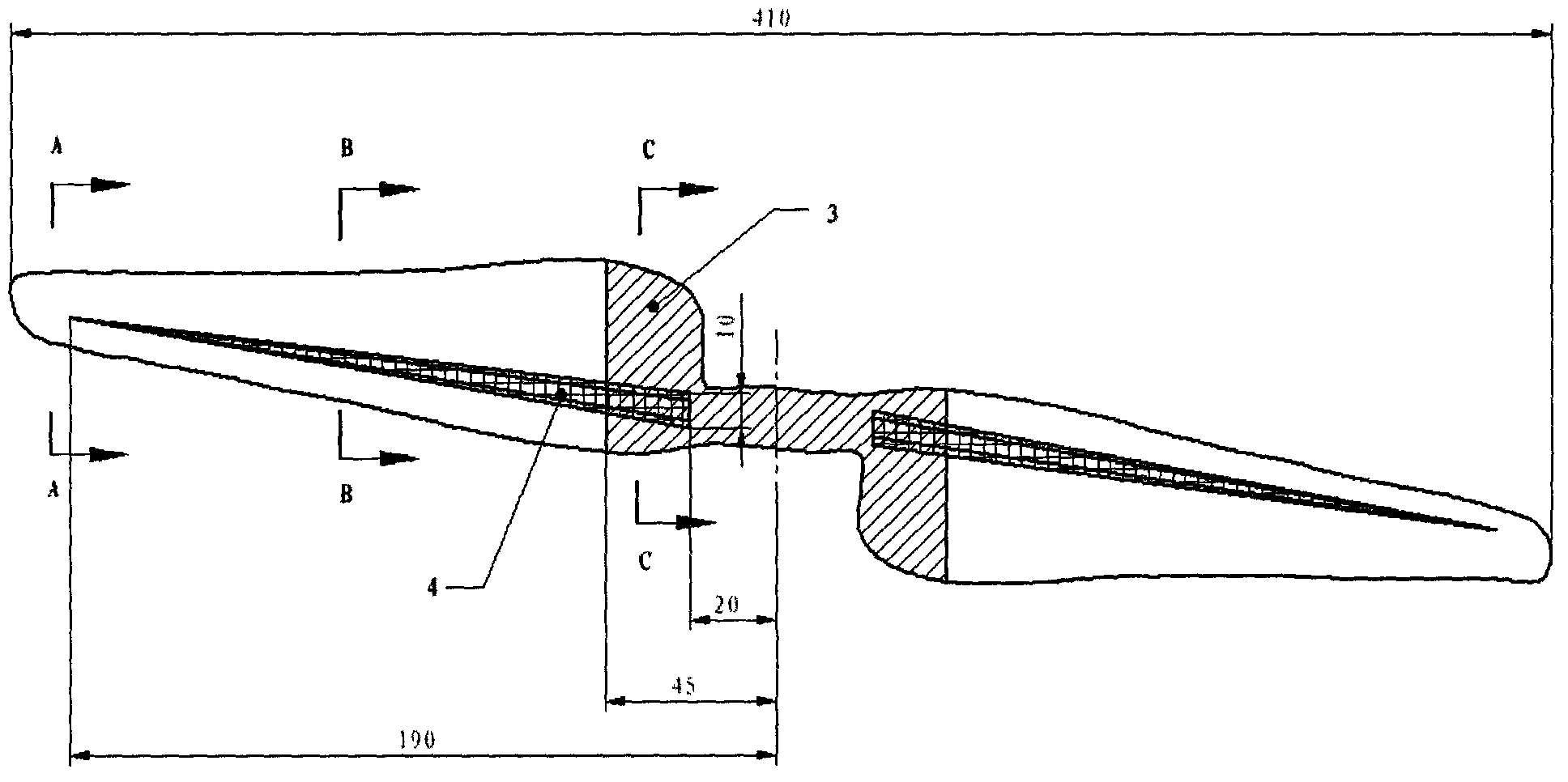

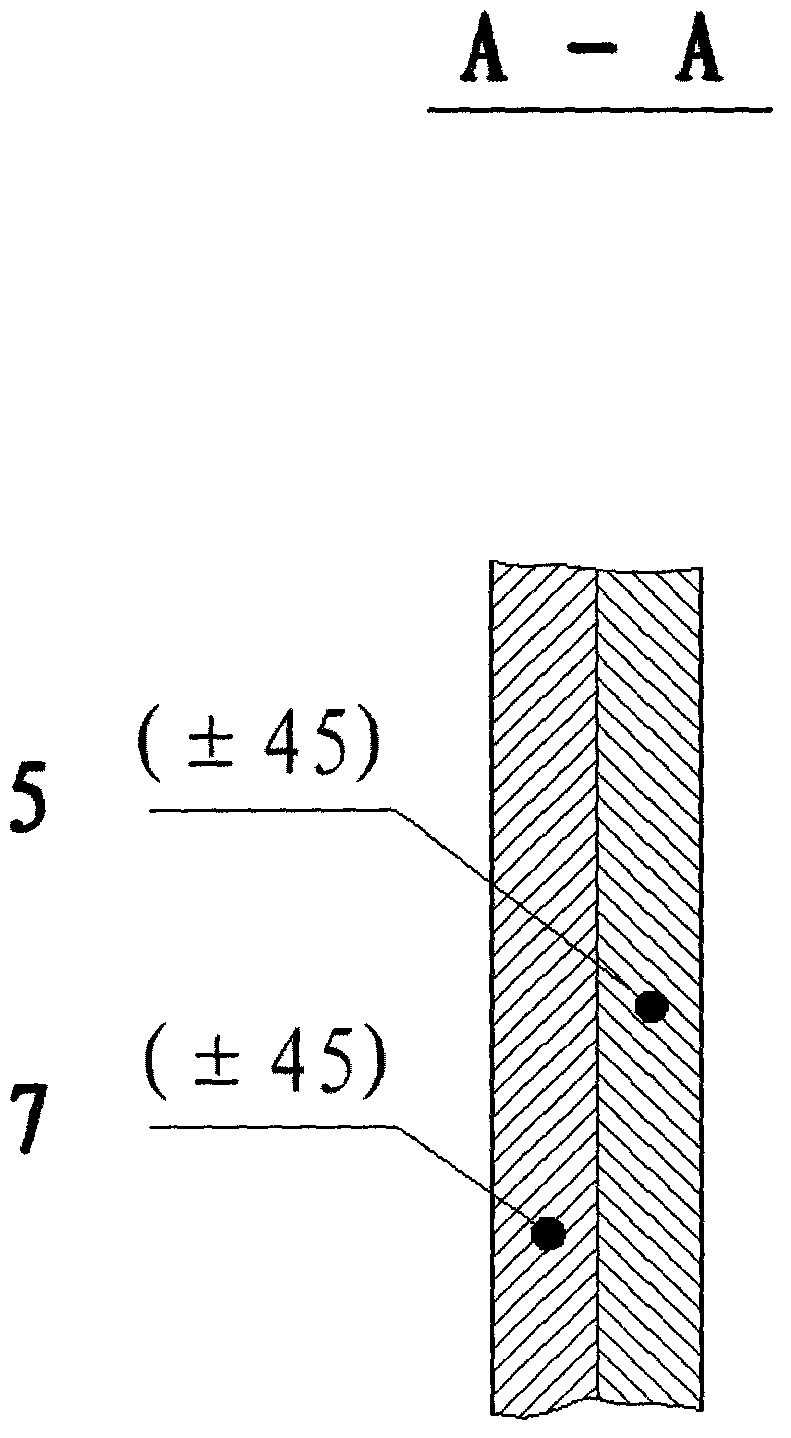

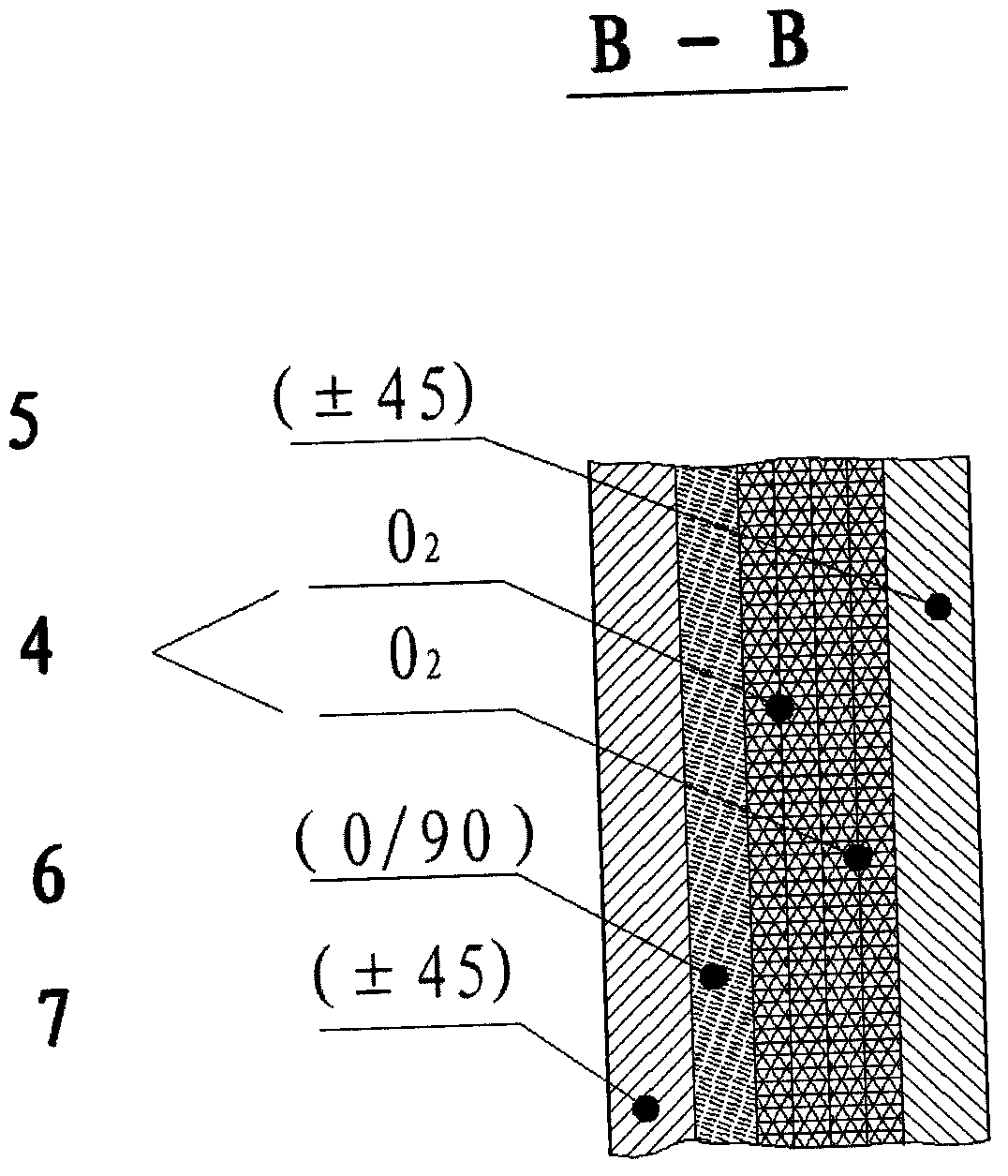

Micro unmanned aerial vehicle carbon fiber rotor wing and preparation method thereof

The invention relates to a micro unmanned aerial vehicle carbon fiber rotor wing and a preparation method thereof, belonging to the technical field of composite material structures. The rotor wing sequentially comprises a wing tip, a wing body and a wing root from two ends to middle; the wing tip sequentially comprises an upper surface layer and a lower surface layer from top to bottom; the wing body sequentially comprises an upper surface layer, a reinforcing rib, a middle layer and a lower surface layer from top to bottom; the wing root sequentially comprises an upper surface layer, a reinforcing rib, a reinforcing layer, a middle layer and a lower surface layer from top to bottom; and each reinforcing rib extends from the wing root to the critical part of the wing body and the wing tip and is narrowed gradually. Compared with a domestic plastic rotor wing with the same specification, the weight of the rotor wing provided by the invention is reduced by 65%; under unit mass, the output power of the rotor wing provided by the invention is 3.4 times that of the plastic rotor wing; under unit power consumption, the output power of the rotor wing provided by the invention is 1.3 times that of the plastic rotor wing; and under the condition of generating the same lifting power, the power consumption of the rotor wing provided by the invention is reduced by 40%, and the rotation speed is reduced by 30%. The rotor wing provided by the invention can improve the lift efficiency of an unmanned aerial vehicle under the conditions of low rotation speed and low power consumption.

Owner:BEIJING SATELLITE MFG FACTORY

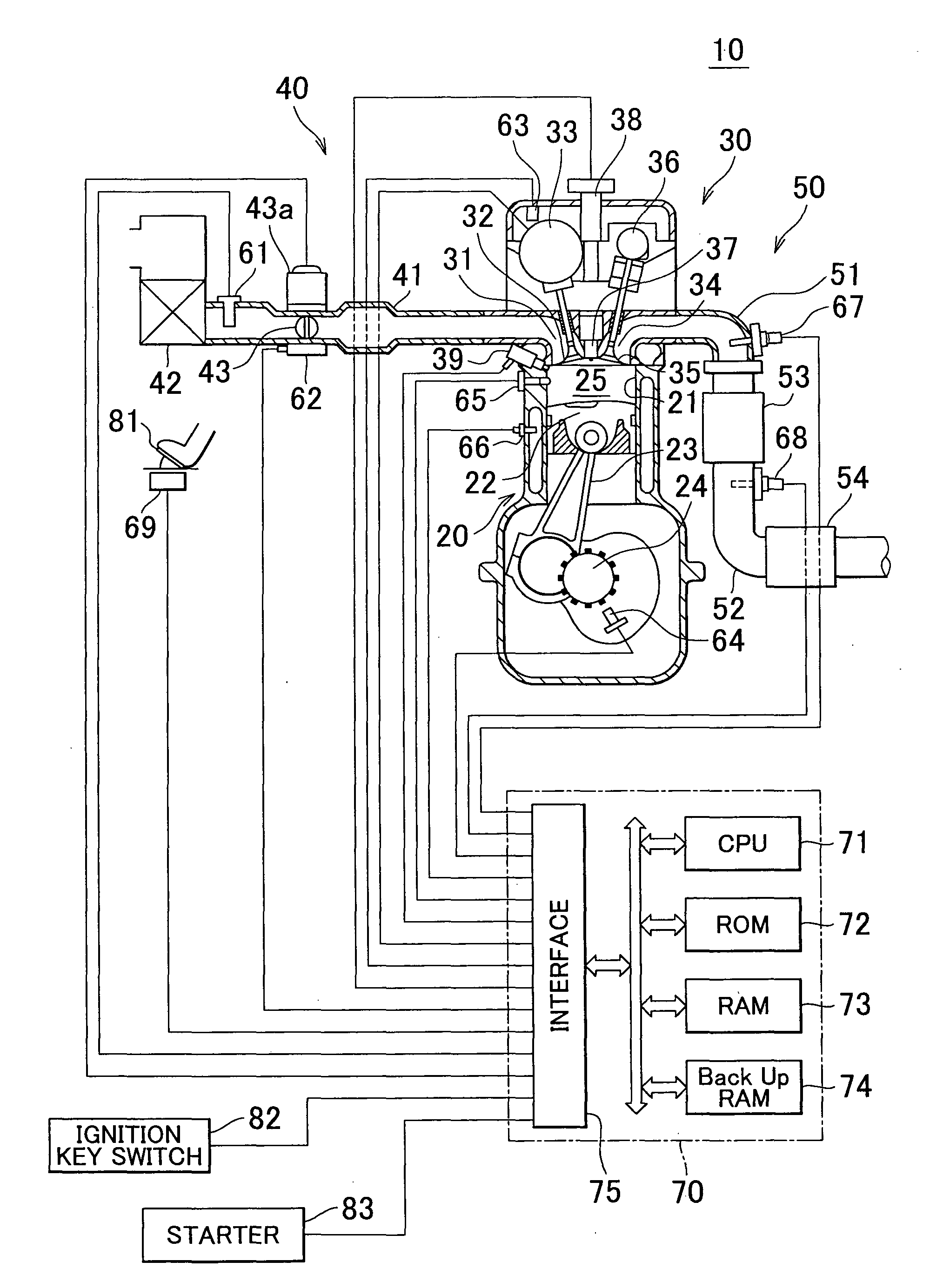

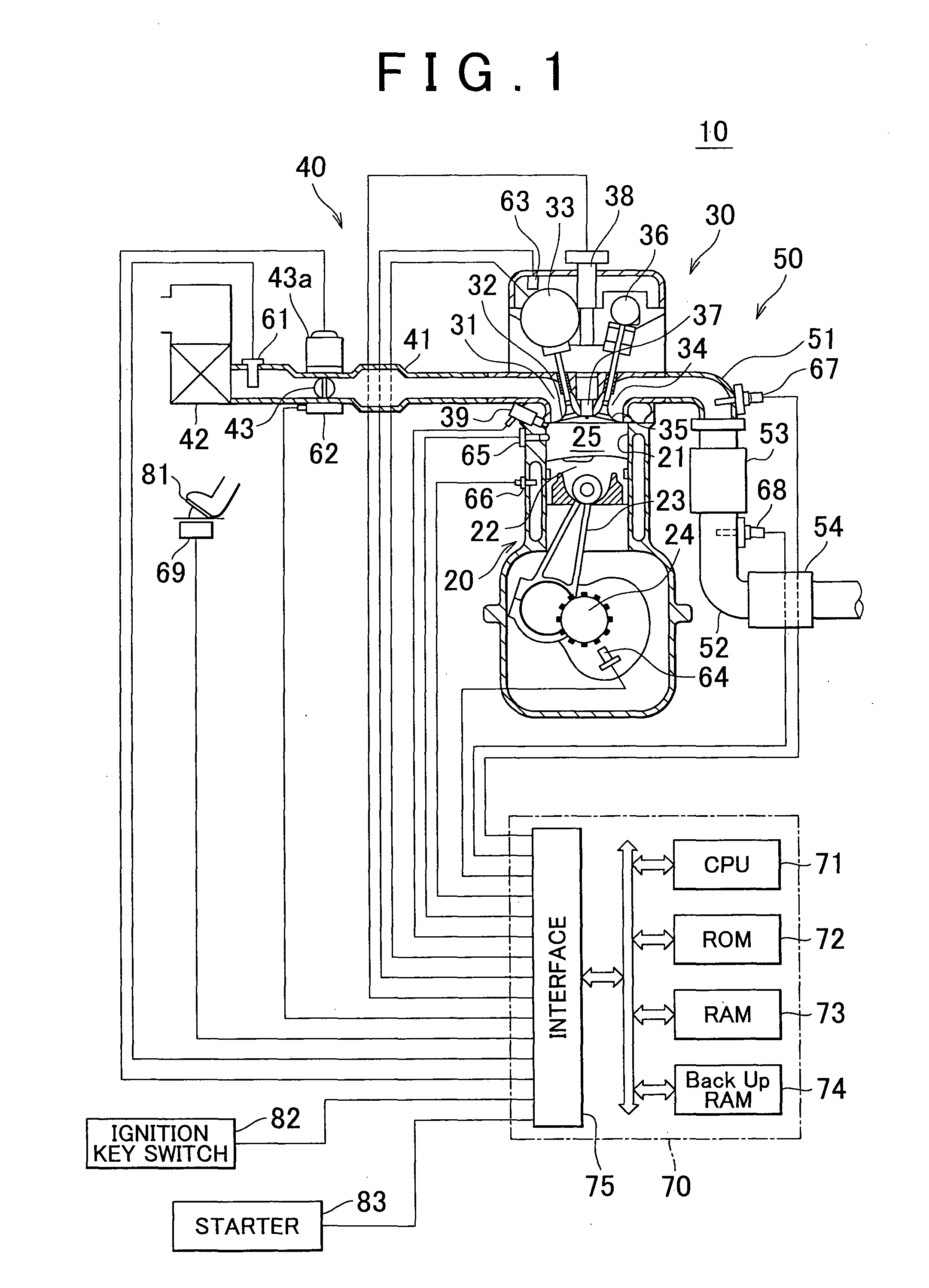

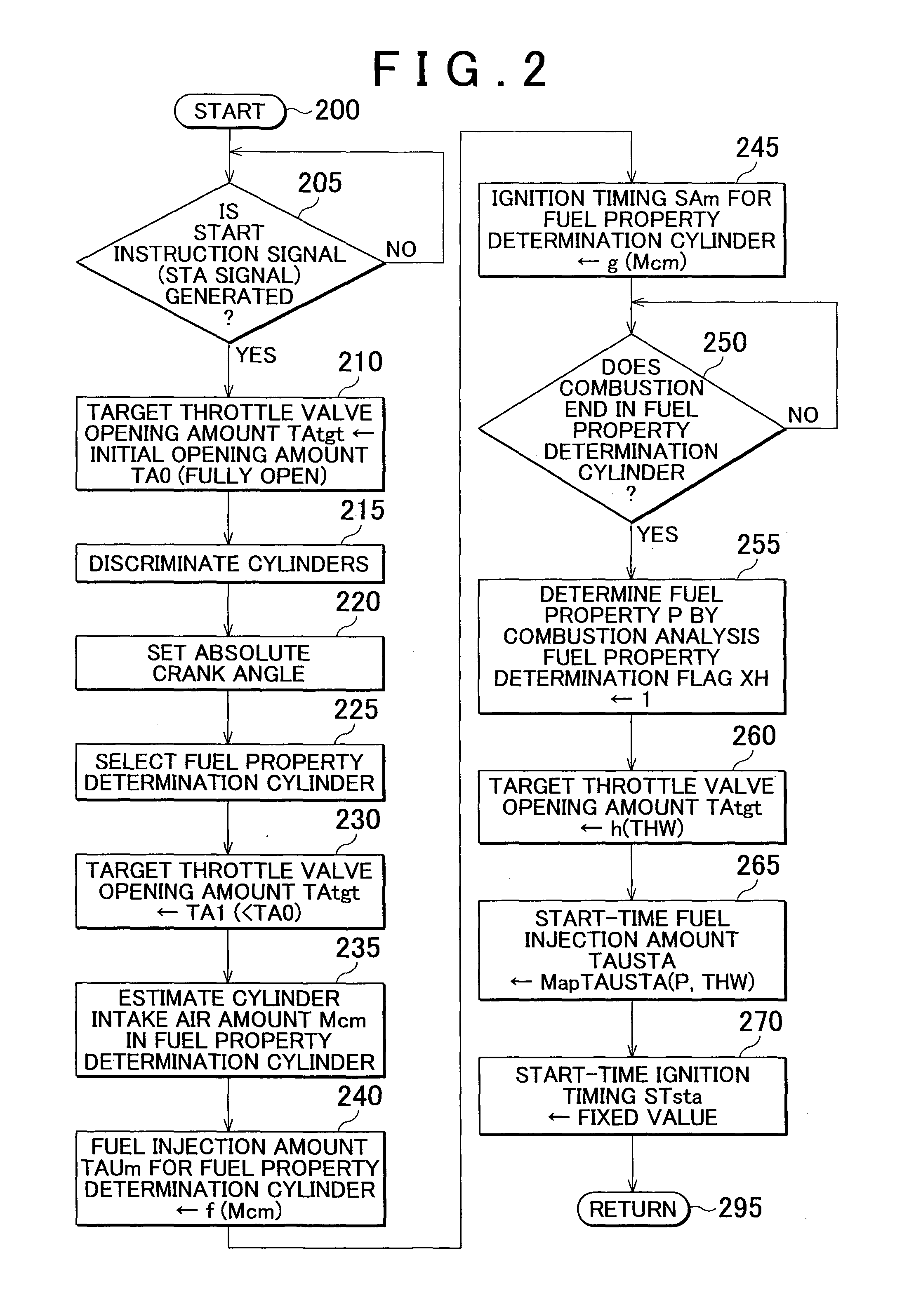

Control apparatus and control method for internal combustion engine

InactiveUS20110301828A1Quickly and accurately determineElectrical controlInternal combustion piston enginesTop dead centerUnit mass

In a control apparatus, when an engine is cranked, “an air-fuel mixture (an air-fuel mixture used for determination of fuel property) including fuel in a first predetermined fuel amount TAUm and air in a first predetermined air amount Mcm”, which generates torque that does not make the engine autonomously operate, is formed in a first cylinder (cylinder used for determination of the fuel property), and the air-fuel mixture is ignited and combusted by a spark at an ignition timing after a compression top dead center. Further, the control apparatus determines “an amount of heat generated per unit mass of the fuel” when the air-fuel mixture is combusted in the first cylinder, and determines a property of the fuel based on the amount of generated heat.

Owner:TOYOTA JIDOSHA KK

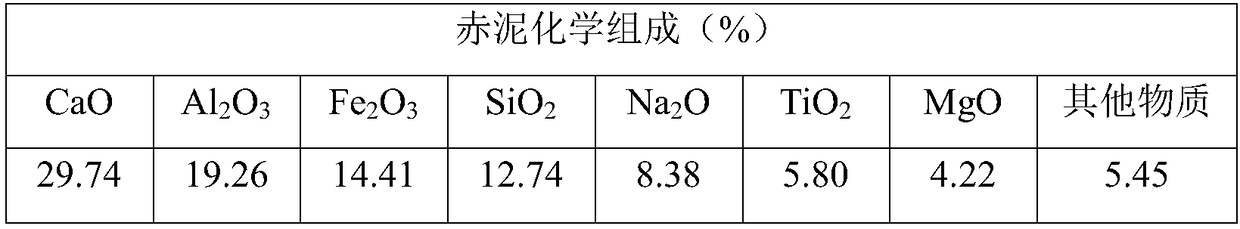

Method for preparing porous granular composite material from red mud and fly ash as raw materials

ActiveCN108264279AHigh activityHigh strengthSolid waste managementOther chemical processesPrillRed mud

The invention provides a method for preparing a porous granular composite material from red mud and fly ash as raw materials. The method utilizes cement waste as a binder and comprises uniformly mixing fly ash, red mud and the binder according to a mass ratio of fly ash to red mud of 10-30% and a mass ratio of the binder of less than or equal to 5%, carrying out granulation through a granulator toobtain raw material particles with the uniform diameters of 5-8mm, adding the raw material particles into a microwave activation reactor with the unit mass power of 5 to 20w / g, feeding water vapor into the microwave activation reactor, carrying out activation for 15-30min, and carrying out cooling at the room temperature to obtain the porous granular composite material. CaO in the red mud can promote the excitation of the fly ash activity. Through microwave heating, a part of metal oxides and silicon oxide in the red mud and fly ash can increase the particle material strength. The fly ash contains unburned carbon and through the microwave activation, the specific surface area of the particles is increased and the porous structure is formed. The produced porous granular composite materialhas the advantages of large specific surface area, strong adsorption property, good temperature resistance stability, simple processes, low energy consumption and environmental friendliness.

Owner:CHINA UNIV OF MINING & TECH

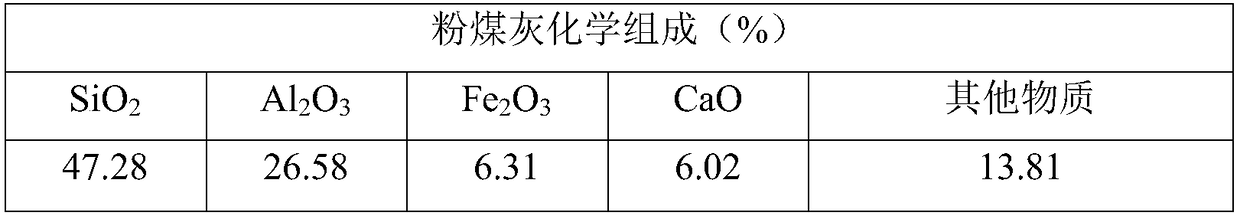

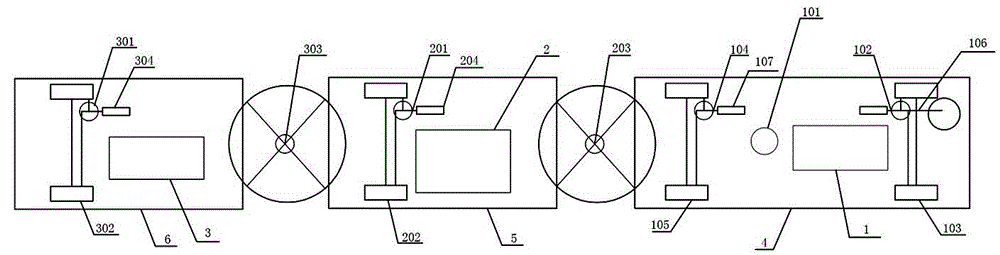

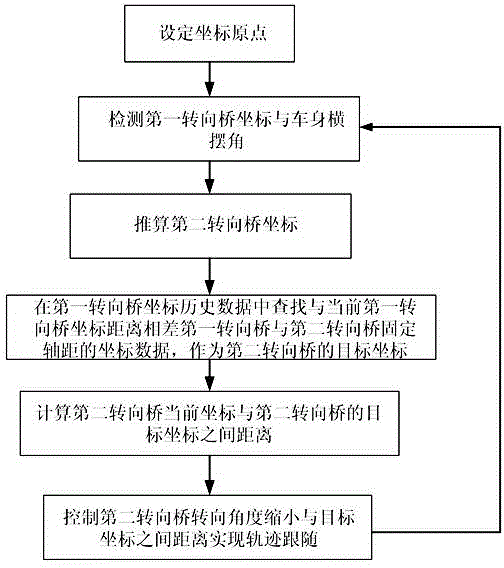

Rubber wheel train track following control system

ActiveCN105620514AEasy modular configurationSimple structureSignalling indicators on vehicleControl systemUnit mass

The invention discloses a rubber wheel train track following control system. The rubber wheel train track following control system comprises a train head track following controller arranged on a train head assembly, a carriage track following controller arranged on a carriage assembly and a train tail track following controller arranged on a train tail assembly. The train head track following controller collects state signals of a train head to obtain the coordinates of a train head unit mass center, calculates coordinate data of a next axle and transmits the coordinate data of the next axle to a track following controller on a next carriage. The carriage track following controller and the train tail track following controller collect the state signals of corresponding carriages and receive the coordinate data of the upper adjacent carriage through communication network transmission to control the motion track of the axle of a carriage. The rubber wheel train track following control system has the advantages of being simple in principle, easy to operate, capable of achieving the optimal control effect and the like.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Preparation method of supported platinum-based alloy catalyst for low temperature fuel cell

InactiveCN109935847ALarge electrochemical active areaImprove electrochemical activityMaterial nanotechnologyCell electrodesHydrazine compoundUnit mass

The invention provides a preparation method of a supported platinum-based alloy catalyst. The catalyst can be used as a low temperature fuel cell catalyst. The preparation method comprises the steps of taking ethylene glycol as a solvent and stabilizer, dispersing a carrier in the solvent, and reducing platinum and non-platinum precursors by strong reducing agents such as borohydride, hydrazine hydrate and tetrabutyl borohydride to obtain supported platinum-based alloy nanoparticles. The preparation method adopted by the invention is simple, effective and free of a problem of difficult removalof the stabilizer. The prepared alloy catalyst has a small particle size and uniform particle size distribution, and has good dispersion on the carrier at the same time. In addition, the catalyst canshow high area specific activity and unit mass Pt specific activity for oxygen reduction reaction, can effectively reduce the platinum consumption and has potential application prospects in the low temperature fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Biomass load type nano-metal catalyst and preparation method and application thereof

ActiveCN104492486AHigh load rateHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsUnit massMetal catalyst

The invention provides a biomass load type nano-metal catalyst and a preparation method and application thereof. The catalyst is MNPs@AOFC, and the loading capacity of MNPs is 1.6-25.8 mg / g. The metal is a precious metal or CU, and the particle size of the metal nano particle is 3-60 nm. In amidoxime group functionalized cellulose, the mass content of the amidoxime group is 3.88-16.84%; the cellulose is bacterial cellulose. The AOFC carrier both serves as a reducing agent and a stabilizer, reaction is carried out for 2 hours under a hydrothermal condition to uniformly load the metal nano particles on the surface of the AOFC carrier, and amidoxime groups with different mass percents can be controlled to obtain the catalyst of the metal nano particles with different particle sizes. The catalyst has good stability, and the metal catalyst with a unit mass can continuously reduce more than 3500 times of p-nitrophenol. The catalyst can be applied to catalytic reduction reaction.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com