Patents

Literature

486results about How to "Easy assessment process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

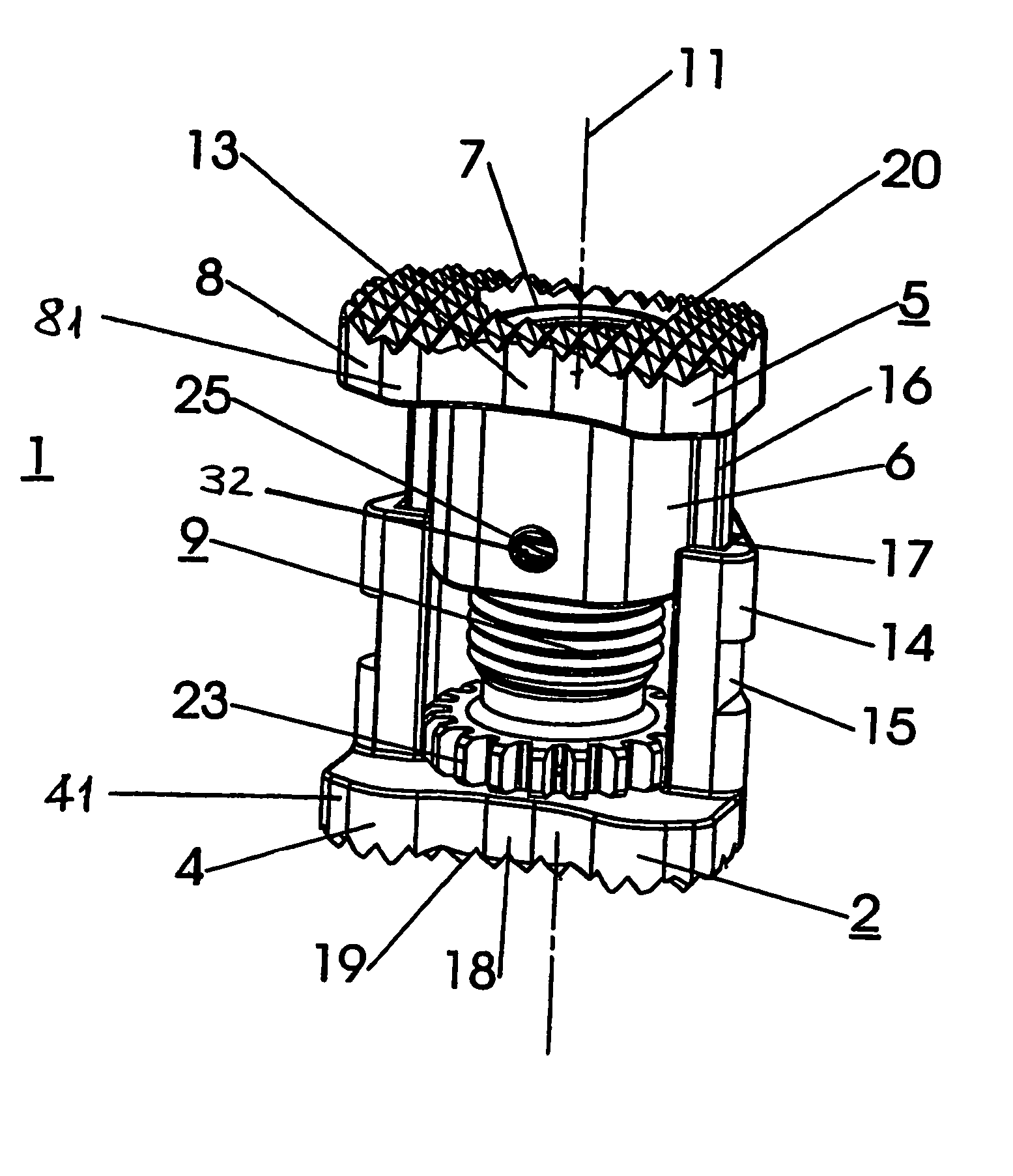

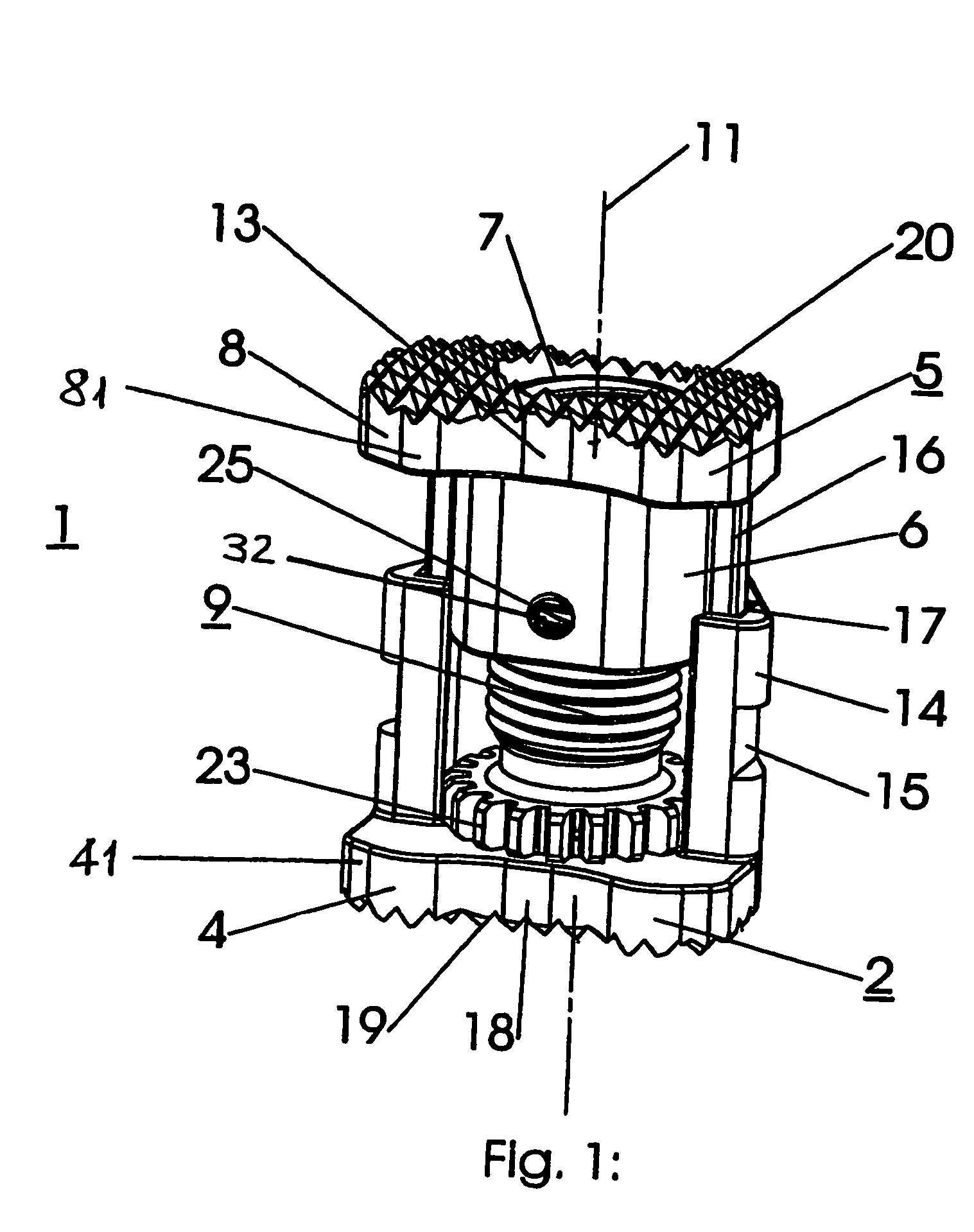

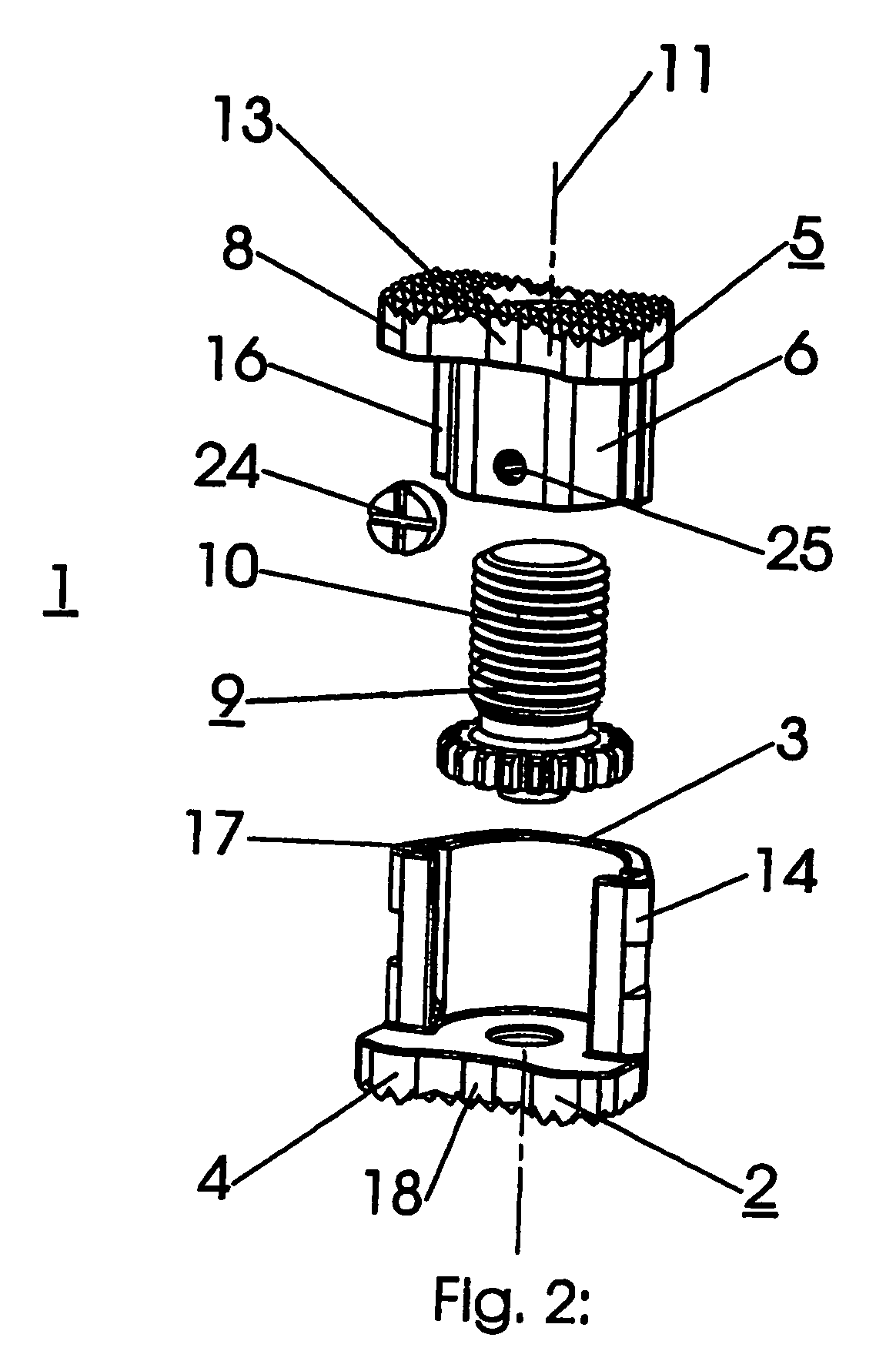

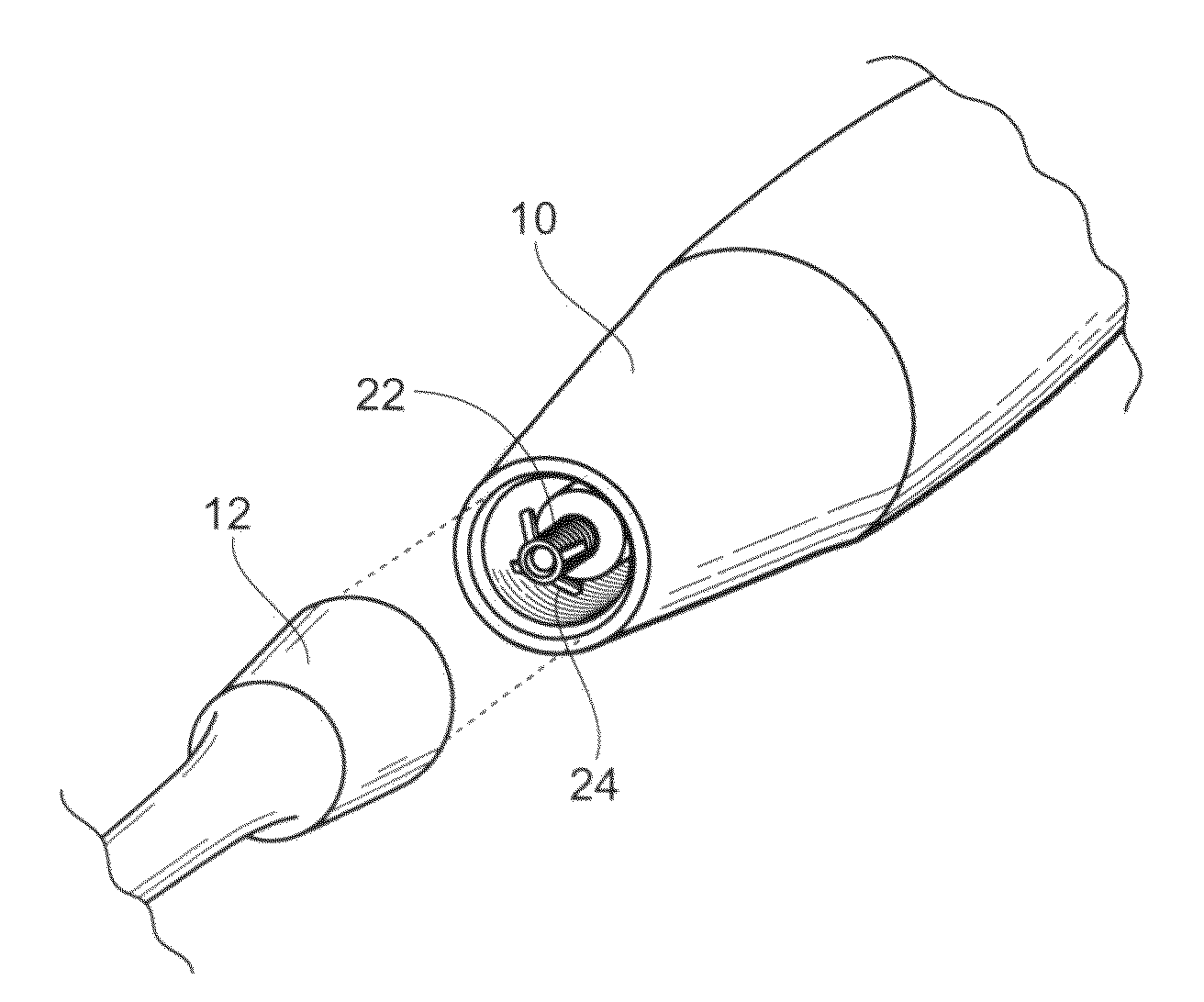

Intervertebral implant

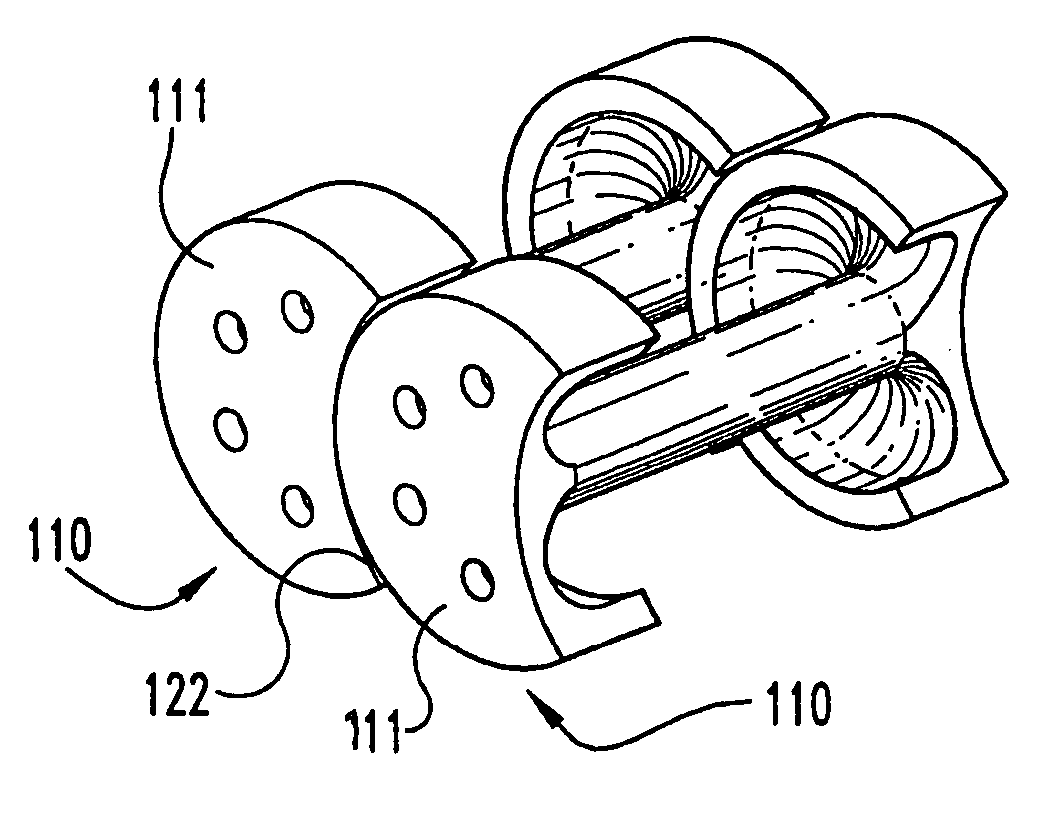

An intervertebral implant comprising a lower implant part, having a central axis and an apposition section, designed to rest against the covering surface of the adjacent lower vertebra and an upper implant part comprising a bore with an internal thread, a central axis and an apposition section, designed to rest against the covering surface of the adjacent upper vertebra. Specifically, the lower and upper implant parts are secured in relation to each other against rotation about the central axis and a threaded screw with an external thread is guided in the upper implant part and connected to the lower implant part, the external thread cooperating with the internal thread. The lower and upper implant parts, and the threaded screw lie coaxially along their common central axis, the threaded screw being connected to the lower implant part so that it is axially fixed but able to rotate.

Owner:SYNTHES USA

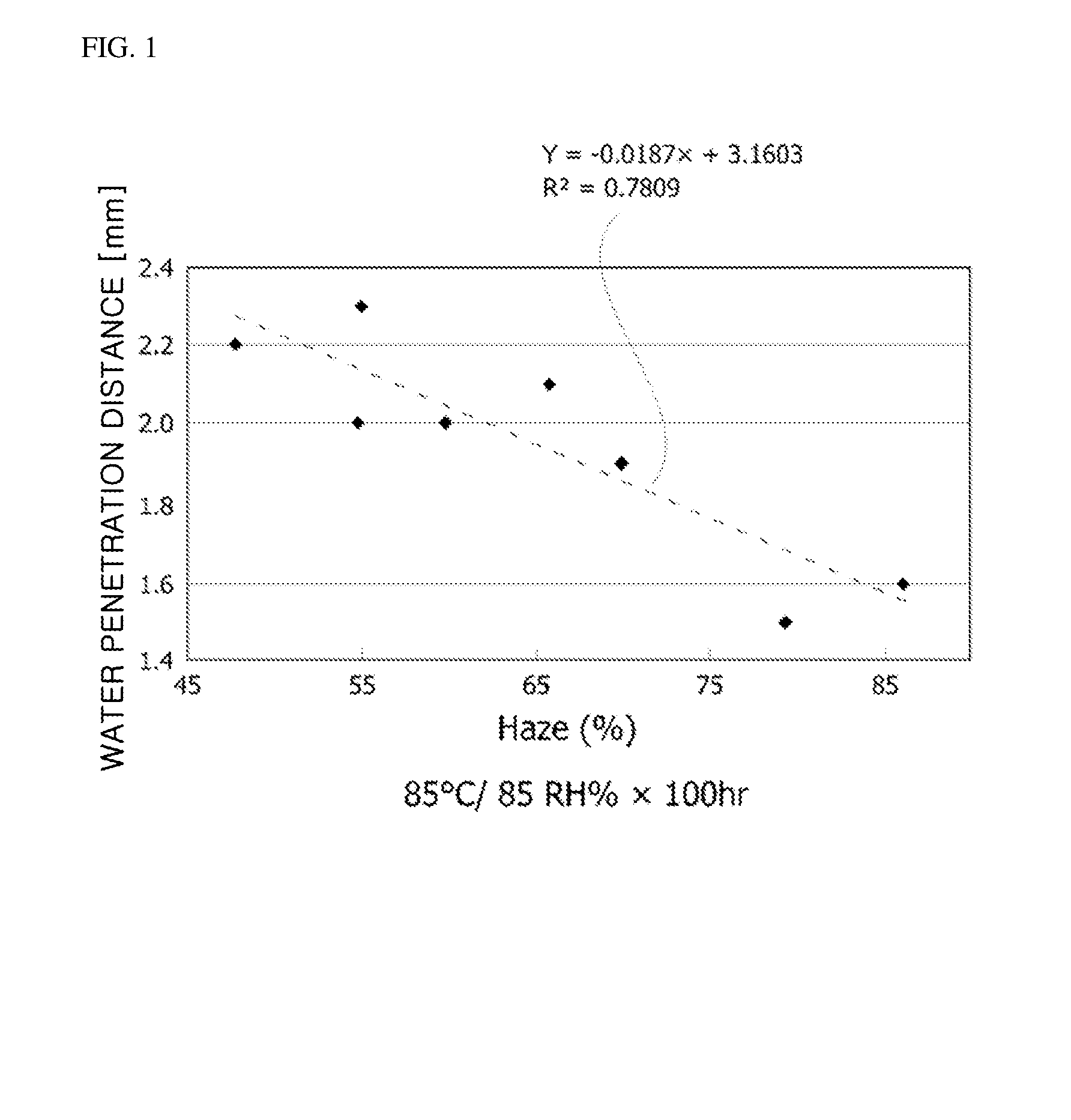

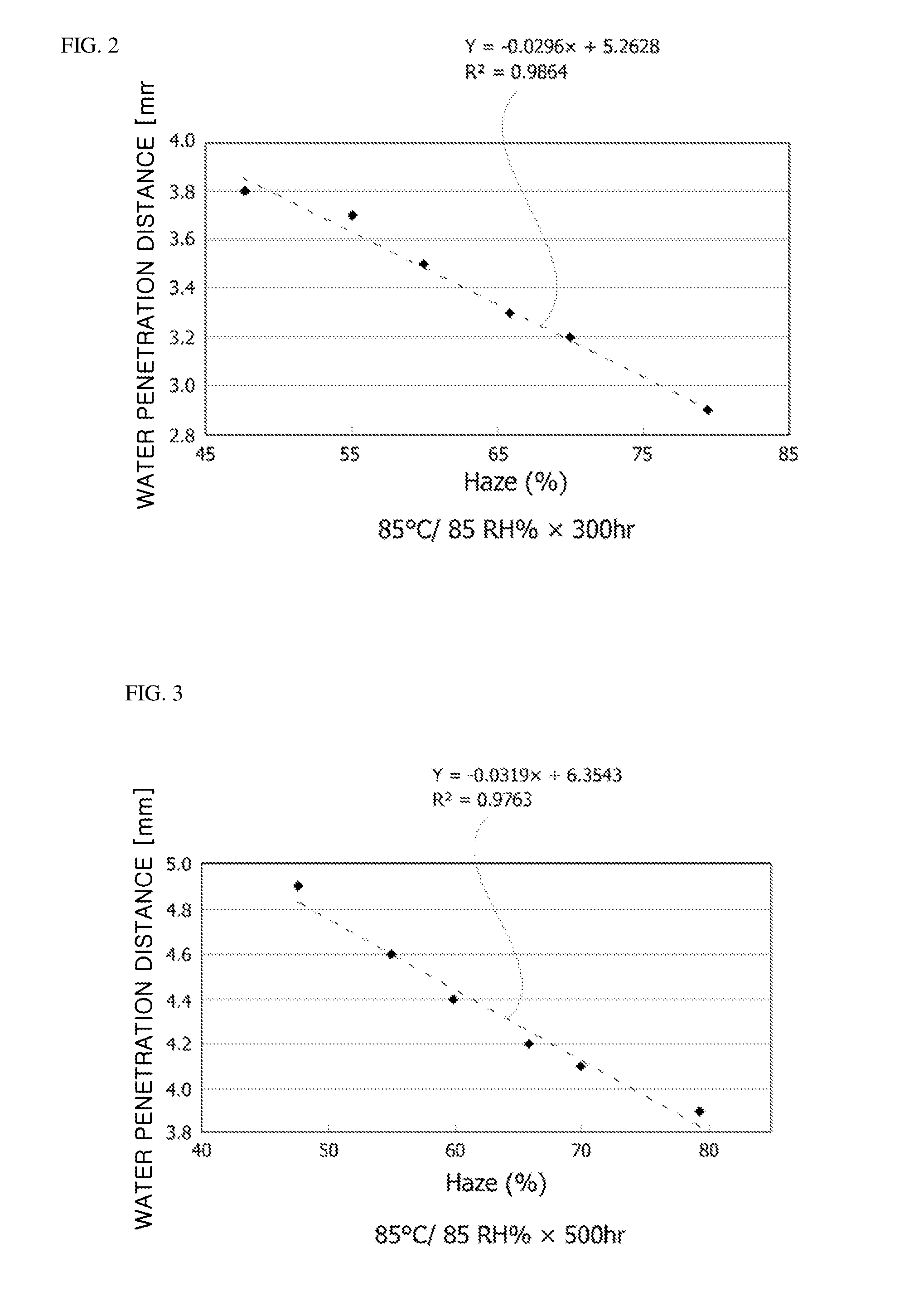

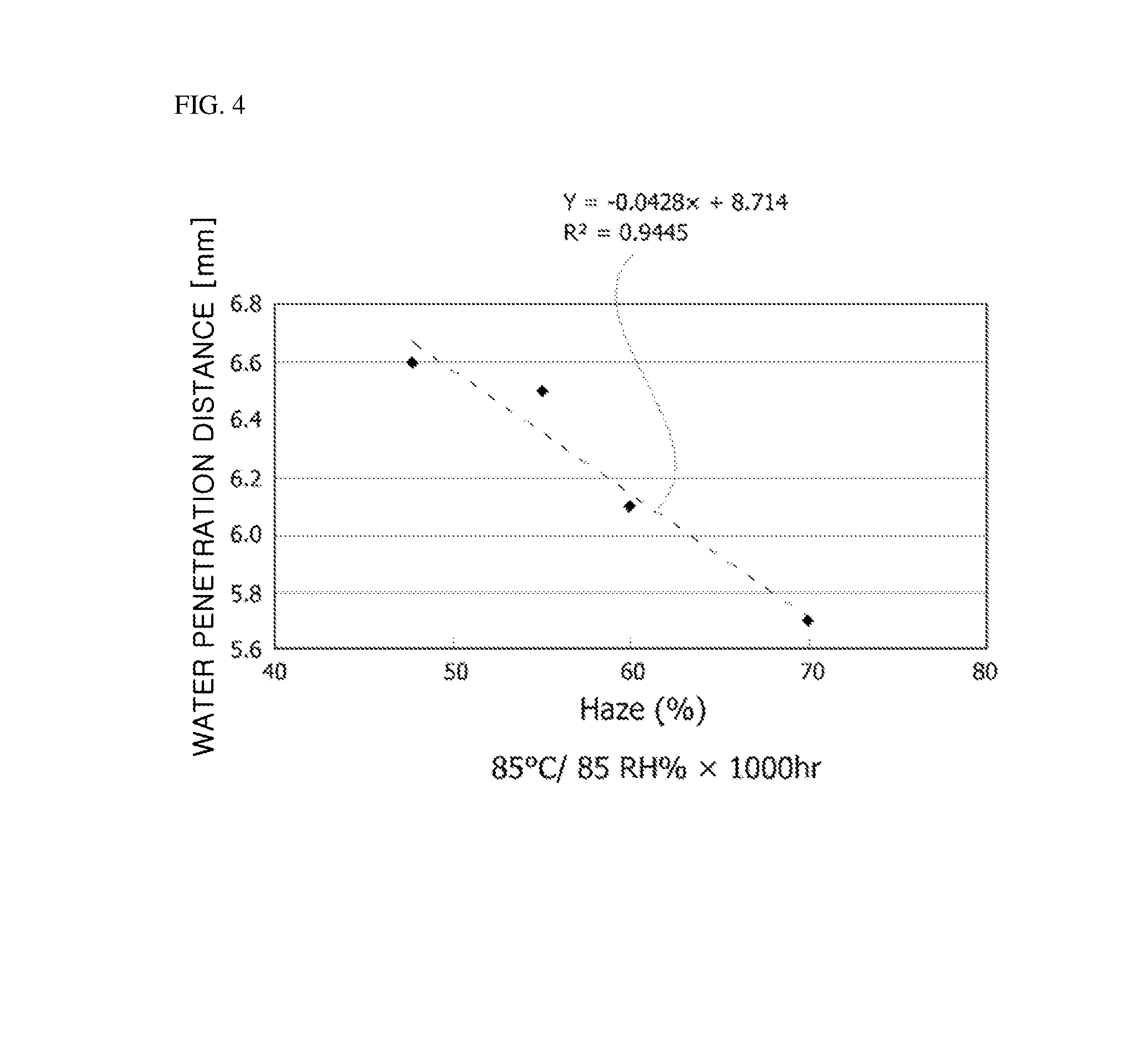

ENCAPSULANT FILM (As Amended)

ActiveUS20160155987A1Easy assessment processSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectron

There are provided a film and an organic electronic device. The present application may provide a film that may be provided for an evaluation method in which reliability of an encapsulant film is simply and easily evaluated only by measuring a haze immediately before the encapsulant film is used, thereby a failure of a product is determined and reliability may be predicted.

Owner:LG CHEM LTD

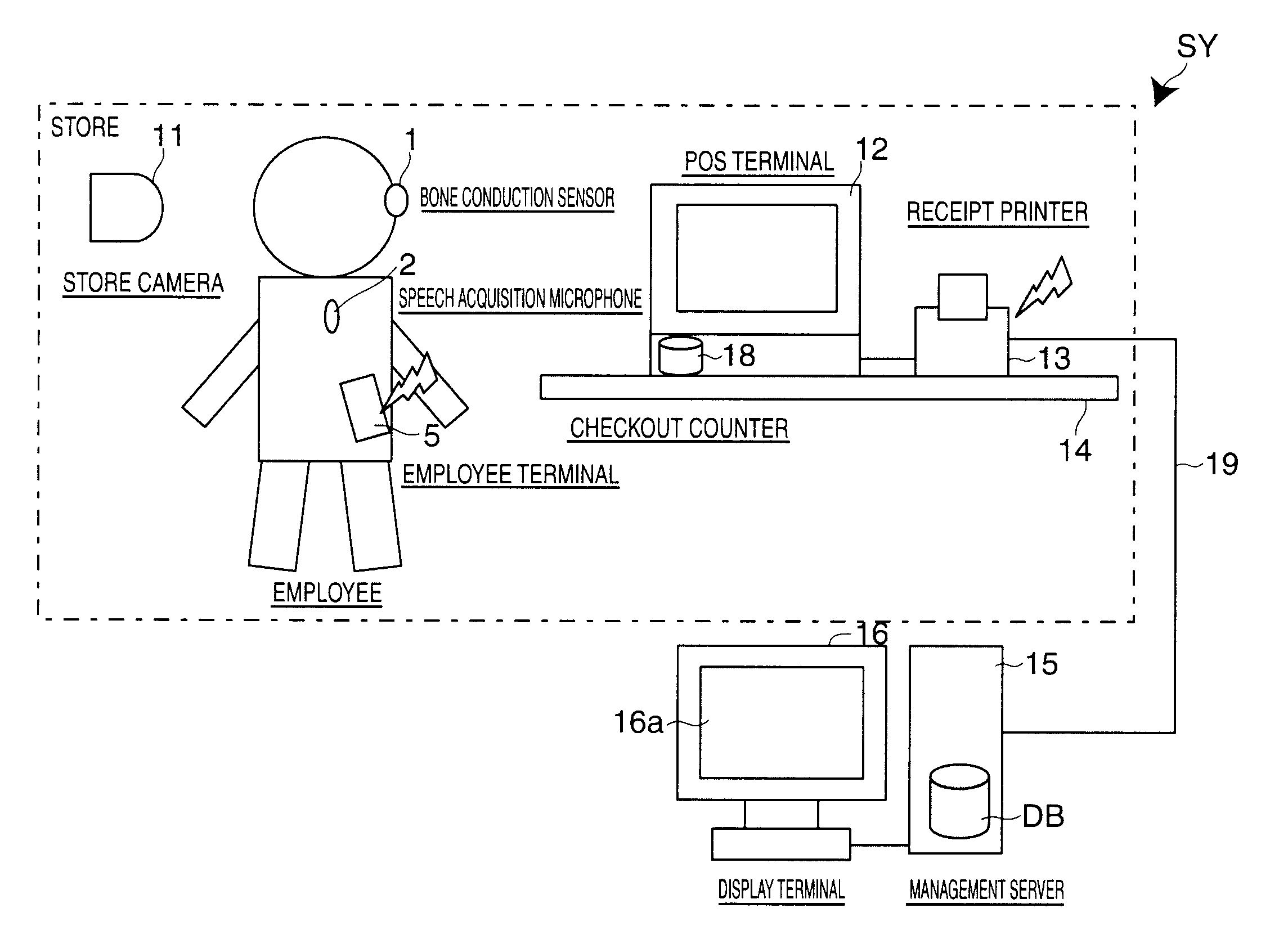

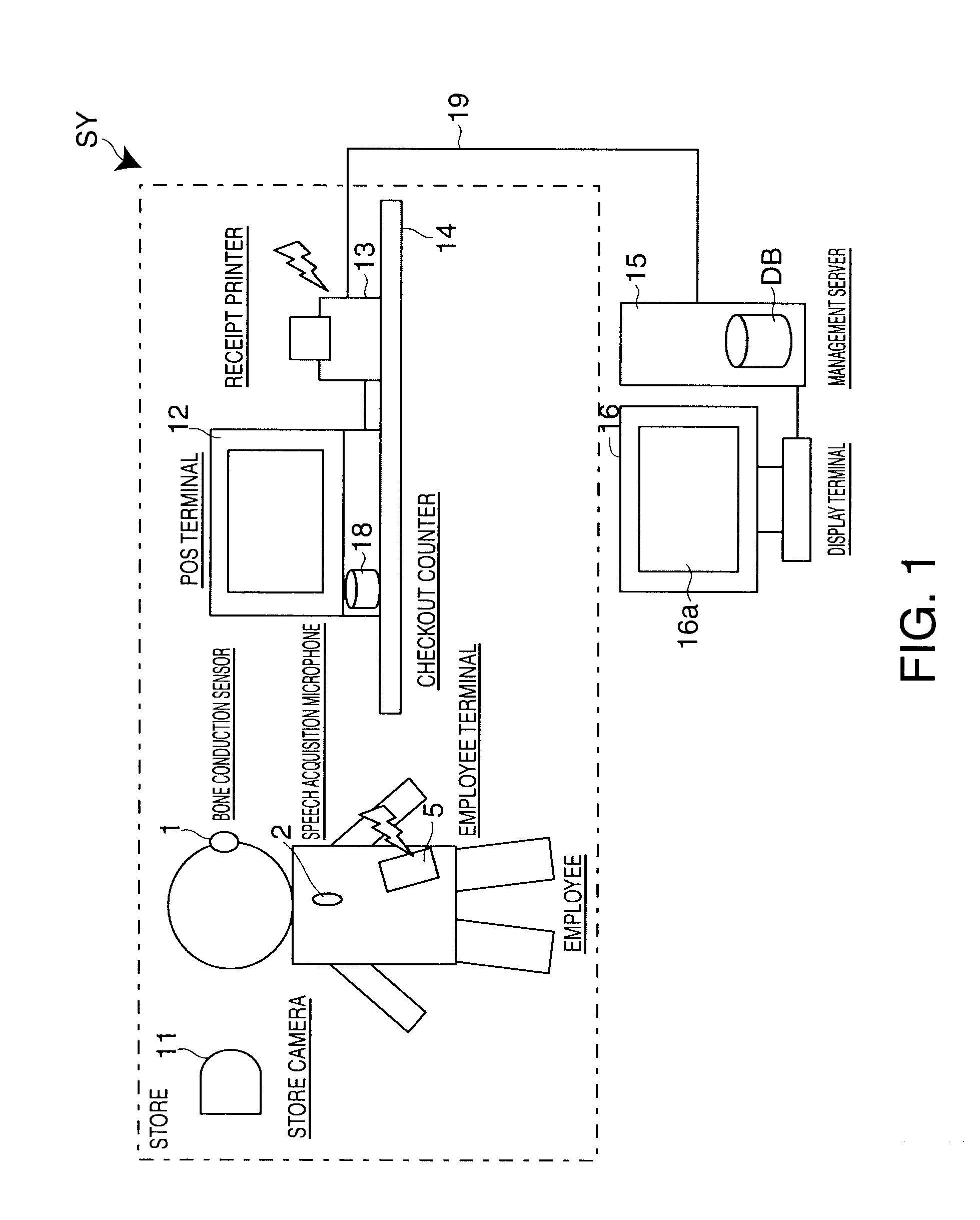

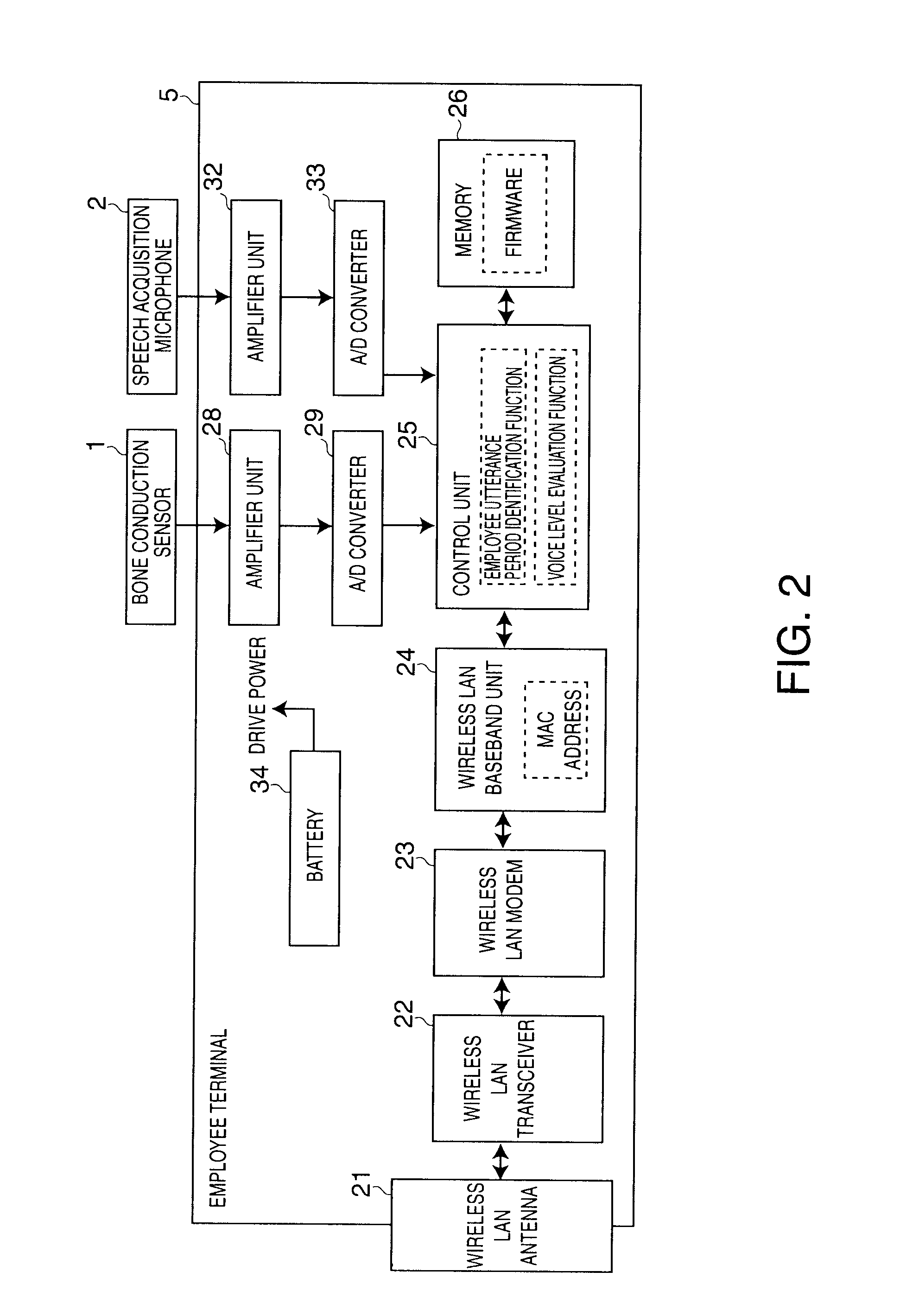

Customer Service Data Recording Device, Customer Service Data Recording Method, and Recording Medium

InactiveUS20110282662A1Improve conversation skillsAccurately identify employee and customer speechSpeech recognitionData recordingSpeech sound

To enable determining the correlation between customer satisfaction and employee satisfaction, a speech acquisition unit 102 acquires conversations between employees and customers; an emotion recognition unit 155 recognizes employee and customer emotions based on employee and customer speech in the conversation; a satisfaction calculator 156, 157 calculates employee satisfaction and customer satisfaction based on the emotion recognition output from the emotion recognition unit 155; and a customer service data recording unit 159 relates and records employee satisfaction data denoting employee satisfaction and customer satisfaction data denoting customer satisfaction as customer service data in a management server database DB.

Owner:SEIKO EPSON CORP

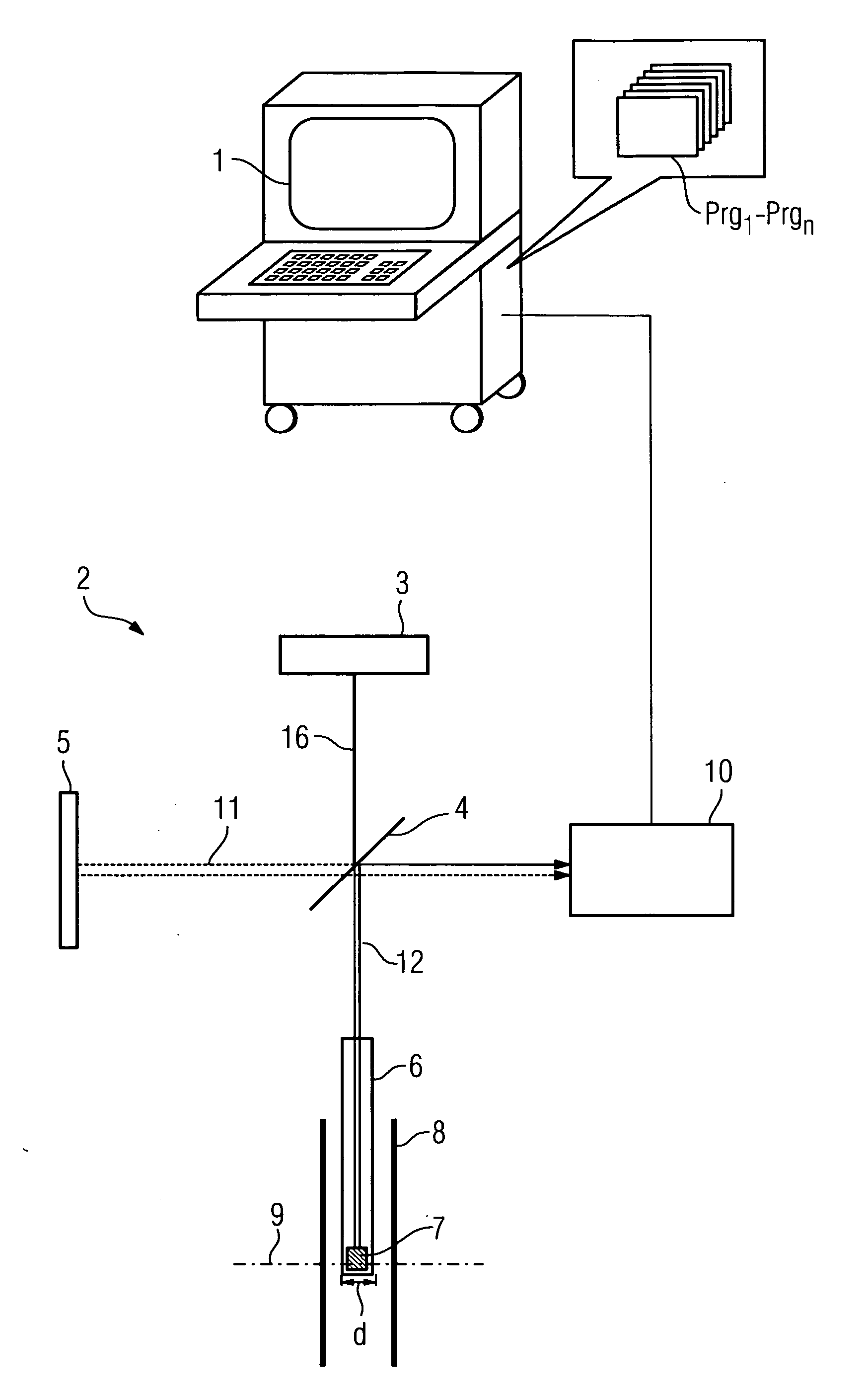

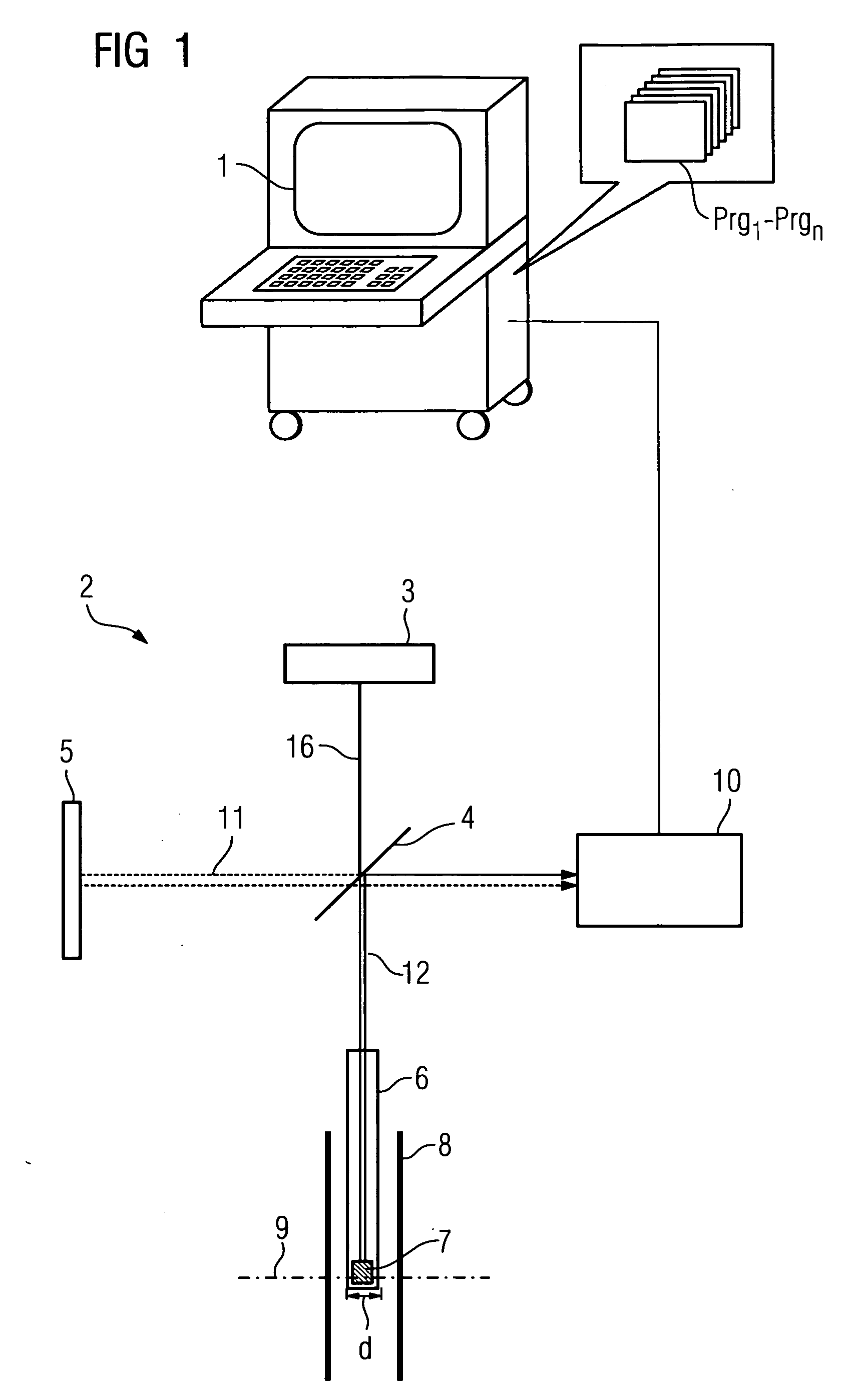

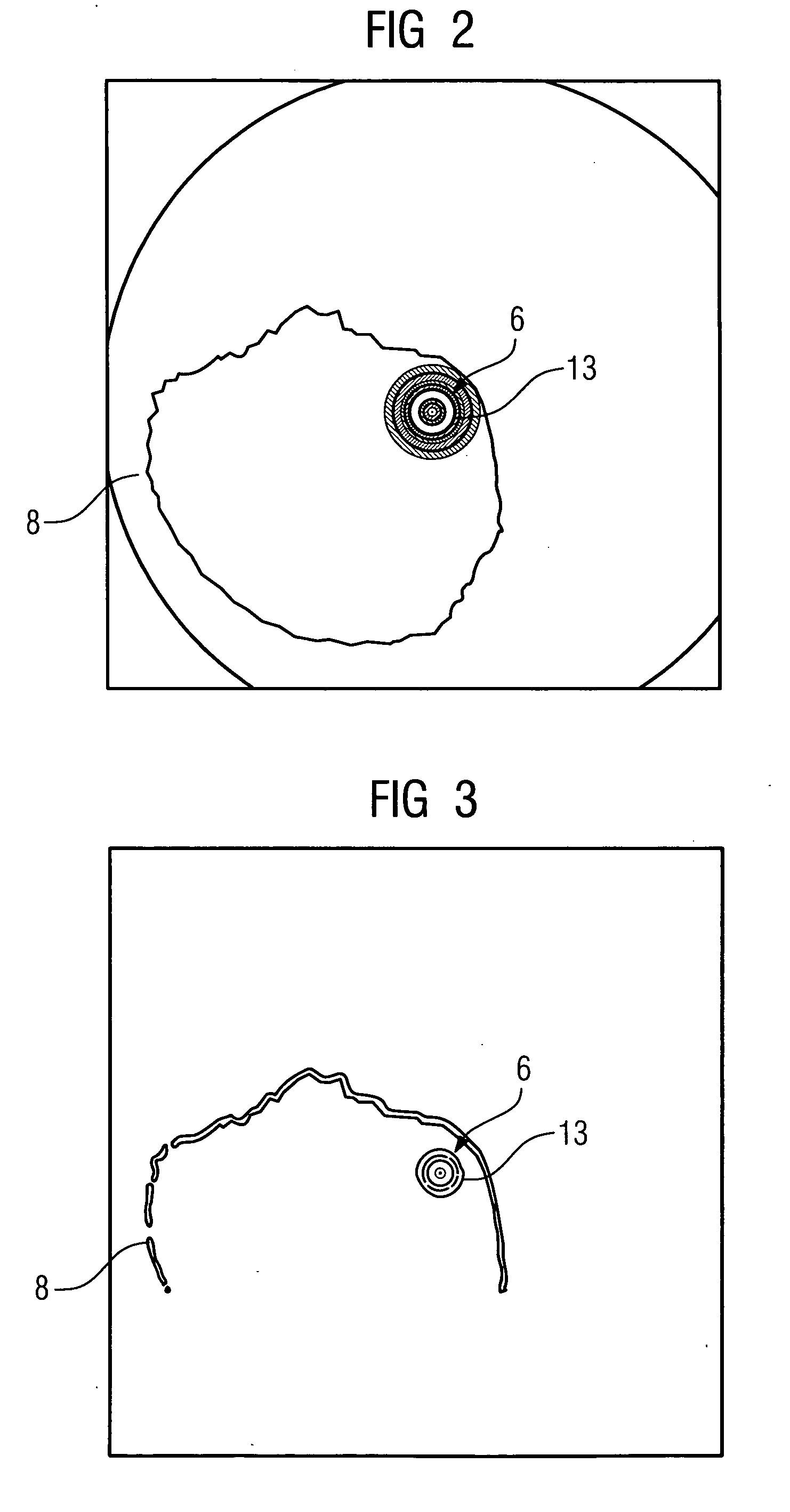

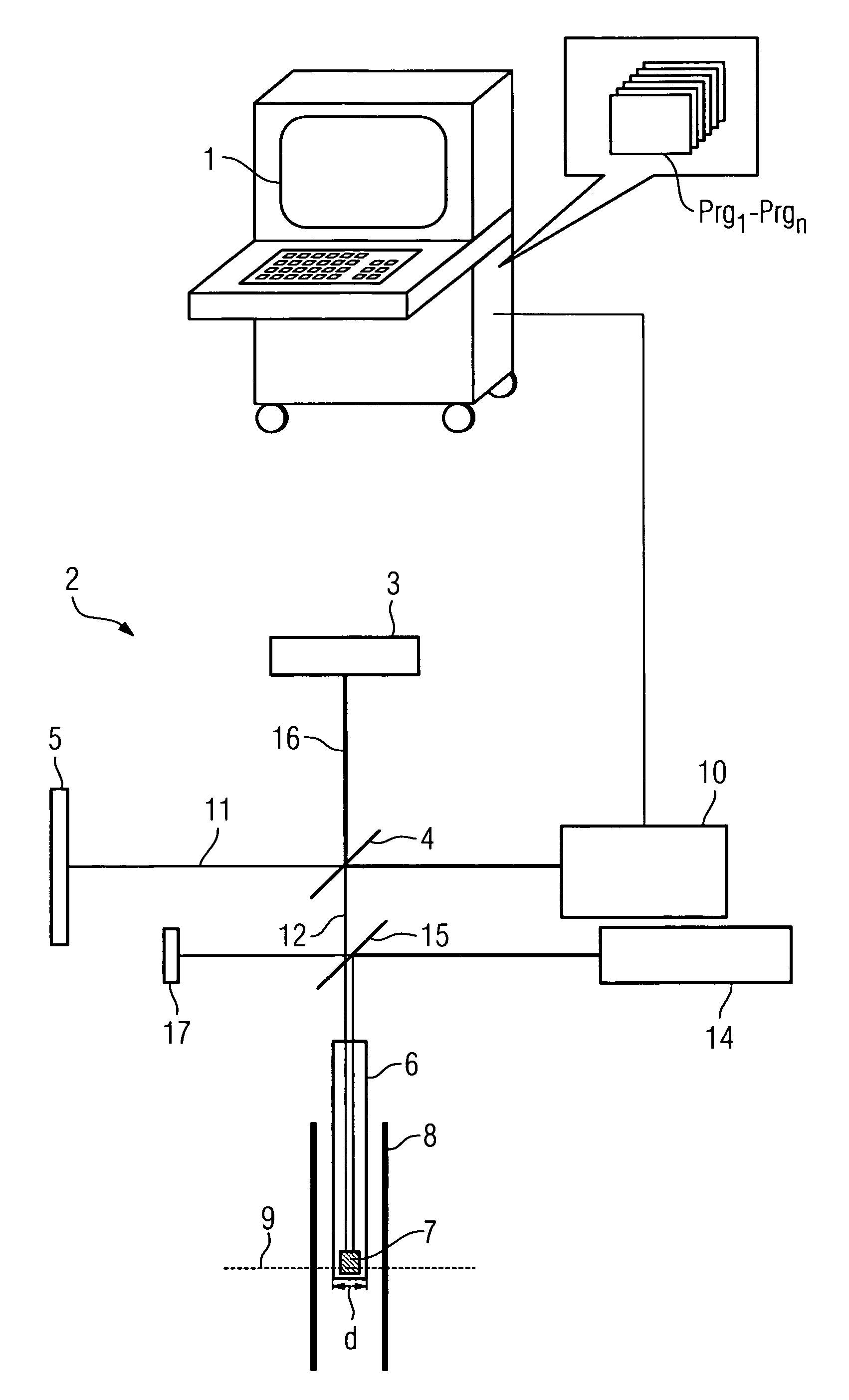

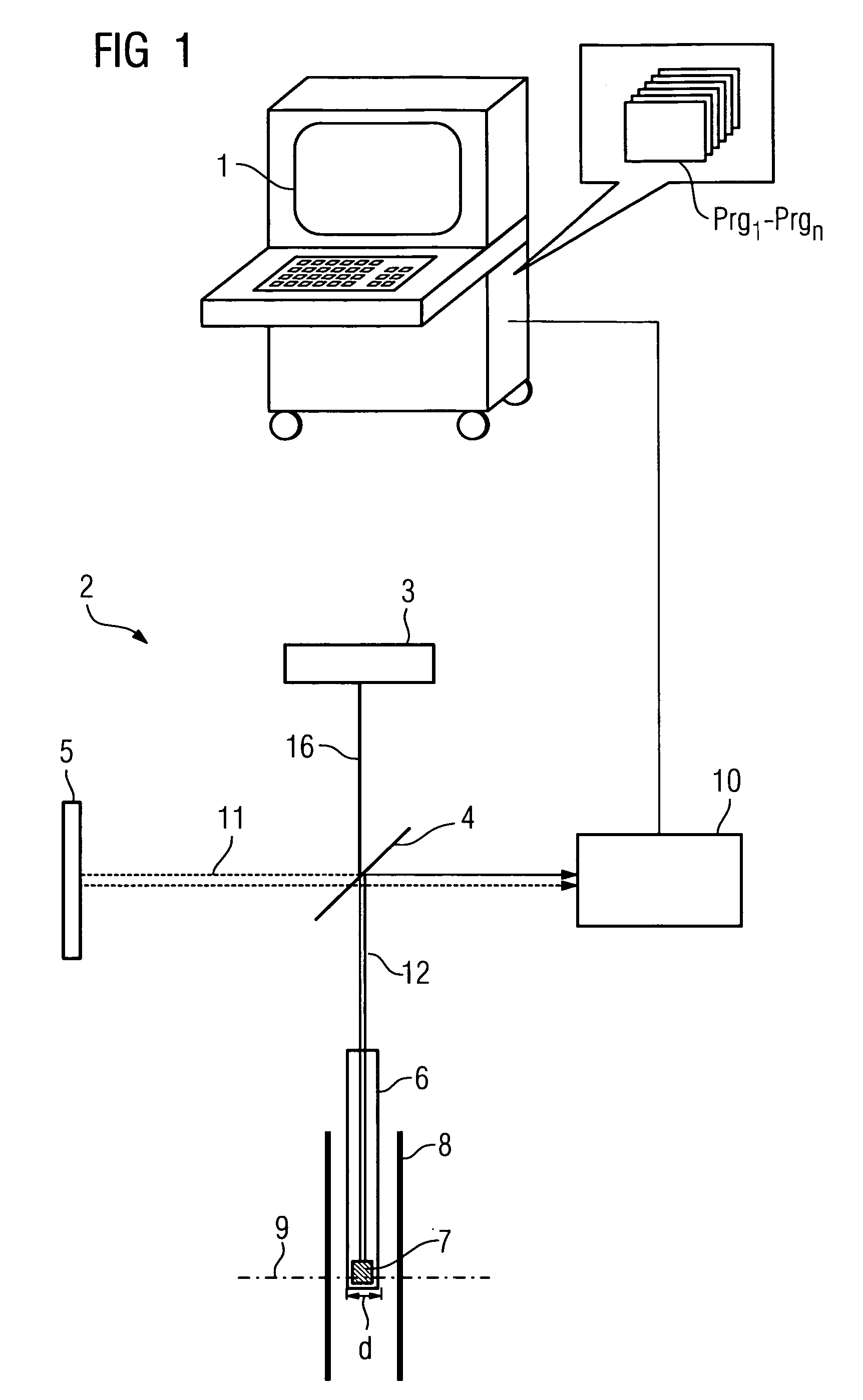

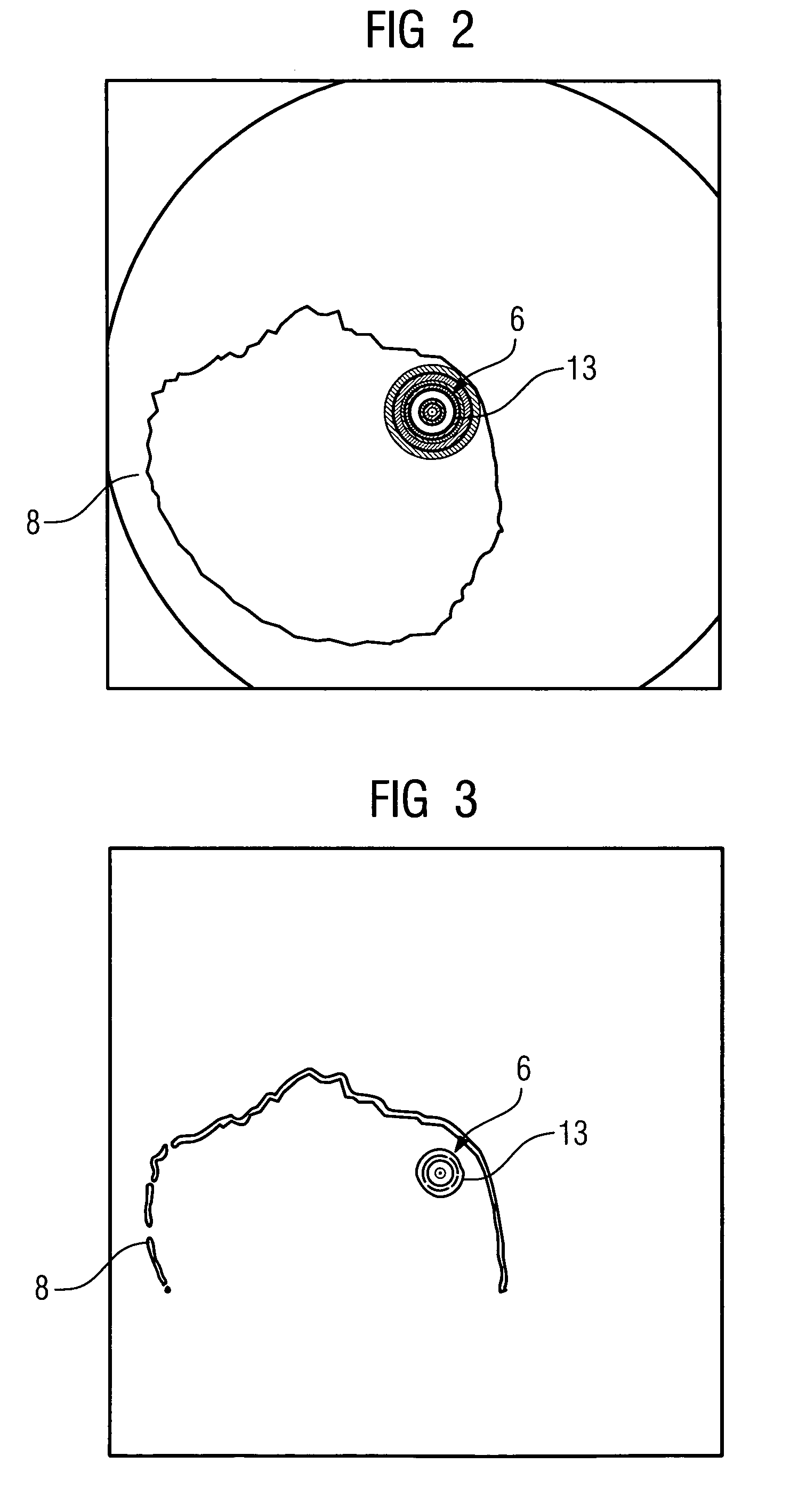

Method for tomographically displaying a cavity by optical coherence tomography (OCT) and an OCT device for carrying out the method

ActiveUS20060264743A1Guaranteed corrective effectEasy to moveCatheterDiagnostic recording/measuringPath lengthLight beam

The invention relates to a method for tomographically displaying a cavity by optical coherence tomography (OCT) and to an OCT device, wherein the path length of a measuring light beam in the catheter can change as a result of a movement of the catheter and brings about a change in the display scale, wherein a possible change in the path length of the measuring light beam in the event of a movement of the catheter is electronically determined and automatically compensated.

Owner:SIEMENS HEALTHCARE GMBH

Monitoring methods and devices for use therein

InactiveUS6451619B1Reduce unreliabilityLimited usefulnessAnimal reproductionAnalysis using chemical indicatorsBacteriuriaAnalyte

Methods, devices and test kits for monitoring the ovulation cycle, involve testing the body fluid, e.g. urinary, concentration of one or more analytes. Preferably estrone-3-glucuronide and luteinizing hormone are both measured, and a reference concentration for E3G is established at about day 6 of the current cycle. Preferably, disposable testing devices are used, in conjunction with a relatively permanent electronic reader / monitor. The number of "daily" tests required per month can be minimized.

Owner:INVERNESS MEDICAL SWITZERLAND GMBH

Methods and Systems for Preventing Diversion Of Prescription Drugs

InactiveUS20080059226A1Readily assess effectiveness of treatment regimenWide applicationMedical communicationData processing applicationsRegimenMedicine

Owner:UNIV OF FLORIDA RES FOUNDATION INC

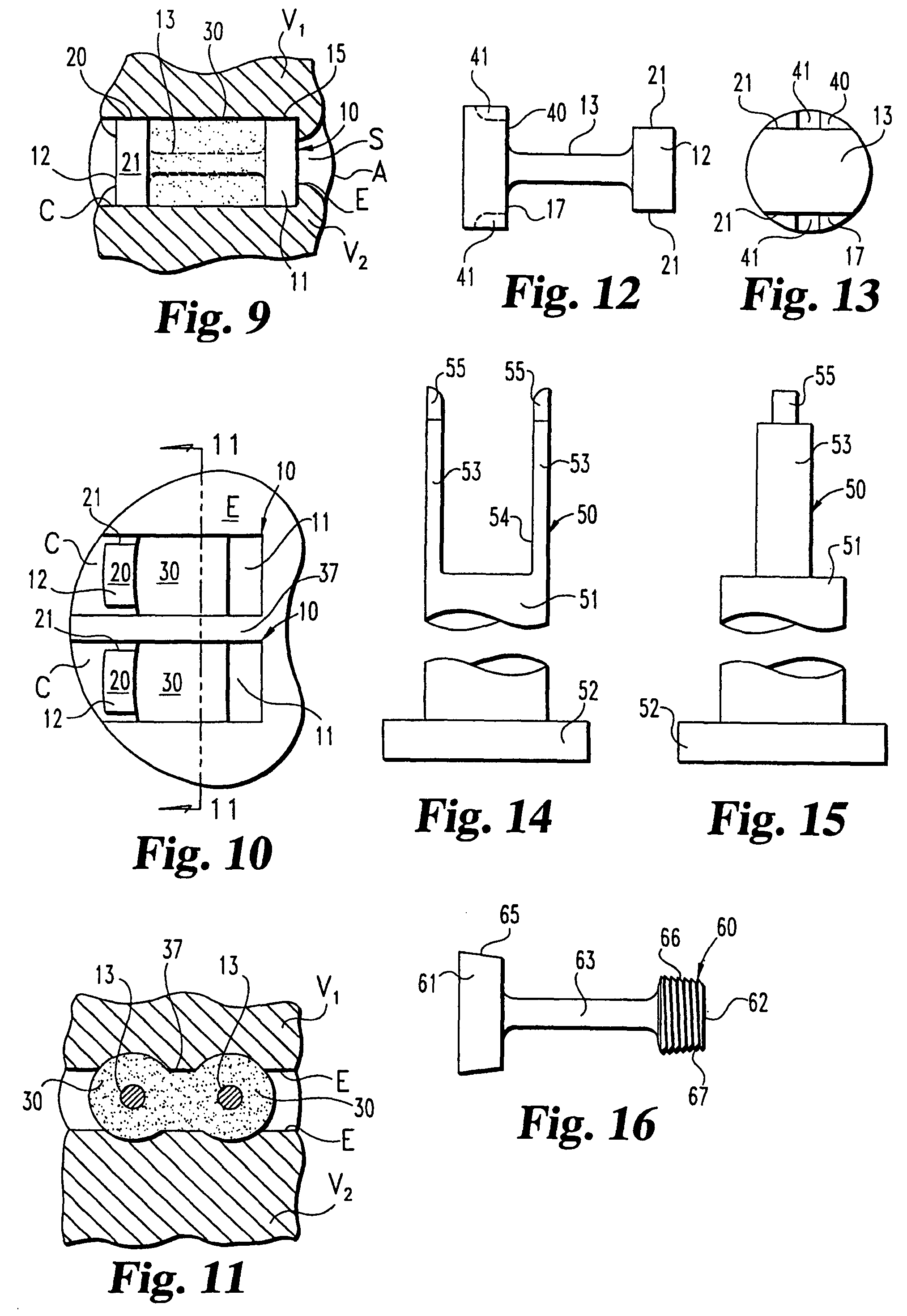

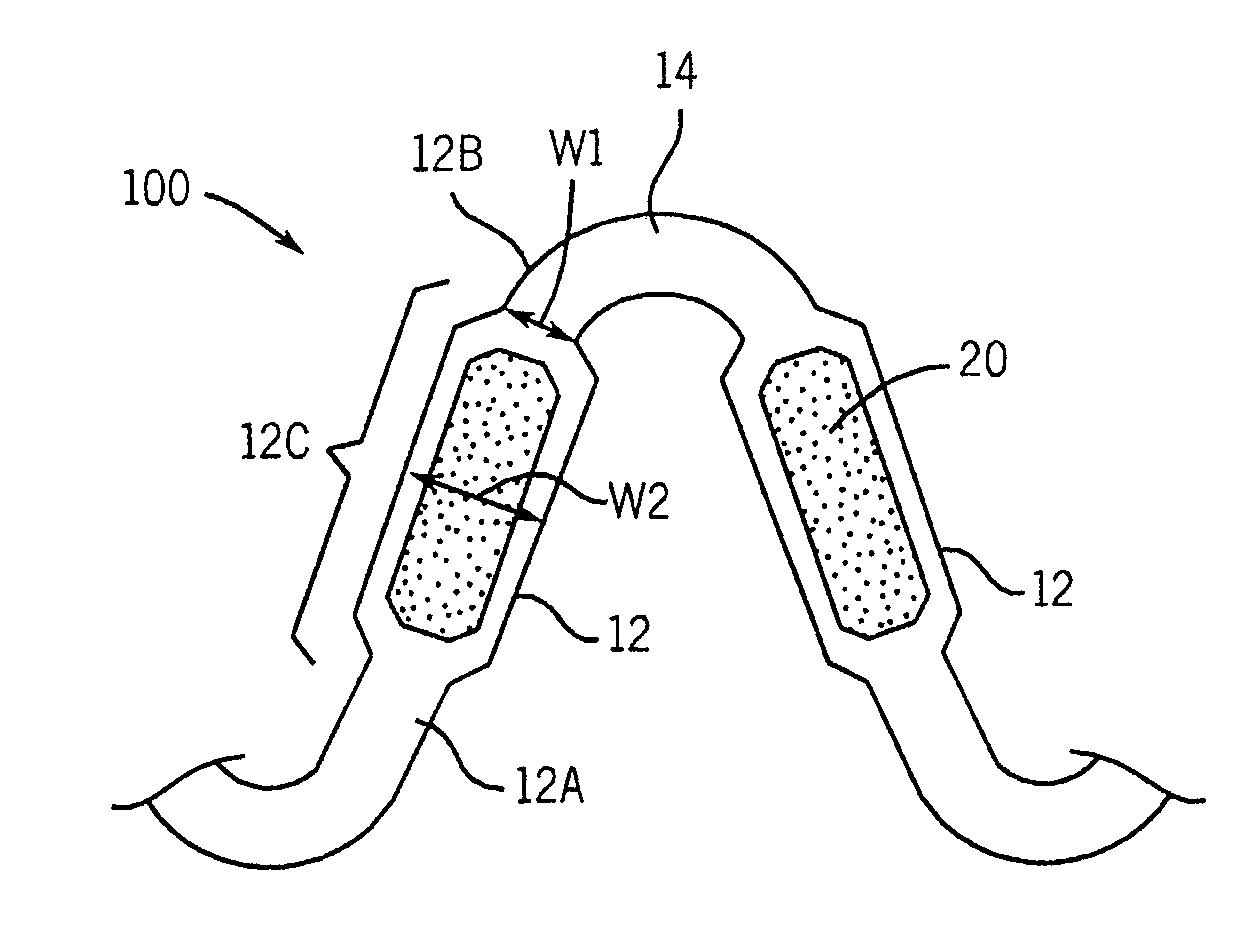

Osteogenic fusion device

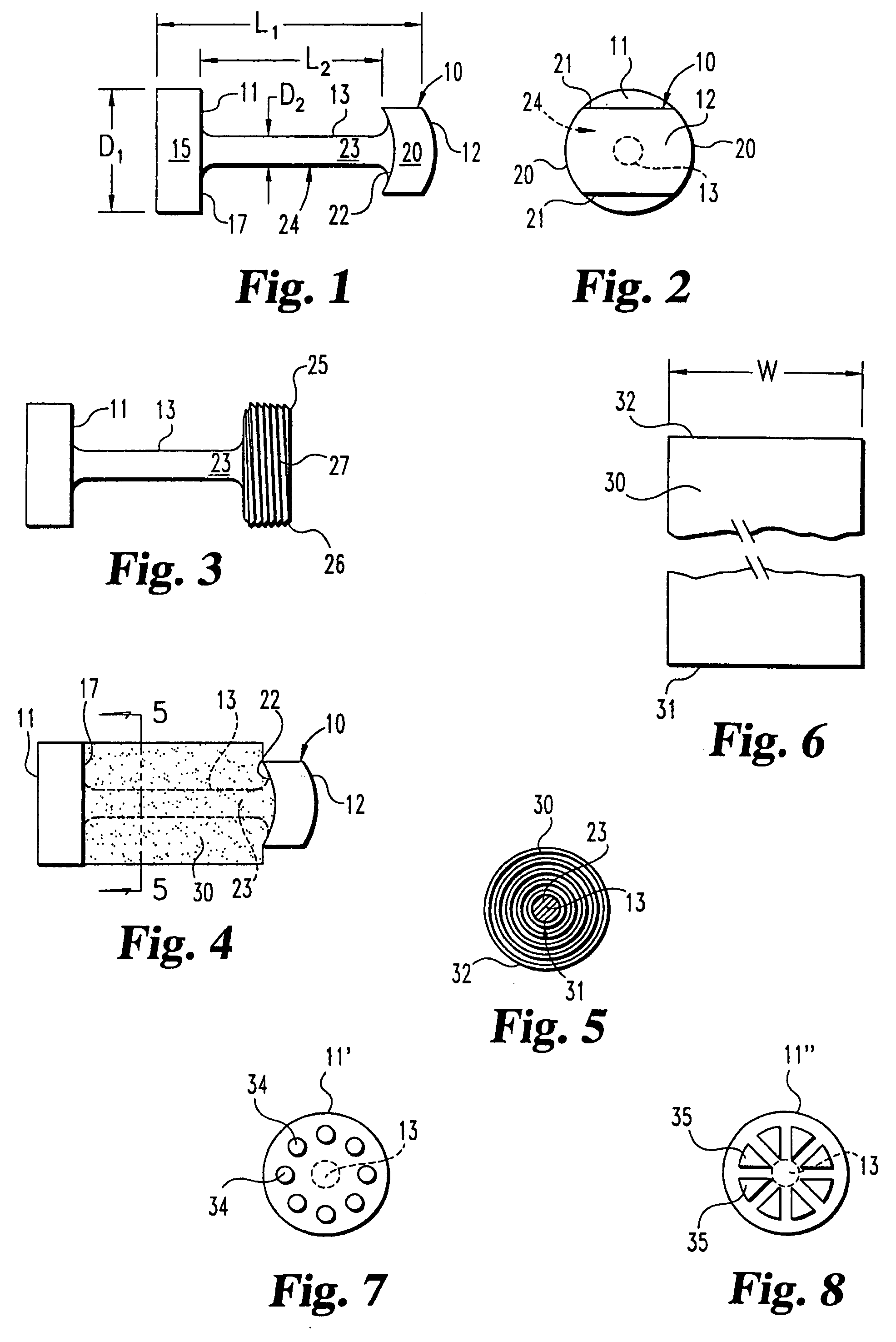

InactiveUS7179293B2Support of loadMinimize radiopacityBone implantJoint implantsDevice formBone growth

An interbody osteogenic fusion device is provided that includes opposite end pieces with an integral central element. The end pieces are sized to maintain the height of an intervertebral disc space. The central element has a much smaller diameter so that the osteogenic fusion device forms an annular pocke around the central element. An osteogenic material is disposed within the annular pocket between the opposite end pieces. In one embodiment,the osteogenic material constitutes a collagen sheet soaked in asolution containing a bone morphogenetic protein. The osteogenic fusion device is configured so that the osteogenic material is in direct contact with the adjacent vertebral bone. In addition to the enhanced area of contact between the vertebral bone and the fusion material, the inventive osteogenic fusion device reduces stress-shielding and minimizes the radiopacity of the implant so that growth of the fusion mass can be continuously assessed. In yet another embodiment, the osteogenic fusion device includes at least one end piece with a truncated surface. The osteogenic fusion devices of the present invention may be combined with other fusion devices to form an implant system. The implant system includes at least one load bearing member having a truncated surface configured to nest within another load bearing member, preferably the load bearing, osteogenic fusion device of the present invention. The invention also provides implant systems comprising adjacent load bearing members connected to one another to resist lateral separation. Methods of promoting fusion bone growth in the space between adjacent vertebrae utilizing devices and systems of the invention are also described.

Owner:WARSAW ORTHOPEDIC INC

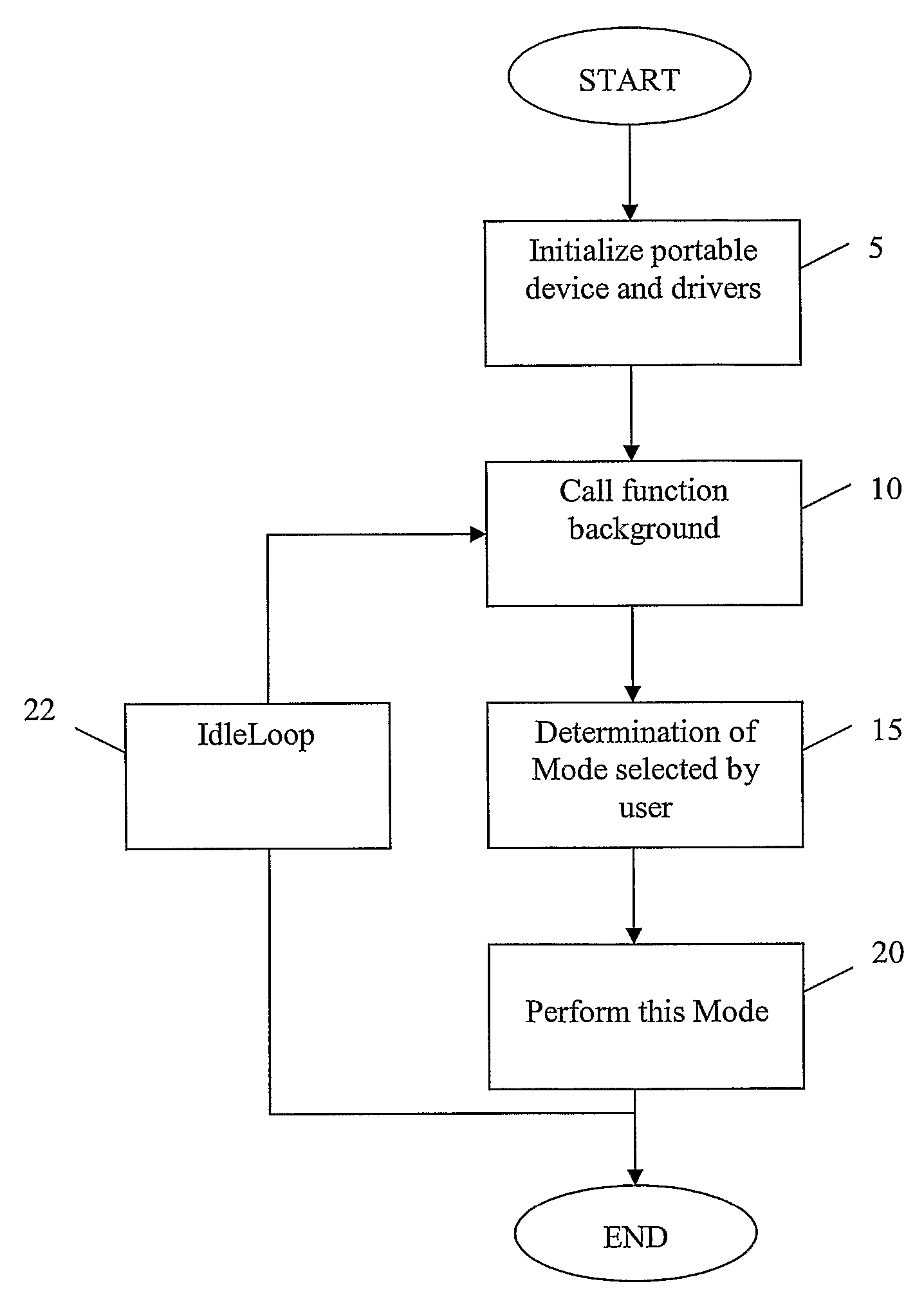

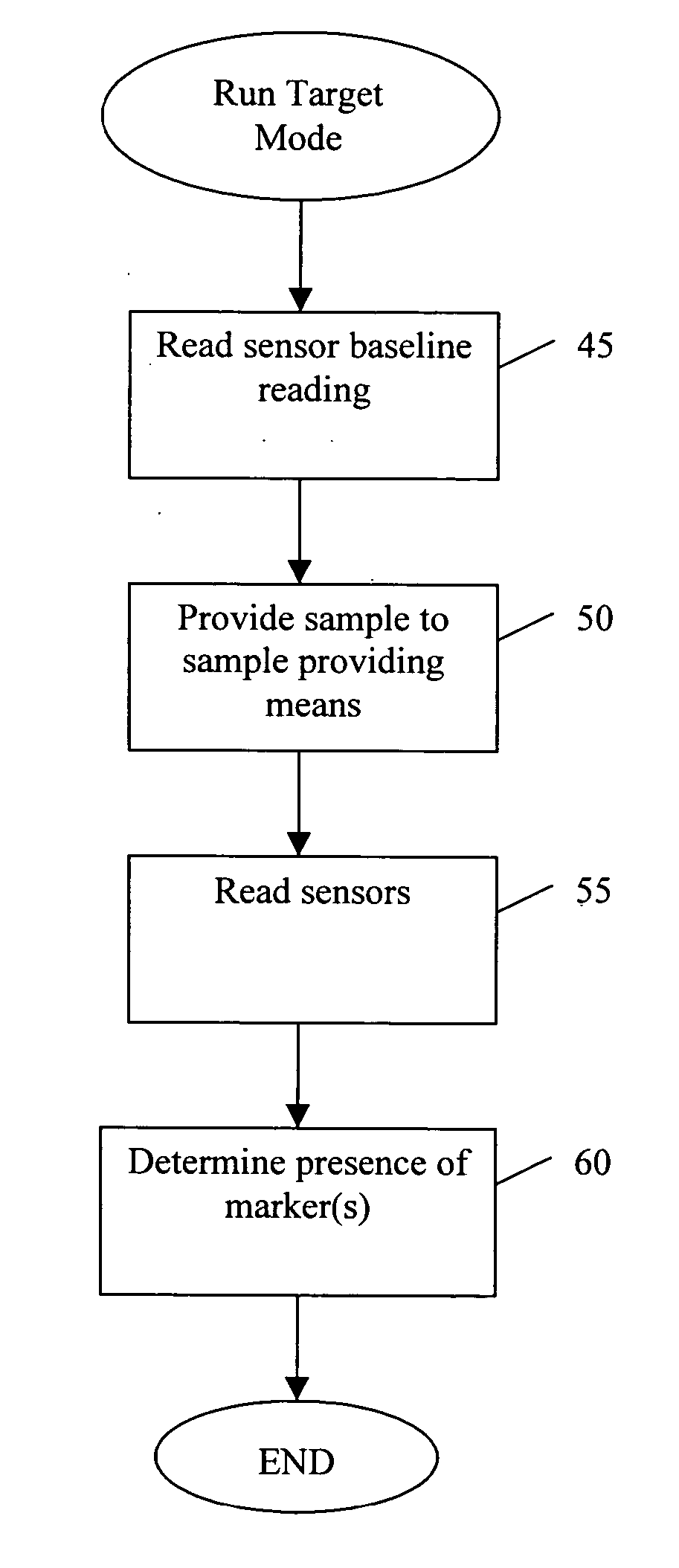

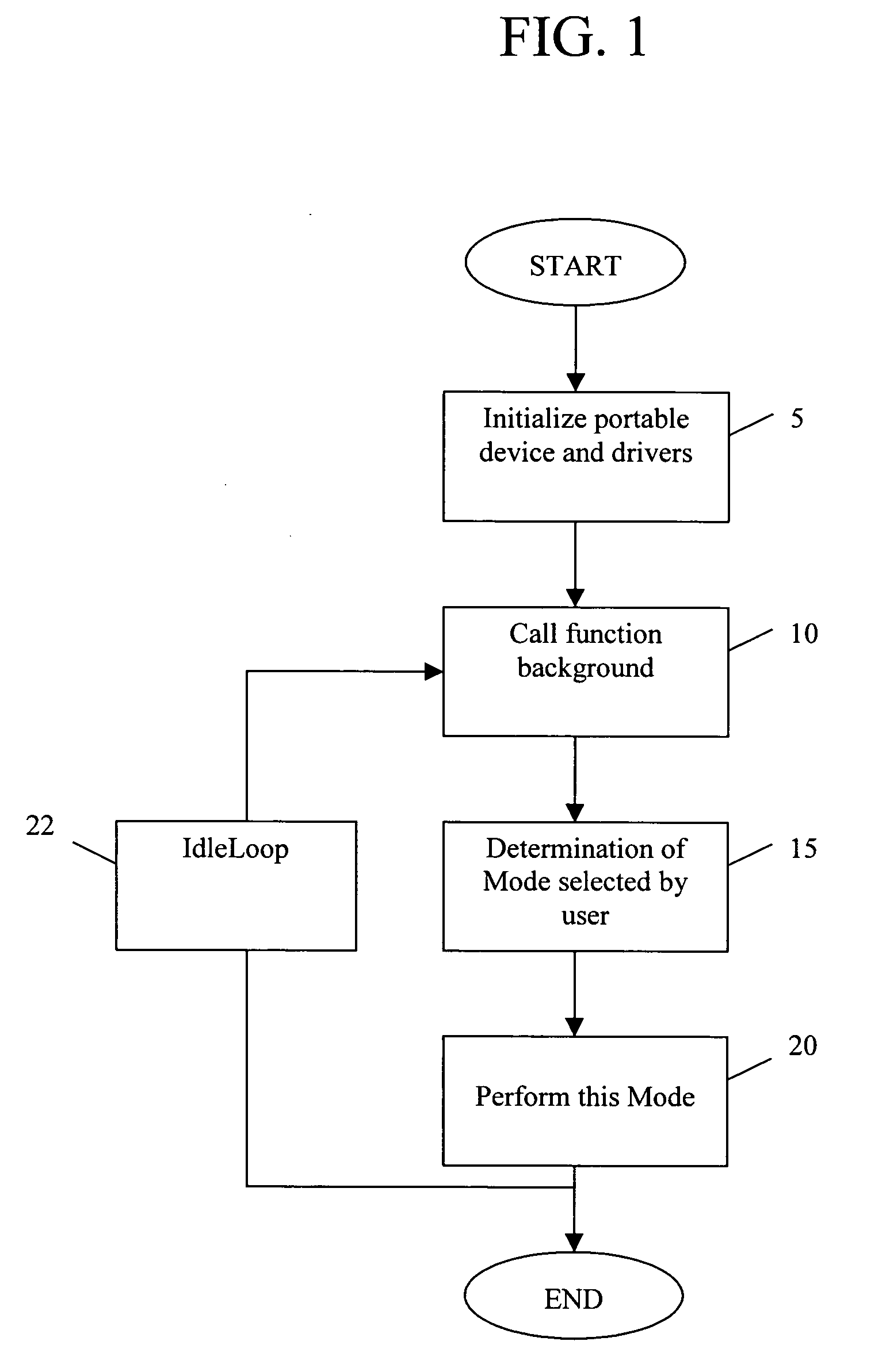

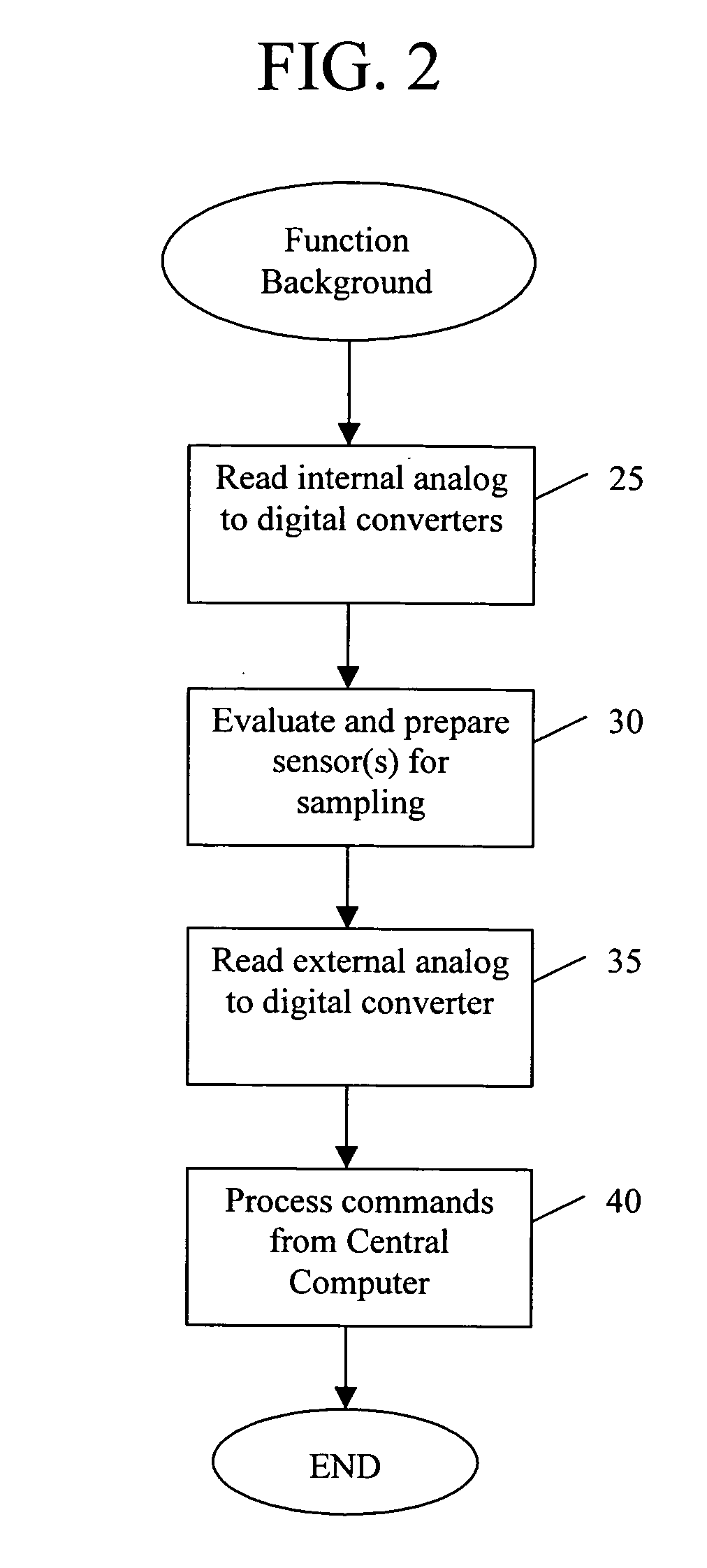

Methods and systems for preventing diversion of prescription drugs

InactiveUS20060062734A1Easy to detectStrong specificityDrug and medicationsComputer-assisted medicine prescription/deliveryRegimenPatient compliance

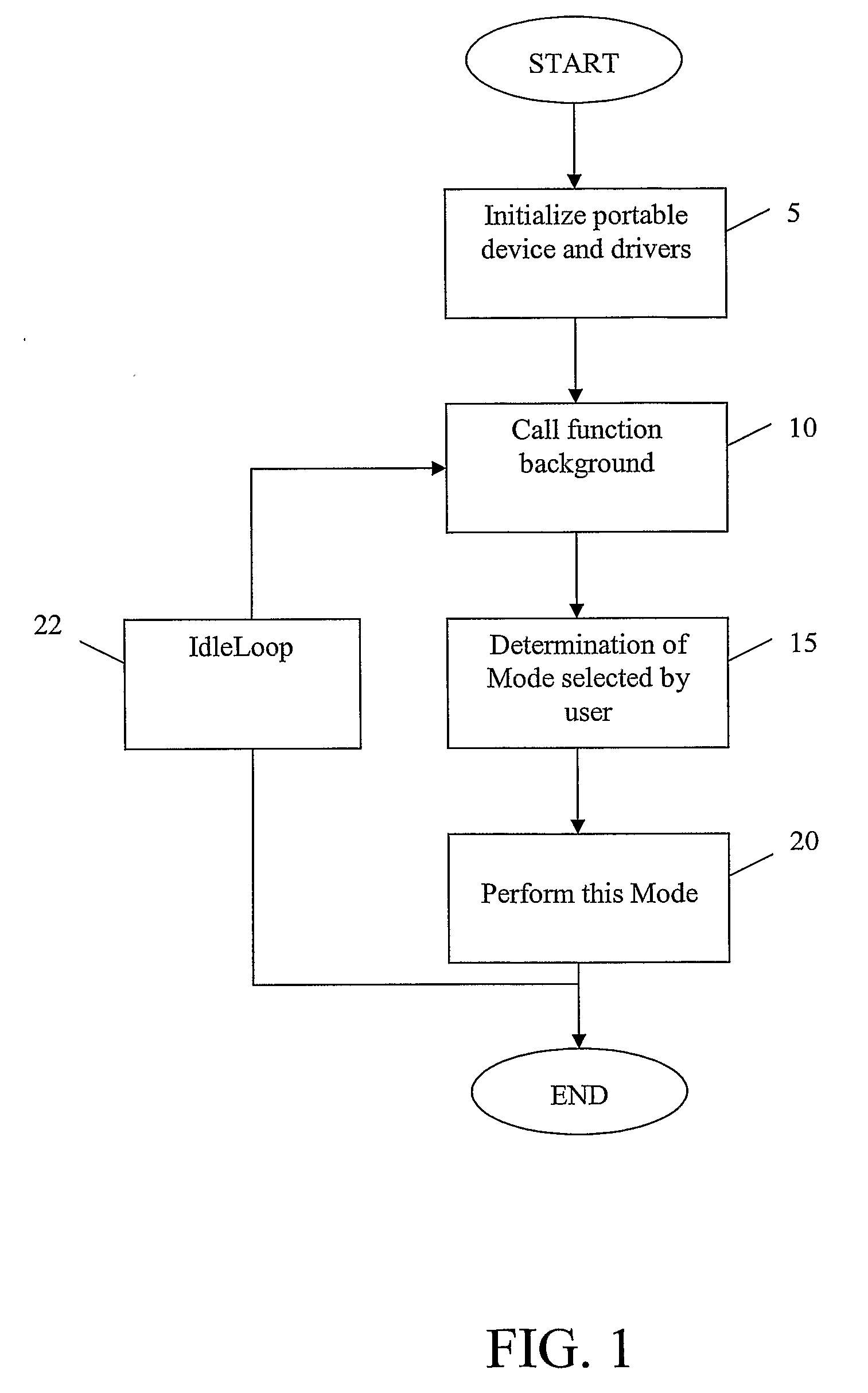

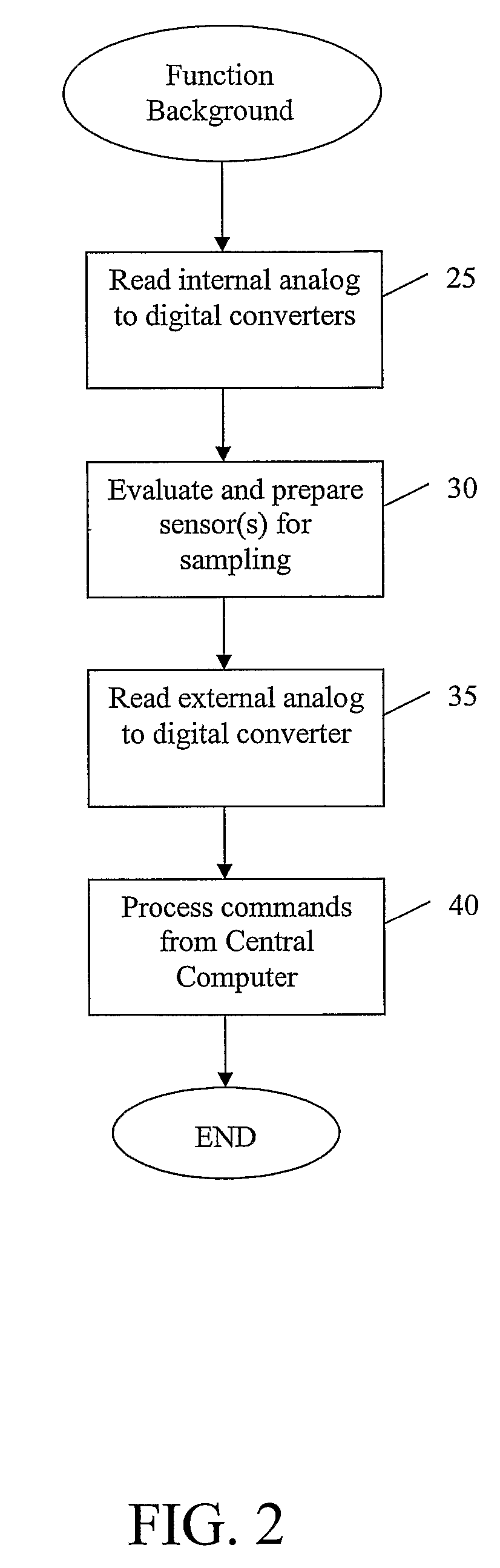

The subject invention provides systems and methods for monitoring prescription medications. In particular, systems and methods are provided for monitoring patient compliance with a given prescribed regimen as well as monitoring the origins of a prescription drug. The subject invention provides a central computer and a portable device, wherein the portable device includes at least one sensor for detecting a target marker. The target marker of the invention represents either the presence of a specific prescribed medication or identify the proper origins of a medication.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

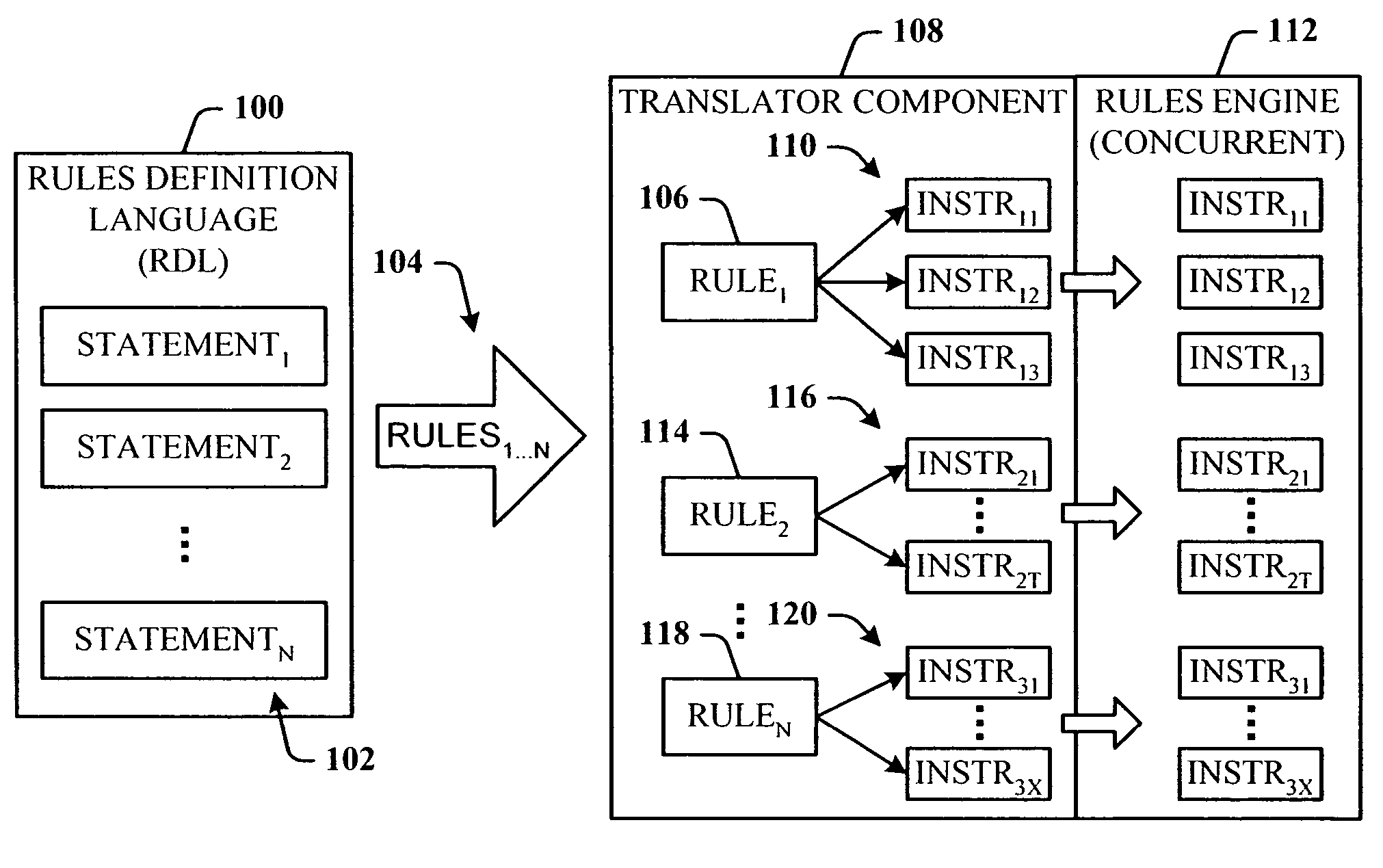

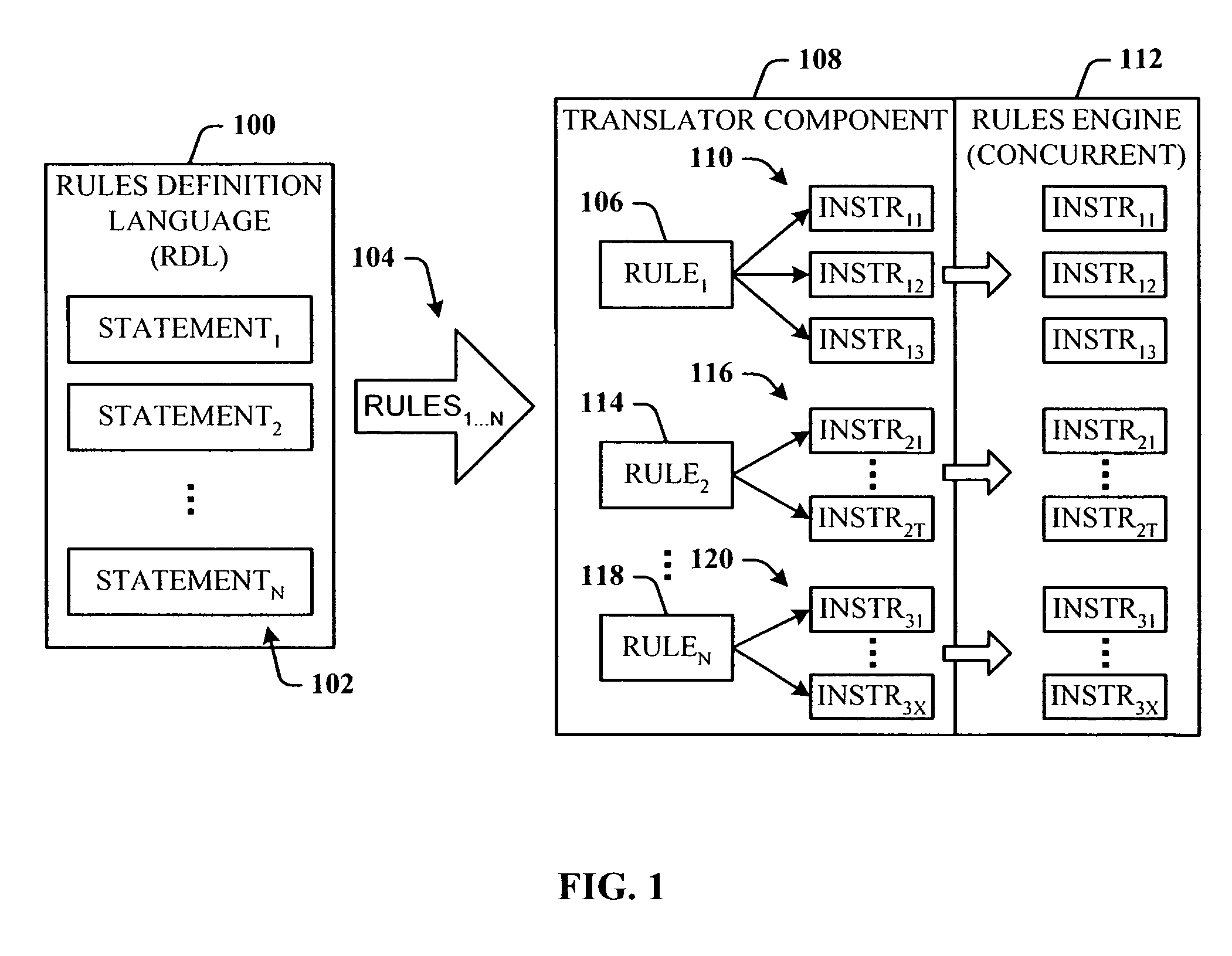

Rules definition language

InactiveUS20050091640A1Improve automationImprove system performanceNon-redundant fault processingKnowledge representationProgramming languageComputer resources

A rules definition language the authoring rules for concurrent processing. The RDL includes statements that facilitate efficient use of computer resources by allowing a rule to be broken down into one or more instructions, and processing these instructions asynchronously to provide more efficient use of the computer resources. Once processed into the instructions, results thereof can be passed among the instructions to facilitate process completion of the rule.

Owner:SERVICENOW INC

Method for tomographically displaying a cavity by optical coherence tomography (OCT) and an OCT device for carrying out the method

ActiveUS7408648B2Easy to moveMaintaining displayCatheterDiagnostic recording/measuringPath lengthLight beam

The invention relates to a method for tomographically displaying a cavity by optical coherence tomography (OCT) and to an OCT device, wherein the path length of a measuring light beam in the catheter can change as a result of a movement of the catheter and brings about a change in the display scale, wherein a possible change in the path length of the measuring light beam in the event of a movement of the catheter is electronically determined and automatically compensated.

Owner:SIEMENS HEALTHCARE GMBH

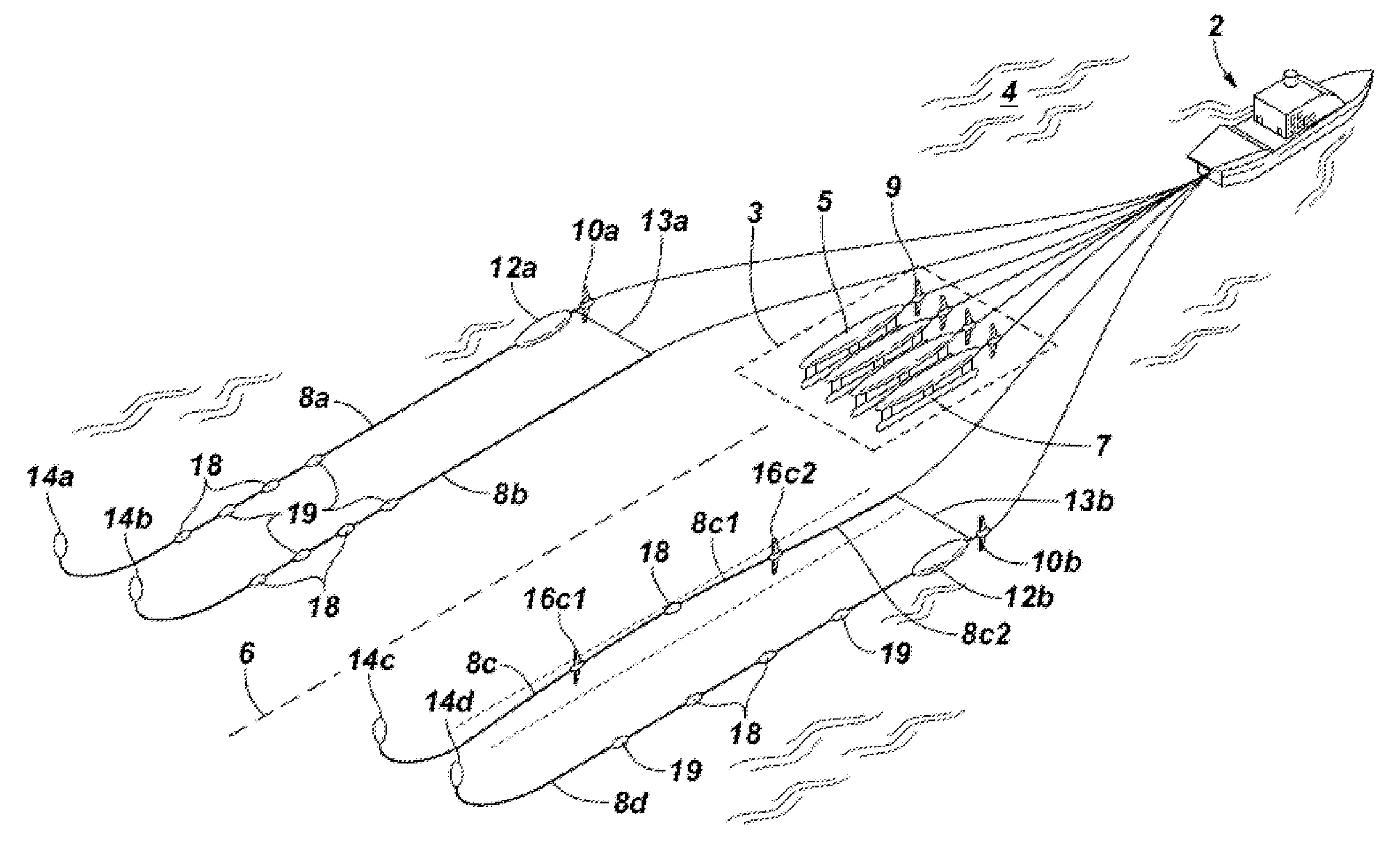

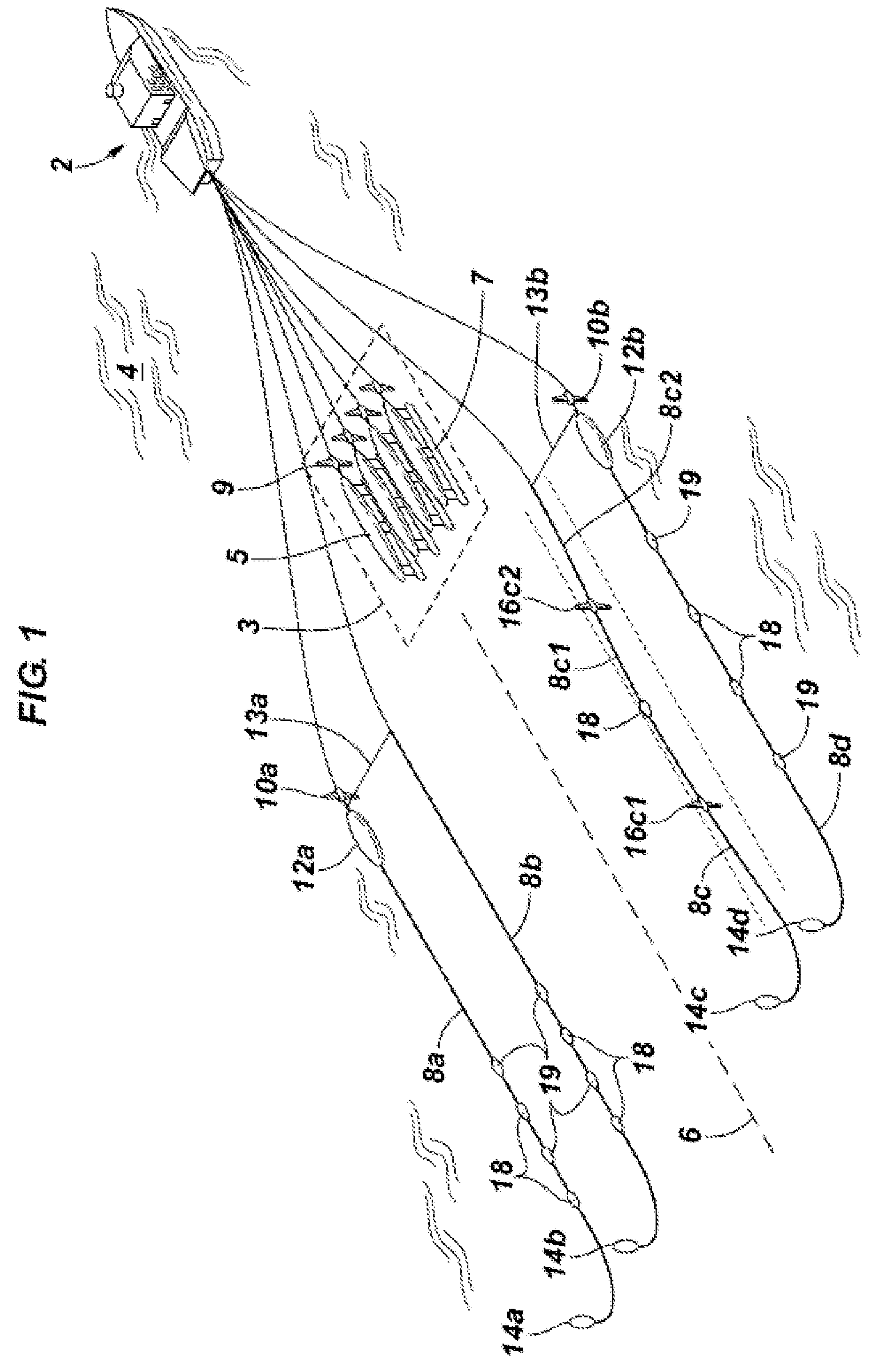

Acoustic propagation velocity modeling methods, apparatus and systems

InactiveUS20080008037A1Easy assessment processSimple structureSeismology for water-covered areasVelocity propogationMathematical modelPropagation time

Methods, apparatus, and systems for accurately estimating acoustic propagation velocity are described. One method comprises deploying in a marine environment a towed seismic spread comprising a plurality of acoustic positioning transmitters and a plurality of positioning point receivers, and using travel times for signals between at least some of the transmitters and point receivers to derive a mathematical model describing acoustic propagation velocity for the marine environment as a function of at least one spread spatial dimension, distances between transmitters and receivers, and any combination thereof. This abstract is provided to comply with the rules requiring an abstract, and allows a reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:WESTERNGECO LLC

Antisense modulation of human mdm2 expression

InactiveUS6184212B1Easy assessment processReduce mdm protein levelPeptide/protein ingredientsGenetic material ingredientsDiseaseMdm2 Protein

Owner:IONIS PHARMA INC

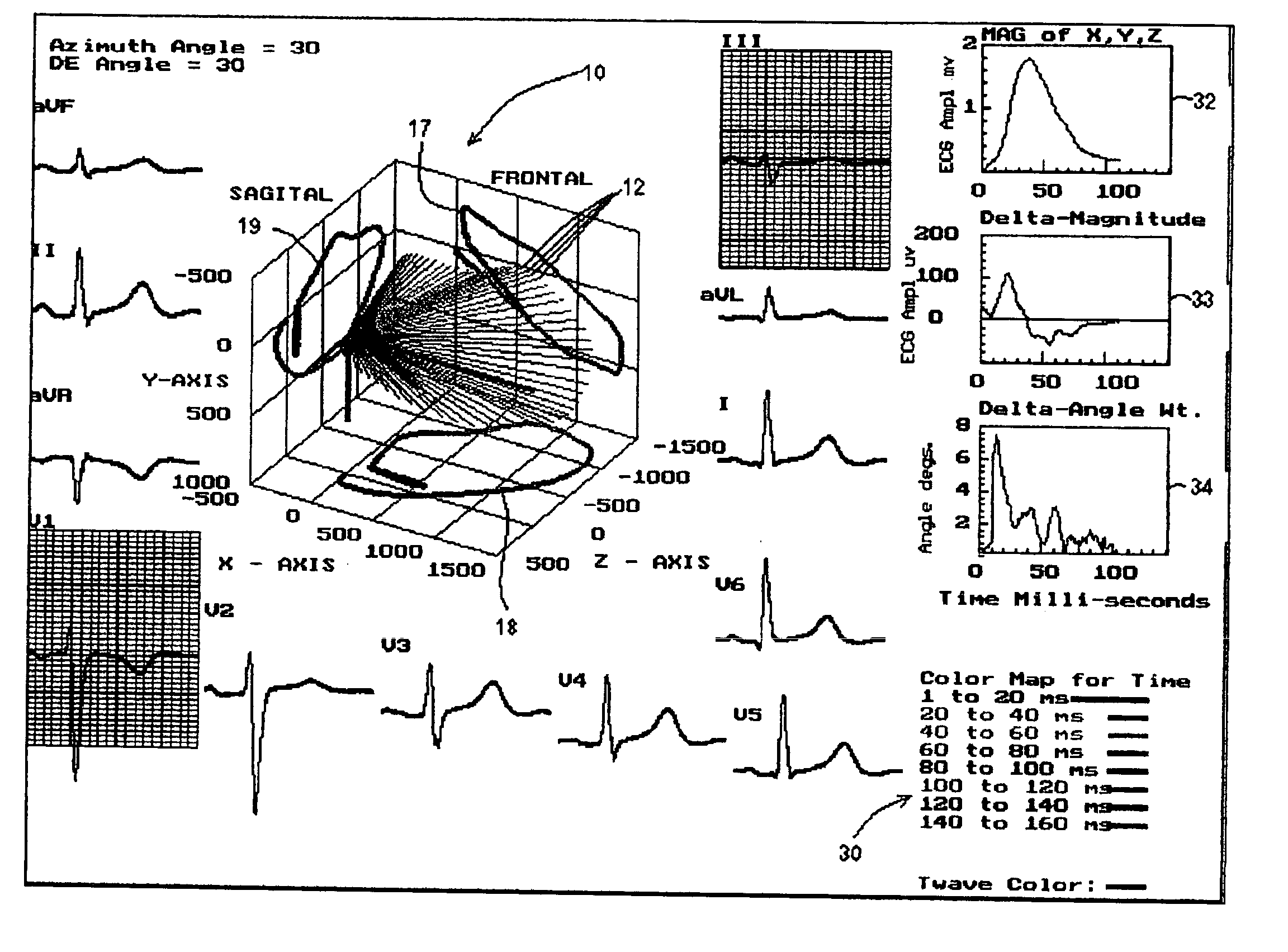

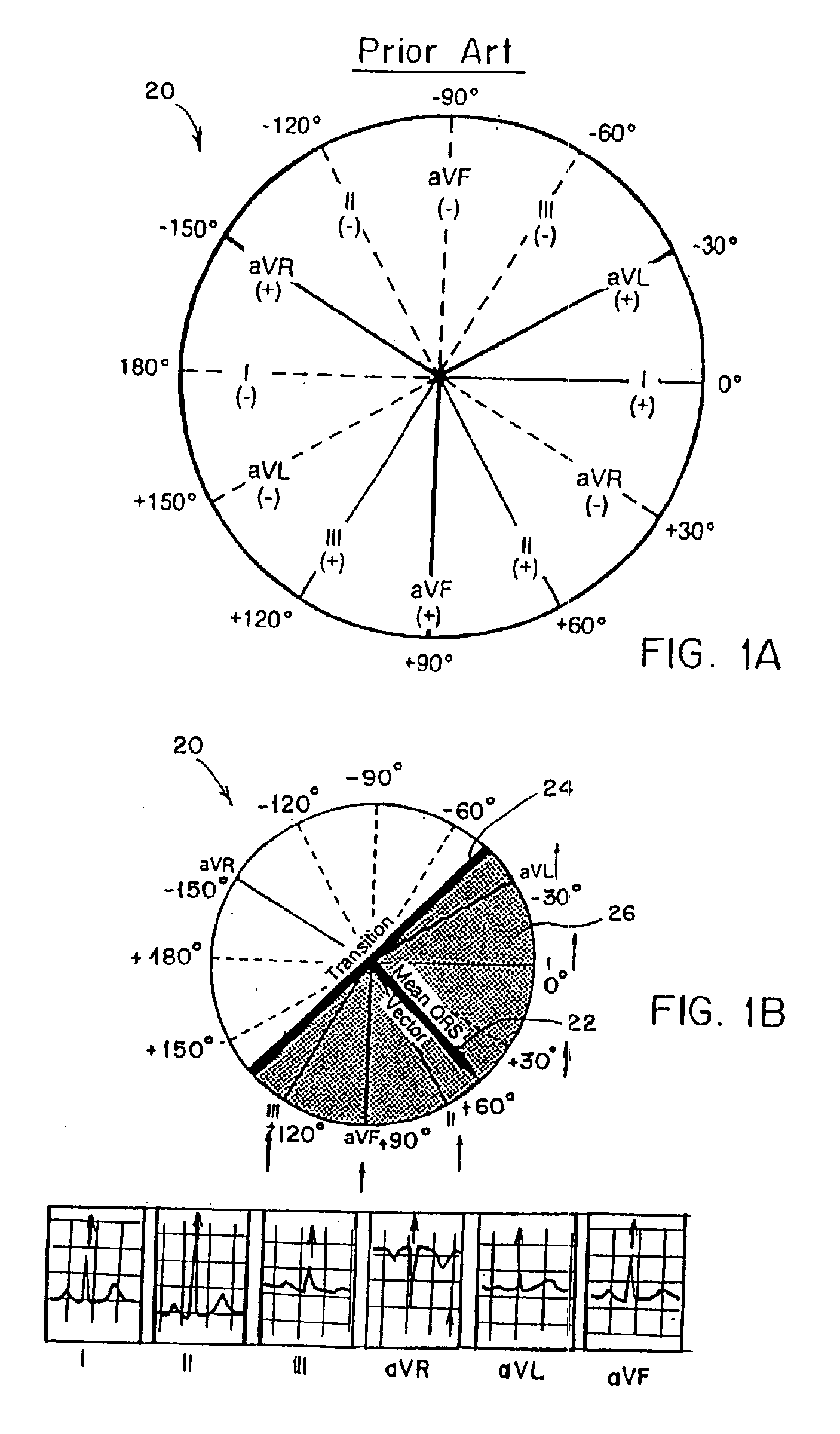

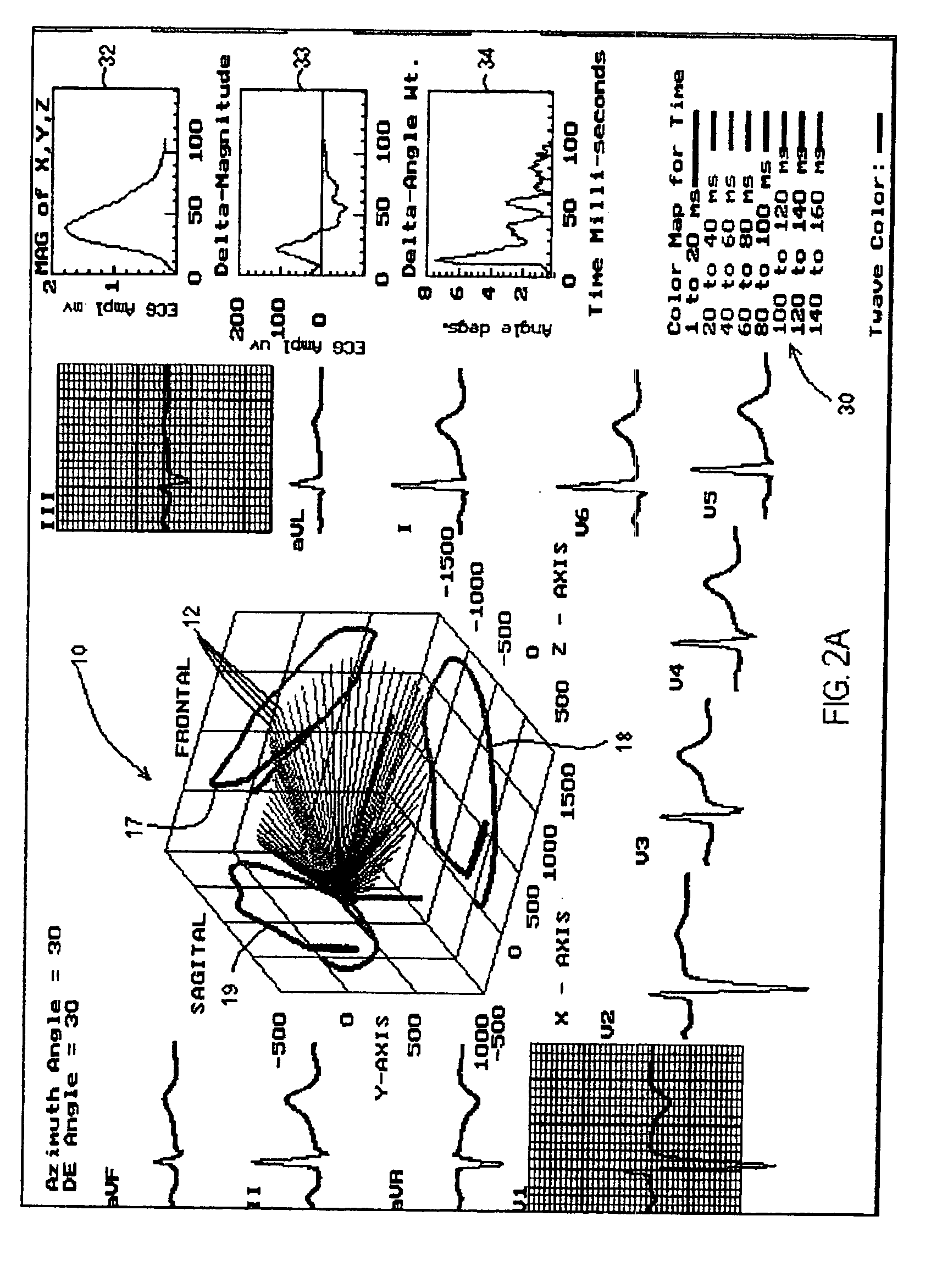

Three dimensional vector cardiograph and method for detecting and monitoring ischemic events

InactiveUS6884218B2Easy to analyzeGood techniqueElectrocardiographyBlood flow measurement devicesMaximum magnitudeT wave

A method of determining an ischemic event includes the steps of: monitoring and storing an initial electrocardiogram vector signal (x, y, z) of a known non-ischemic condition over the QRS, ST and T wave intervals; calculating and storing a J-point of the vector signal and a maximum magnitude of a signal level over the T wave interval; monitoring a subsequent electrocardiogram vector signal over the QRS, ST and T wave intervals; measuring and storing the magnitude (Mag.) of the vector difference between a subsequent vector signal and the initial vector signal; measuring and storing the angle (Ang.) difference between a subsequent vector and the initial vector at points; regressing a line from points about 25 milliseconds prior to the J point and about 60 milliseconds after the J-point and determining the slope of the regression line and the deviation of the angle difference of the regression line; regressing a line from points about 100 milliseconds prior to the maximum magnitude of the signal level over the T wave interval and determining the slope of the regressing line and the deviation of the angle difference of the regression line; and comparing the slope and deviation of the lines from the J point and the T wave interval to a set of known values to determine the presence of an ischemic event.

Owner:ECG TECH CORP

State machine interface system

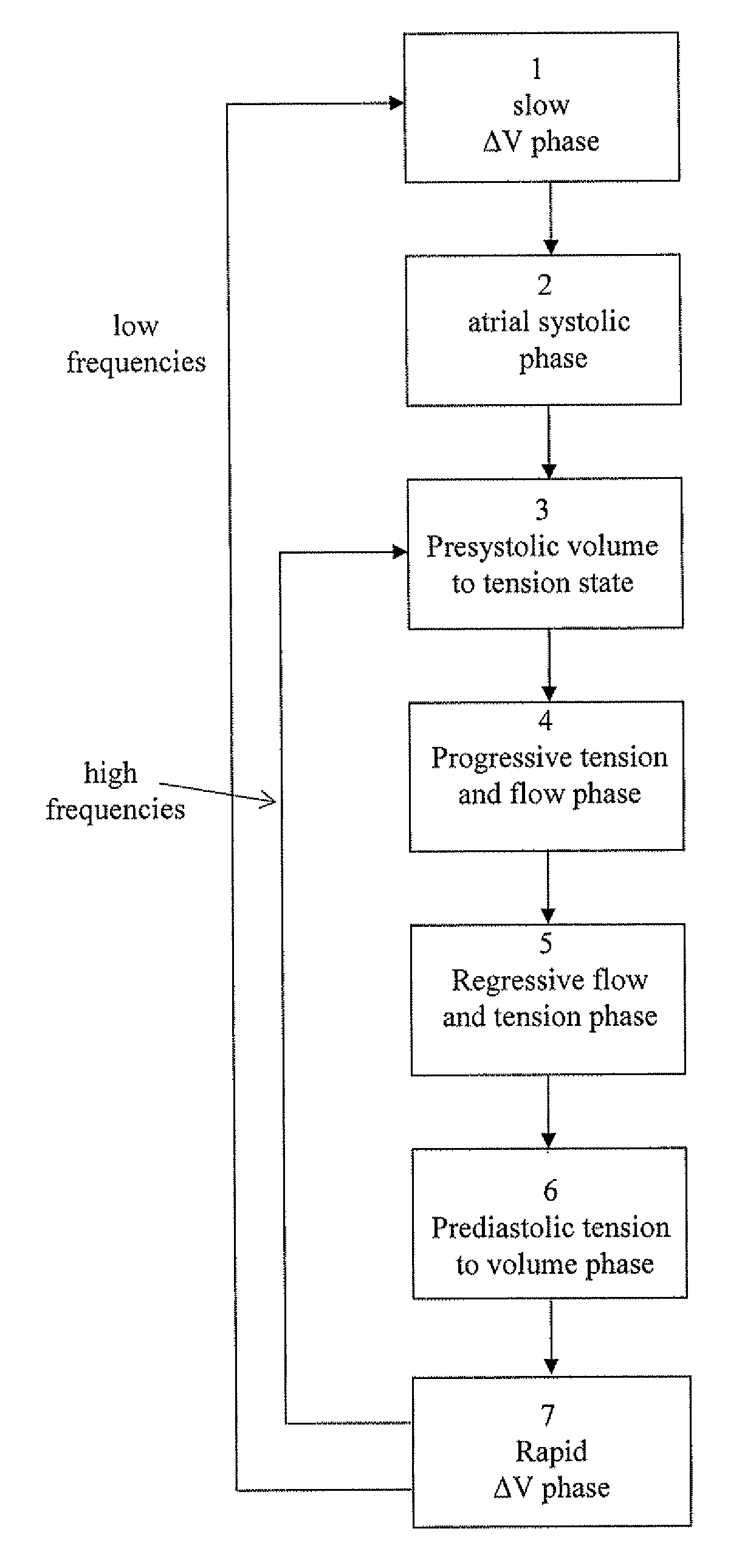

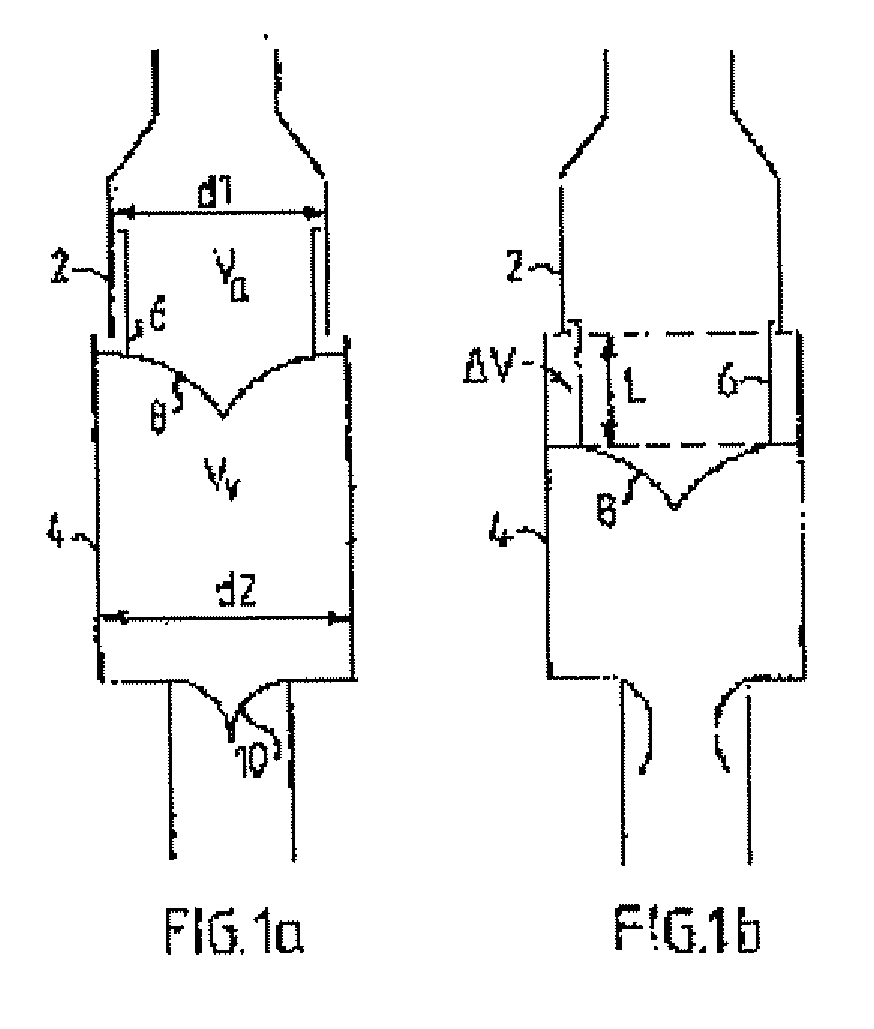

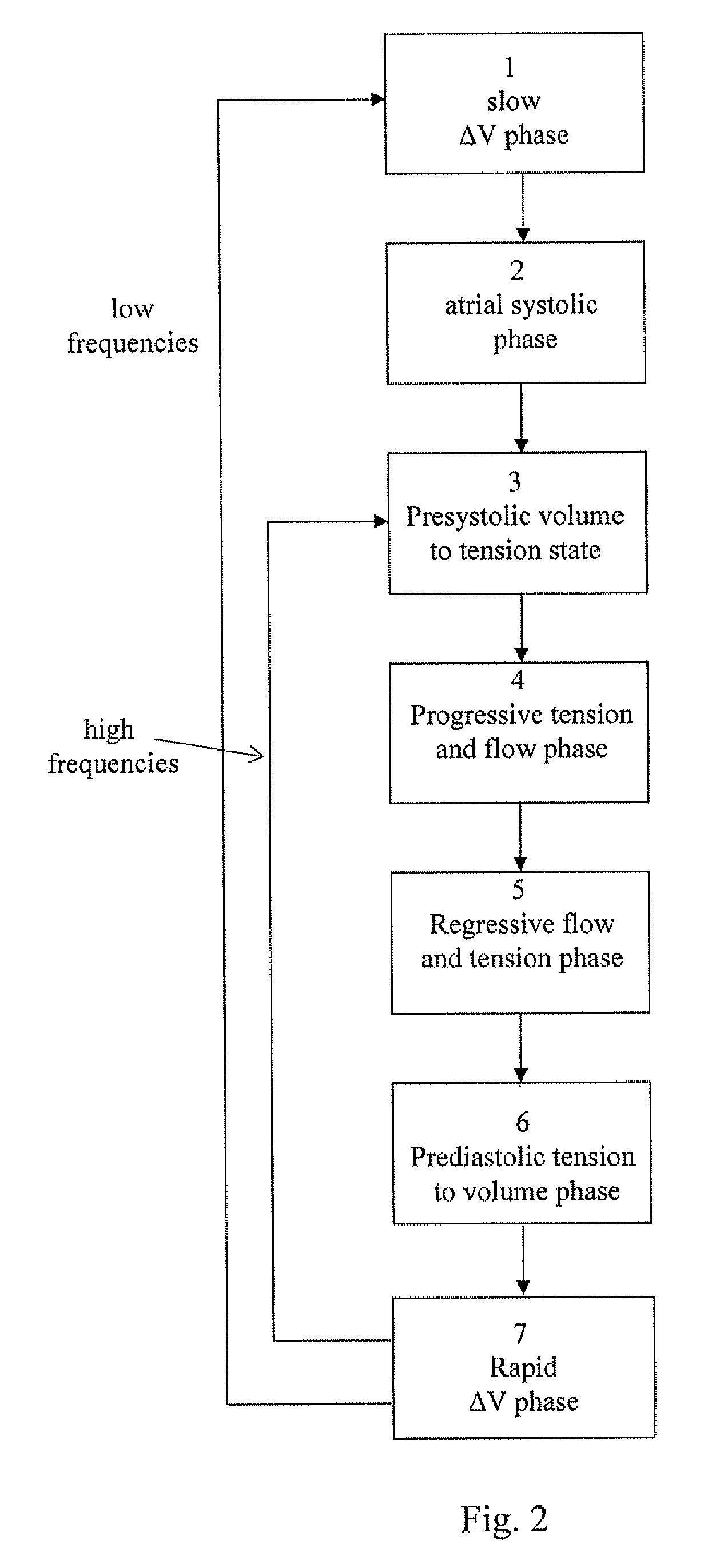

InactiveUS20100030094A1Easy diagnosisEasy assessment processMedical simulationInertial sensorsGraphicsGraphical user interface

State machine interface system, heart state machine analyzer and / or stimulator, comprising state machine algorithms and a graphical user interface, adapted to receive signals from a sensor device that are related to physiological activities of the heart and / or the circulatory system of a living being and the state machine algorithms determine states of heart cycles based upon the signals. The determined heart cycle states are graphically presented at the graphical user interface such that the temporal relation between the different states are illustrated. The graphical user interface may be circular diagrams or bar graphs including parts representing the temporal relation between the different states.

Owner:GRIPPING HEART

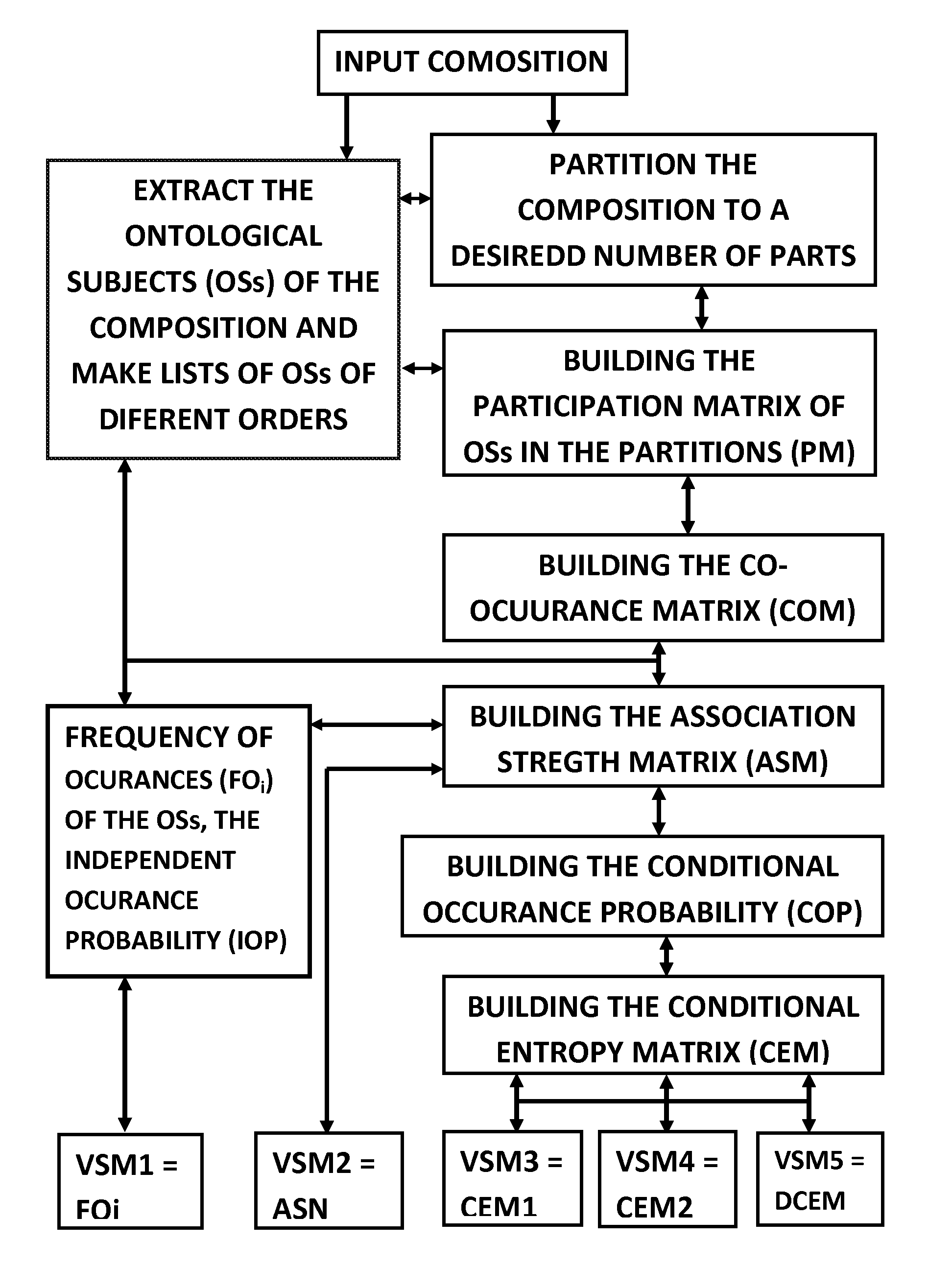

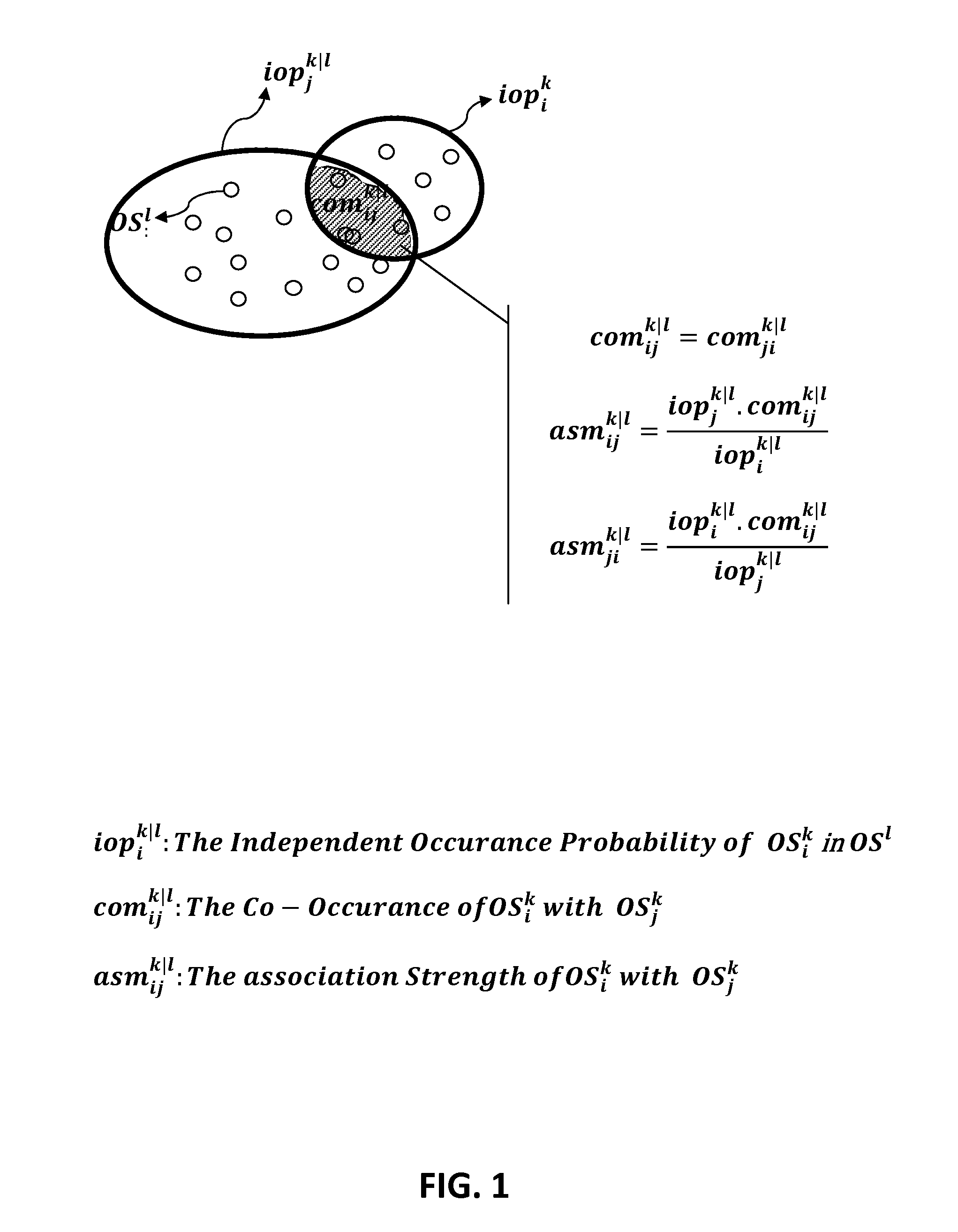

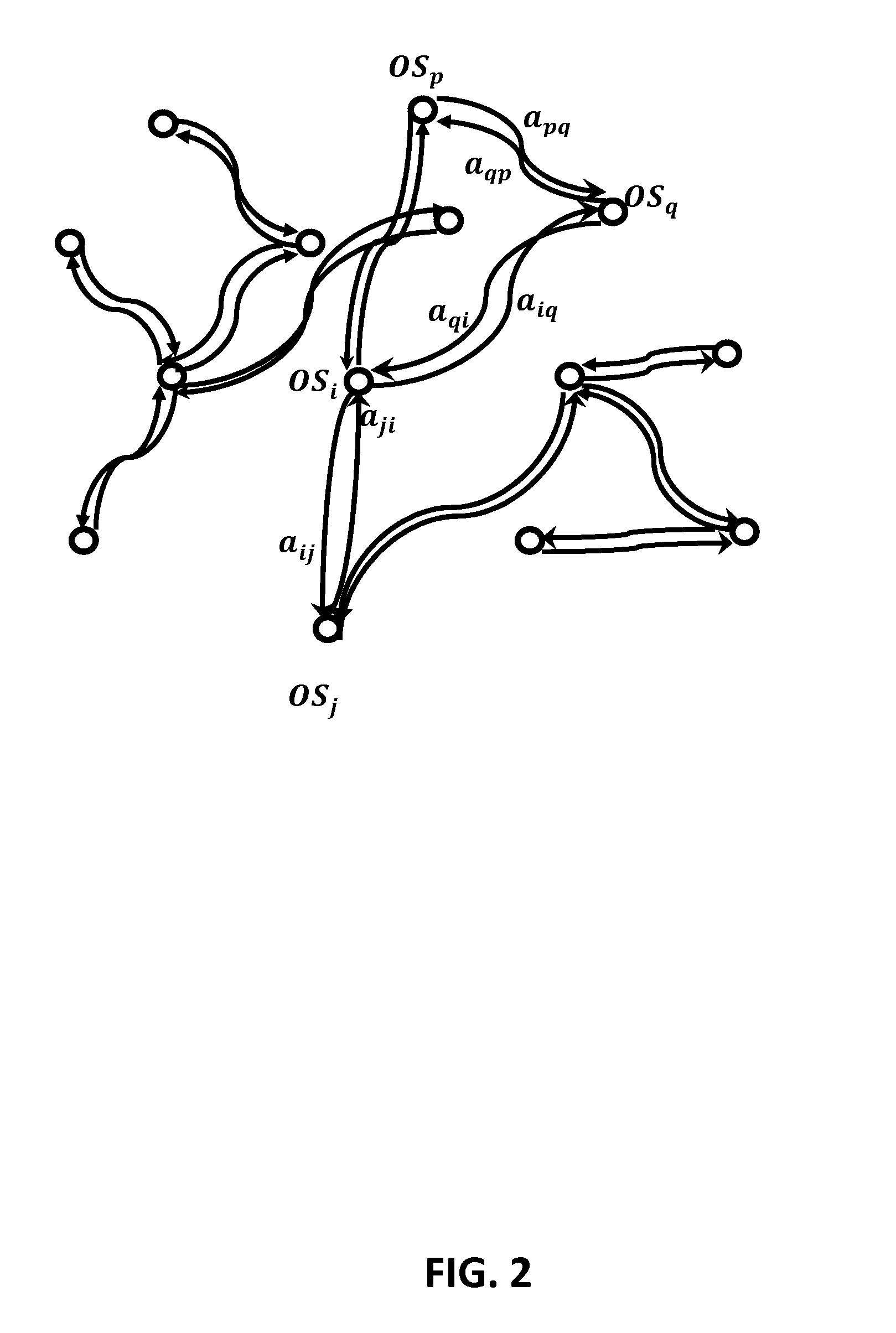

System and Method For Value Significance Evaluation of Ontological Subjects of Networks and The Applications Thereof

ActiveUS20110113095A1KnowledgeProcessDrawing from basic elementsDigital data information retrievalData miningSubject matter

Owner:HATAMA HANZA HAMID

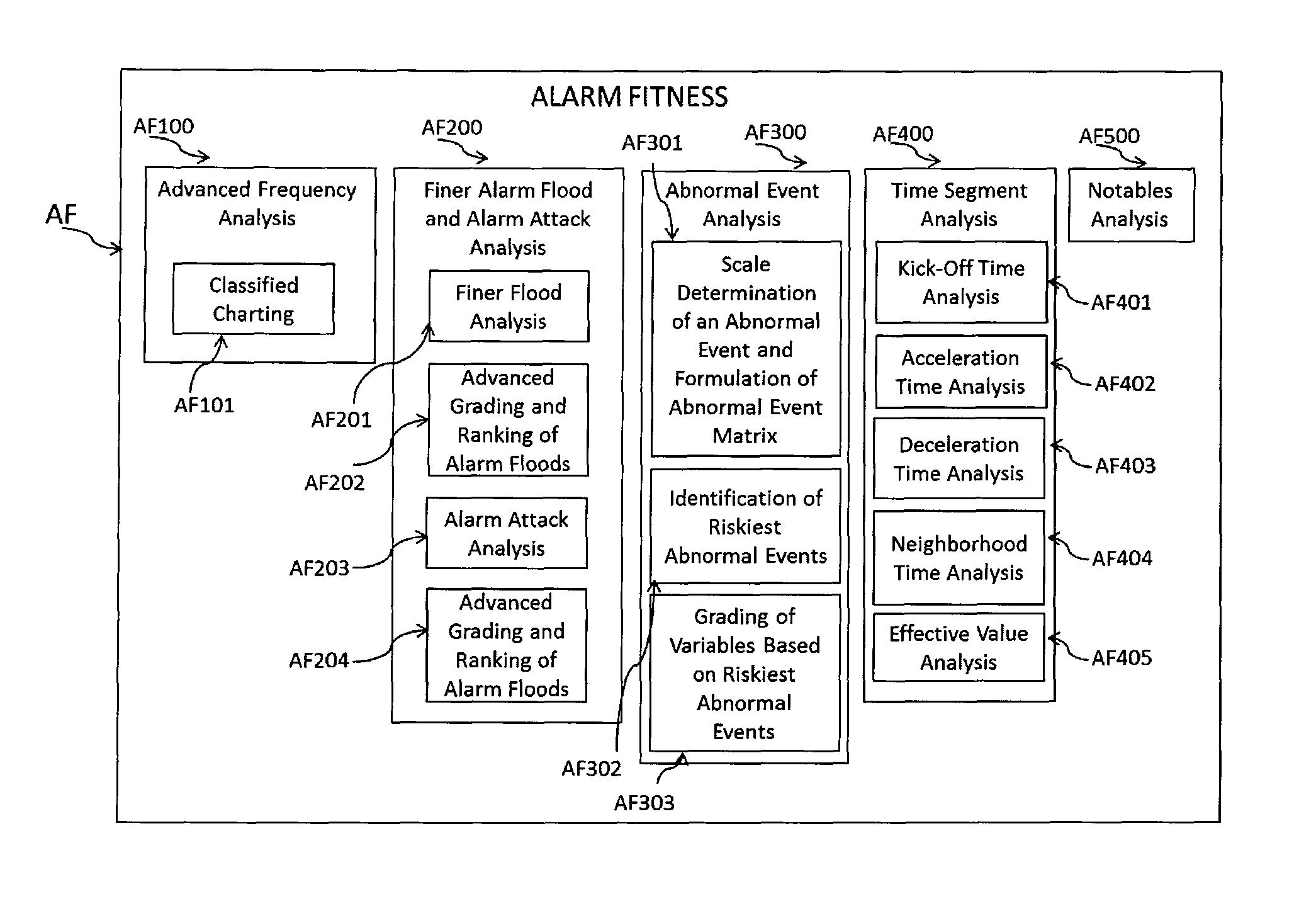

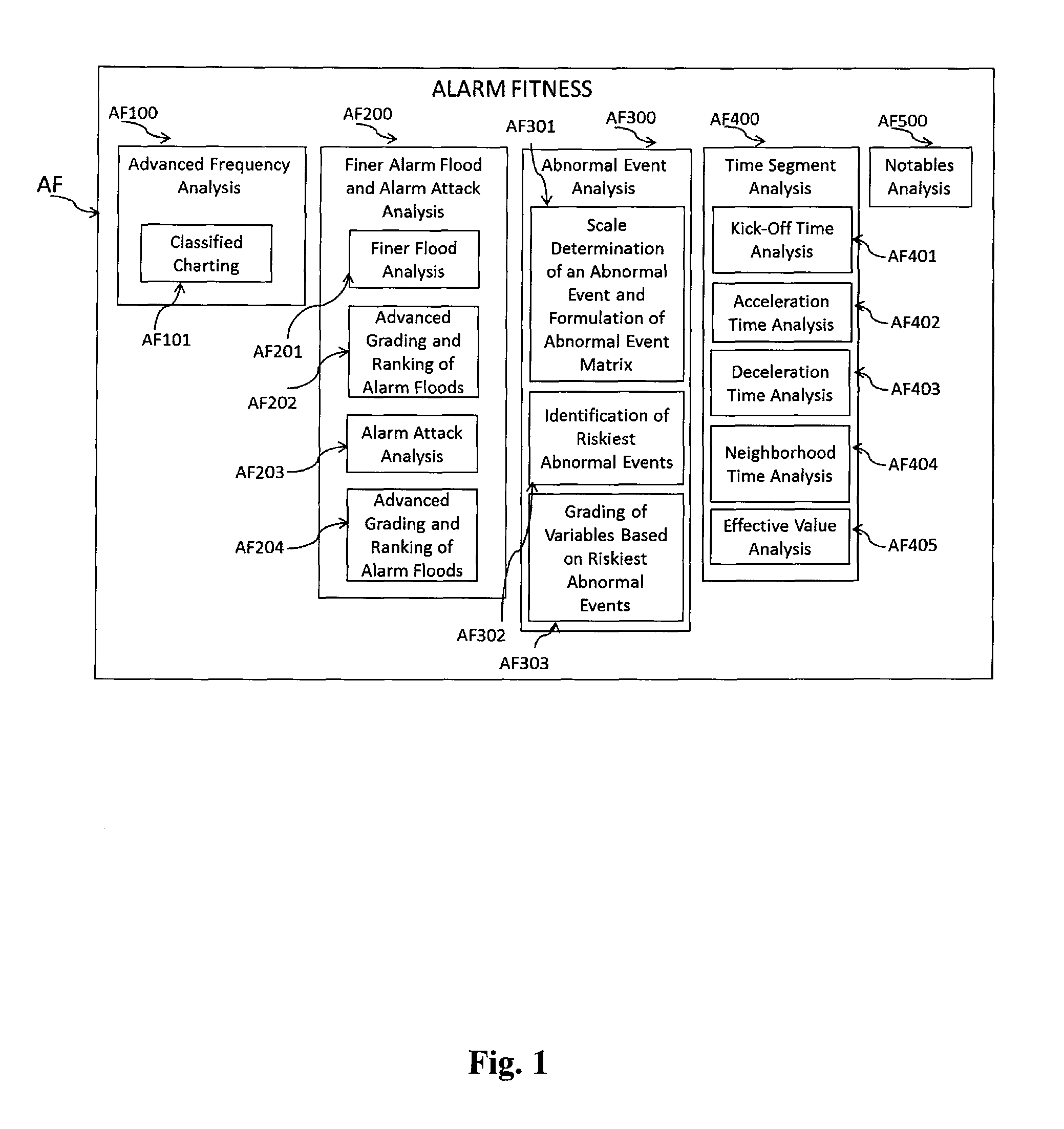

Dynamic prediction of risk levels for manufacturing operations through leading risk indicators

ActiveUS20130063264A1Raise the possibilityImprove securityTesting/monitoring control systemsAlarmsRisk levelDisposal waste

Provided are methodologies to properly assess and manage operational risks at operations sites, e.g., a manufacturing, production or processing facility, such as a refinery, chemical plant, fluid-catalytic-cracking units, or nuclear energy plant, or a biological or waste management facility, airport or even financial institutions, or at any facility in which operations are often accompanied by risk associated with many high-probability, low-consequence events, often resulting in near-misses. In some operations, processes are monitored by alarms, but the invention operates on either process data or alarm data. The methods are based upon measurement of one or more variables, and / or utilization and management of the concept of “hidden process near-miss(es)” to identify a change or escalation, if any, in probability of occurrence of an adverse incident. The methodologies combine a plurality of subsets (also useful independently) of dynamically calculated leading risk indicators for dynamic risk management.

Owner:NEAR MISS MANAGEMENT

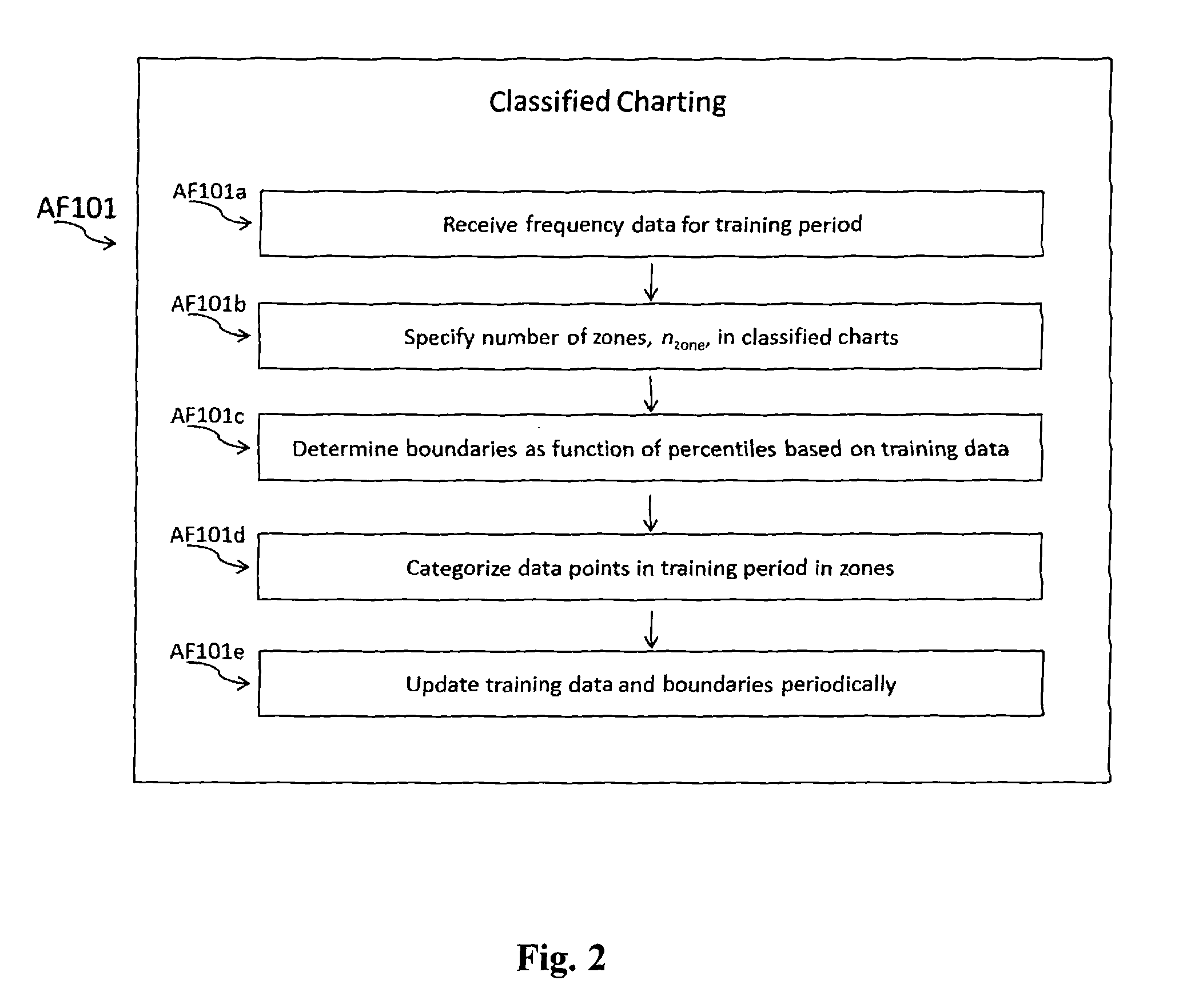

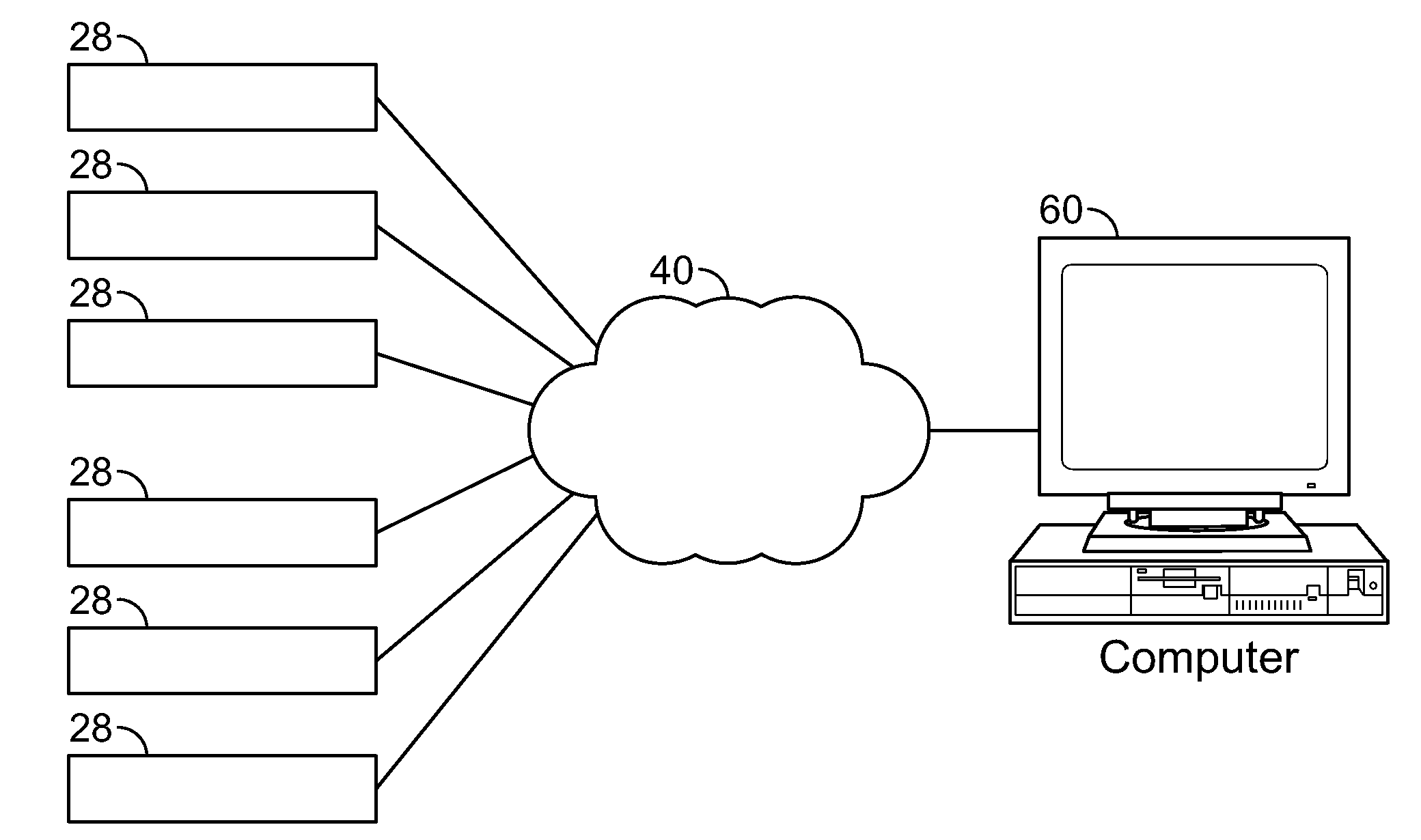

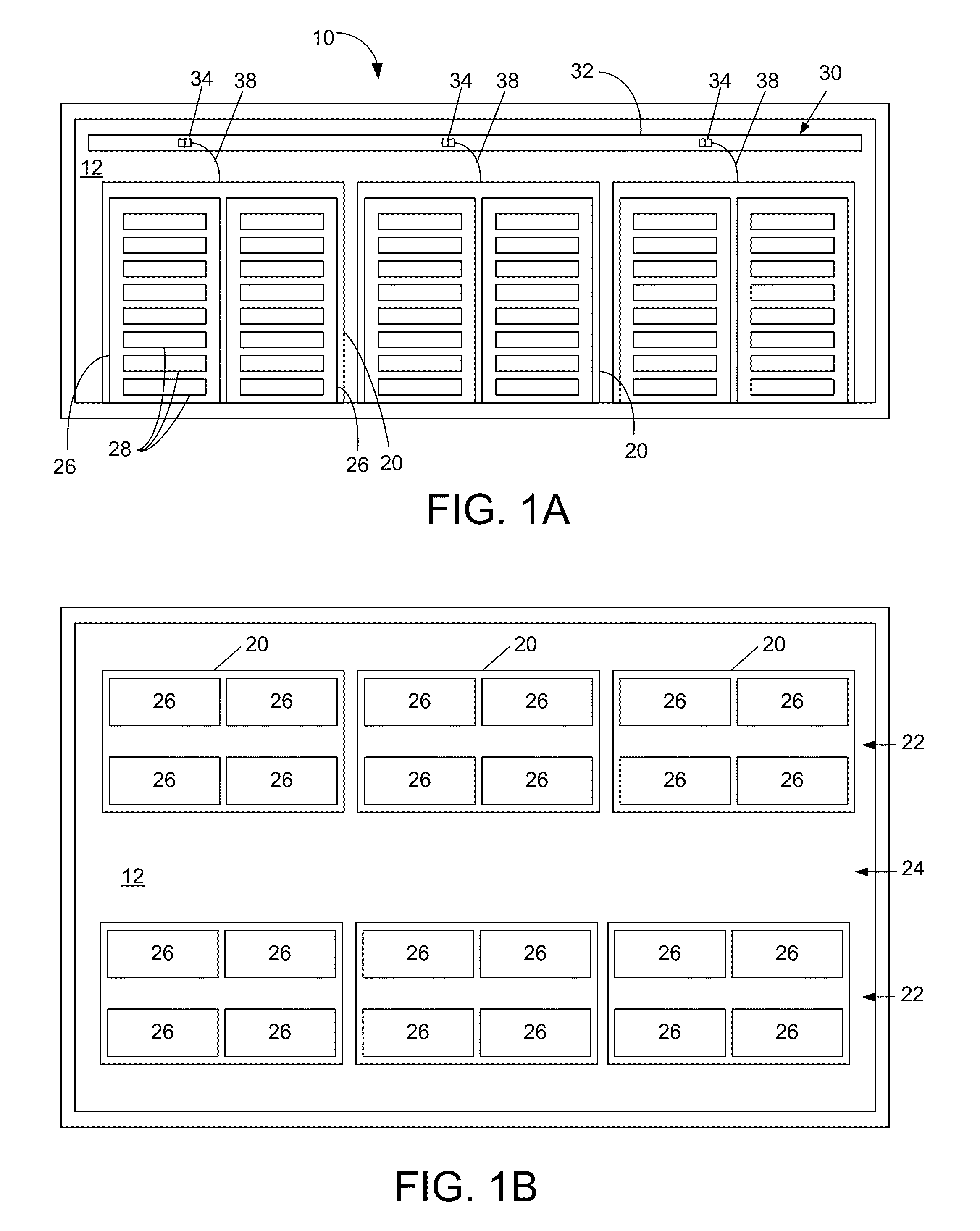

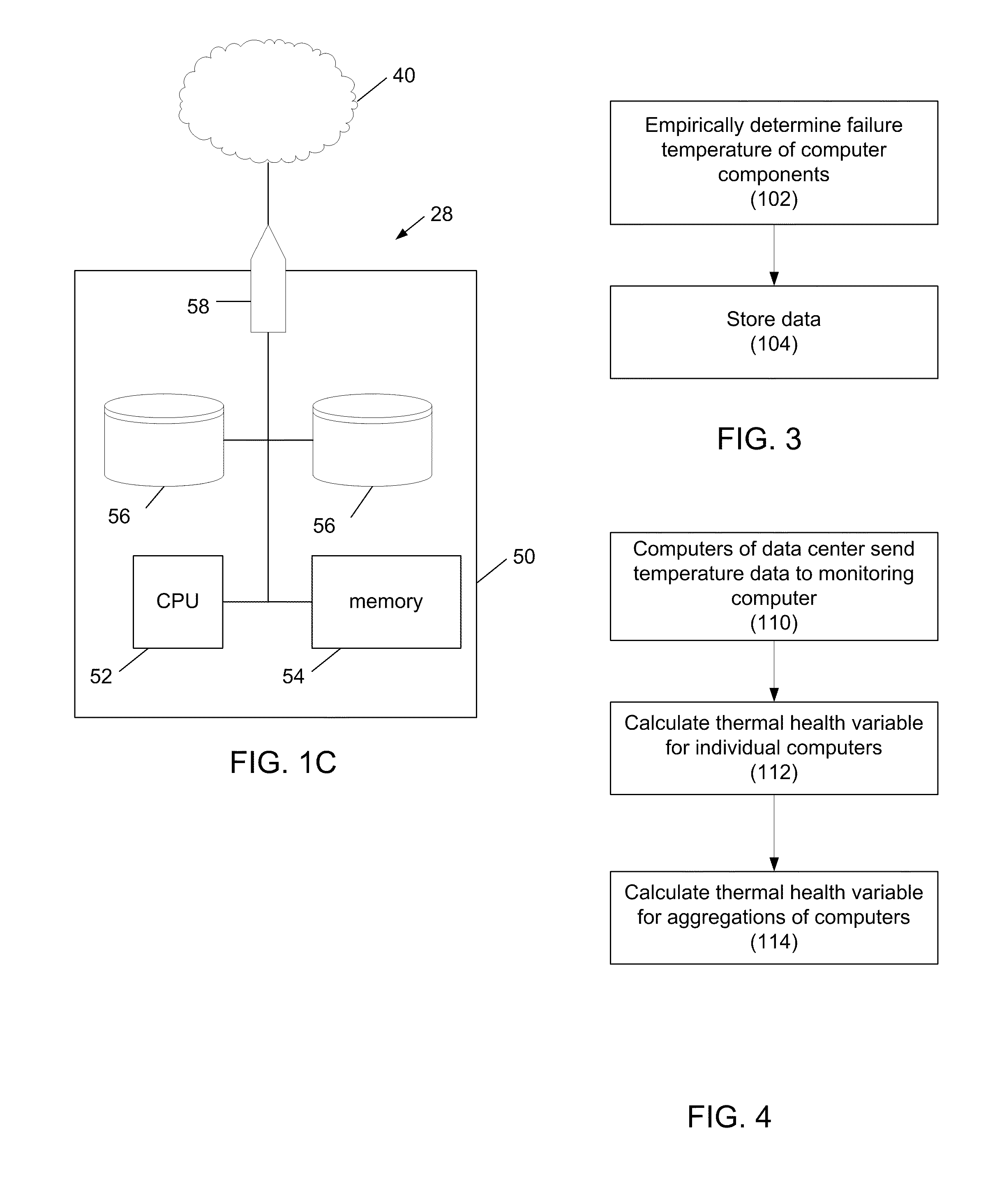

Data center thermal monitoring

ActiveUS20100085196A1Easy assessment processReduce downtimeDigital data processing detailsCompression machines with non-reversible cycleThermal monitoringData center

Owner:GOOGLE LLC

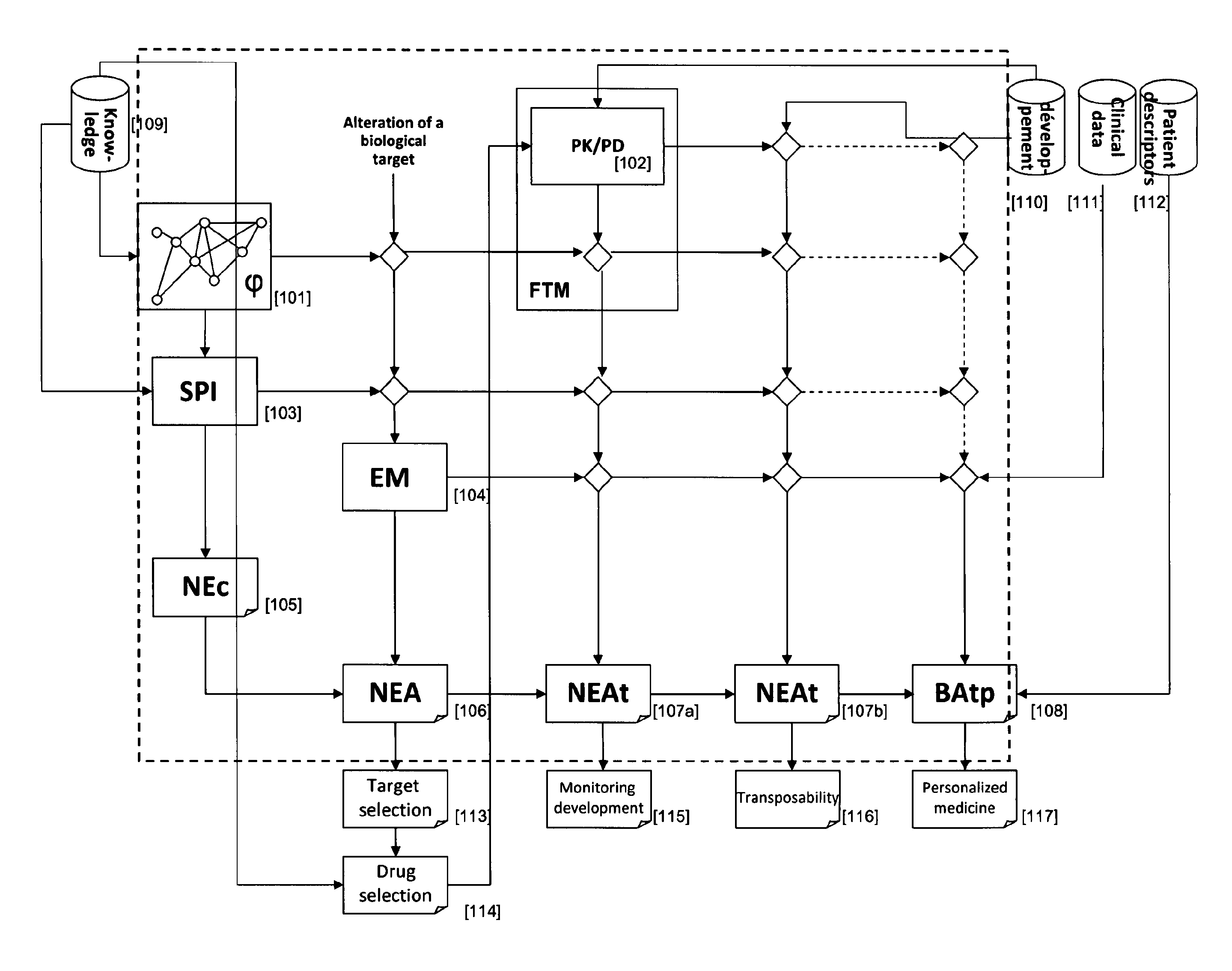

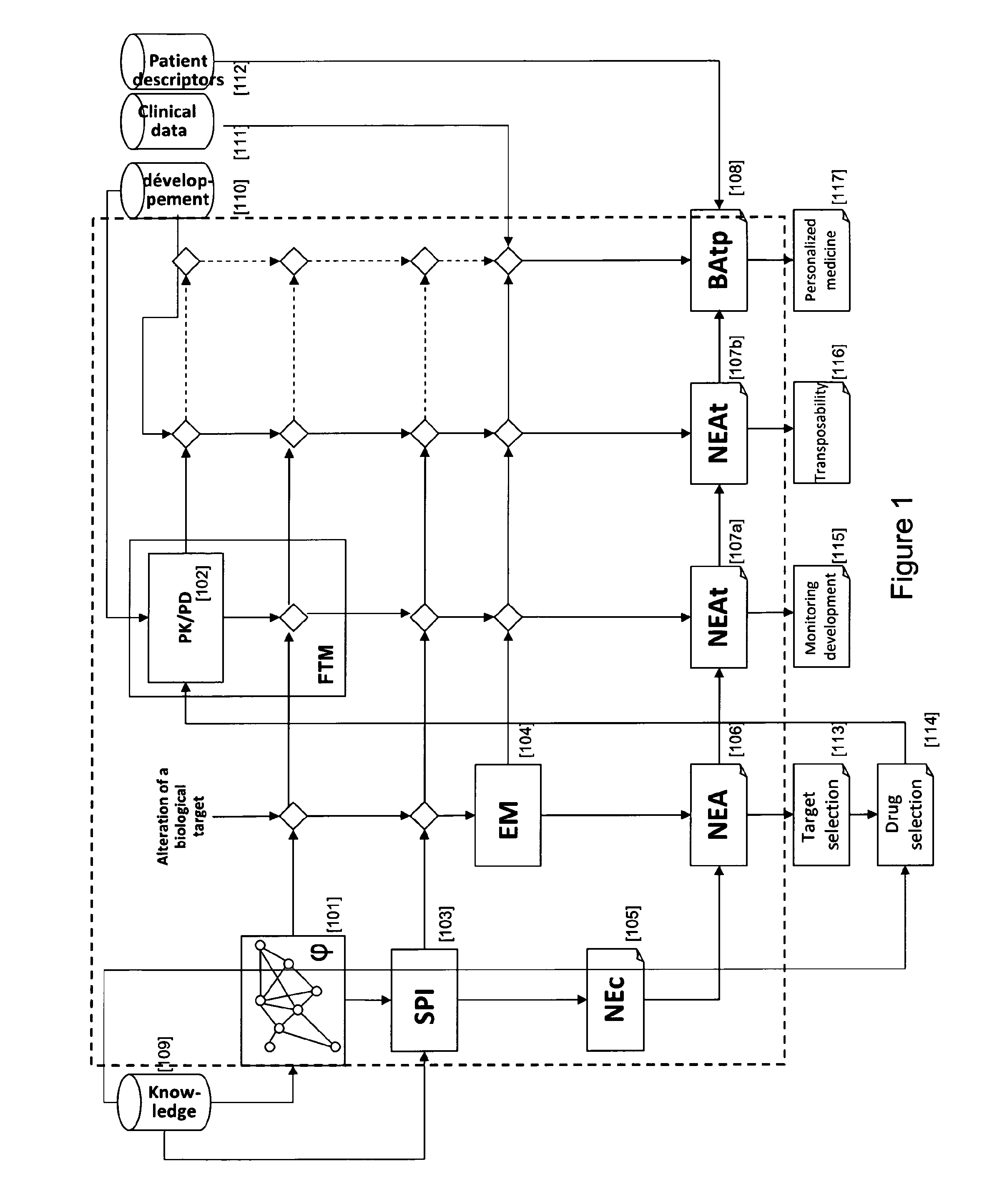

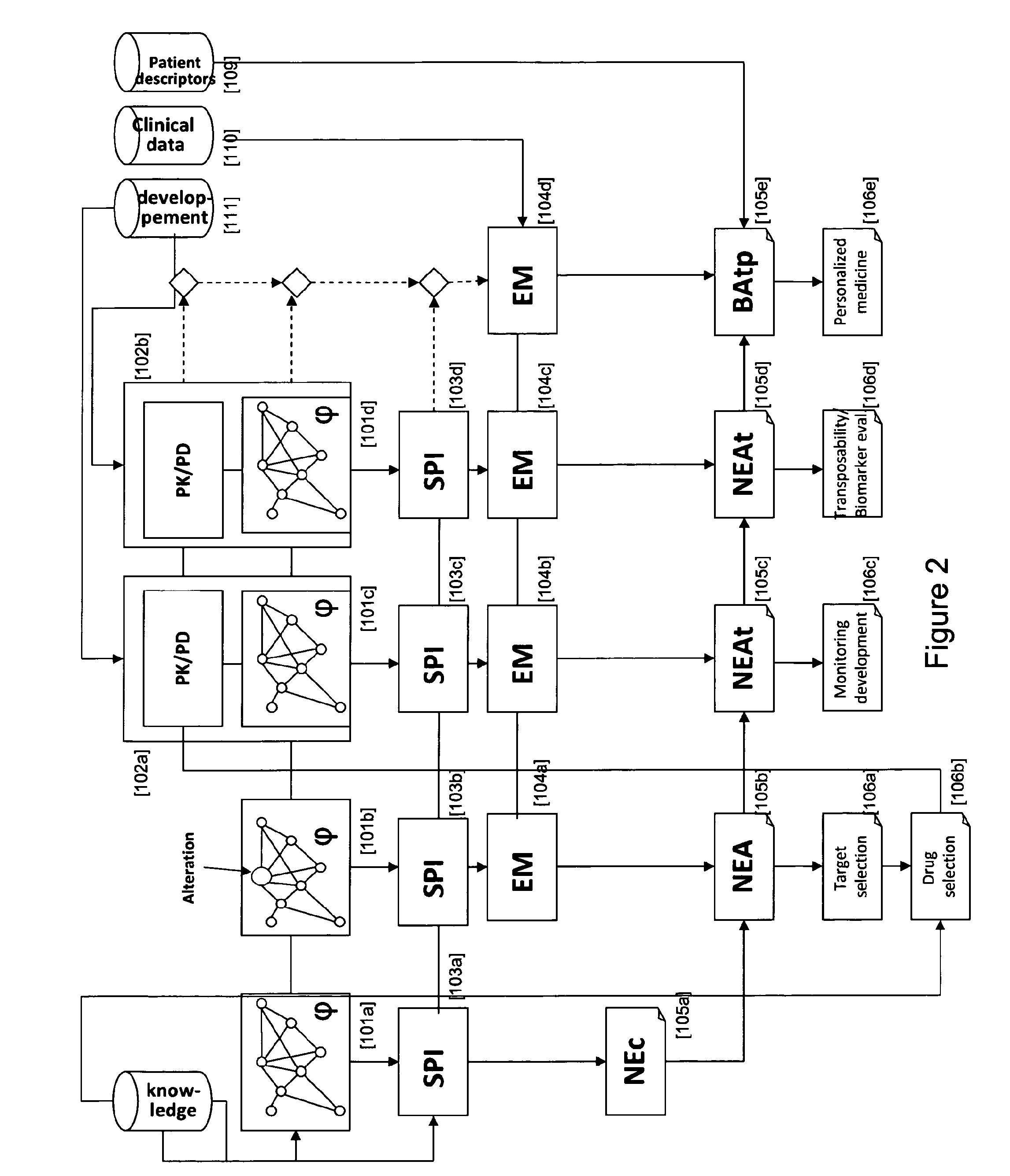

Computer based system for predicting treatment outcomes

InactiveUS20130041683A1Simple systemPotential for errorData processing applicationsBiostatisticsPersonalizationBiomarker discovery

This invention relates to computer systems for conducting drug and biomarker discovery, drug development, and personalized medicine, and more generally managing healthcare, and in particular to a system and method for predicting the therapeutic value of a treatment to an individual. The treatment is associated with a function that describes, in a population of individuals, the benefit from a treatment, generally in terms of occurrence of a medical event under treatment, as a function of the risk (e.g., the occurrence of the medical event) without said treatment.

Owner:NOVADISCOVERY +1

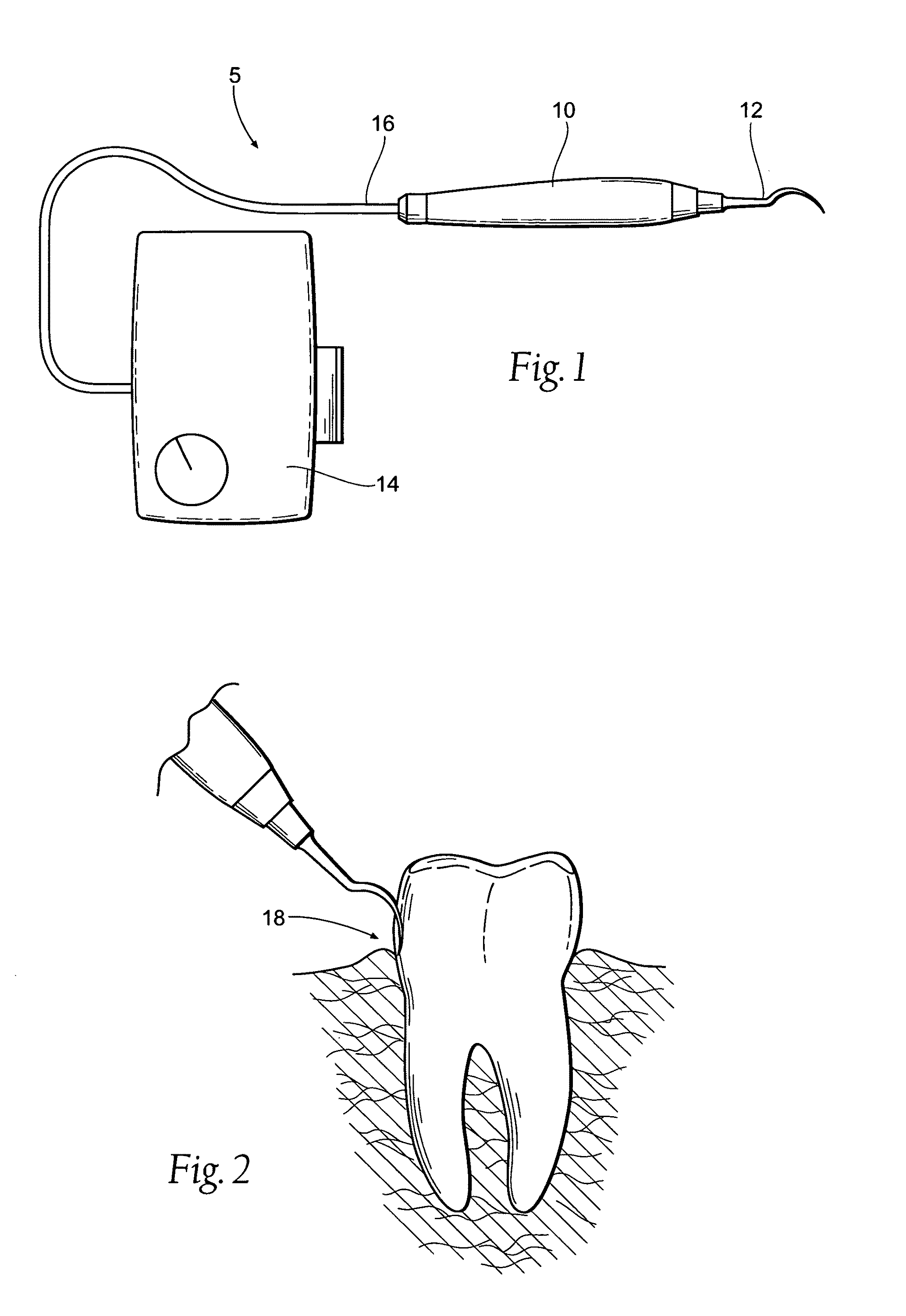

Ultrasonic device having memory capabilities

ActiveUS20110087605A1Sure easyEasily obtain dataTooth pluggers/hammersCommerceEngineeringRadio frequency

A dental device capable of monitoring at least one characteristic of the dental device. The characteristics are monitored by the use of microchips; radio frequency identification devices (RFID), bar codes, resistors, diodes, semiconductors, and magnetic strips.

Owner:INTERMED

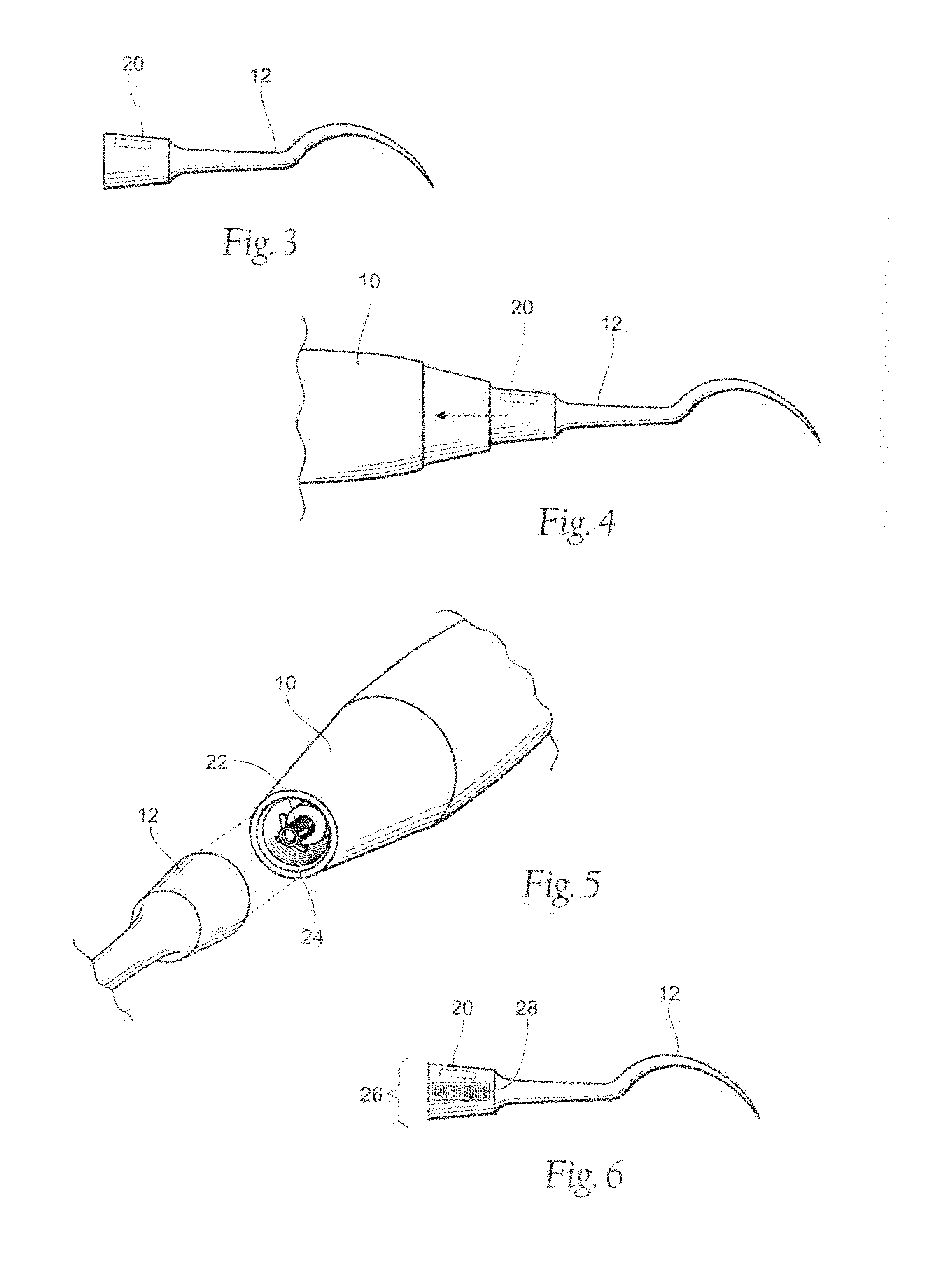

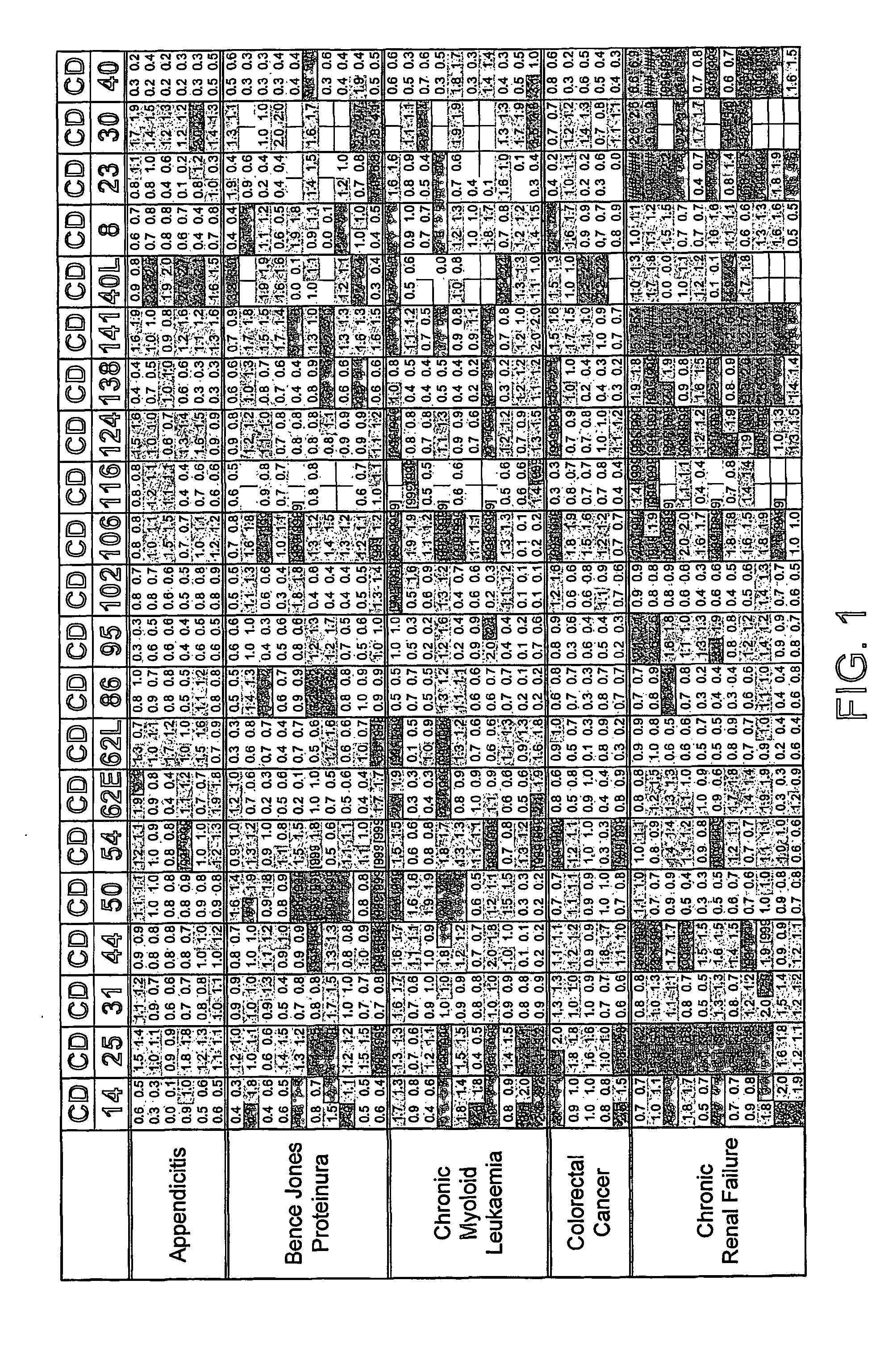

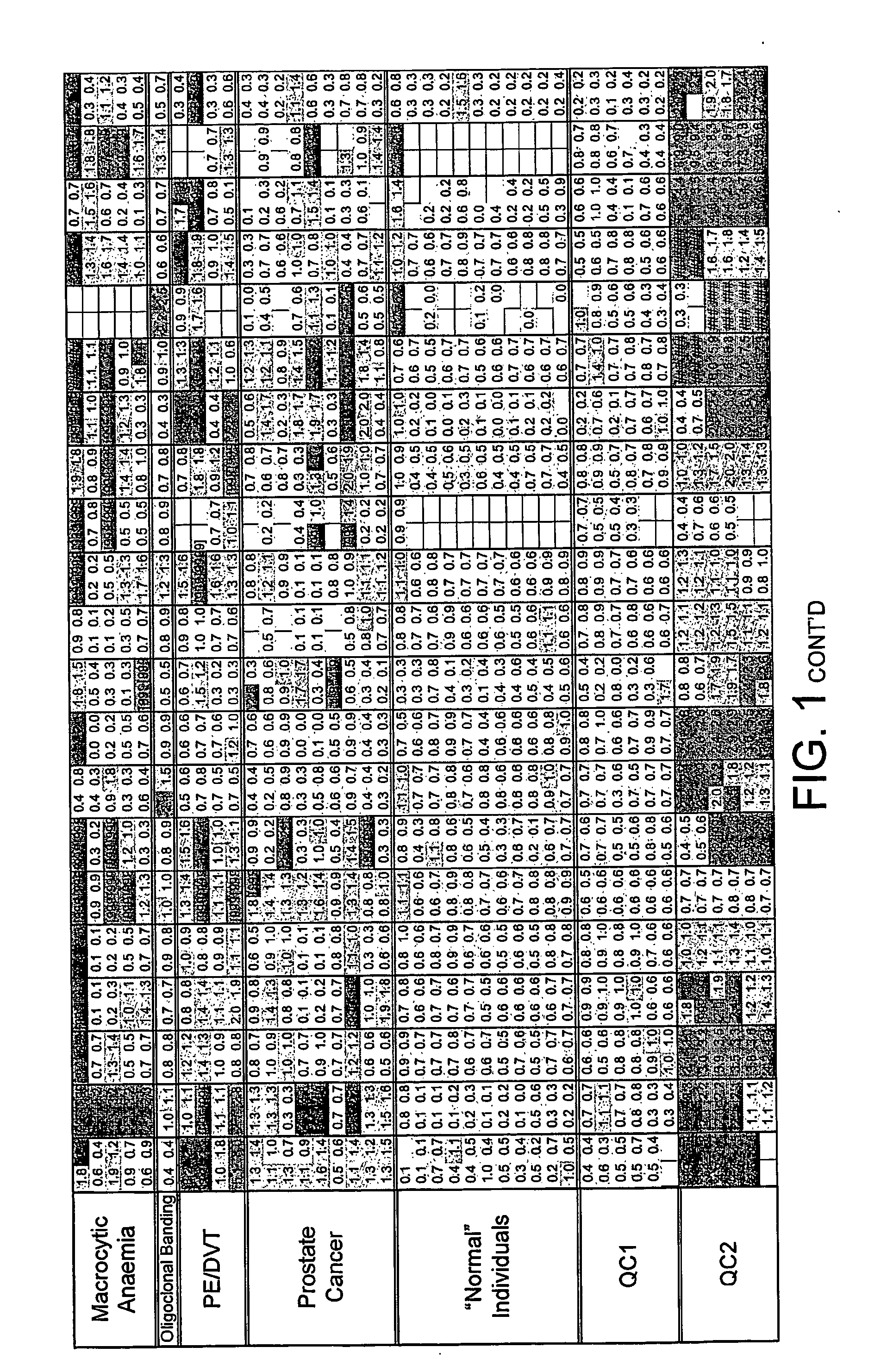

Scd fingerprints

InactiveUS20070233391A1Complicate to obtainMinimize impactData processing applicationsBiological testingDiseaseCluster of differentiation

The present invention relates to the use of cluster of differentiation (CD) molecules in detecting the presence and progression of one or more disease states in an individual. In particular it relates to the use of profiles of shed CD (sCD) molecules in detecting and assessing the progression of one or more disease states in an individual. Further uses of sCD profiles according to the present invention are also described.

Owner:CAMBRIDGE UNIV TECH SERVICES LTD +2

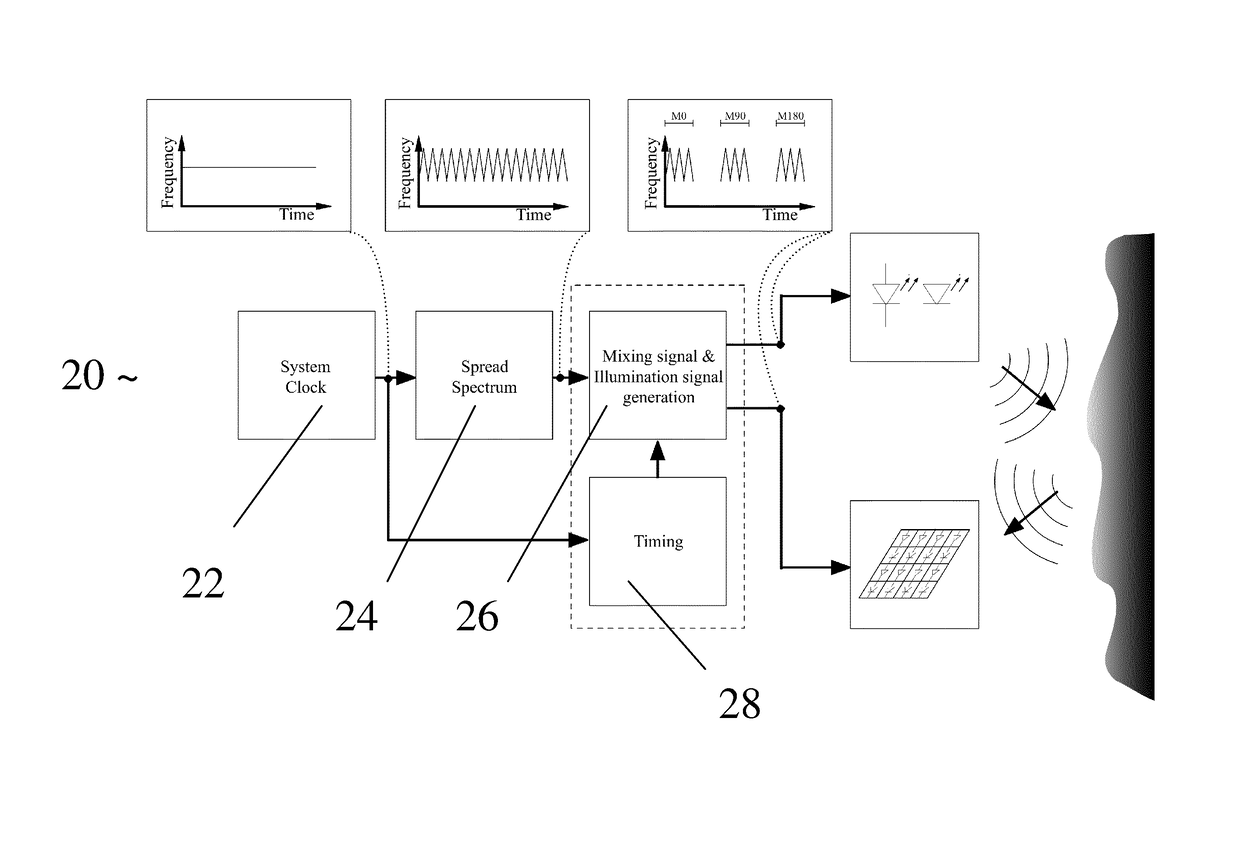

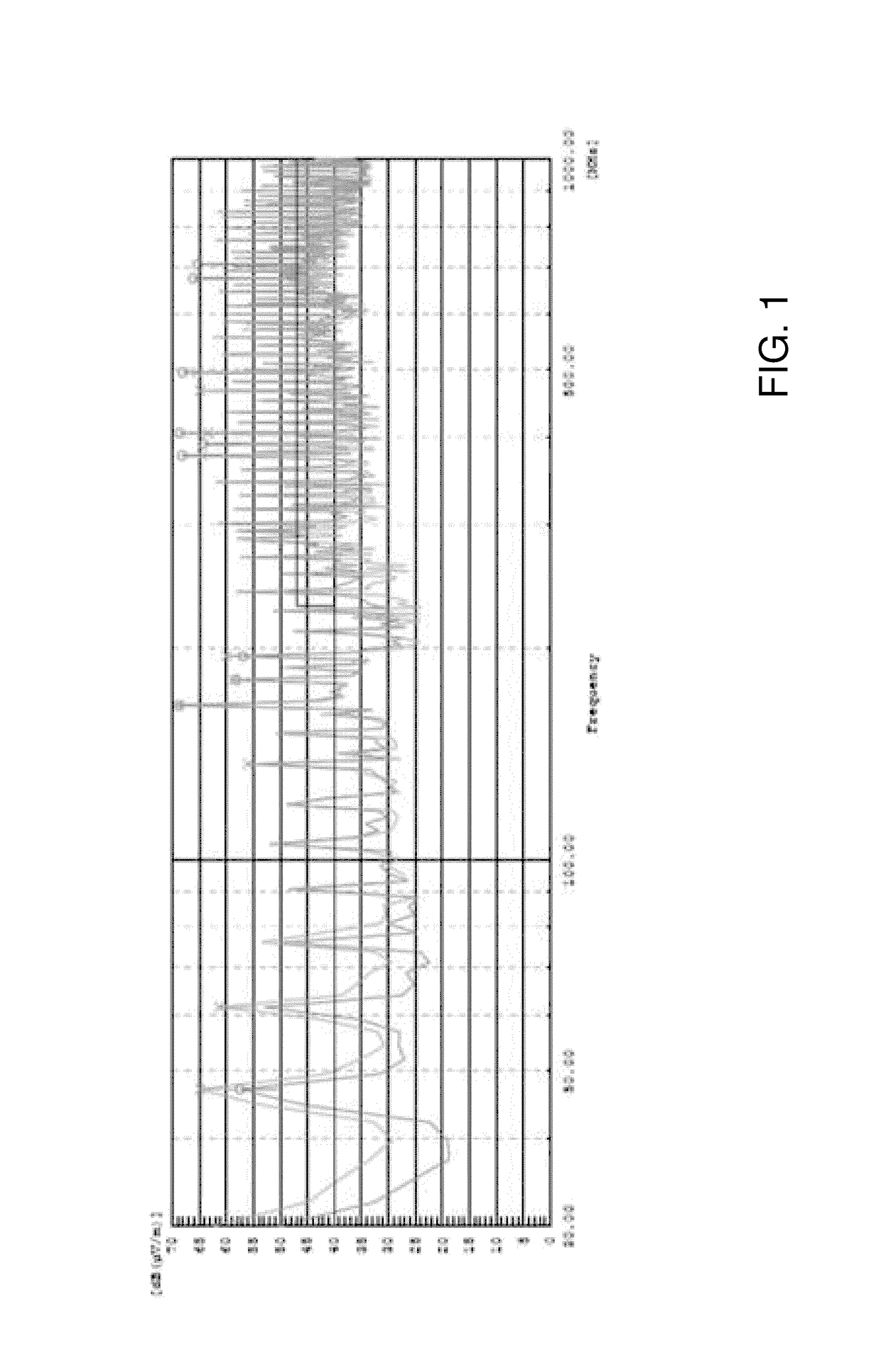

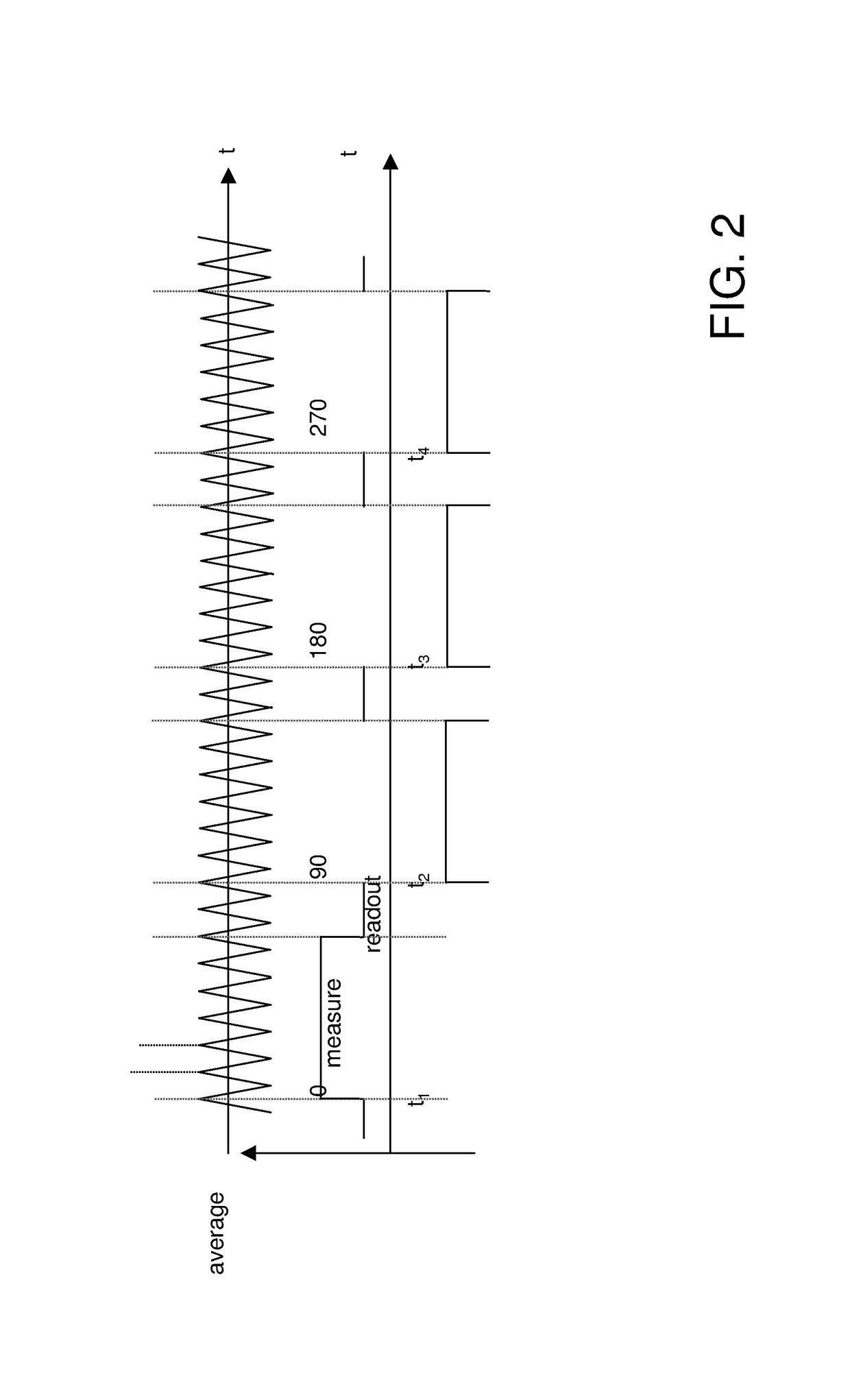

Method and time-of-flight camera for providing distance information

ActiveUS9599712B2Improve accuracyReduce electromagnetic interferenceOptical rangefindersTransmission noise suppressionOptoelectronicsTime-of-flight camera

The invention relates to a method for providing distance information of a scene with a time-of-flight camera (1), comprising the steps of emitting a modulated light pulse towards the scene, receiving reflections of the modulated light pulse from the scene, evaluating a time-of-flight information for the received reflections of the modulated light pulse, and deriving distance information from the time-of-flight information for the received reflections, whereby a spread spectrum signal is applied to a base frequency of the modulation of the light pulse, and the time-of-flight information is evaluated under consideration of the a spread spectrum signal applied to the base frequency of the modulation of the light pulse. The invention further relates to a time-of-flight camera (1) for providing distance information from a scene, whereby the time-of-flight camera (1) performs the above method.

Owner:SOFTKINETIC SENSORS

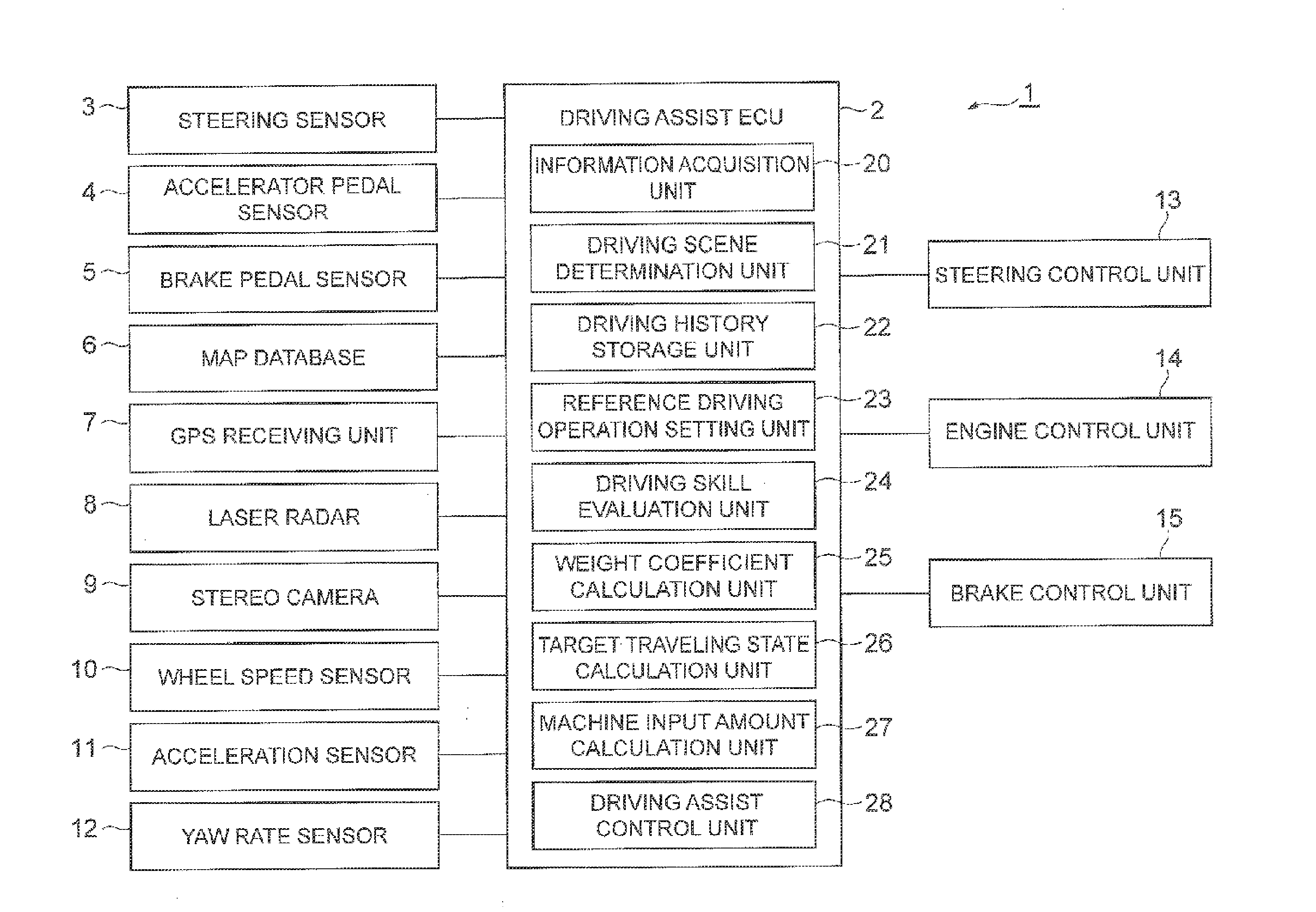

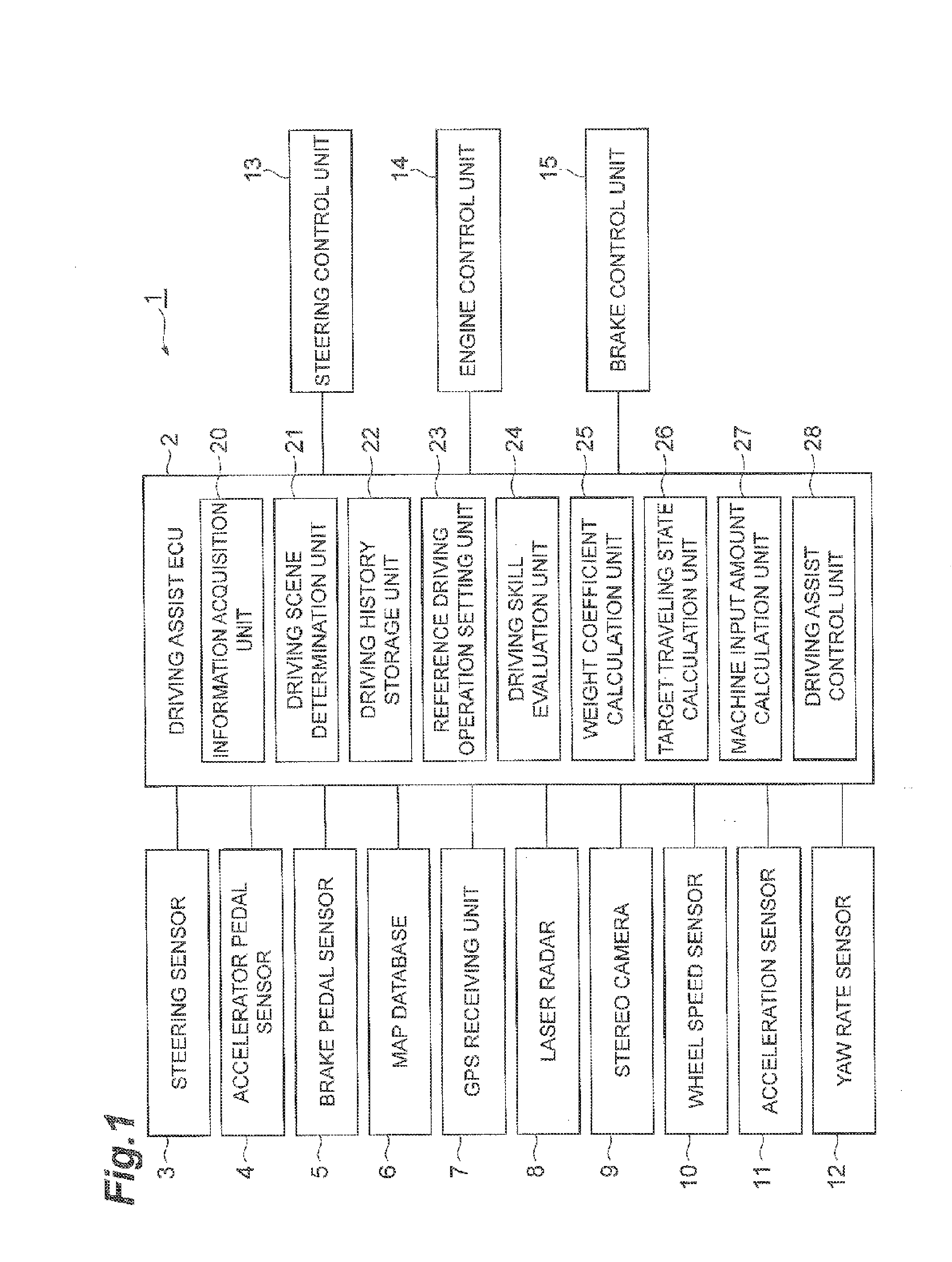

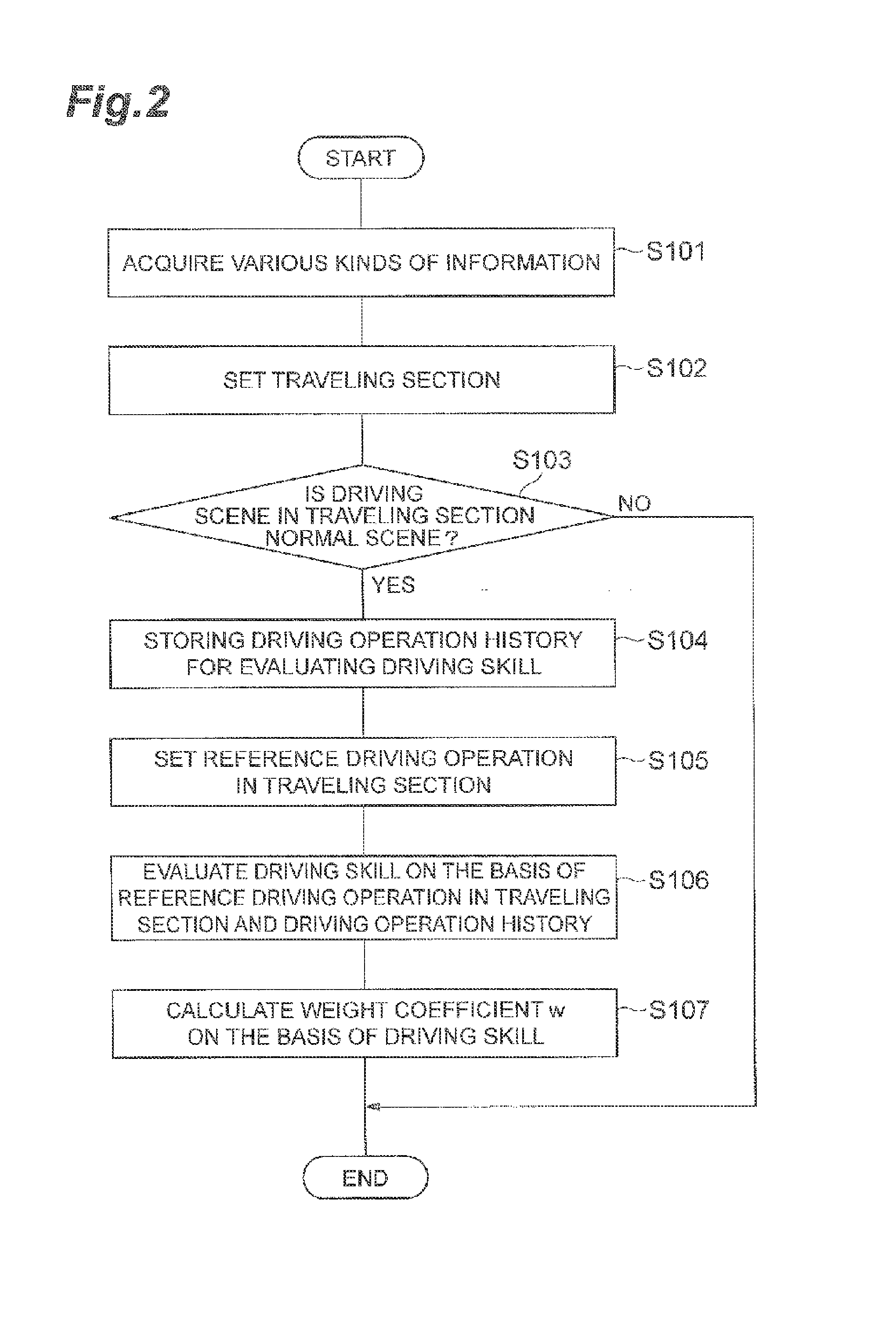

Driving assist device

InactiveUS20150336587A1Reduce loadEasy to limitSteering initiationsDigital data processing detailsSkill setsEngineering

A driving assist device 1 includes: an information acquisition unit 20 that detects a driving operation of a driver for the vehicle; a driving skill evaluation unit 24 that evaluates a driving skill of the driver on the basis of a history of the driving operation of the driver; and a driving assist control unit 28 that performs the driving assist control for the vehicle on the basis of the traveling state of the vehicle and the target traveling state. When the information acquisition unit 20 detects the driving operation of the driver during the driving assist control, the driving assist control unit 28 limits the amount of driving assist control for the vehicle according to the driving skill of the driver evaluated and reflects the driving operation amount of the driver in traveling control for the vehicle.

Owner:TOYOTA JIDOSHA KK +2

Method of generating hydrogen in drinking water using an enerceutical product added to magnesium in a hydrogen permeable but solute impermeable container

InactiveUS20100008850A1Increased hydrogen productionImprove usabilityHydrogen productionHydrogen/synthetic gas productionDialysis membranesWater use

Consuming water with increased hydrogen content can provide clinical benefits to humans and animals through a non-mitochondria alternative cellular energy (ACE) pathway and also as an antioxidant. This application discloses that the hydrogen content of drinking water can be safely increased by placing into the water a hydrogen generating device, such as a mixture of metallic magnesium and EH-101 (HB-101) containing solution, whereby the device allows for the selective passage of the generated hydrogen but restricts the passage of magnesium and EH-101 (HB-101) components. This partitioning of hydrogen from EH-101 (HB-101) components is achieved by using either reverse osmosis membrane, low density plastic material such as polyvinylidene chloride (PVDC or Saran), or low molecular weight cutoff dialysis membrane to create a sealed container of the magnesium and magnesium chloride, that can be placed into drinkable water. The EH-101 (HB-101) can be initially placed into a breakable inner compartment within the hydrogen permeable container. This compartment can be easily broken by simple squeezing just prior to placing the device into the water that is intended to have its hydrogen content increased. The increased hydrogen content can be assessed by the capacity of the water to decolorize a potassium permanganate test sample.

Owner:MARTIN WILLIAM JOHN

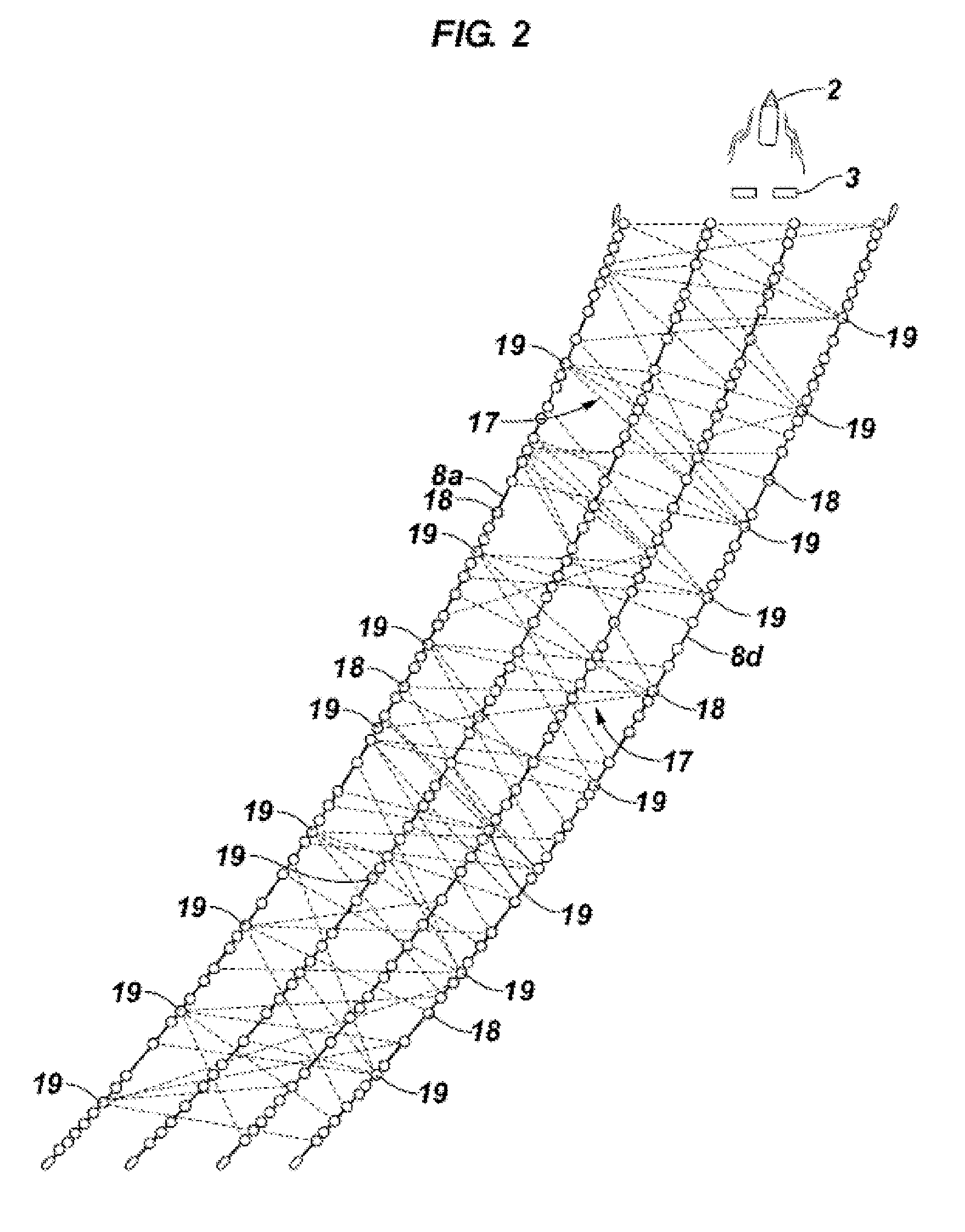

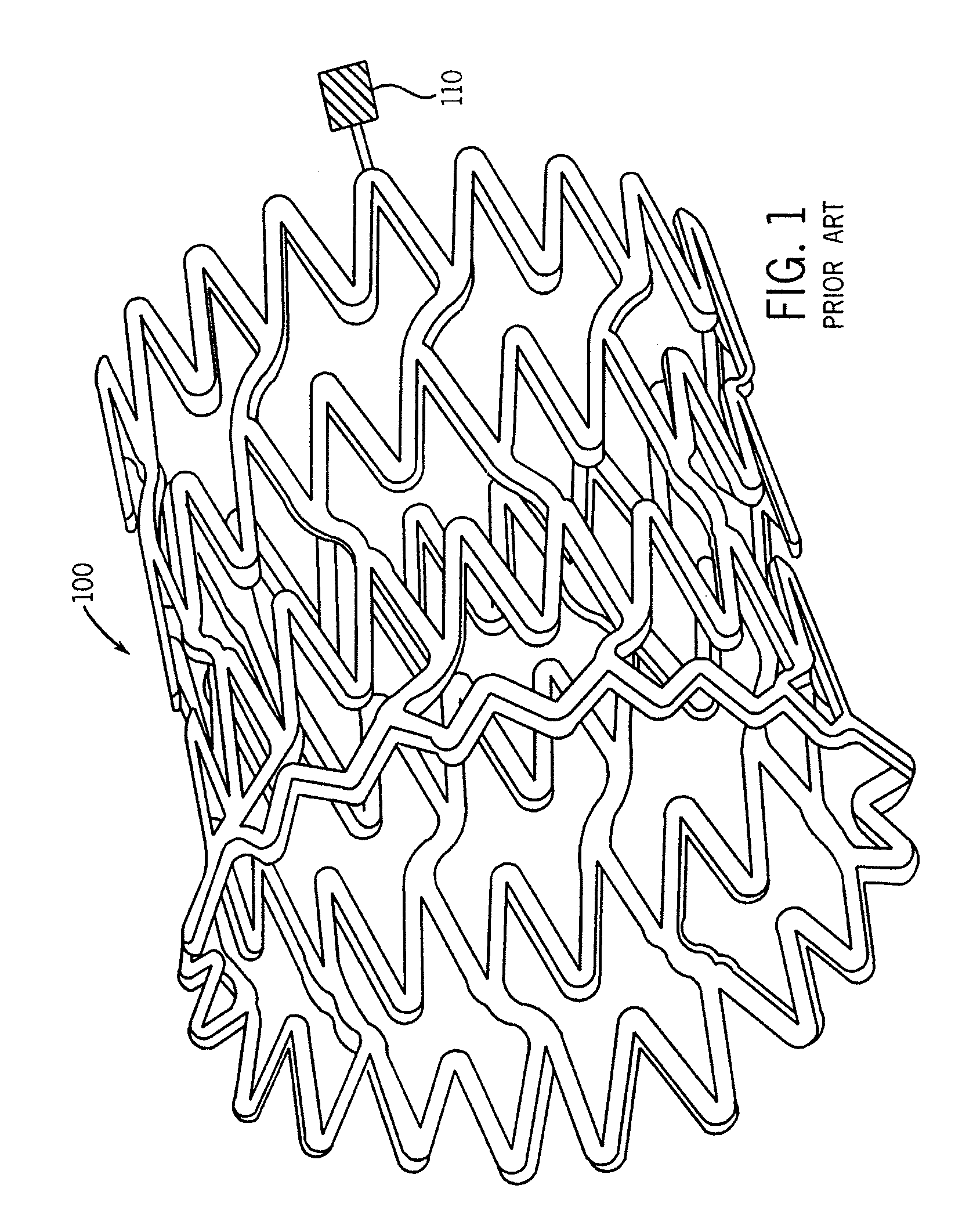

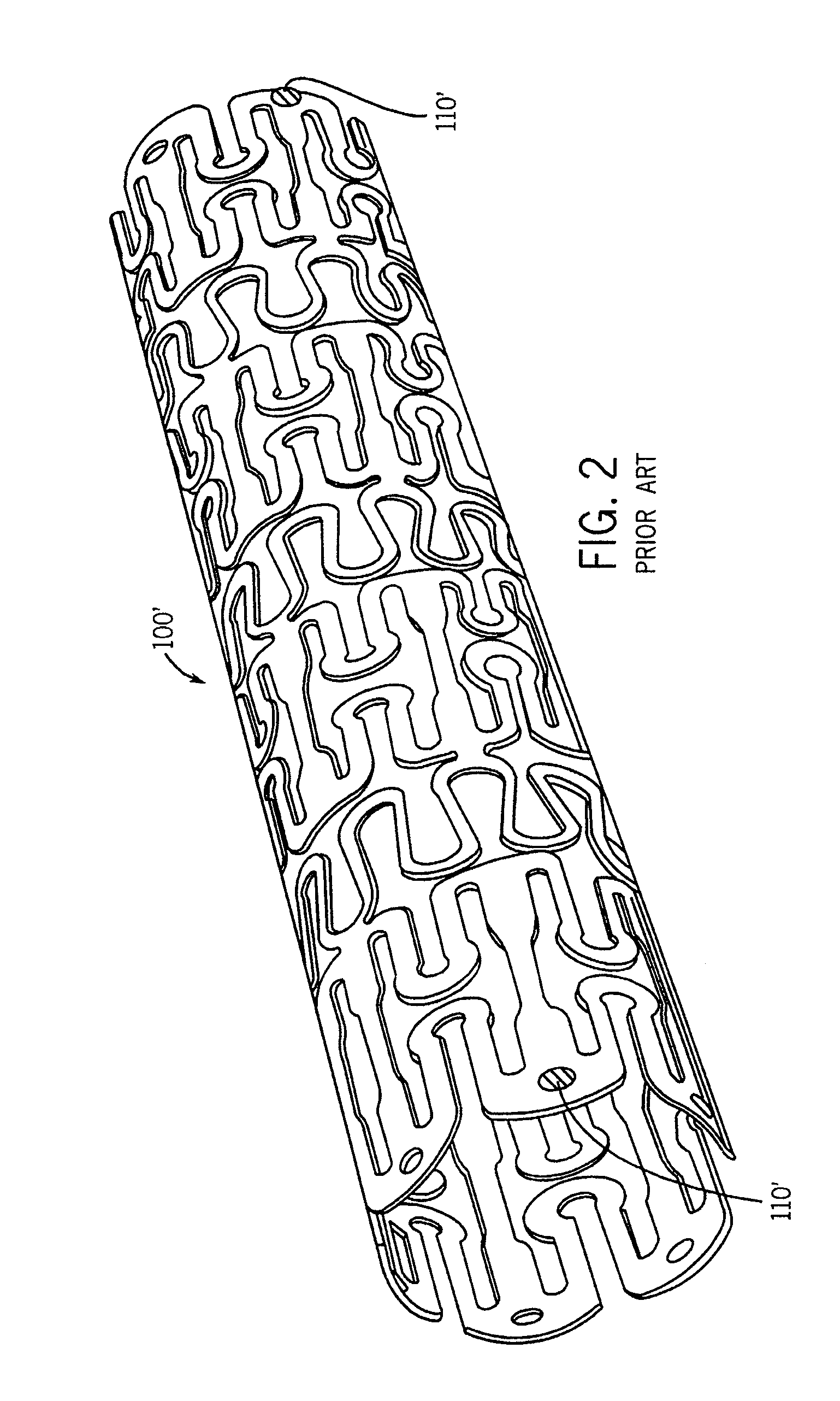

Integration of markers into bar arms using a warm-forming process

InactiveUS20090005858A1Accurate placementEasy assessment processStentsBlood vesselsInsertion stentStent

A stent having a body capable of visualization under X-ray fluoroscopic techniques. The stent body includes radiopaque strut members. The stent body can also have a radiopacity gradient along the length of the stent body.

Owner:ABBOTT LAB INC

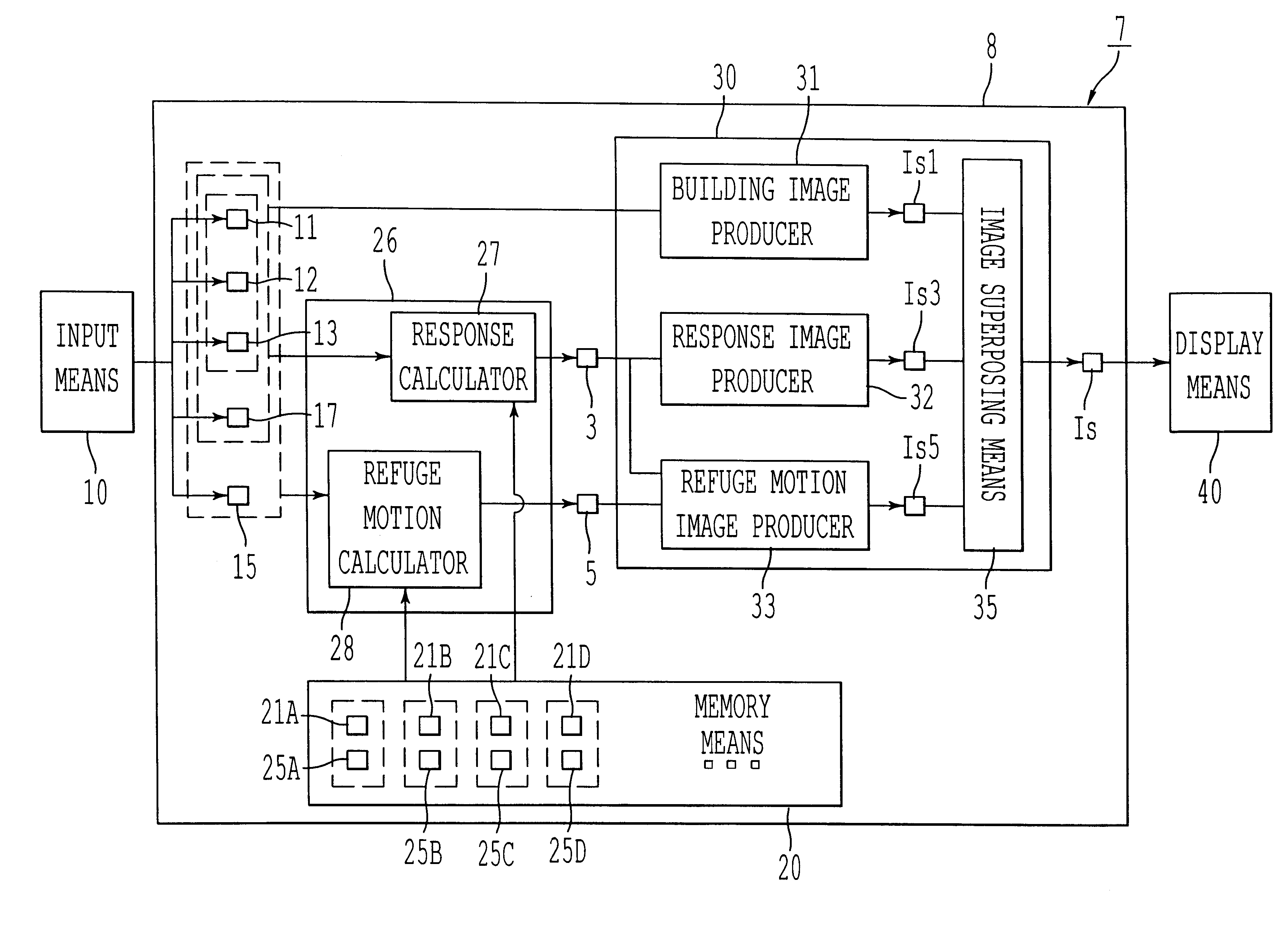

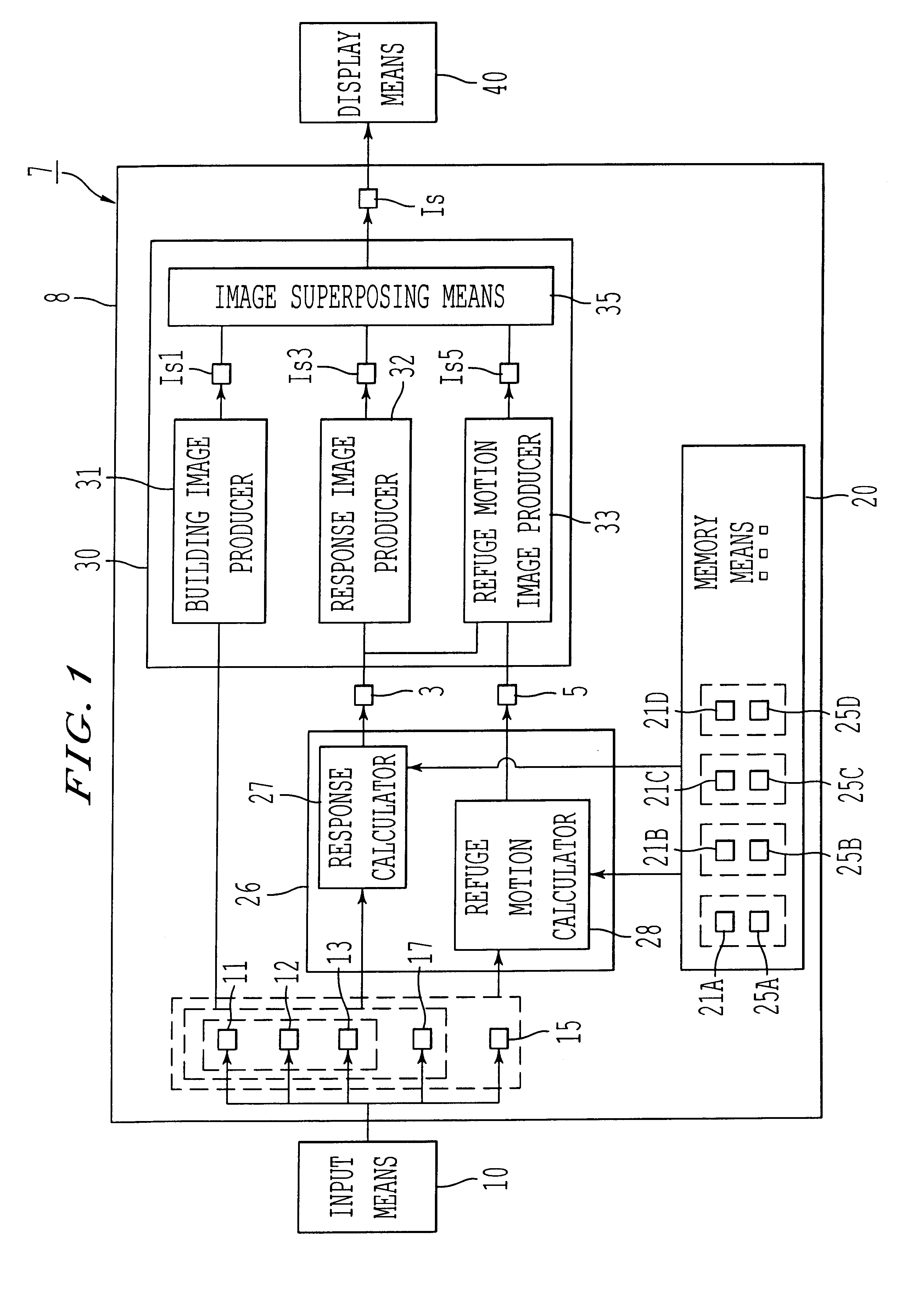

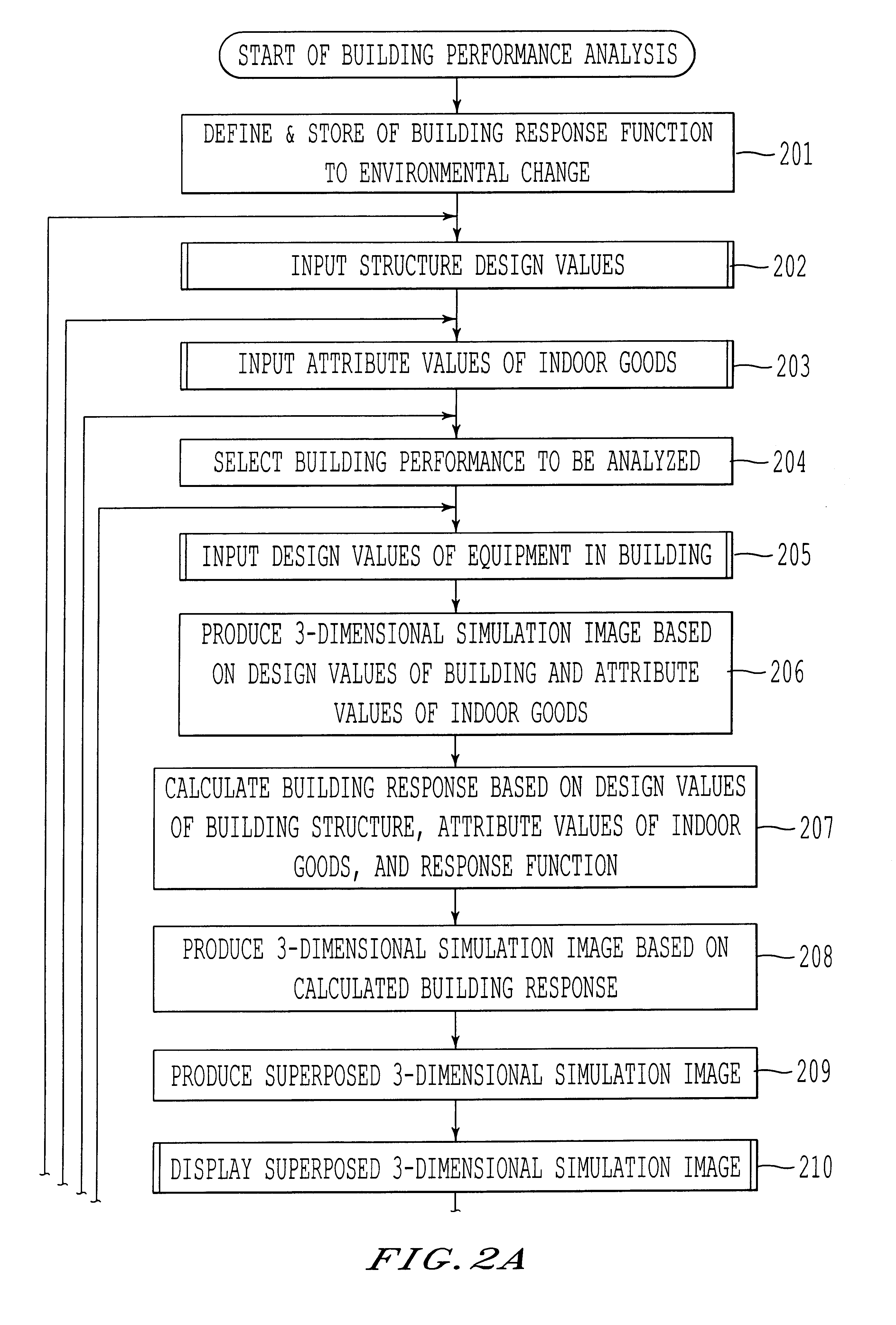

Method and apparatus for analyzing building performance

InactiveUS6701281B2Easy assessment processSmooth formation of consensusGeometric CADBuilding constructionsThree dimensional simulationComputer graphics (images)

A building response function defining a response of a building to specific environmental change, e.g., occurrence of a fire, in terms of the building structure, is stored in a computer. Also stored is a refuge motion function defining the refuge motion of individuals in terms of attributes of the individuals and the building response. The building response is computed by substituting design values of the building structure into the response function. Attributes of persons are inputted to the computer, and individuals' refuge motion is computed by using both inputted attributes and the computed building response. With the inputted and computed values, three-dimensional (3D) simulation images of the building structure, of the building response, and of individuals' refuge motion are computed. Then, a superposed 3D simulation image of the three images is displayed to facilitate analysis of the building performance.

Owner:KAJIMA CORP

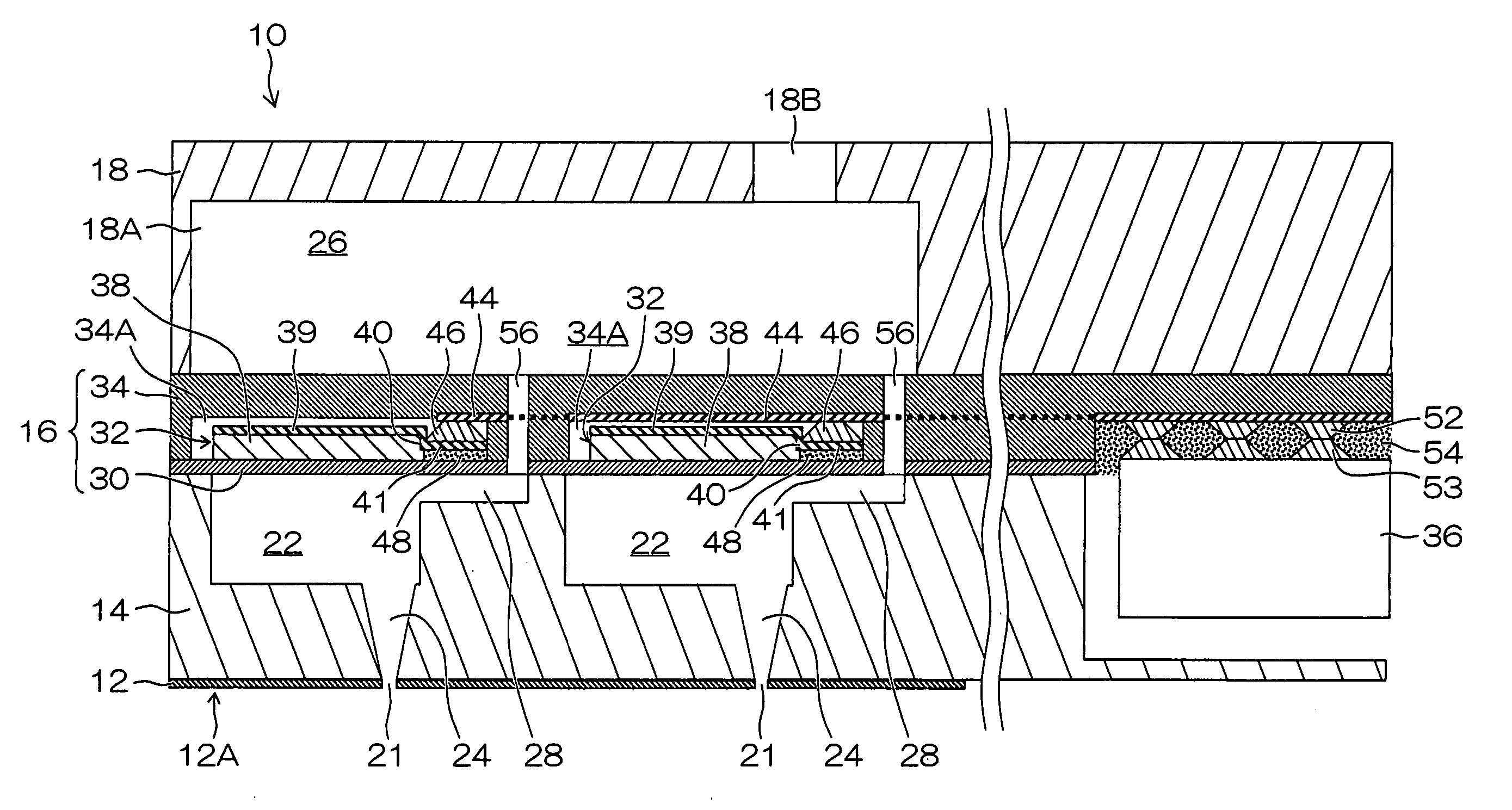

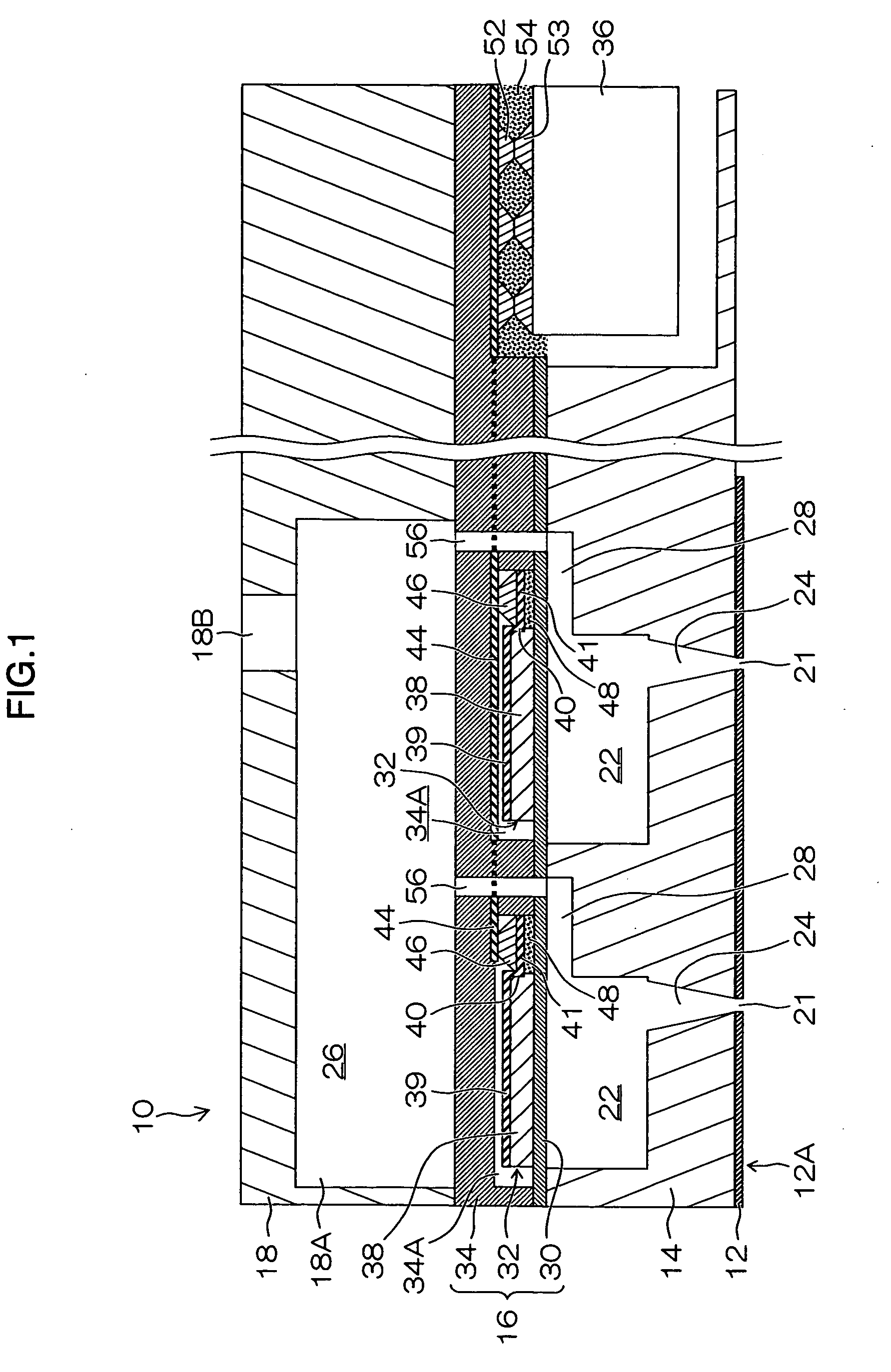

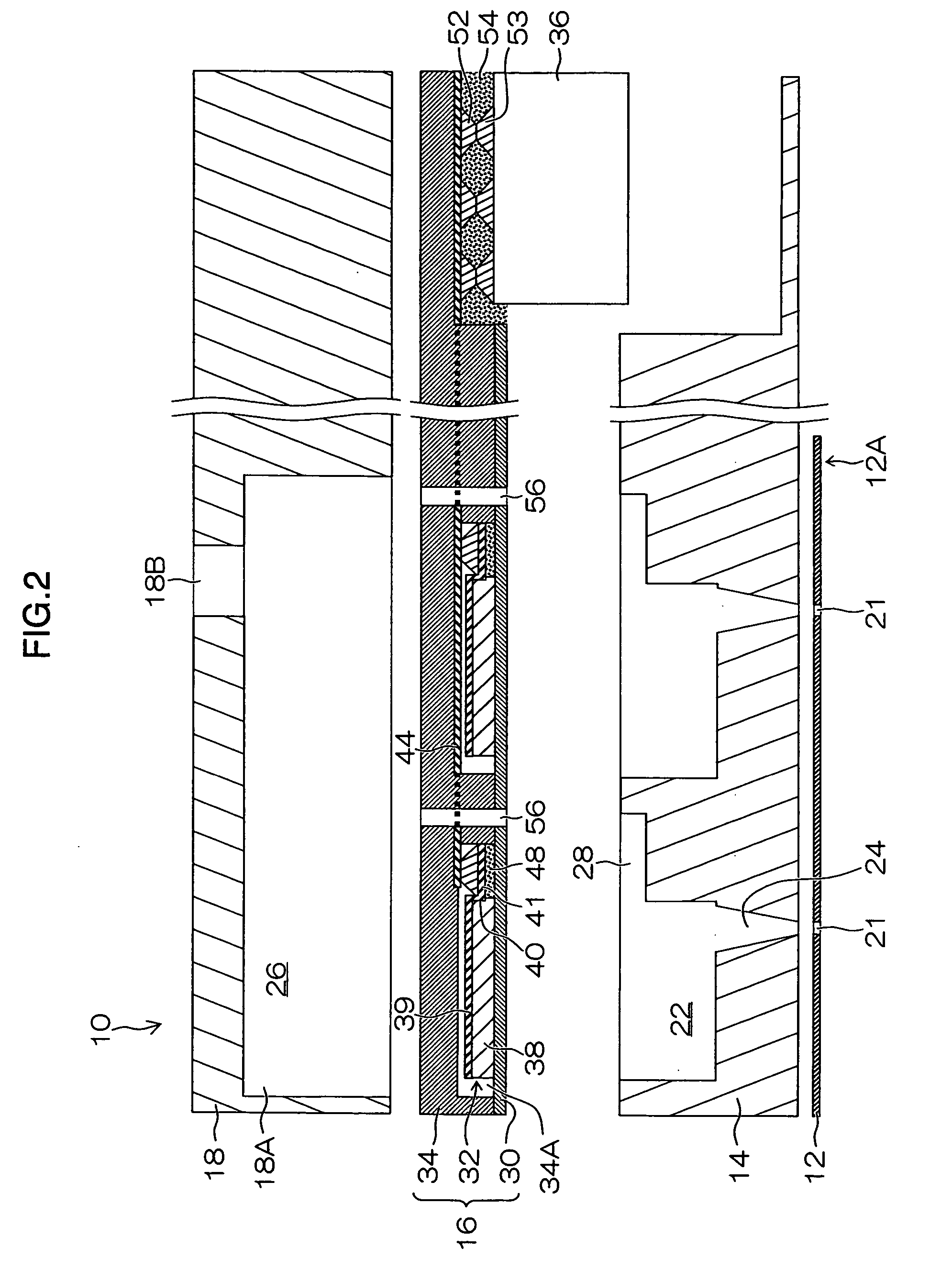

Method of manufacturing liquid ejection head, and image forming apparatus

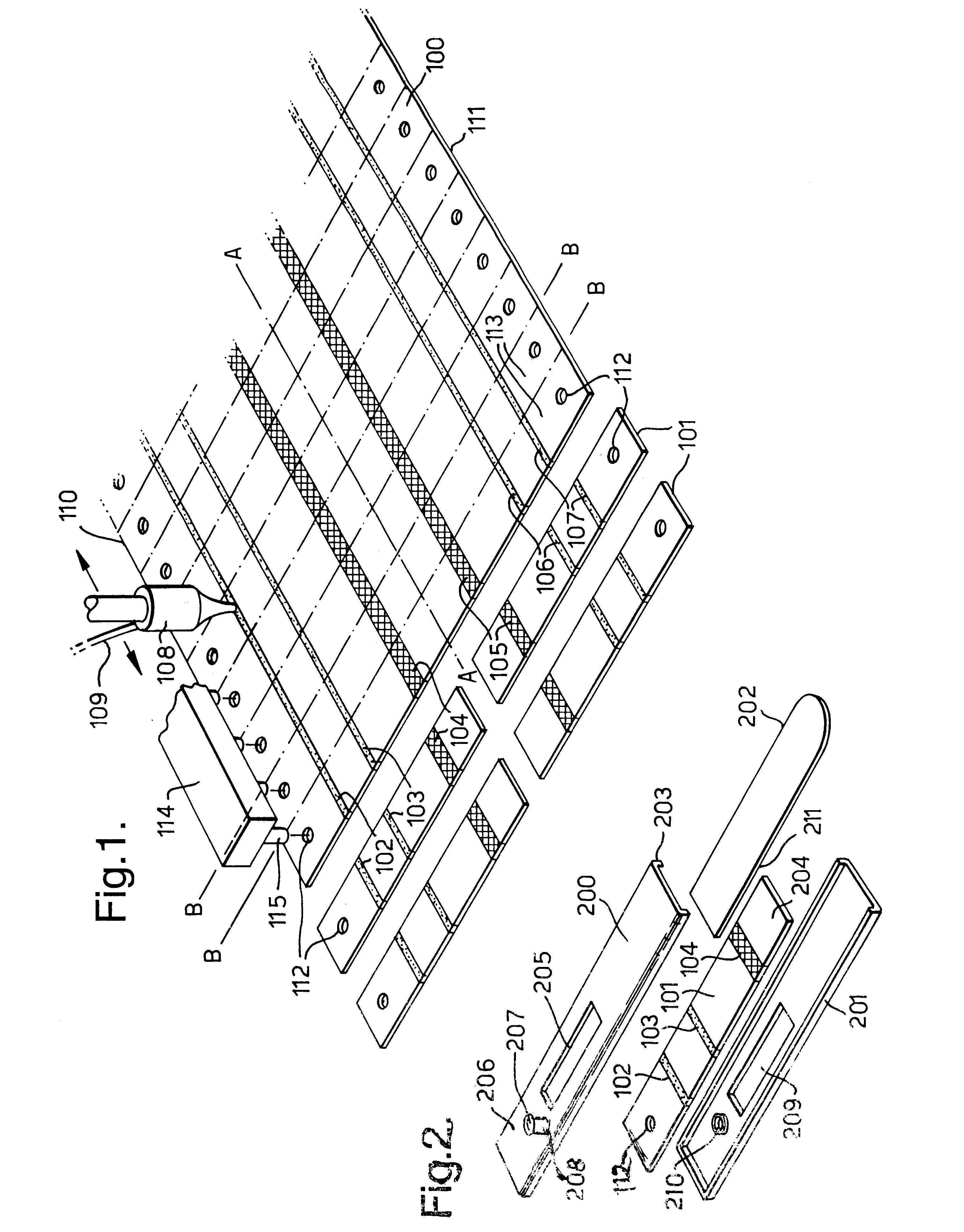

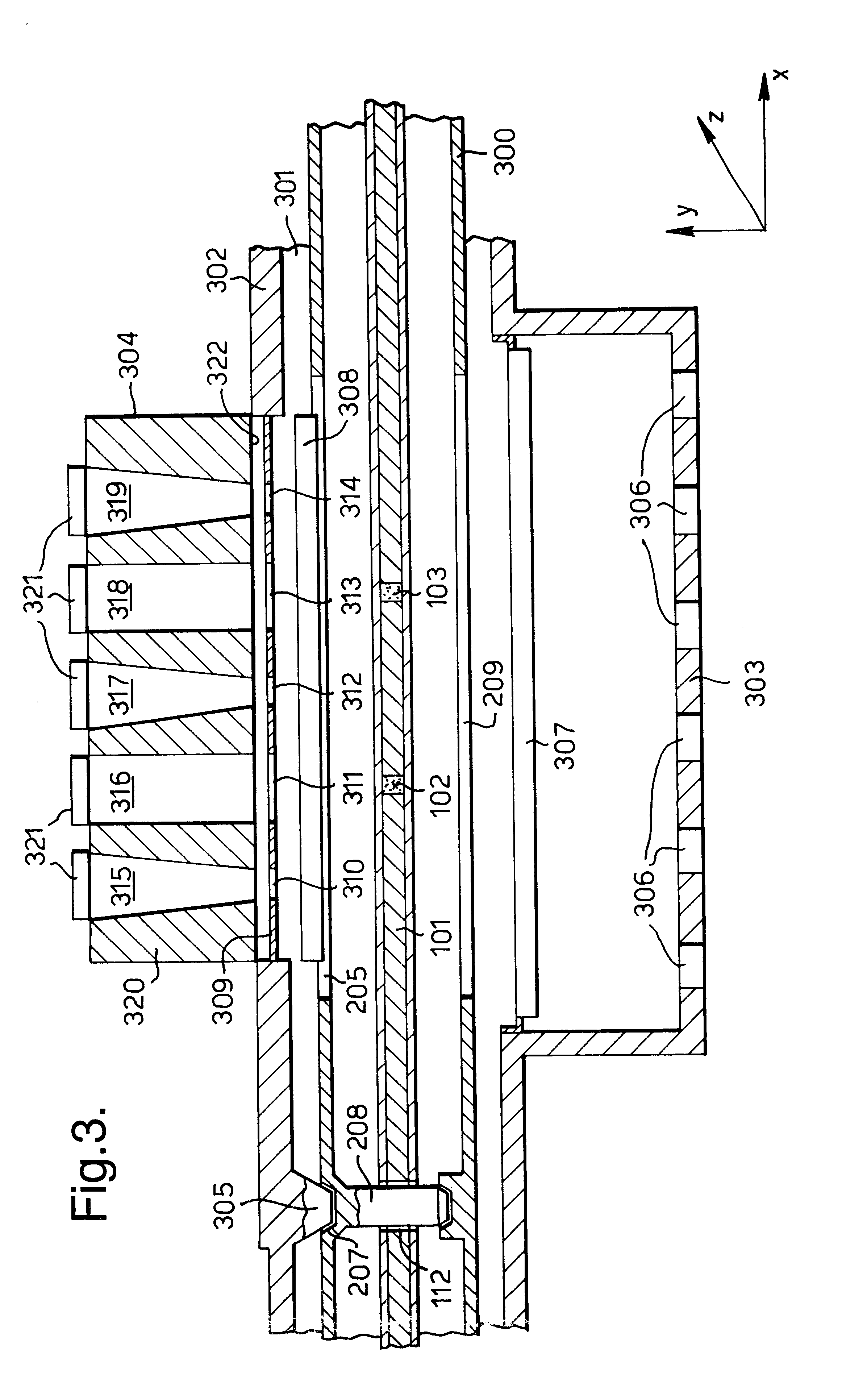

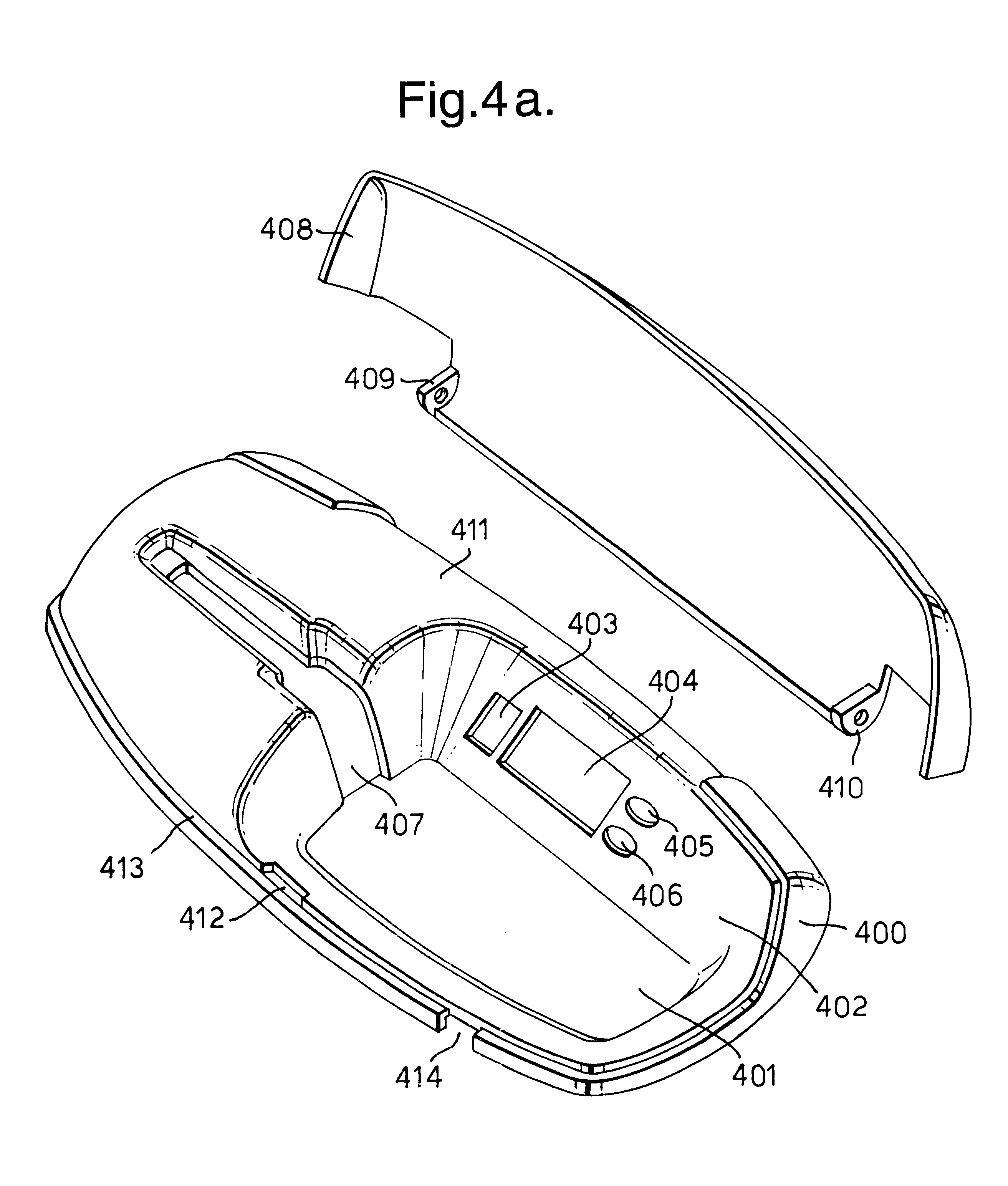

InactiveUS20070052764A1Excellent electrical propertiesImprove production yieldPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusElectrical connectionActuator

The method of manufacturing a liquid ejection head comprises the steps of: forming a plurality of piezoelectric elements on a diaphragm; stacking an intermediate plate which includes recess sections for covering the piezoelectric elements and drive wires connected to the piezoelectric elements, on a surface of the diaphragm on which the piezoelectric elements are formed, in such a manner that peripheral spaces are formed around the piezoelectric elements by means of the recess sections and electrical connections are created between the drive wires and the piezoelectric elements; connecting an integrated circuit to end sections of the drive wires which are opposite to connection sections between the drive wires and the piezoelectric elements; forming an actuator function unit by electrically and mechanically bonding the diaphragm, the piezoelectric elements, the drive wires, the intermediate plate and the integrated circuit after the formation of the piezoelectric elements on the diaphragm, the stack of the intermediate plate on the diaphragm, and the connection of the integrated circuit and the drive wires, in such a manner that the piezoelectric elements are electrically driven via the integrated circuit; measuring displacement of the diaphragm by operating the integrated circuit in the actuator function unit; and bonding a flow path forming member to the actuator function unit after the measurement of the displacement of the diaphragm, the flow path forming member being provided for forming a plurality of pressure chambers connected to a plurality of nozzles and forming a common liquid chamber for storing liquid supplied to the pressure chambers.

Owner:FUJIFILM CORP

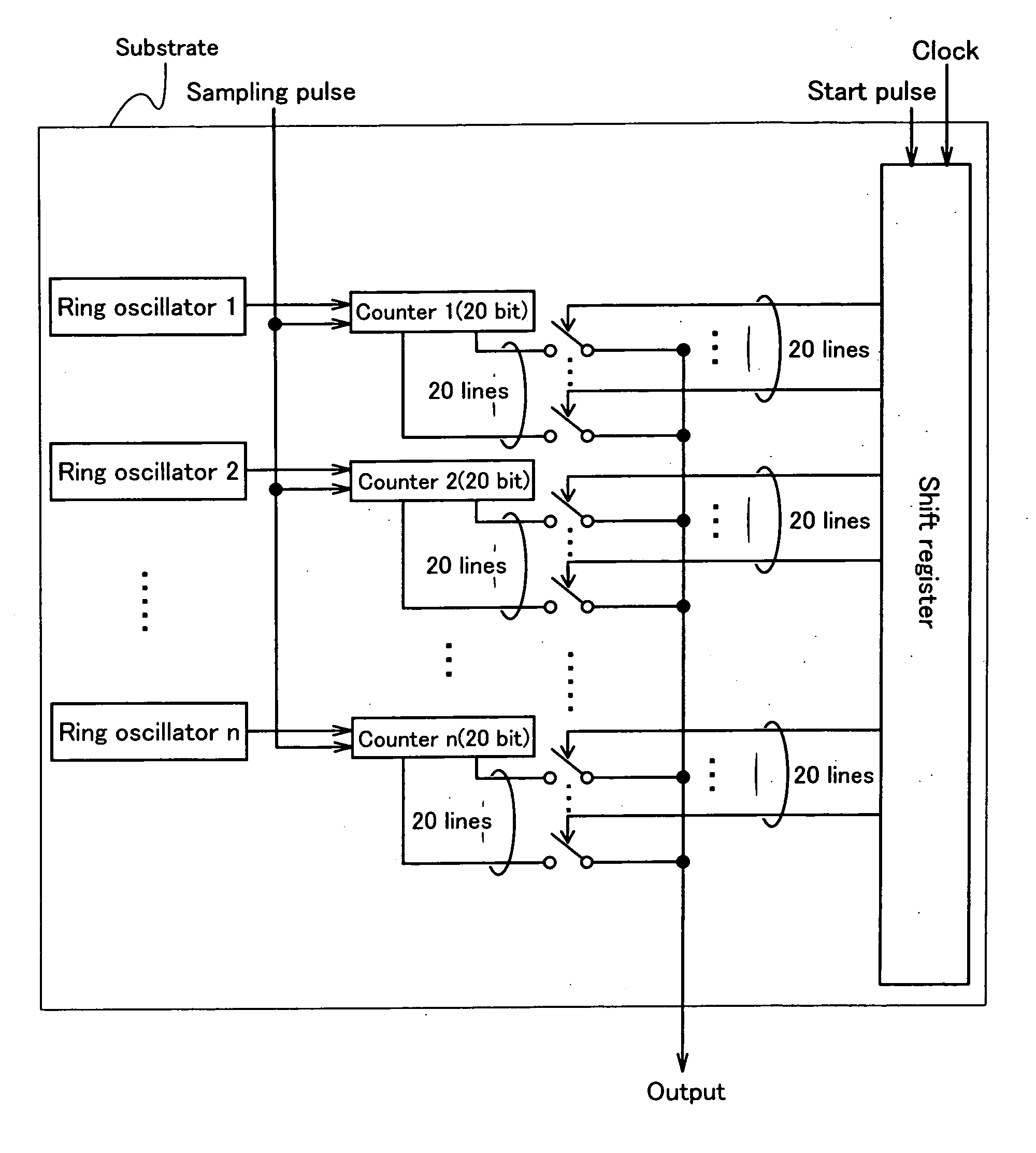

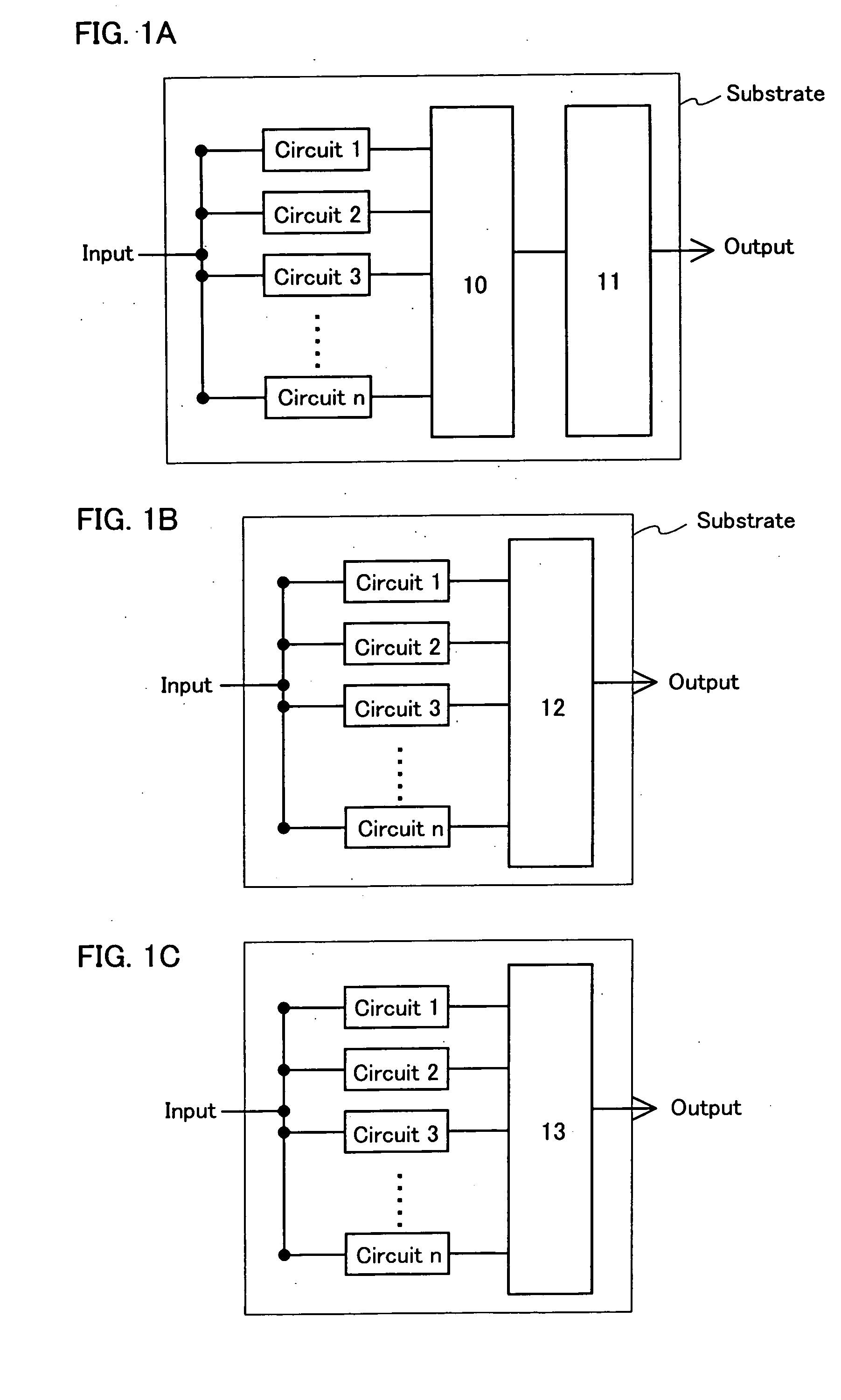

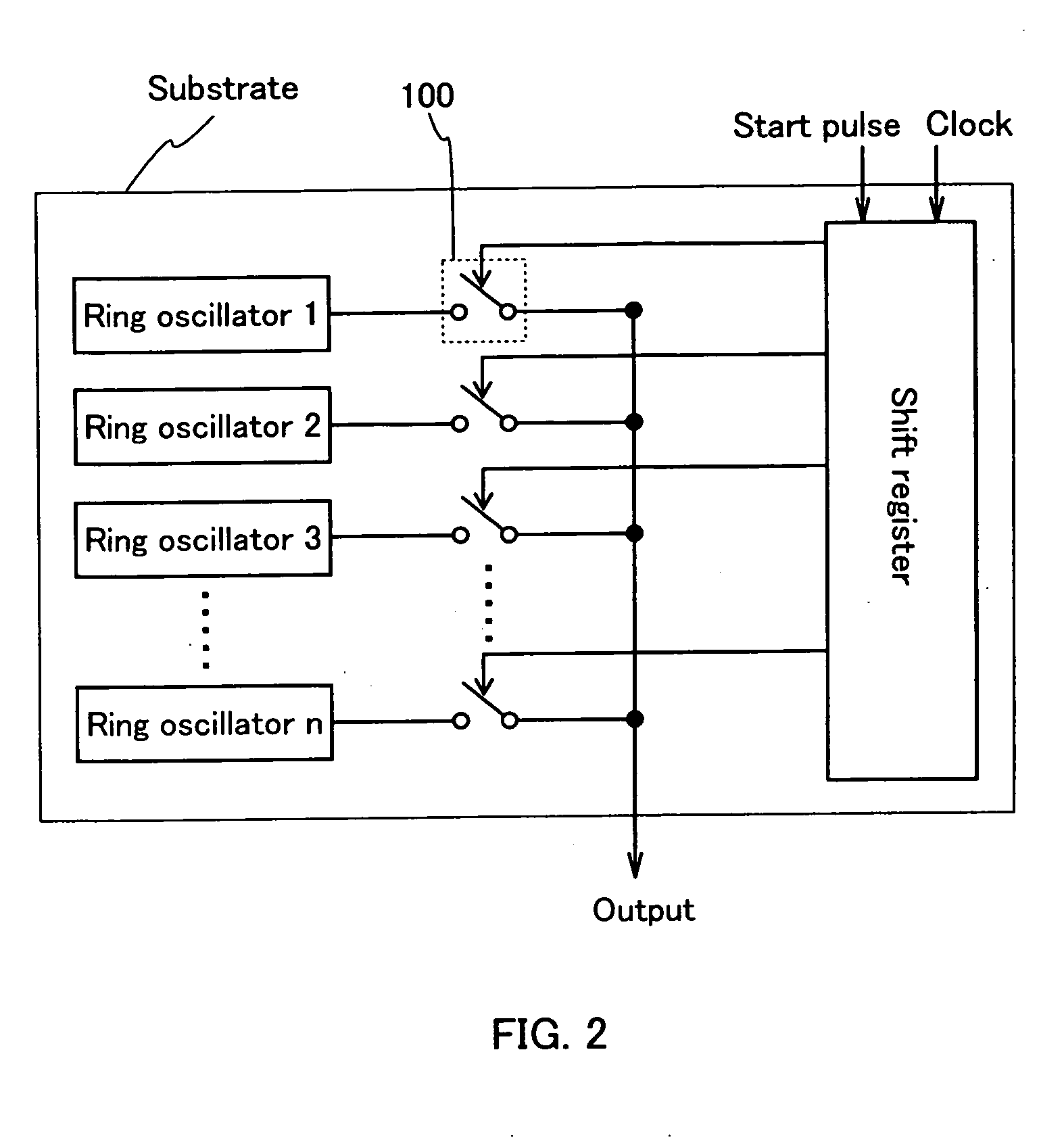

Method for evaluating semiconductor device

InactiveUS20050273290A1Efficient executionEfficient measurementDigital circuit testingResistance/reactance/impedenceDevice materialEngineering

Owner:SEMICON ENERGY LAB CO LTD

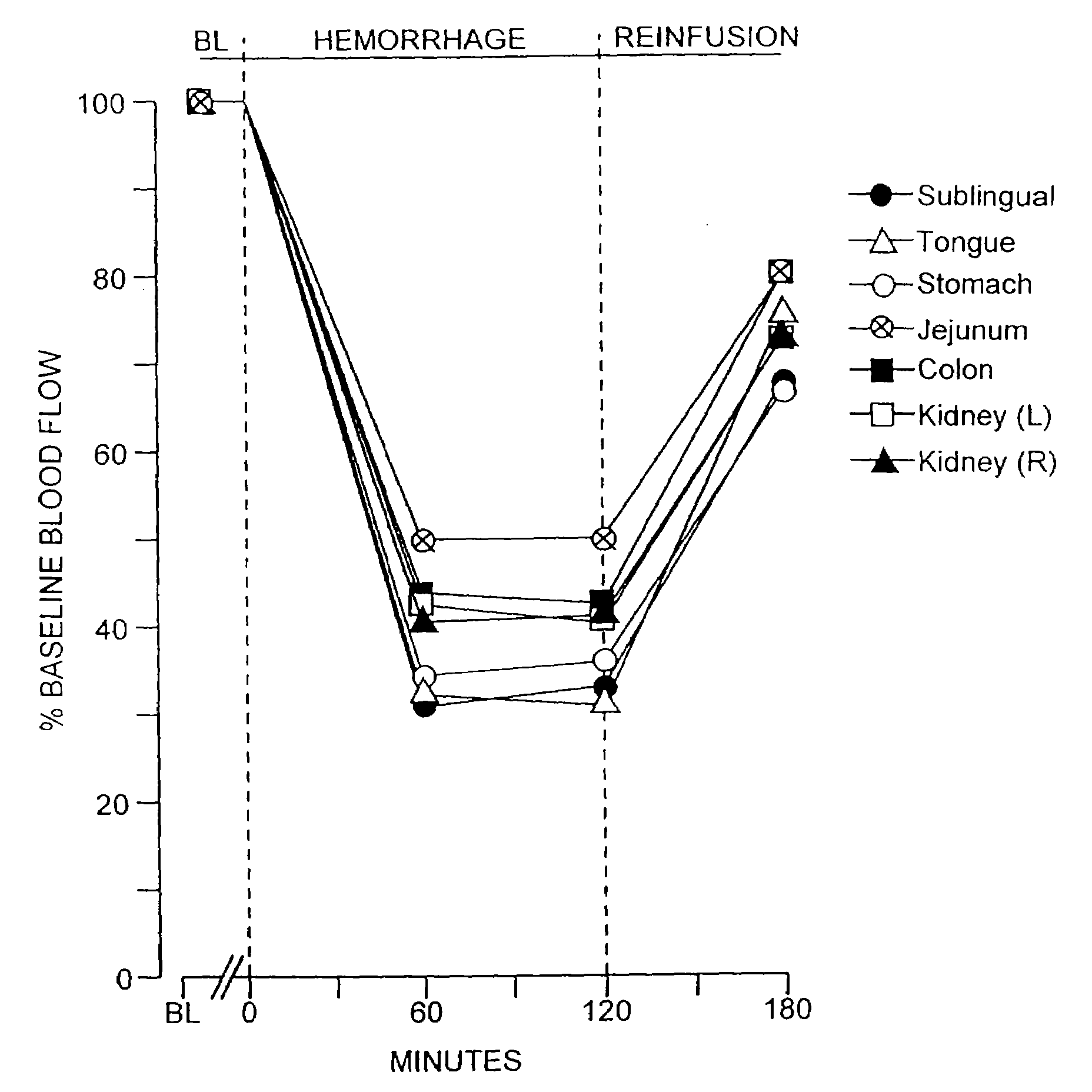

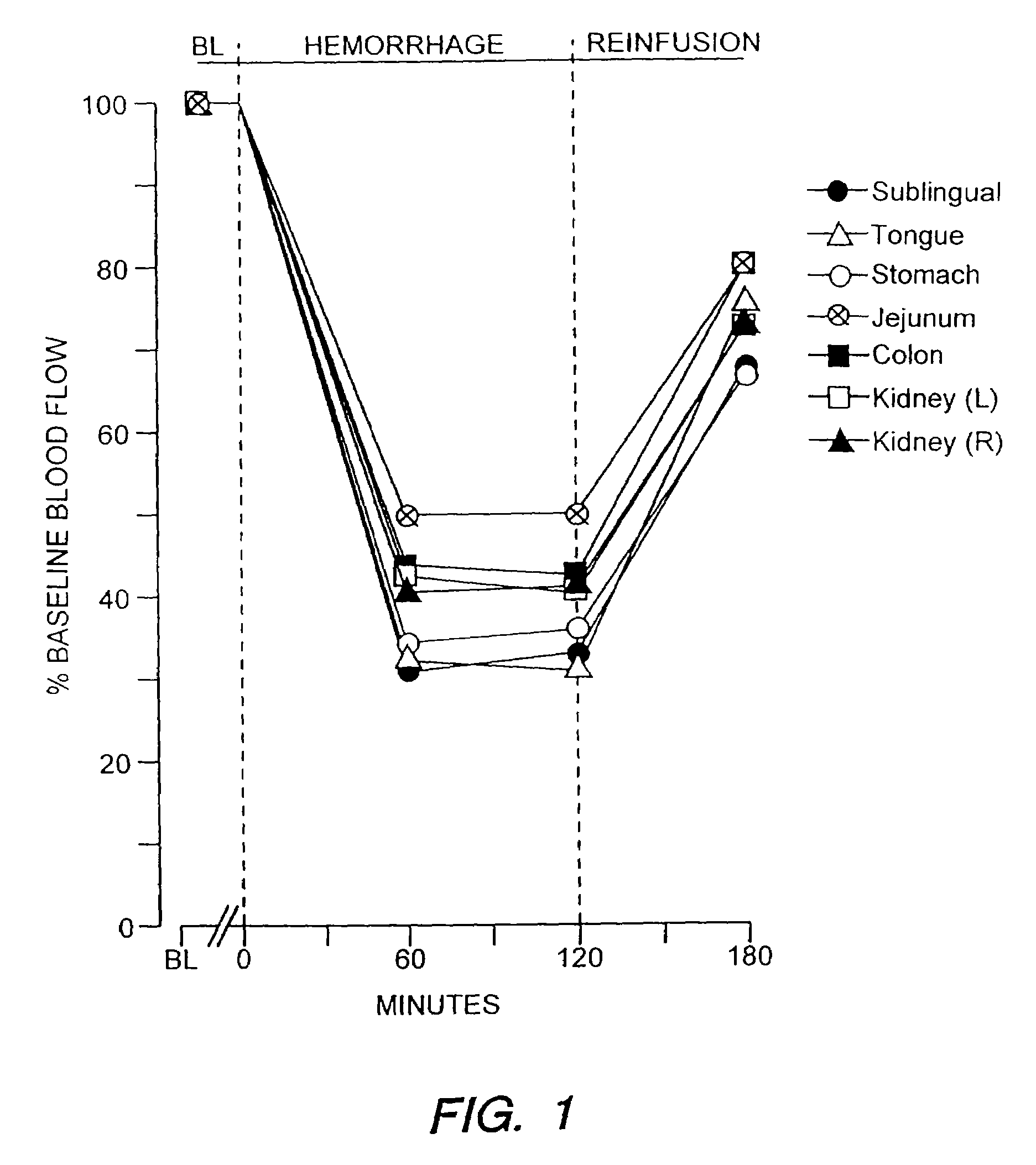

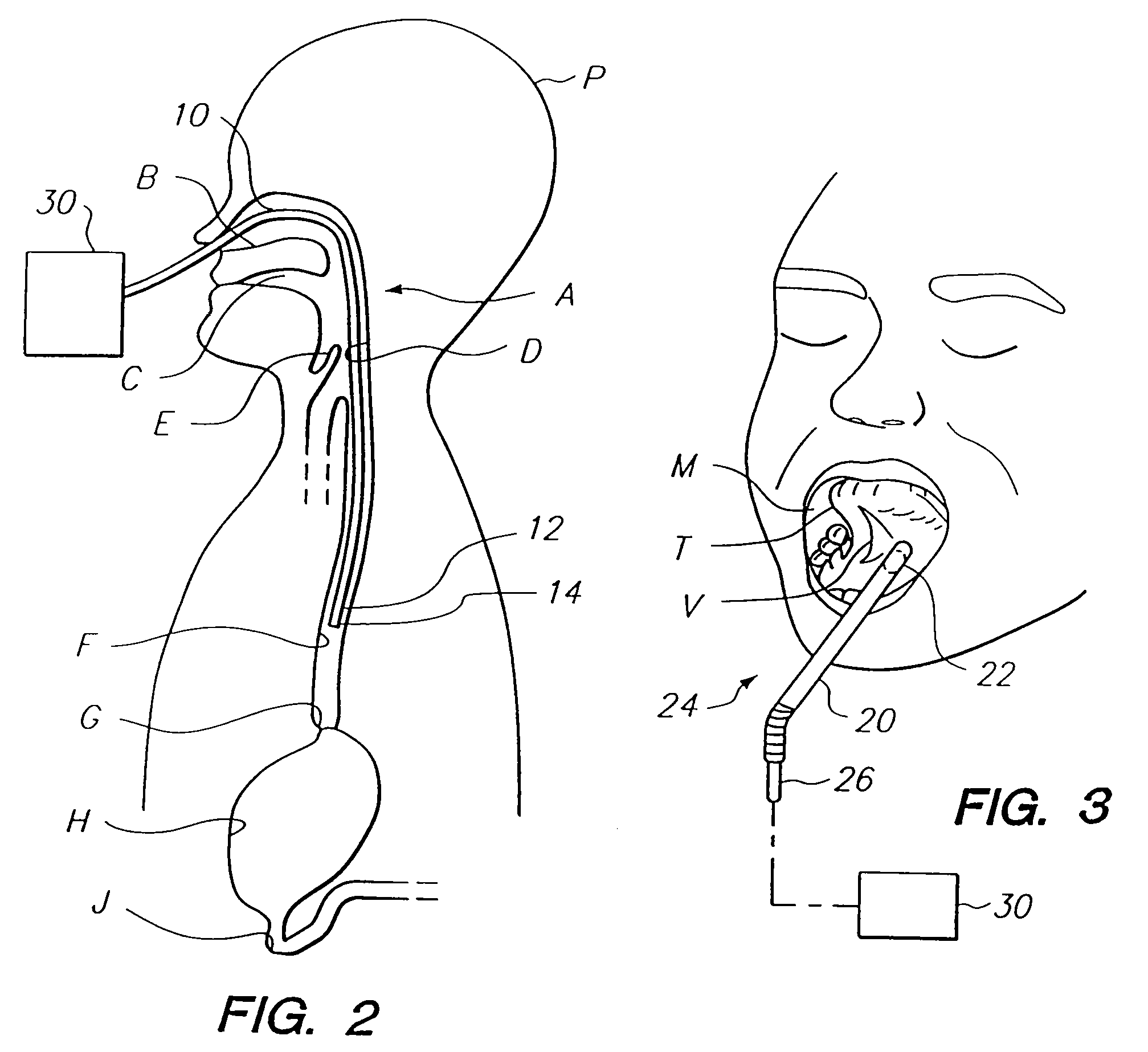

Device for assessing perfusion failure in a patient by measurement of blood flow

A device is provided for assessing impairment of blood circulation in a patient, such as that in perfusion failure, by measurement of blood flow adjacent a mucosal surface accessible by a mouth or nose and connecting with the gastrointestinal tract or upper respiratory / digestive tract of a patient. The device includes a blood-flow sensor adapted to be positioned adjacent a mucosal surface with a patient's body and measuring blood flow in adjacent tissue and a PCO.sub.2 sensor adapted to be positioned adjacent the mucosal surface and measuring PCO.sub.2. In addition a pH sensor may be used in combination with the blood flow determination. A method of detecting perfusion failure is also disclosed. The method includes utilizing blood-flow measurements in conjunction with a surface perfusion pressure index and / or an optical plethysmography index to more accurately assess perfusion failure. These measurements may also be supplement by taking measurements of pH, sublingual PCO.sub.2, and Sa O.sub.2. The invention affords rapid measurement and detection of perfusion failure.

Owner:OPTICAL SENSORS INC

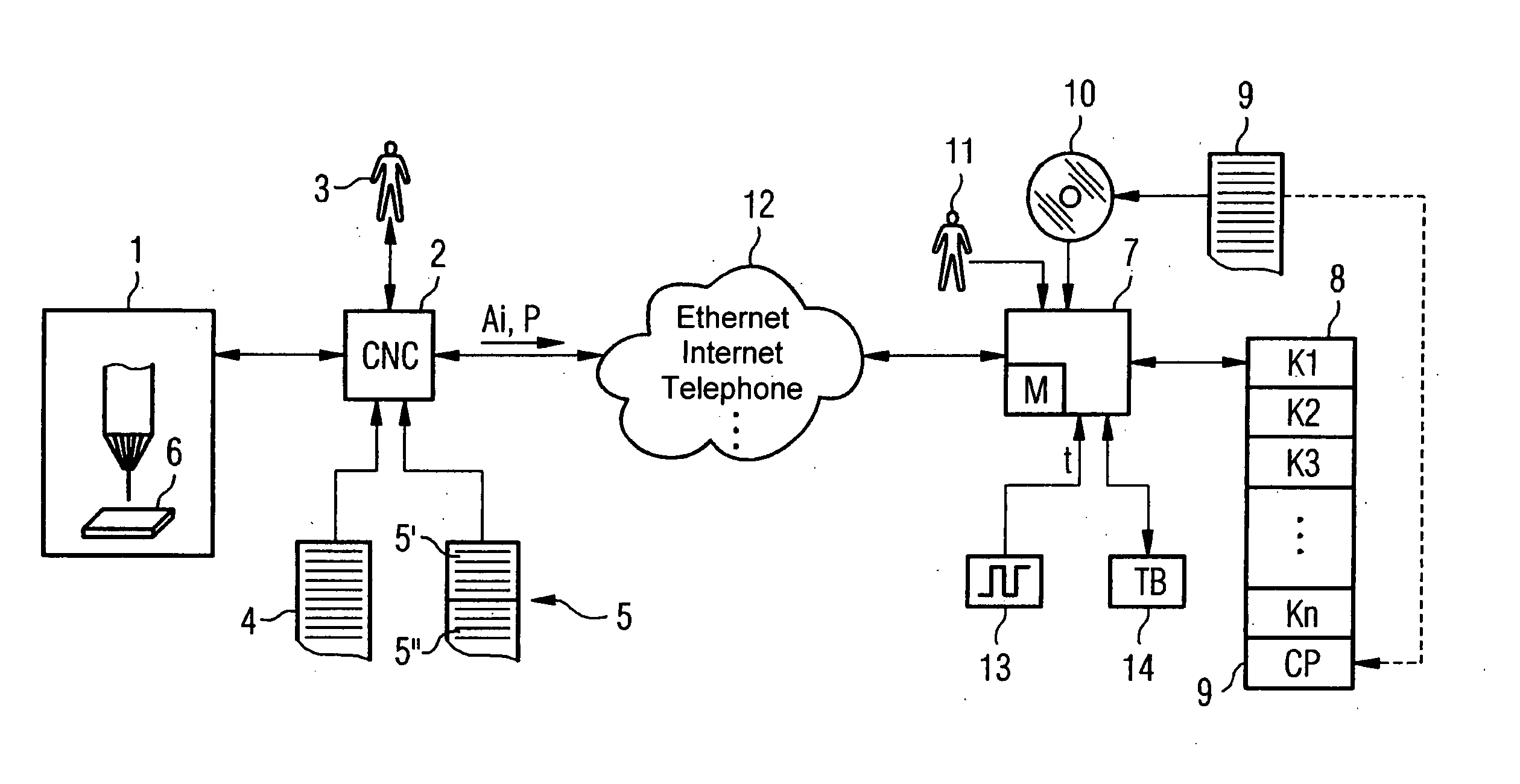

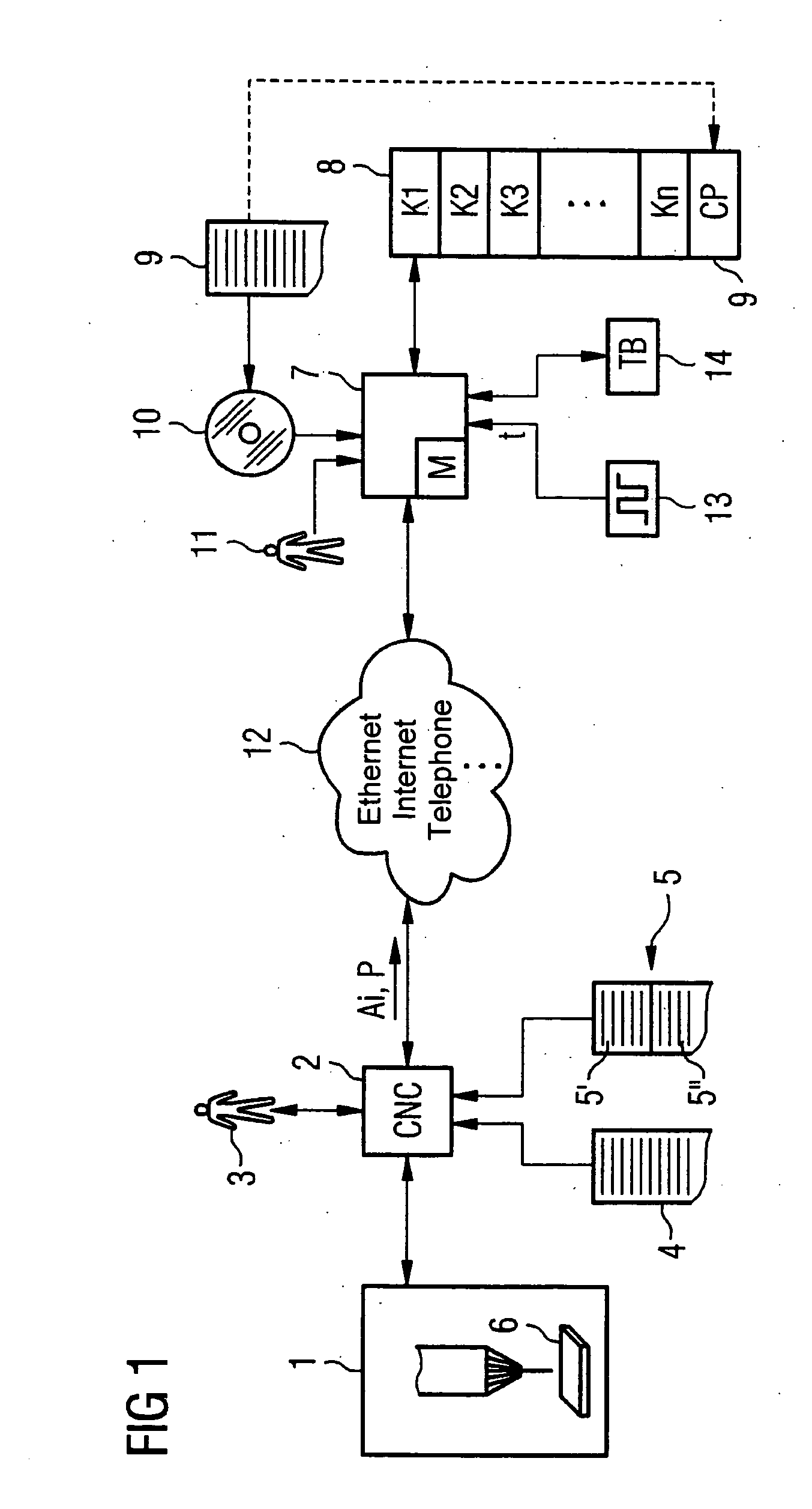

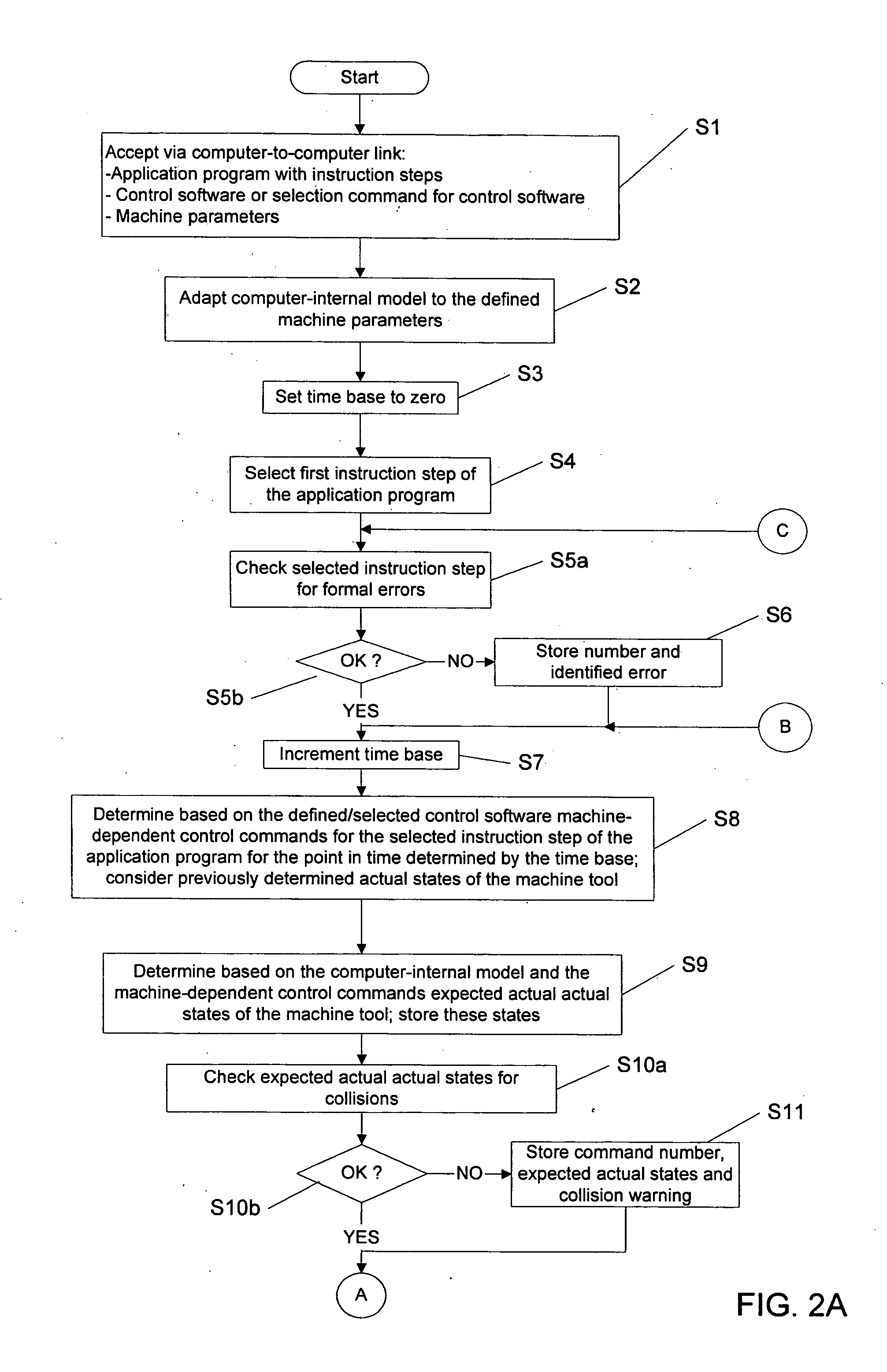

Method and system for simulating processing of a workpiece with a machine tool

ActiveUS20050102054A1Improve simulation accuracyImprove accuracyProgramme controlComputer controlParallel computingSimulation based

An application program that describes processing of a workpiece by the machine tool in form of instruction steps is disclosed. A computer executes the application program and step-by-step determines based on a simulation program machine-dependent control commands for a controller. The machine-dependent control commands depend on a virtual time base that is independent of an actual time base. The computer determines based on a computer-internal model of the machine tool and the determined machine-dependent control commands expected actual states of the machine tool, thereby simulating execution of the machine-dependent control commands by the machine tool. The simulation program is implemented as control software in the controller.

Owner:SIEMENS AG

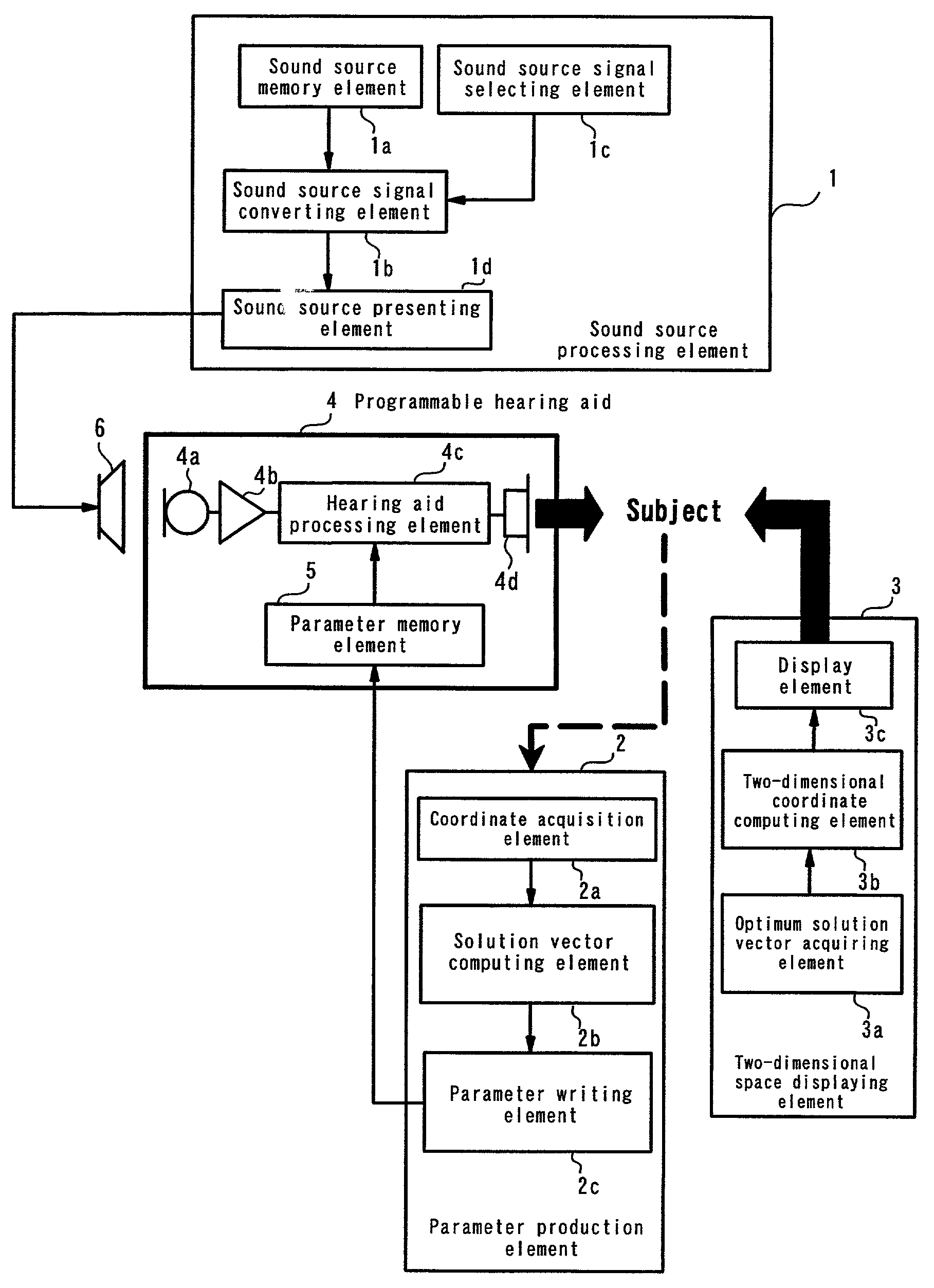

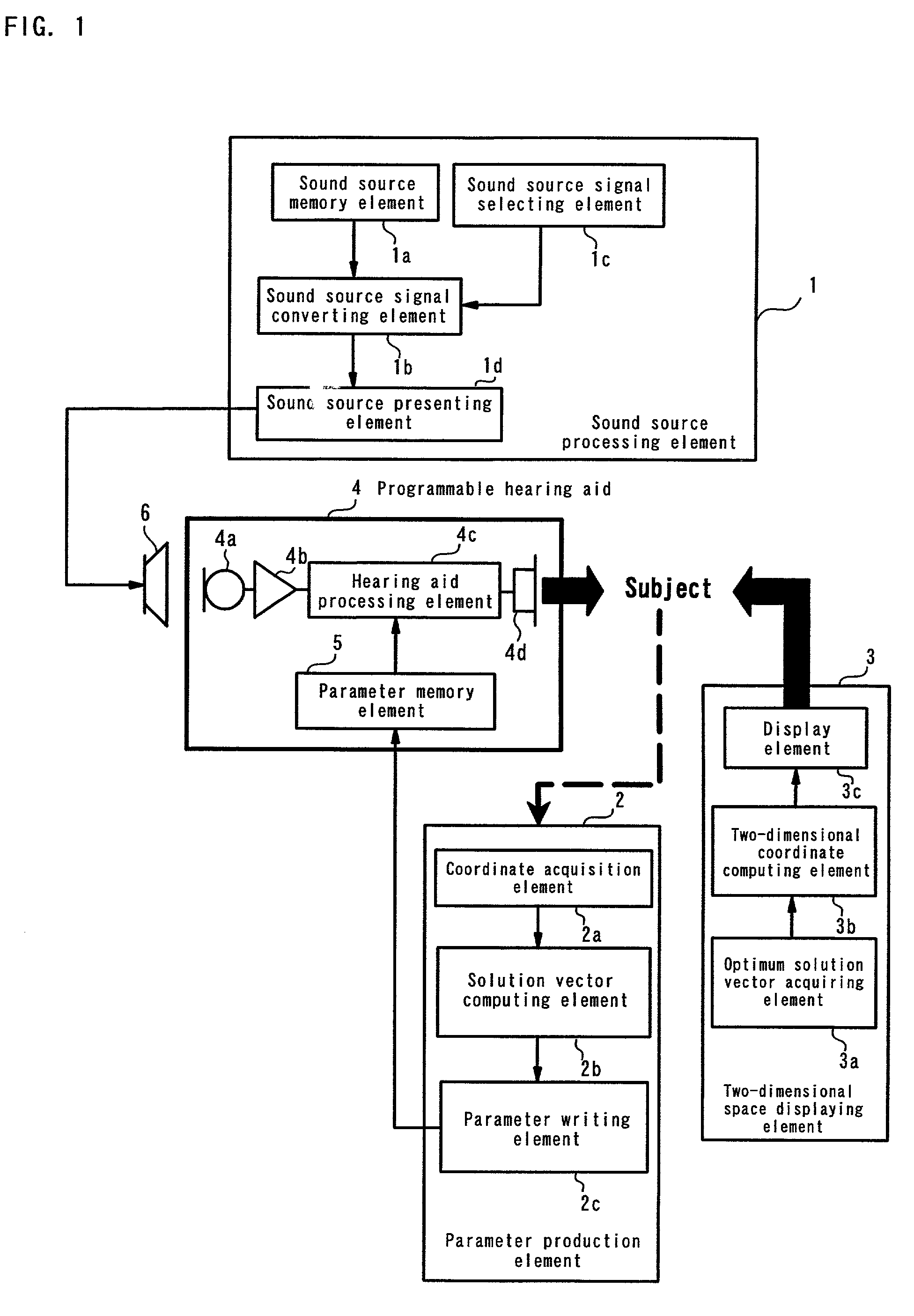

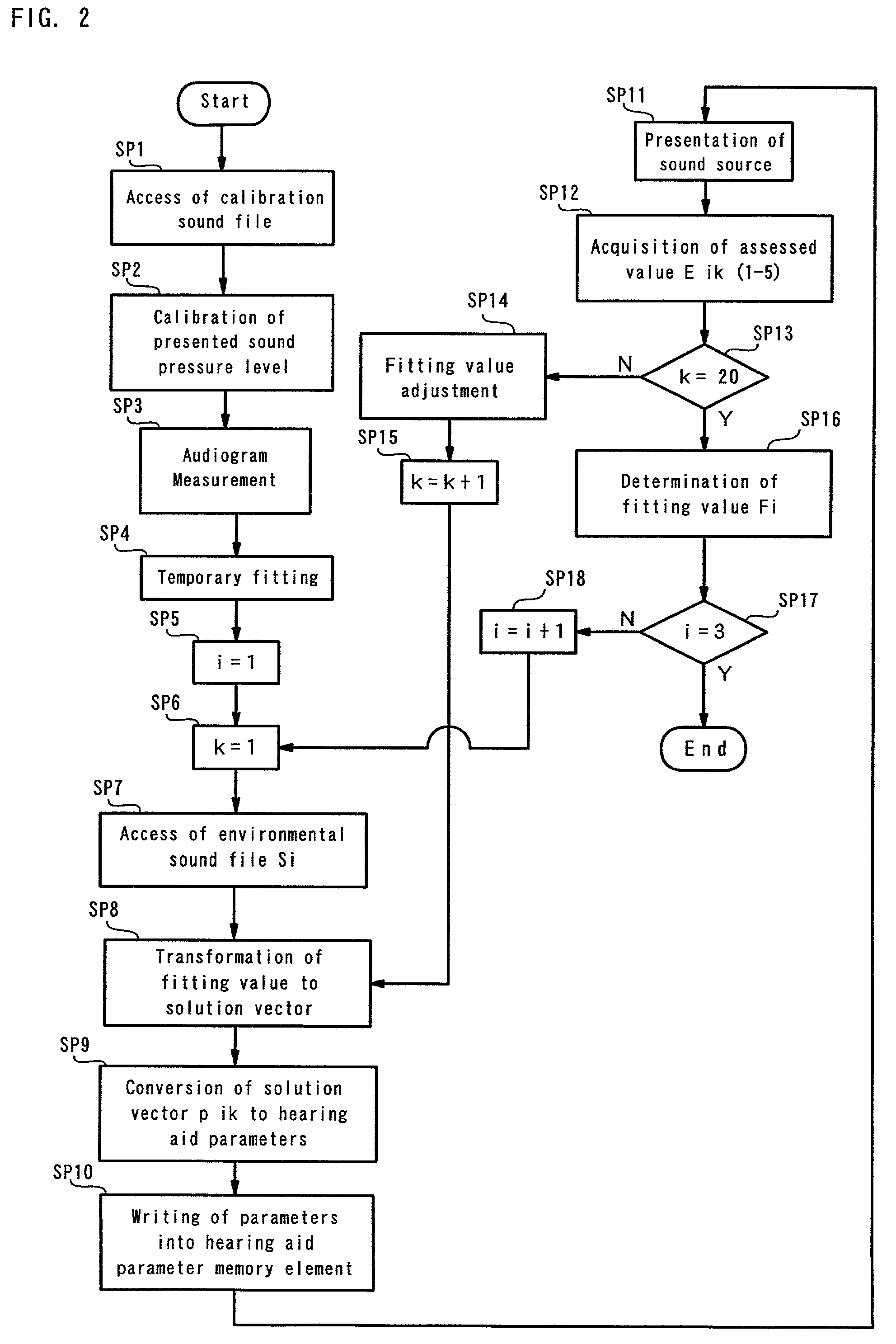

Optimum solution method, hearing aid fitting apparatus utilizing the optimum solution method, and system optimization adjusting method and apparatus

A parameter writing element converts a solution vector found by an optimum solution method that determines optimum n-dimensional solution vector, based on a plurality of optimum n-dimensional solution vector candidates to an adjustment parameter values of a programmable hearing aid and writes the adjustment parameter values into a hearing aid parameter memory element of the programmable hearing aid using a sound source memory element for storing a sound source, and a sound source presenting element for presenting the sound source to the programmable hearing aid.

Owner:RION COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com