Patents

Literature

48165 results about "Chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The chloride ion /ˈklɔːraɪd/ is the anion (negatively charged ion) Cl⁻. It is formed when the element chlorine (a halogen) gains an electron or when a compound such as hydrogen chloride is dissolved in water or other polar solvents. Chloride salts such as sodium chloride are often very soluble in water. It is an essential electrolyte located in all body fluids responsible for maintaining acid/base balance, transmitting nerve impulses and regulating fluid in and out of cells. Less frequently, the word chloride may also form part of the "common" name of chemical compounds in which one or more chlorine atoms are covalently bonded. For example, methyl chloride, with the standard name chloromethane (see IUPAC books) is an organic compound with a covalent C−Cl bond in which the chlorine is not an anion.

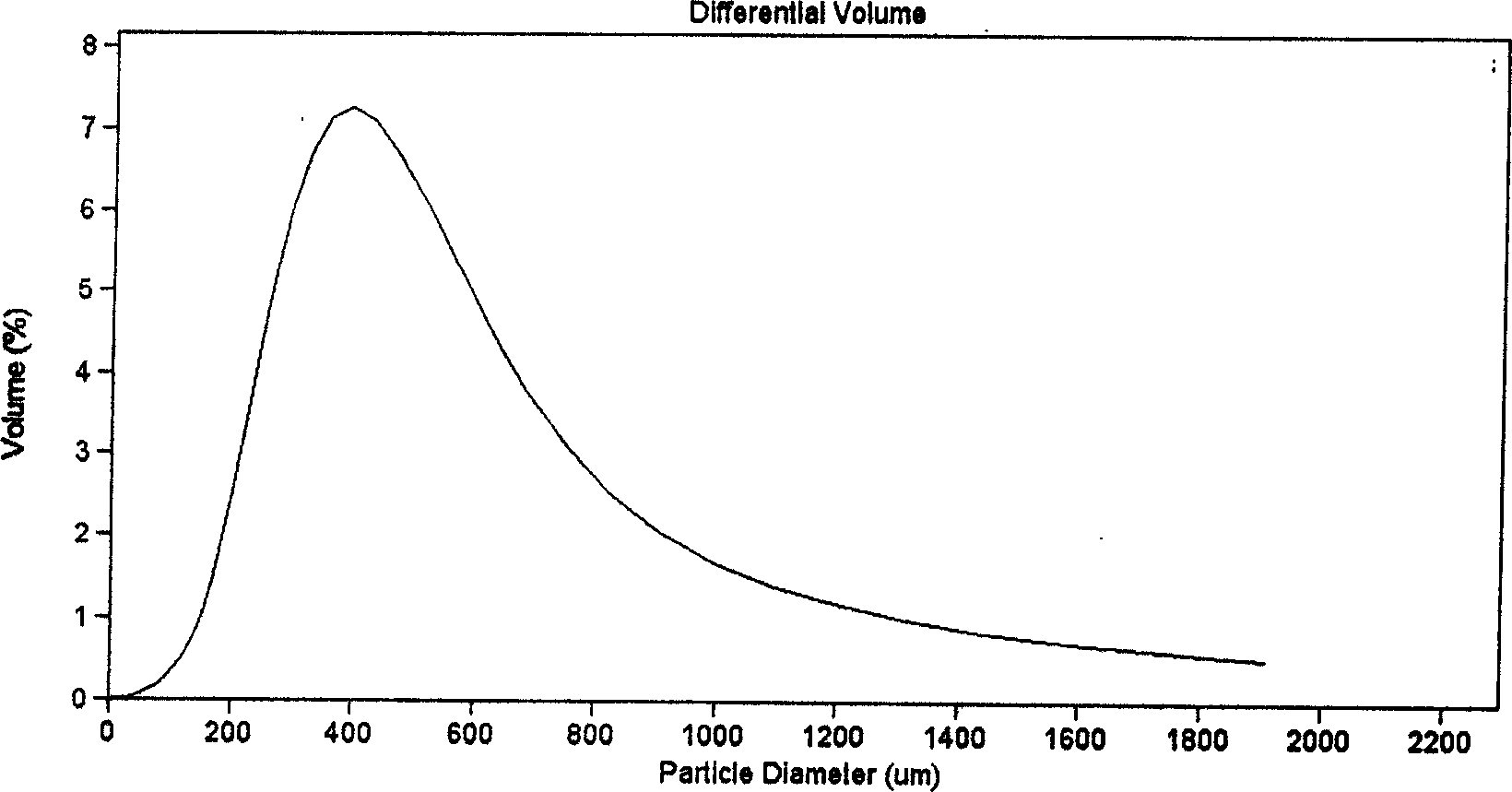

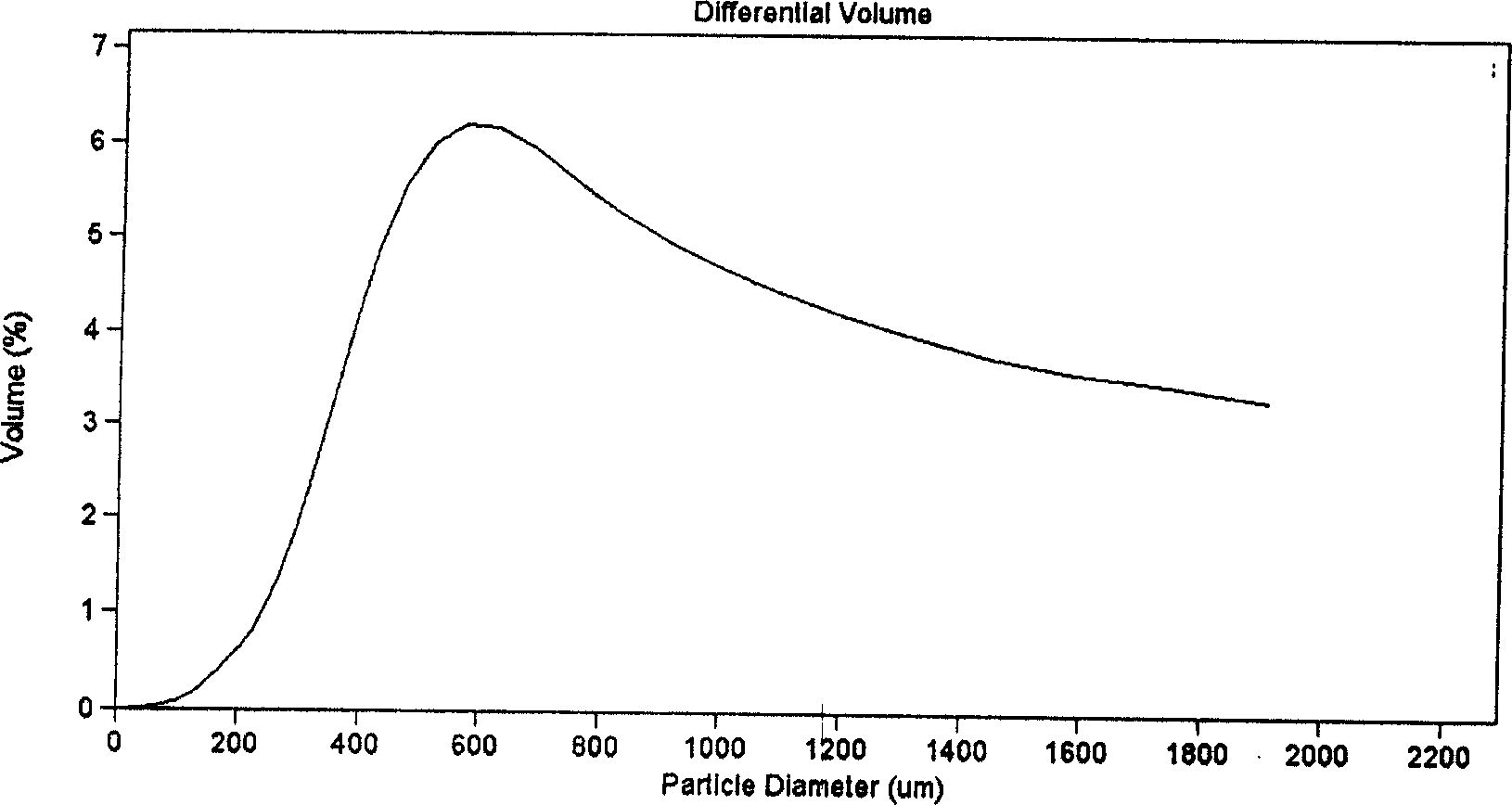

Process for preparing olefin polymerization ball type catalytic component and carrier

The spherical catalyst carrier is prepared with alcoholated magnesium chloride containing double-ether compound in emulsifying pelletizer. Liquid titanium halide compound is carried onto the spherical catalyst carrier to form spherical solid catalyst component in the presence of electron donor. In the X-ray diffraction spectrogram, the spherical solid catalyst component has diffraction peak in 13.3 deg of 2theta angle, strongest diffraction peak in 26.5 deg of 2theta angle and no characteristic diffraction peak of alpha-anhydrous MgCl2 in 15 deg of 2theta angle. The catalyst of the presentinvention has very high activity and may be used to produce polymer with good form, high apparent density and less fine powder. The catalyst is used in homopolymerization and copolymerization of olefin and suitable for various polymerization process.

Owner:YINGKOU XIANGYANG CATALYST

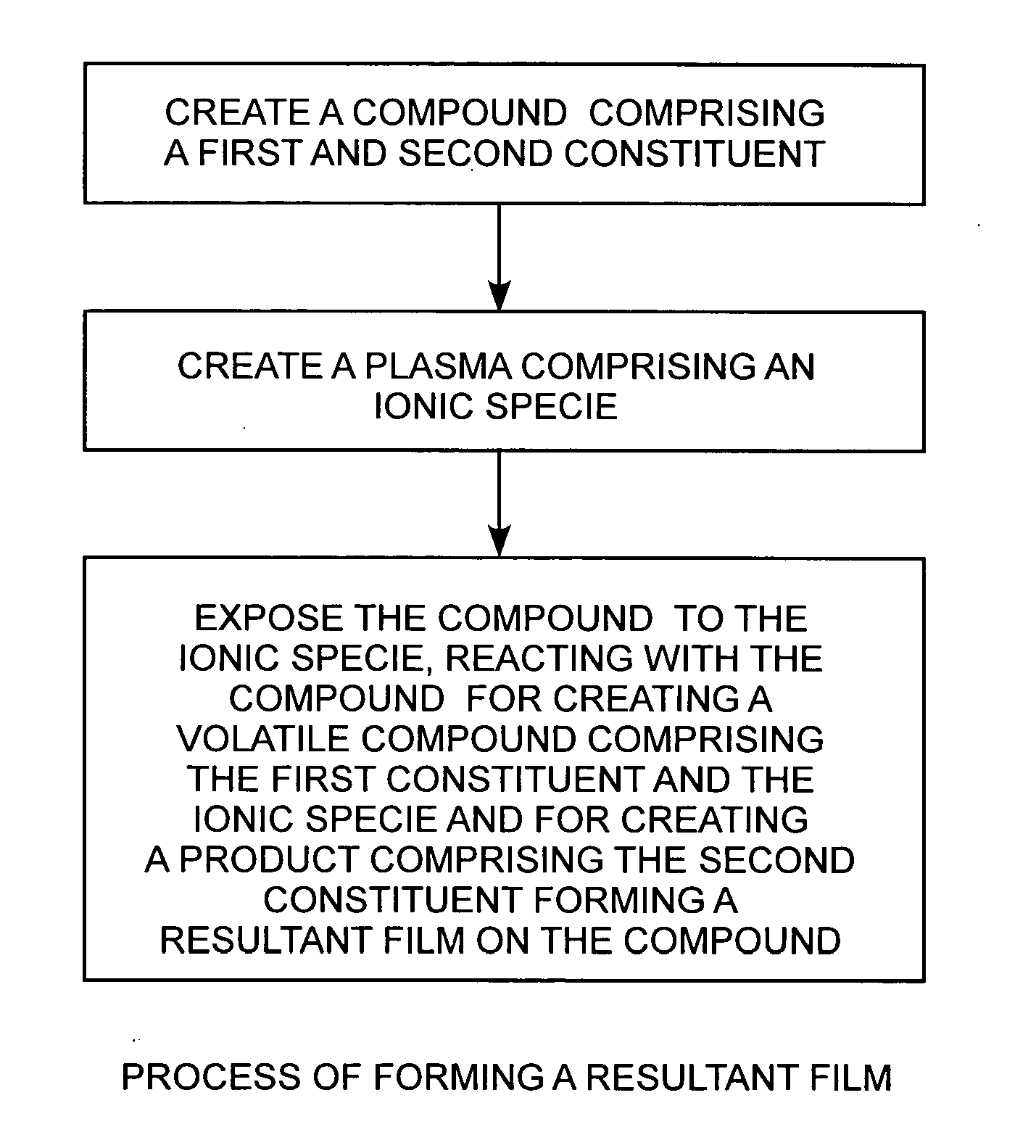

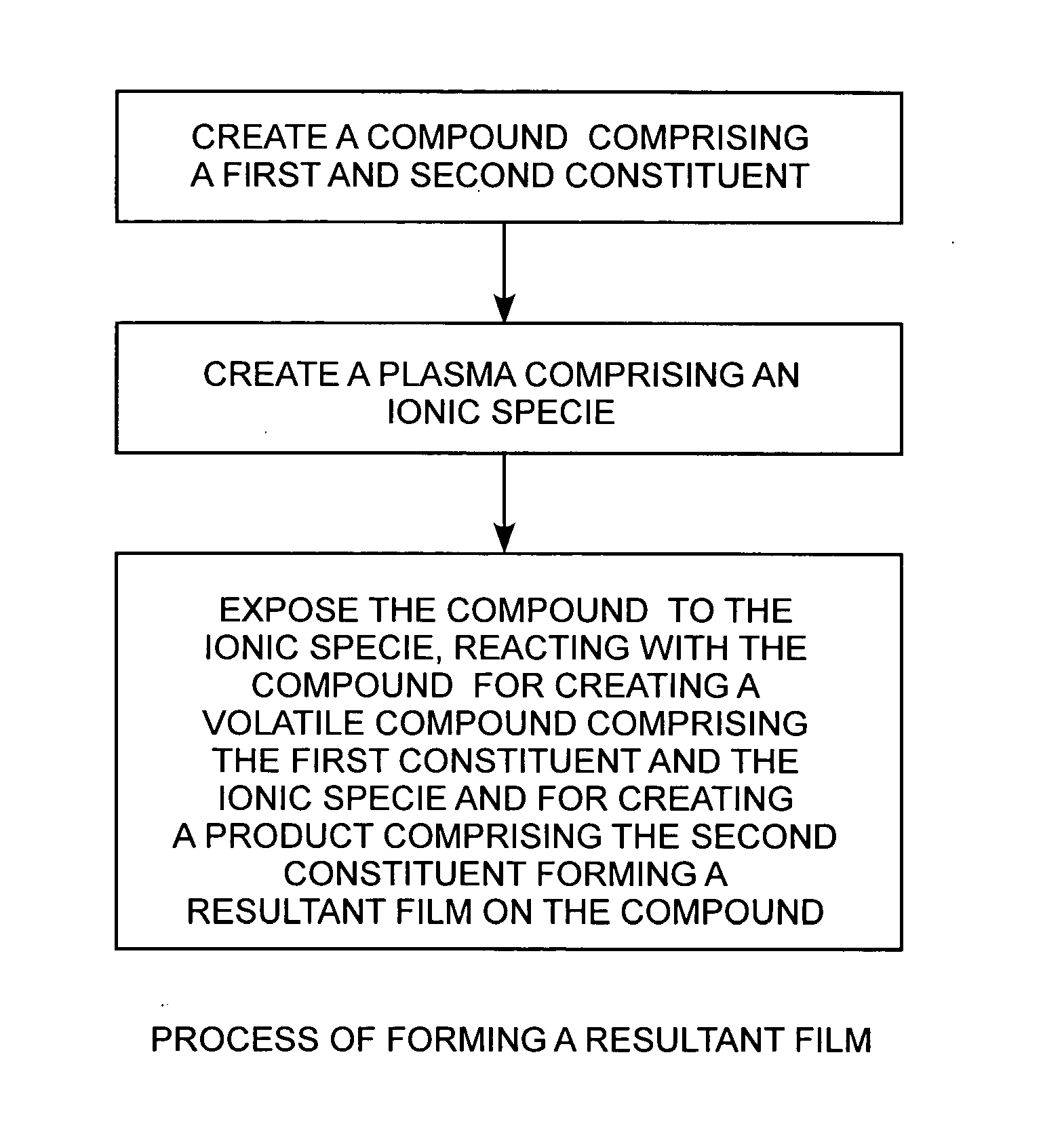

Method for producing carbon surface films by plasma exposure of a carbide compound

InactiveUS20060068125A1Reduce frictionEasy to controlChemical vapor deposition coatingFlexible microstructural devicesCarbon filmCarbon coating

Reactive halogen-ion plasmas, having for example, generating chloride ions, generated from low-pressure halogen gases using a radio-frequency plasma are employed for producing low-friction carbon coatings, such as a pure carbon film, at or near room temperature on a bulk or thin film of a compound, such as titanium carbide.

Owner:THE AEROSPACE CORPORATION

Cationic antiseptic compositions and methods of use

ActiveUS20060051385A1Reduce eliminateReduce and eliminate clinical signAntibacterial agentsBiocideAmmonium compoundsCetylpyridinium

Antimicrobial compositions, especially those useful when applied topically, particularly to mucosal tissues (i.e., mucous membranes), including a cationic antiseptic such as biguanides and bisbiguanides such as chlorhexidine and its various salts including but not limited to the digluconate, diacetate, dimethosulfate, and dilactate salts; polymeric quaternary ammonium compounds such as polyhexamethylenebiguanide; silver and various silver complexes; small molecule quaternary ammonium compounds such as benzalkoium chloride and alkyl substituted derivatives; di-long chain alkyl (C8-C18) quaternary ammonium compounds; cetylpyridinium halides and their derivatives; benzethonium chloride and its alkyl substituted derivatives; and octenidine. The compositions can also include an enhancer component, a surfactant, a hydrophobic component, and / or a hydrophilic component. Such compositions provide effective topical antimicrobial activity and are accordingly useful in the treatment and / or prevention of conditions that are caused, or aggravated by, microorganisms (including viruses).

Owner:3M INNOVATIVE PROPERTIES CO

Coatings for enhancement of properties and performance of substrate articles and apparatus

PendingUS20180044800A1Avoid reactionGood semiconductor performanceSemi-permeable membranesVacuum evaporation coatingCoated surfaceReactive gas

Coatings applicable to a variety of substrate articles, structures, materials, and equipment are described. In various applications, the substrate includes metal surface susceptible to formation of oxide, nitride, fluoride, or chloride of such metal thereon, wherein the metal surface is configured to be contacted in use with gas, solid, or liquid that is reactive therewith to form a reaction product that is deleterious to the substrate article, structure, material, or equipment. The metal surface is coated with a protective coating preventing reaction of the coated surface with the reactive gas, and / or otherwise improving the electrical, chemical, thermal, or structural properties of the substrate article or equipment. Various methods of coating the metal surface are described, and for selecting the coating material that is utilized.

Owner:ENTEGRIS INC

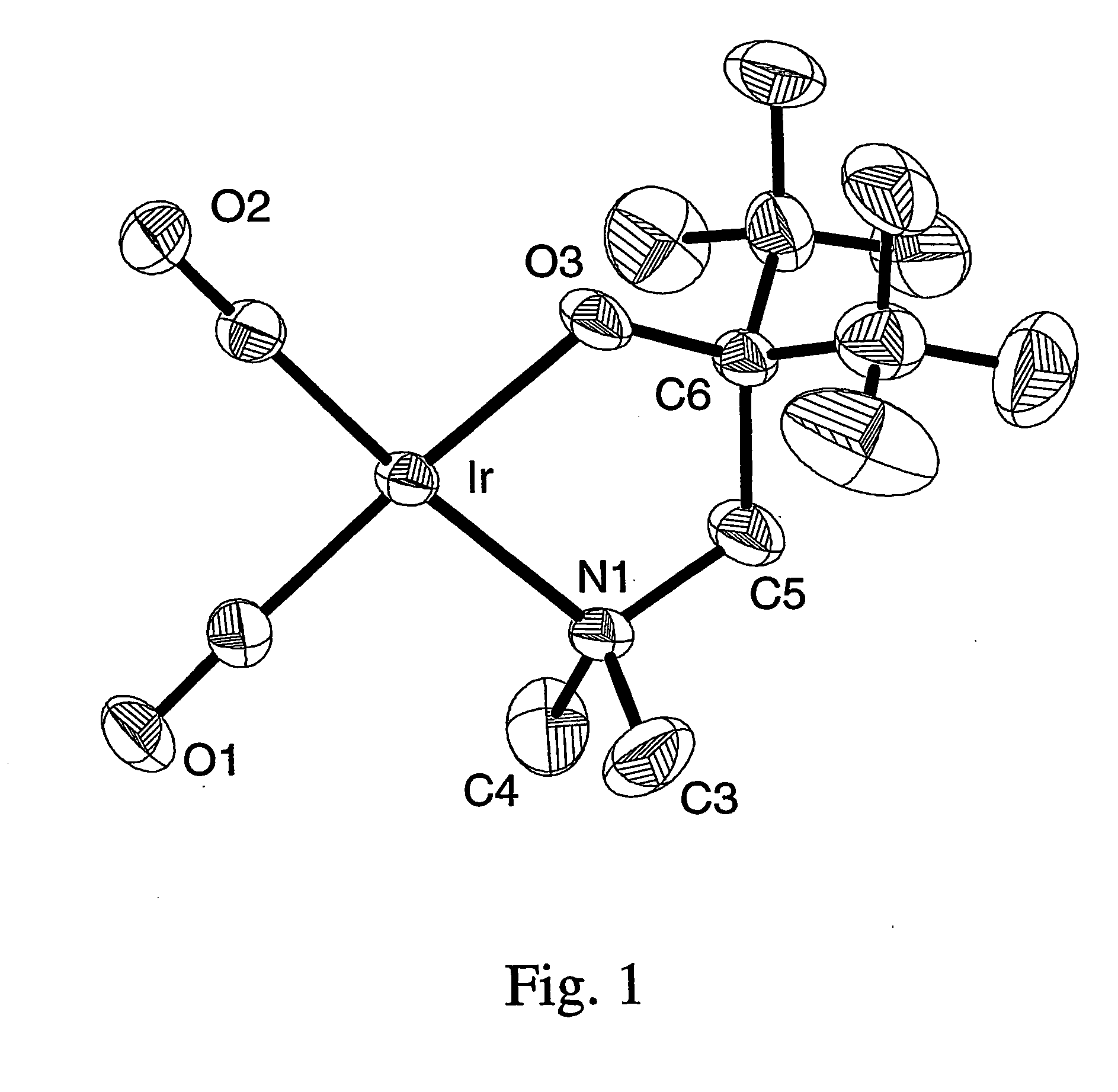

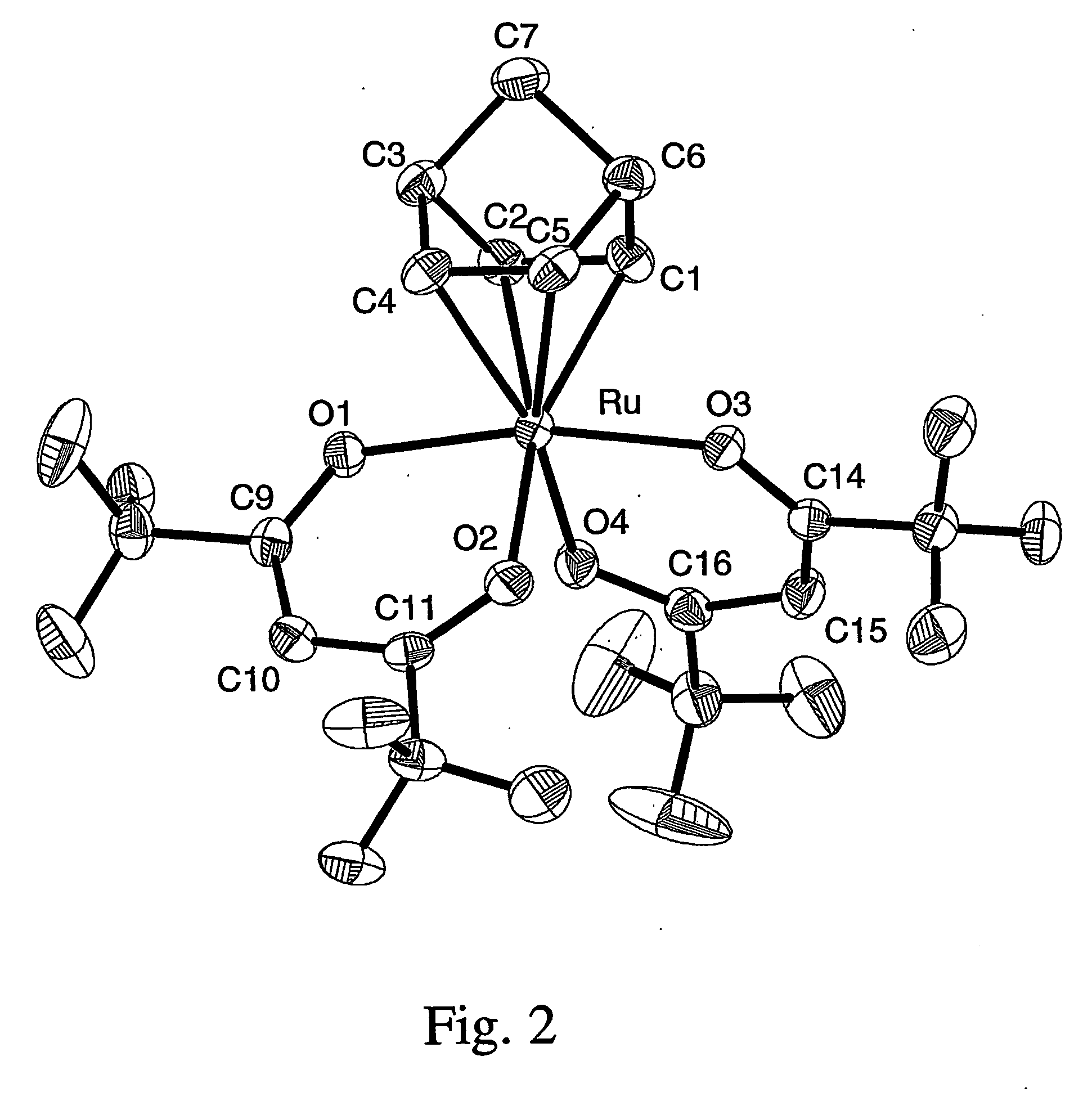

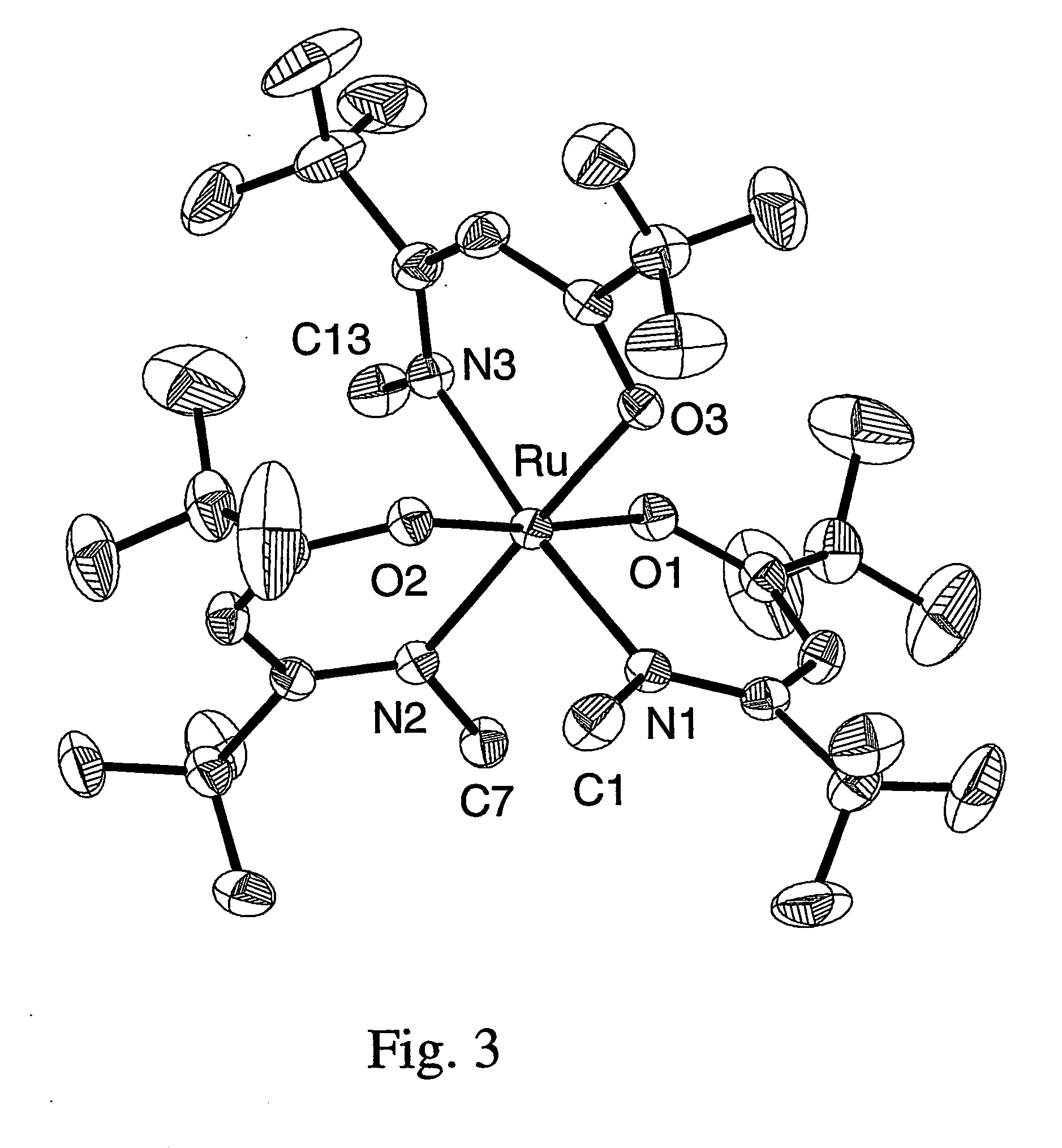

Volatile noble metal organometallic complexes

InactiveUS20050033075A1Reduce Van der Waals interactionBoiling and sublimation temperatureFurnaces without endless coreRuthenium organic compoundsIridiumIodide

A series of noble metal organometallic complexes of the general formula (I): MLaXb(FBC)c, wherein M is a noble metal such as iridium, ruthenium or osmium, and L is a neutral ligand such as carbonyl, alkene or diene; X is an anionic ligand such as chloride, bromide, iodide and trifluoroacetate group; and FBC is a fluorinated bidentate chelate ligand such as beta diketonate, beta-ketoiminate, amino-alcoholate and amino-alcoholate ligand, wherein a is an integer of from zero (0) to three (3), b is an integer of from zero (0) to one (1) and c is an 10 integer of from one (1) to three (3). The resulting noble metal complexes possess enhanced volatility and thermal stability characteristics, and are suitable for chemical vapor deposition(CVD) applications. The corresponding noble metal complex is formed by treatment of the FBC ligand with a less volatile metal halide. Also disclosed are CVD methods for using the noble metal complexes as source reagents for deposition of noble metal-containing films such as Ir, Ru and Os, or even metal oxide film materials IrO2, OsO2 and RuO2.

Owner:NATIONAL TSING HUA UNIVERSITY +1

Loaded method of Non-metallocene catalyst loaded by composite carrier and polymerizing application

ActiveCN1539856AGood particle shapeHigh non-metallocene olefin polymerization catalyst contentChemical treatmentAluminoxane

A process for carrying the non-metallocene catalyst by composite carrier includes such steps as thermally activating silica gel, reacting on the solution of magnesium chloride in tetrahydrofuran-alcohol solution to obtain composite carrier, reacting on chemical treating agent to obtain modified composite carrier and carrying non-metallocene catalyst by solution method or dipping method. Said catalyst can be used for the homopolymerization or copolymerization of C2-C10 olefin, styrene, or ethylene.

Owner:SINOPEC YANGZI PETROCHEM +1

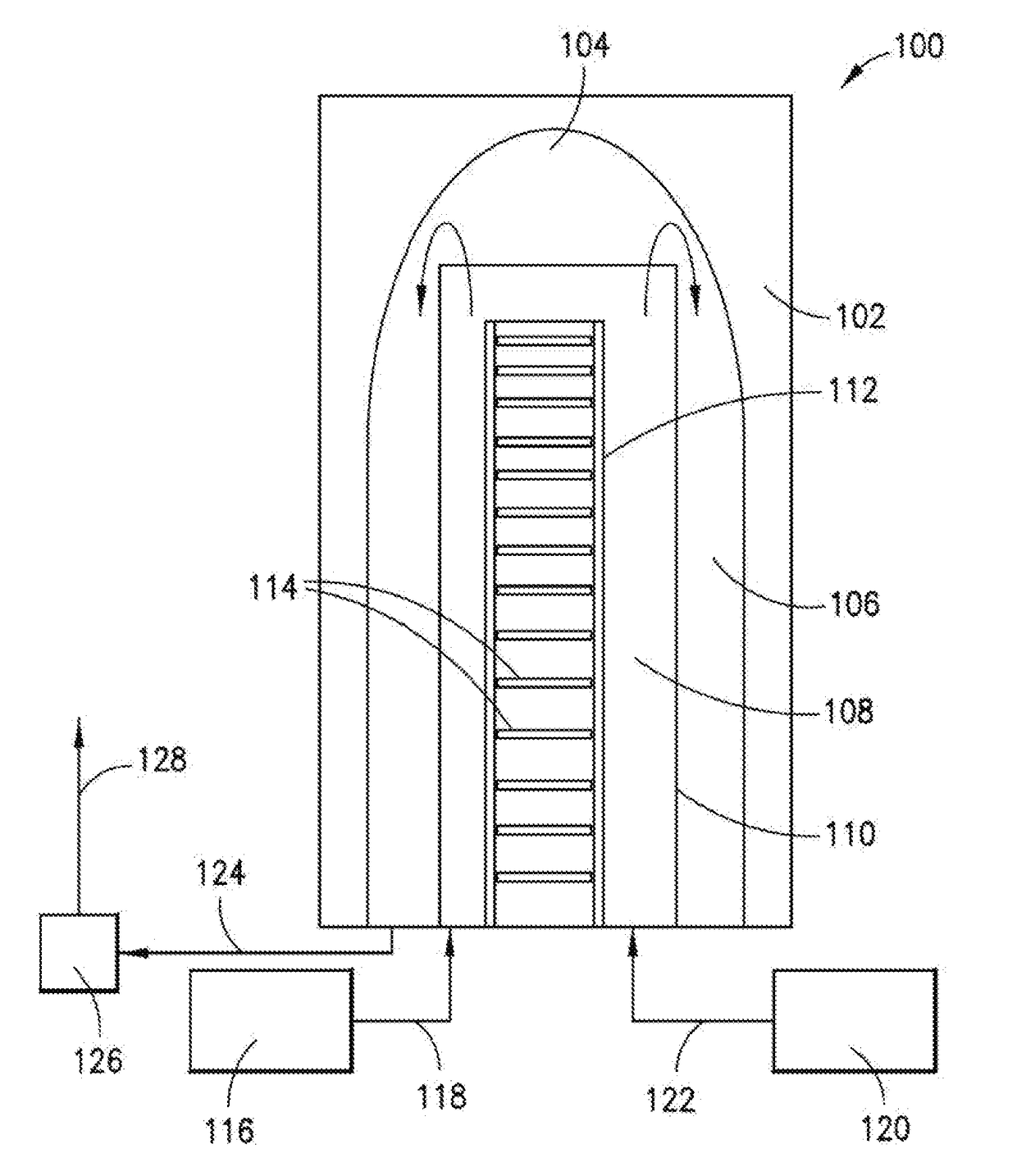

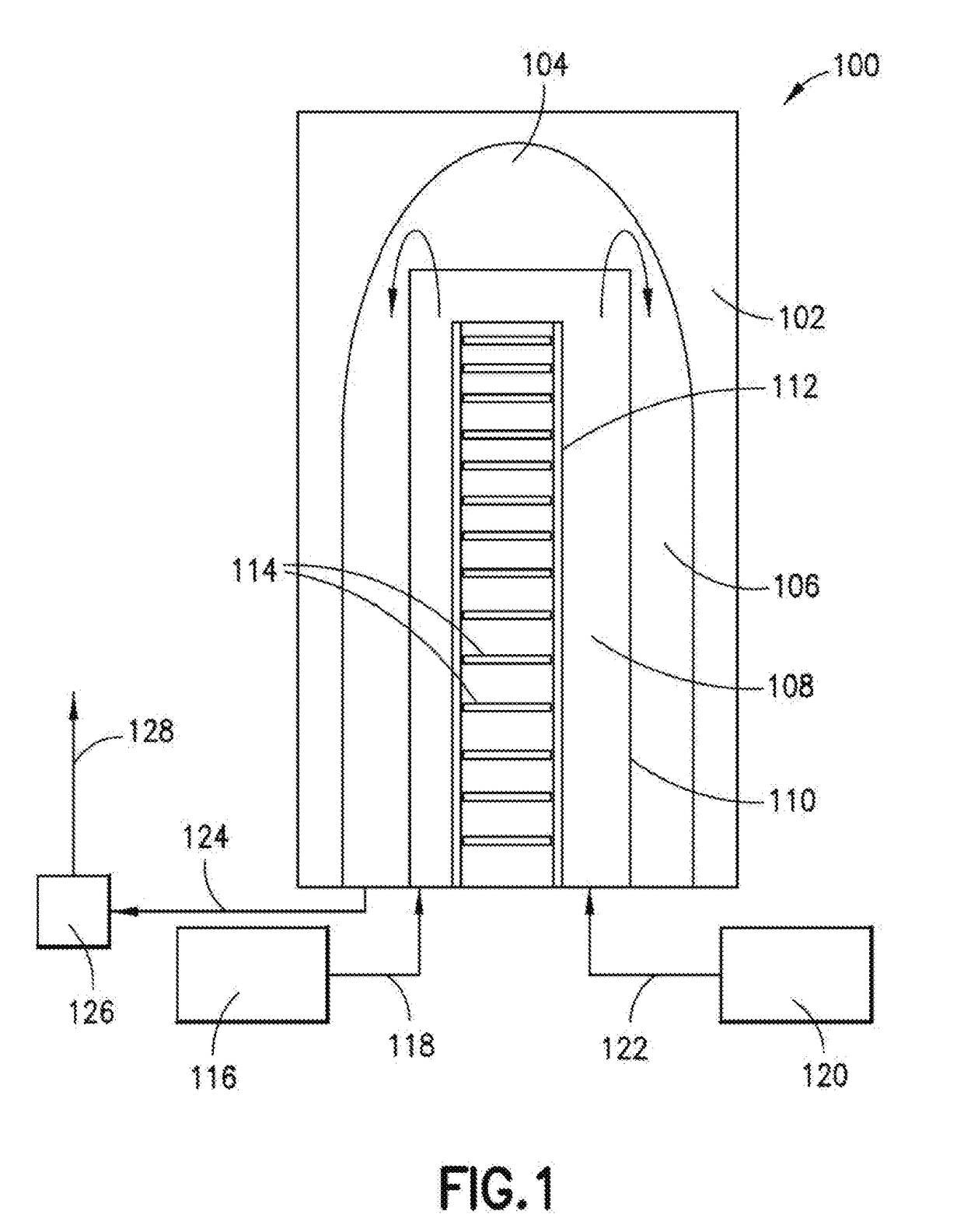

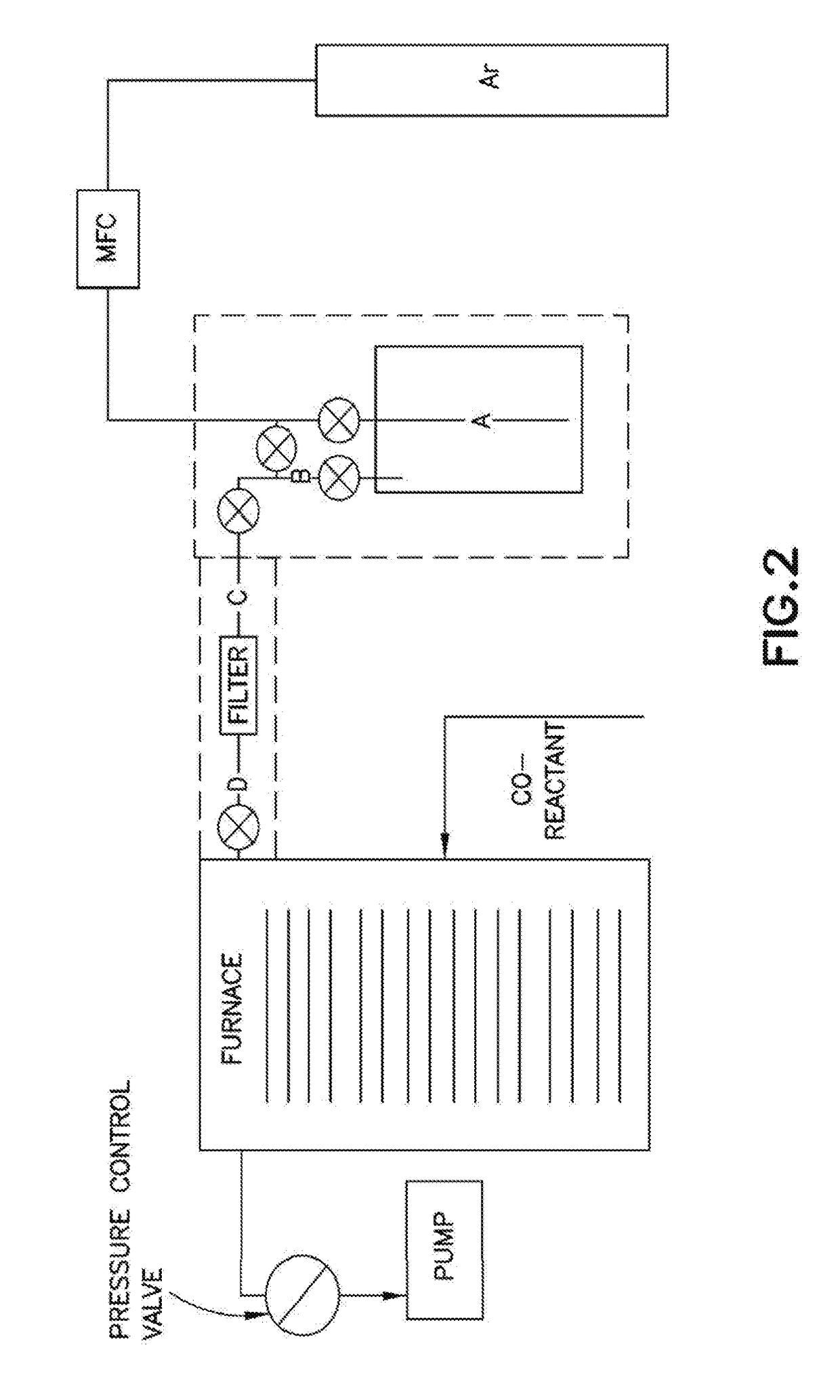

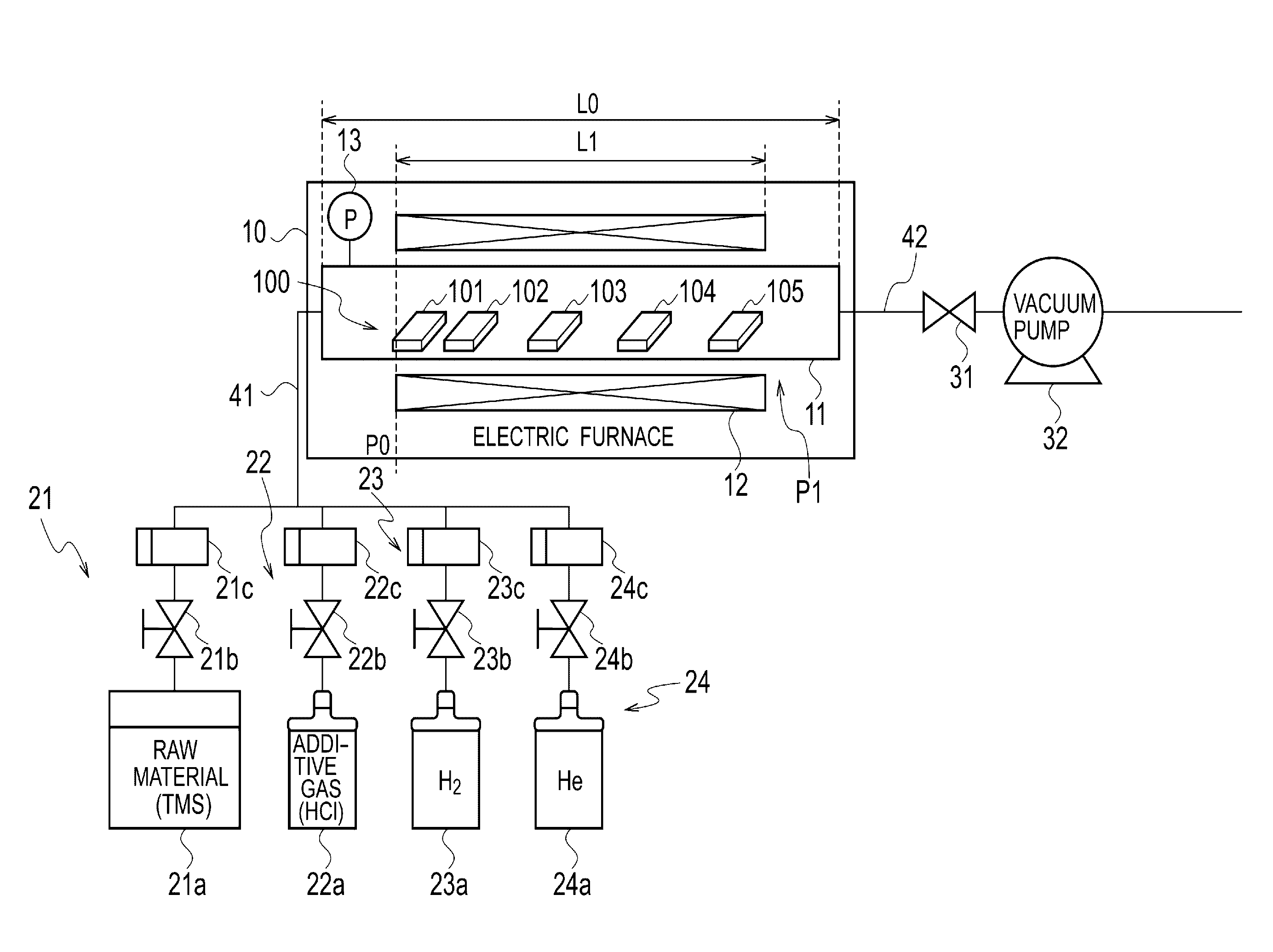

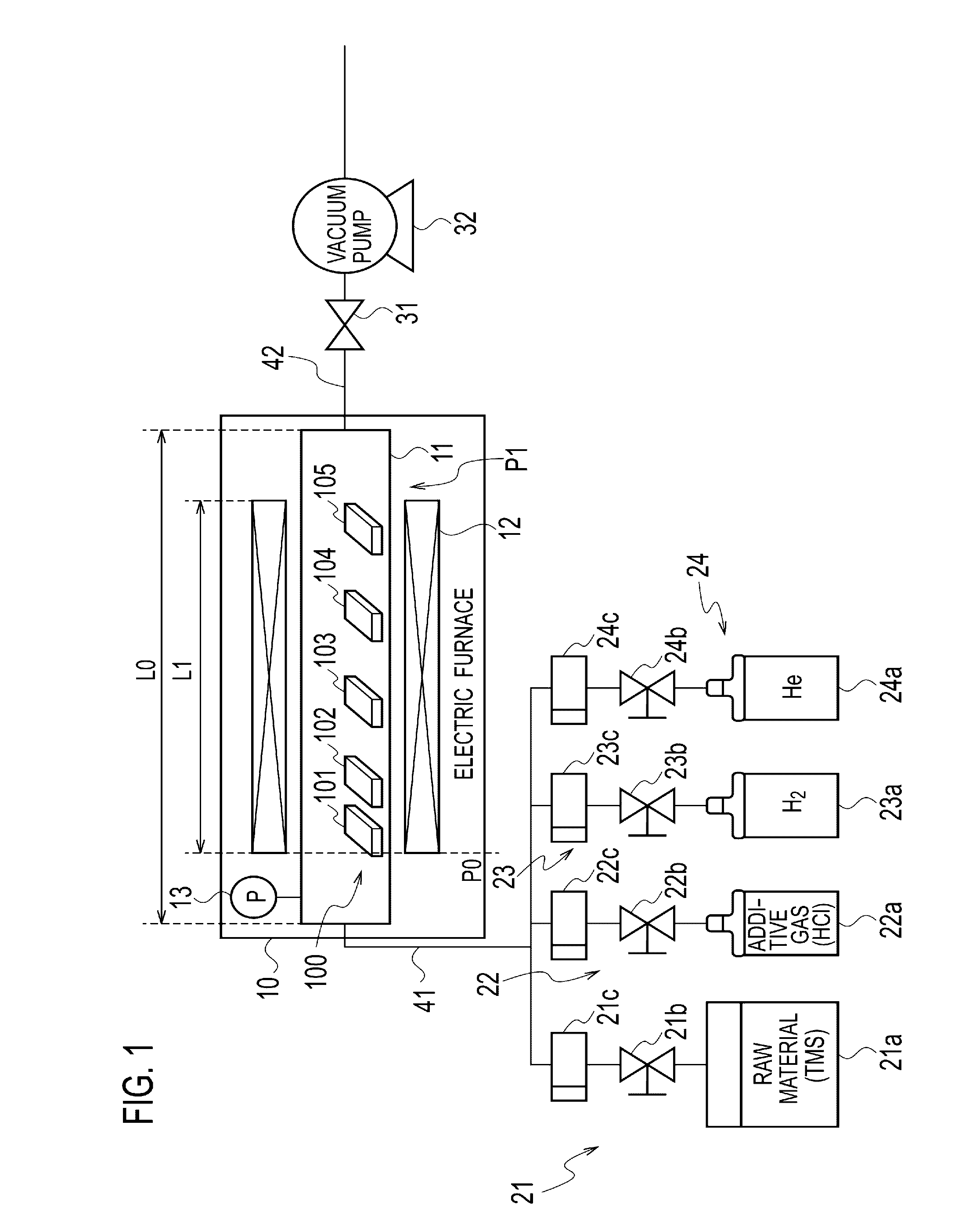

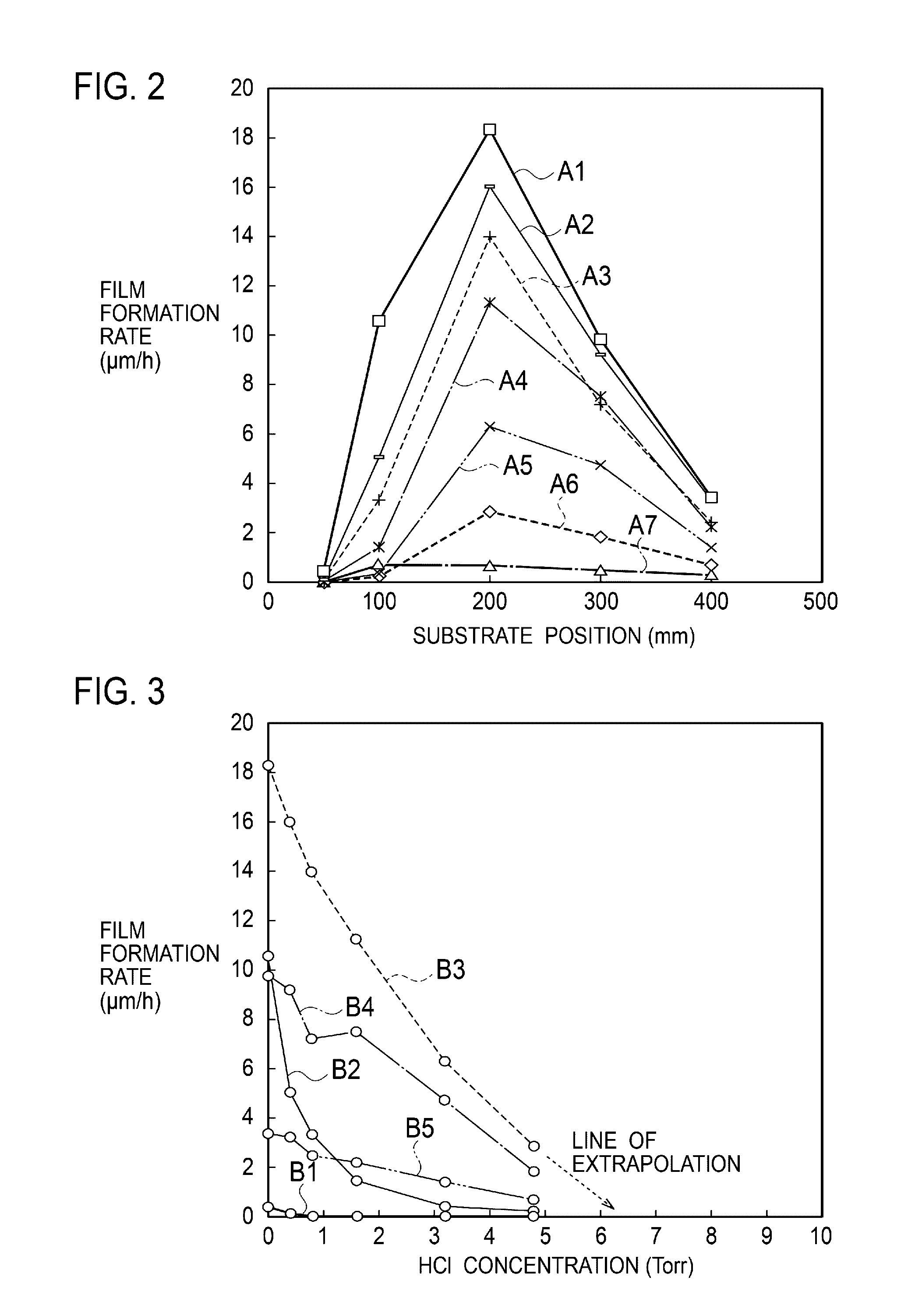

Heat-resistant composite material production method and production device

ActiveUS20160305015A1Reduce generationImprove mass productionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChlorideChemical vapor deposition

In the present embodiment, in the production of a heat-resistant composite material resulting from impregnating a ceramic fiber preform with silicon carbide, a mixed gas containing starting material gas, an additive gas, and a carrier gas is supplied to a substrate having a minute structure such as a preform stored in an electric furnace, silicon carbide is deposited to form a film by means of a chemical vapor deposition method or a chemical vapor infiltration method, and the film formation growth speed and embedding uniformity are controlled by means of the amount of additive gas added to the starting material gas, the starting material gas contains tetramethylsilane, and the additive gas contains a molecule containing chlorine such as methyl chloride or hydrogen chloride. The film formation growth speed and embedding uniformity of the silicon carbide are both achieved.

Owner:IHI CORP +1

Method to form a robust TiCI4 based CVD TiN film

InactiveUS20050112876A1Low resistivityReduce stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChlorideLow leakage

A method is described for a plasma treatment of a TiCl4 based CVD deposited TiN layer that reduces stress, lowers resistivity, and improves film stability. Resistivity is stable in an air ambient for up to 48 hours after the plasma treatment. A TiN layer is treated with a N-containing plasma that includes N2, NH3, or N2H4 at a temperature between 500° C. and 700° C. Optionally, H2 may be added to N2 in the plasma step which removes chloride impurities and densifies the TiN layer. The TiN layer may serve as a barrier layer, an ARC layer, or as a bottom electrode in a MIM capacitor. An improved resistance of the treated TiN layer to oxidation during formation of an oxide based insulator layer and a lower leakage current in the MIM capacitor is also achieved.

Owner:TAIWAN SEMICON MFG CO LTD

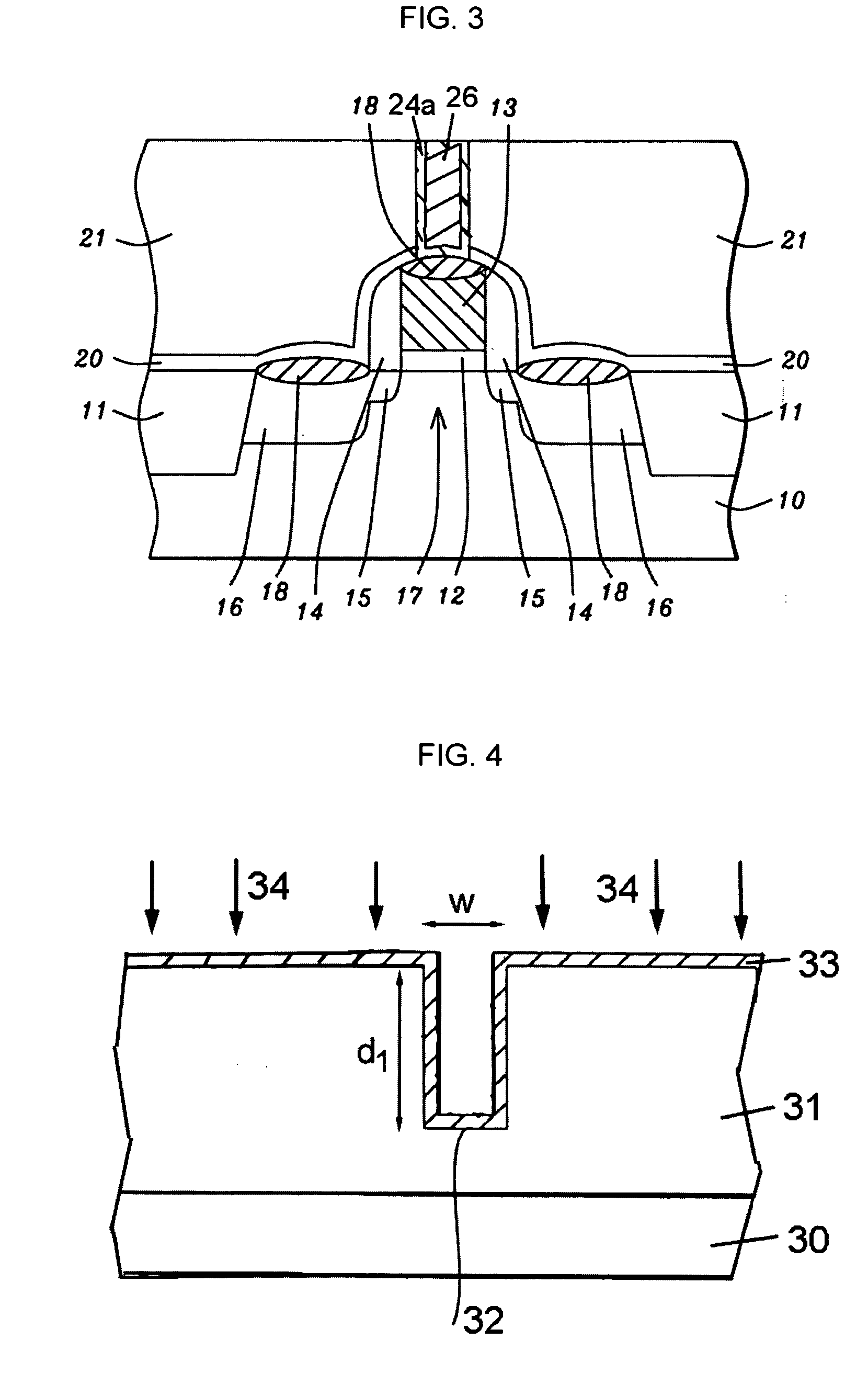

Process for the manufacture of 1, 1, 1, 3, 3-pentachloropropane

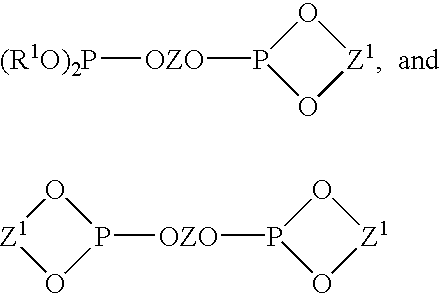

InactiveUS6313360B1Improve degradation rateShorten the timeOrganic chemistry methodsHalogenated hydrocarbon separation/purificationChlorideOrganic phosphates

A process is provided for the production of 1,1,1,3,3-pentachloropropane. The process comprises: (a) producing a product mixture in a reactor by reacting carbon tetrachloride and vinyl chloride in the presence of a catalyst mixture comprising organophosphate solvent, iron metal and ferric chloride under conditions sufficient to produce 1,1,1,3,3-pentachloropropane; (b) subjecting the 1,1,1,3,3-pentachloropropane containing product mixture from step (a) to evaporation such that a fraction enriched in 1,1,1,3,3-pentachloropropane is separated from the product mixture and a bottoms fraction results which comprises the iron metal / ferric chloride catalyst components and heavy end by-products; and (c) recycling at least a portion of the bottoms fraction from step (b) to the reactor.

Owner:OCCIDENTAL CHEM CORP

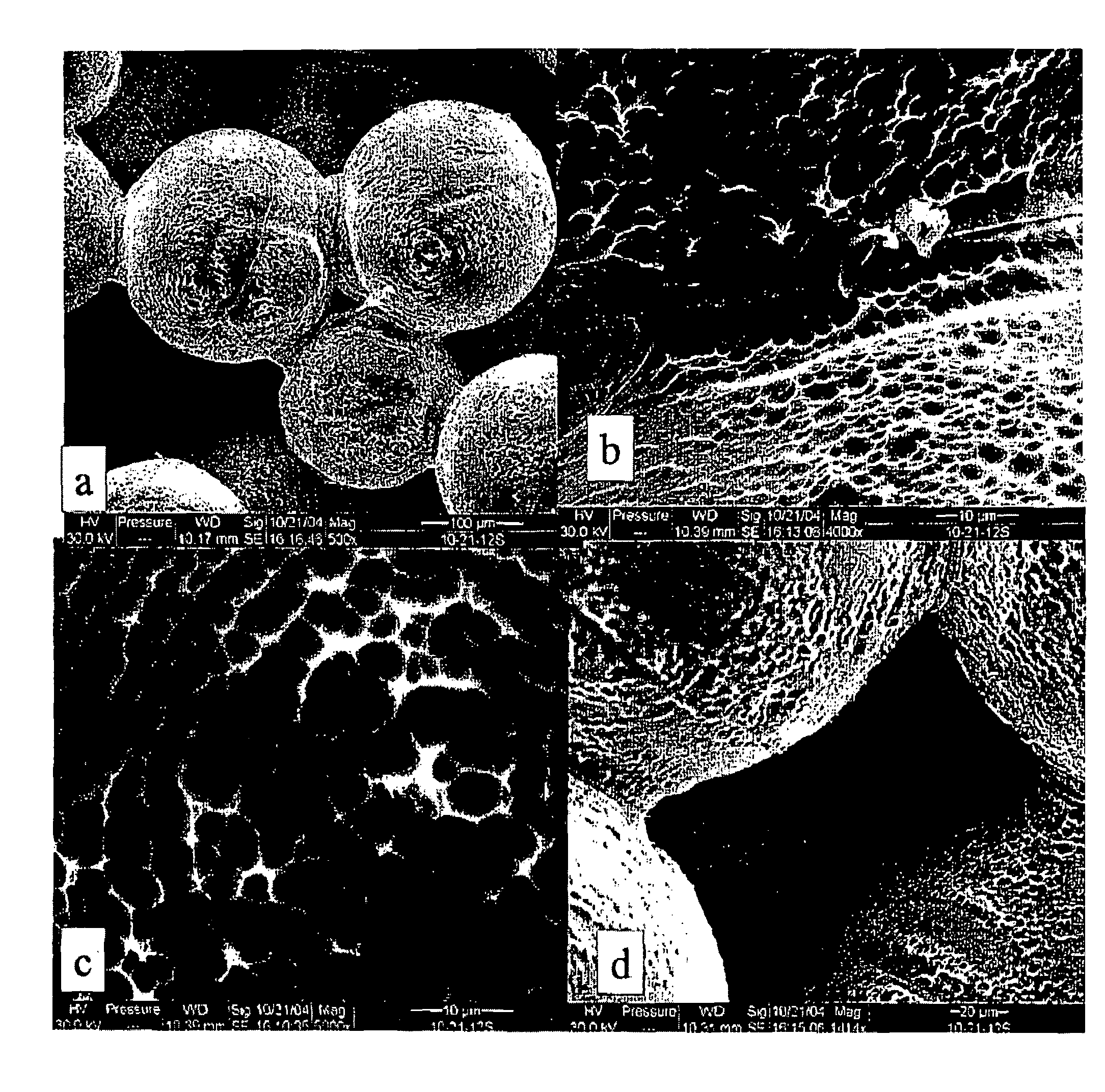

Implants with textured surface and methods for producing the same

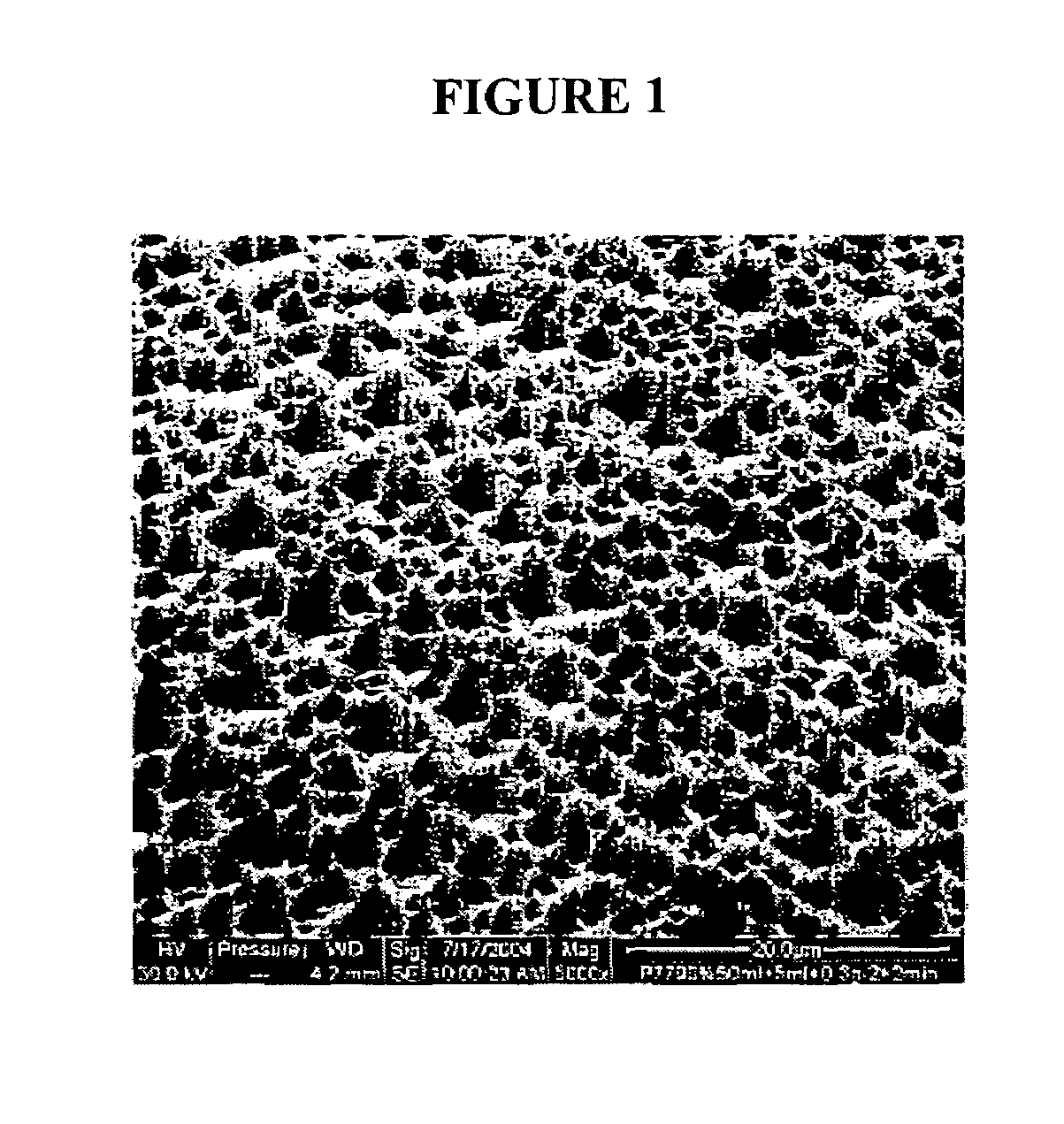

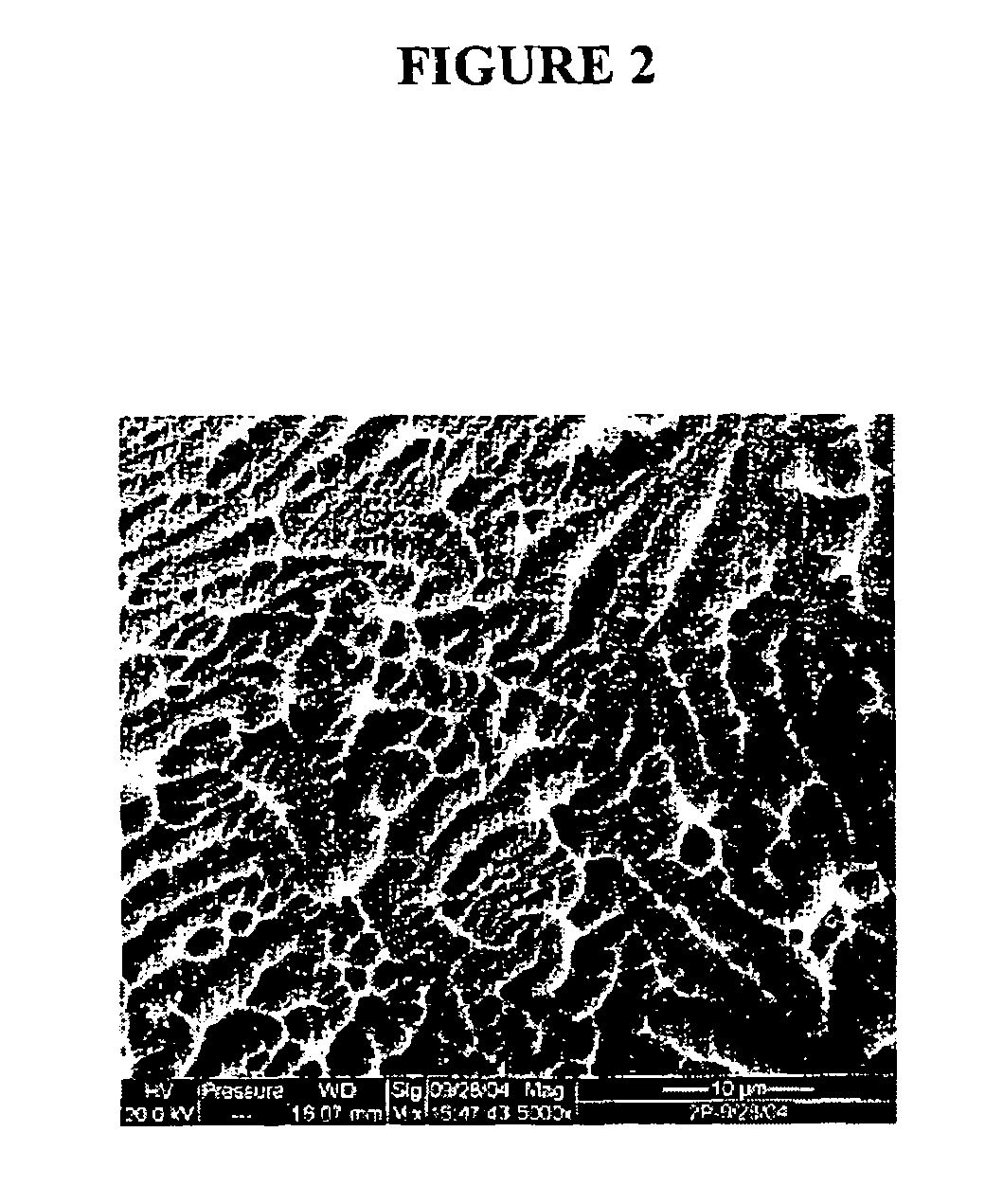

ActiveUS7368065B2High retention rateConvenient coatingImpression capsDecorative surface effectsMicrometerChloride

Compositions and methods are provided for preparing a metal substrate having a uniform textured surface with a plurality of indentations with a diameter in the nanometer and micrometer range. The textured surface is produced by exposing the substrate to an etching fluid comprising a hydrohalic acid and a mixture of a hydrohalic acid and an oxyacid, a chloride containing compound, and an oxidant. The etching solution can be used at ambient temperature. This textured surface enhances adherence of coatings or cells onto the textured surface, improves the retention of proteins on the surface, and encourages bone in-growth.

Owner:DEPUY PROD INC

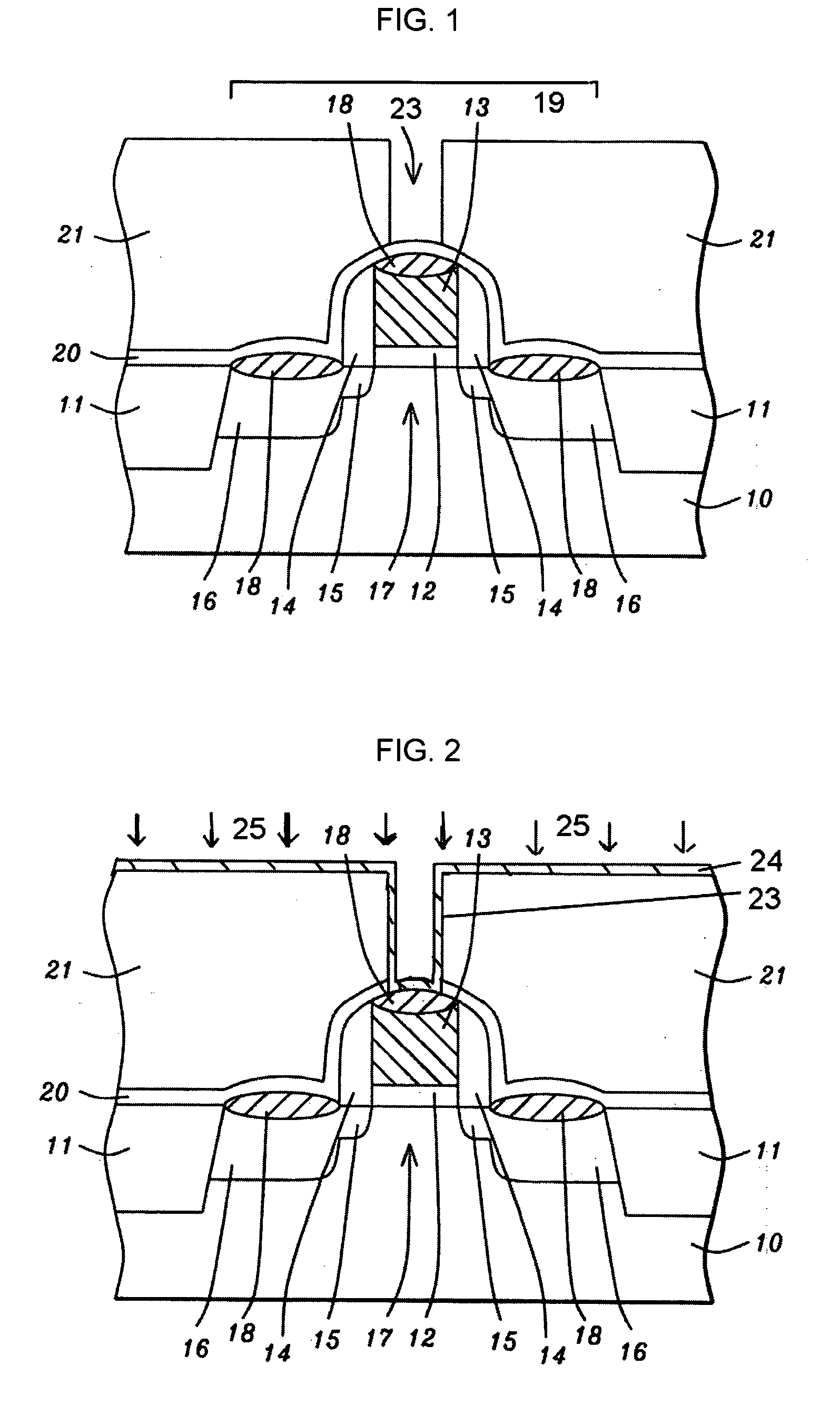

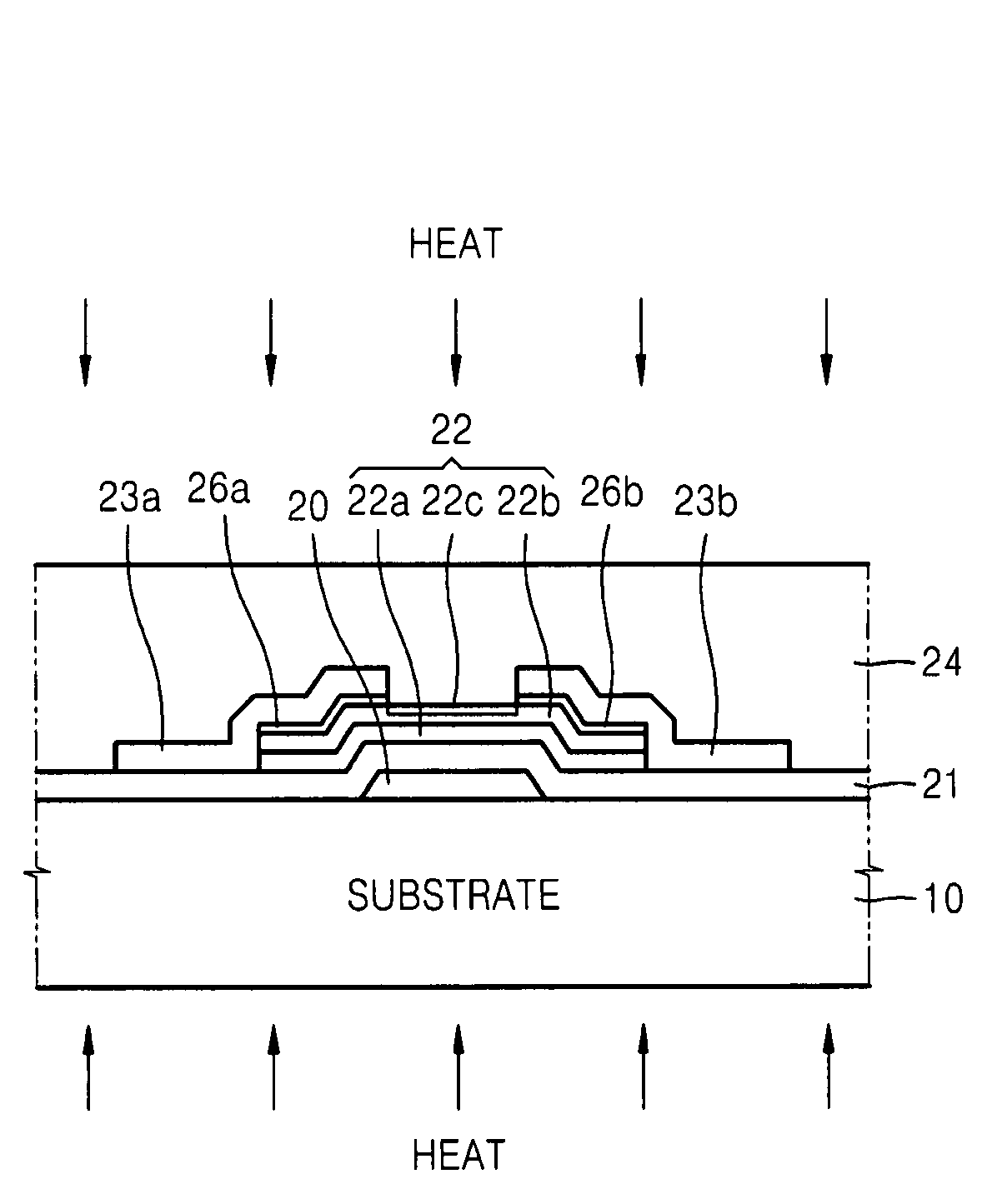

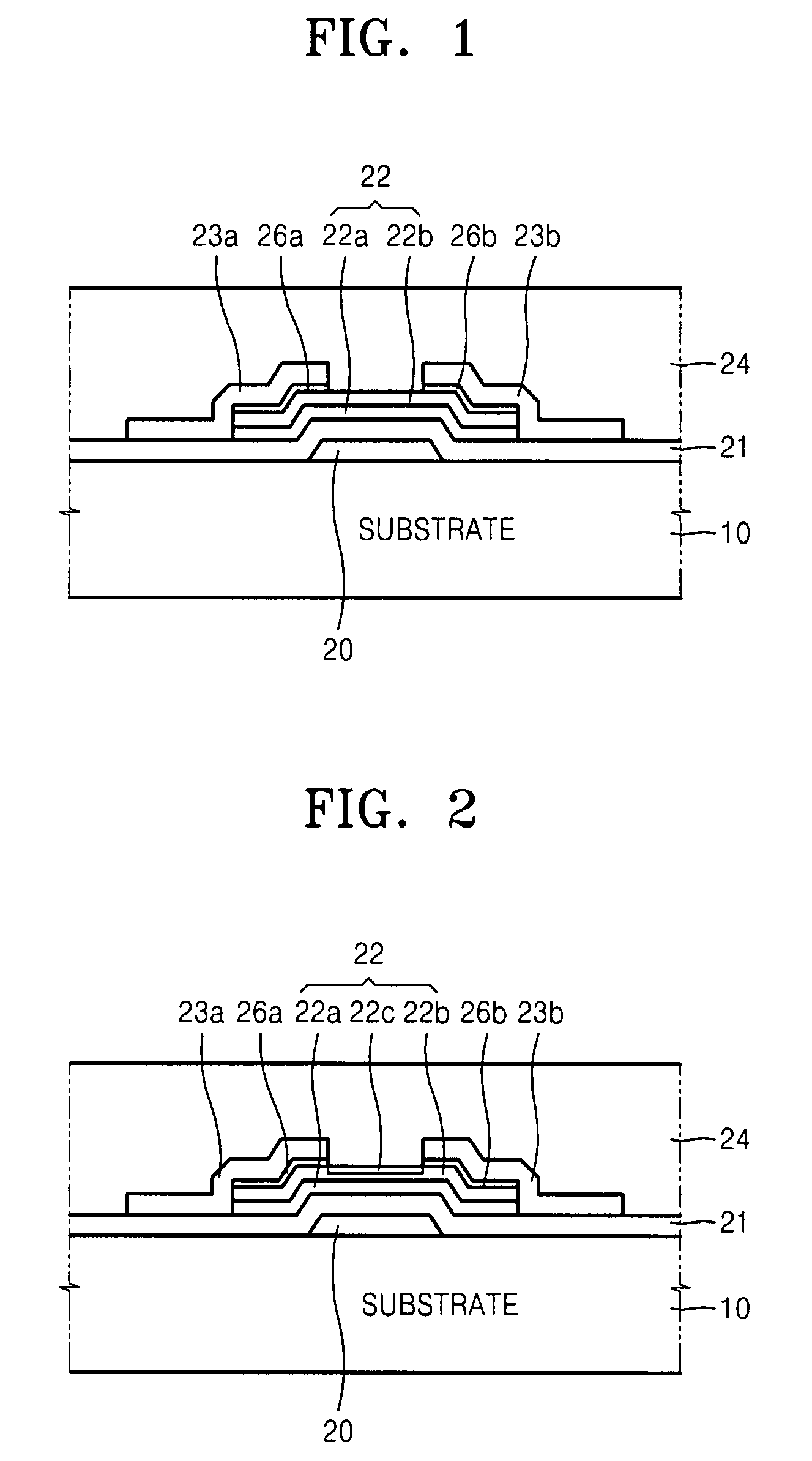

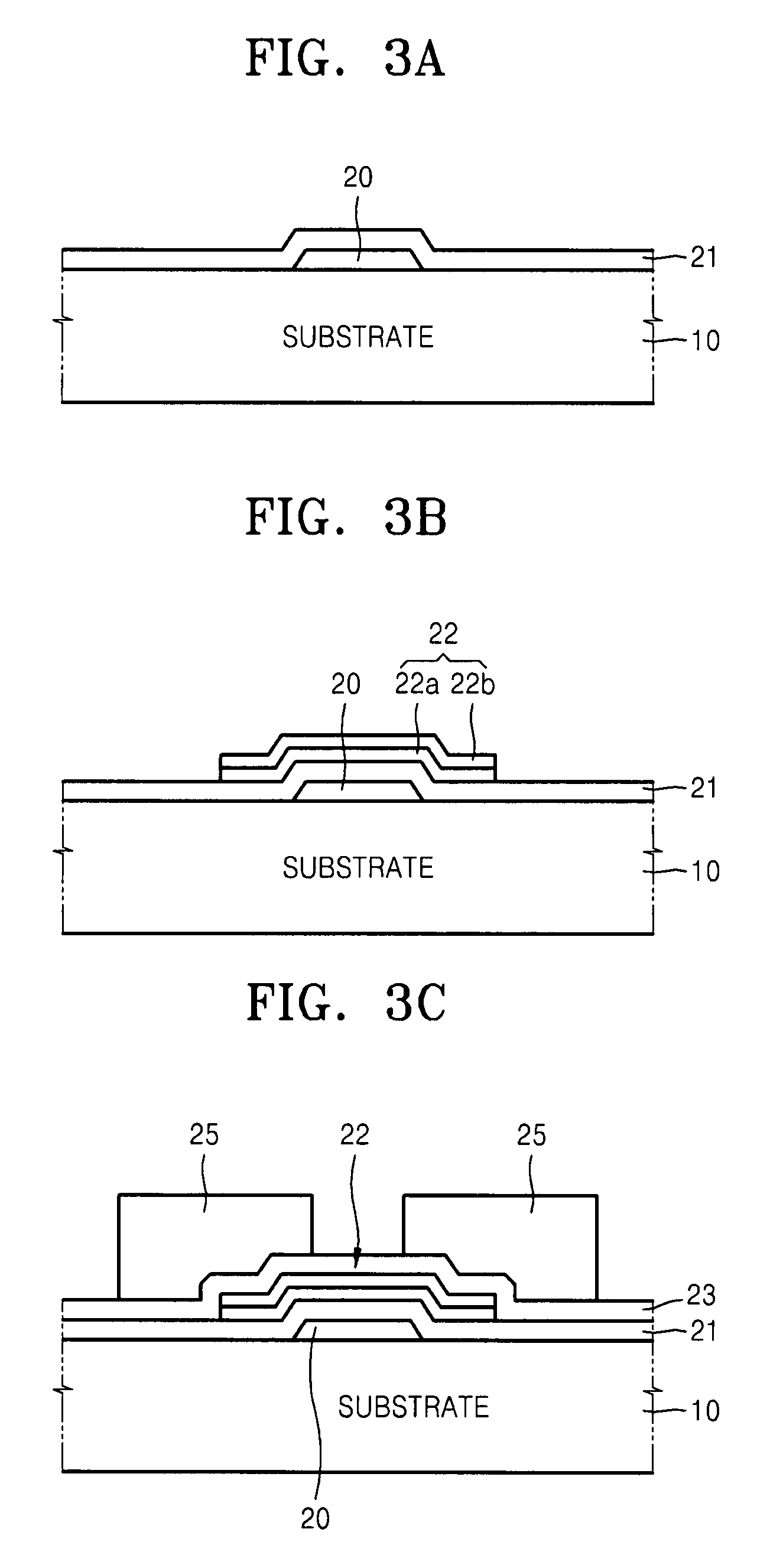

Thin film transistors and methods of manufacturing the same

ActiveUS7923722B2Avoid damageSemiconductor/solid-state device manufacturingSemiconductor devicesOxygen vacancyChloride

A TFT includes a zinc oxide (ZnO)-based channel layer having a plurality of semiconductor layers. An uppermost of the plurality of semiconductor layers has a Zn concentration less than that of a lower semiconductor layer to suppress an oxygen vacancy due to plasma. The uppermost semiconductor layer of the channel layer also has a tin (Sn) oxide, a chloride, a fluoride, or the like, which has a relatively stable bonding energy against plasma. The uppermost semiconductor layer is relatively strong against plasma shock and less decomposed when being exposed to plasma, thereby suppressing an increase in carrier concentration.

Owner:SAMSUNG ELECTRONICS CO LTD

Antimicrobial compositions

InactiveUS20100135949A1Reduce complicationsAvoid difficultyBiocidePretreated surfacesCetrimideO-Phthalaldehyde

Antimicrobial compositions and methods are disclosed. The antimicrobial compositions are particularly useful in providing antimicrobial capability to a wide-range of medical devices. In one aspect the invention relates a UV curable antimicrobial coating comprising a UV curable composition comprising an oligomer, a momoner, and a photoinitiator which are together capable of forming a UV curable polymer composition. The compositions include rheology modifiers as necessary. The compositions also include antimicrobial agents, which may be selected from a wide array of agents. Representative antimicrobial agents include cetyl pyridium chloride, cetrimide, alexidine, chlorexidine diacetate, benzalkonium chloride, and o-phthalaldehyde.

Owner:BECTON DICKINSON & CO

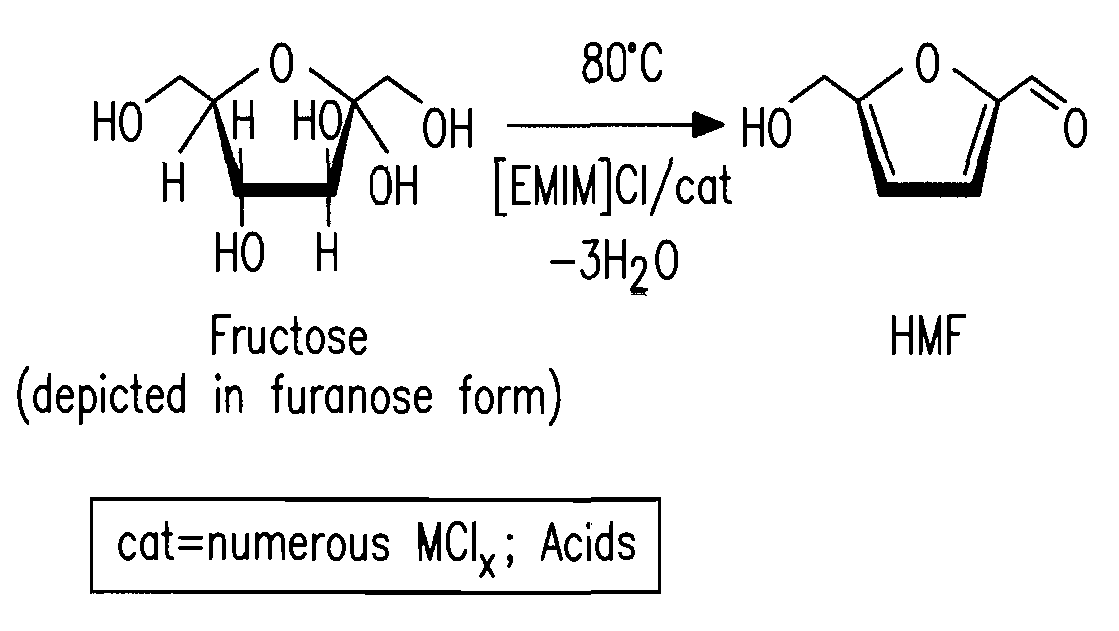

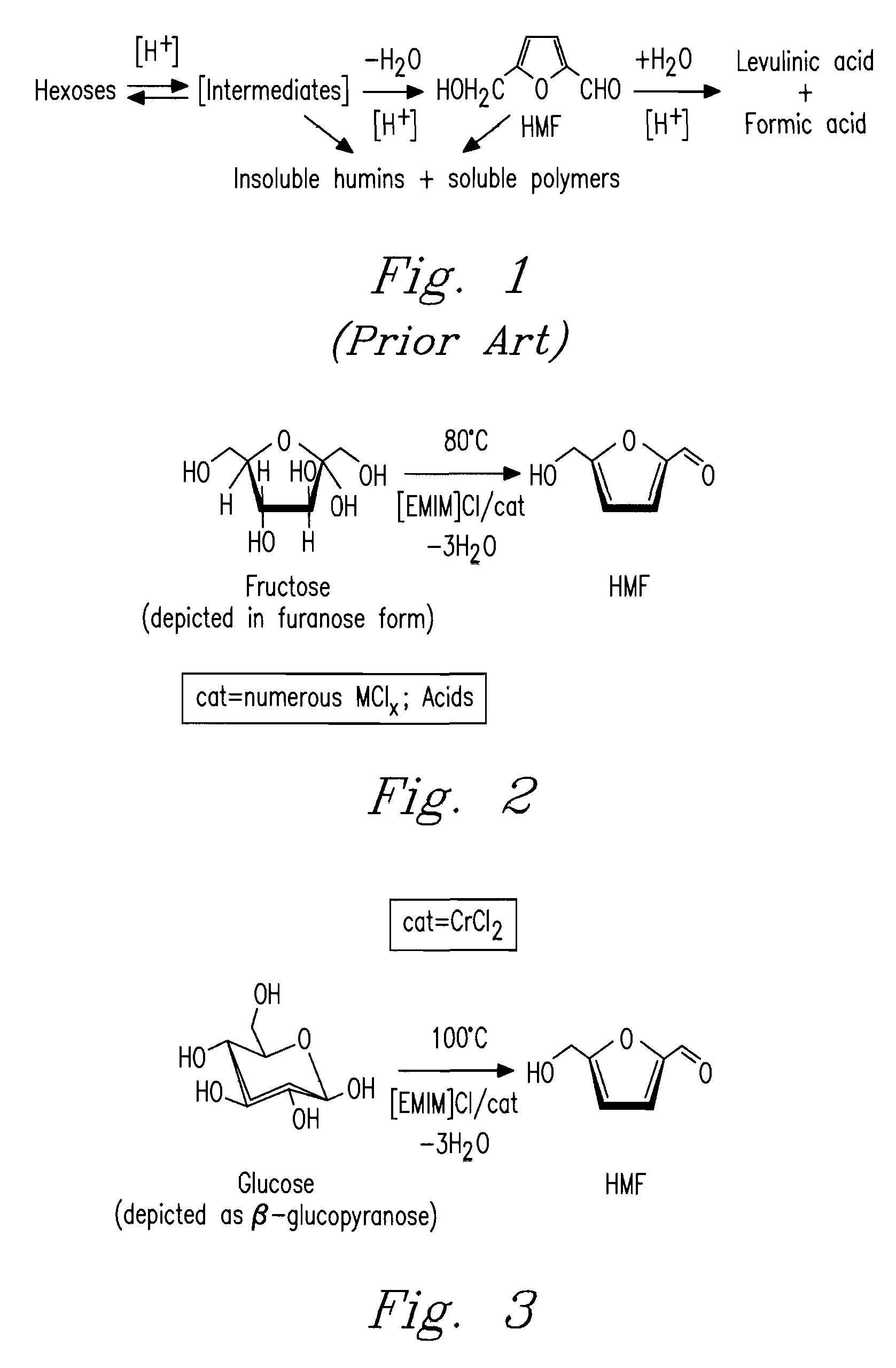

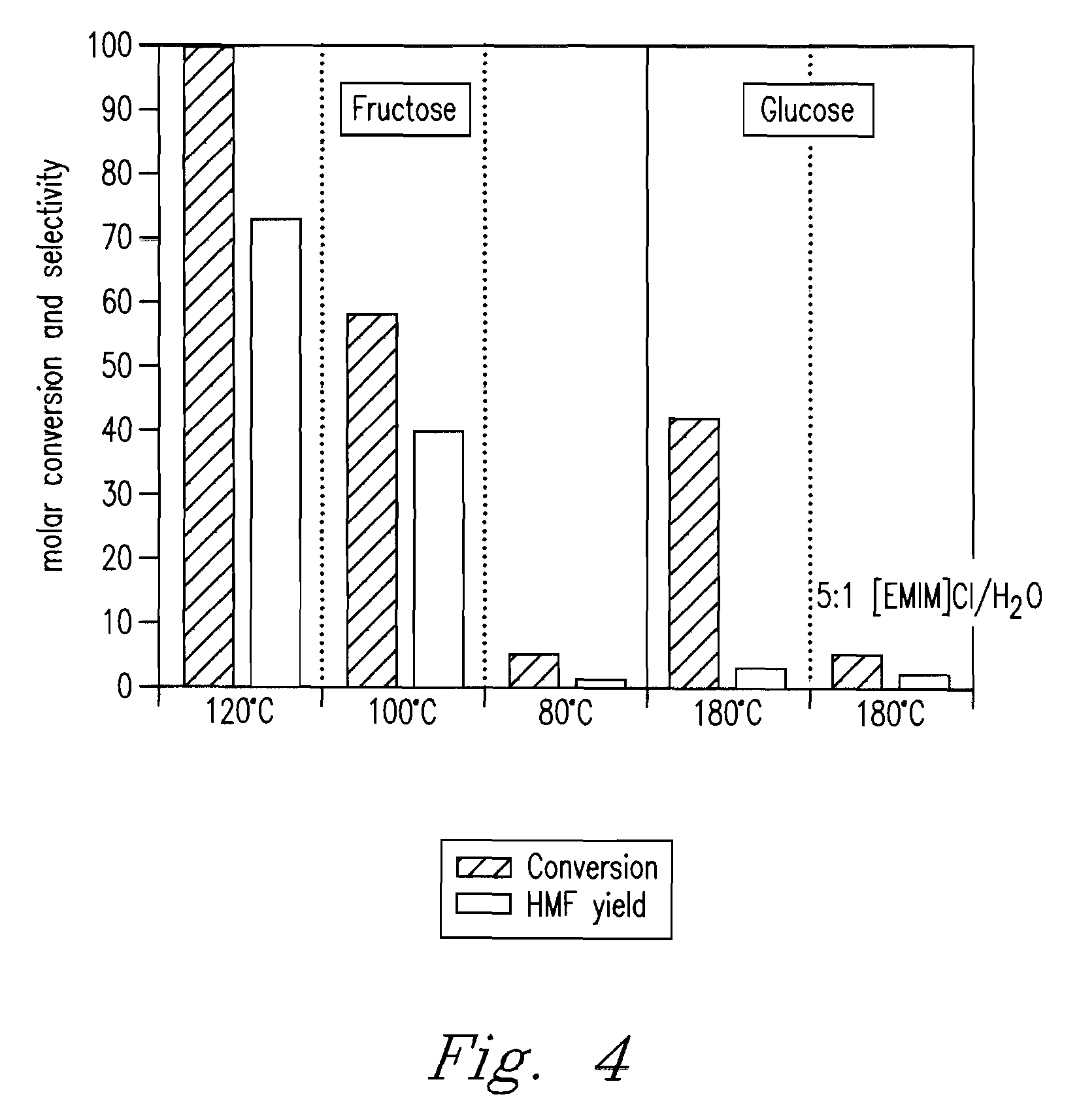

Methods for conversion of carbohydrates in ionic liquids to value-added chemicals

Methods are described for converting carbohydrates including, e.g., monosaccharides, disaccharides, and polysaccharides in ionic liquids to value-added chemicals including furans, useful as chemical intermediates and / or feedstocks. Fructose is converted to 5-hydroxylmethylfurfural (HMF) in the presence of metal halide and acid catalysts. Glucose is effectively converted to HMF in the presence of chromium chloride catalysts. Yields of up to about 70% are achieved with low levels of impurities such as levulinic acid.

Owner:BATTELLE MEMORIAL INST

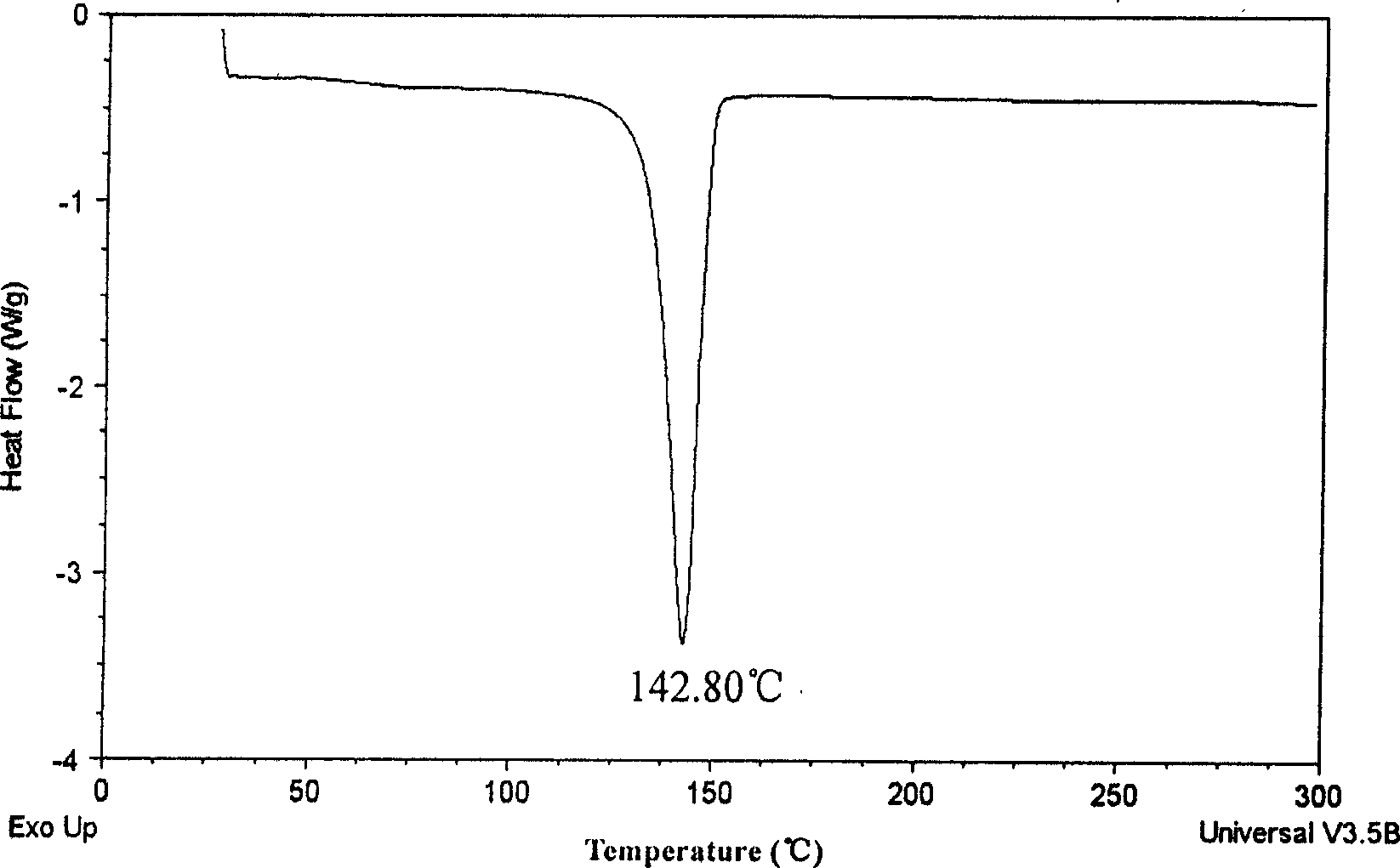

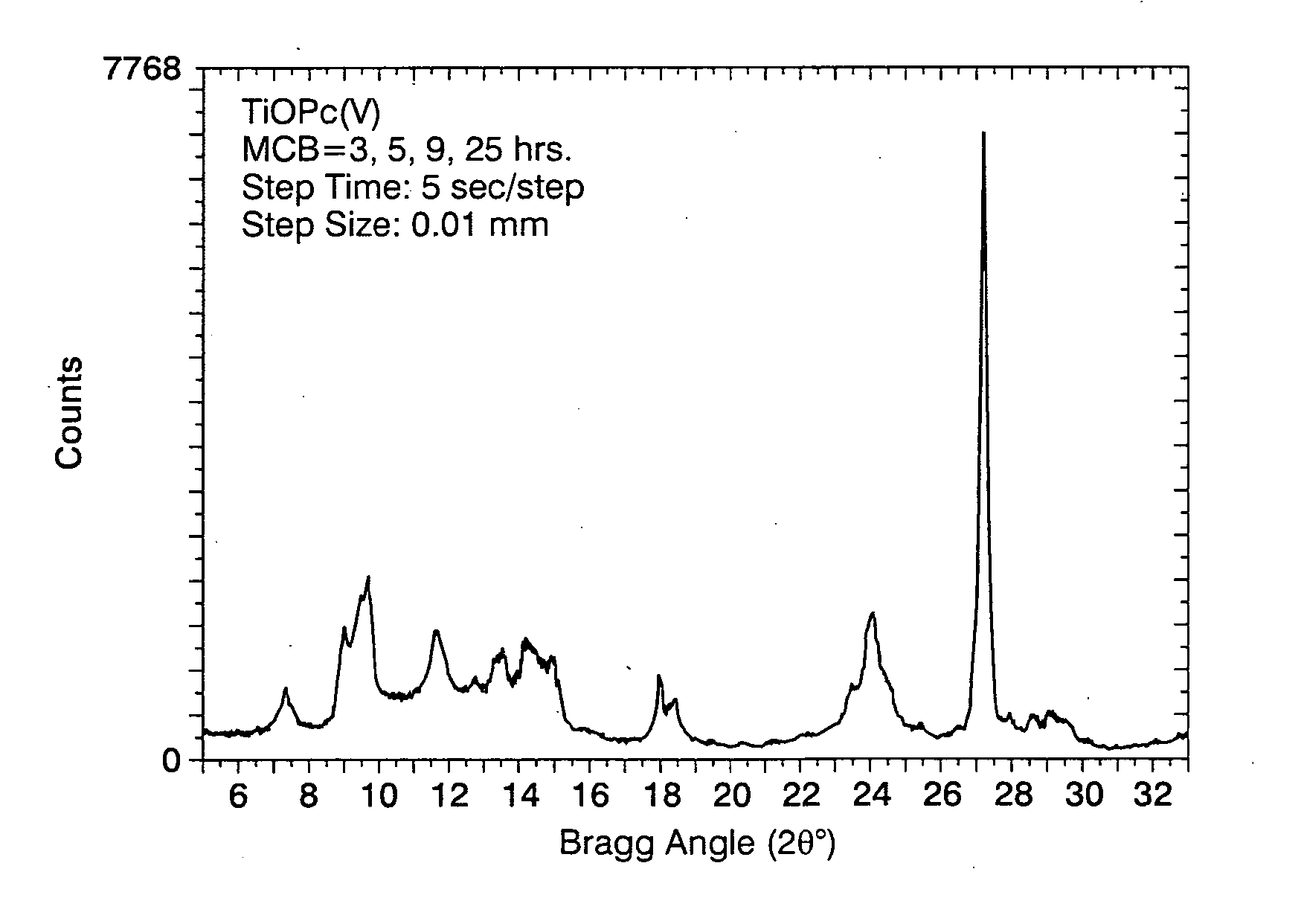

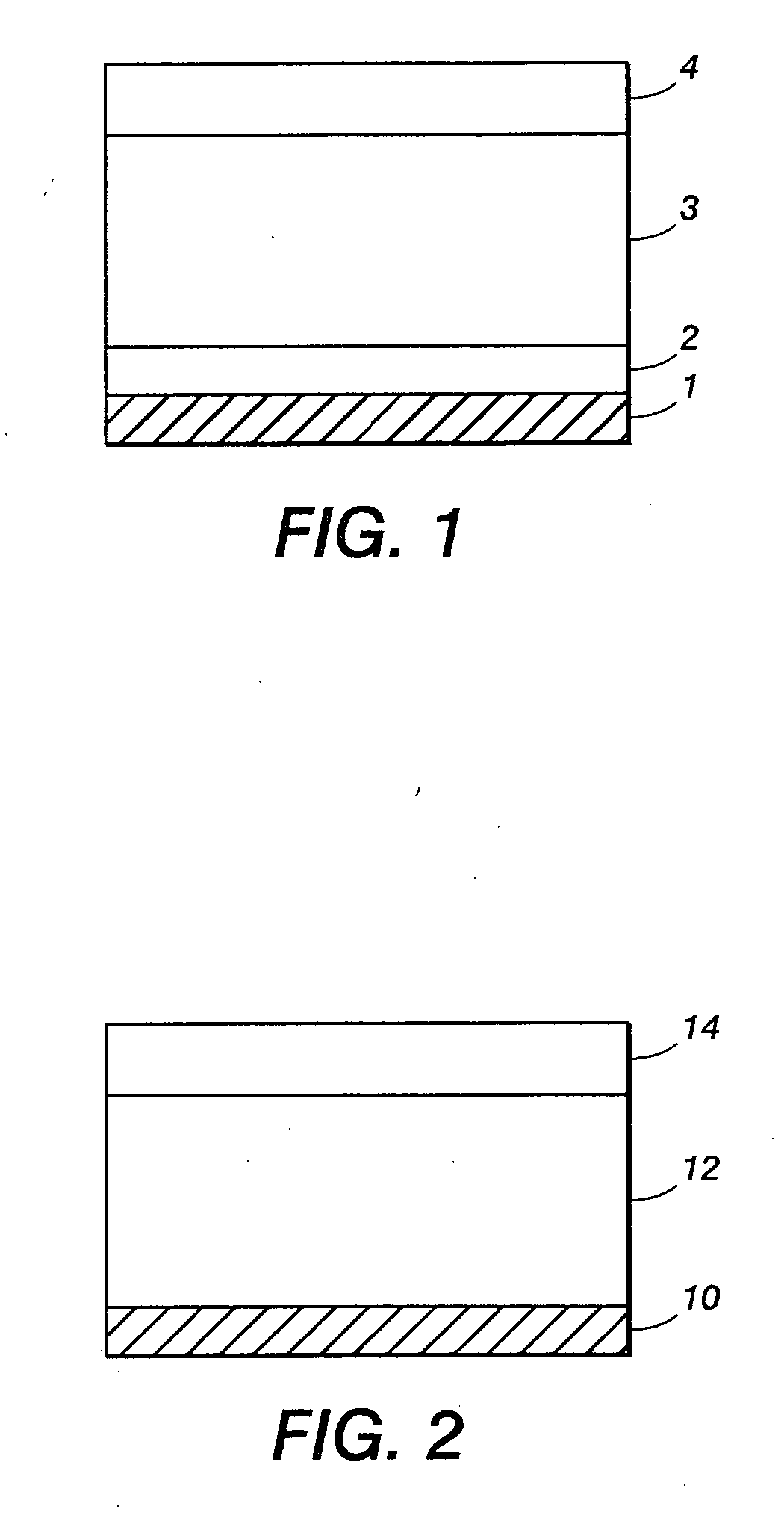

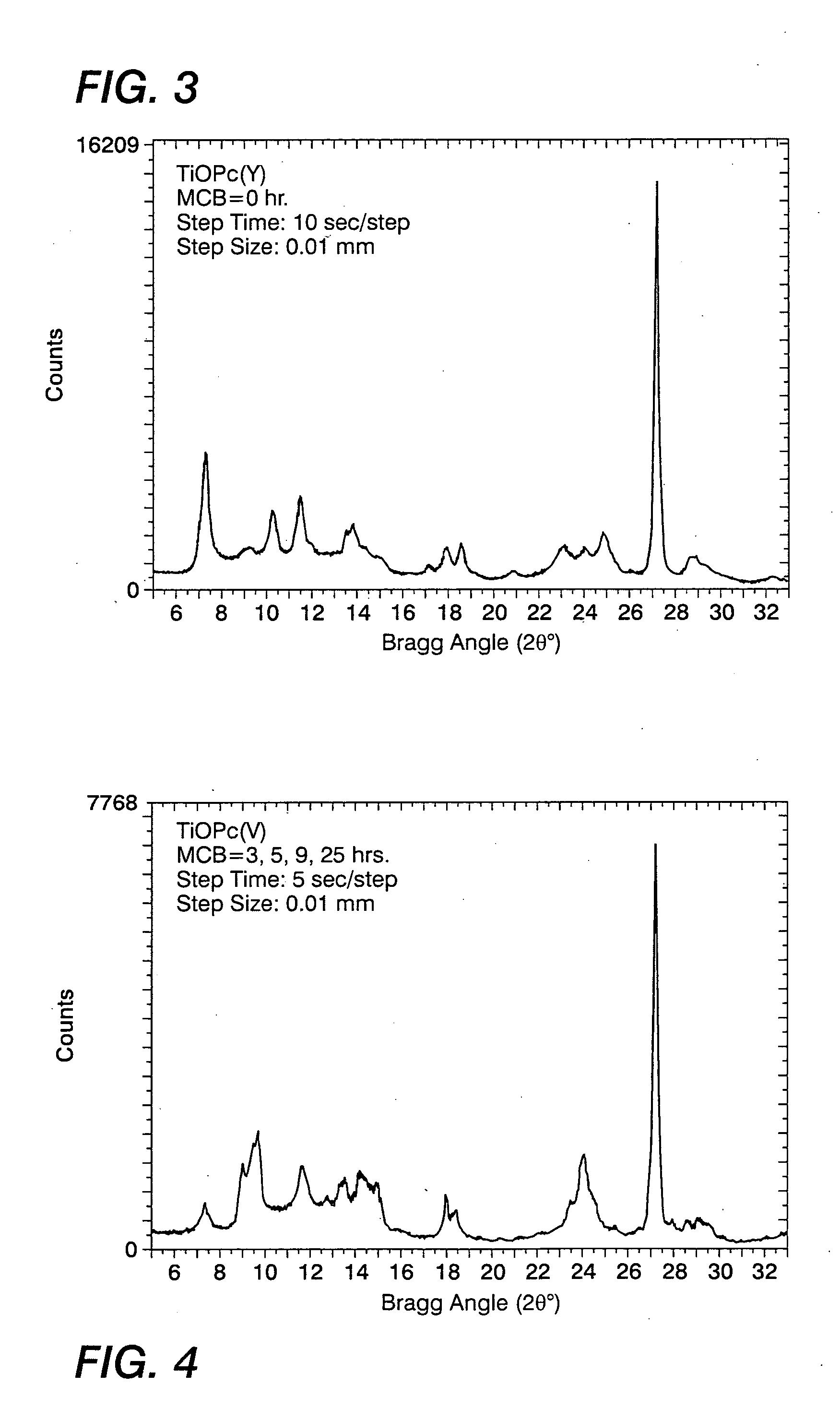

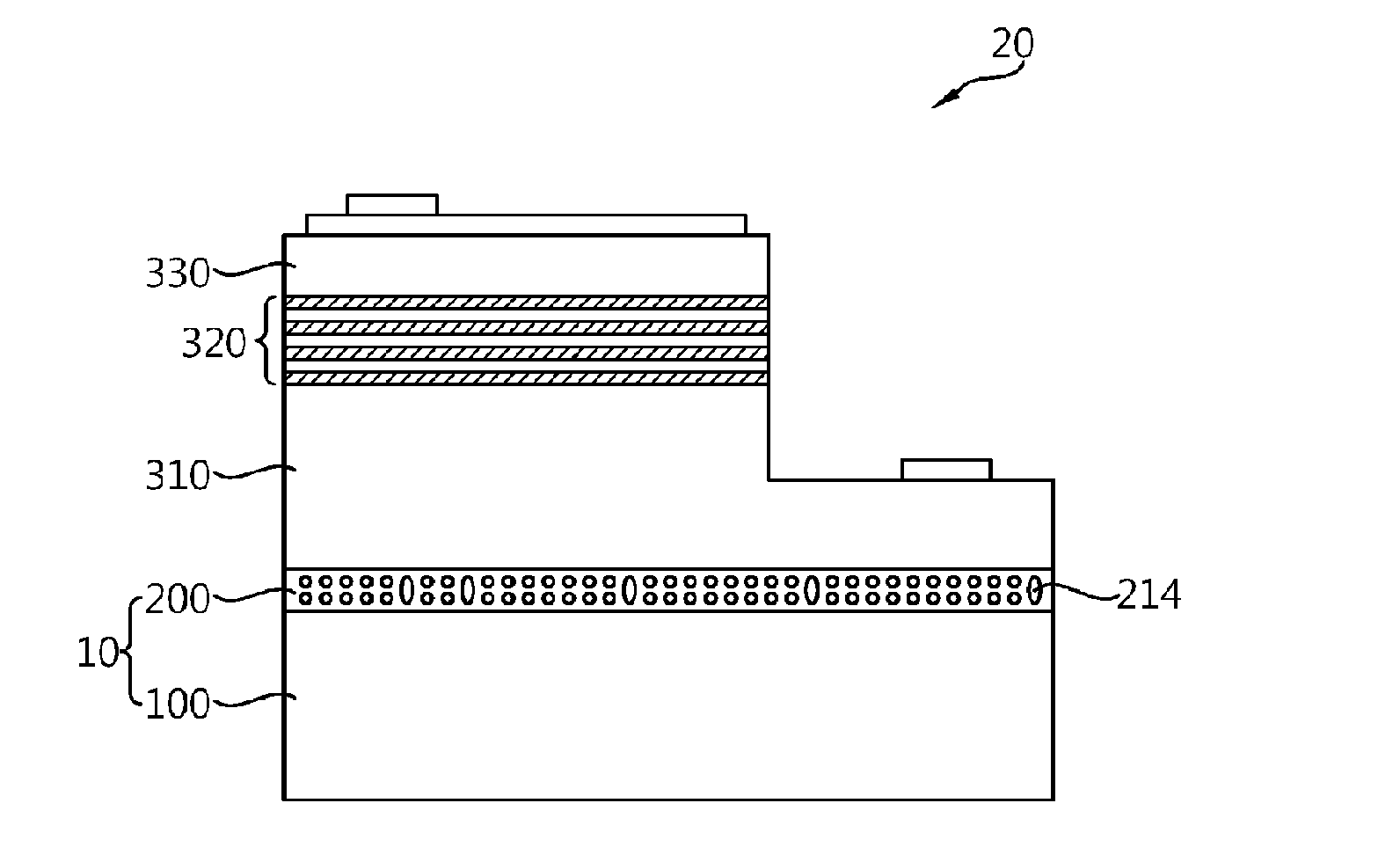

Processes for the preparation of high sensitivity titanium phthalocyanines photogenerating pigments

A process for preparing a high sensitivity titanyl phthalocyanine (TiOPc) pigment includes dissolving a Type I TiOPc in a suitable solvent, precipitating an intermediate TiOPc pigment by quenching the solution comprising the dissolved Type I TiOPc in a solvent system comprising an alcohol and alkylene chloride such as, for example, methylene chloride, and treating the intermediate TiOPc pigment with monochlorobenzene. The resultant TiOPc pigment, which is designated as a Type V TiOPc, is suitable for use as a charge generating material in a photoreceptor of an imaging device.

Owner:XEROX CORP

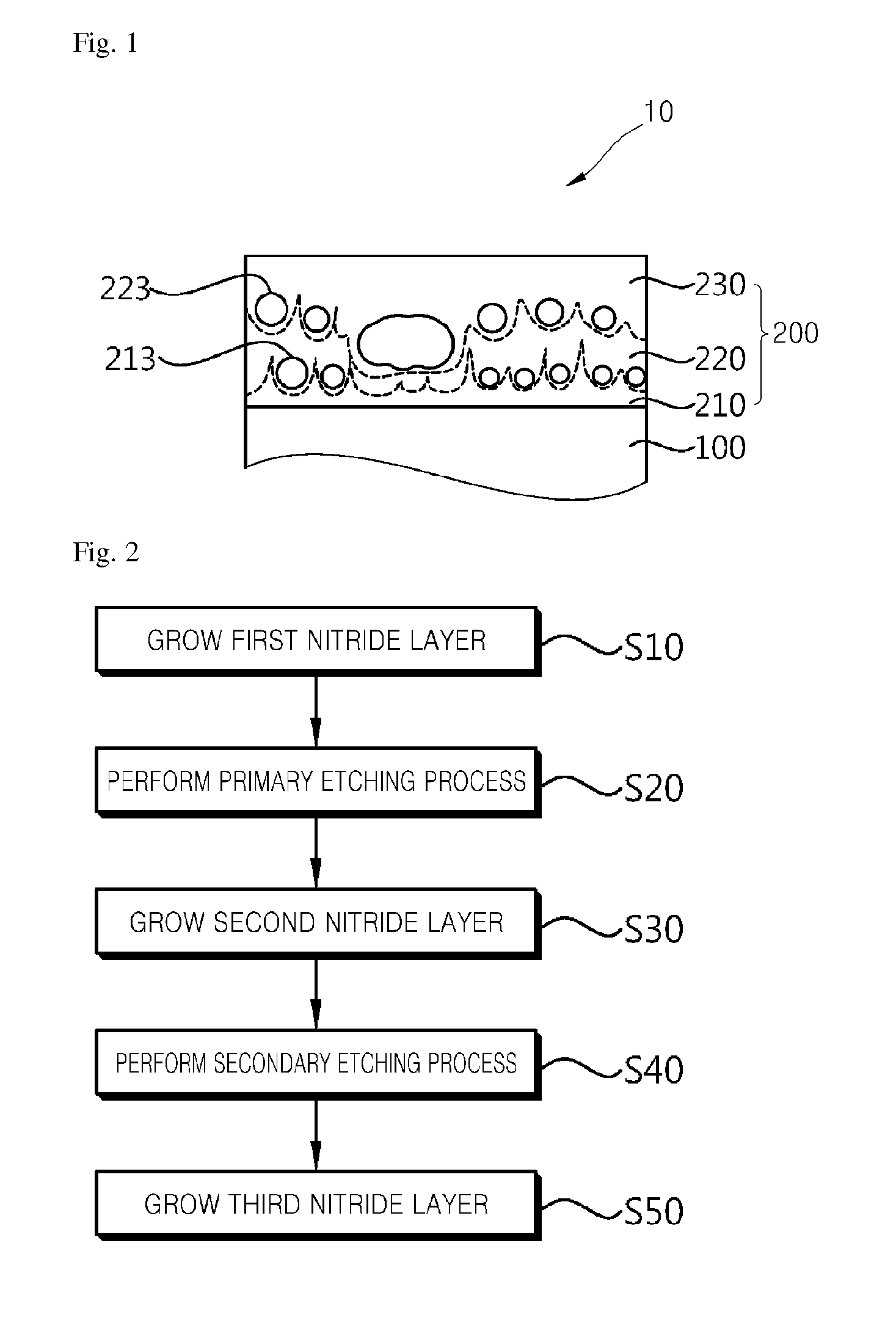

Template, method for manufacturing the template and method for manufacturing vertical type nitride-based semiconductor light emitting device using the template

InactiveUS20120187444A1Relieve pressureAvoid misalignmentAfter-treatment apparatusPolycrystalline material growthChlorideLight emitting device

Disclosed herein is a method for manufacturing a template. The method includes growing a first nitride layer on a substrate; etching a top surface of the first nitride layer by supplying a chloride-based etching gas thereto; forming a plurality of first voids by growing a second nitride layer on the top surface of the first nitride layer; etching a top surface of the second nitride layer by supplying the etching gas thereto; and forming a plurality of second voids by growing a third nitride layer on the top surface of the second nitride layer. A method for manufacturing a nitride-based semiconductor light emitting device using the template is also disclosed. As a result, stress between lattices and dislocation defects are reduced by a plurality of voids formed in a nitride buffer layer, thereby improving quality of nitride layers grown in a template. In the case where a light emitting device is manufactured using the template, it is possible to improve workability of the manufacturing process and to enhance luminous efficacy of the light emitting device.

Owner:SEMIMATERIALS +1

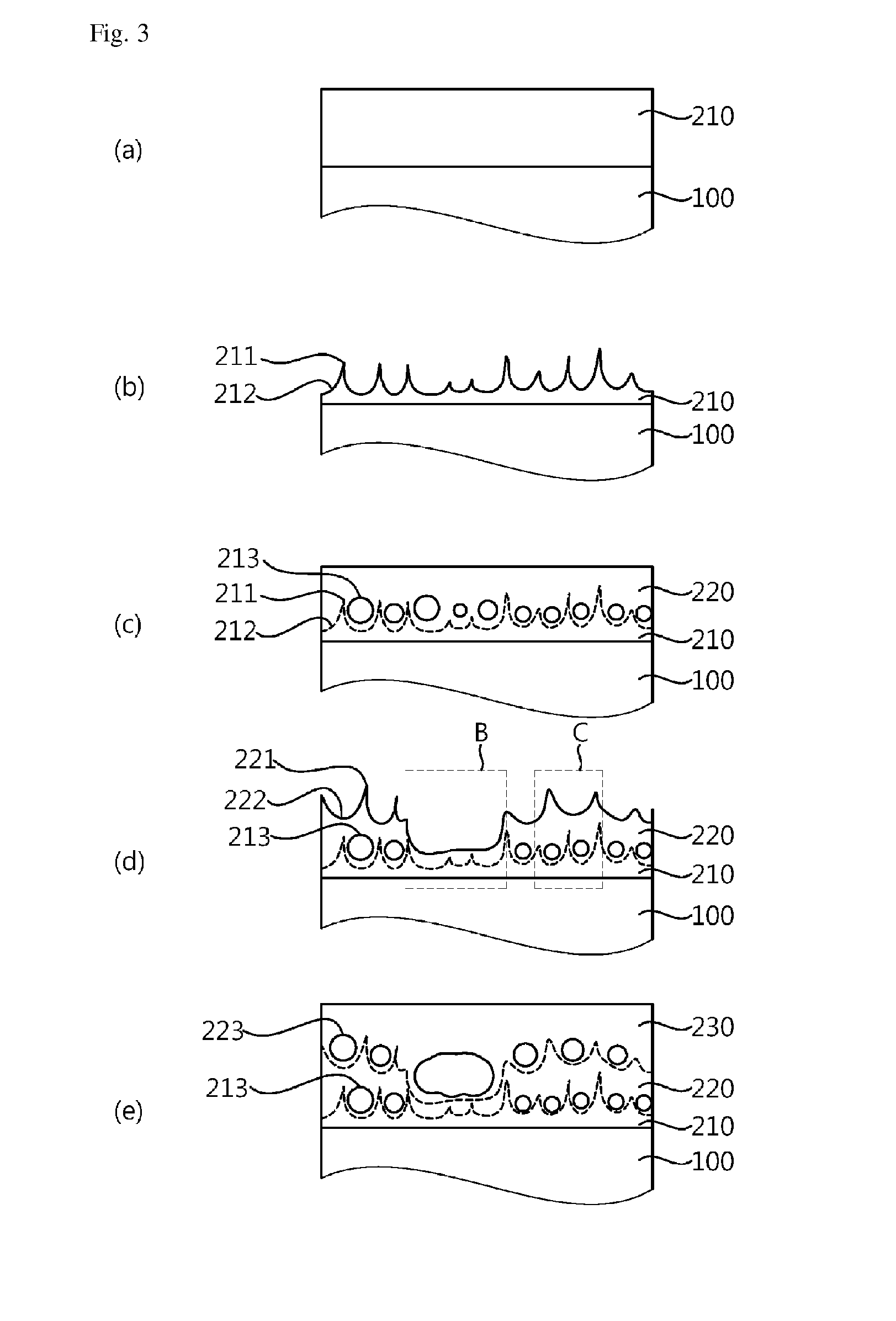

Catalyst composition of ethylene oligomerization and the application

ActiveCN101032695AHigh activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionAryl1-Octene

The present invention relates to catalyst composition for oligomerizing ethylene and its application. The catalyst composition includes complex of acetylacetone chromium, tetrahydrofuran chromium chloride and / or chromium isooctanate; ligand containing P and N; activator of methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; and promoter of X1R6X2, where, each of X1 and X2 is F, Cl, Br, I or alkoxyl, and R6 is alkyl or aryl group; with the molar ratio of the complex, the ligand, the activator and the promoter being 1 to 0.5-10 to 50-3000 to 0.5-10. The catalyst composition is used in oligomerizing reaction of ethylene to prepare 1-octene, and has high catalytic activity and high 1-octene selectivity.

Owner:PETROCHINA CO LTD

Antimicrobial coating compositions

ActiveUS20100137472A1Reduce complicationsSuitable for useAntifouling/underwater paintsPretreated surfacesAlkaneCetrimide

Antimicrobial compositions and methods are disclosed. The antimicrobial compositions are particularly useful in providing antimicrobial capability to a wide-range of medical devices. In one aspect, the invention relates to a mild solvent coating using acrylate-type mild solution coating. These compositions include rheological modifiers as necessary. The compositions also include antimicrobial agents, which may be selected from a wide array of agents. Representative antimicrobial agents include cetyl pyridium chloride, cetrimide, alexidine, chlorexidine diacetate, benzalkonium chloride, and o-phthalaldehyde. Additionally, the compositions comprise one or more suitable mild solvents, such as a low molecular weight alcohol, alkane, ketone, and combinations thereof.

Owner:BECTON DICKINSON & CO

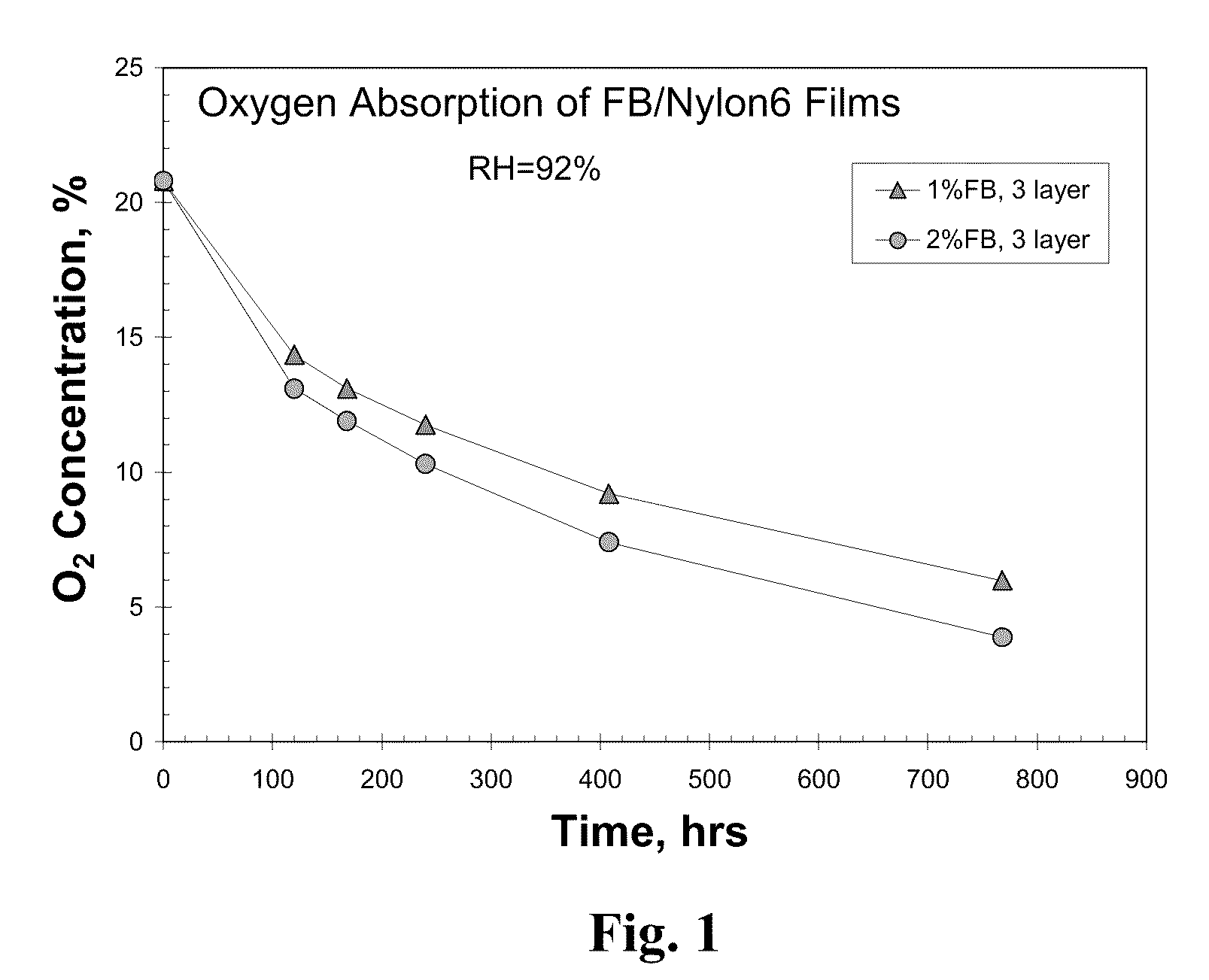

Oxygen scavenging films

InactiveUS20100255231A1Metal-working apparatusGlass/slag layered productsParticulatesAlkaline earth metal

A well dispersed oxygen scavenging particulate compounded in a polymer matrix. The oxygen scavenging formulation consists of iron powder with a mean particle sizes within 1-25 um and pre-coated with at least one or more activating and acidifying powdered compounds, usually in the form of solid organic and inorganic salts of alkaline and alkaline earth metals such as sodium chloride and sodium bisulfate. The pre-coated iron particulate is dispersed into a polymer resin by using a conventional melt processing method such as twin-screw extrusion. The oxygen scavenging compound is mixed with polymer pellets in the solid state prior to melting. The polymer resin pellets and the coated iron powder are preferably treated with a surfactant in the dry state to help dispersing the iron / salt powder with the resin pellets. The melt extruded compounds are pelletized and kept in the dry state to prevent premature activation.

Owner:MULTISORB TECH INC

Process for the preparation of a nickel/phosphorous ligand catalyst for olefin hydrocyanation

A process for preparing a hydrocyanation catalyst comprising contacting a bidentate phosphorous-containing ligand with a molar excess of nickel chloride in the presence of a nitrile solvent and a reducing metal which is more electropositive than nickel. Preferably, the nickel chloride is dried before use.

Owner:INVISTA NORTH AMERICA R L

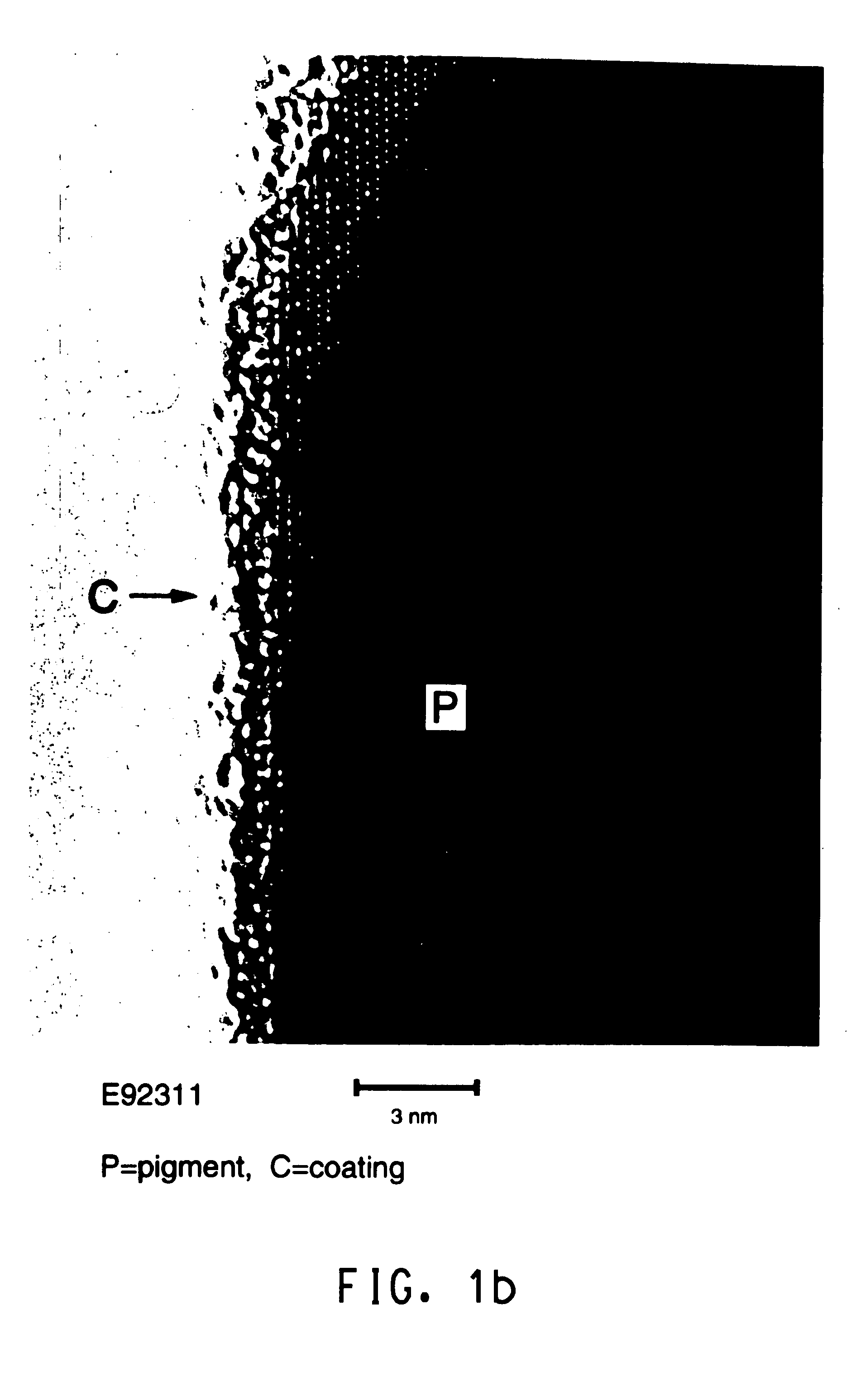

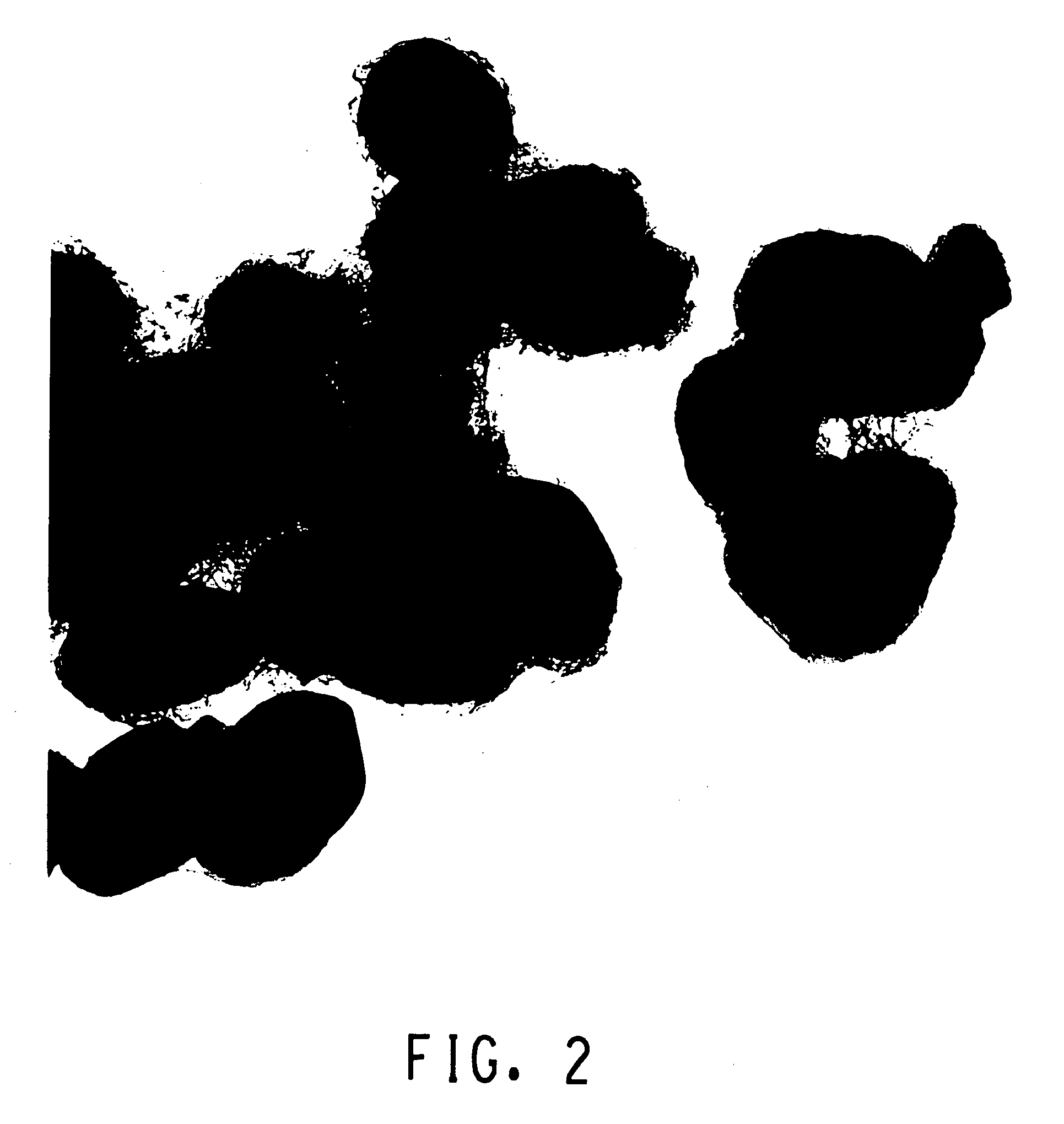

Process for making durable rutile titanium dioxide pigment by vapor phase deposition of surface treatment

The present invention relates to a process for making durable titanium dioxide pigment by vapor phase deposition of surface treatments on the titanium dioxide particle surface by reacting titanium tetrachloride vapor, an oxygen containing gas and aluminum chloride in a plug flow reactor to form a product stream containing titanium dioxide particles; and introducing silicon tetrachloride into the reactor at a point down stream of the point where the titanium tetrachloride and oxygen were contacted and where at least 97% of the titanium tetrachloride has been converted to titanium dioxide or where the reaction temperature is no greater than about 1200° C., and preferably not more than about 1100° C.

Owner:THE CHEMOURS CO FC LLC

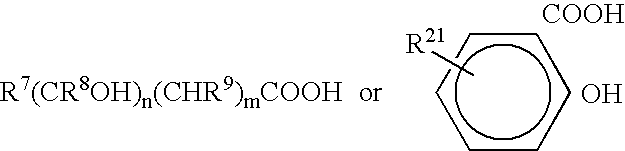

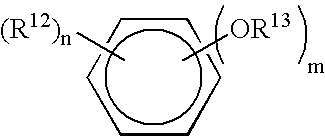

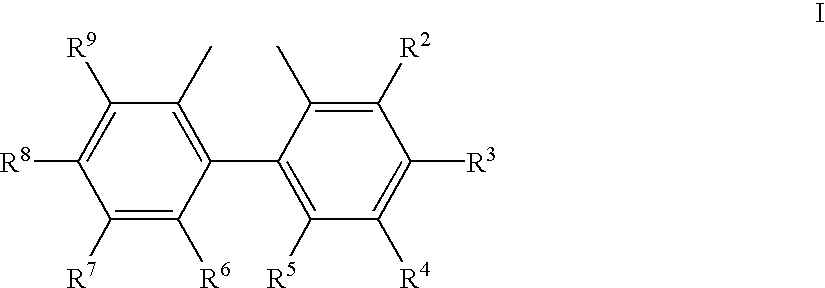

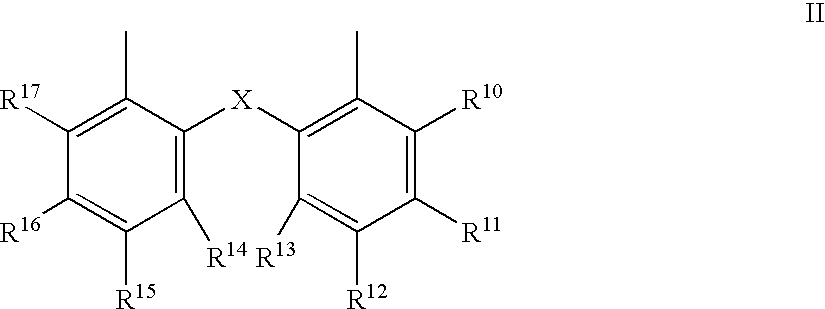

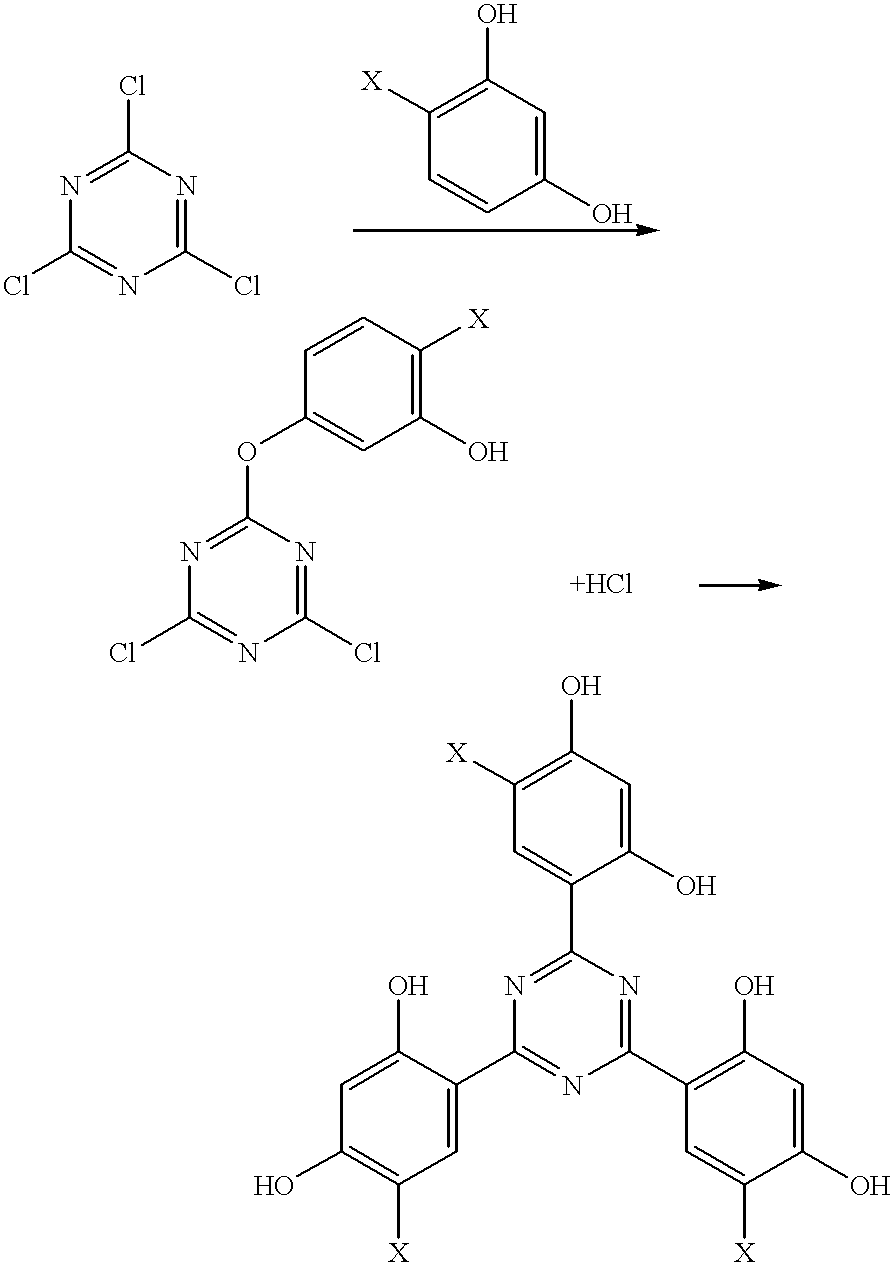

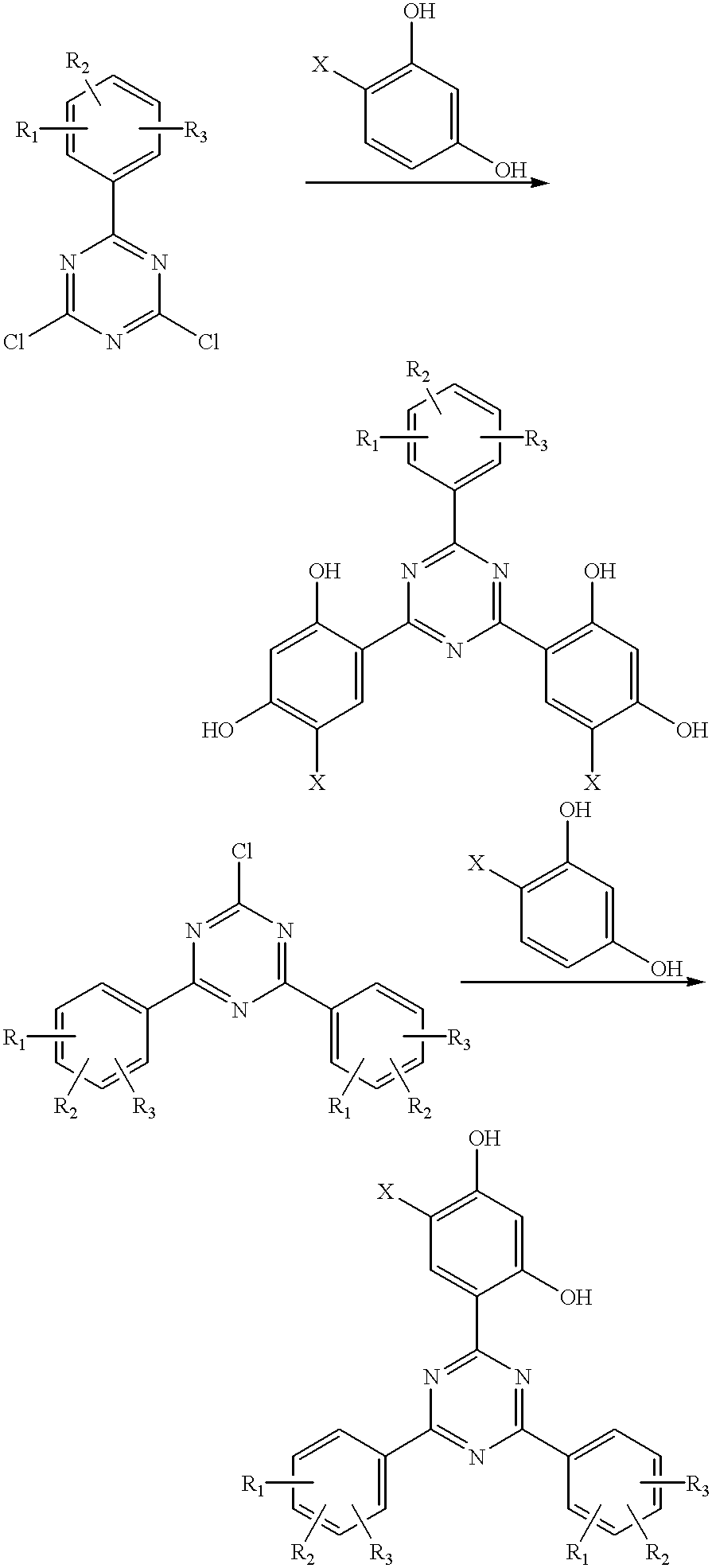

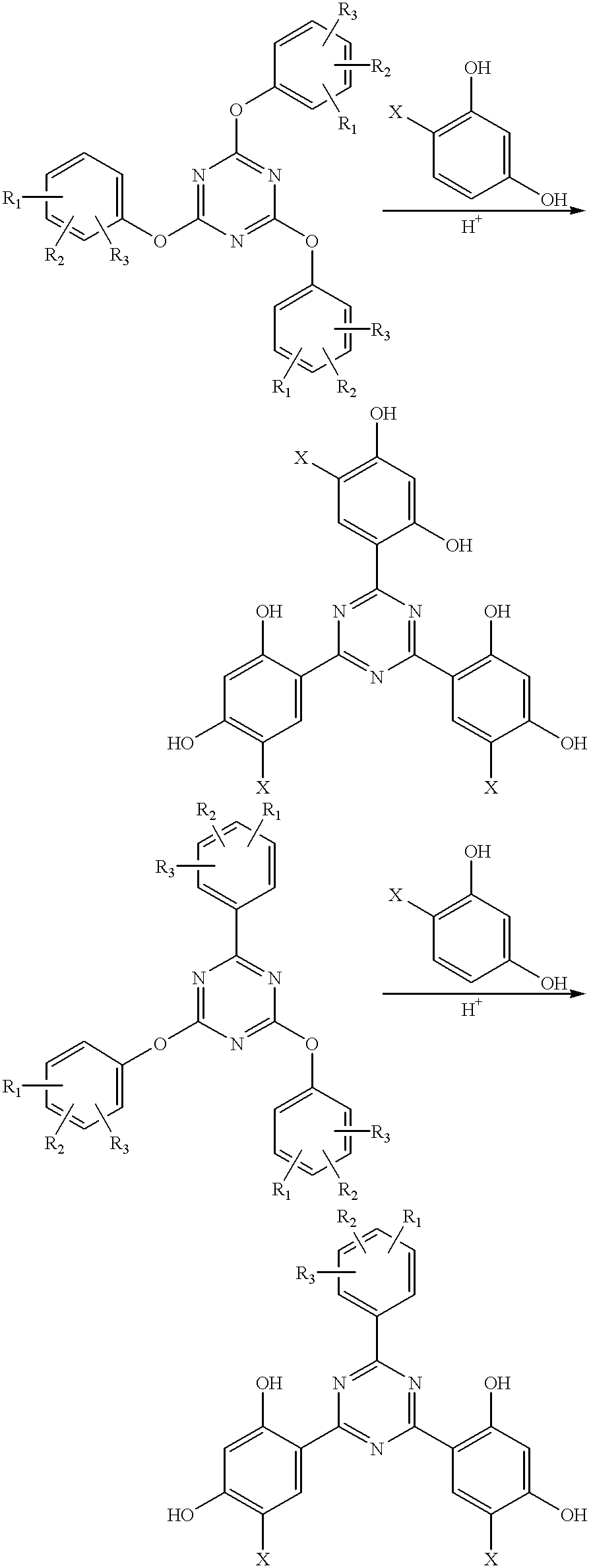

Methods for the preparation of tris-aryl-o-hydroxyphenyl-s-triazines

InactiveUS6242598B1Reduce in quantityPoor leaving groupOrganic chemistryLewis acid catalysisResorcinol

A process for preparing 2-(2,4-dihydroxyphenyl)-4.6-diaryl-s-triazines in three steps starting with cyanuric chloride is described. Step 1 involves the nucleophilic (basic) displacement of one chlorine atom with a phenolic moiety. Step 2 involves a Friedel-Crafts reaction using a Lewis acid catalyst (preferably aluminum chloride) to replace the remaining two chlorine atoms with aryl groups such as xylyl. Finally, step 3 involves replacing the phenolic moiety with resorcinol using either a Lewis acid or protic acid catalyst or combinations thereof. Some additional processes only peripherally related to the three-step process outlined above are also described for the preparation of various s-triazine compounds. The s-triazines prepared are useful as UV absorbers for the stabilization of organic substrates against the adverse effects of actinic light.

Owner:CIBA SPECIALTY CHEM CORP

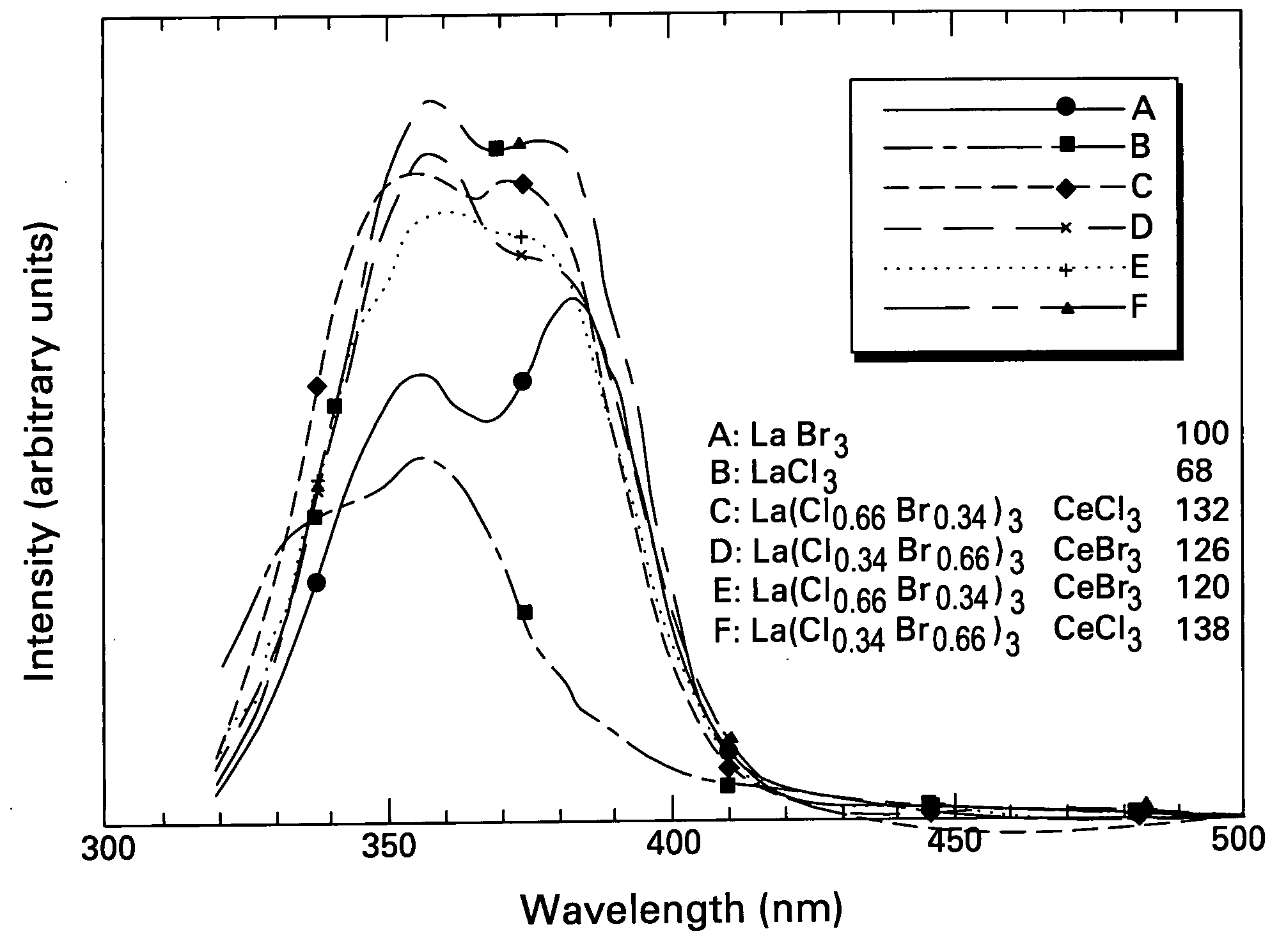

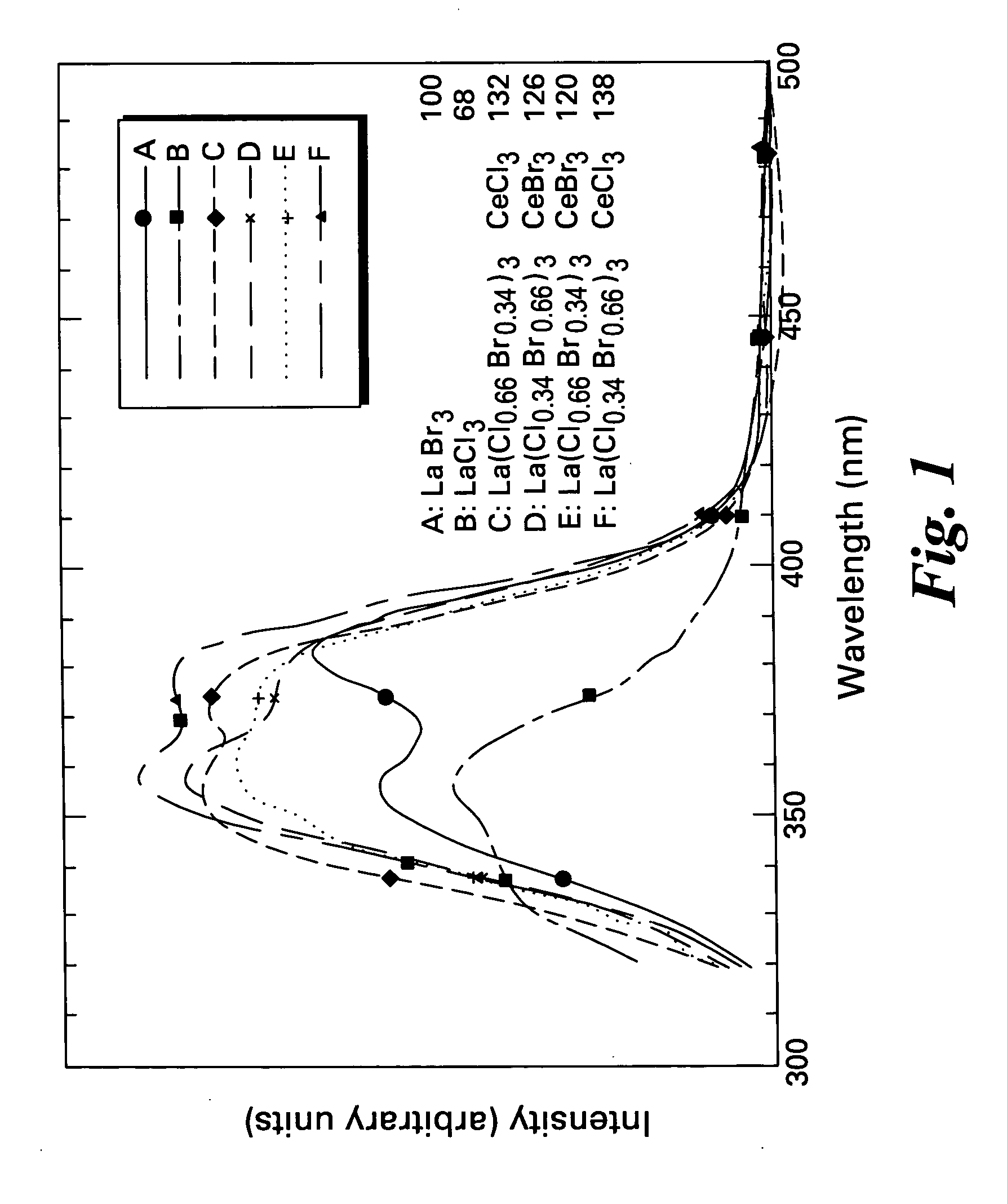

Scintillator compositions, and related processes and articles of manufacture

ActiveUS20050082484A1Improve performanceExcellent and reproducible scintillation responseMaterial analysis by optical meansLuminescent compositionsIodideHigh energy

Scintillator materials based on certain types of halide-lanthanide matrix materials are described. In one embodiment, the matrix material contains a mixture of lanthanide halides, i.e., a solid solution of at least two of the halides, such as lanthanum chloride and lanthanum bromide. In another embodiment, the matrix material is based on lanthanum iodide alone, which must be substantially free of lanthanum oxyiodide. The scintillator materials, which can be in monocrystalline or polycrystalline form, also include an activator for the matrix material, e.g., cerium. Radiation detectors that use the scintillators are also described, as are related methods for detecting high-energy radiation.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

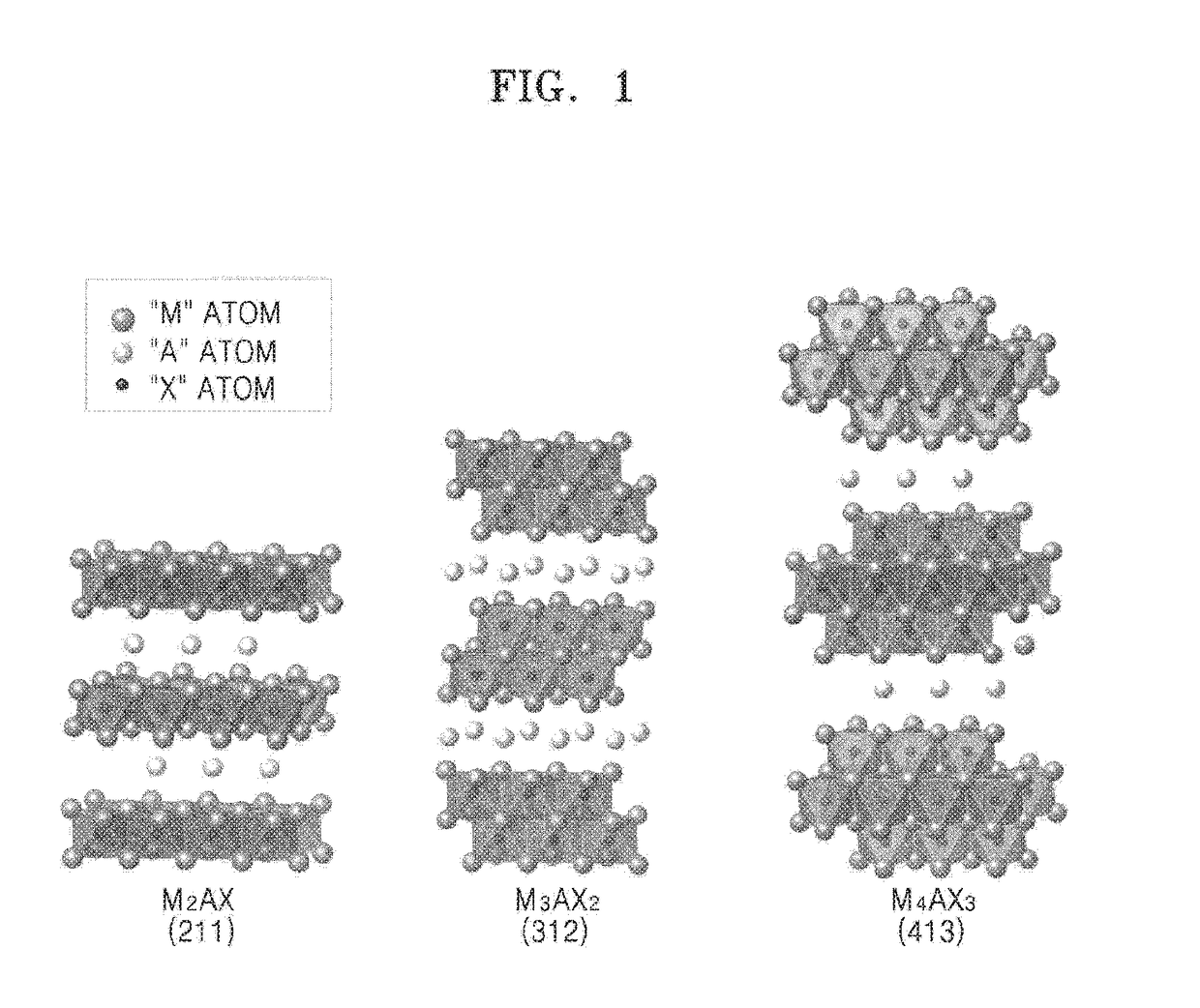

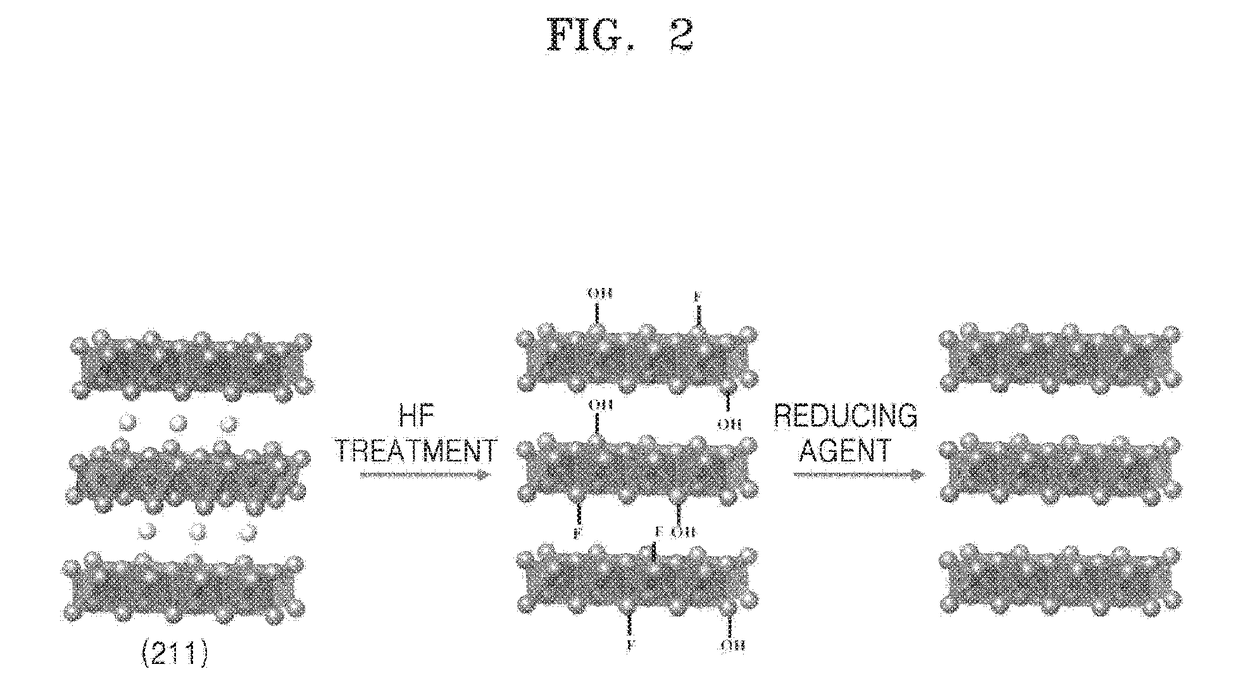

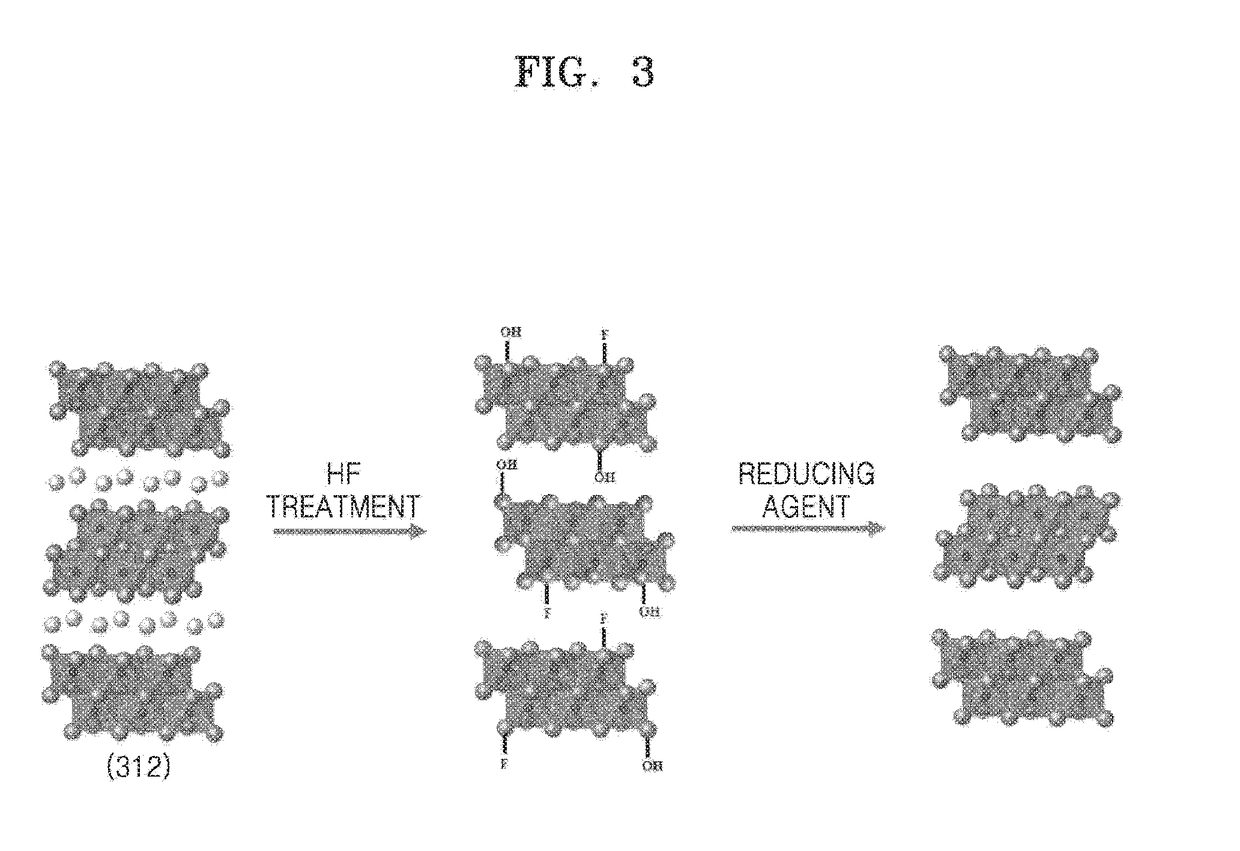

Mxene nanosheet and manufacturing method thereof

ActiveUS20170088429A1Material nanotechnologyNitrogen-metal/silicon/boron binary compoundsIodideInorganic compound

A method of manufacturing a MXene nanosheet includes removing an A atomic layer from an inorganic compound having a formula of Mn+1AXn to form a nanosheet, the nanosheet having a formula of Mn+1XnTs, and reducing the nanosheet having a formula of Mn+1XnTsto form an MXene nanosheet, the MXene nanosheet having a formula of Mn+1Xn, wherein M is at least one of Group 3 transition metal, Group 4 transition metal, Group 5 transition metal, and Group 6 transition metal, A is at least one of a Group 12 element, Group 13 element, Group 14 element, Group 15 element and Group 16 element, X is one of carbon (C), nitrogen (N) and a combination thereof, Ts is one of oxide (O), epoxide, hydroxide (OH), alkoxide having 1-5 carbon atoms, fluoride (F), chloride (Cl), bromide (Br), iodide (I), and a combination thereof, and n is one of 1, 2 and 3.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV +1

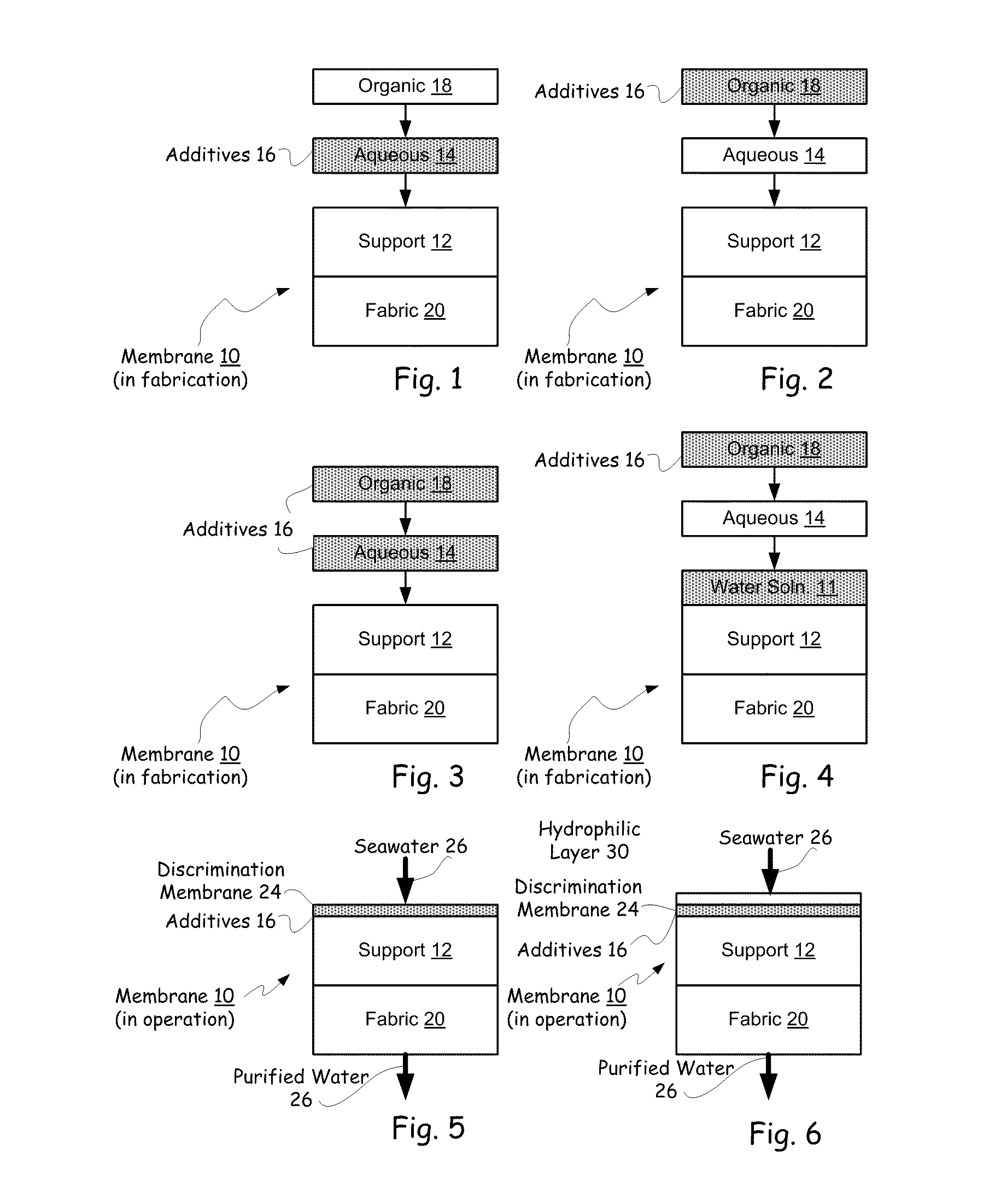

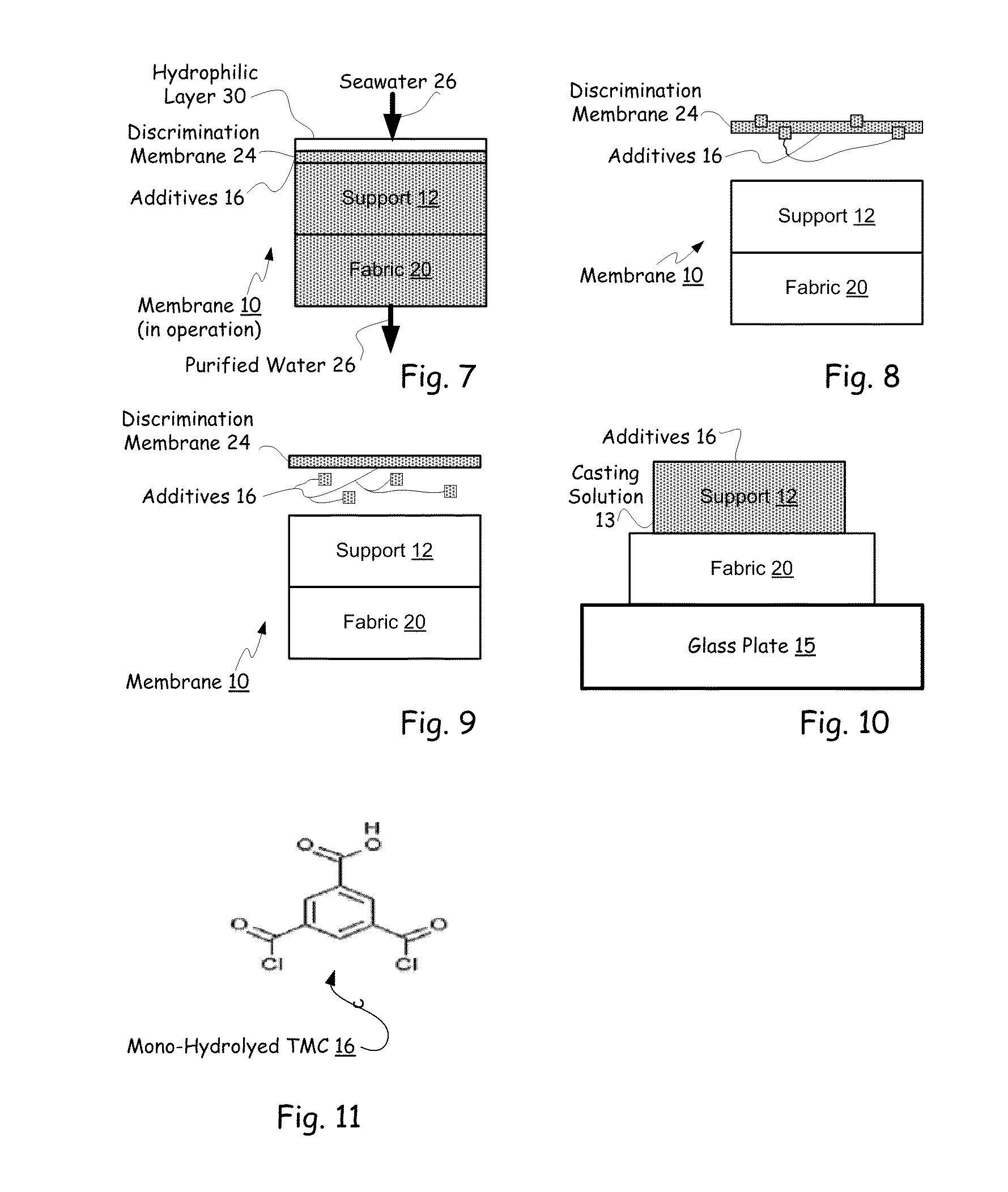

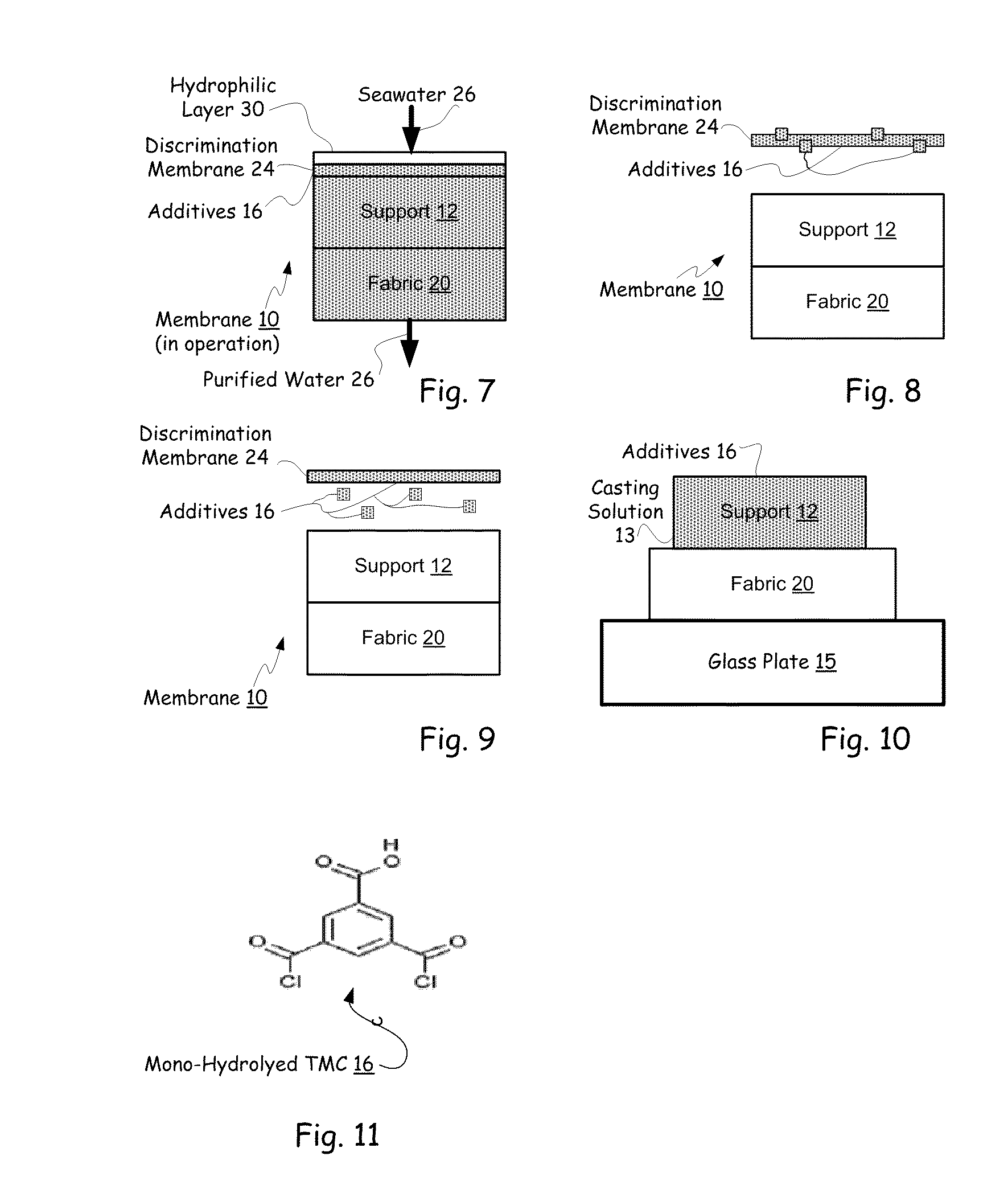

Hybrid tfc ro membranes with nitrogen additives

ActiveUS20110005997A1Increase fluxIncreased rejectionMembranesPretreated surfacesChloramine BAlkaline earth metal

Owner:NANOH2O

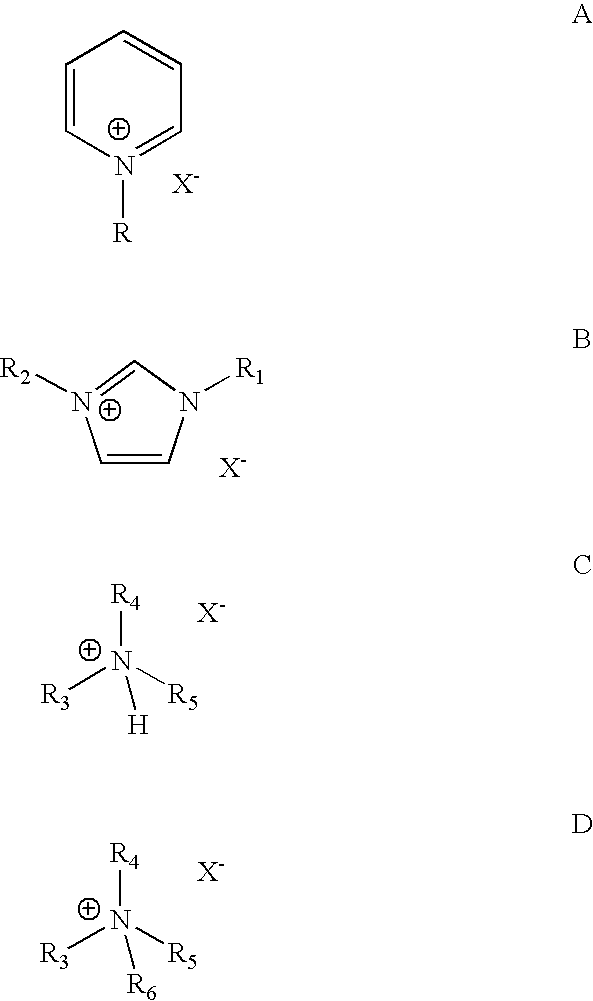

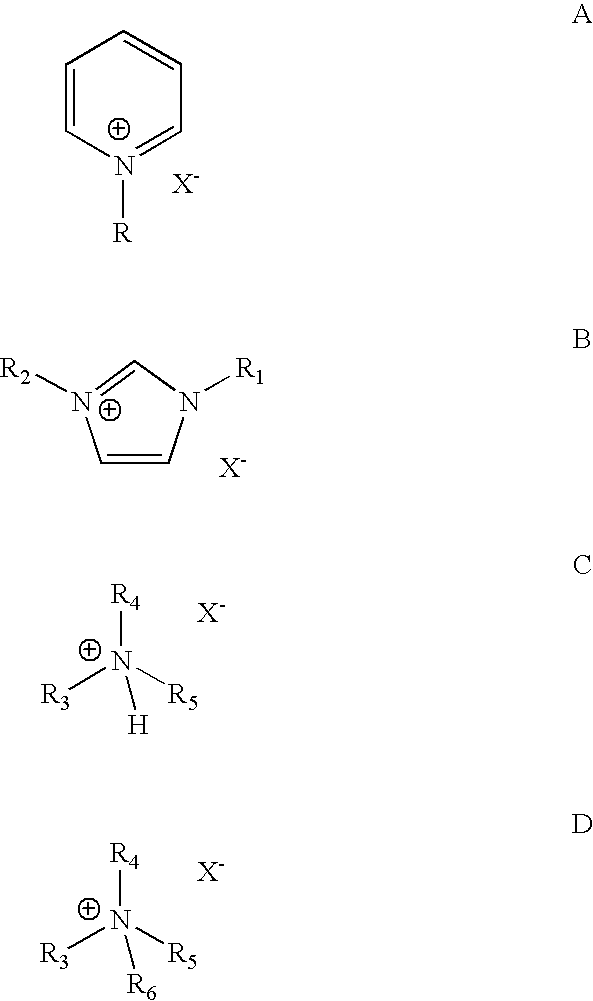

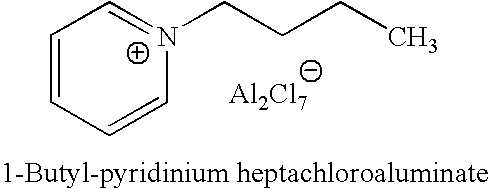

Alkylation process using an alkyl halide promoted ionic liquid catalyst

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The alkylation process comprises contacting a hydrocarbon mixture comprising at least one olefin having from 2 to 6 carbon atoms and at least one isoparaffin having from 3 to 6 carbon atoms under alkylation conditions, said catalyst comprising a mixture of at least one acidic ionic liquid and at least one alkyl halide. In one embodiment, the acidic ionic liquid is chloroaluminate ionic liquid prepared by mixing aluminum trichloride (AlCl3) and a hydrocarbyl substituted pyridinium halide, a hydrocarbyl substituted imidazolium halide, trialkylammonium hydrohalide or tetraalkylammonium halide of the general formulas A, B, C and D, respectively,where R=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a halide and preferably a chloride, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same, and R3, R4, and R5 and R6=methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R3, R4, R5 and R6 may or may not be the same.

Owner:CHEVROU USA INC

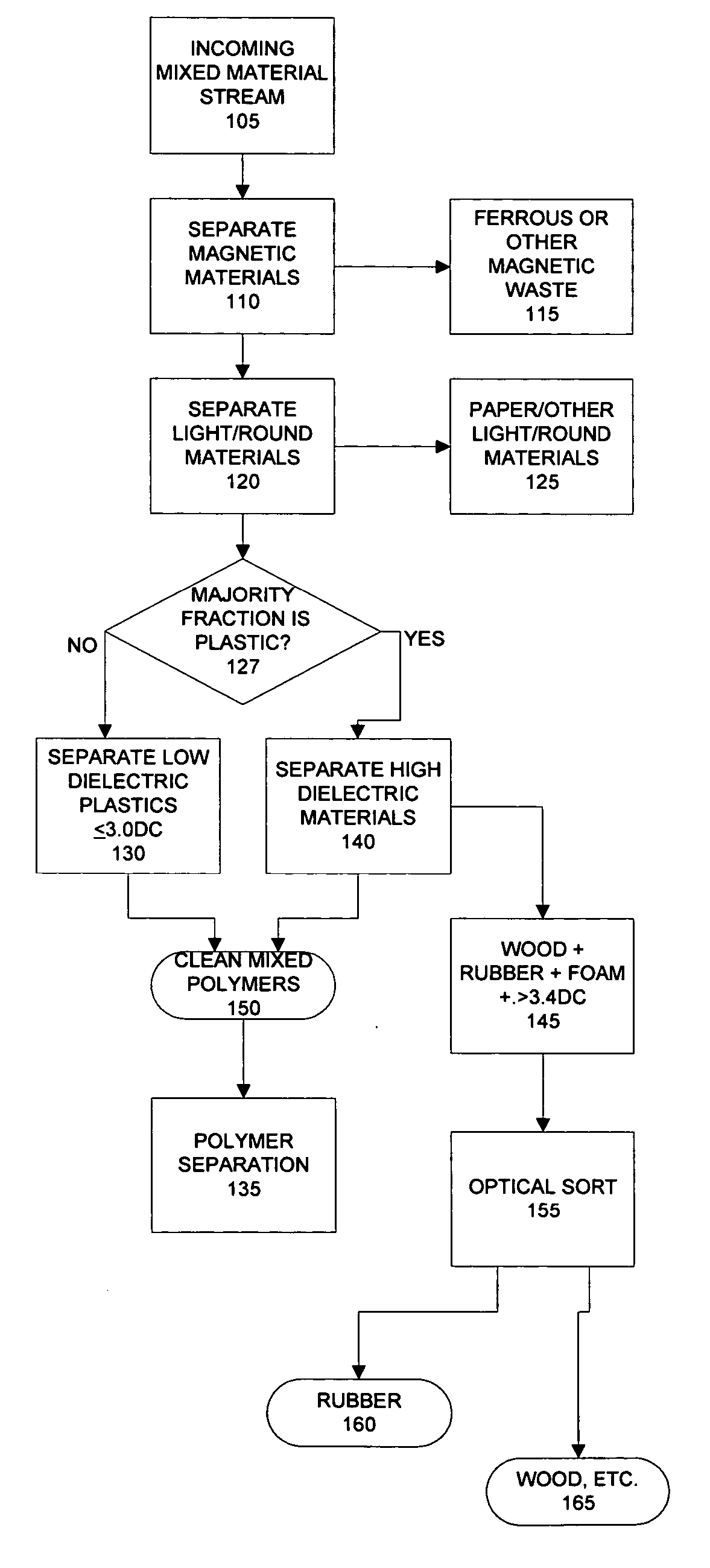

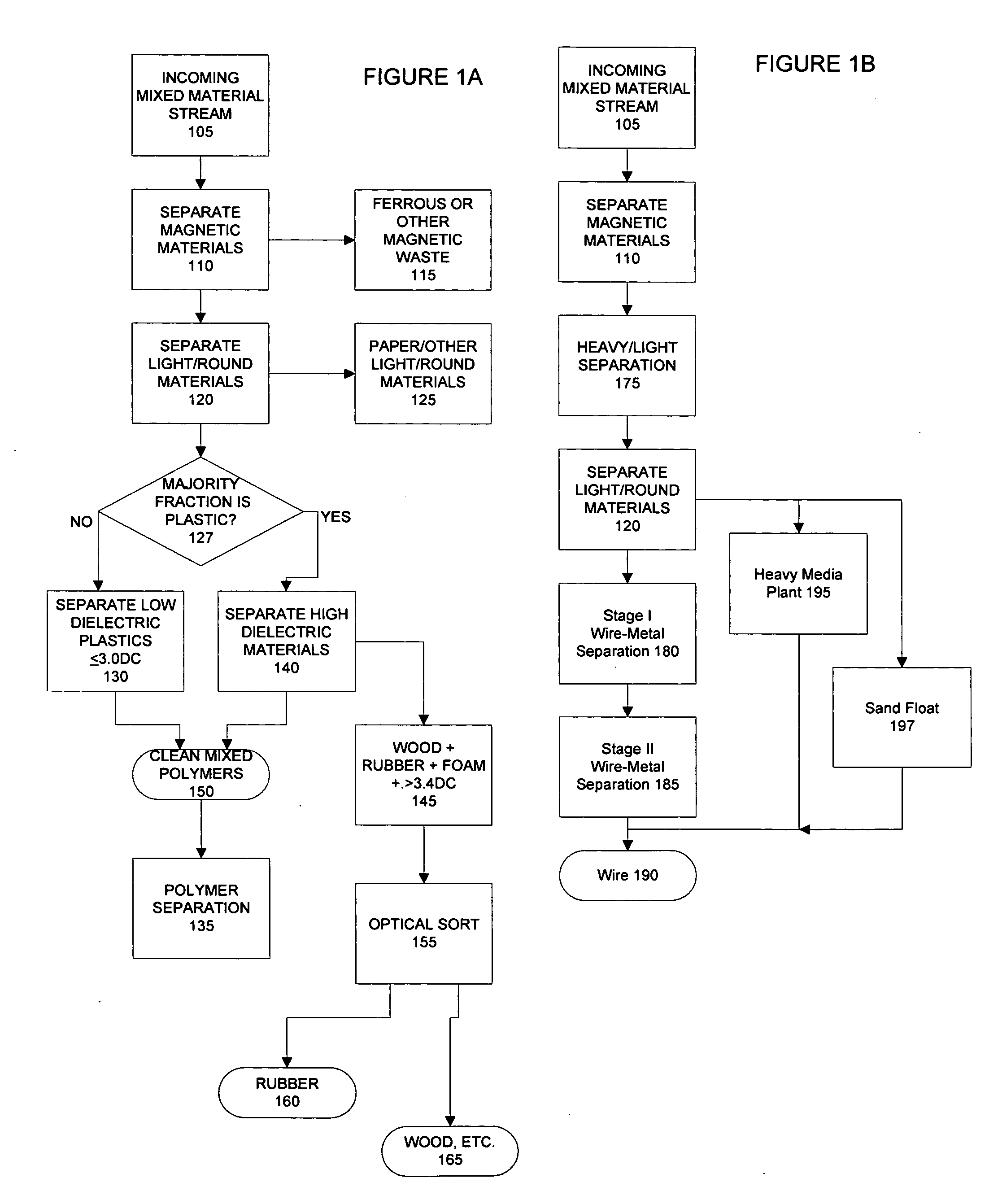

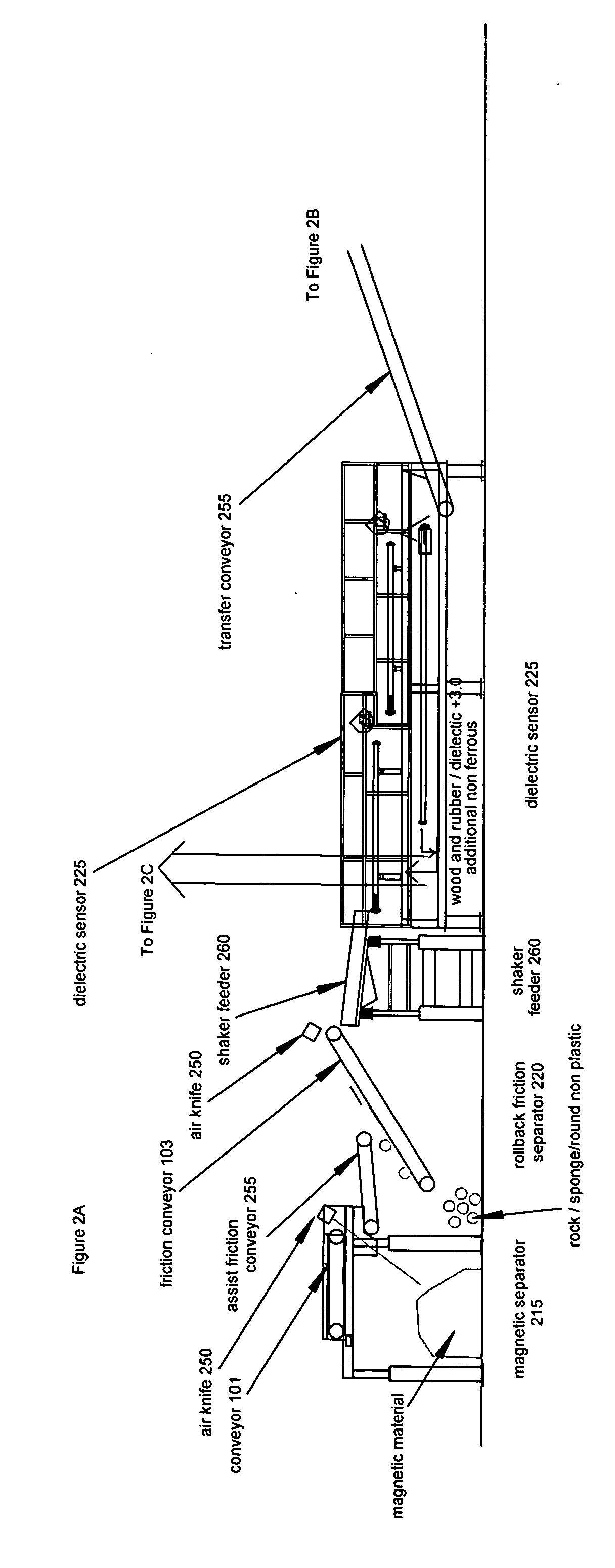

Dissimilar materials sorting process, system and apparata

InactiveUS20070187299A1Improve uniformityUnified operationGas current separationSolid waste disposalElectricityMagnetic separator

An automated system for sorting dissimilar materials, and in particular for sorting plastics from other materials and for sorting different types of plastics from one another comprises, depending upon the embodiment, combinations of a sizing mechanism, a friction separation, an air separator, a magnetic separator, a dielectric sensor sortation bed, shaker screening, a ballistic separator, an inductive sensor sortation system and a float / sink tank. The dielectric sensor sortation system may be either analog or digital, depending upon the particular implementation. One or more float / sink tanks can be used, depending upon the embodiment, each with a media of a different specific gravity. The media may be water, or water plus a compound such as calcium chloride. In addition, multiples of the same general type of module can be used for particular configurations. A heavy media system or a sand float process can be used either alternatively or additionally.

Owner:VALERIO THOMAS A

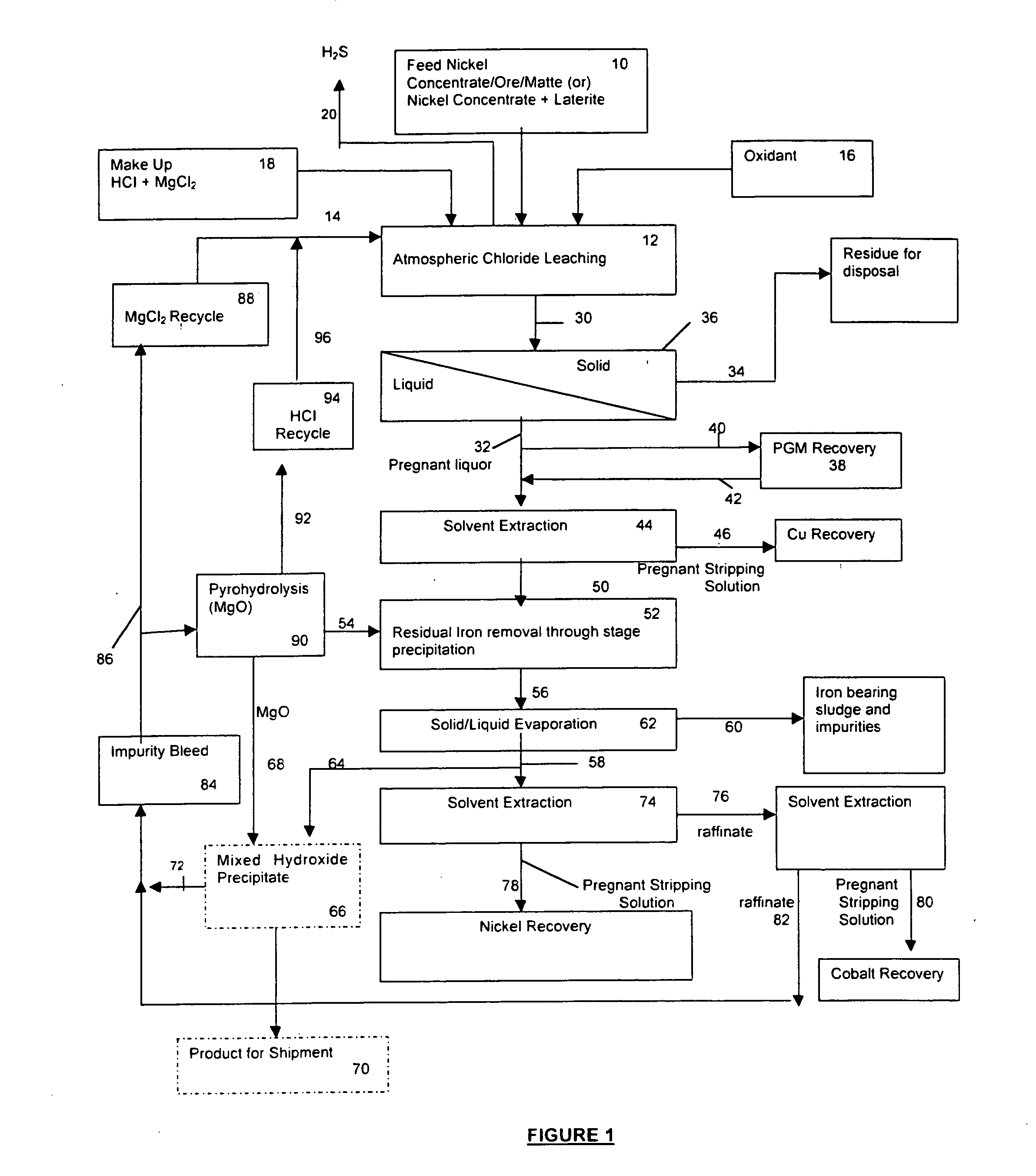

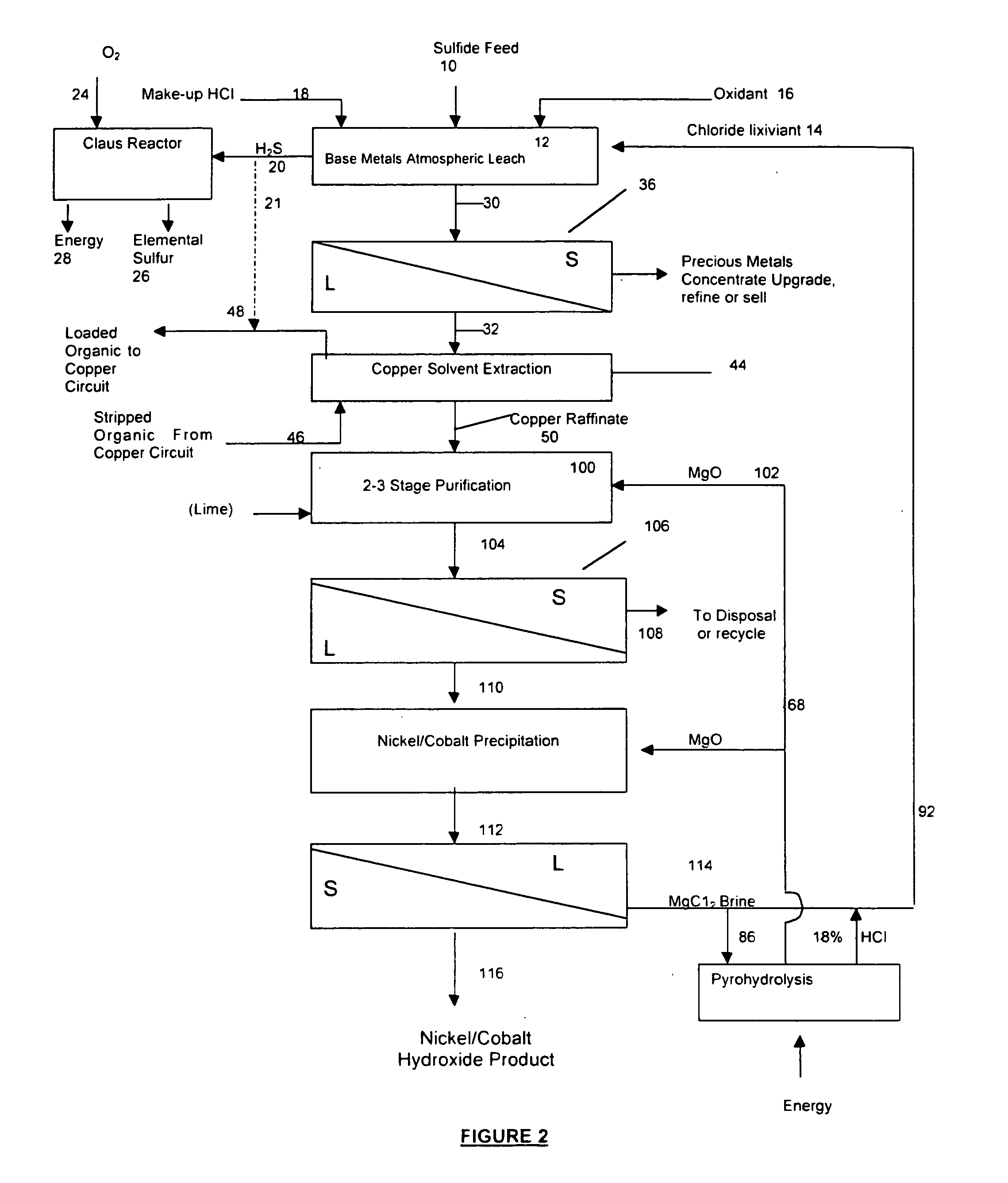

Process for the recovery of value metals from base metal sulfide ores

InactiveUS20050118081A1Simple gas/liquidReduce the amount requiredSulfur compoundsSolid sorbent liquid separationSulfideDissolution

A process for leaching a value metal from a base metal sulfide ore, comprising the step of leaching the ore with a lixiviant comprising a chloride, an oxidant and hydrochloric acid is disclosed. The leaching is controlled, by use of low concentrations of hydrochloric acid and a redox potential, to effect formation of hydrogen sulfide from the base metal sulfide ore. The hydrogen sulfide is stripped from the leach solution, thereby reducing the amount of sulfate generated in the leach to very low levels. The leaching may also be conducted to limit the co-dissolution of platinum group metals and gold with the base value metals. The leach forms a value metal-rich leachate and a solids residue. The solids residue may be subsequently leached to recover the platinum group metals and gold. The value metal-rich leachate can be is oxidized and neutralized to recover the value base metals. In an embodiment, the chloride is magnesium chloride and lixiviant solution is regenerated.

Owner:JAGUAR NICKEL INC

Zeolite colored coating powder having air-purifying function

InactiveCN105272114ASolving difficult-to-disperse reunionsImprove the bactericidal effectPorosityPyrophosphate

The invention discloses zeolite colored coating powder having an air-purifying function. According to the technical scheme, the zeolite colored coating powder having the air-purifying function is characterized in that ingredients include attapulgite pottery clay powder having the air-purifying function, acidified zeolite particles, colored portland cement, Paris plaster, white carbon black, calcium chloride, aerosil, expanded perlite, nanometer silver-loaded antibacterial powder, nanometer titanium dioxide, sodium pyrophosphate and powder defoaming agents. The ingredients of the zeolite colored coating powder having the air-purifying function are input three times into a stirring machine to be stirred evenly and packaged into the finished product. By the adoption of the colored coating, in indoor wall decoration, an artistic emboss effect of various embossed three-dimensional colored patterns can be achieved through spraying and manufacturing, after spraying, a coating is hard, the porosity is high, the specific surface area is large, adhesion is strong, indoor formaldehyde, ammonia nitrogen, benzene and other harmful substances can be adsorbed and decomposed, and the functions of automatic humidification, mould prevention, sterilization, deodorization and air purification are achieved.

Owner:蒋文兰

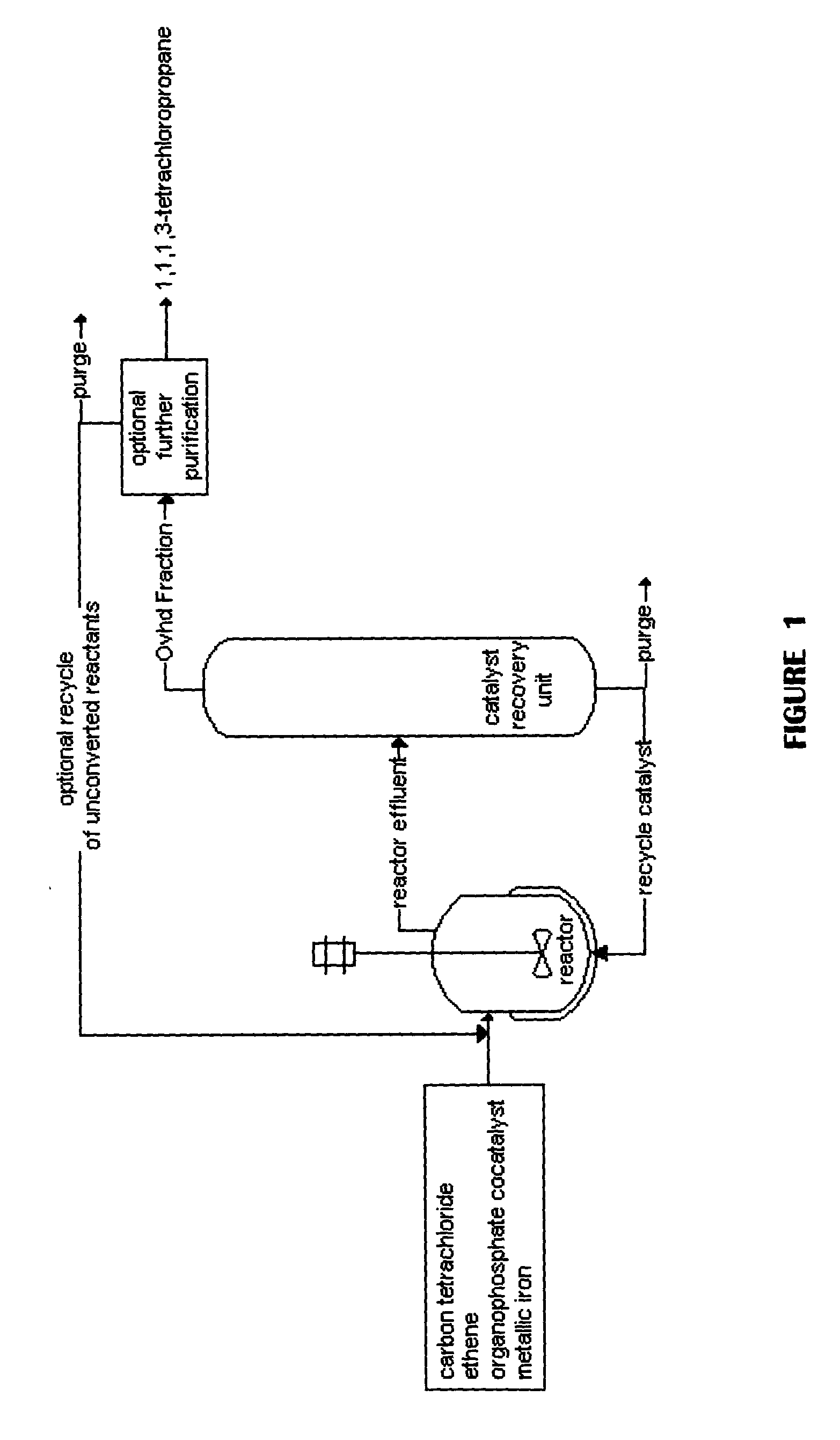

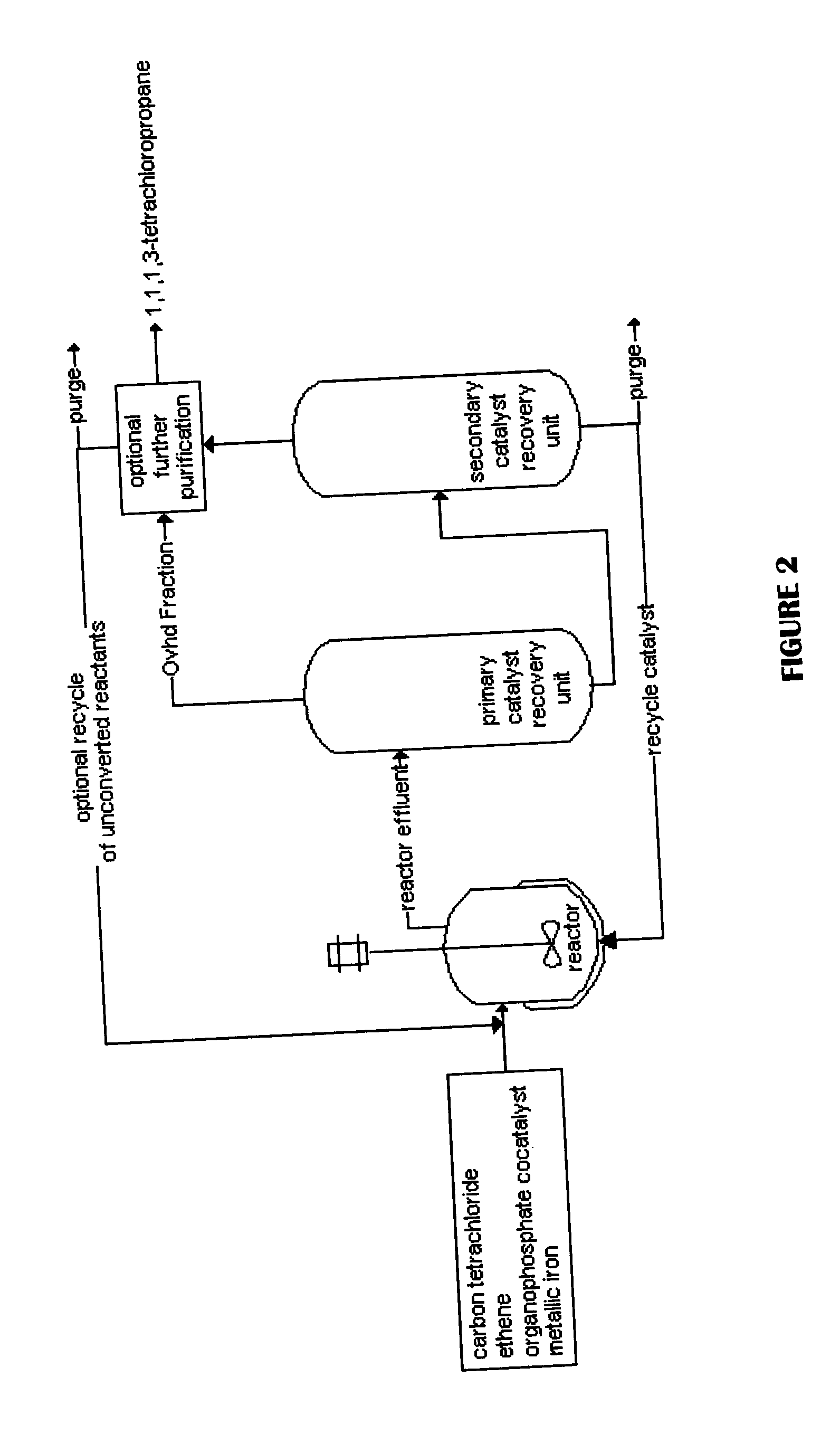

Method for producing 1,1,1,3-tetrachloropropane and other haloalkanes with iron catalyst

InactiveUS20040225166A1Efficient and economical to produceHalogenated hydrocarbon preparationTetrachlorideDistillation

A continuous process is provided for the manufacture of haloalkanes by the reaction of carbon tetrachloride with olefins in the presence of iron metal, trialkylphosphate, and ferric chloride. A fraction of the catalyst and co-catalyst are separated after the reaction and recycled. In a preferred application, the olefin is ethene, and the haloalkane product is 1,1,1,3-tetrachloropropane. Two distillation steps take place in order to enhance the production of 1,1,1,3-tetrachloropropane.

Owner:OCCIDENTAL CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com