Patents

Literature

4717 results about "Olefin polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Olefin Polymerization. Polyolefins, primarily polyethene (PE) and polypropene (PP), are among the most important end-products made from petrochemicals. PE can be made by radical polymerization or metal-catalyzed polymerization; for PP, only the metal-catalyzed route works.

Acidic activator-supports and catalysts for olefin polymerization

ActiveUS7294599B2Increase acidityImprove productivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlkyneOlefin polymerization

This invention relates to the field of olefin polymerization catalyst compositions, and methods for the polymerization and copolymerization of olefins, typically using a supported catalyst composition. In one aspect, this invention encompasses precontacting a metallocene with an olefin or alkyne monomer and an organoaluminum compound, prior to contacting this mixture with the acidic activator-support.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Catalyst composition comprising shuttling agent for ethylene multi-block copolymer formation

ActiveUS7858706B2Improve efficiencySynthetic resin layered productsThin material handlingOlefin polymerizationPolymerization catalysts

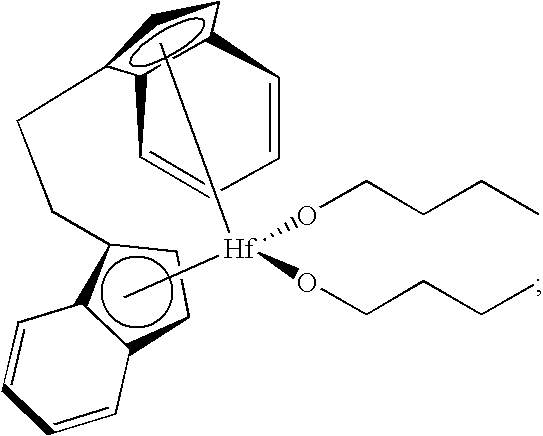

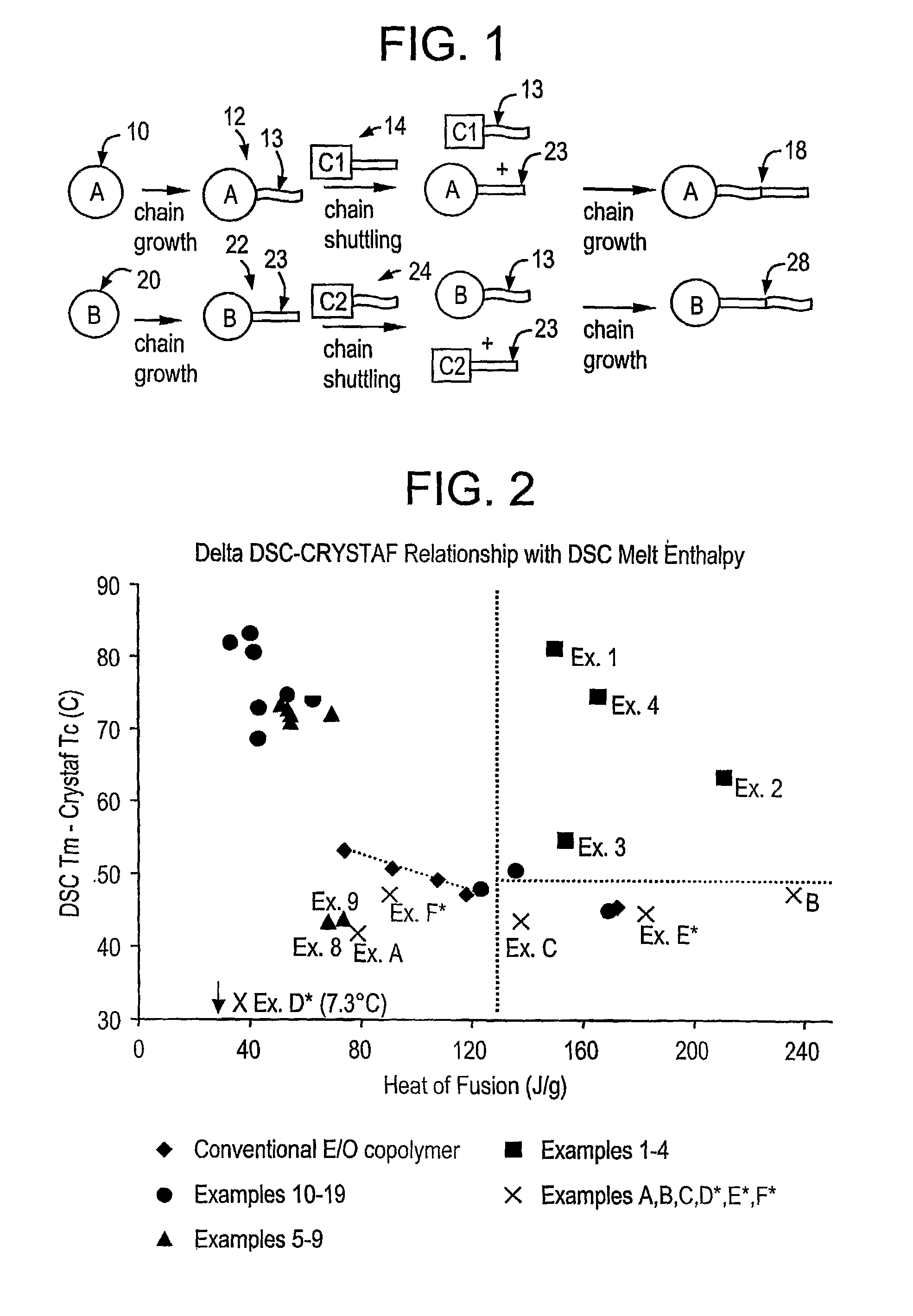

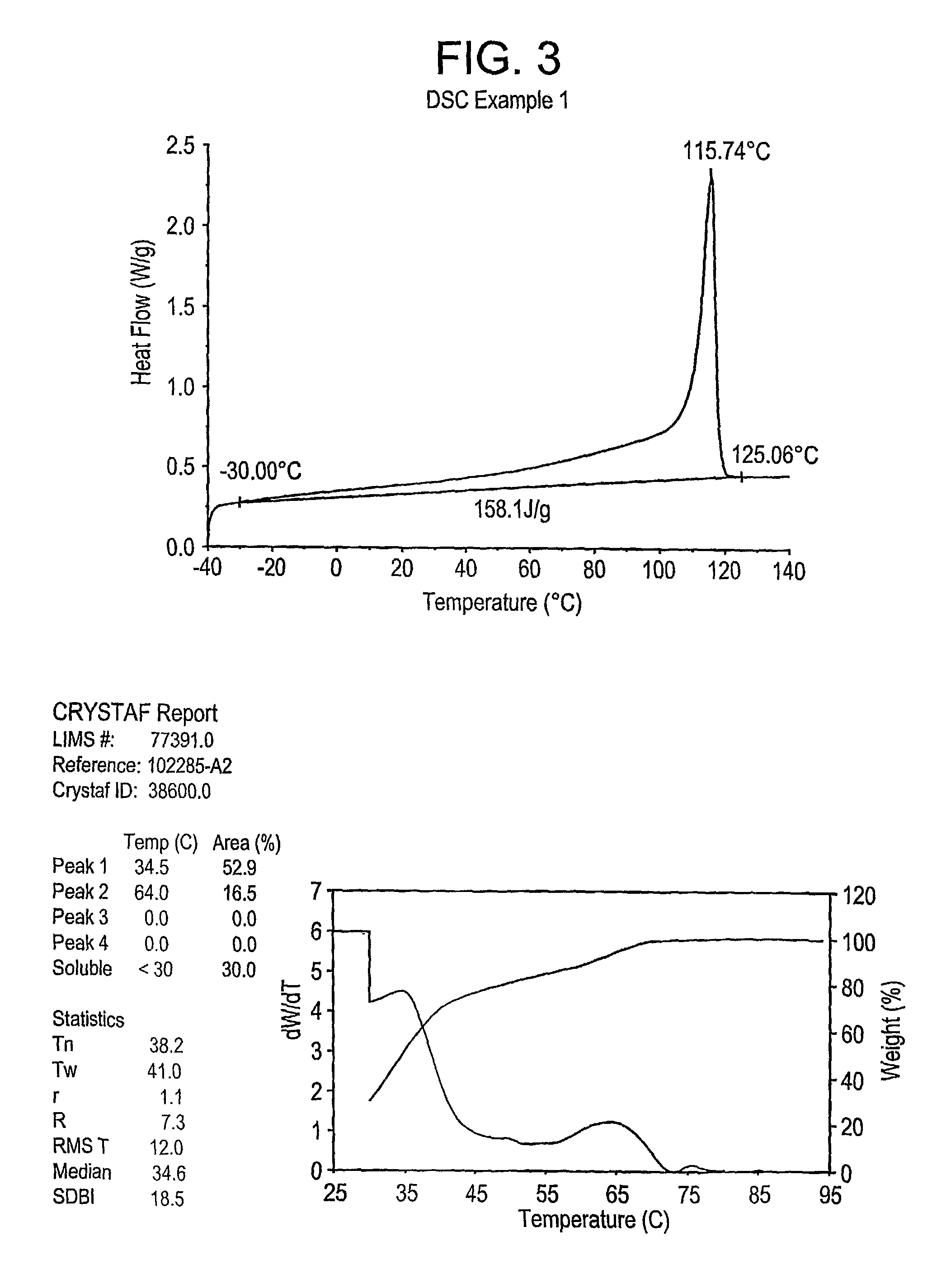

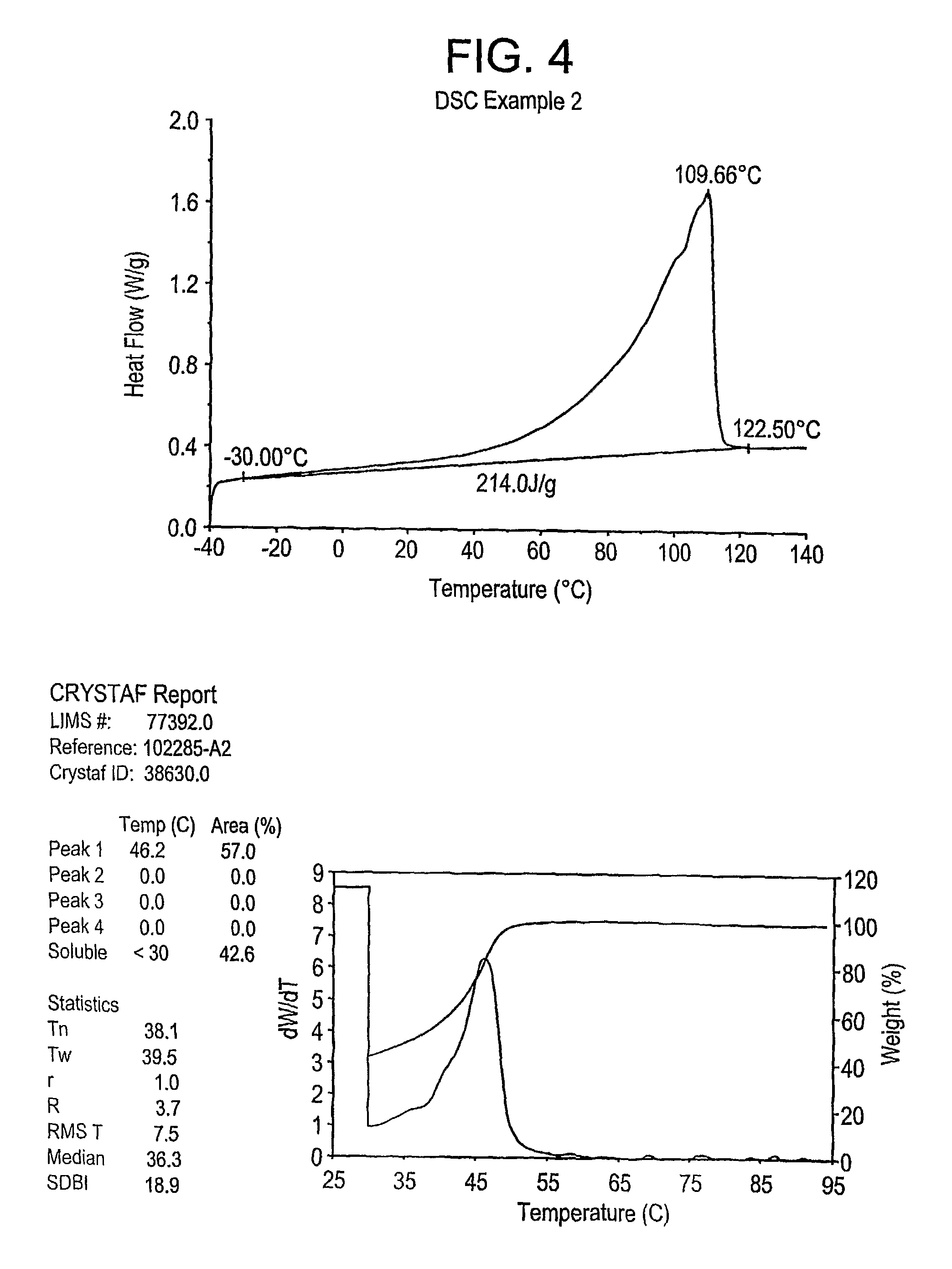

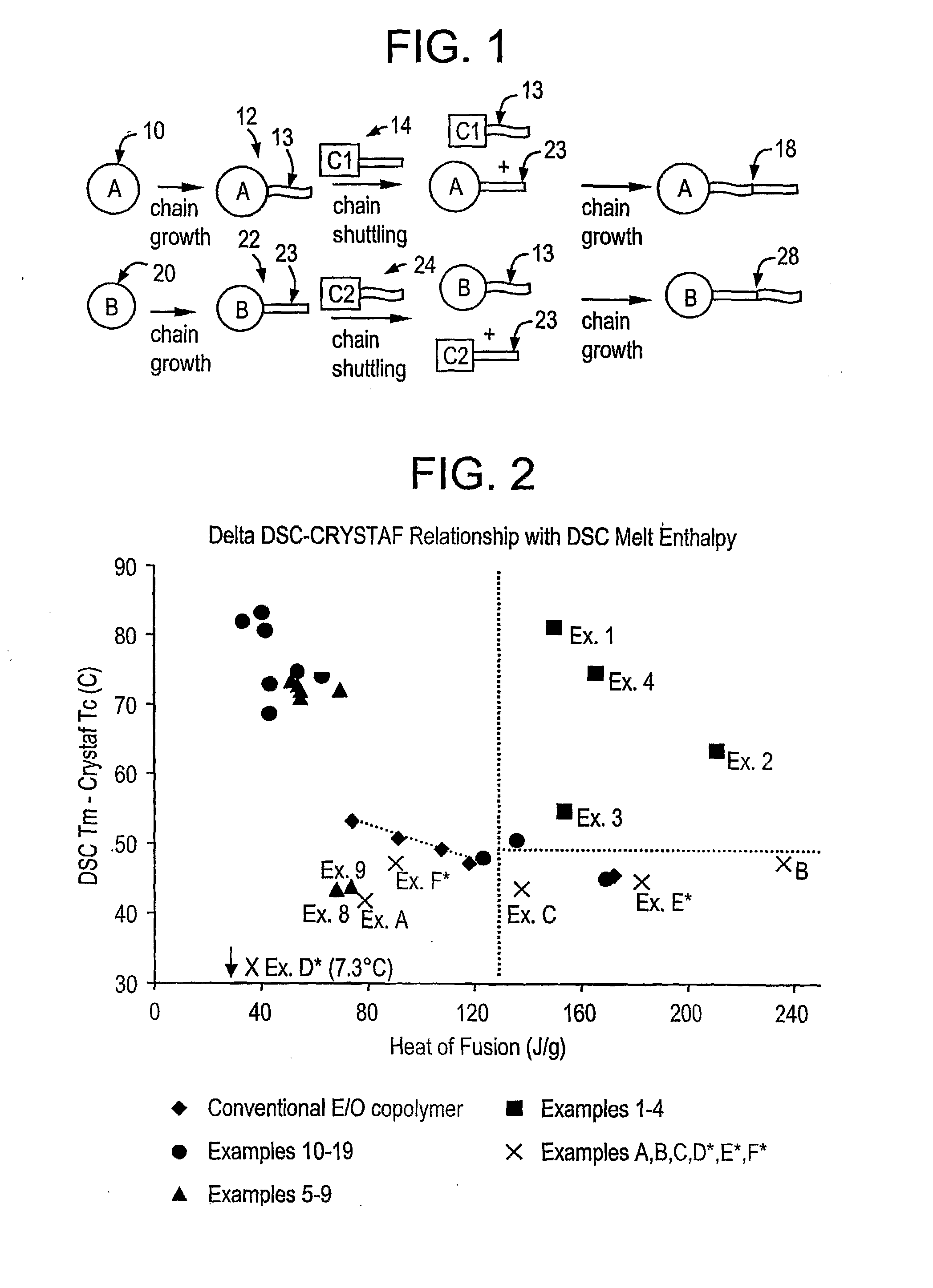

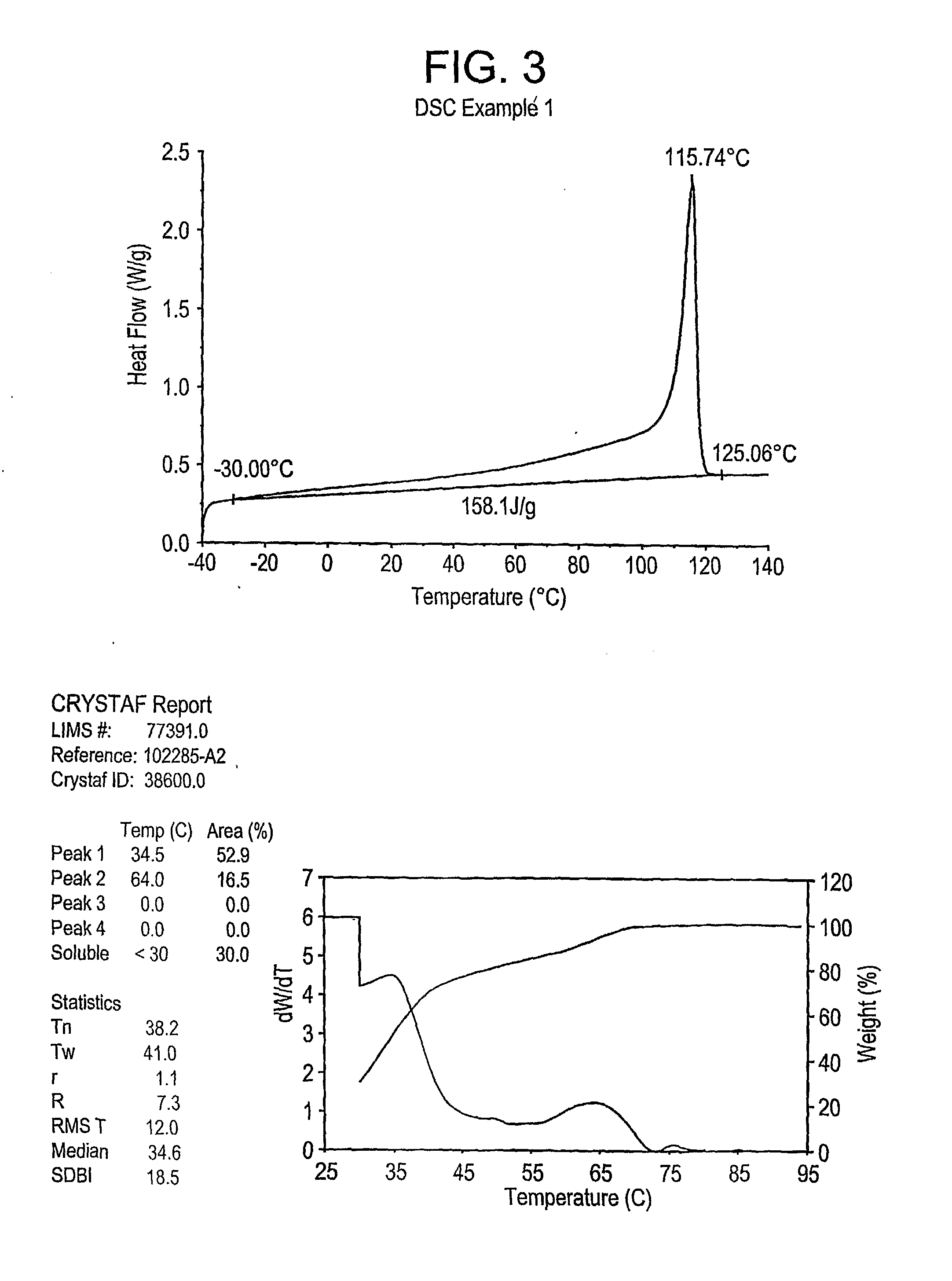

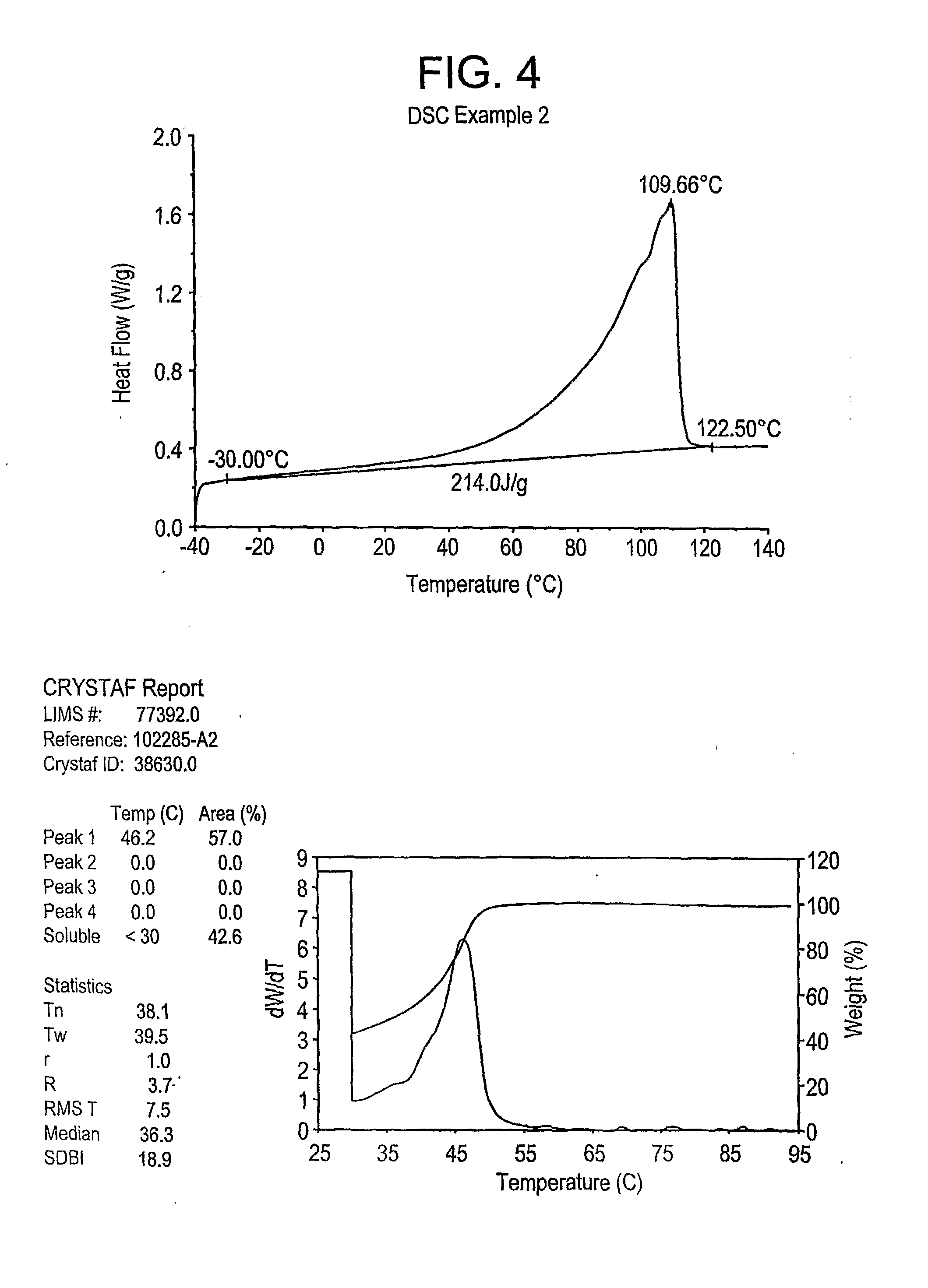

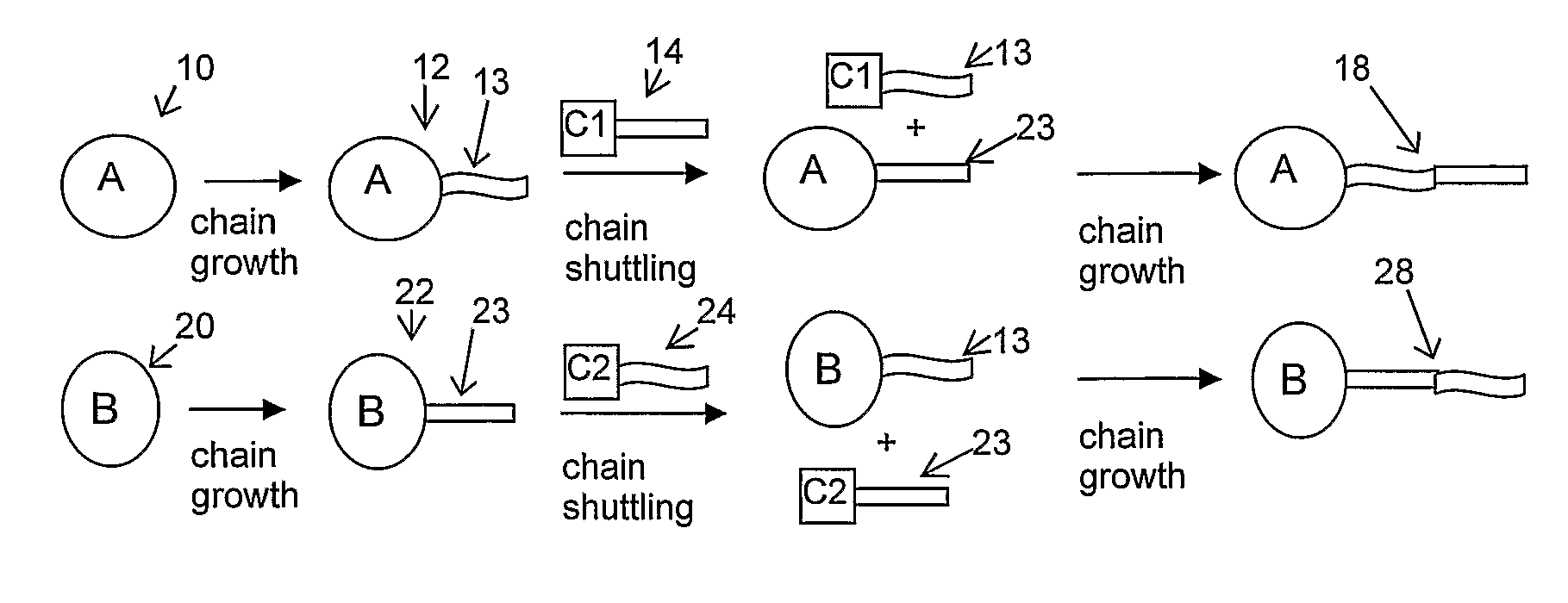

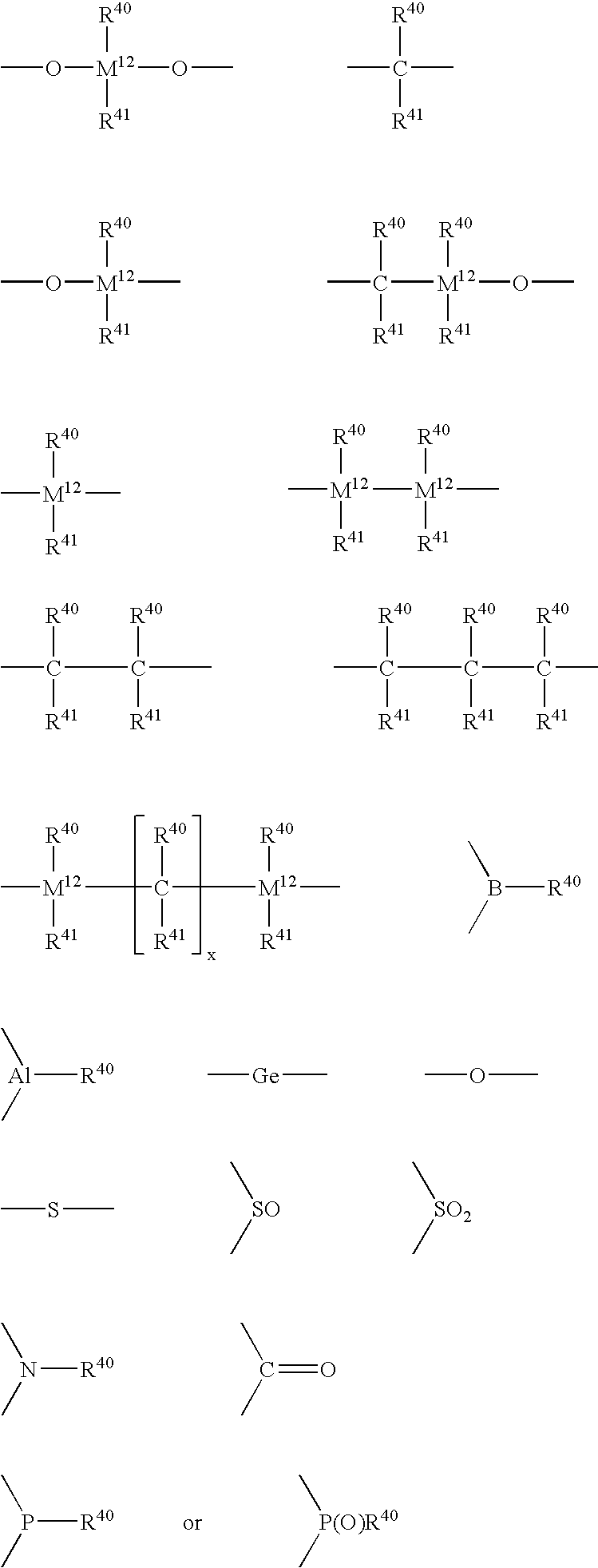

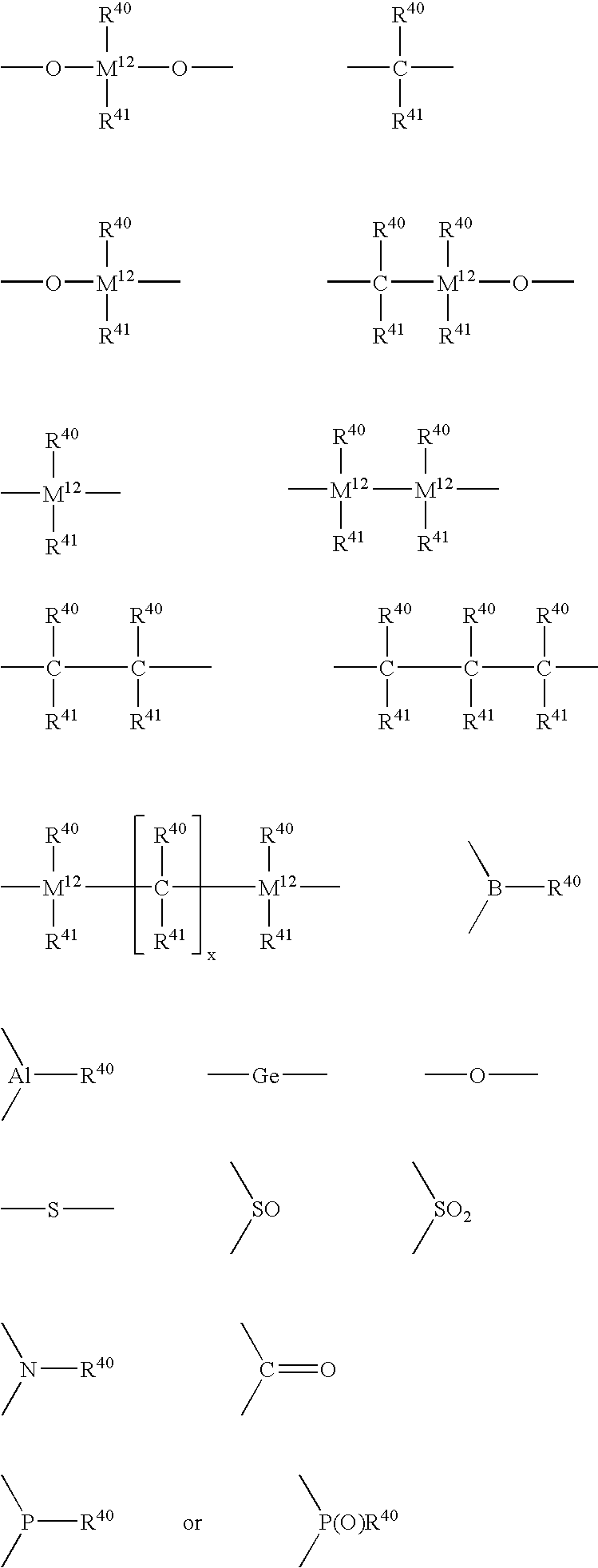

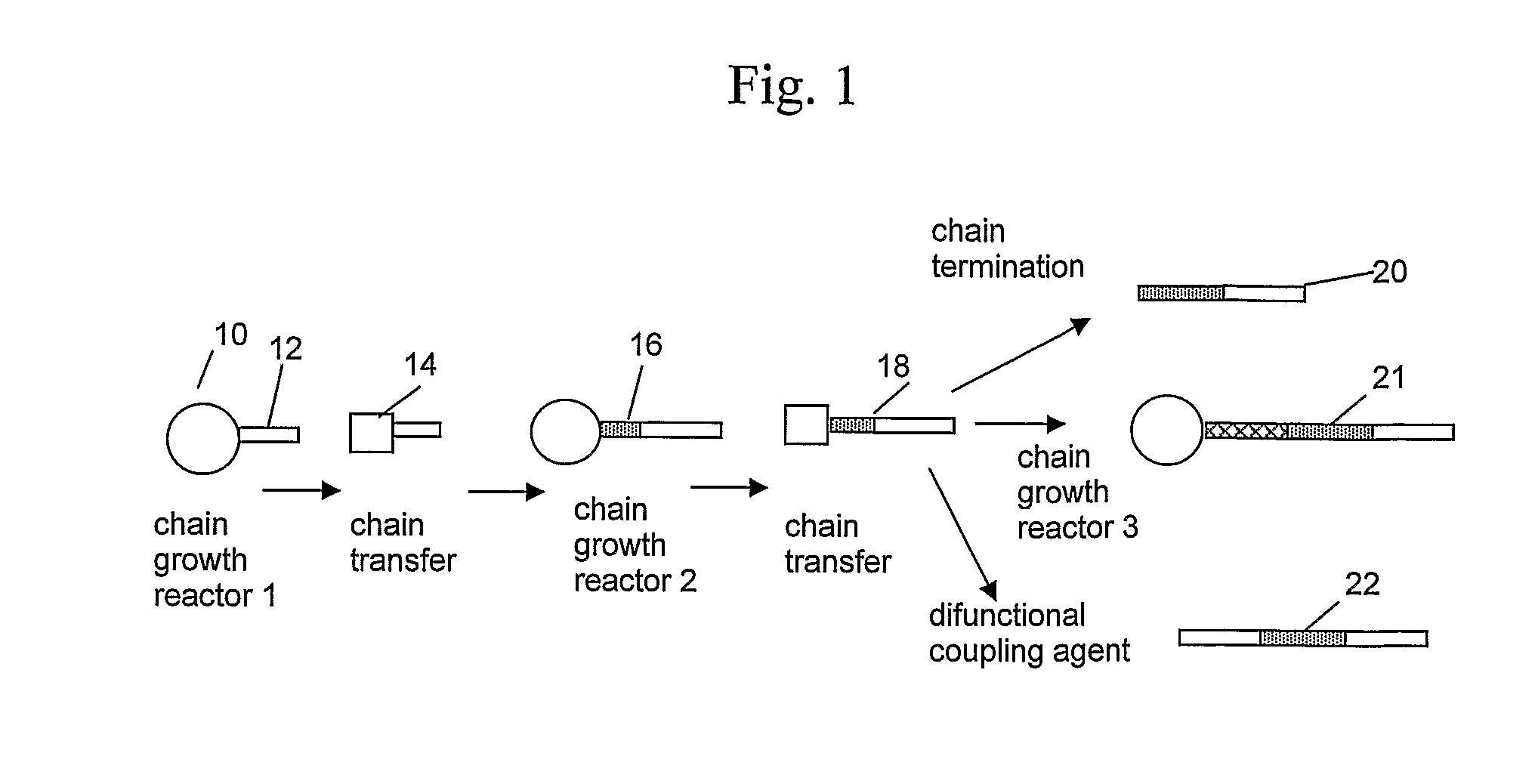

A composition for use in forming a multi-block copolymer, said copolymer containing therein two or more segments or blocks differing in chemical or physical properties, a polymerization process using the same, and the resulting polymers, wherein the composition comprises the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Catalyst for olefine polymerizing reaction and its components

The present invention provides one kind catalyst component for CH2=CHR olifine polymerization, where R is H or alkyl radical or aryl radical of C1-C6. The catalyst component contains Mg, Ti, halogenand electron donor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing olefin polymerization ball type catalytic component and carrier

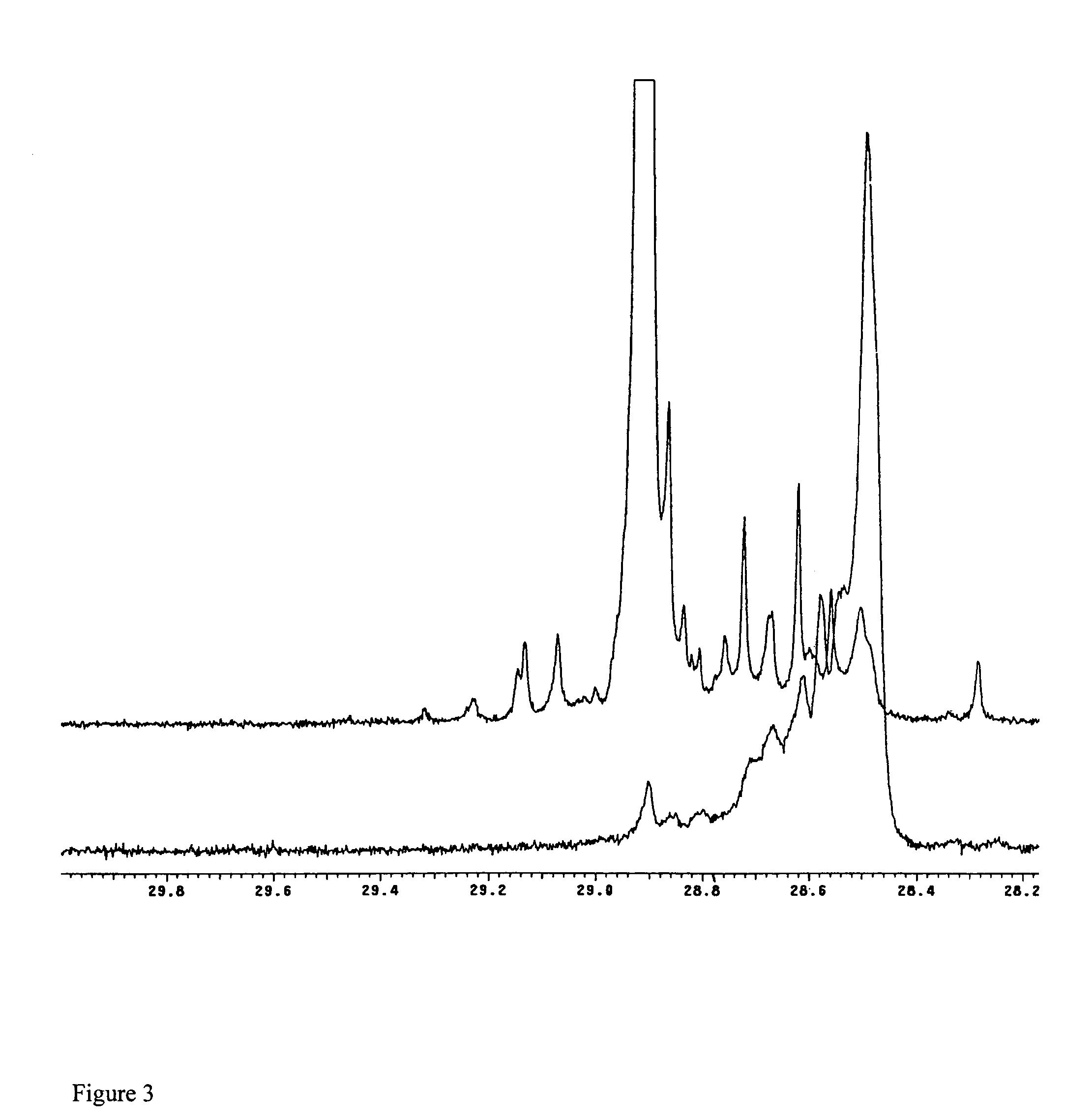

The spherical catalyst carrier is prepared with alcoholated magnesium chloride containing double-ether compound in emulsifying pelletizer. Liquid titanium halide compound is carried onto the spherical catalyst carrier to form spherical solid catalyst component in the presence of electron donor. In the X-ray diffraction spectrogram, the spherical solid catalyst component has diffraction peak in 13.3 deg of 2theta angle, strongest diffraction peak in 26.5 deg of 2theta angle and no characteristic diffraction peak of alpha-anhydrous MgCl2 in 15 deg of 2theta angle. The catalyst of the presentinvention has very high activity and may be used to produce polymer with good form, high apparent density and less fine powder. The catalyst is used in homopolymerization and copolymerization of olefin and suitable for various polymerization process.

Owner:YINGKOU XIANGYANG CATALYST

Catalyst composition comprising shuttling agent for ethylene multi-block copolymer formation

ActiveUS20070167578A1Improve efficiencySynthetic resin layered productsThin material handlingOlefin polymerizationPolymerization catalysts

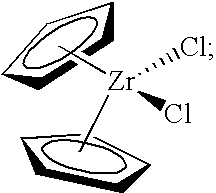

A composition for use in forming a multi-block copolymer, said copolymer containing therein two or more segments or blocks differing in chemical or physical properties, a polymerization process using the same, and the resulting polymers, wherein the composition comprises the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Catalyst Composition Comprising Shuttling Agent for Higher Olefin Multi-Block Copolymer Formation

ActiveUS20080311812A1Improve efficiencyHigh monomer conversion rateWoven fabricsNon-woven fabrics4-Methyl-1-penteneOlefin polymerization

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, are prepared by polymerizing propylene, 4-methyl-1-pentene, or other C4-8α-olefin and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Methods for producing metal-containing sulfated activator-supports

ActiveUS8309485B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOlefin polymerizationPolymerization catalysts

The present invention provides metal-containing sulfated activator-supports, and polymerization catalyst compositions employing these activator-supports. Methods for making these metal-containing sulfated activator-supports and for using such components in catalyst compositions for the polymerization of olefins are also provided.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Aluminum-free monocyclopentadienyl metallocene catalysts for olefin polymerization

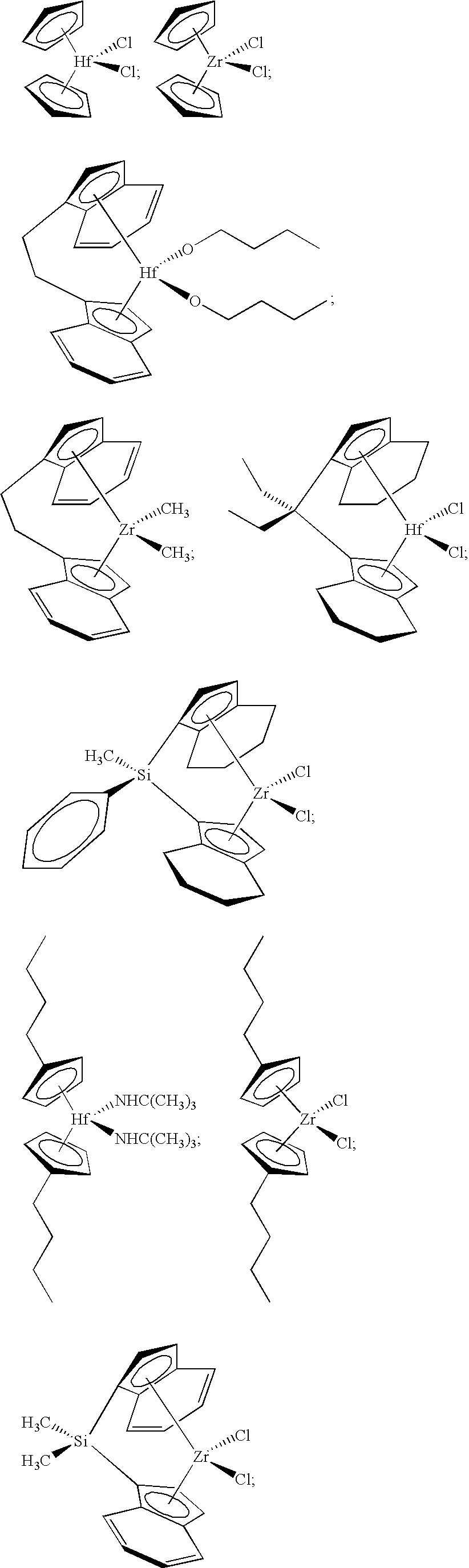

ActiveUS7163907B1Organic-compounds/hydrides/coordination-complexes catalystsMetallocenesPolymer sciencePolyolefin

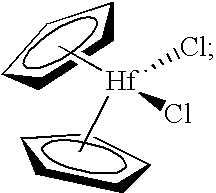

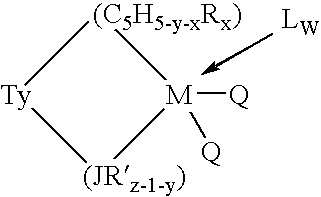

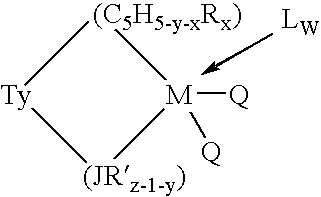

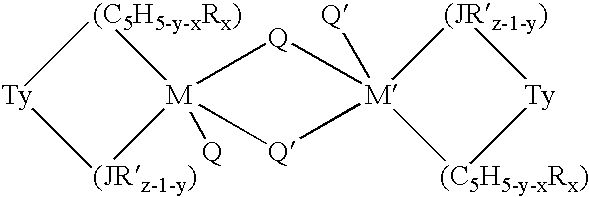

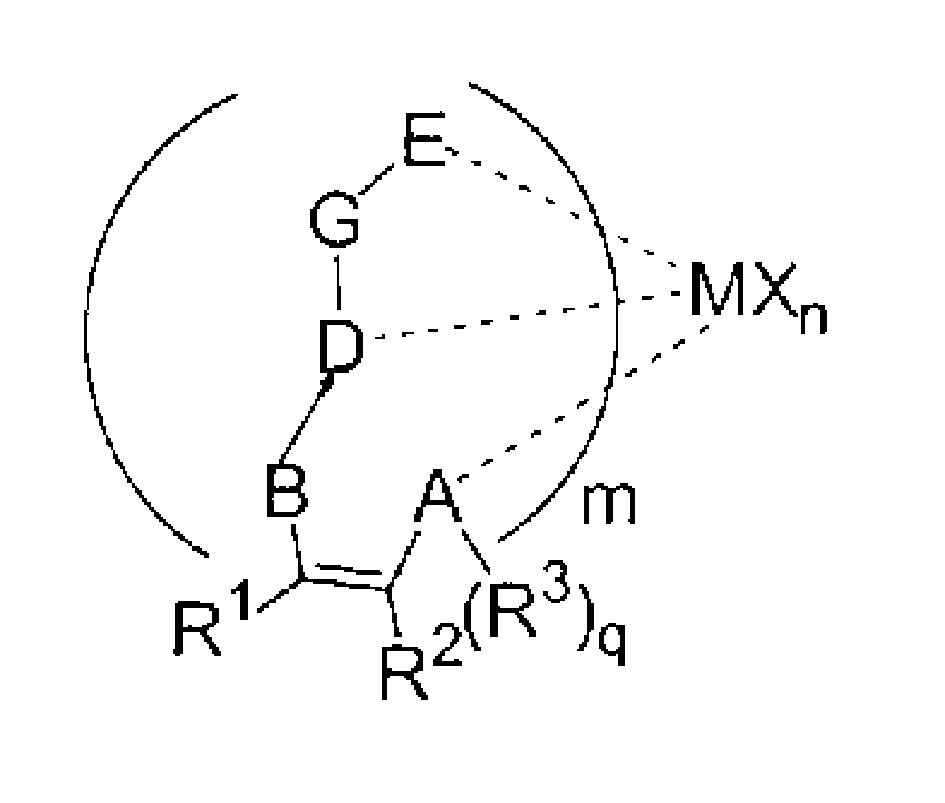

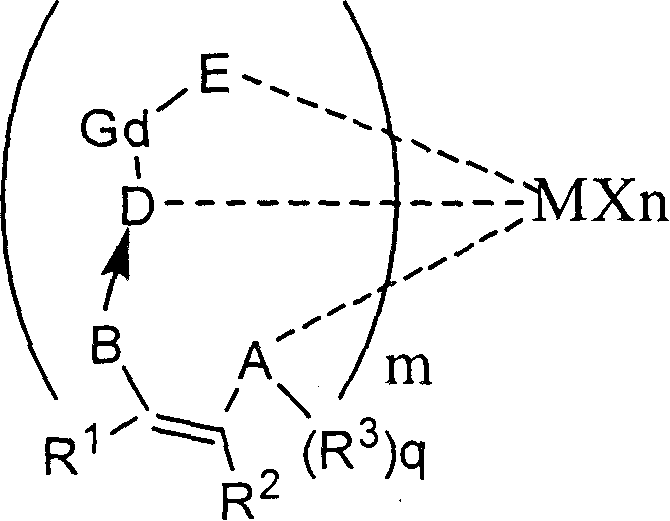

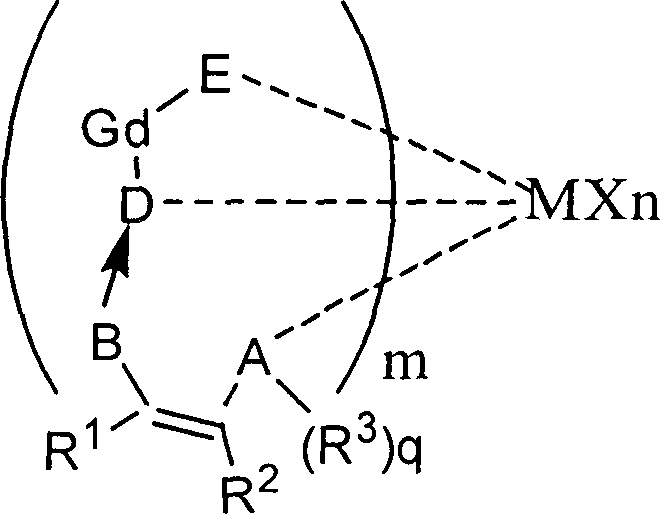

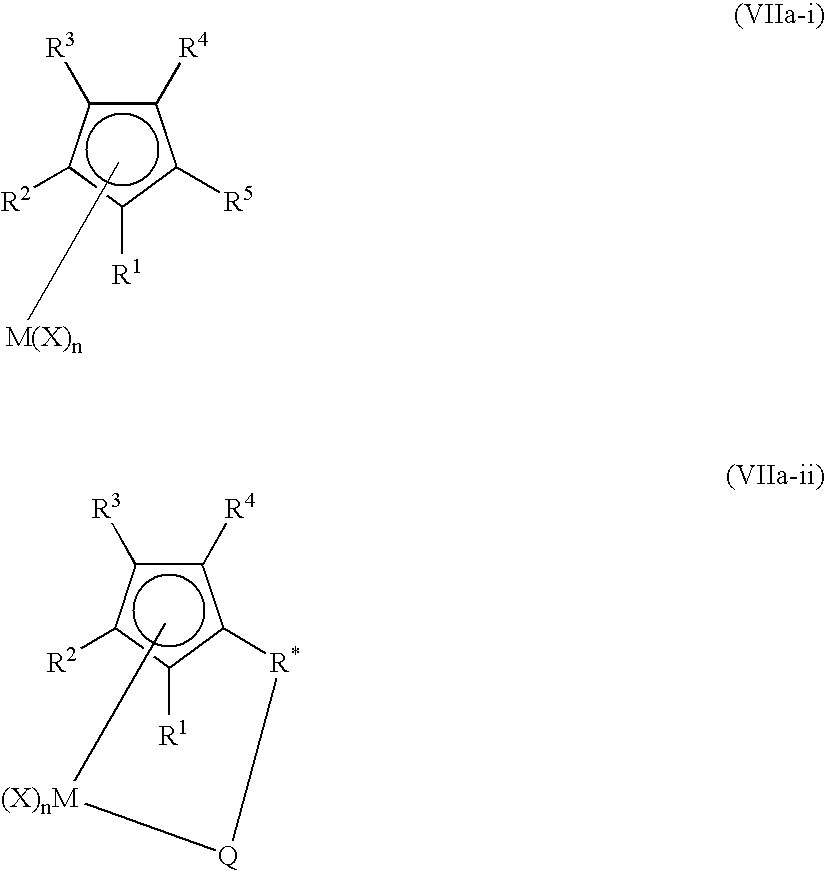

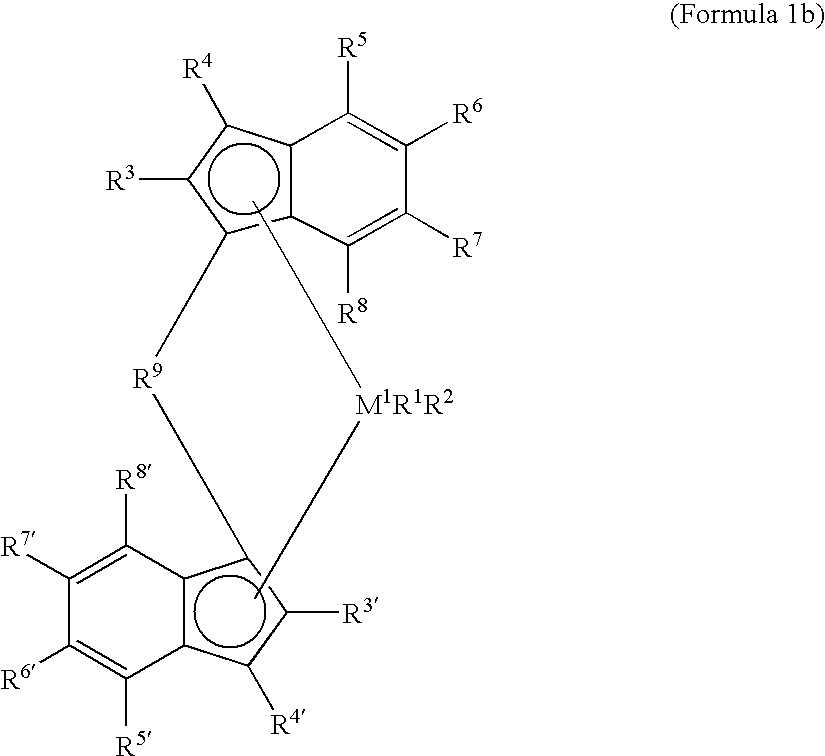

This invention relates to a catalyst system for the production of polyolefins comprising:(A) a Group IV B transition metal component represented by one of the two general formulaewherein(C5H5-y-xRx) is a cylopentadienyl ring(JR′z-l-y) is a heteroatom ligand in which J is an element with a coordination number of three from Group V-A or an element with a coordination number of two rom Group VI-A of the Periodic Table of Elements,each Q is independently, hydride, C1—C20 hydrocarbyl radicals, substituted hydrocarbyl radials wherein one or more hydrogen atoms is replaced by an electron withdrawing group, or C1—C20 hydrocarbyl-substituted metalloid radicals wherein the metalloid is selected from the group consisting of germanium and silicon, provided that Q is not a substituted or unsubstituted cyclopentadienyl ring, or both Q together may be an alkylidene, olefin, acetylene or a cyclometallated hydrocarbyl;“y” is 0 or 1; when “y” is 1, T is a covalent bridging group containing a Group IV-A or V-A element;L is a neutral Lewis base; and “w” is a number from 0 to 3;(B) an activator compound comprising (1) a cation; and (2) a compatible noncoordinating anion.

Owner:EXXONMOBIL CHEM PAT INC

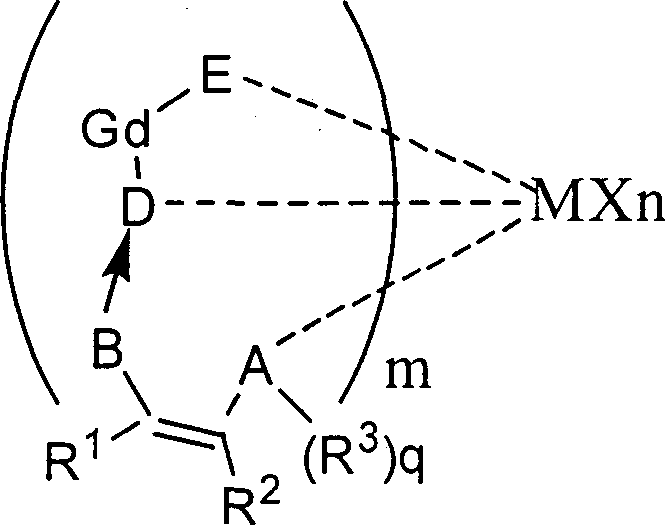

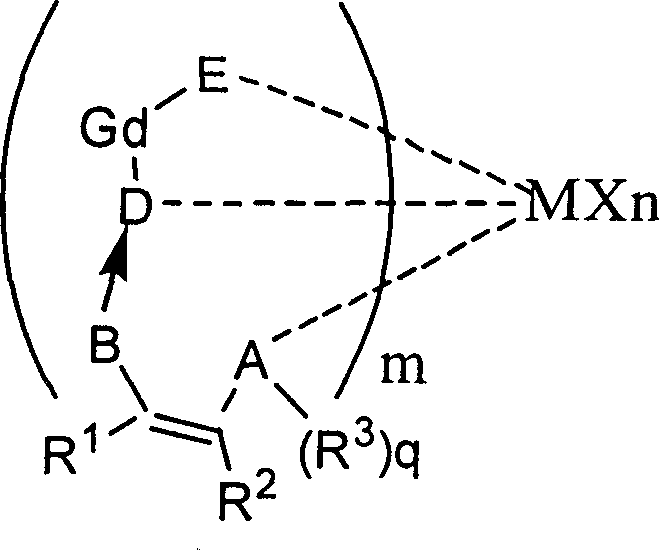

Catalyst for polymerization and copolymerization of olefine and its synthesis and use

The catalyst for polymerization and copolymerization of olefine is one novel kind of group III to group XIII transition metal complex of tridentate ligand.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

New olefine polymerization catalyst

The present invention relates to a catalyst or catalyst system for polymerization and copolymerization of olefine and its synthesis process and the application in catalyzing olefine polymerization. The catalyst is a kind III to XI transition metal compound with multitooth ligand.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

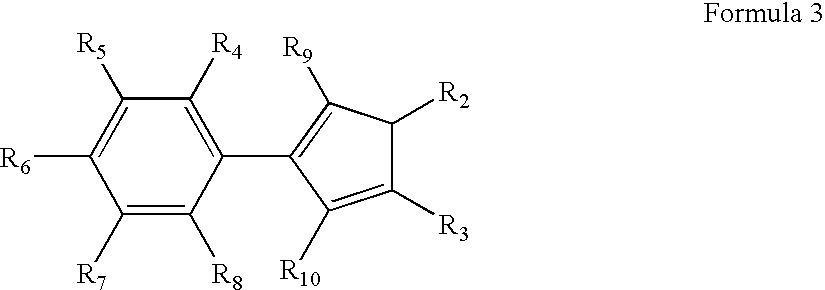

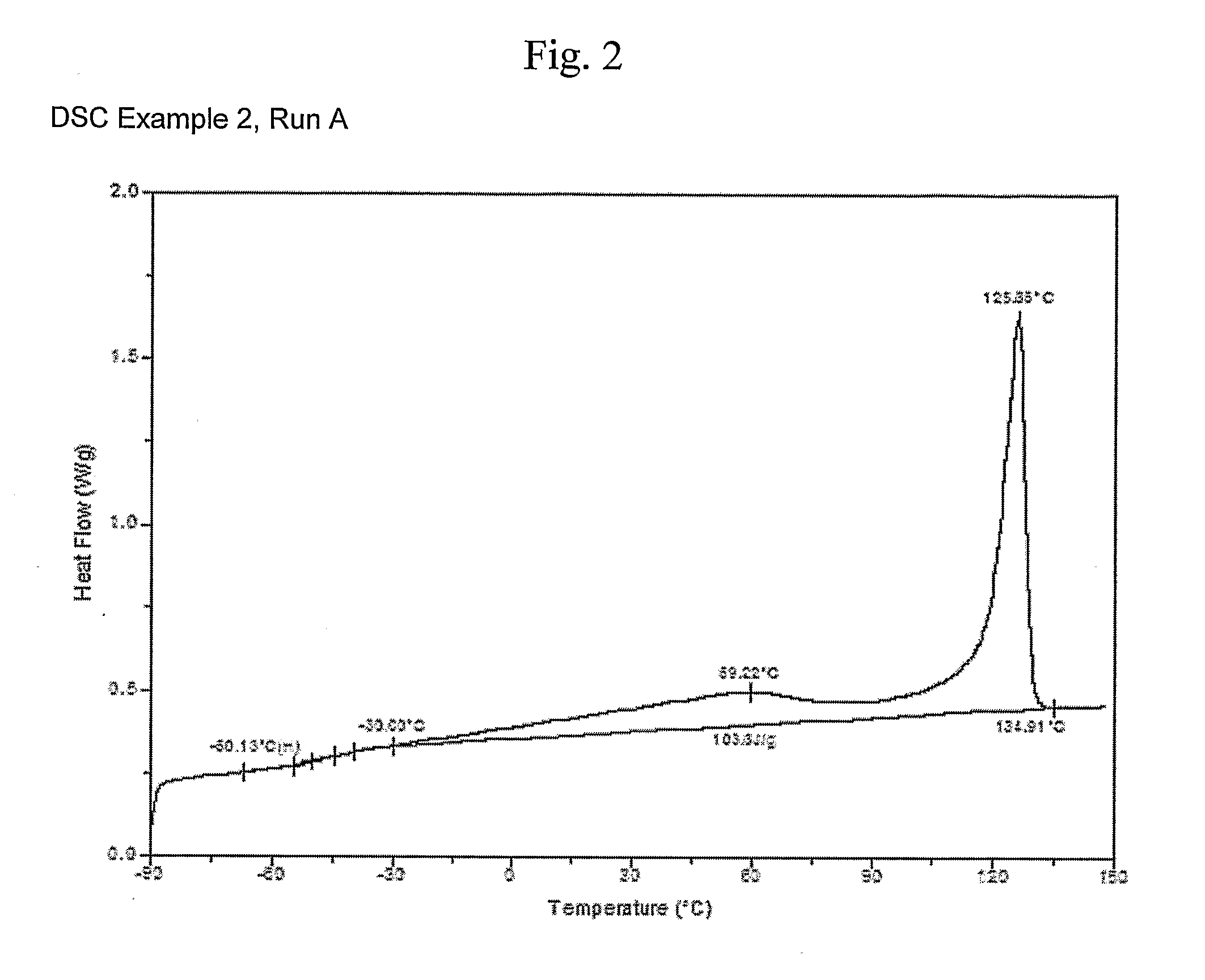

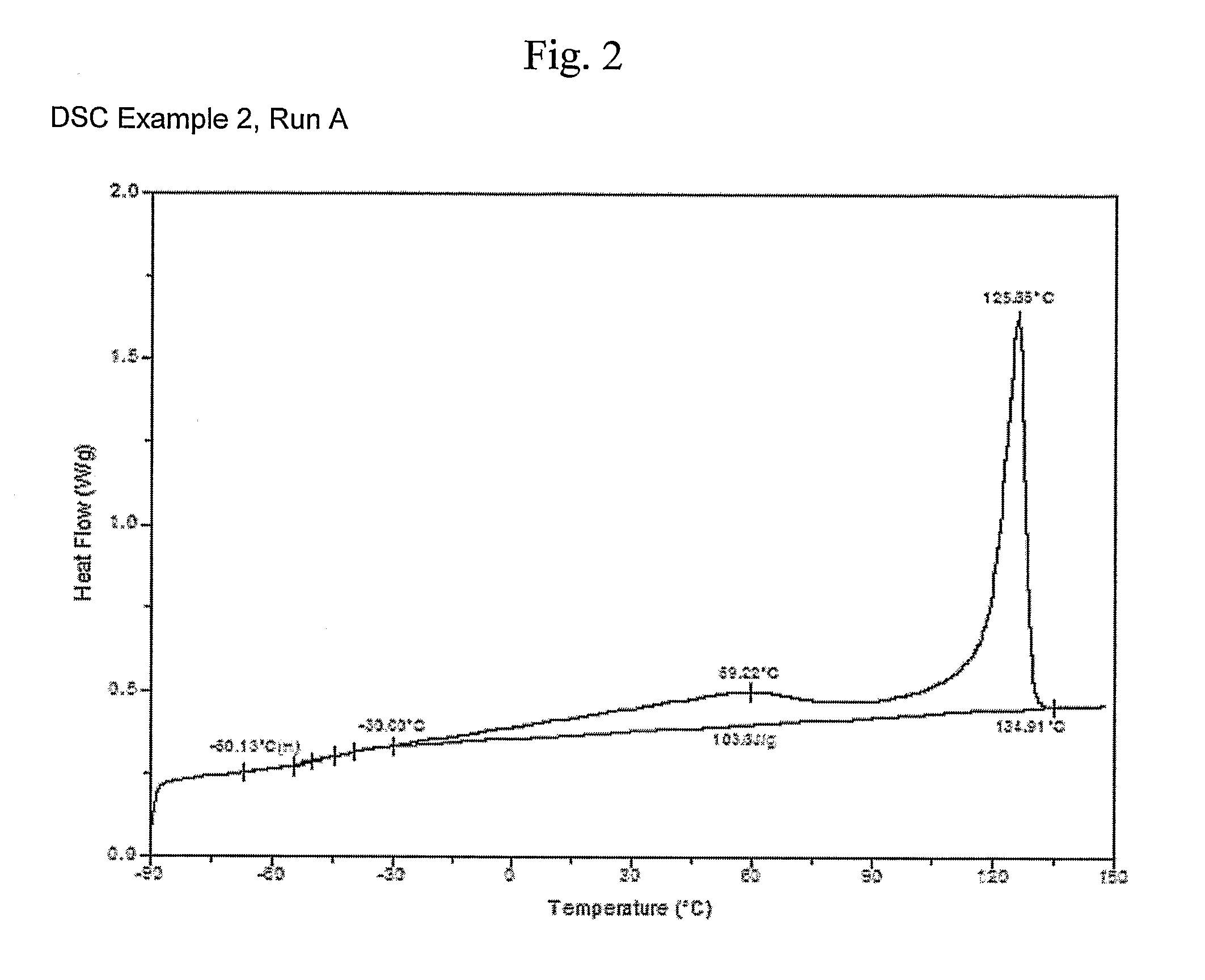

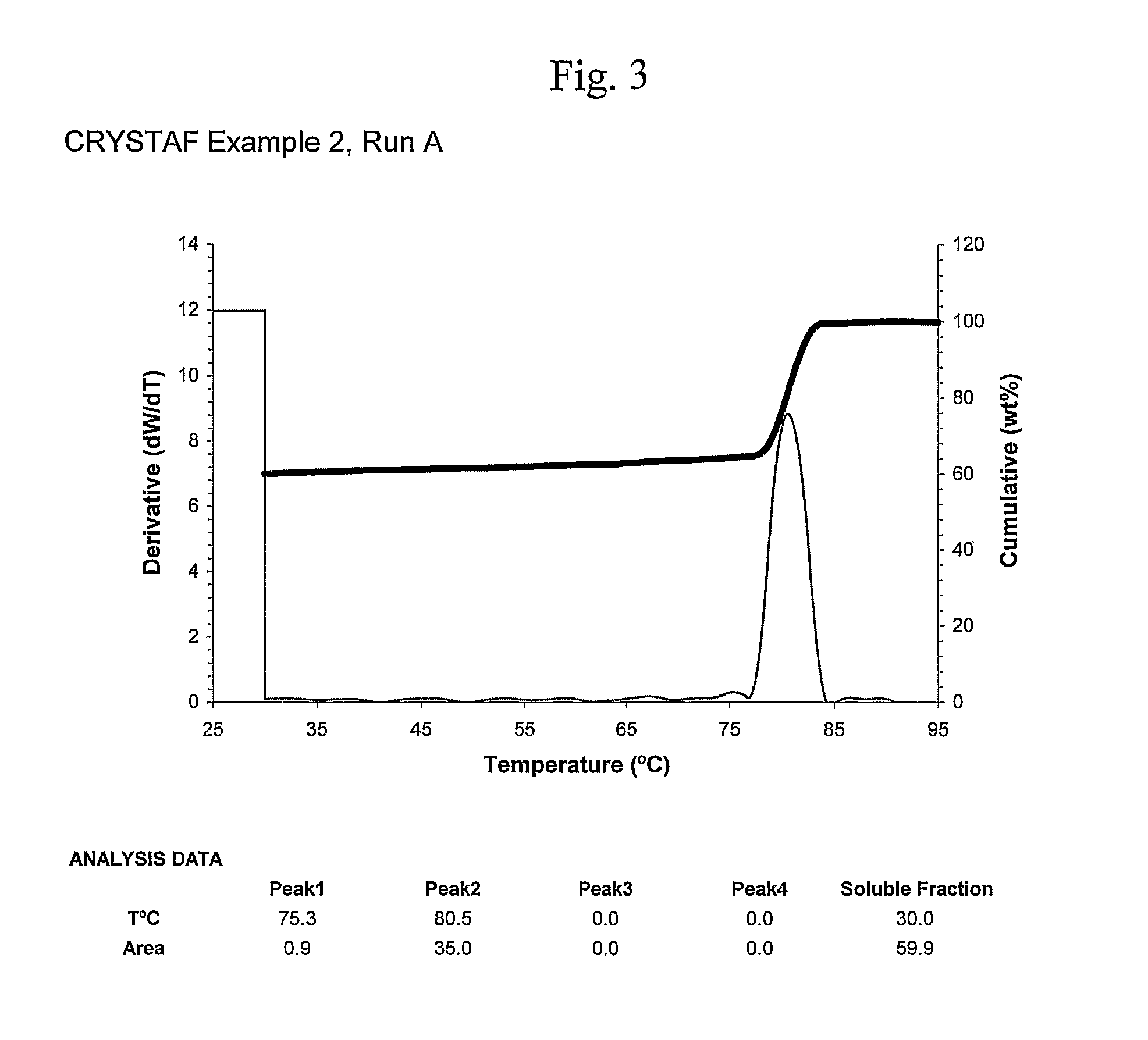

High melting thermoplastic elastomeric alpha-olefin polymers (PRE/EPE effect) and catalysts therefor

InactiveUS6559262B1Activity of fluxional unbridged metallocene polymerization catalystsHigh molecular weightGroup 4/14 element organic compoundsMetallocenesElastomerEthylene Homopolymers

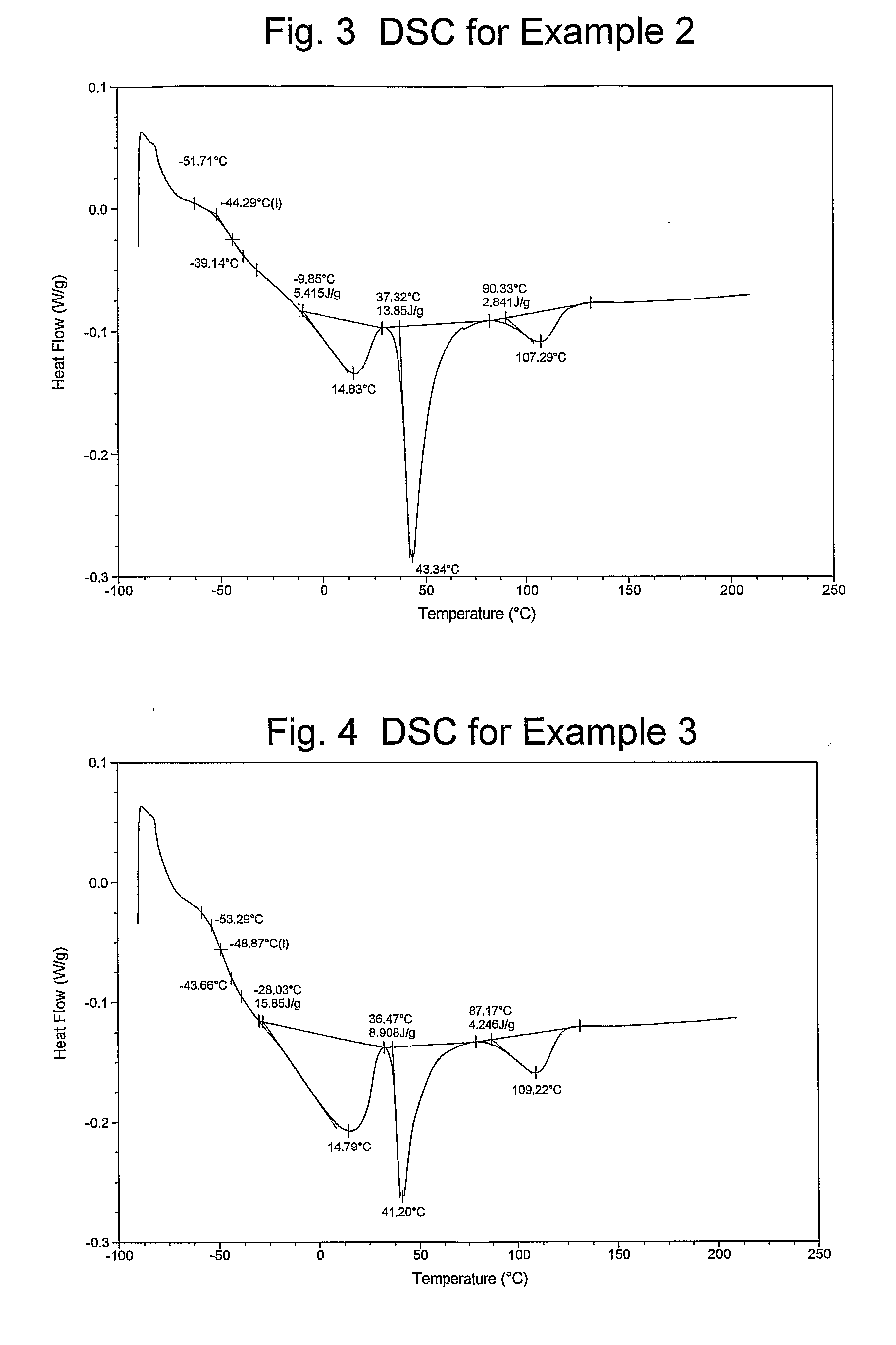

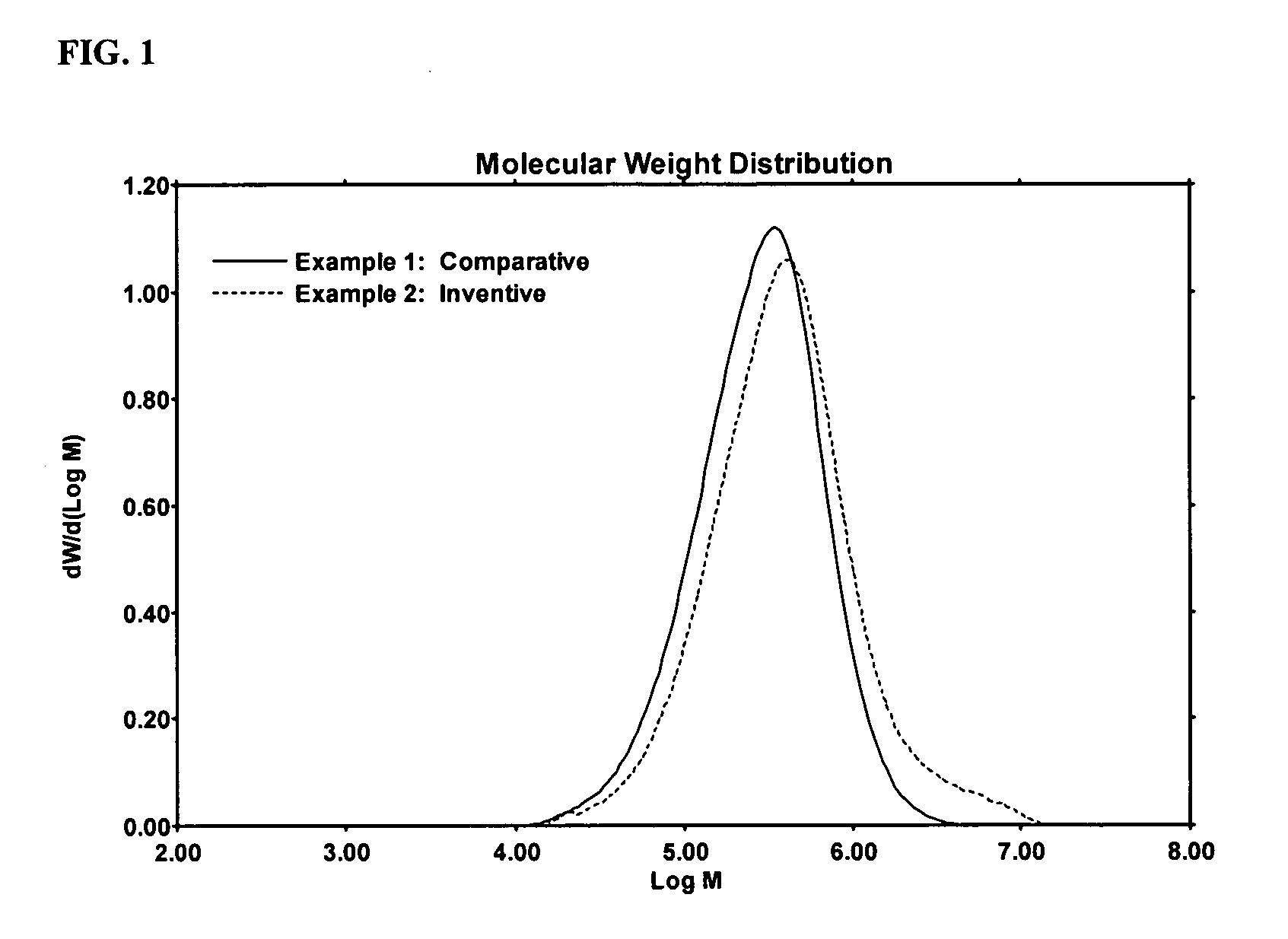

This invention relates generally to low ethylene insertions into I-olefin polymers and processes for production of such polymers using unbridged fluxional metallocenes, primarily substituted aryl indenyl metallocenes, and more particularly to use of unbridged, fluxional, cyclopentadienyl or indenyl metallocene catalyst systems in methods of production of high melting point I-olefin homo- and co-polymers, particularly elastomeric crystalline and amorphous block homo- and co-polymers of I-olefins. The activity of fluxional unbridged metallocene polymerization catalysts containing at least one 2-arylindene ligand is increased 10x or more by the addition of small (typically 0.1-10 wt. %) amounts of ethylene to the polymerization system, which increase is termed the Polymerization Rate-Enhancement effect (PRE), which is measured in terms of an Ethylene Enhancement Factor (EEF) as a dimensionless ratio in the range of from about 1.1 to about 10 or above. The amount of ethylene included in the reaction system can be selected and controlled to be so small as to result in essentially minimal (<2 mole %) incorporation of ethylene units into the resulting elastomeric polymer and the molecular weight may be increased. Amounts of ethylene to generate the PRE effect may be greater than 0.1 wt. % and preferably range up to about 2 wt. %. However, if a polymer with more ethylene is desired, additional ethylene may be incorporated into the polymerization feed, including up to 10 to about 50 mole % based on olefin units. A second important aspect of this invention is the ability to use a PRE activity-enhancing amount of ethylene in an olefin polymerization without substantially affecting the physical properties of the elastomer. In a third important aspect of this invention, I-olefin elastomers are produced through incorporation of ethylene using unbridged fluxional catalyst systems which may not otherwise produce acceptable elastomeric homopolymers. This effect is termed the EPE effect, for Elastomeric Property-Enhancing effect. The EPE amount of ethylene required to produce such elastomers typically overlaps the PRE activity-enhancing amount. Incorporation of up to about 5 mole % or more of ethylene typically will produce an elastomeric polymer using such catalyst systems. Typical useful amounts of incorporated ethylene include about 1 to 3 mole %. Preferred polymers of this invention retain sufficient crystallinity to provide a high melting point (by DSC) of about 80° C., preferably above 100° C., including in the range of from about 120° C. to about 140° C. and above. Novel flexible alpha-olefin homo and copolymers having elongation in excess of 600% and substantially no retained force are disclosed.

Owner:BP CORP NORTH AMERICA INC

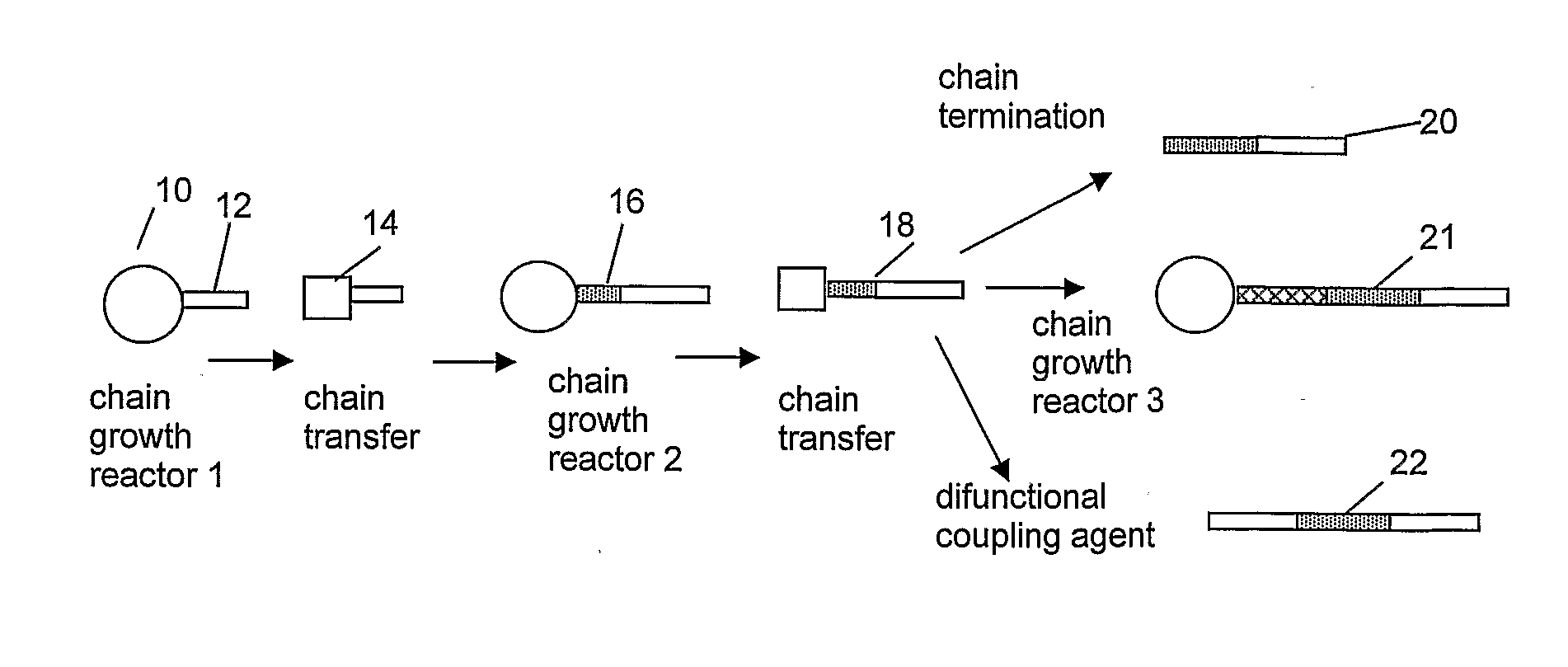

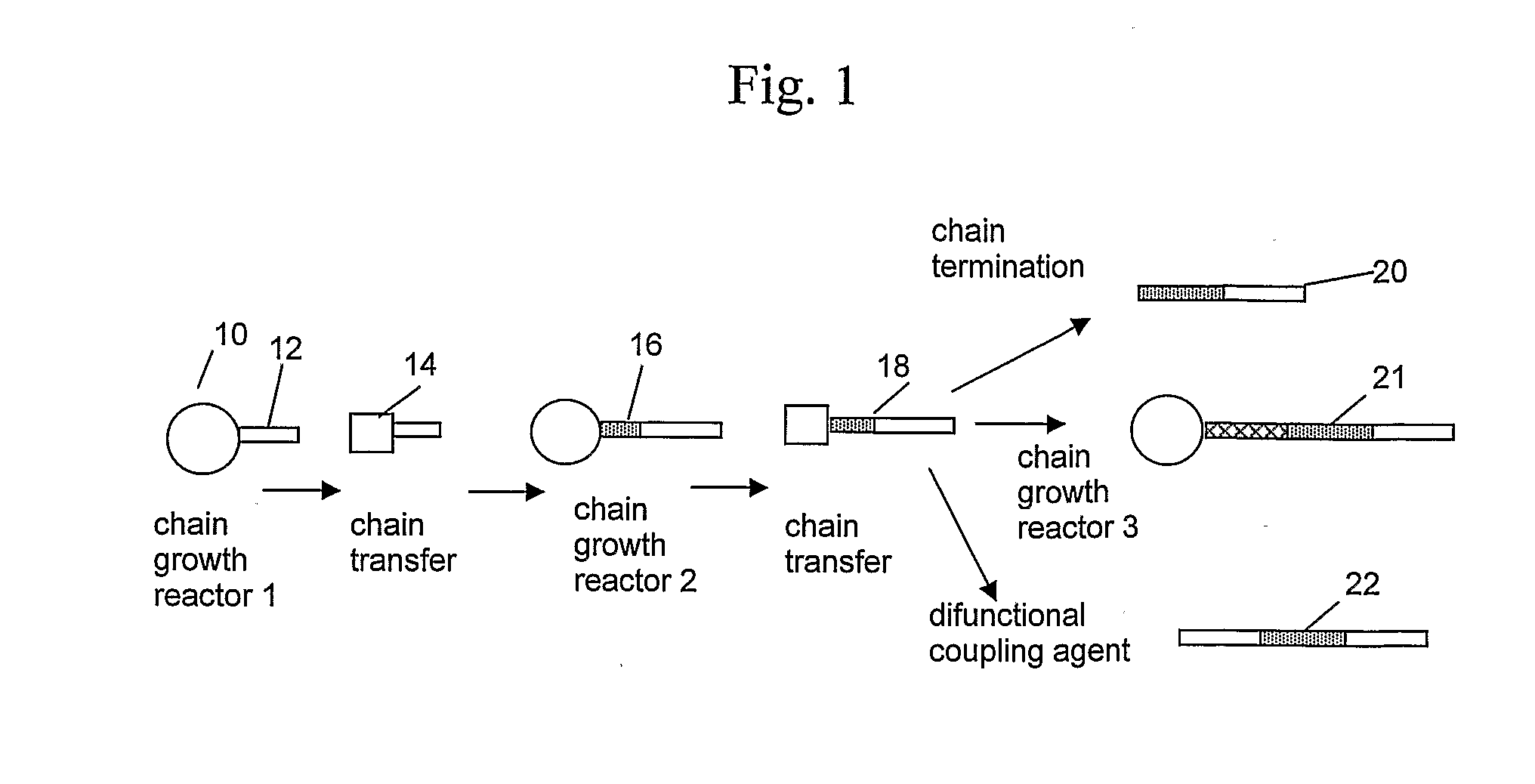

Catalytic Olefin Block Copolymers with Controlled Block Sequence Distribution

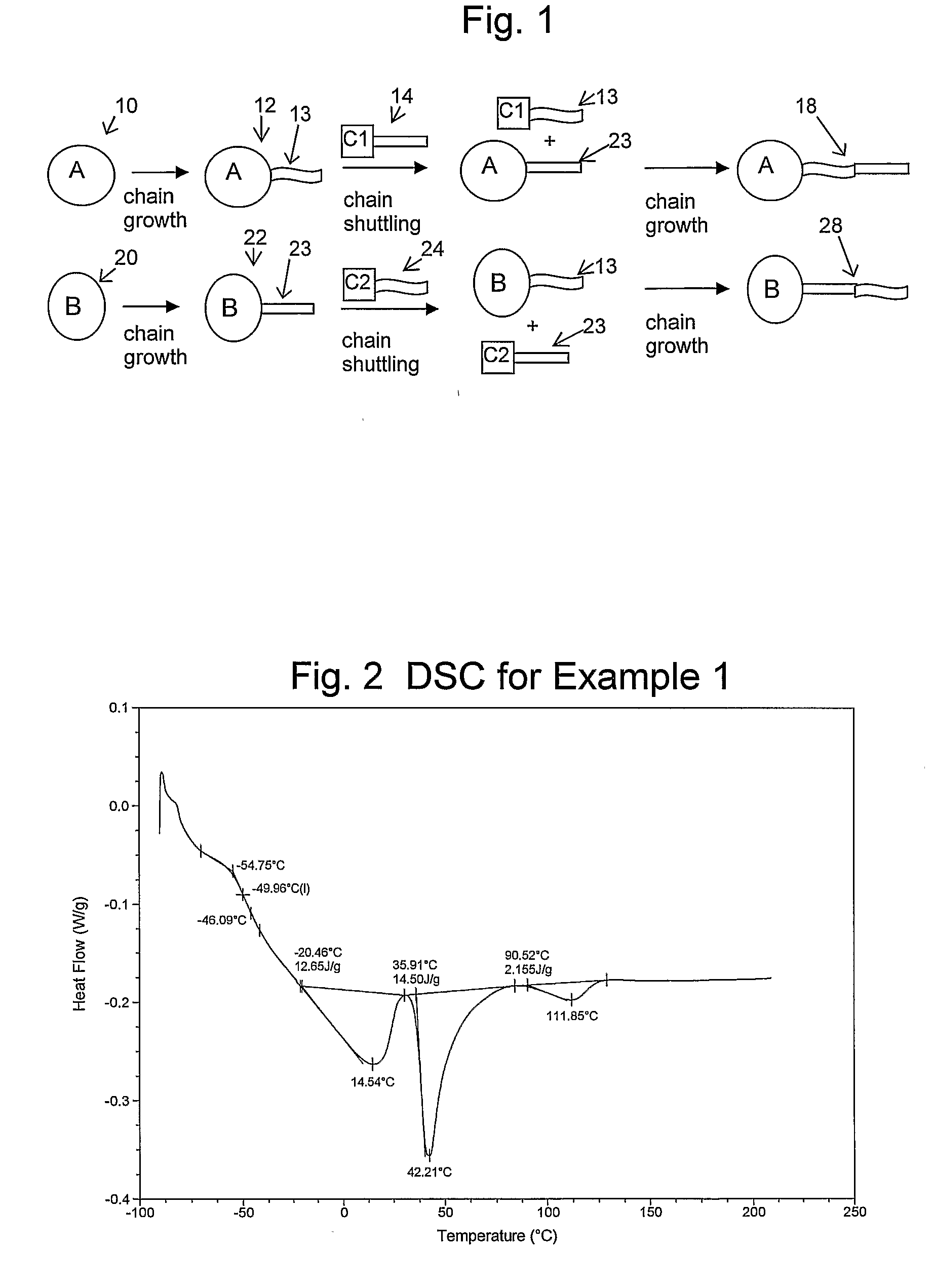

A process for the polymerization of one or more addition polymerizable monomers and the resulting polymer products, said process comprising: 1) contacting an addition polymerizable monomer or mixture of monomers under addition polymerization conditions in a reactor or reactor zone with a composition comprising at least one olefin polymerization catalyst and a cocatalyst and characterized by the formation of polymer chains from said monomer or monomers; 2) transferring the reaction mixture to a second reactor or reactor zone and optionally adding one or more additional reactants, catalysts, monomers or other compounds prior to, commensurate with, or after said transfer; and 3) causing polymerization to occur in said second reactor or reactor zone to form polymer chains that are differentiated from the polymer chains formed in step 1); said process being characterized by addition of a chain shuttling agent to the reaction mixture prior to, during, or subsequent to step 1) such that at least some of the resulting polymer molecules from step 3) comprise two or more chemically or physically distinguishable blocks or segments.

Owner:DOW GLOBAL TECH LLC

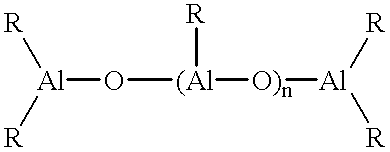

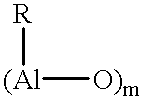

Olefinic polymerization and copolymerization method of supported non-metallocene catalyst

A method of alkene polymerization and copolymarization with f load non- metallocene catalyst: emplying the load non- metallocene catalyst and catalyst promoter forming the catalytic system, introducing polymer monomer or comonomer for alkene polymerization or copolymarization; adding the load non- metallocene catalyst into dissolvent and mixing with catalyst promoter and then transferring the mixture into polymerization reactor, or adding the load non- metallocene catalyst and catalyst promoter into the polymerization reactor in order or simultaneously. The catalyst promoter is chosen from: alkyl aluminium, aluminium oxane, Lewis acid, boralotano, alkyl borane or alkyl borane ammonium salt. The load non- metallocene catalyst is loaded to multiple poral solid by employing methods of solution dipping, equivoluminal dipping or solution dipping-before-equivoluminal dipping to form organic integral of property stable and strong binding force. The invention is characterized by the high alkene polymerization active, high fusion point and good normalization of the produced polymer, and the sastification of the demand of high level product production.

Owner:YANGZI PETROCHEM

Application of supported non-metallocene catalyst in ethene polymerization process by slurry method

The invention discloses an application of load non- metallocene catalyst in the slurry process for vinyl polymerying, the load non- metallocene catalyst and catalyst promoter forming the catalytic system, the alkene polymerization comprising: vinyl homopolymerization, combined polymerization of vinyl with propylene, butylenes, hexane, octane or norbornene; the catalyst carrier being chosen from: inorganic oxide of metallic oxide from IIA, IIIA, IVA, and IVB groups, or oxided mixture and mixing oxide; the catalyst promoter being chosen from: methylaluoxane, ethylaluoxane, isobutylaluoxane, trimethylaluminum,triethylaluminum,triisobutylaluminum,methylaluoxane-trimethylaluminum or methylaluoxane-triethylaluminum; the mole proportion between the catalyst promoter and catalyst being Al / Ti= 1:1-500. The inventioin is characterized by the less methylaluoxane consumption, stable reaction, easy-to-control polymerization temperature and non still-sticking phenomenon. The produced polyolefine possesses perfect granual shape, and the maximum polymer clamp density can reach 0.385 g / ml.

Owner:SINOPEC YANGZI PETROCHEM

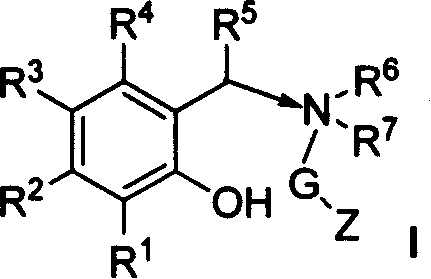

Mono-active center Ziegler-Natta catalyst for olefinic polymerization

The invention relates to a new catalyst for single active central Ziegler-Natta alkene polymerization. Said catalyst takes salicylal containing dentate or substituted salicylal derivatives as electrons, and is prepared by adding pretreated carrier, metallic compound and electrons into magnesium compound / tetrahydrofuran solution. The catalyst can produce ethane homopolymer and copolymer with narrow molecular weight distribution (1.6-3.8) and even comonomer distribution, with high activity and under action of adjuvant catalyst of alkyl aluminium and alkyl aluminoxanes. The ethane polymerization, homopolymerization or combined polymerization of ethane and 1- olefin, ring olefin and polar monomer through slurry method or gas phase method by using said catalyst can be realized.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

Mutliple catalyst system for olefin polymerization and polymers produced therefrom

This invention relates to a polymer of one or more C3 to C40 olefins, optionally one or more diolefins, and less than 15 mole % of ethylene, and polymerization processes for producing the same.

Owner:EXXONMOBIL CHEM PAT INC

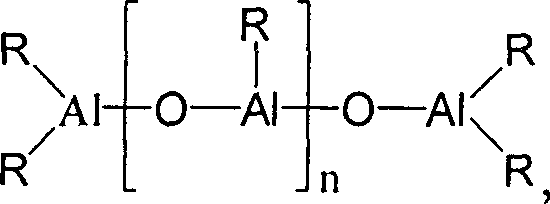

Activated catalyst systems from substituted dialuminoxane complexes

InactiveUS6958306B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationArylHalogen

A catalyst composition and method for preparing a supported catalyst system for olefin polymerization is provided. In one aspect, the catalyst composition includes a reaction product of a dialuminoxane and a halogen substituted aryl borane, wherein the reaction takes place on a support and at conditions sufficient to exchange one or more ligands on the dialuminoxane for one or more ligands on the halogen substituted aryl borane while on the support. In one embodiment, the method for preparing the supported catalyst system includes combining a dialuminoxane with a support to form a treated catalyst support, and combining a halogen substituted aryl borane with the treated catalyst support at conditions sufficient to exchange one or more ligands on the dialuminoxane for one or more ligands on the halogen substituted aryl borane while on the support to form a supported activator. The method further includes reacting one or more polymerization catalysts with the supported activator.

Owner:UNIVATION TECH LLC

Metallocene catalysts, their synthesis and their use for the polymerization of olefins

ActiveUS7169864B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAluminoxaneSolvent

A process for the preparation of a catalyst system includes the steps of combining a support material with a first composition which includes at least one aluminoxane in a first solvent to provide an aluminoxane loaded support; and, contacting the aluminoxane loaded support with a second composition which includes at least one metallocene compound, a second solvent, and a cocatalyst, wherein the cocatalyst includes a second portion of the at least one aluminoxane alone or in combination with an ionic compound and / or a Lewis acid.

Owner:LUMMUS NOVOLEN TECH

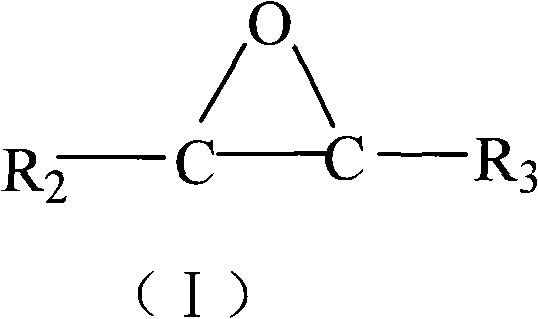

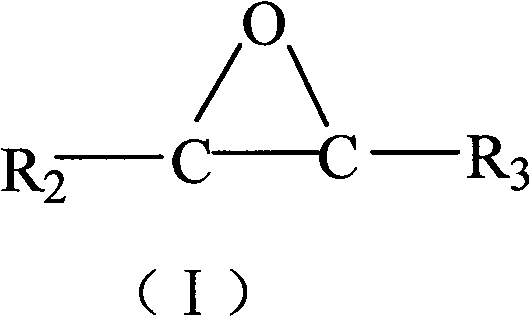

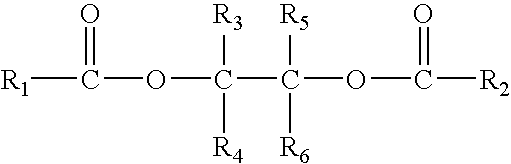

Solid catalyst component for polymerization of olefins, catalyst comprising the same and use thereof

InactiveUS7388061B2High stereospecificitySatisfactory polymerization yieldOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer sciencePtru catalyst

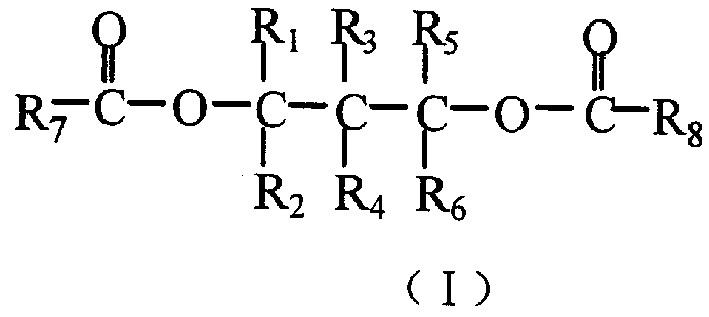

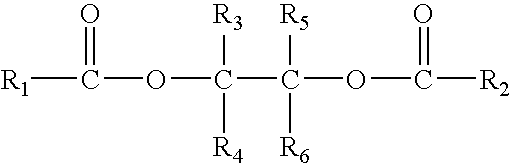

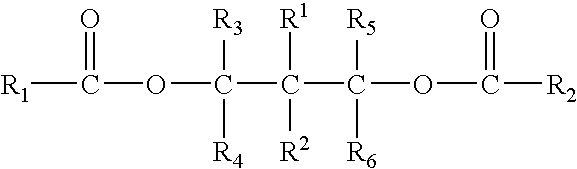

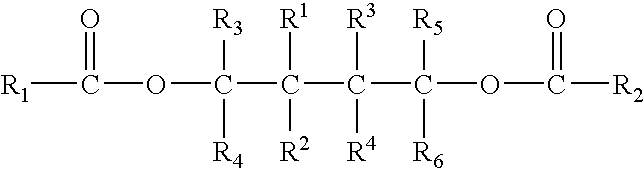

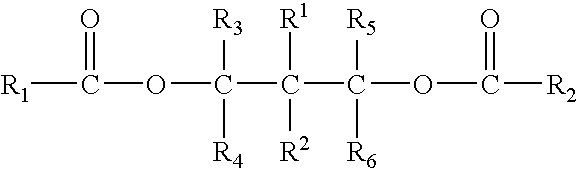

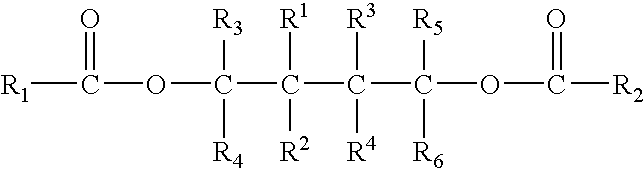

The present invention provides a solid catalyst component for the polymerization of olefins, comprising magnesium, titanium, a halogen and an electron donor, wherein said electron donor comprises at least one selected from the group consisting of ester of polyol of the formula (I):R1CO—O—CR3R4—A—CR5R6—O—CO—R2 (I)wherein, R1 and R2 groups, which may be identical or different, can be substituted or unsubstituted hydrocarbyl having 1 to 20 carbon atoms, R3-R6 groups, which may be identical or different, can be selected from the group consisting of hydrogen, halogen or substituted or unsubstituted hydrocarbyl having 1 to 20 carbon atoms, R1-R6 groups optionally contain one or more hetero-atoms replacing carbon, hydrogen atom or the both, said hetero-atom is selected from the group consisting of nitrogen, oxygen, sulfur, silicon, phosphorus and halogen atom, two or more of R3-R6 groups can be linked to form saturated or unsaturated monocyclic or polycyclic ring A is a single bond or bivalent linking group with chain length between two free radicals being 1-10 atoms, wherein said bivalent linking group is selected from the group consisting of aliphatic, alicyclic and aromatic bivalent radicals, and can carry C1-C20 linear or branched substituents one or more of carbon atom and / or hydrogen atom on above-mentioned bivalent linking group and substituents can be replaced by a hetero-atom selected from the group consisting of nitrogen, oxygen, sulfur, silicon, phosphorus, and halogen atom, and two or more said substituents on the linking group as well as above-mentioned R3-R6 groups can be linked to form saturated or unsaturated monocyclic or polycyclic ring.

Owner:CHINA PETROCHEMICAL CORP +1

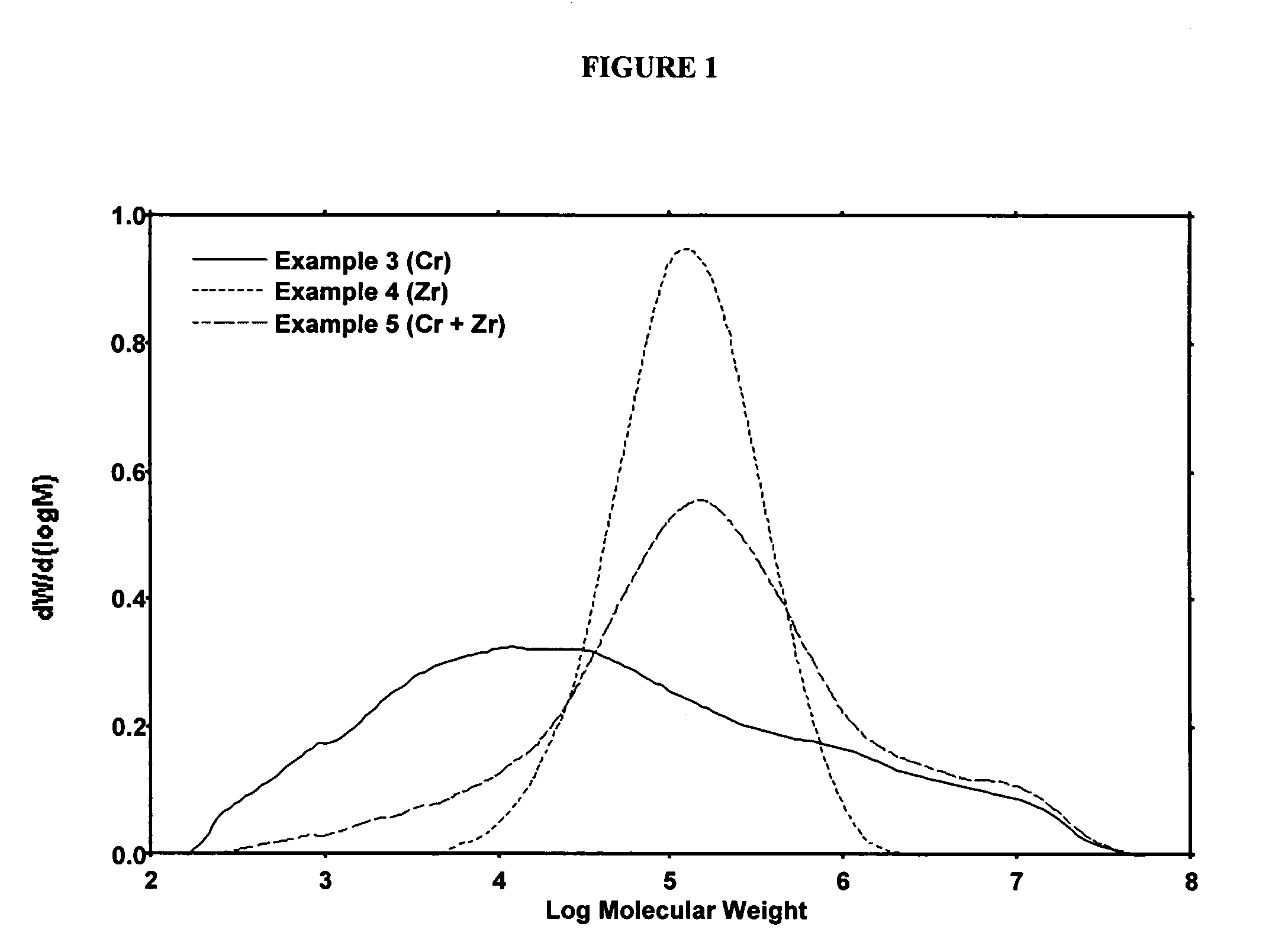

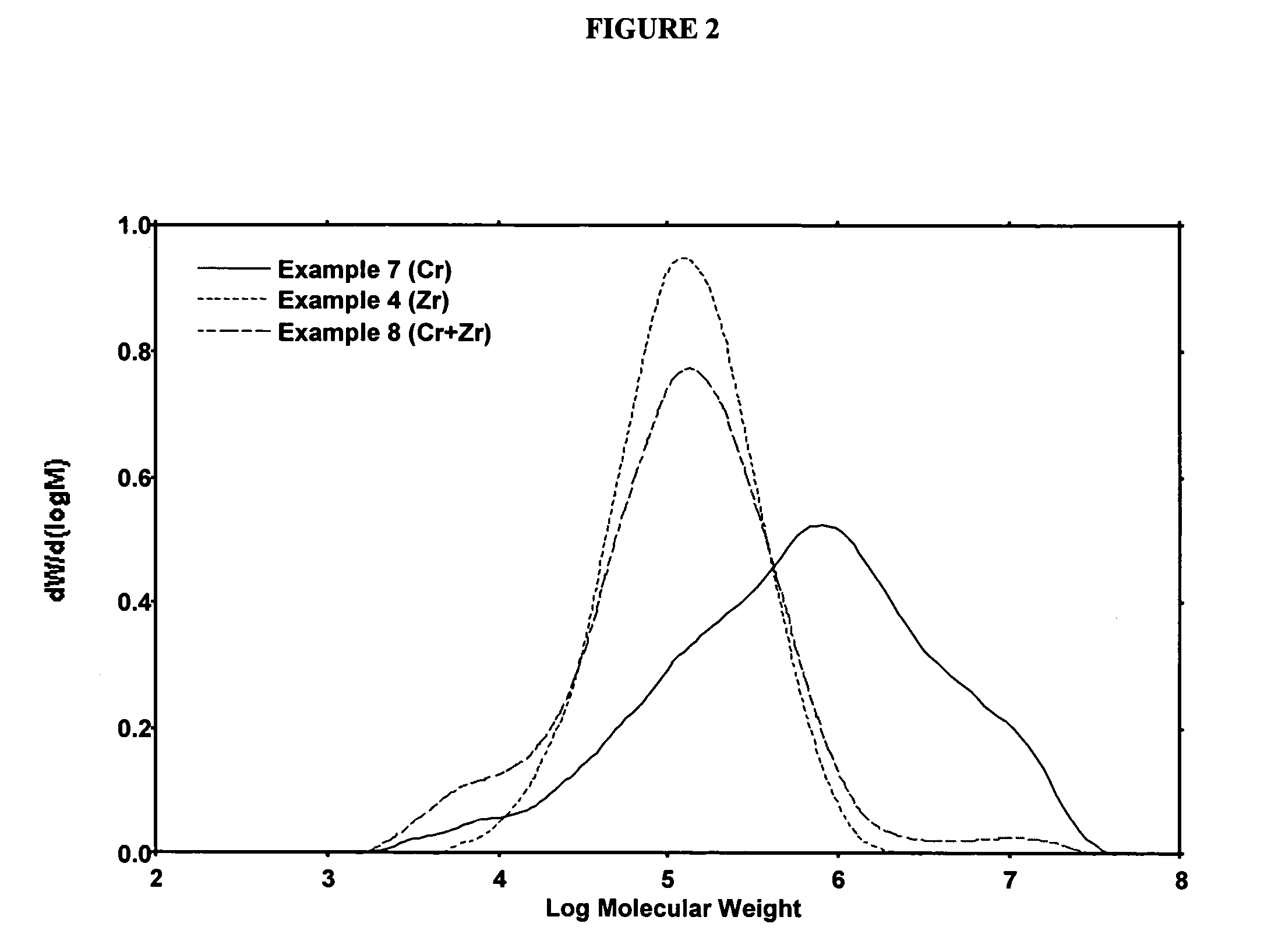

Organochromium/metallocene combination catalysts for producing bimodal resins

ActiveUS7163906B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentOlefin polymerization

This invention relates to the field of olefin polymerization catalyst compositions, and methods for the polymerization and copolymerization of olefins, including polymerization methods using a supported catalyst composition. In one aspect, the present invention encompasses a catalyst composition comprising the contact product of at least one metallocene compound, at least one organochromium compound, at least one chemically-treated solid oxide, and at least one organoaluminum compound.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

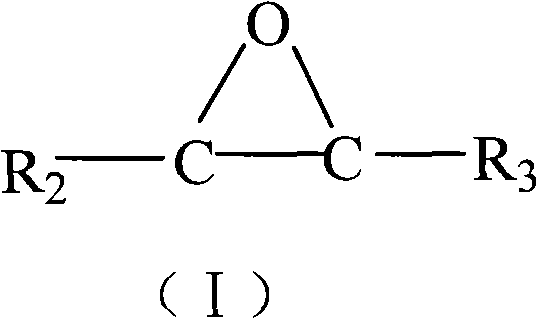

Spherical carriers for olefin polymerization catalyst and preparation method

ActiveCN102040683ANarrow particle size distributionParticles in good shapeParticle-size distributionPhotochemistry

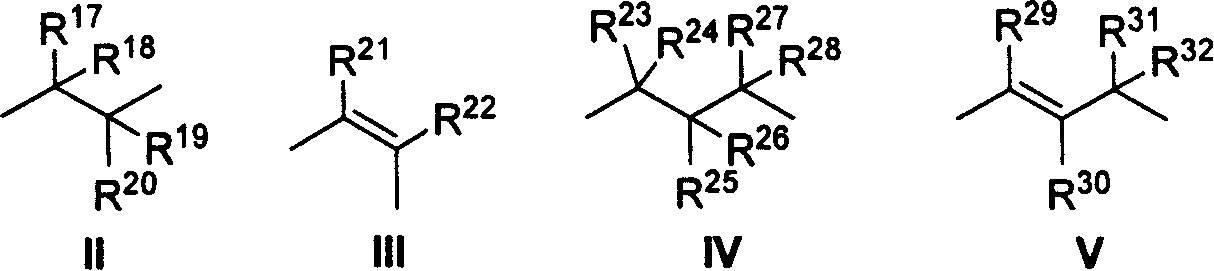

The invention relates to spherical carriers for an olefin polymerization catalyst and a preparation method. Each spherical carrier comprises reaction products of the following components: (1) magnesium halide which is shown as the general formula MgX2, (2) alcohol compounds which are shown as the general formula ROH, and (3) ethylene oxide compounds which are shown as the general formula (I), wherein in the general formula (I), R2 and R3 are alkyls with a C1-C5 straight chain or branched chain; and hydrogen on the alkyls can be randomly substituted by a halogen atom. The spherical carriers have good particle shapes, adjustable particle sizes and narrow particle size distribution, and the preparation method is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

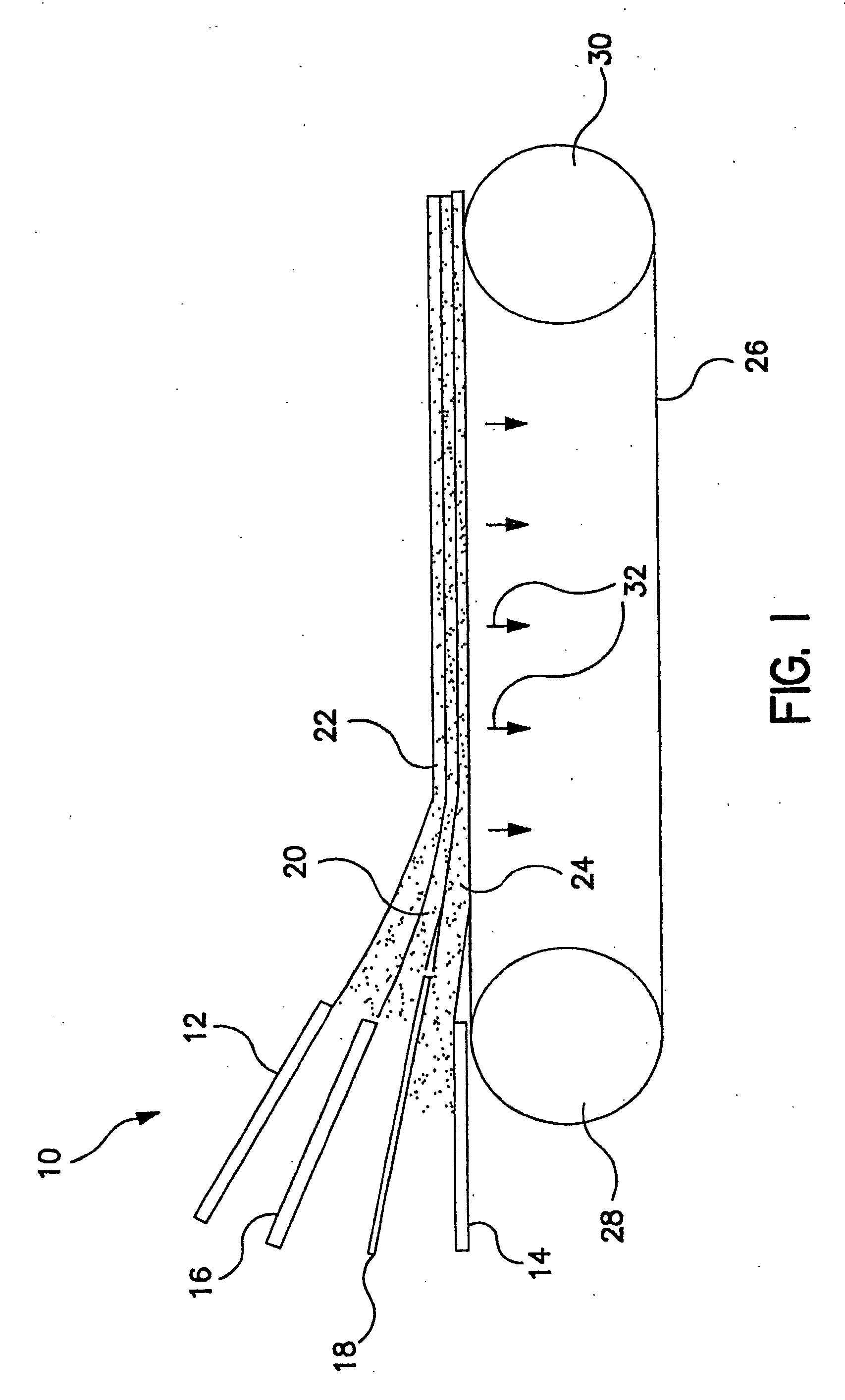

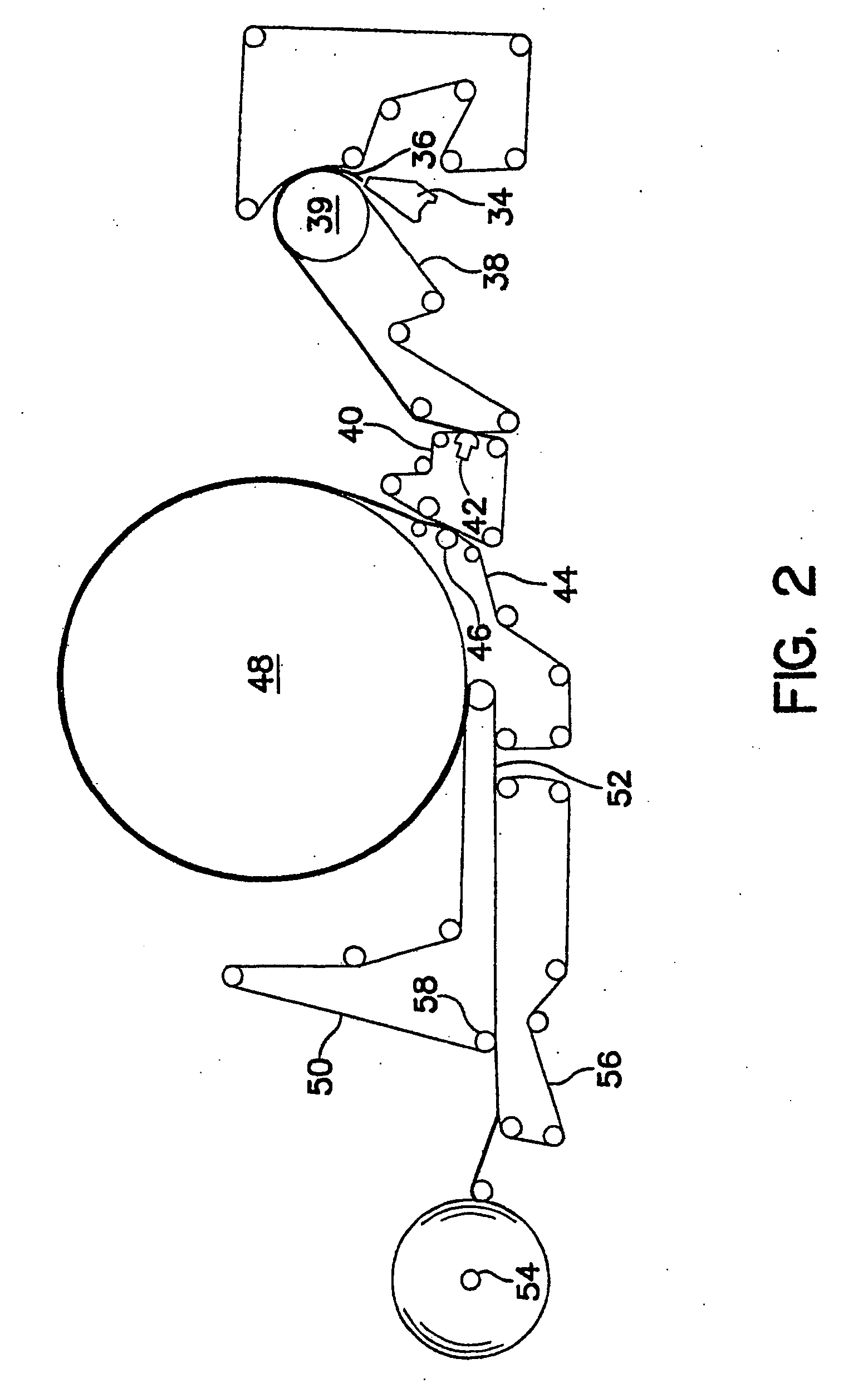

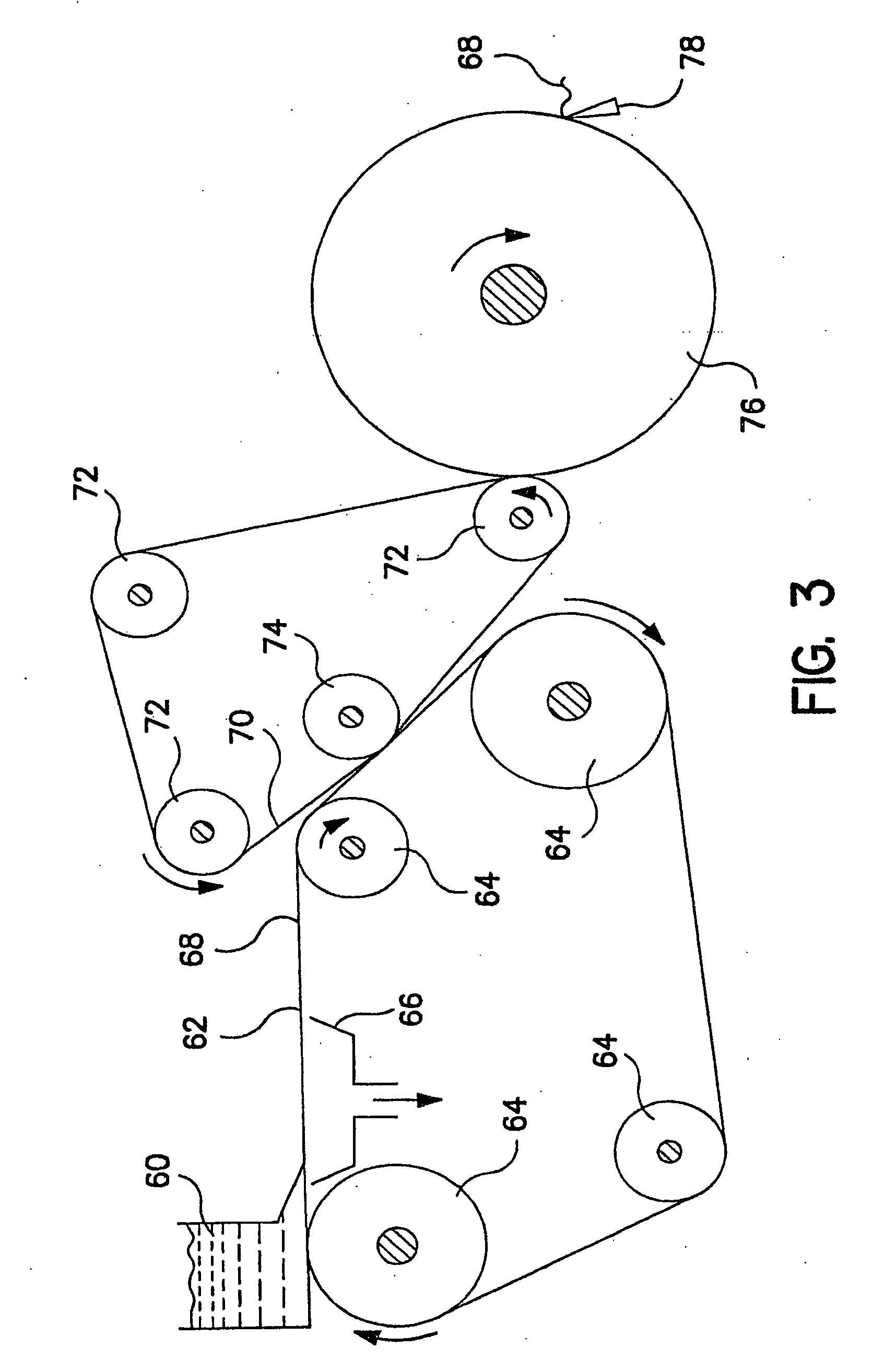

Embossed tissue products

InactiveUS20070137813A1Preserve strengthHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. After the additive composition is applied to the web or otherwise incorporated into the tissue web, the tissue web is embossed. During embossing, the additive composition forms well defined embossments in the web that are water resistant. In one embodiment, the additive composition may also be used to bond multiple tissue webs together to form a multiple ply product during the embossing operation.

Owner:KIMBERLY-CLARK WORLDWIDE INC

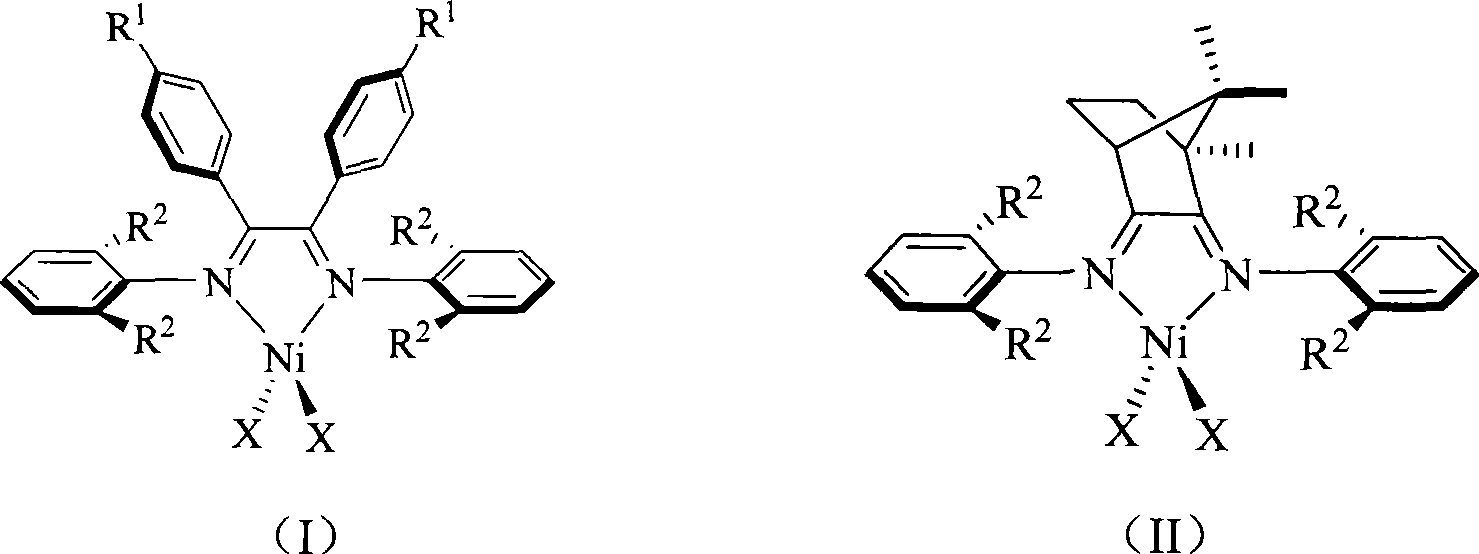

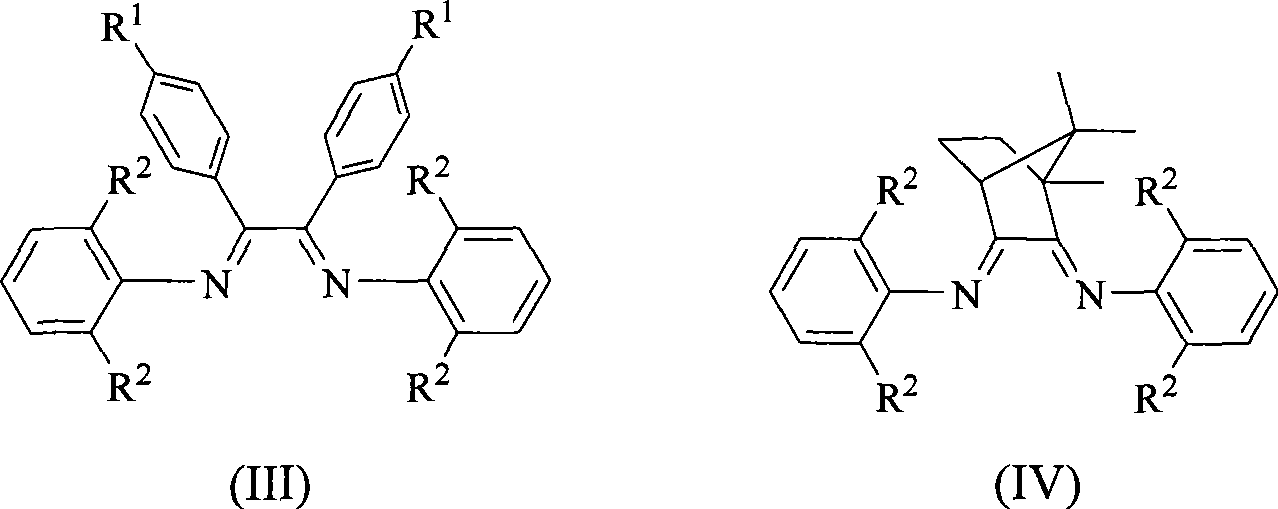

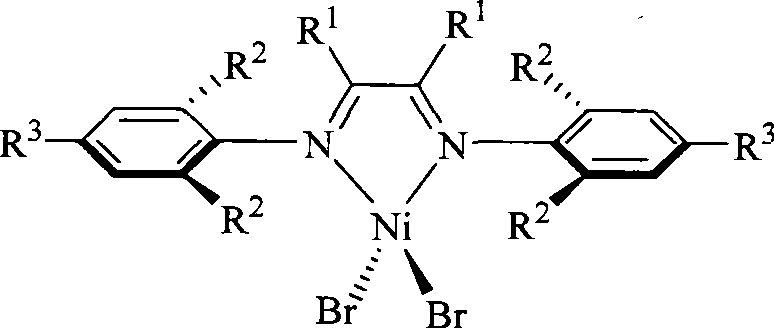

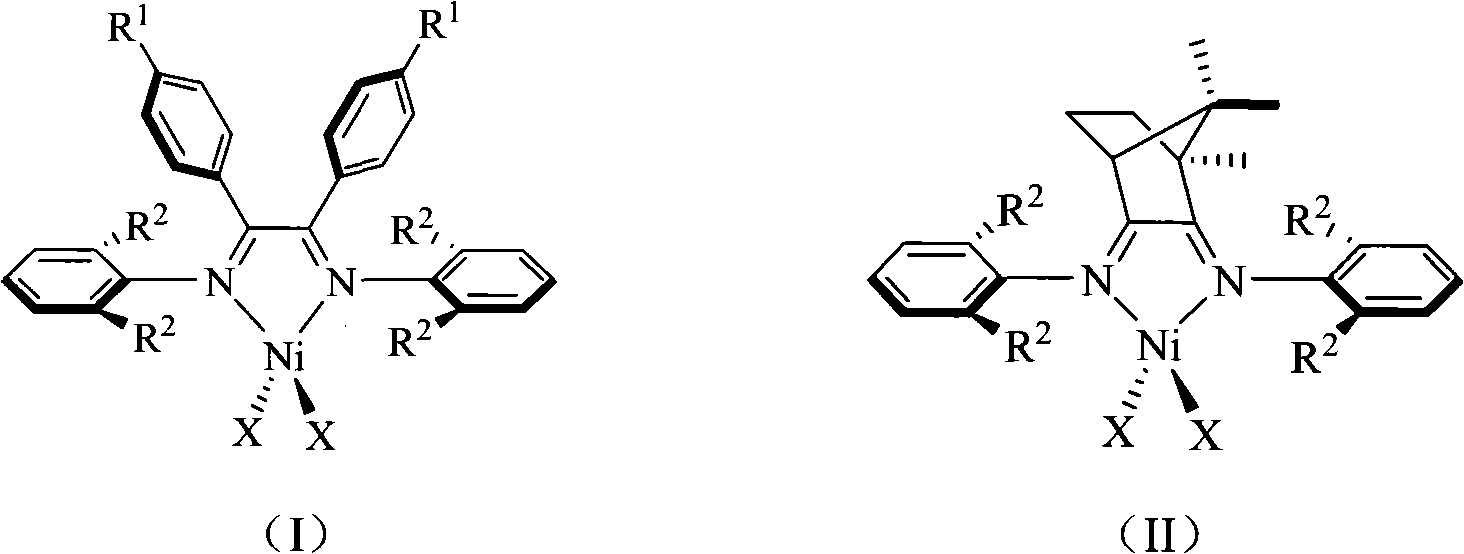

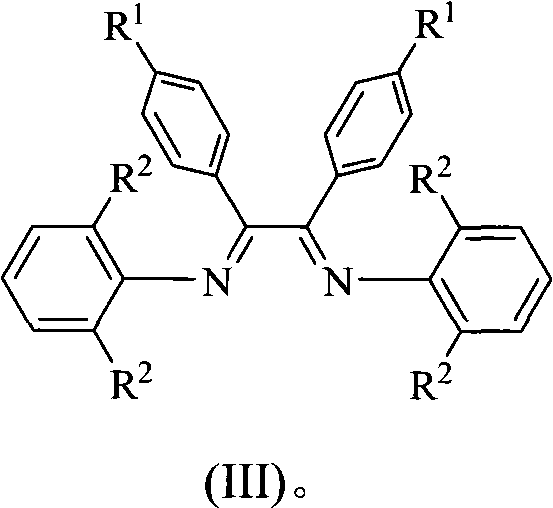

Alpha-nickel diimine compound olefin polymerization catalyst and preparation method thereof, and method for preparing branched polyethylene

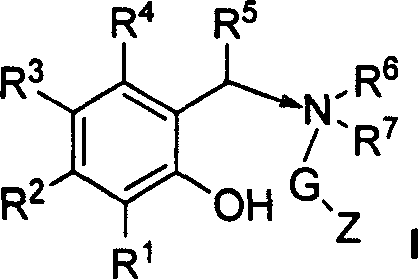

The invention discloses an alpha-nickel diimine compound olefin polymerization catalyst and a preparation method thereof, and a method for preparing branched polyethylene. Structural formulas of the alpha-nickel diimine compound olefin polymerization catalyst are shown as a formula (I) and a formula (II), and the preparation method of the alpha-nickel diimine compound olefin polymerization catalyst is simple and low in cost, and can catalyze ethylene polymerization with high activity at a temperature of more than or equal to 80 DEG C to obtain high molecular weight polyethylene. The polyethylene prepared by catalyzing of the alpha-nickel diimine compound olefin polymerization catalyst has high molecular weight, and can prepare molecular weight which reaches more than 10<2>*kg / mol in the temperature range of between 0 and 80 DEG C.

Owner:SUN YAT SEN UNIV

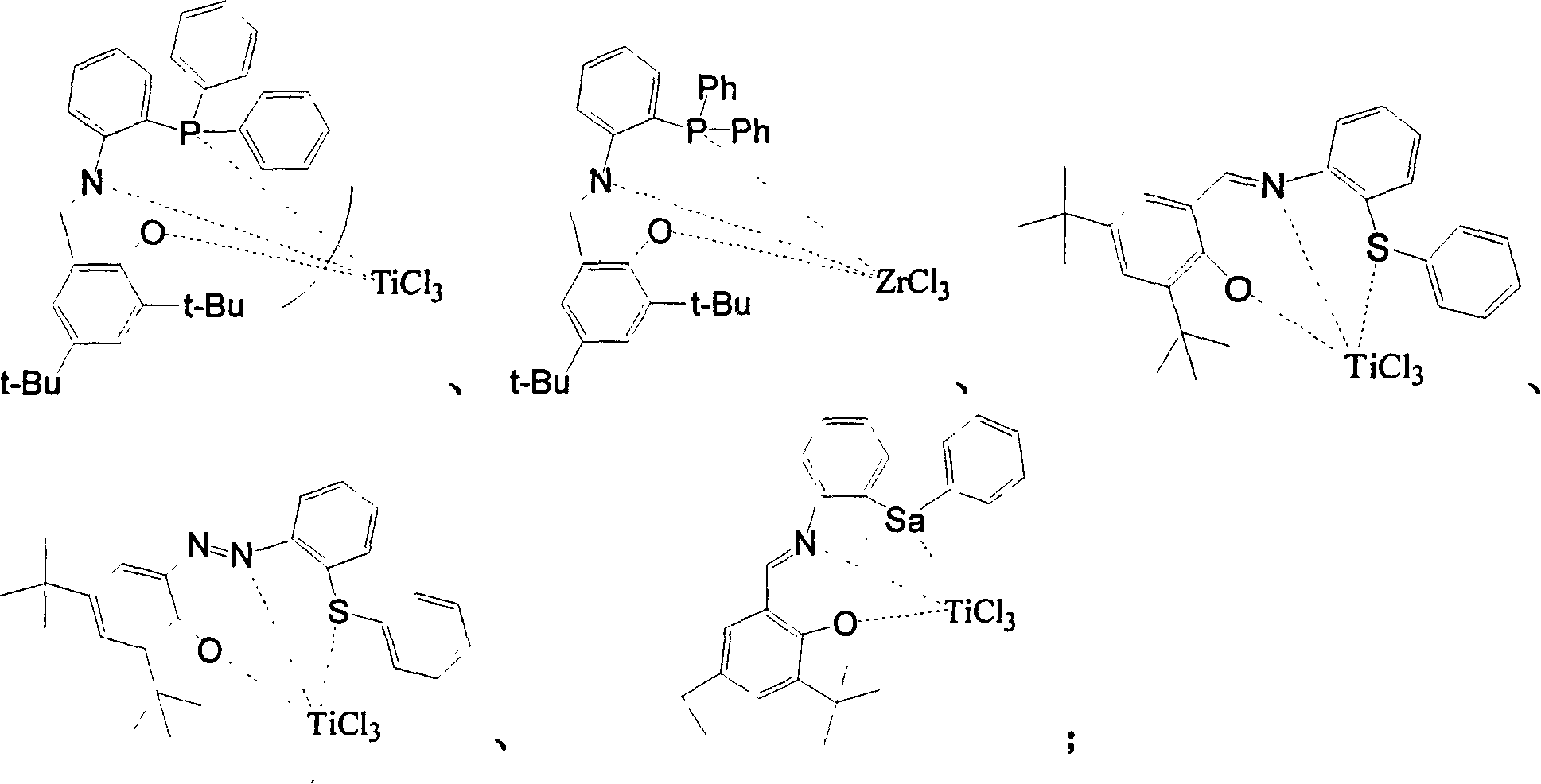

Catalyst system for the polymerization of olefins

InactiveUS6608224B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationArylHalogen

An organometallic compound obtainable by contactinga) a compound having the following formula (I):wherein Ra, Rb, Rc and Rd equal to or different from each other are hydrocarbon groupsb) a Lewis acid of formula (II)wherein Mt is a metal belonging to Group 13 of the Periodic Table of the Elements (IUPAC); R1, equal to or different from each other, are selected from the group consisting of halogen, halogenated C6-C20 aryl and halogenated C7-C20 alkylaryl groups; two R1 groups can also form with the metal Mt one condensed ring.These compounds are useful as cocatalysts for polymerizing olefins.

Owner:BASELL POLYOLEFINE GMBH

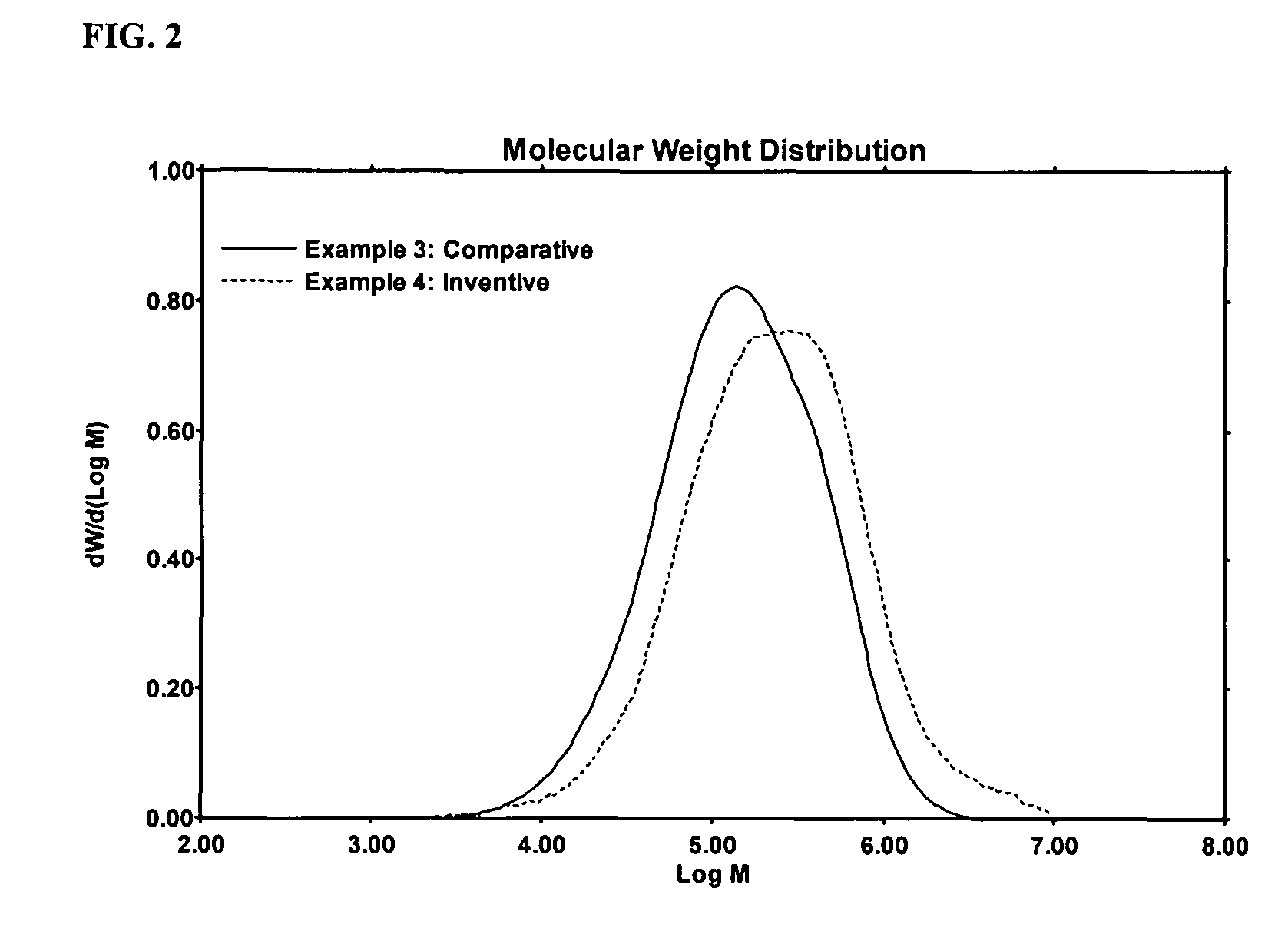

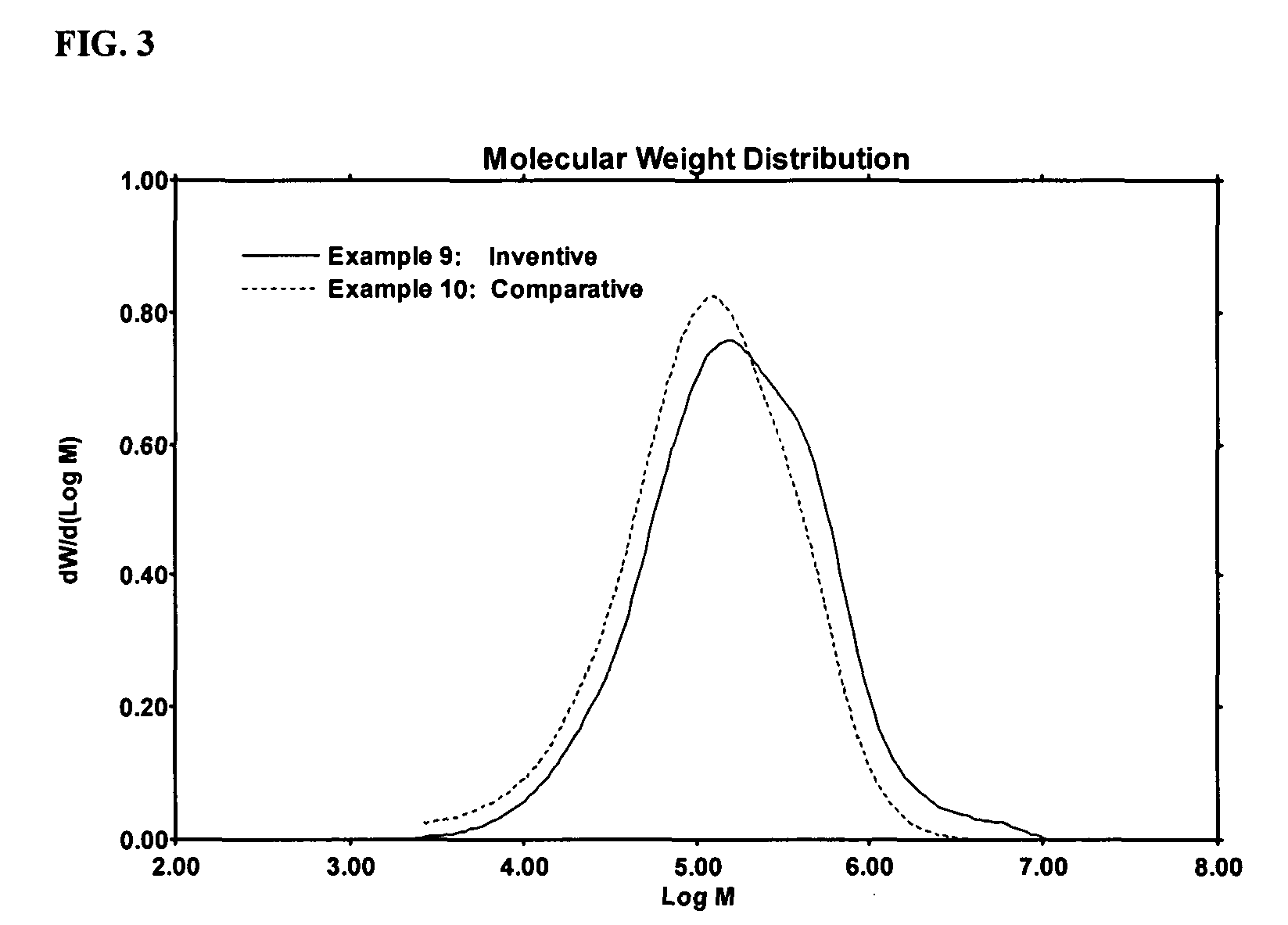

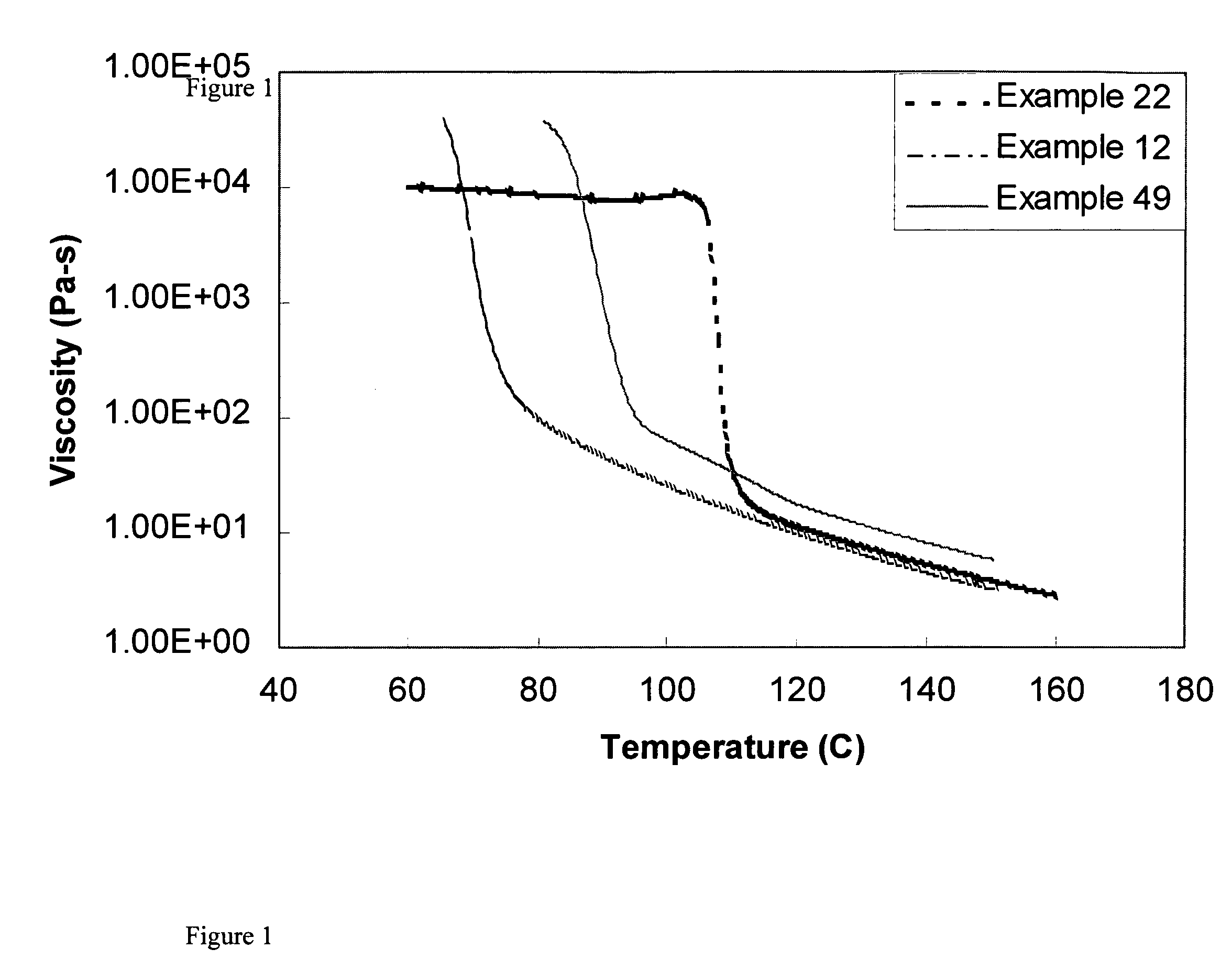

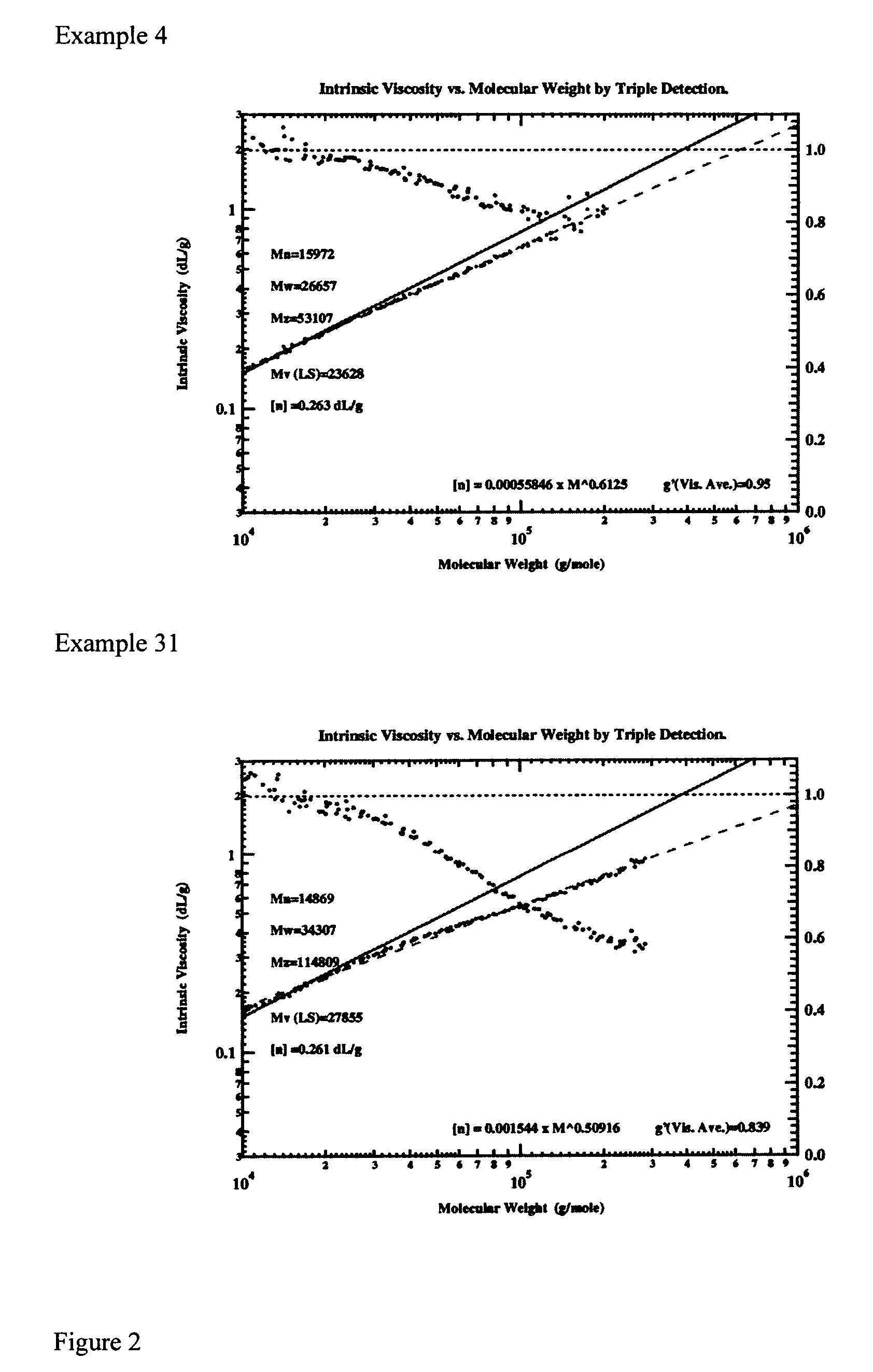

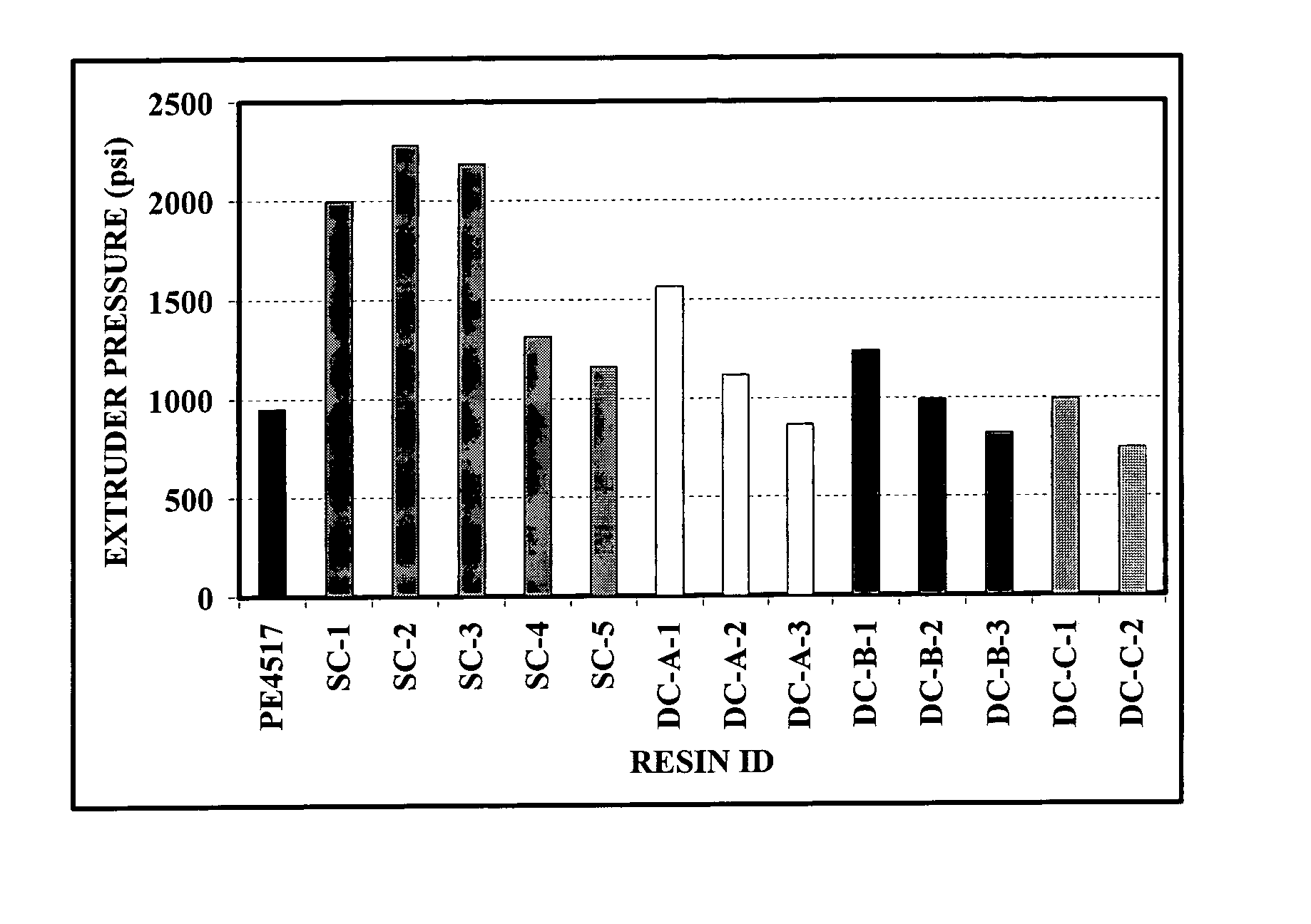

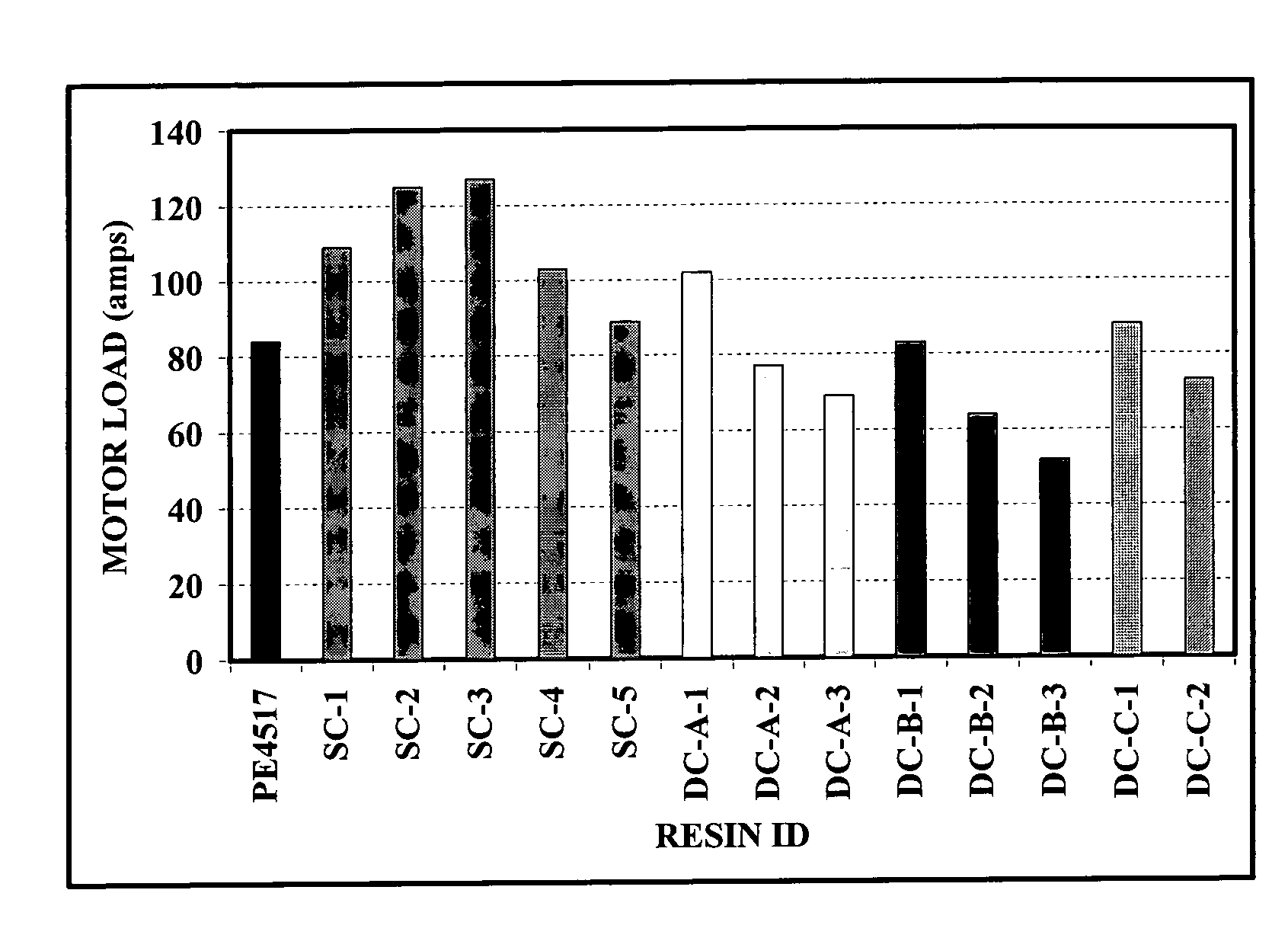

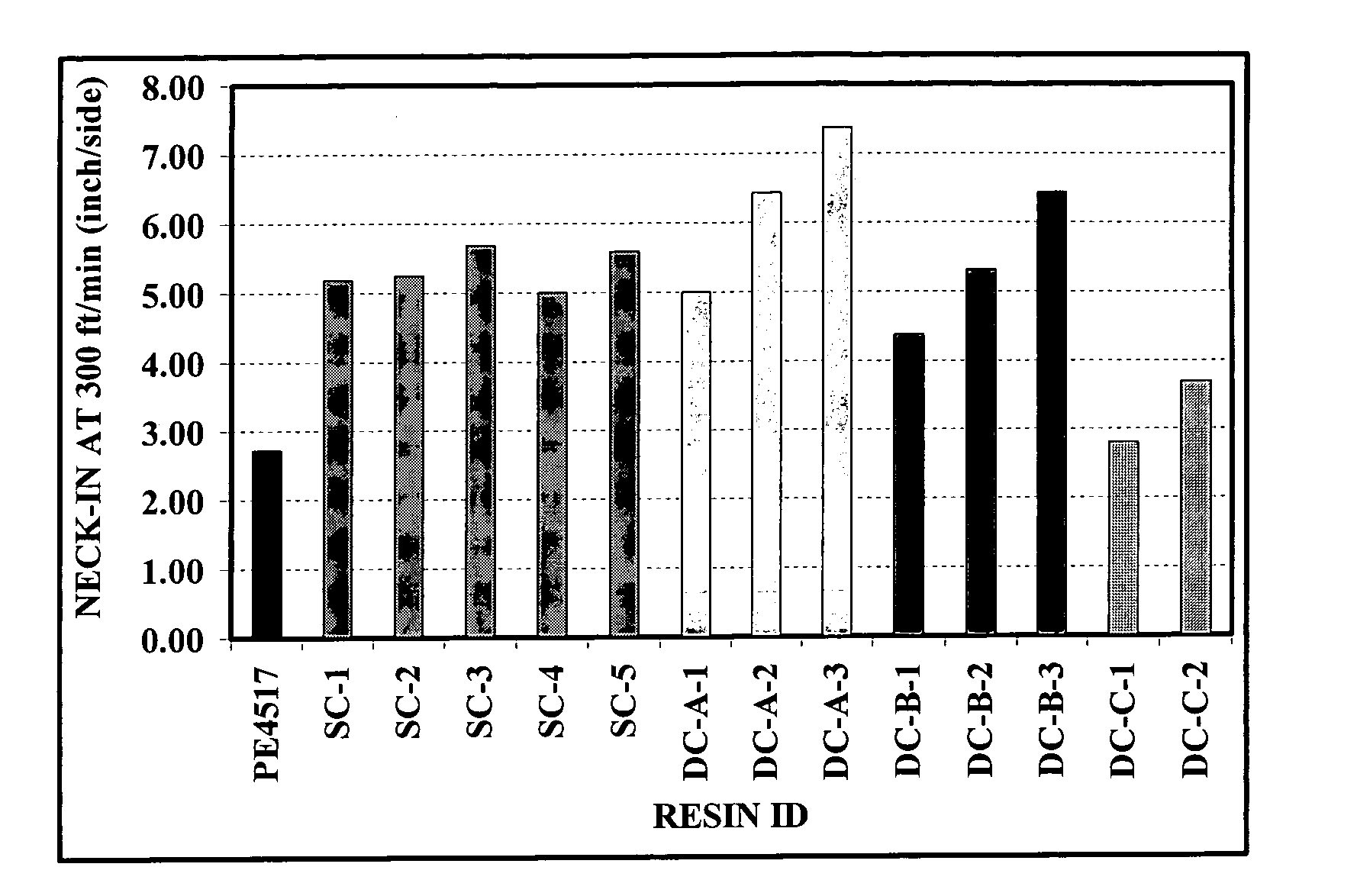

Catalyst compositions and polyolefins for extrusion coating applications

ActiveUS20050153830A1Used in combinationOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinOlefin polymerization

This invention relates to the field of olefin polymerization catalyst compositions, and methods for the polymerization and copolymerization of olefins, including polymerization methods using a supported catalyst composition. In one aspect, the present invention encompasses a catalyst composition comprising the contact product of a first metallocene compound, a second metallocene compound, at least one chemically-treated solid oxide, and at least one organoaluminum compound. The new resins were characterized by useful properties in impact, tear, adhesion, sealing, extruder motor loads and pressures at comparable melt index values, and neck-in and draw-down.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Solid catalyst component for polymerization of olefins, catalyst comprising the same and use thereof

InactiveUS20050239636A1High stereospecificitySatisfactory polymerization yieldOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorOxygen

The present invention provides a solid catalyst component for the polymerization of olefins, comprising magnesium, titanium, a halogen and an electron donor, wherein said electron donor comprises at least one selected from the group consisting of polyol ester compounds of the formula (I): R1CO—O—CR3R4-A-CR5R6—O—CO—R2 (I) wherein, R1 and R2 groups, which may be identical or different, can be substituted or unsubstituted hydrocarbyl having 1 to 20 carbon atoms, R3-R6 groups, which may be identical or different, can be selected from the group consisting of hydrogen, halogen or substituted or unsubstituted hydrocarbyl having 1 to 20 carbon atoms, R1-R6 groups optionally contain one or more hetero-atoms replacing carbon, hydrogen atom or the both, said hetero-atom is selected from the group consisting of nitrogen, oxygen, sulfur, silicon, phosphorus and halogen atom, two or more of R3-R6 groups can be linked to form saturated or unsaturated monocyclic or polycyclic ring; A is a single bond or bivalent linking group with chain length between two free radicals being 1-10 atoms, wherein said bivalent linking group is selected from the group consisting of aliphatic, alicyclic and aromatic bivalent radicals, and can carry C1-C20 linear or branched substituents; one or more of carbon atom and / or hydrogen atom on above-mentioned bivalent linking group and substituents can be replaced by a hetero-atom selected from the group consisting of nitrogen, oxygen, sulfur, silicon, phosphorus, and halogen atom, and two or more said substituents on the linking group as well as above-mentioned R3-R6 groups can be linked to form saturated or unsaturated monocyclic or polycyclic ring.

Owner:CHINA PETROCHEMICAL CORP +1

Alpha-nickel diimine compound olefin polymerization catalyst, preparation method and method for preparing branched polyethylene

InactiveCN101812145AEasy to prepareLow costNickel organic compoundsBulk chemical productionPolymer scienceDiimine

The invention discloses an alpha-nickel diimine compound olefin polymerization catalyst, a preparation method and a method for preparing branched polyethylene. The structural formula of the alpha-nickel diimine compound olefin polymerization catalyst is shown as the formula (I) and the formula (II). The alpha-nickel diimine compound olefin polymerization catalyst has simple preparation method and low cost, and ethylene can be catalyzed to polymerize with high activity at a temperature not lower than 80 DEG C to obtain high molecular weight polyethylene. The polyethylene prepared from the alpha-nickel diimine compound olefin polymerization catalyst by catalyzing has high molecular weight, and the molecular weight can reach higher than 102x kg / mol within the range of 0-80 DEG C.

Owner:SUN YAT SEN UNIV

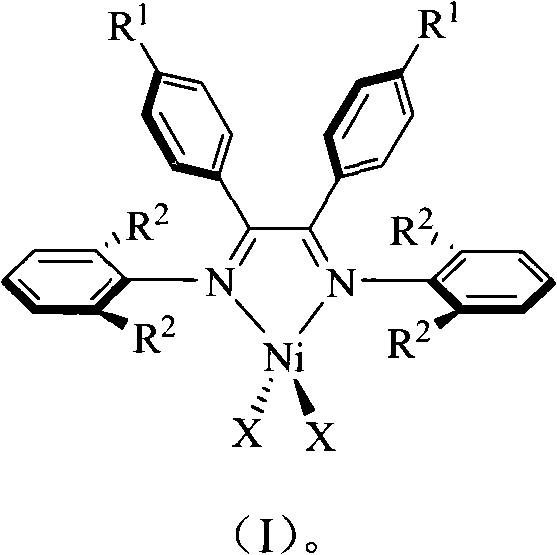

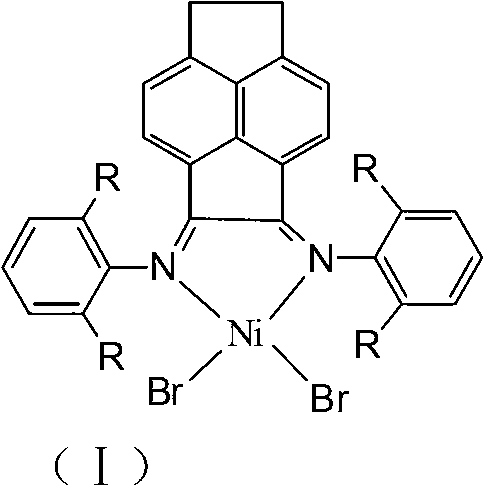

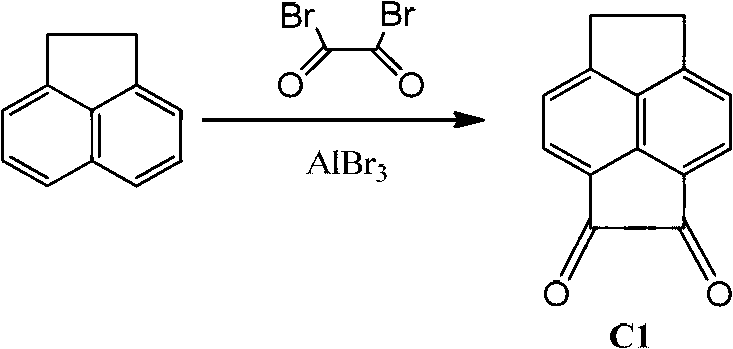

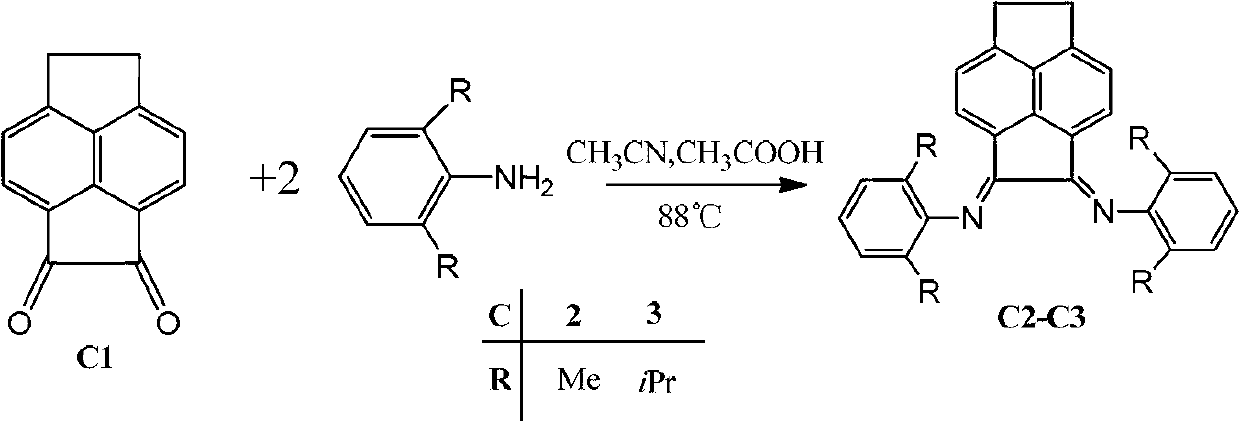

Ethylidene acenaphthene (alpha-diimine) nickel olefin catalyst, and preparation method and application thereof

ActiveCN102827312AHigh activityImprove stabilityBulk chemical productionOlefin polymerizationAluminium

The invention discloses an ethylidene acenaphthene (alpha-diimine) nickel olefin catalyst, and a preparation method and application thereof. The structural formula of the ethylidene acenaphthene (alpha-diimine) nickel olefin catalyst is disclosed as Formula (I). The ethylidene acenaphthene (alpha-diimine) nickel olefin polymerization catalyst disclosed as Formula (I) has the advantages of high activity and high stability, and can catalyze the preparation of high-molecular-weight hyperbranched polyethylene from ethylene at high activity at the temperature of higher than or equal to 60 DEG C. When being used for ethylene polymerization as a catalyst, the thylidene acenaphthene (alpha-diimine) nickel olefin polymerization catalyst has high activity only when the aluminum-nickel ratio is 100. In addition, the preparation method of the olefin polymerization catalyst disclosed by the invention has the advantages of simple technique, short synthetic route, low cost and high yield, and can easily implement industrialization.

Owner:HANGZHOU XINGLU TECH CO LTD

Catalytic olefin block copolymers with controlled block sequence distribution

A process for the polymerization of one or more addition polymerizable monomers and the resulting polymer products, said process comprising: 1) contacting an addition polymerizable monomer or mixture of monomers under addition polymerization conditions in a reactor or reactor zone with a composition comprising at least one olefin polymerization catalyst and a cocatalyst and characterized by the formation of polymer chains from said monomer or monomers; 2) transferring the reaction mixture to a second reactor or reactor zone and optionally adding one or more additional reactants, catalysts, monomers or other compounds prior to, commensurate with, or after said transfer; and 3) causing polymerization to occur in said second reactor or reactor zone to form polymer chains that are differentiated from the polymer chains formed in step 1); said process being characterized by addition of a chain shuttling agent to the reaction mixture prior to, during, or subsequent to step 1) such that at least some of the resulting polymer molecules from step 3) comprise two or more chemically or physically distinguishable blocks or segments.

Owner:DOW GLOBAL TECH LLC

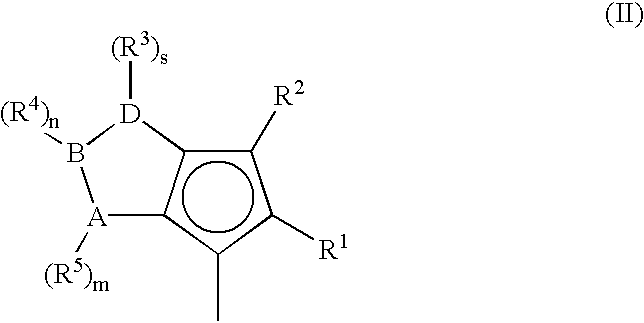

Metallocene compounds, process for their preparation and their use in catalytic systems for the polymerization of olefins

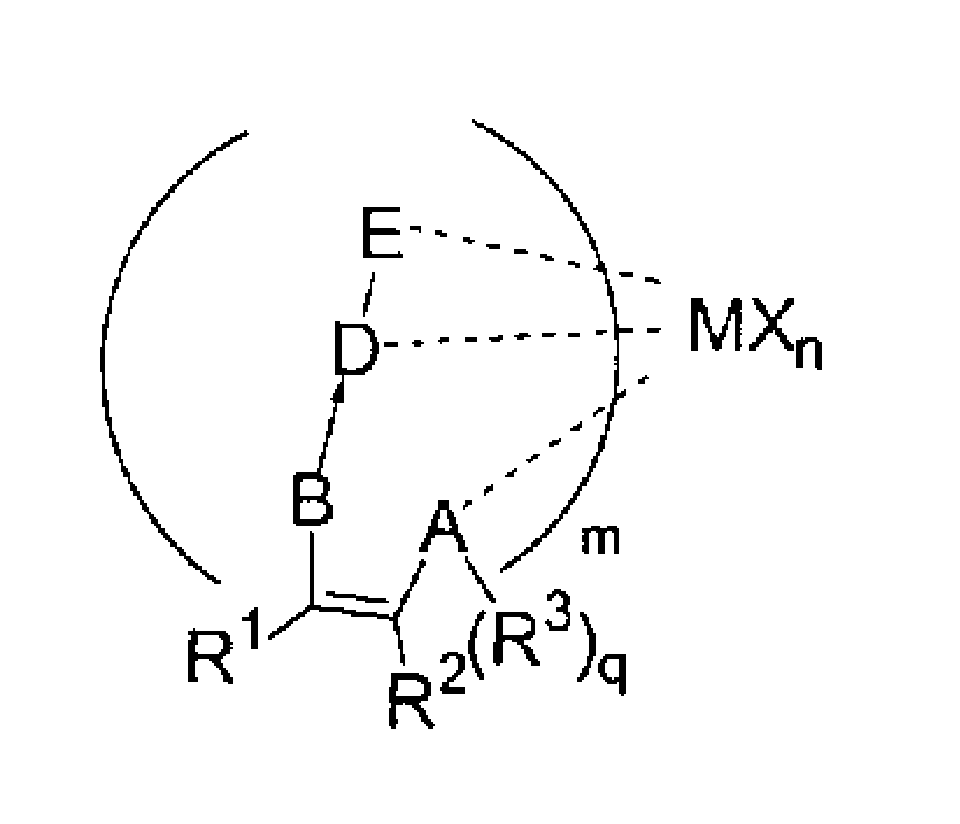

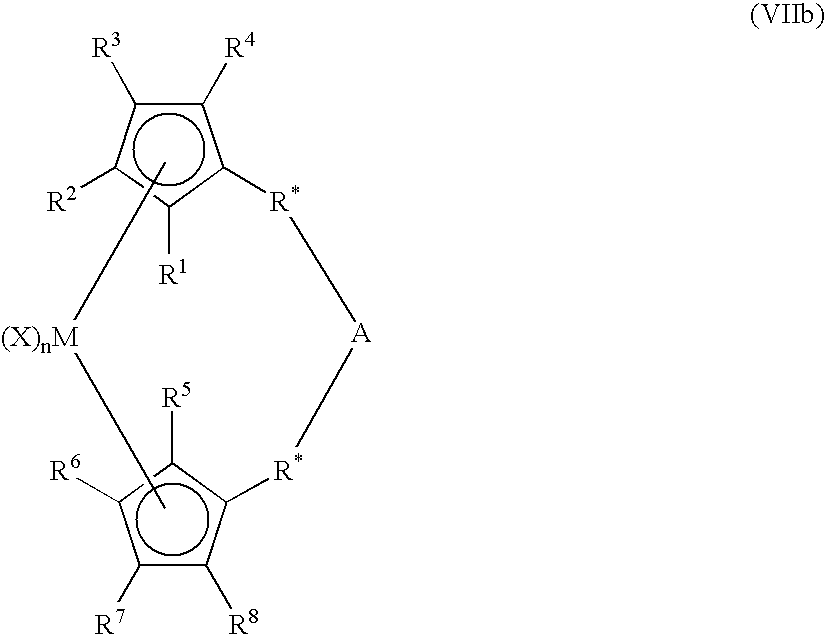

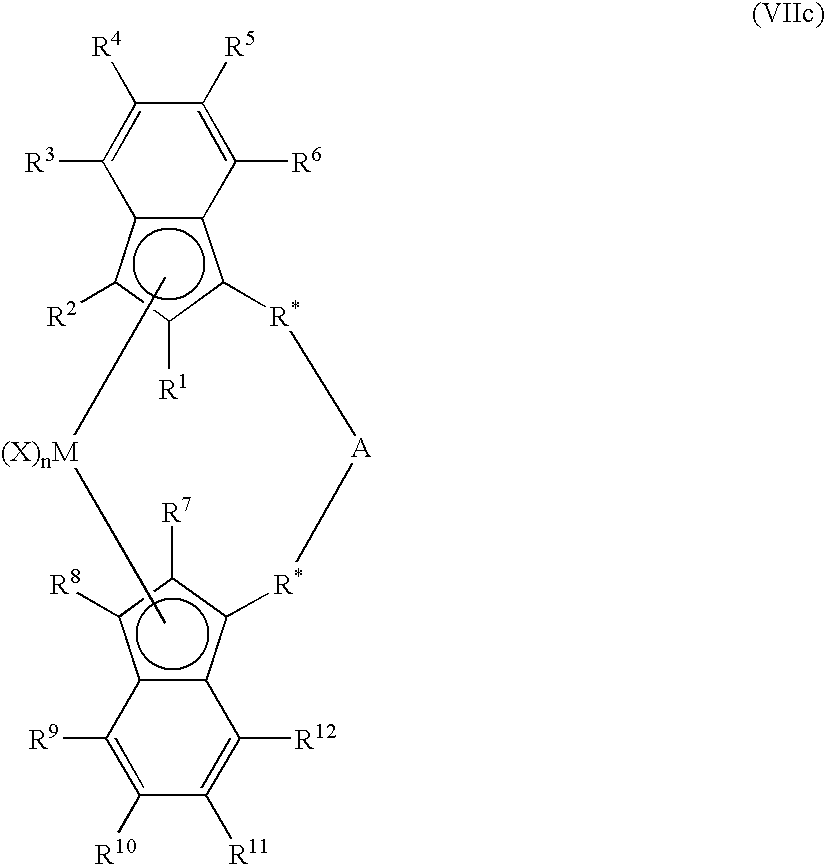

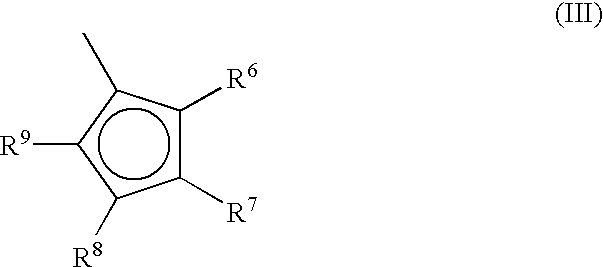

A class of metallocene compounds is disclosed having general formula (I) wherein Y is a moiety of formula (II) wherein A, B, and D, same or different from each other, are selected from an element of the groups 14 to 16 of the Periodic Table of the Elements (new IUPAC version), with the exclusion of nitrogen and oxygen; R<1>, R<2>, R<3>, R<4 >and R<5 >are hydrogen or hydrocarbon groups, Z is selected from a moiety of formula (II) as described above and from a moiety of formula (III) wherein R<6>, R<7>, R<8 >and R<9>, are hydrogen or hydrocarbon groups; L is a divalent bridging group; M is an atom of a transition metal selected from those belonging to group 3, 4, 5, 6 or to the lanthanide or actinide groups in the Periodic Table of the Elements (new IUPAC version), X, same or different, is hydrogen, a halogen, a R<10>, OR<10>, OSO2CF3, OCOR<10>, SR<10>, NR<10>2 or PR<10>2 group, wherein the substituents R<10 >are hydrogen or alkyl groups; p is an integer of from 1 to 3, being equal to the oxidation state of the metal M minus 2. The above metallocenes are particularly useful in the polymerization of propylene.

Owner:BASELL POLYOLEFINE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com