Alpha-nickel diimine compound olefin polymerization catalyst, preparation method and method for preparing branched polyethylene

A technology of olefin polymerization and diimide nickel, which is applied in the production of nickel organic compounds and bulk chemicals, can solve the problems of poor thermal stability, decomposition and deactivation, etc., and achieve the effects of low cost, prolonged catalytic life, and simple preparation methods

Inactive Publication Date: 2010-08-25

SUN YAT SEN UNIV

View PDF0 Cites 118 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But the thermal stability of these diimine catalysts is poor, when R 1 For the above substituents, even if there are bulky substituents in the ortho or para position of aniline, the molecular weight of polyethylene prepared by these α-diimine nickel catalysts will decrease rapidly with the increase of polymerization temperature, generally above 60°C The catalyst rapidly decomposes and deactivates

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

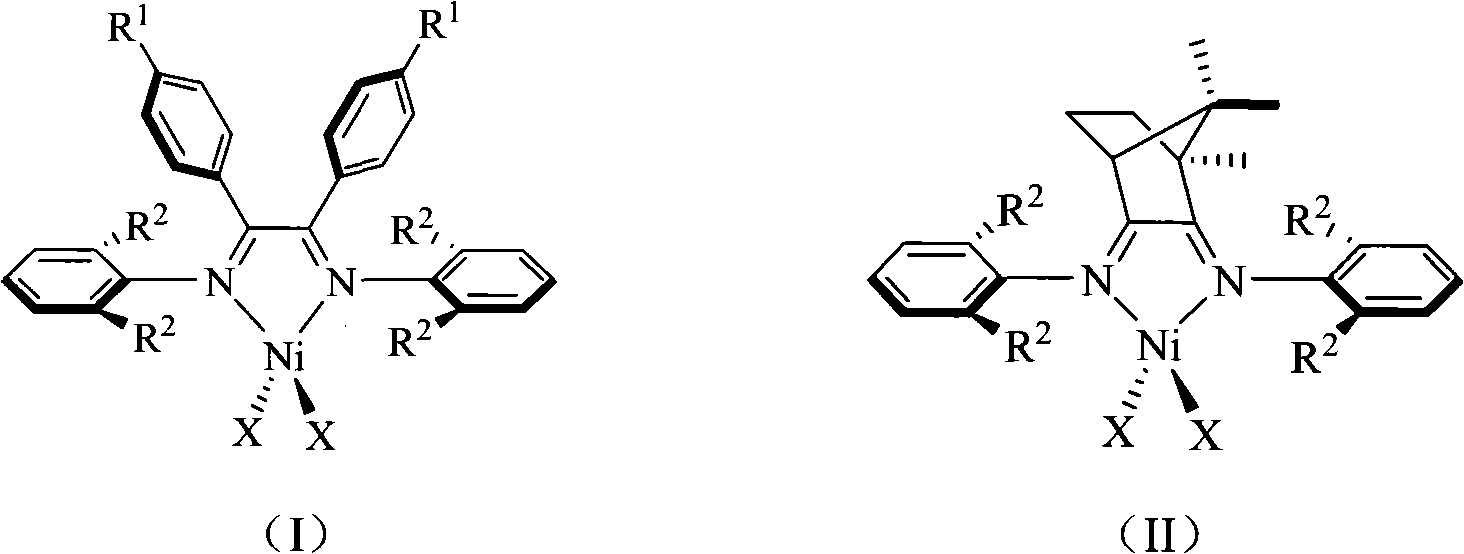

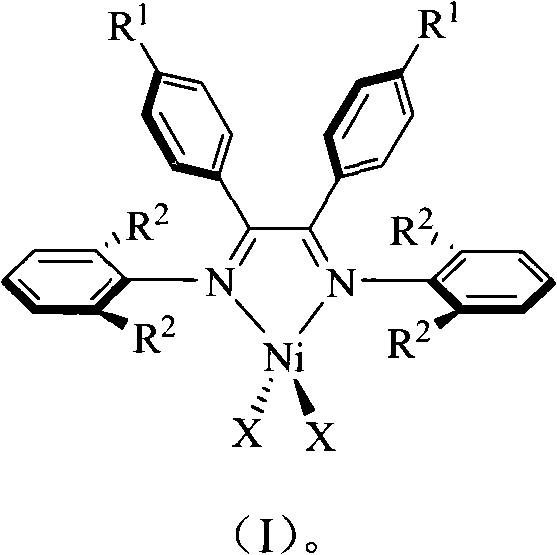

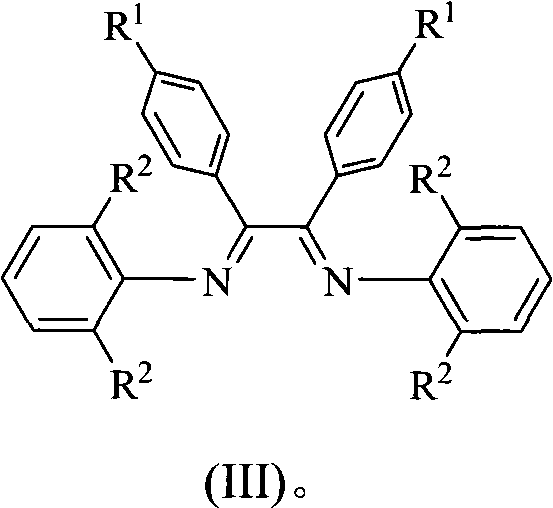

The invention discloses an alpha-nickel diimine compound olefin polymerization catalyst, a preparation method and a method for preparing branched polyethylene. The structural formula of the alpha-nickel diimine compound olefin polymerization catalyst is shown as the formula (I) and the formula (II). The alpha-nickel diimine compound olefin polymerization catalyst has simple preparation method and low cost, and ethylene can be catalyzed to polymerize with high activity at a temperature not lower than 80 DEG C to obtain high molecular weight polyethylene. The polyethylene prepared from the alpha-nickel diimine compound olefin polymerization catalyst by catalyzing has high molecular weight, and the molecular weight can reach higher than 102x kg / mol within the range of 0-80 DEG C.

Description

(This application is a divisional application named: α-diimine nickel complex olefin polymerization catalyst and its preparation method and method for preparing branched polyethylene, application number 200910038504.1, application date 2009.4.8)) technical field The invention relates to the field of catalytic polymerization of olefins, in particular to a type of α-diimine nickel olefin polymerization catalyst and its preparation technology and a method for preparing branched polyethylene by catalyzing ethylene polymerization. Background technique Polyolefin is one of the most widely used resins. Due to its excellent processing and use properties and low price, it has become the largest output and consumption of synthetic resins in the world. It is widely used in people's production and consumption fields. Among them, the development of catalysts is the core technology for the development of the polyolefin industry and the key factor for controlling the structure and perform...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F10/00C08F4/70C08F110/02C07F15/04

CPCY02P20/52

Inventor 伍青刘丰收高海洋张玲祝方明

Owner SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com