Patents

Literature

473results about How to "Reduce catalytic activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

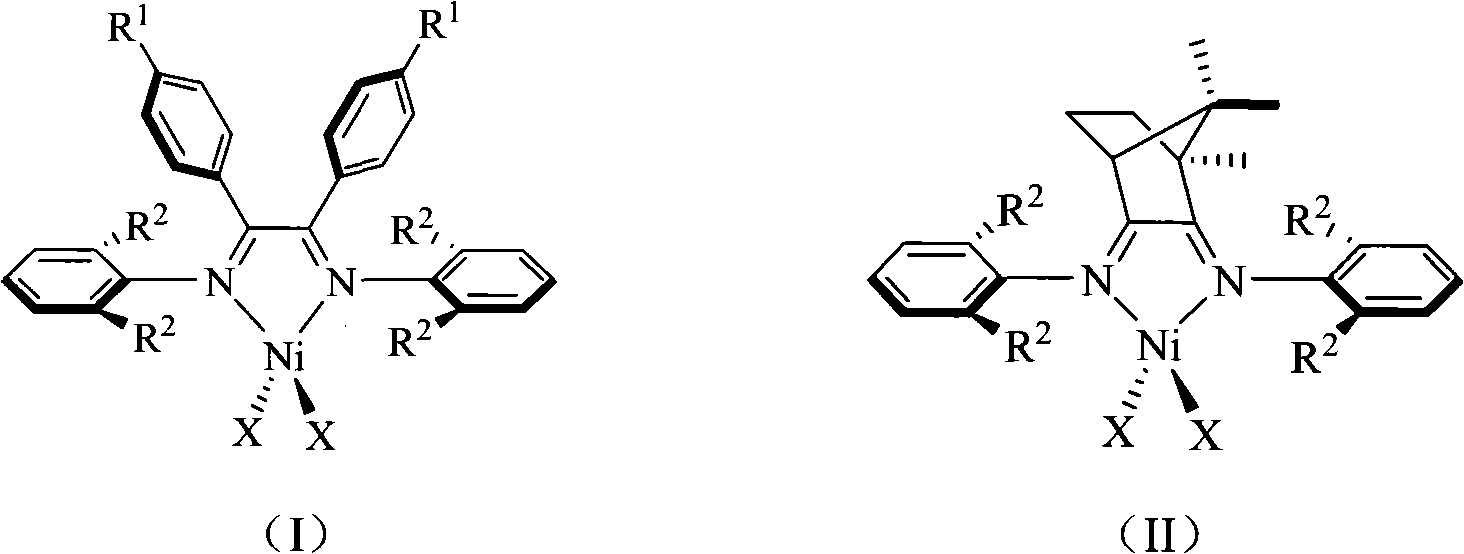

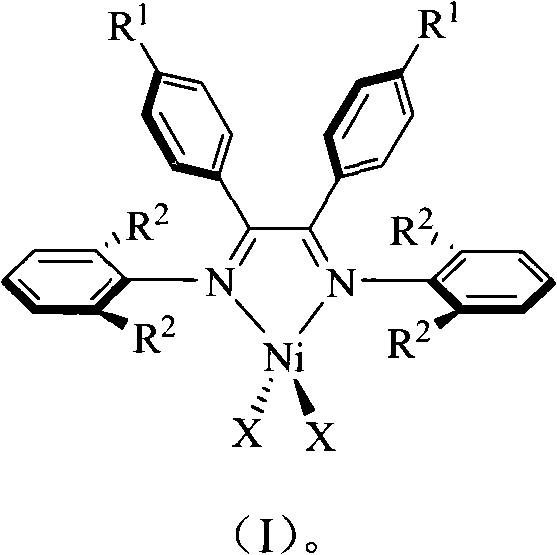

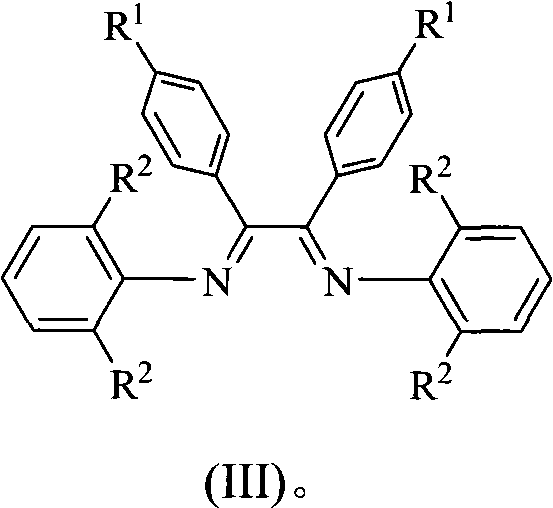

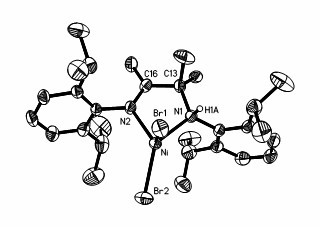

Alpha-nickel diimine compound olefin polymerization catalyst, preparation method and method for preparing branched polyethylene

InactiveCN101812145AEasy to prepareLow costNickel organic compoundsBulk chemical productionPolymer scienceDiimine

The invention discloses an alpha-nickel diimine compound olefin polymerization catalyst, a preparation method and a method for preparing branched polyethylene. The structural formula of the alpha-nickel diimine compound olefin polymerization catalyst is shown as the formula (I) and the formula (II). The alpha-nickel diimine compound olefin polymerization catalyst has simple preparation method and low cost, and ethylene can be catalyzed to polymerize with high activity at a temperature not lower than 80 DEG C to obtain high molecular weight polyethylene. The polyethylene prepared from the alpha-nickel diimine compound olefin polymerization catalyst by catalyzing has high molecular weight, and the molecular weight can reach higher than 102x kg / mol within the range of 0-80 DEG C.

Owner:SUN YAT SEN UNIV

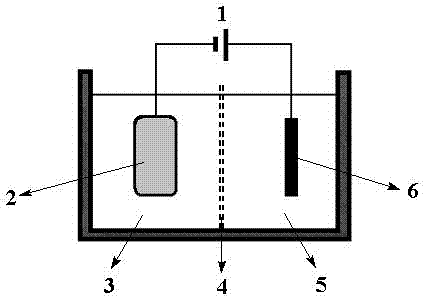

Method for preparing formic acid through electrochemical catalytic reduction of carbon dioxide

InactiveCN102190573AGood solubility and absorption propertiesImprove conductivityOrganic compound preparationCarboxylic compound preparationSupporting electrolyteOrganic solvent

The invention relates to a method for preparing formic acid through electrochemical catalytic reduction of carbon dioxide, and belongs to the technical field of carbon dioxide recycling. In the method, a proton exchange membrane separates an electrolytic tank into a cathode chamber and an anode chamber, organic solvent / ionic liquid / water mixed solution in which a large amount of carbon dioxide is dissolved is injected into the cathode chamber, and aqueous solution containing supporting electrolyte is injected into the anode chamber; and after an electrolysis power supply is connected, the carbon dioxide undergoes electroreduction reaction on the cathode to form the formic acid. By the method, the organic solvent / ionic liquid / water mixed solution with the advantages of good conductivity, low viscosity, high capacity of dissolving the carbon dioxide, wide electrochemical window, and low use cost can be obtained, and when the carbon dioxide is electrically reduced in the mixed solution, the current density in the electroreduction reaction of the carbon dioxide can be improved and the electrocatalytic activity and long-time stability of a cathode material are improved.

Owner:KUNMING UNIV OF SCI & TECH

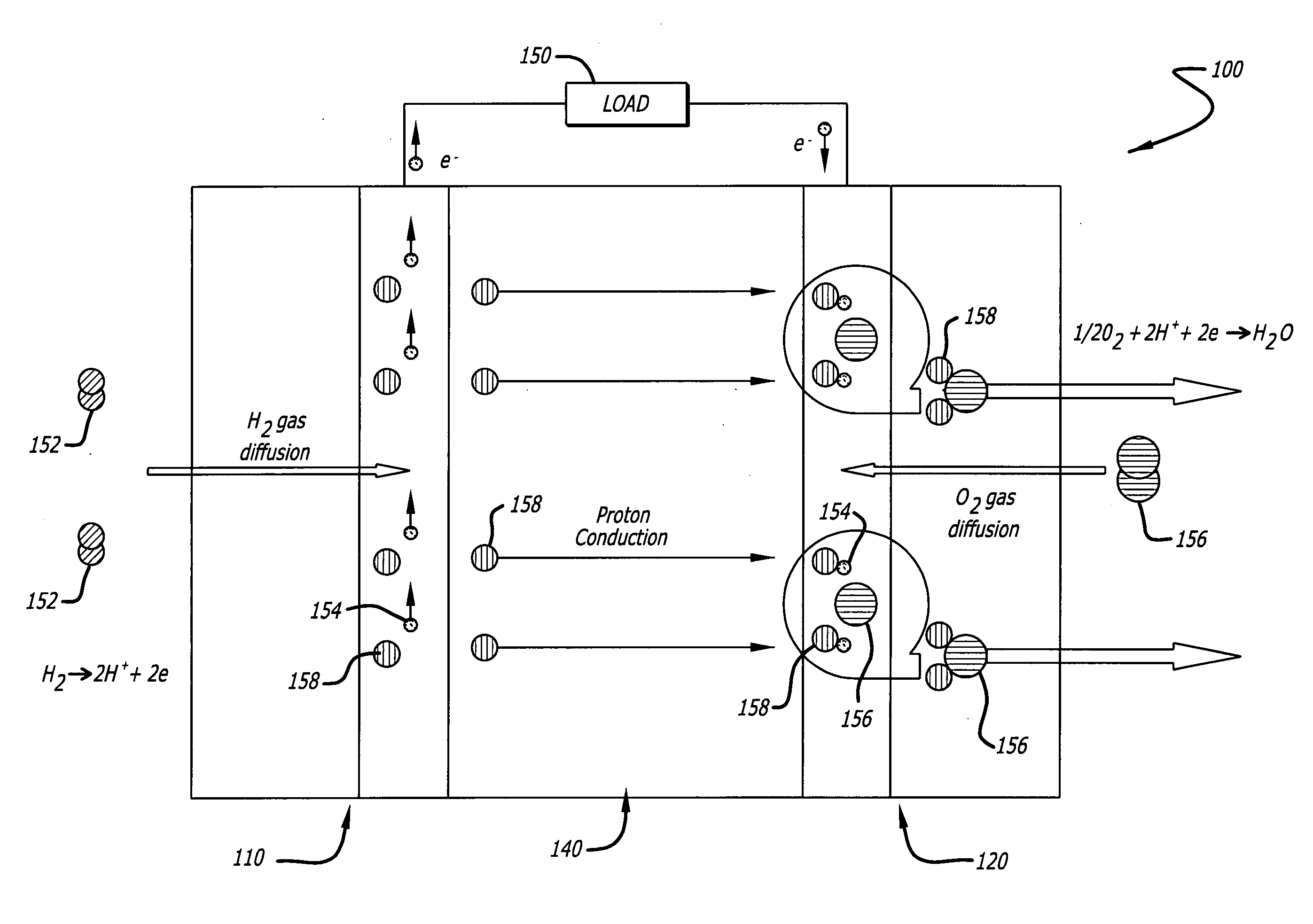

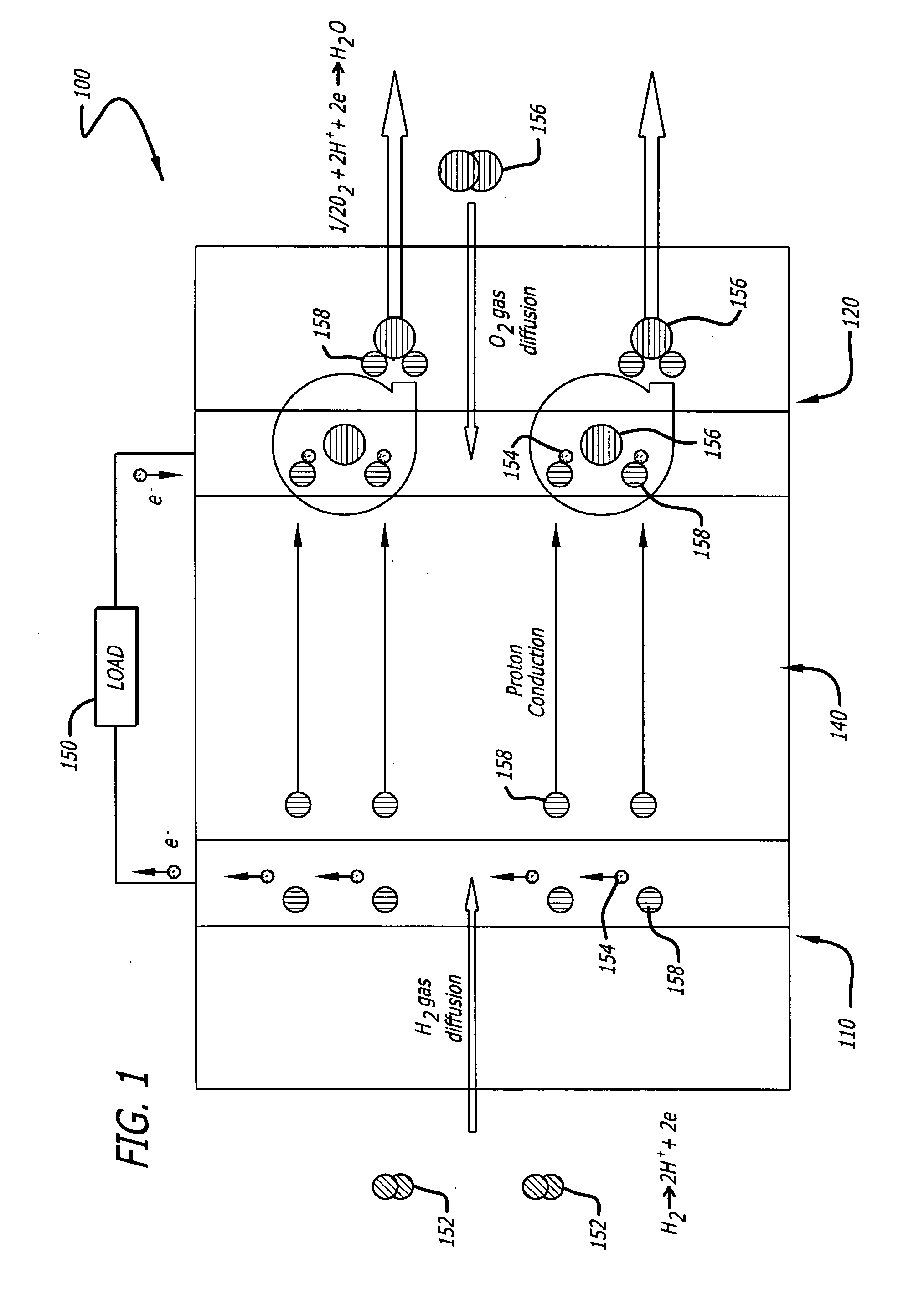

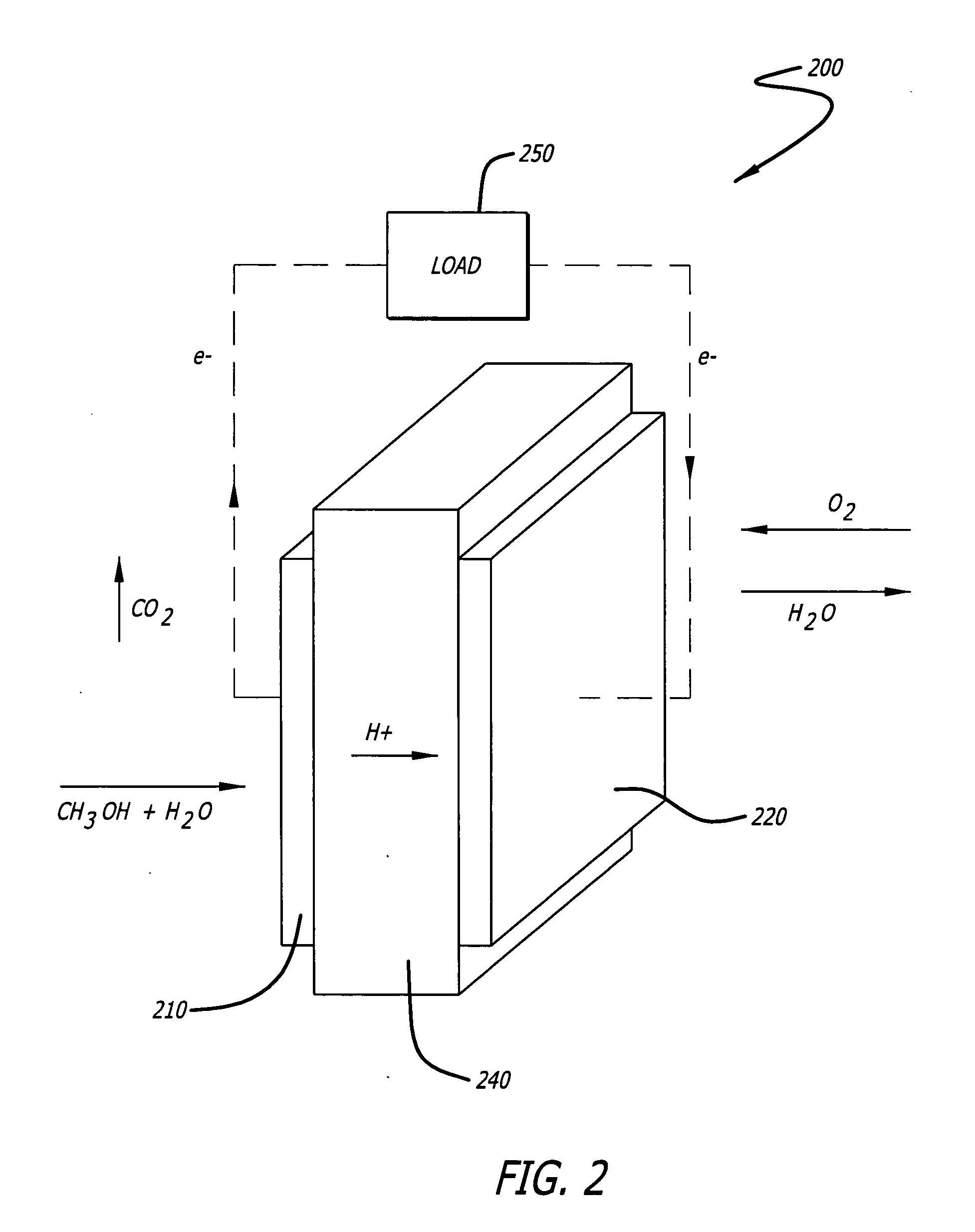

Carbon based electrocatalysts for fuel cells

InactiveUS20100159305A1High utilization rateHigh power densityActive material electrodesCoatingsHot pressPrecious metal

Novel proton exchange membrane fuel cells and direct methanol fuel cells with nanostructured components are configured with higher precious metal utilization rate at the electrodes, higher power density, and lower cost. To form a catalyst, platinum or platinum-ruthenium nanoparticles are deposited onto carbon-based materials, for example, single-walled, dual-walled, multi-walled and cup-stacked carbon nanotubes. The deposition process includes an ethylene glycol reduction method. Aligned arrays of these carbon nanomaterials are prepared by filtering the nanomaterials with ethanol. A membrane electrode assembly is formed by sandwiching the catalyst between a proton exchange membrane and a diffusion layer that form a first electrode. The second electrode may be formed using a conventional catalyst. The several layers of the MEA are hot pressed to form an integrated unit. Proton exchange membrane fuel cells and direct methanol fuel cells are developed by stacking the membrane electrode assemblies in a conventional manner.

Owner:RGT UNIV OF CALIFORNIA

Automobile exhaust purifying catalyst and preparation method thereof

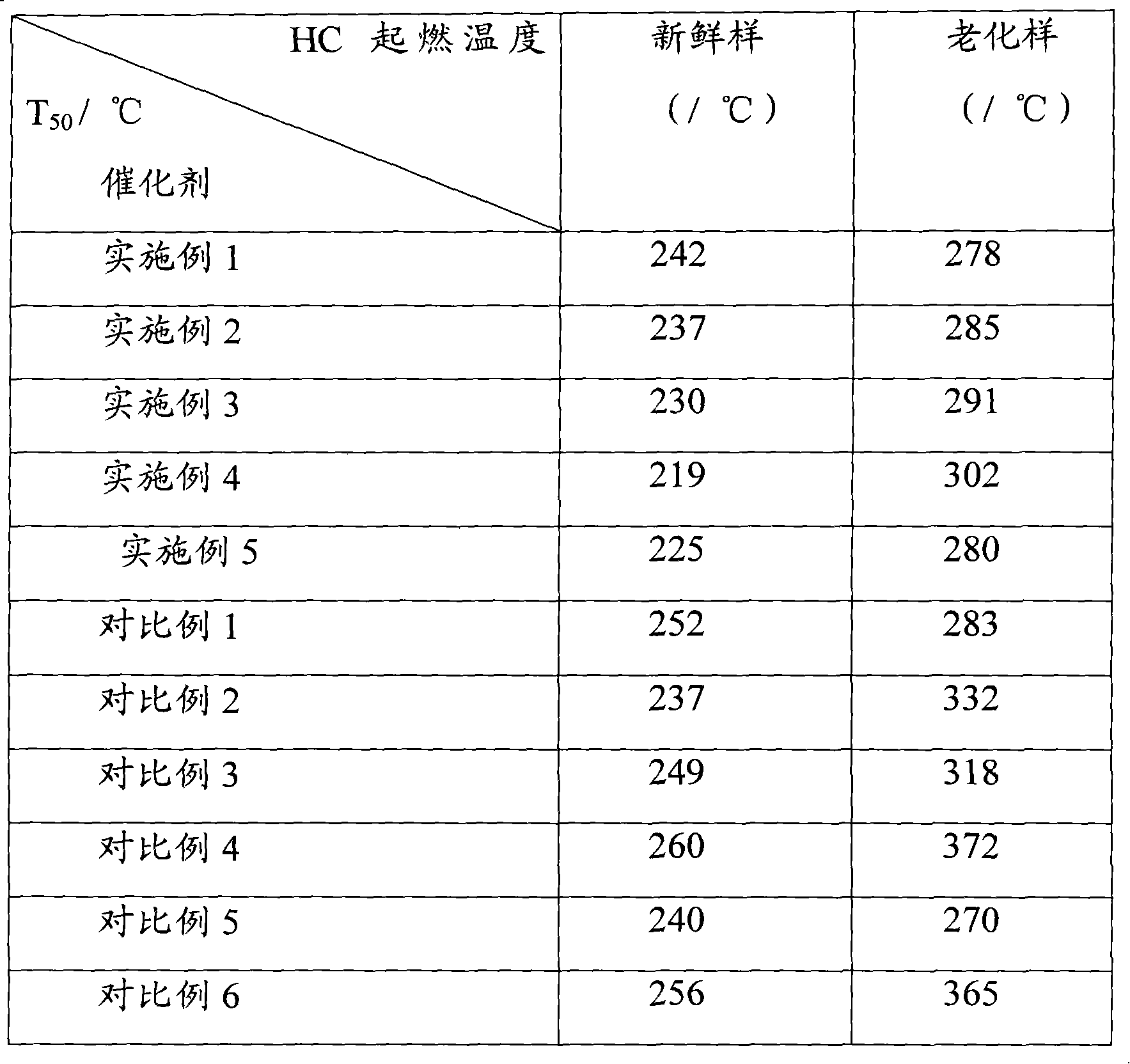

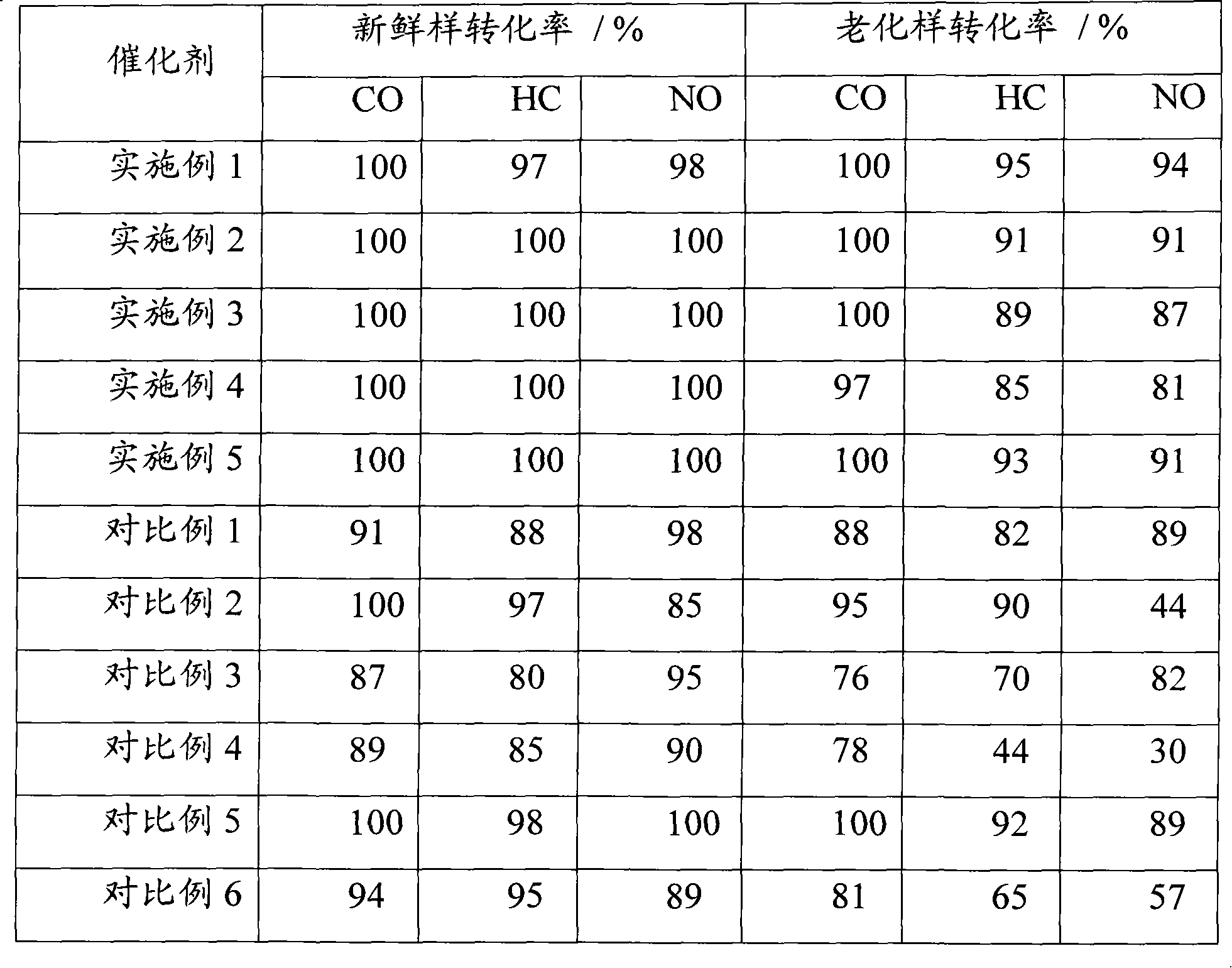

ActiveCN101601999AGood low temperature ignition activityGood aging resistanceDispersed particle separationCatalyst activation/preparationLayered structureChemistry

The invention provides an automobile exhaust purifying catalyst and a preparation method thereof. Honeycomb ceramics are used as a carrier, activated aluminum oxide and an oxygen storage material are used as a coating, noble metals of palladium and rhodium are used as activated components of the catalyst; the coating is of a double-layered structure, wherein a first-layer load is loaded on the carrier, and contains the activated aluminum oxide and the oxygen storage material; a second-layer load is loaded on the first coating and contains the activated aluminum oxide along with or without the oxygen storage material; the activated components of the noble metals of palladium and rhodium are respectively loaded on different materials; a metal and / or oxide load of rhodium is loaded on the first-layer oxygen storage material, and a metal and / or oxide load of palladium is loaded on the second-layer activated aluminum oxide. The automobile exhaust purifying catalyst has the advantages of good low-temperature combustion activity and good anti-aging performance and can satisfy the requirement for low emission.

Owner:常熟华虞环境科技有限公司

Positive pole material of lithium ion battery and preparation method of positive pole material

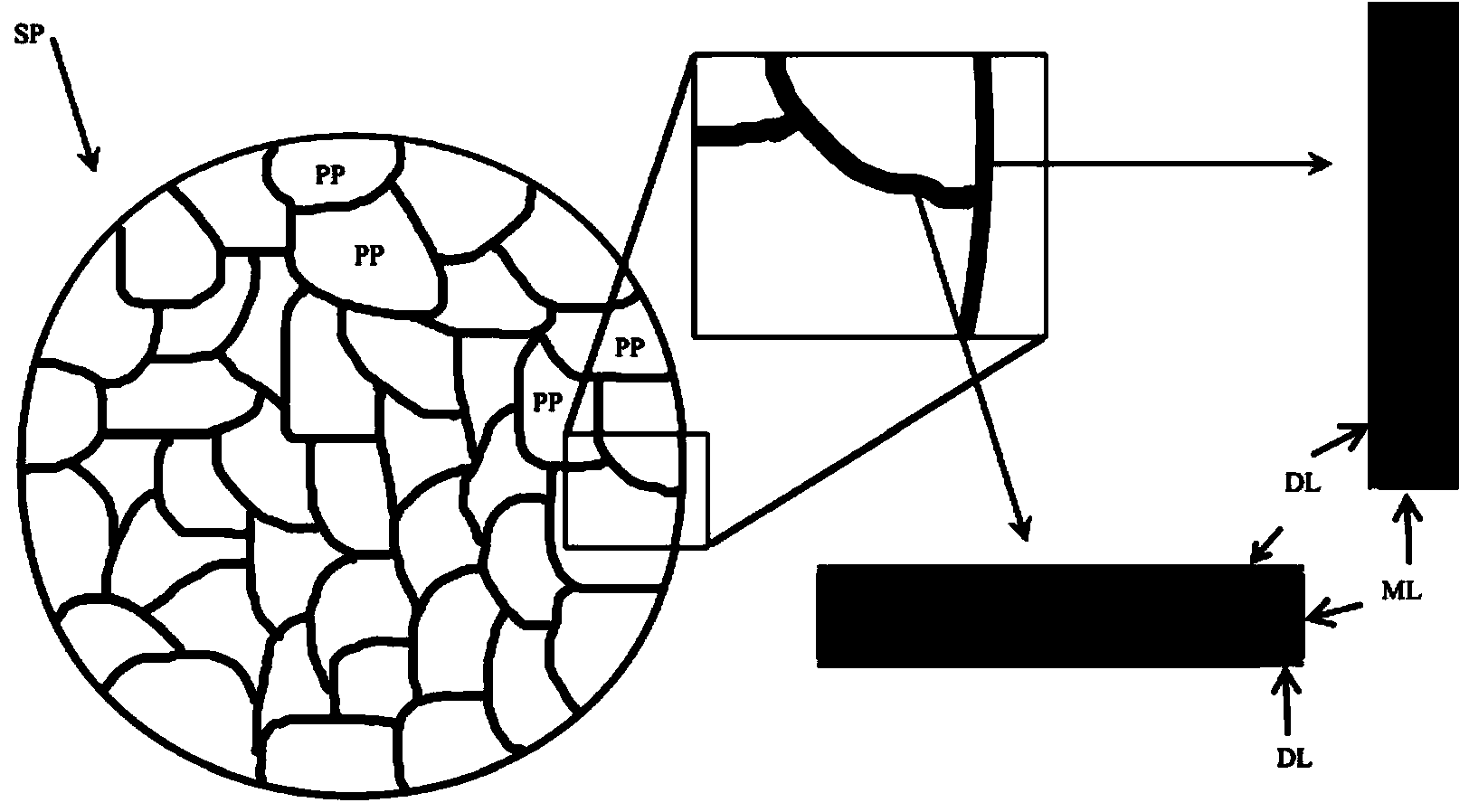

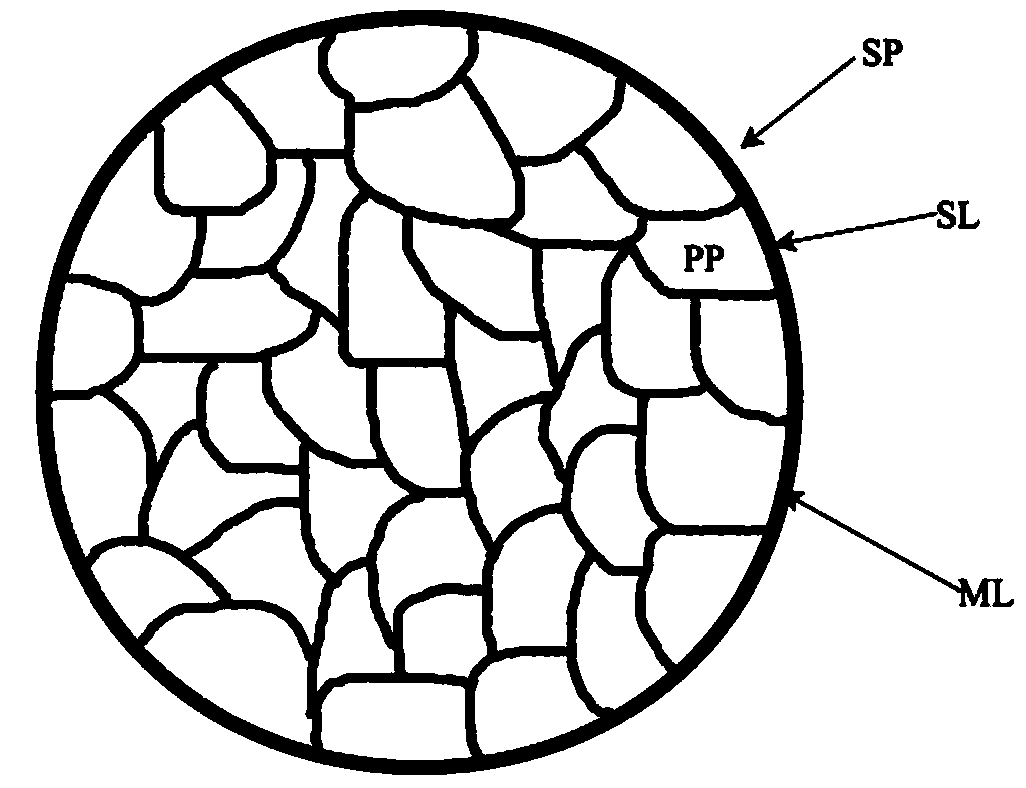

ActiveCN103441255AImprove long-term cycle stabilityAvoid crackingPositive electrodesNickel compoundsPhysical chemistrySodium-ion battery

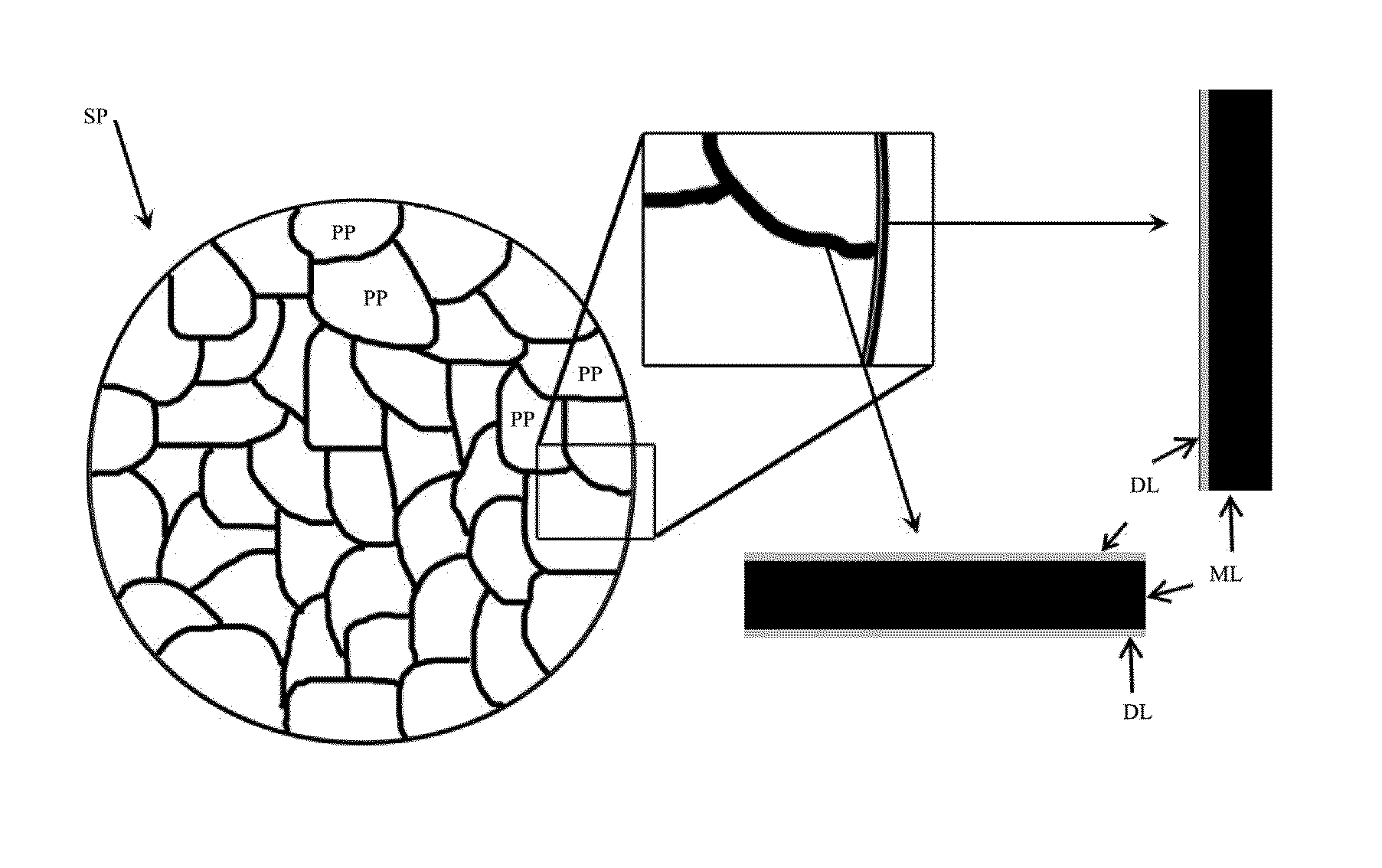

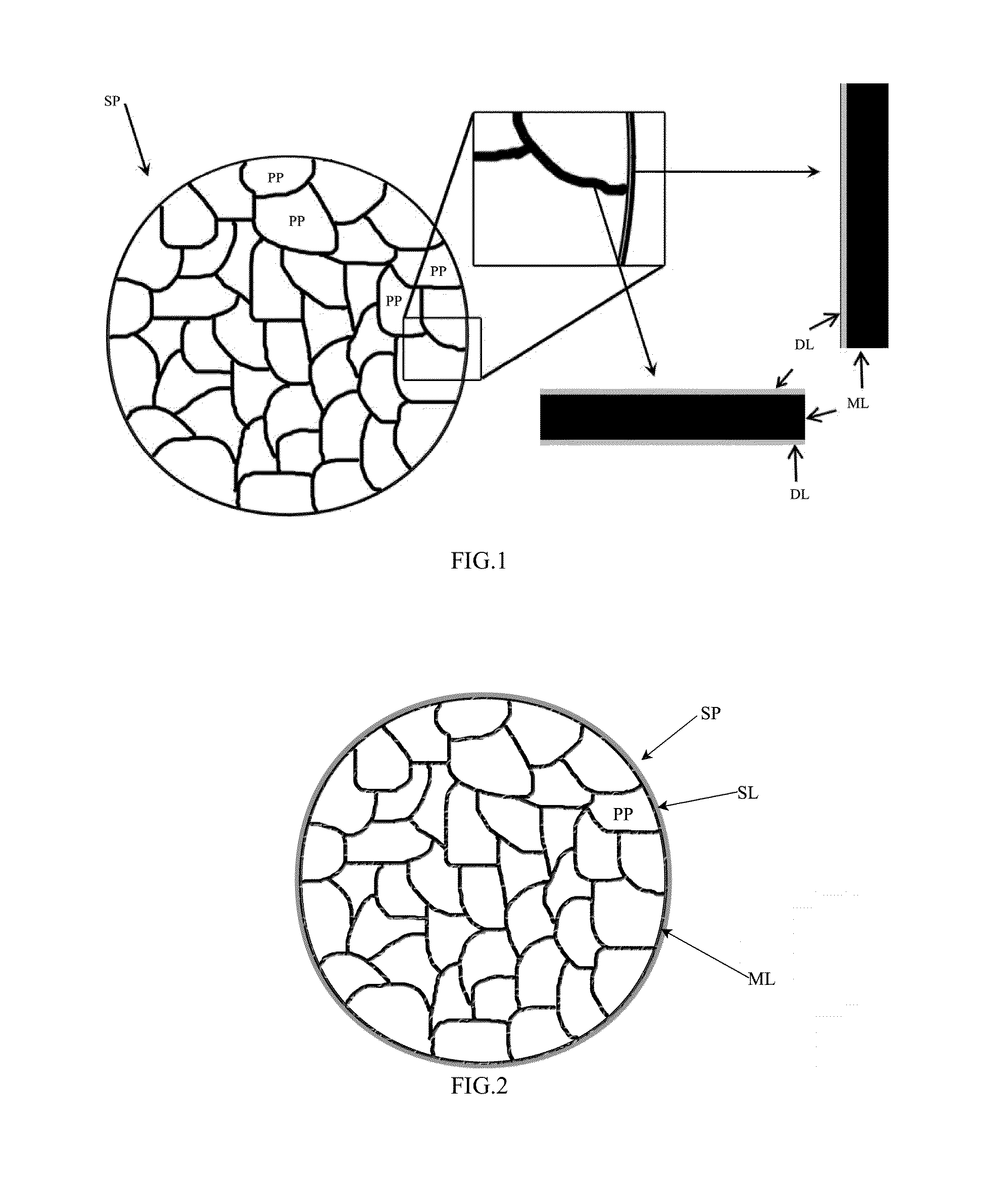

The invention provides a positive pole material of a lithium ion battery and a preparation method of the positive pole material. Secondary particles of the positive pole material of the lithium ion battery comprise primary particles of lithium-containing multi-transition metal oxide and second-phase materials; in a process of forming the secondary particles through the primary particles, the second-phase materials form second-phase material layers which are distributed on the surfaces of the primary particles, and are diffused with the lithium-containing multi-transition metal oxide through atoms to form diffusion layers so as to enable the second-phase material layers to be combined with the primary particles. Therefore, pulverization of the secondary particles of the positive pole material of the lithium ion battery along interfaces between the primary particles can be effectively suppressed, and the sizes of the primary particles and the secondary particles can be effectively controlled. When the positive pole material is applied to the lithium ion battery, the lithium ion battery is high in specific capacity, good in cycle performance and good in safety performance.

Owner:NINGDE AMPEREX TECH +1

Lithium-ion battery positive electrode material and preparation method thereof

InactiveUS20150079471A1Good stretchabilityGood ductibilitySilver accumulatorsPositive electrodesLithium-ion batteryDiffusion layer

The present disclosure provides a lithium-ion battery positive electrode material and a preparation method thereof. In the lithium-ion battery positive electrode material, a secondary particle comprises lithium-containing multi-element transition metal oxide primary particles and a second phase material, a second phase material forms a second phase material layer distributed on a surface of the primary particle and forms a diffusion layer together with the lithium-containing multi-element transition metal oxide by means of atoms mutual diffusion to make the second phase material layer combined with the primary particle during formation of the secondary particle from the primary particles, thereby effectively suppressing chalking of the secondary particle along boundary among the primary particles, and effectively controlling size of the primary particles and the secondary particles, and improving specific capacity, cycling performance and safety performance of a lithium-ion battery to which the lithium-ion battery positive electrode material is applied.

Owner:NINGDE AMPEREX TECH +1

Secondary lithium battery and positive electrode material thereof, and positive electrode material preparation method

ActiveCN105098177AImprove lithium ion conductivityGood chemical stabilityElectrode thermal treatmentPositive electrodesPhosphateSodium-ion battery

The present invention provides a positive active material for use in a lithium ion battery, a method for preparing the positive active material and a lithium ion battery containing the positive active material. The positive active material includes a core of lithium containing transition metal oxide represented by Formula LixMyN1-yO2-αAβ and a coating layer of lithium containing transition metal phosphate represented by Formula LiaMbN′1-bPO4-λBζ in situ formed on the core, wherein 0.9≰x≰1.2, 0.6≰y≰1.0, 0.9≰a≰1.1, 0.6≰b≰1.0, 0≰α≰0.2, 0≰β≰0.4, 0≰λ≰0.5, 0≰ζ≰0.5. The positive active material for use in a lithium ion battery according to the present invention has high capacity, desirable cycling performance and safety performance, as well as desirable thermal stability.

Owner:CONTEMPORARY AMPEREX TECH CO

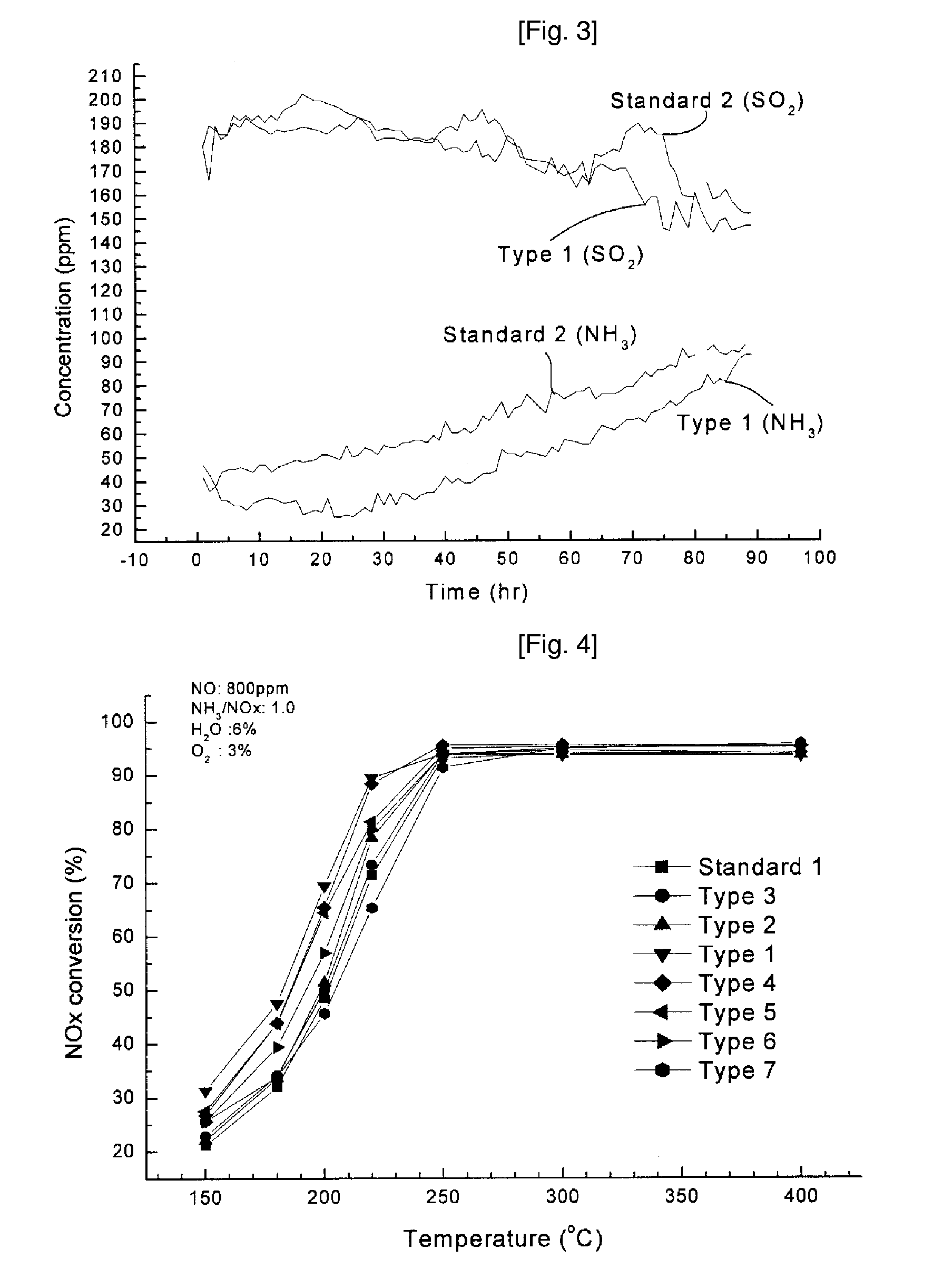

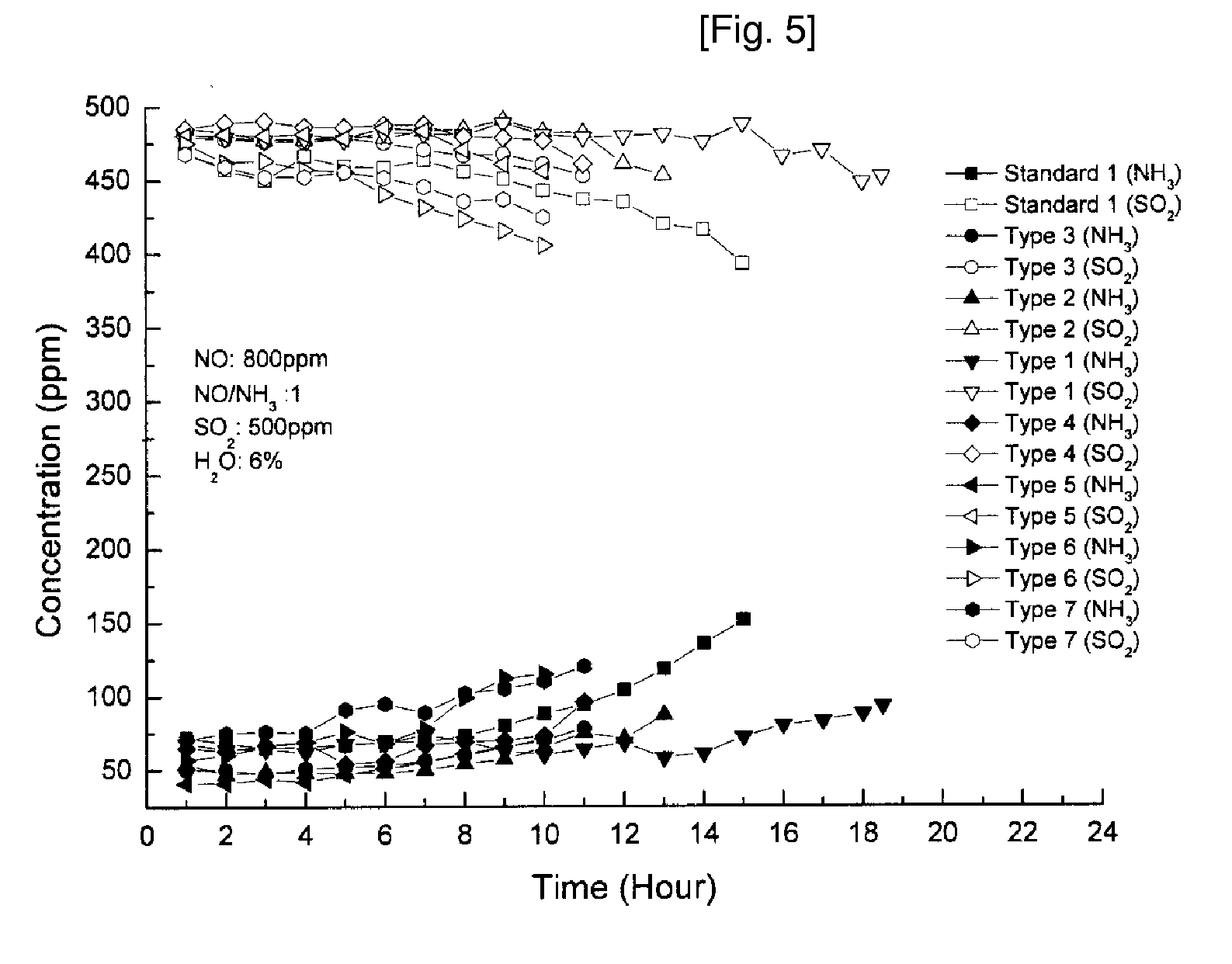

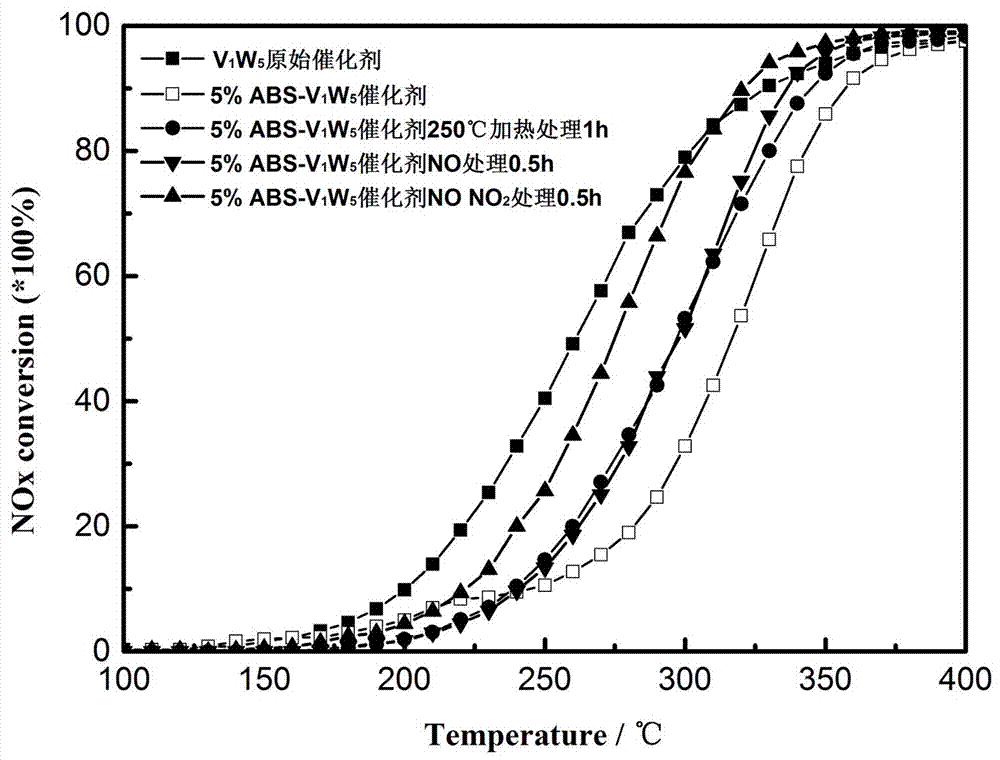

Scr catalyst for removal of nitrogen oxides

InactiveUS20090143225A1Improve responseDecrease addition amountDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurNitrogen oxide

The present invention provides for catalysts for selective catalytic reduction of nitrogen oxides. The catalysts comprise metal oxide supporters, vanadium, an active material, and antimony, a promoter that acts as a catalyst for reduction of nitrogen oxides, and at the same time, can promote higher sulfur poisoning resistance and low temperature catalytic activity. The amount of antimony of the catalysts is preferably 0.5-7 wt %.

Owner:KOREA INST OF SCI & TECH

Method for preparing loaded nano titanium dioxide photocatalysis film

InactiveCN1634653AHigh catalytic activityImprove photocatalytic activityCatalyst activation/preparationChemical reactionTitanic acid

This invention relates to a sol to gel method to process load nanometer titania effective light catalyzer thin film process method, which belongs to light catalyzer materials chemical technique field and comprises the following steps: using the pure titanic acid butonate and absolute ethyl alcohol, aminoethyl alcohol, water, poly-glycol 600 as materials; getting transparent stable light yellow titania sol through common temperature chemical reaction; then adopting the dipping and lifting method to load titania thin film on metal wire surface; finally burning in Muffle furnace under temperature of 450íµ to 550íµ to get the light catalyzer thin film.

Owner:SHANGHAI UNIV

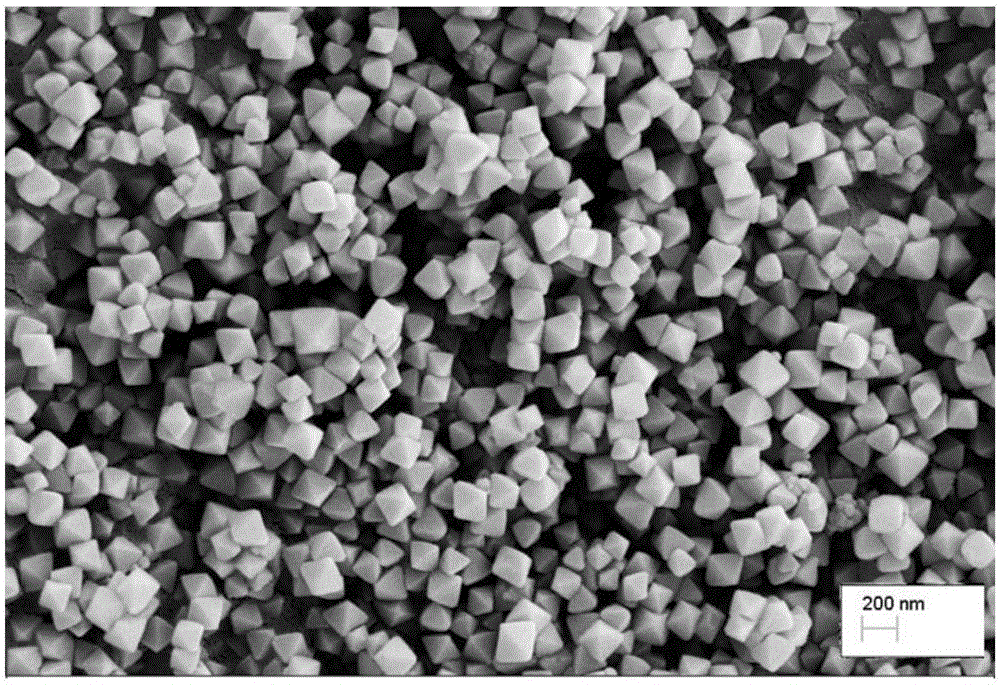

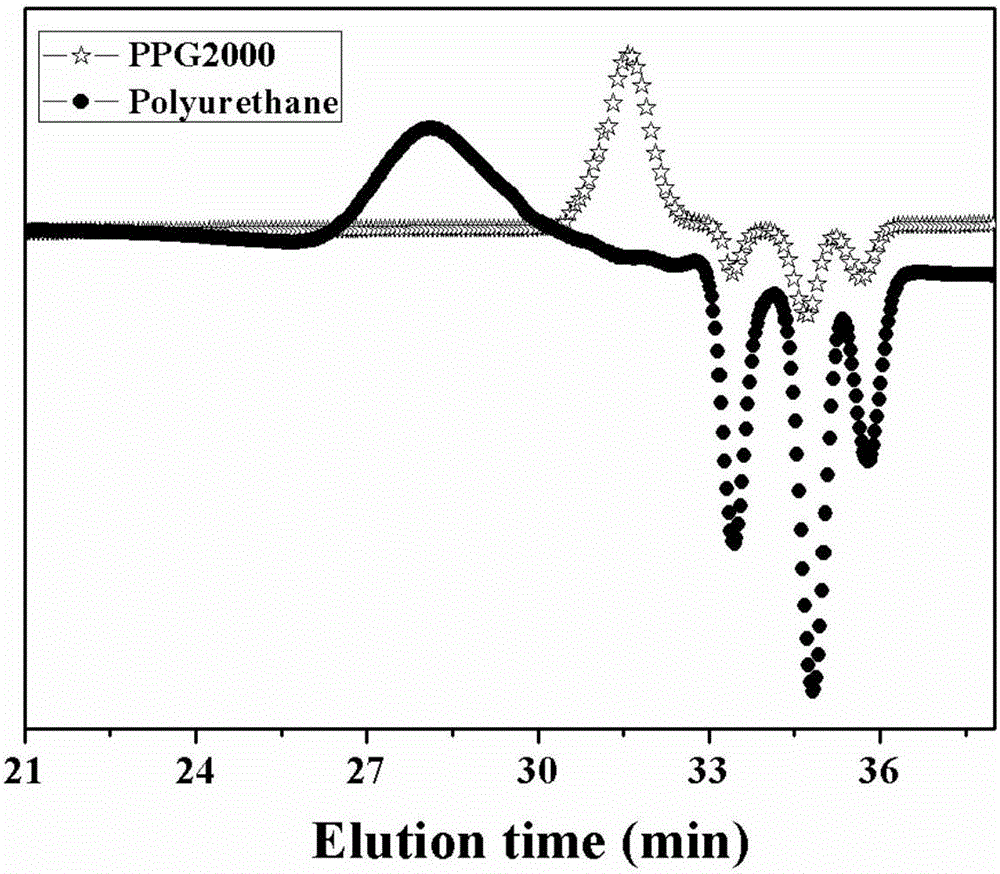

Metal-organic framework nanocrystal loaded polyurethane foam as well as preparation and application thereof

ActiveCN106366636AGood dispersionOvercoming the defects of difficult processingCarboxylic acid nitrile preparationOrganic compound preparationChemical industryMetal-organic framework

The invention discloses a metal-organic framework nanocrystal loaded polyurethane foam as well as a preparation and an application thereof. Polyurethane prepolymer and active amino on MOFs (Metal-Organic Frameworks) are taken to perform chemical doping, the great challenge that MOFs materials are difficult to process is overcome, MOFs nanoparticles are uniformly loaded in the polyurethane foam, a foam reactor is obtained by means of in-situ forming, a new process of building a complex mesoporous-microporous assembly based on microporous metal-organic skeleton nanoparticles as structural units is provided to observe catalysis of the MOFs nanoparticles on knoevenagel condensation; as water serves as a foaming agent and a green chemical method is adopted to prepare an integral flow-by foam reactor to catalyze an organic reaction, aftertreatment of a catalyst is simplified, loss of the catalyst is avoided, continuous flow-by cyclic catalyzation can also be performed, and a new method is provided for the treatment of environmental pollution and chemical industry.

Owner:SHANDONG NORMAL UNIV

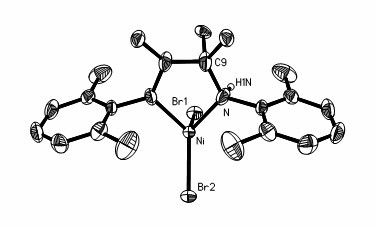

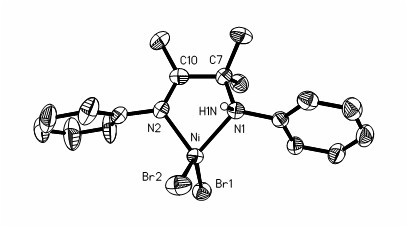

Preparation method and application of amido-imine nickel vinyl polymerization catalyst

ActiveCN102250152AThe synthesis method is simpleRaw materials are cheap and easy to getNickel organic compoundsAnilineBiological activation

The invention discloses a preparation method of an amido-imine nickel catalyst and application of the amido-imine nickel catalyst to catalyzing vinyl polymerization. The complex has the structures of a formula (I) and a formula (II) shown in the specification, wherein R1 is hydrogen or alkyl, R2 is hydrogen or alkyl, R3 is hydrogen or alkyl, R4 is hydrogen or alkyl, and X is halogen. The preparation method of the complex comprises the following steps of: carrying out condensation reaction on a diketone compound and phenylamine through ketoamine to obtain an diimine compound; then reacting with trimethyl aluminum, and hydrolyzing to obtain an amido-imine ligand; finally carrying out coordination reaction on the amido-imine ligand and (DME)NiX2 under the condition without water and oxygen to obtain a nickel complex. The complex disclosed by the invention has a specific ligand replacement structure and can be used for catalyzing the vinyl polymerization under the activation of modified methyl aluminium oxane or alkyl aluminum, showing the characteristics of living polymerization under specific conditions and obtaining the high-molecular-weight narrowly-distributed branched polyethylene.

Owner:SUN YAT SEN UNIV

Surface treatment of electrochemically active materials for rechargeable cells

InactiveUS20130236784A1Improve rate performanceEliminate and reduce catalytic activityElectrode manufacturing processesSecondary cellsCarbon coatingRechargeable cell

Provided herein are methods for processing electrochemically active materials and resulting active material structures for use in rechargeable batteries. The resulting active materials structures include carbon containing coatings that partially or completely cover the surface of the active material structures. In a typical embodiment, the method includes providing a solution of carbon containing precursor in a solvent, dispersing electrochemically active material in the solution to form a mixture, removing the solvent from the mixture to form electrochemically active material coated with the carbon containing precursor, and heating the electrochemically active material coated with the carbon containing precursor in an inert atmosphere at a temperature sufficient to at least partially convert the carbon containing precursor into a carbon coating. Also provided are an electrochemically active material prepared according to the methods described herein, as well as an electrode and a rechargeable electrochemical cell, each containing such electrochemically active material.

Owner:A123 SYSTEMS LLC

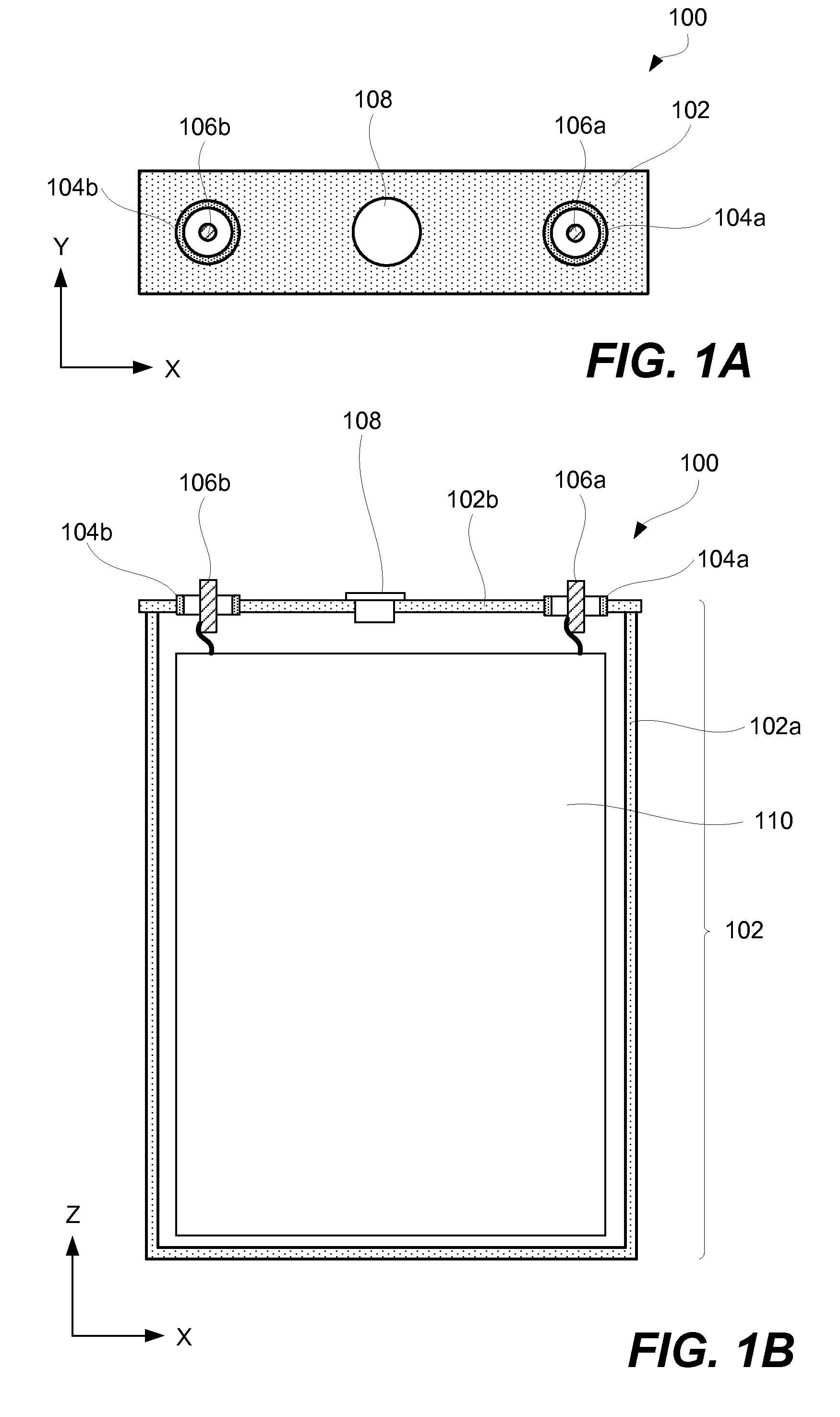

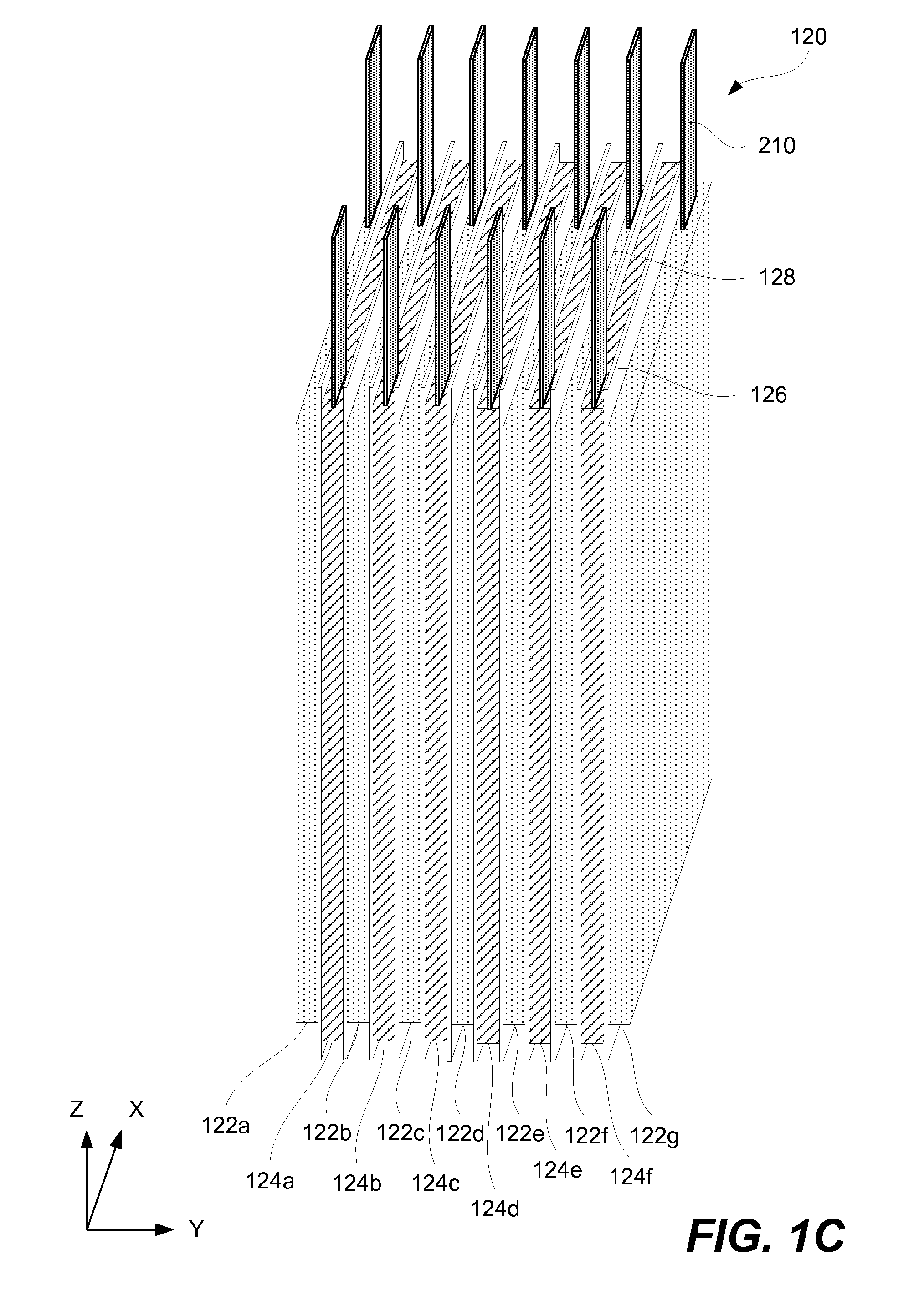

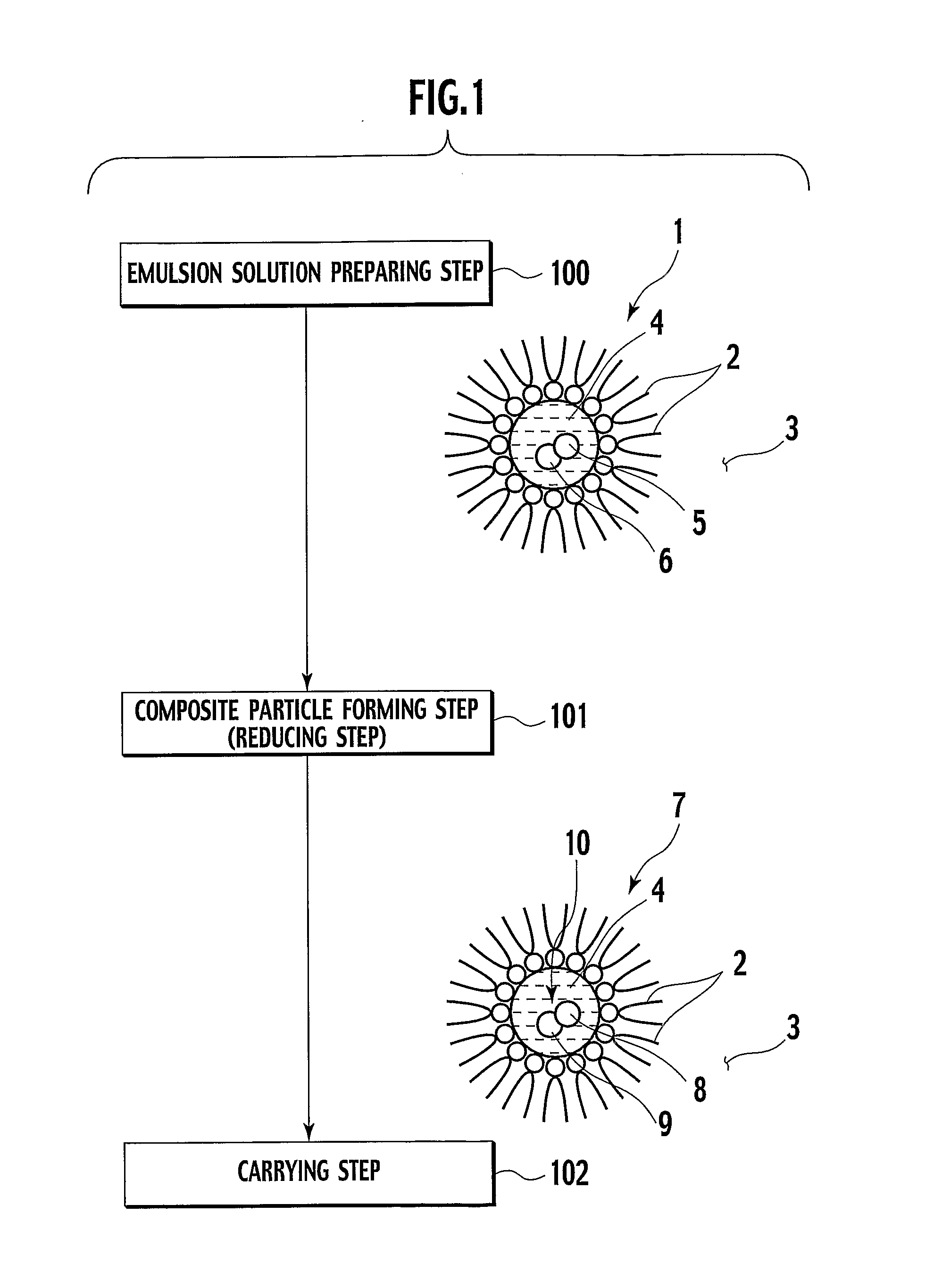

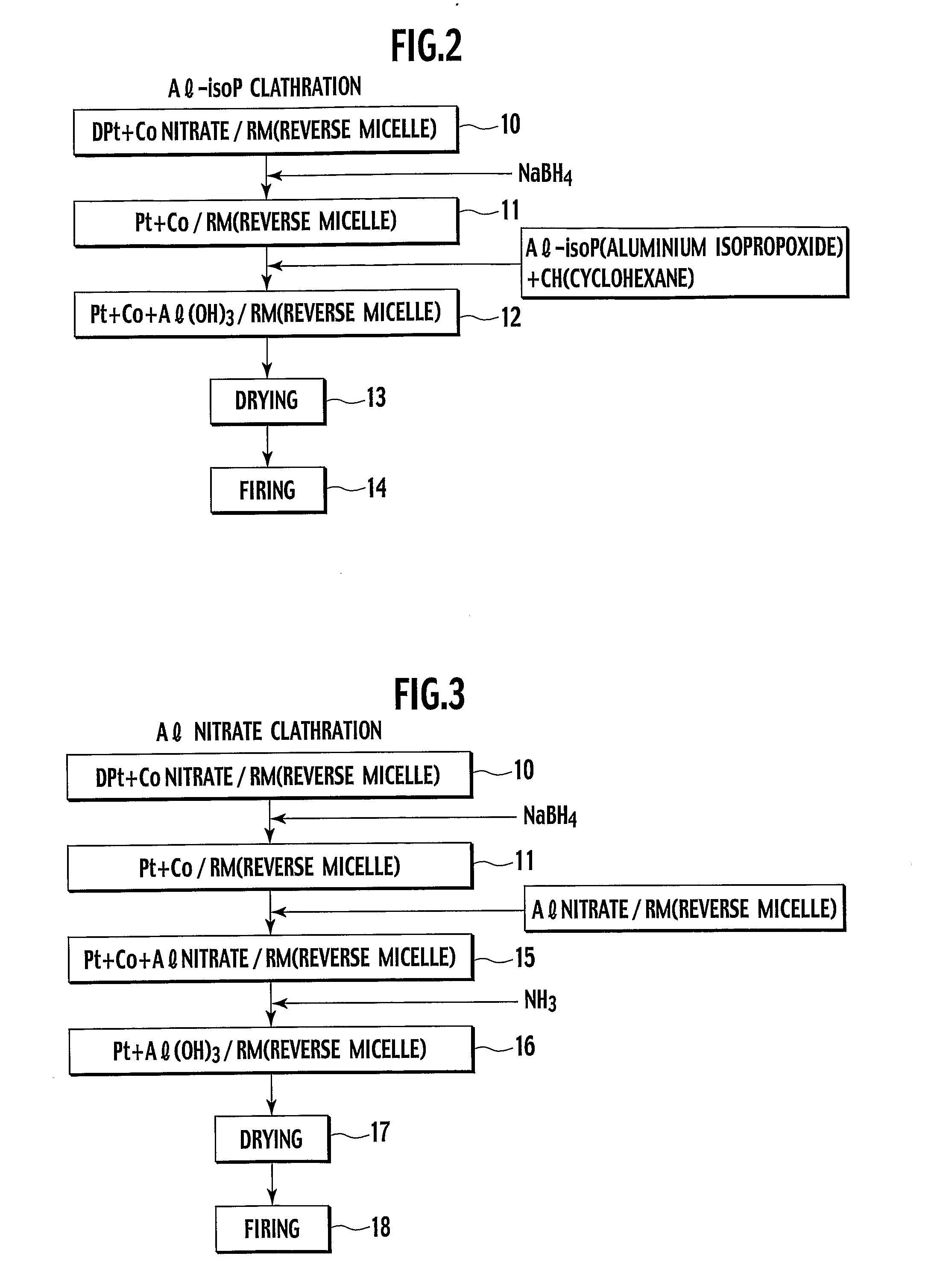

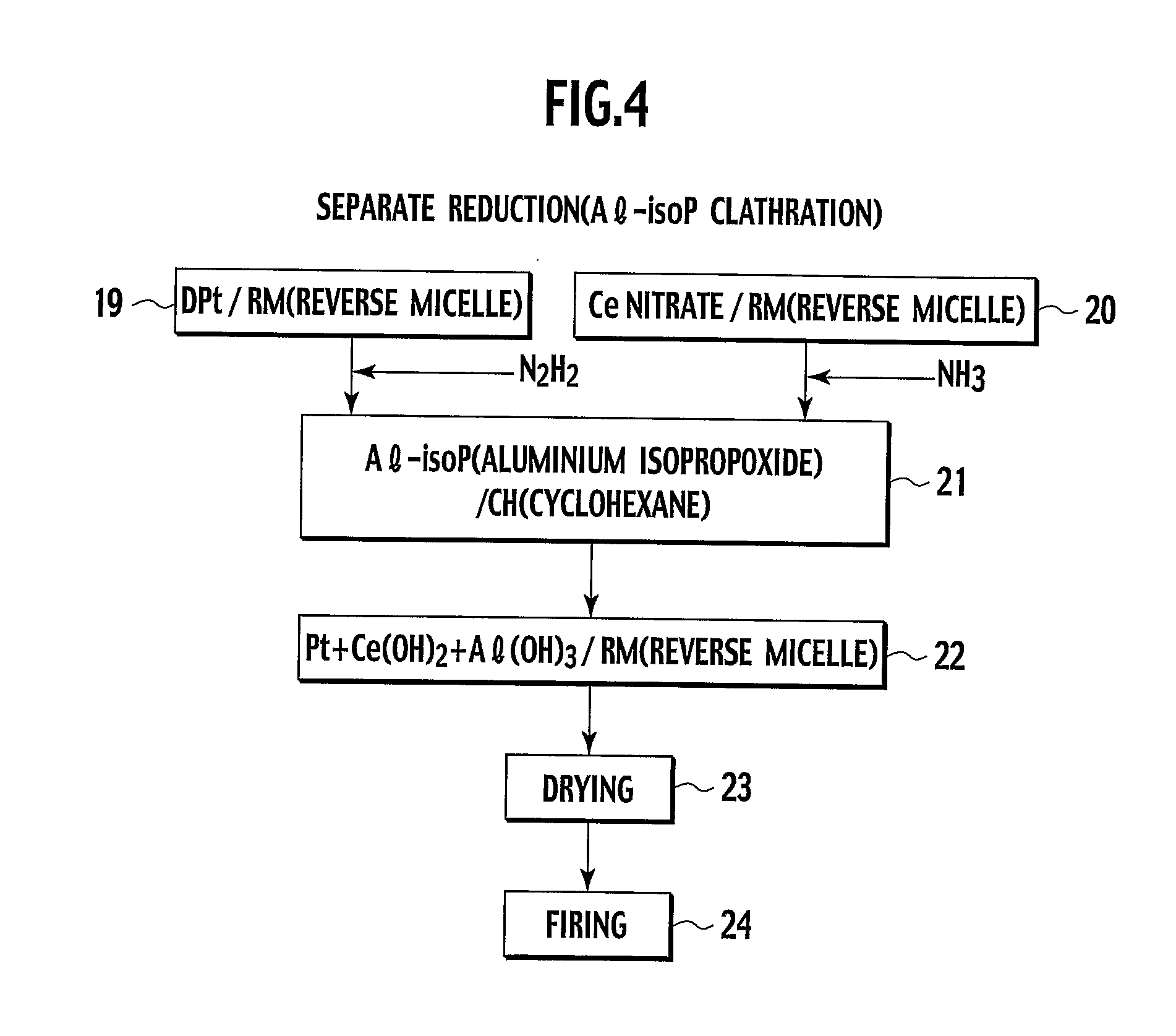

Heat-resistive catalyst and production method thereof

InactiveUS20070167319A1Reduce catalytic activityReduce the amount requiredMaterial nanotechnologyExhaust apparatusCompound (substance)Oxide

A high heat-resistive catalyser formed as a catalyst including a composite particle composed of a noble metal particle and a co-catalytic metal compound particle contacting, as a metal or as an oxide, with the noble metal particle, and a substrate carrying the noble metal particle and the co-catalytic metal compound particle, is produced by having a noble metal salt aqueous solution and a co-catalytic metal salt aqueous solution concurrently provided in a reverse micelle preparing reverse micellar solution containing a noble metal precursor and a co-catalytic metal precursor, and having a substrate carrying a composite particle comprising the noble metal precursor and the co-catalytic metal precursor concurrently reduced as a noble metal particle and a co-catalytic metal particle, respectively.

Owner:NISSAN MOTOR CO LTD

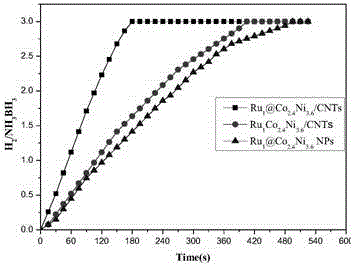

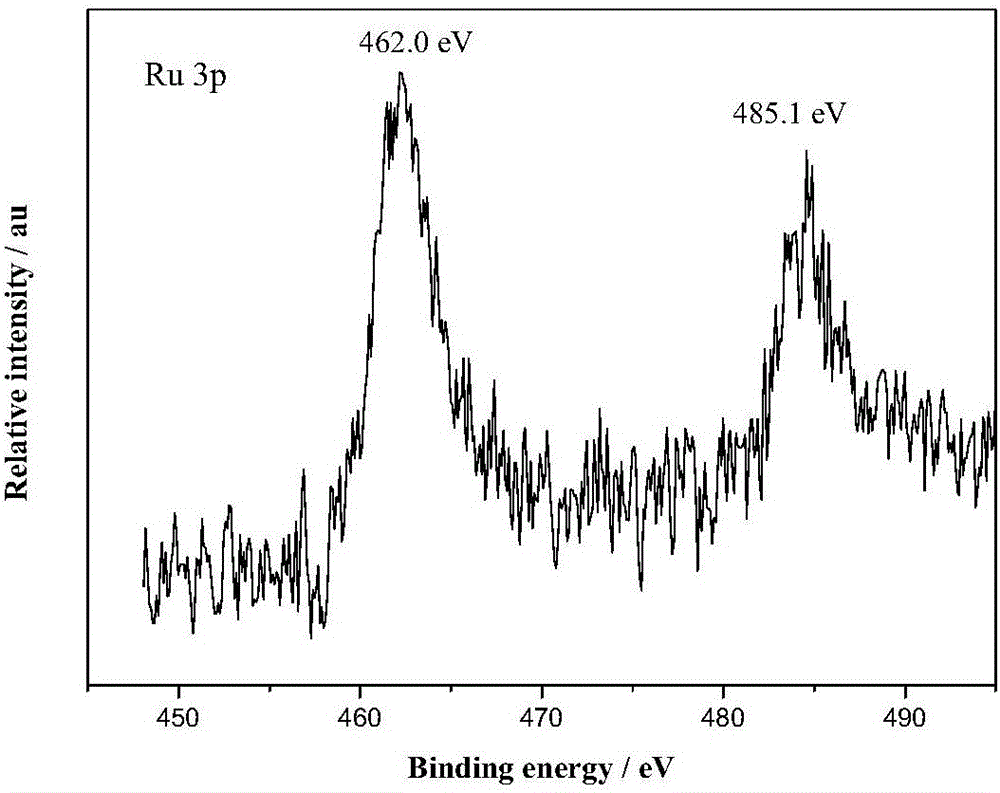

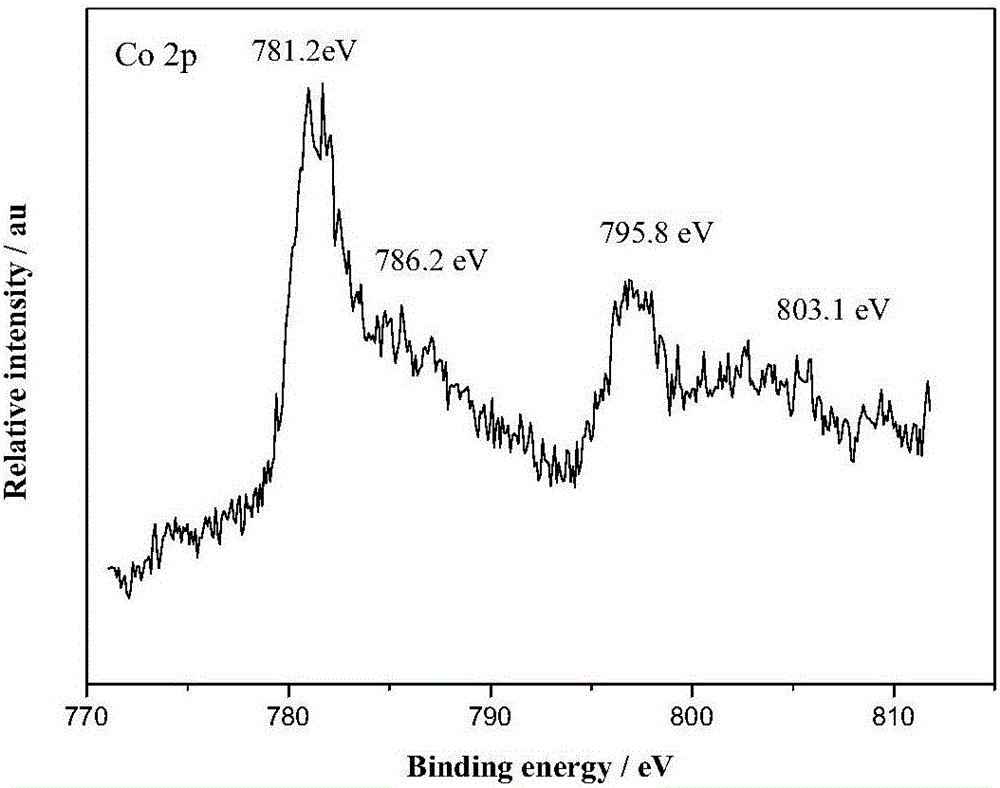

Core-shell structured supported carbon nanotube catalyst and preparation method thereof

InactiveCN106334566ALow costEasy to operateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystNickel salt

The invention relates to a core-shell structured supported carbon nanotube catalyst and a preparation method thereof. The catalyst adopts carbon nanotubes (CNTs) as a carrier and adopts borazane as a reducing agent. The preparation method comprises the following steps: reducing precursors comprising a ruthenium salt, a cobalt salt and a nickel salt, loading the reduced precursors on the CNTs, filtering the above obtained product, washing the filtered product, and drying the washed product to obtain the core-shell structured Ru@CoNi / CNTs nanocatalyst. The average particle size of metals supported on the core-shell structured Ru@CoNi / CNTs nanocatalyst synthesized through the preparation method is 1.5 nm, the catalyst has high catalysis activity on hydrolysis of borazane for releasing hydrogen, the transformation frequency (TOF) is 408.9 H2 min<-1> (mol Ru)<-1>, and the activation energy (Ea) is 23.53 kJ mol<-1>. The catalyst still has good stability after 5 cycle test, the average particle size of metal particles is 1.64 nm, and the metal particles are uniformly dispersed. The noble metal / non-noble metal doped core-shell structured supported nanocatalyst adopting the CNTs as the carrier has the characteristics of uniform metal particle distribution, many catalysis activity sites and good stability; and compared with traditional noble metal catalysts, the nanocatalyst has the advantages of low cost, simplicity in preparation, easy obtaining of the raw materials, and suitableness for industrial production.

Owner:HUBEI UNIV

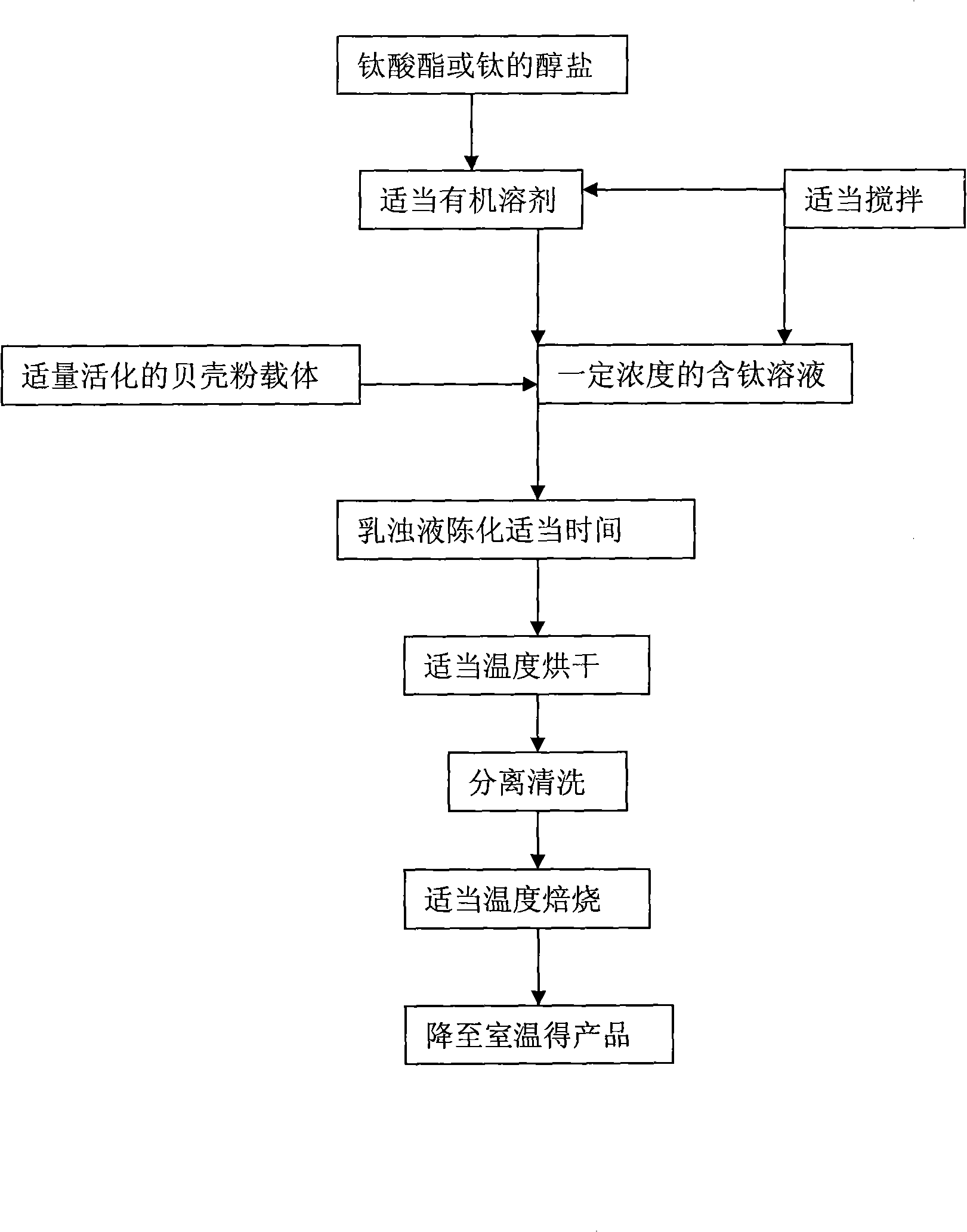

Nano titanic oxide impregnation preparation method using shell powder as carrier

InactiveCN101352674ASolve associativitySolve for uniformityCatalyst carriersCatalyst activation/preparationFiberTitanium oxide

The invention discloses an impregnation preparation method of nanometer titanium oxide which takes shell powder as a carrier, and in particular relates to a reproducible porous nanometer titanium oxide powder which takes the shell powder as the carrier and the preparation method thereof. In the method, titanium oxide is loaded on a shell powder carrier by impregnation; firstly, alkoxide solution of titanium ester or titanium with appropriate concentration is prepared, then an activated shell powder carrier with certain proportion is impregnated in the alkoxide solution, then the obtained solution is stirred and stayed for a certain time, and treated by low temperature and abstersion pretreatment and finally roasted at high temperature, so the nanometer TiO2 forms high-strength bond with the shell powder and promotes the catalytic activity of the nanometer TiO2 at the same time. Impregnation can be conducted for a plurality of times to increase load. The nanometer TiO2 is characterized by small particle size, good compatibility with materials, high catalytic efficiency, good stability, good regenerability, and the like, and can be applied to the fields of plastics, rubbers, fibers, coatings, home electronic appliances, paints, ceramics, water and environmental manipulation, pharmaceutical and hygienic articles, etc. In terms of sources of raw materials and production technology, the preparation method not only reduces the production cost of the nanometer TiO2 catalyst but also is helpful for disposal of the increasingly serious environmental problems, thus bearing great environmental protection significance.

Owner:GUANGDONG OCEAN UNIVERSITY

Process for producing bisphenol A

InactiveUS7129382B2Suppressing deterioration of catalytic activityExtended service lifeOrganic compound preparationOrganic chemistry methodsPhenolIon-exchange resin

There is disclosed a process for producing bisphenol A by subjecting phenol and acetone to condensation reaction in the presence of a catalyst composed of an acid type ion exchange resin which is modified in part with a sulfur-containing amine compound, wherein the ion exchange resin having a modification rate of 10 to less than 20 mol % is used for a methanol concentration in acetone of lower than 250 ppm by weight, and the ion exchange resin having a modification rate of 20 to 65 mol % is used for a methanol concentration in acetone of 250 to 8000 ppm by weight. The above process is capable of producing bisphenol A at high conversion and selectivity by suppressing deterioration of catalytic activity due to methanol as an impurity in acetone.

Owner:IDEMITSU KOSAN CO LTD

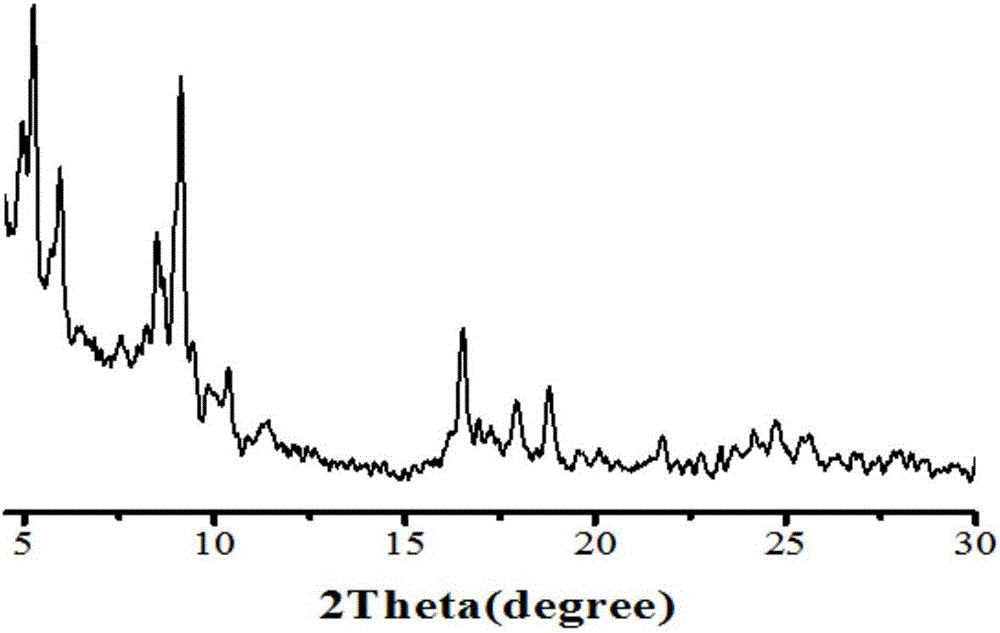

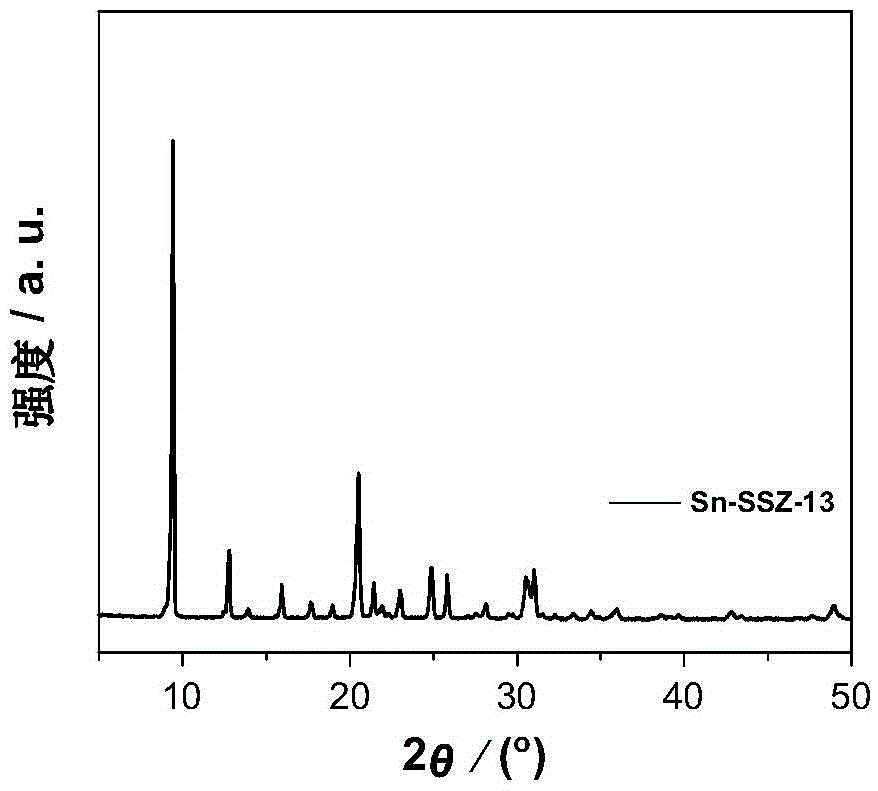

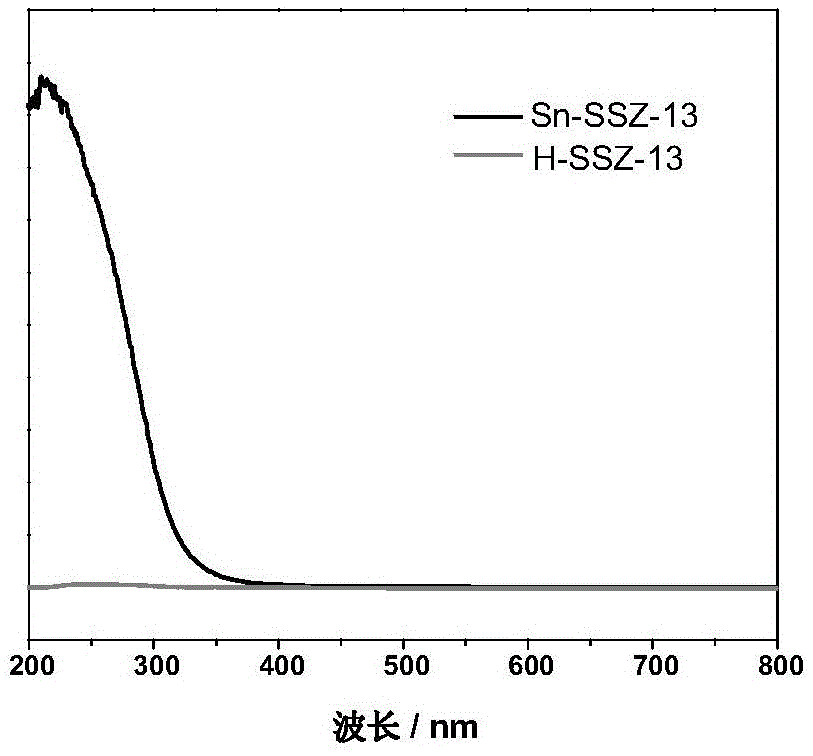

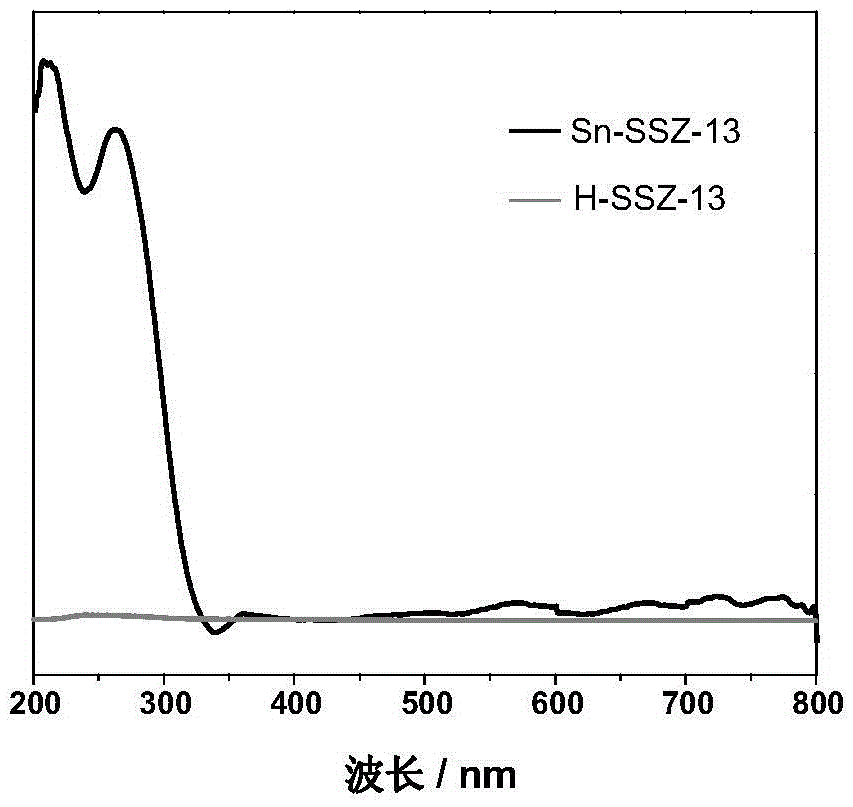

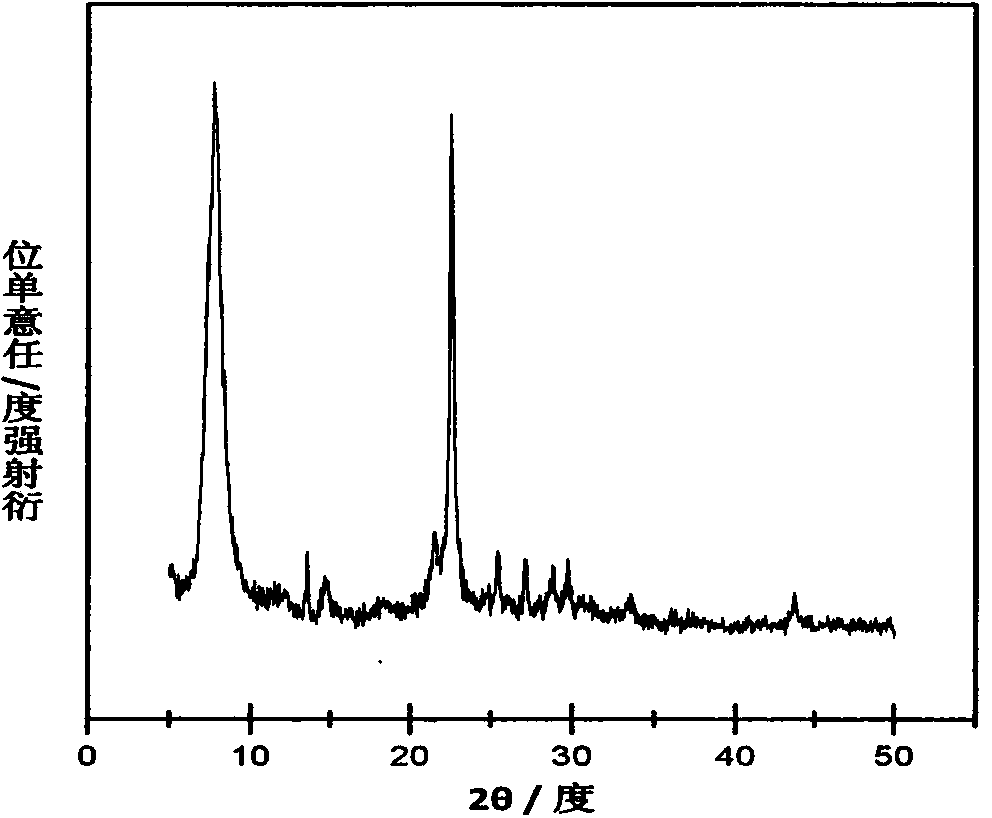

Tin-containing molecular sieve catalyst for hydration of ethylene oxide to prepare ethylene glycol and method of use

ActiveCN104437607BStable structure and performanceReduce catalytic activityMolecular sieve catalystsBulk chemical productionMolecular sievePtru catalyst

The invention relates to a tin-containing molecular sieve catalyst used for preparing ethylene glycol by hydrating ethylene oxide and an application method of the tin-containing molecular sieve catalyst. The tin-containing molecular sieve catalyst is prepared by taking H-SSZ-13 zeolite molecular sieve raw powder as a raw material, carrying out water steam treatment or water steam and acid combined treatment on the raw material, and introducing active central metal in a manner of roasting by a vacuum pipe type furnace. The preparation method comprises the following steps: mixing an H-SSZ-13 zeolite molecular sieve treated by the water steam or acid with an organic metal compound precursor at a ratio and roasting in vacuum. According to the tin-containing molecular sieve catalyst, the problems of high water ratio, high energy consumption, environmental pollution caused in a production process and the like in a traditional process can be solved. According to the catalyst, a carrier is cheap and easy to obtain, a preparation process of the catalyst is simple and the stability of the catalyst is good; and the catalyst has excellent catalyzing activity and selectivity when being applied to a process of preparing ethylene glycol by directly hydrating ethylene oxide under a warm condition, is easy to recycle and can be used for industrial production for preparing ethylene glycol by hydrating ethylene oxide.

Owner:NANKAI UNIV

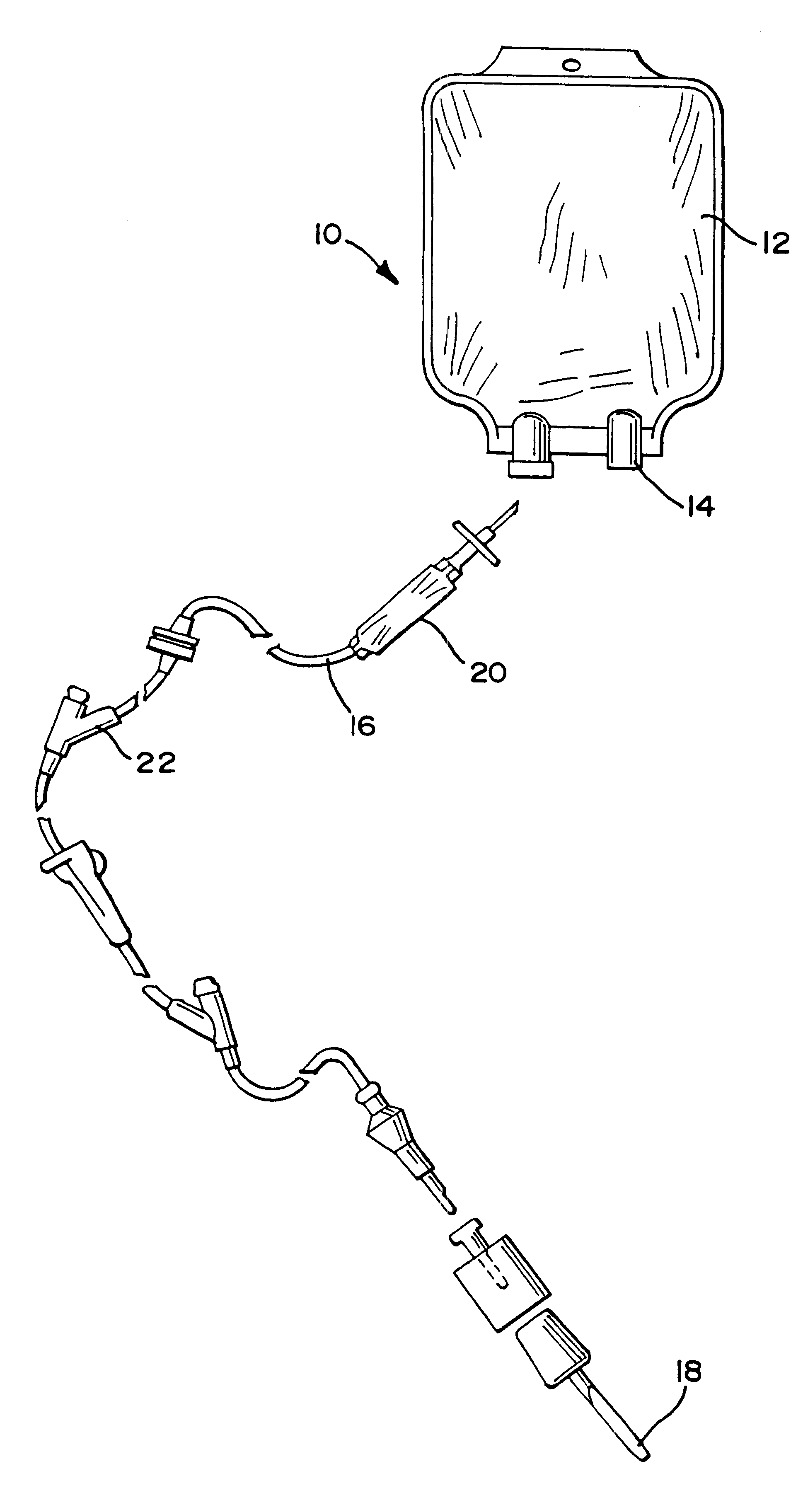

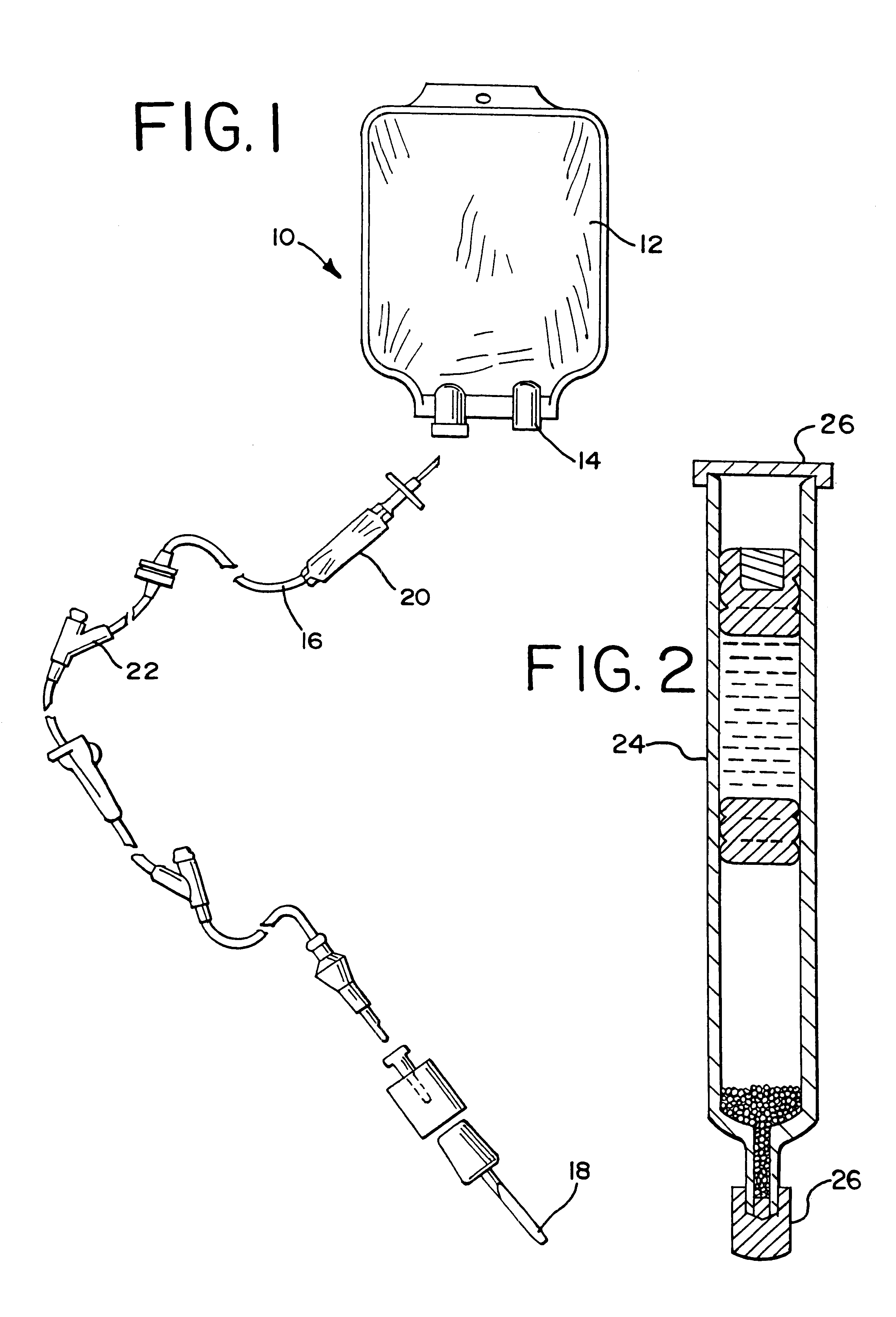

Solvent bonding method for polyolefin materials

InactiveUS6613187B1Reduced responseReduce catalytic activitySynthetic resin layered productsSolventPolyolefin

The present invention provides a method for using a polymeric cement to assemble medical devices. The method includes the steps of: (1) providing a first article of a low crystallinity polymer; (2) providing a second article of a low crystallinity polymer; (3) providing a cement composition having a first component of a cyclic olefin containing polymer or a bridged polycyclic hydrocarbon containing polymer and a second component of an effective amount of a solvent having a solubility parameter of less than about 20 (MPa)1 / 2; applying the cement composition to one of the first and second articles to define a bonding area; and (4) attaching the first article to the second article along the bonding area to fixedly attach the first article to the second article.

Owner:BAXTER INT INC

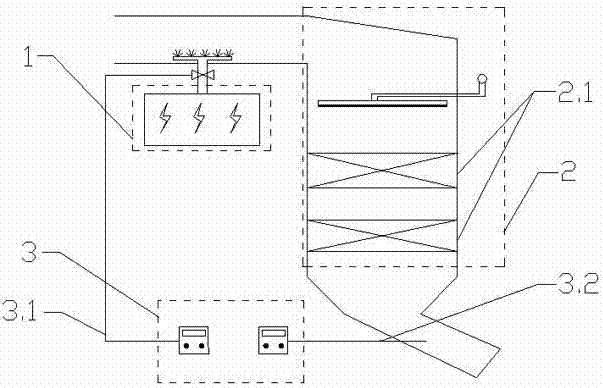

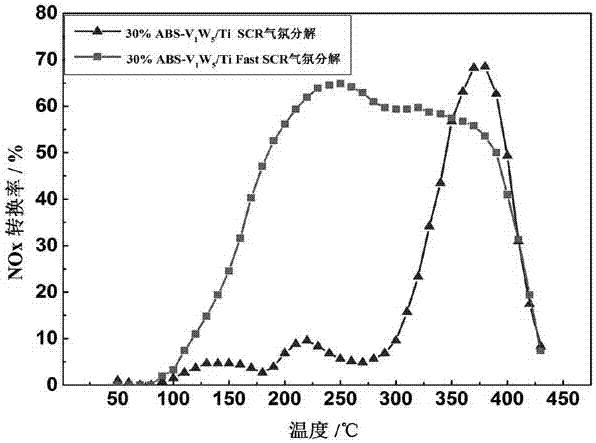

Method and device applied to in-situ regeneration of sulfur-poisoning SCR denitration catalyst

ActiveCN107376930AReduce catalytic activityLower decomposition temperatureGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention provides a method and a device applied to in-situ regeneration of a sulfur-poisoning SCR denitration catalyst. The method comprises the following steps: pre-oxidizing part of smoke before entering to an SCR denitration reactor when the SCR denitration catalyst is deactivated by sulfur poisoning, oxidizing part of NO in the smoke, then enabling the smoke to enter into the SCR denitration reactor, accelerating decomposition of ammonium sulfate on the surface of the catalyst, and carrying out regeneration process of the catalyst. The device applied to in-situ regeneration of the sulfur-poisoning SCR denitration catalyst comprises an ozone generator, an electromagnetic valve, an SCR denitration reactor and a smoke NOx component online monitor. The method and the device are capable of effectively decomposing ammonium sulfate deposited on the surface of the catalyst under the condition with temperature of 200-380 DEG C; the activity of the treated sulfur-poisoning catalyst is improved; the service life of the catalyst is prolonged; the replacement cost of the catalyst is reduced.

Owner:CHONGQING UNIV +1

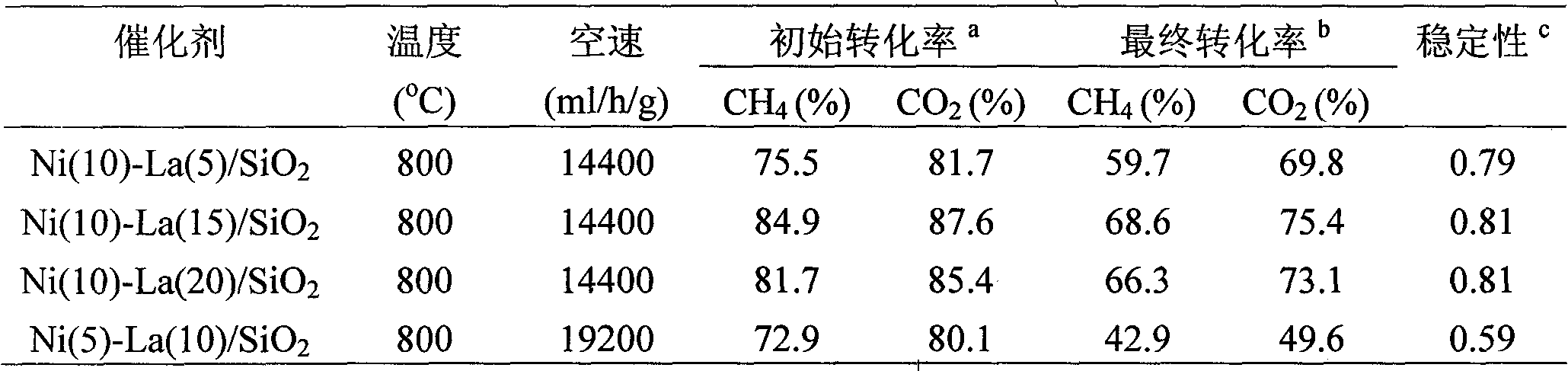

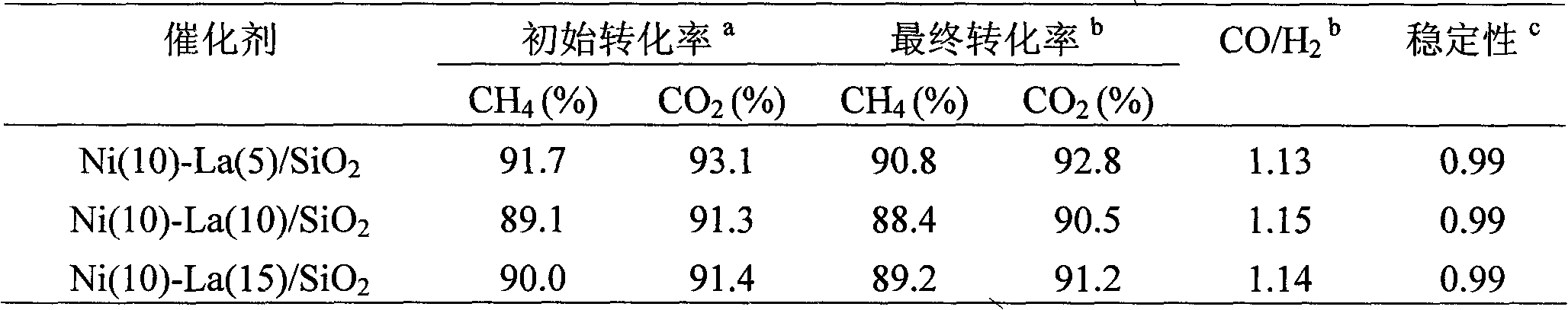

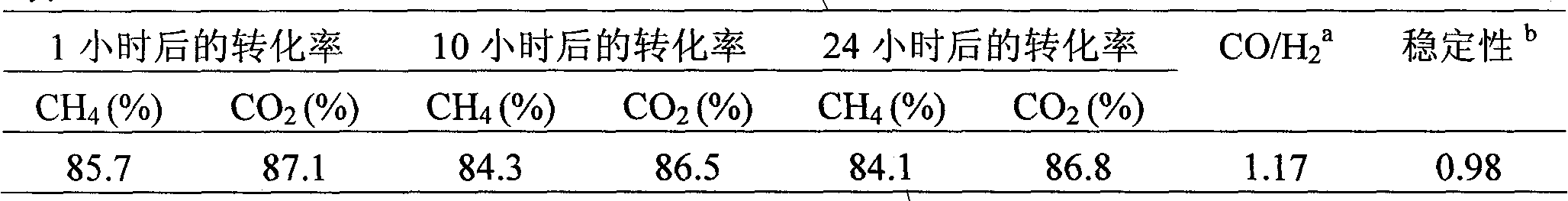

Catalyst for reforming methane with carbon dioxide for preparing synthetic gas and preparation method thereof

InactiveCN101773835AImprove mechanical propertiesImprove thermal stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsActive componentThermal stability

The invention relates to a catalyst for reforming methane with carbon dioxide for preparing synthetic gas, which is a bead catalyst prepared by taking SiO2 as a vector and Ni and La as active components by a co-impregnation method. The catalyst provided by the invention has good mechanical properties and thermal stability, long service life, simple preparation method, low cost and easy acquisition of raw materials, relatively mild reaction conditions and no need of any diluent gas; the catalyst has good catalytic property for reforming the methane with the carbon dioxide for preparing the synthetic gas; the conversion rates of the methane and the carbon dioxide can respectively reach 79.4-90.8% and 86.1%-92.8% under ordinary pressure; and the volume ratio CO to H2 in the prepared synthetic gas is 1.13-1.18.

Owner:SICHUAN UNIV

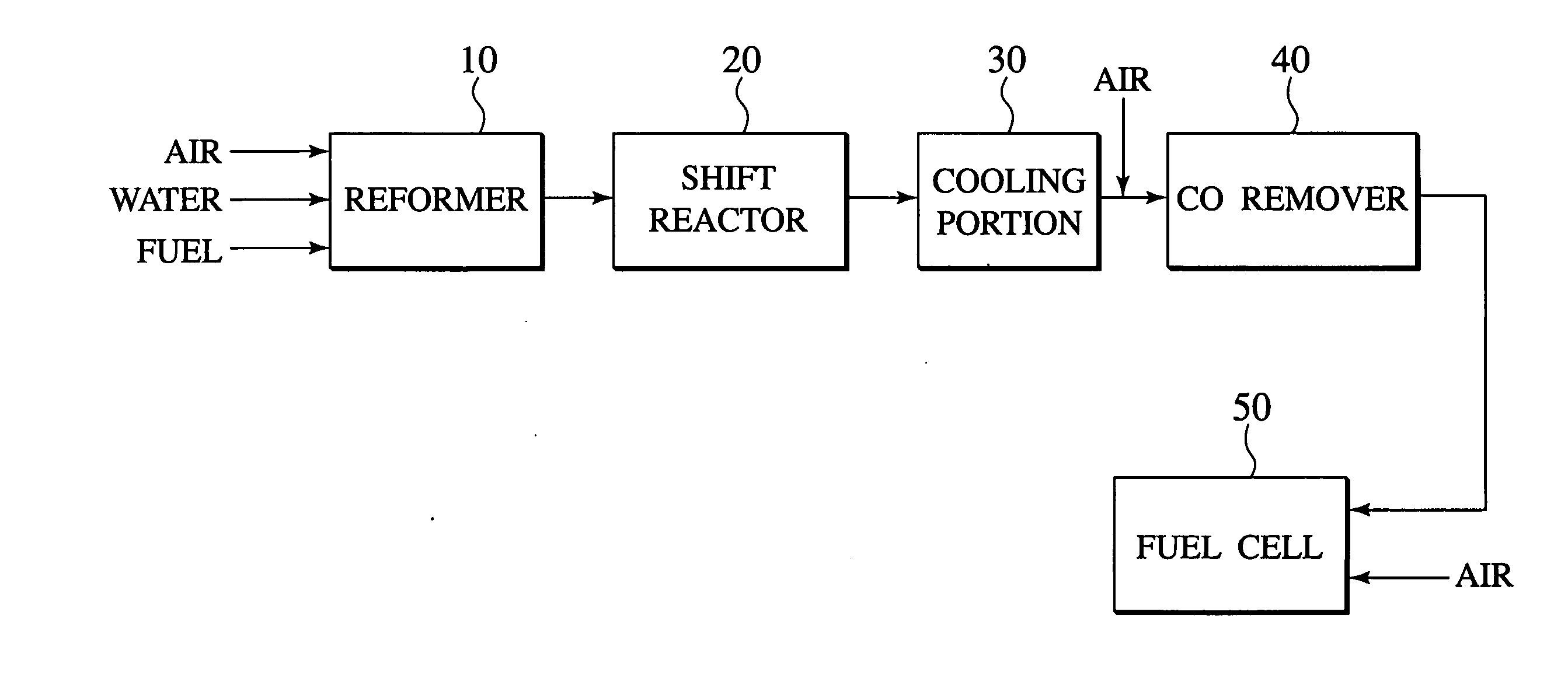

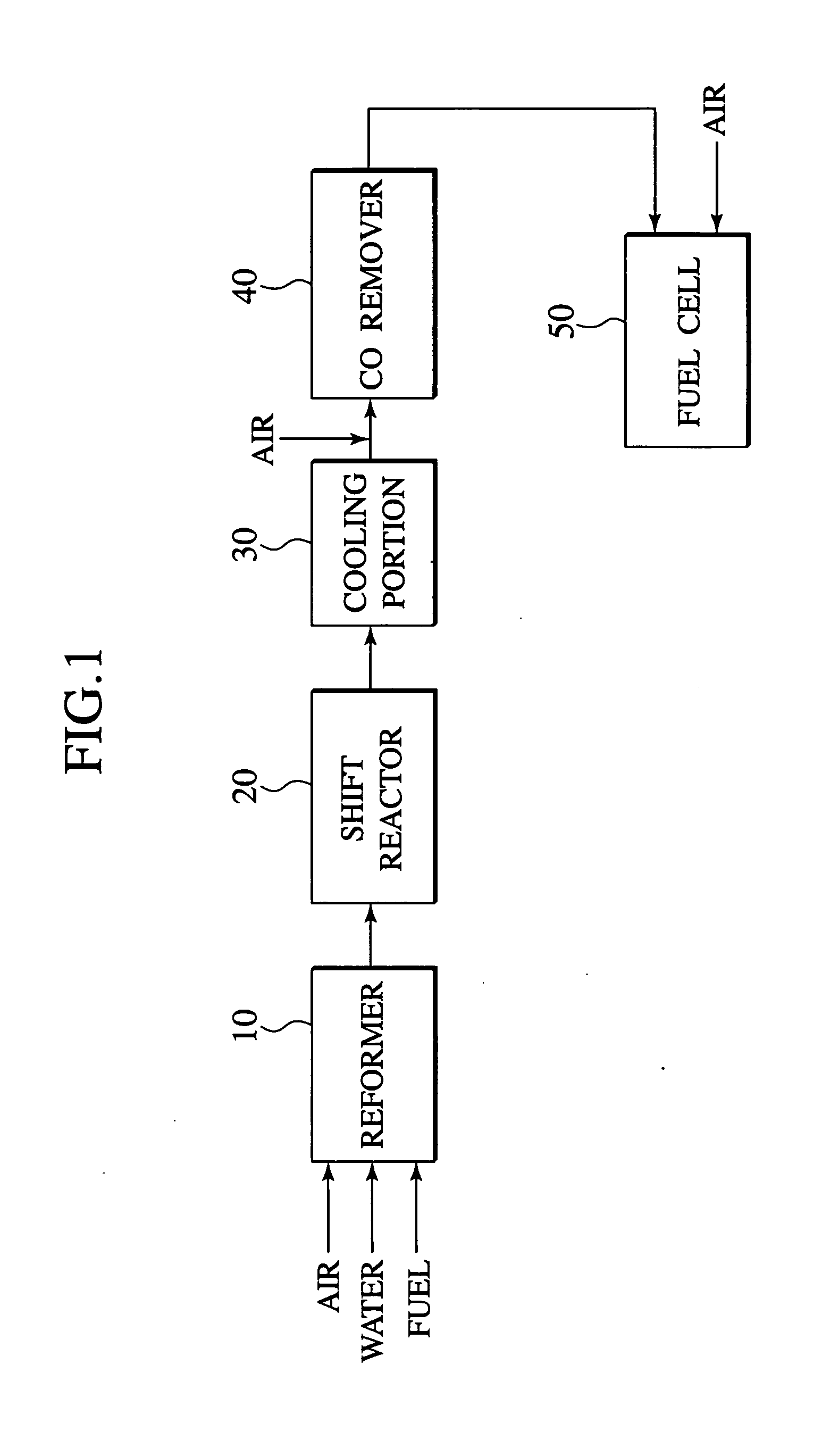

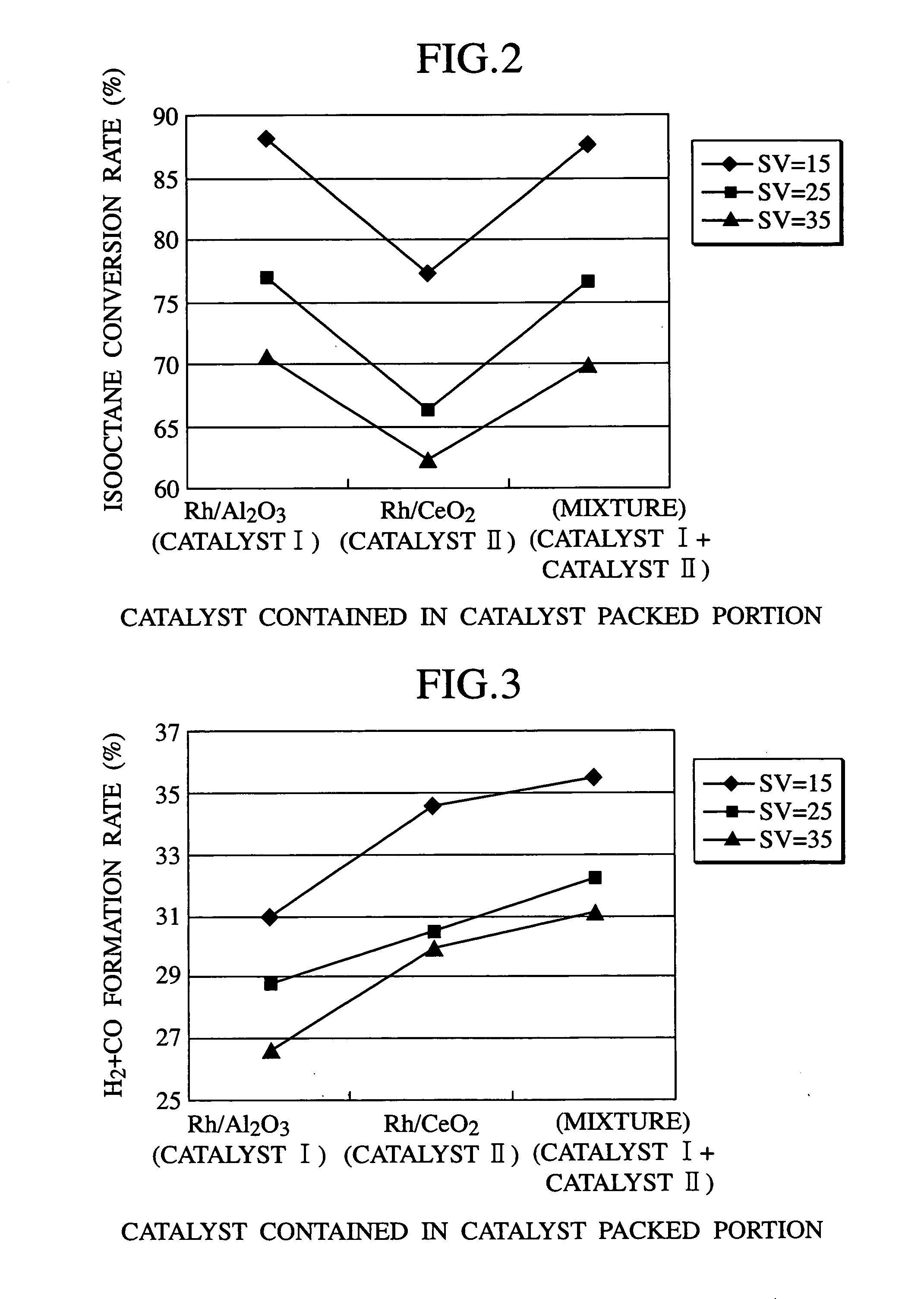

Fuel Reforming Apparatus And Fuel Cell System

InactiveUS20110223502A1Improving starting-up propertyImprove robustnessHydrogenFuel cell applicationsFuel cellsHydrogen

A fuel reforming apparatus includes a catalyst packed portion containing therein fuel reforming catalyst (I) having excellent hydrocarbon conversion rate and fuel reforming catalyst (II) having excellent H2+CO formation rate. Each of catalyst (I) and catalyst (II) especially preferably includes rhodium supported thereon. When the carrier for catalyst (I) is aluminum oxide and the carrier for catalyst (II) is cerium oxide, the hydrogen generation efficiency is excellent particularly even at start-up.

Owner:NISSAN MOTOR CO LTD

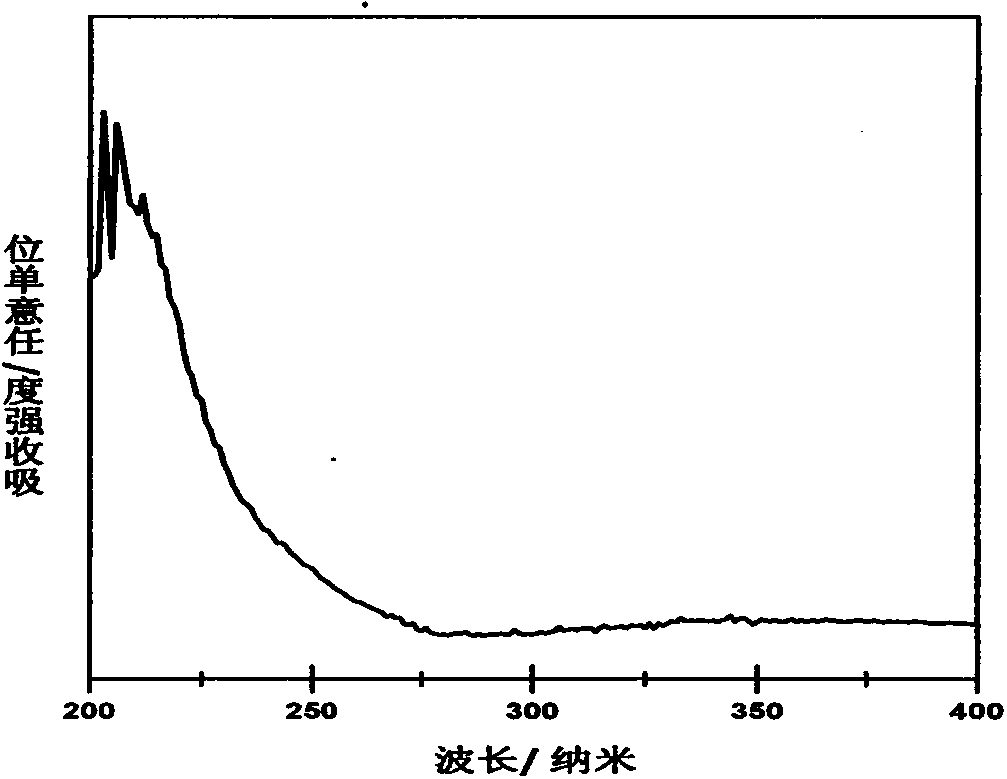

Method for preparing uvioresistant polyester by nanometer titania generated in situ

InactiveCN1300246CSolve reunionReduce dispersionArtifical filament manufactureEngineering plasticUltraviolet

A process for in-situ preparing UV-resistant polyester by use of TiO2 nanoparticles includes such steps as synthesizing the hydrolysis speed controllable glycol salt of Ti, organic stabilizing it, dispersing it in diol, and polymerizing (or copolymerizing) with polyester and other monomers. Its advantage is high UV shielding effect.

Owner:SHANGHAI JIAO TONG UNIV

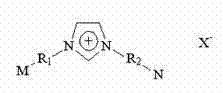

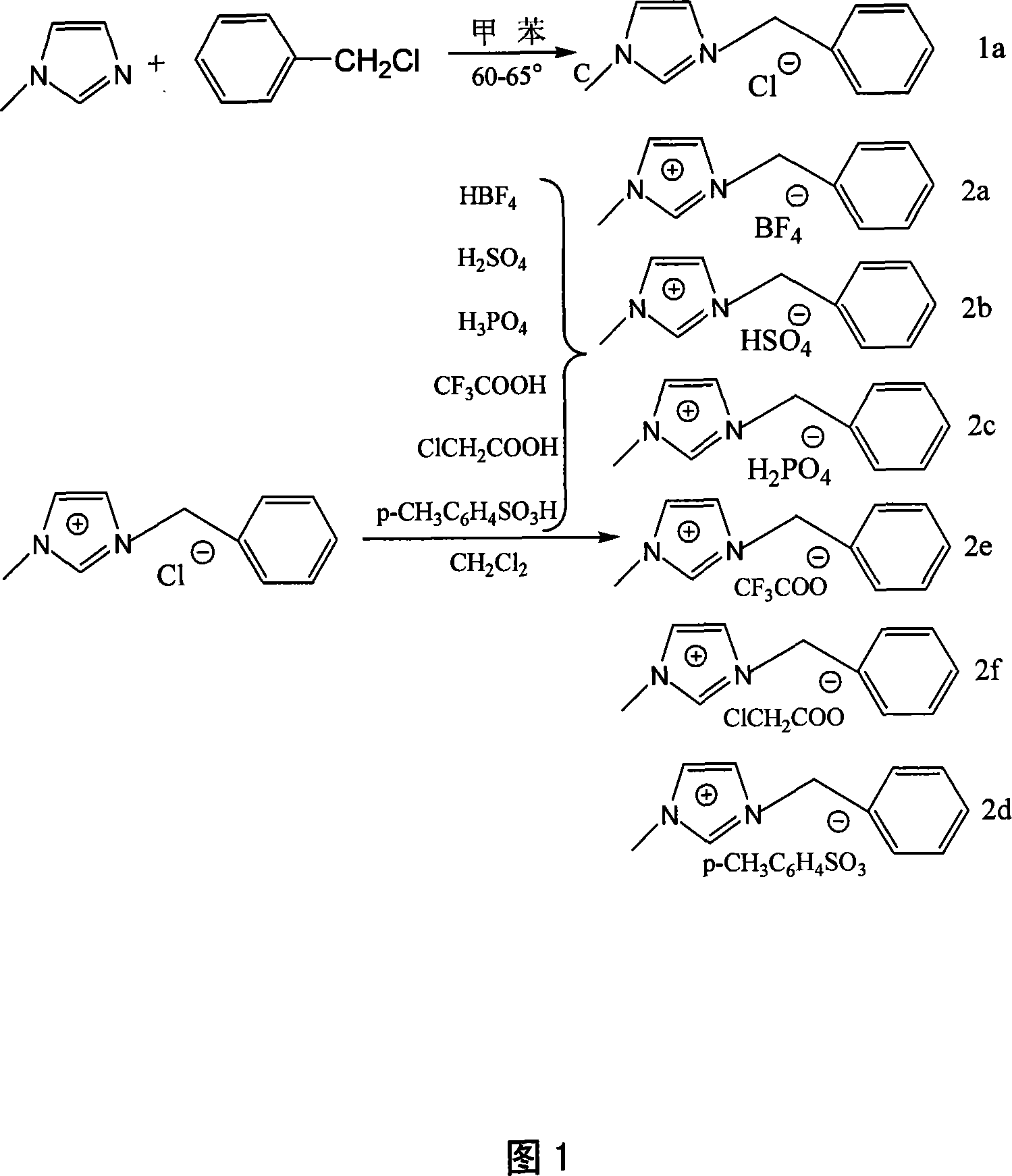

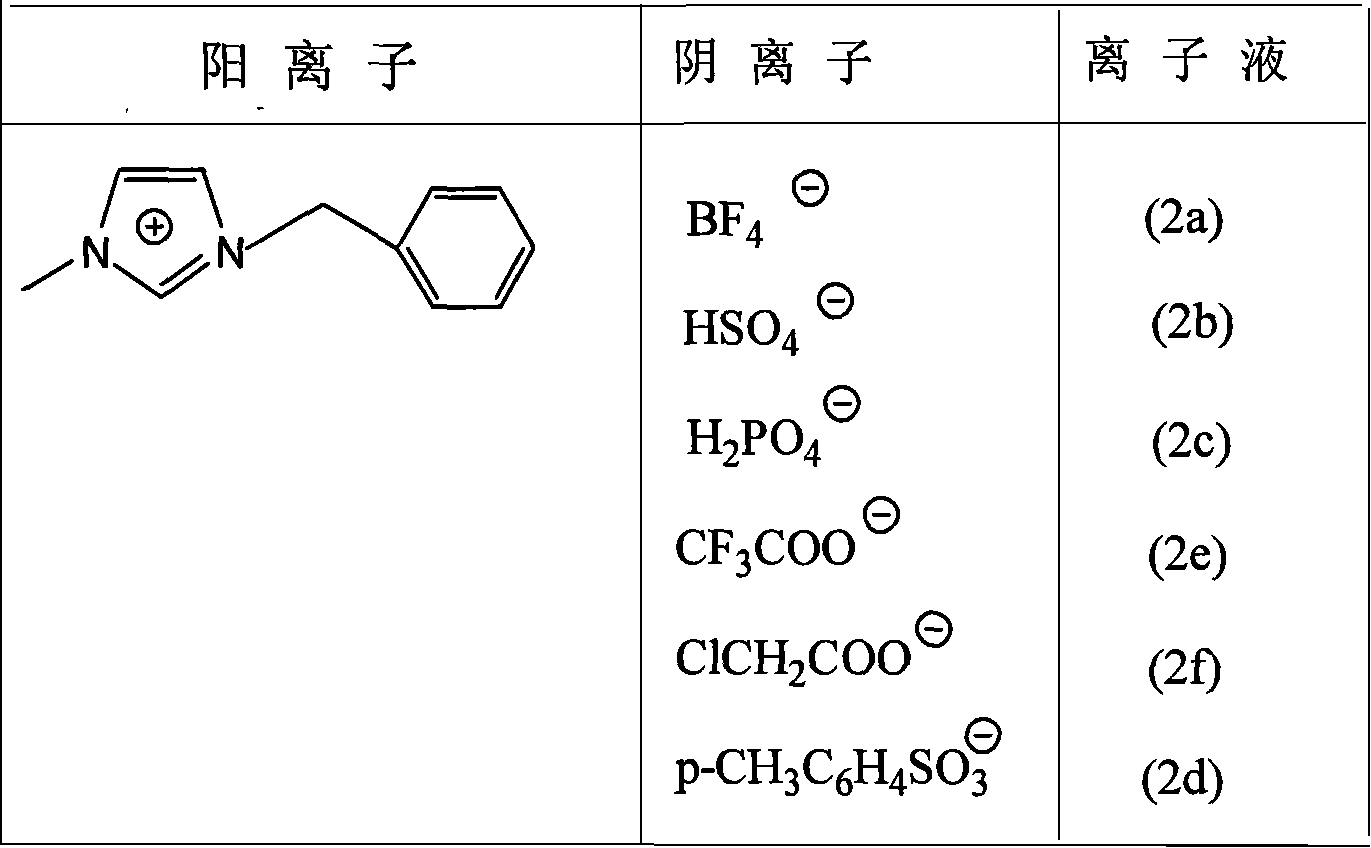

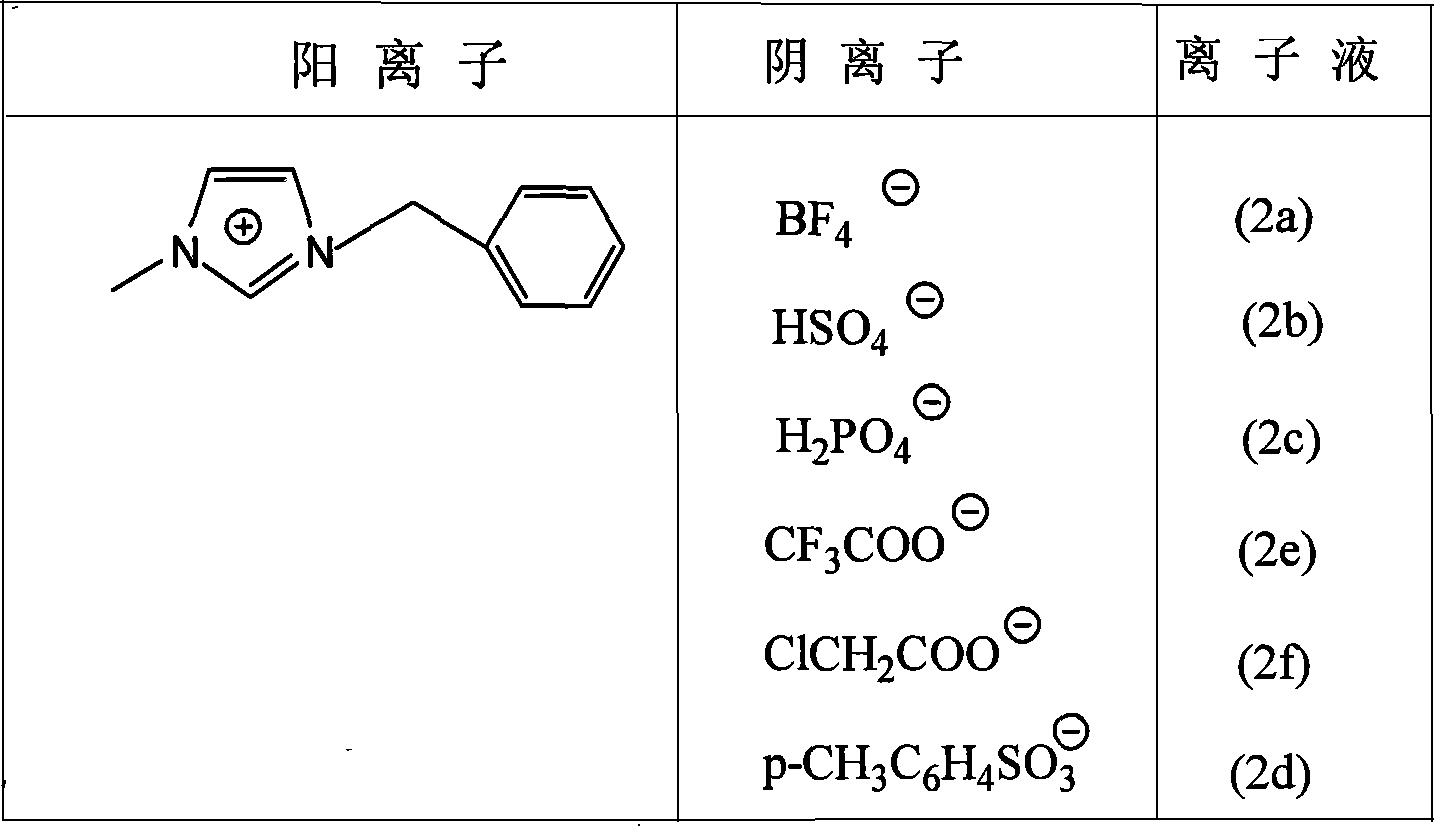

Acidic ionic liquid based on 1-methyl-3-benzyl imidazole cation, synthetic method and use

InactiveCN101058560AAchieve green synthesisEasy to separateOrganic compound preparationCarboxylic acid esters preparationInto-structureSolvent

The invention discloses an acid ion liquid and synthesizing method and application based on 1-methyl-3-benzyl imidazole cation, which is 1-methyl imidazole benzyl methylation organic cation, wherein the inorganic / organic anion is BF4<->,HSO4<->, H2PO4<->, p-CH3C6H4SO<3->, CF3COO<-> and ClCH2COO<->, wherein the ion liquid is liquid phase under indoor temperature, which can repair structure as mother compound due to leading functional group into structure, such as benzene ring, methylene and so on; the BrPhinsted acid can be repeating ring, reacting dielectric and reacting catalytic, which can be used to synthesize important perfume and solvent.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

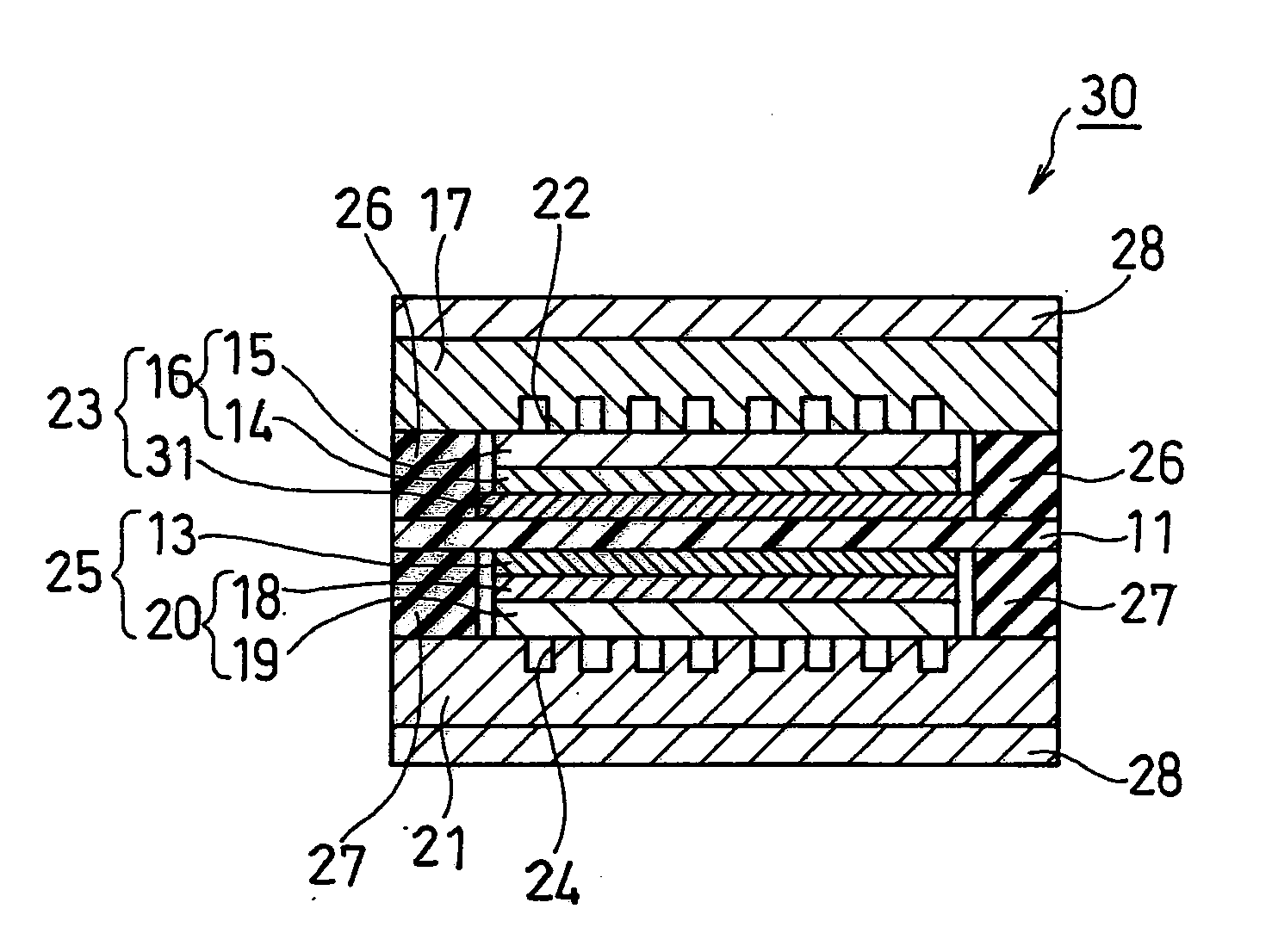

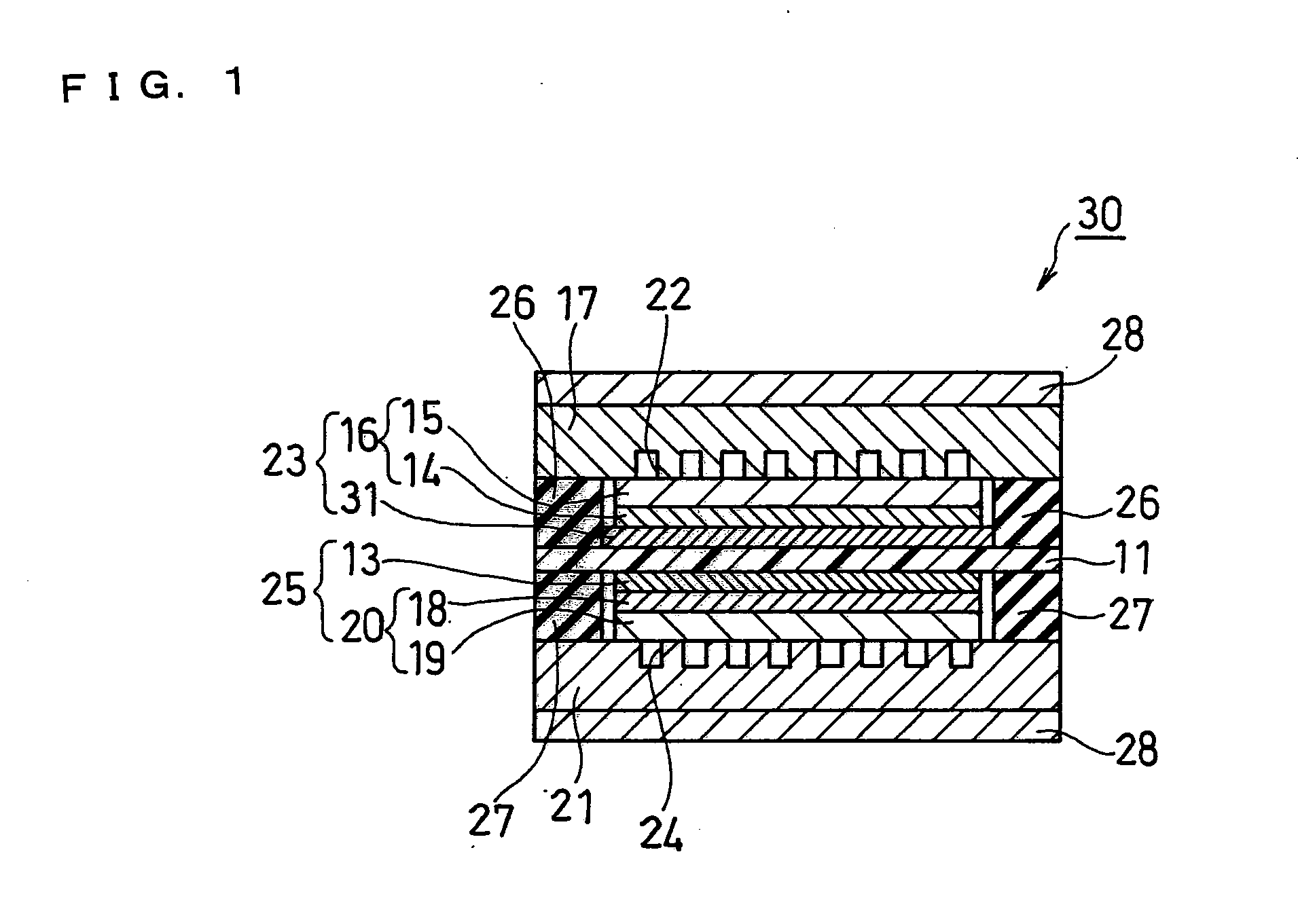

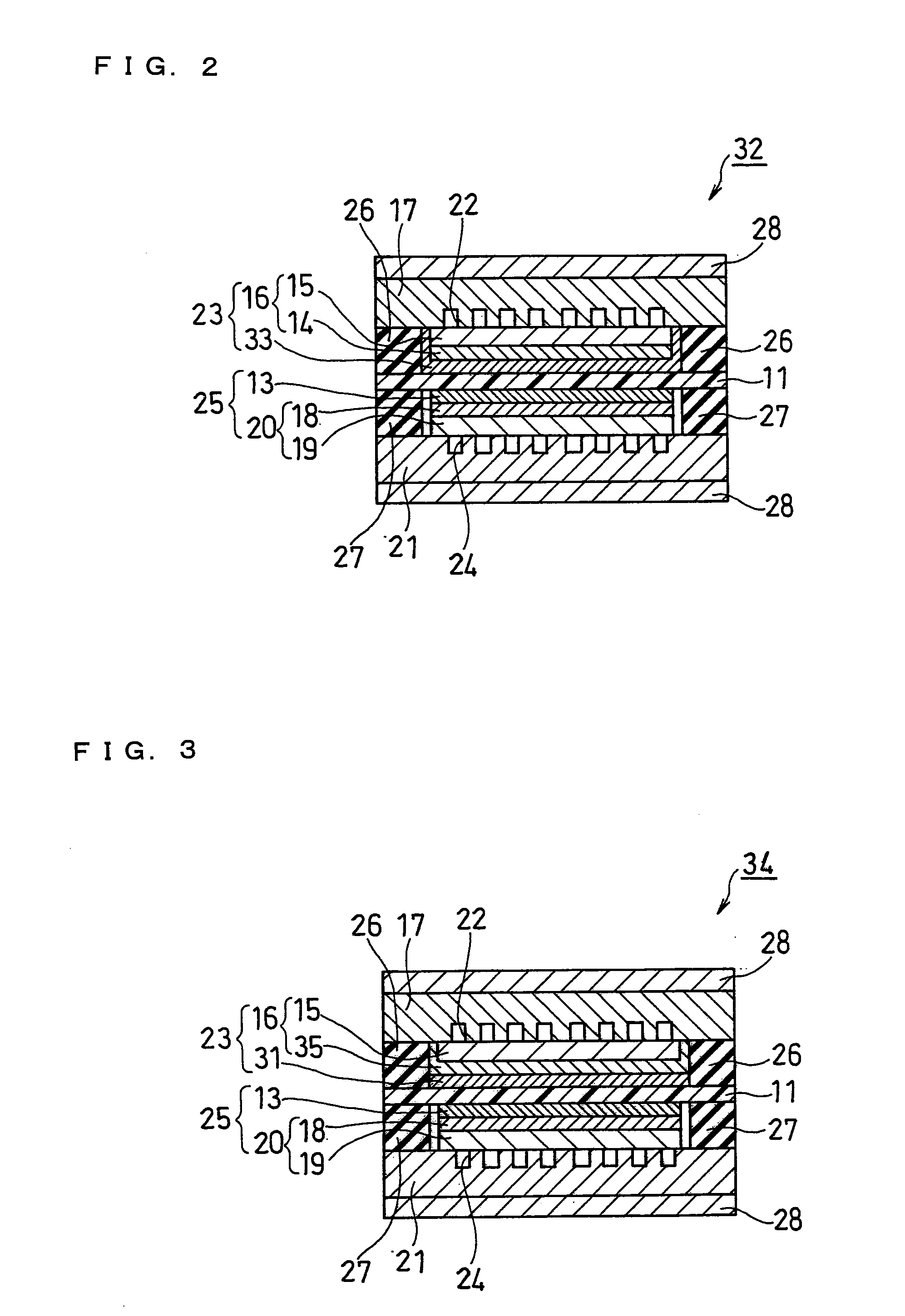

Fuel cell

InactiveUS20100190089A1Prevent fuel leakageIncrease volumeCell component detailsSolid electrolyte fuel cellsPolymer electrolytesPorous substrate

The present invention intends to provide a fuel cell being capable of preventing the methanol crossover in a simple and easy manner and being excellent in fuel utilization rate and the like. A fuel cell 30 of the present invention includes a polymer electrolyte membrane 11, an anode 23 and a cathode 25 sandwiching the polymer electrolyte membrane 11, an anode-side separator 17 having a fuel flow channel, a cathode-side separator 21 having an oxidant flow channel, and gaskets 26 and 27 interposed between the anode-side and cathode-side separators 17 and 21 and the periphery of the polymer electrolyte membrane 11. In the fuel cell 30, the orthographic projection area of the anode catalyst layer 31 included in the anode 23 seen from the direction normal to an MEA is set to be larger than the orthographic projection area of the anode porous substrate 15 included in the anode 23 seen from the direction normal to the MEA.

Owner:PANASONIC CORP

Catalyst for preparing 1,2-glycol by epoxy compound through hydration as well as preparation method and application thereof

InactiveCN103920527AStrong acidEasy to makeMolecular sieve catalystsPreparation by hydrolysisMolecular sieveHydration reaction

The invention relates to a catalyst for preparing a 1,2-glycol by epoxy compound through hydration as well as a preparation method and an application thereof. A beta zeolite molecular sieve is used as a raw material and then is subjected to acid treatment, and active centered metal is introduced through roasting; and the preparation method comprises the steps of mixing the beta zeolite molecular sieve after acid treatment with an organometallic compound precursor according to the proportion, and roasting. The method can solve the problems of high water ratio, high energy consumption and environment pollution caused by a production process in the traditional process; and the catalyst carrier is cheap and easily available, the preparation process of the catalyst is simple and has good stability, and the catalyst has excellent catalytic activity and the good selectivity in the glycol preparation process by the epoxy compound under a mild condition, and can be applied to glycol industrial production through epoxy compound hydration.

Owner:NANKAI UNIV

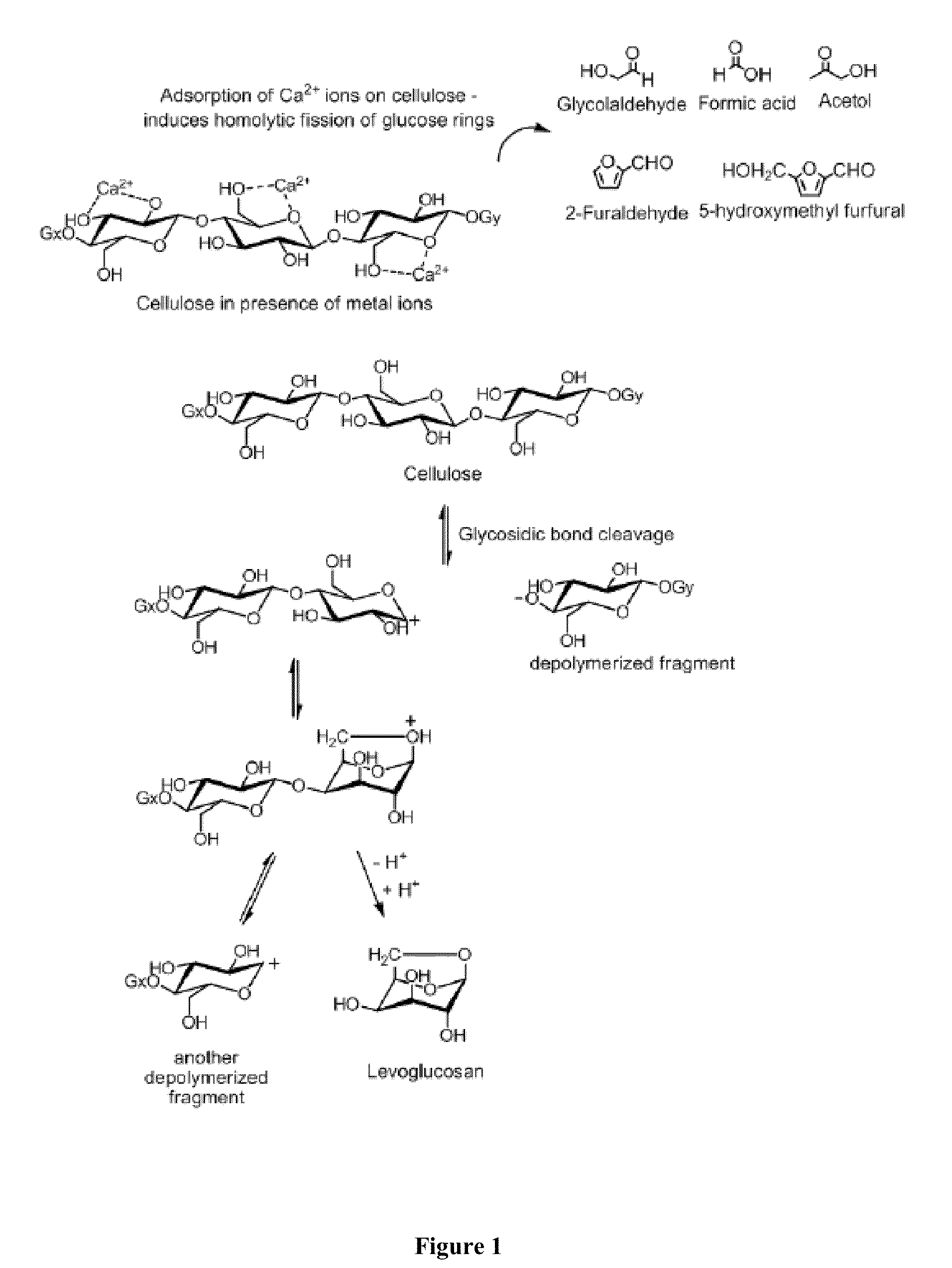

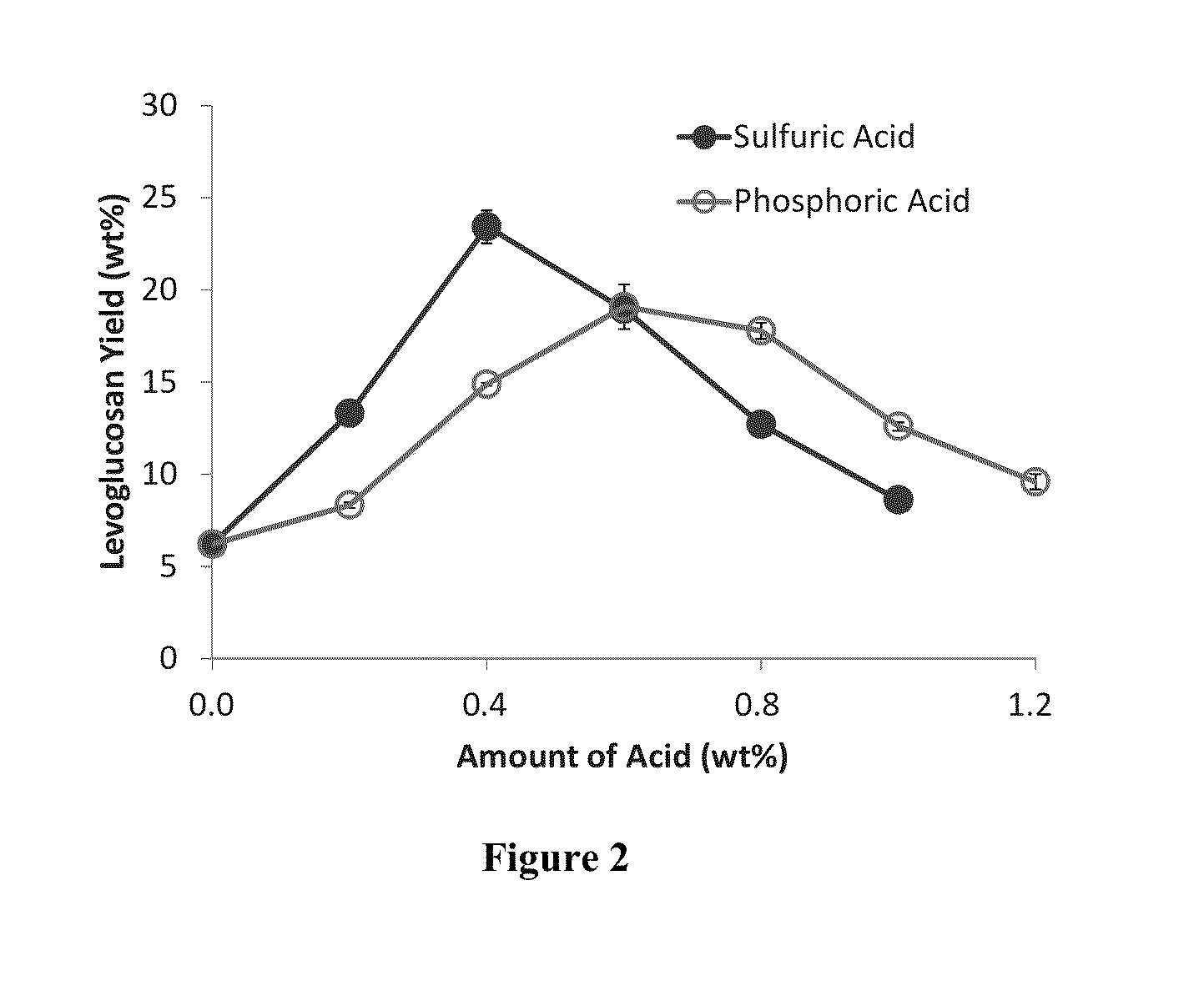

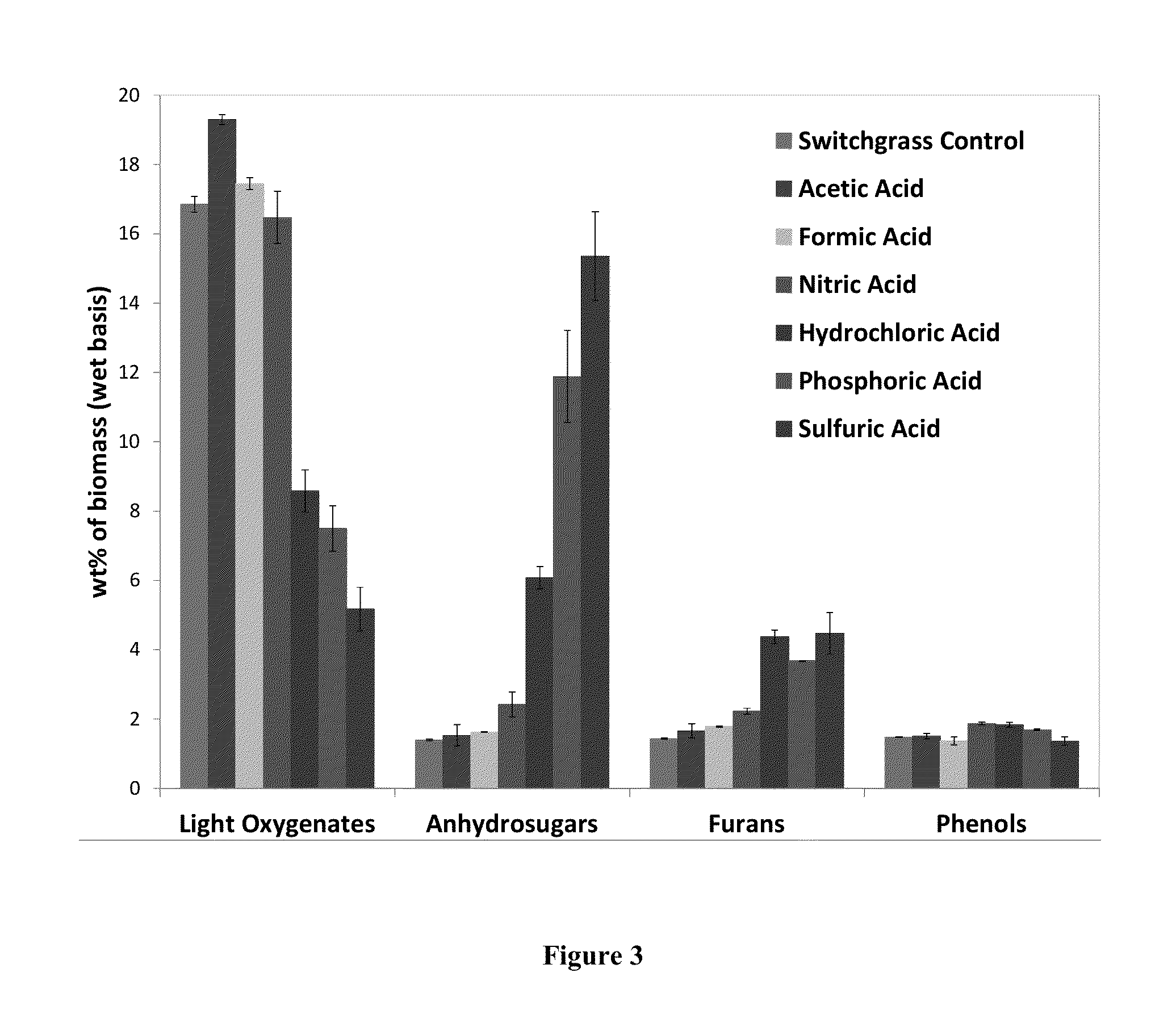

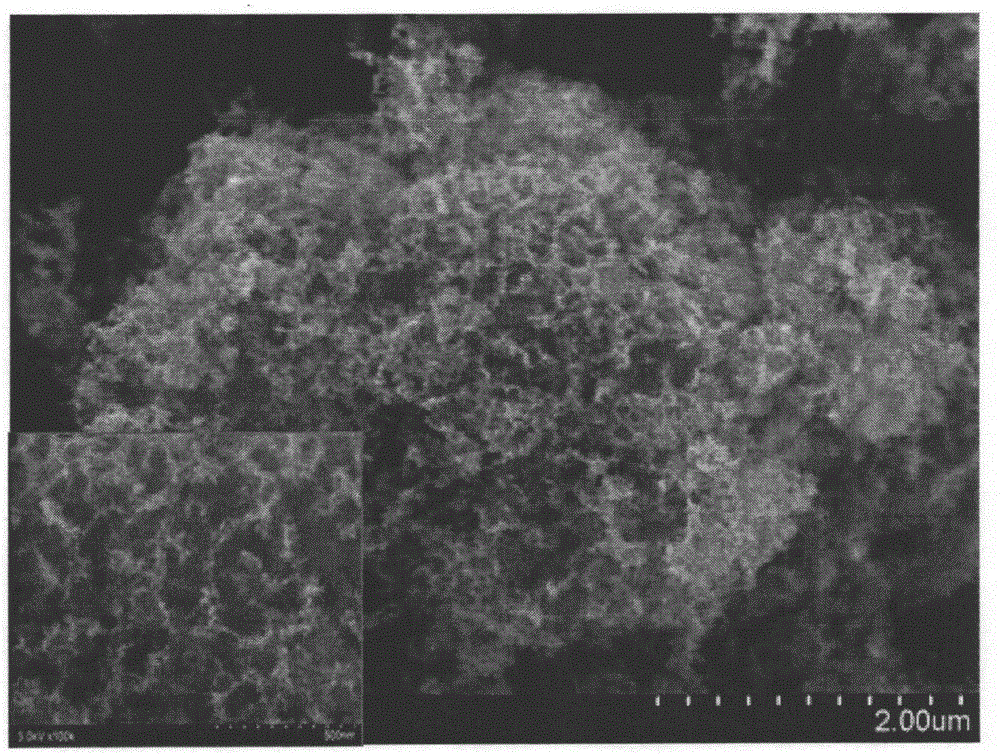

Method for pretreating lignocellulosic biomass

ActiveUS20130340746A1Reduce fragmentationIncrease productionBiofuelsSpecial form destructive distillationCelluloseAlkaline earth metal

The present invention relates to a method for pretreating lignocellulosic biomass containing alkali and / or alkaline earth metal (AAEM). The method comprises providing a lignocellulosic biomass containing AAEM; determining the amount of the AAEM present in the lignocellulosic biomass; identifying, based on said determining, the amount of a mineral acid sufficient to completely convert the AAEM in the lignocellulosic biomass to thermally-stable, catalytically-inert salts; and treating the lignocellulosic biomass with the identified amount of the mineral acid, wherein the treated lignocellulosic biomass contains thermally-stable, catalytically inert AAEM salts.

Owner:IOWA STATE UNIV RES FOUND

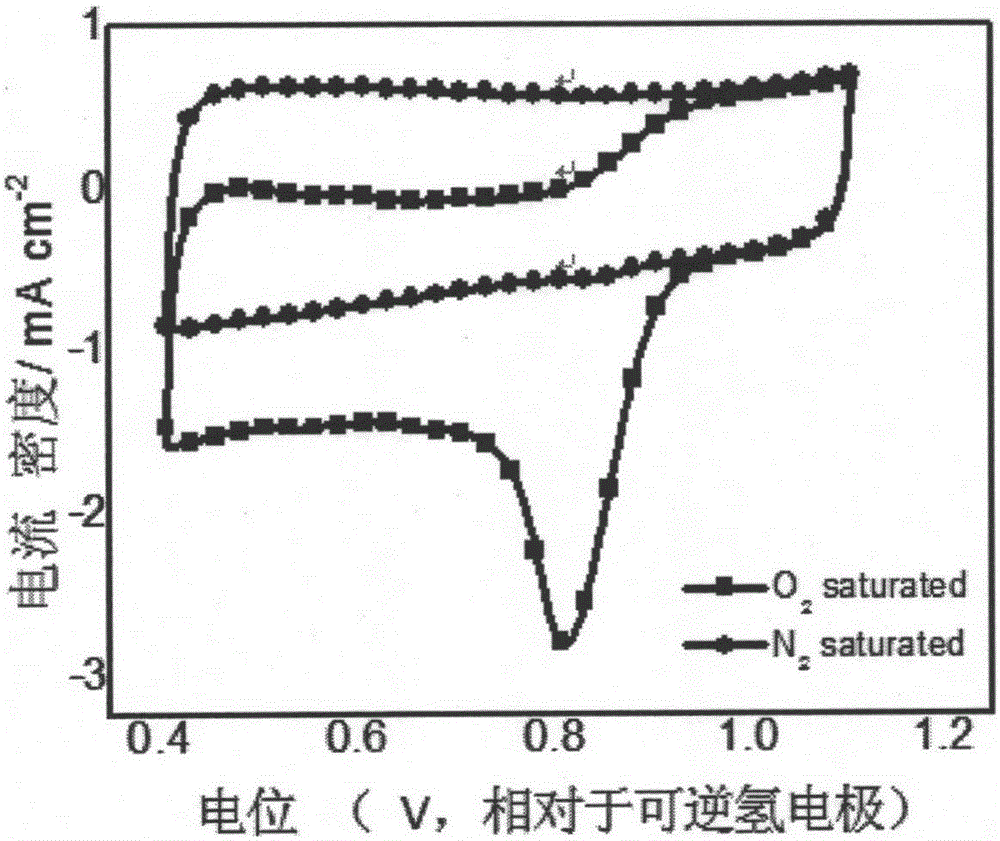

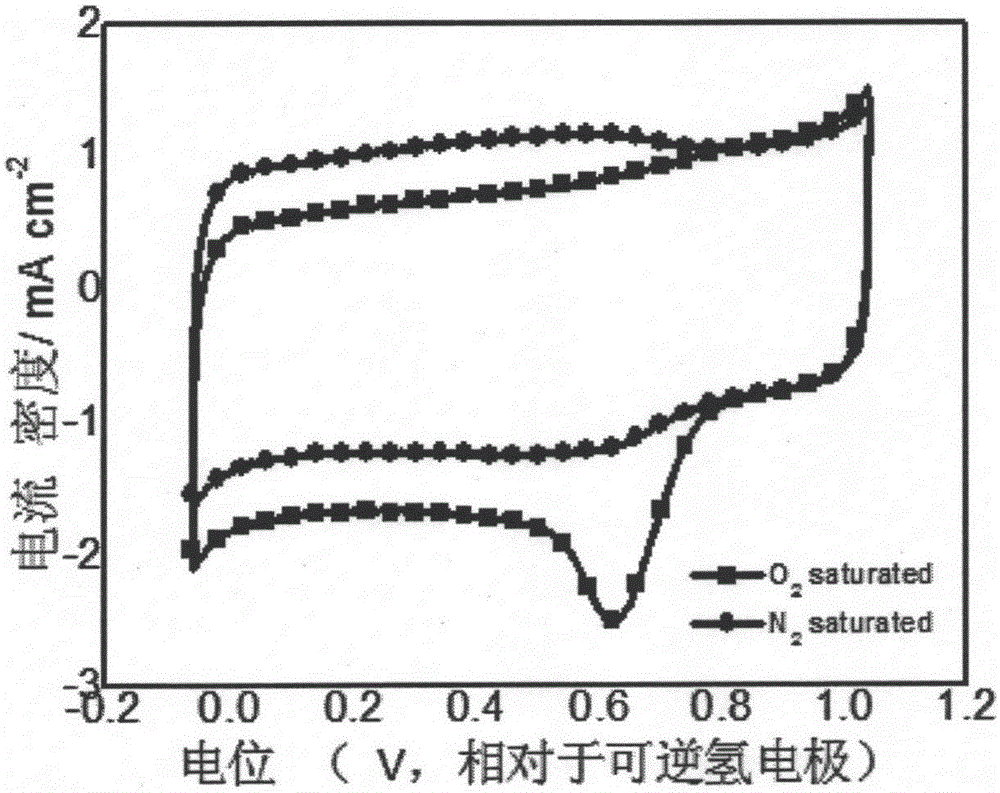

Nitrogen/sulphur/chlorine co-doped multistage hole carbon catalyst and preparation method thereof

InactiveCN105148991AEasy to prepareHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesElectrolysisReduction treatment

The invention provides a nitrogen / sulphur / chlorine co-doped multistage hole carbon catalyst and a preparation method thereof. The nitrogen / sulphur / chlorine co-doped multistage hole carbon catalyst is characterized by being prepared by treating a precursor, wherein the precursor comprises the raw materials: 10-60wt% of a template agent, 10-80wt% of a nitrogen / chlorine containing high polymer, and 5-50wt% of a transition metal salt, and the weight content is based on the total weight of the precursor; the treatment comprises calcination reduction treatment, alkali washing treatment, acid washing treatment and secondary calcination reduction treatment. The preparation method has the characteristics of being simple, easy to operate, low in cost, high in yield and the like; the dependence on noble metal Pt is greatly reduced; a corrosion problem caused by use of a non-noble metal catalyst is overcome; the nitrogen / sulphur / chlorine co-doped multistage hole carbon catalyst has the wide application prospects in fields of acid and alkaline fuel cells, metal-air cells, supercapacitors, CO2 electroreduction, environment waste water treatment and the like.

Owner:DONGHUA UNIV

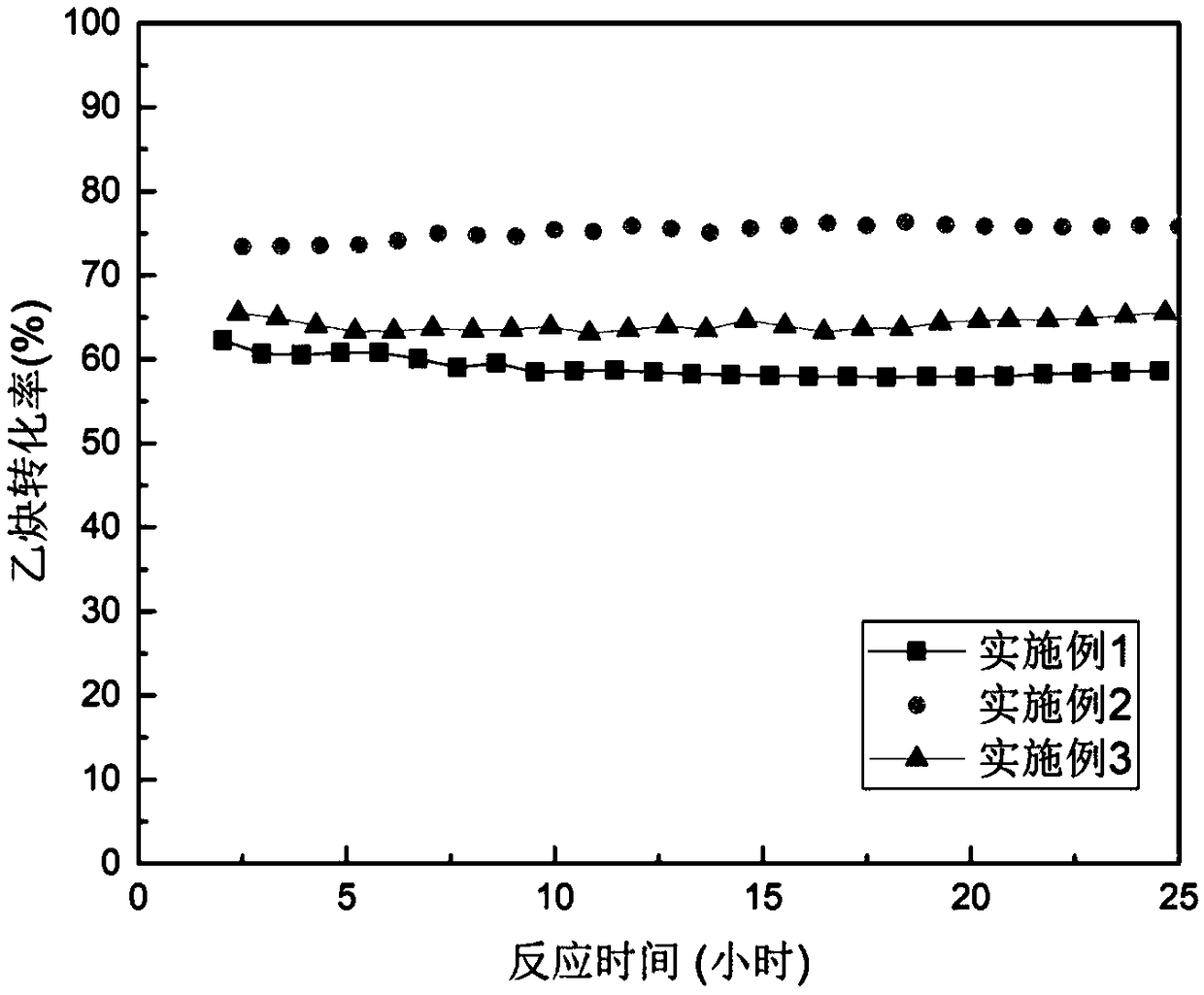

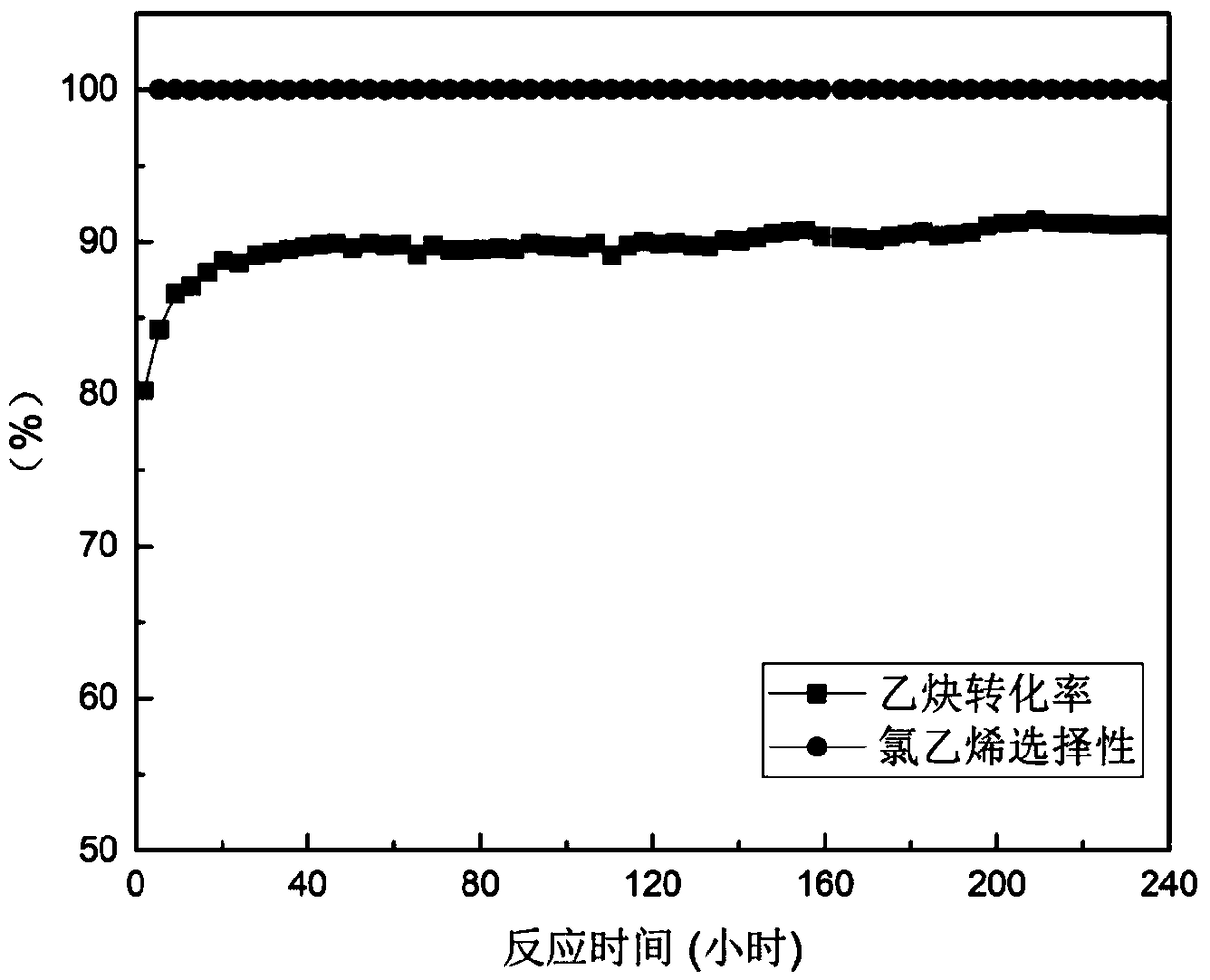

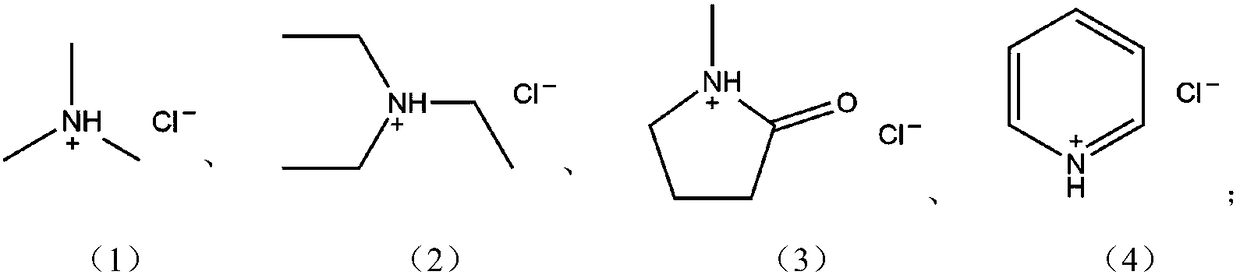

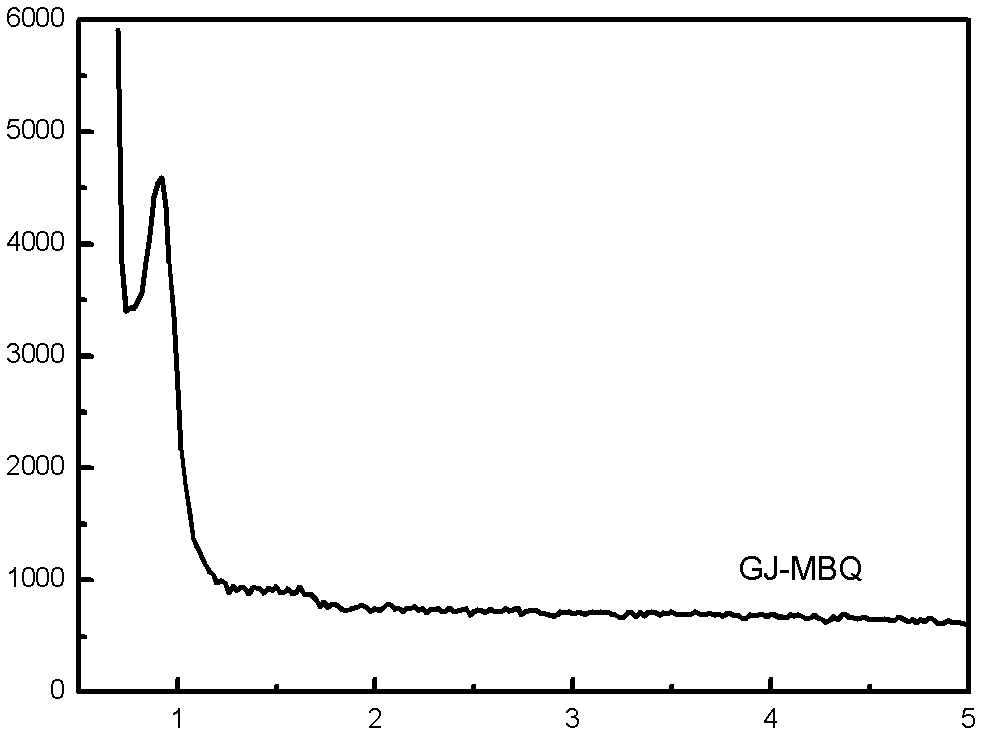

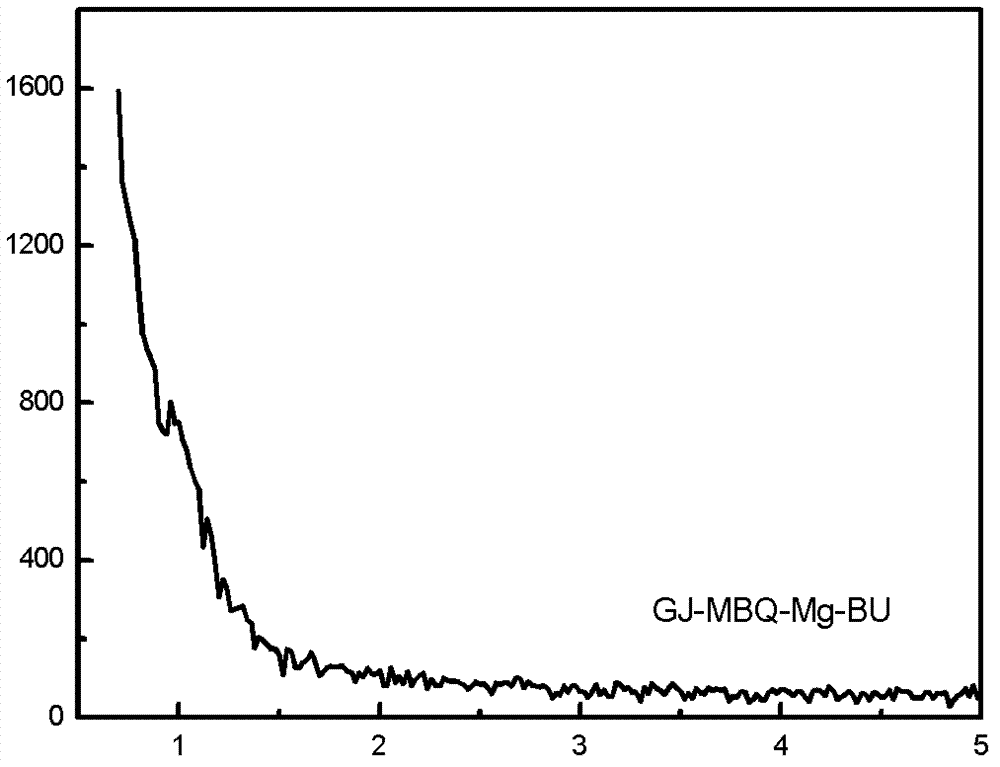

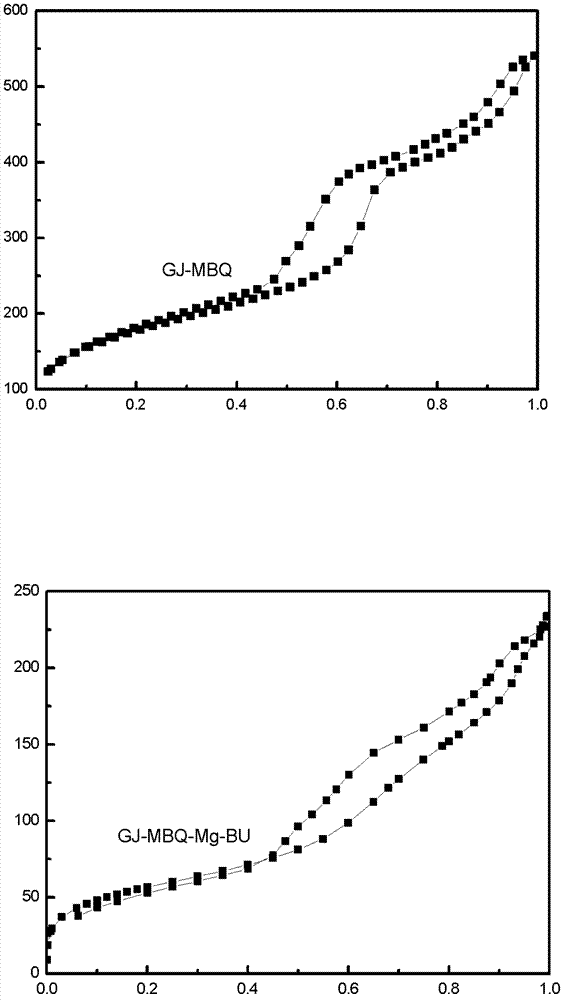

Metal halide acid radical ion liquid for catalyzing acetylene hydrochlorination as well as application method thereof

ActiveCN109158126AAvoid pollutionImprove thermal stabilityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen halideSource material

The invention relates to metal halide acid radical ion liquid for catalyzing acetylene hydrochlorination as well as an application method thereof. The metal halide acid radical ion liquid takes one ofalkyl-containing amine hydrogen halide, alkyl monosubstituted pyrrolidone hydrogen halide and pyridine hydrogen halide as a cationic source material and takes one of halide of zinc, copper, iron andtin as an anionic source material, wherein the molar ratio of the cationic source material to the anionic source material is 1:(0.3-3.0). In a bubbling reactor, the metal halide acid radical ion liquid serves as a catalyst, the reaction raw material gas acetylene and hydrogen chloride are mixed, the mixture is introduced into the metal halide acid radical ion liquid to perform reaction, the reaction temperature is 120 to 200 DEG C, the volume velocity ratio of the acetylene to the hydrogen chloride is 1:(1.0-1.6), the volumetric space velocity of the acetylene is 10 to 100 h<-1>, and under thecondition of not using noble metal, the highest conversion rate of the acetylene can reach to above 90 percent and the selectivity of chloroethylene is still more than 99 percent.

Owner:TIANJIN UNIV +1

Supported metallocene catalyst and preparation method and application thereof

The invention provides a supported metallocene catalyst which comprises a carrier, and an alkylaluminoxane / magnesium chloride complex and a metallocene compound which are supported on the carrier; the carrier is spherical mesoporous silica, wherein the carrier has an average particle diameter of 20-80 microns, a specific surface area of 550-650 square meter / g, a pore volume of 0.4-1.2 ml / g, and a most probable pore size of 1-7 nanometers; the metallocene compound has a structure as shown in formula 1. When the supported metallocene catalyst of the invention is used for catalyzing olefin polymerization, the catalytic efficiency for homopolymerization at 70 DEG C is up to 2.3*10<8> gPE / (mol Zr.h), and the catalytic efficiency for copolymerization at 70 DEG C is up to 2.2*10<8> gPE / (mol Zr.h); the supported metallocene catalyst overcomes the defect of kettle adhesion, has a low polymerization temperature, and thus reduces the energy consumption to some extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com