Patents

Literature

192 results about "Living polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

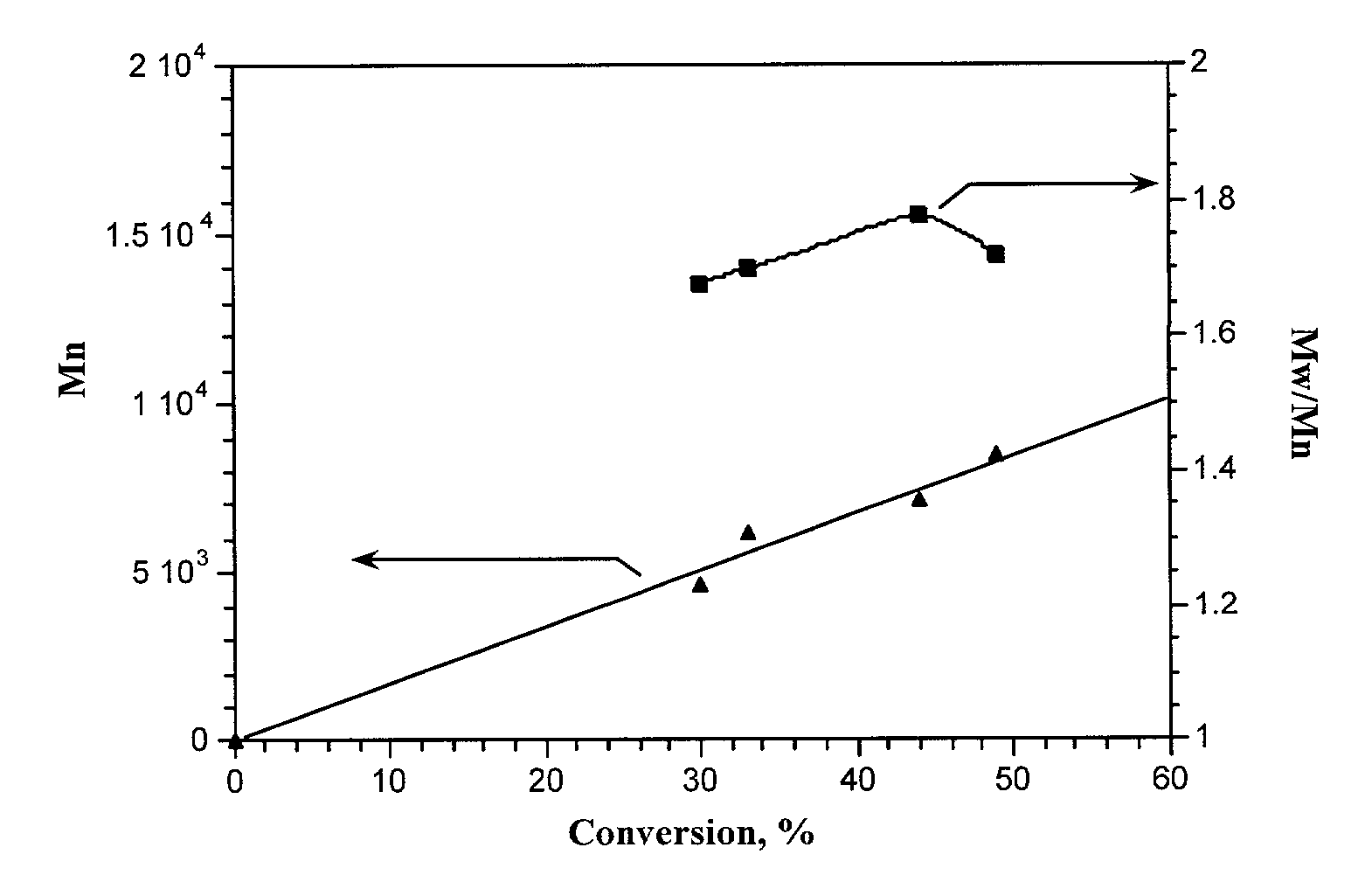

In polymer chemistry, living polymerization is a form of chain growth polymerization where the ability of a growing polymer chain to terminate has been removed. This can be accomplished in a variety of ways. Chain termination and chain transfer reactions are absent and the rate of chain initiation is also much larger than the rate of chain propagation. The result is that the polymer chains grow at a more constant rate than seen in traditional chain polymerization and their lengths remain very similar (i.e. they have a very low polydispersity index). Living polymerization is a popular method for synthesizing block copolymers since the polymer can be synthesized in stages, each stage containing a different monomer. Additional advantages are predetermined molar mass and control over end-groups.

Latex processes

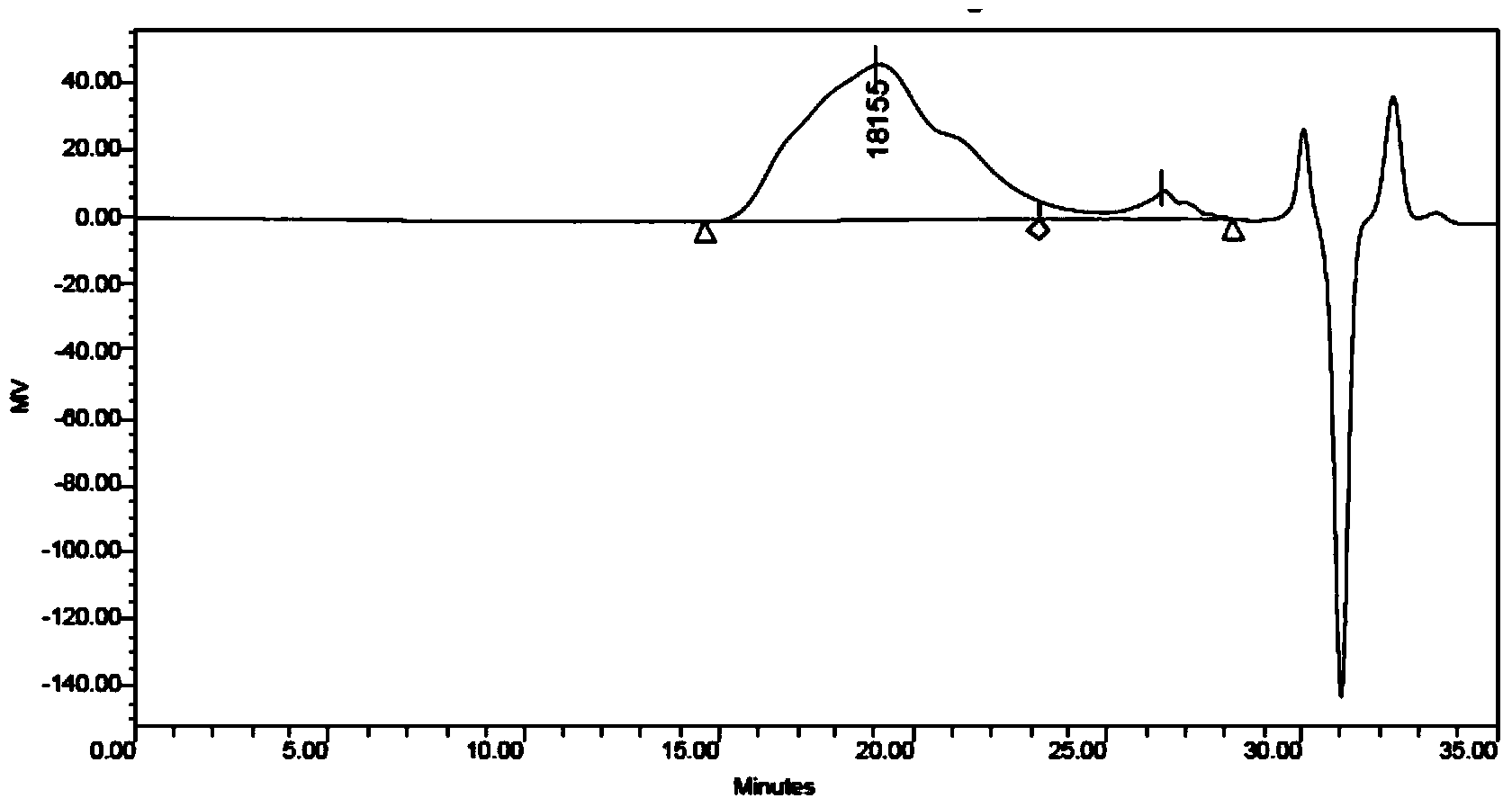

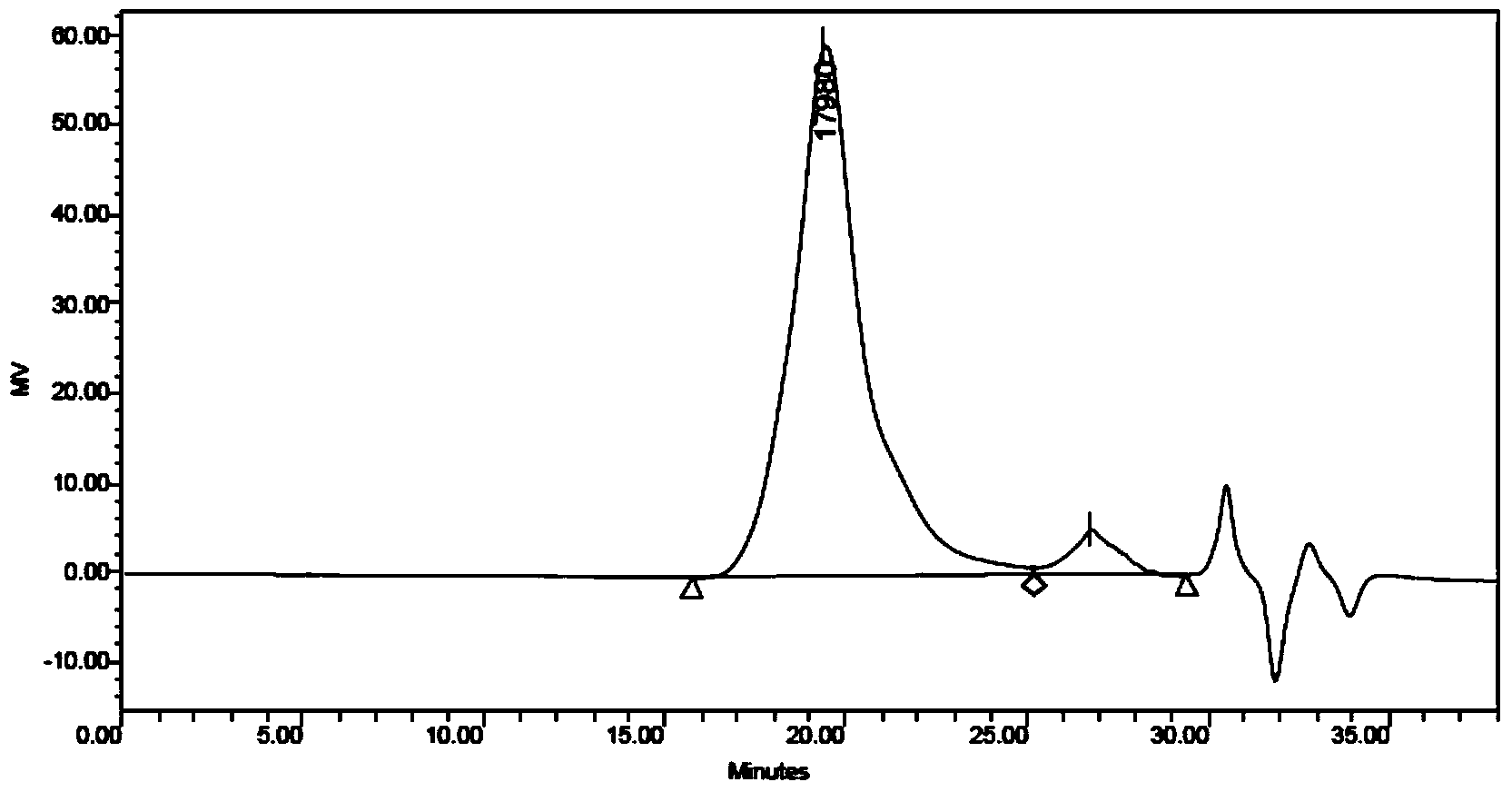

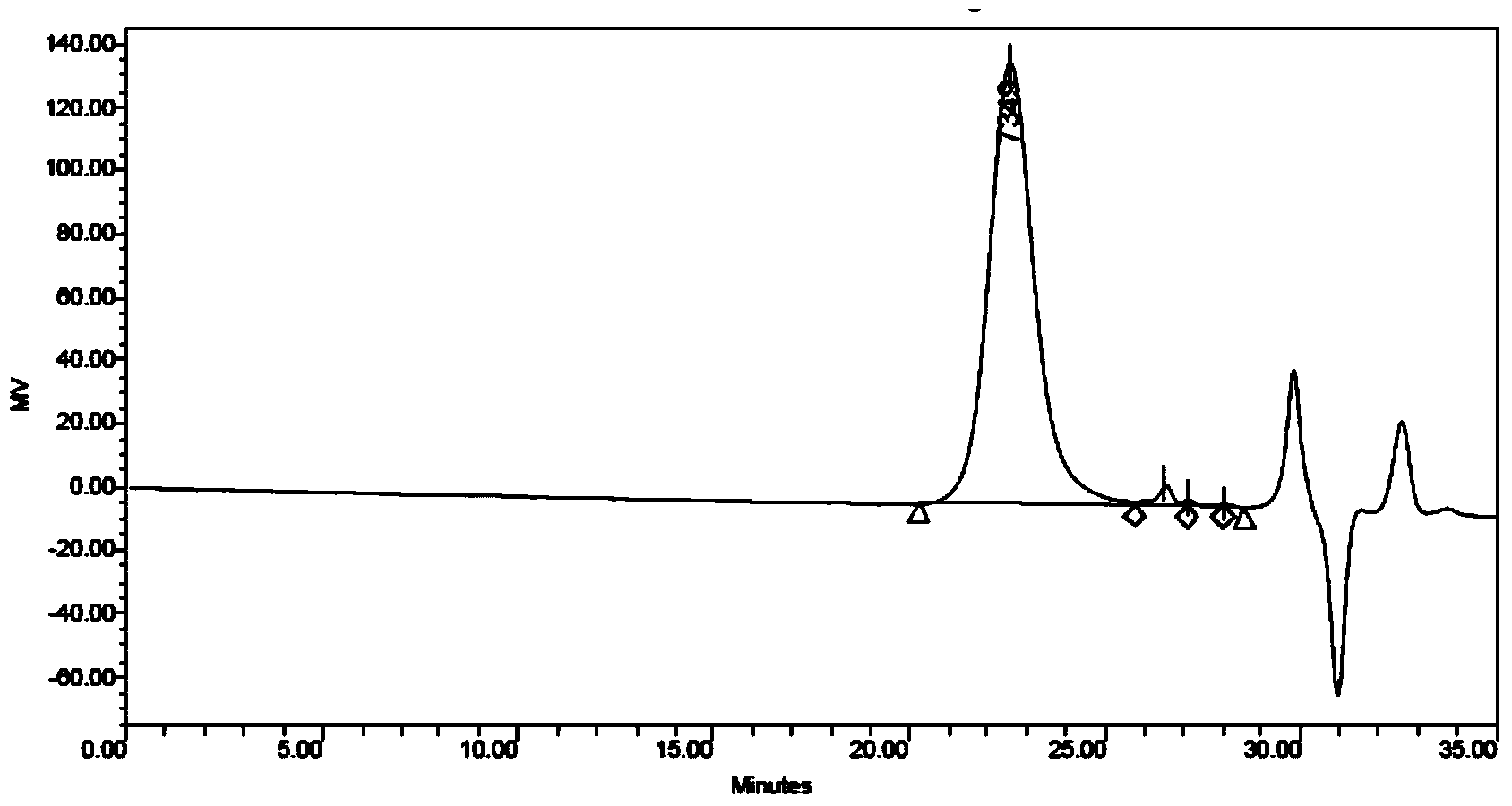

InactiveUS6503680B1Improve performanceImprove featuresDevelopersEmulsion paintsGlass transitionPolymer chemistry

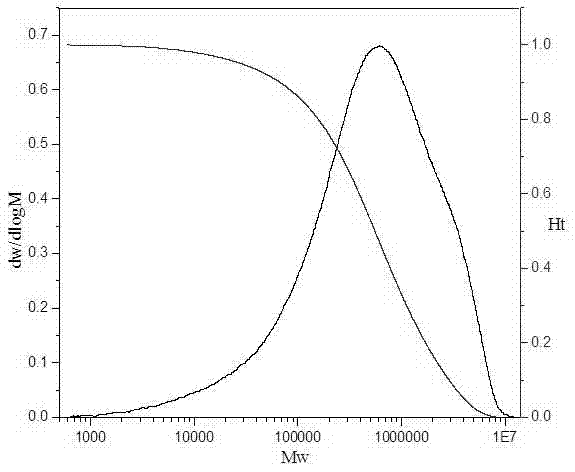

A process for the preparation of a latex polymer consistent with E / A (emulsion / aggregation / coalescence) toner manufacture. The process utilizes a standard (universal) latex composition and involves chain-transfer agent partitioning, emulsion polymerization that provides a latex polymer with a wide range of molecular properties. In particular, the process customizes a wide range Mw (weight average molecular weight) latex, without substantially varying the Mn (number average molecular weight) and hence, without substantially varying Tg (glass transition temperature) such that good toner performance is maintained. In a preferred process, a latex polymer is prepared by mixing a seed particle latex, generated by aqueous emulsion polymerization of a first portion of a monomer emulsion, with a second portion of the monomer emulsion and at least one chain-transfer agent. The mixing is done in the presence of a free-radical initiator and heated, and wherein the monomer emulsion comprises a mixture of polymerization reagents of at least one monomer, at least one chain-transfer agent, at least one surfactant, and water. This process may be applied to core-shell polymerization as well. These latex polymers are ideally suited in the manufacture of toner and developer for electrophotographic imaging and printing.

Owner:XEROX CORP

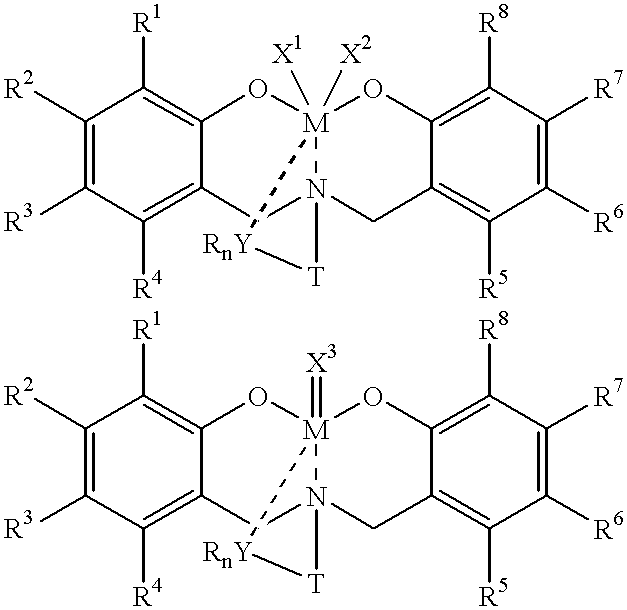

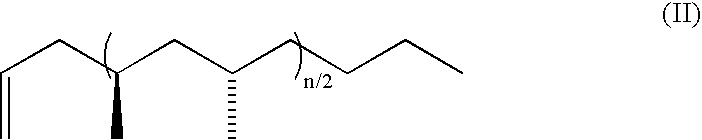

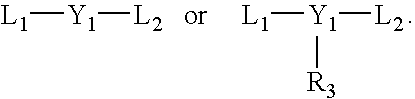

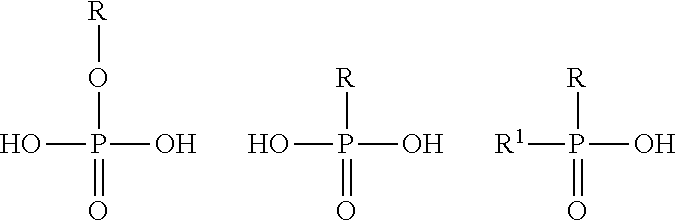

Method for catalytic polymerization of alpha-olefin monomers using an ultra-high activity non-metallocene pre-catalyst

InactiveUS6596827B2High molecular weightLow molecularGroup 4/14 organic compounds without C-metal linkagesOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePolyolefin

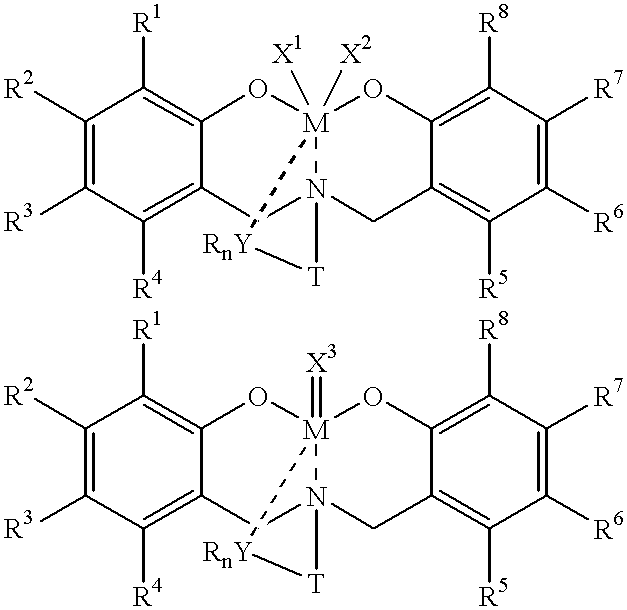

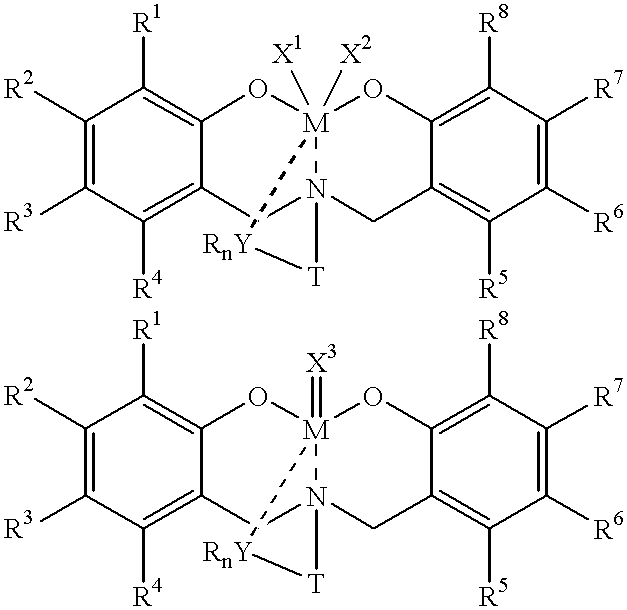

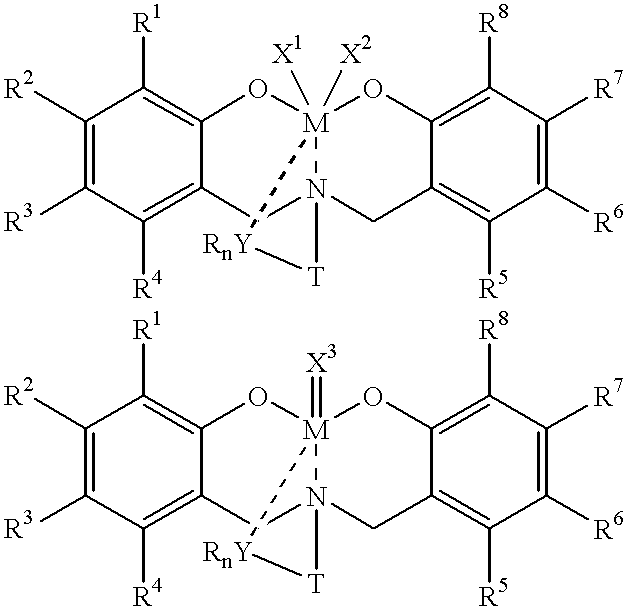

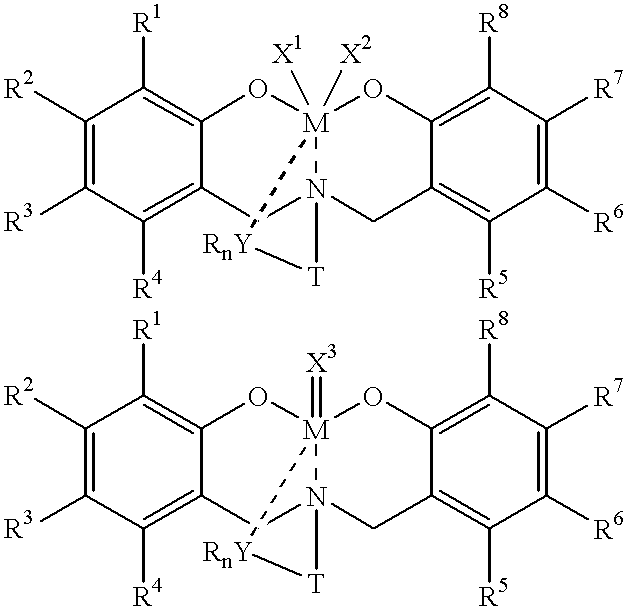

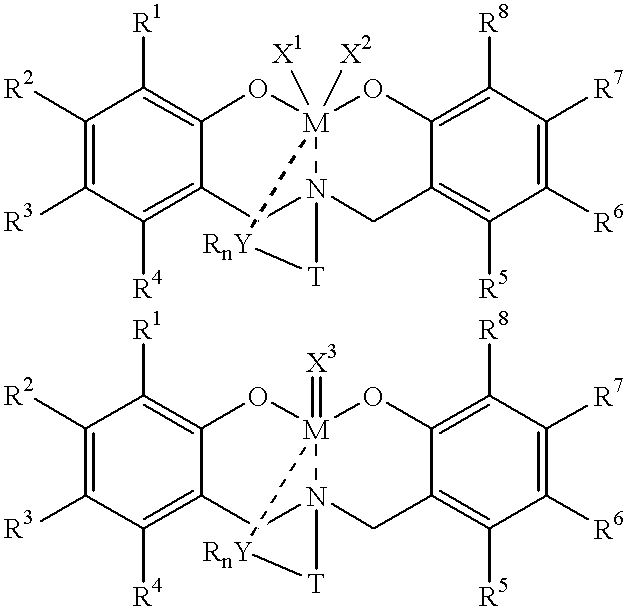

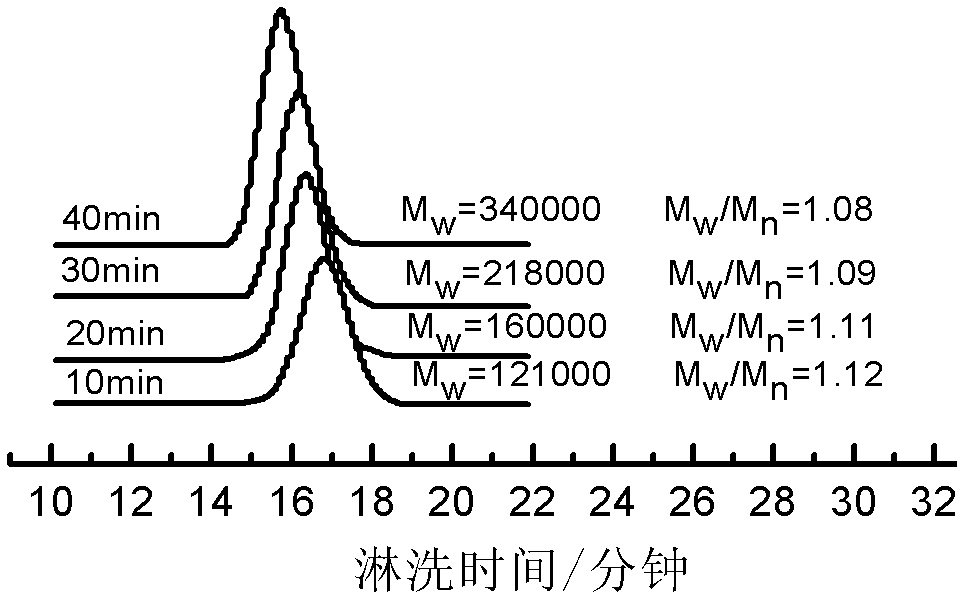

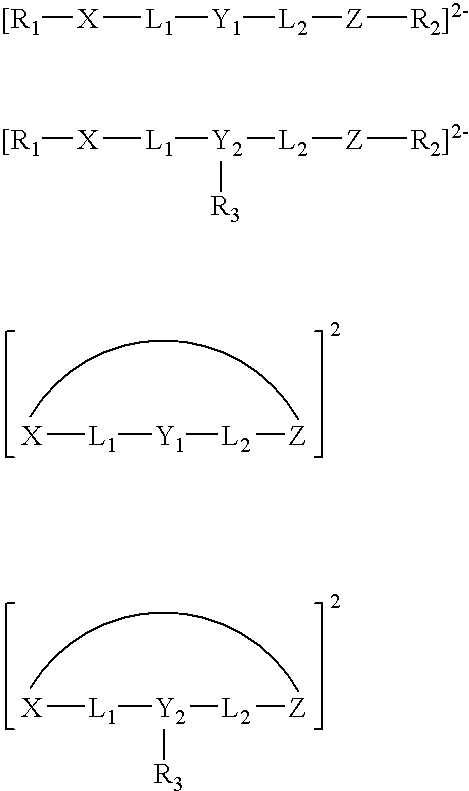

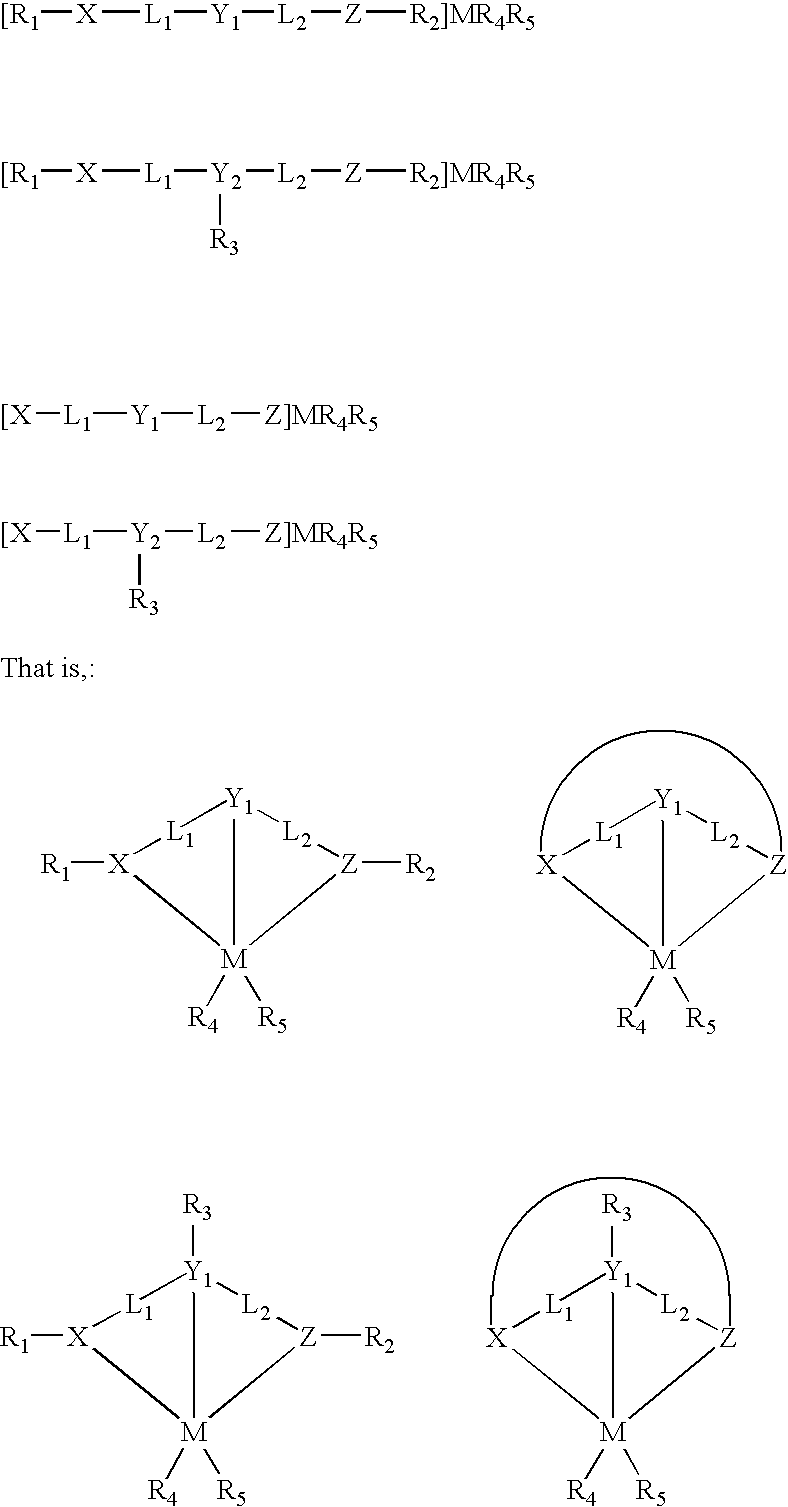

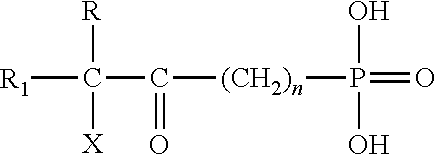

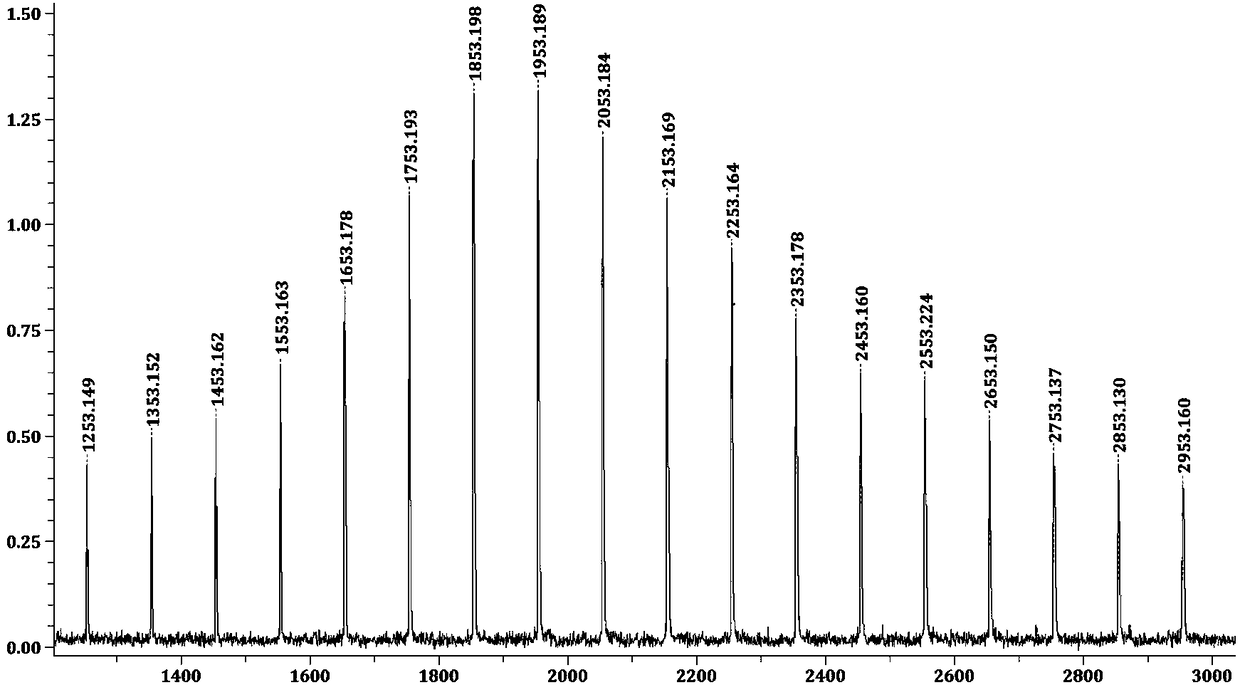

Disclosed are olefin polymerization methods comprising the use of the following compounds:wherein M is a metal atom, R1-R8 are univalent radicals, X1 and X2 are univalent ligands, X3 is a divalent ligand, and (RnY-T) is an optional donor or non-donor group. The relatively stable and simply synthesized pre-catalyst is activated by a co-catalyst under mild reaction conditions, producing exceptionally reactive polymerization of a wide variety of alpha-olefin monomers, and forming a variety of poly(alpha-olefin) products, having high molecular weight and low molecular weight distribution (PDIs close to 1). Living polymerization is performed at or above room temperature, along with achieving block co-polymerization of alpha-olefin monomers at room temperature, and producing polymers and oligomers having a wide range of molecular weights. The catalyst formed during reaction remains "alive' for as long as 31 hours, for producing a polymer with a molecular weight as high as 450,000 grams / mole.

Owner:RAMOT UNIV AUTHORITY FOR APPLIED RES & INDAL DEVMENT

Method for catalytic polymerization of alpha-olefin monomers using an ultra-high activity non-metallocene pre-catalyst

InactiveUS20020019503A1High molecular weightLow molecularGroup 4/14 organic compounds without C-metal linkagesOrganic-compounds/hydrides/coordination-complexes catalystsMetal chelateAlpha-olefin

A method for catalytic polymerization of alpha-olefin monomers using an ultra-high activity non-metallocene pre-catalyst featuring an amine bis(phenolate) ligand-metal chelate, having general formulas of [{(O)1R1R2R3R4(C6)1(CH2)1(RnY-T)N(CH2)2(C6)2R5R6R7R8(O)2}MX1X2] and [{(O)1R1R2R3R4(C6)1(CH2)1(RnY-T)N(CH2)2(C6)2R5R6R7R8(O)2}MX3], where, M, O, and N, are metal, oxygen, and, nitrogen; X1, X2, and X3, are ligands bonded to M; R1 through R8 are radicals; (RnY-T) is an optional non-donor or donor group bonded to N. The relatively stable and simply synthesized pre-catalyst is activated by a co-catalyst under mild reaction conditions, producing exceptionally reactive polymerization of a wide variety of alpha-olefin monomers, and forming a variety of poly(alpha-olefin) products, having high molecular weight and low molecular weight distribution (PDIs close to 1). Living polymerization is performed at or above room temperature, along with achieving block co-polymerization of alpha-olefin monomers at room temperature, and producing polymers and oligomers having a wide range of molecular weights. The catalyst formed during reaction remains "alive' for as long as 31 hours, for producing a polymer with a molecular weight as high as 450,000 grams / mole.

Owner:RAMOT UNIV AUTHORITY FOR APPLIED RES & INDAL DEVMENT

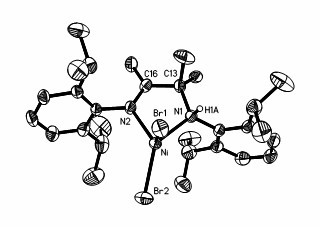

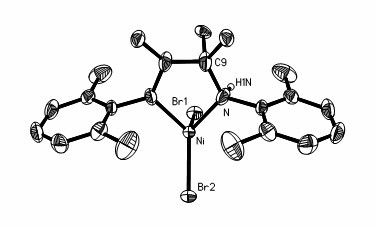

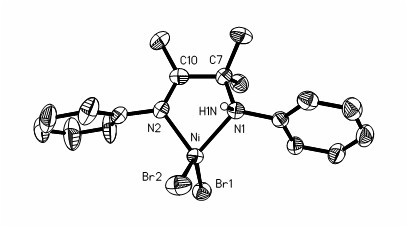

Polymerization method for catalyzing olefin by nickel-diimine catalytic system

The invention provides a polymerization method for catalyzing olefin by a nickel-diimine catalytic system. The system takes[(2,6-i-PrPh)2DABAn]NiBr2 as a main catalyst, methylaluminoxane as an auxiliary catalyst, and C6-C8 chain type saturated hydrocarbon as a solvent to catalyze a homopolymerization reaction of ethylene, propylene and C6-C18 alpha-olefin, or to catalyze a copolymerization reaction of ethylene and C6-C18 alpha-olefin, or to catalyze a copolymerization reaction of propylene and C6-C18 alpha-olefin, wherein the Ai / Ni molar ratio is equal to or less than 1000, and the reaction is carried out at -15-60 DEG C for 30-120 minutes. By adopting the catalyst system, the homopolymerization or the copolymerization of the olefin can be achieved within the polymerization temperature range of -15-60 DEG C, simultaneously, high catalysis efficiency can be kept, and living polymerization can be achieved at -10 DEG C.

Owner:PETROCHINA CO LTD

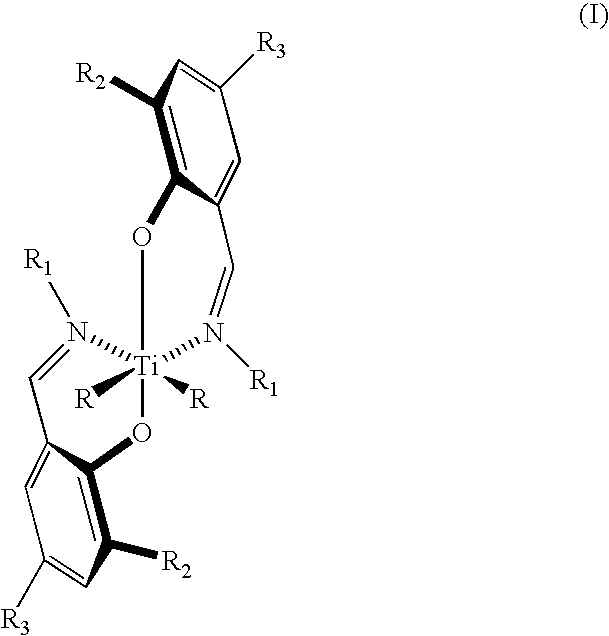

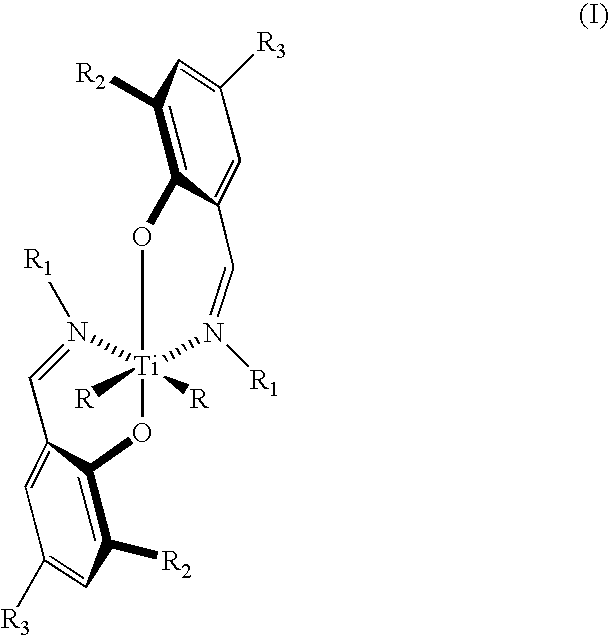

Bis (salicylaldiminato) titanium complex catalysts, highly syndiotactic polypropylene by a chain-end control mechanism, block copolymer containing this

InactiveUS7119154B2Group 4/14 organic compounds without C-metal linkagesOrganic-compounds/hydrides/coordination-complexes catalystsOligomerNitrogen

Bis(salicylaldiminato)titanium complex with optionally substituted phenyl or cyclohexyl on nitrogen catalyzes highly syndiospecific polymerization of propylene. Syndiotactic polypropylene with defects of the type rmr having [rrrr] content greater than 0.70 and block copolymer containing block(s) of the syndiotactic polypropylene and block(s) of poly(ethylene-co-propylene) and / or poly(alpha-olefin-co-propylene) are obtained. Certain of the catalysts provide living polymerization. Living olefin polymers and olefin terminated oligomers and polymers are also products.

Owner:CORNELL RES FOUNDATION INC

Living olefin polymerization processes

InactiveUS7135544B2Inhibition formationSurgical adhesivesGroup 4/14 organic compounds without C-metal linkagesEthylene HomopolymersDouble bond

Processes for the living polymerization of olefin monomers with terminal carbon-carbon double bonds are disclosed. The processes employ initiators that include a metal atom and a ligand having two group 15 atoms and a group 16 atom or three group 15 atoms. The ligand is bonded to the metal atom through two anionic or covalent bonds and a dative bond. The initiators are particularly stable under reaction conditions in the absence of olefin monomer. The processes provide polymers having low polydispersities, especially block copolymers having low polydispersities. It is an additional advantage of these processes that, during block copolymer synthesis, a relatively small amount of homopolymer is formed.

Owner:MASSACHUSETTS INST OF TECH

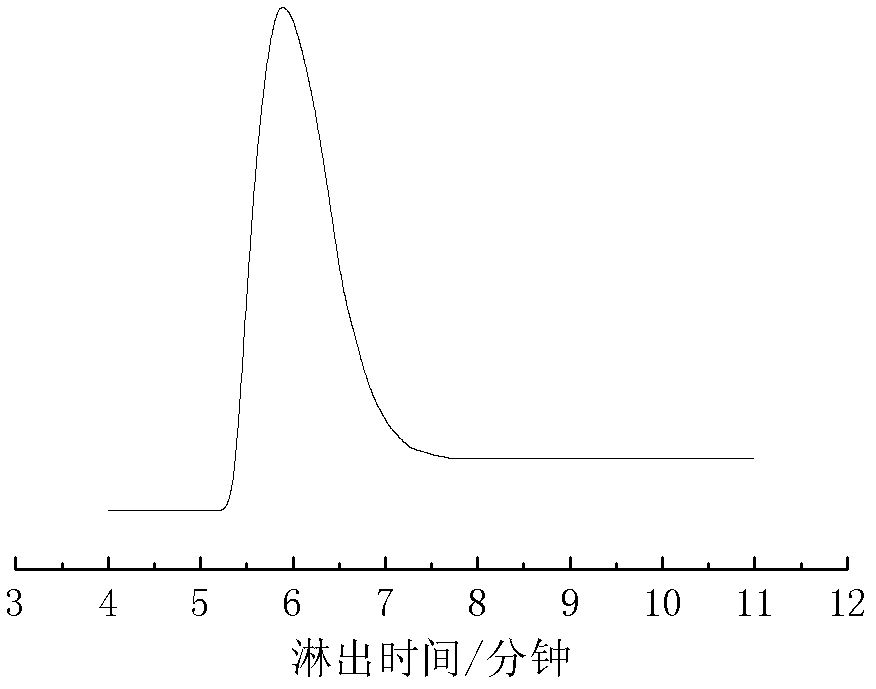

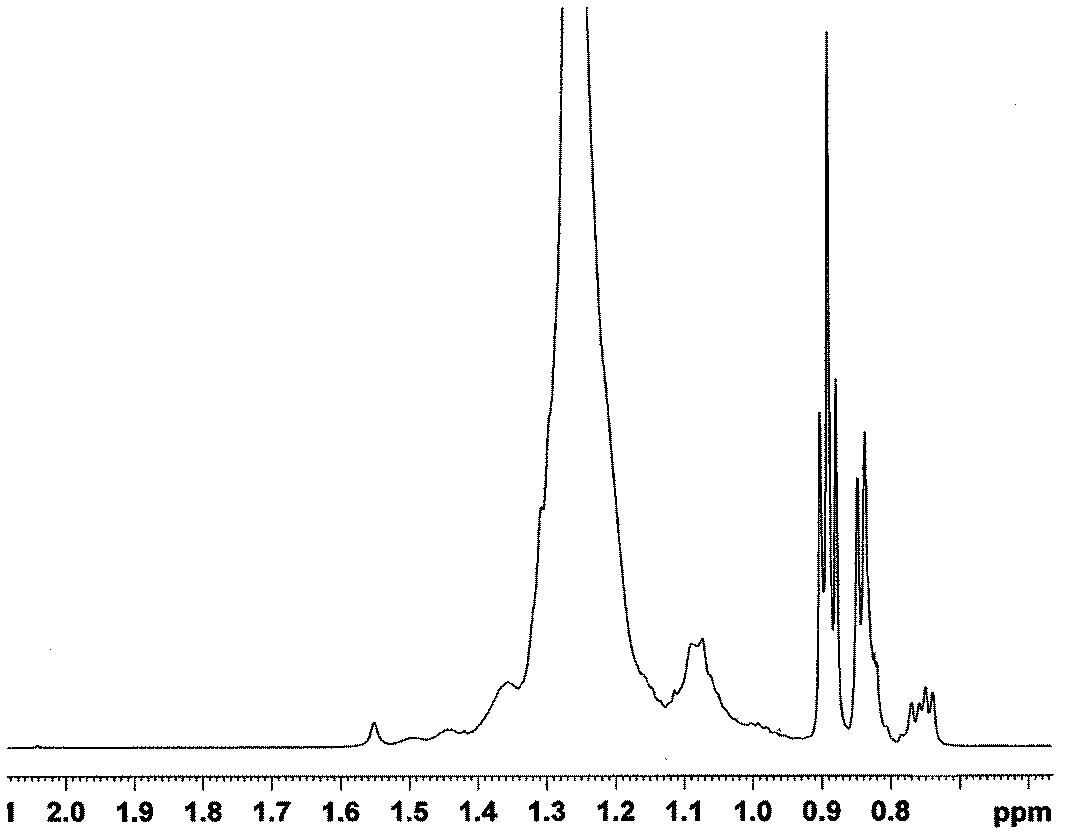

Preparation method and application of amido-imine nickel vinyl polymerization catalyst

ActiveCN102250152AThe synthesis method is simpleRaw materials are cheap and easy to getNickel organic compoundsAnilineBiological activation

The invention discloses a preparation method of an amido-imine nickel catalyst and application of the amido-imine nickel catalyst to catalyzing vinyl polymerization. The complex has the structures of a formula (I) and a formula (II) shown in the specification, wherein R1 is hydrogen or alkyl, R2 is hydrogen or alkyl, R3 is hydrogen or alkyl, R4 is hydrogen or alkyl, and X is halogen. The preparation method of the complex comprises the following steps of: carrying out condensation reaction on a diketone compound and phenylamine through ketoamine to obtain an diimine compound; then reacting with trimethyl aluminum, and hydrolyzing to obtain an amido-imine ligand; finally carrying out coordination reaction on the amido-imine ligand and (DME)NiX2 under the condition without water and oxygen to obtain a nickel complex. The complex disclosed by the invention has a specific ligand replacement structure and can be used for catalyzing the vinyl polymerization under the activation of modified methyl aluminium oxane or alkyl aluminum, showing the characteristics of living polymerization under specific conditions and obtaining the high-molecular-weight narrowly-distributed branched polyethylene.

Owner:SUN YAT SEN UNIV

Diene rubber, process for production thereof, rubber compositions, process for producing the same, and crosslinked rubbers

InactiveUS6984706B2Easy to processHigh tensile strengthSpecial tyresHydrocarbon solventsPolymer science

A diene rubber (A) having a weight average molecular weight (Mw) of 100,000 to 3,000,000, an Mw / number average molecular weight (Mn) ratio of 1.30 to 2.50, and an Mw / peak top molecular weight (Mp) ratio 0.70 to 1.30. A rubber composition comprising the diene rubber (A) and a diene rubber (B) having an Mw of 2,000 to 90,0000 and / or an oil extender for rubber has good processability and can give a rubber vulcanizate having high tensile strength and good abrasion resistance. The diene rubber (A) is produced by conducting a living polymerization of diene monomer in a hydrocarbon solvent; adding a polymerization stopper to a polymerization mixture at a conversion of 5 to 98% to deactivate 10 to 90% by mole of active terminals present as of the initiation of polymerization; and finally adding a polymerization stopper to completely terminate the polymerization reaction.

Owner:ZEON CORP

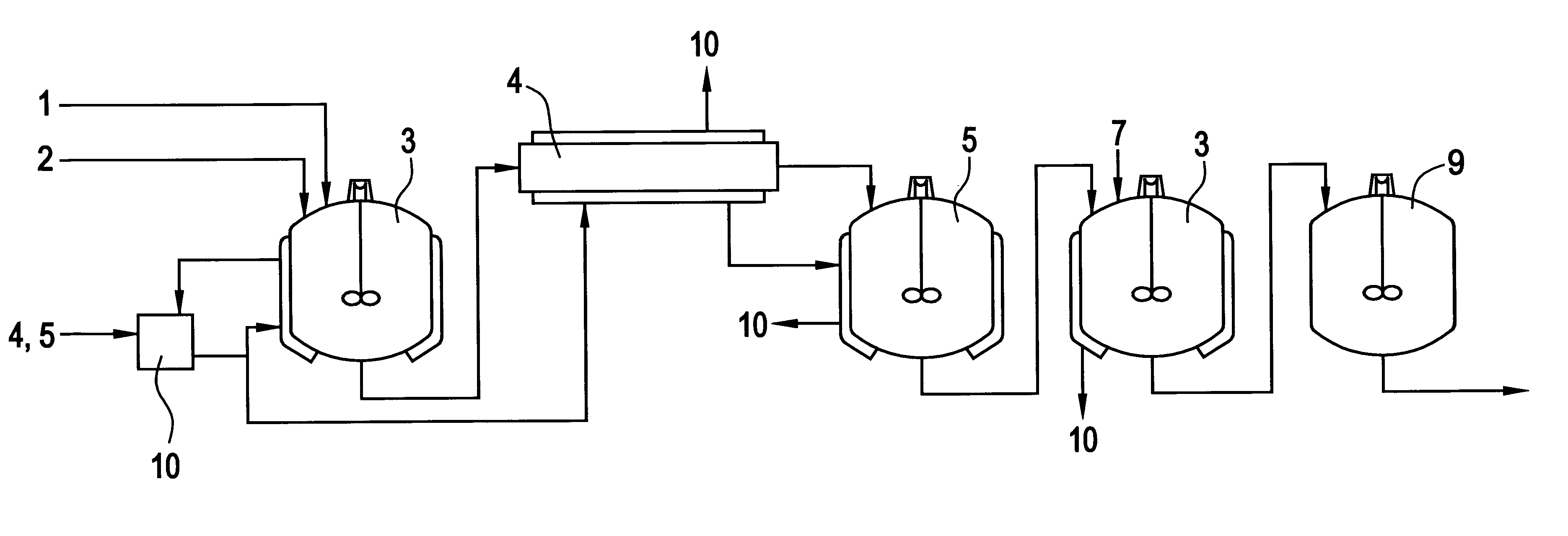

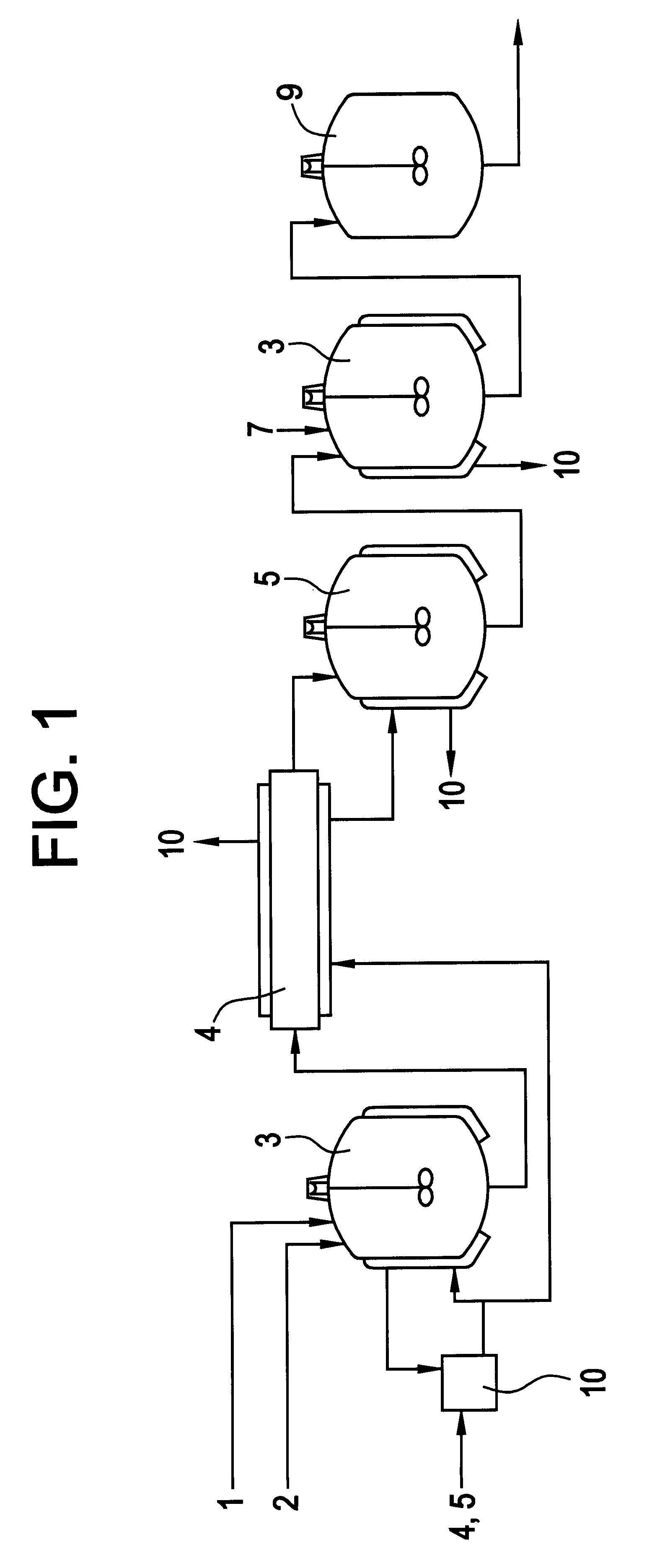

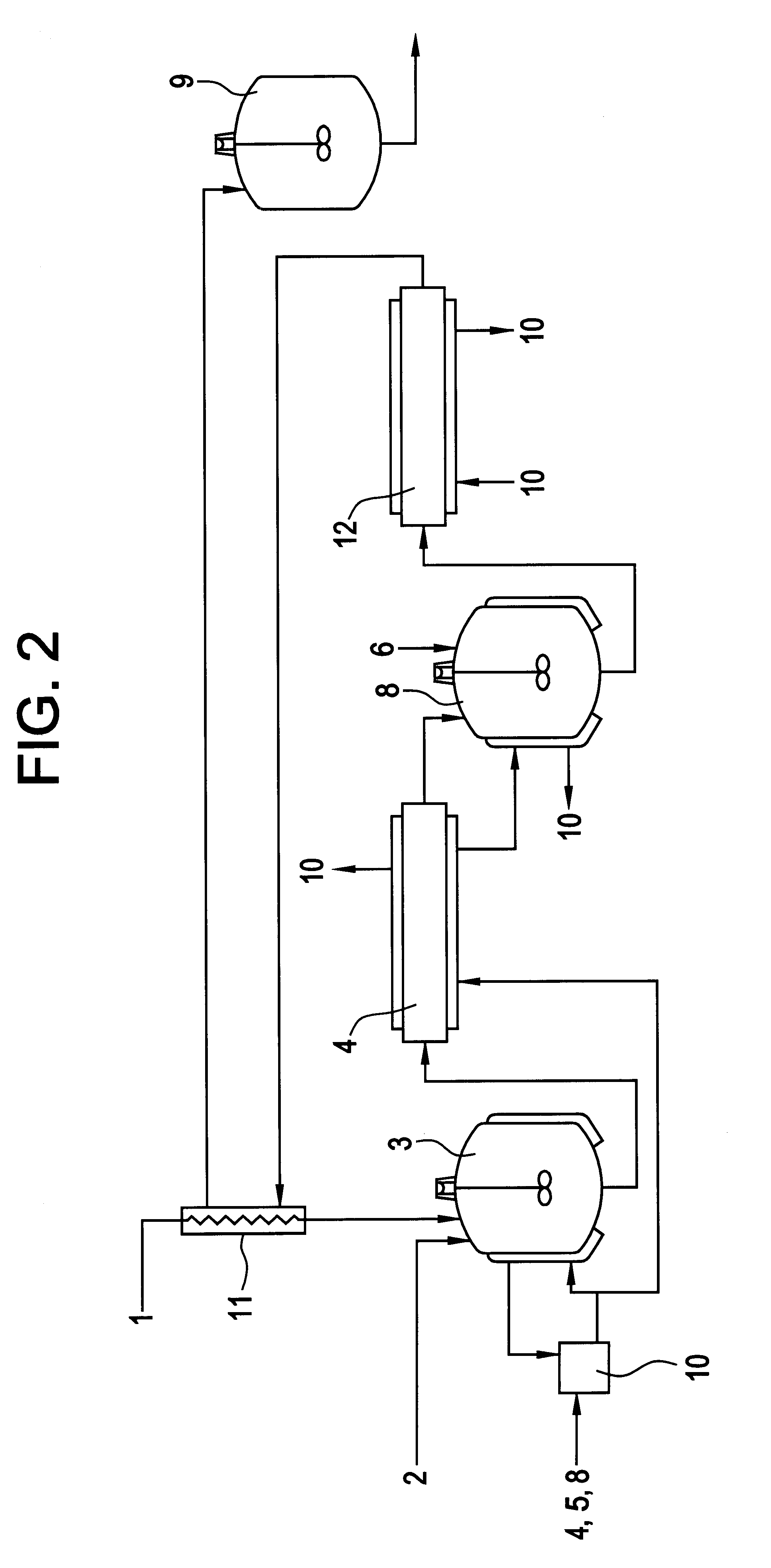

Method of continuous cationic living polymerization

A polymer is produced by feeding a polymerization initiator, a cationically polymerizable monomer component and a catalyst continuously to a flow-through stirring vessel reactor to thereby allow the living polymerization to initiate and feeding a reaction solution from said flow-through stirring vessel reactor to a flow-through tubular reactor continuously to thereby allow the living polymerization to proceed, said reaction solution having a conversion rate of said cationically polymerizable monomer component of not less than 1% by weight to less than 90% by weight.

Owner:KANEKA CORP

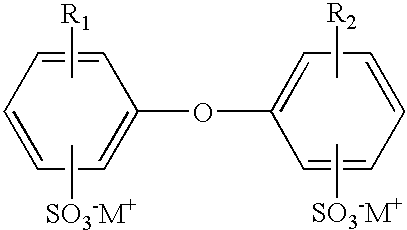

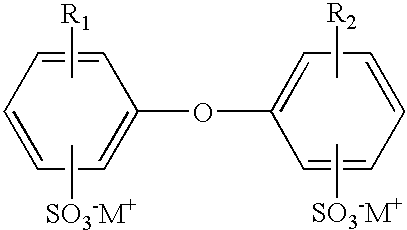

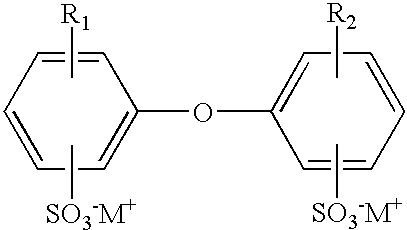

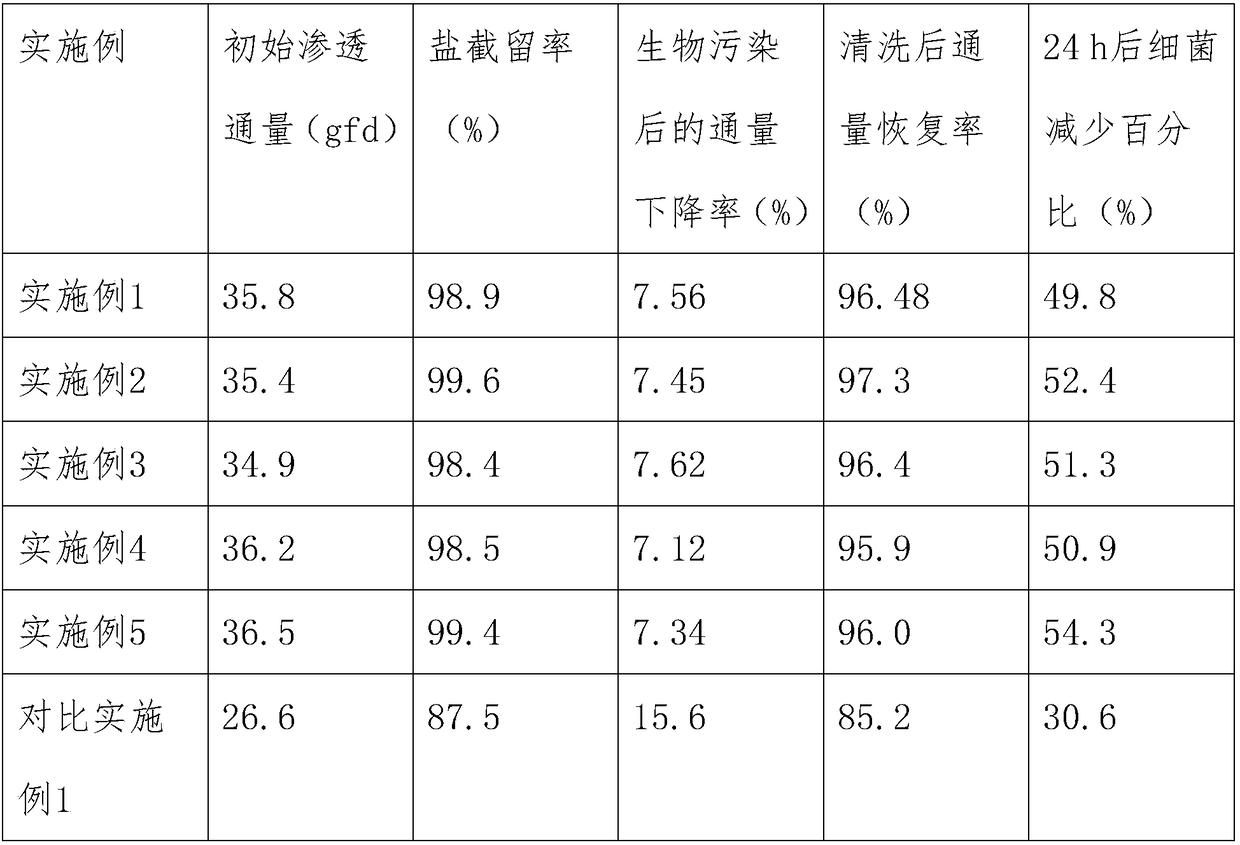

Hydrophilic bactericidal anti-contamination reverse osmosis membrane and preparation method thereof

ActiveCN108057348AImprove anti-pollution performanceGrowth inhibitionMembranesWater/sewage treatment bu osmosis/dialysisReverse osmosisPolyamide

The invention provides a hydrophilic bactericidal anti-contamination reverse osmosis membrane and a preparation method thereof. A bactericidal high-molecular polymer and an antibacterial polymer are grafted on the surface of a reverse osmosis membrane through a reversible addition-fragmentation chain transfer polymerization (RAFT) living polymerization method, so that the hydrophilic bactericidalanti-contamination reverse osmosis membrane is obtained, the method utilizes free amino groups on the surface of a polyamide functional layer to link a RAFT chain transfer agent in situ through an amide condensation reaction, and functional layers with different thicknesses and different molecular weights are controllably grafted, such as an amphoteric ion functional layer with hydrophilic properties and a quaternary ammonium salt functional layer with bactericidal performance. The anti-contamination reverse osmosis membrane prepared by the method still has excellent anti-contamination characteristics without sacrificing the performance of the original membrane, the long-term anti-contamination ability of the original membrane in a complex operating environment is improved, and the purposes of inhibiting the growth of bacteria and reducing attachment of microorganisms on the membrane are achieved.

Owner:VONTRON TECH CO LTD

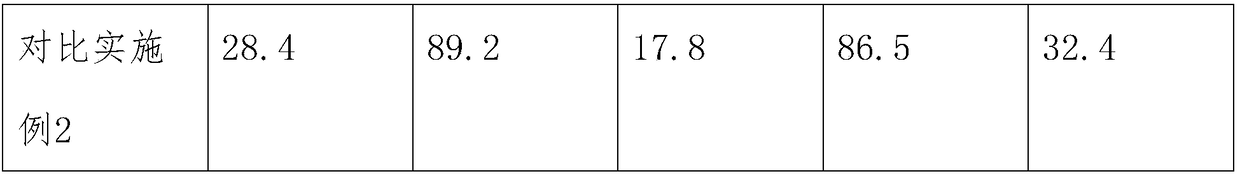

Method for preparing carbon-coated lithium titanate negative electrode material for lithium battery

ActiveCN103730649AMolecular weight controllableSmall molecular weight distributionCell electrodesCarbon layerPolymer science

The invention discloses a method for preparing a carbon-coated lithium titanate negative electrode material for a lithium battery. The method comprises the following steps: preparing a polymer with controllable molecular weight by adopting living polymerization, performing ball milling and mixing with raw materials of lithium titanate, and sintering to obtain a lithium titanate material coated with a conductive carbon layer. The adopted polymerization method has the advantages that range of optional monomers is wide, polymers of different carbon chain lengths can be obtained by adjusting the raw material ratio, the carbon chain length distribution is uniform, and the finally obtained carbon-coated lithium titanate material is uniform and stable in performance. Moreover, the initial charge specific capacity of the obtained lithium titanate material reaches over 160mAh / g under the rate of 1C (1C=175mA / g), and the capacity is kept over 90 percent due to cycle of 800 times.

Owner:中国东方电气集团有限公司

Diene rubber, process for production thereof, rubber compositions, process for producing the same, and crosslinked rubbers

InactiveUS20050154156A1Easy to processHigh tensile strengthSpecial tyresHydrocarbon solventsPolymer science

A diene rubber (A) having a weight average molecular weight (Mw) of 100,000 to 3,000,000, an Mw / number average molecular weight (Mn) ratio of 1.30 to 2.50, and an Mw / peak top molecular weight (Mp) ratio 0.70 to 1.30. A rubber composition comprising the diene rubber (A) and a diene rubber (B) having an Mw of 2,000 to 90,0000 and / or an oil extender for rubber has good processability and can give a rubber vulcanizate having high tensile strength and good abrasion resistance. The diene rubber (A) is produced by conducting a living polymerization of diene monomer in a hydrocarbon solvent; adding a polymerization stopper to a polymerization mixture at a conversion of 5 to 98% to deactivate 10 to 90% by mole of active terminals present as of the initiation of polymerization; and finally adding a polymerization stopper to completely terminate the polymerization reaction.

Owner:ZEON CORP

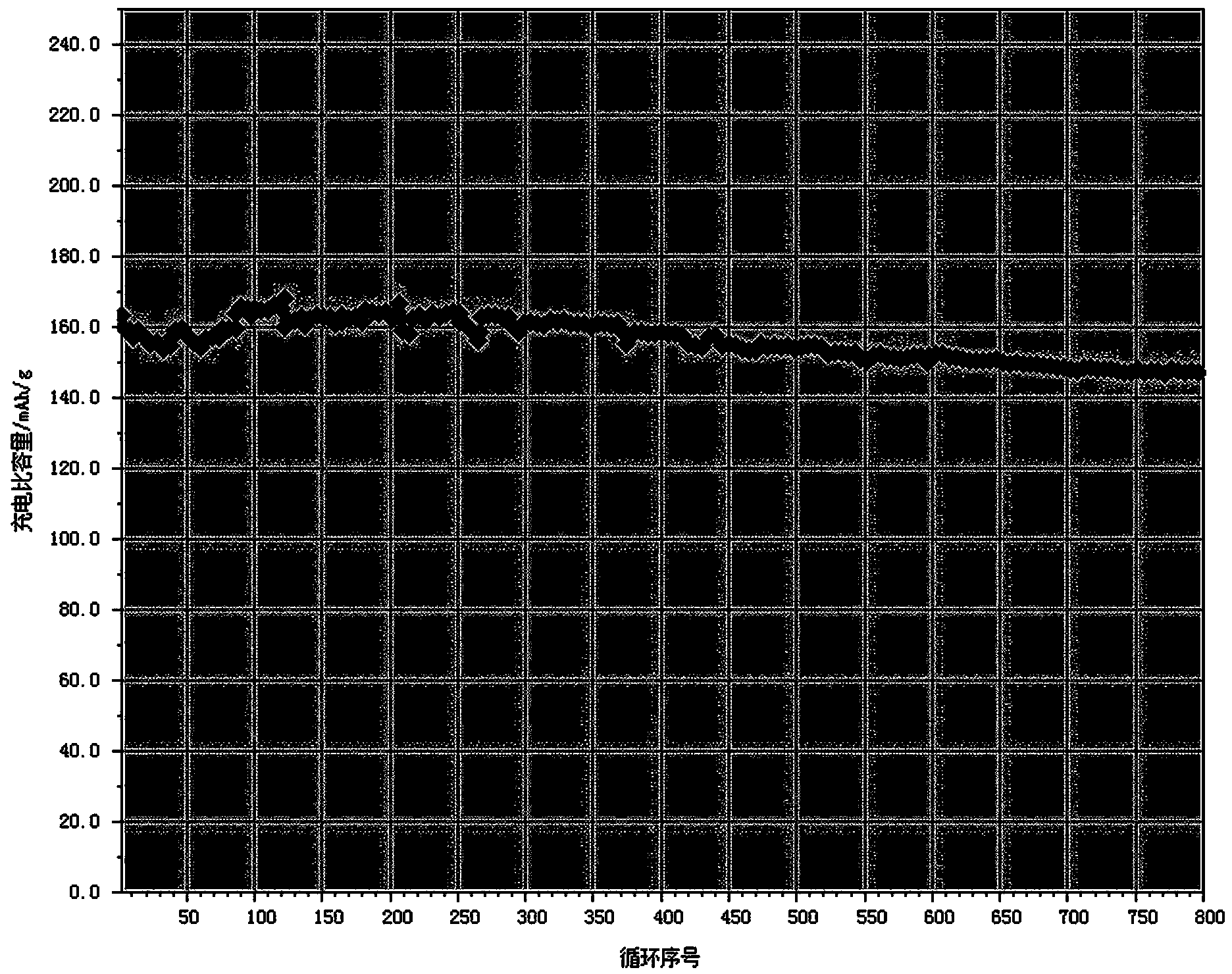

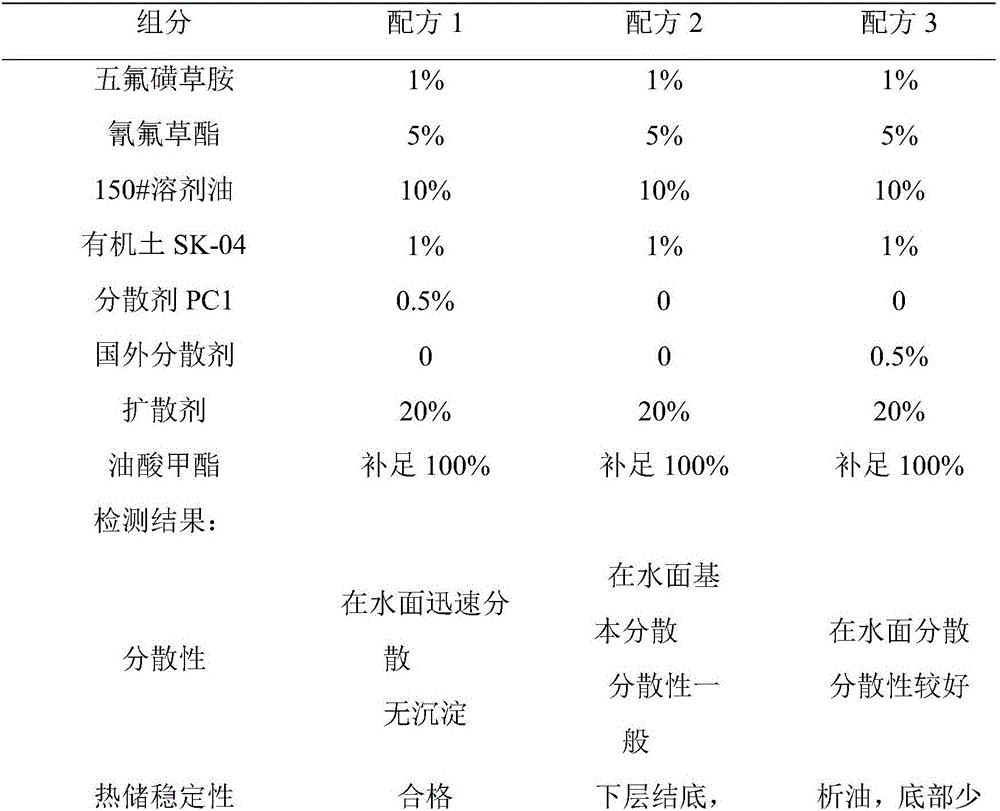

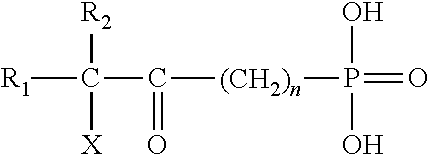

Comb type polymeric dispersant and preparation method and application thereof

InactiveCN106492706AImprove the lubrication effectReduce the chance of collisionBiocideTransportation and packagingPropanoic acidCarboxylic acid

The invention discloses a comb type polymeric dispersant and a preparation method and application thereof. The structural formula of the polymeric dispersant is defined in the specification. The preparation method comprises the steps that the RAFT living polymerization technology is adopted, dodecane sulfenyl sulfo-carbonyl sulfenyl propionic acid serves as a chain transfer agent, azodiisobutyronitrile serves as an initiator, and the comb type polymeric dispersant is obtained through graft copolymerization between unsaturated monomers. According to the application, the dispersant is applied to a spreading oil system, methyl oleate and other environment-friendly solvents are adopted as an organic carrier, an oil-dispersible system is obtained through a wet sanding process, a dispersing agent is added, and spreading oil of different conventional processes is obtained. According to the structure of the comb type polymeric dispersant, polyoxyethylene ether, benzene rings, carboxylic acid groups and other group repetitive units are contained, multipoint adsorption is achieved in the wet sanding process, the dispersant has good compatibility with an oil phase, the lubricating function among particles is improved, the collision probability among the particles is reduced through a macromolecular main chain steric hindrance, and sanding efficiency is improved.

Owner:NANJING UNIV OF TECH +1

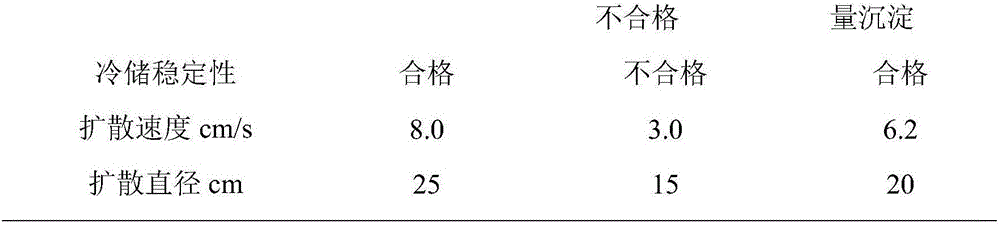

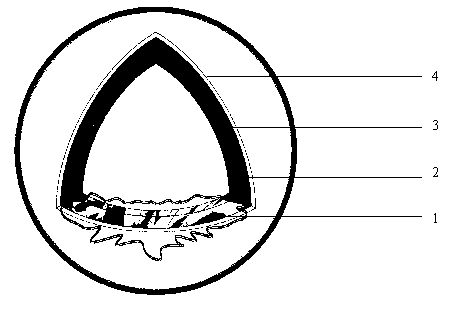

Multilayer microcapsule for self-repair polymer materials and its preparation method

InactiveCN103254372ASimple manufacturing processEliminate residueMicroballoon preparationMicrocapsule preparationMaterials preparationPolymer science

The invention discloses a multilayer microcapsule for self-repair polymer materials and its preparation method. The microcapsule is composed of a capsule core and three layers of capsule wall, wherein the second layer capsule wall material includes an atom transfer radical living polymerization macromolecular initiator and a catalyst, and the capsule core can undergo a room temperature living radical polymerization reaction under initiation of the second layer of capsule wall. Compared with traditional microcapsules, the multilayer microcapsule used for self-repair polymer materials is not only a storage container for reaction substances, but is also a multifunctional intelligent microcapsule integrating monomer and initiator storage, external crack perception, and polymerization reaction stimulation. The multilayer microcapsule disclosed in the invention can be widely applied to preparation of polymer composite materials with a self-repair function, and has the advantages of wide application range of a polymer matrix, strong adaptability of a composite material preparation process, and improvement of the repair efficiency of the composite material. With excellent storage stability, the multilayer microcapsule can realize mass production.

Owner:SUN YAT SEN UNIV

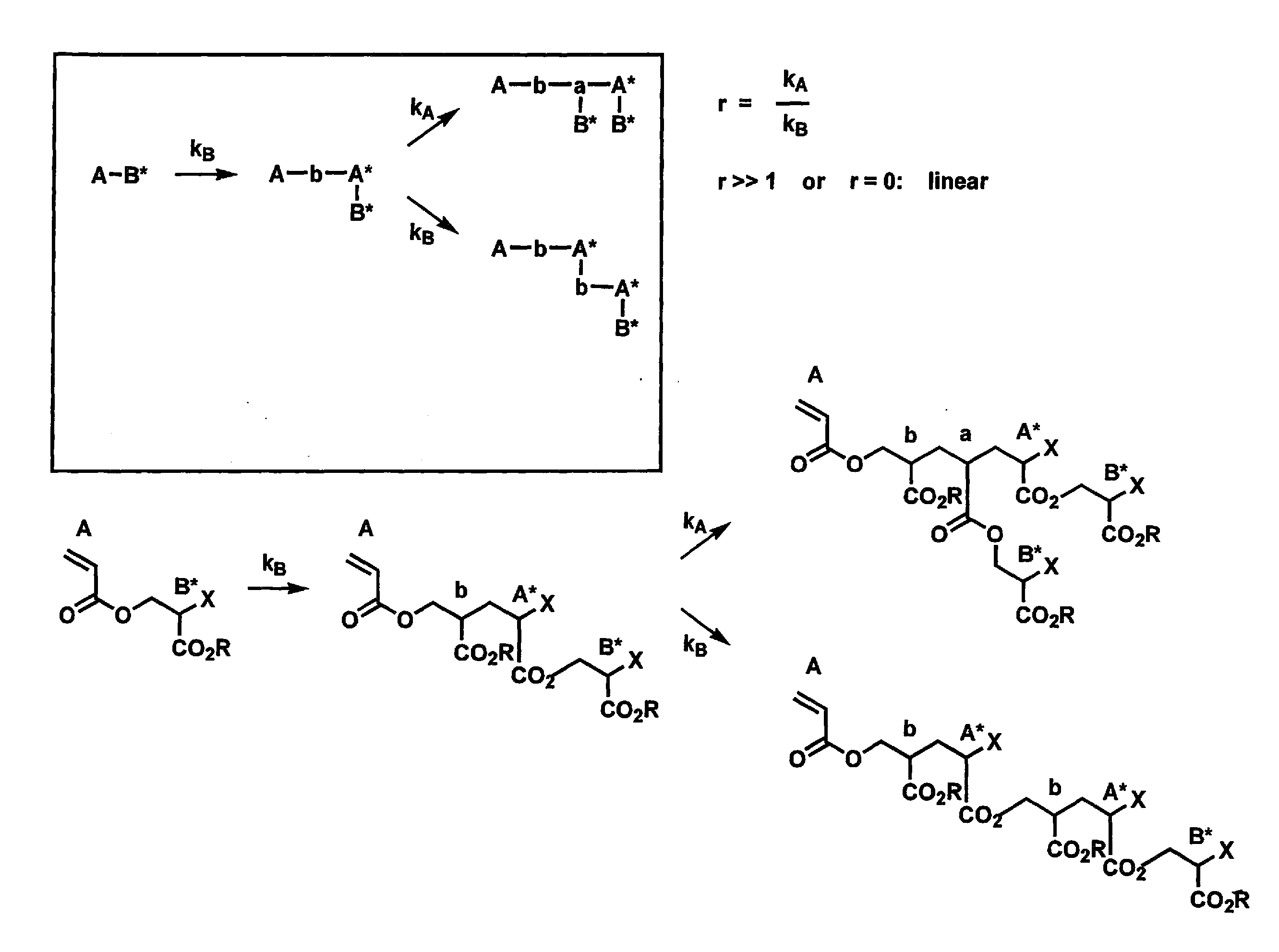

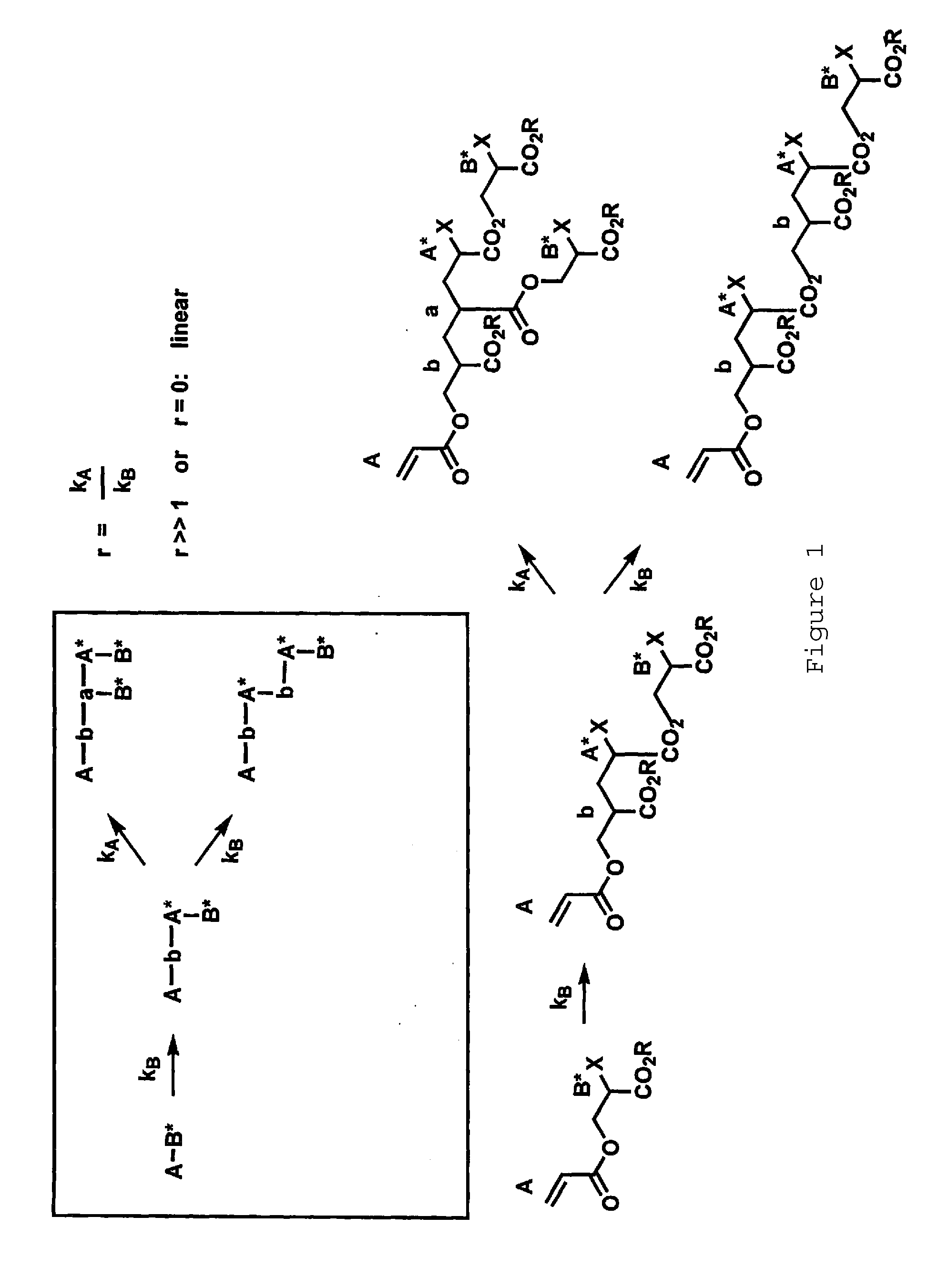

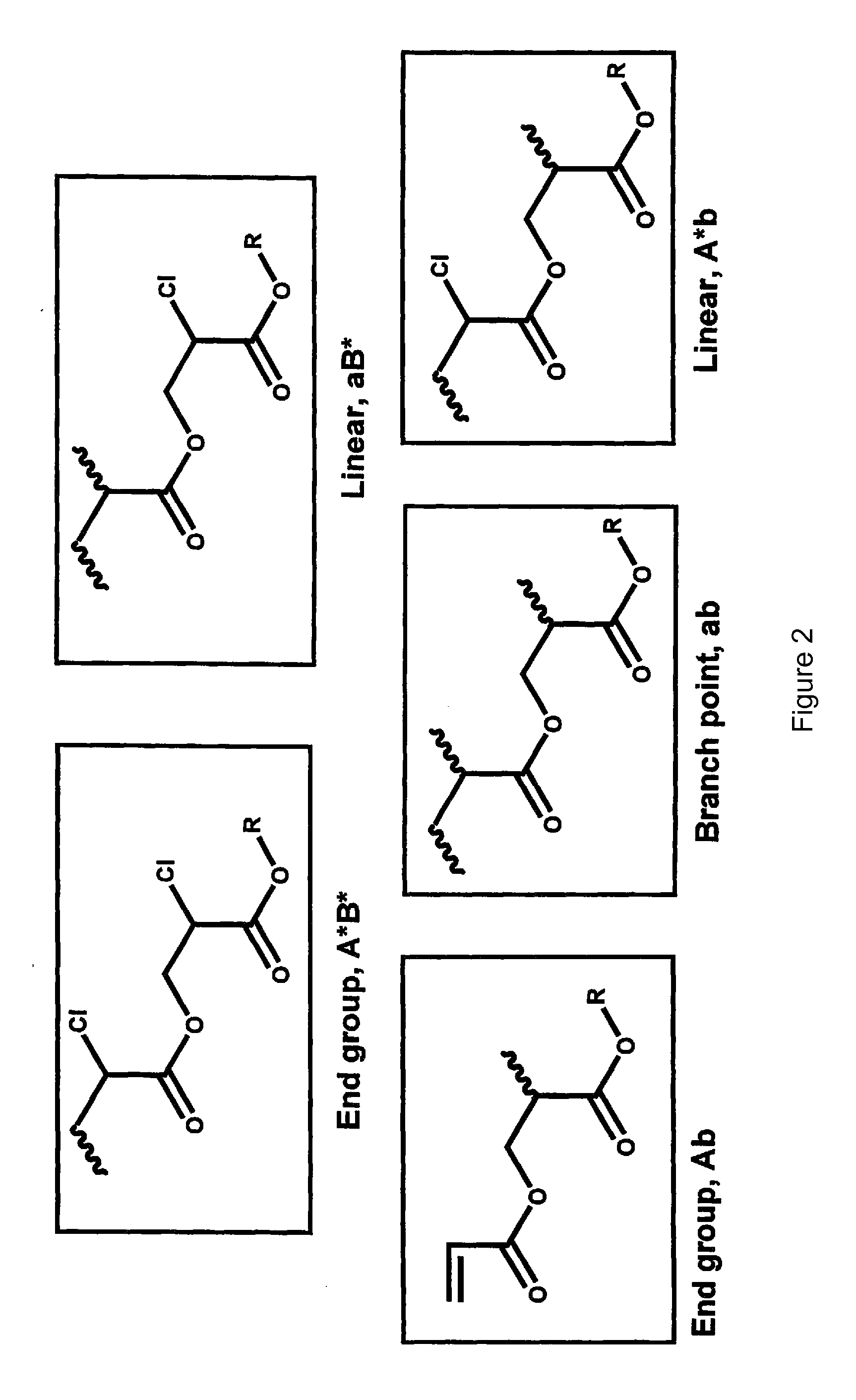

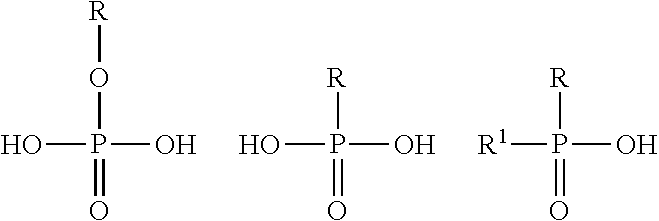

Synthesis of hyperbranched polyacrylates by emulsion polymerizsation of inimers

A method for the production of hyperbranched polyacrylates includes the step of reacting acrylic inimers through controlled living polymerization in aqueous conditions. The inimers may have the formula:Wherein X is a halogen, a thiocarbonylthio or nitroxide group, and R is hydrogen, methyl, dodecyl, and groups containing mesogenin substituents, fluorocarbon substituents, siloxane substituents and oxyethylene substituents. In particular, the aqueous condition is emulsion or miniemulsion. The polymerization may be reverse ATRP, SN&RI and AGET polymerization or RAFT polymerization (with thiocarbonylthio X groups) or nitroxide mediated polyeization (with nitroxide X groups).

Owner:THE UNIVERSITY OF AKRON

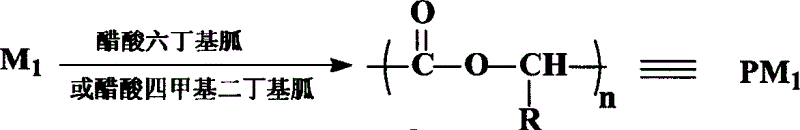

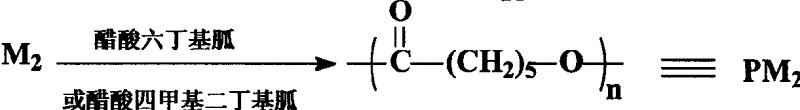

Process of snthesizing medical biological degradative material by acetic acid organic guanidine as catalast

The invention relates to a process method of synthesizing medical biodegradable material by bionic organic carbamidine catalyst, especially a new process method of synthesizing medical biodegradable polyester polymers, and its character: it uses nontoxic metal-free bionic acetic hexabutyl carbamidine and acetic tetramethyl dibutyl carbamidine as catalysts to make the ring-opening polymerization reaction of cyclo-ester monomers (L-lactide, D, L-lactide, glycollide, epsilon-caprolactone), thus synthesizing high-organism safety medical biodegradable materials. The new process method avoids cytotoxinic stannous octoate catalyst. The process adopts body polymerization method and the polymerization reaction has the characters of controlled and active polymerization reaction, not only able to synthesize homopolymers but also be used in synthesizing controlled composed block copolymer.

Owner:NANKAI UNIV

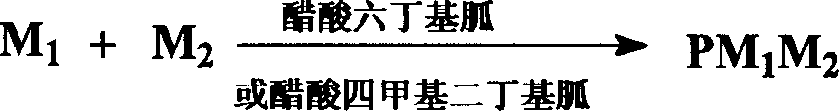

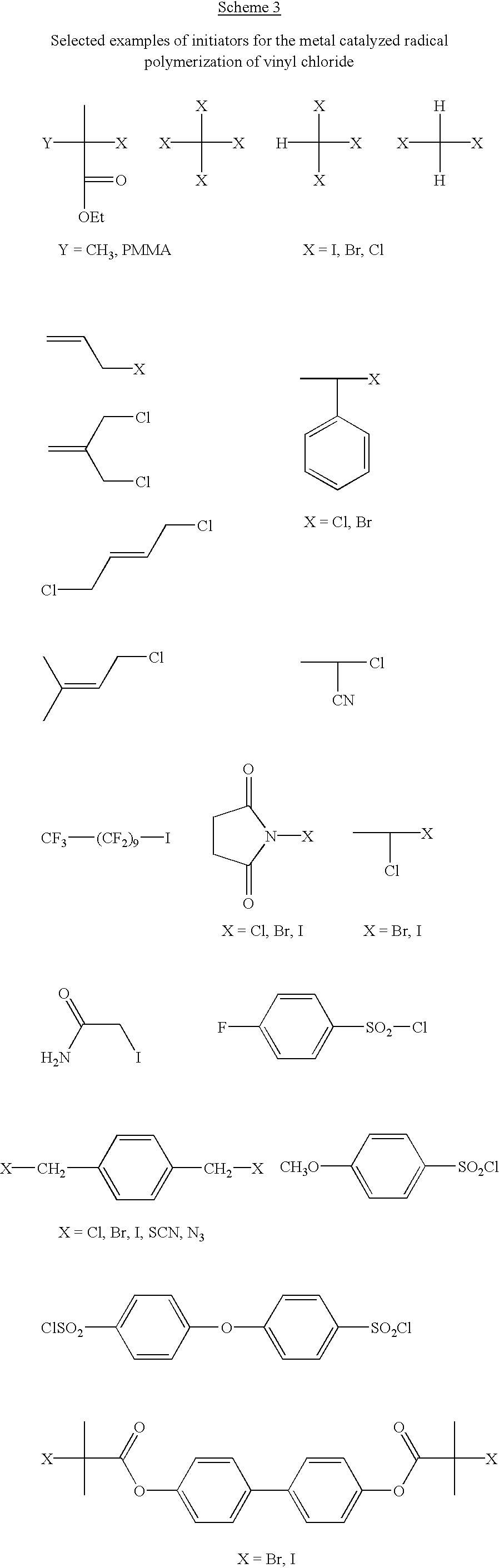

Aqueous room temperature living radical polymerization of vinyl halides

A living polymerization process for preparation of poly(vinyl chloride) (PVC) with controlled molecular weight and molecular weight distribution is described. The polymerization reaction can be initiated by various polyhalocarbon initiators in conjunction with non-metallic reducing single electron transfer reagents as catalysts and accelerated by electron shuttles. The process occurs at room temperature in water or water-organic solvent medium. The polymerization provides PVC with a controlled molecular weight and narrow molecular weight distribution. The halogen containing polymer compositions are useful as, among others, viscosity modifiers, impact modifiers and compatibilizers.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

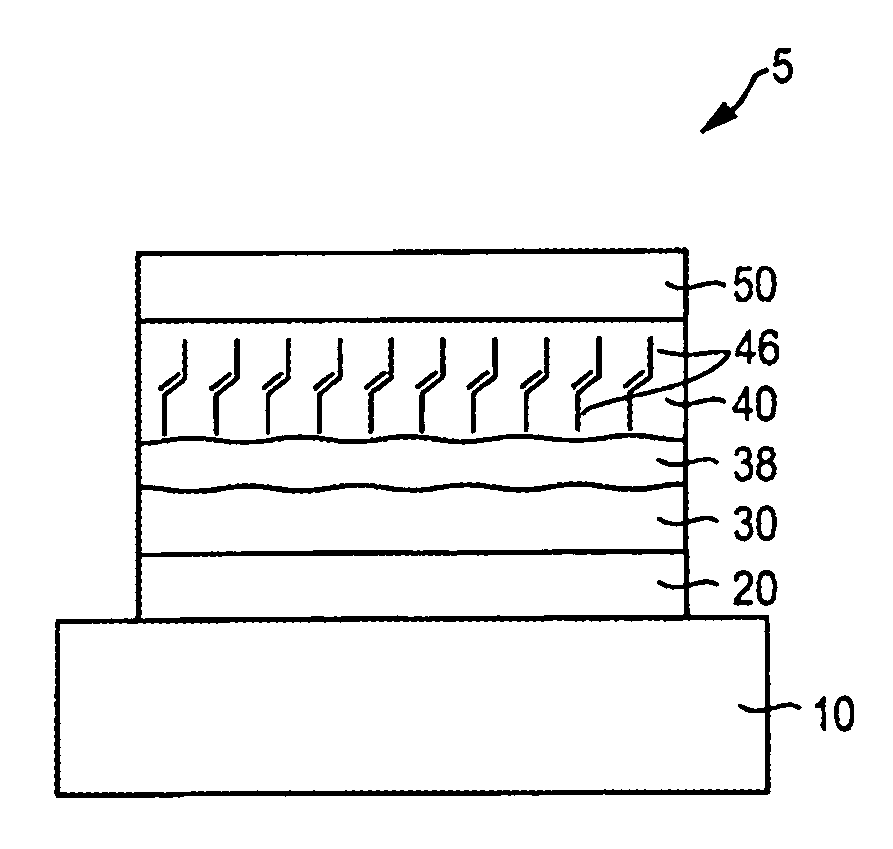

Method to manufacture polymer memory with copper ion switching species

InactiveUS6956761B2Easy and inexpensive to manufactureOverall design flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorOptoelectronics

Owner:MICRON TECH INC

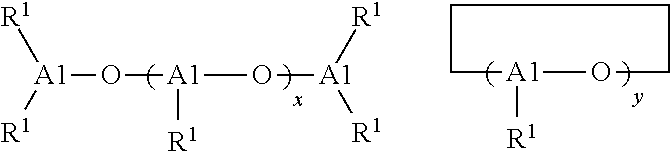

Functional segmented copolymer based on living polymerization as well as preparation method and application of copolymer

ActiveCN103881039AEnhance aggregation abilityPolarity controllablePigment pastesGlycidyl methacrylateOrganic dye

The invention relates to a functional segmented copolymer based on living polymerization. The functional segmented copolymer has a structural formula as shown in the specification, wherein a segment A is prepared by polymerizing at least two olefinic bond unsaturated monomer segments; A1 is a polar olefinic bond unsaturated monomer with an amino functional group, an acid functional group or methacrylic acid glycidyl ester; A2 is a copolymerization prompting monomer; a segment B is prepared by polymerizing at least one or more than one olefinic bond unsaturated monomers; x, y and z are the polymerization degrees; z ranges from 0 to 400; the number-average molecular weight of the segment A is 500-50000; the number-average molecular weight of the segment B is 1000-20000. By introducing the copolymerization prompting monomer A2, the defects in preparing the conventional segmented active copolymer are avoided, not only can the functional segmented copolymer prepared in an ordinary solvent, but also the compatibility of a dispersing agent and a substrate of the functional segmented copolymer is greatly improved, and the functional segmented copolymer is good in dispersion effect for carbon black, organic dye and the like, low in color paste velocity, good in paint film color showing, and particularly high in blackness of the carbon black.

Owner:AFCONA CHEM HAIMEN

Betaine polymer coatings prepared by living polymerization

ActiveUS20140272428A1Improve adhesionMinimal thicknessSynthetic resin layered productsPretreated surfacesPolymer scienceBetaine

A betaine-containing polymer film that can be formed on a substrate surface using living polymerization such as controlled radical polymerization is disclosed.

Owner:ACULON

Method for preparing estradiol molecularly imprinted magnetic microsphere

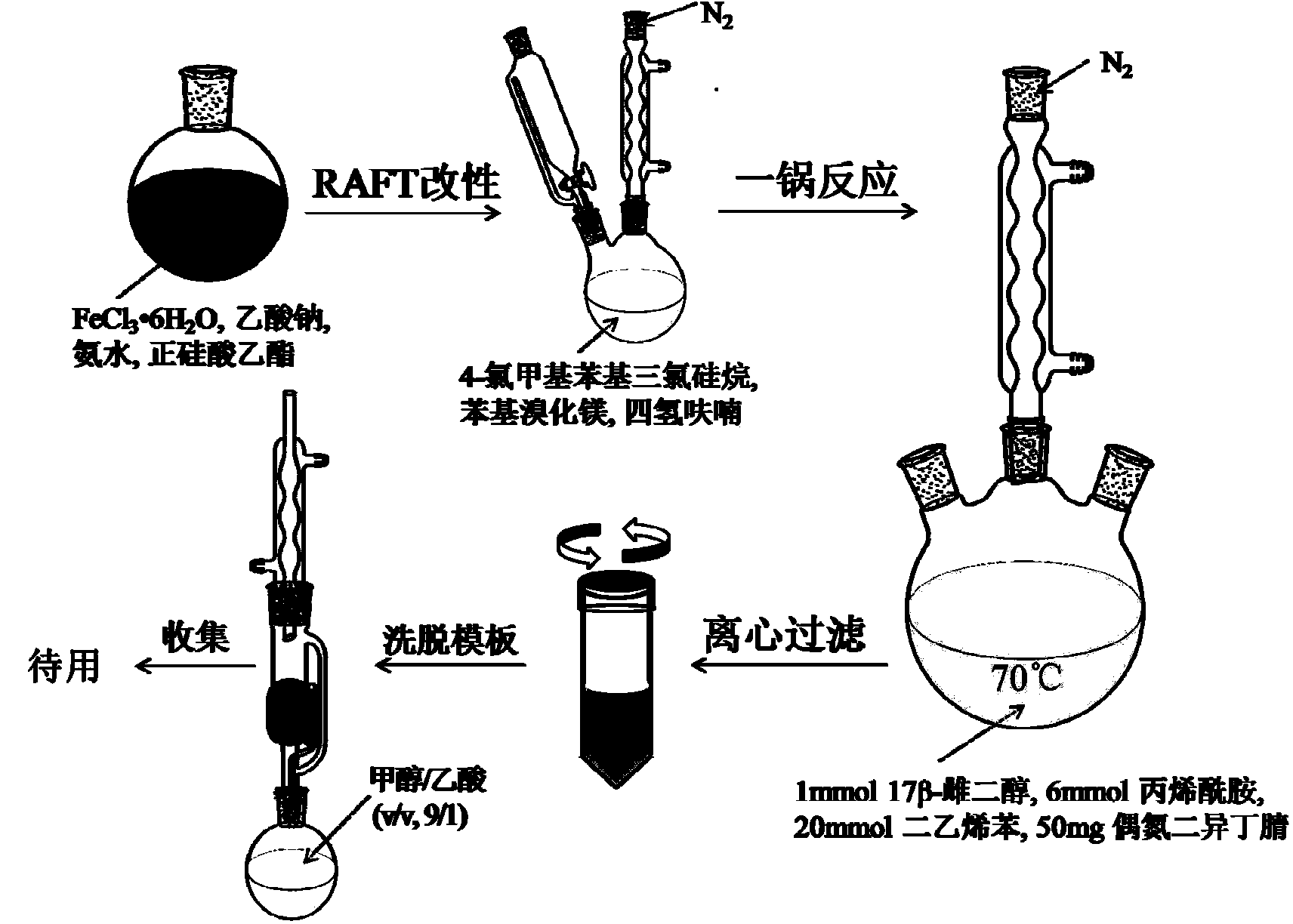

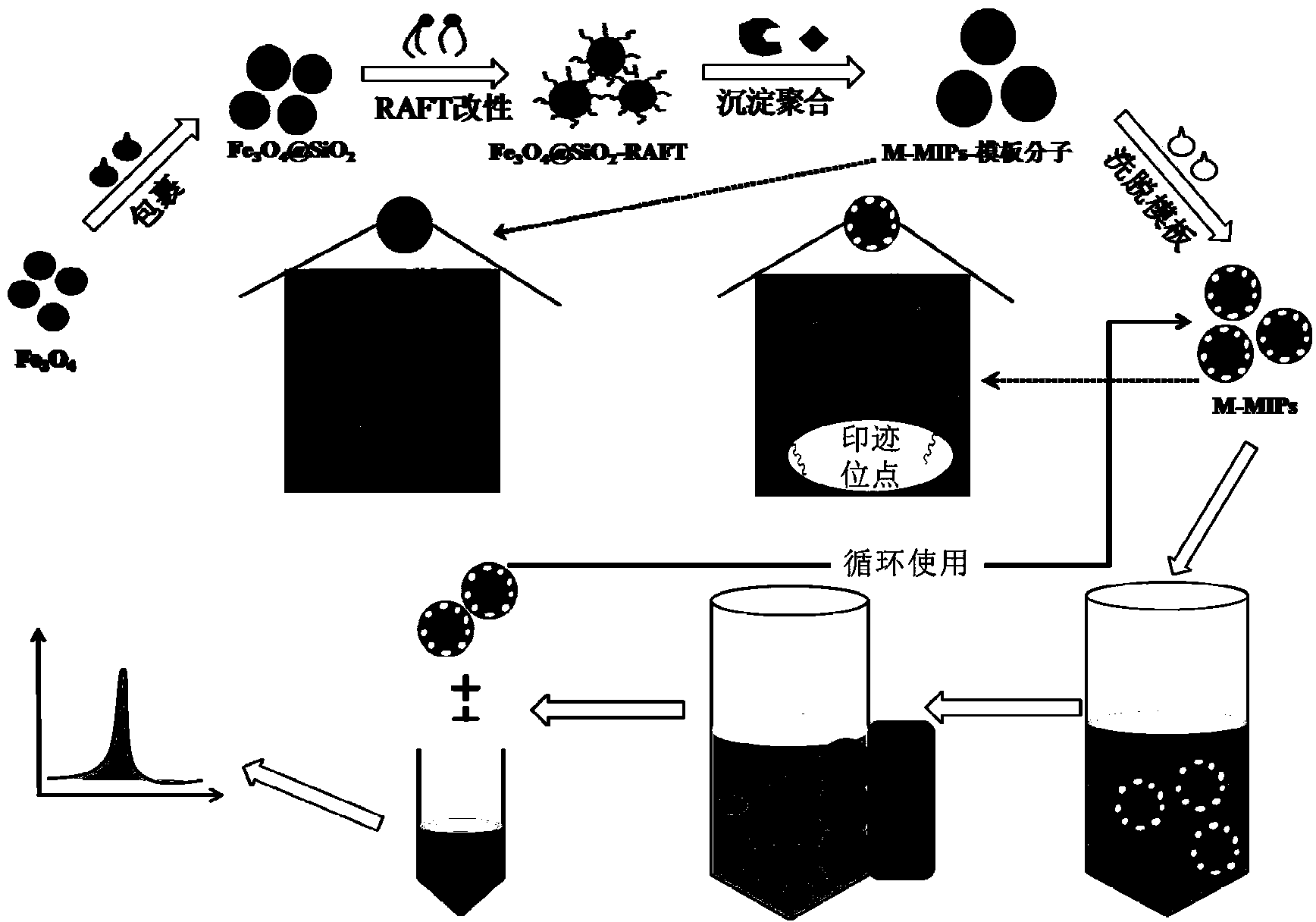

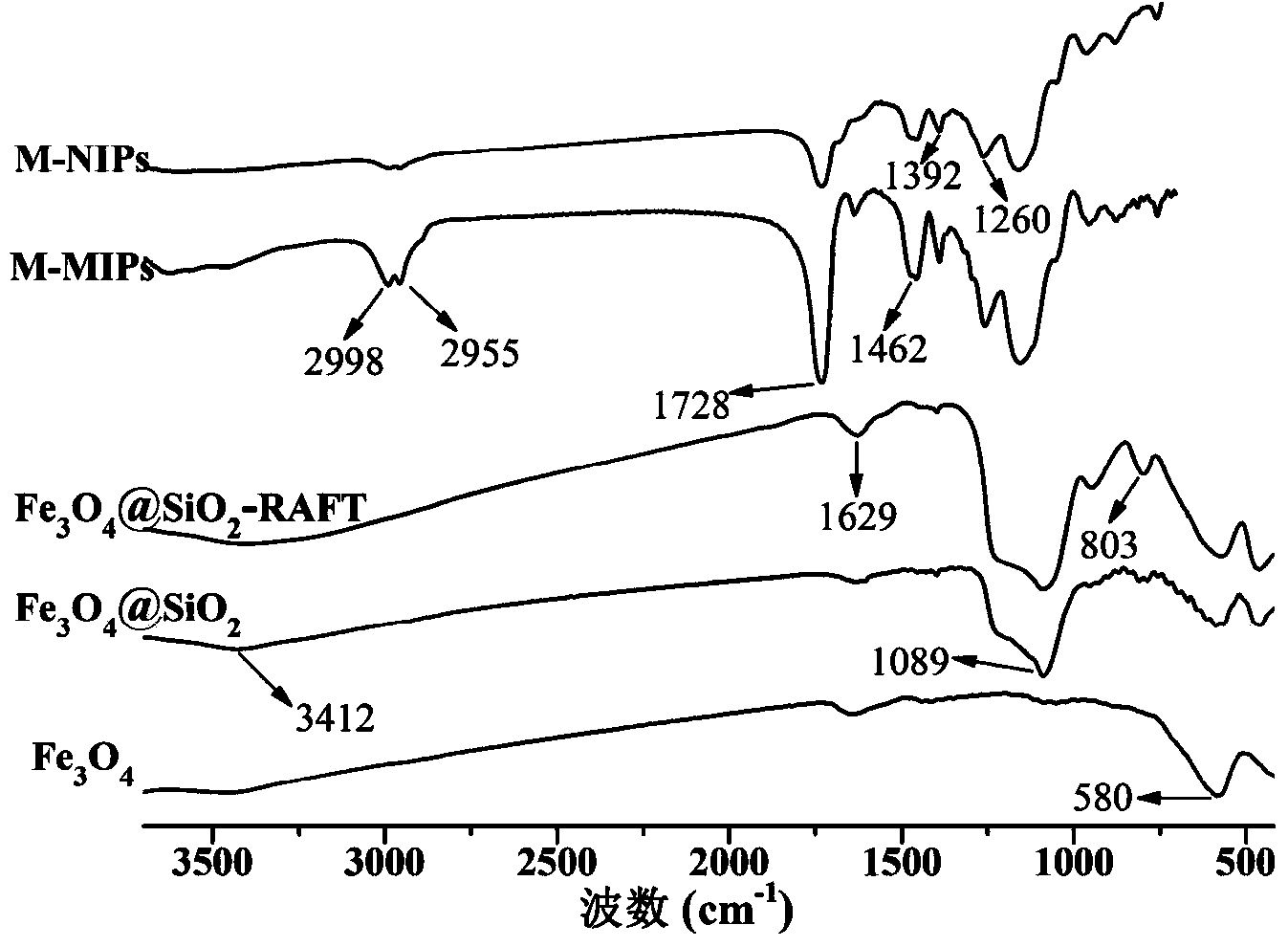

ActiveCN104140487AEasy to operateMild reaction conditionsComponent separationMicrosphereLiving free-radical polymerization

The invention belongs to the field of materials science and engineering and environmental sciences, and particularly relates to a method for preparing an estradiol molecularly imprinted magnetic microsphere in a controllable living polymerization potful compositing mode. According to the method, a reversible addition-fracture chain transfer controllable living free radical polymerization and precipitation polymerization potful compositing mode is adopted, molecularly imprint with 17 beta estradiol as a template and a sensitive material are combined, and then the estradiol molecularly imprinted magnetic microsphere is obtained. The microsphere obtained through the method is high in adsorption capacity for 17 beta estradiol, has the high-speed dynamic character and the superior recognizing and selecting performance, is separated conveniently and quickly under the action of an applied magnetic field, and is good in reusing performance. According to the method, the character of reversible addition-fracture chain transfer controllable living polymerization is utilized fully, step-by-step feeding potful operation is adopted to prepare the core-shell structure printed microsphere, the surface printing process is effectively simplified, the experimental period is shortened, the recognizing speed is greatly improved, and the printing capacity is increased.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

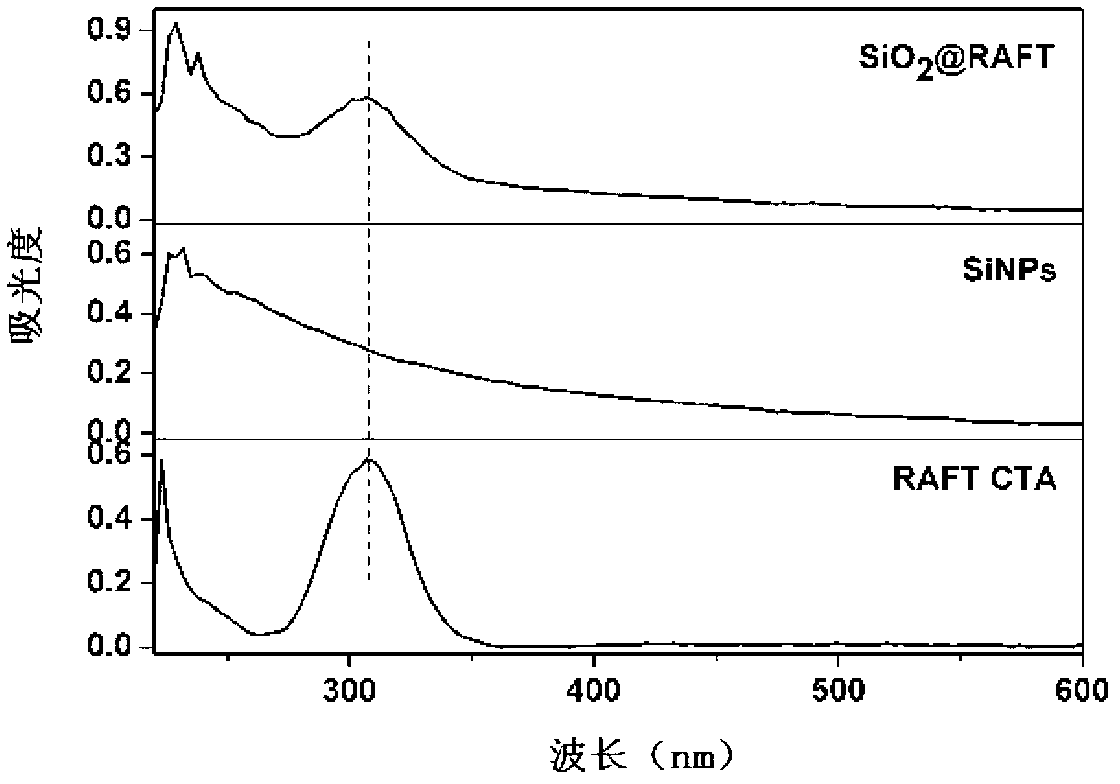

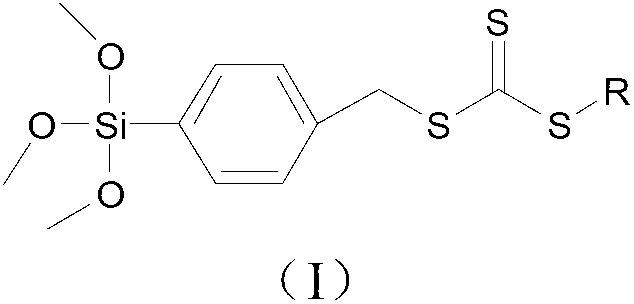

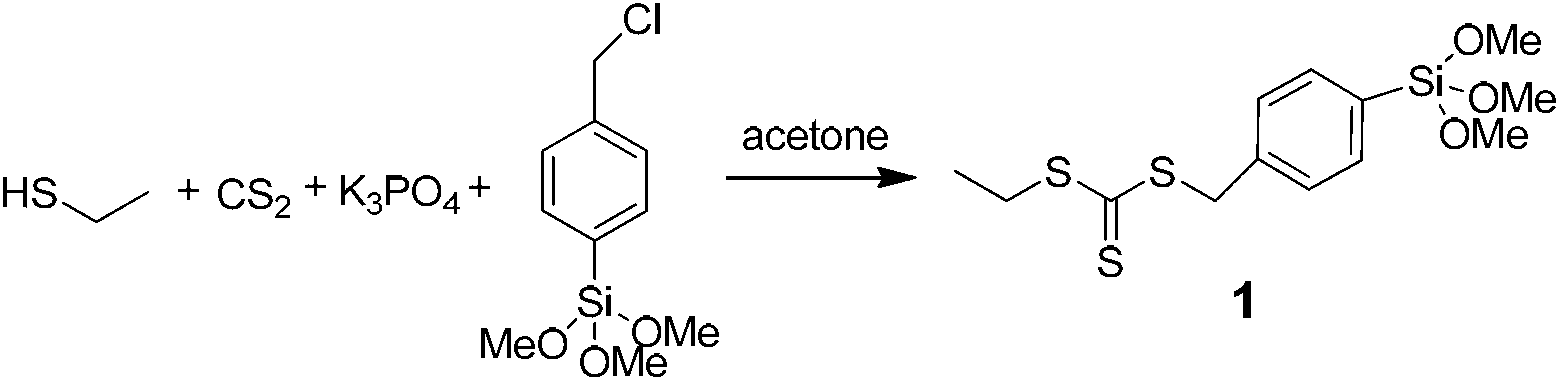

Living polymerization preparation method for polyacrylic acid ball brush and application of polyacrylic acid ball brush

ActiveCN102936321AFixing is simple and convenientHigh densityCarrier-bound/immobilised peptidesPolymer scienceHigh density

The invention discloses a living polymerization preparation method for a polyacrylic acid ball brush and application of the polyacrylic acid ball brush and particularly discloses the polyacrylic acid ball brush prepared by the living polymerization method and the application of the polyacrylic acid ball brush in the protein high density immobilization. The method comprises steps of synthesizing a novel silylanized reversible addition-fragmentation chain transfer (RAFT) polymeric chain transfer reagent; fixing the RAFT polymeric chain transfer reagent to a spherical solid phase carrier surface through a reaction; forming a polyacrylic acid brush structure on the carrier surface which is grafted with the RAFT polymeric chain transfer reagent through the RAFT polymerization; and obtaining the polyacrylic acid ball brush. The polyacrylic acid ball brush material is subjected to activation and protein immobilization, the compound of the ball brush and the protein is obtained, ant the application in the protein high density immobilization is achieved. By the aid of the method, the synthetic process and the synthetic time of the polyacrylic acid ball brush are shortened, the reaction efficiency is improved, and the polyacrylic acid ball brush has high grafting density and carboxyl content and provides more positions for protein immobilization.

Owner:SHANGHAI JIAO TONG UNIV

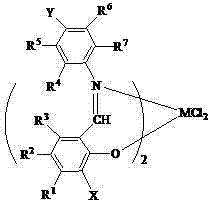

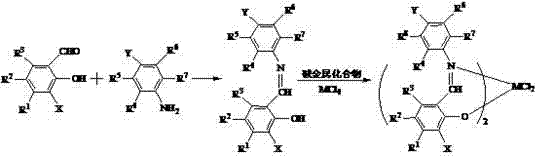

Schiff base transition metal complex containing alkoxy groups, and preparation method and application thereof

InactiveCN102516291AHigh activityEasy to prepareGroup 4/14 organic compounds without C-metal linkagesTitanium organic compoundsPolymer scienceSalicylaldehyde

The invention relates to a Schiff base transition metal complex containing alkoxy groups, a preparation method thereof and application of a catalyst composition composed of the transition metal complex and aluminum alkyl in catalyzing ethene polymerization, belonging to the technical field of catalysts. The preparation method for the Schiff base transition metal complex containing alkoxy groups comprises the following steps: synthesizing Schiff base ligand through a condensation reaction between substituted salicylaldehyde and an amine compound; reacting the ligand with an alkali metal compound to obtain a ligand salt solution; and reacting the ligand salt solution with MCl4 to prepare the Schiff base transition metal complex. The preparation method is simple; and when used for ethene polymerization, the synthesized Schiff base transition metal complex containing alkoxy groups has the following advantages compared to the prior art: common aluminum alkyl is used as a cocatalyst to substitute expensive MAO during polymerization, and the catalyst composition has high activity under the condition of a small usage amount of the cocatalyst. Hexane is used as a solvent to substitute toluene during polymerization, which is favorable for industrial introduction.

Owner:SHENYANG POLYTECHNIC UNIV

Test method for evaluating insoluble polymer growth

InactiveUS6136951AChemical/physical/physico-chemical stationary reactorsActive polymerPolymer science

A method for evaluating the polymer growth inhibition ability of a compound or compounds is disclosed wherein the method comprises: A) weighing a dry seed of insoluble polymer capable of growing via a living polymerization mechanism; B) subjecting the seed of insoluble polymer to conditions capable of causing a living polymer to grow via a living polymerization mechanism; C) drying the seed; and D) weighing the seed a second time to determine any increase in weight; wherein the polymer growth inhibition ability of the compound or compounds is inversely proportional to any increase found in weight of the seed.

Owner:ADDIVANT USA +1

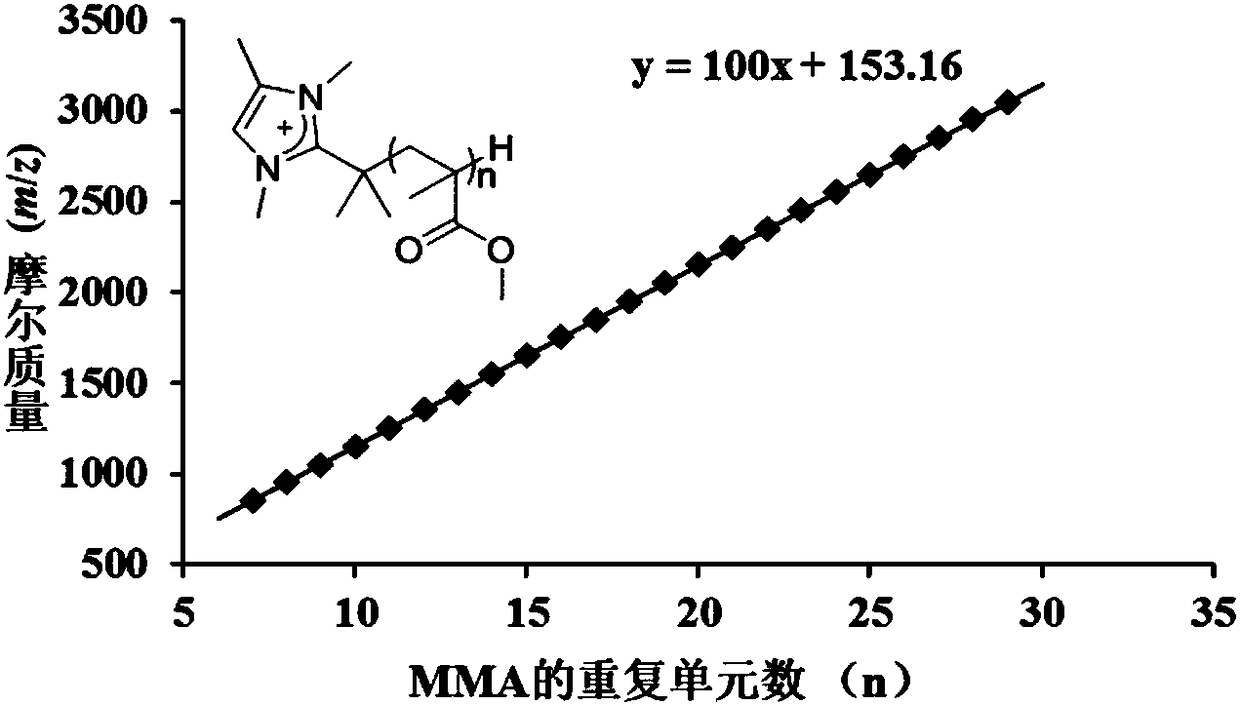

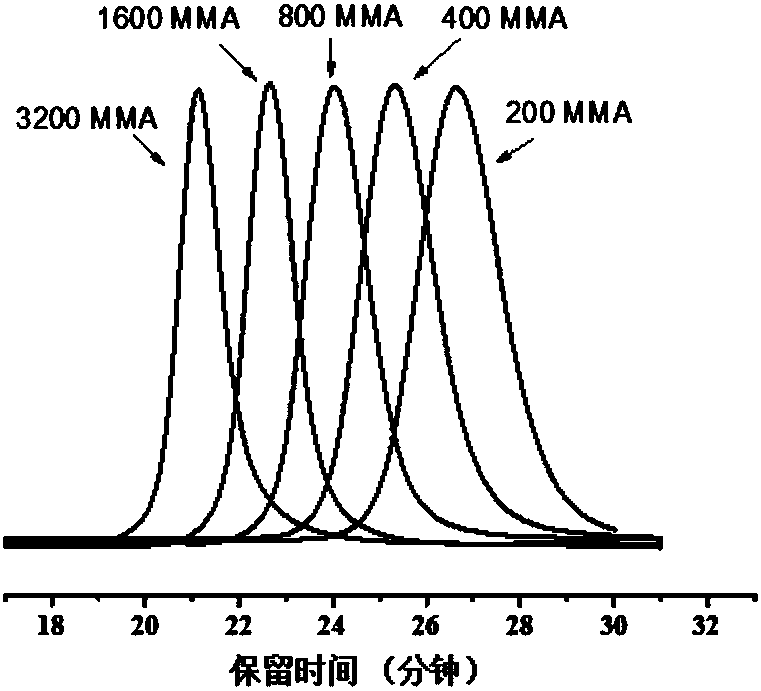

Frustrated Lewis pair FLP catalyzed vinyl polar monomer living polymerization method

ActiveCN108264593ARaw materials are easy to getEasy to operateReaction temperatureMacromolecule synthesis

Belonging to the technical field of polymer synthesis, the invention relates to a frustrated Lewis pair FLP catalyzed vinyl polar monomer living polymerization method. A vinyl polar monomer is adoptedas the monomer raw material for conjugate addition polymerization under the synergic catalysis of a frustrated Lewis pair, in terms of mole, Lewis acid is greater than Lewis base and smaller than themonomer, and the ratio of the monomer to the Lewis base is 20-3200:1, the reaction temperature is room temperature, and the reaction time is 30sec-24h. The method provided by the invention has the characteristics of easily available raw materials, convenient operation, mild reaction conditions, rapidity, high conversion rate, wide monomer adaptability and the like, also the catalyst dosage is small, and the initiation efficiency is close to 100%, therefore the method is living controlled polymerization, and can realize random copolymerization and block copolymerization between different polarmonomers.

Owner:JILIN UNIV

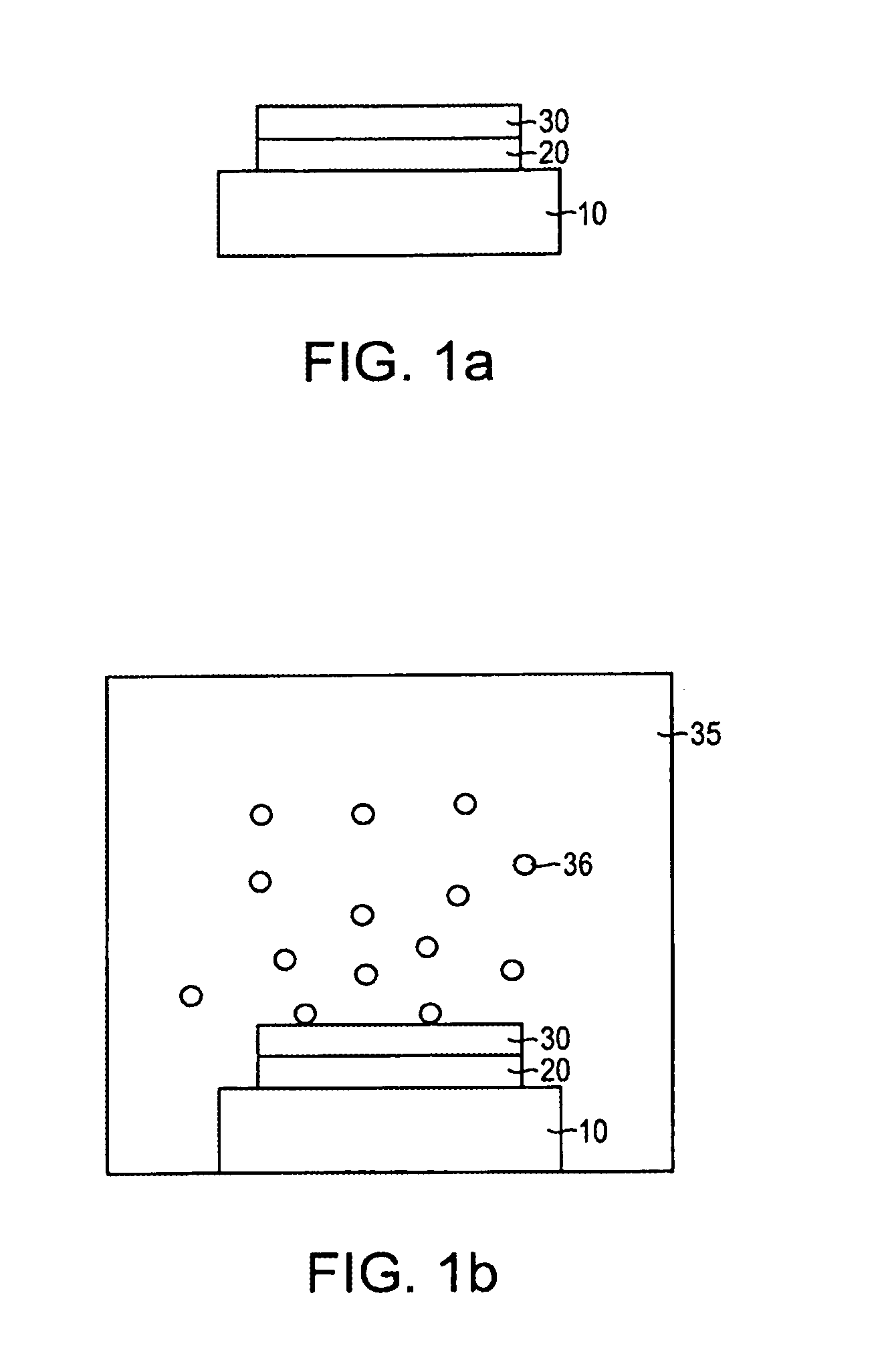

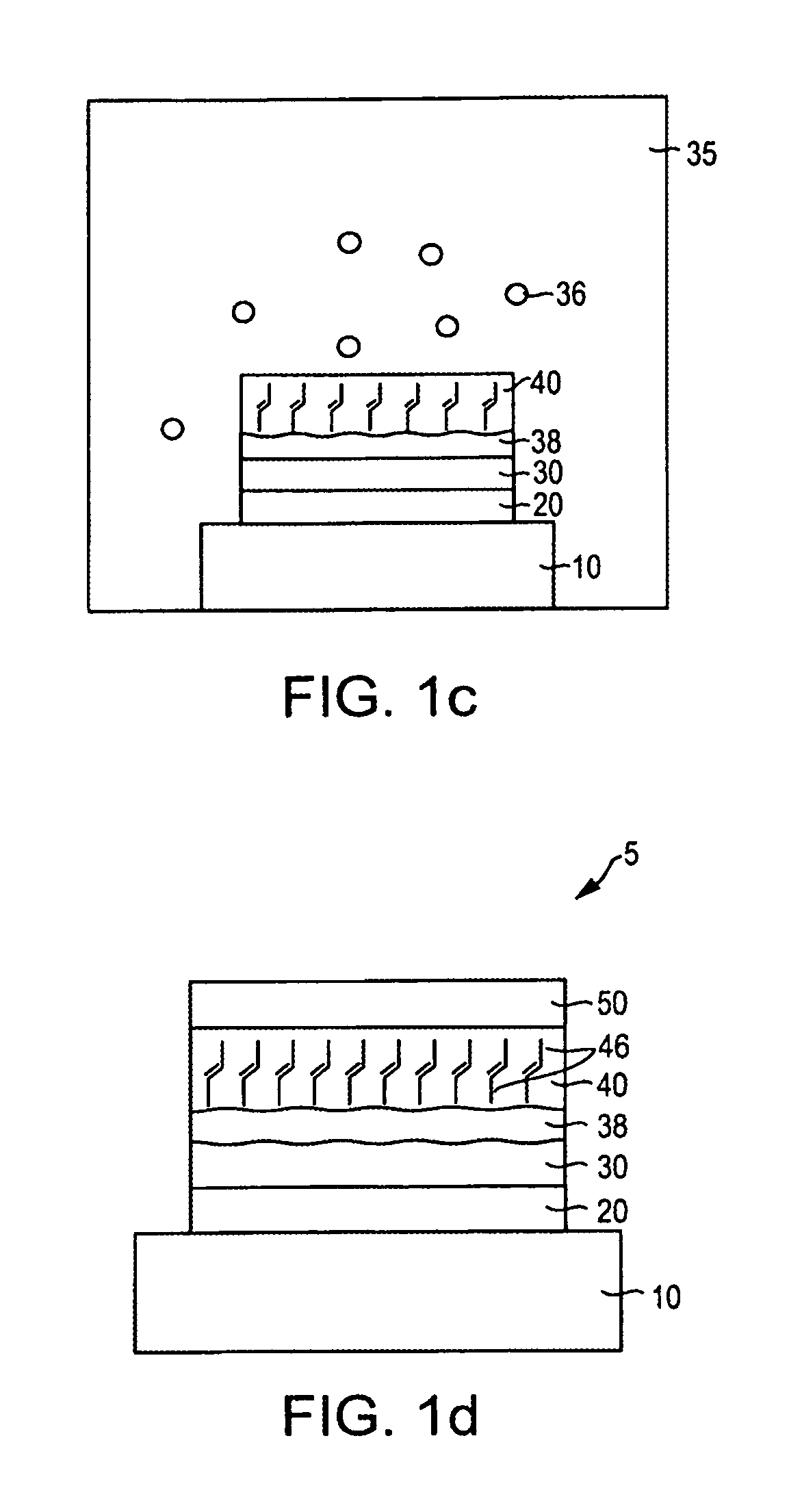

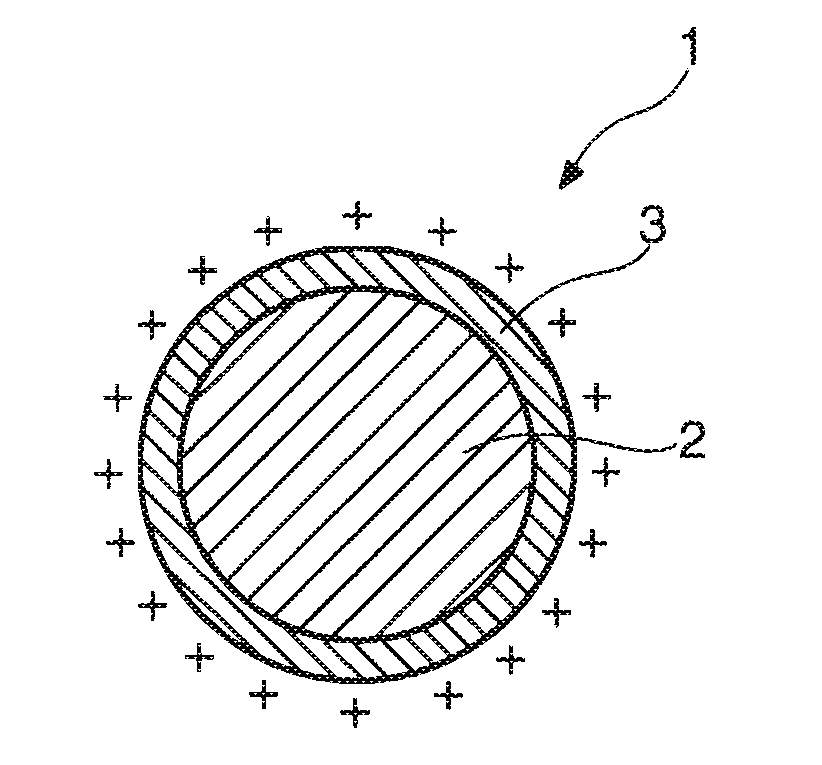

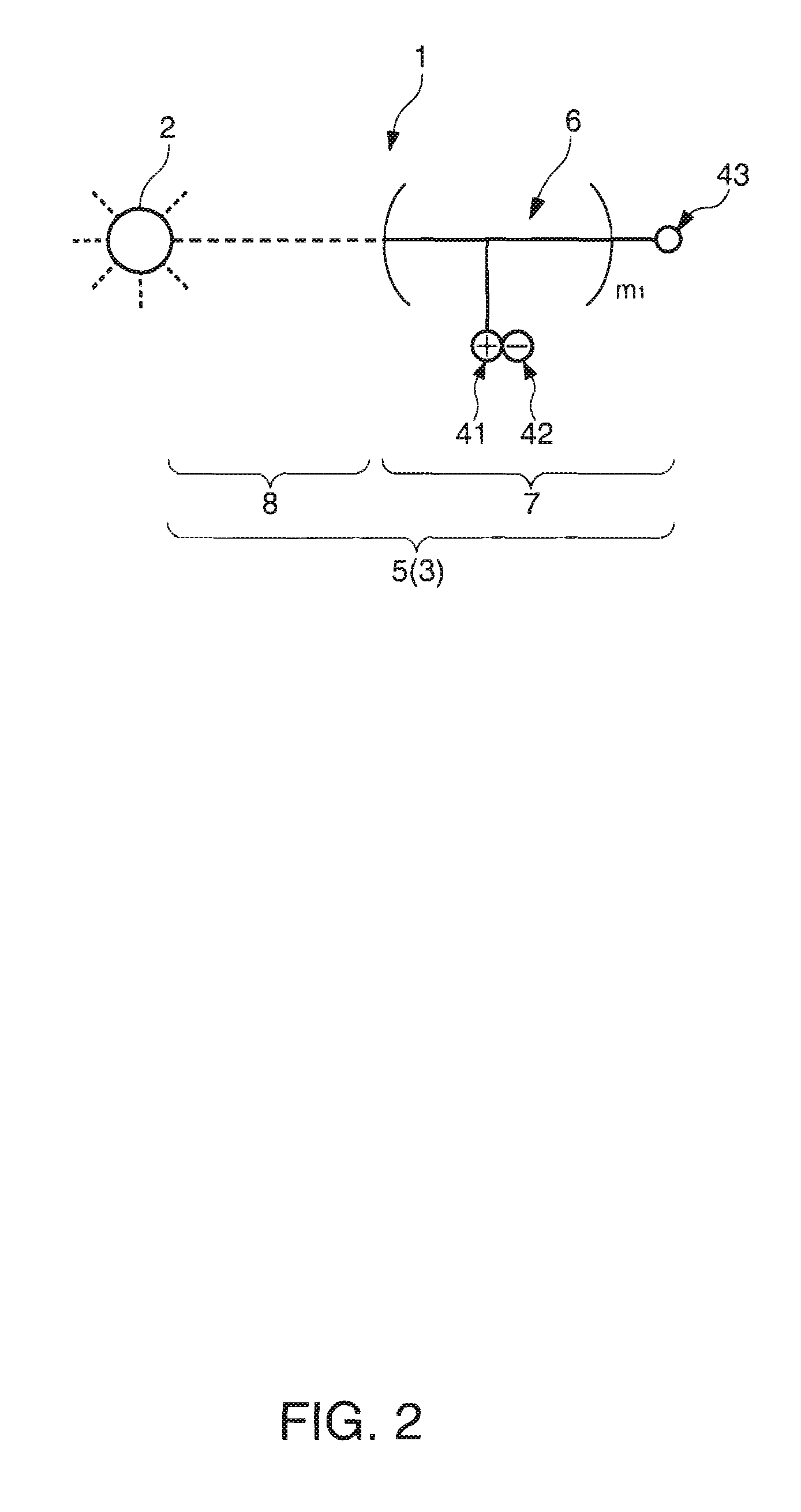

Method of manufacturing charged particle, charged particle, electrophoretic dispersion liquid, electrophoretic sheet, electrophoretic device and electronic equipment

ActiveUS20070195402A1Limited amountNon-linear opticsOptical elementsChemical compoundLiving polymerization

A method of manufacturing a charged particle, comprising: a) providing a mother particle; and b) forming a coating layer that covers at least a part of a surface of the mother particle wherein the step b) includes: coupling a first chemical compound having at least a part where is going to be a starting point of living polymerization to the surface of the mother particle; and polymerizing a second chemical compound having an ionic group or a functional group convertible to an ionic group so as to form a polymer through the living polymerization that starts from the starting point of the first chemical compound.

Owner:E INK CORPORATION

Fluorocarbon polymer coatings prepared by living polymerization

ActiveUS20140272150A1Improve adhesionMinimal thicknessNanotechPretreated surfacesPolymer scienceSelf-assembled monolayer

A process for forming a fluorocarbon polymer film on a substrate is disclosed. A self-assembled monolayer (SAM) containing an initiator for living polymerization such as controlled radical polymerization is formed on the surface of the substrate followed by living polymerization such as controlled radical polymerization of a polymerizable fluorocarbon monomer component.

Owner:ACULON

Controllable polymerization method of industrial-grade monomer

InactiveCN101914173AEasy to operateEase of industrial productionPolymethyl methacrylateAtom-transfer radical-polymerization

The invention relates to a method for carrying out living polymerization by directly using an industrial-grade monomer, in particular to a method for preparing polymethyl methacrylate by carrying out atom transfer radical polymerization (AGET ATRP) reaction generating a catalyst through electron transfer by directly using the monomer, i.e. industrial-grade methyl methacrylate containing a polymerization inhibitor, belonging to the field of organic polymerization. The method comprises the following steps of: adding the monomer, an initiator, the catalyst and a coordinating agent according to the mole ratio of monomer:initiator:catalyst:coordinating agent=(100-1000):1:(0.05-1):(0.15-3) by taking the industrial-grade methyl methacrylate as the monomer; and carrying out the atom transfer radical polymerization (AGET ATRP) reaction generating the catalyst through the electron transfer to synthesize a high molecular polymer under the catalysis of ferric salt. The invention decreases the steps of eliminating the polymerization inhibitor by carrying out the AGET ATRP polymerization by directly using the industrial-grade methyl methacrylate containing the polymerization inhibitor, simplifies the polymerization process and greatly reduces the production cost.

Owner:SUZHOU UNIV

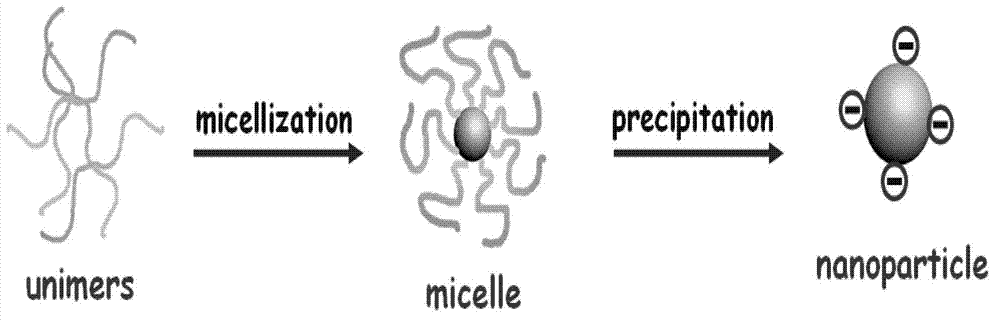

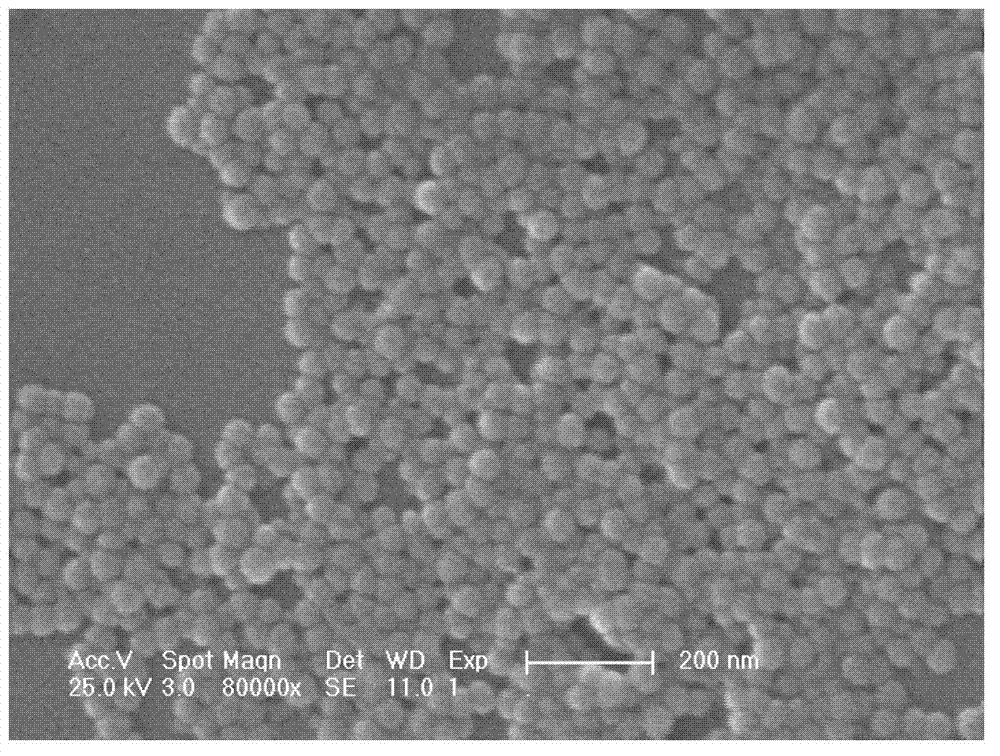

Preparation method for polymeric nanometer microsphere

The invention provides a preparation method for a polymeric nanometer microsphere. The preparation method comprises the following steps: with trithiocarbonate represented by a formula (I) as a chain transferring agent, carrying out RAFT living polymerization to synthesize a gradient copolymer; dissolving the gradient copolymer in an organic solvent and then adding water to form a polymeric micelle solution, wherein the organic solvent and water are intermiscible; and adding the polymeric micelle solution into an aqueous solution of an inorganic salt and carrying out solvent displacement so as to obtain the polymeric nanometer microsphere, wherein a volume ratio of the polymeric micelle solution to the aqueous solution of the inorganic salt is 0.01 to 1. The polymeric nanometer microsphere prepared by using the method has good stability and uniformity, narrow particle size distribution and photoresponse characteristics and the surface of the microsphere is rich in carboxyl groups, thereby facilitating application of the polymeric nanometer microsphere as a good carrier for drugs and proteins. Moreover, the method provided by the invention has the advantages of simpleness, easy practicability, good repeatability, low energy consumption, extensive applicability and easy realization of industrialization.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

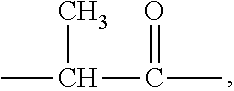

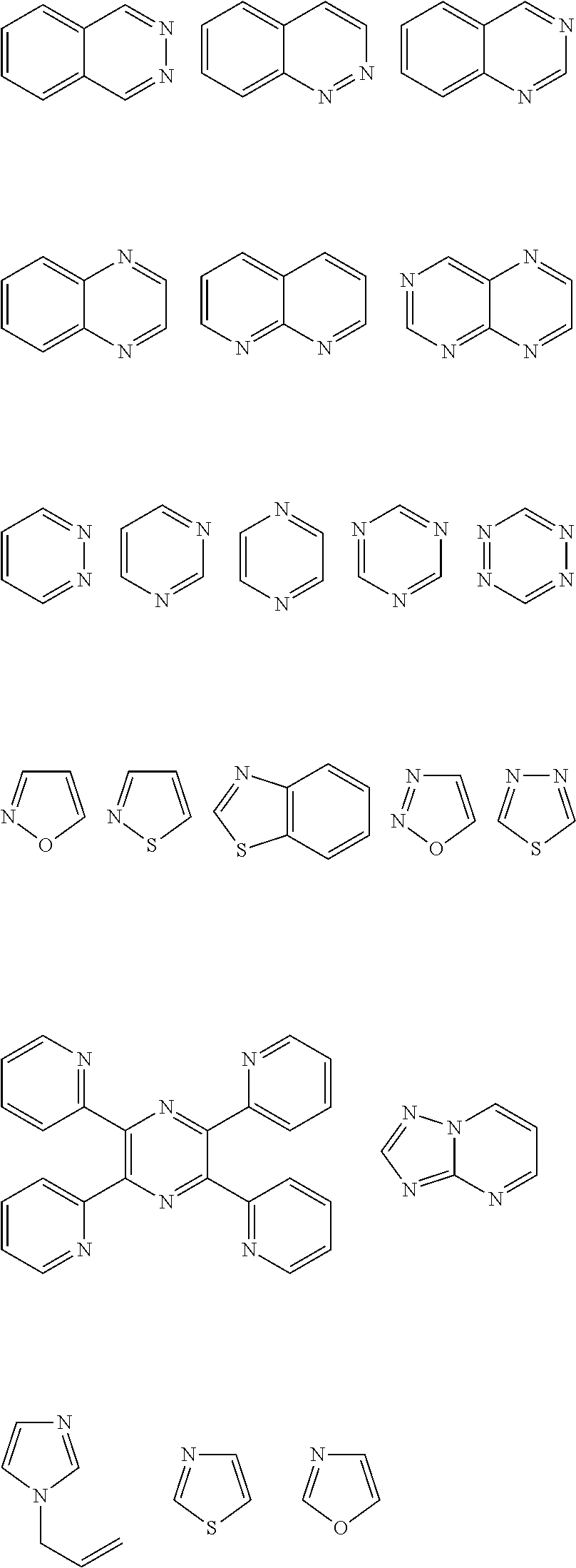

Functionalized polymers and processes for making same

A macromolecule includes at least one polymer chain with at least one functionality. The polymer can include unsaturated mer units and can be provided via anionic and pseudo-living polymerization techniques. In either technique, the functionality can include at least one 5- or 6-membered ring which includes a secondary amine group and at least one additional heteroatom; in the latter technique, the functionality can include a hydrazone radical. Such polymers can be used to provide compositions that also include particulate fillers, such compositions being useful for the production of vulcanizates.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com