Multilayer microcapsule for self-repair polymer materials and its preparation method

A technology of polymer materials and microcapsules, which is applied in the field of multilayer microcapsules for self-healing polymer materials and its preparation, can solve the problems of not conforming to the conventional molding process of thermoplastic materials, and having little application value, so as to improve repair efficiency, Reduce difficulty and increase the effect of polymer chain action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

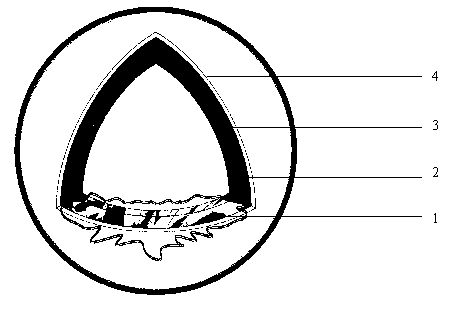

Image

Examples

Embodiment 1

[0041] The preparation of the active macromolecular initiator in the second layer of the capsule wall of the multilayer microcapsule of the present invention: in a glove box full of nitrogen, add the catalyst cuprous bromide / N, N, N', N' in sequence in the reaction bottle , N''-pentamethyldiethylenetriamine complex, phase transfer catalyst tetrabutylammonium bromide and newly refined methyl methacrylate monomer, after using magnetic stirring to completely dissolve the reactants into a uniform solution , adding the initiator 2-bromoisobutyrate ethyl ester, the molar ratio of the reaction raw materials is: methyl methacrylate / 2-bromoisobutyrate ethyl ester / cuprous bromide / N,N,N',N' , N''-pentamethyldiethylenetriamine / tetrabutylammonium bromide=200:1:1:1:8. Carry out polymerization reaction at room temperature, the time is 4h, then polymer product is dissolved, crosses neutral alumina chromatographic column, reprecipitates, obtains the macromolecular initiator active polymeth...

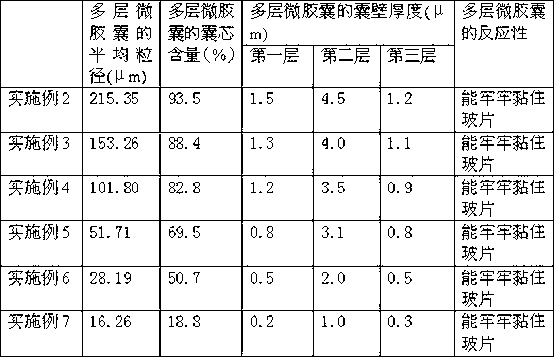

Embodiment 2

[0044] S1. Measure newly prepared 40mL2% sodium dodecylbenzenesulfonate solution, 20mL2% polyvinyl alcohol aqueous solution, and 280mL distilled water in a 1000mL beaker, add 15mL10% acetic acid solution to adjust the pH to about 3.0, pour 80g of formosan Butyl acrylate was homogenized at a speed of 3Kr / min for 5min with a homogenizer. Then the above emulsion was transferred into a 1000ml three-necked round bottom flask and placed in an oil bath at 35°C, and the mechanical stirring speed was adjusted to 300rpm. Add the prepolymer obtained by reacting 25g melamine, 50g formaldehyde solution, 50g distilled water, and two drops of triethanolamine at 70°C for 20 minutes to the above-mentioned emulsion under mechanical stirring, gradually raise the temperature to 60°C, react for 3 hours, cool, wash with water, and sieve , and naturally dried to obtain microcapsules ①;

[0045] S2. Take by weighing 5g microcapsules 1. in a small beaker, add 20ml of dichloromethane solution ...

Embodiment 3

[0050] S1. Measure newly prepared 40mL 2% sodium dodecylbenzenesulfonate solution, 20mL 2% polyvinyl alcohol aqueous solution, and 280mL distilled water in a 1000mL beaker, add 15mL10% acetic acid solution to adjust the pH to about 3.0, pour 80g of glycidyl methacrylate was homogenized at a speed of 4Kr / min for 8min with a homogenizer. Then the above emulsion was transferred into a 1000ml three-neck round bottom flask and placed in an oil bath at 35°C, and the mechanical stirring speed was adjusted to 350rpm. Add the prepolymer obtained by reacting 25g melamine, 50g formaldehyde solution, 50g distilled water, and two drops of triethanolamine at 70°C for 20 minutes to the above-mentioned emulsion under mechanical stirring, gradually raise the temperature to 65°C, react for 3 hours, cool, wash with water, and sieve , and naturally dried to obtain microcapsules ①;

[0051] S2. Take by weighing 5g microcapsules 1. in a small beaker, add 25ml of dichloromethane solution co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com