Patents

Literature

2186 results about "Glycidyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

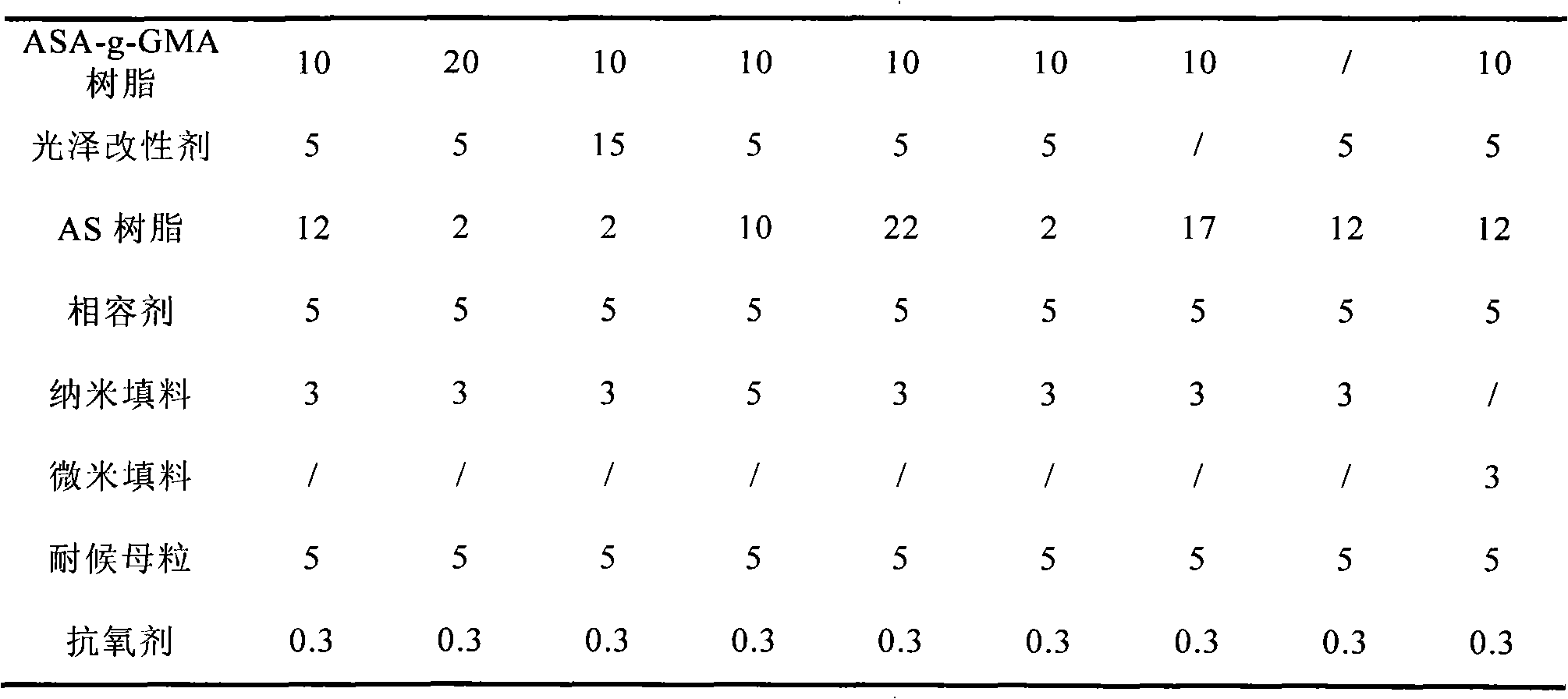

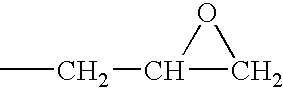

Glycidyl methacrylate (GMA) is an ester of methacrylic acid and glycidol, it is a common monomer used in the creation of epoxy resins. While typical home epoxies contain diglycidyl ether of bisphenol A (DGEBA), glycidyl methacrylate is instead used to provide epoxy functionalization to polyolefins and other acrylate resins. Glycidyl methacrylate is produced by several companies worldwide, including Dow Chemical.

Thermosetting anti-refective coatings

Anti-reflective coating compositions having improved etch rate, inter alia, are prepared from certain acrylic polymers and copolymers, such as, glycidyl methacrylate reacted with non-polycyclic carboxylic acid dyes and non-polycyclic phenolic dyes, all light absorbing at a wavelength of 193 nm.

Owner:BREWER SCI

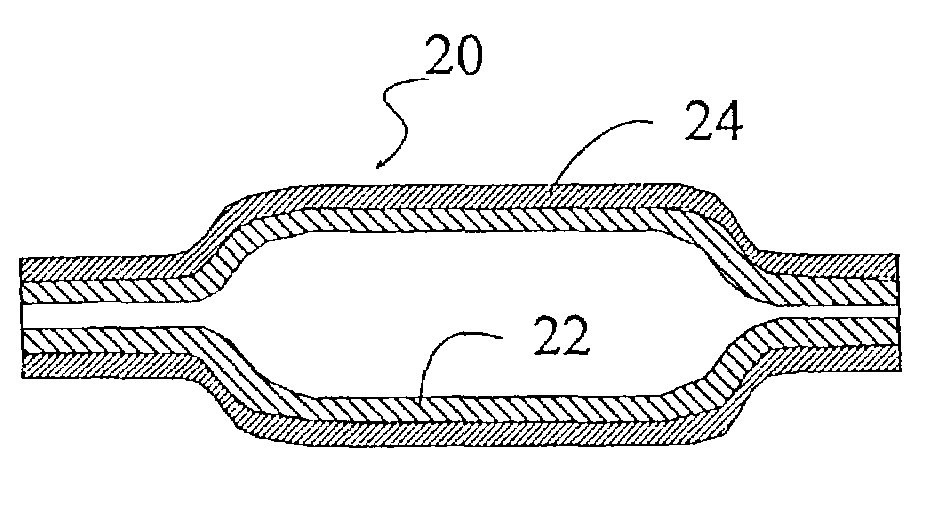

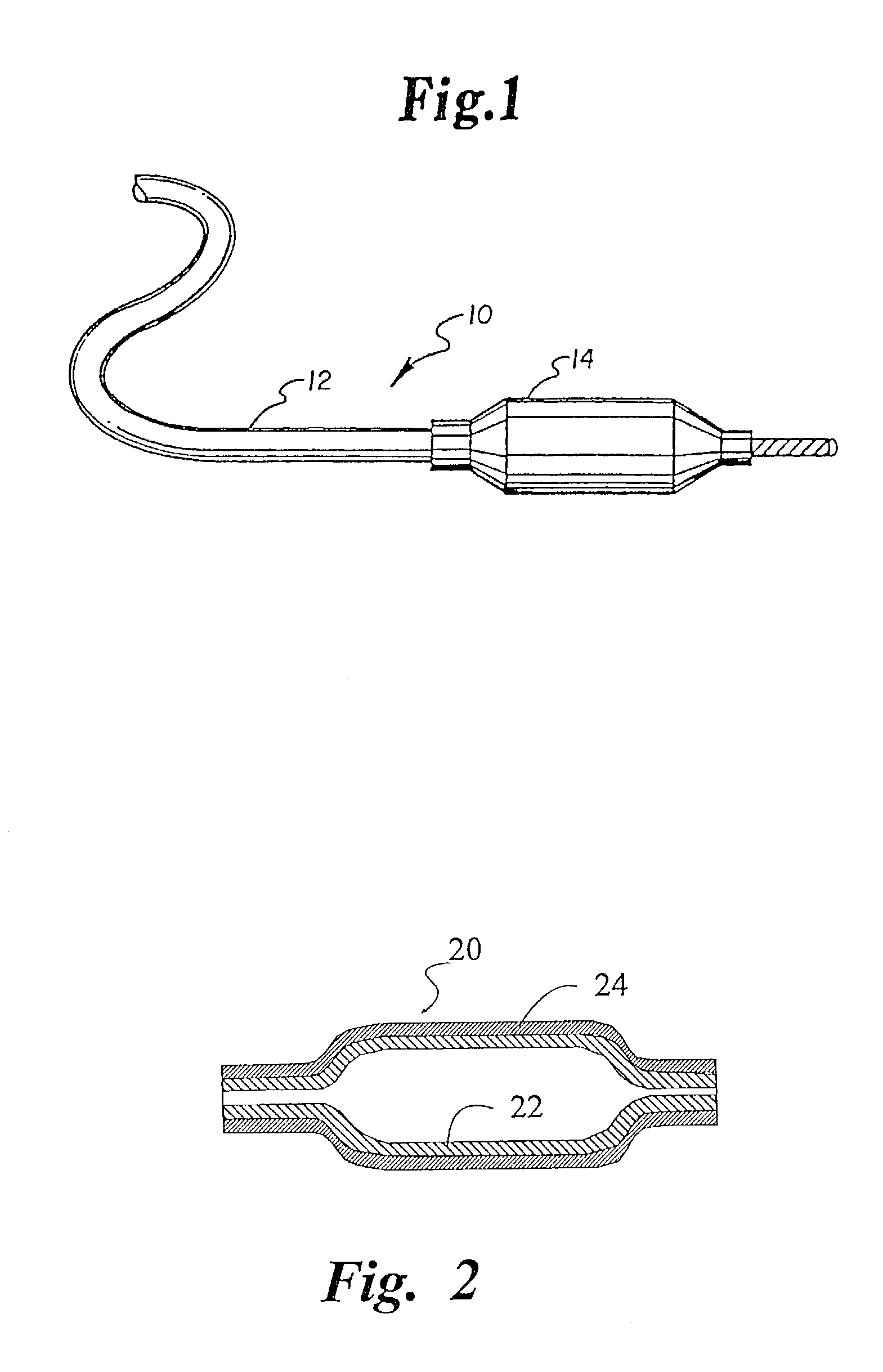

Balloons made from liquid crystal polymer blends

Balloons for use on medical devices such as catheter balloons are formed from polymer blend products which include a liquid crystal polymer (LCP), a crystallizable thermoplastic polymer, especially thermoplastic polyesters such as PET, and a compatabilizer. The compatabilizer may be an ethylene-maleic anhydride copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate-maleic anhydride terpolymer, an ethylene-methyl-methacrylic acid terpolymer, an acrylic rubber, an ethylene-ethyl acrylate-glycidyl methacrylate terpolymer or a mixture of two or more such polymers.

Owner:BOSTON SCI SCIMED INC

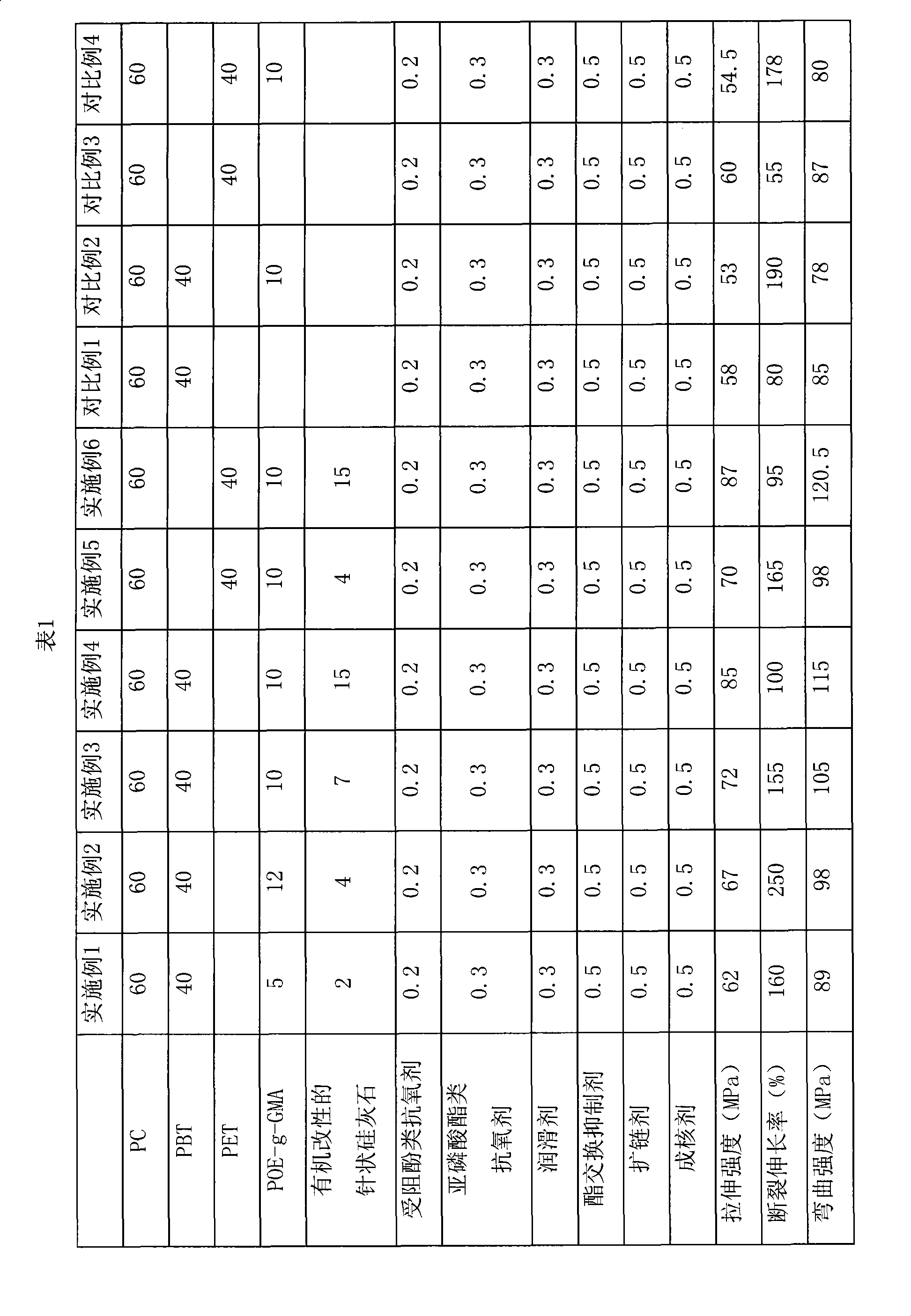

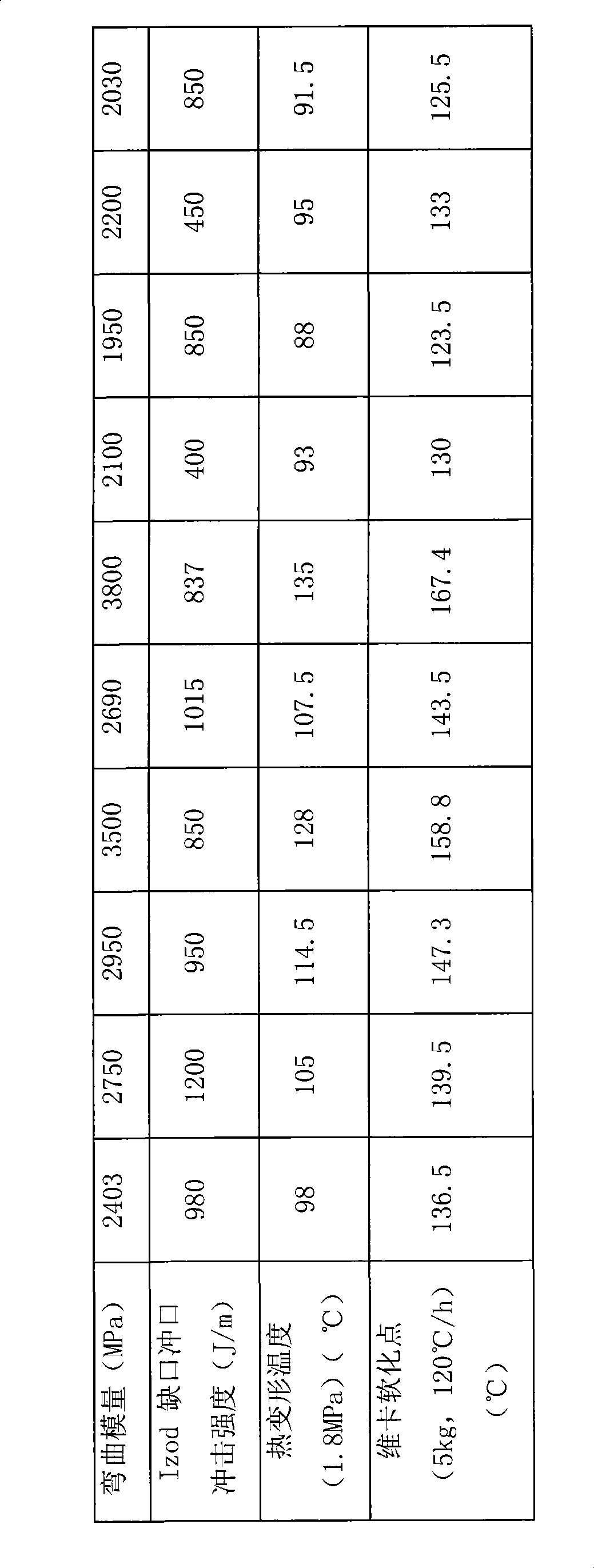

Method of manufacturing polycarbonate/polyester alloy

The invention discloses a preparation method of polycarbonate / polyester alloy. Glycidyl methacrylate grafted ethylene-octylene multipolymer / organic modified needle-shaped aedelforsite composite toughener, i.e. a technology of simultaneously using organic / inorganic rigid particle toughener is adopted; the glycidyl methacrylate grafted ethylene-octylene multipolymer, organic modified needle-shaped aedelforsite, polycarbonate and polyester are melted and mixed in a double-screw extruder, to obtain high-performance alloy material. The prepared polycarbonate / polyester alloy has excellent integrated mechanical properties and size stability, the notched impact strength reaches 1200J / m, the tensile strength reaches 67MPa, the elongation at break reaches 250 percent, the flexural strength is up to 98MPa, the flexural modulus reaches 2750MPa, and the thermal deformation temperature in high load (1.82MPa) is up to 105 DEG C. Therefore, the prepared polycarbonate / polyester alloy can be applied in cars, and to outer decorations, household electrical appliances, IT and the like industrial products.

Owner:SHANGHAI JIAO TONG UNIV +1

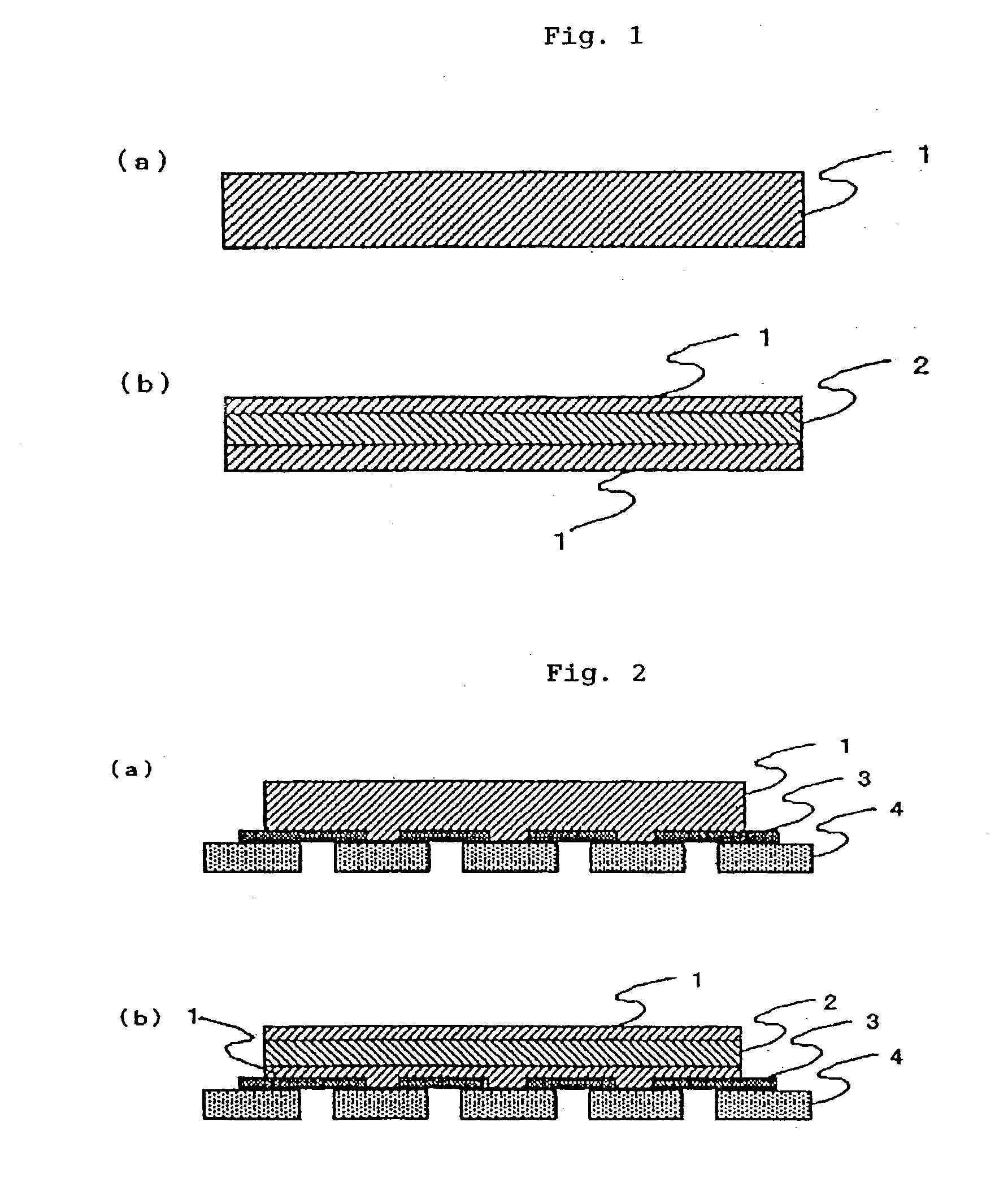

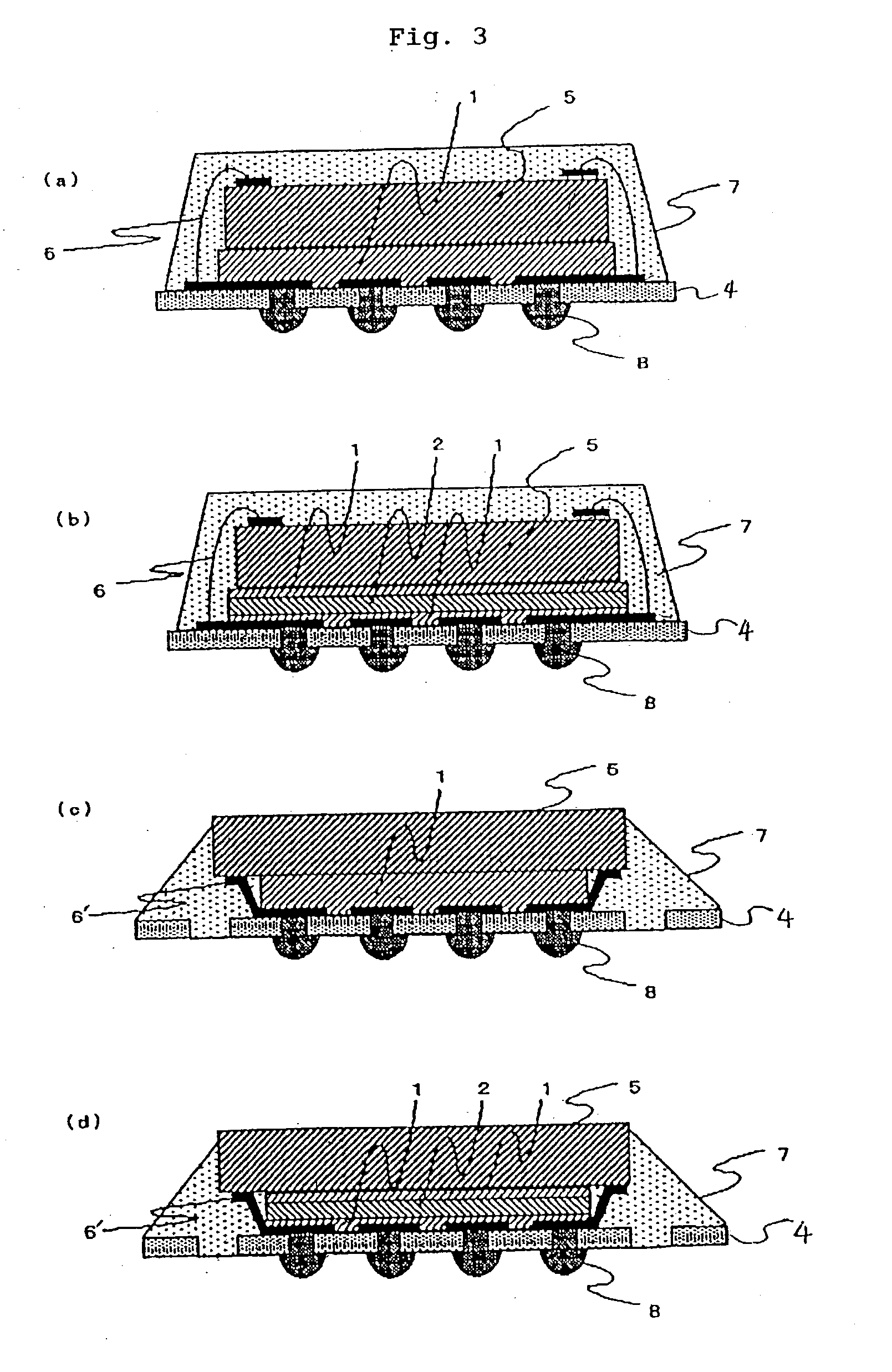

Adhesive, adhesive member, interconnecting substrate for semiconductor mounting having adhesive member, and semiconductor device containing the same

InactiveUS20030145949A1Low elasticity , heat resistanceDifferent coefficientPrinted circuit assemblingSemiconductor/solid-state device detailsChemistryGLYCIDYL ACRYLATE

An adhesive which comprises (1) 100 parts by weight of an epoxy resin and a hardener therefor, (2) 75 to 300 parts by weight of an epoxidized acrylic copolymer having a glycidyl (meth)acrylate unit content of 0.5 to 6 wt. %, a glass transition temperature of -10° C. or higher and a weight average molecular weight of 100,000 or more and (3) 0.1 to 20 parts by weight of a latent curing accelerator; an adhesive member having a layer of the adhesive; an interconnecting substrate for semiconductor mounting having the adhesive member; and a semiconductor device containing the same.

Owner:HITACHI CHEM CO LTD

Pigment dispersant

A pigment dispersant is disclosed comprising a tri-block copolymer having a first block comprising a glycidyl(meth)acrylate reacted with a napthoic acid, a second block comprising (meth)acrylic acid alkyl esters, and a third block comprising (meth)acrylic acid alkyl esters, wherein said third block is different from said second block. The dispersant is suited for use in a nanoparticulate dispersion comprising pigment particles having an average primary particle size of less than 100 nm.

Owner:PPG IND OHIO INC

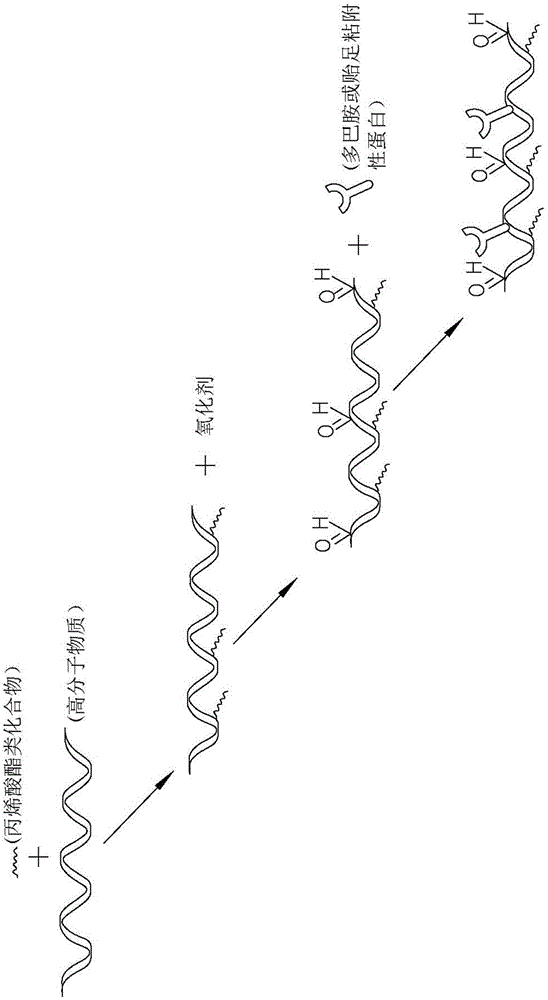

Bioadhesive and preparation method thereof

ActiveCN104623725AImprove biological activityImprove mechanical propertiesSurgical adhesivesMethacrylateGlycidyl methacrylate

The invention discloses a bioadhesive, which contains a polymer and a solvent, wherein the polymer is a graft of dopamine or mussel adhesive protein and oxidized graft A; the graft A is a graft of a macromolecular substance andan acrylate compound; a six-membered ring in a macromolecular substance in the oxidized graft A is bonded with an aldehyde group; the macromolecular substance is selected from at least one of hyaluronic acid, chondroitin sulfate, gelatin, polypeptide, alginic acid and chitosan; and the acrylate compound is selected from one of methyl methacrylate, methacrylate, glycidyl methacrylate and acrylic ester. The invention further provides a preparation method of the bioadhesive. The bioadhesive has the advantages of being good in biological activity, relatively good in mechanical property and biodegradable, and is capable of promoting tissue healing in a moist environment.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Crosslinked hydrogel copolymers

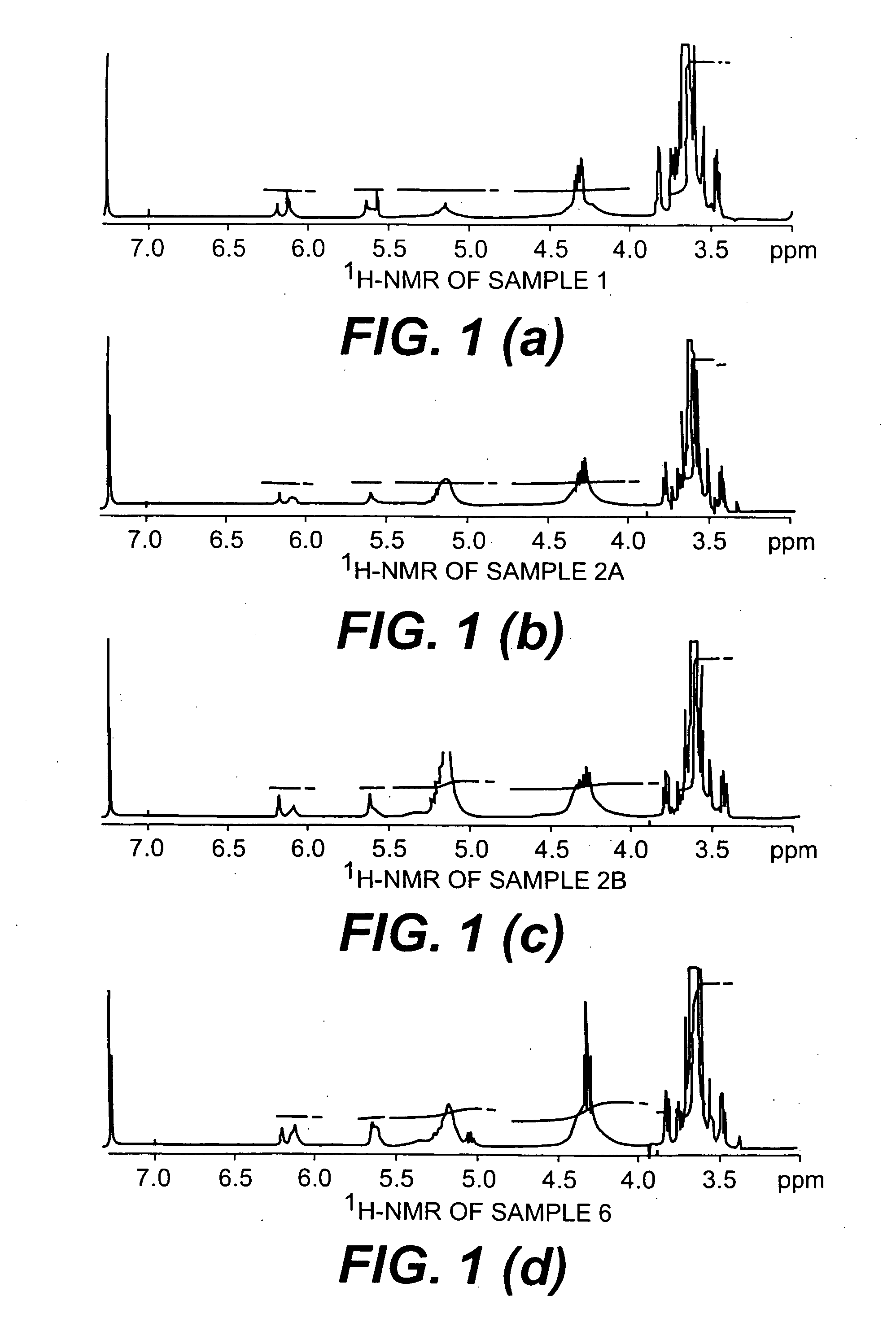

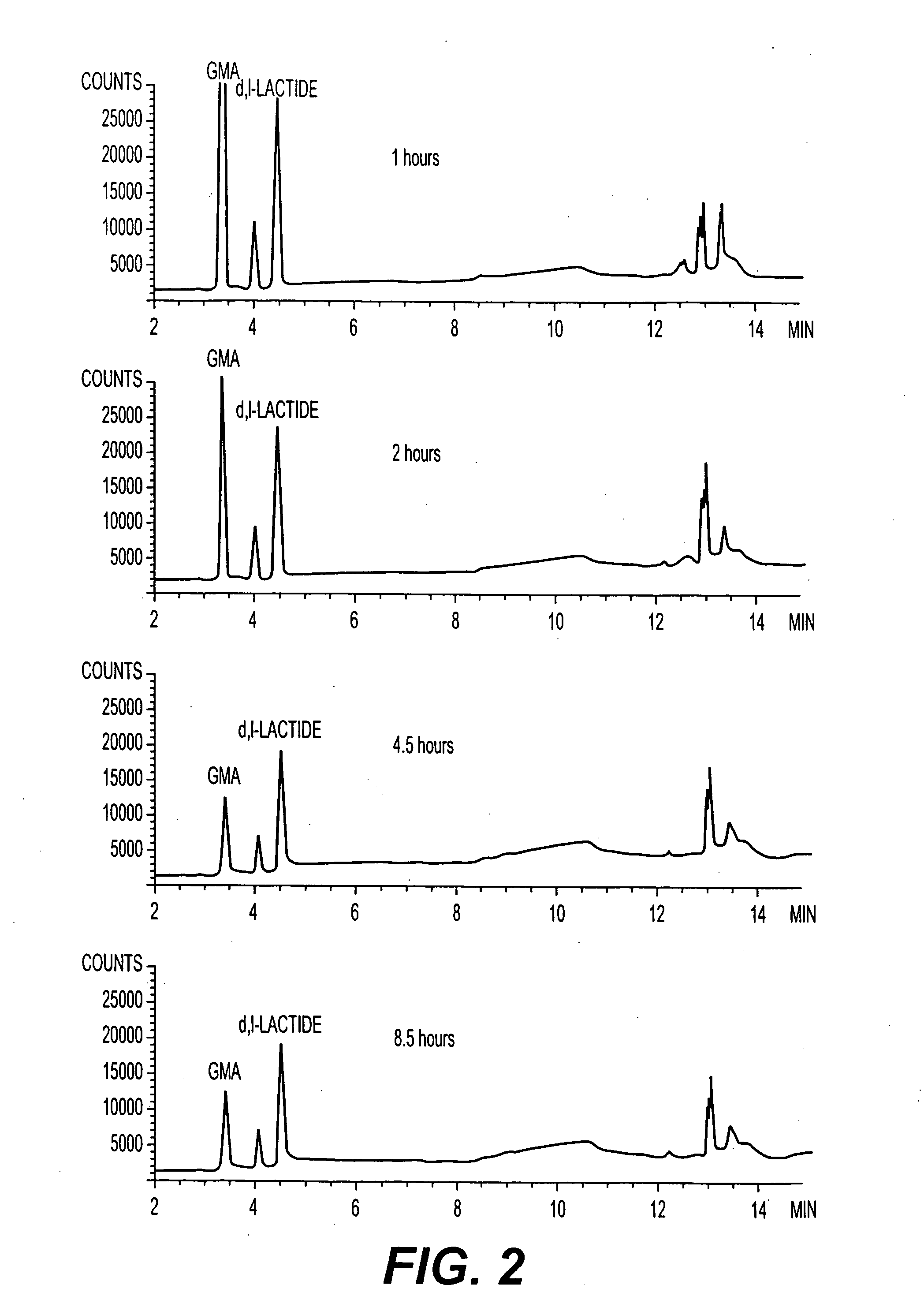

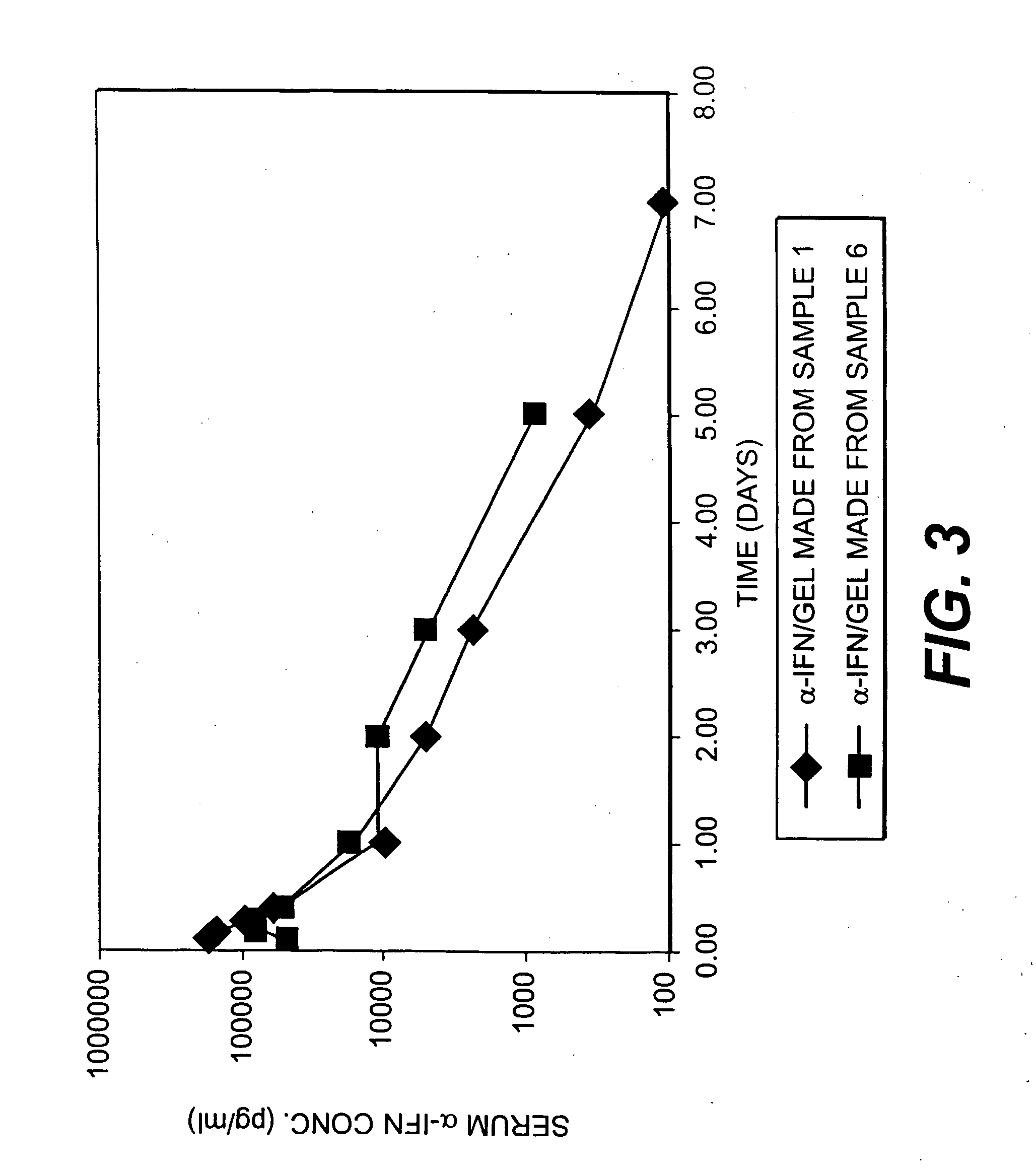

The present invention relates to crosslinked polymers, synthesized through ring-opening polymerization of ethylenically unsaturated epoxides, in combination with α-hydroxy acids using a hydrophilic macroinitiator, such as poly(ethylene glycol), to form substituted copolymers having ethylenically unsaturated functionality randomly distributed along the polyester polymer backbone. That copolymer is subsequently crosslinked to form a hydrogel network. More particularly, the present invention relates to the synthesis of biodegradable poly(α-hydroxy acid-co-glycidyl methacrylate)-block-poly(ethylene glycol)-block-poly(α-hydroxy acid-co-glycidyl methacrylate) copolymers, which are subsequently crosslinked to form hydrogel networks. The invention also relates to the use of these hydrogel networks in various applications, in particular, for the controlled release of drugs and proteins.

Owner:ALKERMES INC

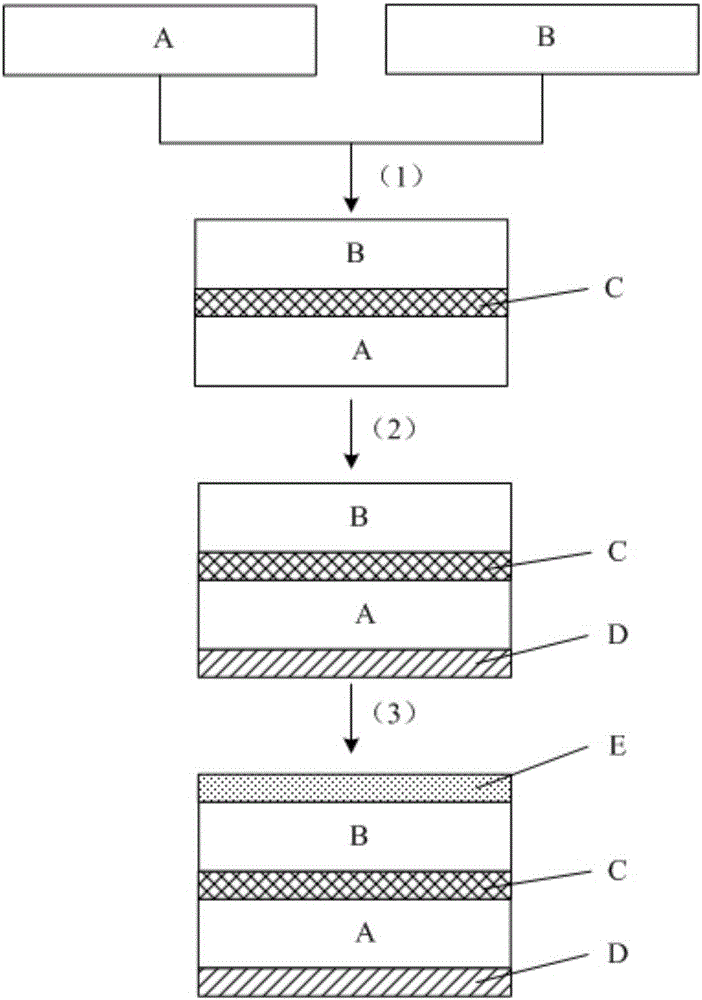

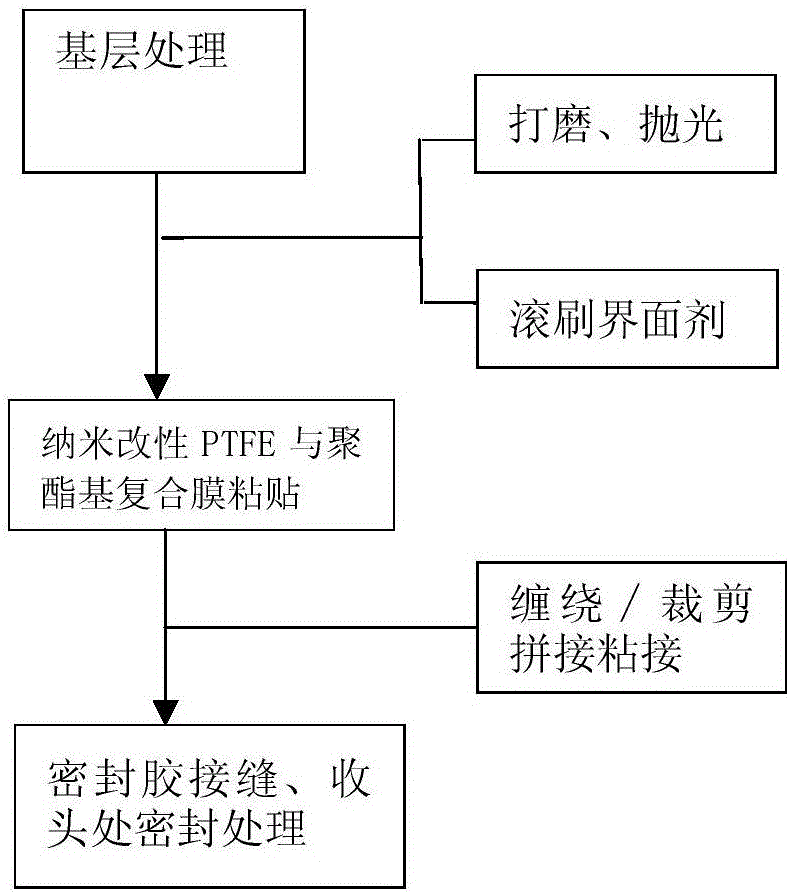

Preparation method and application of nano-modified PTFE and polyester-based composite film for preventing fan blades from icing

ActiveCN106313811ASolving non-adhesive technical problemsConvenient engineering constructionSynthetic resin layered productsLaminationPolyesterComposite film

The invention provides a preparation method and application of a nano-modified PTFE and polyester-based composite film for preventing fan blades from icing. The method includes the steps of PTFE film modification, lamination complexing and photo-crosslinked adhesive application. A modifier is prepared from antimony-doped tin oxide nano-crystals, nano-titanium dioxide, nano-silicon carbide, an organic fluorine waterproofing agent and pentaerythritol tri-(3-aziridinyl)-propionate; in lamination complexing, a bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, (2)ethoxylated bisphenol A dimethacrylate, trimethylolpropane triacrylate and benzoyl peroxide; a photo-crosslinked adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, vinyl acetate, butyl acrylate, an acrylate derivative, a photoinitiator and dimethylformamide. The method and the composite film solve the non-adhesion problem that a PTFE film can not be pasted on the surfaces of fan blades with an adhesive directly.

Owner:NANJING HAOHUI HI TECH CO LTD

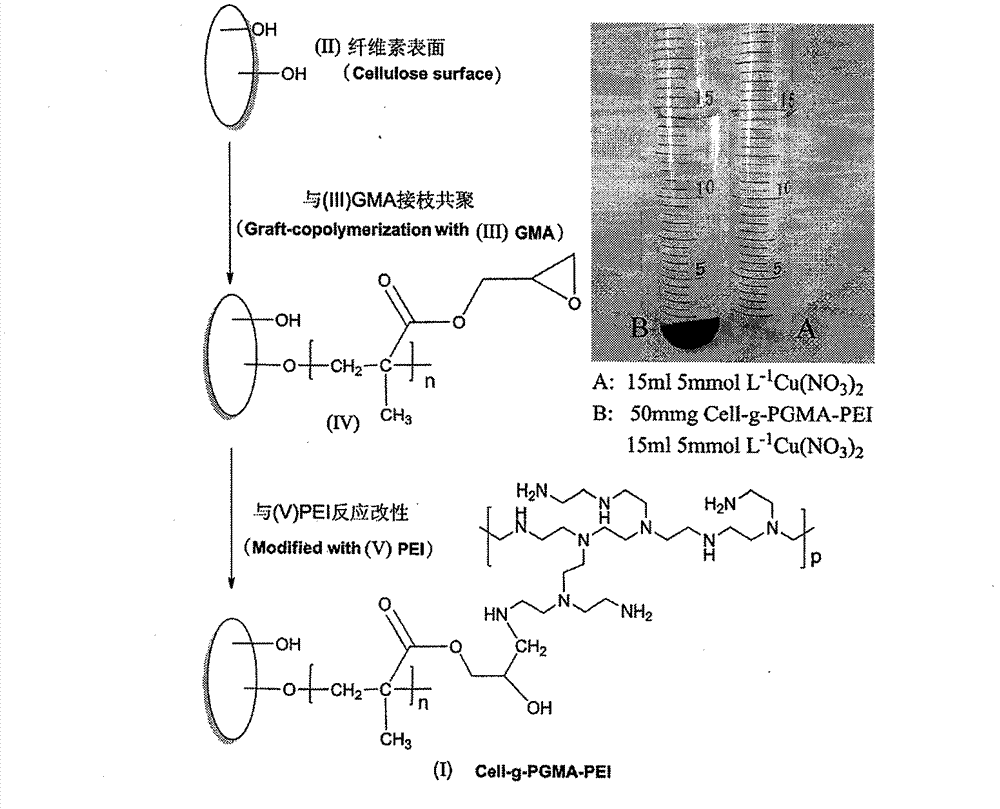

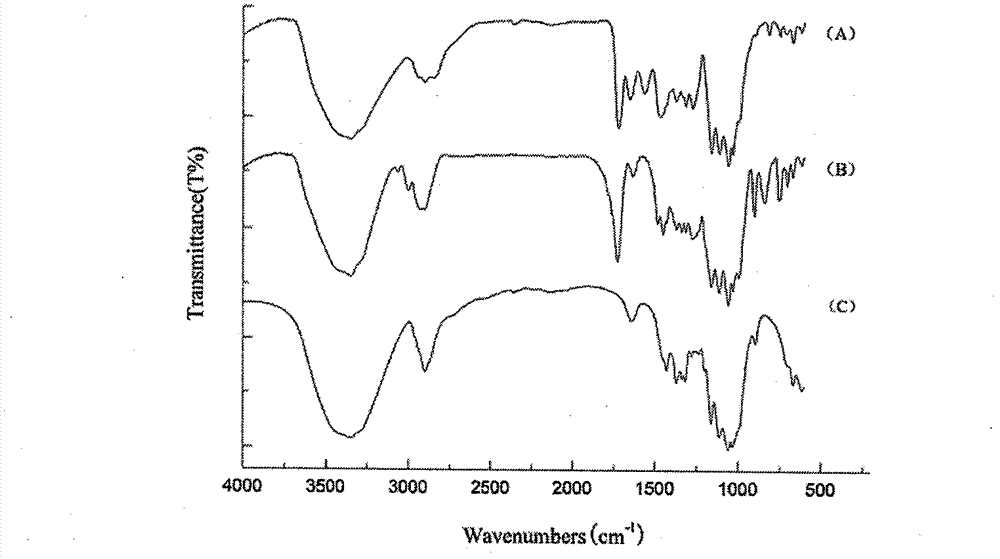

Preparation method of efficient polyethyleneimine modified cellulose-based heavy metal adsorbent

InactiveCN103304820AEasy to useLow toxicityOther chemical processesWater/sewage treatment by sorptionGlycidyl methacrylateBenzoyl peroxide

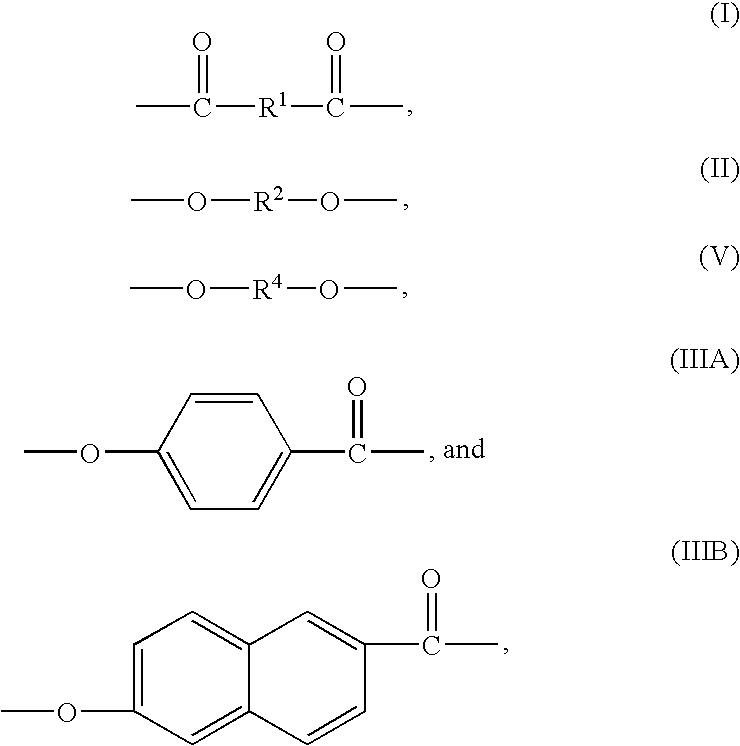

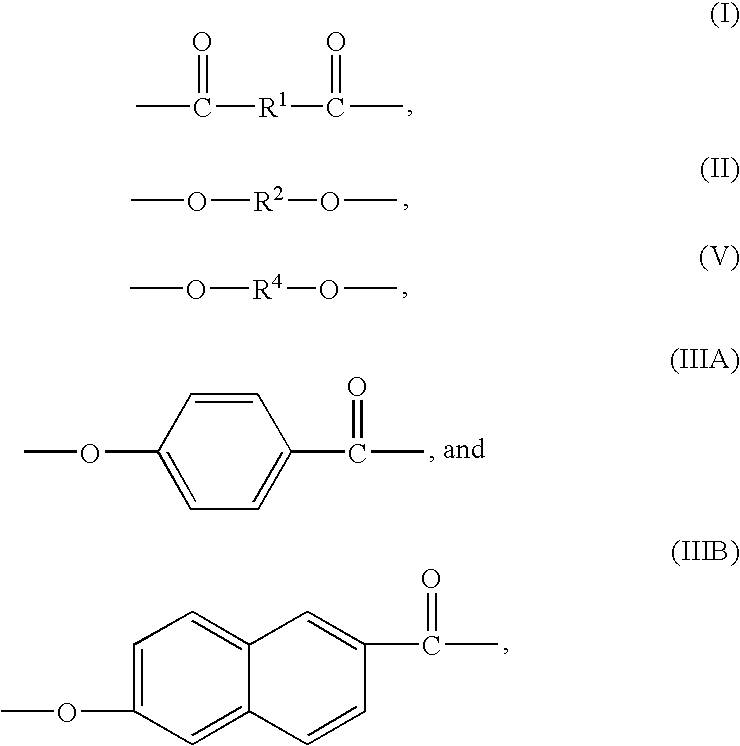

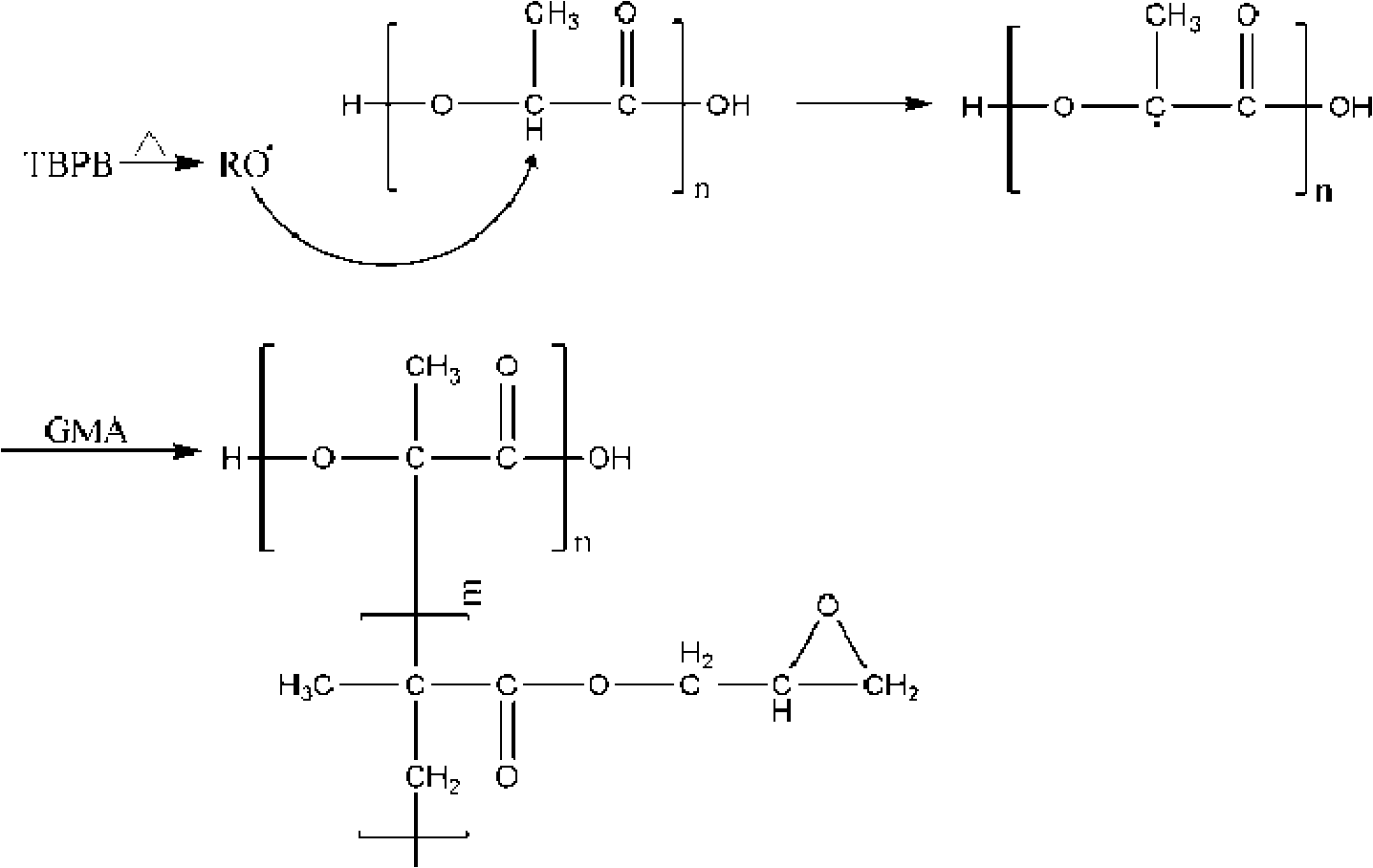

The invention discloses a preparation method of an efficient polyethyleneimine modified cellulose-based heavy metal adsorbent shown by a formula (I), belonging to the technical field of high-molecular function modification and synthesis of a natural material. By adopting cellulose as a framework, benzoyl peroxide (BPO) as an initiator, a mixture of water and acetone as a solvent and glycidyl methacrylate (GMA) shown by a formula (III) as a monomer, the method comprises the following steps of: performing a free radical-initiated graft copolymerization reaction on the surface of microcrystalline cellulose shown by a formula (II); performing amination on a graft product shown by a formula (IV) by use of graft polyethyleneimine (PEI) shown by a formula (V); and washing and drying the product to obtain a powdery solid product, wherein the reaction is easy to operate, and the conditions are mild. The heavy metal adsorbent prepared by the preparation method has the advantages of excellent adsorption property, large adsorption capacity and fast adsorption, can be regenerated and recycled, and has broad application prospects in the water treatment fields such as control of heavy metal industrial pollutants and the like.

Owner:SHANDONG UNIV

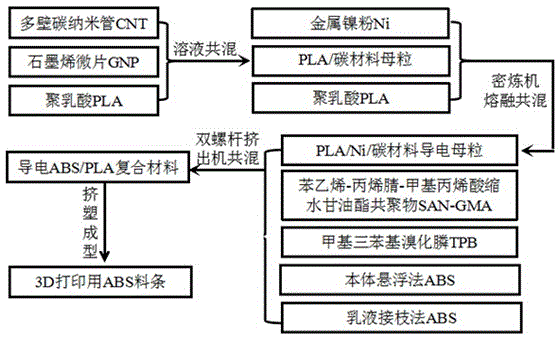

Electric conduction compound ABS/PLA material for 3D printing wires as well as preparation method and application of electric conduction compound ABS/PLA material

ActiveCN105001586AGood compatibility and co-continuityLow conductive additive contentAdditive manufacturing apparatus3d printGlycidyl methacrylate

The invention provides an electric conduction compound ABS / PLA material for 3D printing wires. The electric conduction compound ABS / PLA material is prepared from the following raw materials in percentage by weight: 15-30% of a synthetized material ABS by using a bulk method, 15-30% of a synthetized material ABS by an emulsion method, 1-10% of copolymers of styrene -acrylonitrile -2-methylpropenoic acid glycidyl ester, 0.01-0.05% of triphenylphosphonium bromide, 5-15% of metallic nickel powder , 30-50% of polylactic acid , 1-5% of walled carbon nanotubes and 1-5% of graphene microchips. According to the electric conduction compound ABS / PLA material disclosed by the invention, the nickel powder, the graphene microchips and the carbon nano tubes are optimized and collocated, so that the requirements for electrical conductivity by using lower volume resistivity under the low content of an electric conduction additive are met, the ABS material mixed in different particle diameters enables the particle diameters in the compound material to present bimodal distribution, and the toughness is enhanced; the consistency and the cocontinuity of ABS and PLA are good, so that the electric conduction compound ABS / PLA material is particularly suitable for strip-shaped high electric conduction materials required by 3D printing.

Owner:广州润锋科技股份有限公司

Preparation method for resin with spraying-free metal effect

The invention relates to a preparation method for a resin with a spraying-free metal effect. The method comprises the following steps of: chemically coating and modifying an aluminum pigment by adopting a SAN-GMA (Styrene-Glycidyl Methacrylate) copolymer; and adding into each plastic substrate resin according to a certain proportion for blending at a high speed and extruding and granulating with two screws to obtain the resin with the spraying-free metal effect. Compared with the prior art, the method has the advantages that: the coated aluminum pigment has high dispersity on the basis of keeping high metal luster and has extremely high compatibility with the plastic substrate resin, the problem that flow marks are formed easily due to the introduction of the conventional aluminum pigmentinto the plastic substrate is solved effectively, powerful technical support is provided for the development and application of the resin with the spraying-free metal effect, and the like.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

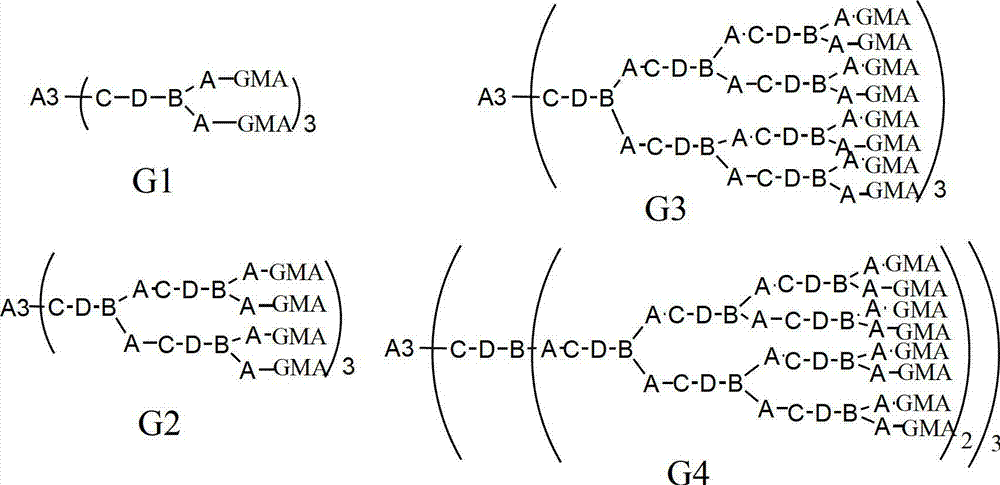

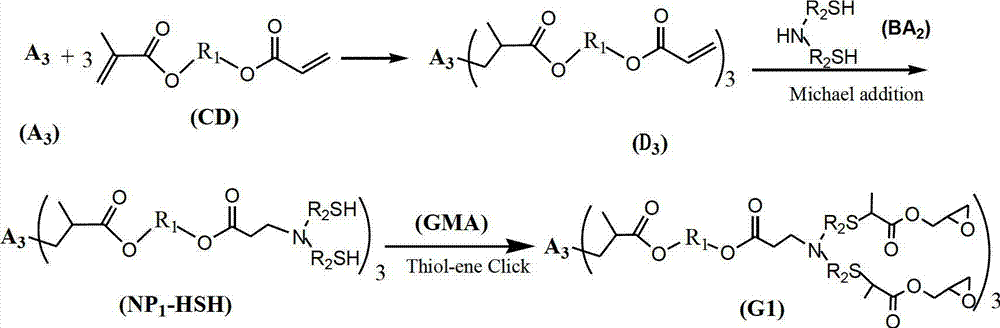

Sulfur-containing hyperbranched epoxy resin and preparation method thereof

The invention belongs to the technical field of epoxy resins and preparation method thereof and in particular discloses a sulfur-containing hyperbranched epoxy resin and a preparation method thereof. The preparation method comprises the following steps: stirring and reacting a trithiol compound and a diolefin compound at the temperature of 10 DEG C below zero and 20 DEG C for 2-5 hours and preparing an acrylate monomer with polyfunctionality; stirring and reacting the monomer and bithiol secondary amine at the temperature of 20-80 DEG C for 5-10 hours and obtaining a first generation mercapto-terminated hyperbranched polymer NP1-HSH; stirring and reacting the NP1-HSH and methacrylic acid glycidyl ester at the temperature of 10 DEG C below zero and 20 DEG C for 2-5 hours and obtaining a first generation sulfur-containing hyperbranched epoxy resin; and sequentially carrying out the previous three reactions on NP1-HSH to prepare a second-fourth generation sulfur-containing hyperbranched epoxy resin with the molecular weight of about 2,000-30,000 g / mol. The method is simple in process and low in reaction temperature, the obtained product can reduce the curing temperature and is expected to be applied to the fields of reinforcing and toughening of epoxy resins, solvent-free coatings and the like.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

ABS (acrylonitrile-butadiene-styrene)/regenerated PET (polyethylene terephthalate) resin composition and preparation method thereof

The invention discloses an ABS (acrylonitrile-butadiene-styrene) / regenerated PET (polyethylene terephthalate) resin composition and a preparation method thereof. The composition comprises the following components: 15-60 wt% of ABS high glue powder, 5-25 wt% of styrene-acrylonitrile (SAN) copolymer, 5-50 wt% of regenerated PET, 1-10 wt% of compatilizer, 0.1-1% of antioxidant and 0.1-2% of lubricant. The preparation method comprises the following steps: thoroughly mixing the ABS high glue powder, SAN copolymer and compatibilizer in a high-speed mixer, discharging, putting the mixture into a screw extruder, extruding and granulating to obtain a compatilizing master batch; and thoroughly mixing the compatilizing master batch and the rest of the components in the high-speed mixer, thoroughly mixing, discharging, putting the mixture into the screw extruder, extruding and granulating to obtain the ABS / regenerated PET resin composition disclosed by the invention. By adding the styrene-acrylonitrile copolymer-glycidyl methacrylate terpolymer, the compatibility of the ABS and PET is effectively improved, so that the ABS / PET resin composition has high impact resistance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

Alloy resin composition and preparation method thereof

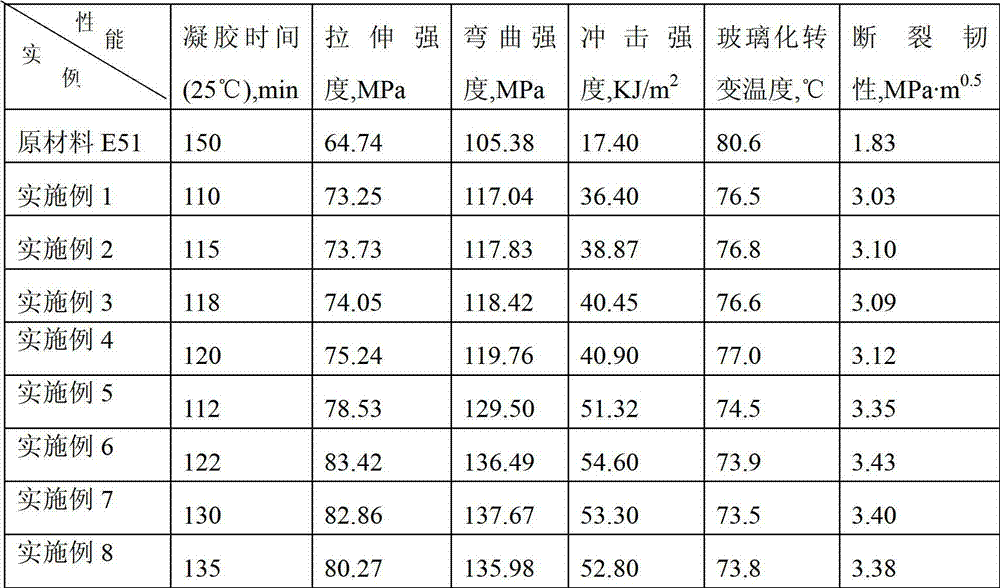

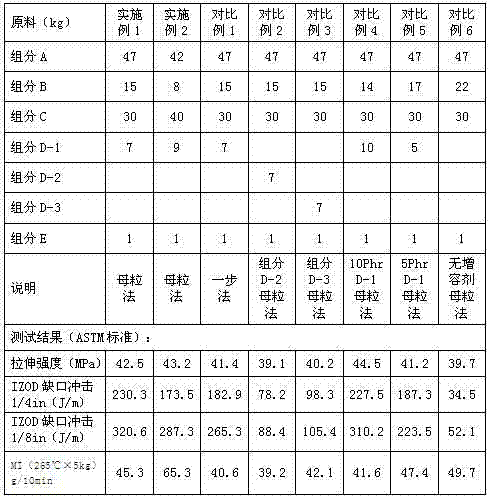

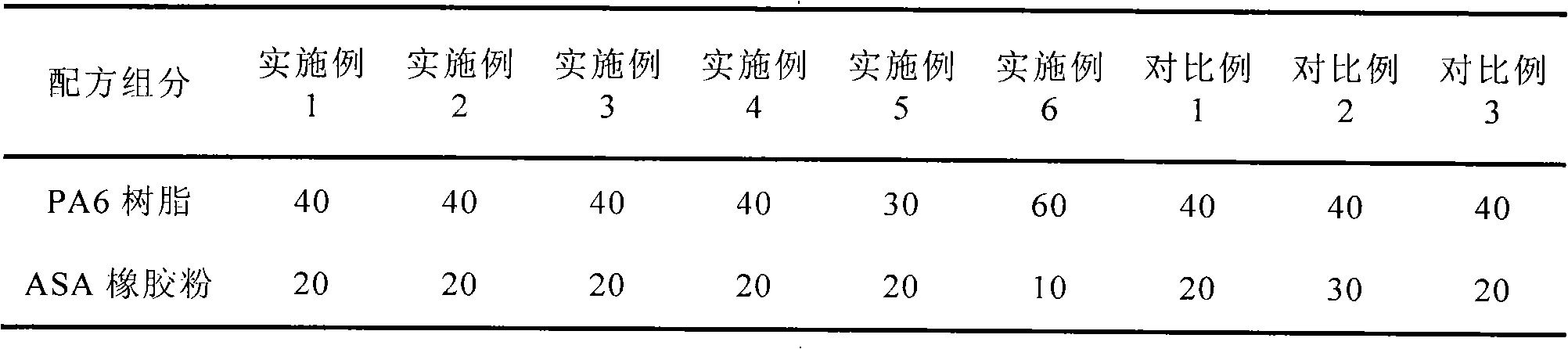

The invention relates to an alloy resin composition and a preparation method thereof. The composition comprises the following components in part by weight: 30-60 parts of polyamide resins, 15-50 parts of ASA (Acetylsalicylic Acid) rubber powder, 10-20 parts of ASA-g-GMA (Glycidyl Methacrylate) resins, 5-15 parts of glossy modifiers, 0-30 parts of AS (Arsenic) resins, 1-8 parts of compatilizers, 5-10 parts of weather-resistant master batch, 1-5 parts of nano fillers and 0.05-0.5 part of antioxidant. The preparation method comprises the following steps of: adding the mixture of all raw materials expect for the weather-resistant master batch to a main charging hole of a double-screw extruder, adding the weather-resistant master batch from a side charging hole, and then carrying out extrusion and pelleting to obtain the product. The alloy resin composition obtained in the method has a softer leopard surface matting effect, a more glossy shiny side lighting effect and better low temperature impact resistance and weather resistance, and is especially suitable for automobile interiors and exteriors with high requirements, such as instrument frames, air outlets of air conditioners, storage boxes, doorknobs, cosmetic mirrors, heat-radiating gratings, rearview mirrors, middle post plates, license plates and the like above wasitlines.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

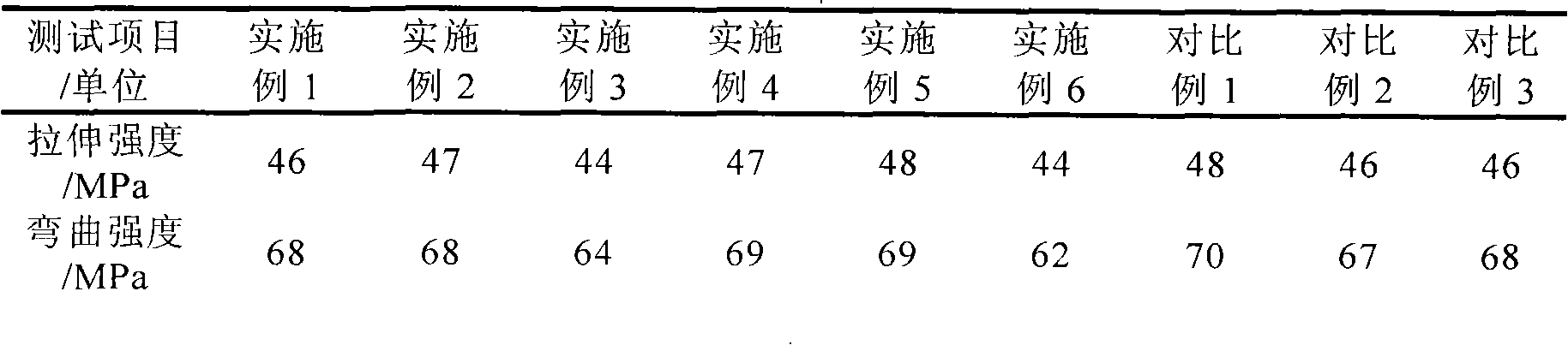

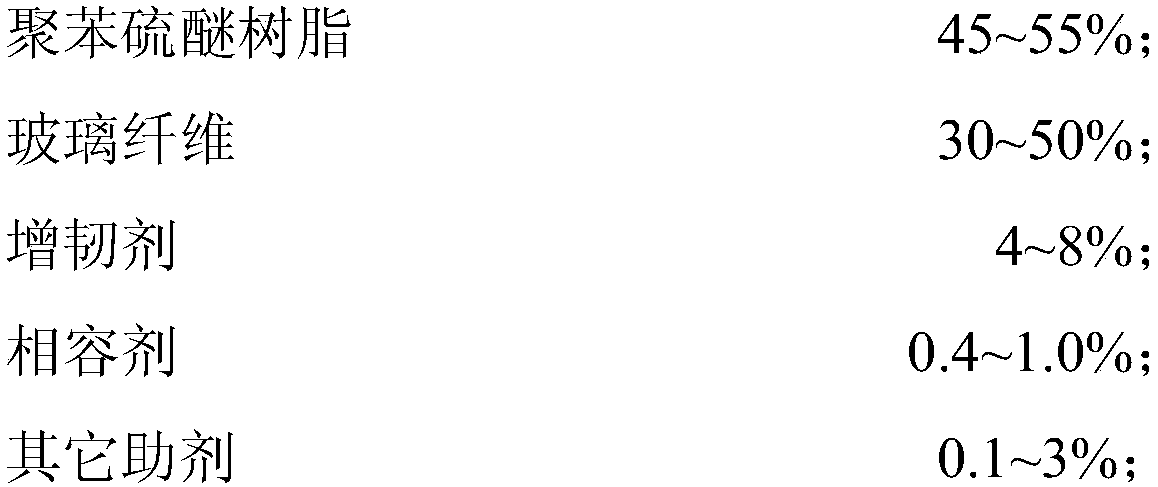

High strengthening and toughening type polyphenylene sulfide composite material and preparation method thereof

The invention discloses a high strengthening and toughening type polyphenylene sulfide composite material. 100 wt% of the composite material comprises 45-55 wt% of polyphenylene sulfide resin, 30-50 wt% of glass fibers, 4-8 wt% of a toughening agent, 0.4-1.0 wt% of a compatibilizer and 0.1-3 wt% of other additives; the surface of the glass fibers is impregnated with a silane coupling agent; the toughening agent is at least one selected from nylon 6, nylon 66, ethylene-methyl acrylate-glycidyl methacrylate and a maleic anhydride grafted styrene-ethylene-butadiene-styrene block copolymer elastomer; and the compatibilizer is selected from epoxy resins. The polyphenylene sulfide composite material disclosed in the invention has the advantage of high rigidity, high toughness and high flame retardation property, is especially suitable for producing small parts and ultrathin parts which have high requirements for the impact performance, and greatly broadens the application range of a phenyl sulfide material.

Owner:CGN JUNER NEW MATERIALS +1

Method for preparing functionalized polyethylene wax

The invention discloses a method for functionalizing polyethylene wax. Petroleum ether is used as a solvent, and functionalized monomers are grafted in a solution. The polyethylene wax can be dissolved and dispersed in the petroleum ether at the temperature of between 90 DEG C and 120 DEG C and is completely separated out when cooled to room temperature; products can be conveniently separated by using difference in solubility; and the solvent can be recycled. Polyethylene wax-grafted-acrylic acid (PEW-g-AA), polyethylene wax-grafted-methacrylic acid (PEW-g-MAA), polyethylene wax-grafted-glycidyl methacrylate (PEW-g-GMA), polyethylene wax-grafted-maleic anhydride (PEW-g-MAH), polyethylene wax-grafted-acrylamide (PEW-g-AM), polyethylene wax-grafted-N-methylol acrylamide (PEW-g-NMAM) and products obtained by neutralization, namely polyethylene wax-grafted-acrylic acid sodium (PEW-g-AAS) and polyethylene wax-grafted-methacrylic acid sodium (PEW-g-AAS), are obtained. The grafting products can be applied to the aspects of polyolefin modification, polyethylene wax emulsion, ink coating and the like. The method has a simple process and can be applied to industrial production.

Owner:张燕妮 +1

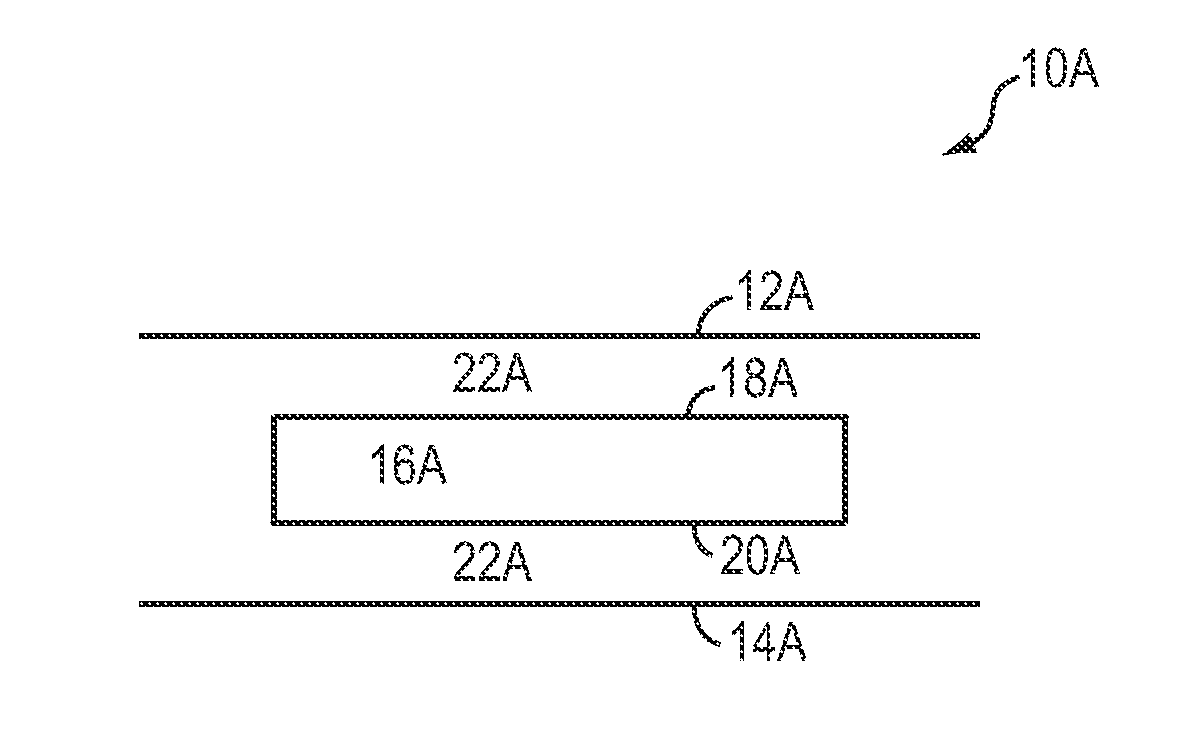

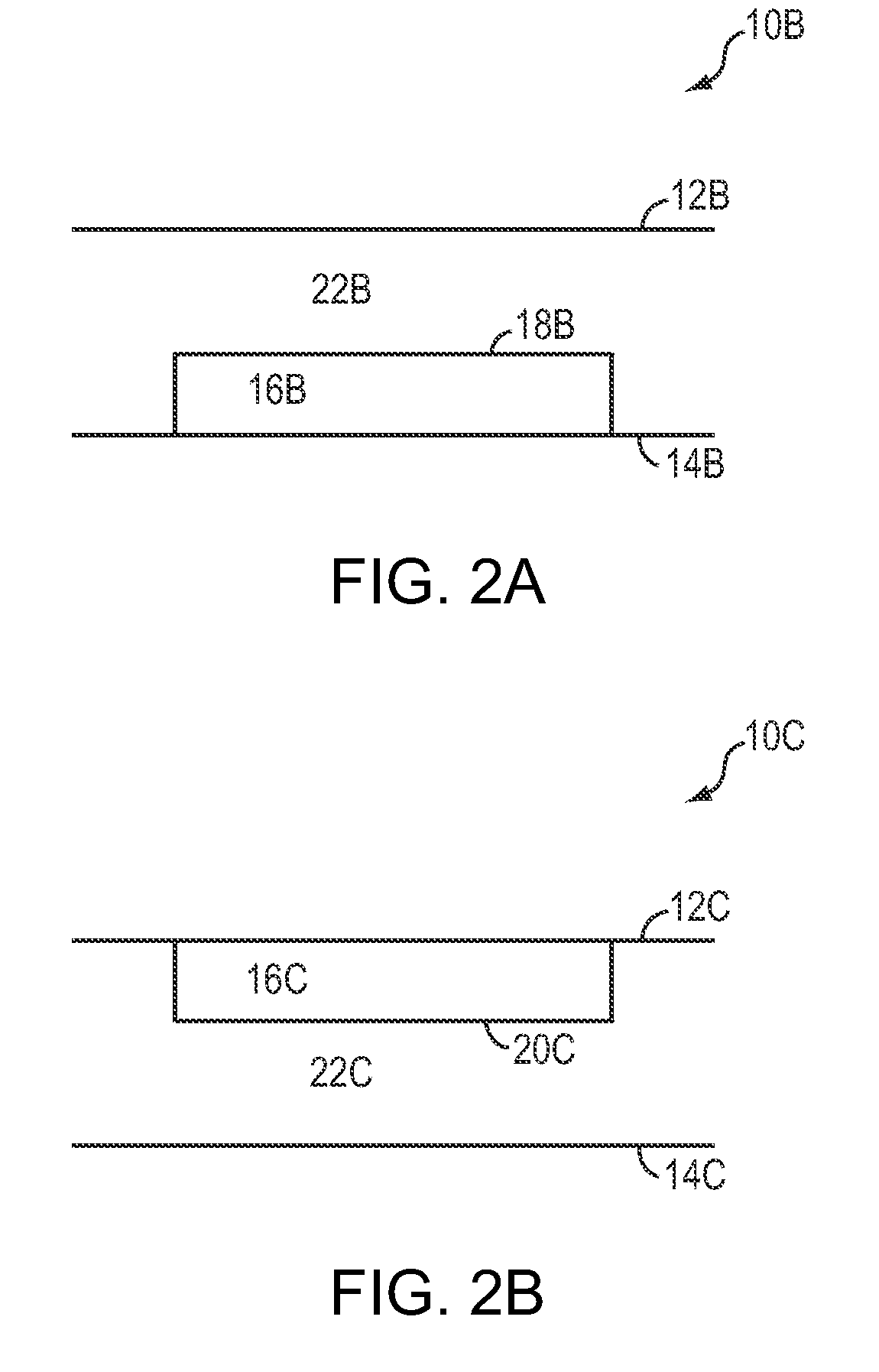

Multilayer composite structure with epoxide containing adhesive layer

The present invention is a multilayer composite structure comprising at least three layers, two of which are adhered to an intervening adhesive layer comprising a copolymer obtained by copolymerizing from about 55 to about 95 weight % ethylene with from about 0.1 to about 10 weight % of an epoxide-containing monomer, and optionally from 0 to about 35 weight % (meth)acrylate ester. Preferred epoxide-containing monomers are glycidyl methacrylate monomers.

Owner:EI DU PONT DE NEMOURS & CO

High-performance 3D printing supply alloy material

InactiveCN103804862AImprove impact performanceImprove the disadvantage of poor temperature resistanceGlycidyl methacrylateAcrylonitrile

The invention provides a high-performance 3D (Three Dimensional) printing supply alloy material. The high-performance 3D printing supply alloy material comprises, in parts by weight, 20.0-50.0 parts of polylactic acid, 50.0-80.0 parts of high impact polystyrene, 0.1-5.0 parts of compatilizer and 0.2-3.0 parts of auxiliaries, wherein the compatilizer comprises one or more than two, matched with each other in use, of a maleic anhydride grafted high polymer, a terpolymer copolymerized with styrene, acrylonitrile and glycidyl methacrylate (SAG), and a terpolymer copolymerized with methyl methacrylate, butadiene and a styrol copolymer (MBS). The high-performance 3D printing supply alloy plastics prepared from the high-performance 3D printing supply alloy material are non-toxic, low-carbon and environment-friendly, low in alloy material cost, excellent in combination properties, and very high in economic value and wide in market prospect.

Owner:芜湖瀚博电子科技有限公司

Polymeric Encapsulants for Photovoltaic Modules and Methods of Manufacture

InactiveUS20100269890A1Strong adhesion to glassGood mechanical integrityPV power plantsSynthetic resin layered productsGlycidyl methacrylateAntioxidant

An encapsulant adapted for use in a photovoltaic module includes a random terpolymer and a random copolymer. In one embodiment, the terpolymer includes ethylene, methyl acrylate, and glycidyl methacrylate, and the copolymer is a heat resistant copolymer. The encapsulant may include a carrier resin and / or one or more additives, such as a UV absorbing material, a hindered amine light stabilizer, a phosphite antioxidant, and / or a silane.

Owner:IGENEON KREBS IMMUNTHERAPIE FORSCHUNGS UND ENTWICKLUNGS +1

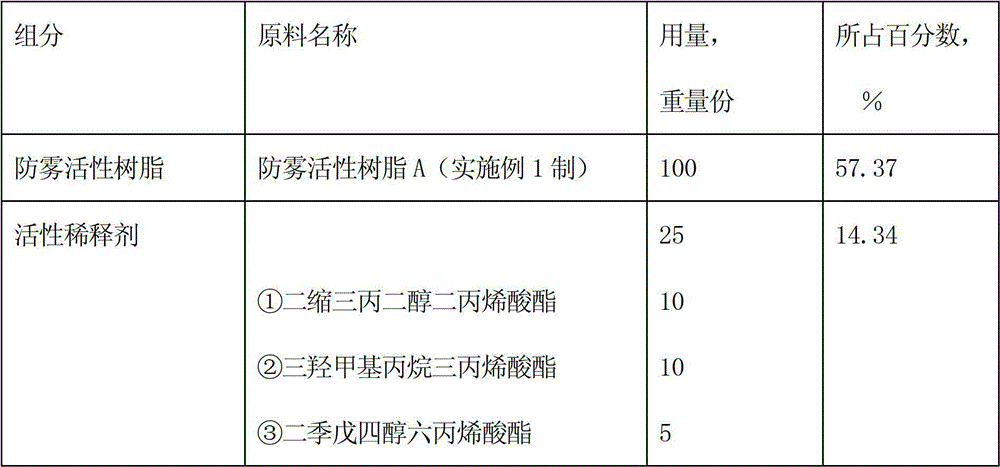

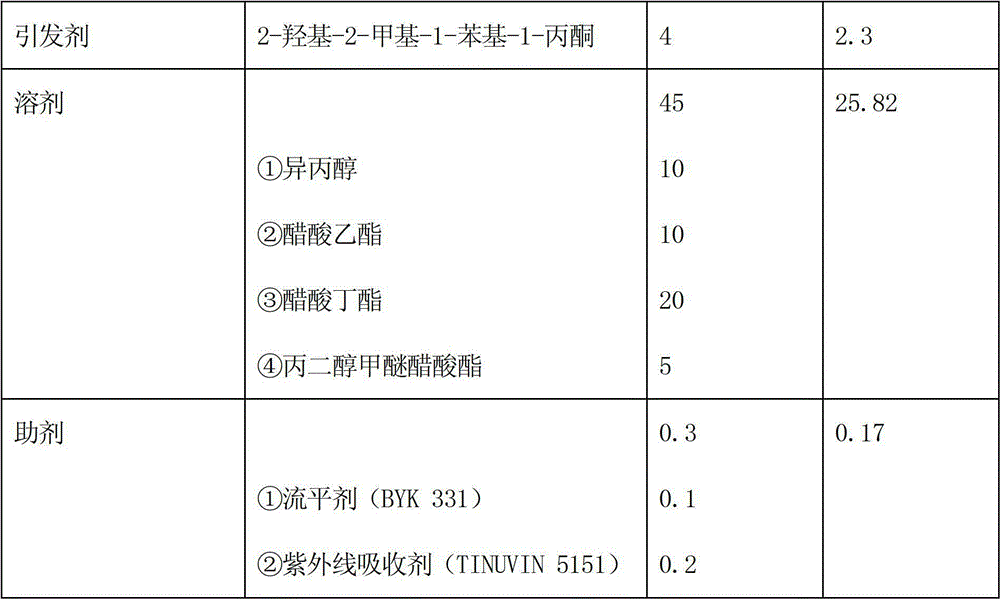

Ultraviolet light cured antifogging coating

ActiveCN102911582ASufficiently hydrophilic structureGood anti-fog durabilityCoatingsGlycidyl methacrylateUltraviolet lights

The invention relates to an ultraviolet light cured antifogging coating. The ltraviolet light cured antifogging coating adopts antifogging activated resin which contains activated double bond and can be cured by ultraviolet light as the main film-forming resin, and is prepared by mixing, based on total weight of the antifogging coating, 32-60% of the antifogging activated resin, 10-25% of activated diluent, 1.5-2.5% of photoinitiator, 25-40% of solvent, and 0.1-1% of adjuvant. The antifogging activated resin is prepared by subjecting reactive nonionic surfactant allyloxy nonyl phenoxy propanol polyoxyethylene ether, (methyl) acrylic acid and (methyl) butyl acrylate to free radical polymerization, and grafting and modifying by the polymer via glycidyl methacrylate, wherein the amount ratio of the glycidyl methacrylate to the (methyl) acrylic acid is 1-1.4. The film formed by the coating cured by the ultraviolet light is high in water resistance performance, durable in antifogging effect and high in hardness, and wiping resistance is improved remarkably.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

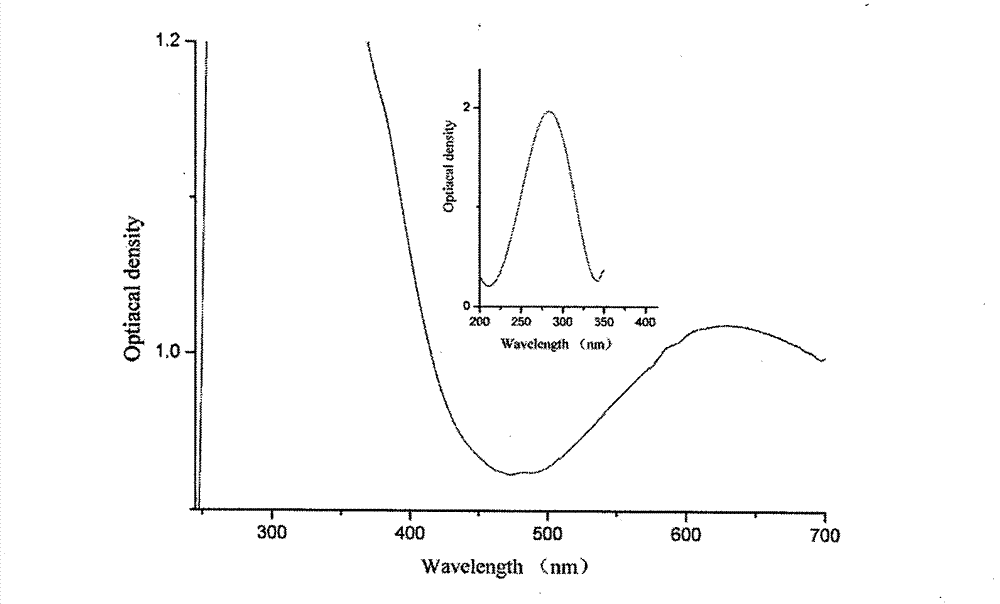

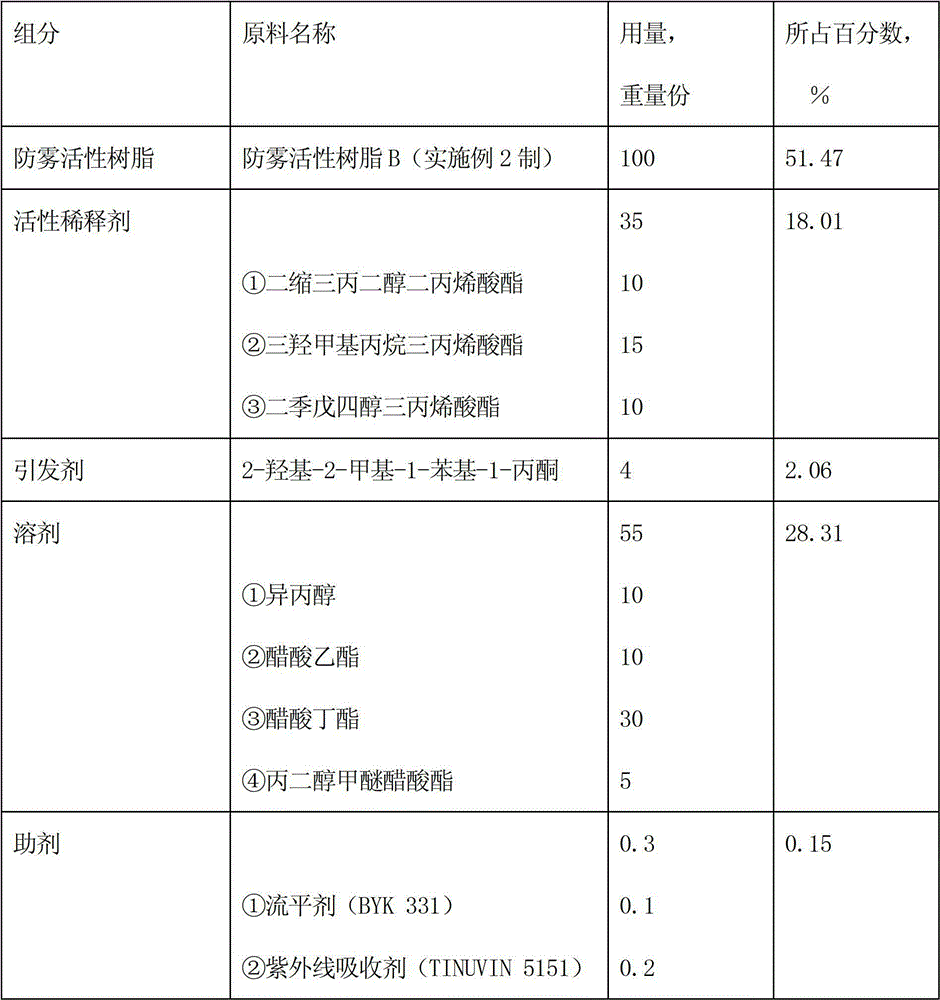

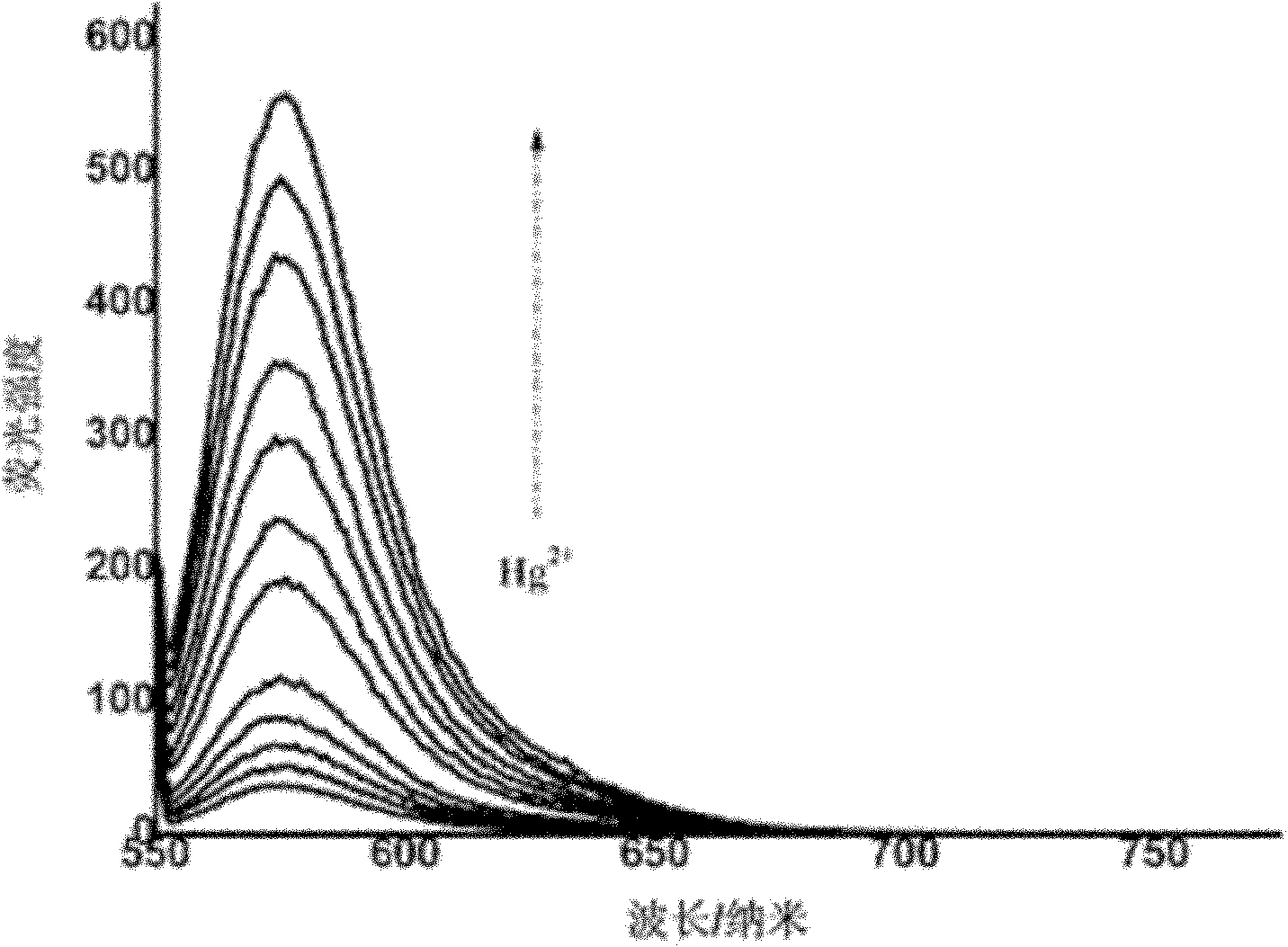

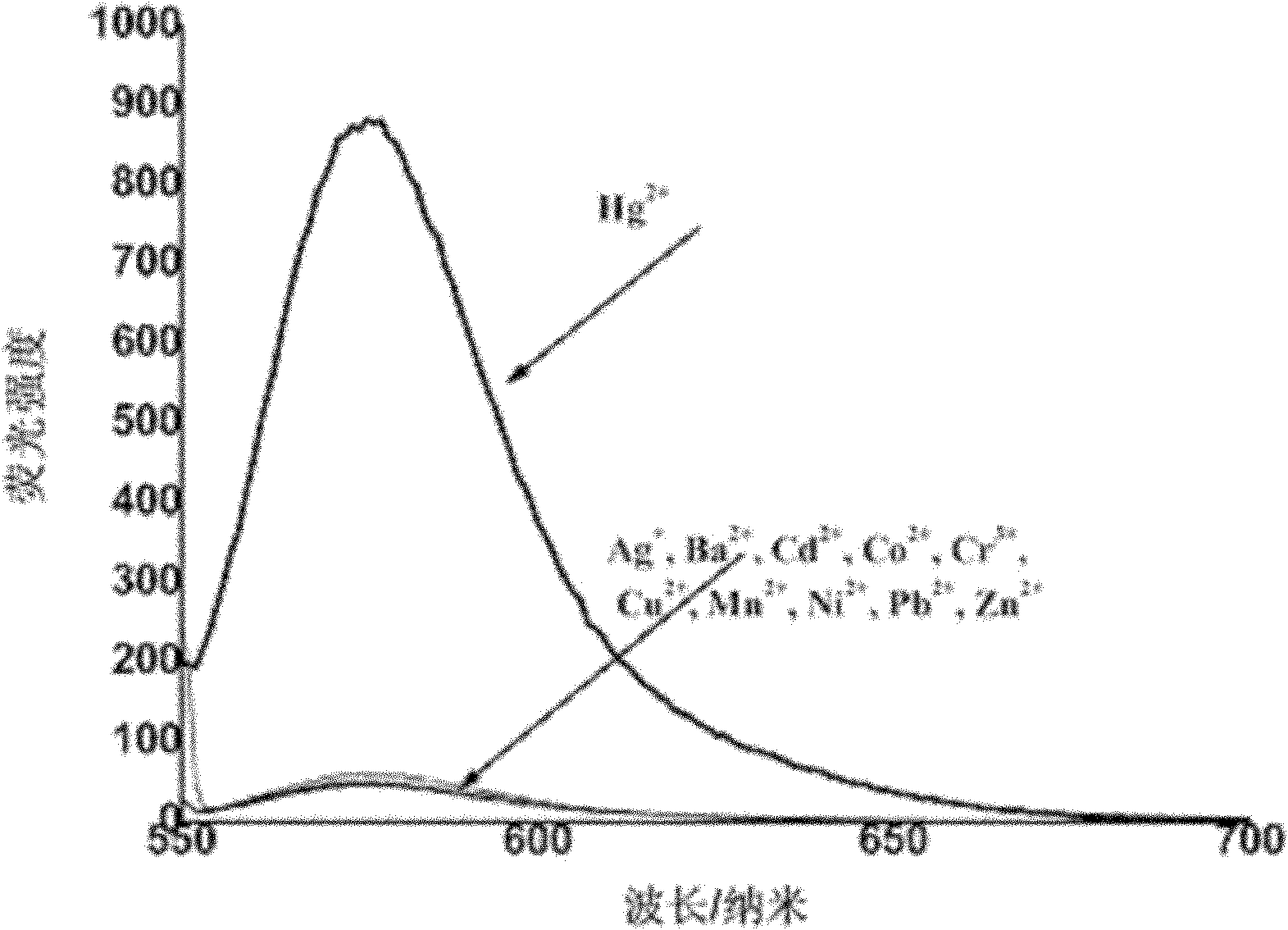

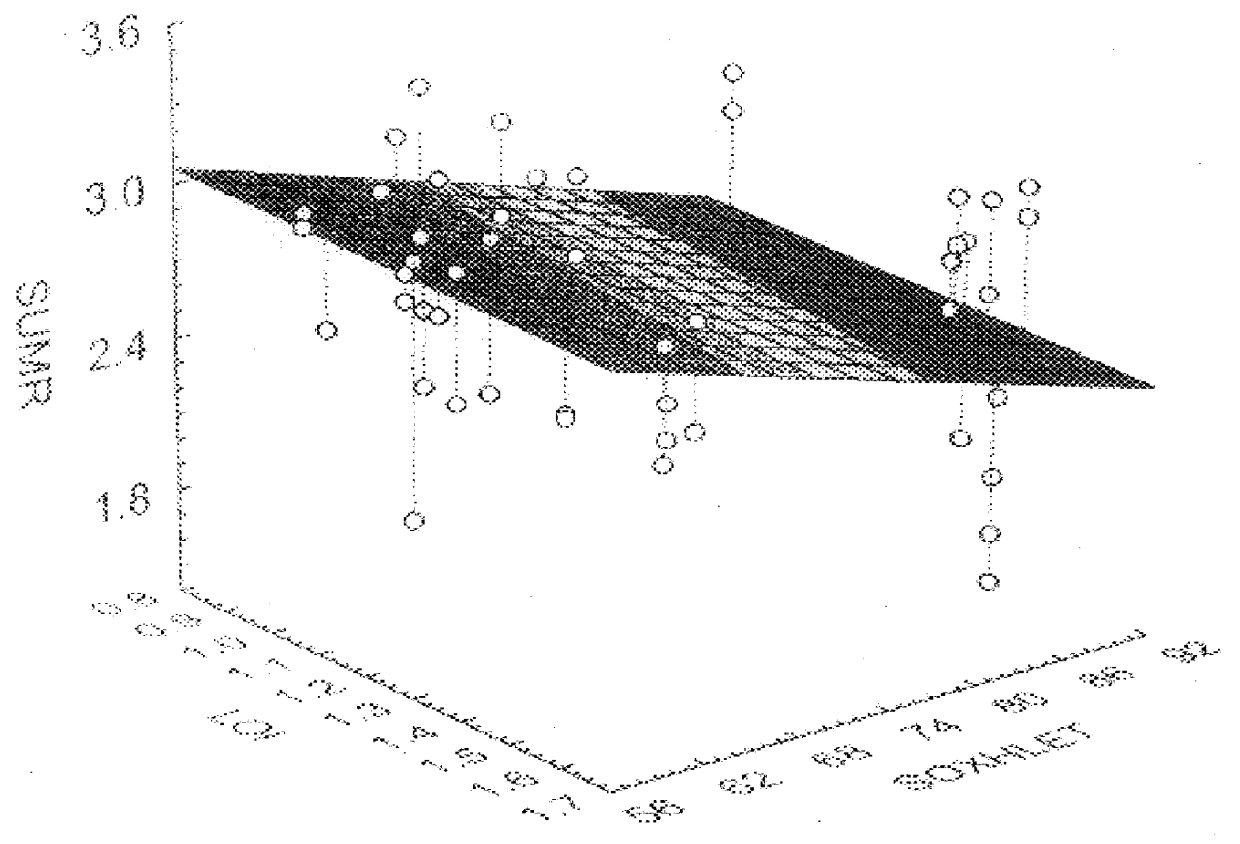

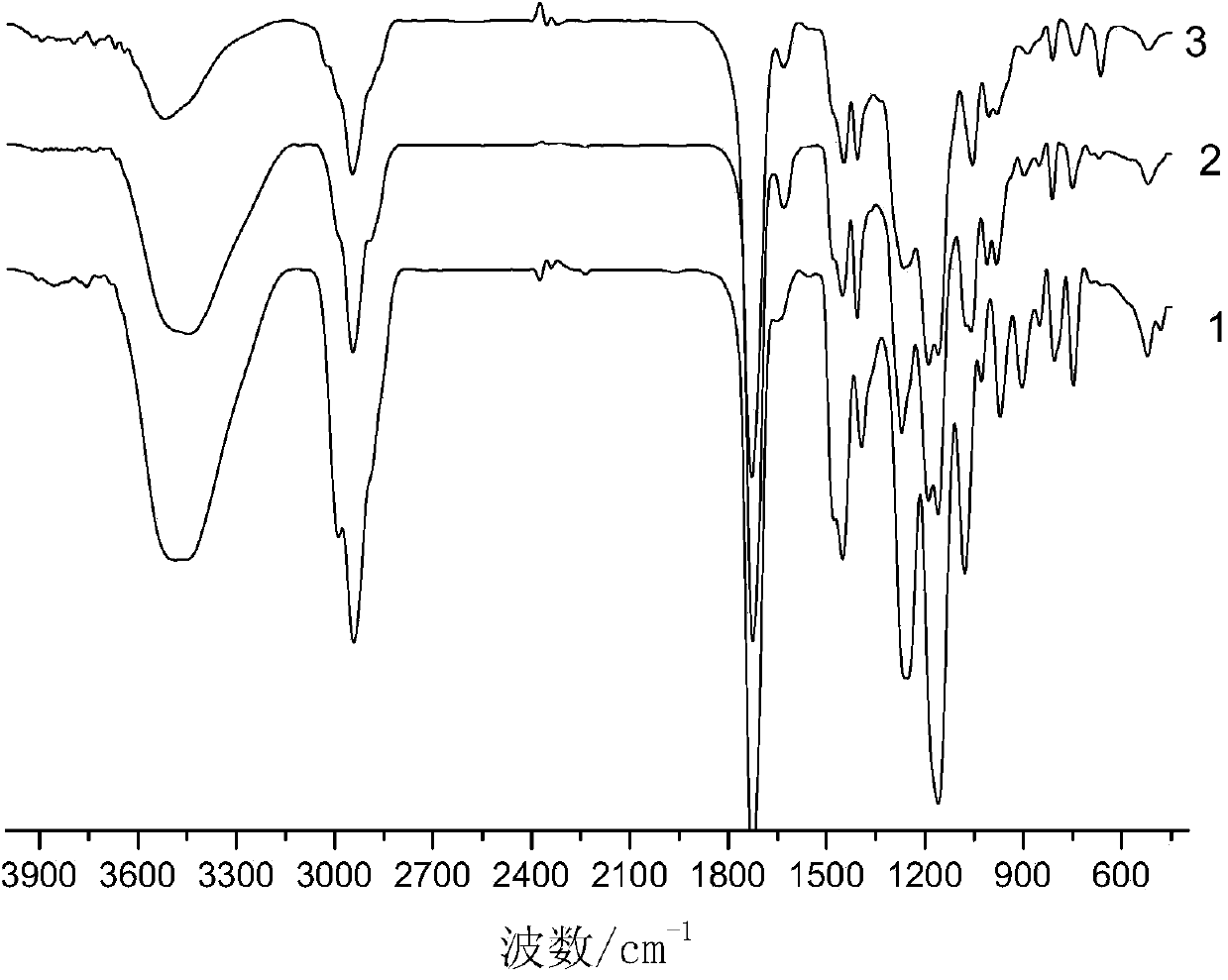

Preparation of hydrophilic polymer and application thereof in detecting mercury ions based on change of fluorescence and color

InactiveCN102153700AIncrease contentQuick responseMaterial analysis by observing effect on chemical indicatorOrganic dyesSolubilityGlycidyl methacrylate

The invention discloses preparation of hydrophilic polymer and application thereof in detecting mercury ions based on the change of fluorescence and color, particularly a rhodamine B hydrazide grafted hydrophilic polymer probe applied to the detection of mercury ions in aqueous medium based on the change of fluorescence and color and a kit and test paper applied to the detection of the mercury ions by using the probe, belonging to the technical field of material preparation and heavy metal ion detection. The polymer containing a rhodamine chromophore is prepared by subjecting rhodamine B hydrazide and propylene oxide on the side chain of polyvinylpyrrolidone-glycidyl methacrylate which is a water-soluble polymer to ring-opening reaction, has good water solubility and can be applied to selectively detecting the mercury ions by using visual colorimetry and fluorescence detection. The probe realizes the high-sensitivity and high-selectivity rapid quantitative or semi-quantitative detection of the trace mercury ions in the aqueous medium, has a simple synthetic route, low cost and convenience of use, is applicable to amplified synthesis and actual production and has great application prospects in the field of medicine, biology and environmental science and the like.

Owner:JIANGNAN UNIV

High solubility size composition for fibers

InactiveUS6025073AImprove featuresIncreases filler loadingLayered productsPretreated surfacesPolyesterFiber

A high solubility size composition is provided which may be applied to glass fibers useful for reinforcing polymeric materials. The size composition includes: a first film former comprising a polyether-based or polyester-based thermoplastic polyurethane derived from a saturated, non-crosslinkable polyether or polyester; a second film former comprising at least one ingredient selected from i) a vinyl acetate glycidyl methacrylate copolymer and ii) a mixture of a vinyl acetate glycidyl methacrylate copolymer and a vinyl acetate homopolymer; a silane coupling agent; and water. Using glass fibers coated with the high solubility size composition allows the advantageous production of low-pigmented or non-pigmented molded parts having enhanced surface appearance and color uniformity.

Owner:OCV INTELLECTUAL CAPITAL LLC +1

Preparation method of high temperature and yellowing resistant alkali-soluble epoxy acrylate UV resin

InactiveCN104086701AHigh glass transition temperatureImprove heat resistanceInksCoatingsGlycidyl methacrylate(Hydroxyethyl)methacrylate

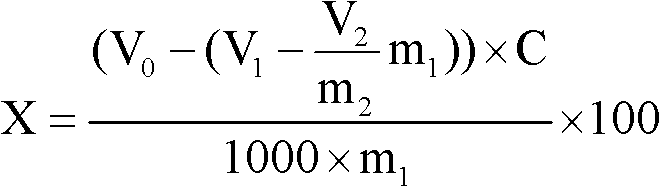

The invention discloses a preparation method of a high temperature and yellowing resistant alkali-soluble epoxy acrylate UV resin. The preparation method comprises the following steps: carrying out free radical polymerization on an alicyclic epoxy acrylate monomer, glycidyl methacrylate, and hydroxyethyl methacrylate or hydroxypropyl methacrylate to prepare an alicyclic epoxy acrylate copolymer; reacting acrylic acid with an epoxy group in the above epoxy acrylate resin, and introducing a double bond to make the resin have photosensitive activity; and reacting acid anhydride with a hydroxy group, and introducing a carboxyl group to make the resin alkali-soluble in order to prepare the high temperature and yellowing resistant alkali-soluble epoxy acrylate UV resin with a carboxyl group. The glass transition temperature of the resin finally obtained in the invention is 65-100DEG C, and the finally obtained resin has the characteristics of good high temperature resistance, yellowing resistance, acid and alkali resistance of a curable film, solvent resistance, excellent mechanical performances and the like, and can be widely applied in yellowing resistant optical imaging solder resistant inks, photoresist, yellowing resistant UV inks and coatings, adhesion promoters, ink crosslinking agents and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

Recycled PC (Polycarbonate) and recycled PET (polyethylene terephthalate)-containing halogen-free flame retardant resin composition and preparation method thereof

ActiveCN102604352ASolve the problem of poor performance stabilityGood notched impact resistanceGlycidyl methacrylatePolyethylene terephthalate

The invention relates to a recycled PC (Polycarbonate) and recycled PET (polyethylene terephthalate)-containing halogen-free flame retardant resin composition and a preparation method thereof. The recycled PC and recycled PET-containing halogen-free flame retardant resin composition comprises the following components by weight percentage: 5 to 50% of native PC, 20 to 63% of recycled PC, 5 to 35% of recycled PET, 5 to 15% of toughener, 10 to 20% of flame retardant, 0.1 to 0.8% of flame-retardant anti-dripping agent, 0.1 to 1% of antioxidant, 0.1 to 2% of lubricant, and 0.2 to 2% of styrene-acrylonitrile-glycidyl methacrylate terpolymer containing 1 to 5% of glycidyl methacrylate and 20 to 33% of acrylonitrile. The preparation method comprises the following steps that: after the components are prepared, the recycled PET, the styrene-acrylonitrile-glycidyl methacrylate terpolymer are fully mixed, led out, subjected to extrusion granulation, and made into masterbatcehs; then the masterbatches and the remaining components are fully mixed, led out, and subjected to extrusion granulation to obtain the recycled PC and recycled PET-containing halogen-free flame retardant resin composition. The recycled PC and recycled PET-containing halogen-free flame retardant resin composition has a higher impact performance and good stability.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Flame-retardant PC/HIPS composite material and preparation method thereof

The invention discloses a flame-retardant PC / HIPS composite material and a preparation method thereof. The composite material is prepared by the following raw materials: polycarbonate, polystyrene, flame retardant, flame-retardant synergist, flexibilizer, compatilizer, antioxidant and other adjuvants; and the preparation method comprises the following steps of: a. forced air drying the polycarbonate and the polystyrene respectively at 100-130 DEG C and 70-90 DEG C for 4-8 hours; b. preparing high impact polystyrene grafting glycidyl methacrylate compatilizer; c. weighing the dried polycarbonate, the polystyrene, the flame retardant, the flame-retardant synergist, the flexibilizer, the compatilizer, the antioxidant and other adjuvants; d. putting the raw materials in the step c into a high-speed mixer for dry mixing for 3-5min;and e. putting the mixed raw materials into a twin-screw extruder for melt extruding and pelleting. The composite material has prominent toughness and excellent flame retardance; in addition, the preparation method is simple, the operation is convenient and the cost is low.

Owner:ANHUI KEJU NEW MATERIALS

Glycidyl methacrylate grafted polylactic acid copolymer material, preparation method for same and application thereof

ActiveCN102603994AImprove interface compatibilityImprove mechanical propertiesPolyesterGlycidyl methacrylate

The invention discloses a glycidyl methacrylate grafted polylactic acid copolymer material, which is made of, in weight percentage, 93%-97% of polylactic resin, 1%-5% of glycidyl methacrylate and 1%-2% of radical initiator. The glycidyl methacrylate grafted polylactic acid copolymer material can serve as a novel efficient coupling agent to be applied to polyester based composite materials, so that the polyester based composite materials embody excellent performances. The invention further discloses a preparation method for the glycidyl methacrylate grafted polylactic acid copolymer material, which includes the steps: weighing the polylactic resin, the glycidyl methacrylate and the radical initiator according to the weight percentage, and uniformly mixing to serve as mixed materials; and adding the mixed materials into a double-screw extruder for melt extrusion and granulation so as to obtain a granular product. The method has the advantages of high production efficiency, low cost, no solvent pollution, high grafting ratio and the like, is easy in large-scale industrial production and has good economic benefit.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Composition of acrylic pressure-sensitive adhesive and surface finishing material comprising the same

ActiveUS20100048077A1Excellent Adhesive PropertiesExcellent fireproof performanceSynthetic resin layered productsOrganic dyesSurface finishMeth-

An acrylic pressure-sensitive adhesive composition according to the present invention comprises: acrylic copolymer (A) formed by copolymerizing i) alkyl (meth) acrylic acid ester monomer wherein the carbon atom of alkyl group is 2 to 14, ii) monomer having a functional group capable of crosslinking, iii) methyl (meth)acrylate monomer, iv) vinyl acetate monomer, v) glycidyl (meth)acrylate, and vi) crosslinking agent having 5 to 15 of alkyleneoxide groups and at least two acrylate group or vinyl group; and flame retardant (B). The acrylic pressure-sensitive adhesive composition improves the adhesive property and the dispersion of the flame retardant by controlling the crosslinking structure of the acrylic copolymer, such that a surface finishing material comprising the same can have the excellent adhesion and fireproof.

Owner:LG CHEM LTD

Friction-reducing and abrasive composite materials with reactive nanometer inorganic particles/epoxy and production thereof

A reactive nanometer inorganic particle / epoxy resin abrasive composite material and its production are disclosed. The composite material consists of epoxy resin 90-99wt%, nanometer inorganic particle 1-10wt% and graft monomer 0.1-5%. The graft monomer is mixture of any kind or several kinds of methyl acrylic acid ethylene oxide ester, acrylic amide, phenylethylene, ethyl acrylate, methyl ethyl acrylate or butyl acrylate. The process is carried out by surface graft modifying nanometer grains, inducing reactive polymer, epoxy resin curing reacting and forming chemical connection between nanometer grains and resin matrix. It has better anti-friction and wear-resistant performances and is simple. It can be used for epoxy resin coating and various miniature devices.

Owner:SUN YAT SEN UNIV

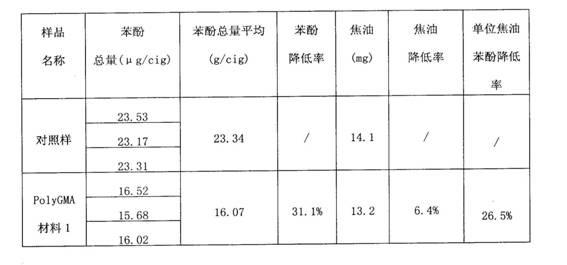

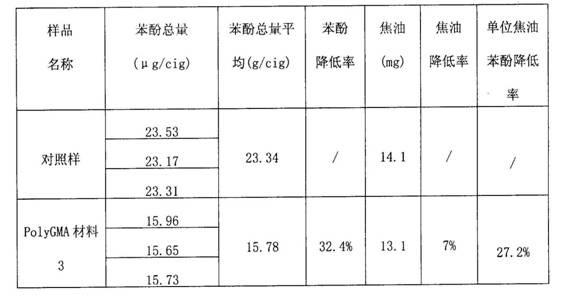

Preparation method and application of poly-glycidyl methacrylate interosculated porous material

ActiveCN101979418ALarge specific surface areaFast transferTobacco smoke filtersPolymer scienceGlycidyl methacrylate

The invention discloses a preparation method and application of a poly-glycidyl methacrylate interosculated porous material. The preparation method is characterized in that the poly-glycidyl methacrylate interosculated porous material (PolyGMA) with an epoxy functional group is obtained through high internal phase emulsion polymerization of glycidyl methacrylate (GMA), and the material can adsorb a harmful substance namely phenol in smoke gases. The material can selectively reduce over 25 percent of the released amount of the phenol in cigarette mainstream smoke gas by adding 10 to 30 mg of the material into each cigarette filter stick, but the released amount of tar is basically not changed or is reduced slightly; and simultaneously, the material does not generate negative effect on the smoking quality of cigarettes, thereby fulfilling the aim of selectively reducing the released amount of the phenol in the cigarette smoke gas.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Method for preparing moisture-cured multi-grafted solvent type adhesive

ActiveCN101781539AImprove solubilityHigh bonding strengthNon-macromolecular adhesive additivesGraft polymer adhesivesCross-linkPolymer science

The invention discloses a method for preparing a moisture-cured multi-grafted solvent type adhesive. Rubber and a styrene type thermoplastic elastomer form a skeleton, and under the initiation of BPO, monomers methyl methacrylate (MMA), methacrylamide (AM) and glycidyl methacrylate (GMA) are grafted to a carbon doublebond of the skeleton, thereby changing the polarity of the adhesive with the modification of the monomers; and a silane coupling agent and epoxy groups undergo a cross linking reaction through silane to form three-dimensional net working so as to fulfill the aim of moisture curing, and enhance the bond strength and heat resistance of the adhesive. The moisture-cured multi-grafted solvent type adhesive prepared by using the method of the invention does not contain any toxic substance, such as benzene and the like, threatening human health, has high component stability, is secure and environmentally-friendly, simultaneously has high bonding power for polar materials and nonpolar materials, can bond a plurality of materials, such as rubber, leather, fabrics, foam, PVC leather, PU leather, plastics, colored printed product surface mount plastics and the like, and is widely applied to the vehicle material market and footwear industry.

Owner:力森诺科材料(无锡)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com